Patents

Literature

47 results about "Distressing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Distressing (or weathered look) in the decorative arts is the activity of making a piece of furniture or object appear aged and older, giving it a "weathered look", and there are many methods to produce an appearance of age and wear. Distressing is viewed as a refinishing technique although it is the opposite of finishing in a traditional sense. In distressing, the object's finish is intentionally destroyed or manipulated to look less than perfect, such as with sandpaper or paint stripper. For example, the artisan often removes some but not all of the paint, leaving proof of several layers of paint speckled over wood grain underneath. This becomes the "finished" piece.

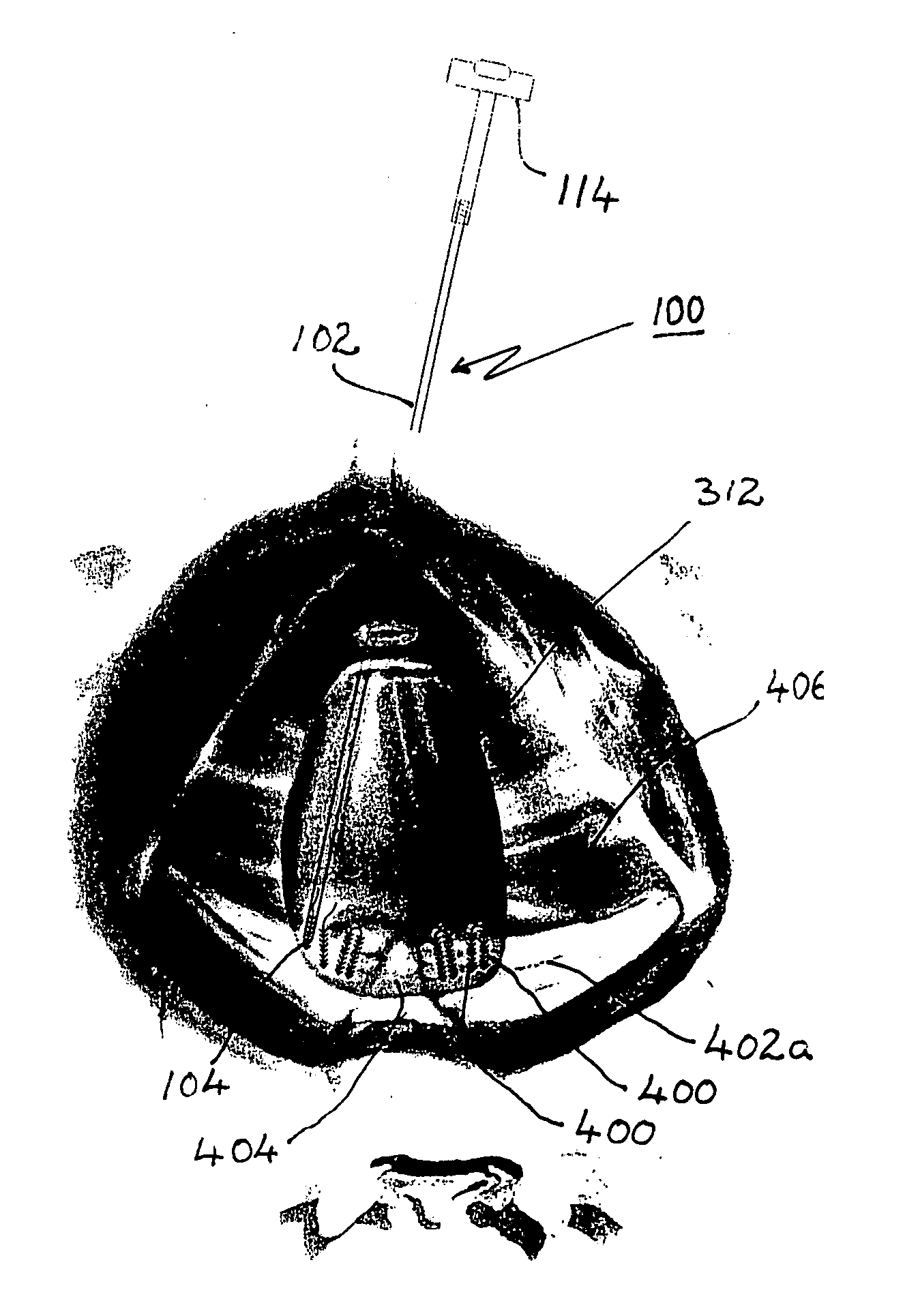

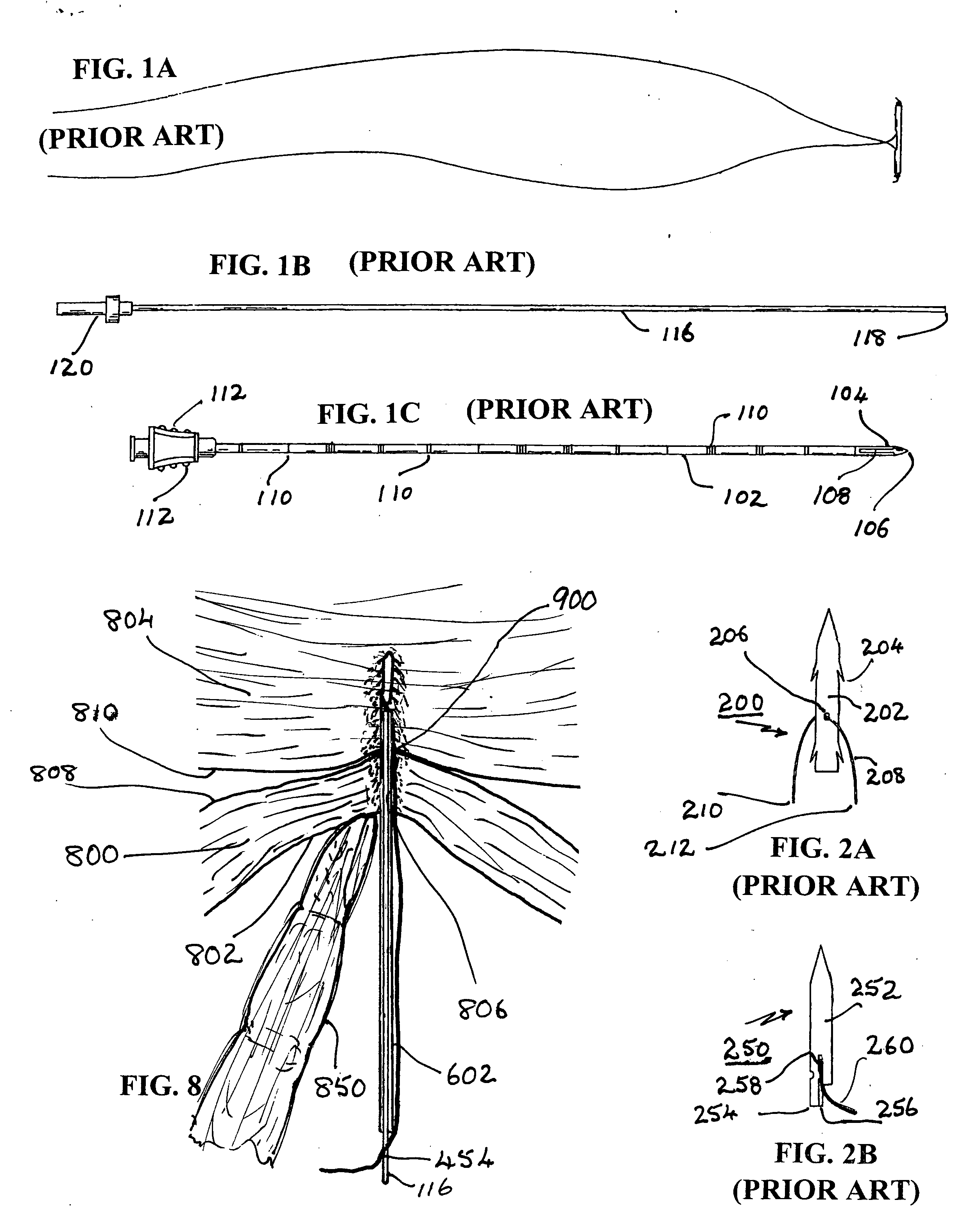

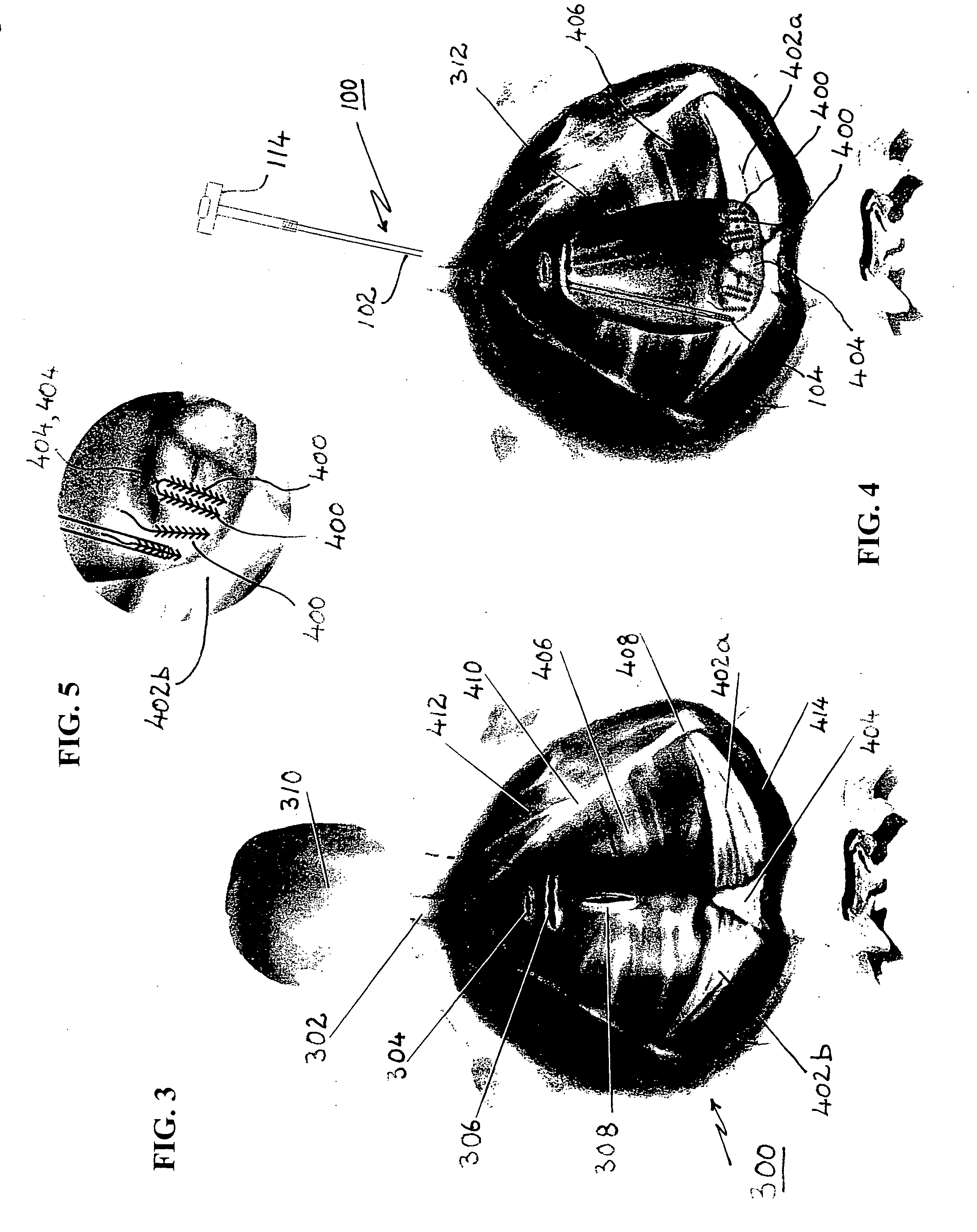

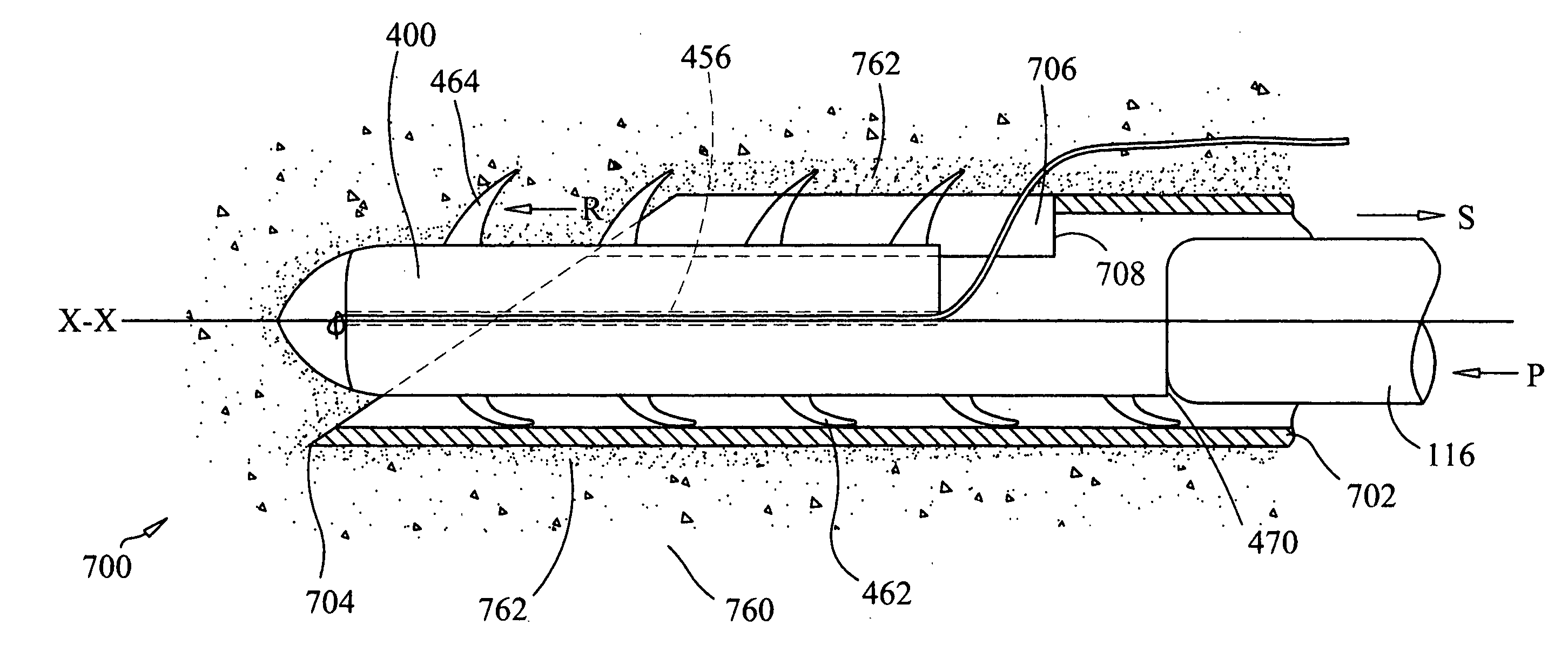

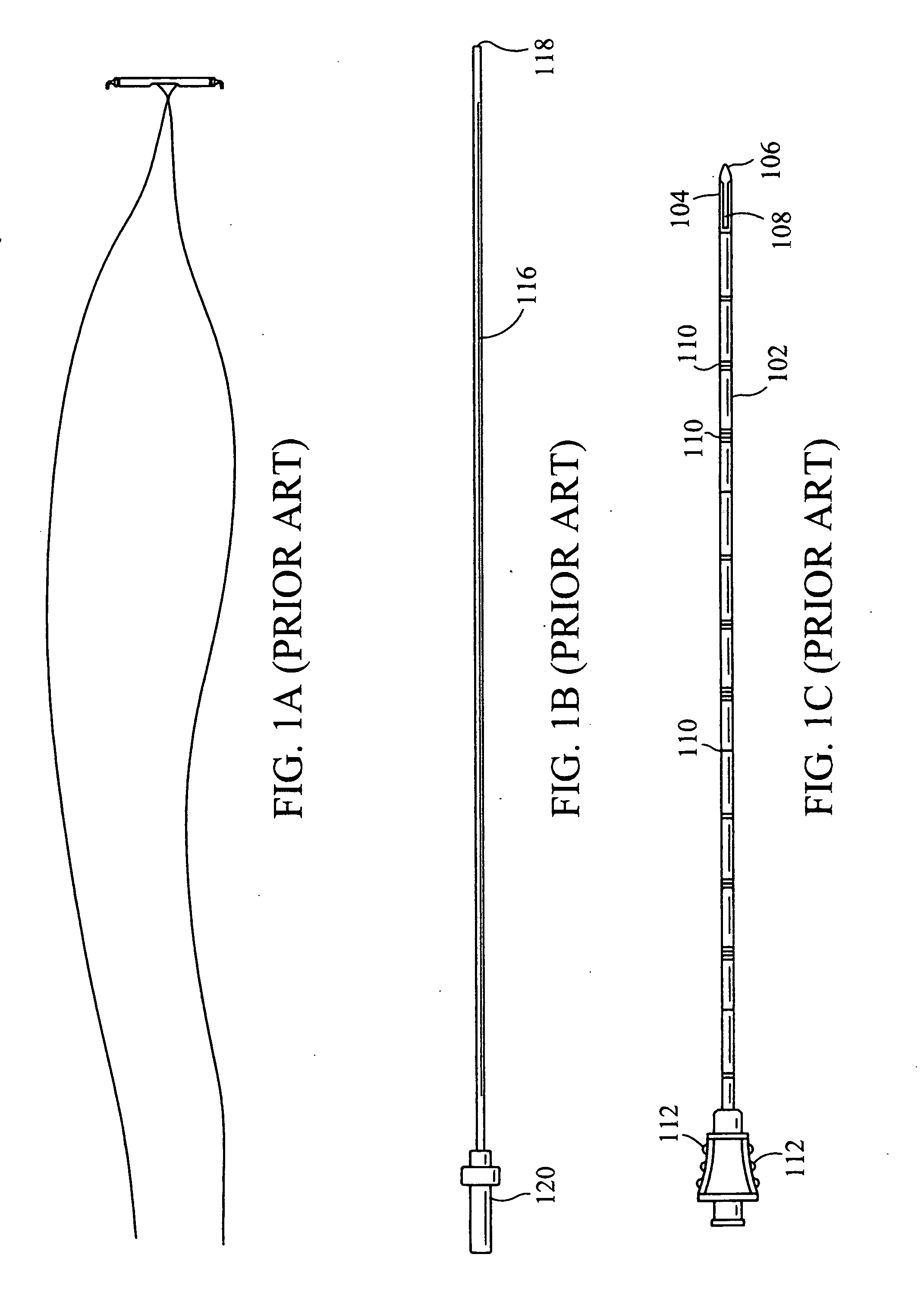

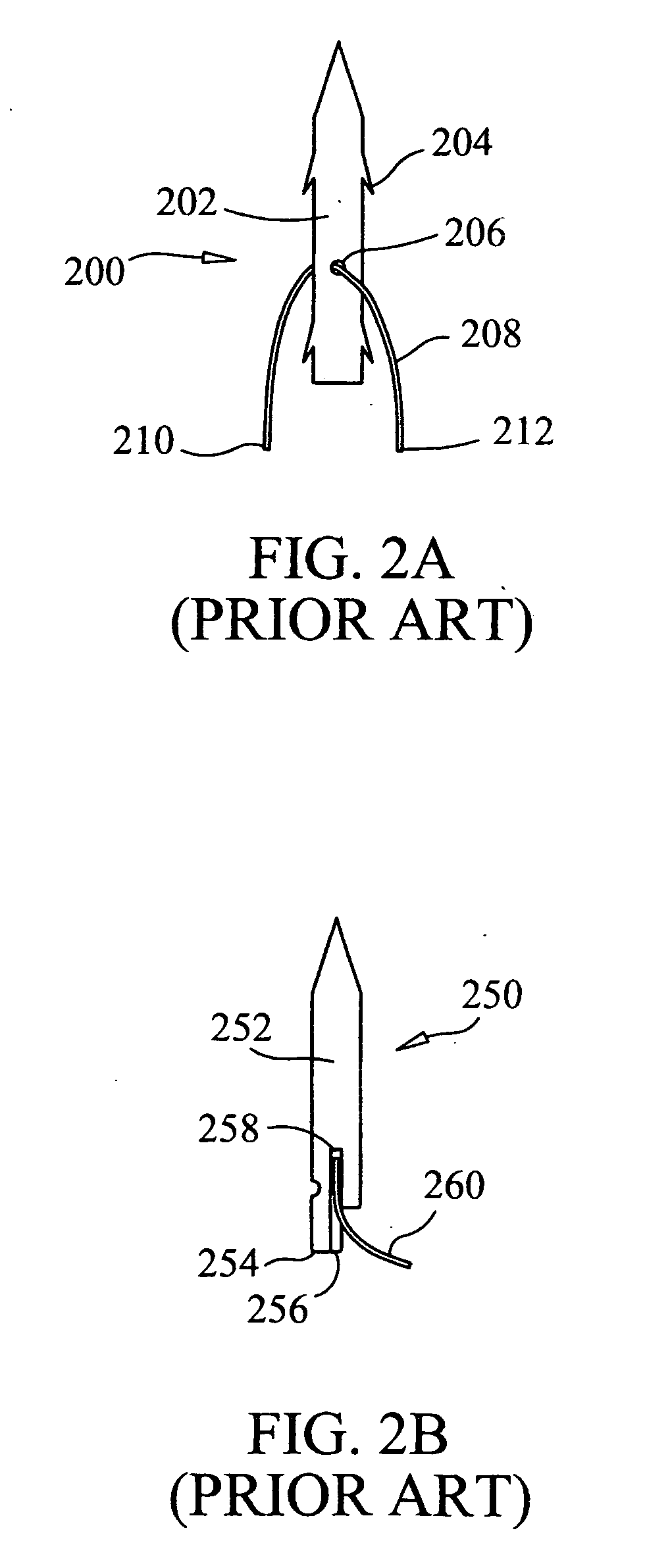

Apparatus and method for incision-free vaginal prolapse repair

InactiveUS20050199249A1Simple, minimally invasive and inexpensiveQuick fixSuture equipmentsBed wetting preventionVaginal ProlapsesDistressing

In a preferred application, e.g., the repair of vaginal prolapse after relocation of the vagina and any organs displaced by the prolapse, corrective surgery is initiated by applying a hollow tubular element, formed to forcibly insert a barbed anchor attached to a distal end of a first length of suture, without any incision, from the inside of the vagina through the vaginal wall (the supported tissue) into selected support tissue within a patient's pelvis. This involves puncturing and thus locally severe physical distressing of both the supported tissue and the support tissue. The barbed anchor is left in the support tissue as the tubular element is then withdrawn from the support tissue and out of the vagina, leaving the proximate end portion of the suture extending through the vaginal wall into the vagina. A second such anchor, with a second length of suture attached thereto, is similarly inserted adjacent to the first anchor. The proximate end portions of the sutures are tied to each other inside the vagina, to thereby secure the vaginal wall to the support tissue with corresponding punctures formed in each by the insertions of the two anchors being thereby held in respective, precisely aligned, intimate contact during healing. This results in a pair of fused scars that cooperate to permanently bond the vaginal wall locally to the support tissue. If the sutures and / or the anchors are made of absorbable material they will all eventually disappear and the fused scars will provide the permanent bonding. If the anchors are made of non-absorbable material they may remain where located. A plurality of such paired fused-scar bonds may be generated, at the surgeon's discretion, to ensure adequate support for the repaired vagina. The apparatus and method can be readily adapted to similarly effect deliberate, local, beneficial bonding between other adjacent living tissues in a patient.

Owner:KARRAM MICKEY M

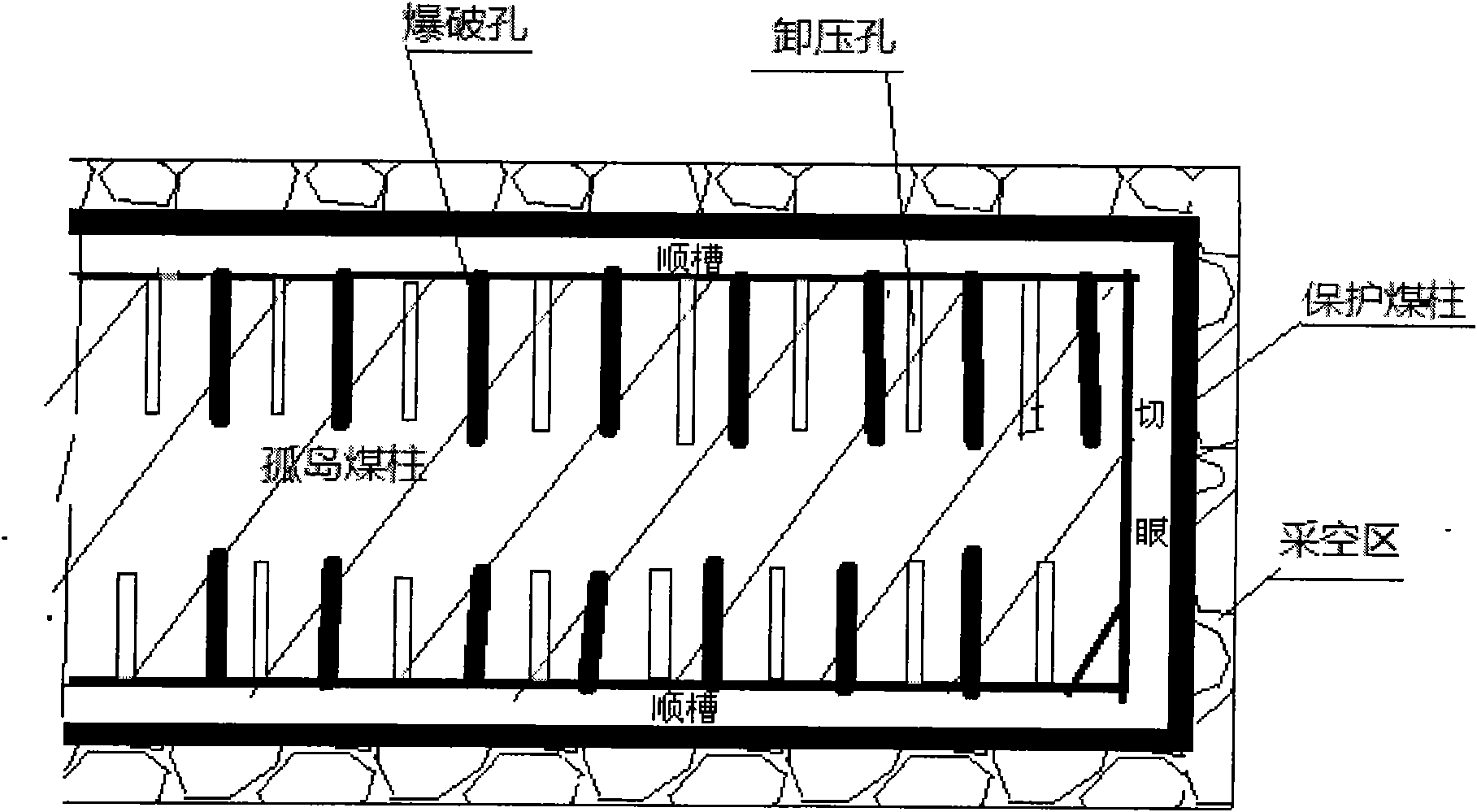

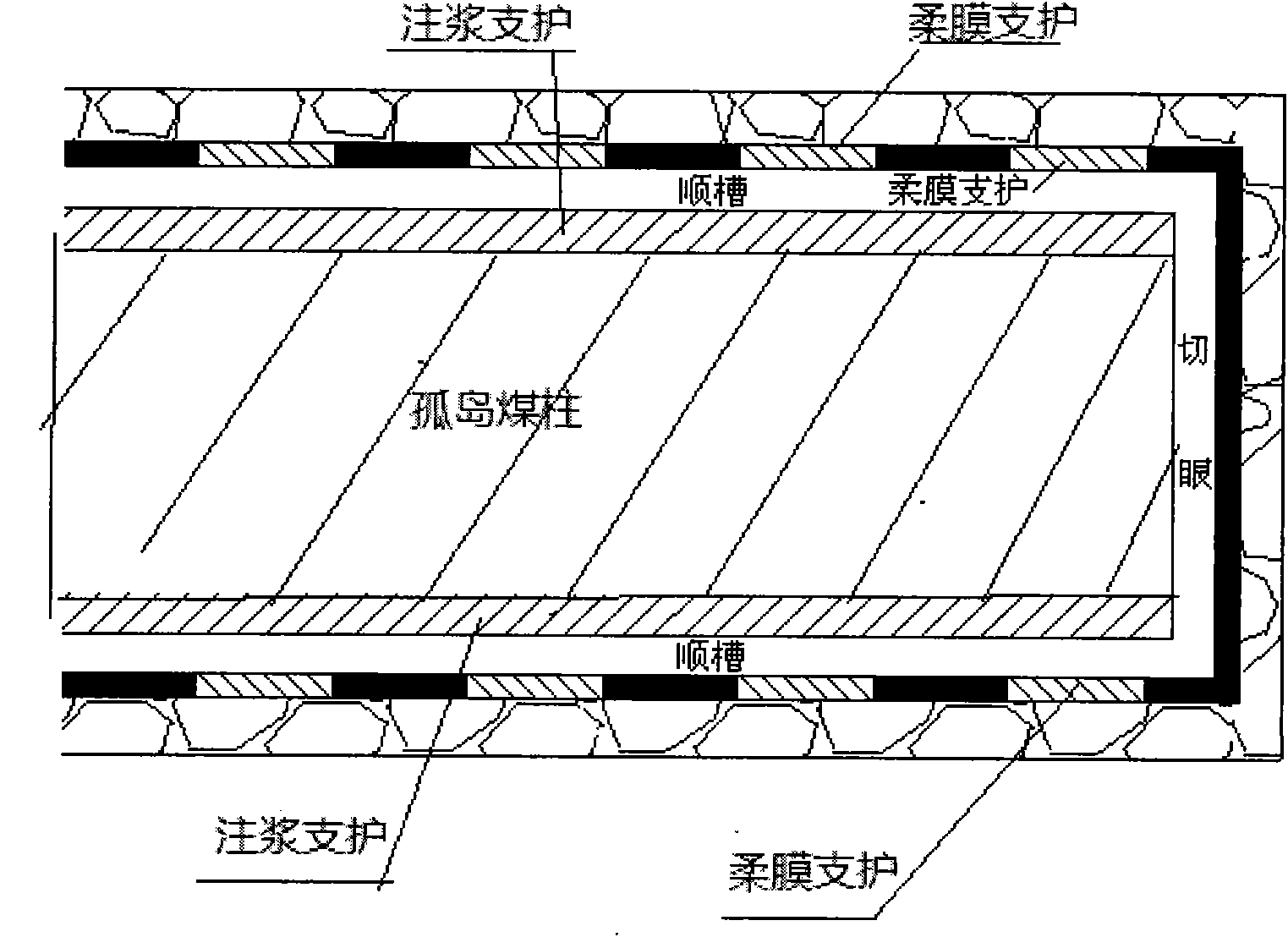

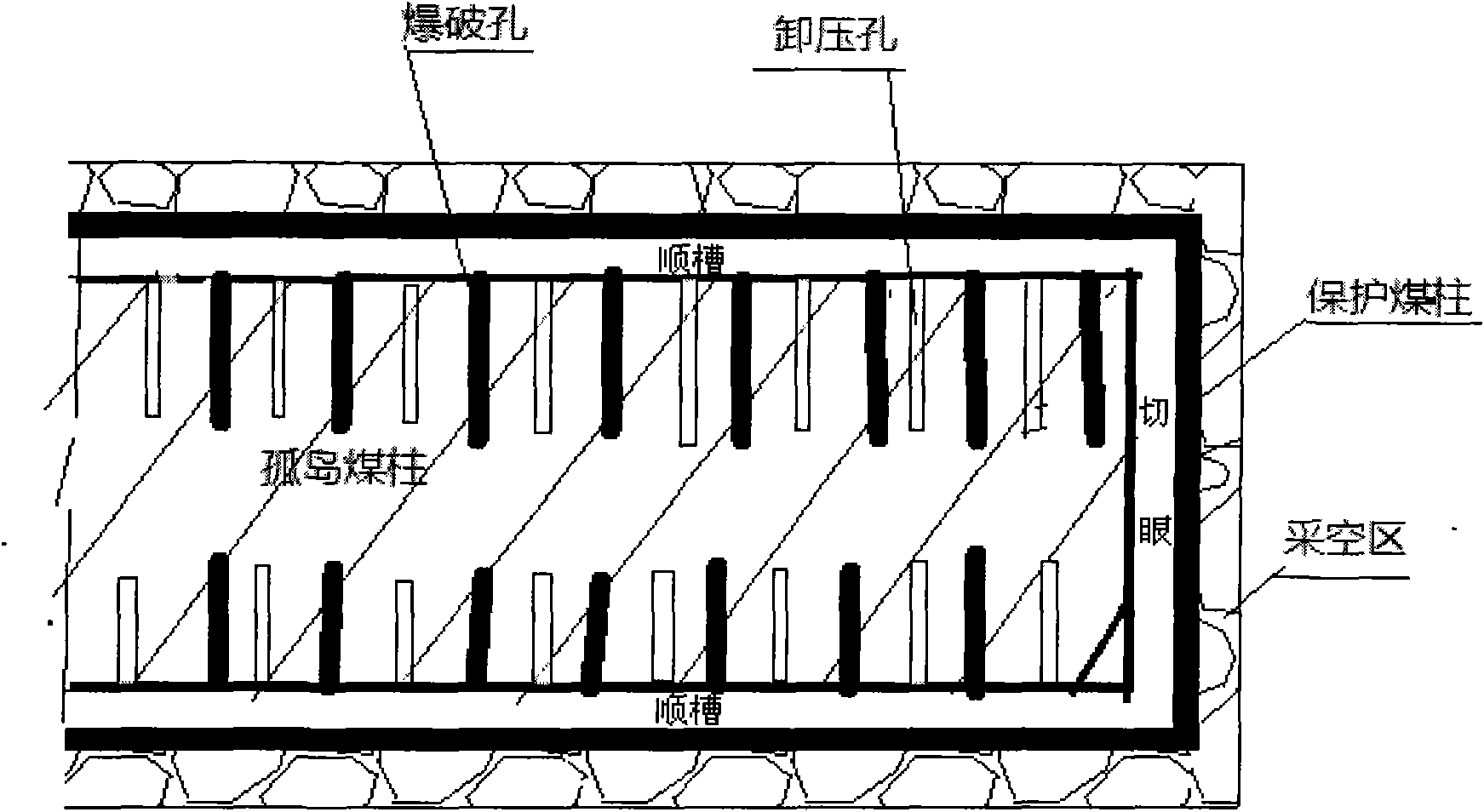

Control method for coal mine insular coal pillar crossheading rock burst

InactiveCN102322262AHigh strengthAct as a protective wallUnderground chambersUnderground miningDistressingCoal pillar

The present invention discloses a control method for coal mine insular coal pillar crossheading rock burst. According to the method, firstly, roadways of a coal mine insular coal pillar are dug and arranged on an upper crossheading, a lower crossheading and a coal face cut; treatments of drilling and blasting distressing are performed on inner side walls of the upper crossheading and the lower crossheading; then, a treatment of interval strong supporting is performed on outer side walls of goaf sides of the upper crossheading and the lower crossheading; finally, a treatment of grouting is applied on the inner side walls of the upper crossheading and the lower crossheading to reinforce the support, wherein the upper crossheading and the lower crossheading are subjected to the blasting distressing. With the present invention, the drilling and the blasting distressing are adopted, the ground pressure of the coal pillar is released, such that the coal body with the impact trend is transformed in the coal body with the weak impact trend; the strong supporting is performed for both side walls, such that the strength of the coal body from the coal wall of the roadway to the deep roadway is improved, the protection wall effect is provided for the roadway, and the safeties of the workers are protected.

Owner:SHANDONG UNIV OF SCI & TECH

Apparatus and method for incision-free vaginal prolapse repair

InactiveUS20090023982A1Simple, minimally invasive and inexpensiveQuick fixSuture equipmentsTubular organ implantsVaginal ProlapsesDistressing

In a preferred application, e.g., the repair of vaginal prolapse after relocation of the vagina and any organs displaced by the prolapse, corrective surgery is initiated by applying a hollow tubular element, formed to forcibly insert a barbed anchor attached to a distal end of a first length of suture, without any incision, from the inside of the vagina through the vaginal wall (the supported tissue) into selected support tissue within a patient's pelvis. This involves puncturing and thus locally severe physical distressing of both the supported tissue and the support tissue. The barbed anchor is left in the support tissue as the tubular element is then withdrawn from the support tissue and out of the vagina, leaving the proximate end portion of the suture extending through the vaginal wall into the vagina. A second such anchor, with a second length of suture attached thereto, is similarly inserted adjacent to the first anchor. The proximate end portions of the sutures are tied to each other inside the vagina, to thereby secure the vaginal wall to the support tissue with corresponding punctures formed in each by the insertions of the two anchors being thereby held in respective, precisely aligned, intimate contact during healing. This results in a pair of fused scars that cooperate to permanently bond the vaginal wall locally to the support tissue. If the sutures and / or the anchors are made of absorbable material they will all eventually disappear and the fused scars will provide the permanent bonding. If the anchors are made of non-absorbable material they may remain where located. A plurality of such paired fused-scar bonds may be generated, at the surgeon's discretion, to ensure adequate support for the repaired vagina. The apparatusand method can be readily adapted to similarly effect deliberate, local, beneficial bonding between other adjacent living tissues in a patient.

Owner:KARRAM MICKEY M

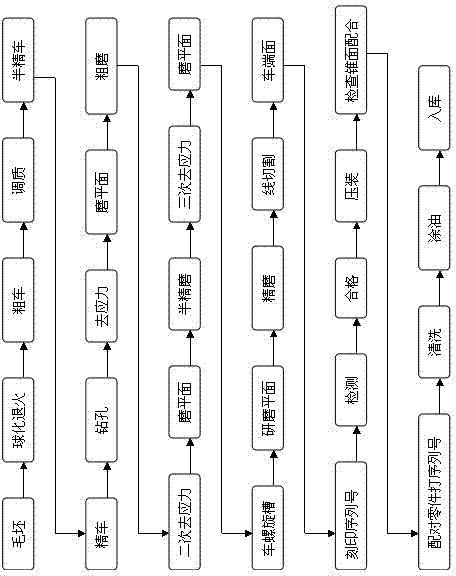

Machining technology for high-precision outer conical surface thin wall sleeve

InactiveCN103495844AMeet the technical requirements of high-precision outer tapered thin-walled sleevesReduce distortionNumerical controlEngraving

The invention relates to the technical field of high-precision part machining process, in particular to a machining technology for a high-precision outer conical surface thin wall sleeve. The machining technology includes the following technology processes of workblank preparing, spheroidizing annealing, rough turning, thermal refining, semi-finish turning, finish turning, hole drilling, distressing, plane grinding, rough grinding, secondary distressing, plane grinding, spiral groove turning, plane lapping, accurate grinding, wire-electrode cutting, end face turning, serial number engraving, detecting, qualified product obtaining, press fitting, conical surface fit detecting, part matching and serial number printing, cleaning, lubricating oil coating and warehousing. A double-end vertical type numerical control grinder is adopted as a finishing machine, and through the machining methods of rough grinding and accurate grinding or rough grinding, semi-accurate grinding and accurate grinding, the technical requirements of the high-precision outer conical surface thin wall sleeve can be met; through the corresponding distressing heating processing technology, residual stress in the machining process is removed, deformation in the machining process can be reduced, the yield of products is improved, and finally the good manufacturing method of the high-precision outer conical surface thin wall sleeve is provided.

Owner:CRRC QISHUYAN CO LTD

Archaizing floorboard manufacturing method

The invention discloses an archaizing floorboard manufacturing method. The archaizing floorboard manufacturing method includes steps of preparing raw materials, to be specifically, slicing and drying oak timber, gluing base materials, veneering, cold pressing, preserving, punching strips, grooving and manually archaizing the surface; producing finished products, specifically, preparing toner according to color needs, painting toner of corresponding color on the raw materials, drying and distressing by water-based color paste and polishing, and coating wax oil or UV (ultraviolet) paint. Archaizing colors similar to black, brown and gray are generated, and compared with conventional painting color matching, the archaizing colors are higher in matching degree with timber color and are more likely to be unified with the timber color, rich and natural. Colors at wood furuncles and positions high in tannin content and other parts gradually change, so that the archaizing floorboard is more colorful.

Owner:SINO MAPLE JIANGSU CO LTD

Machining technology of turbine blade with water corrosion prevention achieved by means of laser cladding

ActiveCN103659201AGuarantee the requirements of machining dimensional accuracyGuarantee cladding qualityStellite alloyDistressing

The invention provides a machining technology of a turbine blade with water corrosion prevention achieved by means of laser cladding. According to the machining technology of the turbine blade, the machining precision of the blade can be guaranteed, the fusion cladding amount is small, and tool loss is reasonable. The machining technology of the turbine blade with the water corrosion prevention achieved by means of laser cladding comprises the steps of (1) blank manufacturing; (2) forming through die forging; (3) heat treatment; (4) rough milling of the molded surface of a blank and milling of a laser cladding groove, wherein a certain redundant amount of a forge piece is removed through milling, and the laser cladding groove is machined until the laser cladding groove is within a certain tolerance range; (5) laser cladding of stellite in the laser cladding groove; (6) correction of a blade by means of a pressing machine after laser cladding; (7) radiographic and penetration inspection of a laser cladding area; (8) repairing welding of an unqualified portion, in the laser cladding area, of the blade through argon arc welding; (9) distressing and heat treatment; (10) comprehensive milling, wherein the blade is machined until the blade is within the tolerance range; (11) polishing, wherein machining tool marks on the surface of the blade are removed through polishing; (12) shot blasting of the surface of the blade.

Owner:WUXI TURBINE BLADE

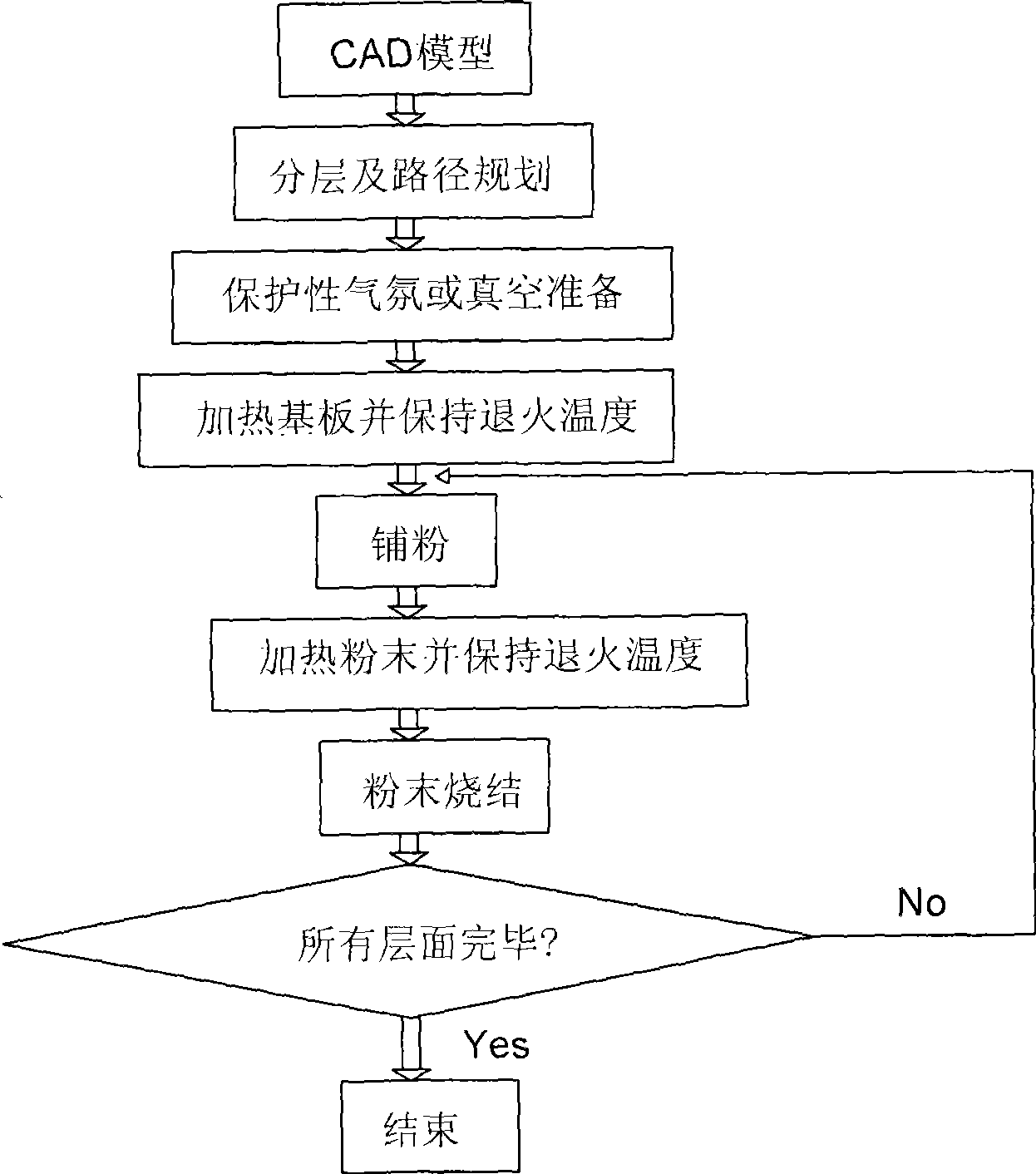

Manufacturing process of metal parts capable of performing shape follow-up annealing heat treatment

The invention discloses a manufacturing process of metal parts which can carry out conformal annealing heat treatment. The process includes the steps: firstly, according to the concrete structure of the part to be formed, the preliminary design of a supporting and temperature control area is carried out, a CAD model for manufacturing parts rapidly is established, layering and scan path planning are carried out to the CAD model, and protective atmosphere or vacuum preparation is carried out to a forming box to enter a forming process; in the forming process, a substrate, each layer of metal powder and the part are all heated and kept at the preset conformal heat treatment temperature, annealing and distressing are carried out while the part is formed, and the part is naturally cooled after forming. The manufacturing process can reduce the energy and time needed by sintering a forming area selected by the scanning of high-energy beams, achieve the aims of reducing deformation and reducing stress, and improve the precision and quality of part forming.

Owner:西安赛隆增材技术股份有限公司

Making technology for copying bronze ware

InactiveCN105921694AReduce wear and tearImprove manufacturing efficiencyFoundry mouldsFoundry coresRolloverDistressing

The invention discloses a making technology for copying bronze ware. The making technology for copying bronze ware comprises the steps of molding, rollover, paraffin mold making, mold trimming, sand lining, hard shell forming, dewaxing, shell sintering, copper melting, casting, sand cleaning, welding, polishing and distressing, and traditional technologies and new materials are combined in the technology, so the technology can be widely used in modern production; and the making technology is used in the making industry. The making technology has the advantages of energy resource loss saving, suitableness for making special-shaped products and works, and increase of the production making efficiency, and is most suitable for copying imitated works.

Owner:李万祥

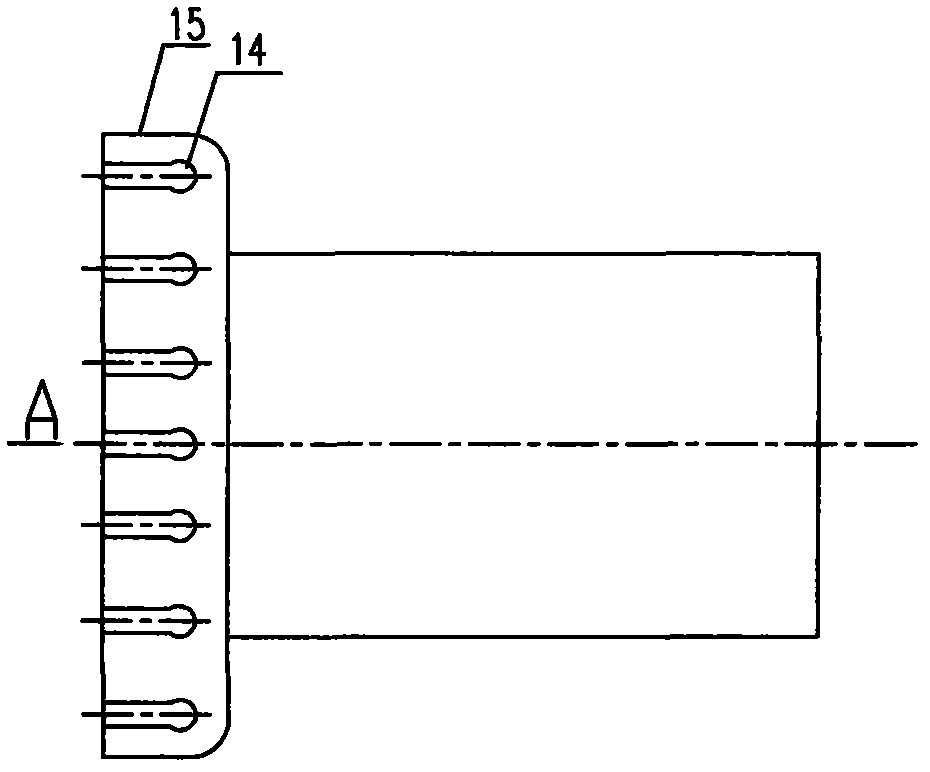

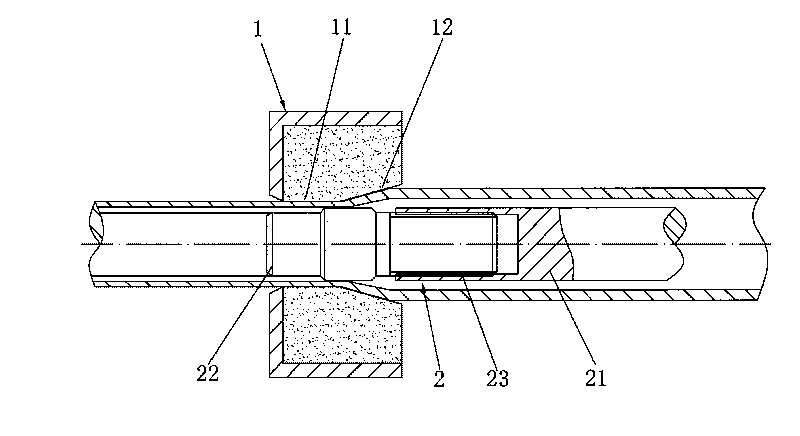

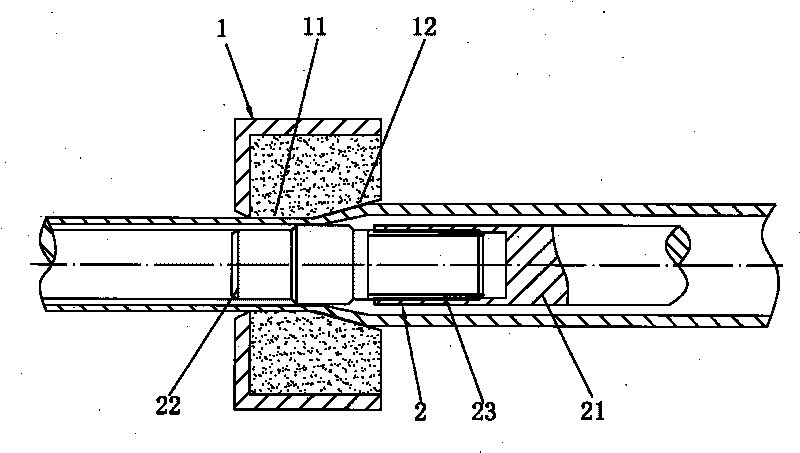

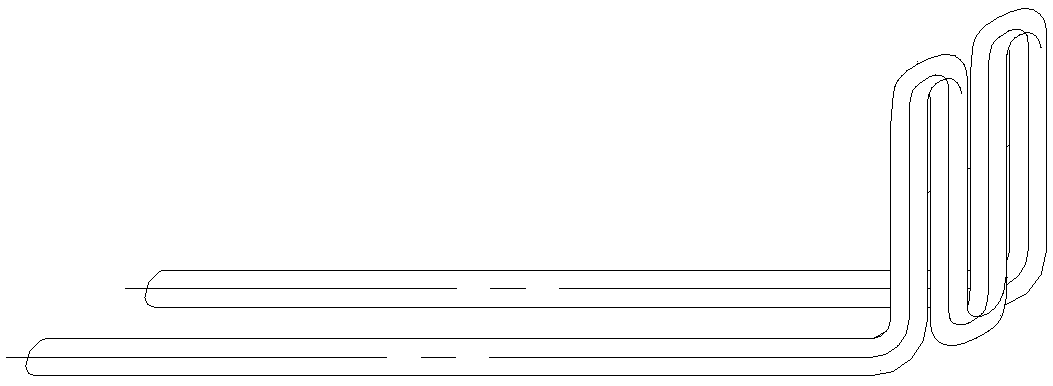

Guide cylinder structure applied on corrugated pipe expansion joint

InactiveCN102135218ANo distortionReasonable designPipeline expansion-compensationAxial displacementDistressing

The invention belongs to the technical field of petrochemical industry, and provides a guide cylinder structure applied on a corrugated pipe expansion joint. The front end of the guide cylinder is provided with a guide cylinder compensation ring (15); the outer side surface of the guide cylinder compensation ring (15) is provided with a plurality of distressing grooves (14) which are distributed along the circumference of a cylinder body; the distressing grooves (14) and the guide cylinder are axially consistent; the hoop stress generated by the heat expansion of the guide cylinder is reduced by the distressing grooves (14), thus the guide cylinder is not subjected to torsion and deformation; and the arc section of the guide cylinder compensation ring is jointed with the shell section of the corrugated pipe expansion joint, when the guide cylinder is expanded caused by heating, the arc transition section absorbs the radial displacement and axial displacement generated by the guide cylinder due to the expansion caused by heating, and absorbs the radial stress and axial stress generated by the guide cylinder due to the expansion caused by heating. According to the invention, through the distressing grooves distributed along the circumference of the cylinder body and the arc transition section of the cylinder body, thus the guide cylinder is not subjected to torsion and deformation when the guide cylinder works at high temperature, and the guide cylinder structure has the characteristics of reasonable design and simple structure.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

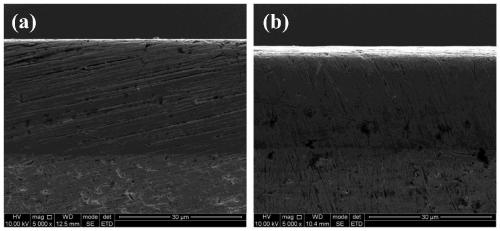

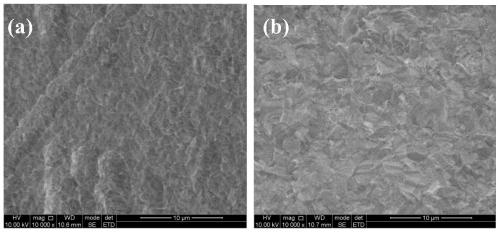

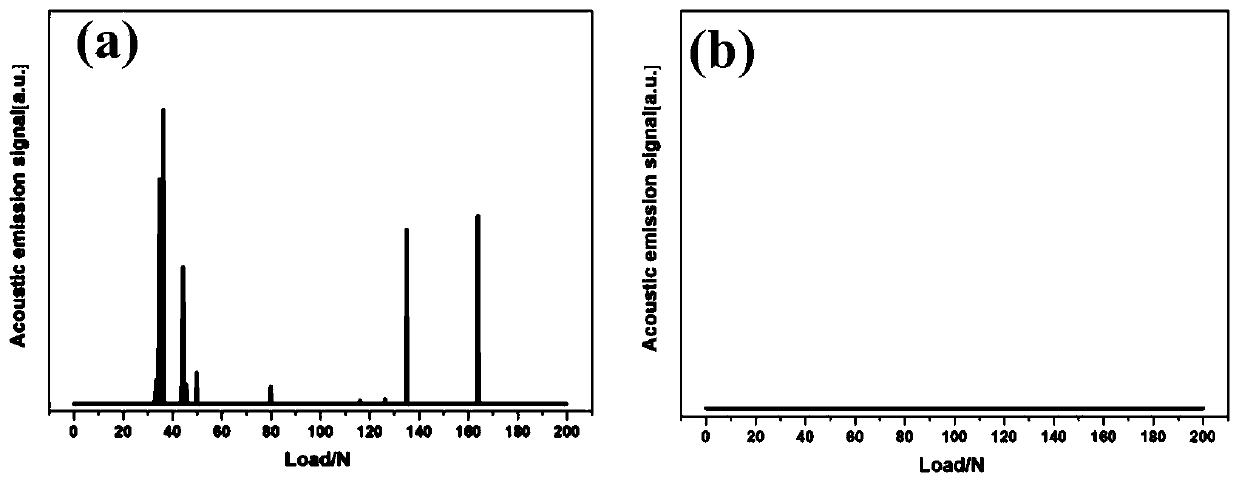

Preparation process for preparing Cr coating on surface of zirconium alloy substrate for nuclear application

ActiveCN110055496AStrong thicknessIncreasing the thicknessVacuum evaporation coatingSputtering coatingSputteringDistressing

The invention discloses a preparation process for preparing a Cr coating on the surface of a zirconium alloy substrate for nuclear application. The zirconium alloy substrate is ground, finally polishing processing is conducted on a metallographic phase polishing machine through polishing paste, and after the zirconium alloy substrate is polished to be smooth, washing is conducted on greasy dirt onthe surface of a zirconium alloy sheet; the zirconium alloy sheet is arranged in a vacuum furnace cavity of an ultrahigh vacuum magnetron sputtering device, and after the vacuum degree reaches the background vacuum 2*10<4> Pa, gas is injected, and bias voltage backwash washing is conducted for 10 minutes; after the backwash washing of the surface of the base sheet is completed and a Cr target israpidly started through a radio-frequency power supply, a baffle is closed, and pre-sputtering is conducted on the surface of the target for 10 minutes to remove surface oxide or adsorption impurities; the Cr target baffle is opened to conduct Cr coating deposition; and under the condition that a vacuum system is not turned off, the zirconium alloy is subjected to furnace cooling till the temperature is 100 DEG C or below, and distressing and deformation correcting processing is conducted. According to the preparation process, due to the adoption of the magnetron sputtering technology, the Crcoating with high binding force and high thickness is deposited on the zirconium alloy substrate for nuclear application.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Distressed active fuel dyed fabric and distressing method thereof

ActiveCN103088679AImprove efficiencySave human effortFibre treatmentDyeing processDistressingPulp and paper industry

The invention discloses a distressed active fuel dyed fabric and a distressing method thereof. The distressing method comprises the following steps of: dying a fabric in an airflow dyeing machine by use of an active dye, washing water for 10 minutes firstly, draining water, blowing air for 15 minutes, spraying high-pressure air by depending on the airflow dyeing machine to ensure that the fabric with water circularly moves in the airflow dyeing machine, then introducing ozone to ensure that the air pressure reaches 0.3-0.5bar, operating for 30 minutes, and exhausting air; introducing ozone to ensure that the air pressure reaches 0.3-0.5bar, operating for 30 minutes, and exhausting air; and introducing ozone to ensure that the air pressure reaches 0.3-0.5bar, operating for 30 minutes, exhausting air and washing water for 6 minutes, draining water, washing circulating water for 6min at a water temperature of 60 DEG C, draining water, removing remained ozone to obtain the distressed active fuel dyed fabric. The distressed active fuel dyed fabric has the characteristics of high efficiency, no damage to the fabric, no pollution to the environment, and the like; and the hand feel of the distressed active fuel dyed fabric can be improved.

Owner:PACIFIC (PANYU) TEXTILES LTD

Method for manufacturing copper pipe with circular outside and irregular inside

The invention discloses a method for manufacturing a copper pipe with a circular outside and an irregular inside, which comprises the following steps of: firstly, after performing hot pressing and cold rolling on a copper alloy ingot, stretching the ingot into a pipe blank, performing complete recrystallization annealing on the pipe blank, and arranging a chuck in an integrated structure or a split connection structure with the pipe blank at the front end of the pipe blank; secondly, stretching the pipe blank into the copper pipe with the circular outside and the irregular inside by finished product stretching equipment, wherein the finished product stretching equipment comprises a stretching die with a stretching hole inside and a stretching lining core which consists of a lining core and a stretching core rod connected with the end part of the lining core; and thirdly, distressing, finishing and annealing the stretched finished pipe under a protective atmosphere to eliminate the residual stress in the pipe. In the copper pipe with the circular outside and the irregular inside manufactured by the method, the inner and outer surfaces of the pipe do not need mechanical machining again; the utilization rate of the raw materials and the yield are improved; the manufacturing cost and resource waste are greatly reduced; the pipe is long in service life; and the maintenance cost caused by the frequent replacement of the corroded pipes is reduced.

Owner:ZHEJIANG HAILIANG

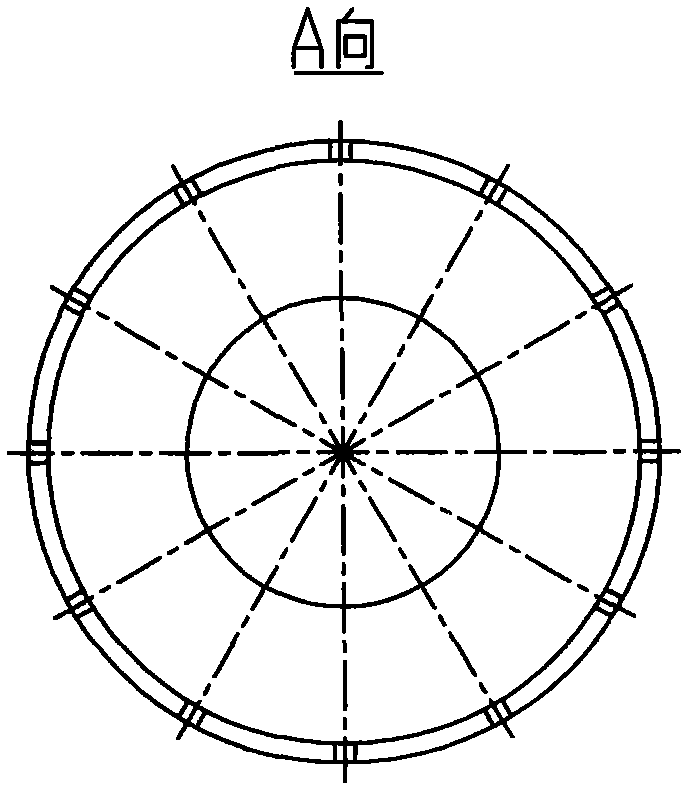

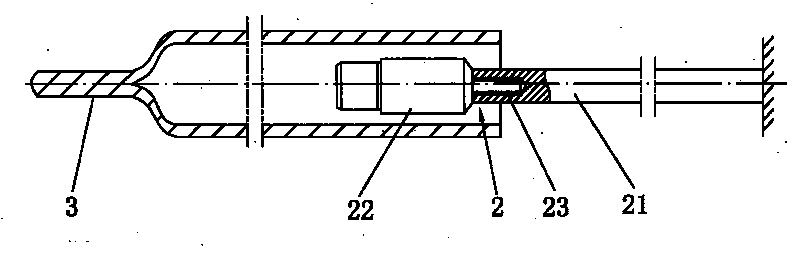

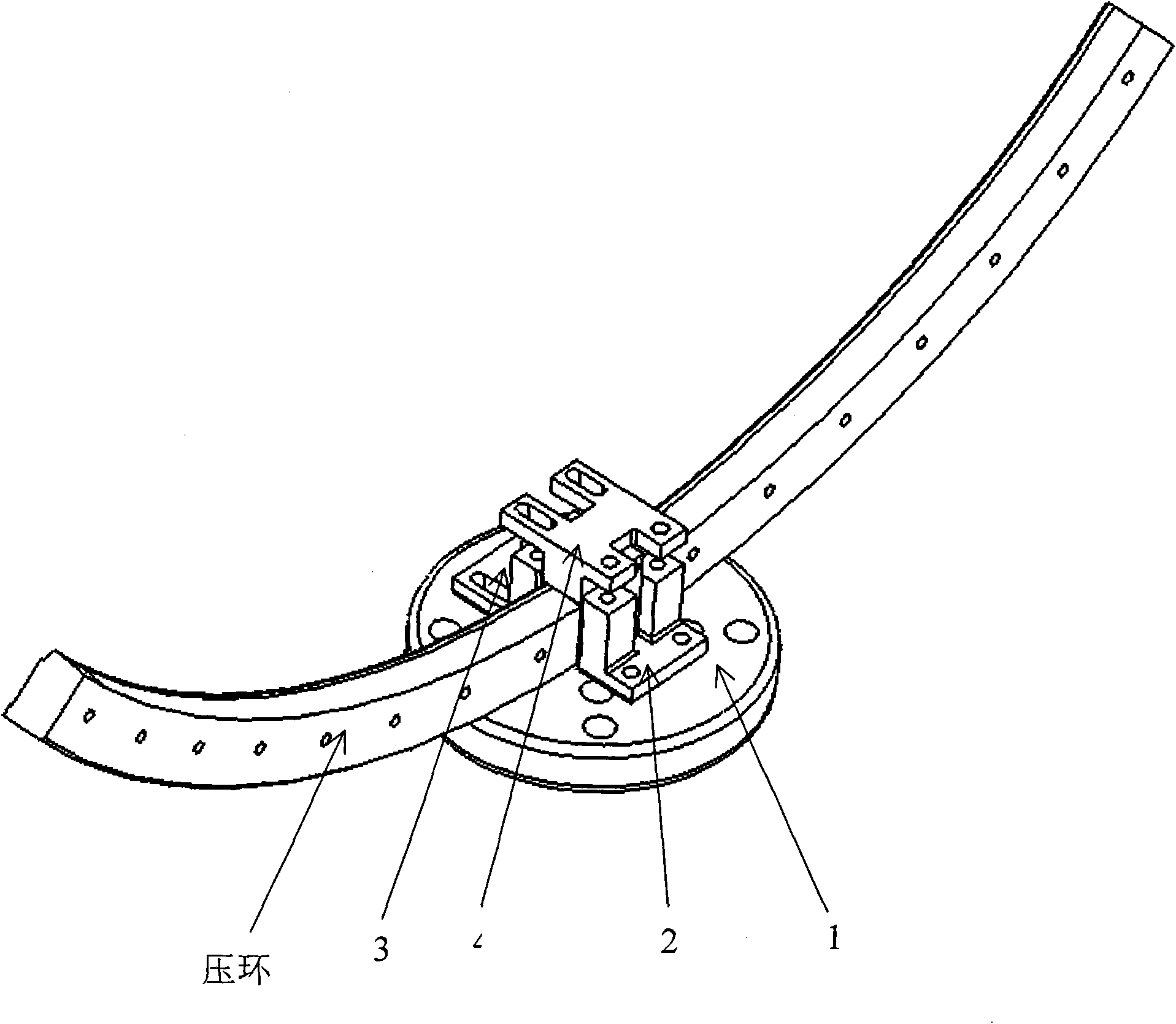

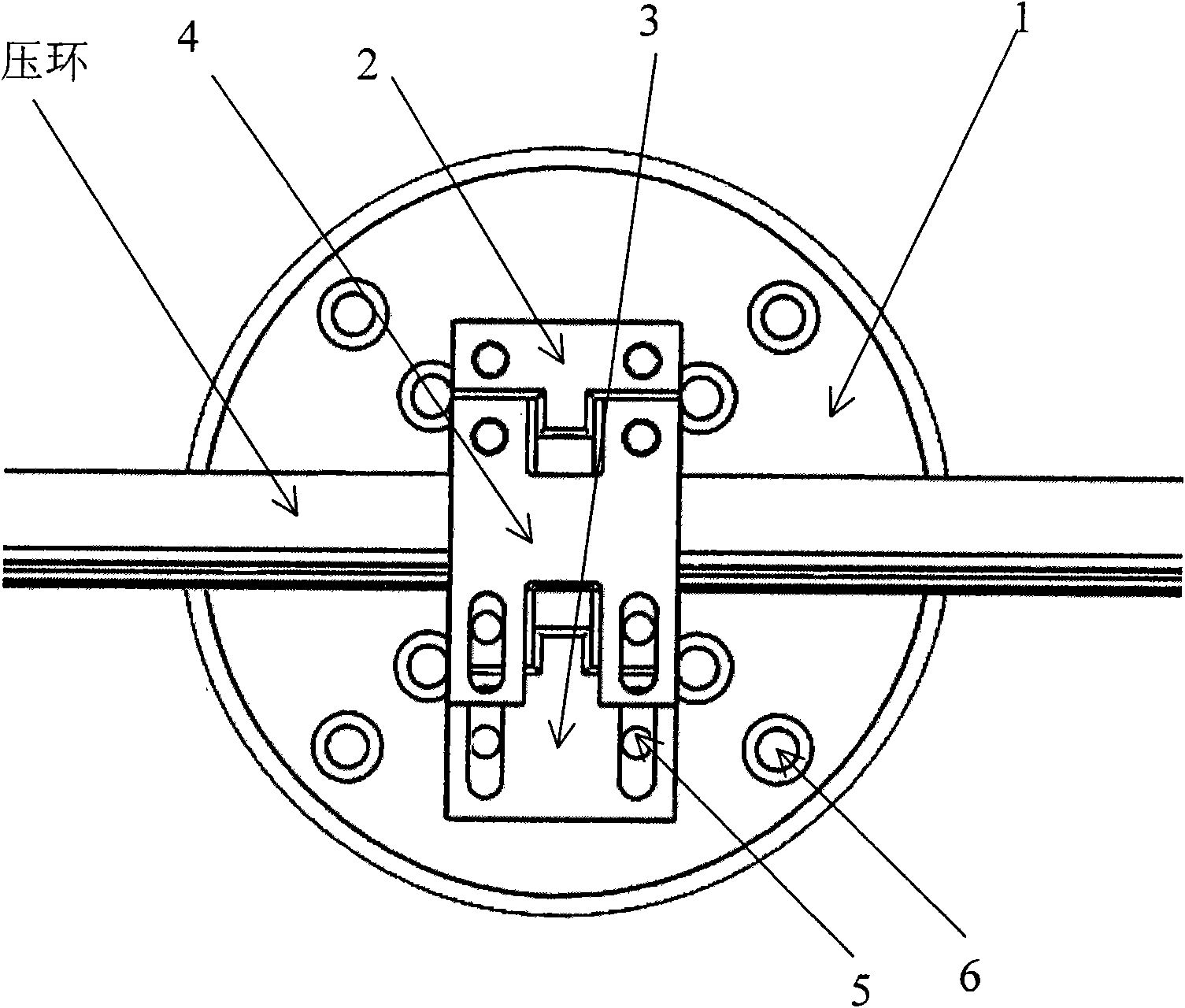

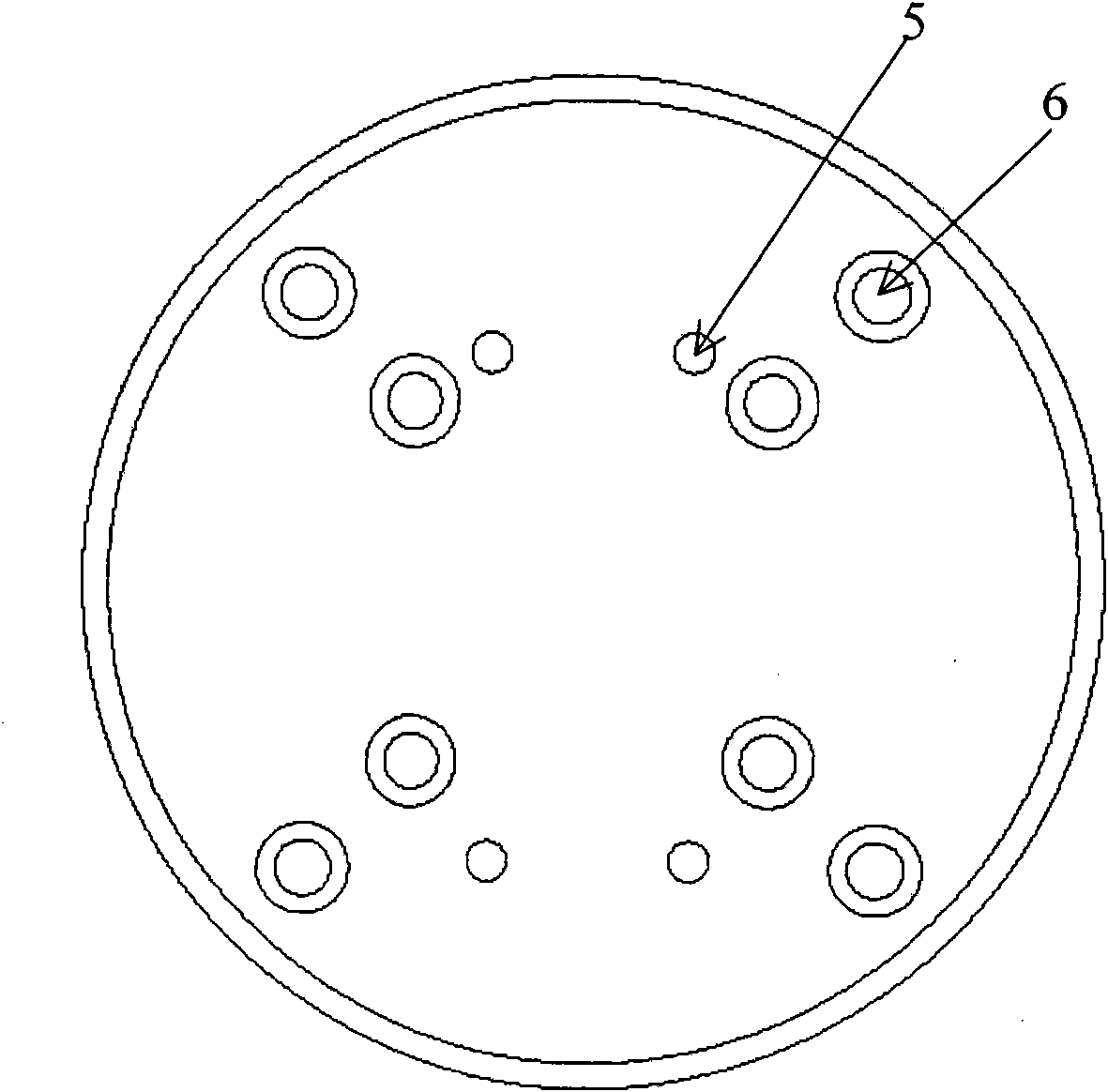

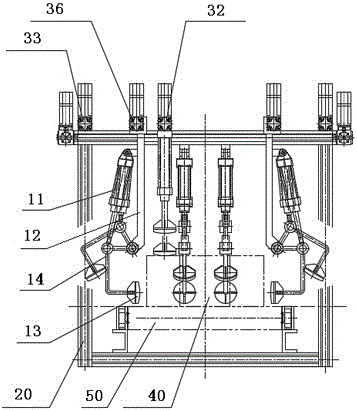

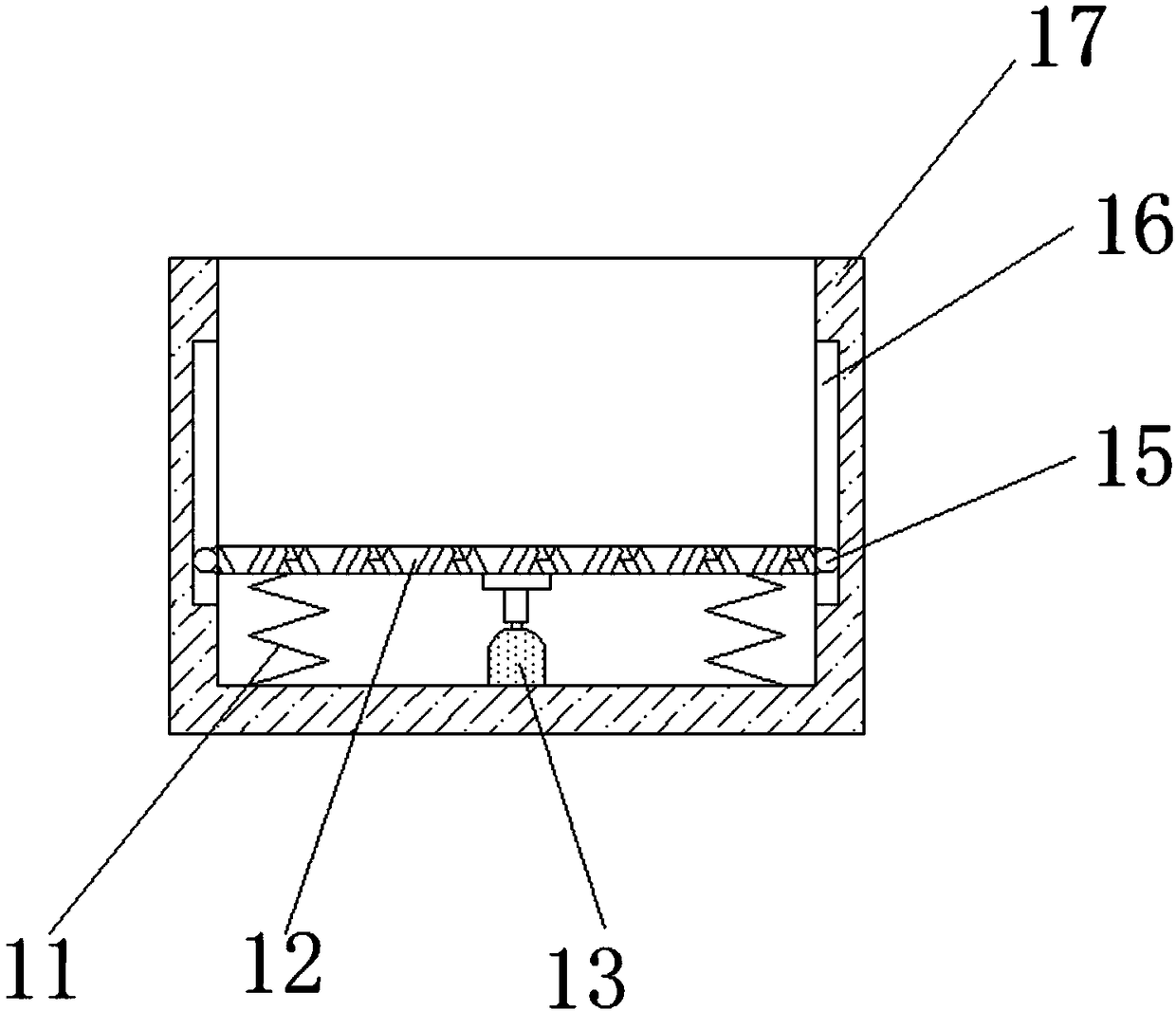

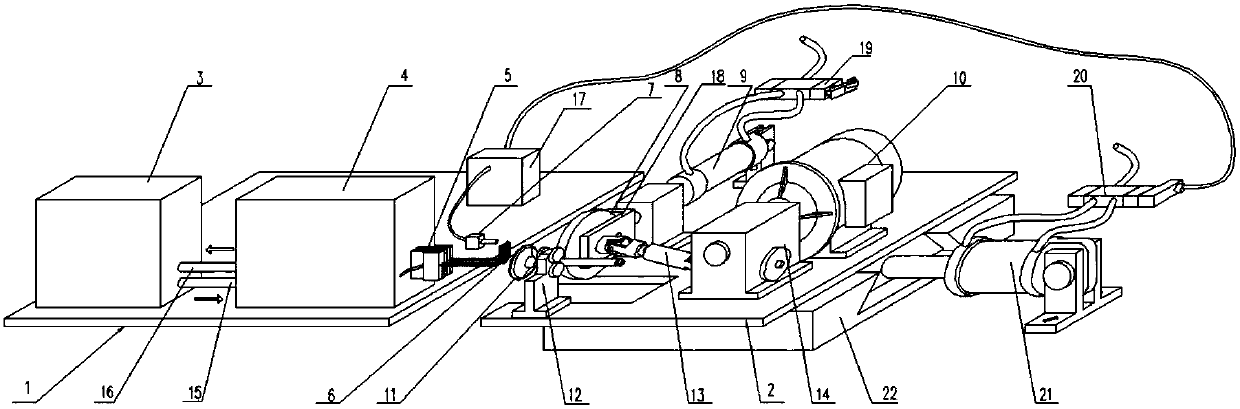

Clamping device in vibration distressing of satellite mechanical experiment pressure ring

InactiveCN102012303ASolving Radial Clamping ProblemsThe radial clamping problem satisfiesVibration testingDistressingEngineering

The invention relates to satellite mechanical experiment equipment, in particular discloses a clamping device in the vibration distressing of a satellite mechanical experiment pressure ring, comprising a vibration distressing clamp (1) with counterbores (6) and screw holes (5). The counterbores (6) are used for connecting a vibration table, the screw holes (5) are used for connecting a vibration distressing fixed block (2) and a vibration distressing sliding block (3), the pressure ring is radially arranged and located between the vibration distressing fixed block (2) and the vibration distressing sliding block (3), and the bottom of a vibration distressing top block (4) contacts with the arc surface at the top of the pressure ring and is connected with the vibration distressing fixed block (2) and the vibration distressing sliding block (3) through four screws. The invention solves the radially pressure ring clamping problem in the vibration distressing of the satellite mechanical experiment pressure ring and acquires the advantages of low manufacture cost, convenient and intuitive use, strong suitability and generalization, and the like.

Owner:SHANGHAI SATELLITE ENG INST

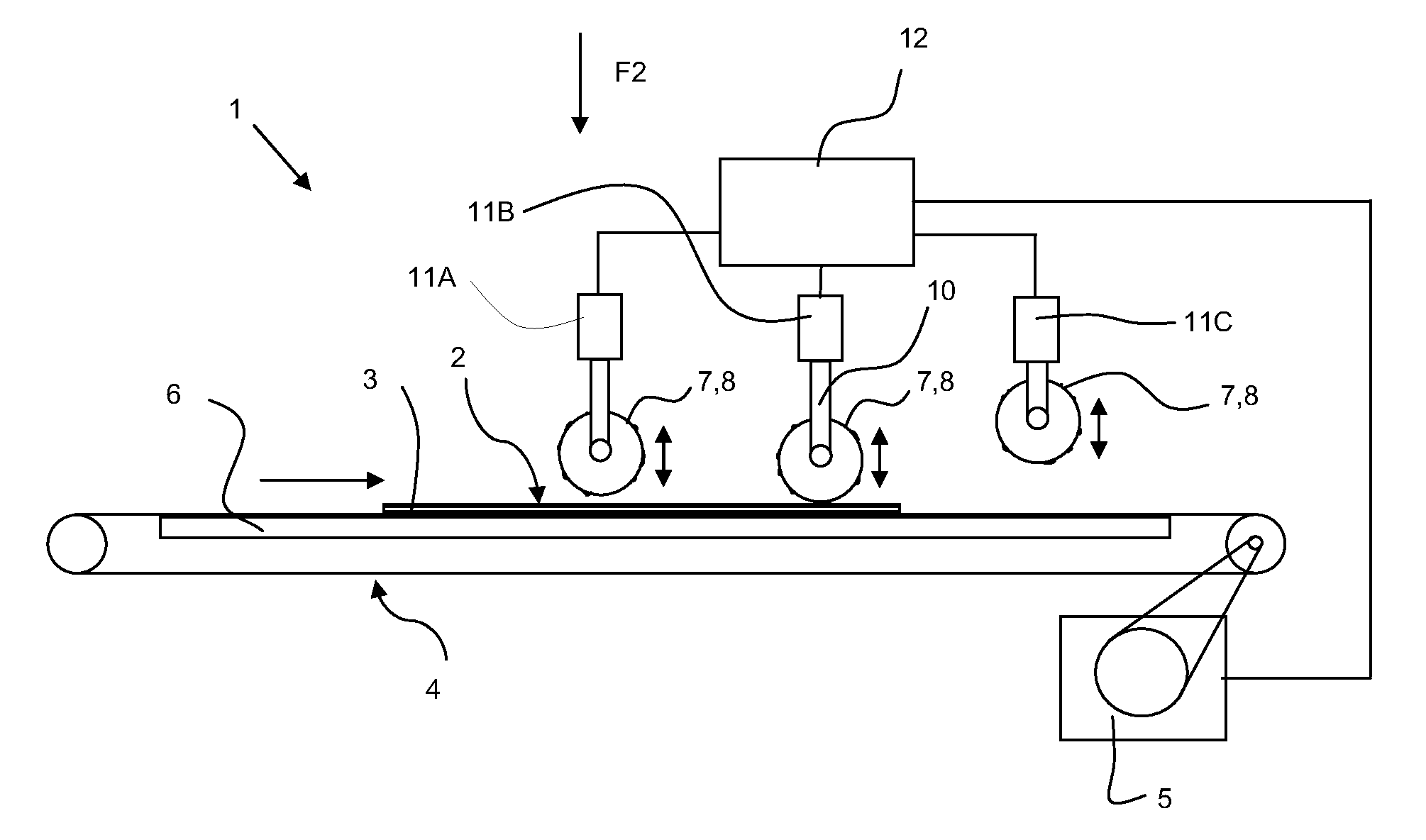

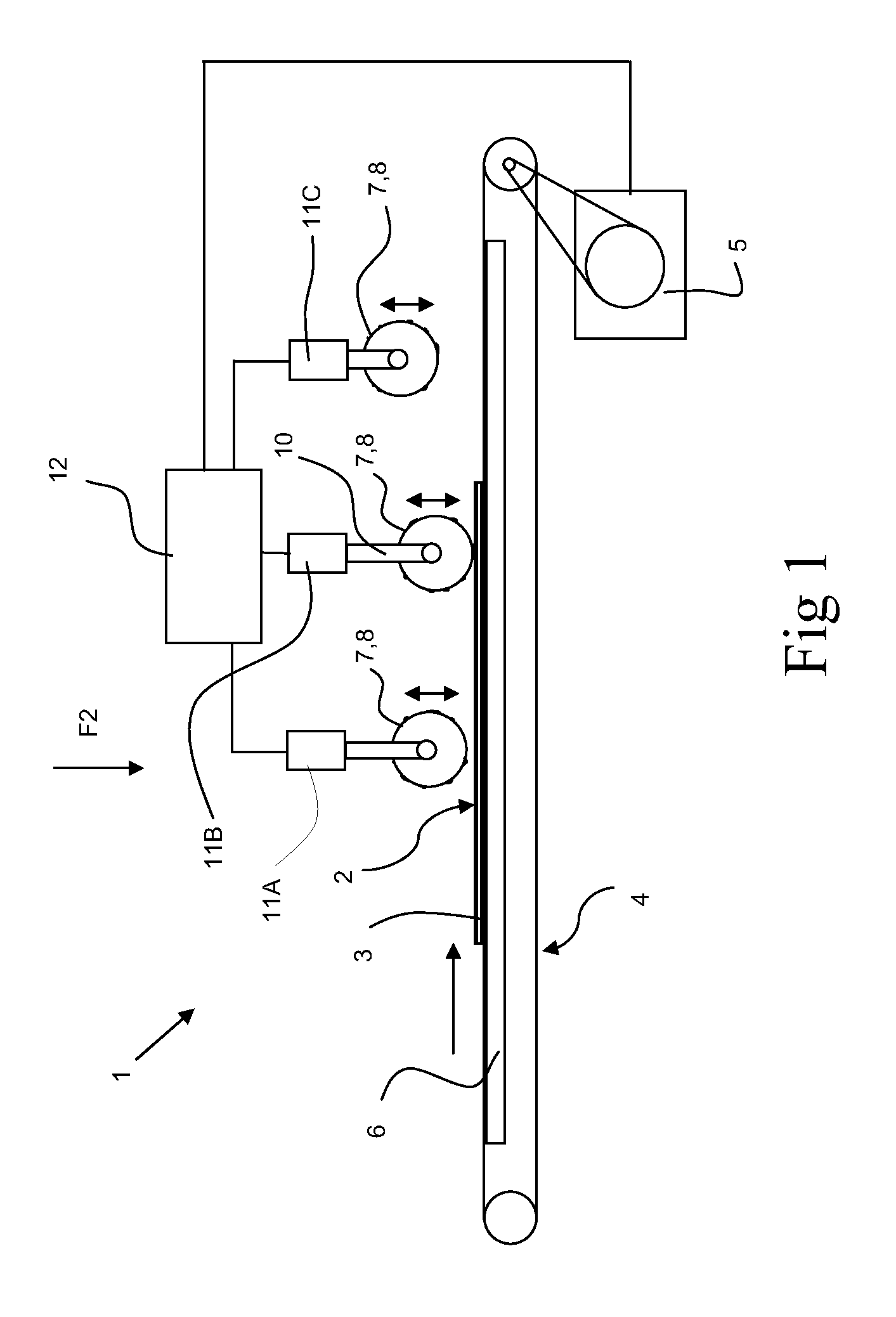

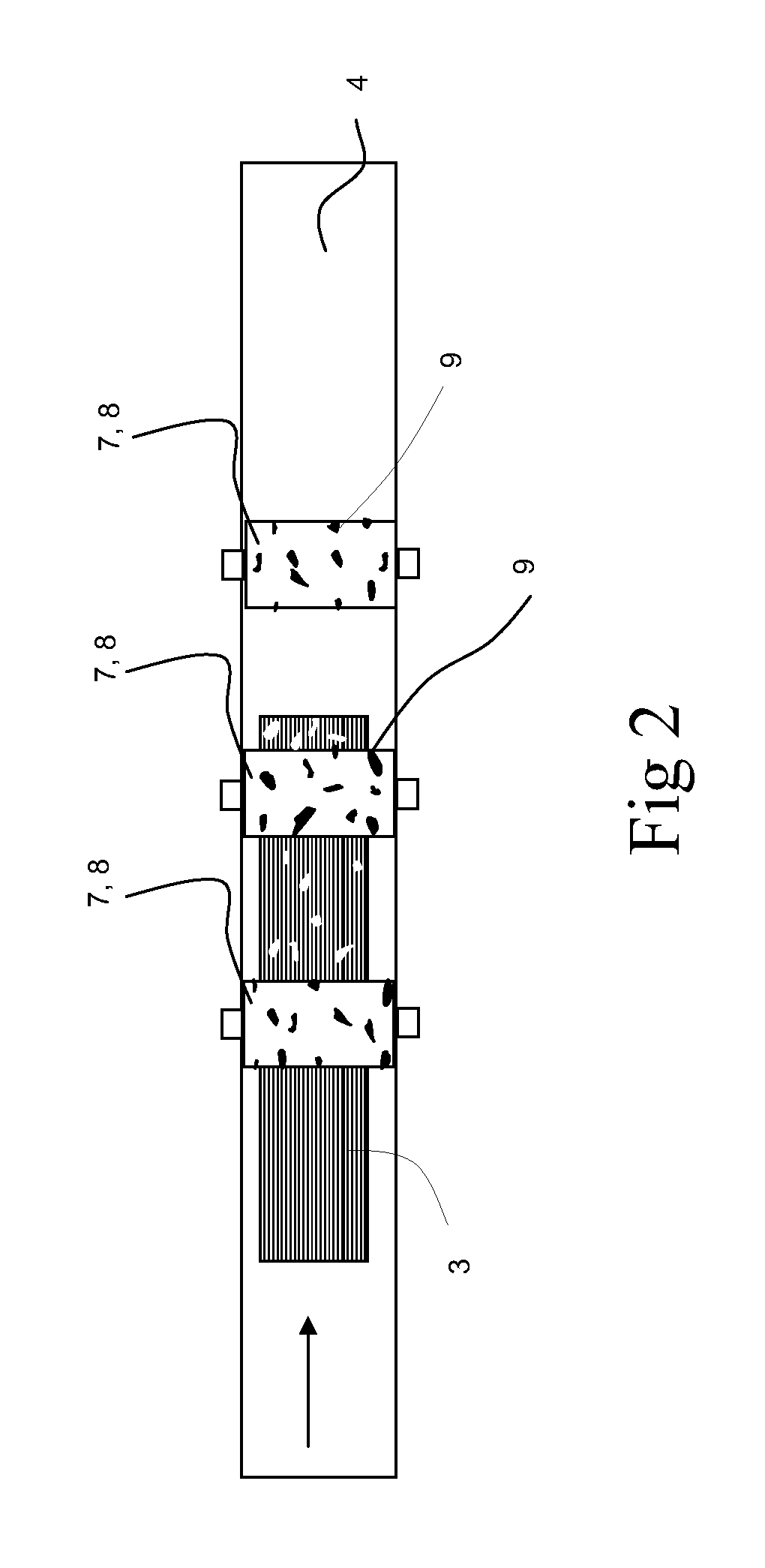

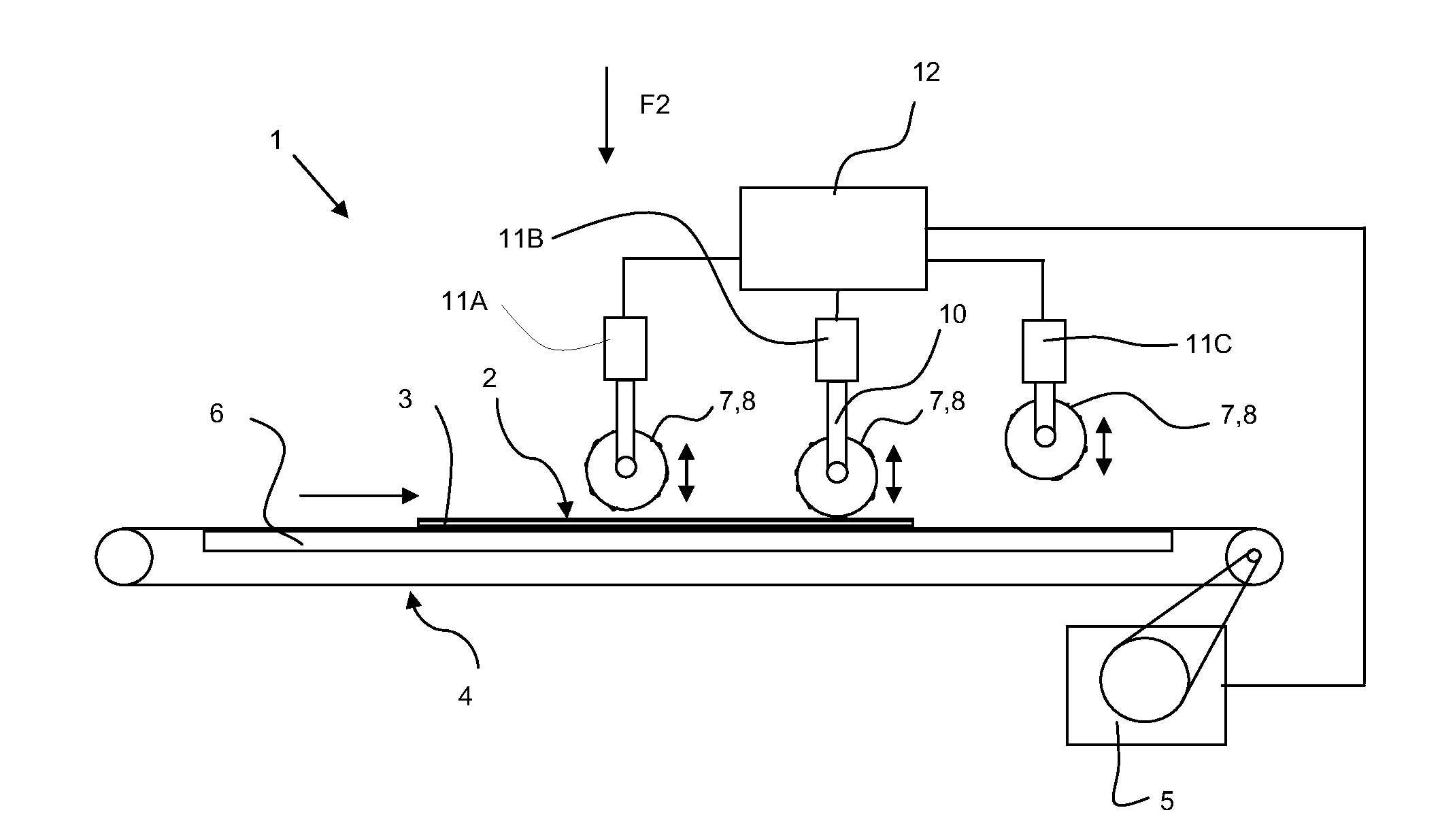

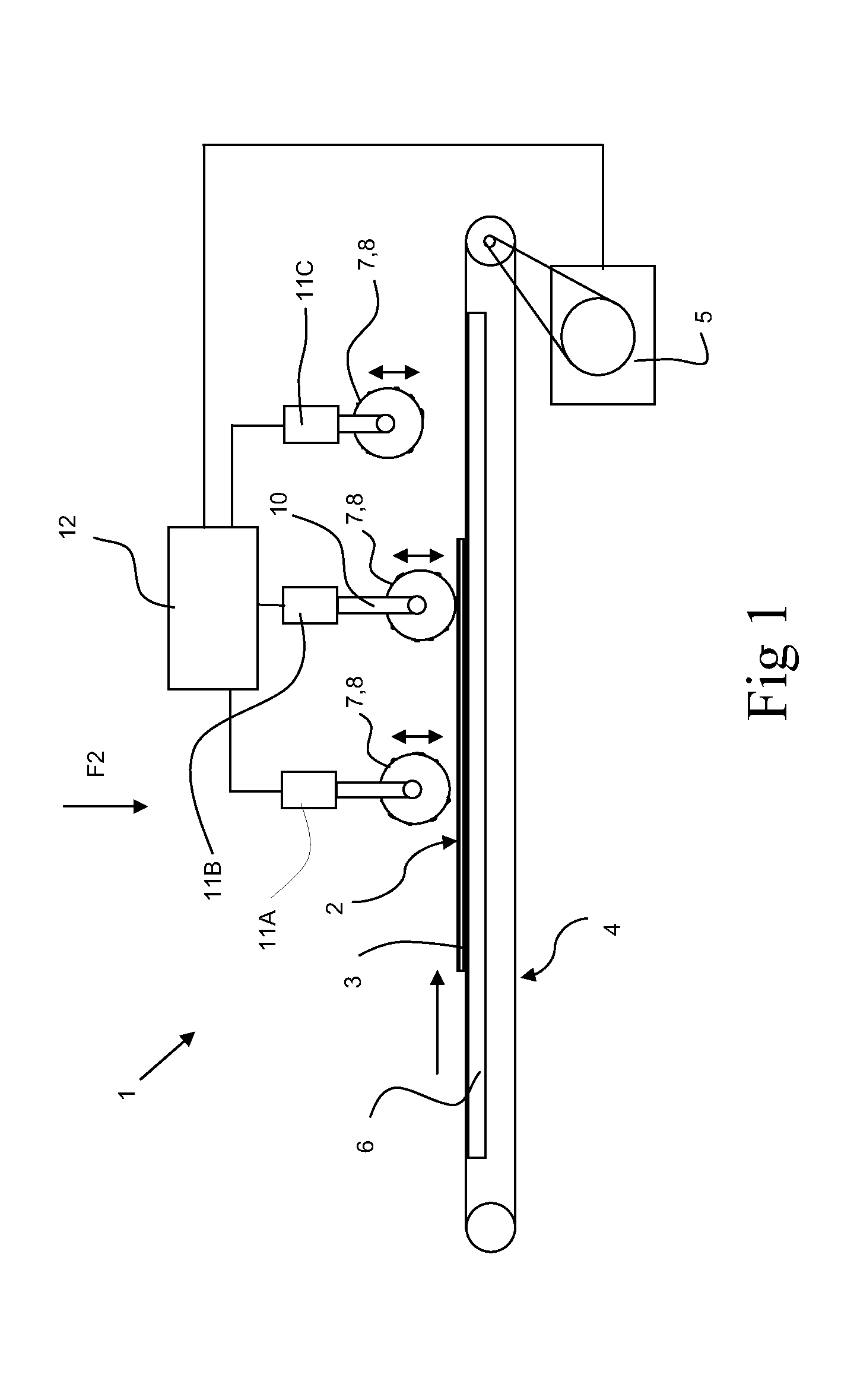

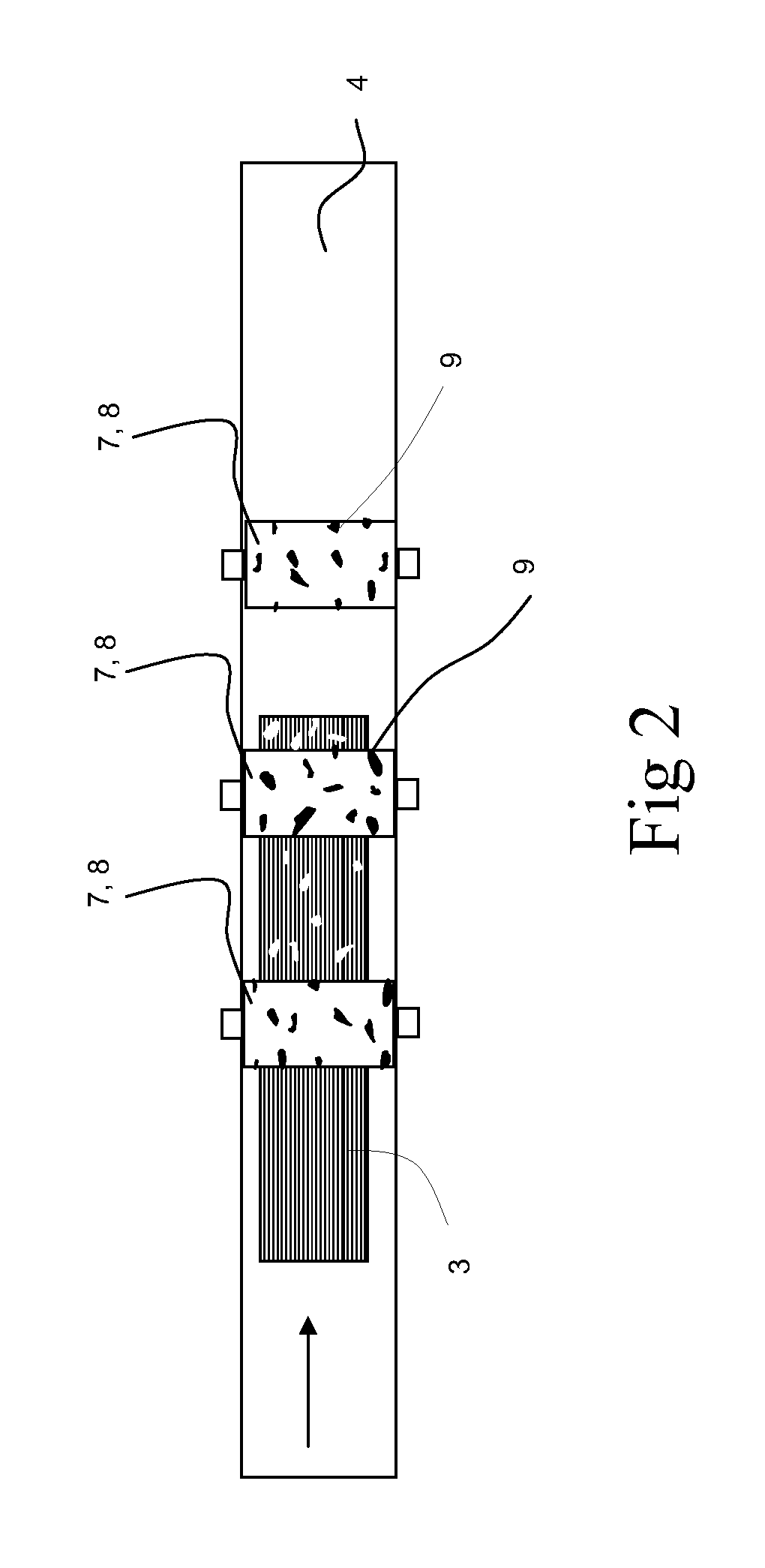

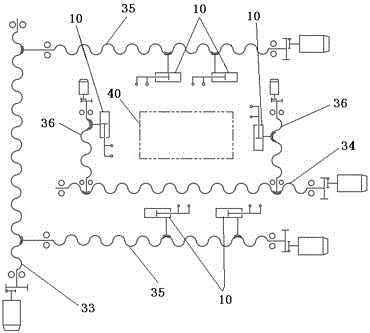

Distressing process and apparatus for applying such process

InactiveUS8051886B2Simple resultWooden sticks manufactureAutomatic control devicesDistressingEngineering

Owner:UNILIN FLOORING NC

Distressing process and apparatus for applying such process

InactiveUS20110139307A1Easy desired irregular resultSimple resultWooden sticks manufactureAutomatic control devicesDistressingEngineering

A method is provided for treating the decorative face of a panel to simulate the visual effect of a distressed panel. The decorative face may include at least a layer of wood or the like. The method may involve passing the panel with respect to two or more distressing tools. The passing may be performed in an automated way by first driving means. The method may also involve advancing the distressing tools intermittently toward the moving panel to apply distress marks. The intermittently advancing may be performed in an automated way by second, third and optional further driving means. At least one of the passing of the panel and the advancing of the distressing tools toward the moving panel may be performed according to an irregular rhythm in order to obtain irregularly spaced distress marks. At least one of the first driving means, the second driving means, the third driving means, and the optional further driving means is steered by and therefore coupled to program means.

Owner:UNILIN FLOORING NC

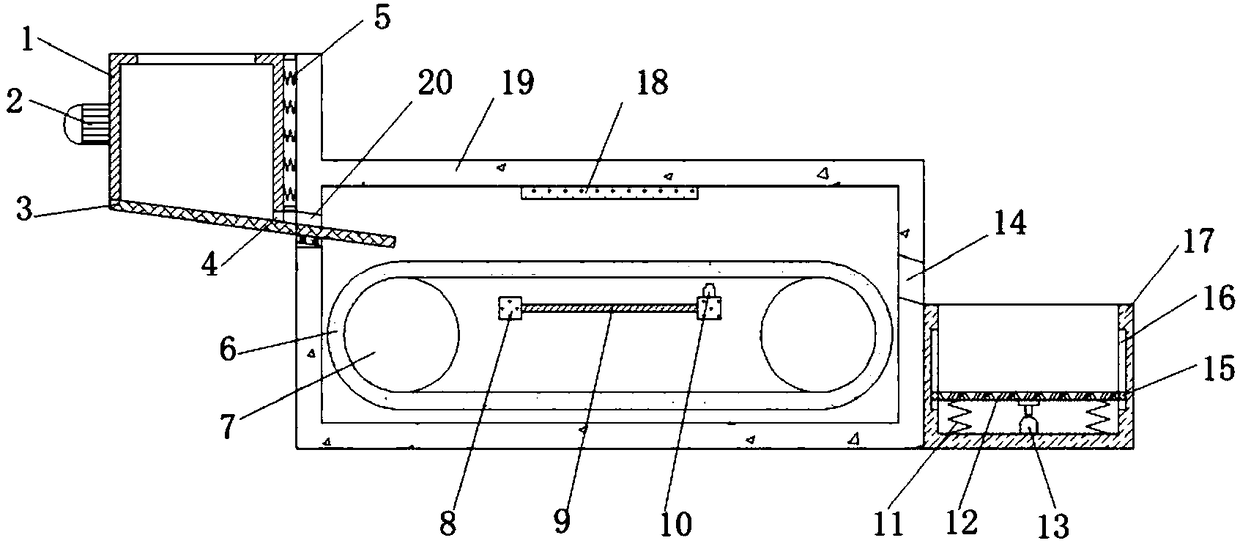

Automatic distressing device for amorphous alloy iron core

PendingCN106244793AIncrease productivityImprove the quality of stress reliefProcess efficiency improvementDistressingReducer

The invention discloses an automatic distressing device for an amorphous alloy iron core. The automatic distressing device comprises distressing mechanisms, a gantry rack and a lead screw transmission mechanism, wherein each distressing mechanism comprises an air cylinder, a distressing mechanism base, a rubber hammer and a connecting rod; the tail of each air cylinder is hinged with the corresponding distressing mechanism base; the head of each air cylinder is hinged with one end of the corresponding connecting rod; the other end of each connecting rod is connected with a corresponding rubber-head bolt; the middle of each connecting rod is hinged with the corresponding distressing mechanism base; in a motion process, each air cylinder is telescopic to push the corresponding connecting rod to rotate around a corresponding central hinged point, and the amorphous alloy iron core is impacted by each rubber hammer for distressing treatment; the impact speed and the impact force can be adjusted in real time by adjusting the flow rate and the air pressure of each air cylinder; the gantry rack spans a roller bed; the bottom of the gantry rack is in bolted connection with the base of the roller bed; the amorphous alloy iron core is arranged on the roller bed; and the lead screw transmission mechanism comprises lead screws, a servo motor and a speed reducer which are connected together. The automatic distressing device disclosed by the invention can replace manual operation, and the production efficiency can be improved.

Owner:上海史密富智能装备股份有限公司

Heat treatment technology for stainless steel

The invention discloses a heat treatment technology for stainless steel. The heat treatment technology includes the first step of blank checking, the second step of degreasing, the third step of solid solution treating, the fourth step of stabilizing treating, the fifth step of distressing and the sixth step of cooling. The heat treatment technology is low in treating cost, durable in use and capable of improving the technology treatment efficiency and the quality of a workpiece.

Owner:WUXI YANGGONG MACHINERY MFG

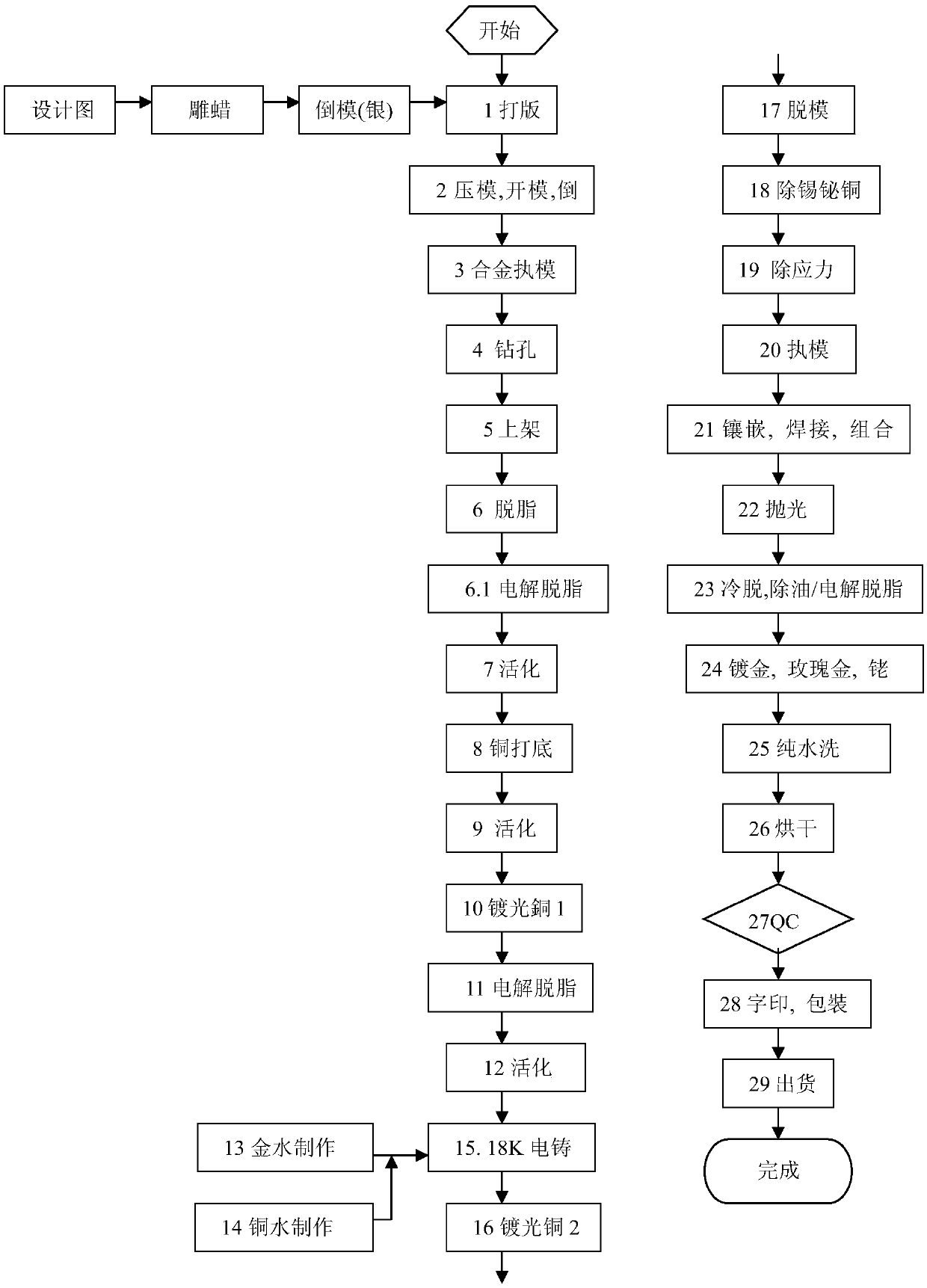

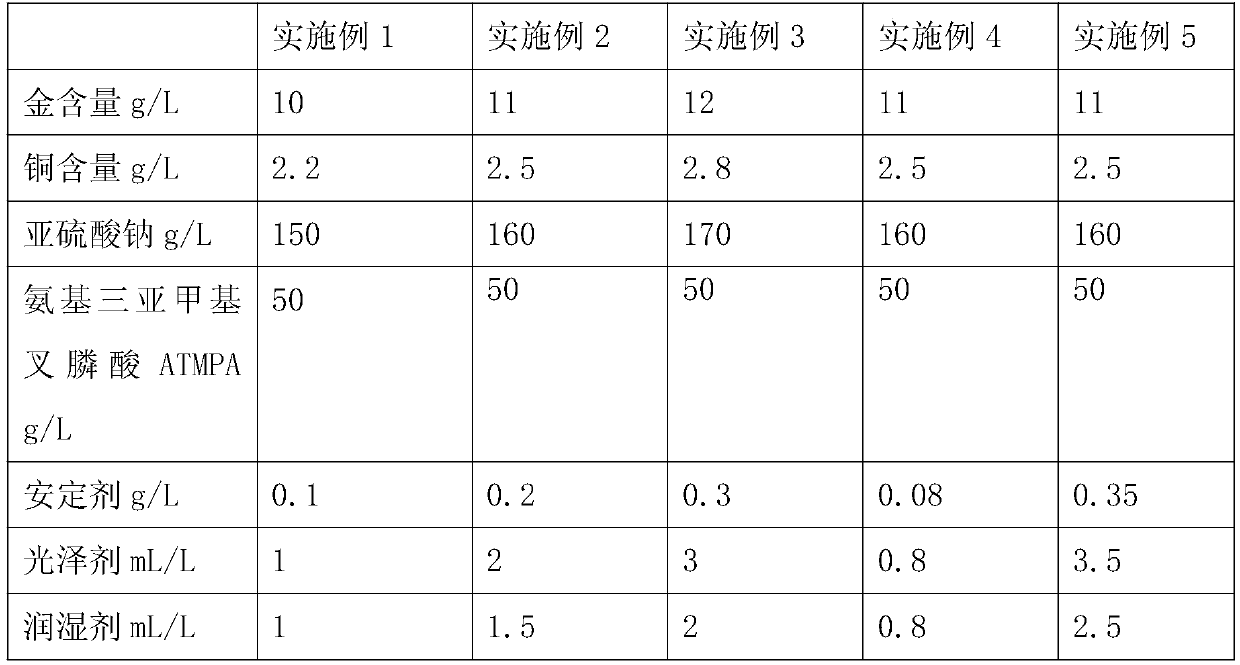

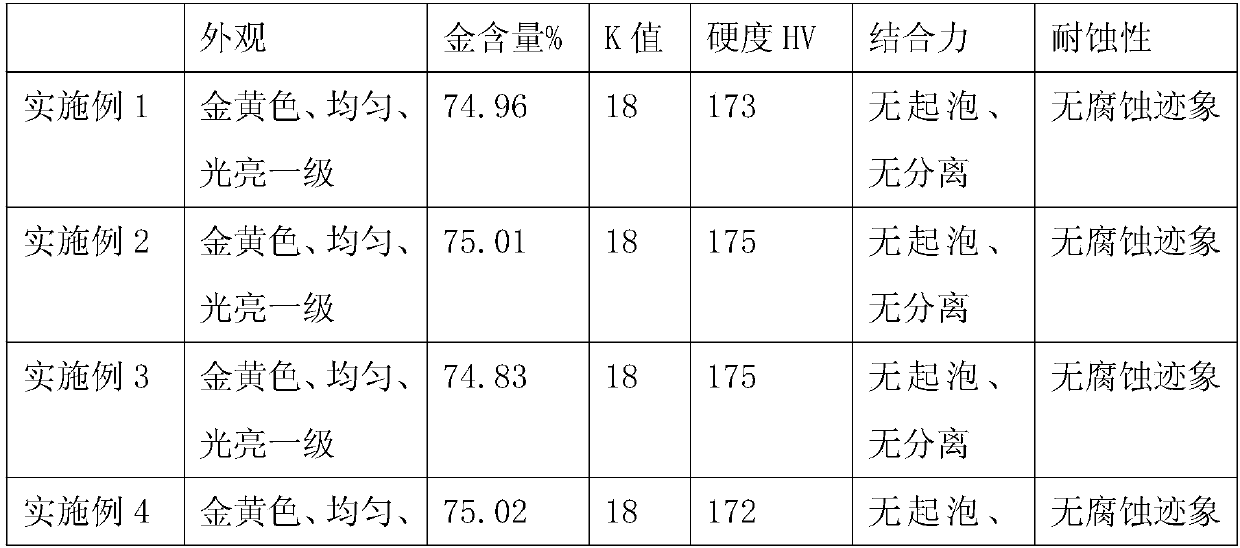

Preparation method for cyanide-free 18 k gold jewelries

The invention discloses a preparation method for cyanide-free 18 k gold jewelries. The preparation method comprises the steps of plate making, mold pressing, opening and reversing, alloy mold carrying, drilling, loading, degreasing, primary activation, copper bottoming, secondary activation, gloss copper 1 plating, electrolytic degreasing, ternary activation, gold water preparation, molten copperpreparation, 18 k electroforming, gloss copper 2 plating, demolding, tin bismuth copper removal, distressing, mold carrying, embedding, welding, combination, polishing, cooling, deoiling, electrolyticdegreasing, gold plating, pure water washing, drying, quality inspection, character printing, packing and delivery in sequence; and then, the cyanide-free 18 k gold jewelries are obtained. The preparation method is simple in process and easy to operate, obviously improves the jewelry quality, reduces the gold loss, and contains no cyanide-contained poisonous substance in the preparation process to achieve environmental protection and safety; the hardness and the toughness of the 18 k gold jewelries are prominently improved to preferably guarantee the stability of the jewelries in the wearingprocess; and further, electroforming liquid is excellent in stability, dispersibility and deep plating capacity, can be prepared beforehand for future use, and improves the production efficiency.

Owner:NANJING INST OF PROD QUALITY INSPECTION

Distressing processing method for rosewood board

InactiveCN106078991AImprove corrosion resistanceClear textureRadiation/waves wood treatmentWood treatment detailsDistressingWood machining

The invention discloses a distressing processing method for a rosewood board and belongs to the technical field of wood processing. The distressing processing method for the rosewood board specifically comprises the following steps: (1), processing raw materials; (2) preparing distressing treatment liquid; (3) conducting distressing processing; and (4) conducting heat preservation and drying. The steps are reasonably cooperated, and the finally processed rosewood board has the advantages of being even in distressing effect, clear in texture, high in glossiness, high in moisture resistance and wear resistance and good in corrosion resistance. The processed rosewood board is provided with a thick patina layer and shows good durability. The distressing processing method has good application and popularization value.

Owner:安徽省阜南志峰工艺品有限公司

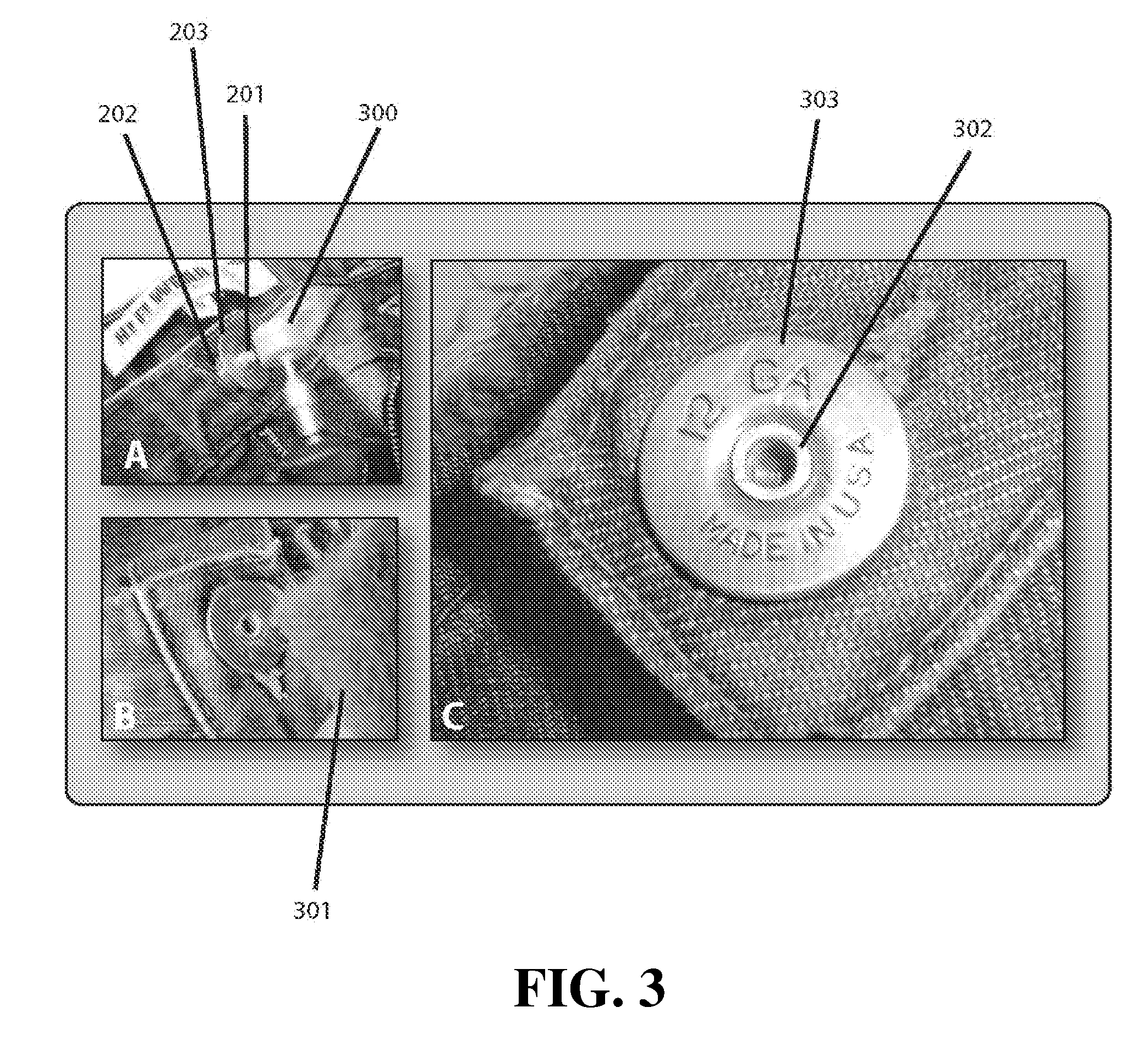

Method of distressing a garment

In order to create or emulate authentic shotgun holes in a garment, a garment is subject to a distressing process with projectiles or other distressing apparatuses. A garment may be distressed without comprising critical components of the garment by positioning it in a stationary form in relation to a distressing apparatus and protecting the garment with a garment protection apparatus. A button for a garment is created by utilizing an authentic shotgun shell base attached to a rivet and spacer.

Owner:ZIAKAS KRIS T

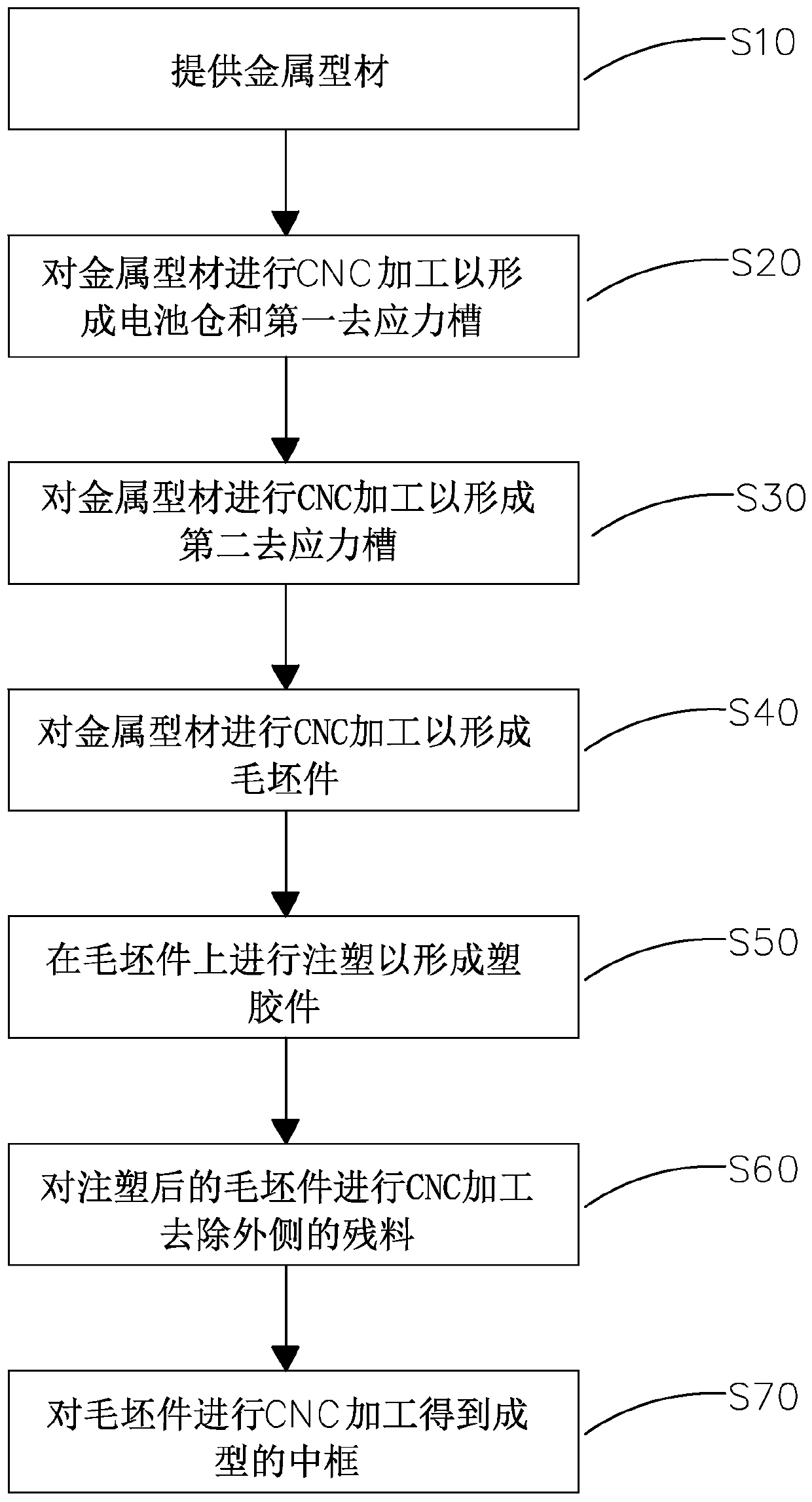

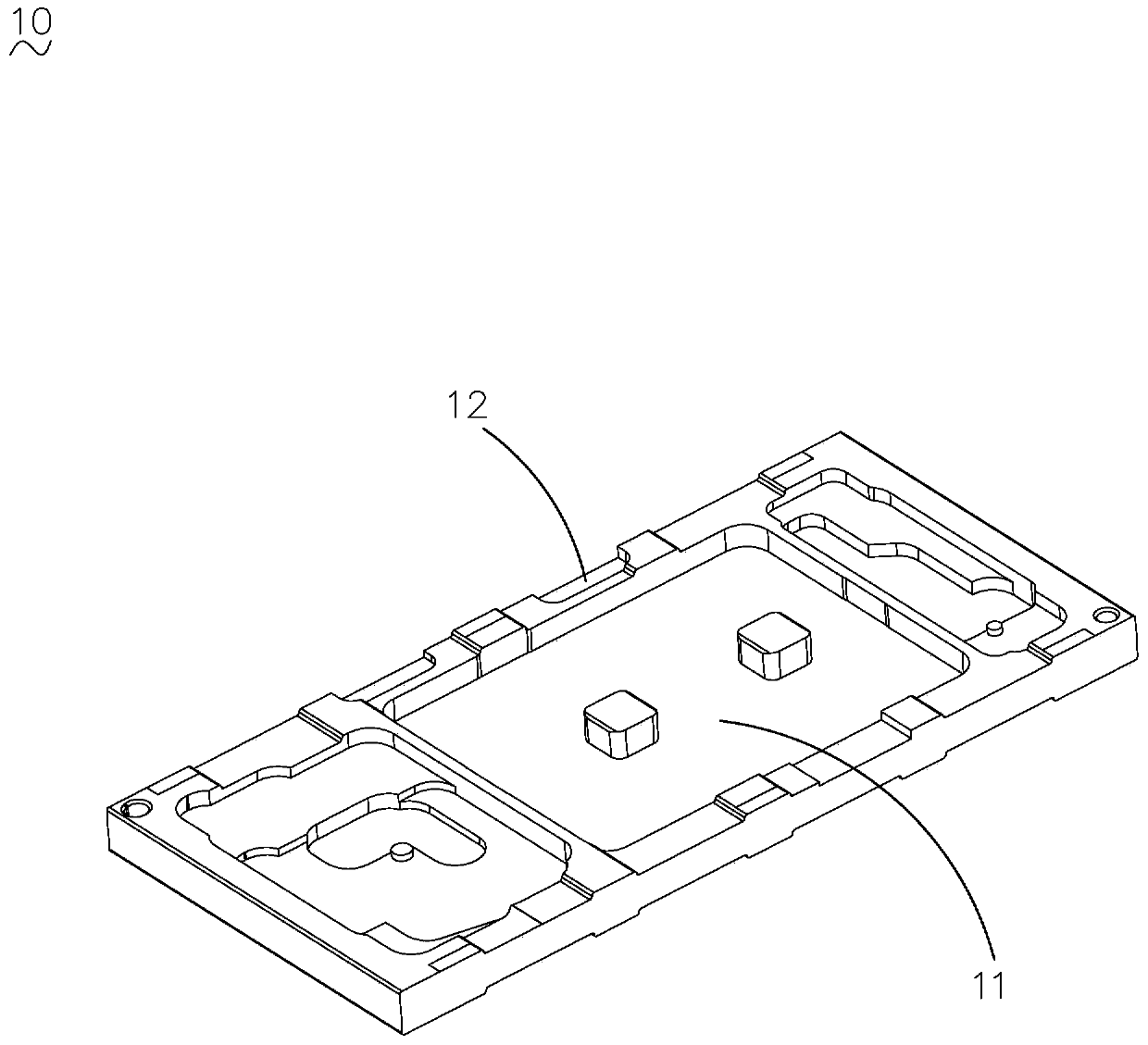

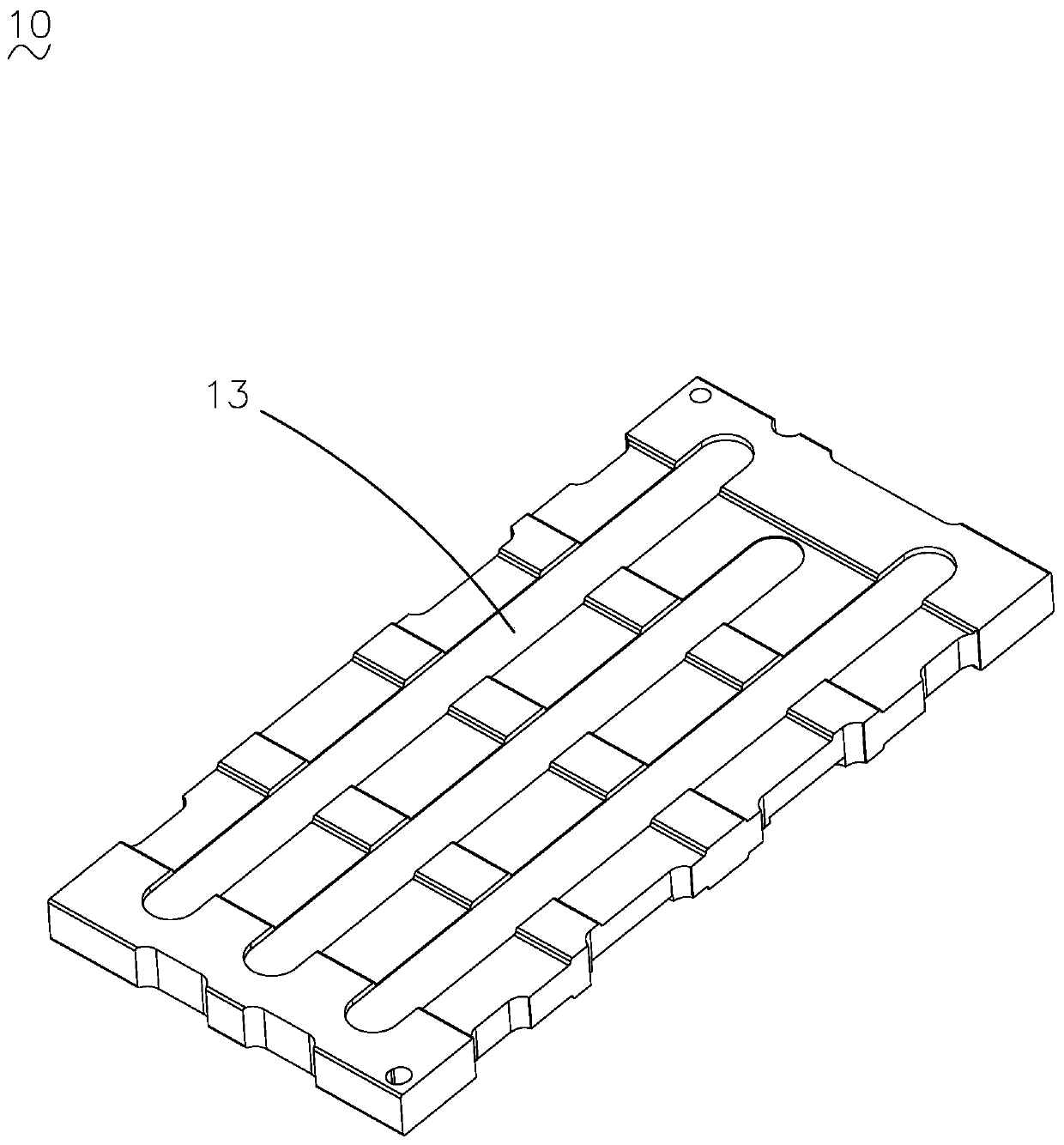

Middle frame manufacturing method, middle frame and electronic equipment

InactiveCN110524788AImprove flatnessImprove yieldTelephone set constructionsNon-linear opticsDistressingEngineering

The invention relates to a manufacturing method of a middle frame. The manufacturing method comprises the following steps: providing a metal profile; carrying out CNC machining on the metal profile toform a battery bin and a first distressing groove; performing CNC machining on the metal profile to form a second distressing groove; carrying out CNC machining on the metal profile to form a workblank, wherein the workblank comprises a frame part and a middle plate part located in the frame part; carrying out injection molding on the workblank to form a plastic part, wherein the plastic part ispositioned on the frame part and the middle plate part; carrying out CNC machining on the workblank so as to remove residual materials on the outer side of the workblank; and carrying out CNC machining on the workblank, and obtaining the formed middle frame. Meanwhile, the invention further provides a middle frame and electronic equipment. The manufacturing method has the beneficial effects that in the middle frame manufacturing process, multiple material reducing procedures are added, internal stress remaining on a workpiece is released, the flatness of the LCD area and the edge of the formedmiddle frame is optimized, and the yield of products is increased.

Owner:GUANGDONG EVERWIN PRECISION TECH

Processing method of cedarwood furniture panels with white rot bacterial plaque

ActiveCN105459243AHigh economic valueMeet the needs of making oldFungiWood treatment detailsDistressingWhite rot

The invention relates to a processing method of cedarwood furniture panels with white rot bacterial plaque. The method comprises the following steps: first, carrying out sterilization and humidification treatment on outsourcing cedarwood ecological panels by adopting high temperature steam, and killing other infectious microbes possibly carried by the outsourcing cedarwood ecological panels to prevent the phenomenon of infectious microbe infection; secondly, preparing a white rot fungi culture solution and finally preparing a white rot fungi bacterial solution; then spraying the white rot fungi bacterial solution to the surface of the cedarwood ecological panels painted with culture medium by using a sprayer, and sending to a constant-temperature constant-humidity chamber for cultivation of the white rot bacterial plaque; and finally, sending the cedarwood ecological panels with surfaces covered by the white rot bacterial plaque to a wood drier for drying, so as to produce a furniture panel material with unique decorative effect. The processing technology is simple and feasible, and the unique cedarwood furniture panels with white rot bacterial plaque can be produced by special technical processing by utilizing cedarwood panels with low cost. The technology can meet the requirement of distressing of furniture and antiquing home decoration materials in home decoration.

Owner:莘县鲁开综合服务有限公司

Silver ornament process technique

The invention discloses a silver ornament process technique. The technique comprises the steps of S1, melting silver, wherein a silver ingot is placed in a crucible, the crucible is placed on a furnace to melt the silver ingot and then clamped by lazy tongs after the silver ingot is molten, and liquid silver obtained after melting is poured into a flat copper mold; S2, taking the silver ingot in the copper mold out to be cleaned; S3, conducting wiredrawing on the silver ingot to form filamentary silver; S4, welding the filamentary silver with an external liner plate with liquid silver as welding flux to form a silver ornament; S5, placing the silver ornament in a vibrator to relieve stress through vibration; S6, soaking the silver ornament in hydrochloric acid; S7, finally placing the silver ingot in clear water to be cleaned, and then conducting inspection and packaging. By the adoption of the technique, influences on the color, quality and appearance of the silver ornament caused by constituent difference of welding powder or welding rods are avoided, and through vibration distressing and hydrochloric acid cleaning, the silver ornament has small welding stress, high firmness and high glossiness.

Owner:GUIZHOU YIHUAZHUANG DEV CO LTD

A silver jewelry processing technology

Owner:GUIZHOU YIHUAZHUANG DEV CO LTD

Distressing device for integrated circuit lead frame

InactiveCN108118133AAchieve initial stress reliefEasy to moveFurnace typesHeat treatment furnacesDistressingEngineering

The invention discloses a distressing device for an integrated circuit lead frame. The distressing device comprises a heating tank, wherein rollers are connected to the middles of two ends of the inner walls on two sides of the heating tank through bearings, the peripheral outer walls of the two rollers are sleeved with the same conveying belt, and a second heating resistor plate is connected to the middle of the inner wall of the top of the heating tank through a fastening bolt. The distressing device is provided with a storage tank, a vibration motor and a first feeding hole, the vibration motor can drive the storage tank and a lead frame in the storage tank to vibrate so as to realize distressing, and materials can be automatically fed into the heating tank through a first feeding hole,so that primary distressing of the lead frame is conveniently and rapidly realized, the movement and transportation of the lead frame is facilitated, and the heating distressing of the lead frame canbe realized; the distressing device is provided with a temperature sensor, so that the temperature in the heating tank can be monitored in real time, and a reciprocating motor can push a placement plate and the lead frame to vibrate up and down so as to finally realize vibration distressing; and by virtue of a heating distressing process and two vibration distressing processes, the distressing working efficiency is increased.

Owner:大连鑫鑫创世科技发展有限公司

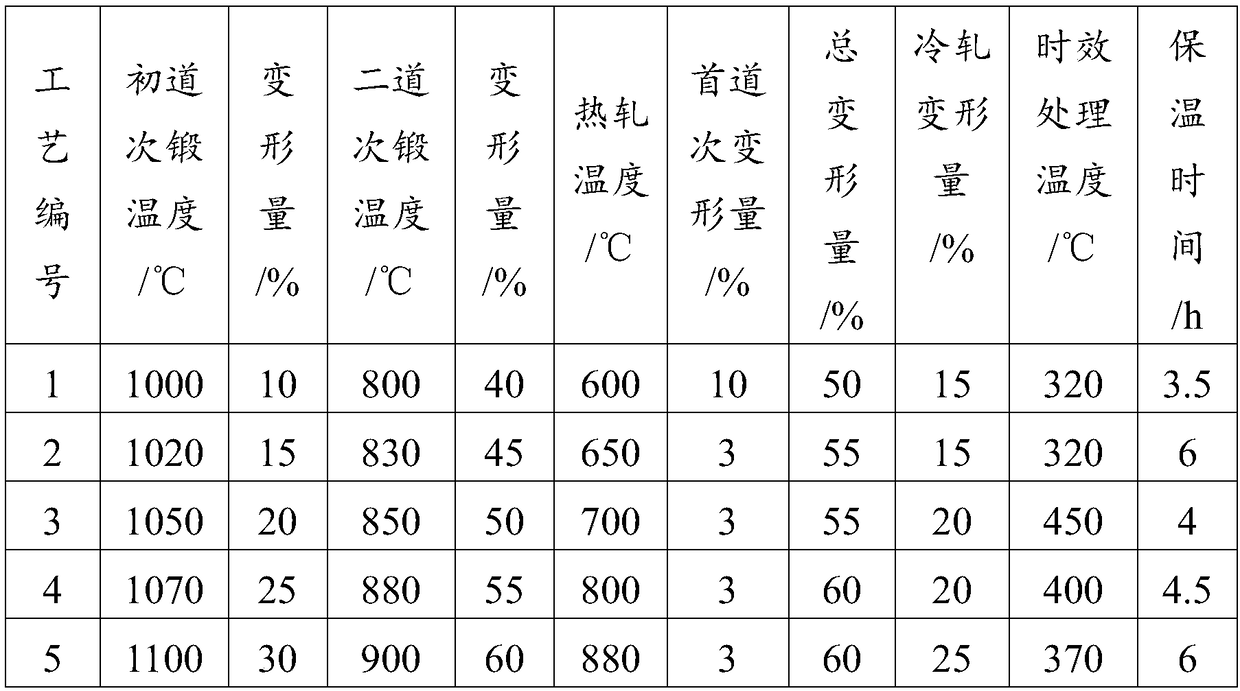

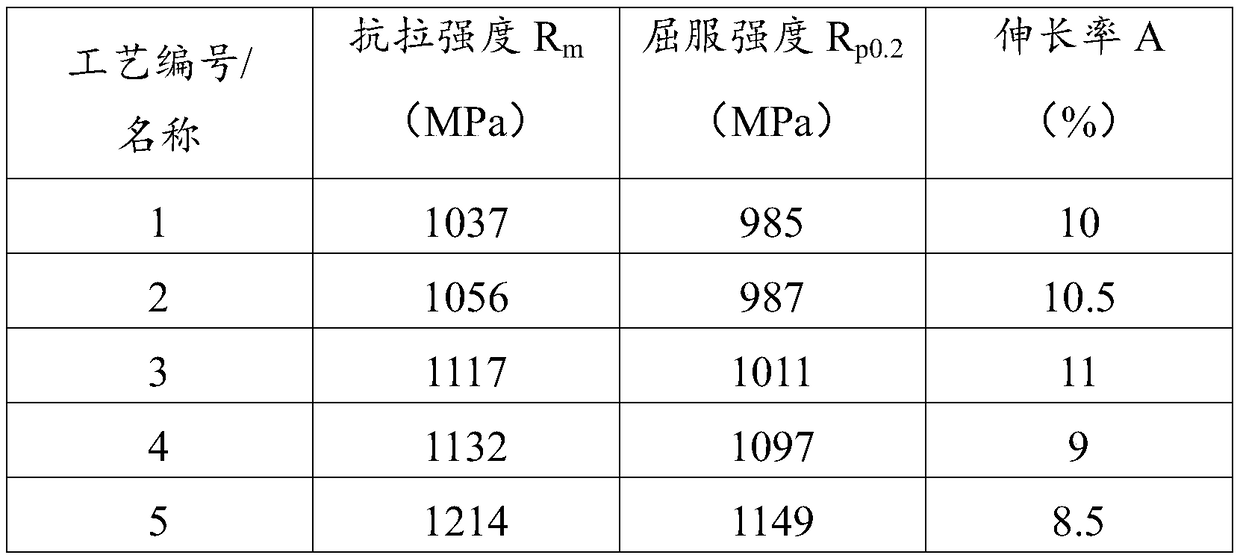

Preparation method of titanium alloy plates

The invention relates to the technical field of titanium alloy preparation, in particular to a preparation method of titanium alloy plates. The preparation method of the titanium alloy plates comprises the following steps that ingot primary forging is performed, specifically, the heating number of forging is two, the primary forging temperature is 1000-1100 DEG C, the deformation amount of the first pass is 10-60%, the forging temperature of secondary heating is 800-900 DEG C, and the total deformation amount is larger than 60%; forged blanks are subjected to distressing and alpha-phase quenched-tempered heat treatment, and are cooled to the room temperature after being subjected to heat preservation; surface scale of the forged blanks is removed; hot rolling treatment is conducted, specifically, the hot rolling temperature is 600-900 DEG C, the deformation amount of the first pass is controlled to be 1-10%, the total deformation amount is larger than 50%, and reversing rolling is conducted in the hot rolling treatment process; cold rolling treatment is conducted, specifically, the total deformation amount is 15-25%; and aging treatment is conducted at the temperature of 300-450 DEG C, and heat preservation is conducted for 3.5-6 h. The method is simple, easy to implement and high in process stability, and titanium alloys of different toughness levels are obtained through densifying treatment on ingots and control over technical conditions of rolling treatment and heat treatment.

Owner:屏效工业技术(苏州)有限公司

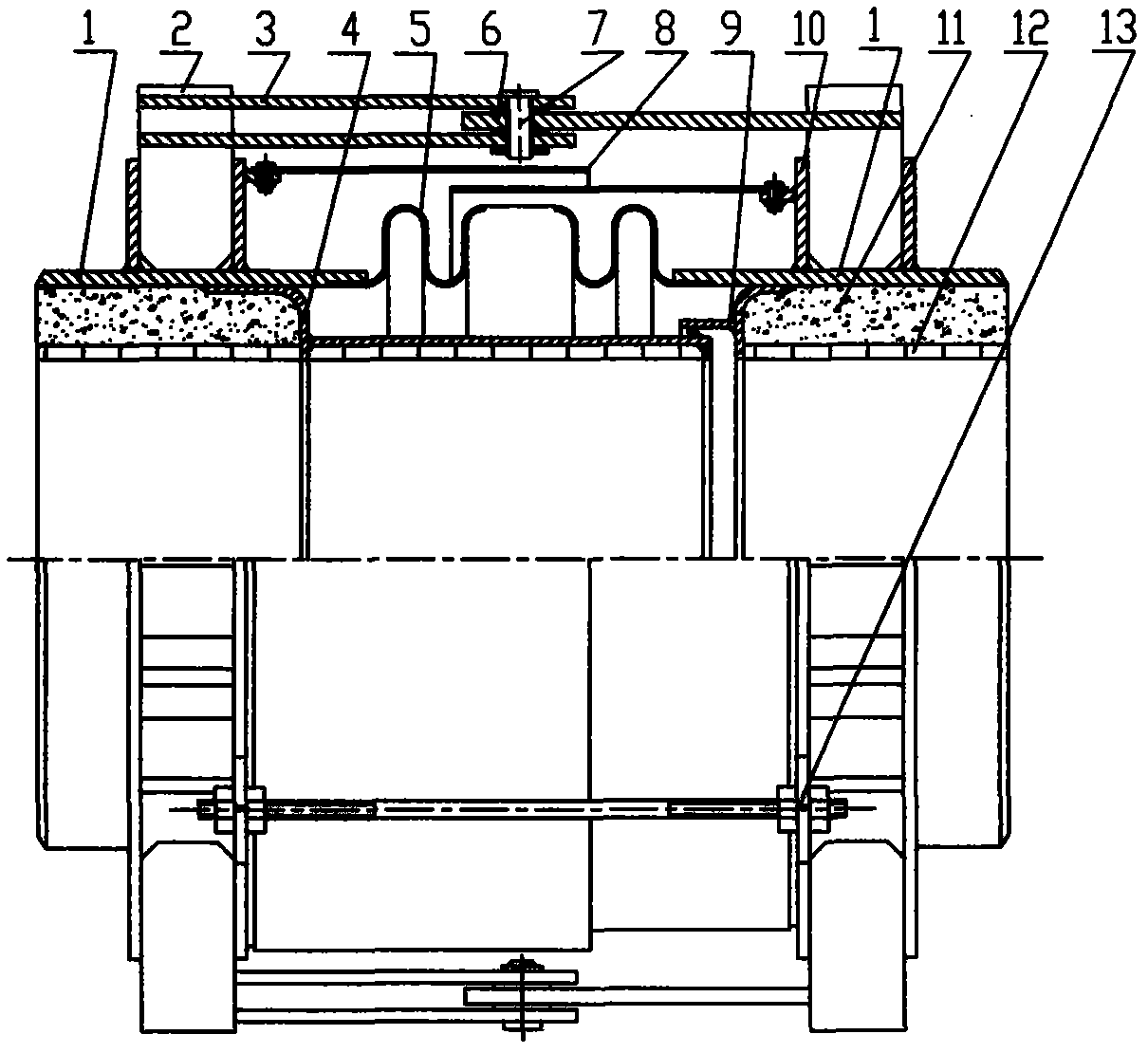

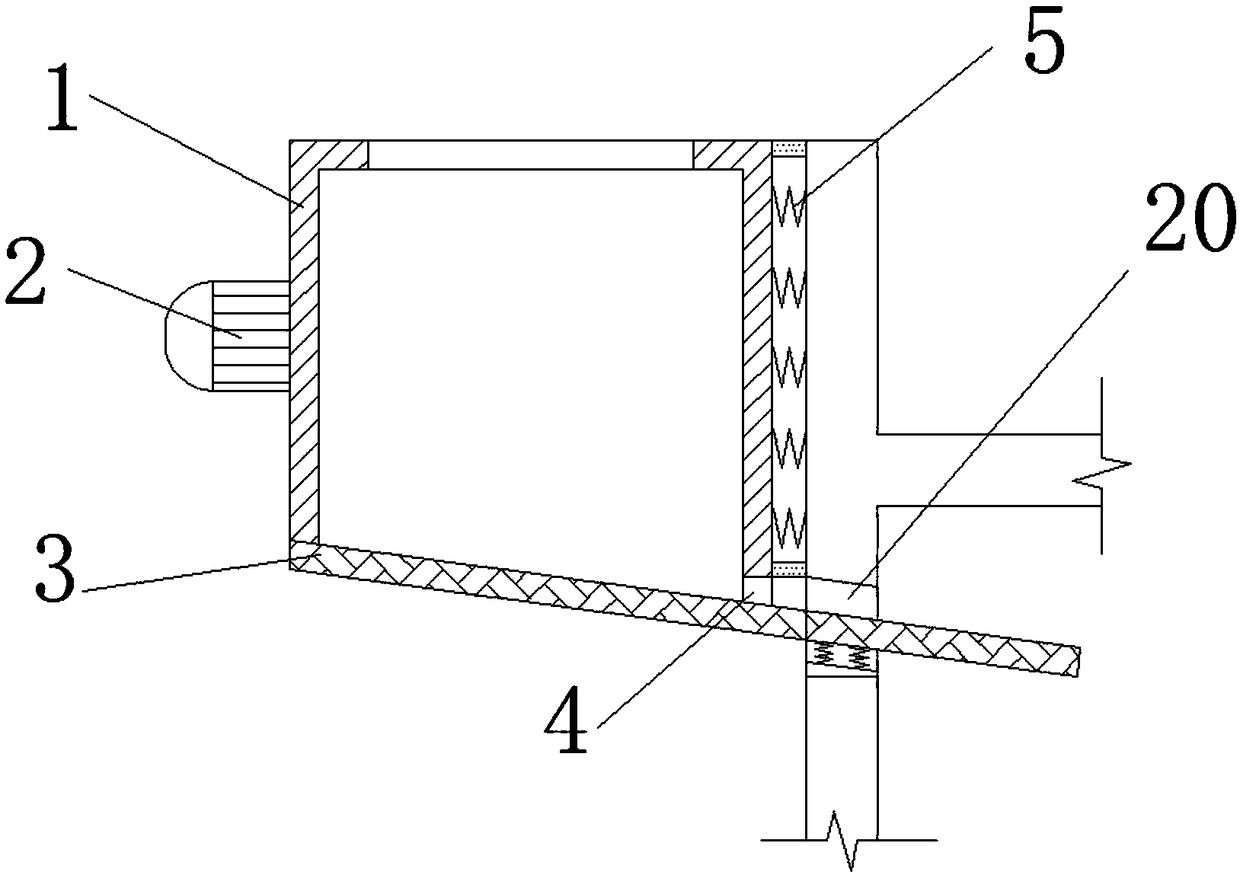

Induction coil and equipment used for eliminating residual stress of engine valve, and method

InactiveCN107586925ASimple structureHeating evenlyFurnace typesIncreasing energy efficiencyDistressingEngine valve

The invention discloses an induction coil and equipment used for eliminating the residual stress of an engine valve. The induction coil is of a V shape, a U shape or a wave type. The invention also discloses equipment used for eliminating the residual stress of the engine valve. The equipment comprises a rack, a workbench, a heating device and a fixture, wherein the workbench comprises a fixed workbench and a movable workbench; the fixed workbench is fixedly installed on the rack; the movable workbench is installed on the rack through a feeding device. The equipment is characterized in that the heating device is installed on the fixed workbench and comprises an induction heating power supply and the induction coil, wherein the induction coil is installed on the output side of the inductionheating power supply and is positioned in front of a fixture fixing tool; the fixture is used for clamping the engine valve and is arranged on a position near the induction coil on the movable workbench. The induction coil and the equipment have the advantages of evenness in heating, low distressing temperature and high product percent of pass, and residual stress generated after the valve is subjected to surfacing can be stably eliminated.

Owner:HUAI JI DENG YUE VALVE CO LTD

Jean fabric distressing water-washing technology

ActiveCN103469536AEven by forceImprove wear performanceDry-cleaning apparatus for textilesPumice dustDistressing

The invention discloses a jean fabric distressing and water-washing technology. The jean fabric distressing water-washing technology comprises the steps of firstly, water-washing a jean fabric for softening, thereby allowing the jean fabric to be evenly stressed in a follow-up distressing technology and avoiding uneven distressing; secondly, water-washing the jean fabric by pumice with appropriate diameter, thereby allowing the water-washed jean fabric to show an old grey feel and to have slightly worn parts; and finally, adopting a manner of combining enzyme water-washing and pumice water-washing to form a layer of soft frosty fluff on the surface of the jean fabric and simultaneously increase the wearing effect of the jean fabric, thereby providing a worn feel for people. The jean fabric distressing water-washing technology is simple to operate and has an even distressing effect; since distressing is performed under a softening condition, the strength of the jean fabric is not reduced, but a real worn feel can be provided for people.

Owner:广东亚纺纺织有限公司

Furniture distressing method

InactiveCN108582390ARealistic and natural texture of furnitureWood working apparatusDistressingEmery paper

The invention discloses a furniture distressing method. The furniture distressing method comprises the following steps that firstly, furniture is polished by a polishing machine; secondly, fading treatment is conducted; thirdly, polishing treatment is conducted, wherein abrasive paper is used for polishing the furniture; fourthly, fine irregular scratches on the surface of the furniture are treated, after scratch treatment, the scratch portions are polished with abrasive paper; fifthly, primer is painted; sixthly, the surface of the furniture is coated with antiquing paint, scratches are drawnon the antiquing paint with a tool; seventhly, painting is conducted; eighthly, polishing and coloring are conducted, wherein after environment-friendly paint is dried, polishing is conducted, coloring is conducted again, and the seventh step and the eighth step are repeatedly conducted until the color of the furniture reaches the designed effect; ninthly, polishing and distressing are conducted;tenthly, conducting crack treatment, wherein scratches are made on the furniture with a cutter, and then the scratch portions are slightly scrubbed with fine abrasive paper. By the adoption of the multiple steps, the distressing treatment is conducted on the furniture, and the manufactured furniture has a lifelike, natural and textured effect.

Owner:蒙城县福美休闲家具有限责任公司

Furniture distressing method

InactiveCN108673696ARealize batch agingSolve the problem that it is difficult to realize the batch aging of furnitureNatural patternsWood treatment detailsDistressingEngineering

The invention relates to the field of furniture processing, in particular to a furniture distressing method. The distressing method comprises the following steps of: hydrochloric acid treatment, varnish spraying, smoking and distressing, and furniture cleaning or the like. According to the furniture distressing method, the furniture is processed by corrosion, painting and smoking or the like, so that distressing the furniture in batch is realized; the problems that conventional furniture distressing method is subjected to a plurality of processes, the process is complicated, and the furnitureis difficult to distress in batch are solved; and the difficulties that the furniture distressing is not ideal, and the gap between the distressed furniture and real old furniture is large are overcome.

Owner:铜陵昌盛家具有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com