Patents

Literature

13784 results about "Metal powder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metal powder is a metal that has been broken down into a powder form. Metals that can be found in powder form include aluminium powder, nickel powder, iron powder and many more. According to Belmont Metals, their design engineers are turning to metal powders because of the benefits such as cost effectiveness, versatility, and quality. There are four different ways metals can be broken down into this powder form...

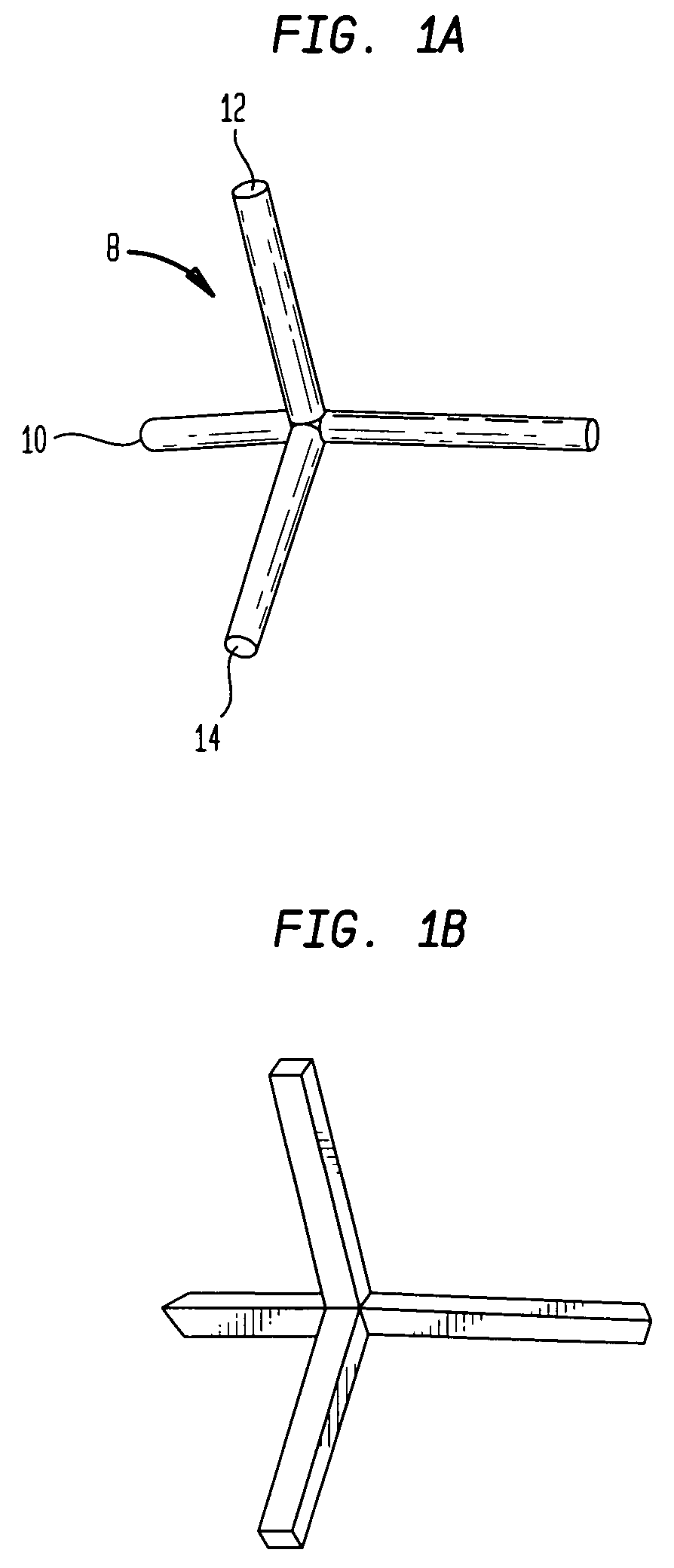

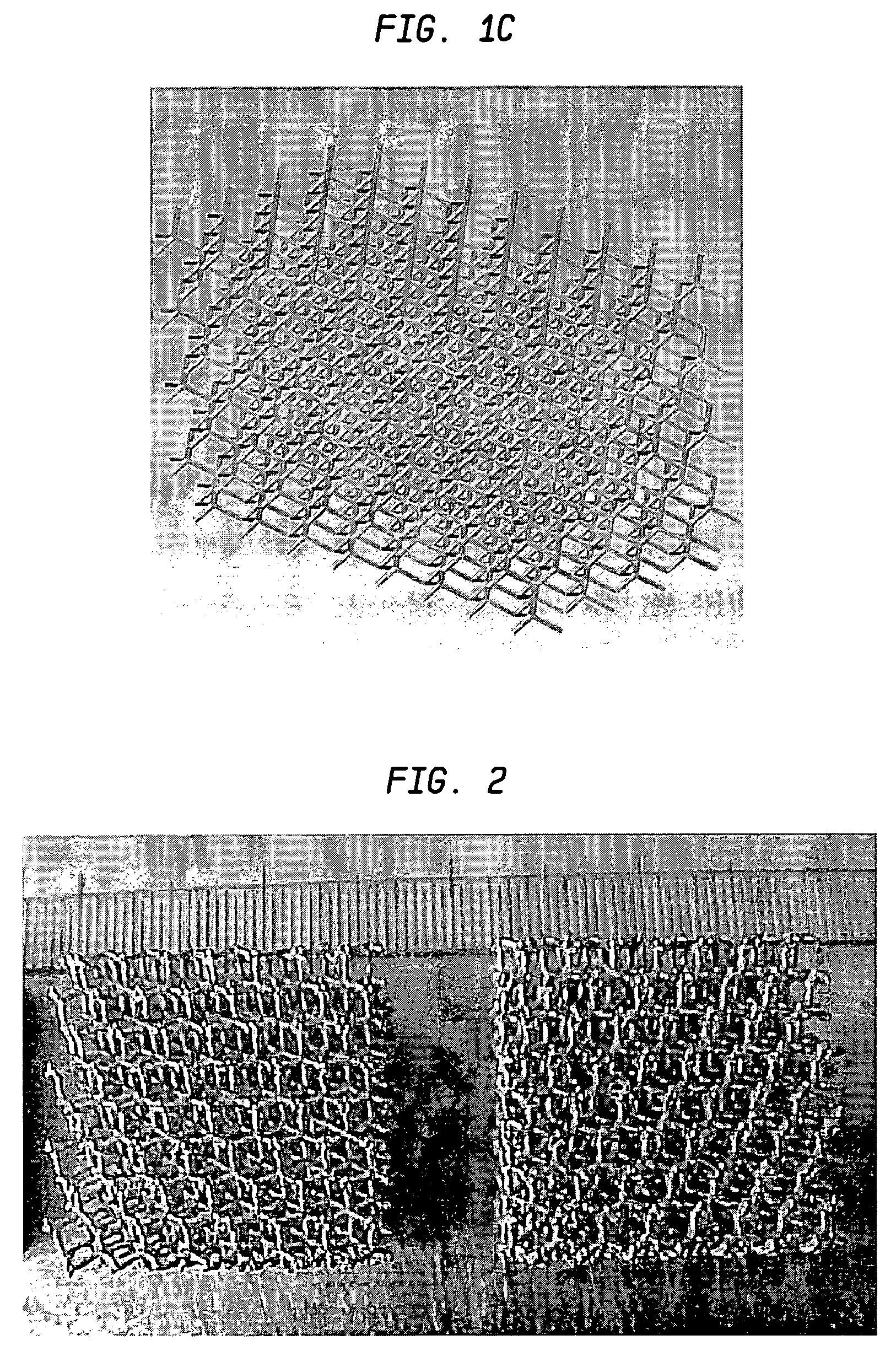

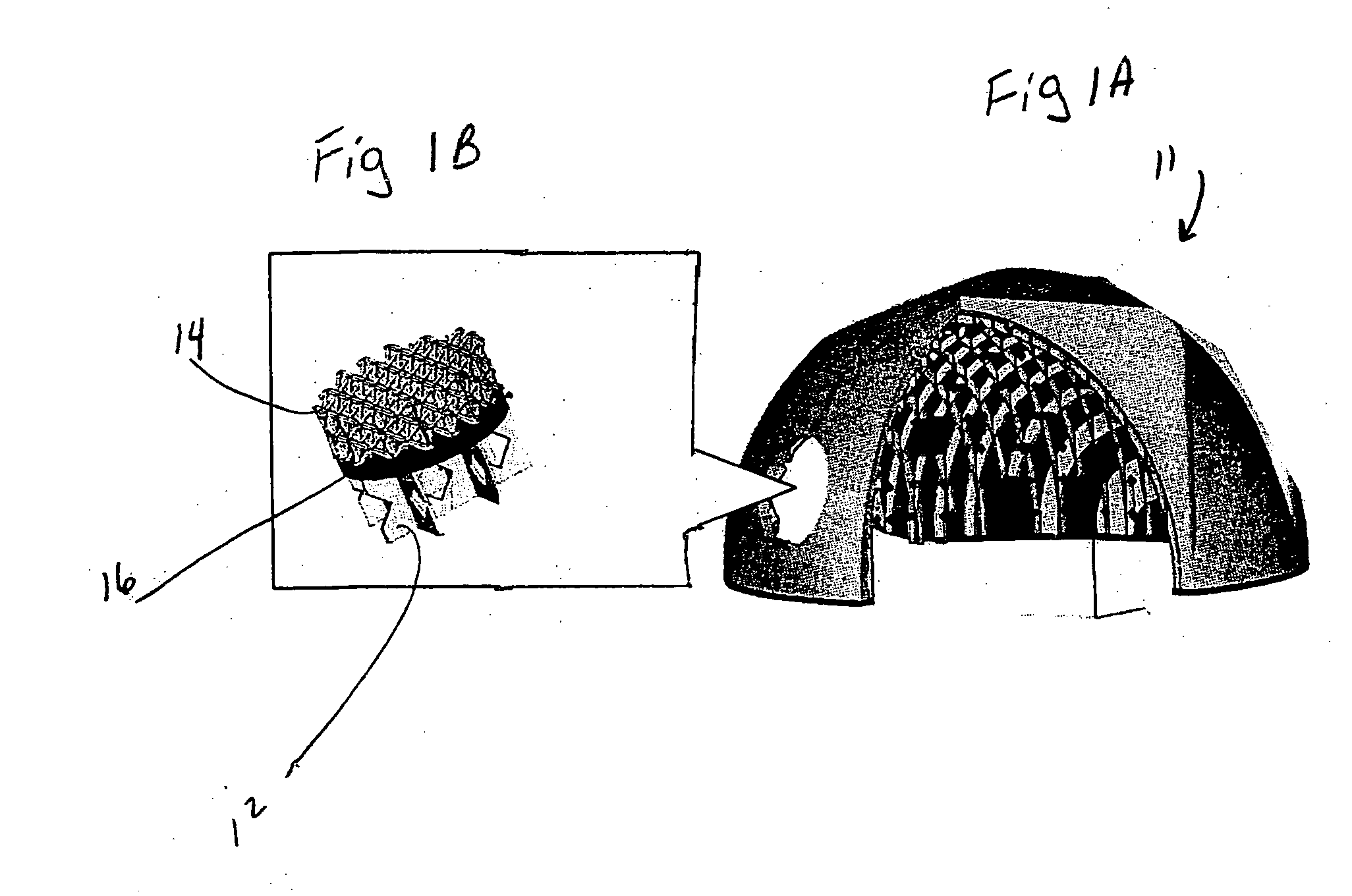

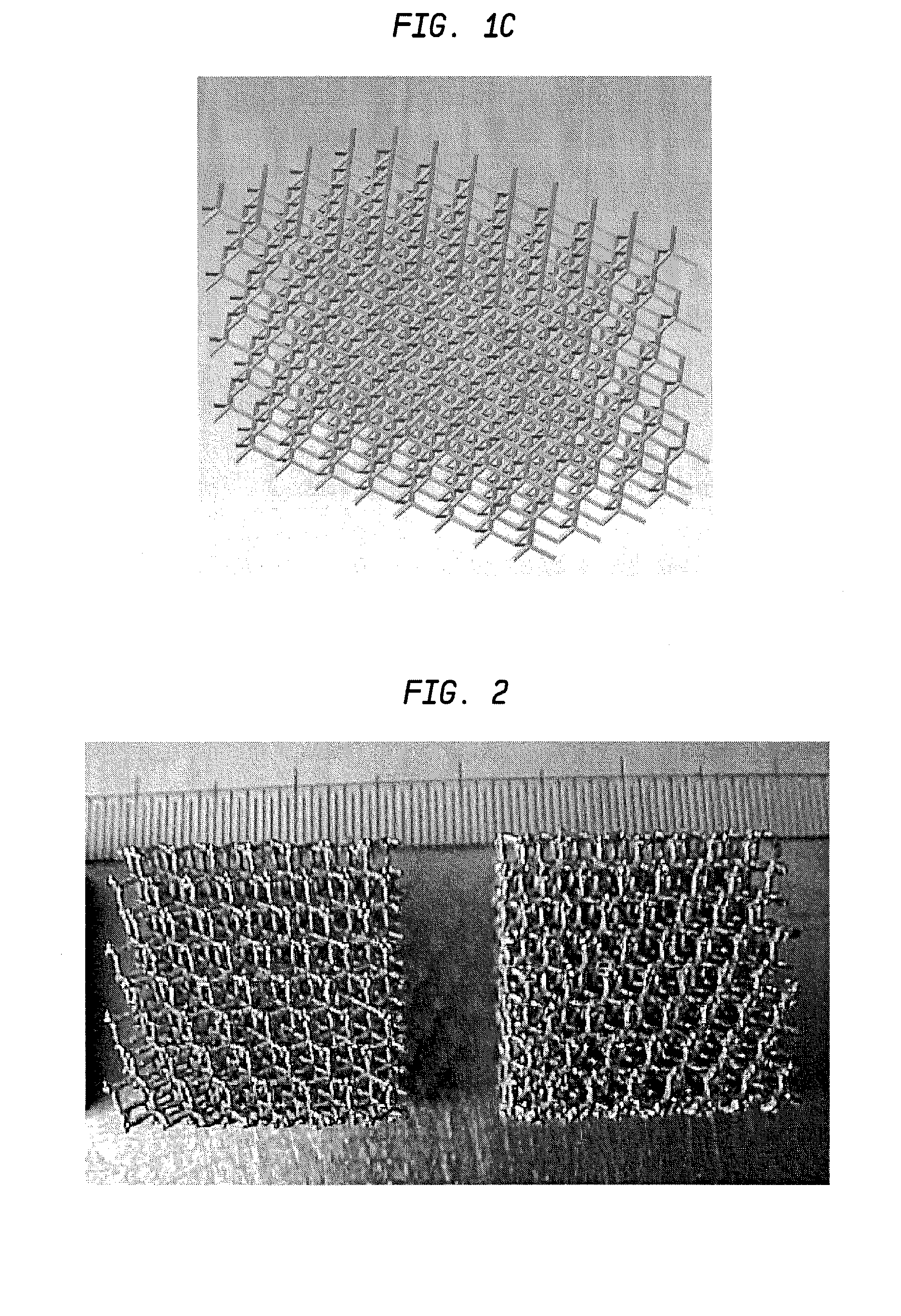

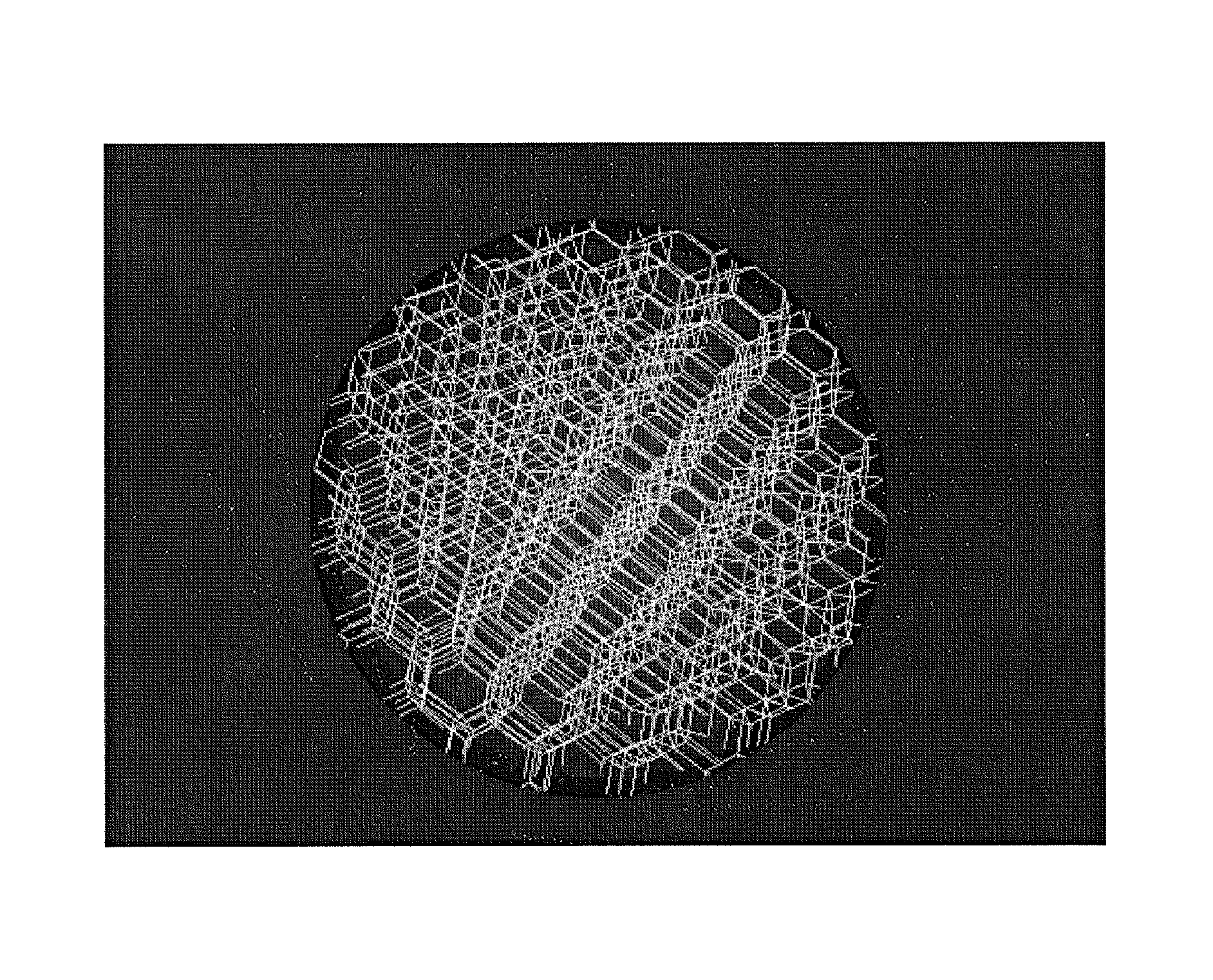

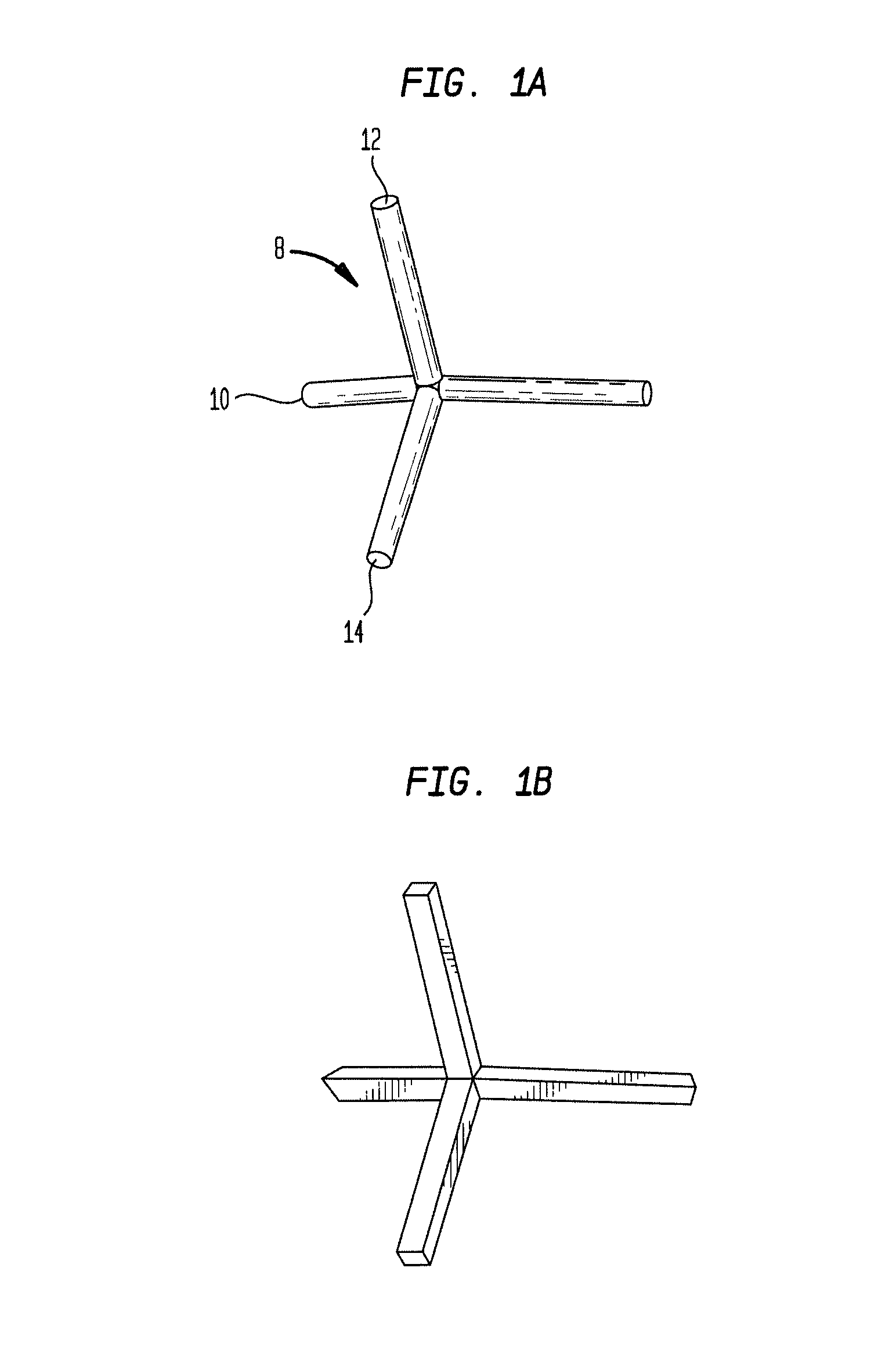

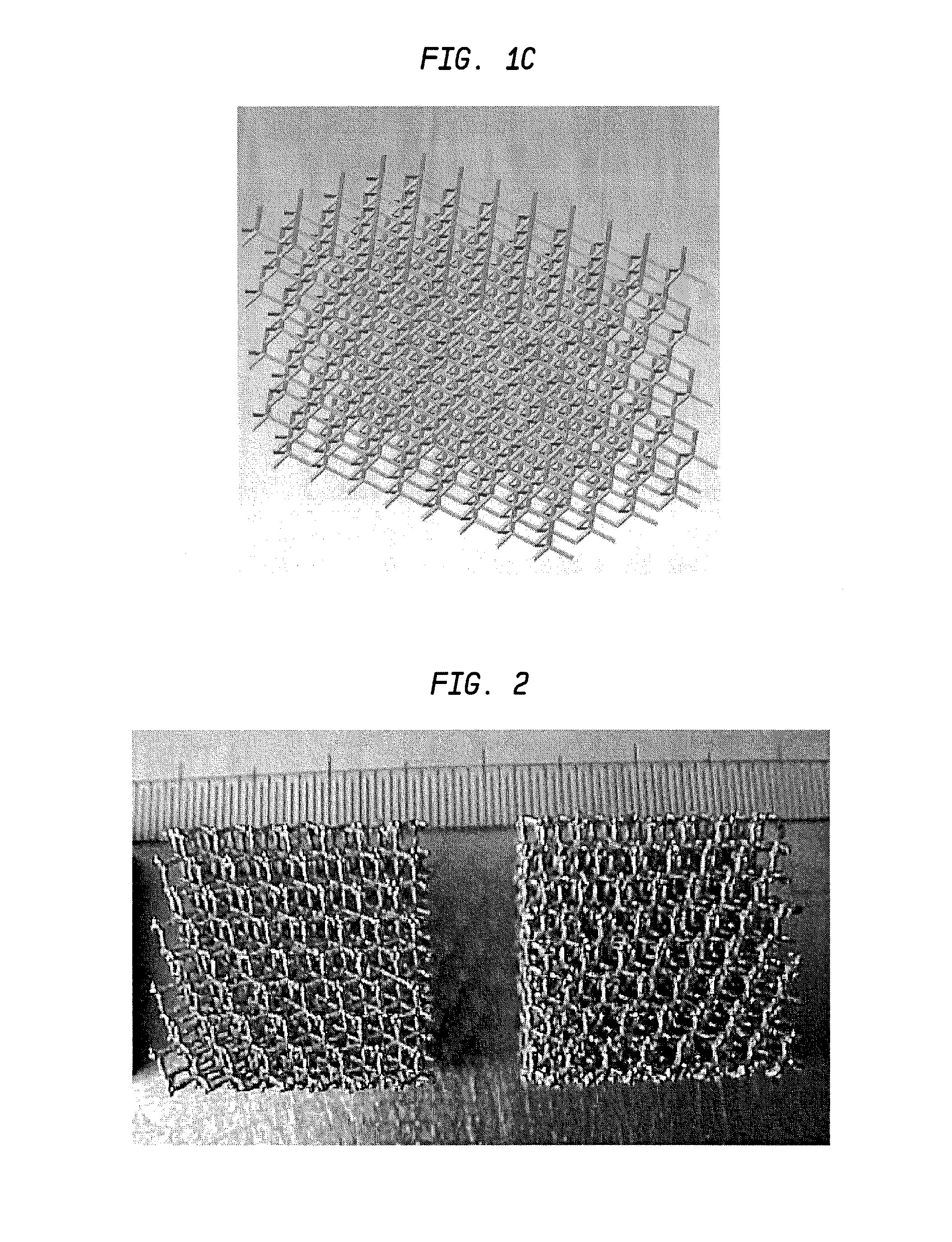

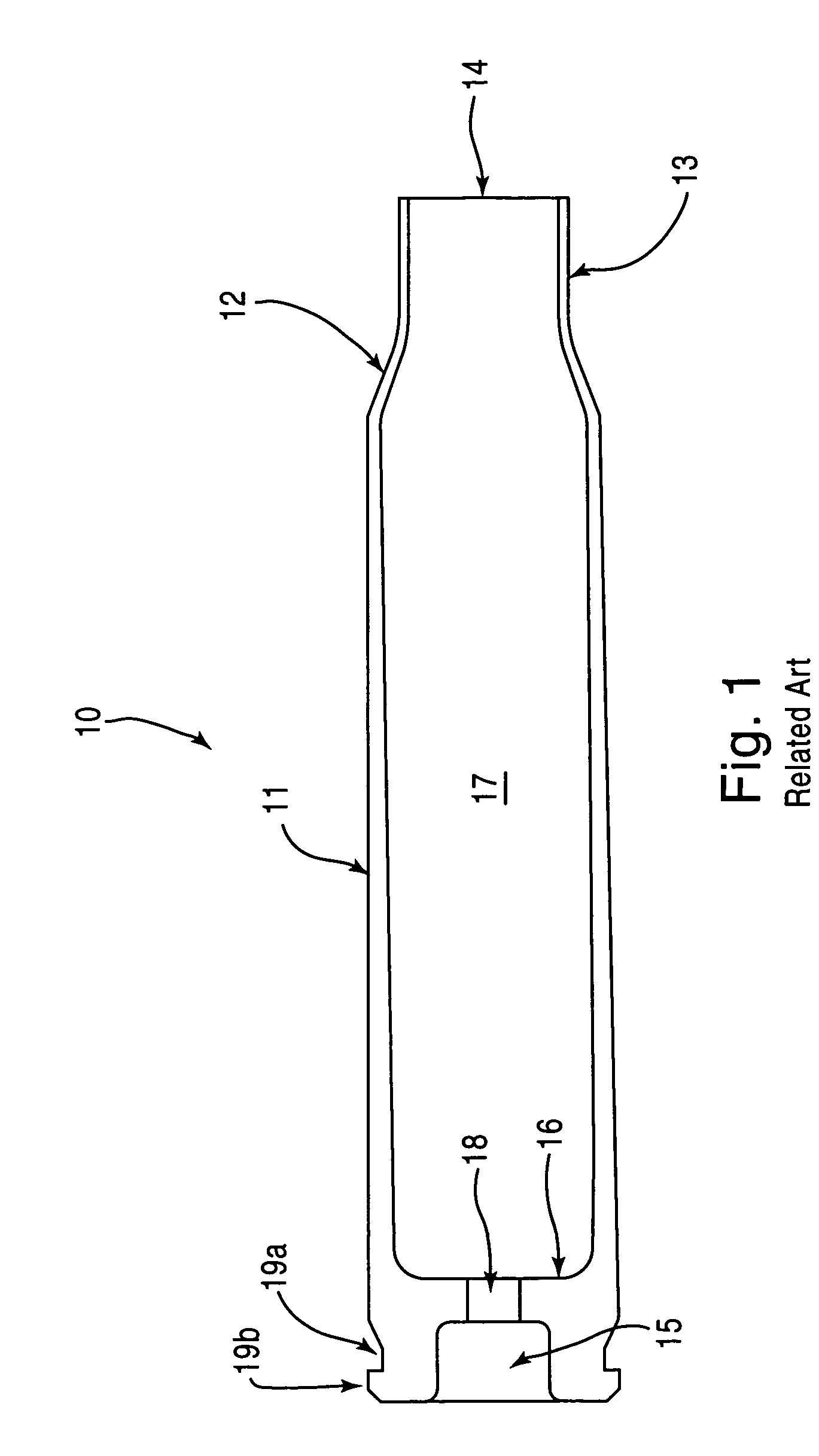

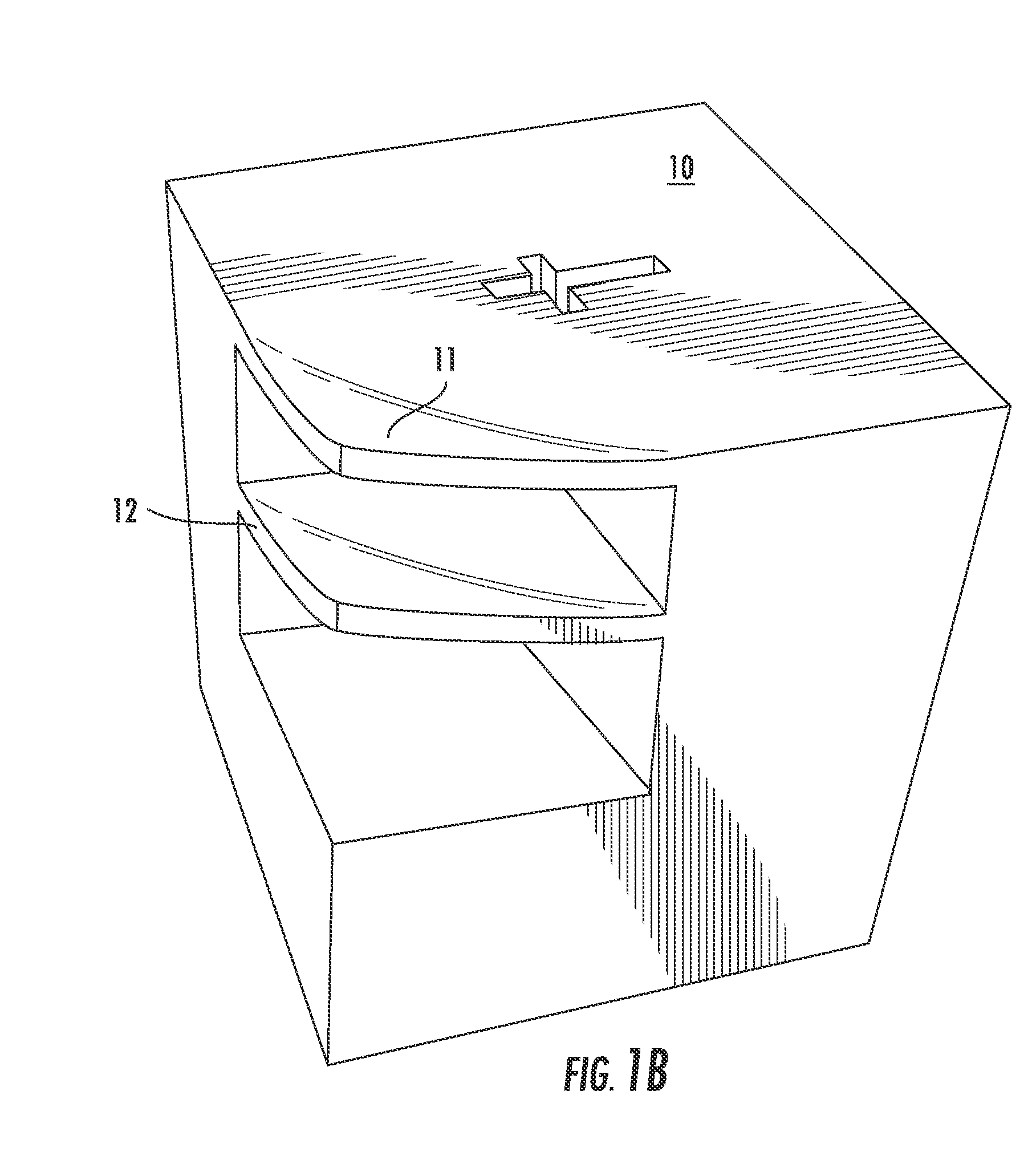

Laser-produced porous structure

The present invention disclosed a method of producing a three-dimensional porous tissue in-growth structure. The method includes the steps of depositing a first layer of metal powder and scanning the first layer of metal powder with a laser beam to form a portion of a plurality of predetermined unit cells. Depositing at least one additional layer of metal powder onto a previous layer and repeating the step of scanning a laser beam for at least one of the additional layers in order to continuing forming the predetermined unit cells. The method further includes continuing the depositing and scanning steps to form a medical implant.

Owner:UNIV OF LIVERPOOL +1

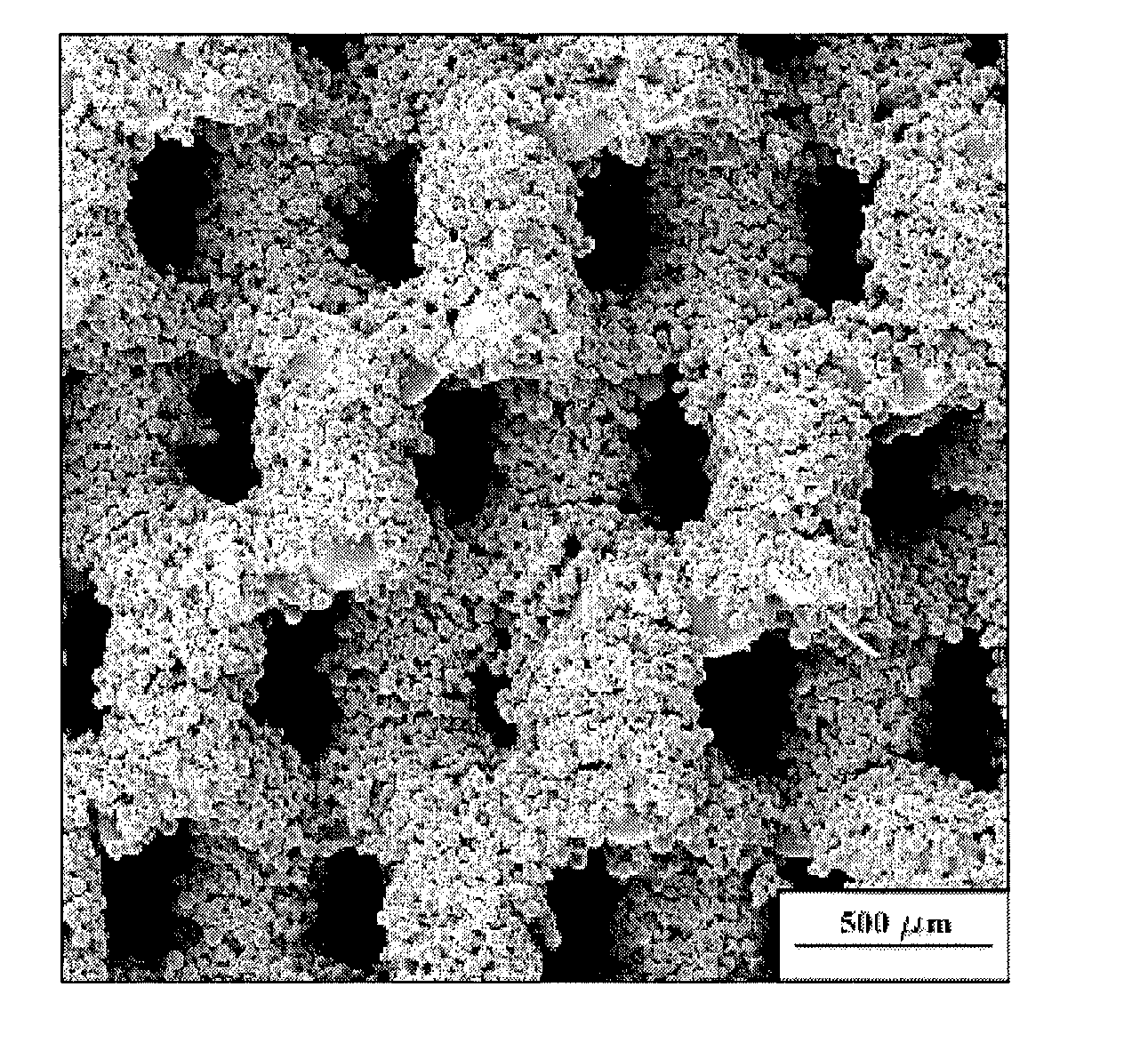

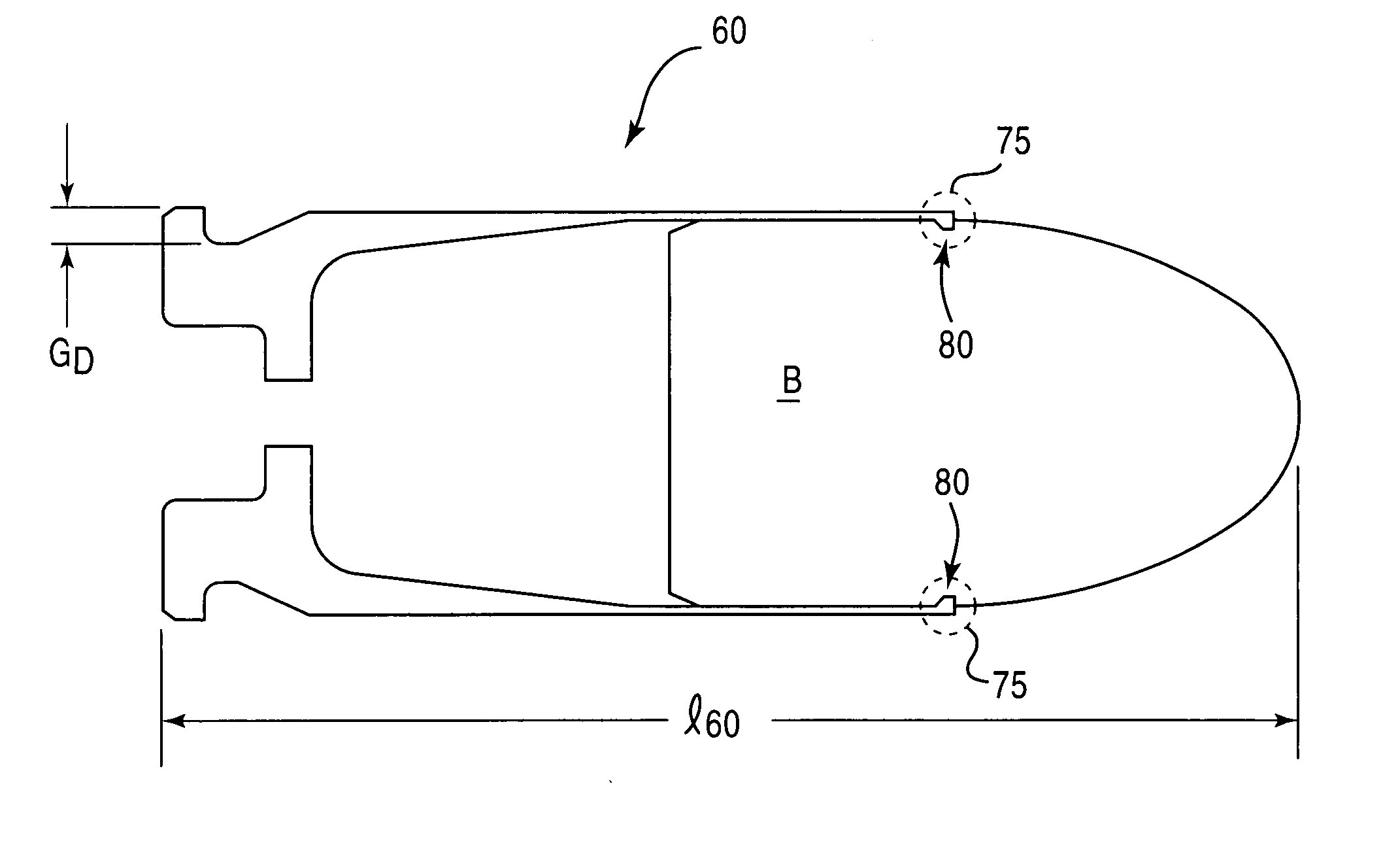

Laser-produced porous surface

ActiveUS20070142914A1Promote bone ingrowthGood stiffness characteristicsAdditive manufacturing apparatusMolten spray coatingLight beamMetal powder

A method of forming an implant having a porous tissue ingrowth structure and a bearing support structure. The method includes depositing a first layer of a metal powder onto a substrate, scanning a laser beam over the powder so as to sinter the metal powder at predetermined locations, depositing at least one layer of the metal powder onto the first layer and repeating the scanning of the laser beam.

Owner:UNIV OF LIVERPOOL +1

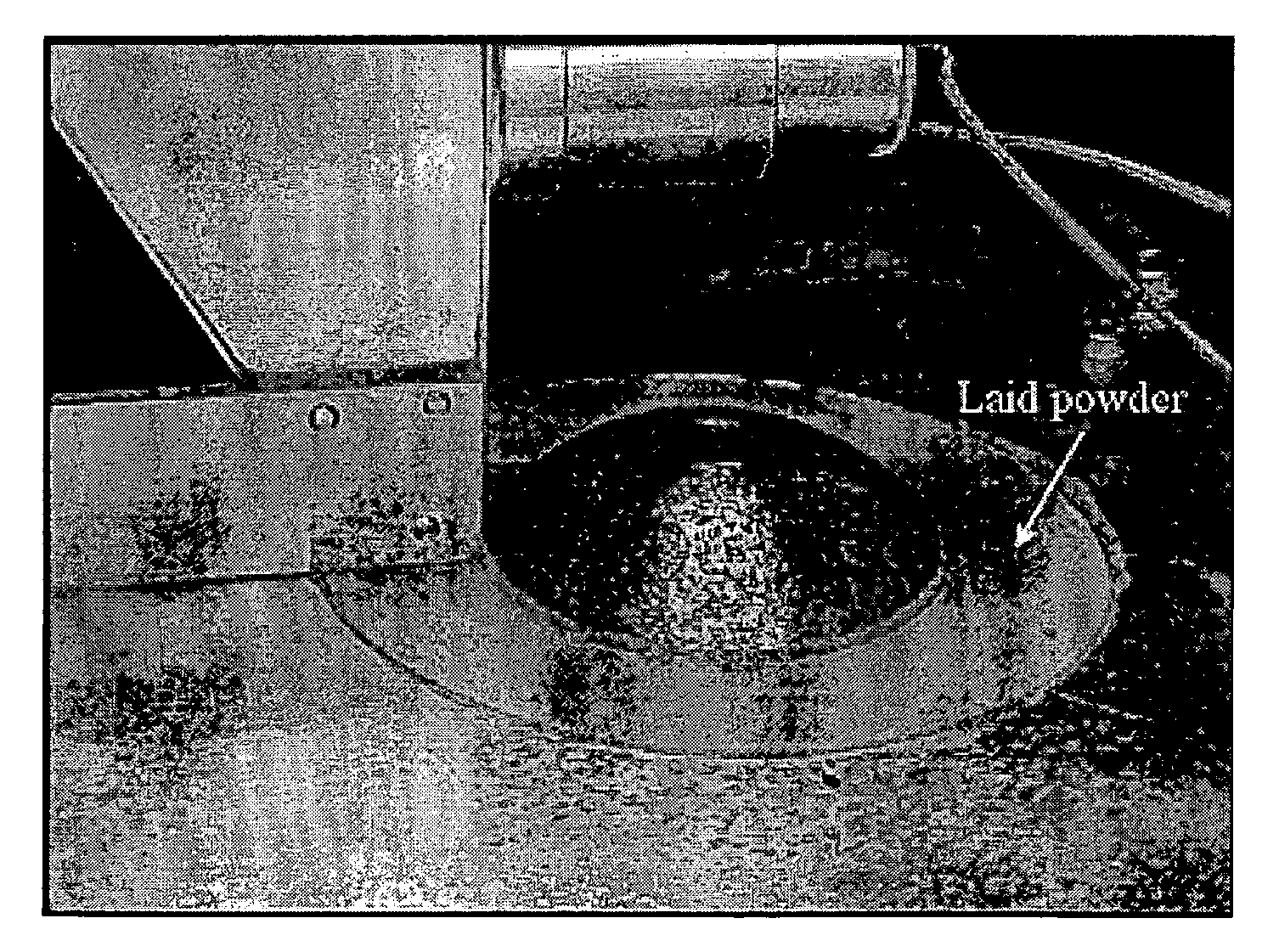

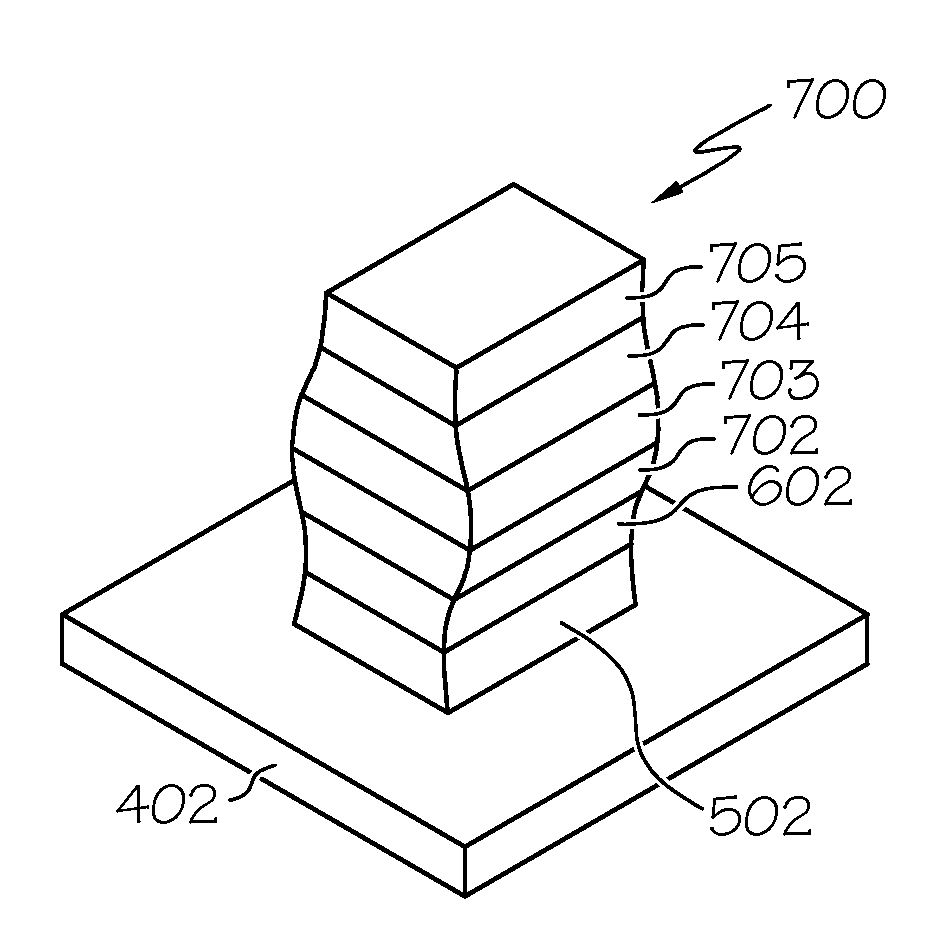

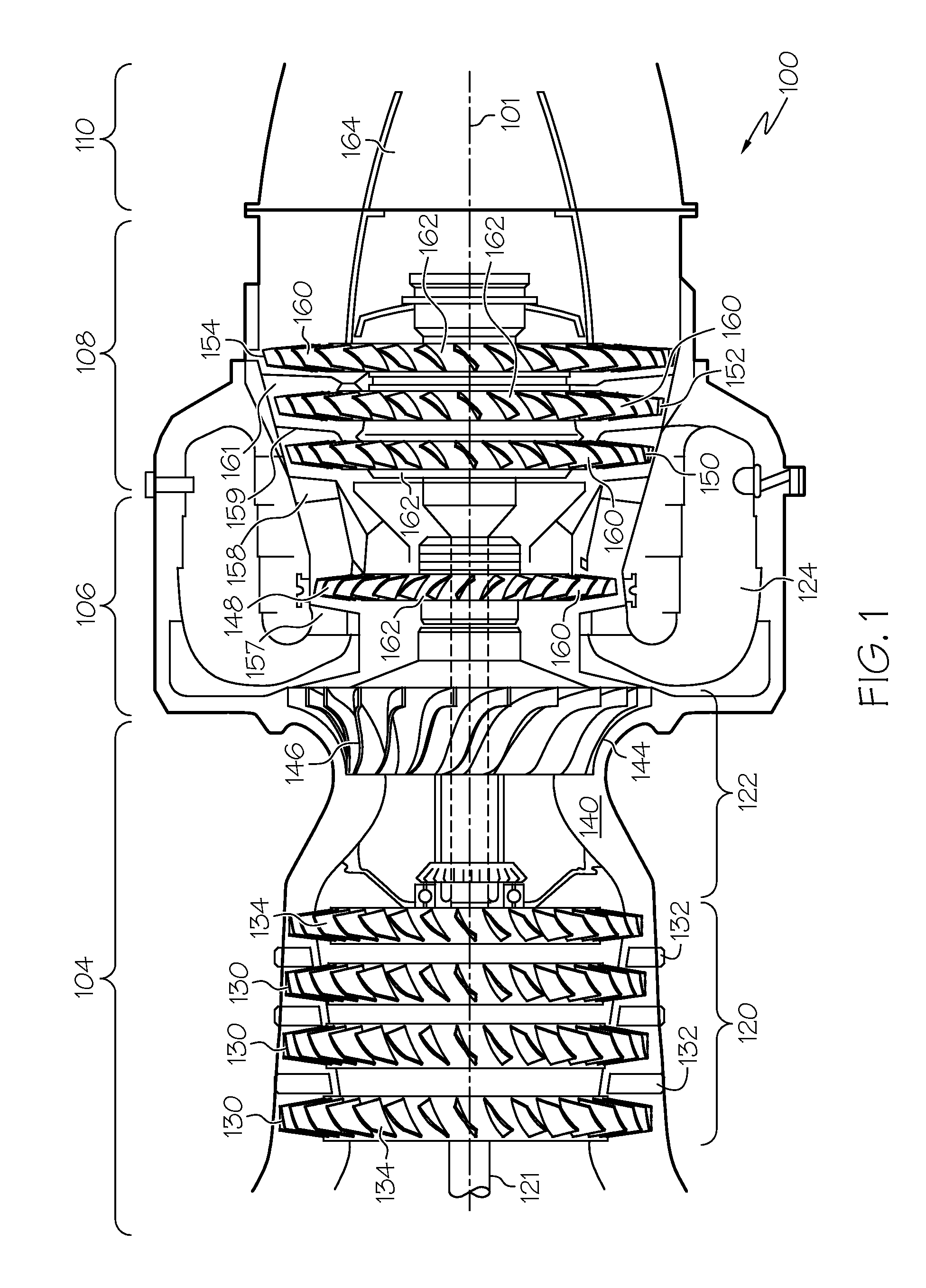

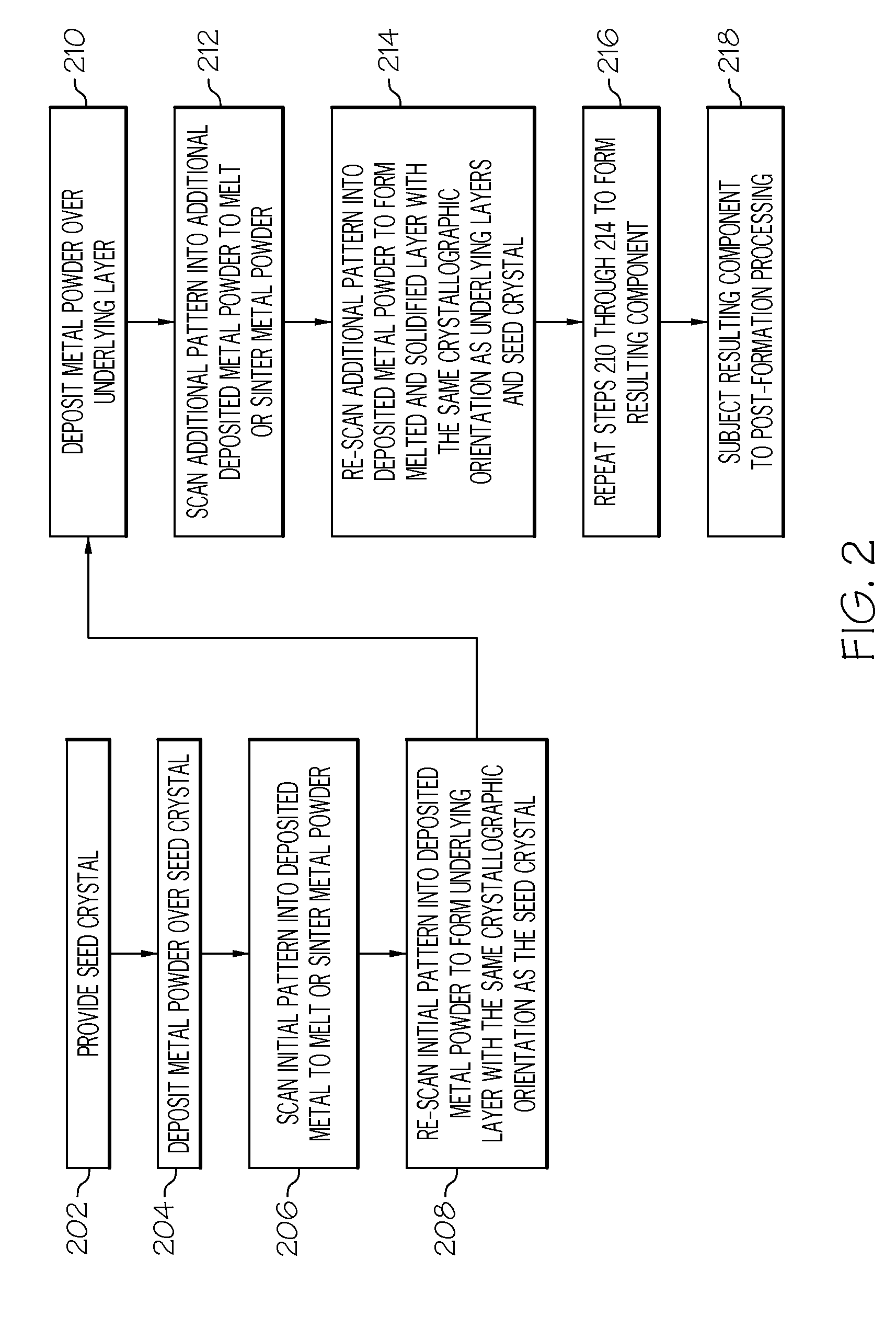

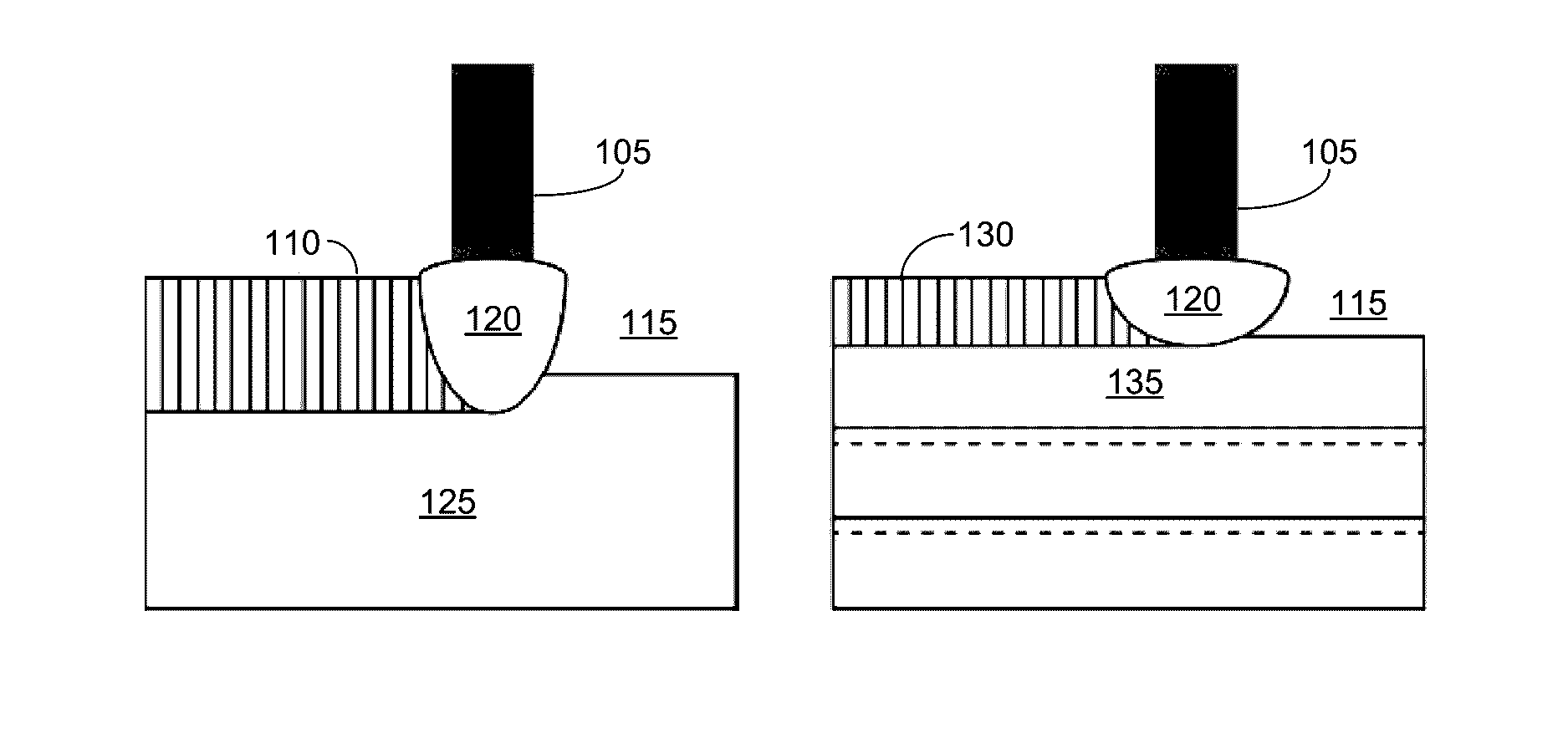

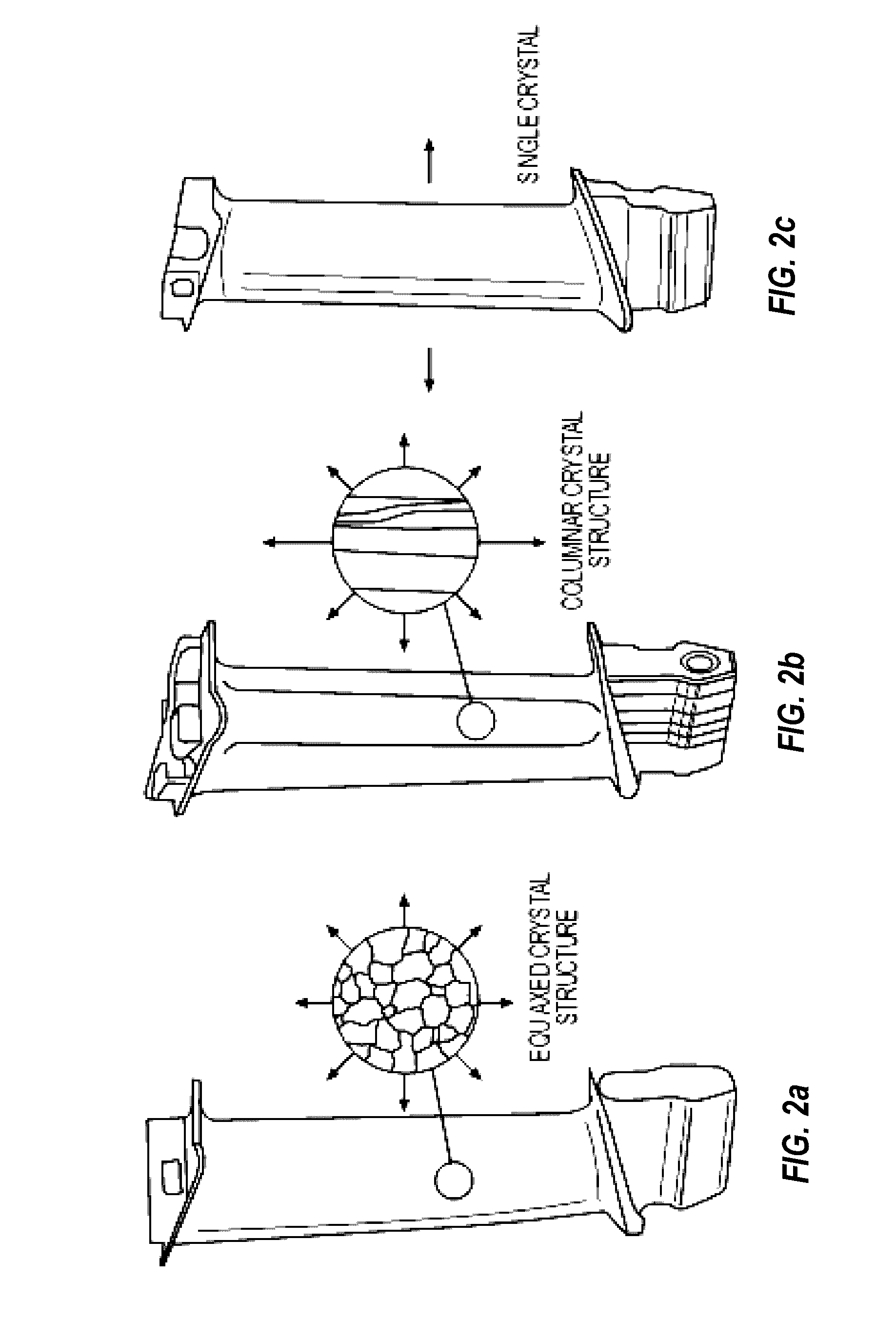

Systems and methods for additive manufacturing and repair of metal components

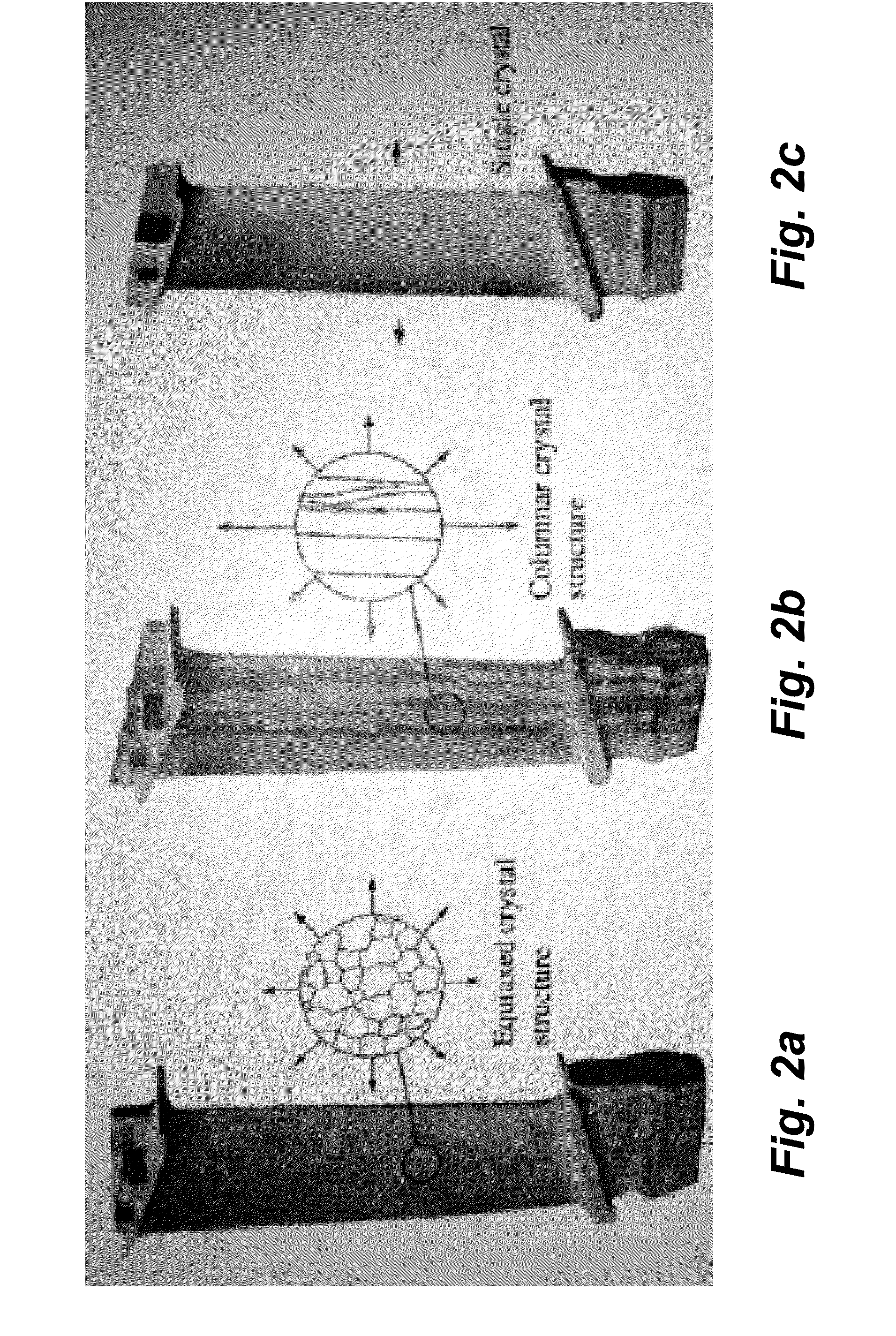

Scanning Laser Epitaxy (SLE) is a layer-by-layer additive manufacturing process that allows for the fabrication of three-dimensional objects with specified microstructure through the controlled melting and re-solidification of a metal powders placed atop a base substrate. SLE can be used to repair single crystal (SX) turbine airfoils, for example, as well as the manufacture functionally graded turbine components. The SLE process is capable of creating equiaxed, directionally solidified, and SX structures. Real-time feedback control schemes based upon an offline model can be used both to create specified defect free microstructures and to improve the repeatability of the process. Control schemes can be used based upon temperature data feedback provided at high frame rate by a thermal imaging camera as well as a melt-pool viewing video microscope. A real-time control scheme can deliver the capability of creating engine ready net shape turbine components from raw powder material.

Owner:GEORGIA TECH RES CORP

Electrical conductors formed from mixtures of metal powders and metallo-organic decomposition compounds

The present invention relates to a thick film formed of a mixture of metal powders and metallo-organic decomposition (MOD) compounds in an organic liquid vehicle and a process for advantageously applying them to a substrate by silk screening or other printing technology. The mixtures preferably contain metal flake with a ratio of the maximum dimension to the minimum dimension of between 5 and 50. The vehicle may include a colloidal metal powder with a diameter of about 10 to about 40 nanometers. The concentration of the colloidal metal in the suspension can range from about 10 to about 50% by weight. The MOD compound begins to decompose at a temperature of approximately about 200 DEG C. to promote consolidation of the metal constituents and bonding to the substrate which is complete at temperatures less than 450 DEG C. in a time less than six minutes. The mixtures can be applied by silk screening, stencilling, gravure or lithography to a polymer-based circuit board substrate for producing rigid and flexible printed wiring boards in a single operation with negligible generation of hazardous wastes. The same mixtures can be used in place of solder to assemble circuits by bonding electrical components to conductors as well as to make the conductors themselves.

Owner:PARELEC

Bullet composition

Owner:HANSEN RICHARD D

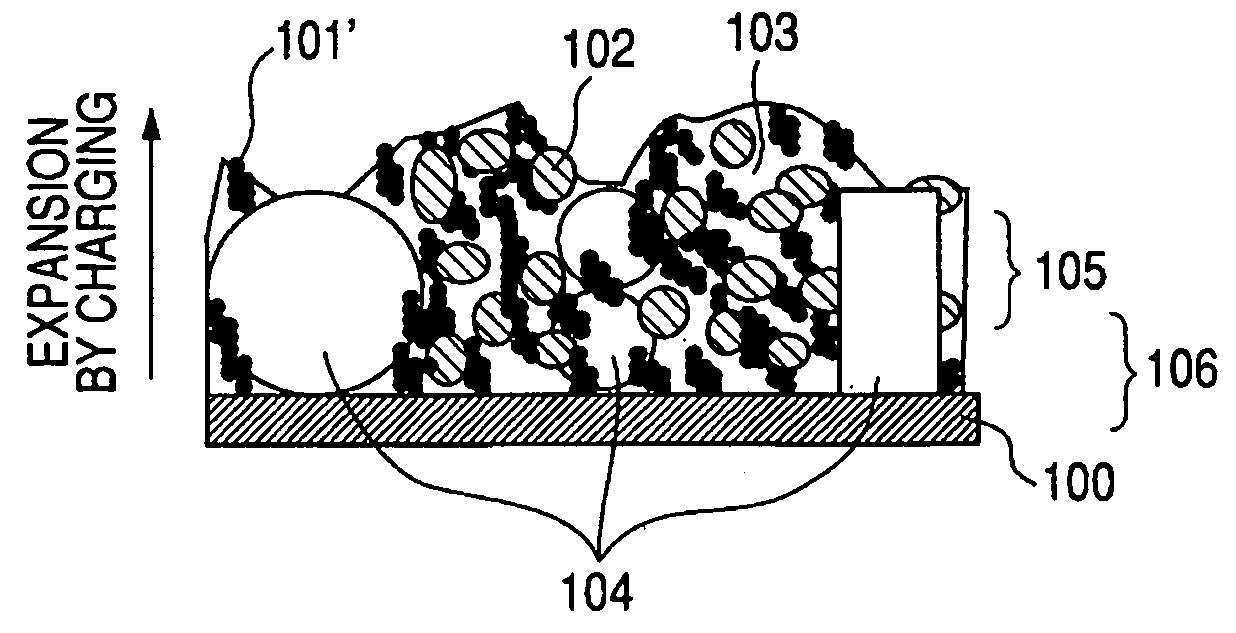

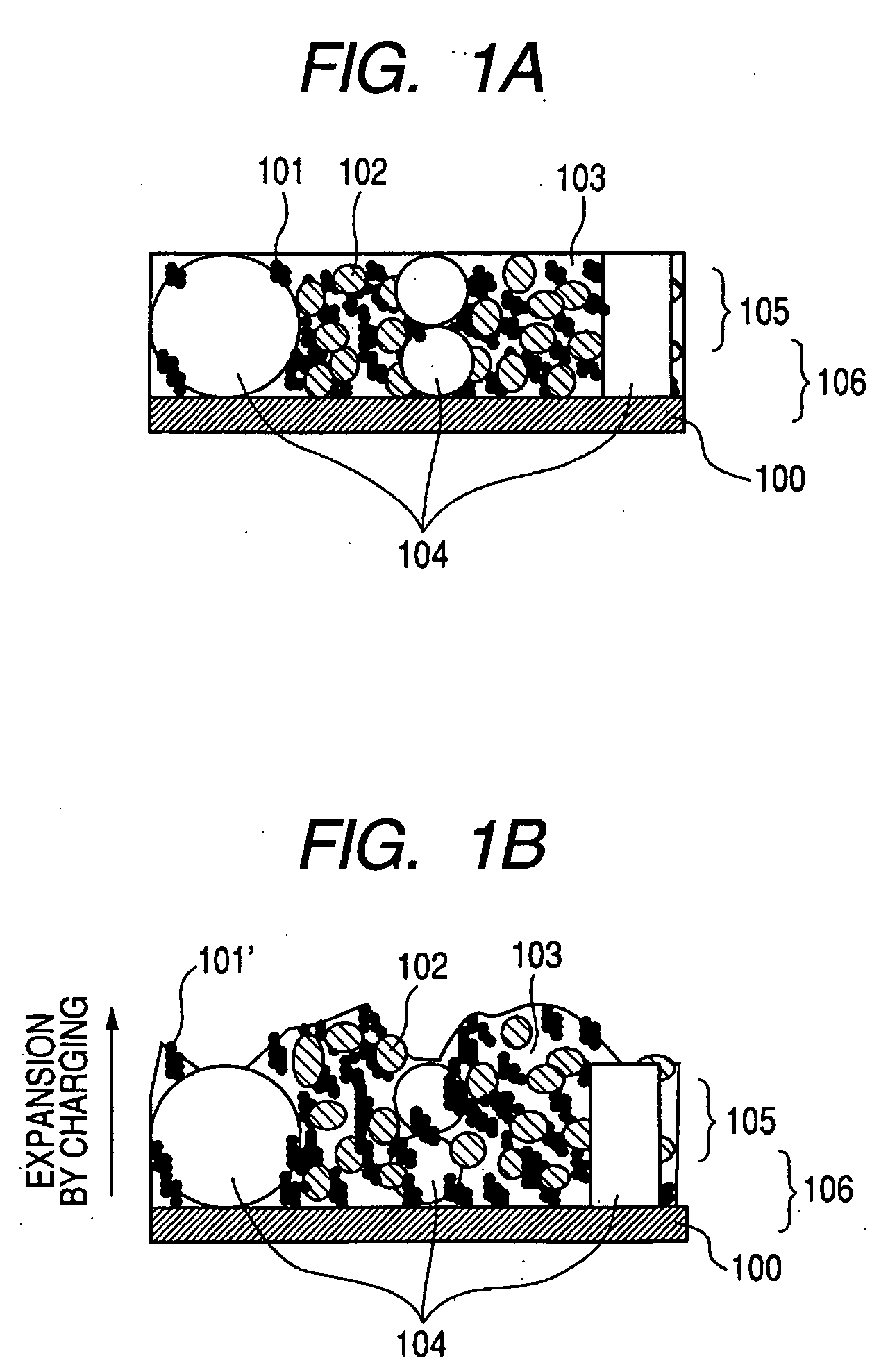

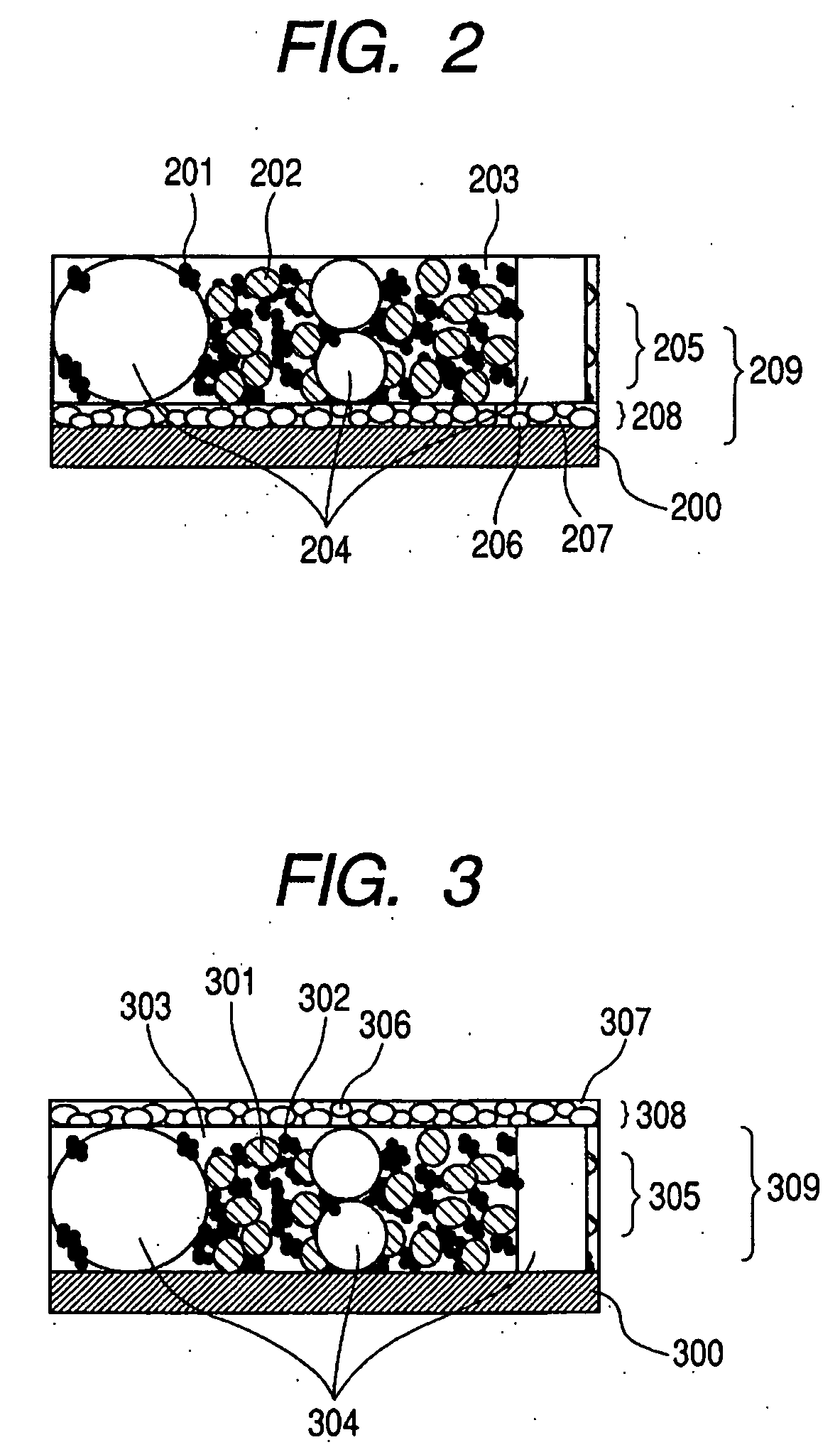

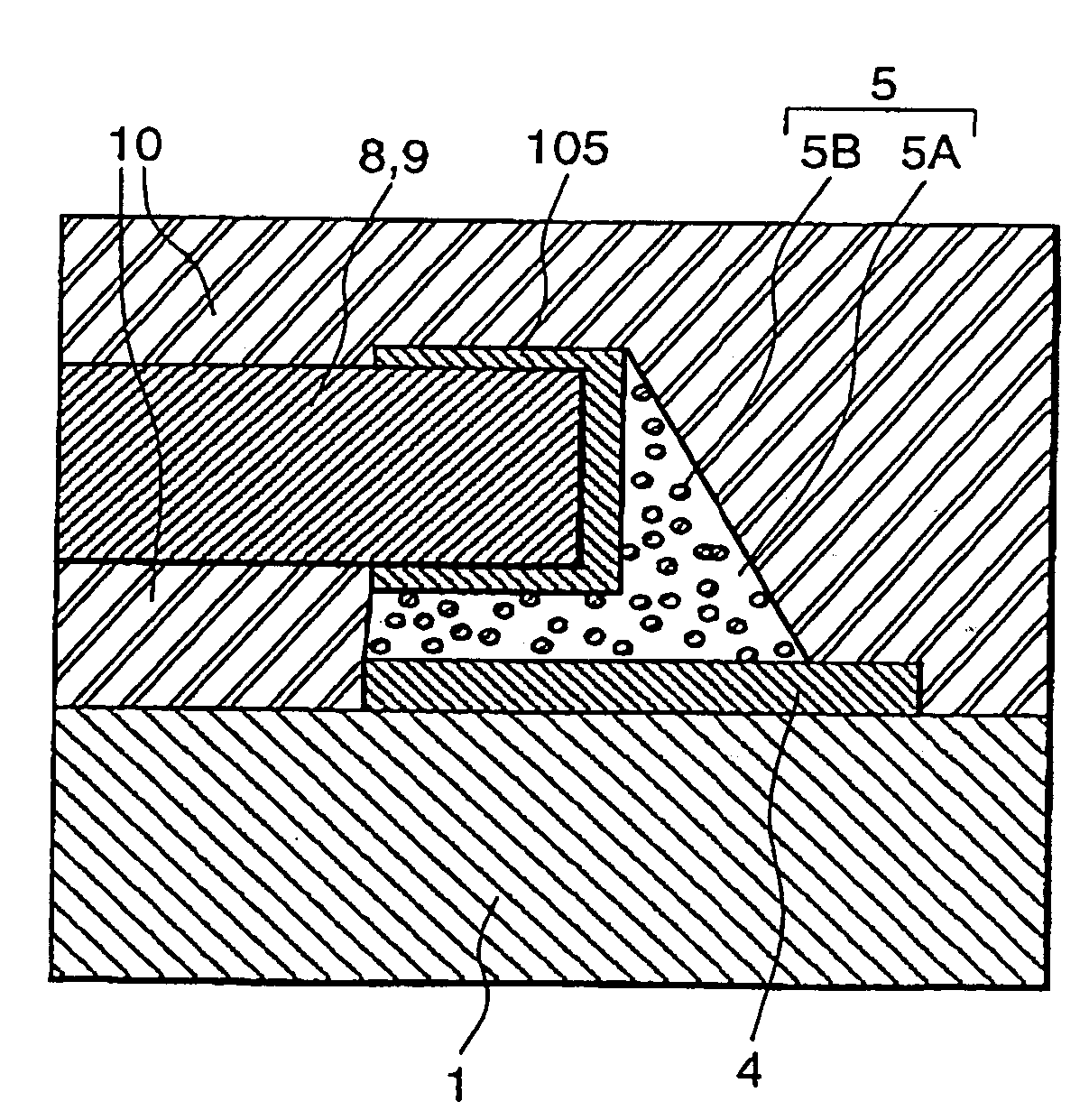

Electrode structure for lithium secondary battery and secondary battery having such electrode structure

InactiveUS20060127773A1Small capacity reductionLarge capacityElectrode manufacturing processesFinal product manufactureElectrochemical responseConductive polymer

In an electrode structure for a lithium secondary battery including: a main active material layer formed from a metal powder selected from silicon, tin and an alloy thereof that can store and discharge and capable of lithium by electrochemical reaction, and a binder of an organic polymer; and a current collector, wherein the main active material layer is formed at least by a powder of a support material for supporting the electron conduction of the main active material layer in addition to the metal powder and the powder of the support material are particles having a spherical, pseudo-spherical or pillar shape with an average particle size of 0.3 to 1.35 times the thickness of the main active material layer. The support material is one or more materials selected from a group consisting of graphite, oxides of transition metals and metals that do not electrochemically form alloy with lithium. Organic polymer compounded with a conductive polymer is used for the binder. There are provided an electrode structure for a lithium secondary battery having a high capacity and a long lifetime, and a lithium secondary battery using the electrode structure and having a high capacity, a high energy density and a long lifetime.

Owner:CANON KK

Laser-produced porous structure

The present invention disclosed a method of producing a three-dimensional porous tissue in-growth structure. The method includes the steps of depositing a first layer of metal powder and scanning the first layer of metal powder with a laser beam to form a portion of a plurality of predetermined unit cells. Depositing at least one additional layer of metal powder onto a previous layer and repeating the step of scanning a laser beam for at least one of the additional layers in order to continuing forming the predetermined unit cells. The method further includes continuing the depositing and scanning steps to form a medical implant.

Owner:UNIV OF LIVERPOOL +1

Two-dimensional fiber cloth reinforced composite material and preparation method thereof

InactiveCN101224989AImprove fracture toughnessImprove use reliabilityMetal powderStructural stability

The invention discloses a two-dimensional fiber cloth reinforced ceramics based composite material and the preparation technique, which adopts the two-dimensional fiber cloth as the reinforcing phase and the ceramic powder or the refractory metal powder as the stuffing, and the carbon and the carborundum as the base. The process steps are following: first the sizing agent with different ceramic powder and metal powder is coated on the two-dimensional fiber cloth, and then overlapping, puncturing and repeated densification are carried out. The preparation method has the advantages of lowering preparation cost and shortening preparation cycle, and the two-dimensional fiber cloth reinforced ceramics based composite material has the advantages of high shear strength between layers, structural stability and high reliability. The types of fiber cloth and the base can be adjusted and optimized in a wider range according to the applications, so as to be applicable for different fields.

Owner:NAT UNIV OF DEFENSE TECH

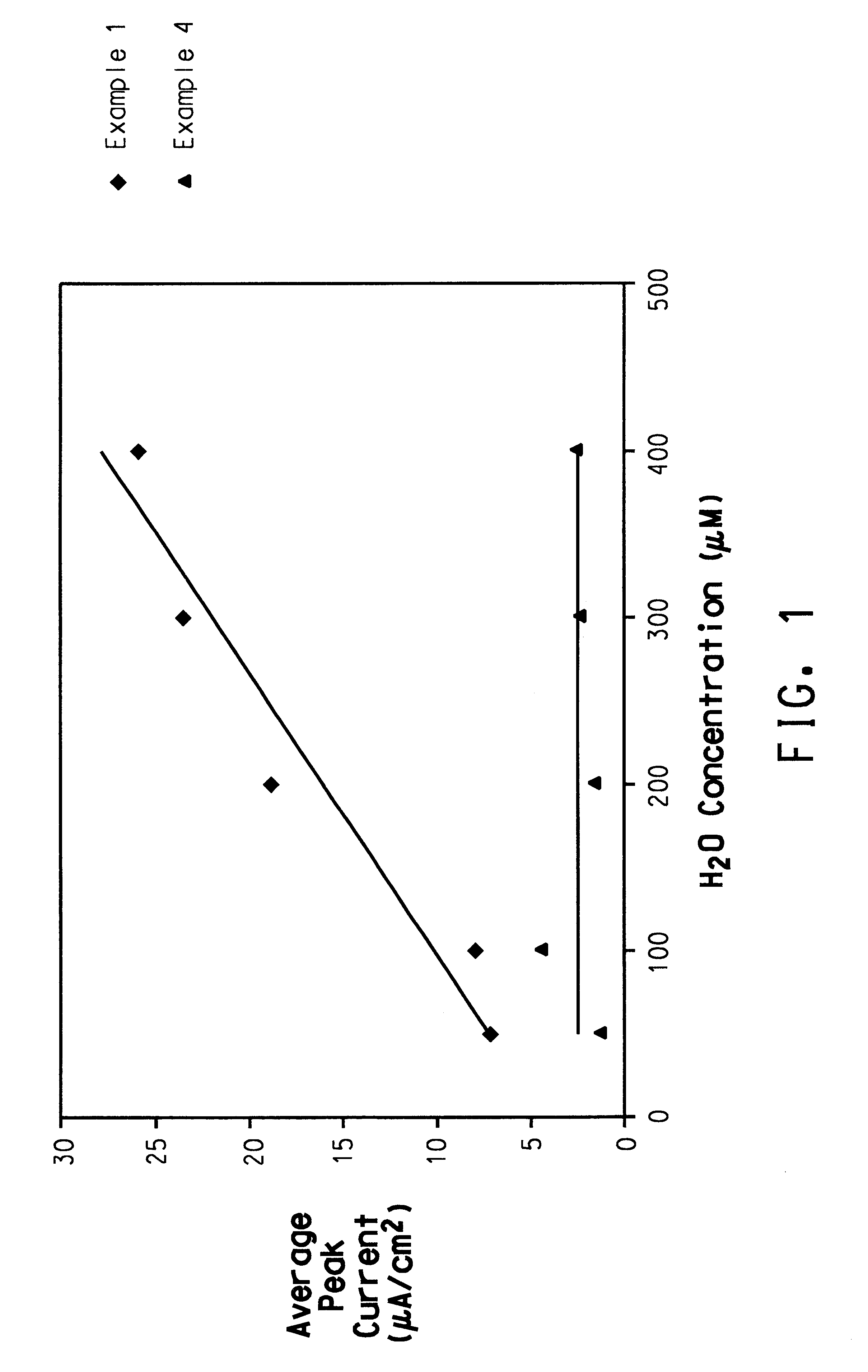

Thick film conductor composition for use in biosensors

InactiveUS6627058B1Immobilised enzymesBioreactor/fermenter combinationsElectrical conductorPolyethylene glycol

This invention is directed to a composition comprising: (a) platinum group metal powder, alloys, or mixtures thereof as a powder or deposited on graphite supports; (b) poly(glycol ether), derivatives, or mixtures thereof; (c) carbon-based electrically conductive filler; and (d) thermoplastic polymer or mixtures thereof. The invention is further directed to a process for dispersing platinum group metal powder, alloys, or mixtures thereof in poly(glycol ether), derivatives, or mixtures thereof. The invention is further directed to the above composition wherein the platinum group metal powder has been dispersed according to the above process.

Owner:EI DU PONT DE NEMOURS & CO

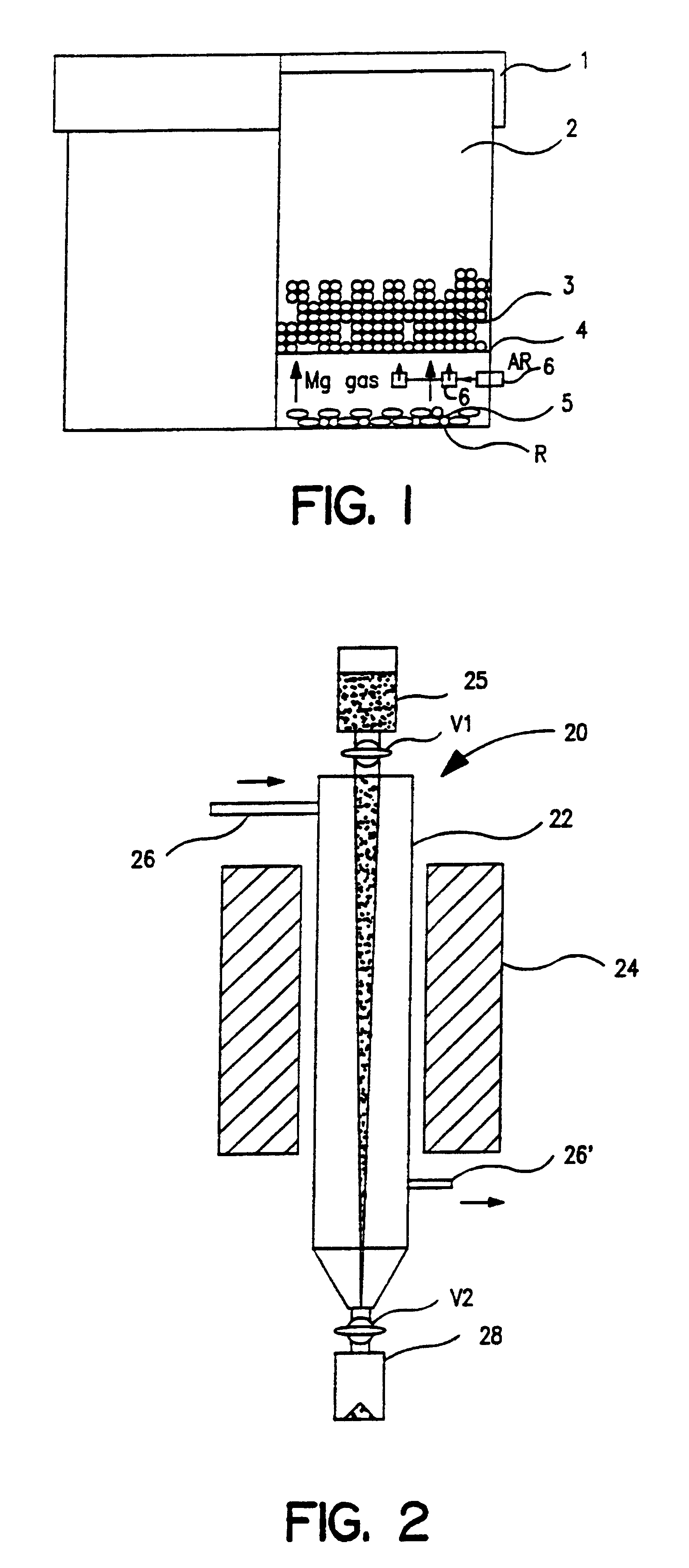

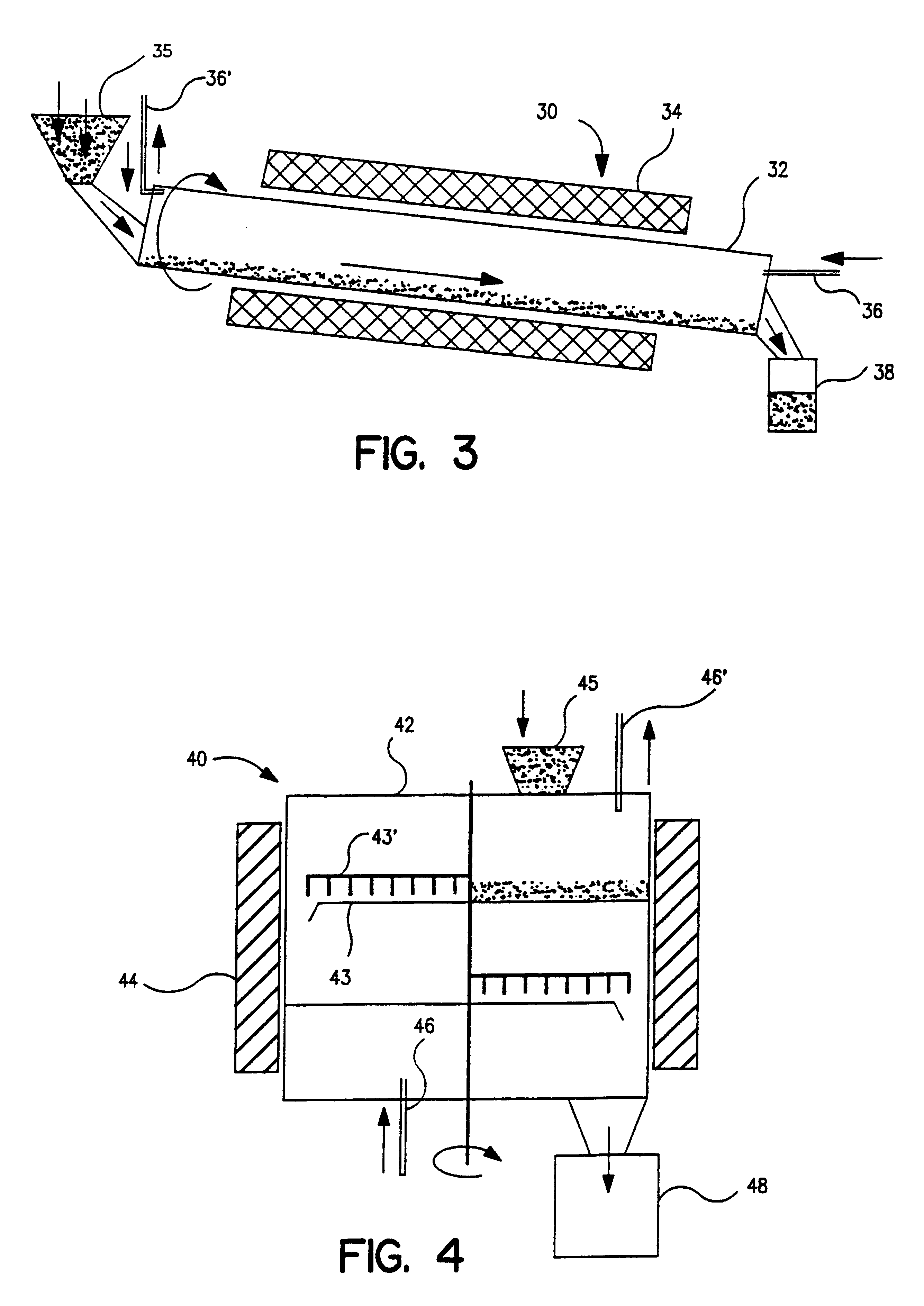

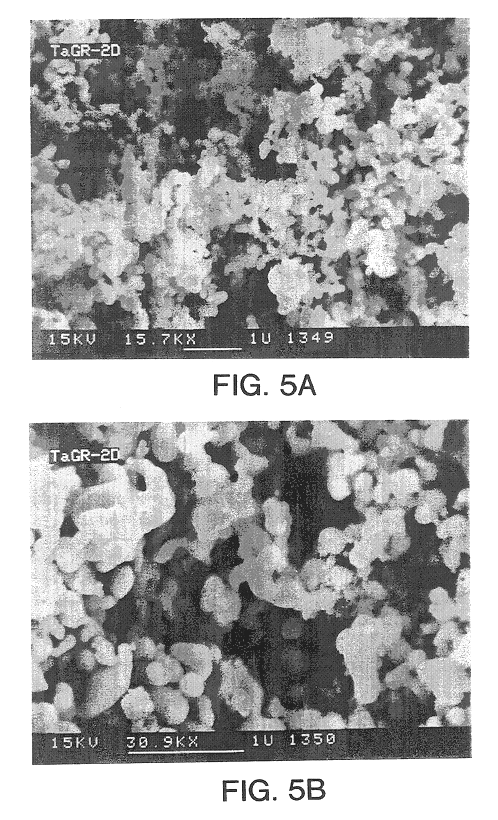

Metal powders produced by the reduction of the oxides with gaseous magnesium

InactiveUS6558447B1Improve performanceEliminate the problemElectrolytic capacitorsTransportation and packagingAlkaline earth metalMetal powder

Metal powder Ta and / or Nb, with or without one or metals from the group Ta, Nb, Ti, Mo, W, V, Zr and Hf, is made in a fine powder form by reduction of metal oxide by contact with a gaseous reducing agent, preferably an alkaline earth metal, to near complete reduction, leaching, further deoxidation and agglomeration, the powder so produced being sinterable to capacitor anode form and processable to other usages.

Owner:H C STARCK TANTALUM & NIOBIUM GMBH

Laser-produced porous structure

The present invention disclosed a method of producing a three-dimensional porous tissue in-growth structure. The method includes the steps of depositing a first layer of metal powder and scanning the first layer of metal powder with a laser beam to form a portion of a plurality of predetermined unit cells. Depositing at least one additional layer of metal powder onto a previous layer and repeating the step of scanning a laser beam for at least one of the additional layers in order to continuing forming the predetermined unit cells. The method further includes continuing the depositing and scanning steps to form a medical implant.

Owner:UNIV OF LIVERPOOL +1

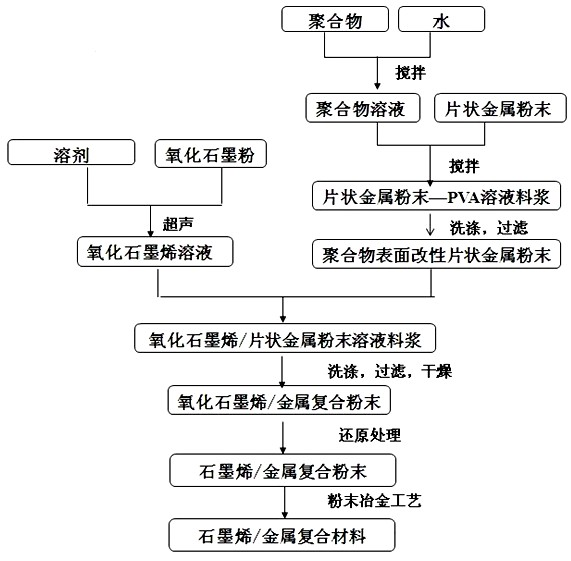

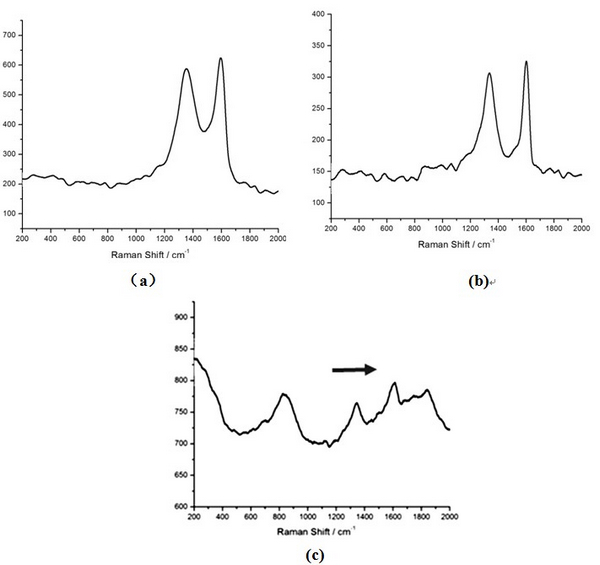

Preparation method of graphene reinforced metal-matrix composite

ActiveCN102329976AFacilitate induced orientation distributionPotential for large-scale applicationMetal matrix compositeCvd graphene

The invention discloses a preparation method of a graphene reinforced metal-matrix composite, which comprises the following steps of: firstly, dispersing the graphene oxide on the surface of the flaky metal powder; and then obtaining the graphene / metal composite powder through the reducing treatment; and at last, carrying out densification treatment by adopting a powder metallurgic technology to obtain the compact graphene reinforced metal-matrix composite. The flaky metal powder has the plane two-dimensional form, is inclined to the directional piling to form a laminated structure, and is helpful for inducing the graphene orientation distribution and giving play to the reinforcing effect. The preparation method disclosed by the invention is simple and feasible, is capable of regulating the graphene content and is suitable for preparing the massive composite.

Owner:SHANGHAI JIAO TONG UNIV

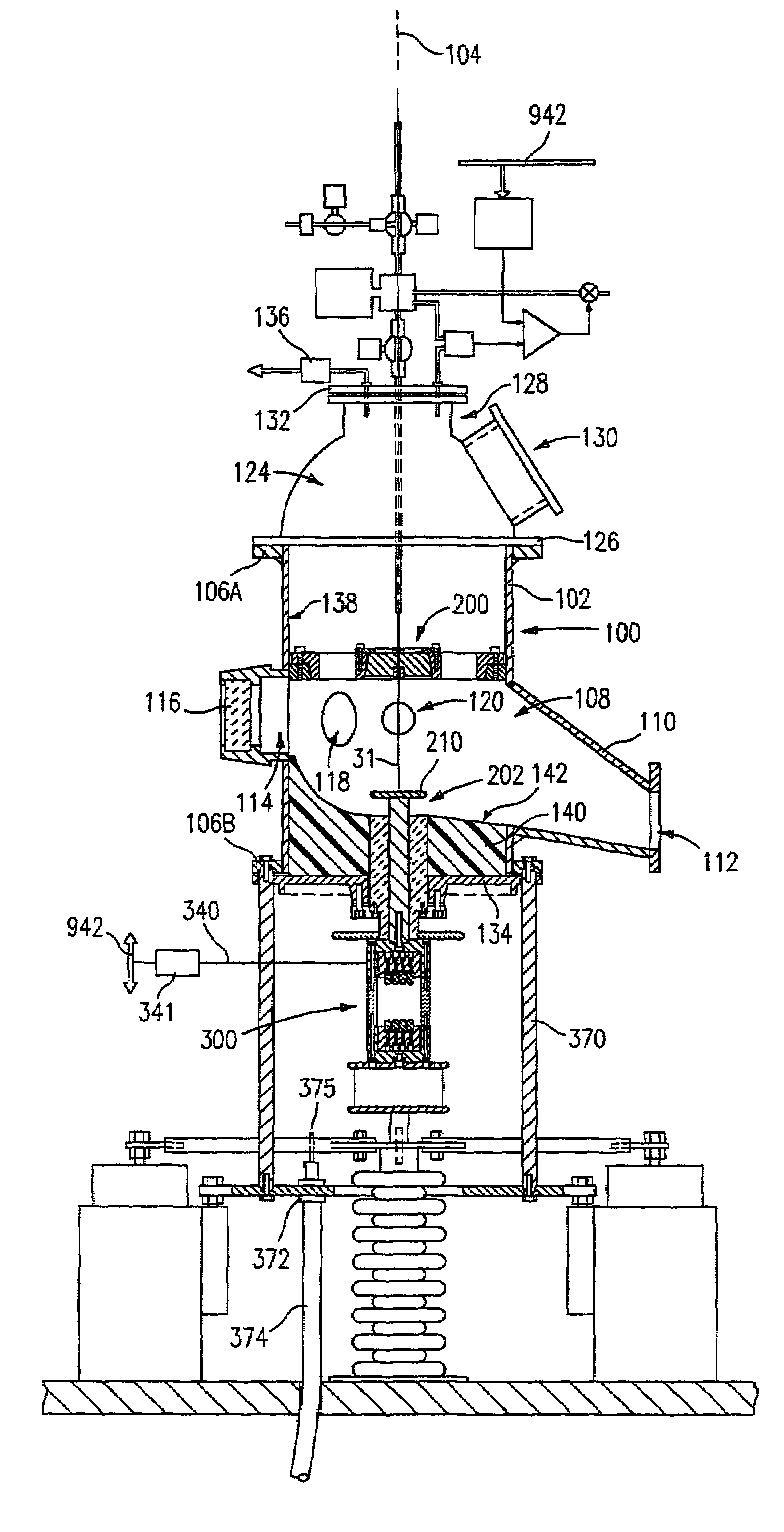

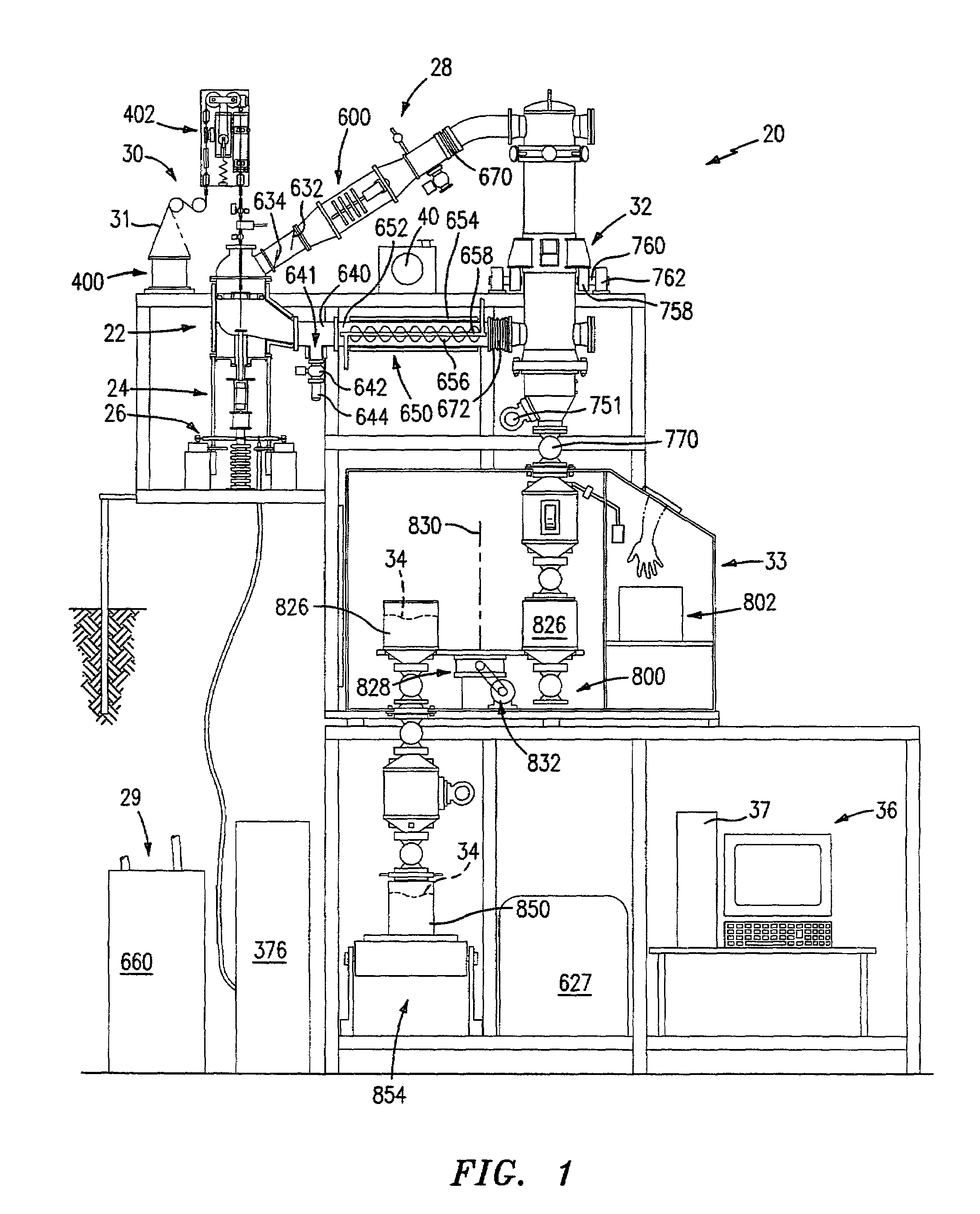

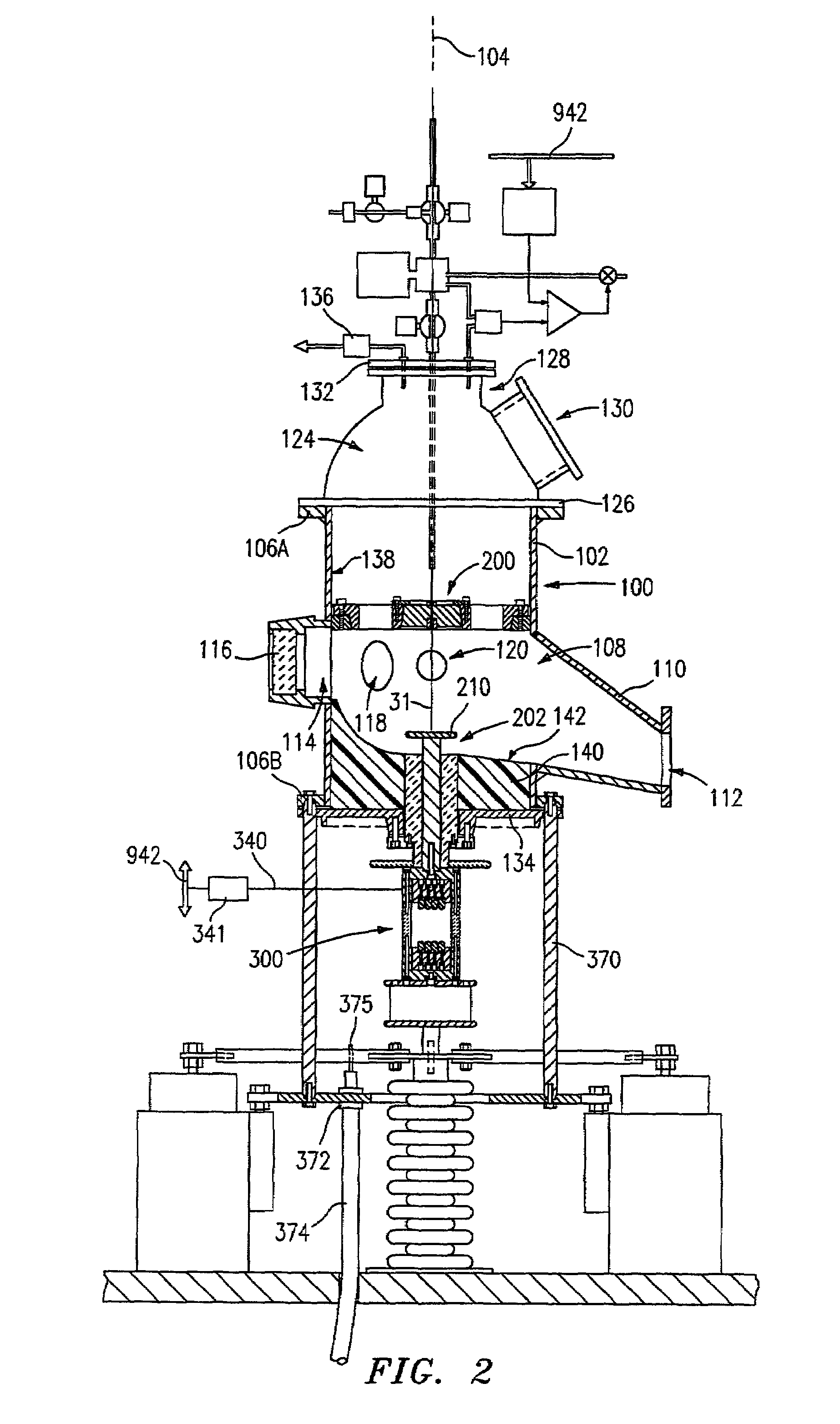

Apparatus and methods for the production of powders

InactiveUS6972115B1Reduce penetrationPrevent spontaneous combustionEnergy based chemical/physical/physico-chemical processesPlasma techniqueParticulatesElectricity

Metallic powders are formed by the electrically exploded wire (EEW) process. An apparatus (20) for manufacturing such powders includes a closed loop recirculating gas path between a reaction chamber (100) and an extractor (32). A wire (31) is delivered from a source (400) along a wire path from ambient conditions outside the chamber to within the chamber. Within the chamber, a first electrode (200) has an aperture circumscribing the wire path and a second electrode (203) is located proximate to a terminal end of the wire path. A source (26) of electrical energy applies a discharge voltage between the electrodes to explode the length of wire therebetween to form an initial particulate. The initial particulate may be selectively extracted and processed to produce desired powders, in particular, energetic powders which are passivated for stability under ambient conditions.

Owner:AMERICAN INTER METALIICS

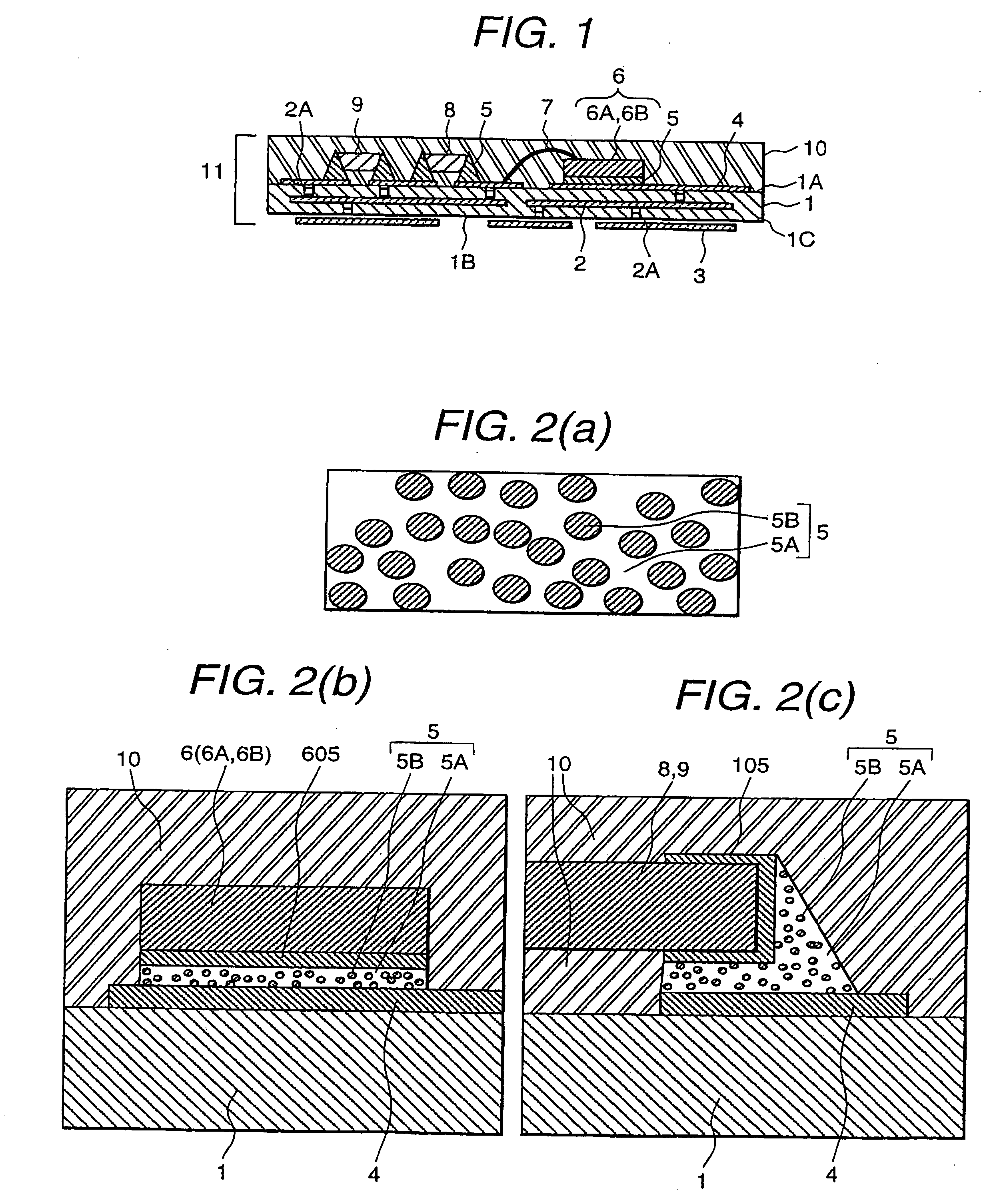

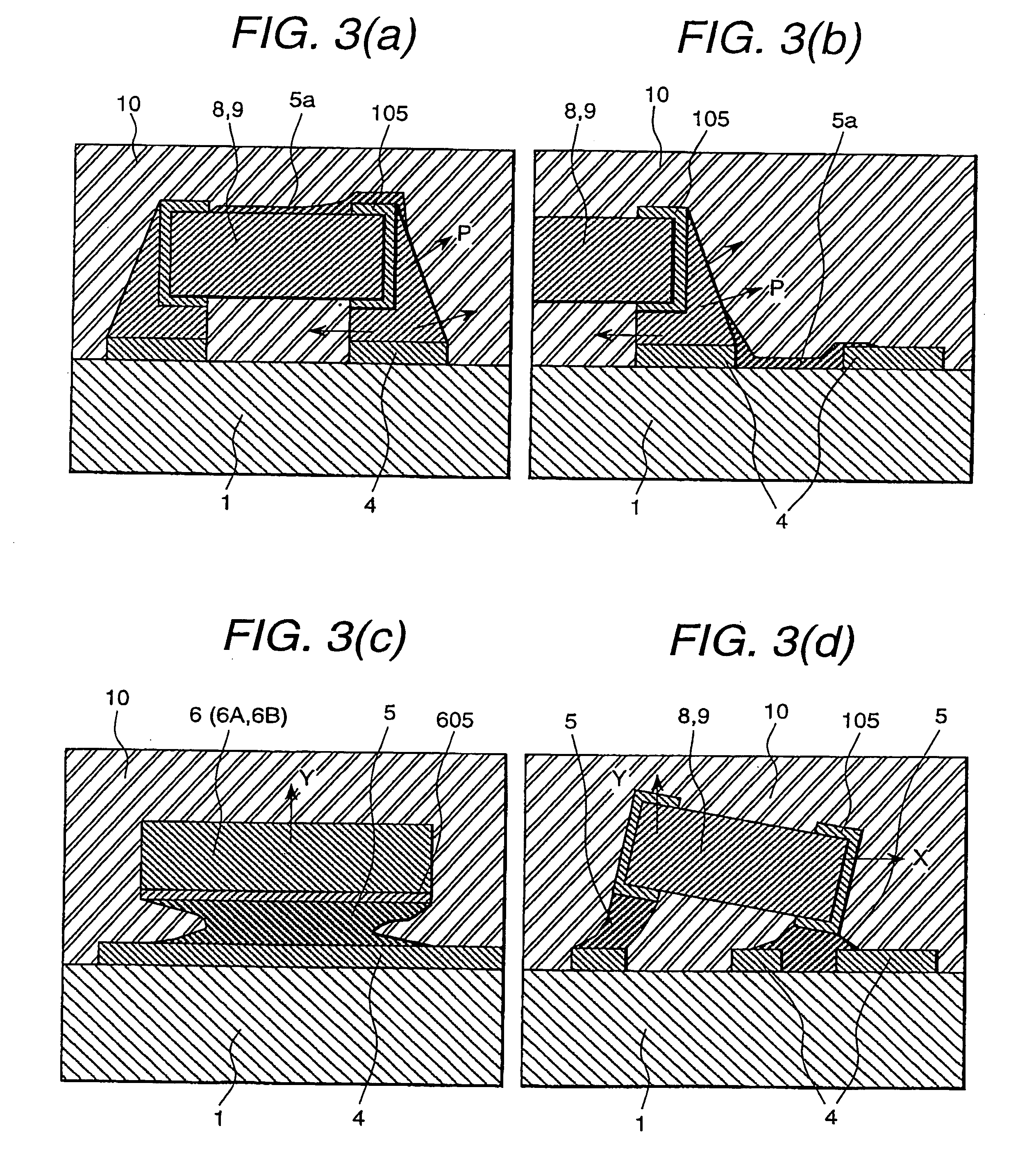

Semiconductor device structural body and electronic device

InactiveUS20050029666A1Prevent outflowPrinted circuit assemblingFinal product manufactureDevice materialMetal powder

A semiconductor device, in which a solder layer bonding chip parts and wiring members are enclosed with the resin layer, and the solder layer is comprised of a compound body in which metal powder is distributed in the matrix metal, is disclosed. When a semiconductor device in which the chip parts are installed in the wiring member with the solders, the soldering part is sealed with the resin is mounted secondly on the external wiring member, the outflow of the solders and the short circuit due to the outflow, the disconnections, and the displacement of the chip parts can be prevented.

Owner:HITACHI LTD +1

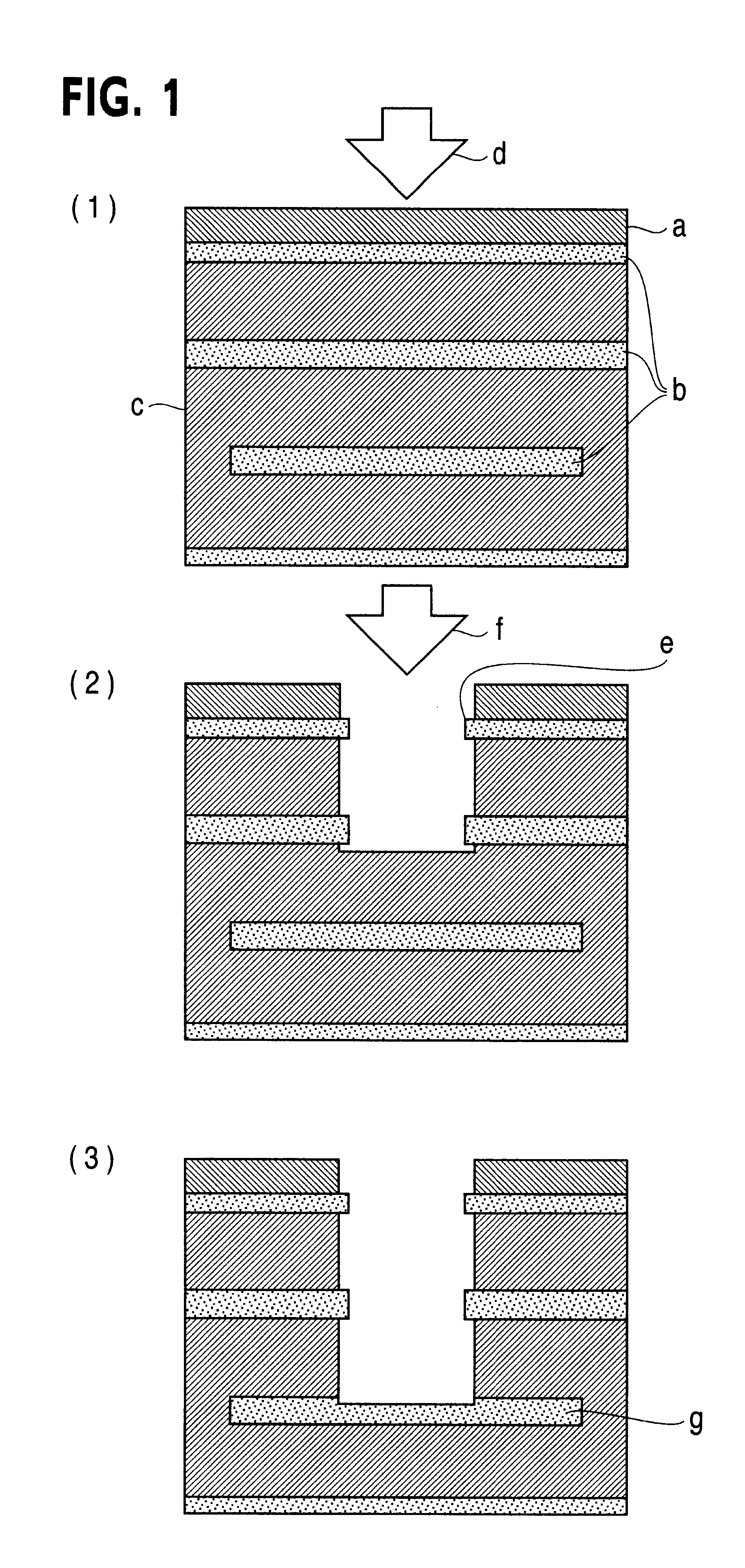

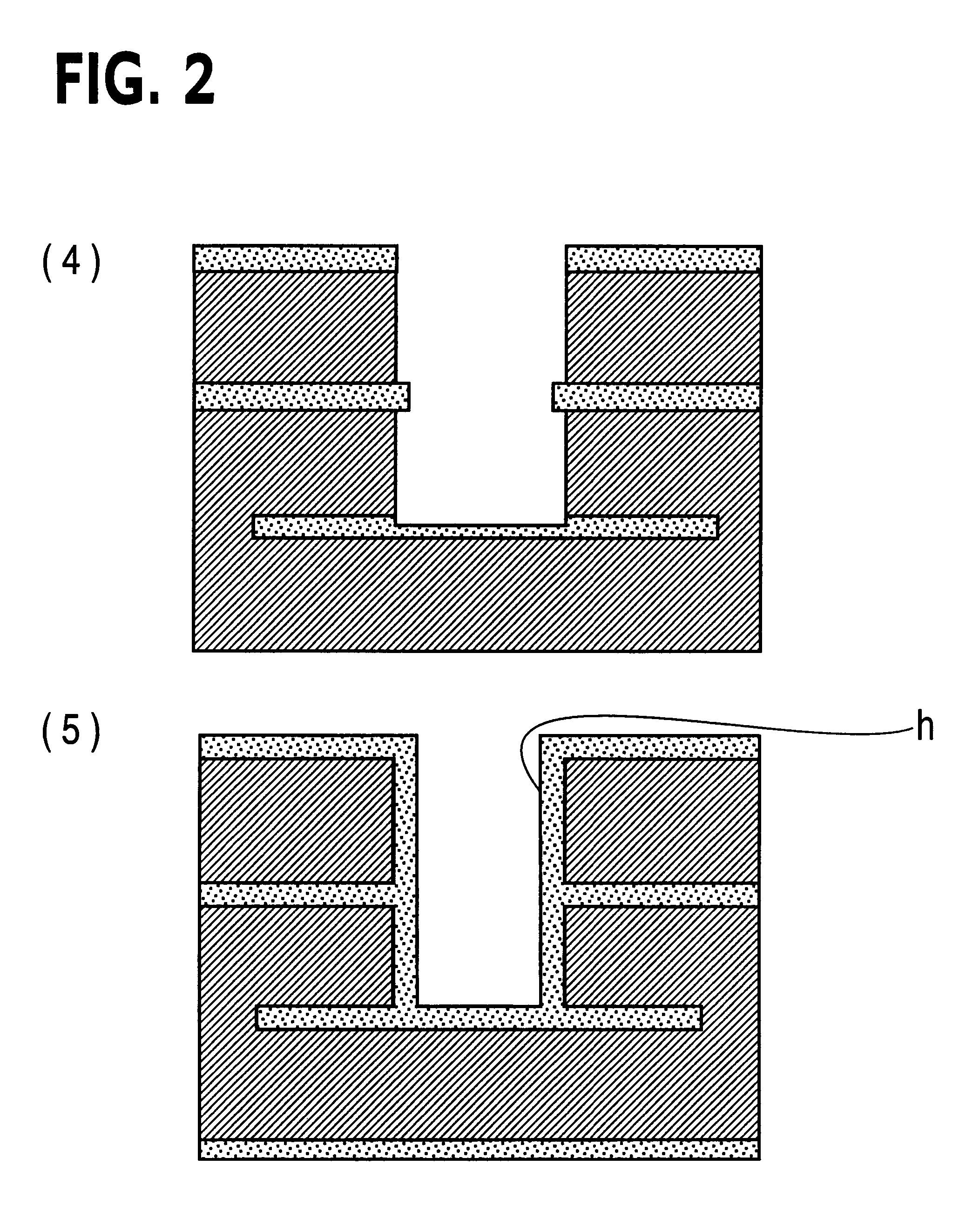

Printed wiring board having highly reliably via hole and process for forming via hole

InactiveUS6280641B1Improve reliabilityImprove productivityLight absorption dielectricsDecorative surface effectsBond energyConductive coating

Disclosed are a printed wiring board having micro-via holes highly reliable for conduction and a method of making the micro-via hole by providing a coating or sheet of an organic substance containing 3 to 97% by volume of at least one selected from a metal compound powder, a carbon powder or a metal powder having a melting point of at least 900° C. and a bond energy of at least 300 kJ / mol on a copper foil as an outermost layer of a copper-clad laminate having at least two copper layers, or providing a coating or sheet of the same after oxidizing a copper foil as an outermost layer, irradiating the coating or sheet with a carbon dioxide gas laser at an output of 20 to 60 mJ / pulse, thereby removing a micro-via-hole-forming portion of at least the copper foil as the outermost layer, then irradiating micro-via-hole-forming portions of the remaining layers with a carbon dioxide gas laser at an output of 5 to 35 mJ / pulse to make a micro-via hole which does not penetrate through the copper foil in a bottom of the micro-via hole, and electrically connecting the copper foil as the outermost layer and the copper foil in the bottom of the micro-via hole with a metal plating or an electrically conductive coating composition.

Owner:MITSUBISHI GAS CHEM CO INC

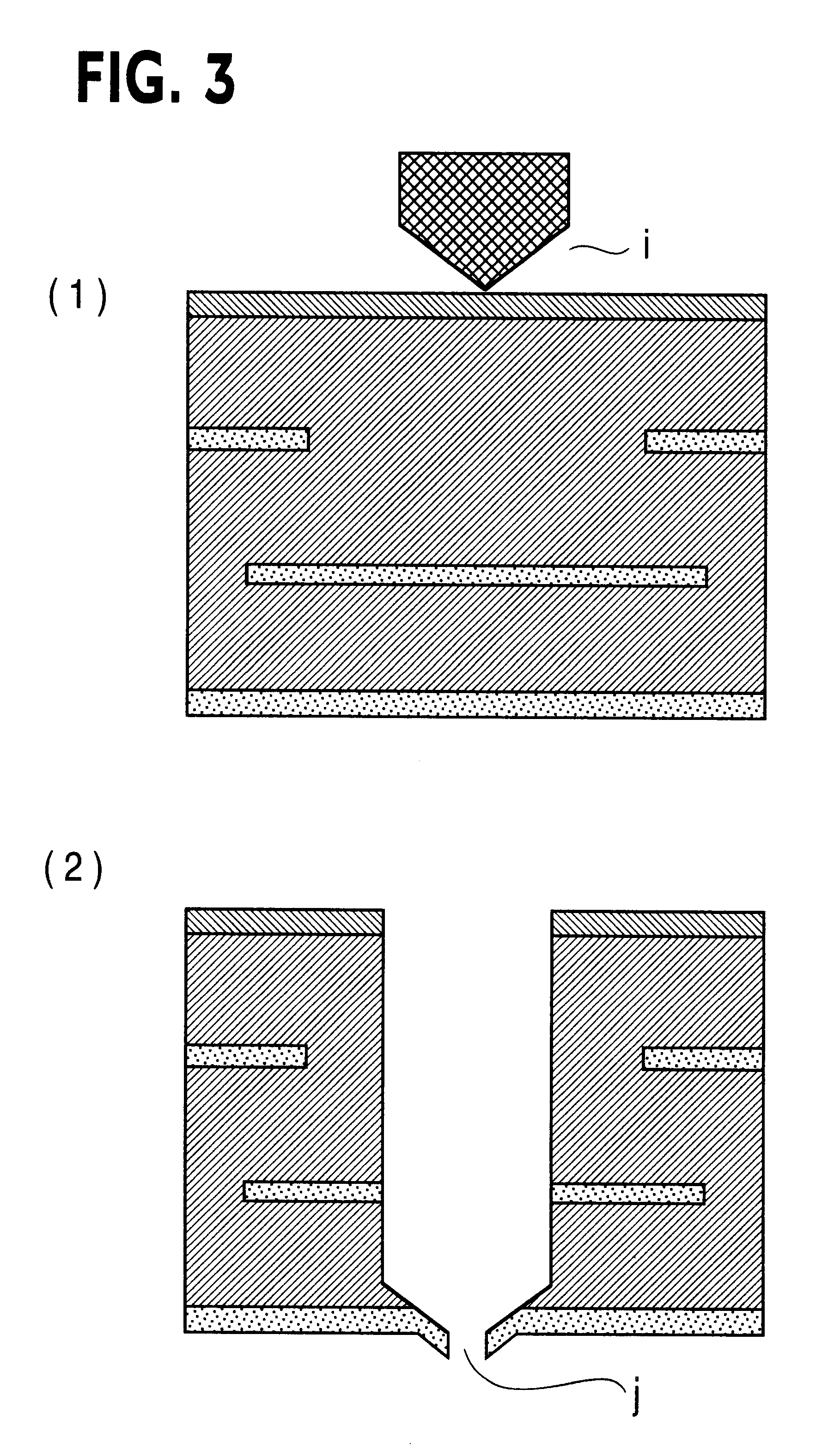

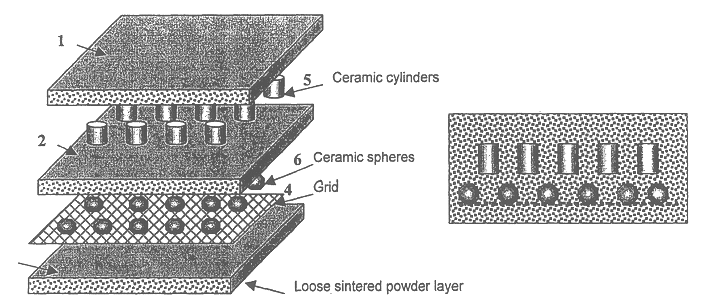

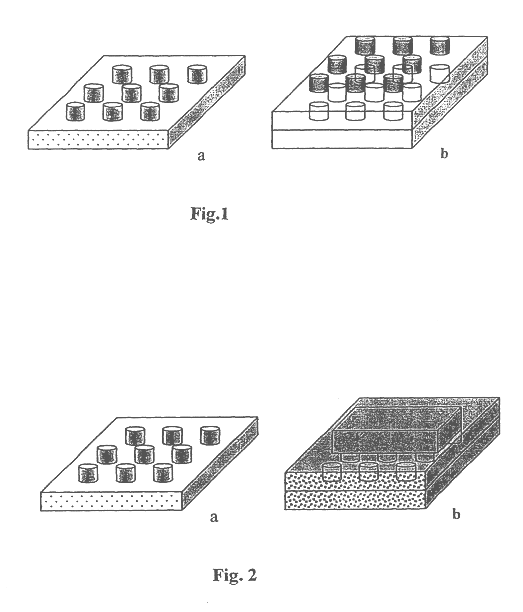

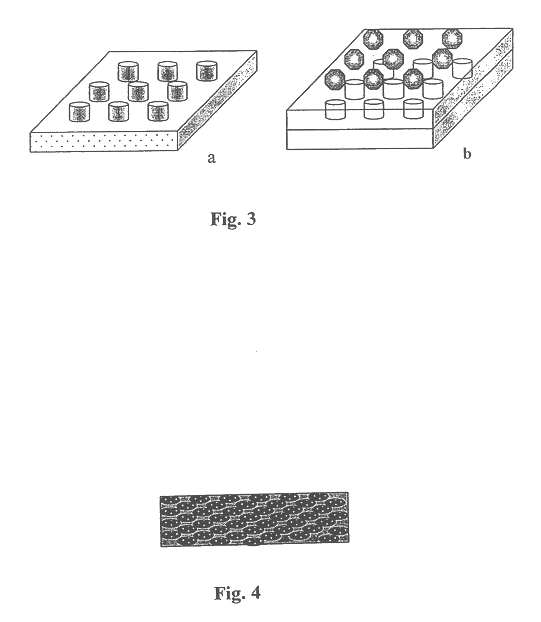

Bulletproof lightweight metal matrix macrocomposites with controlled structure and manufacture the same

InactiveUS6635357B2Stop crack propagation after bullet orPromote reproductionMilitary adjustmentWelding/cutting media/materialsPorosityMetal insert

The lightweight bulletproof metal matrix macrocomposites (MMMC) contain (a) 10-99 vol. % of permeable skeleton structure of titanium, titanium aluminide, Ti-based alloys, and / or mixtures thereof infiltrated with low-melting metal selected from Al, Mg, or their alloys, and (b) 1-90 vol. % of ceramic and / or metal inserts positioned within said skeleton, whereby a normal projection area of each of said inserts is equal to or larger than the cross-section area of a bullet or a projectile body. The MMMC are manufactured as flat or solid-shaped, double-layer, or multi-layer articles containing the same inserts or different inserts in each layer, whereby insert projections of each layer cover spaces between inserts of the underlying layer. The infiltrated metal contains 1-70 wt. % of Al and Mg in the balance, optionally, alloyed with Ti, Si, Zr, Nb, V, as well as with 0-3 wt. % of TiB2, SiC, or Si3N4 sub-micron powders, to promote infiltrating and wetting by Al-containing alloys. The manufacture includes (a) forming the permeable metal powder and inserts into the skeleton-structured preform by positioning inserts in the powder followed by loose sintering in vacuum to provide the average porosity of 20-70%, (b) heating and infiltrating the porous preform with molten infiltrating metal for 10-40 min at 450-750° C., (c) hot isostatic pressing of the infiltrated composite, and (d) re-sintering or diffusion annealing.

Owner:ADVANCED MATERIALS PRODS

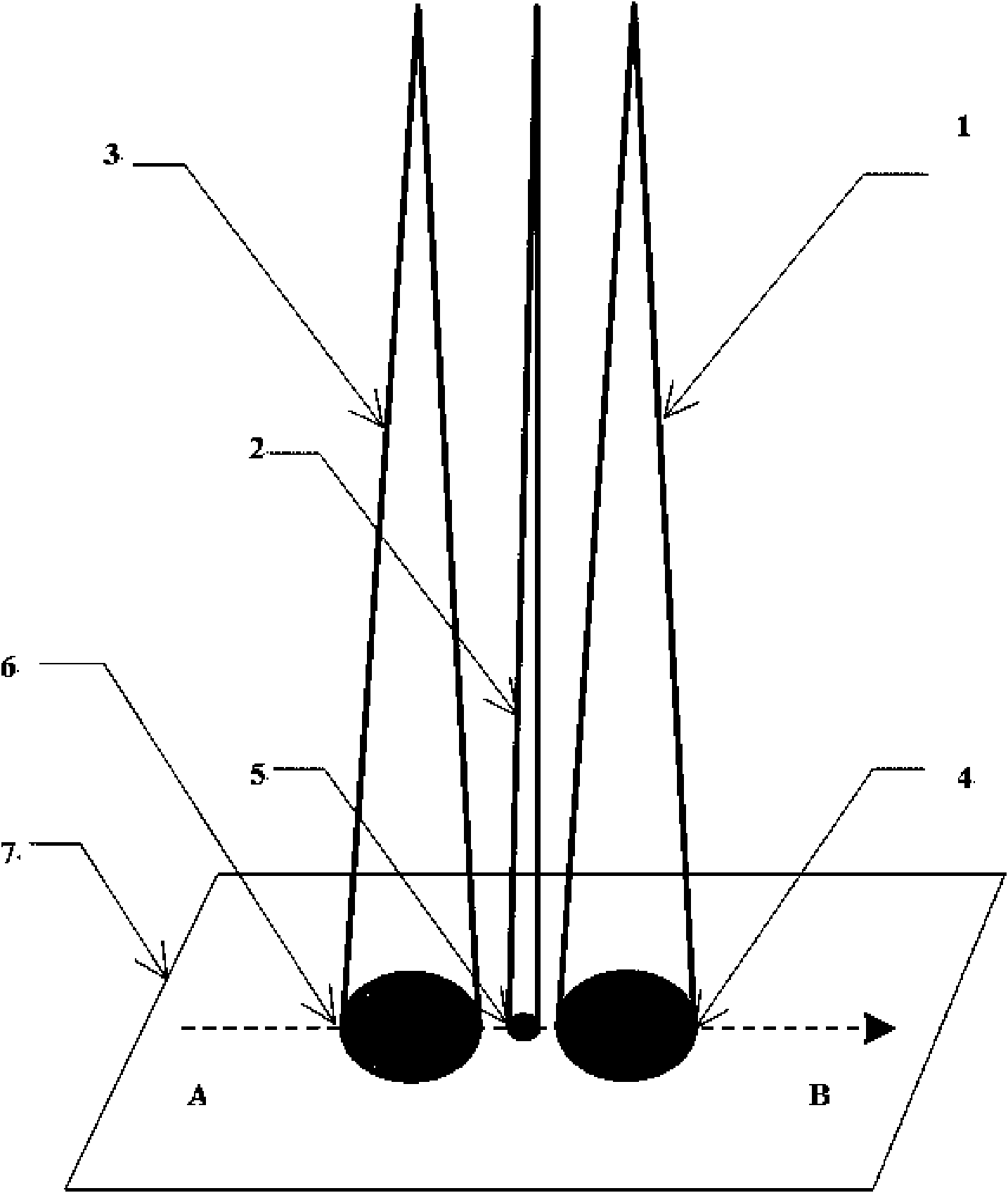

Fast forming method of fusion of metal powder of three beams of laser compound scanning

The invention discloses a fast manufacturing method of three-beam laser compound scanning. The method comprises the following steps of: firstly utilizing long-wavelength laser (CO2 laser) for preheating the metal powder, then utilizing short-wavelength laser (YAG or optical fiber laser) for fusing the metal powder and finally utilizing long-wavelength laser (CO2 laser) to carry out heat treatment to the frozen metal. The fast manufacturing method uses the three beams of laser to carry out compound scanning, namely uses long-wavelength laser to preheat, short-wavelength laser to fuse and then long-wavelength laser to carry out heat treatment, can realize the compound process of preheating, fusion and heat treatment of the metal powder. The three beams of laser compound scanning mode can reduce internal stress of the metal part, avoid warping and cracking, improve organization and improve performance.

Owner:HUAZHONG UNIV OF SCI & TECH

Tungsten/powdered metal/polymer high density non-toxic composites

InactiveUS6916354B2High bulk densityAmmunition projectilesShotgun ammunitionHigh densityVolumetric Mass Density

Owner:ELLIOTT CARTRIDGE COMPANY CANADA

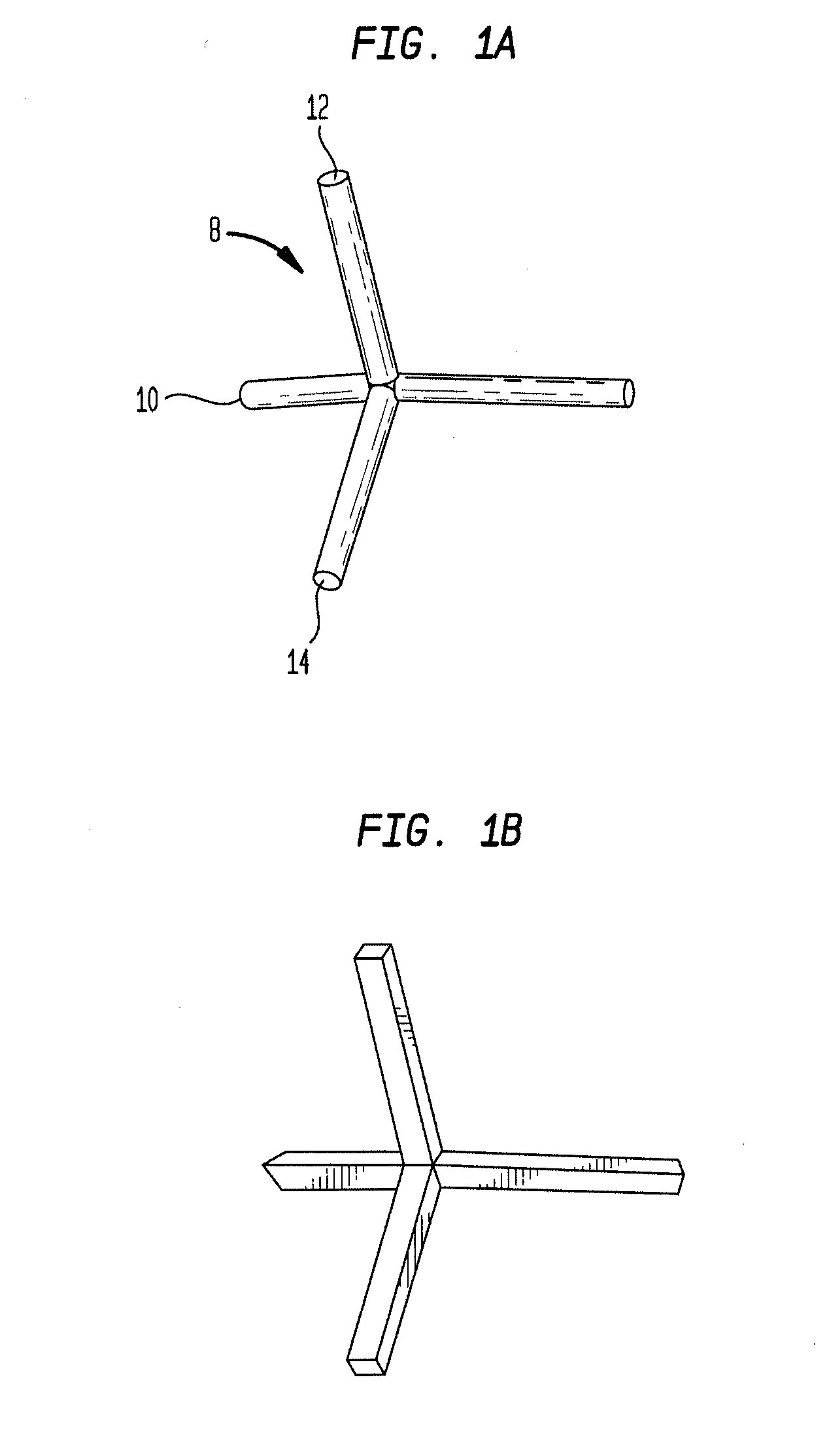

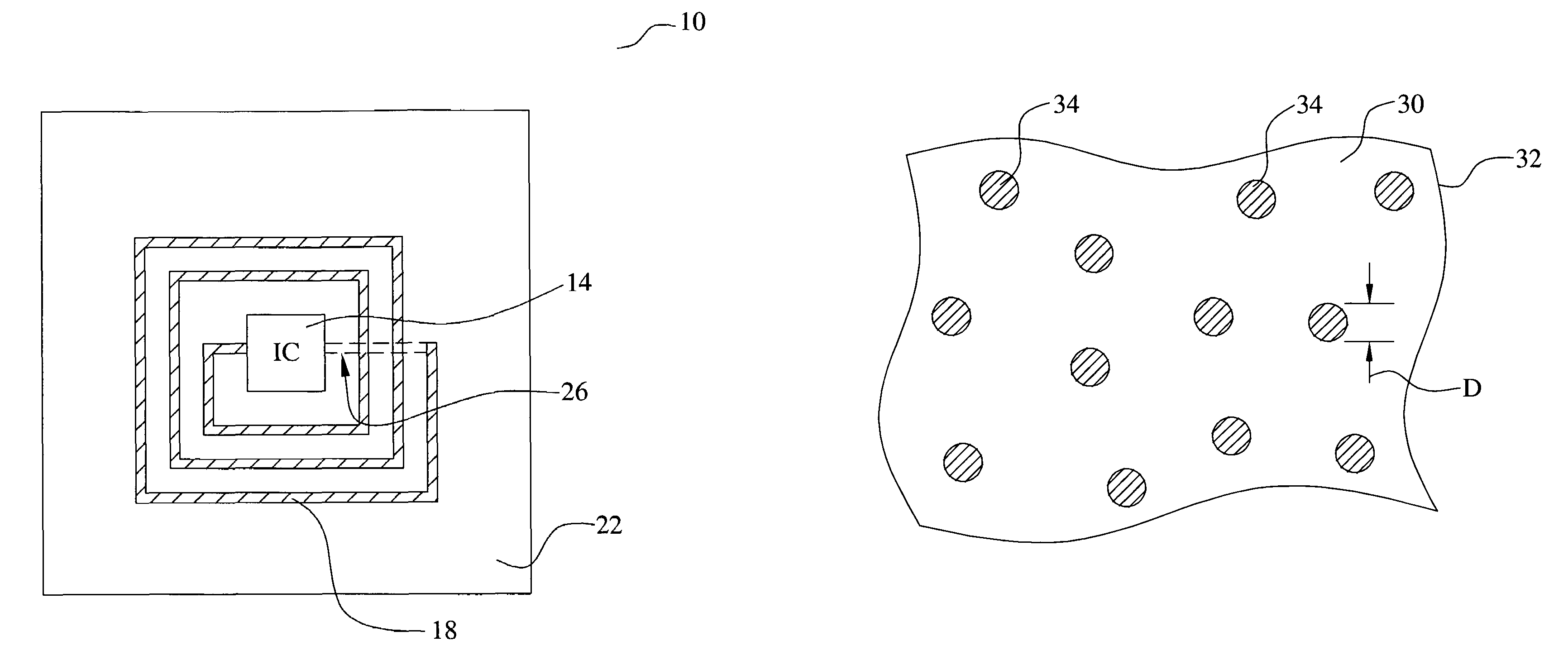

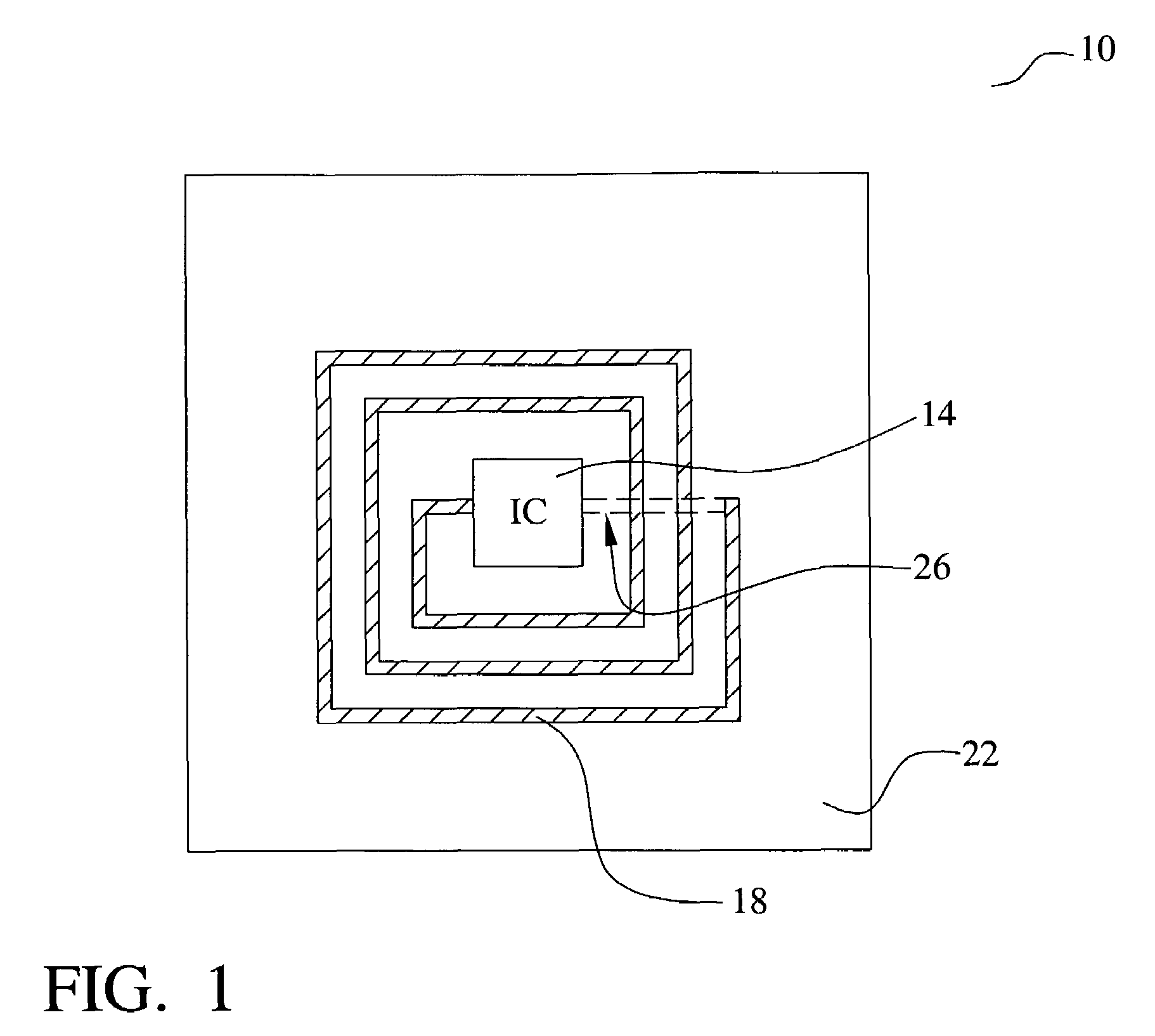

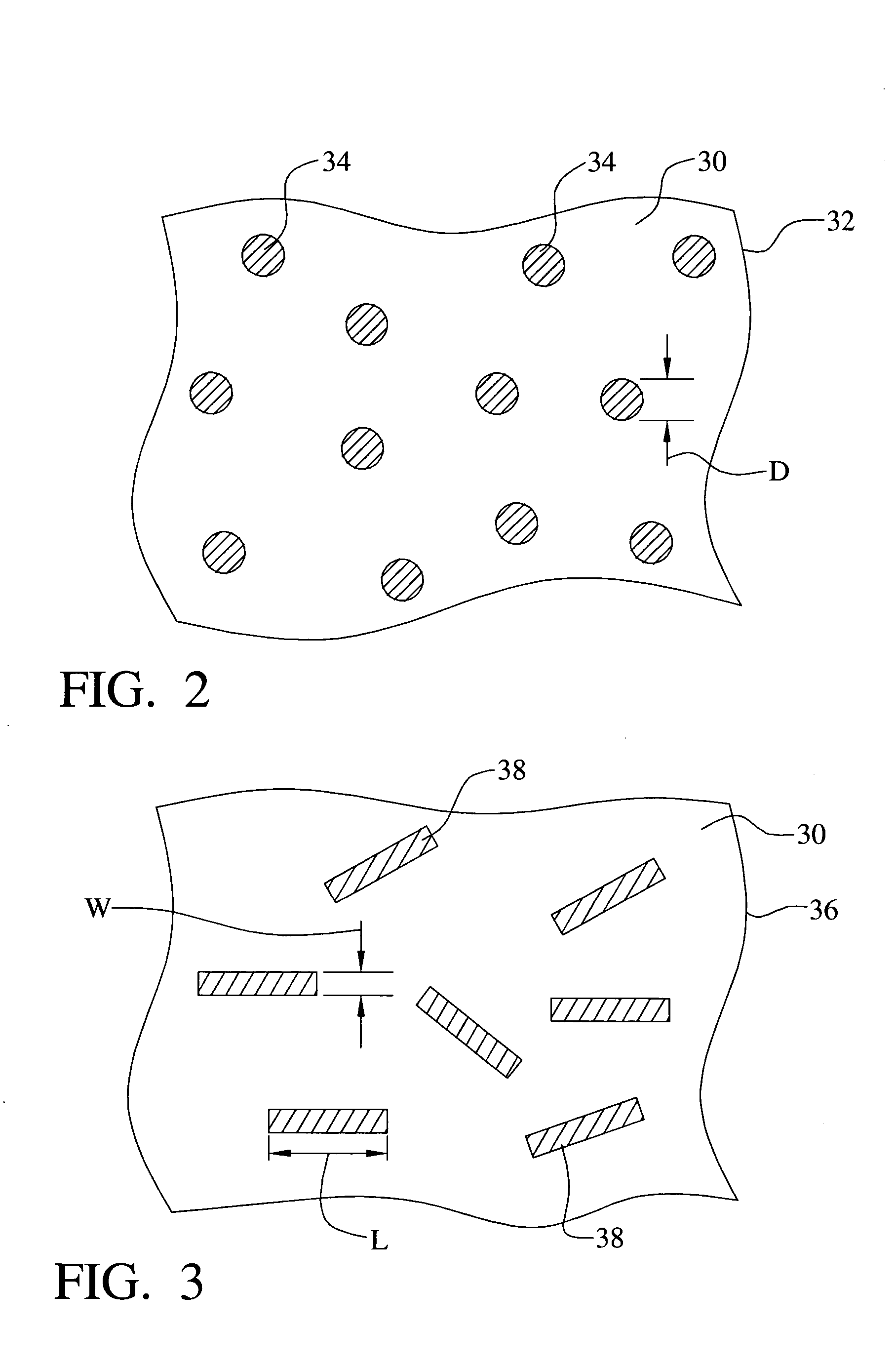

Low cost RFID antenna manufactured from conductive loaded resin-based materials

RFID antennas are formed of a conductive loaded resin-based material. The conductive loaded resin-based material comprises micron conductive powder(s), conductive fiber(s), or a combination of conductive powder and conductive fibers in a base resin host. The percentage by weight of the conductive powder(s), conductive fiber(s), or a combination thereof is between about 20% and 50% of the weight of the conductive loaded resin-based material. The micron conductive powders are formed from non-metals, such as carbon, graphite, that may also be metallic plated, or the like, or from metals such as stainless steel, nickel, copper, silver, that may also be metallic plated, or the like, or from a combination of non-metal, plated, or in combination with, metal powders. The micron conductor fibers preferably are of nickel plated carbon fiber, stainless steel fiber, copper fiber, silver fiber, or the like.

Owner:INTEGRAL TECHNOLOGY INC

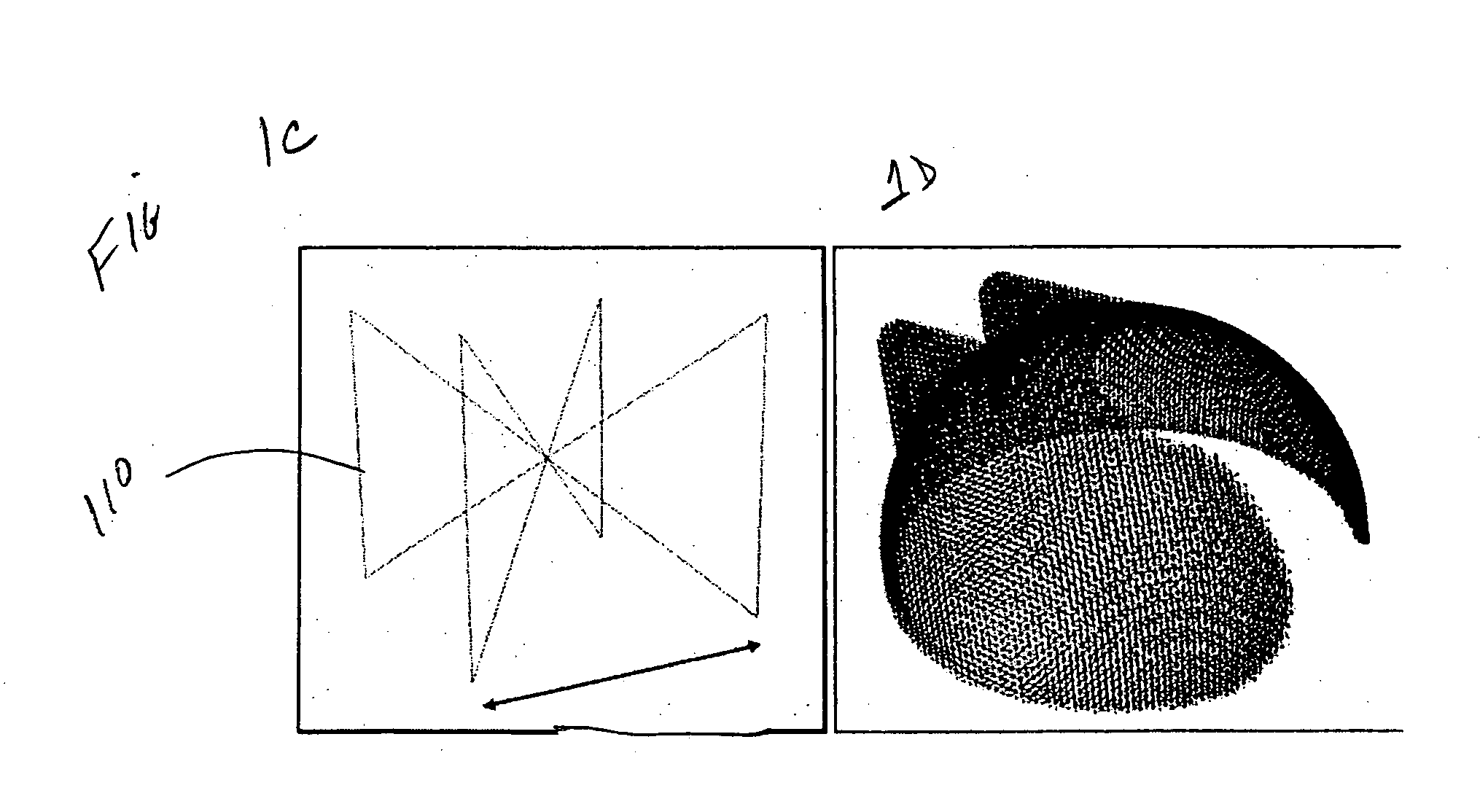

Turbine components for engines and methods of fabricating the same

A method is provided that includes depositing metal powder over a seed crystal having a predetermined primary orientation, scanning an initial pattern into the metal powder to melt or sinter the deposited metal powder, and re-scanning the initial pattern to re-melt the scanned metal powder and form an initial layer having the predetermined primary orientation. The method further includes depositing additional metal powder over the initial layer, scanning an additional pattern into the additional metal powder to melt or sinter at least a portion of the additional metal powder, re-scanning the additional pattern to re-melt a portion of the initial layer and the scanned deposited additional metal powder to form a successive layer having the predetermined primary orientation, and repeating the steps of depositing additional metal powder, scanning the additional pattern, and re-scanning the additional pattern, until a final shape of the component is achieved.

Owner:HONEYWELL INT INC

Lead free, composite polymer based bullet and cartridge case, and method of manufacturing

A lead-free, composite polymer based bullet and cartridge case and methods of manufacturing the same, wherein the composite polymer material includes a tungsten metal powder, nylon 6 / 6, nylon 6, short glass fibers, as well as additives and stabilizers. The cartridge case includes a lip lock configured to matingly engage a cannelure formed along an outer circumferential surface of the bullet. The cartridge case also includes resilient walls wherein the case may snap fit onto the bullet. The bullet and cartridge case may be formed in a single step process by injection molding or a two step process including injection molding and a welding process.

Owner:POLYTECH AMMUNITION

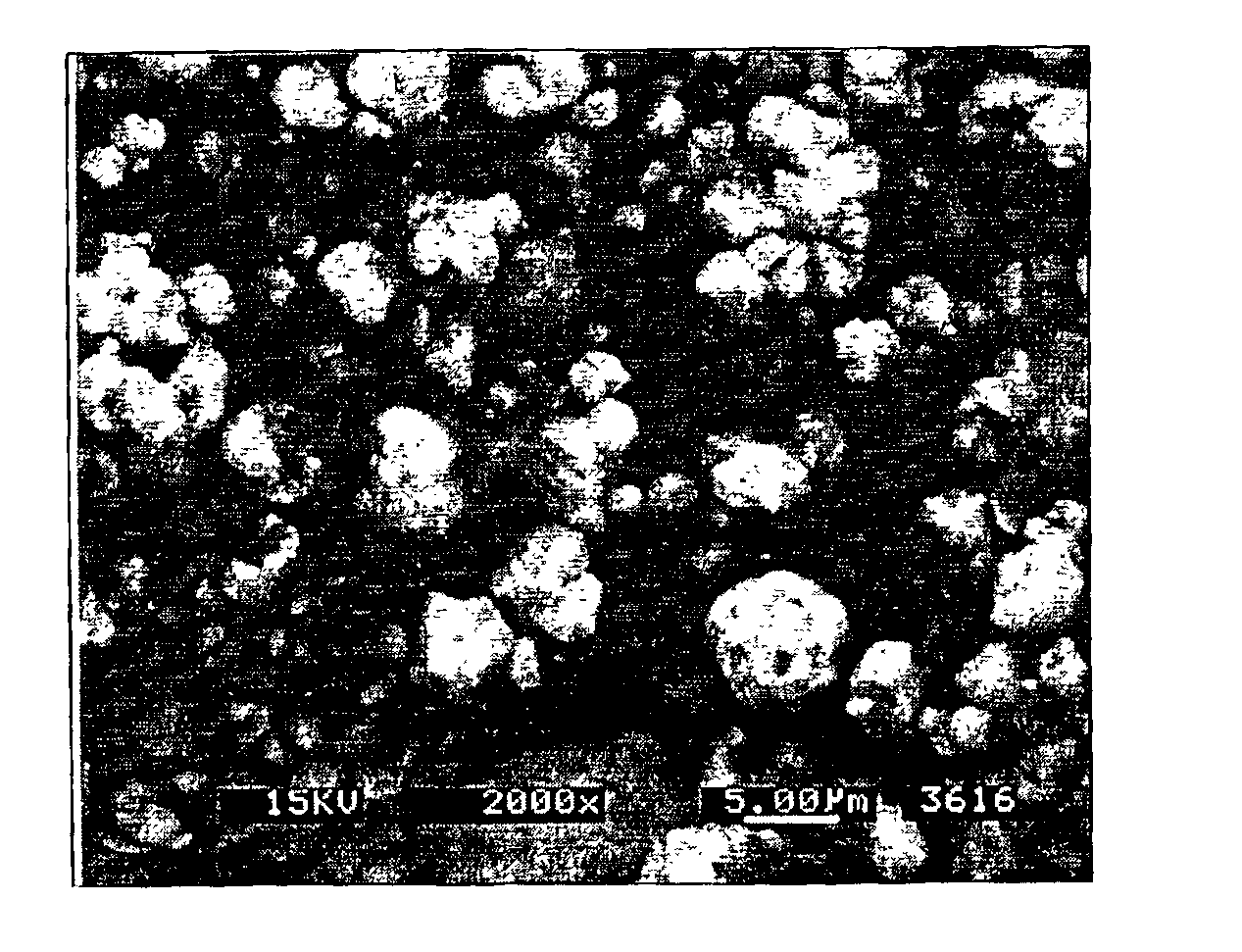

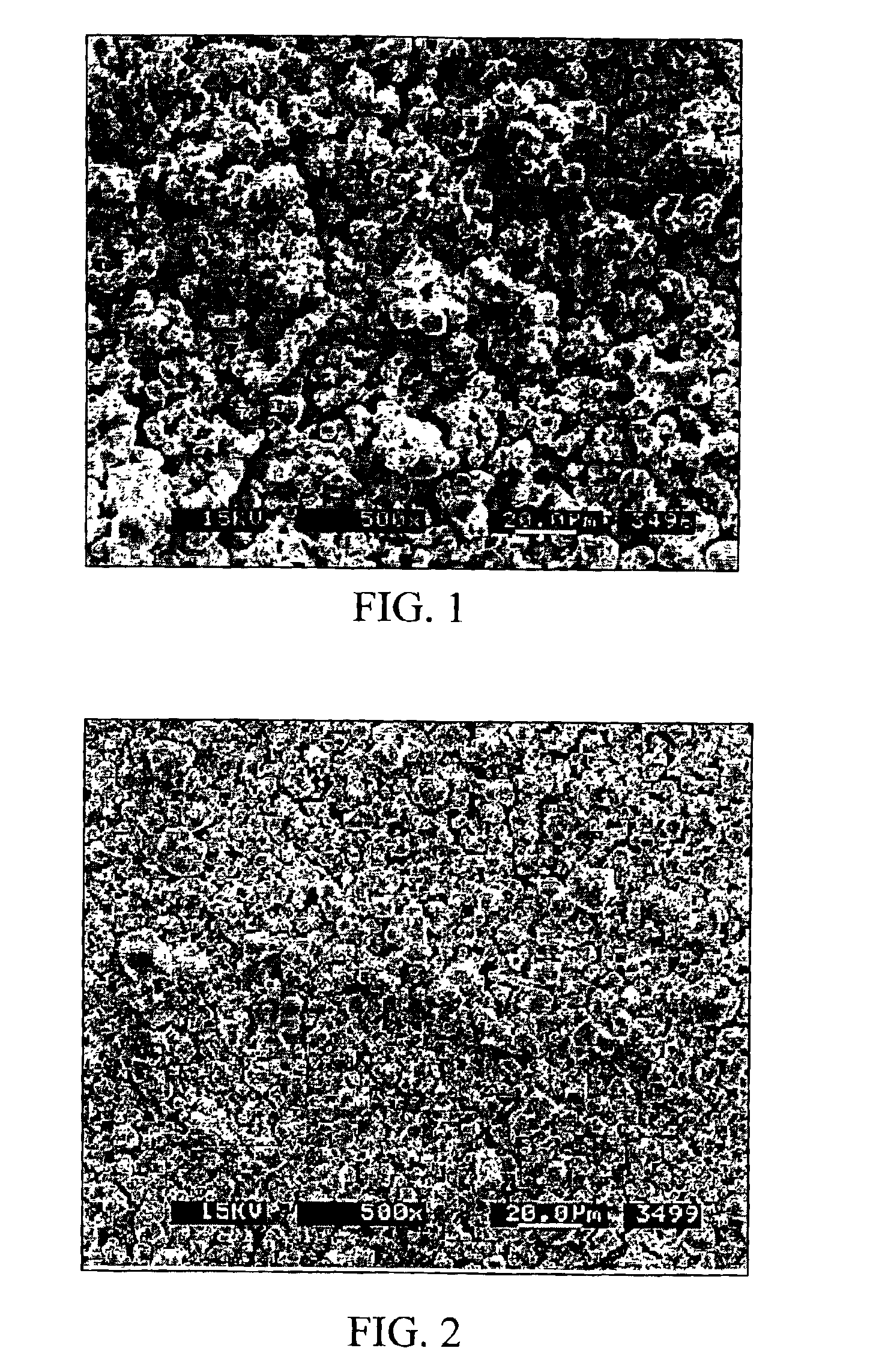

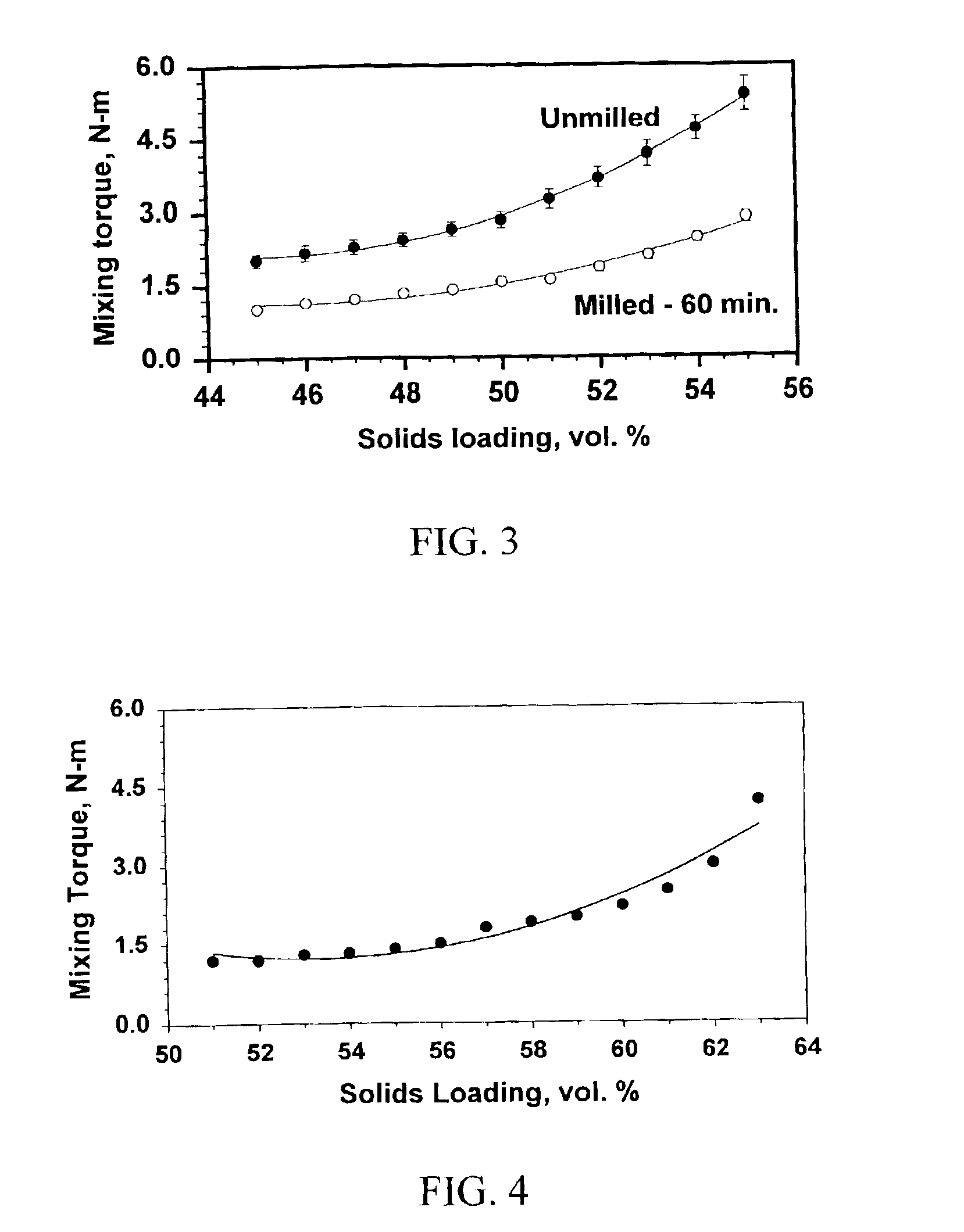

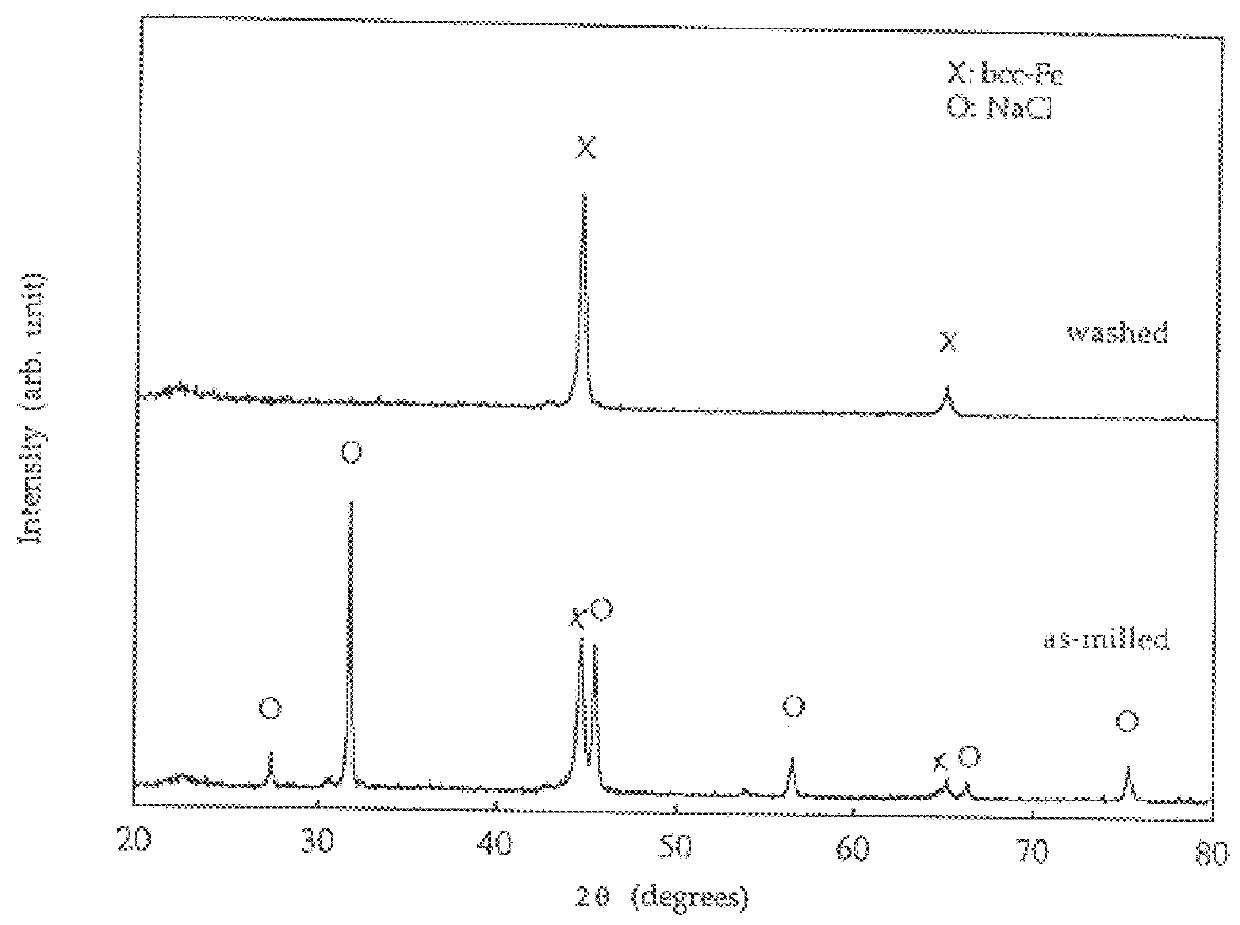

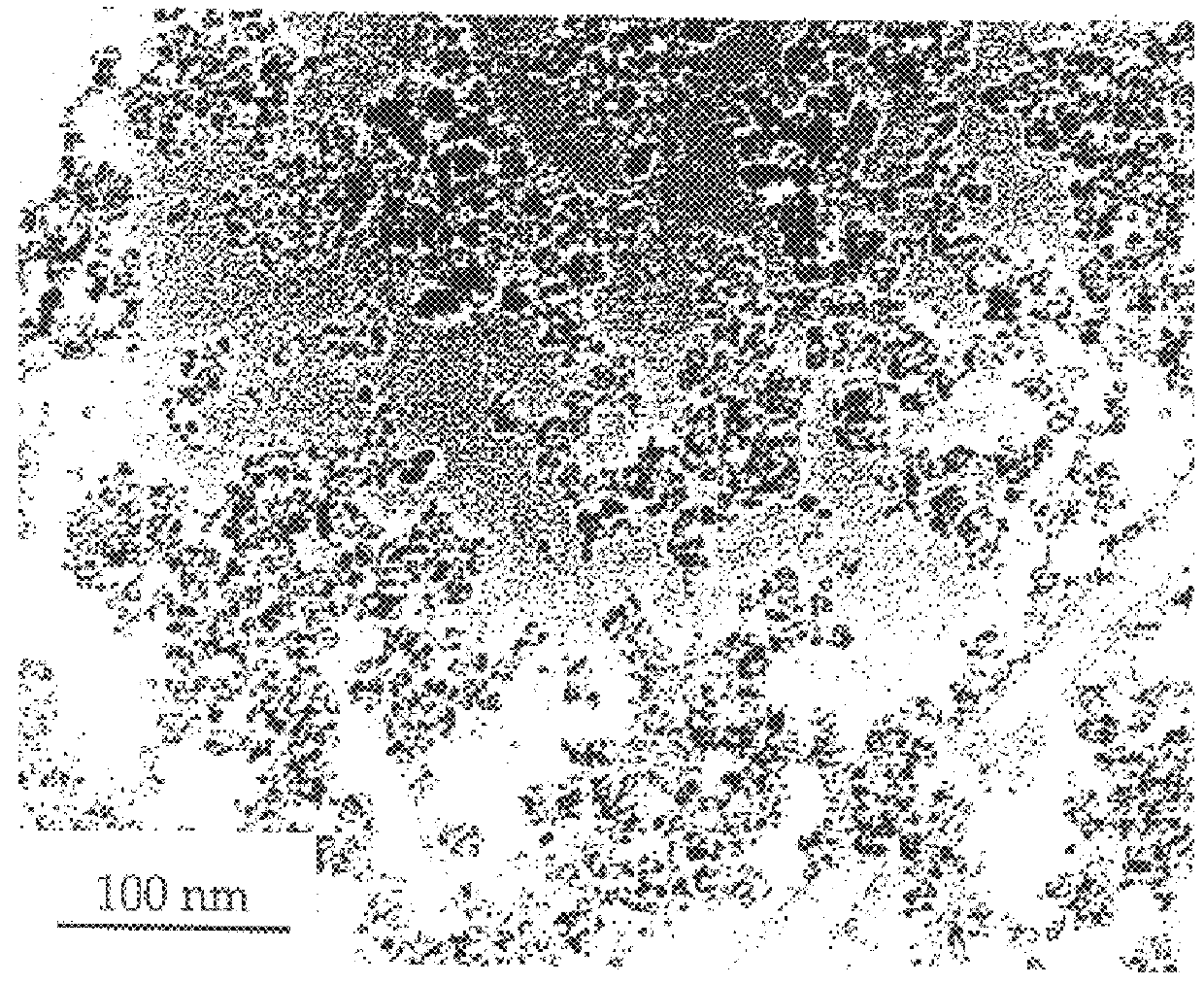

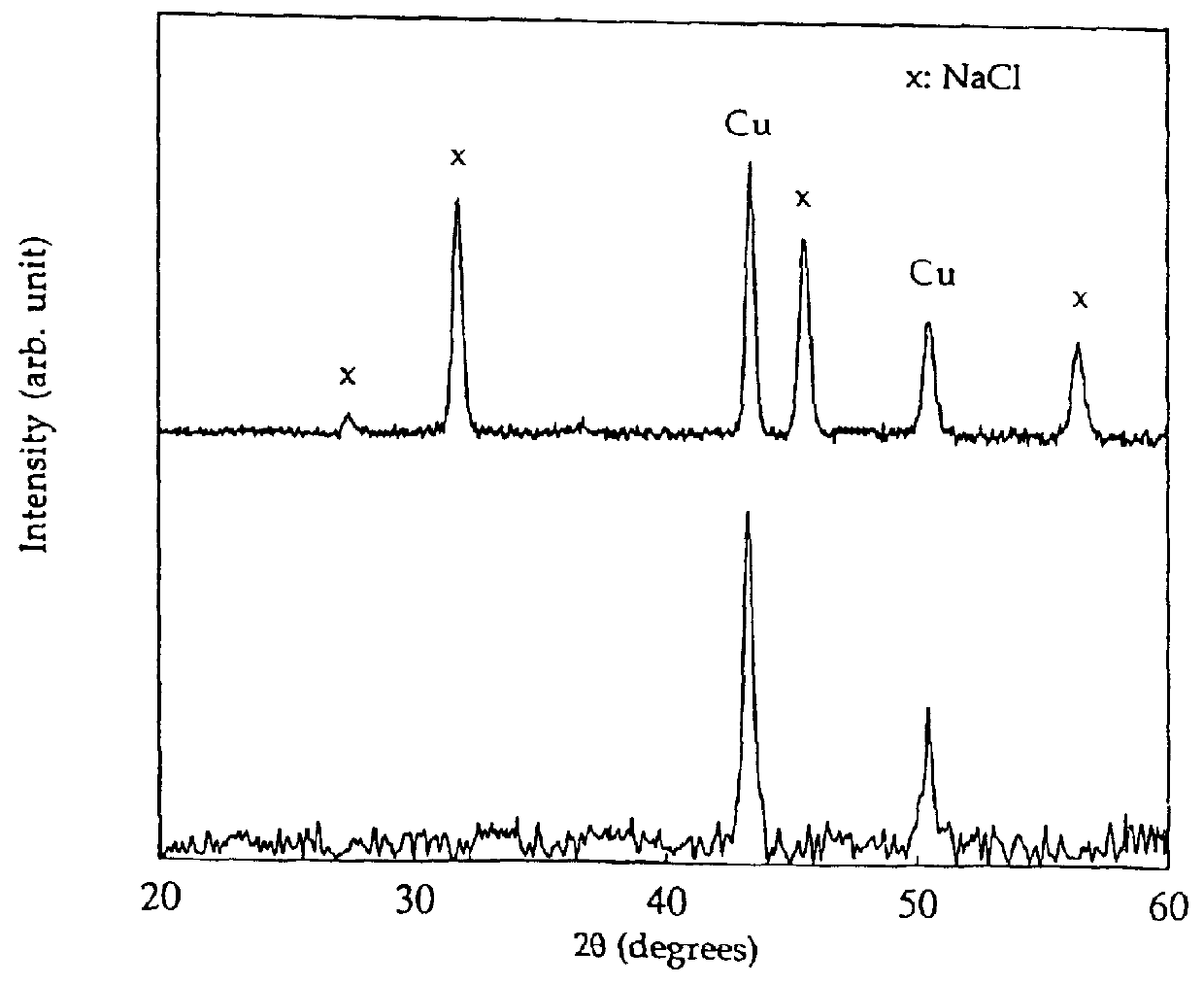

Process for the production of ultrafine particles

A new, cost effective process for the production of ultrafine particles which is based on mechanically activated chemical reaction of a metal compound with a suitable reagent. The process involves subjecting a mixture of a metal compound and a suitable reagent to mechanical activation to increase the chemical reactivity of the reactants and / or reaction kinetics such that a chemical reaction can occur which produces a solid nano-phase substance. Concomitantly, a by-product phase is also formed. This by-product phase is removed so that the solid nano-phase substance is left behind in the form of ultrafine particles. During mechanical activation a composite structure is formed which consists of an intimate mixture of nano-sized grains of the nano-phase substance and the reaction by-product phase. The step of removing the by-product phase, following mechanical activation, may involve subjecting the composite structure to a suitable solvent which dissolves the by-product phase, while not reacting with the solid nano-phase substance. The process according to the invention may be used to form ultrafine metal powders as well as ultrafine ceramic powders. Advantages of the process include a significant degree of control over the size and size distribution of the ultrafine particles, and over the nature of interfaces created between the solid nano-phase substance and the reaction by-product phase.

Owner:WESTERN AUSTRALIA UNIV OF THE

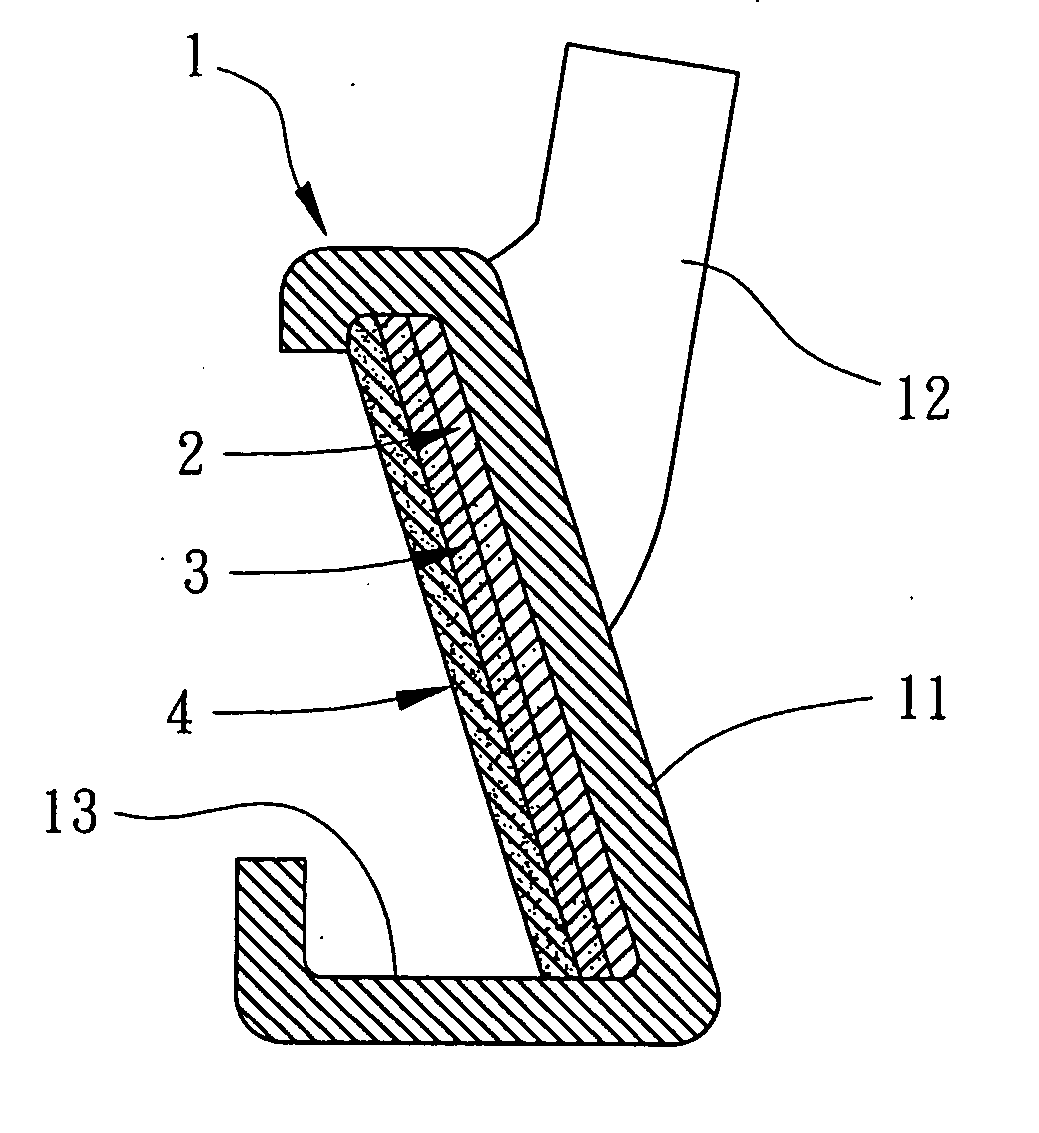

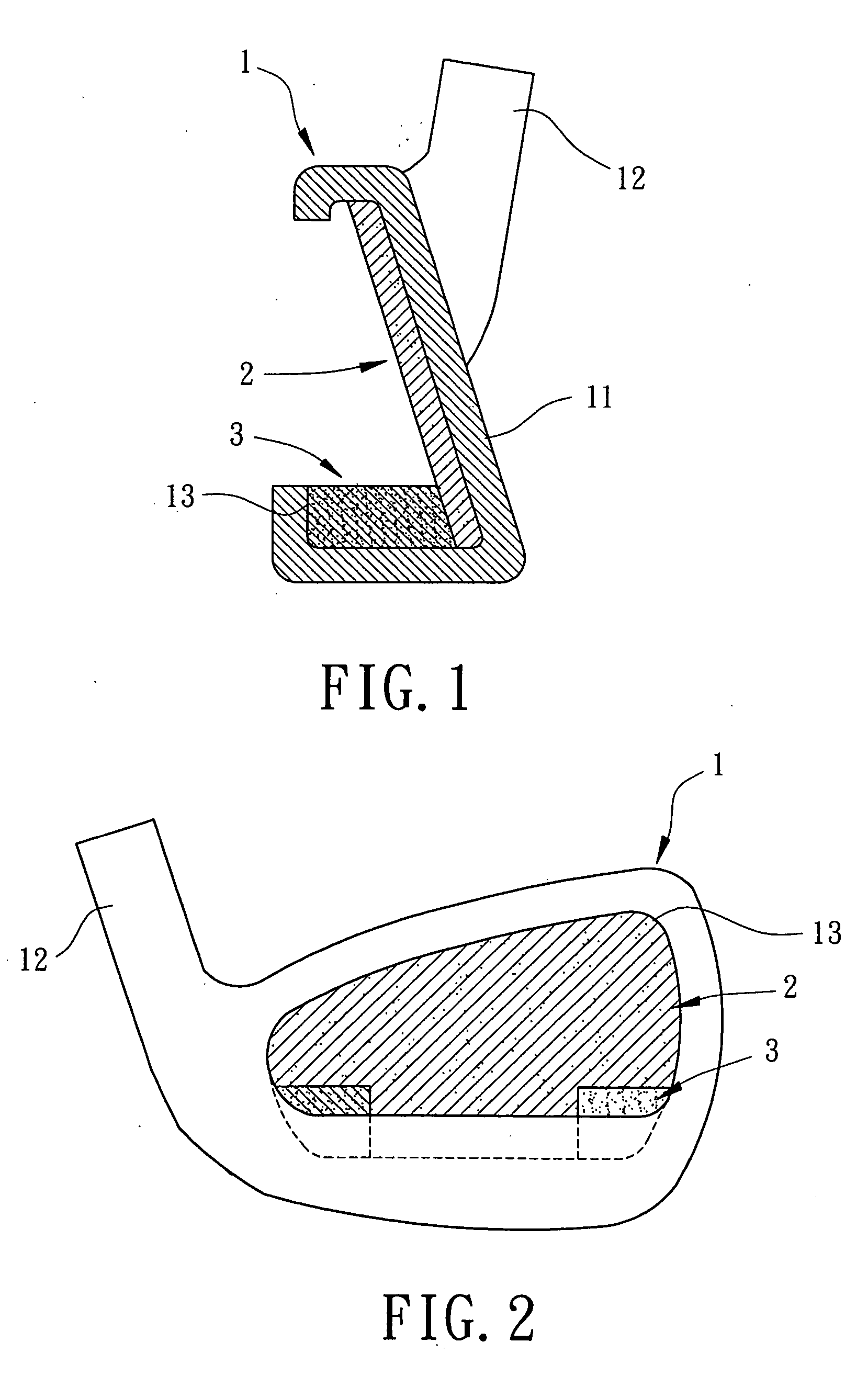

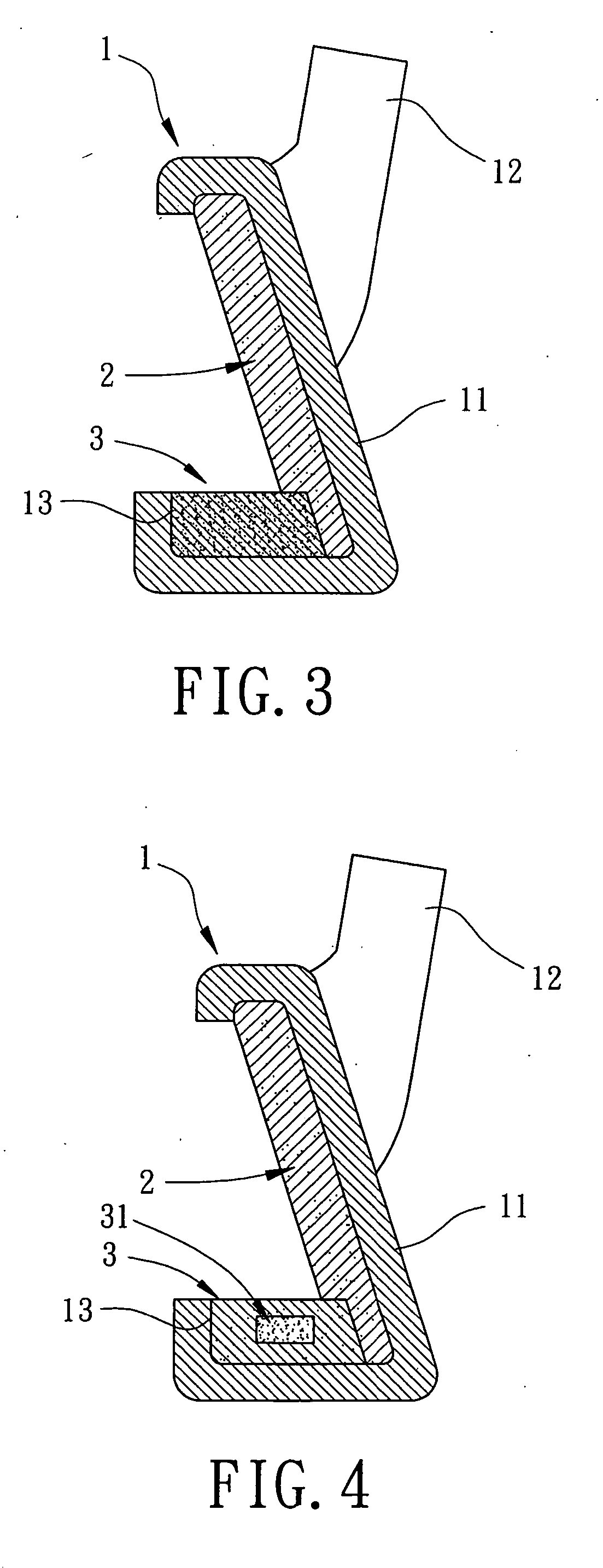

Golf club head with elastic weight members

InactiveUS20060258480A1Improve shock absorptionAdjustable center of gravityGolf clubsRacket sportsElastic matrixElastic vibration

A golf club head includes a body having a striking plate and an assembling portion, a first elastic weight member including an elastic matrix and a metal powder mixed in the elastic matrix, and a second elastic weight member including an elastic matrix and a metal powder mixed in the elastic matrix of the second elastic weight member. The second elastic weight member includes a specific density and an elastic coefficient different from those of the first elastic weight member. The first elastic weight member and the second elastic weight member are mounted in the assembling portion of the body to form a golf club head. The first elastic weight member and the second elastic weight member adjust a center of gravity of the golf club head and provide an elastic vibration-absorbing effect.

Owner:NELSON PRECISION CATING

Formula of wheel-rack solid lubrication additive for railway traffic

The invention discloses a prescription of a wheeltrack lubricant additive, which is characterized by strong bearing capacity, high temperature resistance and long effective time upon one time coating, thereby solving the defect that factigue crack expansion of the wheeltrack is accelerated by traditional grease for the generation of oil wedge effect. The prescription comprises 1 percent-30 percent of metal powder, 3 percent-50 percent of high temperature solid lubricant material and 5 percent-50 percent of fatty acid by weight. The strip solid materials can be produced in virtue of other accessories by the prescription.

Owner:张念

Systems and methods for additive manufacturing and repair of metal components

Scanning Laser Epitaxy (SLE) is a layer-by-layer additive manufacturing process that allows for the fabrication of three-dimensional objects with specified microstructure through the controlled melting and re-solidification of a metal powders placed atop a base substrate. SLE can be used to repair single crystal (SX) turbine airfoils, for example, as well as the manufacture functionally graded turbine components. The SLE process is capable of creating equiaxed, directionally solidified, and SX structures. Real-time feedback control schemes based upon an offline model can be used both to create specified defect free microstructures and to improve the repeatability of the process. Control schemes can be used based upon temperature data feedback provided at high frame rate by a thermal imaging camera as well as a melt-pool viewing video microscope. A real-time control scheme can deliver the capability of creating engine ready net shape turbine components from raw powder material.

Owner:GEORGIA TECH RES CORP

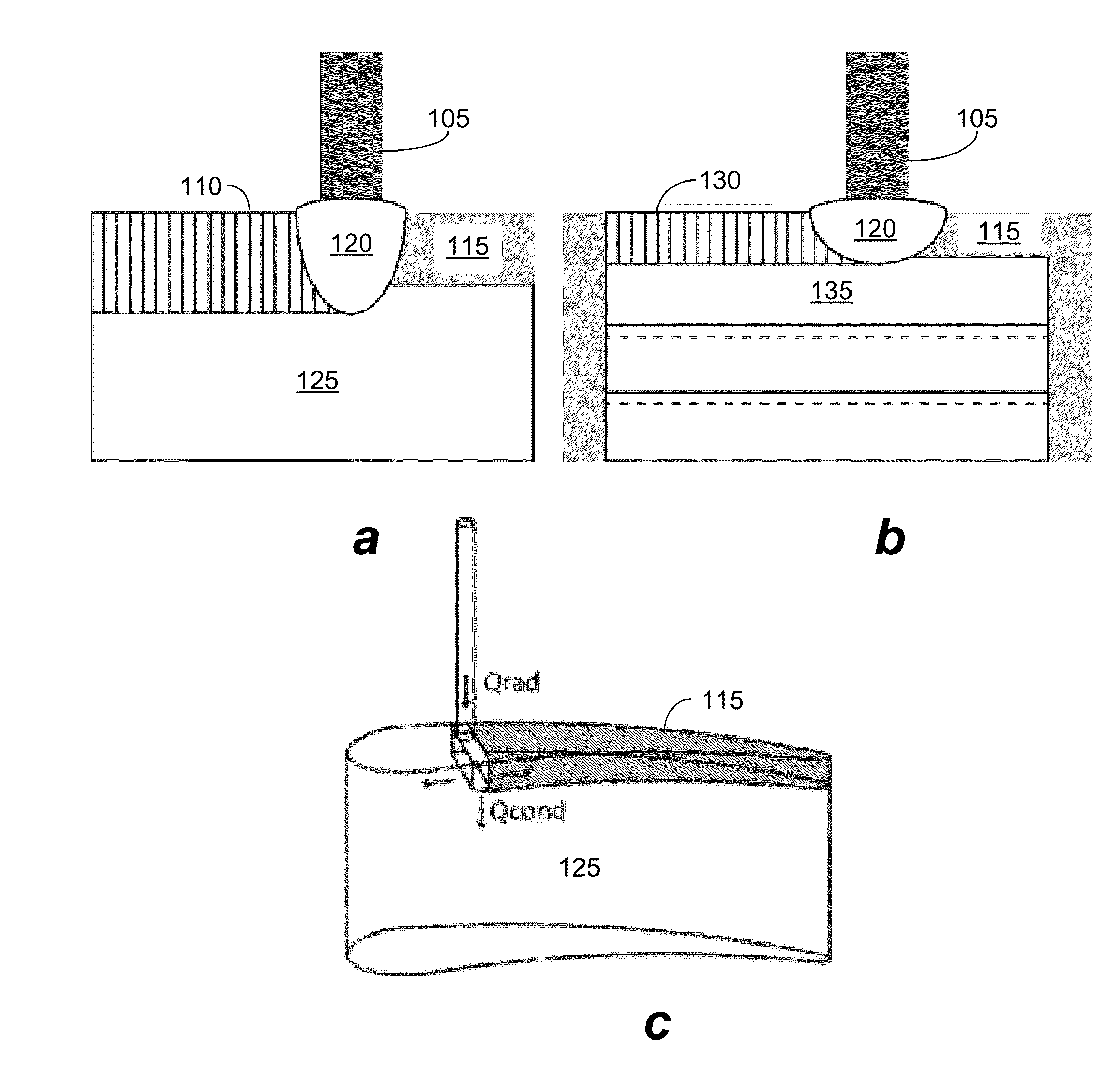

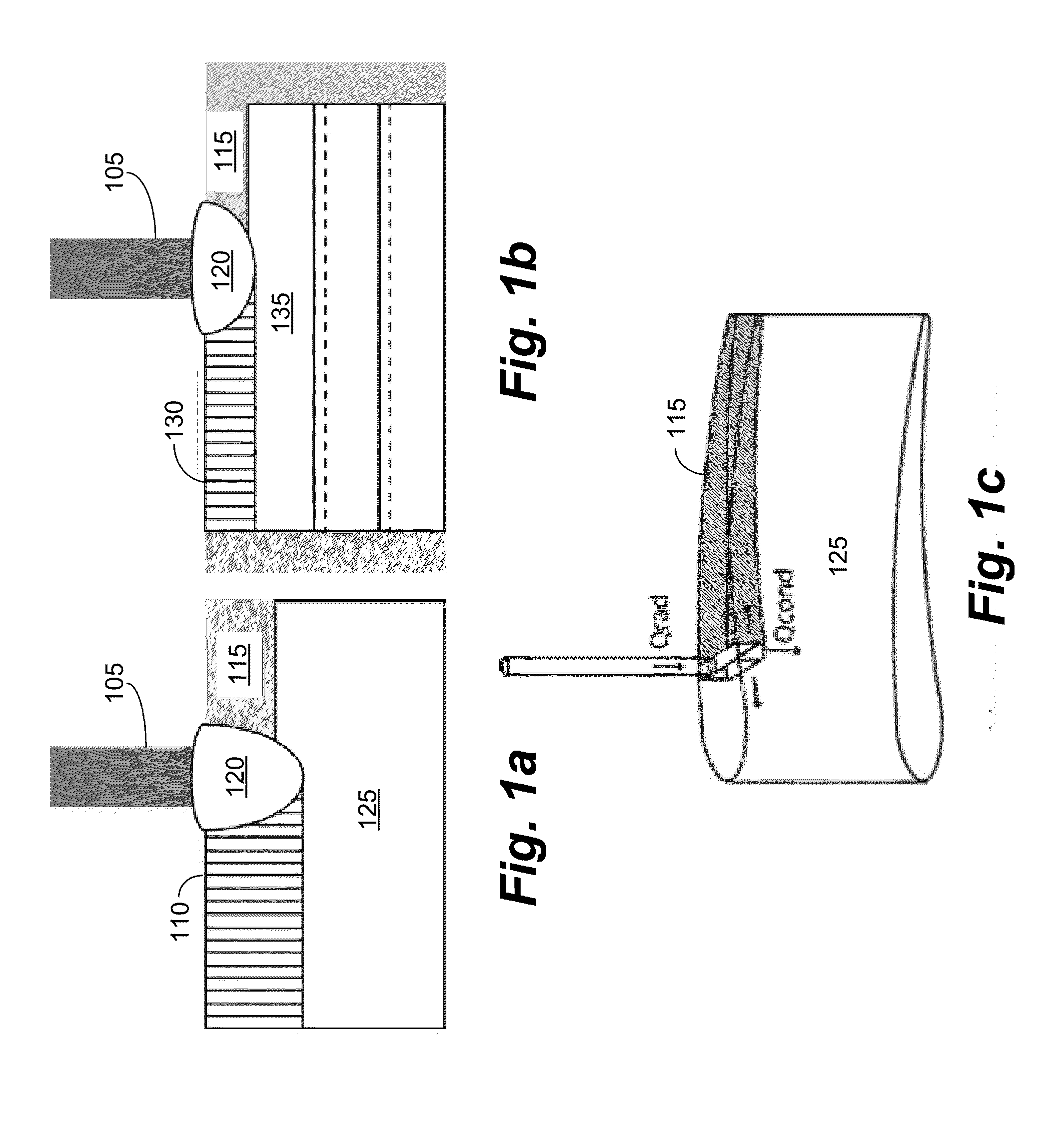

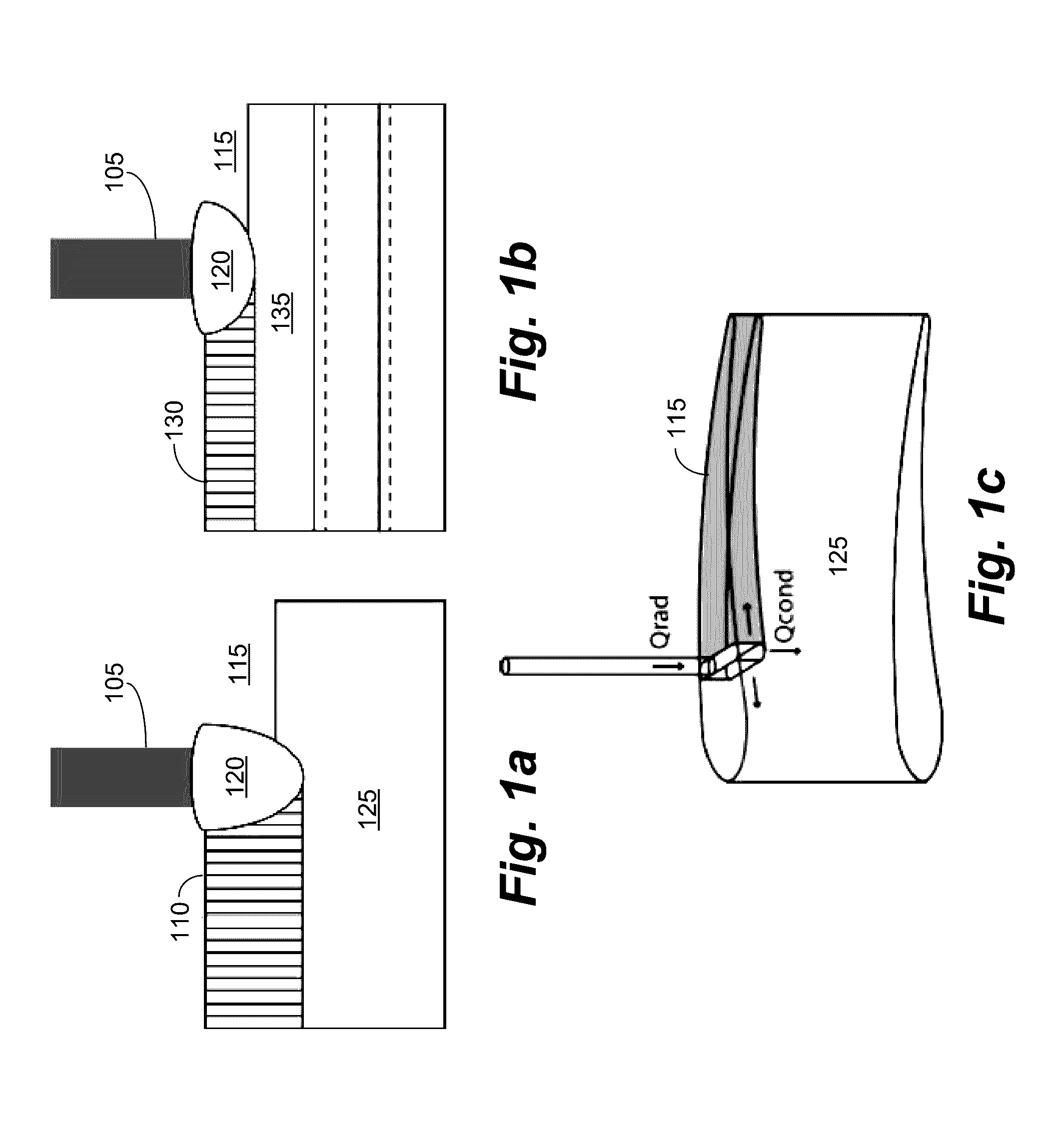

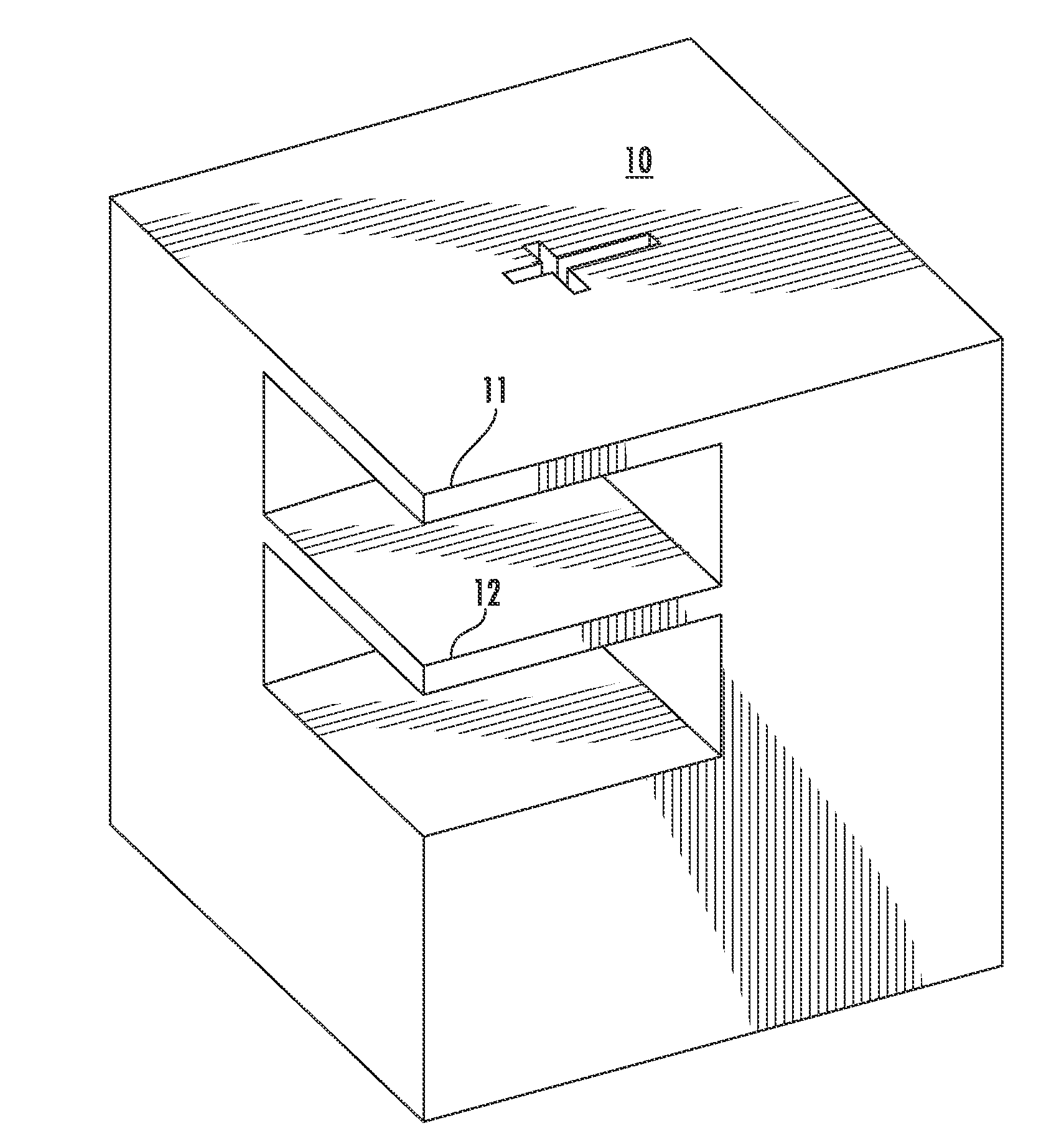

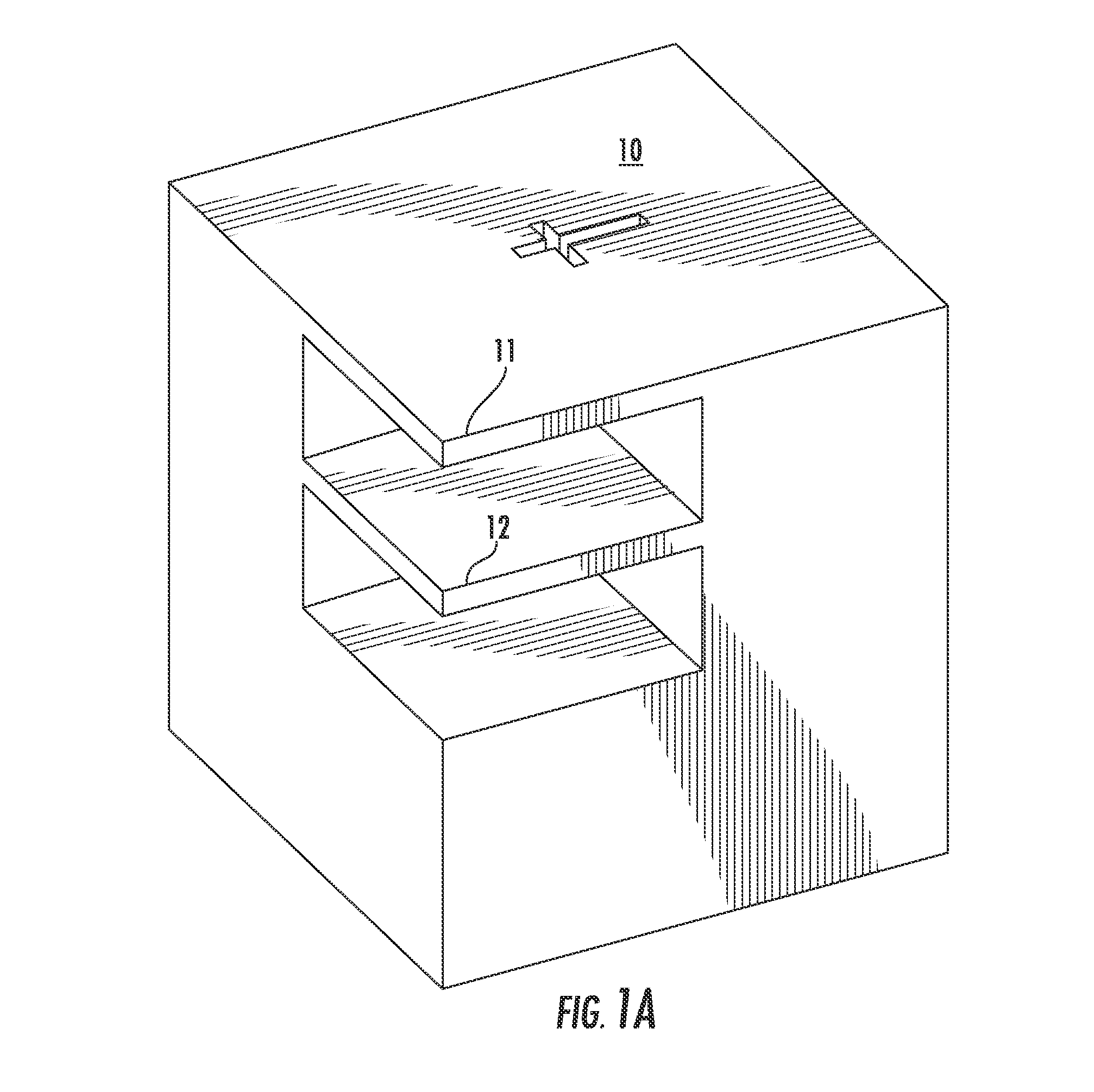

Systems and Methods for Designing And Fabricating Contact-Free Support Structures for Overhang Geometries of Parts in Powder-Bed Metal Additive Manufacturing

ActiveUS20140335313A1Improve heat transfer performanceReduce gradientAdditive manufacturing apparatusLayered productsContact freeMetal powder

Systems and methods are provided for designing and fabricating contact-free support structures for overhang geometries of parts fabricated using electron beam additive manufacturing. One or more layers of un-melted metallic powder are disposed in an elongate gap between an upper horizontal surface of the support structure and a lower surface of the overhang geometry. The powder conducts heat from the overhang geometry to the support structure. The support structure acts as a heat sink to enhance heat transfer and reduce the temperature and severe thermal gradients due to poor thermal conductivity of metallic powders underneath the overhang. Because the support structure is not connected to the part, the support structure can be removed freely without any post-processing step.

Owner:NASA +1

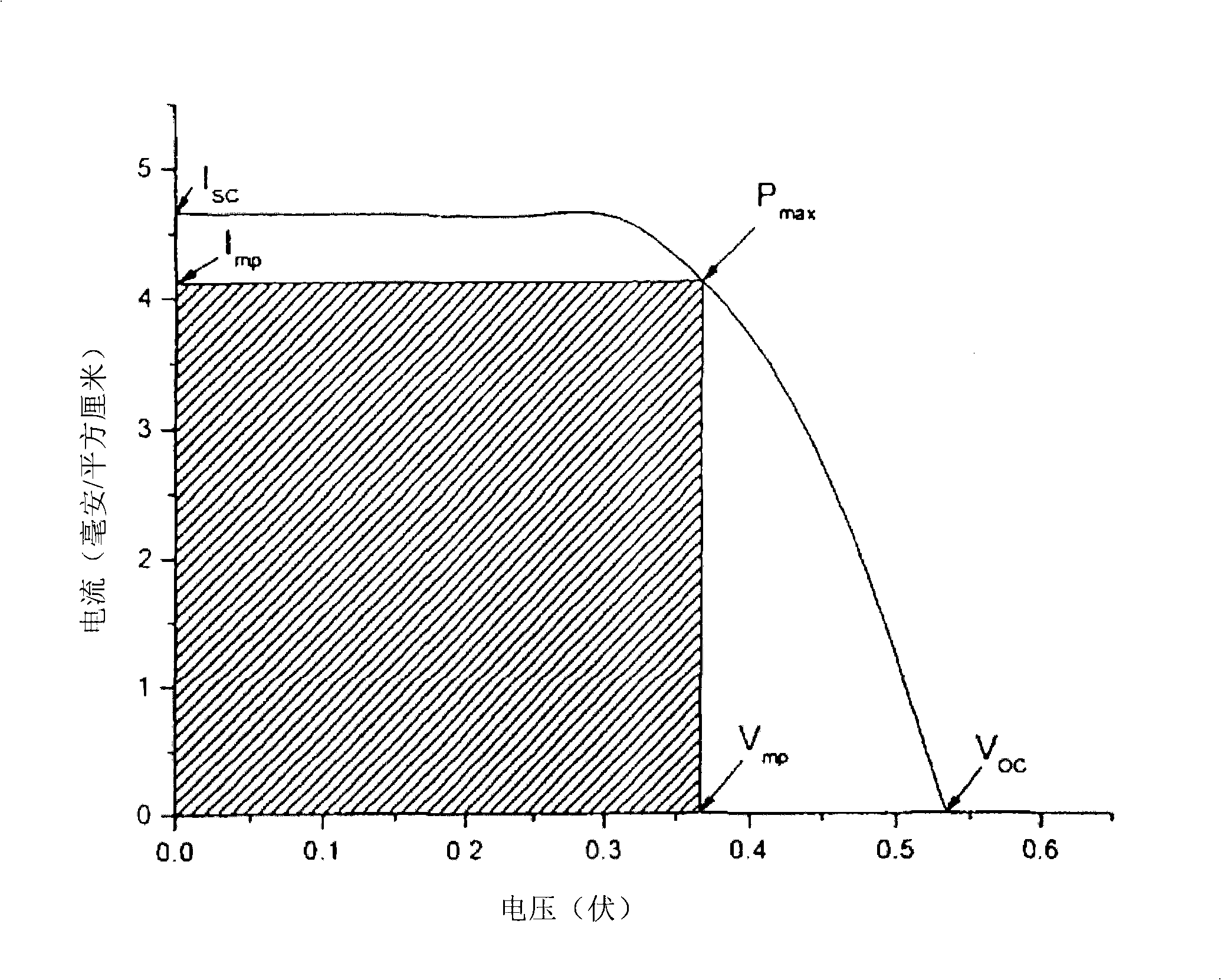

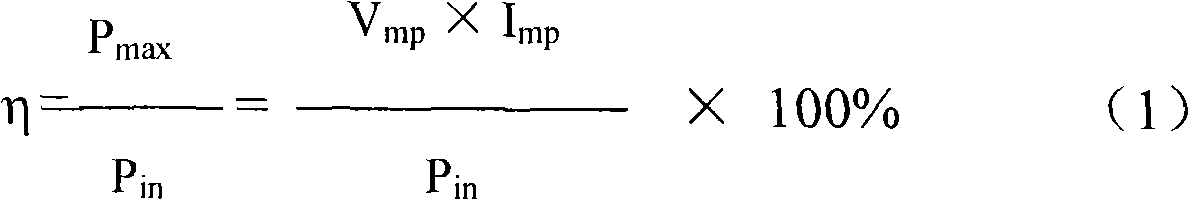

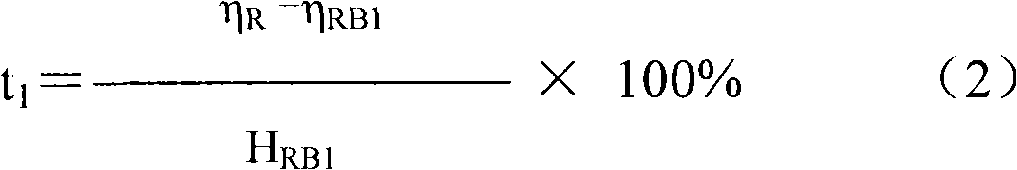

Conductive slurry for solar battery front side electrode and production method thereof

ActiveCN101295739AImprove photoelectric conversion efficiencyImprove adhesionFinal product manufactureNon-conductive material with dispersed conductive materialConductive pasteElectrical battery

The invention relates to a conductive paste for the surface electrode of a solar cell, which comprises conductive metal powders, organic carriers, adhesives, solvents and addition agent, wherein, the conductive paste also comprises additives which are selected from phosphorus pentachloride and one or more VIII group metal halide. The additive in the conductive paste of the invention can help improve the adhesive force between the conductive paste and silicon substrate, and lead adhesion between compounds obtained after electrode sintering and silicon substrate to be more firm; the formed compound does not have cracks and bubbles and the electrode surface is flat and smooth, thus providing the solar cell finally prepared with higher photoelectric conversion efficiency.

Owner:BYD CO LTD

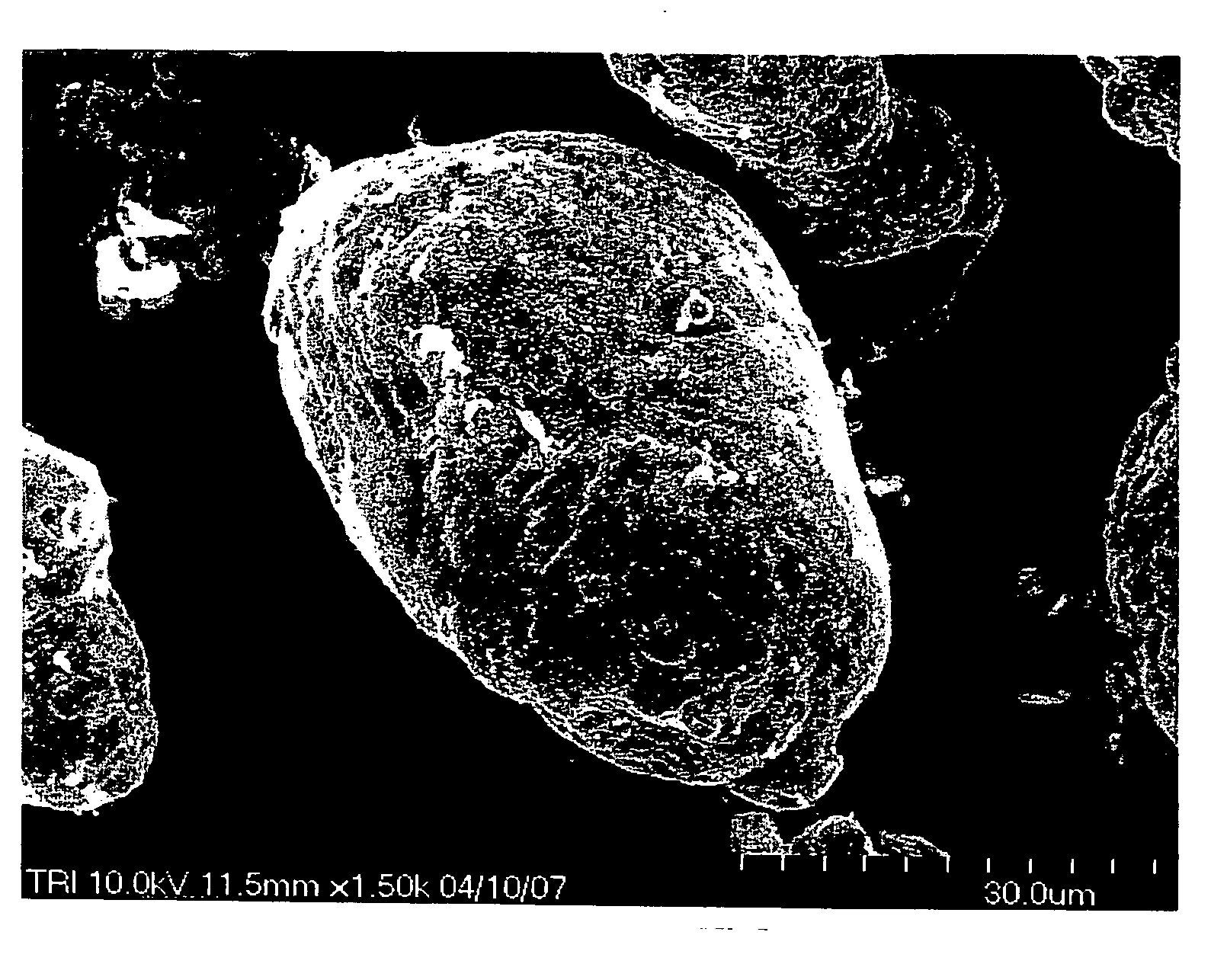

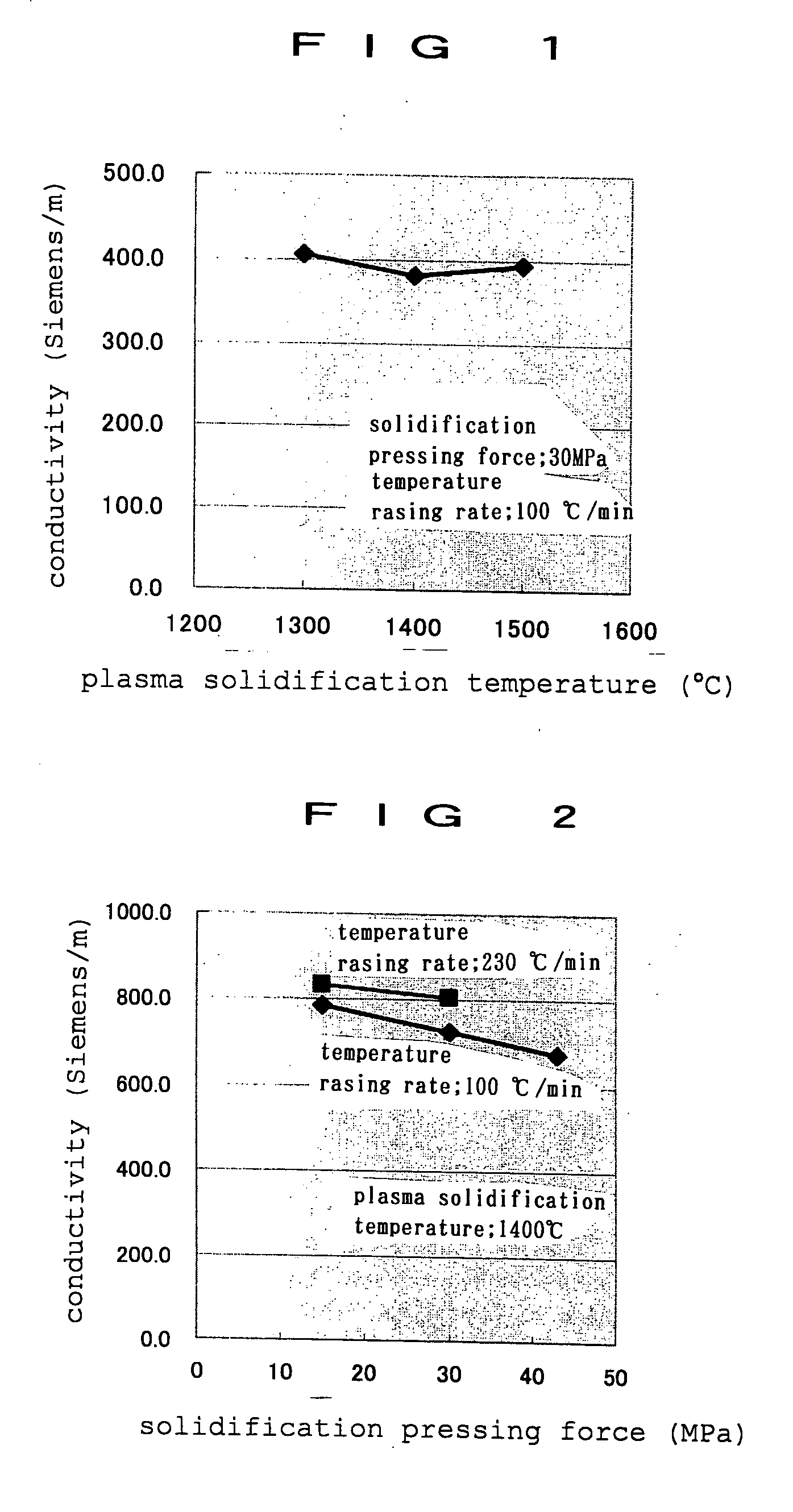

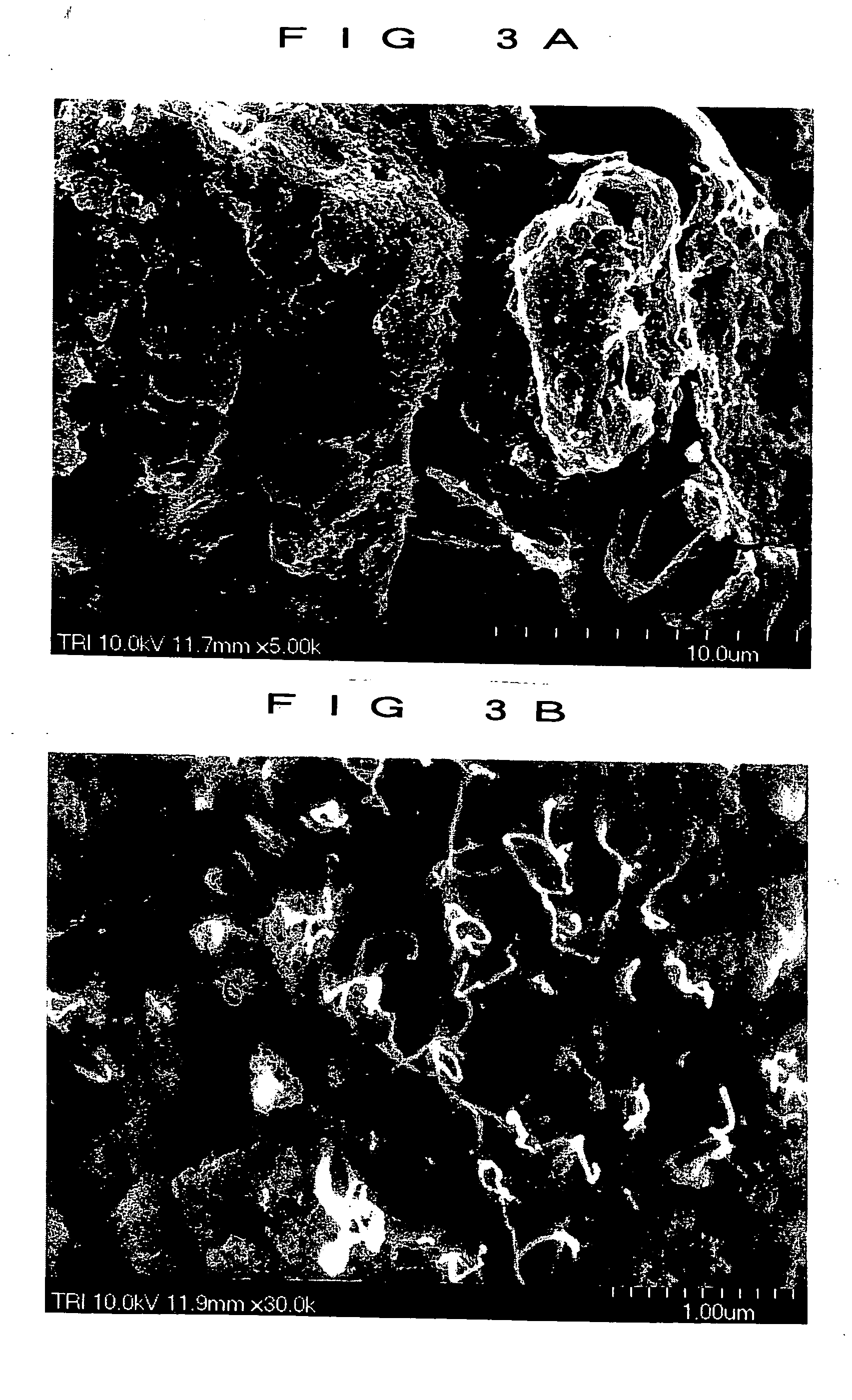

Method for producing carbon nanotube-dispersed composite material

InactiveUS20070057415A1Improve corrosion resistanceExcellent in heat releasabilityMaterial nanotechnologyCell electrodesHeat resistanceCarbon nanotube

The present invention has an object of providing a carbon nanotube dispersed composite material utilizing as much as possible excellent electric conductivity, heat conductive property and strength property owned by a carbon nanotube itself and taking advantage of features of ceramics having corrosion resistance and heat resistance such as zirconia and the like, and a method of producing the same; and long-chain carbon nanotubes (including also those obtained by previous discharge plasma treatment of only carbon nanotubes) are kneaded and dispersed by a ball mill, planet mill and the like together with calcinable ceramics and metal powder, further, the knead-dispersed material is treated by discharge plasma and this is integrated by sintering by discharge plasma, and carbon nanotubes can be thus dispersed in the form of network in the sintered body, and the electric conductivity property, heat conductive property and strength property of the carbon nanotube can be effectively used together with the properties of the ceramics and metal powder base material.

Owner:SUMITOMO PRECISION PROD CO LTD +1

Magnetic recording medium and process for producing the same

InactiveUS20070231606A1Improve the overall coefficientHead contaminationMaterials with cobaltRecord information storageMetal powderCobalt

A magnetic recording medium comprising a substrate and a magnetic layer containing ferromagnetic metal powder and a binder, wherein the ferromagnetic metal powder contains iron, cobalt and form 2 to 20 atom % of yttrium based on a total of iron and cobalt contained in the ferromagnetic metal powder and has an average length of 50 nm or smaller, and the magnetic recording medium has a test value of at least 100 passes in a magnetoresistive head resistance reduction test performed as defined herein.

Owner:FUJIFILM CORP

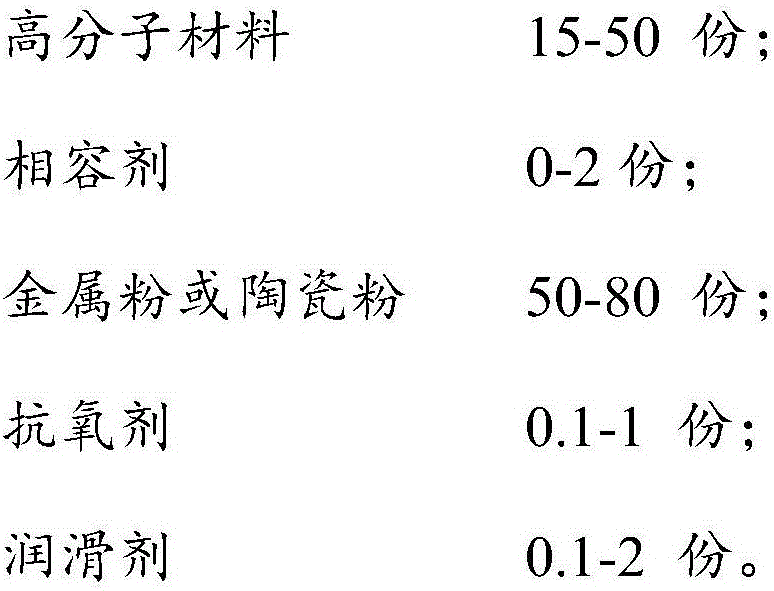

Metal or ceramic consumable item for FDM 3D printing, preparation method for metal or ceramic consumable item and finished product printing method

InactiveCN105665697AEasy to handleUnlimited structureAdditive manufacturing apparatusTransportation and packagingMiniaturizationVolumetric Mass Density

The invention discloses a metal or ceramic consumable item for FDM 3D printing, a preparation method for the metal or ceramic consumable item and a finished product printing method. The metal or ceramic consumable item comprises, by weight, 15-50 parts of a high polymer material, 0-2 parts of a compatilizer, 50-80 parts of metal powder or ceramic powder, 0.1-1 part of an antioxygen and 0.1-2 parts of a lubricating agent. The cost for equipment, the materials and machining is low; a printing structure is free of limitation, collapsing conditions do not exist in the printing process, supports can be removed before fusion sintering of the product, and treatment is easier compared with a manner that the supports are removed after SLS or EBAM fusion sintering; the requirements for the sphericity degree, the size distribution, the mobility and the like are relatively low; the types of metal and ceramic capable of being printed are wider; and the density of the finished products is higher, the strength is high, the degree of finish is higher, the miniaturization capacity is high, the thin-wall capacity is high, the complexity is high, the design tolerance level is high, and the material adaption scope is wide.

Owner:HUIZHOU RES INST OF SUN YAT SEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com