Manufacturing process of metal parts capable of performing shape follow-up annealing heat treatment

A technology for annealing heat treatment and metal parts, applied in the field of metal parts manufacturing process, can solve the problems of unbalanced heating of parts, high temperature gradient, large structure and thermal stress, etc., to improve accuracy and quality, ensure forming stability, reduce The effect of temperature gradients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

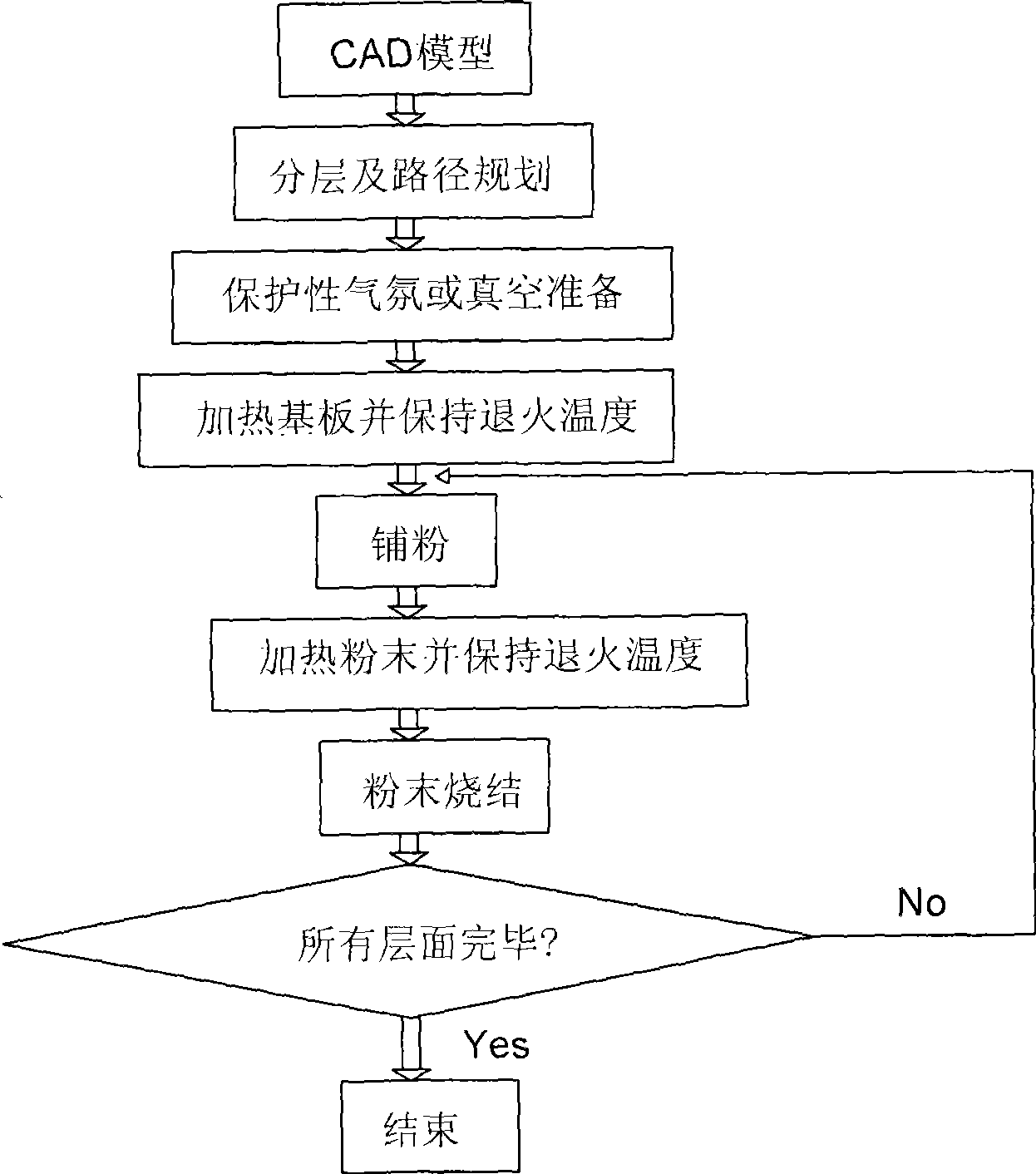

Method used

Image

Examples

Embodiment Construction

[0022] In this embodiment, electron beam conformal heat treatment is used to rapidly manufacture three-dimensional TC4 titanium alloy three-dimensional parts. The material is TC4 titanium alloy powder of -150 to -200 mesh, and the heat treatment temperature of TC4 titanium alloy stress relief annealing is 520°C. In this embodiment, the vacuum degree of the forming chamber used for rapid manufacturing of parts is not higher than 1×10 -2 Pa, the preset conformal heat treatment temperature, that is, the preset holding temperature is above 520°C and around 0-80°C. In practice, the conformal heat treatment temperature is often selected to be 600±5°C. During the entire forming process of the parts, the electric heater under the substrate and the infrared heater above the forming chamber are controlled by the computer to heat the substrate, each layer of metal powder, and the formed parts, so that the parts are formed and kept at 600±5°C at all times, achieving The purpose of shape h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com