Patents

Literature

34results about How to "Save excavation costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

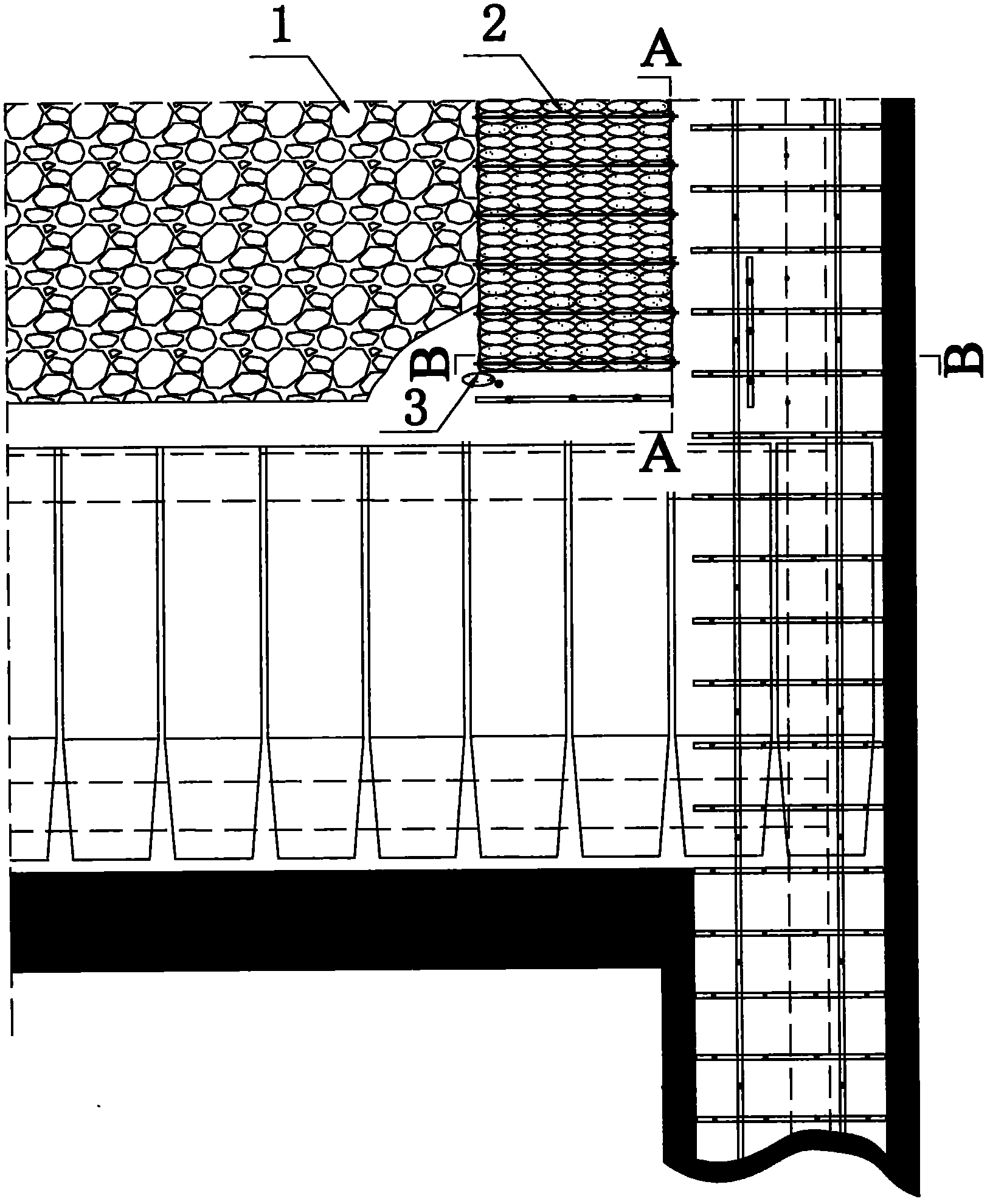

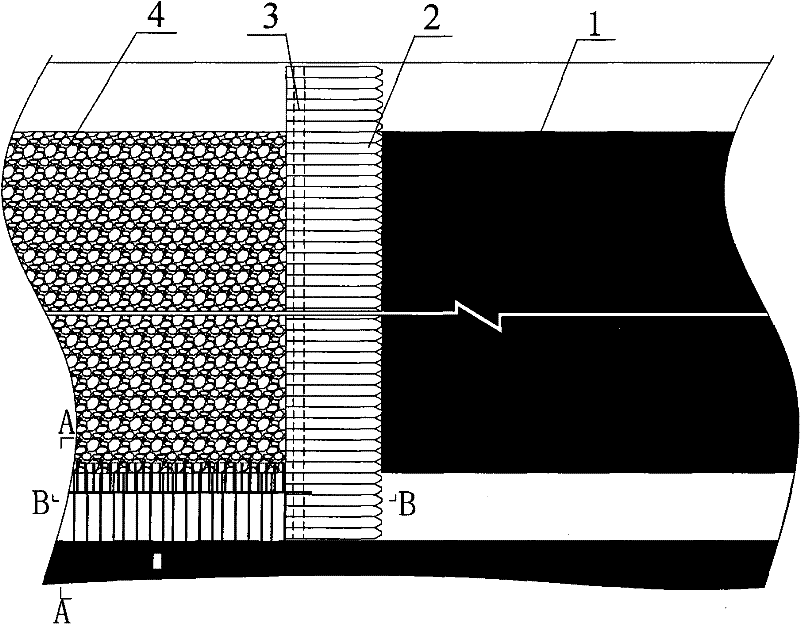

A method of retaining entry along the goaf with solid filling coal mining and building gangue walls

InactiveCN102278140AAvoid lostImprove recovery rateMaterial fill-upAnchoring boltsSolid massMining engineering

The invention relates to a method of solid filling coal mining and building gangue walls along the goaf, which is to build a gangue wall on the side of the filling body in the goaf of the coal mining face, and pack the coal mine gangue into the gangue wall with woven bags or snakeskin bags. If it is full and built into a wall, the coal mine gangue can be directly filled with the gangue filling the coal mining face. Then, the gangue wall needs to be pre-prepared with single-layer metal mesh, "W"-shaped steel belt, ladder beam and double-ended threaded anchor rod. Tight support. As the working face continues to advance, this method can leave a complete gangue wall for the mining of the next working face. The roadway retaining method is simple and practical, has high support strength and low cost.

Owner:XUZHOU ZHONGKUANG BACKFILLING&MINING TECH CO LTD

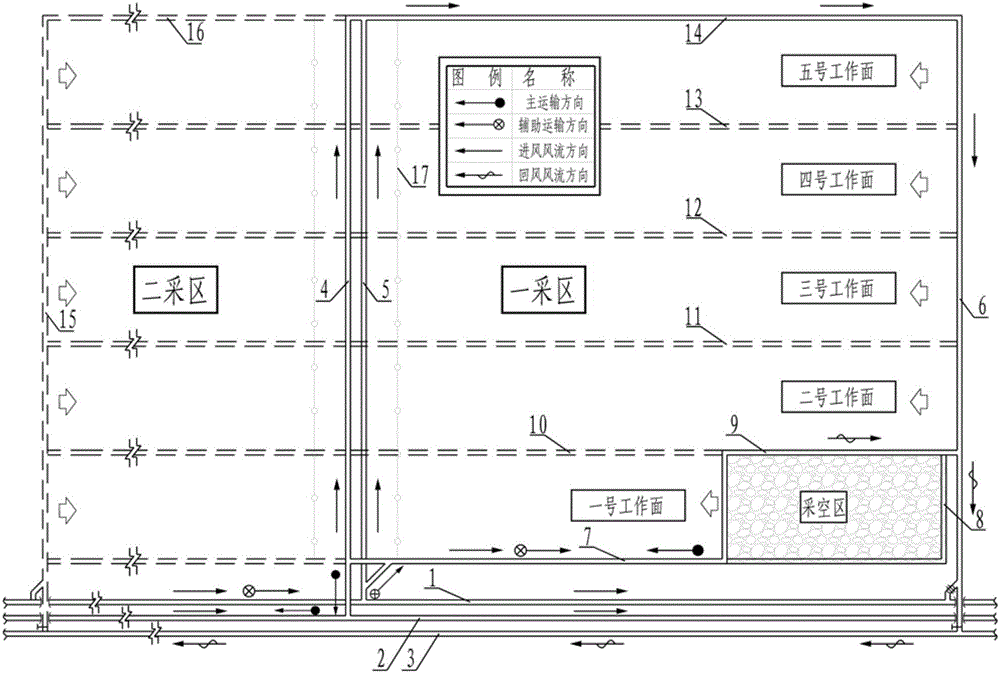

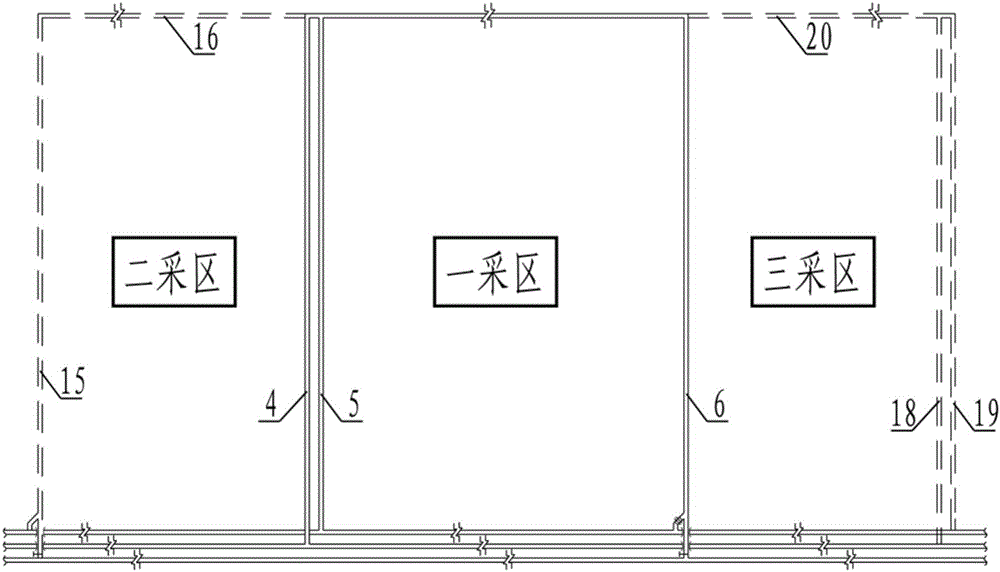

Underground coal mining area type non-excavation-roadway and non-chain-pillar coal mining method

InactiveCN106121646ASave excavation costsShorten tunneling timeUnderground miningSurface miningCoal pillarMineralogy

The invention discloses an underground coal mining area type non-excavation-roadway and non-chain-pillar coal mining method. The coal mining method has the main characteristics that a range suitable for non-excavation-roadway and non-chain-pillar coal mining is assigned, three mining roadways and an end-mining working face ventilation roadway are excavated from a development roadway opening, and the three mining roadways are communicated to form a preparation roadway and a ventilation system for mining areas. The coal mining method comprises the following steps that a working face transportation roadway and a cutting hole of a first working face are excavated to form a first working face mining roadway, and production systems are arranged; the first working face is mined, and a working face ventilation roadway with a certain width is reserved by adopting a gob-side entry retaining technology to be as a second working face transportation roadway; and a third working face mining roadway is formed after a second working face is mined, and subsequent working faces are sequentially mined. Non-excavation-roadway and non-chain-pillar mining is realized. After mining area mining is completed, the three mining roadways can serve for adjacent mining areas and are repeatedly used.

Owner:中煤西安设计工程有限责任公司

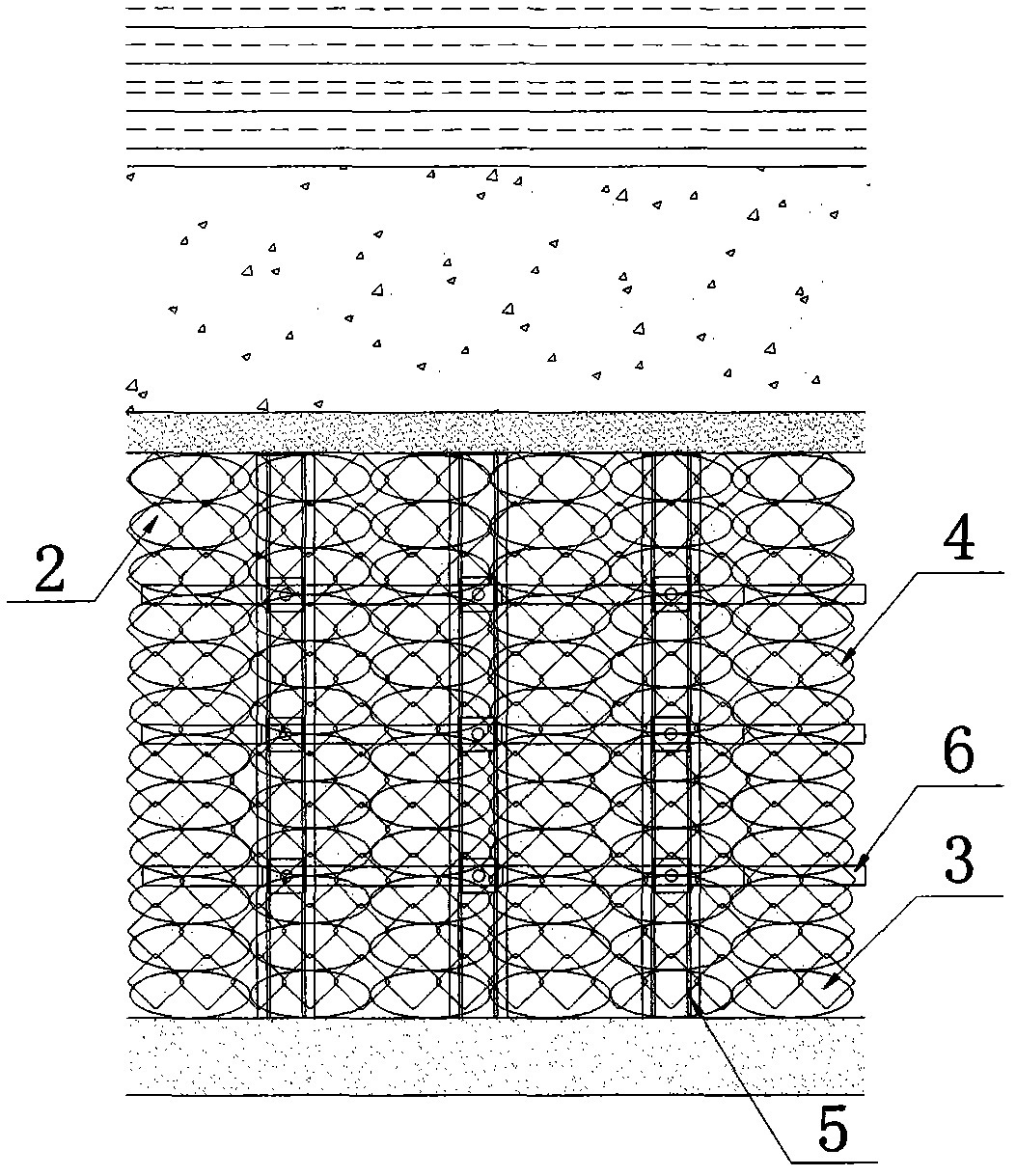

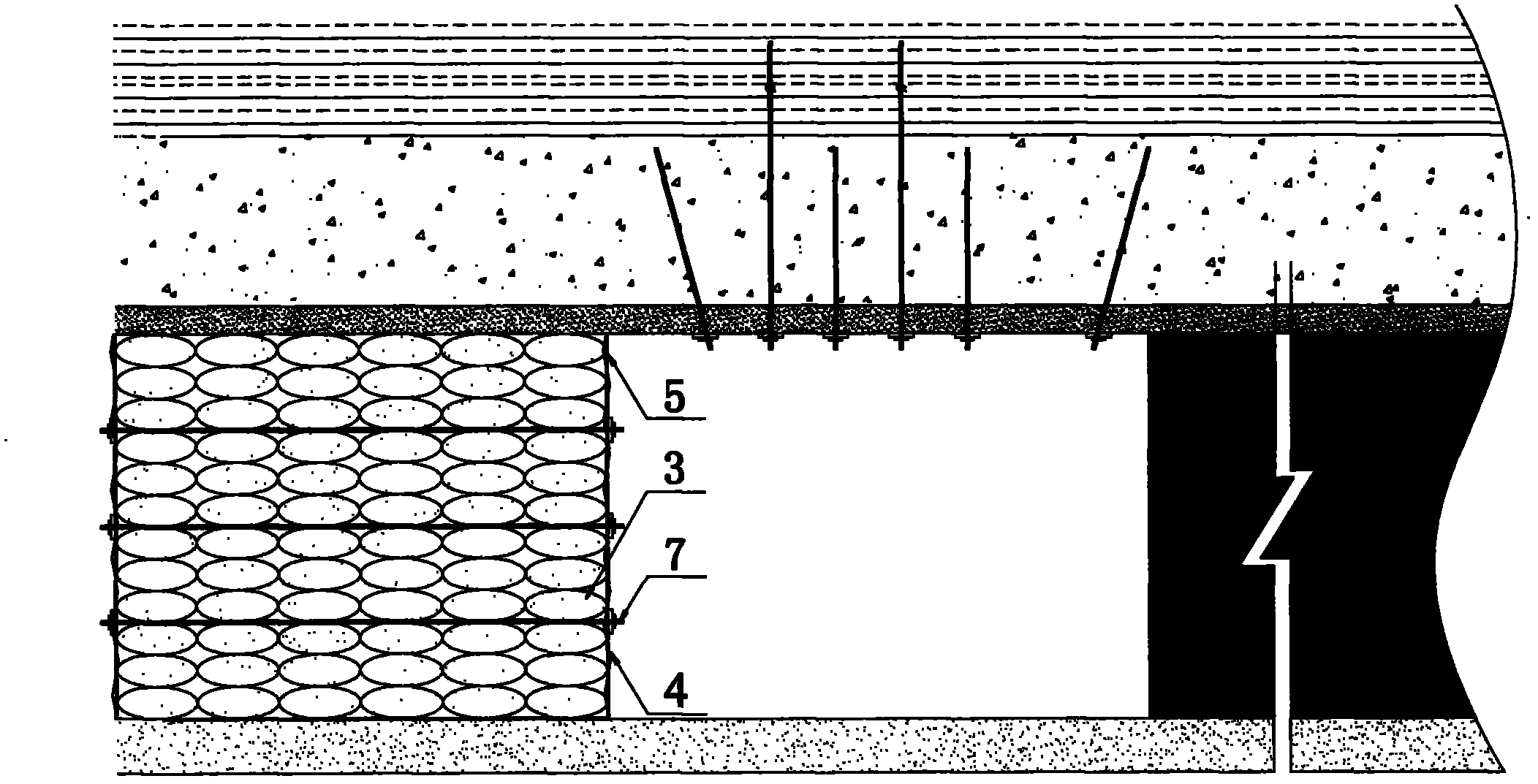

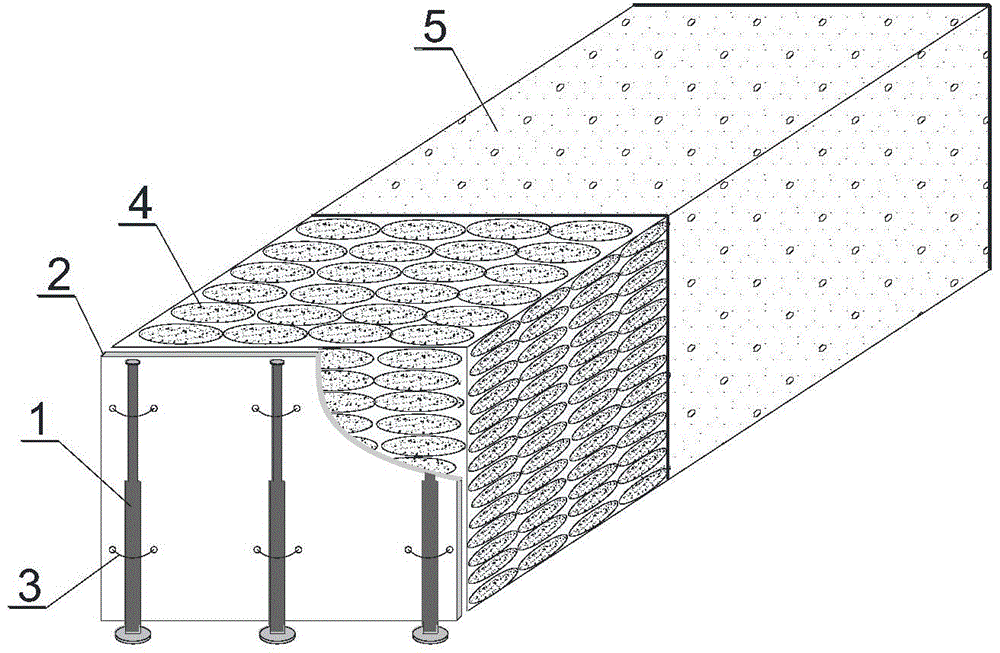

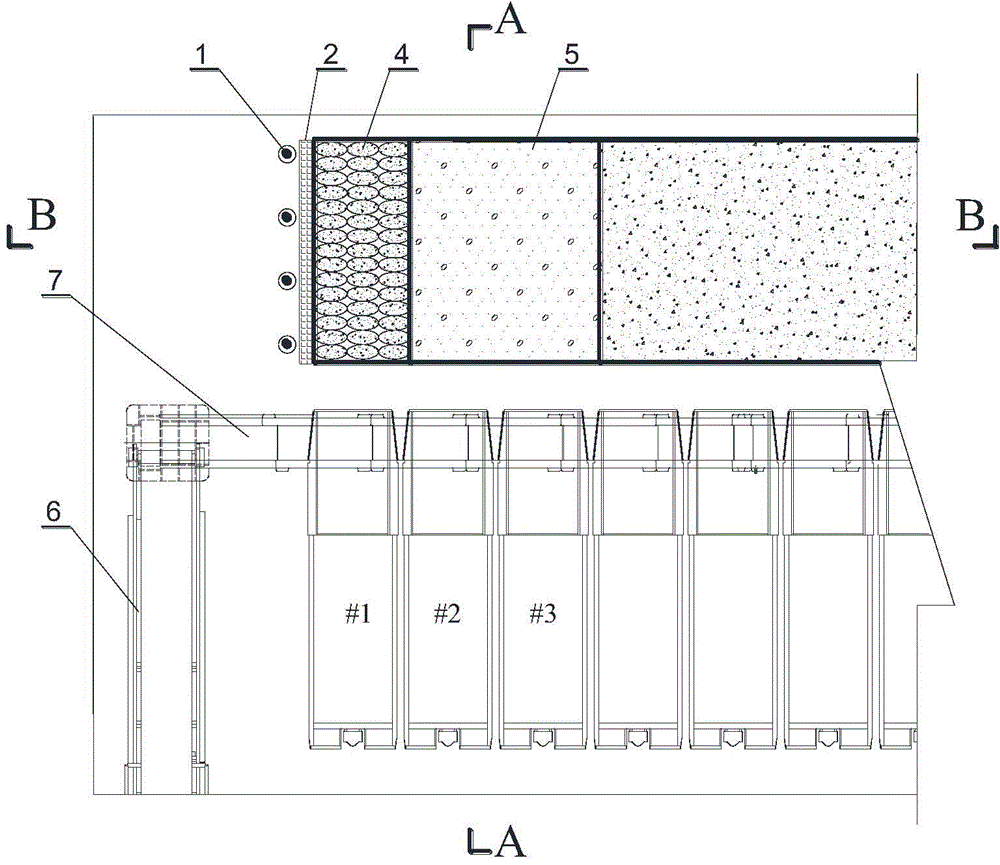

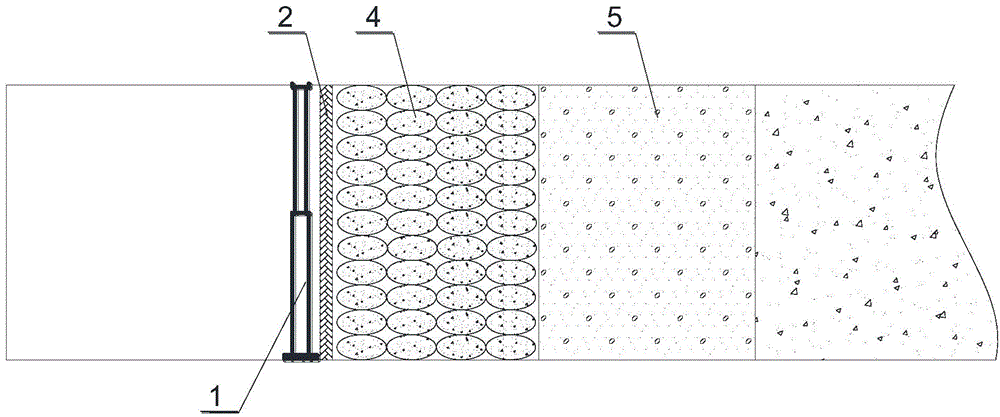

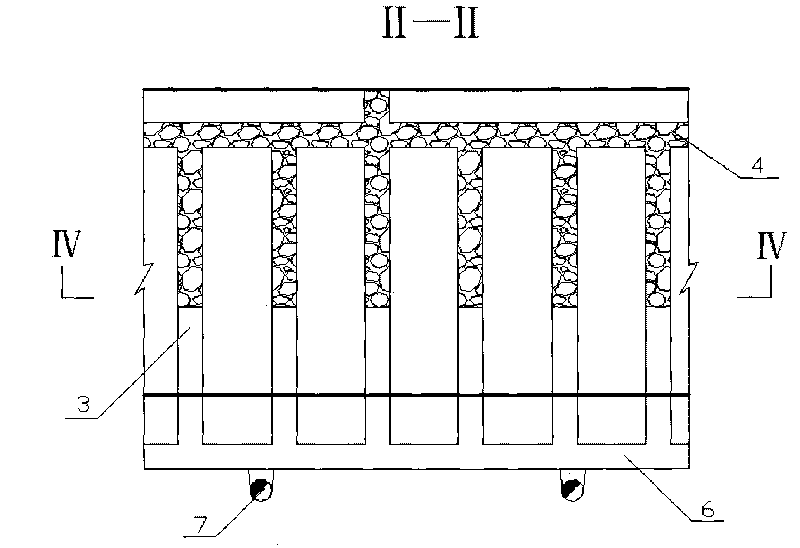

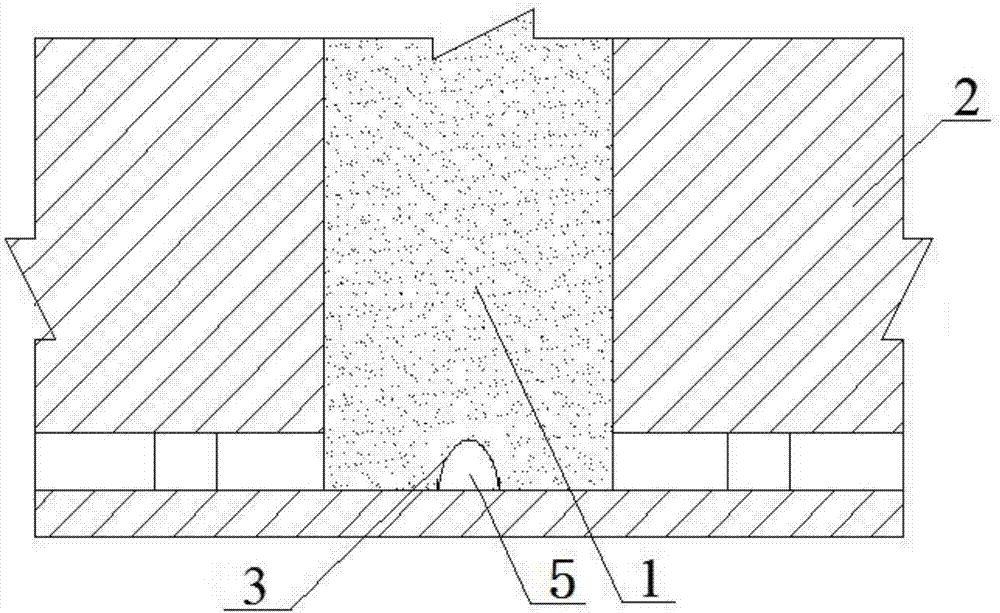

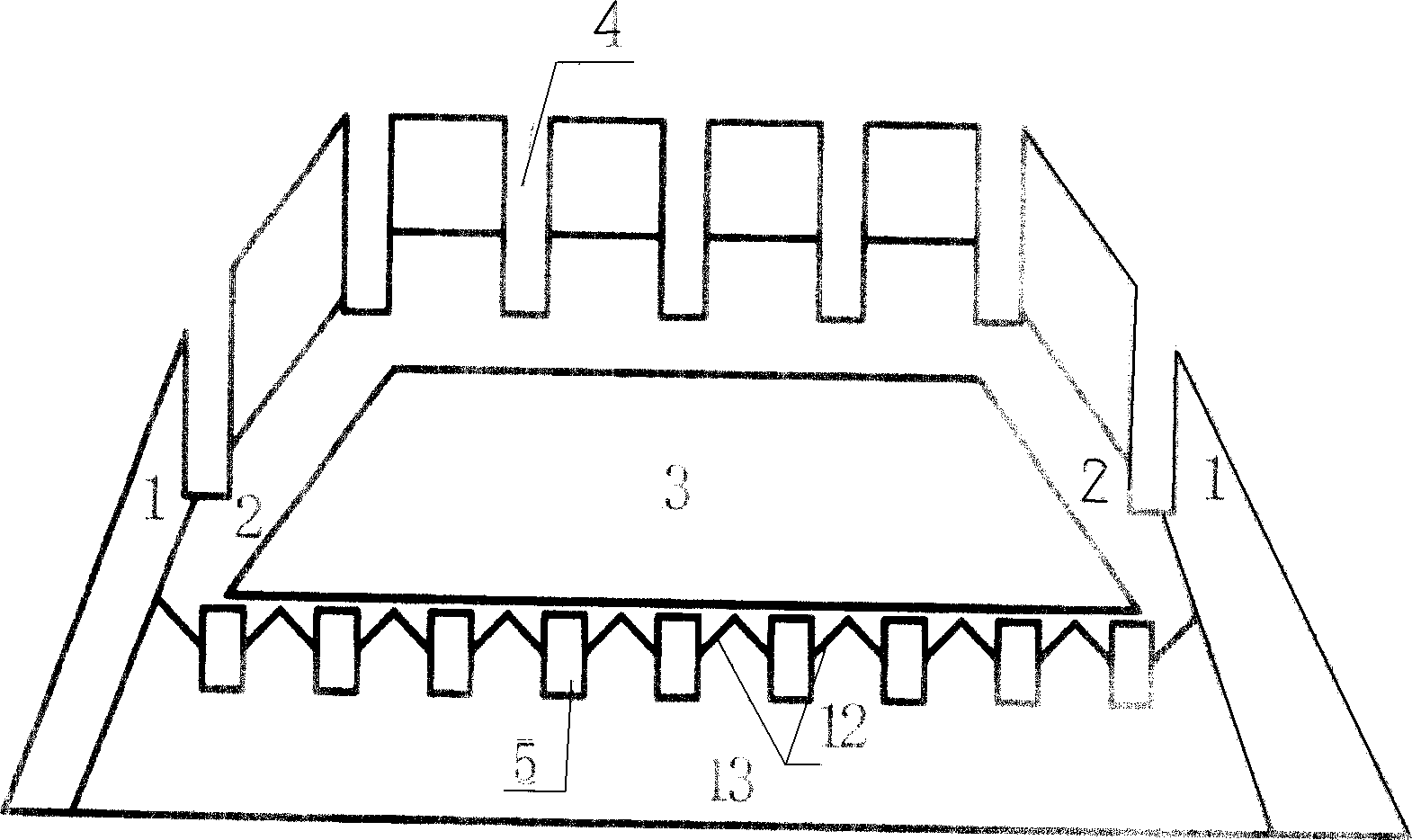

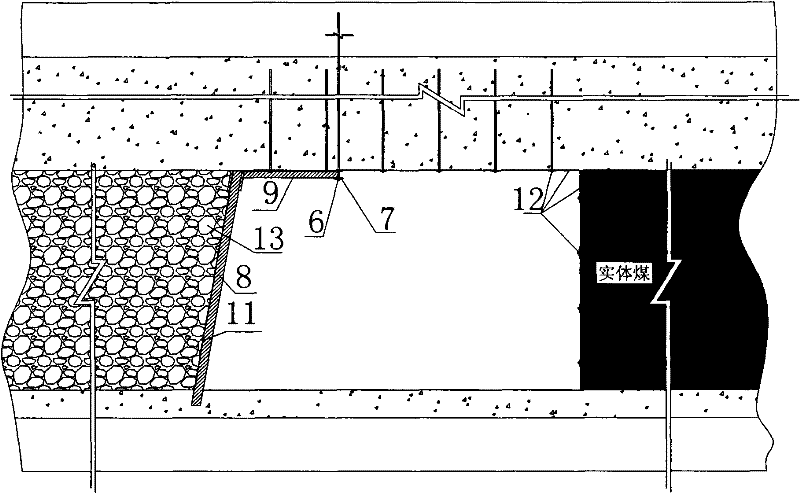

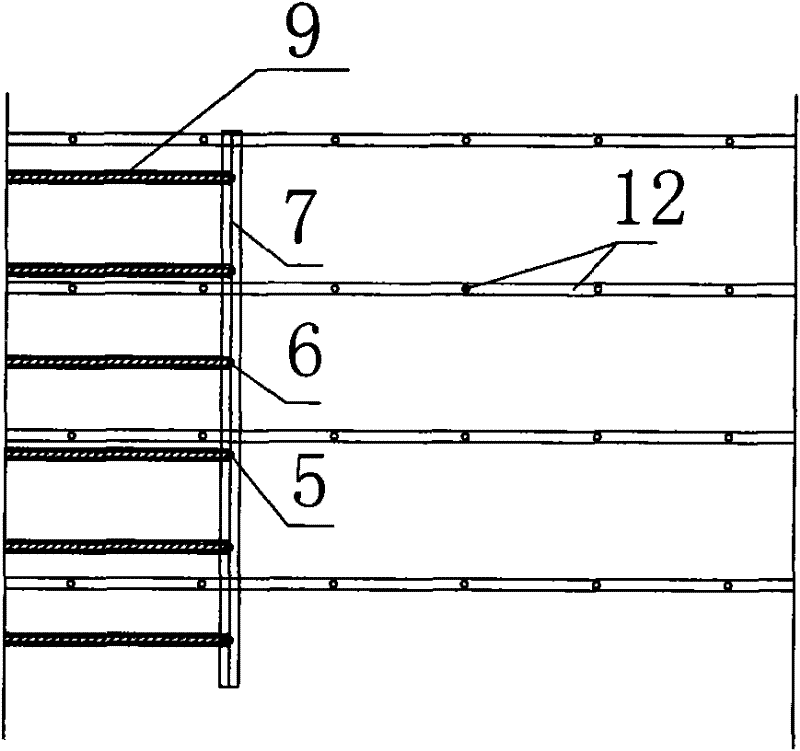

Construction method of gob-side entry retaining wall of solid filling coal mining

InactiveCN104088662AImprove recovery rateSave excavation costsMaterial fill-upSingle supportRetaining wall

The invention discloses a construction method of a gob-site entry retaining wall of solid filling coal mining. The retaining wall is composed of a gangue-piled wall and a compact cementing filling body. The construction method comprises the following steps: cleaning float coal close to an end head after mining and removing frame at a working face; arranging a row of single supporting columns at inner side of a roadway, close to a gob; arranging a wooden backboard at the gob side, close to the single supporting columns; connecting the backboard with the top and bottom; fixing the backboard to the single supporting columns through iron wires; piling the gangue wall at the gob side, close to the backboard; filling the gangue and cement mixing filling material into the gob at the back of two brackets of the gangue-piled wall after the gangue wall is piled; compacting through a rammer compactor to form the compact cementing filling body. With the adoption of the method, the recovery ratio of coal resources can be raised; in addition, the operation at the filling working surface is simple and convenient to carry out, and is also safe and reliable, and high practicability is also brought.

Owner:CHINA UNIV OF MINING & TECH +1

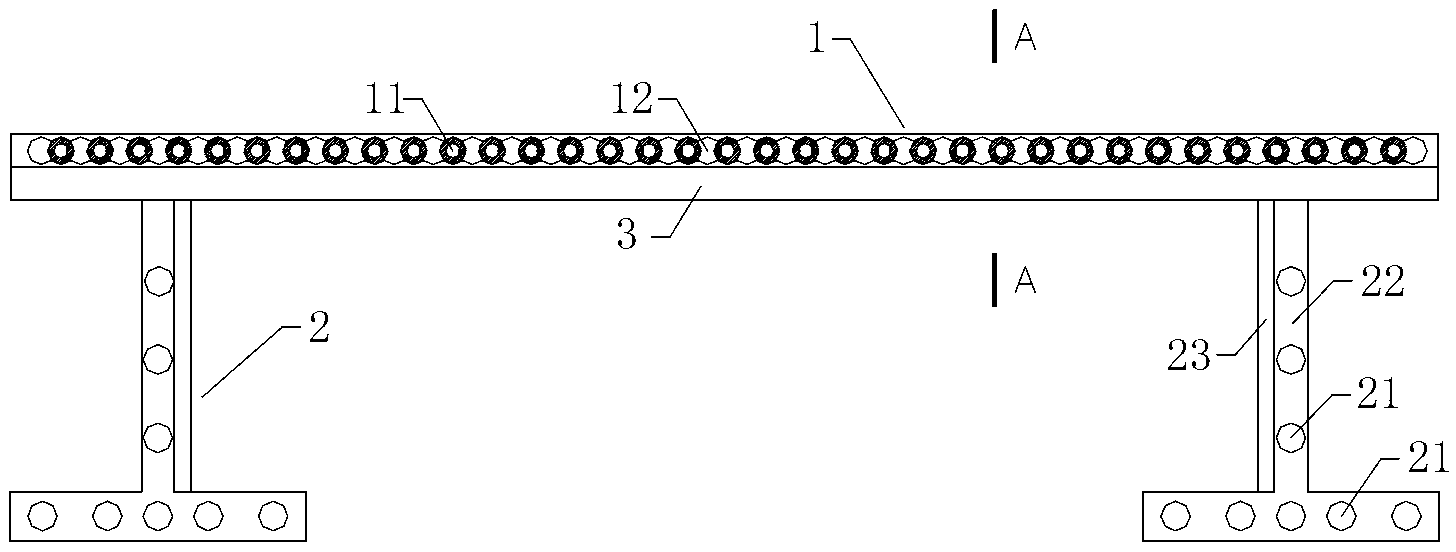

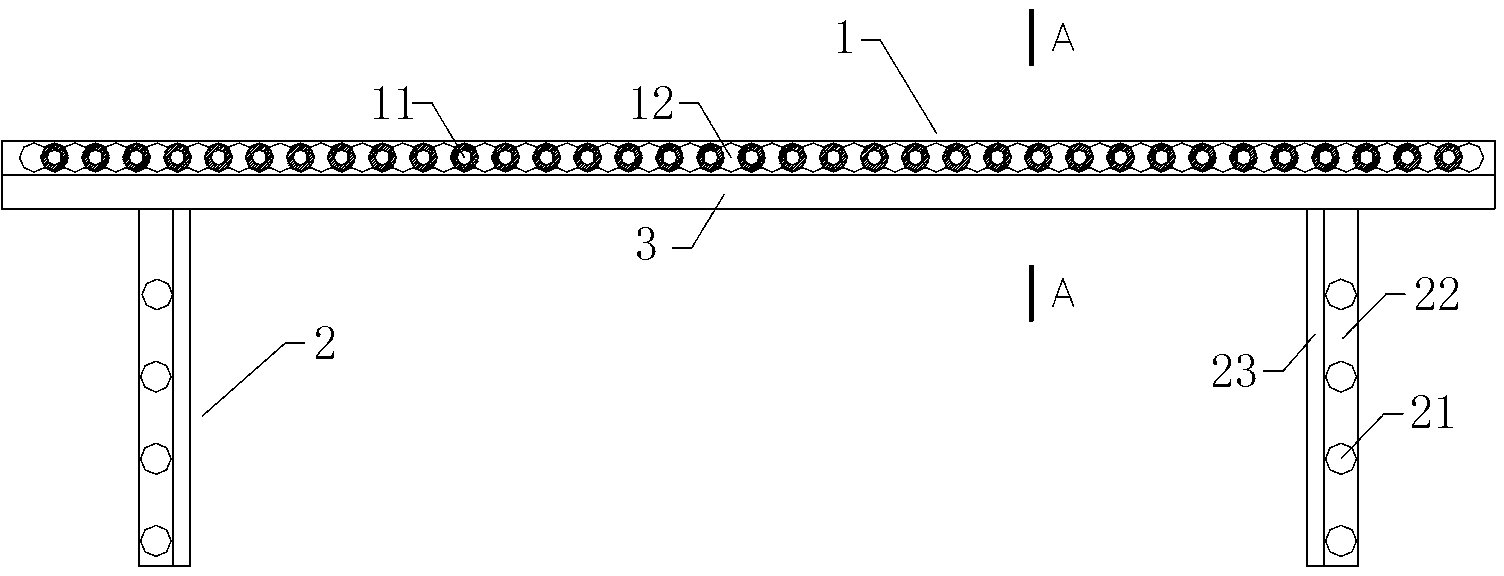

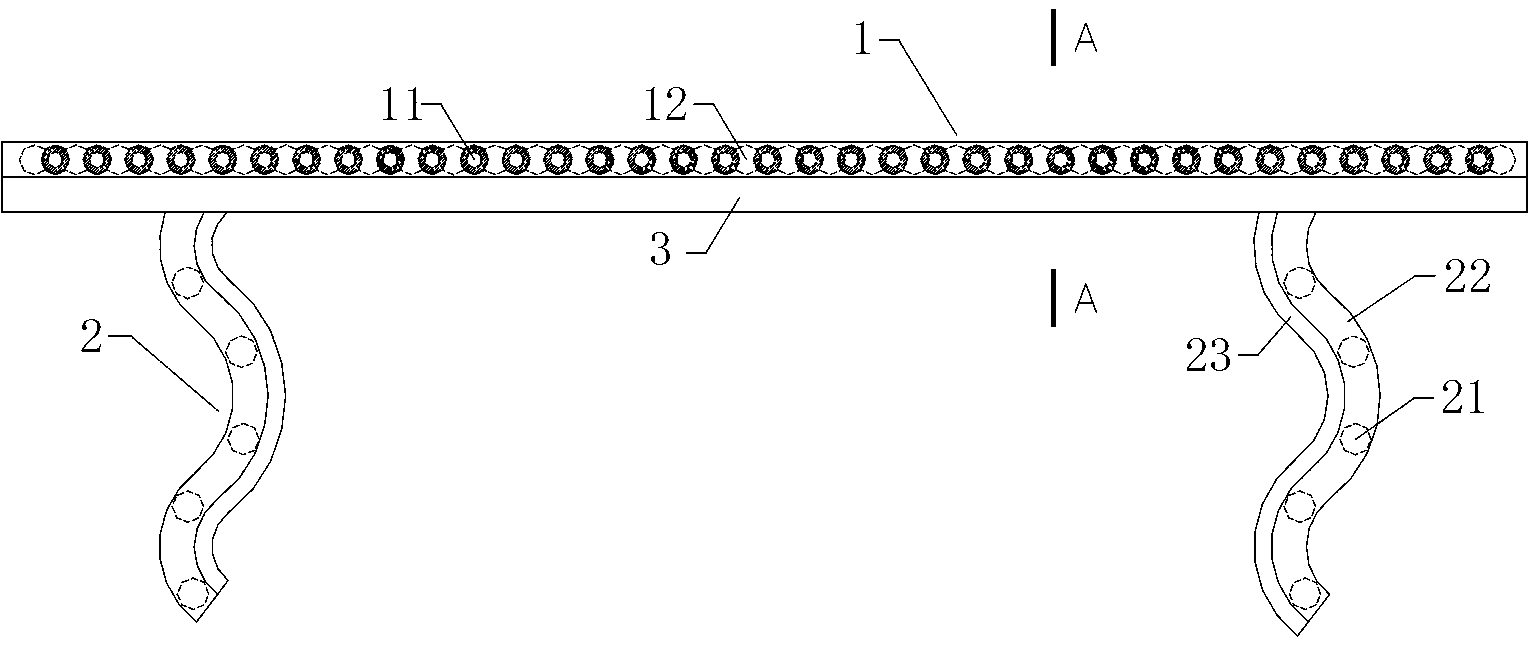

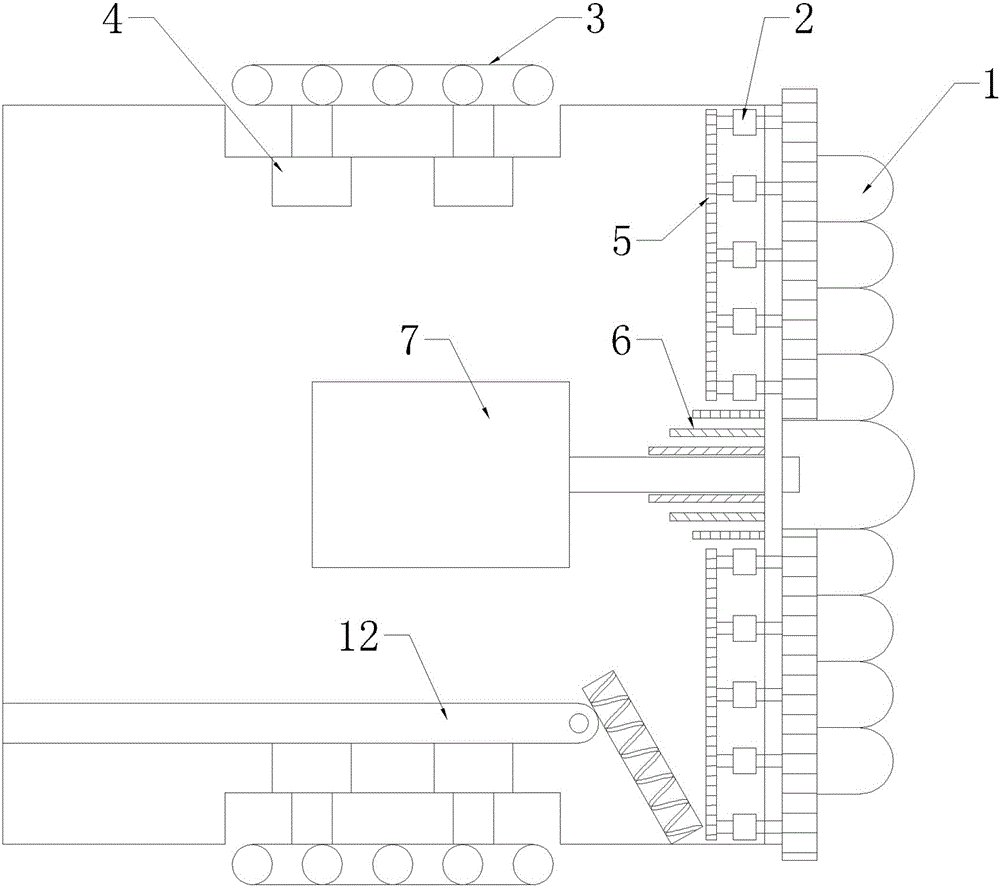

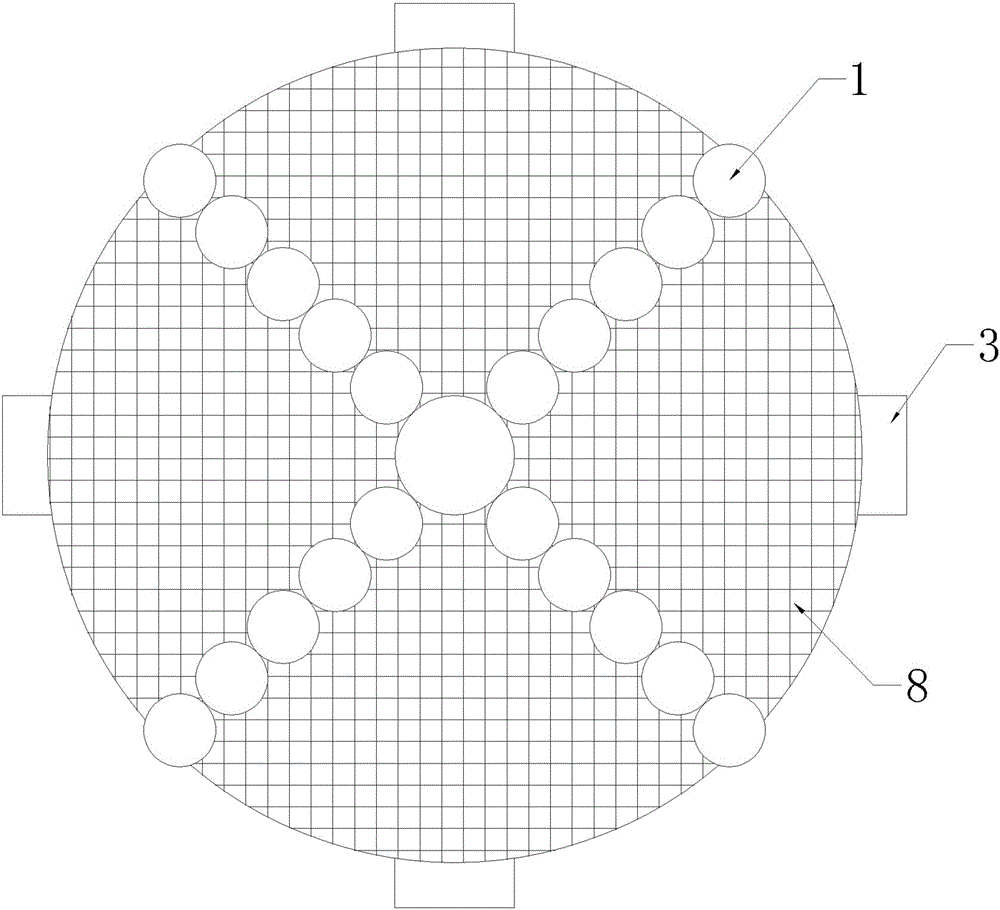

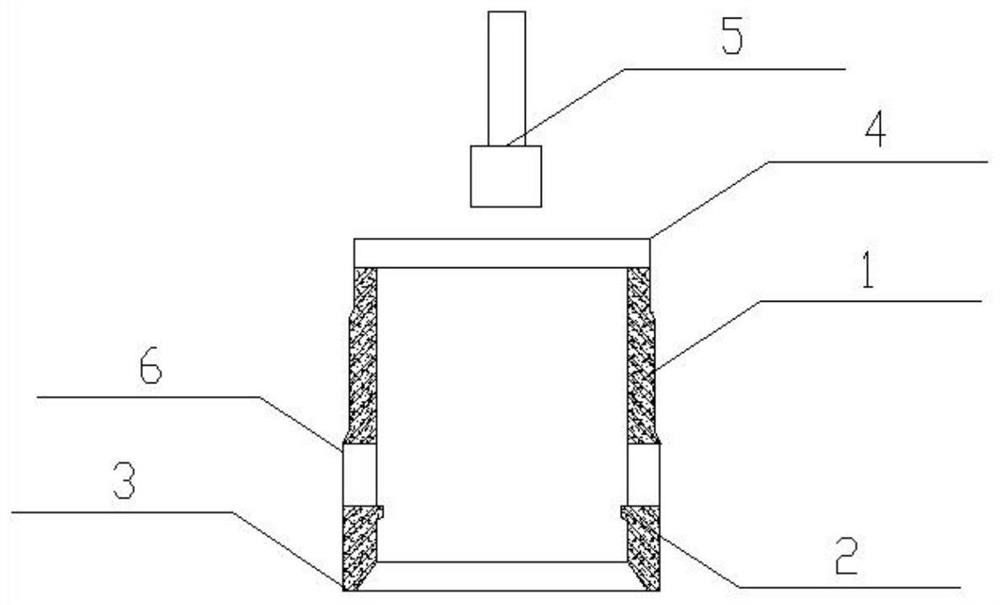

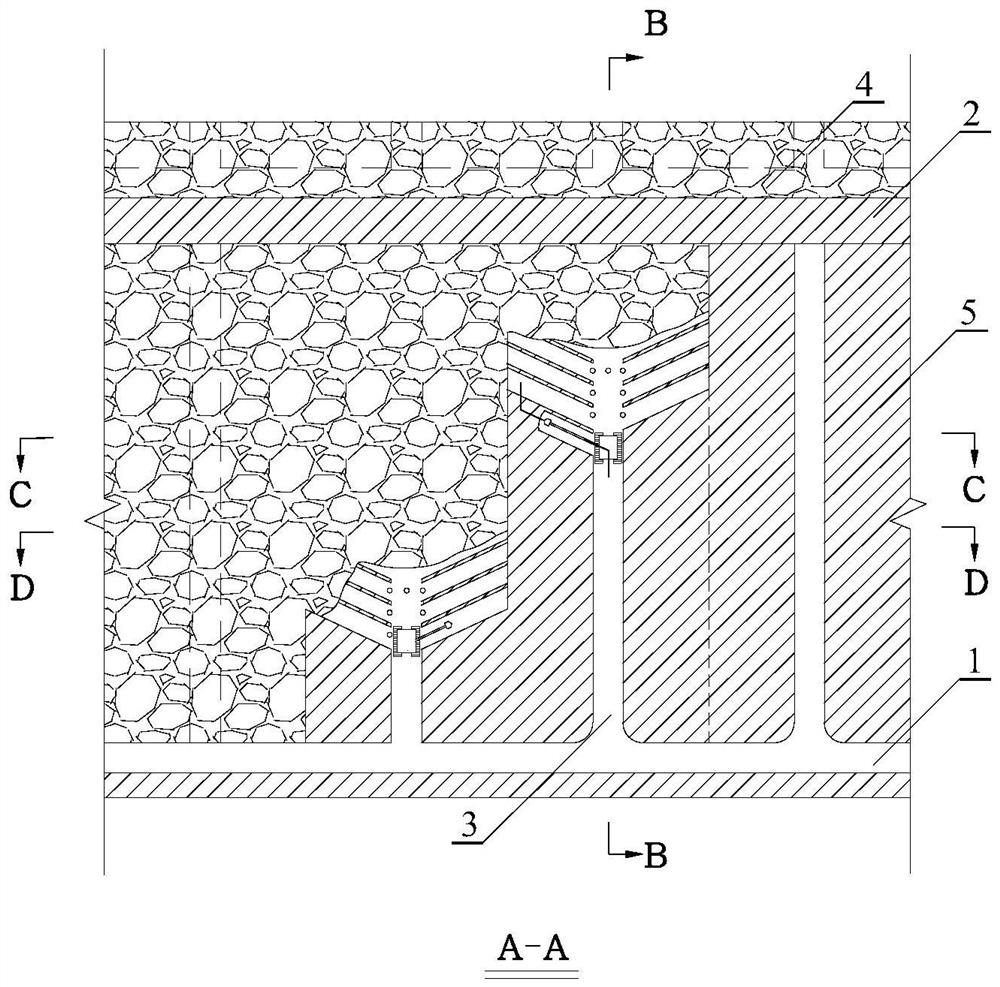

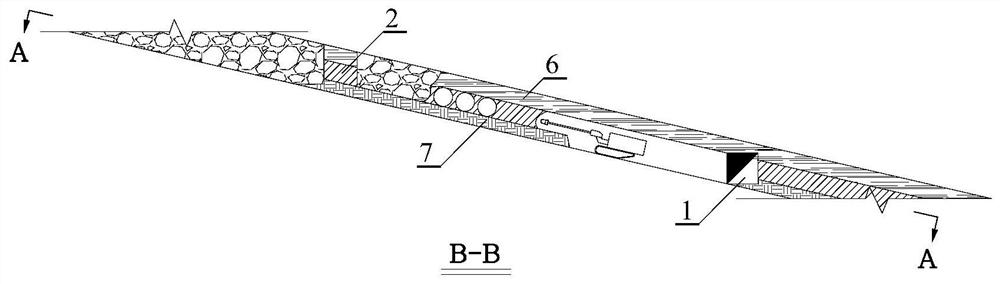

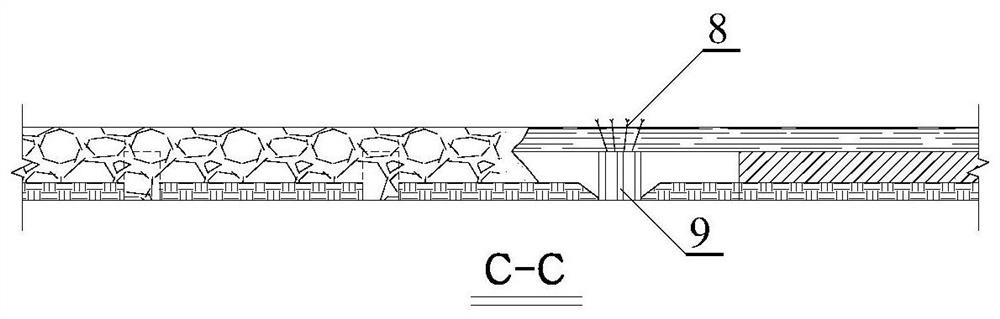

Subdepot pier-type foundation pit support structure and construction method

InactiveCN103074899AAct quicklyReduce the long side effectExcavationsEngineeringBuilding construction

The invention discloses a subdepot pier-type foundation pit support structure and a construction method; the structure comprises soil-retaining and water-stopping row piles, piers and waist beams; at least two piers are arranged; the piers and the soil-retaining and water-stopping row piles are connected through the waist beams; the soil-retaining and water-stopping row piles comprise soil-retaining piles and water-stopping piles which are lined vertically and ring beams which are arranged on the tops of the soil-retaining piles and the water-stopping piles; each pier comprises a pier pile, a pier cover beam and an inclined support; the piers are lined vertically; the pier cover beams are arranged on the tops of the pier piles to connect all the pier piles; one ends of the pier cover beams are connected with the waist beams; each pier pile comprises an upper pier pile which is arranged at the upper part and a lower pier pile which is arranged at the lower part; and one ends of the inclined supports are connected with the waist beams, and the other ends of the inclined supports are connected with the upper pier piles. According to the subdepot pier-type foundation pit support structure and the construction method, the support in a foundation pit is eliminated, the excavation is convenient and the construction speed is high.

Owner:周文松

Method for exploiting soft and broken ore body

InactiveCN101718196AImprove stabilityGuaranteed recovery effectUnderground miningSurface miningStress concentrationSpelunking

The invention discloses a sublevel caving method for exploiting a soft and broken ore body without a sill pillar. By using the method, the problem that developing roadways are destroyed by ground pressure is effectively solved, the stability of the roadway engineering and the utilization rate of the developing roadways are improved, the support cost is lowered, the operational safe condition is improved, the mining cost is lowered, and the ore recovery is raised. The technical proposal comprises the following key points: depressurizing by the sublevel caving method without a sill pillar, firstly tunneling and backstoping a first-section ore body, transferring the pressure above an area to be backstoped of next section to the rock mass around the ore body to ensure no over high stress concentration in the backstoping area so as to form a stress decrease area, and excavating in the stress decrease area, wherein the first section uses a large backstoping roadway distance to ensure the stability of the backstoping roadway. The invention is suitable for exploiting a soft and broken ore body in the high-stress area by the sublevel caving method without a sill pillar.

Owner:KUNMING UNIV OF SCI & TECH

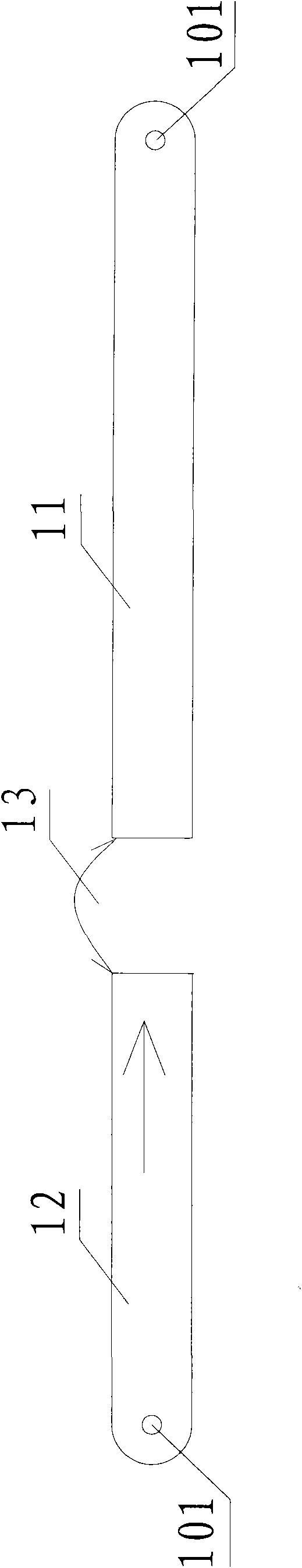

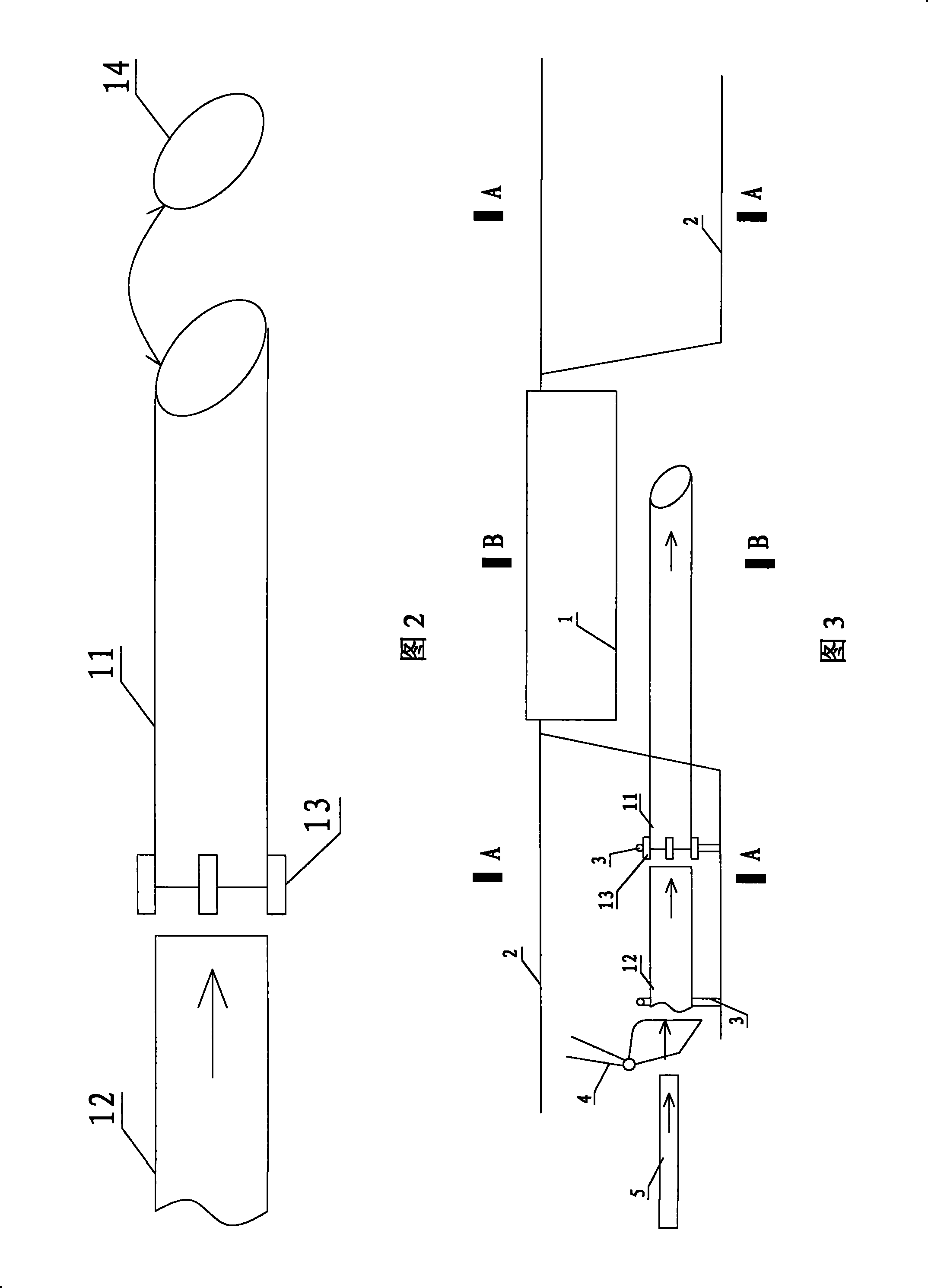

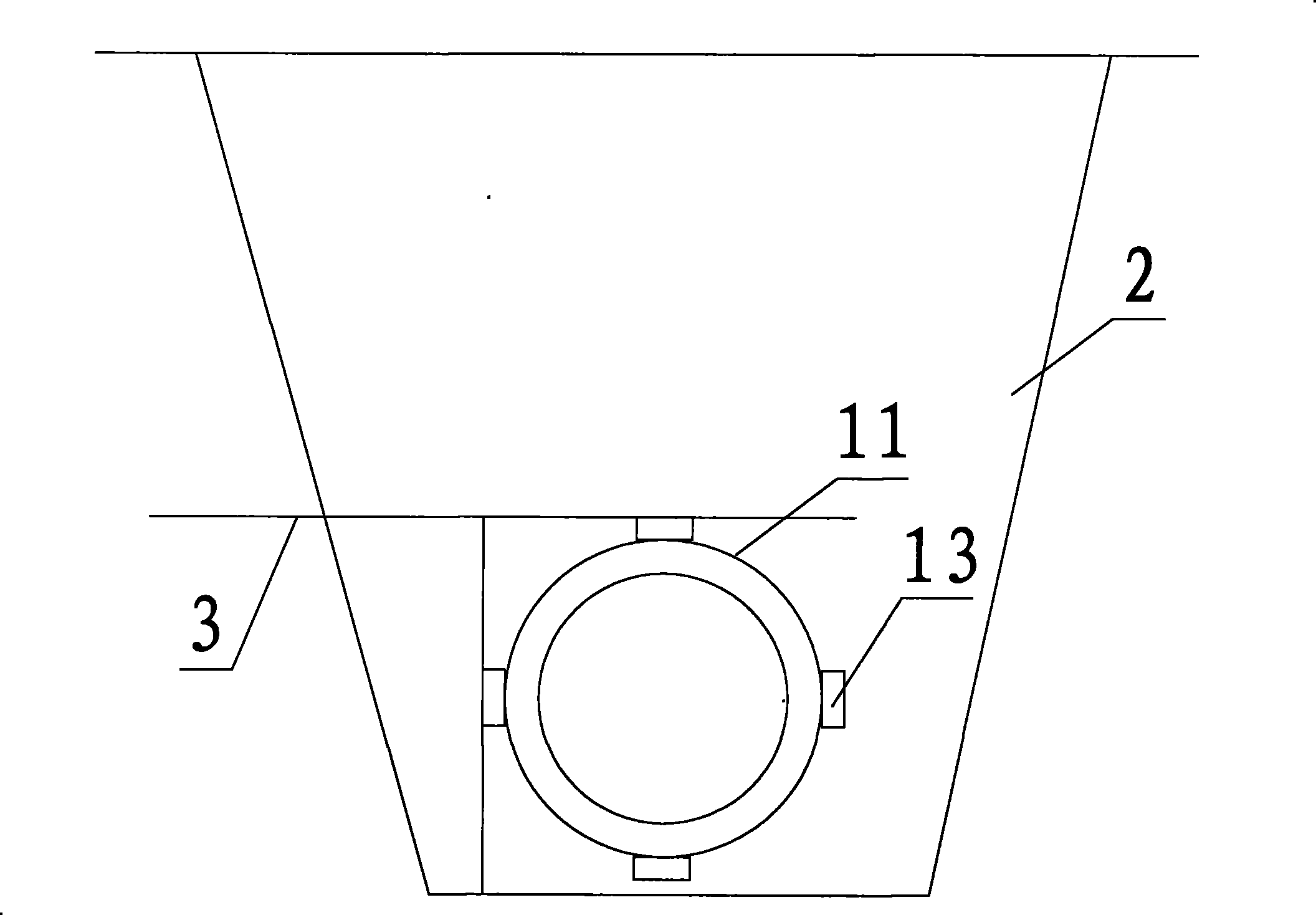

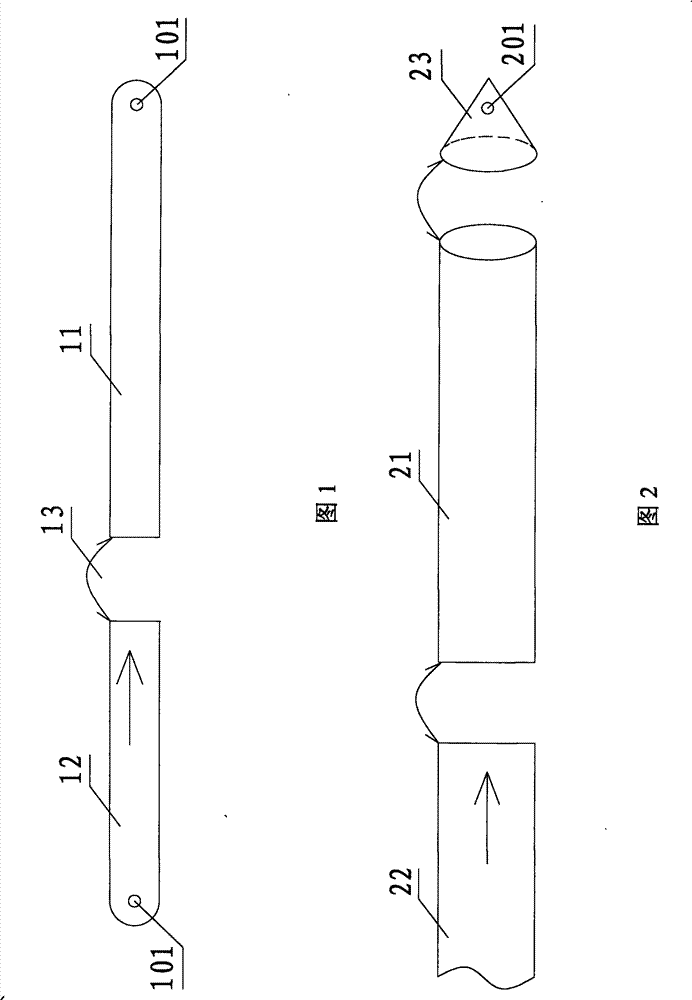

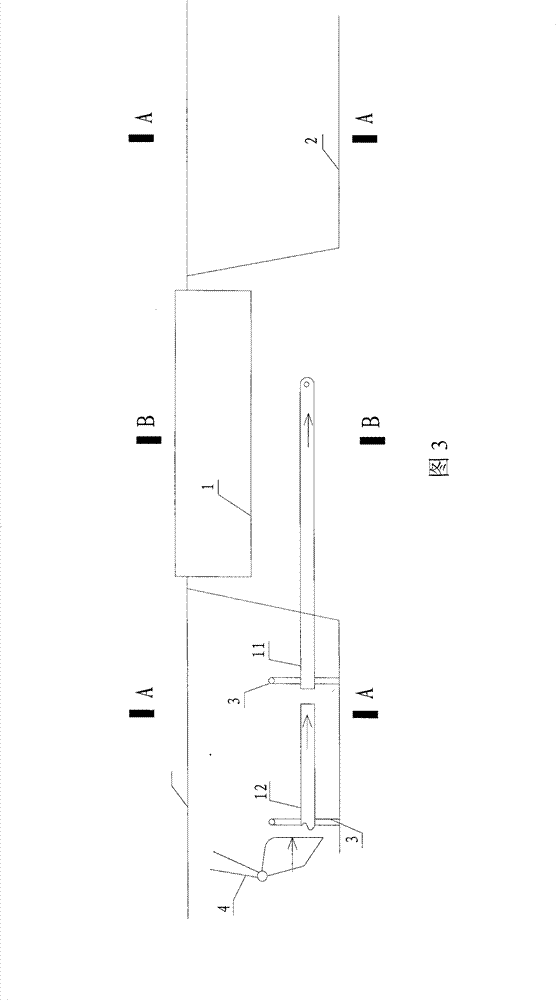

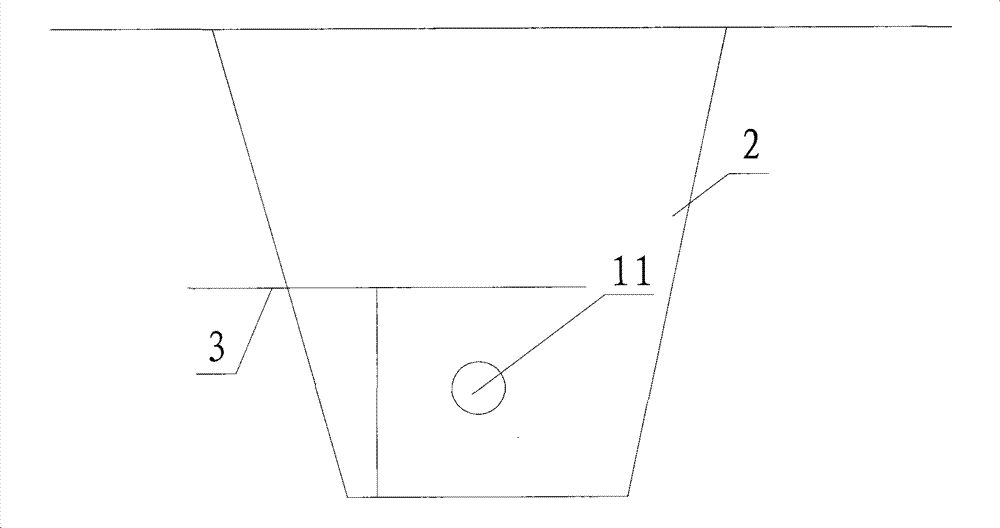

Pull tube mounting method of passing pipeline

ActiveCN101852312AProtection securitySave excavation costsPipe laying and repairArchitectural engineeringGuide tube

The invention relates to the pipeline construction method field of a metallurgy system, in particular to a pull pipe mounting method of a passing pipeline, which comprises the following steps of: unreeling a pipeline; digging pilot trenches; making the pipeline; popping conducts; connecting steel wires; pulling the conducts and the steel wires; pulling sleeves; and penetrating and mounting a construction pipe. The pull pipe mounting method of a passing pipeline is characterized in that when the conducts are popped, the front conduct is popped in by top pressing equipment (4); and then, the rear conduct (12) is popped in; and when the sleeves are pulled, the conducts and the sleeves are connected, the front conduct (11) is pulled, and the rear sleeve (22) is popped in until the front sleeve (21)passes out of a pilot trench (2) at the other side. The invention has low construction cost, short construction period, high mounting quality and high production efficiency.

Owner:MCC5 GROUP CORP SHANGHAI

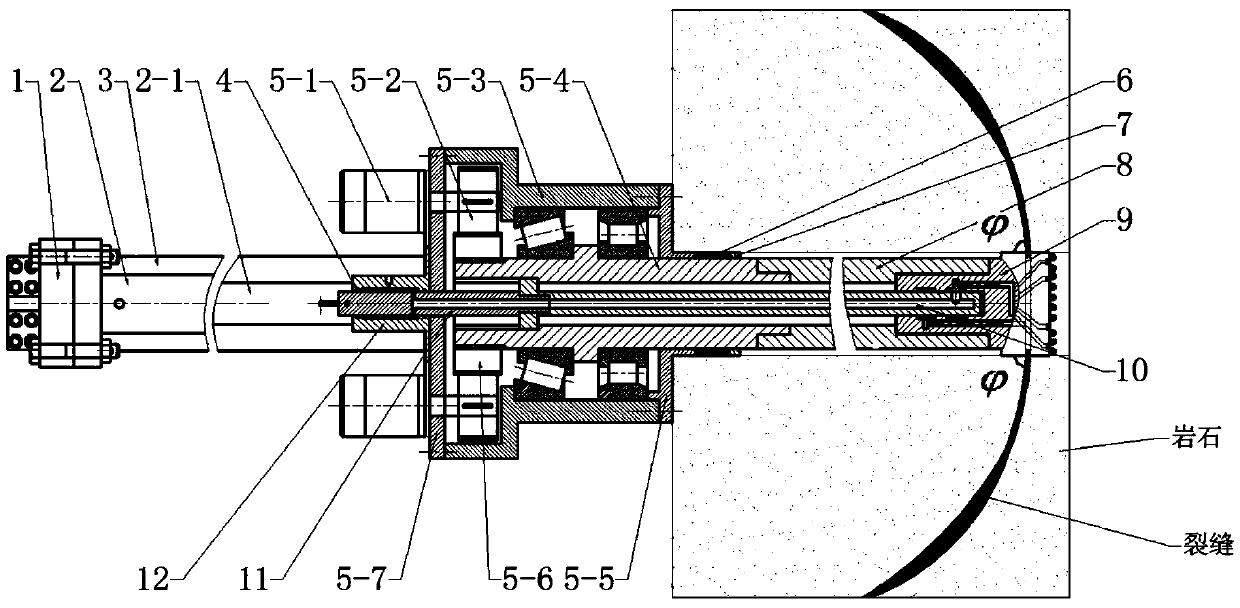

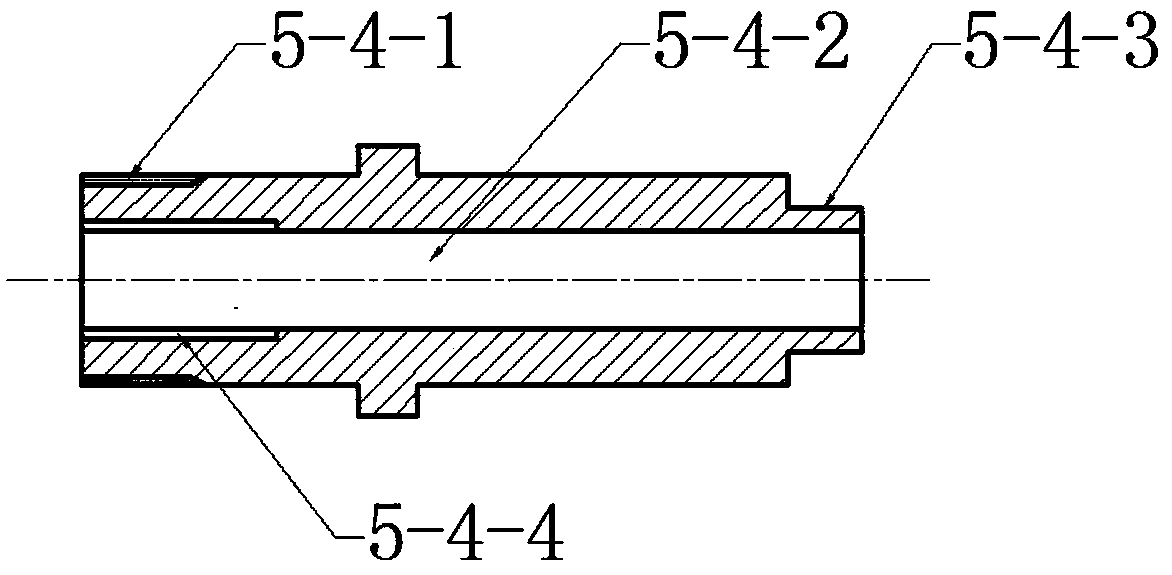

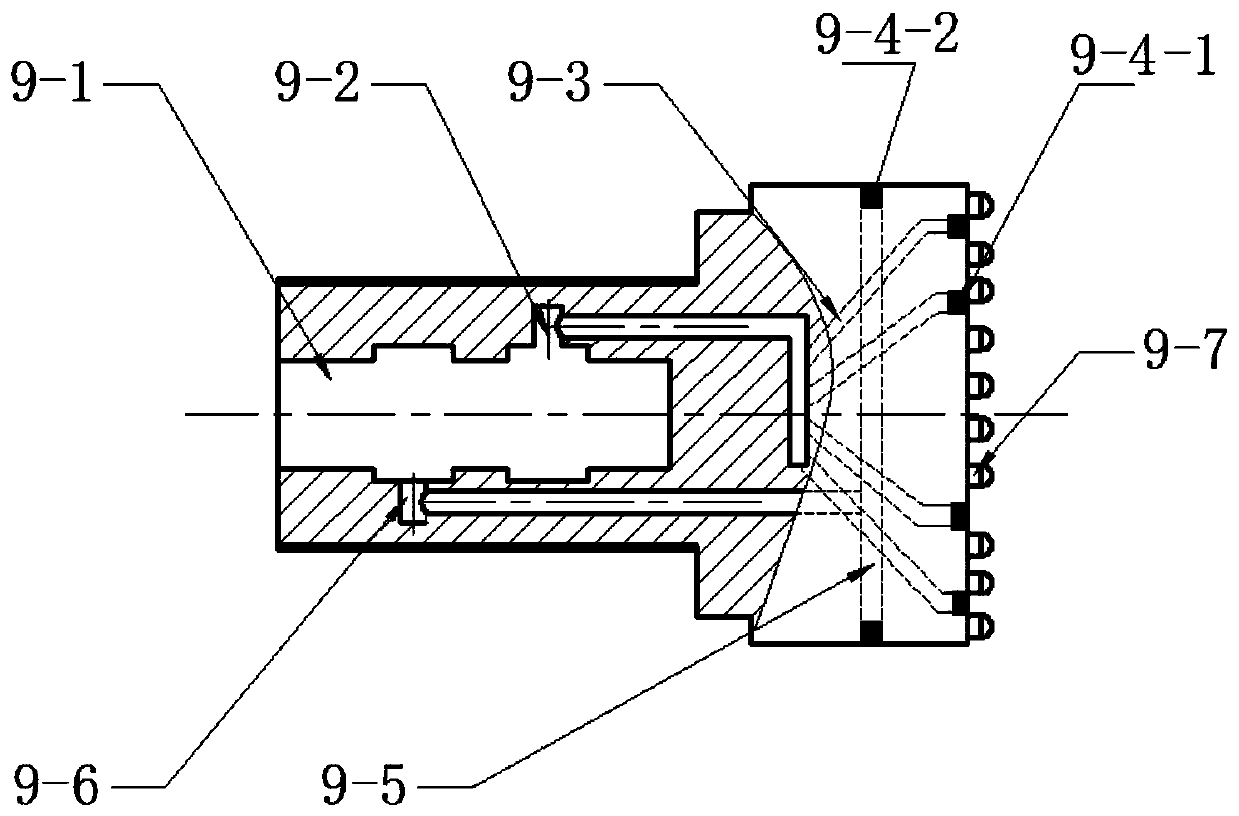

Drilling, joint-cutting and fracturing integrated device for hard rock

The invention discloses a Drilling, joint-cutting and fracturing integrated device for hard rock. The device comprises an oil cylinder supporting base, a pushing oil cylinder, a guide rail, a swing driving device, a rubber ring, a reverse extruding ring, a drill rod, a drill head, a flowing passage shaft, a rotary sealing shaft and a rotary sealing sleeve; the oil cylinder supporting base is fixedto the back end of the guide rail, the swing driving device is slidably connected with the guide rail, and the pushing oil cylinder is fixed to the oil cylinder supporting base; a piston rod of the pushing oil cylinder is connected with the swing driving device, the front end of an output shaft is separately connected with the back end of the drill rod, the front end of the drill rod and the backend of the drill head, and the flowing passage shaft installed on the output shaft and in the drill rod is connected with the back end of the drill head; the rotary sealing sleeve is fixed to the back end of the swing driving device, the rotary sealing shaft penetrating through the rotary sealing sleeve is connected with the flowing passage shaft, and the rubber ring is fixed to the front end ofthe swing driving device and connected with the reverse extruding ring. The device can achieve drilling, joint cutting and fracturing integration operation on hard rock, and has the advantages that the capacity of crushing hard rock (f)10) is high, the efficiency is high, and the quantity of produced dust is low.

Owner:CHINA UNIV OF MINING & TECH

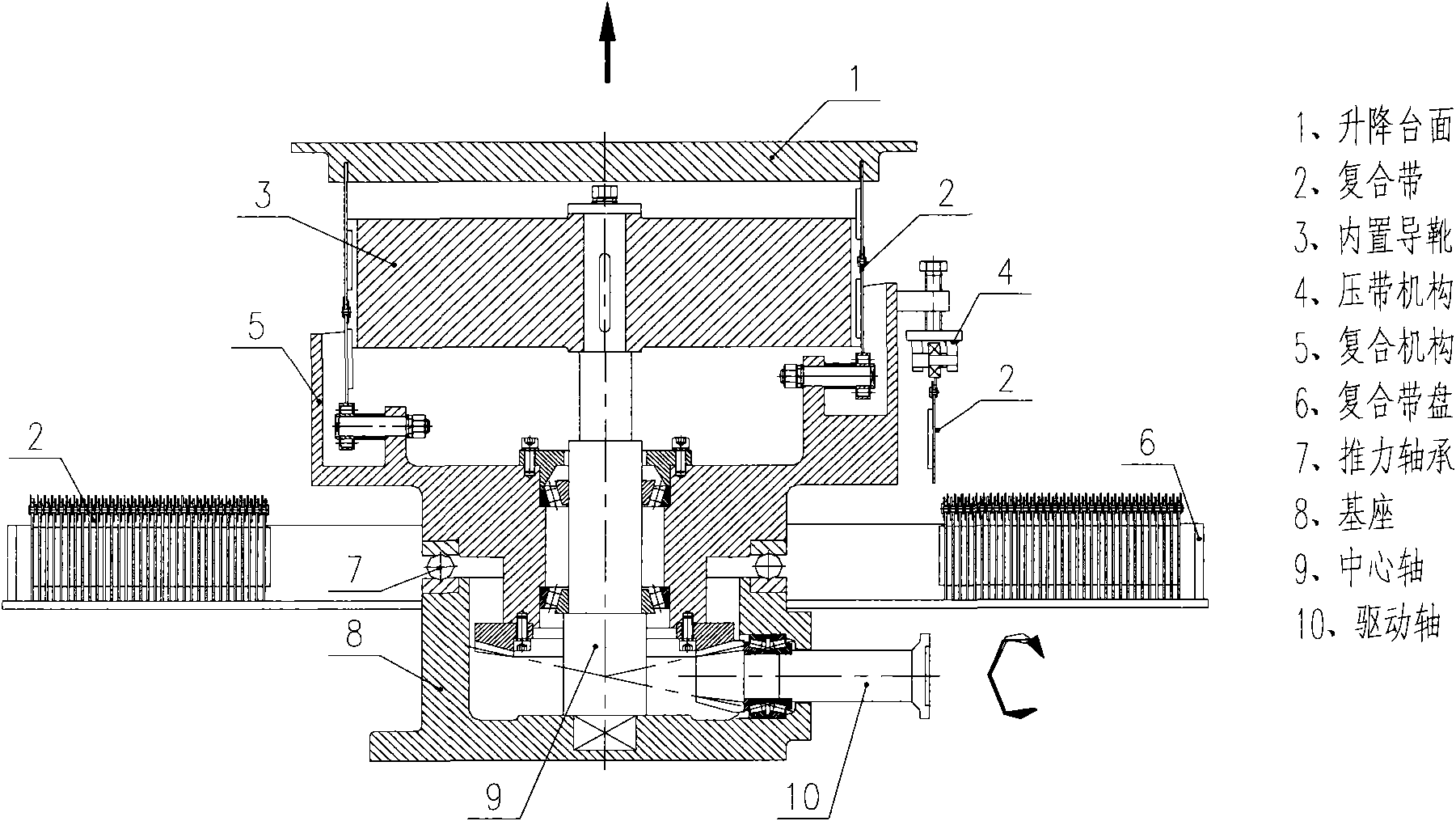

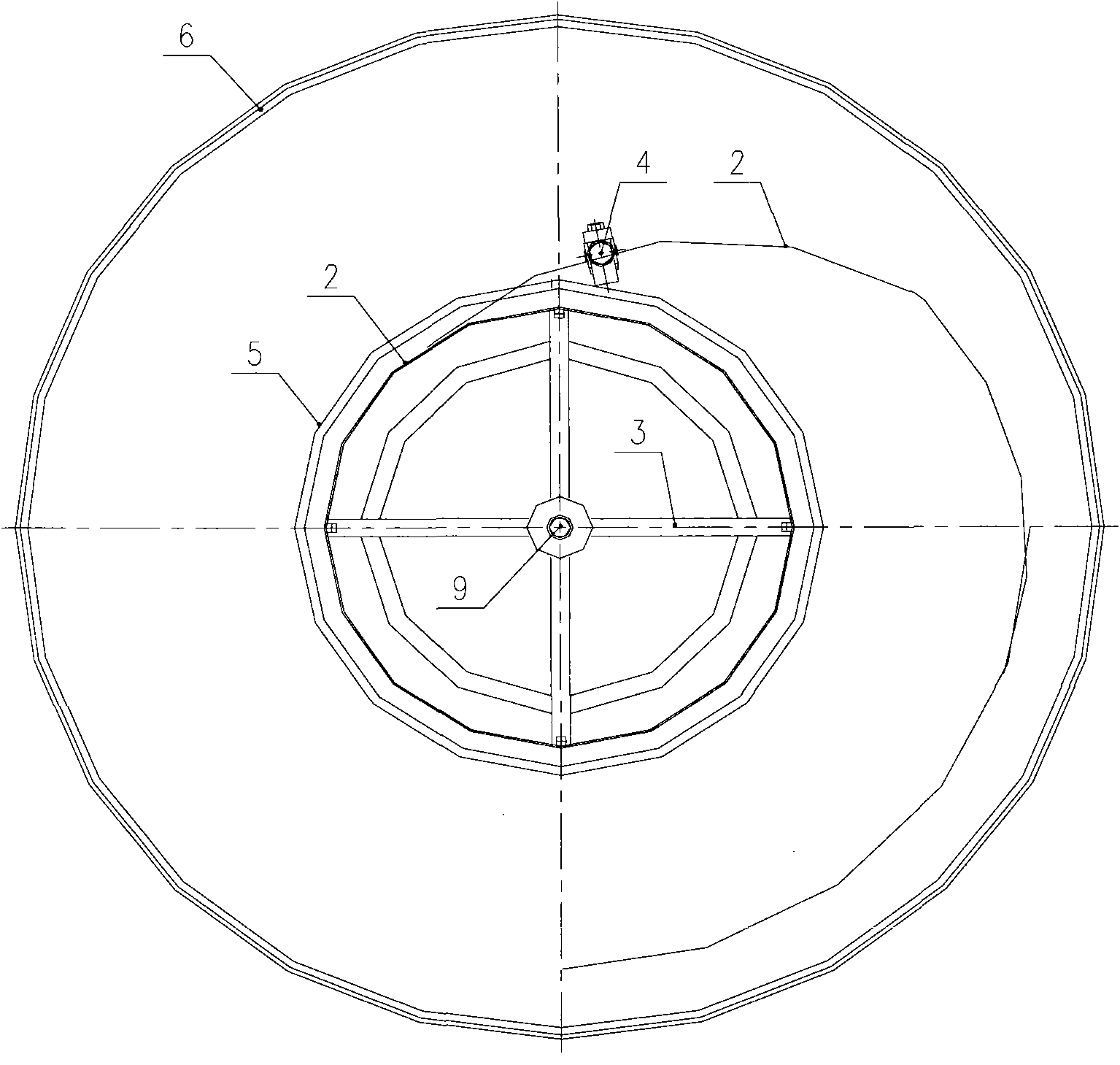

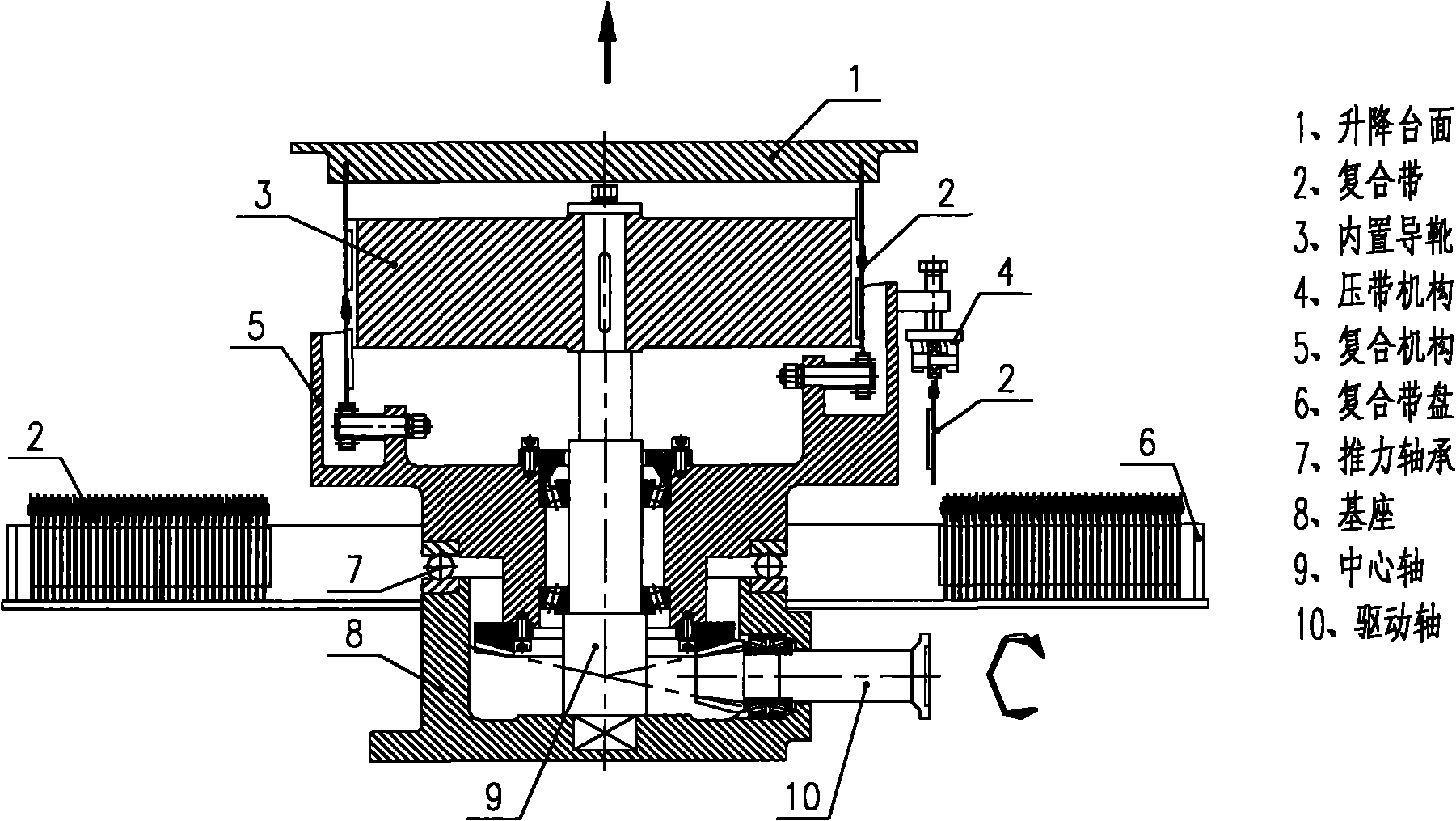

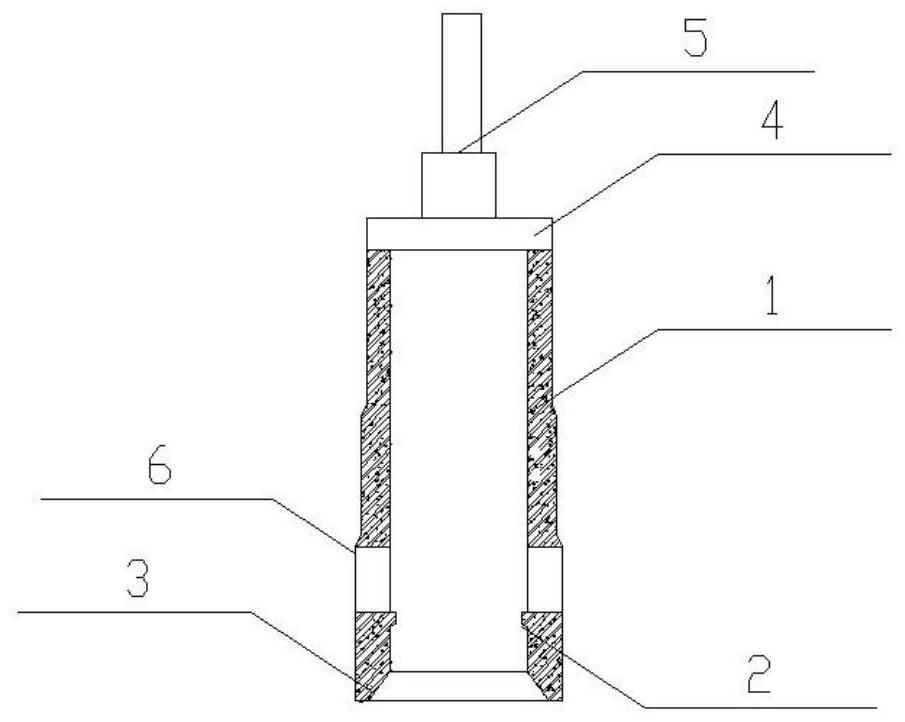

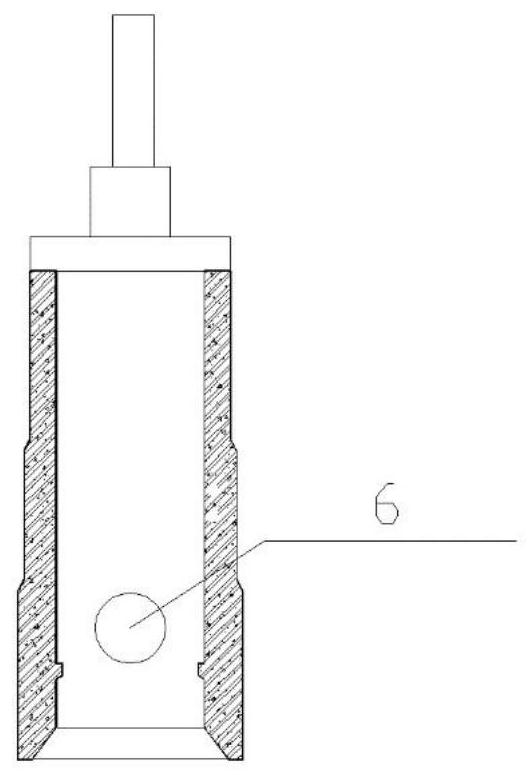

Single liftable compound pipe

The invention provides lifting equipment, which has a self-locking function and low height. In particular, a compound band 2 forms the rising motion of a single liftable compound pipe through a combined motion of a compound mechanism 5 and forms the falling motion of the single liftable compound pipe through decomposed motion of the compound mechanism 5. The single liftable compound pipe can be kept at the stopped position for long time and has shallow foundation pit.

Owner:郑仙丽

Tunneling method capable of weakening hard rock strength

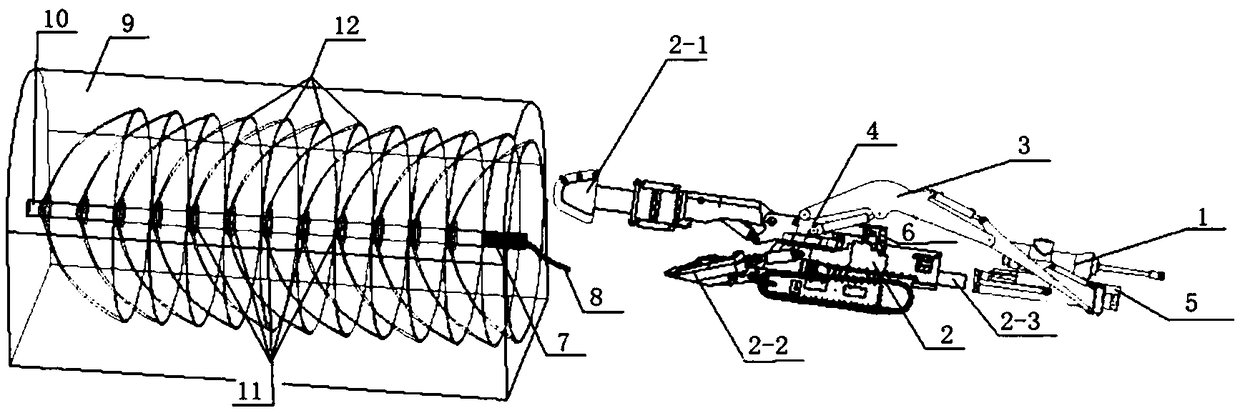

ActiveCN108691508ADrilling heightImprove efficiencyLiquid/gas jet drillingSlitting machinesEngineeringHigh pressure water

The invention discloses a tunneling method capable of weakening hard rock strength. According to the method, a tunneling machine, an integrated grinding jetting drilling machine with the tunneling machine as a carrier, and a high-pressure water pump are arranged on a tunneling working surface; the integrated grinding jetting drilling machine is adopted to form drilled holes in a rock body, and a series of conical crack clusters are formed through cracking cutting on the basis of hole drilling; a high-pressure hole sealing device is used for sealing the tunneling surface for a distance, the high-pressure hole sealing device is communicated with a high-pressure water pump through a water inlet pipe, the characteristic that the rock body is resistant to pressure but not resistant to drawing is utilized, the conical crack clusters in the rock body are expanded to form a dense conical crack net, and therefore the rock strength is weakened; a tunneling machine cutting head is adopted to cutthe rock which has an internal conical crack net, the tunneling efficiency is greatly improved, the service life of the tunneling machine can be prolonged, and the tunneling cost is reduced.

Owner:CHINA UNIV OF MINING & TECH

Smoothwall blasting method for digging tunnel

ActiveCN101799262ASolve the most destructive problemsSimple and economical constructionBlastingDetonatorEngineering

The invention discloses a smoothwall blasting method for digging a tunnel. The method includes the basic processes of marking the shot point, digging and drilling holes, installing the blasting devices, connecting all the blasting devices through detonating fuses, connecting a millsecond detanator and an electric detonator, and finally detonating through a blaster. The method solves the problem of big damage to the wall rocks in the process of digging and blasting the tunnel and is particularly good for controlling over-excavation and under-excavation. The method saves the digging cost and at the same time makes the late support construction of the tunnel simpler and more economic.

Owner:胡铭益

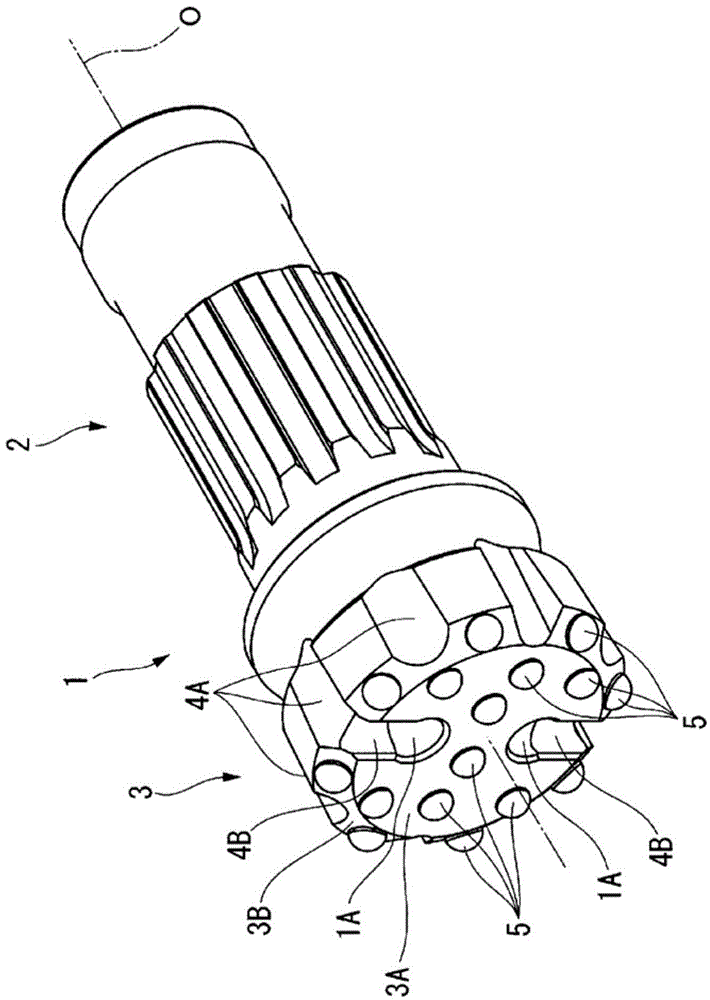

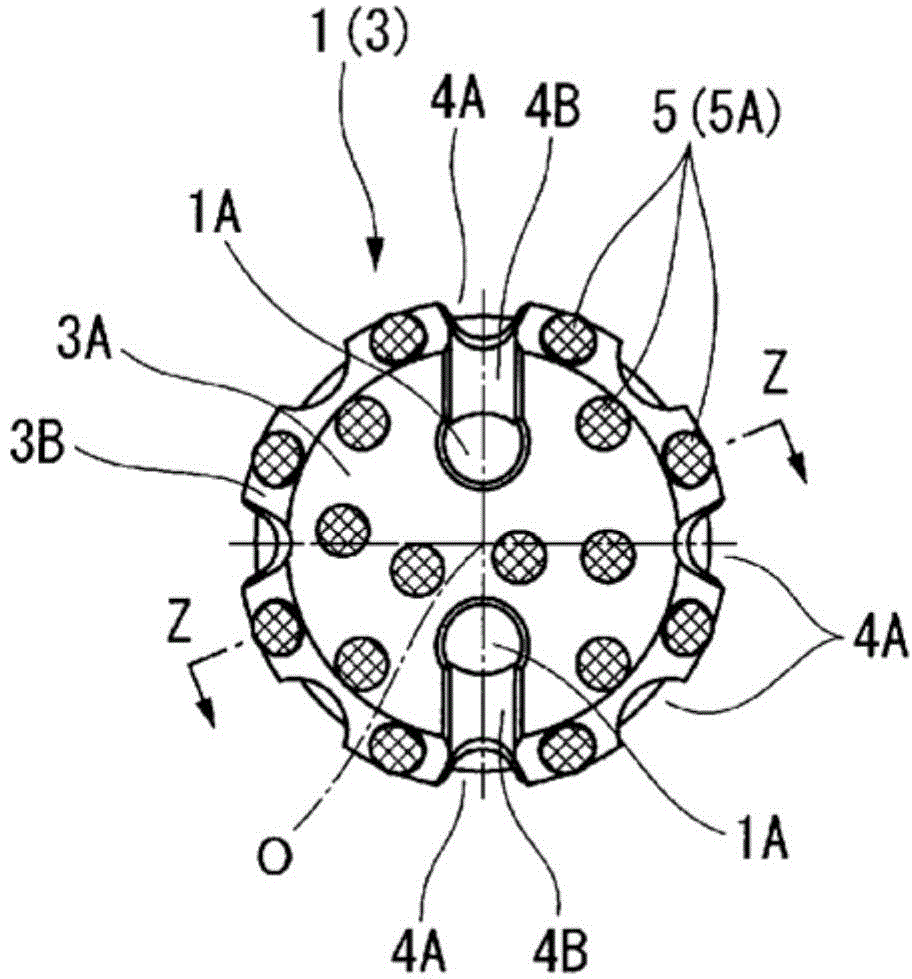

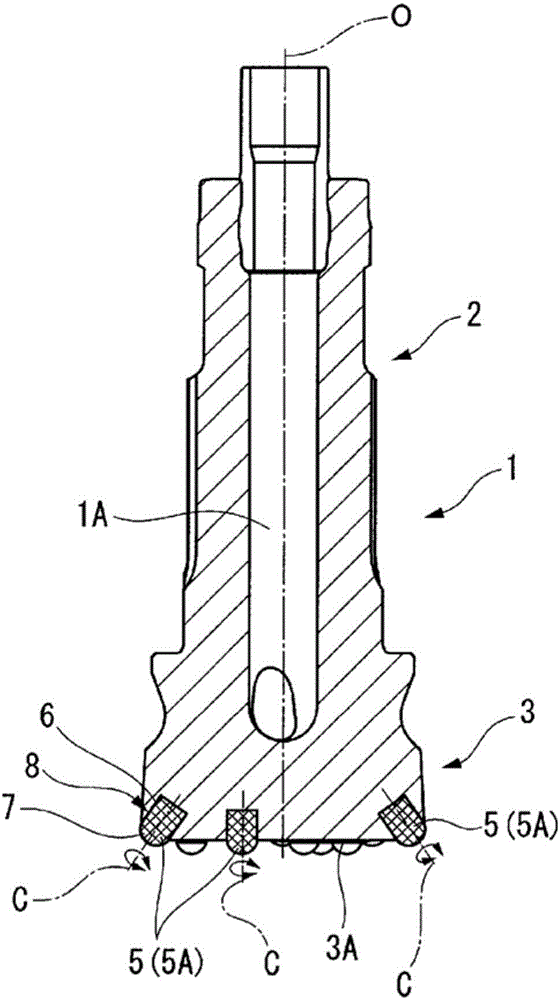

Excavation tool

Owner:RYUKI PRECISION TOOLS CO LTD

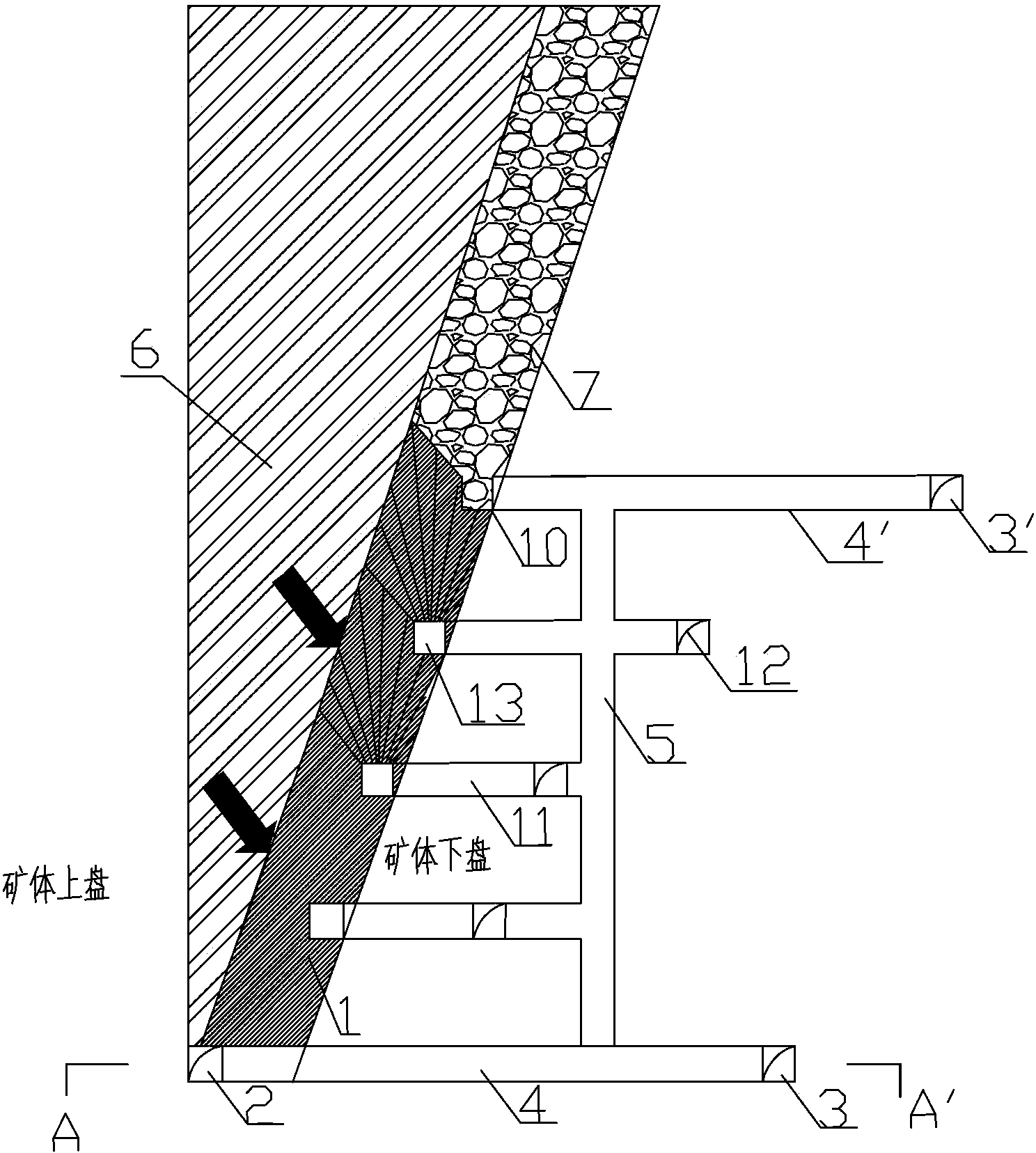

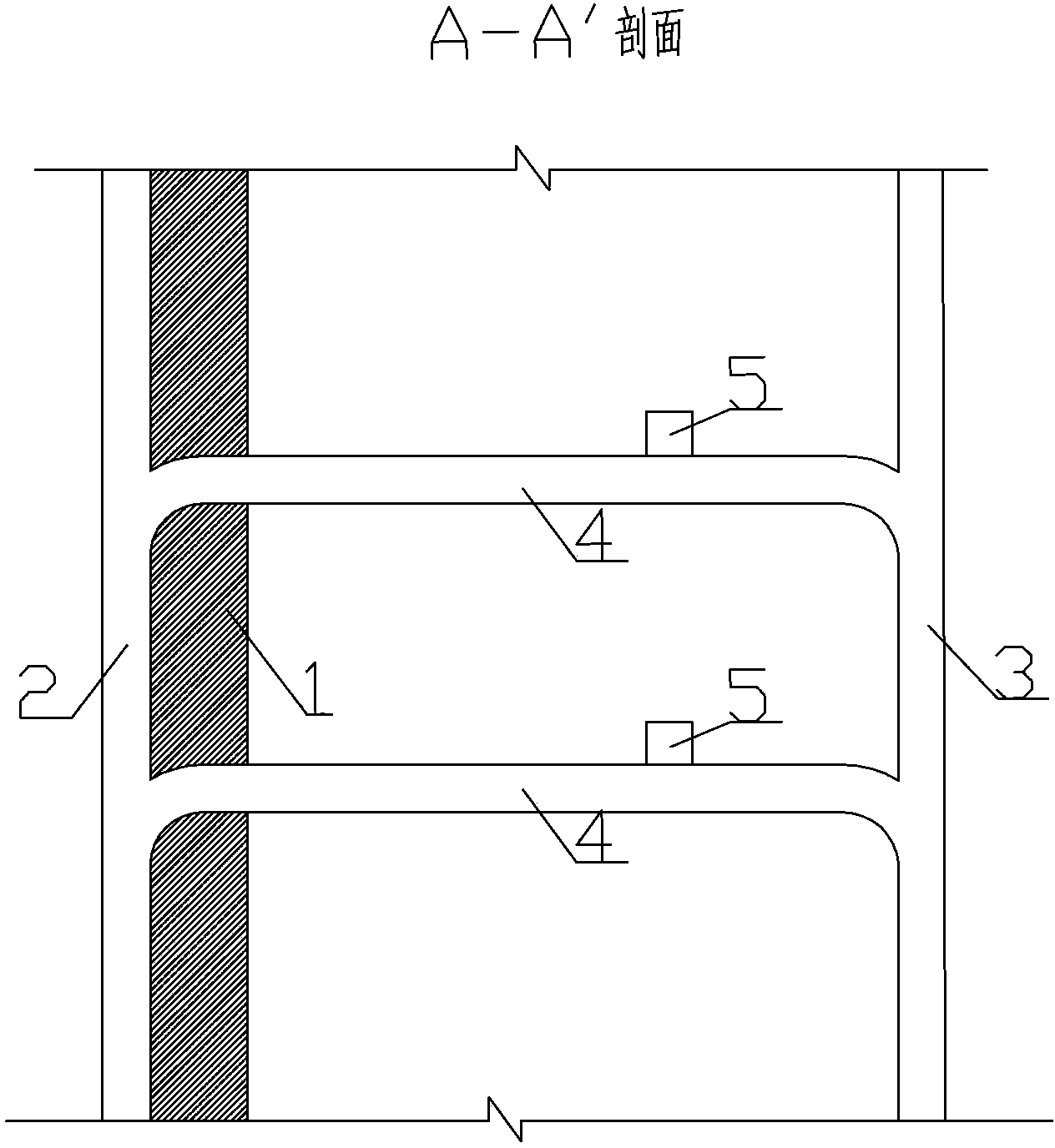

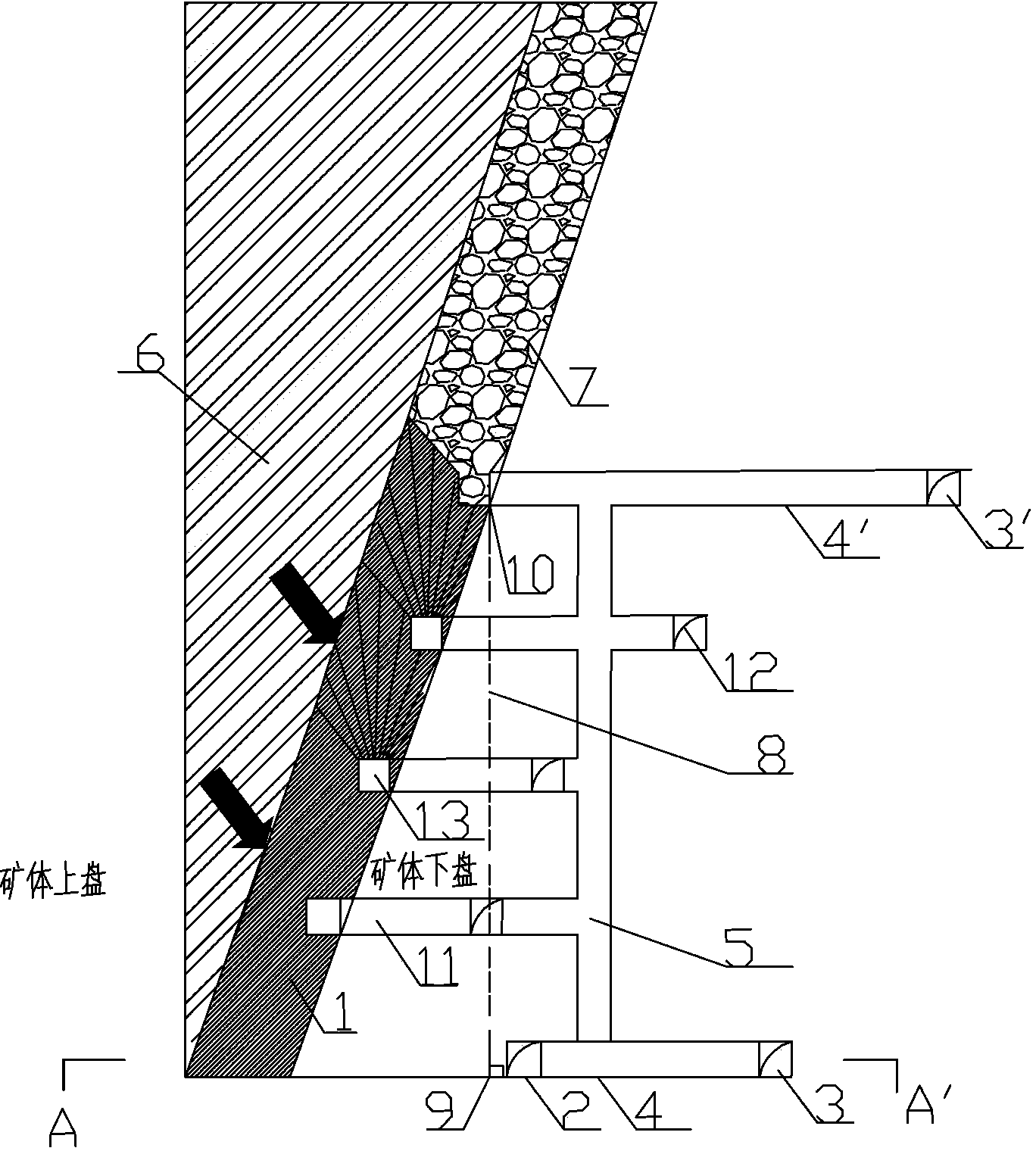

Horizontal transport haulageway for mid-deep and deep mining

InactiveCN103452568ASave excavation costsAvoid additional forceTunnelsUnderground transportDeep miningEnvironmental geology

The invention discloses a horizontal transport haulageway for mid-deep and deep mining, which comprises a haulage level hanging wall haulageway, a footwall haulageway, and an annular haulageway formed by a haulage level transverse drift roadway. The horizontal transport haulageway for mid-deep and deep mining is characterized in that a pressure relief line is made from an angle part of an air return horizontal mining roadway lying side to the transportable horizontal surface; an 90-degree included angle is formed between the pressure relief line and the transportable horizontal surface; an upper side of the hanging wall haulageway is arranged from a boundary of a footwall of an ore body to the outside of the pressure relief line. Through the manner, a position of the horizontal transport haulageway is confirmed, the additional force action of a wedge-shaped pressure body is avoided, the haulageway digging cost is greatly saved, the service life of a main transport haulageway is prolonged, the working conditions of workers is improved, and the recovery rate of ores is improved.

Owner:ANSTEEL GRP MINING CO LTD

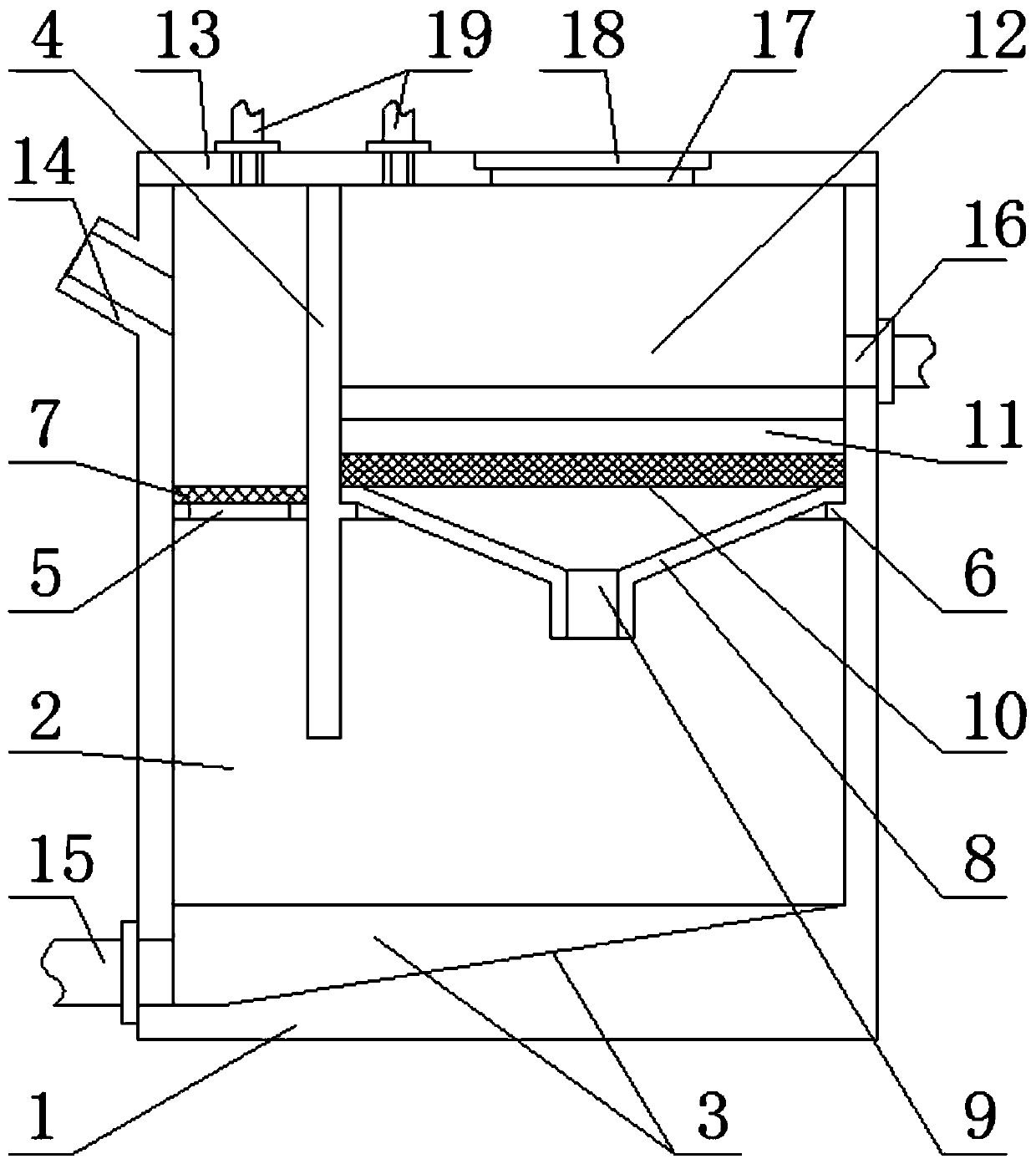

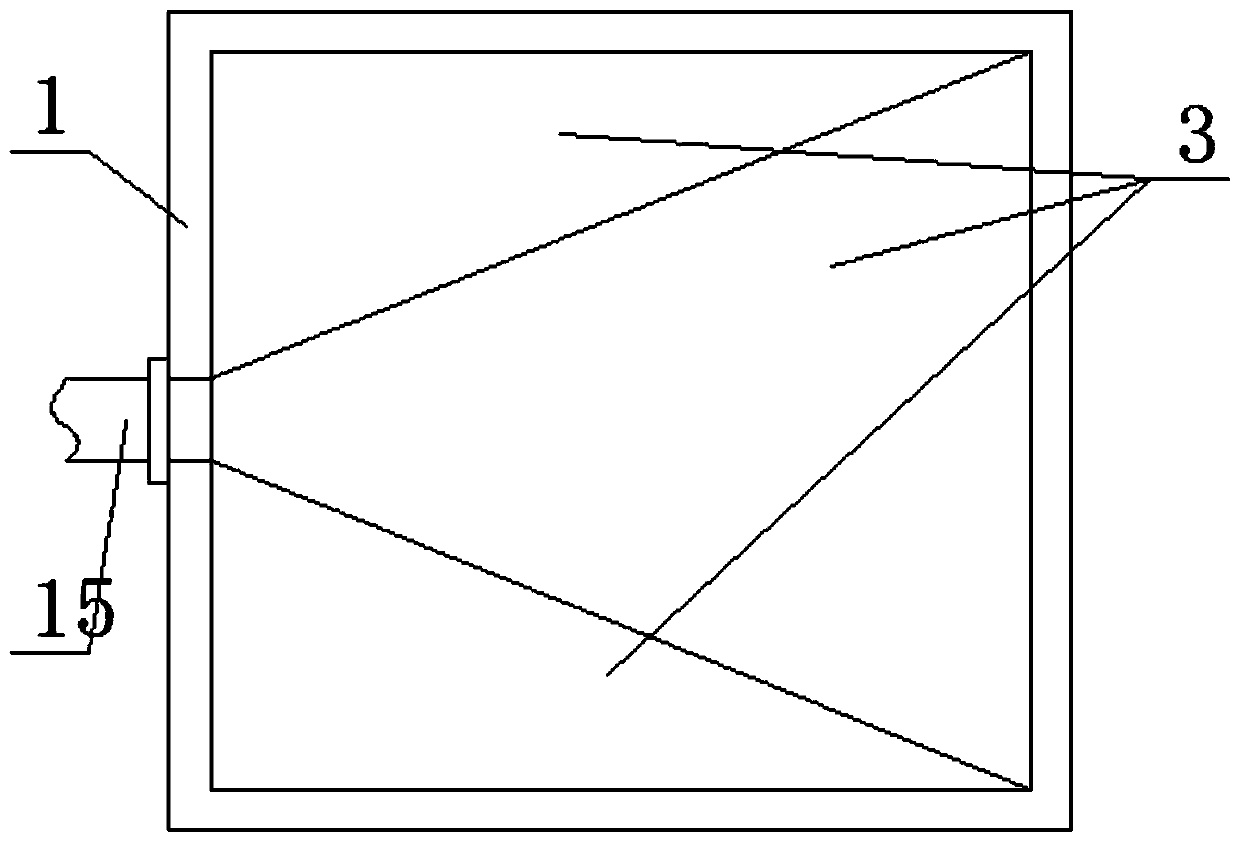

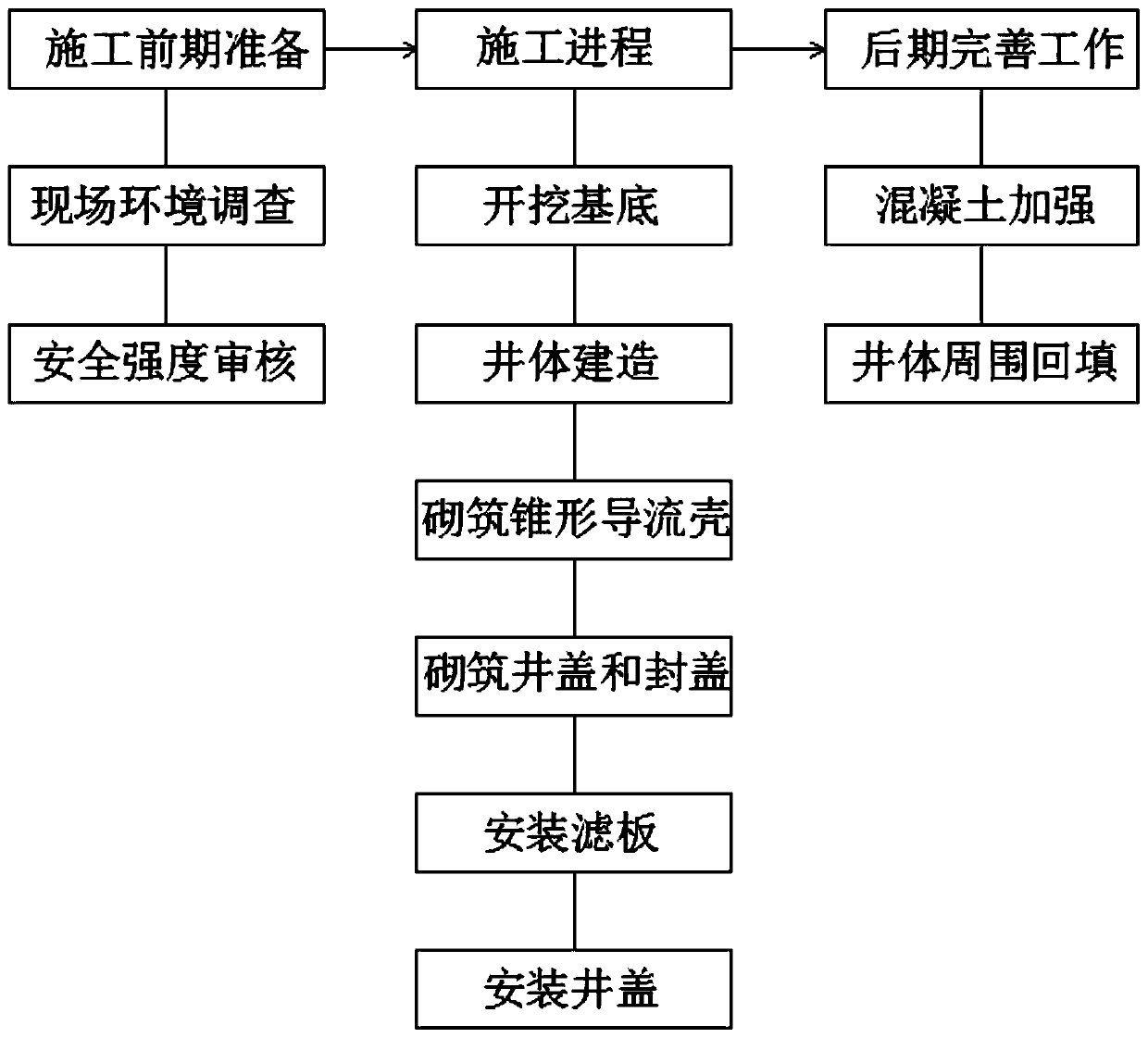

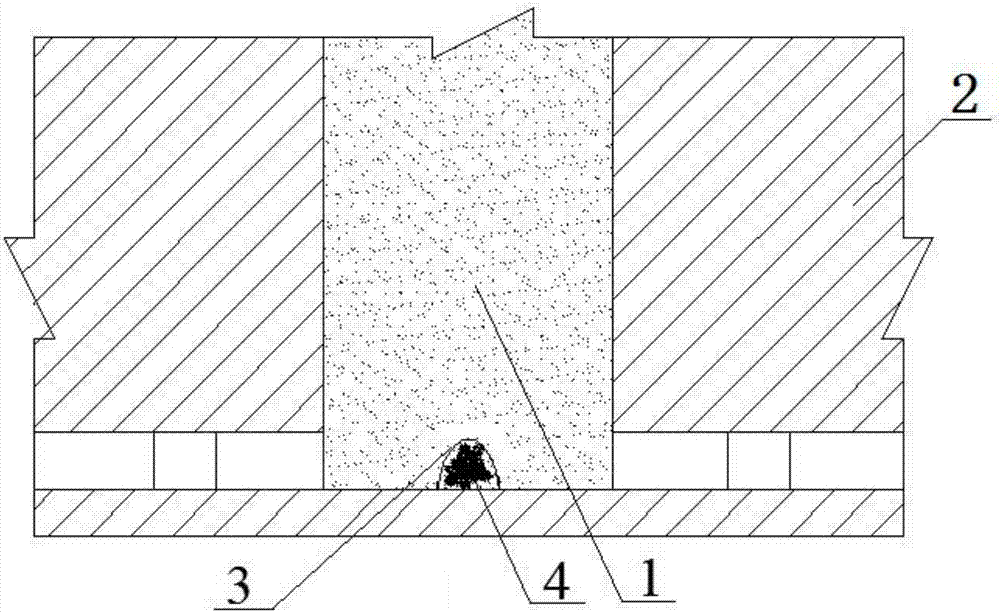

Construction process of sewage collection well

InactiveCN110847328AEasy to removeReduce the impactFatty/oily/floating substances removal devicesSewerage structuresWater storageSewage

The invention discloses a construction process of a sewage collection well. The sewage collection well comprises a well body, wherein a water storage cavity is formed in the well body, and the bottomsurface of the water storage cavity is provided with a inclined bottom. The construction process of the sewage collection well is convenient to construct, suitable for various terrains, shallow in excavation depth, and capable of reducing excavation cost and influence on the environment; due to the adoption of the inclined water inlet pipeline, the sewage can flow into the well body by gravity, the sediment is guided through the inclined bottom with three inclined surfaces, the bottom silt can be removed more conveniently, and the efficiency is higher; and the conical flow guide shell is adopted to guide the supernatant, meanwhile, the sedimentation of the filter substances of the secondary filter plate and the fine filter plate is improved, the convex port can effectively disturb the flow, the liquid flow is reduced, and the sewage is favorably collected.

Owner:春涛国际建筑有限公司

Negative pressure sewage collecting process

InactiveCN110158742AReduce the impactEasy bypassWater resource protectionSewerage structuresRoad surfaceSewage

The invention discloses a negative pressure sewage collecting process. The process comprises the following steps that S1, collecting wells are arranged, specifically, one collecting well is arranged in each rural household, and water inlet pipelines are arranged on the collecting wells correspondingly; S2, a negative pressure collecting tank is arranged, specifically, a collecting tank is arranged, a vacuum pump is arranged in the collecting tank, a plurality of negative pressure pipelines are arranged on the vacuum pump, negative pressure ports are formed in the collecting wells correspondingly, and each negative pressure pipeline extends into the negative pressure port of one corresponding collecting well; and S3, the negative pressure pipelines are paved, specifically, a zigzag laying mode is adopted on a gradient-free road surface, and a bag type vacuum pipeline paving mode is adopted on a continuous uphill road surface. The negative pressure sewage collecting process is good in practicability, the pipeline sealing performance is good, the sewage leakage and rainwater leakage phenomenon can be effectively avoided, the flow speed in the sewage pipelines is relatively large, sewage sedimentation and blocking phenomena can be reduced easily, and operation and management of a sewage collecting pipe network are facilitated.

Owner:安徽富通环保节能科技股份有限公司

Method for presetting roadways by section moulds

ActiveCN107013213AImprove tunneling efficiencyIncrease job securityUnderground miningSurface miningSlurryEngineering

The invention belongs to the technical field of underground mining for mines, in particular to a method for presetting roadways by section moulds. The method comprises the following steps: laying the placeholder section moulds in advance at the mined area bottom of a one-step stope, then filling the placeholder section moulds with non-cemented slurry, starting filling operation of the one-step stope after performing dewatering, after the filling of the one-step stope is completed, using the common digging mode to form ore drawing roadways of a two-step stope, and presetting the ore drawing roadways by the section moulds. The method for presetting the roadways by the section moulds avoids drilling, blasting and tunneling of the ore drawing roadways again in a filling body, so that the tunneling efficiency and operation safety of stope preparation roadways are greatly enhanced, and then the tunneling cost is lowered.

Owner:CHANGCHUN GOLD RES INST

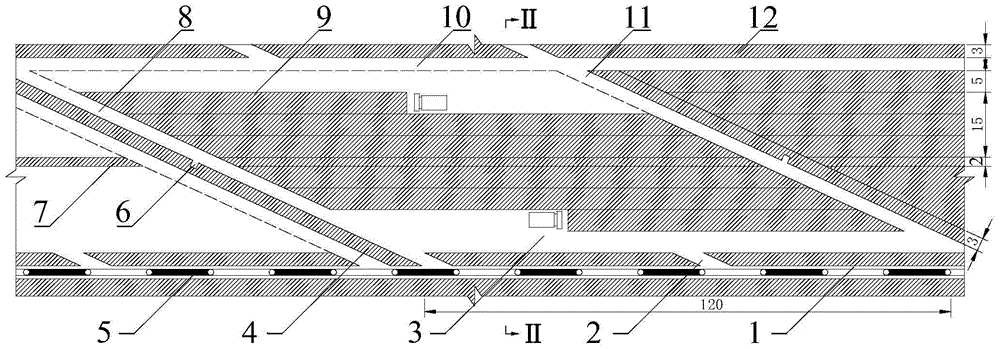

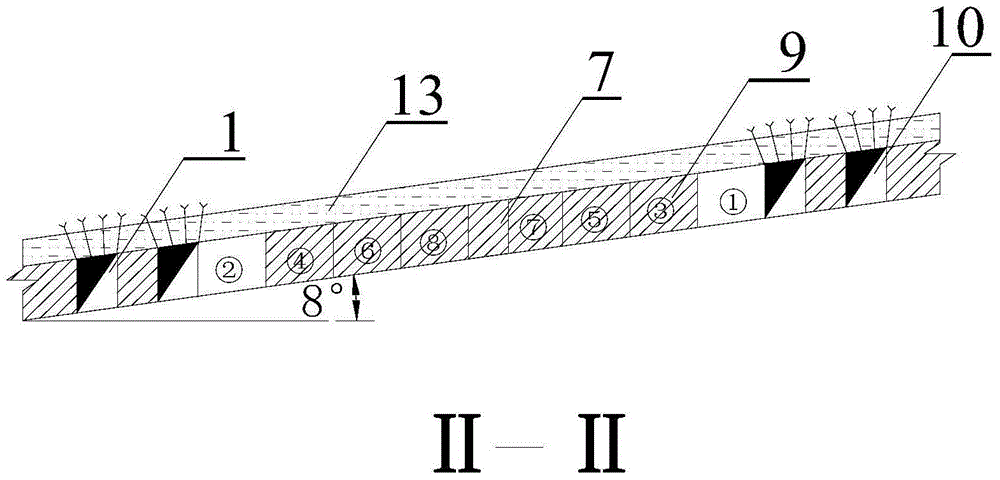

Mechanized continuous mining method of gently inclined thin veins based on mining machine

ActiveCN105019904BIncrease production capacityImprove efficiencyUnderground miningSurface miningEngineeringEarth surface

The present invention discloses a mining- machine- based slowly inclined thin ore vein mechanized continuous mining method, a middle-section tape transport lane is arranged along an ore body, false inclination uphill is tunneled at intervals of a certain distance; a continuous rib pillar and a top pillar or a bottom pillar are arranged between adjacent back- mining units; accurate mining cutting is started from the lower middle section tape transport lane, a mining machine passes, from the back- mining unit edge position, through the top pillar or the bottom pillar for tunneling left and right false inclination uphill to the upper middle section tape transport lane; back- mining is started from the position of the tape transport lane uphill from the right side, the ore body is back mined by the mining machine to left side uphill, the mining machine is in no load, and descends along the left false inclination uphill to the bottom of the back- mining units, the ore body is back mined by the mining machine from left side uphill position to right side uphill, then the mining machine is in no load, and ascends from the right side uphill to the position near the tape transport lane, the mining is performed in the anti-clockwise direction circulation way, a central position reserved ore pillar is left; ores are loaded onto a belt by a carry-scraper for conveying to a ground surface main ore bin. The conveying is easy, work security is high, back- mining efficiency is high, and production capacity is large.

Owner:CENT SOUTH UNIV +1

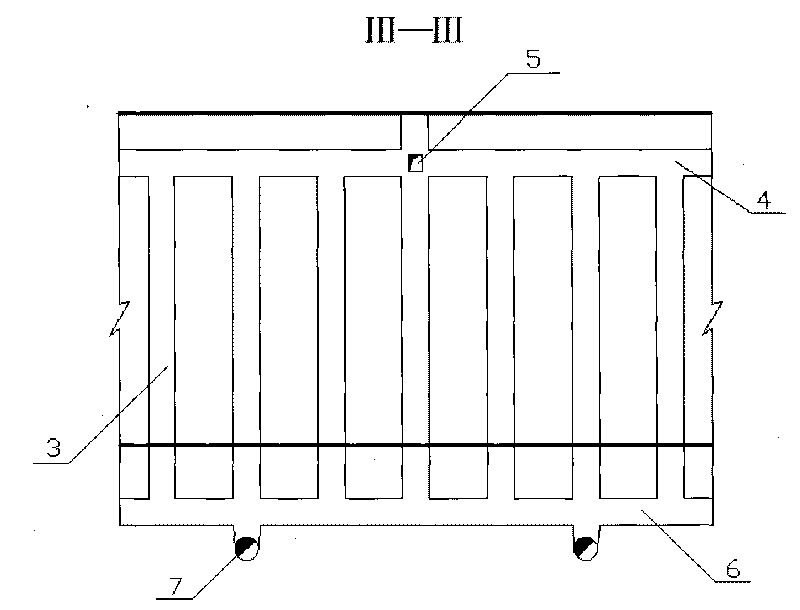

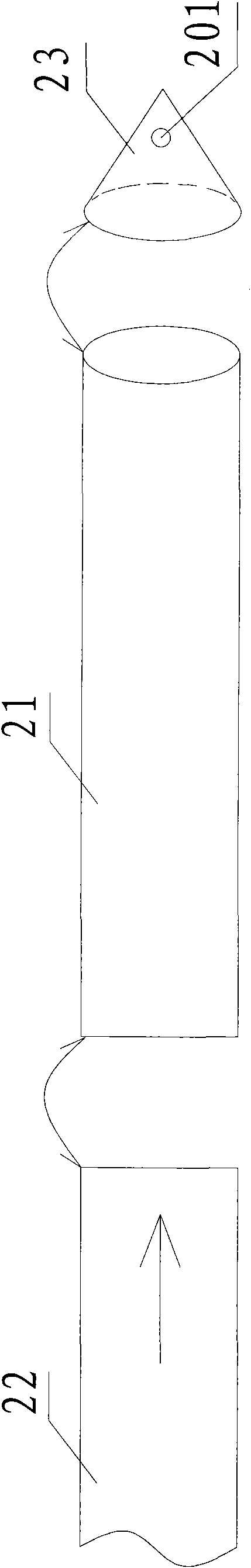

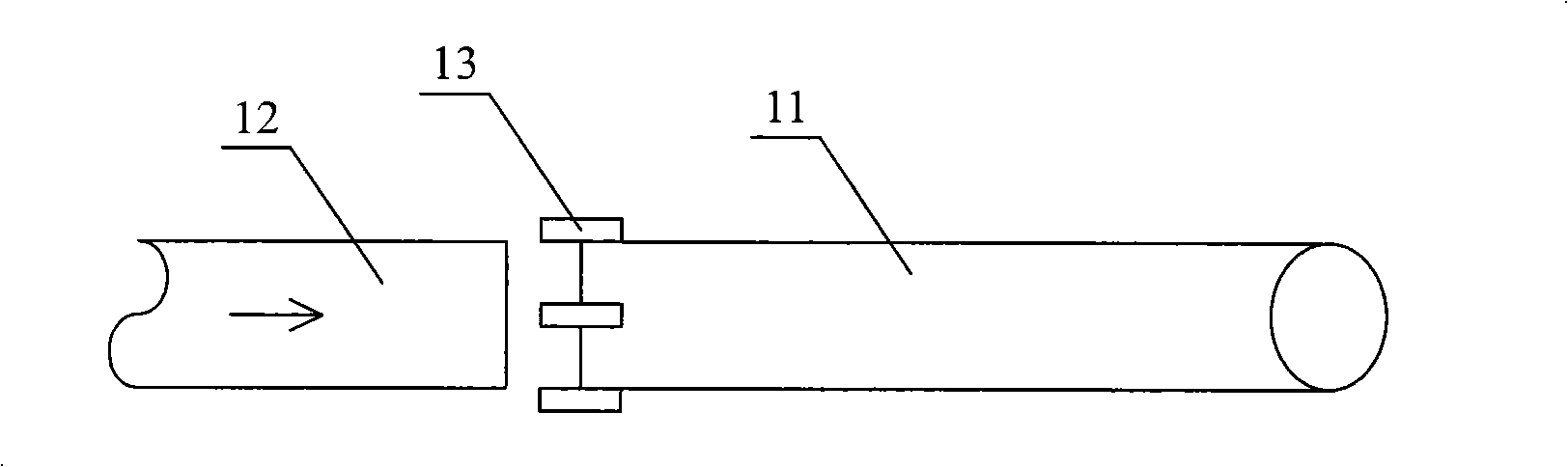

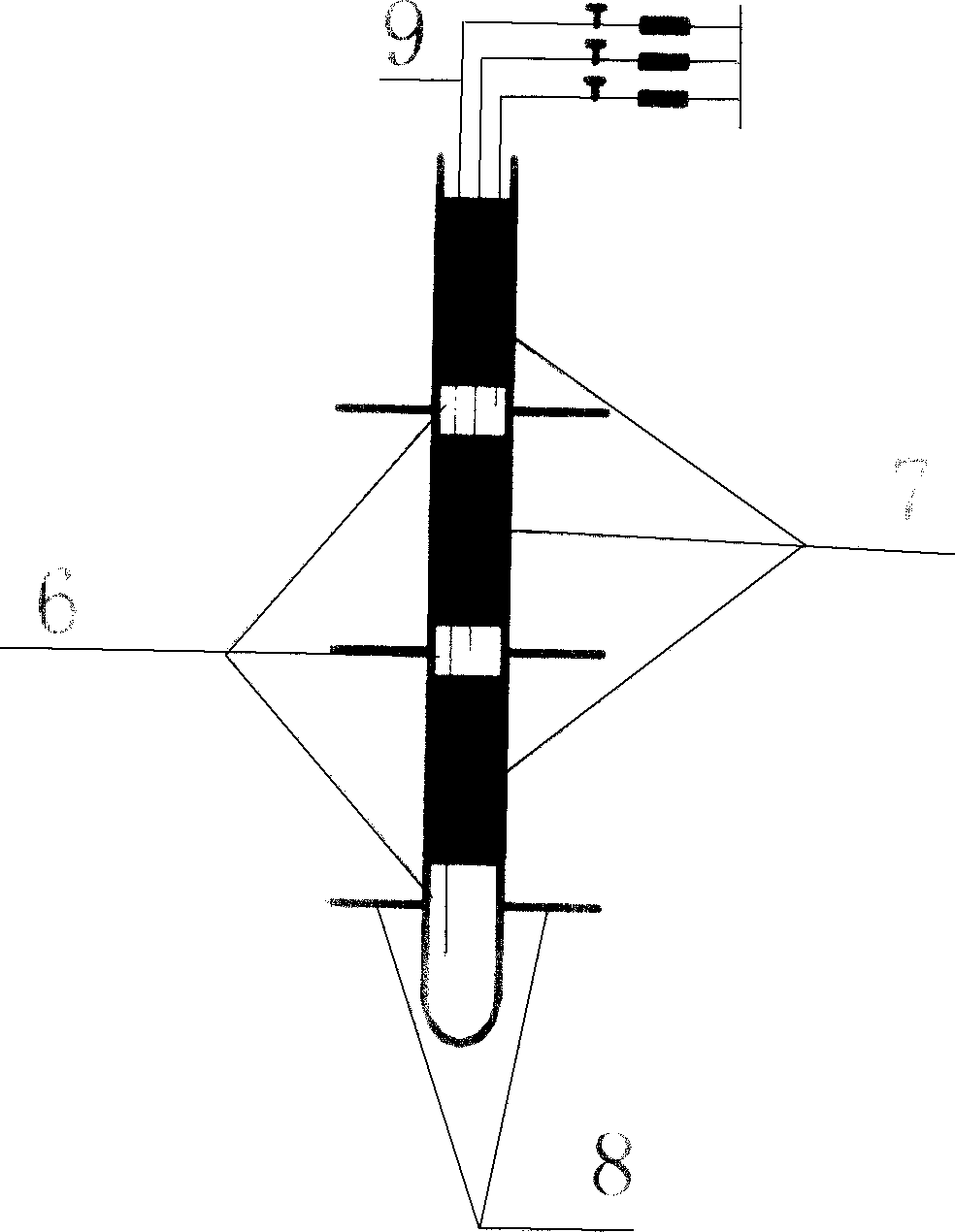

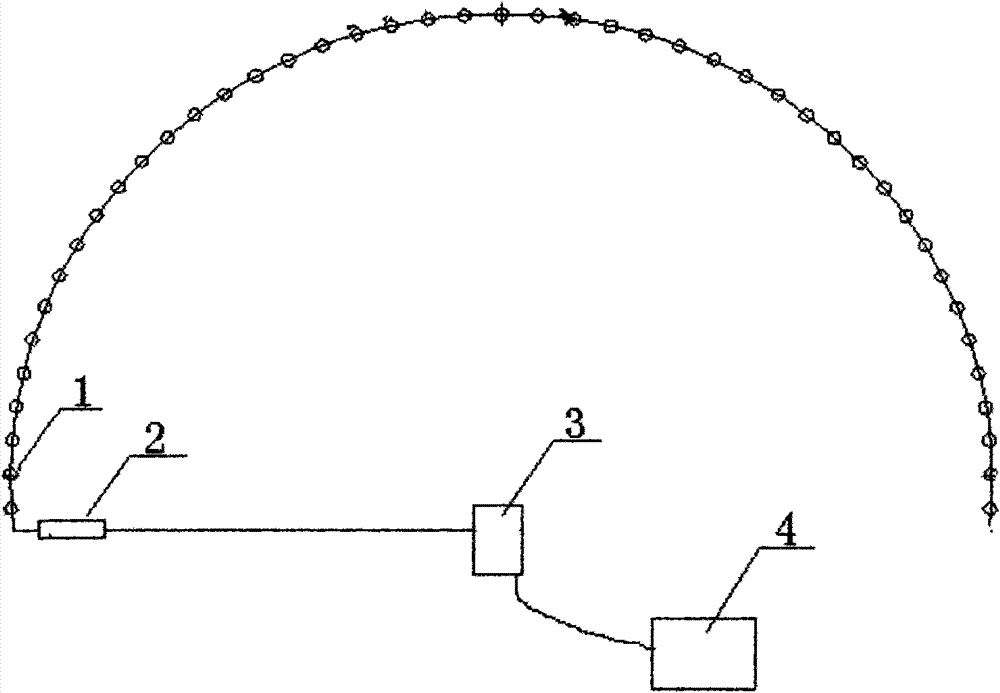

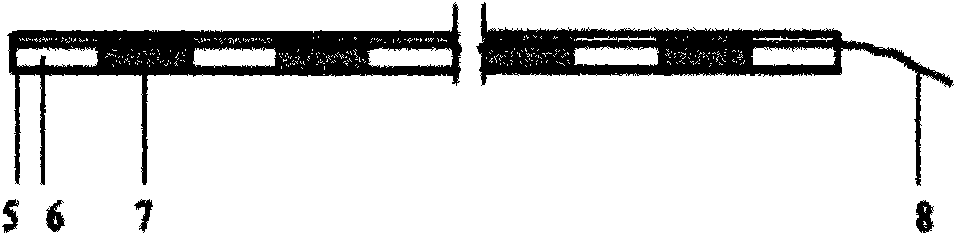

Pipe-jacking installation method of bypass pipeline

ActiveCN101852311BProtection securitySave excavation costsPipe laying and repairEngineeringMechanical engineering

The invention relates to the field of pipeline construction methods in metallurgical systems, in particular to a pipe-jacking installation method of a bypass pipeline. The pipe-jacking installation method of the bypass pipeline comprises the following steps of: paying a pipeline off->excavating a guideway->producing a sleeve->jacking a front sleeve->connecting the sleeves->jacking a rear sleeve->passing through an engineering pipeline and installing. The method is characterized in that: in the process of jacking the front sleeve, the front sleeve (11) is jacked ahead by a jacking device (4), and the rear sleeve (12) is then jacked till the front sleeve (11) is penetrated from the interior of the guideway (2) at the other side. The invention has low construction cost, short construction period, high installation quality and high production efficiency.

Owner:MCC5 GROUP CORP SHANGHAI

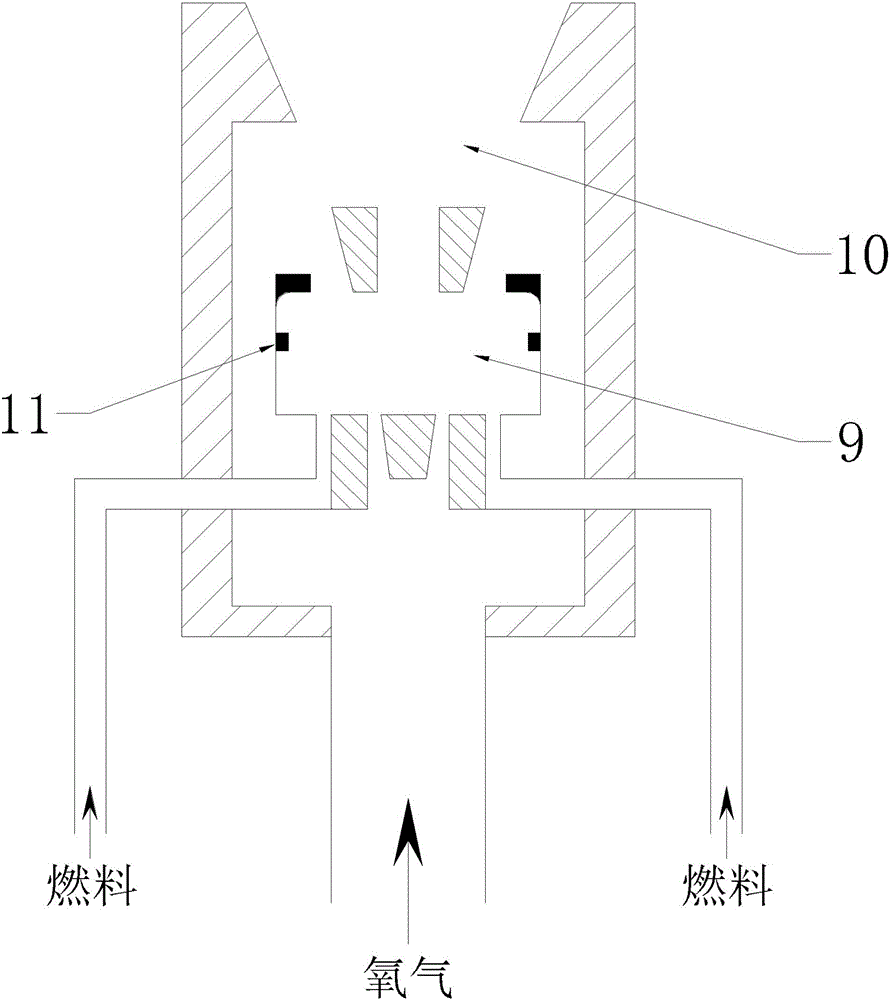

High temperature flame assisted intelligent drilling rig

InactiveCN103527085BReduce the difficulty of digging and drillingSave excavation costsThermal drillingSupporting systemControl system

Owner:杭州易夫禾科技有限公司

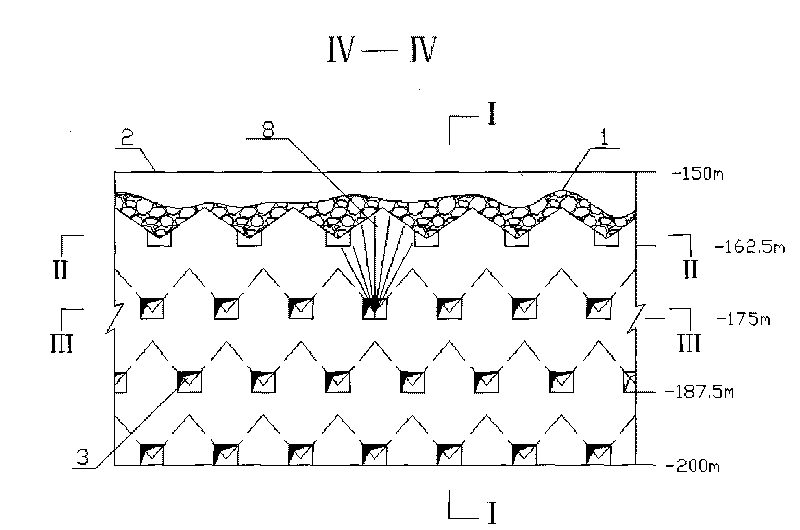

Rude ore mining method for ion type RE ore

InactiveCN100543267CHigh recovery rateReduce leakageUnderground miningSurface miningRare earth ionsColloid

The invention discloses a method for mining ion-type rare earth mines (ion-adsorption-type rare earth mines leaching) in the original mine. The static pressure grouting method of geotechnical engineering is used to inject liquid, and an anti-seepage layer is established in the bottom of the mine layer. The mountain body is mainly composed of V It is composed of drainage holes, liquid injection holes, tunnels, anti-seepage layers and other facilities. The plan is to find out the distribution and thickness of the rare earth ore layer on the mountain first, then design the tunnel to the junction of the rich ore bottom layer and the lean ore layer, and then set V-shaped drainage holes in the upper layer of the soil layer on both sides of the tunnel, and finally under the drainage hole Set anti-seepage layer or horizontal drainage hole; and set layered liquid injection hole or liquid injection tunnel in the mine bed and set drainage hole in the same tunnel to achieve layered liquid injection and layered liquid collection. The invention solves the environmental protection problems caused by the adsorption of rare earth ions by the soil colloid in the rare earth-free ore soil layer and water and soil loss caused by mining.

Owner:林江颖

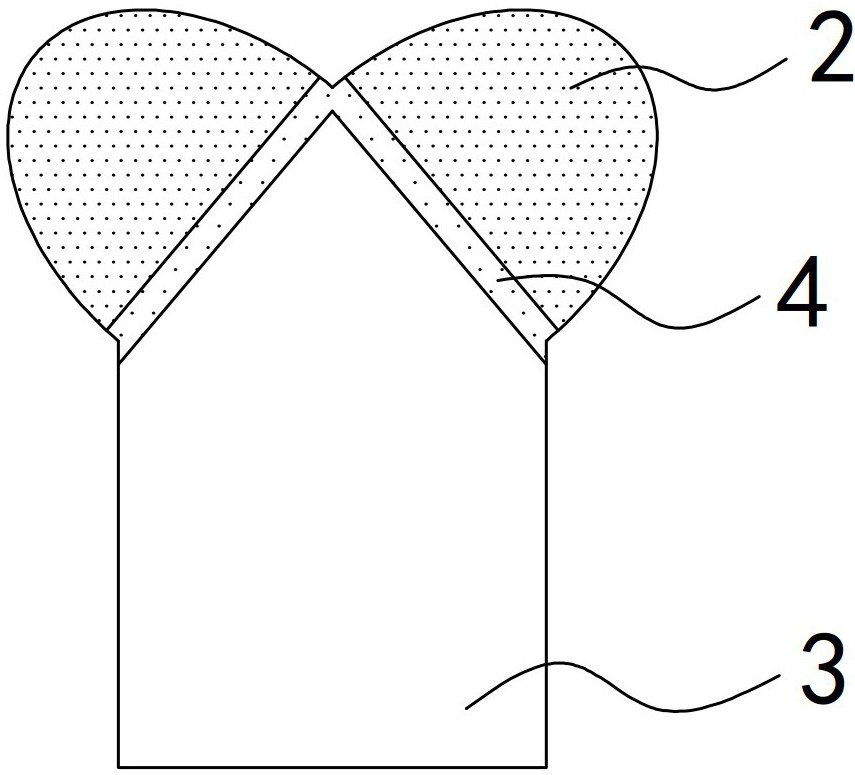

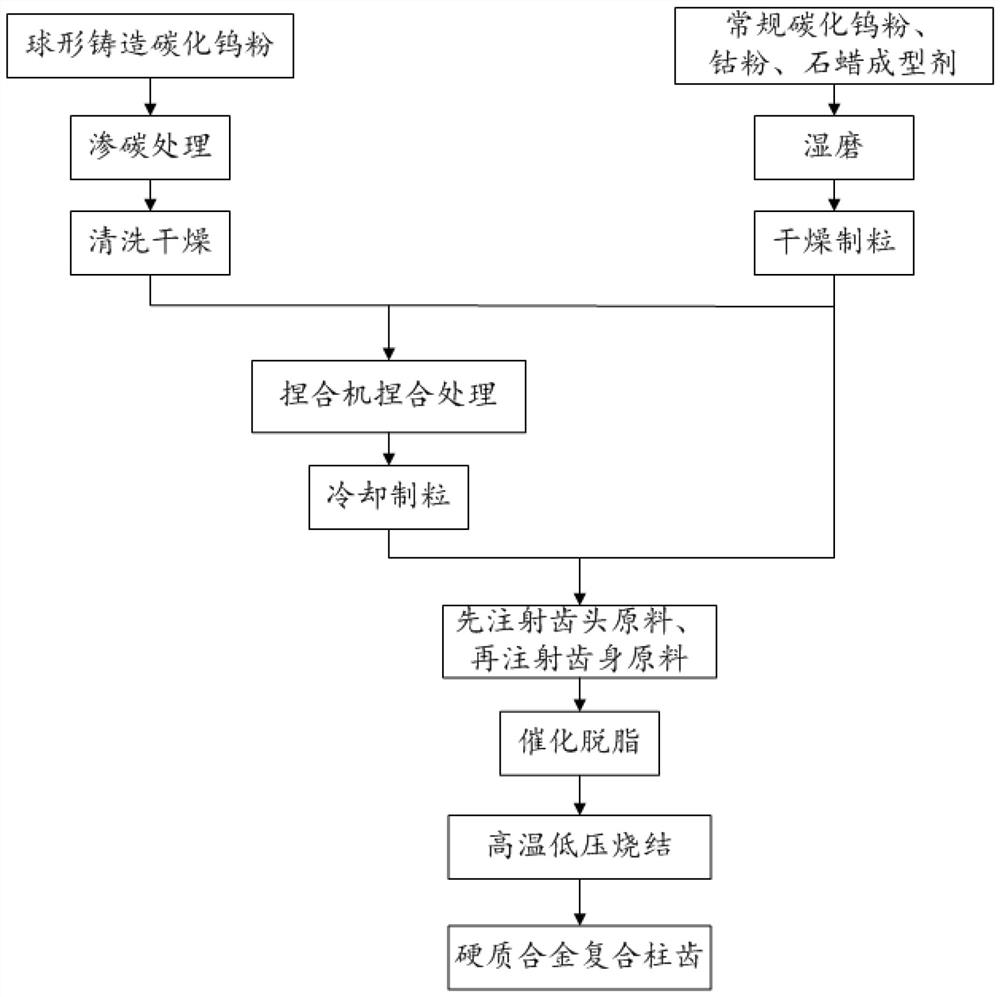

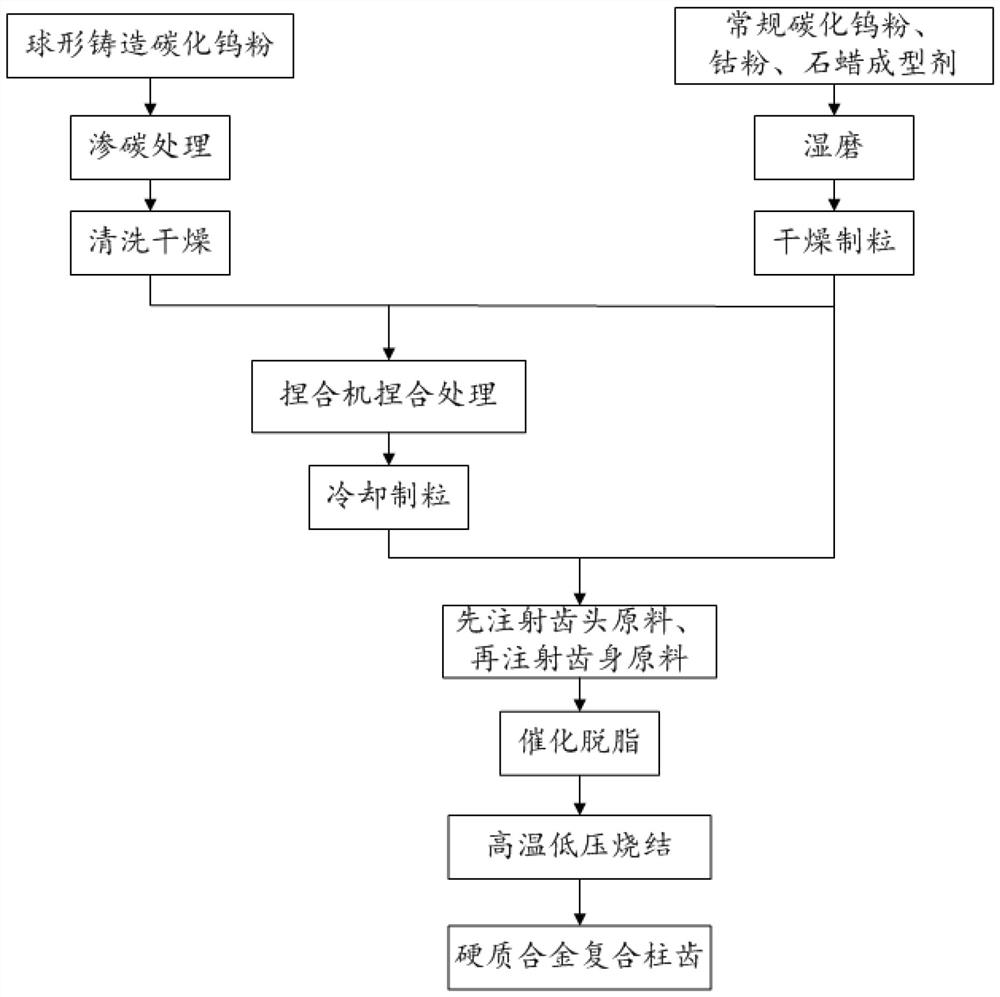

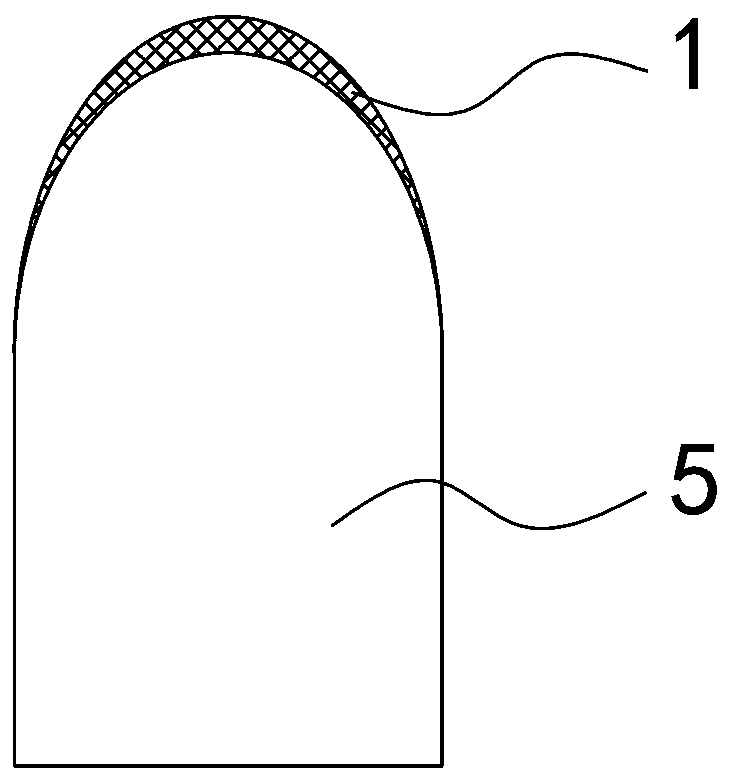

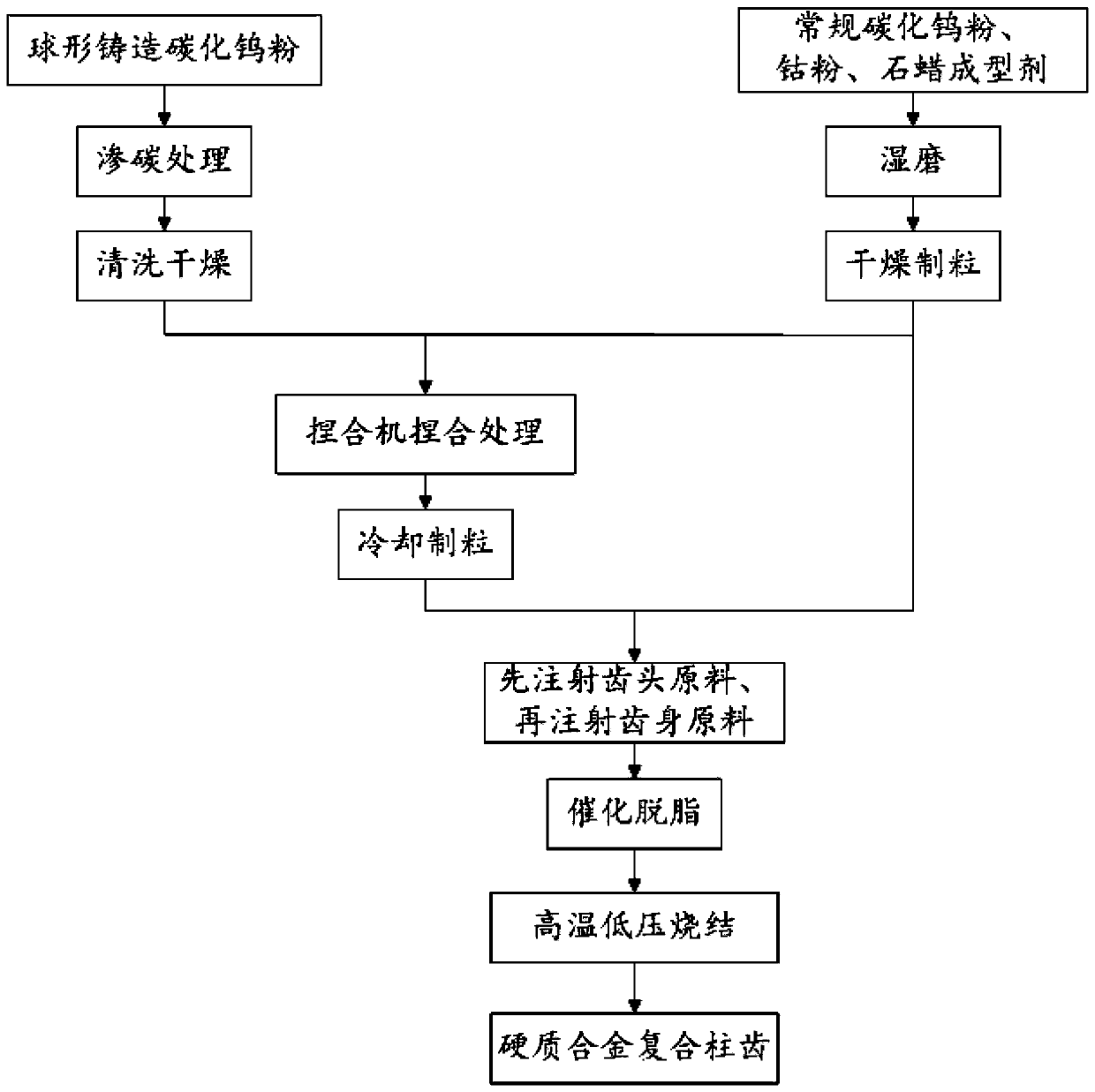

A kind of multi-tooth-head cemented carbide composite column tooth and its preparation method

ActiveCN111451510BImprove toughnessHigh hardnessDrill bitsTransportation and packagingAlloy compositeCemented carbide

A multi-head cemented carbide composite column tooth and a preparation method thereof, wherein the cemented carbide composite column tooth is designed into a tooth head and a tooth body in the height direction, the tooth head includes 2 to 3 tooth heads, and the tooth head It is axisymmetrically distributed, including the steps: Step 1: Prepare the tooth body raw material and the tooth head raw material; the tooth head includes 10~20wt% carbonized spherical cast tungsten carbide particles, 1~7wt% wax-based composite molding agent, and the balance is Tooth material. Step 2: Inject the tooth head raw material and the tooth body raw material into the mold respectively through a co-injection molding method to obtain a soft cylindrical tooth blank with a composite structure. Step 3: Carrying out high-temperature and low-pressure sintering on the soft billet of the column tooth with a composite structure, the metallurgical reaction at the bonding interface of the tooth head and the tooth body forms a transition layer, and integrally forms a cemented carbide composite column tooth with multiple tooth heads. It solves the technical problem that the existing cemented carbide column tooth cannot take into account both wear resistance and toughness at the same time, and significantly improves the wear resistance and rock breaking efficiency of the column tooth, thereby improving the service life and drilling speed of the drilling tool.

Owner:SHAREATE TOOLS

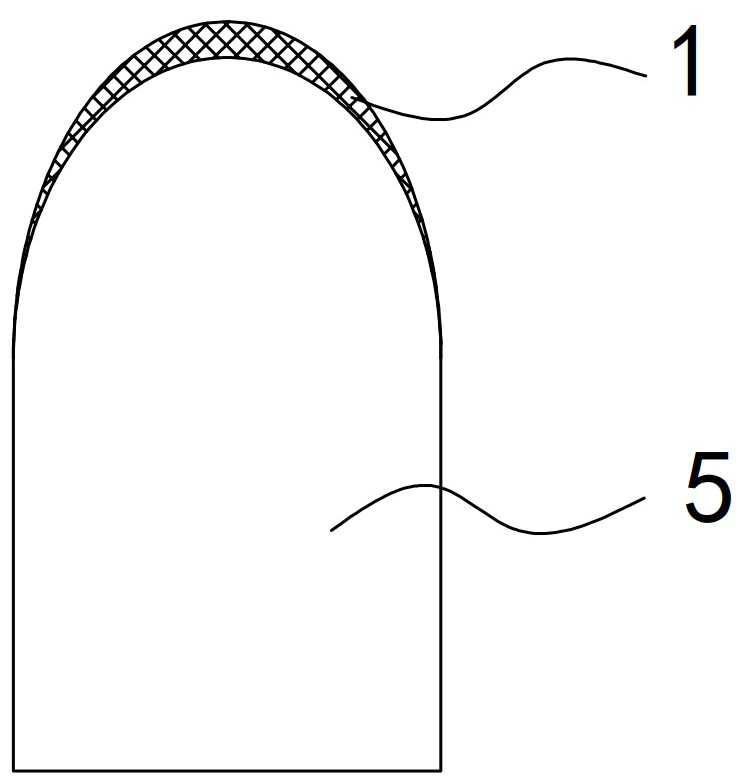

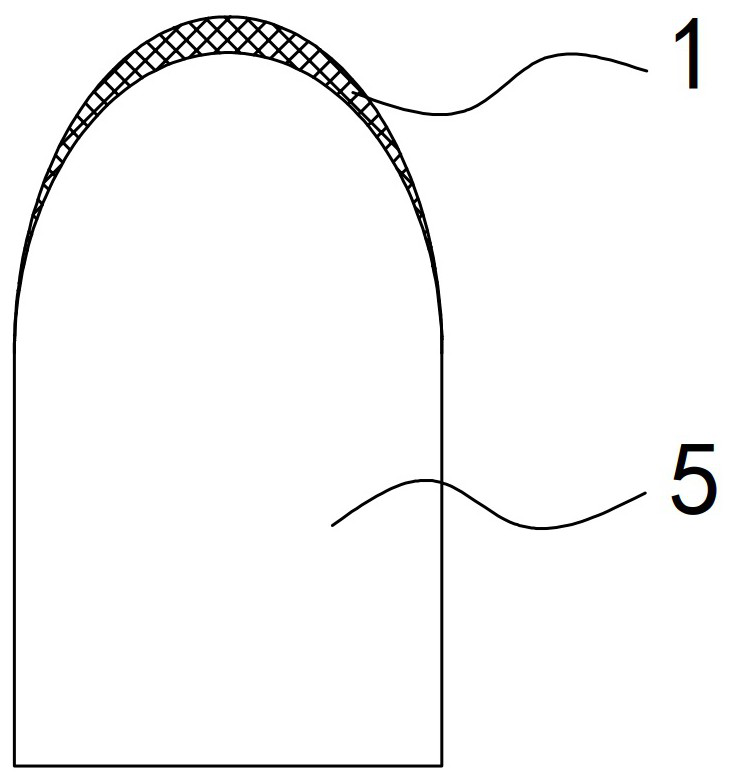

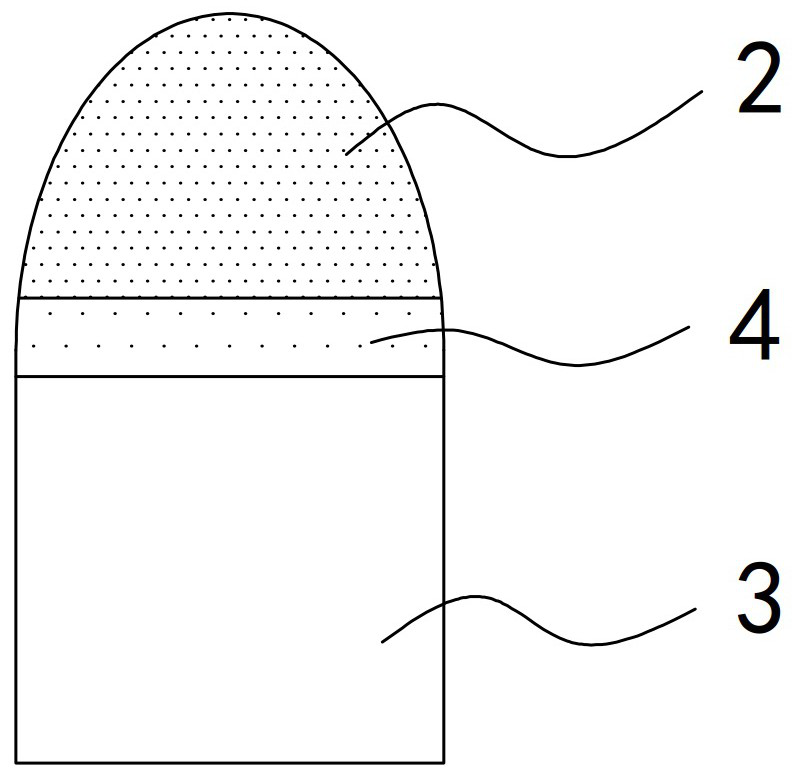

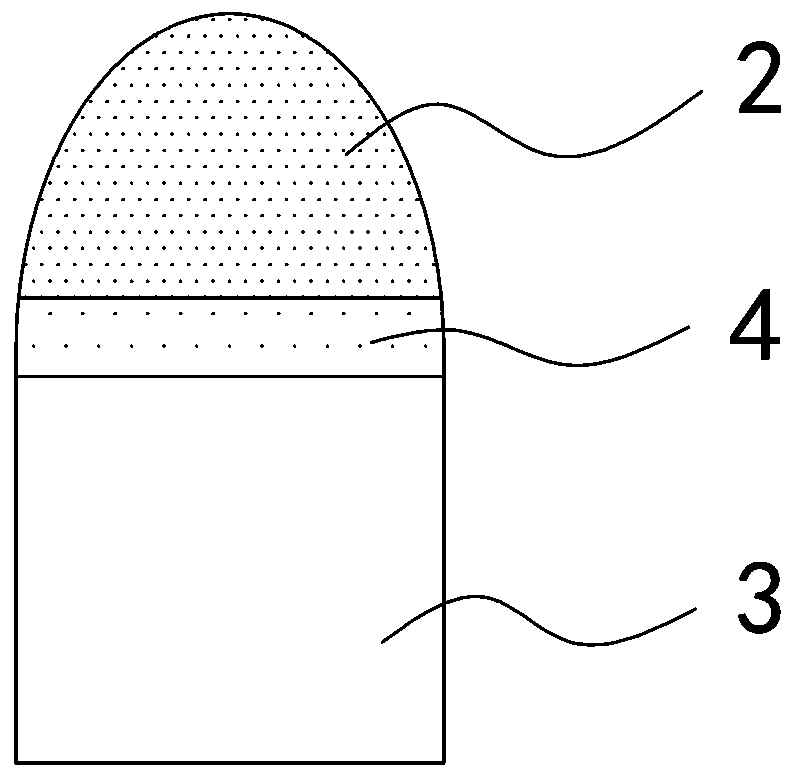

A single tooth head cemented carbide composite column tooth and its preparation method

ActiveCN111558721BImprove toughnessHigh hardnessDrill bitsTransportation and packagingOral problemsCemented carbide

A single-tooth head cemented carbide composite column tooth and its preparation method, the single-tooth head cemented carbide composite column tooth is designed into a tooth head and a tooth body in the height direction, including the following steps: Step 1. Prepare the tooth body Raw materials and tooth head raw materials; the tooth head includes 10~20wt% carbonized spherical cast tungsten carbide particles, 1~7wt% wax-based composite molding agent, and the balance is tooth body raw materials. Step 2. The gear head raw material and the tooth body raw material are respectively added to the mold through a co-injection molding method or a step-by-step charging molding method to obtain a soft cylindrical tooth blank with a composite structure. Step 3. In an inert gas atmosphere, sinter the composite structure of the column tooth soft billet obtained in step 2 under high temperature and low pressure, and a metallurgical reaction occurs at the bonding interface between the tooth head and the tooth body to form a transition layer, and the tooth head and the tooth body are integrally formed. Single tooth head cemented carbide composite column teeth. It solves the technical problem that the existing cemented carbide column teeth cannot simultaneously take into account wear resistance and toughness.

Owner:SHAREATE TOOLS

Single-stud head hard alloy composite stud and preparation method thereof

ActiveCN111558721AImprove wear resistanceLow wear resistanceDrill bitsTransportation and packagingCemented carbideComposite structure

The invention relates to a single-stud head hard alloy composite stud and a preparation method thereof. The single-stud head hard alloy composite stud is designed into a stud head and a stud body in the height direction. The preparation method comprises the following steps of step I, preparing the stud body raw materials and the stud head raw materials, wherein the stud head comprises 10-20wt% ofspherical casting tungsten carbide granules after carbonization, 1-7wt% of ceryl composite molding agents, and the balance stud body raw materials; step II, adding the stud head raw materials and thestud body raw materials to the molds through a joint injection molding method or a batch charging compression moulding forming method to obtain a stud soft blank having a composite structure; and stepIII, under inert gas atmosphere, performing high-temperature low-pressure sintering on the stud soft blank having the composite structure obtained in the step II, enabling a combination interface ofthe stud head and the stud body to generate a metallurgy reaction to form a transition layer, and integrally forming the stud head and the stud body to obtain the single-stud head hard alloy compositestud. Through the adoption of the single-stud head hard alloy composite stud disclosed by the invention, the technical problem that a conventional hard alloy stud cannot take account of wear resistance and tenacity synchronously is solved.

Owner:SHAREATE TOOLS

A tunneling method for weakening strength of hard rock mass

ActiveCN108691508BReduced strengthReduce the difficulty of cuttingLiquid/gas jet drillingSlitting machinesEngineeringHigh pressure water

The invention discloses a tunneling method capable of weakening hard rock strength. According to the method, a tunneling machine, an integrated grinding jetting drilling machine with the tunneling machine as a carrier, and a high-pressure water pump are arranged on a tunneling working surface; the integrated grinding jetting drilling machine is adopted to form drilled holes in a rock body, and a series of conical crack clusters are formed through cracking cutting on the basis of hole drilling; a high-pressure hole sealing device is used for sealing the tunneling surface for a distance, the high-pressure hole sealing device is communicated with a high-pressure water pump through a water inlet pipe, the characteristic that the rock body is resistant to pressure but not resistant to drawing is utilized, the conical crack clusters in the rock body are expanded to form a dense conical crack net, and therefore the rock strength is weakened; a tunneling machine cutting head is adopted to cutthe rock which has an internal conical crack net, the tunneling efficiency is greatly improved, the service life of the tunneling machine can be prolonged, and the tunneling cost is reduced.

Owner:CHINA UNIV OF MINING & TECH

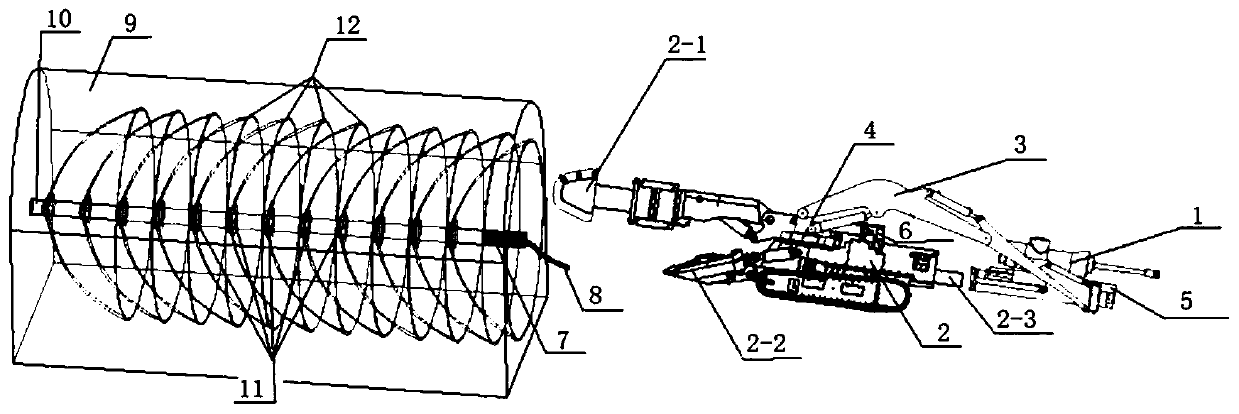

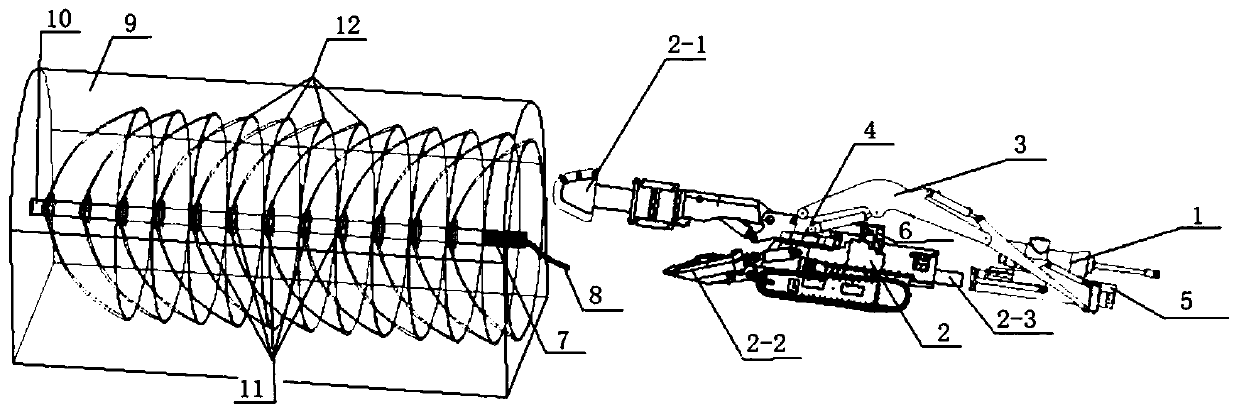

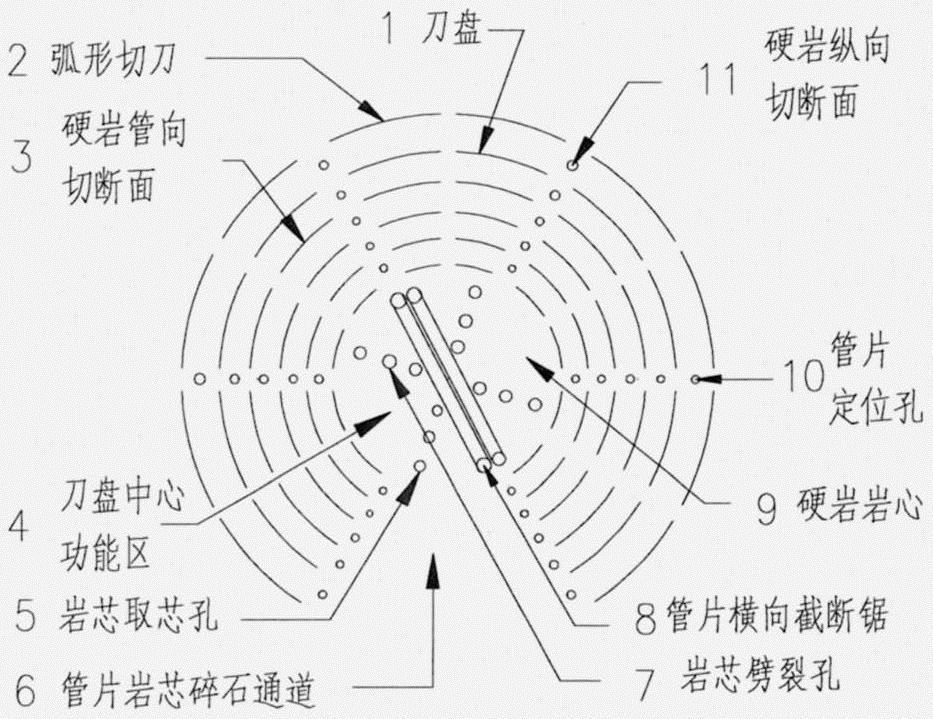

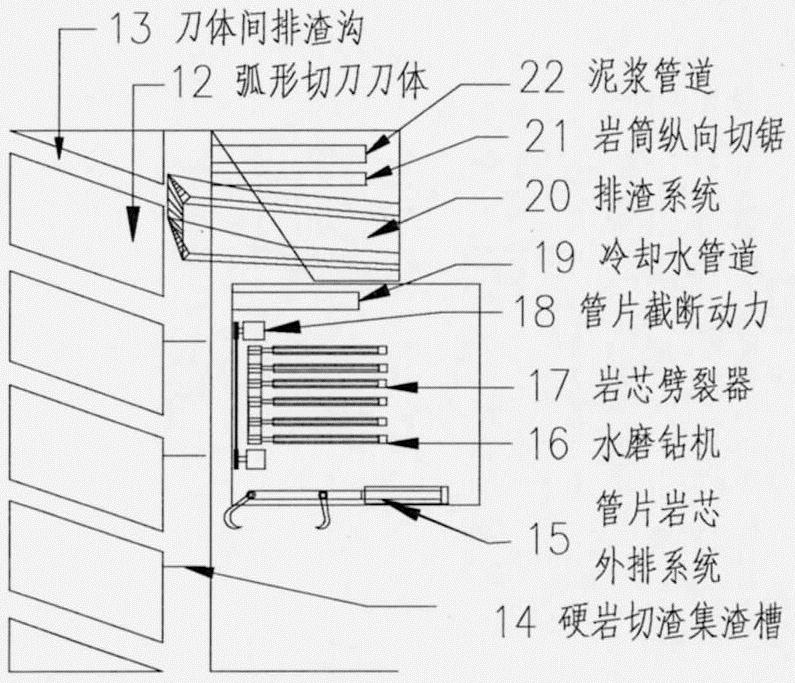

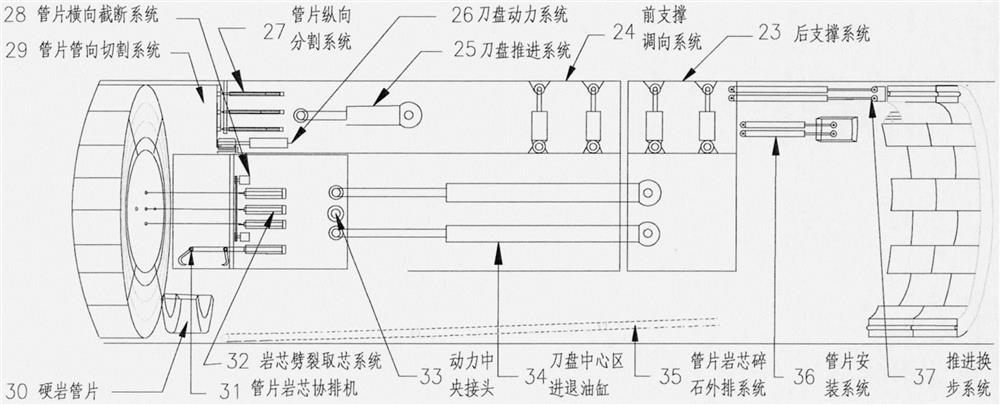

Tube-fin type hard rock tunneling machine

PendingCN111622769AReduce the risk of war damageImprove safety and reliabilityUnderground chambersTunnel liningWatermillResource utilization

The invention relates to a tube-fin type hard rock tunneling machine, belongs to the field of engineering machinery, and is used for solving the problems that according to an existing tunneling technology, the hard rock cutting amount is large, the resources are wasted, the tunneling speed is slow, the tunneling cost is high, concrete pipe sheets are purchased, and the service life of a building is only 100 years. A tunneling technology of the tube-fin type hard rock tunneling machine provided by the invention comprises: a plurality of arc-shaped cutters at the front end of a cutter disc circumferentially cut hard rock in a tunneling space into rock barrels; rock cores are taken out through water milling drills and a splitter in the center of the cutter disk; the rock barrels are cut and sawn into pipe sheets along the longitudinal direction; the pipe sheets and rock bodies are horizontally separated through cut saws in front of the center of the cutter disc; and a feeding and discharging channel at the rear end of the cutter disk is used for feeding cooling cement pastes and discharging the pipe sheets and crushed rocks. Compared with the prior art, according to the tube-fin typehard rock tunneling machine provided by the invention, the tunneling space hard rocks are manufactured into reinforced composite pipe sheets for lining tunneling rock walls, remained pipe sheets are directly sold or increase export revenue to offset the investment, the hard rock cutting amount is small, the resource utilization rate is high, the tunneling speed is fast, the tunneling cost is low,the project investment is low, and the service life of the building can reach to 1000 years.

Owner:CORNELIUS

Sunken prefabricated inspection well and underground construction method thereof

PendingCN113529799ALittle trafficLittle activityArtificial islandsUnderwater structuresDaily livingArchitectural engineering

The invention discloses a sunken prefabricated inspection well and a underground construction method thereof. The sunken prefabricated inspection well comprises a top plate, a bottom plate and a valve well shaft, wherein the top plate and the bottom plate are fixedly arranged and plugged on the end faces of two axial openings of the valve well shaft, an annular blade foot is integrally manufactured at an opening in the bottom of the valve well shaft, a plurality of holes are formed in the lower portion of the valve well shaft in the radial direction, and a bracket extending in the radial direction is integrally manufactured on the inner wall of the valve well below the hole. The underground construction method for the prefabricated inspection well comprises the steps that firstly, a valve well shaft is prefabricated in a factory and vertically hoisted to a preset underground position; secondly, a base plate is laid at a top opening of the valve well shaft, and pressure equipment is erected at the axis position of the top face of the base plate; thirdly, the valve well shaft is pressed to the preset buried depth, and then muck in the valve well shaft is excavated; and fourthly, a concrete bottom plate is poured, and a concrete top plate is installed. The prefabricated inspection well is convenient to use, simple to construct and small in influence on traffic and daily life of nearby buildings and human beings.

Owner:NORTH CHINA MUNICIPAL ENG DESIGN & RES INST

A kind of continuous mining method of auger mining machine for gently inclined extremely thin vein soft rock ore body

ActiveCN109026003BThe void section is completeAvoid stress concentrationUnderground miningSurface miningMining engineeringMechanical engineering

Owner:CENT SOUTH UNIV

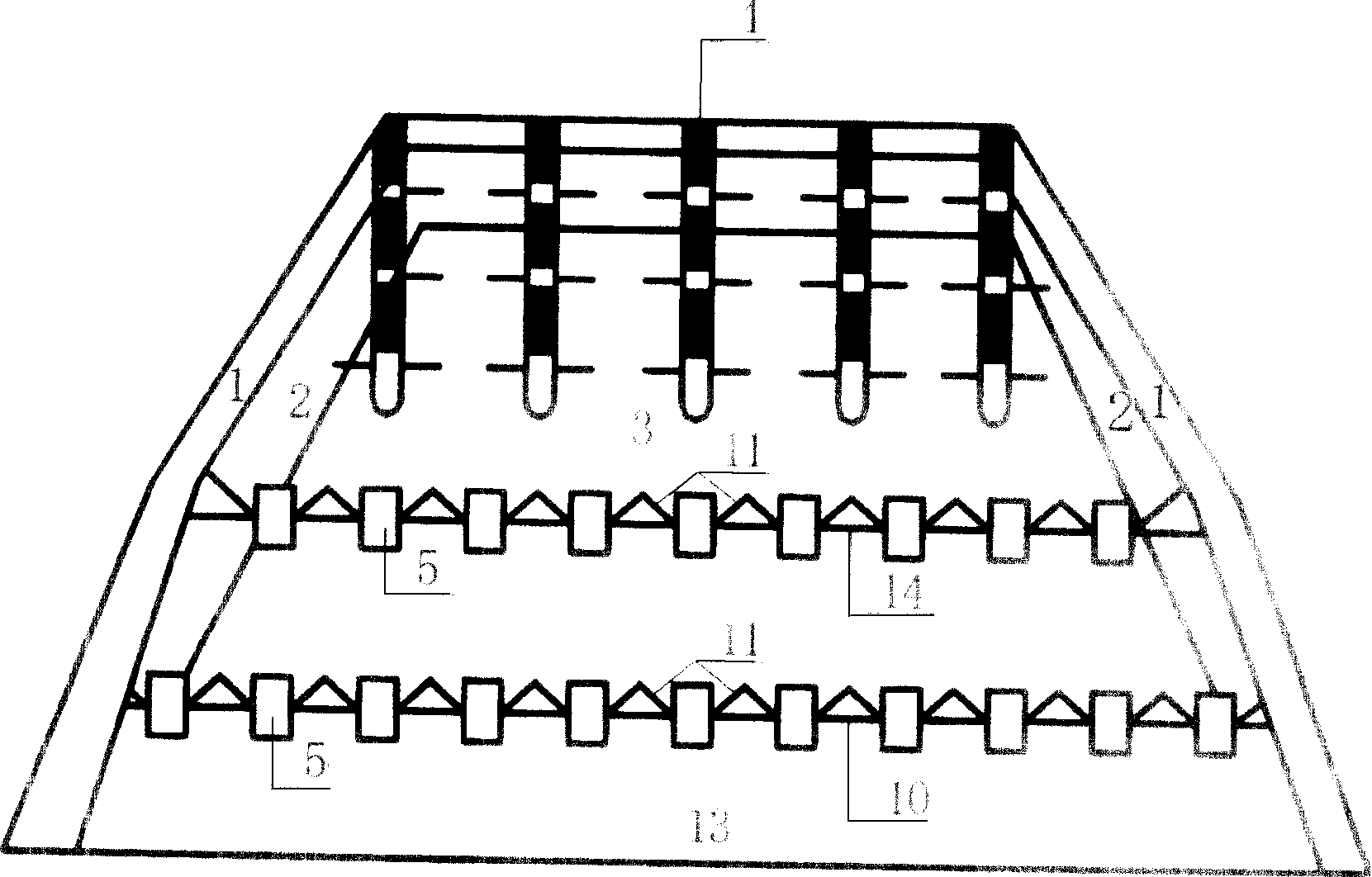

Gob-side entry retaining method of a solid filling coal mining half-section one-leg shed

InactiveCN101761338BAvoid lostImprove recovery rateUnderground miningSurface miningMining engineeringRebar

Owner:CHINA UNIV OF MINING & TECH

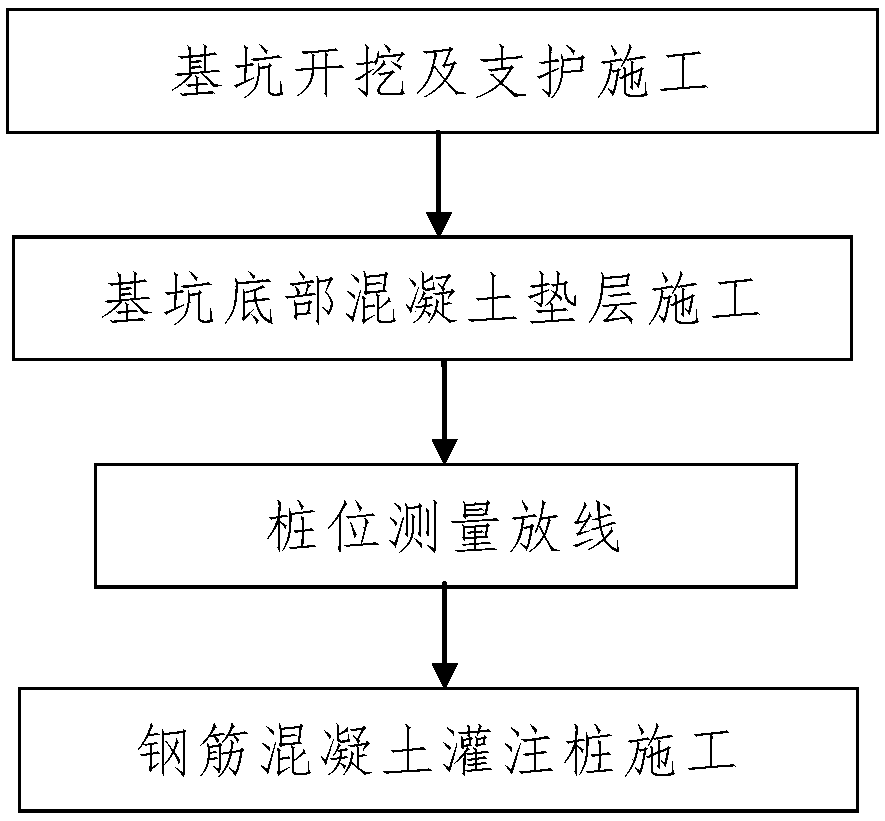

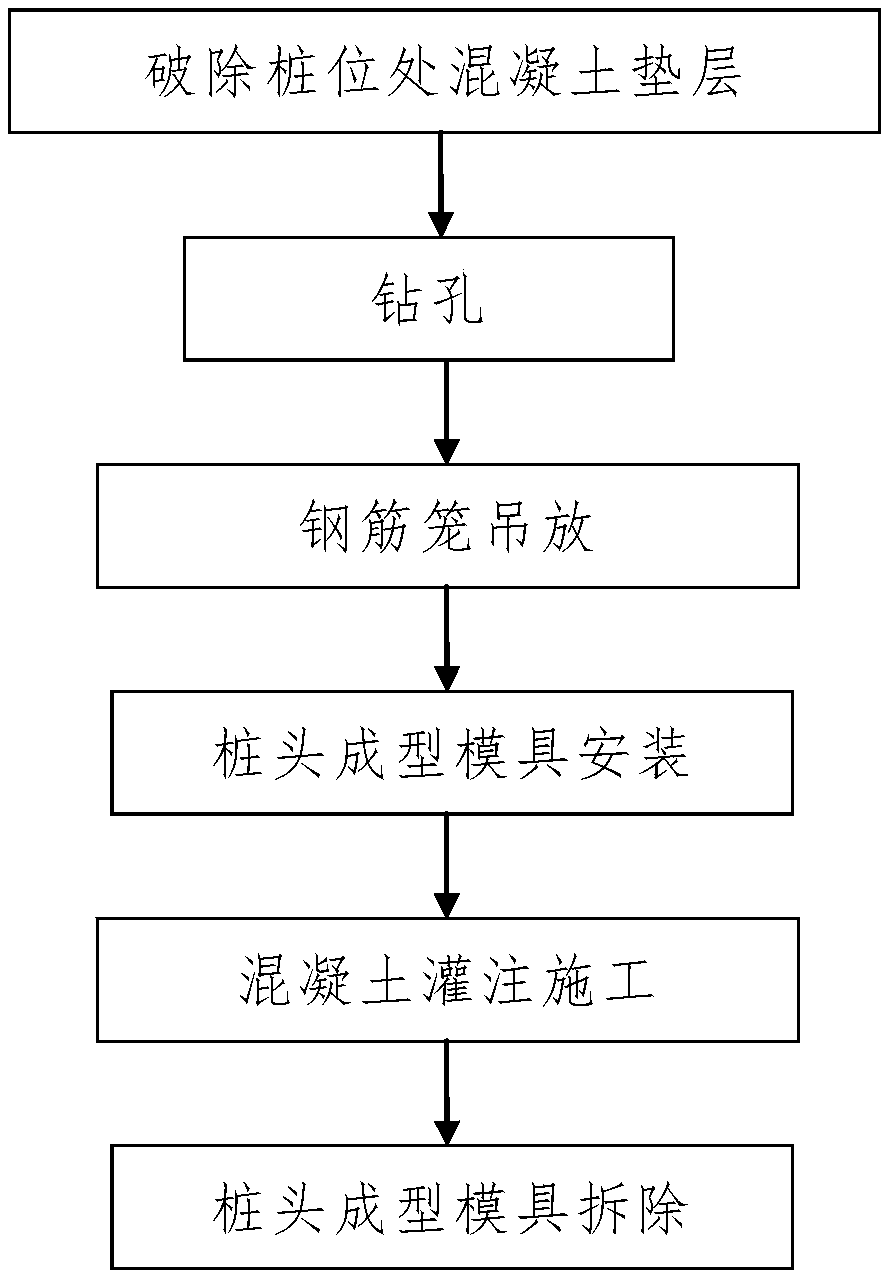

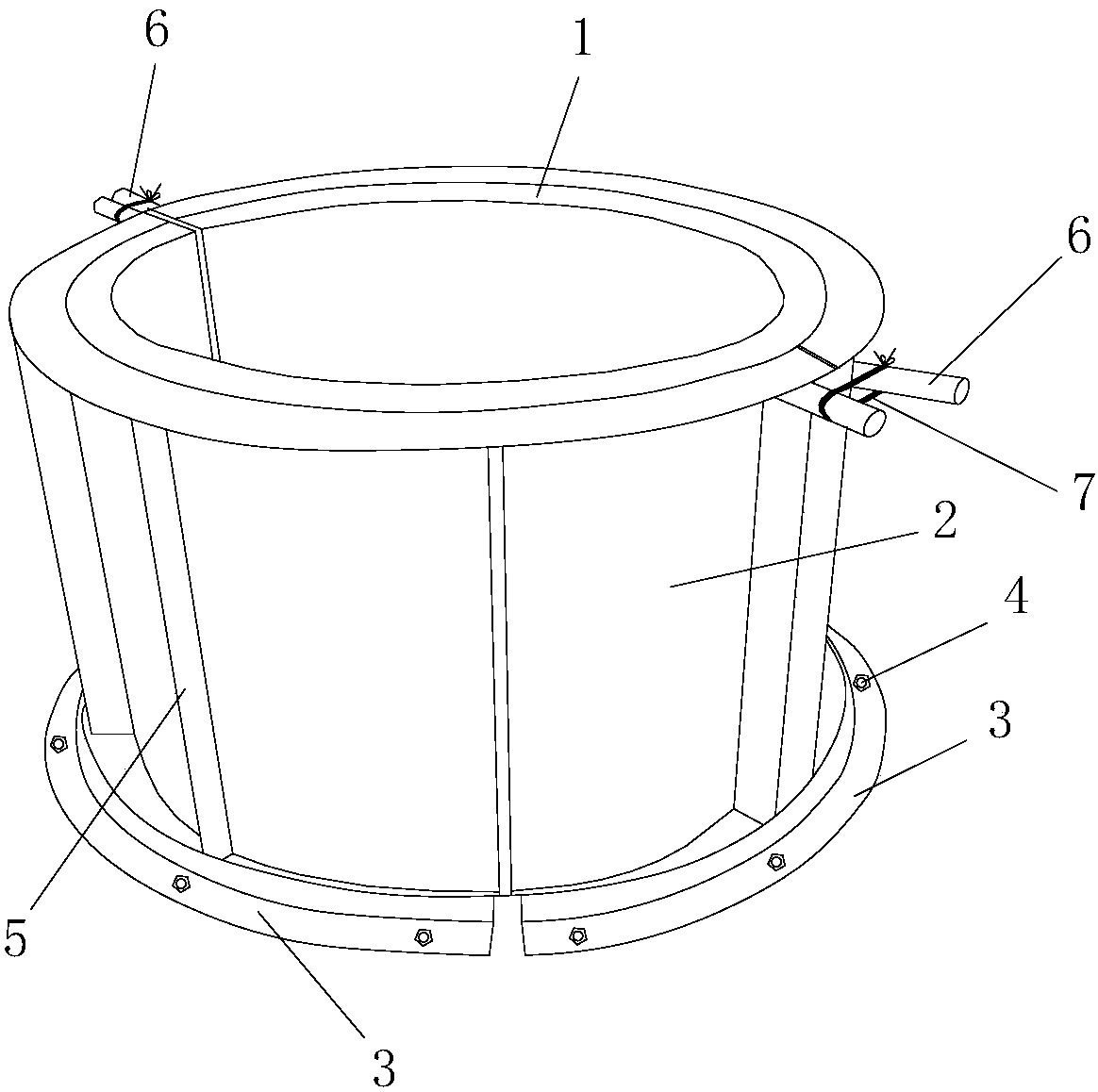

Construction Method of Reinforced Concrete Cast-in-place Pile Without Excavation of Soil Between Pile

The invention discloses a reinforced concrete cast-in-place pile construction method free of excavation of earth among piles. The reinforced concrete cast-in-place pile construction method includes the steps that firstly, foundation pit excavation and support construction are conducted, wherein a construction foundation pit is excavated from top to bottom, and the excavated and formed foundation pit is supported; secondly, construction of a concrete cushion layer at the bottom of the foundation pit is conducted; thirdly, pile position measurement and pay-off are conducted, wherein measurement and pay-off are conducted on pile positions of all reinforced concrete cast-in-place piles needing to be constructed in the foundation pit; and fourthly, reinforced concrete cast-in-place pile construction is conducted, wherein when construction of any reinforced concrete cast-in-place pile is conducted, the process includes the following steps of breaking of the concrete cushion layer at the pile positions, hole drilling, reinforcement cage hoisting and placing, pile head forming mold installation, concrete cast-in-place construction and pile head forming mold detachment. The method is simple in step, reasonable in design, easy and convenient to construct and good in use effect; and by adjusting the construction procedures of pile foundations, the earth-among-pile excavation process in the traditional reinforced concrete cast-in-place pile foundation construction process is omitted, the construction period can be effectively shortened, and the construction cost is saved.

Owner:SCEGC NO 6 CONSTR ENG GRP CO LTD

Smoothwall blasting method for digging tunnel

ActiveCN101799262BSolve the most destructive problemsSimple and economical constructionBlastingDetonatorEngineering

The invention discloses a smoothwall blasting method for digging a tunnel. The method includes the basic processes of marking the shot point, digging and drilling holes, installing the blasting devices, connecting all the blasting devices through detonating fuses, connecting a millsecond detanator and an electric detonator, and finally detonating through a blaster. The method solves the problem of big damage to the wall rocks in the process of digging and blasting the tunnel and is particularly good for controlling over-excavation and under-excavation. The method saves the digging cost and atthe same time makes the late support construction of the tunnel simpler and more economic.

Owner:胡铭益

Pull tube mounting method of passing pipeline

ActiveCN101852312BProtection securitySave excavation costsPipe laying and repairArchitectural engineeringGuide tube

The invention relates to the pipeline construction method field of a metallurgy system, in particular to a pull pipe mounting method of a passing pipeline, which comprises the following steps of: unreeling a pipeline; digging pilot trenches; making the pipeline; popping conducts; connecting steel wires; pulling the conducts and the steel wires; pulling sleeves; and penetrating and mounting a construction pipe. The pull pipe mounting method of a passing pipeline is characterized in that when the conducts are popped, the front conduct is popped in by top pressing equipment (4); and then, the rear conduct (12) is popped in; and when the sleeves are pulled, the conducts and the sleeves are connected, the front conduct (11) is pulled, and the rear sleeve (22) is popped in until the front sleeve (21)passes out of a pilot trench (2) at the other side. The invention has low construction cost, short construction period, high mounting quality and high production efficiency.

Owner:MCC5 GROUP SHANGHAI CORPORATION LIMITED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com