Patents

Literature

30 results about "Autocatalytic reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Autocatalytic reactions are chemical reactions in which at least one of the reactants is also a product. The rate equations for autocatalytic reactions are fundamentally nonlinear. This nonlinearity can lead to the spontaneous generation of order. A dramatic example of this order is that which is found in living systems. This spontaneous order creation seems to contradict the Second Law of Thermodynamics. This contradiction is resolved when the disorder of both the system and its surroundings are taken into account.

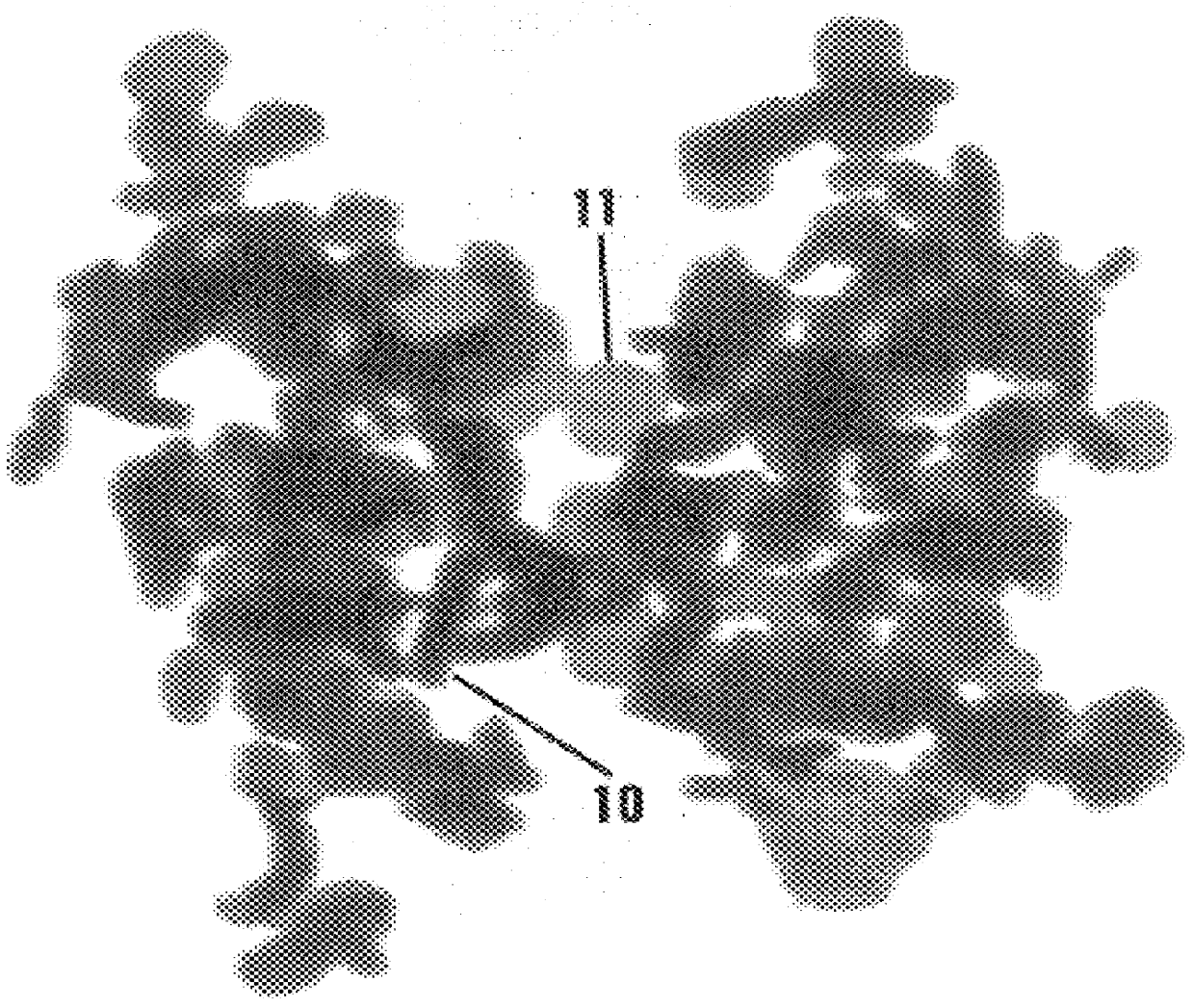

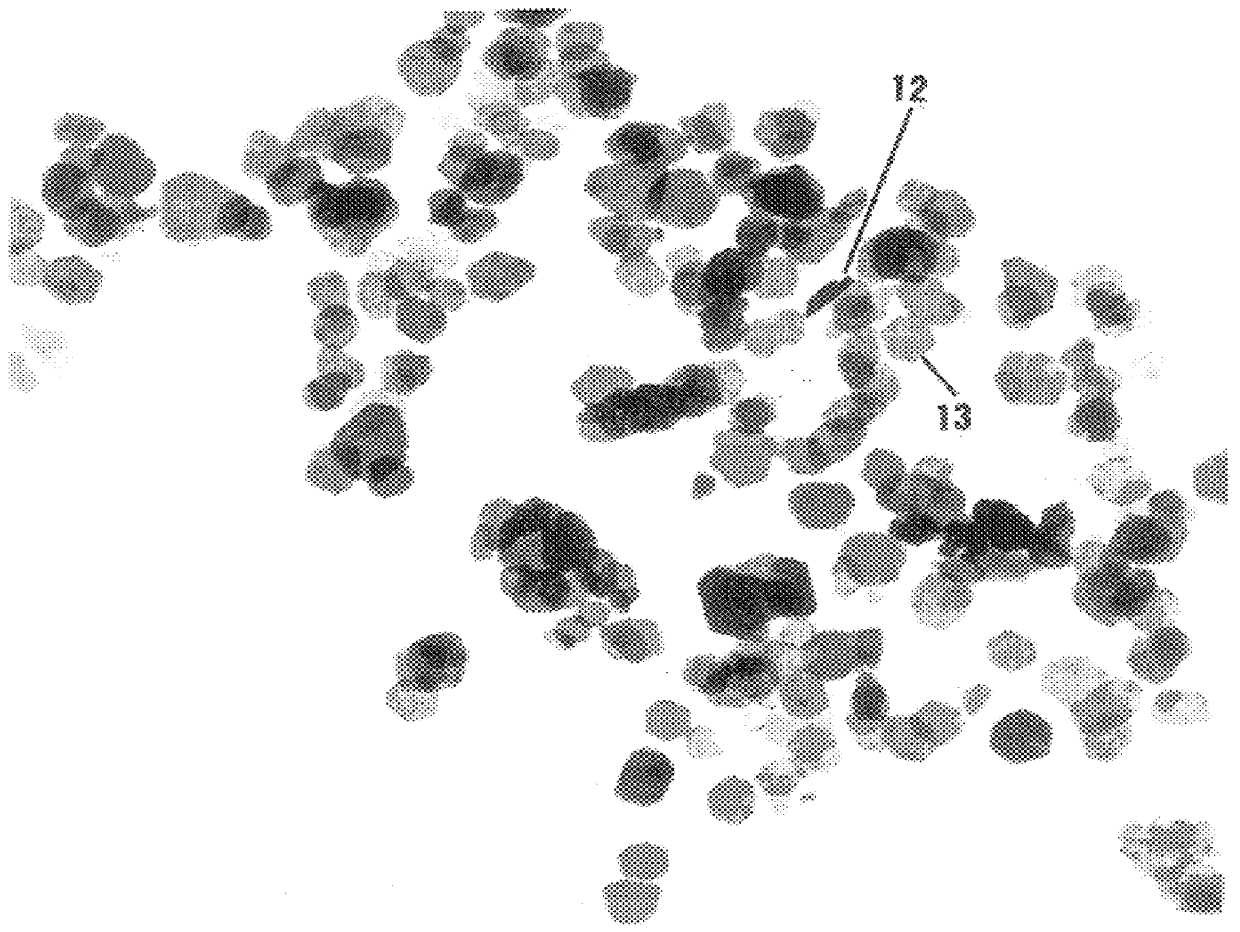

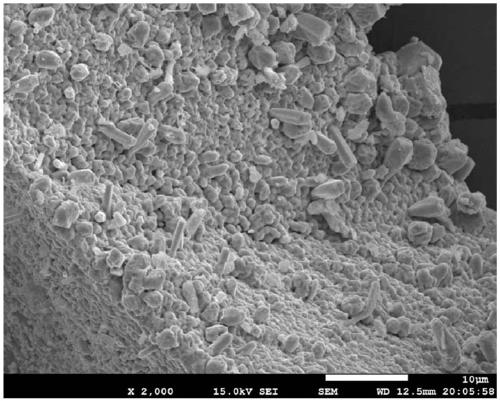

Base metal particles having anisometric morphology

There is disclosed a method of making unsupported particles of a base metal selected from the group consisting of iron, cobalt, and nickel, which comprises combining an aqueous solution or suspension of a base metal salt, a strong base so that the resulting combination has an effective hydroxide ion concentration, and a reducing agent, which is then subjected to an autocatalytic reaction at about atmospheric pressure to form a precipitate of the metal. The unsupported base metal particles exhibit an anisometric morphology, generally platetlet or disk-shaped, and have a relatively high aspect or width to thickness ratio, which is preferably three or greater, exhibit ferromagnetic properties, and one or more of these base metals may be formed to exhibit a single magnetic domain. The resulting precipitate of metal particles may be formed as an agglomerate as by subjecting the precipitate to aging or to external means.

Owner:WISYS TECH FOUND

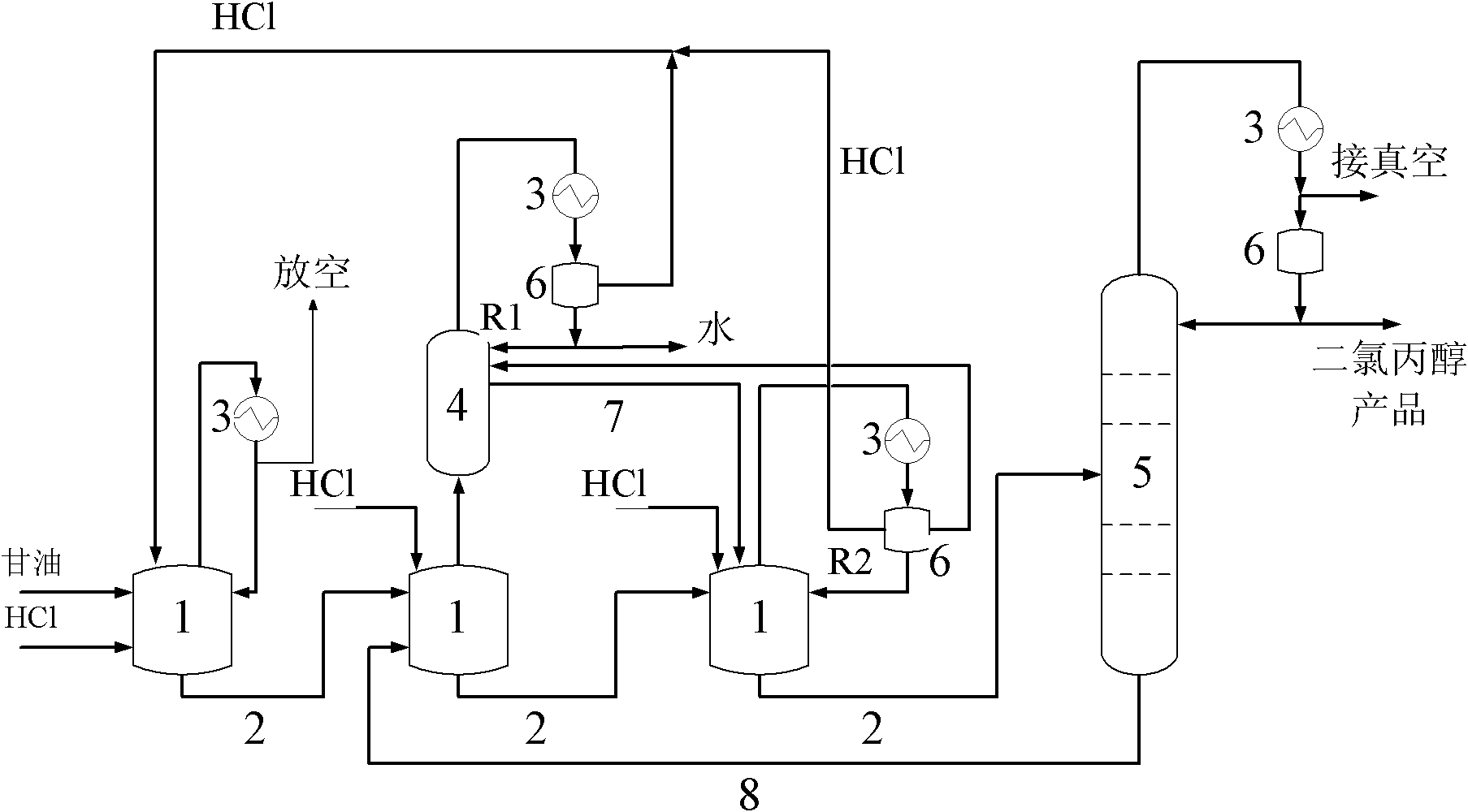

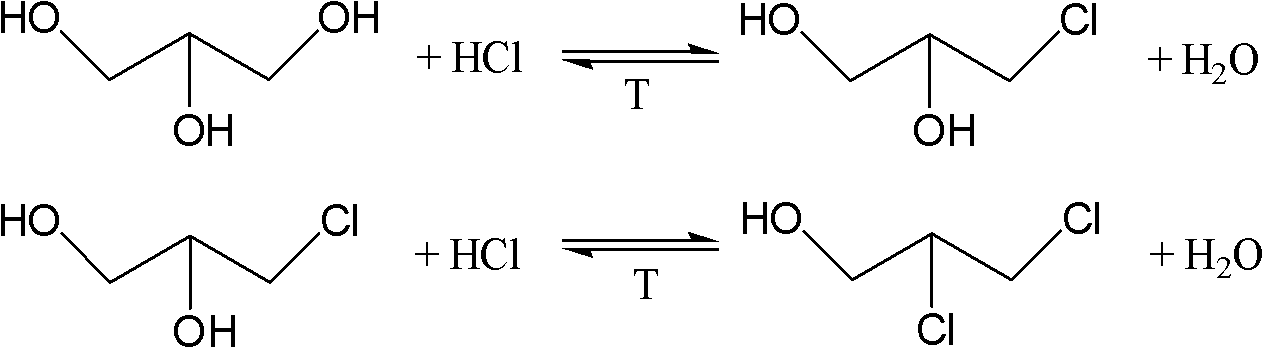

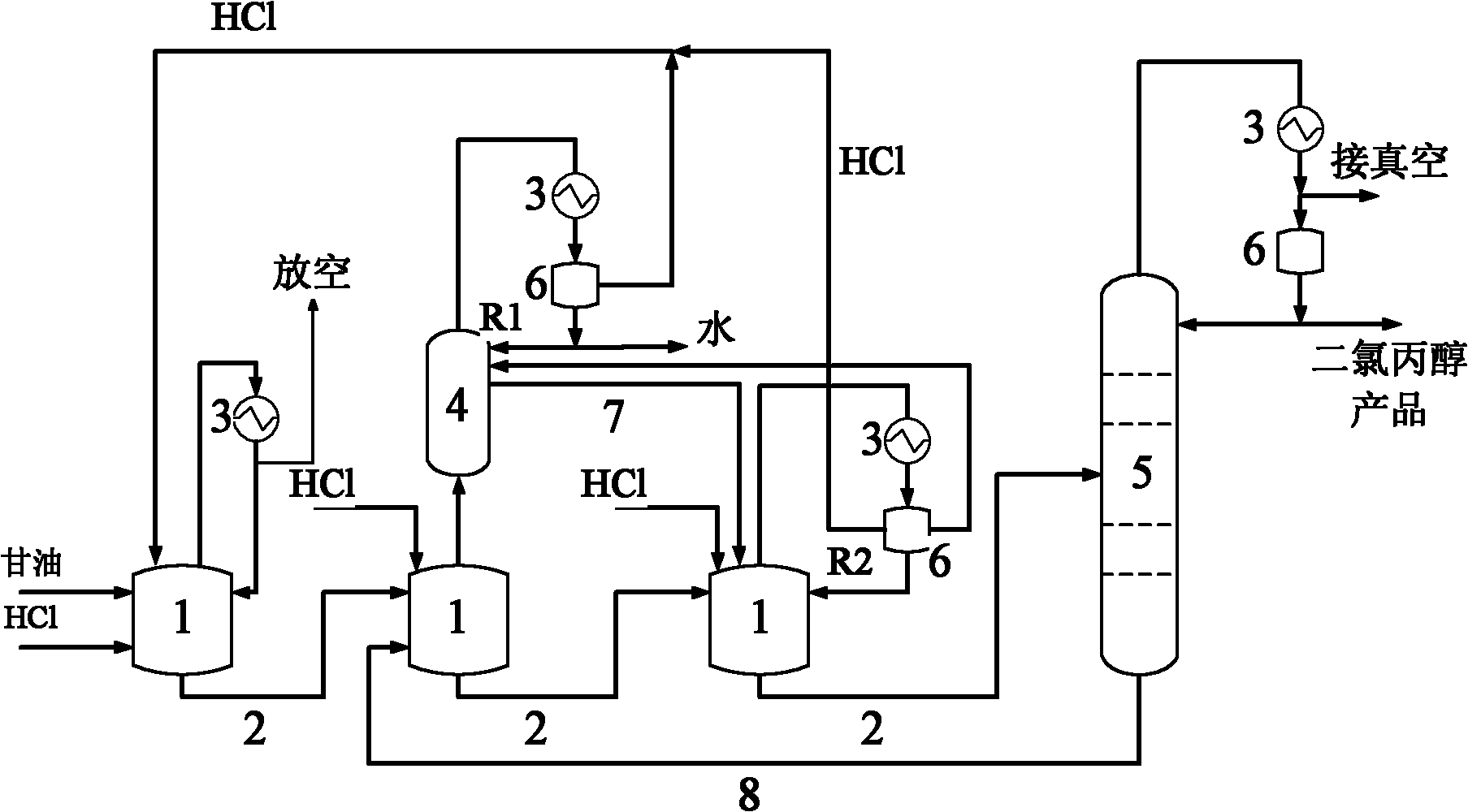

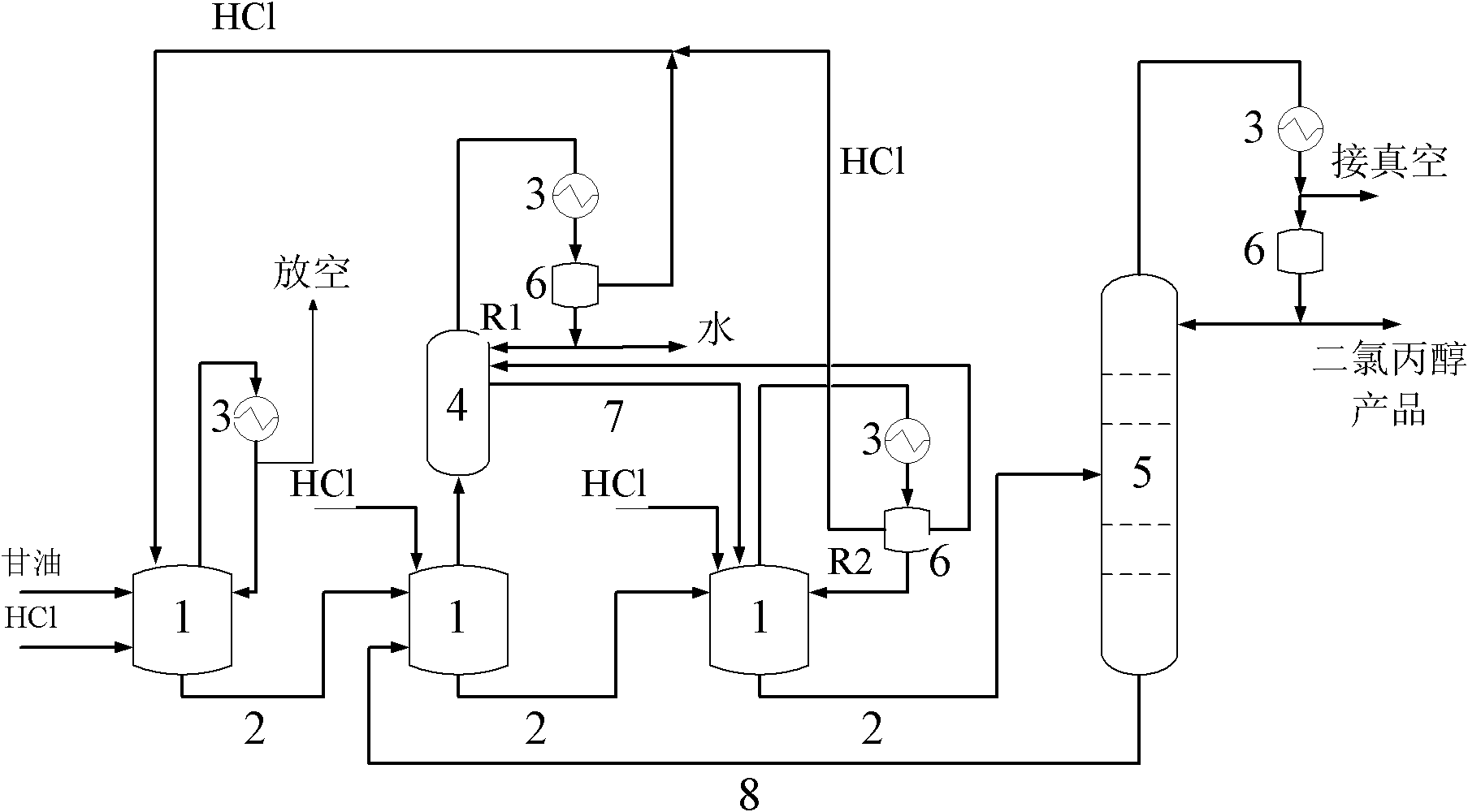

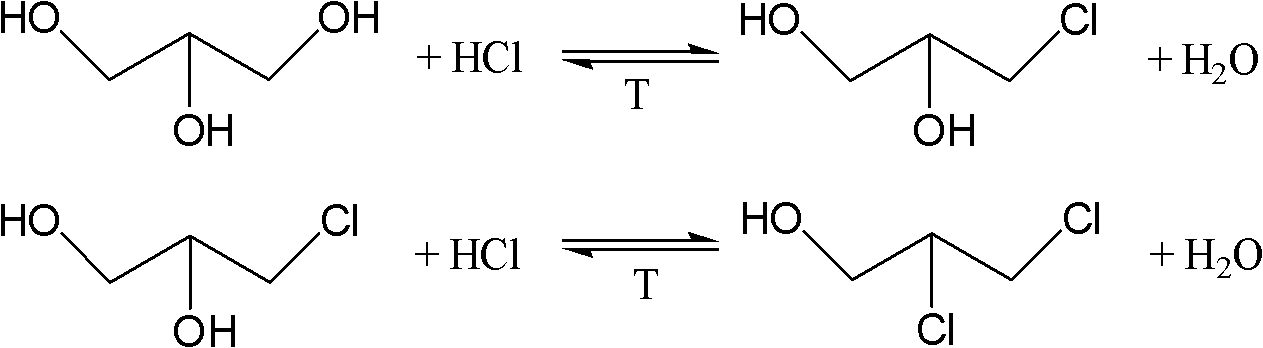

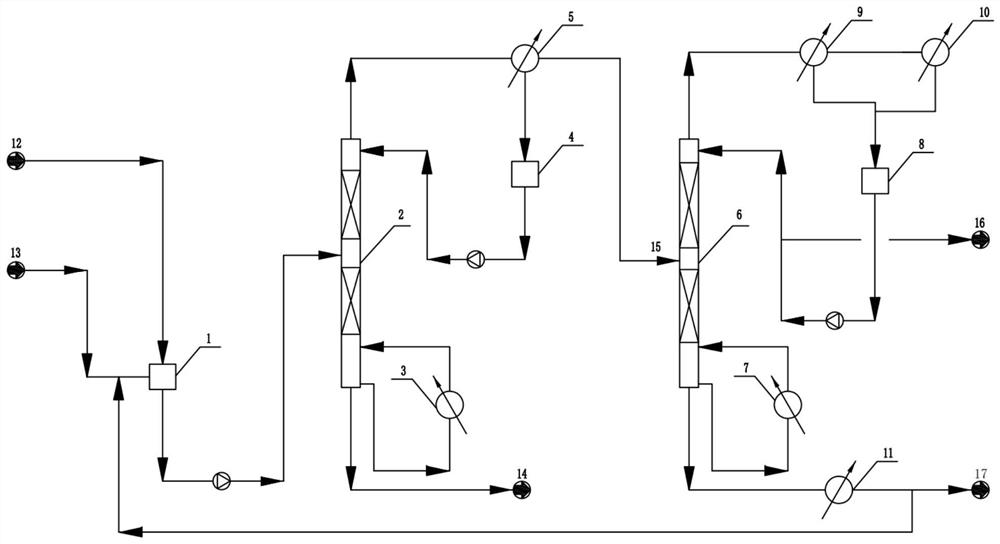

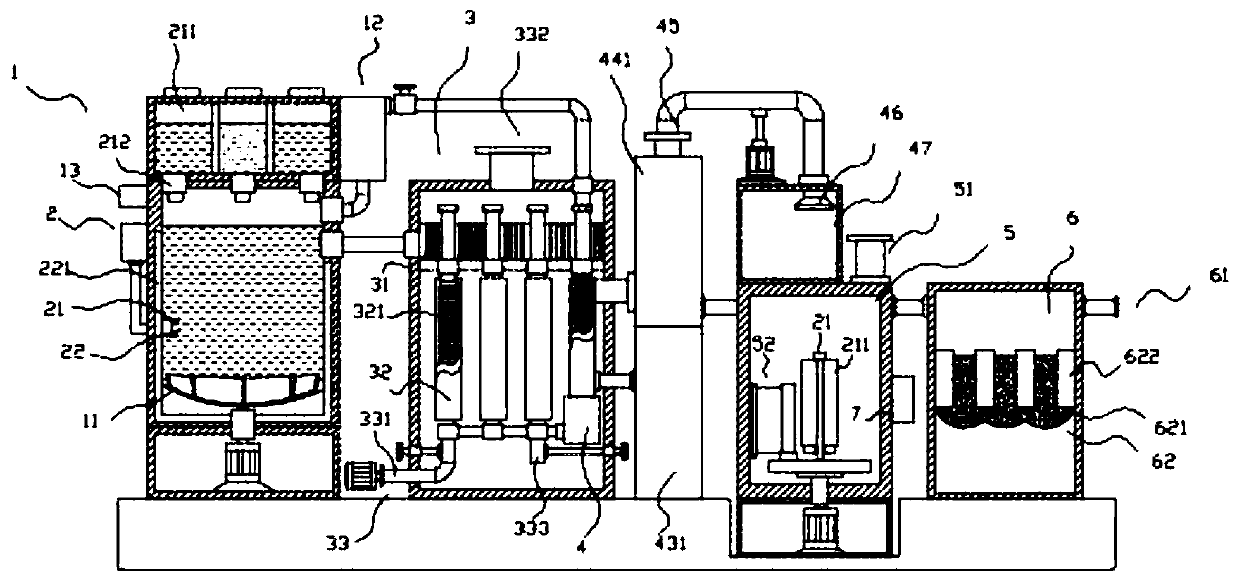

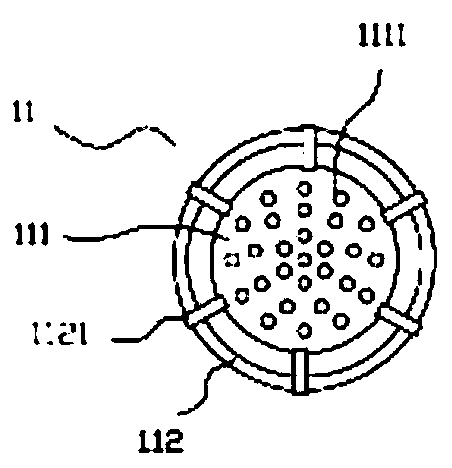

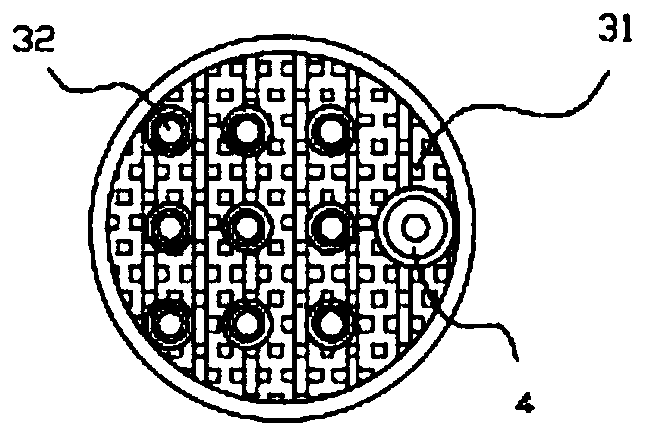

System for preparing dichloropropanol by autocatalytic reaction of glycerol and hydrogen chloride

ActiveCN102040479AReduce usageEliminate formationPreparation by halogen introductionBoiling pointGlycerol

The invention discloses a process for preparing dichloropropanol by an autocatalytic reaction of glycerol and hydrogen chloride. The process comprises the following steps: the glycerol and the hydrogen chloride gas perform the autocatalytic reaction at the temperature of between 105 and 160 DEG C and pressure of between 0.05 and 0.5MPa, and generated water is distilled and removed during the reaction. The invention also discloses a system for preparing the dichloropropanol by the autocatalytic reaction of the glycerol and the hydrogen chloride. The invention adopts the technology of the autocatalytic reaction of the glycerol and the hydrogen chloride without using a catalyst, so that the production cost is remarkably reduced, formation of high boiling side products is eliminated, and the reaction selectivity is improved. The invention has the advantages of simple process and low production cost. The system can ensure that the glycerol is completely converted and greatly improves the selectivity of the dichloropropanol, so that the purity of the finally prepared dichloropropanol is more than 99.5 percent.

Owner:NANTONG TIANSHI CHEM

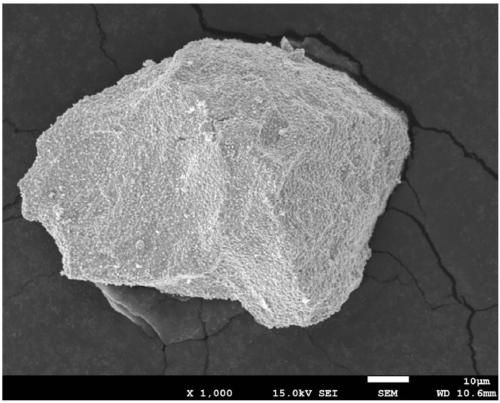

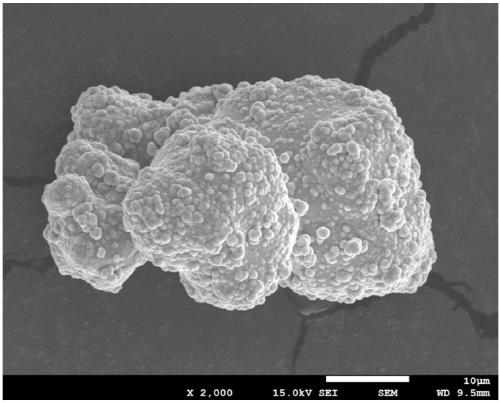

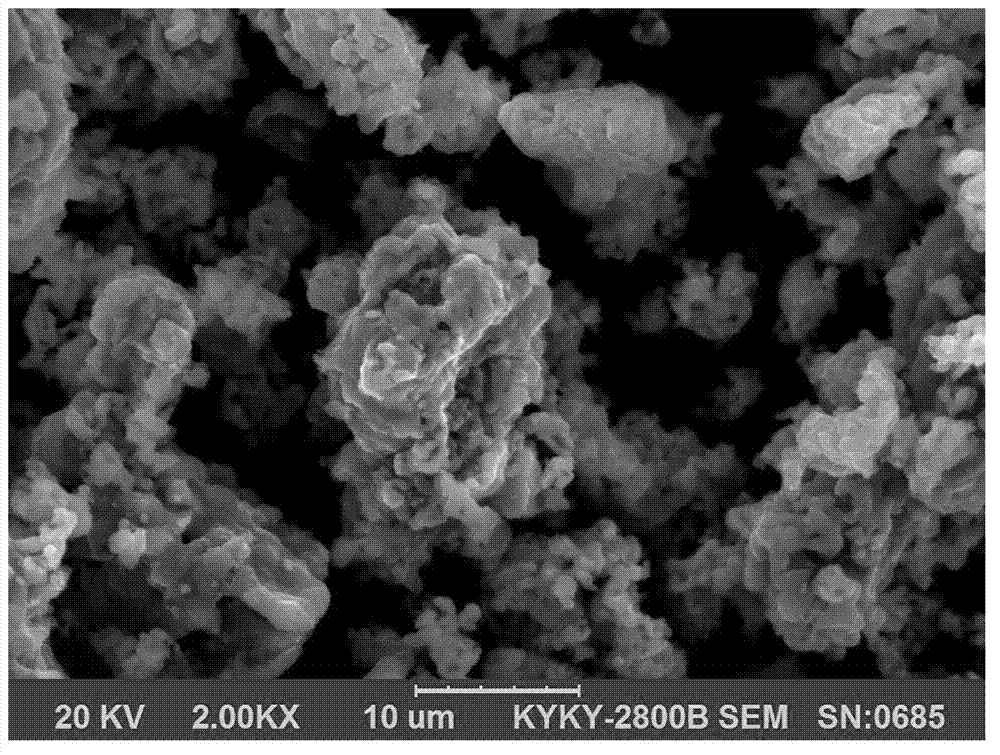

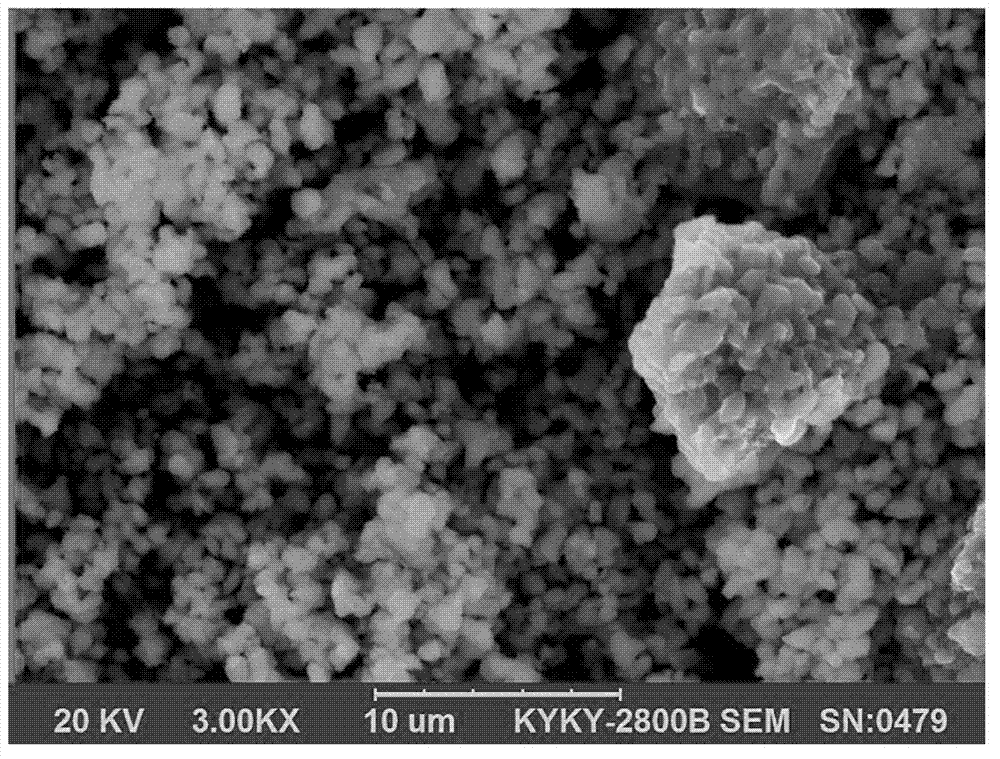

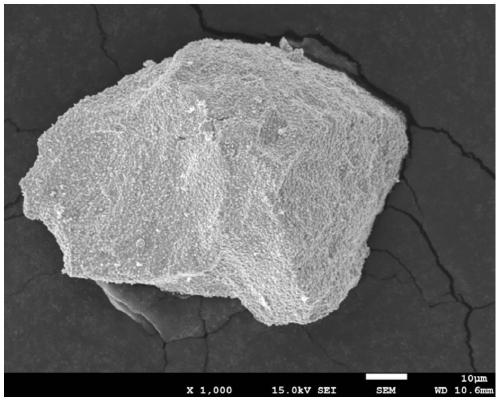

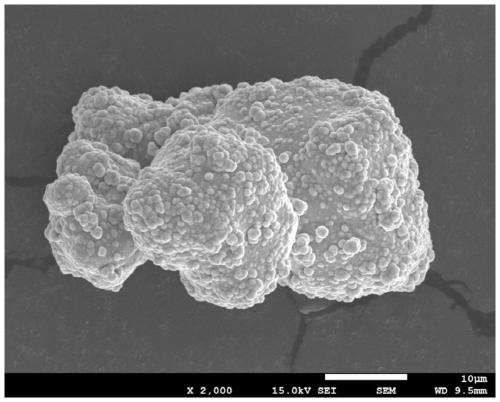

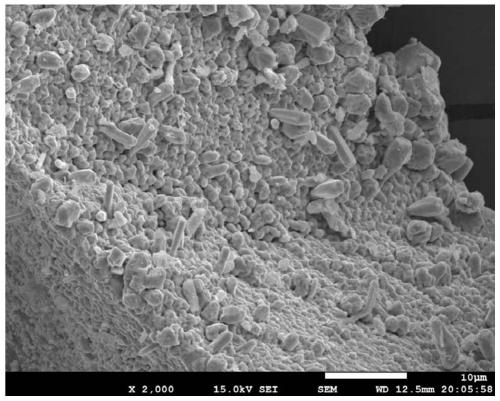

Preparation method for metal-ceramic composite powder of core-shell structure

ActiveCN109365802ASimple processShorten the timeTransportation and packagingMetal-working apparatusWater bathsPalladium catalyst

The invention discloses a preparation method for metal-ceramic composite powder of a core-shell structure. The preparation method comprises the following step (1) of performing catalytic activation treatment to ceramic powder particles, placing the ceramic powder particles in a reactor, and heating reactive materials; using carrier gas for carrying reactive material steam to enter the reactor, andadding hydrogen gas for reduction reaction, so that catalytic metal is deposited on the surface of the ceramic powder particles; the step (2) of placing the ceramic powder particles obtained in the step (1) in the reactor in a water bath, and adding metal salt raw material and reducing agents; and forming a metal coating through autocatalytic reaction, and obtaining the metal-ceramic composite powder. According to the preparation method, the procedures of coarsening, sensitization and reactivation in a traditional chemical metal coating process are omitted, and expensive palladium chloride catalysts are not required; the introduction of impurity palladium is avoided, and the metal coating is achieved at lower temperature; the metal content of the coating is controllable, and the overall coating technology is simple, and the preparation method is applied to industrial mass production.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

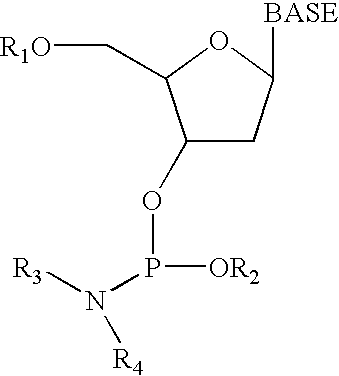

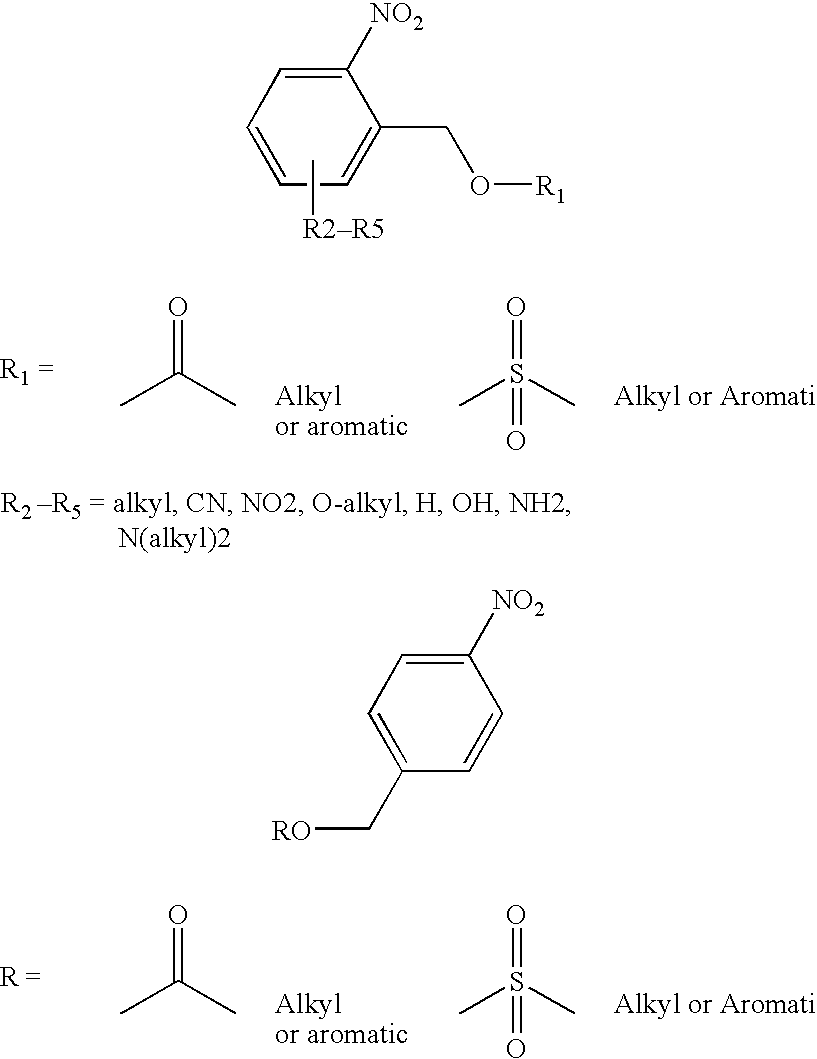

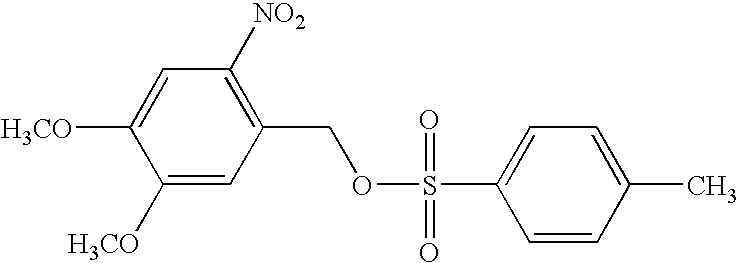

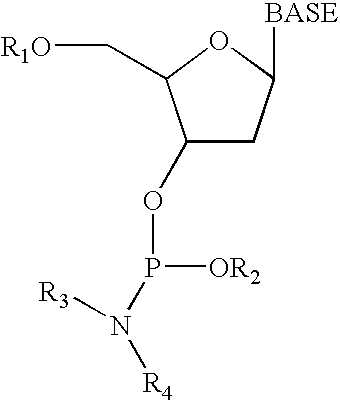

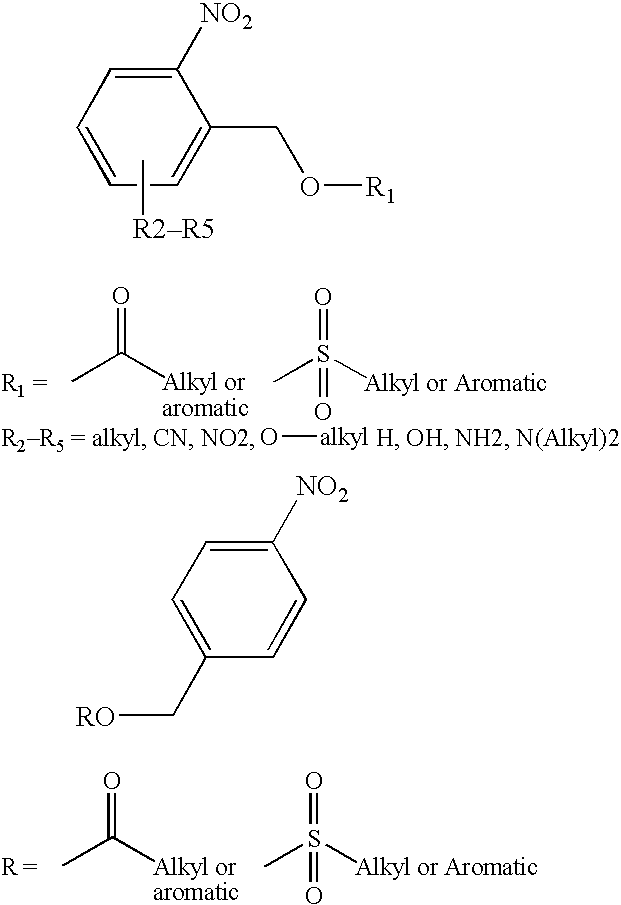

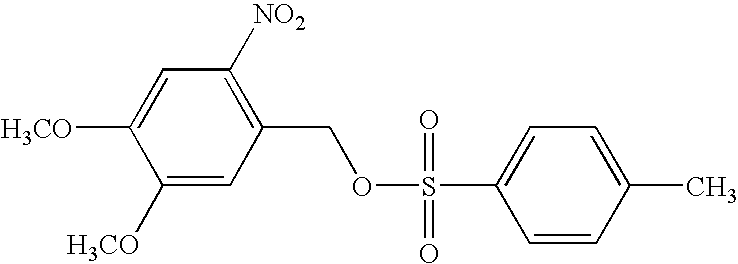

Chemical amplification for the synthesis of patterned arrays

InactiveUS20040203056A1High resolutionEasy to irradiateMaterial nanotechnologySequential/parallel process reactionsPtru catalystCombinatorial synthesis

Radiation-activated catalysts (RACs), autocatalytic reactions, and protective groups are employed to achieve a. highly sensitive, high resolution, radiation directed combinatorial synthesis of pattern arrays of diverse polymers. When irradiated, RACs produce catalysts that can react with enhancers, such as those involved in autocatalytic reactions. The autocatalytic reactions produce at least one product that removes protecting groups from synthesis intermediates. This invention has a wide variety of applications and is particularly useful for the solid phase combinatorial synthesis of polymers.

Owner:AFFYMETRIX INC

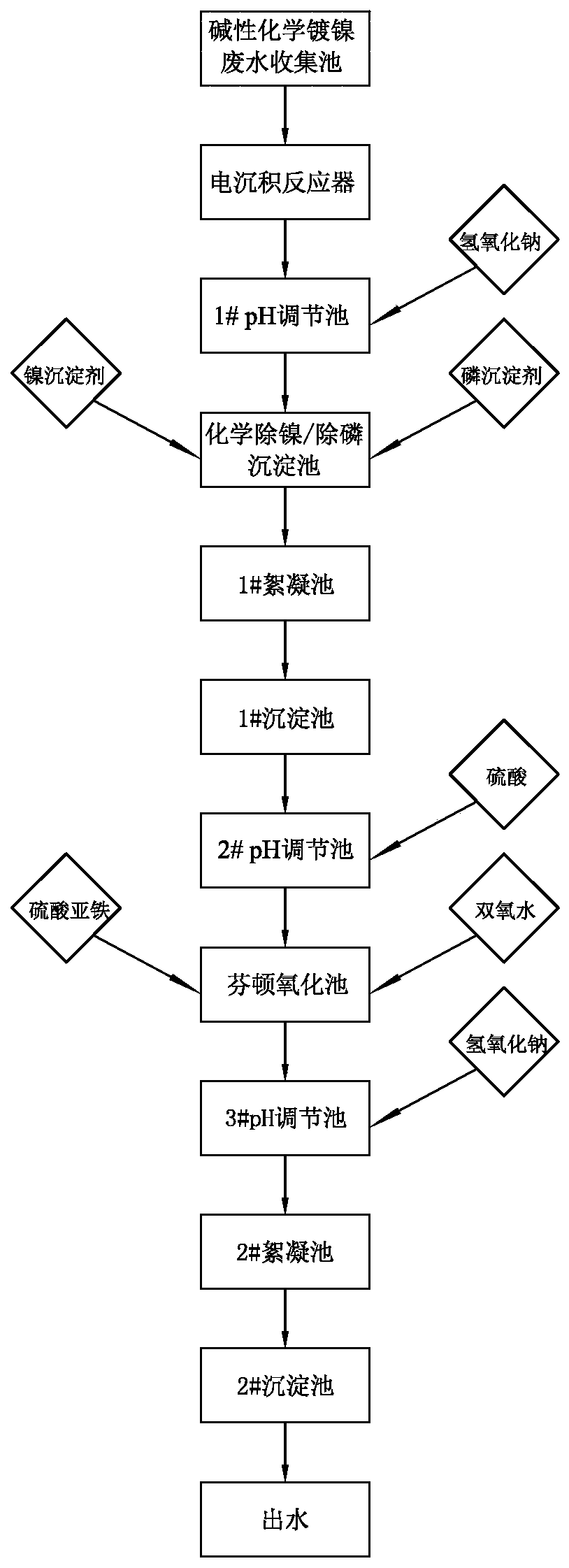

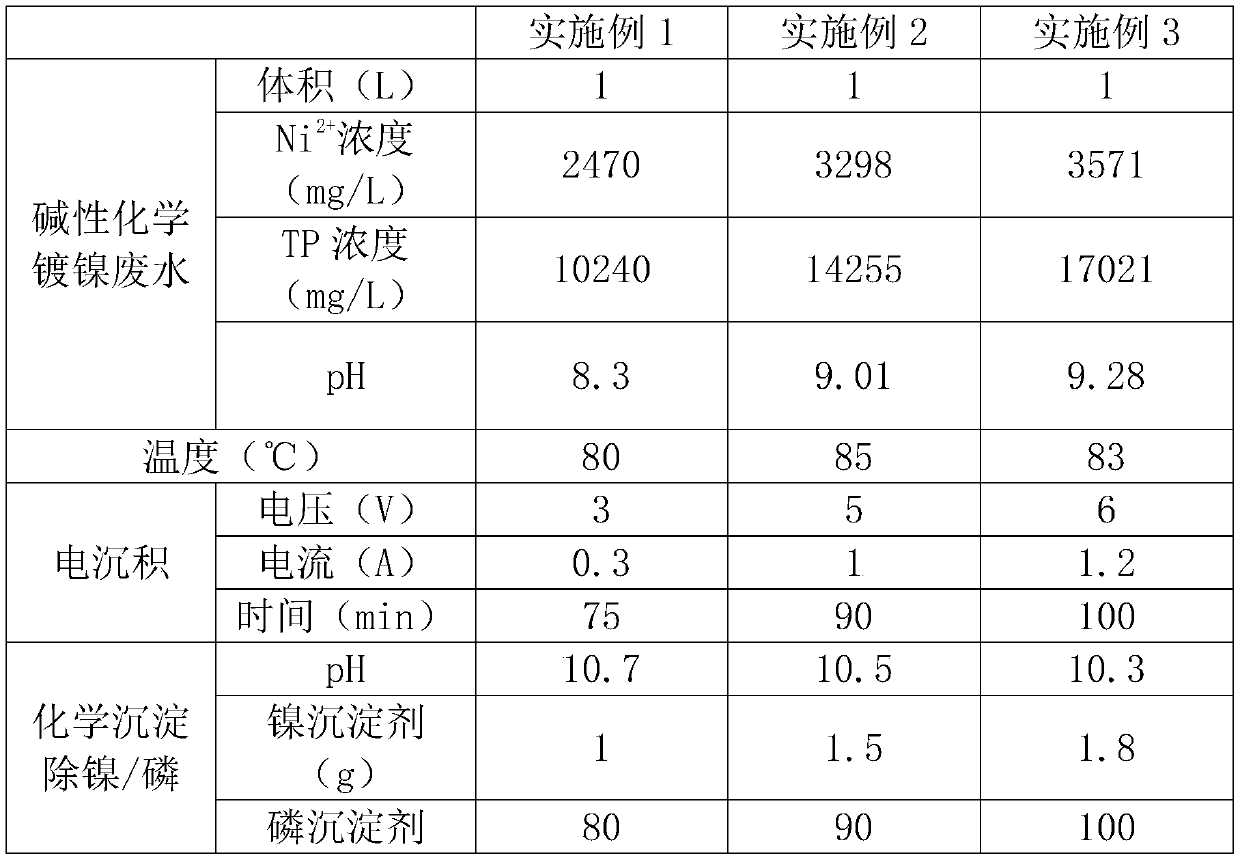

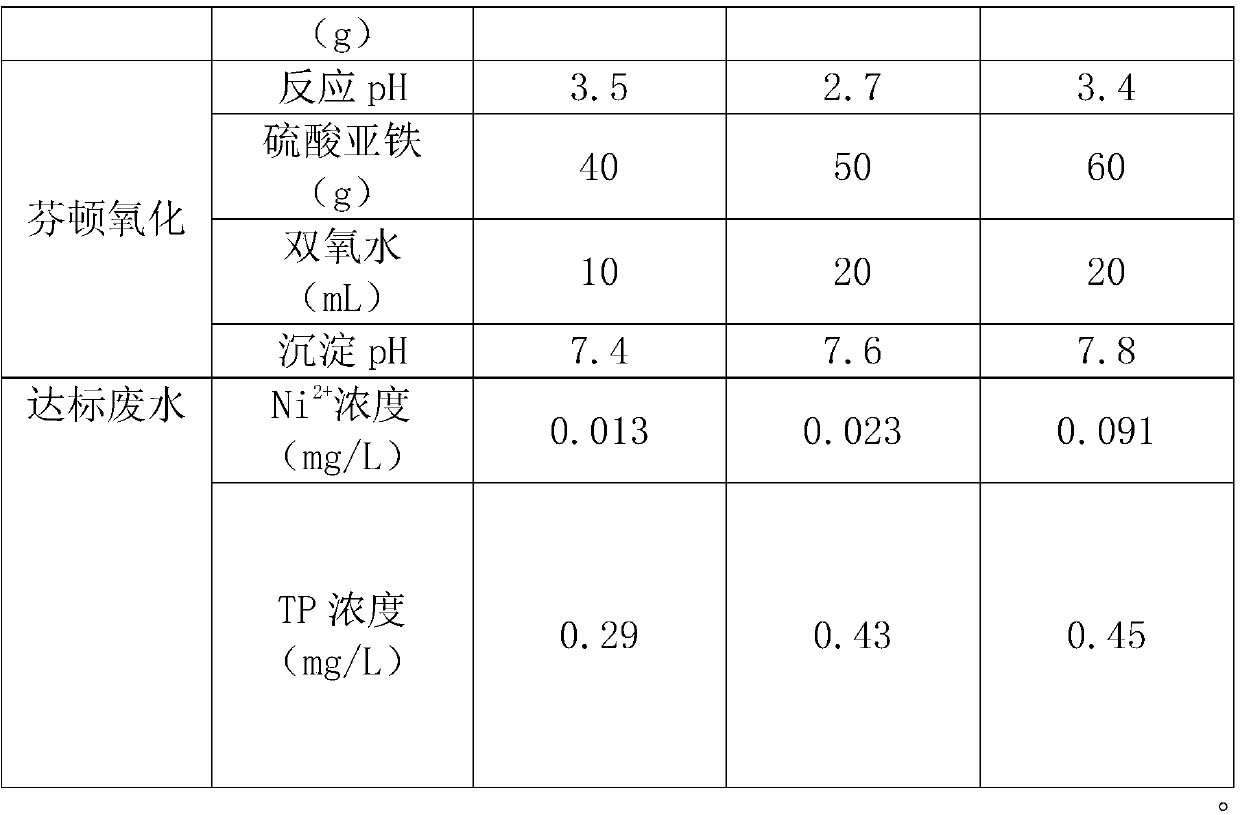

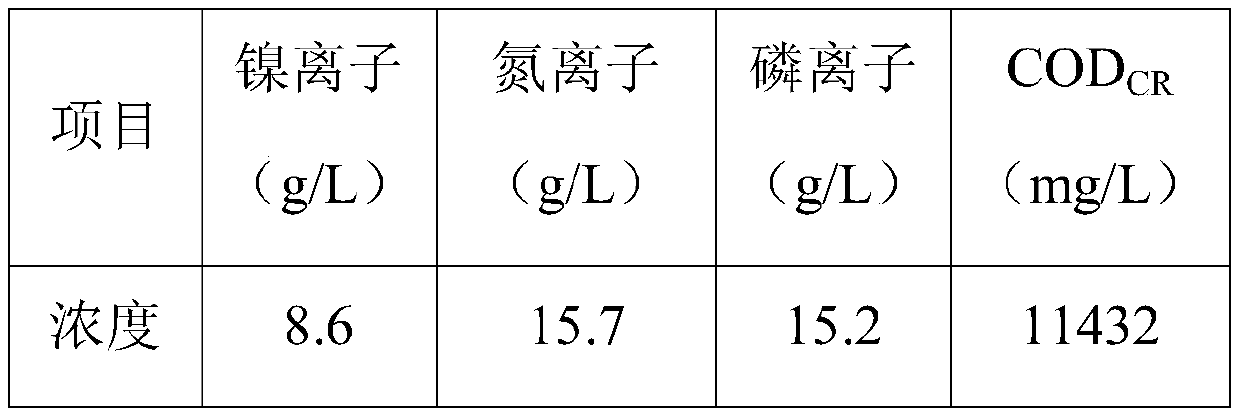

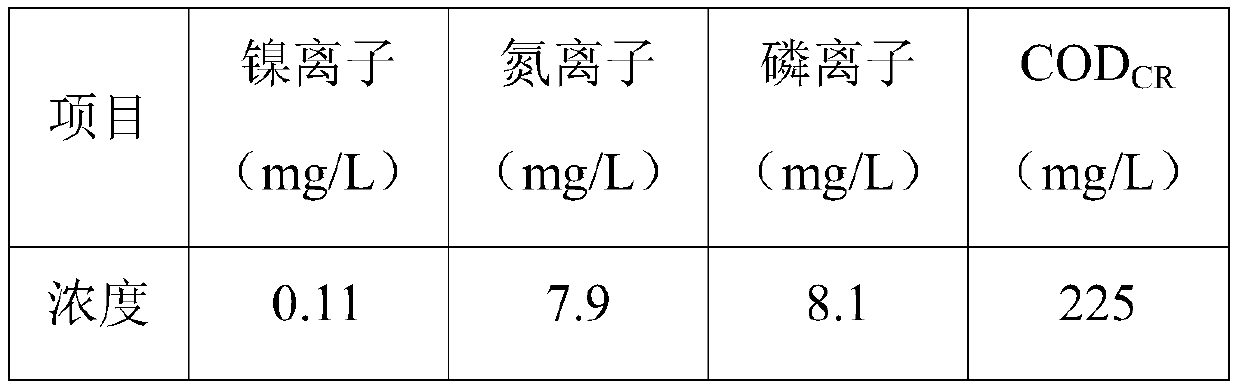

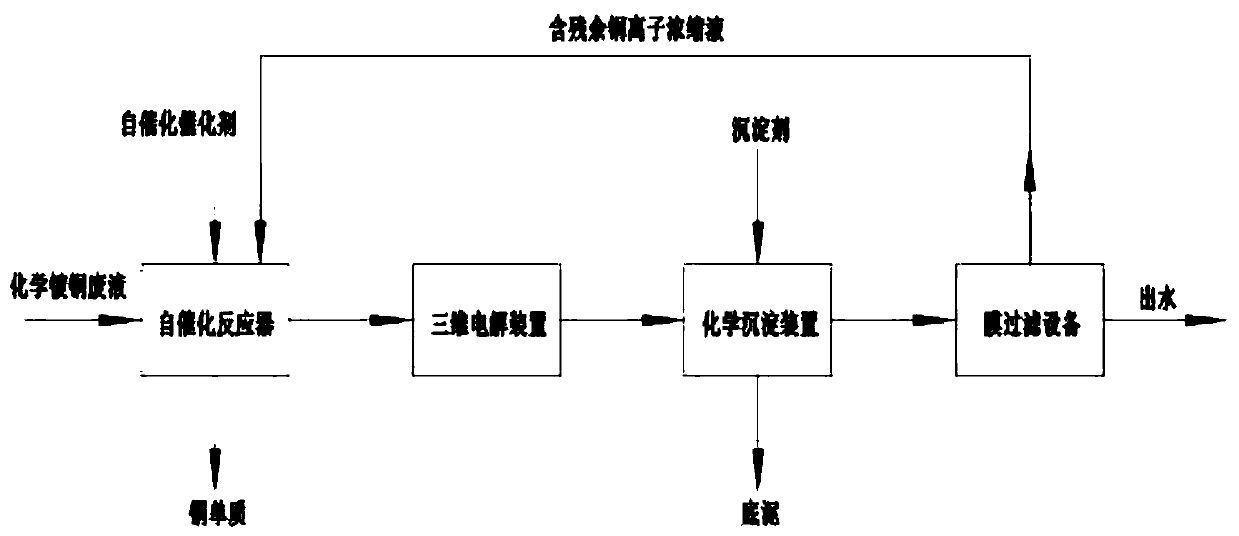

Methods and systems for treating alkaline chemical nickel plating wastewater

PendingCN110668533AEasy to handleWater treatment parameter controlWater treatment compoundsElectrolysisIon exchange

The invention discloses a method and a system for treating alkaline chemical nickel plating wastewater. The method and the system can reduce the treatment cost of nickel-containing wastewater, improvethe cyclic utilization rate of nickel resources and enable nickel in the alkaline chemical nickel plating wastewater to reach the standard. The method comprises the following steps: 1) pumping wastewater with the pH value of 8.0-10 into a collecting tank; 2) heating the wastewater to 80-90 DEG C; 3) carrying out an electrolytic reaction by adopting an electro-deposition reactor; and 4) carrying out an autocatalytic reaction on nickel ions released after anodic oxidation in the nickel-containing complex state by taking metallic nickel, generated by reduction on a cathode, as an initiator to quickly reduce the nickel ions into elemental metal nickel on the cathode. The system adopts a multistage reaction device, so that the alkaline chemical nickel plating wastewater with high nickel and high phosphorus content can be quickly treated, the treated wastewater reaches the discharge standard specified by national standards, the nickel content of the treated wastewater is less than 0.1 ppm,and the TP value of the treated wasteater is less than 0.5 ppm. The method can replace the existing processes such as a chemical precipitation method, an ion exchange resin method, a membrane separation technology and the like.

Owner:深圳市世清环保科技有限公司

Preparation method of lithium vanadium phosphate of lithium ion batteries cathode materials

InactiveCN102832390AWell mixedSmall primary particlesCell electrodesPhosphorus compoundsPhosphateLithium compound

The invention relates to a preparation method of lithium vanadium phosphate of lithium ion batteries cathode materials, which comprises the following steps: weighing a vanadium-containing compound, a lithium-containing compound and phosphate according to mol ratio of 1:(2.8-3.2):3; weighing citric acid which accounts for 30%-60% of mass of raw material, adding distilled water to prepare a 20%-50% of solution, uniformly mixing the vanadium-containing compound, the lithium-containing compound and phosphate, adding 15-45% of deionized water and reacting for 0.5-2 hours; adding a citric acid solution in the reactive raw material and heating to obtain a solid phase, drying, performing ball milling, putting into an inert atmosphere furnace and heating to the temperature of 300-1000 DEG C, and keeping the temperature for 2-24 hours to prepare lithium vanadium phosphate. The preparation method provided by the invention uses an autocatalytic reaction to uniformly mix the raw material, and is good for providing primary particles with small size to lithium vanadium phosphate.

Owner:TIANJIN UNIV

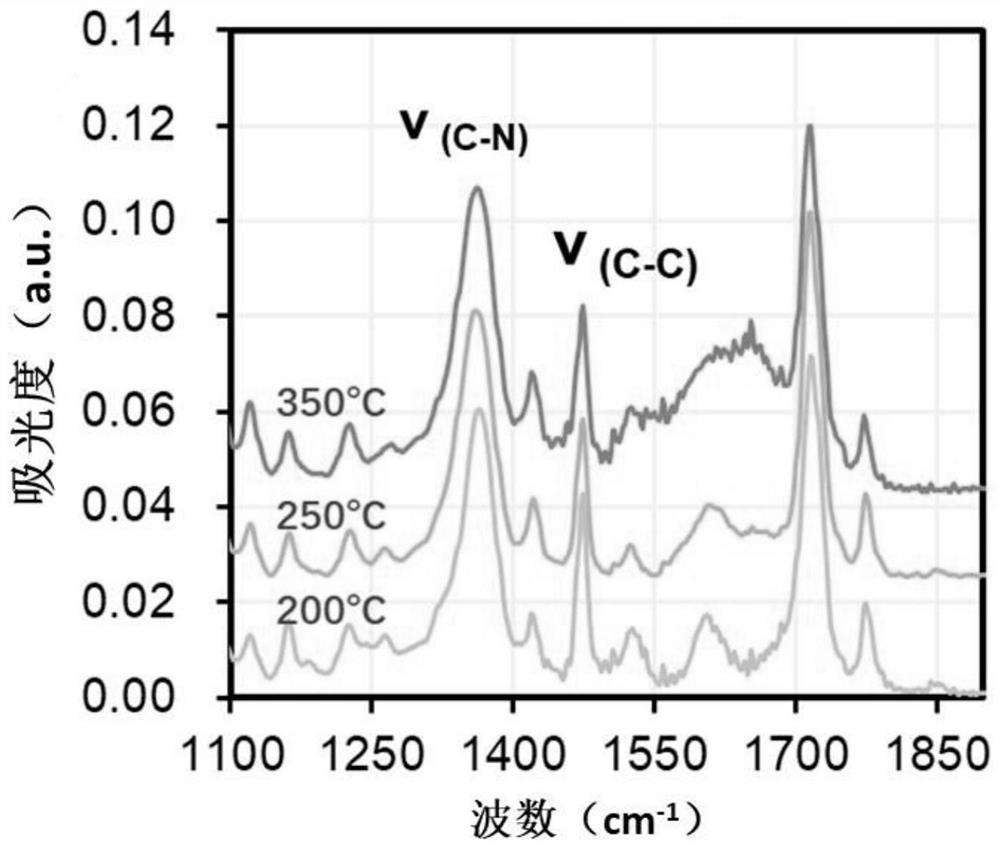

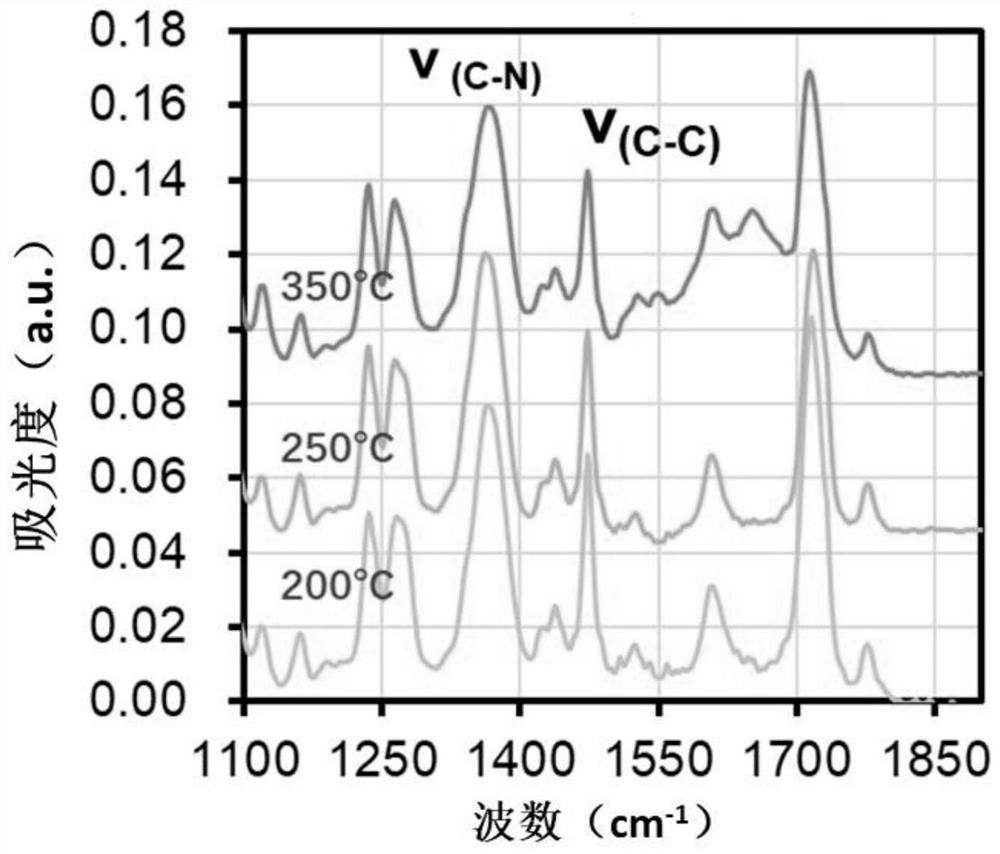

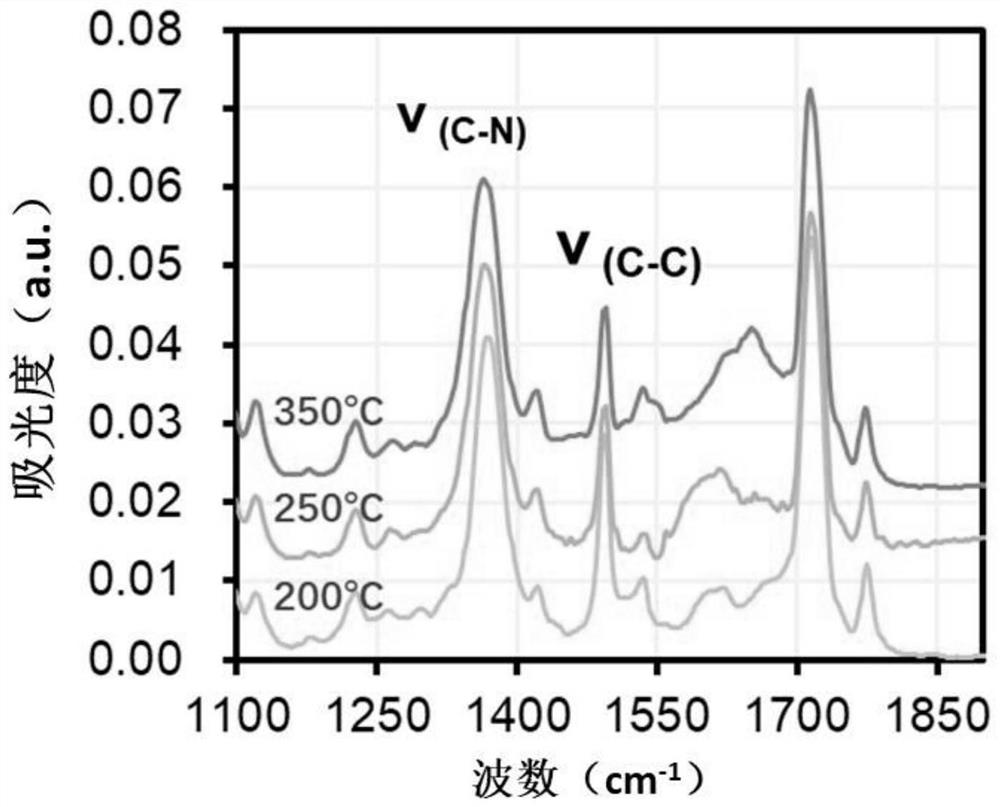

Polyimide precursor resin as well as preparation method and application thereof

ActiveCN114249892AAchieve solidificationImprove imidization ratePhotosensitive materials for photomechanical apparatusImidePolymer science

The invention provides polyimide precursor resin as well as a preparation method and application thereof. The polyimide precursor resin is obtained through polycondensation of a diamine monomer and aromatic tetracarboxylic dianhydride. The diamine monomer comprises at least one compound with a structure as shown in a formula I and is a diamine monomer containing an aza-aromatic ring, the diamine monomer with the structure can be subjected to an autocatalytic reaction in a heated and cured polyimide precursor resin, the imidization reaction process is accelerated, and the reaction time is shortened. The imidization rate of the polyimide precursor resin at low temperature is obviously improved. The polyimide precursor resin can be cured at low temperature to obtain a polyimide film with excellent mechanical property and thermal stability, so that high stress residue caused by high-temperature curing is effectively avoided; therefore, the application requirements of the polyimide precursor resin in low-temperature processing environments such as microelectronic chip materials, packaging materials and interlayer dielectric layers are fully met.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

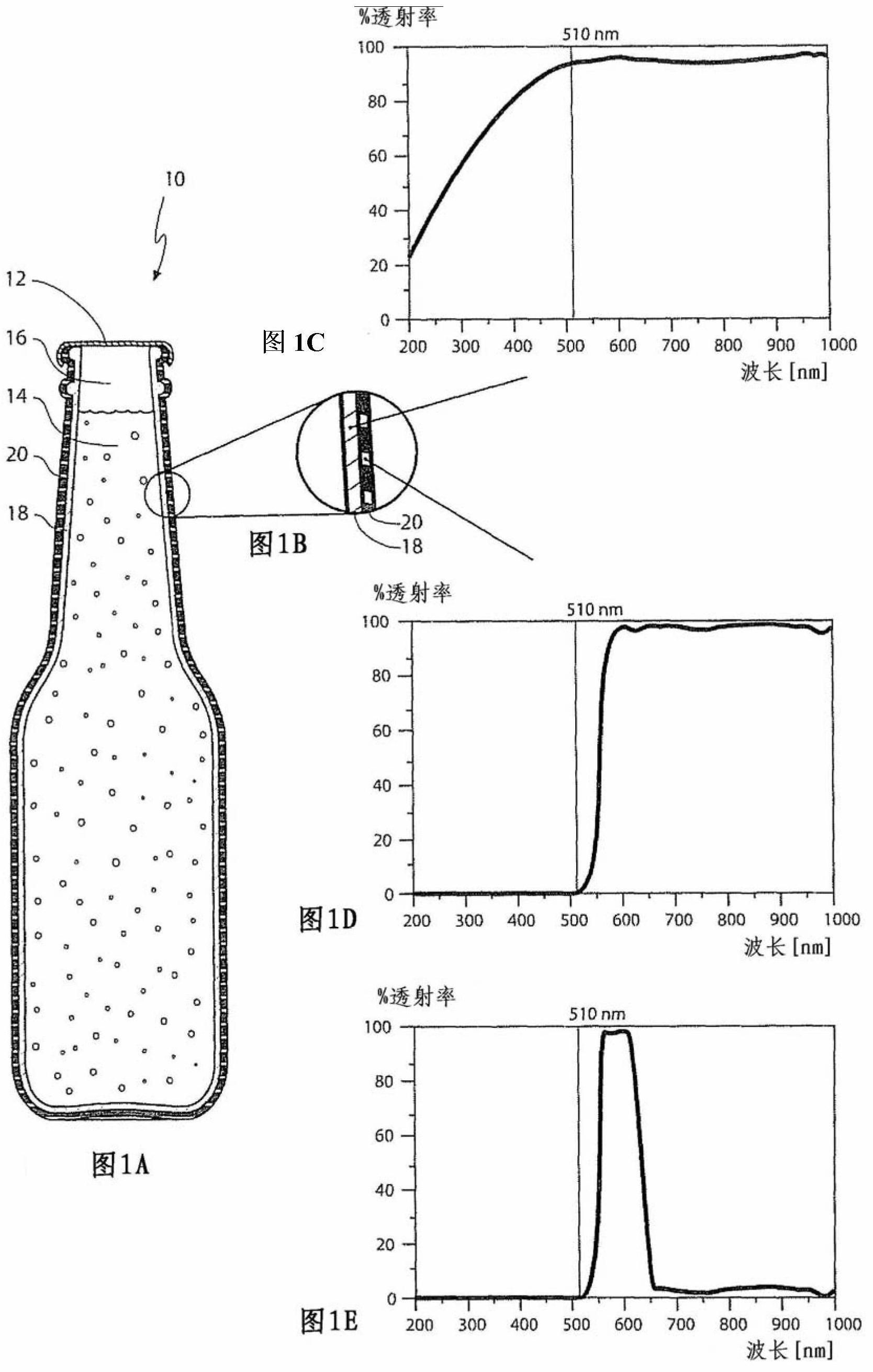

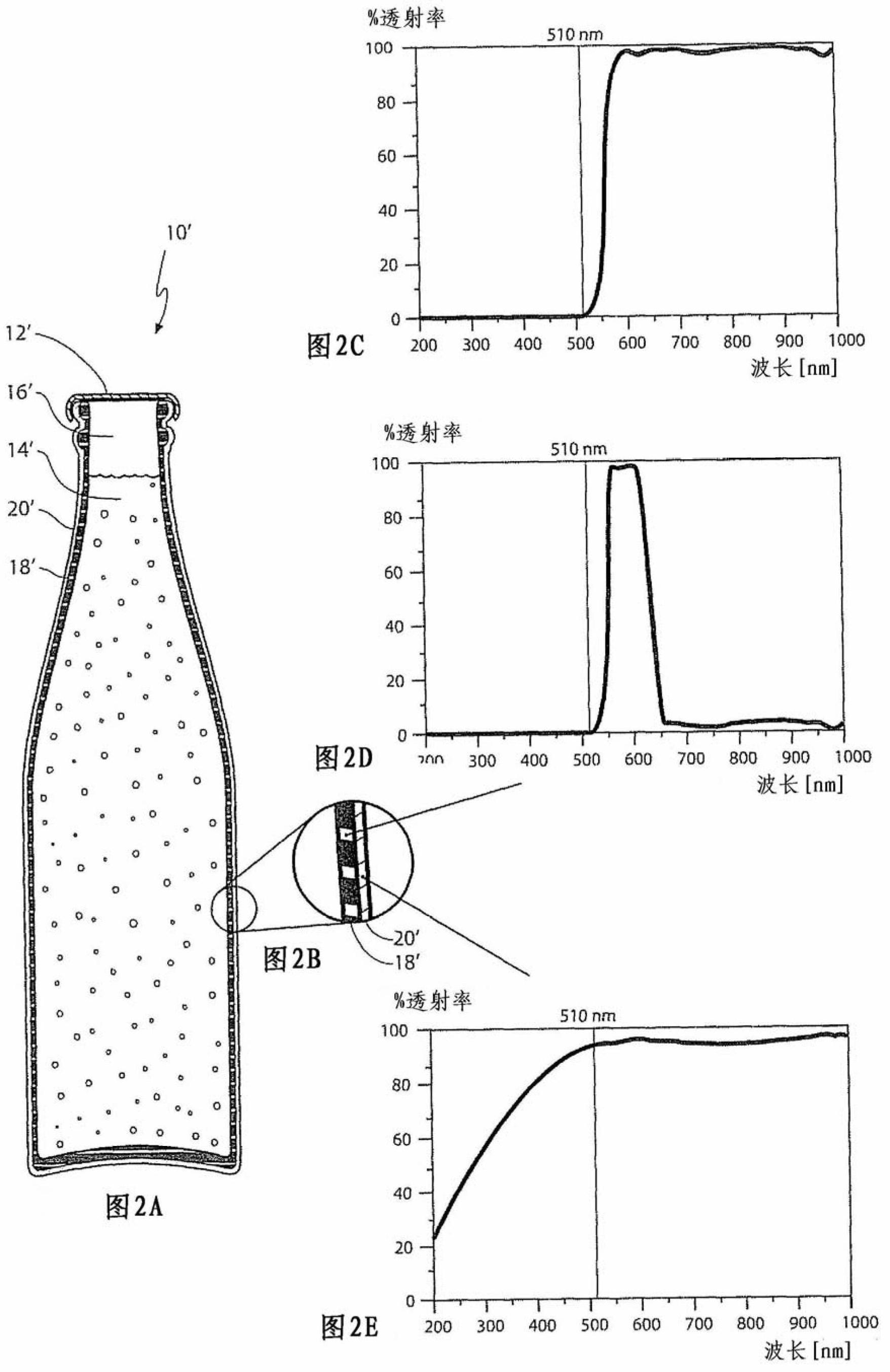

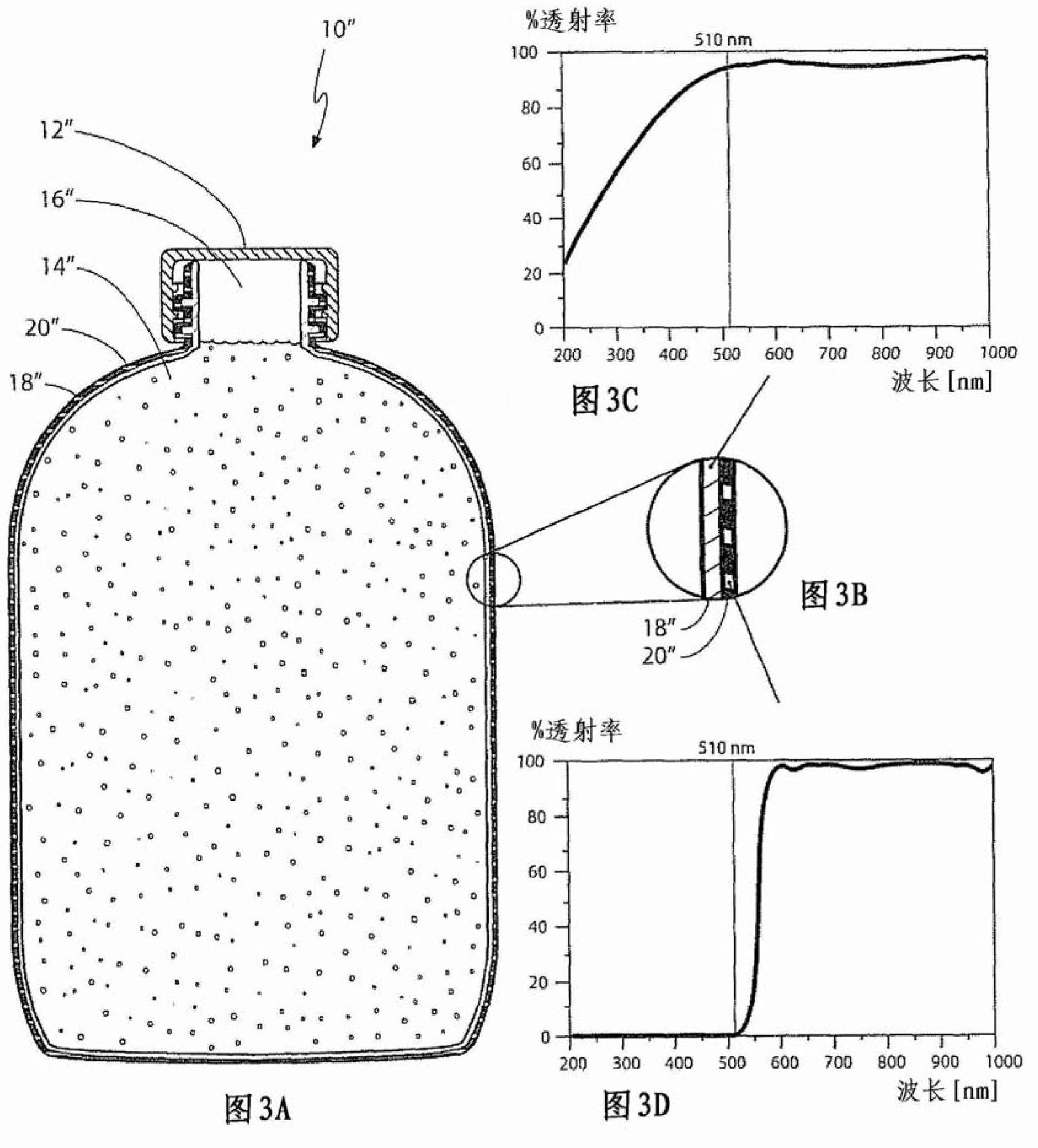

Eliminating the generation of MBT in a hops based beverage

A bottle (10), container or beverage glass for containing a hops based beverage, in particular beer, includes a concentration between 10 [mu]g / l and 10 mg / l of Riboflavin. The bottle, container or beverage glass are at least partially transparent or translucent to visible light and have an optical filter characteristic preventing light transmission of wavelengths between 200 nm and 510 nm to a level preventing generation of more than a tasteable concentration of MBT in the beverage through photochemical reactions and photochemically initiated auto-catalytic reactions involving the Riboflavin. The tasteable concentration is between 1 ng / l and 35 ng / l, preferably between 5 ng / l and 25 ng / l, and more preferably 10 ng / l.

Owner:CARLSBERG BREWERIES AS

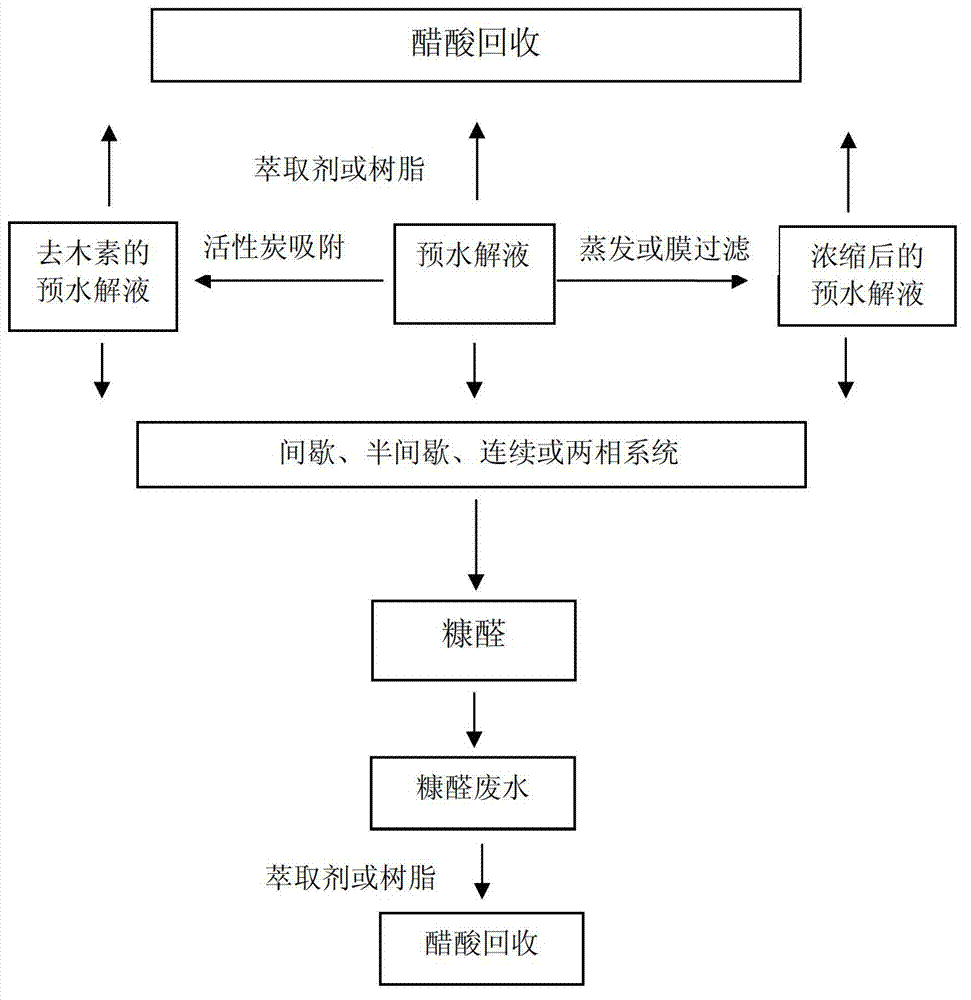

Dissolving pulp prehydrolysis solution autocatalysis furfuraldehyde preparation method and recycling method for acetic acid in prehydrolysis solution waste water and furfuraldehyde waste water

InactiveCN102863405AOxygen-containing compound preparationOrganic compound preparationAcetic acidFuraldehyde

The invention discloses a dissolving pulp prehydrolysis solution autocatalysis furfuraldehyde preparation method and a recycling method for acetic acid in prehydrolysis solution waste water and furfuraldehyde waste water after prehydrolysis solution autocatalysis furfuraldehyde preparation. The dissolving pulp prehydrolysis solution autocatalysis furfuraldehyde preparation method includes that dissolving pulp prehydrolysis solution for preparing furfuraldehyde comprises dissolving pulp prehydrolysis solution A, dissolving pulp prehydrolysis solution B from which lignin is eliminated, dissolving pulp prehydrolysis solution C which is evaporated and concentrated and dissolving pulp prehydrolysis solution D which is subjected to membrane filtration and concentration; and the prehydrolysis solutions are placed in high-pressure reactors respectively, catalysts such as sulfuric acid, hydrochloric acid or acetic acid is not required to be added for autocatalysis reaction, during the reaction, pentosan is hydrolyzed into pentose, and the pentose is dehydrated and cyclized to obtain the furfuraldehyde. The acetic acid in the prehydrolysis solution waste water and the furfuraldehyde waste water after prehydrolysis solution autocatalysis furfuraldehyde preparation is recycled through a trioctylamine / n-caprylic alcohol mixture or resin. The methods are practical and operable, and the preparation method is an environmental-friendly preparation method which can turn waste into wealth.

Owner:TIANJIN UNIV OF SCI & TECH

Chemical amplification for the synthesis of patterned arrays

InactiveUS20060141511A1High resolutionIncrease contrastBioreactor/fermenter combinationsMaterial nanotechnologyCombinatorial synthesisProtecting group

Radiation-activated catalysts (RACs), autocatalytic reactions, and protective groups are employed to achieve a highly sensitive, high resolution, radiation directed combinatorial synthesis of pattern arrays of diverse polymers. When irradiated, RACs produce catalysts that can react with enhancers, such as those involved in autocatalytic reactions. The autocatalytic reactions produce at least one product that removes protecting groups from synthesis intermediates. This invention has a wide variety of applications and is particularly useful for the solid phase combinatorial synthesis of polymers.

Owner:AFFYMETRIX INC

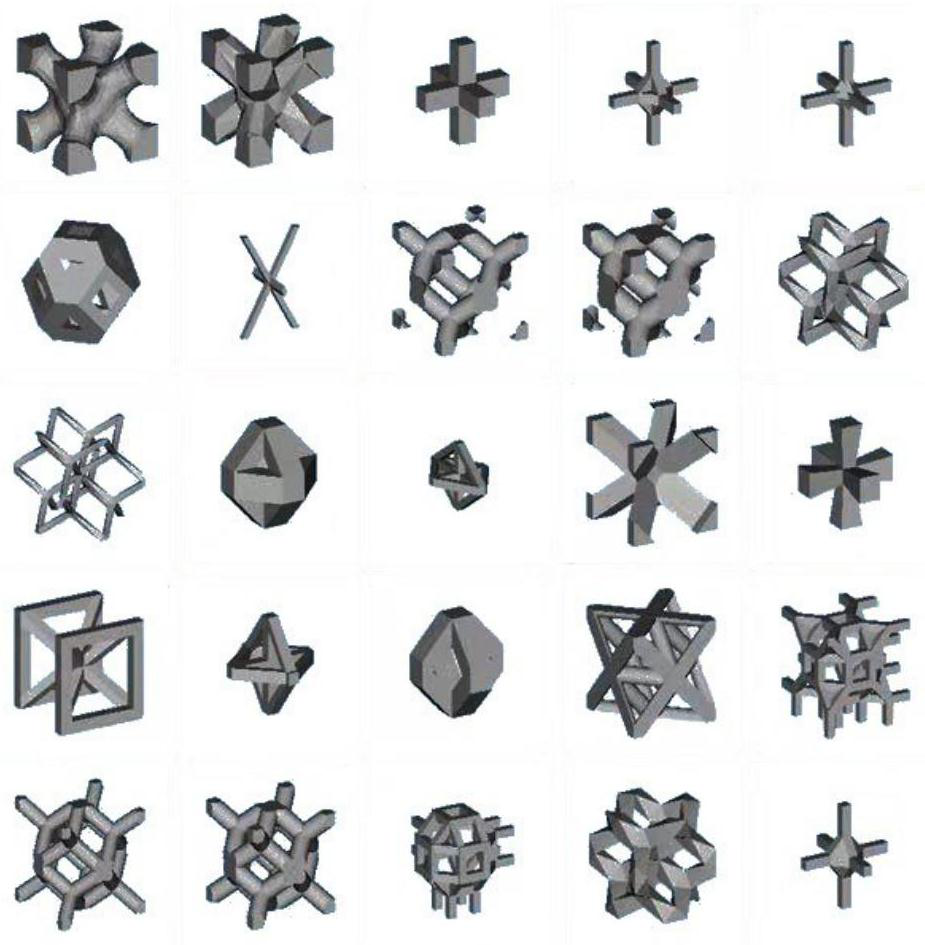

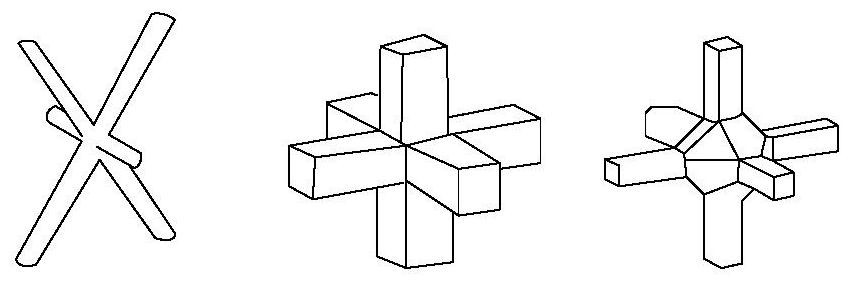

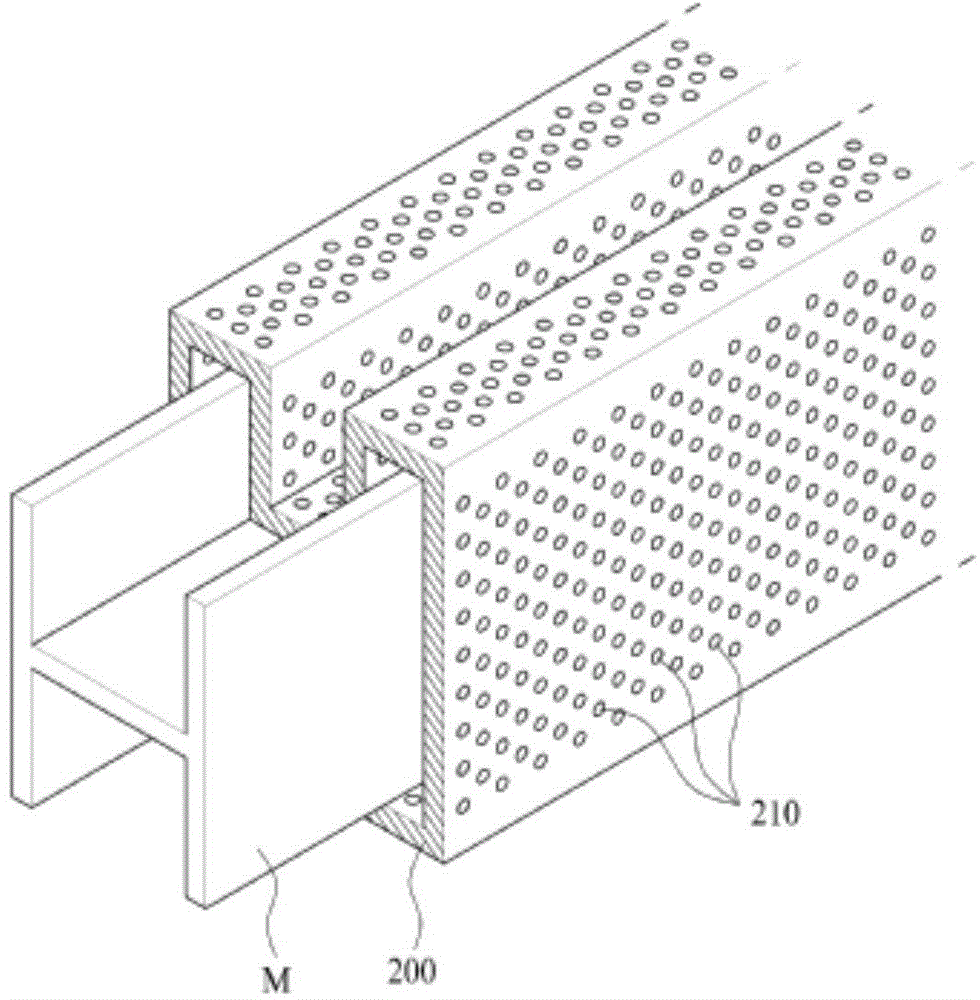

Metal-based autocatalytic reactor based on 3D printing as well as preparation method and application of metal-based autocatalytic reactor

PendingCN114042424AIncrease the effective catalytic areaOptimizing Catalytic FunctionAdditive manufacturing apparatusChemical/physical processesPtru catalystReduction treatment

The invention provides a metal-based autocatalytic reactor based on 3D printing and a preparation method and application of the metal-based autocatalytic reactor. The preparation method comprises the following steps that: (1) a structure of the autocatalytic reactor is generated through three-dimensional software, and a framework of the structure is filled with repeated structural units; (2) metal powder is adopted as a printing raw material, printing parameters are set, and 3D printing is conducted under the protective atmosphere; 3) annealing is conducted: a printed piece is separated from a substrate; and 4) roasting and reduction treatment are conducted. The metal-based autocatalytic reactor integrally formed through the 3D printing technology has the double functions of a reactor and a catalyst, the integral forming speed is high, the structural precision is high, the mechanical strength is high, and the catalyst is not prone to falling off; and the problems that a traditional catalyst is insufficient in mechanical strength and prone to pulverization and breakage after long-term use to cause reaction channel blockage, and surface active components fall off to reduce reaction activity can be effectively solved.

Owner:上海簇睿低碳能源技术有限公司

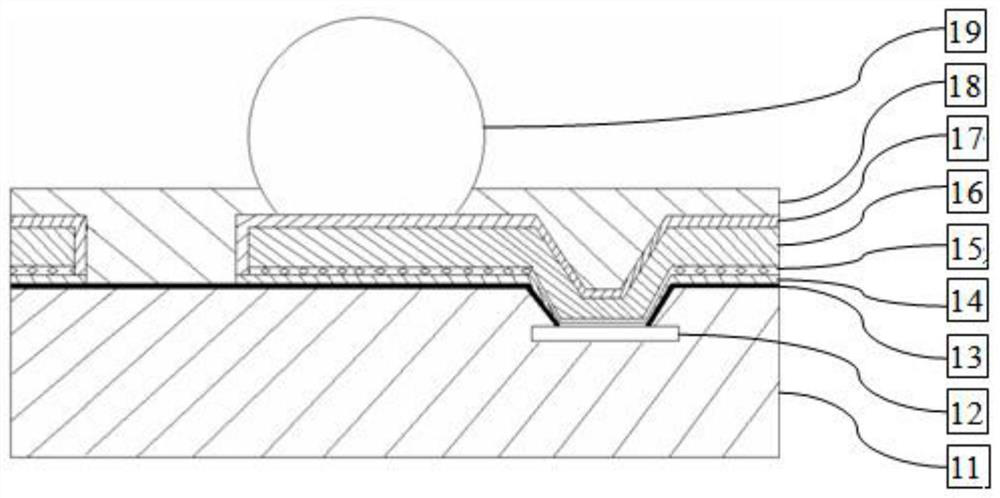

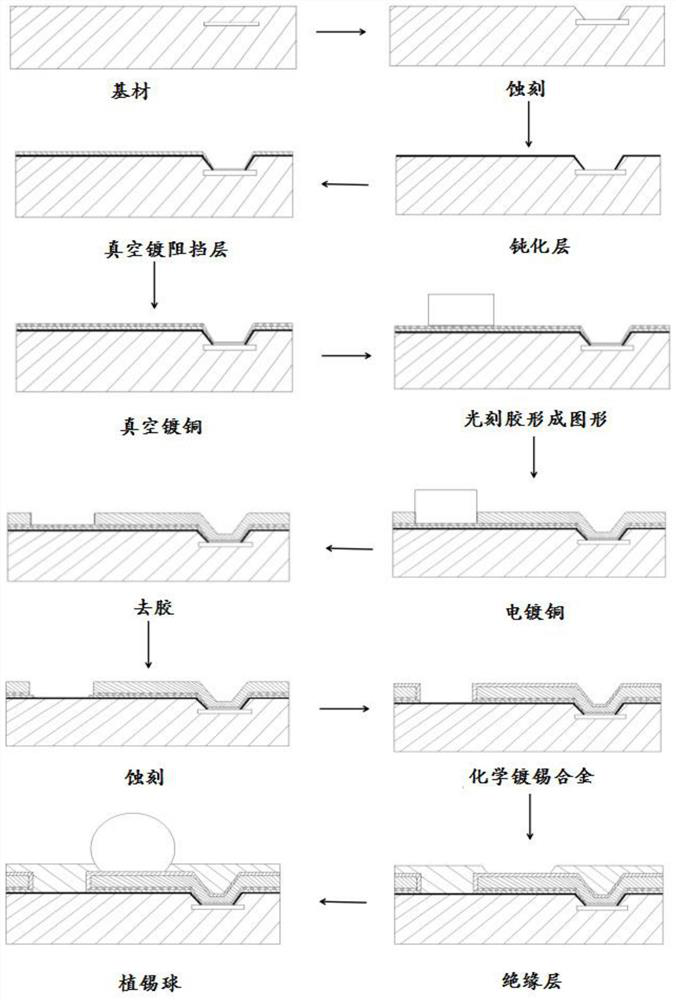

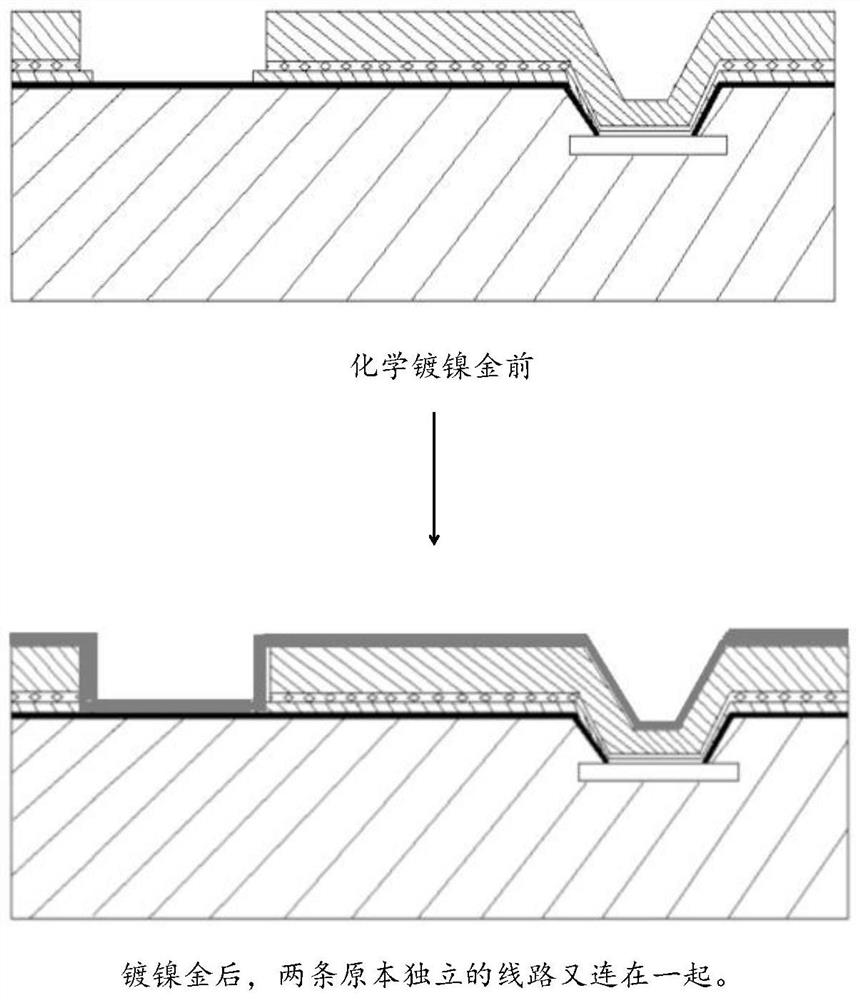

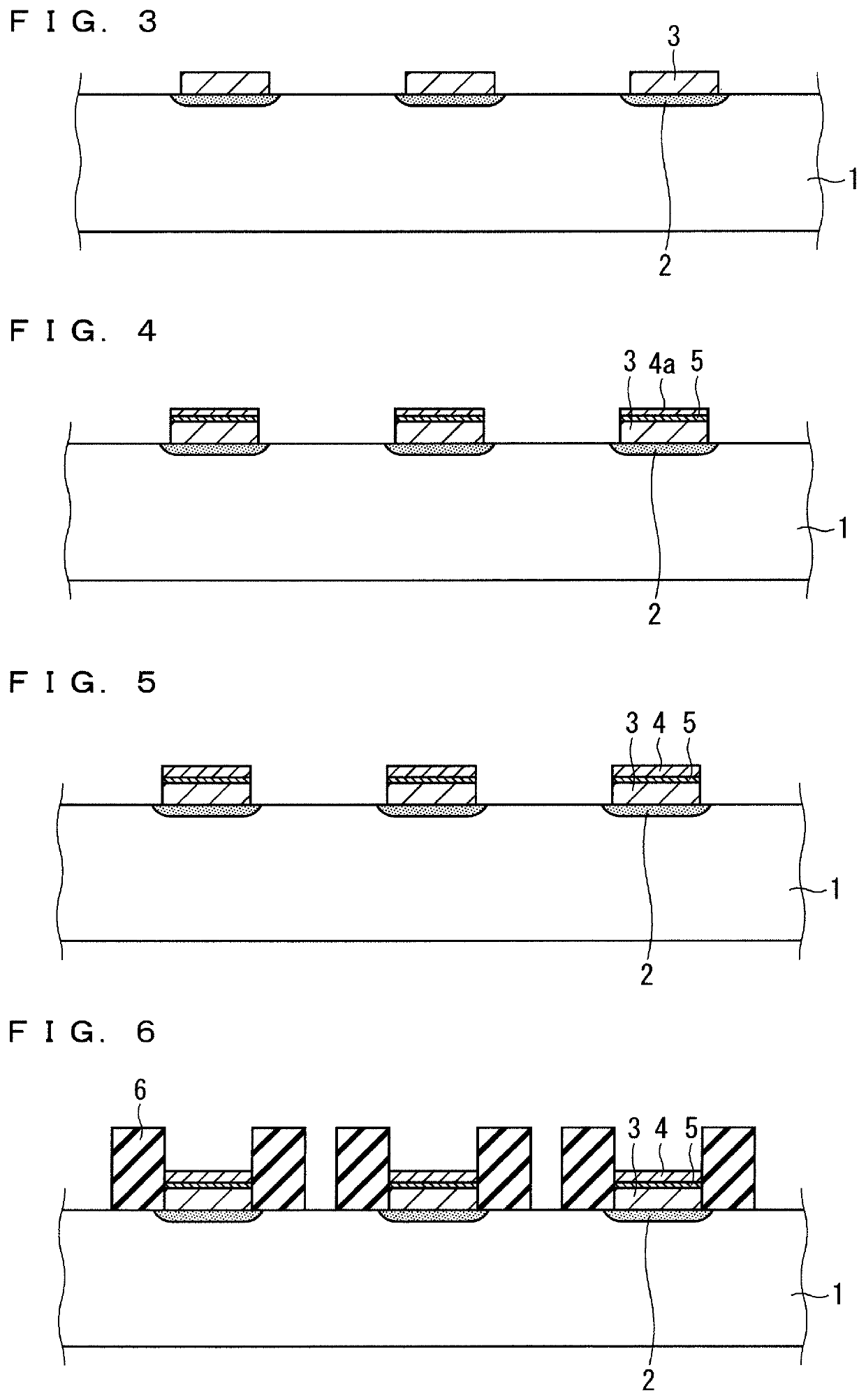

Process for manufacturing metallized coating under wafer bump and coating structure thereof

ActiveCN112382579AOvercome the limitation of line width and line spacingThere is no risk of leakage platingSemiconductor/solid-state device detailsSolid-state devicesWaferTin plating

The invention discloses a process for manufacturing a metallized coating under a wafer bump and a coating structure thereof. A substrate in the process is a silicon or silicon carbide semiconductor; wherein a conductive circuit area and a non-conductive area are arranged on the surface of the substrate, and the conductive circuit area on the surface of the substrate sinks downwards to form an inverted wafer bump. The coating obtained through a chemical tin alloy plating process is a chemical replacement type coating, electrification is not needed, a traditional chemical auto-catalytic reactionis not needed, and only a replacement reaction is needed. The under bump metallization (UBM) and the redistribution line (RDL) obtained by the method provided by the invention not only can have binding property, but also have good weldability.

Owner:SHENZHEN CHENGGONG CHEM

Method for treating chemical nickel-plating waste liquid by utilizing autocatalytic reaction

InactiveCN111592151AEfficient catalytic reactionFacilitate recyclingCalcareous fertilisersWater contaminantsElectroless nickelChloride

The invention discloses a method for treating chemical nickel-plating waste liquid by utilizing an autocatalytic reaction. The method comprises the following steps: (1) adjusting the pH value of to-be-treated chemical nickel-plating waste liquid to be 10-11; (2) adding a treatment preparation into the to-be-treated chemical nickel-plating waste liquid subjected to ultrasonic dispersion; (3) standing and layering the reaction liquid; (4) adding halogen powder into the solution obtained in the step (3); (5) putting the solution filtered in the step (4) into a cathode chamber of an electrolytic cell for electrolysis; and (6) adding a calcium chloride solution into the solution obtained after electrolysis. According to the method, the mechanism of the chemical nickel autocatalytic reaction isutilized, various elements are recycled at a time, the cost is low, the process is short, the efficiency is high, operation is easy and convenient, and recycling and reusing of nickel resources are facilitated.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP +1

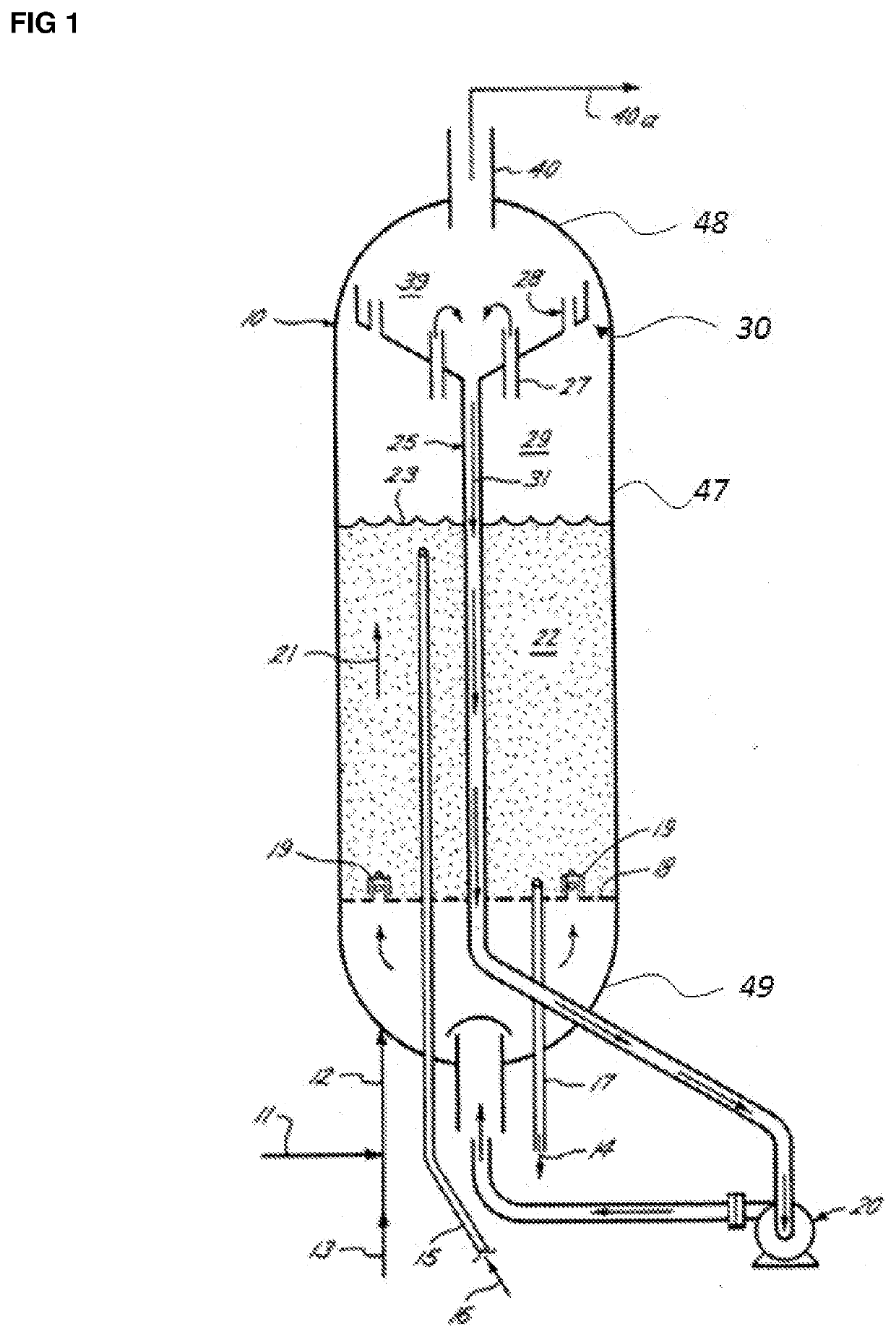

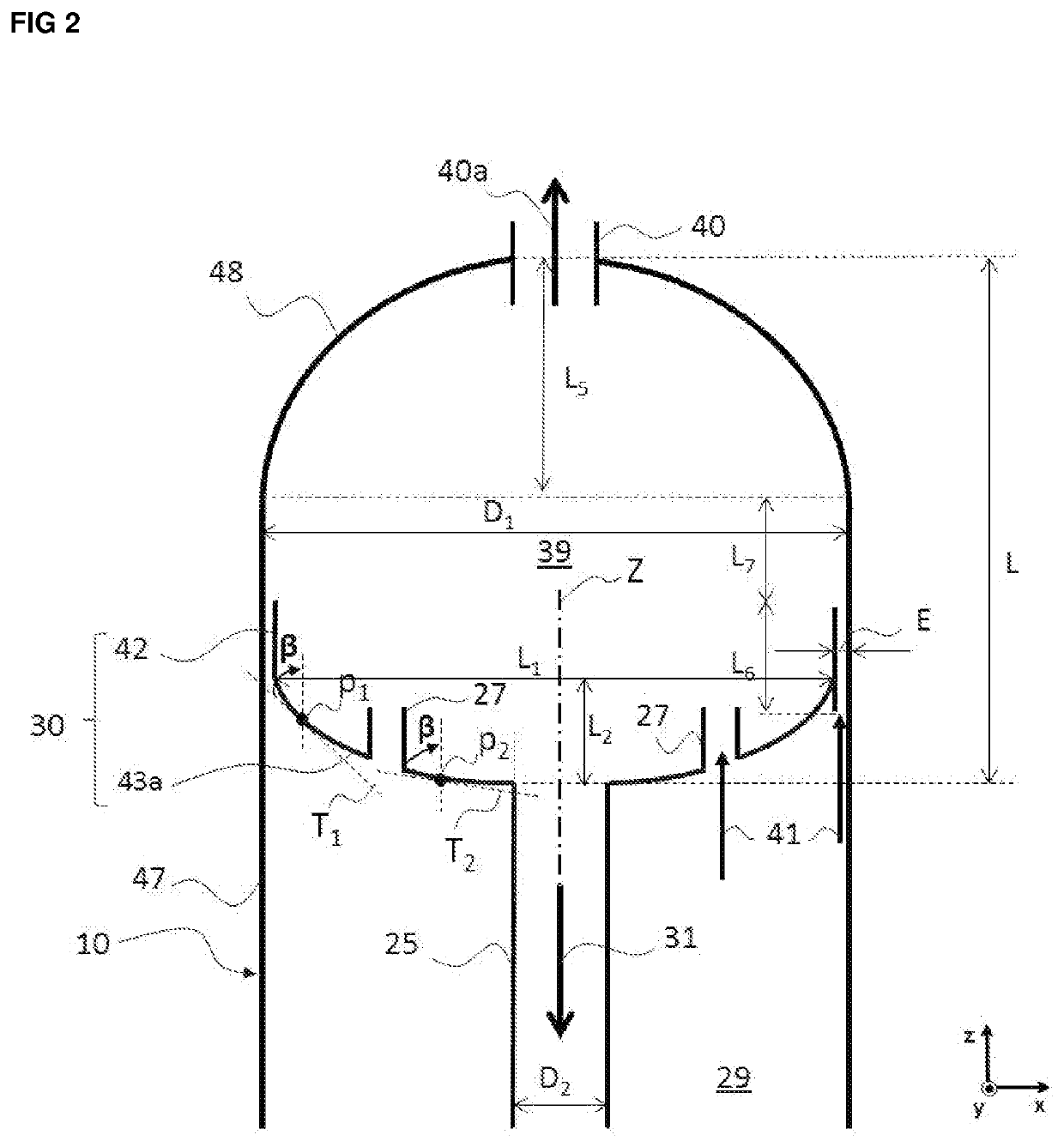

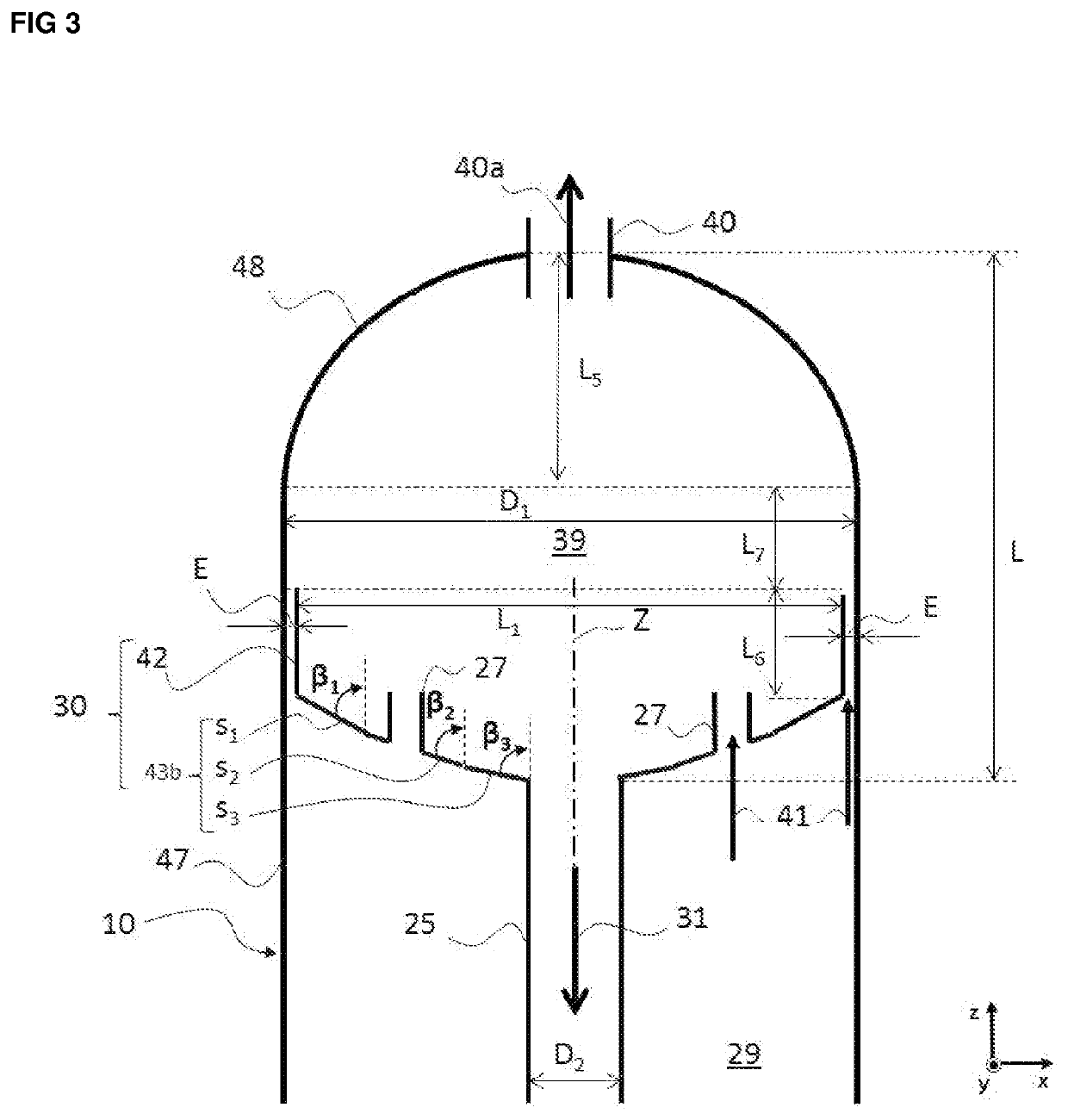

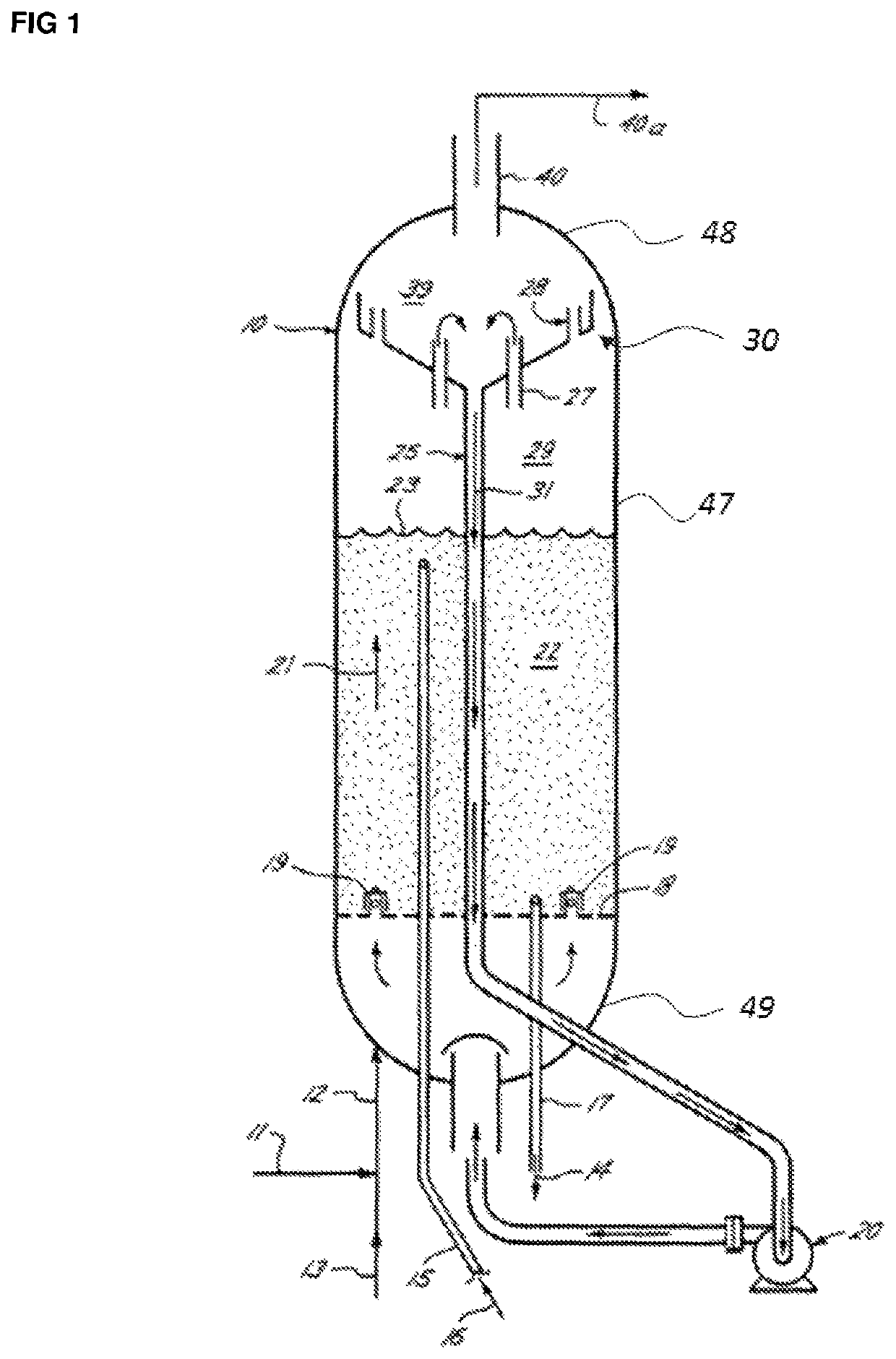

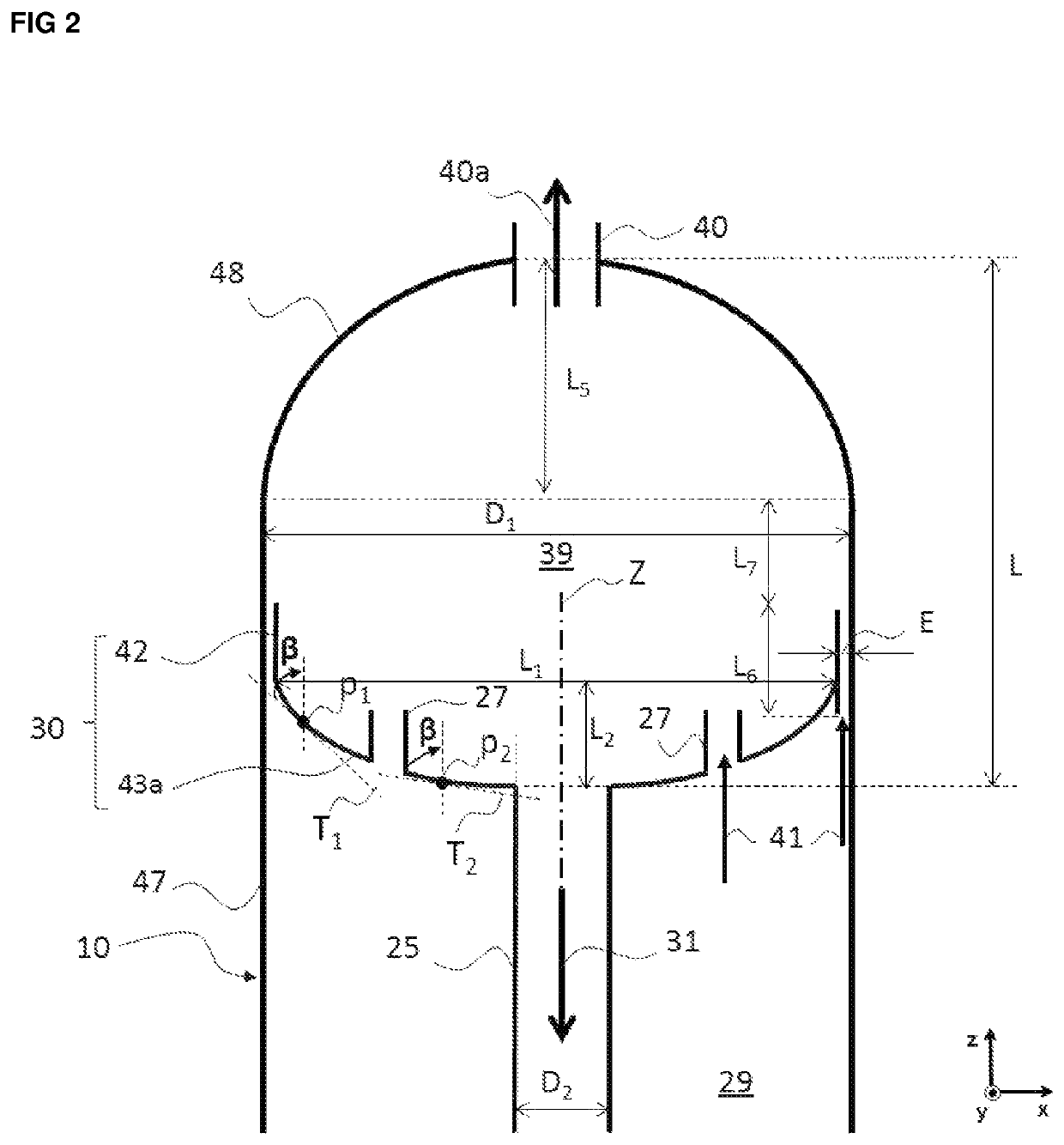

Three-phase reactor with recycle cup of decreasing section and of variable angle of inclination

ActiveUS20200324261A1Improve performance qualityReduced deposit formationLiquid degasificationChemical/physical processesThermodynamicsVapor–liquid separator

The present invention relates to a three-phase reactor for the reaction of a hydrocarbon feedstock with hydrogen and to a hydroconversion process, for example of H-Oil™ type, employing it, comprising a chamber with an upper end and a gas / liquid separation device comprising:a recycle cup, above the catalytic reaction zone and delimiting, with the upper end, a recycle zone, comprising a cylindrical upper part extended by a lower part of decreasing section and of variable angle of inclination, provided with vertical pipes for the passage of a gas / liquid mixture originating from a catalytic reaction zone, and having a fixed angle of inclination β of between 50° and 85° with respect to the axis of the cylindrical part,a pipe for recycle of the liquid at the apex of the lower part, in fluidic communication with the lower end of the chamber by recirculation means.

Owner:INST FR DU PETROLE

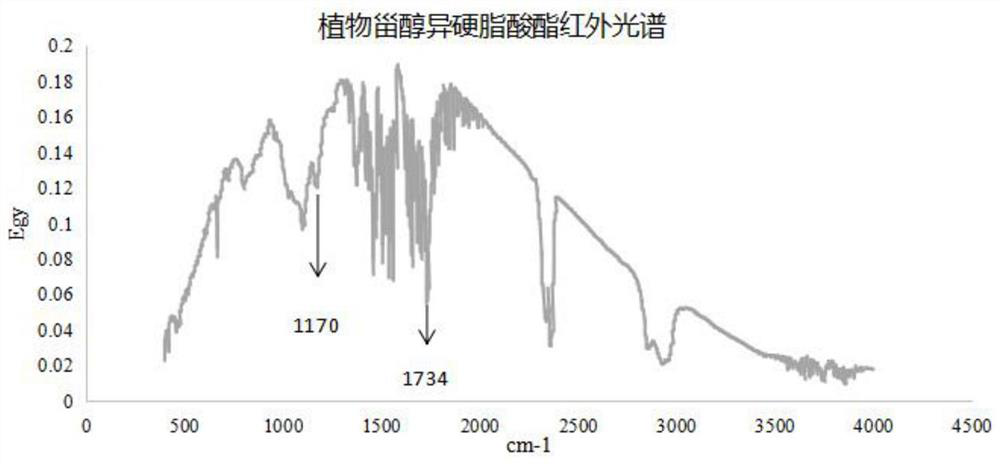

Phytosterol isostearate and preparation method thereof

PendingCN113563406AImprove conversion rateSimple production technologySteroidsIsostearic acidPlant sterol

The invention relates to phytosterol isostearate and a preparation method thereof. The preparation method comprises the steps of preparation of a mixture solution, preparation of a membrane casting solution, coating, soaking, autocatalytic reaction of phytosterol isostearate, concentration of eluent and the like. Compared with the prior art, the preparation method of the phytosterol isostearate has the advantages of high conversion rate and simple production technology. The preparation method does not need high temperature, and the phytosterol isostearate molecularly imprinted membrane can specifically separate a product from a reaction system; and the purity of the product can reach 99.9% or above by weight, and the product is good in color and does not need to be decolored.

Owner:SHAANXI HEALTHFUL BIOLOGICAL ENG

System for preparing dichloropropanol by autocatalytic reaction of glycerol and hydrogen chloride

ActiveCN102040479BReduce usageEliminate formationPreparation by halogen introductionBoiling pointGlycerol

The invention discloses a process for preparing dichloropropanol by an autocatalytic reaction of glycerol and hydrogen chloride. The process comprises the following steps: the glycerol and the hydrogen chloride gas perform the autocatalytic reaction at the temperature of between 105 and 160 DEG C and pressure of between 0.05 and 0.5MPa, and generated water is distilled and removed during the reaction. The invention also discloses a system for preparing the dichloropropanol by the autocatalytic reaction of the glycerol and the hydrogen chloride. The invention adopts the technology of the autocatalytic reaction of the glycerol and the hydrogen chloride without using a catalyst, so that the production cost is remarkably reduced, formation of high boiling side products is eliminated, and the reaction selectivity is improved. The invention has the advantages of simple process and low production cost. The system can ensure that the glycerol is completely converted and greatly improves the selectivity of the dichloropropanol, so that the purity of the finally prepared dichloropropanol is more than 99.5 percent.

Owner:NANTONG TIANSHI CHEM

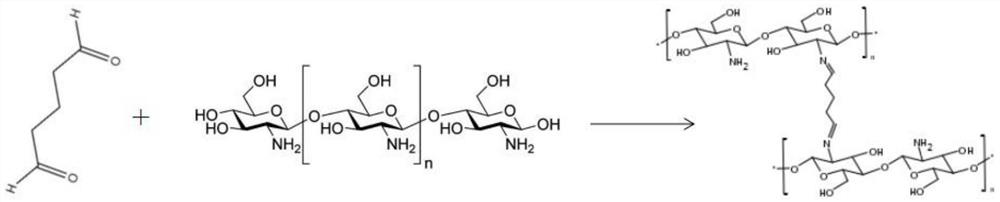

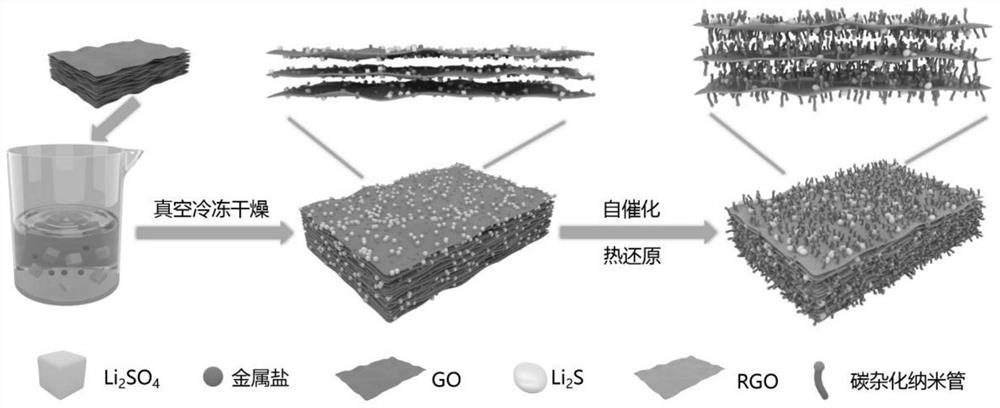

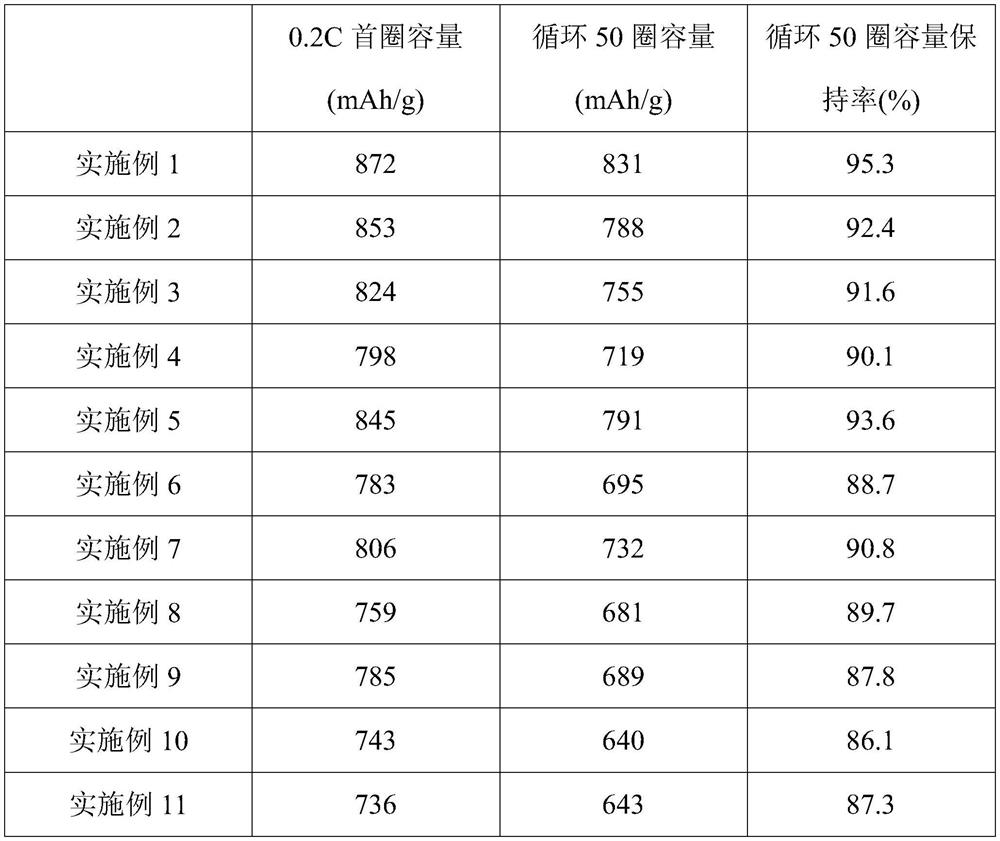

Lithium sulfide/carbon composite material with multilevel structure as well as preparation method and application of lithium sulfide/carbon composite material

PendingCN114497499AStable structureImprove conductivityMaterial nanotechnologyPositive electrodesCarbon compositesOrganic compound

The invention provides a multilevel structure lithium sulfide / carbon composite material and a preparation method and application thereof.The preparation method comprises the steps that a lithium source, a metal salt solution and a graphene oxide solution are mixed and dried to obtain a precursor material, and the precursor material and organic compound powder are subjected to annealing treatment together to obtain the multilevel structure lithium sulfide / carbon composite material. And carrying out autocatalytic reaction and thermal reduction reaction under the annealing treatment condition to obtain the lithium sulfide / carbon composite material with the multilevel structure. The multilevel structure lithium sulfide / carbon composite material obtained by the preparation method disclosed by the invention can stabilize the structure and improve the conductivity through the composite action of the lithium sulfide, the reduced graphene oxide and the carbon hybrid nanotube, and meanwhile, can effectively relieve the volume change of the lithium sulfide / carbon composite material in the charging and discharging process, so that the performance of the lithium sulfide / carbon composite material is improved. And the material has excellent cyclic specific capacity and capacity retention ratio.

Owner:CHINA AUTOMOTIVE INNOVATION CORP

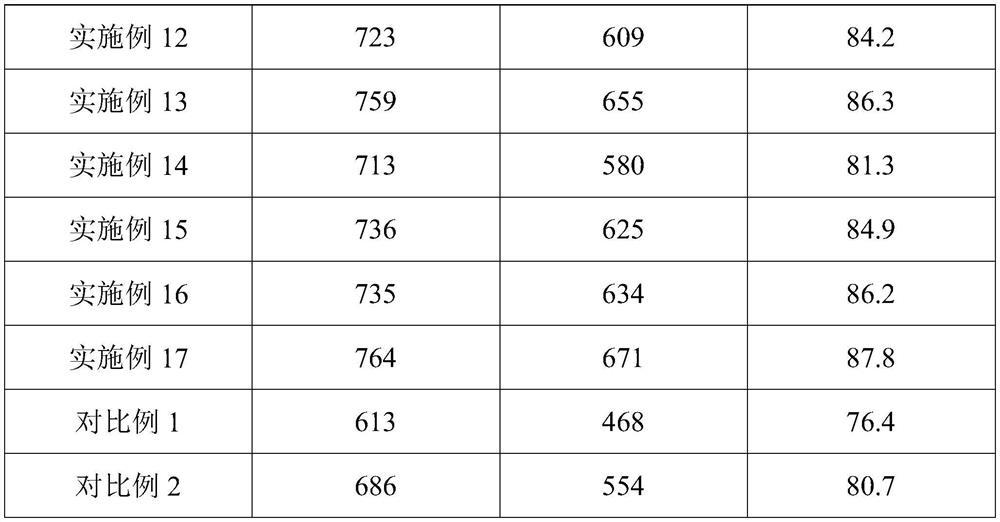

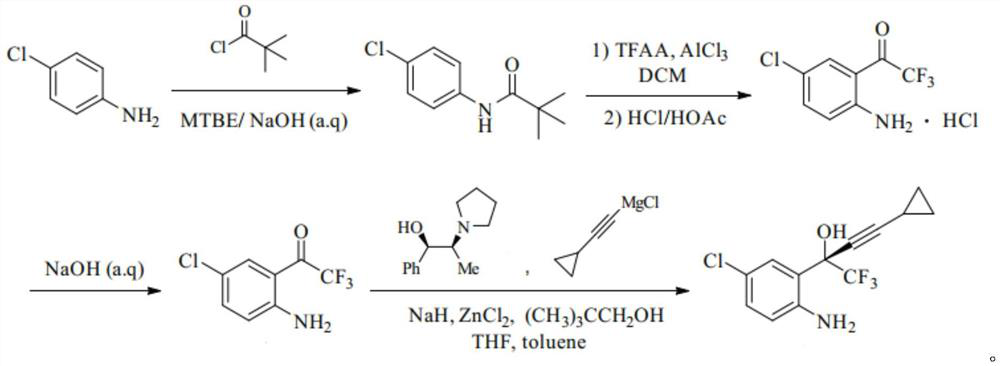

A kind of synthetic method of efavirenz key intermediate

ActiveCN108947855BLow toxicityRaw materials are cheap and easy to getOrganic compound preparationOrganic chemistry methodsP-chloroanilineChlorobenzene

Owner:JIANGSU SHAXING CHEM

A kind of preparation method of metal-ceramic composite powder with core-shell structure

ActiveCN109365802BSimple processShorten the timeTransportation and packagingMetal-working apparatusChemical platingCeramic composite

The invention discloses a method for preparing a metal-ceramic composite powder with a core-shell structure. The preparation method comprises the following steps: 1) Catalyzing and activating the ceramic powder particles: placing the ceramic powder particles in a reactor, heating The reaction raw material, using the carrier gas to carry the reaction raw material vapor into the reactor, passing through hydrogen gas to undergo a reduction reaction, so that the catalytic metal is deposited on the surface of the ceramic powder particles; 2) The reaction of placing the ceramic powder particles obtained in step 1) in a water bath Add metal salt raw materials and reducing agent to the device, and coat the metal coating layer through self-catalyzed reaction to obtain metal-ceramic composite powder. The present invention saves the roughening, sensitization and activation processes in the traditional electroless metal plating process, does not need to use expensive palladium chloride catalyst, avoids the introduction of impurity palladium, and realizes metal plating and cladding at a relatively low temperature. The metal content is controllable, the overall coating process is simple, and it is suitable for large-scale industrial production.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Online resourceful treatment method for chemical copper plating waste liquid

PendingCN111499086AHigh recovery rateReduce the burden onTreatment involving filtrationWaste water treatment from metallurgical processAmmoniacal nitrogenPtru catalyst

The invention discloses an online resourceful treatment method for chemical copper plating waste liquid. A copper-based catalyst is employed and used for carrying out an autocatalytic reaction on thechemical copper plating waste liquid in an autocatalytic reactor; copper ions in the waste liquid are reduced into elemental copper and are recycled; the treated waste liquid enters a three-dimensional electrolysis device; organic substances such as a reducing agent and a complexing agent in the waste liquid are efficiently oxidized; then, the method includes further flocculating and precipitatingthe waste liquid by adopting a chemical precipitation method to remove ammonia nitrogen and macromolecular substances in the water; and finally, membrane filtration equipment is adopted for purification treatment and is used for further intercepting residual copper ions in the wastewater and returning the residual copper ions to the autocatalytic reactor for circular treatment, so that the copperions in the waste liquid can be recycled to the greatest extent.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP +2

Three-phase reactor with recycle cup of decreasing section and of variable angle of inclination

ActiveUS11090623B2Improve performance qualityReduce formationLiquid degasificationChemical/physical processesThermodynamicsVapor–liquid separator

Owner:INST FR DU PETROLE

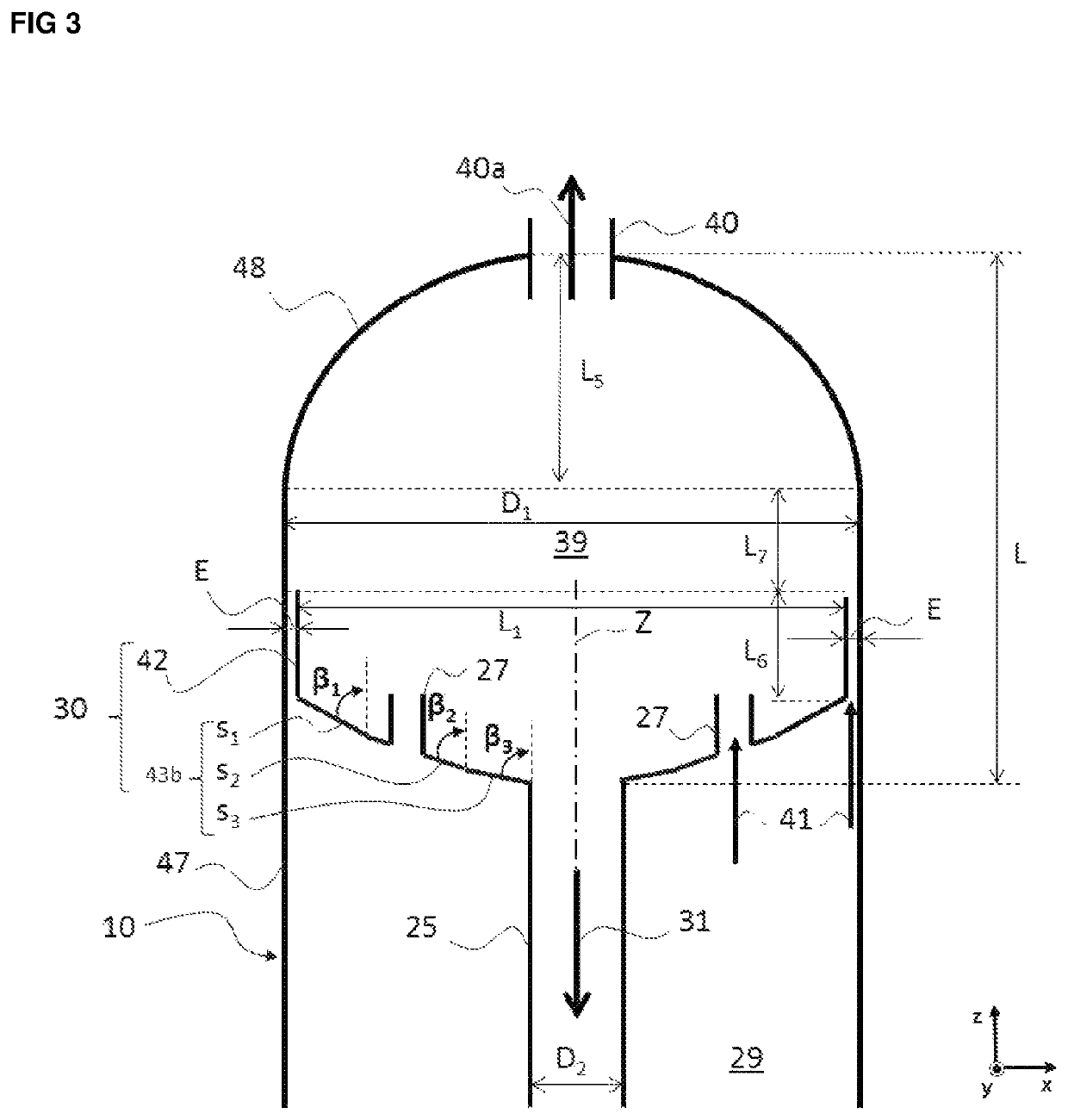

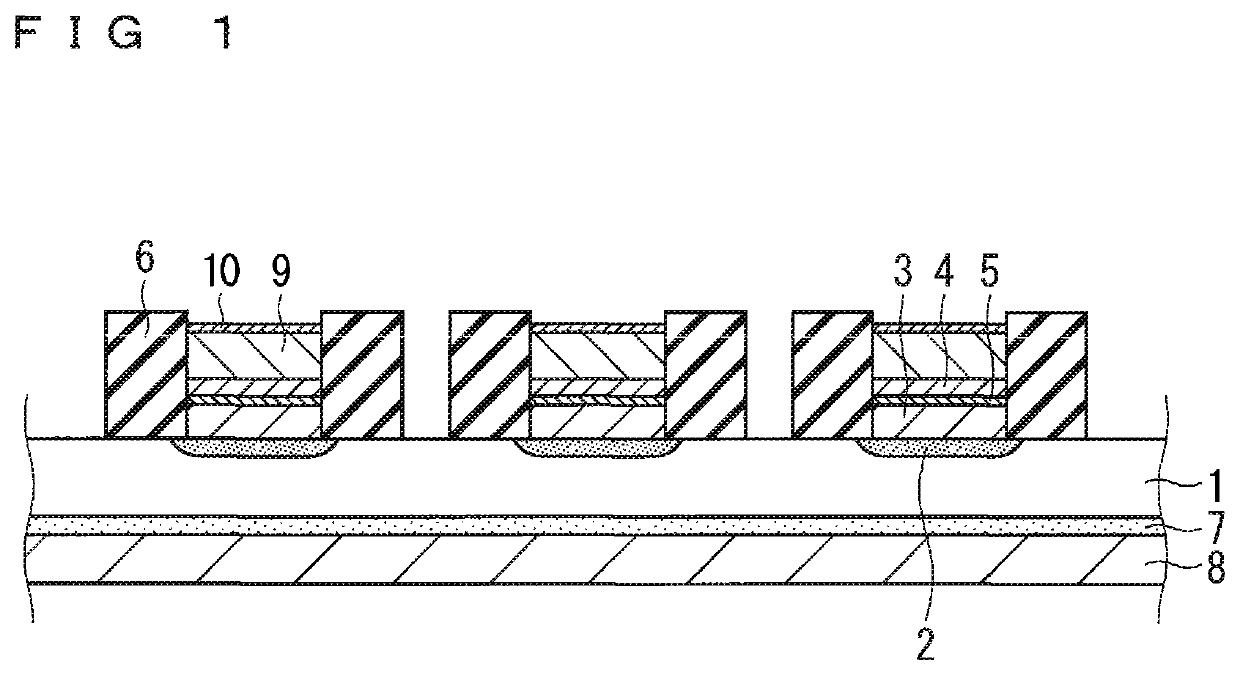

Semiconductor device including a reactant metal layer disposed between an aluminum alloy film and a catalyst metal film and method for manufacturing thereof

ActiveUS10937657B2Reduce pollutionSemiconductor/solid-state device detailsVacuum evaporation coatingElectroless nickelPtru catalyst

A technology capable of reducing contamination of a semiconductor substrate above which a nickel film is disposed is provided. A semiconductor device includes: a semiconductor substrate; an aluminum alloy film disposed on at least one of a front surface and a back surface of the semiconductor substrate; a catalyst metal film disposed above the aluminum alloy film and exhibiting catalytic activity for autocatalytic reaction that deposits nickel; an electroless nickel plating film disposed on the catalyst metal film; and a reactant layer disposed between the aluminum alloy film and the catalyst metal film and containing metal of the catalyst metal film.

Owner:MITSUBISHI ELECTRIC CORP

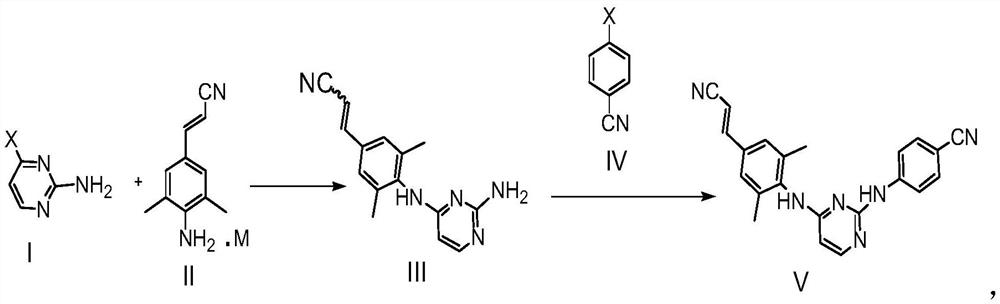

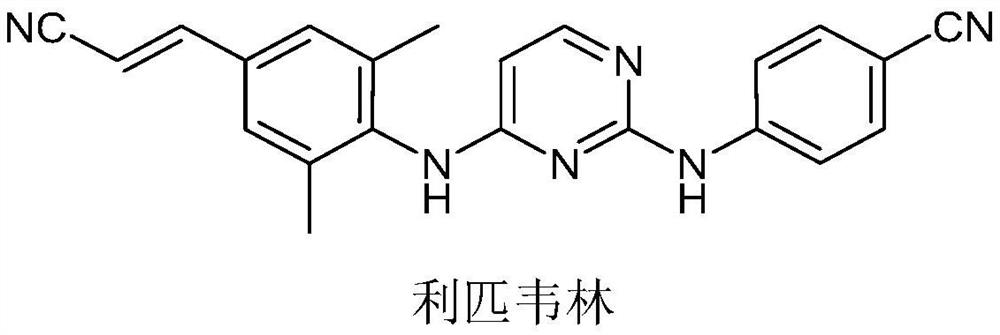

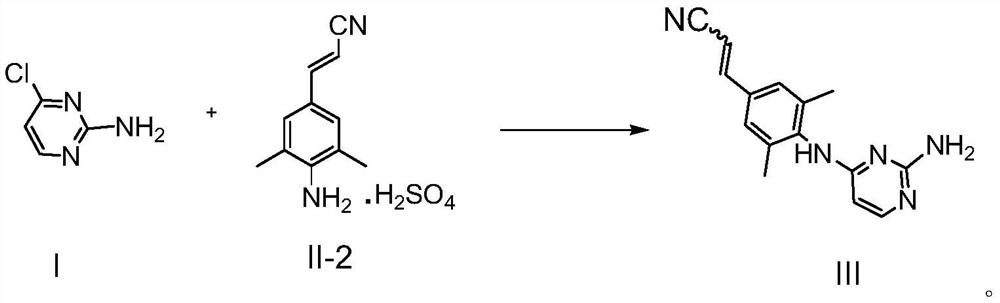

Intermediate for synthesizing rilpivirine, synthesis method thereof and synthesis method of rilpivirine

The invention relates to the technical field of medicine synthesis, in particular to an intermediate for synthesizing rilpivirine, a synthesis method of the intermediate and a synthesis method of the rilpivirine. The intermediate is synthesized according to the following synthesis route: wherein X is a halogen atom, and M is an acid. According to the method, the compound shown in the formula II can generate acid by itself, and then an acid environment is provided for the reaction, so that the compound shown in the formula I and the compound shown in the formula II can be directly subjected to autocatalytic reaction on the basis of not carrying out amino protection on the compound shown in the formula I; and the compound shown in the formula I and the compound shown in the formula II react to form the required intermediate, and the overall yield of the synthesized rilpivirine is increased.

Owner:ANHUI BIOCHEM UNITED PHARMA CO LTD

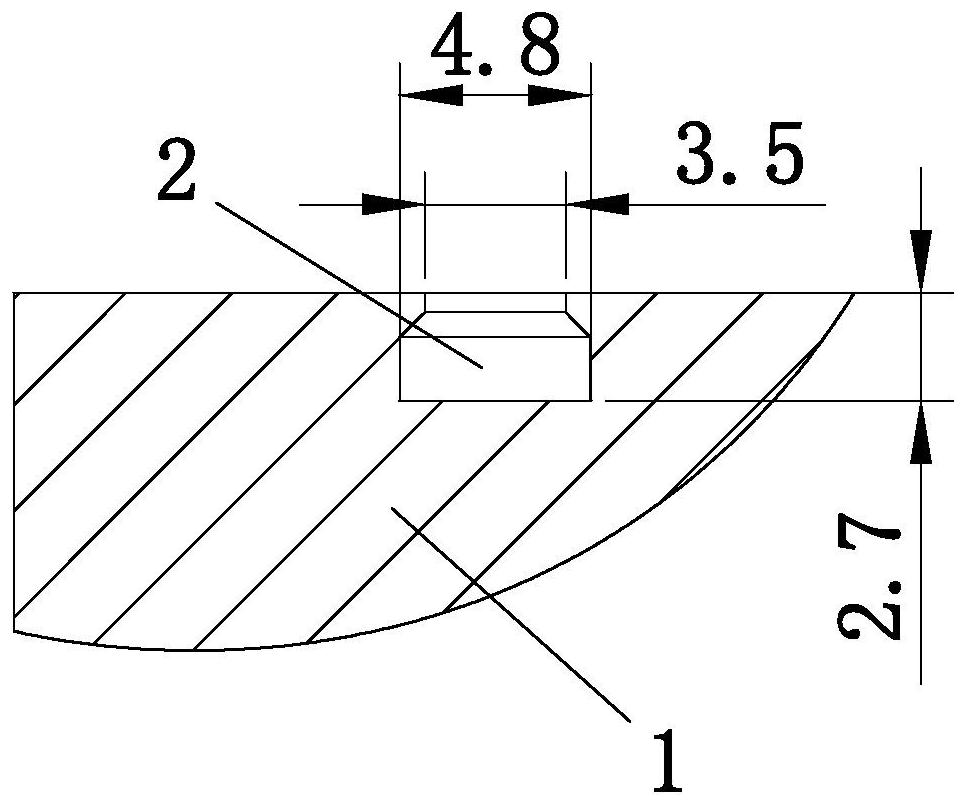

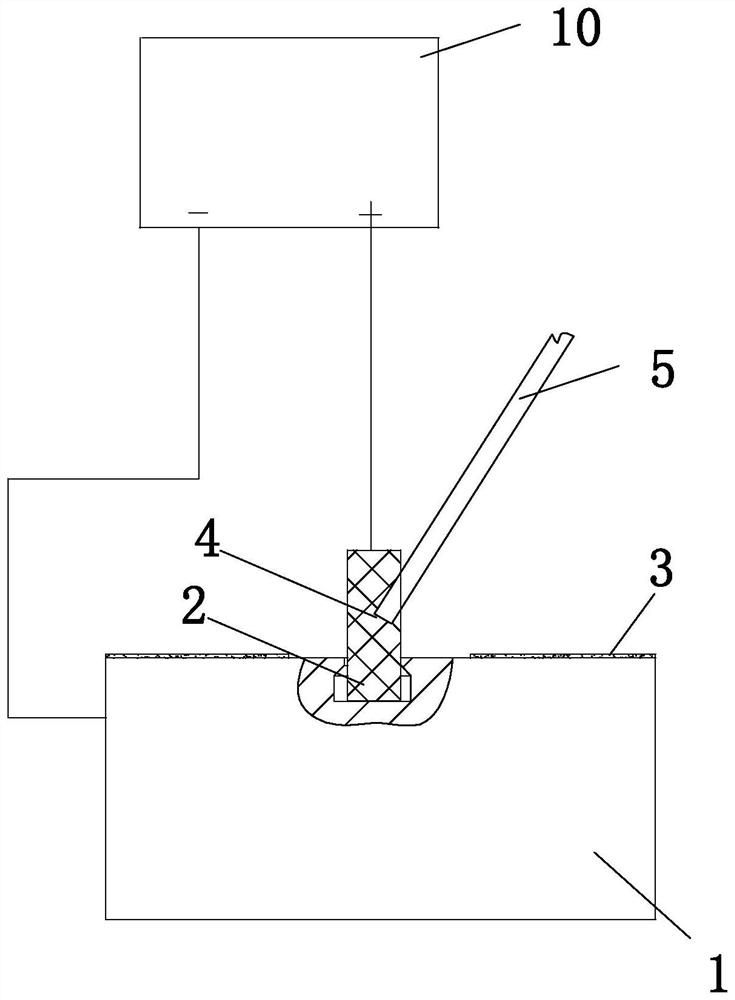

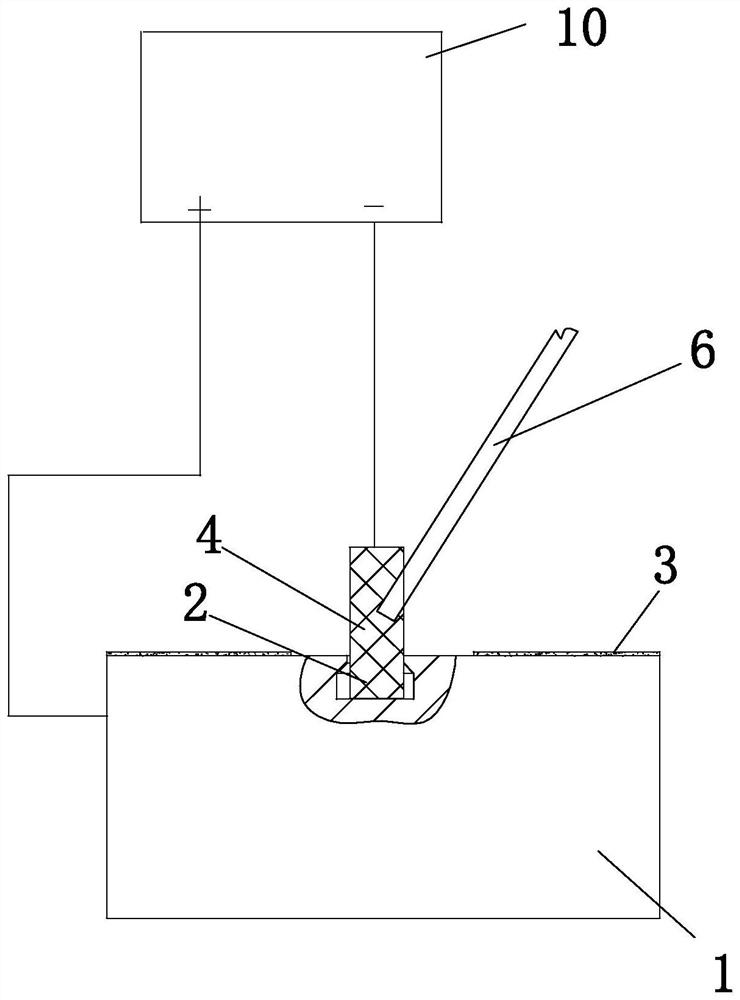

Brush plating method for selective nickel plating in tank

PendingCN114561676AImprove one-time success rateReduce the difficulty of operationElectrolysis componentsProcess efficiency improvementElectrolytic agentMetallurgy

The invention discloses a brush plating method for selective nickel plating in a groove. The brush plating method comprises the following steps: step 1, removing marks and dirt in the groove; step 2, surface preparation; 3, material detection preparation; 4, electrolytic decontamination in the to-be-plated bath: starting forward voltage, adding electrolyte into the to-be-plated bath, and brushing back and forth in the to-be-plated bath by using a nickel plating arc-shaped small brush handle along the same direction; 5, activating the metal surface of the to-be-plated bath: starting a reverse voltage, adding an activating solution into the to-be-plated bath, and brushing back and forth in the to-be-plated bath by using a nickel plating arc-shaped small brush in the same direction so as to activate the metal surface of the to-be-plated bath; and 6, nickel plating through autocatalytic reaction deposition, specifically, forward voltage is started, nickel plating liquid medicine is added into a liquid medicine pipe, meanwhile, brush plating is conducted back and forth above the groove opening face of the to-be-plated groove along with the nickel plating liquid medicine pipe in the same direction through a large plane brush, the nickel plating liquid medicine and the metal surface of the part are subjected to the autocatalytic reaction, and a nickel plating layer is formed. A plating layer can be uniform, natural and attractive, and the qualification rate of brush plating is high.

Owner:ZHEJIANG XIANDAO PRECISION MACHINERY CO LTD

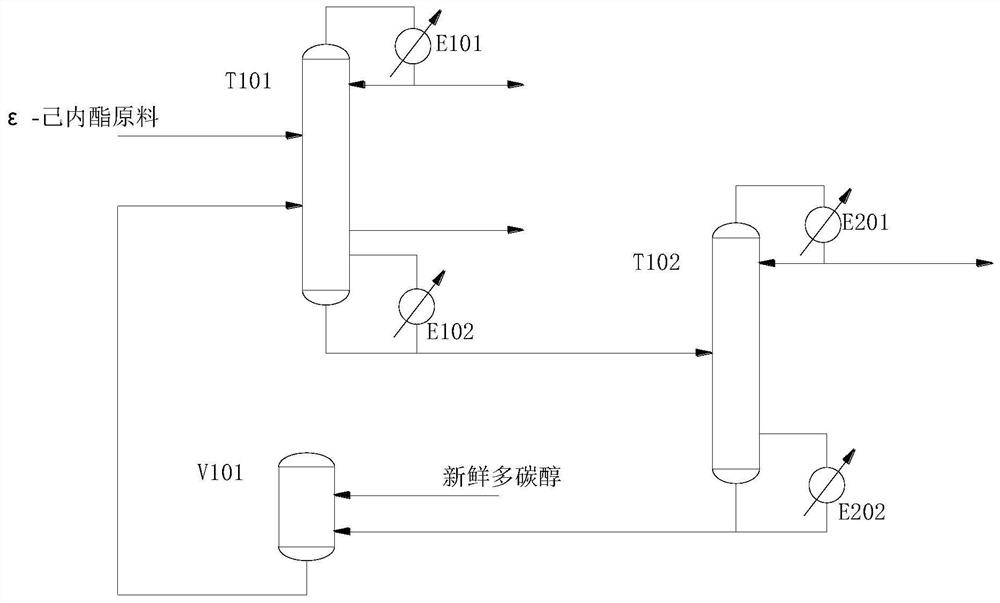

A continuous refining method and device for high-purity ε-caprolactone

The present invention proposes a continuous refining method and device for high-purity ε-caprolactone. The present invention proposes a continuous refining method for high-purity ε-caprolactone, using refined ε-caprolactone as raw material, Using multi-carbon alcohols as entraining agents, in the reactive distillation column, poly-carbon alcohols, polybasic acids, and hydroxycaproic acid undergo autocatalytic reactions to generate corresponding esters, thereby changing the difficulty of separation from ε-caprolactone, and The azeotropic property of water and polycarbonate alcohols can also effectively separate water and ε‑caprolactone. Effectively remove water, polyacids and hydroxycaproic acid from ε-caprolactone through reactive distillation-azeotropic distillation. This process is simple and easy to implement, and can realize continuous production of high-purity ε-caprolactone. The purity of the obtained ε-caprolactone is ≥99.95%, and the yield is ≥99%. Not only can the polycaprolactone produced by ε-caprolactone be used in the medical field, but also greatly improve the economic and social benefits of the enterprise.

Owner:安徽卓泰化工科技有限公司

Continuous esterification production process of trimethyl borate

PendingCN114195815AWill not introduceWill not formGroup 3/13 element organic compoundsPtru catalystTrimethyl borate

The invention relates to a trimethyl borate continuous esterification production process, which comprises the following steps: proportioning methanol and boric acid, carrying out pre-reaction in a pre-reactor, feeding into an esterification tower after pre-reaction, and continuing to carry out autocatalytic reaction; heat coupling of esterification and rectification is completed in the esterification tower, crude trimethyl borate is extracted from the tower top of the esterification tower, and water is extracted from the tower bottom of the esterification tower; a crude trimethyl borate gas phase extracted from the tower top of the esterification tower enters a refining tower, a qualified trimethyl borate product is extracted from the tower top of the refining tower, qualified recovered methanol is obtained from the tower bottom of the refining tower, and the methanol returns to a reaction system for recycling. According to the invention, no catalyst is added, and reactants are adopted for autocatalysis to complete esterification reaction; the esterification reaction operation and the rectification operation are coupled to be completed in one esterification reaction tower, so that the reaction conversion rate and the reaction yield can be improved; the esterification reaction is an exothermic reaction, the esterification reaction and the rectification operation are completed in the esterification reaction tower at the same time, the esterification reaction heat can be applied to the rectification operation, and the energy consumption of the system is greatly reduced.

Owner:烟台国邦化工机械科技有限公司

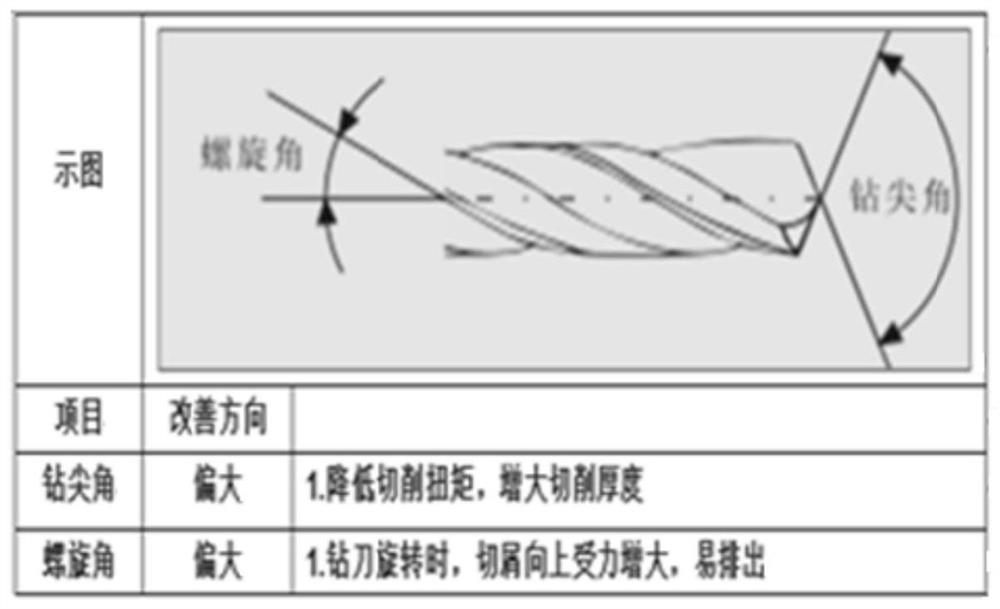

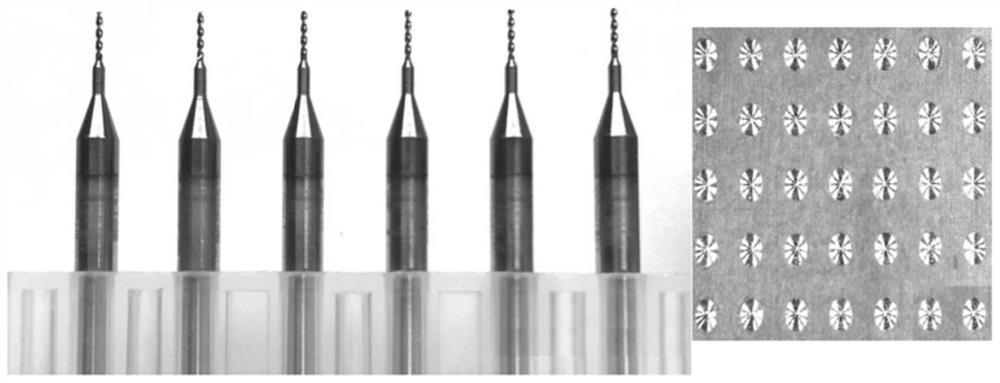

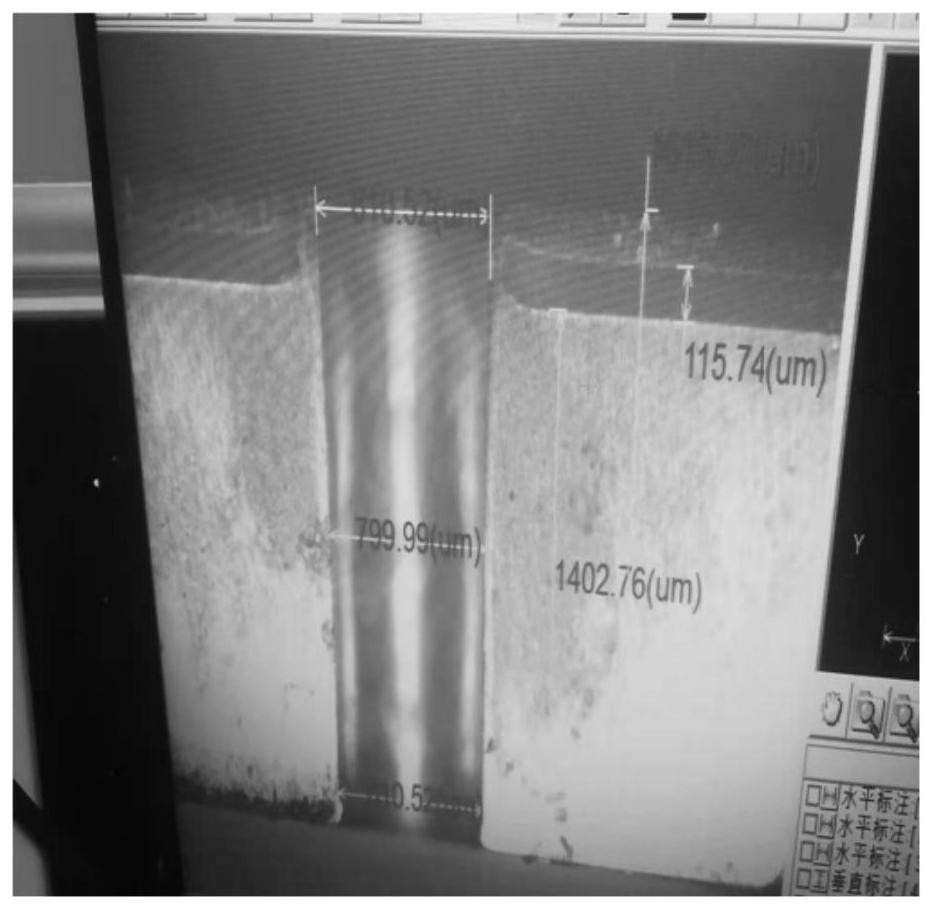

Preparation process of gold finger gold plating and chemical gold copper-based circuit board

ActiveCN114227150AImprove qualityReduce processing efficiencyCircuit susbtrate materialsSolder maskMaterials science

The invention discloses a preparation process of a gold finger gold plating and chemical gold copper-based circuit board. Comprising a solution to the problem that a drilling tool is easy to wear / break, a solution to the technical difficulty of electroplating and hole plating of a copper substrate, a solution to the technical difficulty of solder mask printing of a thick copper plate, a solution to the technical difficulty of surface treatment nickel gold electroplating and chemical gold plating, and a solution to the technical difficulty of molding processing of a metal copper substrate. According to the invention, through the overall process design of the preparation of the gold finger gold plating and chemical gold copper-based circuit board, the cutter and parameter selection for processing the small hole of the copper substrate are optimized; a chemical copper deposition autocatalytic reaction is induced through activation of the palladium core, and after treatment in the step, a layer of chemical copper can be deposited on the surface or the hole wall of the metal copper substrate to be precisely combined with the surface and the hole wall of the metal copper substrate; through flow optimization, the solder resist printing quality of the thick copper plate is improved; as the integration level of the IC is higher and higher, the IC pins are more and denser; the laser has high applicability and sensitivity, and the influence range of cutting is reduced.

Owner:BOLUO KONKA EXACTITUDE SCI TECH

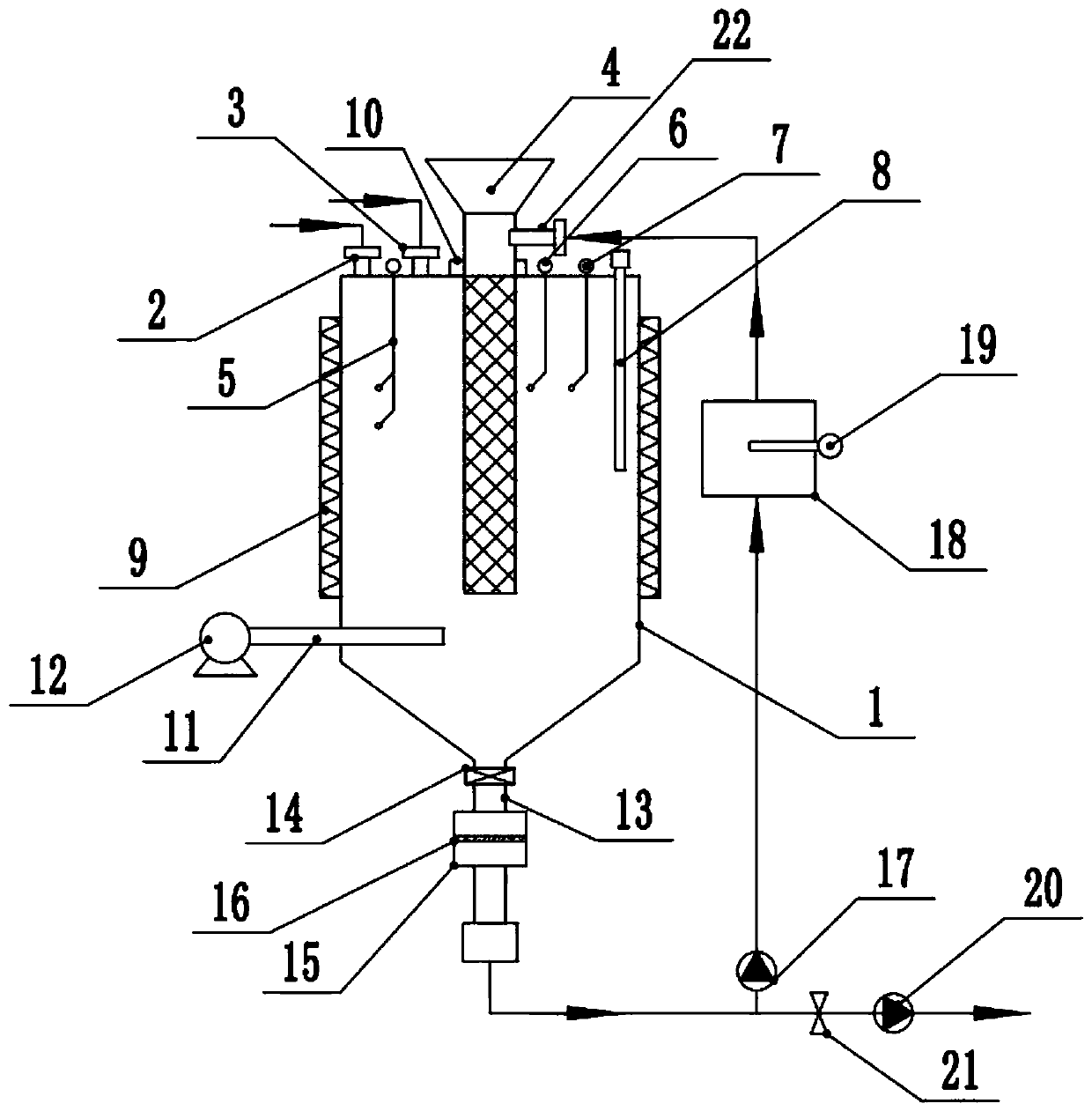

Chemical nickel plating solution treatment device and treatment method thereof

PendingCN111484181AReduce concentrationReduce consumptionWater treatment parameter controlWater treatment compoundsSolution treatmentPhysical chemistry

The invention discloses a chemical nickel plating solution treatment device. The device mainly comprises an autocatalytic reaction tank, a filter tank, a concentration structure, a precipitation crystallization tank and a chemical precipitation tank, the autocatalytic reaction tank comprises a control mechanism, a catalysis mechanism and a steam box, the filter tank comprises a plurality of filtering pipes, a backwashing mechanism and a concentration structure, fiber filter elements are arranged in the filtering pipes, the concentration structure comprises a steam inlet pipe, a water inlet pipe, a condensate water outlet pipe and a concentrated solution outlet pipe, and the precipitation crystallization tank comprises a hydrogen peroxide inlet, a stirring mechanism and an adjuster; the chemical nickel plating solution treatment device is good in chemical nickel plating solution treatment effect, low in cost and suitable for wide popularization.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP +2

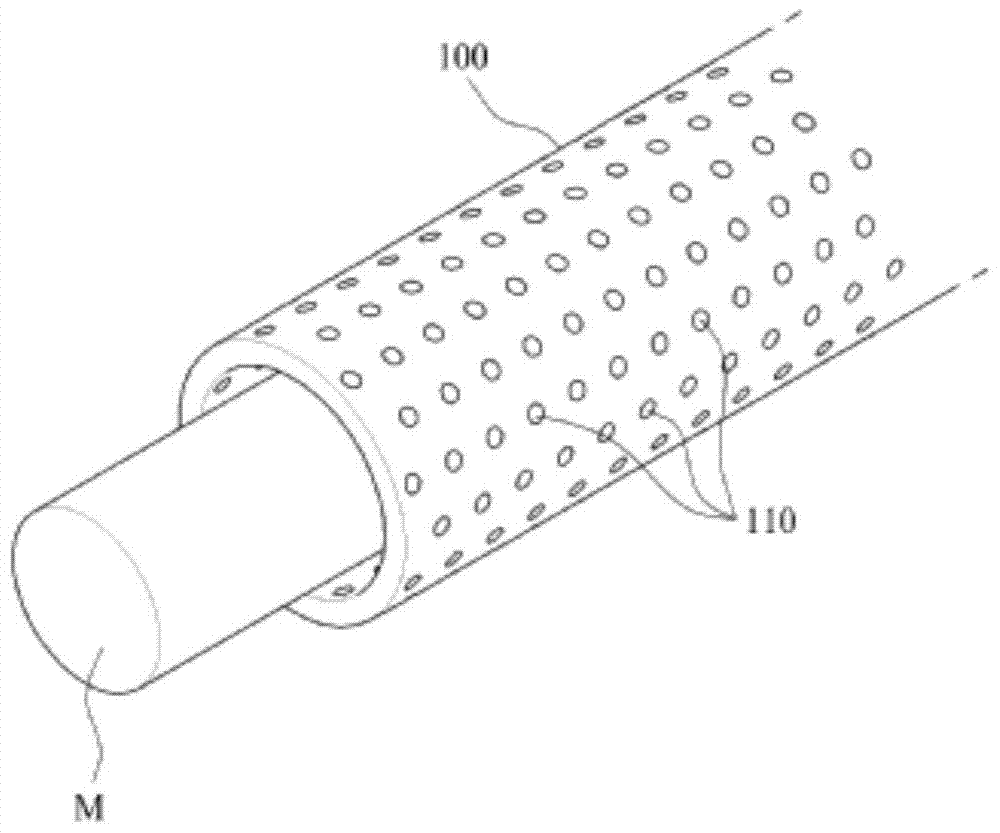

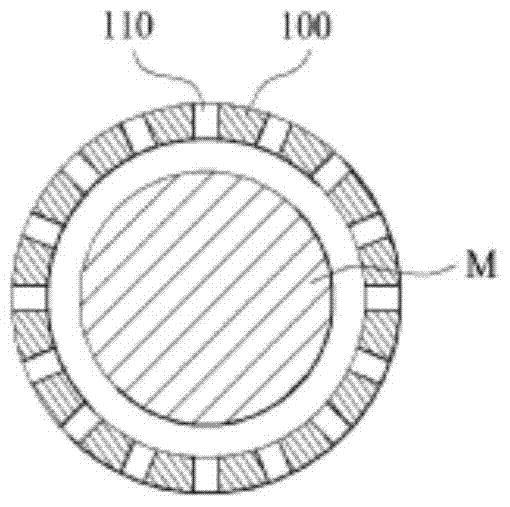

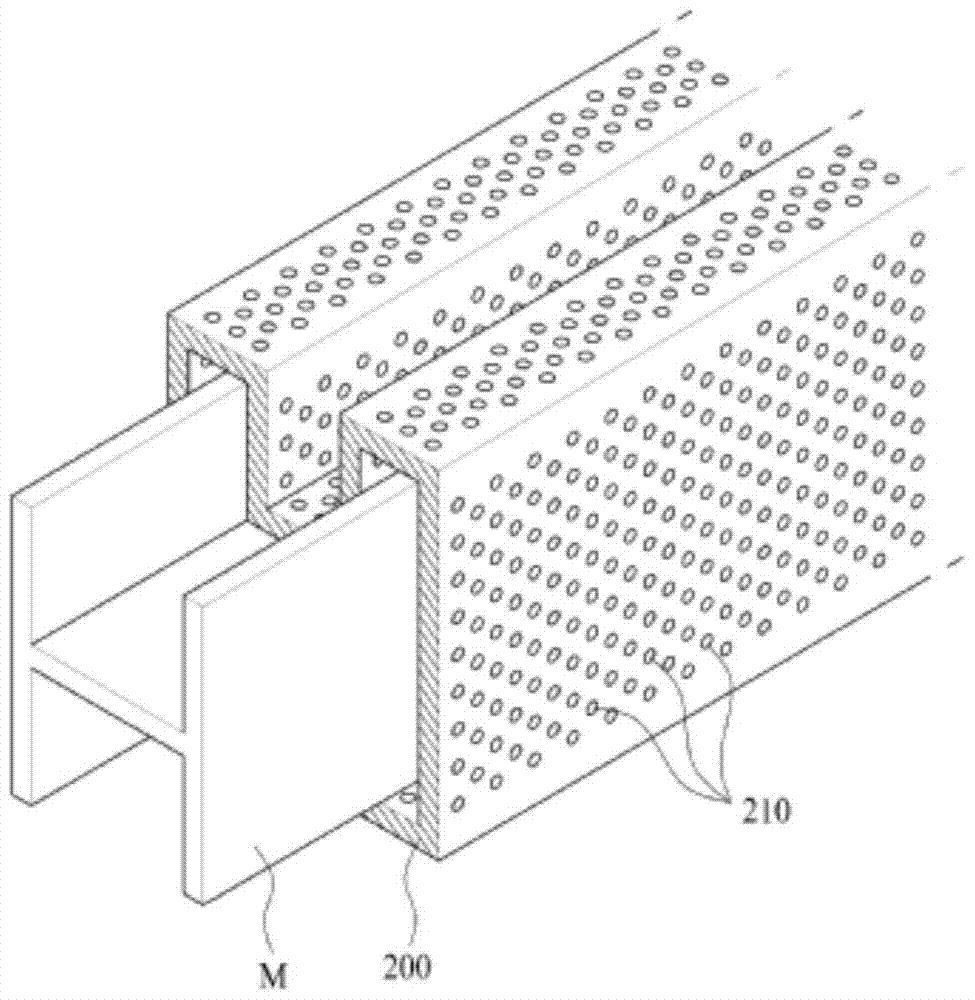

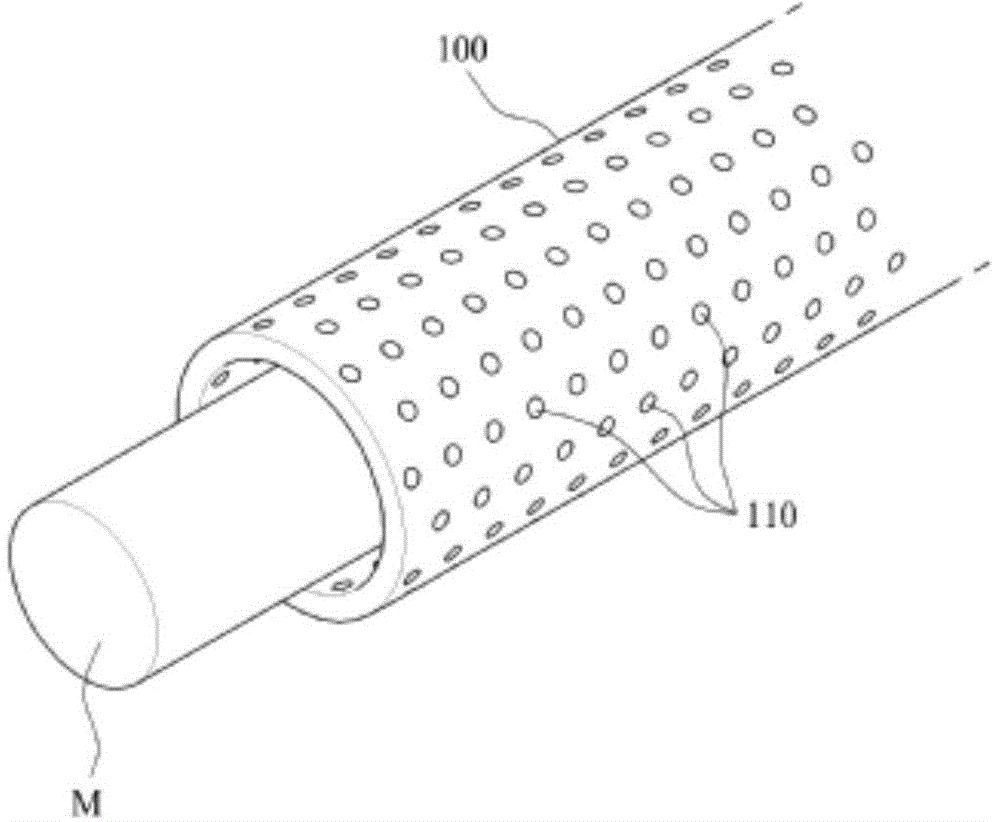

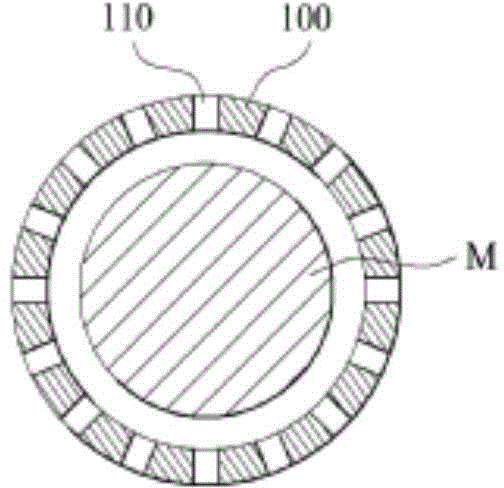

Metal surface treatment device and metal surface treatment method using the same

ActiveCN104870681BImprove wear resistanceImprove corrosion resistanceSolid state diffusion coatingProduct gasTreatment use

A metal surface treatment device, according to the present invention, is a metal surface treatment device which carries out surface treatment for a target metal heated at a temperature for which surface treatment is possible, the device comprising: a reaction chamber which has a shape corresponding to an outer shape of the target metal and is arranged within a certain interval from the outer side of the target metal, and which accommodates at least a part of the target metal; and a raw gas supply unit for supplying raw gas which is necessary for an autocatalytic reaction with the target metal accommodated within the reaction chamber. Furthermore, a metal surface treatment method using the same comprises the steps of: positioning a target metal within the reaction chamber, which has the shape corresponding to the outer form of the target metal and is arranged within a certain interval from the outer side of the target metal and which accommodates at least a part of the target metal; and forming a raw gas layer in the target metal through an autocatalytic reaction by supplying raw gas to the inside of the reaction chamber through the raw gas supply unit.

Owner:KOREA INST OF IND TECH

Metal surface treatment device and metal surface treatment method using same

ActiveCN104870681AImprove wear resistanceImprove corrosion resistanceSolid state diffusion coatingProduct gasGas supply

A metal surface treatment device, according to the present invention, is a metal surface treatment device which carries out surface treatment for a target metal heated at a temperature for which surface treatment is possible, the device comprising: a reaction chamber which has a shape corresponding to an outer shape of the target metal and is arranged within a certain interval from the outer side of the target metal, and which accommodates at least a part of the target metal; and a raw gas supply unit for supplying raw gas which is necessary for an autocatalytic reaction with the target metal accommodated within the reaction chamber. Furthermore, a metal surface treatment method using the same comprises the steps of: positioning a target metal within the reaction chamber, which has the shape corresponding to the outer form of the target metal and is arranged within a certain interval from the outer side of the target metal and which accommodates at least a part of the target metal; and forming a raw gas layer in the target metal through an autocatalytic reaction by supplying raw gas to the inside of the reaction chamber through the raw gas supply unit.

Owner:KOREA INST OF IND TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com