Method for exploiting soft and broken ore body

A mining method and technology for ore bodies, which are applied in the field of sub-pillar-free caving mining, can solve the problems of poor operation safety conditions, large amount of supporting works, and high mining costs, reduce requirements, ensure mining effects, and improve ore mining. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

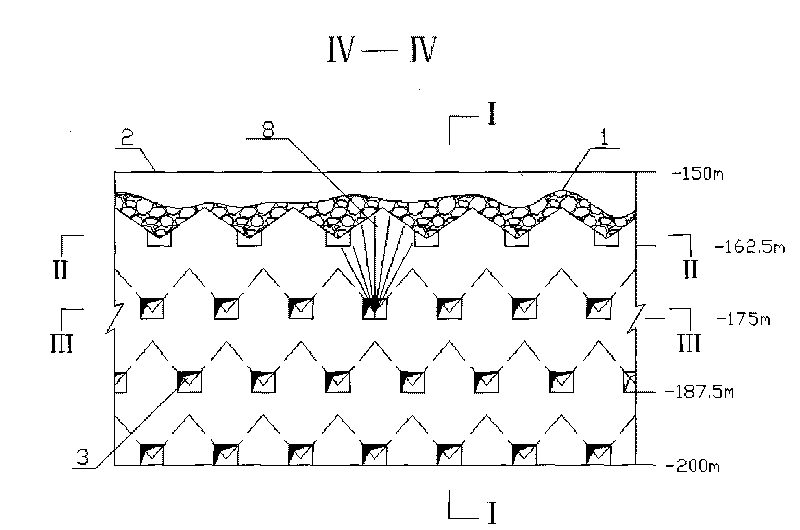

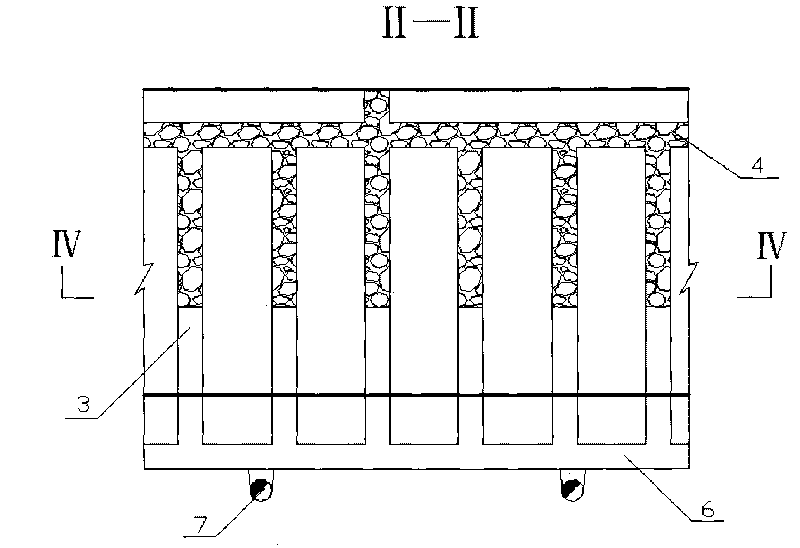

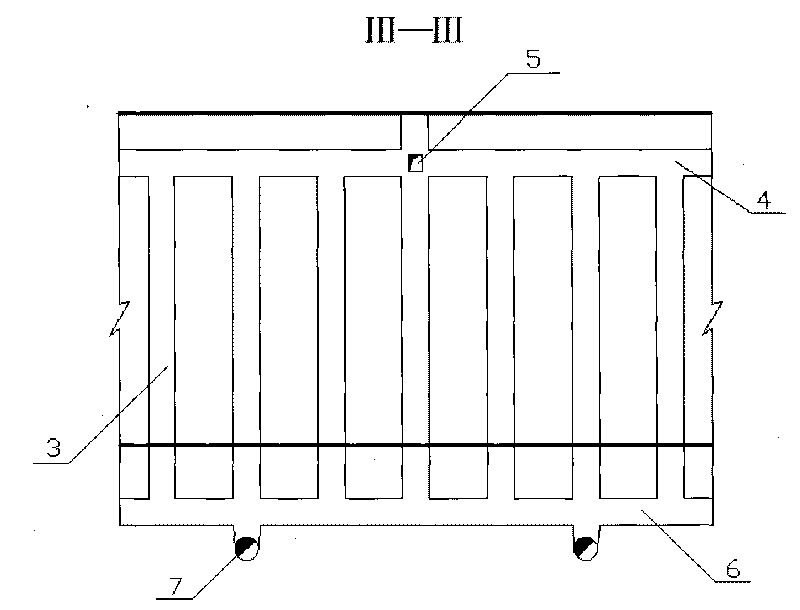

[0014] Example: such as Figure 1 ~ Figure 4 In a certain ore body, the buried depth is below -150 meters, the average horizontal thickness is 50 meters, the average dip angle is 60°, and the ore rock is soft and broken.

[0015] Caving pressure relief without pillars is adopted. Firstly, the ore body of the first segment is excavated and recovered, and the pressure above the lower (second and below) segments to be mined is transferred to the rock mass around the ore body, so that There is no excessive stress concentration in the mining area, and the mining operation is carried out under the condition of pressure relief; the stability problem of the first segmented mining roadway is solved by supporting and increasing the spacing.

[0016] The first segmental mining roadway adopts support forms such as shotcrete anchors, anchor net spraying, etc., and the blasting work requires that the ore body between the mining roadways be collapsed to form a continuous goaf; the lower segm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com