Patents

Literature

4211results about How to "Avoid introducing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

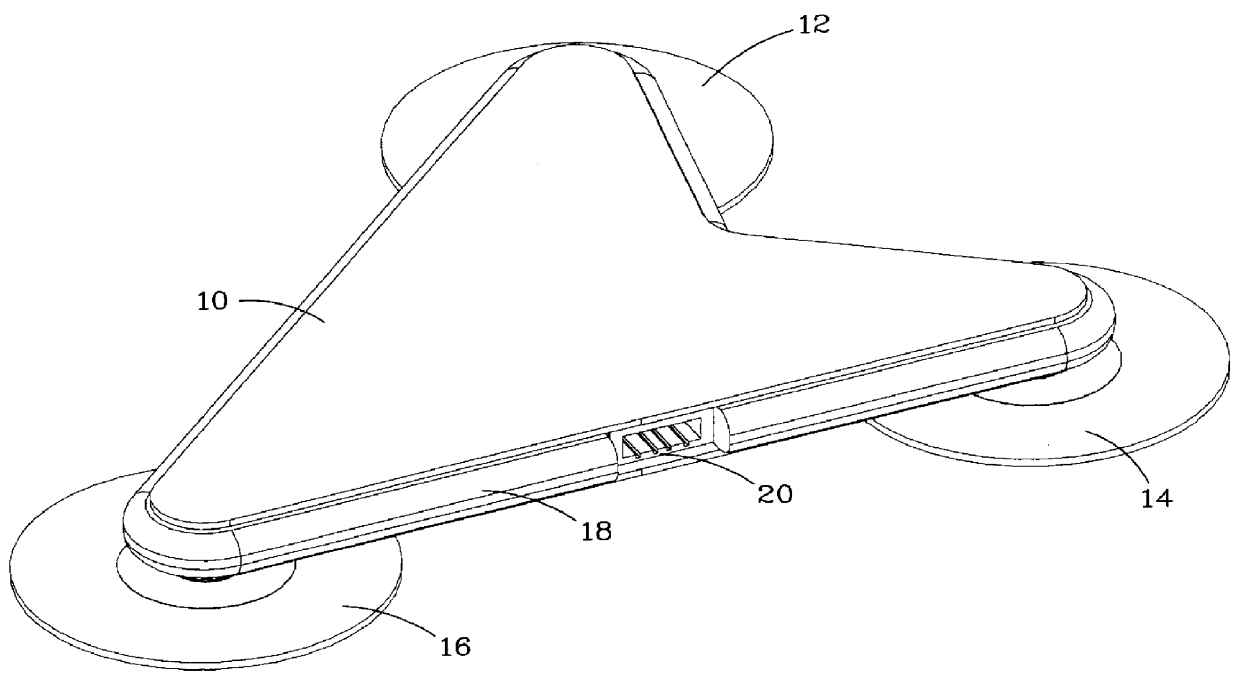

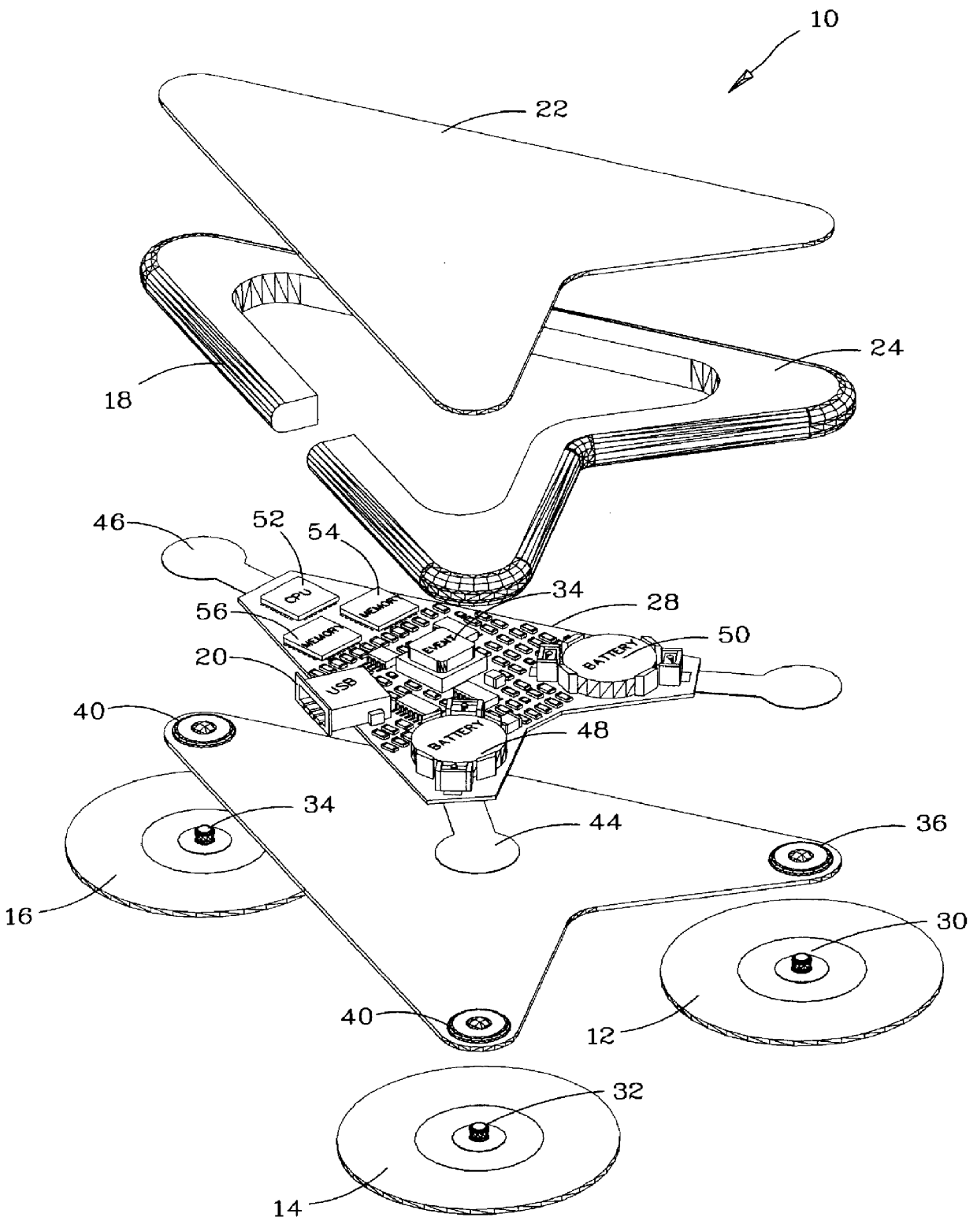

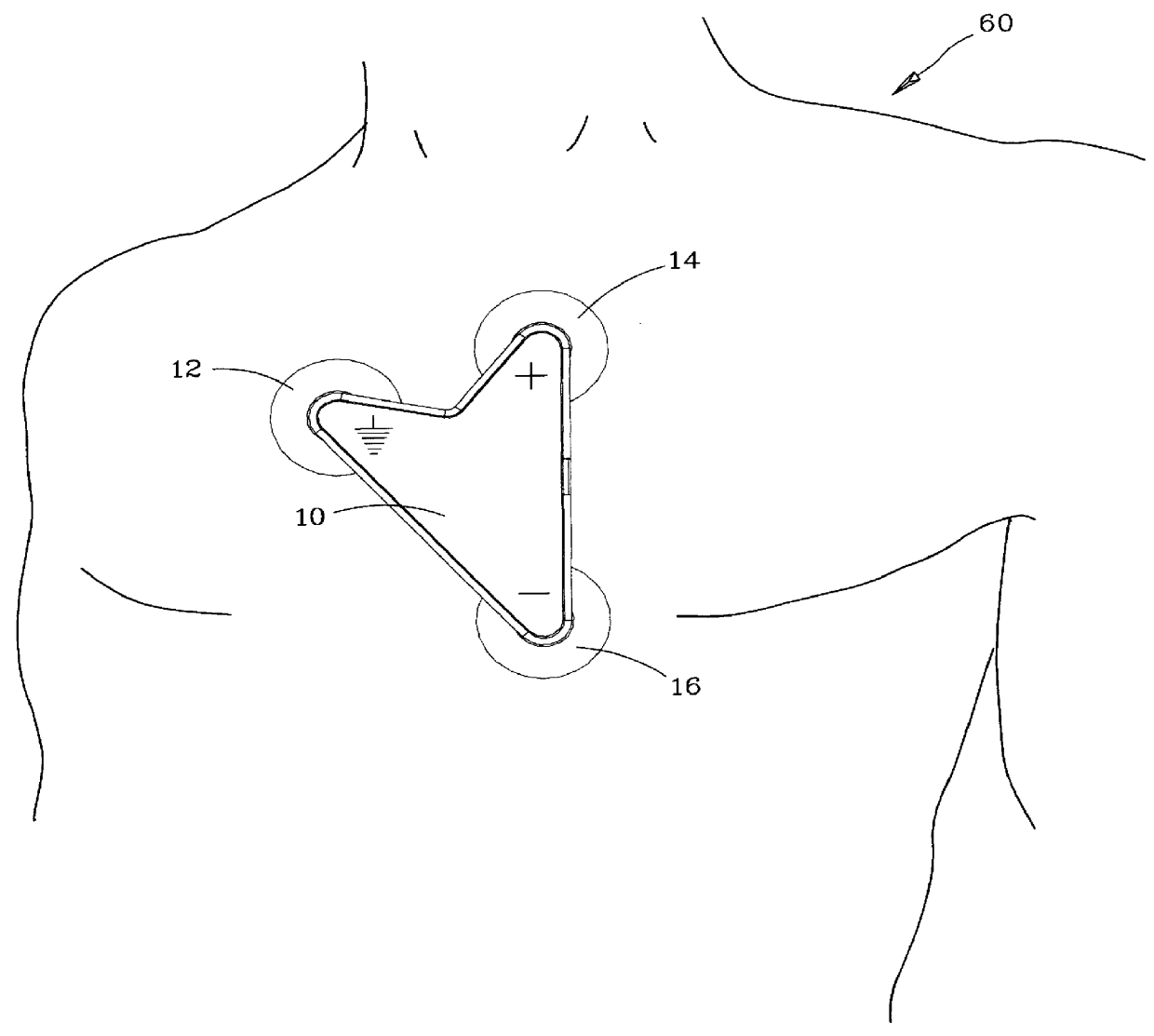

Long-term, ambulatory physiological recorder

InactiveUS6117077AComplete and reliableAchieve electrical continuityElectrocardiographySensorsTransducerEngineering

A self contained, compact, long term, ambulatory physiological recorder is designed for mounting directly to the body of a patient, immediately adjacent to the organ or system that is to be monitored, and is adhesively and covertly held there in place and comfortably under clothing by the very transducer, skin electrodes that detect the physiological information to be recorded, and thereby increasing continuity and decreasing artifact by obviating the need for numerous and cumbersome, hanging electrode leads as well as unsightly and cumbersome recorder pouches suspended from shoulder straps or belts.

Owner:SPACELABS HEALTHCARE LLC

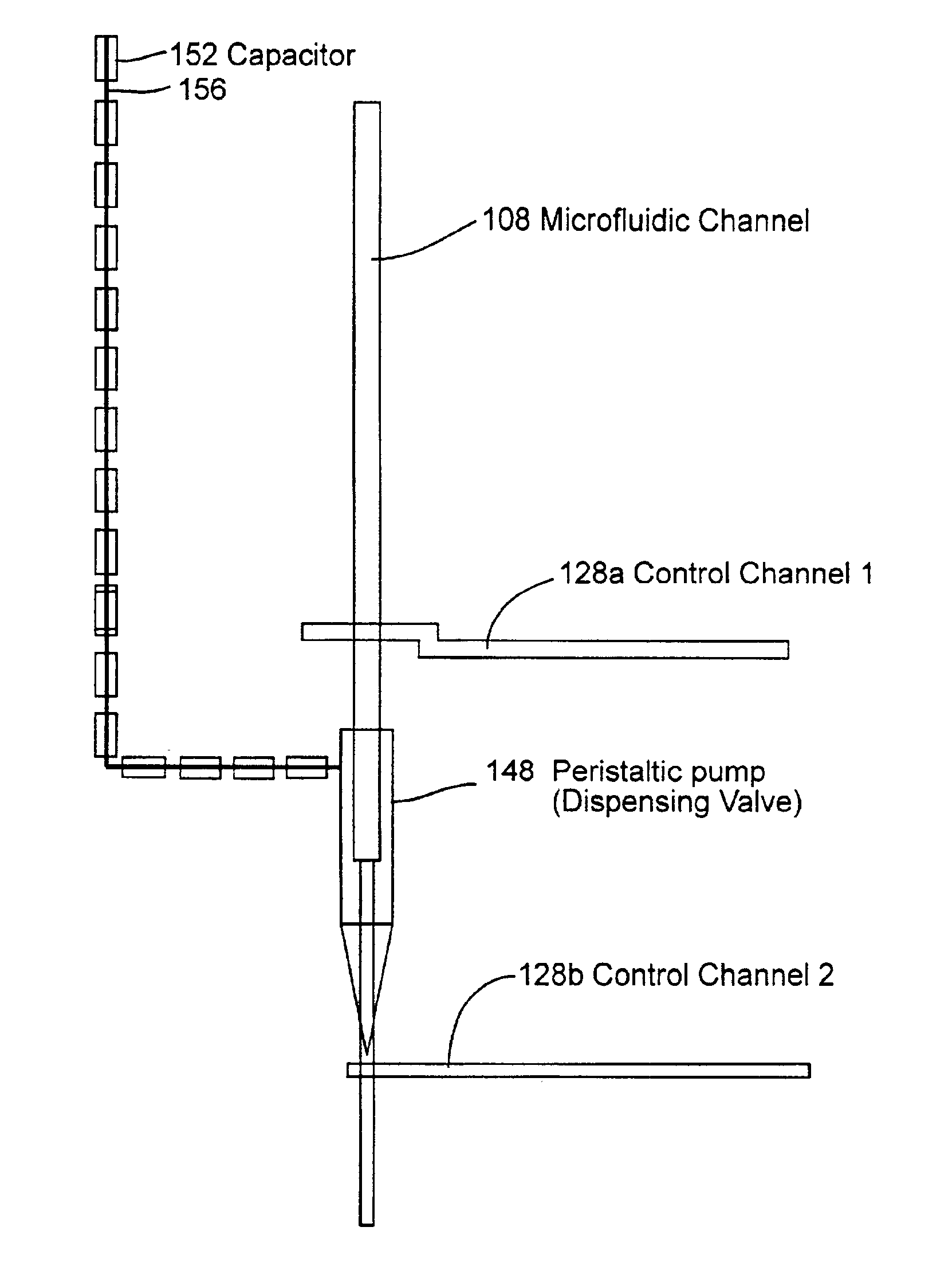

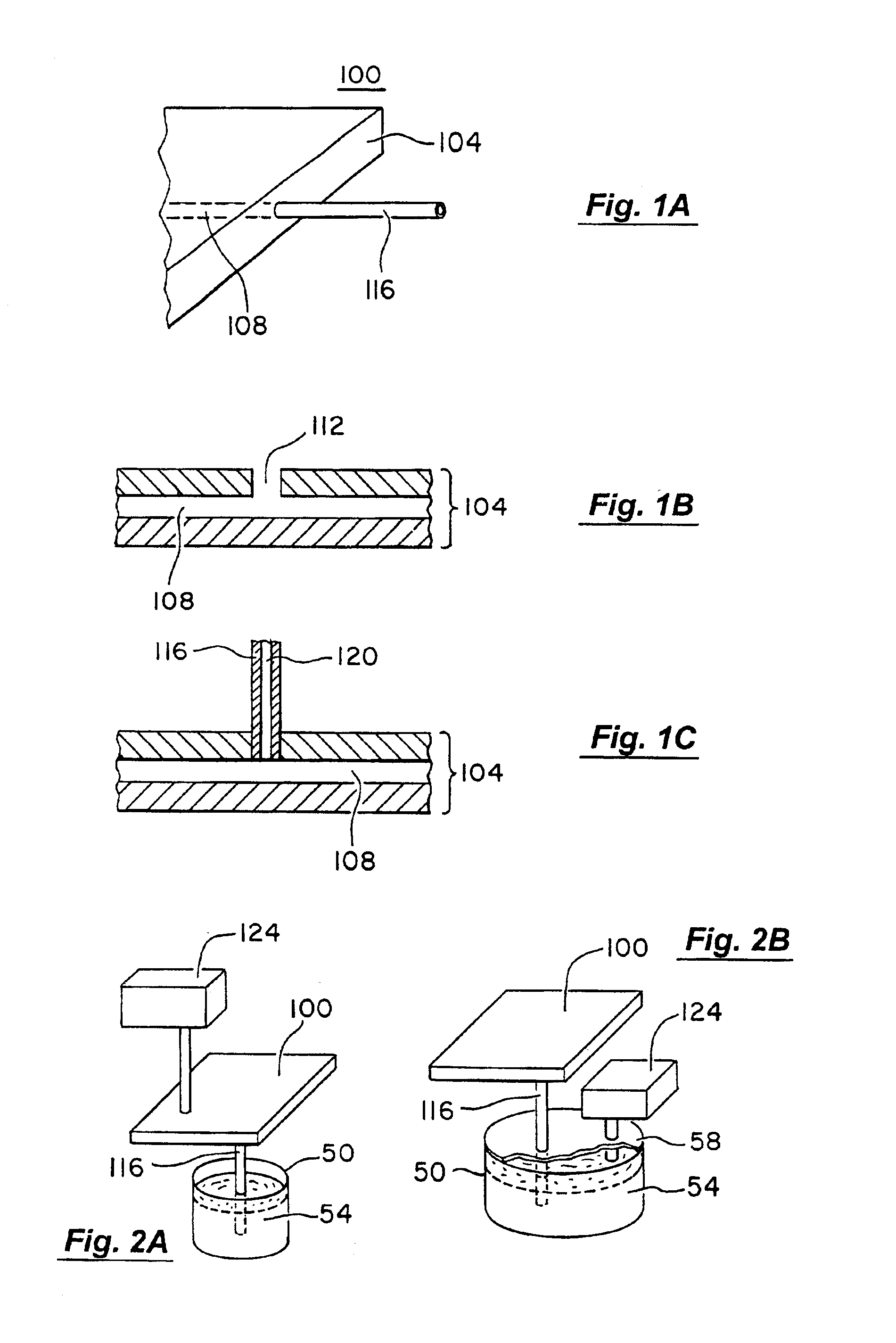

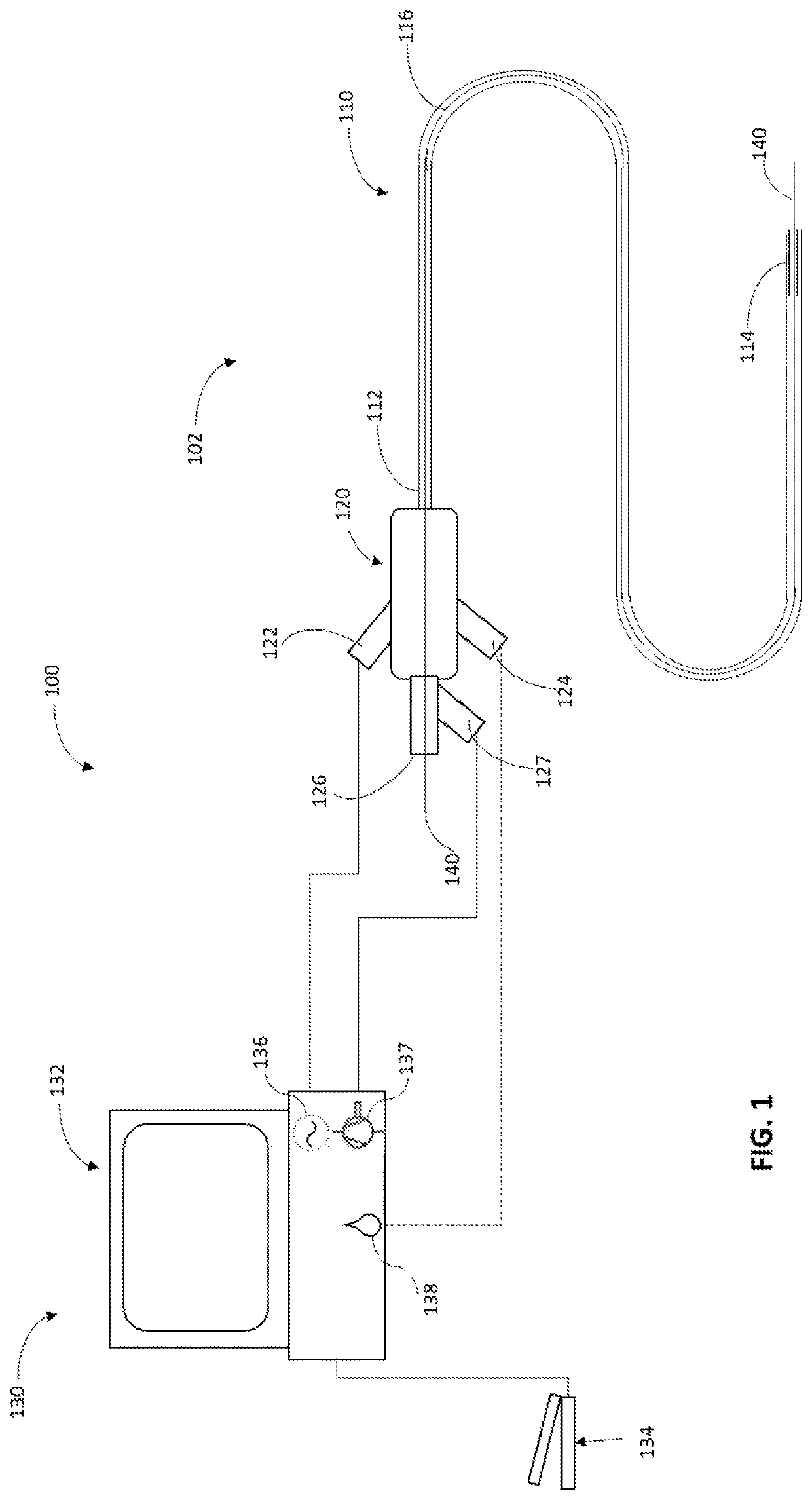

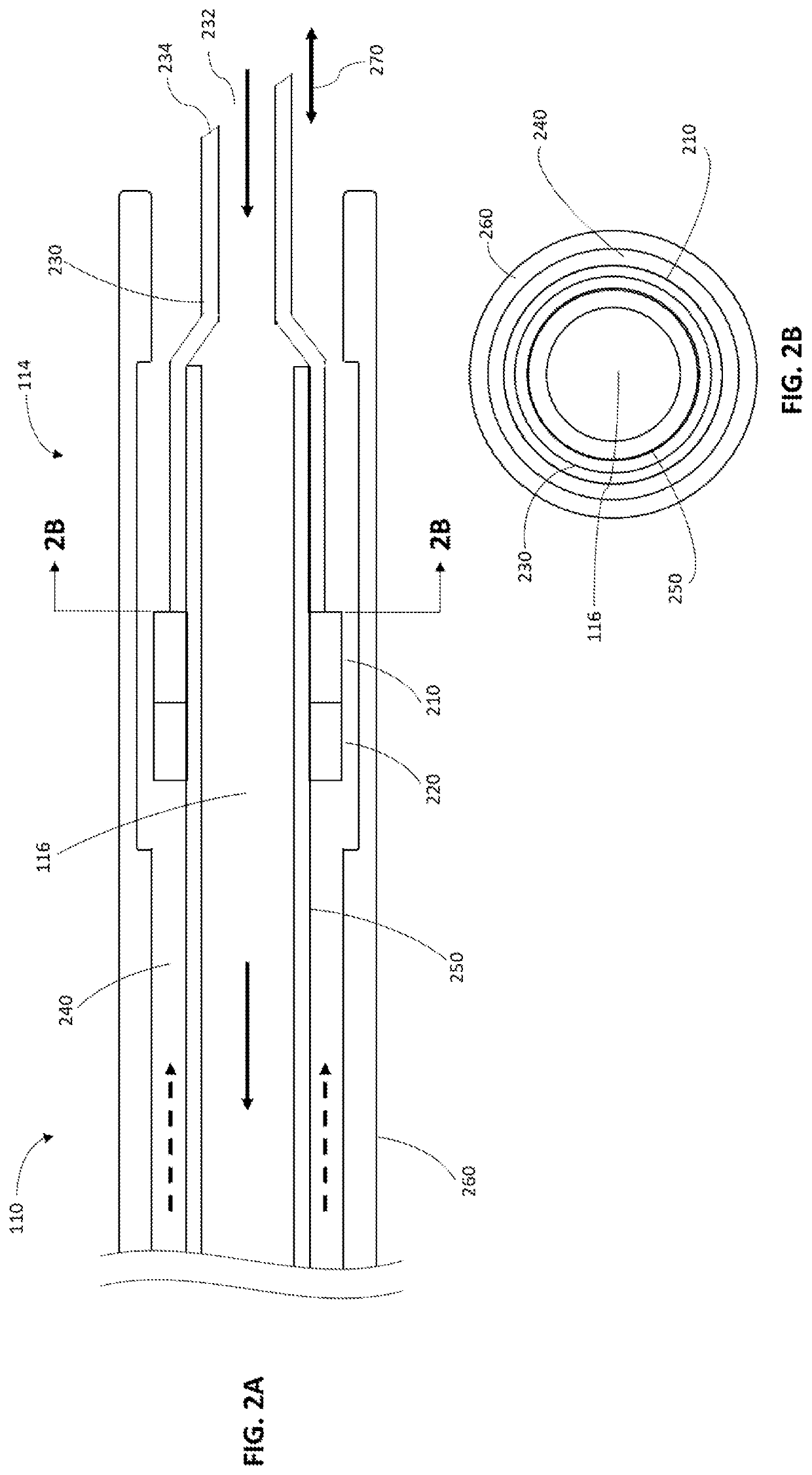

Microfluidic devices for introducing and dispensing fluids from microfluidic systems

InactiveUS6951632B2EasyEasily inserted into portElectrolysis componentsFixed microstructural devicesMicrofluidic channelBiomedical engineering

The present invention provides microfluidic devices, systems and methods for using the same, which facilitate the introduction of fluid to and from a microfluidic channel located within the microfluidic devices.

Owner:FLUIDIGM CORP

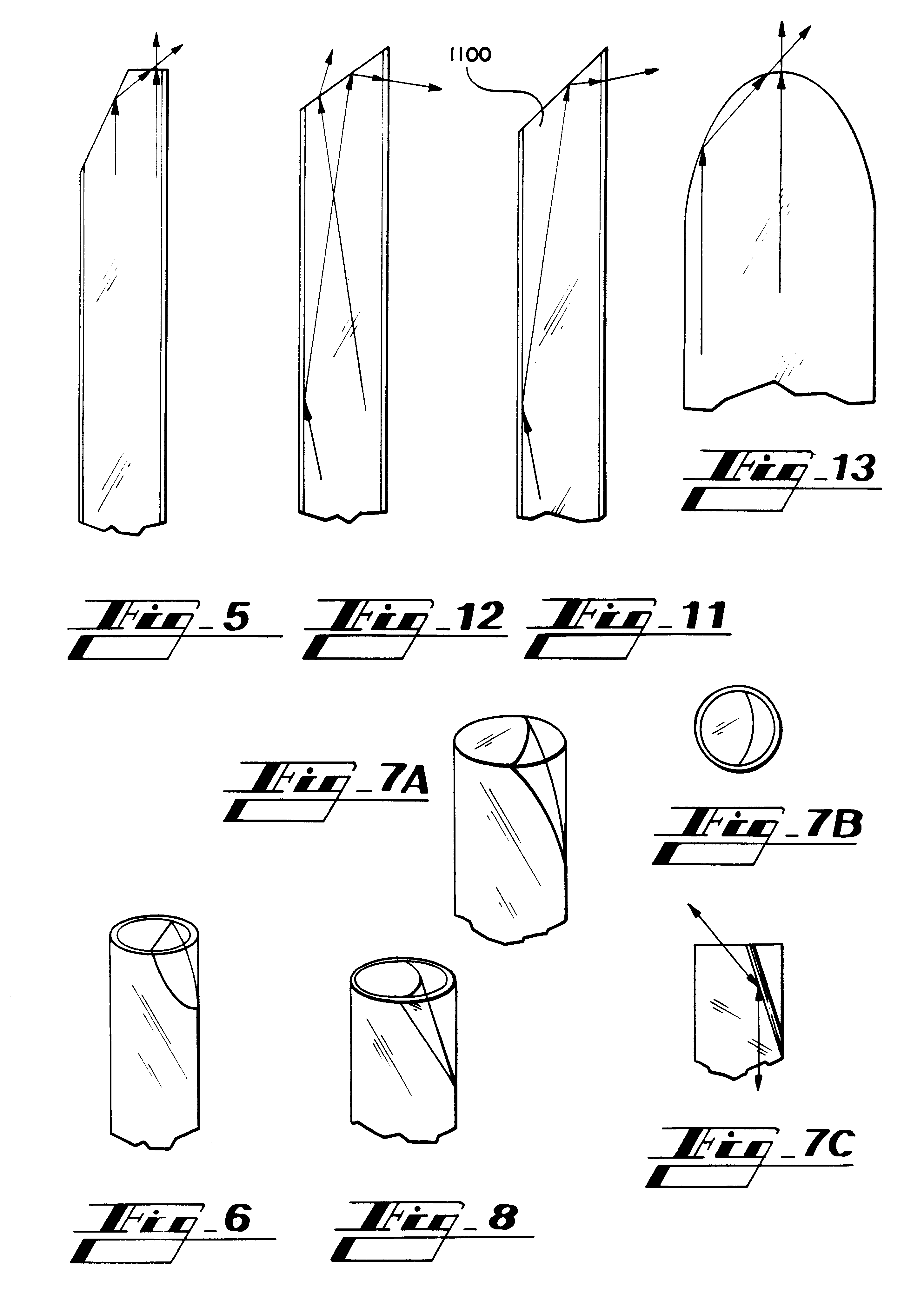

Methods and apparatus for filtering an optical fiber

InactiveUS6222970B1Improve responseReduce sensitivityCladded optical fibreMaterial analysis by observing effect on chemical indicatorHigh energyPhotonics

Filtering of optical fibers and other related devices. High-energy methods for depositing thin films directly onto the ends of optical fibers can be used to produce high-quality, high-performance filters in quantity at a reasonable cost. These high-quality filters provide the high performance needed for many demanding applications and often eliminate the need for filters applied to wafers or expanded-beam filtering techniques. Having high-quality filters applied directly to optical fiber and faces permits production of high-performance, micro-sized devices that incorporate optical filters. Devices in which these filters may be used include spectroscopic applications including those using fiber optic probes, wavelength division multiplexing, telecommunications, general fiber optic sensor usage, photonic computing, photonic amplifiers, pump blocking and a variety of laser devices.

Owner:CIRREX SYST

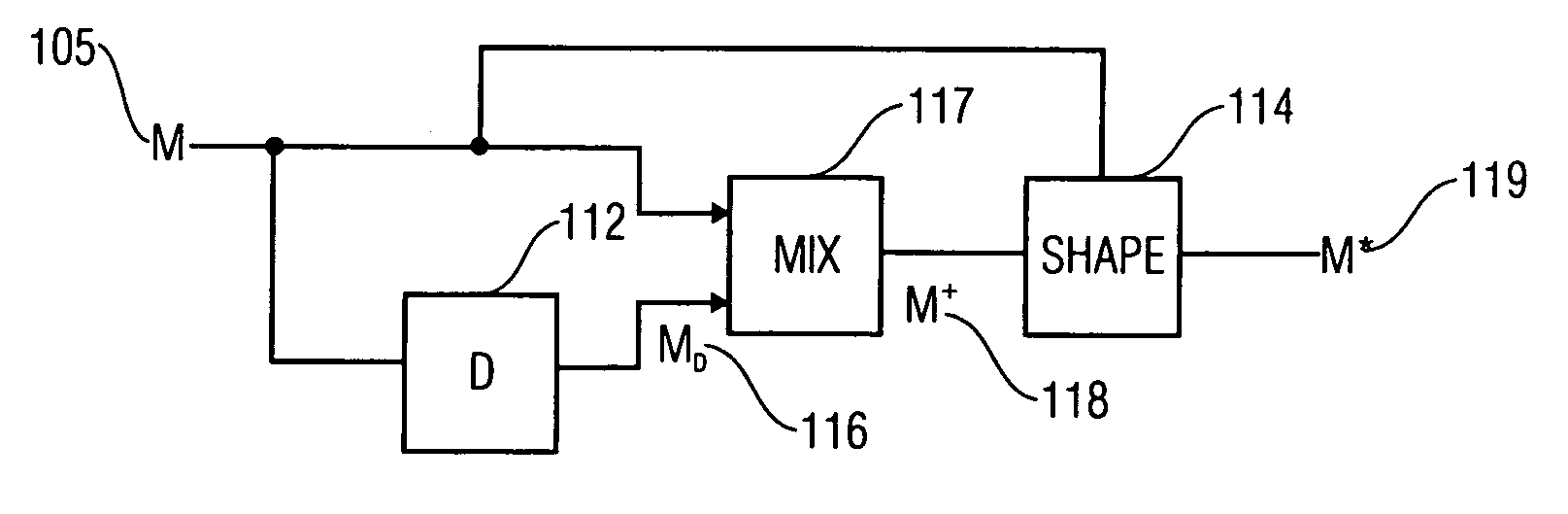

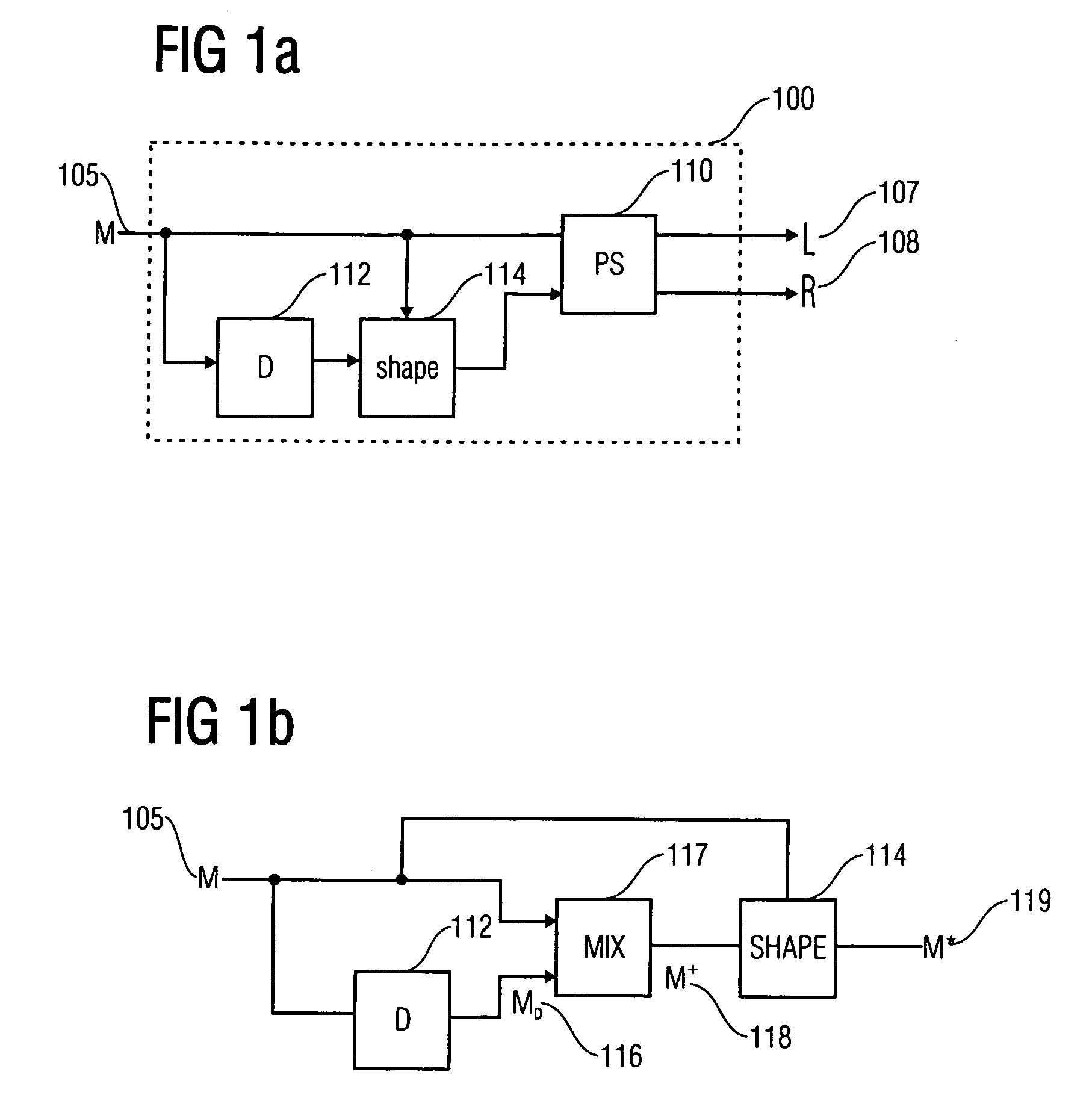

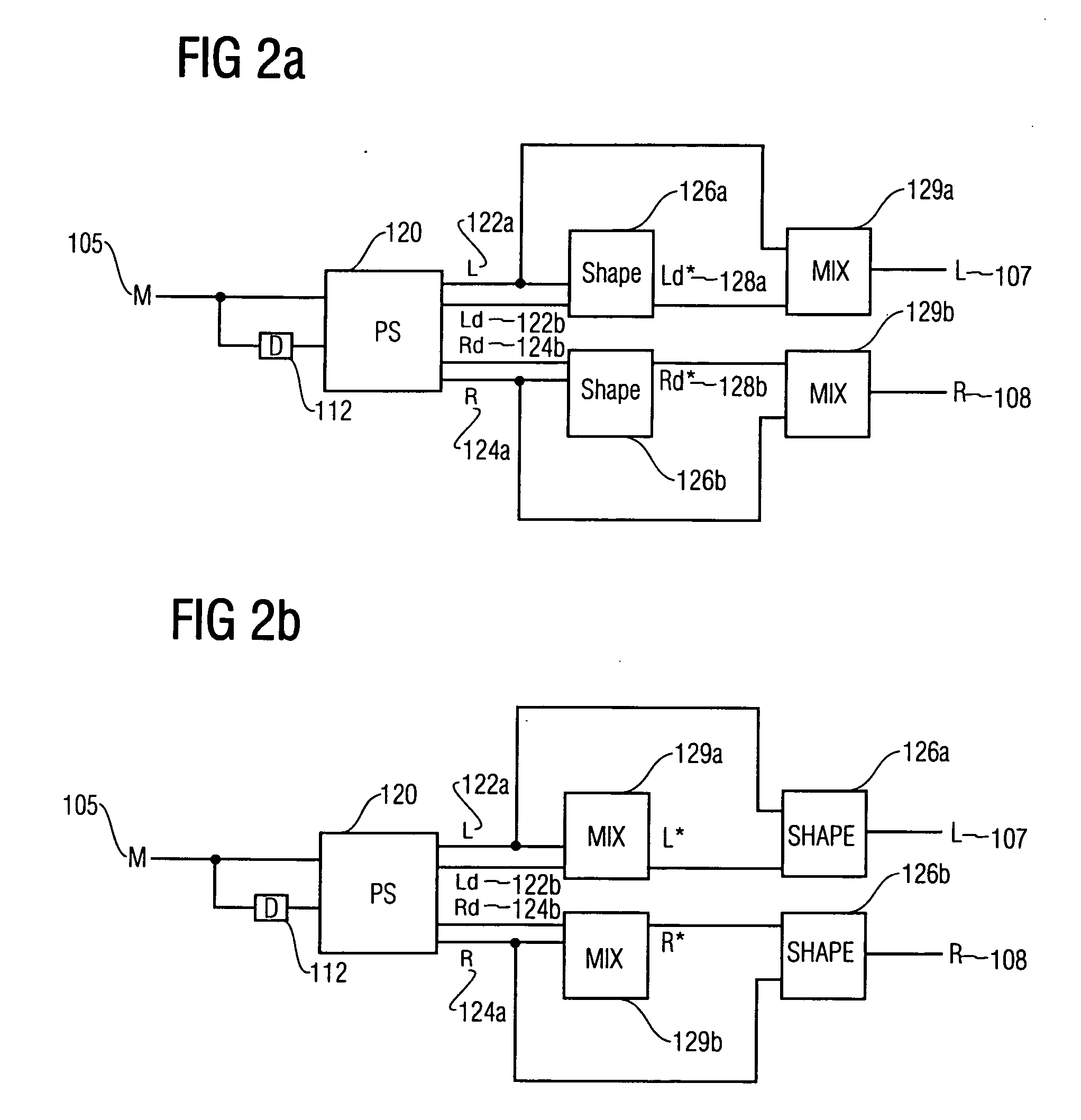

Envelope shaping of decorrelated signals

ActiveUS20060239473A1Avoid introducingEffective shapingSpeech analysisPseudo-stereo systemsFrequency spectrumDistortion

The envelope of a decorrelated signal derived from an original signal can be shaped without introducing additional distortion, when a spectral flattener is used to spectrally flatten the spectrum of the decorrelated signal and the original signal prior to using the flattened spectra for deriving a gain factor describing the energy distribution between the flattened spectra, and when the so derived gain factor is used by an envelope shaper to timely shape the envelope of the decorrelated signal.

Owner:DOLBY INT AB +1

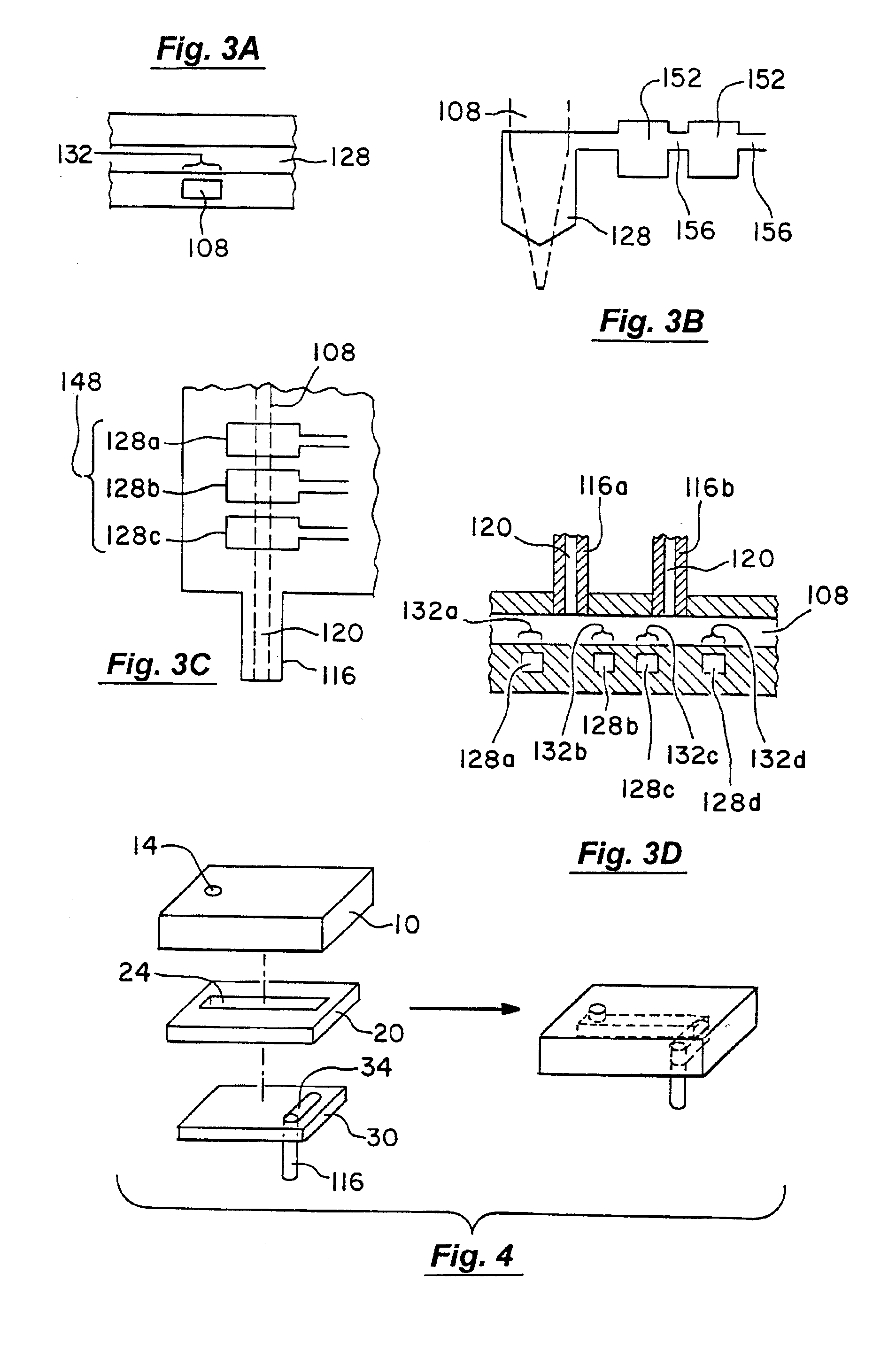

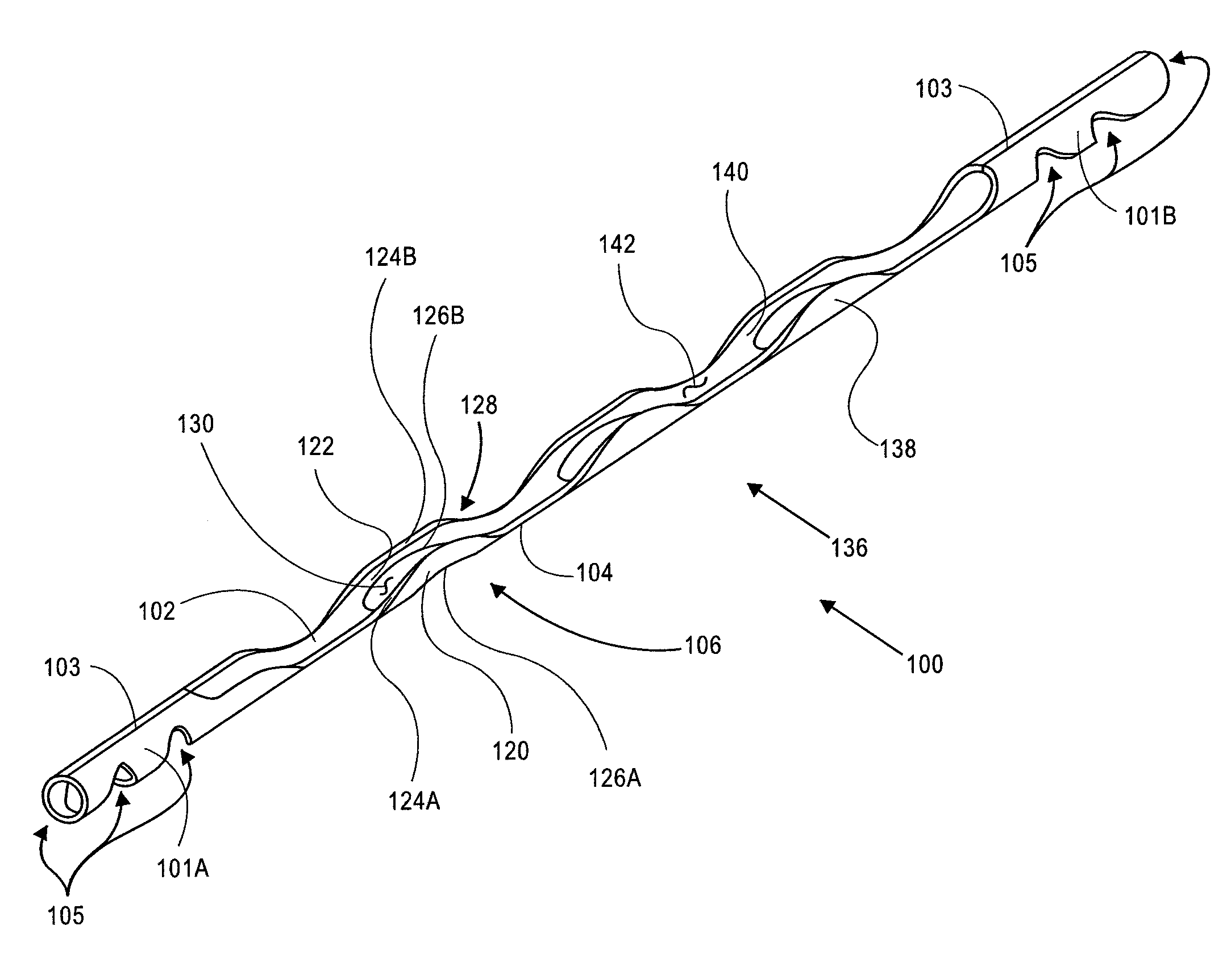

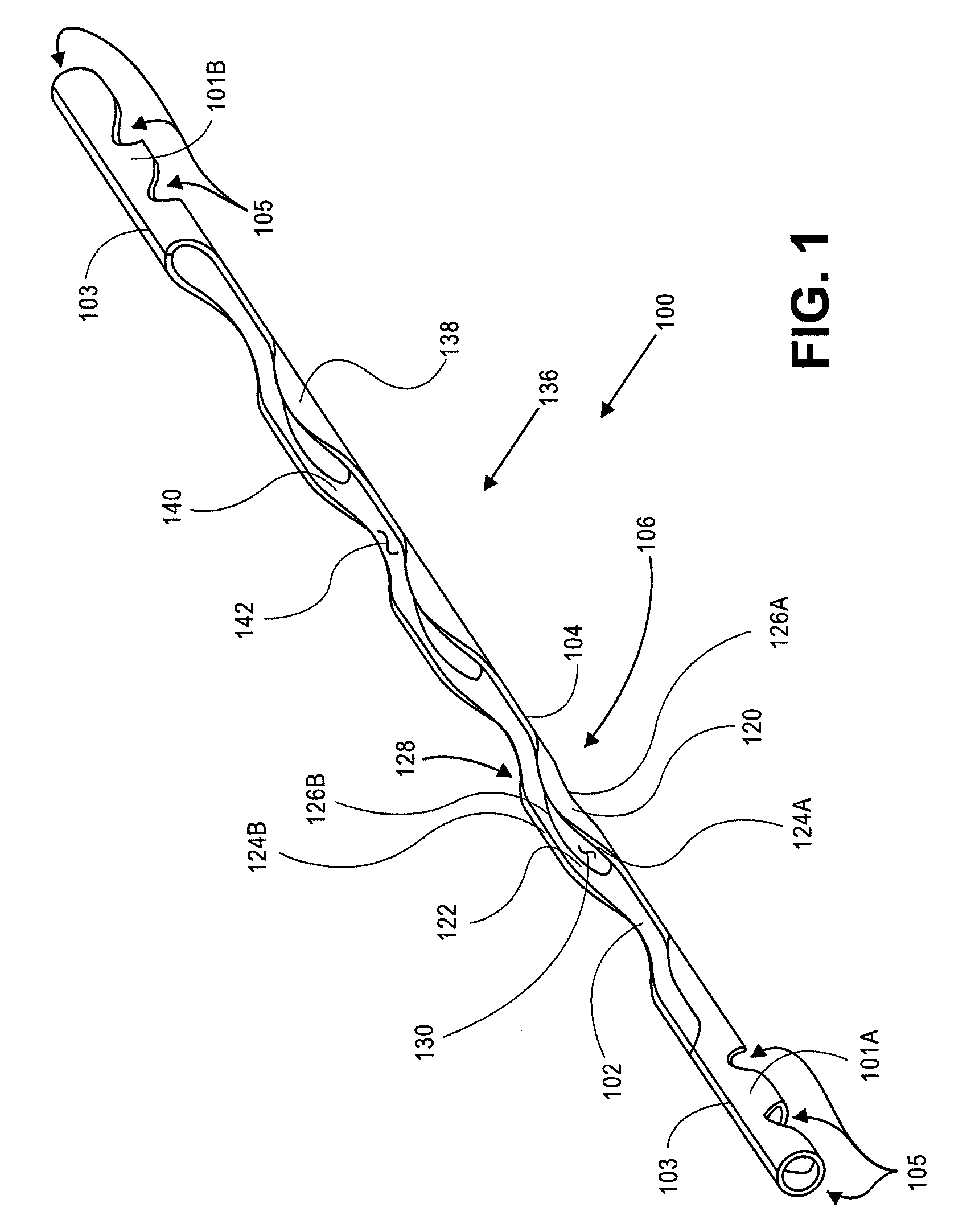

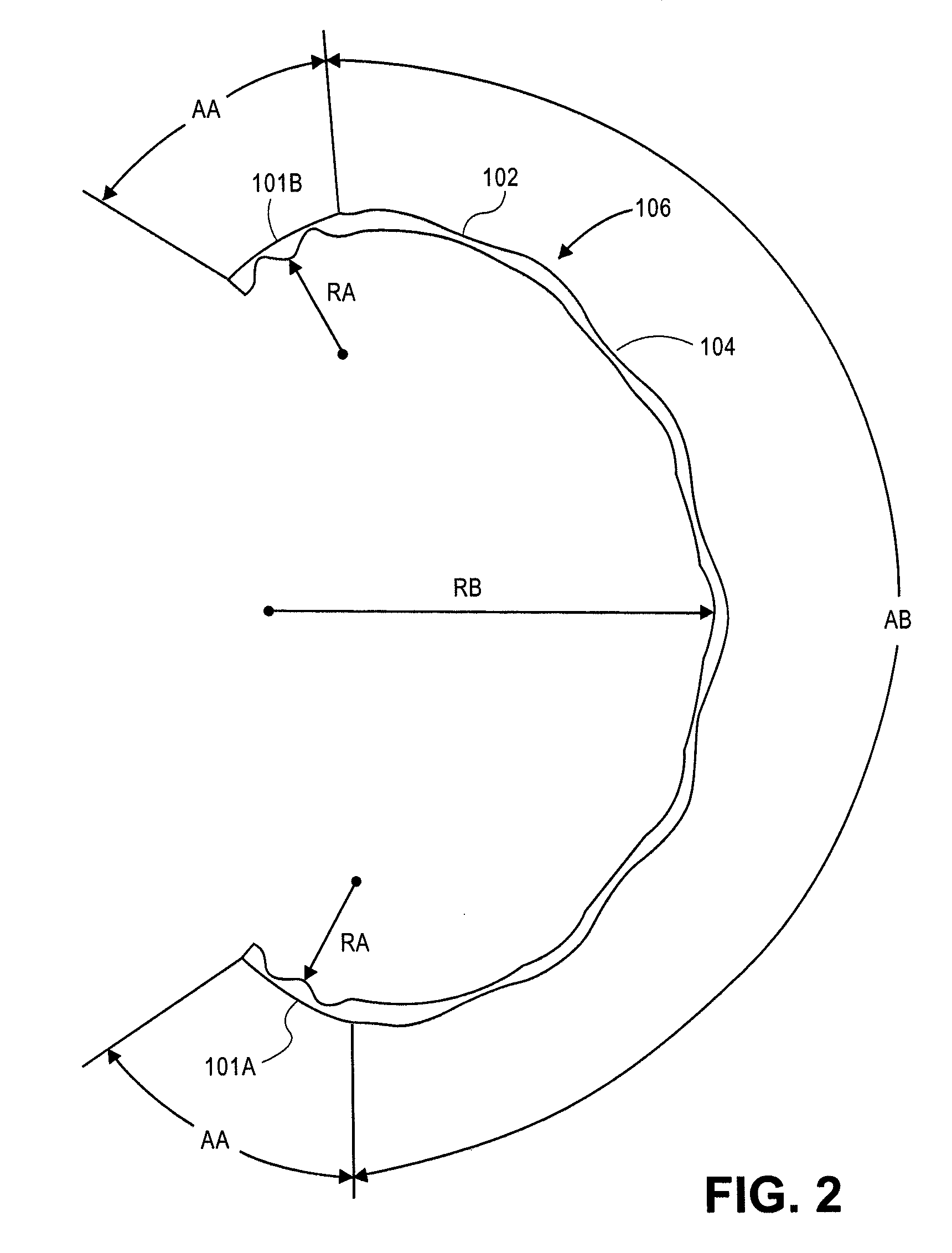

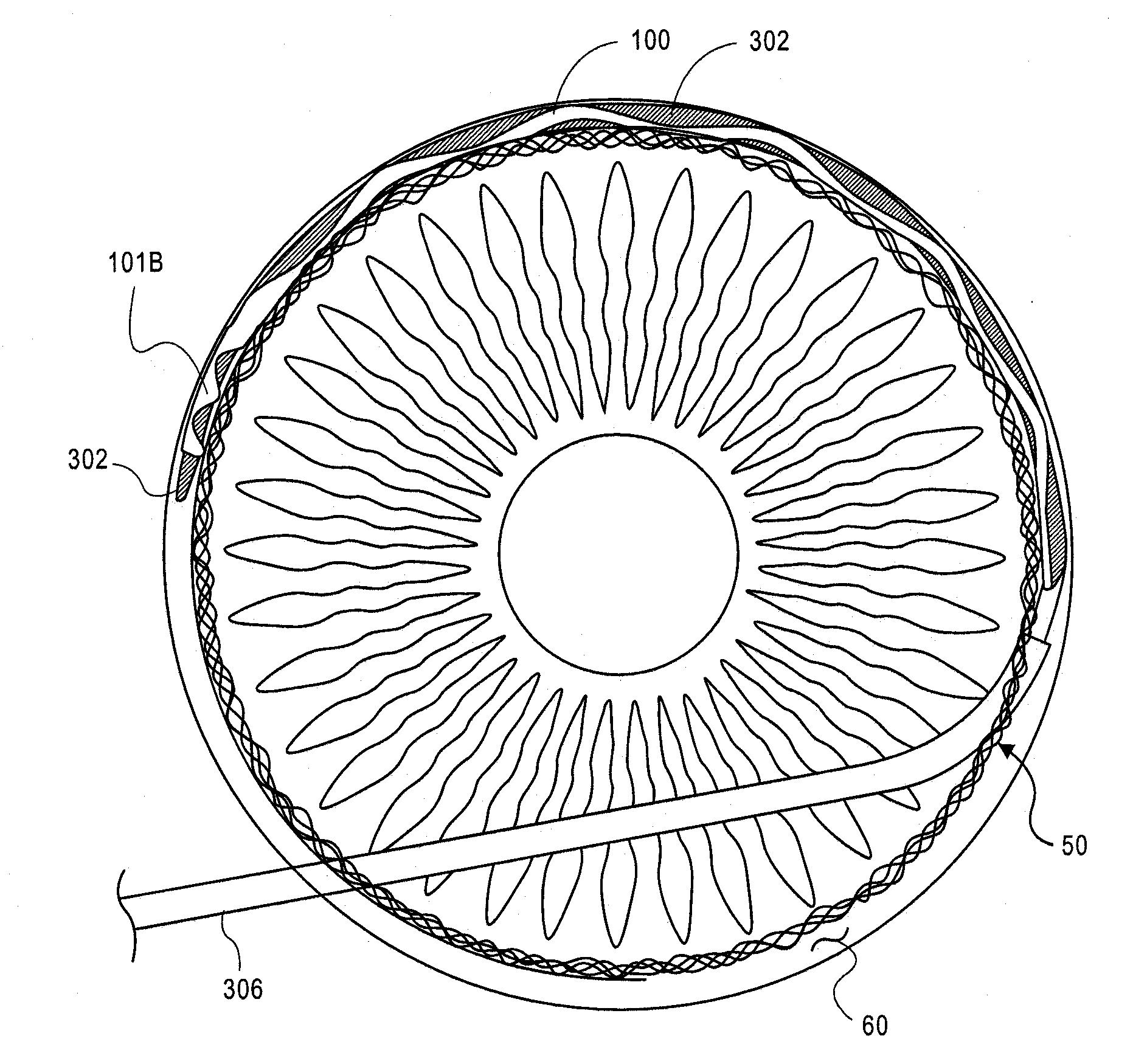

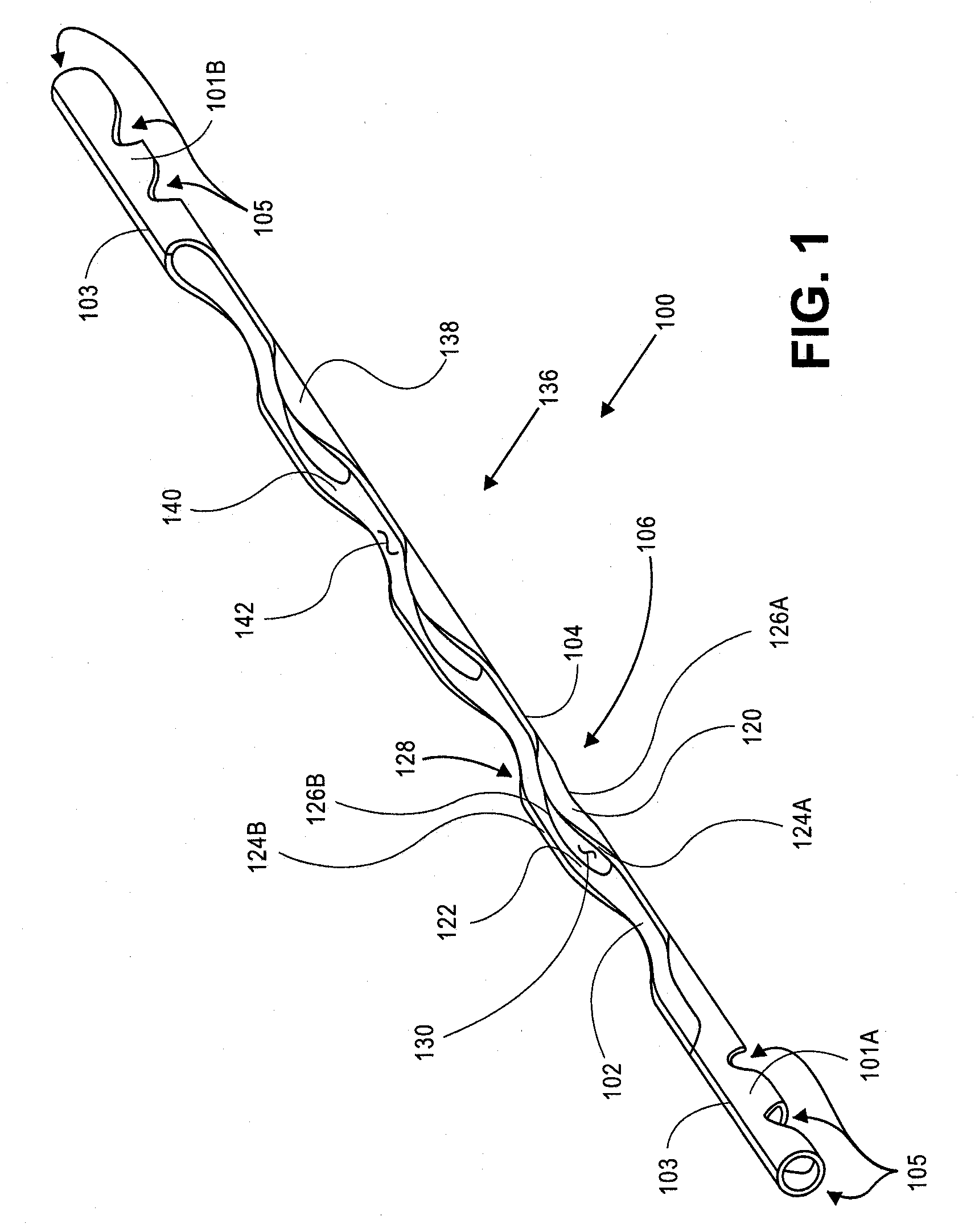

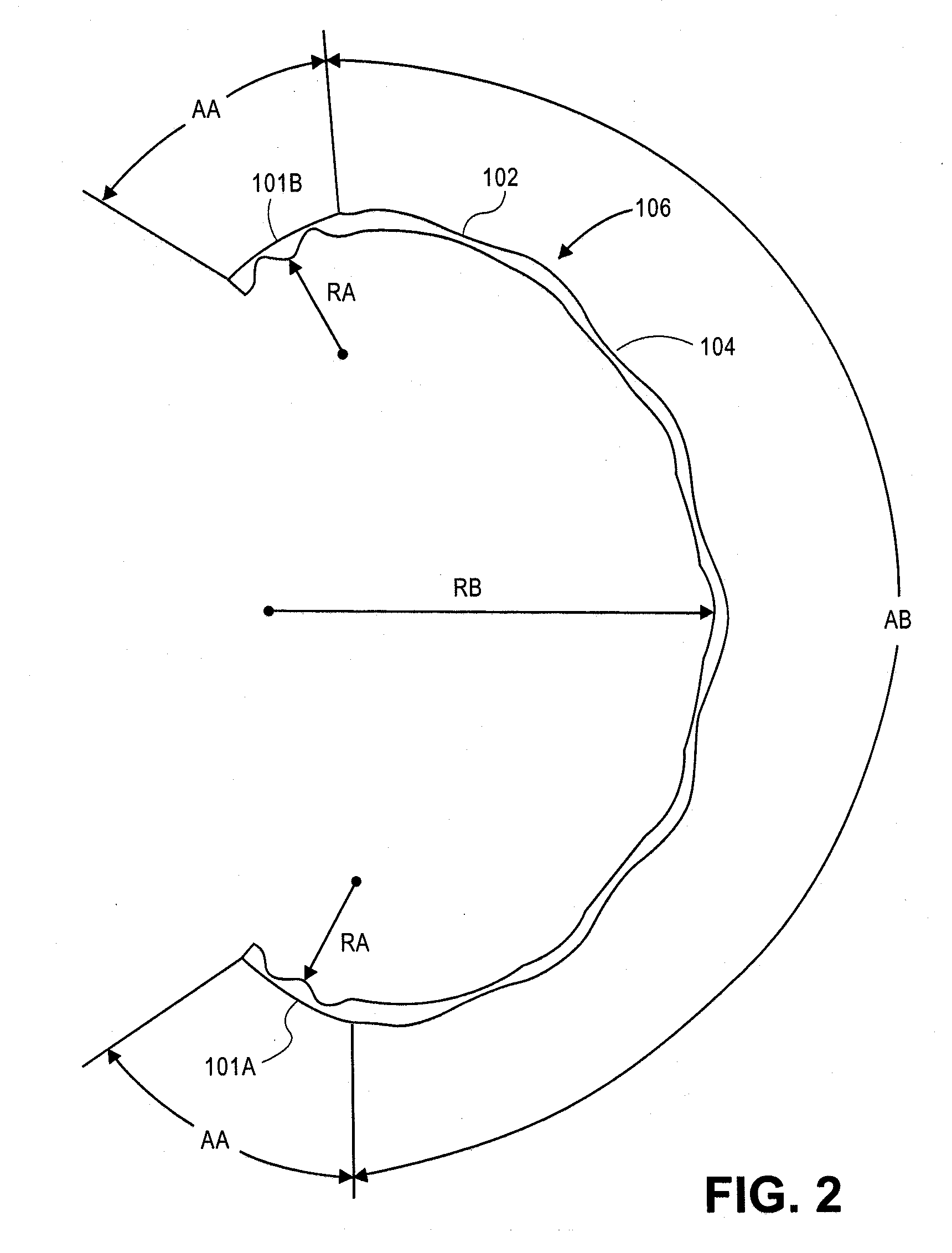

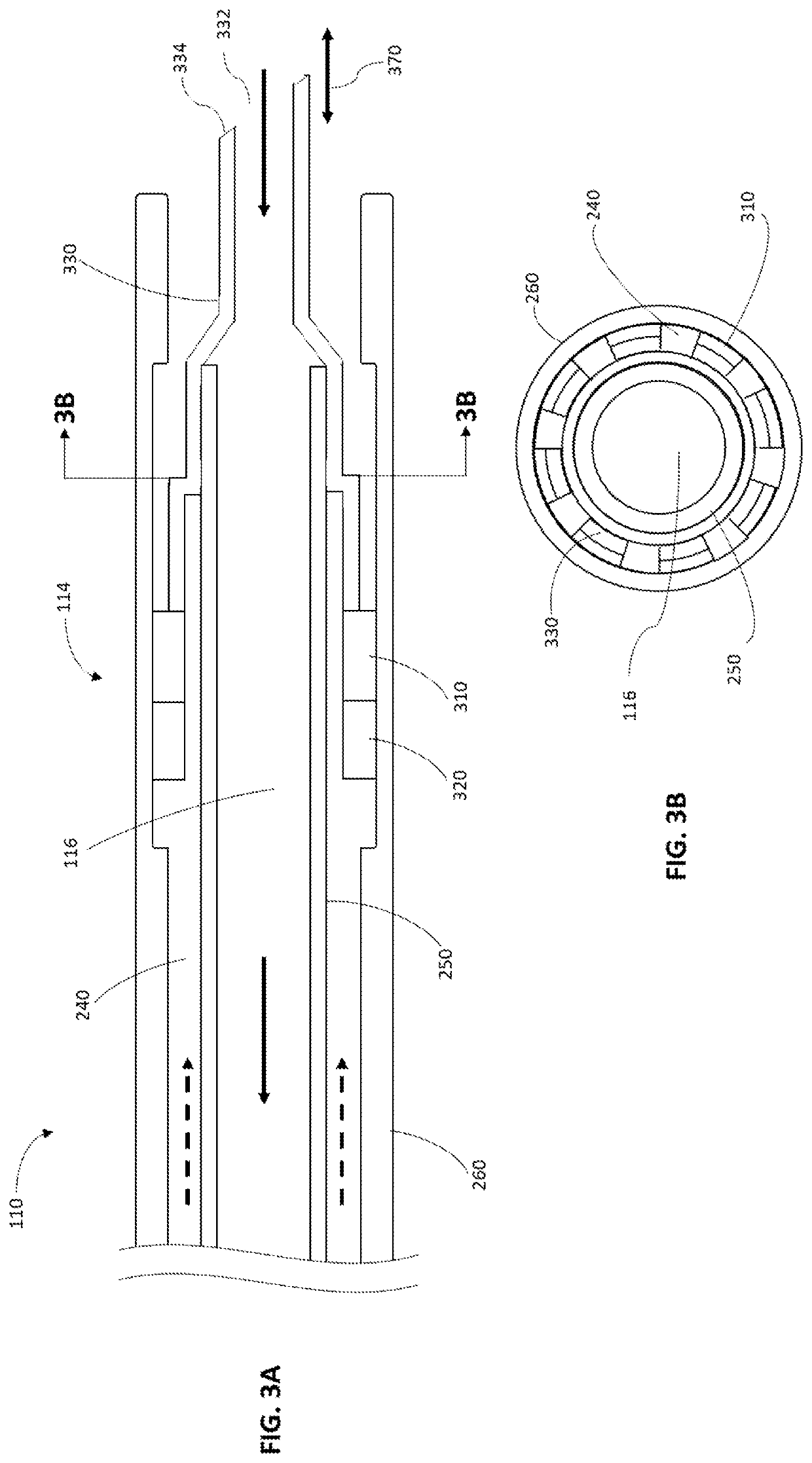

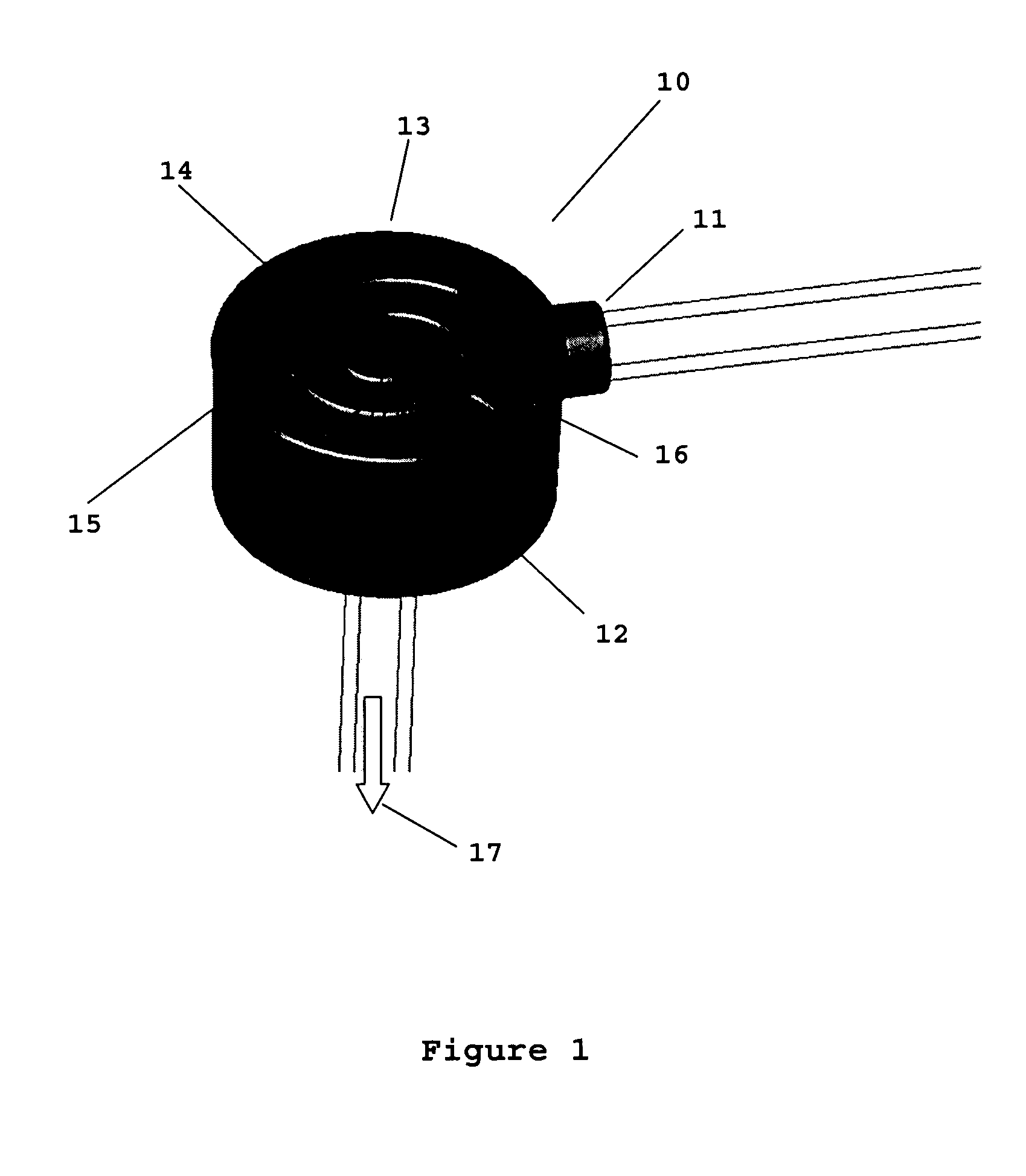

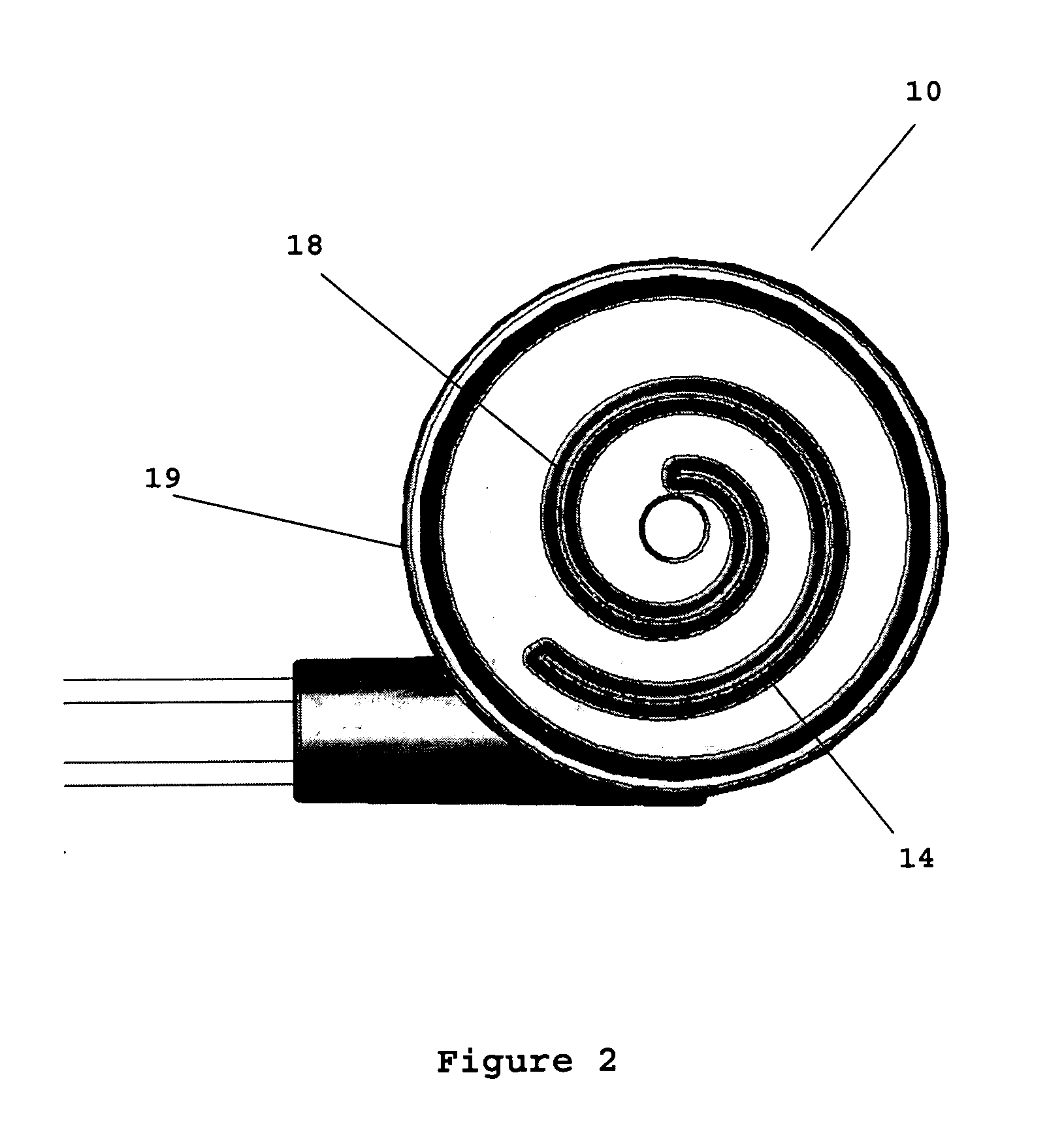

Methods and apparatus for treating glaucoma

ActiveUS8267882B2Reduce the possibilityImprove fluid flowLaser surgeryEar treatmentSchlemm's canalOcular implant

An ocular implant for treating glaucoma is provided, which may include any number of features. More particularly, the present invention relates to implants that facilitate the transfer of fluid from within one area of the eye to another area of the eye. One feature of the implant is that it includes a proximal inlet portion and a distal inlet portion adapted to be inserted into the anterior chamber of the eye, and an intermediate portion adapted to be inserted into Schlemm's canal. Another feature of the implant is that it can be biased to assume a predetermined shape to aid in placement within the eye.

Owner:ALCON INC

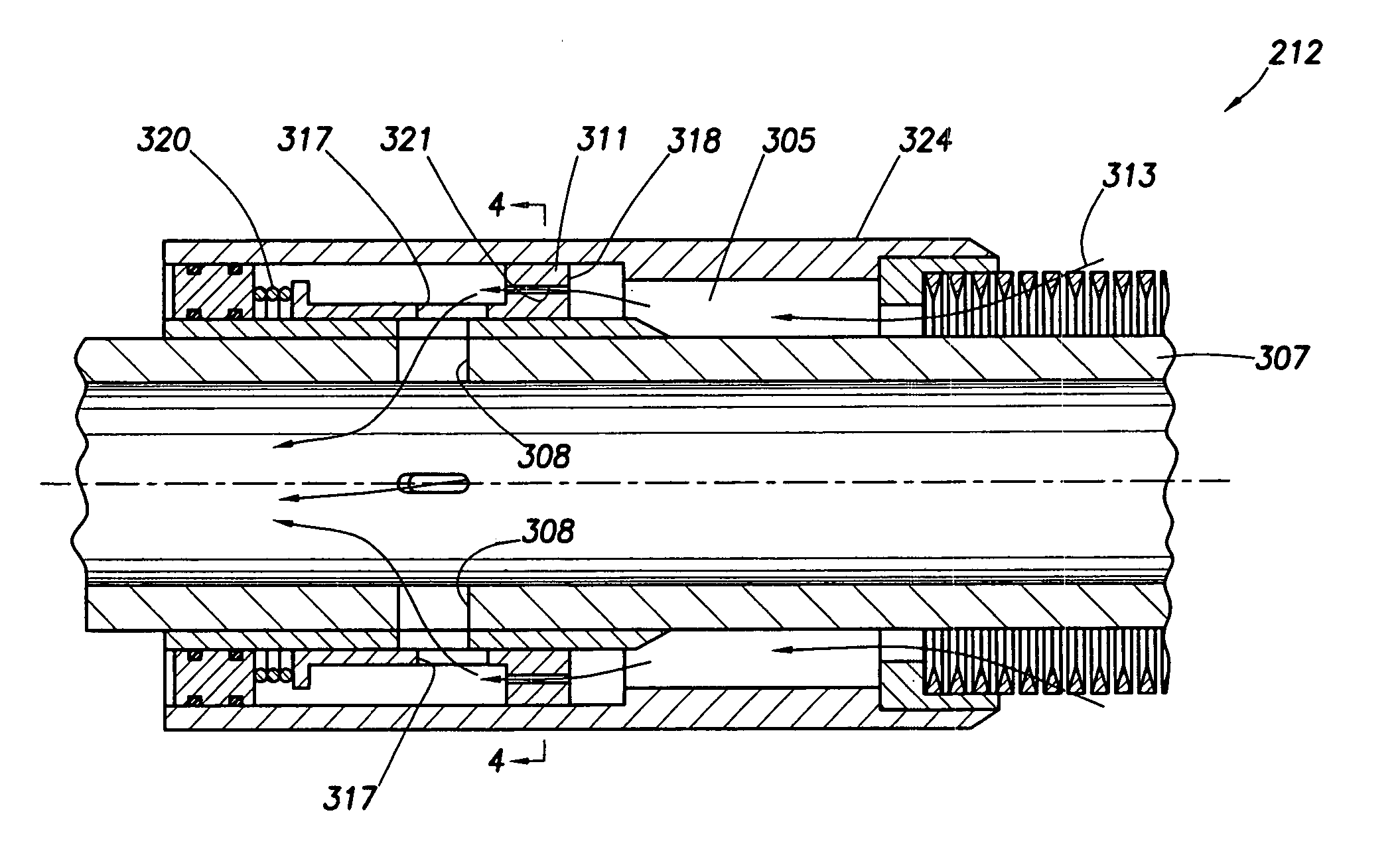

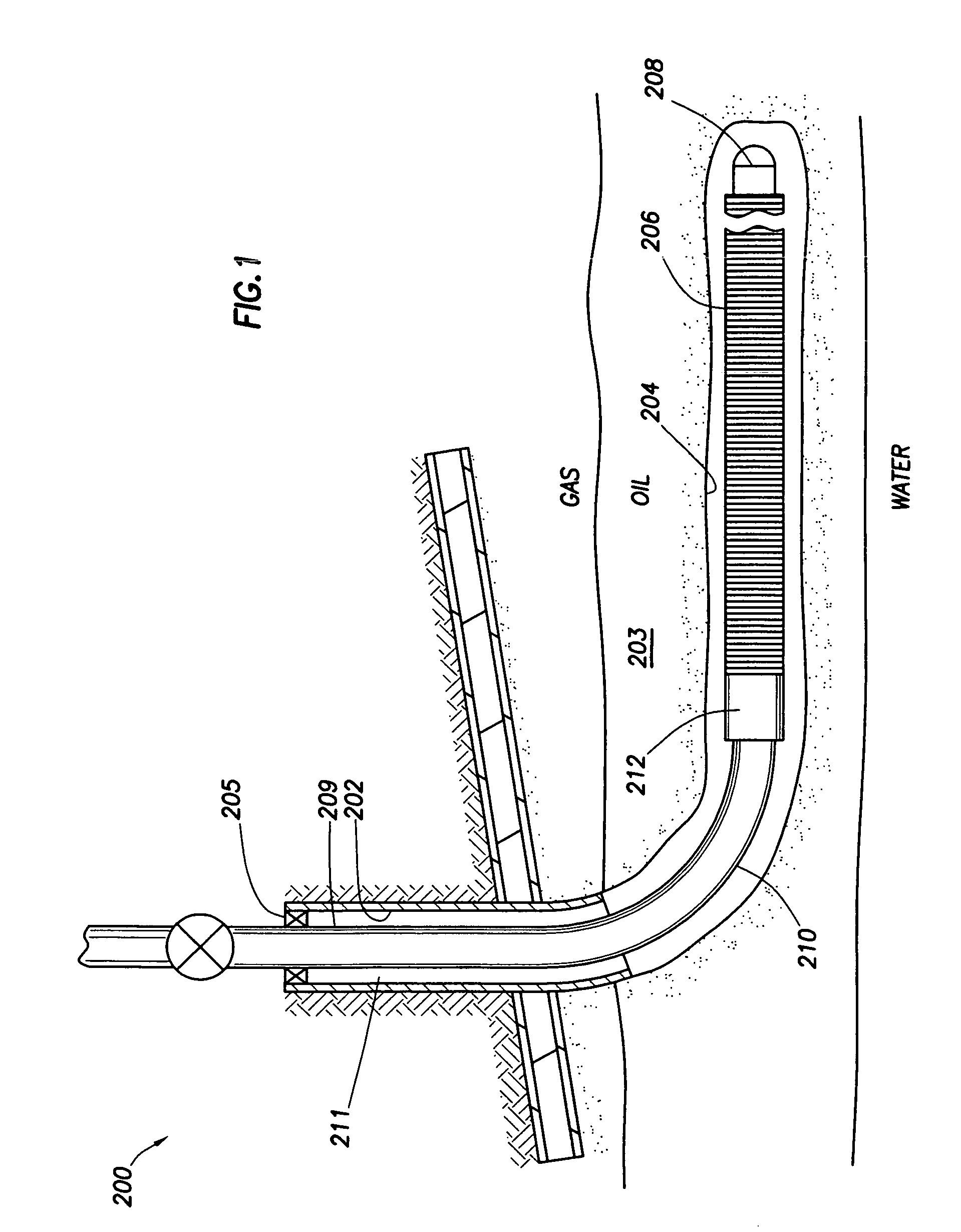

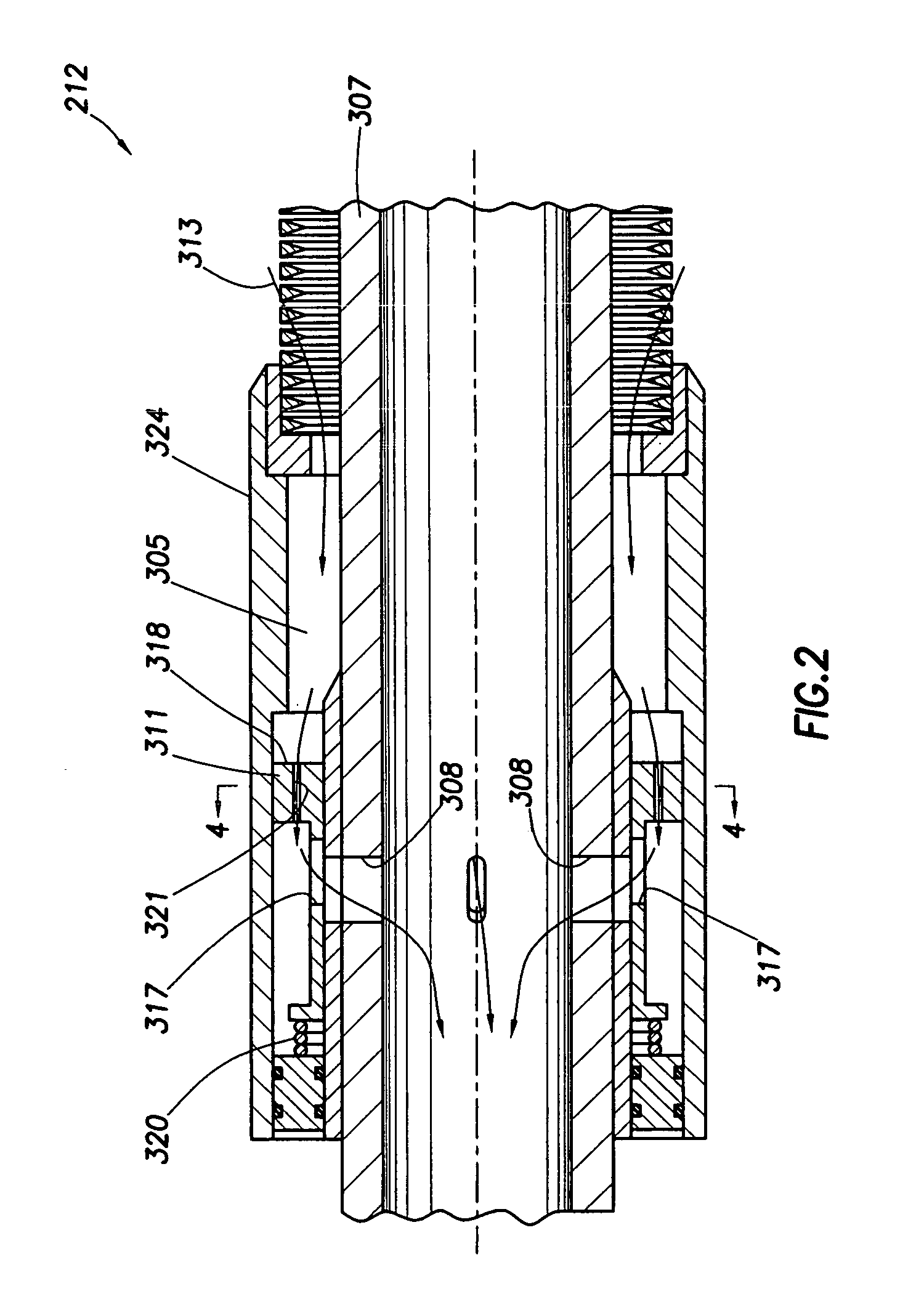

Flow control apparatus for use in a wellbore

Methods and apparatus for use in a wellbore to meter and choke certain components from being produced, based upon their density relative to the density of oil are disclosed. The device includes an inner tubular body portion having apertures in the wall thereof for passing oil, an outer tubular body and at least one metering orifice therebetween to meter production. Disposed around the inner body is an axially movable member to selectively cover and expose the apertures of the inner body, thereby permitting fluid to flow therethrough.

Owner:WEATHERFORD TECH HLDG LLC

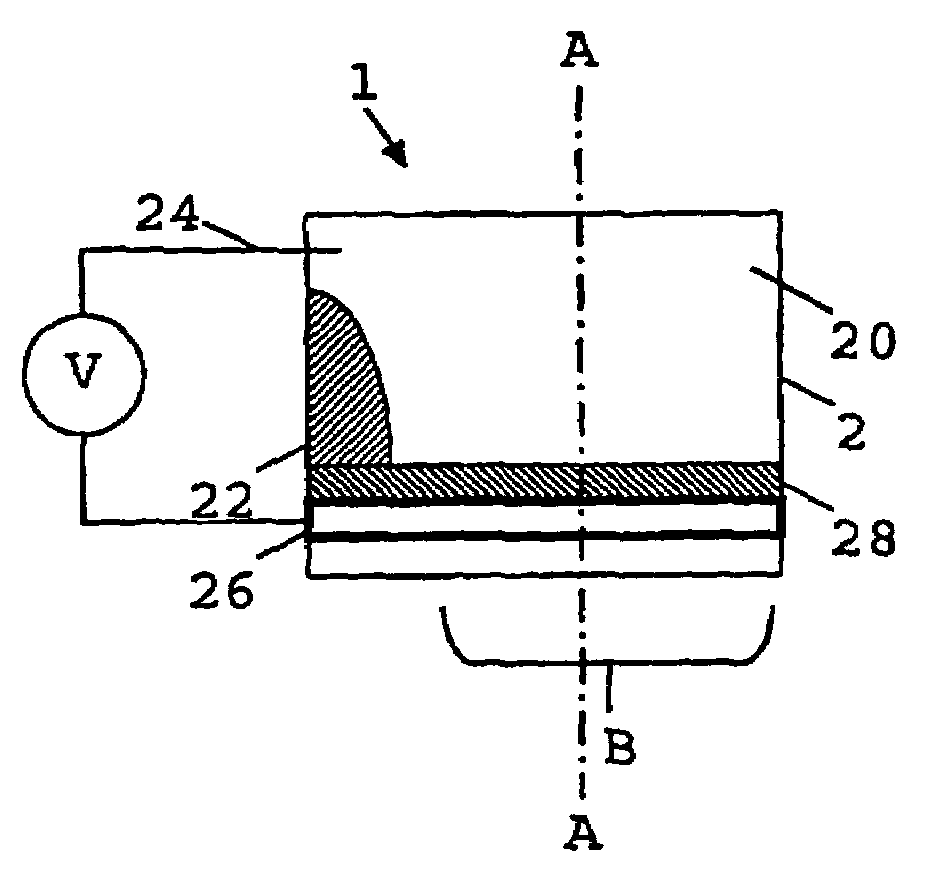

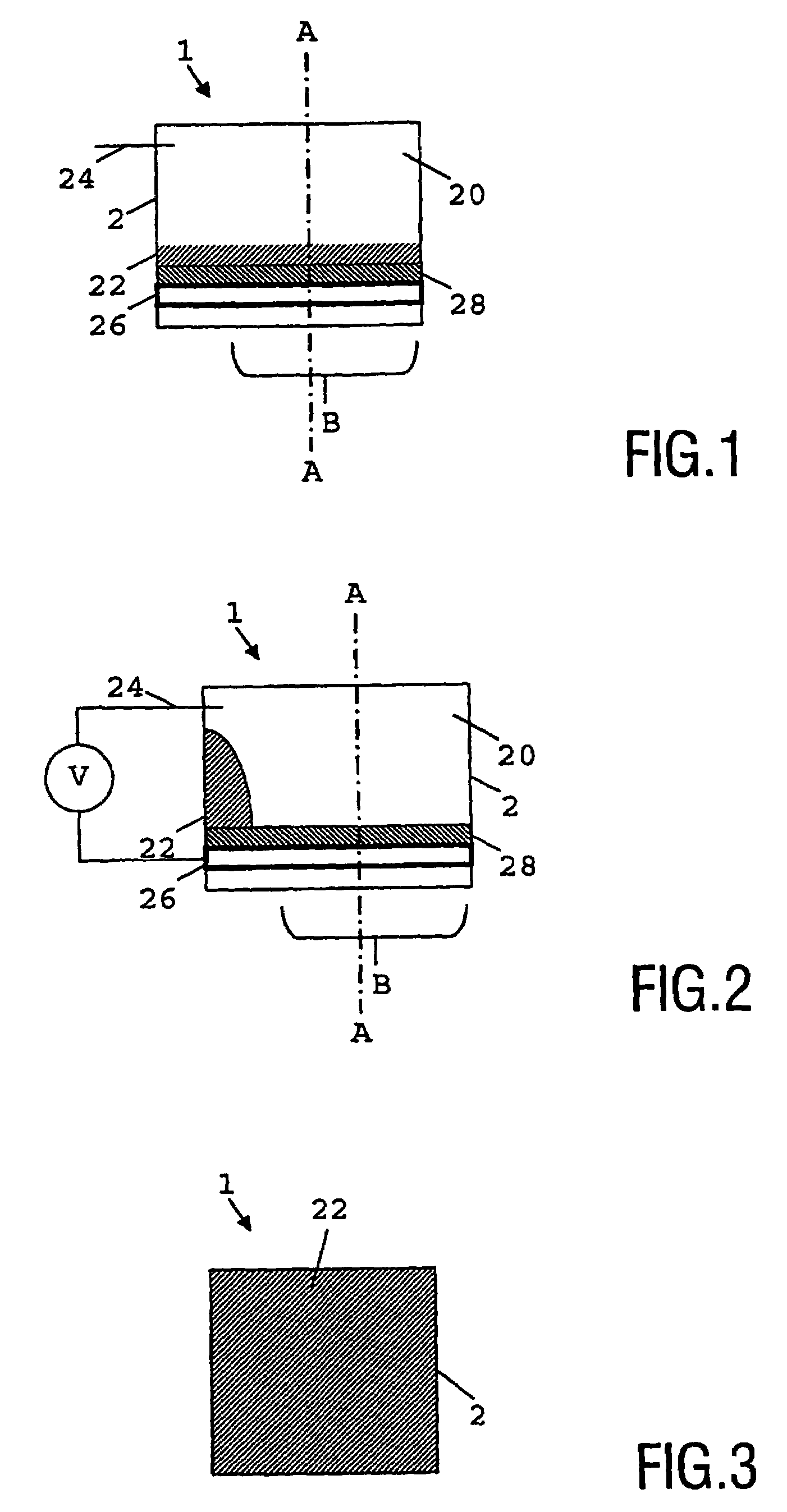

Switchable optical element

ActiveUS7508566B2Improve evenlyAvoid introducingRecord information storageOptical beam guiding meansOptical axisClassical mechanics

A switchable optical element has a fluid chamber including immiscible first and second bodies of fluid disposed relative to one another along an optical axis of the element. The second body of fluid is movable in a direction away from the optical axis (A) by electro-wetting action, giving the switchable optical element a changeable transmissivity along the optical axis.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

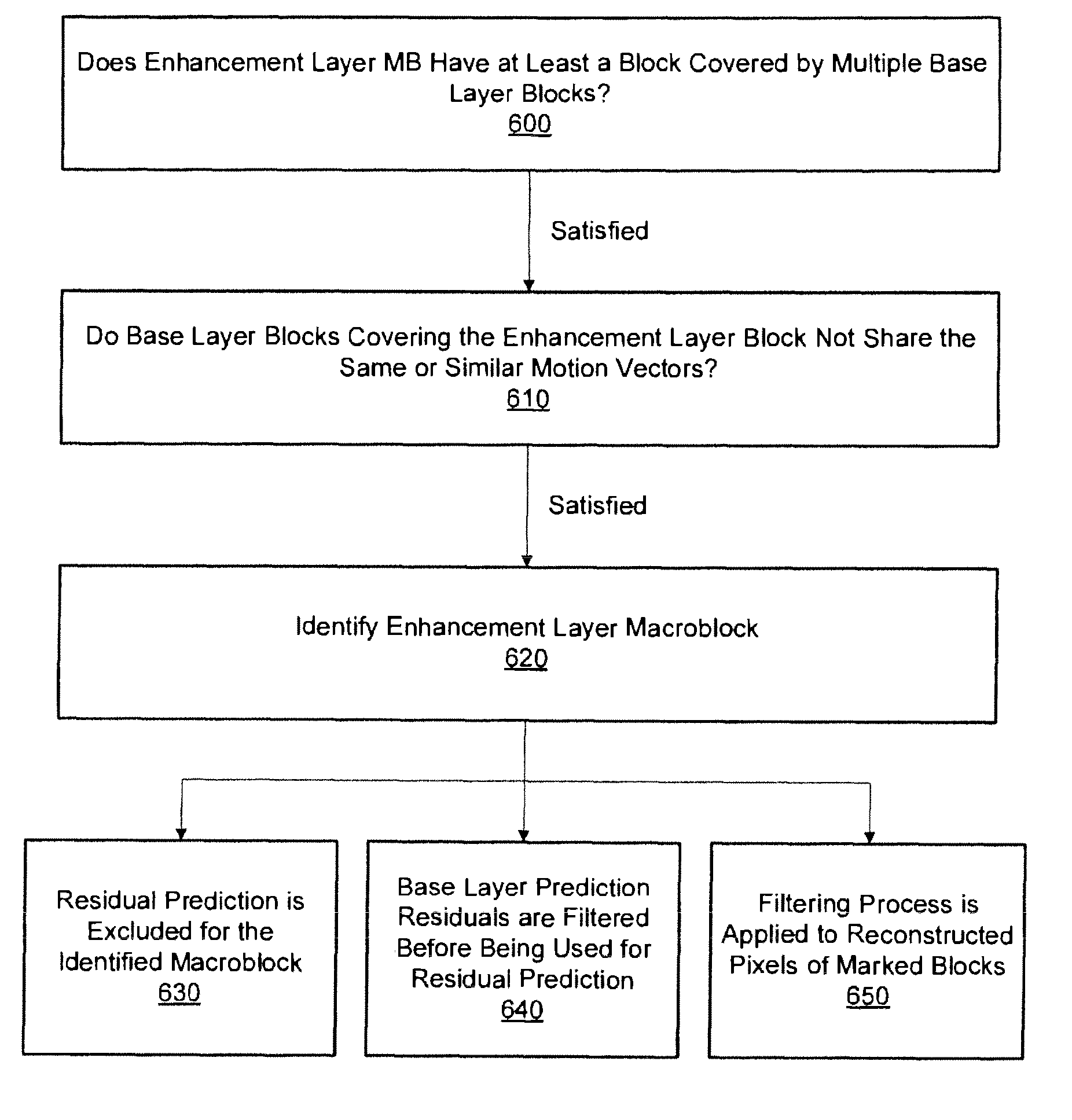

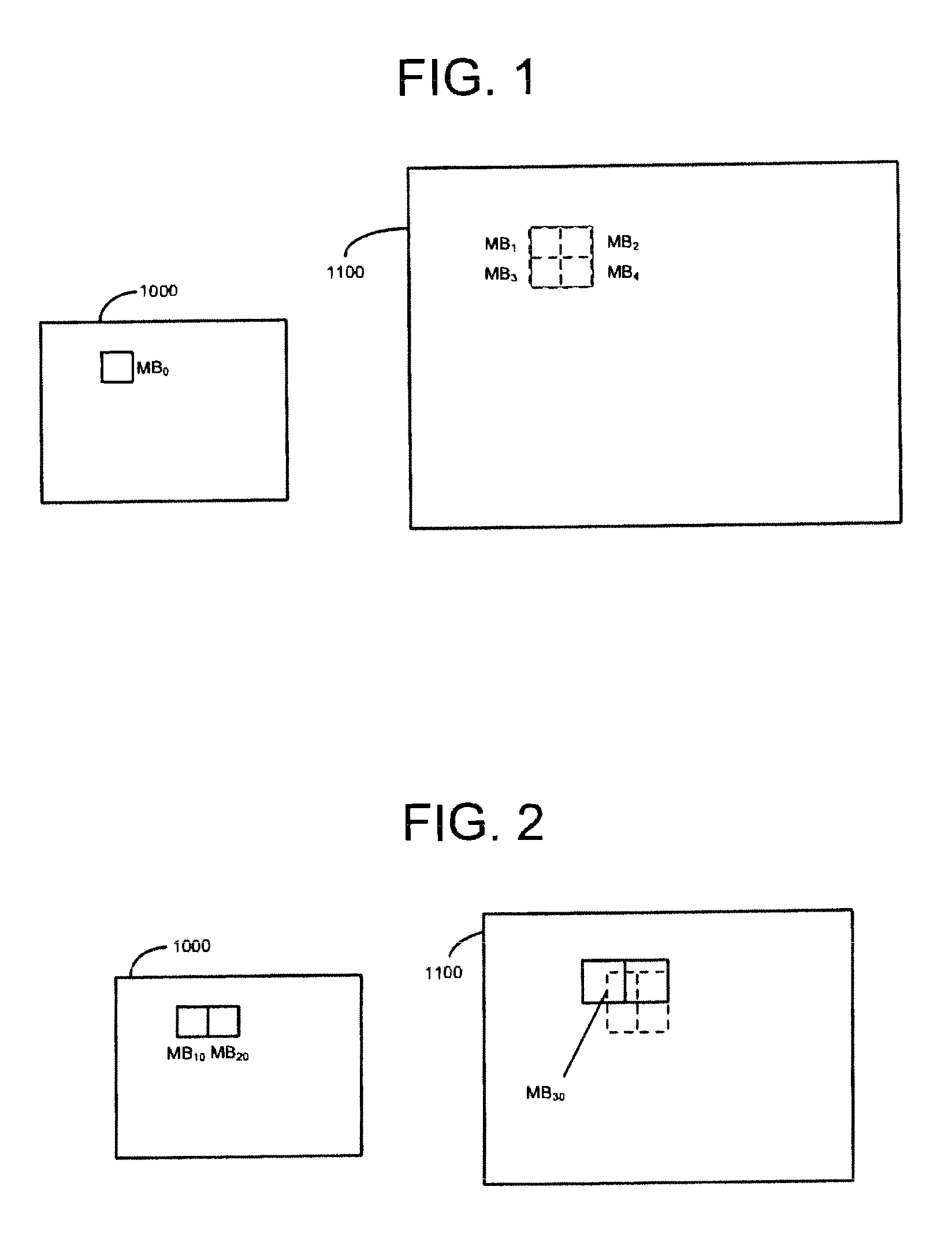

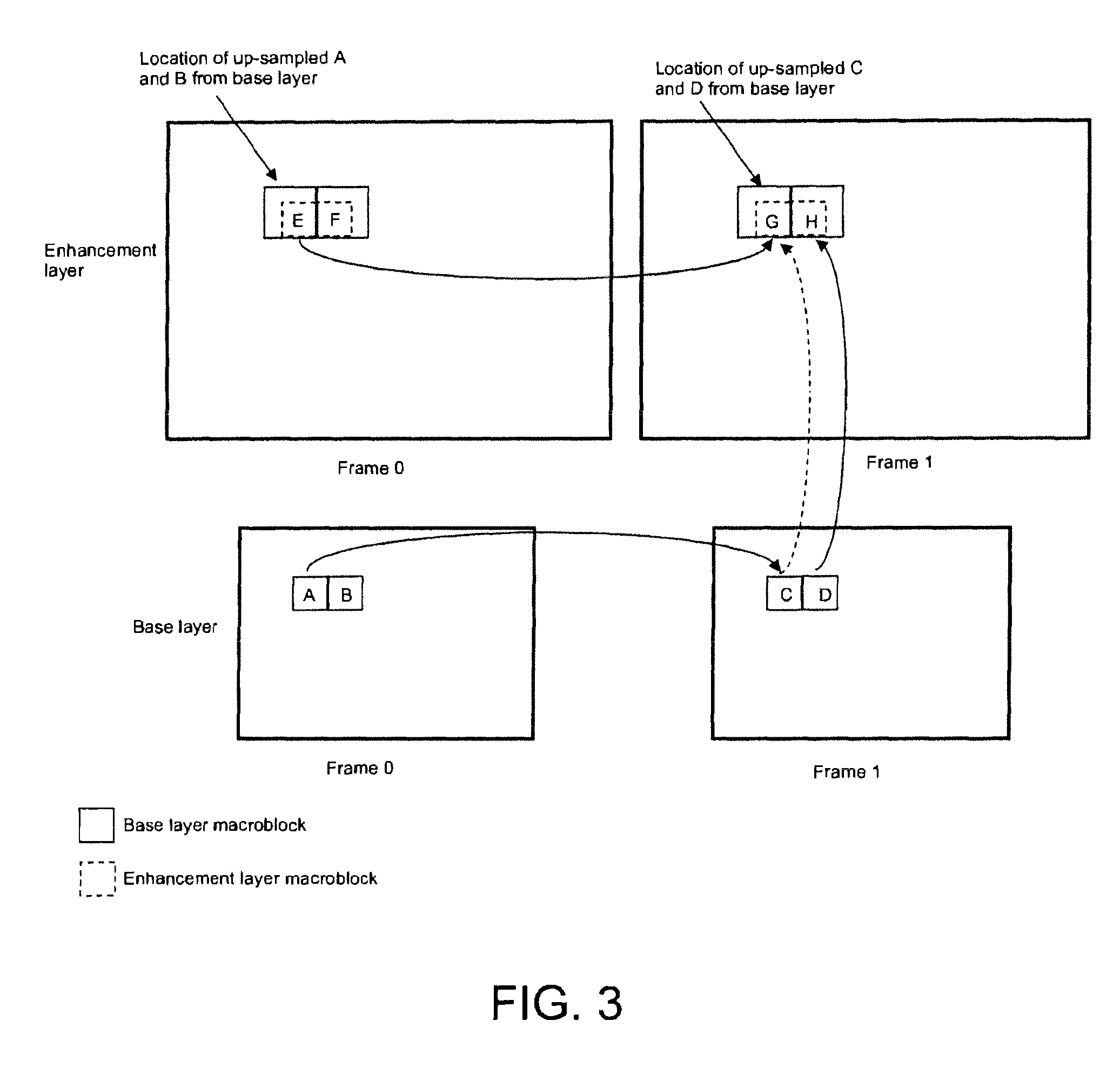

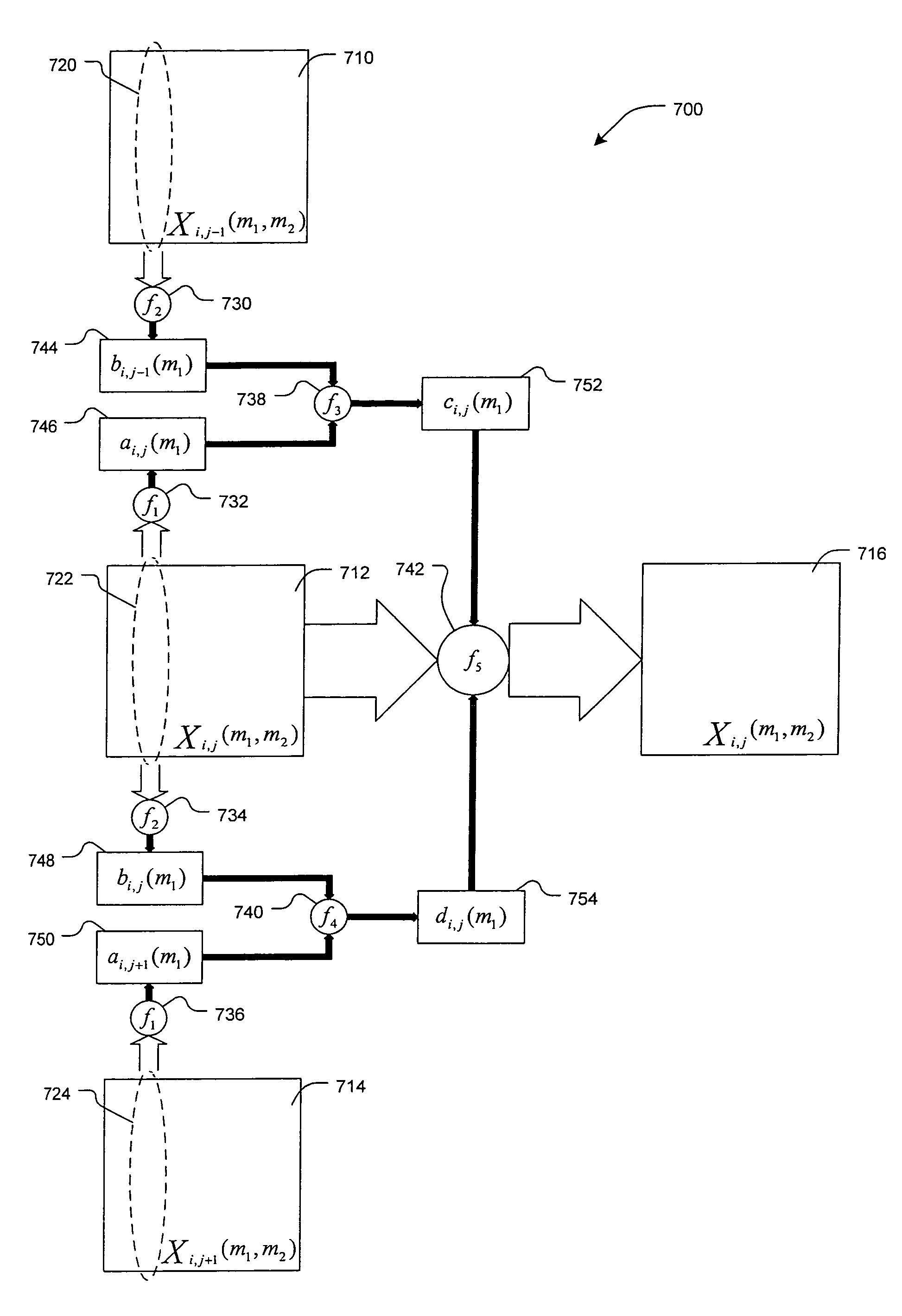

System and method for providing improved residual prediction for spatial scalability in video coding

InactiveUS20080225952A1Improving residual predictionAvoid introducingColor television with pulse code modulationColor television with bandwidth reductionMultiple criteriaVisual artifact

A system and method for providing improved residual prediction for spatial scalability in video coding. In order to prevent visual artifacts in residual prediction in extended spatial scalability (ESS), each enhancement layer macroblock is checked to determine if the macroblock satisfies a number of conditions. If the conditions are met for an enhancement layer macroblock, then it is likely that visual artifacts will be introduced if applying residual prediction on the macroblock. Once such locations are identified, various mechanisms may be used to avoid or remove the visual artifacts.

Owner:NOKIA CORP

Methods and Apparatus for Treating Glaucoma

ActiveUS20090227934A1Improve fluid flowReduce the possibilityLaser surgeryEar treatmentSchlemm's canalOcular implant

An ocular implant for treating glaucoma is provided, which may include any number of features. More particularly, the present invention relates to implants that facilitate the transfer of fluid from within one area of the eye to another area of the eye. One feature of the implant is that it includes a proximal inlet portion and a distal inlet portion adapted to be inserted into the anterior chamber of the eye, and an intermediate portion adapted to be inserted into Schlemm's canal. Another feature of the implant is that it can be biased to assume a predetermined shape to aid in placement within the eye.

Owner:ALCON INC

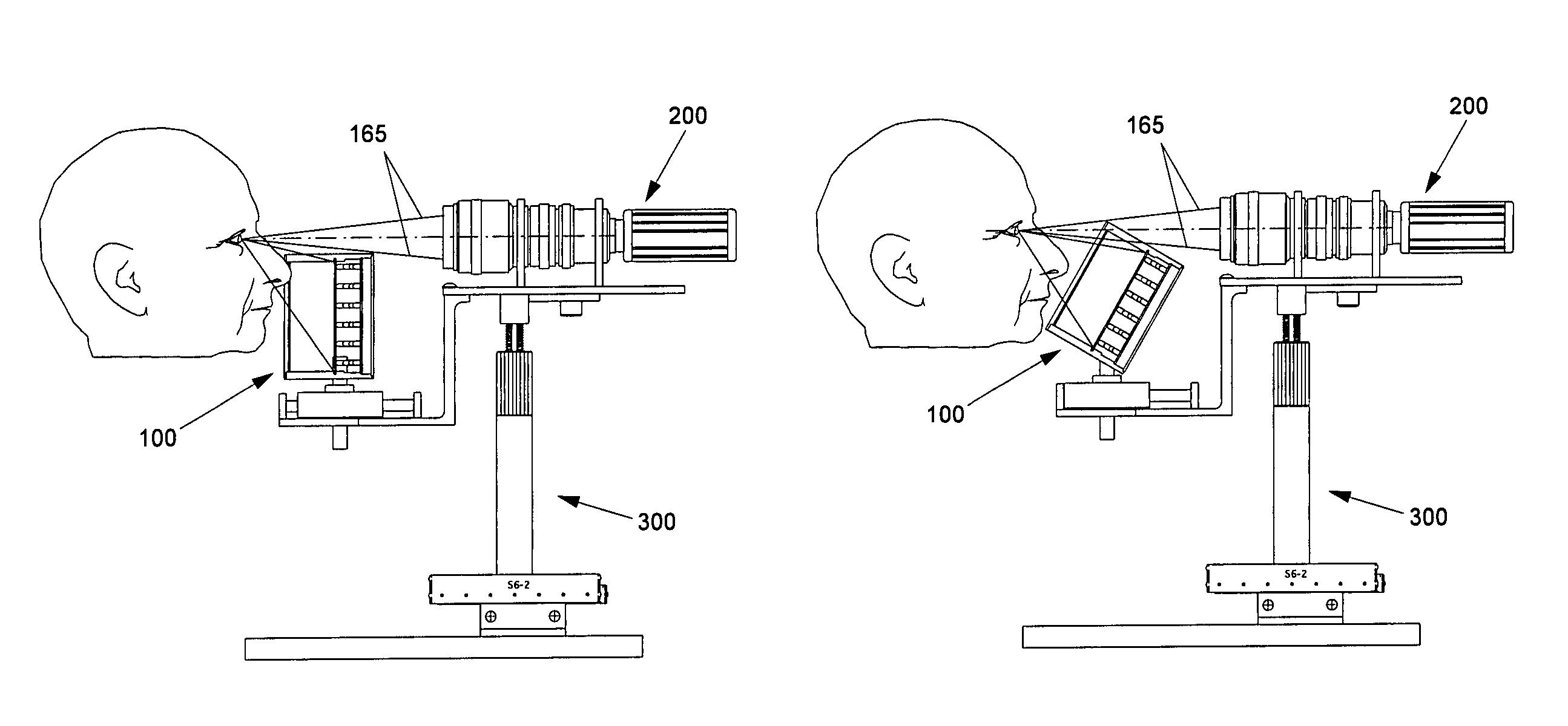

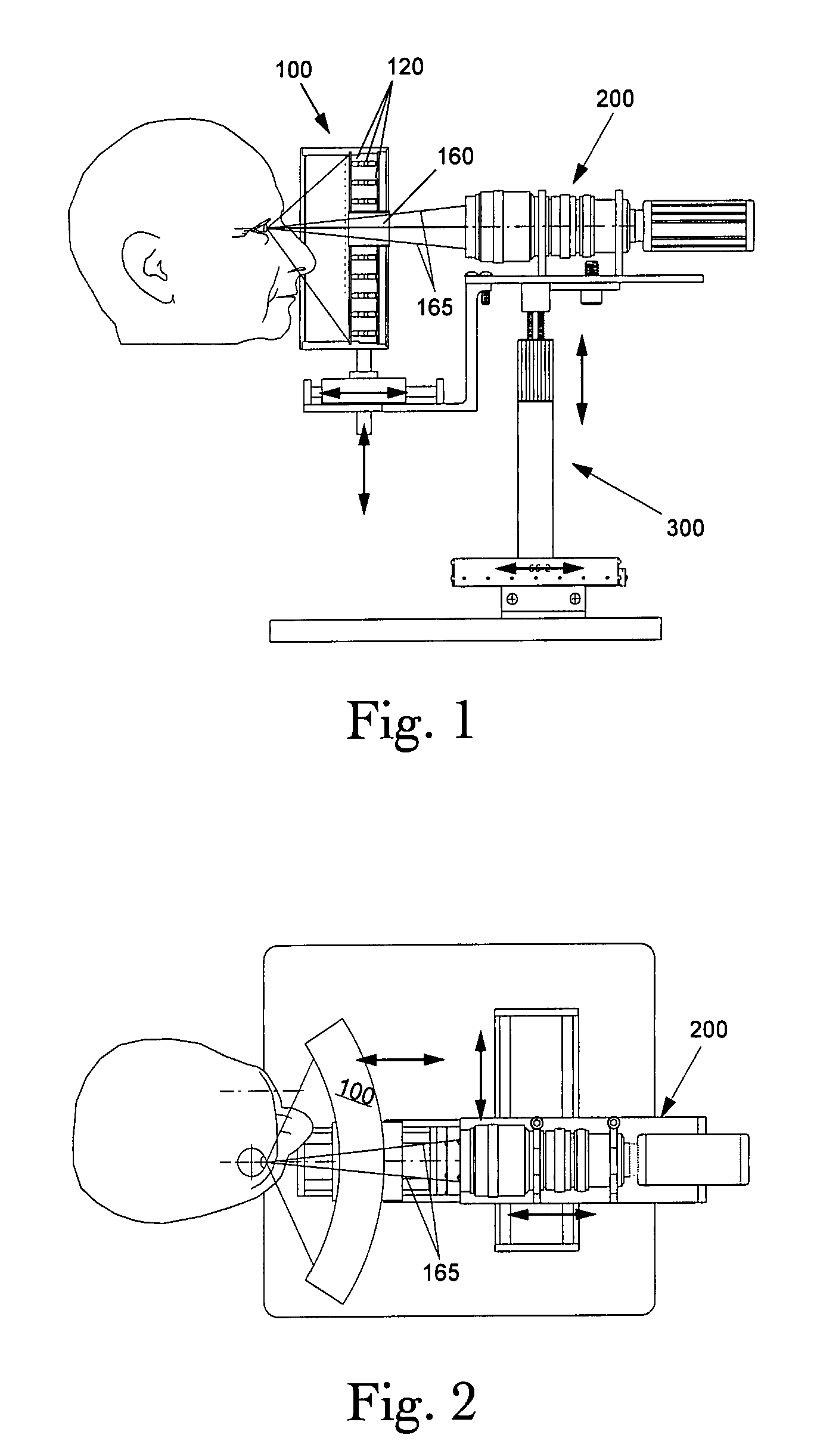

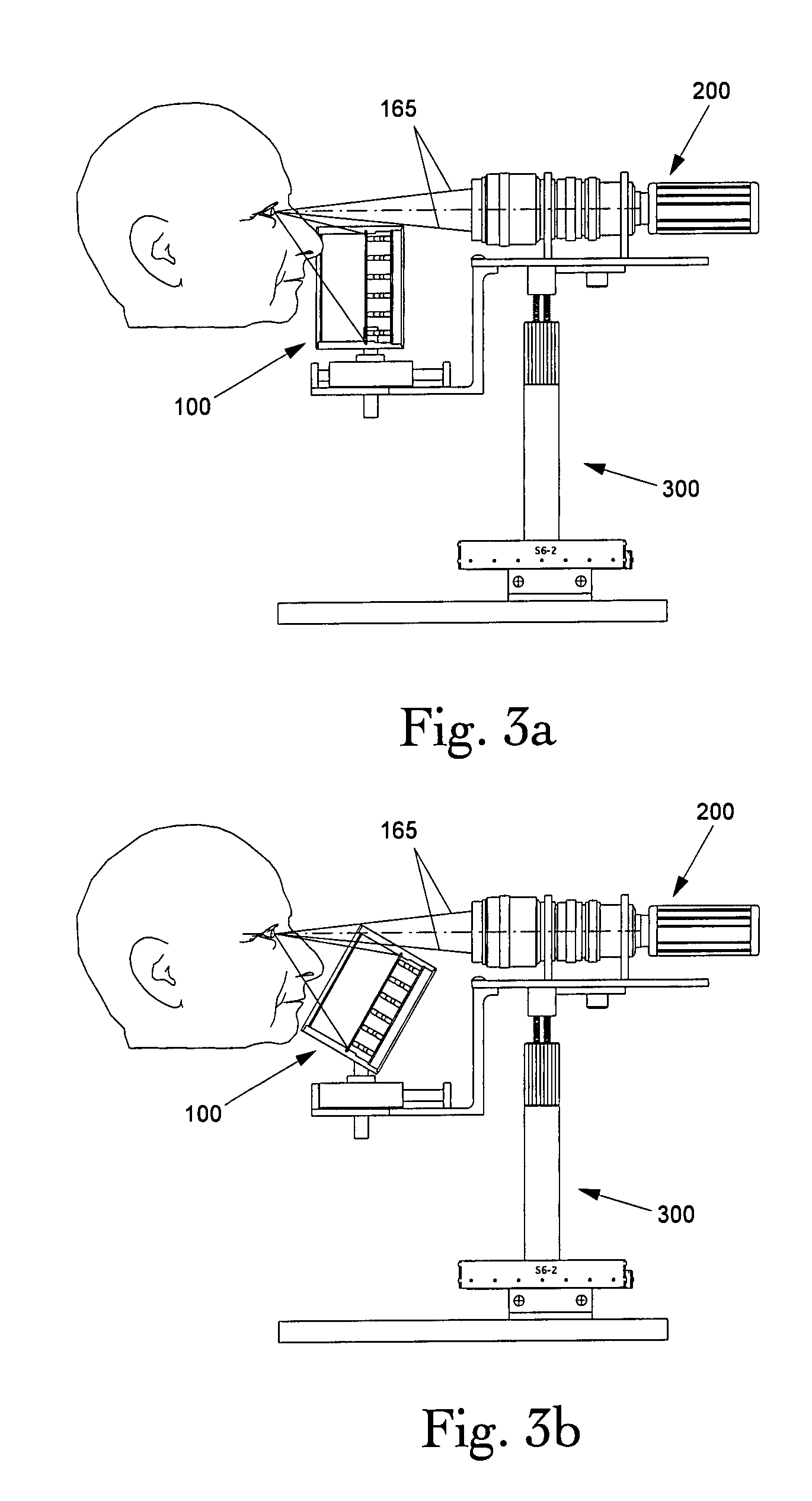

Tear film measurement

ActiveUS7758190B2Avoid introducingReduce light intensityUsing optical meansEye diagnosticsTearsFARR assay

Owner:TEARSCIENCE INC

Surgical systems with sesnsing and machine learning capabilities and methods thereof

PendingUS20210007760A1Improves clot fragmentation/emulsification efficacyAvoid introducingDiagnosticsSurgical needlesBiomedical engineeringPhysical therapy

Systems and methods for determining surgical system settings during a surgical procedure are disclosed. The surgical systems comprise of a control system, a means for tissue removal, sensing capabilities and machine learning application(s). The sensing capabilities and machine learning application(s) are configured to determine type and / or properties of the removed tissue and to predict preferred surgical settings for optimized removal and surgical outcomes. The learning machine application(s) communicates these preferred settings to a surgical control system.

Owner:CAZE TECH

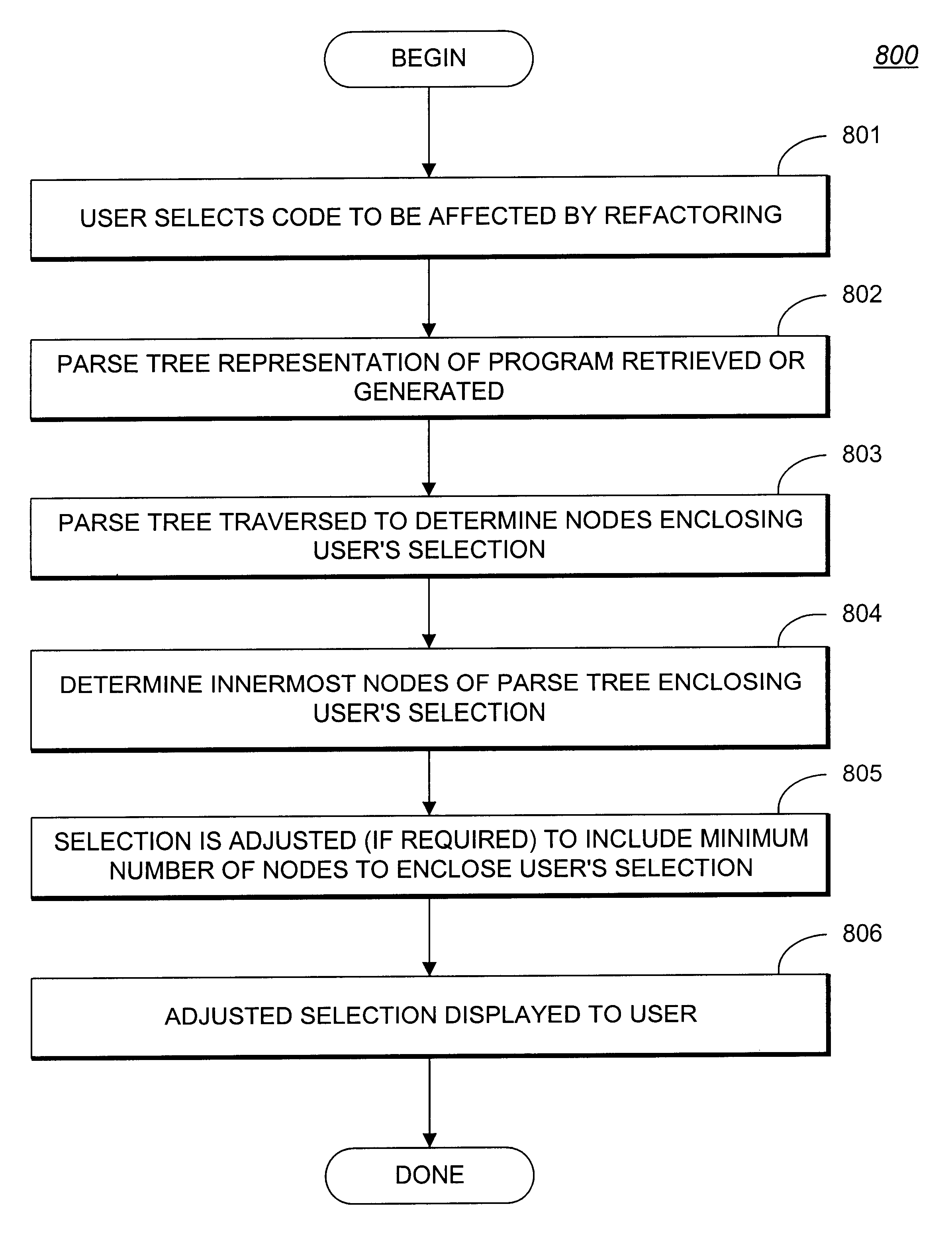

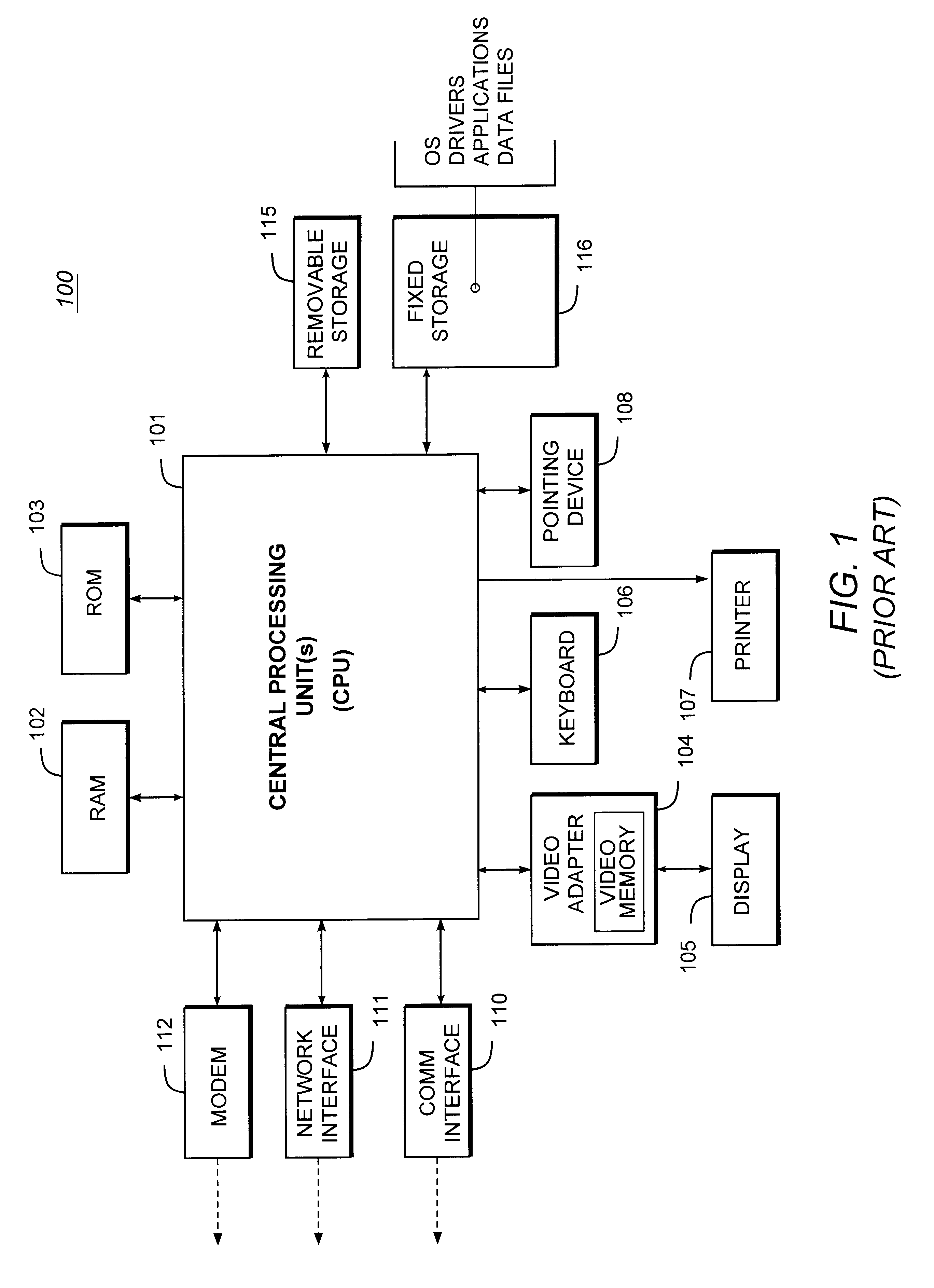

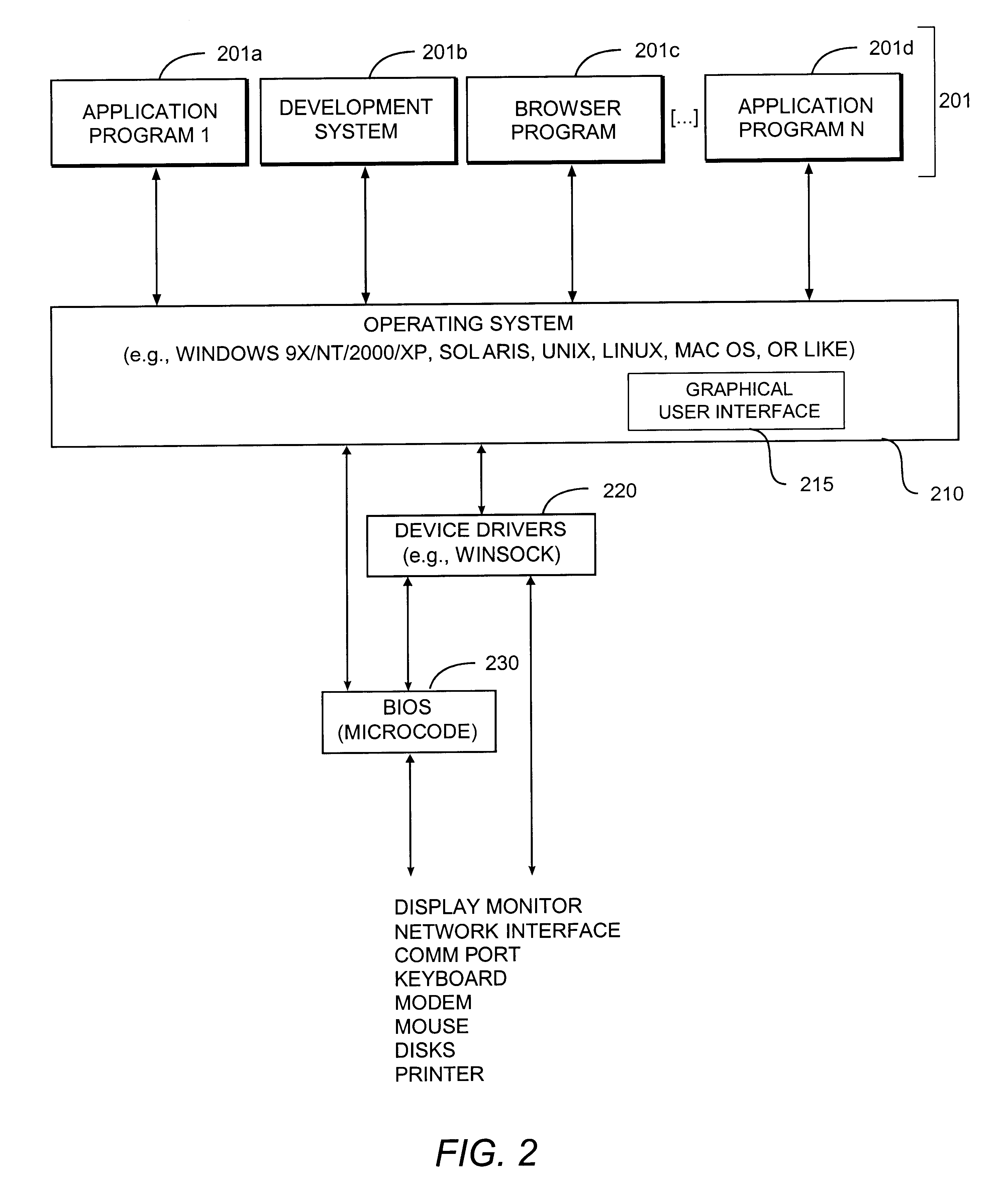

System and methodology providing automated selection adjustment for refactoring

InactiveUS6807548B1Simple internal structureSimplifying additionData processing applicationsCode refactoringUser inputSource code

A system providing methods for adjusting a user's selection of source code of a program to correspond with a parsed version of the program is described. The method commences with user input of a selection of source code of a program for performing an operation such as a refactoring. The user's selection is compared with a parsed version of the program. If the user's selection does not correspond with the parsed version of the program, the user's selection is adjusted to achieve correspondence with the parsed version of the program.

Owner:CODEGEAR

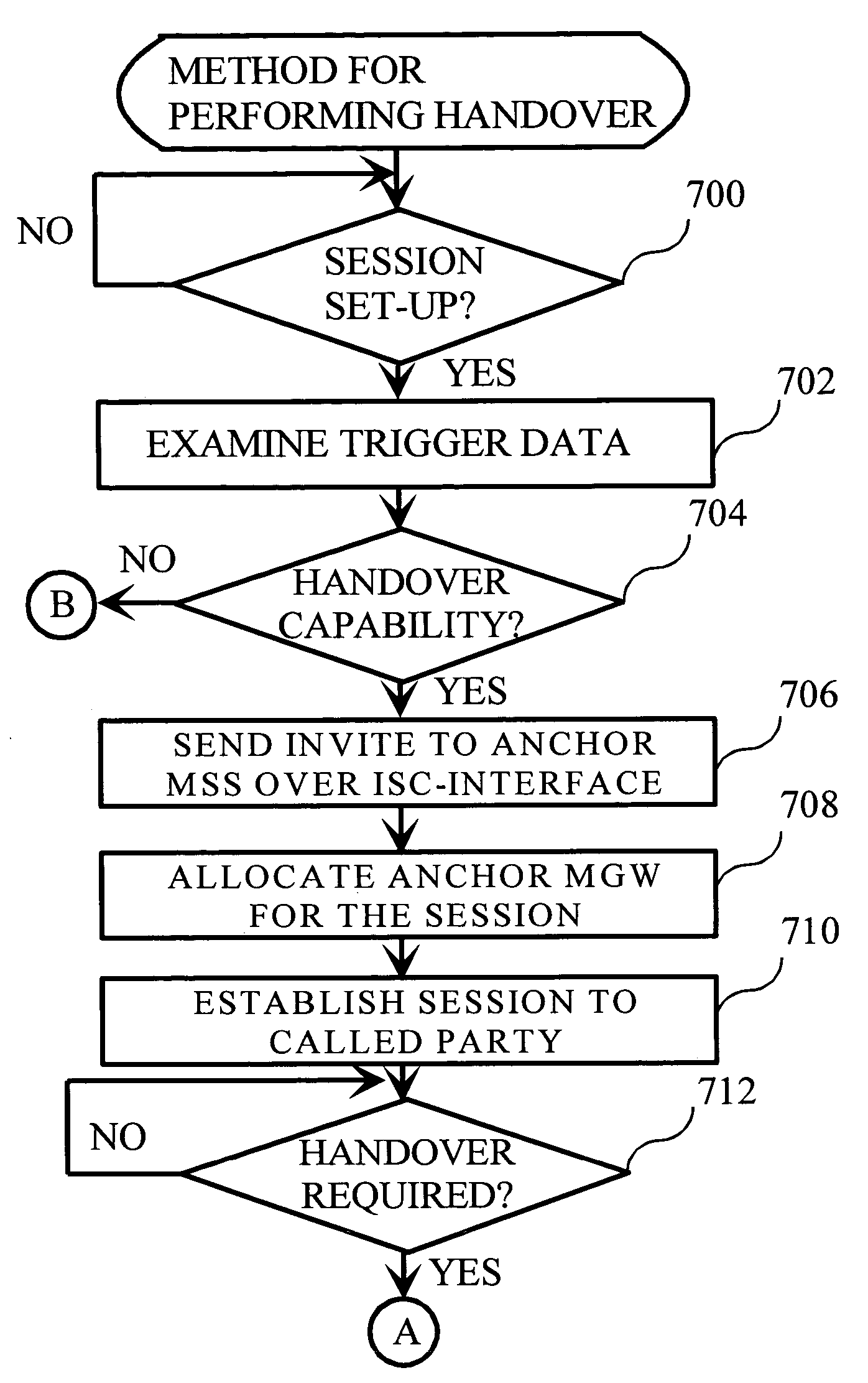

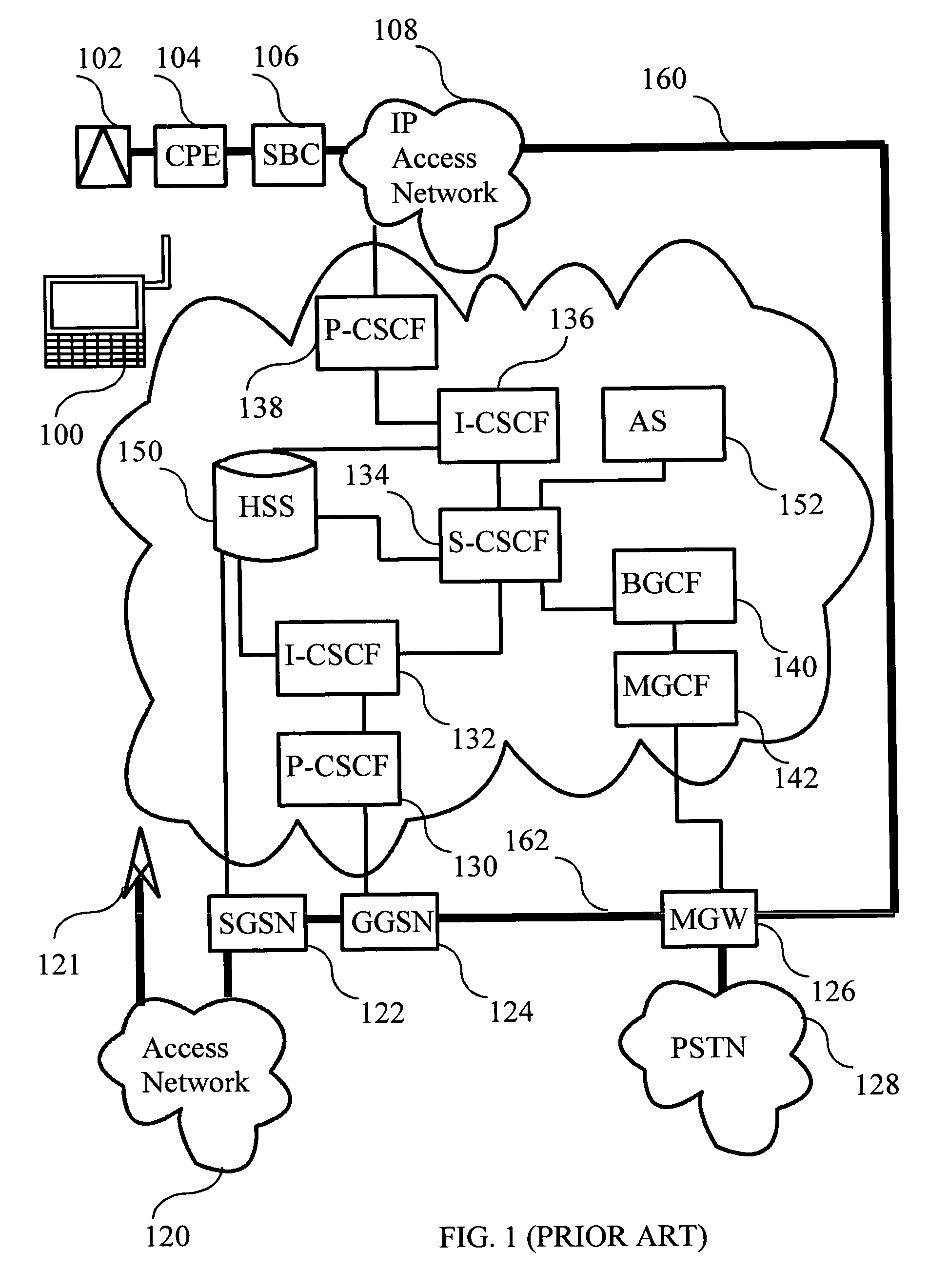

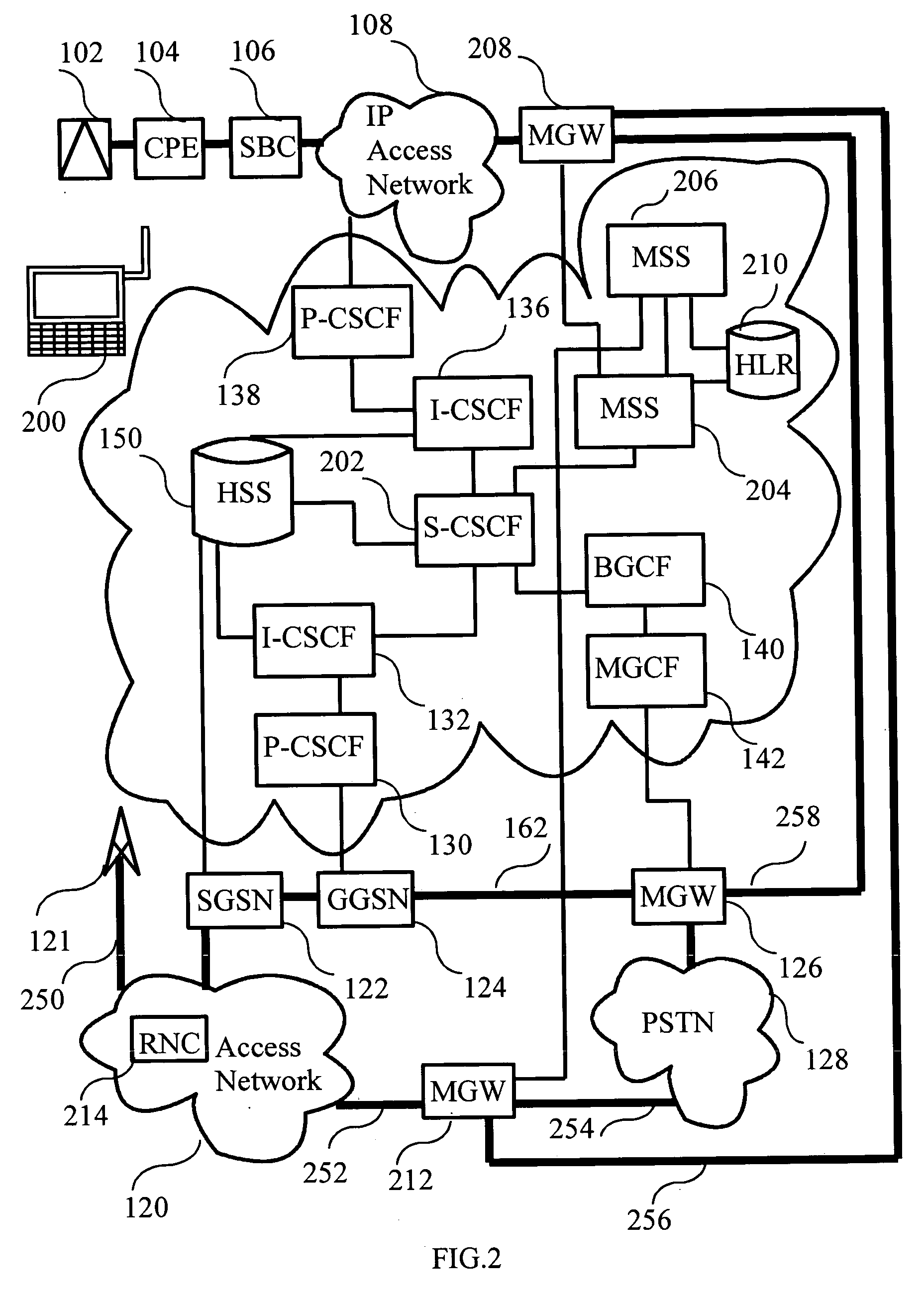

Method for performing inter-system handovers in a mobile communication system

InactiveUS20060258358A1Avoid introducingEasy to mergeConnection managementData switching by path configurationCommunications systemRadio networks

The invention relates to a method for performing inter-system handovers in a communication system comprising at least a mobile station, a call state control function, a first and a second call control node, a first and a second media gateway and a radio network node. The handover is achieved by way of connecting a call control node to a call state control function. The call control node allocates a media gateway for the session established. The session media bearers are routed via the media gateway. The call control node acts as an anchor node for the handover. As the mobile station moves to a new cell a media bearer is established to the media gateway from the mobile station via the new cell.

Owner:RPX CORP

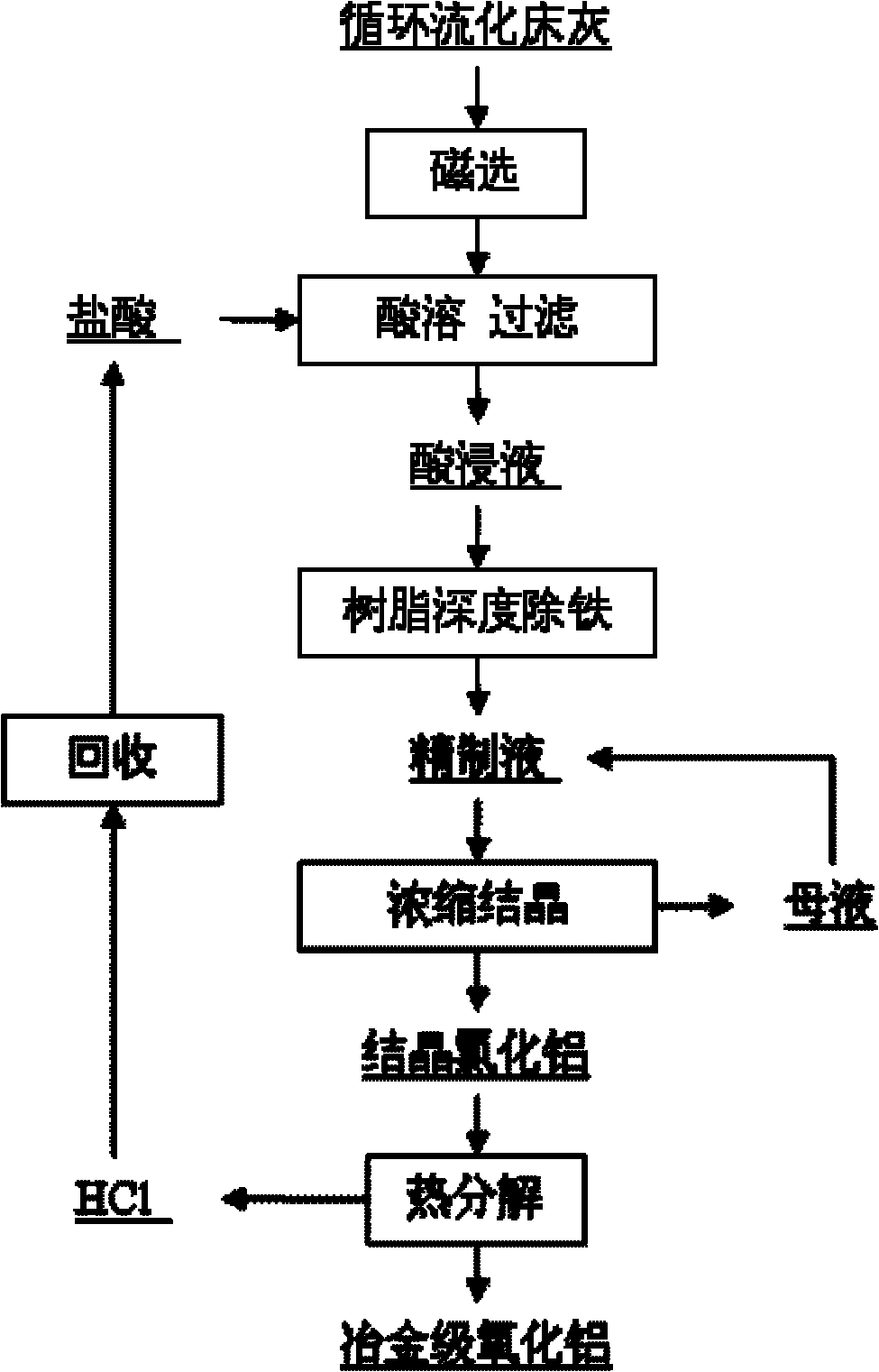

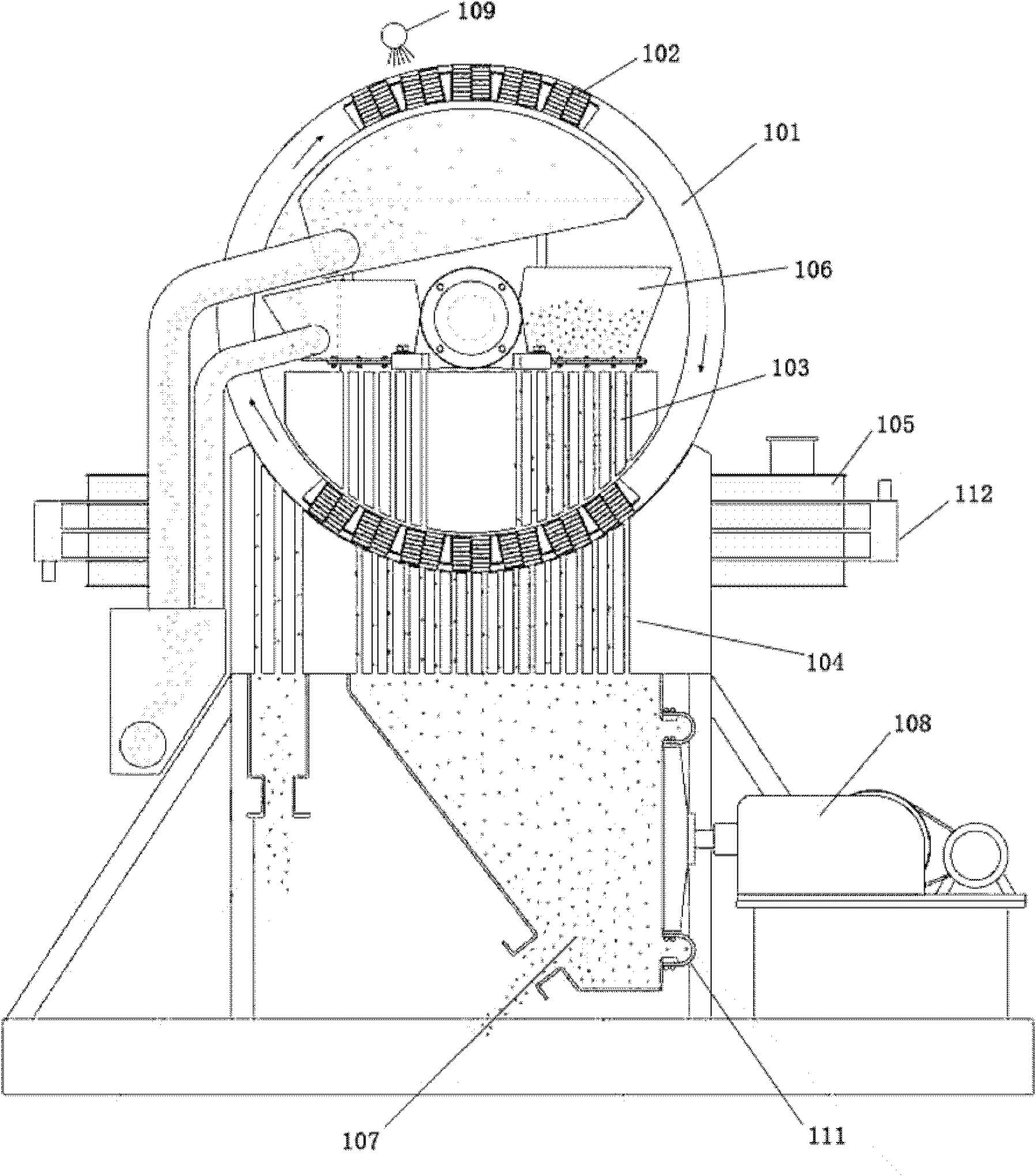

Method for preparing metallurgy-level aluminum oxide by using fluidized bed pulverized fuel ash

ActiveCN102145905AHigh extraction rateReduce manufacturing costSolid waste disposalTransportation and packagingAluminium chloridePulverized fuel ash

The invention discloses a method for preparing metallurgy-level aluminum oxide by using fluidized bed pulverized fuel ash as a raw material. The method comprises the following steps of: a) grinding the pulverized fuel ash, and removing iron by a wet magnetic separation method; b) reacting the pulverized fuel ash subjected to magnetic separation with hydrochloric acid to obtain hydrochloric acid immersion liquid; c) allowing the hydrochloric acid immersion liquid to pass through a large pore type cation resin column for further iron removal to obtain refined aluminum chloride solution; d) concentrating the refined aluminum chloride solution, and crystallizing to obtain an aluminum chloride crystal; and e) calcining the aluminum chloride crystal and decomposing to obtain the metallurgy-level aluminum oxide. The method has a simple process and an easily-controlled production process, and is high in aluminum oxide extraction efficiency, low in production cost and stable in product quality.

Owner:CHINA SHENHUA ENERGY CO LTD

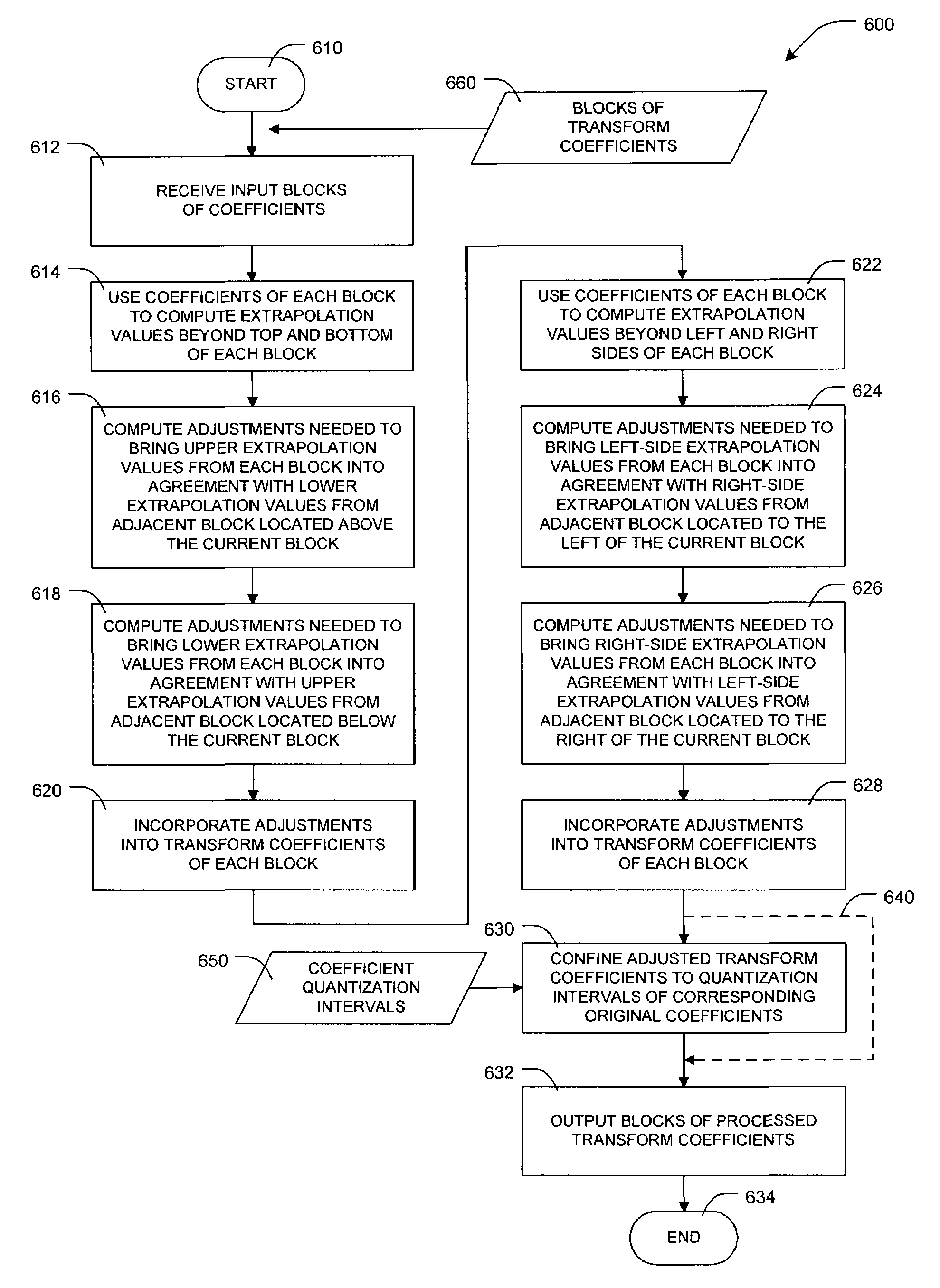

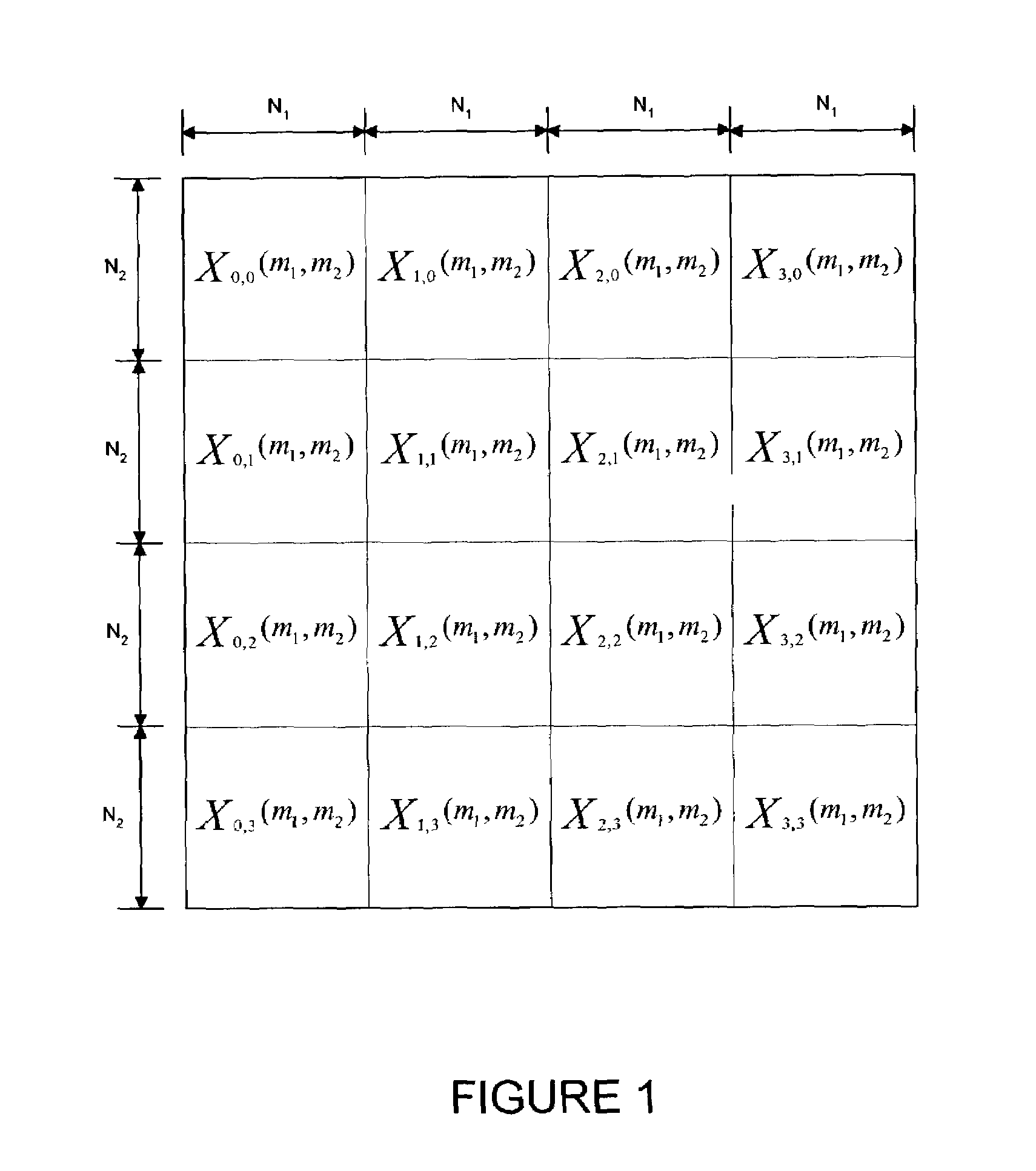

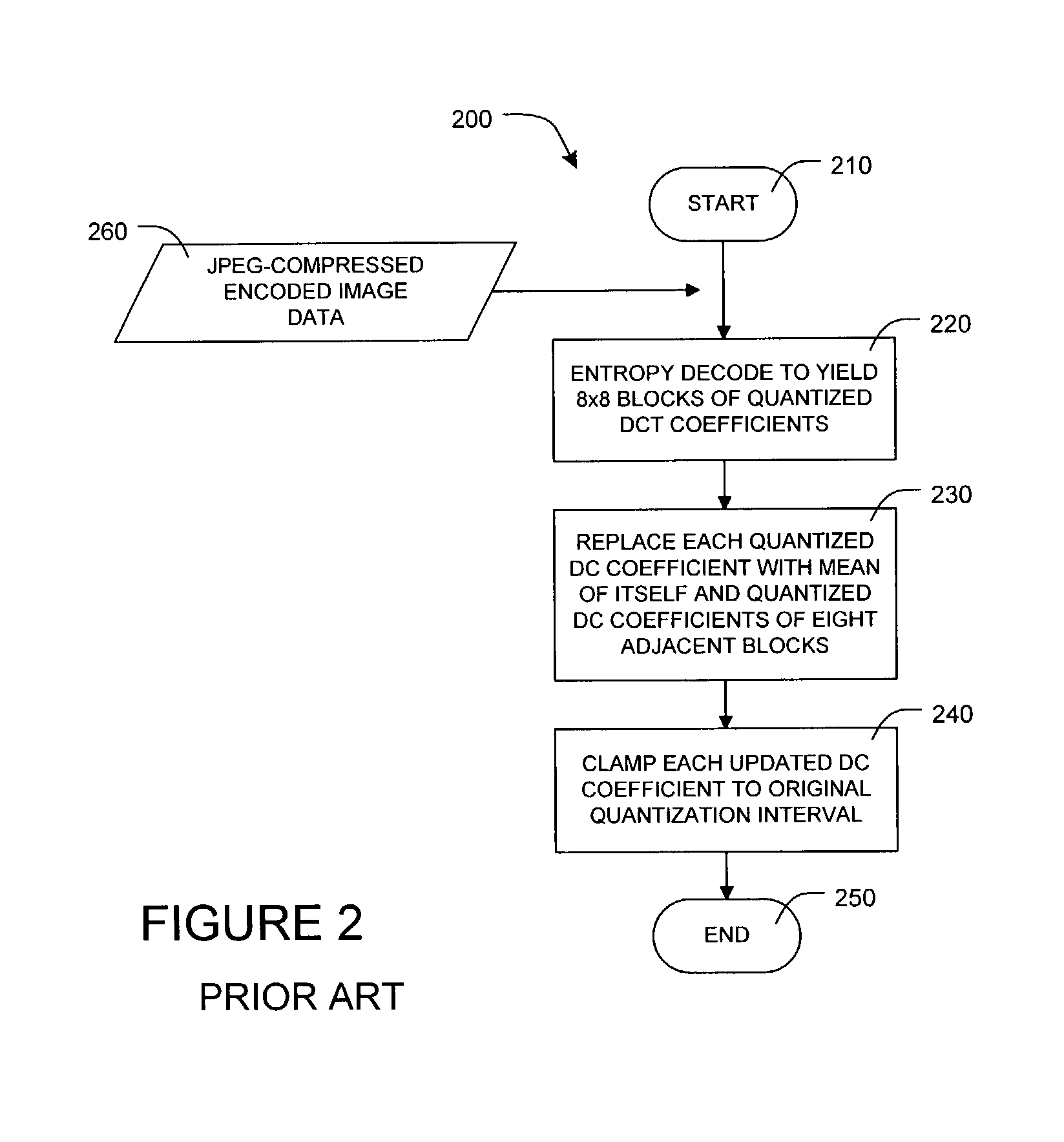

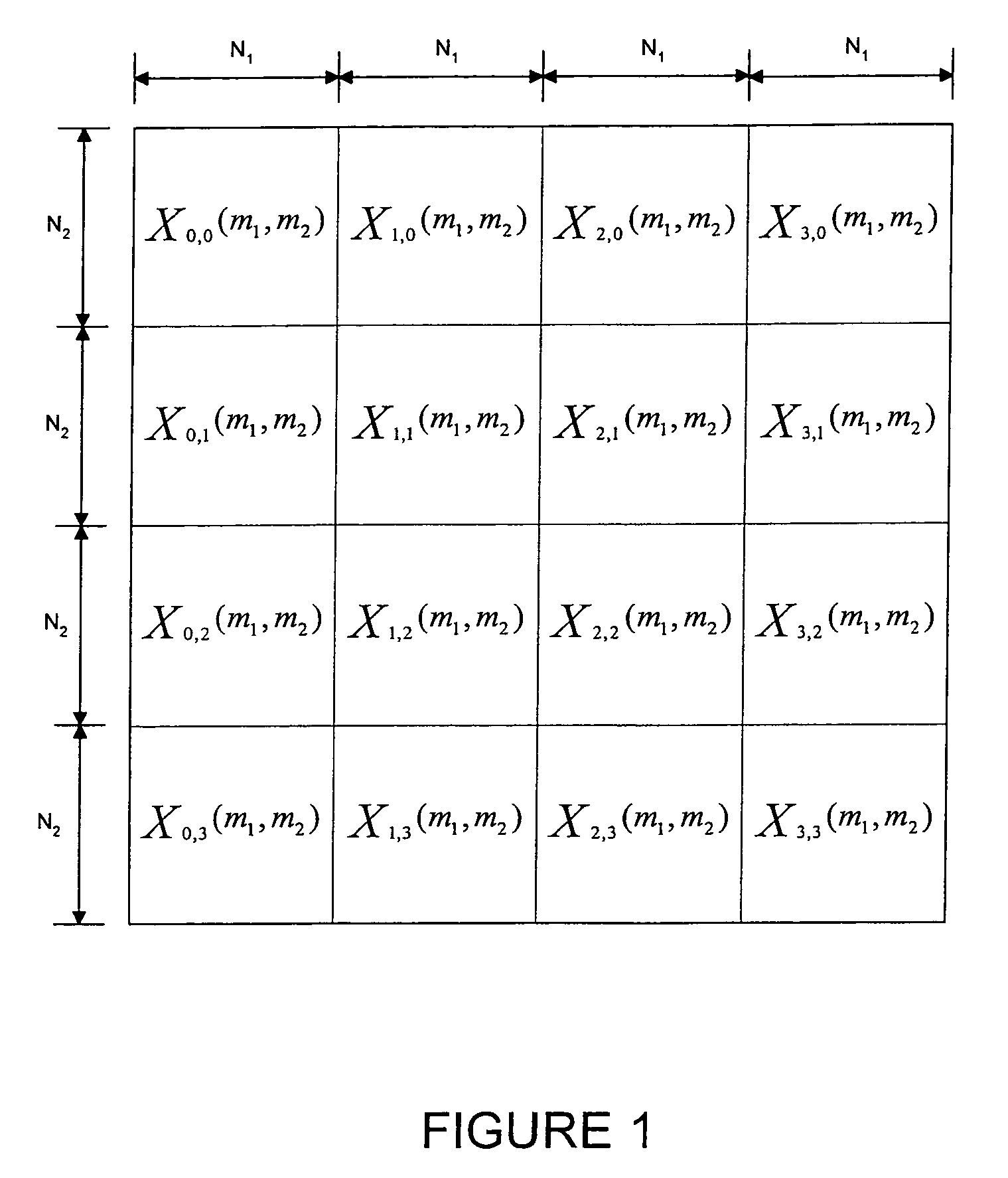

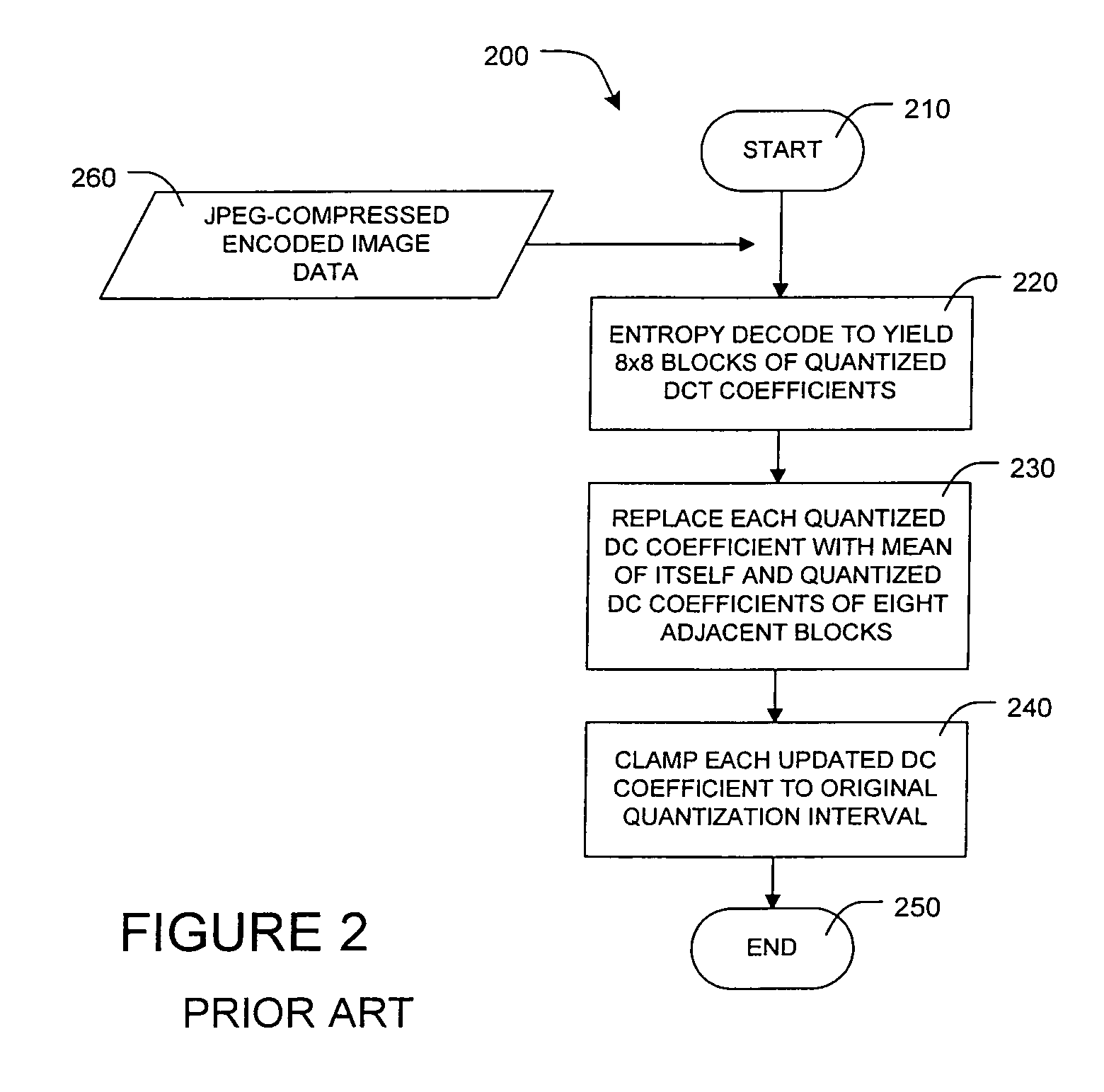

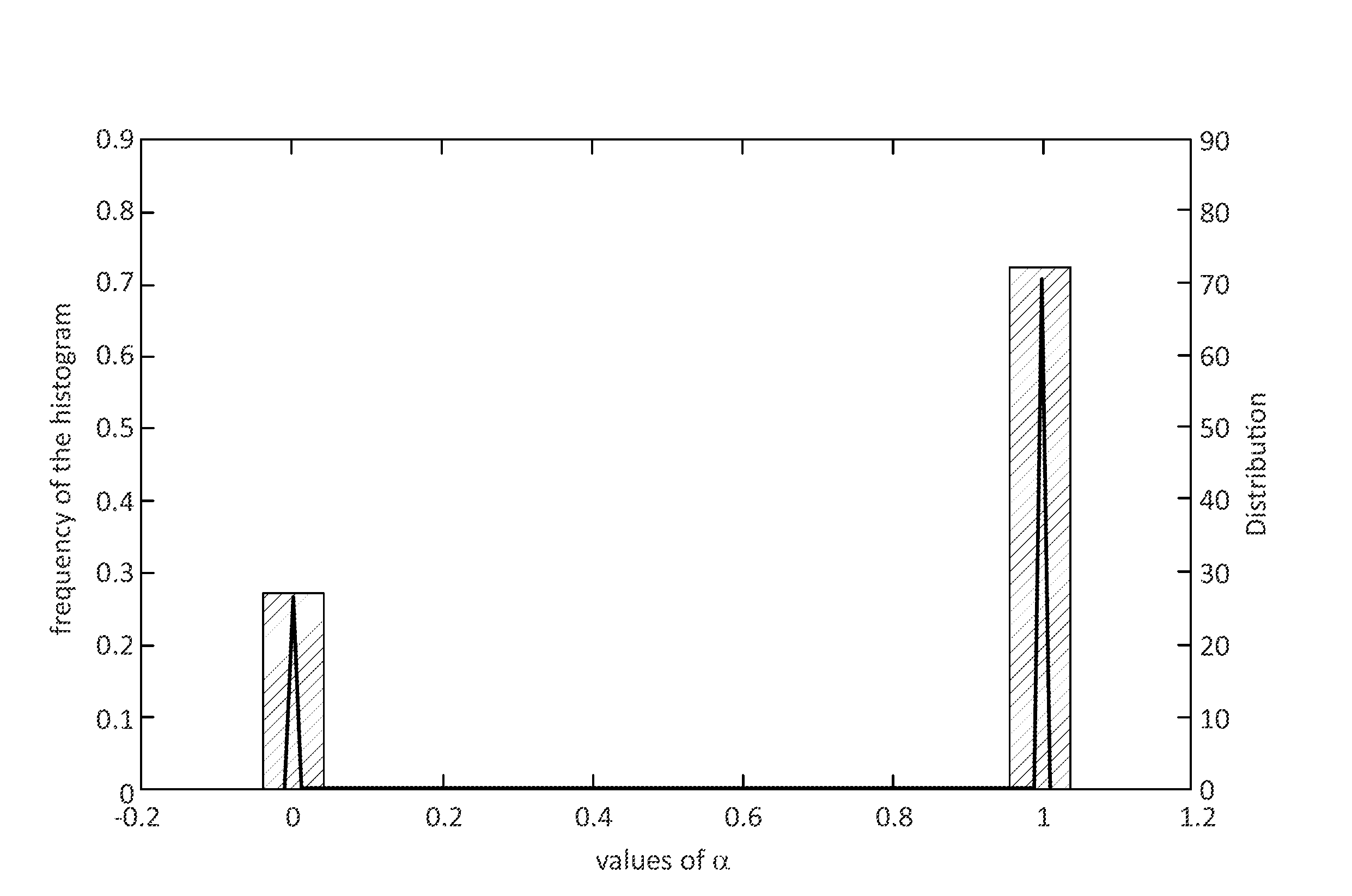

Methods and apparatus for improving quality of block-transform coded images

ActiveUS7003170B1Effective and efficient in artifactImprove image qualityCharacter and pattern recognitionDigital video signal modificationImaging processingCoding artifacts

Block-based image processing methods and apparatus that provide a reduction in block-transform image coding artifacts are described. In various embodiments, the invention is directly incorporated into a decoding process. In such embodiments, transform coefficients are modified in simple but particularly effective ways that reduce or eliminate many of the artifacts that were caused by the quantization of the transform coefficients during encoding and / or by independent block processing during encoding. In other embodiments, the invention is used on an image that has already been decoded. In such embodiments image data values are directly modified in a block-based fashion or a forward block transform is applied and then the methods of the invention for processing transform coefficient blocks are used, followed by an inverse transform operation to generate pixel values from the resulting processed transform coefficient blocks.

Owner:ACCUSOFT CORP

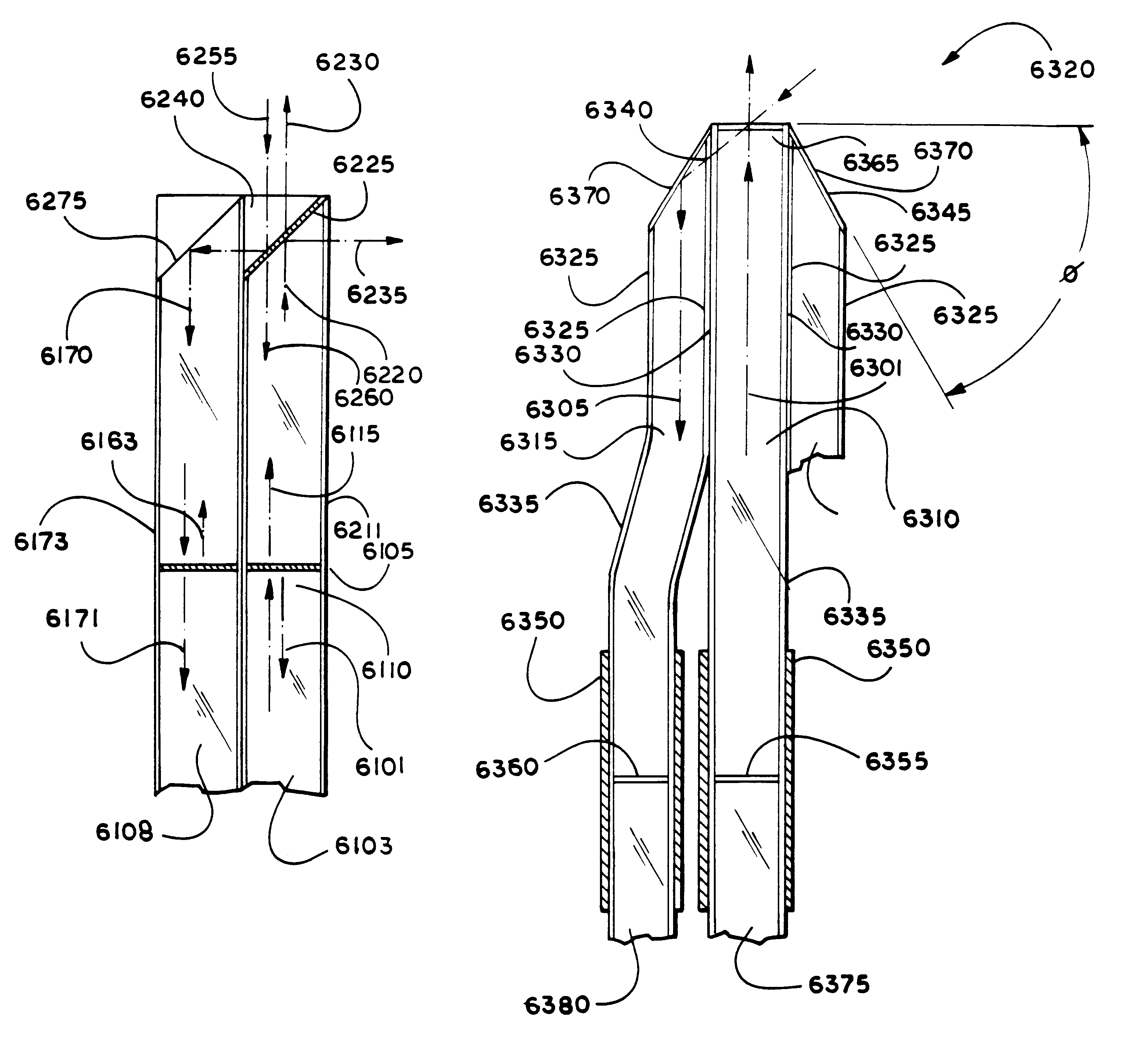

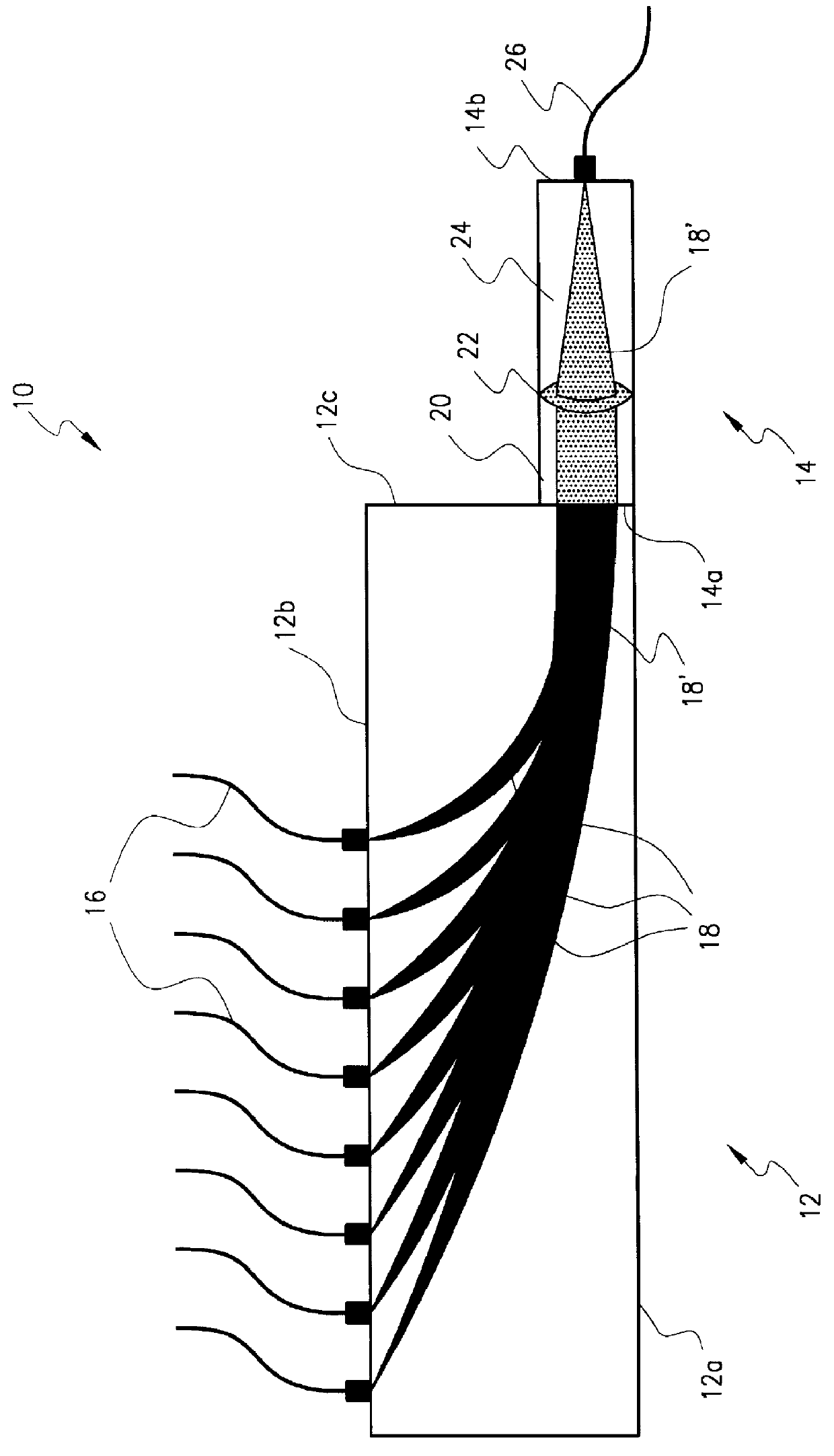

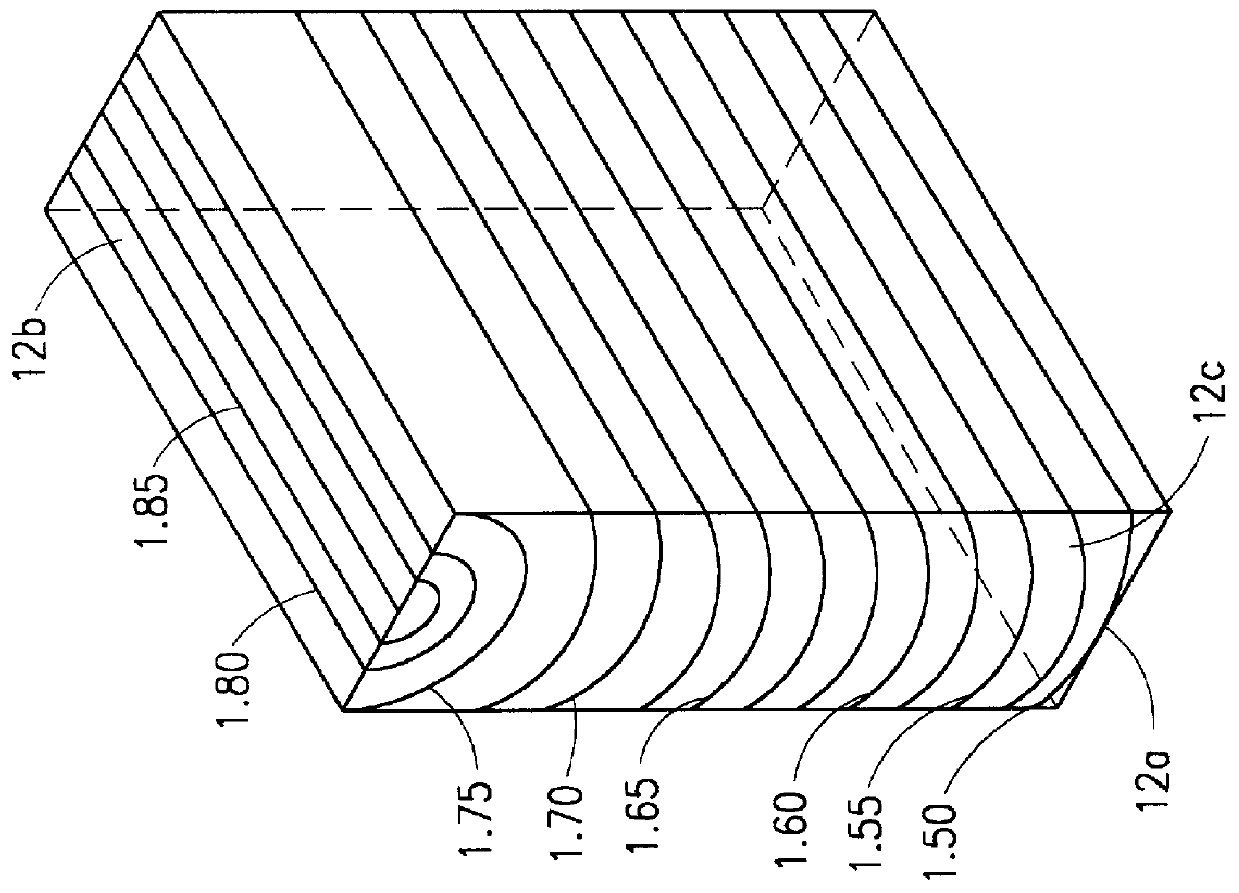

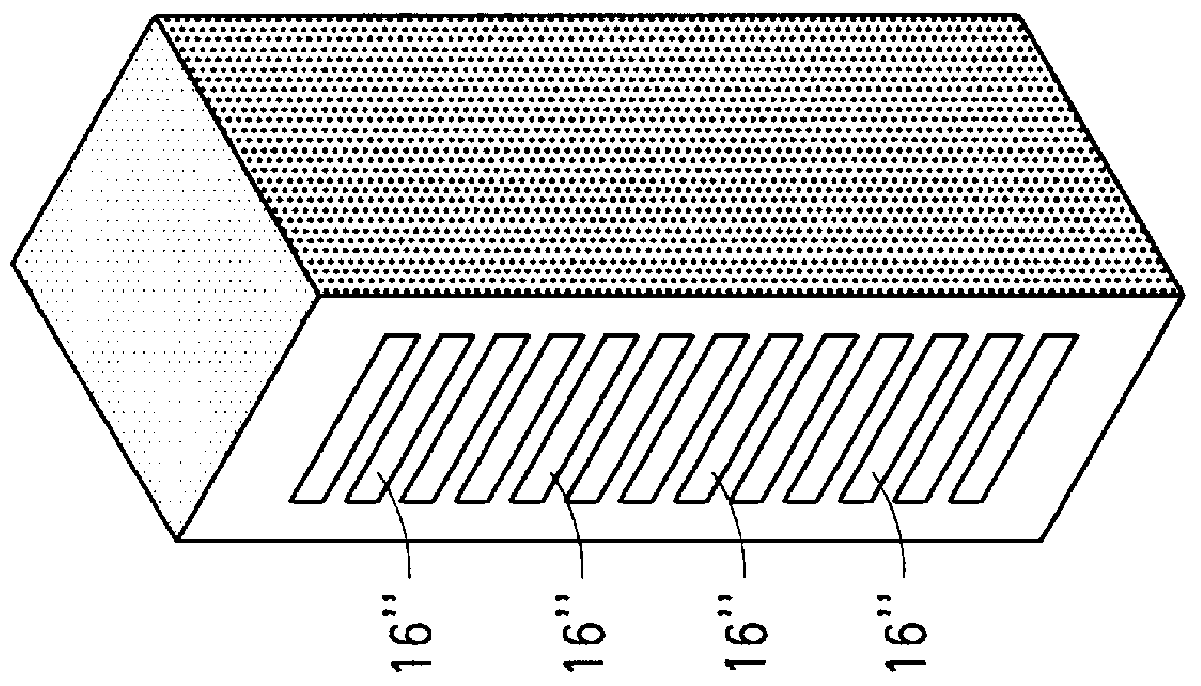

Integrated bi-directional gradient refractive index wavelength division multiplexer

A wavelength division multiplexer integrating a dispersive element having a gradient refractive index with optical lenses to provide efficient coupling from a plurality of input optical fibers (each delivering a plurality of discrete wavelengths to the device) which are multiplexed to a single polychromatic beam for output to a single output optical fiber. The device comprises: (a) an input means for accepting a plurality of optical input beams of different wavelengths from a plurality of optical sources, the means including a planar front surface onto which the optical beams are incident; (b) a dispersive element comprising a radial (or axial) gradient refractive index for combining the plurality of optical input beams into a single optical beam and operatively associated with the planar front surface; (c) a coupler subsystem secured to the dispersive element and comprising (1) a first homogeneous index boot lens having a planar front surface onto which the single optical beam from the dispersive element is incident, (2) an axial gradient refractive index collimating lens affixed to the first homogeneous index boot lens, and (3) a planar back surface from which the single optical beam exits, operatively associated with the axial gradient refractive index collimating lens; and (d) an output means for outputting at least one multiplexed, polychromatic output beam to an optical receiver, the means including the planar back surface. The device is fully bi-directional and may be operated in the forward direction as a multiplexer and in the reverse direction as a demultiplexer.

Owner:AUXORA

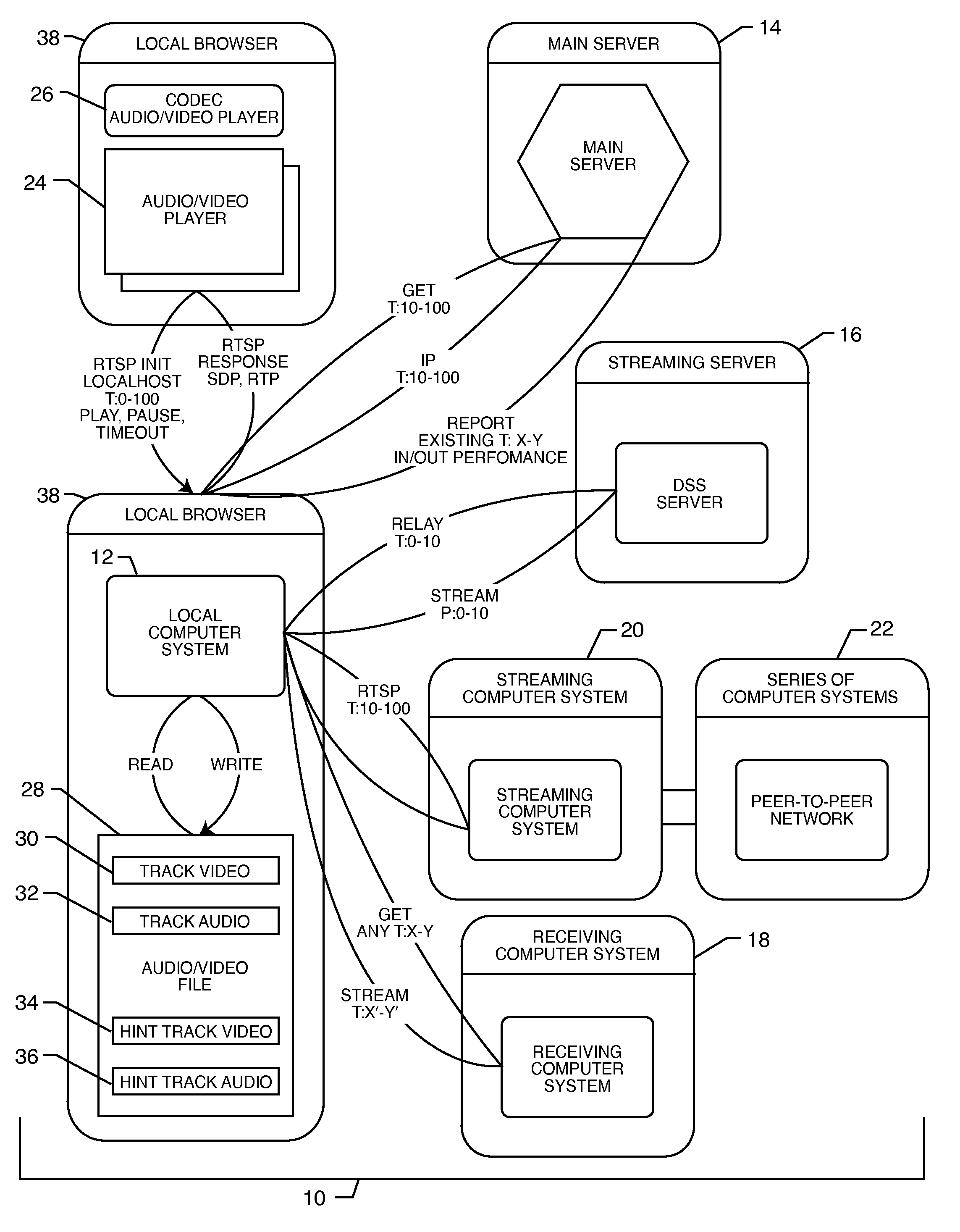

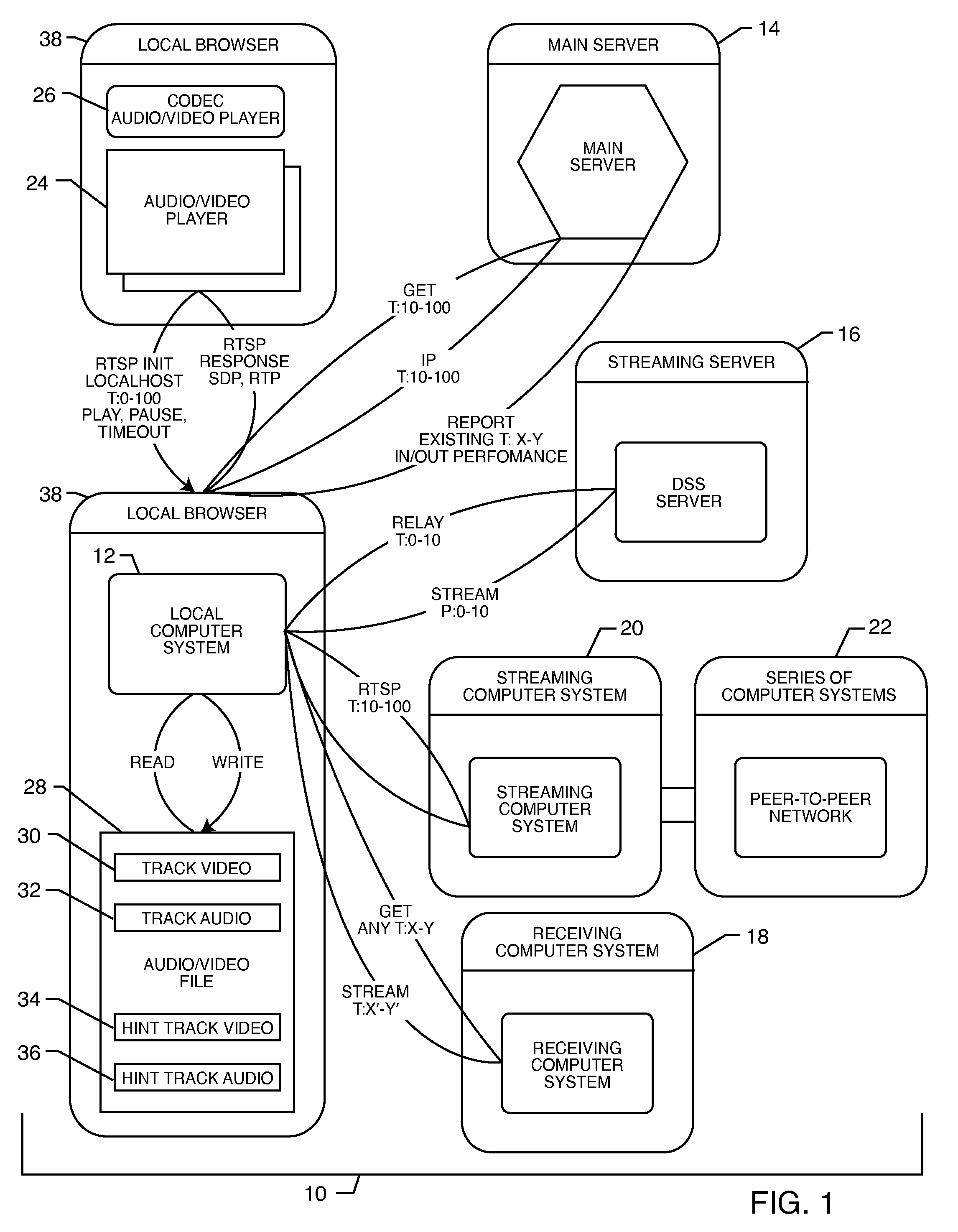

Process for streaming media data in a peer-to-peer network

InactiveUS20080256255A1Active connectionEasy data transferMultiple digital computer combinationsTransmissionTime segmentByte

The process for streaming media data in a peer-to-peer (P2P) network includes the step of submitting a request through the P2P network to play a time segment of a media file. A local computer is connected through the P2P network to a streaming computer having the desired time segment. Thereafter, an initial data byte is located in the time segment via a conversion table associated with the media file. The time segment is streamed from the streaming computer to the local computer starting with the initial data byte. The time segment is stored on the local computer for playback through a corresponding media player.

Owner:METRO ENTERPRISES INC

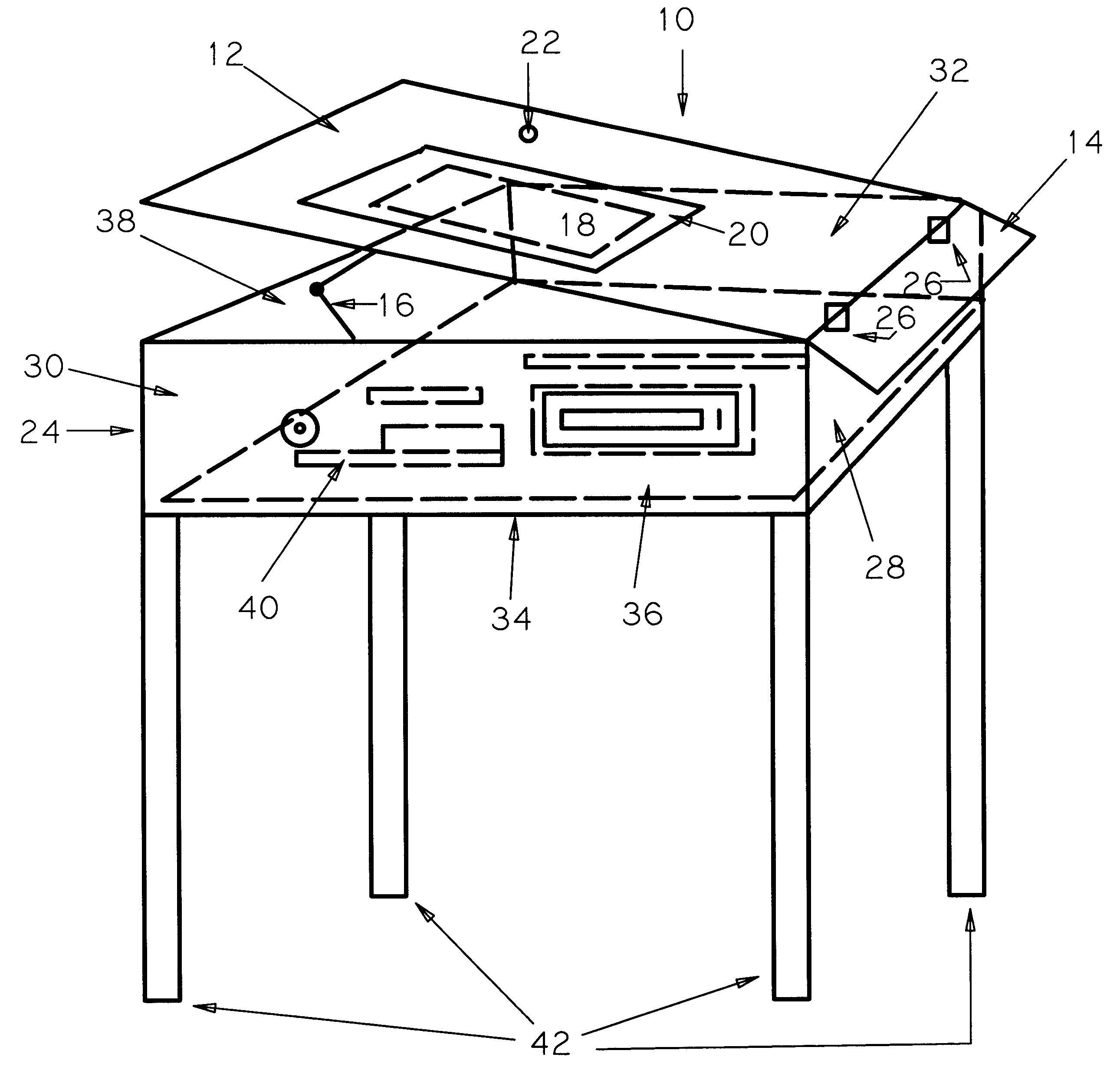

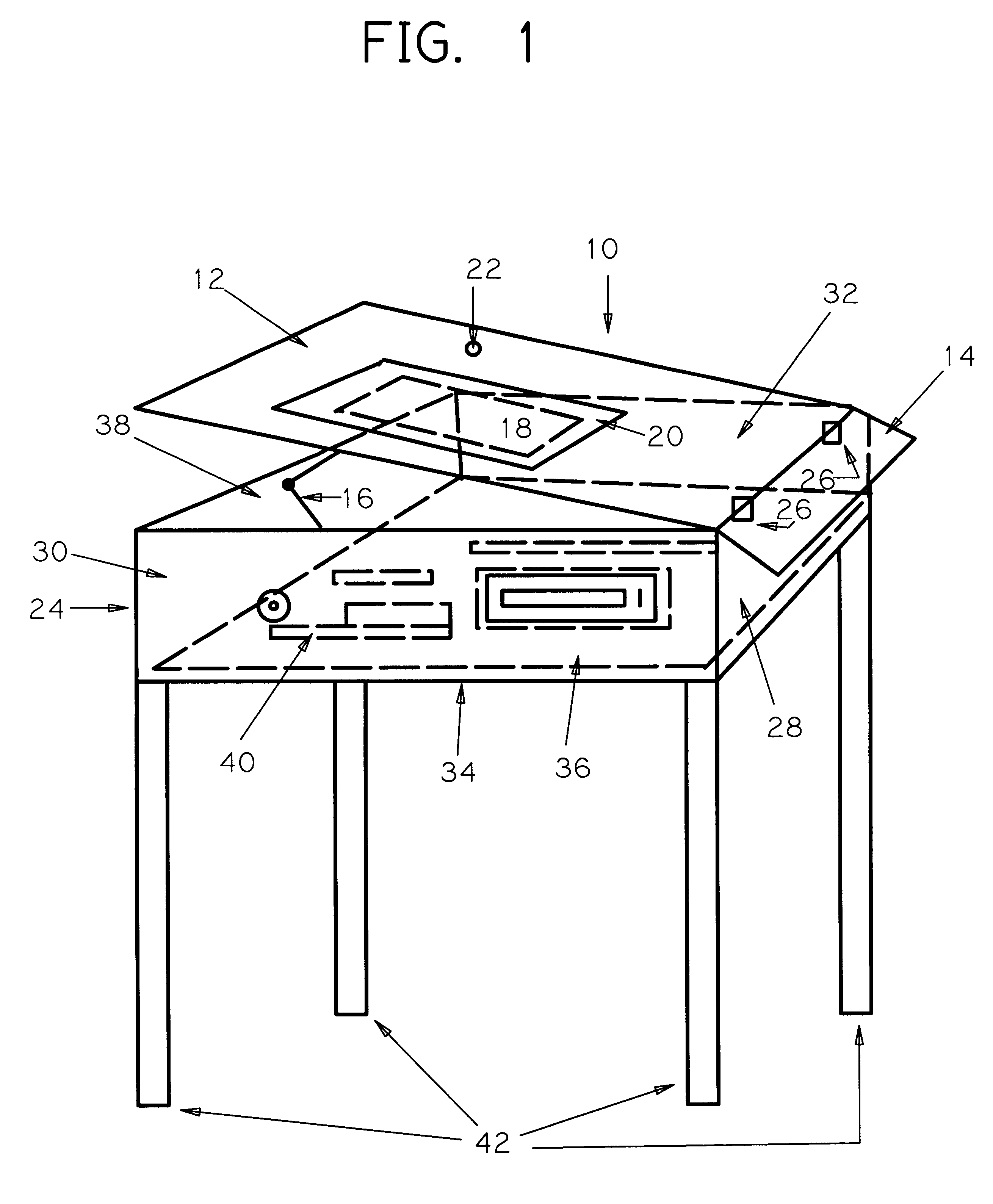

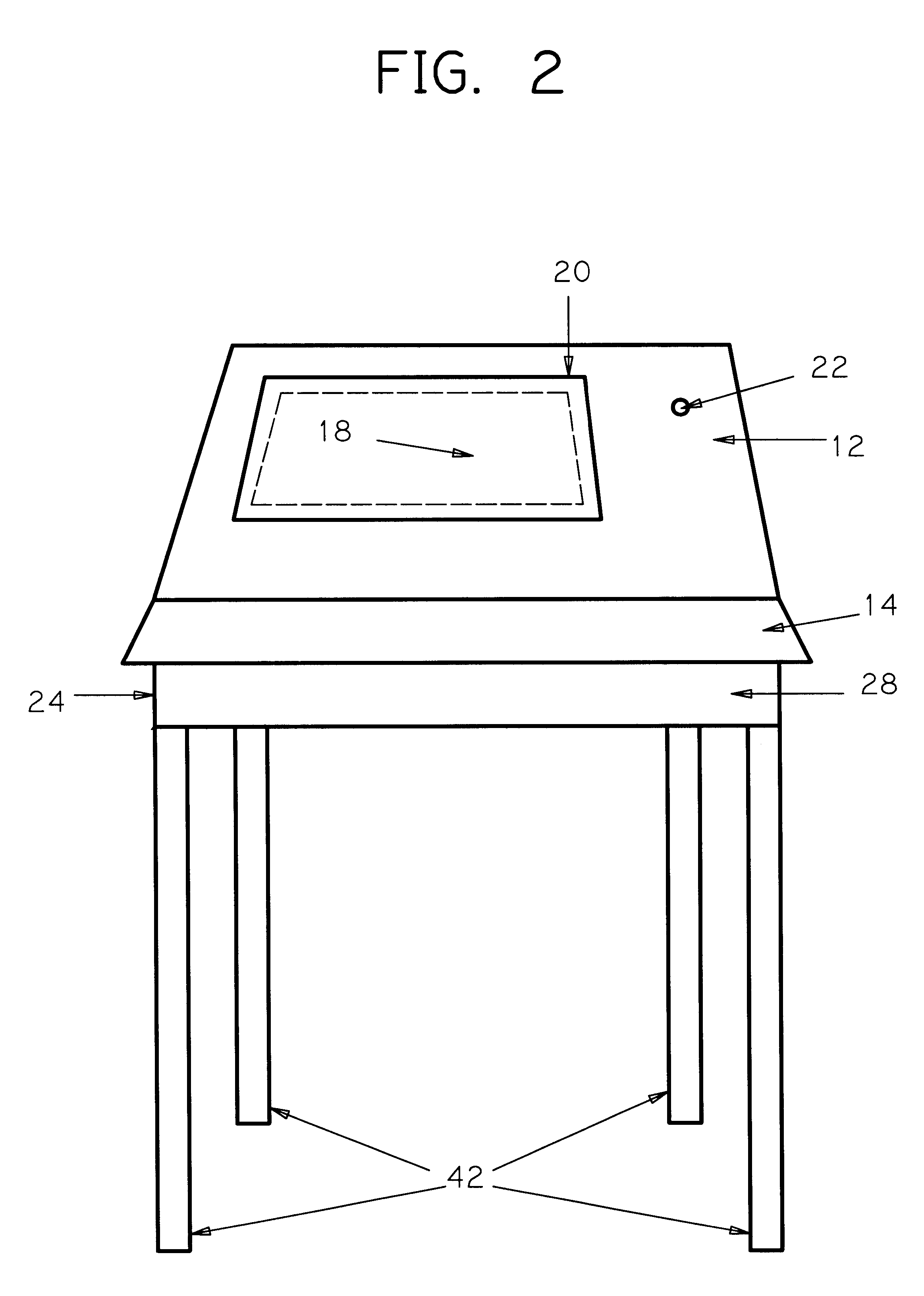

Computer in a desk

A school, home or commercial desk that can be used for traditional tasks and yet provides readily available access to computer equipment. The computer in a desk (10) is comprised of a desk body (24) that houses the internal components of a standard computer; a desk top (12) that houses the flat panel screen (18) beneath a view panel (20) that is mounted flush with the surface of the desk top (12); a keyboard tray (14) that holds the standard computer keyboard; and a support system of four adjustable legs (42). The desk top (12), keyboard tray (14), and legs (42) are all adjustble to suit the users specific ergonomic needs. The desk body (24) consists of a front panel (28), back panel (30), right side panel (32),and left side panel (34), bottom panel (36), and top panel (38) that give the computer in a desk (10) its shape, support and access to available, installed computer components. Furthermore, the computer in a desk (10) can be used for traditional and computer related tasks regardless of the user adjusted.

Owner:JYRINGI CRAIG

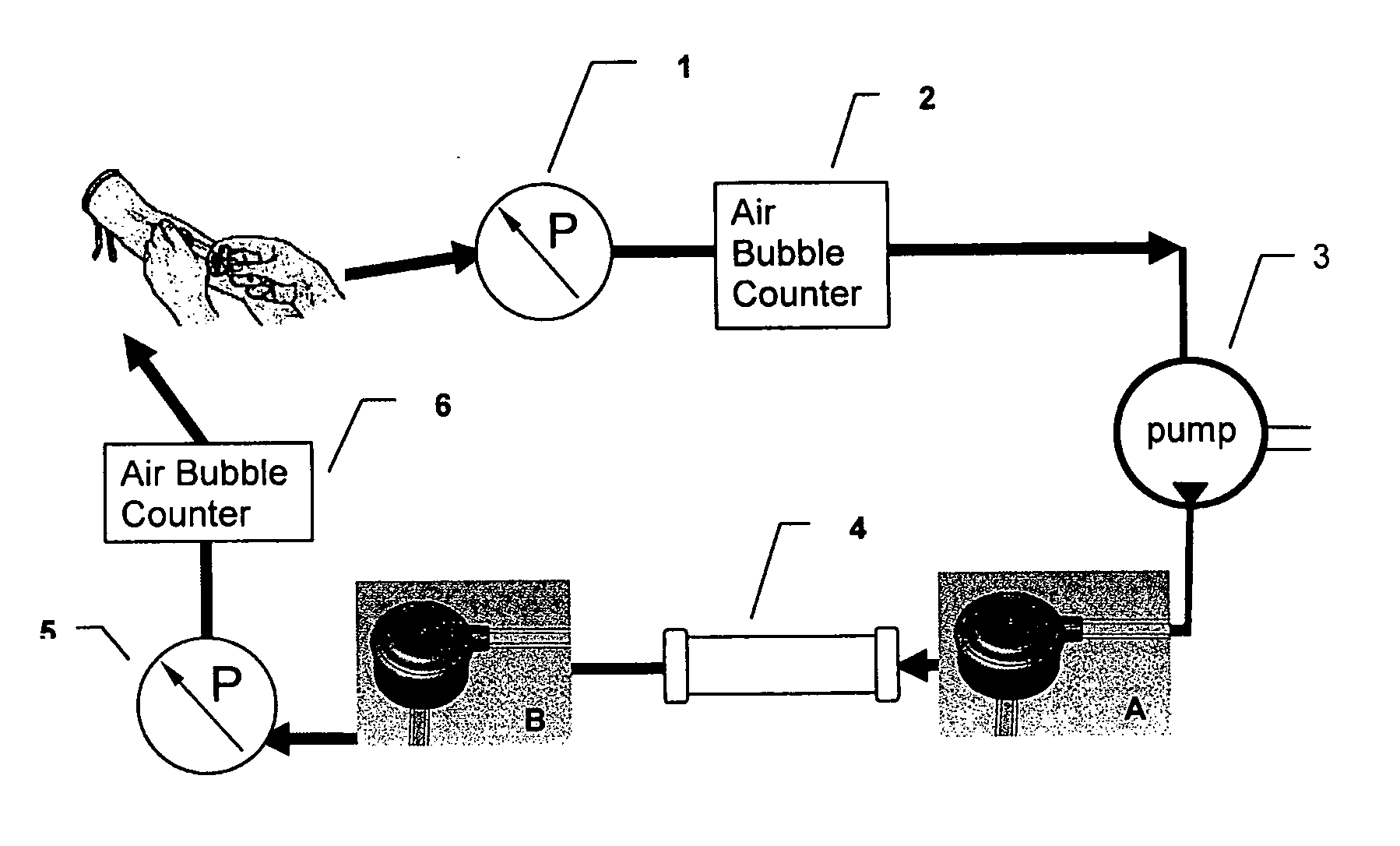

Degassing device

ActiveUS20110092875A1Maximize advantageReduced effectivenessDialysis systemsMedical devicesHaemodialysis machineEngineering

Owner:GAMBRO LUNDIA AB

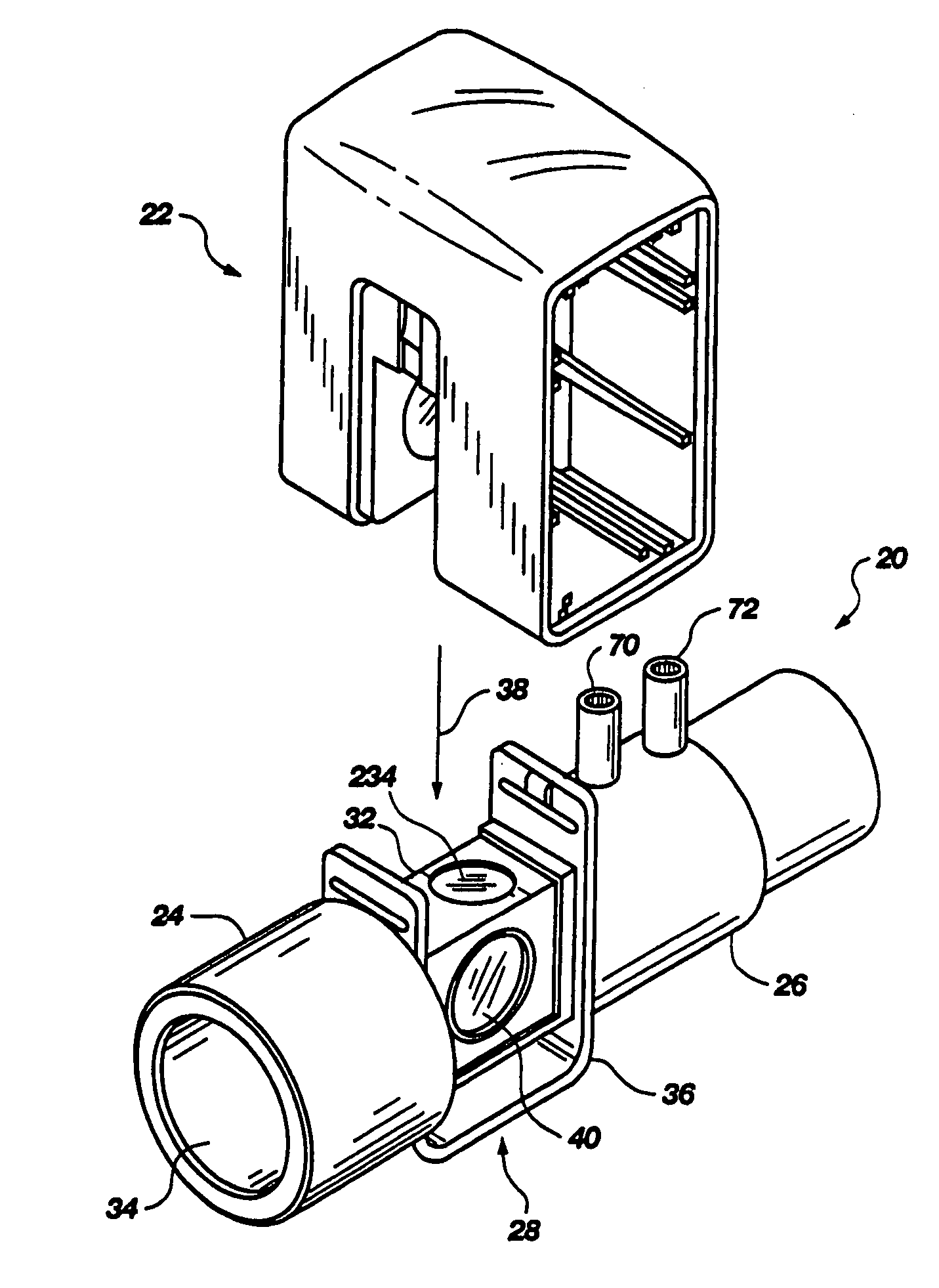

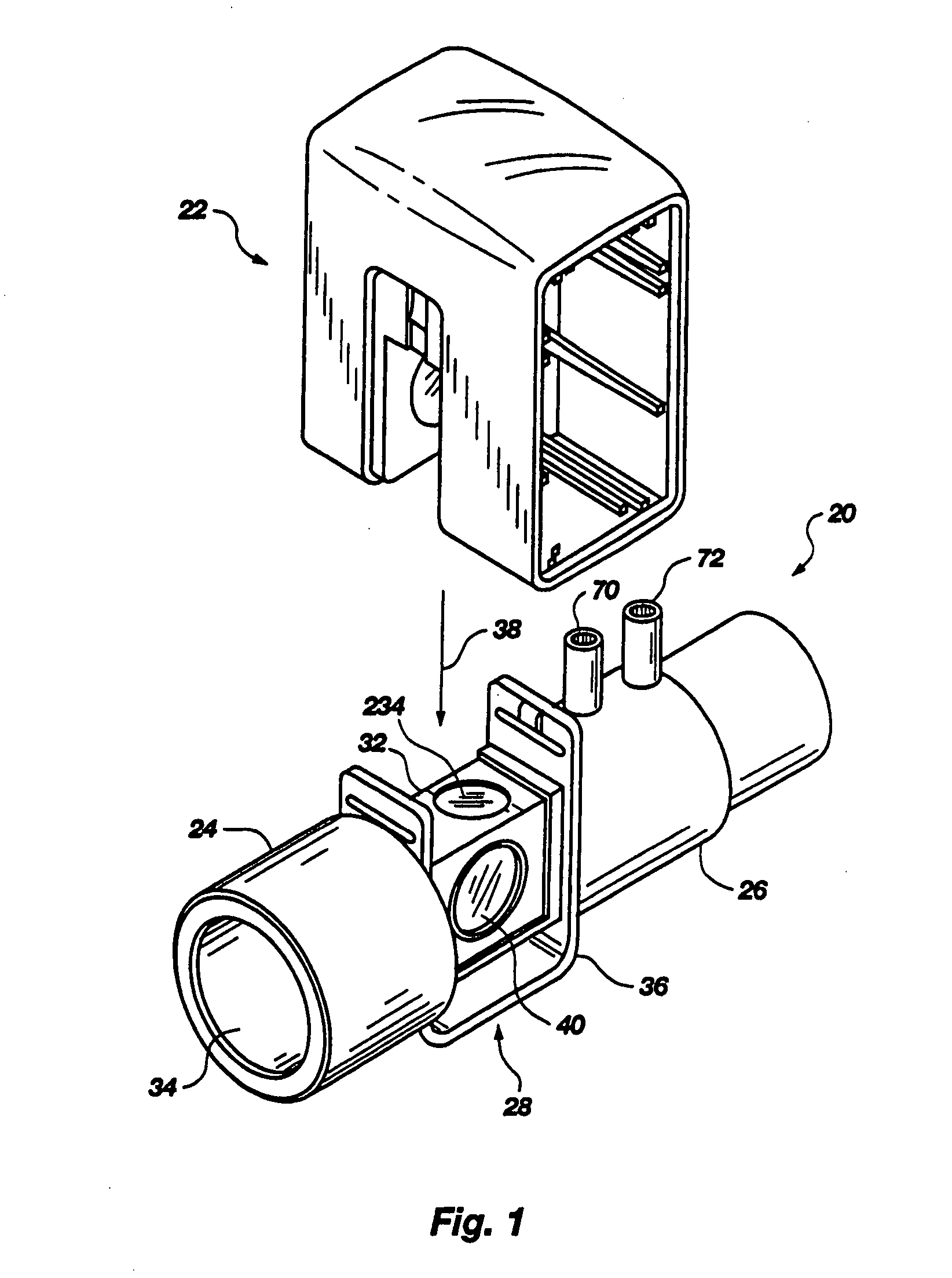

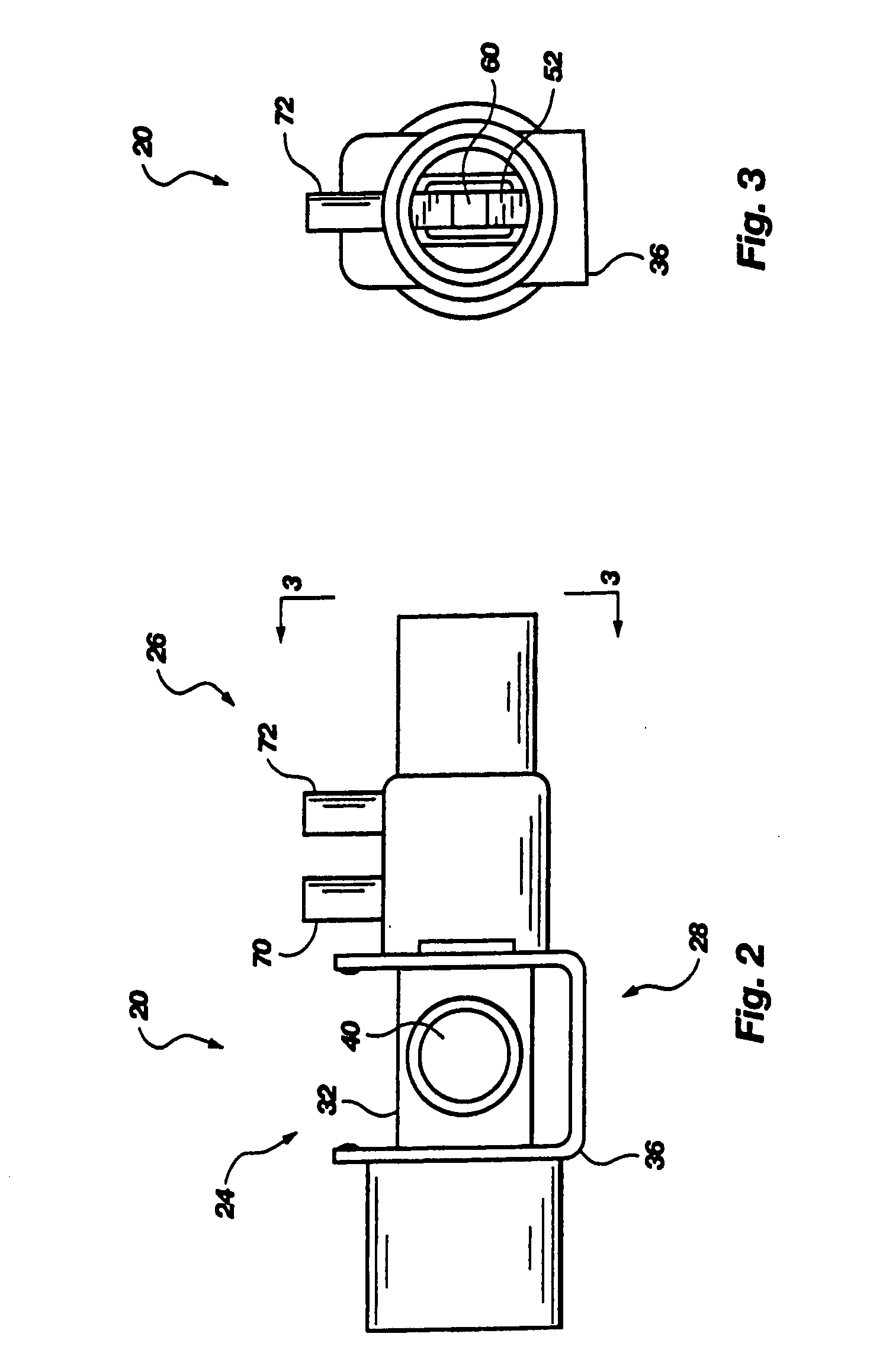

Metabolic measurements system including a multiple function airway adapter

InactiveUS20070225612A1Easy to reusePromote generationRespiratory organ evaluationSensorsAnesthetic AgentRespiratory flow

A system for measuring a metabolic parameter. The system includes an integrated airway adapter capable of monitoring any combination of respiratory flow, O2 concentration, and concentrations of one or more of CO2, N2O, and an anesthetic agent in real time, breath by breath. Respiratory flow may be monitored with differential pressure flow meters under diverse inlet conditions through improved sensor configurations which minimize phase lag and dead space within the airway. Molecular oxygen concentration may be monitored by way of luminescence quenching techniques. Infrared absorption techniques may be used to monitor one or more of CO2, N2O, and anesthetic agents.

Owner:RIC INVESTMENTS LLC

Methods and apparatus for improving quality of block-transform coded images

InactiveUS7209594B1Improve image qualityEffective and efficient reduction in block-transform image coding artifactsCharacter and pattern recognitionDigital video signal modificationImaging processingCoding artifacts

Owner:ACCUSOFT CORP

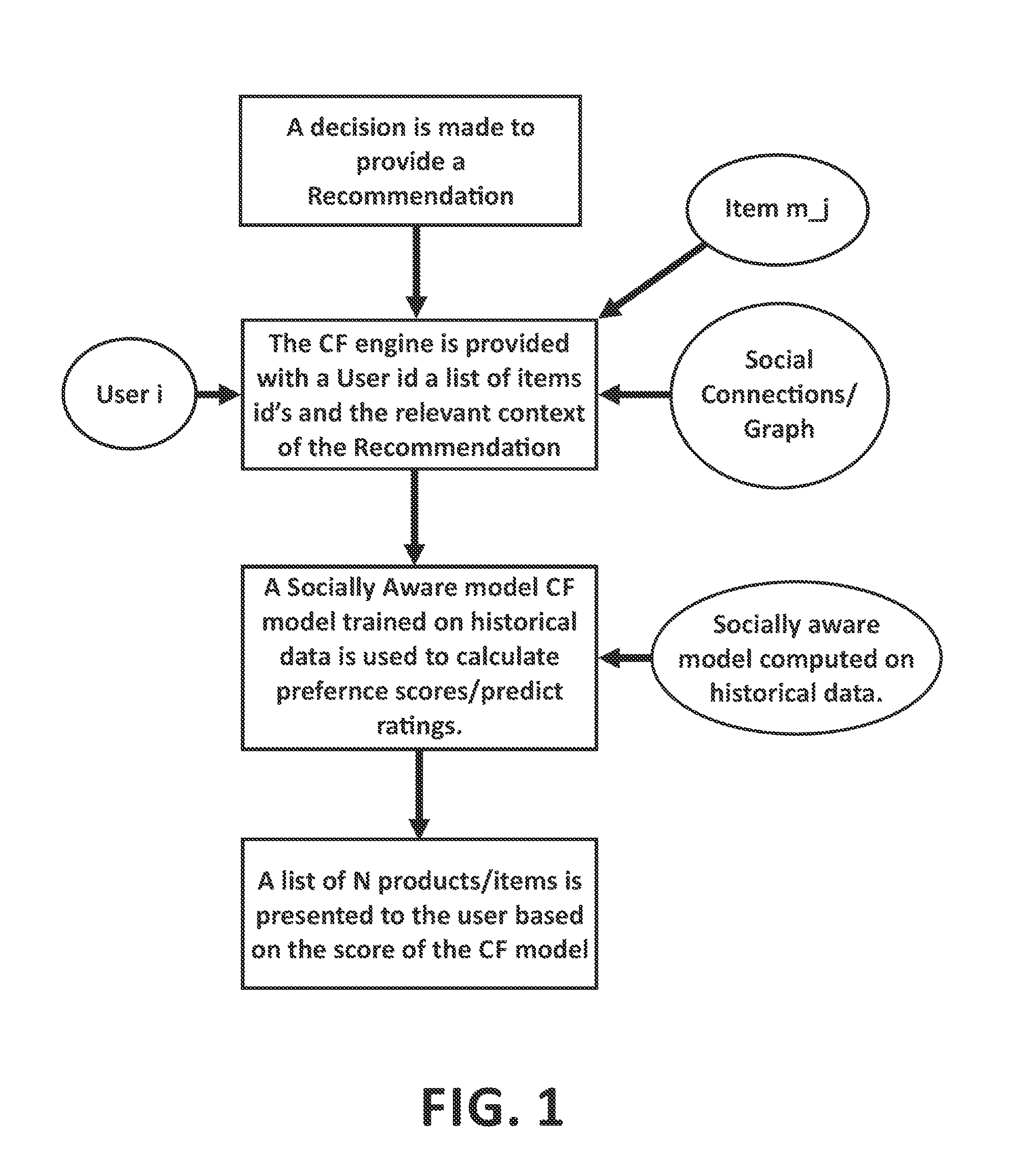

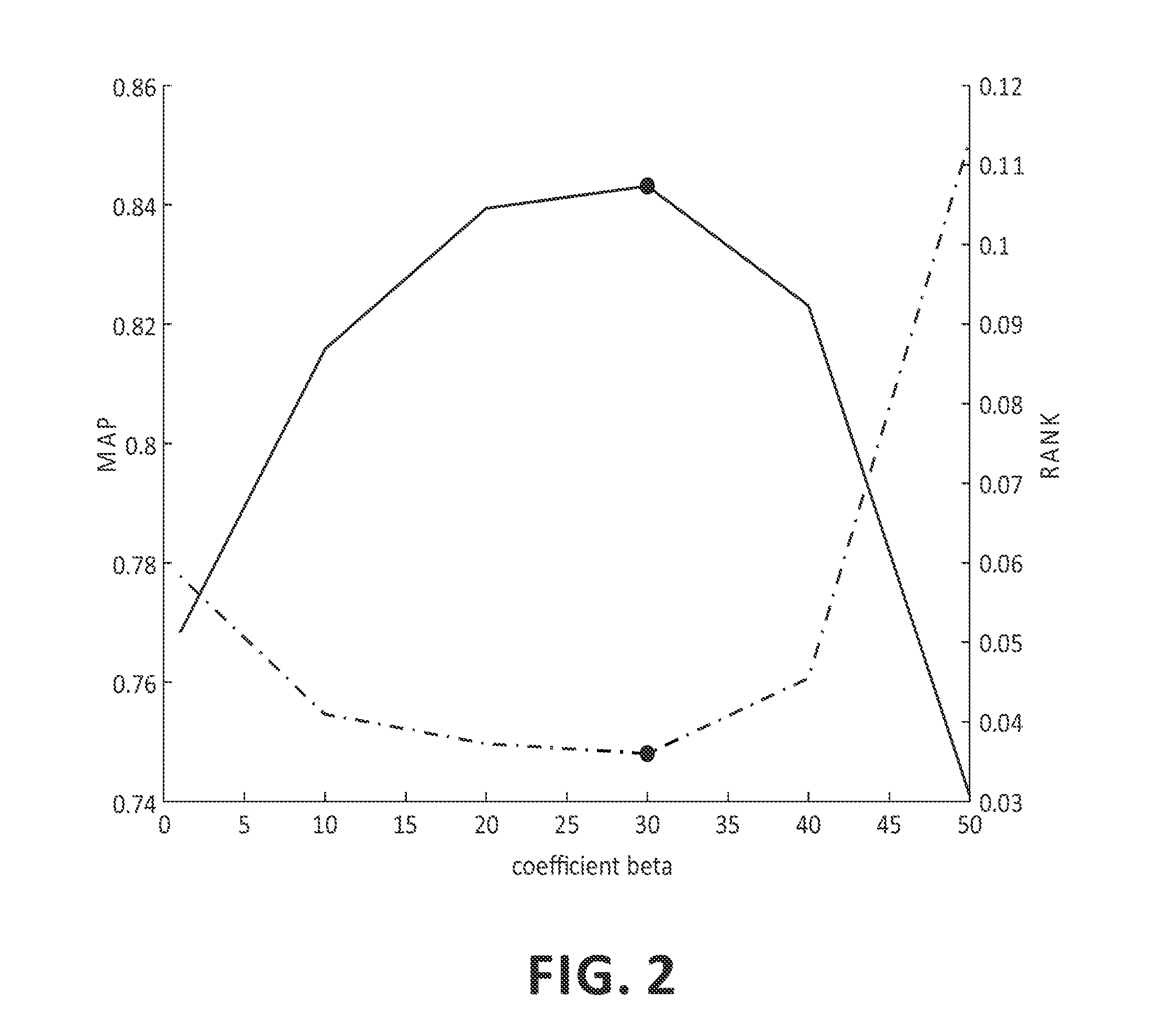

System and Method for Socially Aware Recommendations Based on Implicit User Feedback

InactiveUS20150187024A1Good performanceIntroduce noiseMarket data gatheringData scienceUser feedback

A content recommender based on collaborative filtering and implicit user feedbacks comprising retrieving a social graph split into a user and the user's relationship network in order to obtain a social aware model of the user's preferences based on preferences of the users belonging to the user's relationship network, minimizing the objective function for all the response values of the whole user-item matrix, the response values meaning implicit and explicit feedback data, providing a list of content recommendations obtained by a score function computed using the social aware model.

Owner:TELEFONICA DIGITAL ESPANA S L U

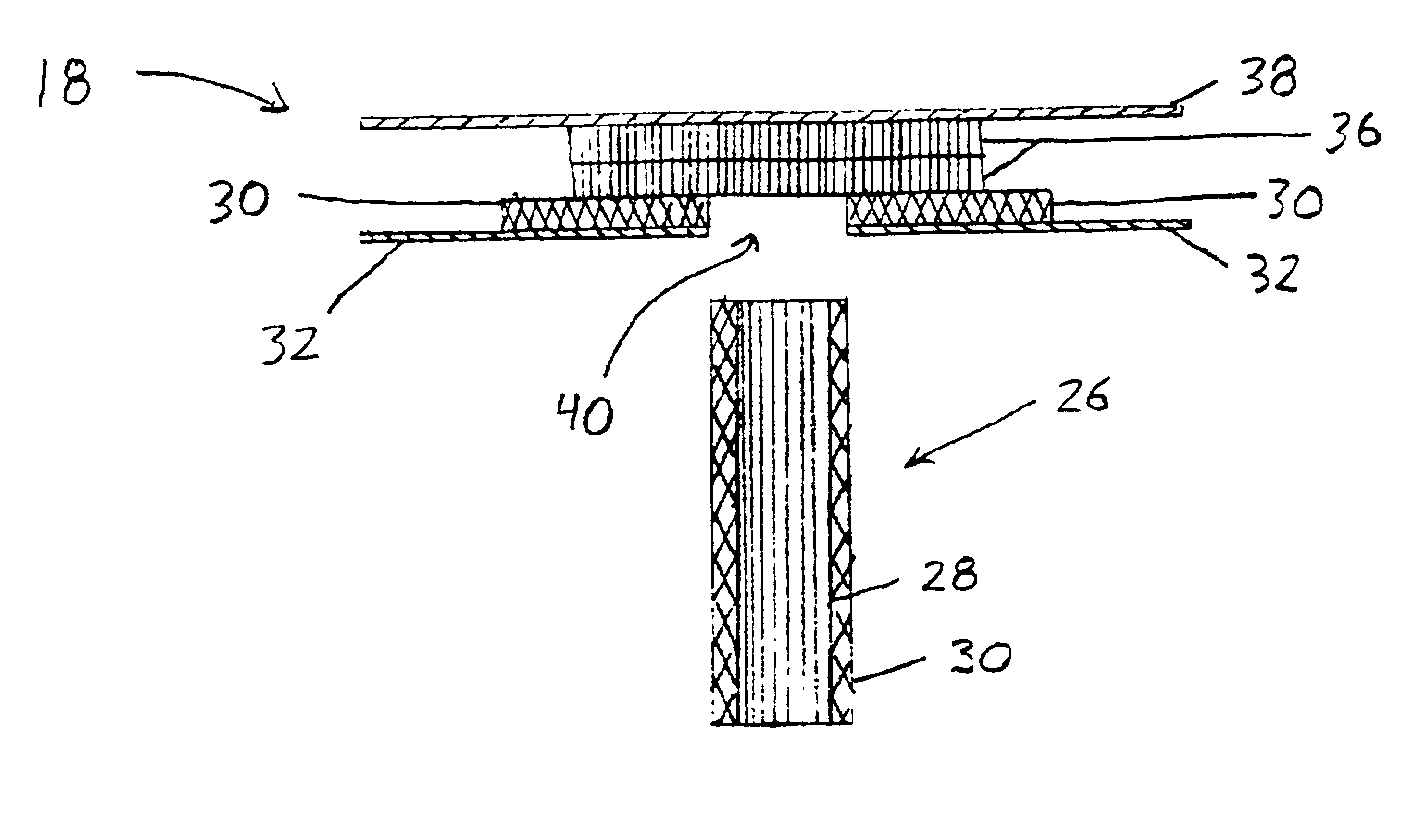

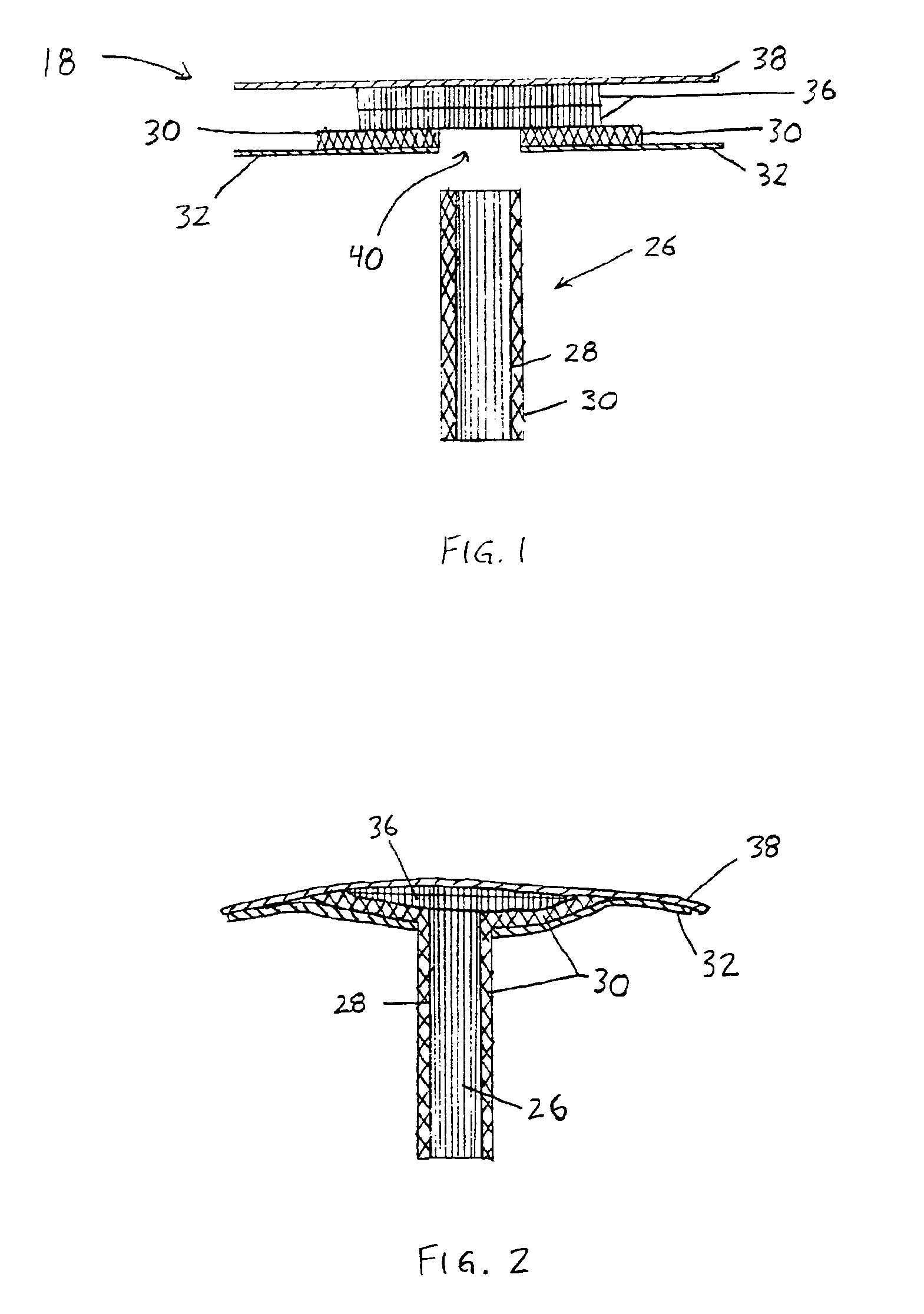

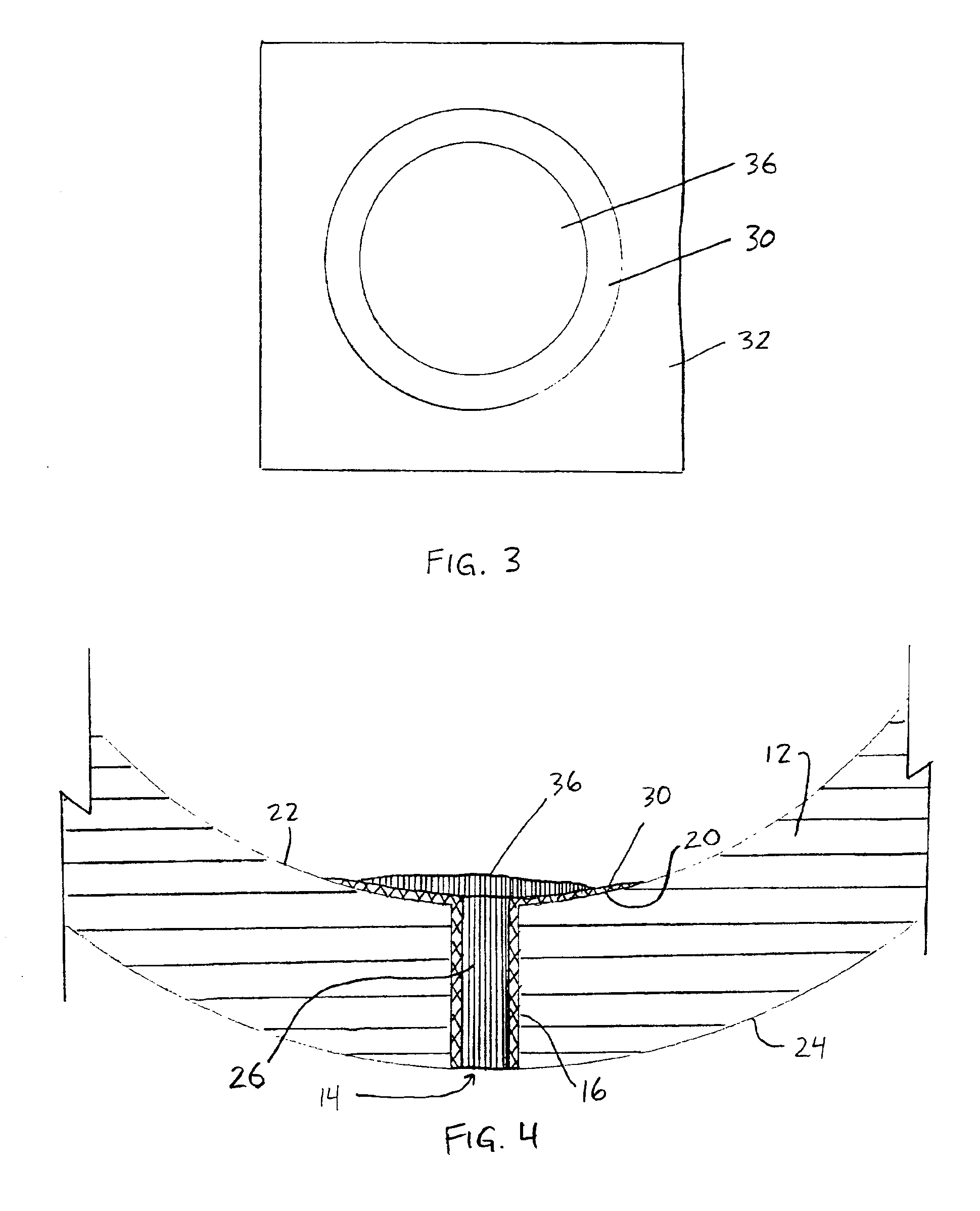

Patch plug

A patch plug is provided that has a coating continuous over both the patch and plug portions, providing a strong and continuous seal to prevent seal failure and water and air introduction. The patch and plug portions may be formed separately, each with a coating element, and fused together in a press which bonds the coatings of the patch and plug portions together to form a single, continuous coating. Means known in the art, for example rubber cement, can also be employed to further ensure a firm seal between the patch plug and the tire. Methods of manufacturing and using the patch plug are also taught herein.

Owner:4254563 MANITOBA

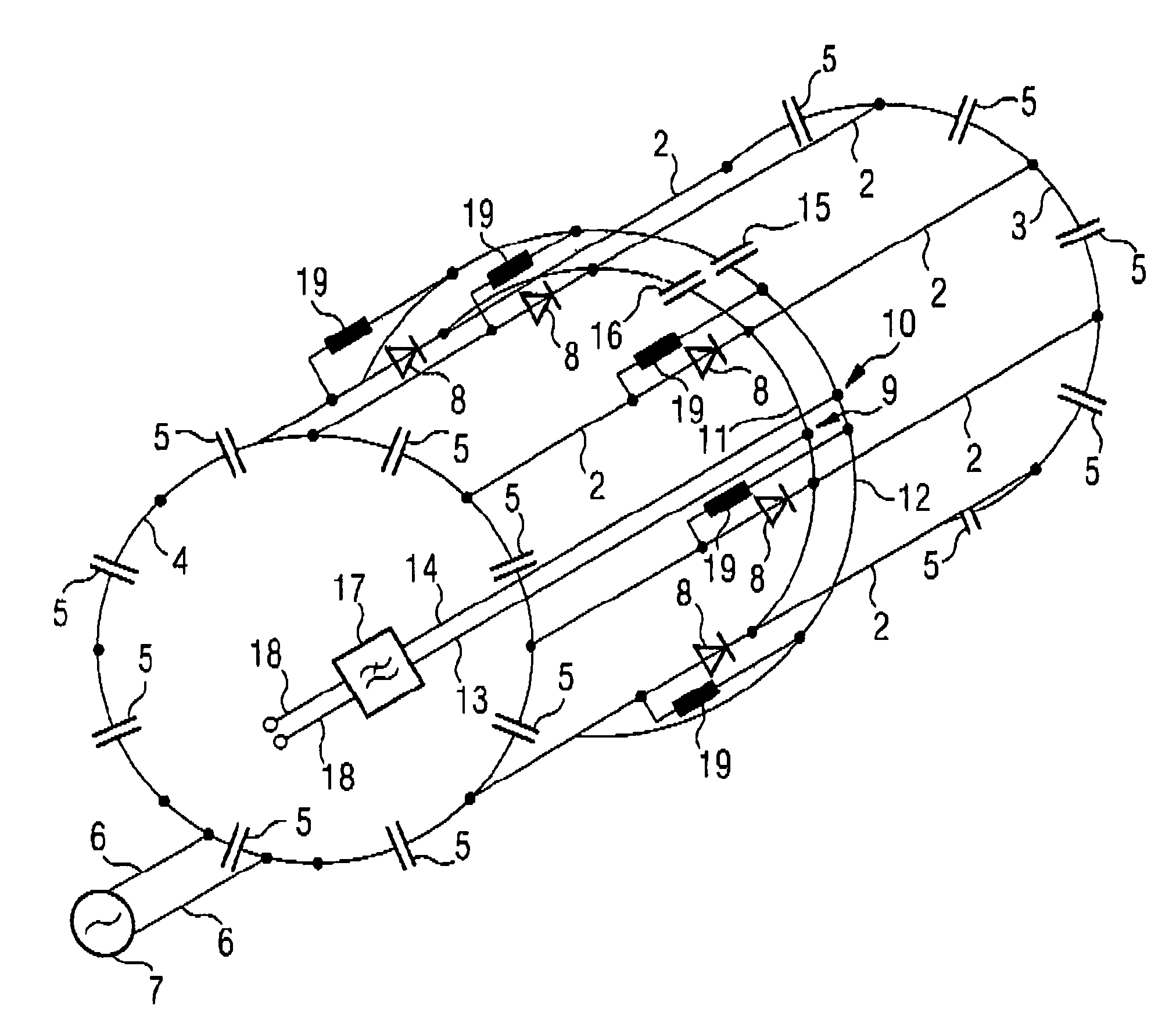

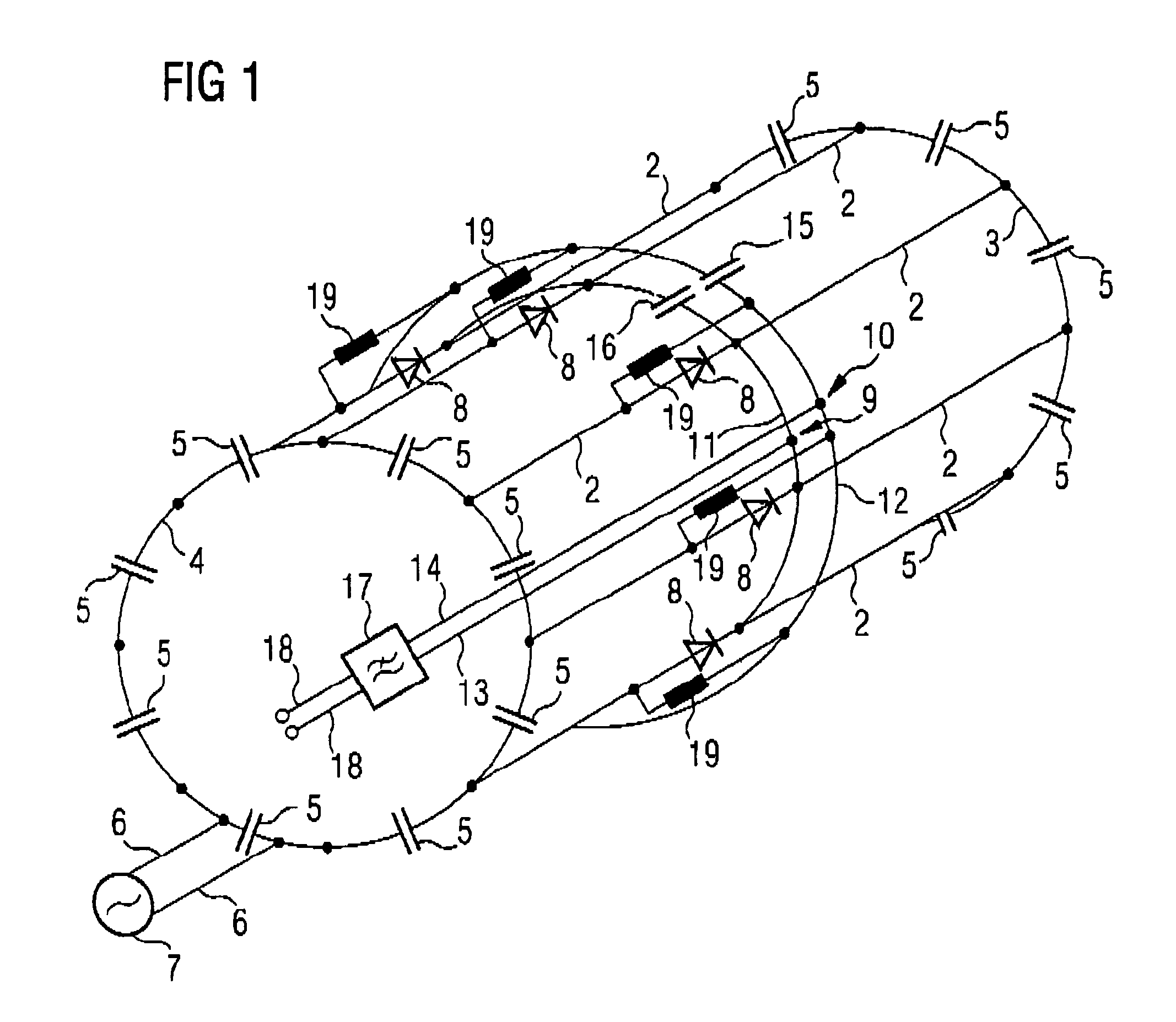

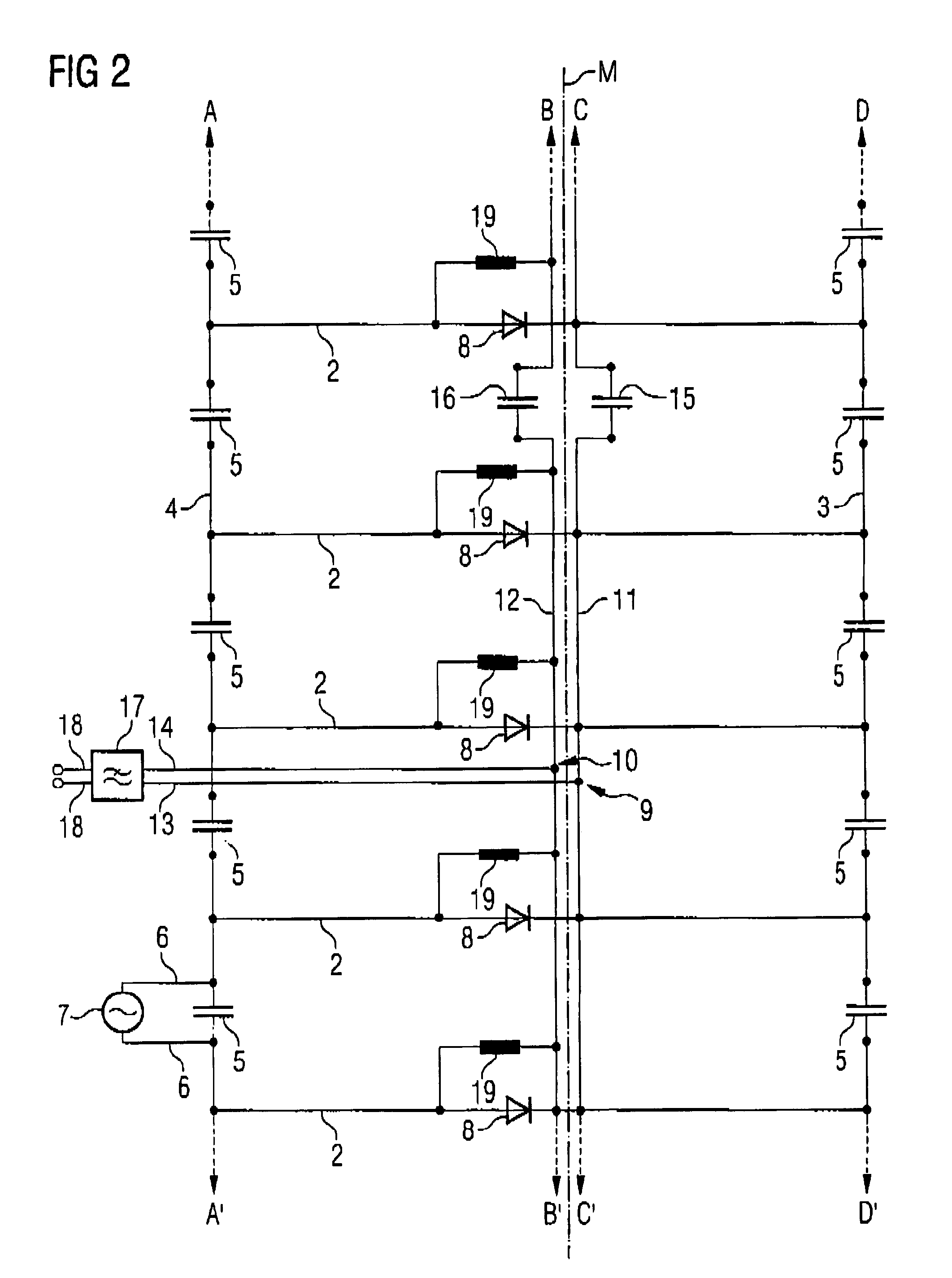

Magnetic resonance antenna

ActiveUS6943551B2Low switching voltageSimple and cost-effectiveElectric/magnetic detectionMeasurements using magnetic resonanceResonanceRadio frequency

A magnetic resonance antenna has longitudinal antenna rods in a birdcage structure, and antenna ferrules connecting the longitudinal antenna rods at their ends in terms of radio-frequency. The magnetic resonance antenna has a number of radio-frequency switching elements that interrupt, in terms of radio-frequency, at least one part of the longitudinal antenna rod to detune the eigen-resonance frequency of the antenna with respect to an operating magnetic resonance frequency. For this purpose, the magnetic resonance antenna is provided with two switching lines, directed to the radio-frequency switching elements from outside of the birdcage structure, the switching lines having a ring line connected thereto running annularly on or in the birdcage structure and transverse to the longitudinal antenna rods.

Owner:SIEMENS HEALTHCARE GMBH

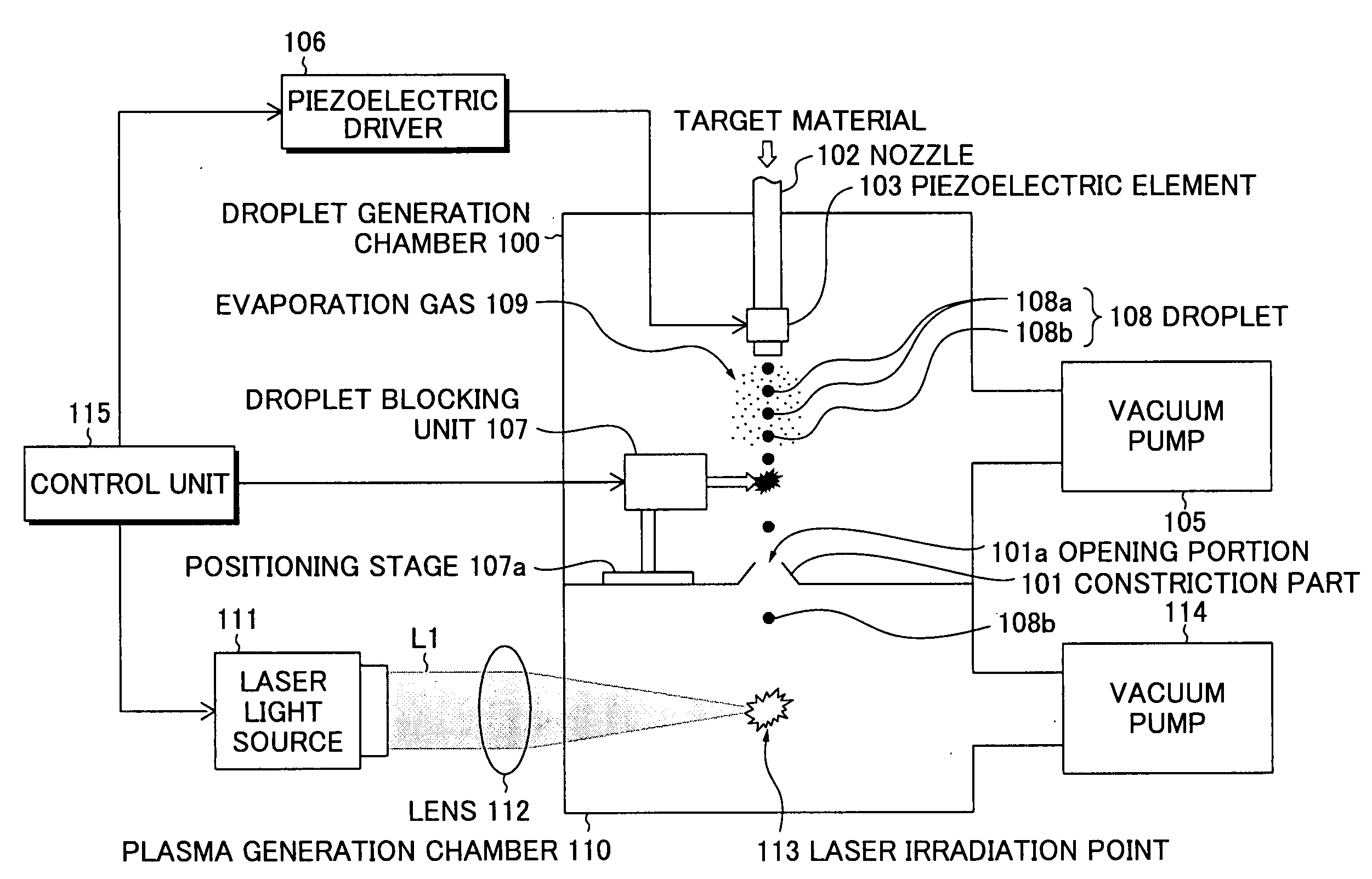

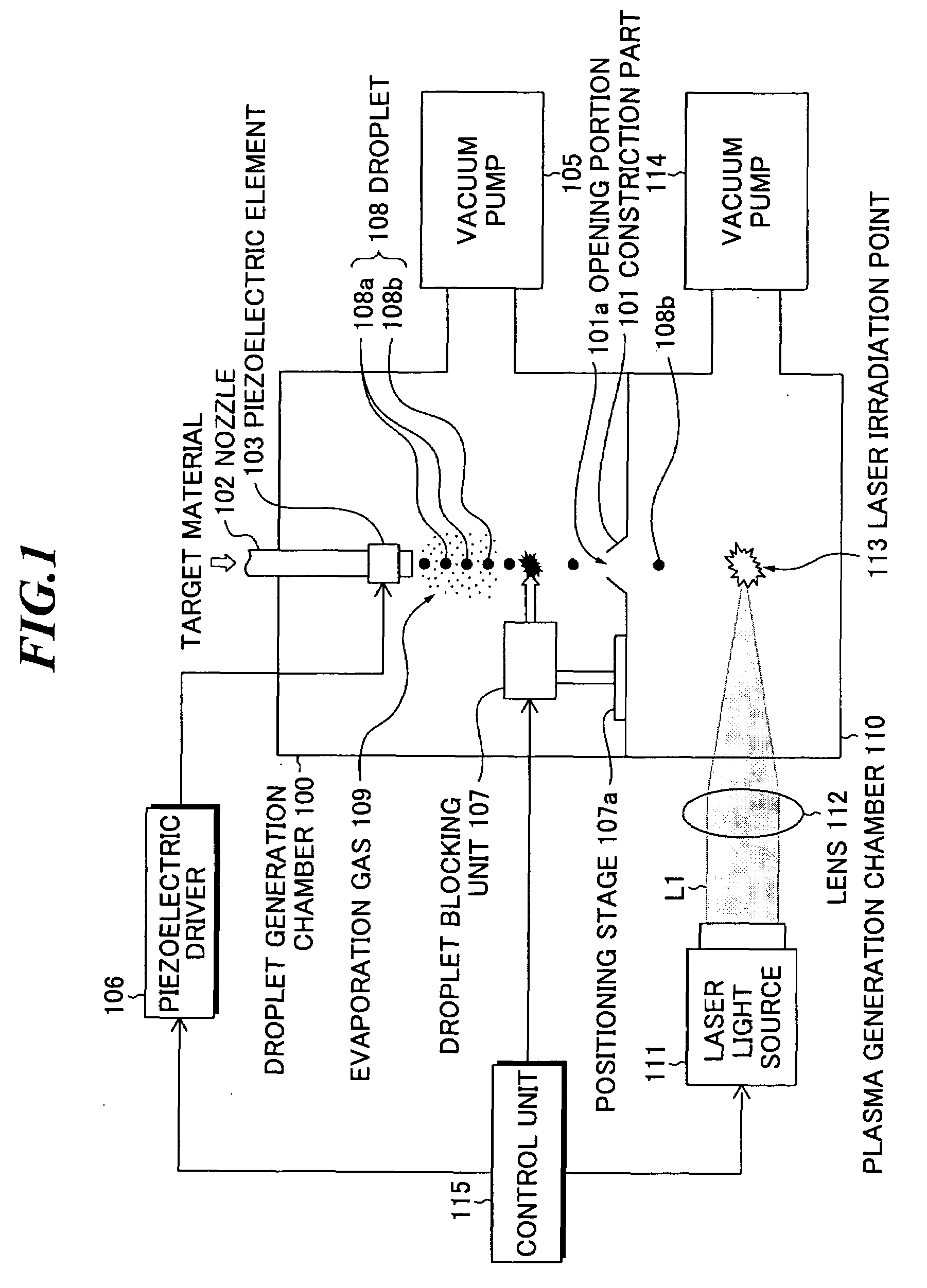

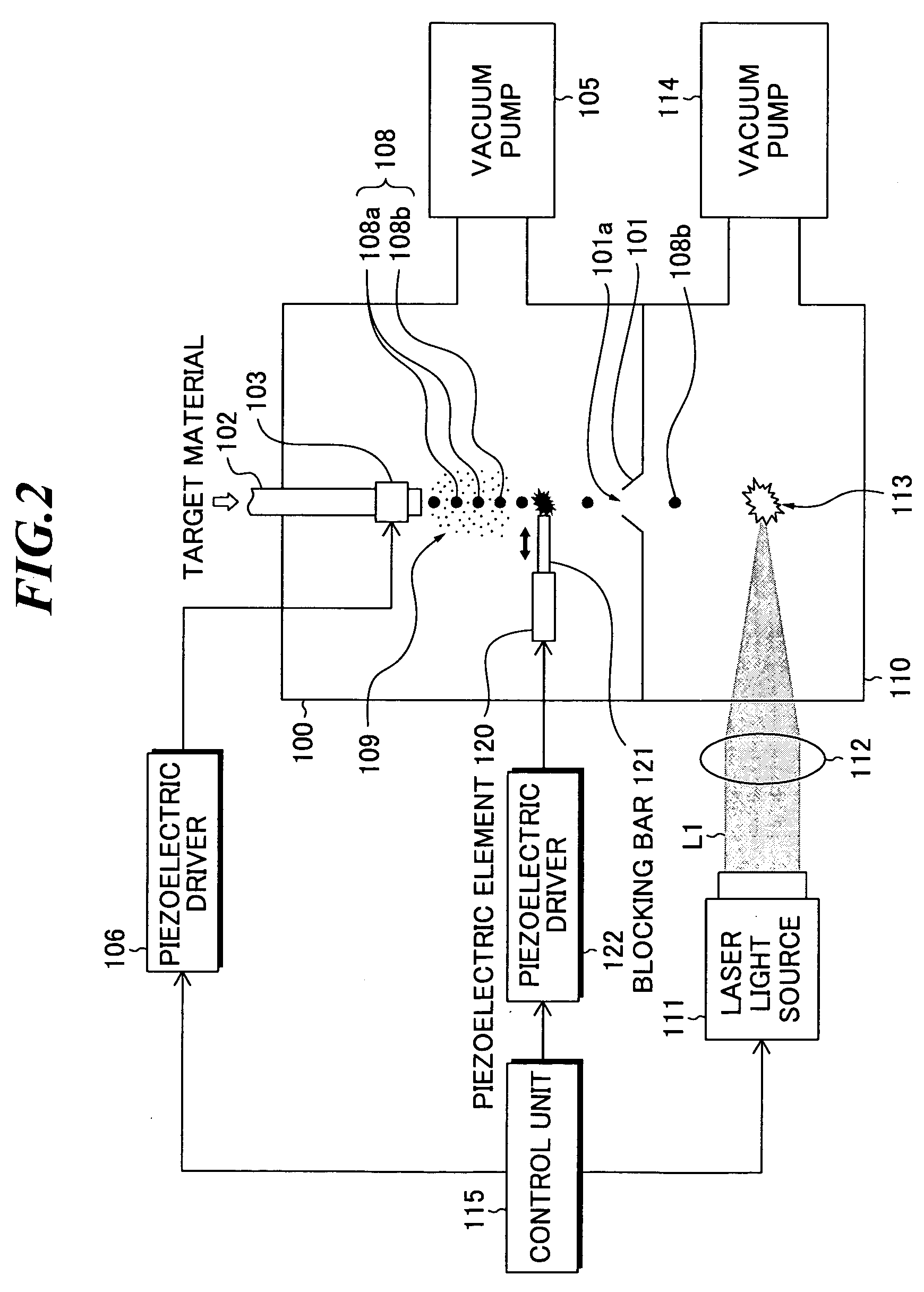

Extreme ultra violet light source device

ActiveUS20070170377A1Improve of cleannessDegree of improvementRadiation pyrometryPhotometryUltravioletLaser light

An EUV (extreme ultra violet) light source device in which a degree of vacuum or cleanness in a plasma generation chamber is improved while the construction is simplified. The device includes: a first chamber; a second chamber connected to the first chamber through an opening portion; a target supplier that supplies a target material into the first chamber; a droplet generating unit that generates droplets of the target material of molten metal repetitively dropping based on the target material supplied by the target supplier; a blocking unit that prevents the droplets of the target material generated by the droplet generating unit from passing through the opening portion; control unit that controls the blocking unit to operate at predetermined timing; a laser light source; and an optical system that leads a laser beam to the droplets of the target material introduced into the second chamber.

Owner:GIGAPHOTON

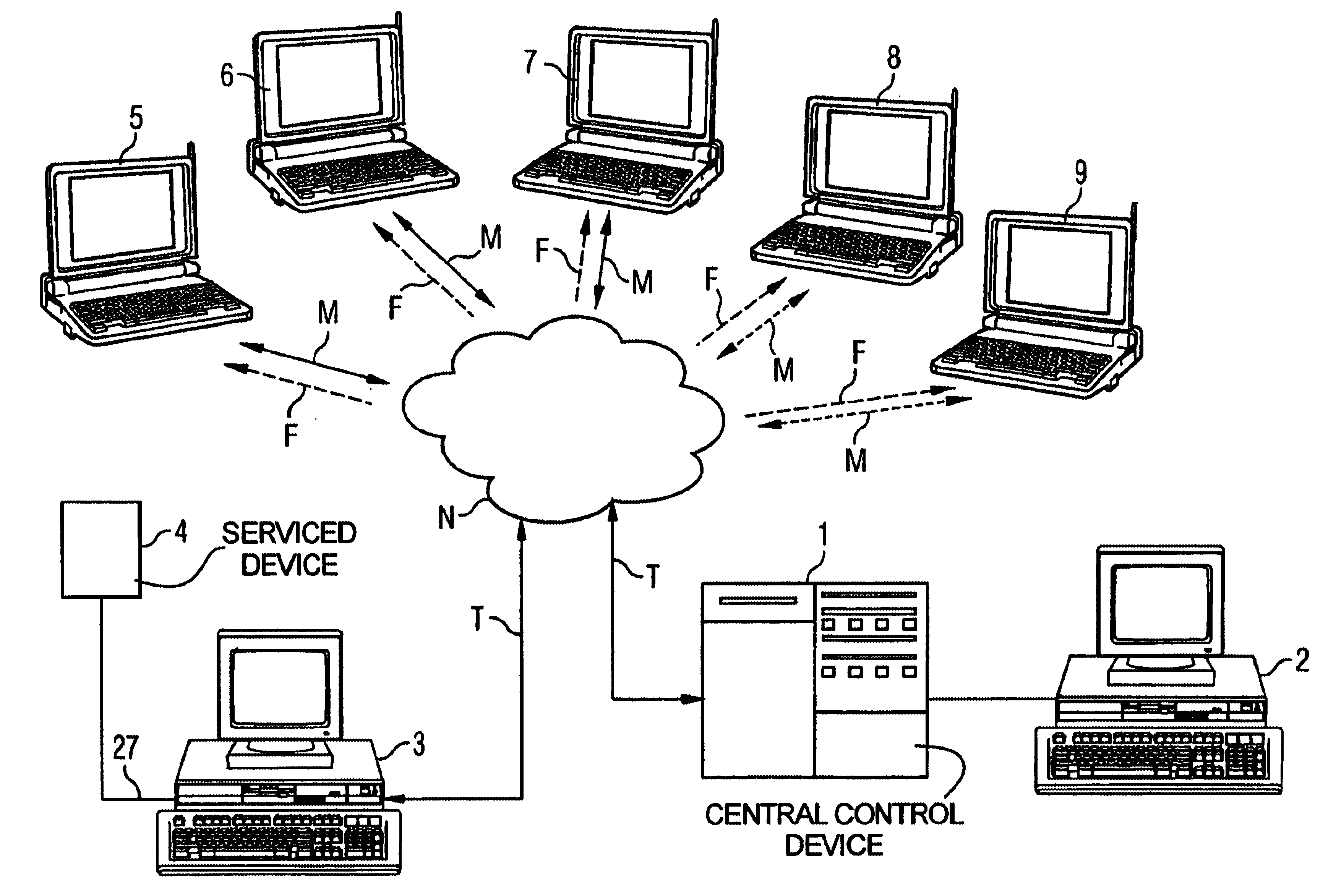

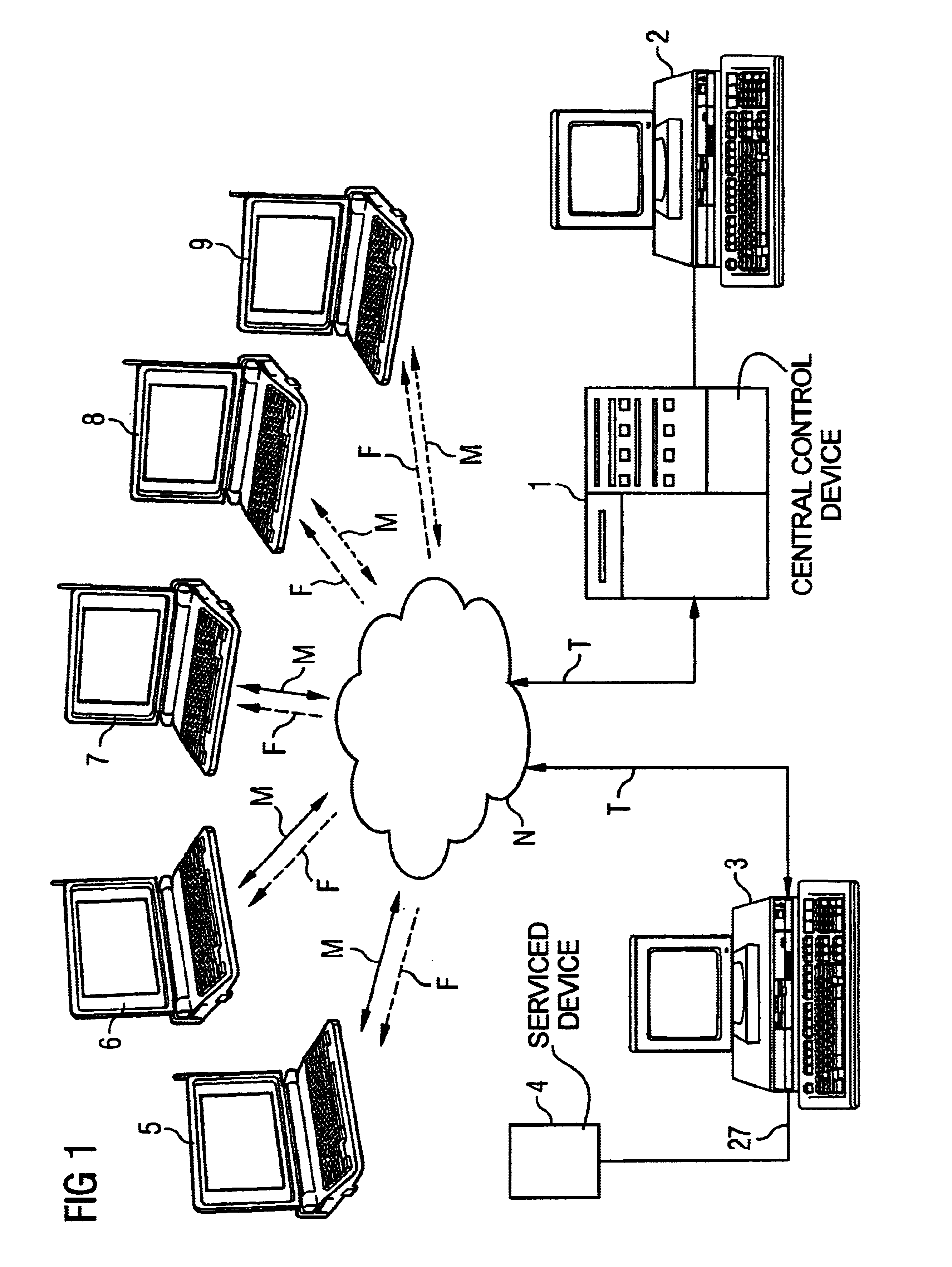

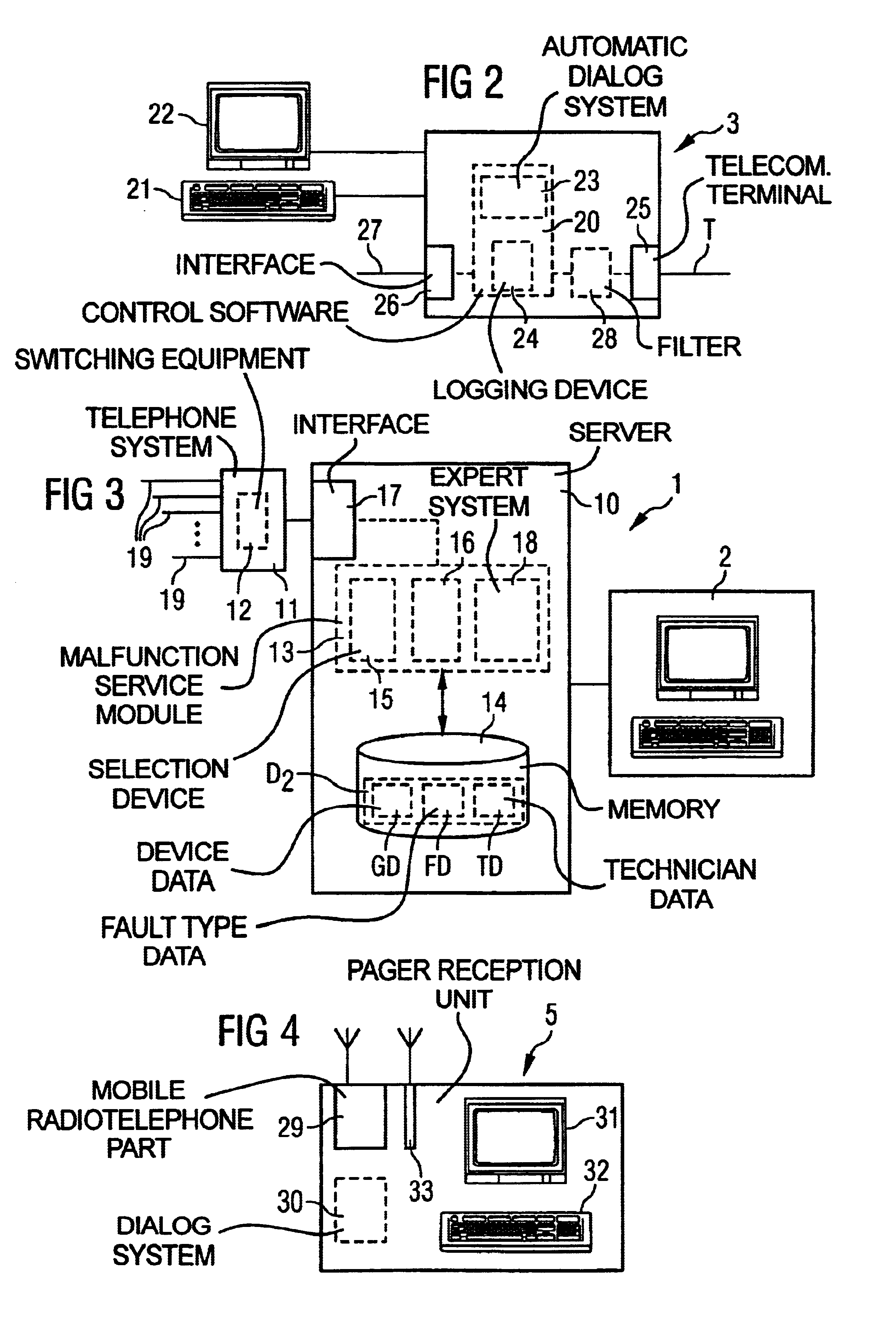

Control method and system for automatic pre-processing of device malfunctions

InactiveUS6925367B2Fast preprocessingShorten the timeVehicle testingRegistering/indicating working of vehiclesTerminal equipmentComputer terminal

In a control method and a system for the automatic pre-processing of device malfunctions, first data about a device malfunction are sent to a central control device by means of first terminal equipment. On the basis of the first data and on the basis of stored second data, the central control device automatically selects a group of second terminal equipment that are allocated to various service technicians. A malfunction incident signal and at least a part of the data are then sent to the selected terminal equipment and output thereat. The terminal equipment respectively acquires preliminary diagnosis data relating to the malfunction and availability data from the respective service technician. These data are communicated to the central control device, which automatically evaluates the existing data, selects a specific second terminal equipment from the group and communicates an assignment signal to the selected second terminal equipment.

Owner:SIEMENS HEALTHCARE GMBH

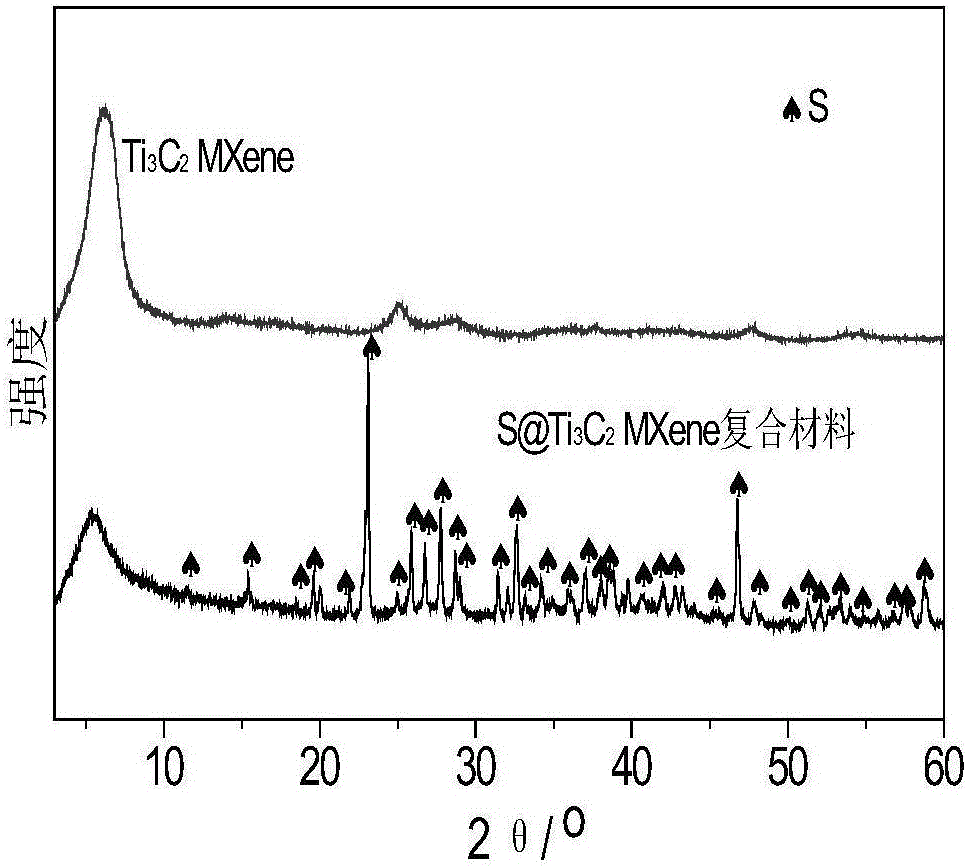

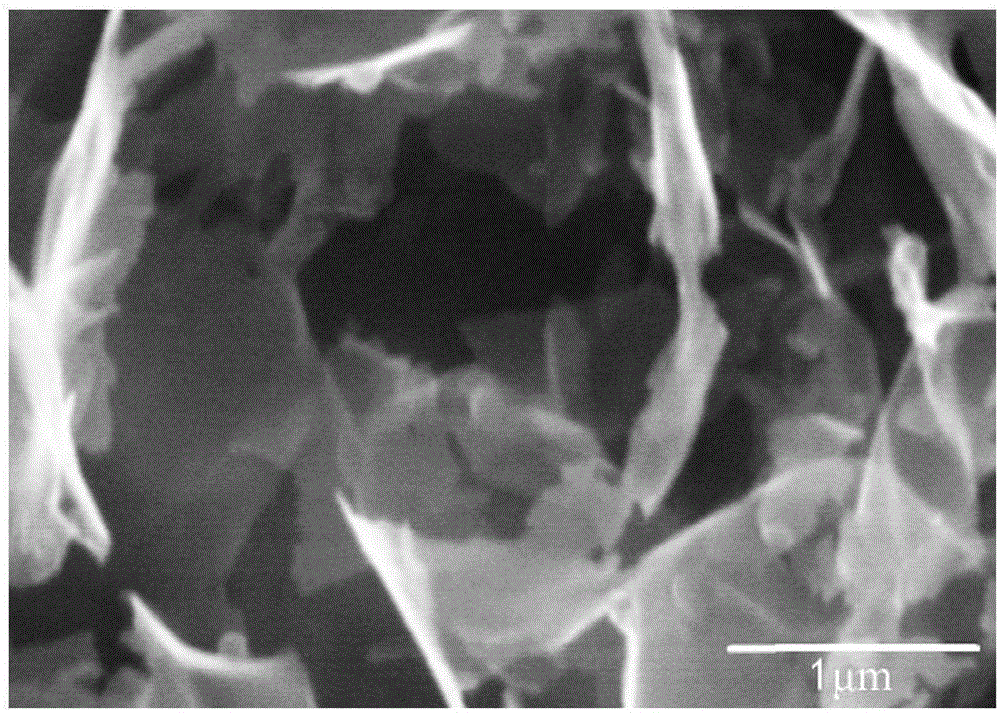

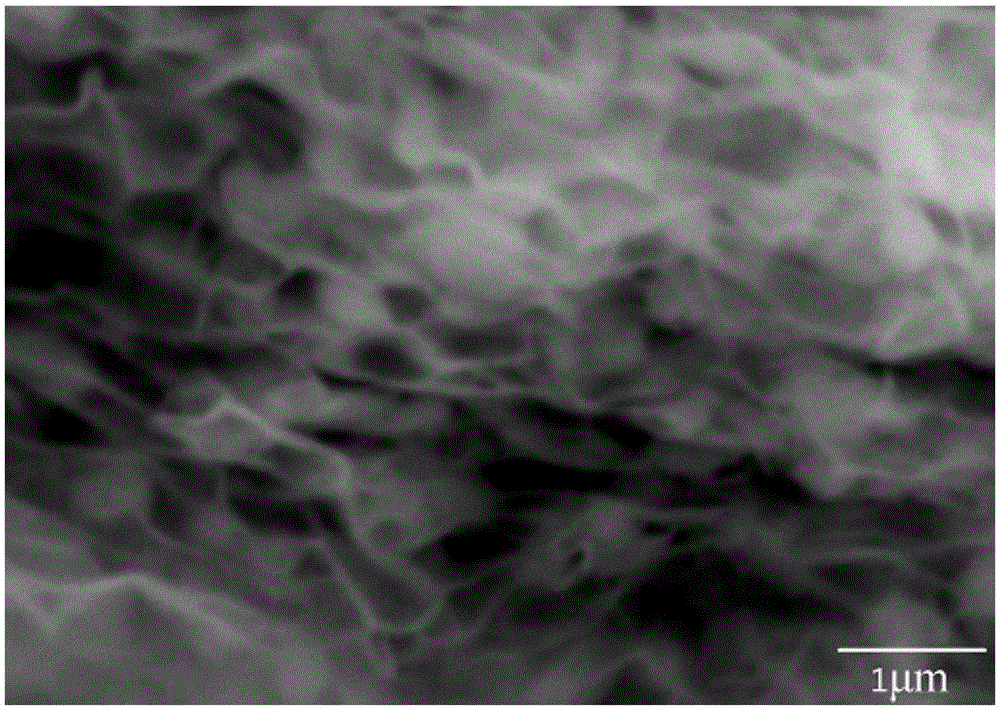

Two-dimensional transition metal carbide (nitride) and nano sulfur particulate composite as well as preparation and application thereof

ActiveCN106450205AGive full play to the sulfur fixation effectEvenly dispersedMaterial nanotechnologyNon-aqueous electrolyte accumulator electrodesSodium polysulfideReducing agent

The invention relates to a two-dimensional transition metal carbide (nitride) and nano sulfur particulate composite as well as preparation and application thereof. The composite is formed by two-dimensional transition metal carbide (nitride) MXene nanosheets and nano sulfur particles, wherein the nano sulfur particles grow on the surface of the two-dimensional transition metal carbide (nitride) MXene nanosheets in an in-situ manner, marked as S@MXene. The stable suspension of a single layer or a few layers of two-dimensional transition metal carbide (nitride) MXene nanosheets is mixed with a sodium thiosulfate or sodium polysulfide solution; with formic acid as a reducing agent, the nano sulfur generated by the reaction uniformly grows on the surface of the two-dimensional MXene nanosheet; and the two-dimensional transition metal carbide (nitride) and nano sulfur particulate composite is obtained through neutralization, washing and centrifugation and serves as the anode of a lithium-sulfur battery. According to the invention, a high-conductivity two-dimensional transition metal carbide (nitride) MXene nanosheet carrier is uniformly compounded with nano sulfur particles, introduction of a binder and a conductive agent is not needed, and the composite has excellent electrochemical performance as the anode of a lithium-sulfur battery; and moreover, the technology is simple and can meet the requirements of large-scale production.

Owner:NANJING TECH UNIV

Apparatus and method for minimizing waste and improving quality and production in web processing operations

InactiveUS20090020211A1Reduce wasteQuality improvementLamination ancillary operationsControlling laminationProximateVisual inspection

Apparatus and methods are provided to minimize waste and improve quality and production in web processing operations. The apparatus and methods provide defect detection both before and after application of component patches to a traveling web to create a product. Web defect detection may be provided by way of at least one visual inspection station located upstream from the patch applicator. Patch defect detection may be accomplished by way of a visual inspection station located proximate the patch applicator. If defects are detected in either the traveling web or the component patch prior to patch application, patch application may be prevented until both a satisfactory web and patch are provided. If defects are detected after patch application, the resulting product may be culled. Furthermore, the apparatus may be provided with diagnostic software to warn against extant or imminent machine complications.

Owner:CURT G JOA

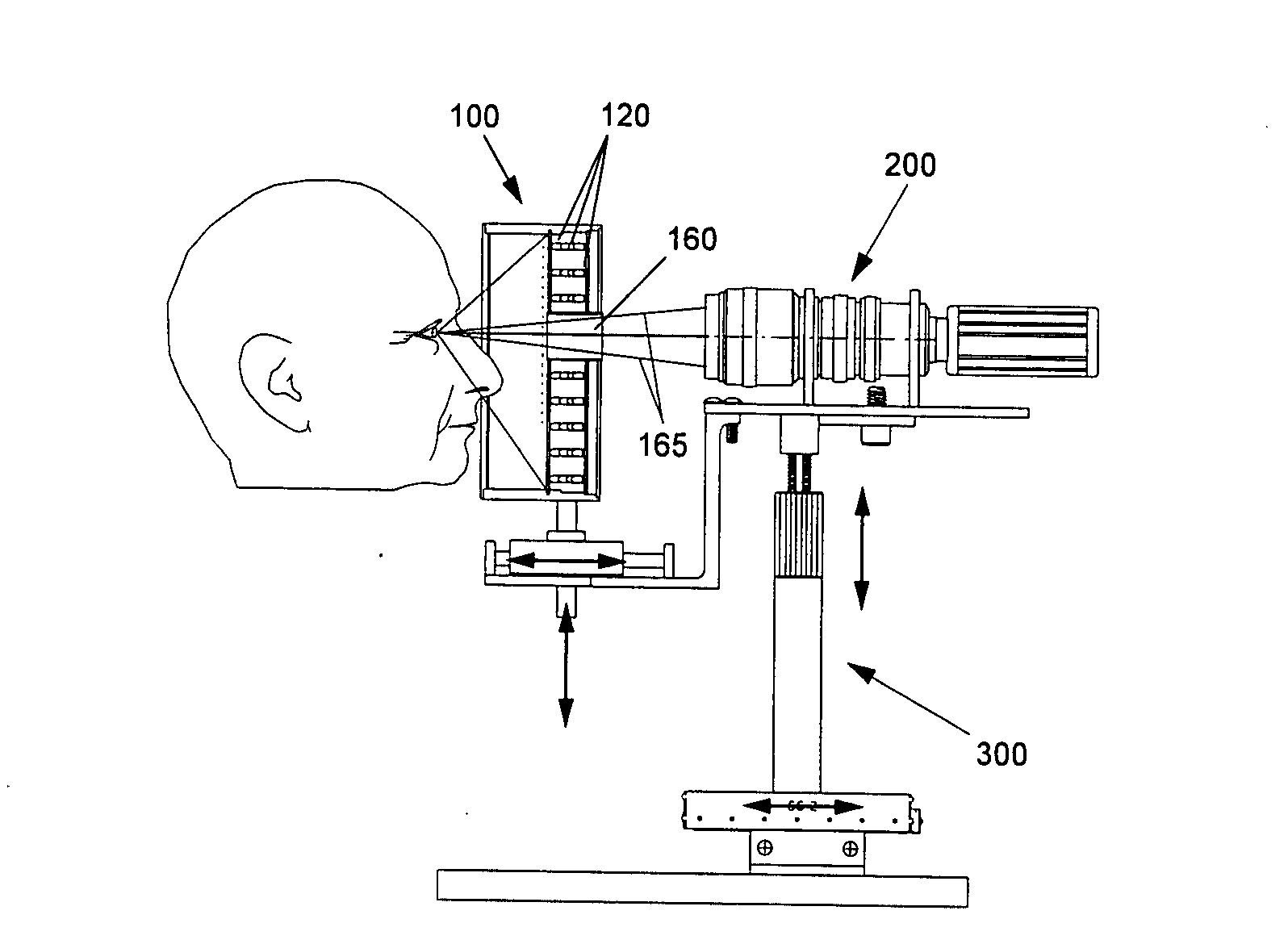

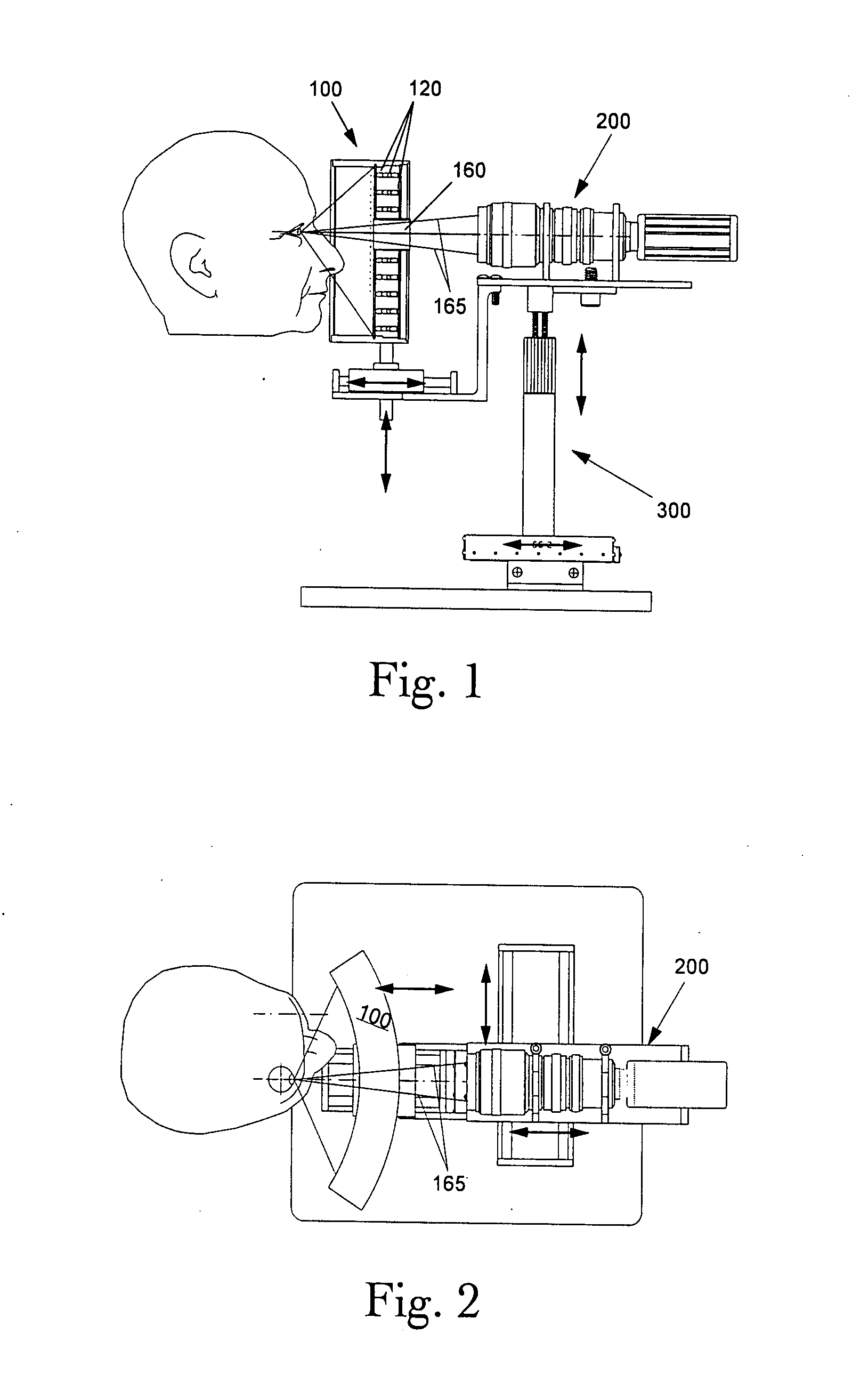

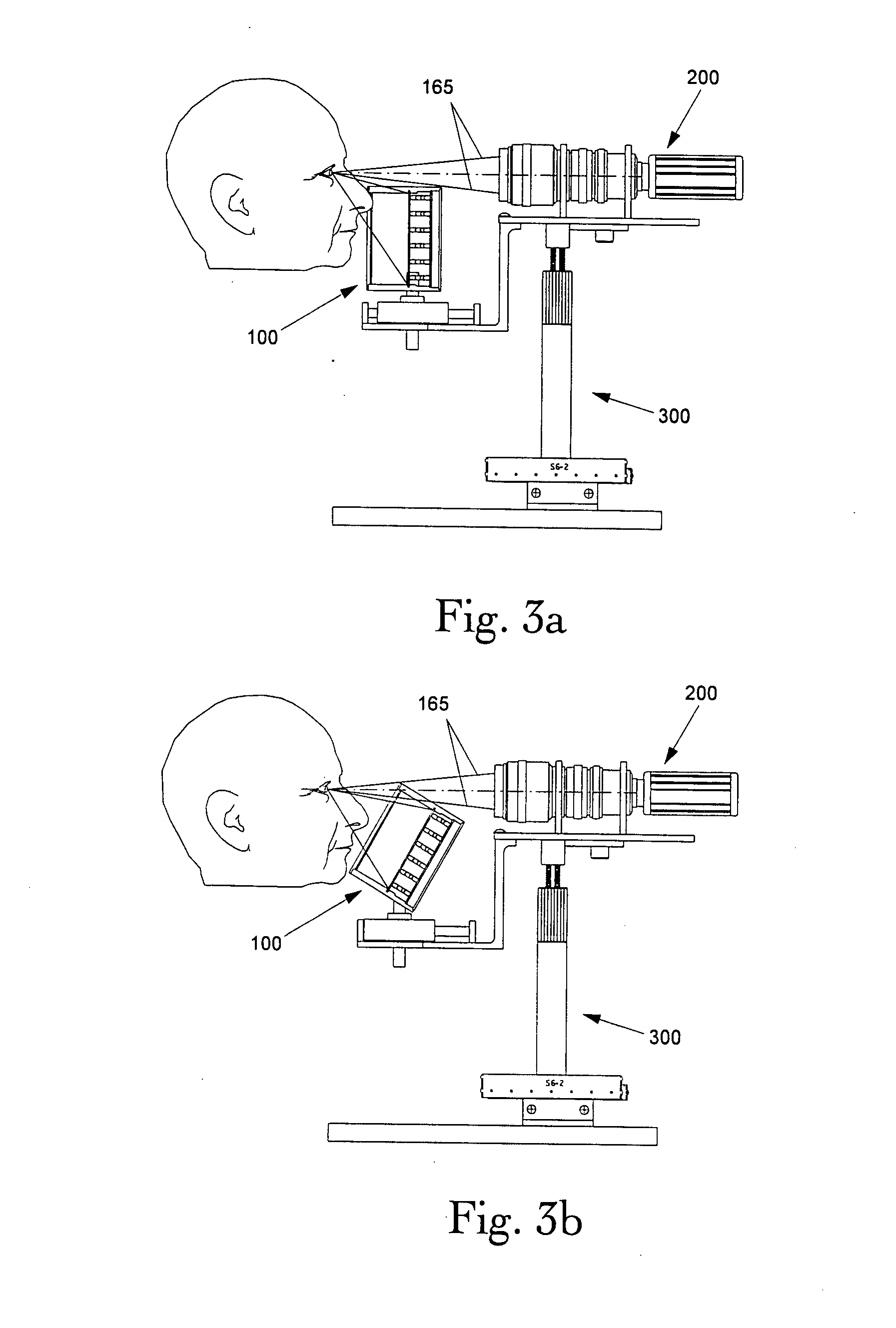

Tear film measurement

ActiveUS20080319323A1Avoid introducingReduce intensityEye diagnosticsRadiation diagnosticsEngineeringLight source

The invention comprises a method for measuring the relative thickness of the lipid layer component of the precorneal tear film on the surface of an eye after distribution of the lipid layer subsequent to blinking. Light is directed to the lipid layer of a patient's eye with an illuminator. The illuminator is a broad spectrum light source covering the visible region and is a lambertion light emitter such that the light source is specularly reflected from the lipid layer and undergoes constructive and destructive interference in the lipid layer. The specularly reflected light is collected and focused using a collector such that the interference patterns on the tear film lipid layer are observable. The collector also produces an output signal representative of the specularly reflected light which is suitable for further analysis, such as projection on to a high resolution video monitor or analysis by or storage in a computer. In order to facilitate ease of measurement, the patient's head may be positioned on an observation platform when the illuminator directs light to the lipid layer of the patient's eye.

Owner:TEARSCIENCE INC

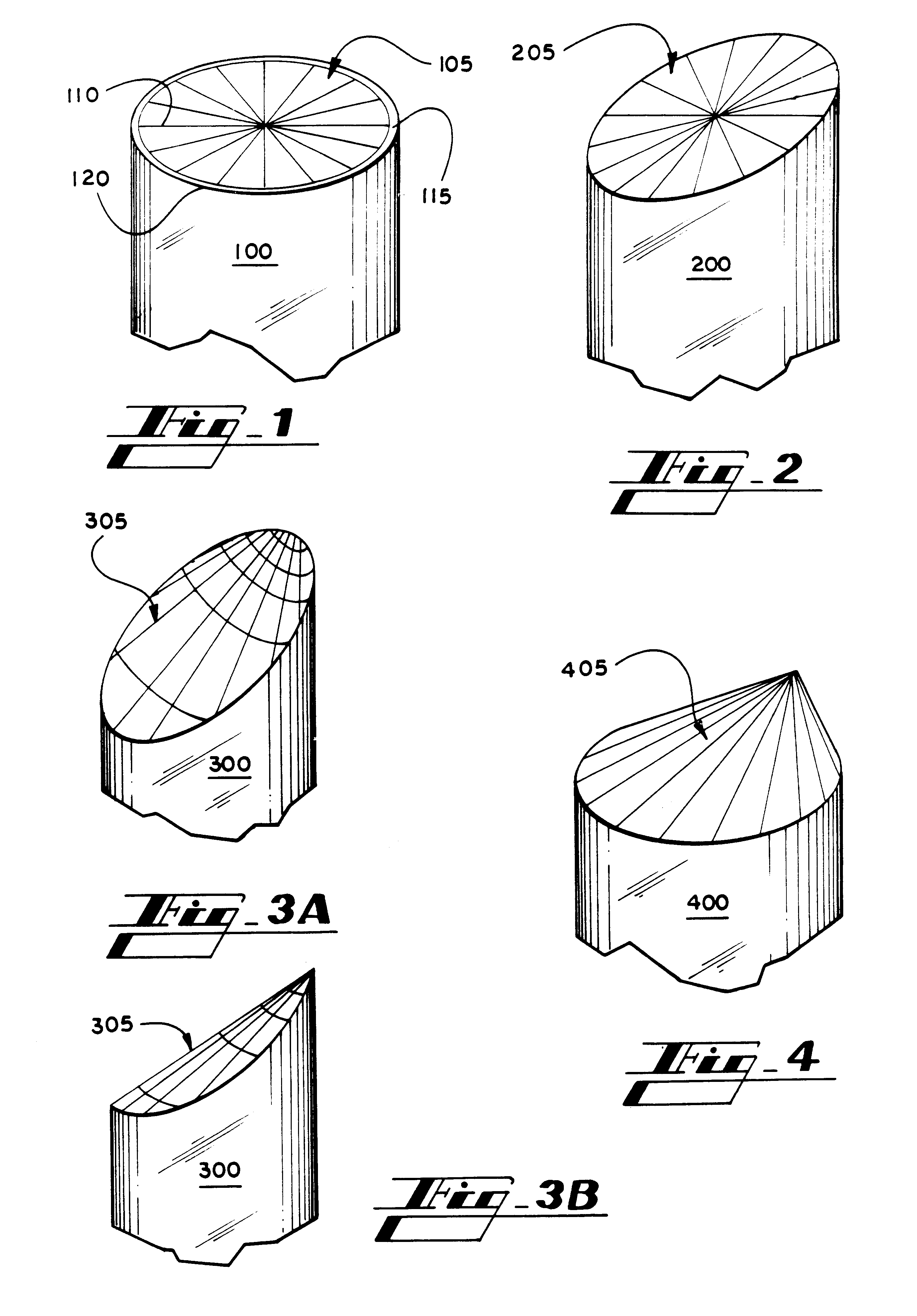

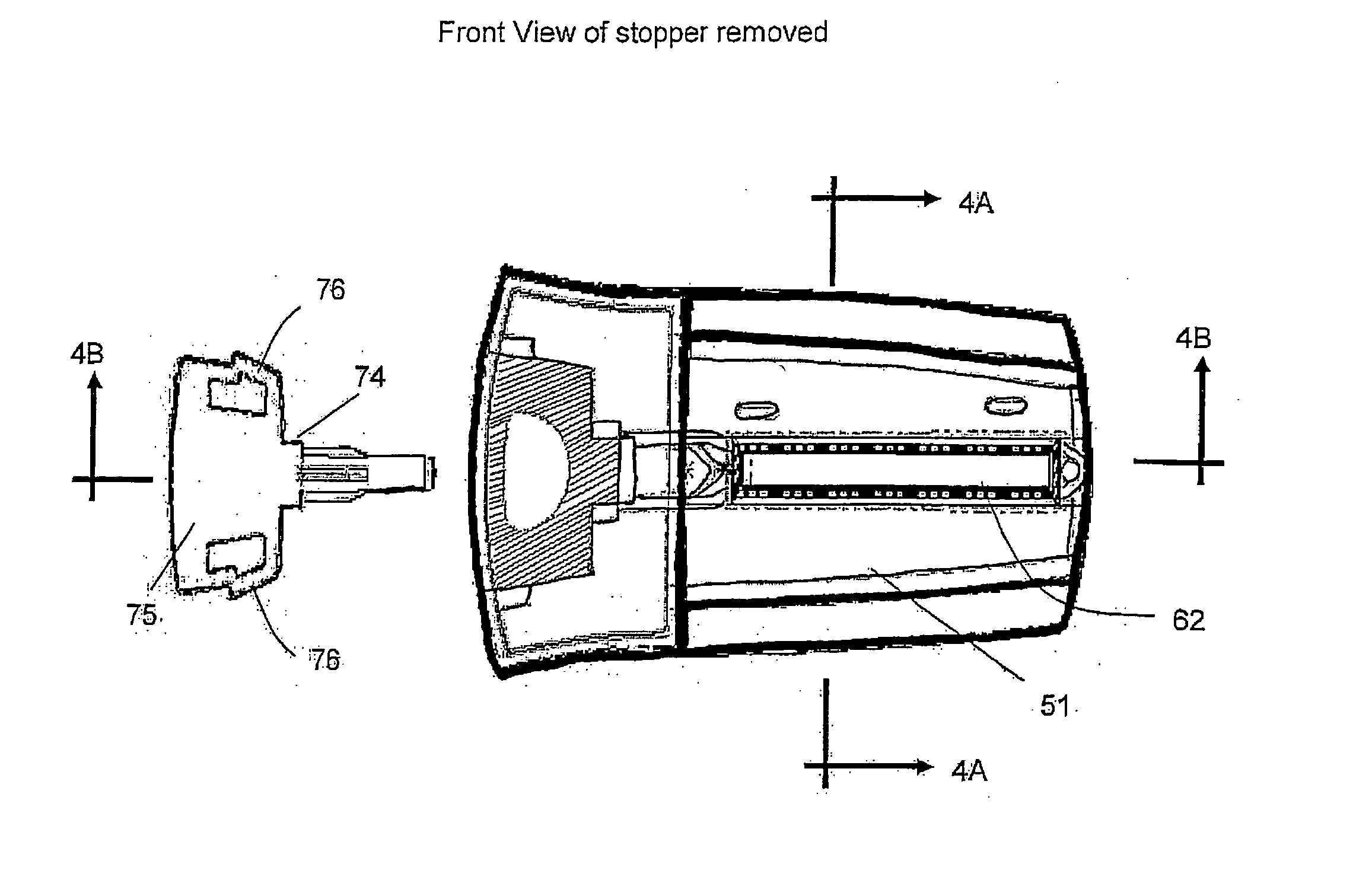

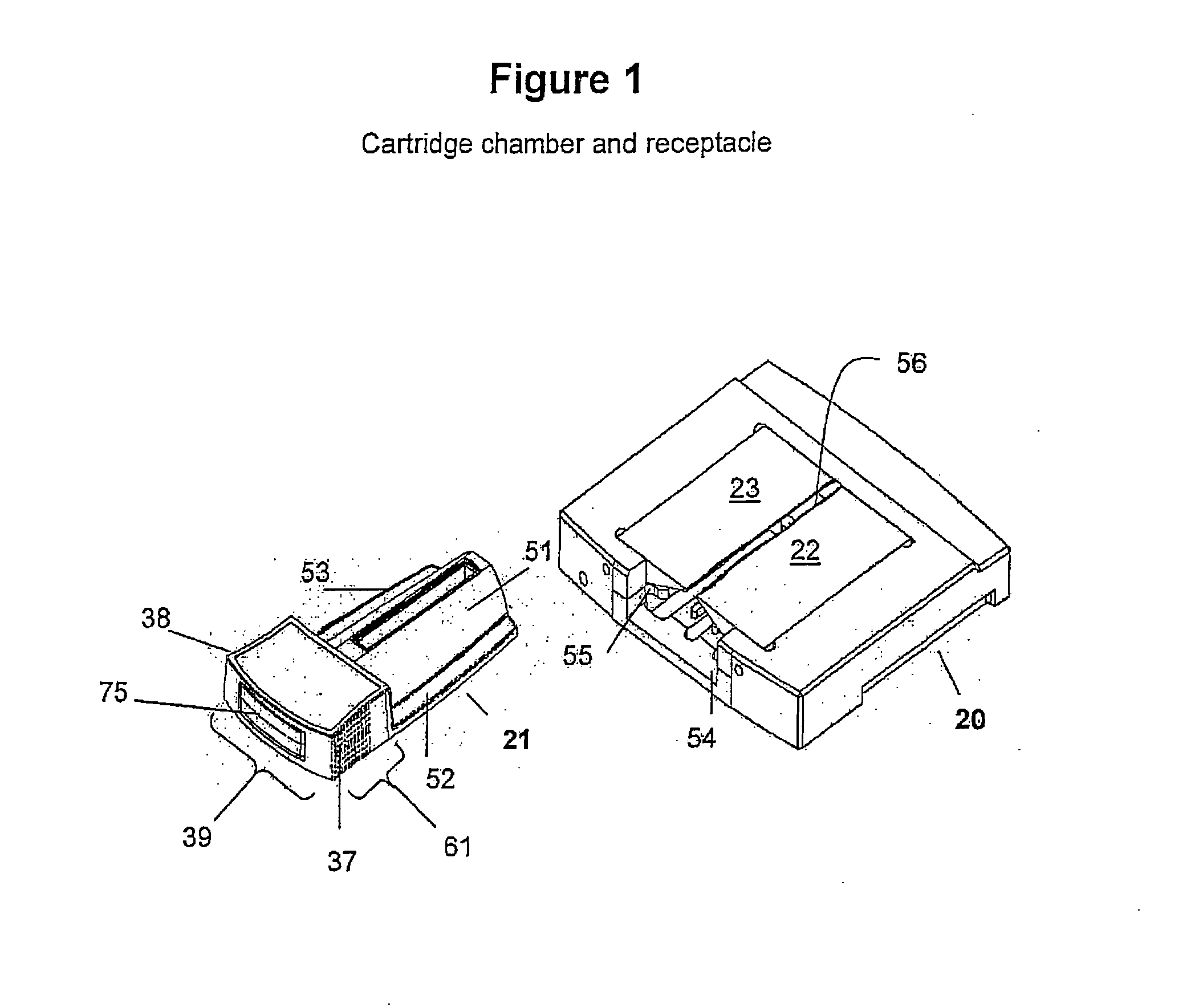

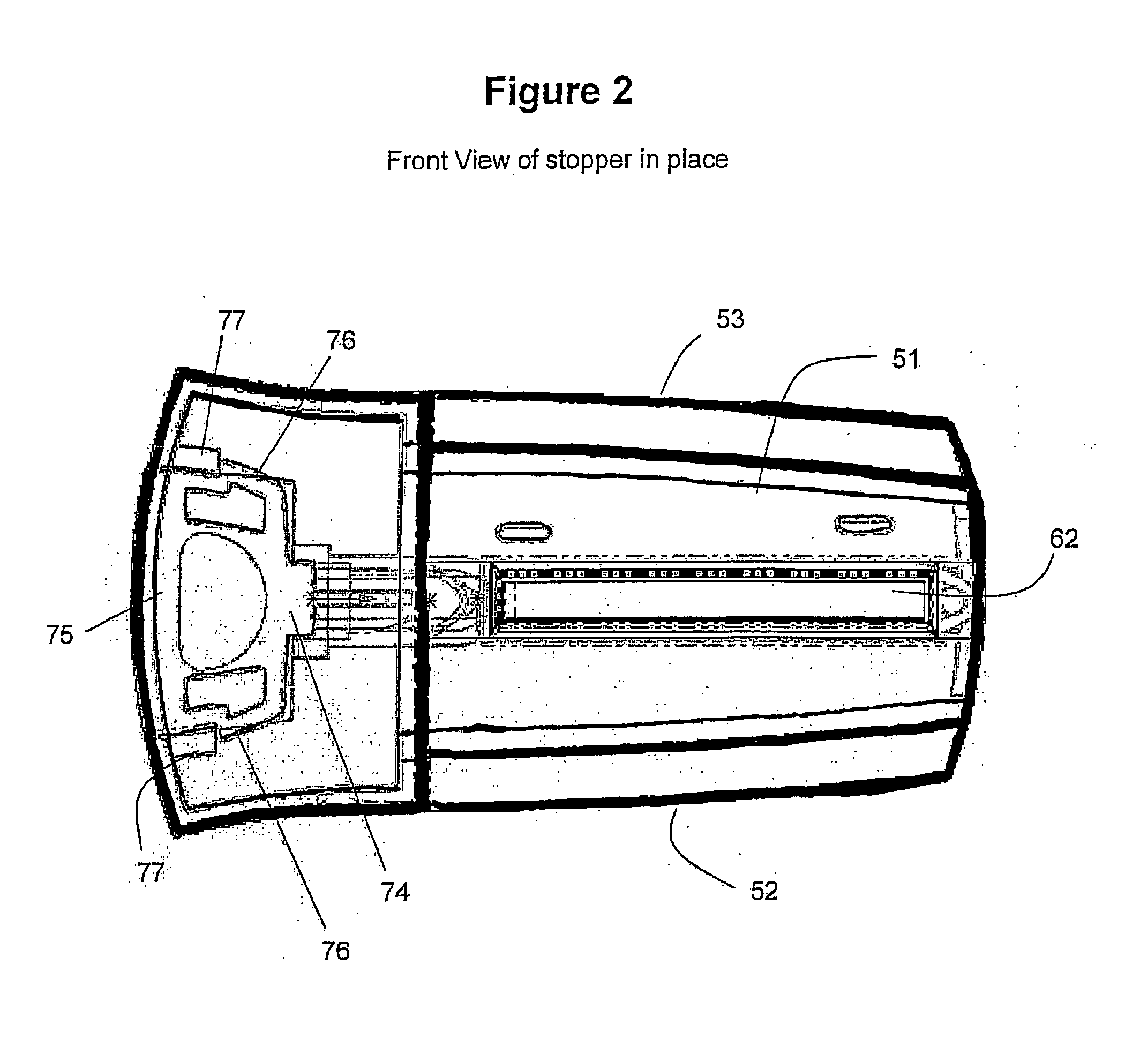

Cartridge for containing a specimen sample for optical analysis

ActiveUS20060115380A1Clear and uniform areaImprove analysisAnalysis using chemical indicatorsLaboratory glasswaresElastomerLocking mechanism

An improved cartridge for holding a fluid sample with a small volume is disclosed herein. The cartridge has a test chamber and a vestibule through which the test fluids are inserted into the test chamber. Improved grips are flared-out to aid manipulation. The handle portion is reinforced to prevent flexing, and a prefabricated trough along the edge of the land surface prevents introduction of the adhesive into the region for analysis. The cartridge has a stopper having a dual sealing mechanism, which seals the test chamber inlet between the vestibule and the test chamber, and the mouth of the vestibule so that when the stopper is in place, the test chamber is closed to the admission of air or other contaminants. The vestibule is similarly closed against escape of the overflow from the test chamber. The stopper is composed of a single elastomer. An improved locking mechanism has two flexible walls on either side of the handhold that locks into their respective keepers on the cartridge to provide a secure lock. Additionally, an improved method for loading the cartridge allows for an even distribution of magnetically responsive particles contained within a fluid sample to be viewed in an array through the optically clear land surface portion of the cartridge.

Owner:MENARINI SILICON BIOSYSTEMS SPA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com