Patents

Literature

35results about How to "Reduced support requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

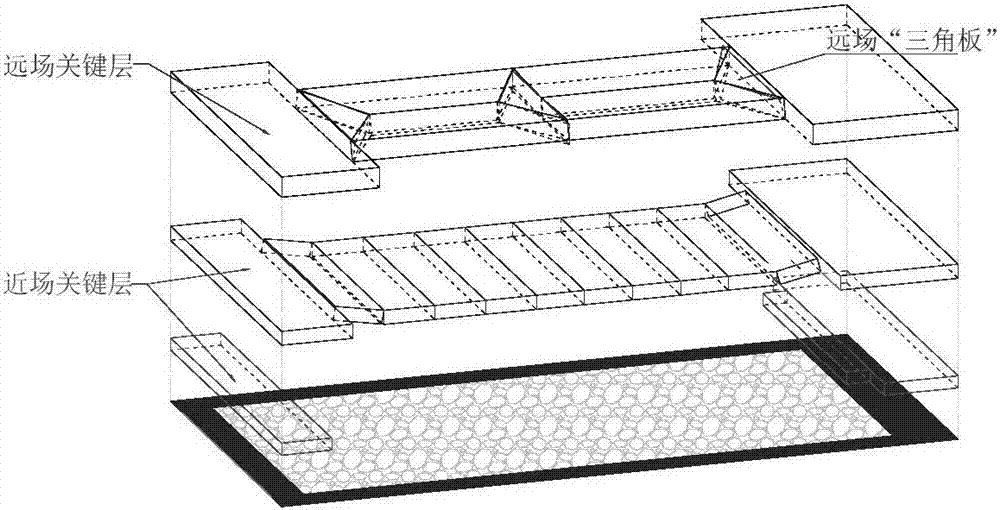

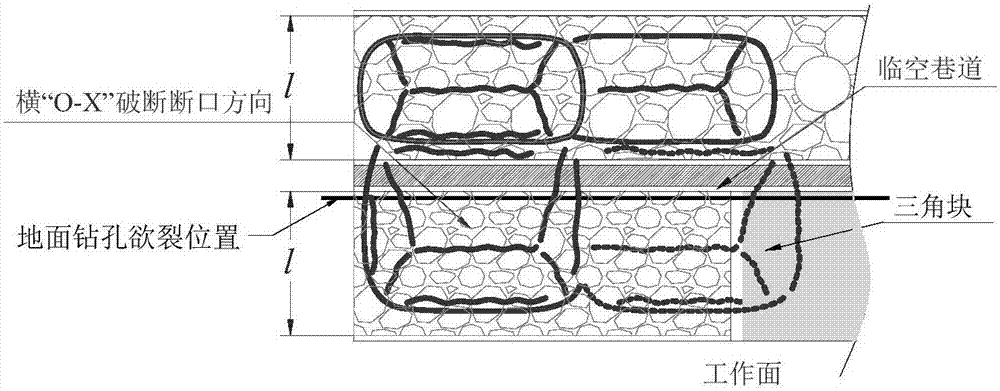

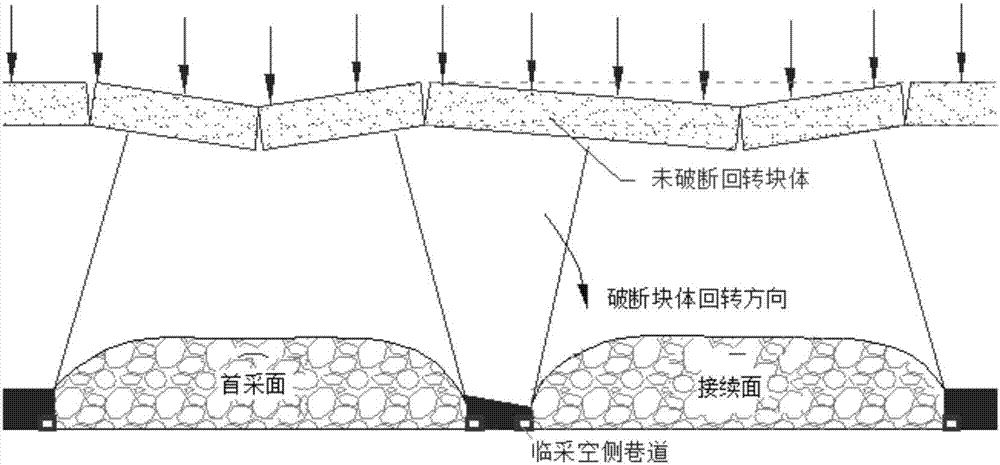

Far field key stratum roof cutting and pressure releasing roadway protection method based on triangular plate structure model

InactiveCN106894816AAlleviate the appearance of strong mine pressureSafe and smoothUnderground miningSurface miningEconomic benefitsEngineering

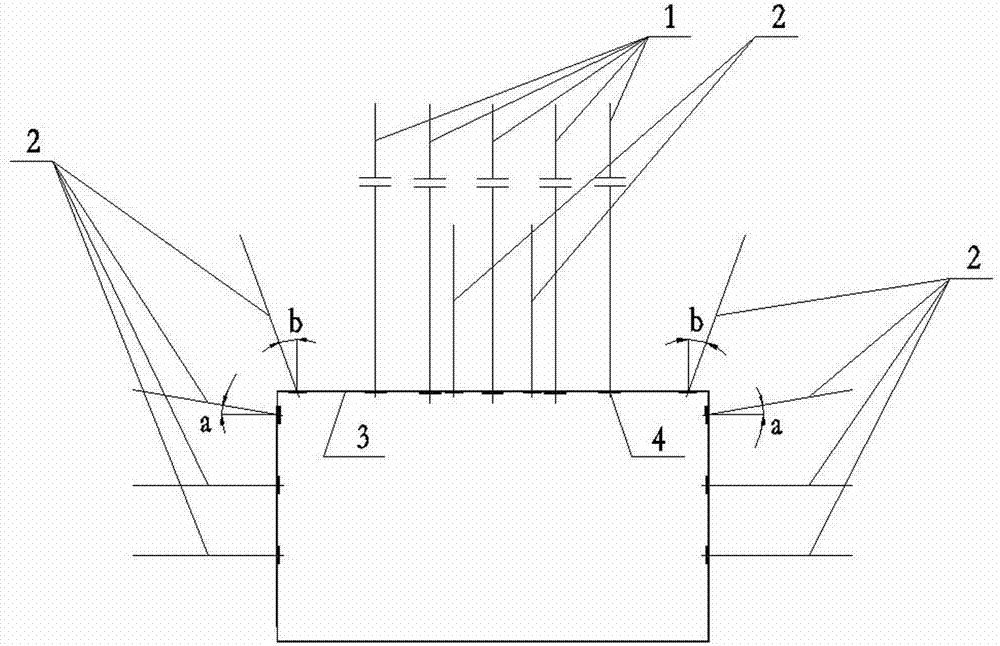

The invention discloses a far field key stratum roof cutting and pressure releasing roadway protection method based on a triangular plate structure model and belongs to the field of coal mining. The method comprises the steps that the stratum position of a far field key stratum influencing working face free roadway mine pressure behavior is determined; the arranged position coordinate of ground drilling is determined, and drilling construction is conducted; and a complete cutting fracture plane parallel to a coal pillar is formed on the far field key stratum through the ground drilling fracturing technology. Presplitting of the far field key stratum above a free roadway in advance is facilitated, and the cutting plane parallel to the coal pillar is formed on the far field key stratum, so that stress transferring is obstructed, mine pressure is released, the length of a lateral rotation block body of a fractured side original roof rock stratum of the free roadway is reduced, the strong mine pressure behavior of the free roadway can be relieved essentially, the supporting requirement of a roof is reduced, accordingly the reserved width of the coal pillar is reduced greatly, the coal recovery rate is increased effectively, and economic benefits are increased.

Owner:CHINA UNIV OF MINING & TECH

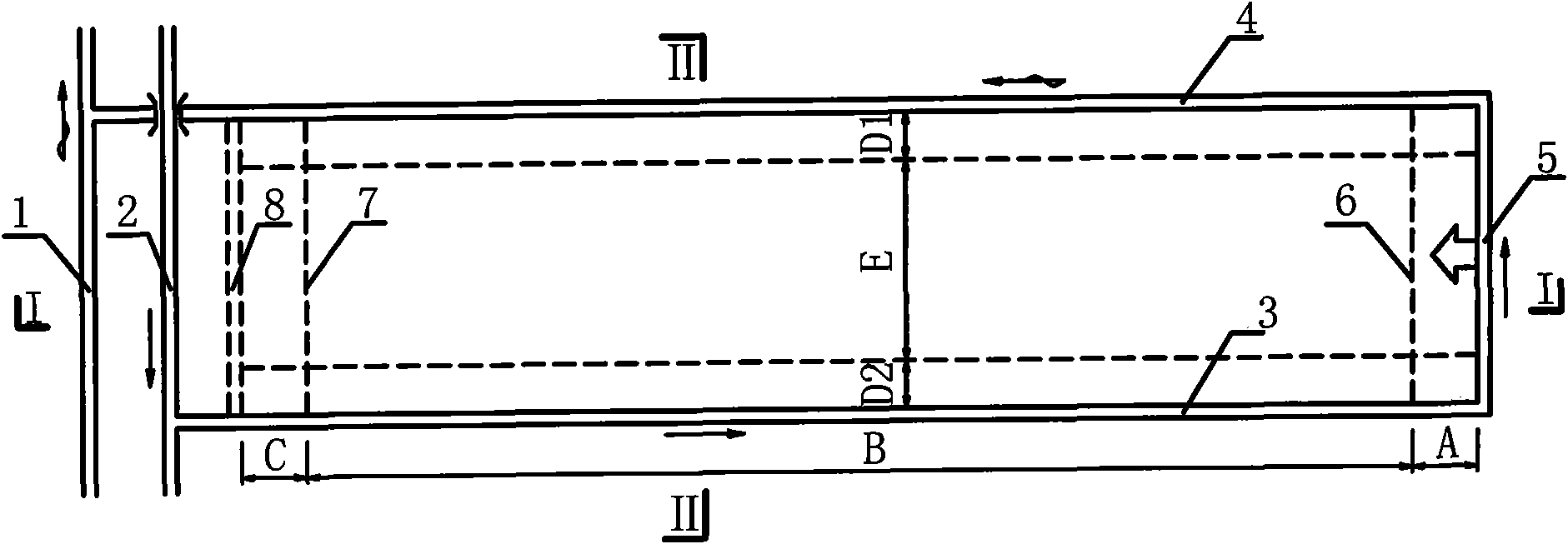

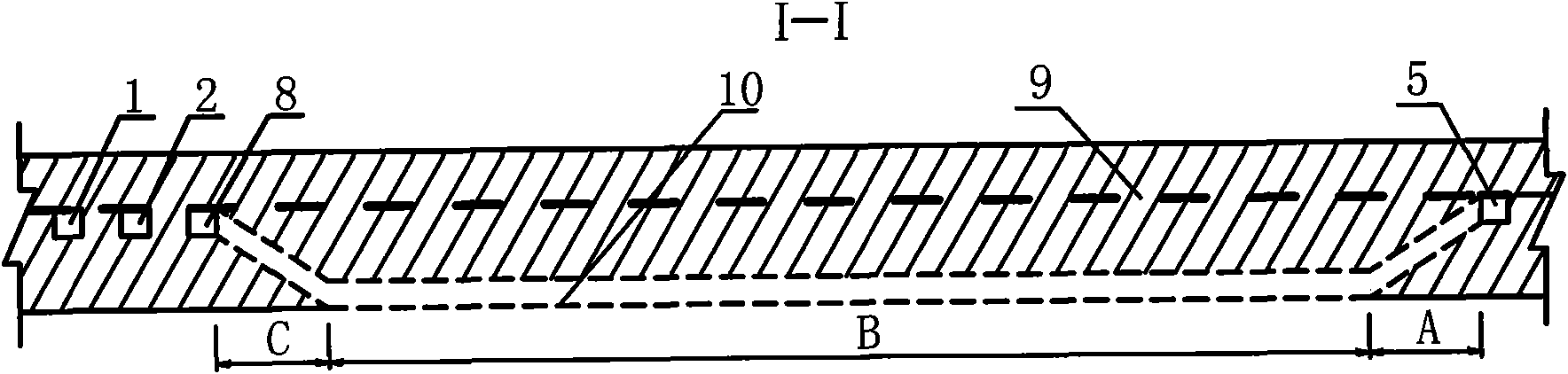

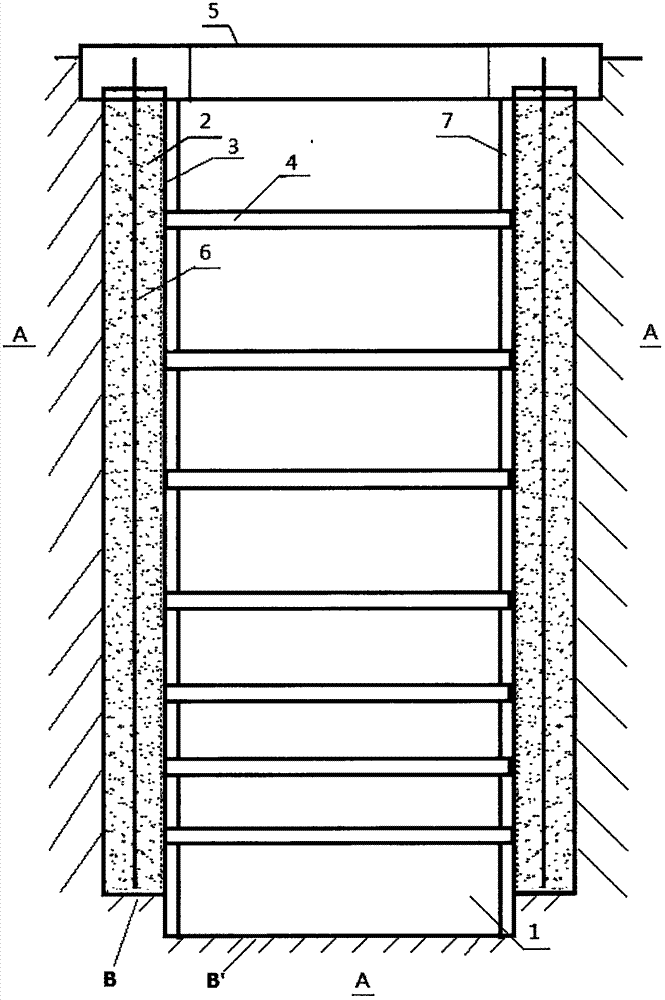

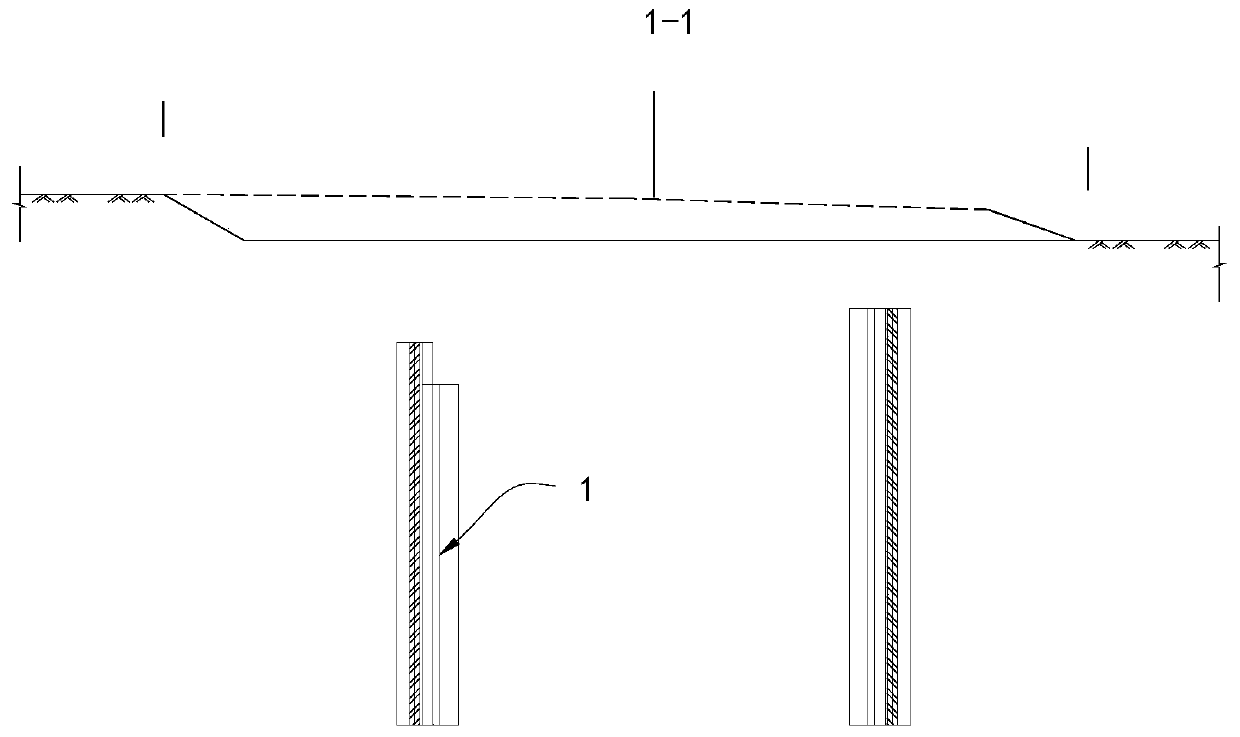

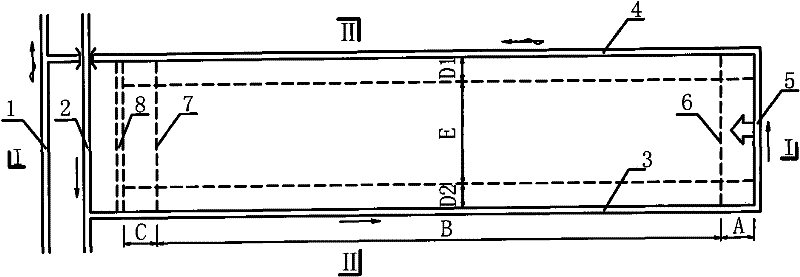

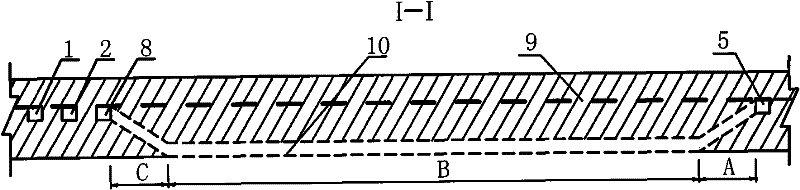

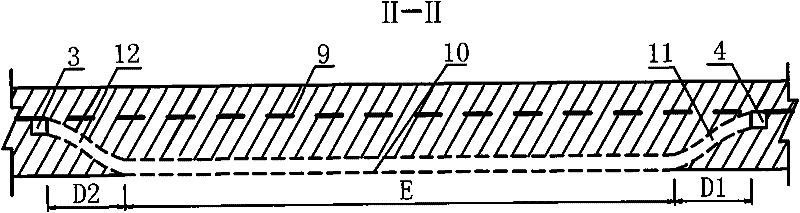

Bidirectional U-shaped coal-mining method of thick coal bed by gateway layout along stability layer

InactiveCN101915099AIncrease the speed of excavationMinimize loss of coal pillarsUnderground miningSurface miningCoal pillarEngineering

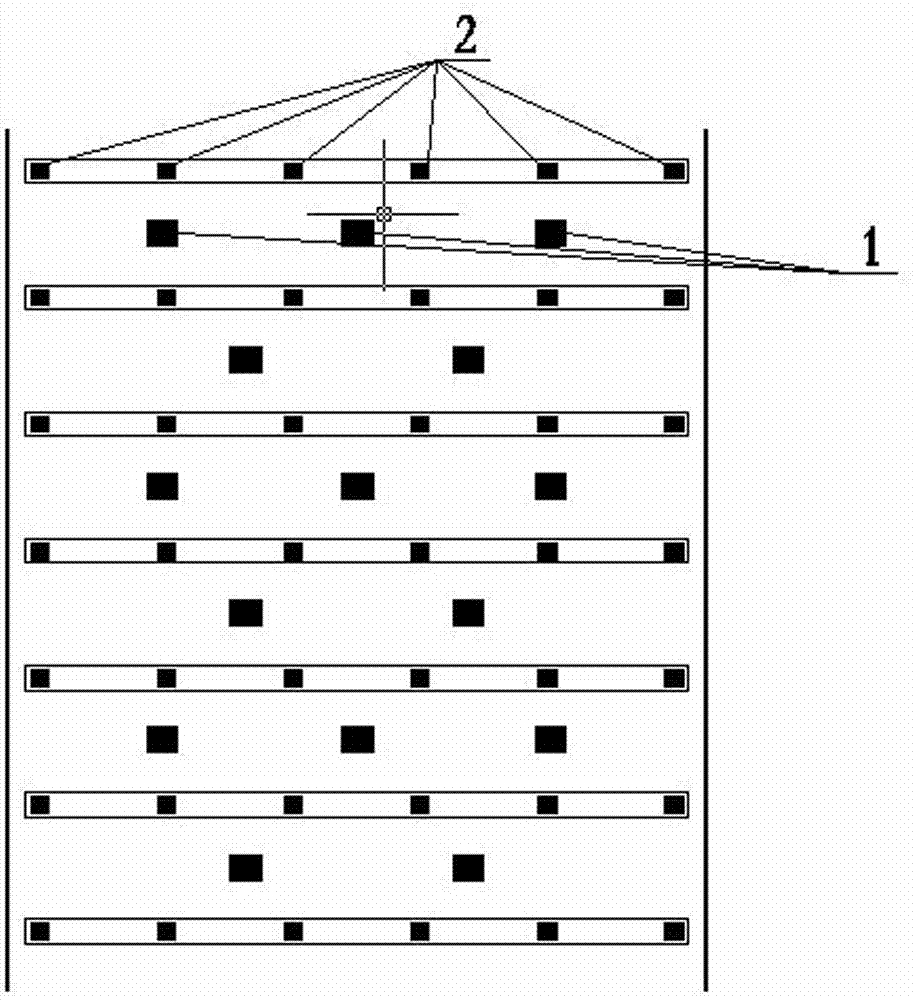

The invention relates to a bidirectional U-shaped coal-mining method of a thick coal bed by gateway layout along a stability layer. The method comprises the following steps of: firstly, tunneling all gateways of a mine along the stability layer so that top plates of the tunnels form the stability layer of the coal bed; and arranging actual mining gateways along the stability layer so that working surfaces form a bidirectional U shape along the lengths and the advancing directions, wherein a three-section actual mining process, including sapping, leveling and climbing, is adopted on the actual mining of the working surfaces along the lengths and the advancing directions. The method radically solves the difficulties in tunneling and supporting of gateway layout along soleplate in a thick coal bed in the prior art, lessens the coal pillar loss among adjacent working surfaces and is beneficial to the gas drainage of the working surfaces particularly at an upper corner. The invention is suitable for the fully-mechanized mining with large mining height and the sub-level caving mining of the loose and broken thick coal bed.

Owner:TAIYUAN UNIV OF TECH

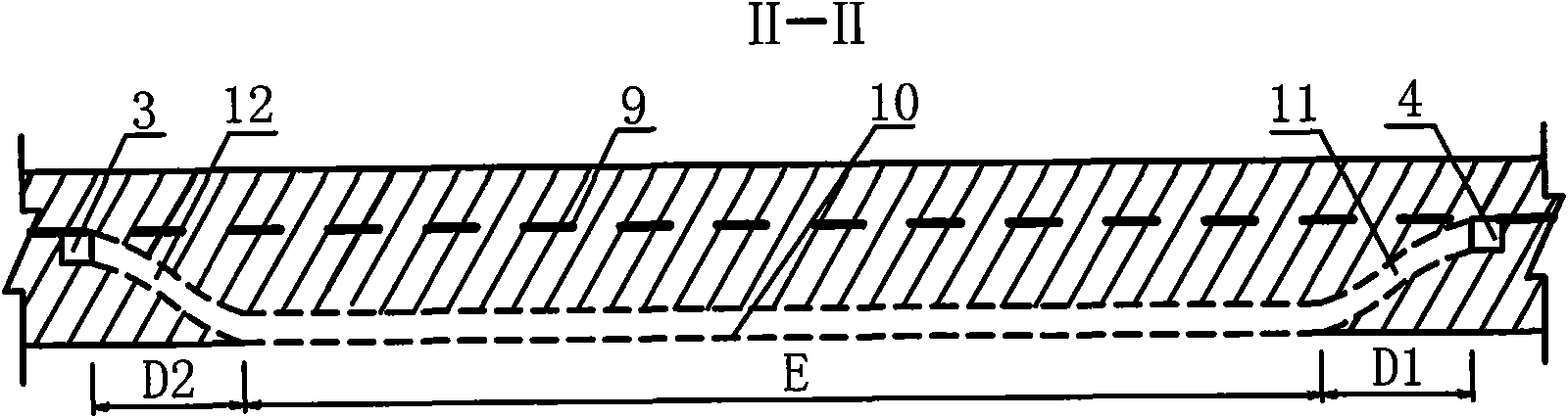

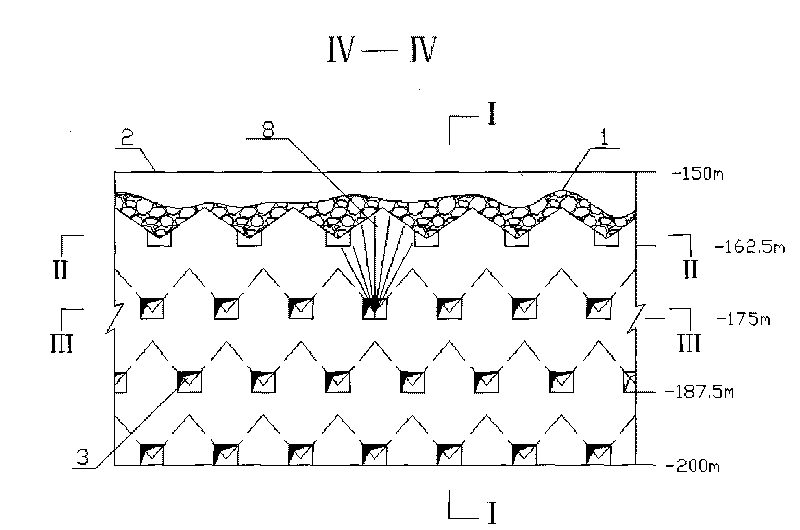

Method for exploiting soft and broken ore body

InactiveCN101718196AImprove stabilityGuaranteed recovery effectUnderground miningSurface miningStress concentrationSpelunking

The invention discloses a sublevel caving method for exploiting a soft and broken ore body without a sill pillar. By using the method, the problem that developing roadways are destroyed by ground pressure is effectively solved, the stability of the roadway engineering and the utilization rate of the developing roadways are improved, the support cost is lowered, the operational safe condition is improved, the mining cost is lowered, and the ore recovery is raised. The technical proposal comprises the following key points: depressurizing by the sublevel caving method without a sill pillar, firstly tunneling and backstoping a first-section ore body, transferring the pressure above an area to be backstoped of next section to the rock mass around the ore body to ensure no over high stress concentration in the backstoping area so as to form a stress decrease area, and excavating in the stress decrease area, wherein the first section uses a large backstoping roadway distance to ensure the stability of the backstoping roadway. The invention is suitable for exploiting a soft and broken ore body in the high-stress area by the sublevel caving method without a sill pillar.

Owner:KUNMING UNIV OF SCI & TECH

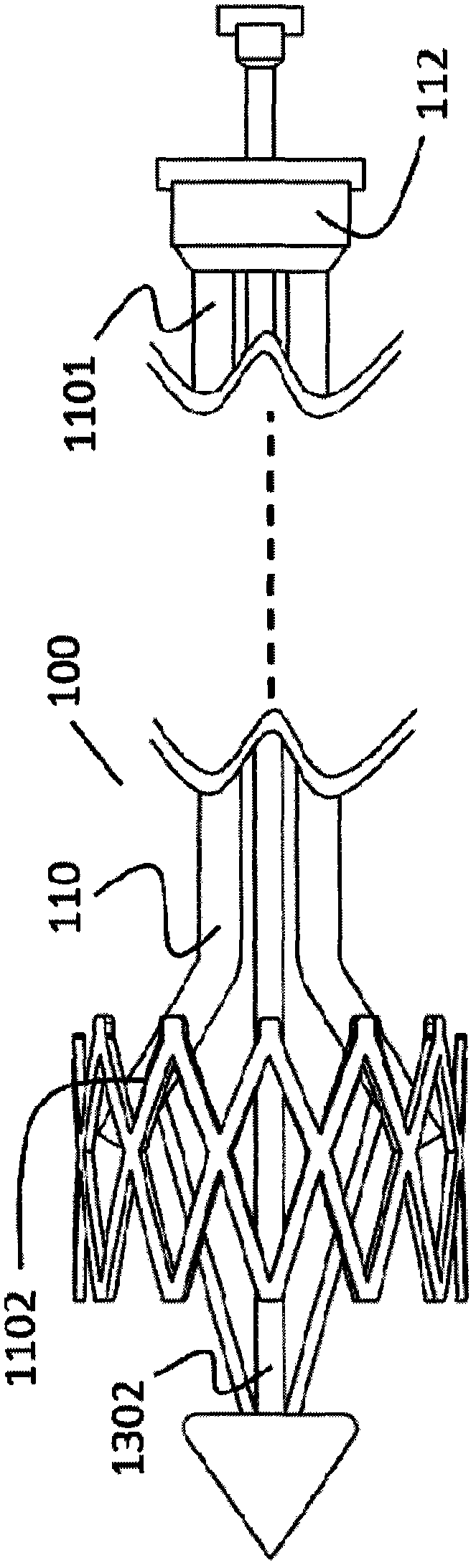

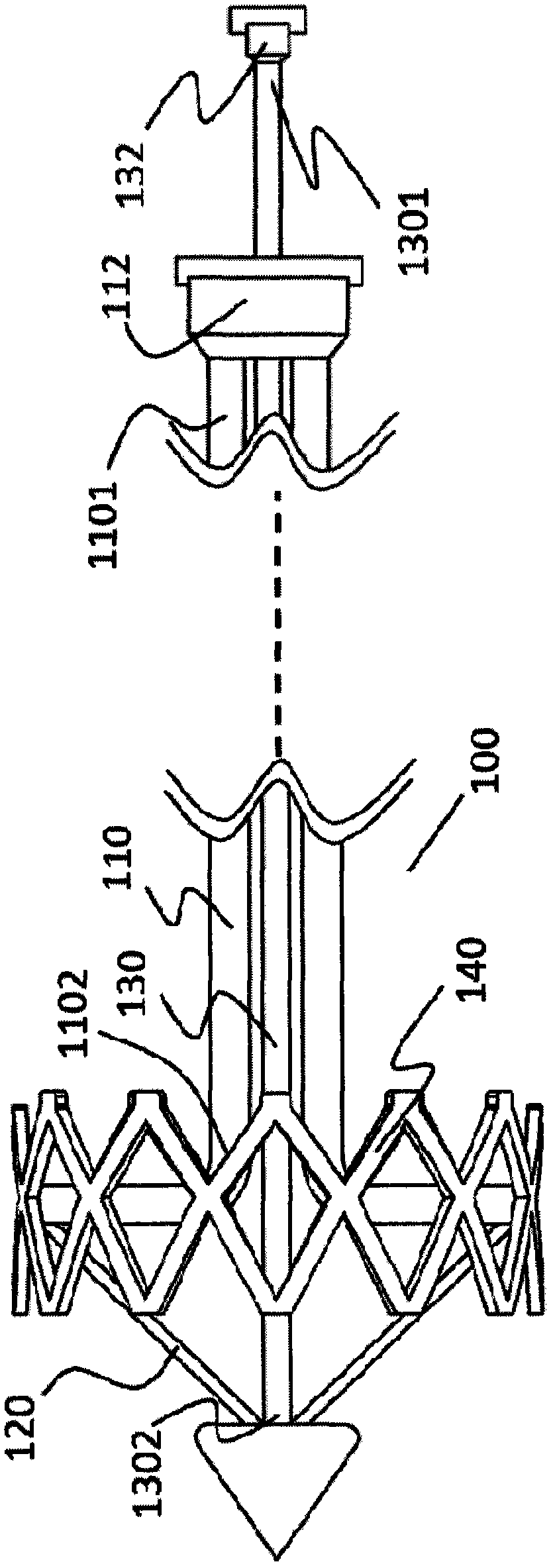

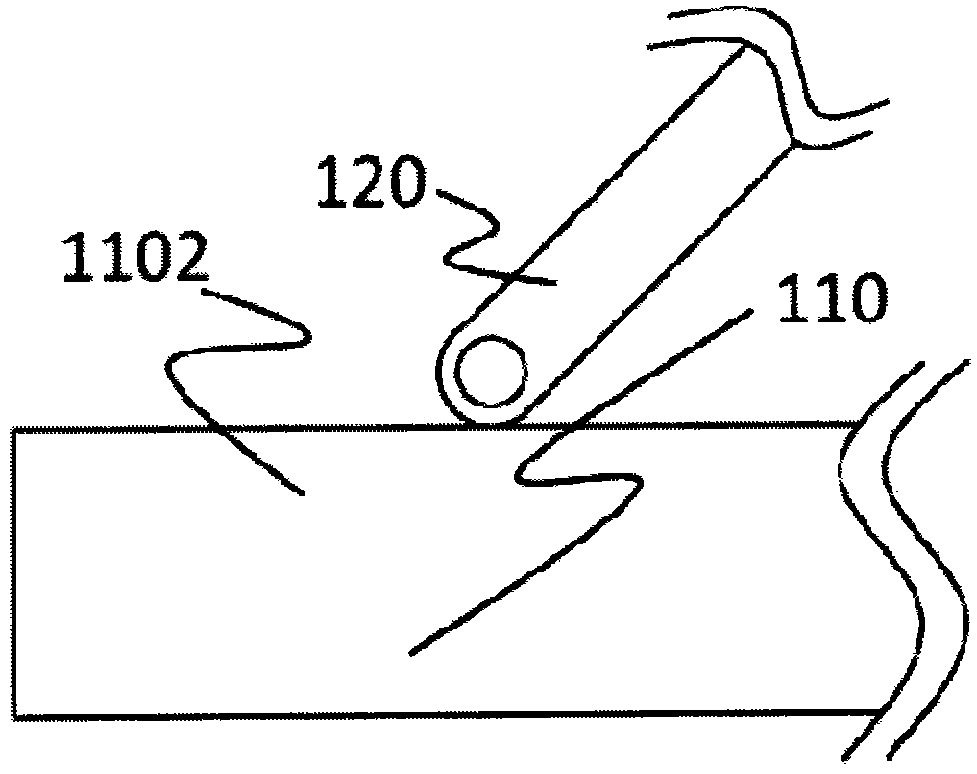

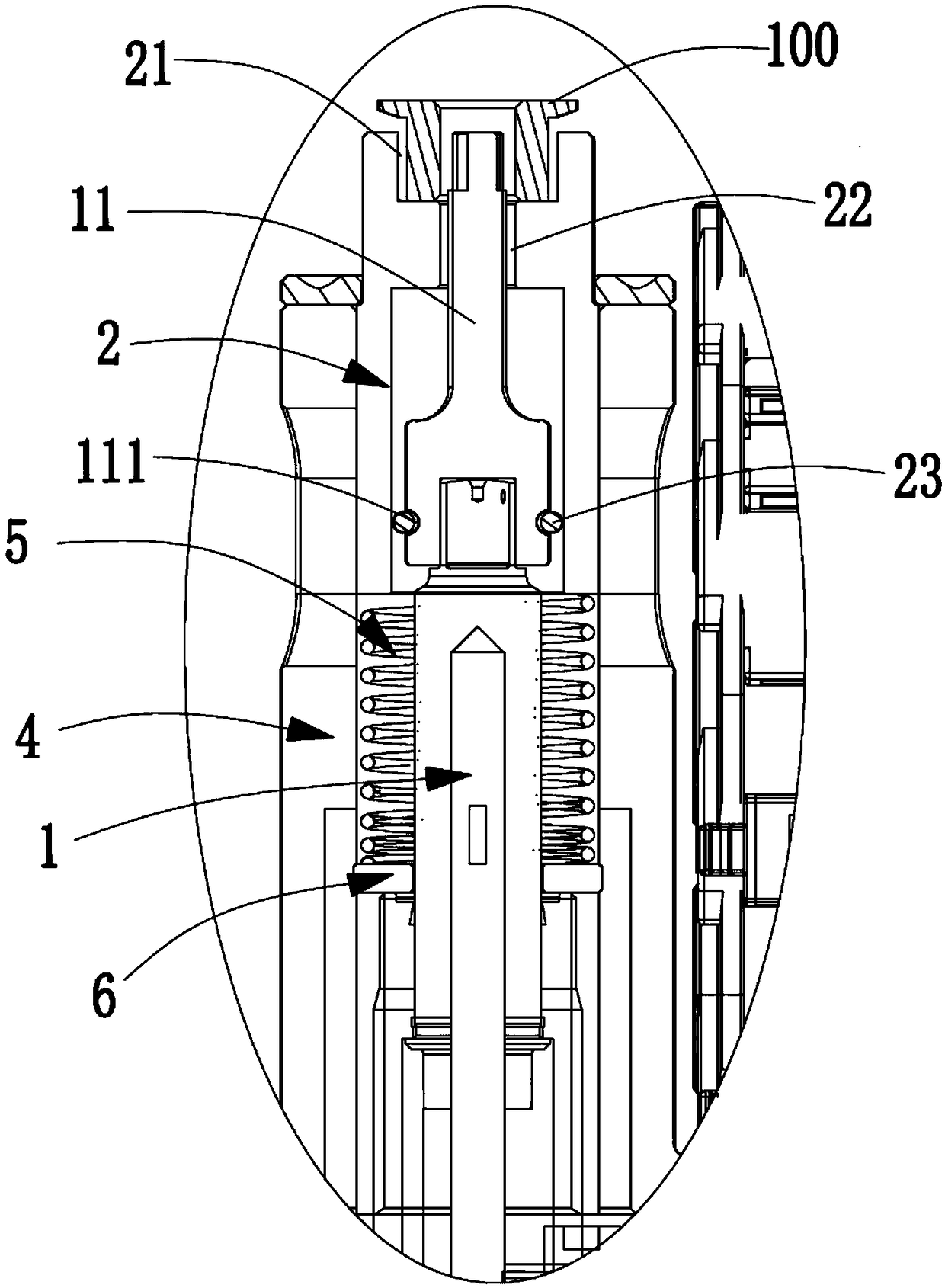

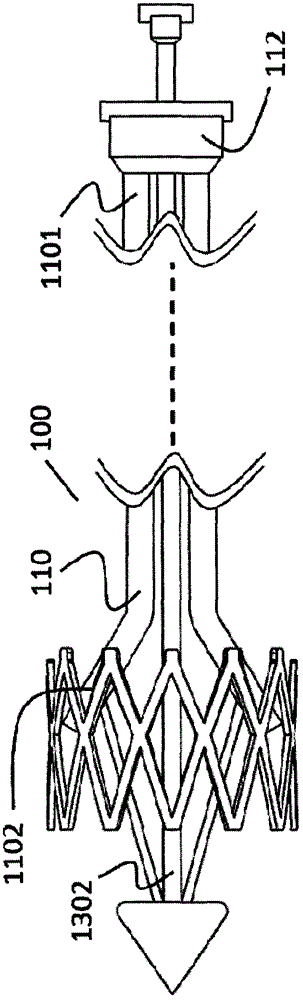

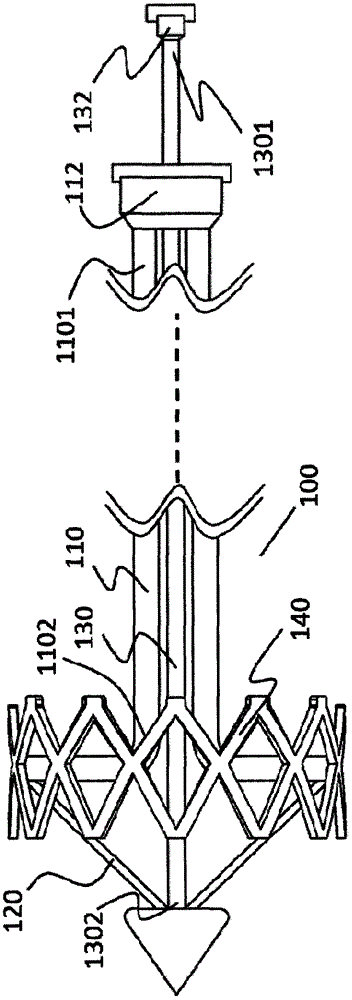

Novel implantation instrument releasing device

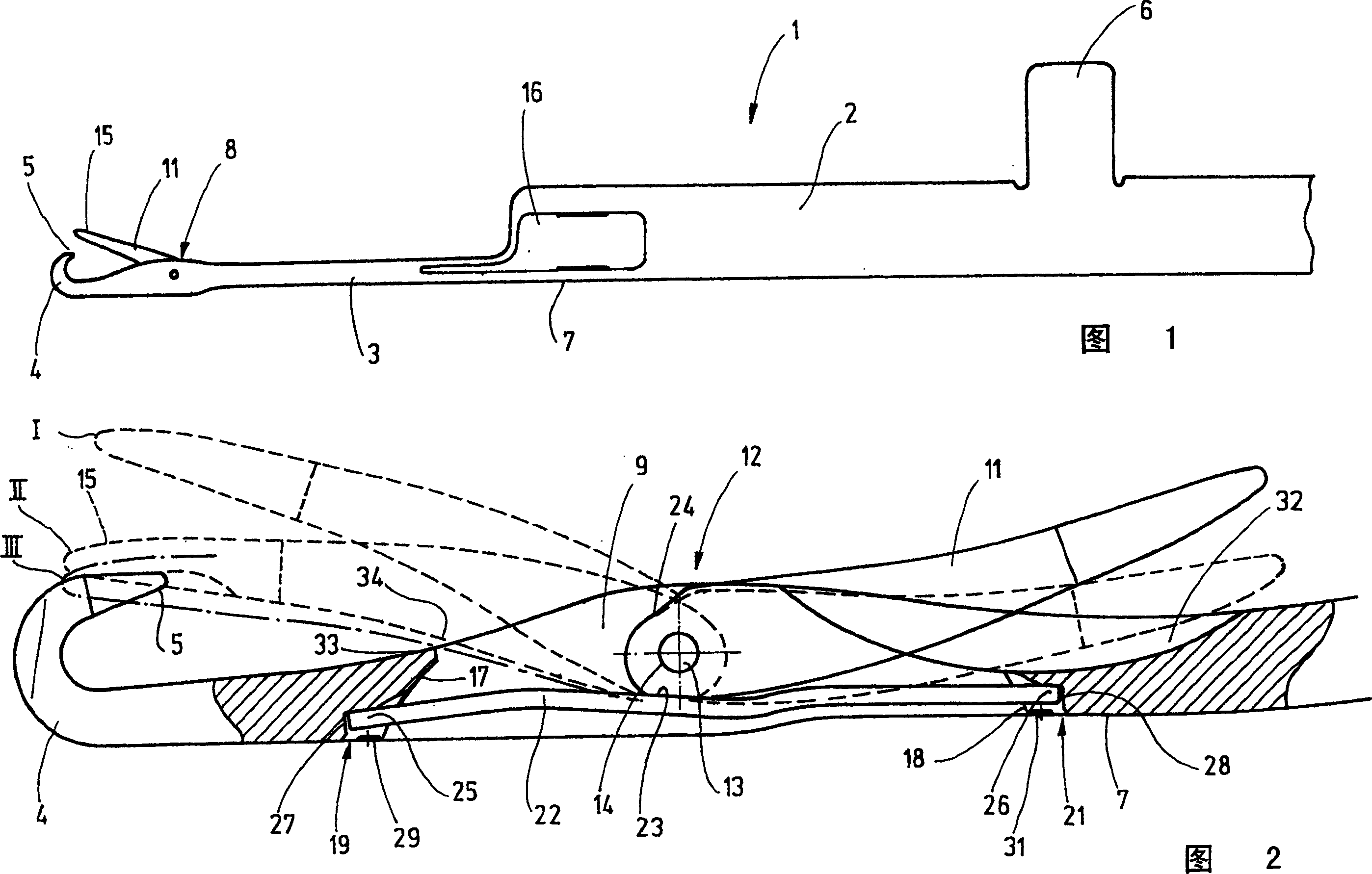

The invention relates to a novel implantation instrument releasing device which comprises an unfolding rod, a unfolding rod operation piece, a control rod, a movement rod and a movement rod operation piece, the unfolding rod is a hollow pipe, the far end of the unfolding rod can be overall bent or partially bent, the near end of the unfolding rod is fixedly connected with the unfolding rod operation piece, one end of the control rod is connected to the far end of the unfolding rod, the other end of the control rod is connected to the far end of the movement rod, the near end of the movement rod is fixedly connected with the movement rod operation piece, the movement rod operation piece is moved relative to the unfolding rod operation piece, and the unfolding rod can be opened and closed. The releasing device further comprises an anchoring needle and an anchoring needle push rod, the anchoring needle and the anchoring needle push rod are arranged in the unfolding rod, and the far end of the anchoring needle push rod is arranged at the near end of the anchoring needle. An implantation instrument connected to the novel implantation instrument releasing device can be controllably released, accurate locating is facilitated, and the surgery success rate is improved.

Owner:NINGBO JENSCARE BIOTECHNOLOGY CO LTD

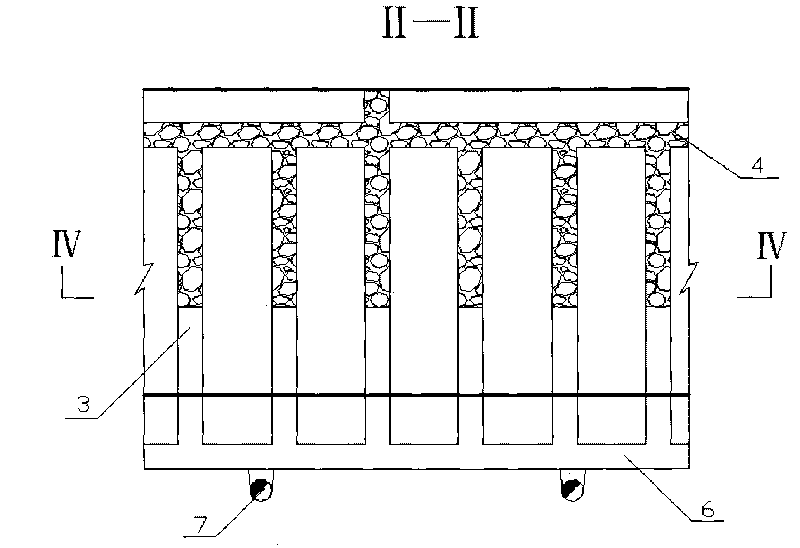

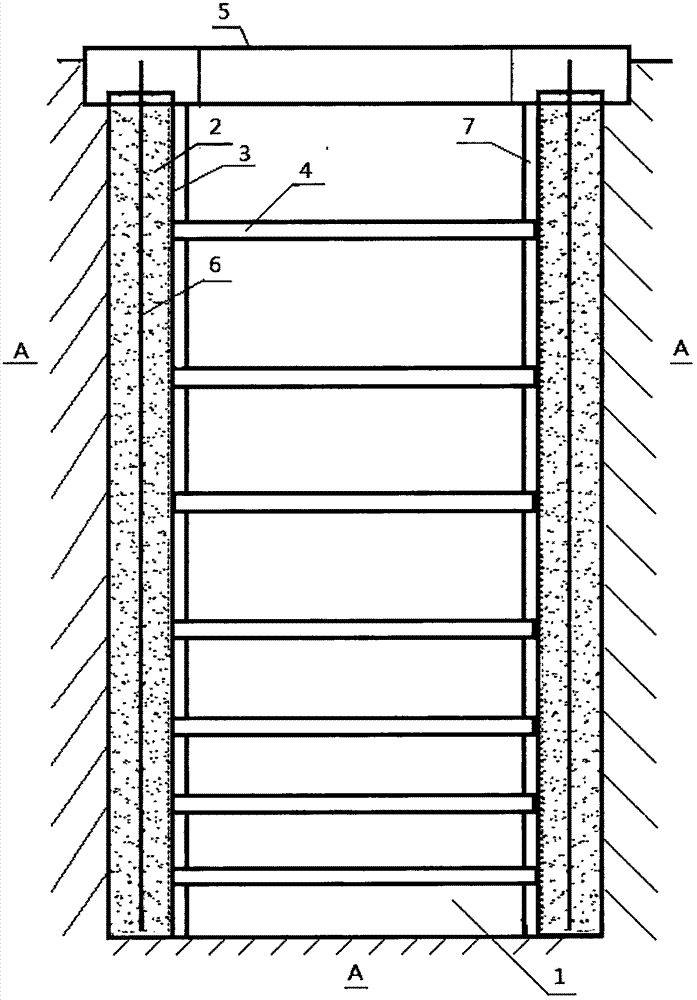

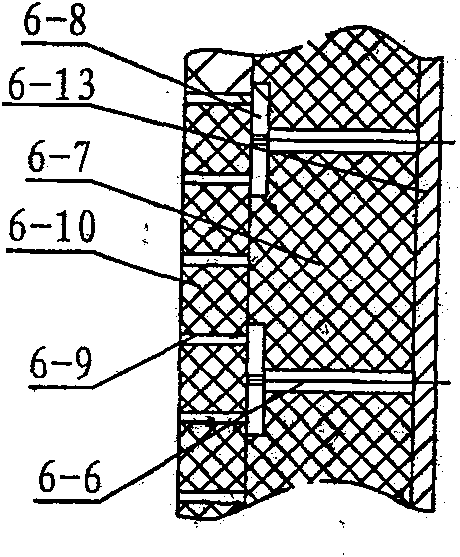

Support method for extra-thick broken coal seam employing nest anchored ropes

InactiveCN102733832ARealize joint supportImprove stabilityAnchoring boltsProtective coversMining engineeringCoal

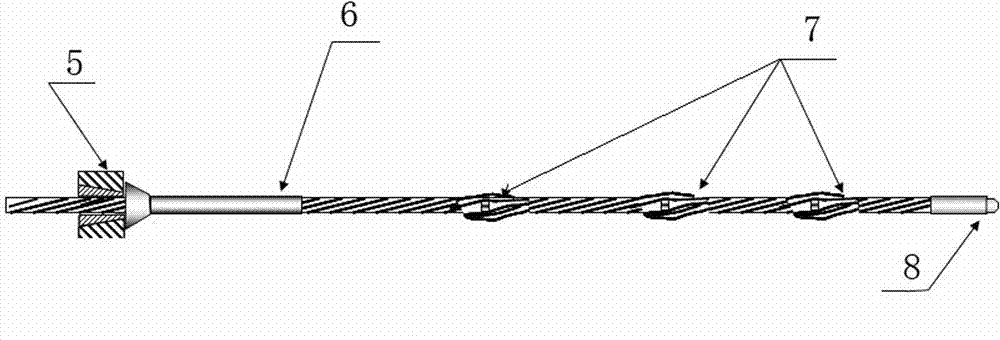

The invention relates to a support method for an extra-thick broken coal seam employing nest anchored ropes. The invention assists in solving a problem of lack of the support reinforcing method for an extra-thick broken coal seam tunnel. According to the invention, integrated combined support of anchor poles, nest anchored ropes, W steel bands and metal meshes is realized by utilizing preferable support parameters and adopting nest anchored ropes which are specially designed; a deformation degree of the super high breaking coal seam tunnel is substantially reduced; requirements for super high breaking coal seam roadway support are satisfied; safety of the super high breaking coal seam roadway is ensured; and production is guaranteed.

Owner:DATONG COAL MINE GRP

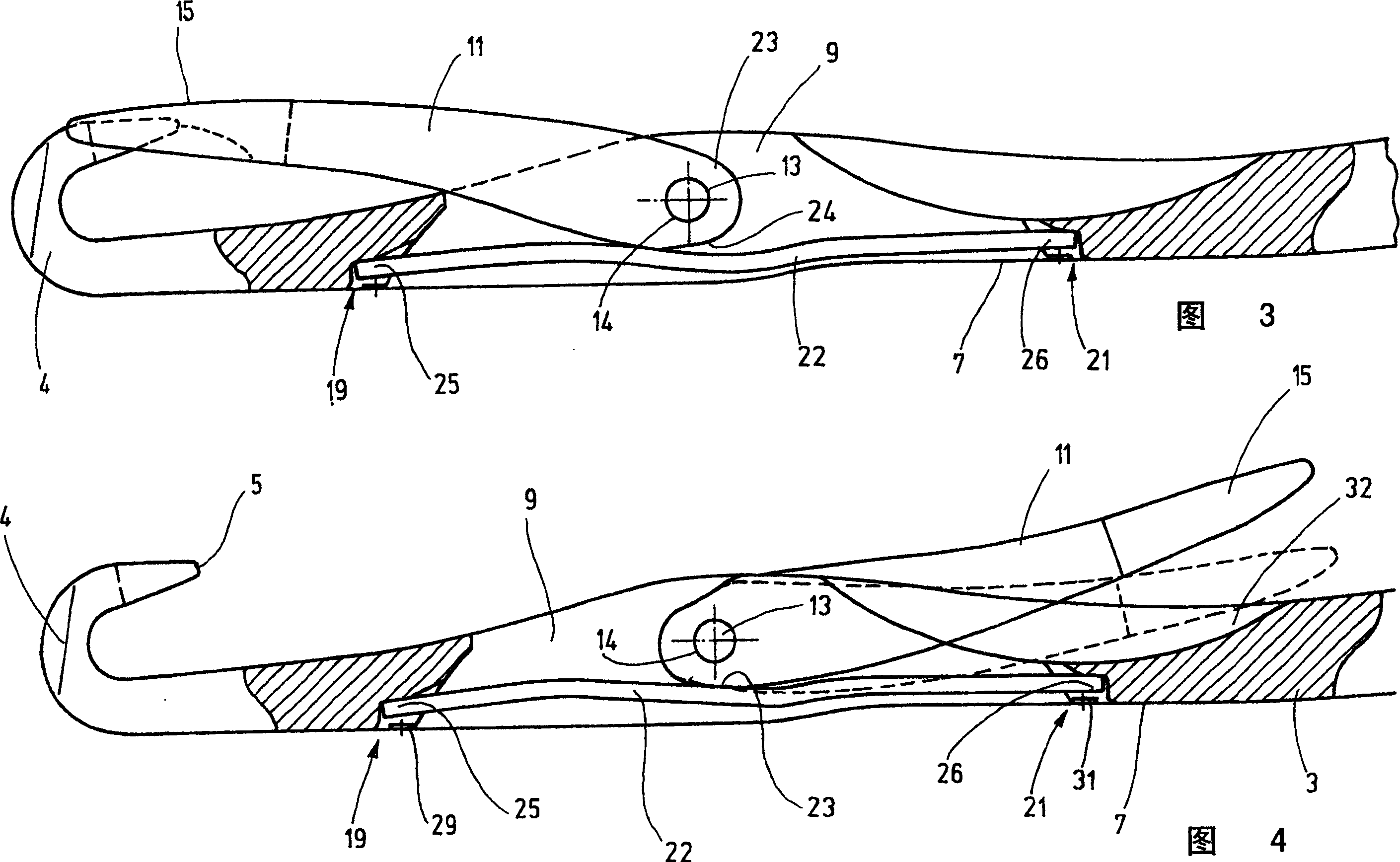

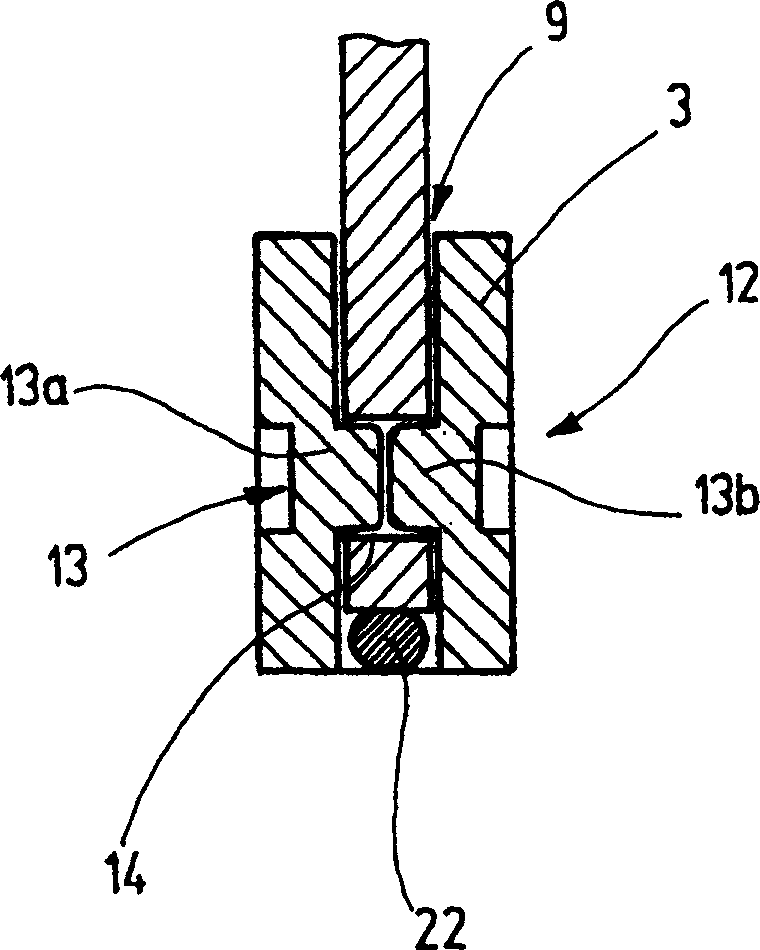

Latch needle

Owner:GROZ BECKERT KG

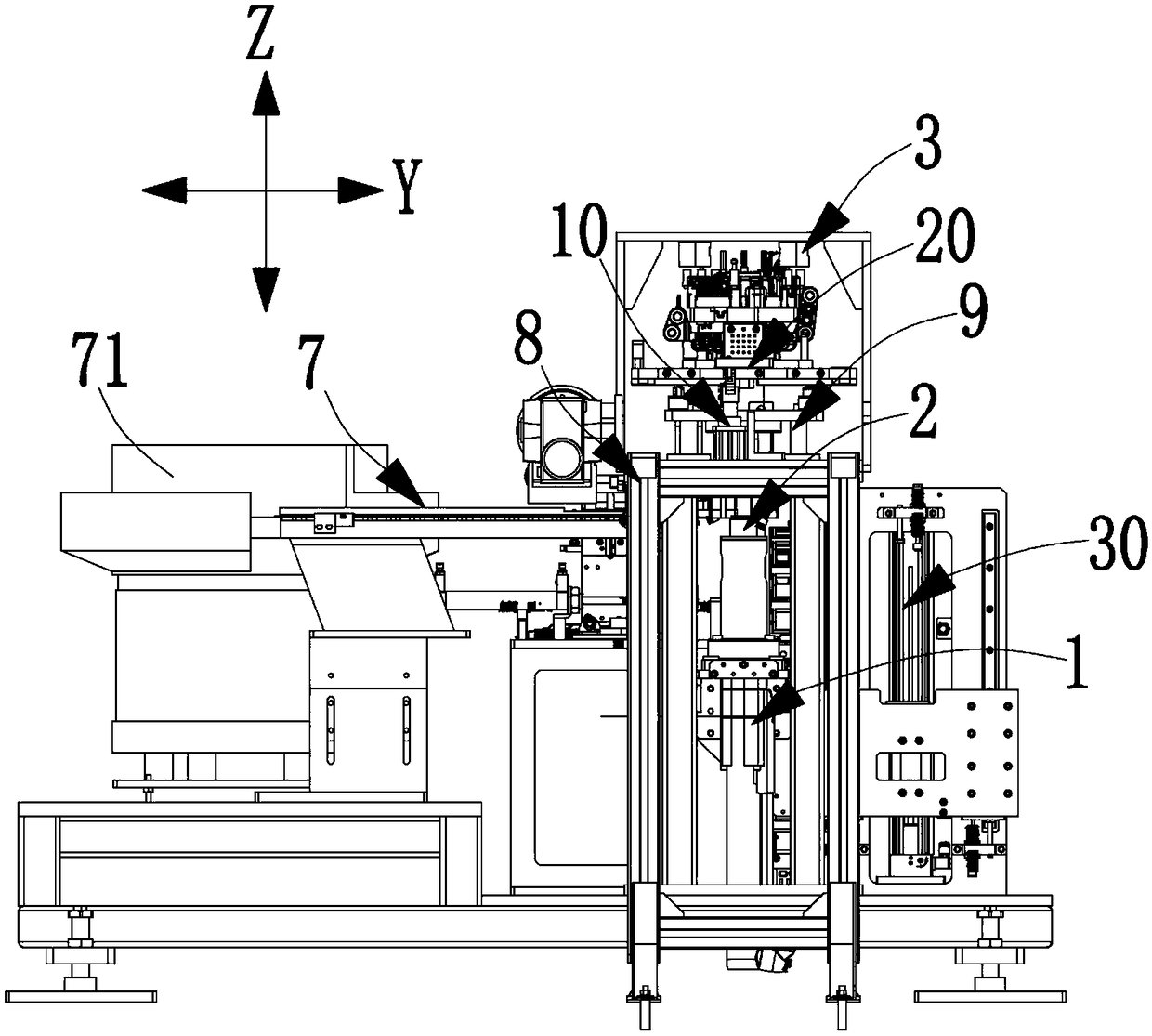

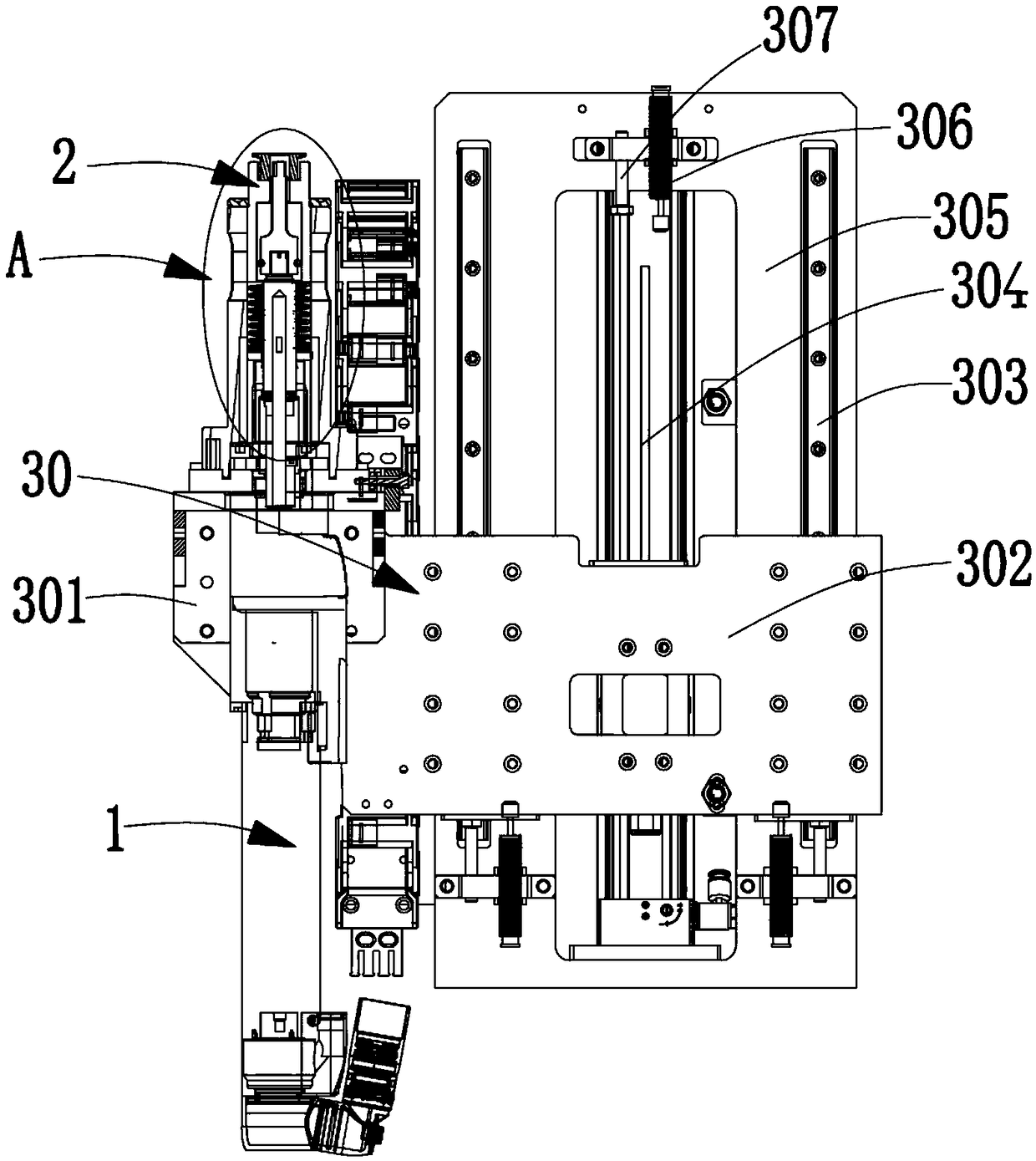

Ejecting type nut screwing machine and screwing method thereof

ActiveCN108971955ARelieve stressImprove protectionManufacturing dynamo-electric machinesMetal working apparatusEngineeringMechanical engineering

The invention discloses an ejecting type nut screwing machine and a screwing method thereof. The screwing machine comprises an electric screwdriver, a floating sleeve and a fixing device, wherein theelectric screwdriver at least can perform longitudinal reciprocating movement, and an electric screwdriver head of the electric screwdriver faces upwards; in a normal state, the floating sleeve sleeves the electric screwdriver head of the electric screwdriver, and can float up and down relative to the electric screwdriver head, and a hole used for limiting a nut is formed in the top part of the floating sleeve, and the electric screwdriver head extends into the hole in the normal state; and the fixing device is used for fixing a second component and enabling a self-rotating to-be-screwed parton the second component to be coaxial with the floating sleeve. According to the machine and the method, the design is ingenious, the structure is simple, the ejecting mode is adopted for the screwing, so that the pressure generated by conventional operation on a conveying line and a material tray is avoided, and protection of the conveying line and the material tray can be facilitated; when in assembly, an ingenious floating structure is combined with the electric screwdriver, a mode of driving a rotor shaft to rotate and ejecting the nut is adopted, so that the assembling of a belt wheel andthe rotor shaft is effectively achieved, the structure of fixing the rotor shaft is omitted, and the simplifying of the overall structure of the equipment is facilitated.

Owner:KUNSHAN JIEYUN INTELLIGENT EQUIP CO LTD

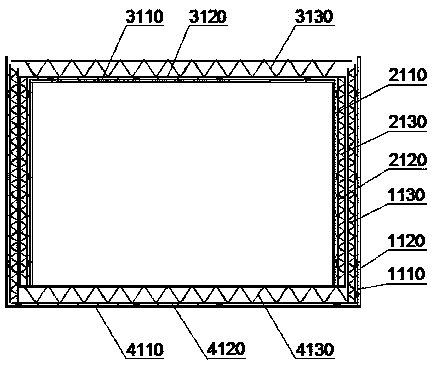

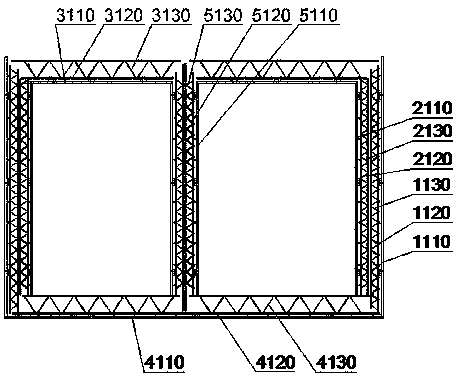

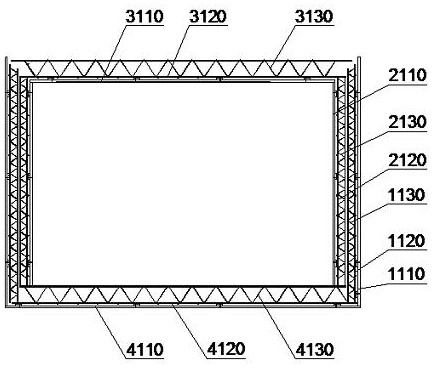

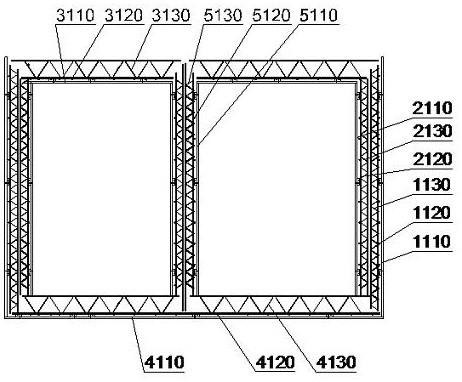

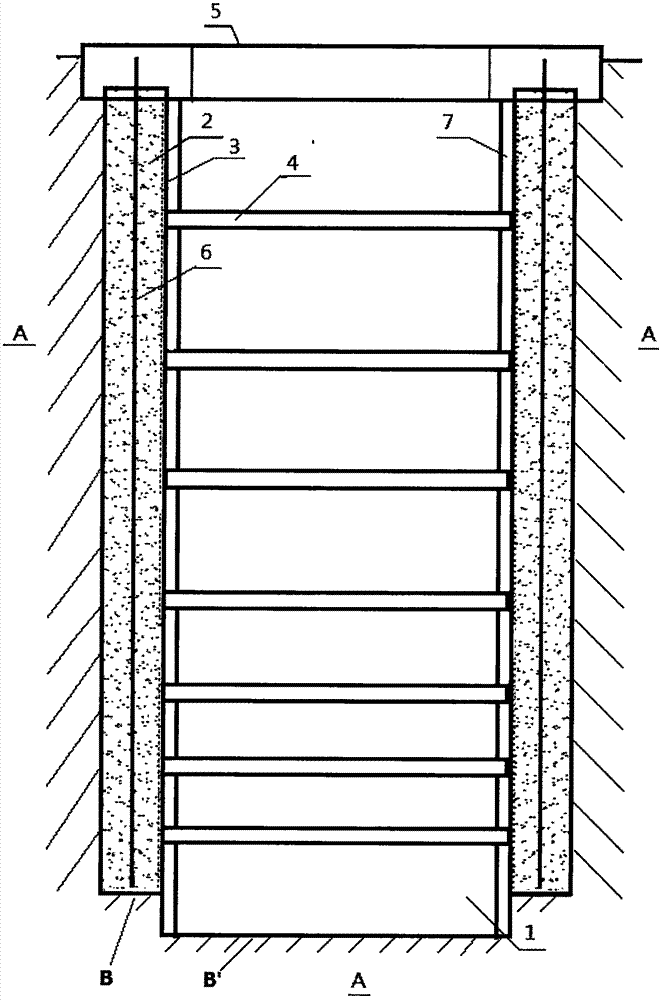

Formwork-free concrete single-cabin pipe gallery or multi-cabin pipe gallery and construction method thereof

ActiveCN111074939AHigh degree of automationHigh quality and precisionArtificial islandsUnderwater structuresReinforced concreteArchitectural engineering

The invention relates to a formwork-free concrete single-cabin pipe gallery or multi-cabin pipe gallery and a construction method thereof. The pipe gallery comprises a top plate, a bottom plate and awall body which are connected with one another, wherein the wall body comprises an outer wall body and further comprises or does not comprise a partition wall body; the wall body adopts a cast-in-place reinforced concrete structure and is mainly composed of wall body fixing formworks positioned on the two sides of the wall body and a wall body concrete layer poured between the wall body fixing formworks on the two sides; the wall body fixing formworks adopt steel bar truss fixing formworks; each steel bar truss fixing formwork comprises a panel, a steel bar net and a steel bar truss, wherein the steel bar net and the steel bar truss are positioned on one side of the panel; and the top plate and the bottom plate are preferably of cast-in-place concrete structures. The construction method comprises the steps of bottom plate construction, wall body construction, top plate construction and necessary concrete oxidation. According to the formwork-free concrete single-cabin pipe gallery or multi-cabin pipe gallery and the construction method thereof, the workload and the labor intensity of pipe gallery construction can be reduced, the influence degree of human factors on the building quality is reduced, the construction cost is reduced, and the adverse effects on the environment and the society in the pipe gallery construction process are reduced.

Owner:ZHONGQINGDA TECH HLDG CO LTD

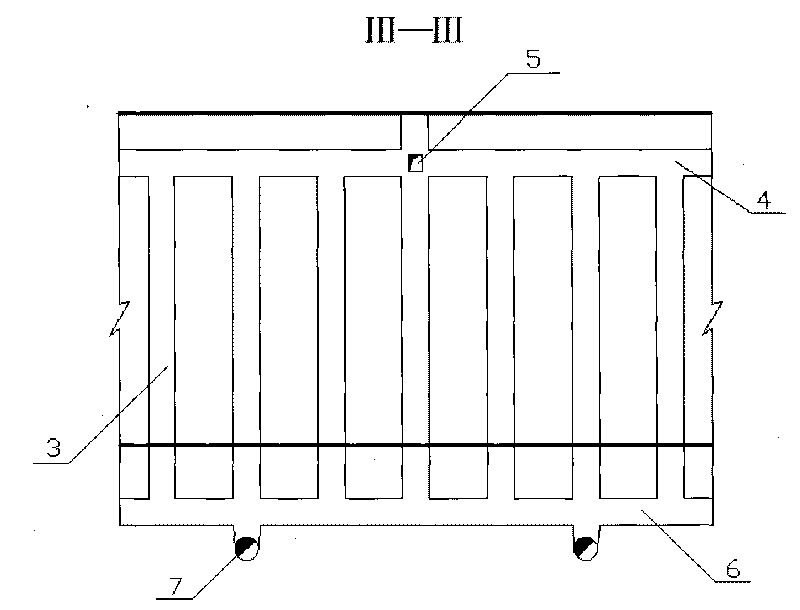

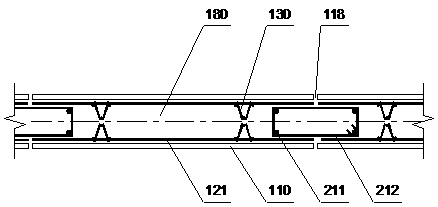

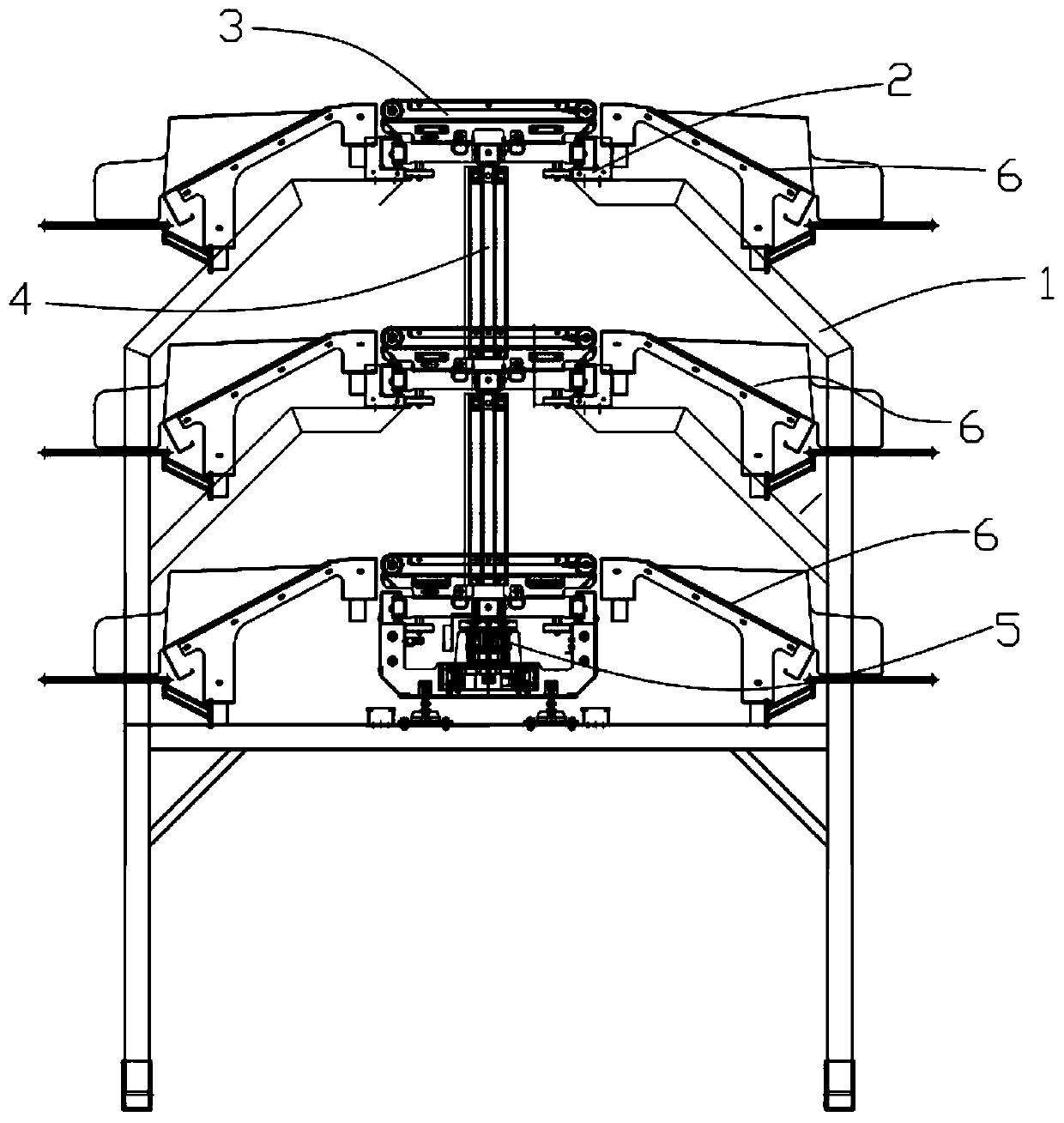

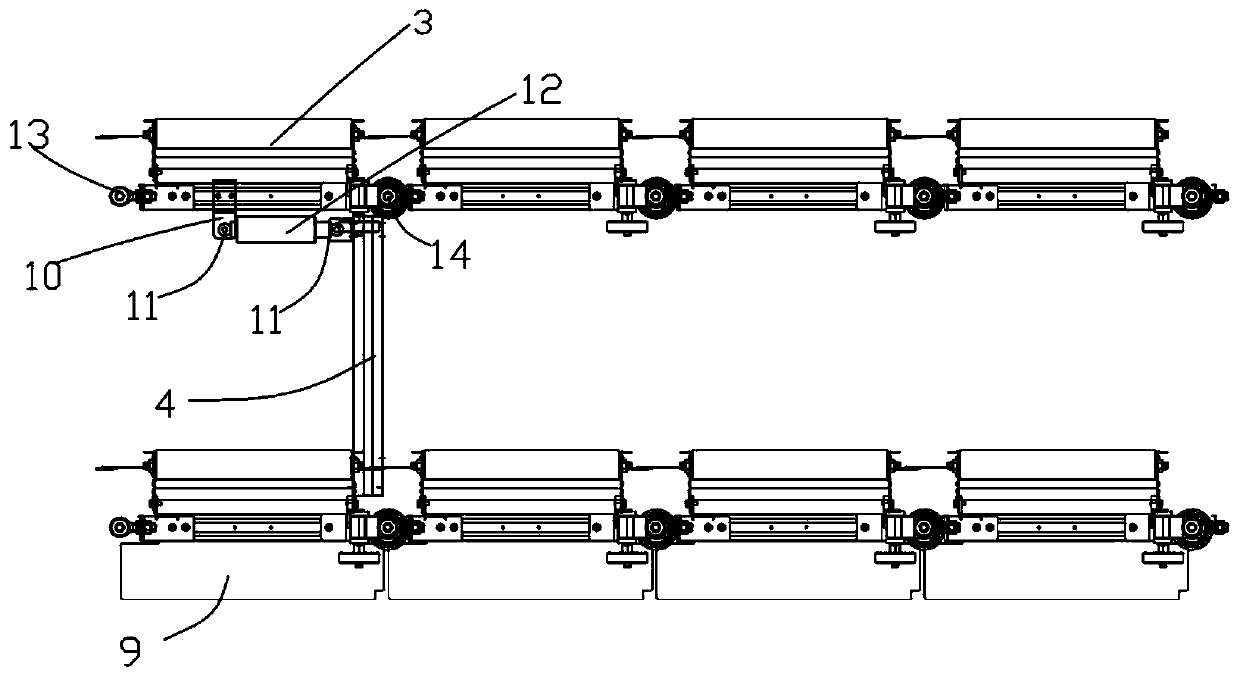

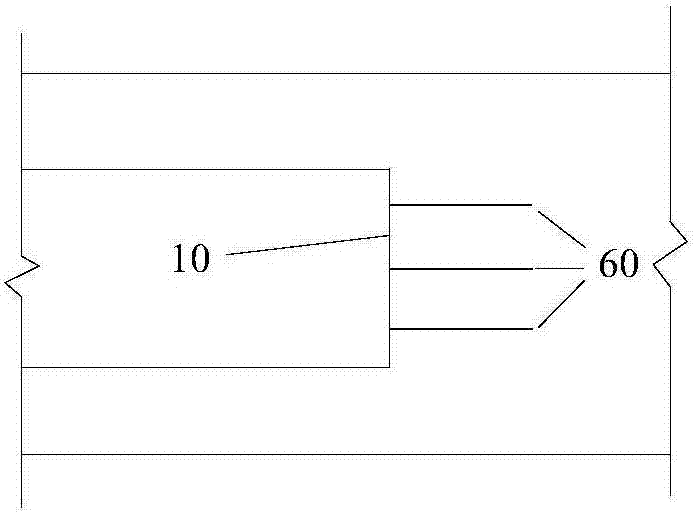

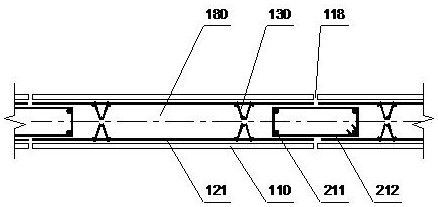

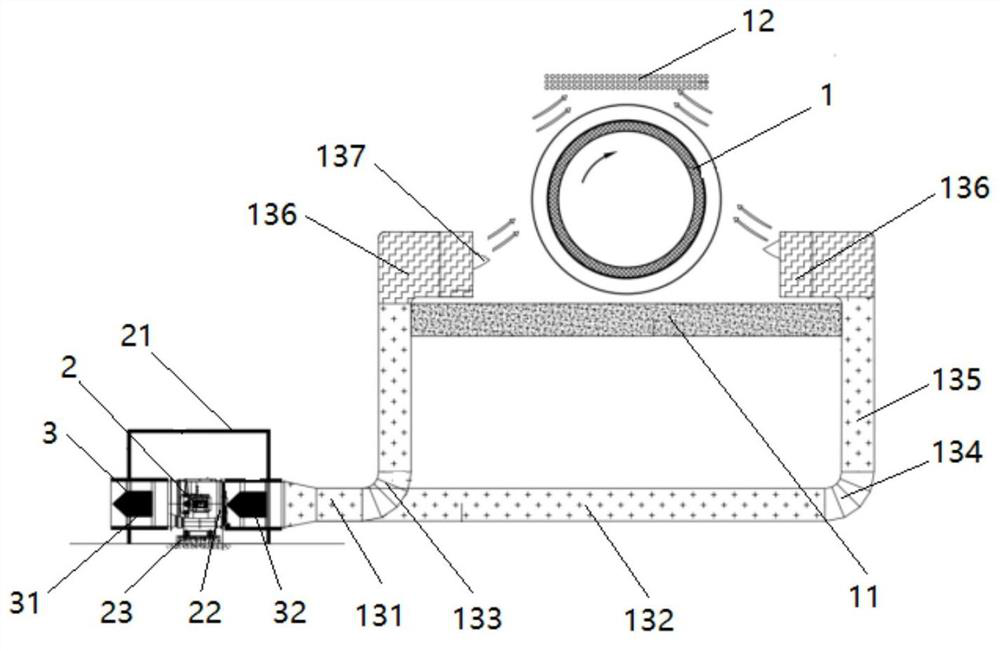

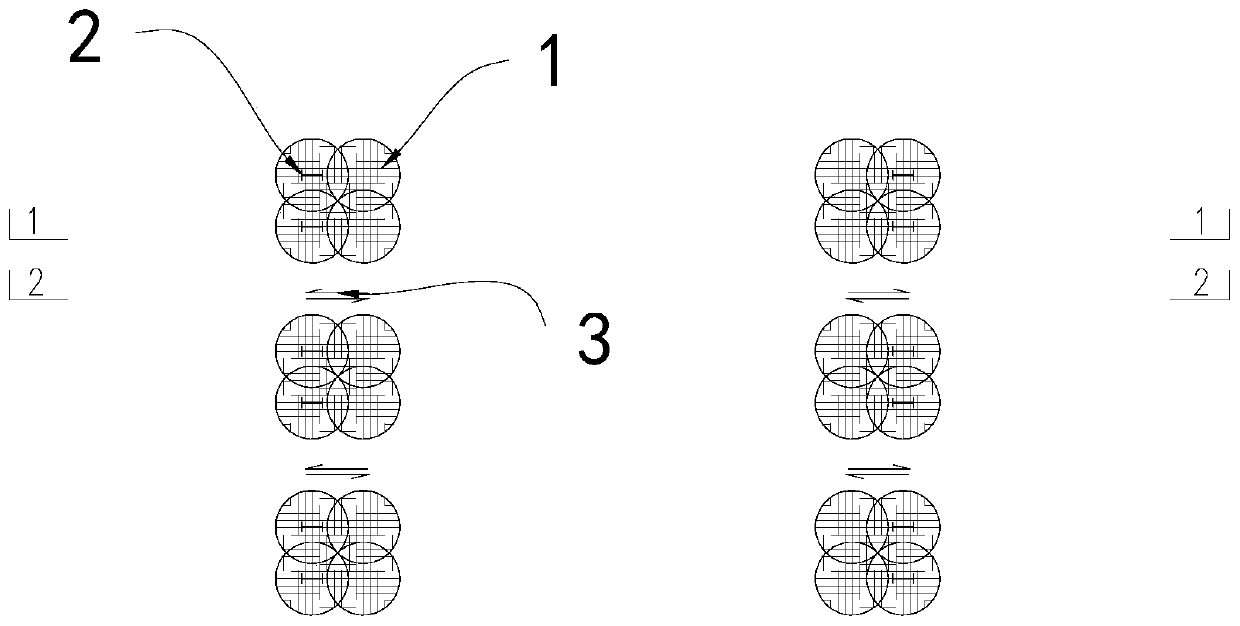

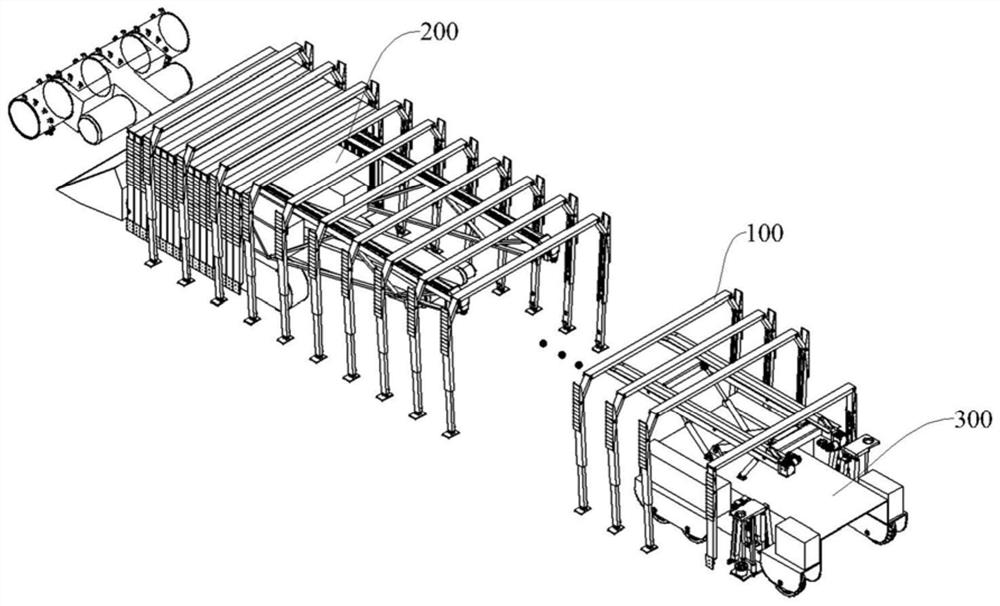

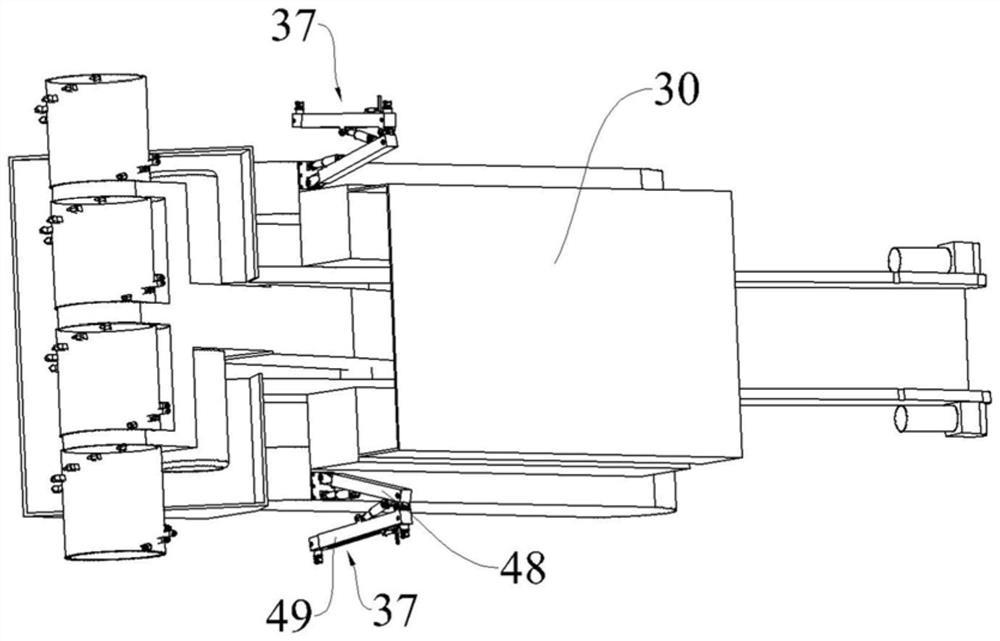

Multi-track sorting trolley conveying mechanism

PendingCN110861882AReduced support requirementsReduce weightMechanical conveyorsIndustrial engineeringElectrical and Electronics engineering

The invention provides a multi-track sorting trolley conveying mechanism. The conveying mechanism comprises at least two layers of supporting frames, the supporting frames are provided with multi-layer sliding rails, the sliding rails are provided with a plurality of trolleys, the trolley heads and tails are continuously arranged, the trolleys at different layers are provided with connecting rods,the connecting rods are used for connecting one group of corresponding trolleys at the upper and lower layers, and the bottom layer of the supporting frames is provided with a power mechanism which drives the trolleys to move. According to the multi-track sorting trolley conveying mechanism, the weight of the trolleys is pressed on the frame of each layer through the multi-layer conveying mechanism, so that the requirements for the supporting force of the frame is reduced; at the same time, only one trolley is provided with the connecting rods, the power is arranged on the trolley on the lowest part, so that the multi-row trolleys are driven to move, the weight of the whole device is reduced, the energy consumption is reduced, the structure is simplified, and at the same time, a floatingmechanism is arranged, so that the position deviation between trolleys on different layers is adjusted.

Owner:SHANGHAI XINBA AUTOMATION TECH CO LTD

L-type impact air flow attenuator

InactiveCN103438323AReduce couplingExhaust flow requirements guaranteedPipe elementsEngineeringChange positions

The invention discloses an L-type impact air flow attenuator which comprises an air flow buffer cavity. An air inlet pipe and an air outlet pipe are installed on the air flow buffer cavity, wherein the air inlet pipe and the air outlet pipe are communicated with a cavity body inside the air flow buffer cavity, the direction changing position of an evacuation pipeline is communicated with the air outlet pipe through the air inlet pipe on the air flow buffer cavity, the air inlet pipe is perpendicular to the air outlet pipe, and L-type layout is arranged inside the air flow buffer cavity. According to the L-type impact air flow attenuator, the characteristics of impact air flow and the evacuation pipeline are comprehensively considered, the basic principles of an interference type air flow buffer, a perforated plate and a hole plate acoustic filter are fused, and the characteristics of the flow exhaust requirements and of the evacuation pipeline and the small installation site of the attenuator are comprehensively considered. For the evacuation pipeline with pipeline steering at the position of an outlet in a security valve, the L-type impact air flow attenuator achieves the effects of dissipating the impact air flow energy, reducing the pipeline coupling, and ensuring the gas exhaust flow requirements to the greatest extent by arranging the air flow buffer cavity and communicating the direction changing position of the evacuation pipeline by the air inlet pipe and the air outlet pipe of the air flow buffer cavity.

Owner:XI AN JIAOTONG UNIV

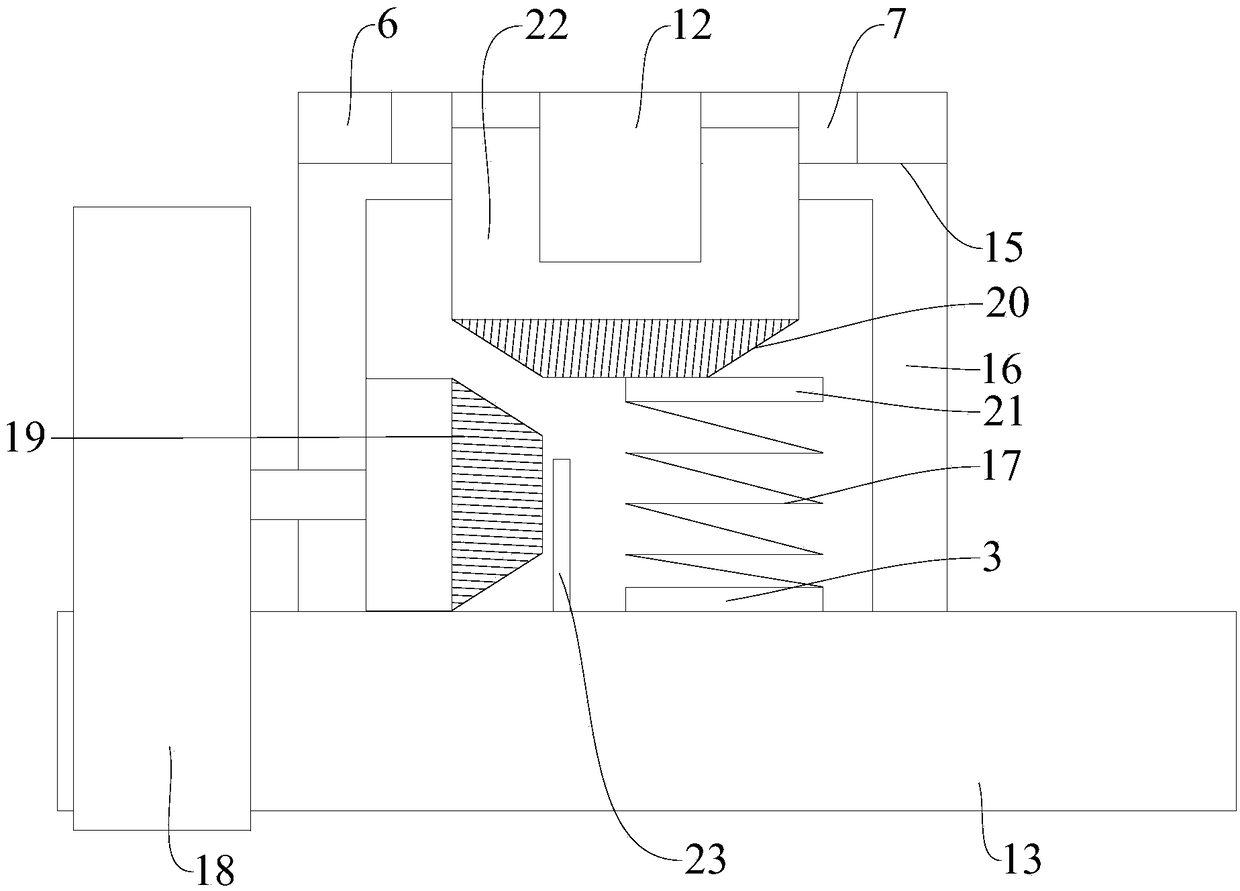

Easily adjustable mounting bracket for shadowless lamp in clean operating room

PendingCN109210508AImprove regulation efficiencyReduce weightMechanical apparatusLighting support devicesLow speedAssistive technology

The invention relates to the technical field of auxiliary lighting in a clean operating room, in particular to an easily adjustable mounting bracket for a shadowless lamp in the clean operating room.The easily adjustable mounting bracket for the shadowless lamp in the clean operating room comprises the shadowless lamp in the clean operating room, a high-torque low-speed motor, an electromagnet and a top fixed frame fixed to a ceiling of the clean operating room. According to the easily adjustable mounting bracket for the shadowless lamp in the clean operating room, the top fixed bracket is fixed to the top of the ceiling, and the height and the angle of the mounting bracket are separately switched and adjusted by utilizing the high-torque low-speed motor in the top fixed bracket and the electromagnet positioned in an internal adjusting box, so that the adjusting efficiency of the mounting bracket is greatly improved, and labor is saved; and meanwhile, a single motor and the electromagnet can be used for enabling the mounting bracket to be switched and controlled, so that the weight of the mounting bracket can be prevented from being reduced by placing the motor at top, and the requirement on the supporting of the bracket is reduced.

Owner:JIANGSU PANASIA MEDICAL TECH GRP CO LTD

A Novel Device Release Device for Implantation

ActiveCN104055601BReduced support requirementsReduced anatomical site requirementsStentsHeart valvesDistractionControl release

Owner:NINGBO JENSCARE BIOTECHNOLOGY CO LTD

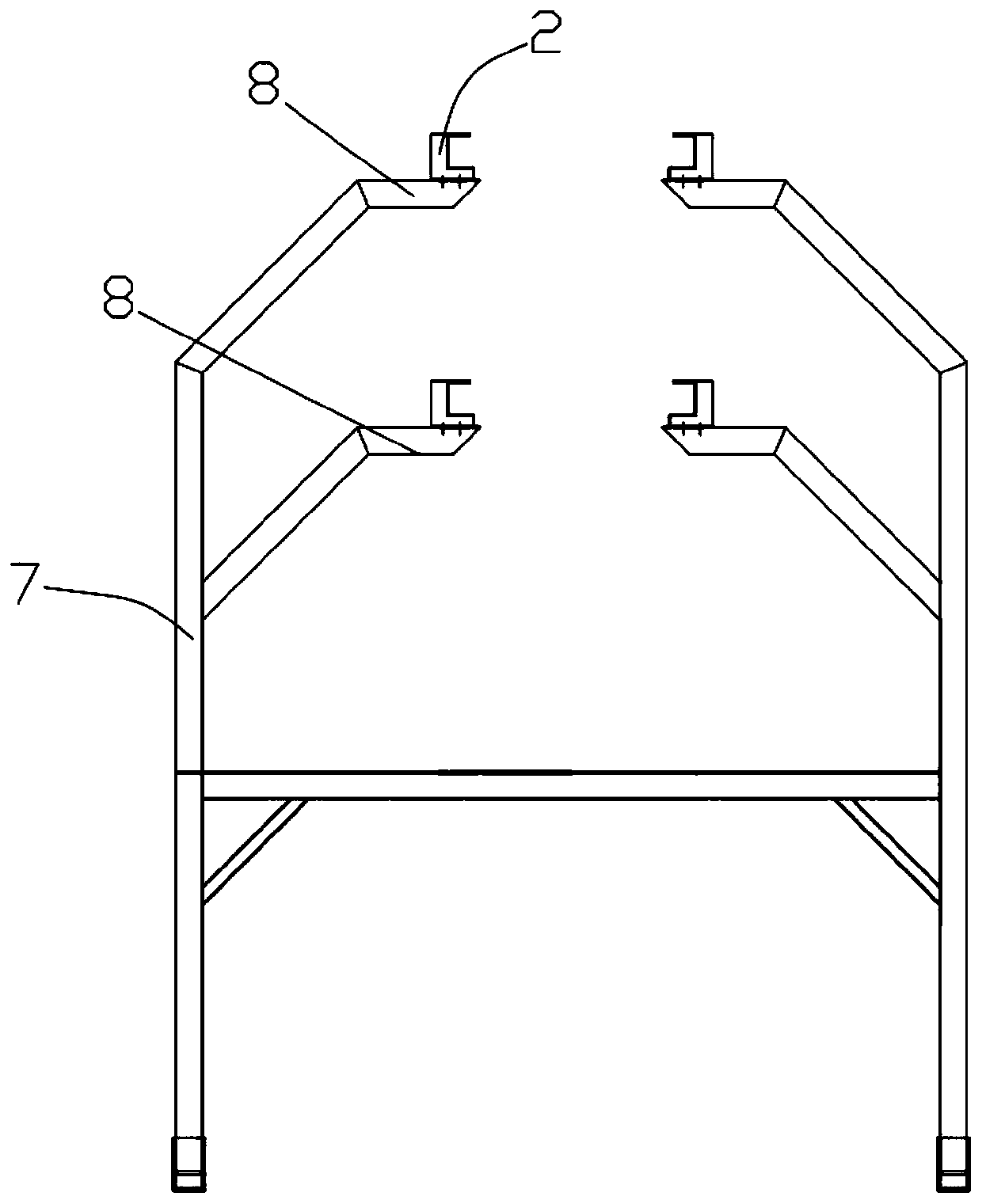

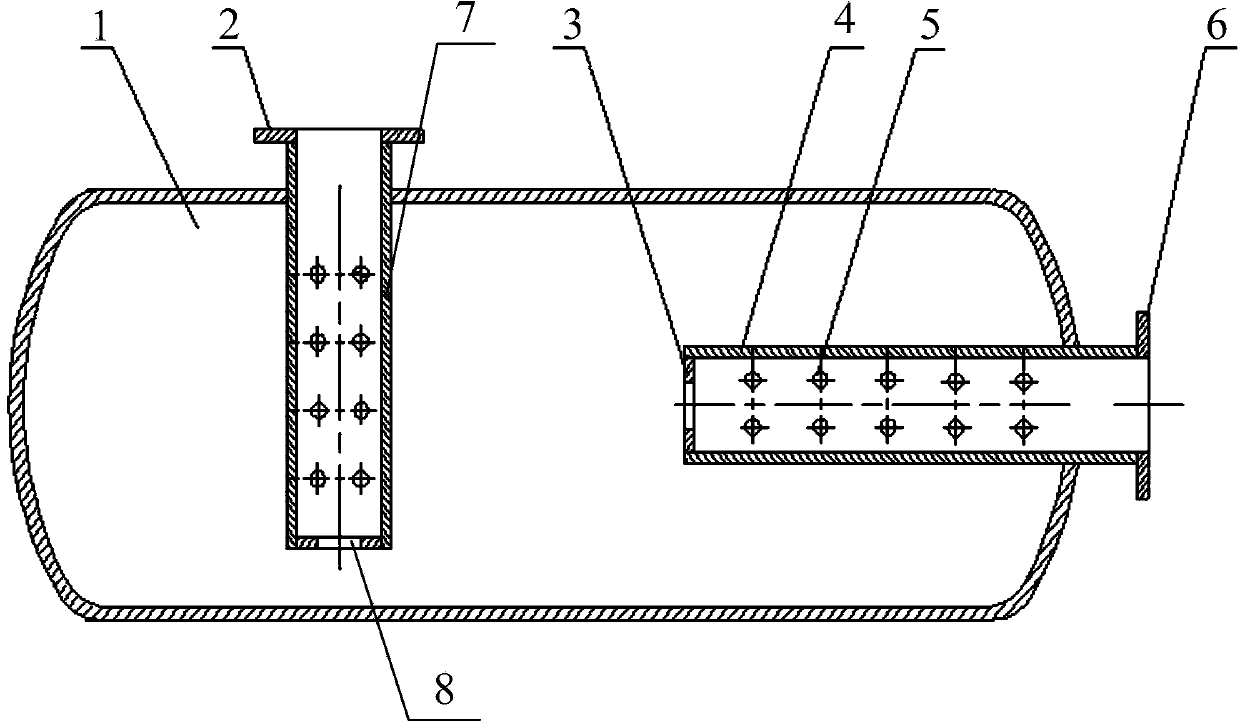

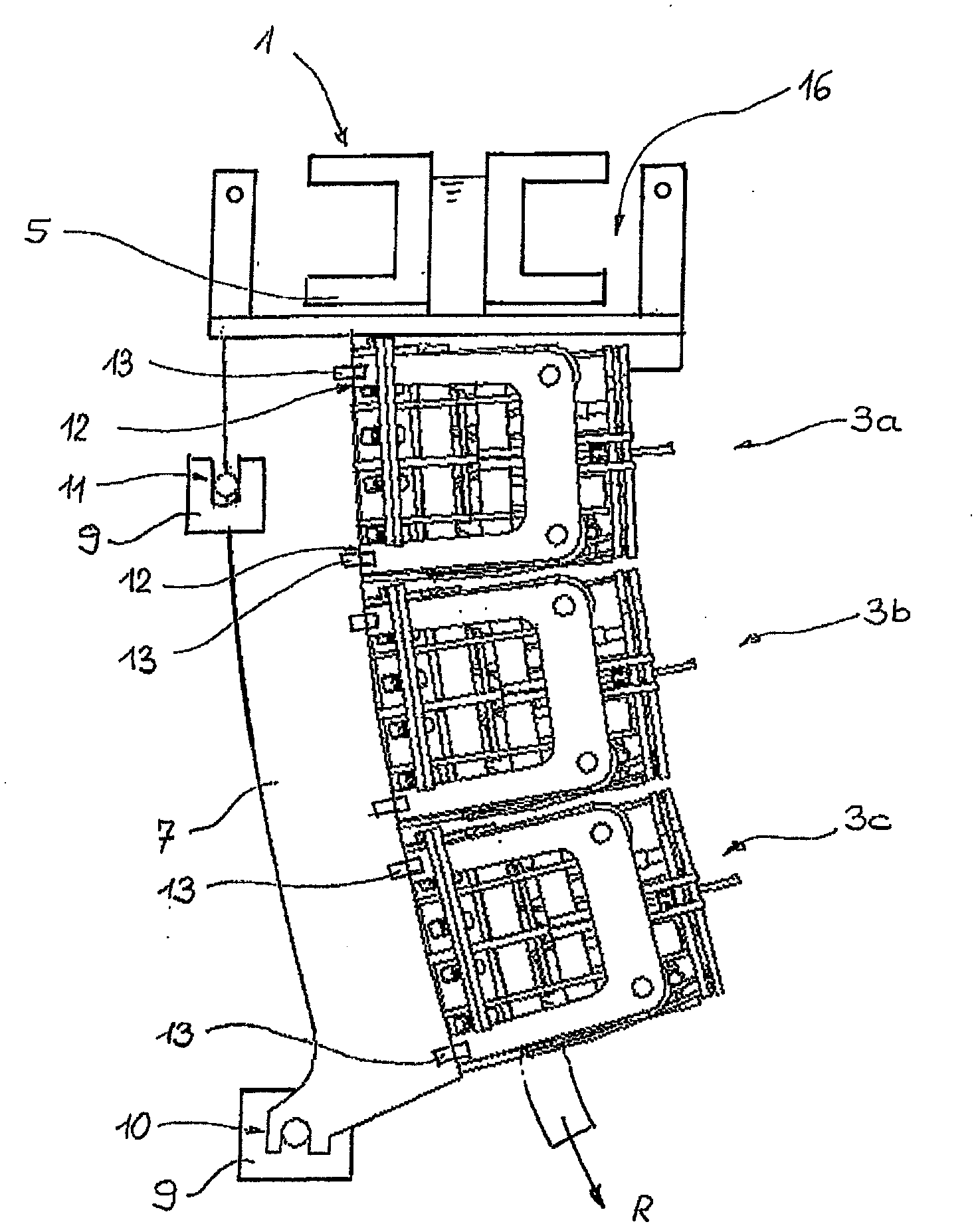

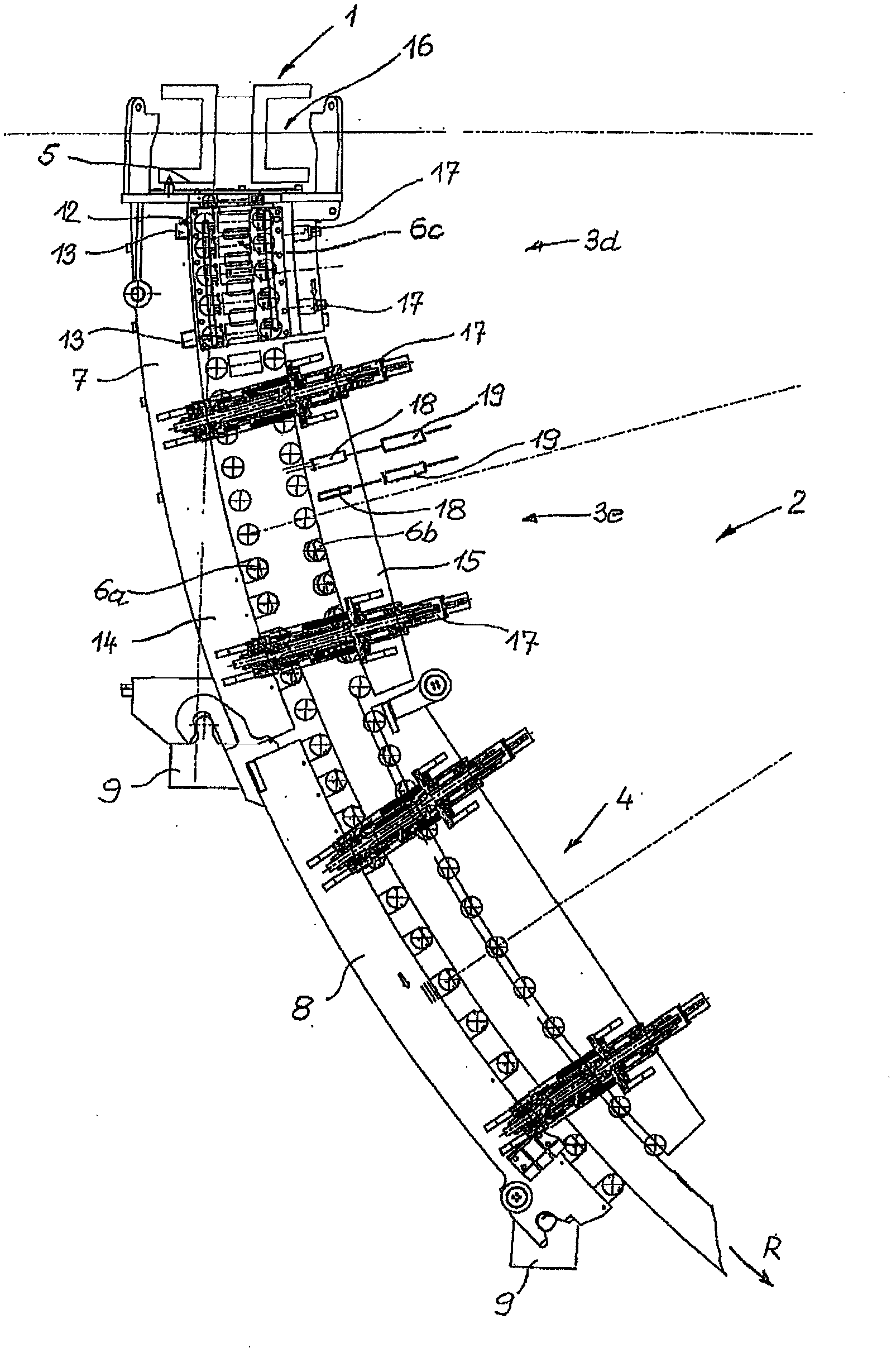

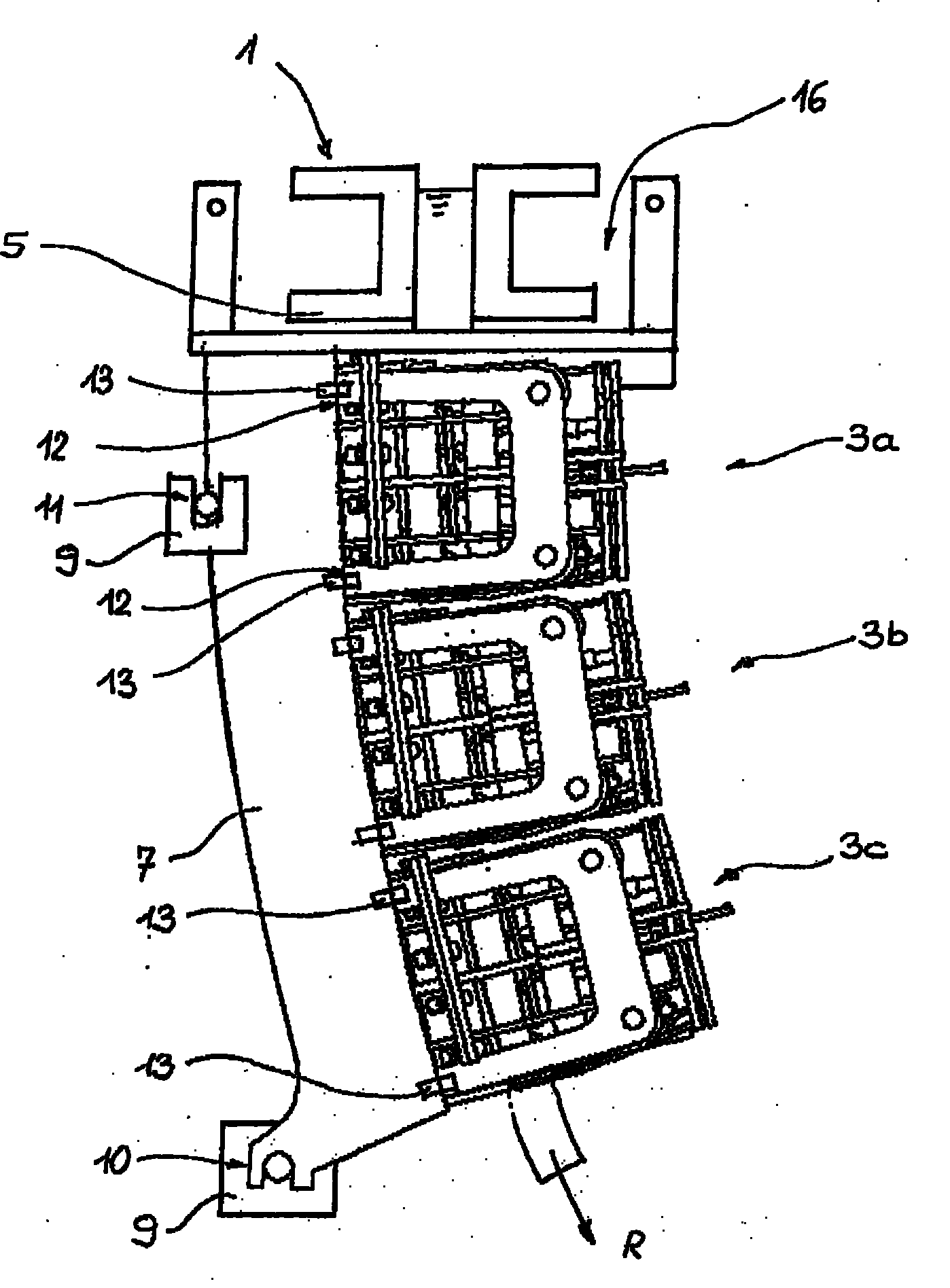

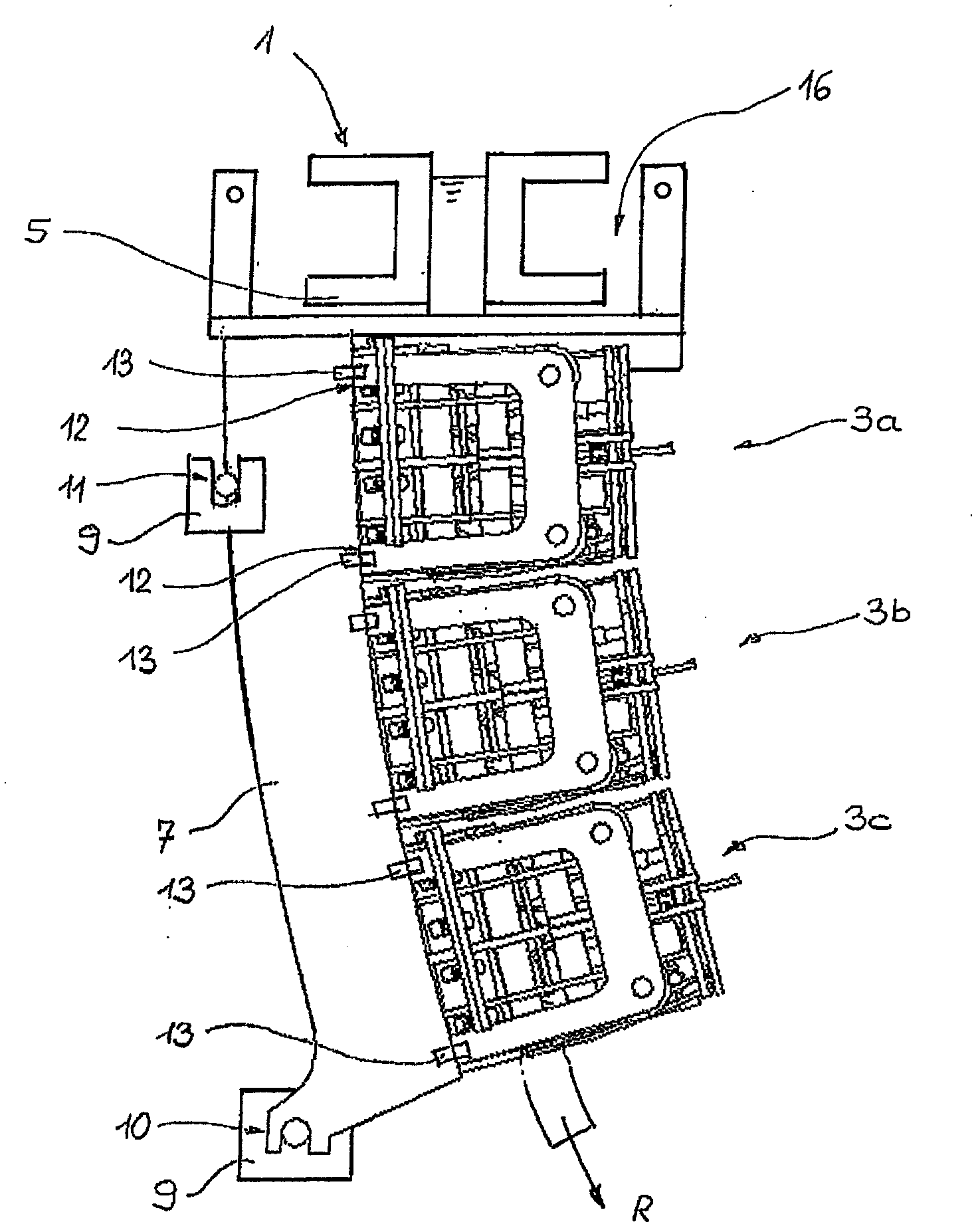

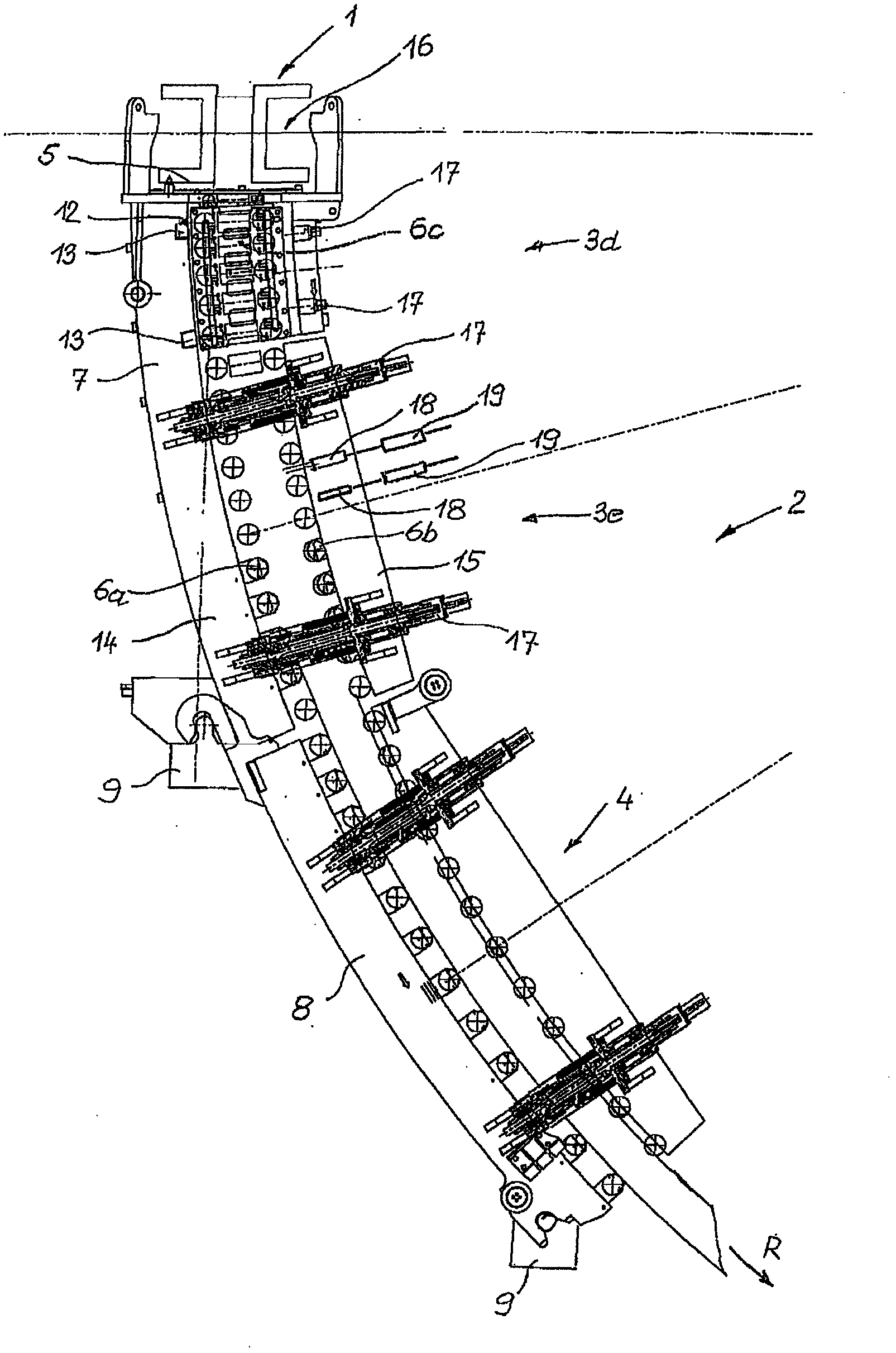

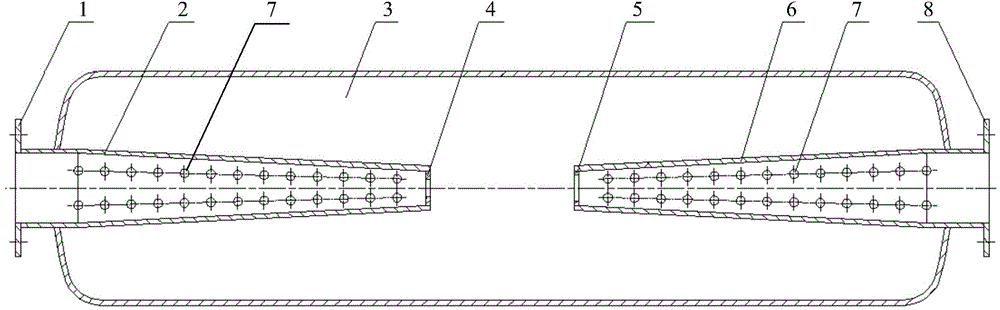

Continuous casting system for casting a metal strand having a billet or bloom cross-section

The invention relates to a billet or bloom continuous casting system, comprising a mold for forming a metal strand and a strand guide (2) connected to the mold (1) for supporting and guiding the metal strand, wherein the strand guide is formed by multiple strand guide segments (3a, 3b, 3c, 3d, 3e, 4), and each strand guide segment is supported via a segment support frame (7, 8) in the system support framework of the continuous casting system, and a first segment support frame (7) directly following in the strand guide of the mold supports at least two strand guide segments. In order to minimize the maintenance expense, the first strand guide segment (3a, 3d) directly following the mold is detachably mounted on the first segment support frame on substantially vertical support surfaces (12), and is configured such that the same can be installed into and uninstalled from the continuous casting system independently of the subsequent strand guide segments (3b, 3c, or 3e), and at least the last strand guide segment (3c, 3e) supported on the first segment support frame (7), exclusively together with said frame, forms an assembly unit that can be installed and removed.

Owner:PRIMETALS TECH AUSTRIA GMBH

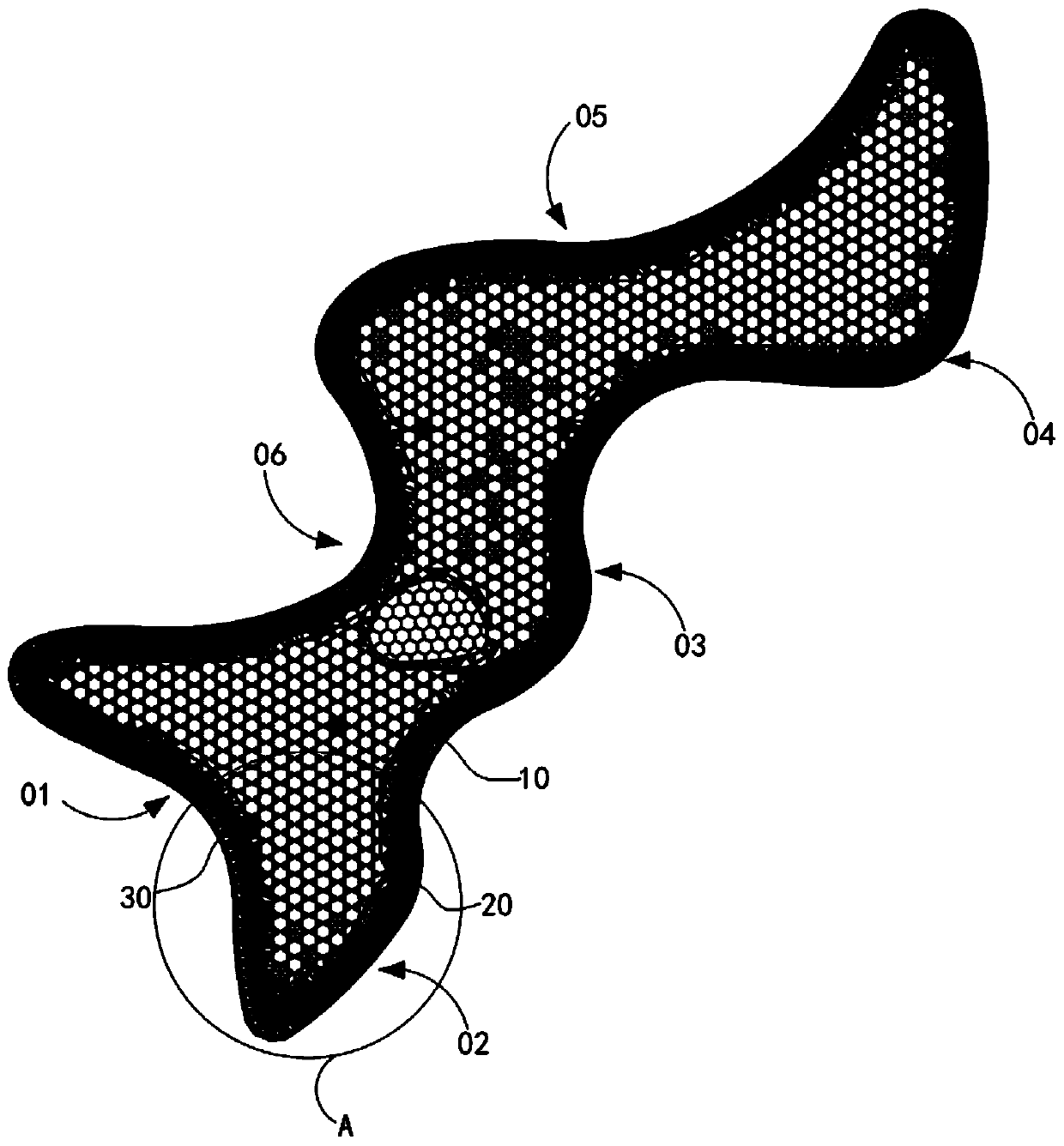

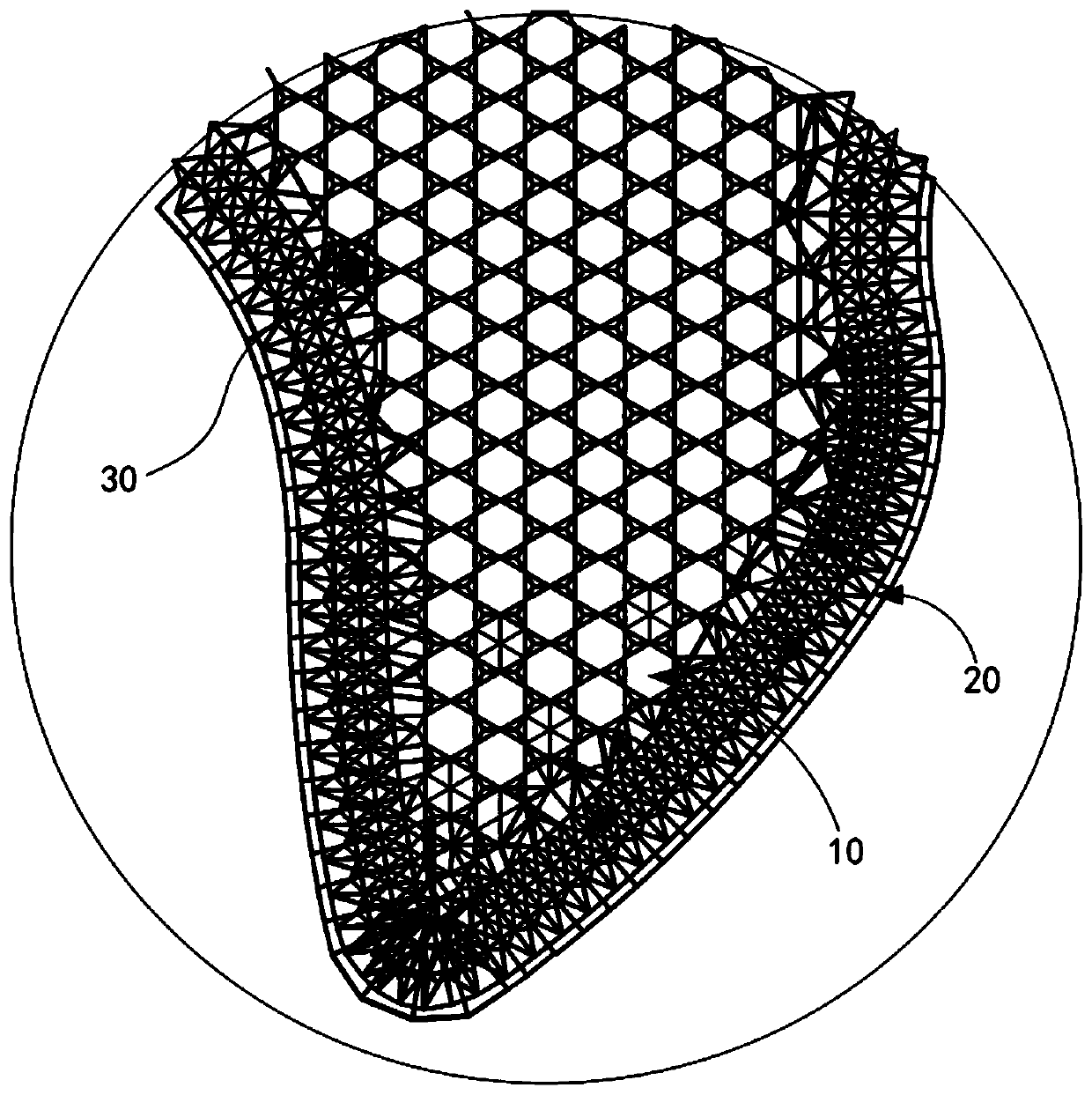

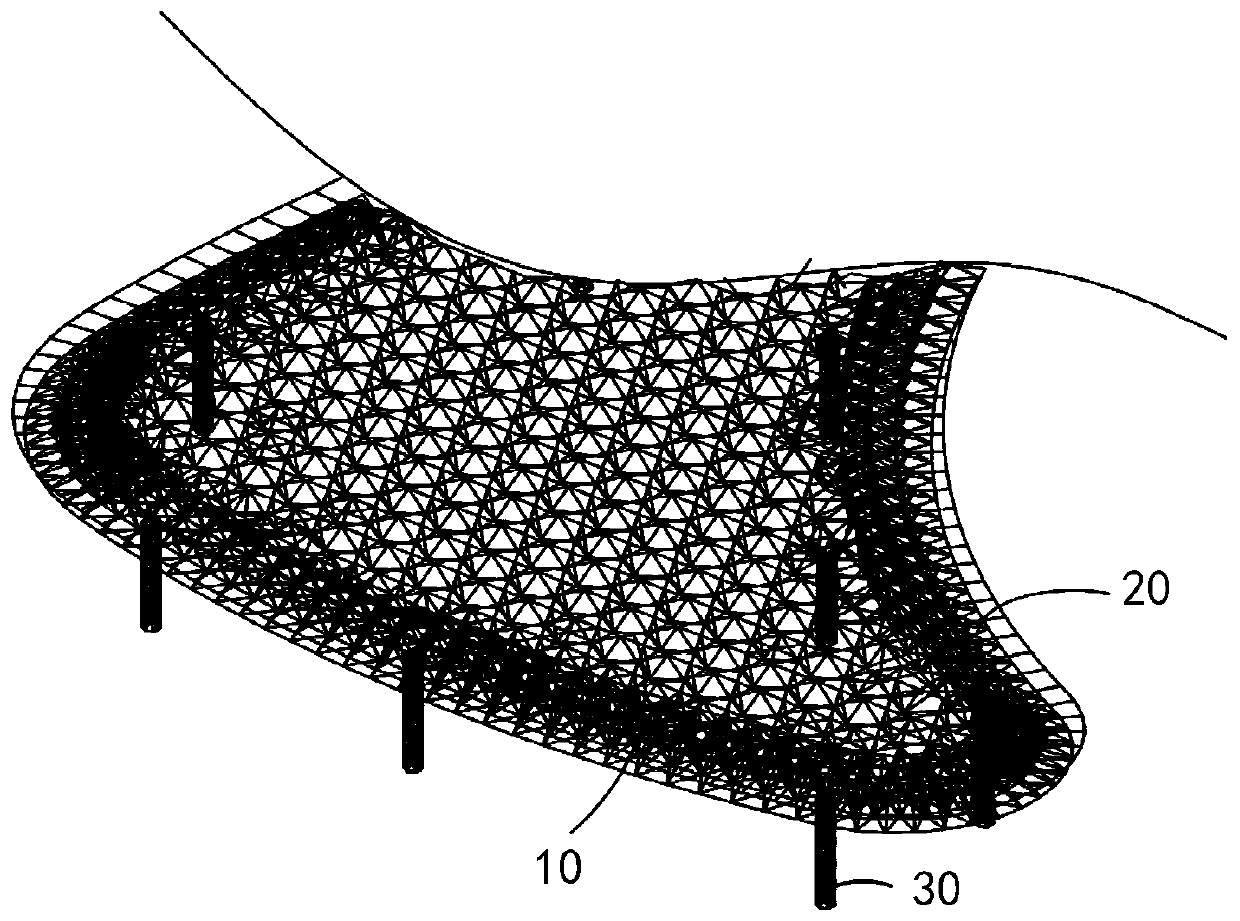

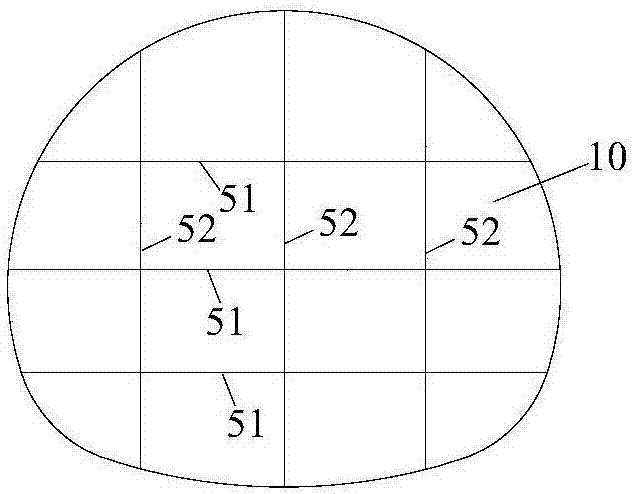

Net rack structure with irregular boundary

PendingCN110468958AThe connection node is firmFirmly connectedBuilding constructionsAerospace engineering

The invention discloses a net rack structure with an irregular boundary. The net rack structure comprises a middle net rack, an edge net rack and a lower bearing structure, wherein the middle net rackis a honeycombed triangular pyramidal net rack; the edge net rack is annularly arranged on the outer edge of the middle net rack and is connected with the outer edge of the middle net rack; and the lower bearing structure is positioned below the edge net rack and is connected with the edge net rack and / or the middle net rack. According to the net rack structure with the irregular boundary, provided by the embodiment of the invention, the edge net rack is arranged on the outer edge of the honeycombed triangular pyramidal net rack, and the edge net rack is fixedly connected with the honeycombedtriangular pyramidal net rack, so that stable and effective connection nodes are formed for the honeycombed triangular pyramidal net rack by the edge net rack, the honeycombed triangular pyramidal net rack is horizontally restrained, and the whole honeycombed triangular pyramidal net rack is applicable to a point bearing system and is changed from a changeable system to a geometrically unchangeable system.

Owner:SHENZHEN GENERAL INST OF ARCHITECTURAL DESIGN & RES

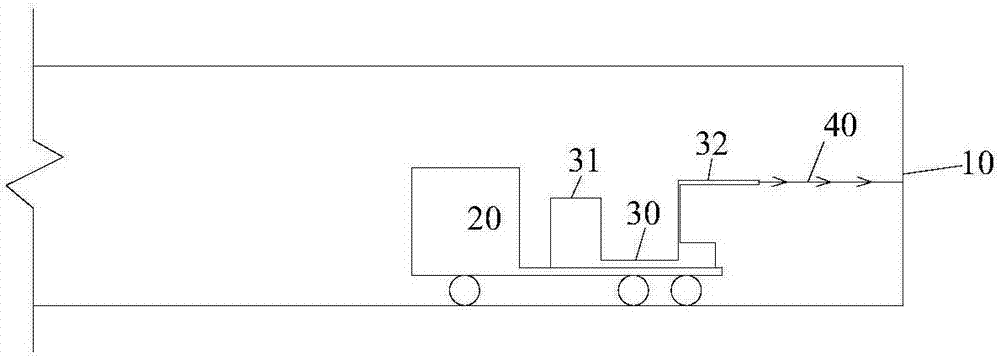

Non-contact type surrounding rock stress release method based on high pressure waterjet

InactiveCN107165639AAvoid constructionGuarantee personal safetyTunnelsHigh pressure waterHigh pressure

A non-contact surrounding rock stress release method based on high-pressure water jet can be used for the treatment of rock bursts, so as to safely and efficiently release the stress of hard rock tunnels with high in-situ stress and avoid rock bursts during tunnel construction. In the present invention, the vehicle-mounted platform carrying the high-pressure water jet device is moved to a certain distance from the face, and the high-pressure water jet device is activated to use the high-pressure water jet generated by the high-pressure pump to cut from the face of the face to the deep surrounding rock, forming a certain distance from the face of the face. Grooving in depth and width to relieve surrounding rock stress by grooving and cutting water flow.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

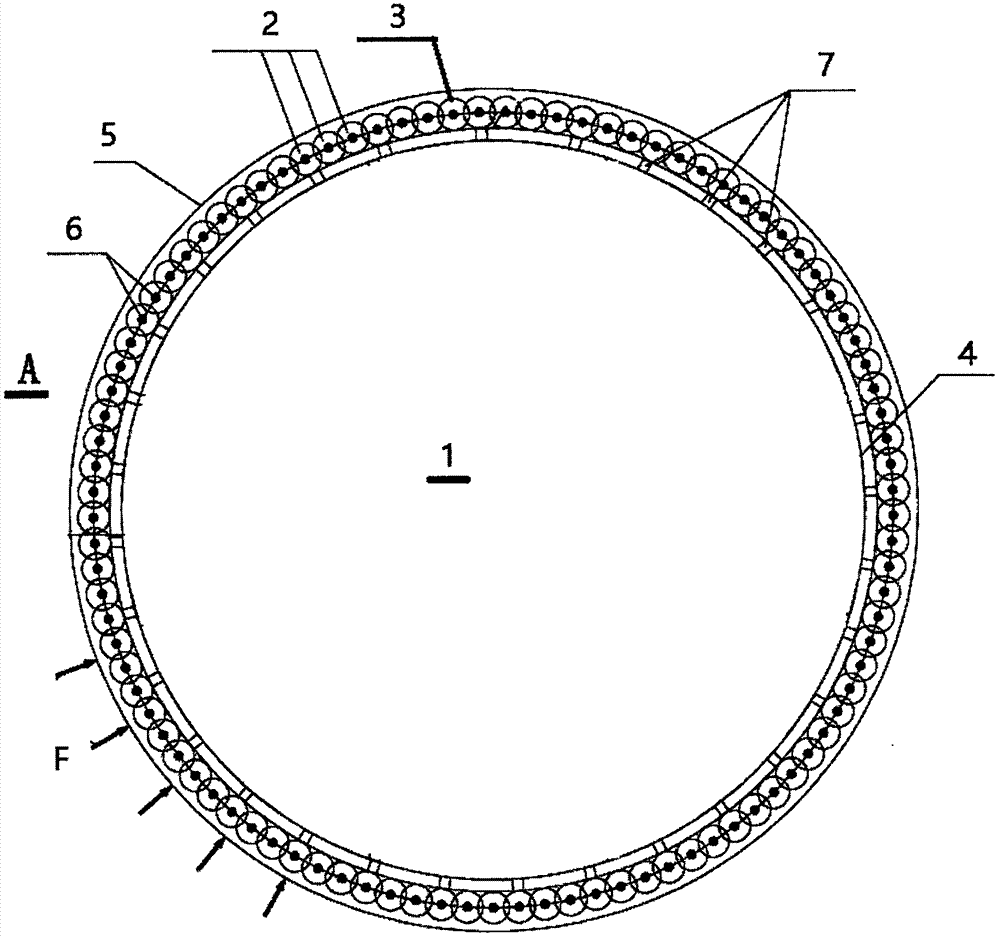

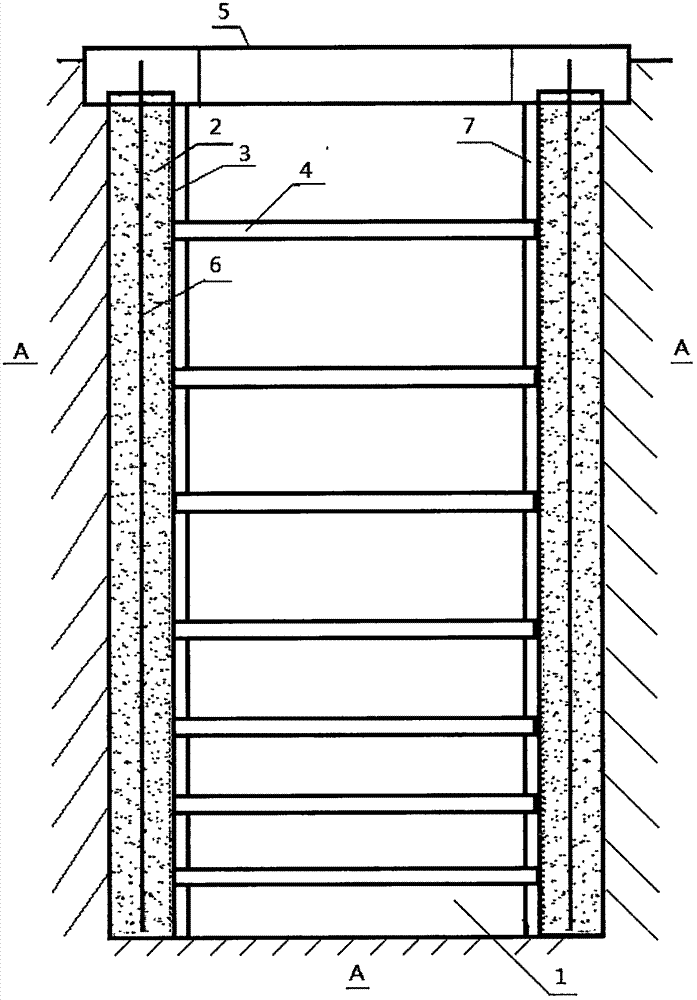

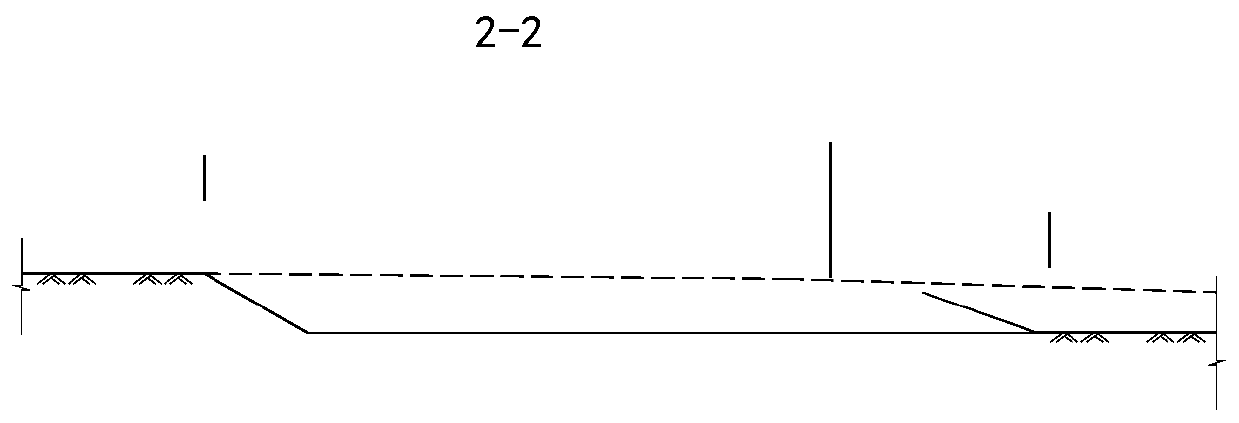

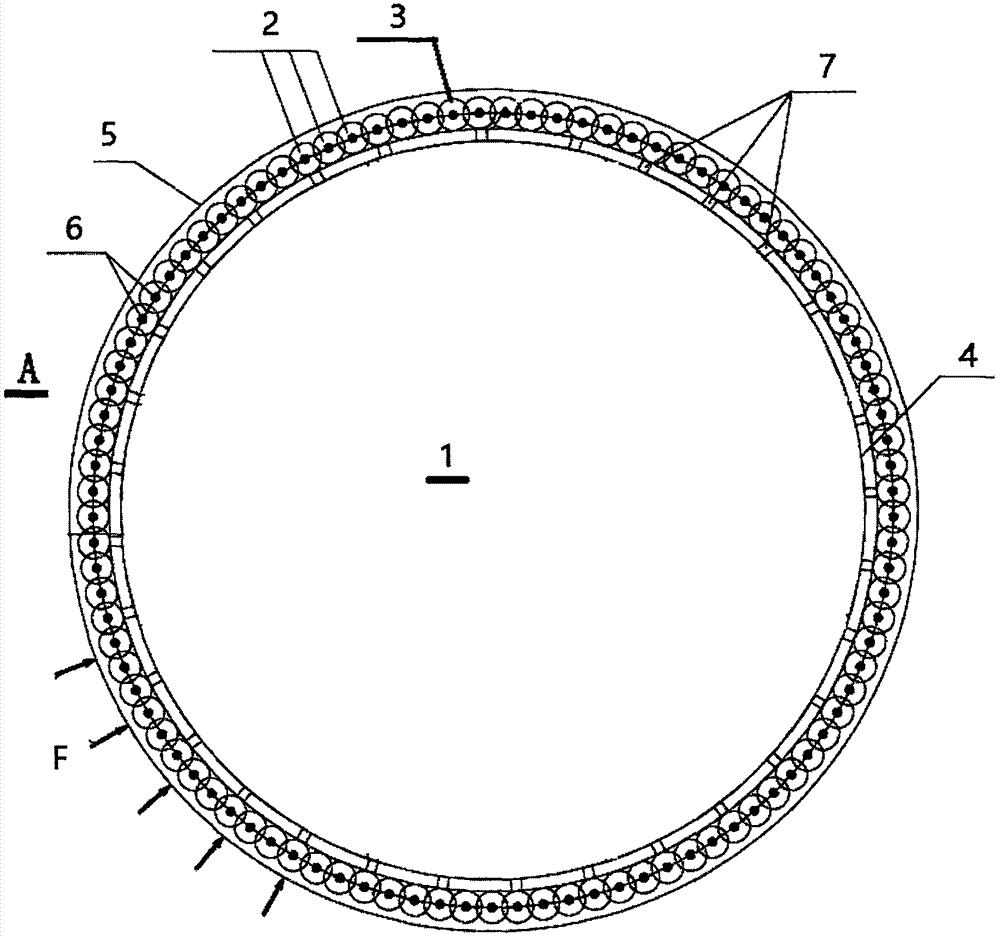

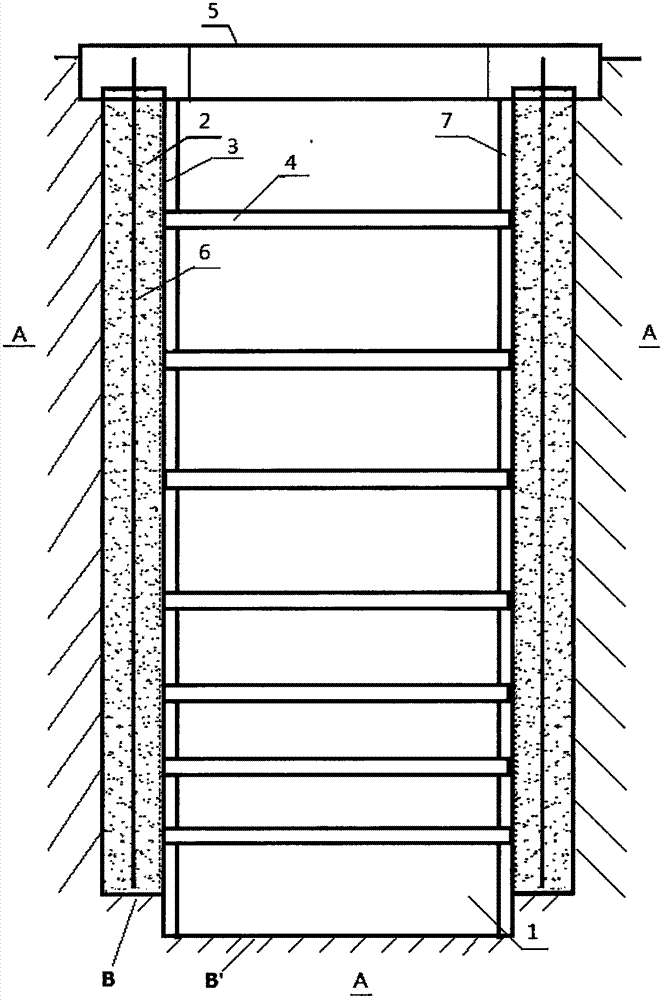

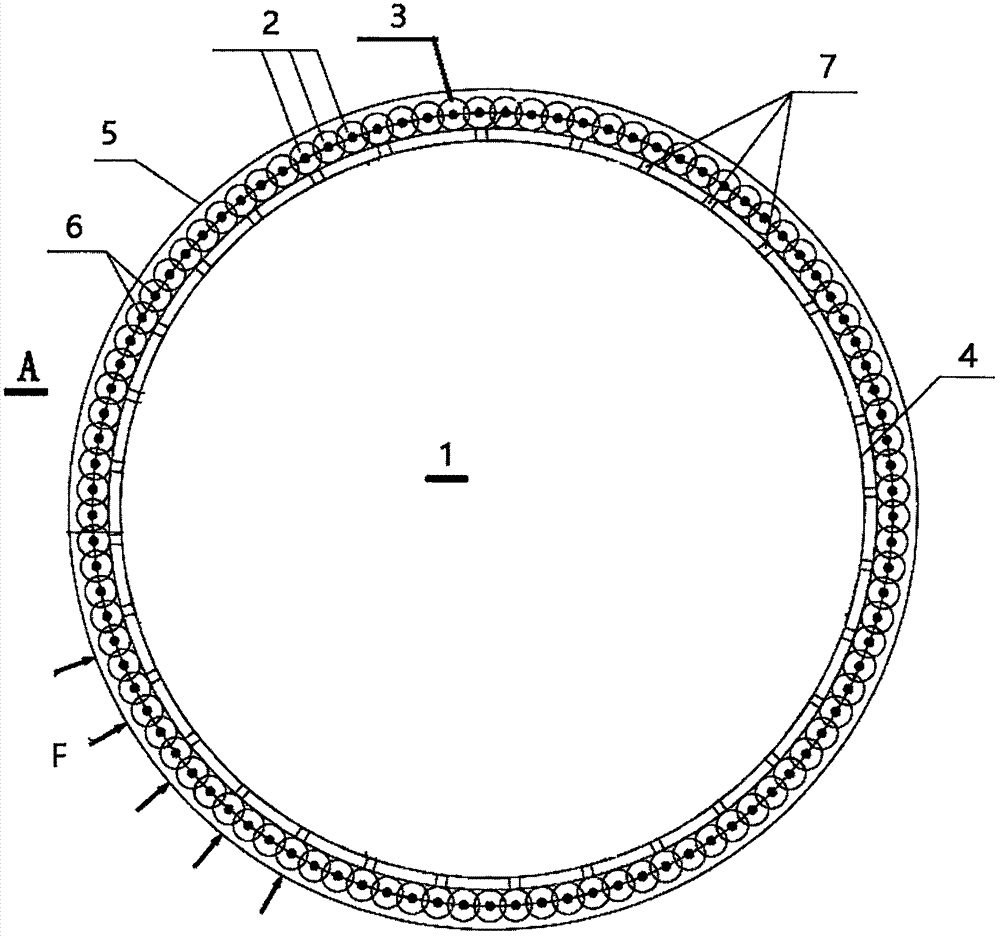

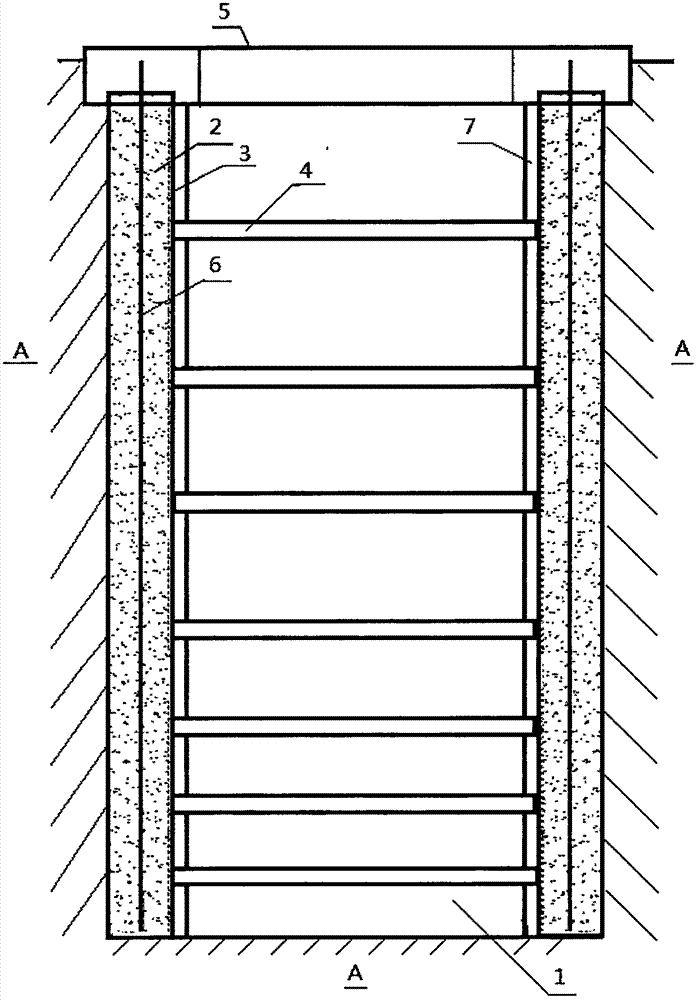

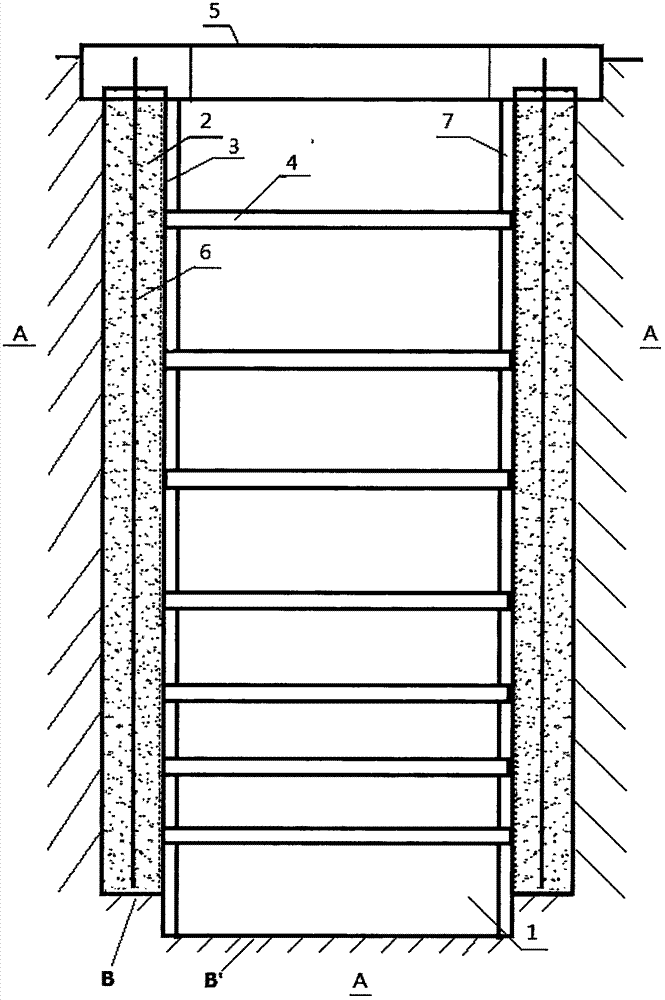

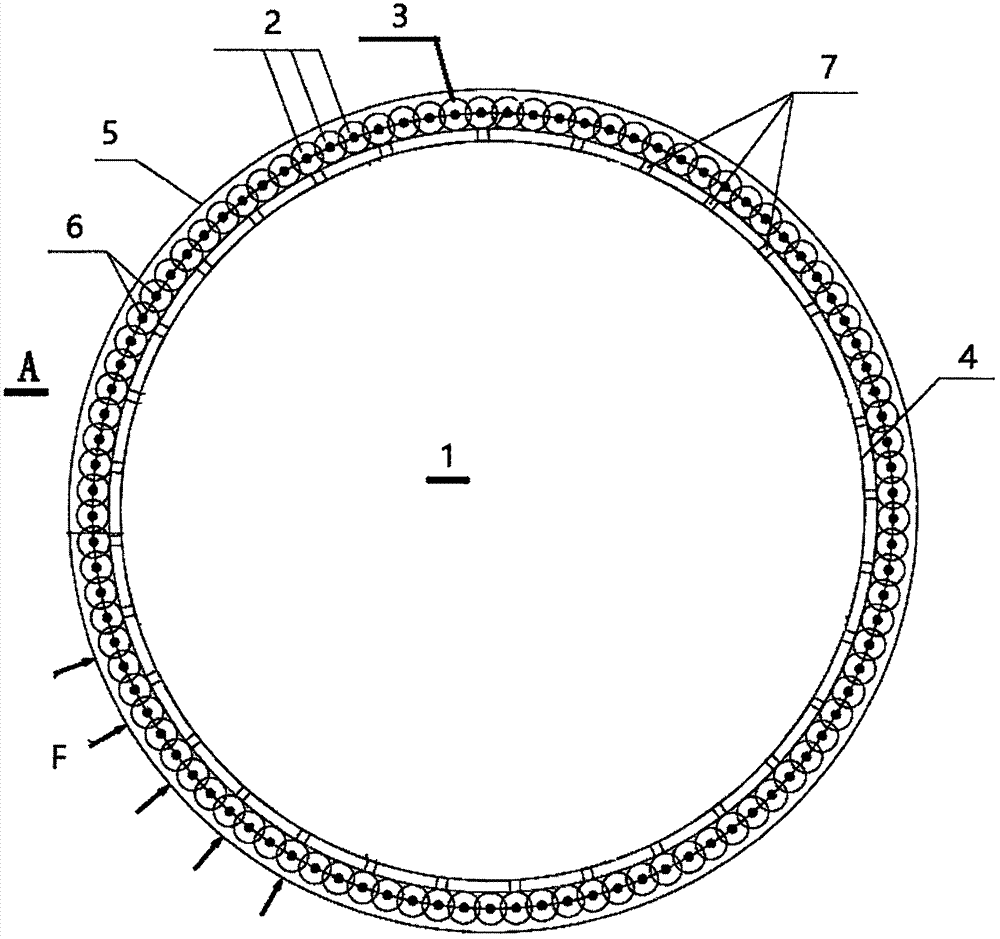

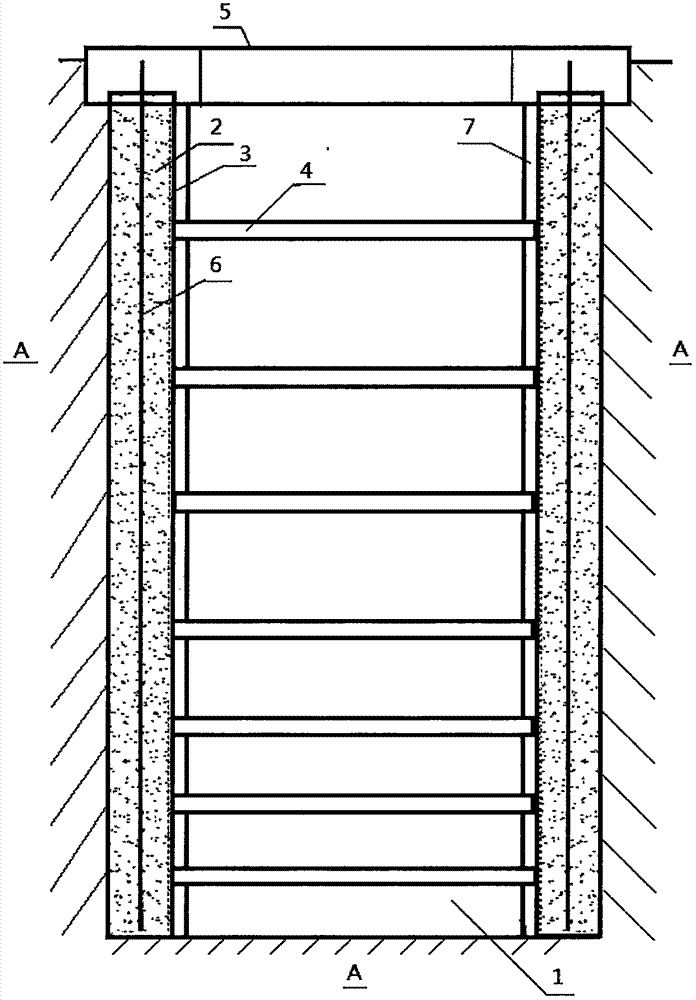

Deep foundation pit underground space structure and construction method thereof

InactiveCN107313433ALess consumablesLow costArtificial islandsExcavationsSpatial structureEngineering

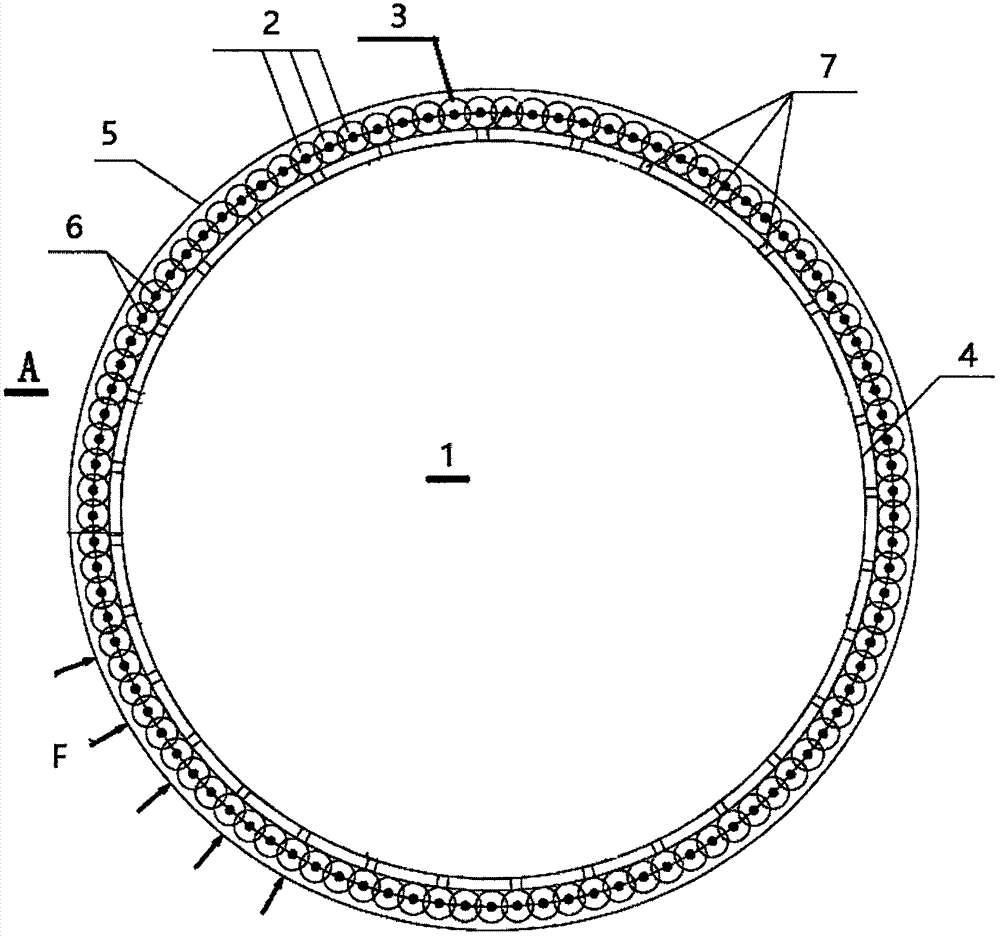

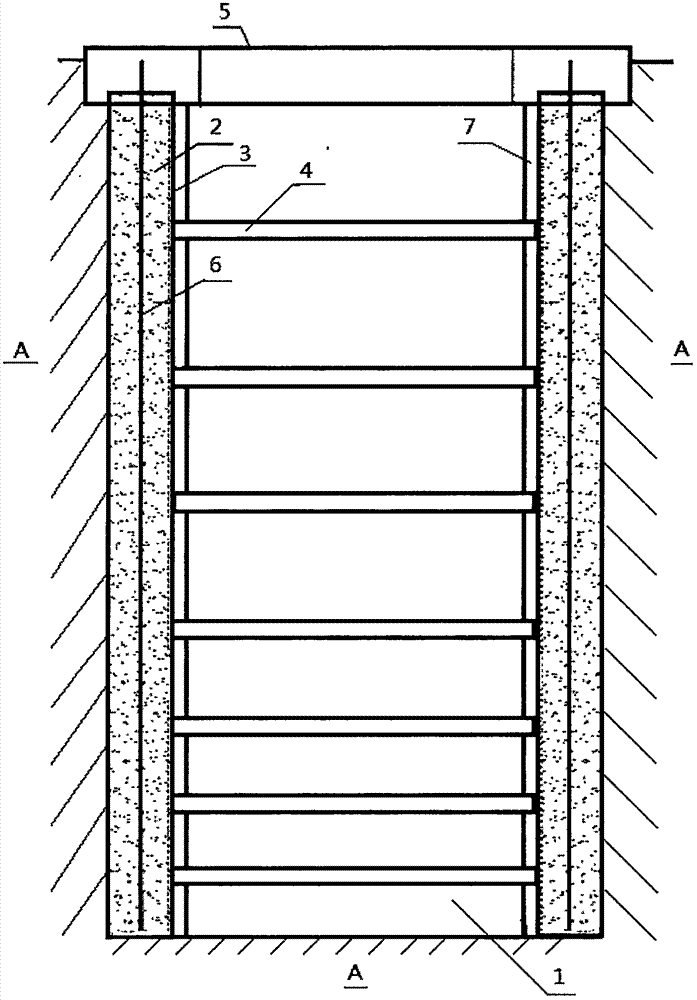

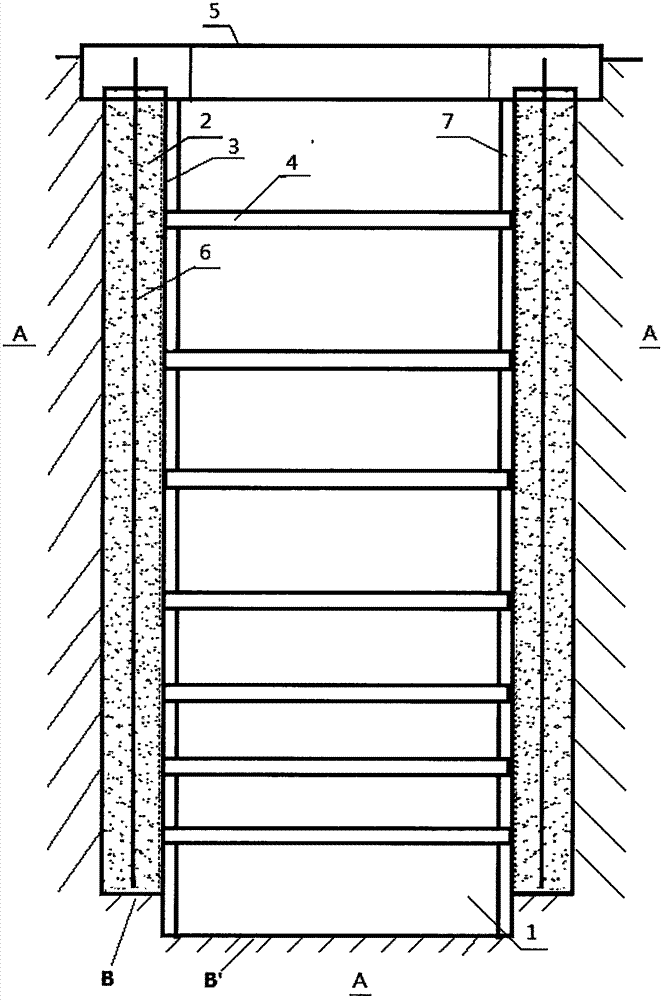

The invention relates to a deep foundation pit underground space structure. The deep foundation pit underground space structure comprises a foundation pit which is in the shape of a barrel, a plurality of pile bodies which are annularly arranged along the pit wall of the foundation pit and are mutually engaged with one another to form a retaining wall which is closed in the peripheral direction, and an inner supporting structure which is annularly arranged along the inner wall of the retaining wall and supports the retaining wall from the interior of the foundation pit to soil, and the bottom ends of the pile bodies are supported on the bottom face of the foundation pit. Due to the adoption of the design, the pile bodies only serve as media of retaining bodies, the pile bodies do not generate reactive force by means of soil anchored below the bottom face of the foundation pit to absorb the side pressure applied to the pile bodies by soil on the periphery of piles, the side pressure is transmitted to inner supporting ring beams, the inner supporting structure bears more side pressure, and the effect of 'strong supporting and weak piles' is achieved. By additionally arranging the inner supporting ring beams to absorb the side pressure of the soil, needed materials are far less than material needed when the pile bodies are inserted into the foundation part.

Owner:JIANGXI JIYE SCI & TECH

A formwork-free concrete single-cabin pipe gallery or multi-cabin pipe gallery and its construction method

ActiveCN111074939BHigh degree of automationHigh quality and precisionArtificial islandsUnderwater structuresReinforced concreteArchitectural engineering

The invention relates to a formwork-free concrete single-chamber pipe gallery or a multi-chamber pipe gallery and a construction method thereof. The pipe gallery includes a top plate, a bottom plate and a wall that are connected to each other. The wall includes an outer wall, and also includes or does not include a partition wall. The walls are all cast-in-place reinforced concrete structures. The wall solid formwork on both sides of the wall and the wall concrete layer poured between the wall solid formwork on both sides are constituted, and the wall solid formwork adopts a reinforced truss fixed formwork, and the reinforced truss fixed formwork includes a panel and a The steel mesh and steel truss on one side of the panel, and the top and bottom plates are preferably cast-in-place concrete structures. The construction method includes floor construction, wall construction, roof construction and necessary concrete oxidation. The invention is beneficial to reduce the workload and labor intensity of pipe gallery construction, reduce the degree of influence of human factors on building quality, reduce construction costs, and reduce the adverse impact on the environment and society during the construction of the pipe gallery.

Owner:ZHONGQINGDA TECH HLDG CO LTD

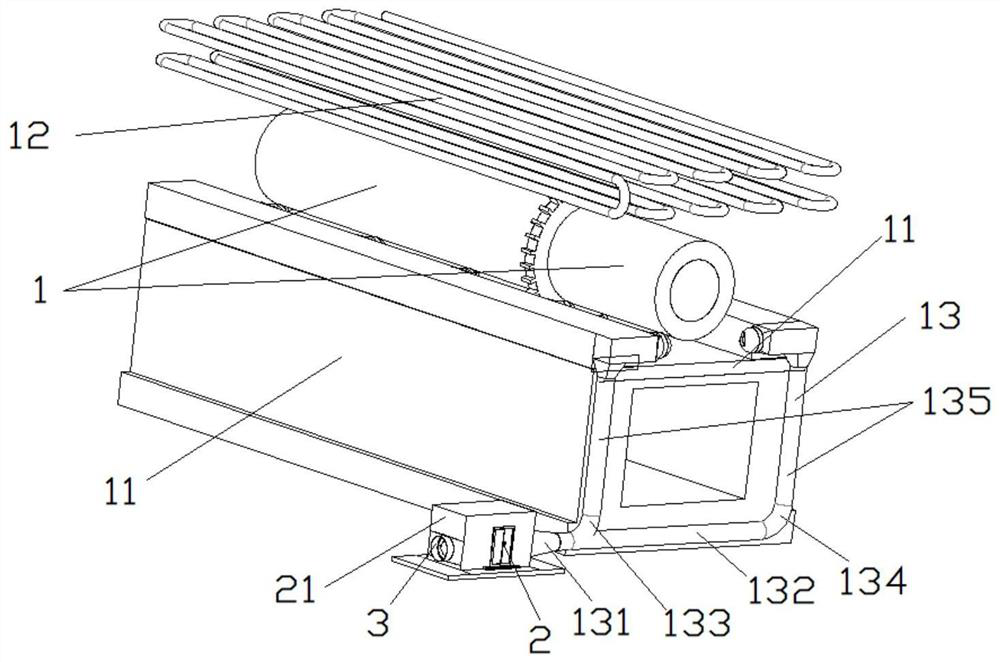

Cement rotary kiln comprehensive noise reduction and heat recovery system

PendingCN114111326AImprove efficiencyCancel noisePump componentsRotary drum furnacesThermal pollutionNoise elimination

The invention discloses a comprehensive noise reduction and heat recovery system for a cement rotary kiln. The comprehensive noise reduction and heat recovery system comprises a rotary kiln platform arranged at the bottom of the rotary kiln, a cooling coil arranged at the top of the rotary kiln, air pipe air supply units arranged at the two ends of the rotary kiln platform, fans arranged at the input ends of the air pipe air supply units and noise elimination mechanisms arranged on the fans. A fan shock absorber is arranged below the fan; the draught fan is covered with a draught fan sound insulation cover. The silencing mechanism comprises a fan inlet silencer and a fan outlet silencer, and fan noise is jointly reduced through the fan inlet silencer, the fan outlet silencer, a fan sound insulation cover and a fan shock absorber; cooling air from the air pipe air supply unit is changed into hot air after cooling the rotary kiln, the cooling coil recovers heat from the hot air and heat radiation of the rotary kiln, then the rotary kiln body is cooled and waste heat is recovered in the rotary kiln production process of the cement plant, noise reduction and heat recovery are comprehensively considered, the noise reduction effect is guaranteed, heat recovery is increased, and the production efficiency is improved. And carbon emission and thermal pollution are reduced.

Owner:宁波源海博创科技有限公司

Construction method of urban hydrophilic ecological river channel

PendingCN111350168AReduce excavation and dumpingReduce pollutionArtificial water canalsBulkheads/pilesEnvironmental resource managementReinforced concrete

The invention discloses a construction method of an urban hydrophilic ecological river channel. By using mixing piles, the functional requirements of a river bank retaining wall can be met, the earthexcavation, filling, abandonment and transport of the retaining wall are reduced, the engineering construction efficiency is improved, the construction period is shortened by about one half compared with that of a cast-in-place pile structure, and the construction method is more economical than that of the cast-in-place pile structure. As soil is reinforced in situ, compared with a grouted rubblegravity or reinforced concrete L-shaped retaining wall cantilever-type structure needing bulk excavation and supporting for base expansion, the in-situ retaining wall structure does not need earth andmud discharge, causes low noise and little environmental pollution, does not disturb adjacent soil during construction, has low supporting requirements and will not cause ground sinking, house tilting and road cracking. The construction method is used in the technical field of remediation of the hydrophilic ecological river channel.

Owner:GUANGZHOU MUNICIPAL ENG DESIGN & RES INST CO LTD

Deep foundation pit underground garage and construction method thereof

InactiveCN107476311ALess consumablesLow costExcavationsBulkheads/pilesMaterial consumptionRetaining wall

The invention discloses a deep foundation pit underground garage. The deep foundation pit underground garage comprises a foundation pit, a plurality of pile bodies, and an inner support structure, wherein the foundation pit is in the shape of circular barrel; the pile bodies are arranged in annular mode along the pit wall of the foundation pit, and are engaged with one another to form a peripherally sealed retaining wall; the inner support structure is arranged in the annular mode along the inner wall of the retaining wall; the inner part of the foundation pit faces towards a soil body to support the retaining wall; and the bottom ends of the pile bodies are supported on the bottom surface of the foundation pit. With the adoption of the design, the pile bodies are only used as media of a retaining body, the pile bodies do not depend on the soil body anchored under the bottom surface of the foundation pit to generate counter-acting force to absorb side pressure, applied to the pile bodies, of the soil body outside the pile bodies, but transmit the side pressure to an inner support ring beam, and the inner support structure bears more side pressure, so that the effects of strong support and weak piles are achieved. Materials needed for absorbing the side pressure of the soil body by additionally arranging the inner support ring beam are much less than materials needed for inserting the pile bodies into the foundation pit. With the design, the deep foundation pit underground garbage is less in material consumption and is lower in cost on the premise of realizing same soil-retaining capacity.

Owner:JIANGXI JIYE SCI & TECH

Deep foundation pit underground grain depot and construction method thereof

The invention relates to a deep foundation pit underground grain depot. The deep foundation pit underground grain depot comprises a foundation pit, a plurality of pile bodies and an inner support structure, wherein the foundation pit is in a shape of a drum; the plurality of pile bodies are circularly arranged along the pit wall of the foundation pit and are engaged with each other so as to form a circumferentially-closed retaining wall; the inner support structure is circularly arranged along the inner wall of the retaining wall so as to support the retaining wall from the interior of the foundation pit to soil; and the bottom ends of the pile bodies are supported to the bottom surface of the foundation pit. By adopting the design, the pile bodies are only used as media of a blocking body, side pressure which is applied to the pile bodies by soil around piles is not absorbed by the pile bodies by virtue of counterforce generated by soil which is anchored under the bottom surface of the foundation pit, but the side pressure is transferred to an inner support ring beam, and more side pressure is borne by the inner support structure, so that the effects of strong support and weak piles are achieved. Materials required for absorbing the side pressure of the soil by the additional inner support ring beam are far less than materials required for inserting the pile bodies into the foundation pit.

Owner:JIANGXI JIYE SCI & TECH

Bidirectional U-shaped coal-mining method of thick coal bed by gateway layout along stability layer

InactiveCN101915099BEasy to excavateAdd supportUnderground miningSurface miningEngineeringCoal pillar

The invention relates to a bidirectional U-shaped coal-mining method of a thick coal bed by gateway layout along a stability layer. The method comprises the following steps of: firstly, tunneling all gateways of a mine along the stability layer so that top plates of the tunnels form the stability layer of the coal bed; and arranging actual mining gateways along the stability layer so that workingsurfaces form a bidirectional U shape along the lengths and the advancing directions, wherein a three-section actual mining process, including sapping, leveling and climbing, is adopted on the actualmining of the working surfaces along the lengths and the advancing directions. The method radically solves the difficulties in tunneling and supporting of gateway layout along soleplate in a thick coal bed in the prior art, lessens the coal pillar loss among adjacent working surfaces and is beneficial to the gas drainage of the working surfaces particularly at an upper corner. The invention is suitable for the fully-mechanized mining with large mining height and the sub-level caving mining of the loose and broken thick coal bed.

Owner:TAIYUAN UNIV OF TECH

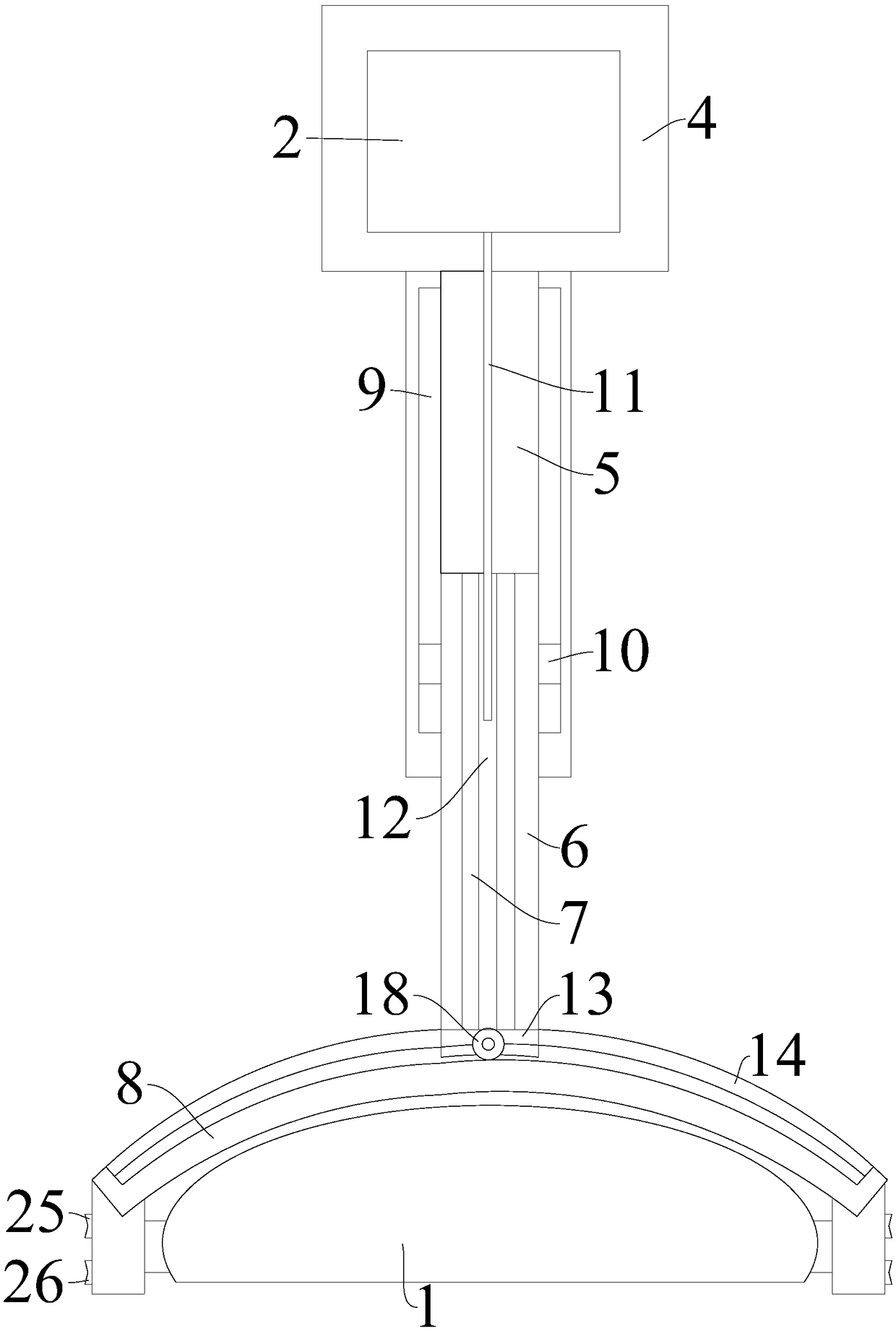

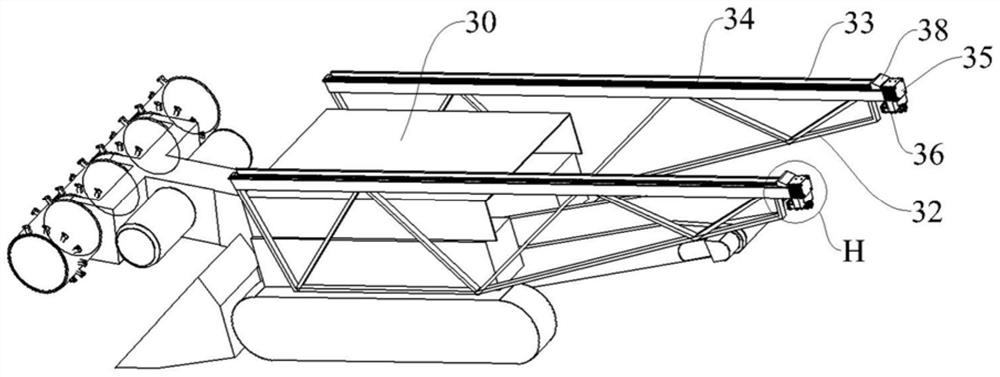

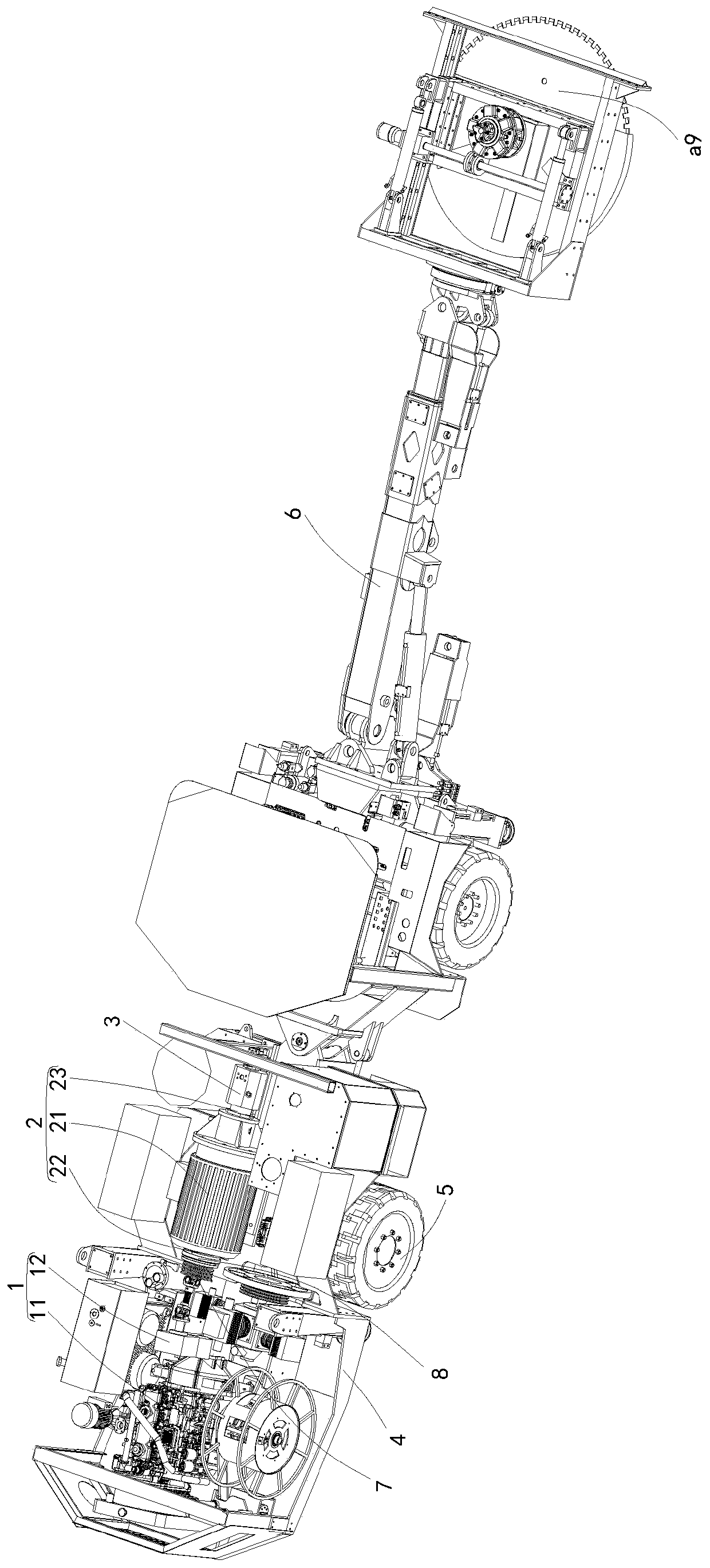

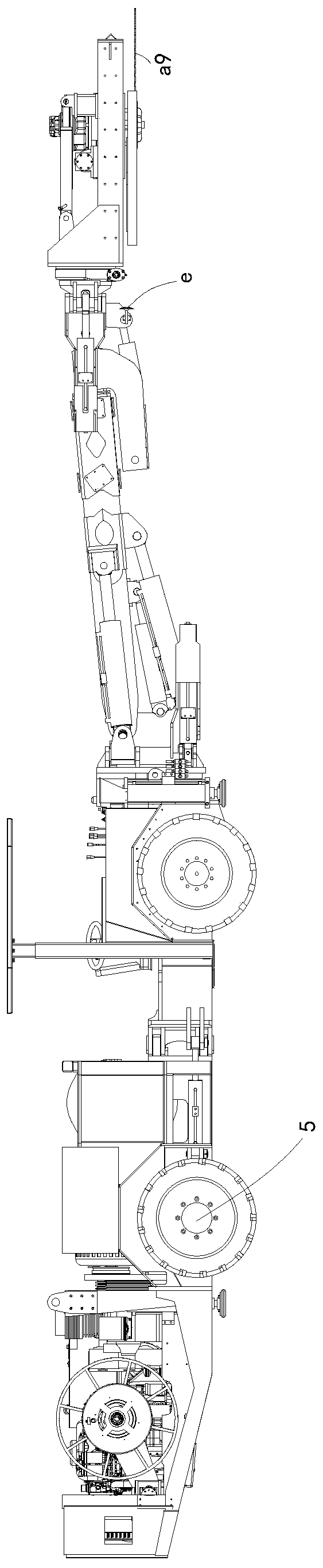

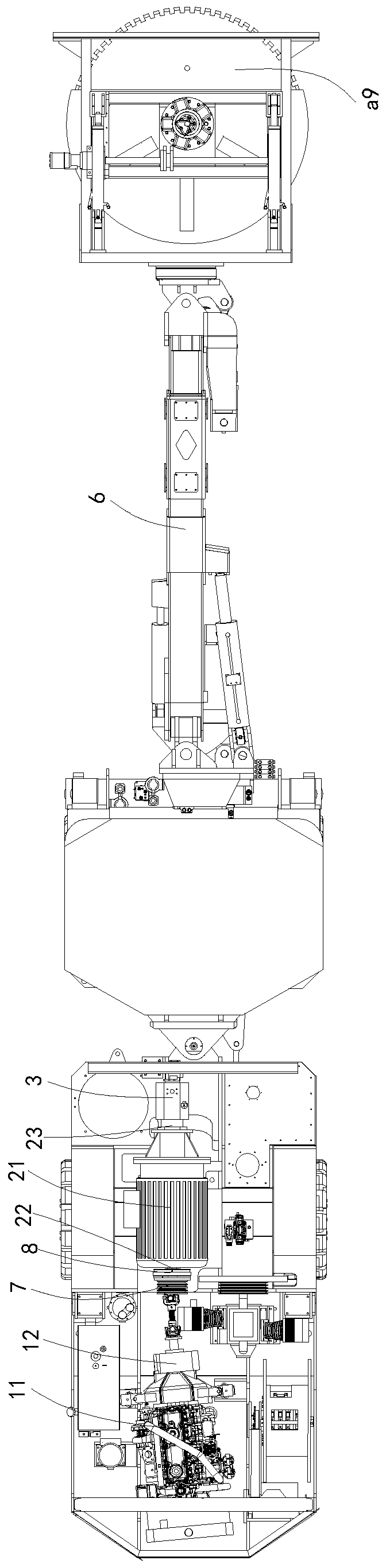

Roadway supporting equipment

ActiveCN114017050AReduced support requirementsLightweightTunnelsProps/chocksEngineeringStructural engineering

The invention relates to the technical field of roadway supporting and discloses roadway supporting equipment which comprises a mounting arm and a supporting shed frame, wherein the supporting shed frame comprises a top beam, two shoulder beams, two supporting columns and two upper connecting boots, the top beam is suitable for abutting against the top of a roadway; first ends of the shoulder beams are rotatably connected with one end of the top beam, and the two shoulder beams are connected with two ends of the top beam respectively; the supporting columns are rotatably connected with second ends of the shoulder beams, the two supporting columns are connected with the two shoulder beams respectively, and the supporting columns are telescopic; the upper connecting boots are rotatably connected with the second ends of the shoulder beams, the upper connecting boots are located on the outer side of the shoulder beams and the outer side of the supporting columns, and the upper connecting boots are suitable for abutting against the side wall of the roadway; the mounting arm is suitable for being mounted on an engineering vehicle and detachably connected with the supporting shed frame. The roadway supporting equipment provided by the invention has advantages of light weight, small size and easiness in carrying, dismounting and mounting, automation and unmanned operation during working face tunneling can be realized, the risk that workers suffer from occupational diseases is reduced, and construction efficiency is improved.

Owner:CHINA COAL RES INST

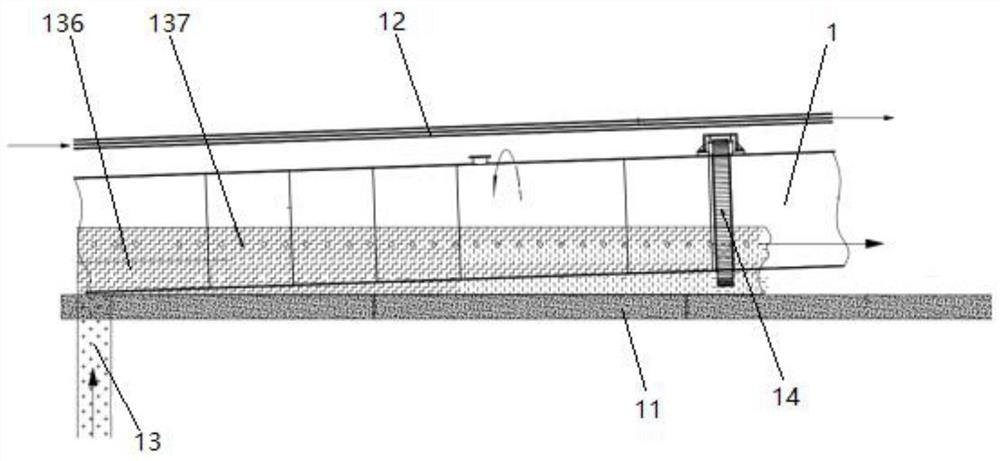

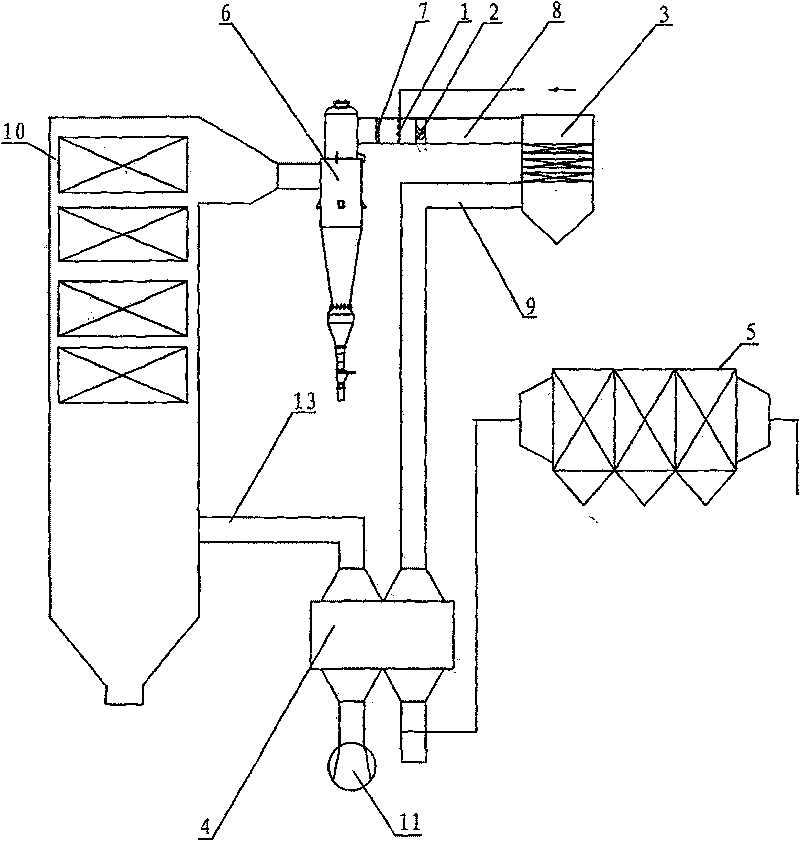

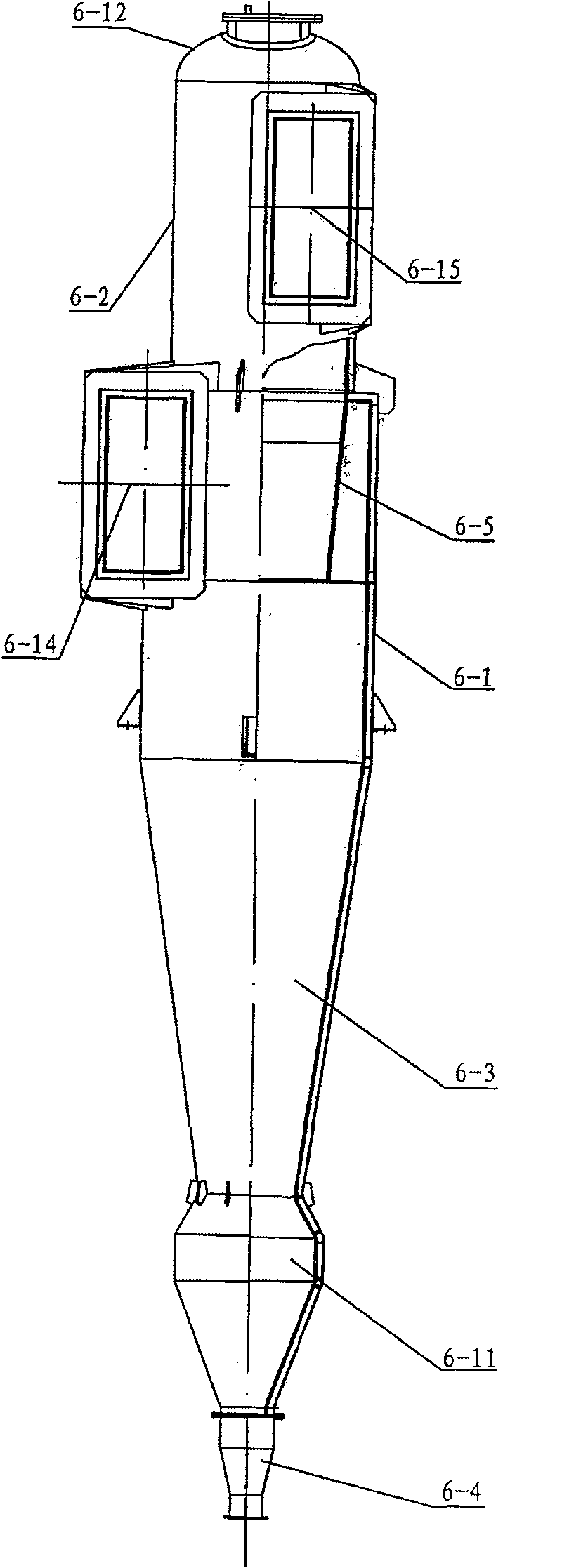

Flue gas denitrating technique with preposed whirlwind beforehand dust removal SCR

The invention discloses a preposing cyclone pre-dedusting SCR flue gas denitration technique. The flue gas extracted from a boiler economizer (12) primarily passes through a high temperature resistantcyclone separator (6), then passes through a flue gas current equalizer (7) and a static mixer (2) to unify the flow direction of the flue gas evenly; meanwhile, the flue gas after being mixed evenlywith ammonia is preprocessed before reacting with a catalyst of an SCR reactor (3); finally, the flue gas is output after the temperature is reduced through an air preheater (4) and the flue gas is dedusted through an electrical precipitator (5). The invention reduces the volume of the catalyst and the SCR reactor, reduces the requirements of the support, eliminates an SCR bypass and greatly reduces engineering cost of the SCR; meanwhile, the invention also prolongs the service life of the catalyst and the cleaning period of the air preheater without installing a soot blower or prolonging theperiod of sootblowing.

Owner:CPI YUANDA ENVIRONMENTAL PROTECTION ENG +1

Non-sticking wall template material and preparation method thereof

InactiveCN112979243AHigh strengthAccelerated disengagementForms/shuttering/falseworksBasalt fiberFire retardant

The invention provides a non-sticking wall template material and a preparation method thereof, and relates to the field of buildings. The non-sticking wall template material is prepared from the following substances in parts by weight: 25-35 parts of Portland cement, 10-15 parts of pottery clay powder, 5-10 parts of fly ash, 5-10 parts of sepiolite, 1-5 parts of basalt fiber, 5-10 parts of glass fiber, 1-5 parts of chitosan, 1-5 parts of nano silicon aerogel powder, 5-10 parts of calcium oxide, 1-2 parts of an insect-resist agent and 1-2 parts of a flame retardant. The surface of the wall formwork is subjected to micro-carving treatment, the adhesive force of all components on the wall formwork is improved, natural falling is prevented, the service life is prolonged, under the action of basalt fibers and glass fibers, the strength of the wall formwork can be improved, then the supporting requirement in construction can be reduced, separation of a poured wall can be promoted, and the pouring wall body is better protected.

Owner:天造机器人科技(广东)有限公司

Diesel-electric dual-using mine cutting car

PendingCN109838234AAchieve normal workImprove environmental adaptabilityDriving meansCutting machinesElectricityCircular disc

The invention discloses a diesel-electric dual-using mine cutting car. The diesel-electric dual-using mine cutting car is characterized in that the diesel-electric dual-using mine cutting car comprises an engine, a motor, a hydraulic pump set, a car body skeleton, rear wheels, a mechanical arm, a round disc cutting machine, a main control hydraulic valve set and an auxiliary control hydraulic valve set, the engine, the motor, the hydraulic pump set, the mechanical arm, the main control hydraulic valve set and the auxiliary control hydraulic valve set are all mounted on the car body skeleton; when the motor is connected with a power supply, the hydraulic pump set is directly driven to work, when the motor is not connected with a power supply, workers can start engine, the torque of the engine can be passed to the hydraulic pump set through a rotor indirectly to drive the hydraulic pump to work, thus normal work of the mine cutting car can be also realized in places lacking electricity,and the environment adaptive capacity of the mine cutting car is improved; and the round disc cutting machine cuts a groove on the fracture surface of the mine in the side direction, then a breaking hammer is used for hammering the mine side direction fracture surface on the upper part of the groove, and thus the mine side direction fracture surface on the hammering position is broken.

Owner:宜昌鄂奥图机械制造有限公司

Retaining wall used for foundation pit supporting and construction method for retaining wall

The invention discloses a retaining wall used for foundation pit supporting. A foundation pit is in the shape of circular barrel; the retaining wall comprises a plurality of pile bodies, and an inner support structure, wherein the pile bodies are arranged in an annular mode along the pit wall of the foundation pit, and are engaged with one another to form a peripherally sealed wall body; the inner support structure is arranged in the annular mode along the inner wall of the retaining wall; the inner part of the foundation pit faces towards a soil body to support the wall body; and the bottom ends of the pile bodies are supported on the bottom surface of the foundation pit. With the adoption of the design, the pile bodies are only used as media of a retaining body, the pile bodies do not depend on the soil body anchored under the bottom surface of the foundation pit to generate counter-acting force to absorb side pressure, applied to the pile bodies, of the soil body outside the pile bodies, but transmit the side pressure to an inner support ring beam, and the inner support structure bears more side pressure, so that the effects of strong support and weak piles are achieved. Materials needed for absorbing the side pressure of the soil body by additionally arranging the inner support ring beam are much less than materials needed for inserting the pile bodies into the foundation pit.

Owner:JIANGXI JIYE SCI & TECH

Continuous casting system for casting metal strand having billet or bloom cross-section

The invention relates to a billet or bloom continuous casting system, comprising a mold for forming a metal strand and a strand guide (2) connected to the mold (1) for supporting and guiding the metal strand, wherein the strand guide is formed by multiple strand guide segments (3a, 3b, 3c, 3d, 3e, 4), and each strand guide segment is supported via a segment support frame (7, 8) in the system support framework of the continuous casting system, and a first segment support frame (7) directly following in the strand guide of the mold supports at least two strand guide segments. In order to minimize the maintenance expense, the first strand guide segment (3a, 3d) directly following the mold is detachably mounted on the first segment support frame on substantially vertical support surfaces (12), and is configured such that the same can be installed into and uninstalled from the continuous casting system independently of the subsequent strand guide segments (3b, 3c, or 3e), and at least the last strand guide segment (3c, 3e) supported on the first segment support frame (7), exclusively together with said frame, forms an assembly unit that can be installed and removed.

Owner:PRIMETALS TECH AUSTRIA GMBH

I-type impact air flow attenuator

InactiveCN103453317BReduce couplingGuaranteed exhaust flow requirementsContainer filling methodsContainer discharging methodsEngineeringSafety valve

The invention discloses an I-type impact air flow attenuator. The I-type impact air flow attenuator comprises an air flow buffering cavity, wherein an air inlet pipe and an air outlet pipe which are communicated with an inner cavity of the air flow buffering cavity are arranged at the two ends of the air flow buffering cavity; straight pipe sections of an emptying pipeline are communicated by the air inlet pipe and the air outlet pipe on the air flow buffering cavity; the air inlet pipe and the air outlet pipe on are arranged on a same straight line and are distributed in an I shape in the air flow buffering cavity. According to the I-type impact air flow attenuator, the properties of impact air flow and the emptying pipeline are considered comprehensively, basic principles of an interference type air flow buffer, a porous plate and a pore plate acoustic filter are integrated and extraction flow requirements of the emptying pipeline and the dynamic property of the impact air flow are considered comprehensively; the I-type impact air flow attenuator can be mounted on the straight pipe sections of the emptying pipeline outside a safety valve horizontally or vertically; the air flow buffering cavity is arranged, and the turning parts of the emptying pipeline are communicated by the air inlet pipe and the air outlet pipe on the air flow buffering cavity, so as to realize the effects of dissipating the energy of the impact air flow, reducing a coupling effect of the pipelines and guaranteeing the requirements of extraction flow.

Owner:XI AN JIAOTONG UNIV

Deep-foundation-pit reservoir and construction method thereof

The invention discloses a deep-foundation-pit reservoir. The deep-foundation-pit reservoir comprises a foundation pit, multiple pile bodies and an inner support structure, wherein the foundation pit is in a drum shape; the multiple pile bodies are arranged along the pit wall of the foundation pit in a ringlike manner and occlude with one another, so that a circumferentially-closed barrier wall isformed; the inner support structure is arranged along the inner wall of the barrier wall in a ringlike manner, and the inner support structure is in the direction from the interior of the foundation pit to a soil body, so that the barrier wall is supported; and the bottom ends of the pile bodies are arranged on the bottom face of the foundation pit in a support manner. By means of the deep-foundation-pit reservoir, the pile bodies only serve as a medium of a barrier body; the situation that the pile bodies rely on the soil body anchored below the bottom face of the foundation pit to generate counter-acting force to absorb the side pressure applied by the surrounding soil body outside piles to the pile bodies is avoided, and the side pressure is transmitted to inner support ring beams, so that the inner support structure bears more side pressure; and the effect that the inner support structure is reinforced, and the piles are weakened is achieved. The side pressure of the soil body is absorbed by additionally arranging the inner support ring beams, and the required materials are far fewer than those required for inserting part of the pile bodies into the foundation pit.

Owner:JIANGXI JIYE SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com