Preparation method for metal-ceramic composite powder of core-shell structure

A metal-ceramic composite and core-shell structure technology, applied in the field of powder metallurgy, can solve problems such as affecting performance, high price, pollution, etc., and achieve the effects of strong interface bonding ability, reduced production cost, and high coating integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Cobalt chloride is used as a chemical vapor deposition cobalt source, nitrogen is the carrier gas, cobalt chloride is heated to 650℃, hydrogen is used as the reducing gas, the temperature is 750℃, a small amount of cobalt is deposited on the tungsten carbide powder with a particle size of 50μm, deposition time For 1 minute, the mass fraction of cobalt in the obtained cobalt-coated tungsten carbide composite powder is 0.01%. Put this powder into a stirred reactor for autocatalytic cobalt plating, heat the water bath to 50°C, control the pH to 8, use cobalt sulfate as the cobalt salt, hydrazine hydrate as the reducing agent, and the reaction time for 60 minutes to obtain cobalt-coated carbonization In the tungsten composite powder, the mass fraction of the metal cobalt coating is 30%.

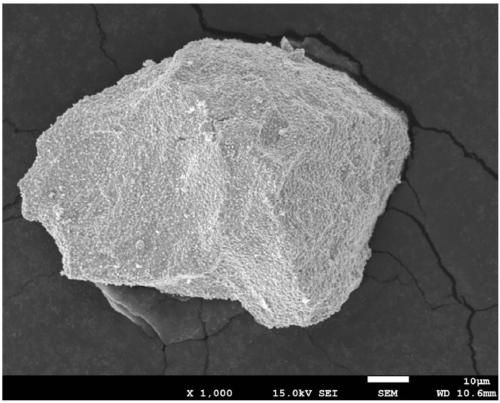

[0032] The field emission scanning electron microscope image of cobalt-coated tungsten carbide composite powder is as follows figure 1 Shown from figure 1 It can be seen that the metal cobalt...

Embodiment 2

[0034] Nickel chloride is used as the chemical vapor deposition nickel source, argon is the carrier gas, nickel chloride is heated to 680°C, hydrogen is used as the reducing gas, and the temperature is 720°C. A small amount of nickel is deposited on titanium carbide powder with a particle size of 100μm. The time is 5 minutes, and the nickel mass fraction in the obtained nickel-coated titanium carbide composite powder is 0.1%. Put the powder into a stirred reactor for autocatalytic nickel plating, heat the water bath to 70℃, control the pH to 12, use nickel chloride as the nickel salt, sodium hypophosphite as the reducing agent, and the reaction time for 120min to obtain nickel The coated titanium carbide composite powder has a mass fraction of metal nickel coating of 50%.

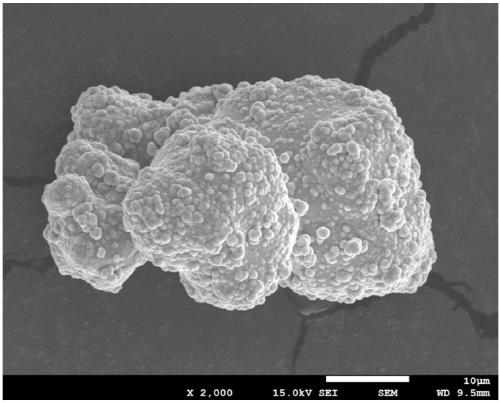

[0035] The field emission scanning electron microscope image of nickel-coated titanium carbide composite powder is as follows figure 2 Shown from figure 2 It can be seen that metallic nickel is completely de...

Embodiment 3

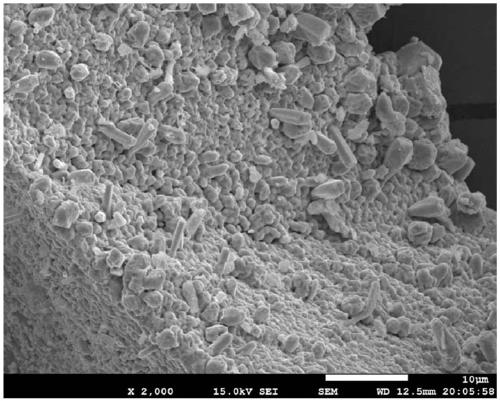

[0037] Using ferrocene as the iron source for chemical vapor deposition, neon gas as the carrier gas, heating the ferrocene to 150°C, hydrogen as the reducing gas, at 900°C, depositing a small amount of iron on silicon carbide powder with a particle size of 500μm. The time is 10 minutes, and the mass fraction of iron in the obtained iron-coated silicon carbide composite powder is 1%. Put the powder into a stirred reactor for autocatalytic iron-nickel plating, heat the water bath to 90°C, control the pH to 10, use ferrous sulfate as the iron salt, nickel sulfate as the nickel salt, and sodium borohydride as the reducing agent to react The time is 60 minutes to obtain iron-nickel coated silicon carbide composite powder, in which the mass fraction of the metal coating amount is 10%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com