Fluorine/butadiene rubber composite glove and manufacturing method thereof

A technology of nitrile butadiene rubber and fluororubber is applied in the directions of gloves, rubber layered products, chemical instruments and methods, etc., which can solve the problems of limited general application, high cost, high price of fluororubber, etc., and achieves simple production process and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

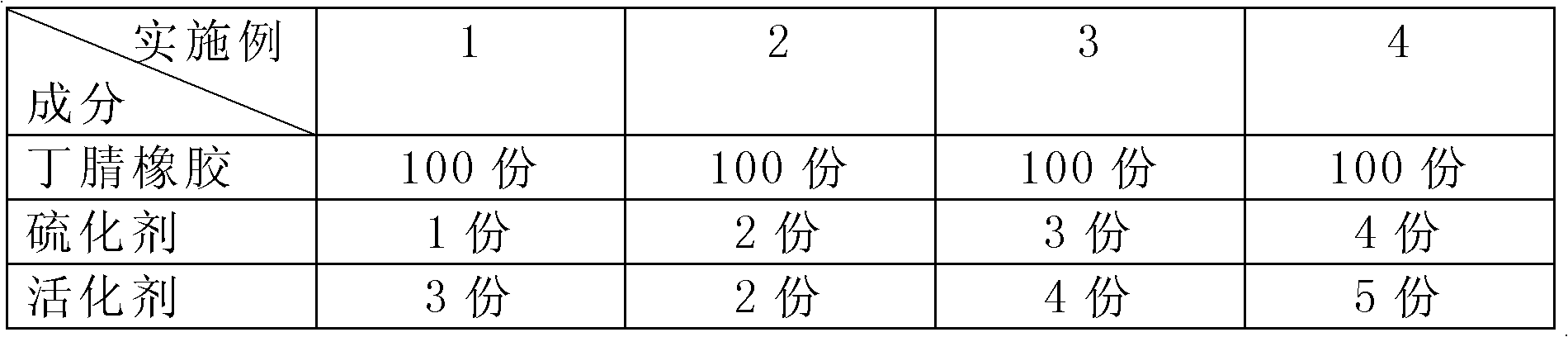

Examples

Embodiment 2

[0030] The content of acrylonitrile in the nitrile rubber in Example 2 is 25-30%, the vulcanizing agent is sulfur, the activator is 1 part of calcium hydroxide, and 1 part of magnesium oxide.

Embodiment 3

[0031] The content of acrylonitrile in the nitrile rubber in embodiment 3 is 20-25%, the described vulcanizing agent is sulfur, the described activator is 2 parts of calcium hydroxide, 2 parts of magnesium oxide.

Embodiment 4

[0032] The acrylonitrile content in the nitrile rubber in embodiment 4 is 25-30%, the described vulcanizing agent is sulfur, the described activator is 2 parts of calcium hydroxide, 3 parts of magnesium oxide.

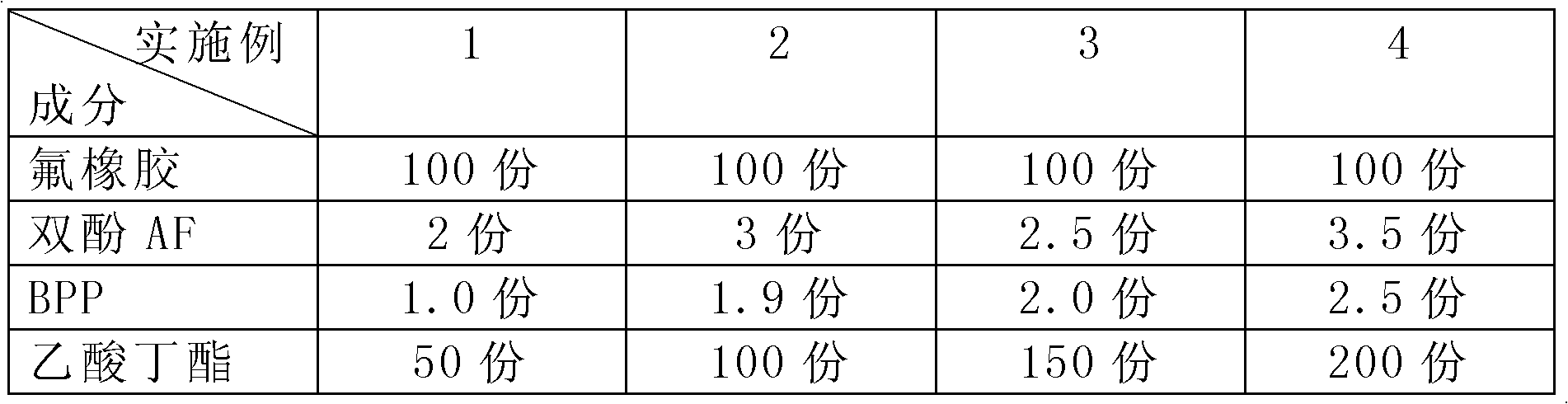

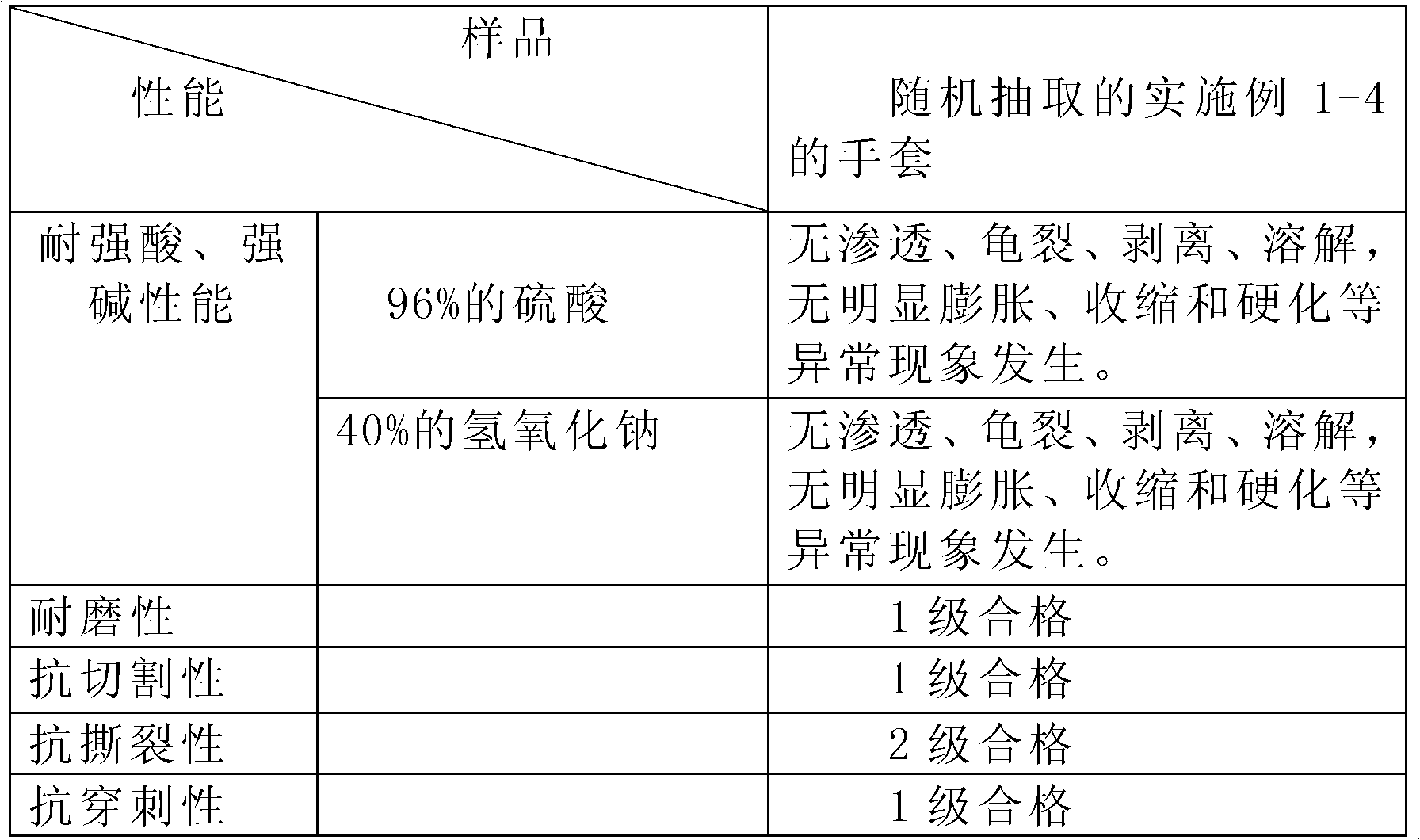

[0033] Composition (parts by weight) of fluororubber slurry in the present embodiment

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com