Circular weft knitting machine with cylindrical coordinate robot

A technology of circular knitting machine and cylindrical coordinates, applied in the directions of knitting, manipulators, manufacturing tools, etc., can solve the problems of insufficiency, increased number of broken yarns, occupying the operator's time, etc., and achieve the effect of quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

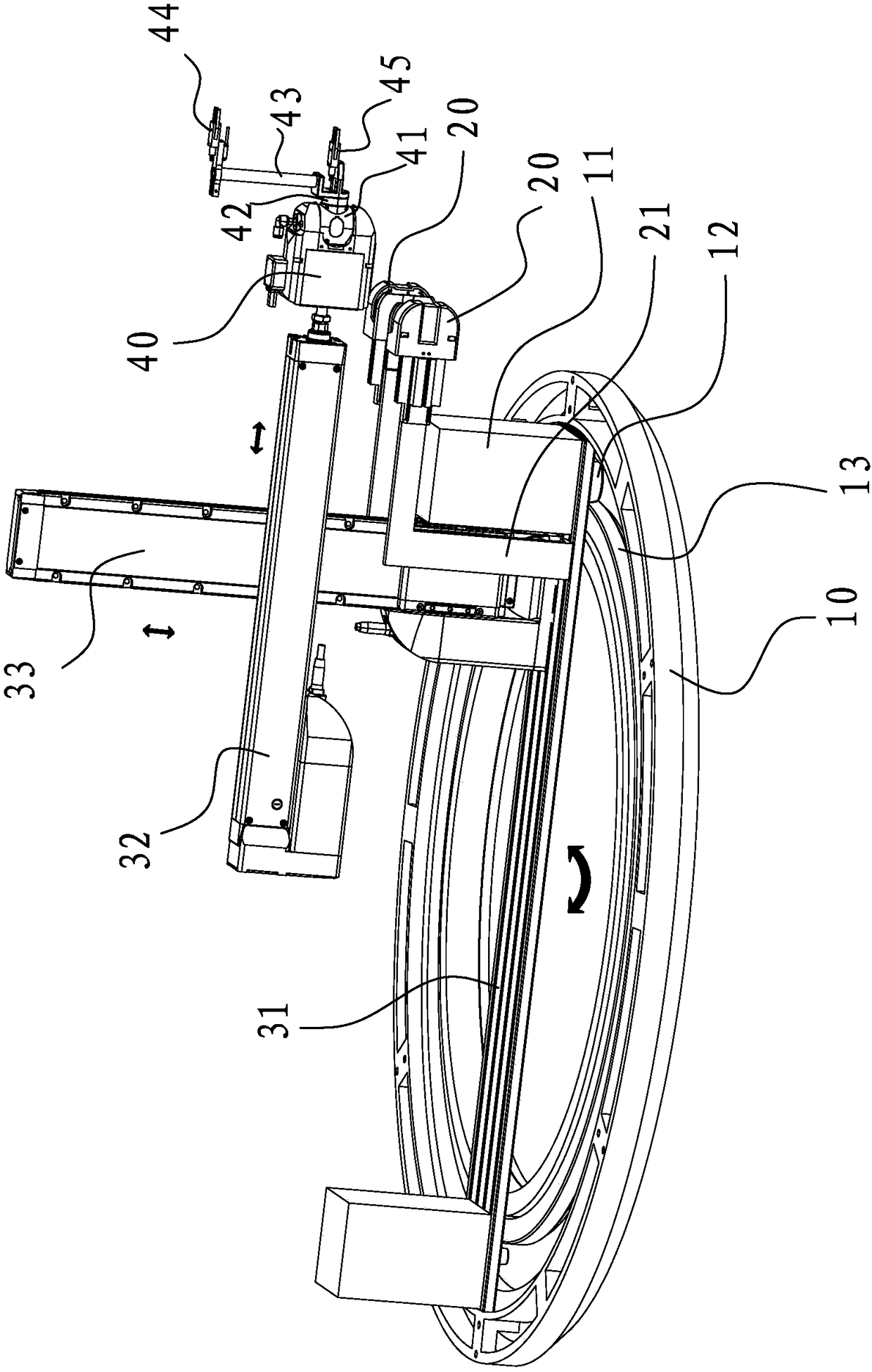

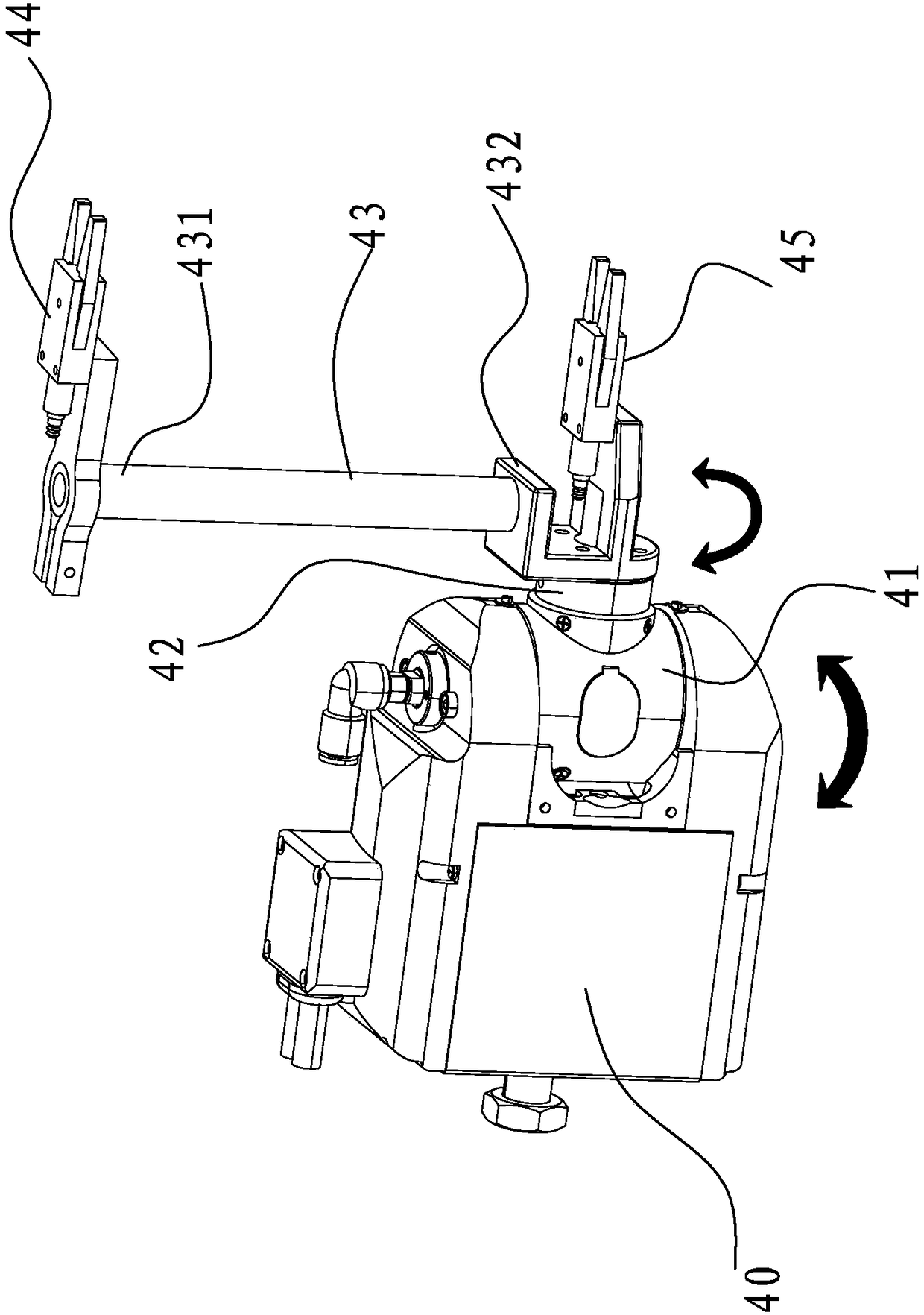

[0032] In order to further explain the technical solution of the present invention, it will be described in detail below in conjunction with the accompanying drawings. In the figure, the arrows indicate the moving direction or the rotating direction of the corresponding components.

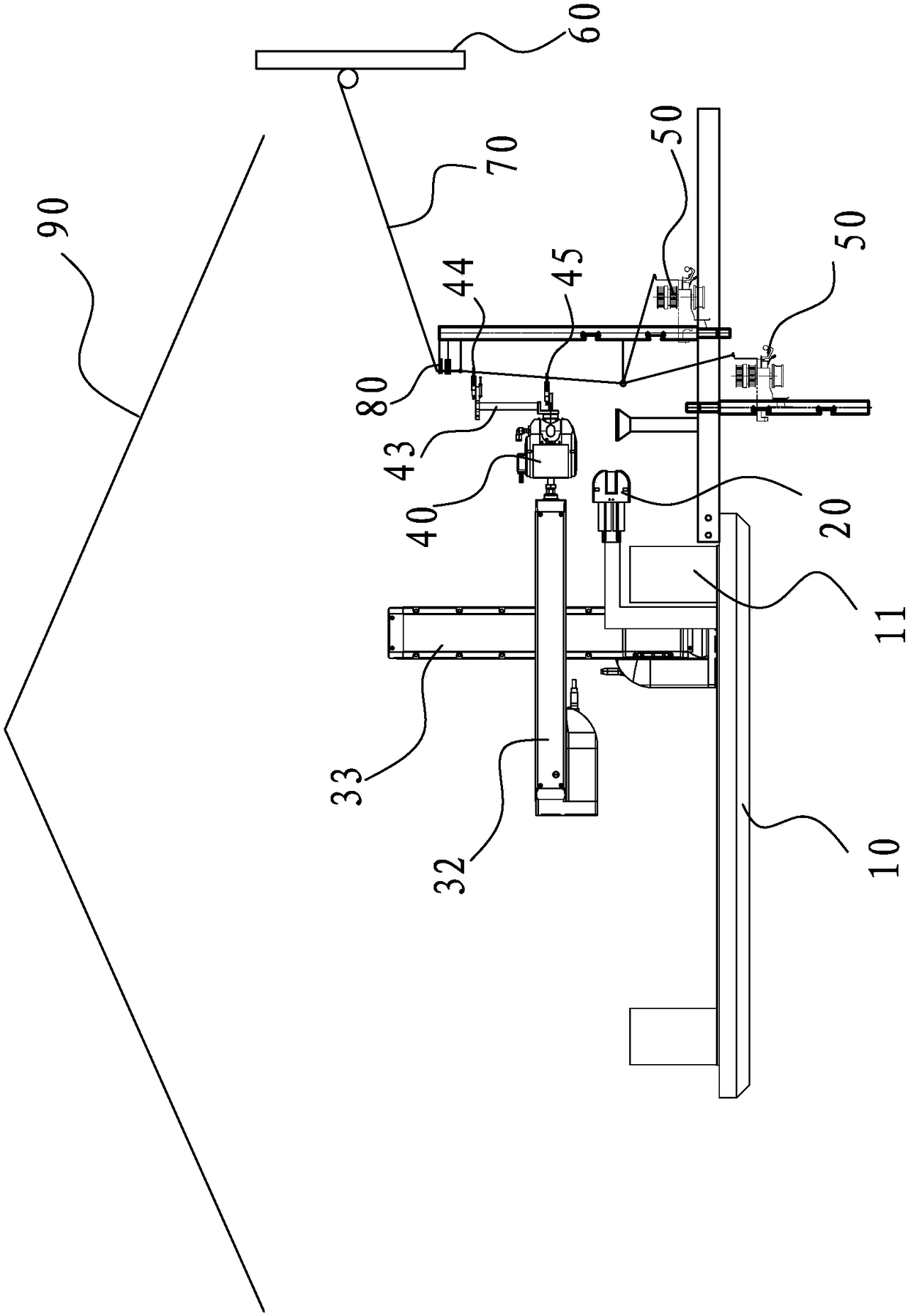

[0033] refer to Figure 1 to Figure 3 , a circular knitting machine with a cylindrical coordinate robot, including a circular knitting machine body, the circular knitting machine body adopts an existing circular knitting machine, which includes a yarn feeding mechanism, a weaving mechanism, a pulling and winding mechanism, and a transmission mechanism, The yarn feeding mechanism includes the creel 60 and the yarn feeder 50 which will be introduced below, and the yarn 70 is threaded on the creel 60 and the yarn feeder 50. These basic structures have been introduced in the existing circular knitting machines. No more detailed description here.

[0034] The present invention also includes a cylindr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com