Unilateral cantilever type water survey platform system

A cantilever, platform technology, applied in the direction of floating buildings, etc., can solve the problems of difficulty in recycling, affecting the speed of lifting up and down, and pollution of the water environment, so as to reduce environmental pollution, improve lifting capacity, and increase safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

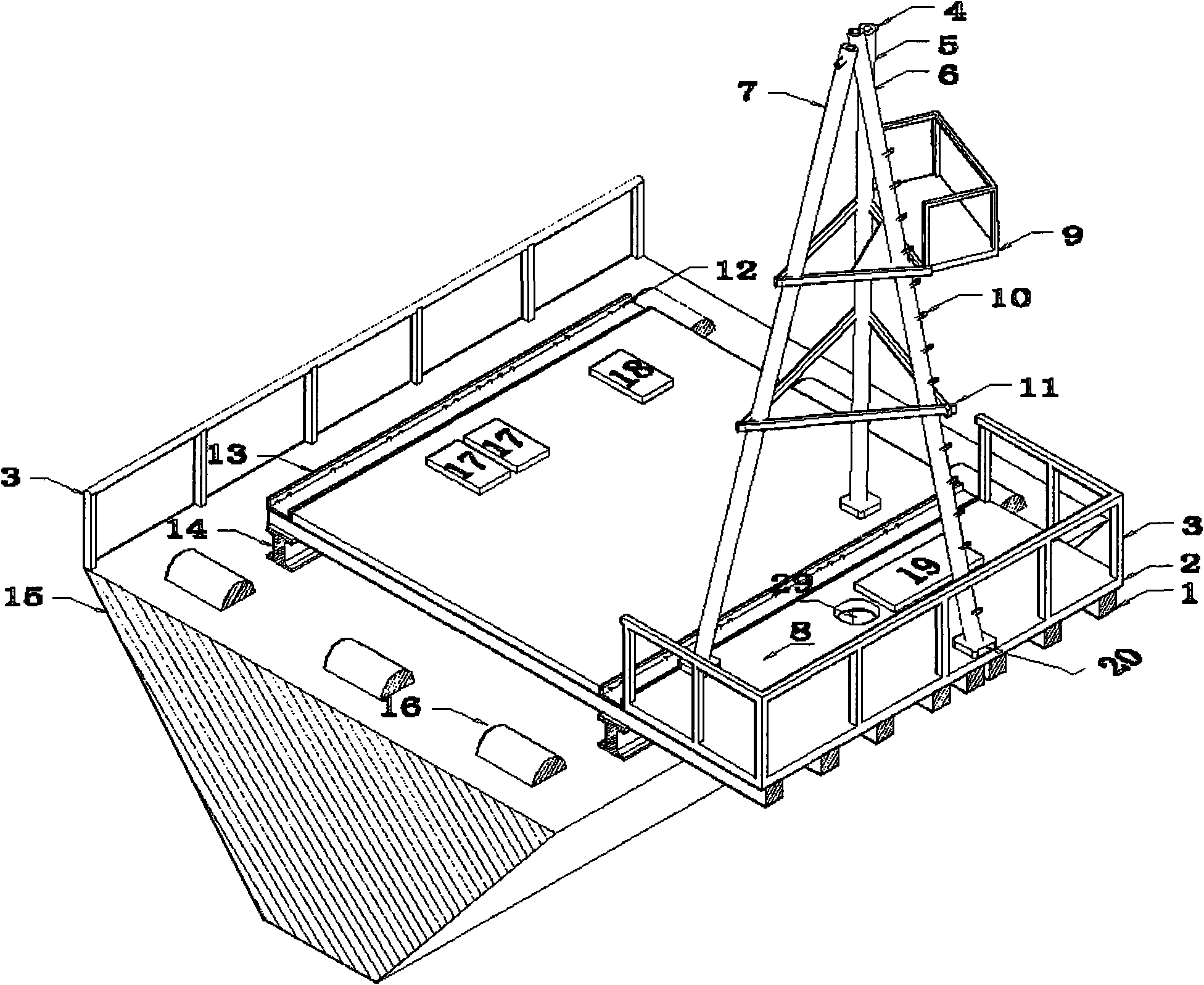

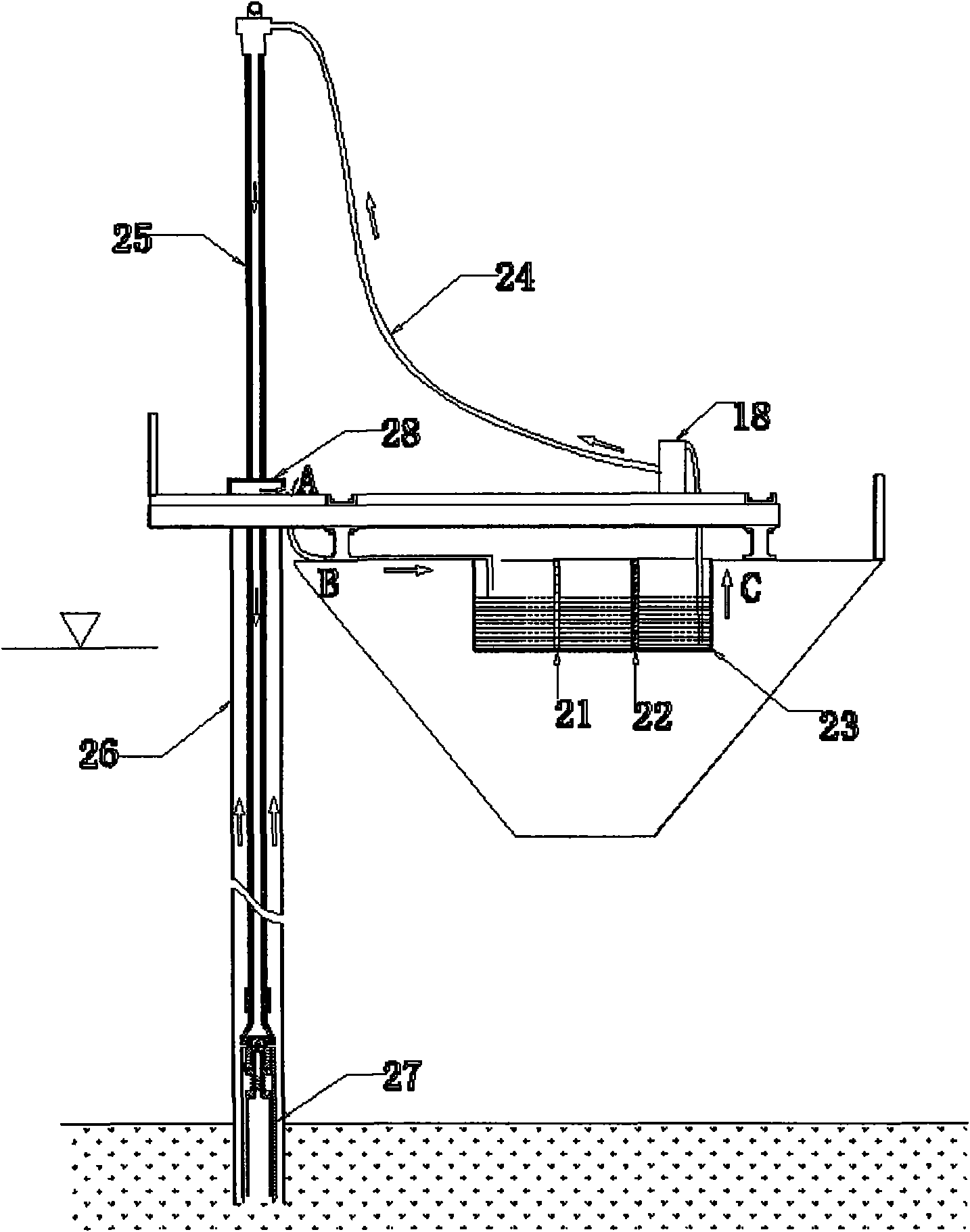

[0023] see figure 1 , The exploration platform system includes a workboat, and windlasses 16 are installed at the bow and stern of the hull 15 for anchoring and positioning on water. According to the needs of climate, water depth, drilling depth, etc., select a suitable single self-propelled flat-bottomed engineering ship, equipped with 4 to 6 iron anchors and matching electro-hydraulic windlass 16, so that it is suitable for engineering geological exploration. When positioning, the 4 anchors are distributed in a cross, and the 6 anchors are distributed in a meter shape, which are connected with the single self-propelled flat-bottomed engineering ship.

[0024] An exploration platform is built on the workboat hull 15 . Two I-beams 14 are arranged in parallel on the main deck, and the span is determined according to the width of the ship. I-beam 14 is welded (rigid) connected with hull 15 . Several wooden squares 1 are established across two I-beams 14 . On the wooden squar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com