Patents

Literature

217results about How to "Avoid force deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

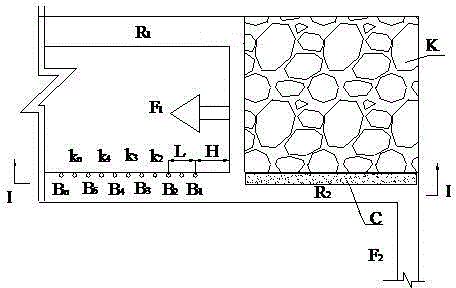

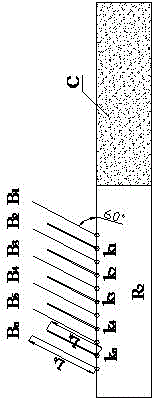

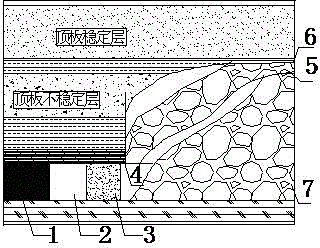

Roadside packing gob-side entry retaining top-cutting explosion pressure relief method

InactiveCN104790954ARelieve pressureEliminate problems such as support difficultiesUnderground miningSurface miningStructural engineeringDeep hole

The invention discloses a roadside packing gob-side entry retaining top-cutting explosion pressure relief method which comprises the following four steps: I, confirming a top-cutting method, the drilling construction time and a drilling construction site; II, confirming top-cutting pressure relief explosion drilling parameters; III, drilling deep-hole explosion holes and explosive filling and sealing holes; IV, performing explosion top-cutting pressure relief. The roadside packing gob-side entry retaining top-cutting explosion pressure relief method is applied to roadside packing gob-side entry retaining top-cutting explosion pressure relief.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

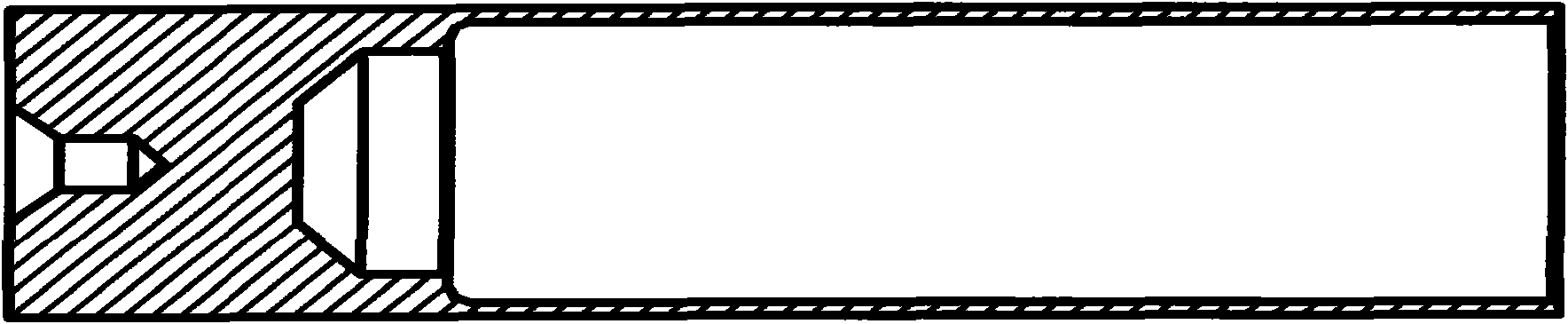

Processing method of parts with long shaft and thin wall and processing clamp thereof

InactiveCN102079045AReduce the difficulty of clampingReduce processing difficultyOther manufacturing equipments/toolsPositioning apparatusMetallic materialsMachining

The invention discloses a machining processing method of parts with a long shaft and a thin wall, belonging to the technical field of mechanical machining. The processing method comprises the following steps: firstly selecting the required metal material, then performing baiting, thermal refining, roughly machining, ageing at high and low temperatures, half precisely machining and precisely machining, and finishing the machining after the passed inspection; during the half precise machining, the outer circle of the part with the long shaft and thin wall is preserved with the machining residue; during the precisely machining, an expandable shoulder plunger piston clamp is used for matching with the part to machine; the other end of the part is reserved with a technical handle and provided with a central hole so as to locate through the outer diameter of the clamp and the inner hole of the part; and the outer diameter of the clamp is regulated so that the outer diameter is properly matched with the inner hole of the part. By using the processing method, the problems that the part with the long shaft and thin wall is easy to deform during the mechanical machining, is incapable of reaching the requirement of the technical parameter, and is low in machining yield are solved.

Owner:贵州航天控制技术有限公司

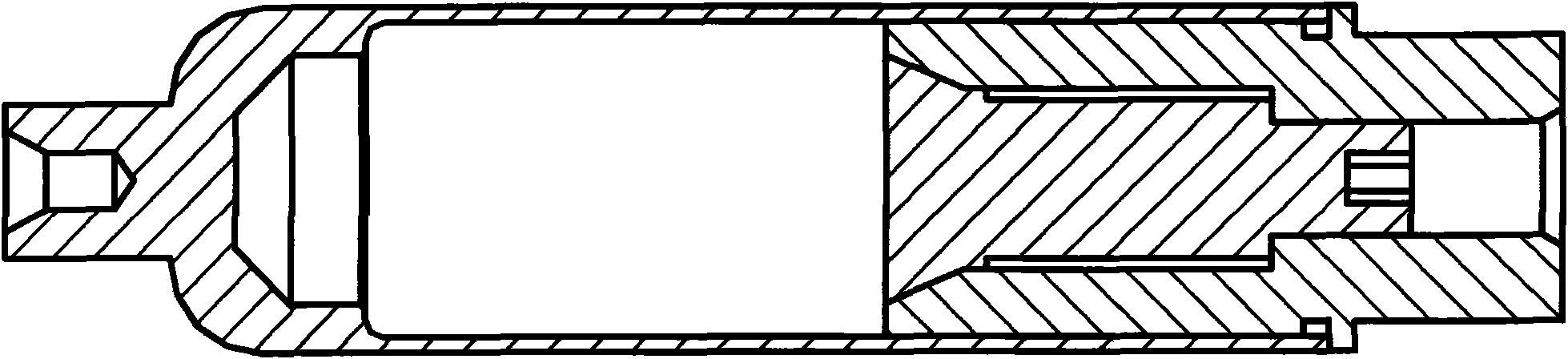

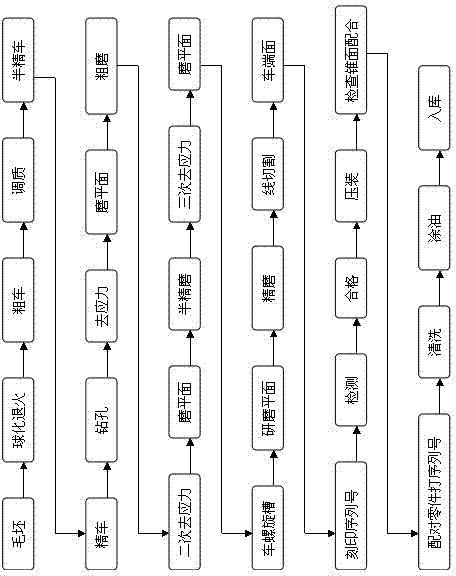

Machining technology for high-precision outer conical surface thin wall sleeve

InactiveCN103495844AMeet the technical requirements of high-precision outer tapered thin-walled sleevesReduce distortionNumerical controlEngraving

The invention relates to the technical field of high-precision part machining process, in particular to a machining technology for a high-precision outer conical surface thin wall sleeve. The machining technology includes the following technology processes of workblank preparing, spheroidizing annealing, rough turning, thermal refining, semi-finish turning, finish turning, hole drilling, distressing, plane grinding, rough grinding, secondary distressing, plane grinding, spiral groove turning, plane lapping, accurate grinding, wire-electrode cutting, end face turning, serial number engraving, detecting, qualified product obtaining, press fitting, conical surface fit detecting, part matching and serial number printing, cleaning, lubricating oil coating and warehousing. A double-end vertical type numerical control grinder is adopted as a finishing machine, and through the machining methods of rough grinding and accurate grinding or rough grinding, semi-accurate grinding and accurate grinding, the technical requirements of the high-precision outer conical surface thin wall sleeve can be met; through the corresponding distressing heating processing technology, residual stress in the machining process is removed, deformation in the machining process can be reduced, the yield of products is improved, and finally the good manufacturing method of the high-precision outer conical surface thin wall sleeve is provided.

Owner:CRRC QISHUYAN CO LTD

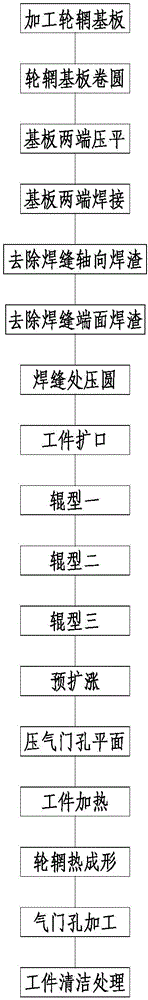

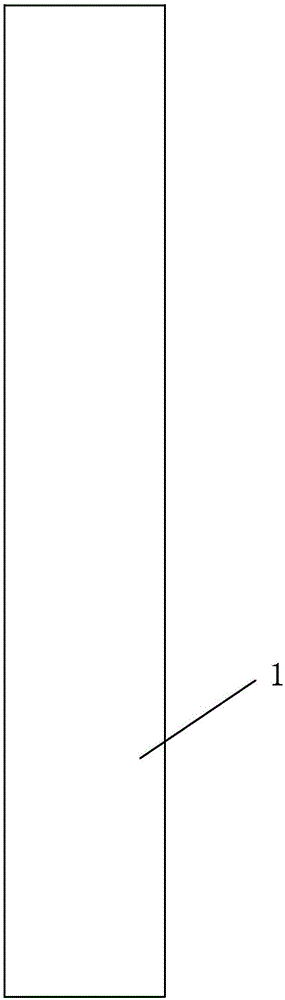

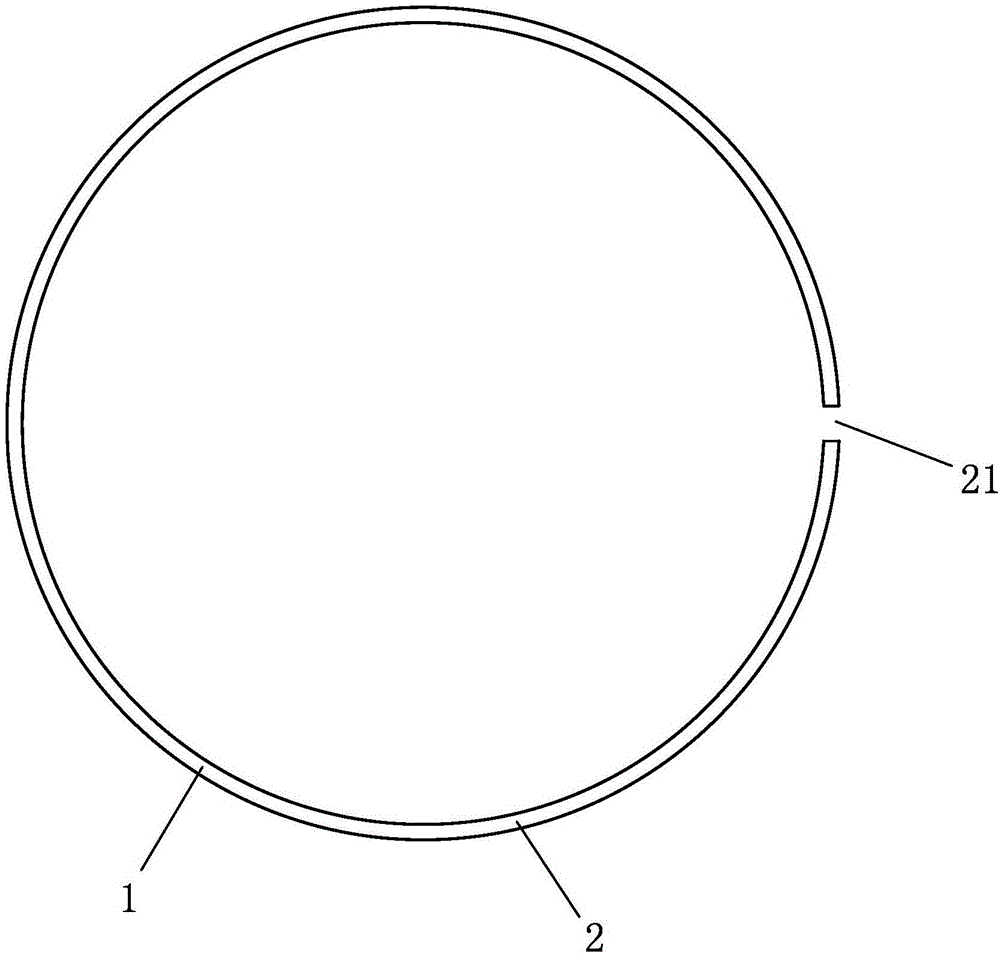

Manufacturing method of hot forming rim

ActiveCN106363353ANot prone to crackingAvoid deformationVehicle componentsEngineeringMechanical engineering

The invention relates to a manufacturing method of a hot forming rim. The manufacturing method comprises following manufacturing steps of A1, rim round pipe forming, wherein a metal plate is used for manufacturing a closed round pipe with the closed circumferential direction; A2, rim workblank forming, wherein the closed round pipe is manufactured into a rim workblank with the diameter smaller than the rim designed diameter; A3, rim workblank pre-expanding, wherein the rim workblank is subject to pre-expanding, and the diameter of the expanded rim reaches 99.5% to 99.9% of the designed diameter; A4, rim workblank heating, wherein the rim workblank is heated to the designed temperature; A5, expansion finishing, wherein through the expansion manner, the diameter of the workblank reaches the designed size; A6, stamping and hardening, wherein the strength of the rim workblank is improved to above 1300MPa. Before heating, pre-expanding is carried out, the expansion amount during hot forming is reduced, the size precision of the rim is improved, and the expanding traces are reduced; the precision of out-of-roundness of the rim is improved; after heating, the manner of expansion finishing and stamping and hardening is adopted, and the forming precision and the forming strength are more effectively improved.

Owner:ZHEJIANG JINGU CO LTD

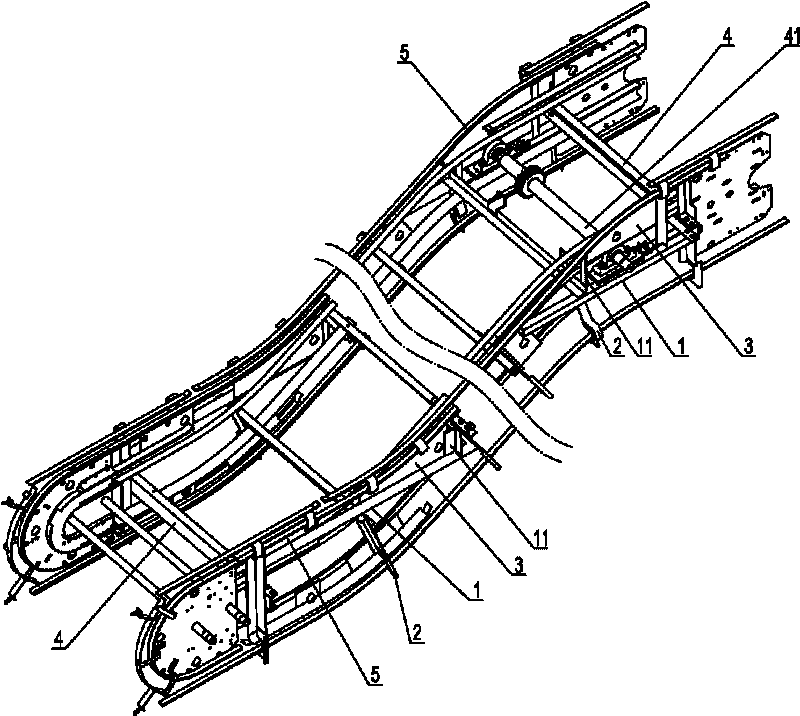

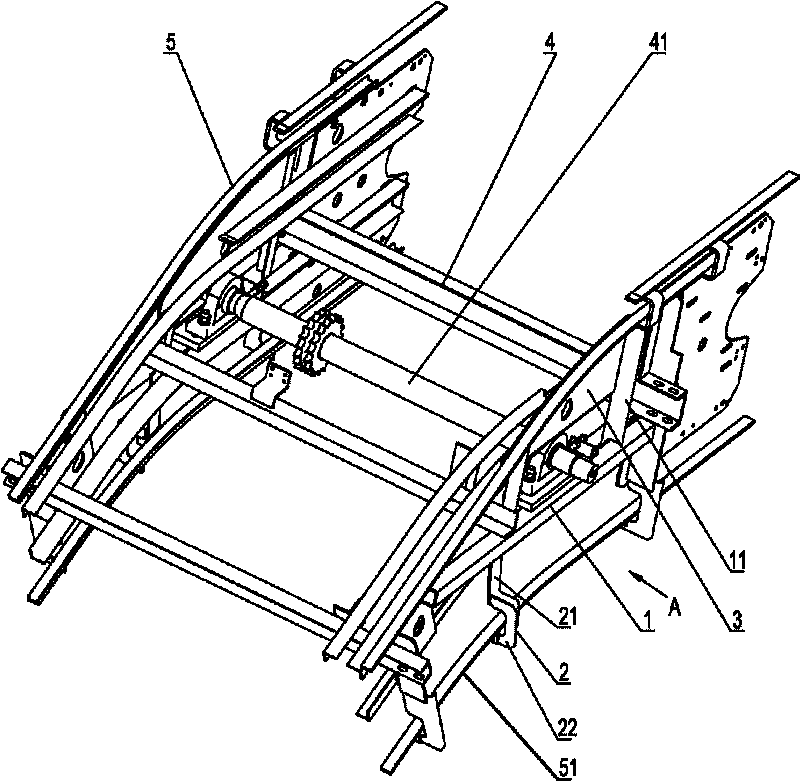

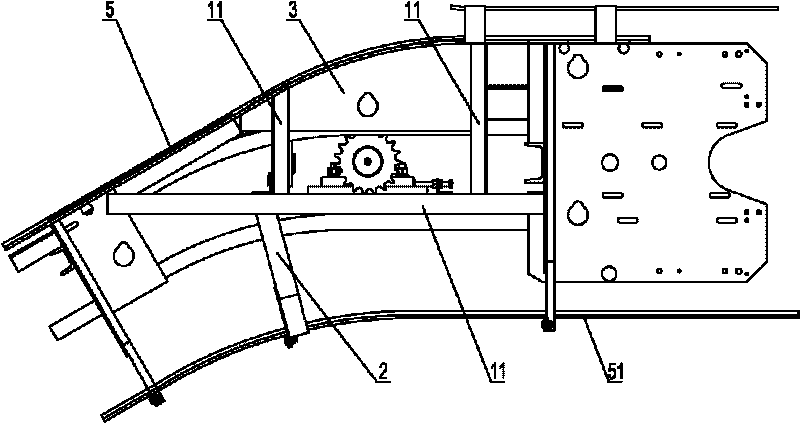

Head ladder way and escalator thereof

The invention discloses a head ladder way and an escalator thereof. The head staircase way comprises vertical frames which are parallel on the left and right sides, a plurality of connecting rods and a plurality of bearing plates; the vertical frames are formed by a plurality of stiffeners which are staggered mutually; the vertical frames on the left and right sides are connected integrally through at least two horizontal beams inbetween; the bearing plates are fixedly connected with the vertical frames and the connecting rods; and each guide rail of the head ladder way is fixedly connected with the bearing plates and the connecting rods. In the escalator adopting the head ladder way of framed structure, the vertical frames on the two sides of the head ladder way are provided with horizontal connecting plates for mounting the bearings of balustrade driving parts respectively and oblong assembly holes are formed on the connecting plates. The rigidity and stability of the head ladder way are obviously improved by adopting the head ladder way of framed structure; and the escalator changes the assembly mode of the bearing bases of the driving parts, so the arrangement is convenient and the head ladder way is prevented from deforming by force.

Owner:XIZI OTIS ELEVATOR

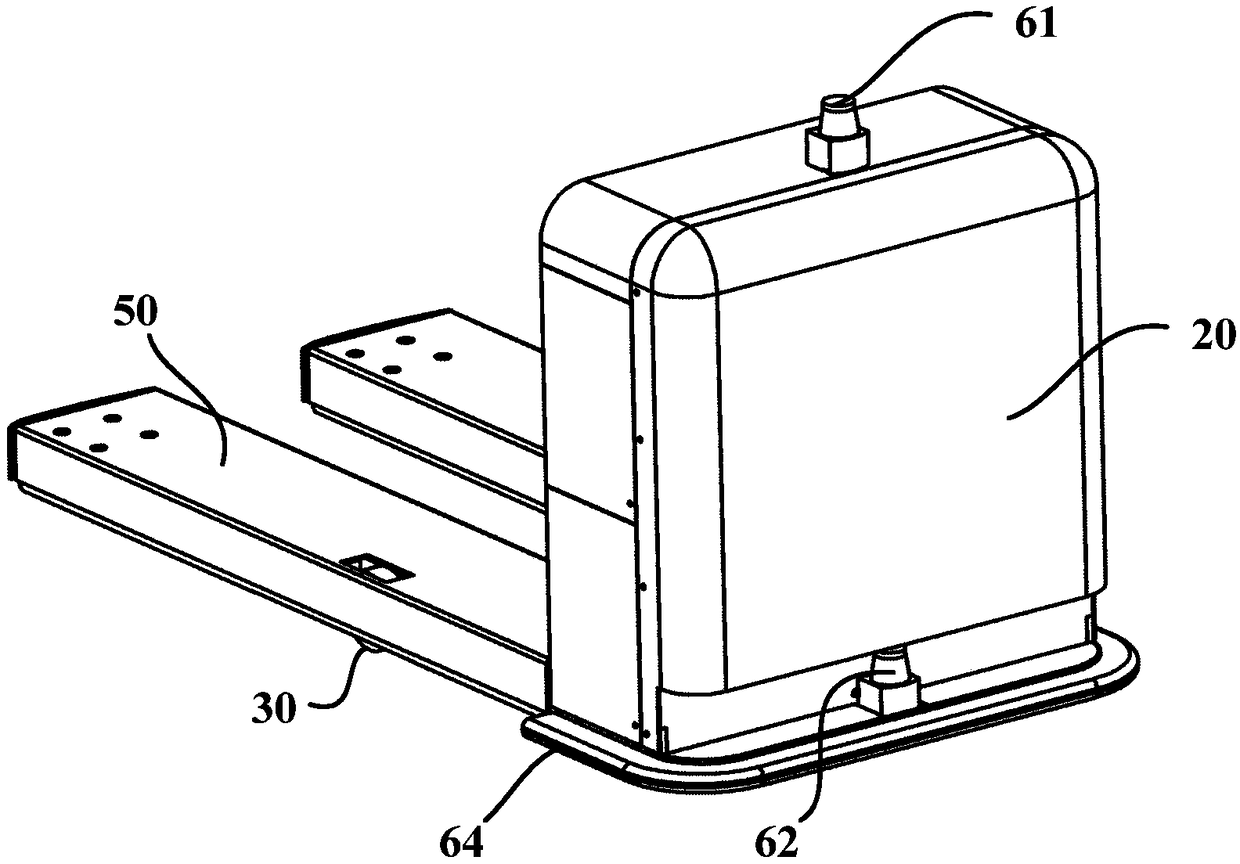

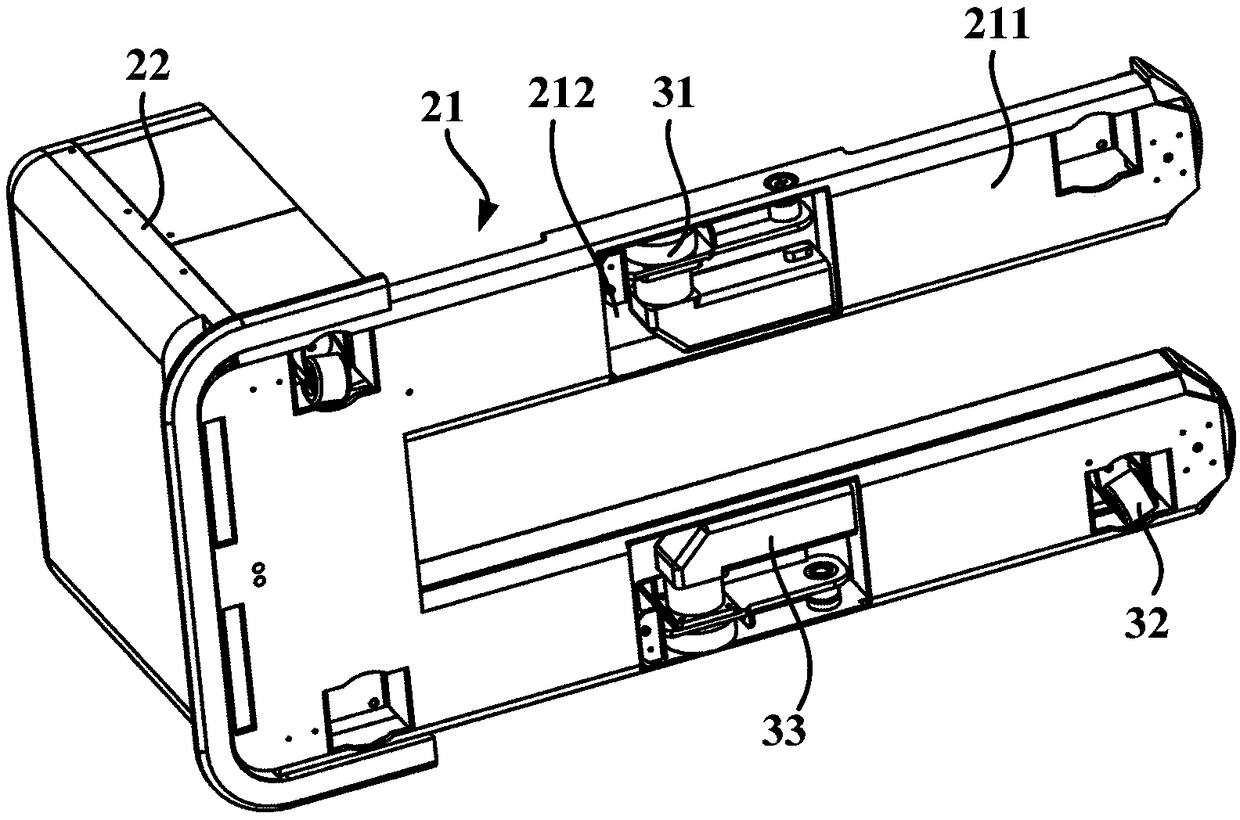

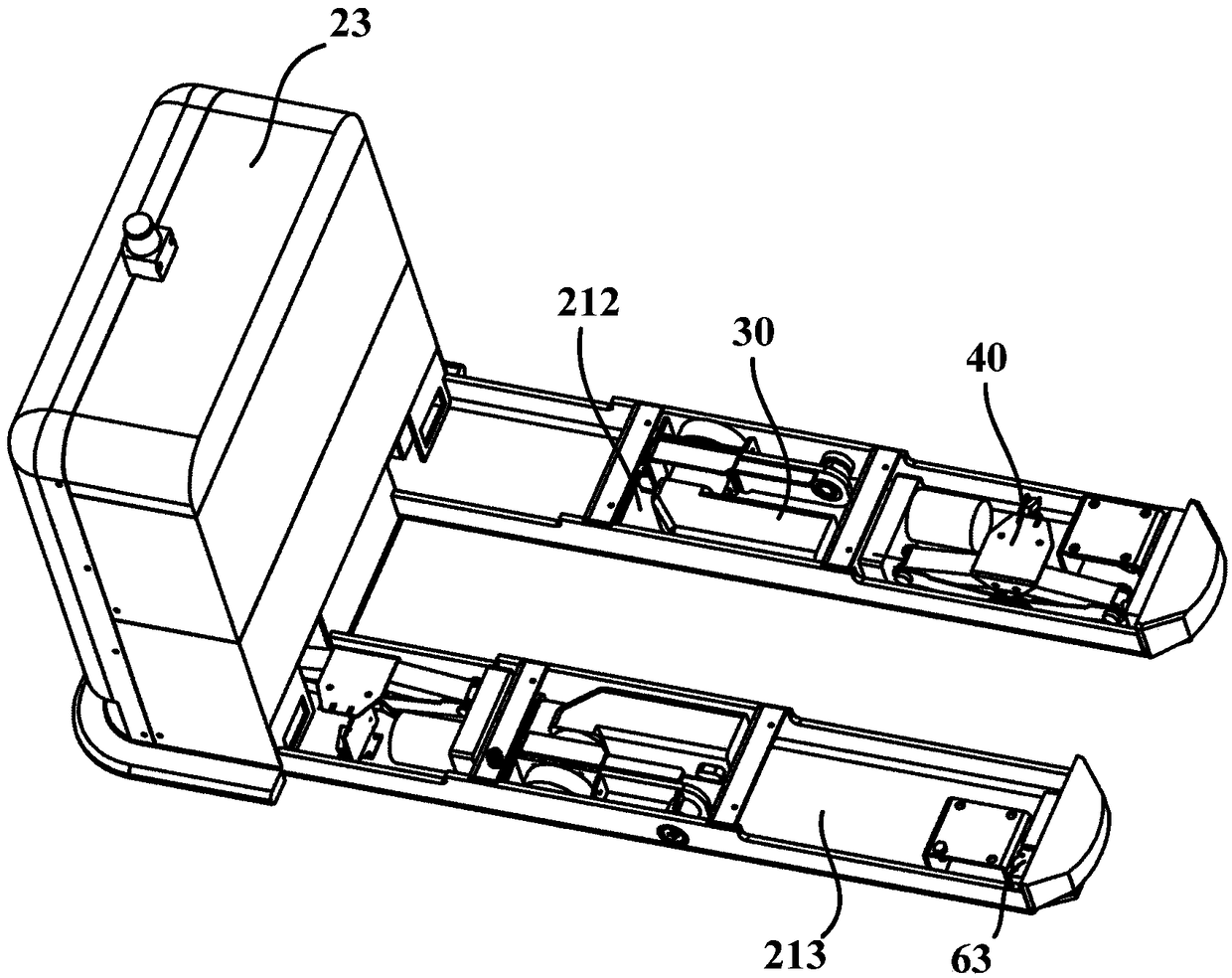

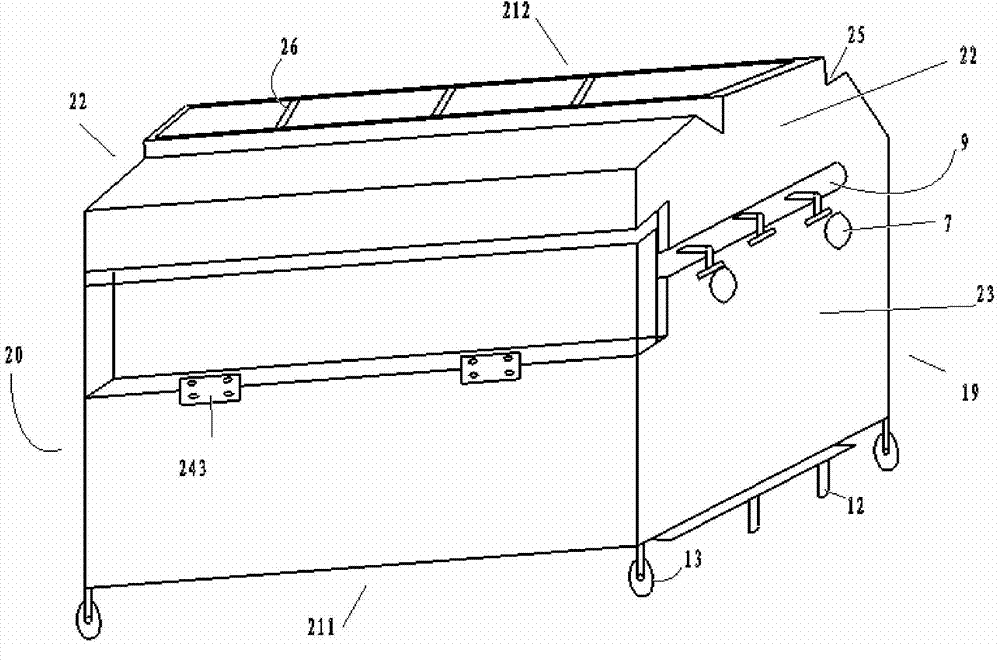

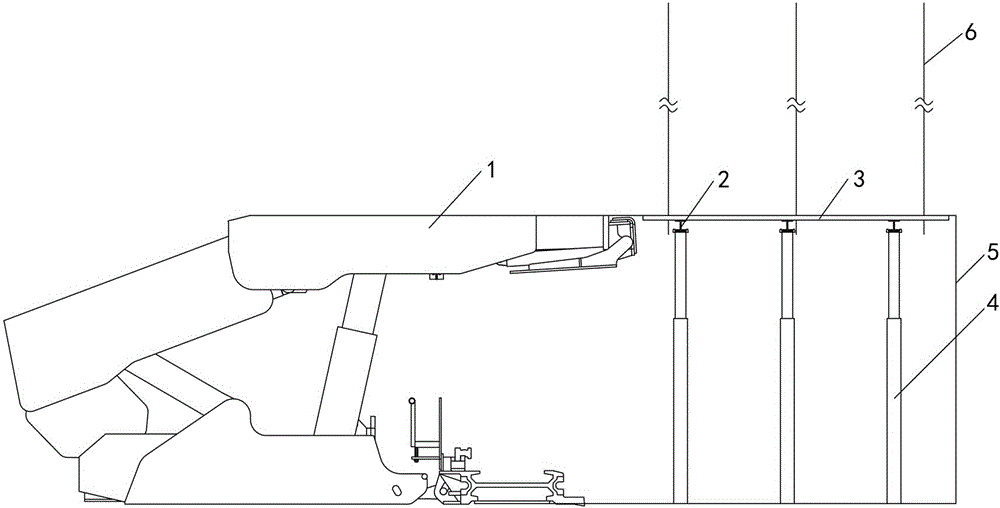

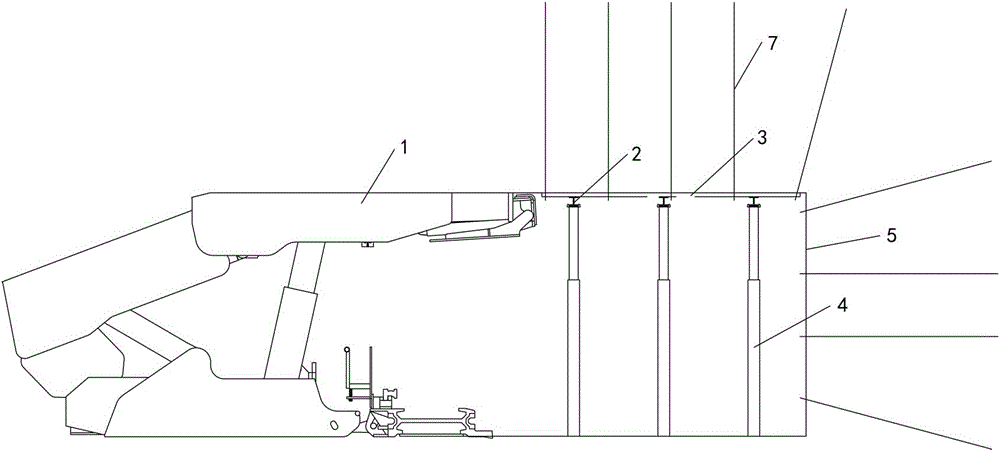

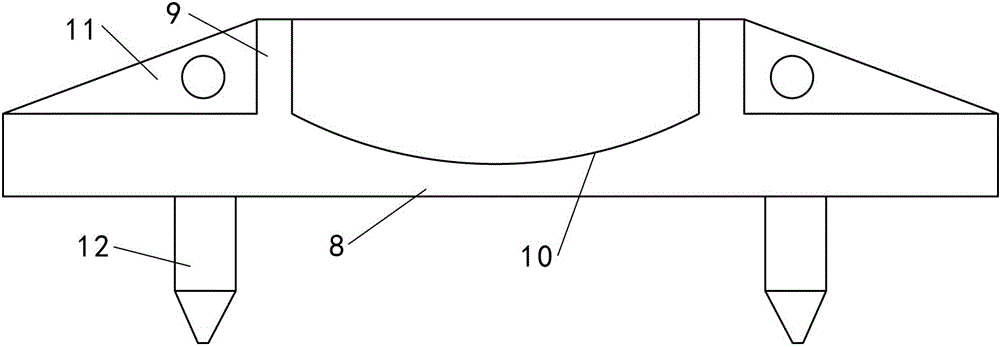

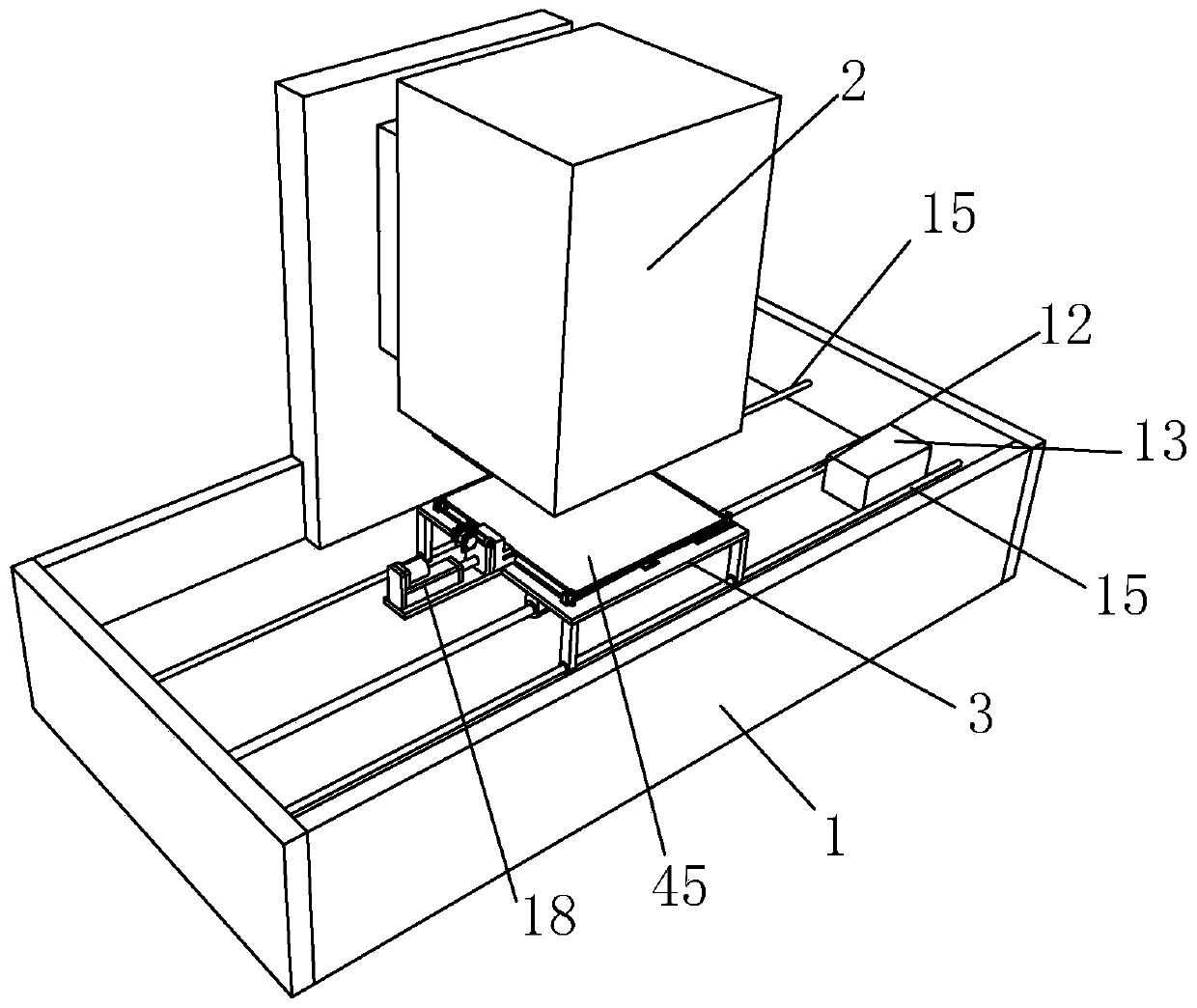

Multifunctional automatic guide transport vehicle

The invention relates to a multifunctional automatic guide transport vehicle. The multifunctional automatic guide transport vehicle comprises a vehicle body, a vehicle driving system, a multi-point jacking device, two supporting plates, a bus system and a safety guide device, wherein the vehicle body is provided with a chassis, and the chassis is provided with two fork foot base frames which are arranged in parallel; the vehicle driving system is provided with two driving wheels, a plurality of universal wheels and two first driving devices used for correspondingly driving the two driving wheels to rotate; the two driving wheels are arranged on the lower portions of the two sides of the middle of the chassis in the front-back direction correspondingly; the multi-point jacking device is provided with a plurality of lifting devices and second driving devices used for correspondingly driving the plurality of lifting devices to perform lifting motion; each supporting plate is provided withat least two lifting devices; the bus system synchronously controls the plurality of second driving devices; and the safety guide device is provided with a solid state laser radar, a laser obstacle avoidance sensor, a contact type sensor, a mechanical anti-collision strip arranged in the vehicle body, a sound-light alarm and an emergency stop button. According to the multifunctional automatic guide transport vehicle, the height of a cargo fork can be reduced to the largest extent, and turning can be realized at the minimum radius.

Owner:ZHEJIANG FIELD INTELLIGENT EQUIP CO LTD

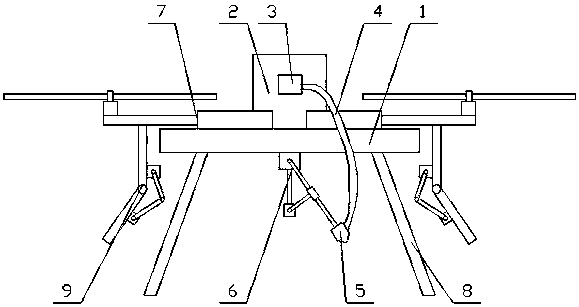

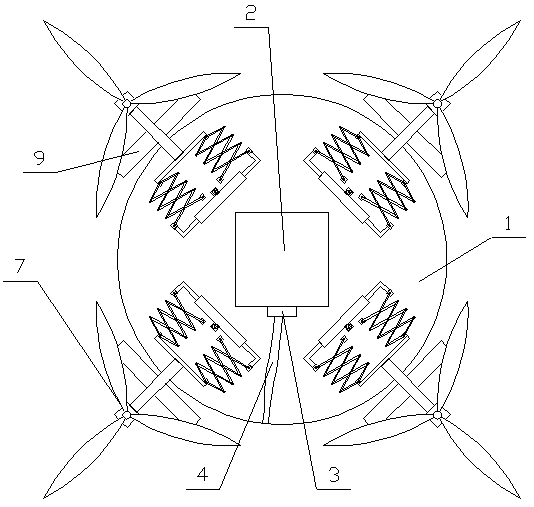

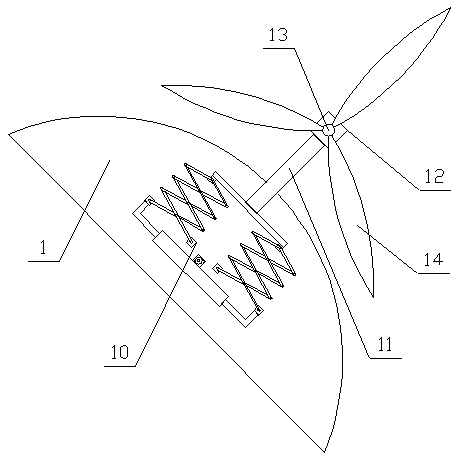

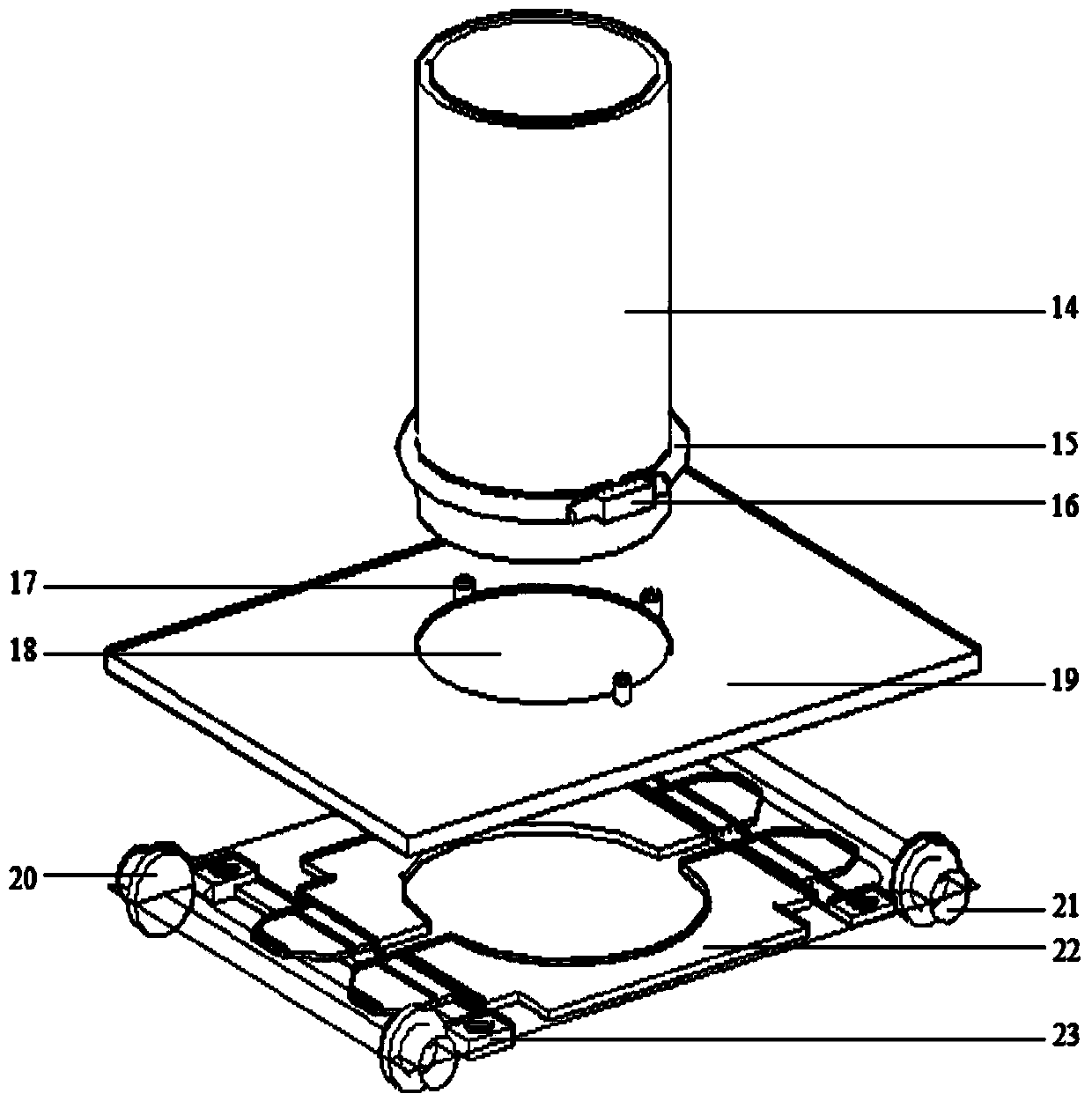

Intelligent plant protection unmanned aerial vehicle with accurate spraying and used for agricultural production

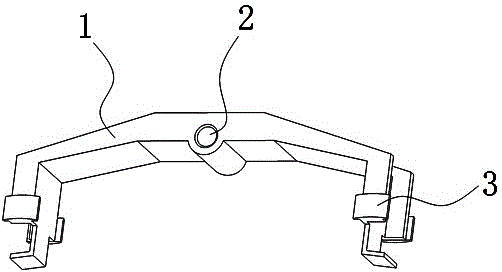

InactiveCN109526913AAvoid force deformationGuaranteed accuracyAircraft componentsInsect catchers and killersAgricultural engineeringElectric machinery

The invention relates to an intelligent plant protection unmanned aerial vehicle with accurate spraying and used for agricultural production. The unmanned aerial vehicle includes a main body, a spraying mechanism, multiple flight mechanisms and multiple wind-guiding mechanisms; the flight mechanisms include telescoping assemblies, side rods and flight assemblies; each telescoping assembly includesa driving unit, a connection board and two telescoping units; and each wind-guiding mechanism includes a fixing plate, a wind-guiding plate, a second motor, a second connecting rod, a third connecting rod and a third articulated block. According to the unmanned aerial vehicle, the flight assemblies can move outward through the telescoping assemblies in the flight mechanisms, so that air flow canbe prevented from deforming leaves of crops when pesticide is sprayed, and the crops can normally absorb the pesticide when the unmanned aerial vehicle flies away; and as the angles of wind-guiding plates can be changed through the wind-guiding mechanisms, an air flow directions under rotors can be adjusted, so that influences on the pesticide and the crops when the pesticide is sprayed can be prevented, and therefore, the accuracy of spraying the pesticide can be further guaranteed, and the practicality of equipment can be enhanced.

Owner:JIANGSU HUAXIA INTPROP SERVICE CO LTD

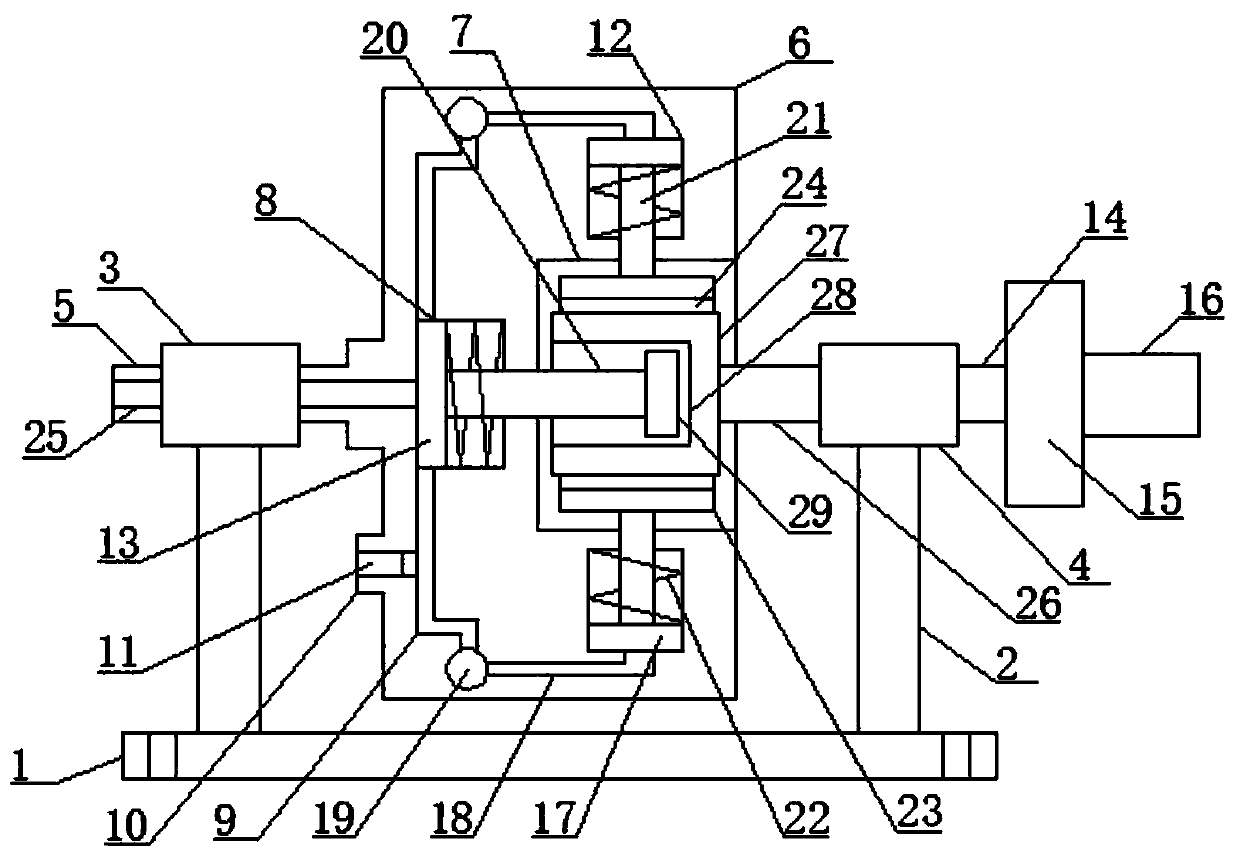

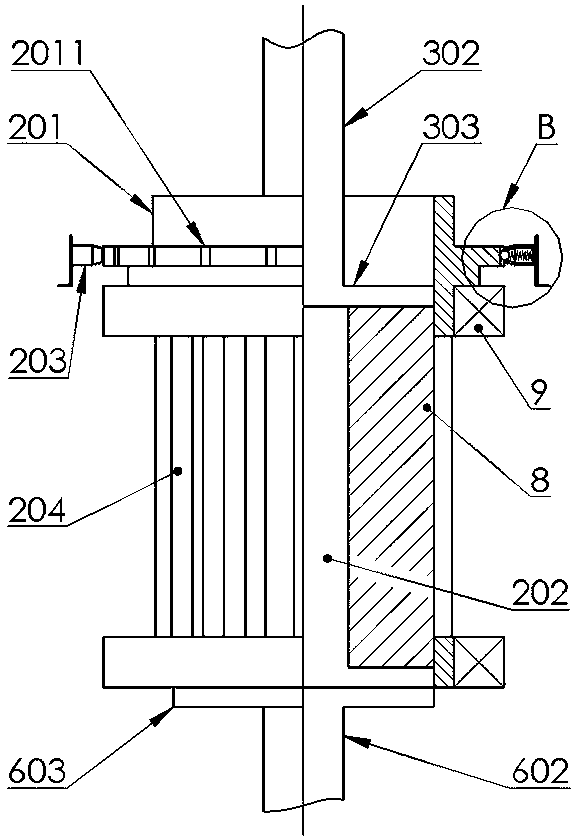

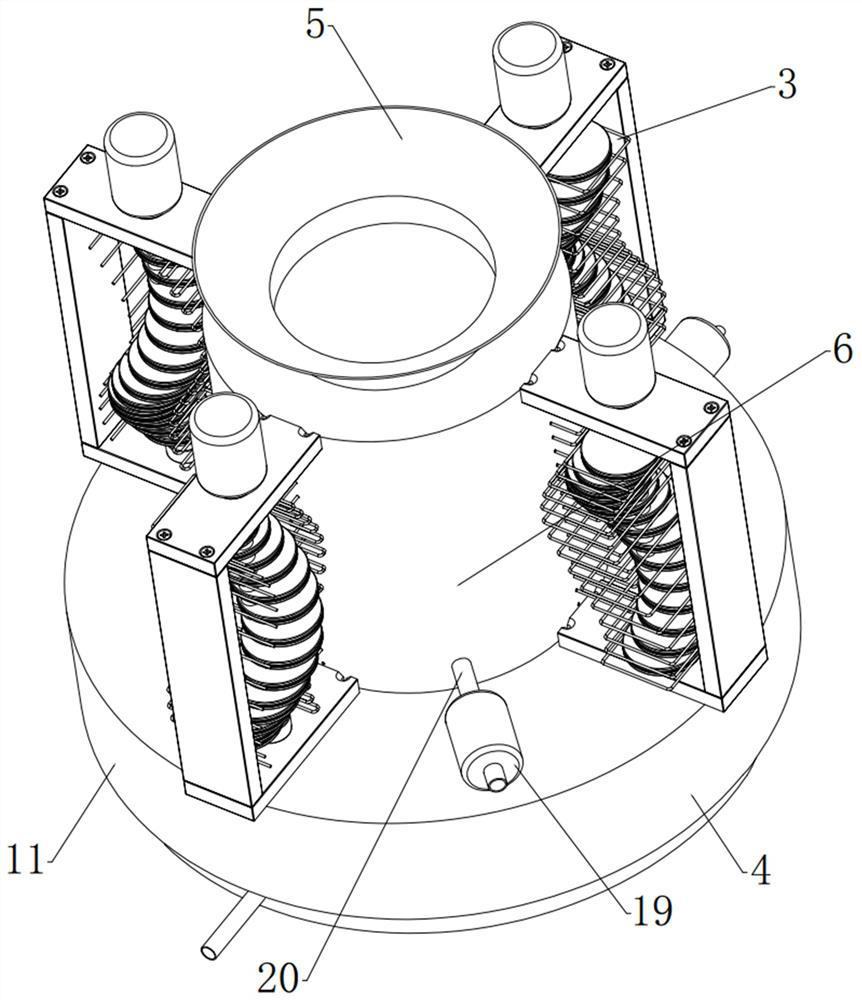

Braking device for building tower crane rotation shaft

ActiveCN110371883ARelieve pressureGuaranteed service lifeCranesHoisting equipmentsRotational axisCoil spring

The invention discloses a braking device for a building tower crane rotation shaft. The braking device for the building tower crane rotation shaft comprises a main mounting plate. The braking device for the building tower crane rotation shaft uses liquid power in the same drive source, can perform braking action of relative positions of the inner round end face and the outer side face of a rotation column, achieves omni-directional frictional contact, enlarges the contact area, reduces pressure on surfaces of components in braking, and guarantees braking strength on the premise of guaranteeinguse life of the components, and additionally the braking device for the building tower crane rotation shaft is provided with a spiral spring compression colliding type maximum liquid pressure difference control mechanism, and prevents a force-induced deformation phenomenon caused by overlarge liquid pressure difference to the hollow rotation column from occurring, and the braking device for the building tower crane rotation shaft is provided with a ring array spiral spring colliding type maximum rotation strength control mechanism, and prevents a steel wire fracture phenomenon caused by overlarge barking strength from occurring in the braking, and additionally the braking device for the building tower crane rotation shaft is provided with a rotation shaft spiral structure type mounting fixing mechanism, and can perform mounting fixing on different dimeters of shaft bodies.

Owner:陕西奥翔建设有限公司

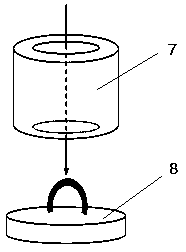

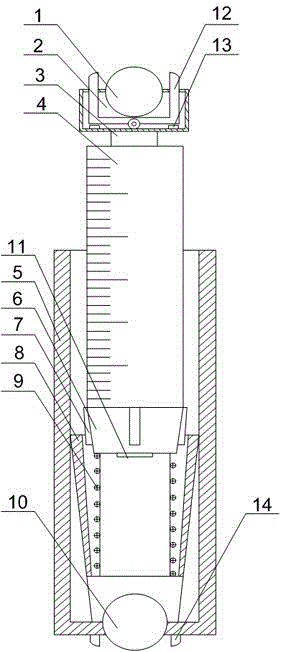

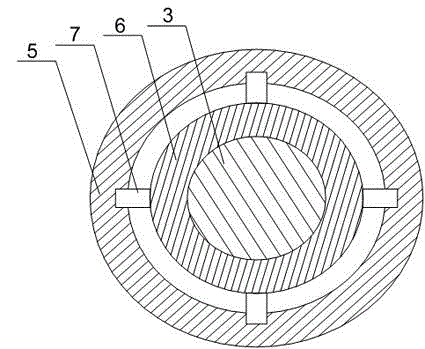

Air-suspending T-shaped rail slider

InactiveCN101935965AAvoid force deformationAvoid Air Gap VariationsRailway tracksEngineeringSurface plate

The invention provides an air-suspending T-shaped rail slider, relating to a rail system and providing an air-suspending T-shaped rail slider capable of effectively overcoming unstable structure problem occurred at the time of air-suspending movement and reducing friction interference in the system. The slider comprises a top panel, a left panel and a right panel, wherein the left panel and the right panel are L-shaped plates; the lower part of the left panel is partially provided with at least one air hole for blowing a guide rail base surface; the lower part of the right panel is partially provided with at least one air hole for blowing the guide rail base surface; and at least one air hole for blowing the guide rail base surface is an one-way air hole or / and an two-way air hole.

Owner:XIAMEN UNIV

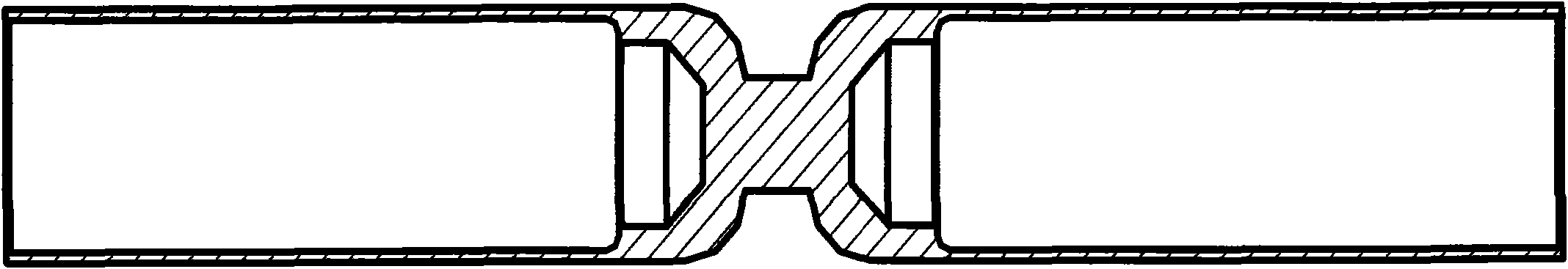

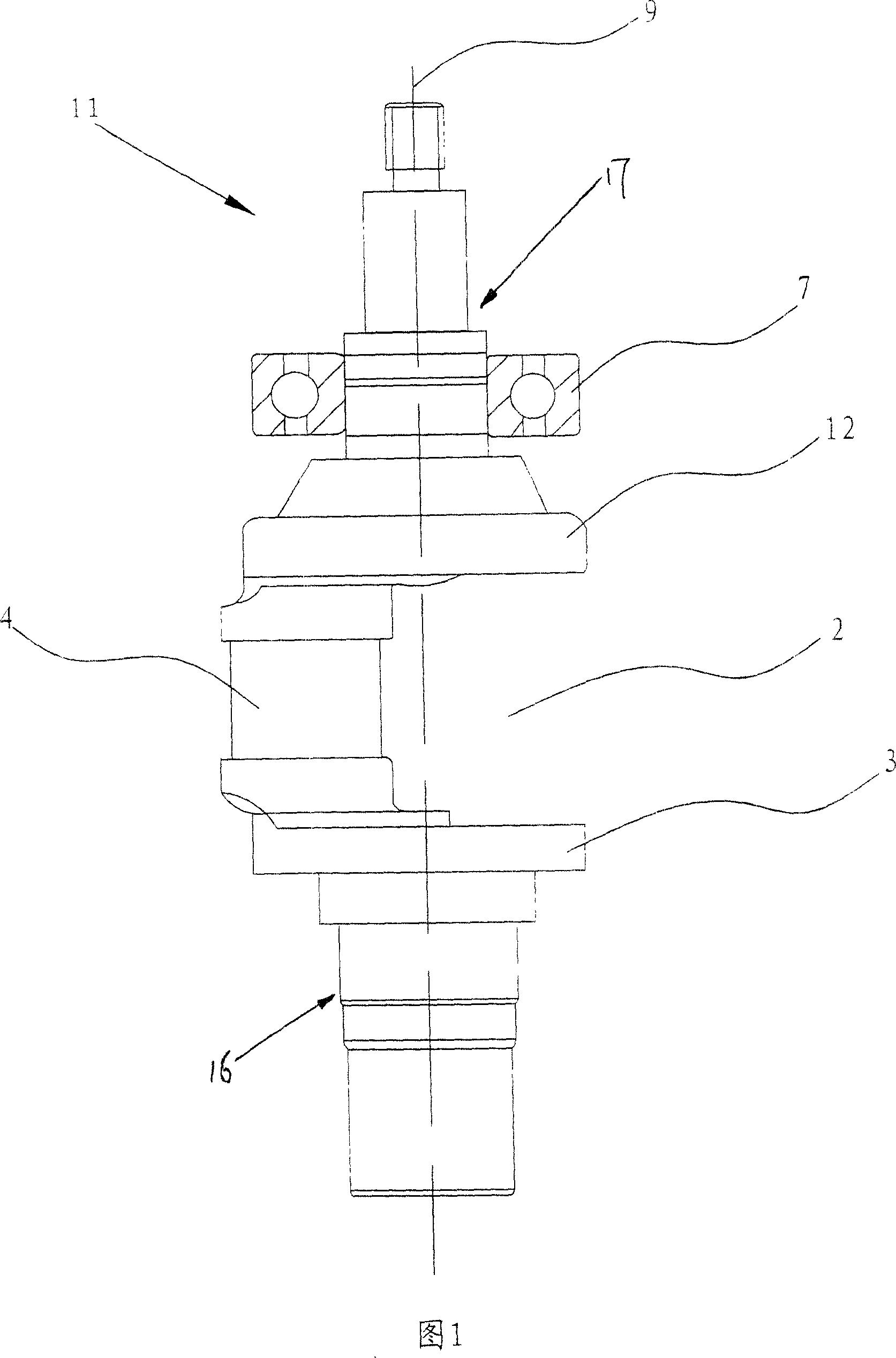

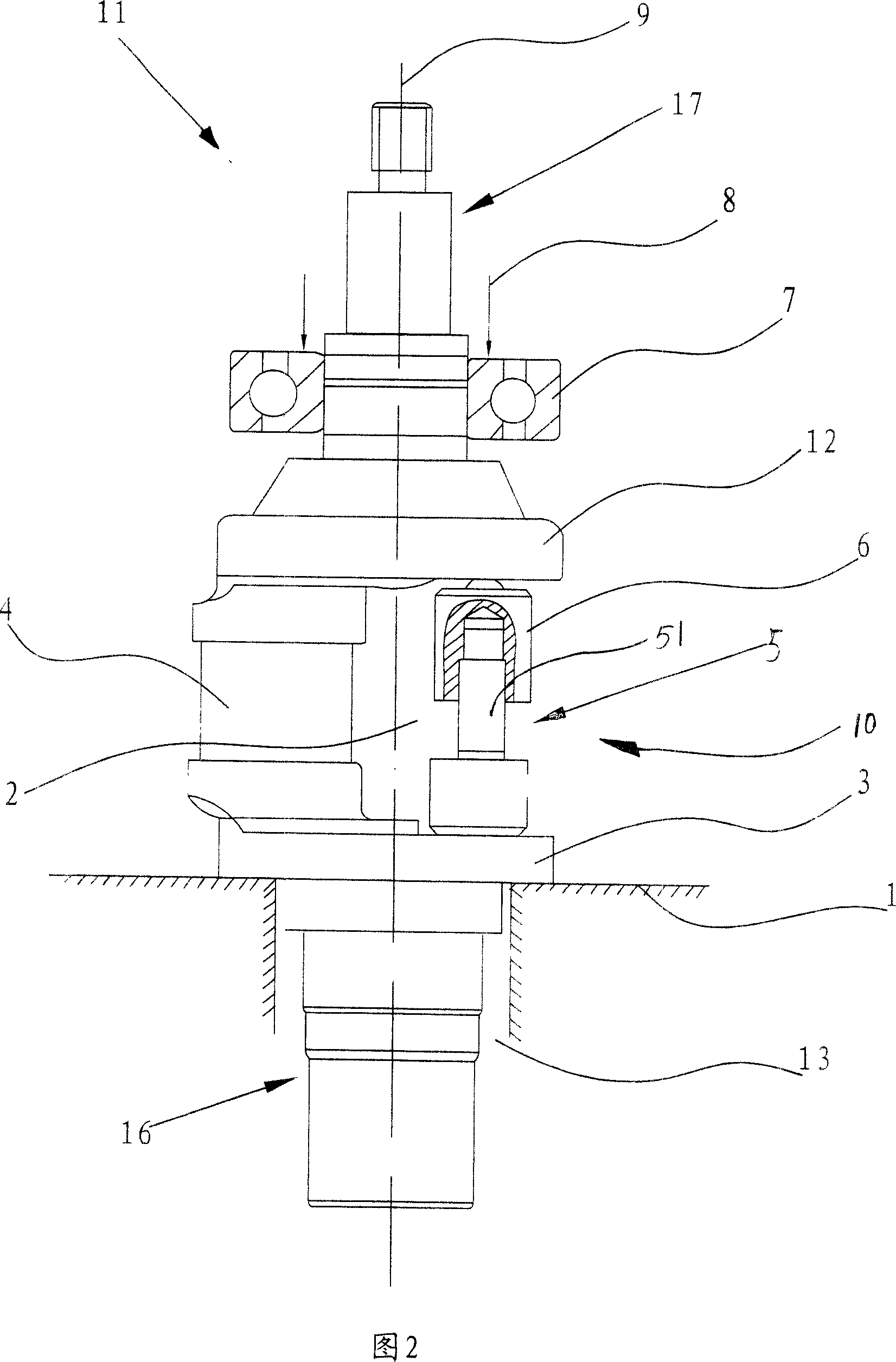

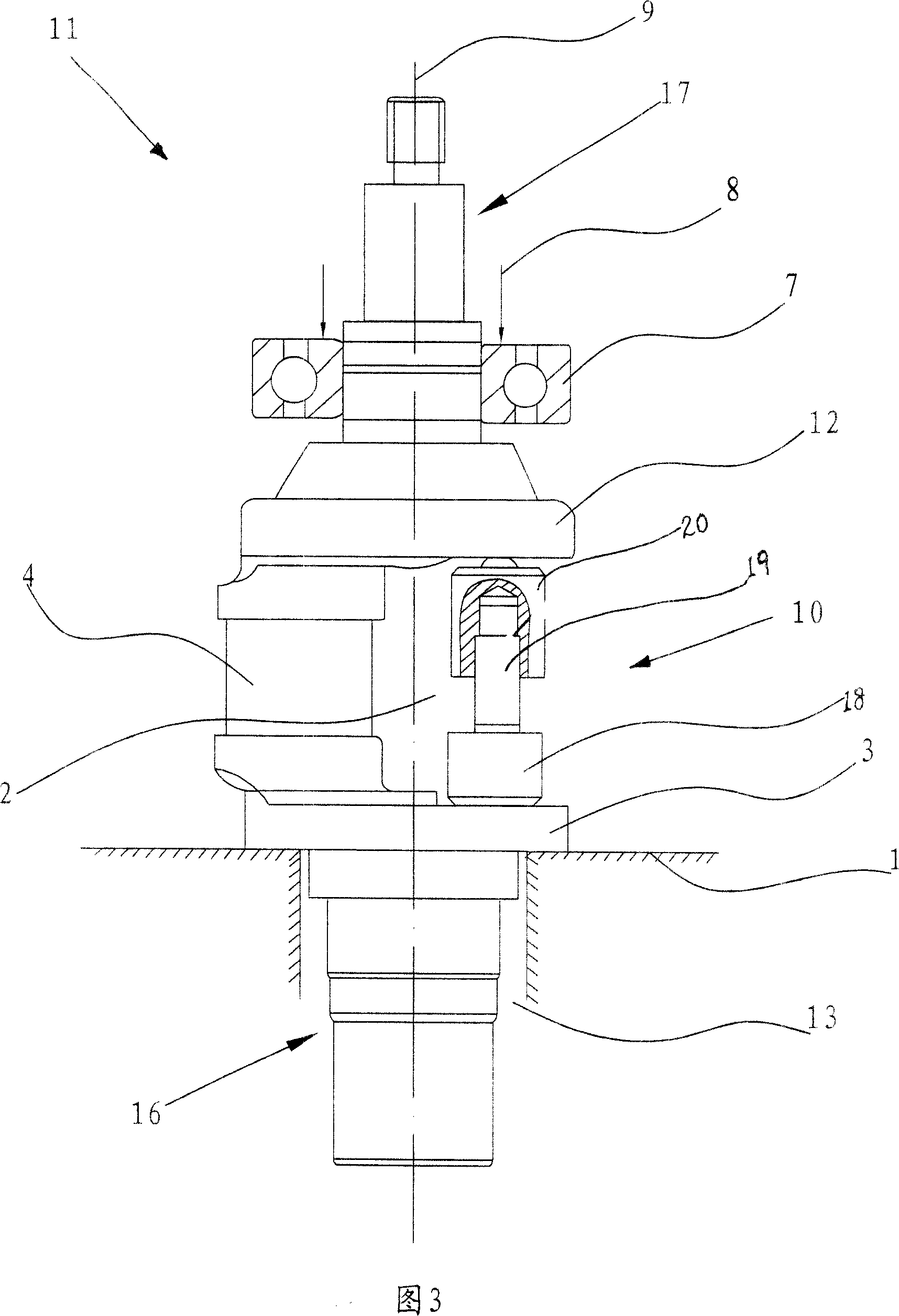

Method of pressing bearing on crankshaft

InactiveCN100999047AAvoid force deformationGuarantee the quality of pressingWork holdersMetal working apparatusCrankshaftSupport plane

The present invention relates to a method for press-mounting bearing on crankshaft. Said method includes the following steps: firstly, fixing the crankshaft on a supporting frame; then making the bearing to be mounted by cover-placed on the upper side of mounting portion of said crankshaft and making axis of bearing be coincident with axis of said crankshaft; in the notch position of said crankshaft placing a pusher along the axial direction of said crankshaft and making two end portions of pusher be respectively tightly contacted with first main shaft neck and second main shaft neck; finally applying pressure to said bearing until the described bearing is fixed on the mounting portion of said crankshaft.

Owner:JIANGSU WANGONG TECH GRP CO LTD

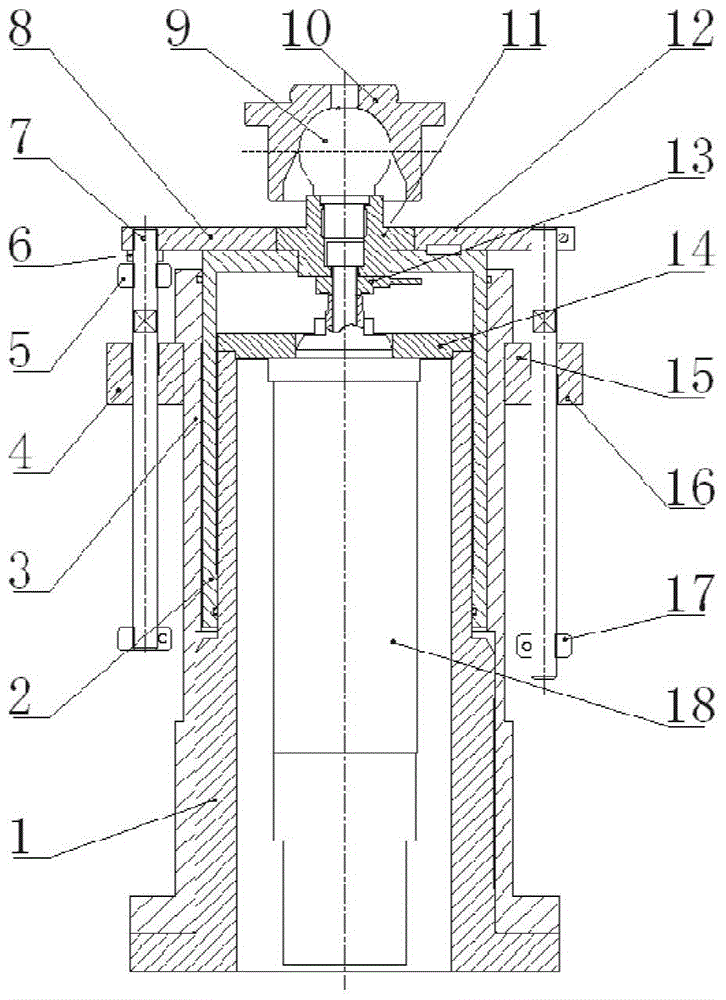

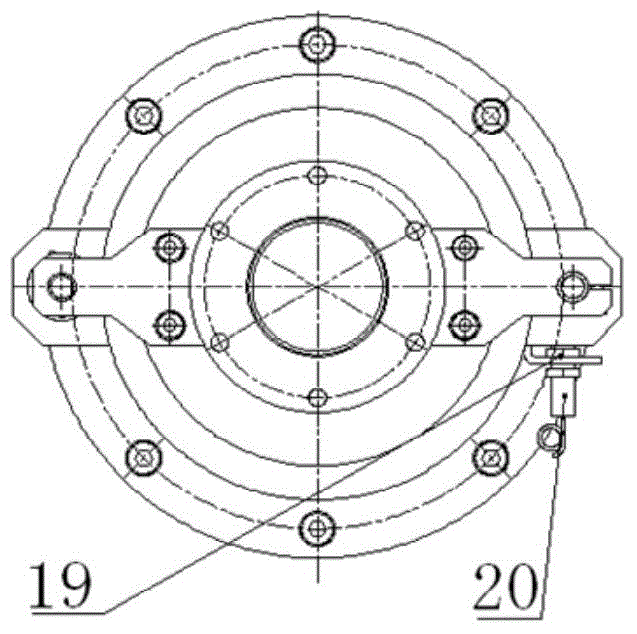

Unconfined compressive strength part and demolding and strength measuring integrated testing machine

ActiveCN104198246AEasy to assemble and disassembleImprove performancePreparing sample for investigationMaterial strength using tensile/compressive forcesEngineeringCompressive strength

The invention discloses an unconfined compressive strength part and a demolding and strength measuring integrated testing machine which can be used for finishing high-efficiency and high-quality test detection operation. The testing machine comprises fixing nuts, an upper bearing plate, upright posts, clamping parts, jackscrews, a frame, a lower bearing plate, a motor, a lifting jack, rails, a data line, a pressure sensor, a hydraulic pipe, a test mold, an annular stirrup, an adjusting screw rod, vehicle panel fixing fasteners, a round plate with an annular groove, a sliding trolley panel, wheels, axles, clamping plates and clamping plate slideways. According to the design of the double upright posts, the overall weight is reduced; bottom feet are designed on the lower bearing plate, and thus stress deformation of the lower bearing plate is avoided; due to the design of the clamping parts with a jackscrews and the annular stirrup added to the test mold, a novel mode of simple and feasible demolding is created. According to the invention, the various parts can be convenient to detach and assemble, the equipment performance is stable, the operation is simple, labor force is saved, the labor intensity is reduced, and the working efficiency is improved.

Owner:UNIV OF SCI & TECH LIAONING

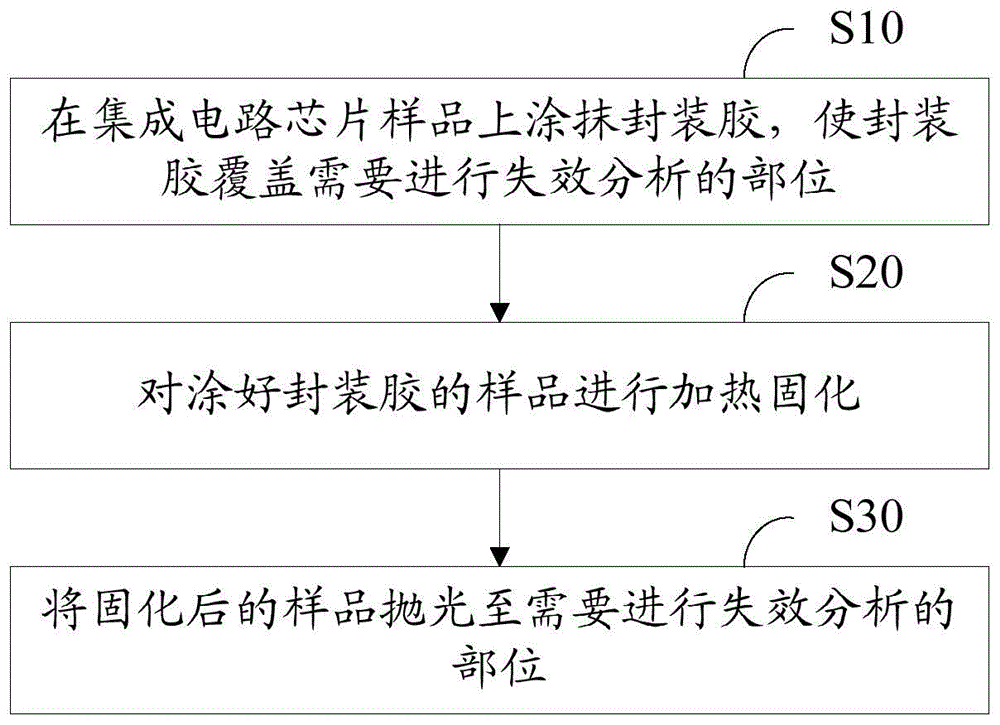

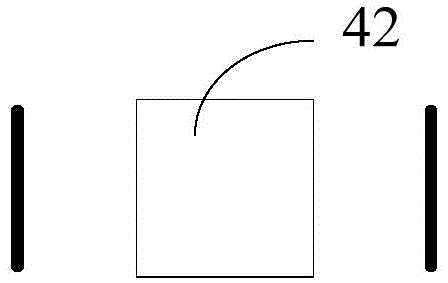

Preparation method of integrated circuit chip failure analysis sample

ActiveCN105334084AAvoid force deformationRetain the original shapePreparing sample for investigationSemiconductor/solid-state device manufacturingFailure analysisAnalytic Sample Preparation Methods

The invention relates to a preparation method of an integrated circuit chip failure analysis sample. The method includes the following steps: smearing a packaging glue on the integrated circuit chip sample to cover the part required for failure analysis by the packaging glue; heat-curing the sample with packaging glue; and polishing the cured sample until part requiring failure analysis. The method uses cured packaging glue to strengthen the part requiring failure analysis, so as to avoid deformation in the polishing process, and preserve the original appearance. The preparation process does not need expensive equipment and the preparation conditions can be met easily.

Owner:CSMC TECH FAB2 CO LTD

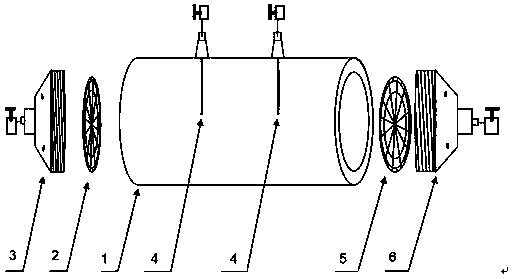

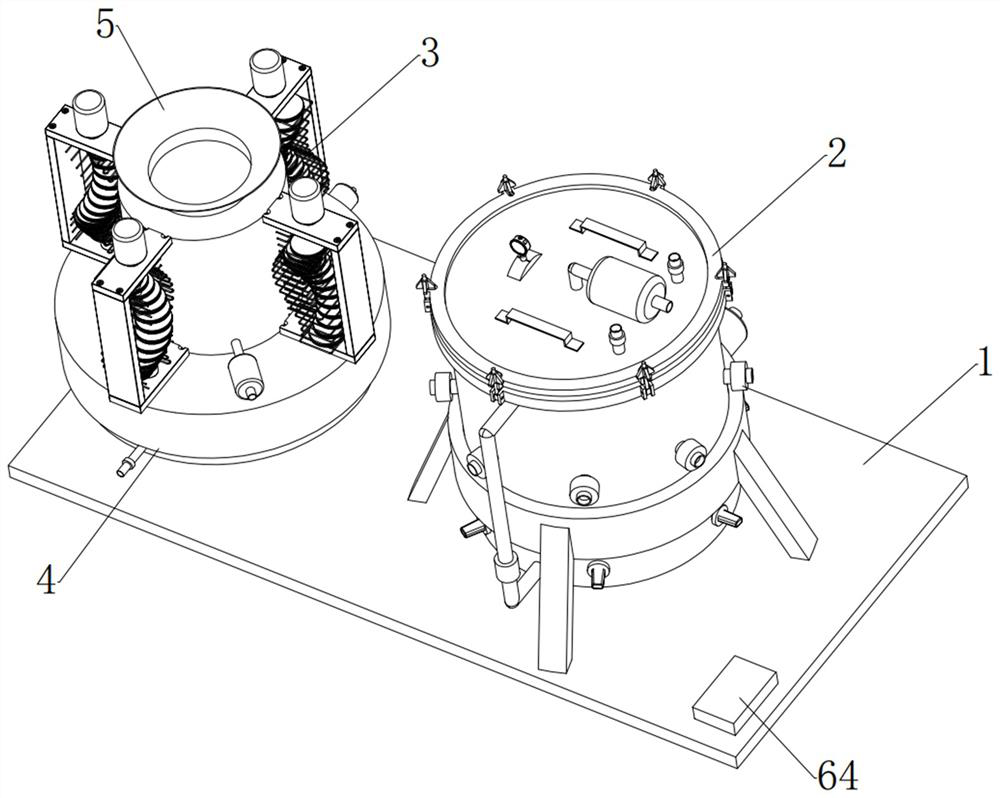

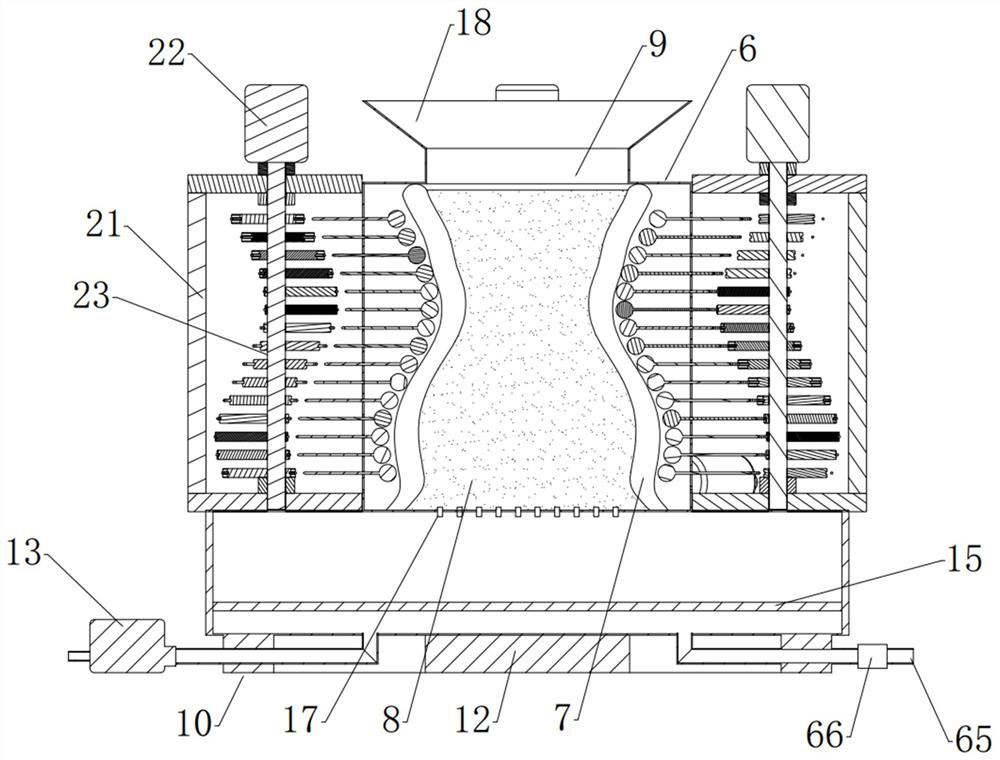

Specially-prepared large-diameter sand filling model device for physical simulation experiments and method thereof

ActiveCN107831052AAchieving a mixed wetting stateHigh compressive strengthSurveyPreparing sample for investigationEngineeringBottom water

The invention discloses a specially-prepared large-diameter sand filling model device for physical simulation experiments and a method thereof, wherein the device includes a model pipe body; the modelpipe body comprises a main pipe body; the main pipe body is a cut-through pipe body, the left end and the right end of the main pipe body are respectively blocked with a left pipe end seal cover anda right pipe end seal cover; the inner end face of the left pipe end seal cover is provided with a left screen pressing plate, and a coarse screen and a fine screen are respectively mounted between the inner end face of the left pipe end seal cover and the left screen pressing plate; a right screen pressing plate is mounted at an inner end face of the right pipe end seal cover, and a coarse screenand a fine screen are respectively mounted between the inner end face of the right pipe end seal cover and the right screen pressing plate; the main pipe body is provided with a simulation injection-production well hole or a pressure measuring hole. The device and the method not only can simulate the edge-bottom water characteristics of an actual oil reservoir, but also can simulate the artificial gas-cap drive characteristics of a mine field.

Owner:CHINA PETROLEUM & CHEM CORP +1

Smokeless barbecue oven

The invention discloses a smokeless barbecue oven, which comprises an oven body bracket, wherein a horizontal support block is arranged on the upper part of the inner side of the oven body bracket; cuboidal carbon grooves are formed in the positions, close to the front and rear sides of the oven body bracket, of the support block in the length direction of an oven body; air vents are formed in the bottoms of the carbon grooves; a cuboidal water tank is arranged between the two carbon grooves; thermal flow guide plates inclined towards the upper parts of the inner sides are arranged on the upper parts of the carbon grooves; a skewer placement frame is arranged at an opening between the upper ends of the thermal flow guide plates; the lower ends of the thermal flow guide plates are positioned above the positions of the outer sidewalls of the carbon grooves; the opening is matched with the width of the front-back direction of the water tank; the widths of horizontal projections of the thermal flow guide plates in the front-back direction are matched with the widths of the carbon grooves in the front-back direction; the left and right sides of the thermal flow guide plates are connected with side sealing plates respectively. According to the smokeless barbecue oven, heat produced by the burning of charcoal in the carbon grooves is used for baking meat products at the temperature of about 250 DEG C, so that the production of oily fume and unburned and incompletely burned soot and carbon granules are eliminated, and the problem of food and environmental pollution is solved.

Owner:苏玉科

Method using pilot tunnel to process tilting and dumping hydraulic support

The invention relates to a method for dealing with crooked and inverted frames of a hydraulic support by using a guide tunnel, comprising the following steps: 1) carrying out guide tunnel construction in front of the tilted or toppled hydraulic support; 2) using an I-shaped steel shed to reinforce the guide tunnel Support; 3) Pull the hydraulic support into the position of the guide tunnel; 4) Upright the hydraulic support in the guide tunnel. The beneficial effect of the present invention is that: the present invention adopts the principle of "controlling the roof first, suppressing roof caving, and then straightening the support", and implements the guide tunnel method to control the surrounding rock, that is, the coal wall is stripped ahead of the coal wall in the crooked frame area of the working face , The stripping area adopts the combined use of anchor rods and steel ladders, the combined use of anchor cables and anchor cable beams, the rhombus net, and the combined support of single pillars and sheds.

Owner:济宁矿业集团有限公司

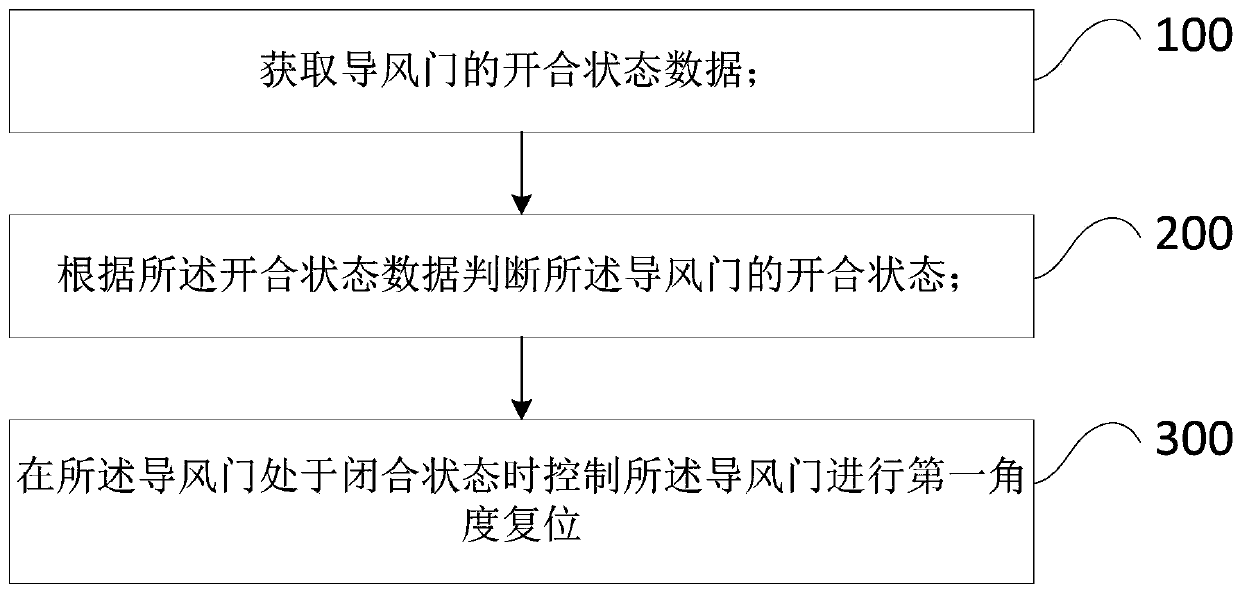

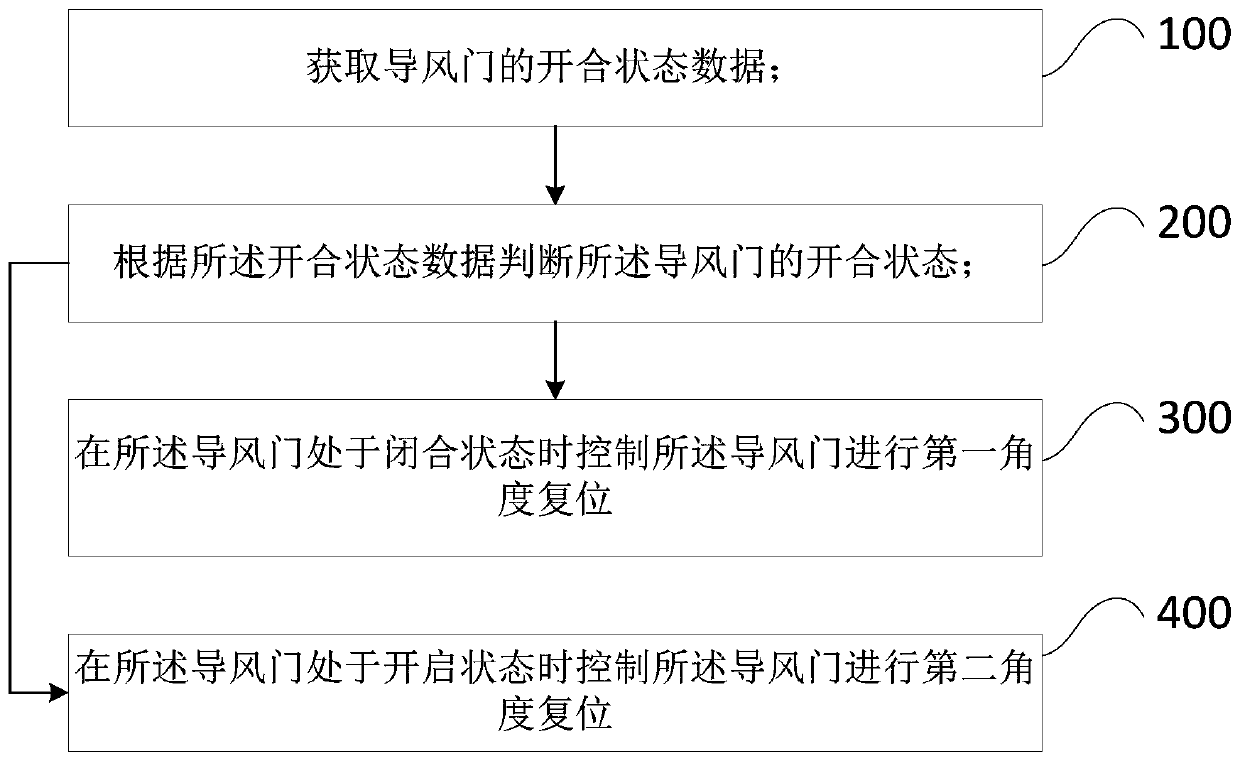

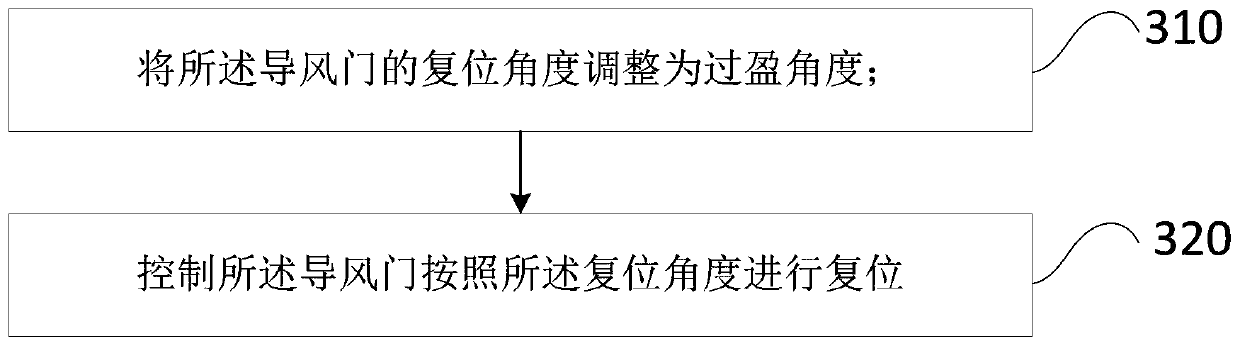

Air guiding door power-on reset control method and device and air conditioner

InactiveCN110195907AAvoid force deformationAvoid service lifeMechanical apparatusSpace heating and ventilation safety systemsPower-on resetElectricity

The invention provides an air guiding door power-on reset control method and device and an air conditioner. The control method comprises the steps of obtaining open / closed state data of an air guidingdoor; according to the open / closed state data, judging the open / closed state of the air guiding door; and when the air guiding door is in the closed state, controlling the air guiding door to conductfirst angle reset. In this way, the closed state of the air guiding door is judged; if the air guiding door is in the closed state, a rest angel is set to be a first angle instead of the sum of the maximum open degree and an interference angle of the air guiding door of the air conditioner; and therefore, the closed stuck state of the air guiding door lasts for a short time, and furthermore, theproblems that due to the fact that an air guiding door is stuck in the closing process, the air guiding door is stressed to deform, the service life of an air guiding motor is shortened, and reliability is lowered are avoided.

Owner:NINGBO AUX ELECTRIC +1

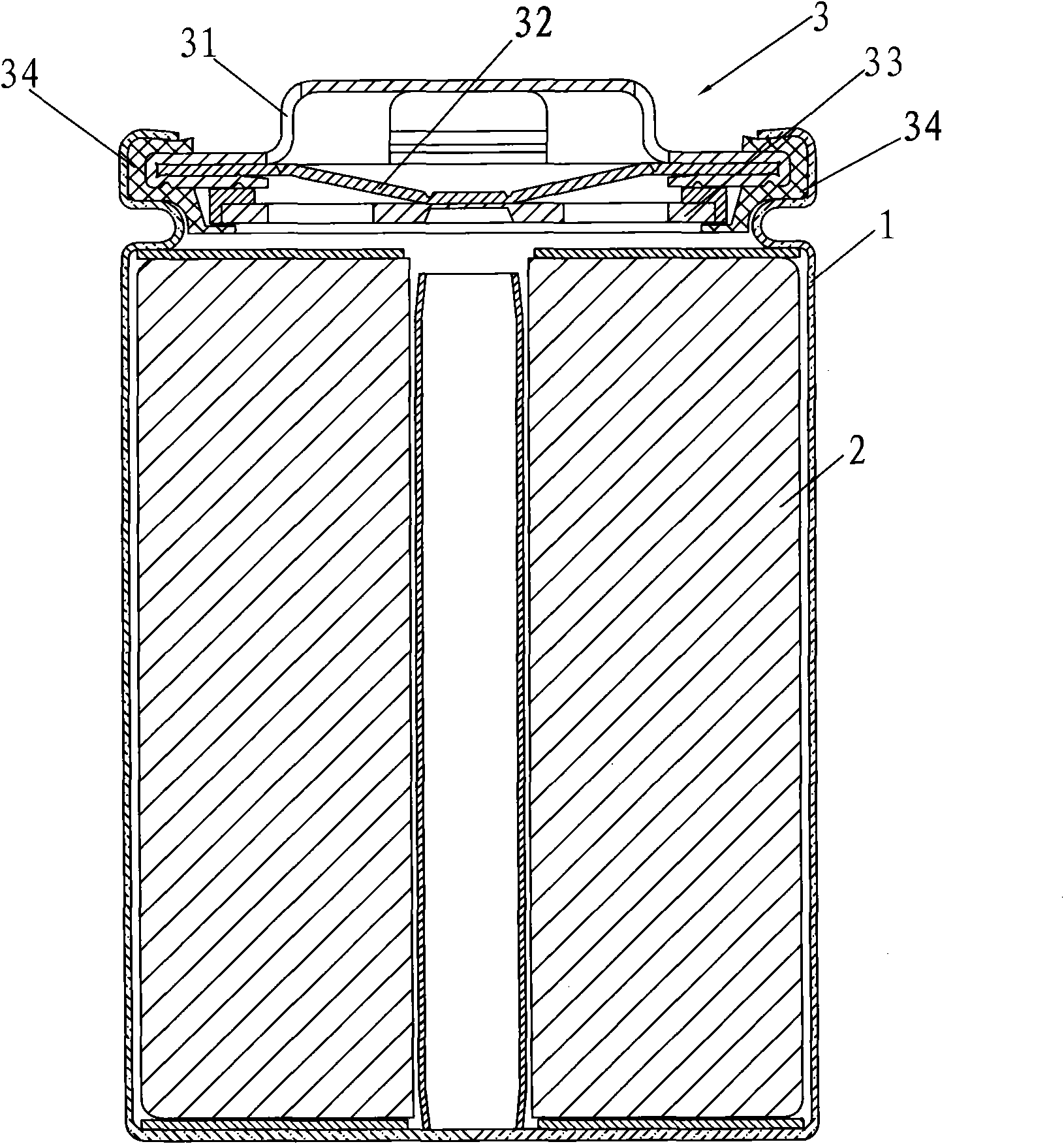

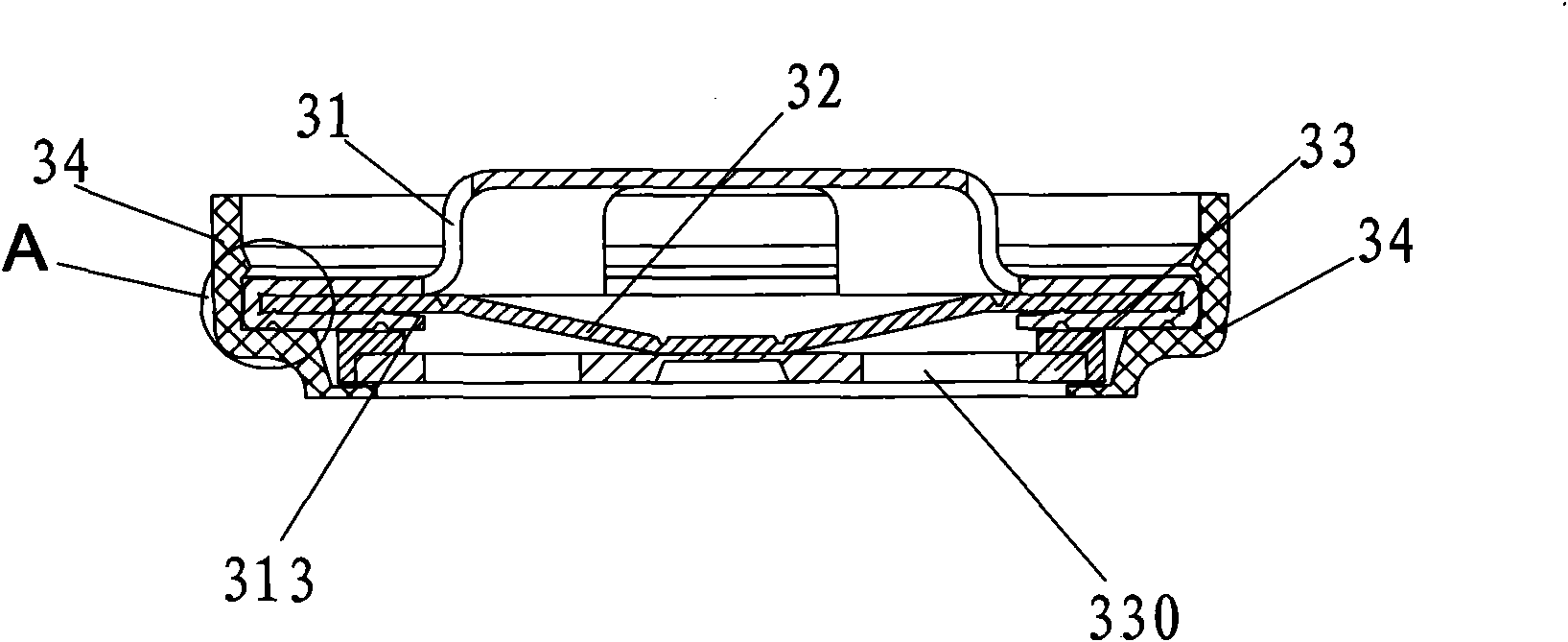

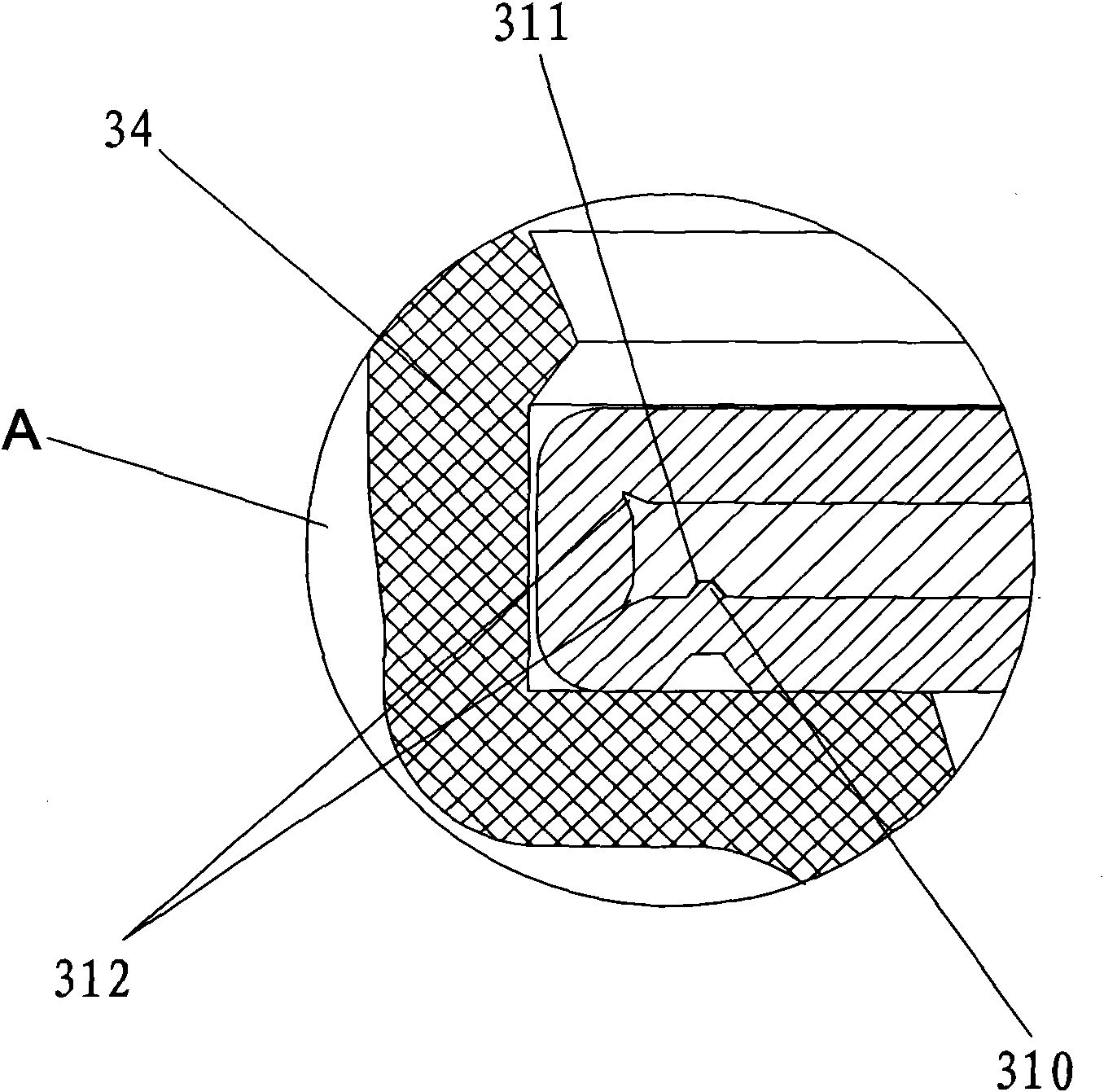

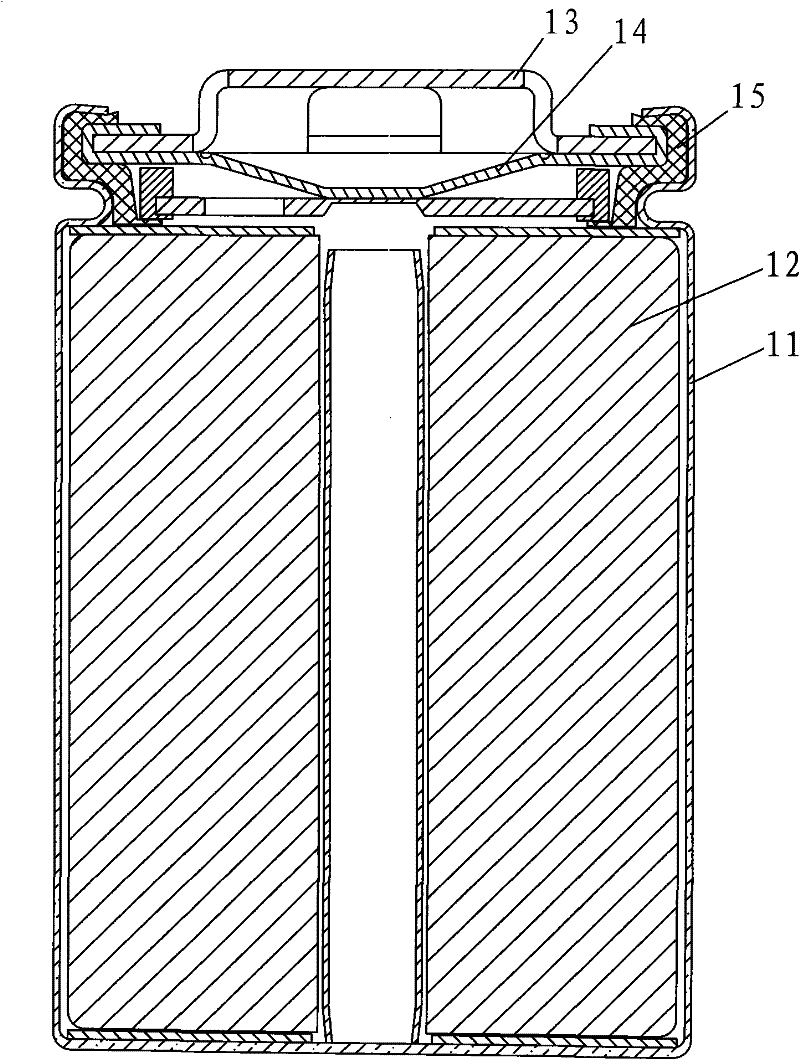

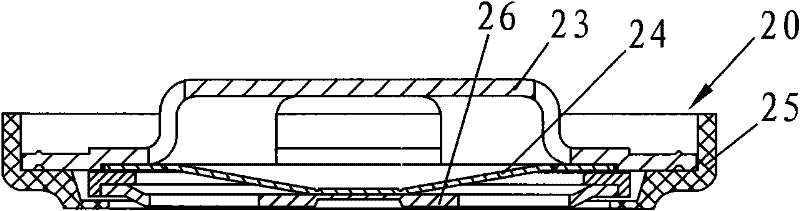

Cylindrical lithium ion battery

ActiveCN102810650AImprove stabilityImprove sealingCell component detailsCombustionLithium-ion battery

The invention discloses a lithium ion battery, which comprises a battery shell, a pole sheet group accommodated inside the battery shell, an electrolyte filled in the battery shell, and a battery cover cap forming a sealing group connection on the battery shell, wherein a top cover folds inward along the edge of an explosion-proof sheet to form the coated explosion-proof sheet from three directions, and the end part of the top cover is provided with concave-convex sealing steps, such that effects of rigidity increasing, avoidance of the explosion-proof sheet deformation due to exerted force, and sealing increasing in the sealing port are provided. In the prior art, due to deformation or leakage, the pressure relief value of the explosion-proof sheet becomes large or the explosion-proof sheet does not burst so as to cause occurrence of combustion, explosion, and other safety problems. According to the present invention, problems in the prior art are prevented, stability, sealing and safety of the cylindrical lithium ion battery are improved, and capacity of the battery is increased.

Owner:DONGGUAN AMPEREX TECH +2

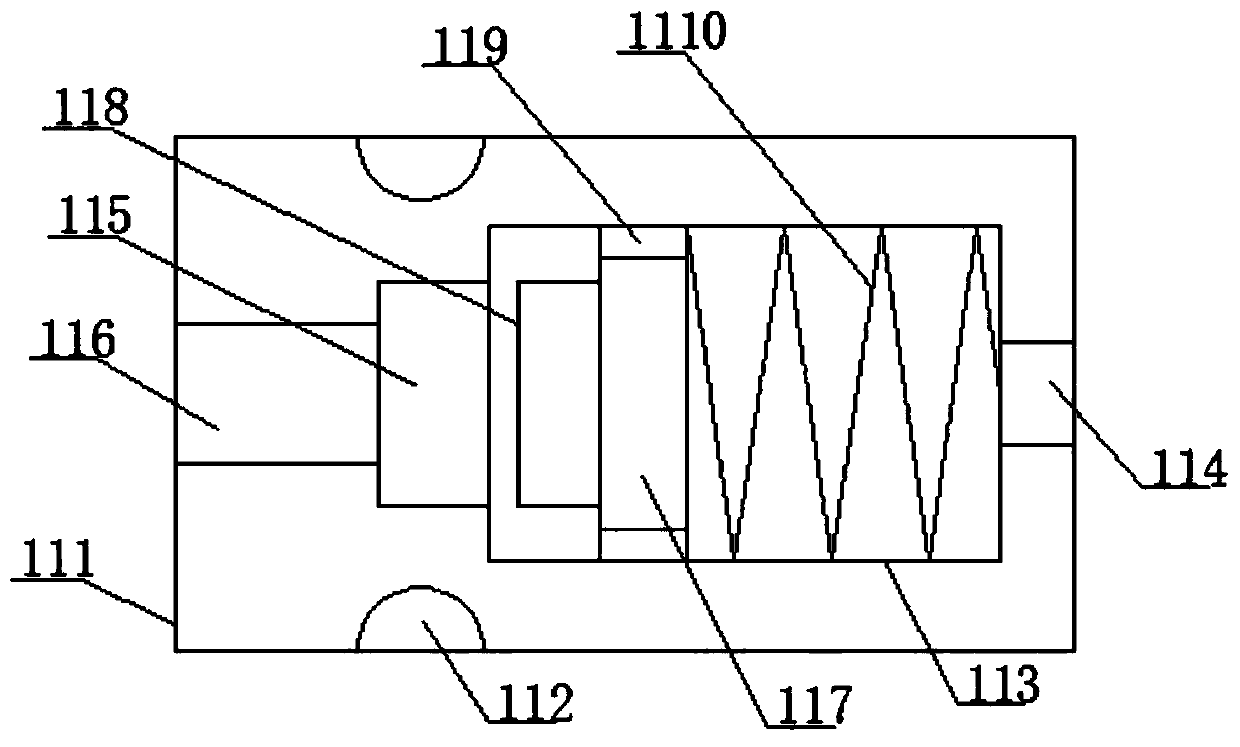

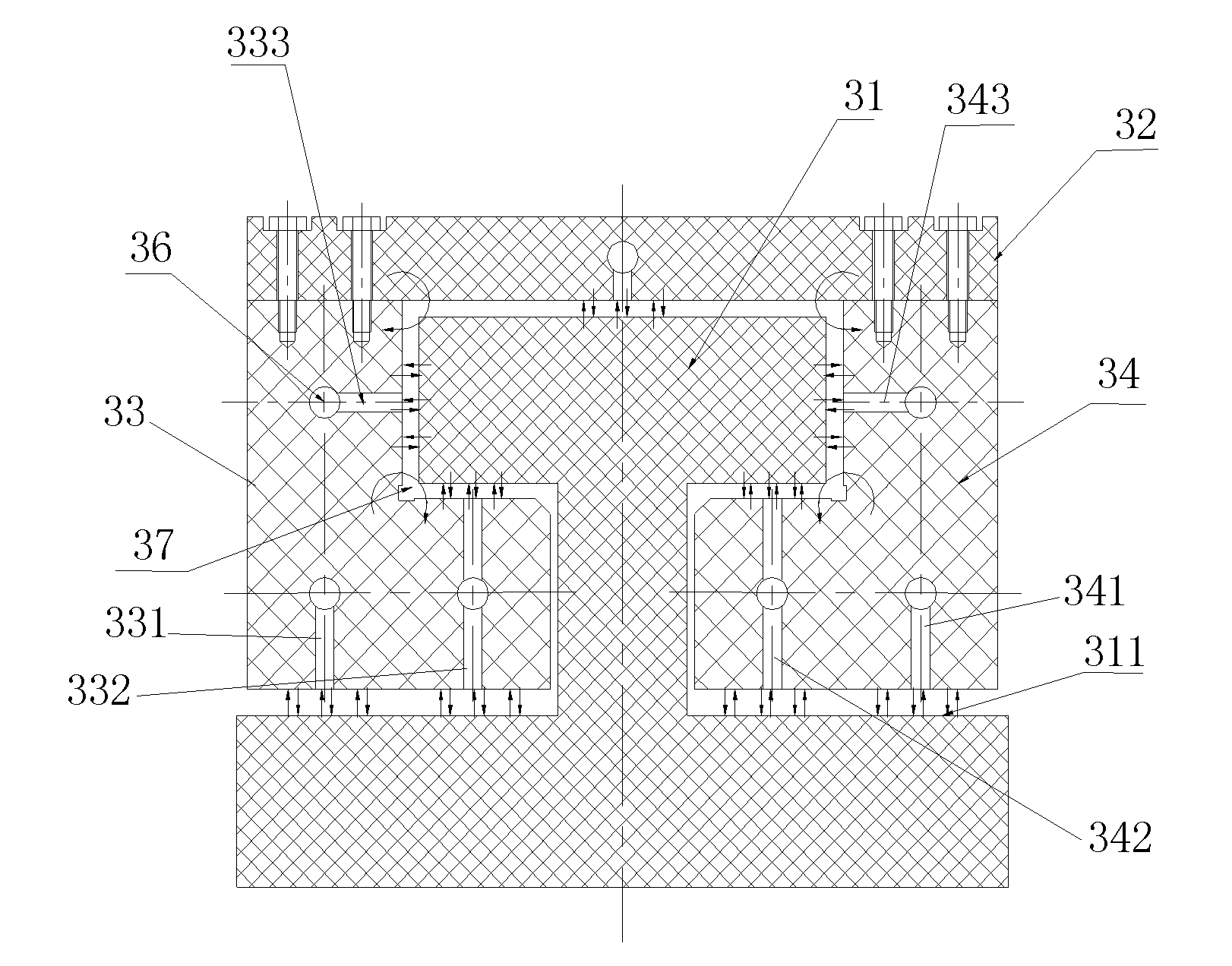

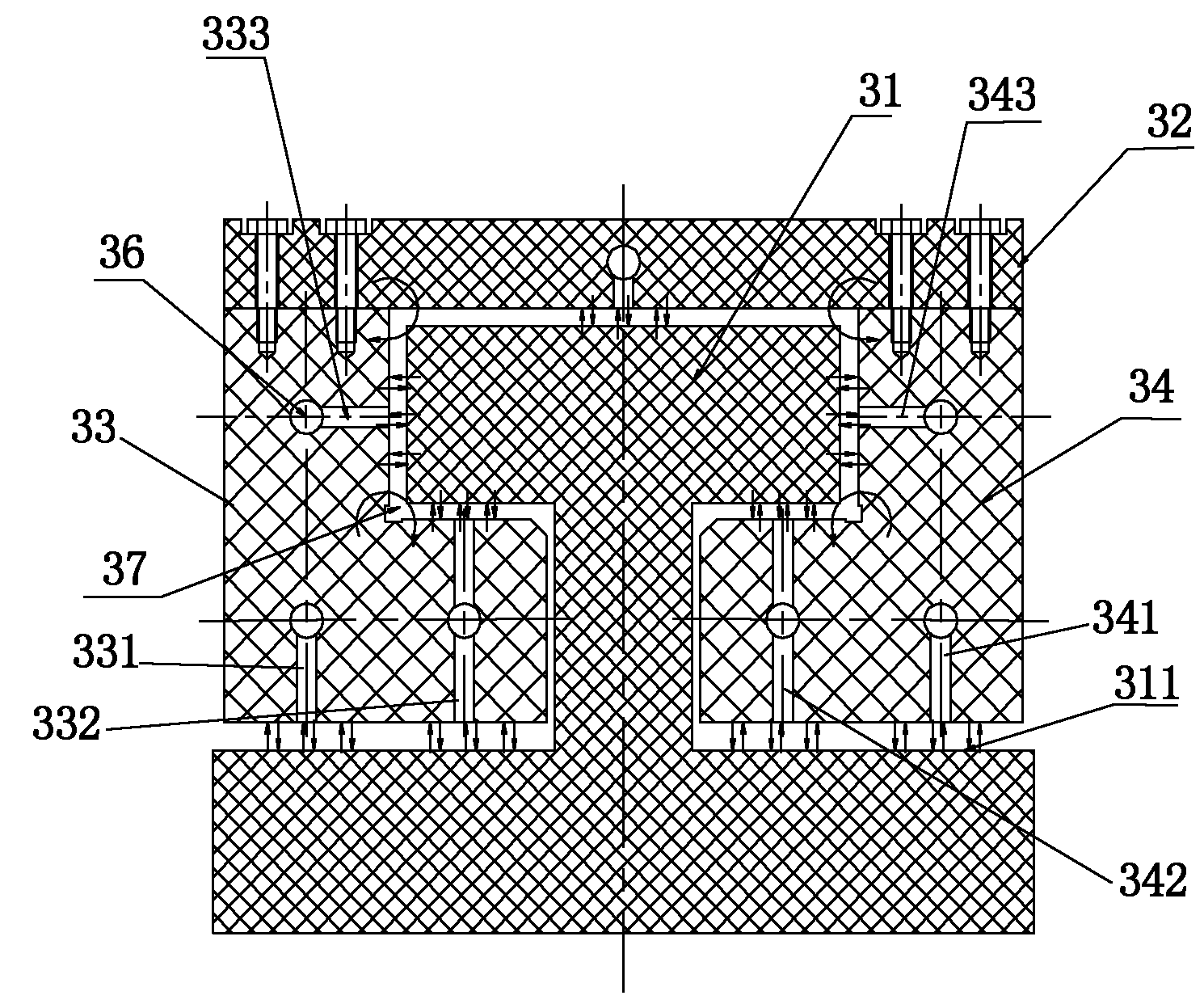

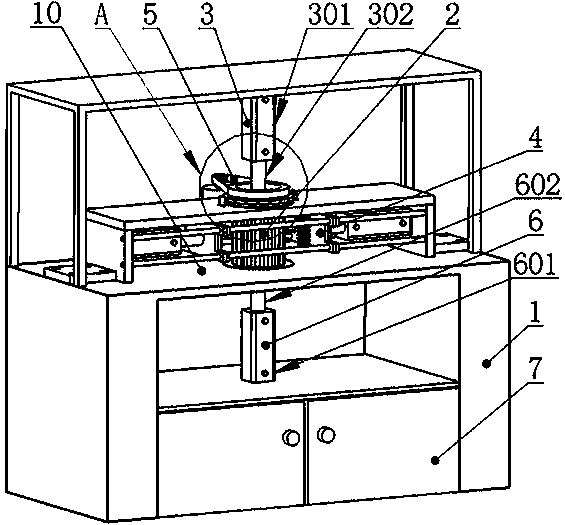

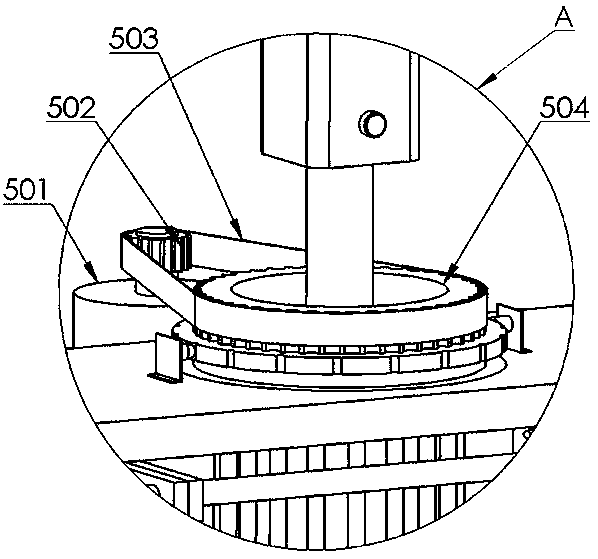

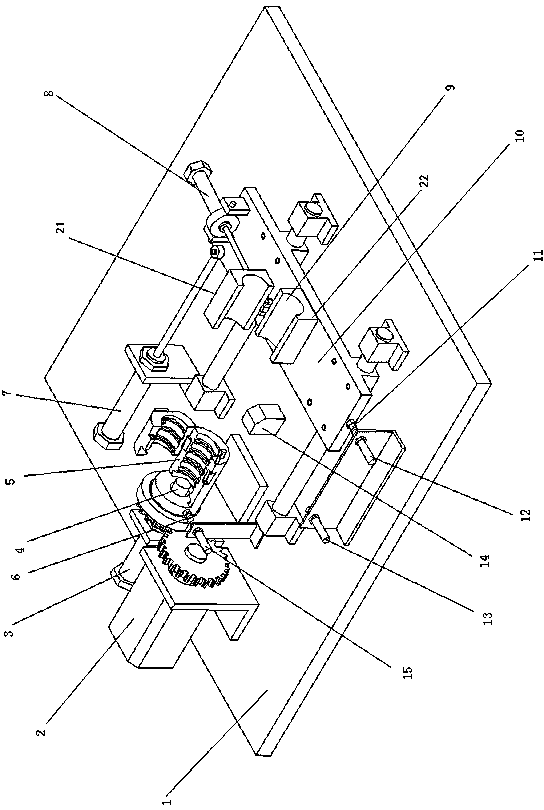

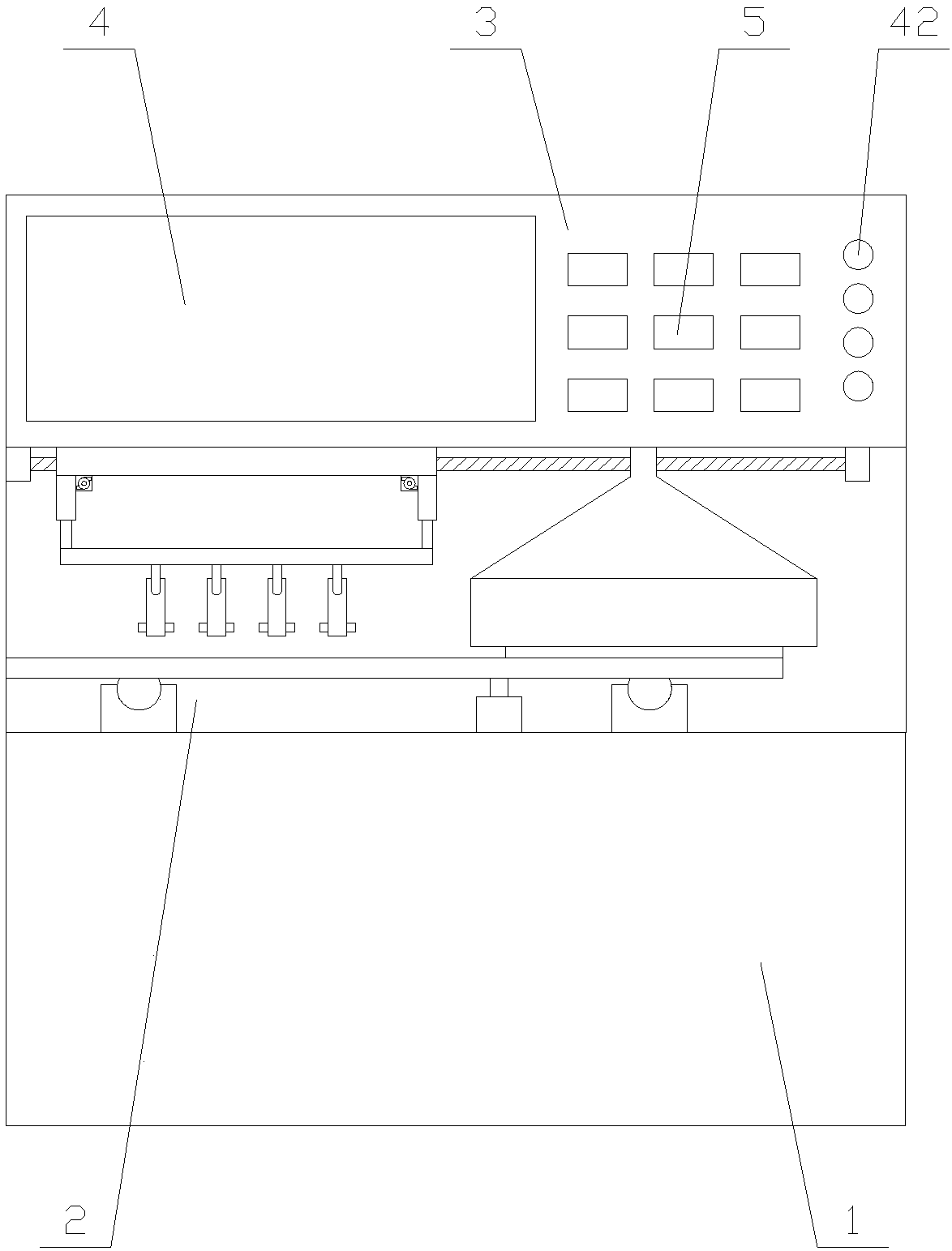

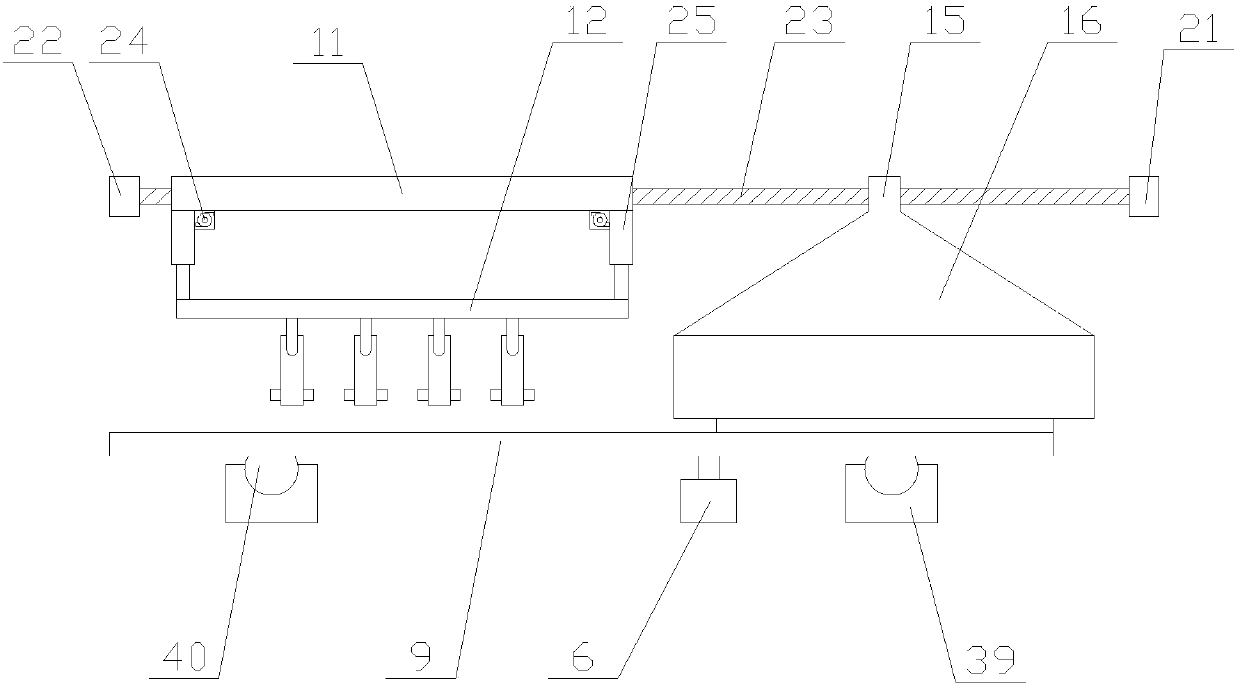

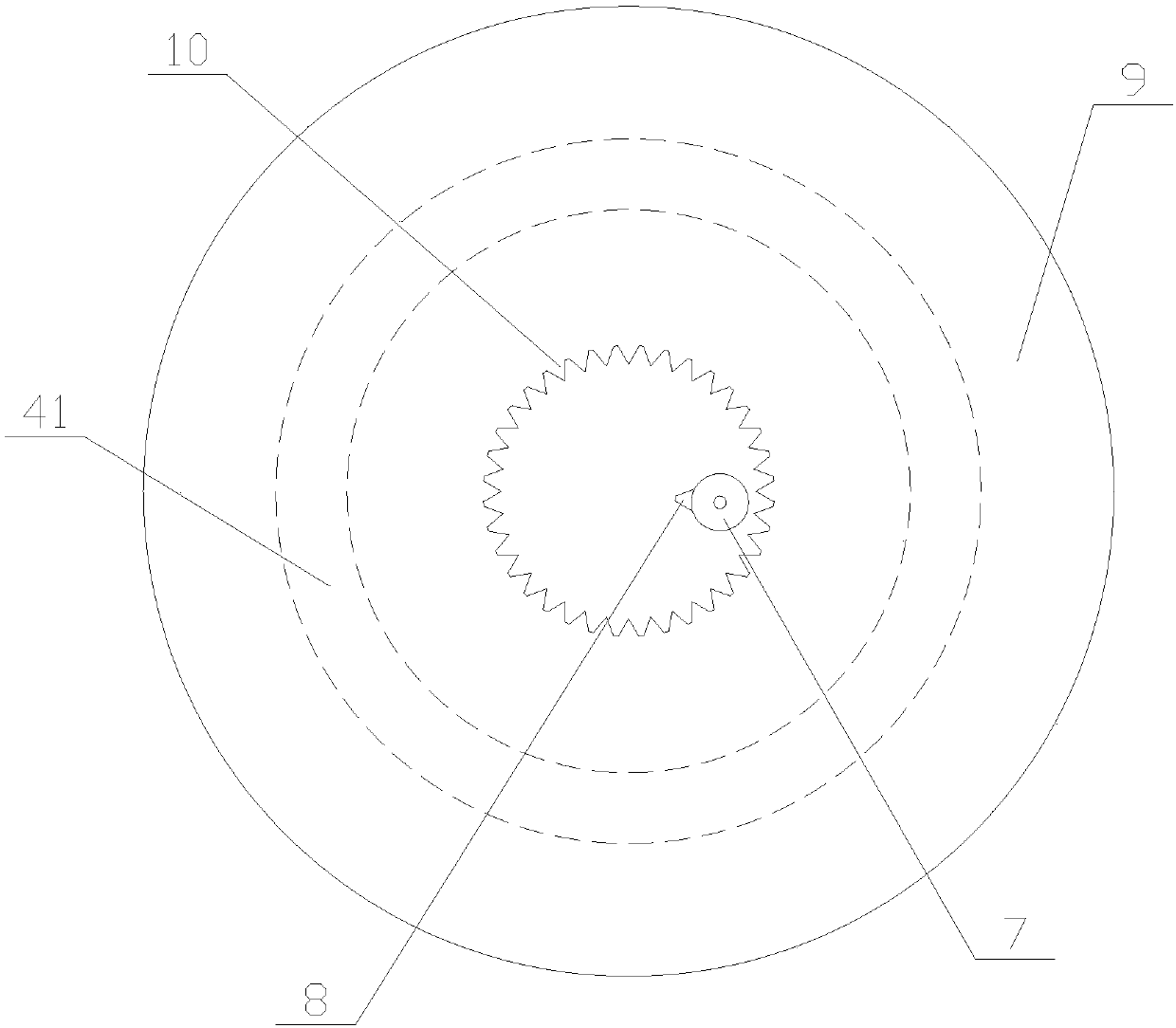

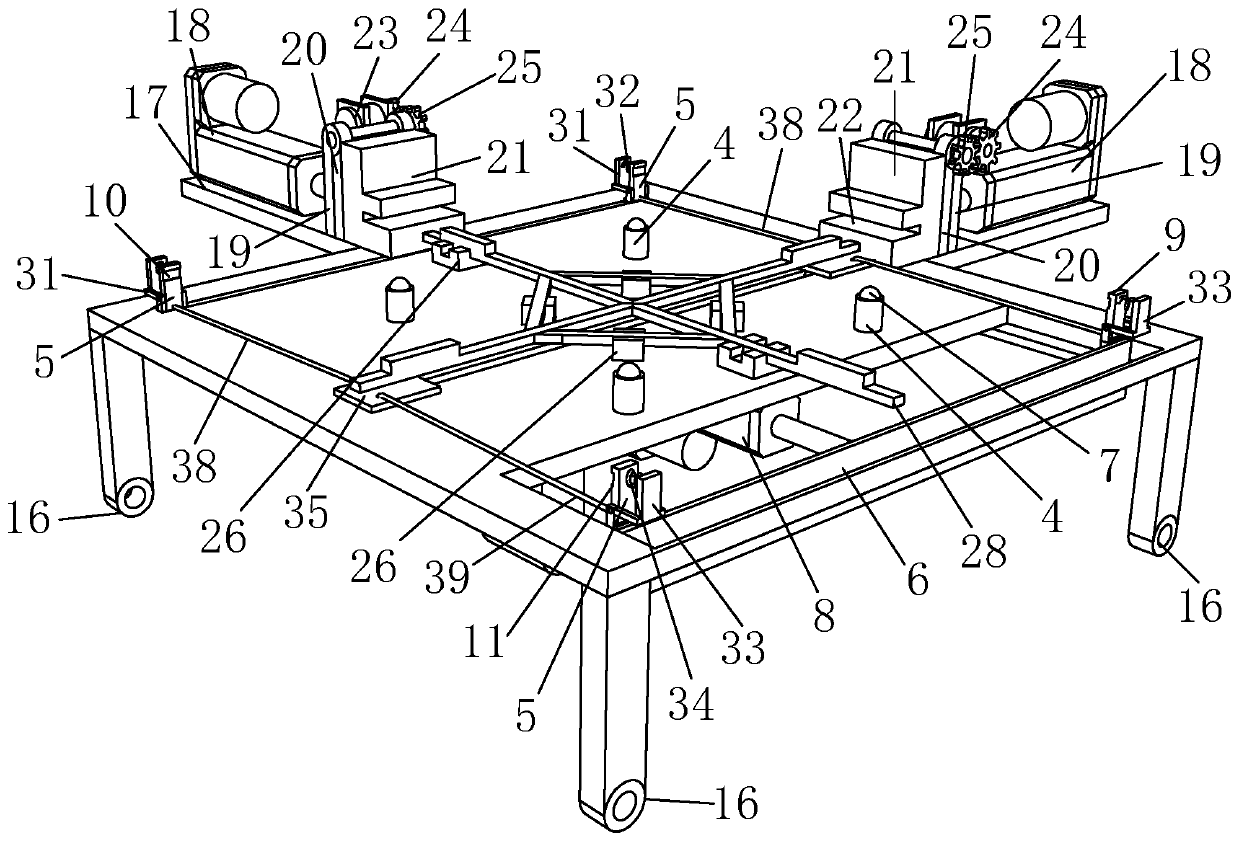

Automatic filter element hole pricking equipment

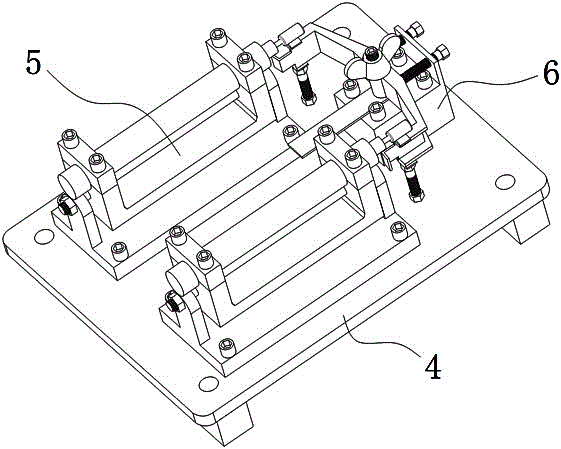

InactiveCN109834753AAvoid force deformationAvoid torqueMetal-working feeding devicesMetal working apparatusBiochemical engineeringFilter element

The invention discloses automatic filter element hole pricking equipment. The automatic filter element hole pricking equipment comprises a machine frame, a clamp, a pressing device, hole pricking devices, a rotating device, an ejecting device, a control device and an operation table, wherein the clamp, the pressing device, the hole pricking devices, the rotating device, the ejecting device, the control device and the operation table are installed on the machine frame; the clamp is installed in the center of the operation table, the pressing device is arranged right above the clamp, the hole pricking devices are symmetrically arranged on the left side and the right side of the mouse cage of the clamp; the rotating device is arranged right behind the clamp; the ejecting device is arranged under the clamp; the control device is arranged below the ejecting device. According to the automatic filter element hole pricking equipment, when the equipment works, the filter element to be puncturedis fixed by the pressing device in the clamp, the hole pricking devices are matched with the rotating device to realize 360-degrees rapid and uniform hole pricking of the filter element, the deformation of the filter element is small, and the working efficiency and the hole pricking quality are greatly improved.

Owner:CHANGZHOU INST OF LIGHT IND TECH

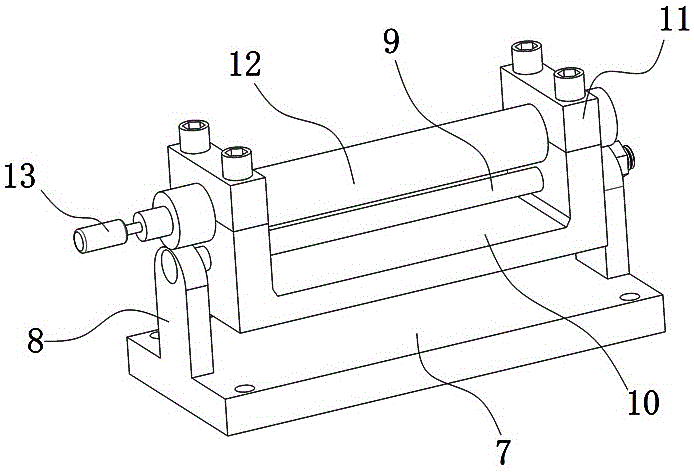

Peeling device for hollow spiral electrifying hose of dust collector and application method thereof

ActiveCN110086125AAchieve reductionRealize accurate positioning of cutting positionApparatus for removing/armouring cablesEngineeringMechanical engineering

The invention relates to the technical field of electrifying hose processing, and relates to a peeling device for a hollow spiral electrifying hose of a dust collector and an application method thereof. The peeling device comprises a base, a rotary cutter, a servo motor, a first cylinder, a second cylinder, a third cylinder, a guide rail sliding table, a hose clamping device, a hose inner jackingrod, a first induction switch, a second induction switch, a third induction switch and a fourth induction switch. The peeling device can accurately position and cut external rubber of the hollow spiral electrifying hose through the cooperation of the devices, accurately controls the cutting length, reduces the difficulty of manual peeling and improves the production efficiency.

Owner:常熟市雷得双金属复合管业有限公司 +1

Intelligent palm shape recognition instrument

InactiveCN107818315AAvoid spreading infectionAvoid force deformationCharacter and pattern recognitionDrive wheelIdentity recognition

The invention relates to an intelligent palm shape recognition instrument, and the recognition instrument is convenient for standard placement and bacterial infection prevention. The recognition instrument comprises a detection box, a support plate, and a display box. A translation mechanism, a positioning mechanism, a cleaning mechanism and a placement mechanism are disposed between the detectionbox and the display box. The placement mechanism comprises a first motor, drive wheels, drive teeth, and a glass plate. The positioning mechanism comprises a moving plate, a positioning plate, two lifting assemblies, and four positioning components. The cleaning mechanism comprises a moving block, a connecting block, a frame, and a cleaning block. The recognition instrument enables the posture ofa palm to be standard through the positioning mechanism, facilitates the accurate recognition, and improves the judgment efficiency and precision of equipment. Moreover, after identity recognition, the glass plate is driven by the first motor to rotate, and is cleaned through the cleaning mechanism, thereby preventing the bacteria on the glass plate from spreading to the palms of other users, andimproving the practicality of the equipment.

Owner:苏州奥柯图葳机电科技有限公司

Mixed cleaning type thermal expansion type metal surface all-dimensional lossless rust removal machining device

ActiveCN114453990ARealize self-vibrationRealize full packageEdge grinding machinesGrinding carriagesThermal dilatationPolishing

The invention discloses a mixed cleaning type thermal expansion type metal surface all-dimensional lossless rust removal machining device which comprises a bottom plate, a temperature difference convection type two-way change self-vibration thermal expansion pretreatment mechanism, a multi-step gradual hammering and extruding mechanism, a preloading pneumatic type feeding mechanism and a flexible pneumatic film magnetic mud mixed full-grinding mechanism. The invention belongs to the technical field of metal rust removal processing, and particularly provides a method for pre-processing a rusty metal part through circulating hot air flow, and for thin and soft metal and precise metal parts which are irregular in surface shape, easy to deform and difficult to fix, machining the rusty metal part through the circulating hot air flow under the condition that no positioning element exists. Magnetic mud and metal particles are driven to generate multi-angle and all-directional friction with pretreated metal through a multi-step progressive hammering and extruding mechanism, so that lossless full polishing of metal parts is truly realized, and the metal parts can be fully polished without any dust removal mechanism. And on the contrary, the mixed cleaning type thermal expansion type metal surface all-dimensional lossless rust removal machining device is good in dust removal effect.

Owner:徐州中顺尚奕机械制造有限公司

Device and method for automatically detecting flatness of surfaces of circuit boards

PendingCN111495793AEasy accessShorten the timeMeasurement devicesSortingStructural engineeringElectrical and Electronics engineering

Owner:浙江新连宇电子有限公司

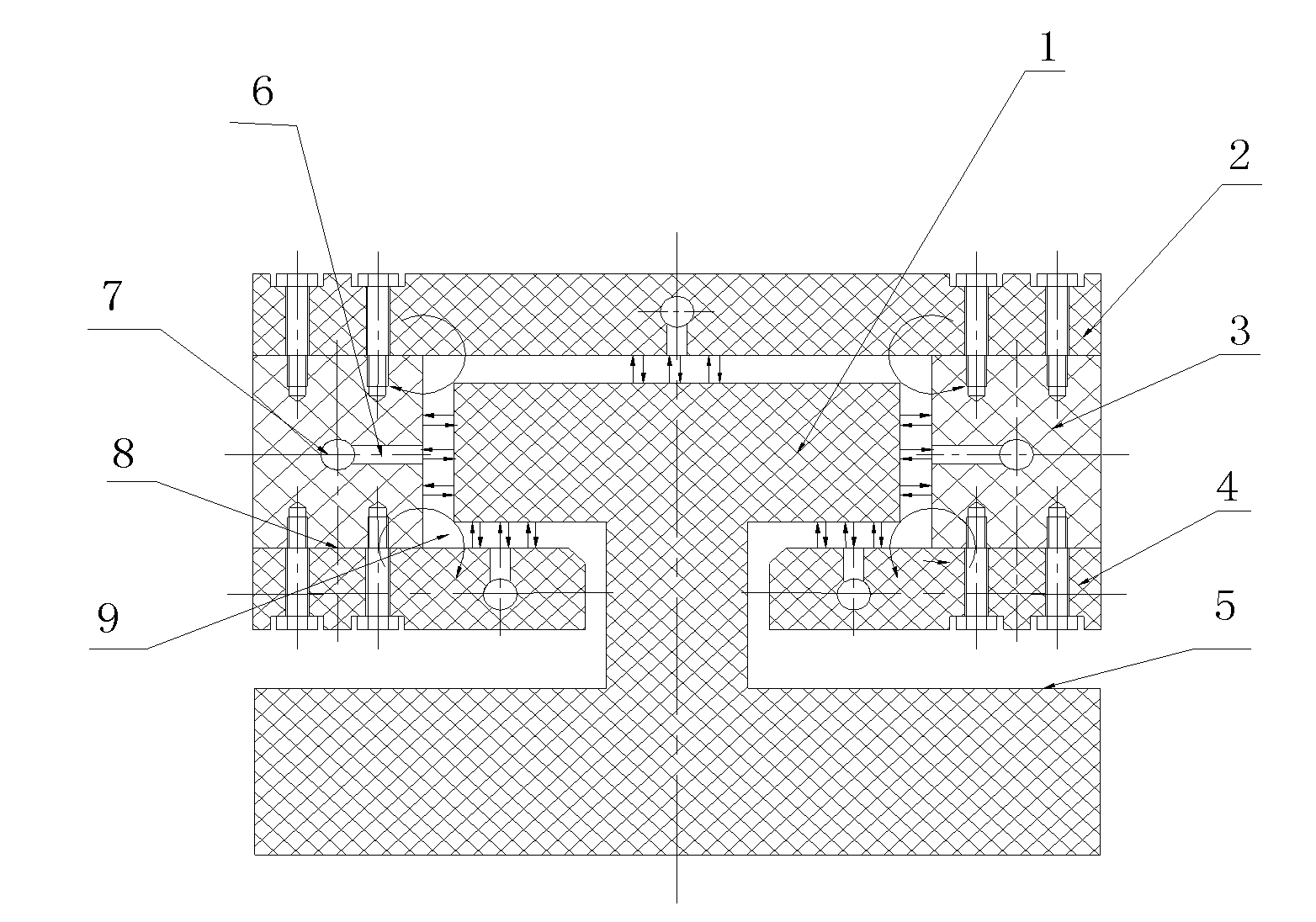

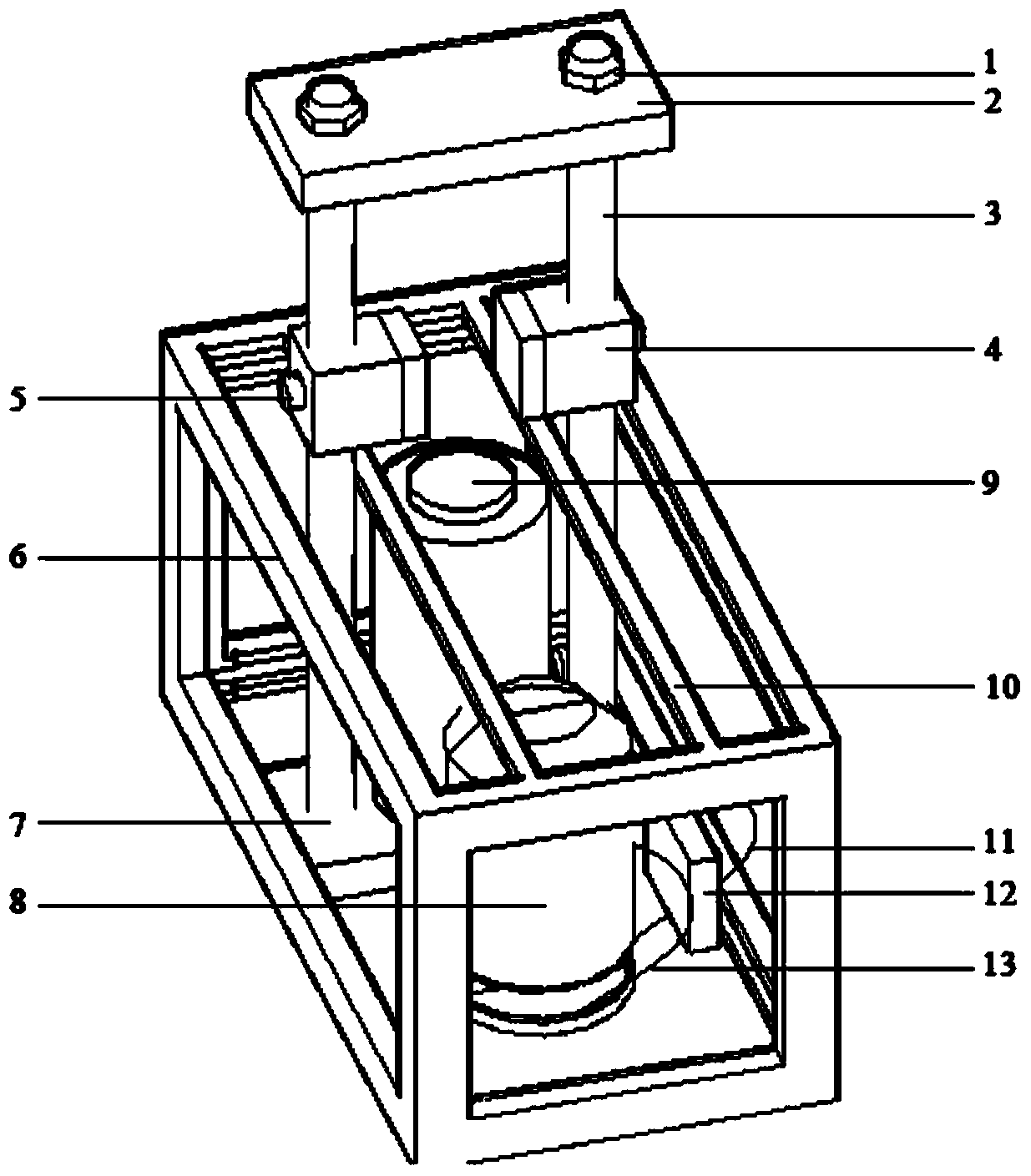

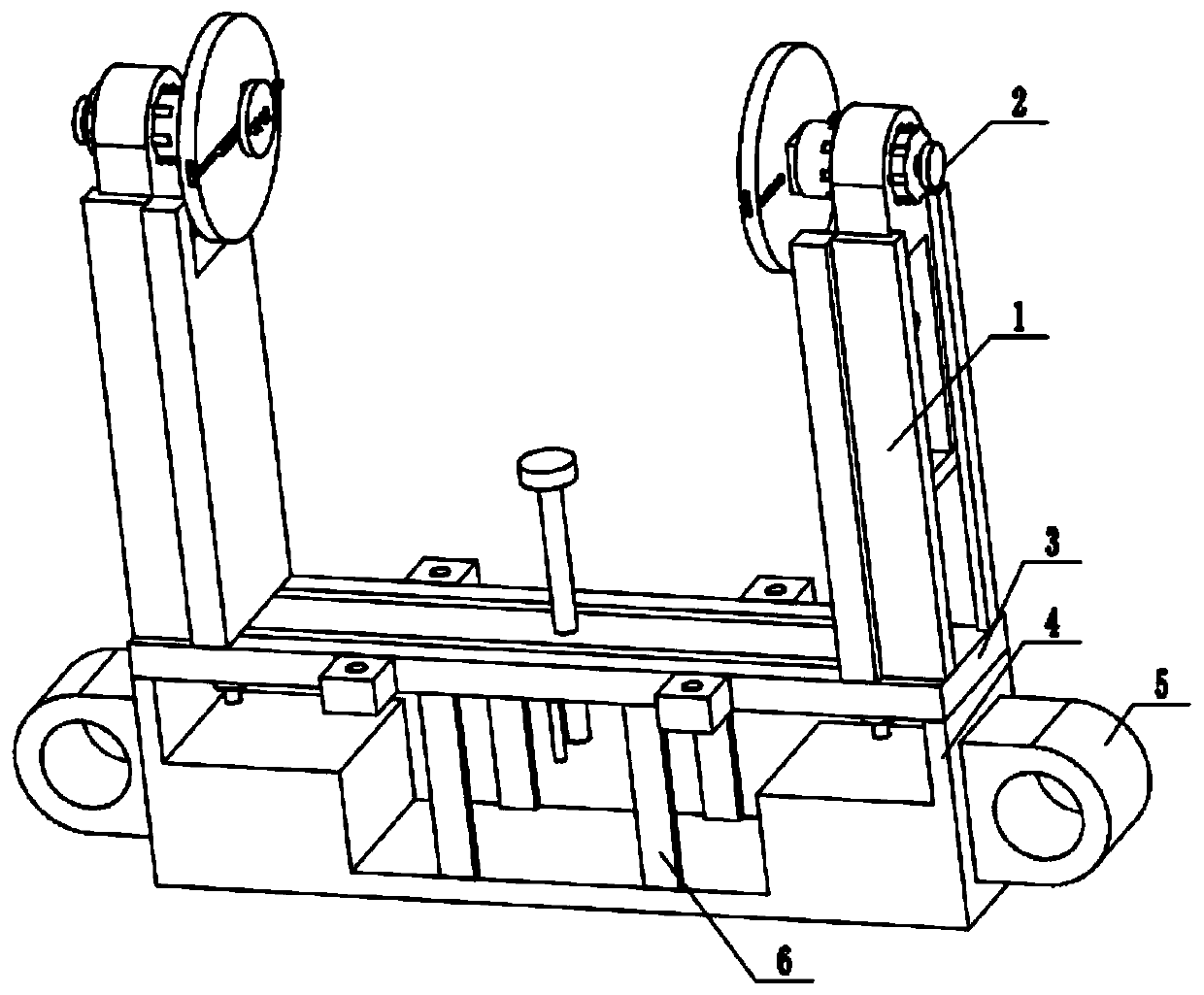

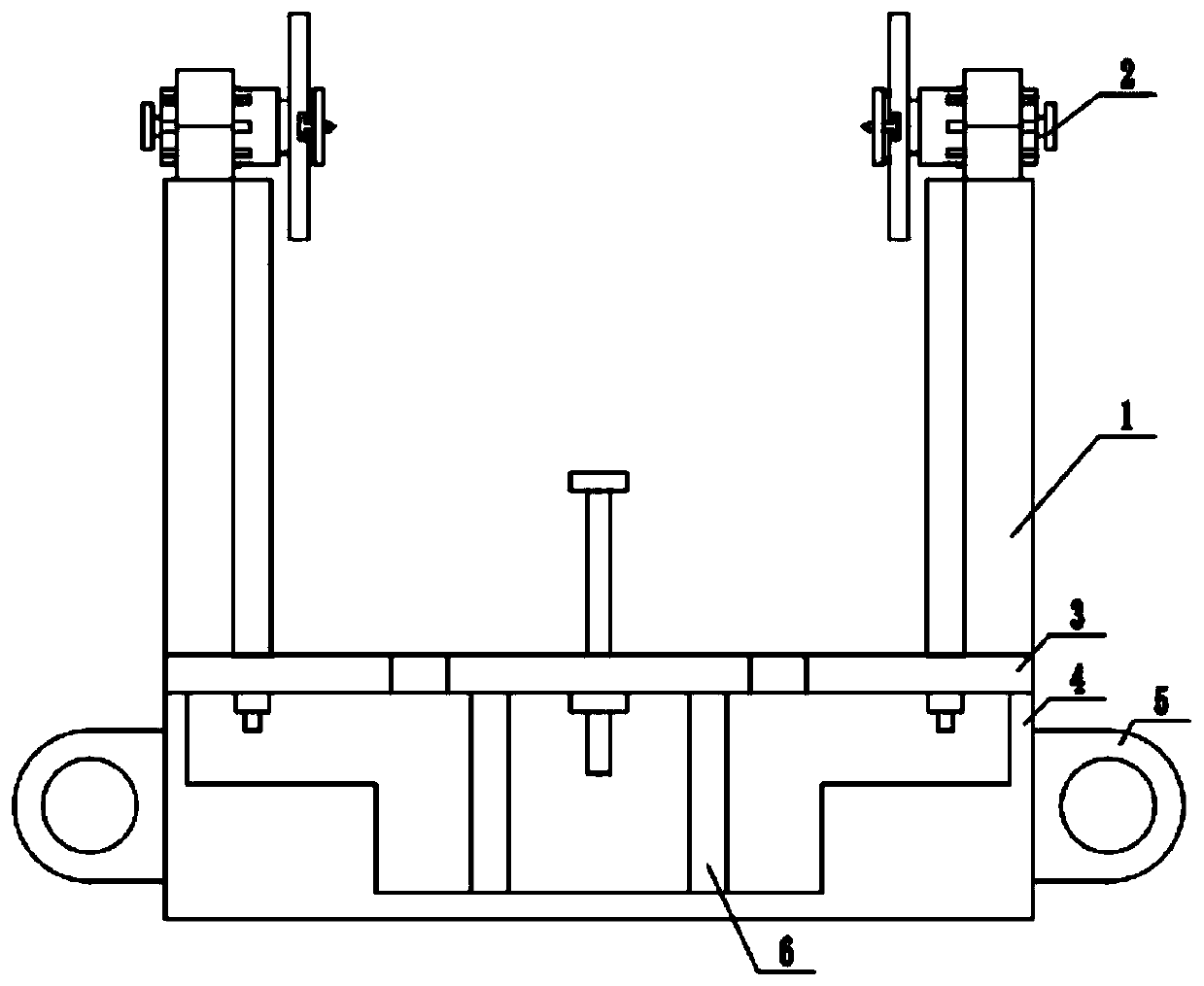

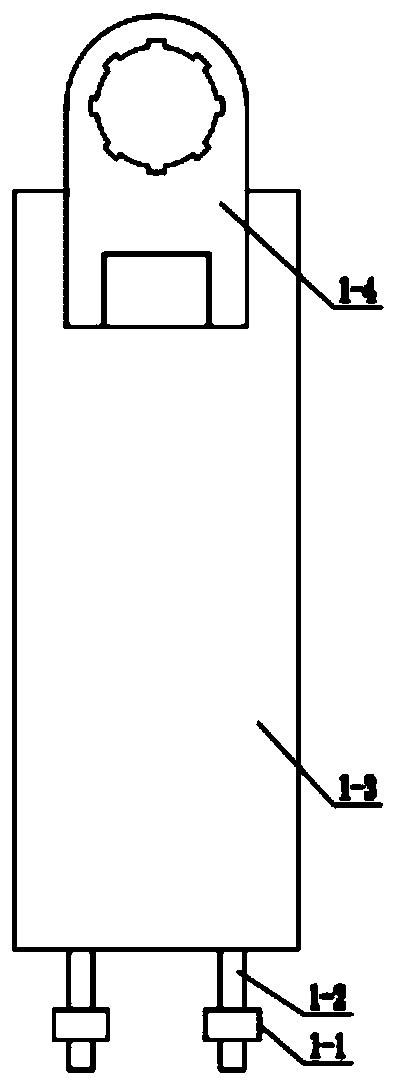

Adjustable clamp for numerically-controlled machine tool

InactiveCN110640508AAvoid force deformationAvoid damagePositioning apparatusMetal-working holdersNumerical controlClassical mechanics

The invention relates to a machine tool clamp, in particular to an adjustable clamp for a numerically-controlled machine tool. The adjustable clamp comprises lifting adjusting devices, workpiece clamping devices, a workpiece supporting device, a fixed base, hoisting frames and supporting rods. The workpiece clamping devices are mounted on the lifting adjusting devices through keys, and the two lifting adjusting devices are mounted on the workpiece supporting device. The workpiece supporting device is fixedly mounted above the fixed base, and the hoisting frames are fixedly mounted on the fixedbase. The supporting rods are fixedly mounted on the workpieces supporting device, and the other ends of the supporting rods are fixedly mounted on the fixed base. The number of the supporting rods is four. According to the adjustable clamp, the height of the two ends and the distance between the two ends can be independently adjusted, and the device can adapt to parts of multiple sizes; the device is provided with a jacking device, and it can be avoided that the parts bear force to deform when machined, and consequently machining errors are caused; and due to the fact that the device is provided with the hoisting frames, a crane can be prevented from damaging the device in the device is hoisted.

Owner:夏涌

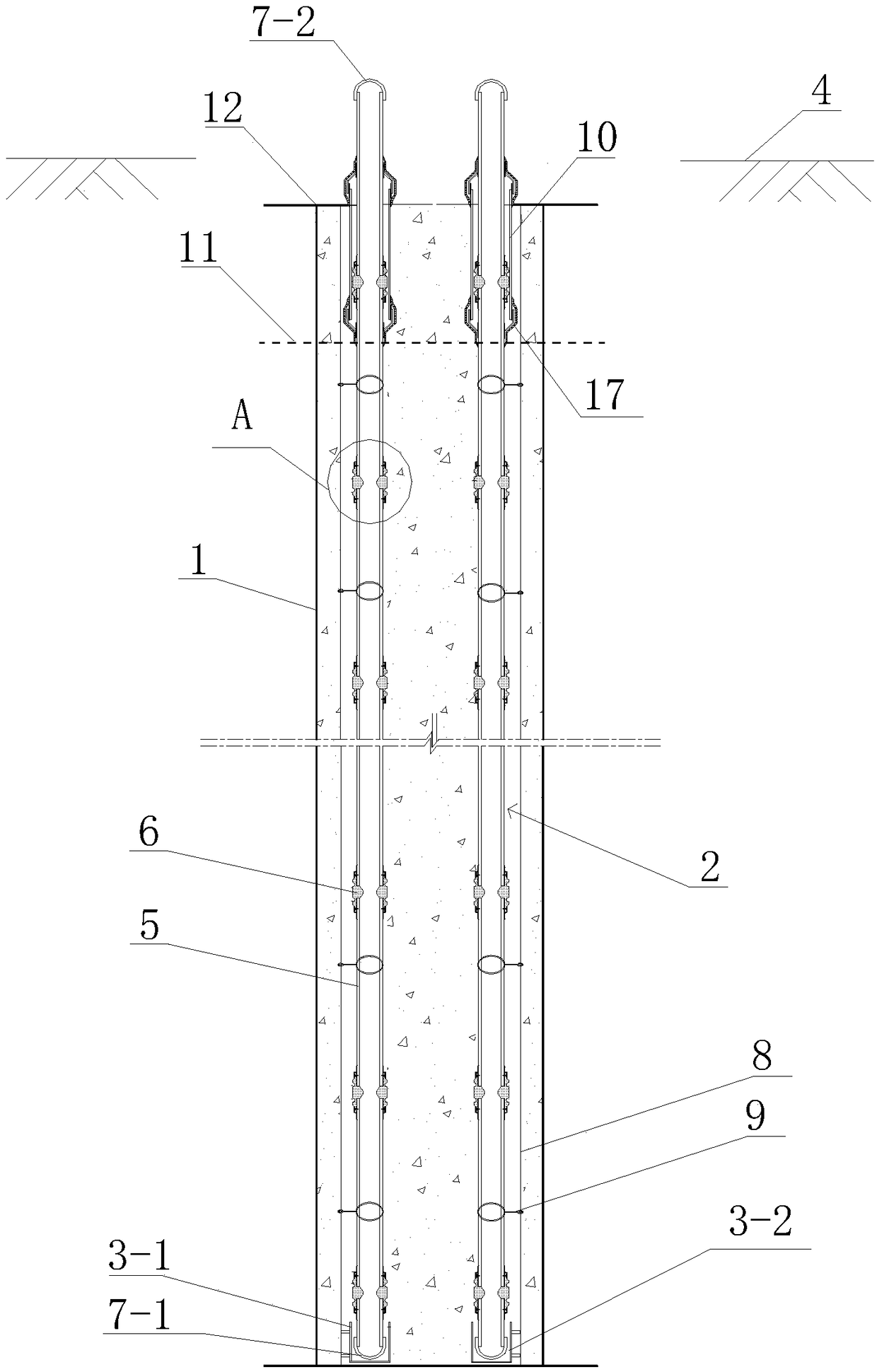

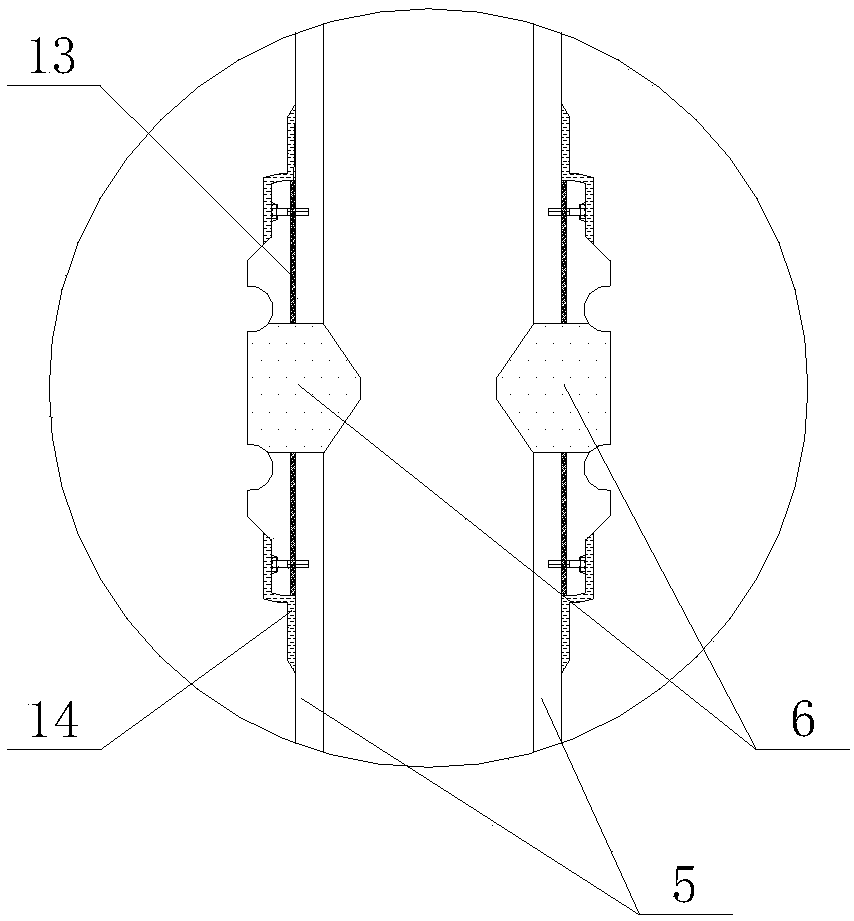

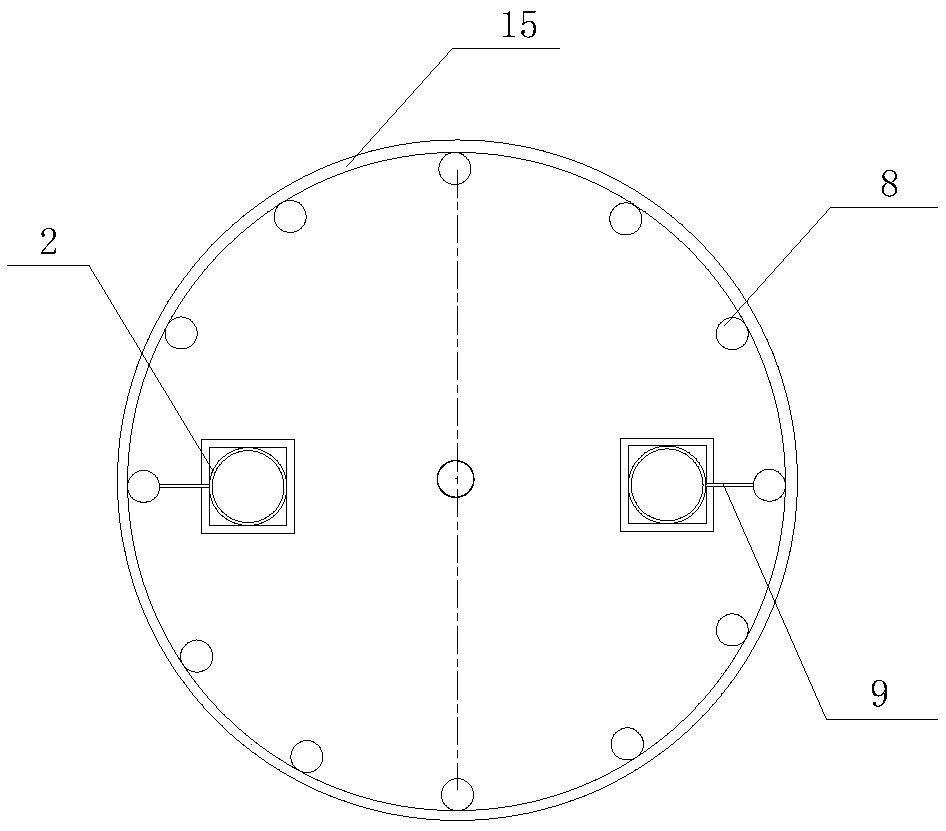

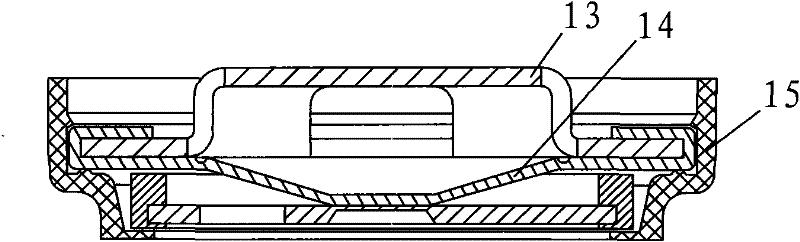

Test pipe for testing internal force of reinforced concrete cast-in-place pile and installing method thereof

PendingCN109372037ASimple structureEasy installation and layoutFoundation testingReinforced concreteEngineering

The invention discloses a test pipe for testing internal force of a reinforced concrete cast-in-place pile and an installing method thereof. The test pipe comprises a reinforcement cage installed in areinforced concrete grouting drill hole and two test pipe bodies vertically installed in the reinforcement cage. The reinforcement cage comprises multiple reinforcement cage sections sequentially connected from bottom to top. A lower test pipe cover is arranged at the bottom end of each test pipe body. An upper test pipe cover is arranged at the top end of each test pipe body. Each test pipe bodycomprises multiple test pipe sections sequentially connected from bottom to top. The method comprises the following steps of tying of the reinforcement cage sections, splicing of the test pipe sections, down hoisting and installing of the test pipe sections and the reinforcement cage sections and installing of protecting pipes. The test pipe is reasonable in design and low in cost, tying and installing time is short, the test position of the test pipe located in the reinforced concrete cast-in-place pile is ensured, thus strain of a pile body can be tested accurately, and the problems that when an existing test pipe installing method is used, the test pipe deforms, or distorts or breaks off are solved.

Owner:CHINA JK INST OF ENG INVESTIGATION & DESIGN +1

Bury pipeline construction method with self-adjusting function

ActiveCN103644370AAvoid force deformationAvoid damagePipe laying and repairExpansion jointSelf adjusting

The invention discloses a bury pipeline construction method with the self-adjusting function. The method includes the steps that first, a pipeline trench is excavated, and expansion joint burying foundation pits are excavated in the pipeline trench at the interval of 30-50 meters; second, thick medium sand with the thickness of 300-500mm is laid at the bottom of the trench; third, pipes are welded and buried; fourth, elbow type expansion joints are installed in the expansion joint burying foundation pits, and the two ends of the elbow type expansion joints are connected with the pre-buried pipes respectively; fifth, the first step, the second step, the third step and the fourth step are repeated till mounting of a whole pipeline is completed; sixth, the pipeline trench is backfilled. Compared with the prior art, the elbow type expansion joints are additionally arranged between the pipes with the adjacent distance of 30-50 meters, when the pipes are influenced by differential settlement, expansion deformation can be transmitted to the elbow type expansion joints, stressed deformation of the pipelines is avoided, the pipelines are prevented from being damaged, and the service life of the pipelines is prolonged.

Owner:CHINA PETROCHEMICAL CORP +2

Cylindrical lithium ion battery

ActiveCN102332601AAvoid force deformationImprove stabilitySecondary cellsCell component detailsRubber ringPole piece

The invention relates to the technical field of lithium ion batteries, in particular to a cylindrical lithium ion battery. The cylindrical lithium ion battery comprises a battery casing, a pole piece group accommodated in the battery casing, electrolyte filled in the battery casing and a cap which is sealed and assembled to the battery casing, wherein the cap comprises a top cover; the circumferential edge of the top cover is outwards bent to form a bent step; an explosion-proof sheet is covered at the bottom of the top cover; and the circumferential edge of the explosion-proof sheet is connected with the bottom of the bent step in a sealing manner. Compared with the prior art, in the cylindrical lithium ion battery disclosed by the invention, the top cover, a rubber ring and the casing in a sealing port participate in sealing connection; and sealing stepped grooves are respectively arranged on the upper surface and the lower surface of the circumferential edge of the top cover, thus the explosion-proof sheet in the sealing port is prevented from being deformed due to stress; a pressure release value of the explosion-proof sheet is prevented from being increased or not being opened by exposing; safety problems such as burning, explosion and the like are reduced; and the stability, the sealing property, safety performances and the capacity space of the cylindrical lithium ion battery are improved.

Owner:DONGGUAN AMPEREX TECH +1

PCCP pipe diameter measuring device

InactiveCN104677241APrevent sideways movementImprove viewing angleMechanical diameter measurementsEngineeringSteel ball

The invention discloses a PCCP pipe diameter measuring device. The PCCP pipe diameter measuring device comprises a fixed cylinder, a limiting cylinder which is mounted in the fixed cylinder, a truncated cone-shaped moving block and a fixed seat; a steel ball is rotatably arranged at the bottom of the limiting cylinder; the steel ball is partially protruded from the bottom end of the fixed cylinder; a spring is mounted in the fixed cylinder; the moving block is connected with the free end of the spring and is connected with the fixed seat through a graduated scale; a plurality of bulges are formed on the outer wall of the moving block; a plurality of grooves which are matched with the bulges are formed in the inner wall of the fixed cylinder; a rolling ball is rotatably arranged on the upper surface of the fixed seat. When the axis of the fixed cylinder is overlapped with the straight line in which the diameter of a pipeline is positioned, the data on the graduated scale is read, and is the displacement generated by the linear movement of the moving block; the inside diameter of the pipeline can be obtained by calculating, namely subtracting the linear displacement of the moving block from the linear distance between the bottom end of the steel ball and the top end of the rolling ball.

Owner:重庆巨龙管业有限公司

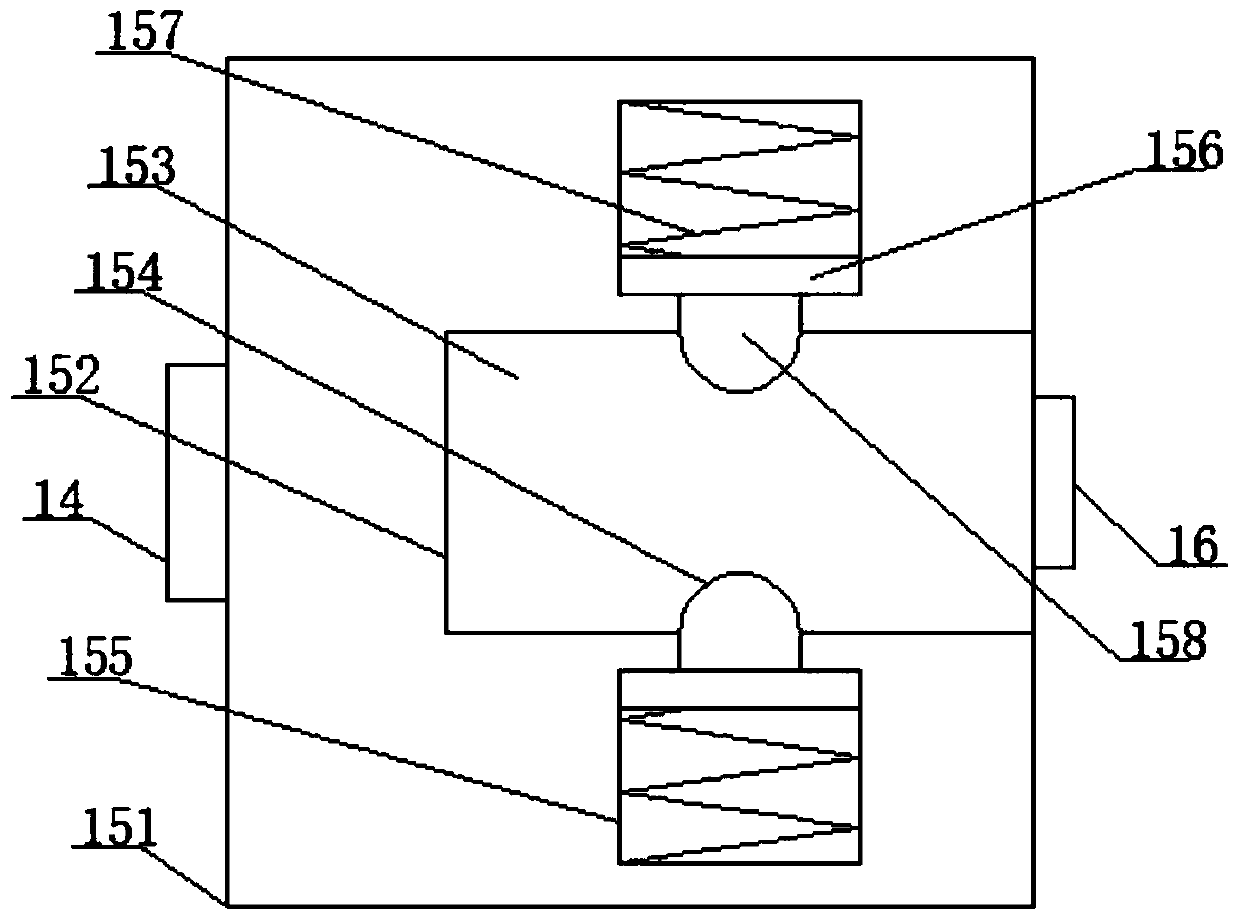

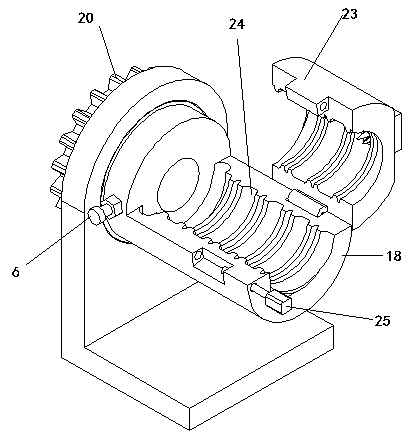

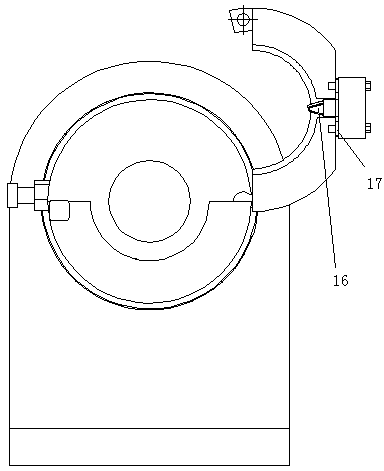

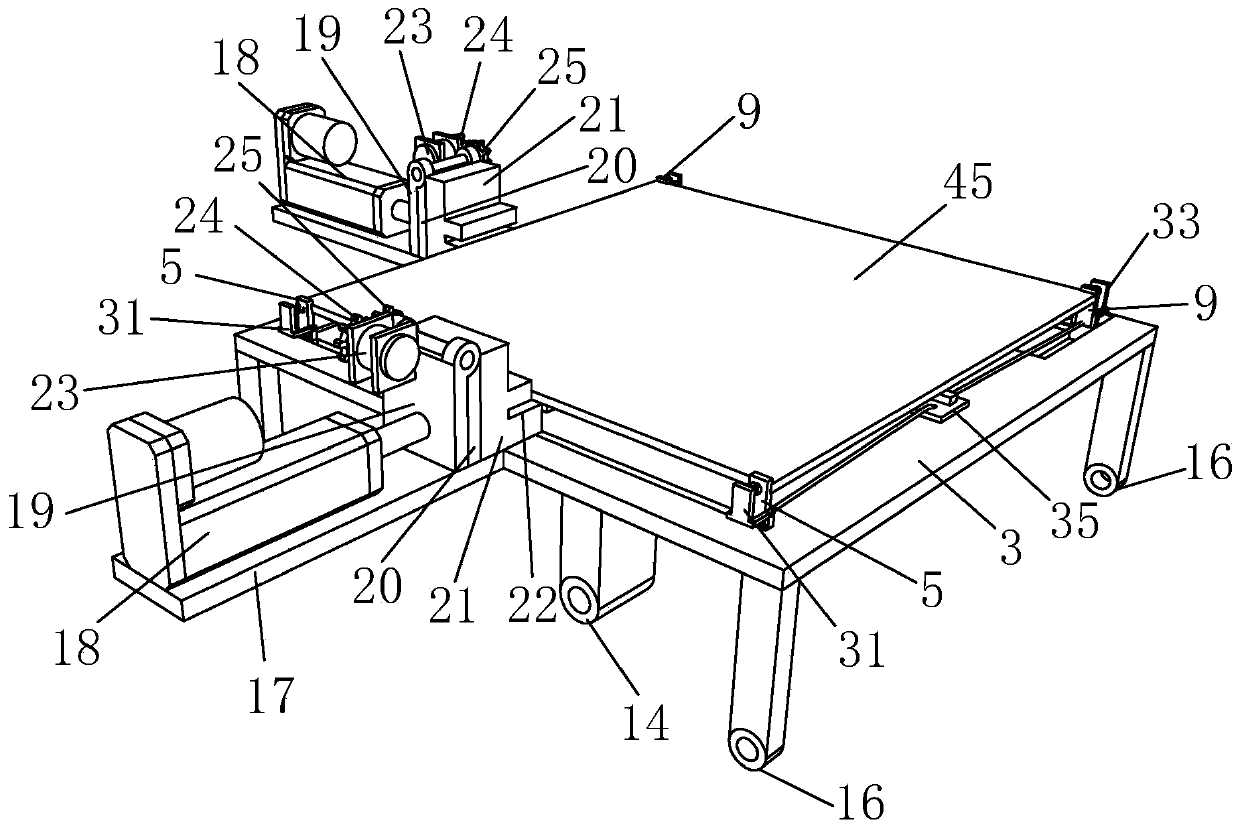

Profiling grinding repairing device for end surface of arresting gear of aero-engine

ActiveCN106392799AReduce labor intensityReduce manufacturing costGrinding drivesPlane surface grinding machinesArresting gearAero engine

The invention relates to a profiling grinding repairing device for the end surface of an arresting gear of an aero-engine. The profiling grinding repairing device comprises a base, a swinging mechanism, a clamping mechanism and a grinding mechanism; the swinging mechanism is fixedly mounted on one side above the base; the clamping mechanism is fixedly mounted on the other side above the base; the grinding mechanism is mounted on the swinging mechanism; the arresting gear is fixed to the clamping mechanism; an output end of the grinding mechanism grinds the arc end surface of the arresting gear; the output end of the grinding mechanism can perform reciprocating arc swinging relative to the arc end surface under the swinging action of the swinging mechanism. The profiling grinding repairing device has the advantages that the grinding trajectory is amplified by utilizing a profiling principle; profiling grinding is performed on the end surface of the arresting gear by adopting the profiling swinging mechanism of the arresting gear; the profiling grinding repairing device is low in manufacturing cost and easy to operate; batch production is easy to realize; through a transmission mechanism, the labour intensity of an operator is reduced; the operation is simple; the grinding efficiency is high; the grinding consistency is high; the precision is high.

Owner:国营川西机器厂

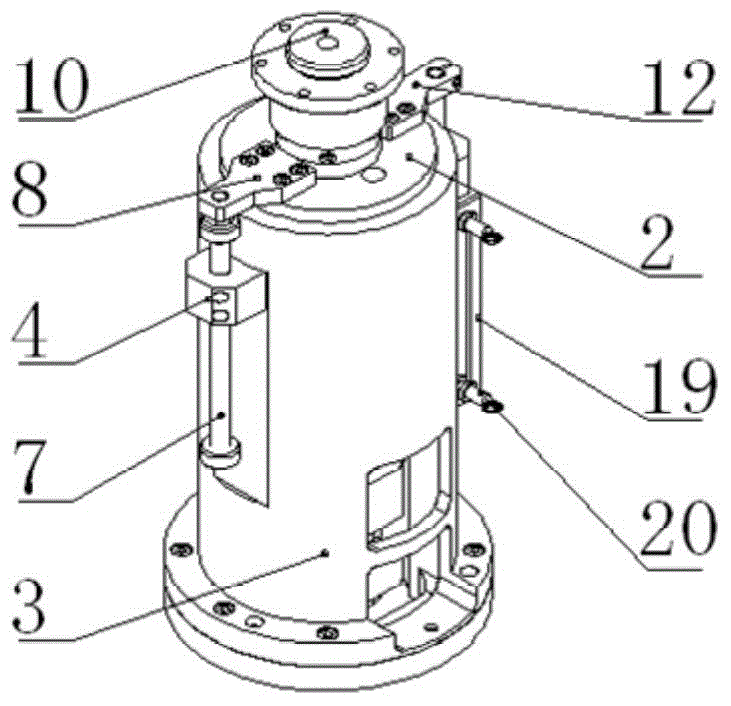

Vertical supporting device

The invention relates to a vertical supporting device which comprises an inner guiding base and an outer guiding sleeve located on the outer layer of the inner guiding base, wherein a guiding pillar which can slide along the axial direction is disposed between the inner guiding base and the outer guiding sleeve, a motor installation base is installed on the end part of the inner guiding base, a servo electric cylinder is placed inside the inner guiding base and fixed with the motor installation base, a connecting base connected with a push rod of the servo electric cylinder is installed on the guiding pillar, a supporting bulb is installed on the connecting base, and the supporting bulb is placed on a ball socket supporting base to form ball joint floating supporting; and an anti-rotation connecting plate is fixed on the guiding pillar, an anti-rotation base is fixed on the side wall of the outer guiding sleeve, an anti-rotation rod is disposed in parallel with the axial direction of the push rod of the servo electric cylinder, one end of the anti-rotation rod is fixed on the anti-rotation base, and the other end passes through a guiding hole in the anti-rotation base. A guiding part and a transmission part coincide at positions and heights, and both the inner guiding and the outer guiding are adopted in the guiding pillar to keep good guiding performance and rigidity. As vertical guiding, the guiding pillar has large rigidity, so that guiding deviation caused by force carrying does not take place.

Owner:WENZHOU UNIVERSITY

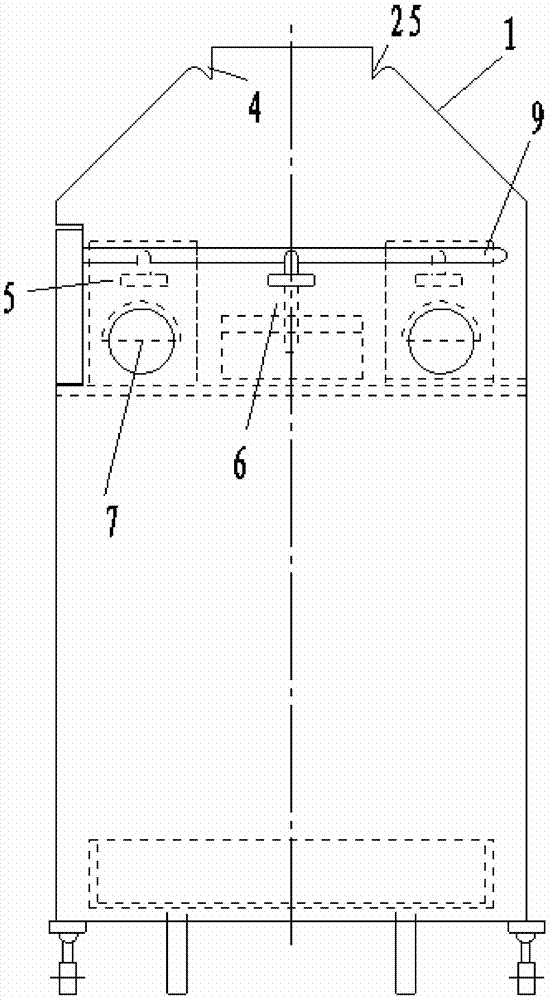

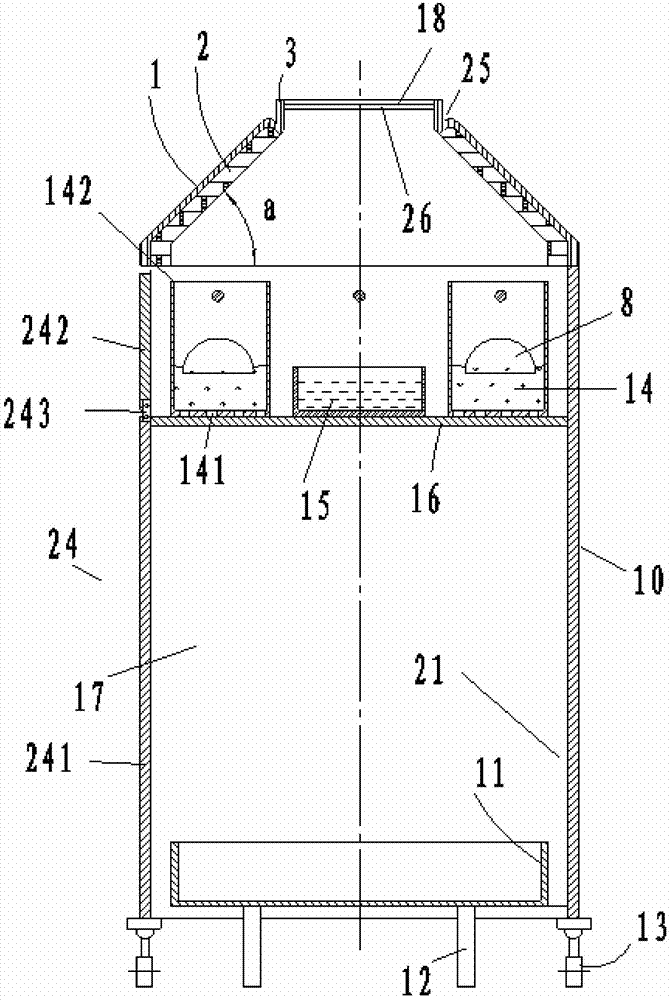

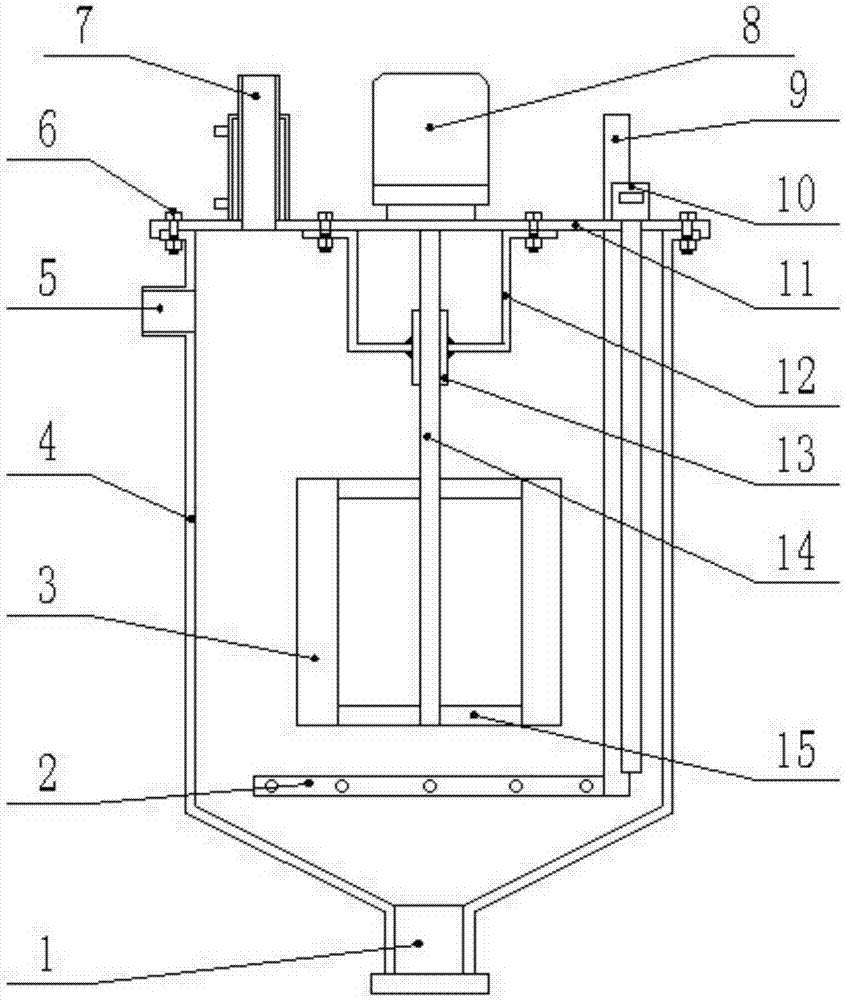

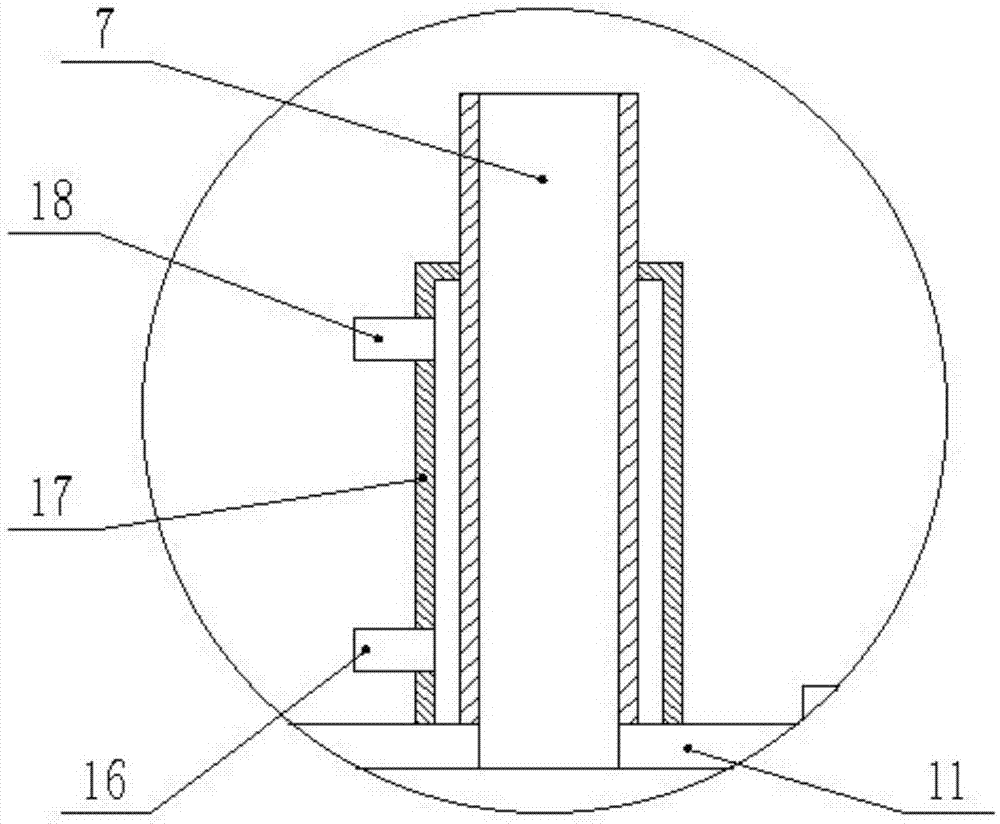

Ventilation type bioreactor

InactiveCN106906124AEasy to cleanEasy maintenanceBioreactor/fermenter combinationsBiological substance pretreatmentsDrive shaftAgricultural engineering

The invention provides a ventilation type bioreactor, and relates to the technical field of biological equipment. The ventilation type bioreactor comprises an upper cover and a tank body, wherein a charging opening and a discharging opening are respectively formed in upper and lower parts of the tank body; the upper cover is arranged on the tank body through a bolt, a seam is formed in the upper cover and is matched with the upper edge of the tank body; a vent short pipe, a liquid indicator, an air input pipe and a motor are arranged on the upper cover; a cooling water jacket is arranged outside the vent short pipe; a cooling water inlet and a cooling water outlet are respectively formed in the upper part and the bottom part of the side face of the cooling water jacket; the liquid indicator passes through the upper cover and extends to the bottom of the tank body; the air input pipe also passes through the upper cover and extends to the bottom of the tank body; the lower end of the air input pipe is connected with an air-flow distribution annular pipe; the driving shaft of the motor passes through the upper cover and extends into the tank body, and is provided with a stirring rack; at least two stirring blades are arranged on the stirring rack; a centralizing rack is arranged under the upper cover; a centralizing casing is fixed at the center of the righting rack; the driving shaft passes through the inner hole of the righting casing; and the inner hole of the righting casing is in clearance fit with the driving shaft.

Owner:嘉泽成华(天津)科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com