Patents

Literature

209 results about "Rubber cement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rubber cement is an adhesive made from elastic polymers (typically latex) mixed in a solvent such as acetone, hexane, heptane or toluene to keep them fluid enough to be used. Water-based formulae, often stabilised by ammonia, are also available. This makes it part of the class of drying adhesives: as the solvents quickly evaporate, the "rubber" portion remains behind, forming a strong, yet flexible bond. Often a small percentage of alcohol is added to the mix.

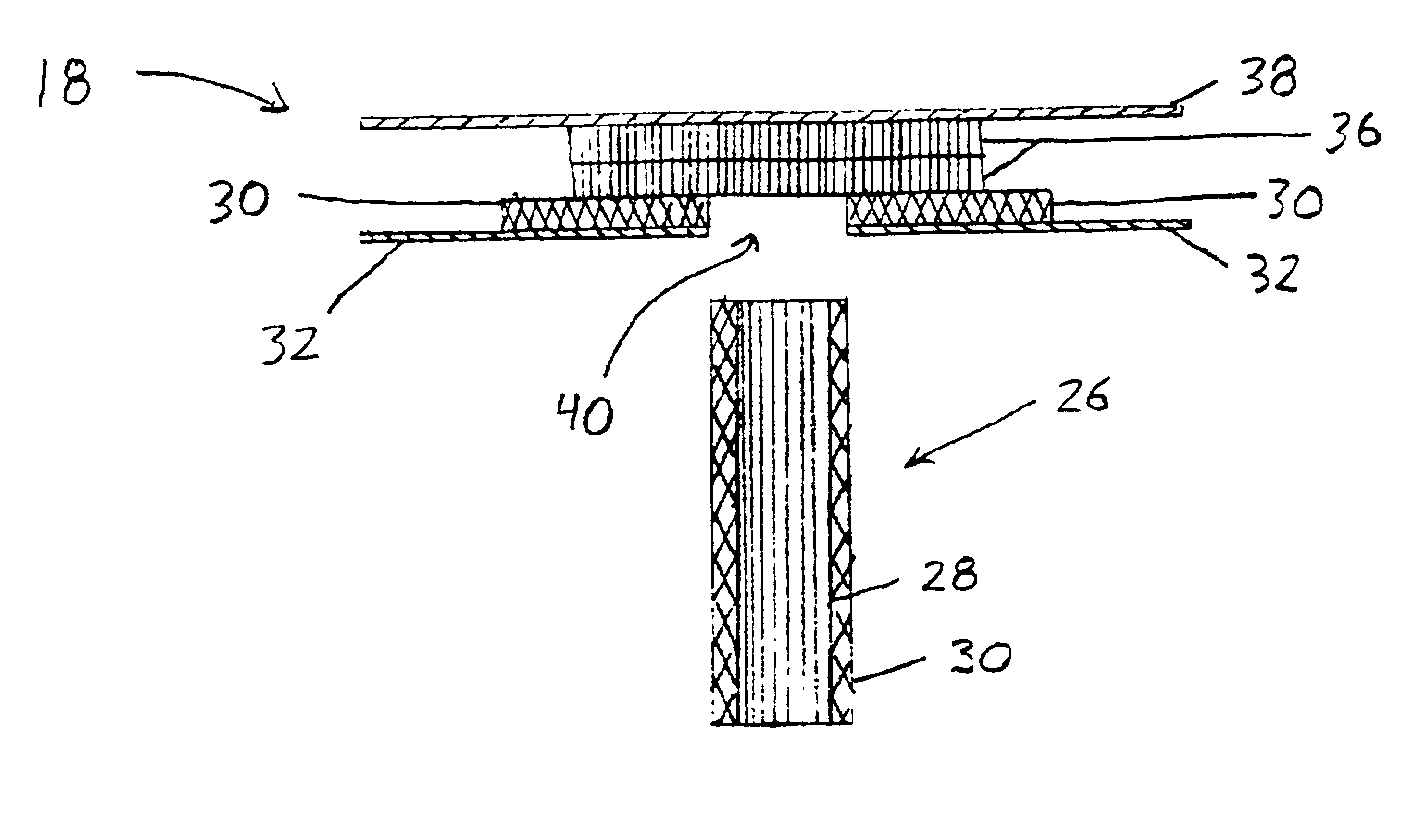

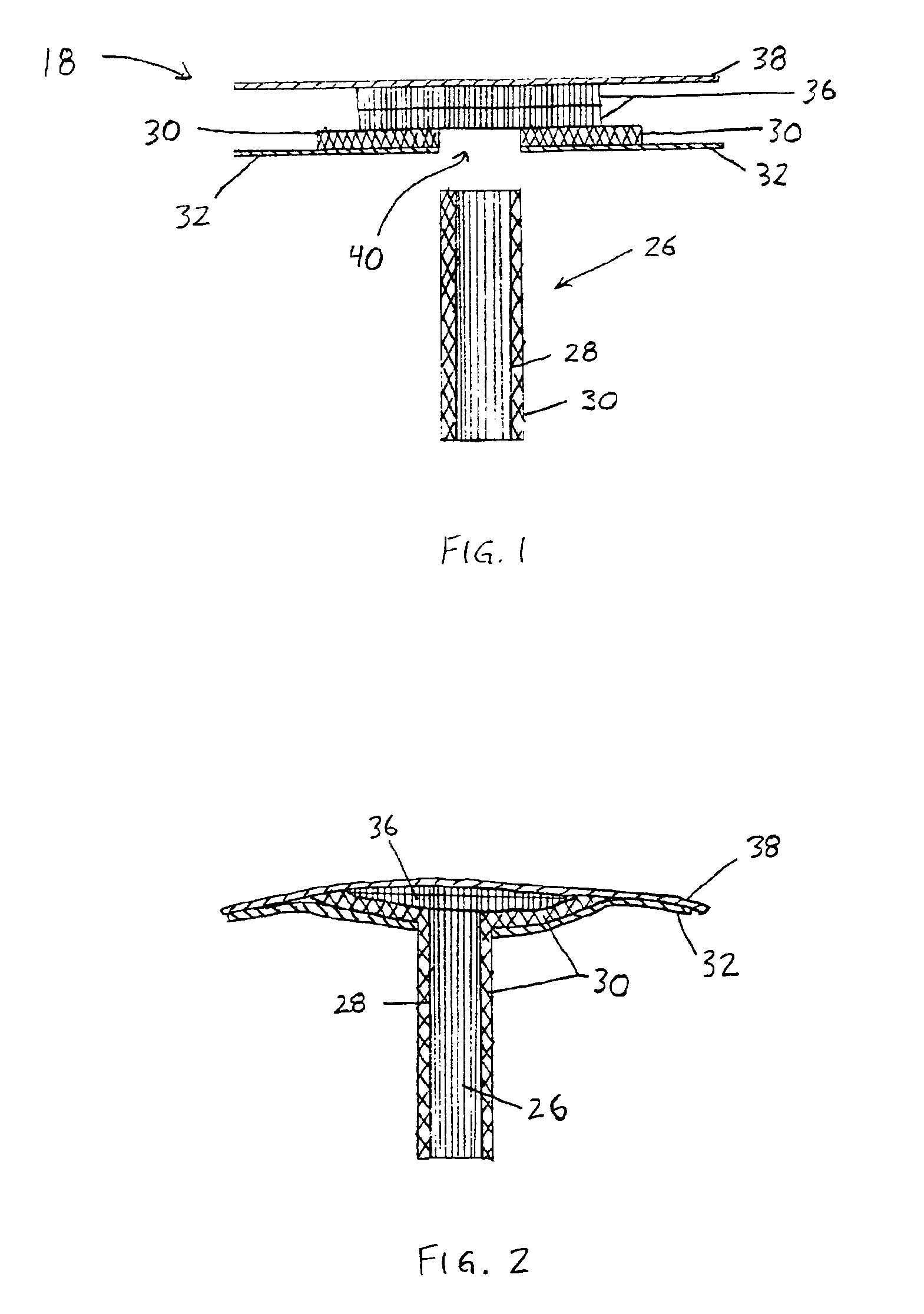

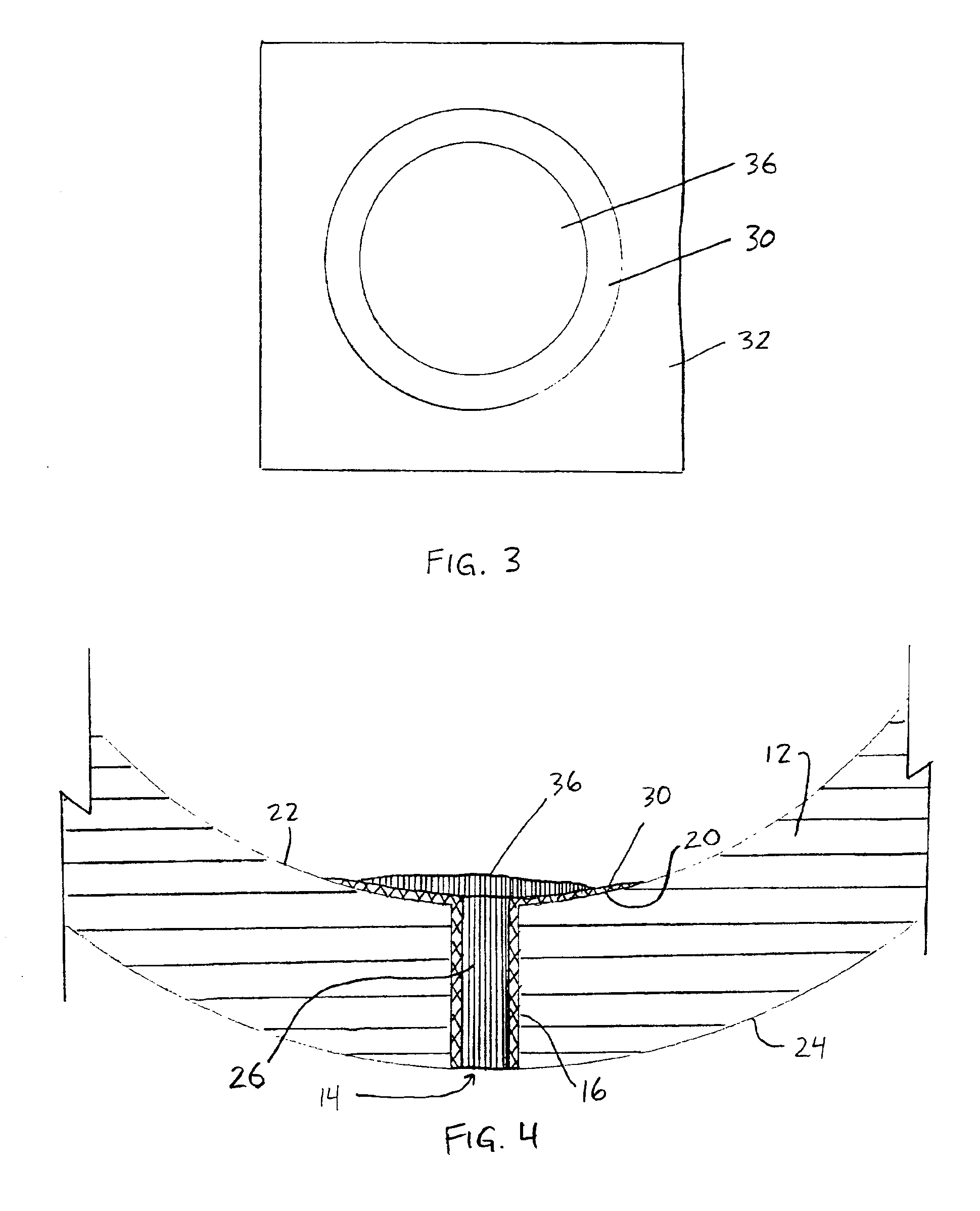

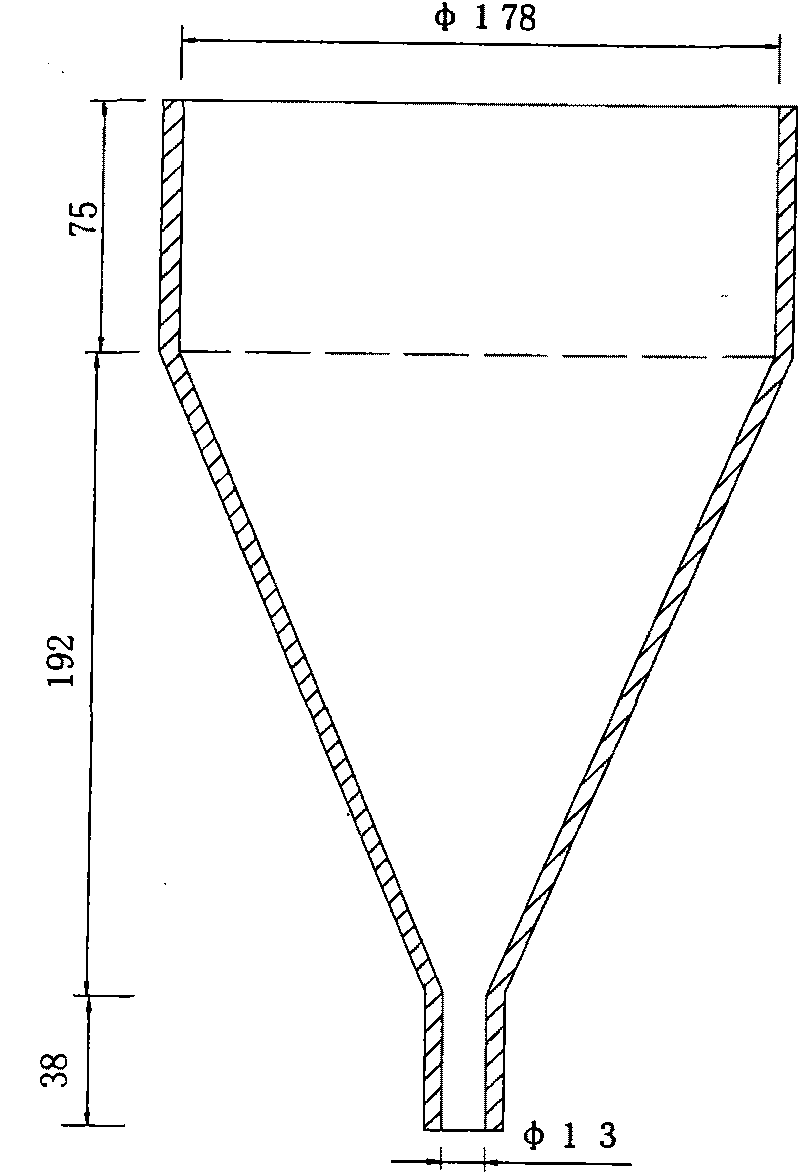

Patch plug

A patch plug is provided that has a coating continuous over both the patch and plug portions, providing a strong and continuous seal to prevent seal failure and water and air introduction. The patch and plug portions may be formed separately, each with a coating element, and fused together in a press which bonds the coatings of the patch and plug portions together to form a single, continuous coating. Means known in the art, for example rubber cement, can also be employed to further ensure a firm seal between the patch plug and the tire. Methods of manufacturing and using the patch plug are also taught herein.

Owner:4254563 MANITOBA

Composite rubber material

InactiveCN103627330ALow costReduce manufacturing costPolyureas/polyurethane adhesivesInorganic adhesivesRubber materialPolymer science

The invention relates to a bonding rubber material, especially provides a binder or a thermosetting molding rubber cement for bonding and reinforcement of door cores of a fireproof door an antitheft door and bonding and production of building and decoration materials, and aims to provide a composite rubber material, with low cost, good bonding strength and rapid surface dry, which can be cured at room temperature. The composite rubber material is characterized in that the composite rubber material is composed of a water-based A material and a polyurethane prepolymer-containing B material, the ratio (weight ratio) of the A material to the B material is 0.5-1:0.5-1, the A material comprises 30-70% of water and / or water glass and / or silica sol, 19.5-48% of organic modifiers, and 12-55% of additives, the B material comprises polyurethane prepolymers with a content of being more than 30%, 8-24% of -NCO group, and 0-30% of synergists, The synergists are one or combination of more than one selected from a polymerization inhibitor, a blocking agent, a water glass curing agent and a diluting agent. The composite rubber material is advantaged by good bonding strength, flame retardance, thermal insulation, low price and environmental protection.

Owner:CHONGQING LIERDA SCI & TECH DEV +1

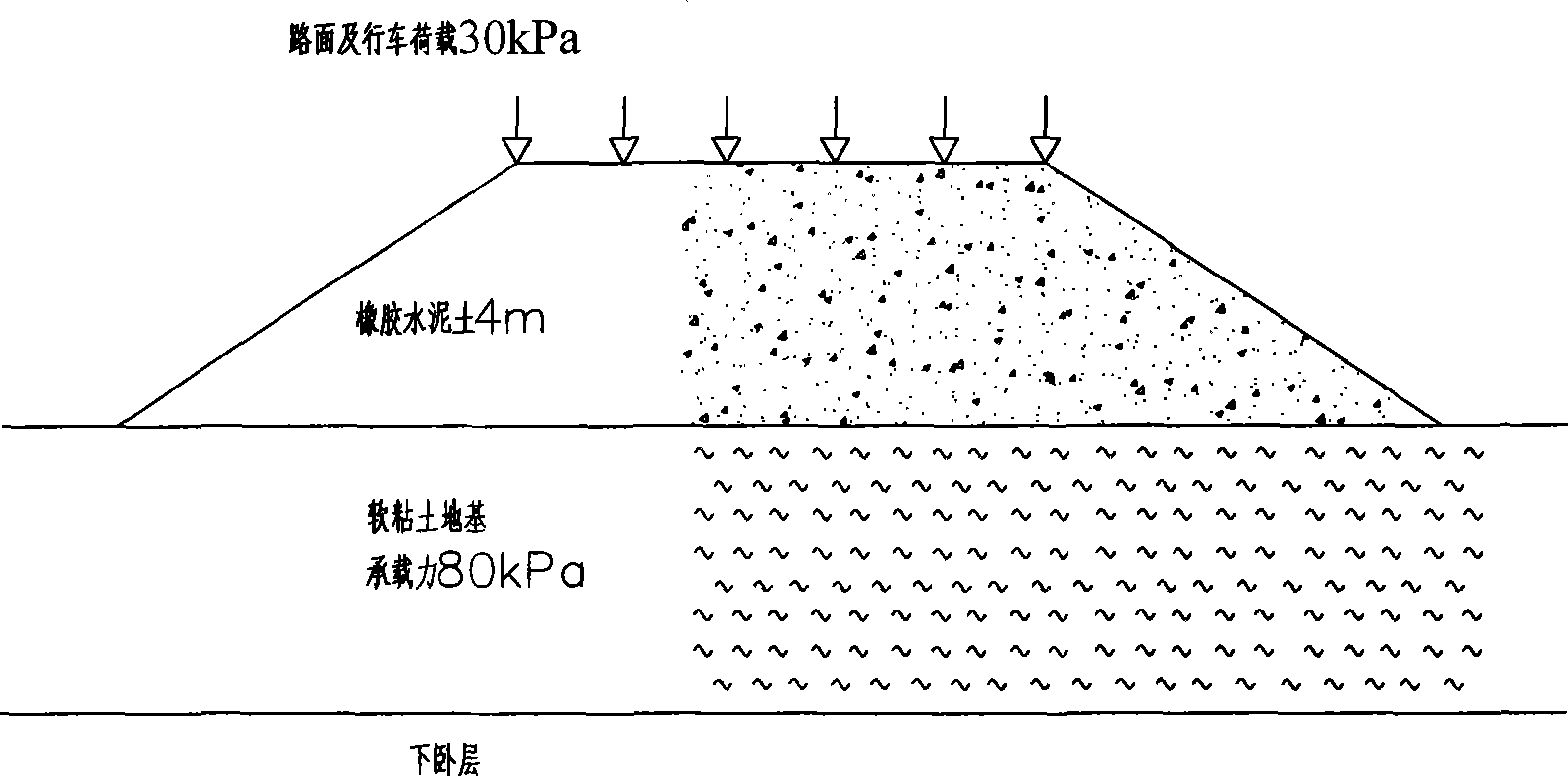

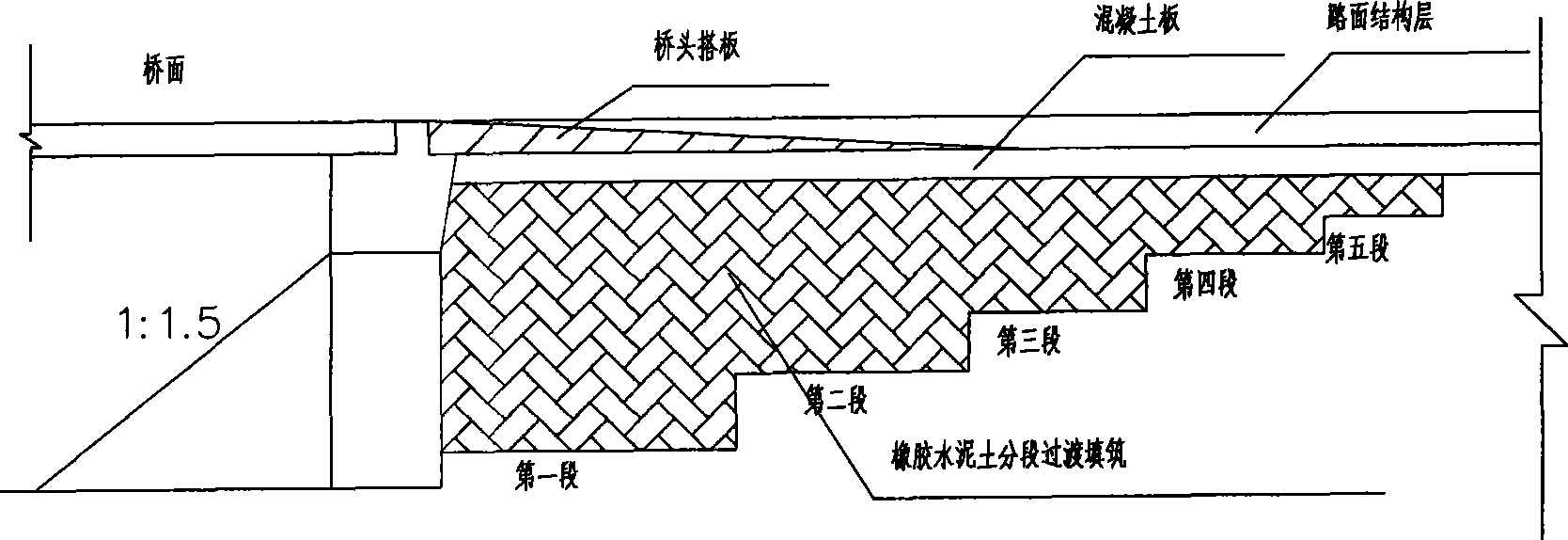

Rubber-cement grouting material applied to semi-flexible pavement

ActiveCN101700970ASmall mechanical propertiesImprove premature crack shrinkageSolid waste managementRoad surfacePulverized fuel ash

The invention relates to a rubber-cement grouting material applied to a semi-flexible pavement, belonging to waste recycling field in the environmental protection field and the application field of highway engineering. The rubber-cement grouting material applied to the semi-flexible pavement is characterized by being formed by mixing the components based on parts by weight: 100 parts of cement, 10-50 parts of pulverized fuel ash, 5-30 parts of expanding agent, 1-30 parts of rubber powder, 10-50 parts of sand, 0.1-5 parts of water reducing agent, 0.1-5 parts of early strength agent and 40-70 parts of water. The rubber-cement grouting material has high fluidity and anti-cracking property, lower contraction and higher early strength, and can meet the groutability and pavement performance of the semi-flexible pavement material.

Owner:WUHAN MUNICIPAL CONSTR GROUP

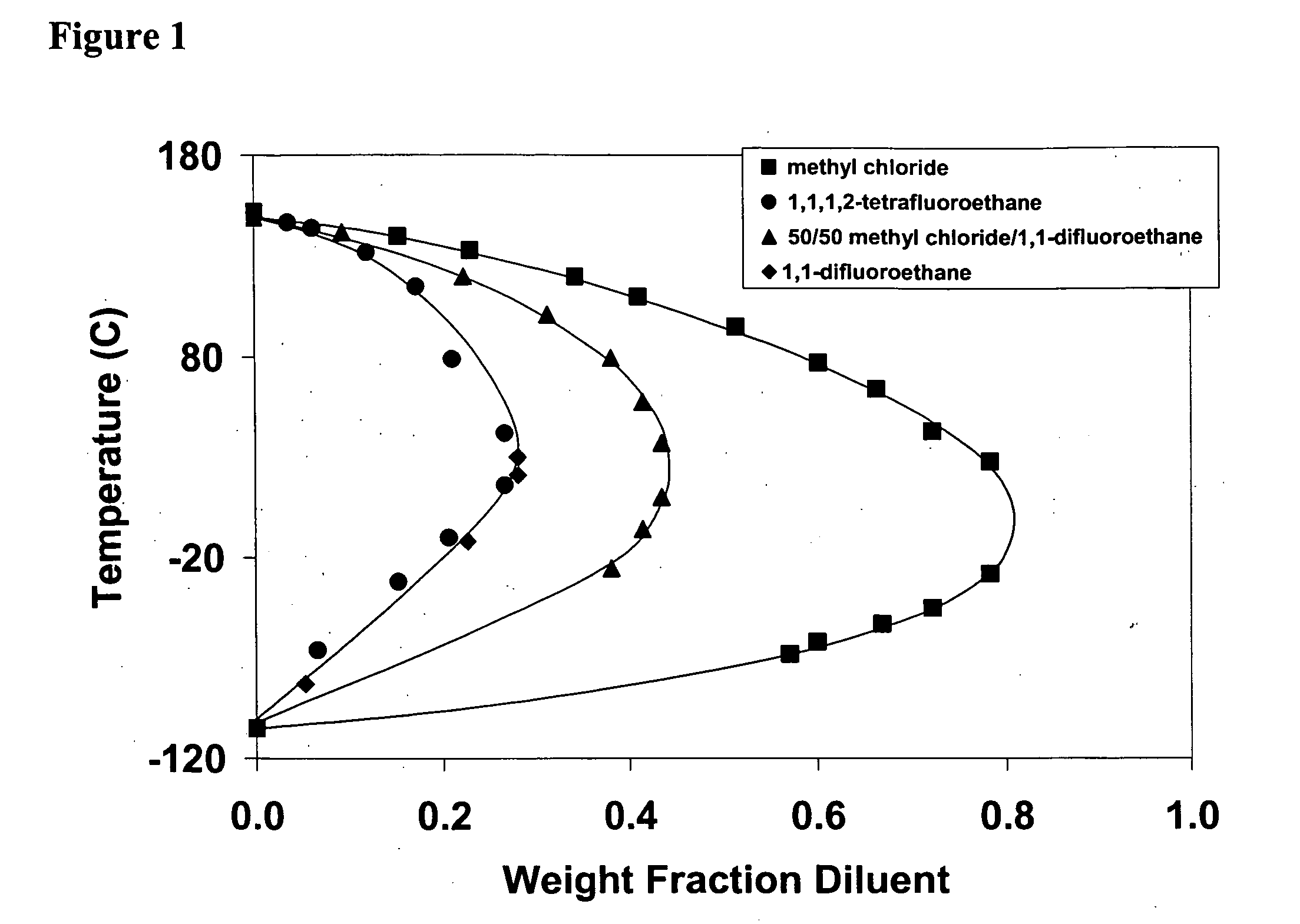

Process to produce a hydrocarbon rubber cement utilizing a hydrofluorocarbon diluent

ActiveUS20070299190A1Quality improvementHydrocarbon purification/separationSpecial tyresHydrocarbon solventsPolymer science

Provided for herein is a process to produce an essentially homogeneous single liquid phase hydrocarbon-rubber cement from a polymer slurry comprising a hydrocarbon-rubber, a diluent, and unreacted monomer(s), the process comprising:(a) contacting the polymer slurry with a hydrocarbon solvent; and(b) removing the diluent in amounts not sufficiently more than is necessary to produce the essentially homogeneous single liquid phase hydrocarbon-rubber cement wherein the mass fraction of monomer(s) in the hydrocarbon-rubber cement, based on the total amount of hydrocarbon-rubber present in the hydrocarbon-rubber cement, is less than the mass fraction of monomer(s) in the hydrocarbon-rubber slurry, based on the total amount of hydrocarbon-rubber present in the hydrocarbon-rubber slurry,wherein the diluent comprises a hydrofluorocarbon.

Owner:EXXONMOBIL CHEM PAT INC

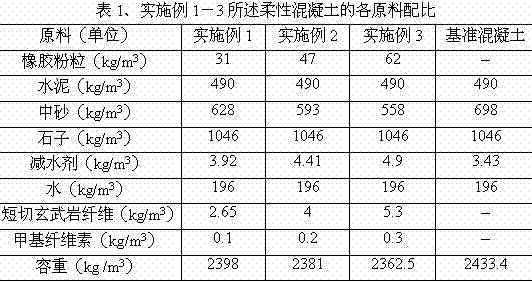

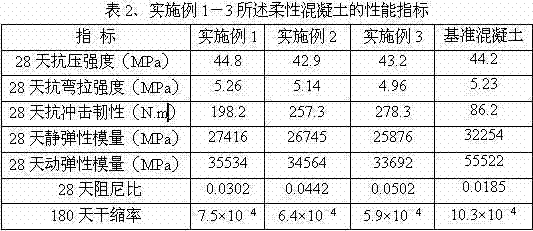

Mineral fiber-modified flexible rubber concrete

InactiveCN102557555AImprove stress resistanceImprove flexural strengthSolid waste managementCelluloseRoad engineering

The invention relates to mineral fiber-modified flexible rubber concrete. The mineral fiber-modified flexible rubber concrete comprises rubber cement concrete, chopped basalt fiber and a dispersant methylcellulose, wherein the rubber cement concrete consists of rubber particles, cement, sand, stones, a water reducing agent and water; and the chopped basalt fiber is 0.1 to 0.5 percent of the volume of the rubber cement concrete, and the dispersant is 0.05 to 0.2 percent of the weight of the water. The concrete is applicable to road engineering, and has high compressive strength, bending tensile strength and deformability, and low modulus of elasticity.

Owner:HENAN UNIVERSITY

Rubber reinforced cement functional composite material and preparation method thereof

InactiveCN101857399AWith noise reductionWith sound insulationSolid waste managementNoise barrierAdhesive

The invention discloses a rubber reinforced cement functional composite material and a preparation method thereof. The rubber reinforced cement functional composite material is prepared from waste rubber and cement or cement mortars by the following steps of: applying coupling adhesives to surfaces of waste rubber grains and / or powder by using coupling agents; mixing the waste rubber grains and / or powder with the cement or the cement mortars; adding water into the rubber-cement mixed materials for uniform stirring, and performing pavement, pressing, demoulding and maintaining to obtain the functional composite material product having a high mechanical strength and endurance. The composite material has the characteristics of noise reduction, sound isolation, high impact resistance, damping vibration attenuation, wear resistance, static resistance, water resistance and the like, has the advantages of insulation, environmental protection and the like and can be used in the field of functional materials, such as buildings, roads, railways, tunnels, noise barriers and the like. The functional composite material and the method thereof also provide a new way for solving the global problem of 'black pollution' of increasing waste tyres and have a wide application prospect.

Owner:CHINA BUILDING MATERIALS ACAD

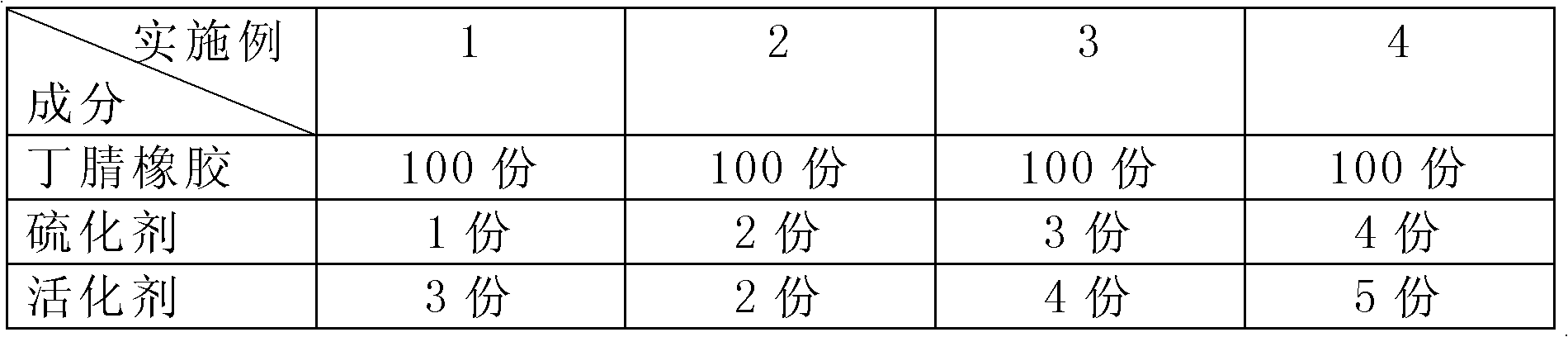

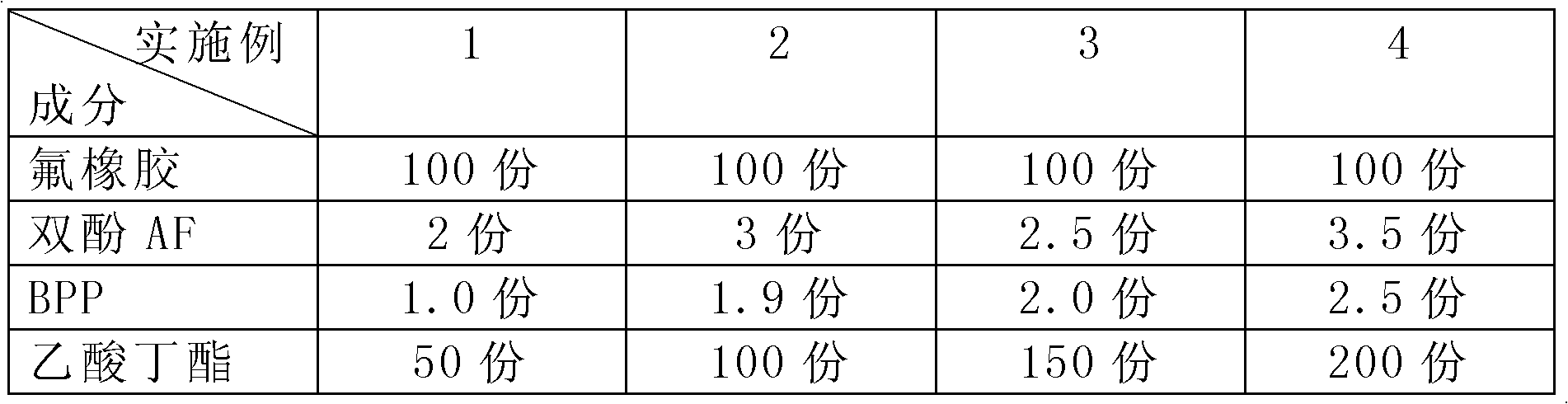

Fluorine/butadiene rubber composite glove and manufacturing method thereof

The invention relates to a fluorine / butadiene rubber composite glove and a manufacturing method thereof, belonging to the technical field of labour protection appliances. The glove comprises a fiber glove lining, the surface of the fiber glove lining is coated with a butyronitrile emulsion layer, the surface of the butyronitrile emulsion layer is coated with a fluorine rubber layer, and fluorine rubber particles are sprayed on the surface of the fluorine rubber layer, wherein the butyronitrile emulsion layer comprises the components such as butyronitrile rubber, a vulcanizer and an activator,and the fluorine rubber cement comprises the components of the fluorine rubber, the vulcanizer, a vulcanization accelerator and an ester solvent. The method for manufacturing the glove comprises three steps burdening, soaking cement and pouring cement. The glove and the manufacturing method in the invention have the following advantages: the performances of resistances to chemicals, strong acid, strong alkali and corrosion are achieved, and the cost is lower; and meanwhile, the method for manufacturing the glove adopts a flow line production manner during the production process, the product process is simple, the cost is lowers, and the glove is applicable to large-scale industrialized production.

Owner:台州达顿安防科技有限公司

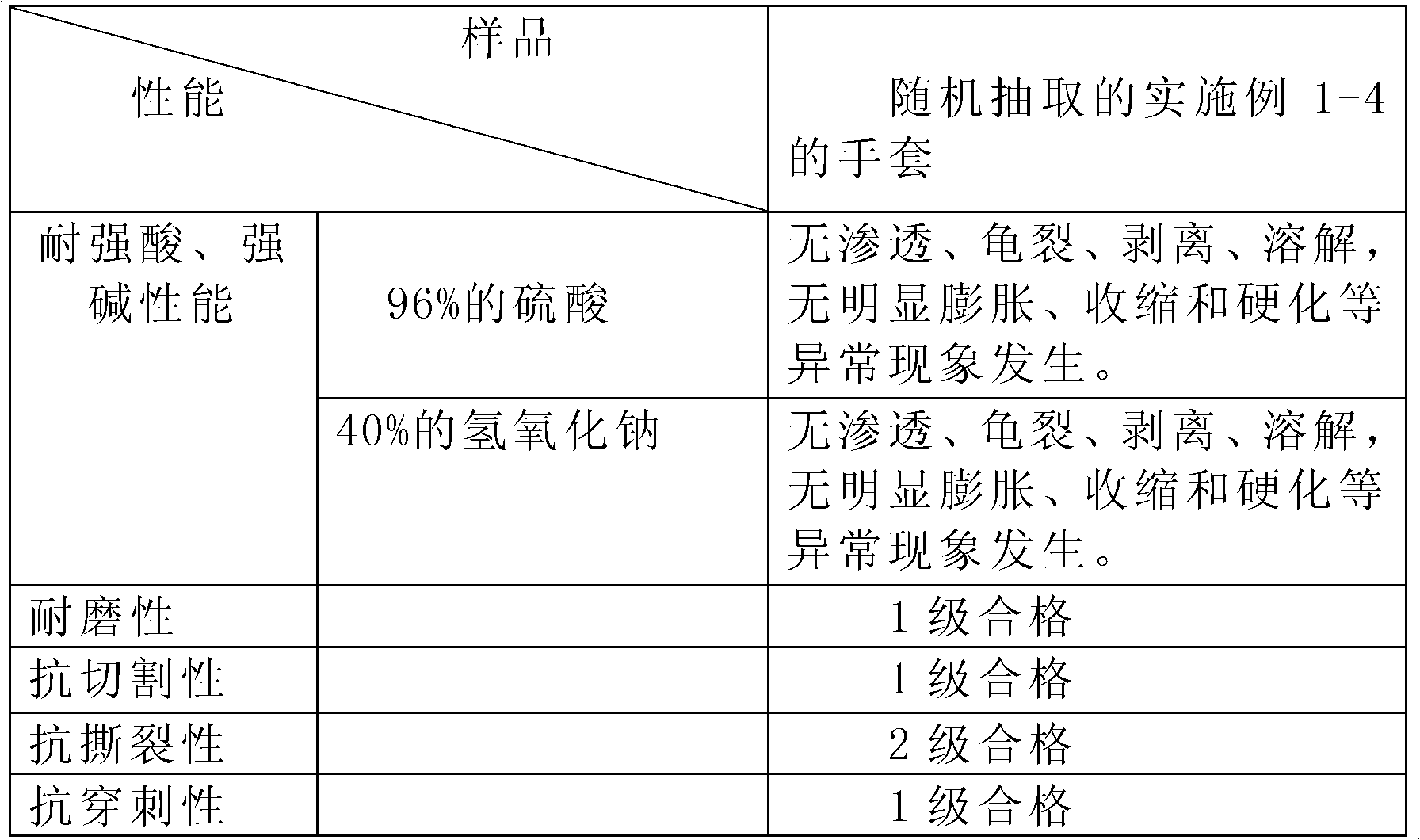

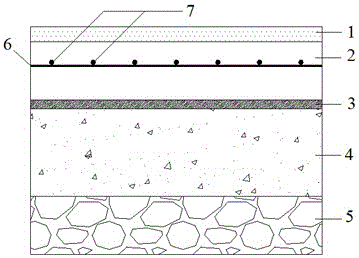

Cement concrete pavement structure provided with continuous steel bars

ActiveCN104988823AReduce maintenance and repair costsGood driving comfortPaving reinforcementsIn situ pavingsRoller-compacted concreteCrushed stone

The invention discloses a cement concrete pavement structure provided with continuous steel bars. The pavement structure comprises a base layer. Roller compacted concrete is adopted in the base layer. A broken stone hardcore is laid below the base layer. Cement concrete surface layers are laid on the base layer. The cement concrete surface layers include the upper surface layer and the lower surface layer. Rubber cement concrete is adopted in the upper surface layer. A transverse induction kerf is arranged on the edge of the upper surface layer on the left side of the driving direction. The continuous transverse steel bars, the continuous longitudinal steel bars and a slidable support are arranged at the portion, within the range of a carriageway and one half of the width (L) of a hardened verge, of the lower surface layer. Plain concrete is formed at the portion, within the other half of the width (L) of the hardened verge, of the lower surface layer. A longitudinal joint is arranged at the portion one half of the width of the hardened verge. A bituminous concrete anti-scouring layer is arranged between the base layer and the surface layers. The pavement structure can solve the problems of existing cement concrete pavements and continuous reinforced concrete pavement structures and can be widely applied to high-grade highways, tunnel pavements and the like on the heavy-duty traffic condition.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

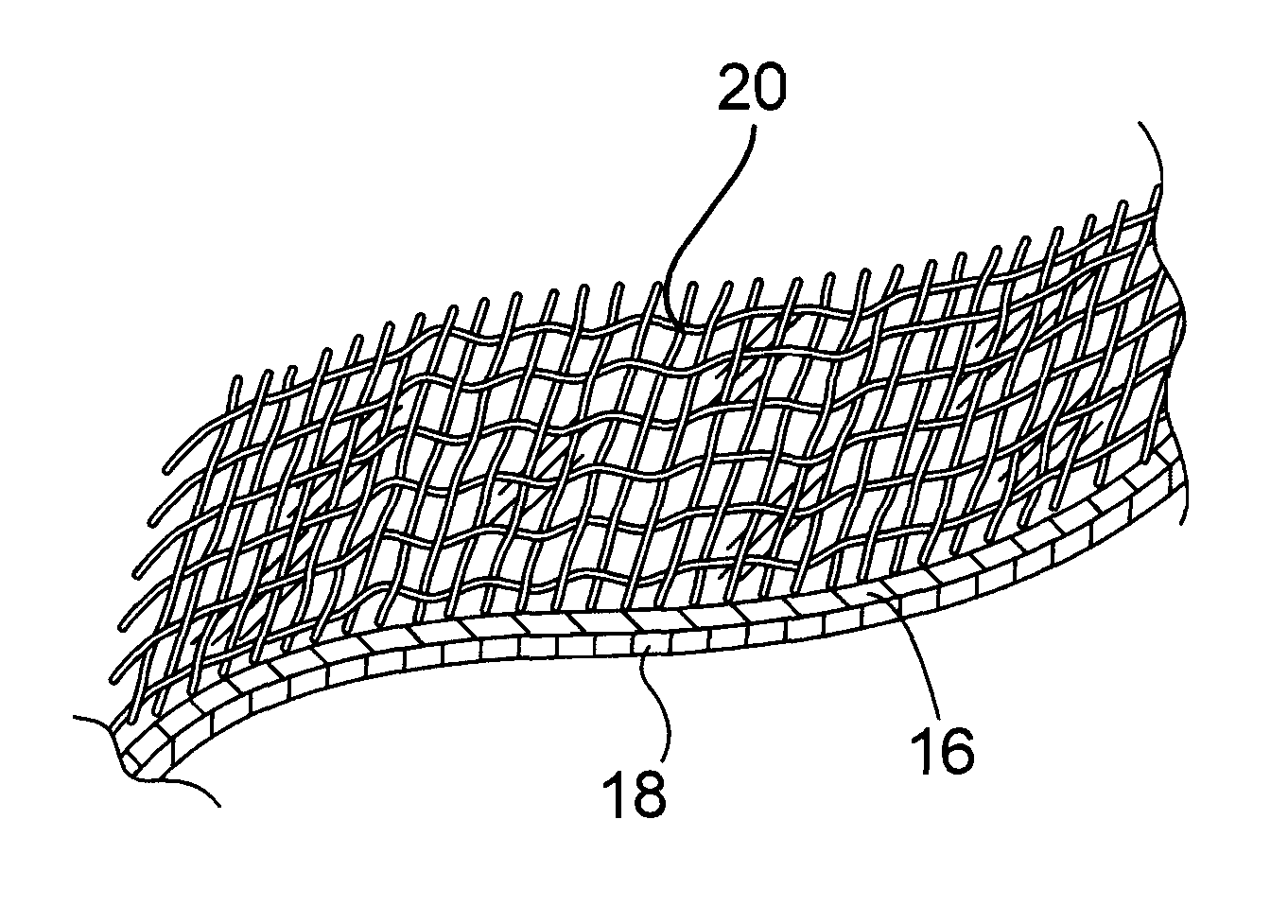

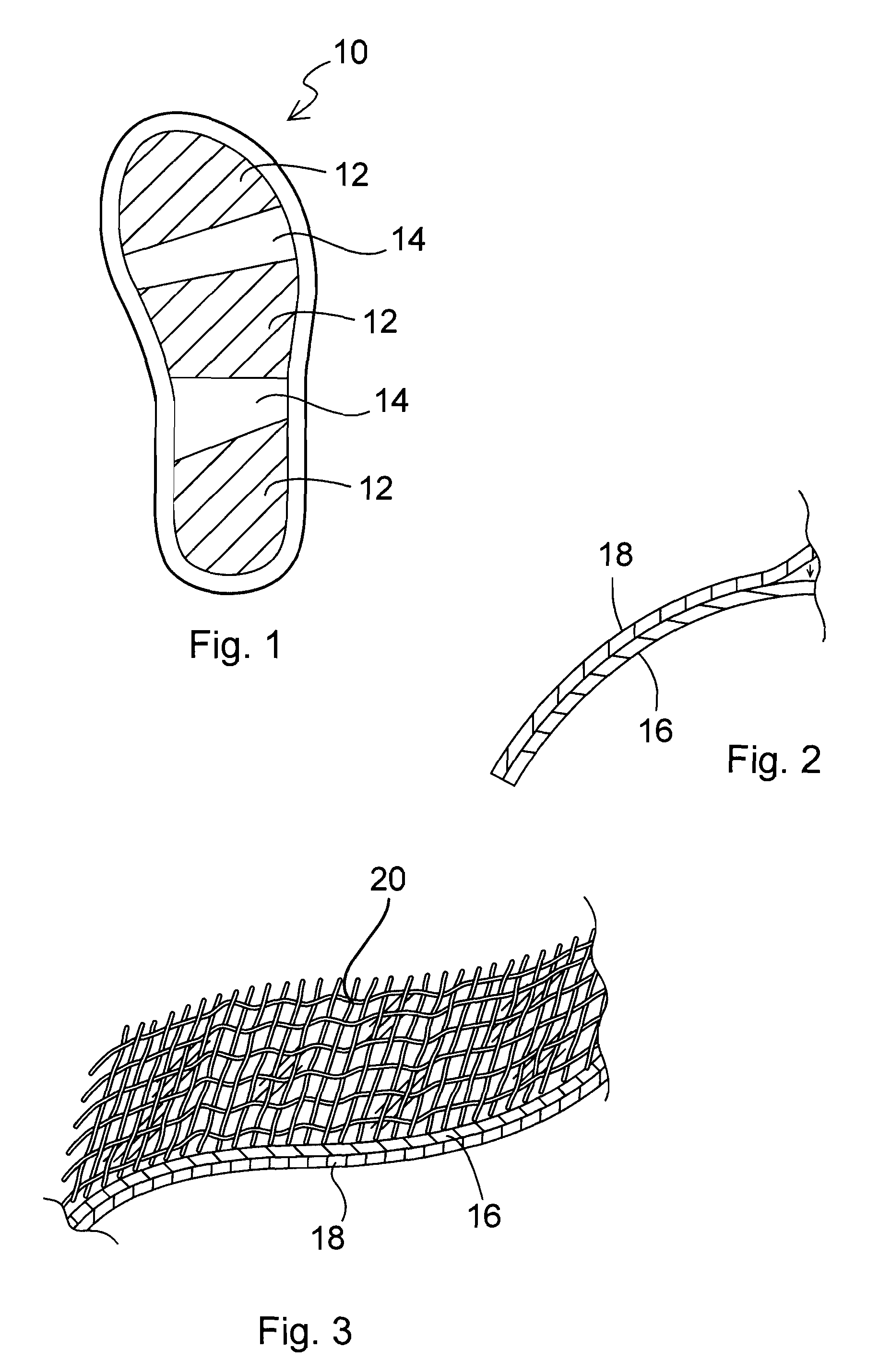

Fabric-earing outsoles, shoes bearing such outsoles and related methods

A method for making a shoe outsole comprises placing rubber against a coating of cured rubber cement on a segment of fabric, heating the rubber to a temperature below the melting points of the cured rubber cement and the rubber, but high enough to render the cured rubber cement and the rubber tackily adherent to each other and vulcanizing the rubber, thereby to adhere the segment of fabric to the rubber, and cooling the vulcanized rubber to form an outsole having an exposed ground-contacting surface that includes the segment of fabric.

Owner:CALSON INVESTMENT

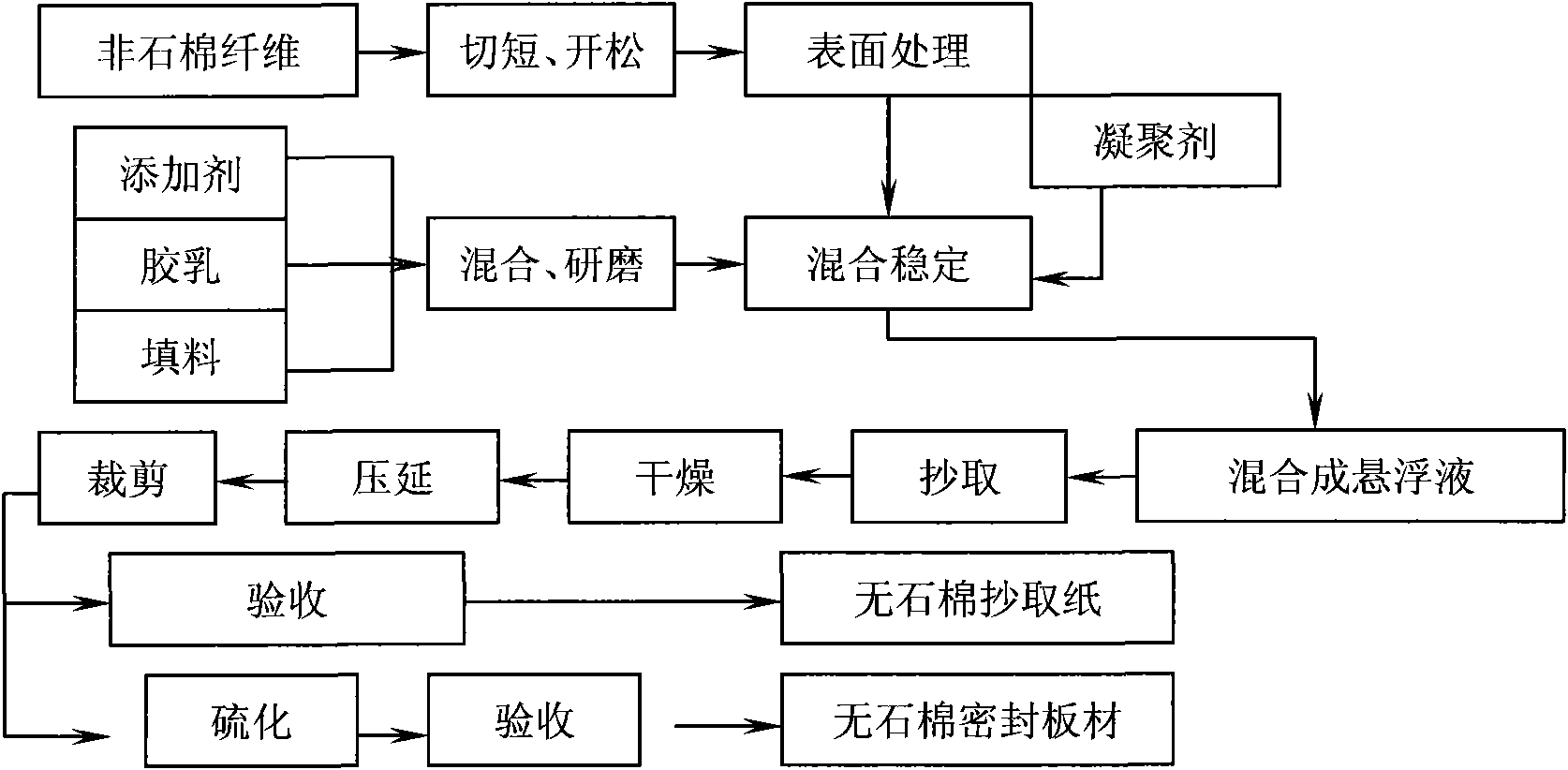

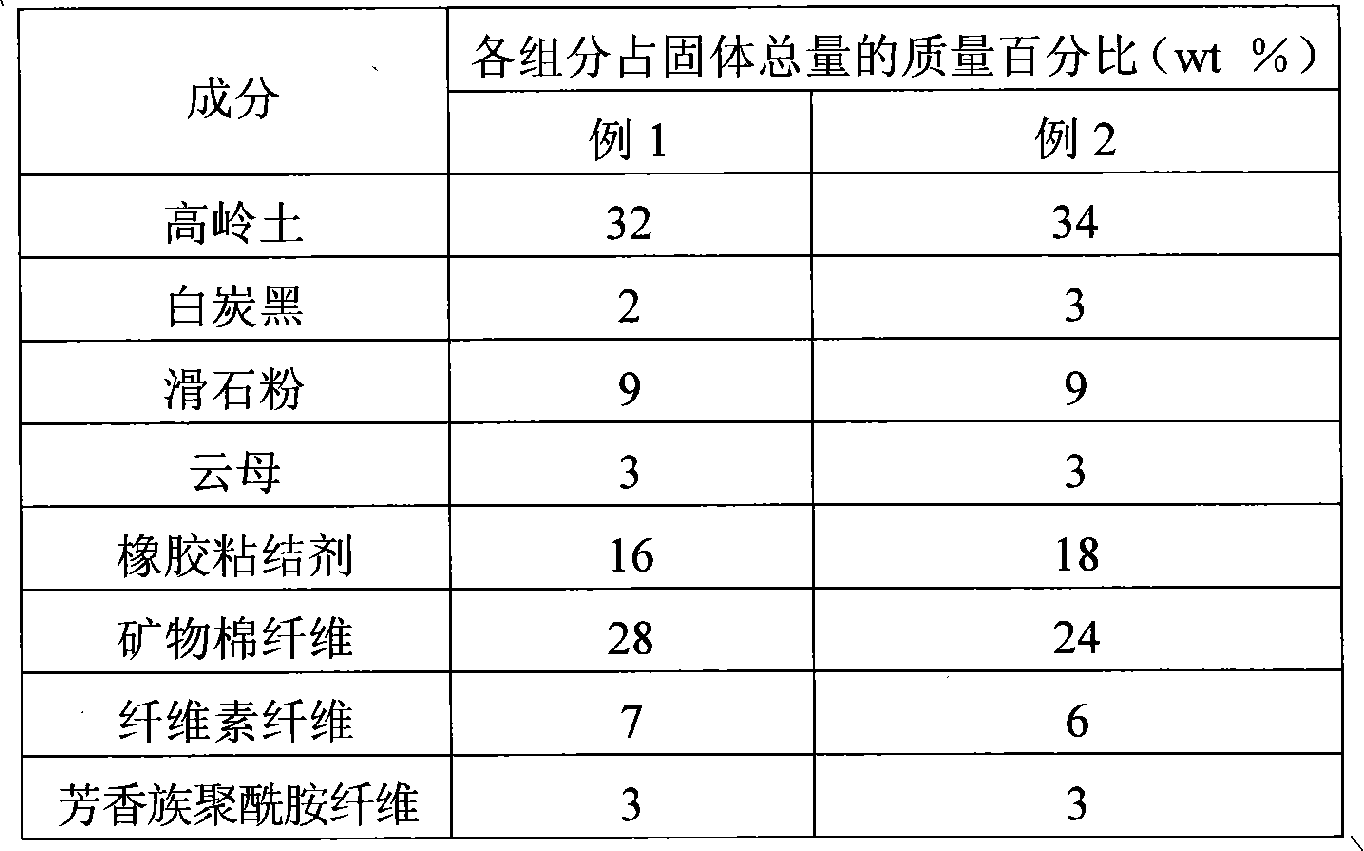

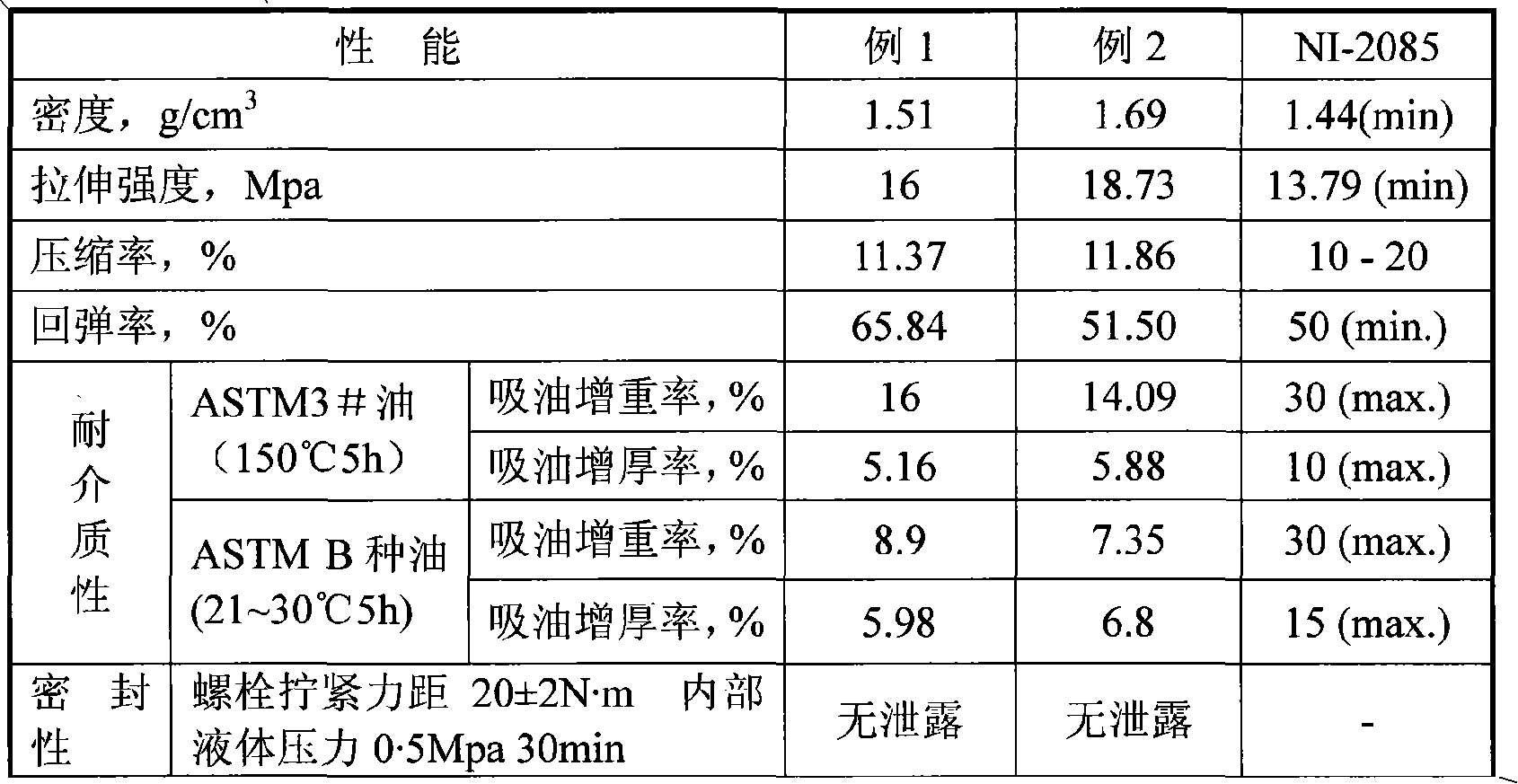

Method for preparing copy sheet used for sealing gasket

InactiveCN101575829AReasonable choiceNo pollution in the processFibreboardInorganic fibres/flakesAsbestos sheetVulcanization

The invention relates to a method for manufacturing a sealing gasket, in particular to a method for preparing a copy sheet used for a sealing gasket which does not contain asbestos fiber, belonging to the field of sealing materials. The copy sheet contains the main components of mineral cotton fiber, cellulose fiber, aromatic polyamide fiber, rubber cement and kaoline; the components are mixed to a dispersed system containing water, then a paper-making technique is adopted to dehydrate gradually and form a layer, and a finished product of the copy sheet is manufactured by compression, drying and vulcanization. The sealing gasket manufactured by the sheet has tensile strength, compression resilience performance, medium resistance and sealing performance and the like equivalent to that of the copying asbestos sealing gasket and can completely replace asbestos sheets for manufacturing the sealing materials of the gasket and the like.

Owner:KUNMING UNIV OF SCI & TECH +1

Automobile shock-reducing rubber spring and preparation process thereof

The invention discloses an automobile shock-reducing rubber spring and a preparation process thereof, and relates to the technical field of production of automobile rubber. The automobile shock-reducing rubber spring comprises the following components in parts by weight: 100Phr of natural rubber, 3-7Phr of zinc oxide, 0.5-3.5Phr of an anti-aging agent RD, 2-5Phr of an anti-aging agent 4010NA, 1-3Phr of a dispersant, 1-3Phr of stearic acid, 35-50Phr of carbon black, 2-5Phr of an accelerant, 7-13Phr of paraffin, 4-9Phr of aromatic hydrocarbon oil, 1-3Phr of sulfur S8 and 2-5Phr of a coupling agent. The invention also discloses a preparation process of the automobile shock-reducing rubber spring, and the preparation process comprises twelve process steps of plastifying, standing, mixing, slice discharging, strip cutting, metal frame treatment, surface treatment, rubber cement spraying, vulcanization, trimming, checking and warehousing. The rubber spring produced by the method disclosed by the invention is excellent in mechanical property, good in fatigue resistance and shock-reducing property, wide in material source and low in preparation cost.

Owner:ANHUI WEIWEI RUBBER PARTS GRP

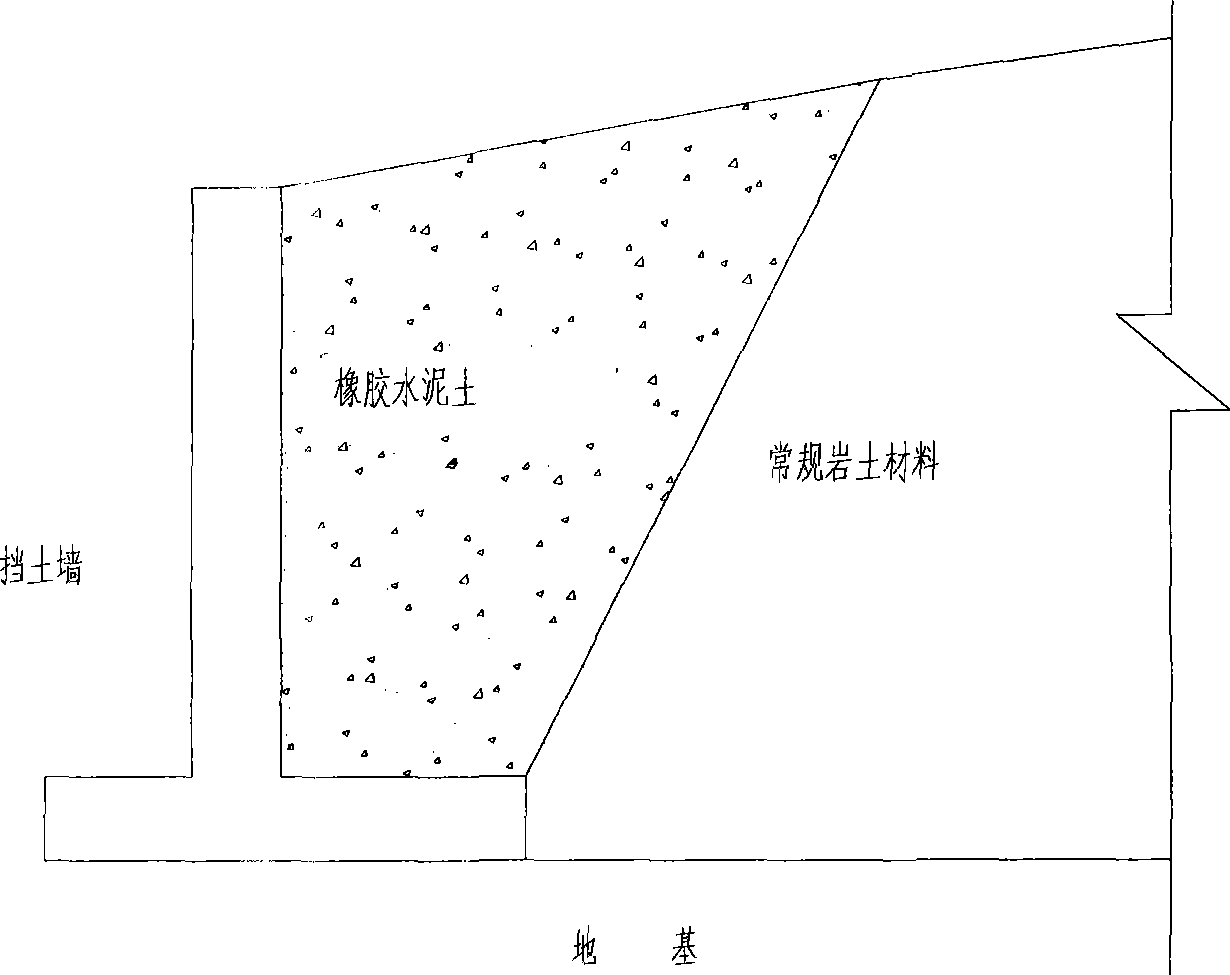

Rubber cement soil and preparation method thereof

InactiveCN101519293AImprove recycling ratesReduce pollutionSolid waste managementWaste rubberRubber solvent

The invention relates to rubber cement soil which is prepared from waste rubber granules, cement, water and sand with the weight percent of 1 to 2.5:1:0.3 to 0.5:0 to 1. The granule sizes of the waste rubber granules are from 0.1 mm to 10 mm. The rubber cement soil is applied to the filed of geotechnical engineering by researching the property of the waste rubber, effectively solves the problem that the waste rubber pollutes the environment, and provides a new way for processing the waste rubber. The invention also discloses the preparation method of the rubber cement soil.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

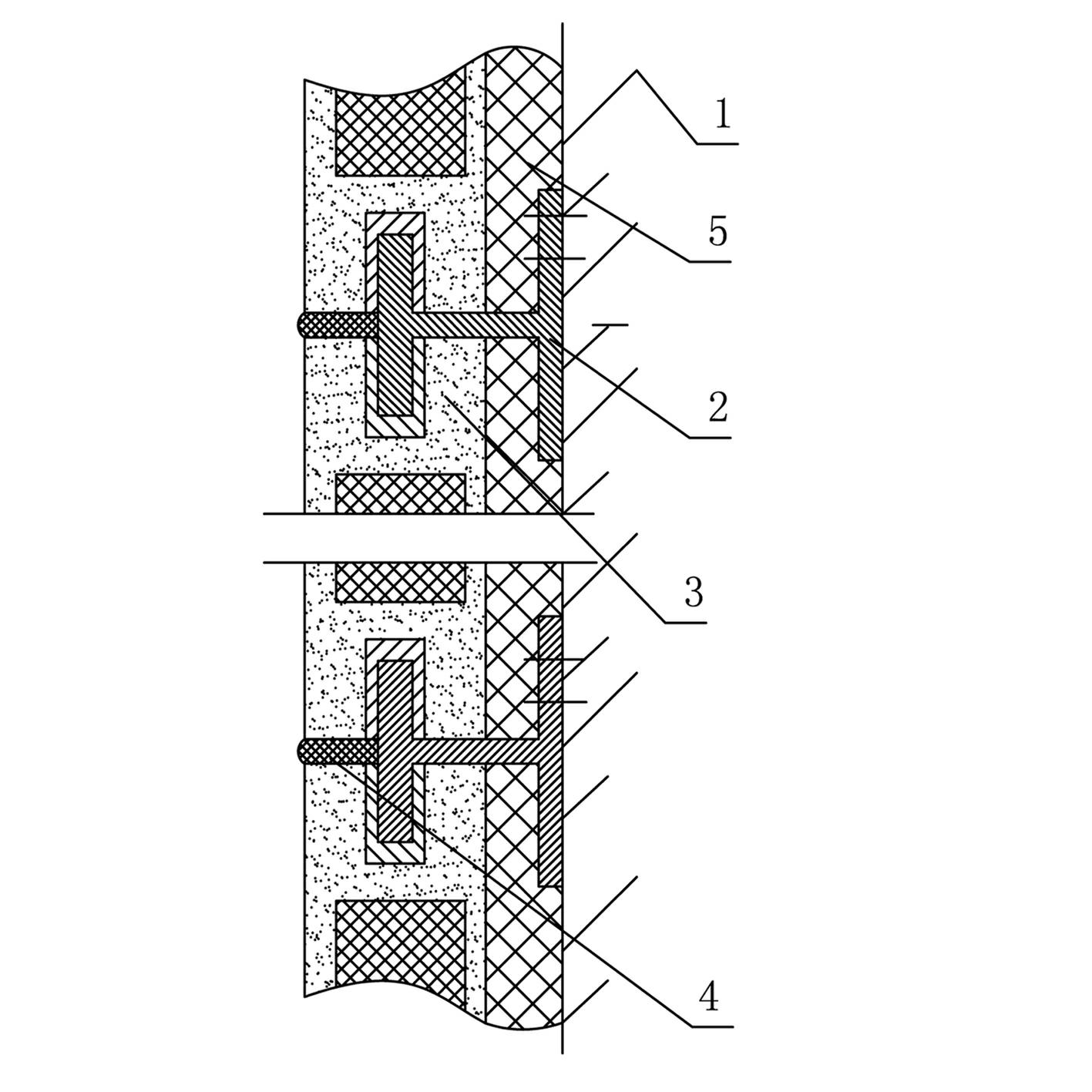

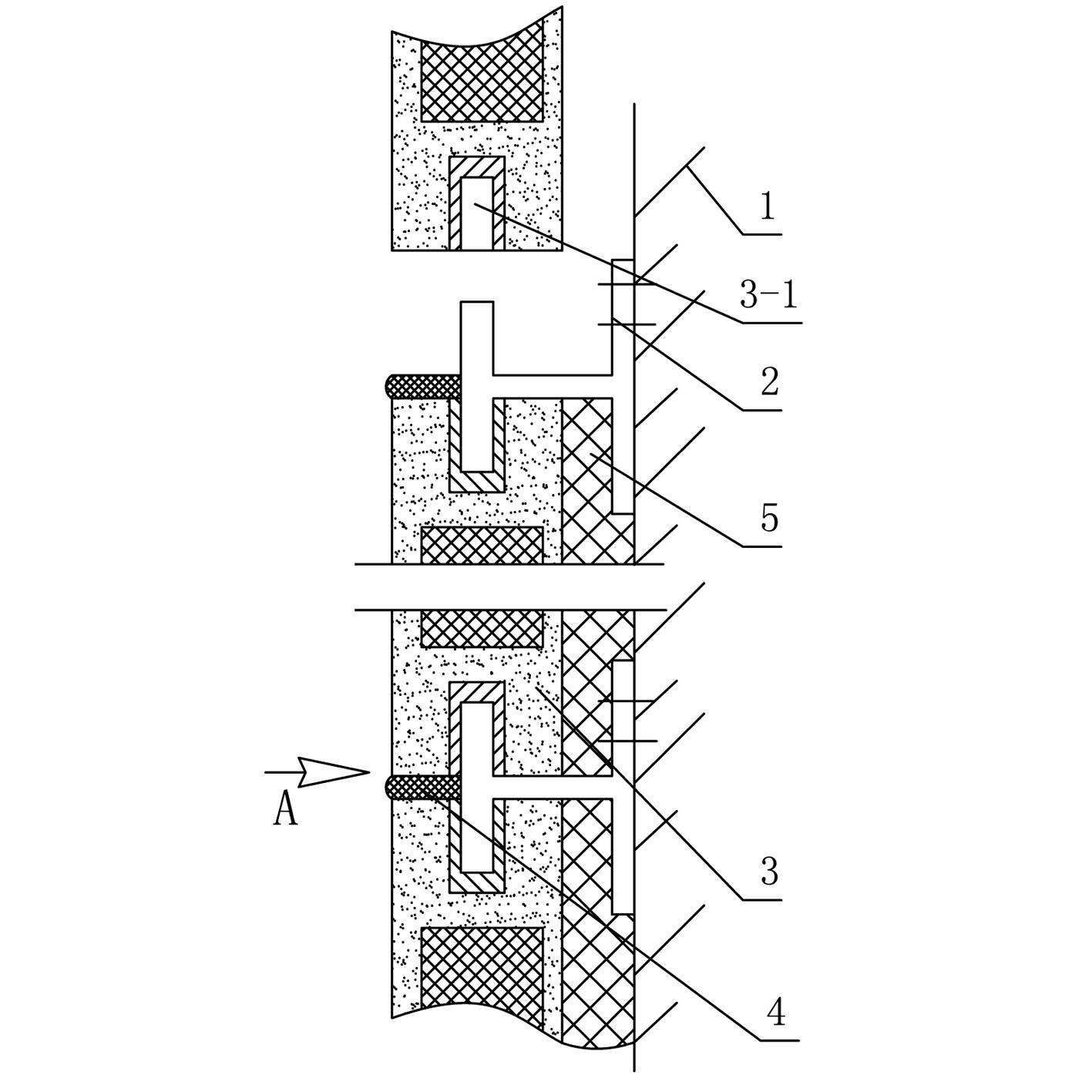

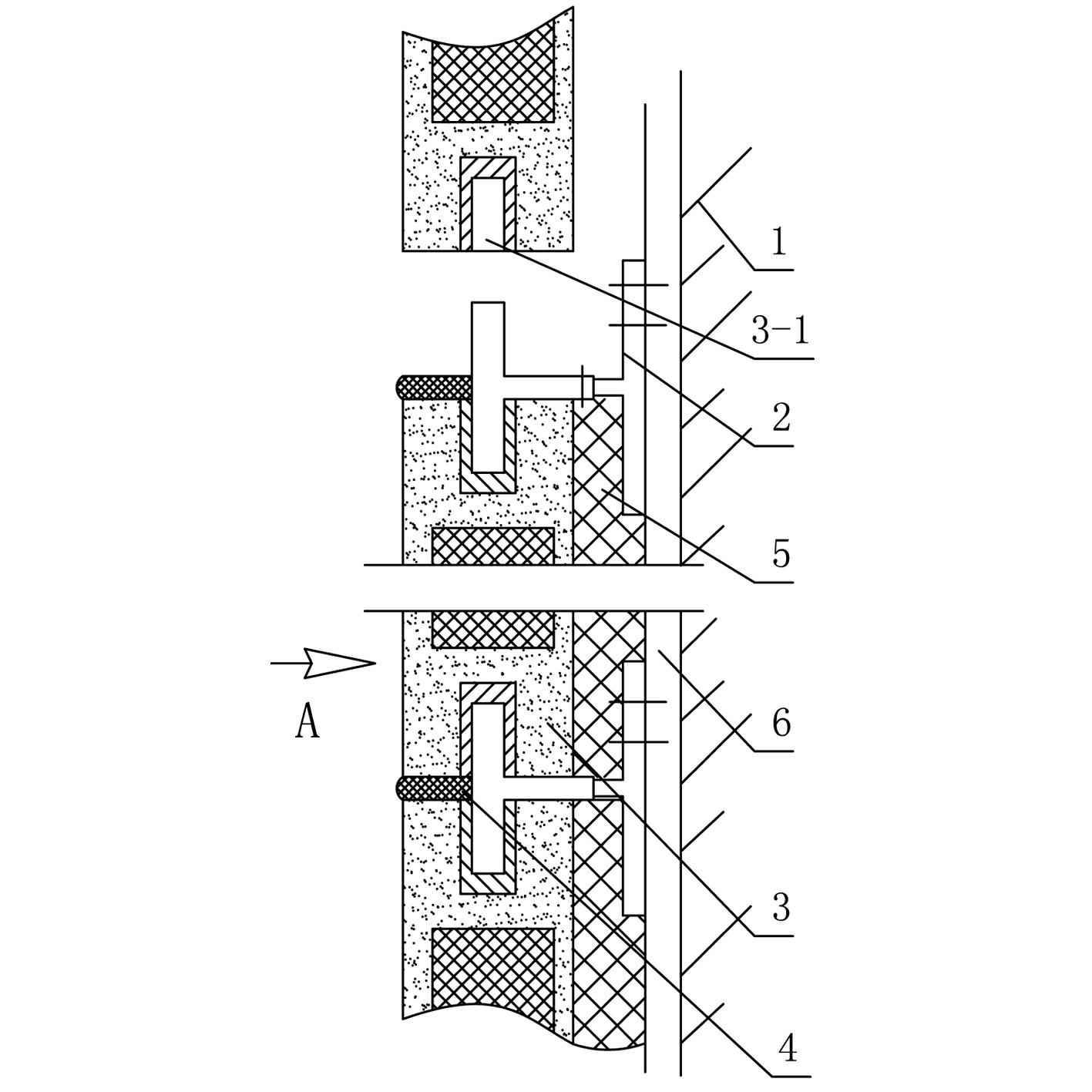

Fixed mounting method for integrated decorative and heat-preservation board of exterior wall of building and fixed support connecting seat for fixed mounting method

The invention discloses a fixed mounting method for an integrated decorative and heat-preservation board of an exterior wall of a building and a fixed support connecting seat for the fixed mounting method. The problem about the mounting of an integrated heat-preservation board is solved. The fixed mounting method comprises the following steps of: (1) arranging the fixed support connecting seats on the exterior wall; (2) regulating a distance and perpendicularity between each fixed support connecting seat and the exterior wall of the building; (3) inserting connecting clamping grooves on the integrated decorative and heat-preservation boards into clamping pin plates of the fixed support connecting seats (2); (4) filling a sealant between the contact surfaces of adjacent integrated decorative and heat-preservation boards; and (5) after the mounting of the integrated decorative and heat-preservation boards on the same horizontal plane is finished, pouring heat-preservation rubber cement into spaces formed by the integrated decorative and heat-preservation boards and the exterior wall of the building to bond the integrated decorative and heat-preservation boards and the exterior wall of the building into a whole. The fixed support connecting seat comprises a clamping pin plate, a fixed bottom plate and a connecting plate, wherein the clamping pin plate and the fixed bottom plate are arranged in parallel, and are connected into a transverse H shape through the connecting plate. The fixed mounting method and the fixed support connecting seat have the beneficial effects of low mounting cost, convenience for construction, connection firmness and applicability to various wall surfaces.

Owner:曲金丽 +1

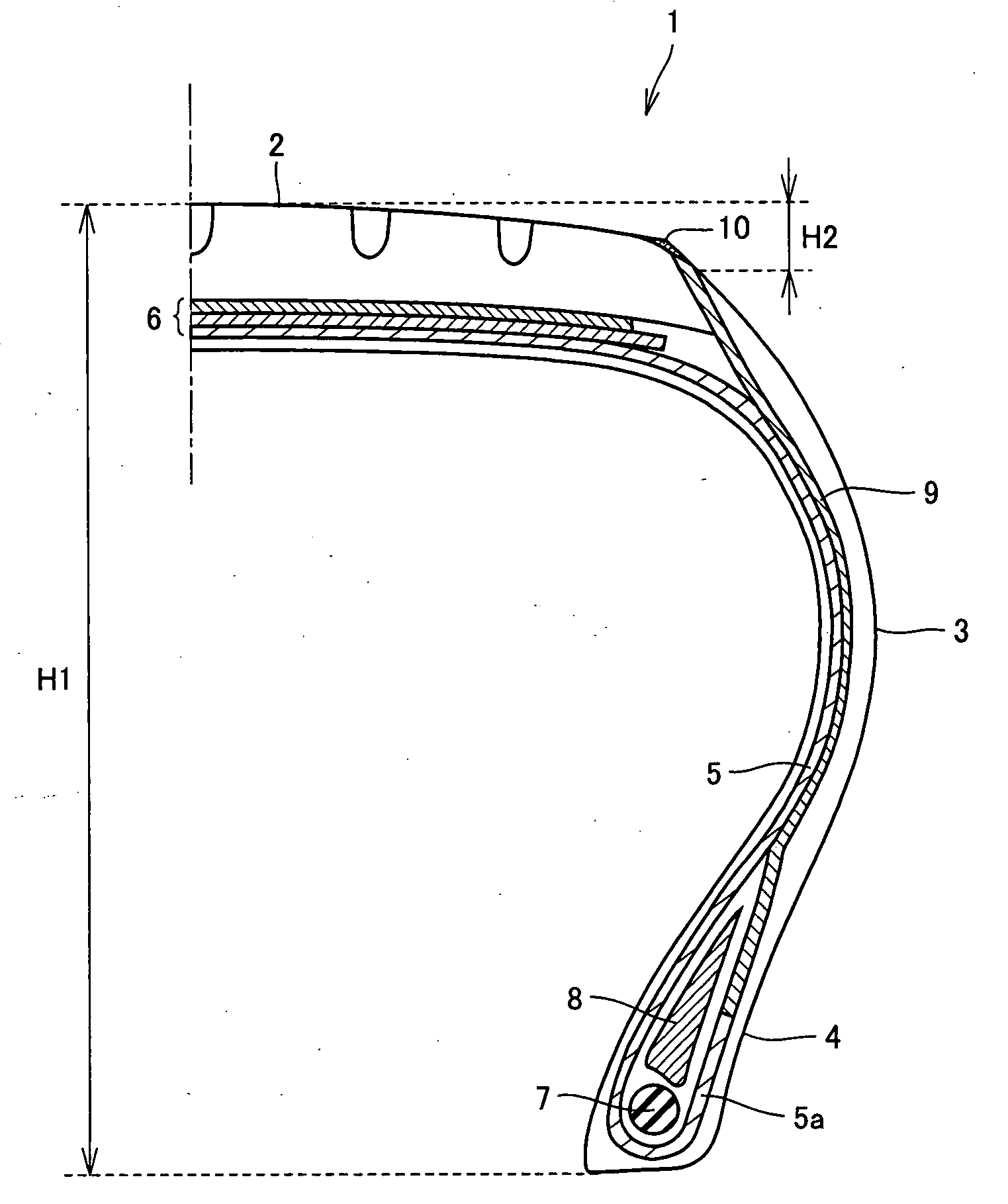

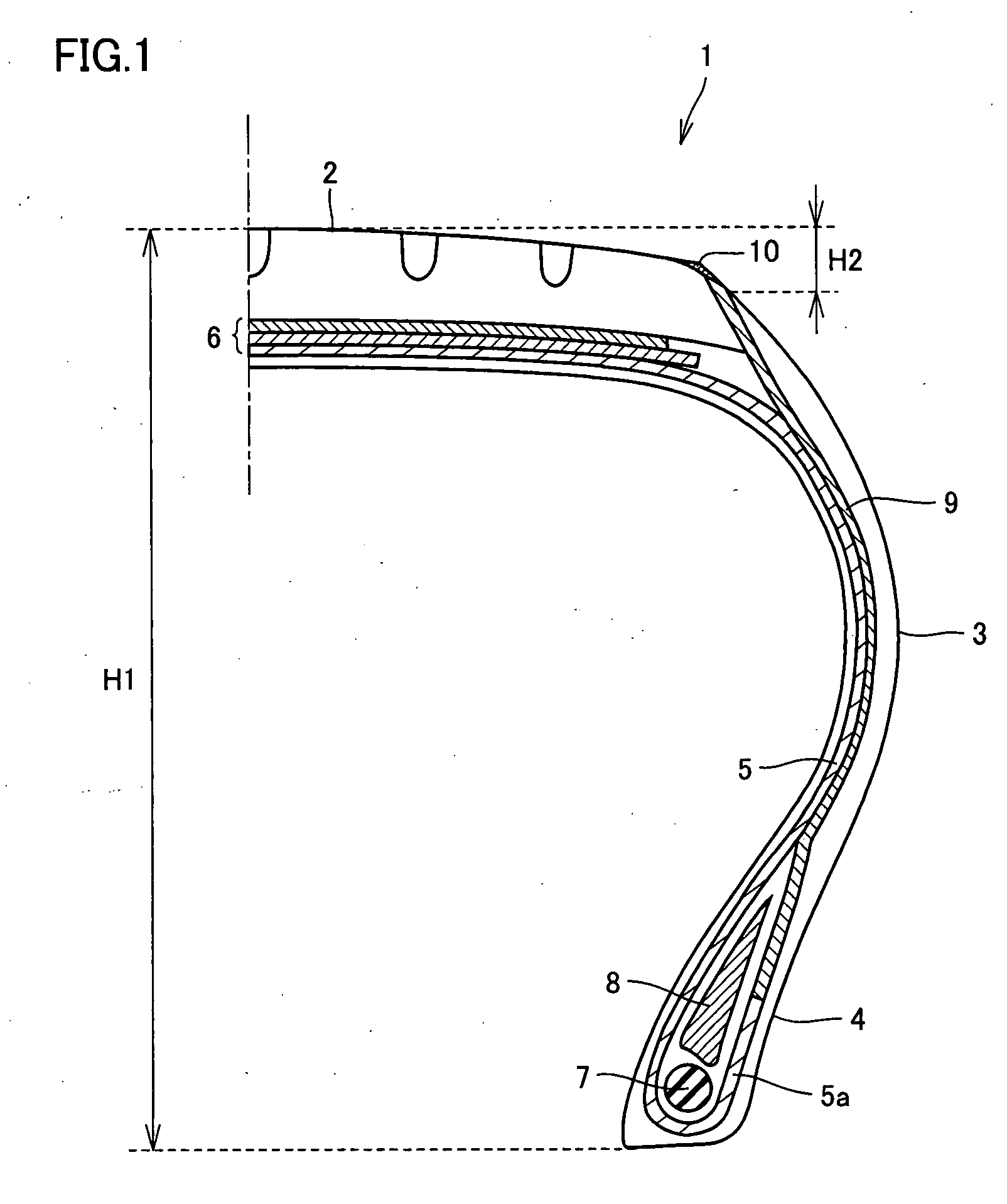

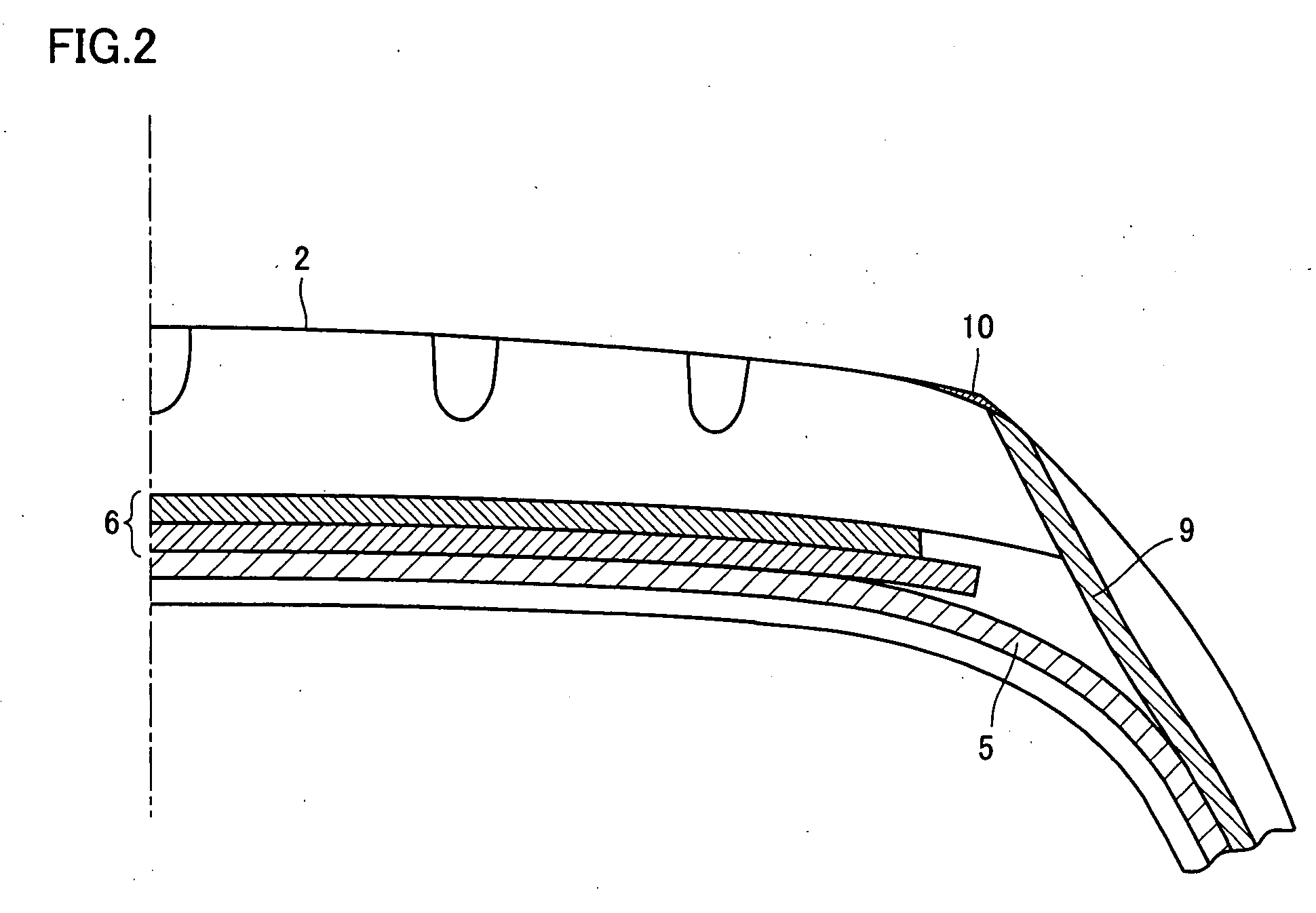

Pneumatic tire

InactiveUS20070227636A1Generates staticImprove securitySpecial tyresTyre tread bands/patternsEngineeringRoad surface

A pneumatic tire is equipped with at least a tread part, a sidewall part, a bead part, and a carcass extending from tread part through sidewall part to bead part, and provided with a breaker part on the outside of carcass in the radial direction of the tire. The volume resistivity of each of a tread rubber, a sidewall rubber, a breaker rubber, and a carcass rubber formed in the tread part, the sidewall part, the breaker part, and the carcass respectively is set to 1×1012 Ω·cm or more. A conductive layer having volume resistivity of 1×1011 Ω·cm or less is provided between a carcass ply constituting the carcass and the sidewall rubber and has an exposed part to the tire surface. A rubber cement layer contacting with at least a part of the exposed part of the conductive layer and at least a part of the region that becomes a grounding surface in the tread part to the road surface is provided.

Owner:SUMITOMO RUBBER IND LTD

Rubber cement for static balance patching of aircraft tire

ActiveCN103289596AHigh tensile strengthHigh tear strengthNatural rubber adhesivesNon-macromolecular adhesive additivesAdhesiveMechanical engineering

The invention discloses a rubber cement for the static balance patching of an aircraft tire. The rubber cement comprises a main material natural rubber, and main auxiliary materials comprising styrene butadiene rubber, an adhesive SL-3090, an adhesive A, a high-dispersivity white carbon black, a silane coupling agent, high-wear-resistance carbon black, an antioxidant BLE, a tackifying resin TKM-M, insoluble sulfur, a sulfonamide promoter and a thiuram promoter. The rubber cement is prepared through mixing by an open mixing machine or a closed mixing machine to prepare a gross rubber, and mixing the gross rubber with a solution gasoline according to a weight ratio of 1:2-5. The adhesive strength between a static balance patch using the rubber cement and the tire liner of the tire is high, so the shedding of the static balance patch is difficult during the use of the tire. The rubber cement has the advantages of high tensile strength and tear tensile, good thermal ageing resistance, fast vulcanization speed, no use of toxic materials comprising polyisocyanate or toluene, and protection of the health of operators.

Owner:中国化工集团曙光橡胶工业研究设计院有限公司

Processing method for waste old rubber powder used for cement-based material

ActiveCN103819109AHigh bonding strengthHigh densitySolid waste managementPolymer scienceWaste rubber

The invention discloses a processing method for waste old rubber powder used for a cement-based material. The processing method comprises the following steps: mixing an inert inorganic powder material with waste rubber particles, and then embedding the inert inorganic powder material into the waste rubber powder through a physical method. In this processing method, the inert organic material and the rubber particles can be mixed in any ratio according to the needs, moreover, the inert organic powder material is embedded into the rubber powder through a physical method, thus the adhering strength between the rubber cement-based powder and the cement slurry is prominently increased, at the same time the density of the rubber cement-based powder is also increased, and thus the rubber cement-based powder can be evenly distributed in the concrete.

Owner:SICHUAN GOLDMILL ENVIRONMENTAL PROTECTION NEW MATERIALS

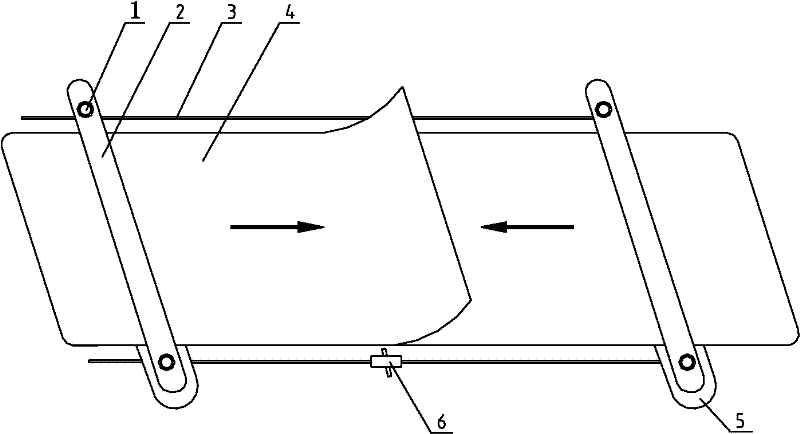

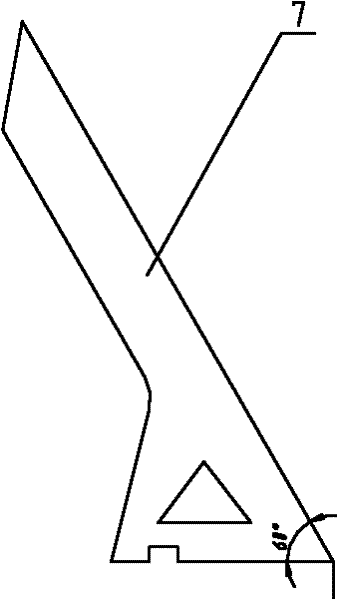

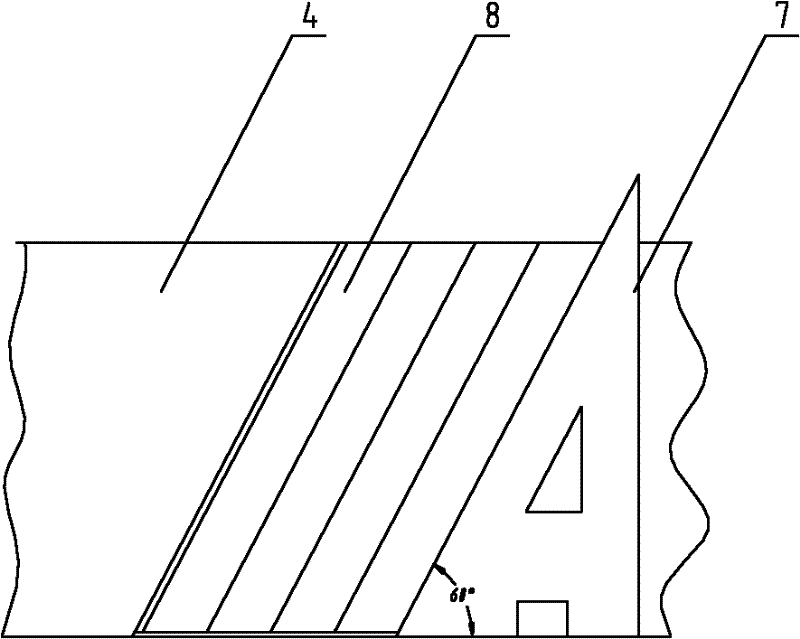

Vulcanization bonding process by template method for conveying belt

The invention relates to a vulcanization bonding process by a template method for conveying belts, which comprises: cutting a cloth layer and a glue layer of a belt joint part into symmetric gradient according to a certain form and angle, smearing rubber cement for bonding, then heating for a certain time to perform a vulcanization reaction at a certain pressure and temperature so as to allow rawrubber to become vulcanized rubber and provide the joint with optimal bonding strength. The invention introduces a bold innovation based on the original thermal bonding process, establishes a new process of lineation cutting and peeling for vulcanization bonding template; the process greatly shortens the bonding time; the new cutting and bonding process for the vulcanization bonding template method is safe, simple and rapid, saves human and material resources, improves working efficiency, increases the quality by 15-20%, and fills a gap in belt vulcanization bonding technology.

Owner:TIANJIN JINBIN PETROCHEM EQUIP

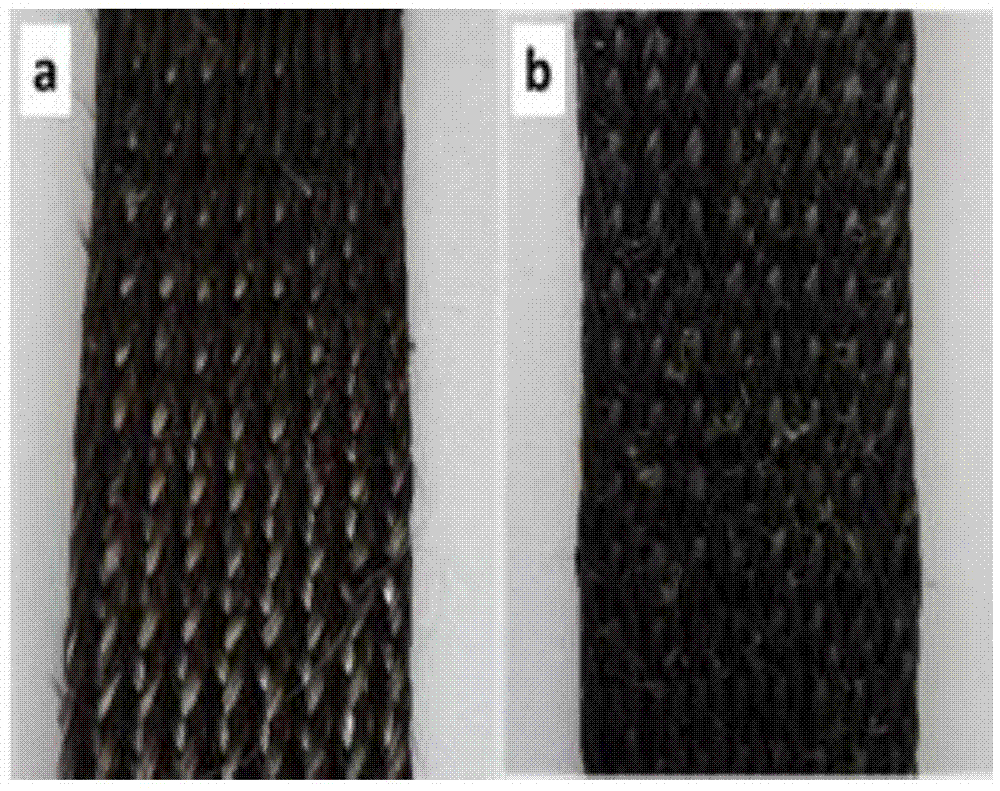

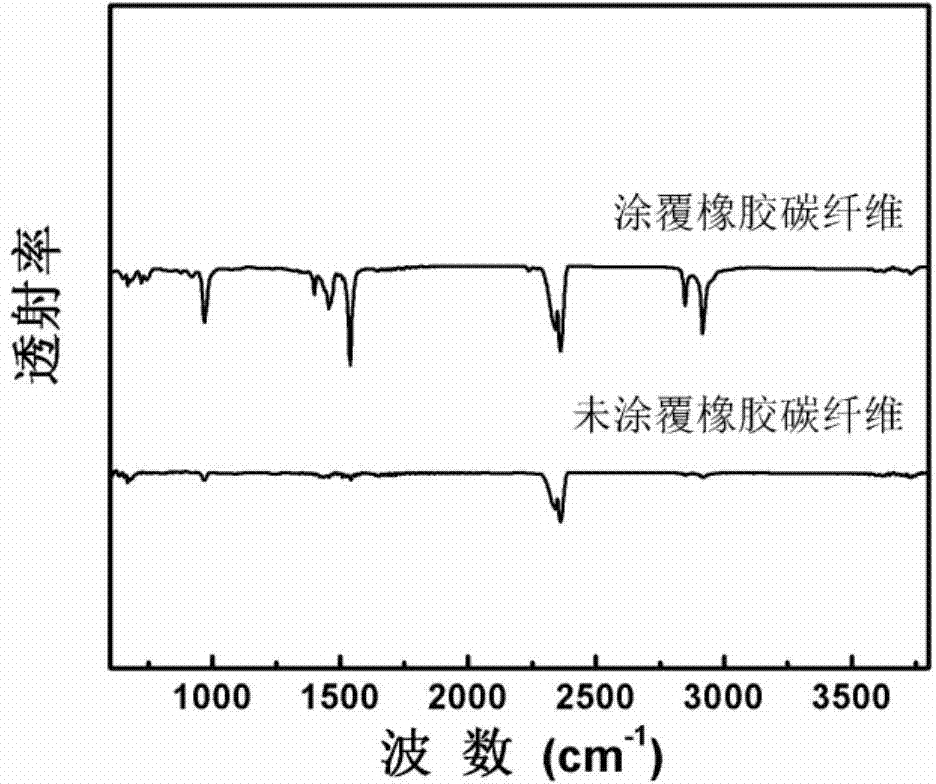

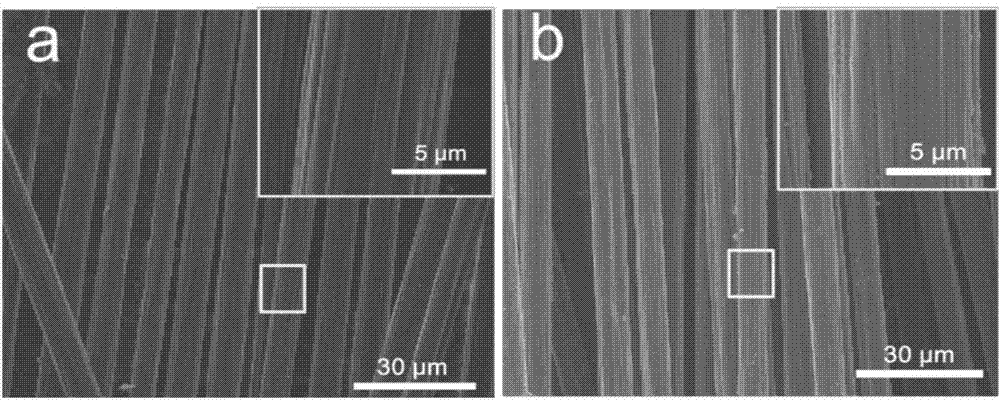

Preparation method of three-dimensional woven rubber coating carbon-fiber-reinforced composite material

The invention provides a preparation method of a three-dimensional woven rubber coating carbon-fiber-reinforced composite material, which comprises the following steps: preparing filler mixed powder; preparing a filler mixed solution; preparing an unvulcanized nitrile-butadiene rubber mixed solution; preparing nitrile-butadiene rubber mixed rubber cement; taking the dissolved unvulcanized nitrile-butadiene rubber mixed solution, and pouring the filler mixed solution while stirring; sequentially adding plasticizers DOA and DOS to obtain yellow viscous nitrile-butadiene rubber mixed rubber cement; preparing a rubber coating carbon fiber fabric; and preparing a damping composite material. The behaviors of the fiber-rubber interface and rubber-base interface are adjusted to implement the organic connection between the fiber and base, thereby obtaining the three-dimensional woven composite material with excellent damping characteristic.

Owner:TIANJIN UNIV

Rubber cement for improving printing rubbing color fastness and dryness and preparation method thereof

ActiveCN102505527ASolve the disadvantage of hard feelingImprove printing effectDyeing processCross-linkPolymer science

The invention discloses rubber cement for improving printing rubbing color fastness and dryness. The rubber cement comprises the following raw materials in part by weight: 50 to 80 parts of acrylate emulsion, 5 to 20 parts of biomass white solid powder, 0.5 to 1 part of dispersing agent, 5 to 10 parts of emulsifying wax solution, 0.5 to 1 part of thickener and 10 to 25 parts of purified water. The rubber cement is high in printing performance, rubbing color fastness and dryness, and overcomes the defect that a color fixing agent or a cross-linking agent is needed to be used in the traditionalprinting process, raw materials are readily available and moderate in cost, and the production cost of a printing coating is reduced. The invention also discloses a preparation method for the rubber cement. The method is simple, low in cost, environment-friendly and safe.

Owner:DONGGUAN CTL NEW MATERIAL TECH

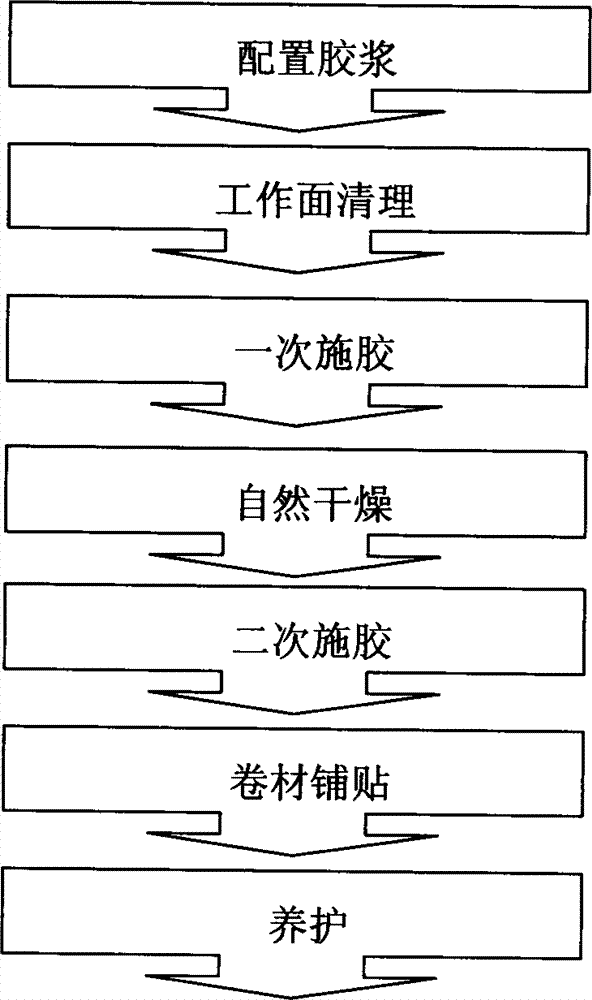

Polyethylene dacron coiled material-cementitious capillary crystalline waterproofing construction method

InactiveCN103924782AReduce constraintsImprove structural strengthBuilding material handlingBuilding insulationsExtensibilitySurface layer

Disclosed is a polyethylene dacron coiled material-cementitious capillary crystalline waterproofing construction method. Applied materials include polymer rubber powders, common silicate 42.5 cement, cementitious capillary crystalline waterproofing coatings, polyethylene dacron water-proof coiled materials, early strength antifreezing agents and water. The construction method includes rubber cement preparing, working face cleaning, primary cementing, natural drying, secondary cementing, coiled material paving and maintaining. Advantageous performances of the polyethylene dacron coiled materials and the cementitious capillary crystalline waterproofing coatings are combined, most of upstream face water or other fluids can be baffled, cementing materials meet water to form a crystalline rigid water-proof layer, and the comprehensive water-proof effect can reach an extra high level. The polyethylene dacron coiled material-cementitious capillary crystalline waterproofing construction method has the advantages that the structural strength is high, the surface layer extensibility is good, the service life is long, the water-proof performance is good, the construction is convenient, rapid and simple, the method is suitable for being massively popularized and applied, limit of operating environment is small, resistance to high temperature and low temperature can be achieved, and the water-proof effect is quite good.

Owner:YONGSHENG CONSTR GRP

Interface finishing agent improving rubber-cement stone substrate in rubber concrete

InactiveCN101182157ANo adverse effects on workabilityImprove interfacial bond strengthSolid waste managementPolymer scienceCarvacryl acetate

The invention relates to an interface treatment agent for improving the rubber-cement matrix in rubber concrete, which belongs to the technical field of concrete admixtures. At present, the interface treatment agents for improving the rubber particle-cement stone matrix mainly include: water washing, Na(OH) solution corrosion and carbon tetrachloride solution cleaning treatment, etc. But above-mentioned material use effect is unsatisfactory. The present invention is characterized in that it is prepared by uniformly mixing three materials: styrene-acrylic acid ester-silicon coupling agent copolymer, ethylene-vinyl acetate copolymer, and polyvinyl alcohol coupling agent (PVA). The weight percentages of each component are: styrene-acrylate-organic silicon coupling agent copolymer accounts for 40-70%, ethylene-vinyl acetate copolymer accounts for 20-40%, and PVA coupling agent accounts for 10-20%. . Compared with the rubber aggregate concrete without surface treatment, the interface agent of the present invention can effectively improve the interface bonding strength between the rubber particles and the cement stone matrix, thereby increasing the compressive strength of the rubber aggregate concrete by more than 6%. The workability of the concrete was not adversely affected.

Owner:BEIJING UNIV OF TECH

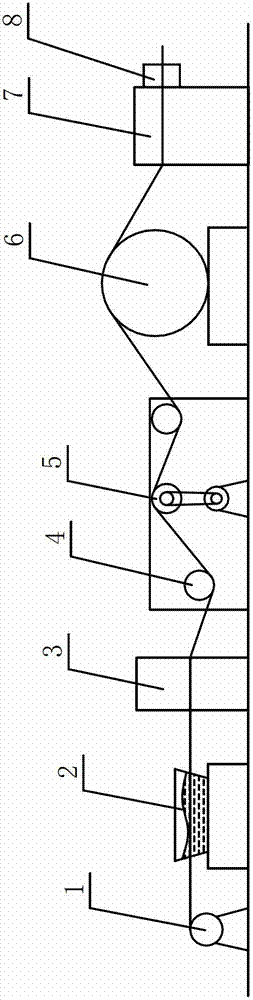

One-time forming process of belt blank of transmission V-shaped belt blank

The invention discloses a one-time forming process of a belt blank of a transmission V-shaped belt blank. The one-time forming process comprises the following steps of: 1) carrying out warp cutting and weft splicing on a film by an automatic splicing machine to form rolls, and enabling fiber to be in weft distribution in the film; 2) attaching surface rubber on a wind arranging wheel of a forming machine; 3) attaching thin skin outside the surface rubber; 4) enabling a line to penetrate through a rubber cement groove by a pay-off stand, and wind on the thin skin by a guide wheel and a traction wheel through the drying procedure; 5) attaching bottom rubber and then carrying out double-knife cutting; and 6) carrying out chamfering and cloth covering procedures and finishing one-time forming of the belt blank. The one-time forming process disclosed by the invention integrates all the procedures in the forming of the belt blank, and has the advantages of high production efficiency and reliable and stable product quality.

Owner:锐牛股份有限公司

Repairing method of local damage of steel-core rubber belt

The invention relates to a repairing method of a local damage of a steel-core rubber belt. The method is characterized by being realized through the six steps of cutting off the damaged rubber belt, polishing, spreading rubber cement, preparing a rubber repairing block, repairing the rubber belt, and sulfidizing. Compared with the prior art, the invention has the advantages that a steel-core rubber belt with 10-35 percent of broken and lost steel wire ropes and a damage with a longitudinal tearing length of 1.6-20m of a steel-core rubber belt can be repaired by using the method, and the repaired steel-core rubber belt can reach the mechanical properties of the original steel-core rubber belt and prevent secondary degumming and core breaking phenomena; the repairing time is short, and the repairing work can be finished within 7-12 hours generally; the labor intensity of maintenance workers is low, and the operation rate of equipment is high; and the influences on production are obviously reduced, and the cost is reduced.

Owner:TAIYUAN IRON & STEEL GROUP

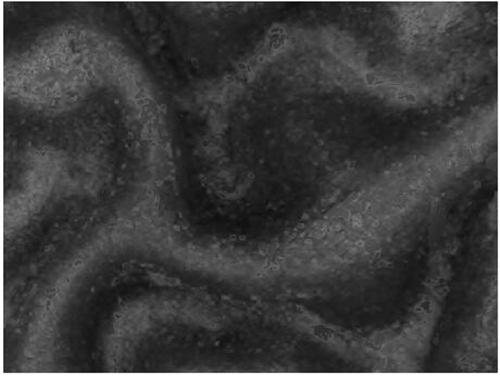

Preparation method of wear-resistant butyronitrile gloves and wrinkling liquid used therefor

The invention discloses a preparation method of wear-resistant butyronitrile gloves and wrinkling liquid used therefor. The preparation method comprises the following steps: immersing a glove blank into butyronitrile wrinkling rubber cement for gum dipping and gum homogenization, immersing the glove blank subjected to gum homogenization into the wrinkling liquid for surface treatment, and vulcanizing the glove blank subjected to surface treatment. The formula of the butyronitrile wrinkling mucilage is optimized, and particularly, the cellosilk is added into the butyronitrile wrinkling mucilage, so that wrinkle agglomeration is facilitated, and the wrinkling density is increased. According to the invention, the formula of the wrinkling liquid is optimized, and especially the phenolic resinis added, so that wrinkles formed after curing are stronger in stereoscopic impression and shorter in wrinkling time. A three-stage vulcanization process is adopted, so that the consistency and uniformity of wrinkles are further improved, and the wear resistance of the glove is improved.

Owner:山东景元记劳保用品有限公司

Adhesive for black rubber shoe topline sponges as well as preparation method and application of adhesive

InactiveCN106189926AIncrease crosslinking stressIncrease sewing speedNatural rubber adhesivesNon-macromolecular adhesive additivesPolymer scienceAdhesive

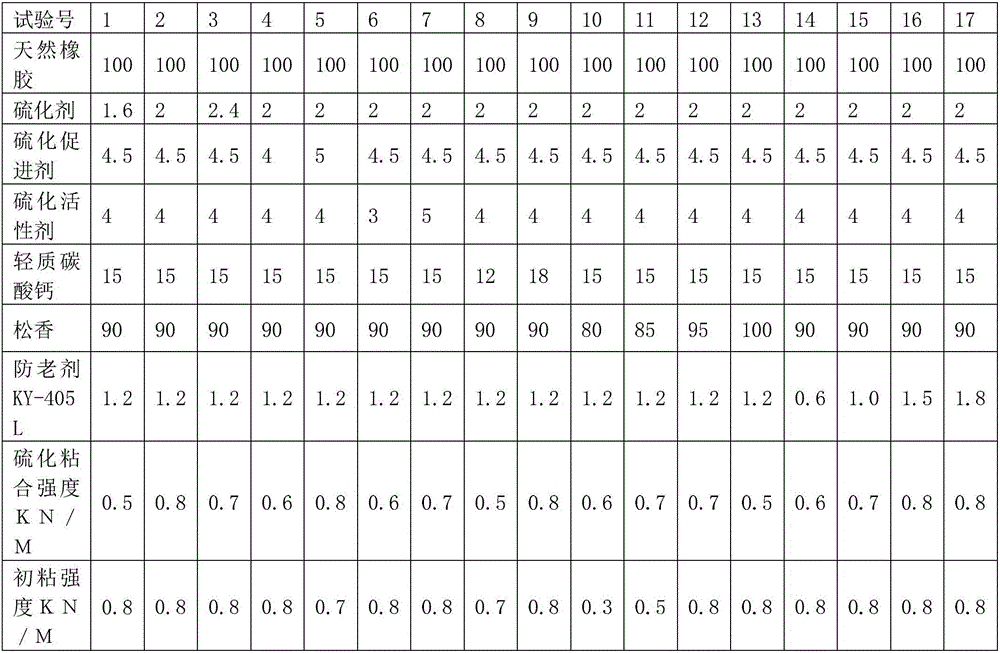

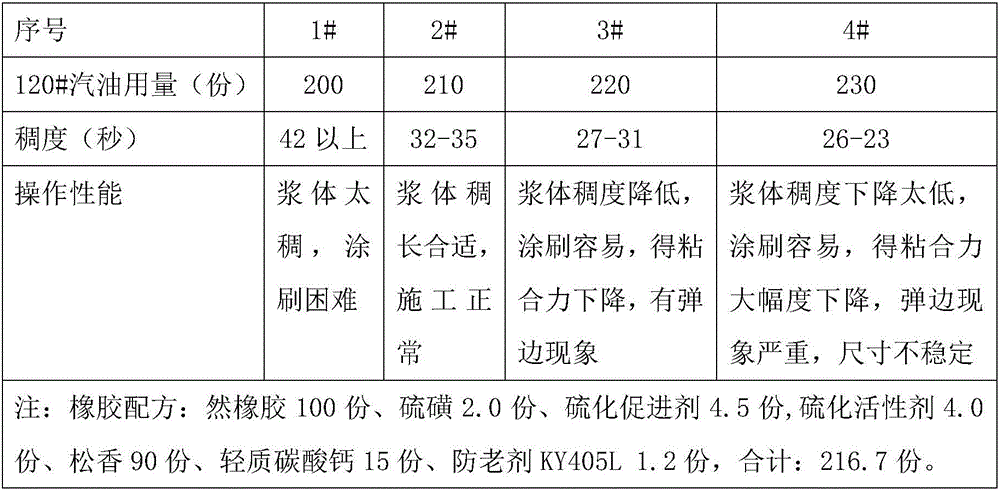

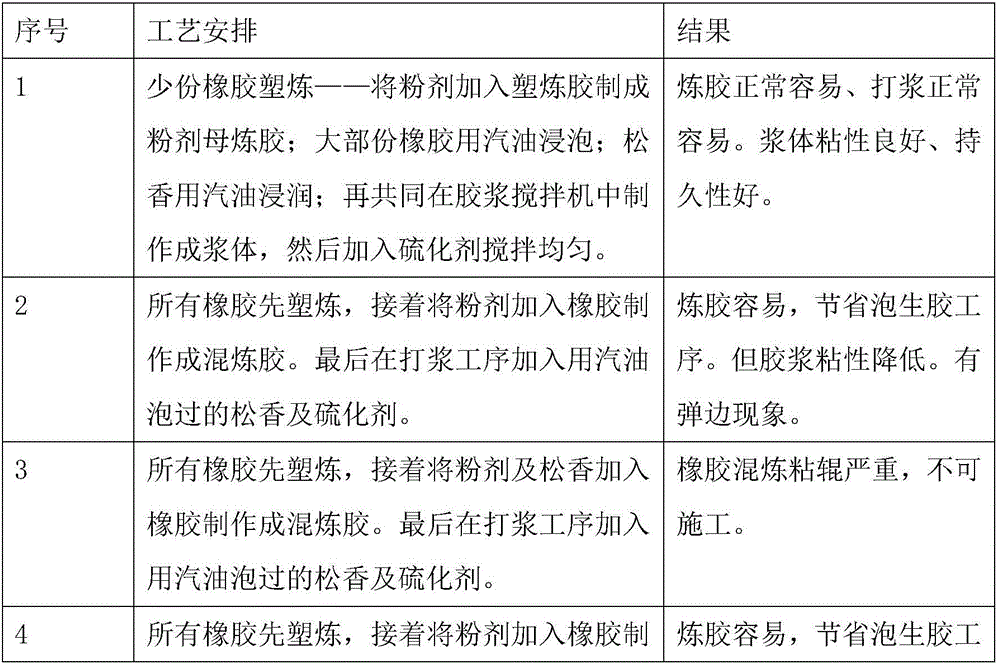

The invention discloses an adhesive for black rubber shoe topline sponges as well as a preparation method and an application of the adhesive. The adhesive is prepared from natural rubber, sulfur, a vulcanizing accelerator, a vulcanizing activator, rosin and 120# gasoline as raw preparation materials. The crosslinking stress of the adhesive is improved, the adhesion stress is higher than compression resilience force of polyurethane foamed plastics and bending bounce of composite topline cloth, furthermore, the crosslinking forming speed of rubber cement is increased, the composite topline cloth is tightly fixed on an upper lining, and by means of a method for adhering covering sponges to the topline cloth and a heel part in advance, the problem of non-uniform appearance quality of a rear topline of a rubber shoe due to inaccurate positioning of the topline cloth and non-uniform press-fit tightness of the covering sponges in a sewing process of the topline cloth and the heel part is solved and the sewing speed and the production efficiency of the covering sponges for an upper topline can be greatly increased. With the adoption of the adhesive, the reworking rate of the covering sponges for the rubber shoe topline is reduced to 0 from original 5%, and the production efficiency is improved by 15%.

Owner:JIHUA 3537 SHOE MAKING

Process and apparatus for production of halogenated butyl rubber with reduced emissions

ActiveUS9644041B2Mitigate issueReduction tendencyChemical/physical/physico-chemical reactor detailsChemical/physical/physico-chemical stationary reactorsPolymer scienceOrganic solvent

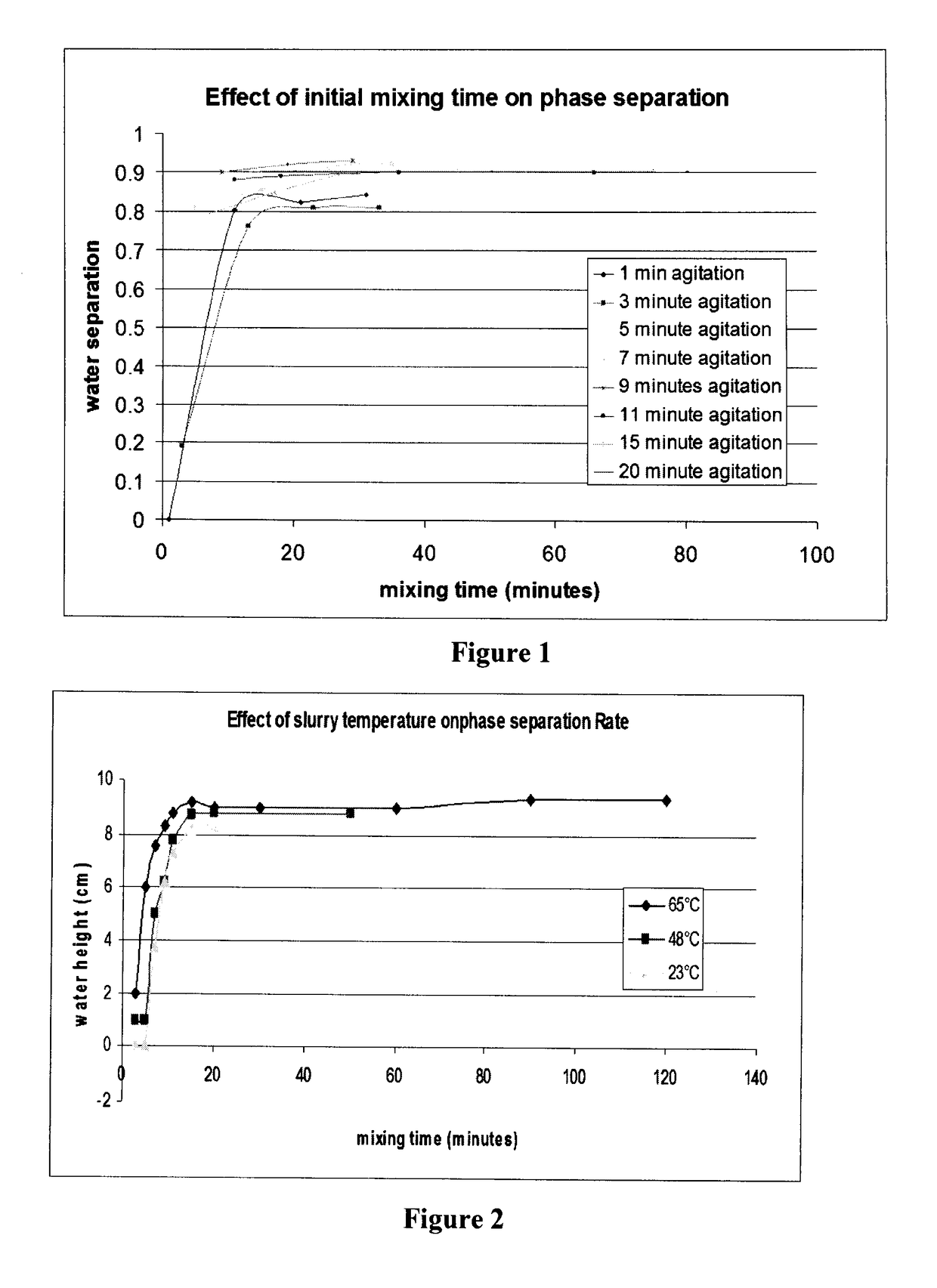

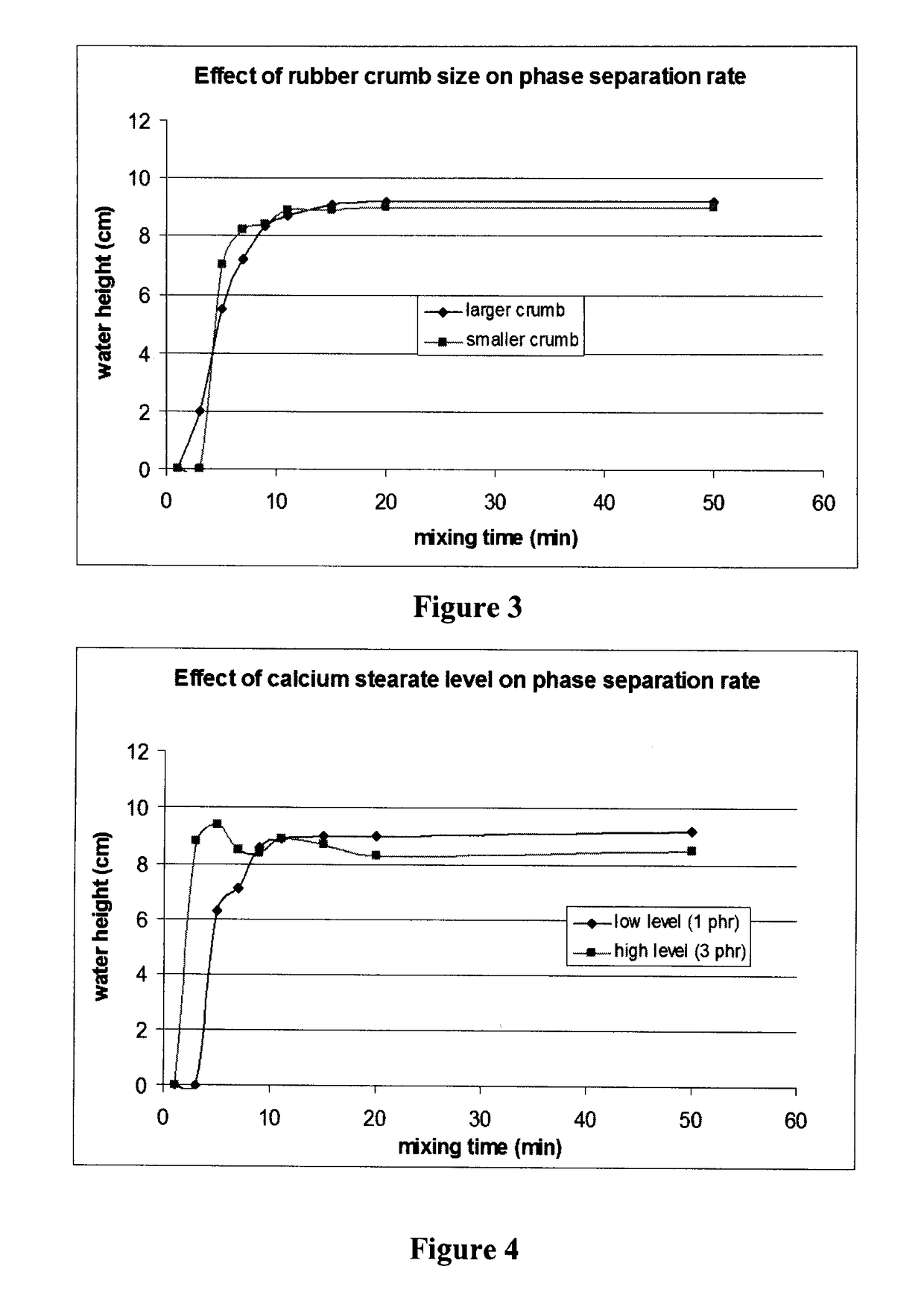

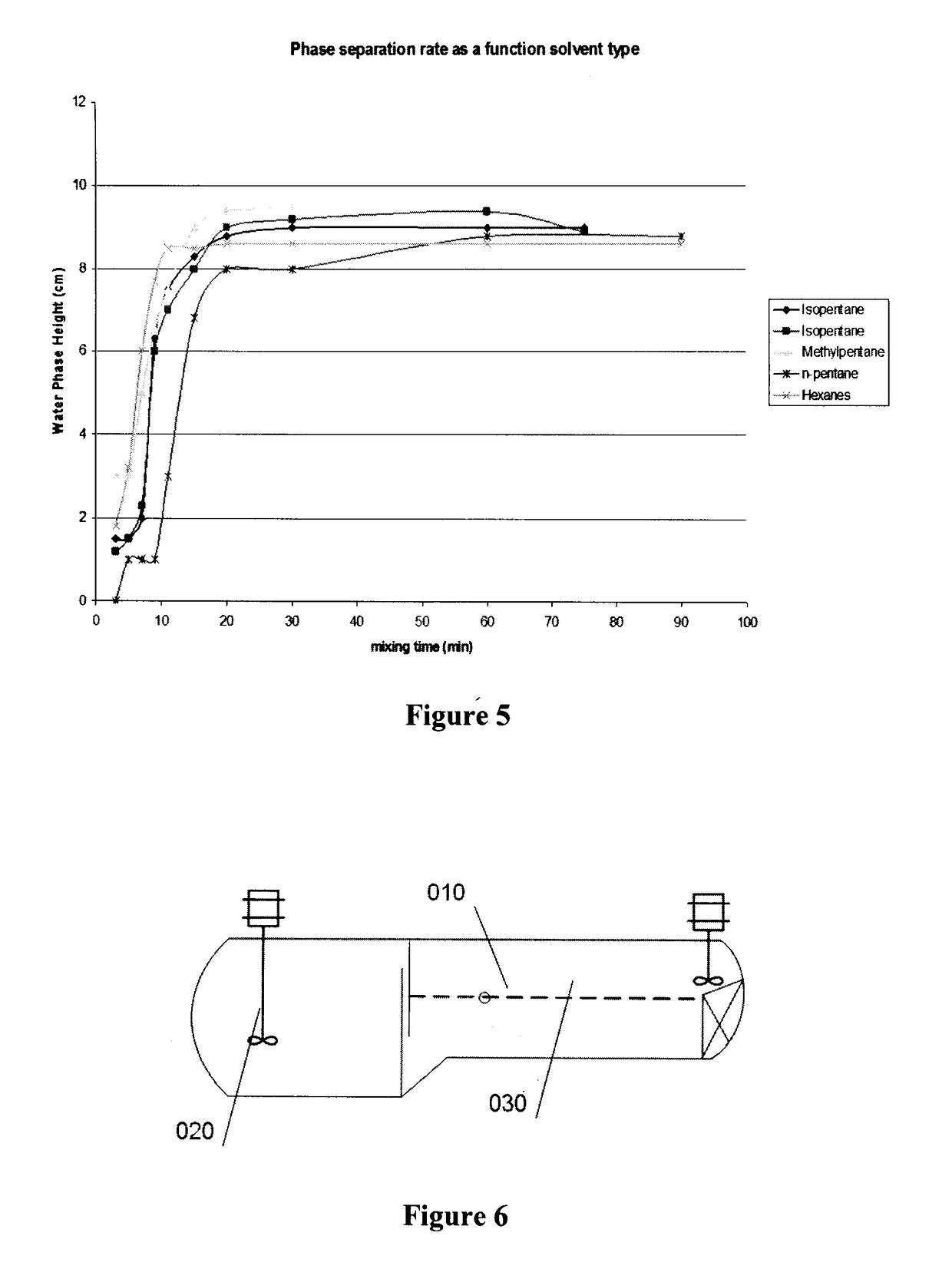

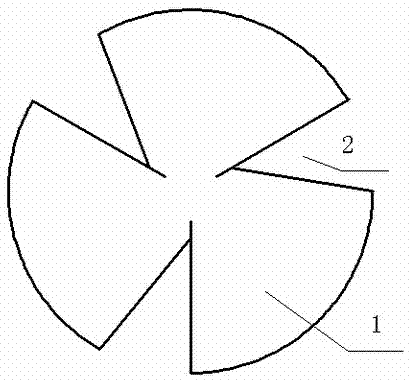

The present invention relates to a process for the production of halogenated butyl rubber and an apparatus for the production of rubber cement for use in the production of halogenated butyl rubber. The process and apparatus permit direct mixing of aqueous rubber slurry with a non-halogenated organic solvent to make a rubber cement solution. The water layer is then separated from the partially dissolved rubber cement and the cement phase is sent for halogenation. The apparatus is an enclosed vessel comprised of at least one dissolving zone and at least one separator zone. The process and apparatus advantageously employ recycle of rubber cement in order to disrupt an interface layer that forms between the water and rubber cement, to thereby improve continuously operation of the process.

Owner:ARLANXEO DEUT GMBH

Thin silicon rubber and fabric composite product and mold pressing vulcanizing forming process thereof

The invention provides a thin silicon rubber and fabric composite product and a mold pressing vulcanizing forming process thereof. The thickness of the product is smaller than or equal to 1.2 mm. The mold pressing vulcanizing forming process comprises the following steps that (1) fabric degreasing is conducted; (2) surface treatment is conducted; (3) rubber cement preparation is conducted; (4) rubber coating is conducted; (5) silicon rubber preforming is conducted; (6) compositing is conducted, specifically, fabric is placed between two pieces of preformed silicon rubber, pressed and cut into a clover-shaped wafer with the corresponding diameter size; (7) mold preheating is conducted; (8) vulcanizing is conducted, specifically, a mold core is coated with the clover-shaped rubber wafer, and mold assembling, pressurizing and vulcanizing are conducted; (9) after being taken out from a vulcanizing machine, a mold is cooled; and (10) the product is taken out from a mold cavity and subjected to post vulcanizing for 4 h. According to the mold pressing vulcanizing forming process of the thin silicon rubber and fabric composite product, the silicon rubber and the fabric are subjected to mold pressing vulcanizing forming and are firmly connected, and the fabric is uniformly placed between the inner-layer silicon rubber and the outer-layer silicon rubber; demolding is conducted through cooling, the shrinkage rate of the silicon rubber is consistent with that of the fabric, and the product is strict in size control, not deformed and good in sealing performance; and the situation that the fabric is exposed and eccentric is avoided.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

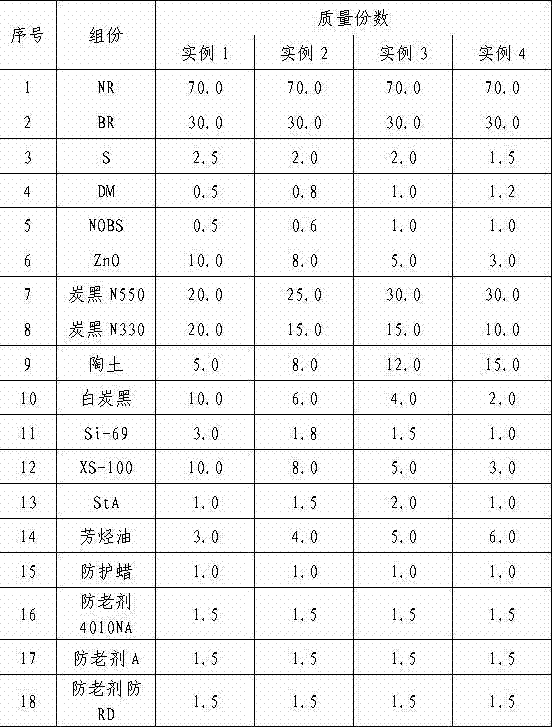

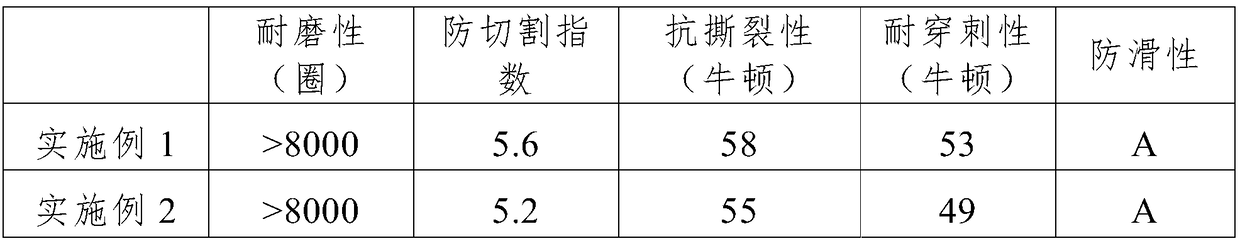

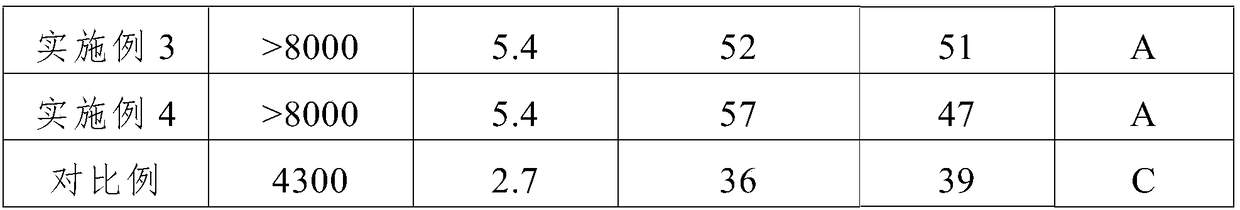

Natural/butadiene rubber formula for hovership finger and manufacturing method thereof

The invention discloses a natural / butadiene rubber formula for a hovership finger and a manufacturing method thereof. The manufacturing method comprises the following step of: carrying out banburying, opening, batching-off and vulcanizing on NR (Natural Rubber), BR (Butadiene Rubber), S, DM, NOBS (N-(Oxidiethylene)-2-benzothiazolyl sulfonamide), ZnO, carbon black N550, carbon black N330, argil, white carbon black, Si-69, a rubber cement XS-100, StA, aromatic oil, protection wax, anti-aging agent 4010NA, anti-aging agent A and RD. The BR is used in the NR, the compound cement XS-100 with good dispersing property is adopted and is high in feeding; and the manufacturing method is simple and easy to operate; and a less quantity of BR is adopted in the NR, so that the abrasive resistance is improved; and the white carbon black and si-69 are matched for use, so that the bonding strength of rubber and a framework material can be greatly improved.

Owner:TIANJIN RUBBER IND RES INST

Manufacturing method of anti-skid and anti-chemical frosted gloves

ActiveCN108556390AGood chemical resistanceImprove skid resistanceGarment special featuresGlovesInorganic saltsPolymer science

The invention relates to a manufacturing method of anti-skid and anti-chemical frosted gloves. The manufacturing method comprises the steps that 1, an assistant agent is added in prevulcanized neoprene latex to prepare dipping rubber cement; 2, a glove blank is dipped in the dipping rubber cement prepared in the step 1, and then rubber dropping and homogenizing are carried out; 3, a foaming material is dipped; 4, inorganic salt is sprayed, so that a frosted surface is formed; 5, soaking in clean water is carried out; and 6, low-temperature prevulcanization and drying are carried out at first,high-temperature prevulcanization and drying are carried out finally, and thus the anti-skid and anti-chemical frosted gloves are obtained. Compared with existing latex frosted gloves, the anti-skid and anti-chemical frosted gloves prepared according to the method have relatively good anti-chemical performance and anti-skid effect, the anti-skid and anti-chemical frosted gloves are softer and morecomfortable to wear compared with butyronitrile frosted gloves, the EN388 grade of the gloves reaches 4231, and under low temperature, the warping strength is good, and the anti-chemical performancecan reach level 3.

Owner:SHANDONG XINGYU GLOVES

Rubber powder cement mortar for construction heat insulation and preparation thereof

InactiveCN101302090AWorkability is goodEasy constructionSolid waste managementCement mortarReducing agent

The invention belongs to the building material technical field, in particular relating to rubber cement mortar used for construction heat-insulation and a method for preparing the same. The cement mortar consists of cement, water reducing agent, air-entraining agent, rubber powder, sand, polymer powder, cellulose ether and water. The velocity of the cement mortar is about 80 mm, the layering degree of the cement mortar is about 20 mm, the dry apparent density of the cement mortar reaches 850 kg.m<3>, the thermal conductivity is about 0.08 W.m<-1>, the softening coefficient reaches 1.00, the folding strength is 410 KPa, the pressive strength is 640KPa, the linear shrinkage factor is about 0.09 percent, and the 56 d pressure and shear cohesional strength is 120 KPa. The cement mortar is suitable for various heat-insulation projects.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com