Patents

Literature

79results about "Materials with cobalt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnetic tape and magnetic tape cartridge

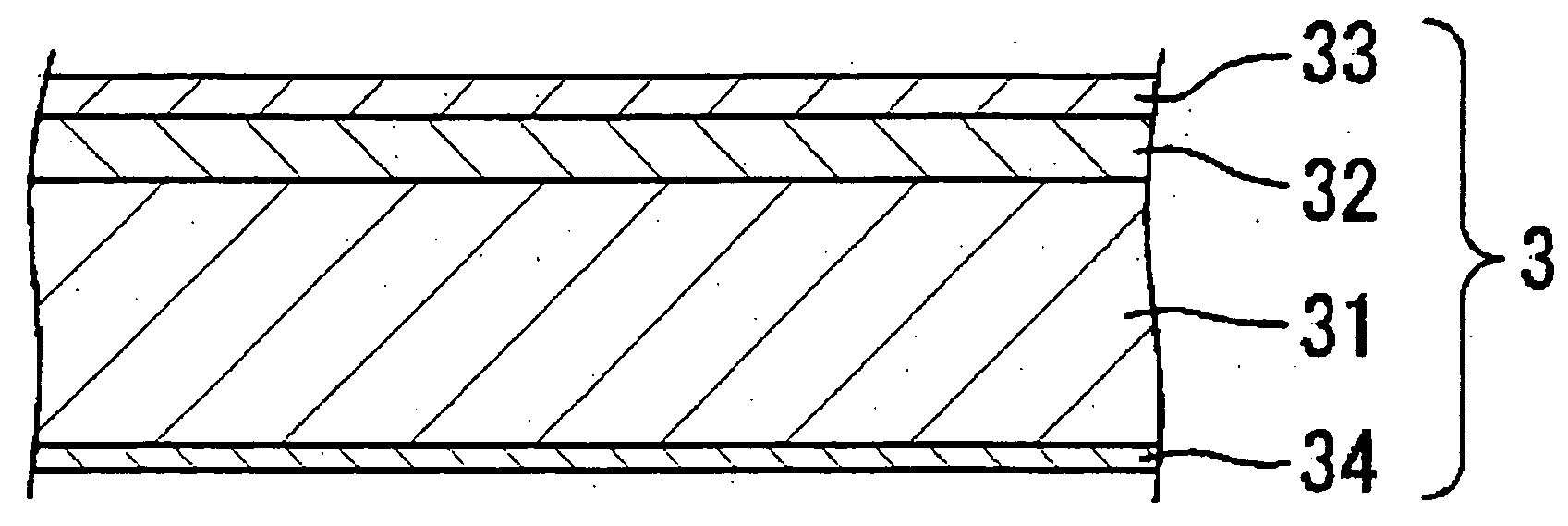

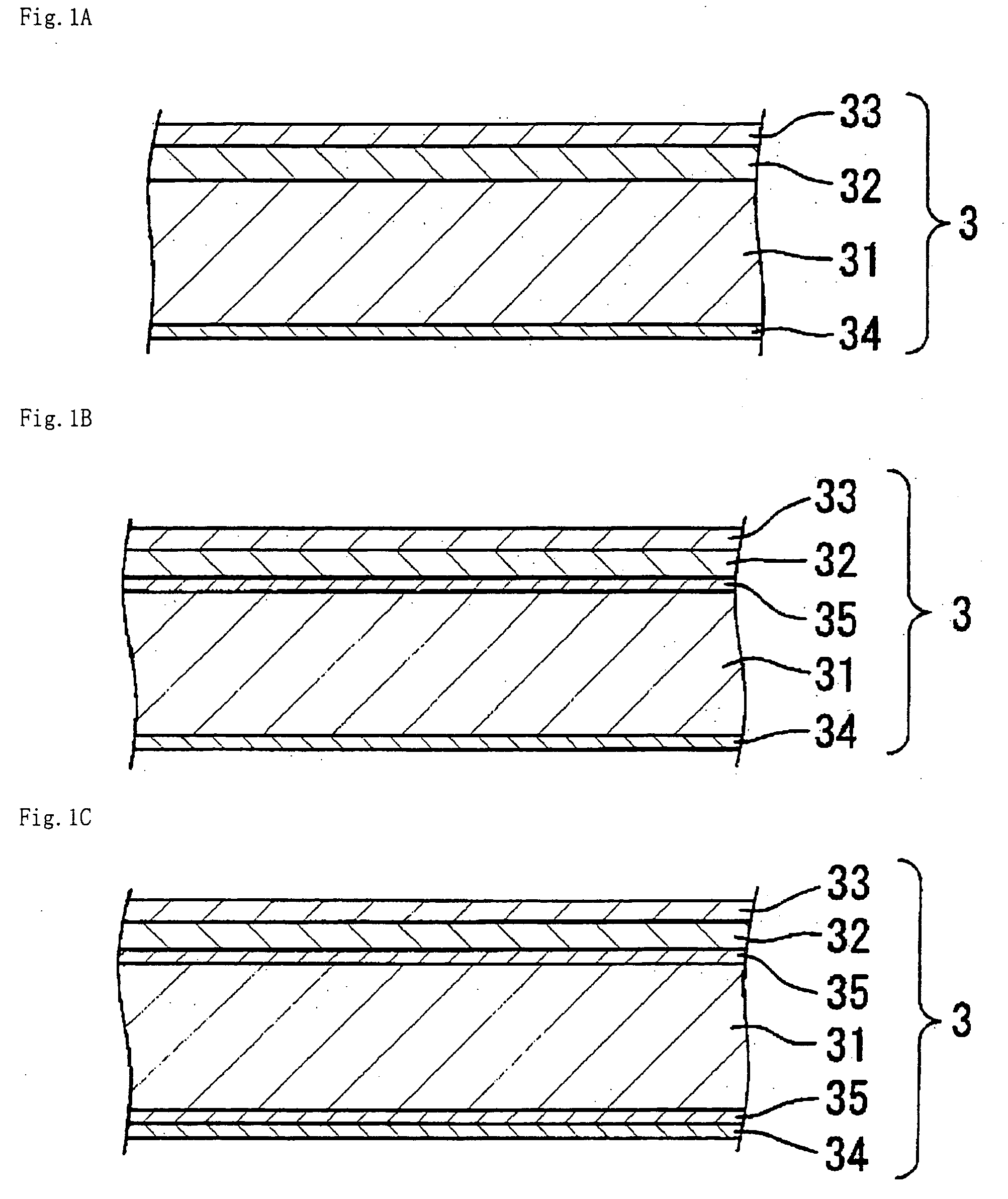

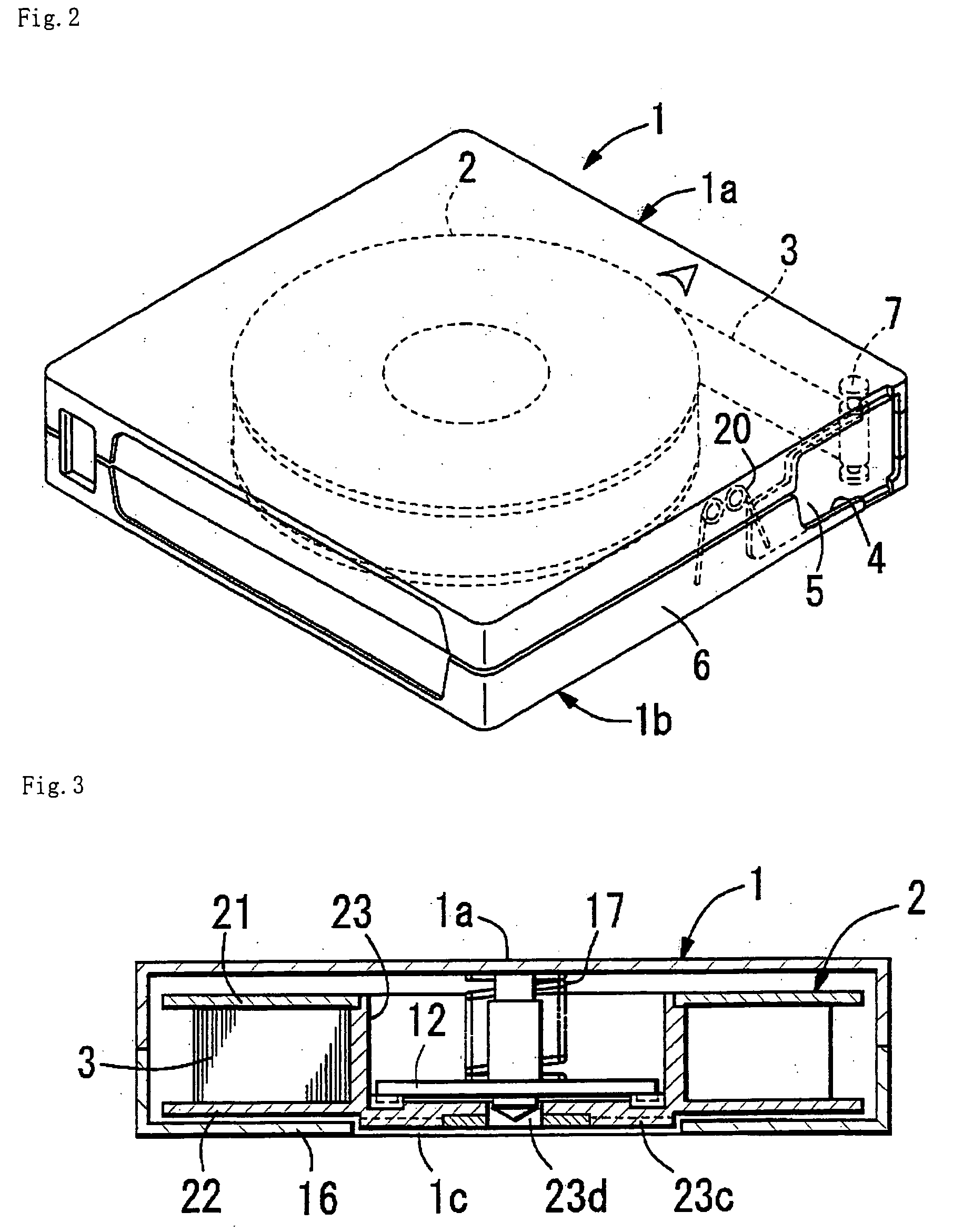

InactiveUS20050153170A1Improved in performanceGood dimensional stabilityMaterials with ironLayered productsMagnetic tapeThermal expansion

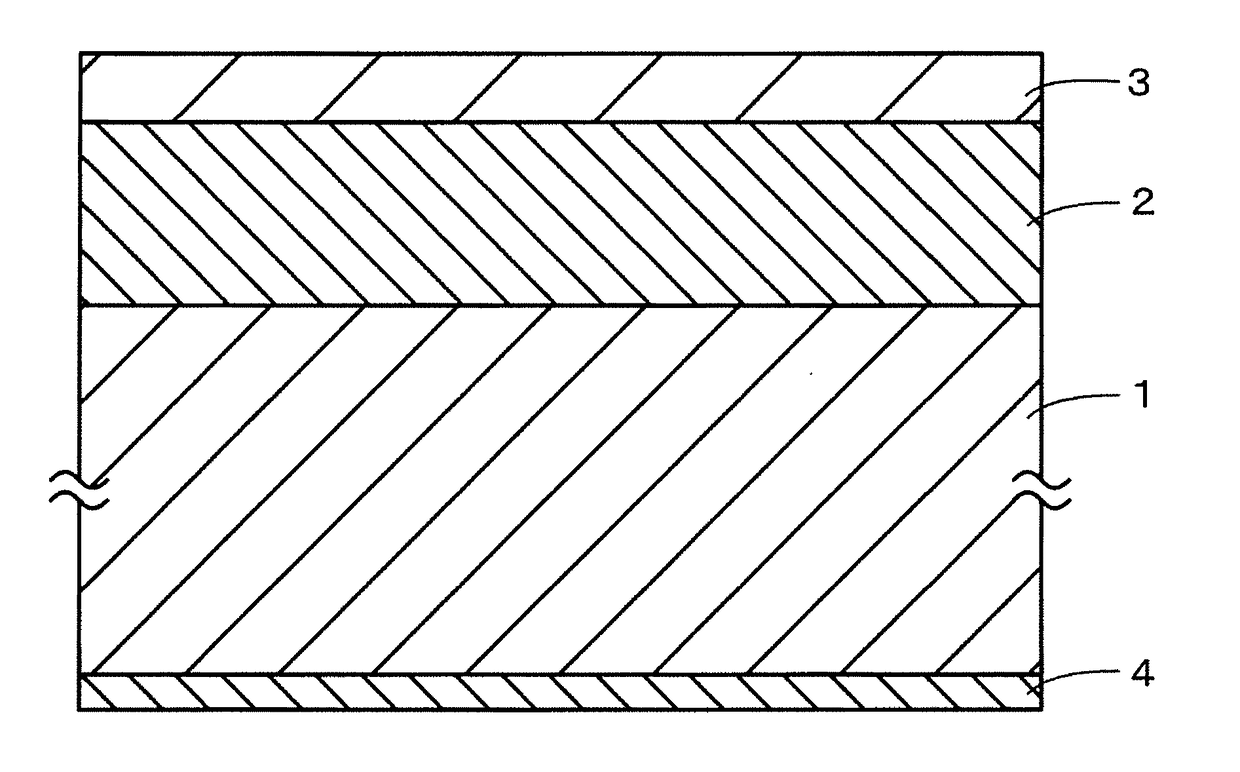

There is provided a magnetic tape comprising a non-magnetic support, and a primer layer and a magnetic layer both formed on a surface of the non-magnetic support, and a backcoat layer formed on the other surface of the non-magnetic support, wherein the magnetic layer contains magnetic powder which comprises needle-like iron-based magnetic particles, and has a thickness of 0.09 μm or less; and the primer layer contains non-magnetic powder which comprises plate-like non-magnetic oxide particles with an average particle size of 10 to 100 nm. Further, the thermal expansion coefficient of the magnetic layer in the tape widthwise direction is (0 to 8)×10−6 / ° C., and the humidity expansion coefficient of the magnetic layer in the tape widthwise direction is (0 to 10)×10−6 / % RH; and the amount of edge weave which is formed on either of the edges of the tape serving as the side of reference for the feeding of the tape is 0.8 μm or less. This magnetic tape is excellent in performance for recording / reproducing signals with short wavelengths and hardly causes a decrease in reproducing output due to off-track.

Owner:HITACHT MAXELL LTD

Magnetic recording medium and process for producing the same

InactiveUS20070231606A1Improve the overall coefficientHead contaminationMaterials with cobaltRecord information storageMetal powderCobalt

A magnetic recording medium comprising a substrate and a magnetic layer containing ferromagnetic metal powder and a binder, wherein the ferromagnetic metal powder contains iron, cobalt and form 2 to 20 atom % of yttrium based on a total of iron and cobalt contained in the ferromagnetic metal powder and has an average length of 50 nm or smaller, and the magnetic recording medium has a test value of at least 100 passes in a magnetoresistive head resistance reduction test performed as defined herein.

Owner:FUJIFILM CORP

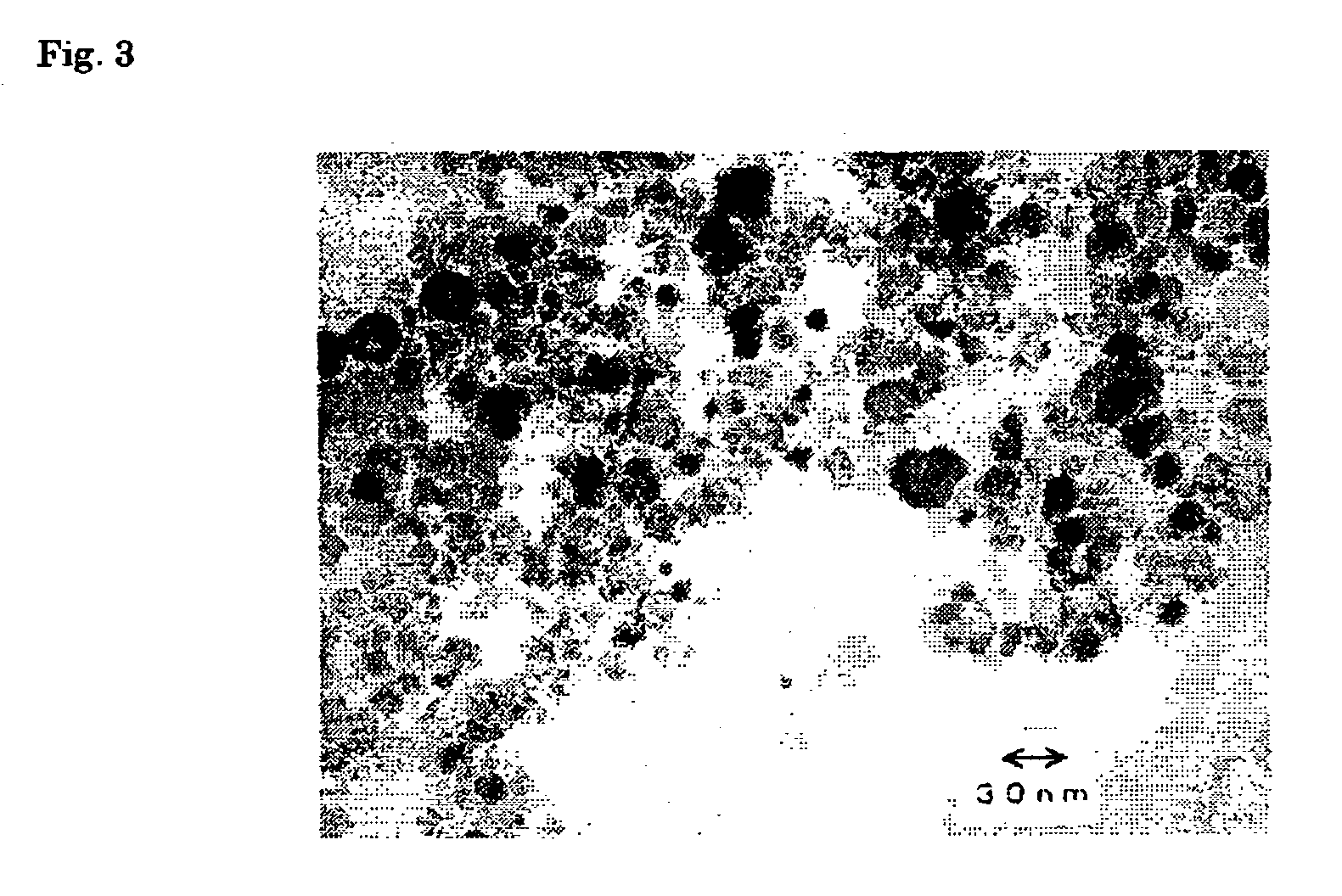

Metal alloy fine particles and method for producing thereof

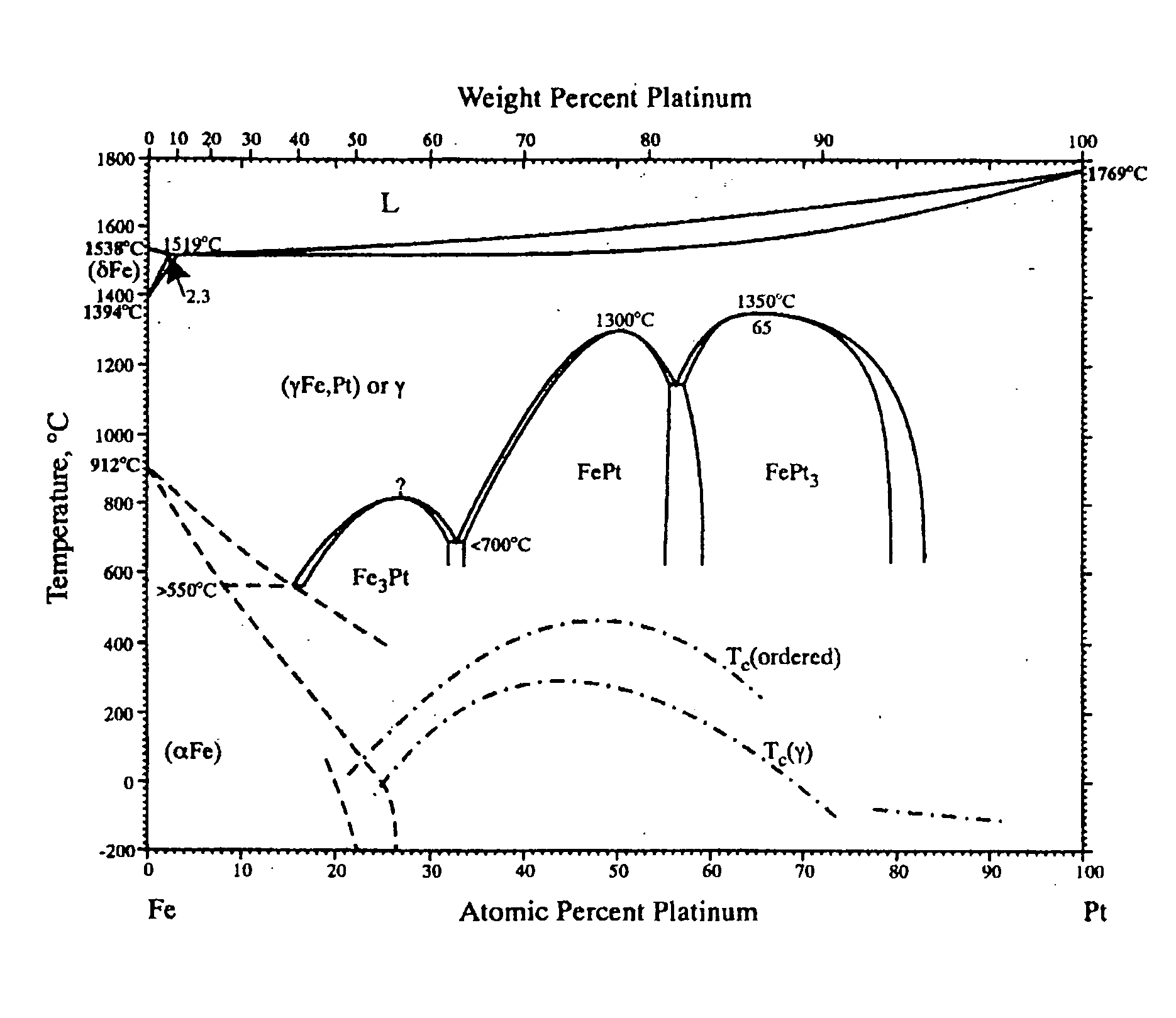

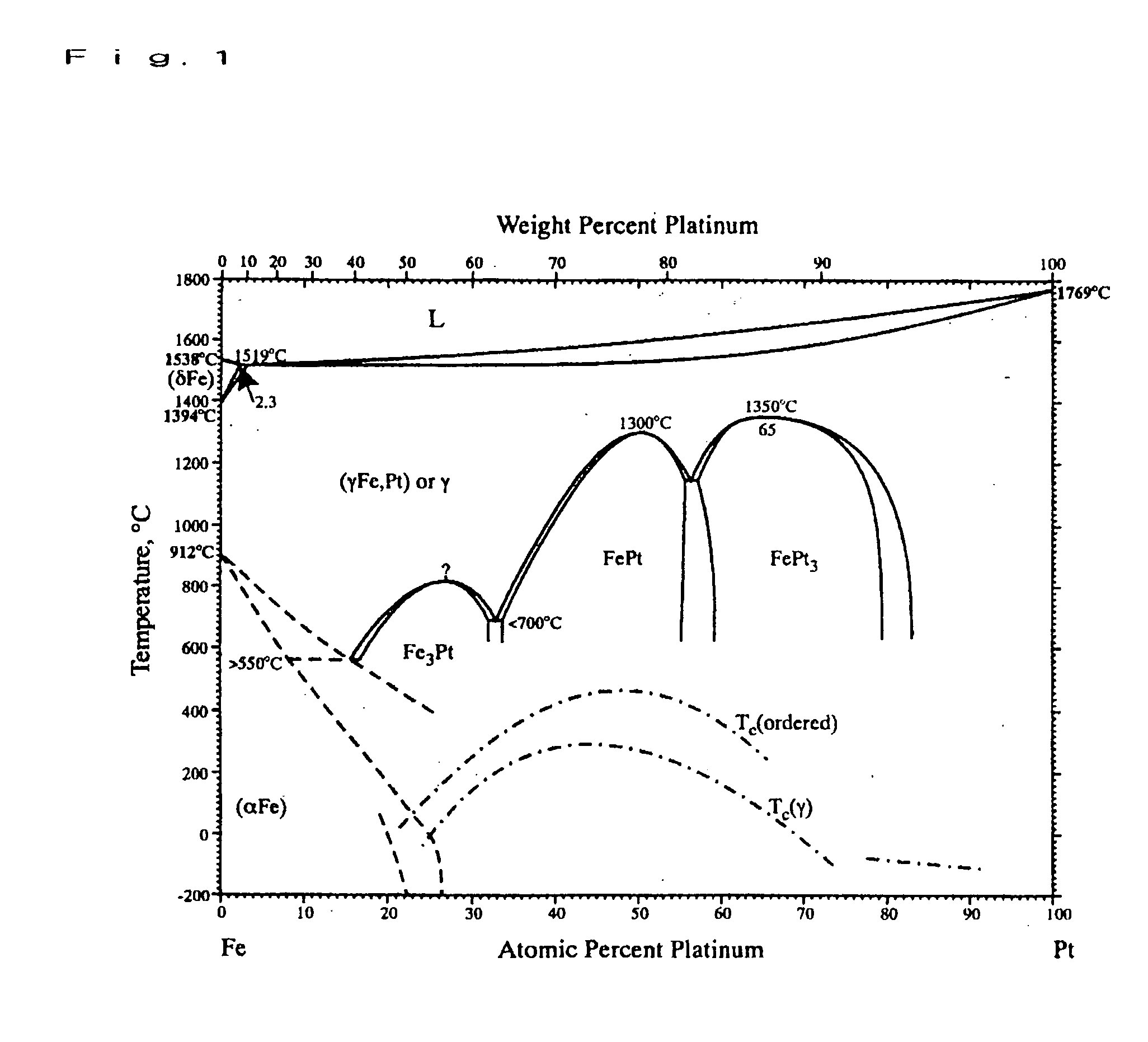

A novel method for preparing fine particles comprising a transition metal and a noble metal which are monodispersed and have almost no particle diameter distribution, and are transferable to a CuAu-I type L10 ordered phase, with safety and at a low cost, wherein a salt or a complex of at least one transition metal selected from Fe and Co and a salt or a complex of at least one transition metal selected from Pt and Pd (exclusive of the combination of Co—Pd) is dissolved in an organic solvent miscible with water or an alcohol in the presence of an organic protecting agent, and the resultant solution is heated under reflux in the presence of an alcohol in an inert atmosphere, to thereby prepare a binary alloy comprising a transition metal and a noble metal, or a salt or a complex of at least one element selected from the group consisting of Cu, Bi, Sb, Sn, Pb and Ag is further dissolved in the above solvent and the resultant solution is heated under reflux in the presence of an alcohol in an inert atmosphere, to thereby prepare a ternary alloy comprising a transition metal, a noble metal and an additional element.

Owner:HITACHT MAXELL LTD

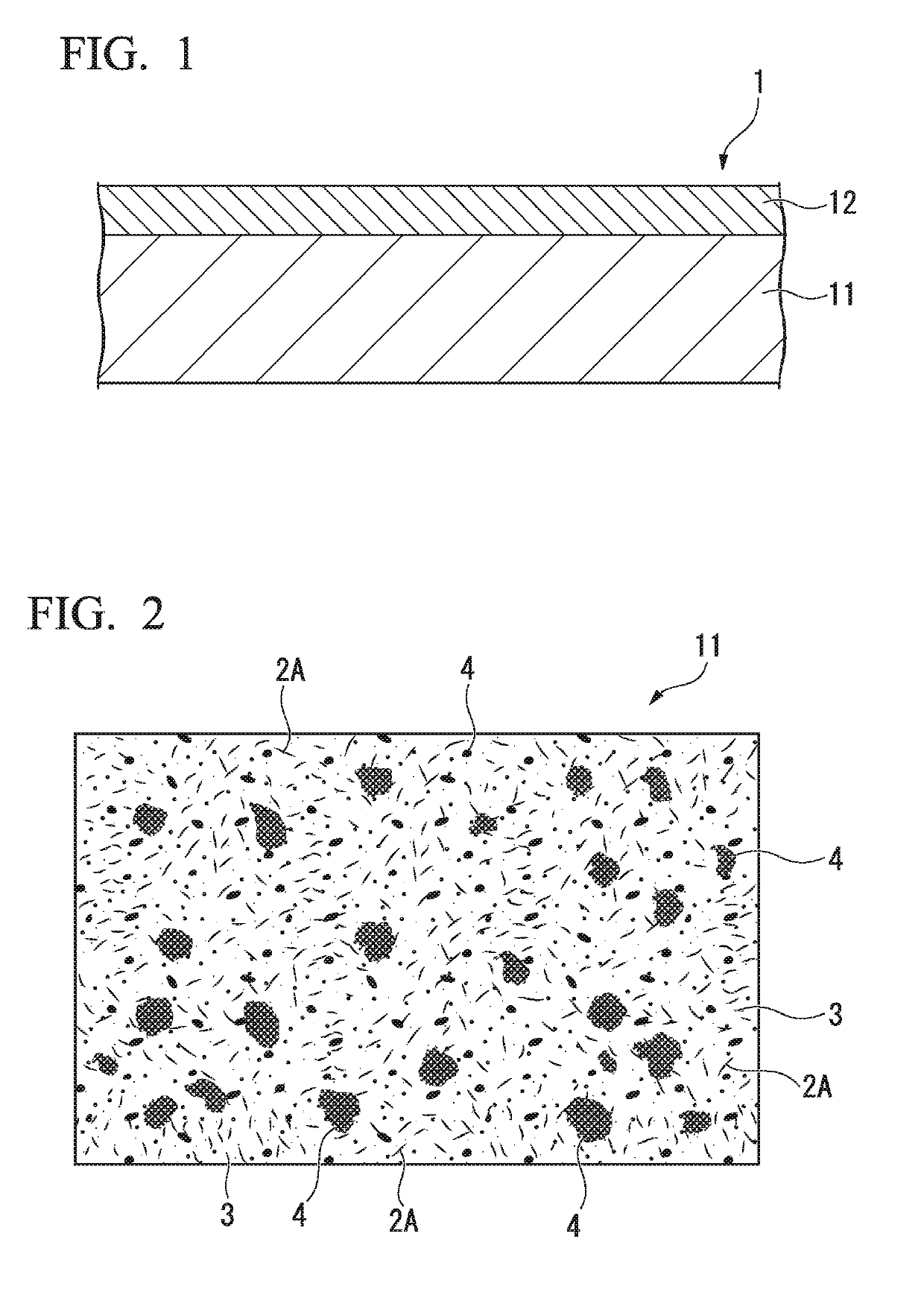

Magnetic recording medium

ActiveUS20170162220A1Improve signal-to-noise ratioMaterials with cobaltRecord information storageMaterials scienceMagnetic layer

The magnetic recording medium includes a support and a magnetic layer containing a magnetic powder. The magnetic powder includes at least either of a magnetic particle containing a cubic ferrite and a magnetic particle containing an ε-phase iron oxide. The magnetic powder has a mean particle size of 10 nm or more and 14 nm or less, the magnetic powder has a mean aspect ratio of 0.75 or more and 1.25 or less, and the magnetic layer has a ten-point mean roughness Rz of 35 nm or less.

Owner:SONY CORP

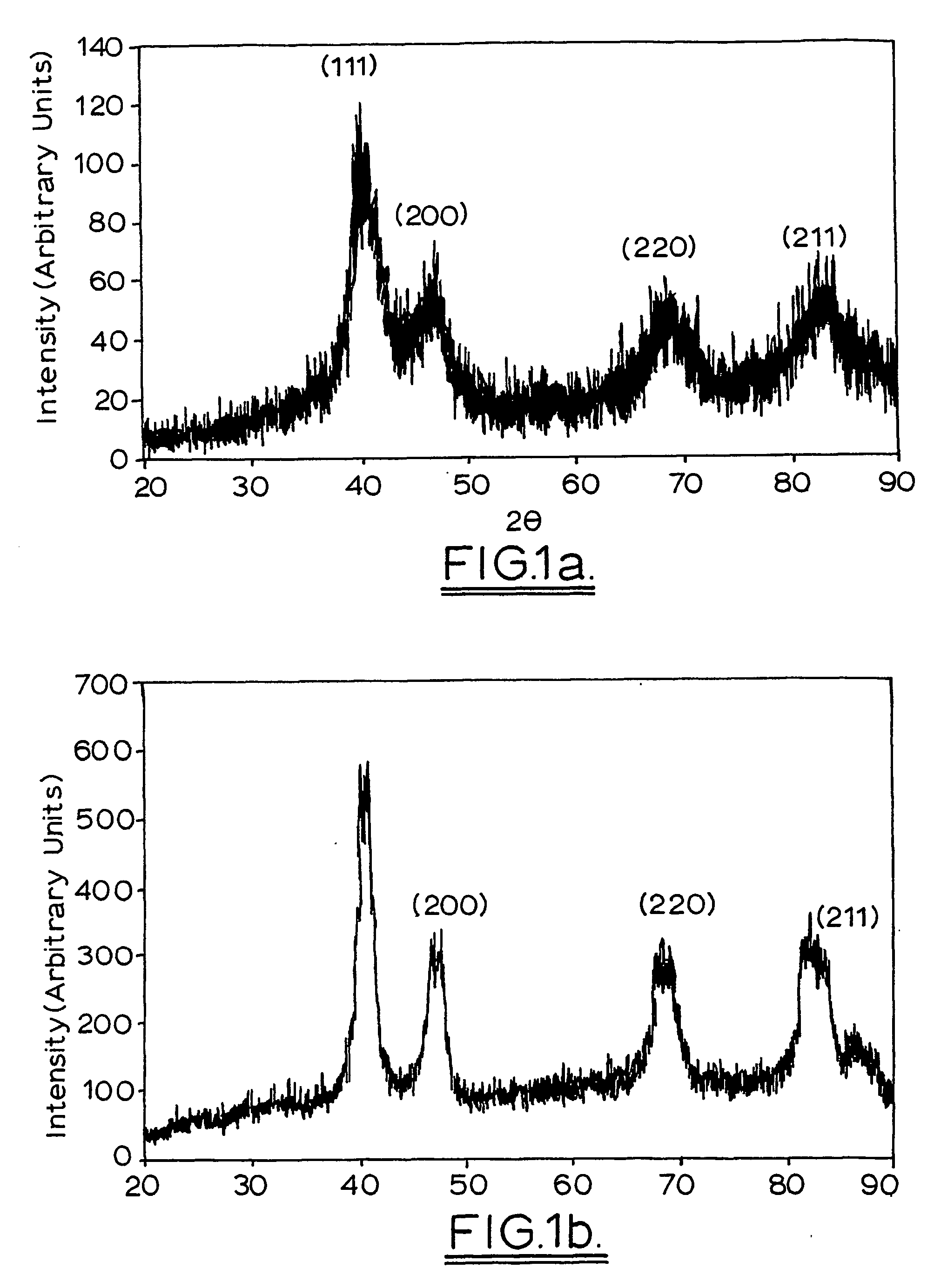

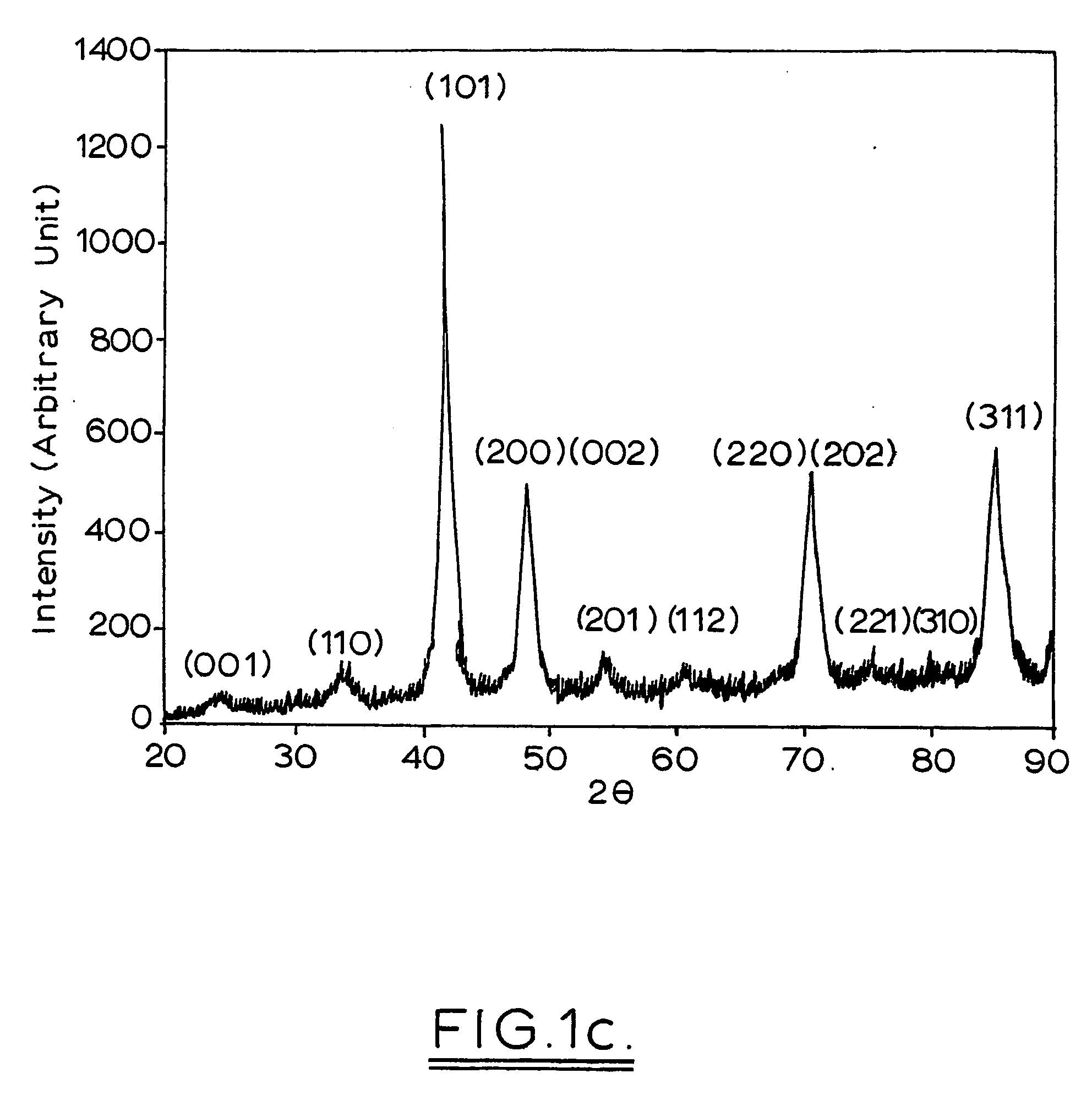

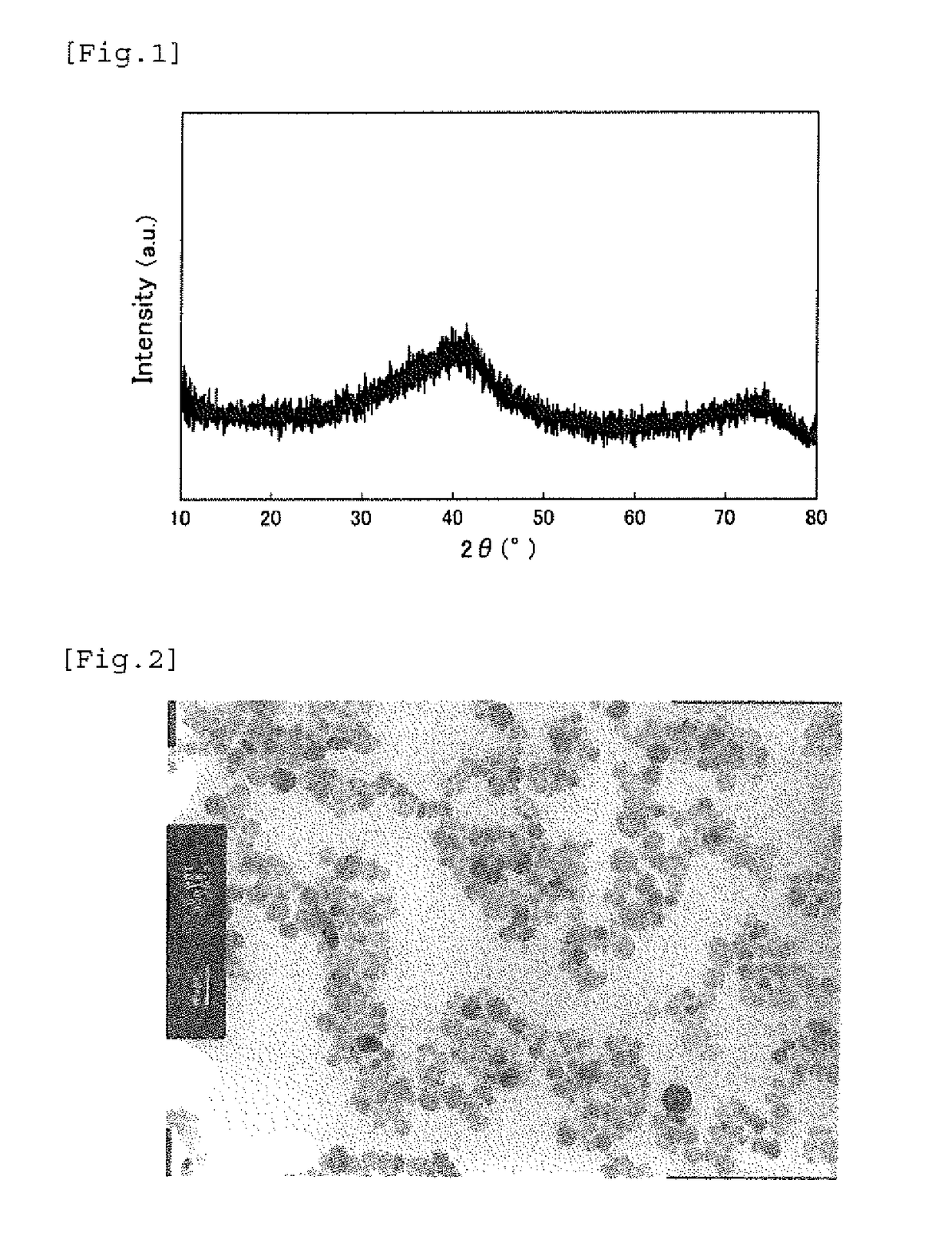

Face-centered cubic structure alloy particles and method of manufacturing same

InactiveUS20060032330A1Improve distributionLower transition temperatureMaterial nanotechnologyMaterials with ironAlloyCrystallinity

Alloy particles of an alloy having a face-centered cubic structure comprise at least one selected from Fe and Co and at least one selected from Pt and Pd as principal components. The alloy particles have a TEM-measured average grain size (DTEM) of not more than 50 nm, and a single crystallinity (DTEM) / (DX) that is less than 1.50, where (DX) is X-ray crystallite size. These alloy particles can be advantageously manufactured by using the polyol process to synthesize the alloy particles in the presence of a complexing agent.

Owner:DOWA ELECTRONICS MATERIALS CO LTD

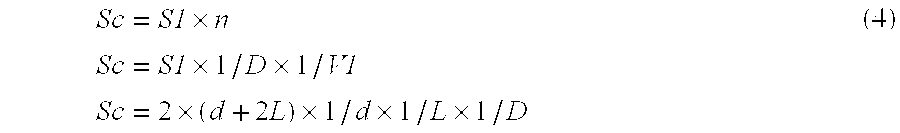

Magnetic recording medium

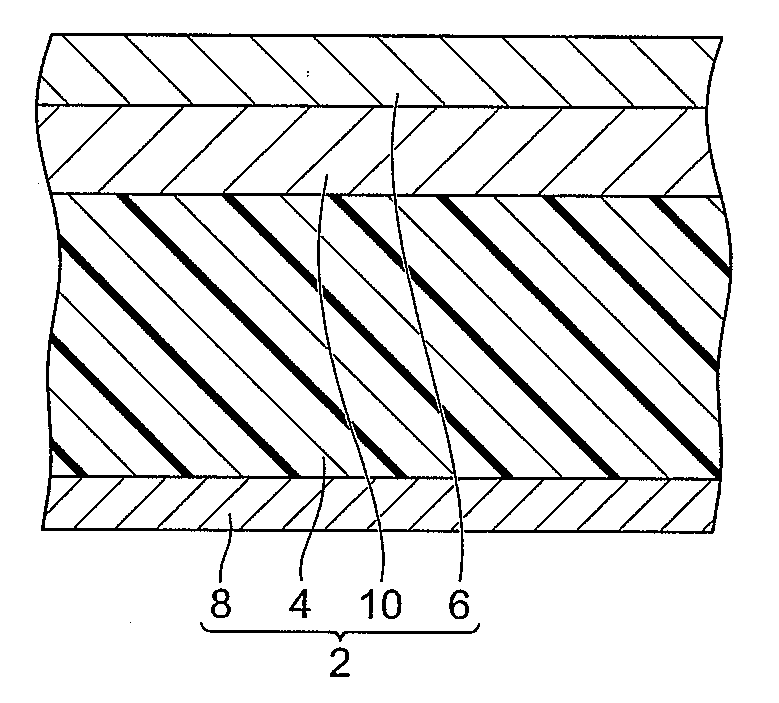

InactiveUS6852404B2Improve featuresGood dispersibilityBase layers for recording layersLayered productsAlloyNon magnetic

The average major-axis length (L) of a ferromagnetic alloy powder primarily contained together with a binder in a magnetic layer provided on at least one surface of a non-magnetic support is less than 0.10 μm, and the ferromagnetic alloy powder contains Co at a content of 15 to 28 at % relative to Fe, and furthermore, contains Y at a content of 22 μmol / m2 or more with respect to a specific surface area (Sc) calculated from the above-mentioned average major-axis length (L) and the crystallite diameter (d). A coating-type high-recording-density magnetic recording medium has excellent surface properties, an excellent electromagnetic transducing characteristic especially in short wavelength regions and high reliability.

Owner:TDK CORPARATION

Magnetic recording medium

InactiveUS6074724ARaise the potentialGood electromagnetic propertiesMaterials with cobaltSynthetic resin layered productsEtherFerromagnetism

A magnetic recording medium is disclosed, which comprises a support having thereon a magnetic layer comprising a binder and a ferromagnetic powder dispersed therein, wherein said binder comprises a polyurethane resin having at least one cyclic hydrocarbon group and at least one ether linkage, and said ferromagnetic powder is a ferromagnetic metallic powder which comprises Fe and has a mean major-axis length of from 0.05 to 0.19 .mu.m and a crystallite size of from 100 to 230 .ANG.; and further a magnetic recording medium is disclosed, comprising a support having thereon in succession an undercoat layer comprising a binder U and an inorganic powder dispersed therein and a magnetic layer comprising a binder M and a ferromagnetic powder dispersed therein, wherein at least either of the binder U or M comprises a polyurethane resin having at least one cyclic hydrocarbon group and at least one ether linkage and said ferromagnetic powder is a ferromagnetic metallic powder which comprises Fe and has a mean major-axis length of from 0.05 to 0.19 .mu.m and a crystallite size of from 100 to 230 .ANG..

Owner:FUJIFILM HLDG CORP +1

Magnetic powder, method for producing the same and magnetic recording medium comprising the same

InactiveUS6964811B2Recording characteristicImprove recording effectMaterials with ironNanomagnetismEllipsoidal particleMagnetization

A magnetic powder consisting of substantially spherical or ellipsoidal particles comprising a transition metal which comprises iron and a rear earth element which is mainly present in the outer layer of the magnetic powder particles, and having a particle size of 5 to 200 nm, a coercive force of 80 to 400 kA / m and a saturation magnetization of 10 to 25 uWb / g.

Owner:FUJIFILM CORP

Magnetic recording medium

ActiveUS20180358046A1Improve signal-to-noise ratioImprove scratch resistanceMaterials with cobaltRecord information storageTO-18Greek letter epsilon

Provided is a magnetic recording medium including: a non-magnetic support; and a magnetic layer including particles of at least one kind of epsilon type iron oxide-based compound selected from the group consisting of ε-Fe2O3 and a compound represented by Formula (1), an abrasive, and a binding agent, at least on one surface of the non-magnetic support, in which an average equivalent circle diameter of the particles of the epsilon type iron oxide-based compound is 7 nm to 18 nm, an average equivalent circle diameter of the abrasive in a plan view of the magnetic layer is 20 nm to 1,000 nm, and a coefficient of variation of the equivalent circle diameter of the abrasive is 30% to 60%. In Formula (1), A represents at least one kind of metal element other than Fe and a satisfies a relationship of 0<a<2.ε-AaFe2-aO3 (1)

Owner:FUJIFILM CORP

Magnetic recording layer

ActiveUS20050053804A1Reduce coefficient of frictionGood tape pack qualityMaterials with cobaltRecord information storageRecording layerMaterials science

A magnetic recording medium comprising a backcoating layer, a support, and a magnetic layer containing ferromagnetic powder, the backcoating layer having 800 to 1500 projections of 50 nm or more and less than 75 nm in height per 6400 μm2 and 600 or less projections of 75 nm or more in height per 6400 μm2.

Owner:FUJIFILM HLDG CORP +1

Magnetic powder, method for producing the same and magnetic recording medium comprising the same

InactiveUS20060008645A1Quick reversalRecording characteristicMaterials with ironNanomagnetismEllipsoidal particleMagnetization

A magnetic powder consisting of substantially spherical or ellipsoidal particles comprising a transition metal which comprises iron and a rear earth element which is mainly present in the outer layer of the magnetic powder particles, and having a particle size of 5 to 200 nm, a coercive force of 80 to 400 kA / m and a saturation magnetization of 10 to 25 μWb / g.

Owner:FUJIFILM CORP

Base metal particles having anisometric morphology

There is disclosed a method of making unsupported particles of a base metal selected from the group consisting of iron, cobalt, and nickel, which comprises combining an aqueous solution or suspension of a base metal salt, a strong base so that the resulting combination has an effective hydroxide ion concentration, and a reducing agent, which is then subjected to an autocatalytic reaction at about atmospheric pressure to form a precipitate of the metal. The unsupported base metal particles exhibit an anisometric morphology, generally platetlet or disk-shaped, and have a relatively high aspect or width to thickness ratio, which is preferably three or greater, exhibit ferromagnetic properties, and one or more of these base metals may be formed to exhibit a single magnetic domain. The resulting precipitate of metal particles may be formed as an agglomerate as by subjecting the precipitate to aging or to external means.

Owner:WISYS TECH FOUND

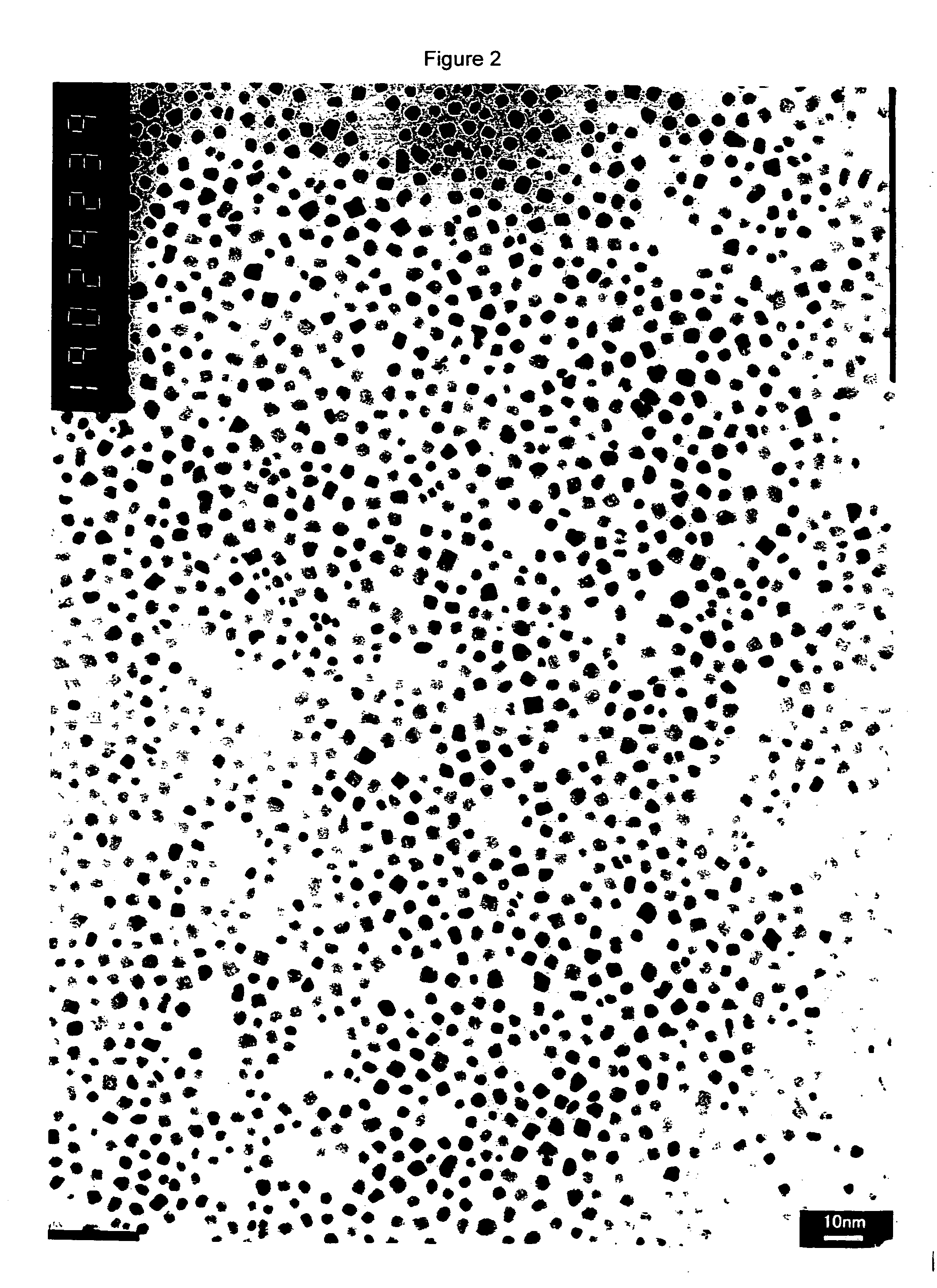

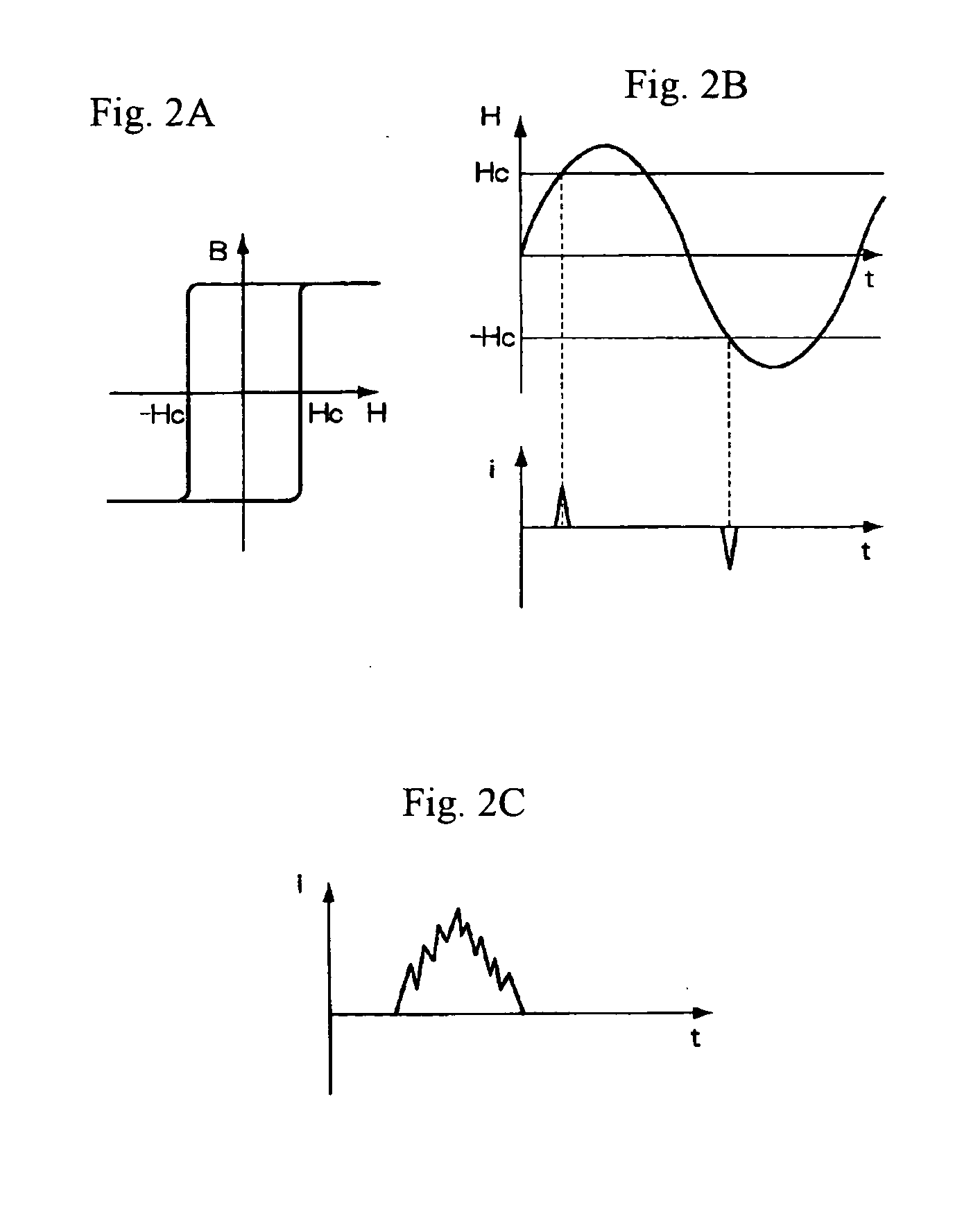

Magnetic nanoparticles

Nanoparticle sized metal or alloy is synthesized through a reverse micelle system which includes the steps of a) forming a concentrated aqueous solution of transition metal salts with platinum salts b) dispersing the metal salt solution in a non aqueous solution of a surfactant c) adding a reducing agent to reduce the metal salts to metallic alloy nano-particles in the absence of oxygen d) separating the metallic alloy nanoparticles 1s) heating the metallic alloy nanoparticles under controlled time, atmosphere and temperature conditions sufficient to form particles of a desired size and magnetic characteristics. The, precipitated metal or alloy nanoparticle has an average size of 3 nm and is superparamagnetic. Through controlled annealing treatment, the magnetic characteristics of the nanoparticles can be manipulated to achieve specific values in the final product that is suitable for predetermined applications. The nanoparticles exhibiting superparamagnetism are suitable for magnetic bio-bead applications. Weakly ferromagnetic magnetic alloy nanoparticles are suitable for actuator applications. The strongly ferromagnetic magnetic alloy nanoparticles exhibiting high coercivity can be potential candidate for magnetic data storage applications.

Owner:MEMS ID

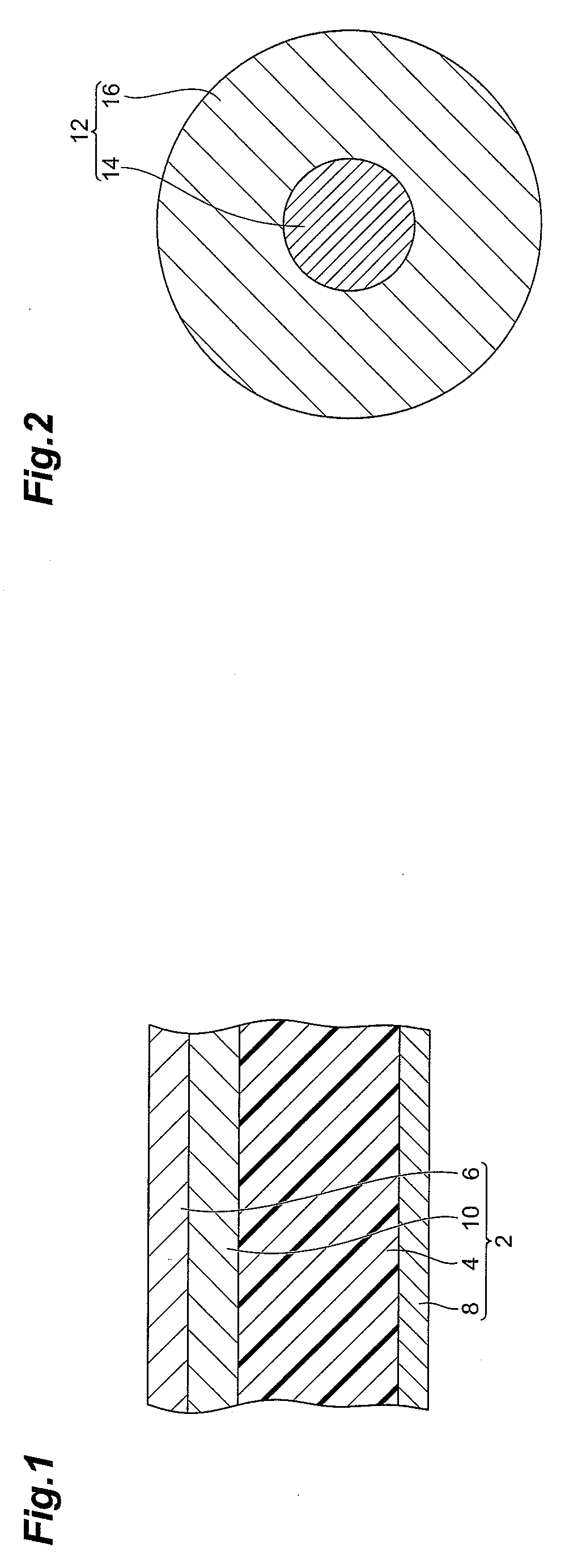

Magnetic recording medium and magnetic recording cassette

InactiveUS20050276999A1Improve recording densityMaterials with ironNanomagnetismRare-earth elementEllipsoidal particle

A magnetic recording medium comprising a non-magnetic support, at least one primer layer formed on one surface of the non-magnetic support, comprising a non-magnetic powder and a binder resin, at least one magnetic layer formed on the primer layer, comprising a magnetic powder and a binder resin, and a back layer formed on the other surface of the non-magnetic support, wherein the magnetic powder contained in the uppermost layer of the magnetic layer is a rare earth metal-iron type magnetic powder of substantially spherical or ellipsoidal particles comprising a rare earth element and iron or a transition metal which comprises iron, and has a number average particle size 5 to 50 nm and an average axis ratio of 1 to 2, and the total thickness of the magnetic recording medium is less than 6 μm. This magnetic recording medium can achieve an excellent block error rate, which cannot be realized with magnetic recording media comprising conventional acicular magnetic powders.

Owner:FUJIFILM CORP

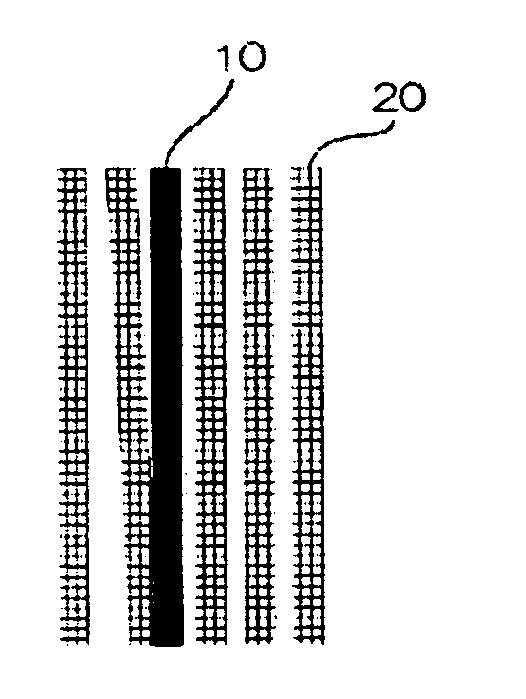

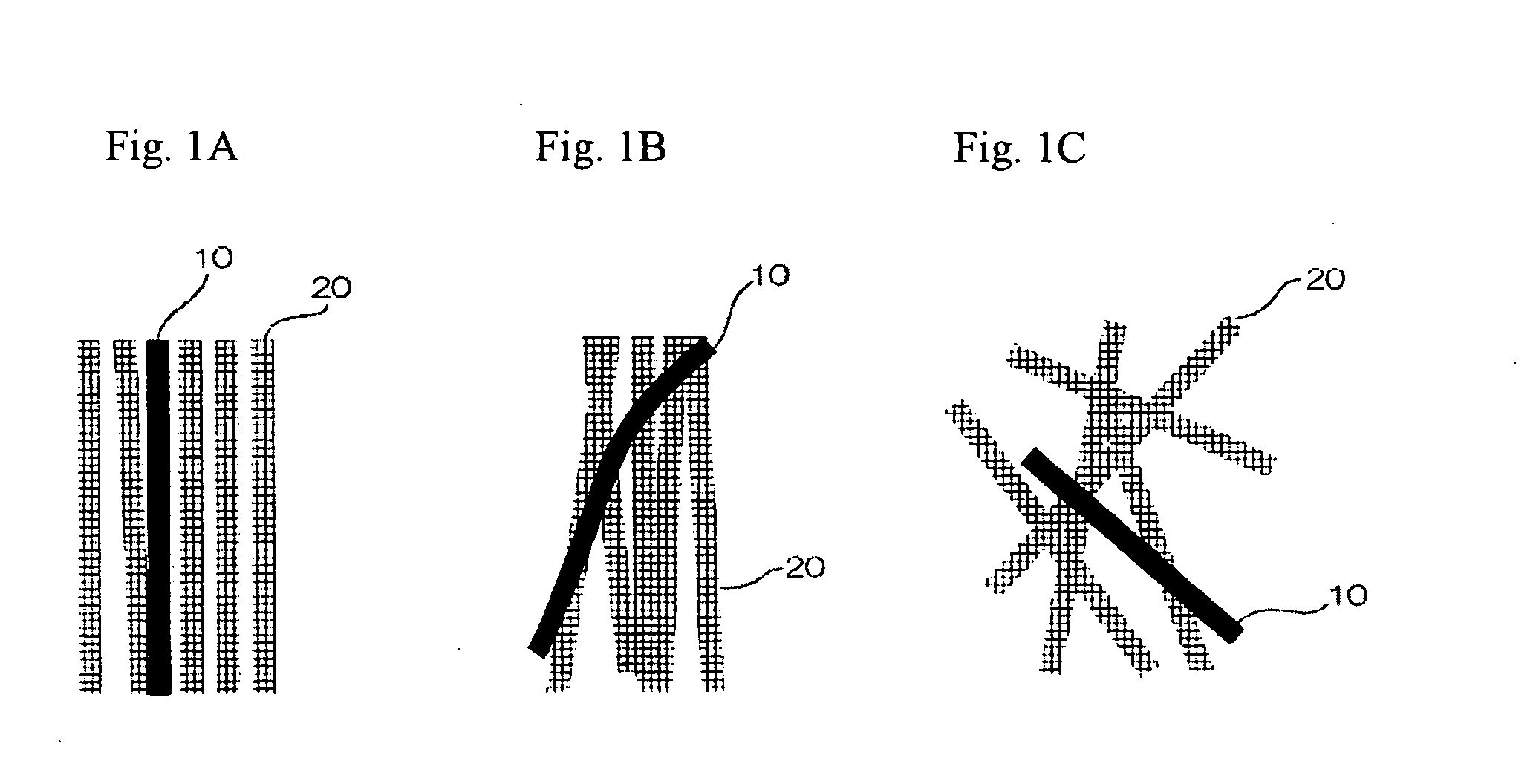

Recording paper

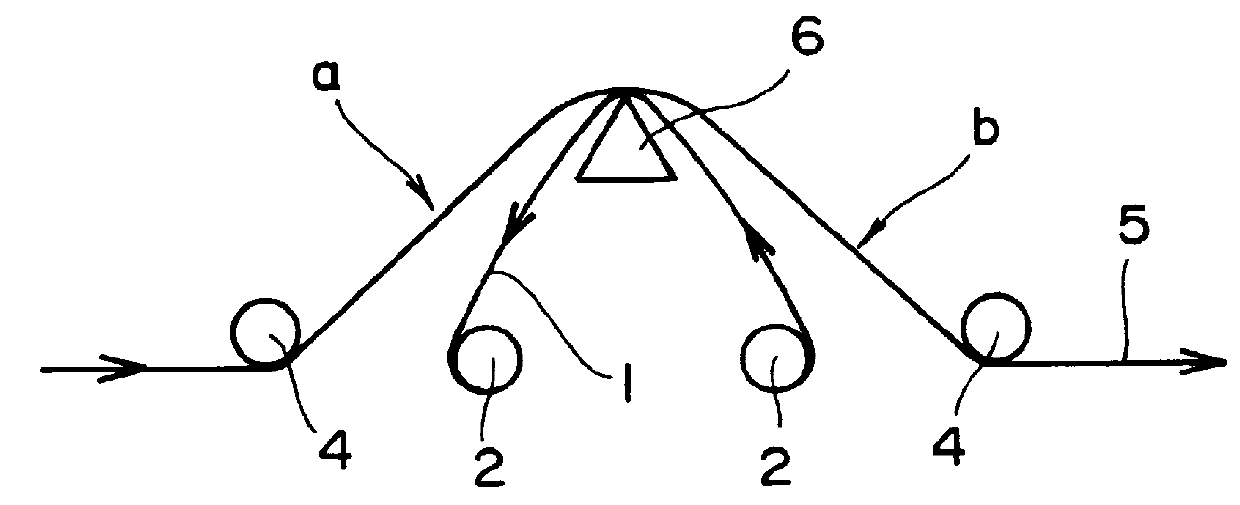

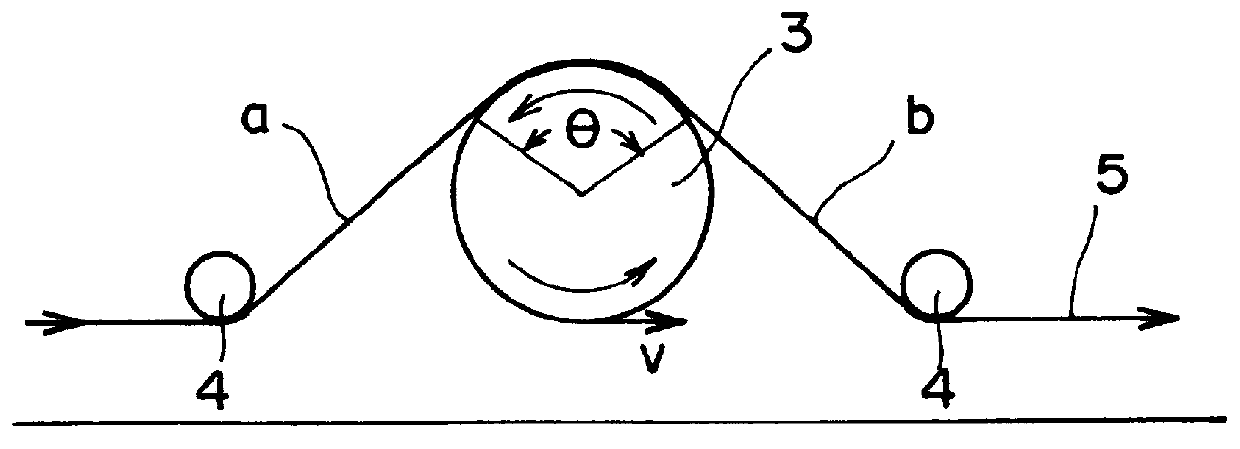

ActiveCN101054782ASuppress wrinklesCoatings with pigmentsMaterials with cobaltFiber orientationWave velocity

Disclosed is a recording paper containing pulp fibers and magnetic fibers, in which the fiber orientation ratio is within a range selected from the range from 1.8 to 3.0 and the range from 1.0 to 1.3 as measured by an ultrasonic wave velocity method.

Owner:FUJIFILM BUSINESS INNOVATION CORP

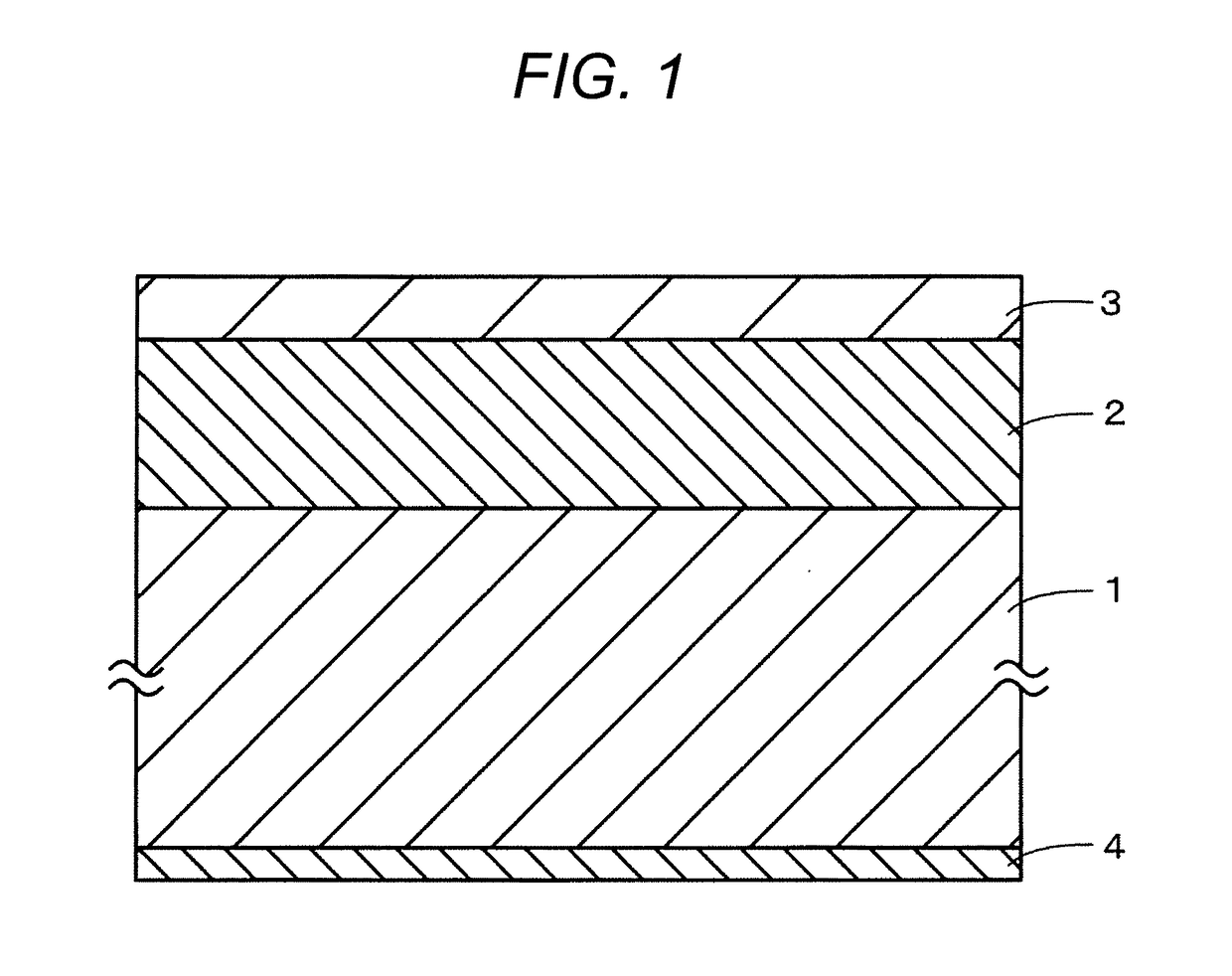

Magnetic recording medium

InactiveUS20180358044A1Improve coercive forceImprove magnetic propertiesMaterials with cobaltRecord information storageMagnetic force microscopeNon magnetic

Provided is a magnetic recording medium including: a non-magnetic support; and a magnetic layer including particles of at least one kind of epsilon type iron oxide-based compound selected from the group consisting of ε-Fe2O3 and a compound represented by Formula (1), and a binding agent, at least on one surface of the non-magnetic support, in which an average area Sdc of a magnetic cluster in a DC demagnetization state measured with a magnetic force microscope satisfies a relationship of 500 nm2<Sdc<3,000 nm2, and coercivity Hc satisfies a relationship of 319 kA / m<Hc<957 kA / m. In Formula (1), A represents at least one kind of metal element other than Fe and a satisfies a relationship of 0<a<2.ε−AaFe2-aO3 (1)

Owner:FUJIFILM CORP

Magnetic recording layer

ActiveUS7011899B2Improved backcoating layerReduce error rateMaterials with cobaltRecord information storageRecording layerMaterials science

A magnetic recording medium comprising a backcoating layer, a support, and a magnetic layer containing ferromagnetic powder, the backcoating layer having 800 to 1500 projections of 50 nm or more and less than 75 nm in height per 6400 μm2 and 600 or less projections of 75 nm or more in height per 6400 μm2.

Owner:FUJIFILM HLDG CORP +1

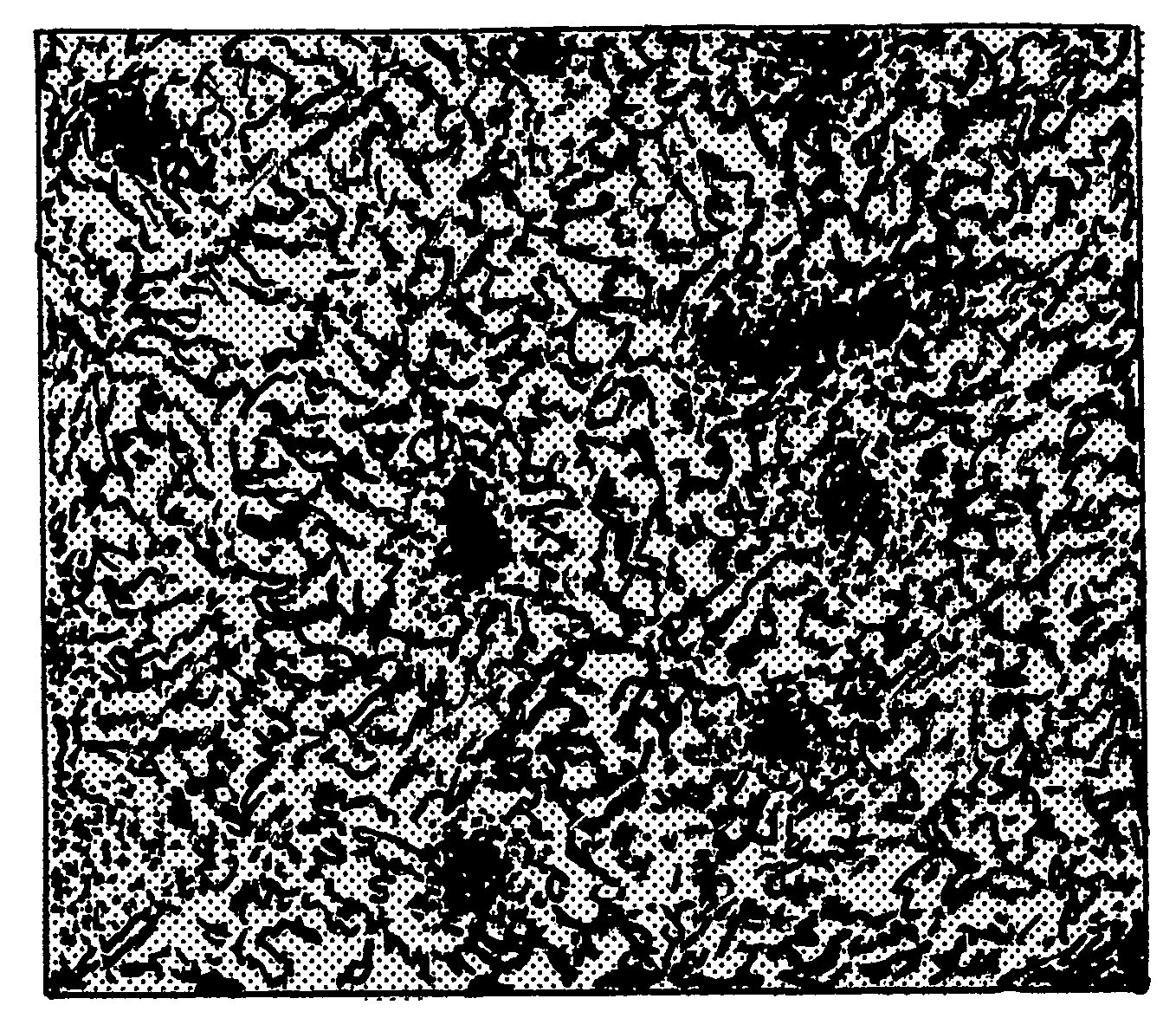

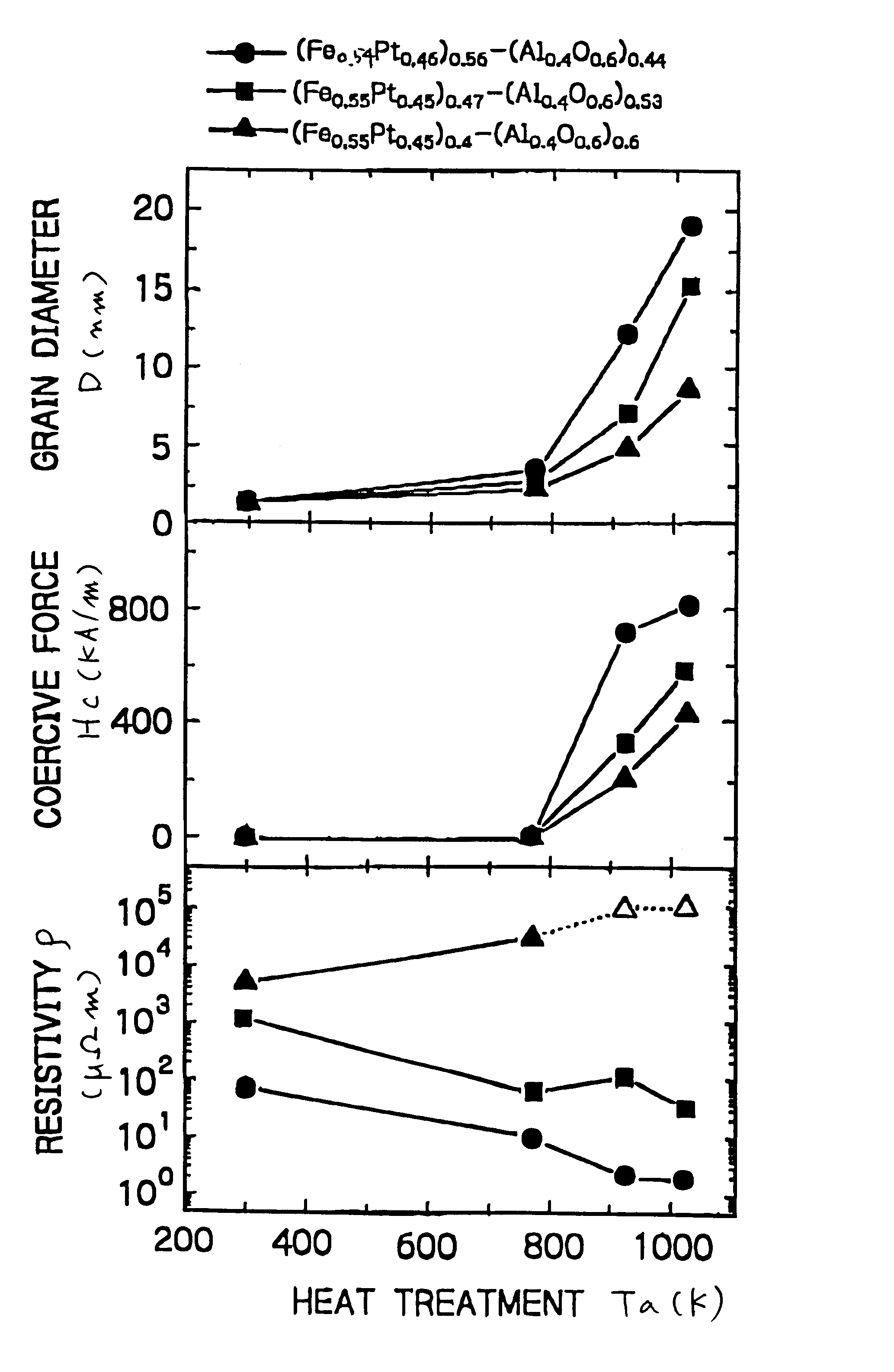

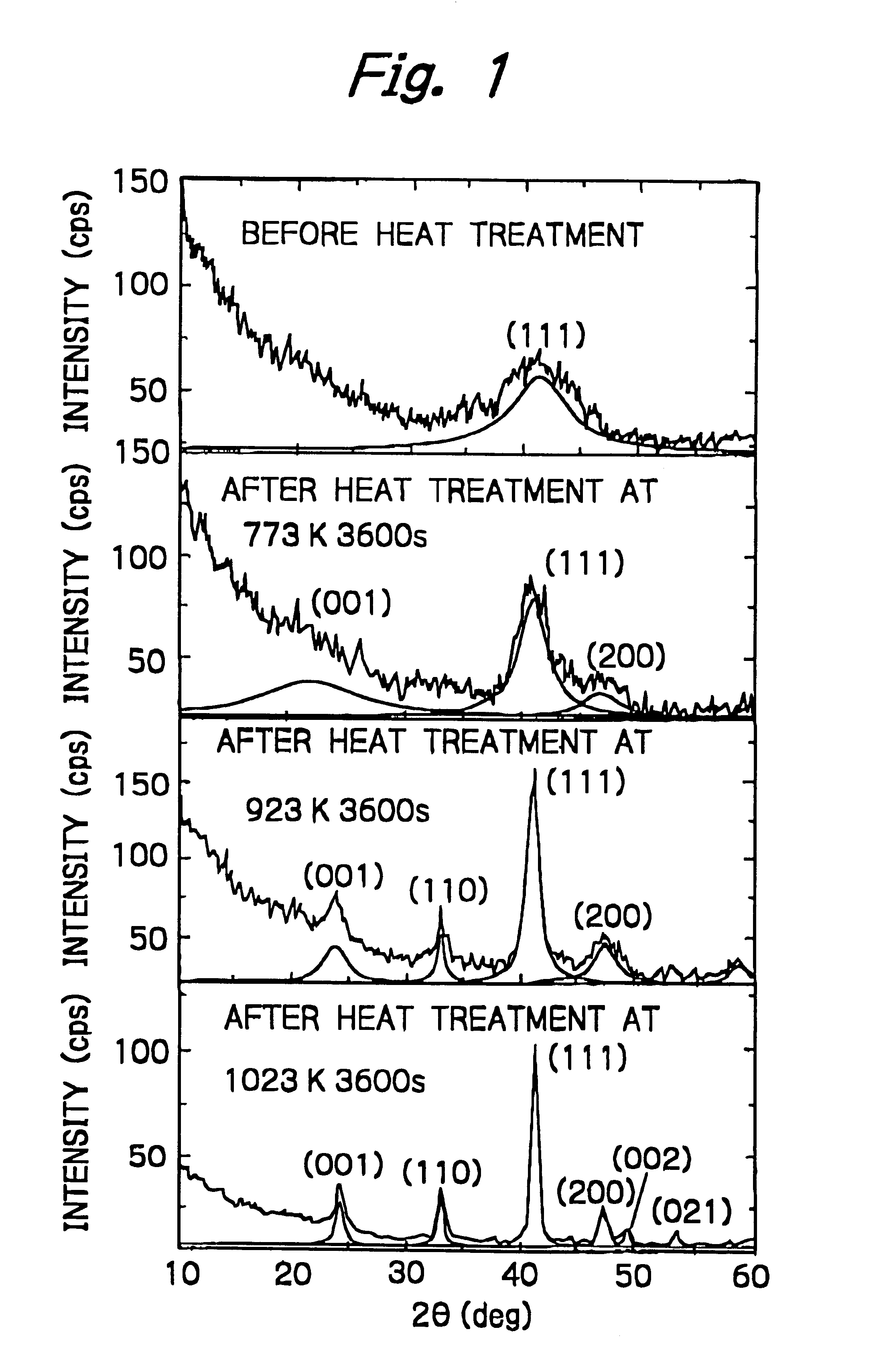

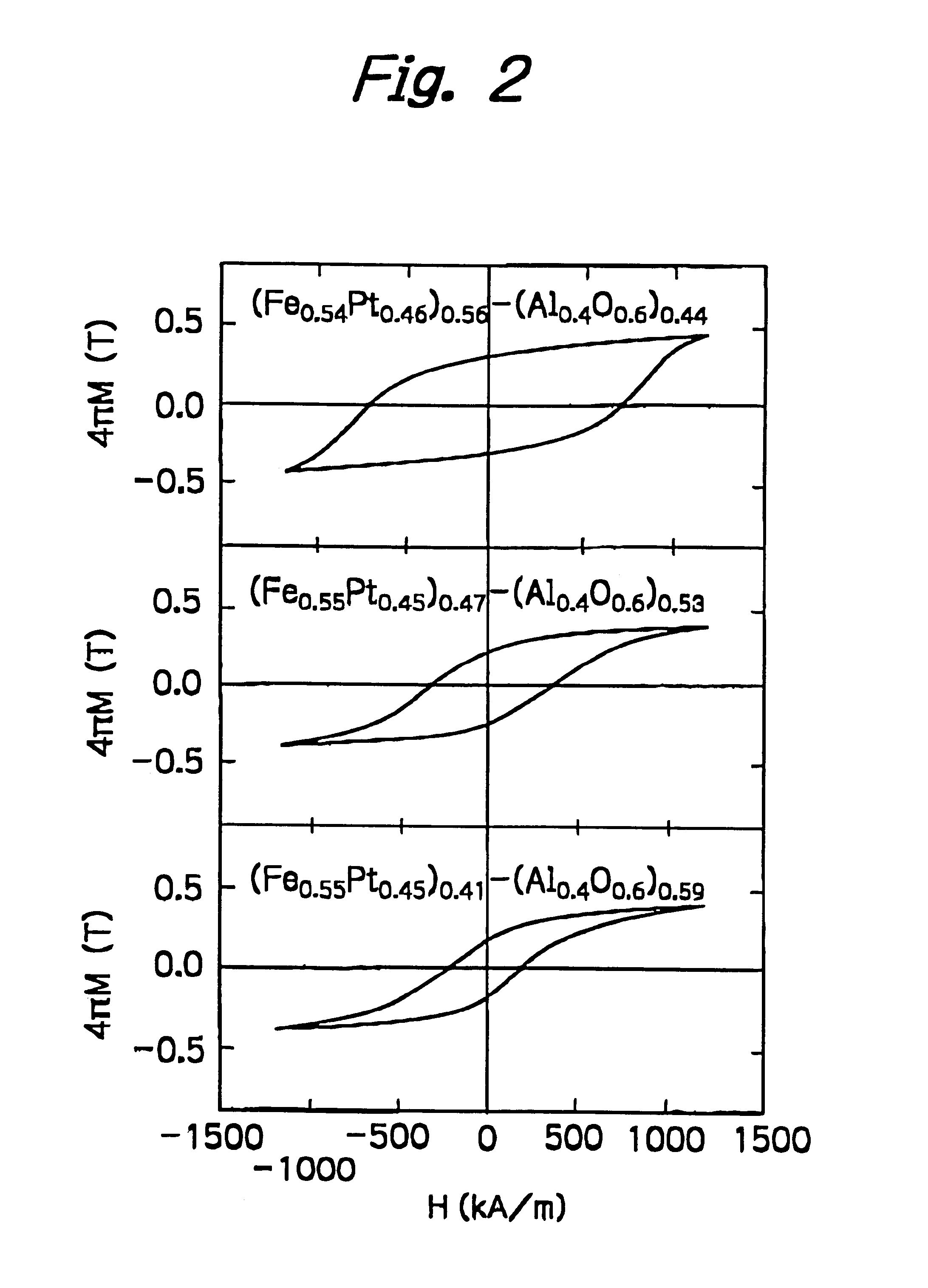

Nanogranular thin film and magnetic recording media

InactiveUS6623857B2Improve thermal stabilityReduce noiseNanomagnetismMaterials with cobaltNanoparticleOptoelectronics

A nanogranular thin film consisting of nonmagnetic matrix and ferromagnetic fine particles in nano scale is improved to enhance the thermal stability and the S / N ratio. The ferromagnetic fine particles consist of (FeaCo1-a)1-xPtx, (0.3<=x<=0.7, 0.1<=a<=1), (FeaCo1-a)1-xPdx, (0.3<=x<=0.7, 0.1<=a<=1) or (FeaCo1-a) 1-x(PtbPd1-b)x, (0.3<=x<=0.7, 0.1<=a<=1, and 0<b<1).

Owner:FOUND THE RES INST FOR ELECRTRIC & MAGNETIC MATERIALS THE

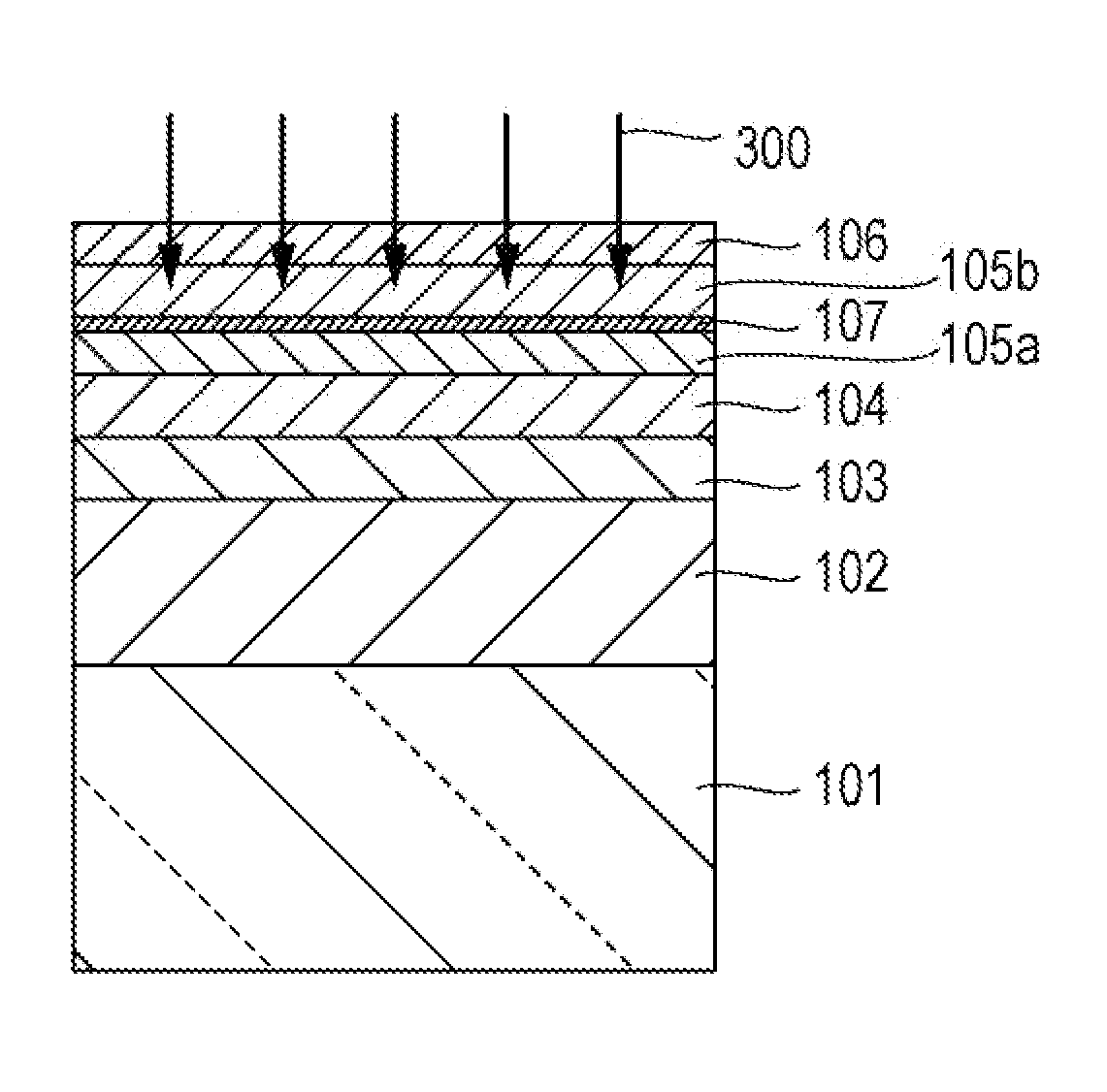

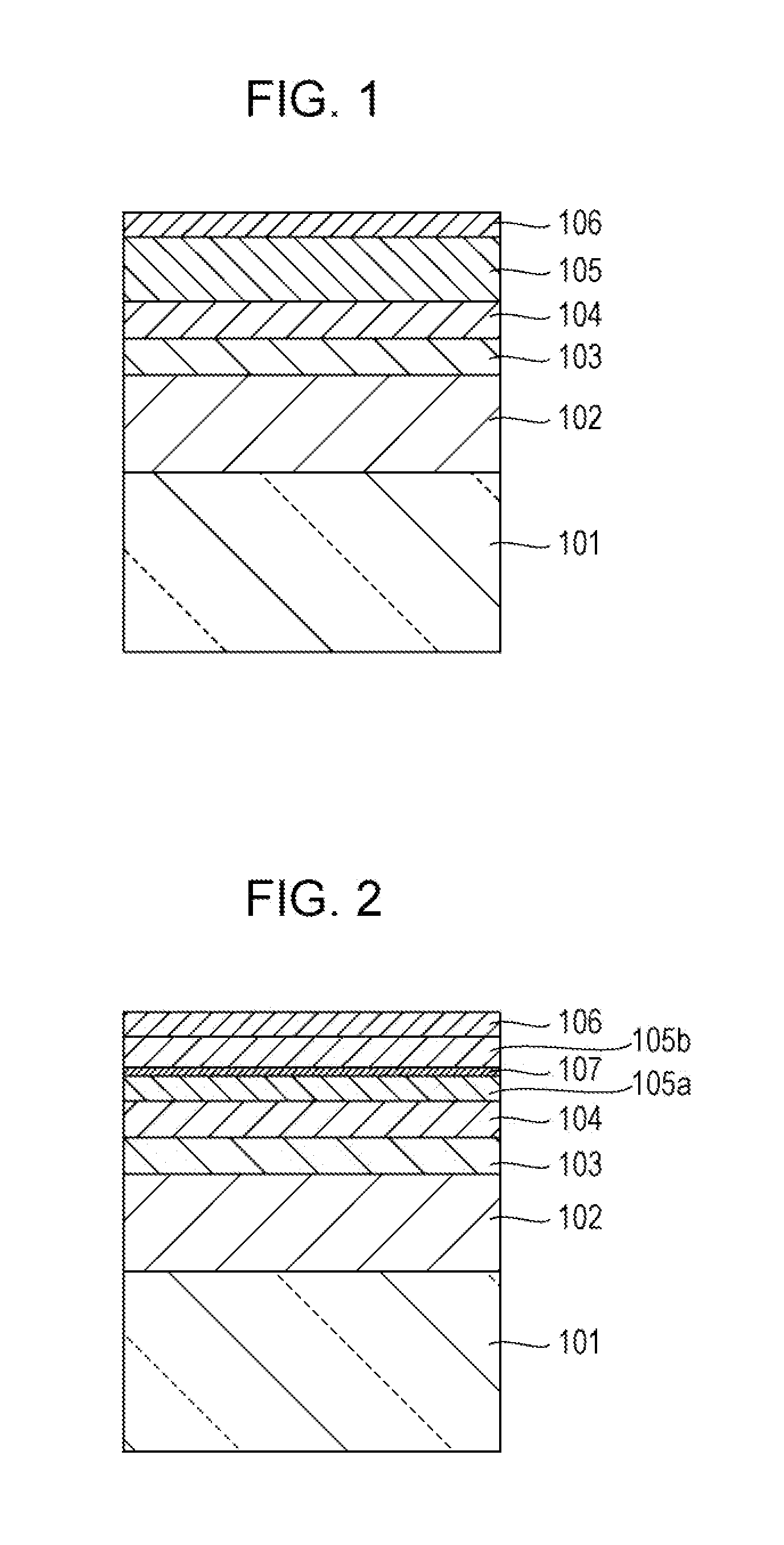

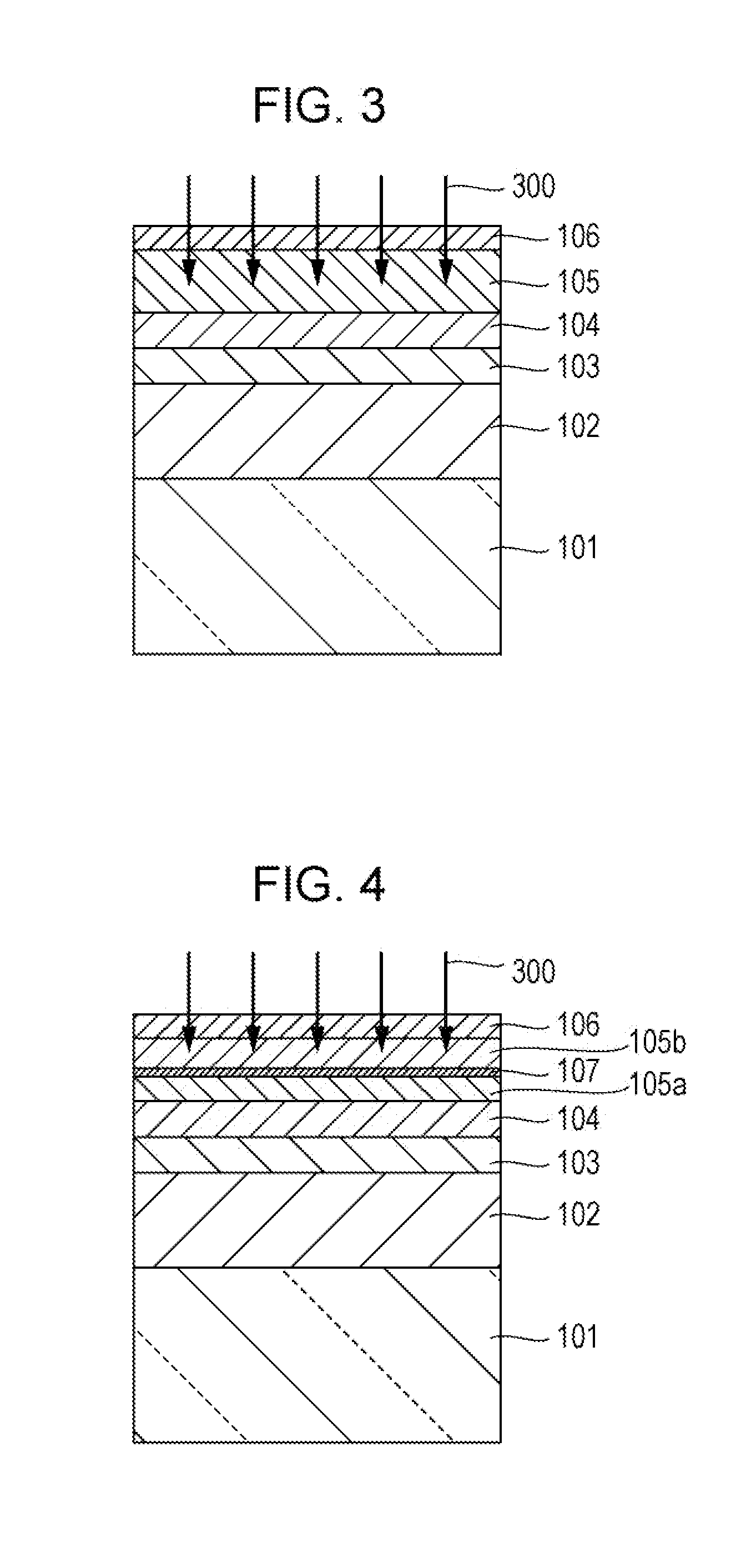

Magnetic recording medium, method for manufacturing magnetic recording medium, and magnetic recording or reproducing apparatus

InactiveUS20130242430A1Narrow down the frequency rangeMaterials with cobaltVacuum evaporation coatingMagnetic anisotropyAlloy

Ion irradiation is applied to the surface of a recording layer which has a granular structure containing ferromagnetic particles which are composed of an L10 ordered alloy and a non-magnetic intergranular layer, thereby the ferromagnetic particles in the side of the substrate are transformed into an L10 ordered alloy having a high magnetic anisotropy, and the ferromagnetic particles in the side of the surface of the medium are transformed into an A1 disordered alloy having a low magnetic anisotropy.

Owner:TDK CORPARATION

Magnetic recording medium

InactiveUS20050064243A1Improve reliabilityHigh densityBase layers for recording layersLayered productsInter layerMetal alloy

A magnetic recording medium comprising a substrate, an underlayer, an intermediate layer, and a magnetic layer in this order, the underlayer being made of Ru, the intermediate layer being made of an RuCo alloy, and the magnetic layer having a granular structure made up of a Co-containing ferromagnetic metal alloy and a non-magnetic oxide.

Owner:FUJIFILM CORP +1

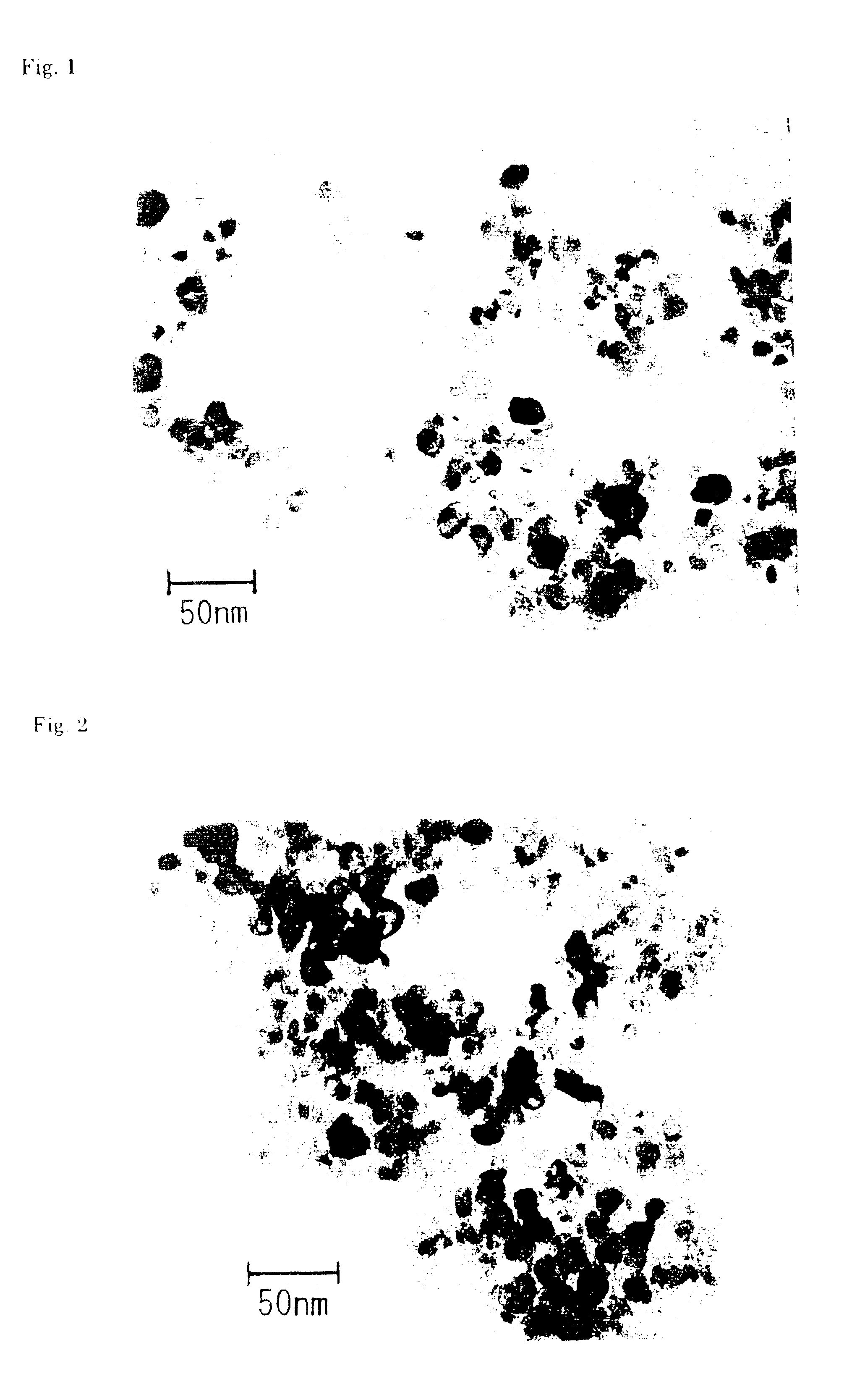

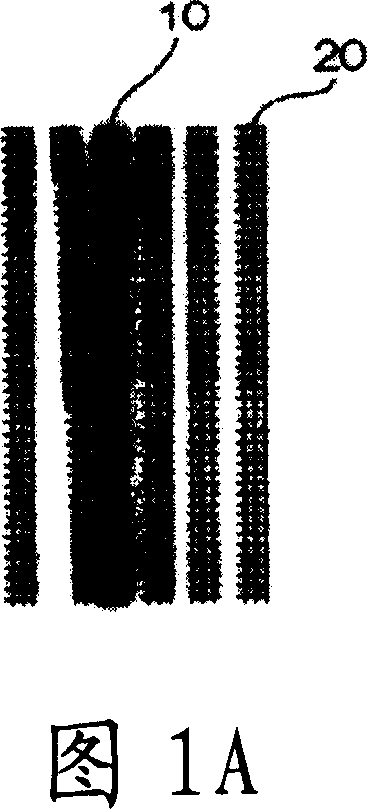

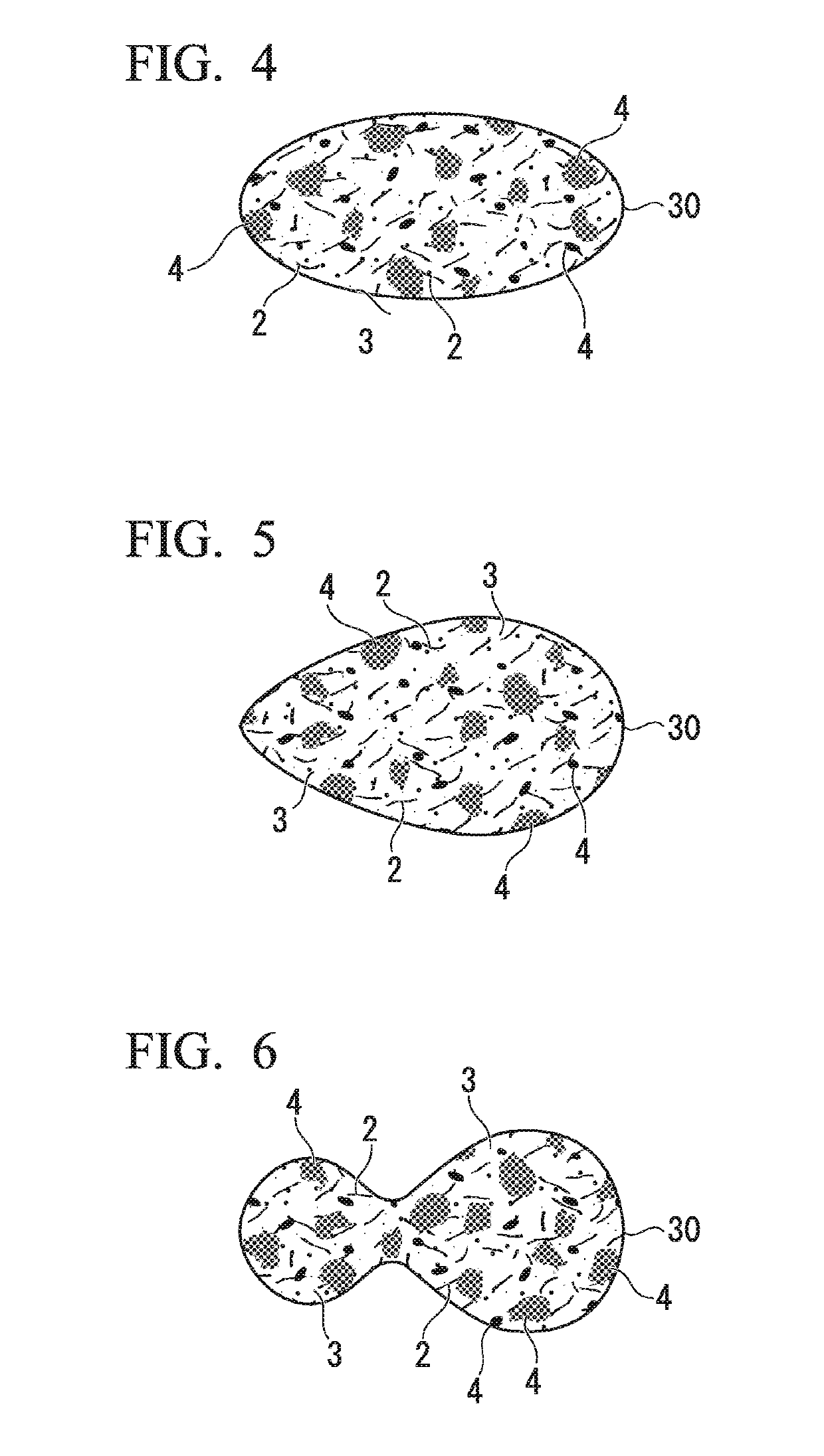

Ferromagnetic powder, and coating material and magnetic recording medium using same

InactiveUS20070059557A1Reduce noiseImprove carrier-to-noise ratioMaterials with cobaltSynthetic resin layered productsVolumetric Mass DensityMaterials science

A magnetic powder is provided composed of particles having a balanced shape and distribution, the particles having a small, uniform volume, making it possible to achieve improved density and reliability of a coating type magnetic recording medium. The magnetic powder has Fe as a main component, and is comprised of particles having a cross-section perpendicular to the particle major axis that is substantially round or elliptical, wherein a standard geometrical deviation indicating the variation in cross-sectional area thereof is within the range of 1.01 to 3.0. The invention is also directed to a magnetic powder in which the standard geometrical deviation indicating the variation in the particle volume is within the range of 1.01 to 4.0, and the standard geometrical deviation indicating variation in the flat acicularity is within 1.01 to 2.0.

Owner:DOWA ELECTRONICS MATERIALS CO LTD

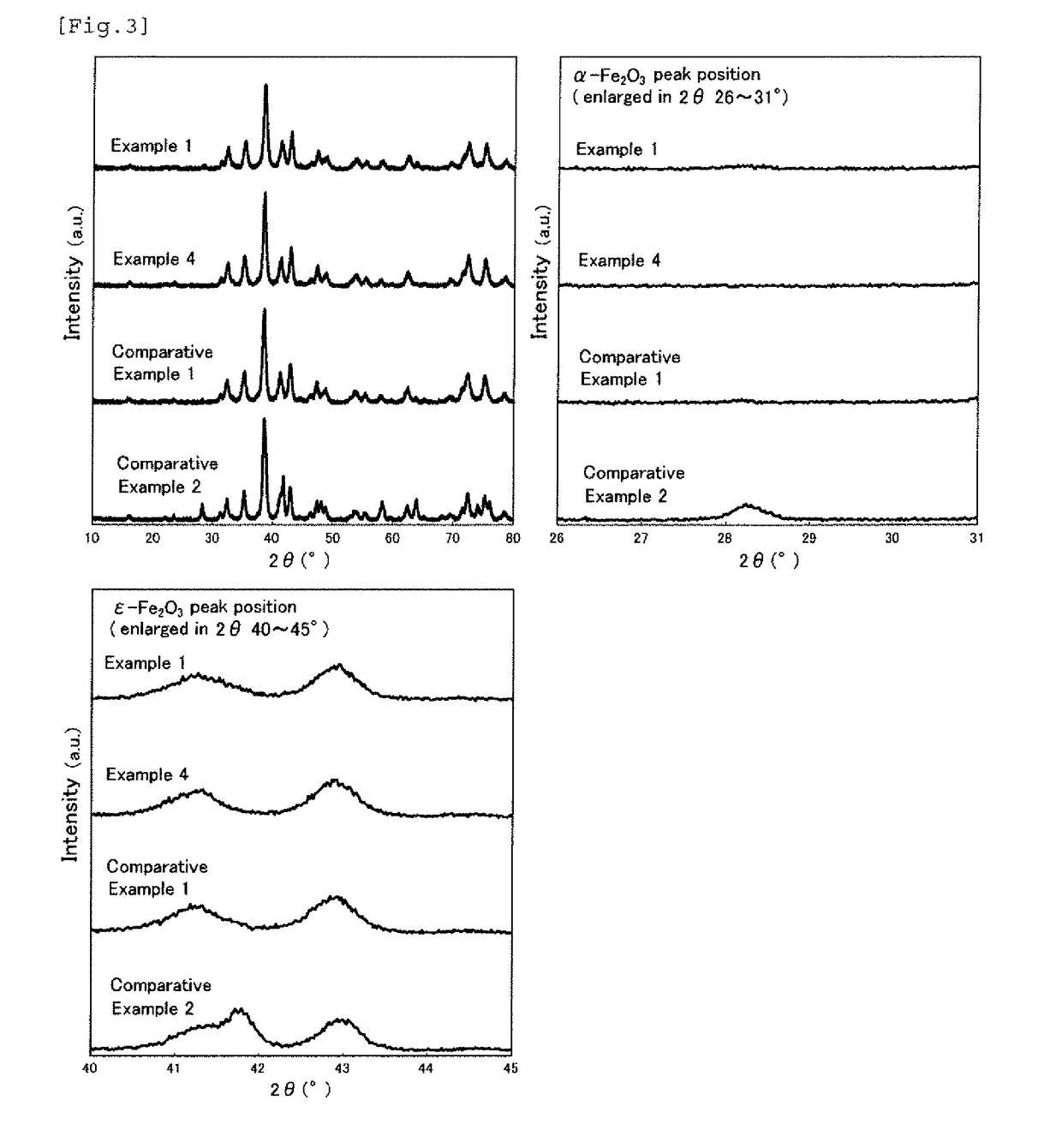

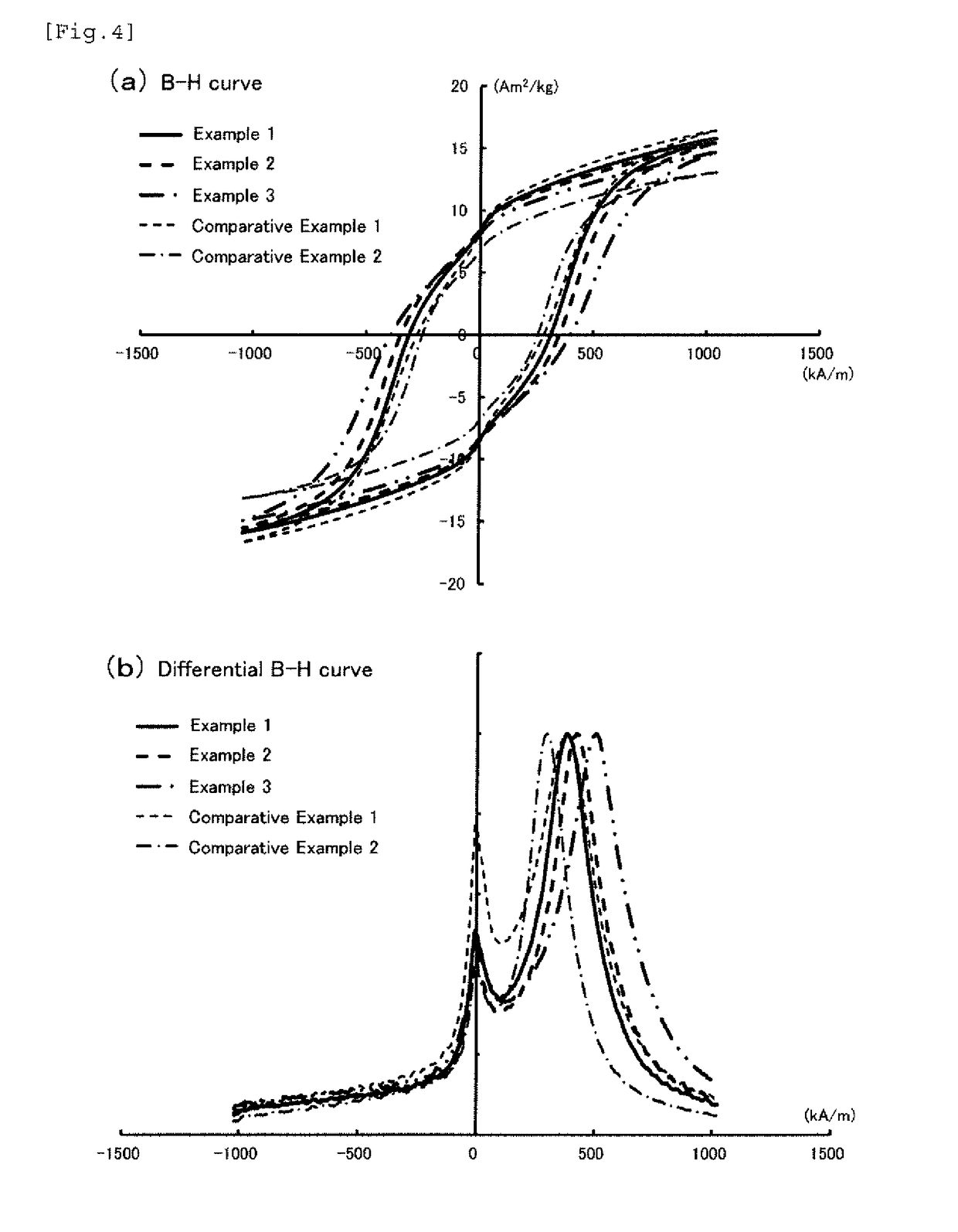

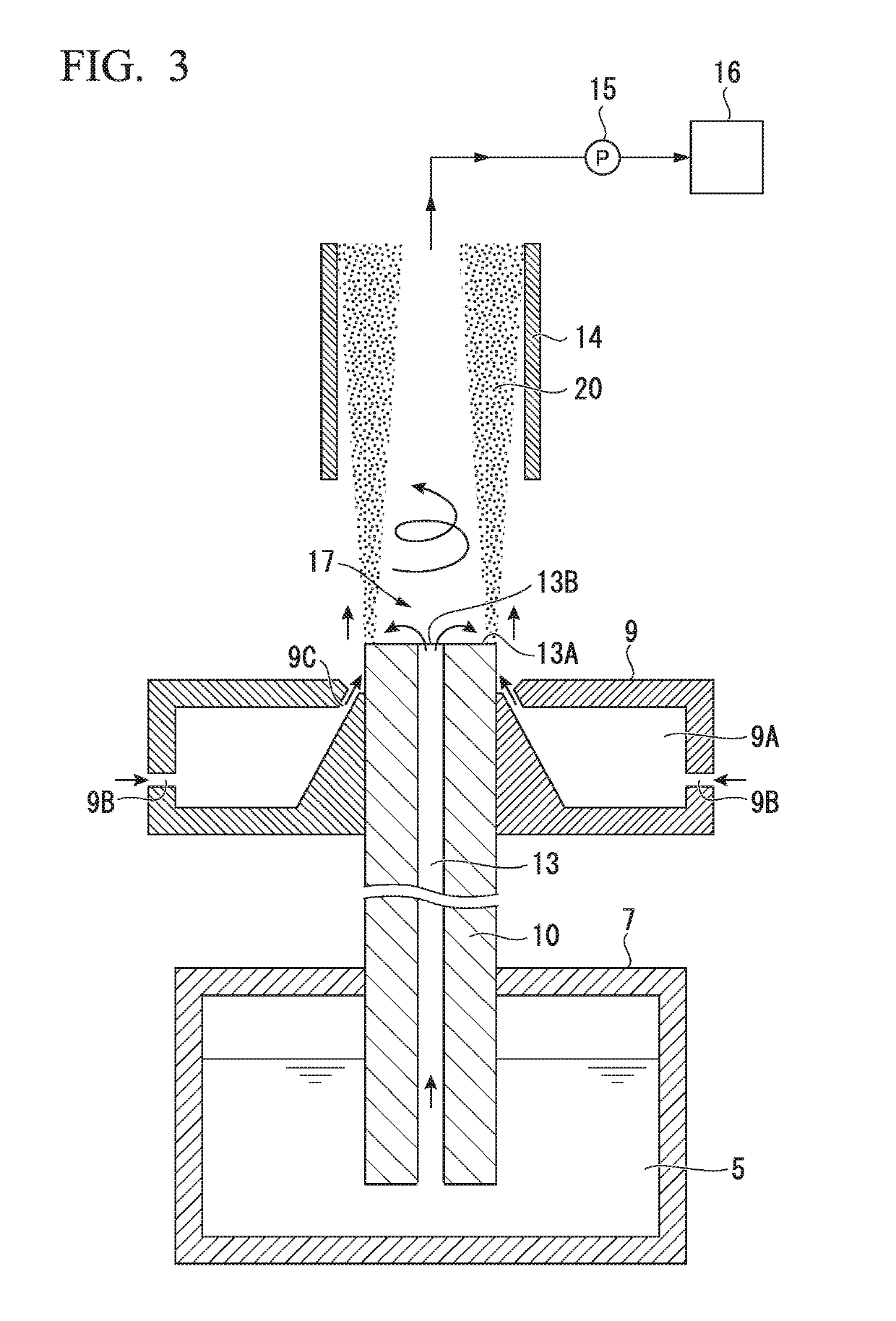

Method for producing iron-based oxide magnetic particle powder

ActiveUS20180208479A1Improve featuresNarrow distributionMaterials with cobaltRecord information storageMicroparticleSilicon oxide

To provide iron-based oxide magnetic particle powder that has a narrow particle size distribution and a small content of fine particles that do not contribute to the magnetic recording characteristics, which result in a narrow coercive force distribution, and is suitable for the enhancement of the recording density of the magnetic recording medium, and a method for producing the same. An alkali is added to an aqueous solution containing a trivalent iron ion and an ion of the metal substituting a part of Fe sites to neutralize the aqueous solution to pH of 1.0 or more and 3.0 or less; a hydroxycarboxylic acid D is added in an amount providing a molar ratio D / Fe with respect to the amount of the trivalent iron ion or a molar ratio (D / (Fe+M)) with respect to the total amount of the trivalent iron ion and the ion of the metal M in the case where the substituting metal ion is contained of 0.125 or more and 1.0 or less; an alkali is further added to neutralize to pH of 7.0 or more and 10.0 or less; and then the iron oxyhydroxide containing the substituting metal element is coated with a silicon oxide and heated, so as to provide ε-type iron-based oxide magnetic particle powder containing the substituting metal element.

Owner:DOWA ELECTRONICS MATERIALS CO LTD

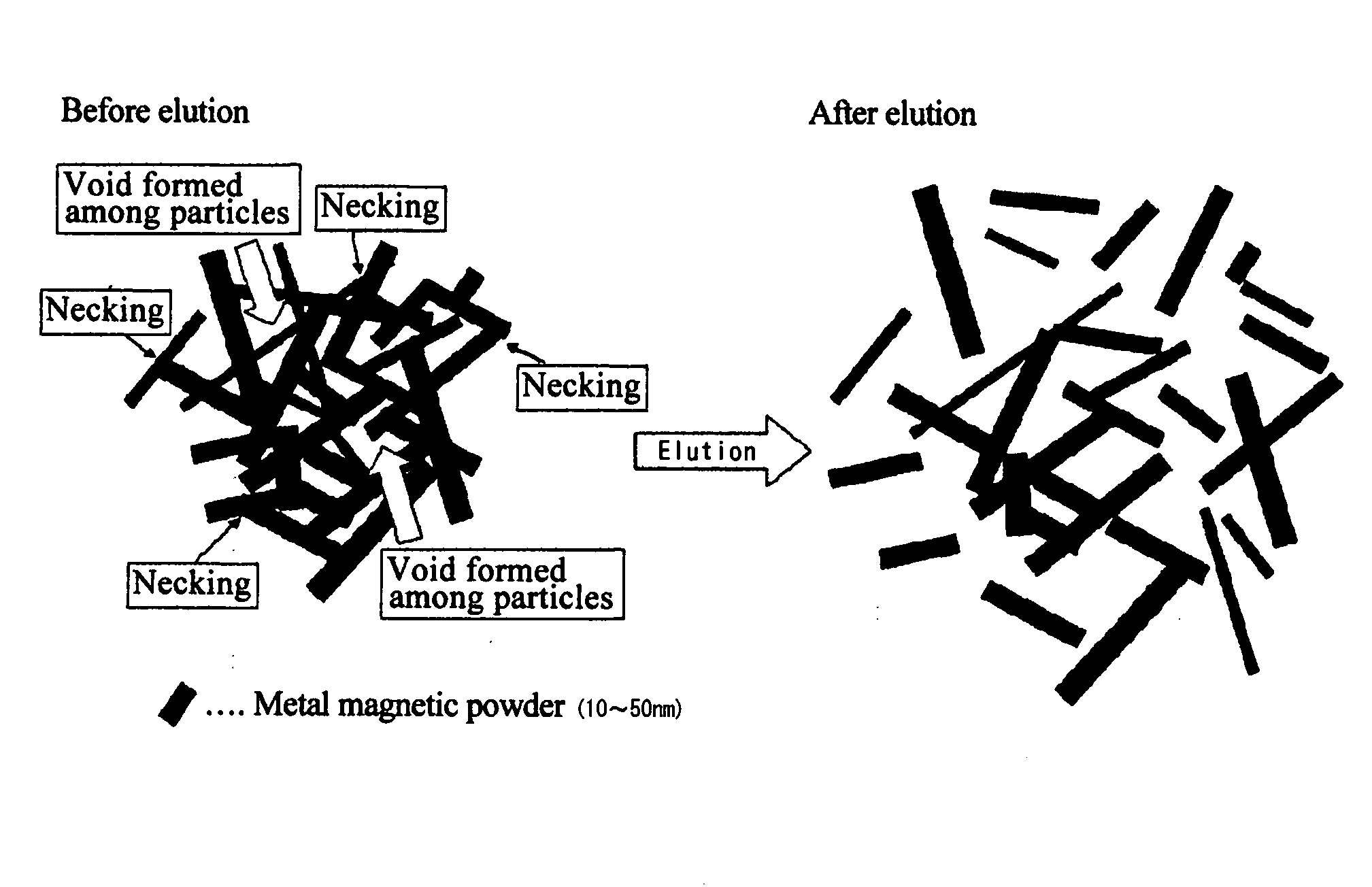

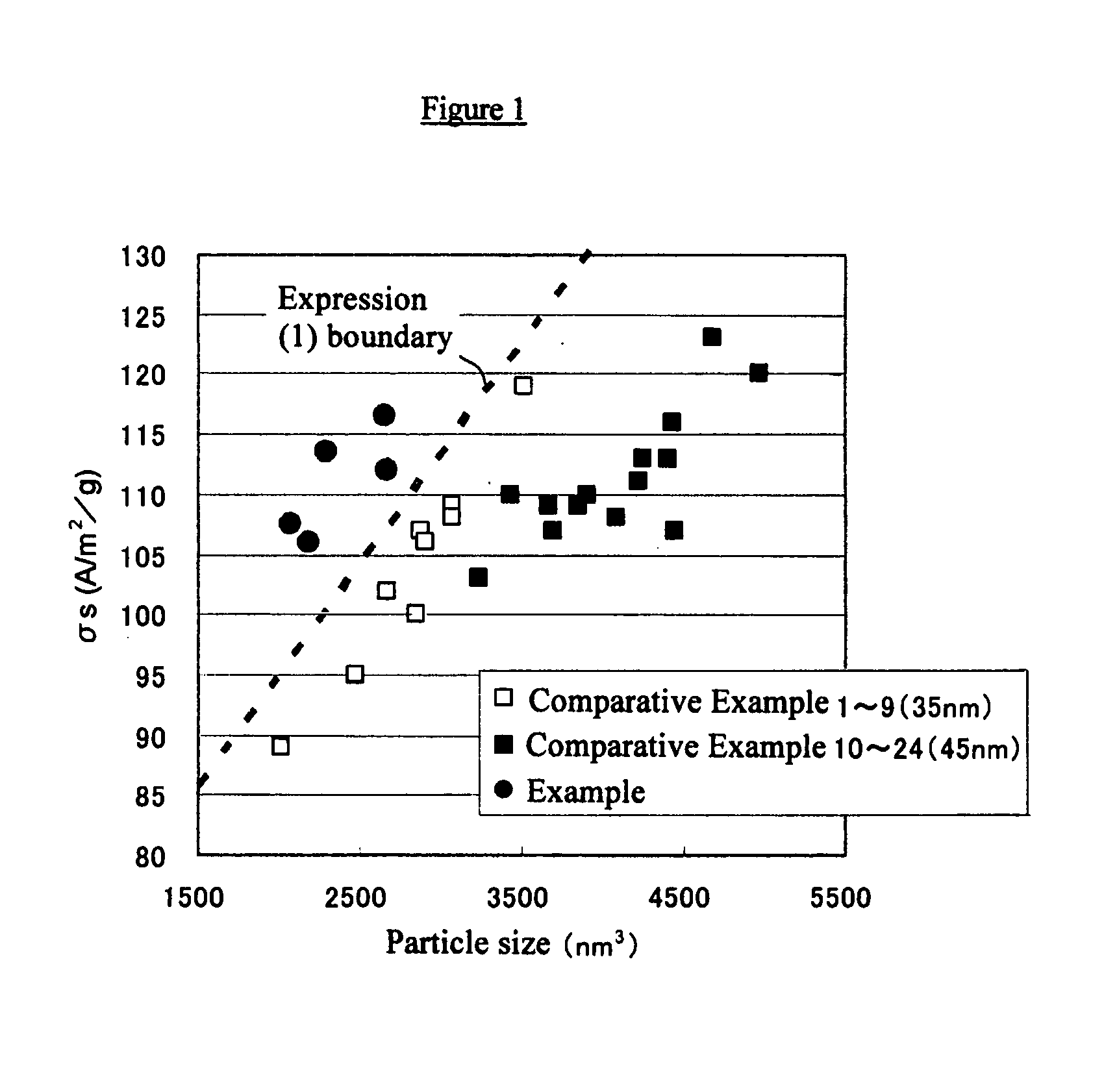

Magnetic metal powder suitable for use in magnetic recording media and method of manufacturing the powder

InactiveUS20070227302A1Reduce the amount requiredReducing thickness of oxide layerMaterials with ironMaterials with cobaltRare-earth elementMagnetic phase

A metal magnetic powder for a magnetic recording medium is provided whose particles have a metal magnetic phase, composed mainly of Fe or Fe plus Co, and an oxide layer, wherein the average major axis length of the powder particles is 10-50 nm, the average particle volume including the oxide layer is 5,000 nm3 or less, the atomic ratio (R+Al+Si) / (Fe+Co) calculated using the content values (at. %) of the elements contained in the powder particles is 20% or less, where R is rare earth element (Y being treated as a rare earth element). The metal magnetic powder is obtained by using a complexing agent and a reducing agent to elute nonmagnetic constituents after firing. The metal magnetic powder exhibits a large saturation magnetization σs for its particle volume while maintaining weatherability comparable to the conventional level and is suitable for a coated-type magnetic recording medium.

Owner:DOWA ELECTRONICS MATERIALS CO LTD

Magnetic recording medium and process for production of magnetic recording medium

InactiveUS20090136783A1Prevent oxidationGood weather resistanceLayered productsMaterials with cobaltWeather resistanceNanoparticle

The invention provides a magnetic recording medium with both weather resistance and high recording density. The magnetic recording medium of the invention has a magnetic layer comprising at least SmCo-based magnetic fine particles and a hydrophobic binder, wherein the SmCo-based magnetic fine particles include a core composed of SmCo-based nanoparticles and a hydrophilic polymer covering at least a portion of the surface of the core.

Owner:TDK CORPARATION

Surface-modified iron-based oxide magnetic particle powder, and method for producing same

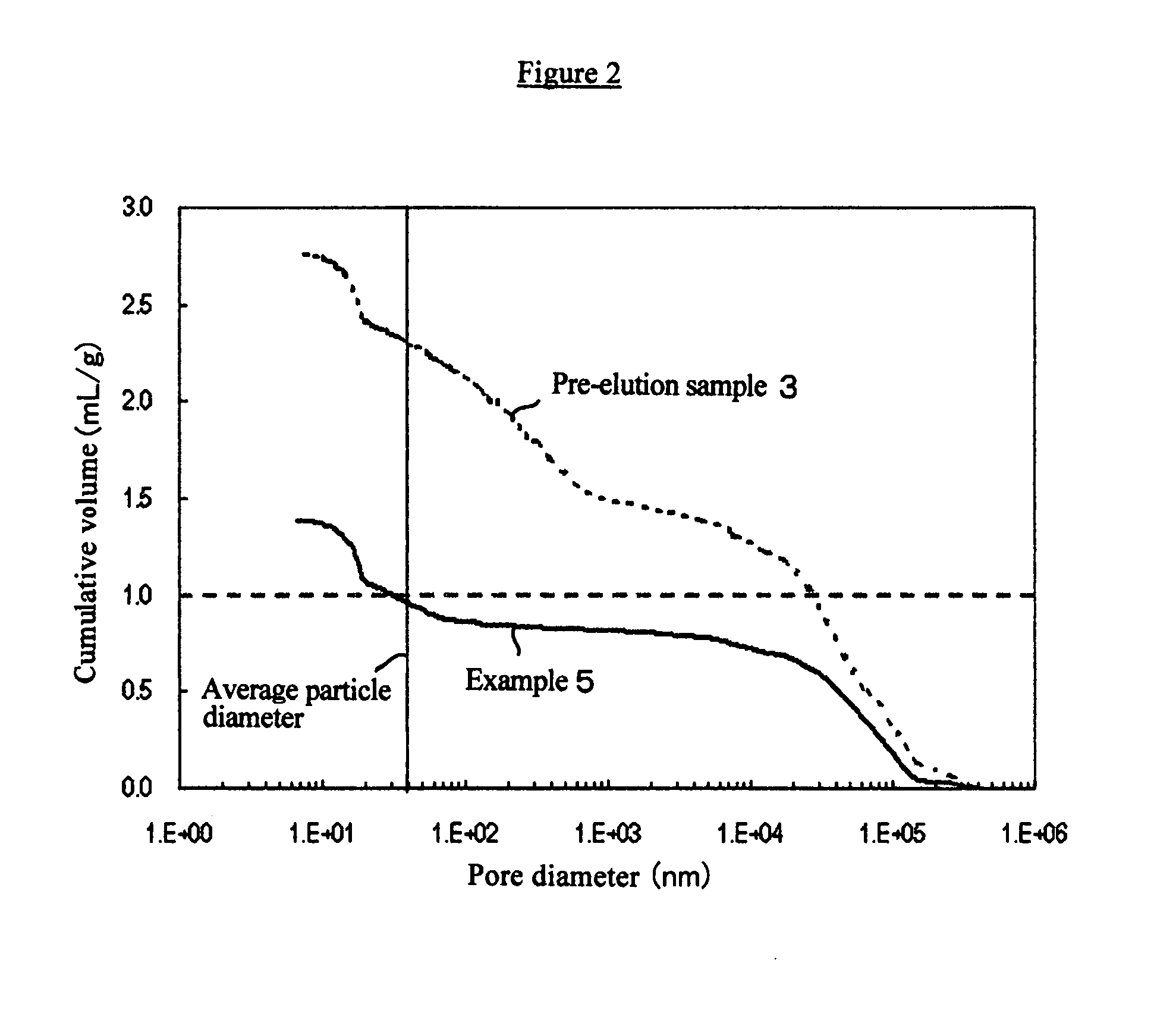

ActiveUS20180033528A1Improve recording densityEasy to separateMaterials with ironMaterials with cobaltElutionSilicon oxide

A surface-modified iron-based oxide magnetic particle powder has good solid-liquid separation property in the production process, has good dispersibility in a coating material for forming a coating-type magnetic recording medium, has good orientation property, and has a small elution amount of a water-soluble alkali metal, and to provide a method for producing the surface-modified iron-based oxide magnetic particle powder. The surface-modified iron-based oxide magnetic particle powder can be obtained by neutralizing a solution containing dissolved therein a trivalent iron ion and an ion of the metal, by which the part of Fe sites is to be substituted, with an alkali aqueous solution, so as to provide a precursor, coating a silicon oxide on the precursor, heating the precursor to provide e-type iron-based oxide magnetic powder, and adhering a hydroxide or a hydrous oxide of one kind or two kinds of Al and Y thereto.

Owner:DOWA ELECTRONICS MATERIALS CO LTD

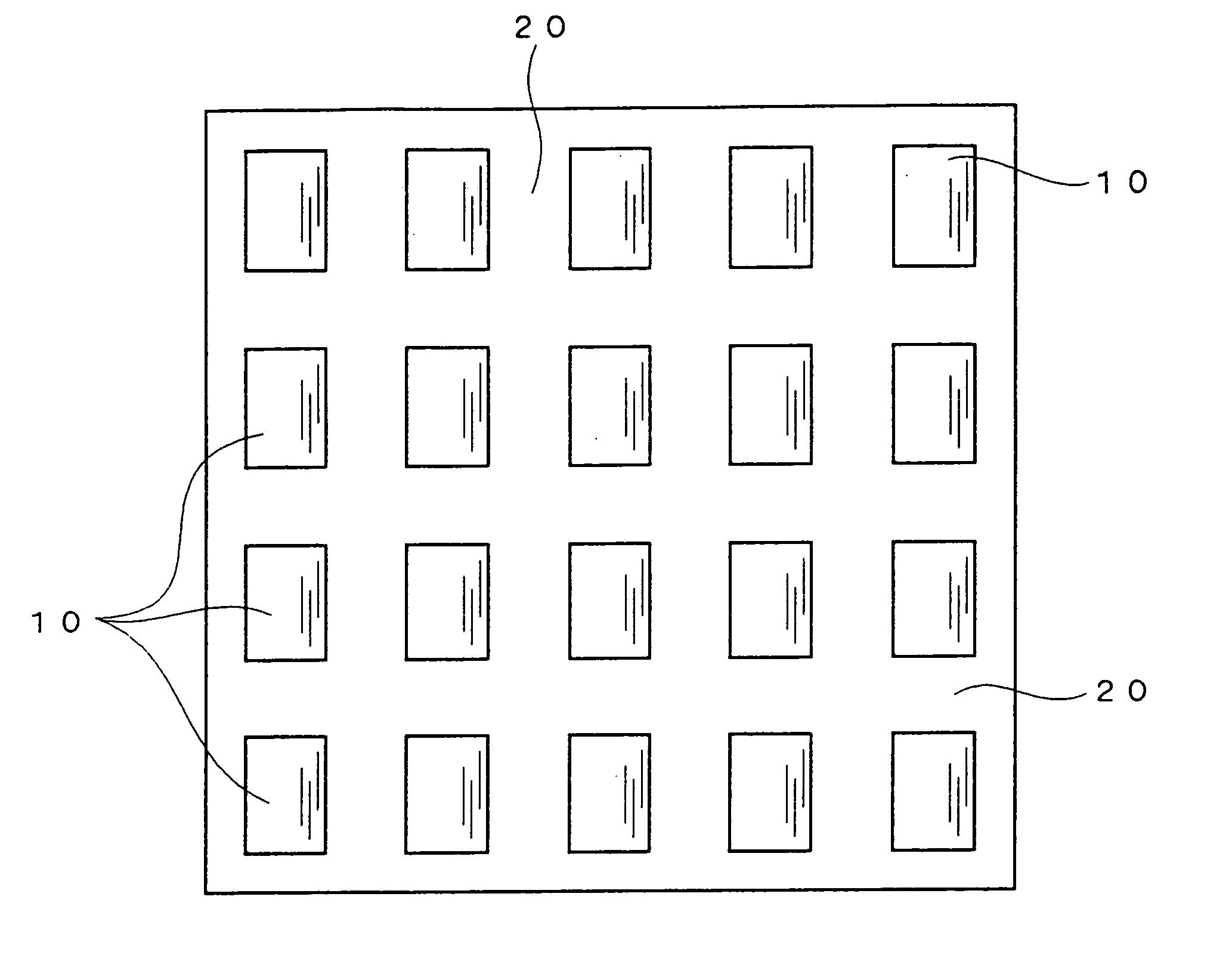

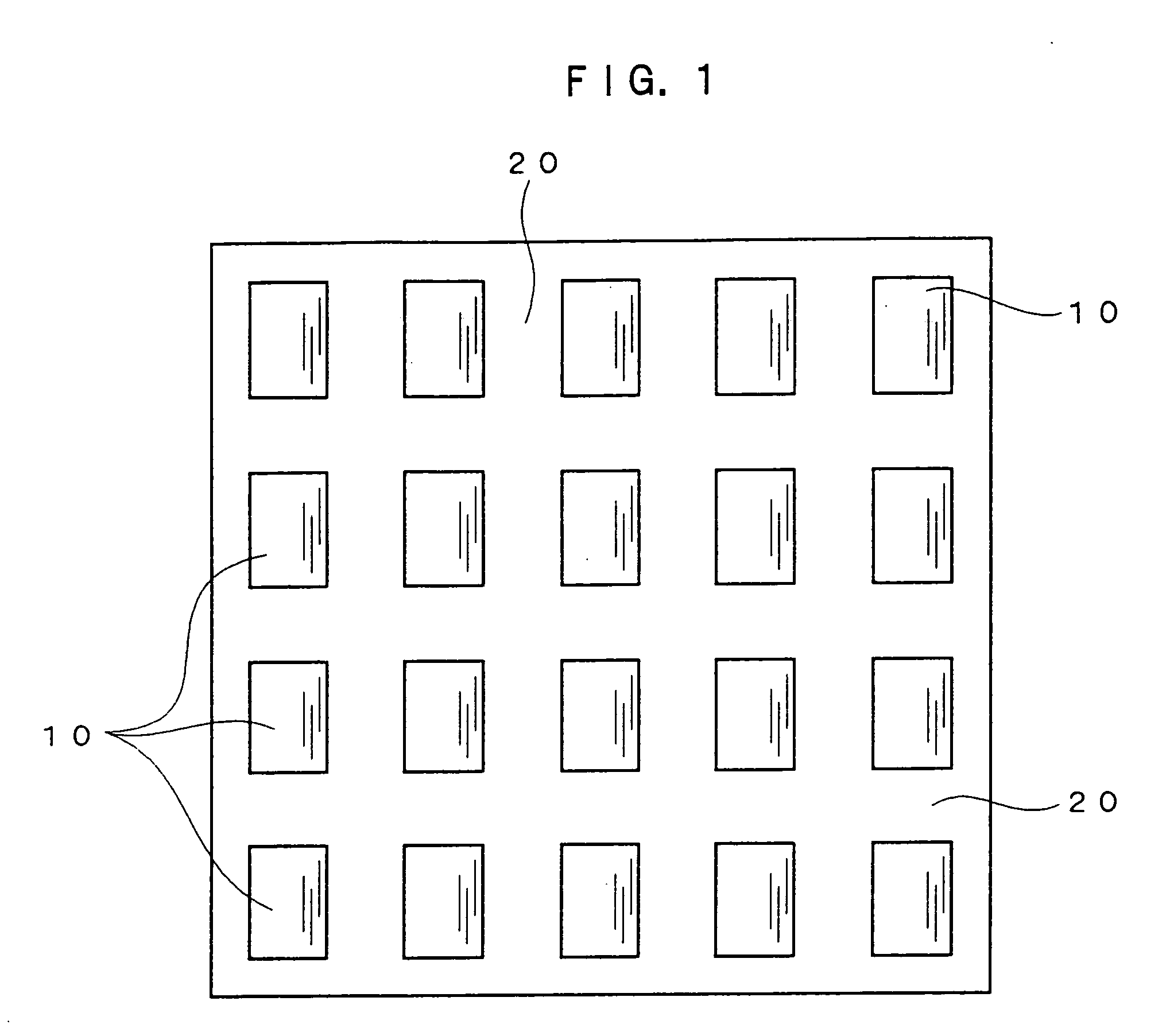

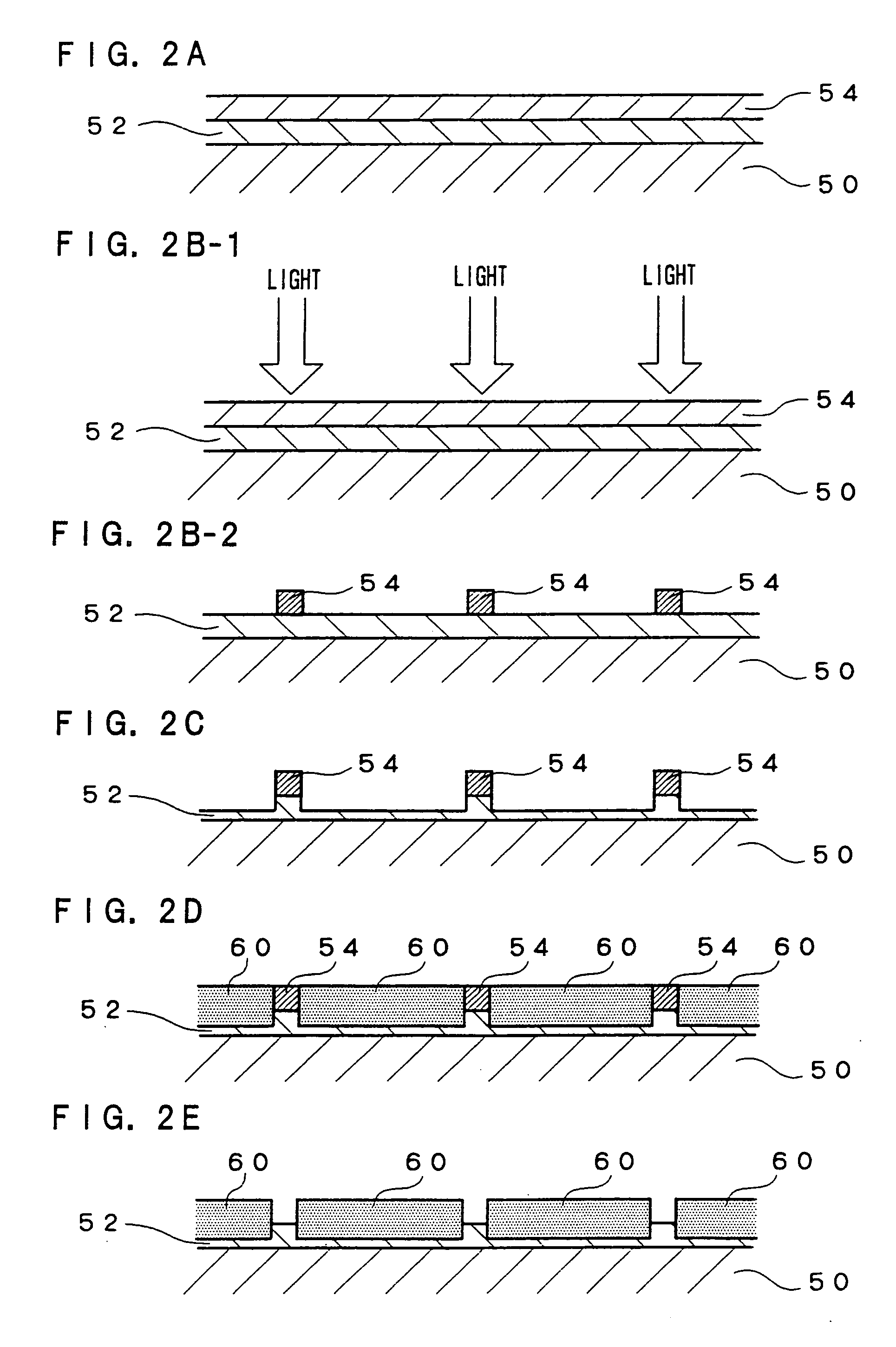

Magnetic recording medium and method for manufacturing the same

InactiveUS20060068231A1Reduces transition noiseInhibit aggregationMaterials with ironNanomagnetismFerromagnetic orderPhotopolymer

The invention is a magnetic recording medium which contains magnetic regions and non-magnetic regions. There are two or more of the magnetic regions with each of the regions containing a ferromagnetic ordered alloy, of either a CuAu-type or Cu3Au-type, and a matrix agent, and each of the magnetic regions is formed as a physically separate shape. The invention also includes a manufacturing method for manufacturing the magnetic recording medium which comprises forming magnetic regions using a mask which uses a photopolymer to form the magnetic regions containing the ferromagnetic ordered alloy, of either a CuAu-type or Cu3Au-type, and the matrix agent.

Owner:FUJIFILM CORP +1

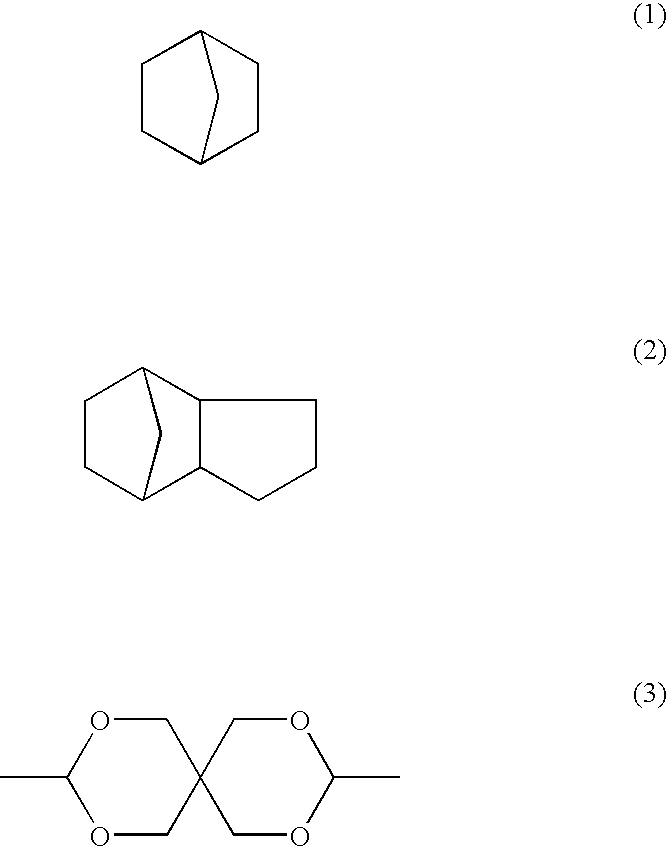

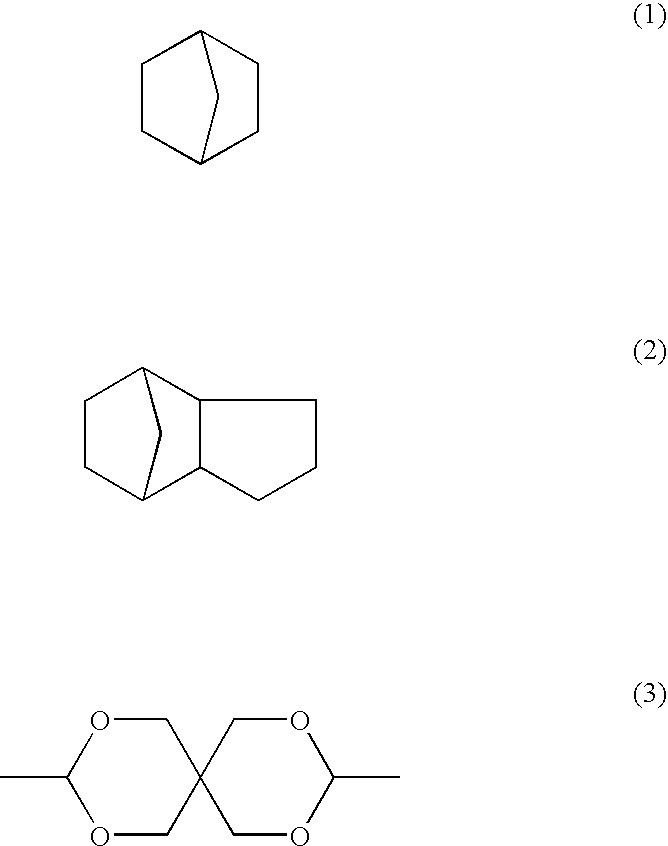

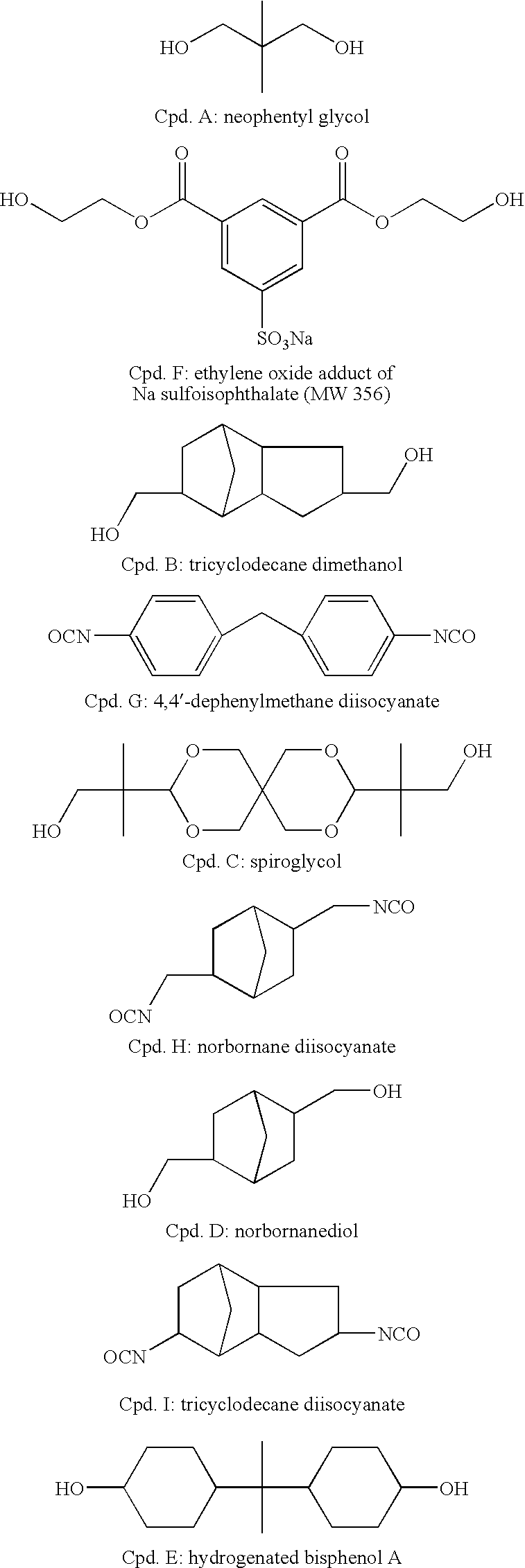

Magnetic recording medium

InactiveUS20050112409A1Improved electromagnetic conversion characteristicImproved repetitive transport durabilityMagnetic paintsMaterials with cobaltNon magneticMagnetic layer

A magnetic recording medium is provided that includes a non-magnetic support and at least one magnetic layer provided on or above the non-magnetic support, the magnetic layer containing a ferromagnetic powder dispersed in a binder, the binder containing a polyurethane resin having a bridged hydrocarbon structure or a spiro structure, and the ferromagnetic powder containing an acicular ferromagnetic substance having a major axis length of 20 to 50 nm or a tabular ferromagnetic substance having a plate size of 10 to 50 nm. There is also provided the magnetic recording medium wherein it further includes a non-magnetic layer provided between the non-magnetic support and the magnetic layer, the non-magnetic layer containing a non-magnetic powder dispersed in a binder, and the binder of the non-magnetic layer containing a polyurethane resin having a bridged hydrocarbon structure or a spiro structure.

Owner:FUJIFILM HLDG CORP +1

Recording paper

InactiveUS20070243403A1Control conditionReduce opacityDuplicating/marking methodsMaterials with cobaltUltrasonic velocityFiber orientation

Disclosed is a recording paper containing pulp fibers and magnetic fibers, in which the fiber orientation ratio is within a range selected from the range from 1.8 to 3.0 and the range from 1.0 to 1.3 as measured by an ultrasonic wave velocity method.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Magnetic recording particulate medium

InactiveUS6149989AMinimal in head wearRunning durability freeMaterials with cobaltSynthetic resin layered productsParticulatesPolyester

The present invention discloses a magnetic recording particulate mediumhaving amagnetic layer on anonmagnetic support, the magnetic layer containing a ferromagnetic metal powder and a binder and having a coercive force of 1,400 to 1,700 Oe, wherein the ferromagnetic metal powder is spindle-shaped particles consisting essentially of Fe and having a Co / Fe ratio of from 1 to 5 atomic %, an Al / Fe ratio of from 5 to 15 atomic %, an average major axis length of 0.1 to 0.2 mu m and a specific surface area of 40 to 50 m2 / g, and the binder contains a polyurethane consisting essentially of a diol component comprising a polyether polyol and a polyester polyol and a polyisocyanate component. This magnetic recording particulate medium is characterized by minimal head wear, freedom from head clogging, and satisfactory electromagnetic characteristics.

Owner:FUJIFILM CORP +1

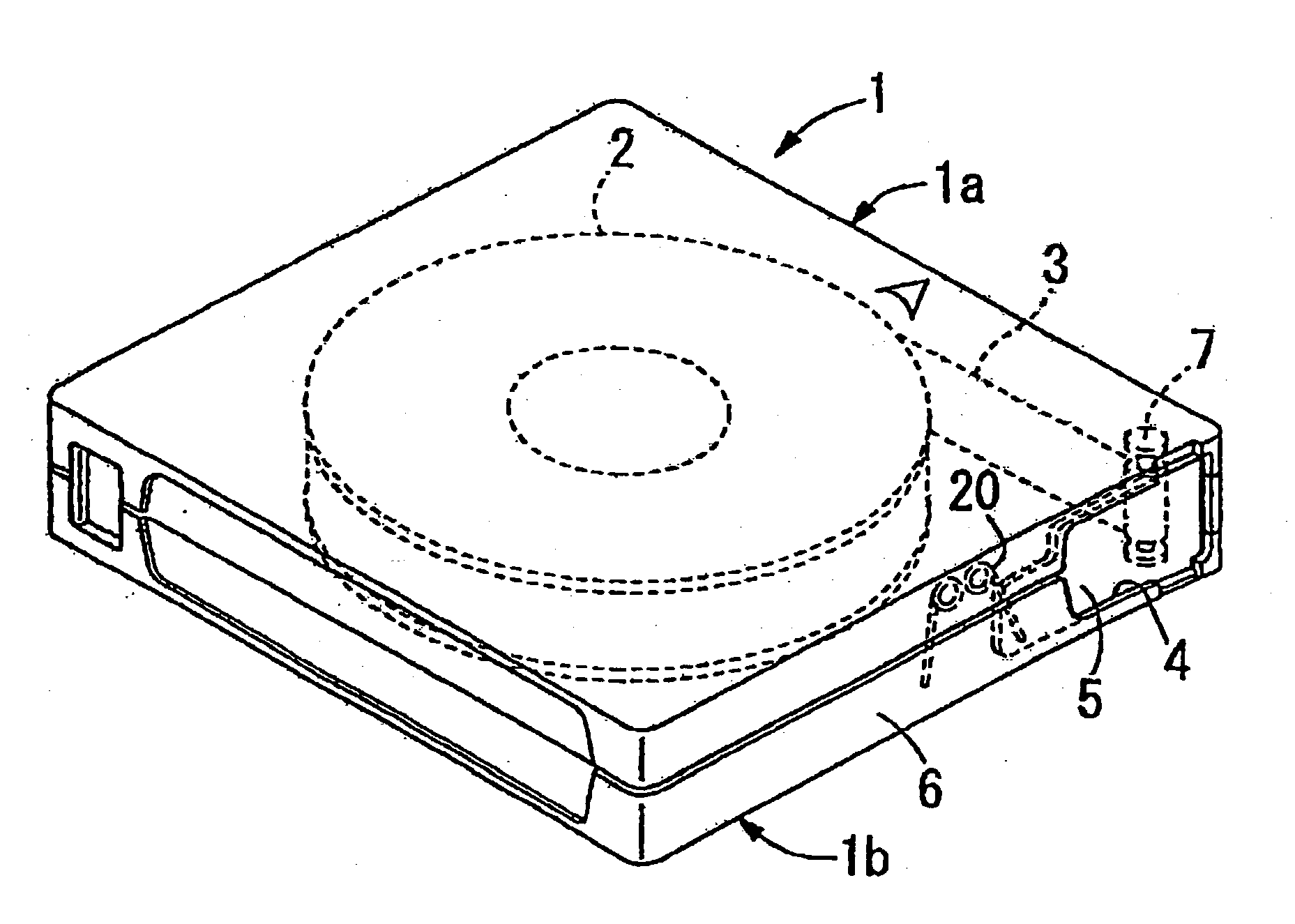

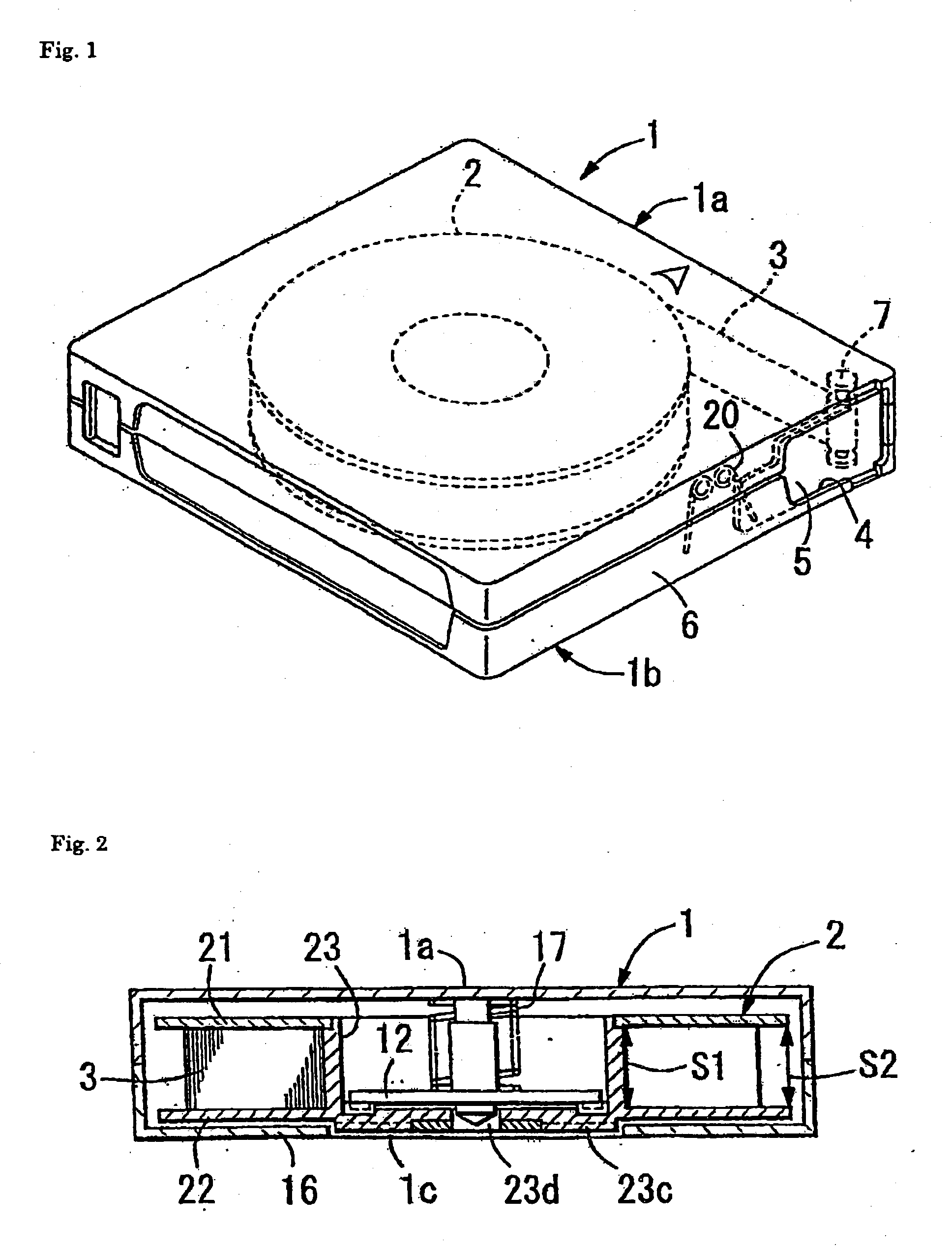

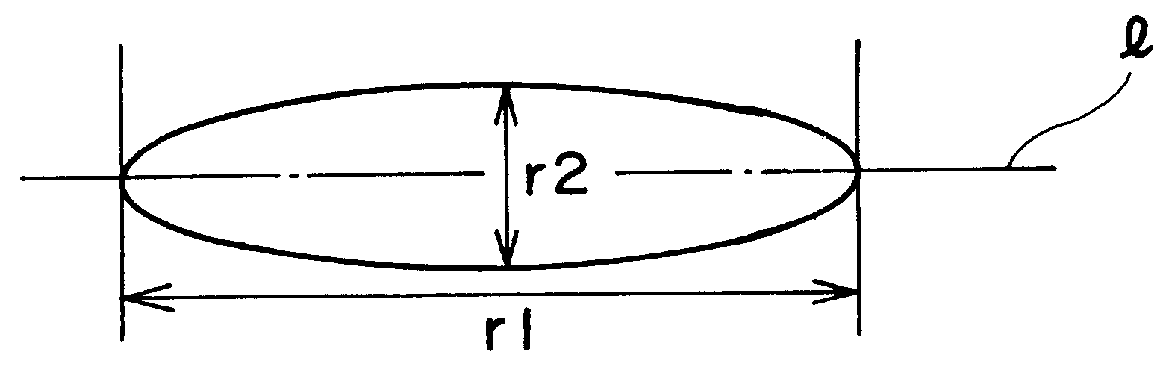

Aluminum alloy substrate for magnetic recording medium and method for manufacturing the same, substrate for magnetic recording medium, magnetic recording medium, and hard disc drive

ActiveUS20190228798A1Improve the plating effectEasy to produceTransportation and packagingMaterials with cobaltHard disc driveMaximum diameter

This aluminum alloy substrate for a magnetic recording medium has a metal structure made of an Al alloy having a composition including Si in a range of 18.0% by mass to 22.0% by mass, Fe in a range of 4.0% by mass to 6.0% by mass, Cu in a range of 2.5% by mass to 4.0% by mass, and Mg in a range of 0.8% by mass to 1.5% by mass with a remainder being Al, a primary-crystal Si precipitate having a maximum diameter of 0.5 μm or more and an average particle diameter of 2 μm or less is dispersed in the metal structure, a diameter is in a range of 53 mm to 97 mm, and a thickness is in a range of 0.2 mm to 0.9 mm.

Owner:RESONAC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com