Photocuring hammer paint

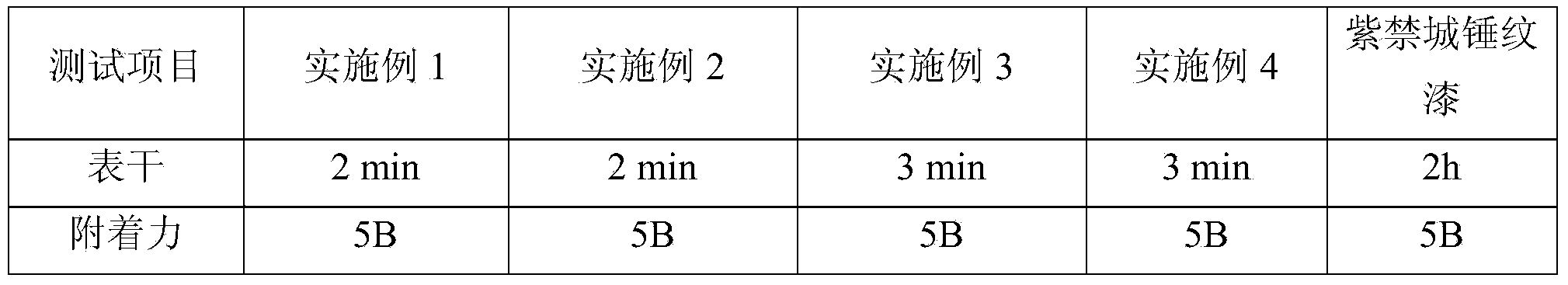

A hammer paint and light curing technology, applied in the field of coatings, can solve problems such as long curing time and environmental pollution, and achieve the effects of improving crack resistance, reducing paint film stress, and excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited thereto.

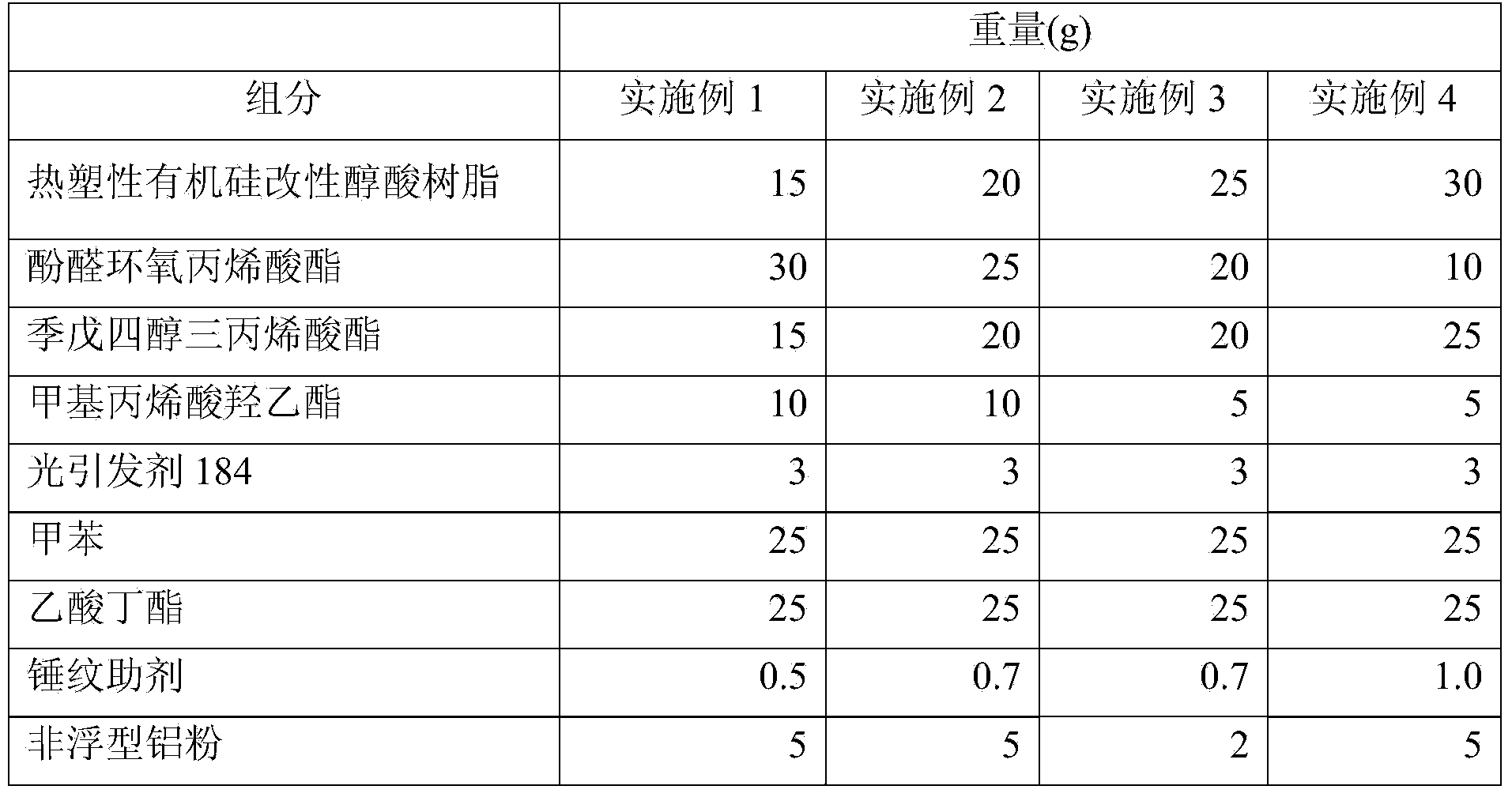

[0024] According to the data shown in Table 1, thermoplastic silicone modified alkyd resin (such as Huizhi Technology (China) Co., Ltd. DSI-050), novolac epoxy acrylate (Dongtou Hengli Printing Materials Co., Ltd., HL-183 ), pentaerythritol triacrylate (Shanghai Ruishuo Chemical Co., Ltd.), hydroxyethyl methacrylate (Mitsubishi Japan), photoinitiator 184 (Jiangsu Baosheng Chemical Co., Ltd.), toluene (Ningbo Tianhong Petrochemical Co., Ltd.), Butyl acetate (Kaiming Chemical Co., Ltd.), hammer grain additive (Zhengzhou Zhongyue Coating Additive Co., Ltd., ZY-1) and non-leafing aluminum powder (Guangzhou Haiwan Chemical Co., Ltd.) were added to the container with agitator in sequence , stir and disperse evenly to obtain the hammer paint used in Examples 1 to 4.

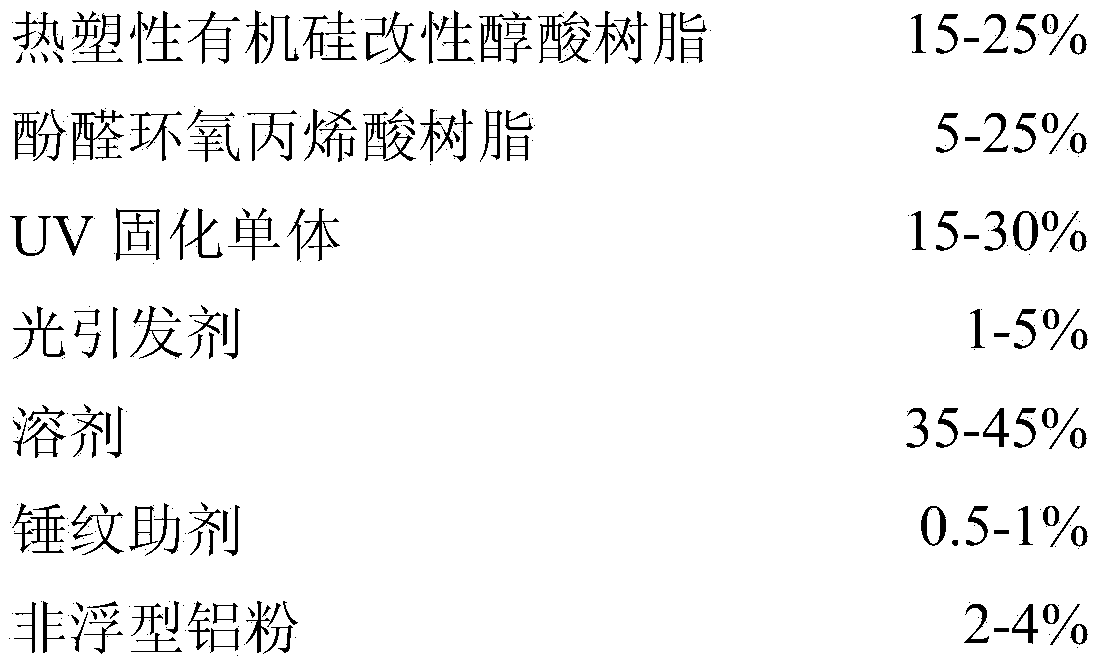

[0025] The distribution ratio of each component...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com