A connection structure of double air outlet housing

A technology with double air outlets and connection structure, which is applied in heating/cooling equipment, vehicle parts, transportation and packaging, etc. It can solve the problems that the gap and surface difference are not easy to guarantee, the clamping force of double air outlets is weak, and it is easy to deform and open. Achieve the effect of reducing design risk, standardization of structure, and not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is further detailed in conjunction with the accompanying drawings and specific examples.

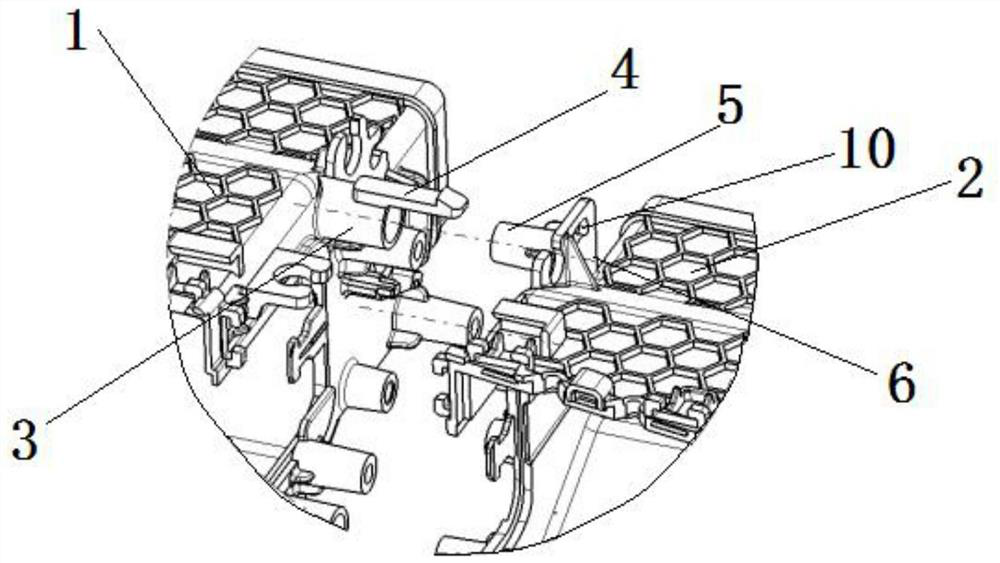

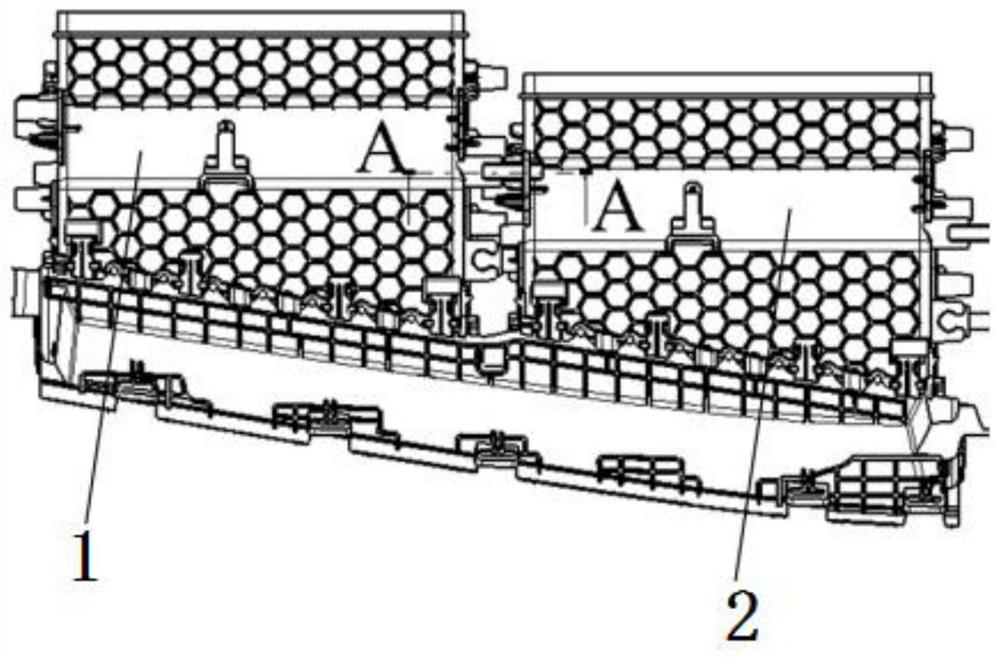

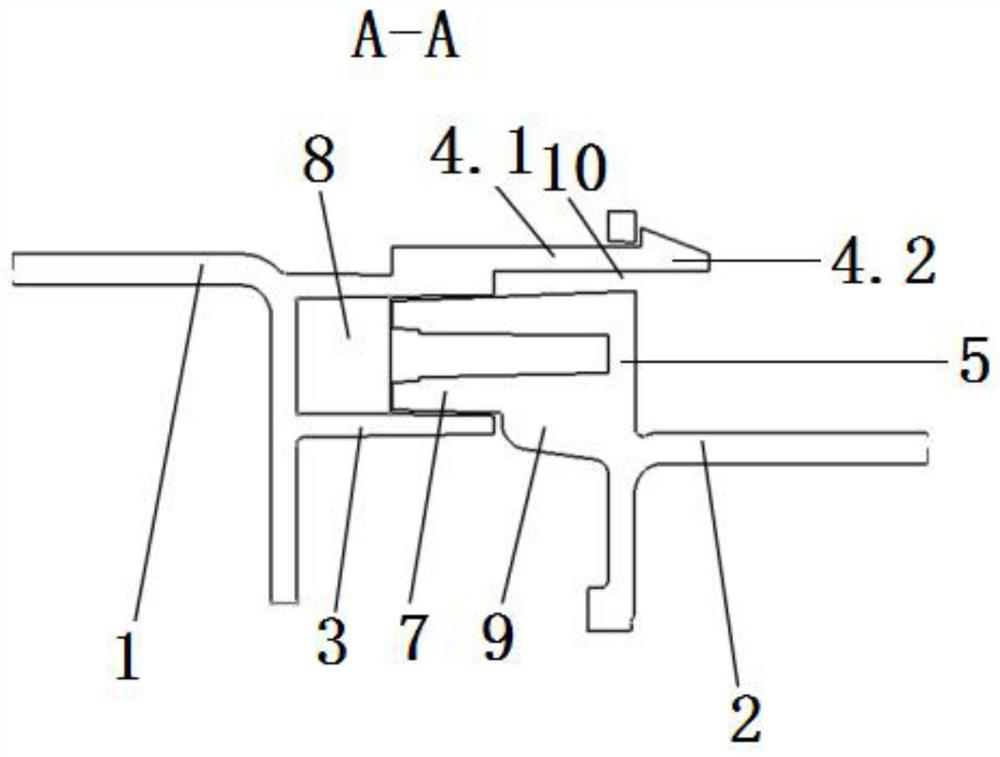

[0021] Such as figure 1 The connection structure of the double outlet housing shown in -3 includes a first air outlet housing 1 and the second air outlet housing 2 arranged side by side, and the first air outlet housing 1 and the second air outlet casing 2 are opposed. Sub-surface surfaces are provided, and the pin sleeve structure and pin structure fixed to each other, the first outlet housing 1 and the second air outlet housing 2, respectively, including fixed pin sleeves 3 and latch 4, The pin structure includes a fixed pin shaft 5 that is inserted and fixed to the fixed pin sleeve 3, and the latching hole plate 6, the latch 4 and the insertion orifice plate 6 can be combined with each other to prevent the fixed pin 3 and The fixed pin 5 is a non-off mechanism.

[0022] The fixed pin sleeve 3 is a cylindrical pin perpendicular to the side surface of the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com