Patents

Literature

1351results about "Knitting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

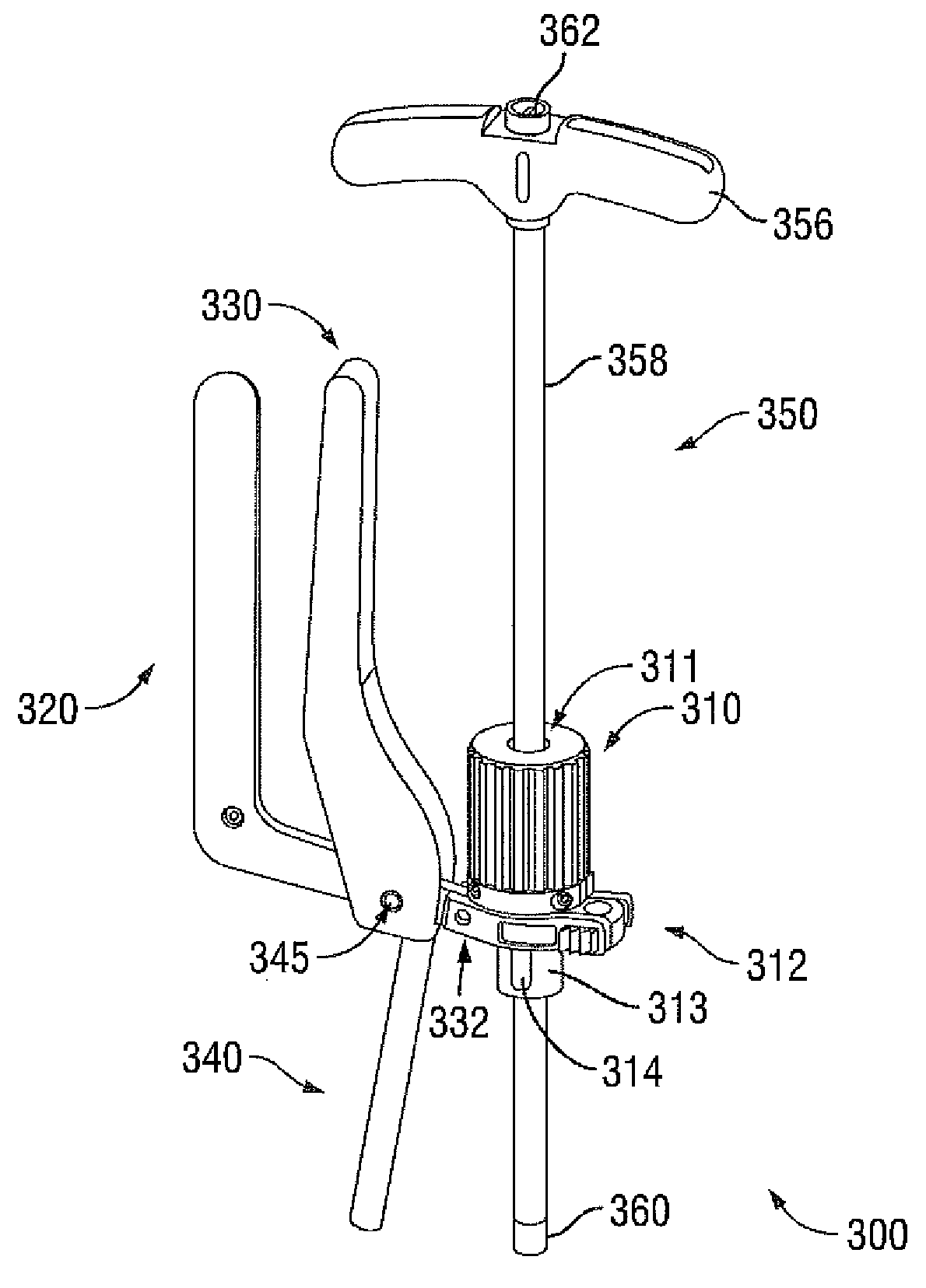

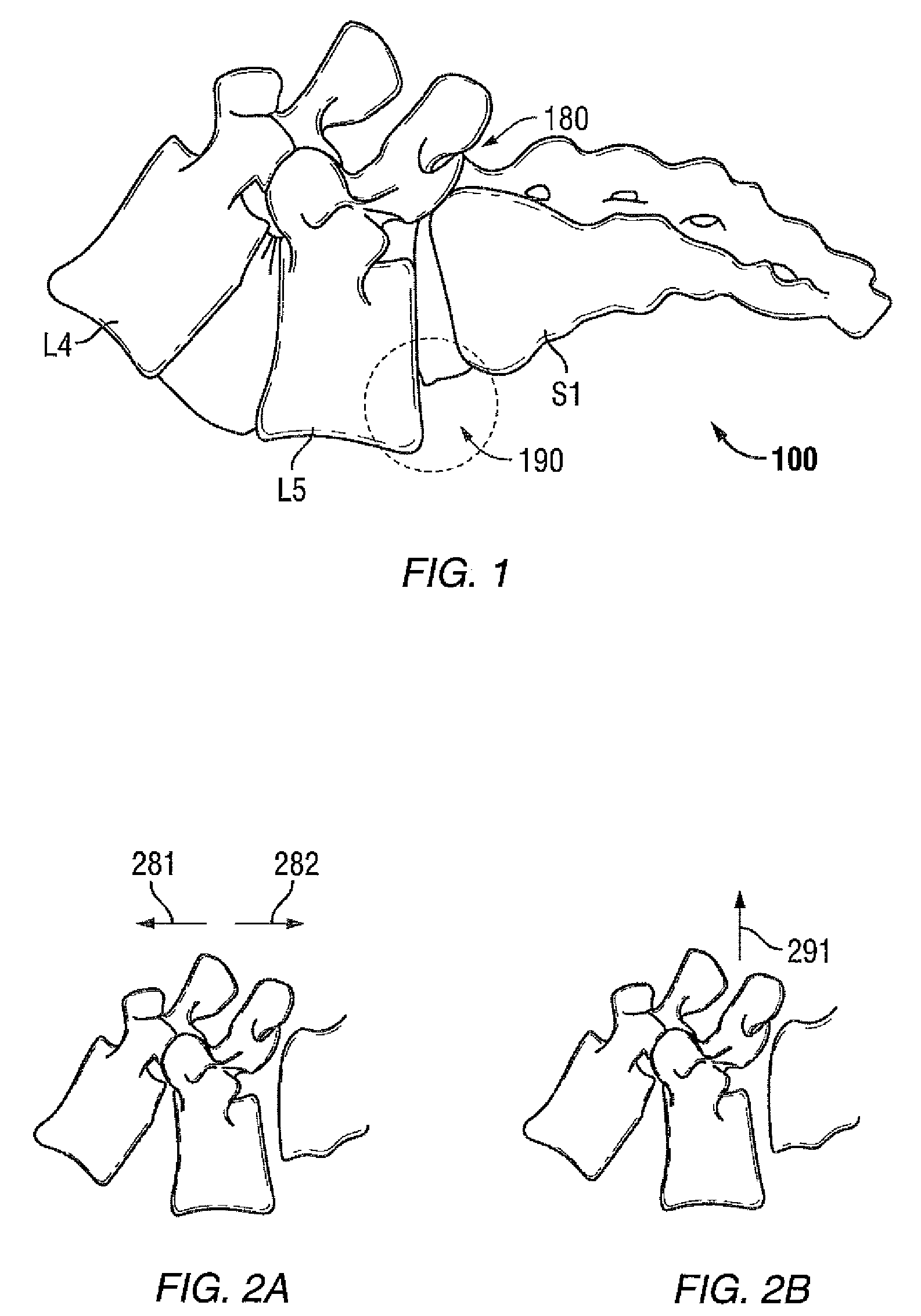

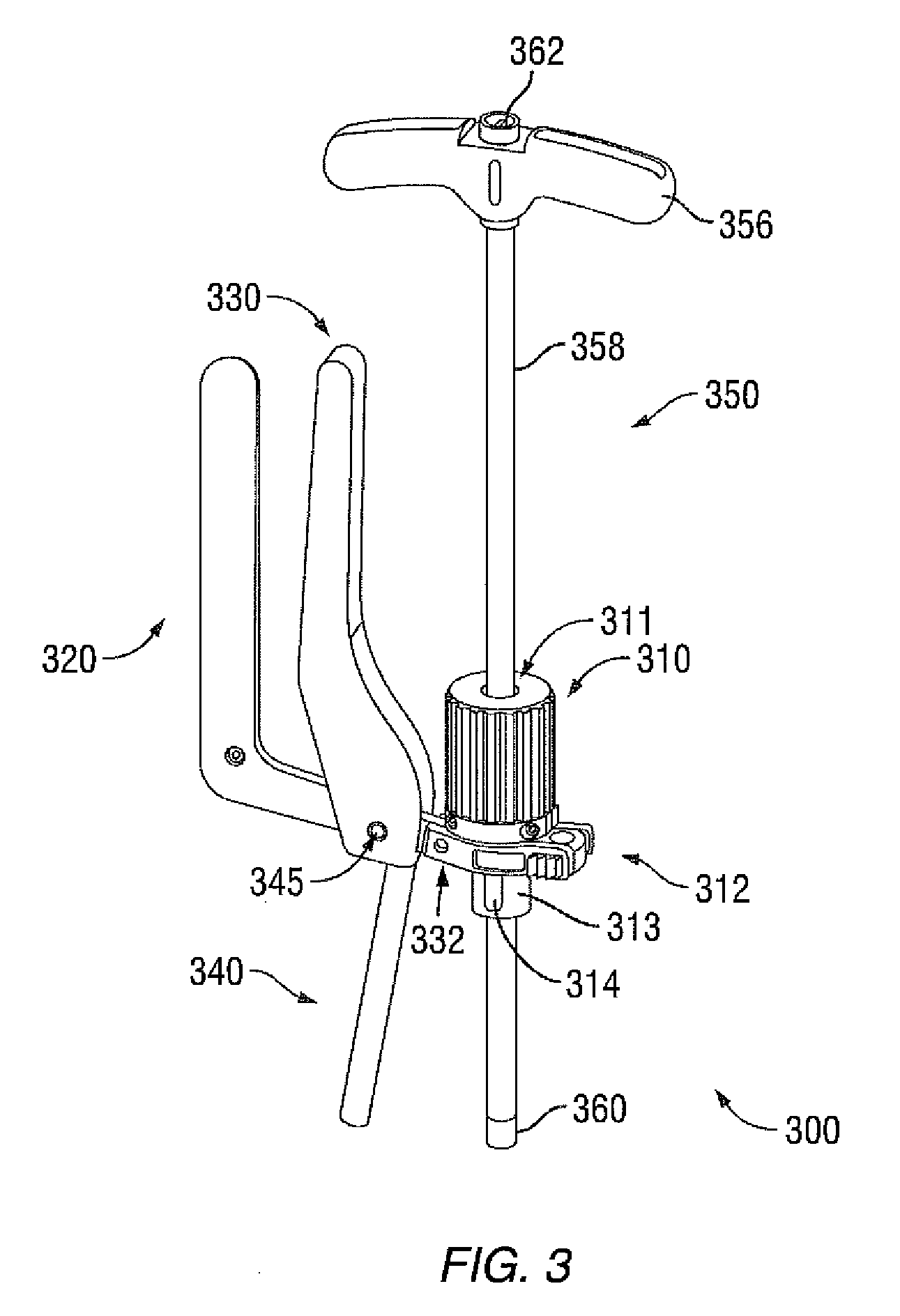

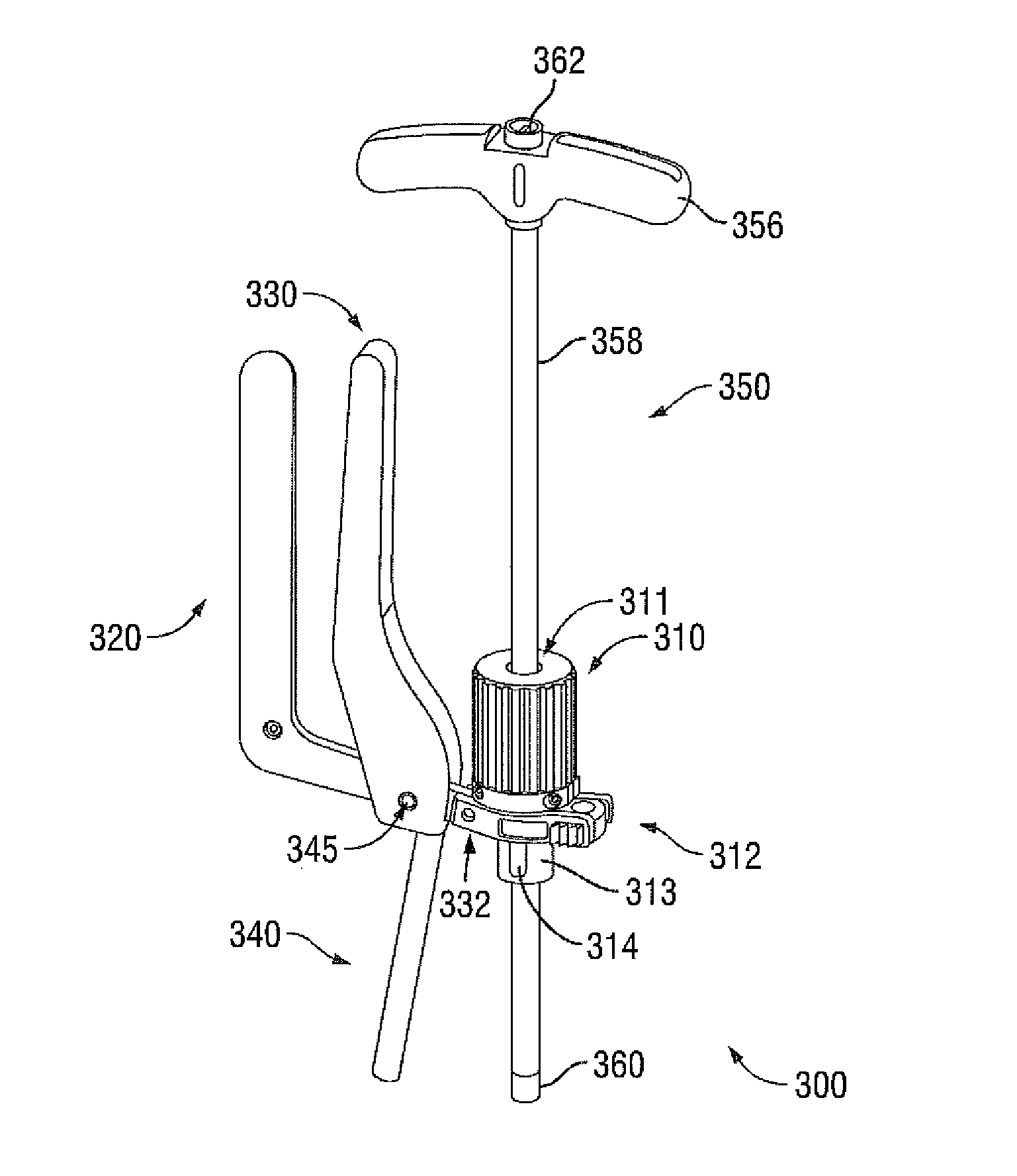

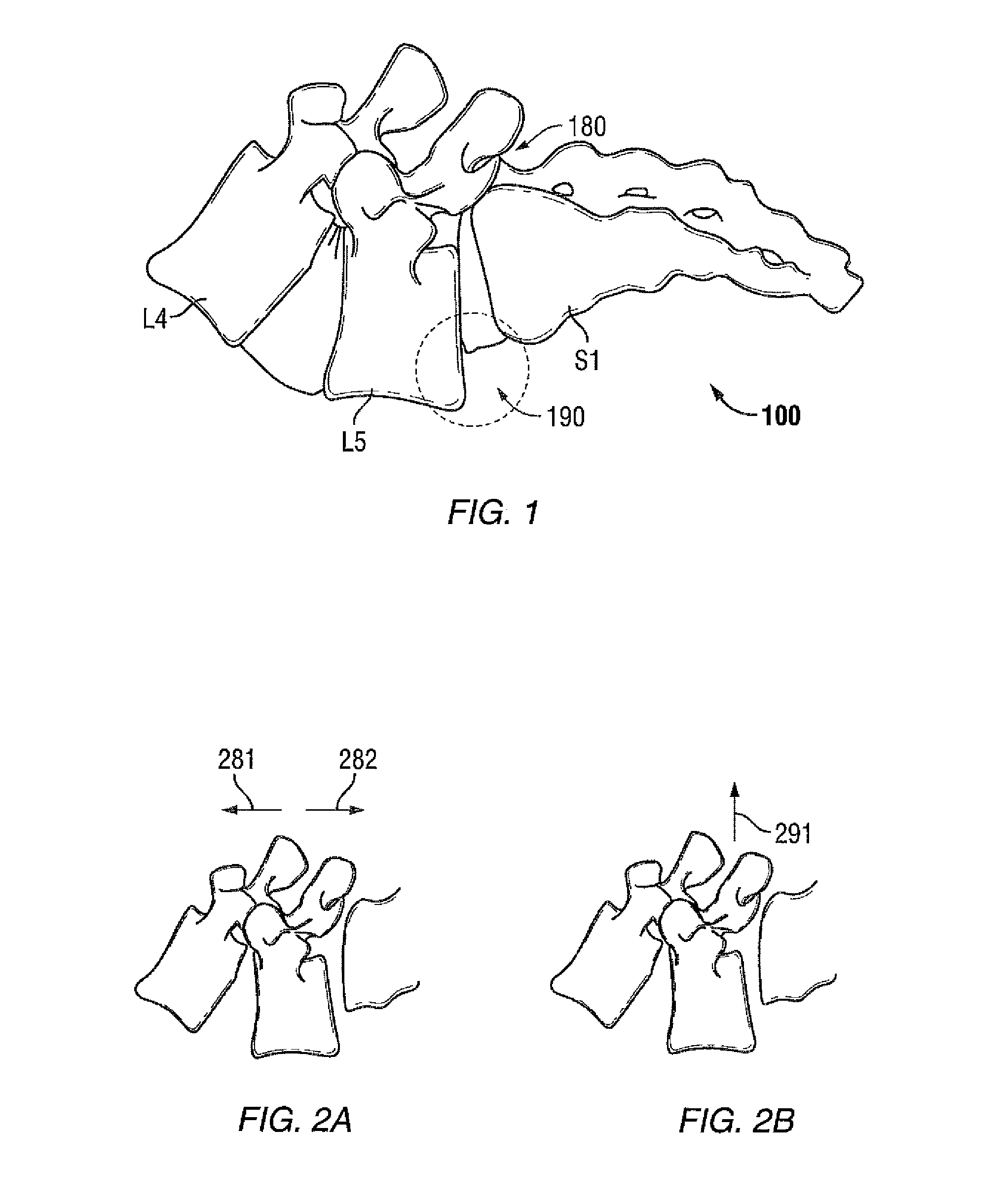

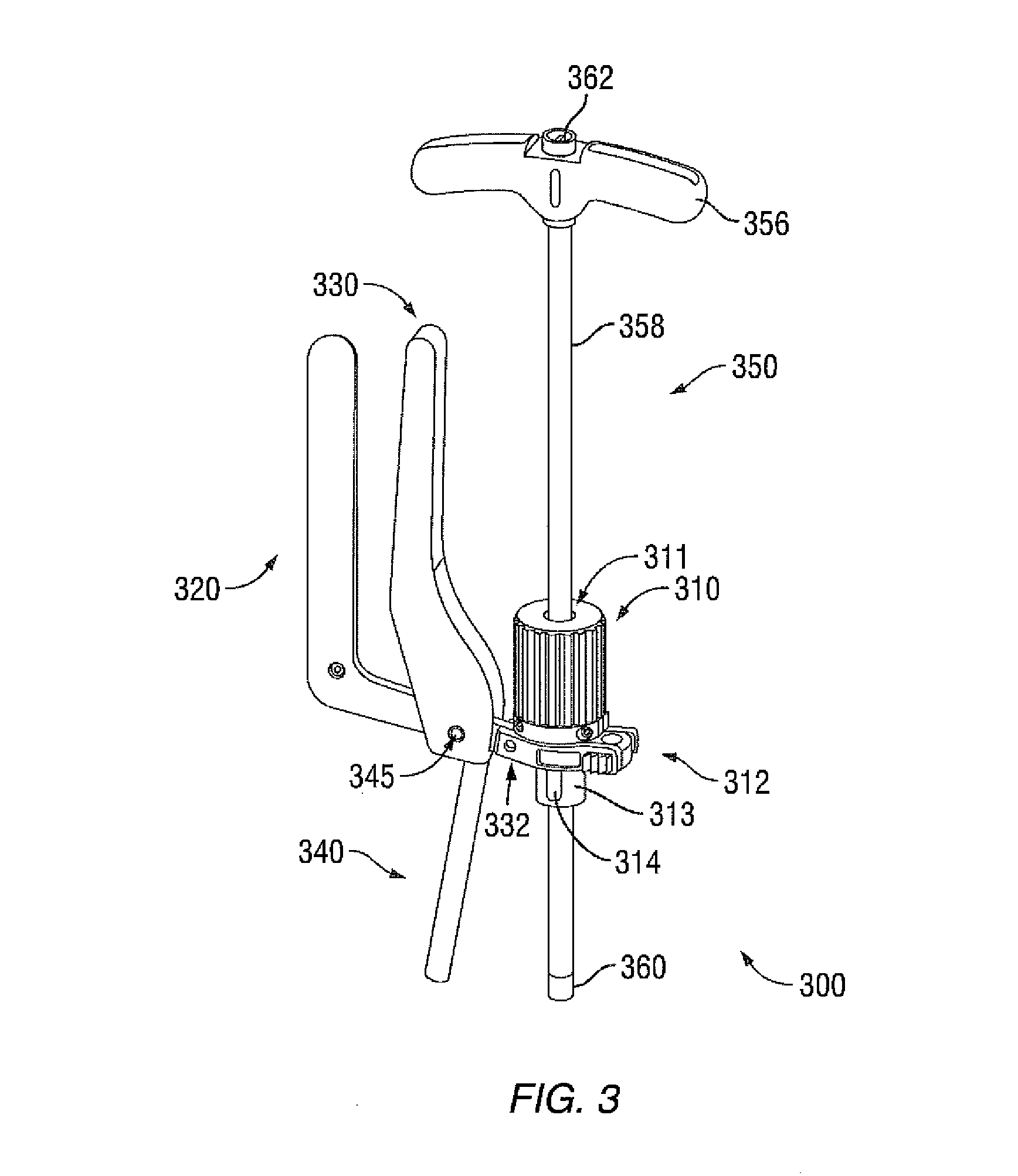

Surgical Instrument With Integrated Reduction And Distraction Mechanisms

ActiveUS20100024487A1Shorten operation timeImprove efficiencyInternal osteosythesisFractureDistractionPosterior fixation

Embodiments of a surgical instrument disclosed herein can include mechanisms for reduction and distraction as well as compression. Some embodiments of the surgical instrument may comprise a reducer knob having a first passage through which a first shaft of a driver is acceptable, a connecting element coupled to the reducer knob and having a second passage through which the first shaft of the driver is acceptable, a compressor handle coupled to the connecting element at a first end and having a through hole, and a common handle coupled to the compressor handle via the through hole and pivots between the reducer knob and the compressor handle. With embodiments of a surgical instrument disclosed herein, surgical personnel can distract and hold vertebrae in a distracted state and perform a reduction without having to switch or add instruments. Some embodiments disclosed herein can be particularly useful for reducing spondylolisthesis during posterior fixation.

Owner:ZIMMER BIOMET SPINE INC

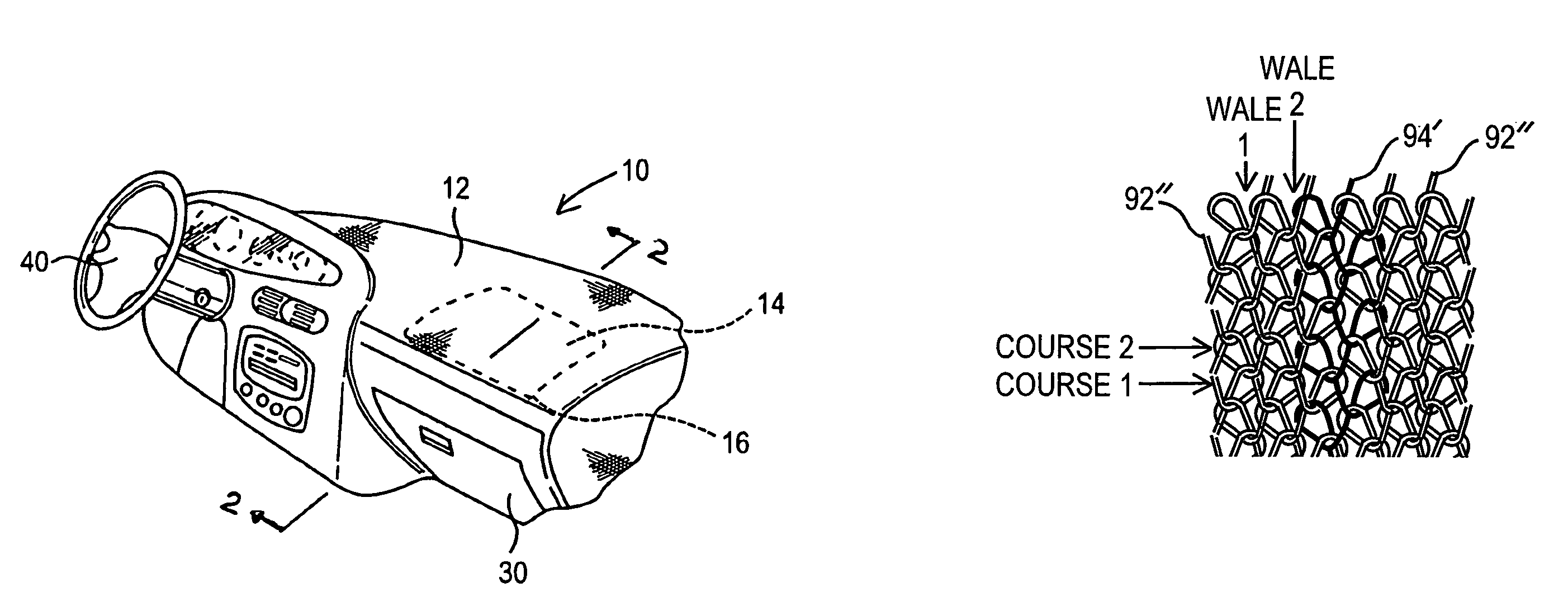

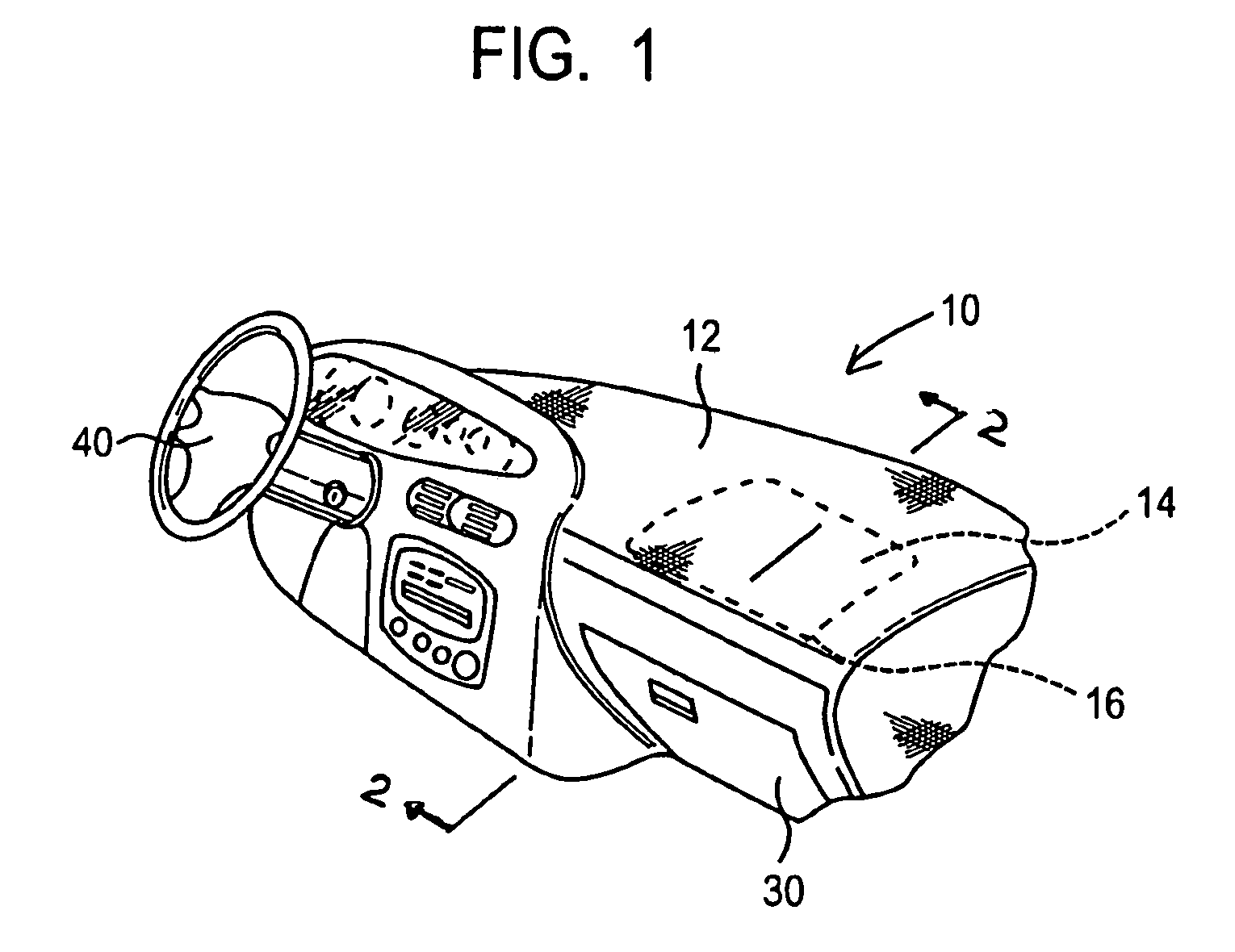

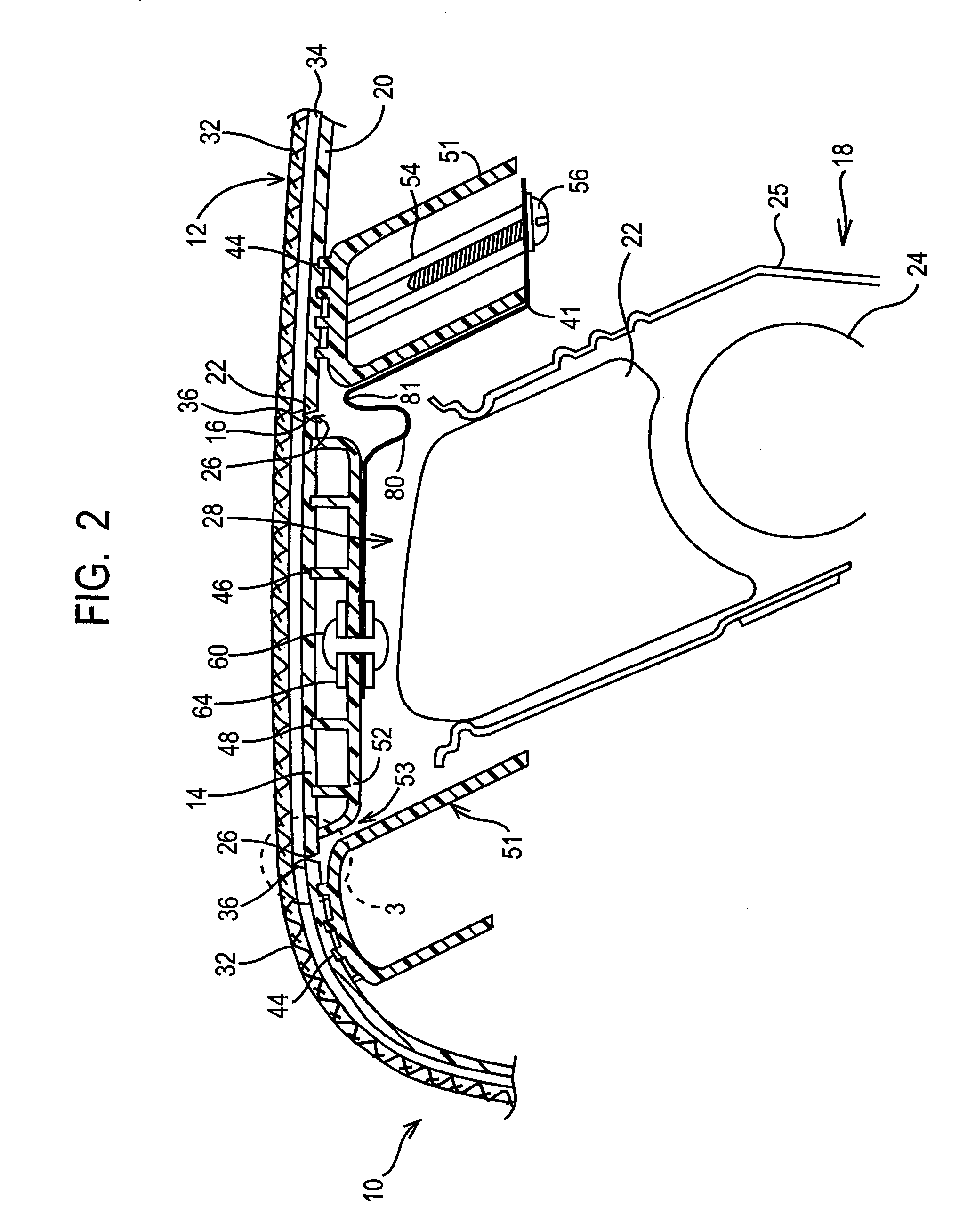

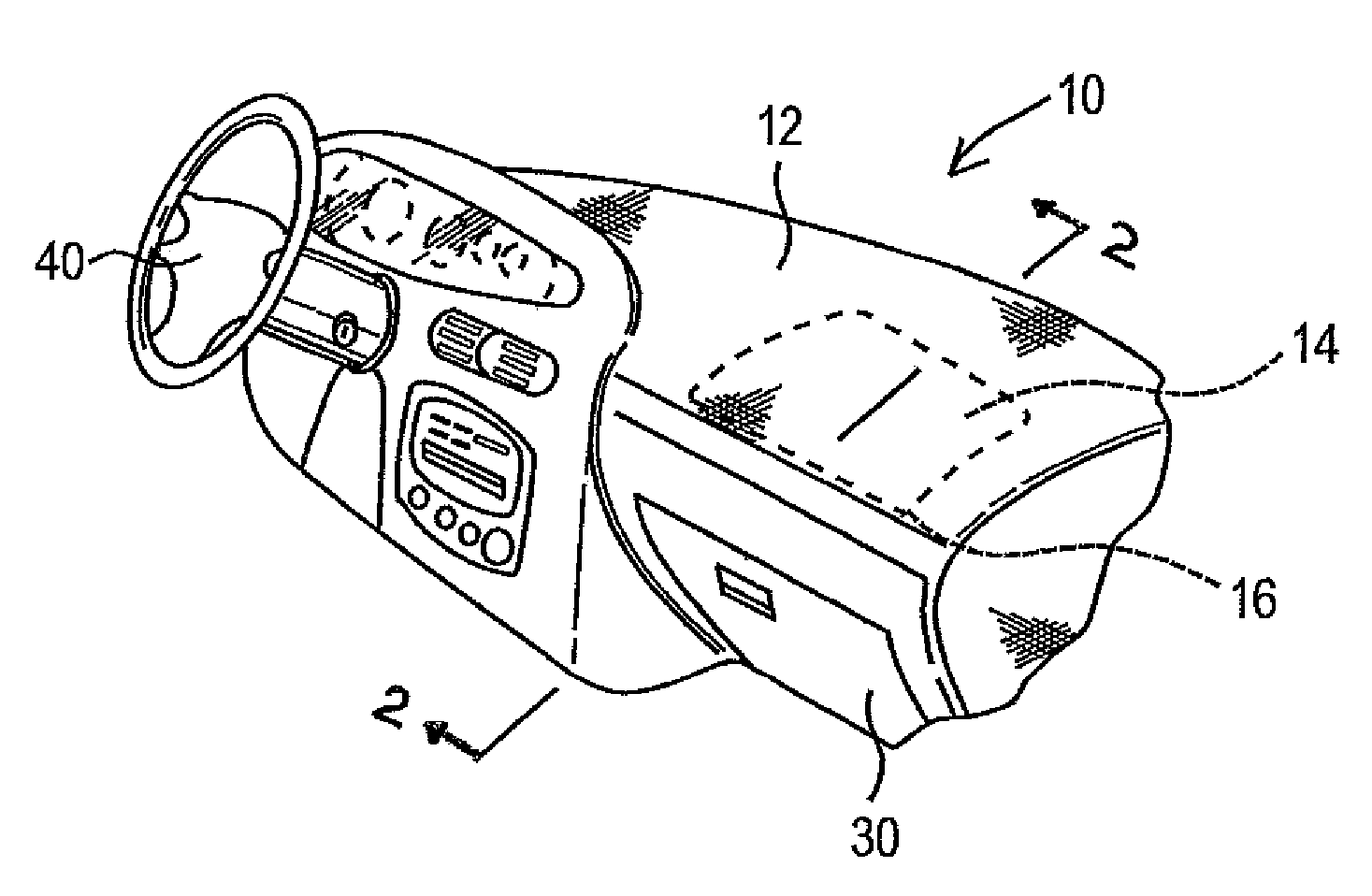

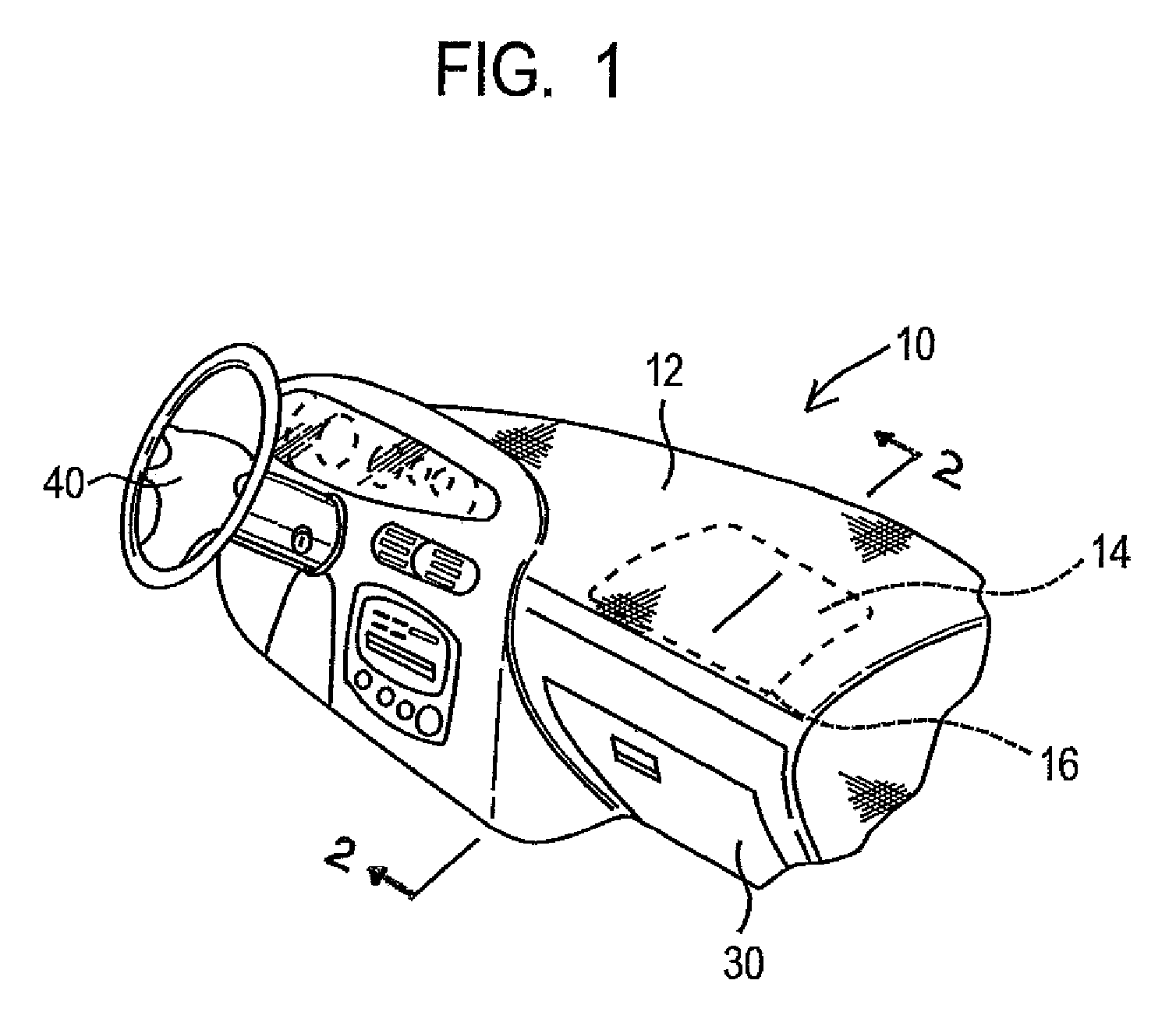

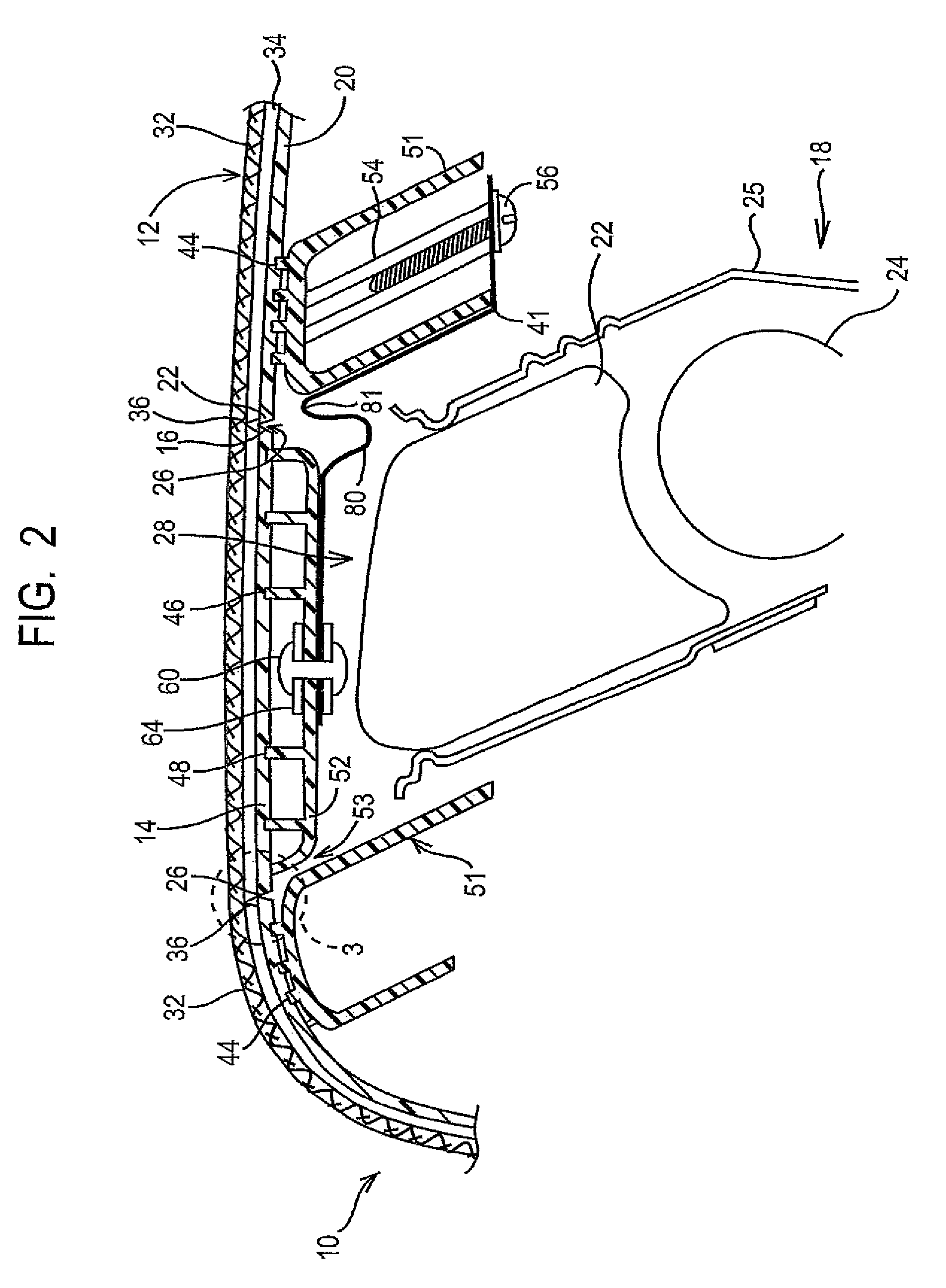

Pre-weakening of fabric covered airbag doors

A variety of embodiments are disclosed, in both apparatus and method form, that relate to the use of fabric material in the manufacture of an air bag deployment system. In addition, fabric weakening is disclosed according to a technique that does not result in physical alteration of the fabric. This invention therefore includes an air bag cover for an air bag safety system for a vehicle comprising a fabric outer layer having a frontside and a backside and a substrate containing an opening wherein the opening has a periphery. The substrate is preferably formed by low pressure molding, wherein the fabric outer layer overlies the opening in the substrate, and wherein the fabric outer layer is weakened at a location that is adjacent or overlies the substrate opening periphery.

Owner:COLLINS & AIKMAN AUTOMOTIVE CO INC

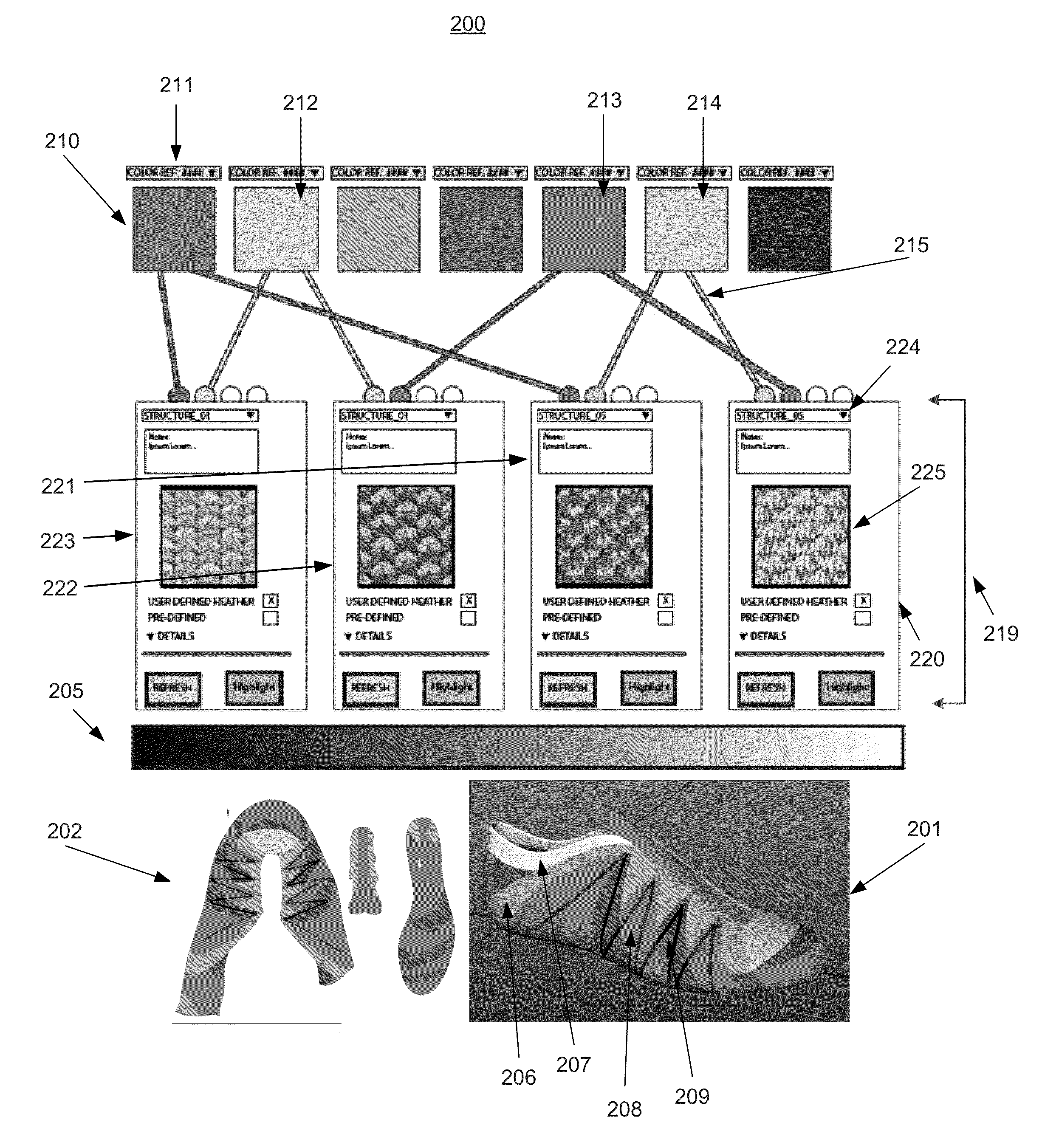

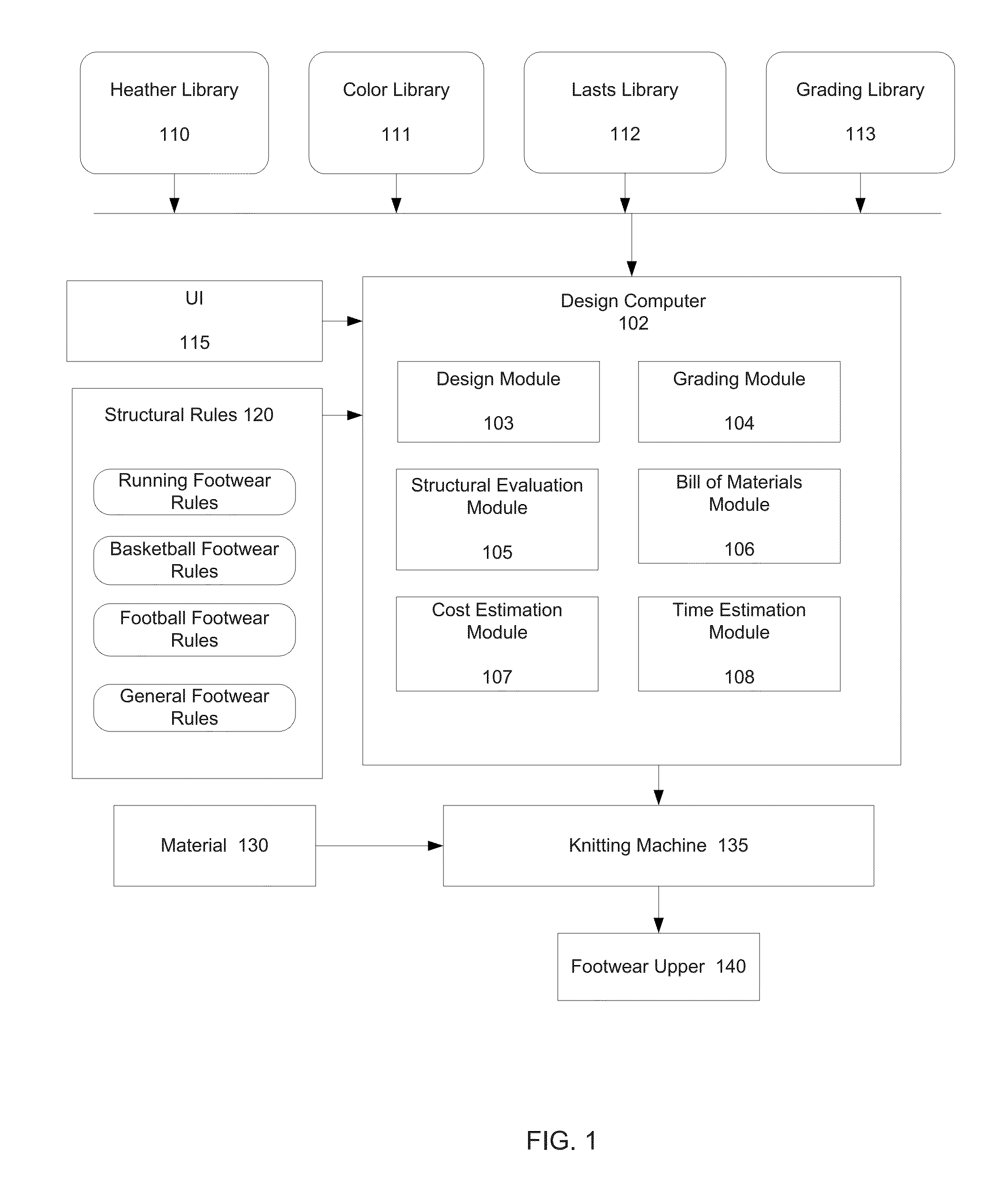

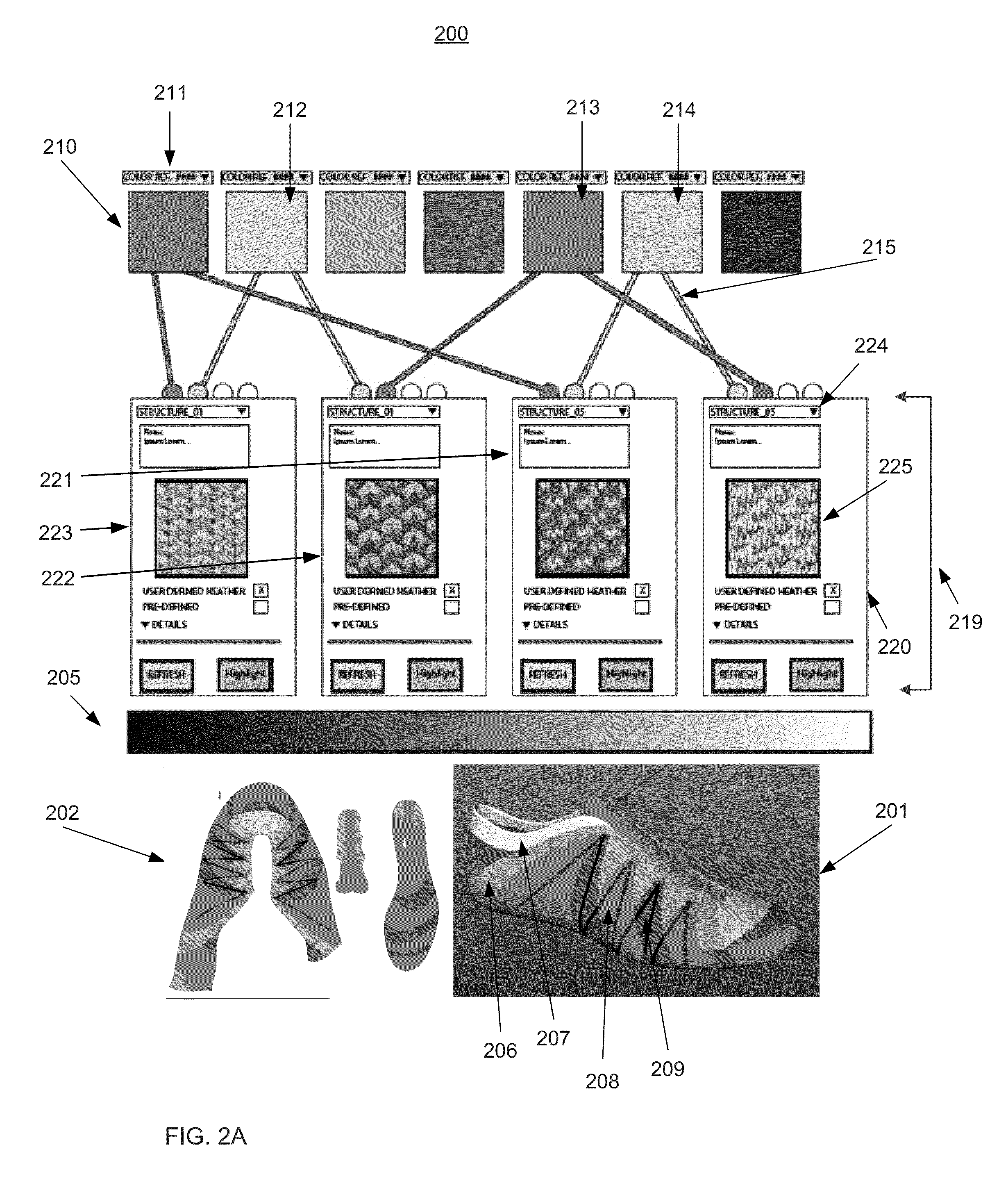

Footwear Designing Tool

ActiveUS20150366293A1Satisfies needDesign optimisation/simulationUpperComputer basedDesign characteristics

Computer based systems and methods for designing (e.g., customization) of consumer products, articles of footwear, knit footwear uppers, and the like. In some embodiments, a user may generate and / or modify footwear designs using a footwear design interface. Additionally or alternatively, the footwear design interface may be configured to simulate the layout and / or operation of a knitting machine to provide the user with the impression of physically designing and / or manufacturing an article of footwear. In other embodiments, the system may disallow prospective footwear design changes based on limitations associated with inventory availability and the footwear design characteristics.

Owner:NIKE INC

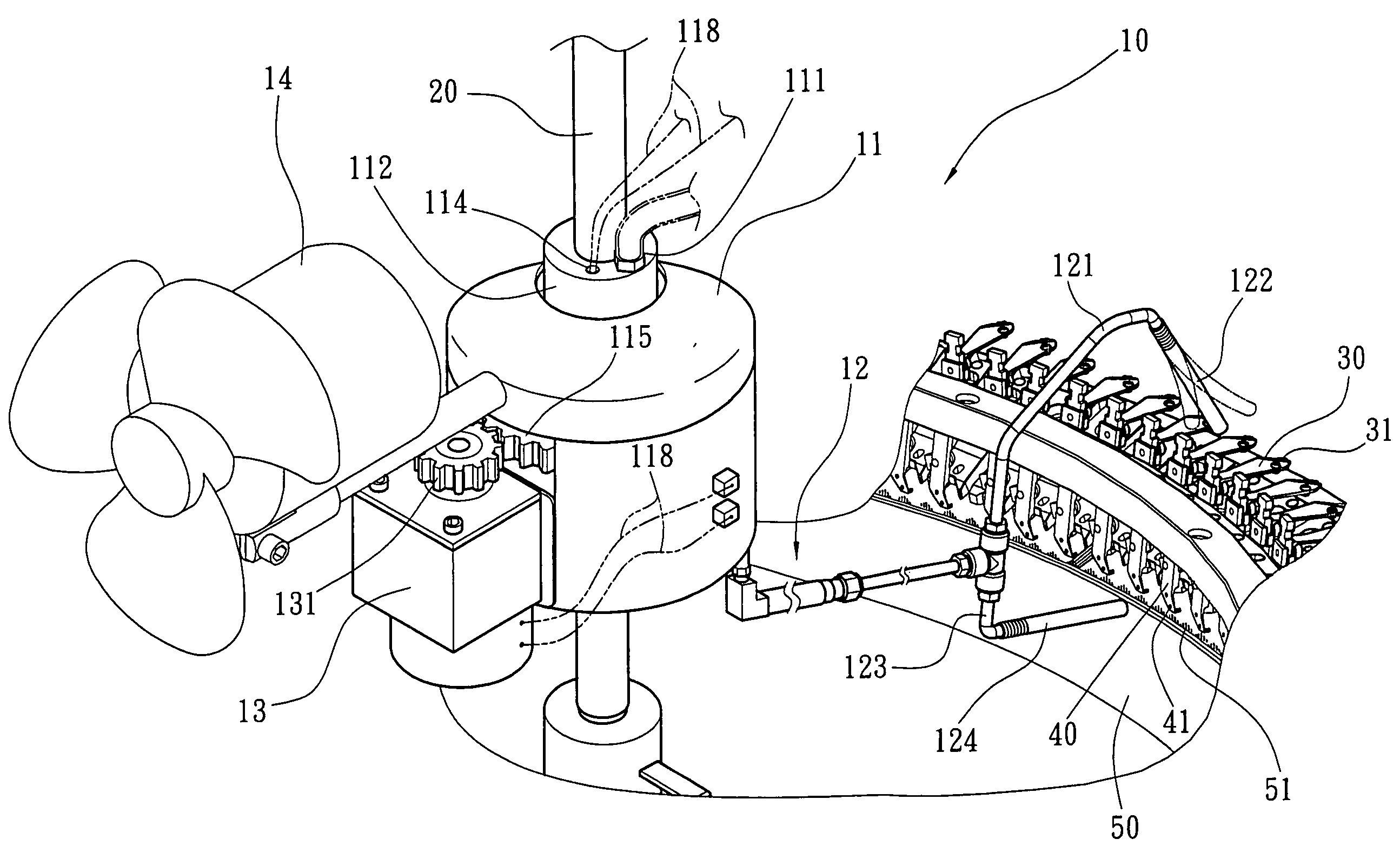

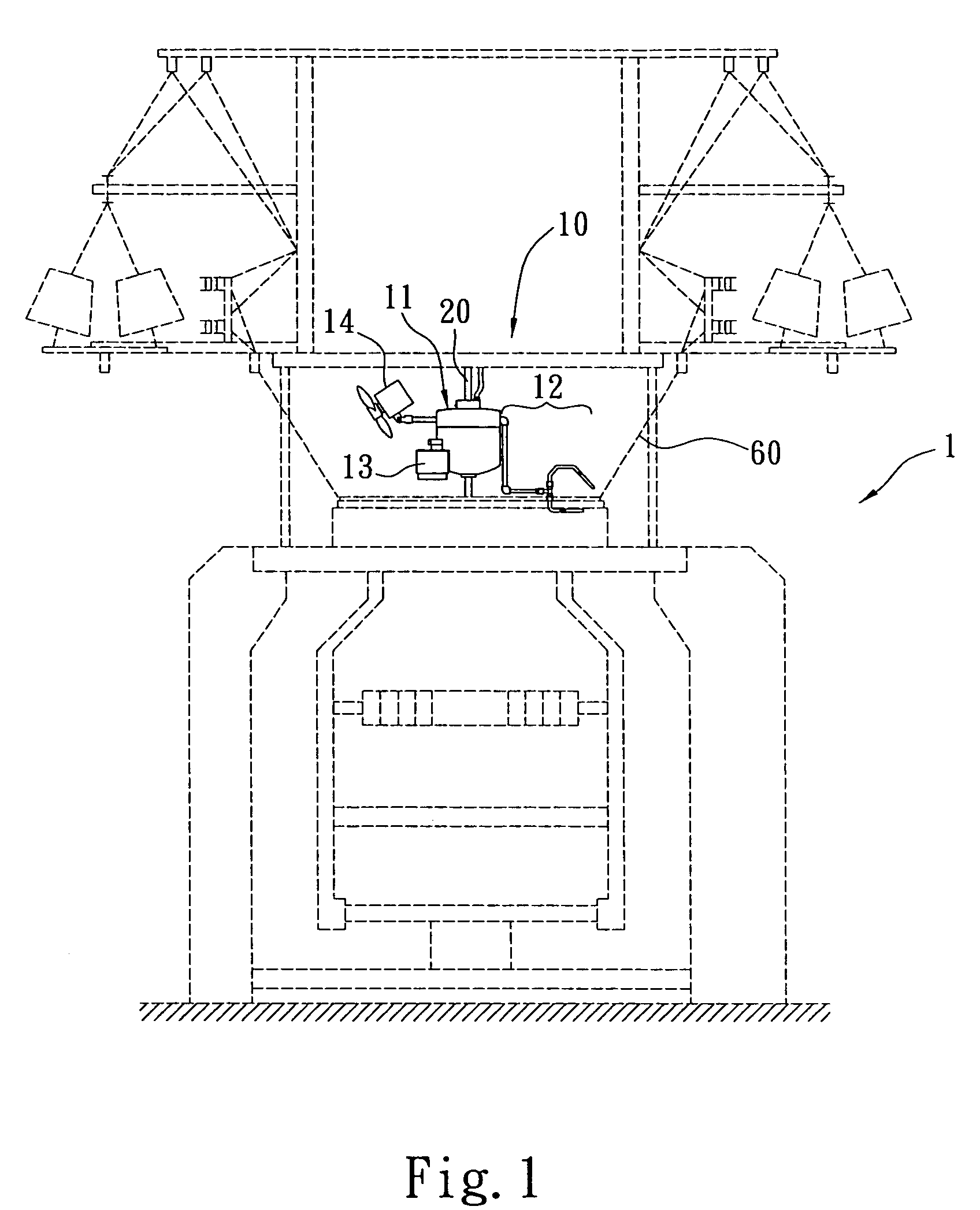

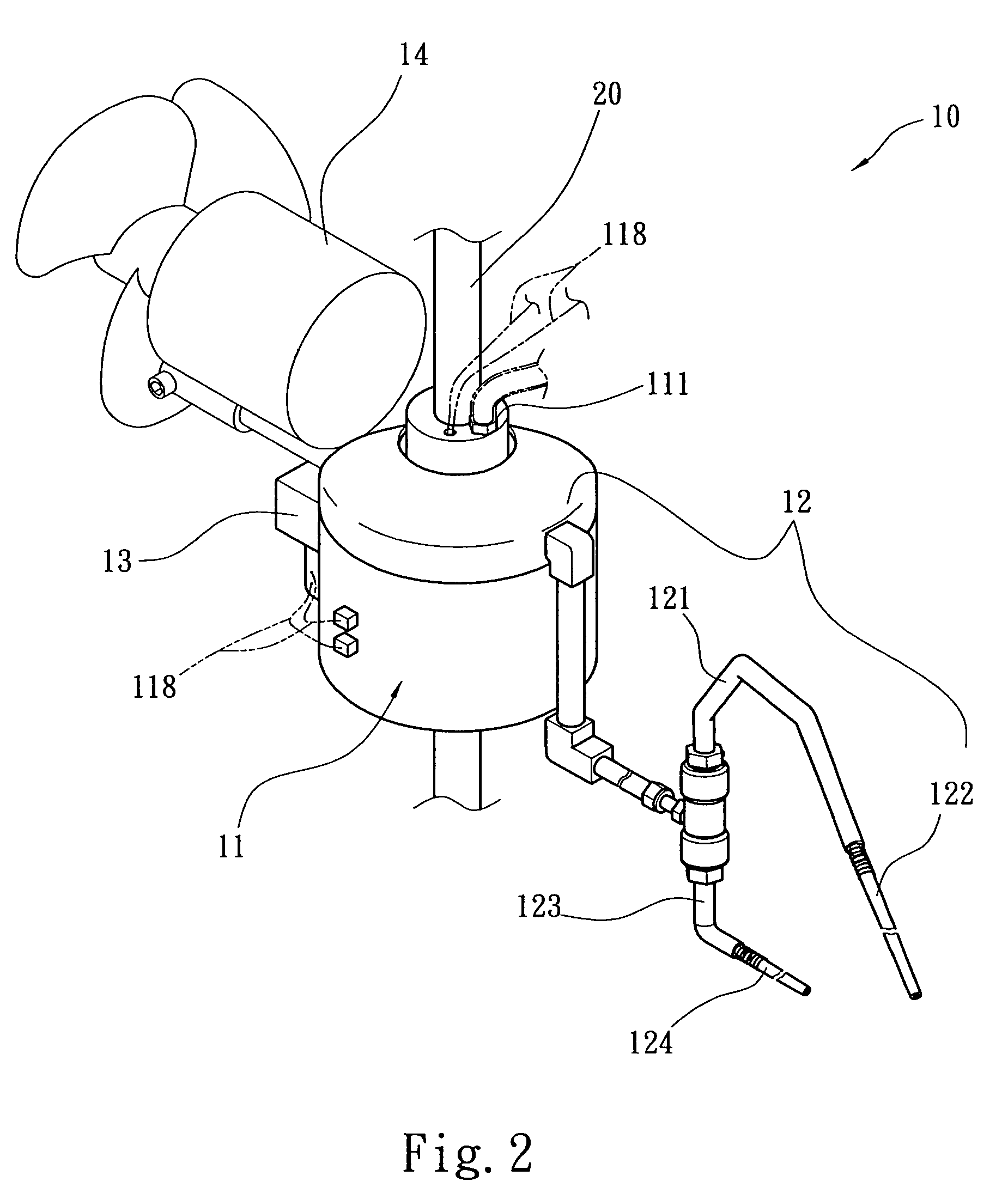

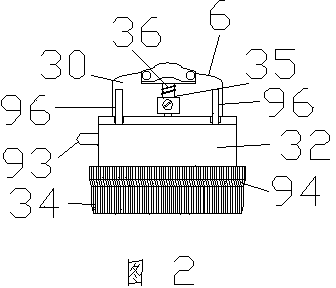

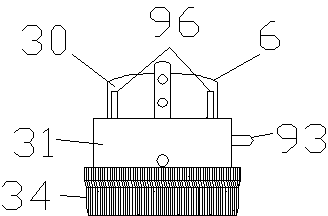

Fiber blowing and heat dissipating system of single-sided circular knitting machine

A fiber blowing and heat dissipating system of single-sided circular knitting machine includes a fixed rod, a revolving supply device, and a fiber blowing device, wherein the revolving supply device includes a fixed rod, a rotary air supply section, and a driving motor. The fixed axle has an air inlet at its top, and the rotary air supply section has an air passage interconnected with the air inlet and connected to the fiber blowing device, such that the driving motor is driven to rotate around the fixed axle to centralize the air flow to blow away the cotton fibers easily produced at a yarn passing eyelet of the yarn passing plate and the yarn feeding eyelet of a yarn feeding nozzle and a knitting needle. The invention also can lower the heat produced by the friction between the rotation of the needle cylinder and the knitting needle.

Owner:PAI LUNG MACHINERY MILL CO LTD

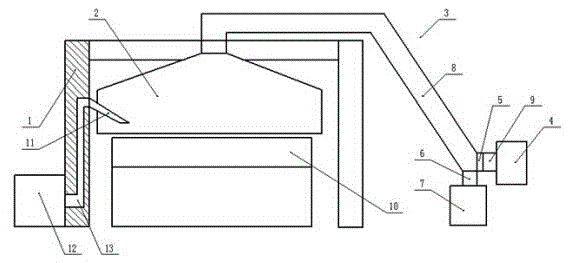

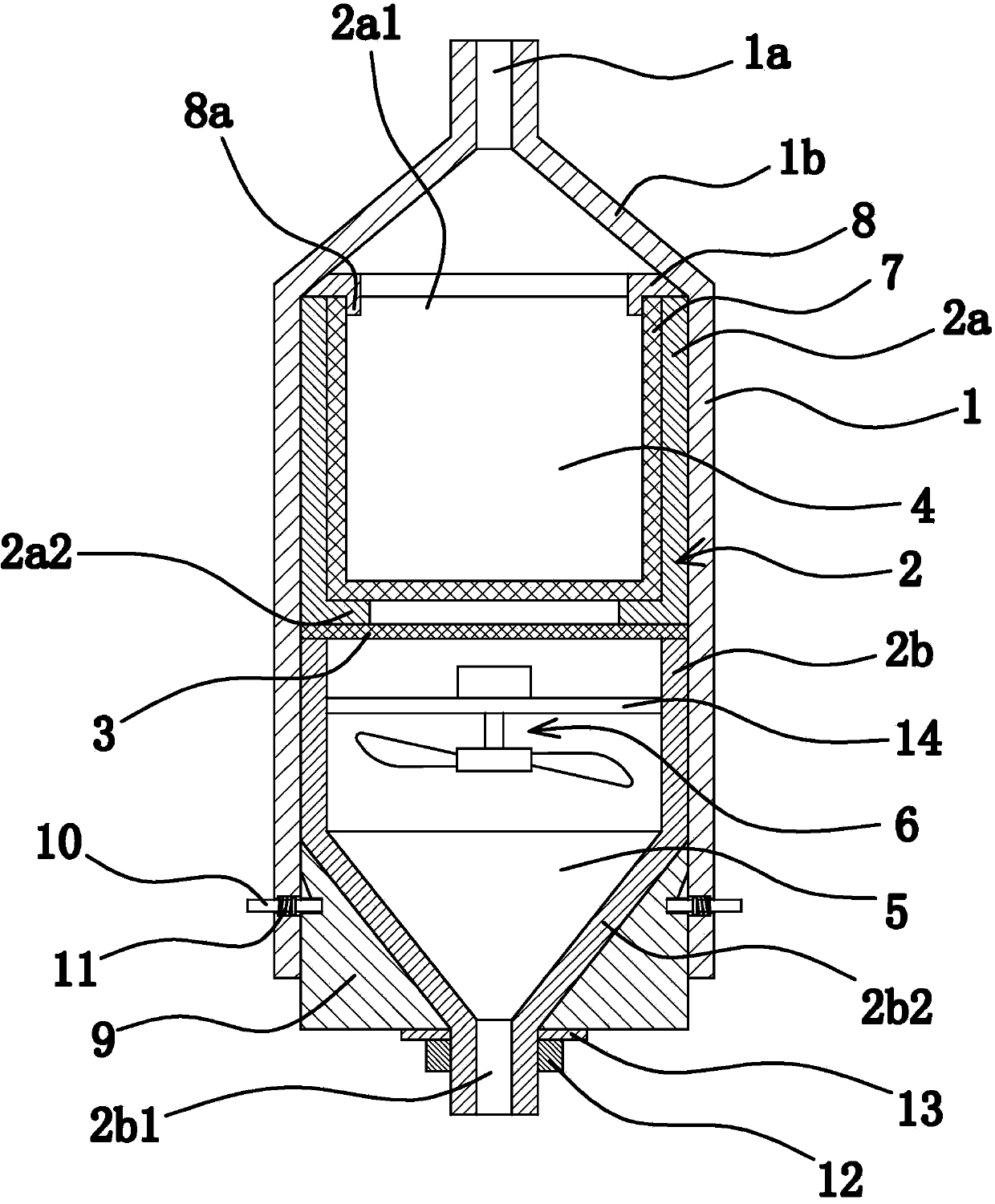

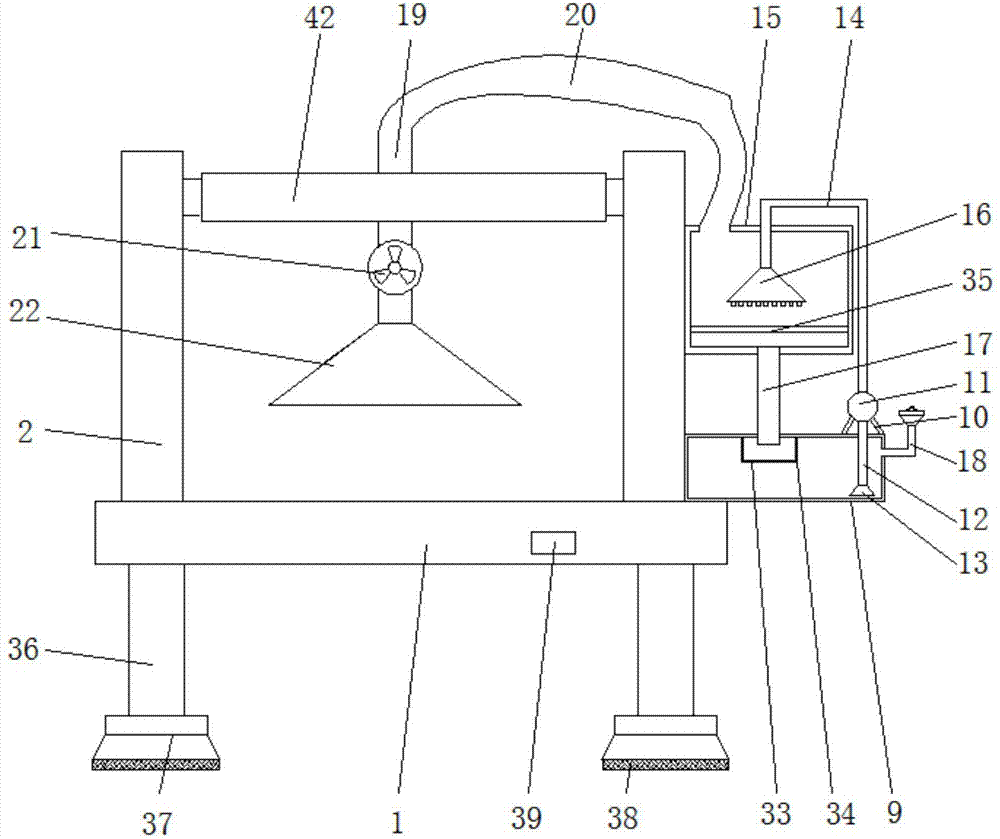

Textile machine dust removal device

InactiveCN104404698AImprove cleanlinessPhysical health threatAuxillary apparatusKnittingEngineeringAir blower

The invention discloses a textile machine dust removal device. The textile machine dust removal device comprises a support, a filter screen and a spinning device; a collection bucket is arranged on the support; the lower end of the collection bucket can rightly cover above the spinning device; a collection pipe which is communicated with a collection chamber of the collection bucket is arranged on the collection bucket; the collection pipe is communicated with an input end of an exhaust fan; the collection pipe comprises an inclined pipe; the inclined pipe is communicated with a straight pipe; the filter screen is arranged inside the collection pipe; the collection pipe at the front end of the filter screen is communicated with a dust outlet pipe; an outlet end of the dust outlet pipe is arranged inside a collection bag; an air blower is arranged outside the left side of a machine frame; the air blower is connected with an air channel which is formed inside the machine frame; an outlet of the air channel is provided with a dust blowing opening. According to the textile machine dust removal device, the structure is simple, dust can be blocked through the filter screen, then the dust falls into the collection bag through the dust outlet pipe, and accordingly collection of the dust is achieved, the clean and tidy degree of a workshop is guaranteed, and meanwhile threat to health of workers from the dust is avoided.

Owner:SUQIAN CITY SUYU DISTRICT ZHUOWEI SILK

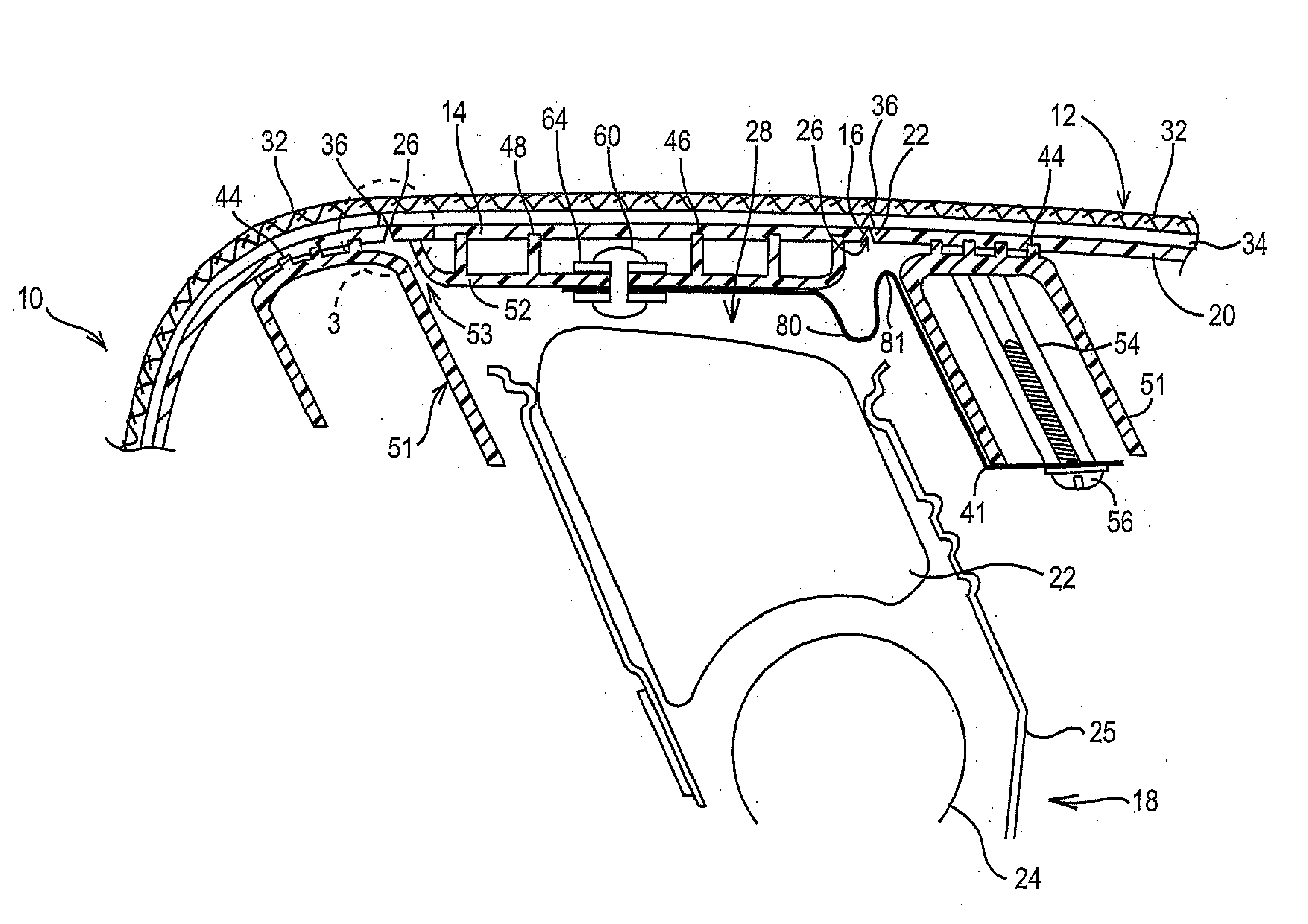

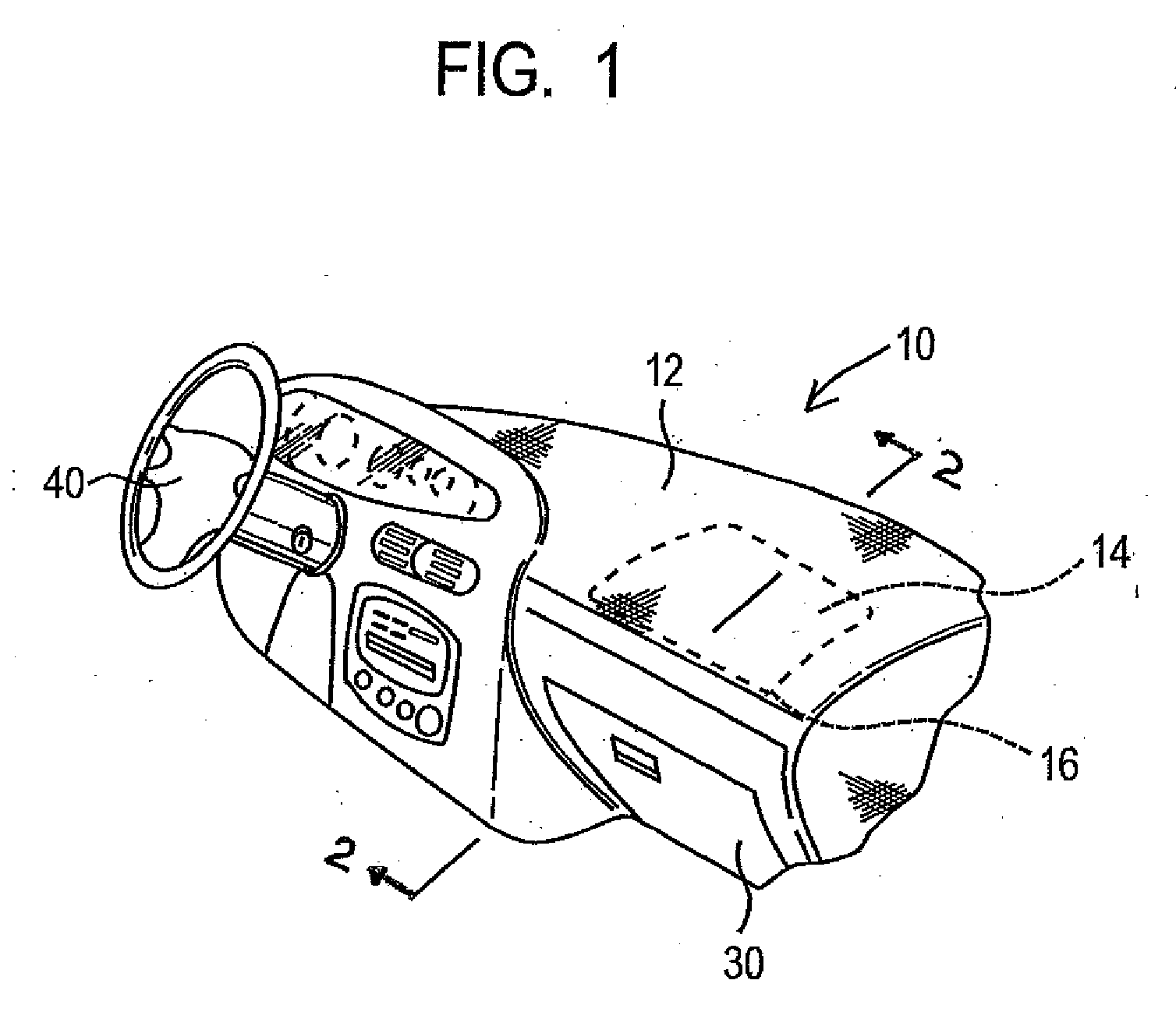

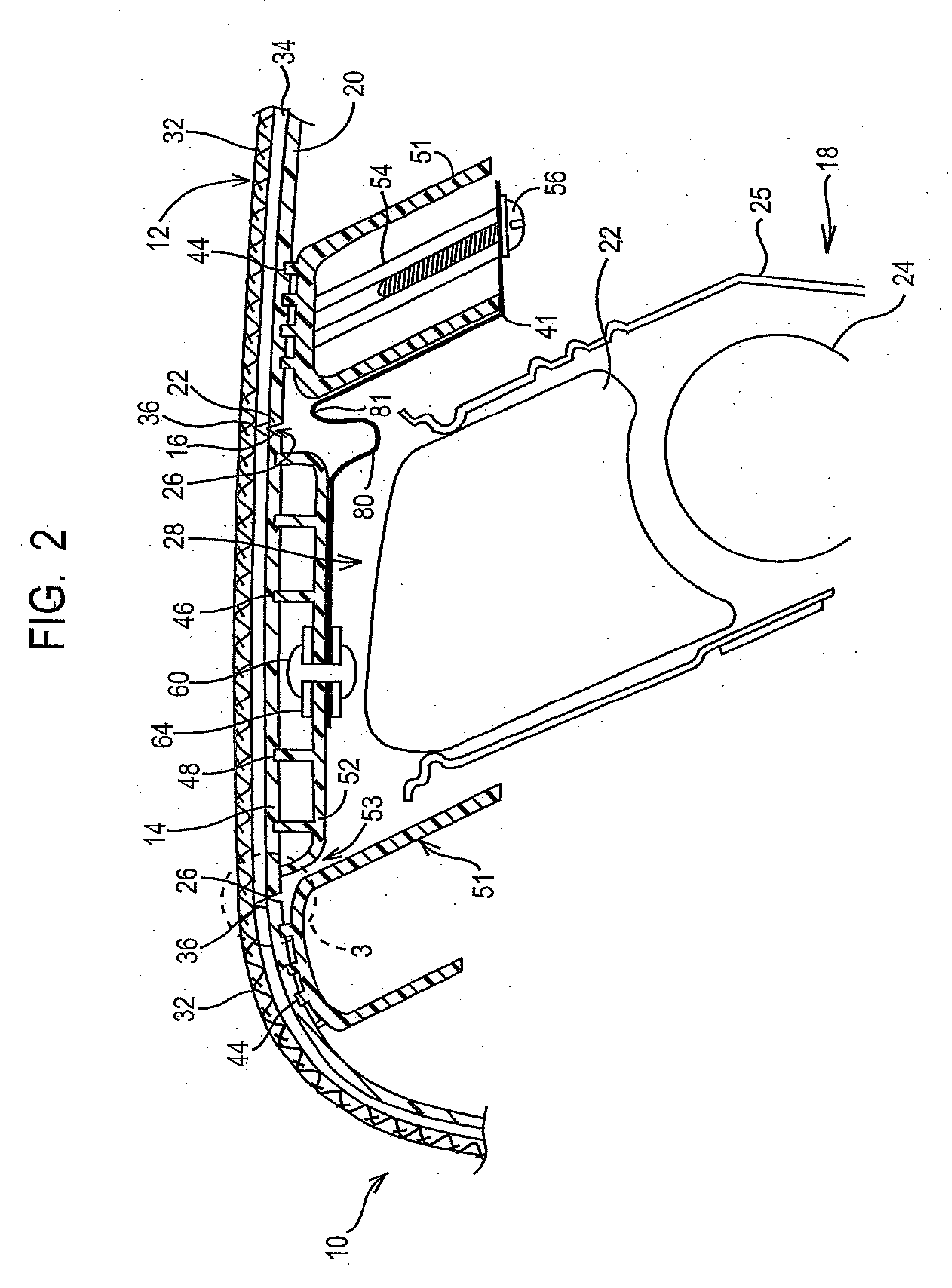

Pre-Weakening Of Fabric Covered Airbag Doors

A variety of embodiments are disclosed, in both apparatus and method form, that relate to the use of fabric material in the manufacture of an air bag deployment system. In addition, fabric weakening is disclosed according to a technique that does not result in physical alteration of the fabric. This invention therefore includes an air bag cover for an air bag safety system for a vehicle comprising a fabric outer layer having a frontside and a backside and a substrate containing an opening wherein the opening has a periphery. The substrate is preferably formed by low pressure molding, wherein the fabric outer layer overlies the opening in the substrate, and wherein the fabric outer layer is weakened at a location that is adjacent or overlies the substrate opening periphery.

Owner:COLLINS & AIKMAN AUTOMOTIVE CO INC

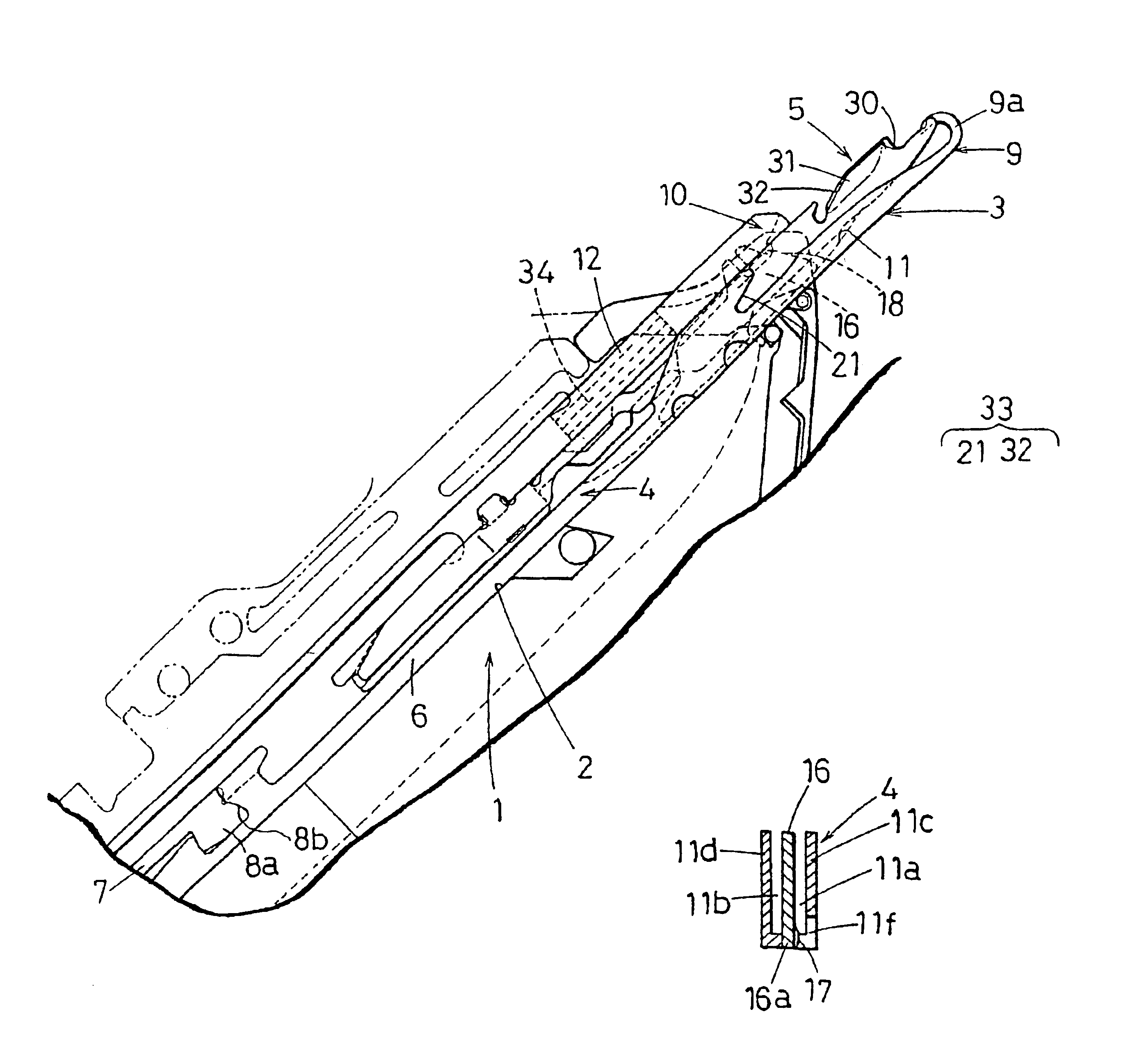

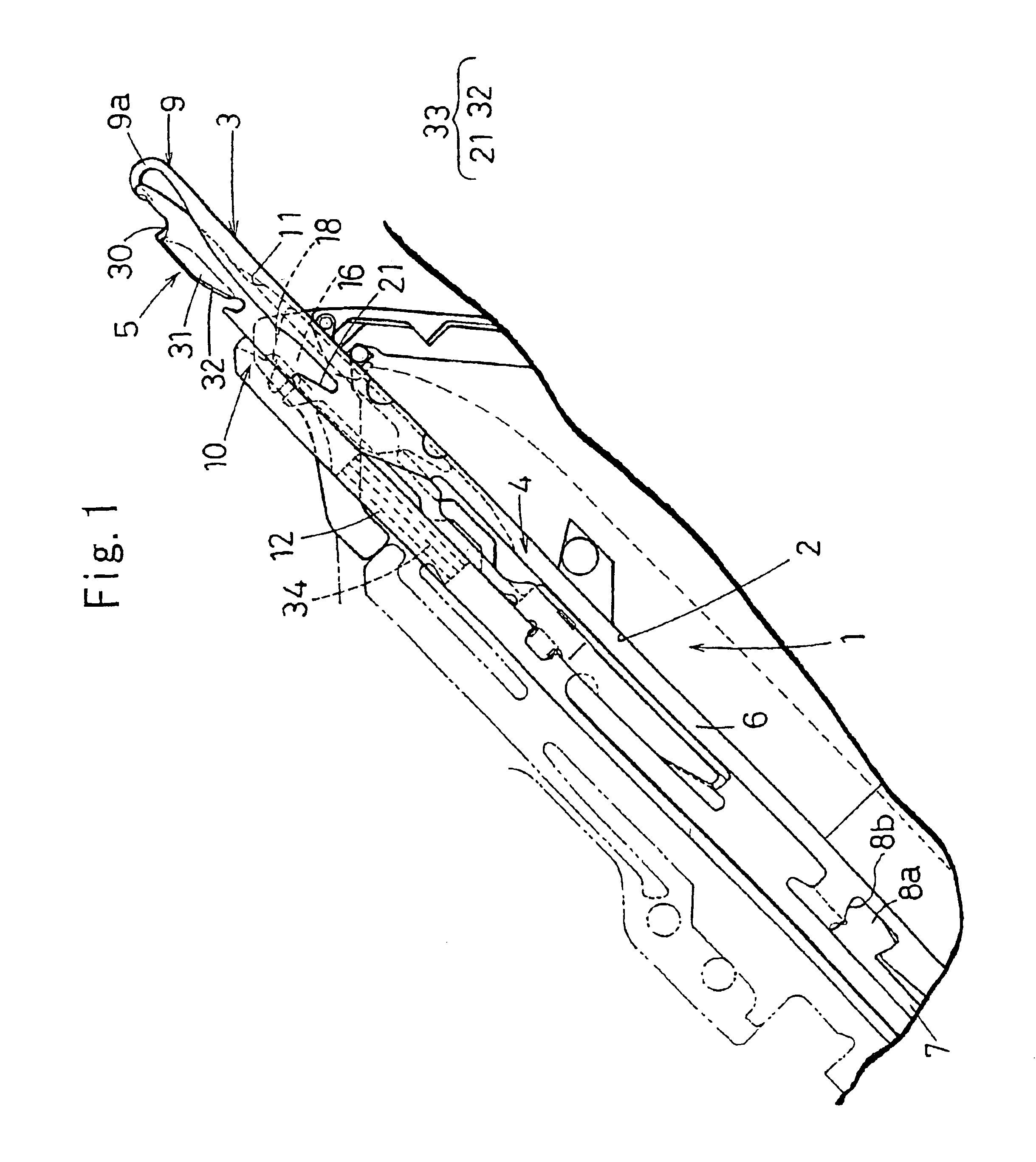

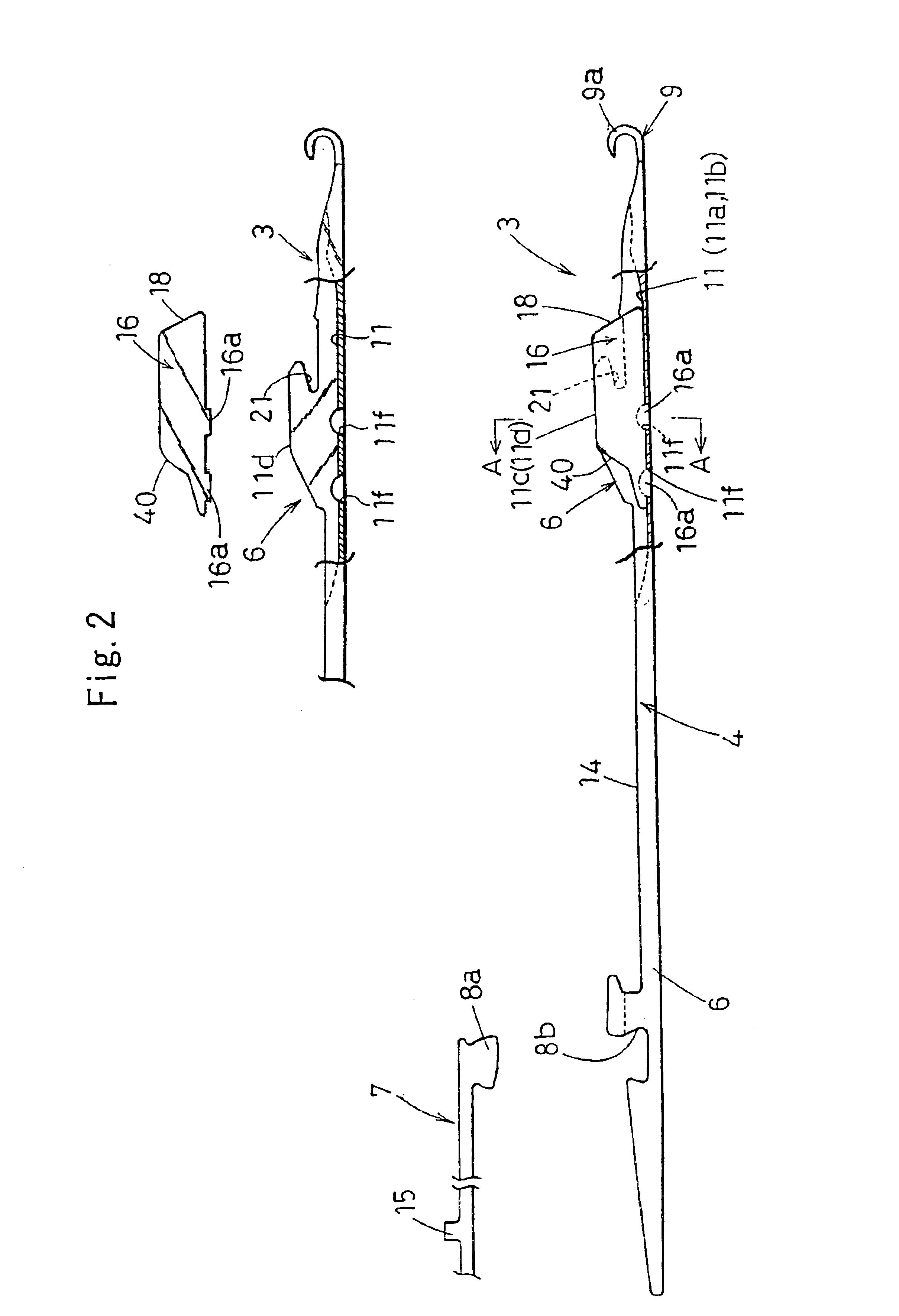

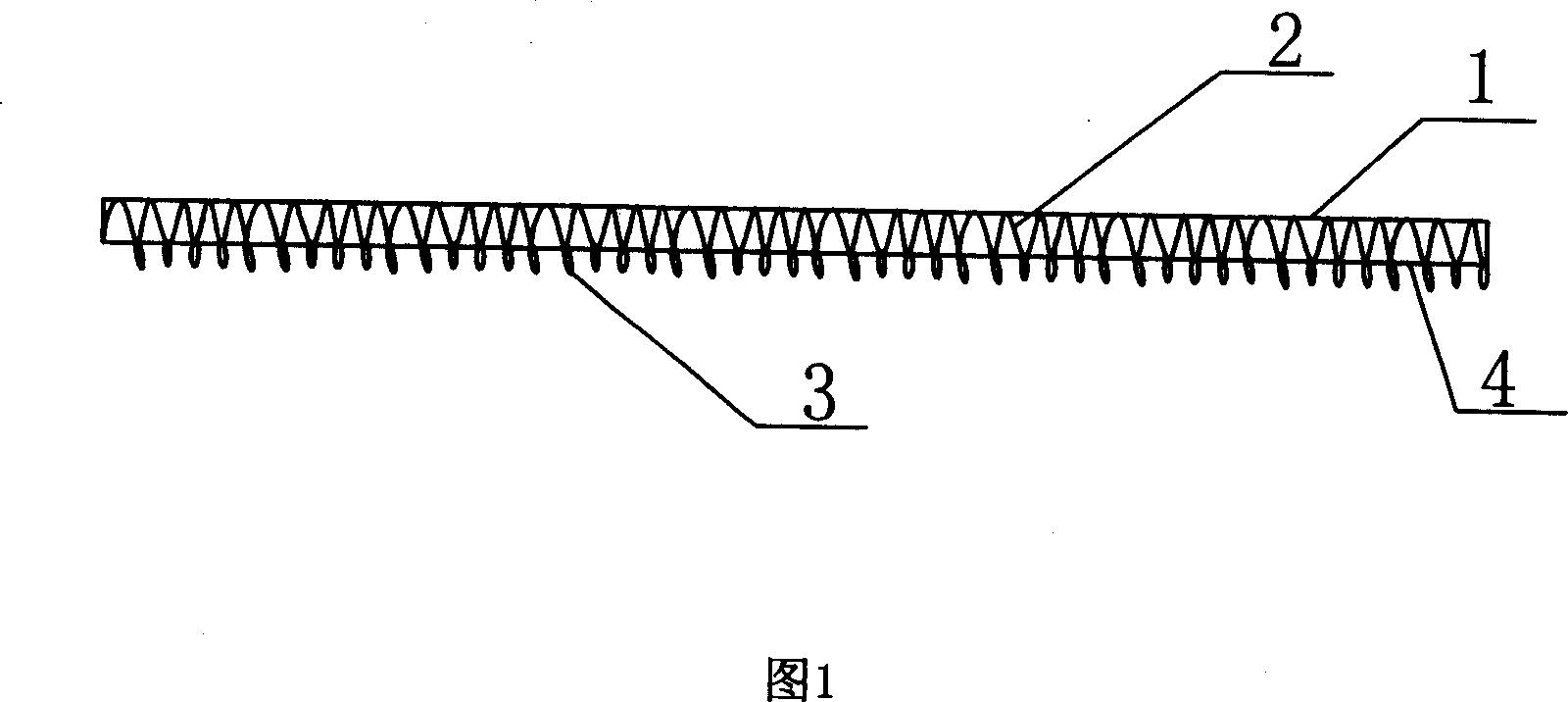

Composite needle of knitting machine

A composite needle of a knitting machine, comprises: a needle body having at a tip end a hook; a slider formed by superposing two blades, wherein the composite needle of the knitting machine is formed such that a blade groove provided in the needle body supports the blades of the slider when the needle body and the slider can separately slide in forward and backward directions; and a dust-collecting plate that is seperately formed from the needle body and that extends, when viewed from a side, from the blade groove of the needle body in an upward direction and to a hook side of the needle such that the dust-collecting plate is provided at a tip end of the slider proximate to the hook.

Owner:SHIMA SEIKI MFG LTD

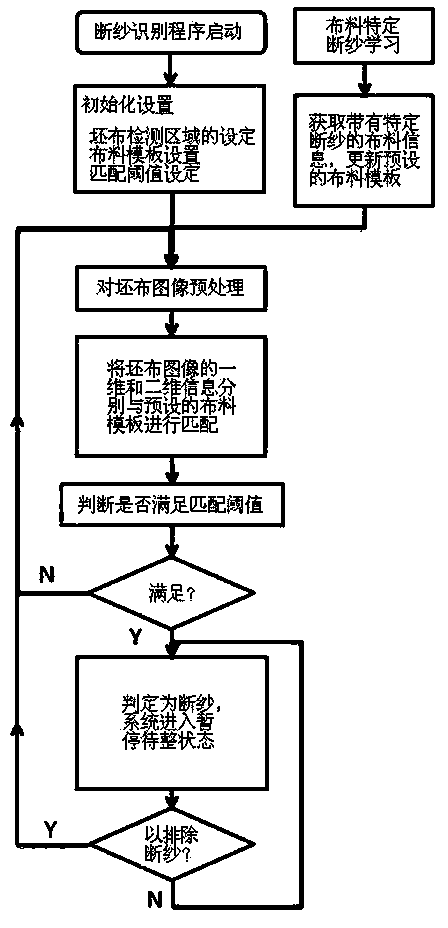

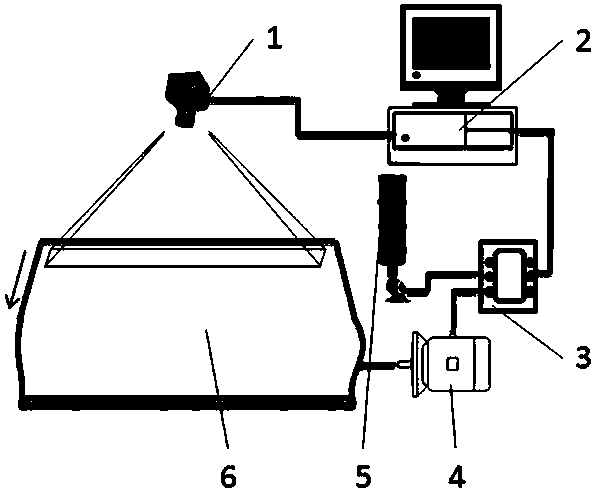

Gray fabric broken yarn online detection method based on computer vision

ActiveCN103451846AAutomatically identify or avoid yarn breakageAvoid false positive downtimeKnittingComputer moduleVisual perception

The invention relates to a gray fabric broken yarn online detection method based on computer vision, which is characterized by comprising the following steps: Step 01, providing an industrial camera to shoot to-be-detected gray fabric so as to obtain a gray fabric picture; Step 02, providing a control computer to read the gray fabric picture and performing pretreatment on the picture; Step 03, utilizing broken yarn recognition program to compare the gray fabric picture with a preset fabric template by the control computer, and when the matching ratio can not meet the preset matching threshold value, sending a halt command to the communication port by the control computer; Step 04: providing a control module to receive the halt command so as to control a warp knitting machine to run a motor to cut off power supply and stop, so that the system is suspended and waits for settlement. According to the gray fabric broken yarn online detection method based on computer vision, disclosed by the invention, the defects of the traditional broken yarn detection method are eliminated, the detection accuracy, efficiency and capacity of resisting disturbance are improved by combing the method of one-dimensional and two-dimensional signal of the picture, the variety of to-be-detected gray fabric is increased, and better universality is realized.

Owner:FUZHOU UNIV

Pre-weakening of fabric covered airbag doors

A variety of embodiments are disclosed, in both apparatus and method form, that relate to the use of fabric material in the manufacture of an air bag deployment system. In addition, fabric weakening is disclosed according to a technique that does not result in physical alteration of the fabric. This invention therefore includes an air bag cover for an air bag safety system for a vehicle comprising a fabric outer layer having a frontside and a backside and a substrate containing an opening wherein the opening has a periphery. The substrate is preferably formed by low pressure molding, wherein the fabric outer layer overlies the opening in the substrate, and wherein the fabric outer layer is weakened at a location that is adjacent or overlies the substrate opening periphery.

Owner:COLLINS & AIKMAN AUTOMOTIVE CO INC

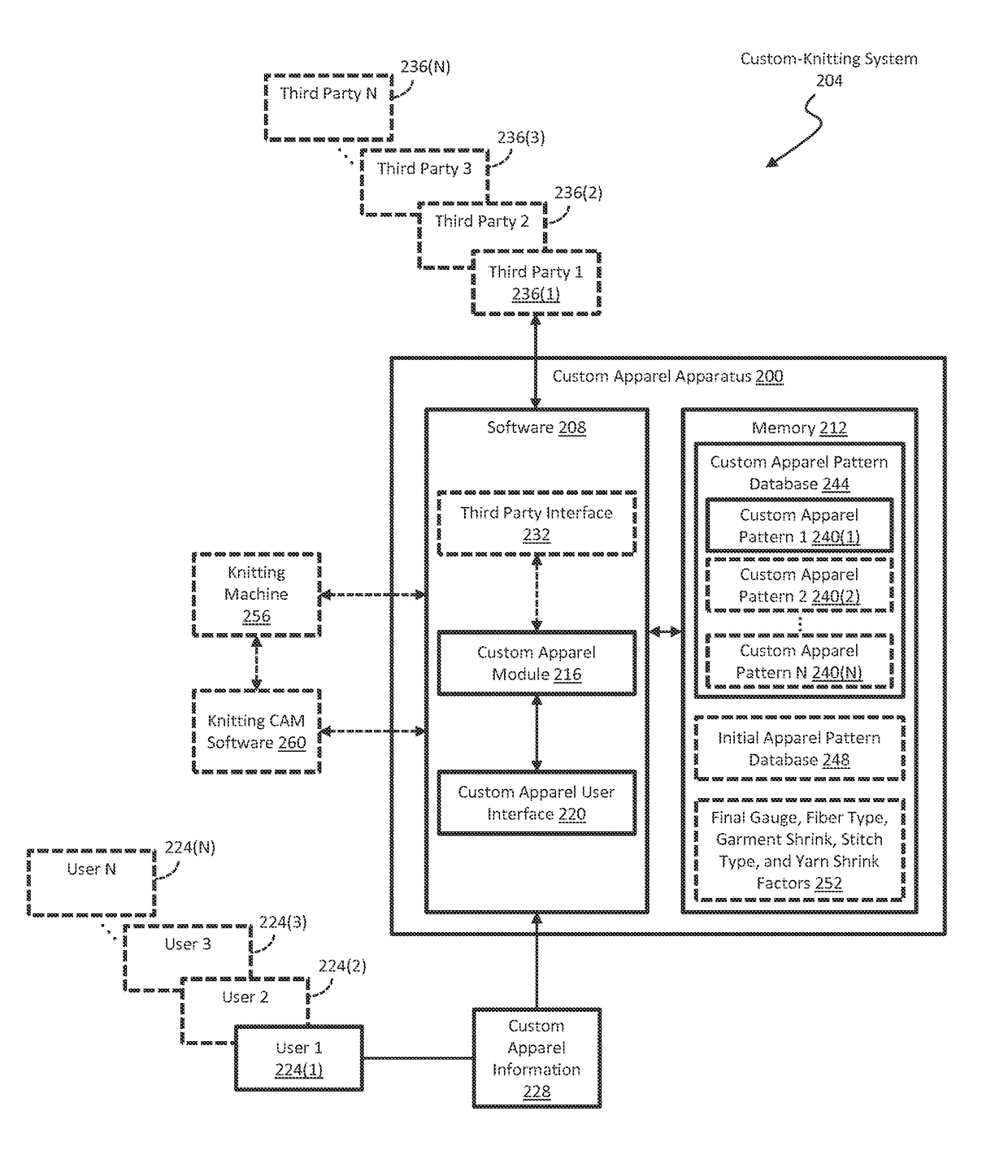

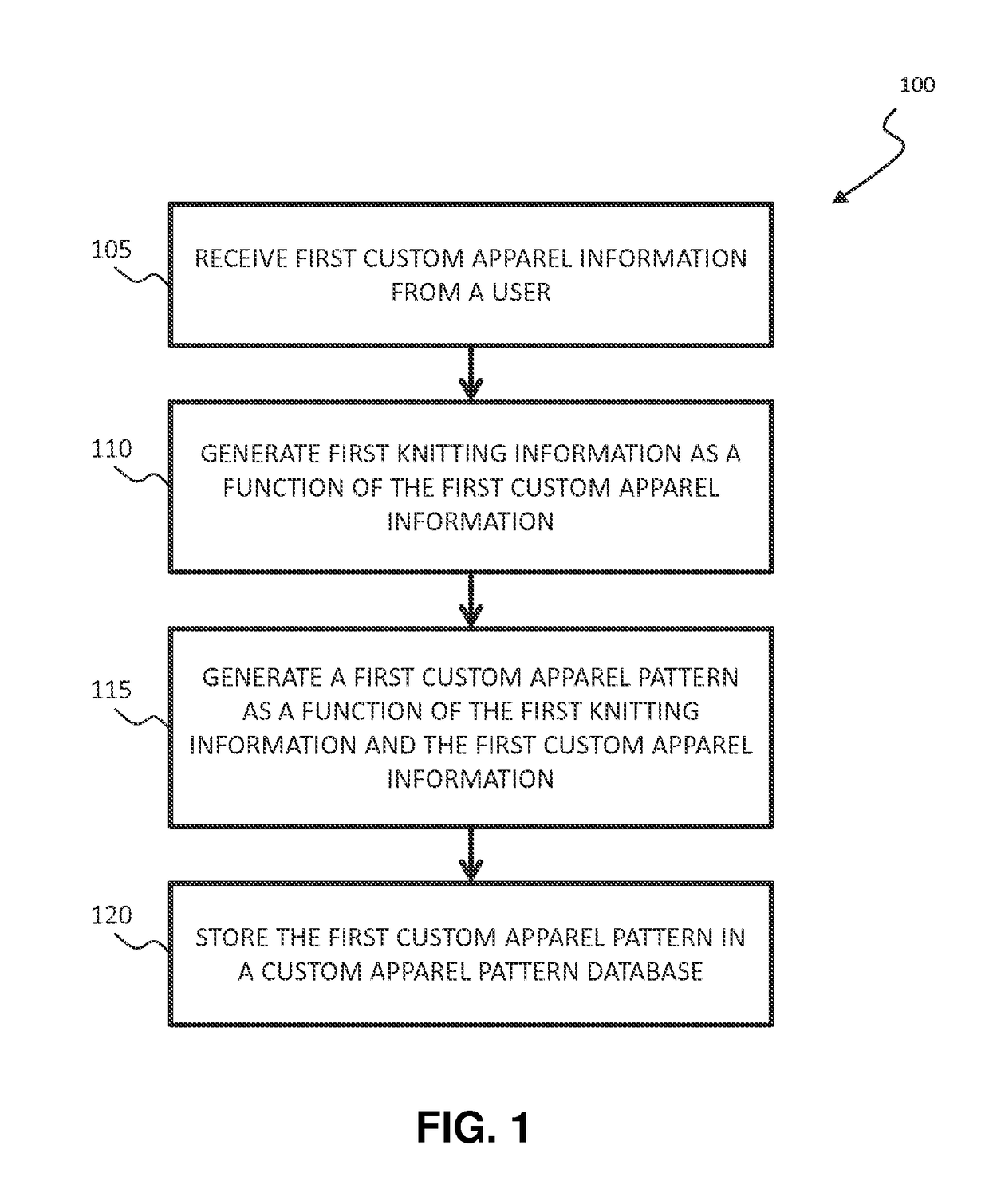

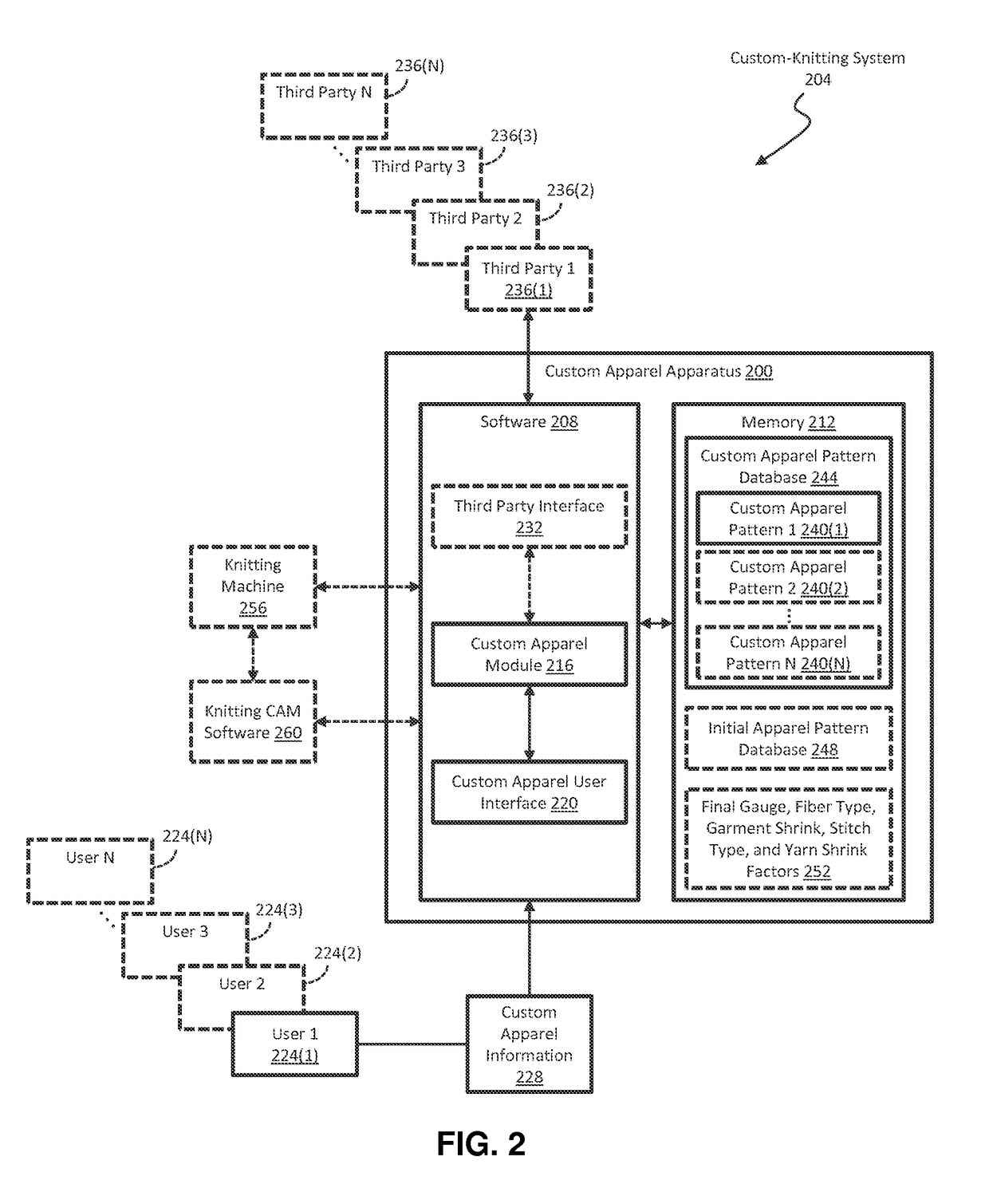

Systems, methods, and software for manufacturing a custom-knitted article

Apparel patterns may be generated as a function of custom apparel information provided by a user, such as one or more measurements, colors, etc., such that the user can have apparel custom-knitted to their particular size and shape without having to acquiesce the high expense and long wait times typically associated with custom-fit clothing. After a custom apparel pattern is generated, a custom-knitted article can be manufactured based on the pattern by transmitting appropriate information to a knitting machine. Data produced while generating custom apparel patterns can be stored and used to optimize and improve the manufacturing of customized knitwear for subsequent users. Further, such data can be shared with third parties such that manufacturers or others can utilize one or more beneficial aspects of the present disclosure without having to implement all of the functionality that would otherwise be required to obtain such benefits.

Owner:NIMBLY INC

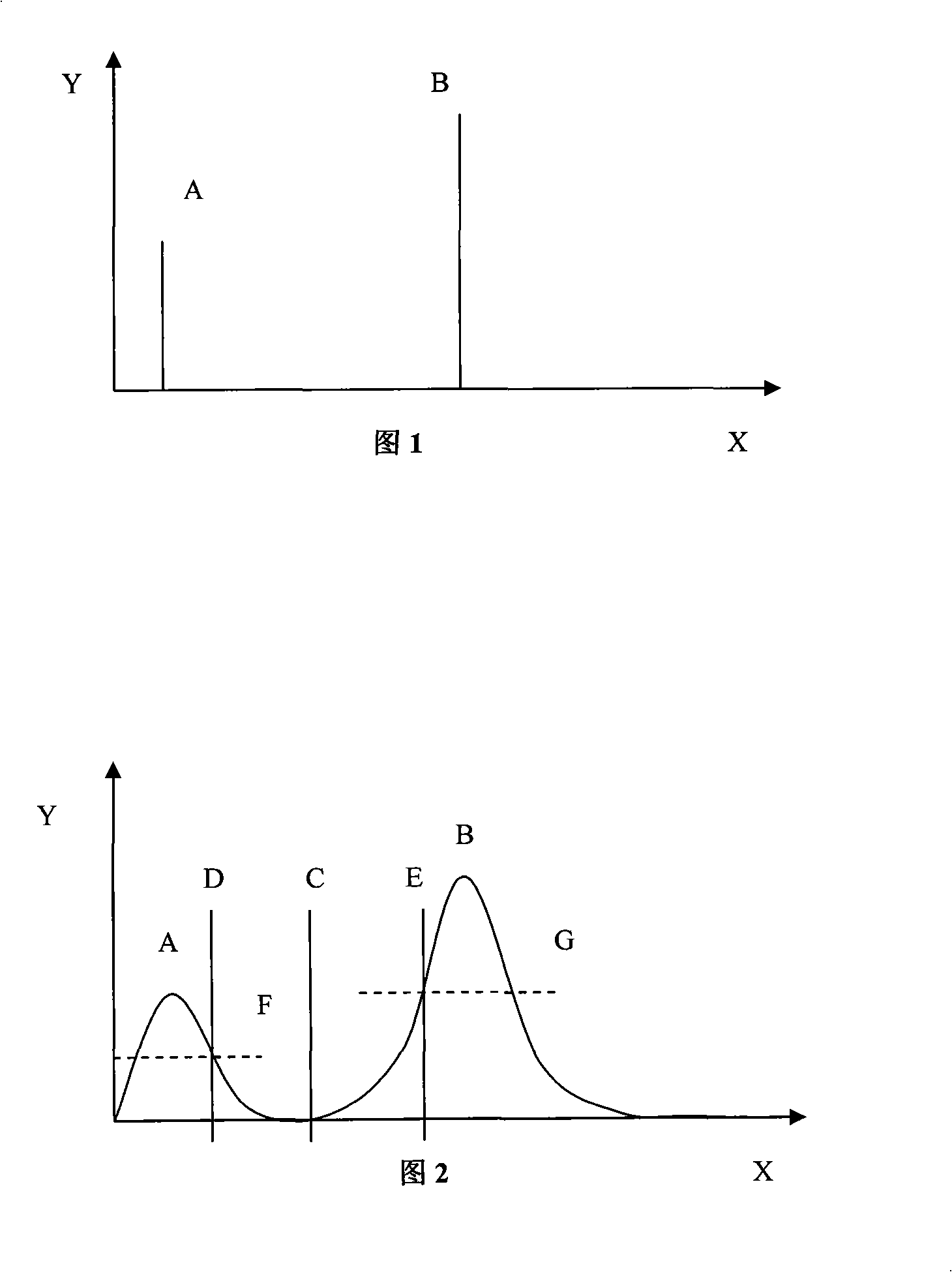

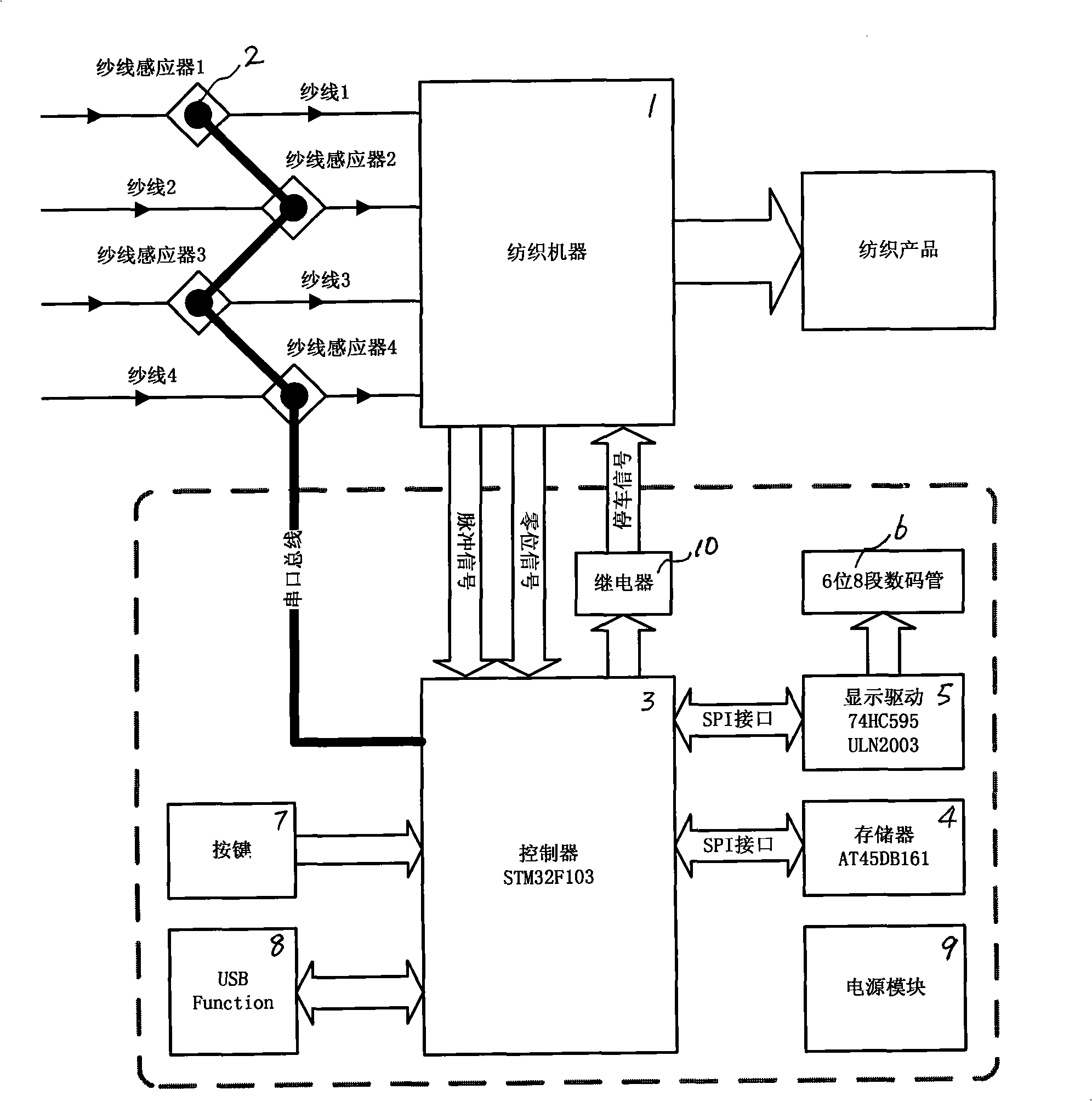

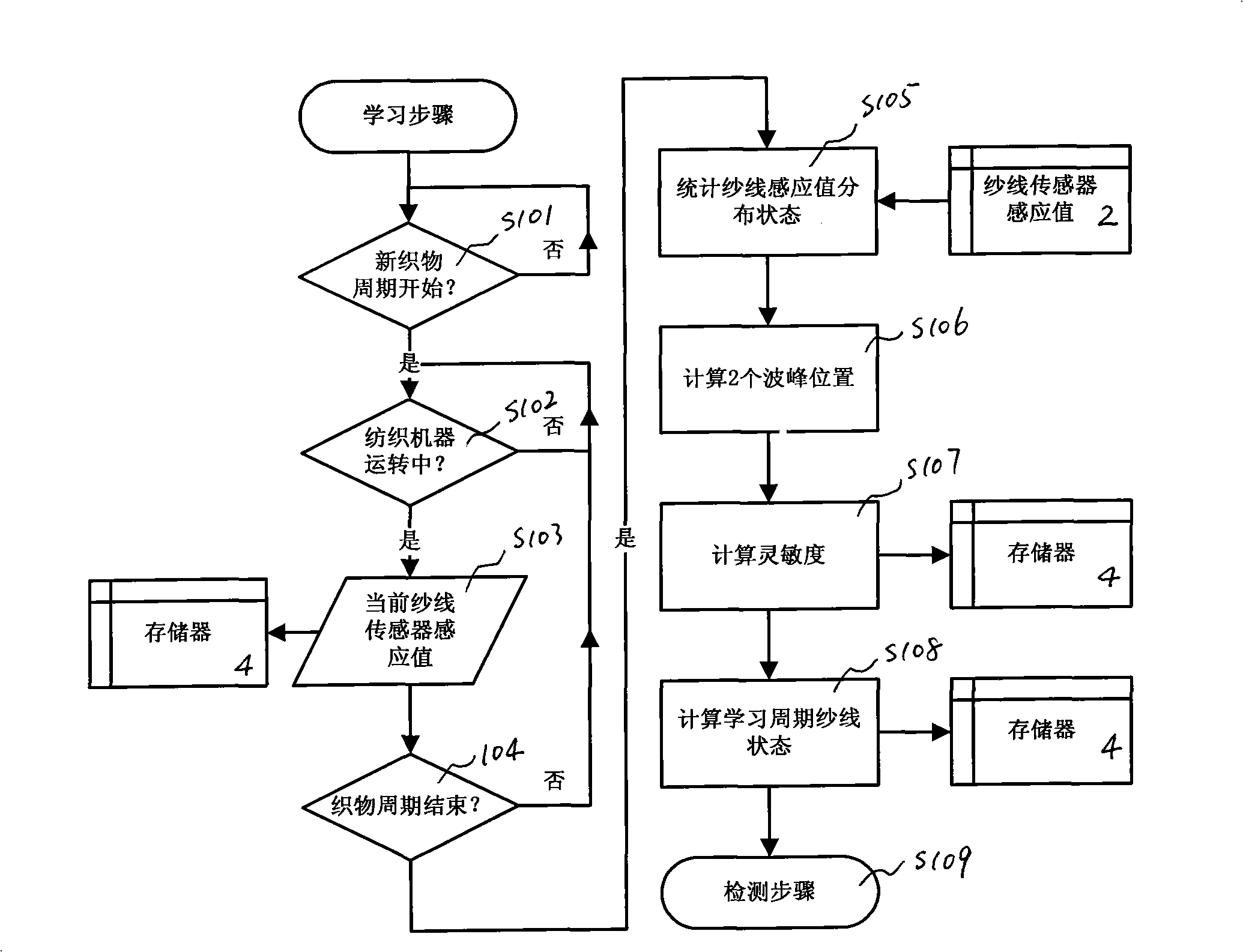

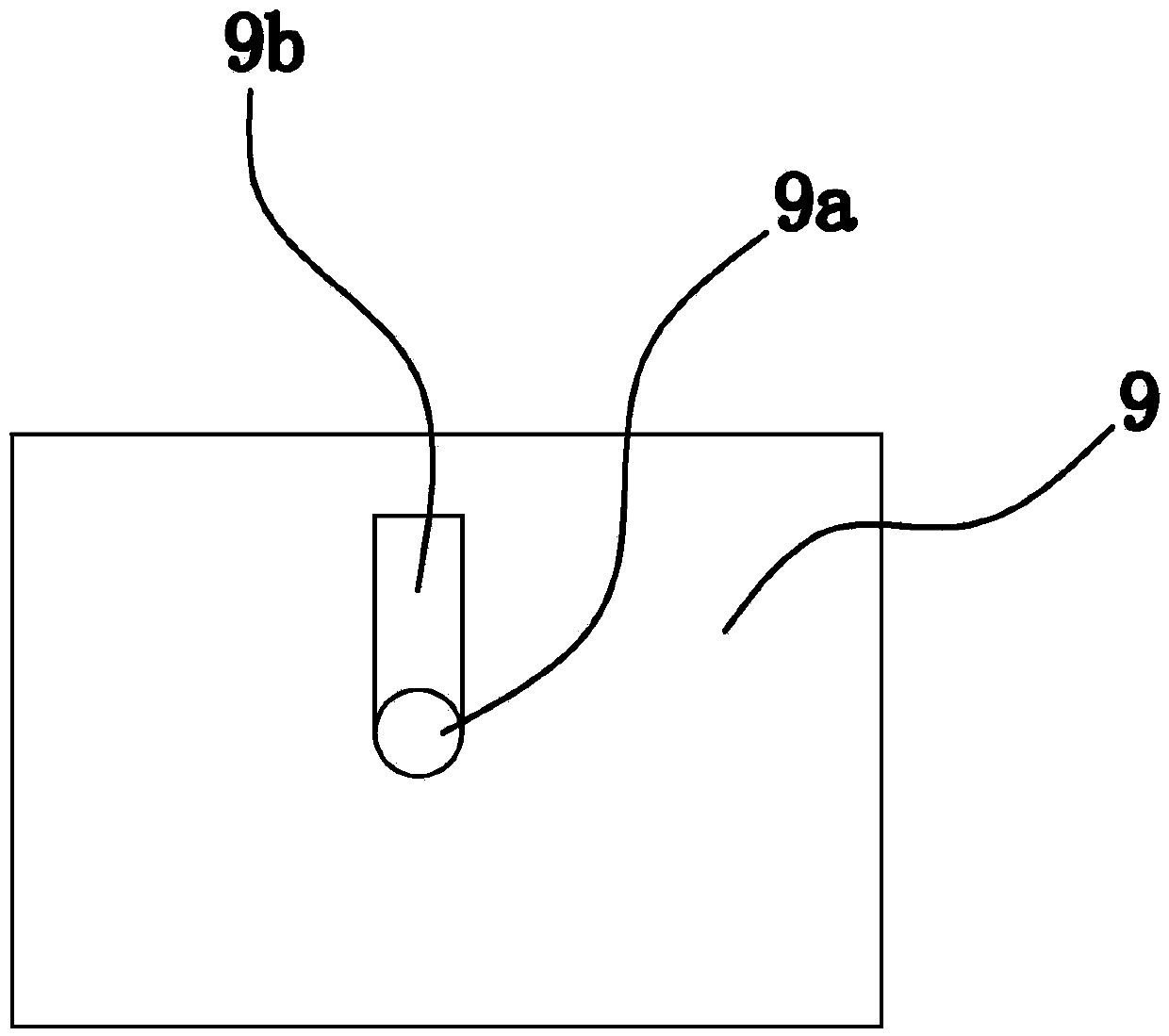

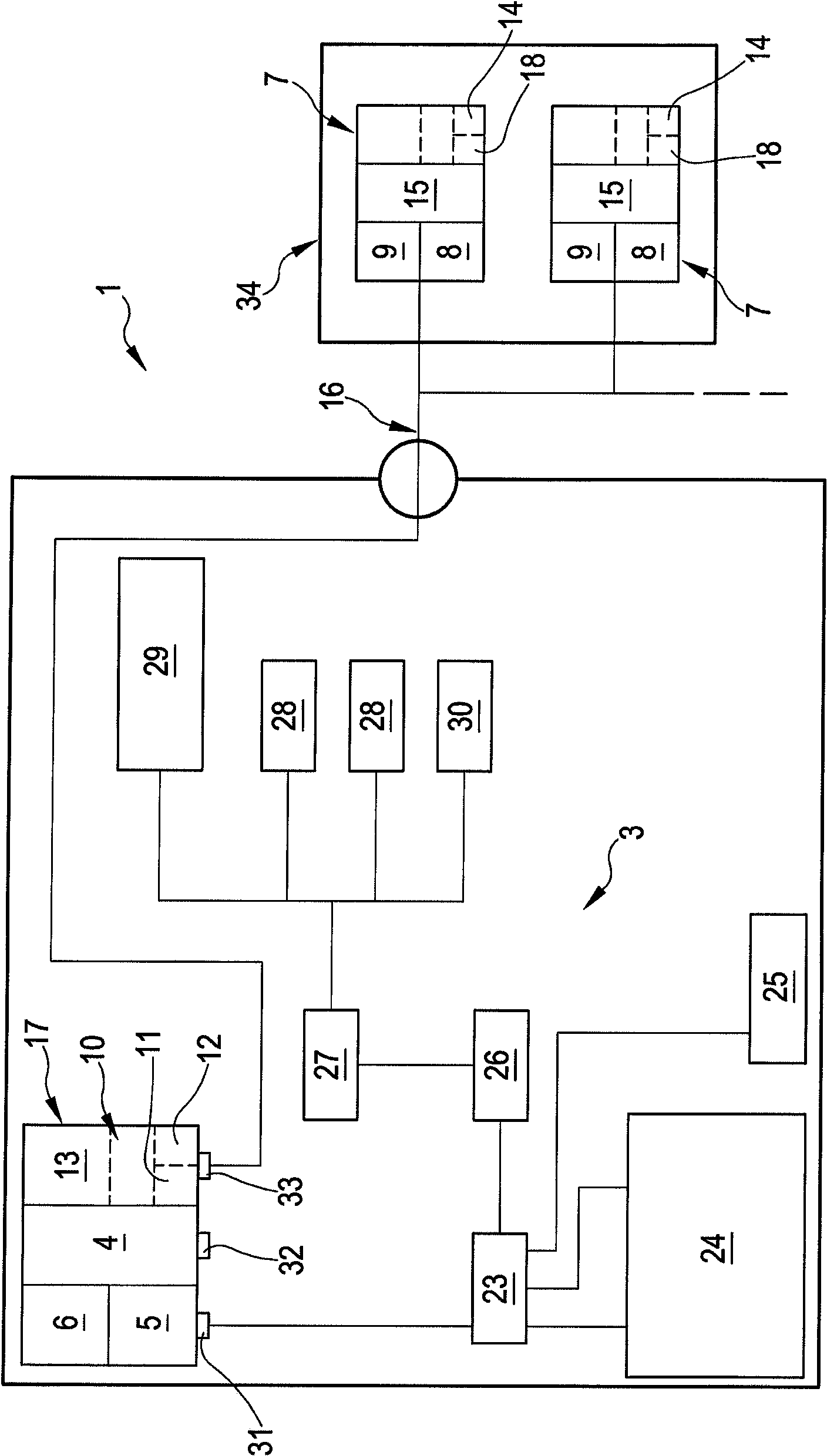

Device for monitoring yarn moving state and monitoring method for same

InactiveCN101515166APrevent malfunctionReduce workloadProgramme controlComputer controlYarnElectricity

The invention discloses a device for monitoring the yarn moving state and a monitoring method for the same, having the objective that the sensitivity matched with the monitored yarn is automatically calculated out according to the data collected by a yarn sensor by the monitoring method. The invention has the technical solution that the device is electrically connected with a textile machine and used for monitoring the yarn moving state; the monitoring device comprises a controller connected with a memory by a data line interface, the memory may be an external memory or integrated in the controller and connected with a display driver by a data line interface, the display driver is connected with a display module; the controller is connected with a group of yarn sensor at the input end of the textile machine by a serial port bus; the textile machine can transmit the running state of the machine to the controller by a pulse signal line and a zero signal line, the stop signal is transmitted to the textile machine by a controller through a switch. The invention is suitable for the textile machine for producing the textile by using the yarn as the raw material.

Owner:HANGZHOU JIA AUTO TECH

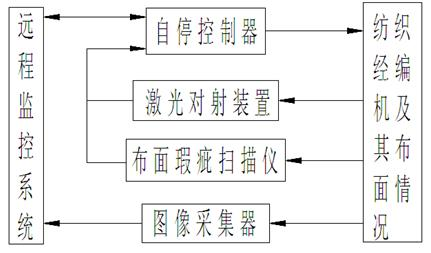

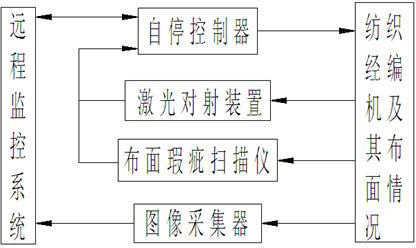

Remote monitoring automatic thread stop system for textile tricot machine

The invention relates to a remote monitoring automatic thread stop system for a textile tricot machine. The system comprises (1) an image acquisition unit, (2) a remote monitoring system, (3) a cloth cover defect scanner, (4) a laser correlation device and (5) an automatic stop controller. The cloth cover defect scanner and the laser correlation device scan and monitor a broken yarn of the textile tricot machine, and are matched with the automatic stop controller to realize automatic stop when a yarn is broken, the image acquisition unit acquires the quality of a cloth cover of the textile tricot machine and transmits the quality to the remote monitoring system, a monitoring worker monitors the working condition of the textile tricot machine and the quality of the cloth cover, and if the cloth cover defect scanner and the laser correlation automatic control device miss detection, the remote monitoring worker can locate cloth cover defects through the monitoring system and send a stop instruction. The system can automatically detect and monitor the yarn breaking condition, reduce the labor intensity of a knitter, improve labor productivity, remove the harm of noise and dust, and ensure that the productivity of the machine and the quality of the cloth cover are greatly improved.

Owner:CHANGLE MAIYE JINGBIAN FITTINGS MFG

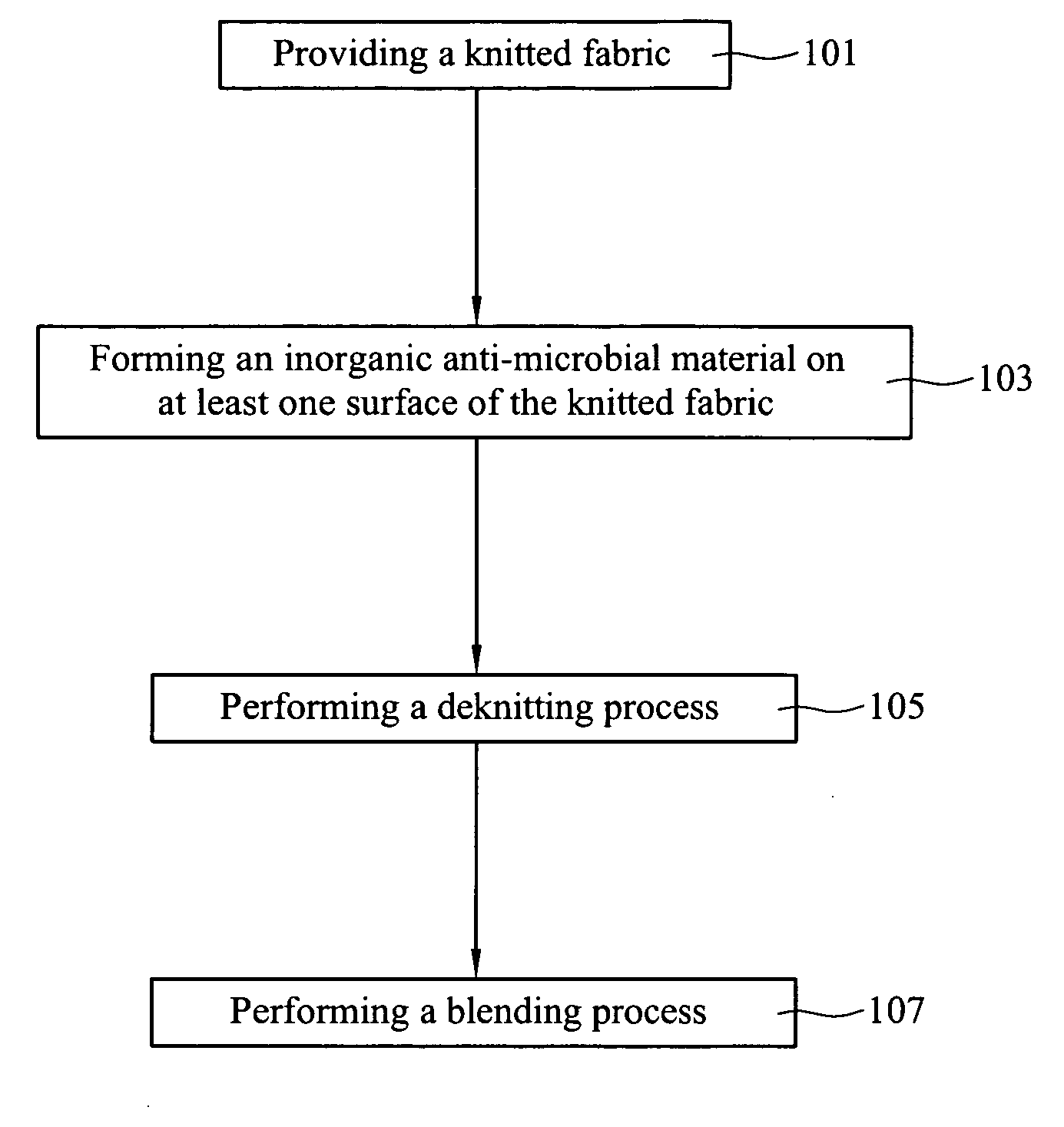

Method for producing durably anti-microbial yarns

InactiveUS20060134390A1Improve adhesionReduce processing costsBiocideBiochemical fibre treatmentYarnEngineering

A method for producing durably anti-microbial yarns is disclosed. An inorganic anti-microbial material is formed on at least one surface of a knitted fabric by a physical vapor deposition method, and then the knitted fabric is deknitted to anti-microbial yarns. The anti-microbial yarns provide a better wash ability and durably anti-microbial effect, and are suitable to be blended with other yarns to a softer anti-microbial fabric.

Owner:TAIWAN TEXTILE RESEARCH INSTITUTE

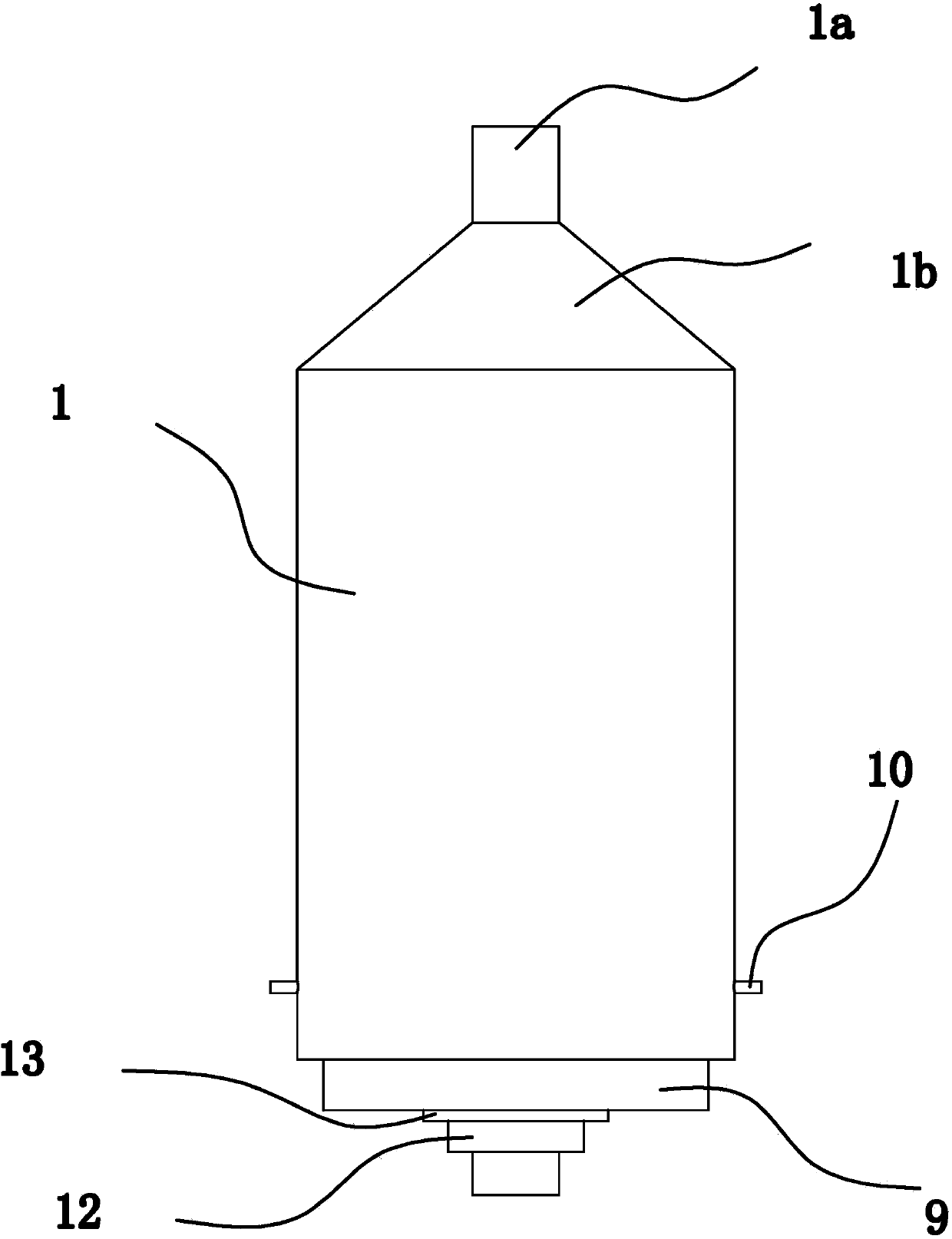

Dust removal device of automatic sock knitter

InactiveCN104190166AImprove positional stabilityIncrease contact areaDispersed particle filtrationKnittingPulp and paper industryAirflow

The invention provides a dust removal device of an automatic sock knitter, belonging to the technical field of machines. The dust removal device of the automatic sock knitter comprises a dust removal cylinder, wherein the dust removal cylinder is connected to a knitter rack; the dust removal cylinder comprises an outer cylinder body and an inner cylinder body; the inner parts of the outer cylinder body and the inner cylinder body are cavities; an inlet is formed in the upper end of the inner cylinder body; an outlet is formed in the lower end of the inner cylinder body; the inner cylinder body is internally connected with a filter screen; the filter screen is used for separating the inner cylinder body into an upper cavity and a lower cavity which are adjacent with each other; the inlet is formed in the upper cavity; the outlet is formed in the lower cavity; the lower cavity is also connected with a fan capable of enabling airflow in the upper cavity to flow into the lower cavity; a connection hole communicated with the inlet is formed in the top part of the outer cylinder body; a positioning mechanism capable of positioning the outer cylinder body and the inner cylinder body together is arranged between the outer cylinder body and the inner cylinder body. The dust removal device of the automatic sock knitter is good in dust removal effect and compact in structure.

Owner:刘杰

Stereoscopic knitting face fabric

The invention relates to a textile structure, in particular to a solid knitting material which has double warm keeping function. The invention comprises an inner layer, an outer layer and a middle layer. The invention is characterized in that the inner layer comprises a fur ring and a knitting layer; the outer layer is the knitting surface; the long silk connects the inner layer and the outer layer; the long silk forms the middle layer; and a plurality of spaces are formed between the long silks. The invention provides a solid knitting material which is closed fit and has good touch feeling, and is quick to remove the wet and keeps warm; the invention solves the disadvantages of the prior art which has high cost, poor warm keeping effect and poor touch feeling; the solid knitting material can be used as the warm keeping surface material of the winter clothes, further can be used as the surface material of the sports clothes which has a high wet absorbing and sweat removing function.

Owner:马建荣

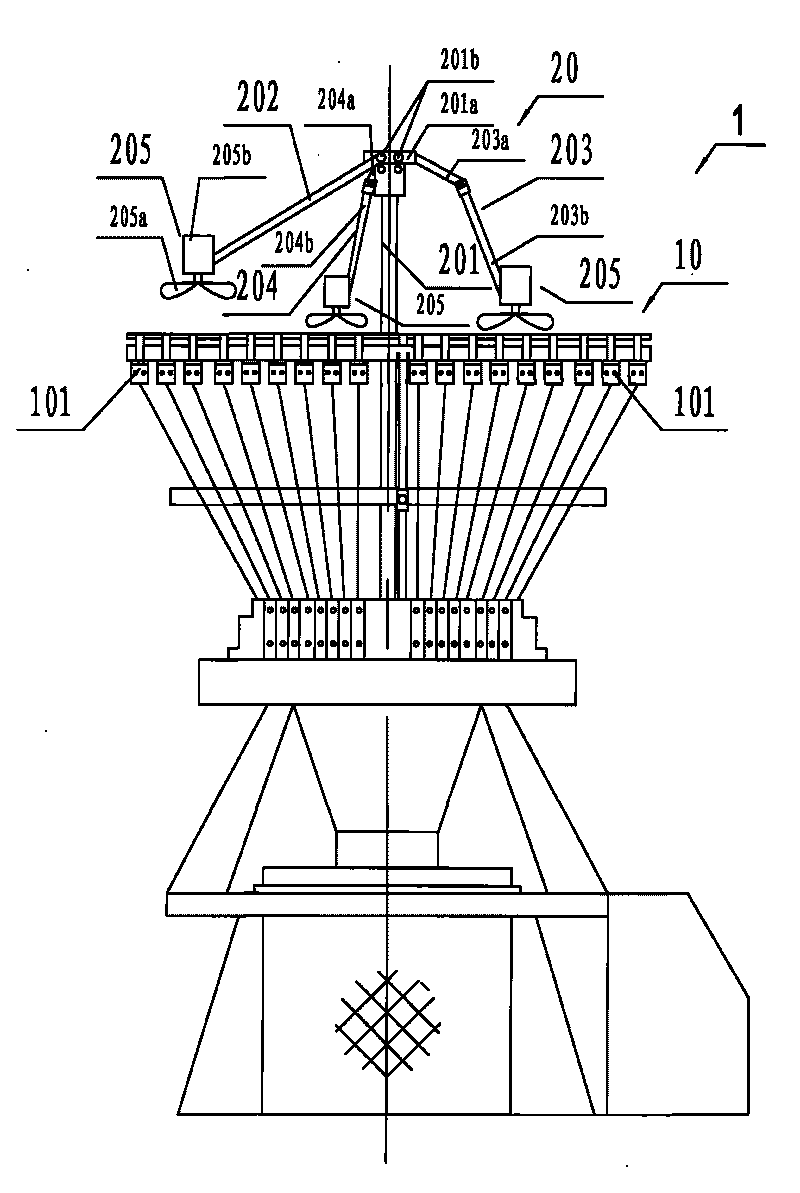

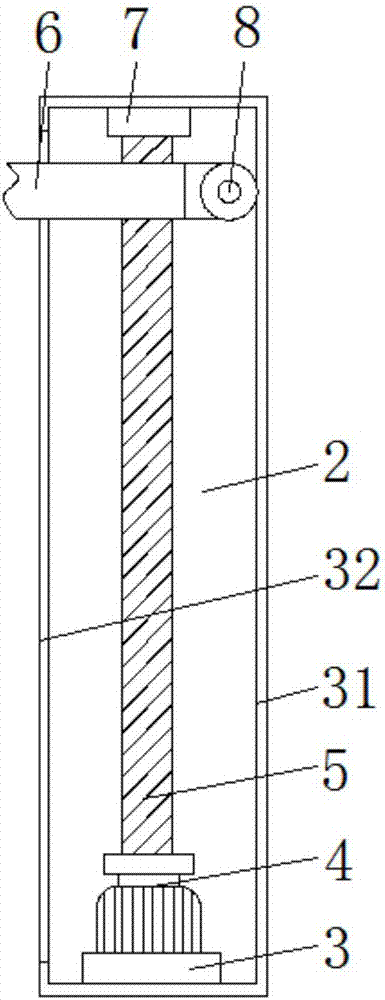

Synchronous cylinder shaping device installed on circular weaving machine

InactiveCN103352315AEliminate pre-setting processPrevent dead foldsShaping/stretching tubular fabricsKnittingComing outProcess equipment

The invention provides a synchronous cylinder shaping device installed on a circular weaving machine, and belongs to the field of achieving heat shaping of fabrics with thermoplastic fibers through high-frequency electromagnetic induction heating. The device solves the technical problems that surfaces of the unshaped fabrics with the thermoplastic fibers are wrinkled, the size is not stable, the woven fabrics with the thermoplastic fibers have to be preshaped in a dying and finishing procedure, and the process is complicated. According to the technical scheme, a high-frequency induction heating device is installed between a weaving device and a gray fabric dragging and rolling device of the circular weaving machine. The cylinder woven fabrics slip off from the surface of a high-frequency induction heating cylinder so as to be shaped after the fabrics are woven and before the fabrics come out of the circular weaving machine. The synchronous cylinder shaping device has the advantages that the shaped woven fabrics are obtained on the circular weaving machine, the preshaping processing for the fabrics in the dying and finishing procedure is eliminated, and the problems that traditional process equipment is large in investment, long in process procedure, high in energy consumption, high in repairing rate and the like are solved.

Owner:QINGDAO JIFA GROUP

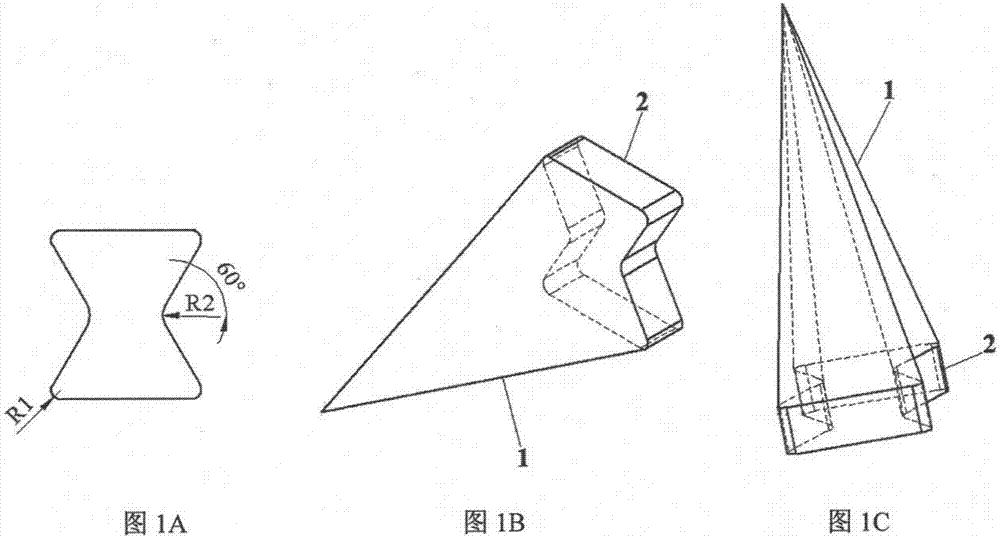

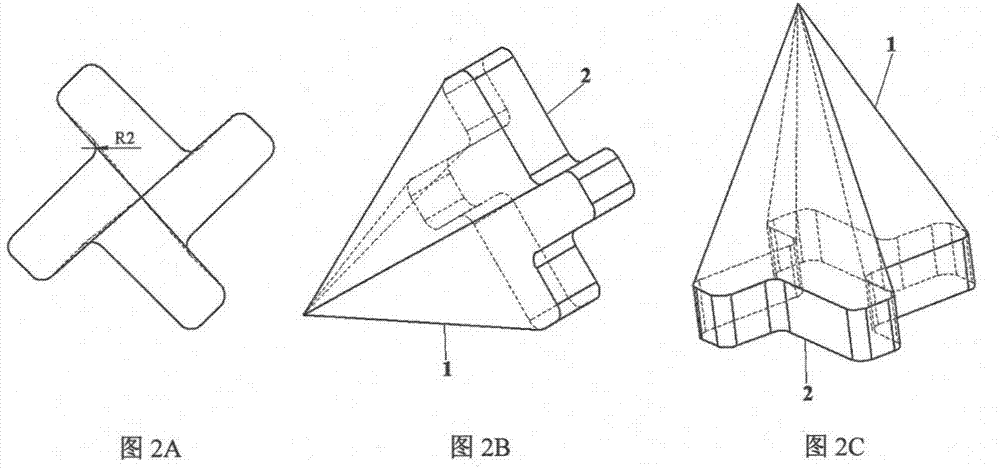

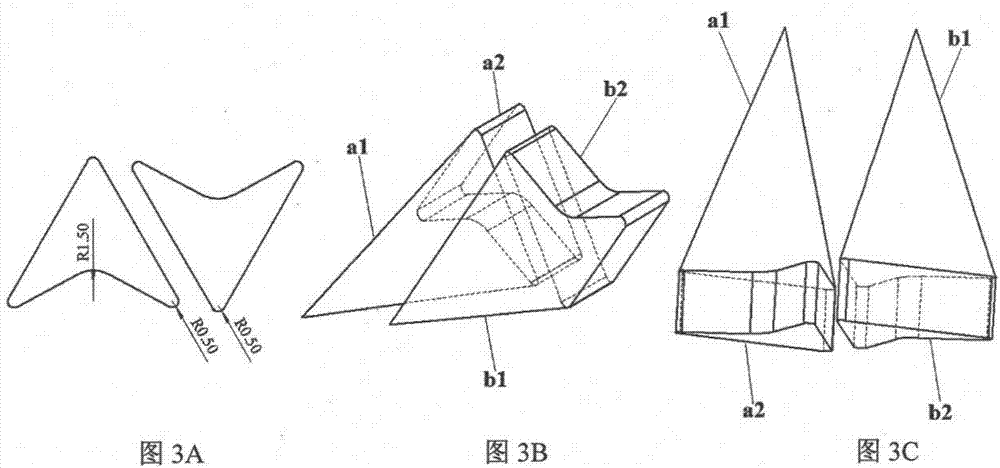

Composite needle for two-dimensional negative Poisson's ratio structure textile and purpose thereof

The invention discloses a composite needle for two-dimensional negative Poisson's ratio structure textile, and the composite needle comprises a needle heel and a needle consolidated on the needle heel; the needle has a conical body; the needle heel is a cylinder that has a uniform cross section; the lower end section of the needle and the surface at one end of the needle heel have the same cross section shape; the cross section shapes of both the needle and the needle heel have a negative Poisson's ratio structure. Based on different molding structures and sizes, the height and the negative Poisson's ratio shape of the composite needle (comprising the needle and the needle heel) are selected; the composite needles are arranged to form a needle group through a certain array shape; a number of needle groups are used to form a needle-bar that can be used to process textile in great width. In this way, the textile with negative Poisson's ratio effect can be obtained. The process is simple, rapid and precise; the method is suitable for materials like non-fabrics, composite material, foam, rubber, membrane, plastic, timber and metal; the two-dimensional negative Poisson's ratio structure can be constructed by puncturing, and the negative Poisson's ratio effect can be applied in the material.

Owner:DONGHUA UNIV

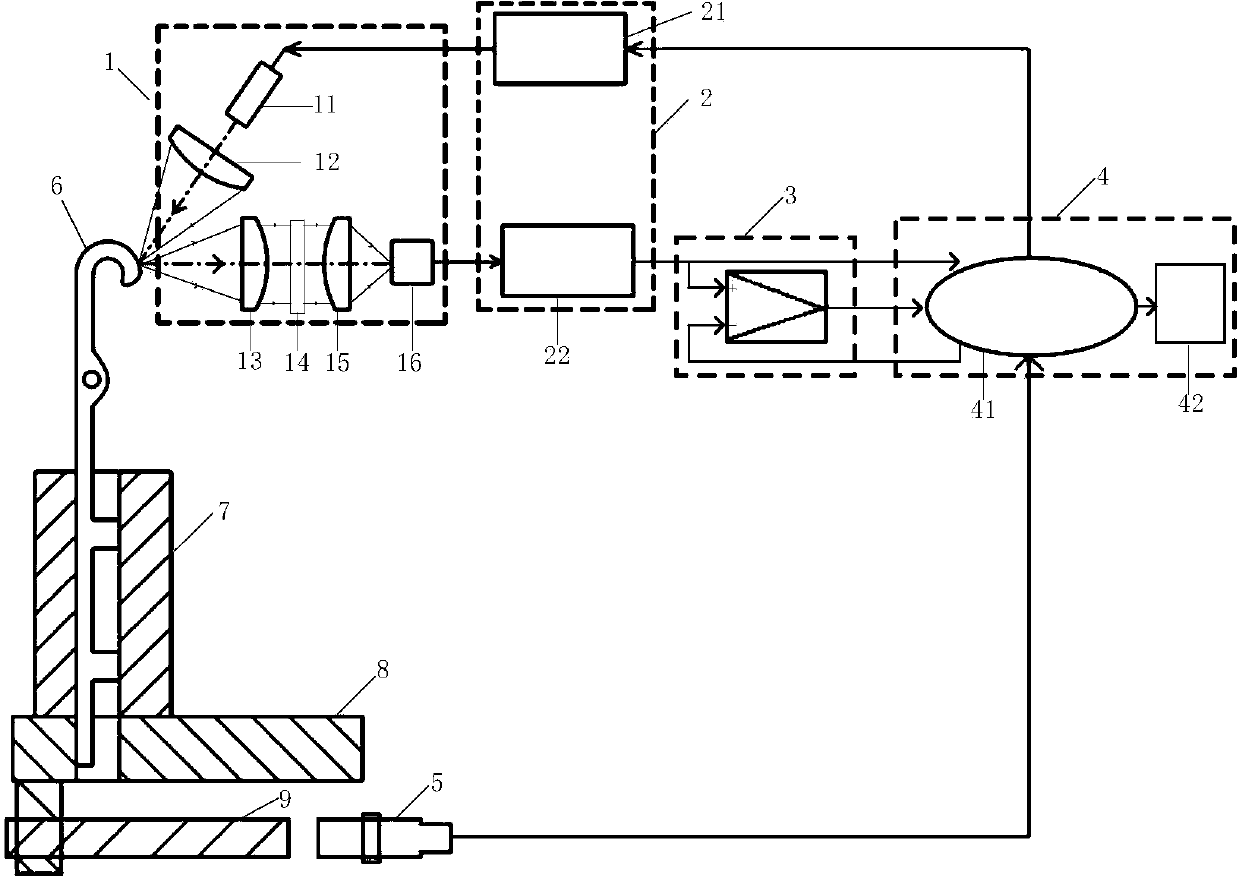

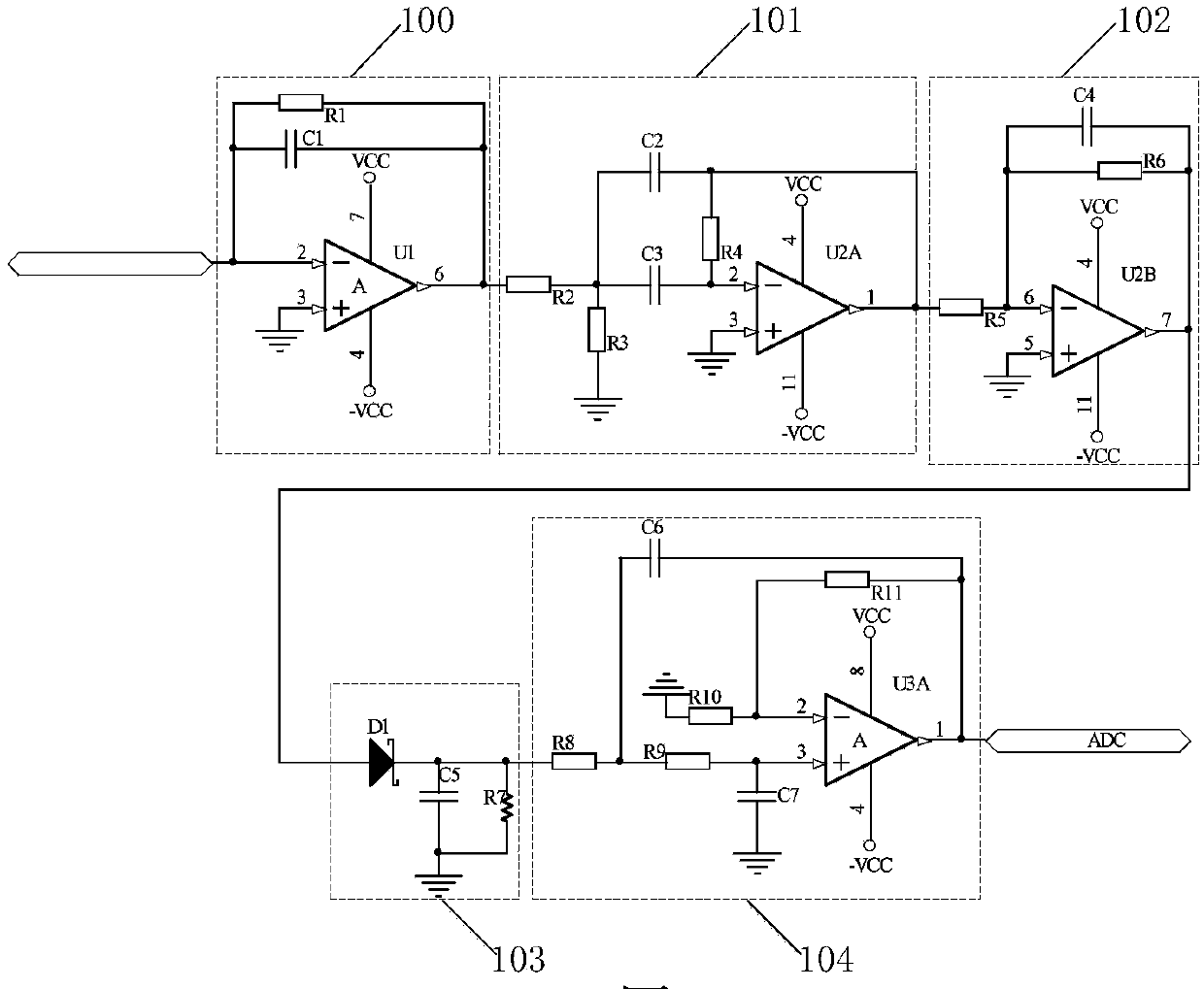

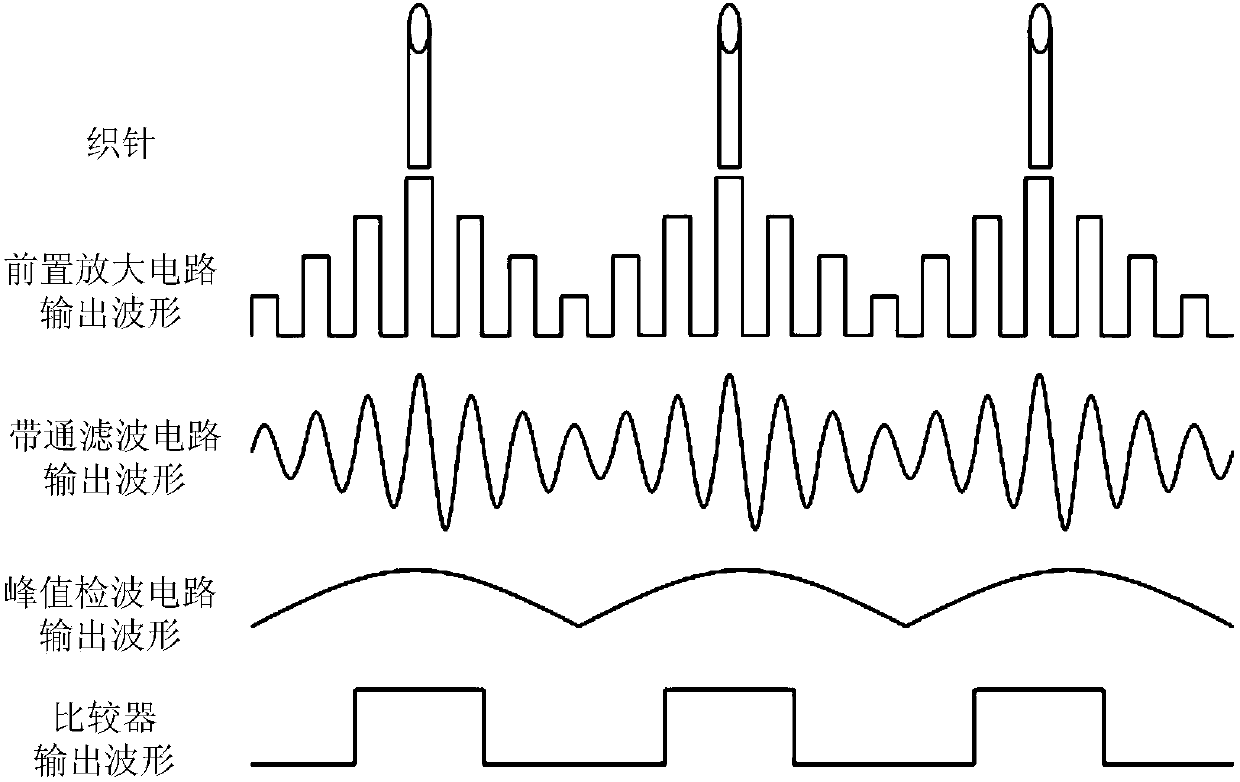

Online detection device and detection method for knitting needles of knitting machine

ActiveCN103469472ABoost electrical signalHigh measurement sensitivityKnittingMicrocomputer controlPosition sensor

The invention relates to an online detection device and detection method for knitting needles of a knitting machine. The device comprises a photoelectric sensing unit, a modulation-demodulation unit, a comparator, a microcomputer control unit and a position sensor. Damaged knitting needles including broken needles and crooked needles can be accurately detected, the knitting needles can be encoded, and the relative positions of the damaged knitting needles are positioned, so that the damaged knitting needles are conveniently and timely replaced by operators. The device has the advantages of long working distance, small size, low cost, high detection sensitivity, fine real-time performance and the like.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

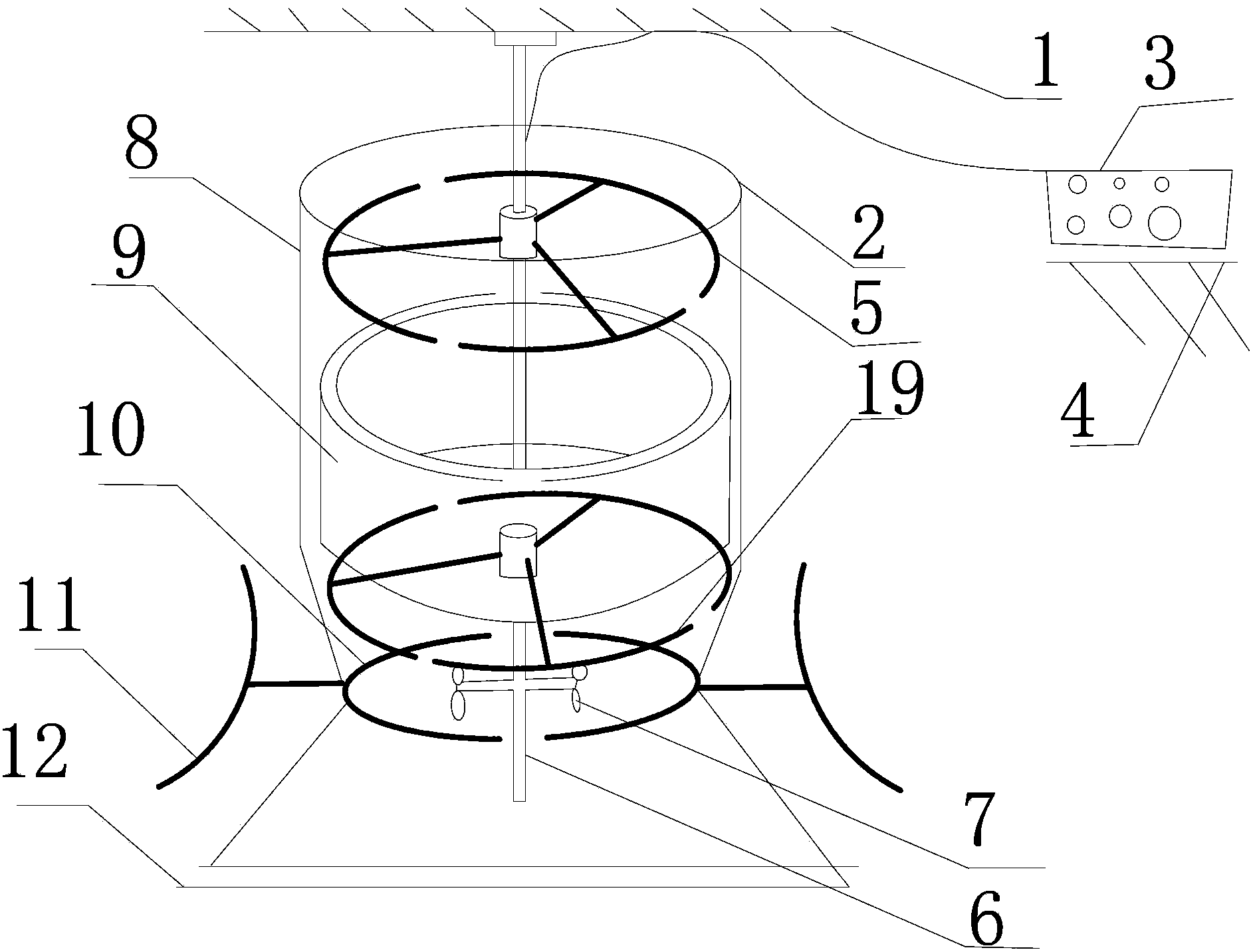

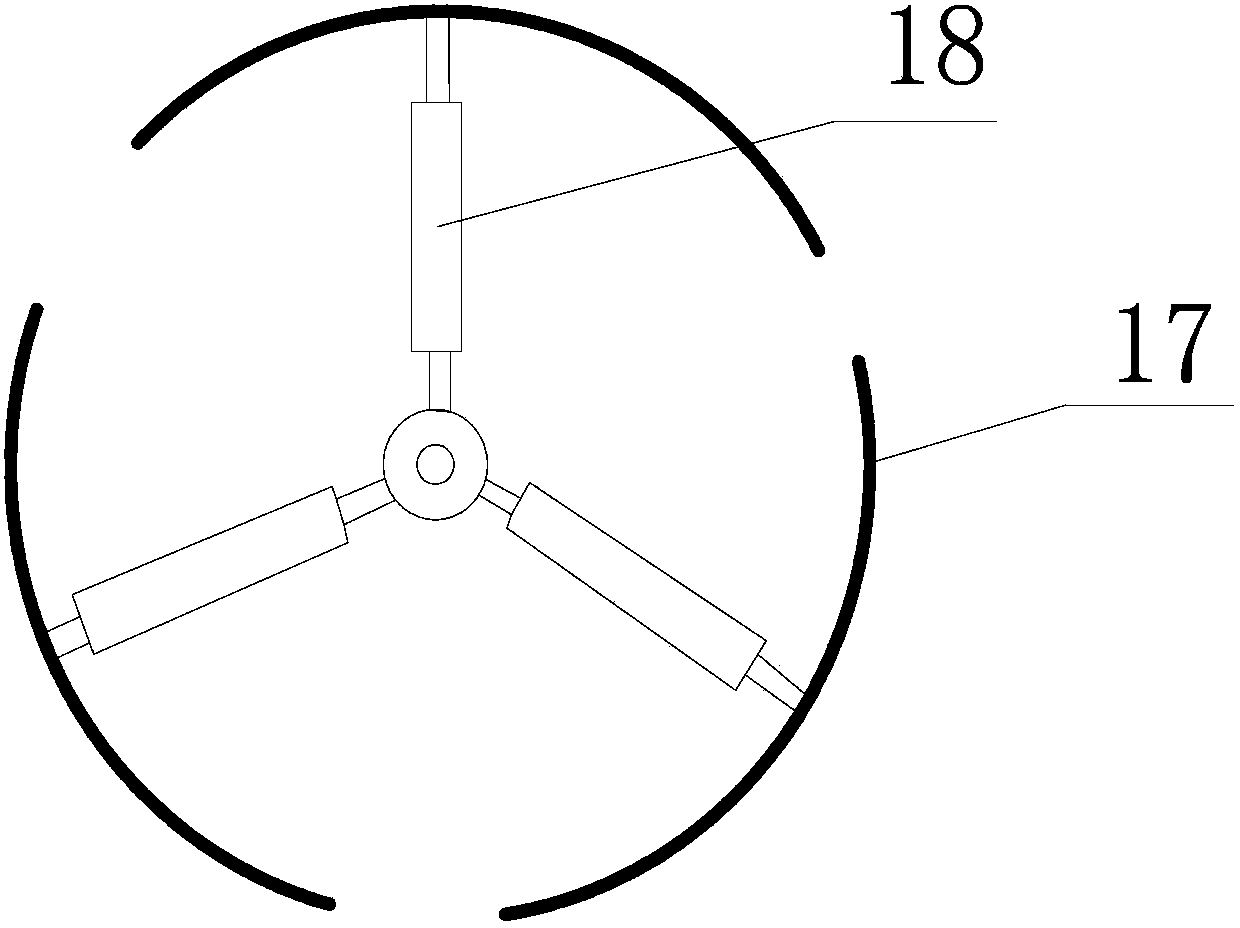

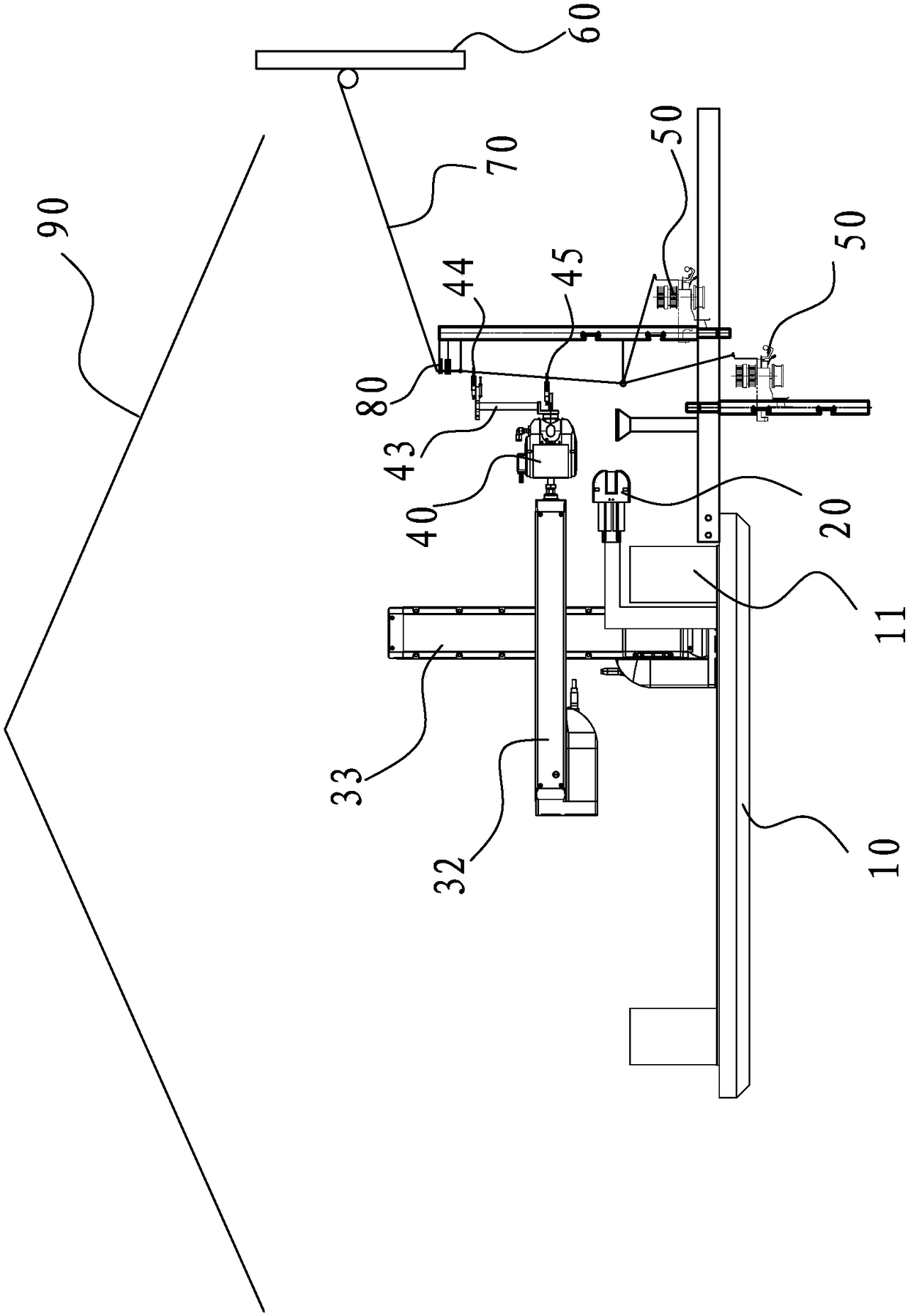

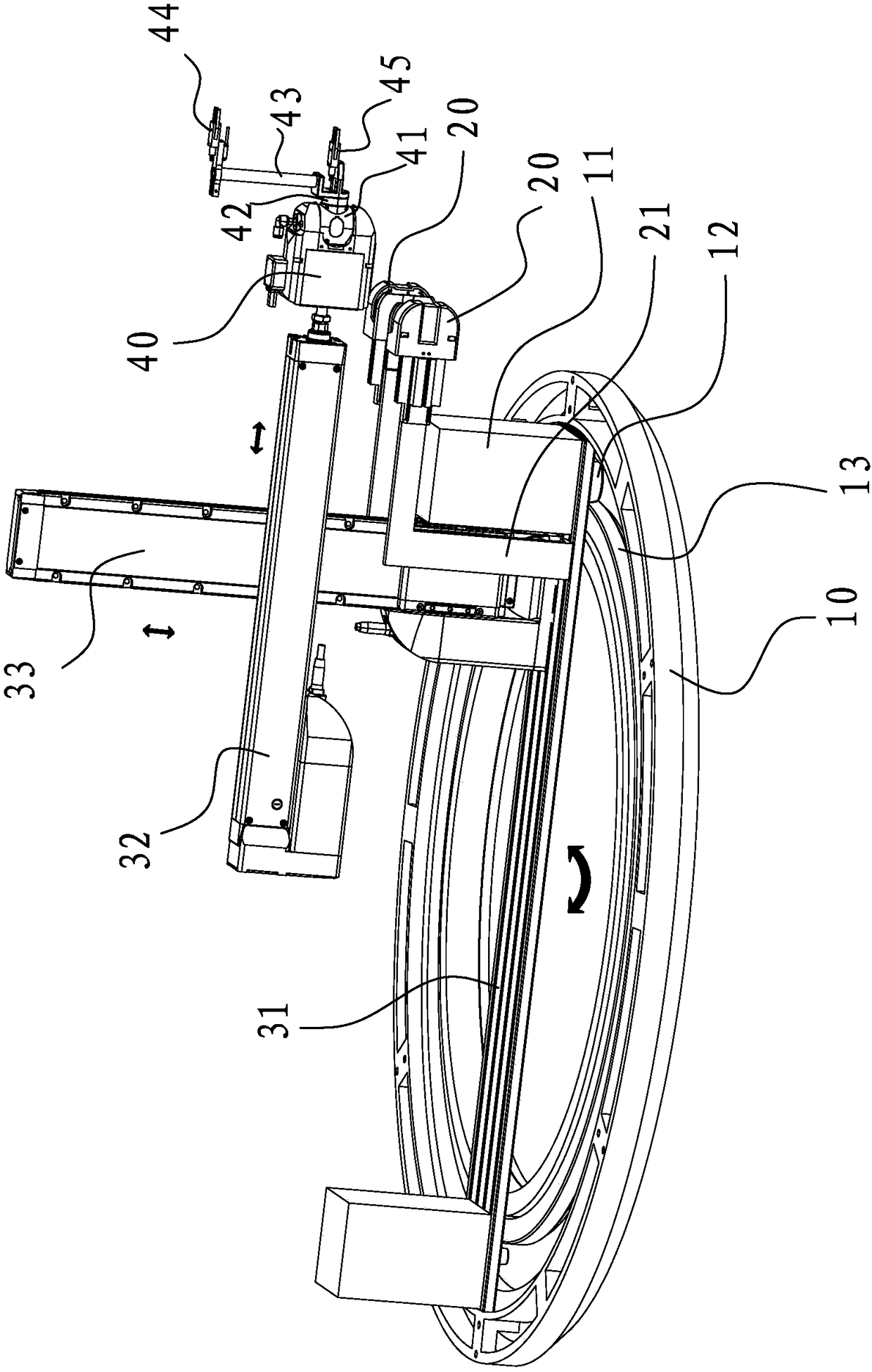

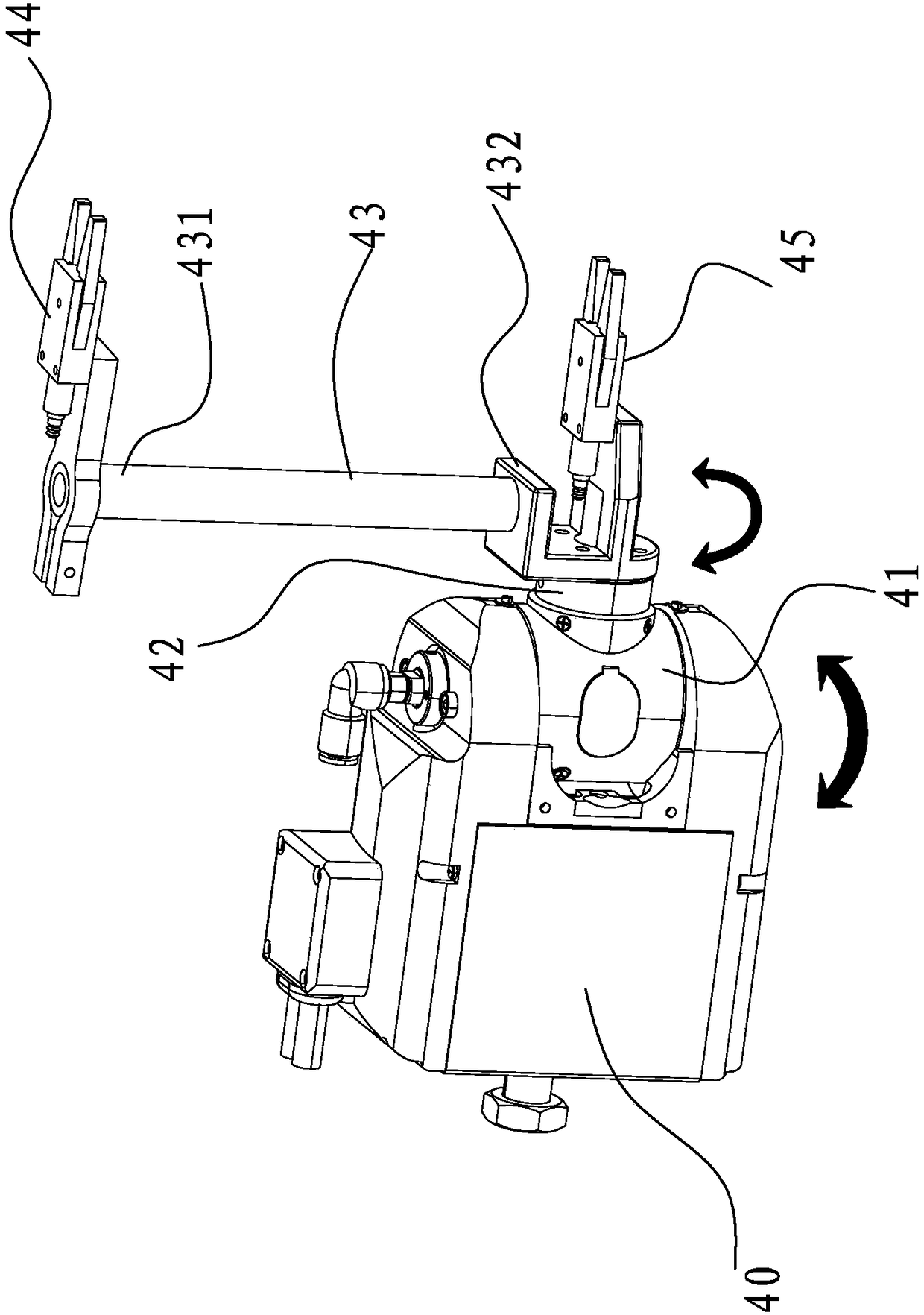

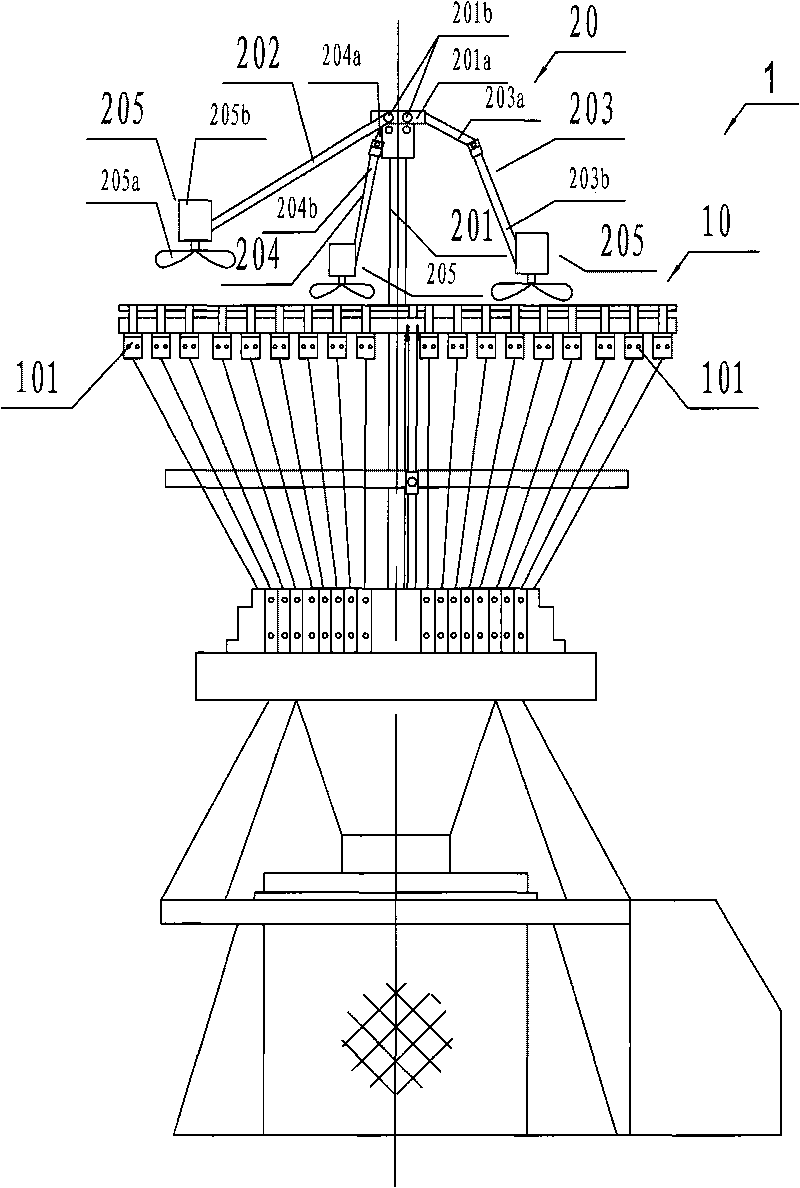

Circular weft knitting machine with cylindrical coordinate robot

ActiveCN108396456ARealize recyclingQuality Control and ImprovementProgramme-controlled manipulatorFilament handlingYarnConnection - action

Owner:SHISHI BAOXIANG KNITTING MACHINERY

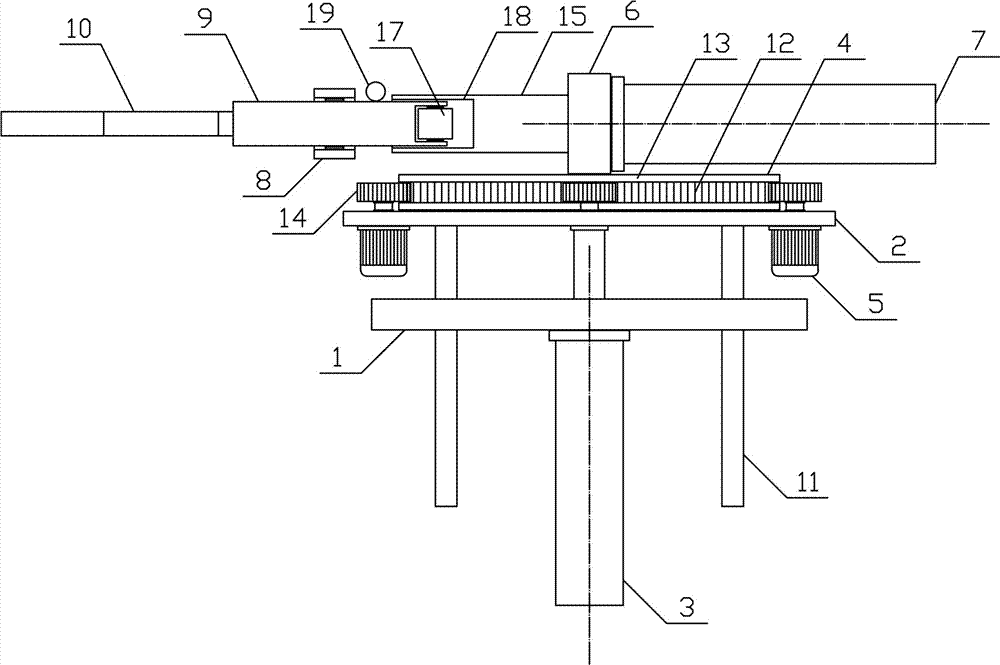

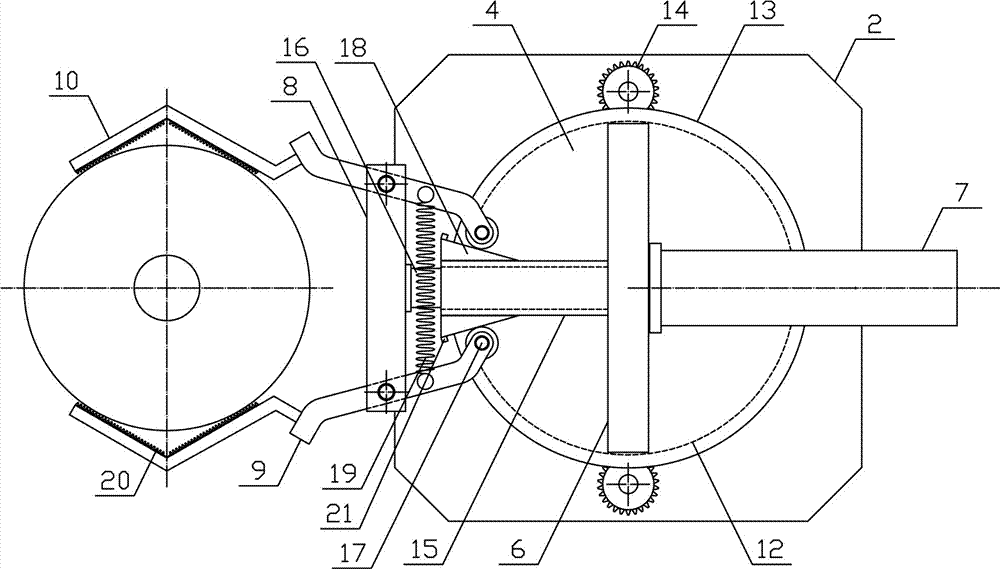

Spool transferring and feeding mechanism

InactiveCN107298303AEfficient and accurate transferReasonable structural designConveyorsKnittingMotor driveEngineering

The invention discloses a spool transferring and feeding mechanism and belongs to the field of textile processing machinery and equipment. The spool transferring and feeding mechanism comprises a fixing support, a lifting support, a lifting cylinder, a rotating disc, a transferring motor, a grabbing support, a grabbing cylinder, a translation plate, grabbing connection rods and clamping rods, the lifting support is horizontally arranged on the upper side of the lifting support, the rotating disc is horizontally arranged on the upper side of the lifting support, a rotating rack is horizontally arranged in the middle of the outer side of the rotating disc, the transferring motor drives a rotating gear, the grabbing cylinder is horizontally arranged in the middle of one side of the grabbing support, a piston rod is slidably arranged on a translation sleeve along the horizontal direction, the translation plate is horizontally arranged at one end of the piston rod, the grabbing connection rods are symmetrically arranged on two sides of the translation plate horizontally, and the clamping rods are horizontally arranged at one ends of the grabbing connection rods. The spool transferring and feeding mechanism is reasonable in structural design and can quickly and firmly clamp a spool and stably and accurately transfer the spool to realize automatic feeding of the spool so as to meet needs of production and use.

Owner:浙江正辉针织科技股份有限公司

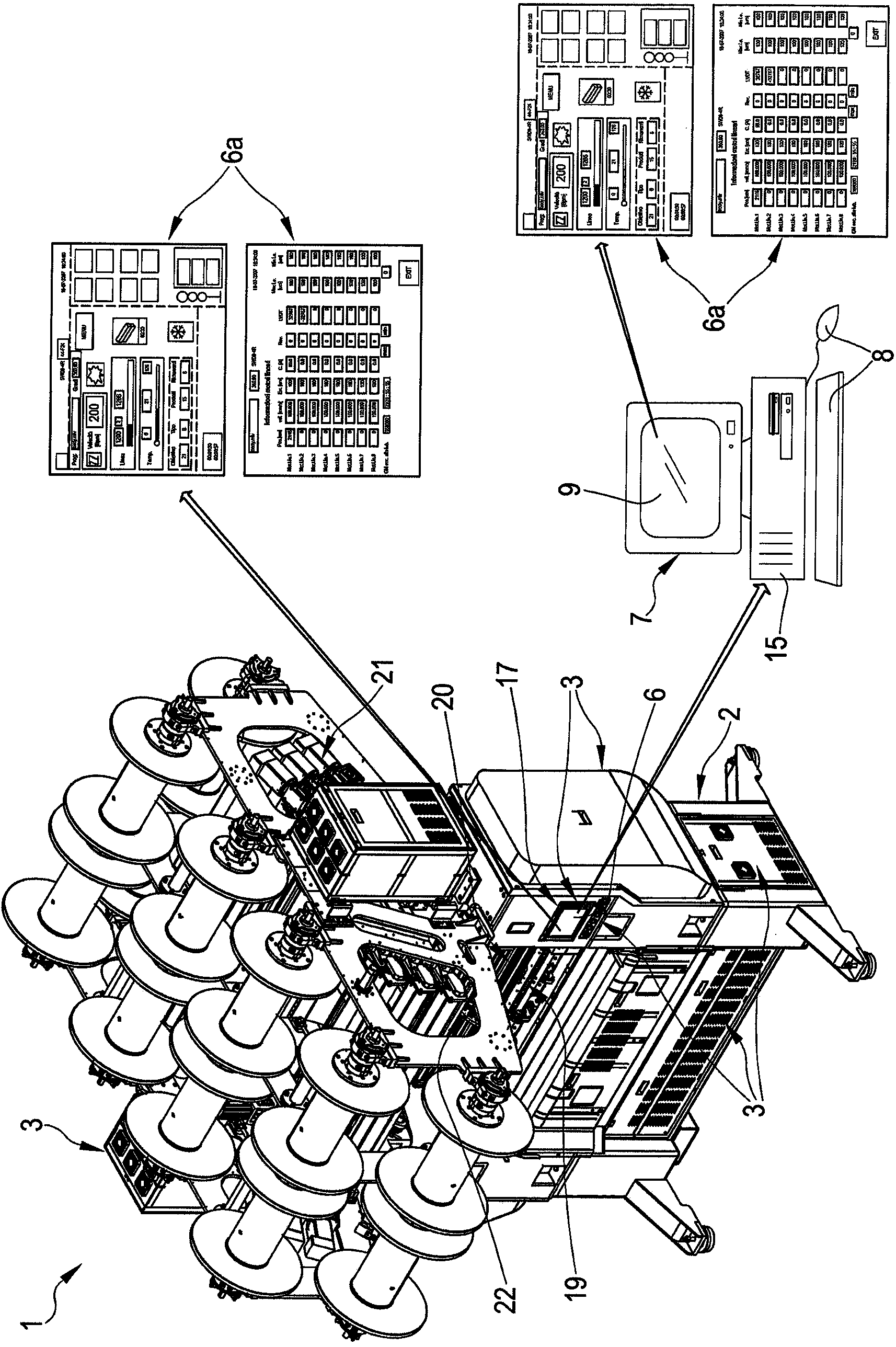

A warp knitting machine and a method for access to and control of the machine

A warp knitting machine comprises: a bearing structure (2); knitting means (19); at least a thread-guide bar (20), at least a supply device (21) of yarn, activating means (22) and electric and electronic means (3) operatively connected to the activating means (22) and destined to command functioning of the warp knitting machine (1), and comprises at least a control unit (4) for at least sending command signals to, and receiving data from, the electric and electronic means (3), a device (5) for entering data to be supplied to the control unit (4) in order to enable a user to generate the command signals for the electric and electronic means (3), a display (6) for displaying at least a part of the data received by the control unit (4) in relation to the electric and electronic means (3) and comprises remote access and control means (10) for enabling a remote unit (7) to take control of a predetermined number of functions of the warp knitting machine (1).

Owner:KARL MAYER R&D GMBH

Knitting circular weft knitting machine

The invention relates to a knitting circular weft knitting machine, which is used for knitting yarns into a double faced fabric, wherein the knitting is finished by a needle cylinder. The top part of the circular weft knitting machine is provided with a plurality of yarn feeders distributed on the circumference; the central part of the circular weft knitting machine is provided with a rotating rod; a plurality of brackets are distributed on the rotating rod; the brackets are provided with electric fans which are used for blowing away flying cotton wools near the yarn feeders and blow uniformly; in a plurality of the brackets, at least part of the brackets are provided with bendable structures to ensure that the electric fans arranged on the brackets can blow to different positions. The knitting circular weft knitting machine treats the flying cotton wools near the yarn feeders in time, has a large treatment range, and effectively prevents the flying cotton wools from being adhered to the yarn feeders, so the working efficiency of the yarn feeders is improved.

Owner:吴江天龙针织有限公司

Textile dust collecting device for textile workshop

InactiveCN112176475AAchieve angle adjustmentExpand the vacuum rangeUsing liquid separation agentSeparation devicesFiberReciprocating motion

The invention discloses a textile dust collecting device for a textile workshop. The textile dust collecting device comprises a box body, a driving bin and a dust removing bin are arranged in the boxbody, an angle adjusting mechanism and a negative pressure mechanism are arranged in the driving bin, and a dust falling mechanism is arranged in the dust removing bin. By arranging the angle adjusting mechanism, angle adjustment of a dust collecting cover is achieved, and the dust collecting range is enlarged; by arranging the negative pressure mechanism, a sliding rod drives a piston plate to reciprocate while reciprocating left and right, negative pressure is generated at a cover opening of the dust collecting cover through movement of the piston plate, dust collection is conducted on the surrounding environment through an air guide pipe, an induced draft fan does not need to be additionally arranged, and the production cost is reduced; textile dust sucked into the dust removing bin issubjected to efficient dust falling by arranging the dust falling mechanism; and impurities such as the dust and cotton fibers are filtered by arranging a filter screen, filtered clear water flows into a water tank again, cyclic utilization of water is achieved, and water resources are saved.

Owner:蒋秀兰

Spinning equipment with dedusting function

ActiveCN107326511AWith dust removal functionThorough dust removalAuxillary apparatusKnittingEngineeringThreaded rod

The invention provides spinning equipment with a dedusting function, and relates to the field of textiles. The spinning equipment with the dedusting function comprises a spinning worktable; the two sides of the top of the spinning worktable are both fixedly connected with supporting rods, and the bottom of the inner wall of each supporting rod is fixedly connected with a base; the end, away from the inner wall of the corresponding supporting rod, of each base is fixedly connected with a first motor, the output end of each first motor is fixedly connected with a threaded rod, and the end, away from the corresponding first motor, of each threaded rod is in threaded connection with a bearing base. The spinning equipment with the dedusting function is simple in structure and convenient to operate; a fixation box is arranged in an air suction opening, and a second motor in the fixation box rotates, so that a brush on a fixation plate rotates through a rotating rod, the brush rotates to make debris and dust on cloth fly up, and therefore the spun cloth is dedusted more thoroughly through the air suction opening, and the problem is solved that current spinning equipment does not have the dedusting function.

Owner:浙江东进新材料有限公司

Surgical instrument with integrated reduction and distraction mechanisms

ActiveUS9066763B2Increase efficiency and accuracyReduce difficultyInternal osteosythesisFractureDistractionSurgical operation

Embodiments of a surgical instrument disclosed herein can include mechanisms for reduction and distraction as well as compression. Some embodiments of the surgical instrument may comprise a reducer knob having a first passage through which a first shaft of a driver is acceptable, a connecting element coupled to the reducer knob and having a second passage through which the first shaft of the driver is acceptable, a compressor handle coupled to the connecting element at a first end and having a through hole, and a common handle coupled to the compressor handle via the through hole and pivots between the reducer knob and the compressor handle. With embodiments of a surgical instrument disclosed herein, surgical personnel can distract and hold vertebrae in a distracted state and perform a reduction without having to switch or add instruments. Some embodiments disclosed herein can be particularly useful for reducing spondylolisthesis during posterior fixation.

Owner:ZIMMER BIOMET SPINE INC

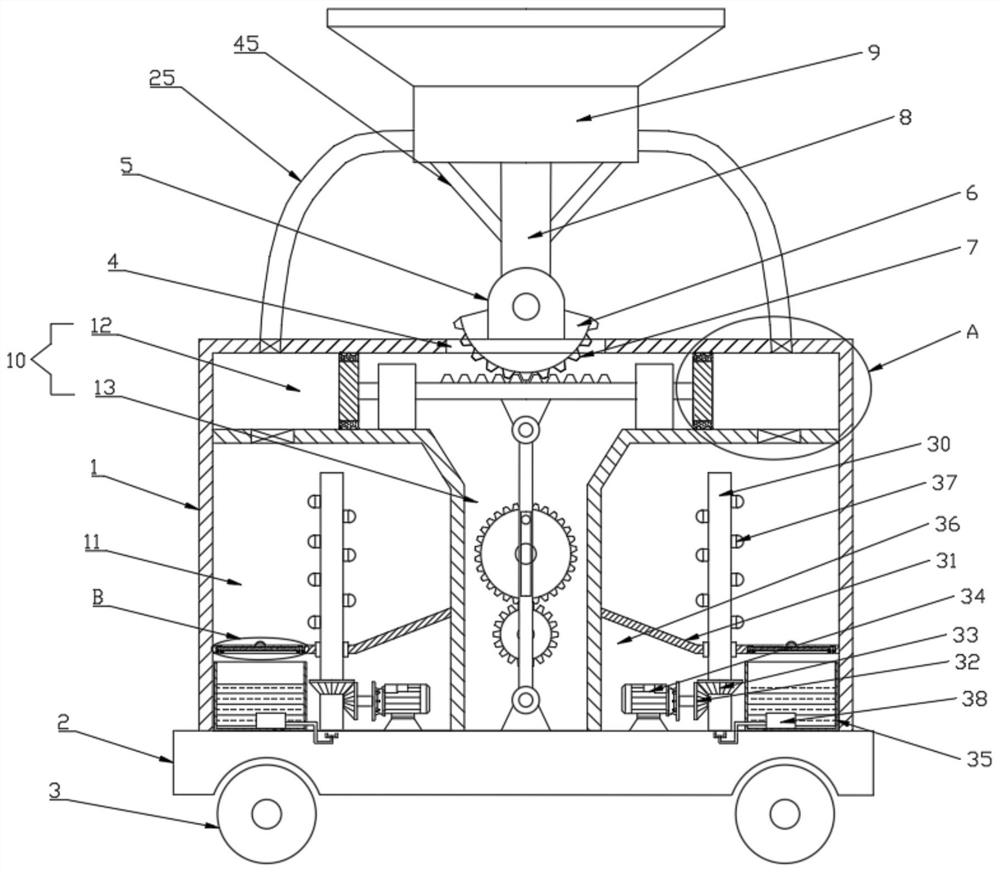

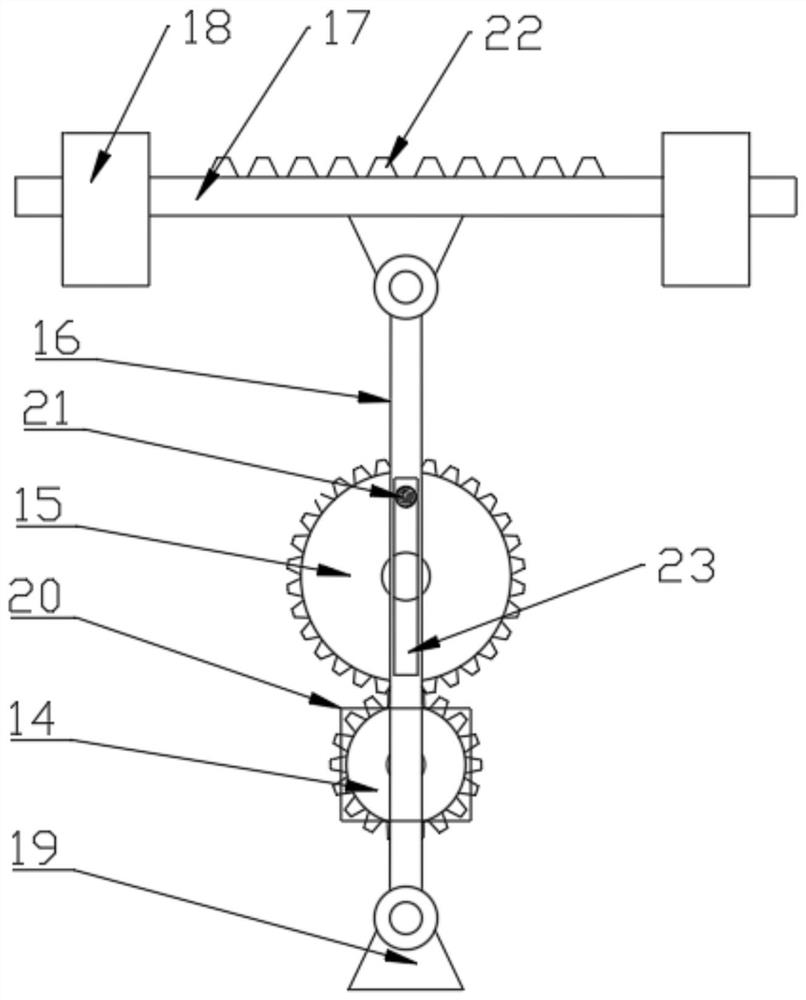

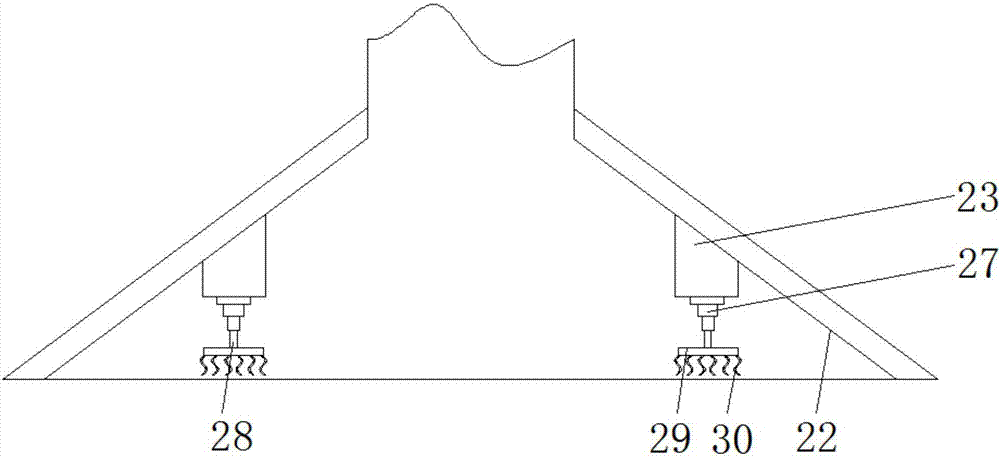

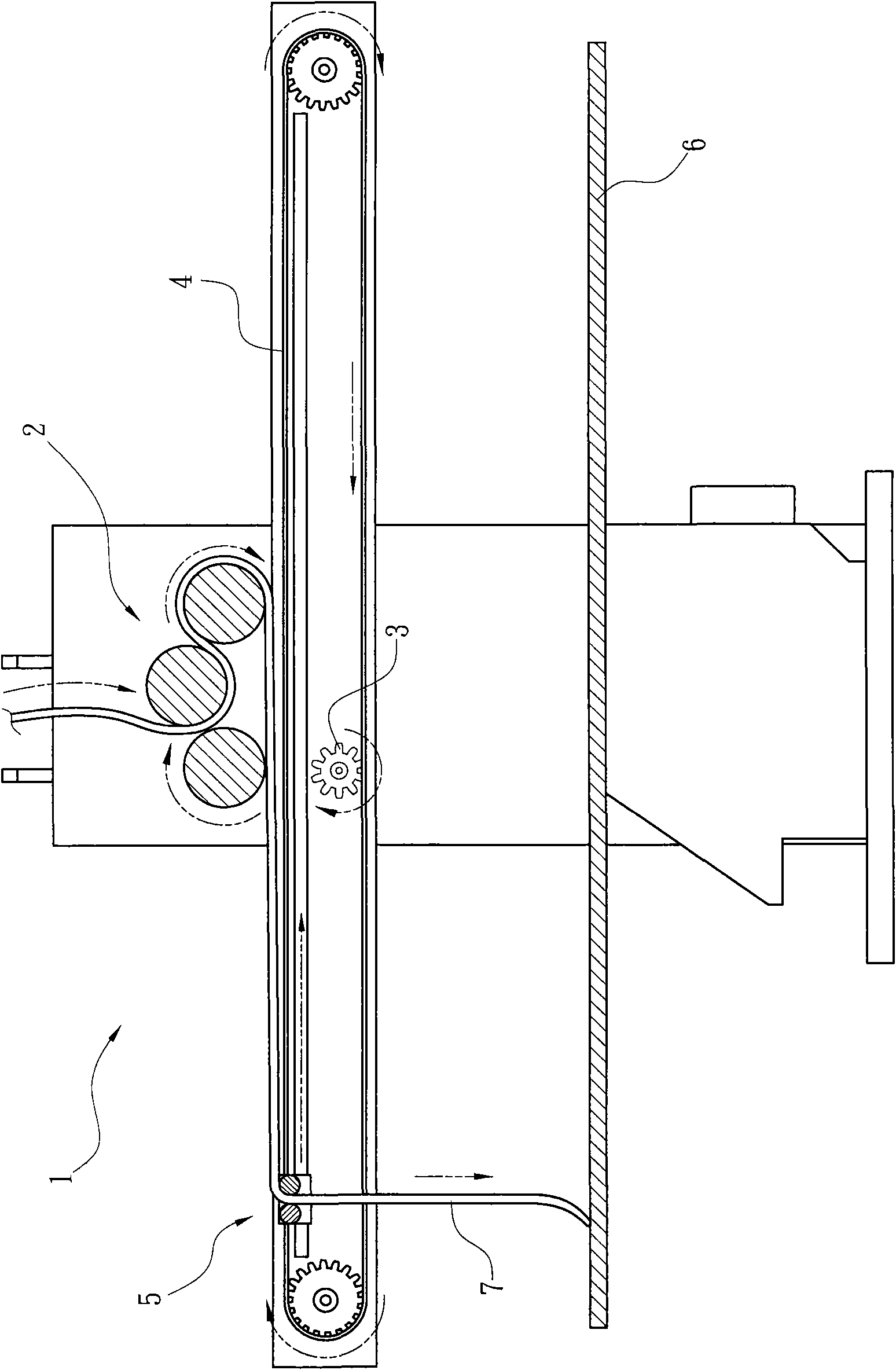

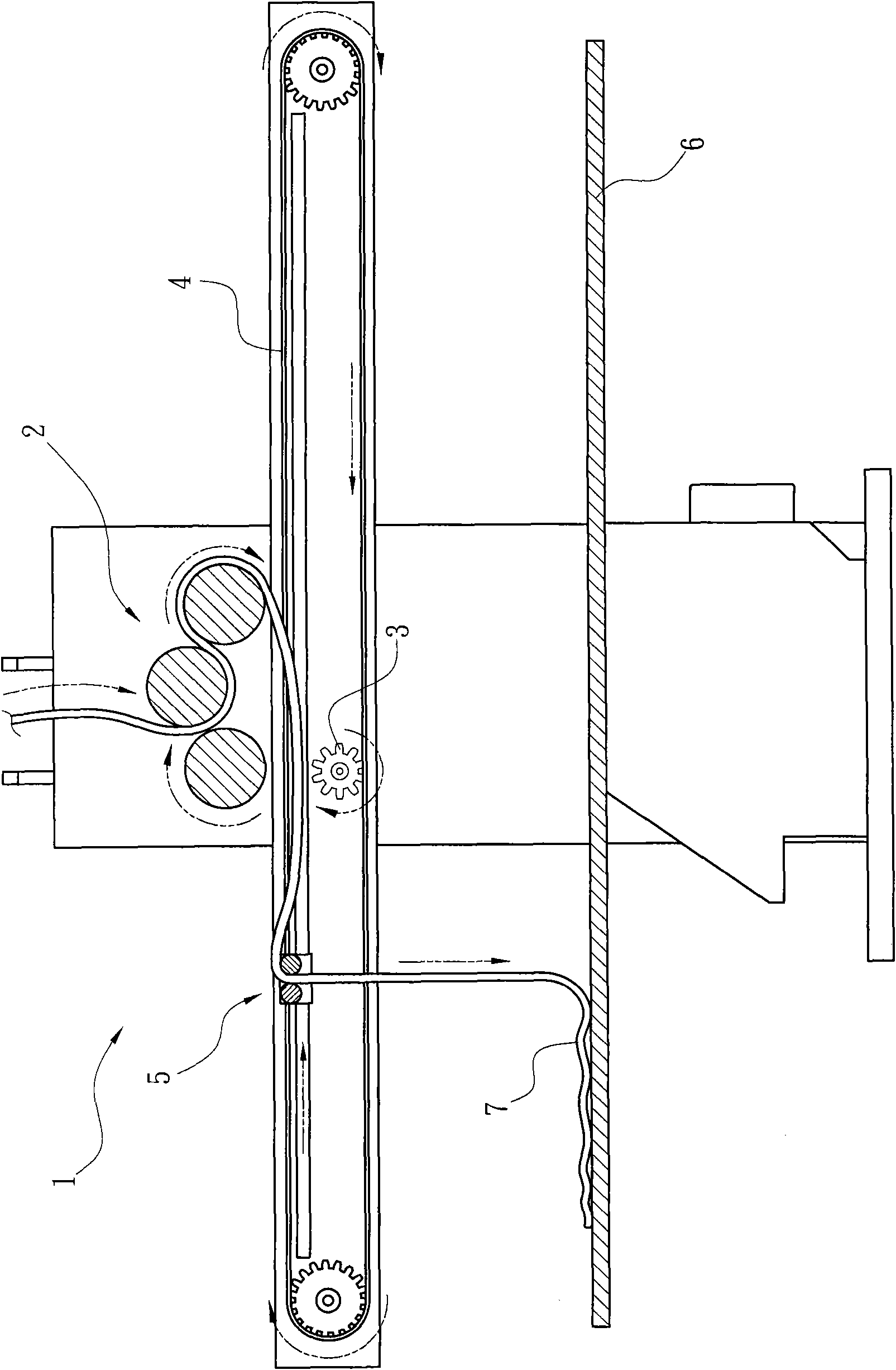

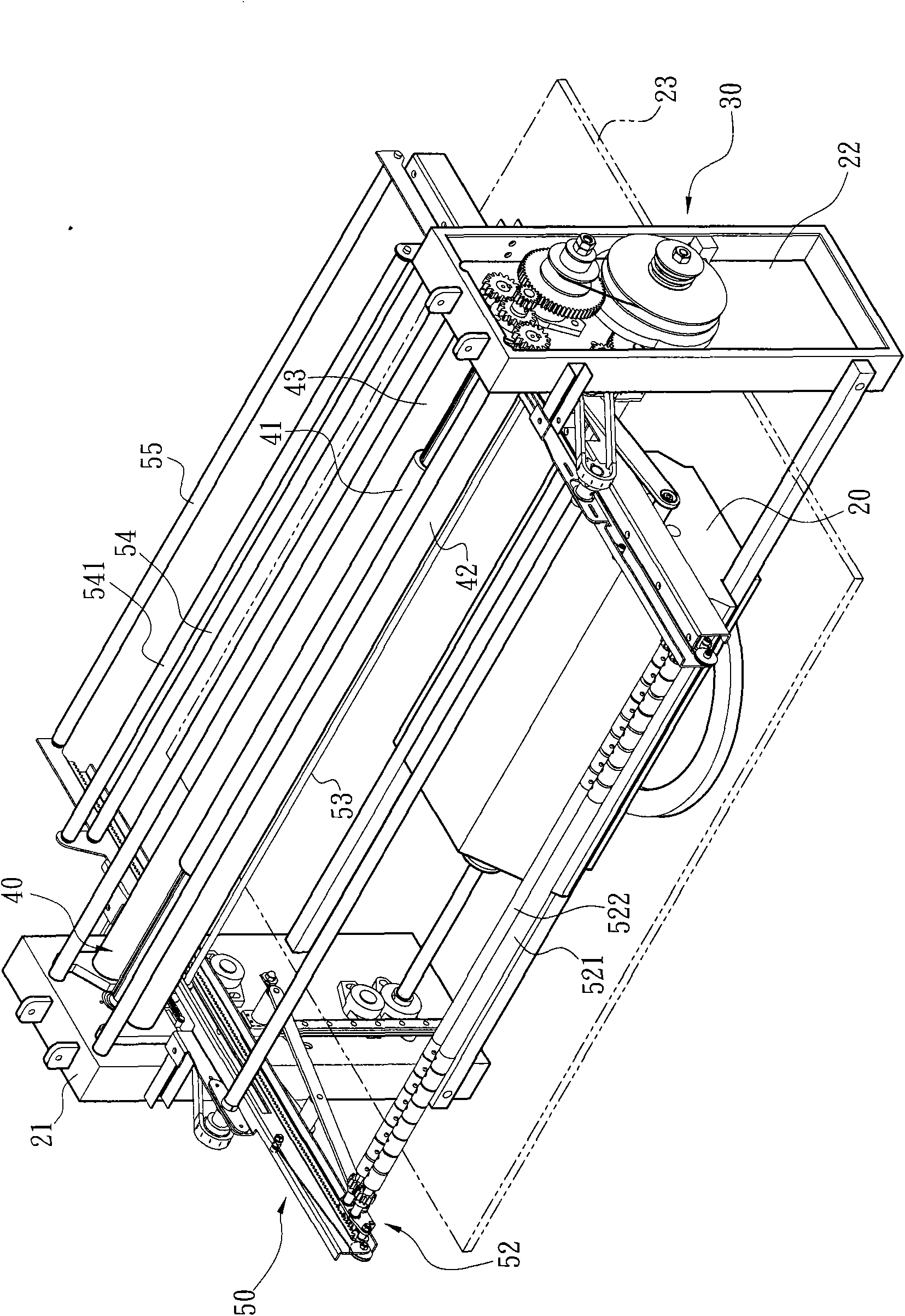

Method and mechanism for equivalently lowering and folding cloth woven by circular knitting machine according to cloth quantity

InactiveCN102051762ALarge amount of clothLow costFolding thin materialsKnittingEngineeringMechanical engineering

The invention discloses a method and a mechanism for equivalently lowering and folding cloth woven by a circular knitting machine according to cloth quantity. The cloth woven by the circular knitting machine is fed out after passing through a buffering temporary storage mechanism which can store the cloth temporarily and is partitioned into three section cloth lengths; the decrement of a third section cloth length on the lower side is equal to the summation of the increment of a first section cloth length and the increment of a second section cloth length; the increment of the first section cloth length is equal to that of the second section cloth length; the increment of the third section cloth length is equal to the summation of the decrement of the first section cloth length and the decrement of the second section cloth length; the decrement of the first section cloth length is equal to that of the second section cloth length; and the three section cloth lengths are mechanically complemented with one another through the buffering temporary storage mechanism, so that cloth above a cloth folding rod which moves and lowers the cloth in a reciprocating way keeps fixed tension, and cloth continuously woven by the circular knitting machine is equivalently lowered and folded on a cloth carrying plate if the cloth above the cloth folding rod keeps the fixed tension.

Owner:PAI LUNG MACHINERY MILL CO LTD

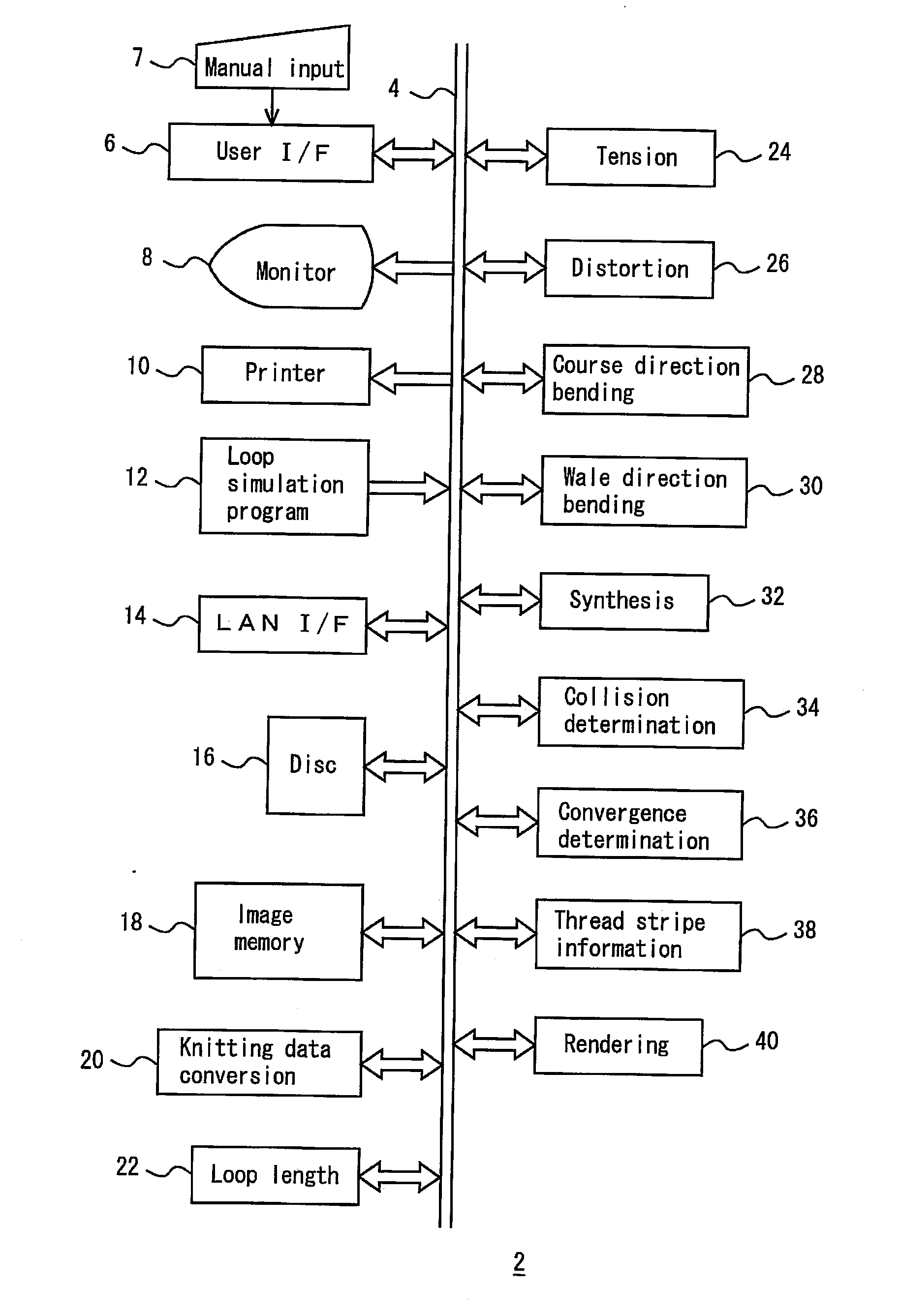

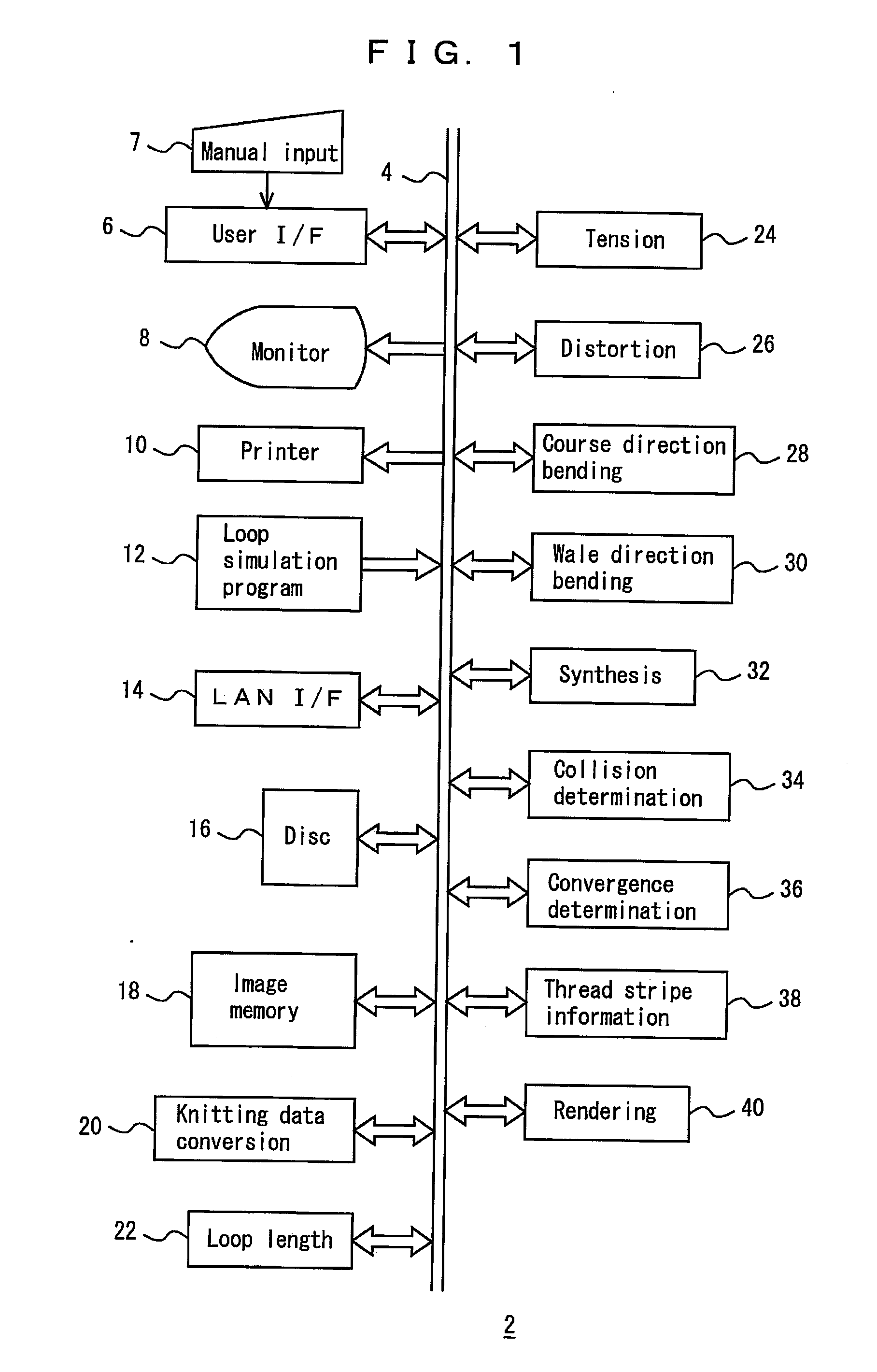

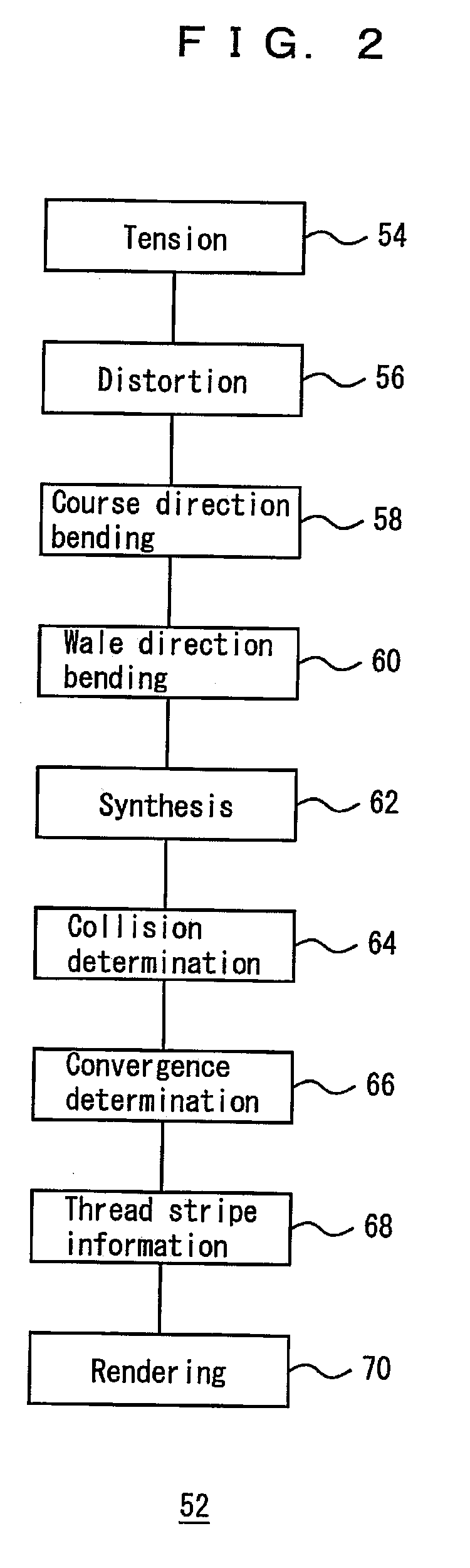

Loop simulation apparatus, method and program thereof

ActiveUS20100145495A1Easy to determine tensionEasy to distortion angle angleSpecial data processing applicationsKnittingEngineering

Owner:SHIMA SEIKI MFG LTD

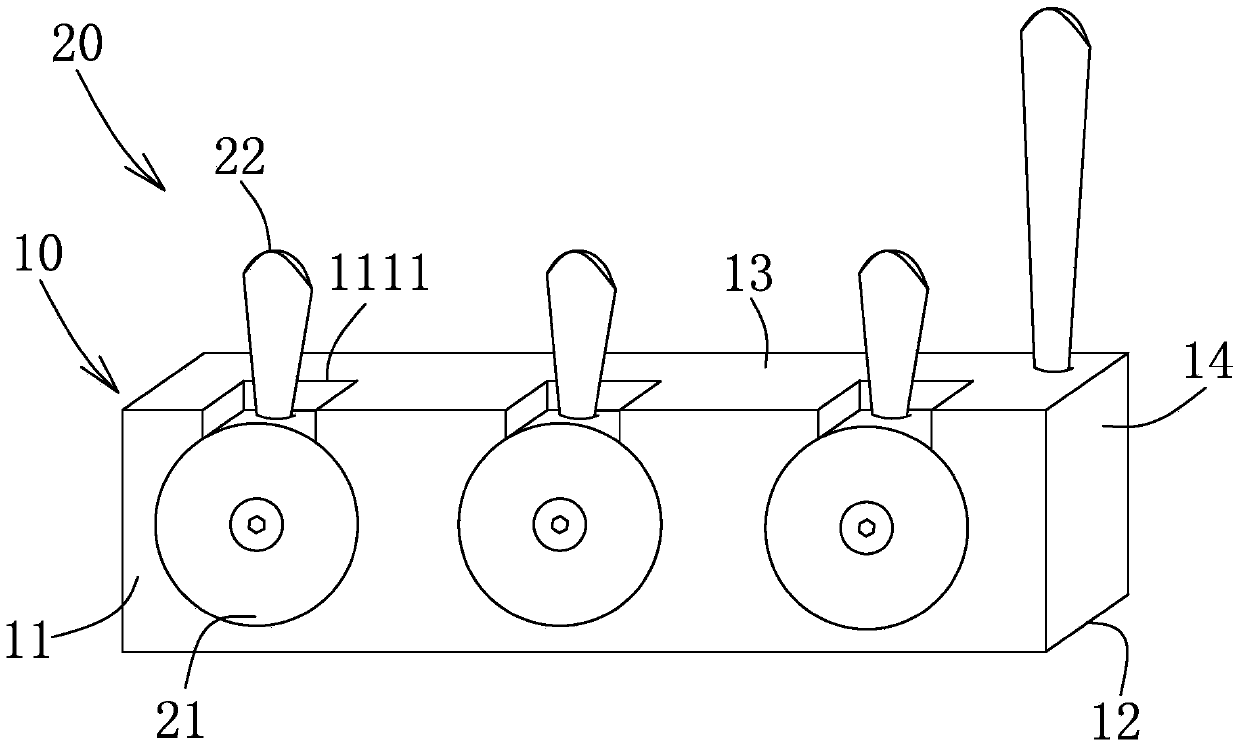

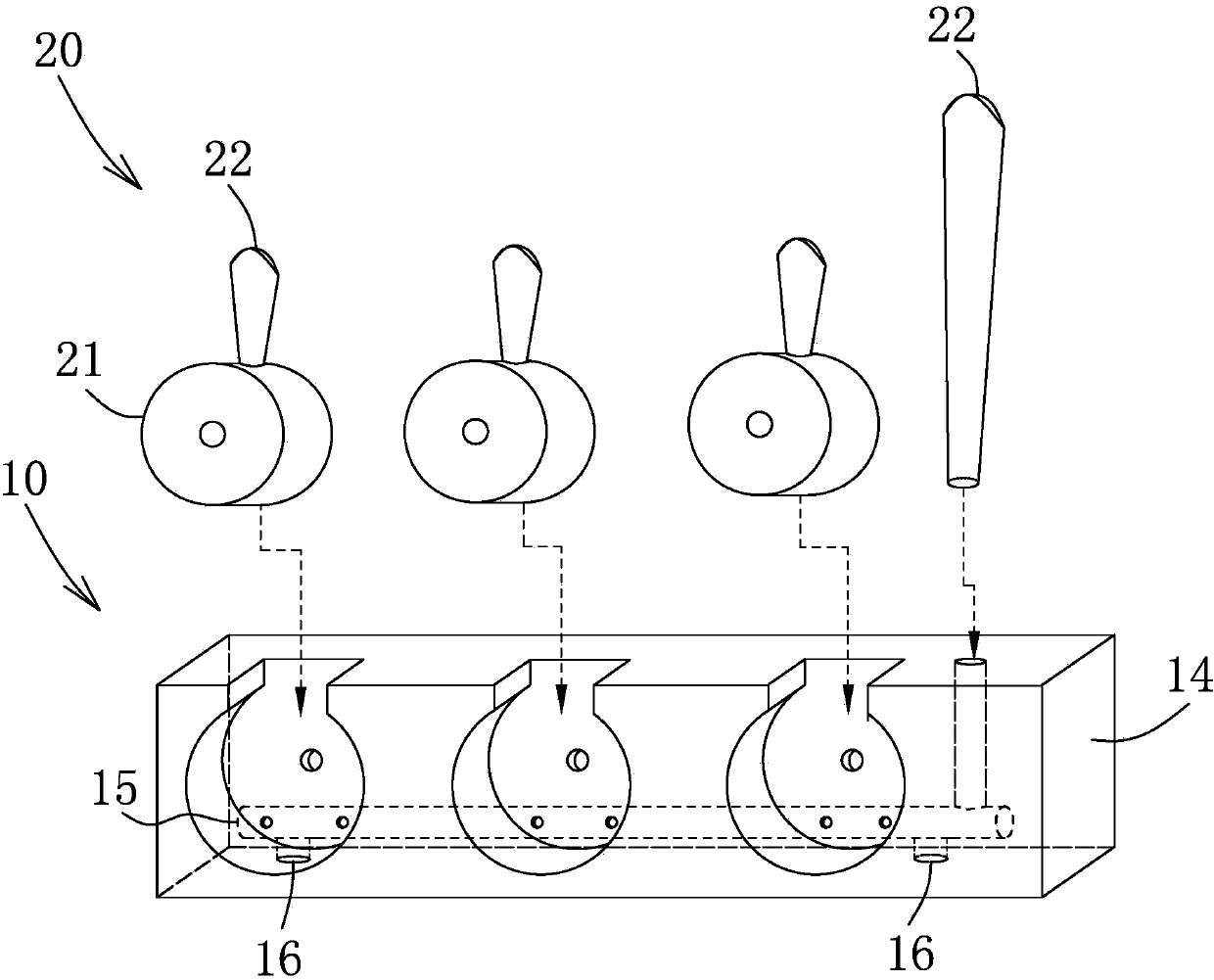

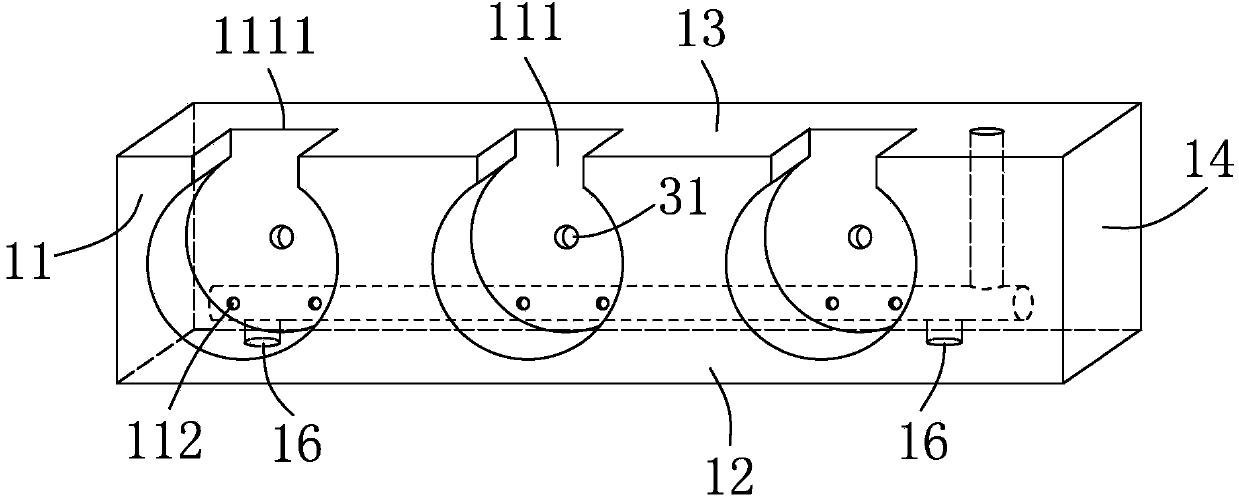

Multi-nozzle air injection dust removal device with air injection angle adjustable

The invention discloses a multi-nozzle air injection dust removal device with the air injection angle adjustable. The device comprises a base (10), at least one air inlet (14) is formed in the base (10), an air channel (15) communicated with the air inlet is formed in the base, a plurality of air injection nozzles (20) with the angle adjustable are arranged on the base, all the air injection nozzles (20) are communicated with the air channel (15), and the air injection angle of the device can be adjusted by rotating the air injection nozzles (20). The angle of the air injection nozzles of the device can be adjusted flexibly according to requirements, and therefore air injection dust removal can be performed on different portions of a knitting machine, and the device has the advantages of being high in dust removal efficiency, good in dust removal effect, convenient to use, practical and the like.

Owner:陆粉干

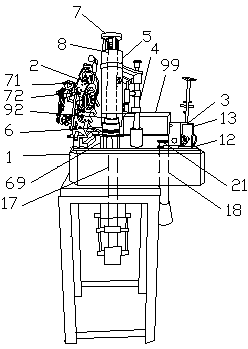

Integrated sock making machine with binding-off function

ActiveCN103966760AWith sock sewing functionIncrease productivityLinking machinesSpool-pin assembliesMagnetic valveManufacturing engineering

The invention discloses an integrated sock making machine with a binding-off function. The integrated sock making machine comprises a work table and a sock weaving machine installed on the work table, the work table is further provided with a binding-off machine, a rotary stand column, a work plate, a sock discharging platform and an electromagnetic control box, a sock turning ejecting rod is matched with the work plate, a sock discharging cylinder is matched with the sock discharging platform, and the sock weaving machine, the binding-off machine, the rotary stand column, a sock absorbing cylinder, the sock turning ejection rod and the sock discharging cylinder are all connected with the electromagnetic control box. The integrated sock making machine has a sock sewing function and has the advantages that only one work procedure is needed from sock production to a finished product, production efficiency is effectively improved and labor and materials are saved.

Owner:浙江海润精工机械有限公司

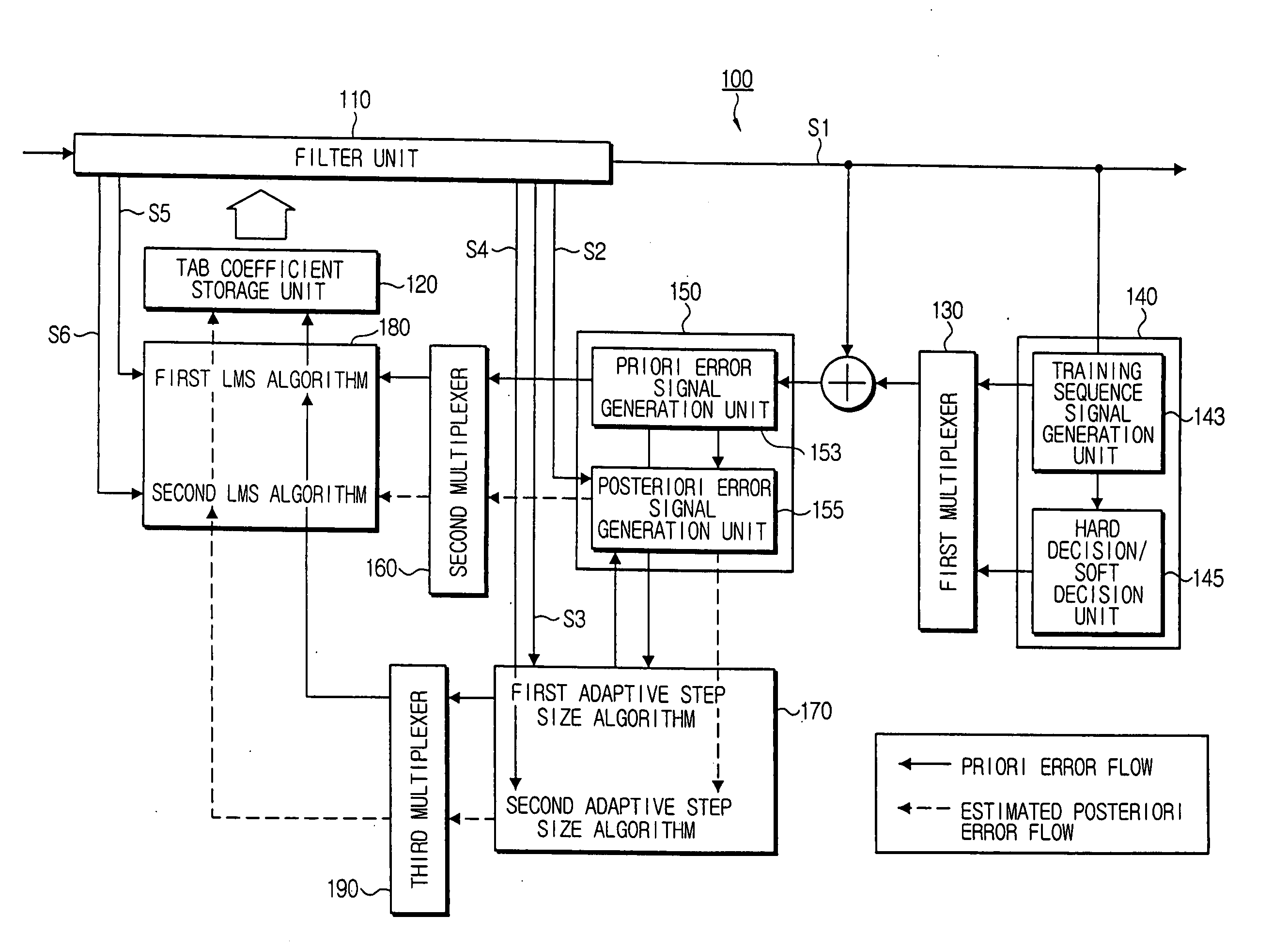

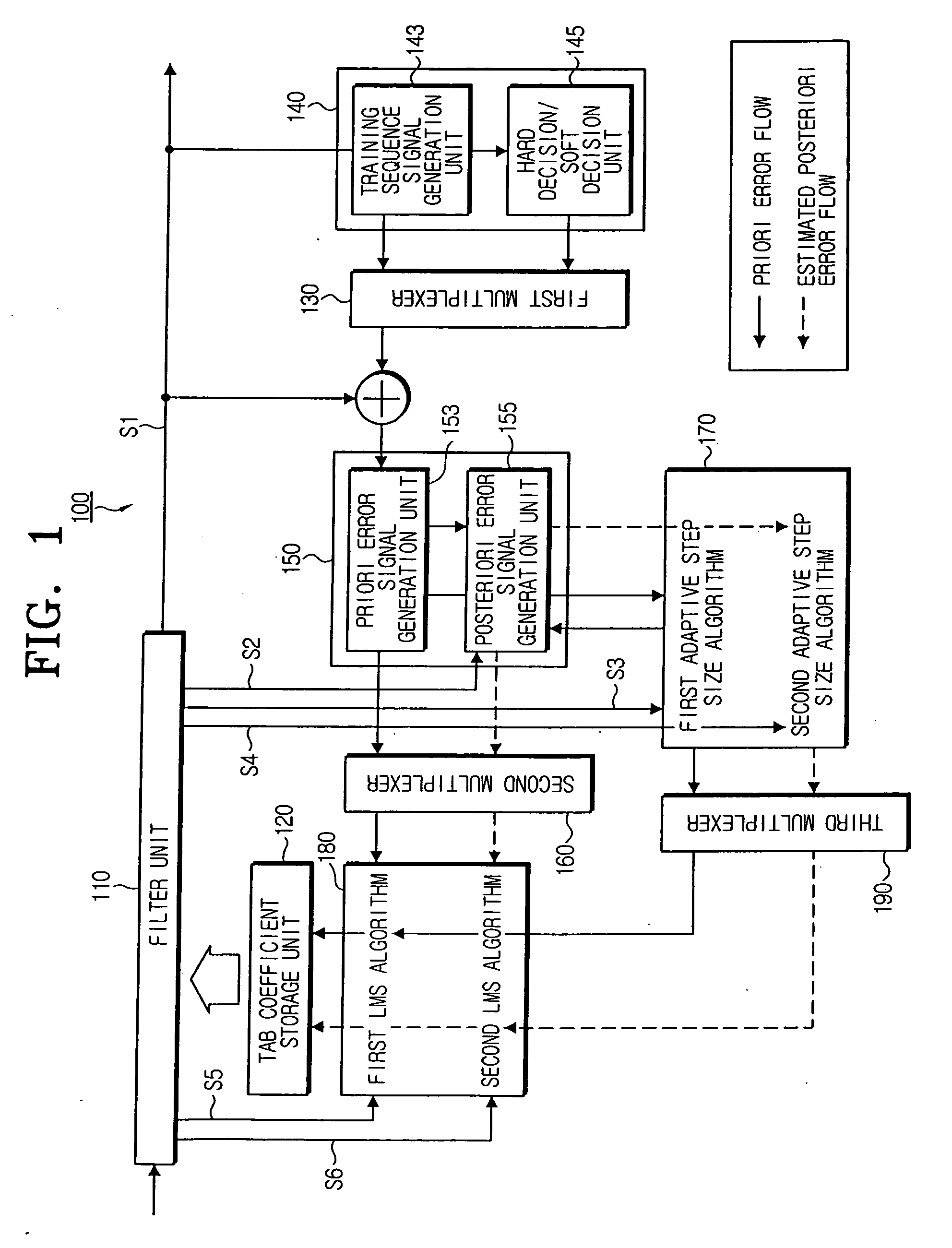

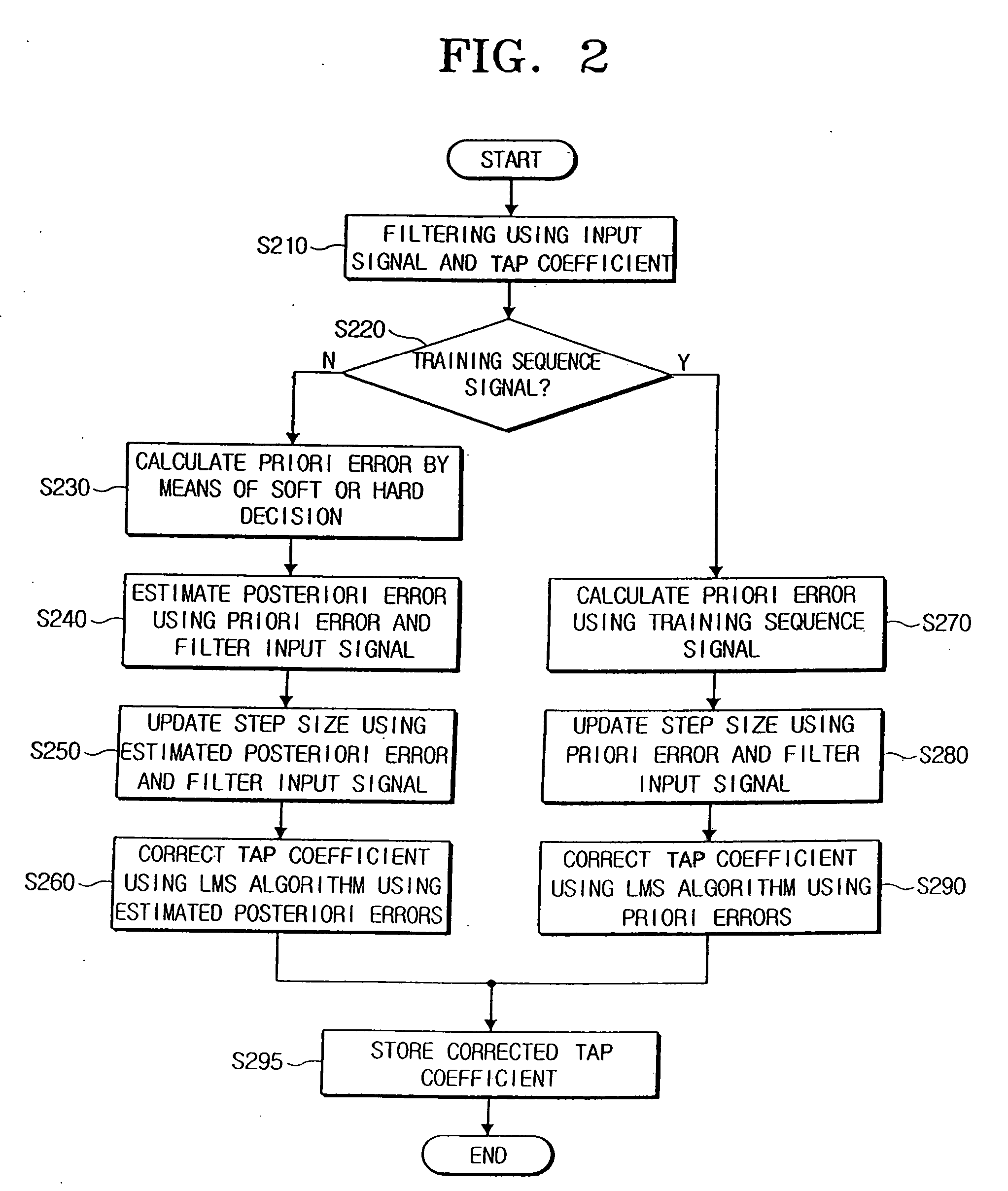

Channel equalizer and method of equalizing a channel

InactiveUS20060200511A1Television system detailsSelective content distributionSequence signalMultiplexer

A channel equalizer and a method of equalizing a channel. The channel equalizer includes a filter unit to filter an input training sequence signal and an input data signal according to a tap coefficient, a first multiplexer to calculate a priori error of each of the training sequence signal and the data signal, a decision unit to generate the training sequence signal and to soft-determine or hard-determine an output signal of the filter unit, an error signal generation unit to generate a priori error signal using an output signal of the decision unit and to generate an estimated posteriori error signal using the priori error signal, a first correction unit to correct a first adaptive step size algorithm using the signal input to the filter unit and the generated priori error signal and to correct a second adaptive step size algorithm using the signal input to the filter unit and the estimated posteriori error signal, and a second multiplexer to select one of the corrected first adaptive step size algorithm and the corrected second adaptive step size algorithm to be applied to the training sequence signal and the data signal, respectively.

Owner:SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com