Patents

Literature

33352results about "Sieving" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

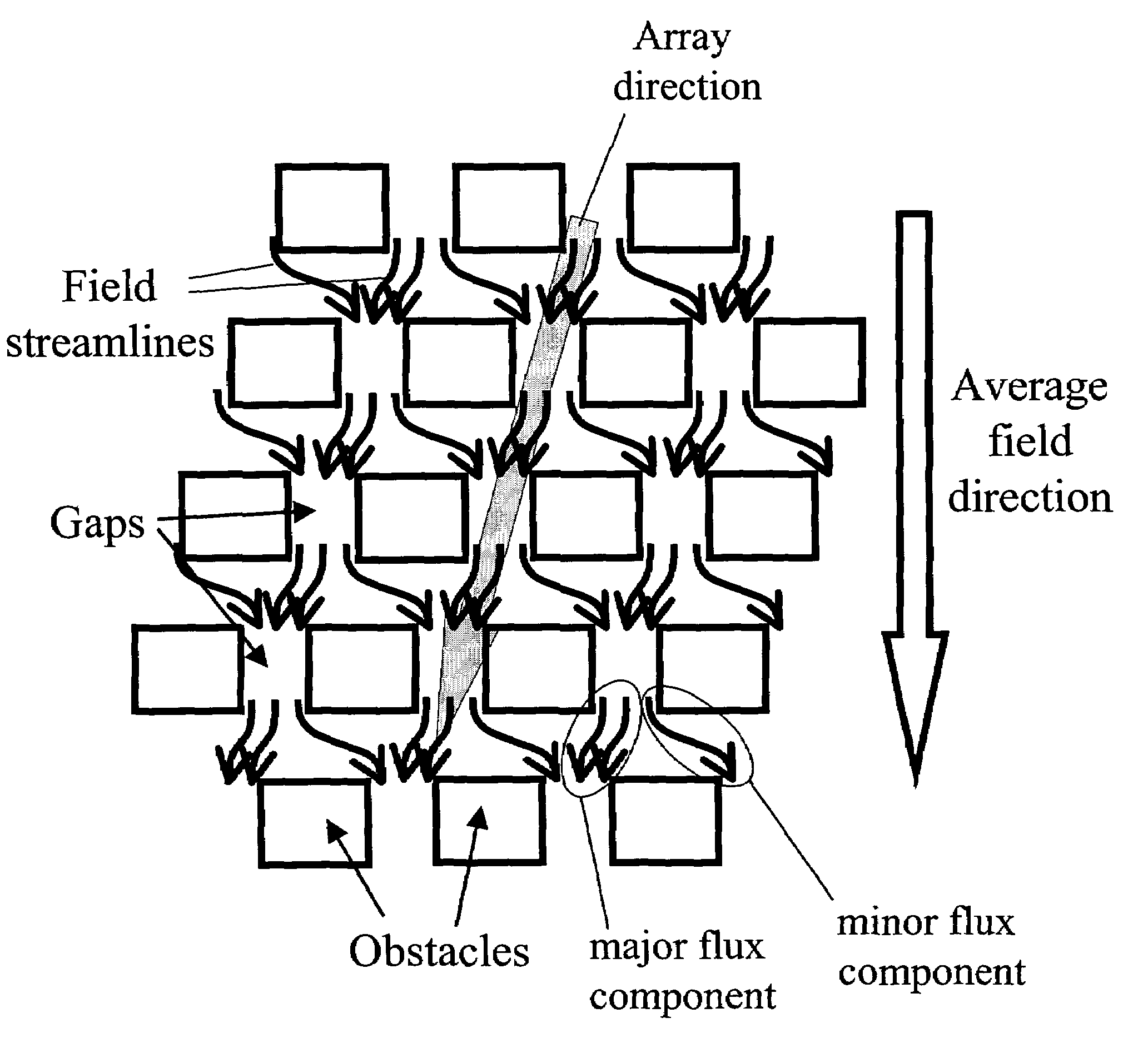

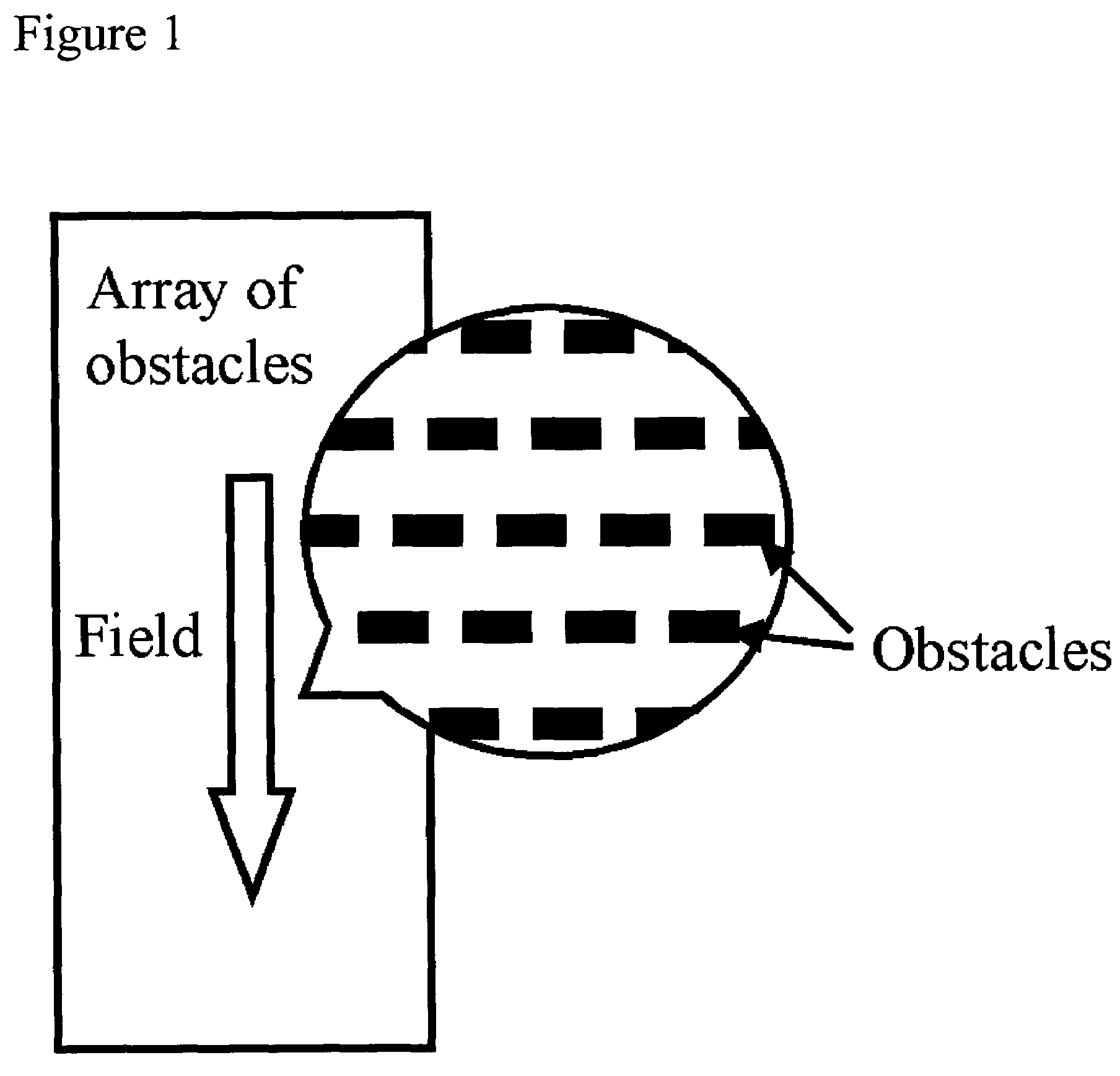

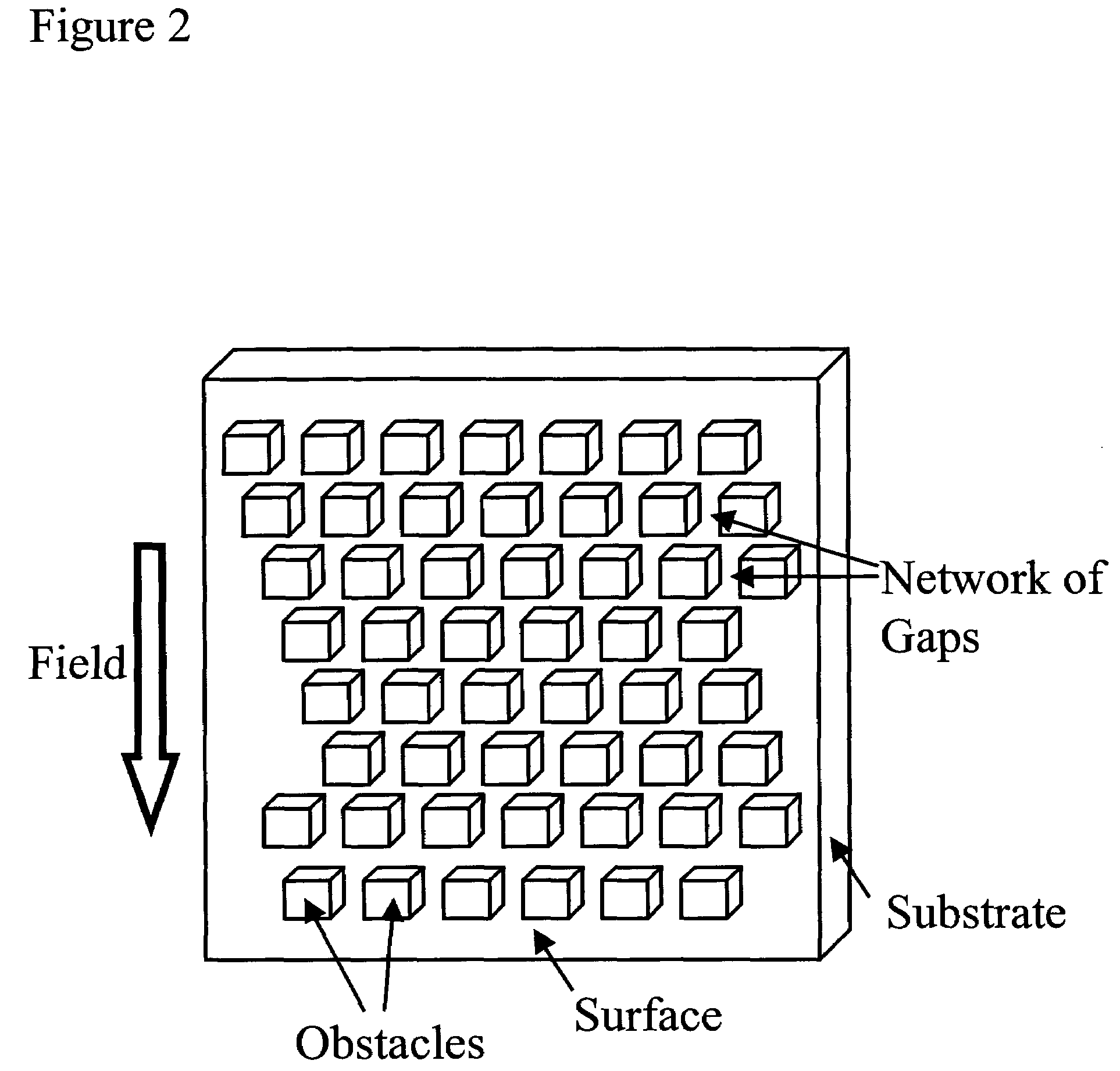

Method for continuous particle separation using obstacle arrays asymmetrically aligned to fields

The present invention relates to methods and devices for separating particles according to size. More specifically, the present invention relates to a microfluidic method and device for the separation of particles according to size using an array comprising a network of gaps, wherein the field flux from each gap divides unequally into subsequent gaps. In one embodiment, the array comprises an ordered array of obstacles in a microfluidic channel, in which the obstacle array is asymmetric with respect to the direction of an applied field.

Owner:THE TRUSTEES FOR PRINCETON UNIV

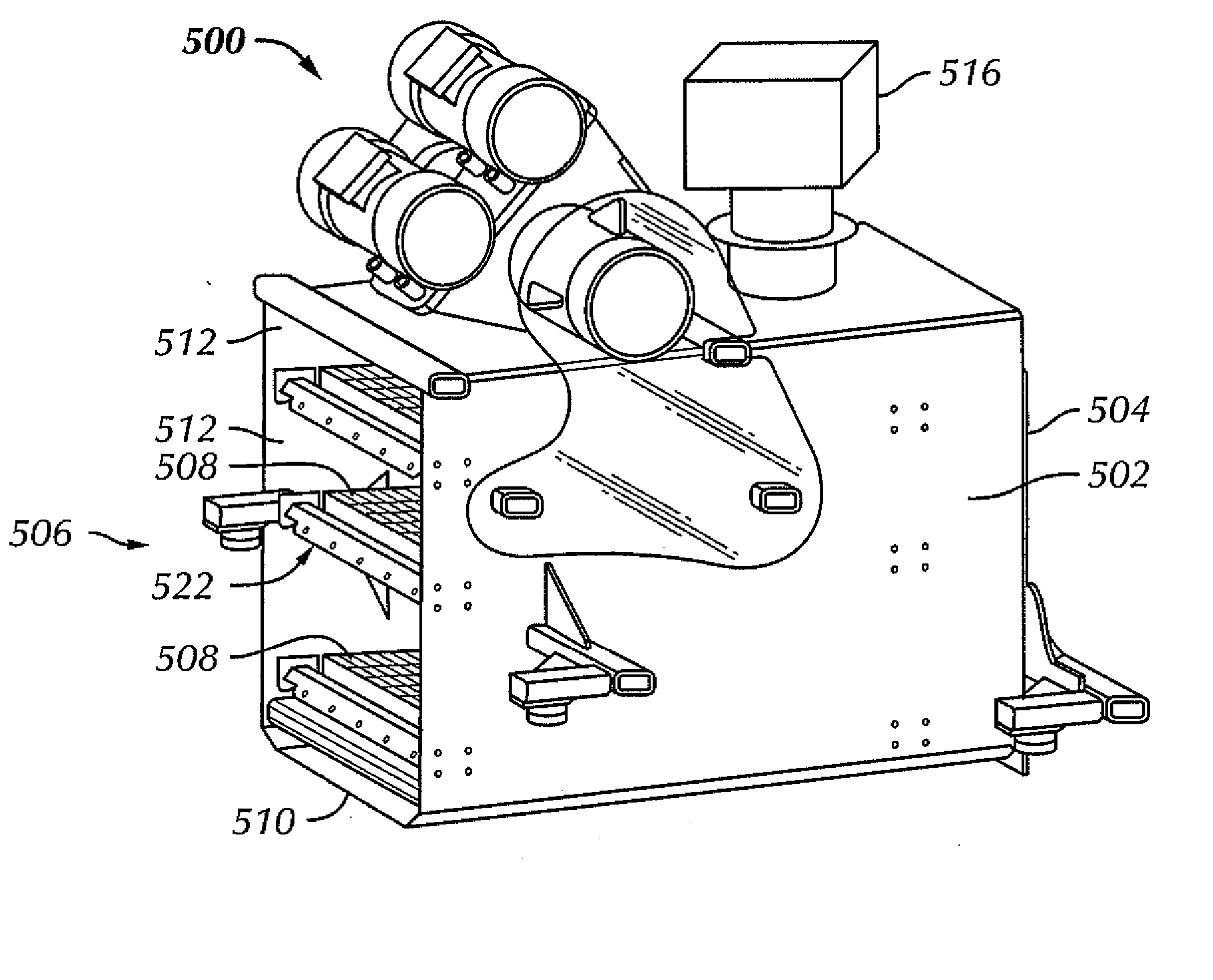

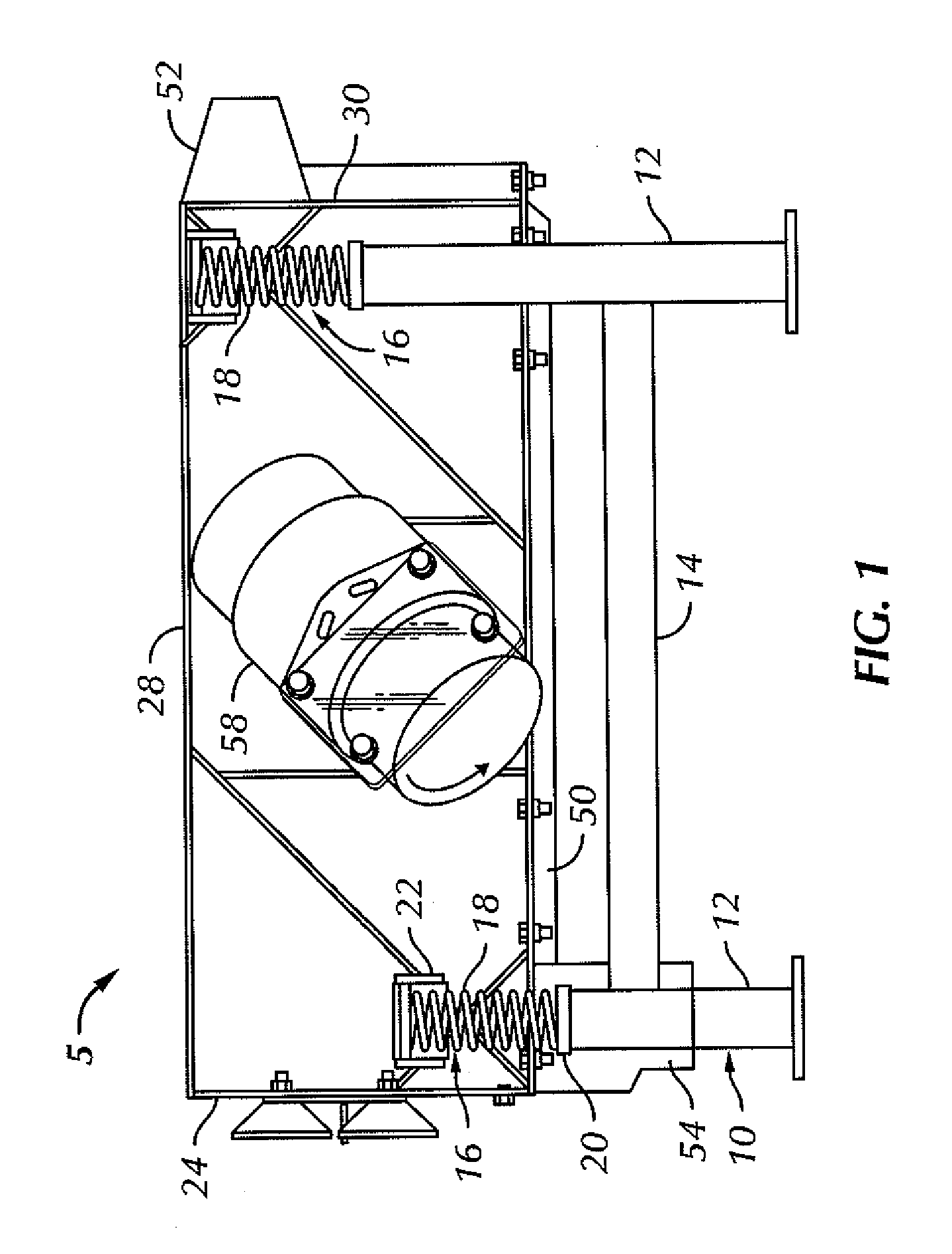

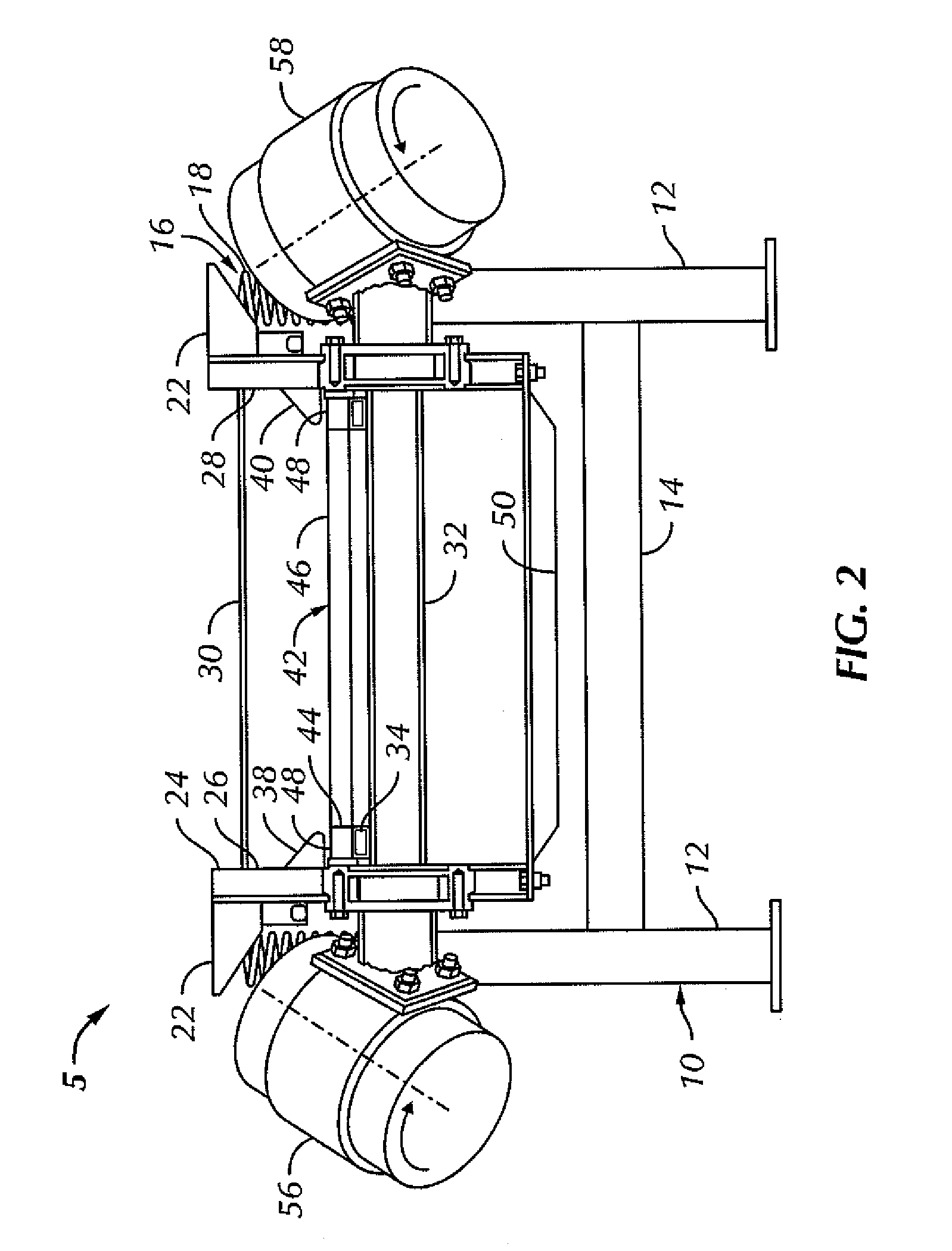

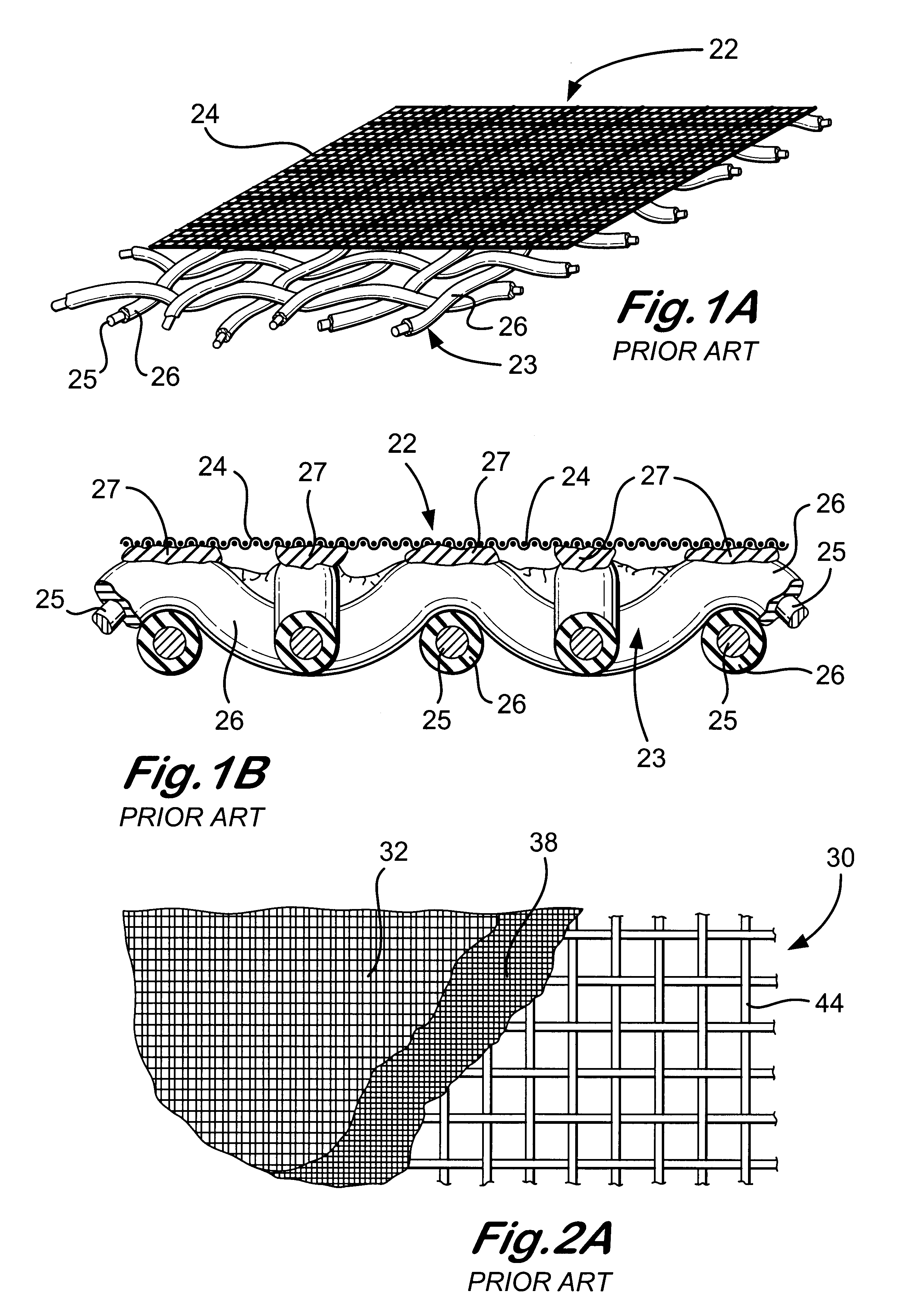

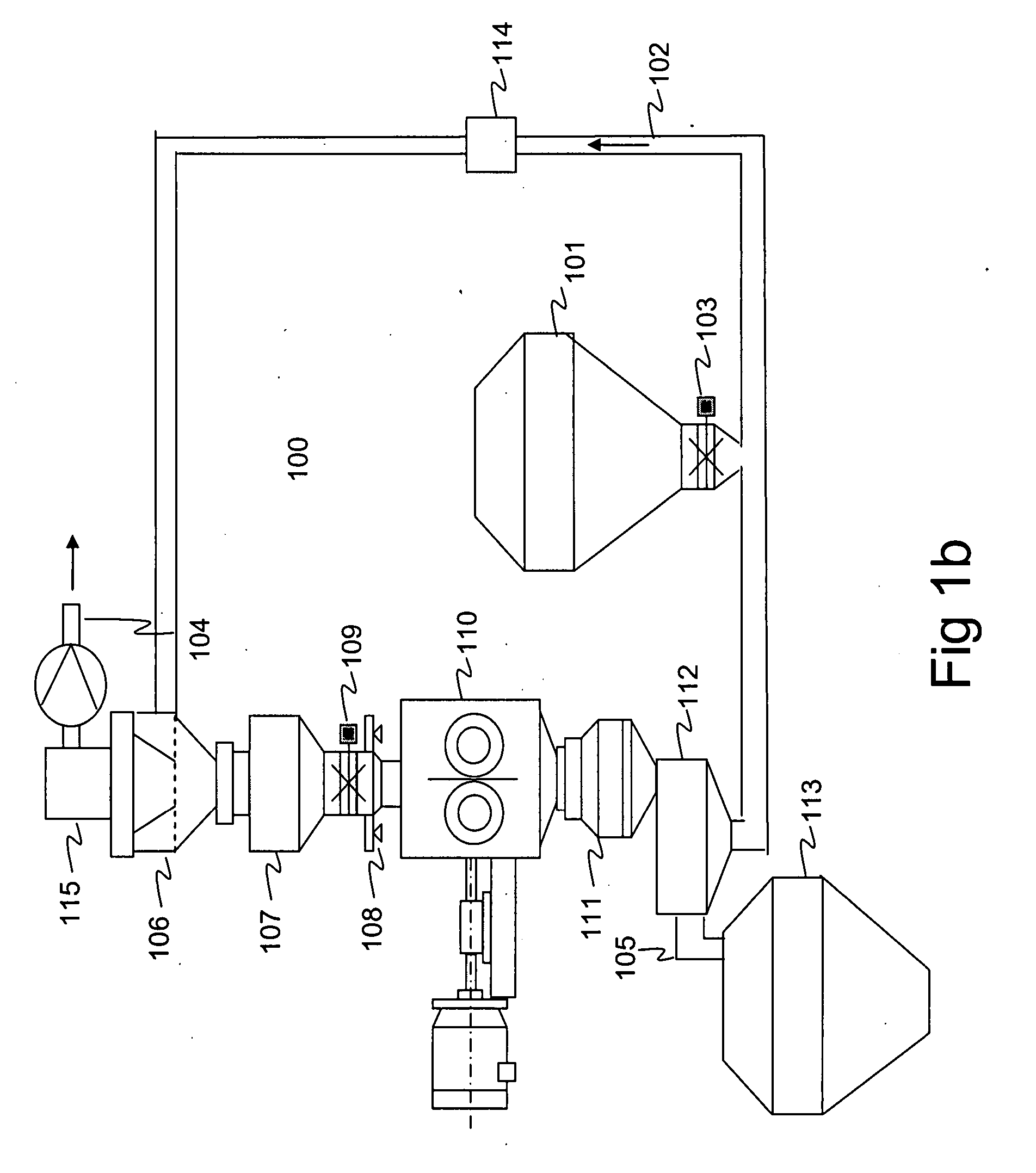

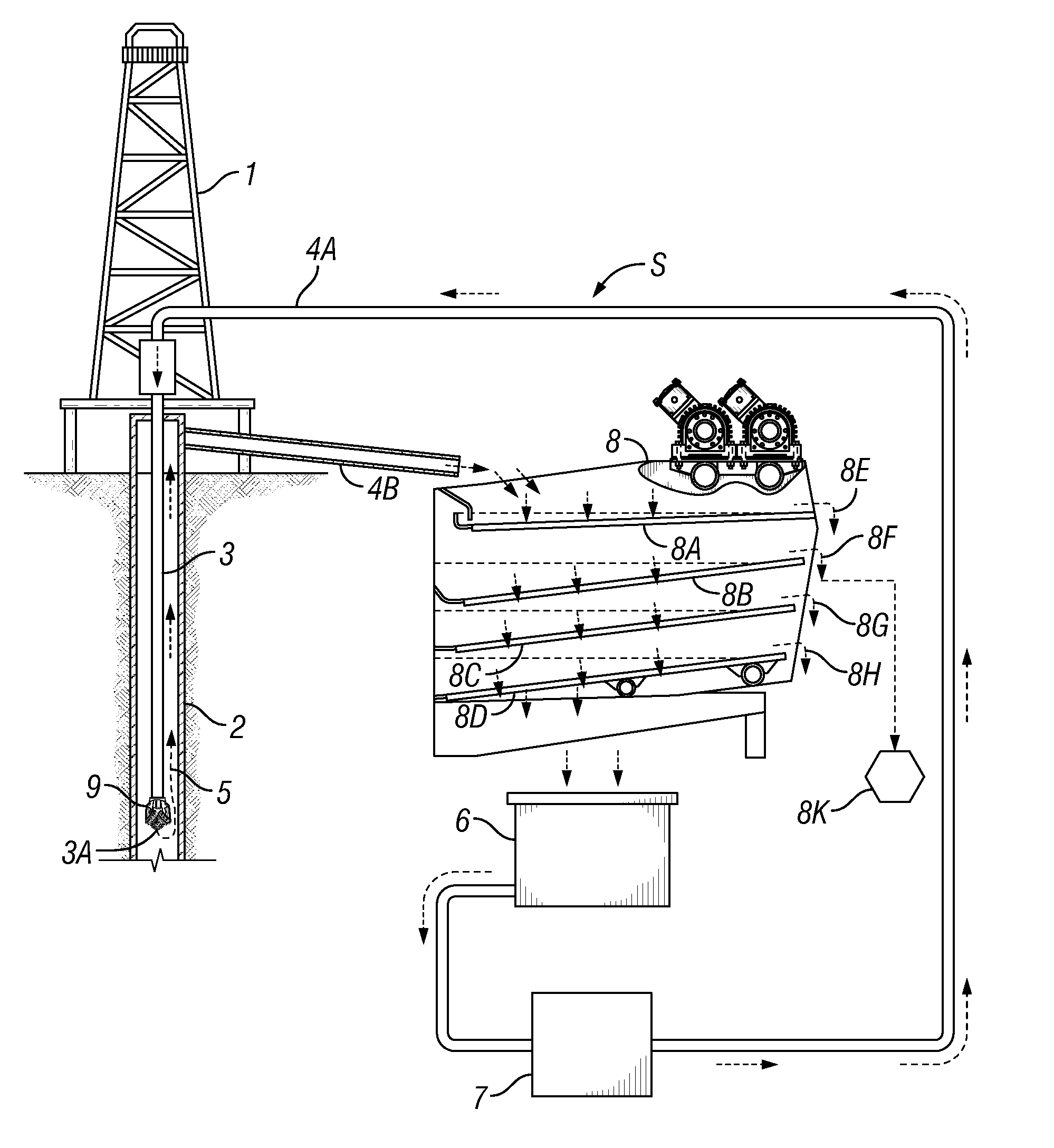

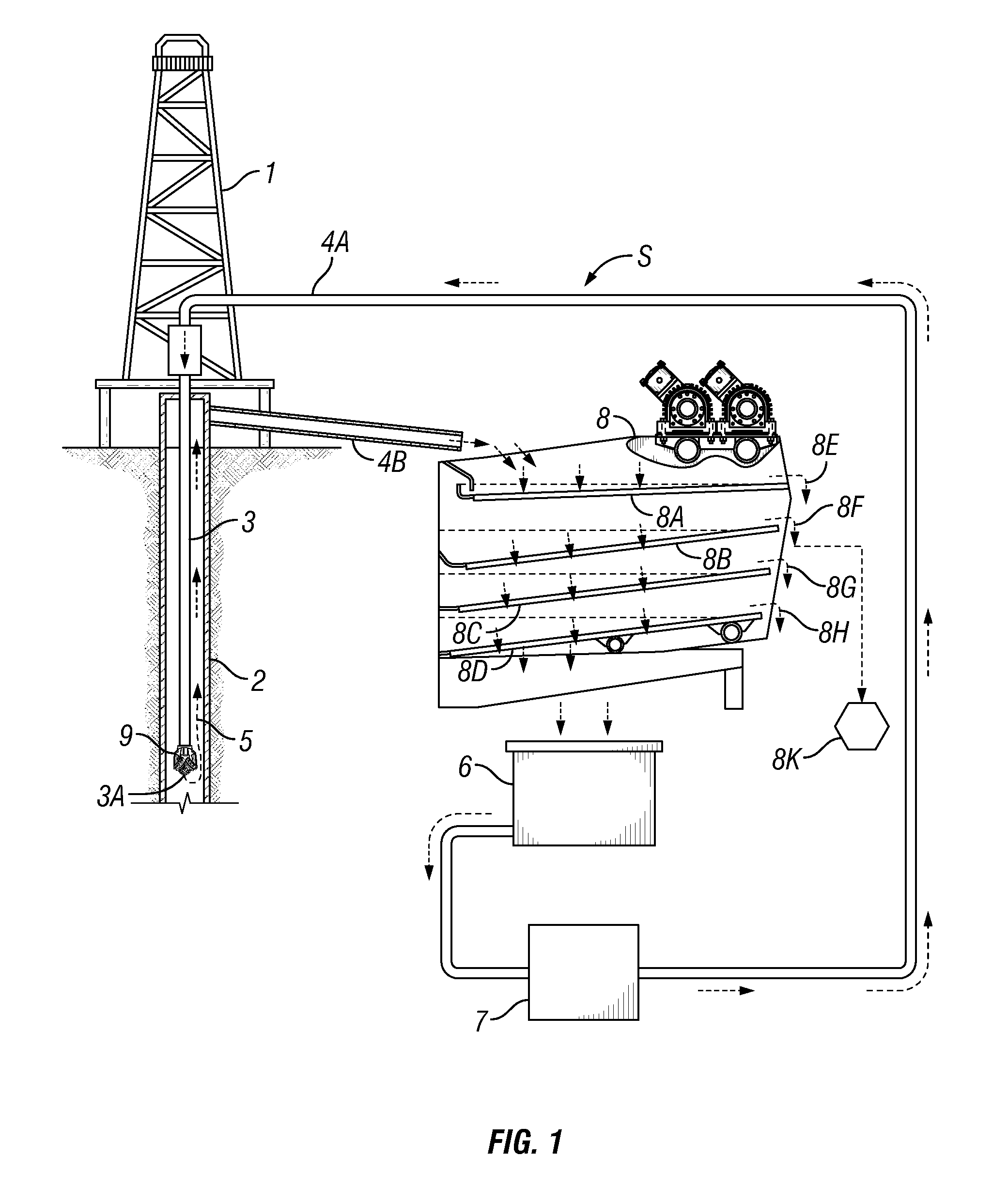

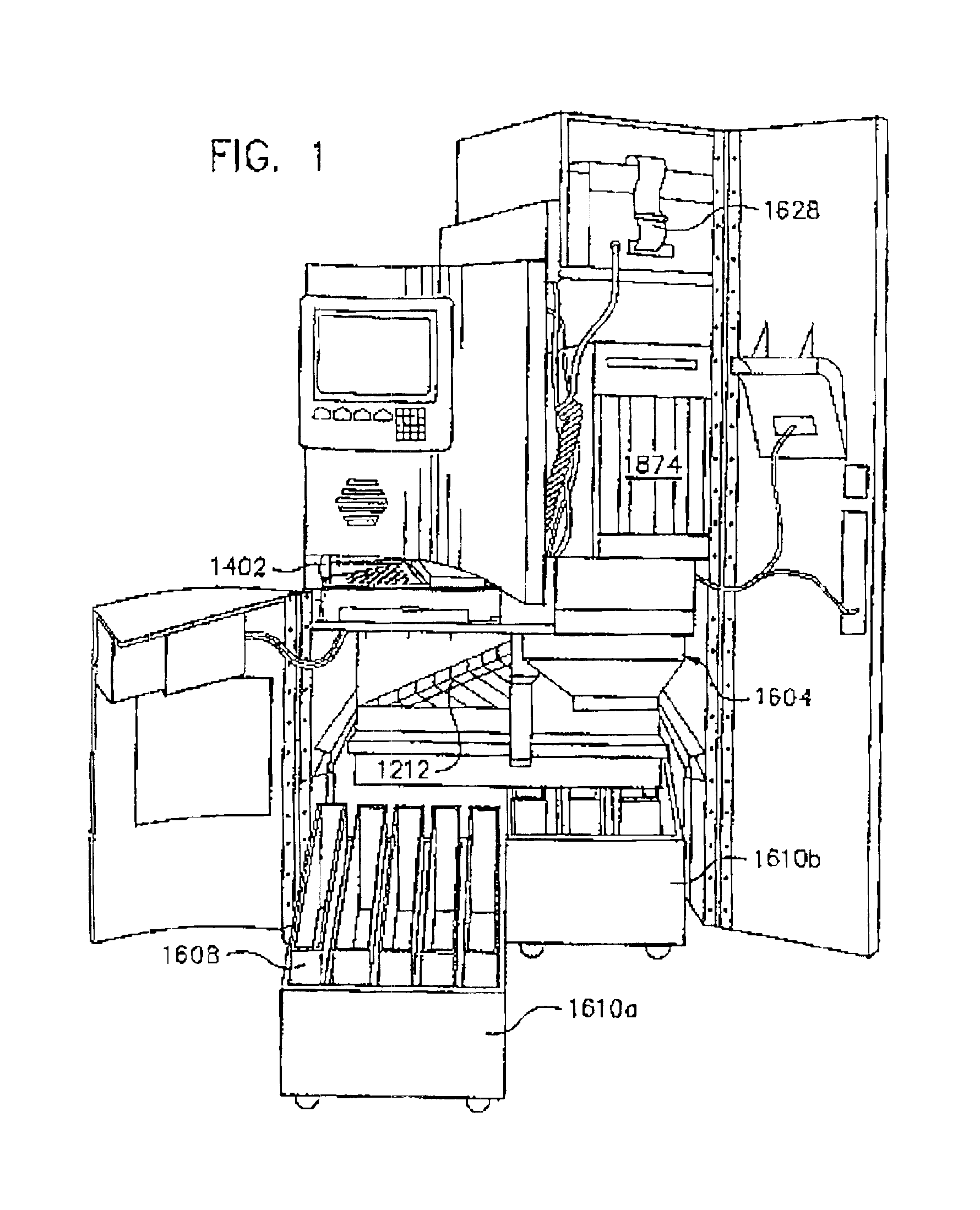

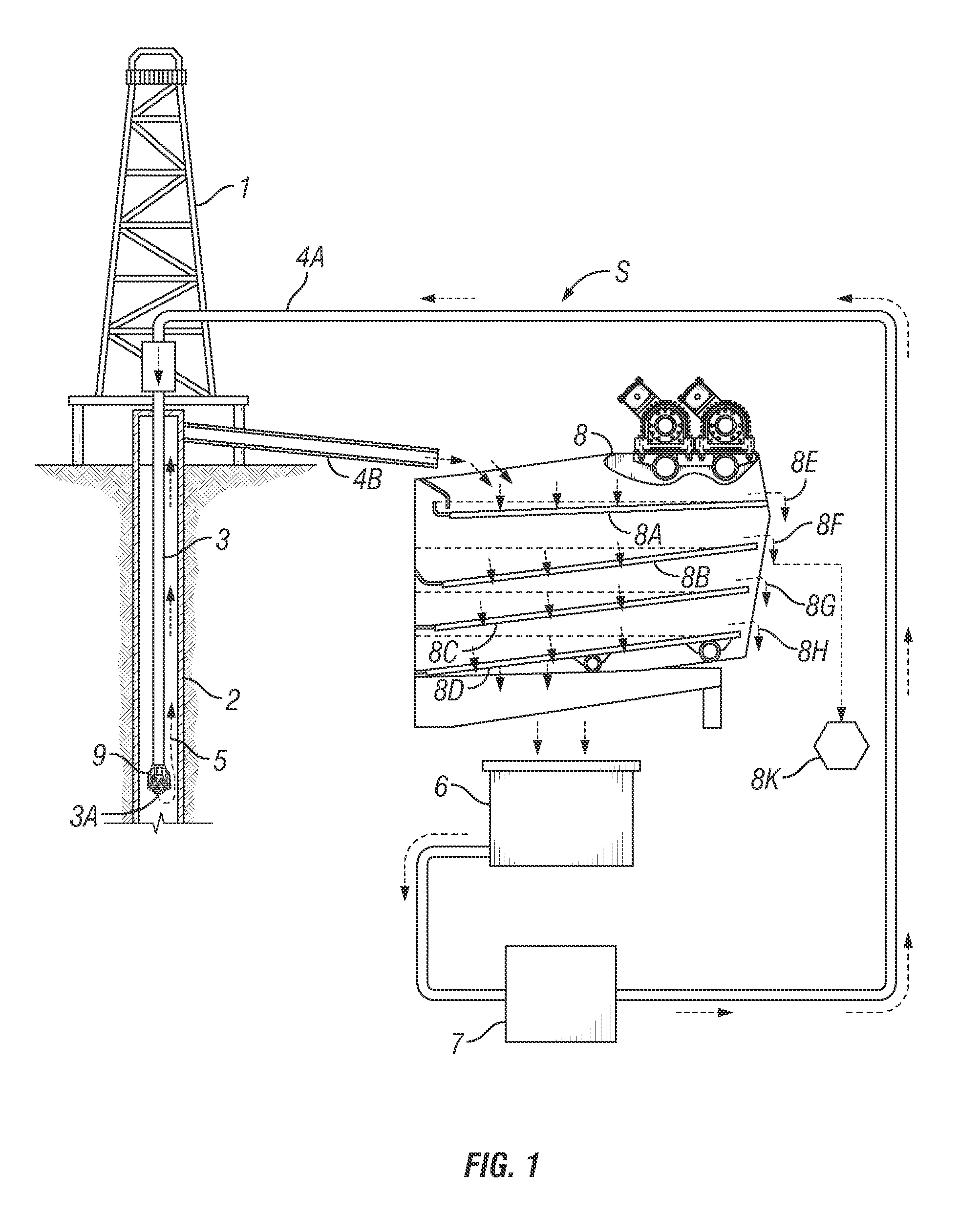

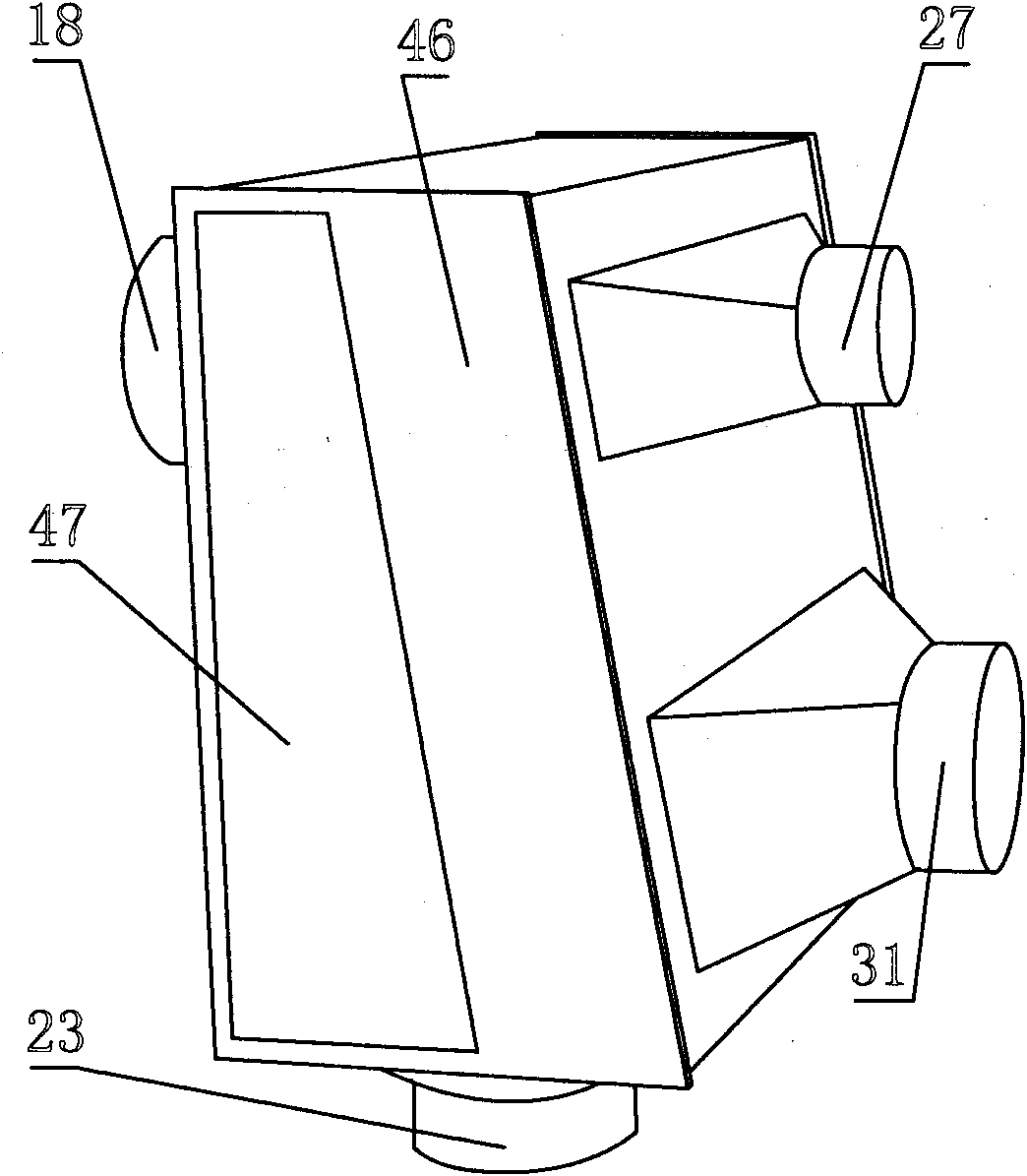

Shaker and degasser combination

A system for separating components of a slurry is disclosed, the system including a housing; a basket for holding at least one shaker screen, the basket movably mounted in the housing; at least one vibrator coupled to the basket; a sump disposed below the basket to collect at least a portion of the slurry passing through the at least one shaker screen; a pressure differential device fluidly connected to the sump for developing a pressure differential across the at least one shaker screen; and a toggling device for toggling the pressure differential across the screen. A system including a degassing chamber fluidly connected to a sump and a pressure differential device, wherein the degassing chamber is disposed between the sump and the pressure differential device, and a fluid conduit fluidly connected to the degassing chamber for recovering a degassed fluid is also disclosed.

Owner:MI

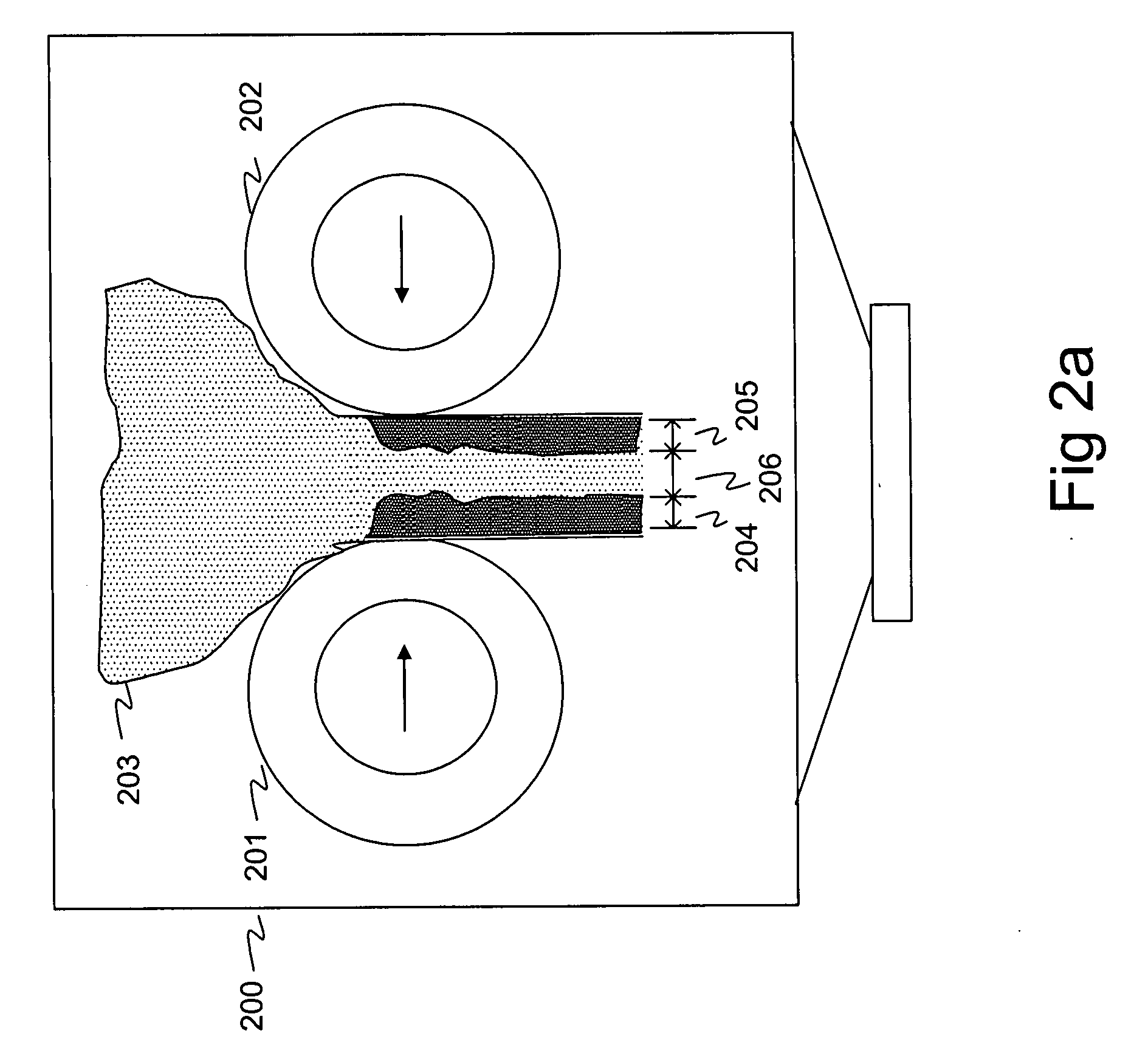

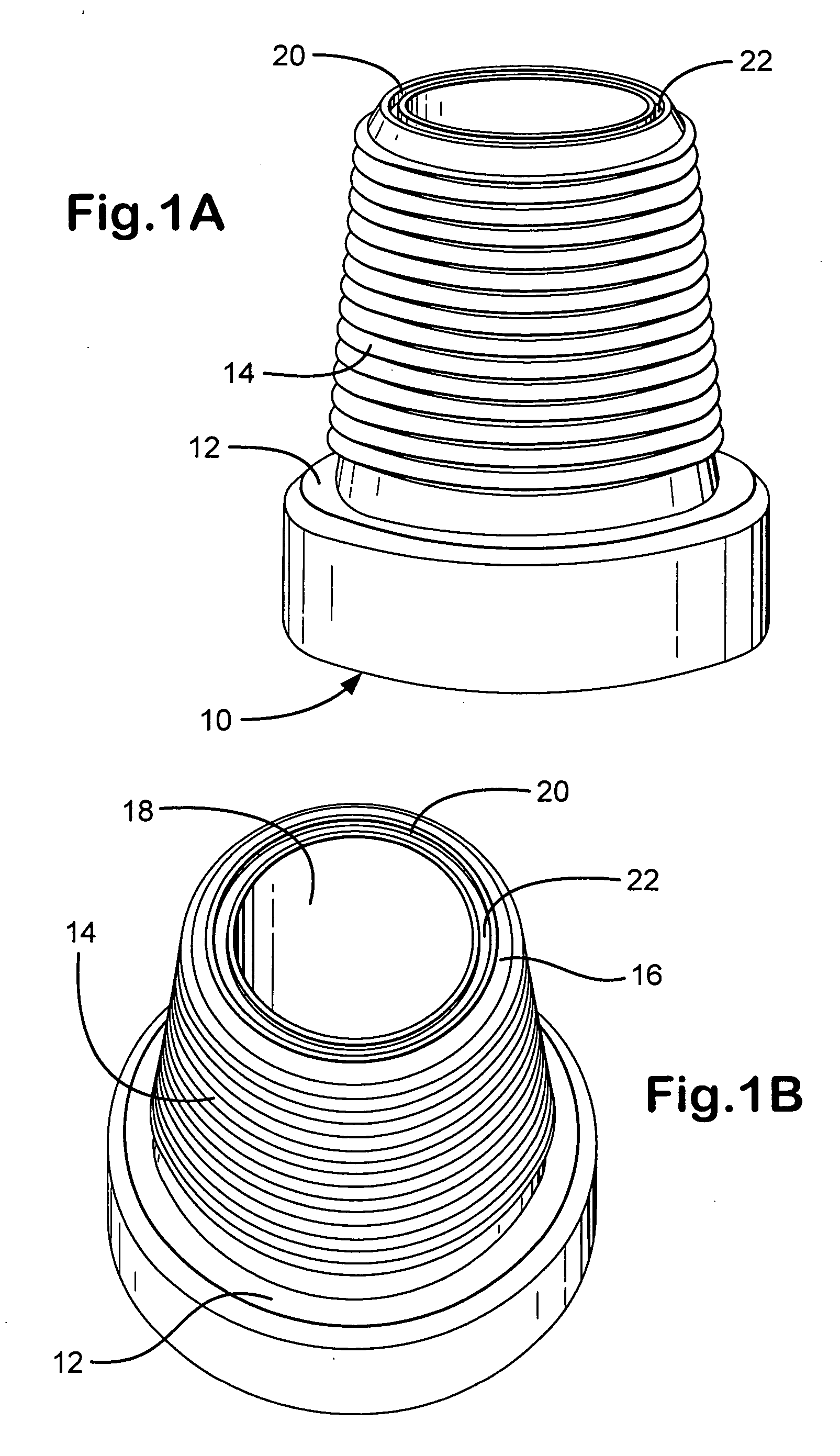

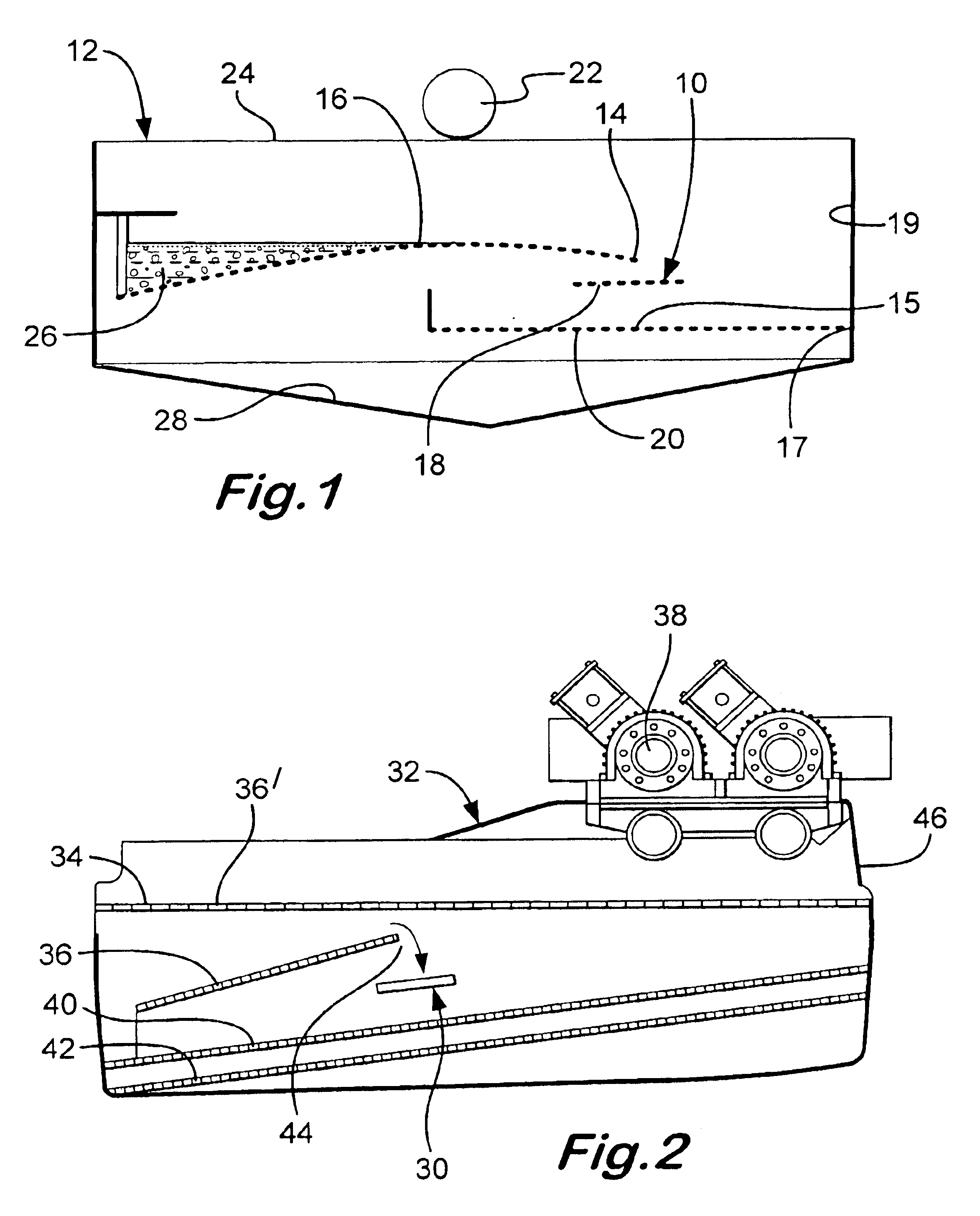

Proppant Particles Formed From Slurry Droplets and Method of Use

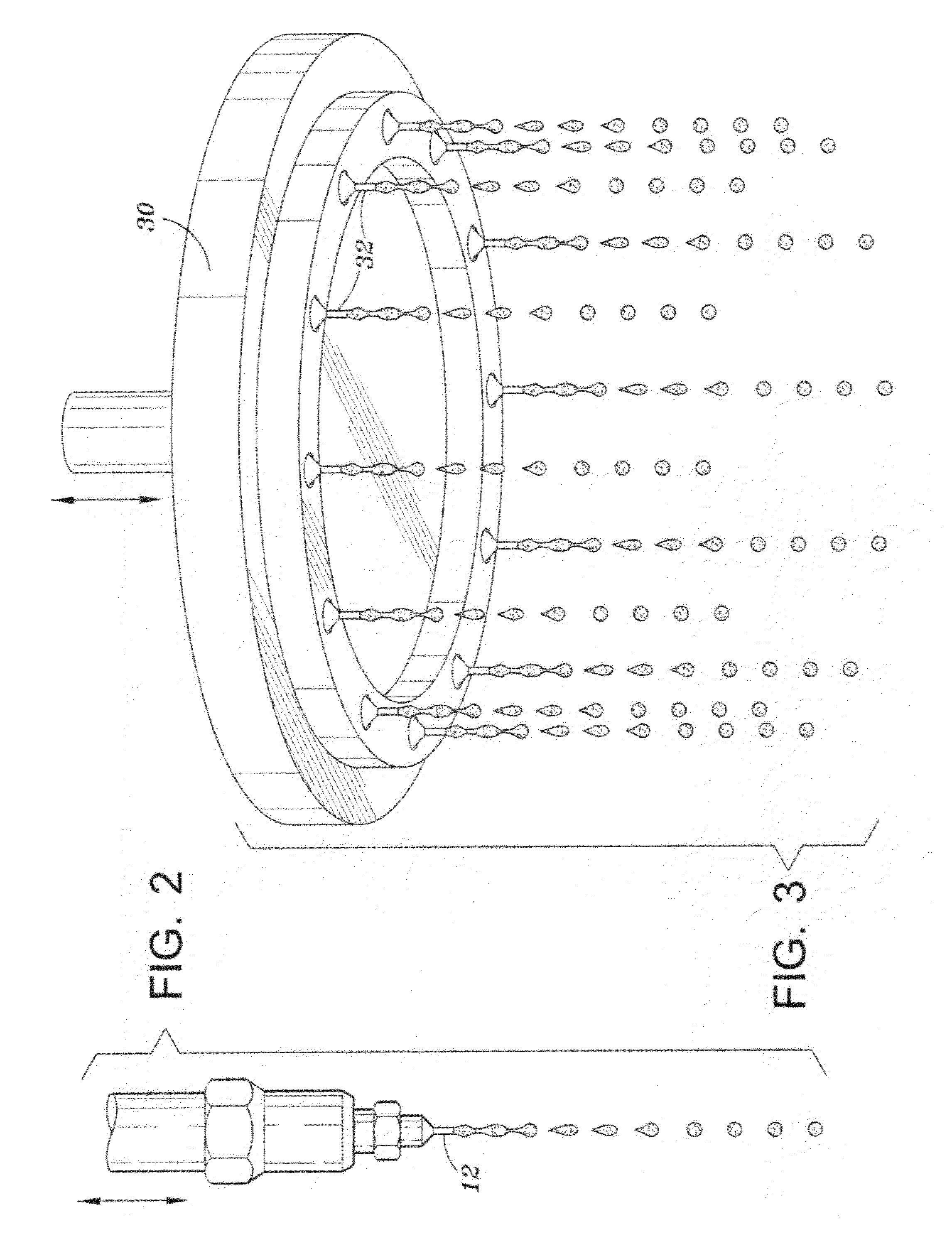

Proppant material for hydraulic fracturing is provided. The particles of the proppant are formed by drip casting. A slurry of finely divided ceramic particles is flowed through nozzles and formed into droplets under the influence of vibration. Uniform sized, smooth surface, spherical green particles are formed. The green particles are dried and sintered to form the proppant. The proppant is used in the process of hydraulic fracturing of wells.

Owner:CARBO CERAMICS

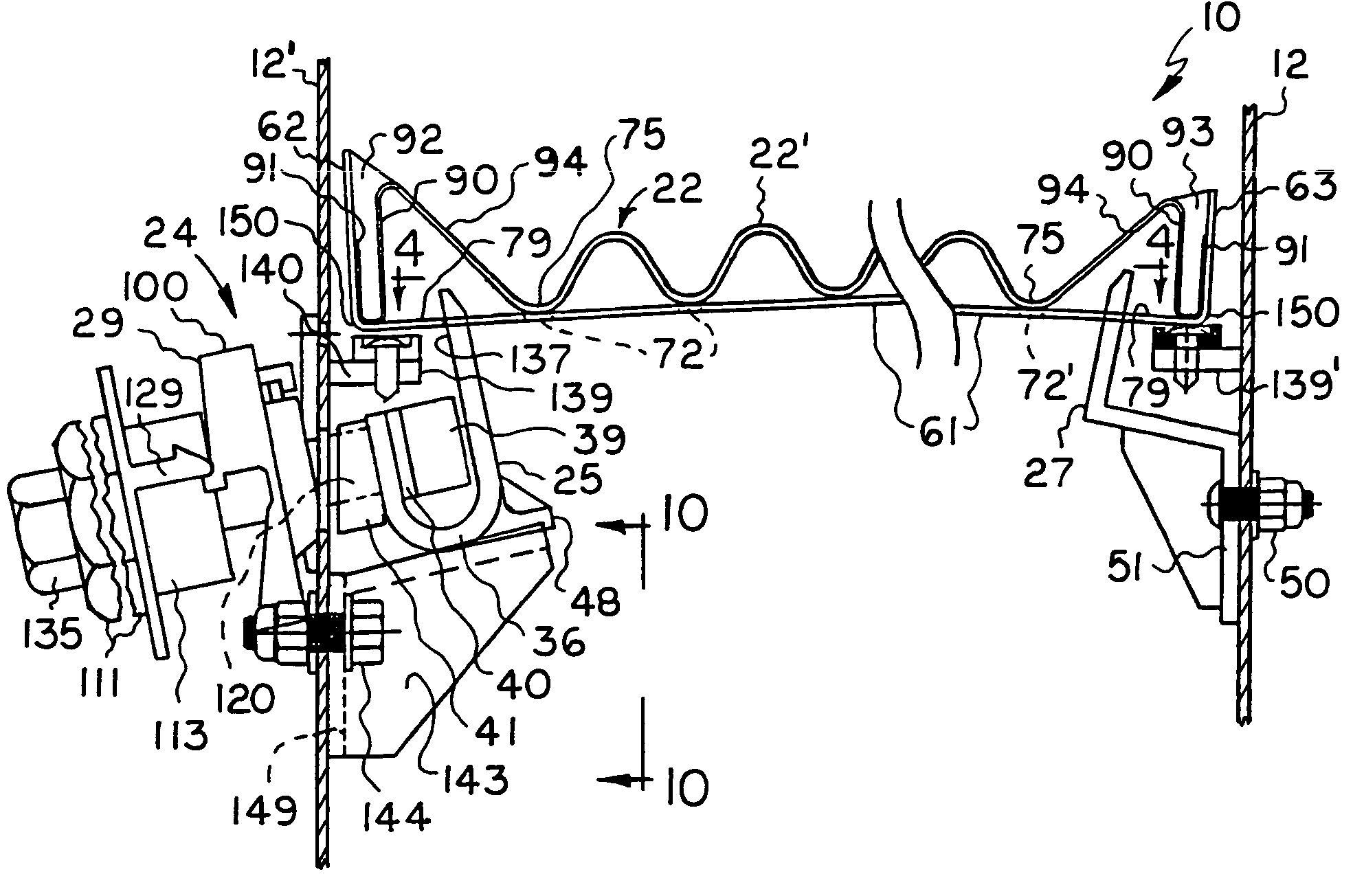

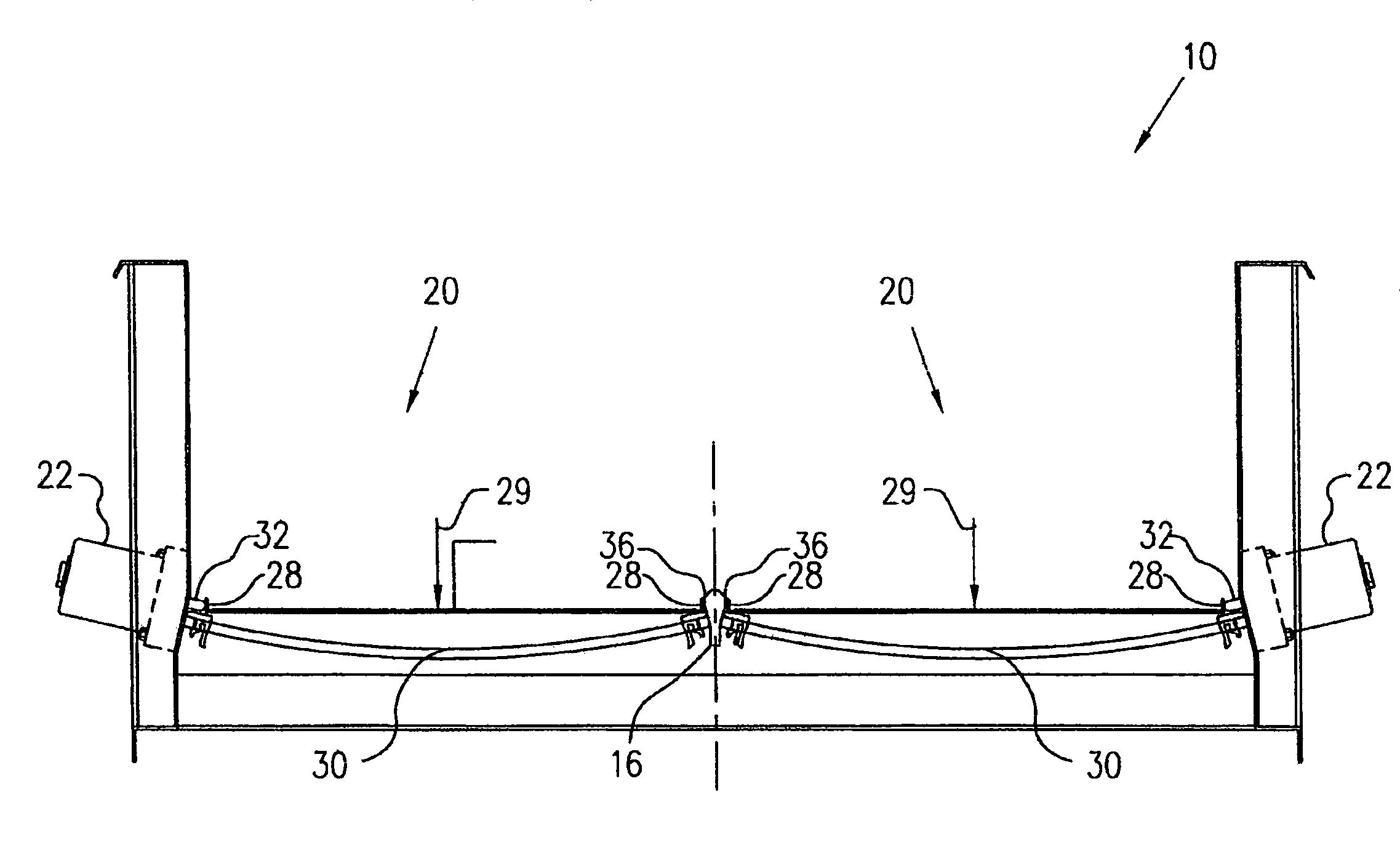

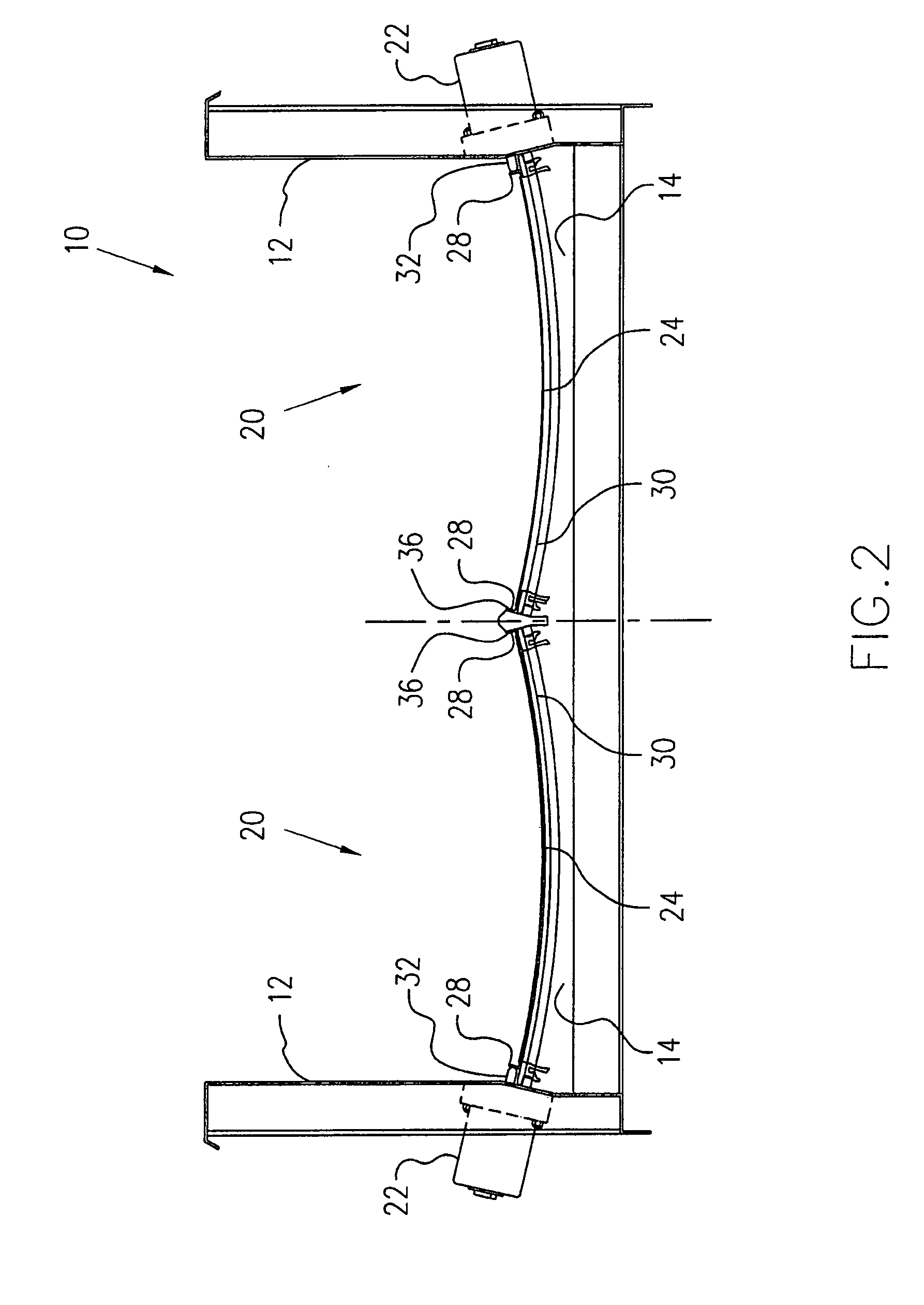

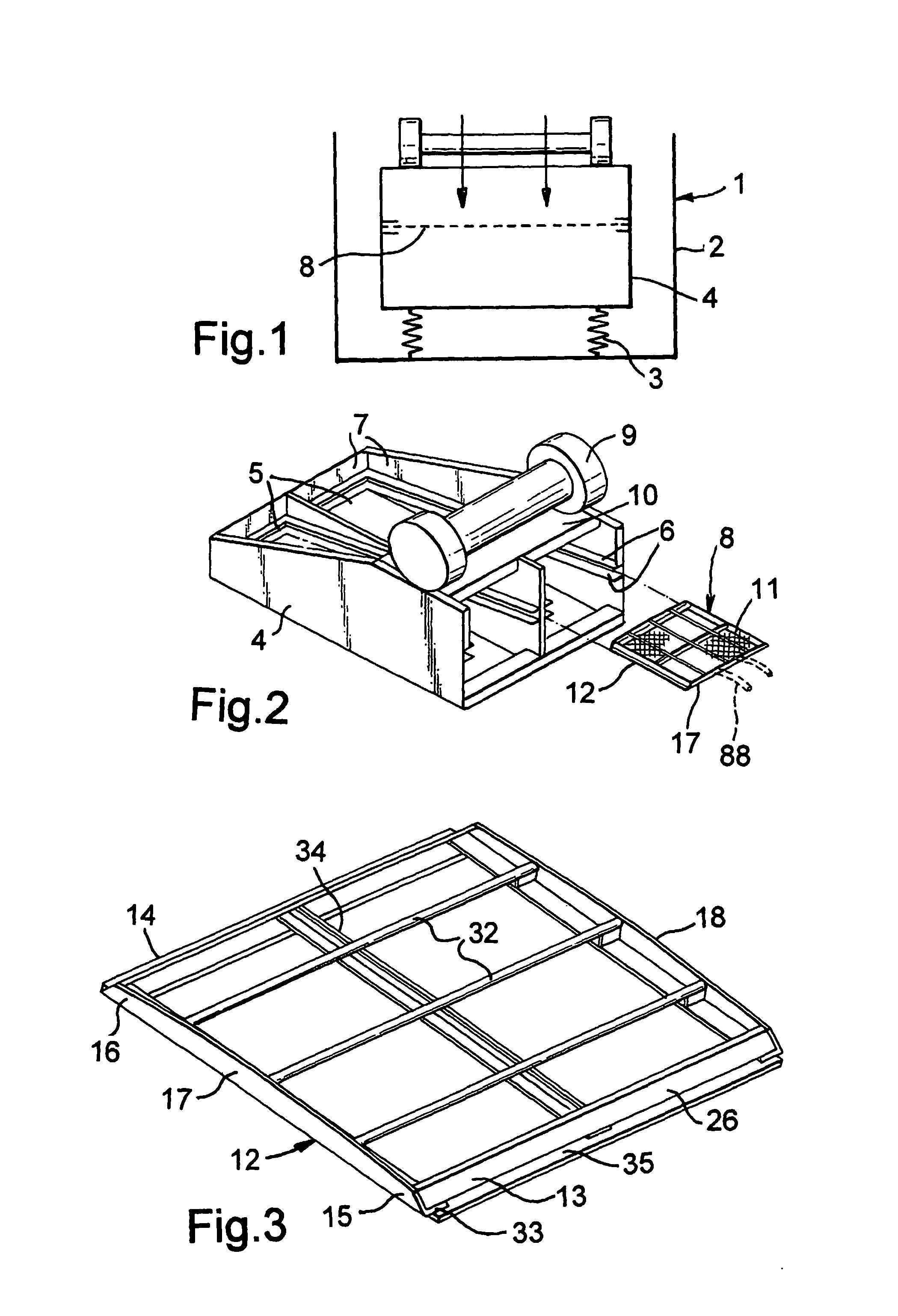

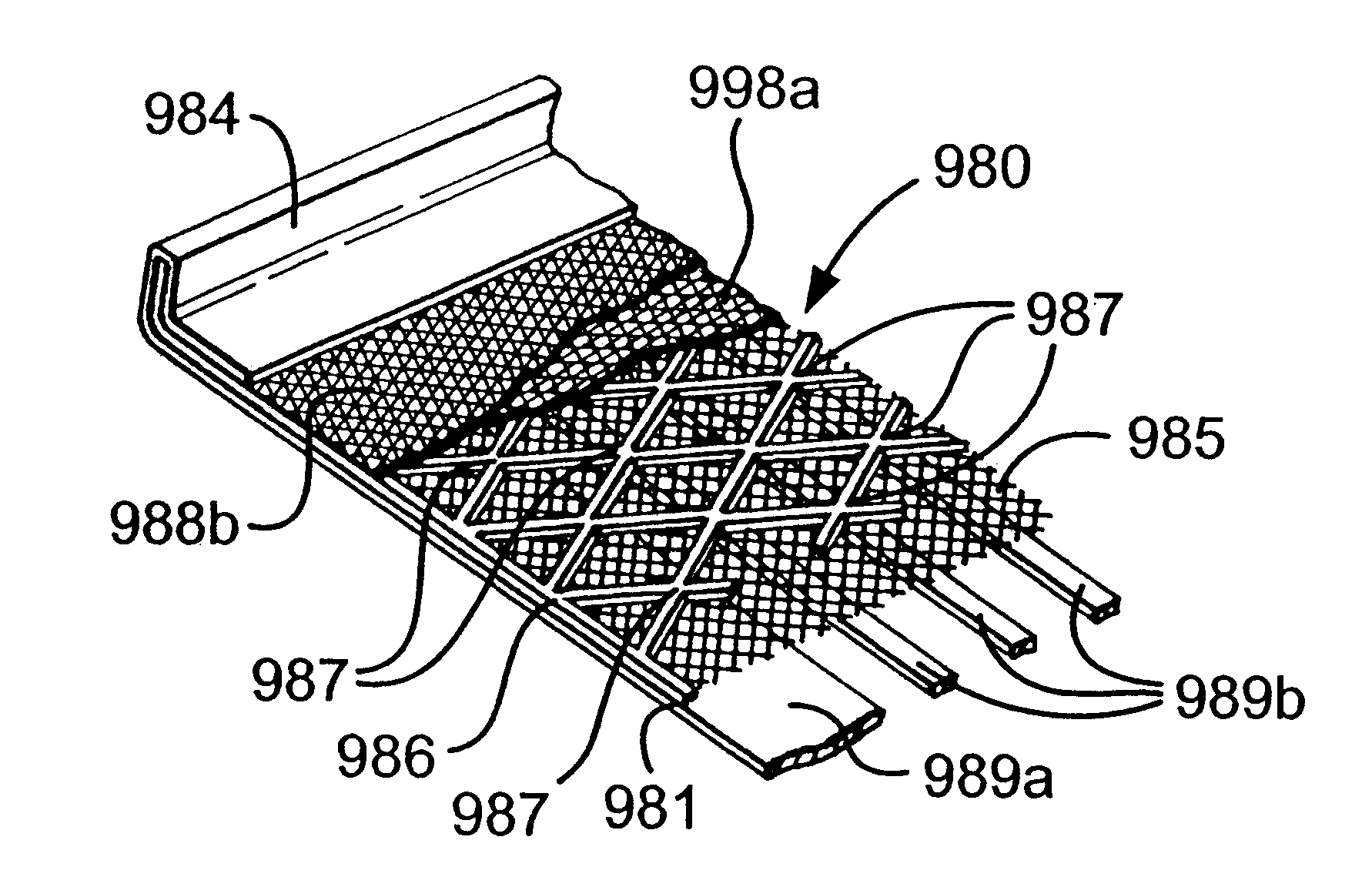

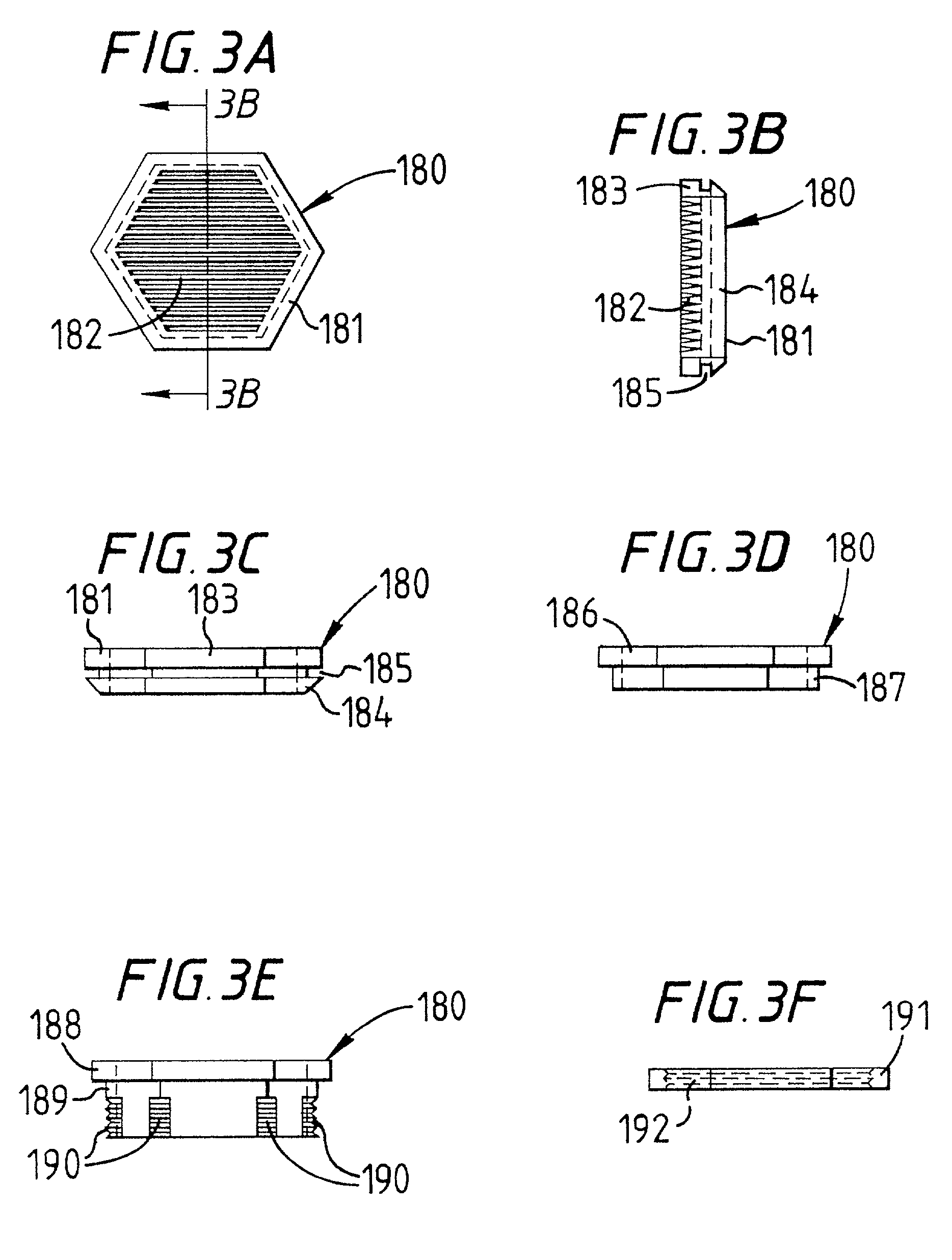

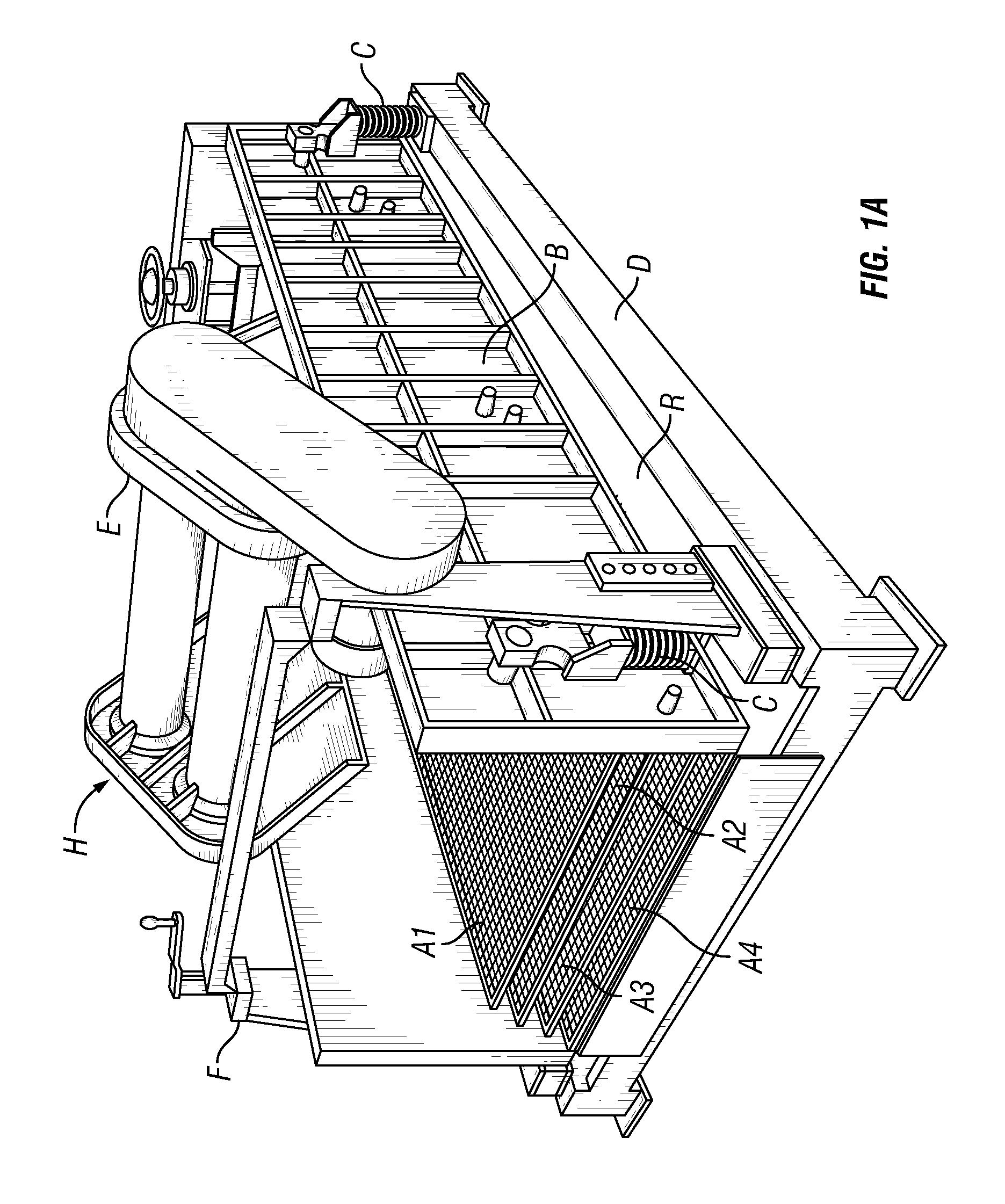

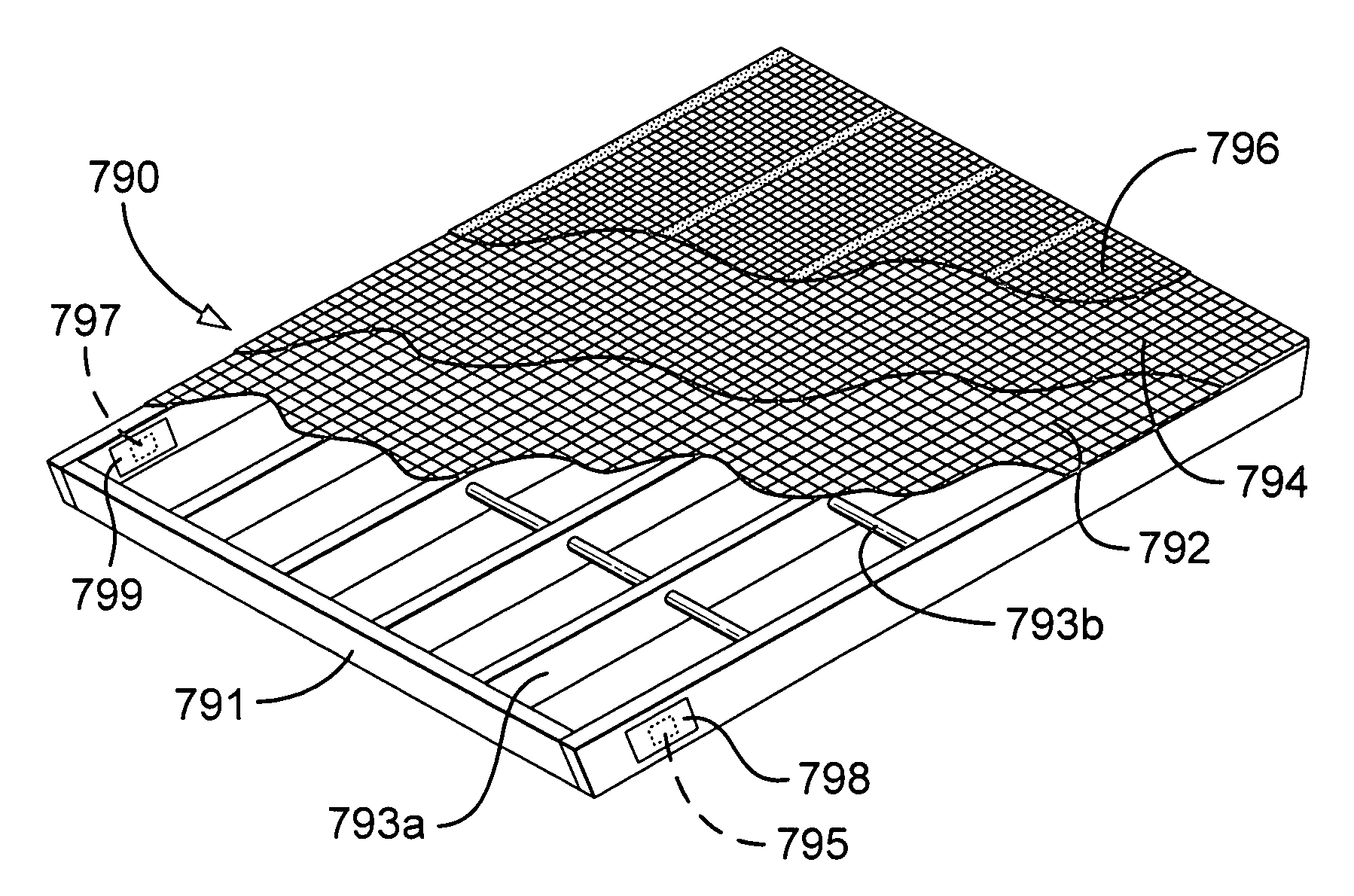

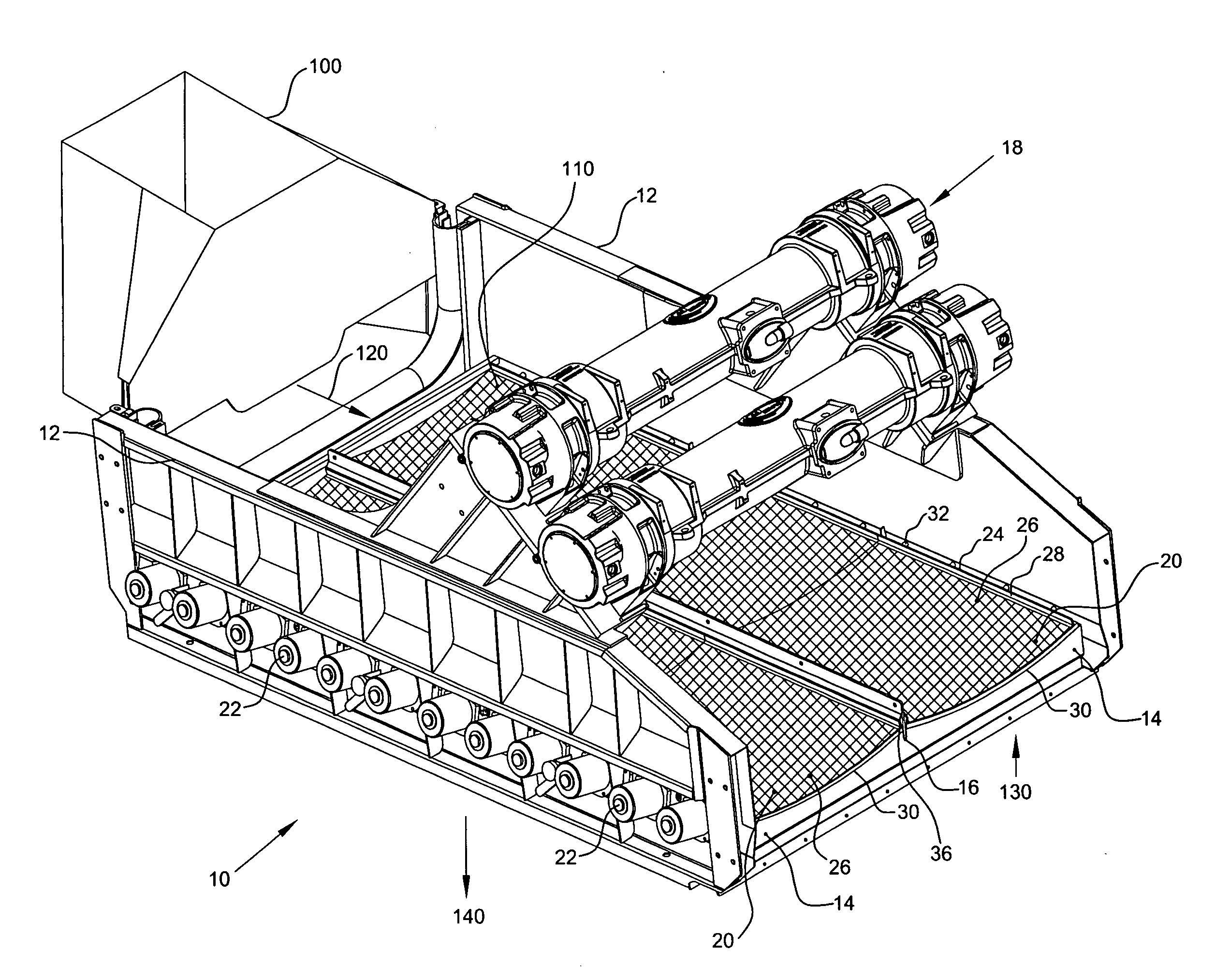

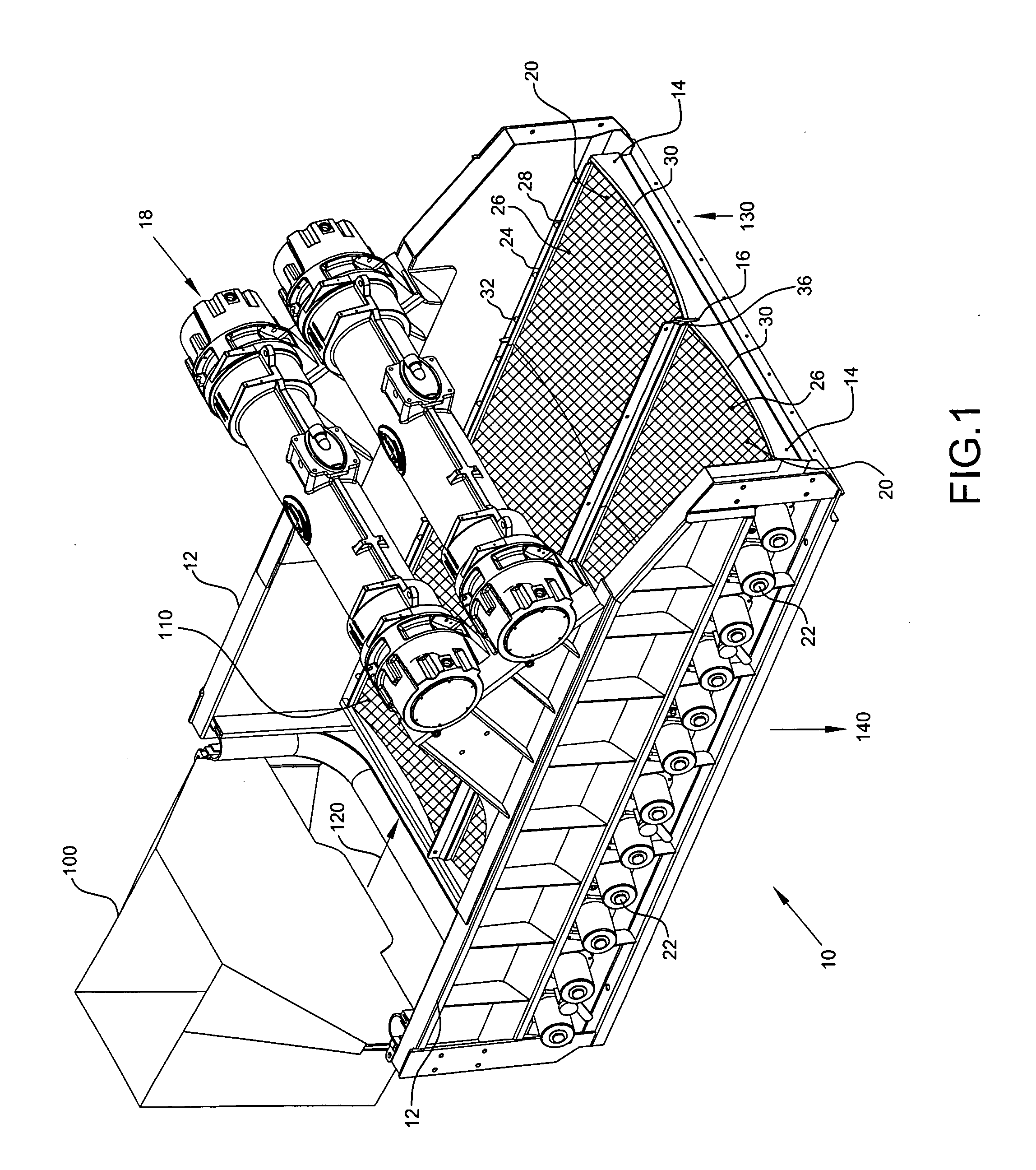

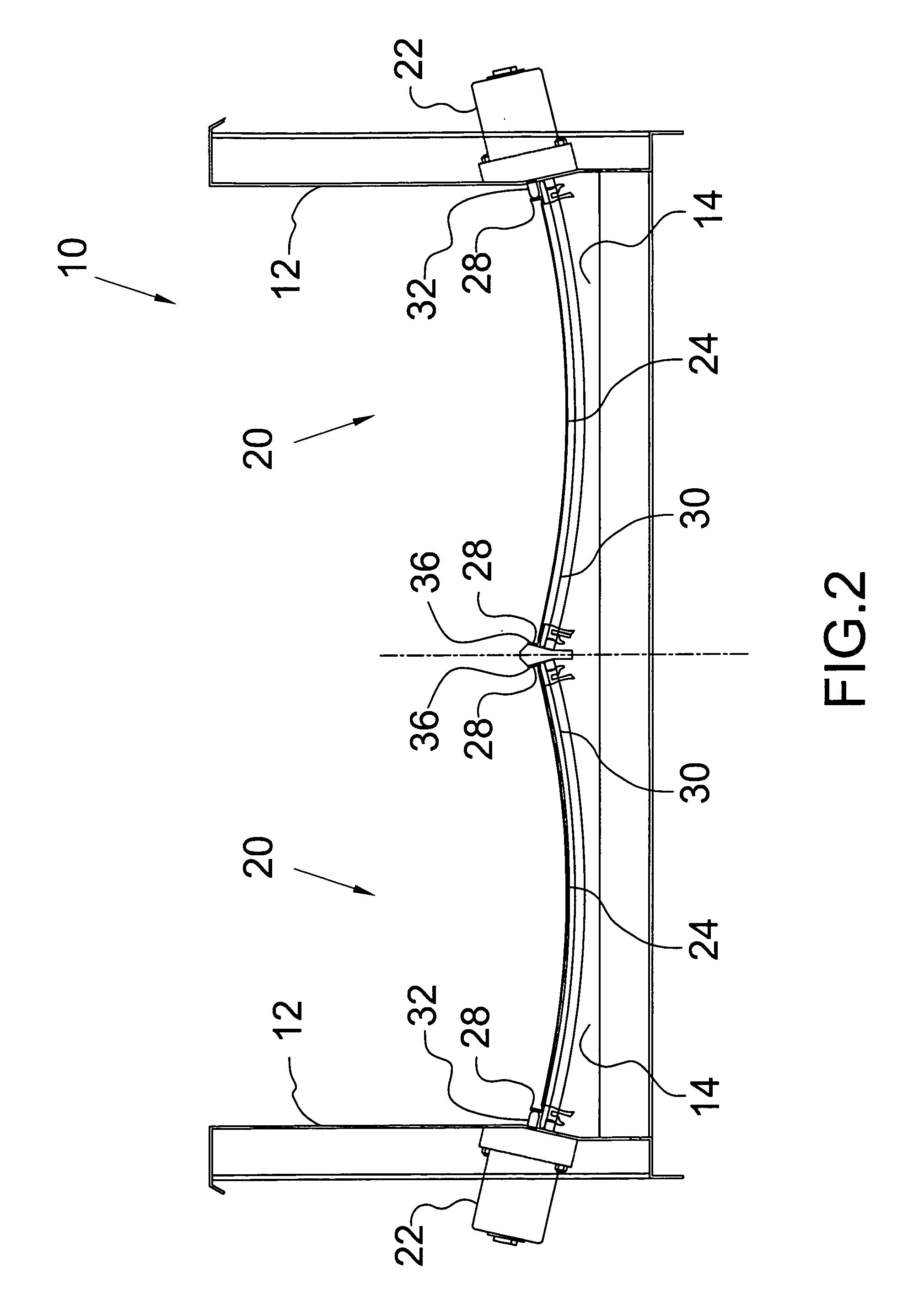

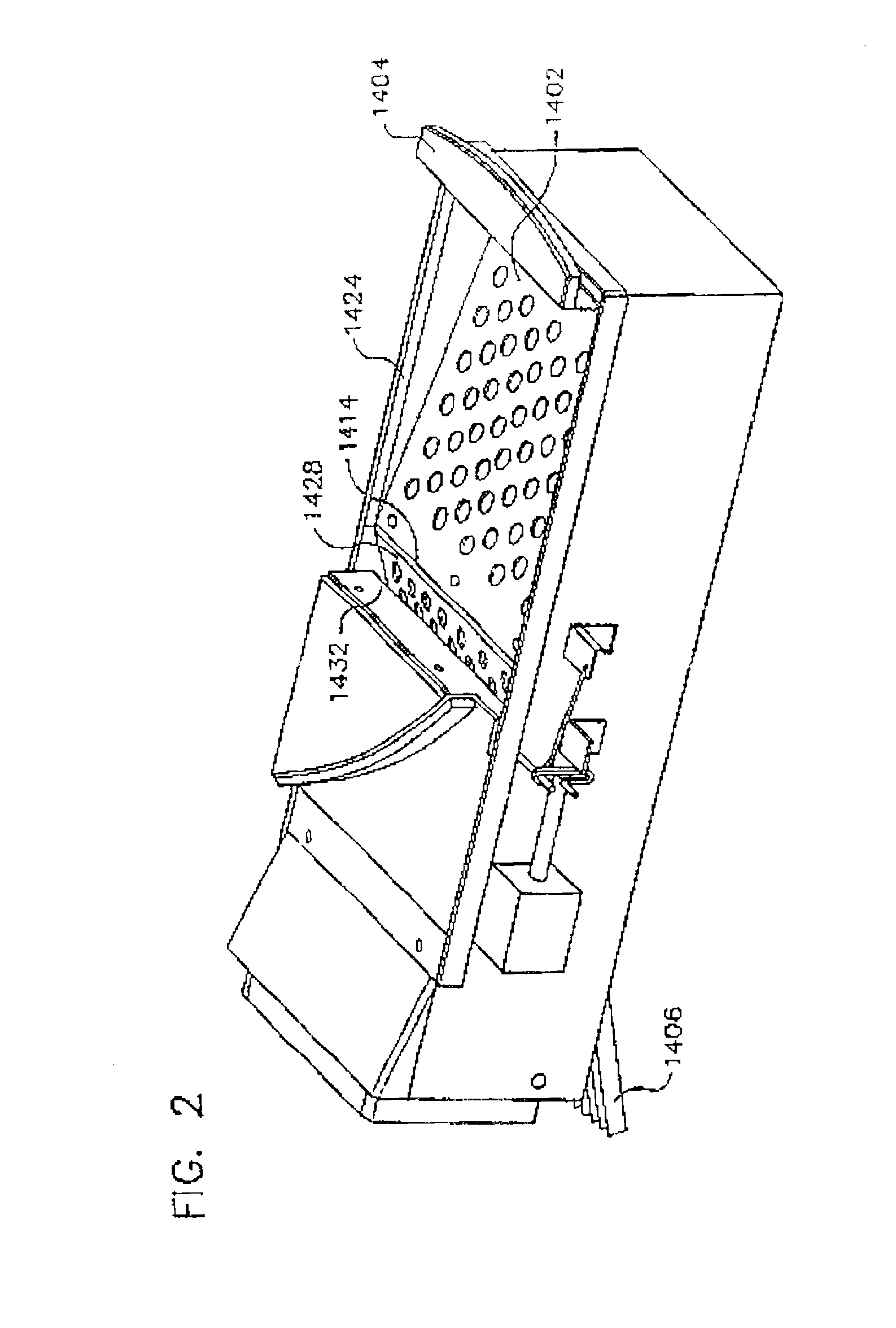

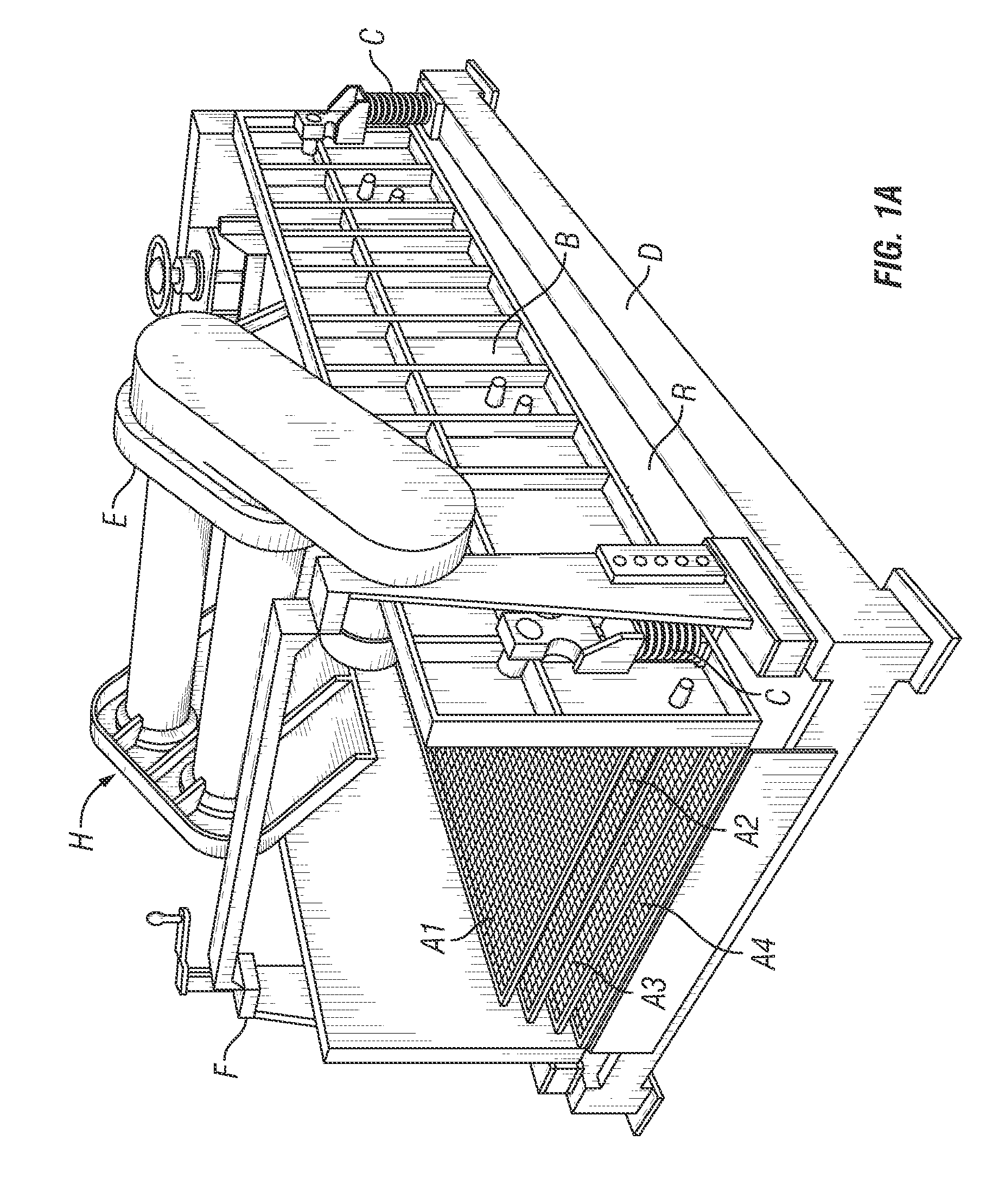

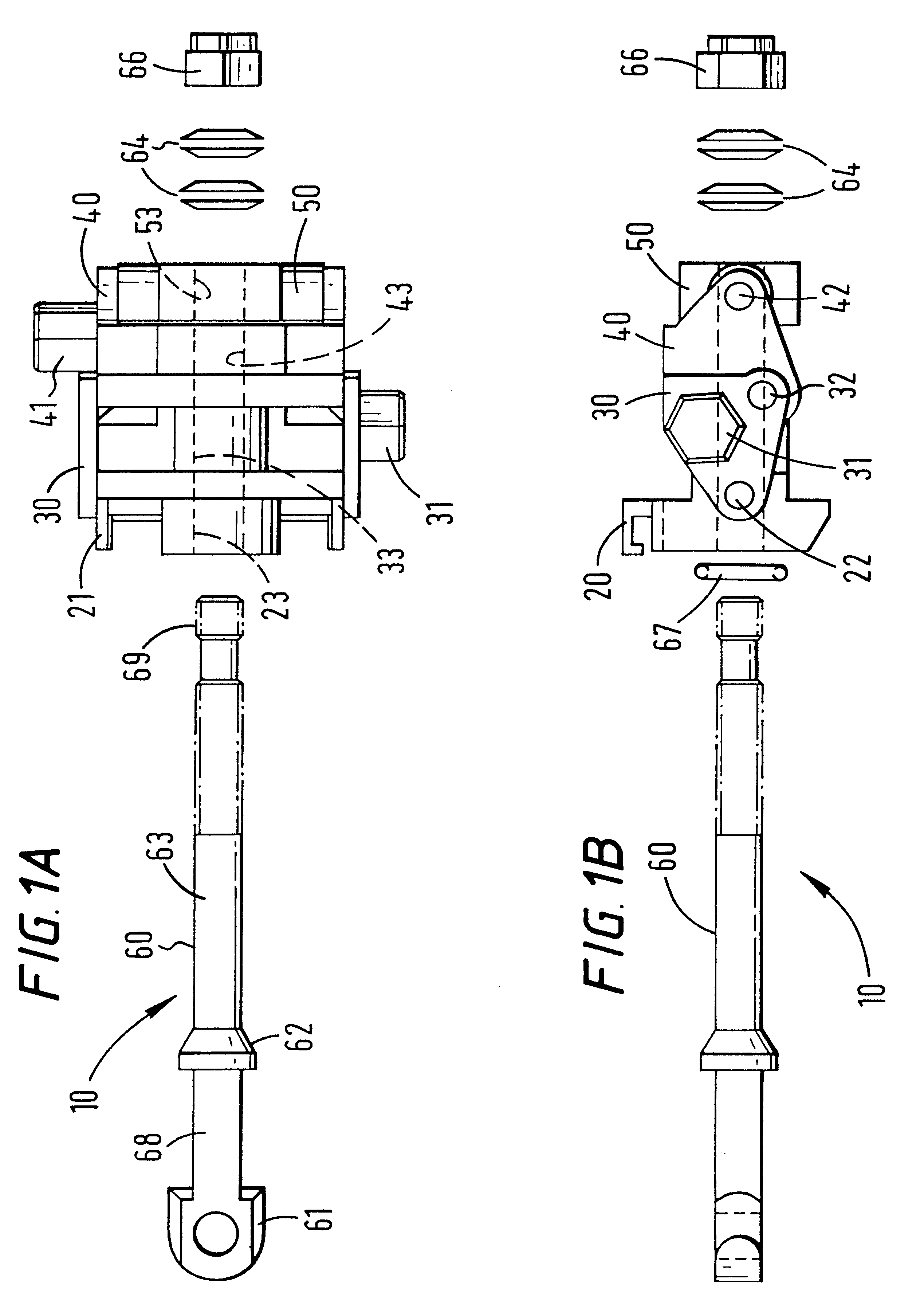

Vibratory screening machine and vibratory screen and screen tensioning structure

InactiveUS7228971B2Rapid mounting and demountingEasy to install and arrangeSievingScreeningEngineeringMechanical engineering

A vibratory screening machine having opposite sides with a plurality of stationary aligned tensioning members mounted on one side and a plurality of nut actuated movable tensioning members mounted on the opposite side and a vibratory screening screen mounted on the stationary and movable tensioning members. The tensioning members have upstanding fingers which are received in apertures in the plates of the vibratory screen, and the edge portions of the vibratory screen include screening material which extends all of the way to the extreme edges of the supporting plate and the fingers are below the screening material. Also, the tensioning structure is mounted on the side walls of the vibratory screening machine below the vibratory screen.

Owner:DERRICK CORP

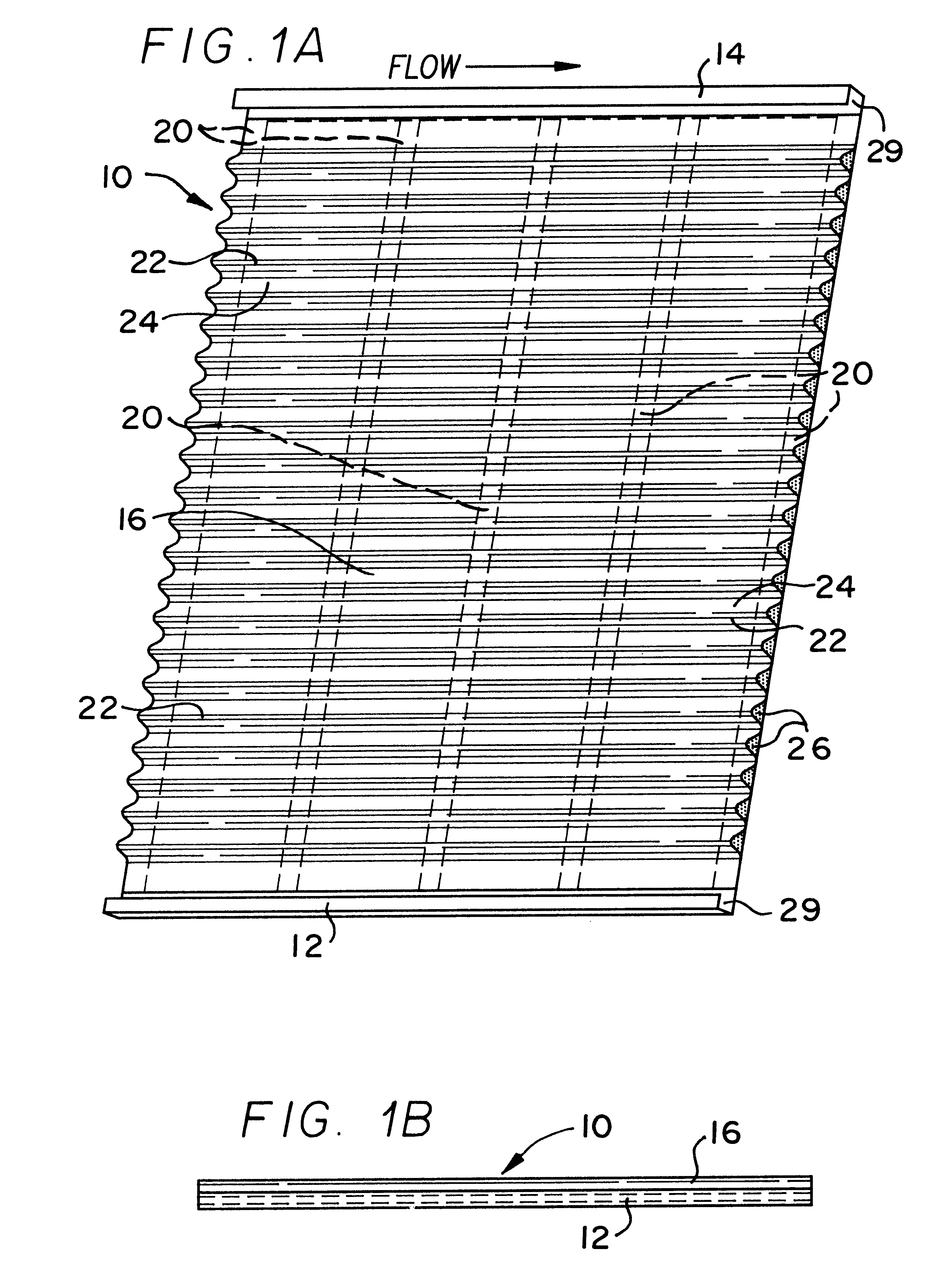

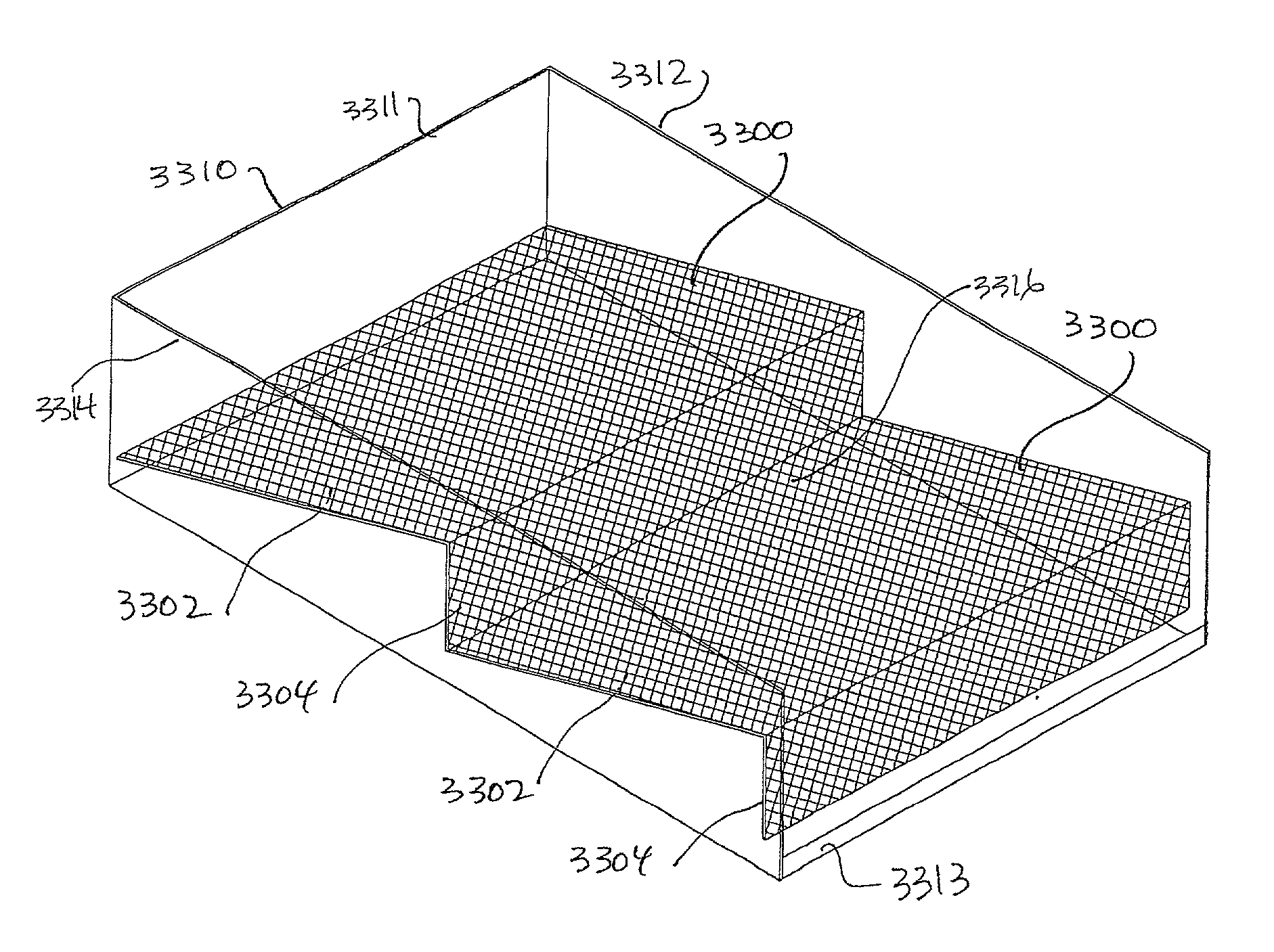

Screens for vibratory separators

InactiveUS6510947B1Material is facilitatedShorten the timeSievingScreeningElectrical and Electronics engineeringEngineering

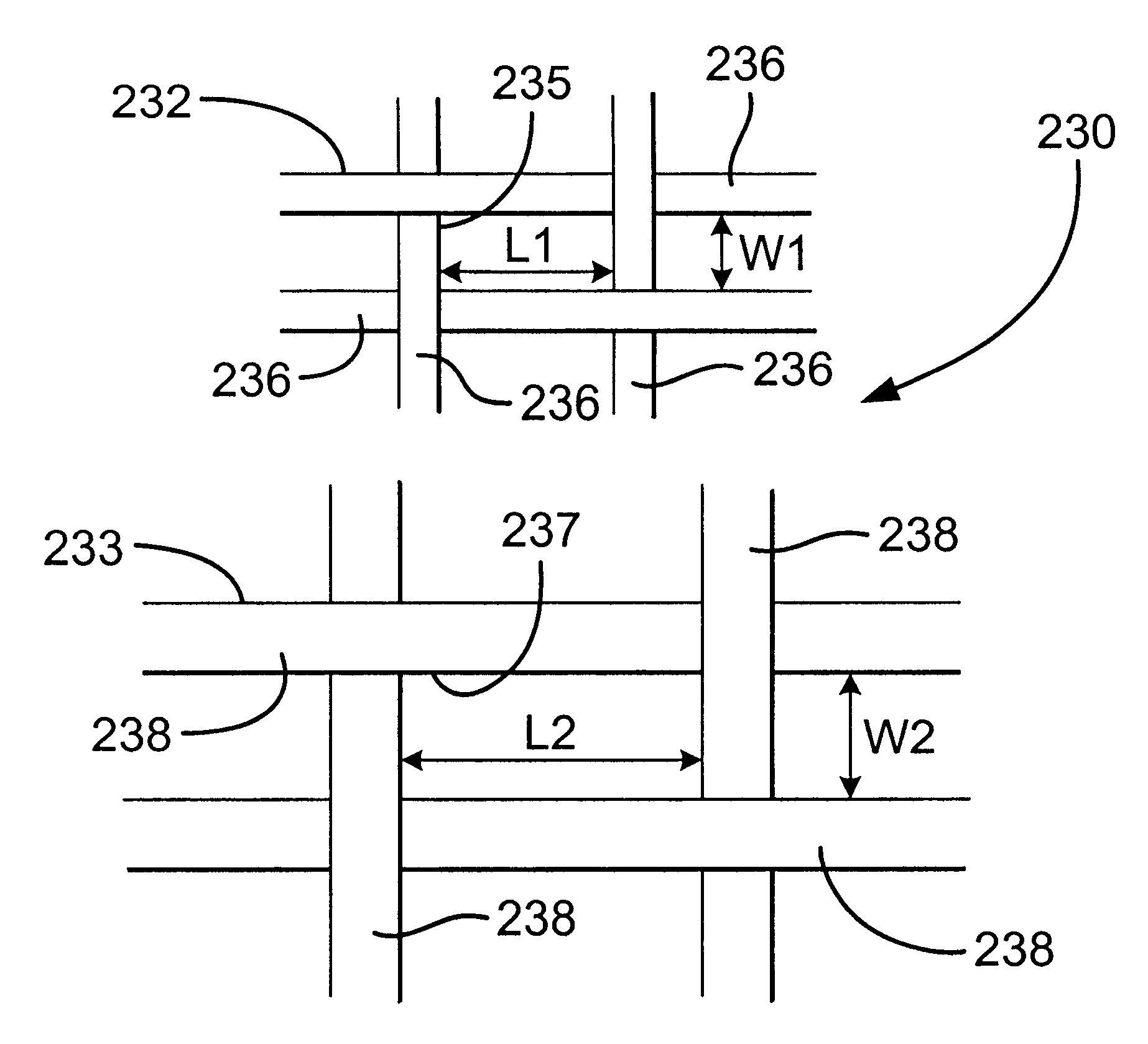

A screen assembly and methods for using it, the screen assembly including, in certain aspects, at least two layers of screening material one on top of the other and including at least a first layer over a second layer, each layer having screen mesh with rectangular openings as viewed from above, the first layer having first rectangular openings, and the second layer having second rectangular openings, each of the first rectangular openings having a first width and a first length, and each of the second rectangular openings having a second width and a second length, the ratio of the first length to the first width ranging between 1.55 and 2.00, the ratio of the second length to the second width ranging between 1.55 and 2.00, the ratio of the first length to the second width ranging between 0.95 and 1.05, and the lengths of the first rectangular openings are parallel to lengths of the second rectangular openings.

Owner:VARCO I P INC

Granules, tablets and granulation

ActiveUS20080111269A1Quick cureEasy to assemblePowder deliveryElectrostatic separationMaterials scienceAirflow

The invention provides, inter alia, a method for producing granules from a powder, characterized in that a low compaction force is applied to the powder to produce a compacted mass comprising a mixture of fine particles and granules and separating fine particles from the granules by entraining the fine particles in a gas stream. Also provided are apparatus for use in the process and tablets formed by compression of the resultant granules.

Owner:ATACAMA LABS OY

Method and apparatuses for screening

Owner:DERRICK CORP

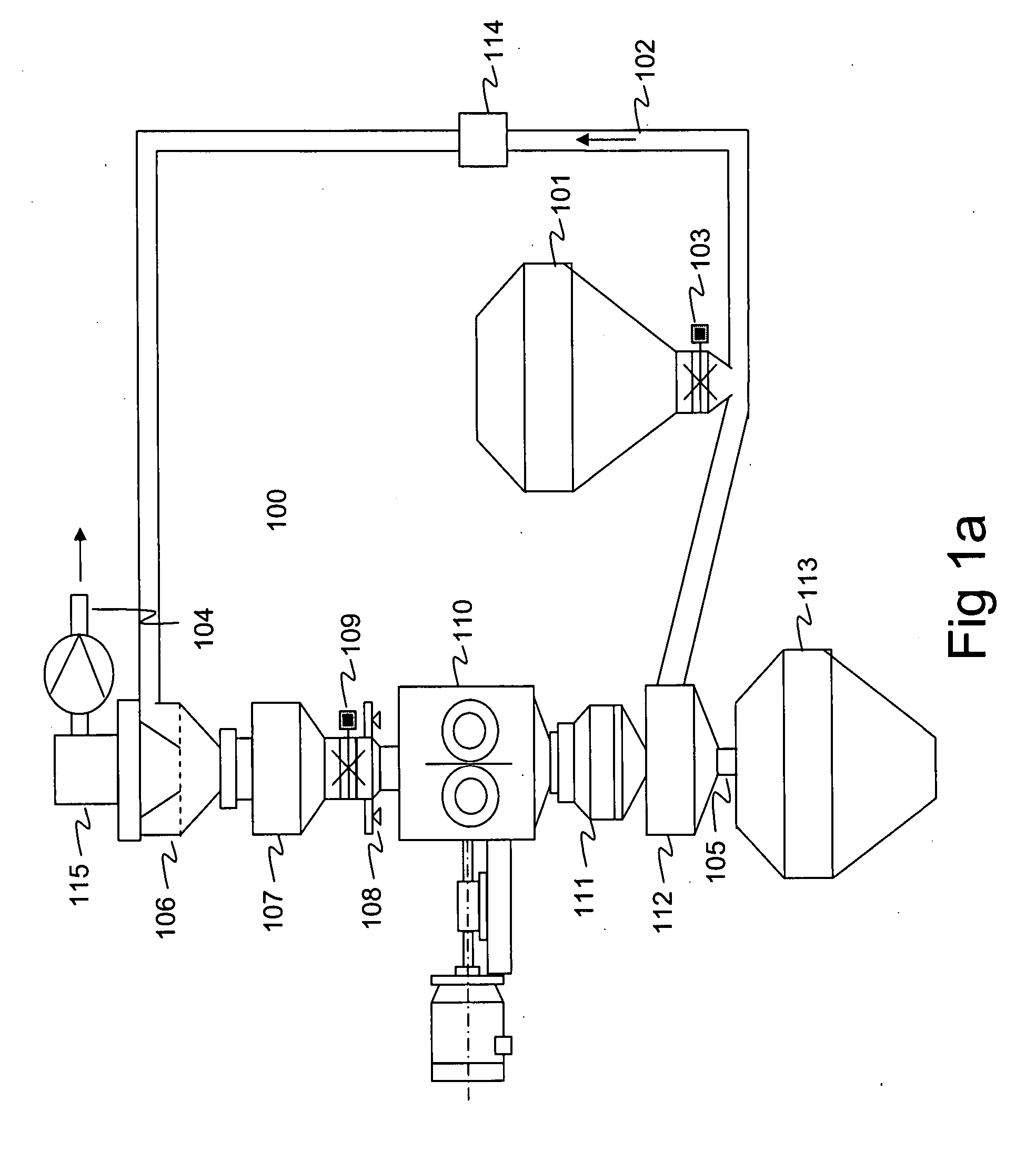

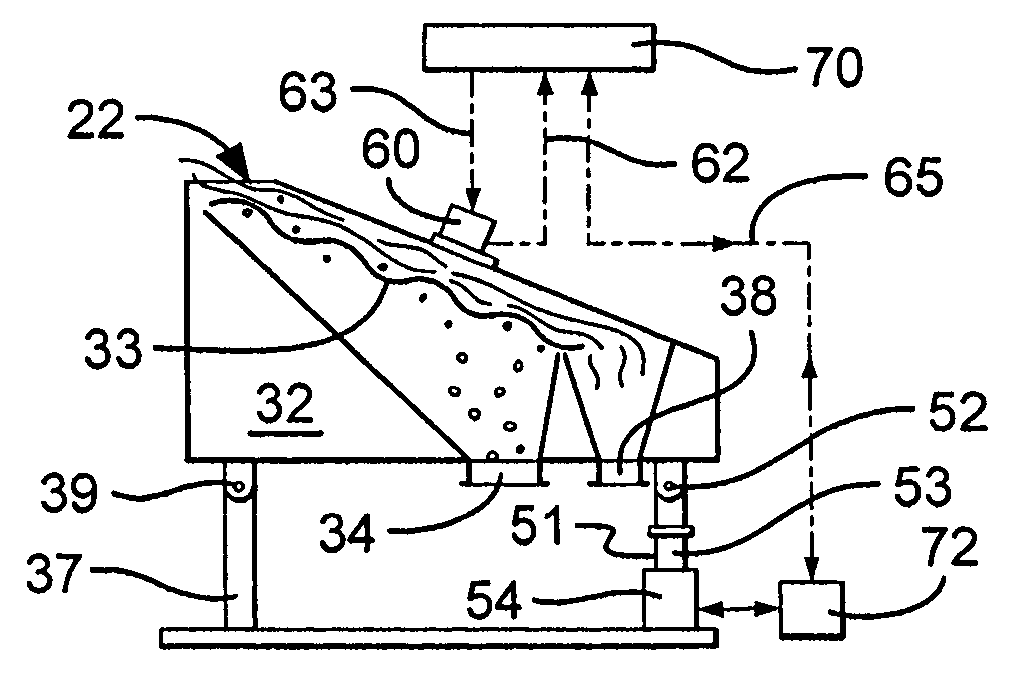

Automatic separator or shaker with electromagnetic vibrator apparatus

InactiveUS20060243643A1Affect effectivenessAffect screening efficiencySievingScreeningMechanical engineeringDrilling fluid

A vibratory separator (in one aspect, a shale shaker) and methods for using it, the separator in certain aspects having a base, a basket movably mounted on the base, screen apparatus on the basket, material flowing onto the screen apparatus for treatment, at least a portion of the screen apparatus not inclined downhill (e.g. said portion horizontal or uphill), electromagnetic vibratory apparatus connected to the basket for vibrating the basket and the screen apparatus, driving apparatus for driving the electromagnetic vibratory apparatus, and control apparatus (on-site and / or remote) for controlling the driving apparatus and the electromagnetic vibratory apparatus; the material, in one aspect, being drilling fluid material with solids therein.

Owner:VARCO I P INC

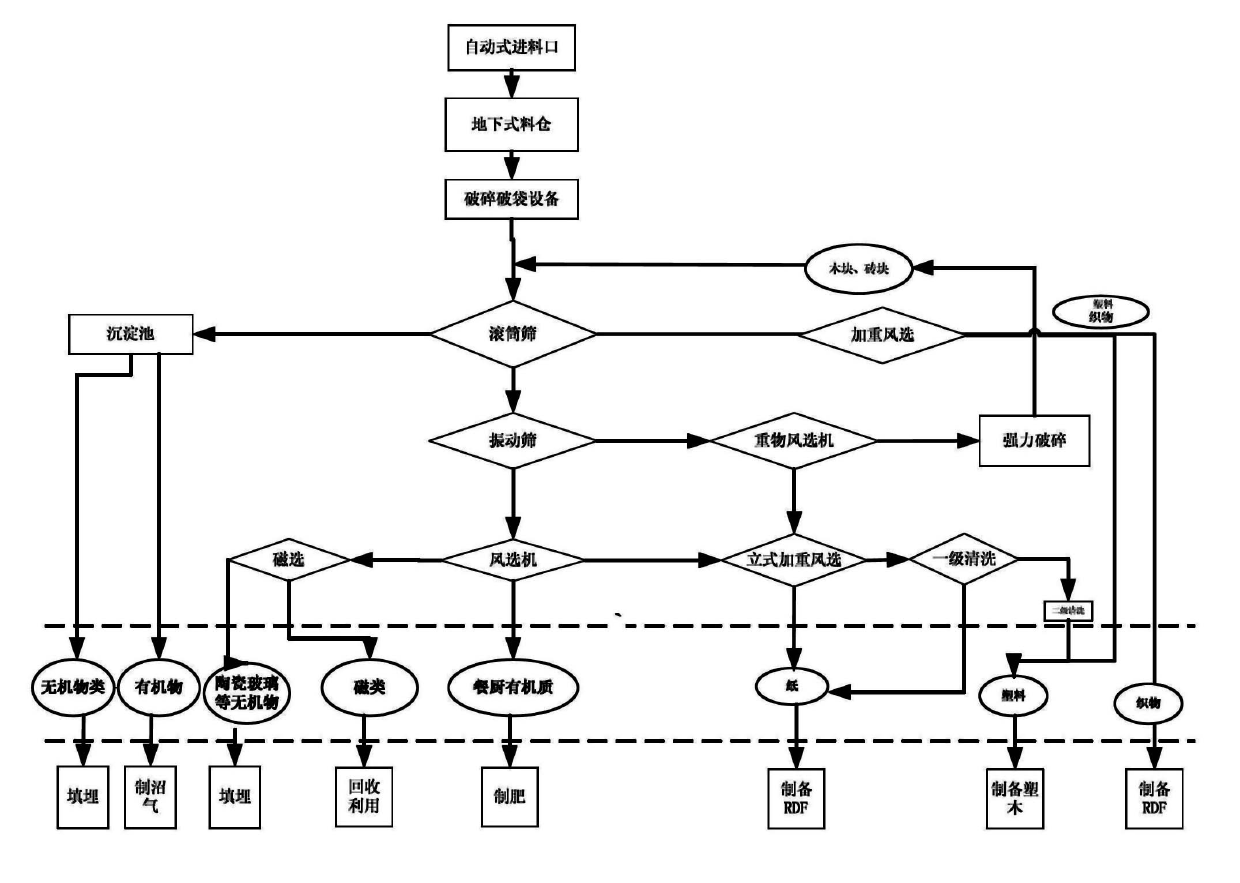

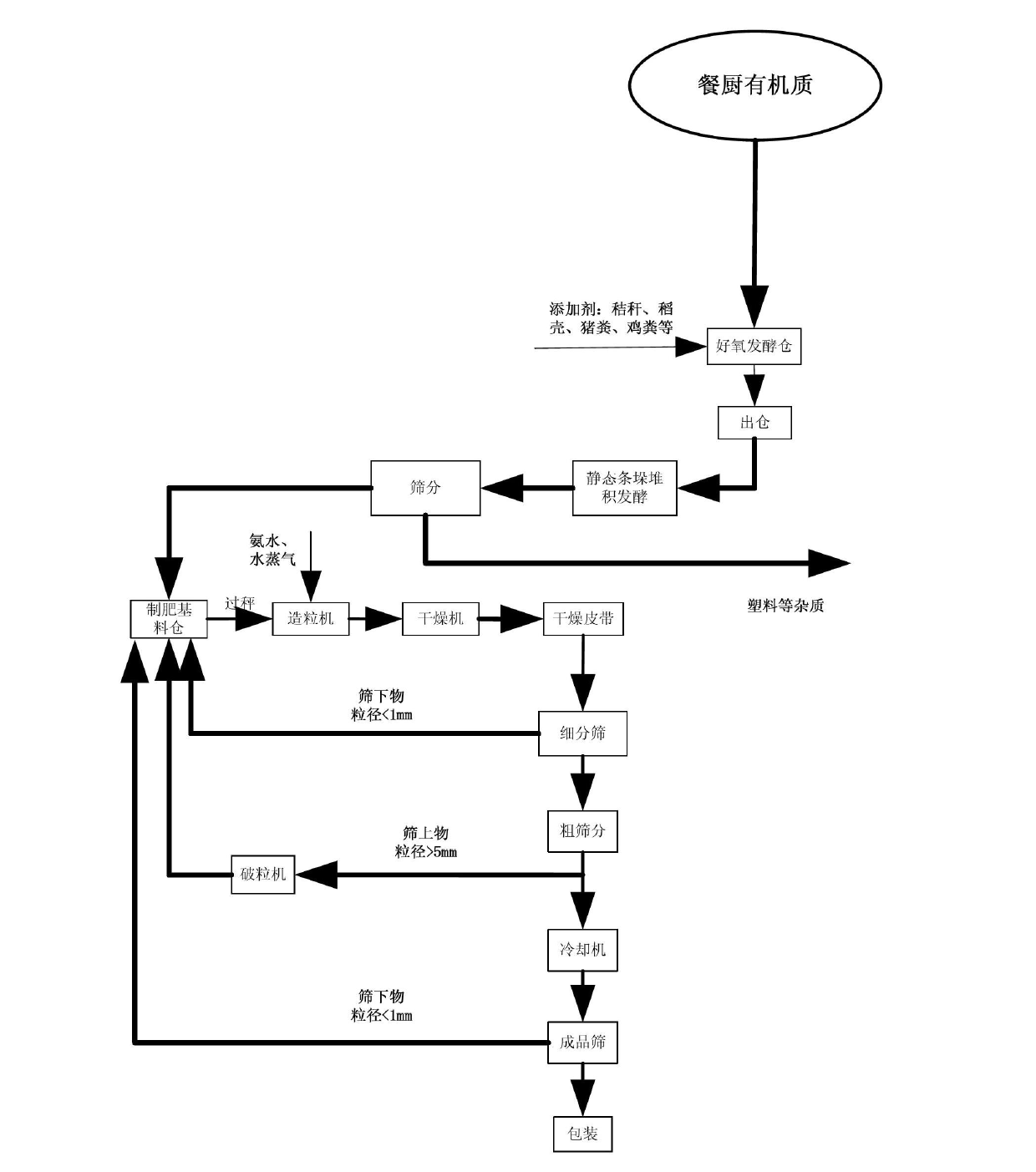

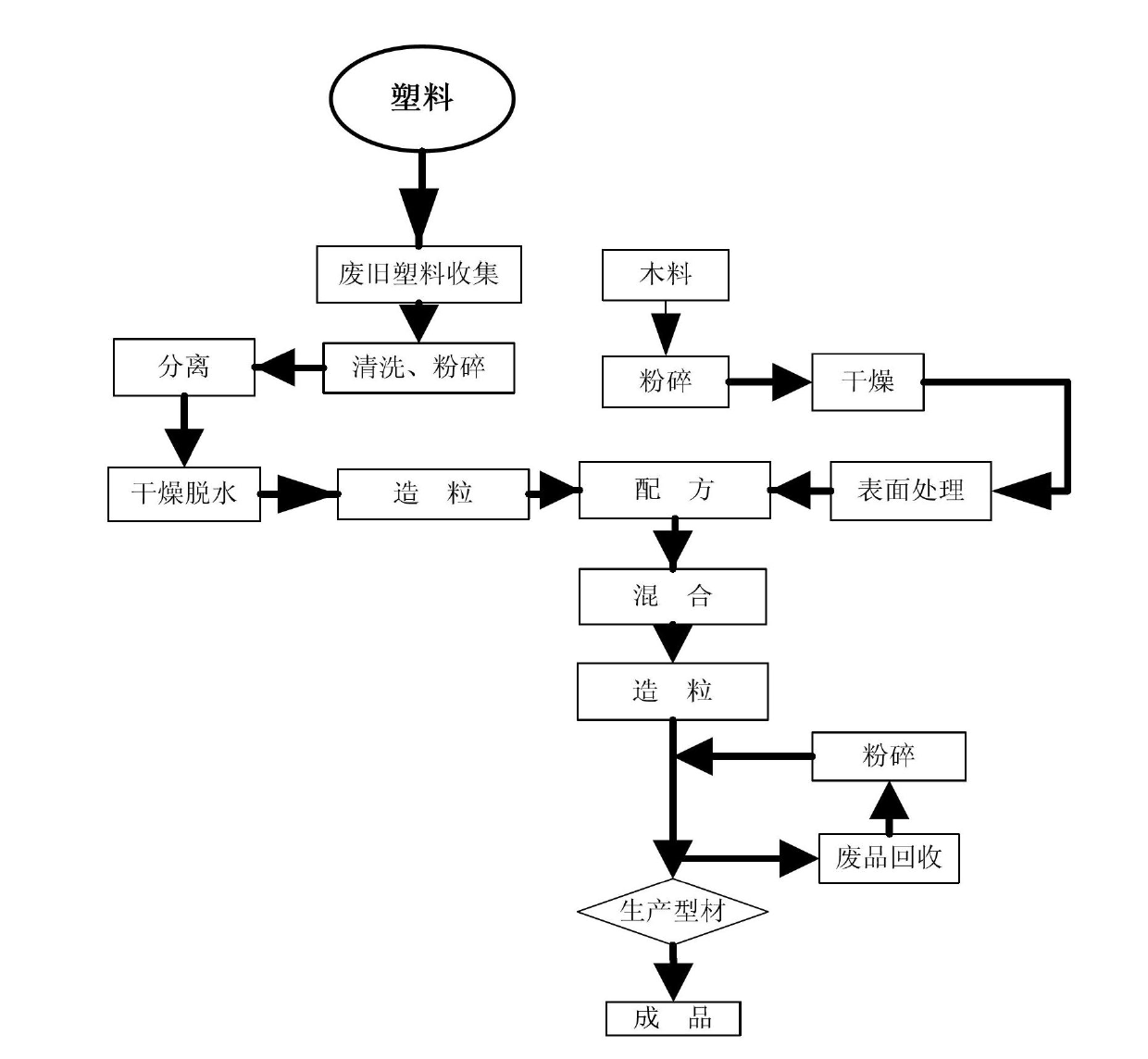

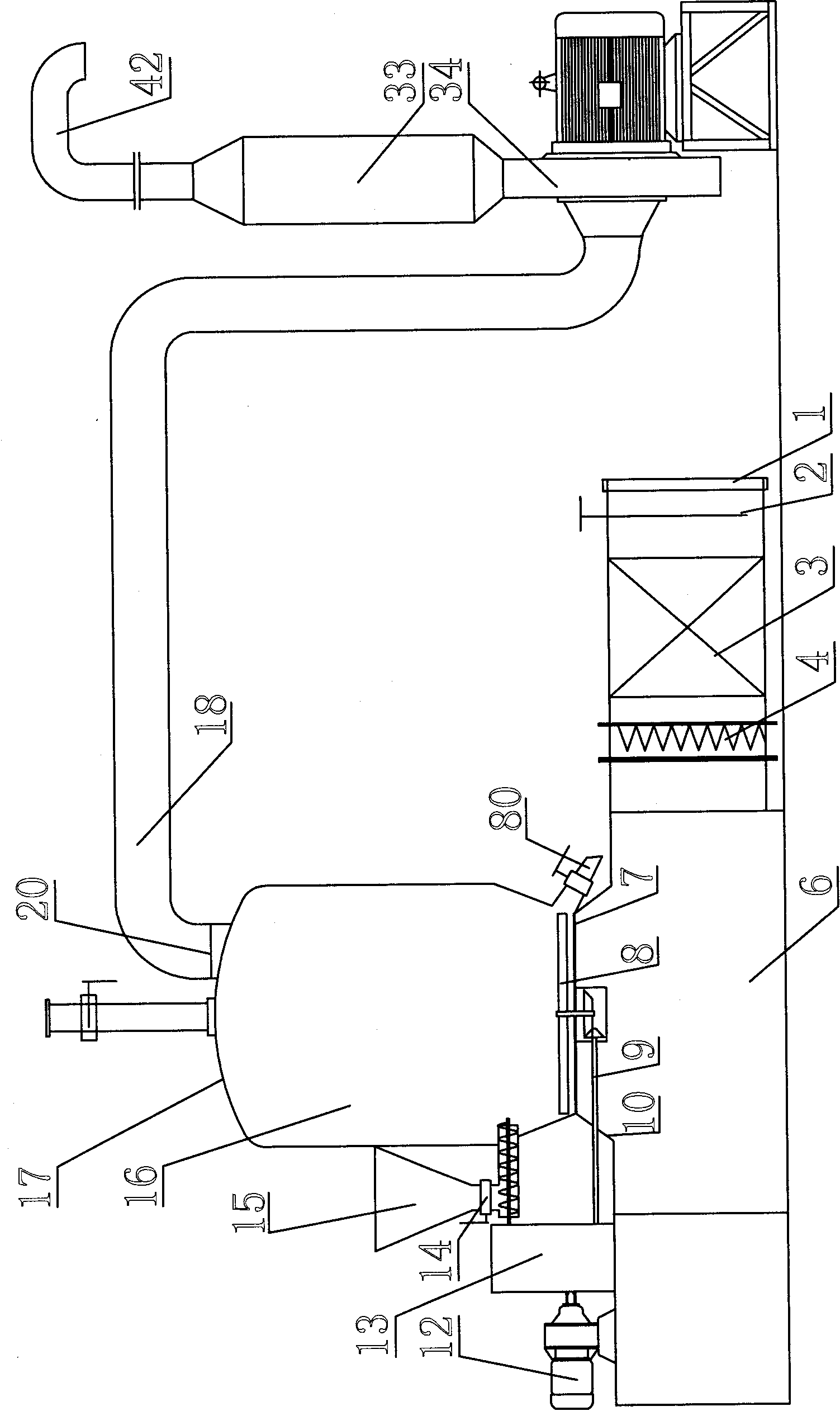

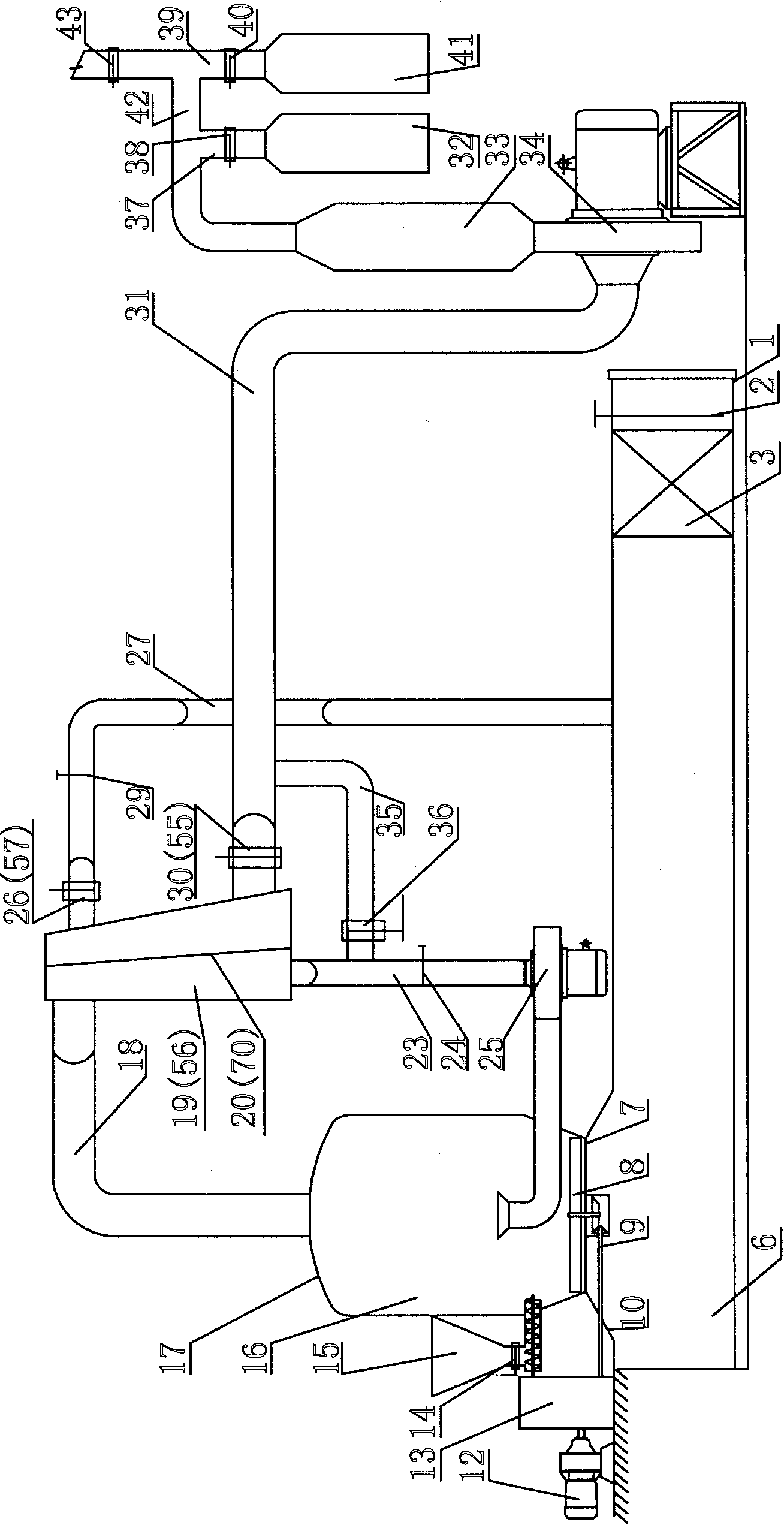

Method for sorting and comprehensively using urban mixed garbage

InactiveCN102671928AStructural innovationRealize full mechanizationBio-organic fraction processingSolid waste disposalRefuse-derived fuelPulp and paper industry

The invention discloses a method for sorting and comprehensively using urban mixed garbage. The method comprises the following steps: 1) allowing the urban mixed garbage to enter a feed bin through a feeding hole, discharging, and introducing into crushing and bag breaking equipment; 2) breaking garbage bags and crushing block garbage by using the crushing and bag breaking equipment; 3) feeding the garbage subjected to crushing and bag breaking into a two-stage rotary screen, screening out dust of which the grain size is less than 3mm, and picking out strip substances; and 4) feeding the mixed garbage into a vibration screen, separating inorganic cakes, large-sheet plastics and paper from an oversize material by using a heavy winnowing machine, and winnowing heavy substances, light substances and intermediate substances from an undersized material in a double-wind chamber multifunctional winnowing machine. Sorting equipment is effectively combined, so that the mixed garbage is efficiently sorted and recycled; and the sorted paper and textiles, plastics and kitchen organics are respectively used for preparing garbage derived fuel, plastic wood and fertilizers.

Owner:SICHUAN CRUN ENVIRONMENTAL PROTECTION ENERGY TECH CO LTD +1

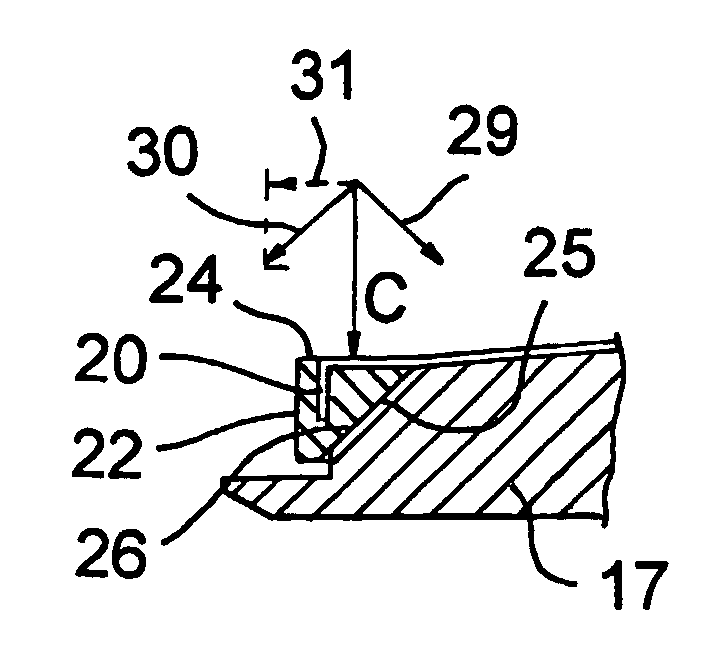

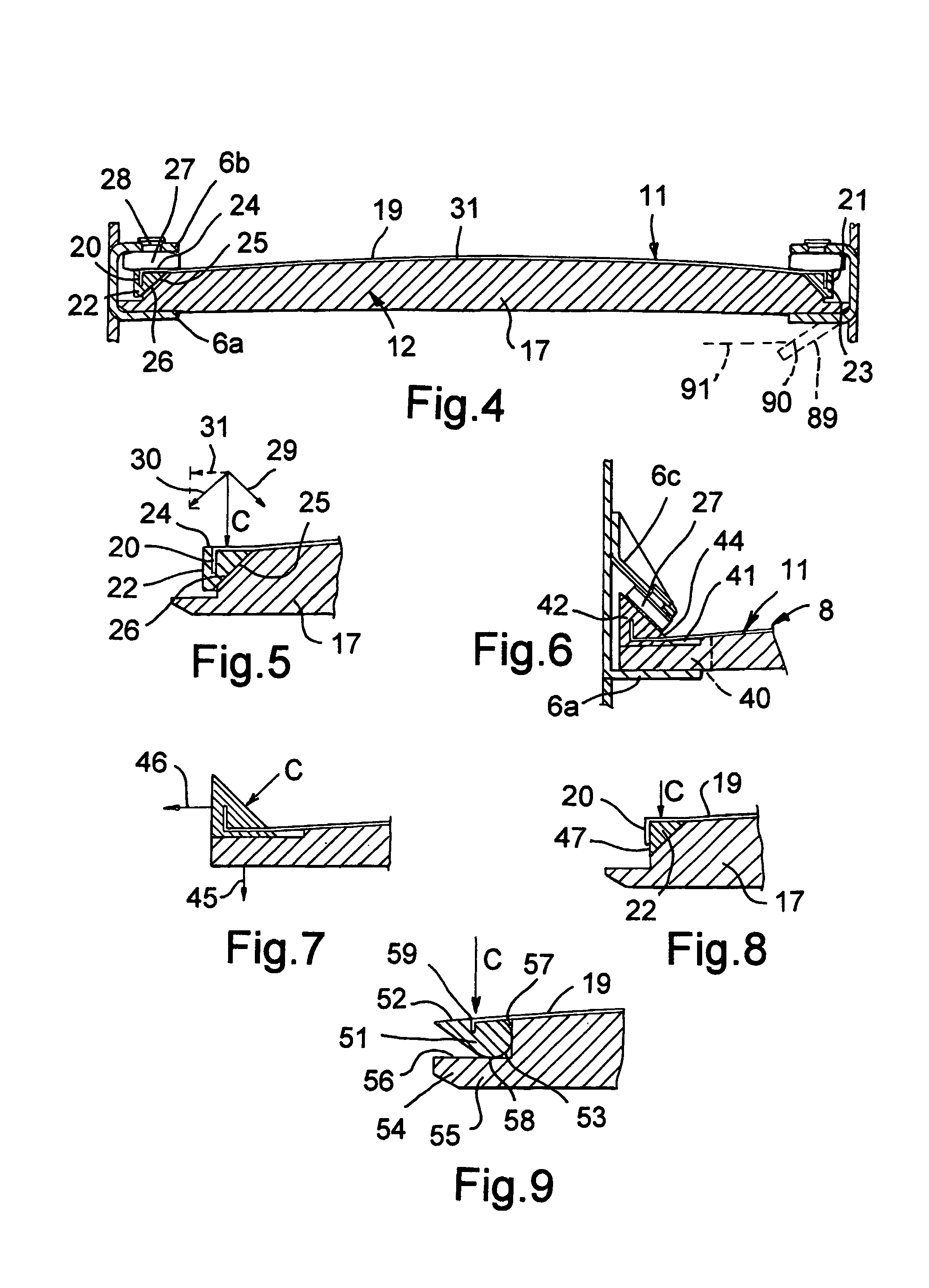

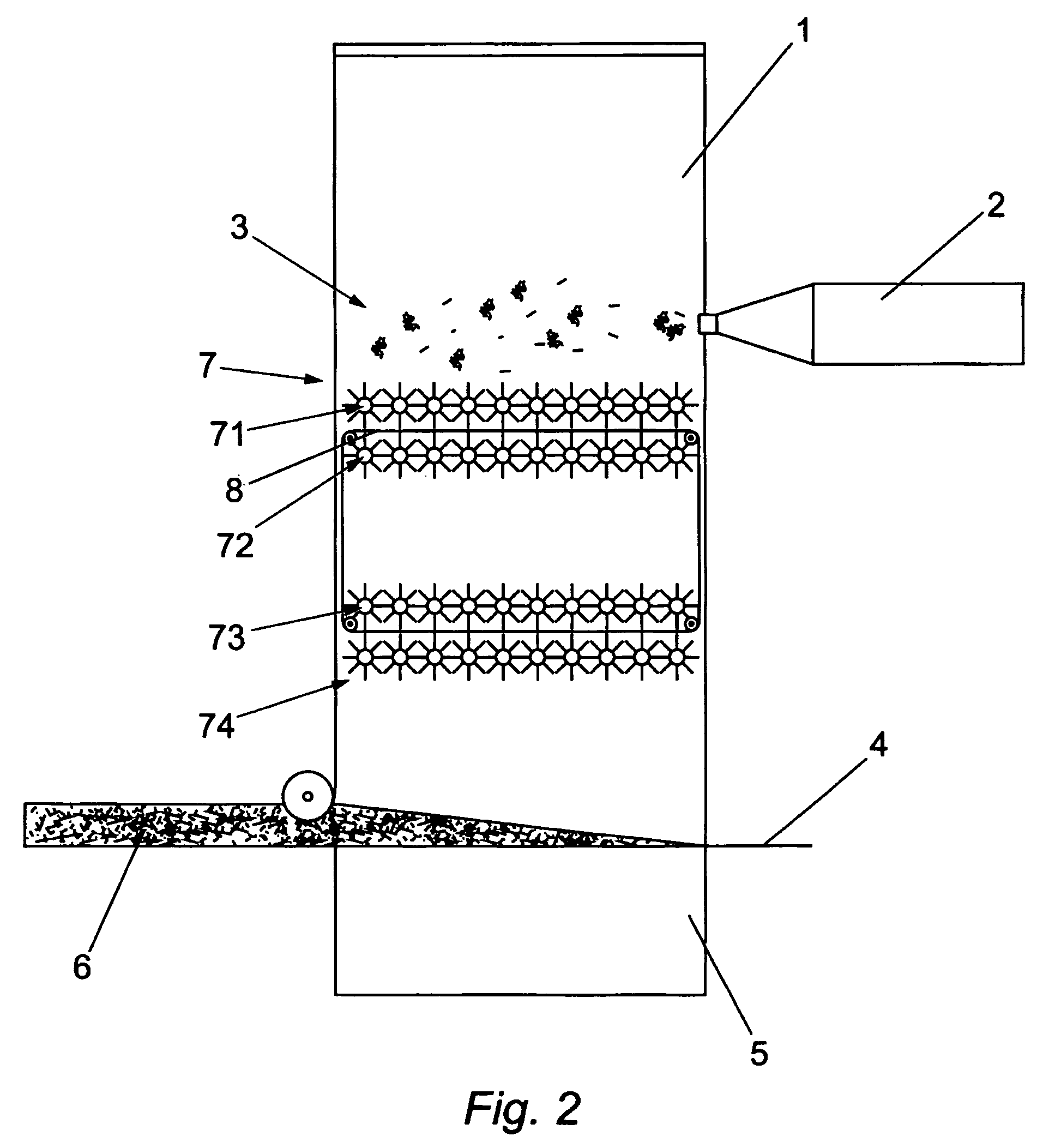

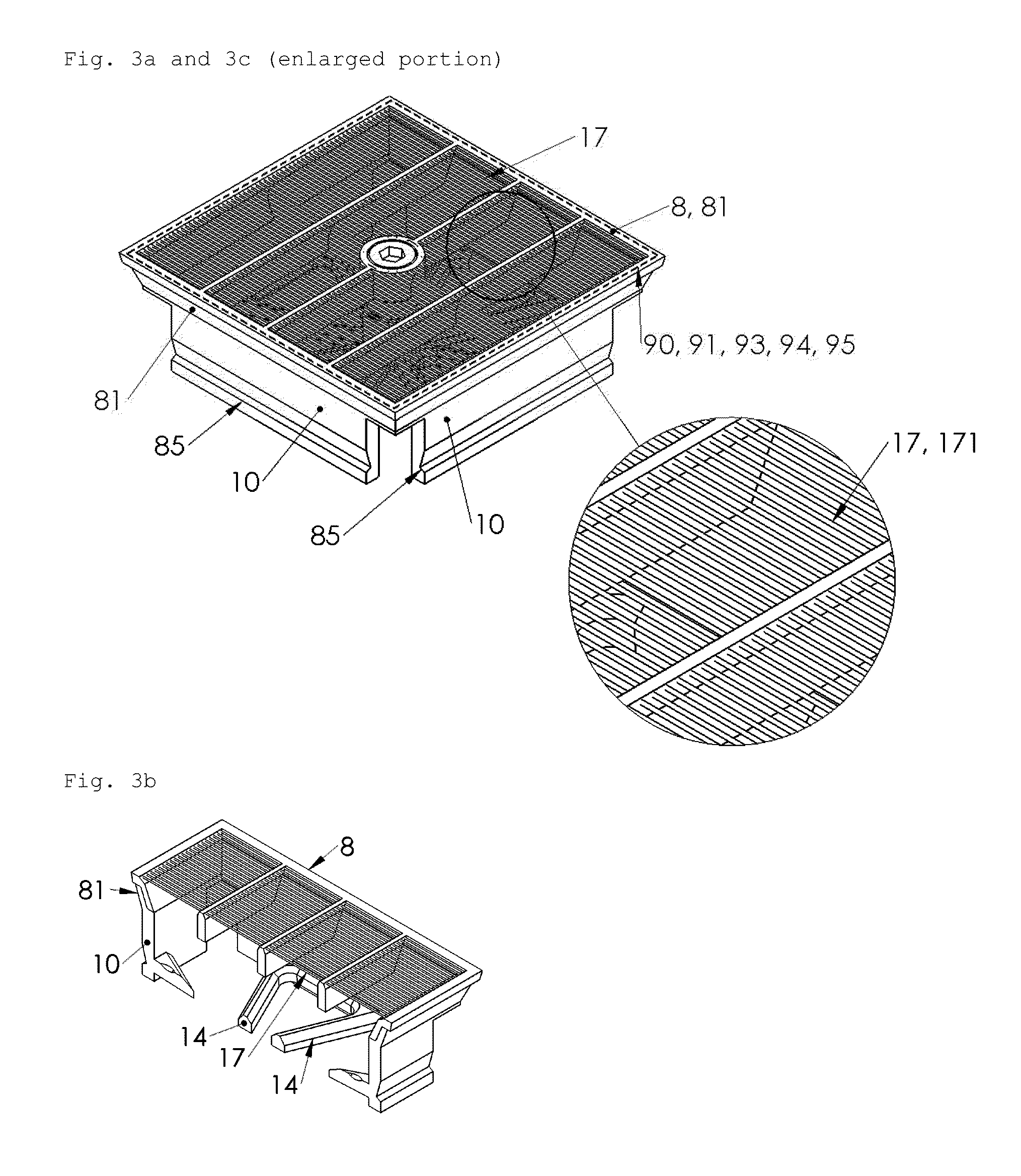

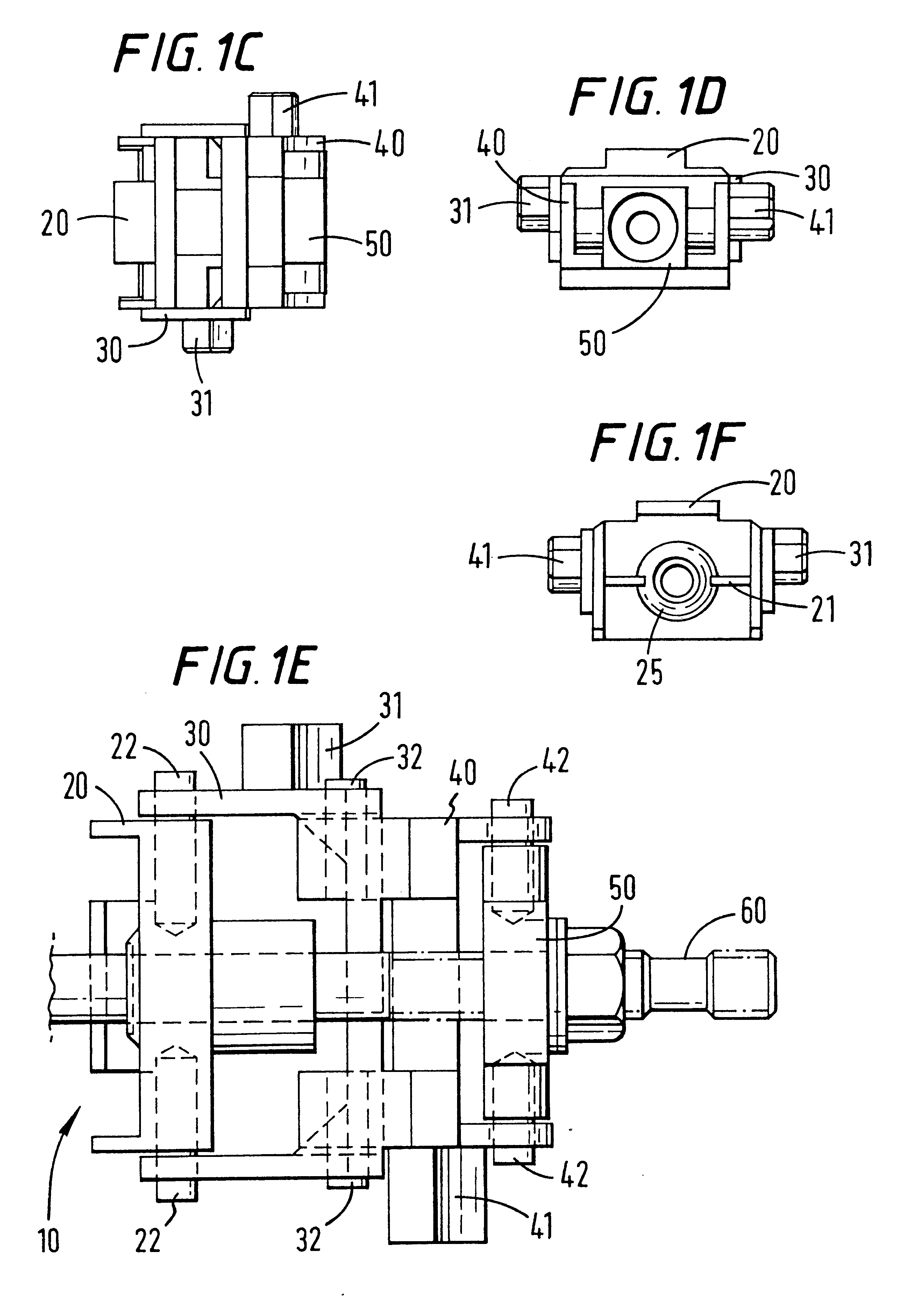

Screen system

InactiveUS7216768B2Avoid and minimize disadvantageSievingWater/sewage treatment by centrifugal separationSurface plateEngineering

The present invention provides a screen system (8) suitable for use in a vibratory screen apparatus (1), and comprising: a screen element (11) and a support frame (12) therefor, as well novel screen elements (11) and mesh panels (19) therefor, and the use thereof. The screen element (11) consists essentially of a mesh panel (19) provided with first and second elongate support members (22, 23) extending along opposite end portions of the mesh panel (19). The support frame (12) has spaced apart first second elongate frame elements (13, 14) for engagement with the screen element support members (22, 23) and further elongate frame elements (17, 18) extending there between for supporting the mesh panel (19). The screen element support members (22, 23) and said first and second frame elements (13, 14) are formed and arranged for secure interengagement in use of the screen system, with at least one of said screen element support members and the respective one of said first and second frame elements being formed and arranged so that when clamped together, the mesh panel (19) is securely held under tension against said further frame elements (17, 18).

Owner:NAT OILWELL VARCO UK

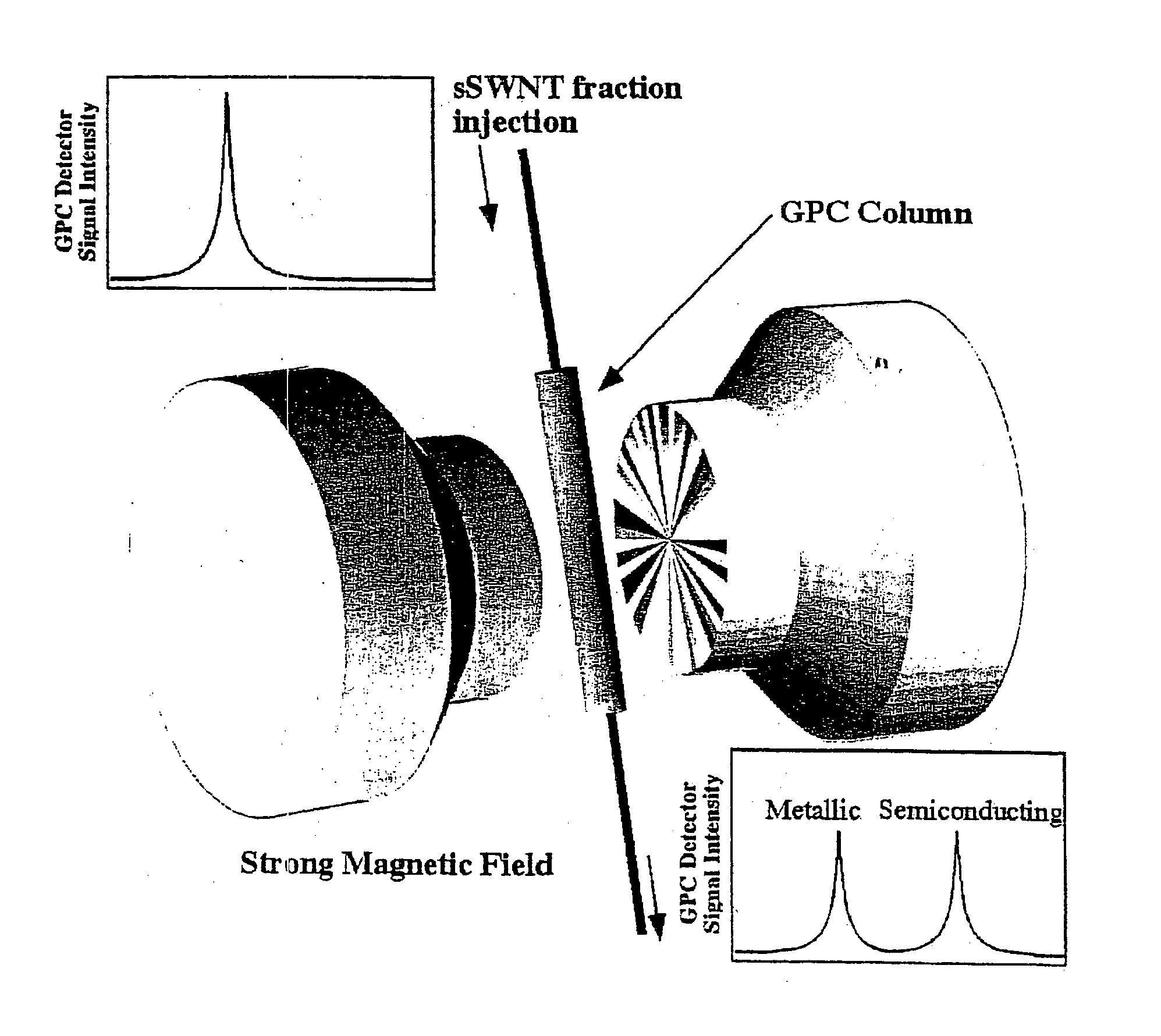

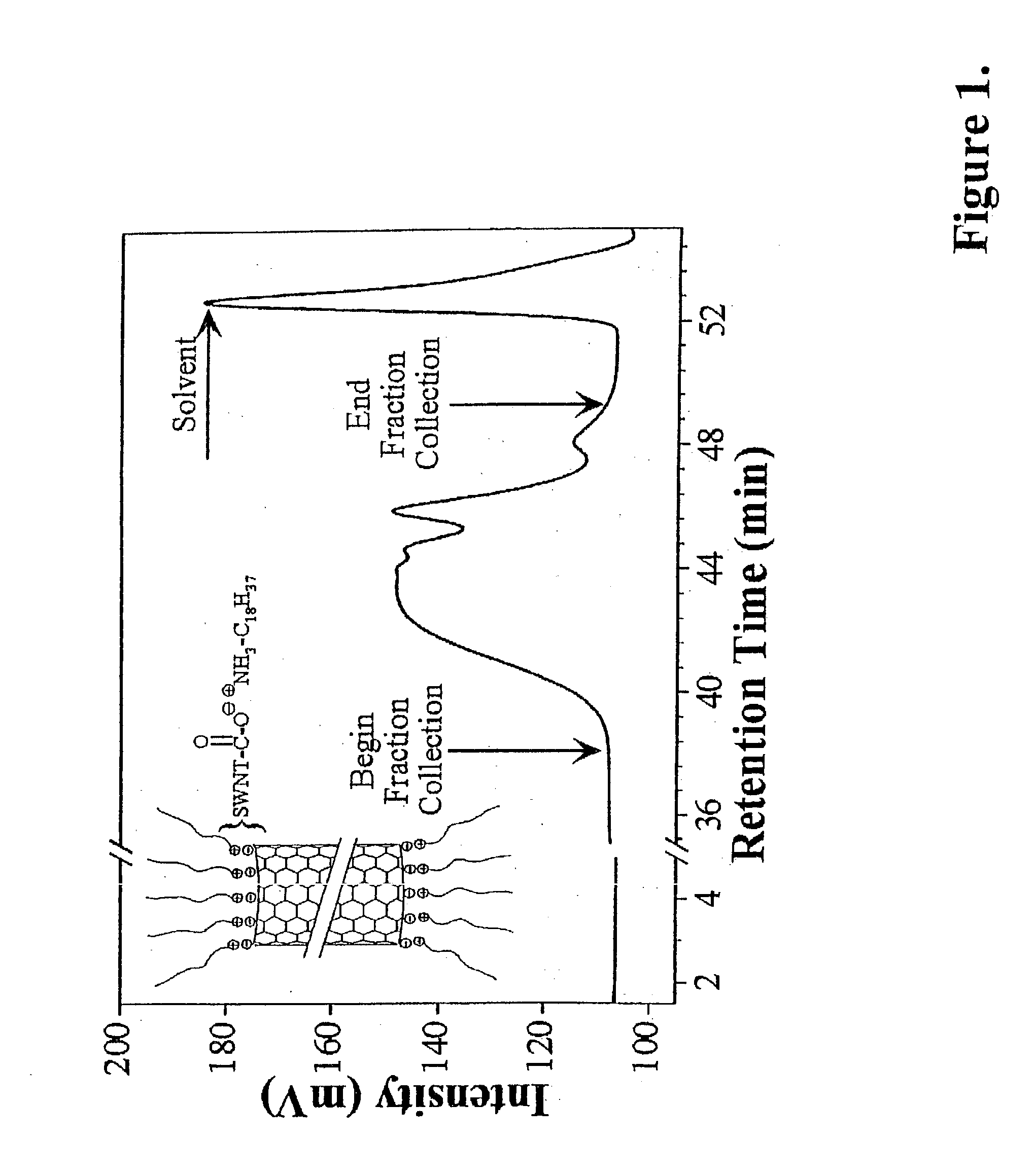

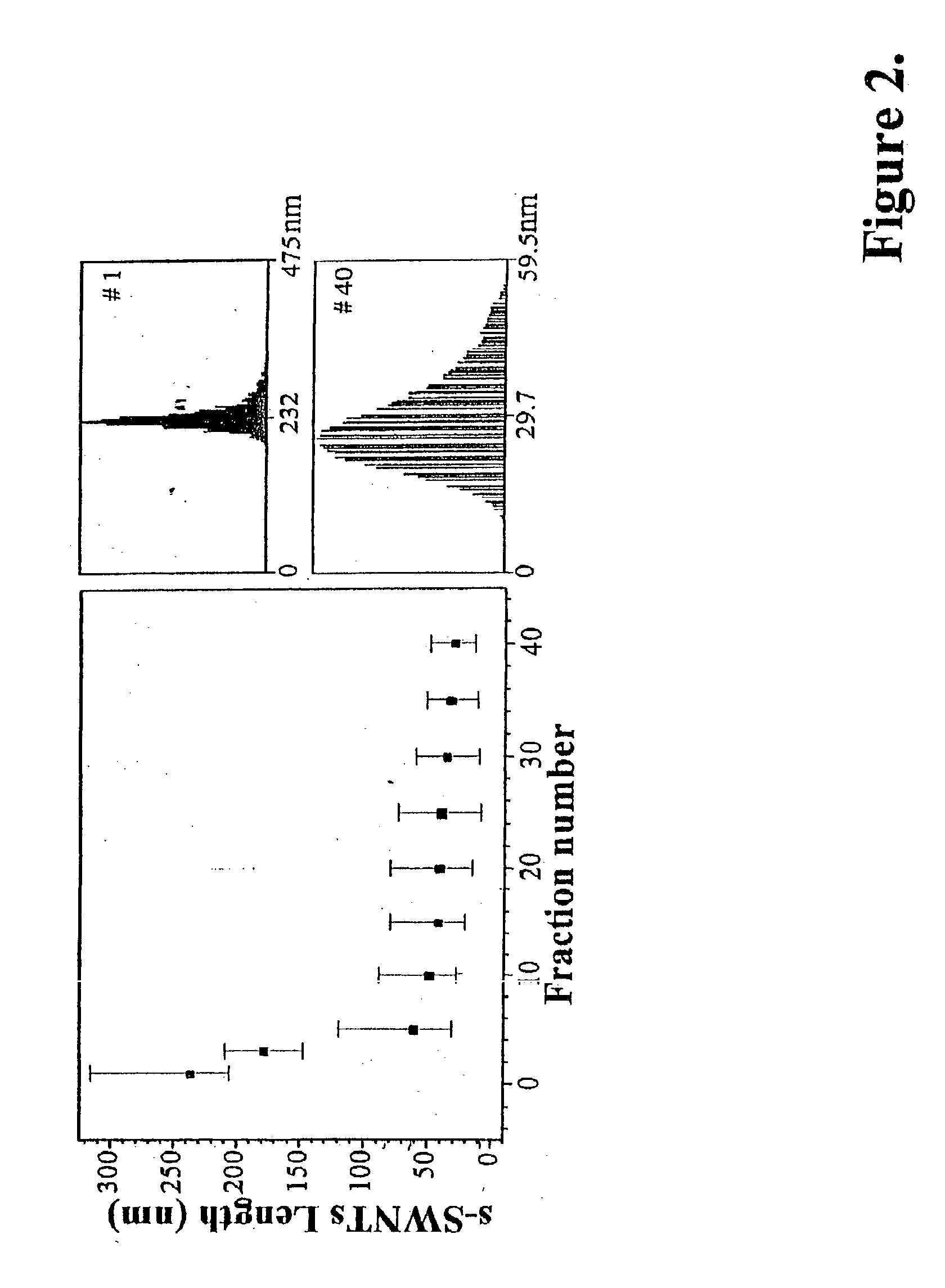

Separation of single wall carbon nanotubes

ActiveUS20030168385A1Good solubilization effectImproved size fractionationSievingMaterial nanotechnologySemiconductorNanotube

A method has been developed for the post-synthesis separation of nanotubes by size and / or type. Solubilized, functionalized nanotubes are passed over a GPC column such that length-separated fractions are collected. These length-separated fractions can then further be separated by diameter or type. Particularly useful are methods for separating nanotubes into metallic and semiconducting fractions.

Owner:UNIV OF CONNECTICUT

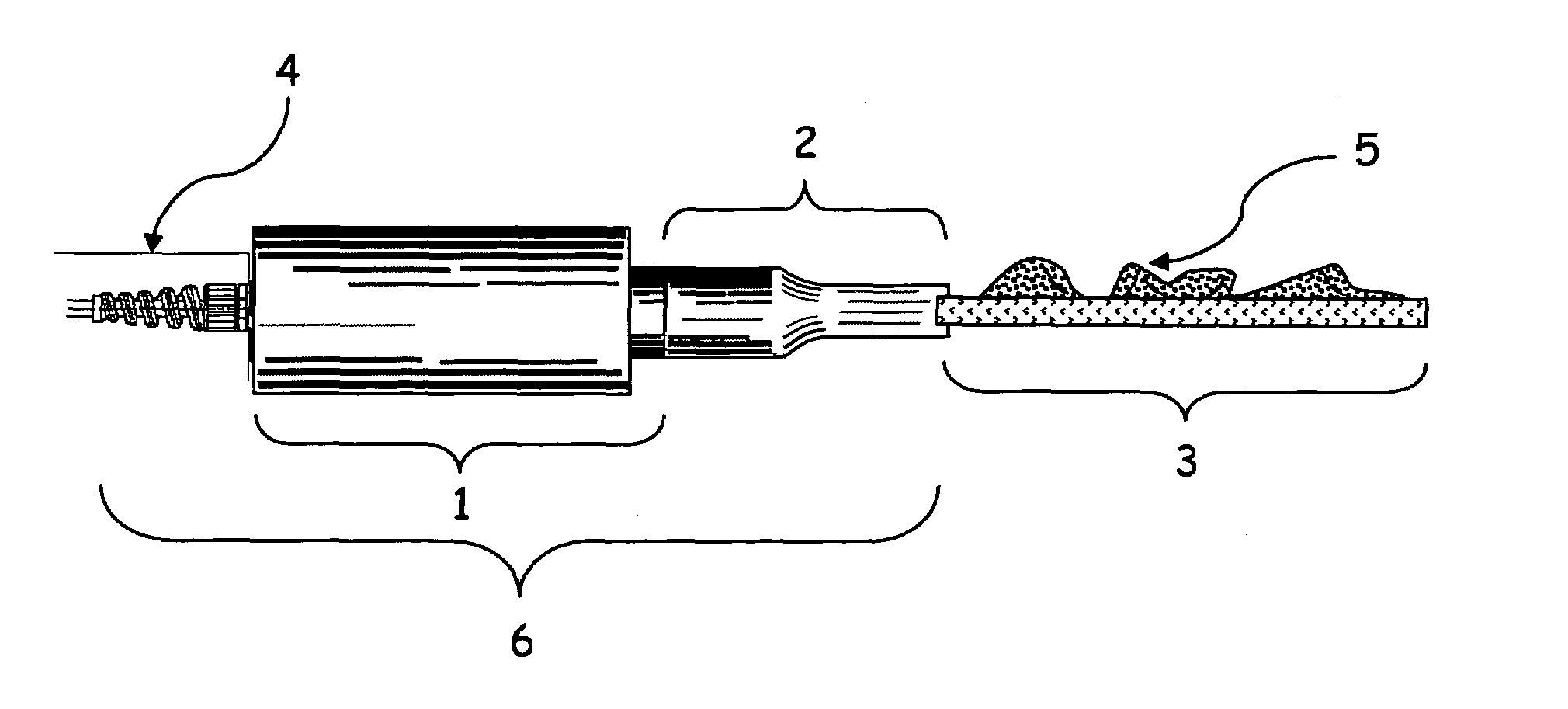

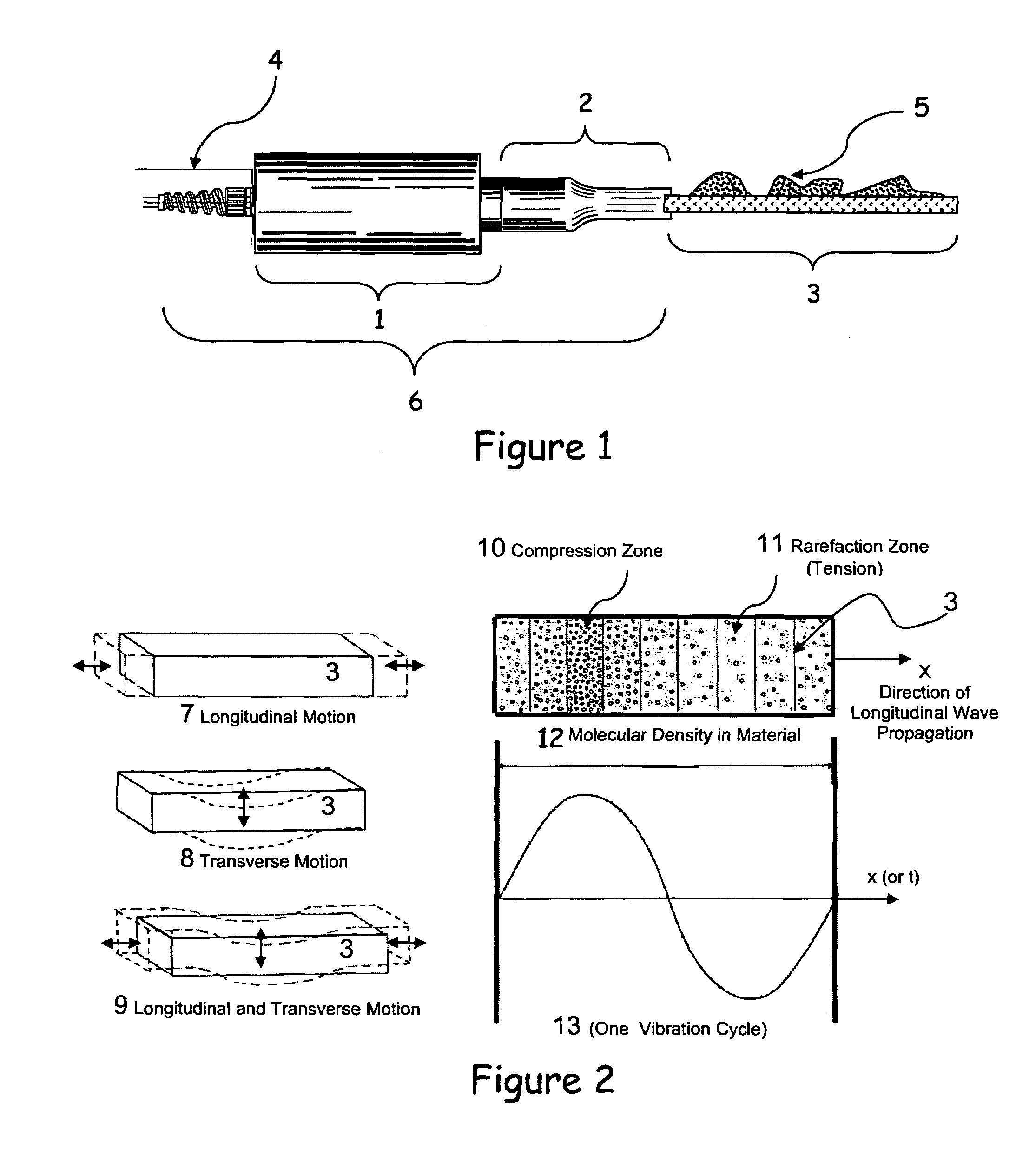

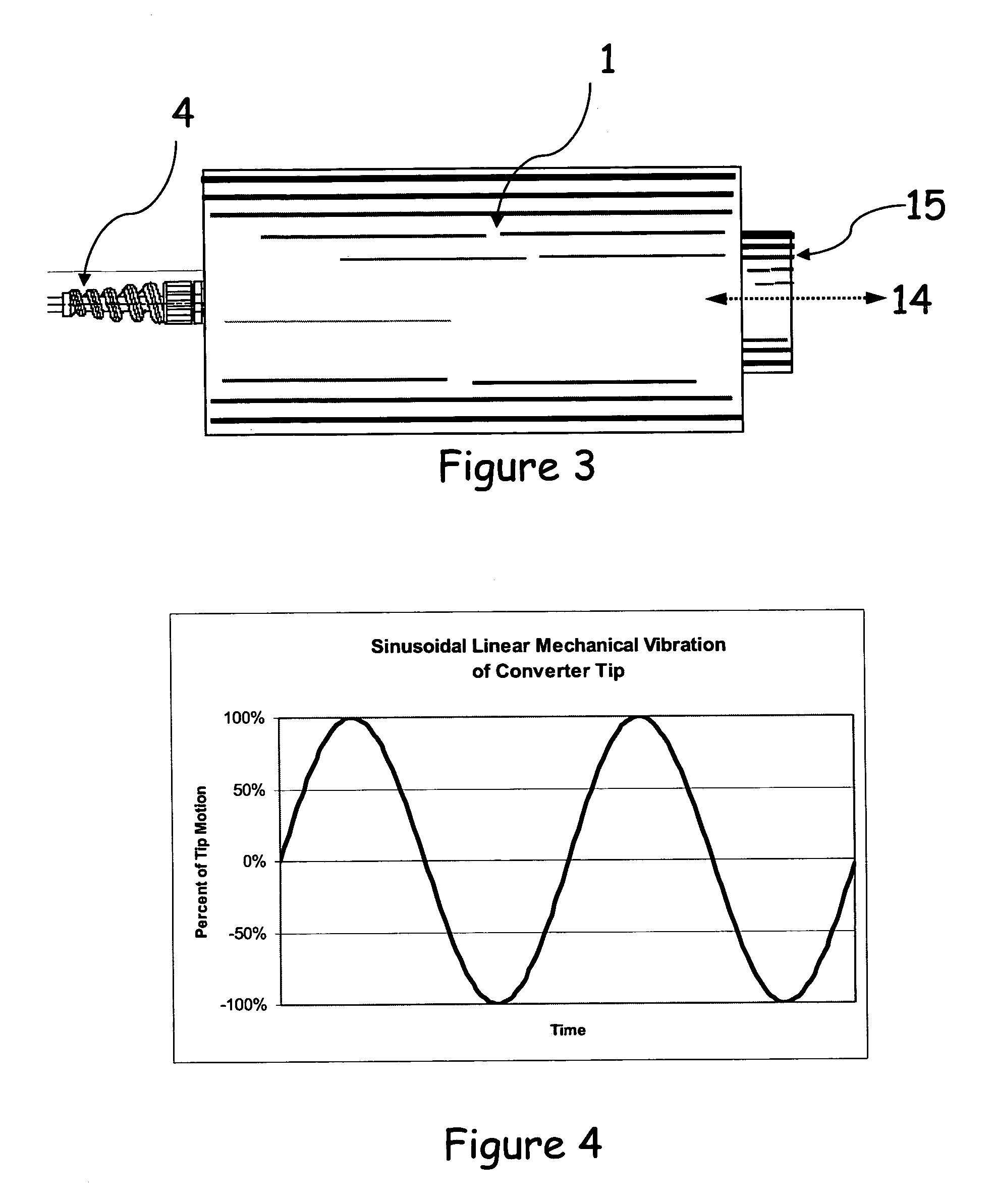

Vibrating debris remover

InactiveUS7084553B2Efficient disseminationOvercomes drawbackSievingPiezoelectric/electrostriction/magnetostriction machinesEngineeringTransverse wave

This invention relates to a device which is either permanently attached or removable to the edge of a material such as a vehicular glass window. This device may be comprised of a converter sub-unit (vibrator) and an amplifying coupler. These elements are arranged so as to propagate mechanical motion generated by the converter sub-unit through the amplifying coupler and into the edge of the attached material. The resulting vibration motion in the material, which could take the form of a longitudinal compression / rarefaction wave, transverse wave, or a combination of the two waveforms, is of a sufficient magnitude so as to cause the adhesive bond between the material's surface and other solid debris, such as ice, to be quickly broken. This allows the debris to fall away while not damaging the material. The vibration motion in the material is also of sufficient magnitude to remove a liquid such as water from the material surface.

Owner:LUDWICZAK DAMIAN R

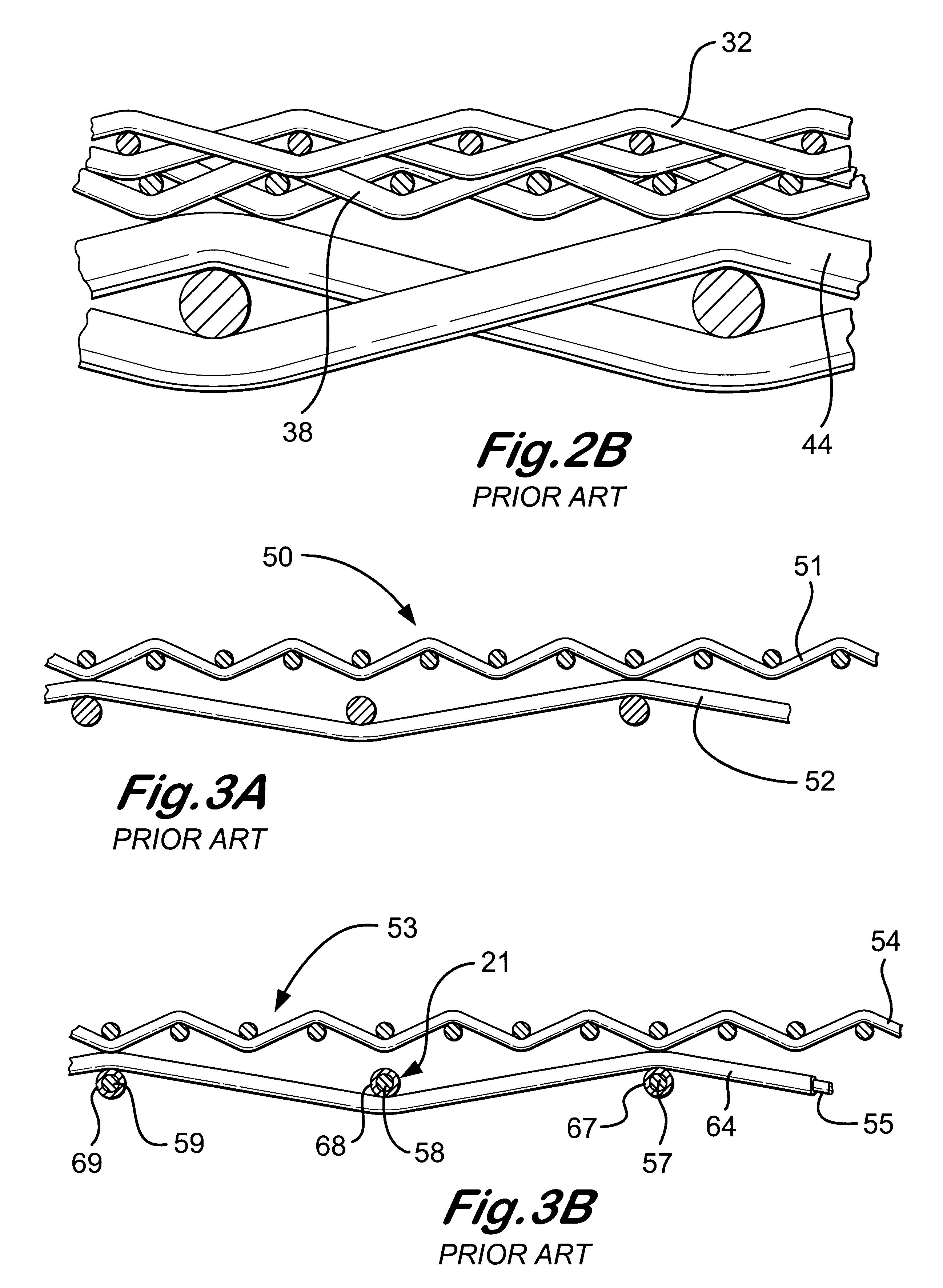

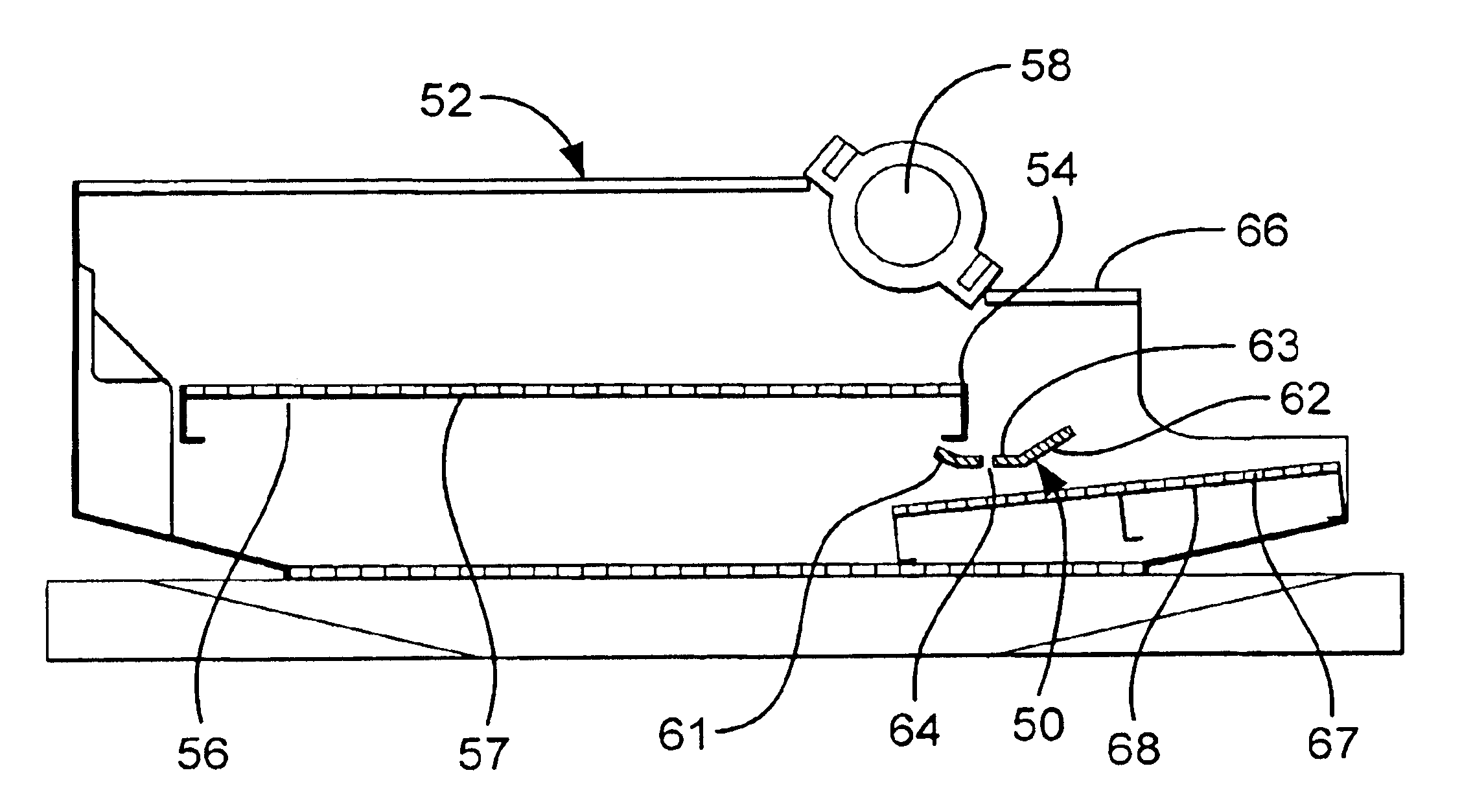

Screen apparatus for vibratory separator

InactiveUS6325216B1Convenient hookIncrease capacitySievingScreeningEngineeringMechanical engineering

A screen assembly for a vibratory separator, the screen assembly including at least one lower coarse screen member, at least one upper fine screen member above the at least one lower coarse screen member and fused with plastic to the at least one lower coarse screen member, and a strip member beneath and adhered to the at least one lower coarse screen member. In one aspect the strip member includes two side strips, two end pieces, and a plurality of spaced-apart strips parallel to the two side strips each with an end terminating at, in, or on each of the end pieces.

Owner:VARCO I P INC

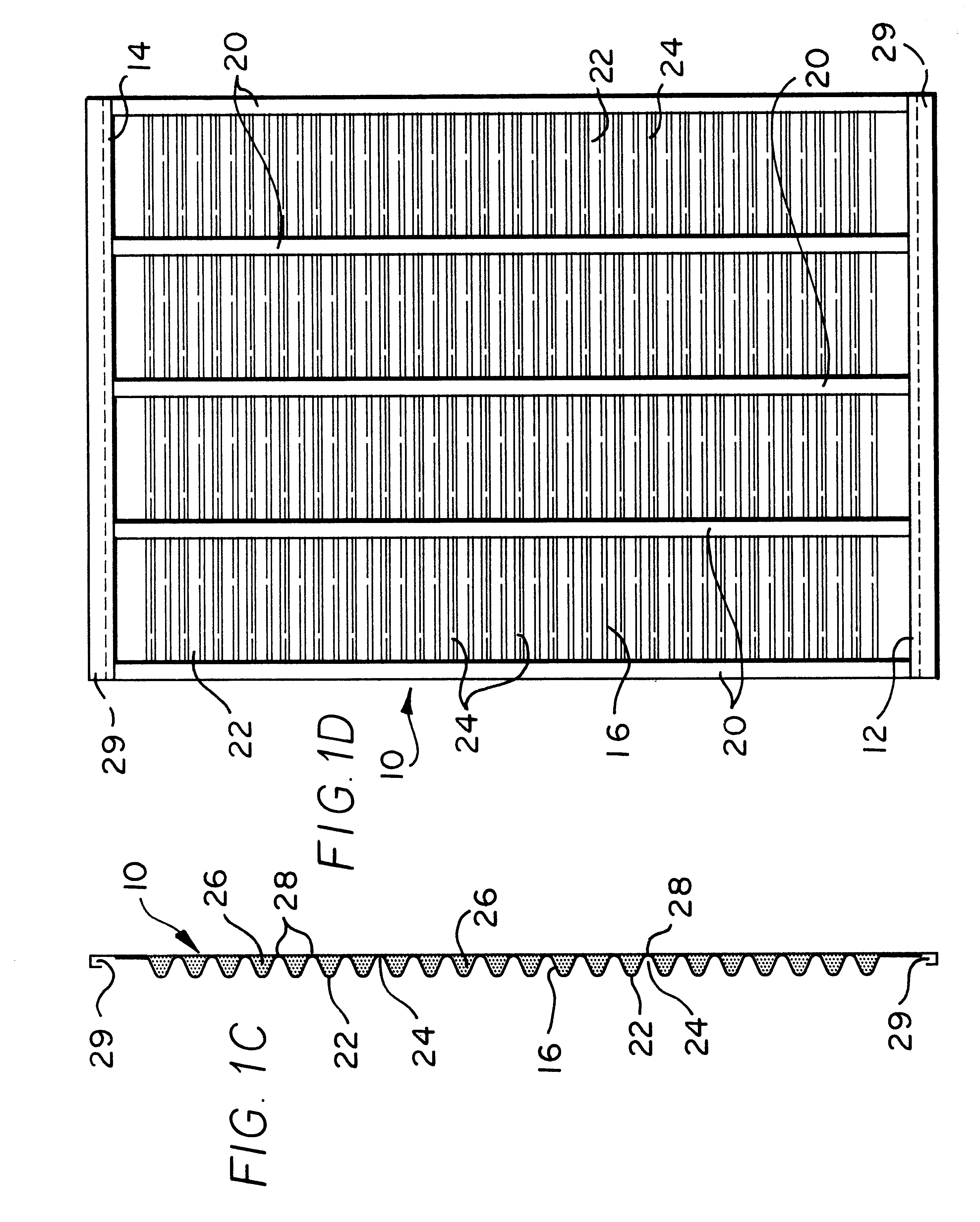

Fiber distribution device for dry forming a fibrous product and method

Owner:FORMFIBER DENMARK APS

Screen assemly for vibratory separators

A screen assembly for a vibratory separator, the screen assembly having a first screen portion having a first end and a second end spaced apart from the first end, and a second screen portion formed integrally of or connected to the second end of the second screen portion. A screen assembly with a first portion of screening material and a second raised portion of screening material, the second raised portion extending from a material introduction end of the screen assembly to a material exit end thereof, the raised portion, in one aspect, culminating in an apex above the first portion of screening material.

Owner:VARCO I P INC

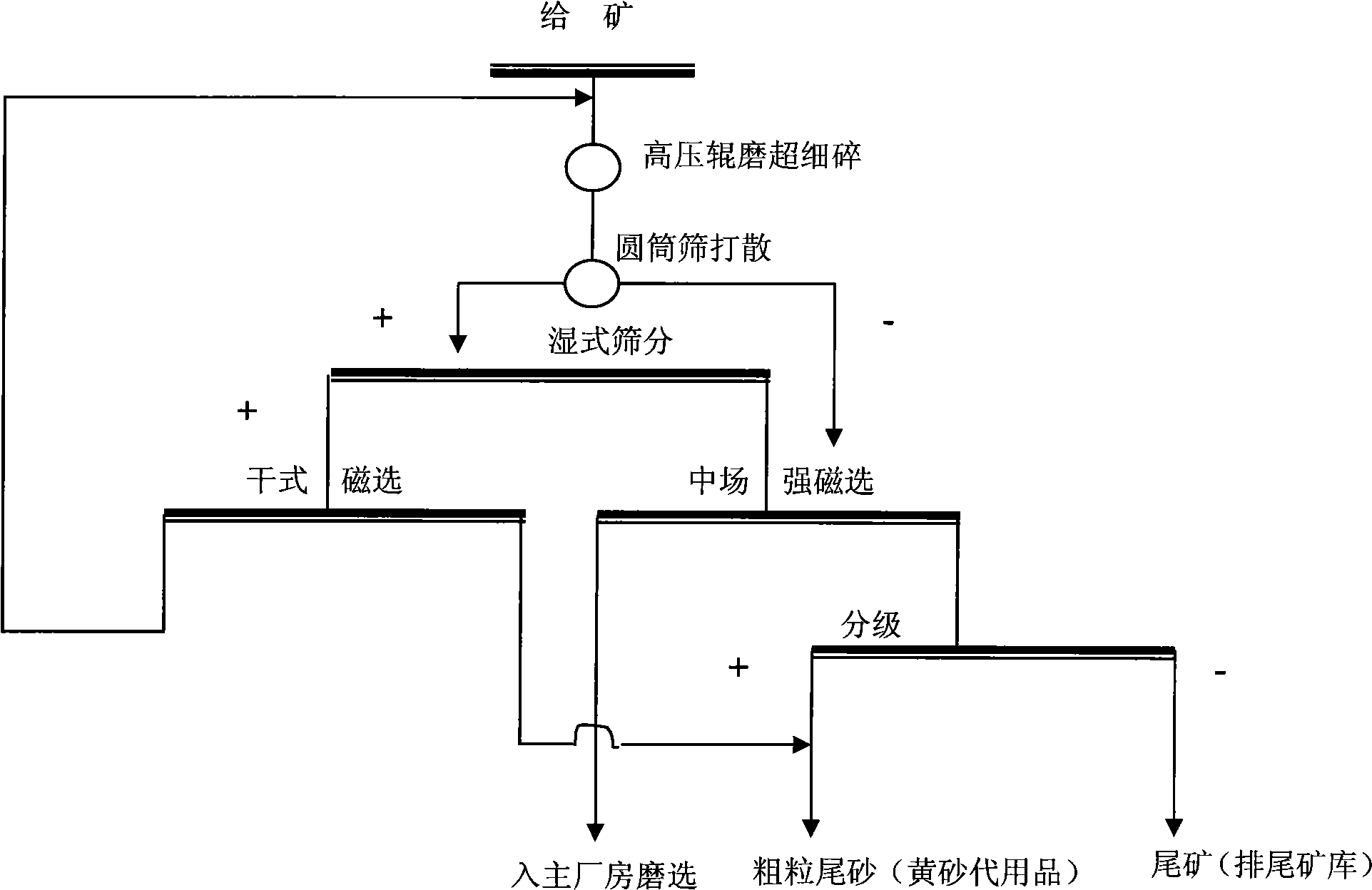

Pre-selection method of low-ore grade magnetic iron ore

InactiveCN101502819ASolve the costSolve the problem of large tailingsSievingScreeningSeparation technologyMagnetite

The invention discloses a preselecting method of low-grade magnetic iron ore, comprising the steps of crushing the raw ore of the magnetic iron ore by coarse crushing, intermediate crushing and fine crushing operations, conveying to subject to ultra-fine crushing operation, and then crushing by a high-pressure roller mill, scattering the crushed product by a wet cylindrical sieve, conveying the ore on the cylindrical sieve to the vibrating sieve by a belt to perform wet gradation, conveying the ore on the vibrating sieve to a dry magnetic separator by the belt to discard the waste, returning the ore concentrate of the dry magnetic separator to the high-pressure roller mill to crush the ore concentrate again, perform magnetic separation and discarding tailings of the ore concentrate below the vibrating sieve and the ore concentrate below the cylindrical sieve in a wet coarse grain intermediate-field intensity magnetic separator, and selecting the coarse ore concentrate of the intermediate-field intensity magnetic separator by a grinding separation technology. The invention has the advantages that the invention selects quantities of qualified mine tailings by wet magnetic separation before grinding ore, reduces ore grinding work, reduces ore grinding energy consumption and has high system processing capacity; the invention can be widely used in magnetic ore dressing plant, and in particular suitable for treatment of preselecting low-grade magnetic iron ore with the iron grade lower than or equal to 22%.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +1

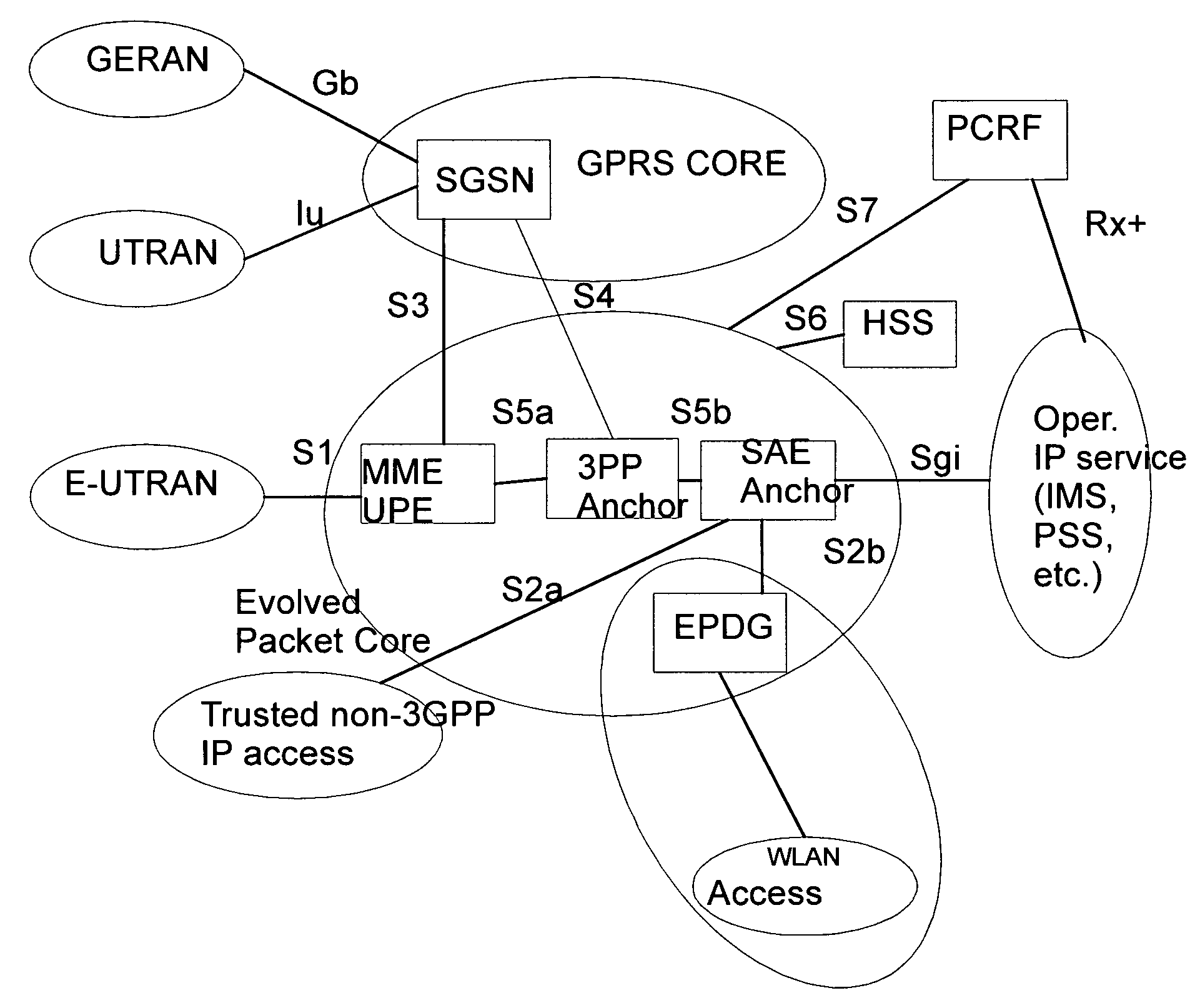

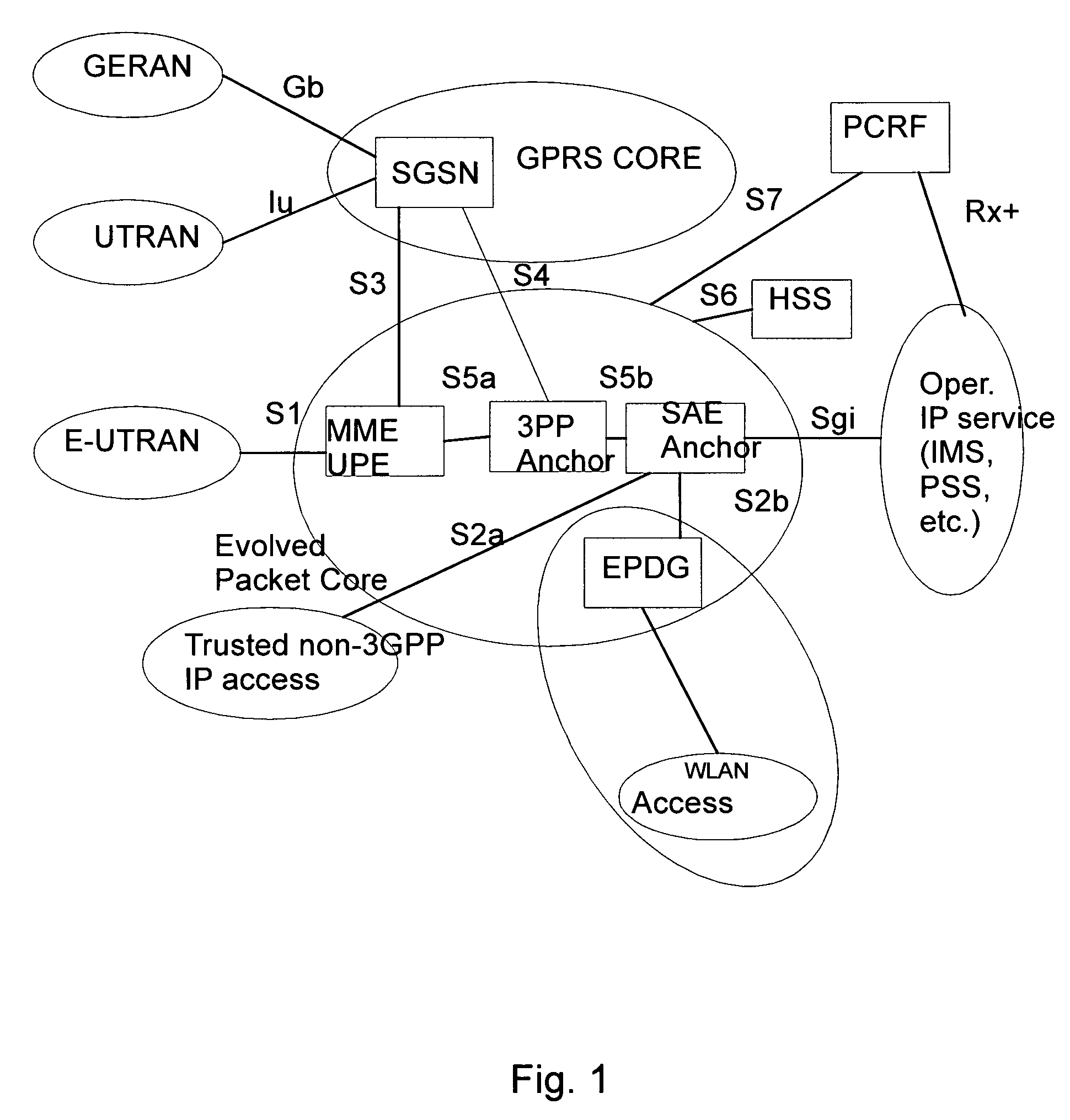

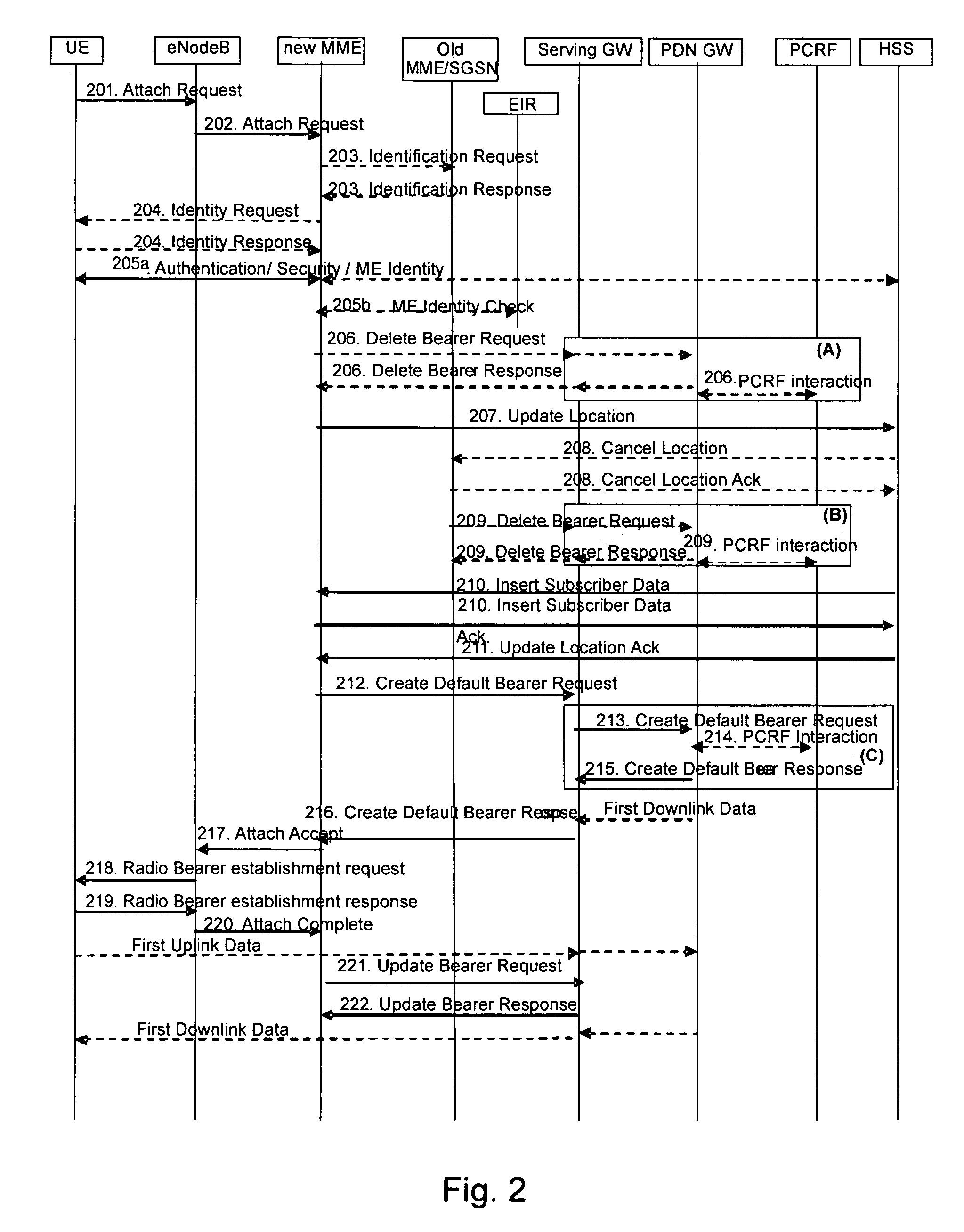

Transition between IP protocol versions

ActiveUS20090232022A1Reduce setup timeSimpler and more dynamic solutionSievingAssess restrictionTTEthernetIp address

A method comprising: receiving, in a network element of a packet data core network, a network resource request from a user equipment, said request including indication on the user equipment's Internet Protocol (IP) version capability; creating, in said network element, a set of parameters for guiding the user equipment in IP address allocation at least in one packet data network, said set of parameters including at least a recommended version of IP address type to be used; and signalling said set of parameters to the user equipment as a response to the network resource request.

Owner:NOKIA TECHNOLOGLES OY

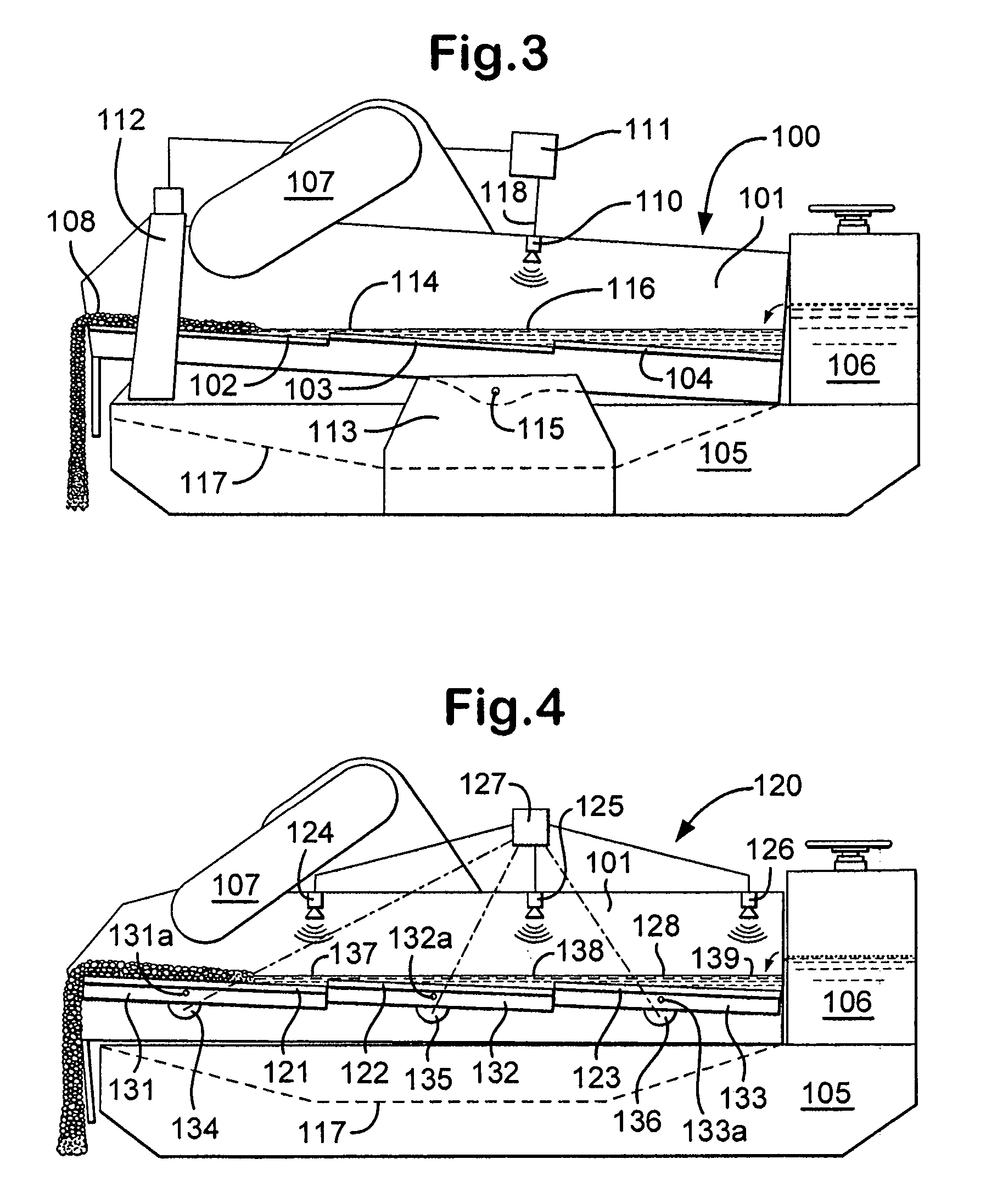

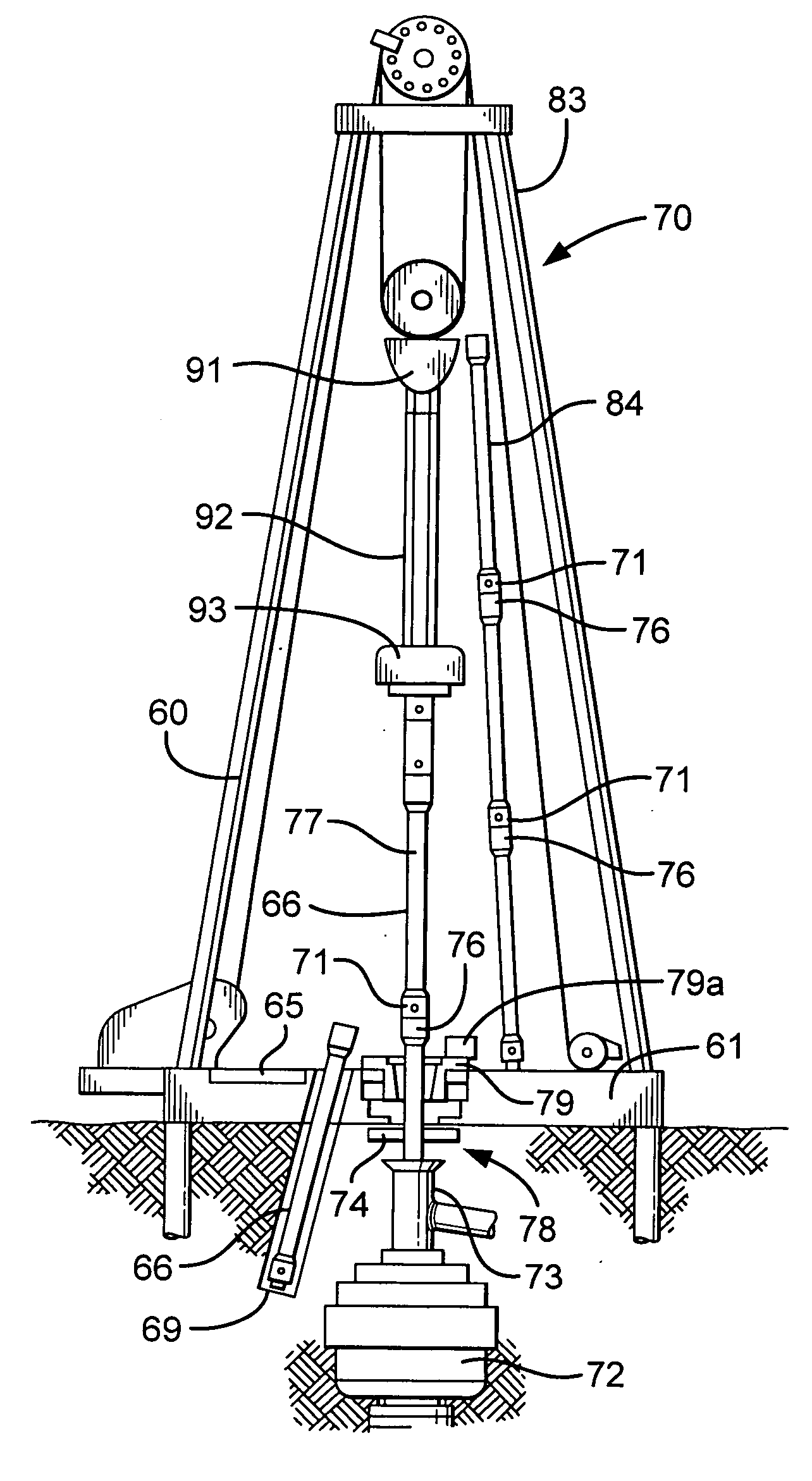

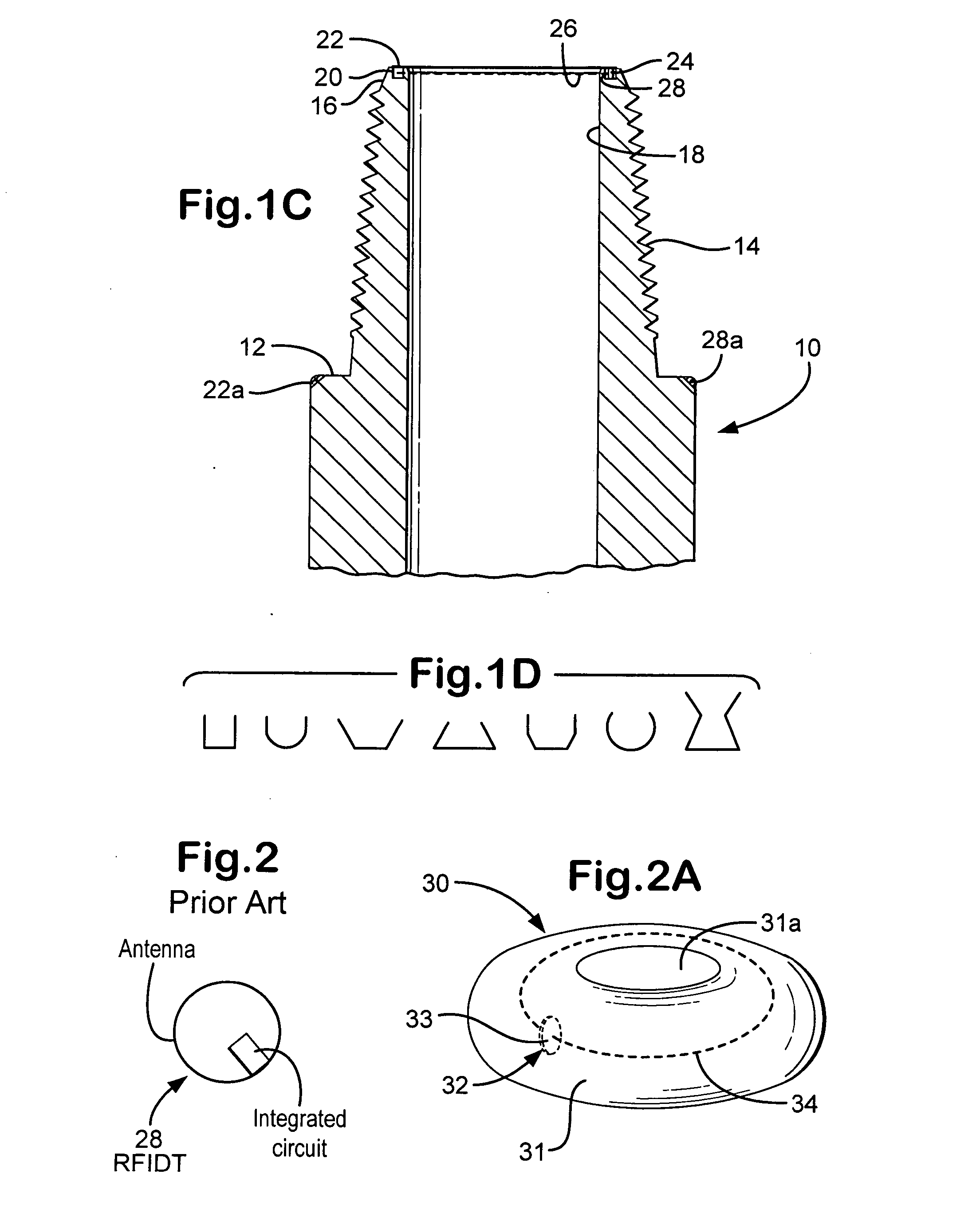

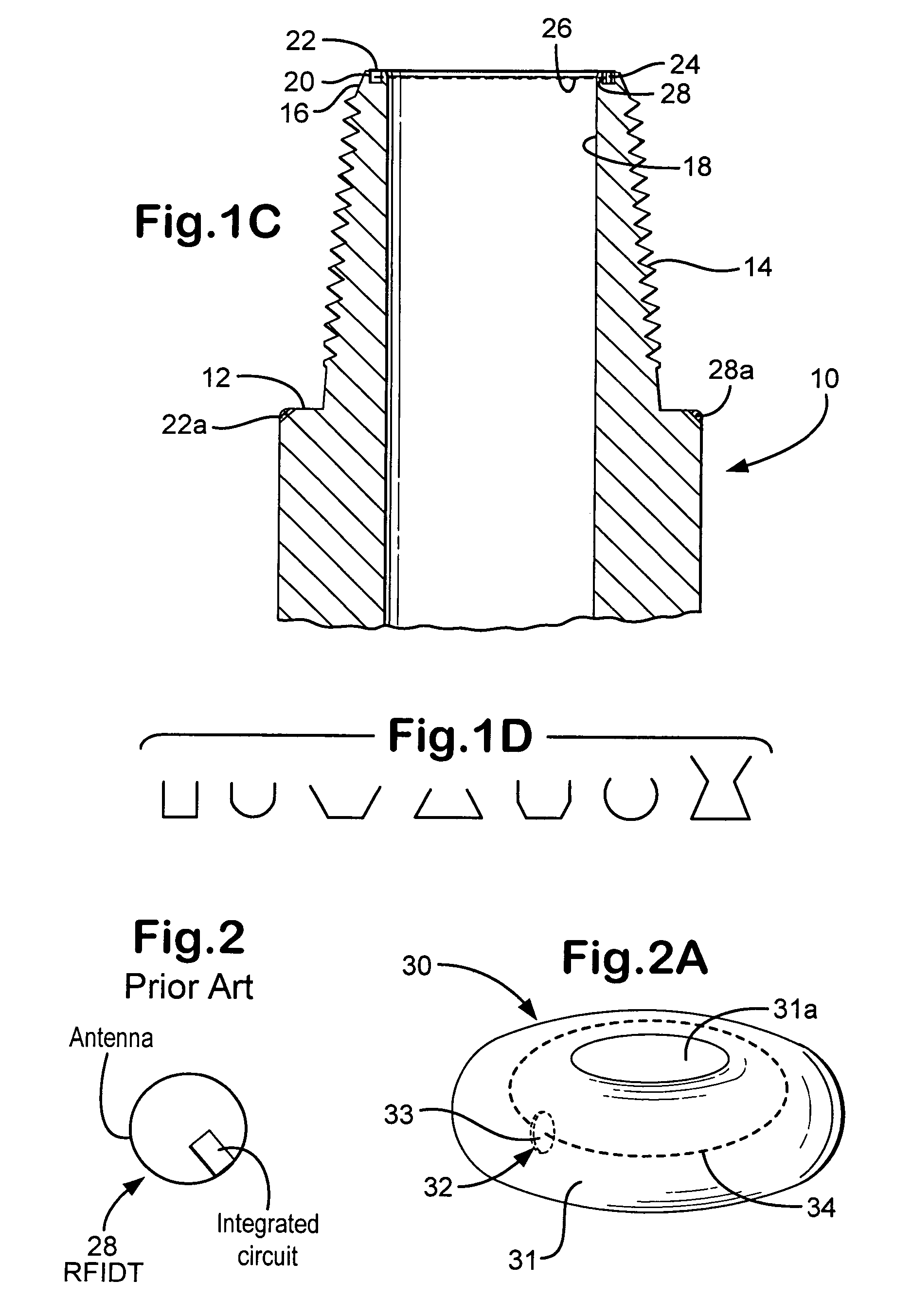

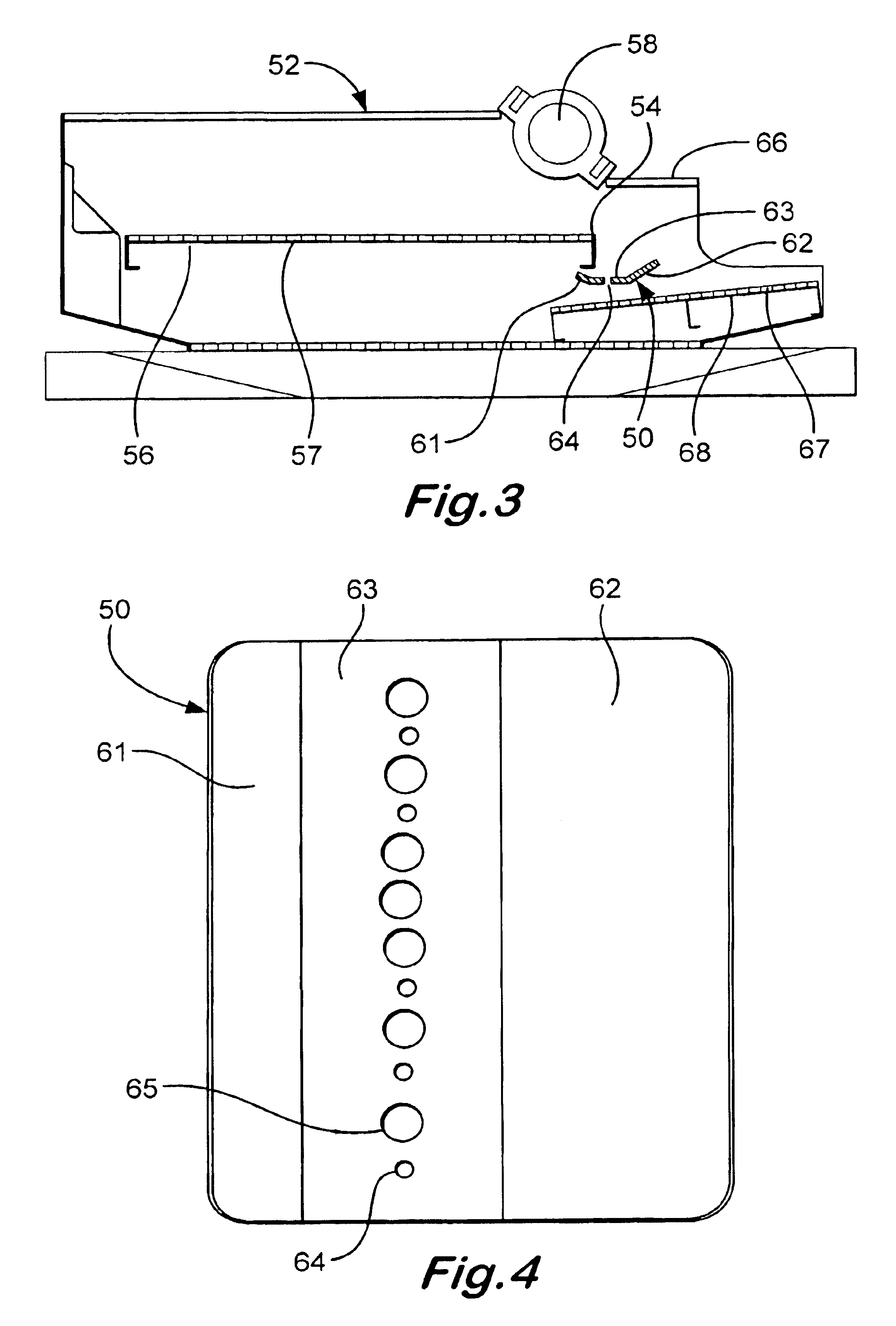

Shale shakers and screens with identification apparatuses

A screen apparatus, which in certain aspects is a screen apparatus having a support, screening material on the support, and energizable identification apparatus on (exteriorly, interiorly, and / or within) the support for identifying the screen apparatus; a vibratory separator with such a screen apparatus; and a vibratory separator or shaker with energizable identification apparatus.

Owner:VARCO I P INC

Shale Shakers with Selective Series/Parallel Flow Path Conversion

Methods and systems are disclosed employing a shale shaker for processing a mixture of drilling fluid and solids with multiple screen assemblies and conversion apparatus for switching flow to the screen assemblies between series flow and parallel flow; and in one aspect, a screen or screens for screening lost circulation material.

Owner:NAT OILWELL VARCO LP

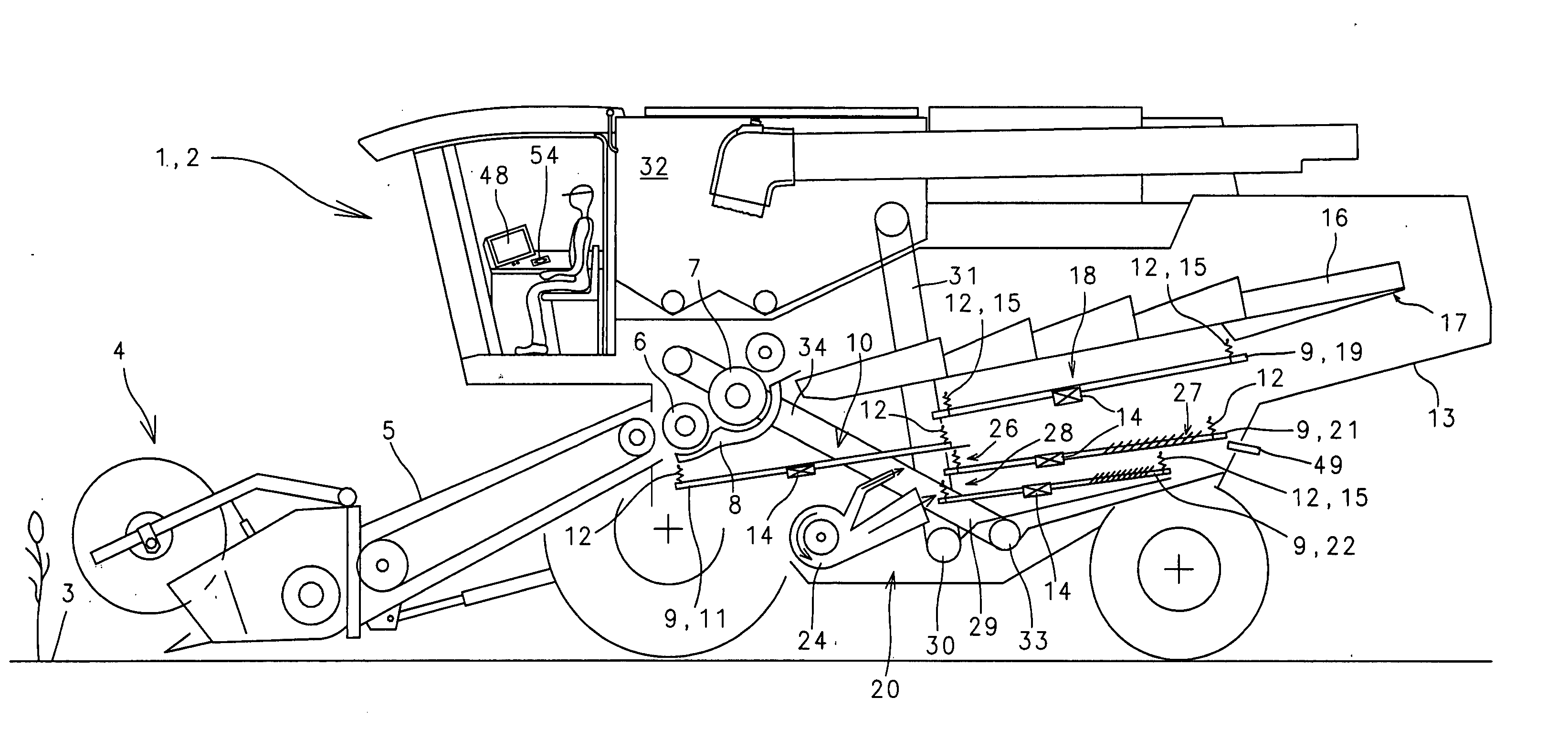

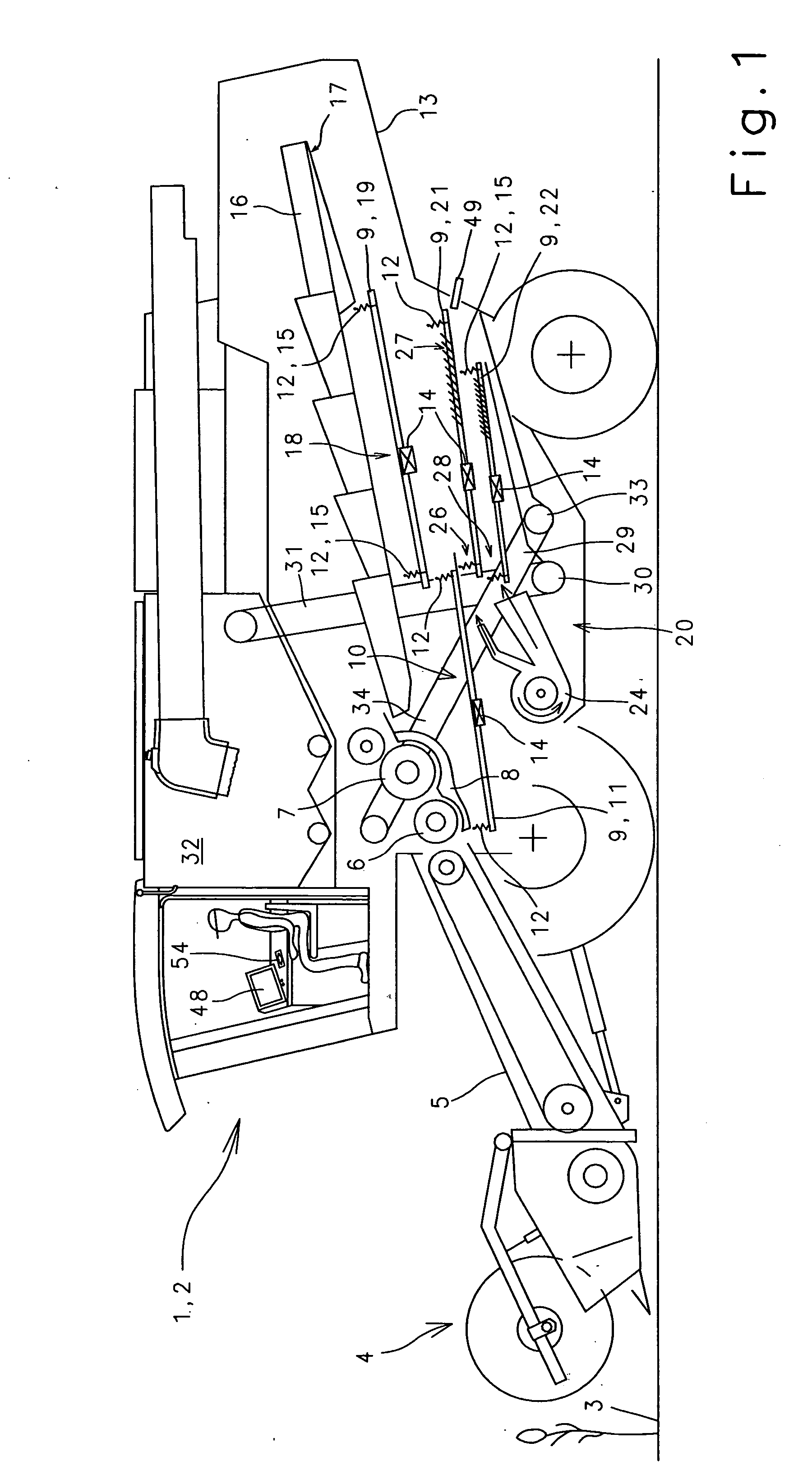

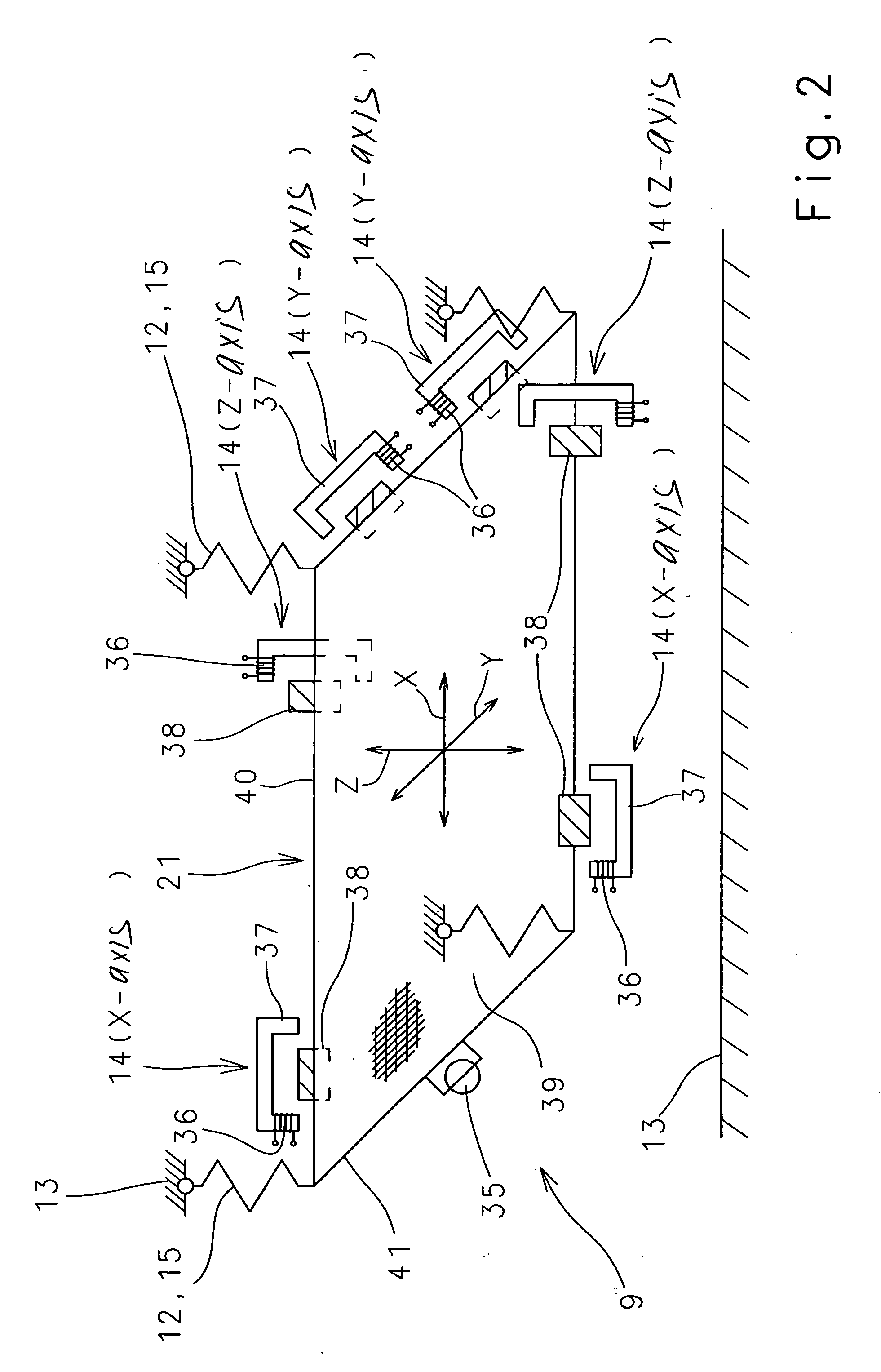

Drive system for a crop conveying device

InactiveUS20060229119A1Simple functional geometryFunction increaseSievingScreeningEngineeringVariation of parameters

In a method and a device for driving a crop conveying unit composed substantially of at least one pan with at least one sieve the pen and receive are hung in an oscillation-facilitating manner in a machine housing, at least one oscillation-reducing drive unit is provided, drive unit is formed by a linearly-oscillation unit, and the drive unit is controlled via a change in a parameter selected from the group consisting of frequency, stroke, and both.

Owner:CLAAS SELBSTFAHRENDE ERNTEMASCHINEN GMBH

Shale shakers and screens with identification apparatuses

A screen apparatus, which in certain aspects is a screen apparatus having a support, screening material on the support, and energizable identification apparatus on (exteriorly, interiorly, and / or within) the support for identifying the screen apparatus; a vibratory separator with such a screen apparatus; and a vibratory separator or shaker with energizable identification apparatus.

Owner:VARCO I P INC

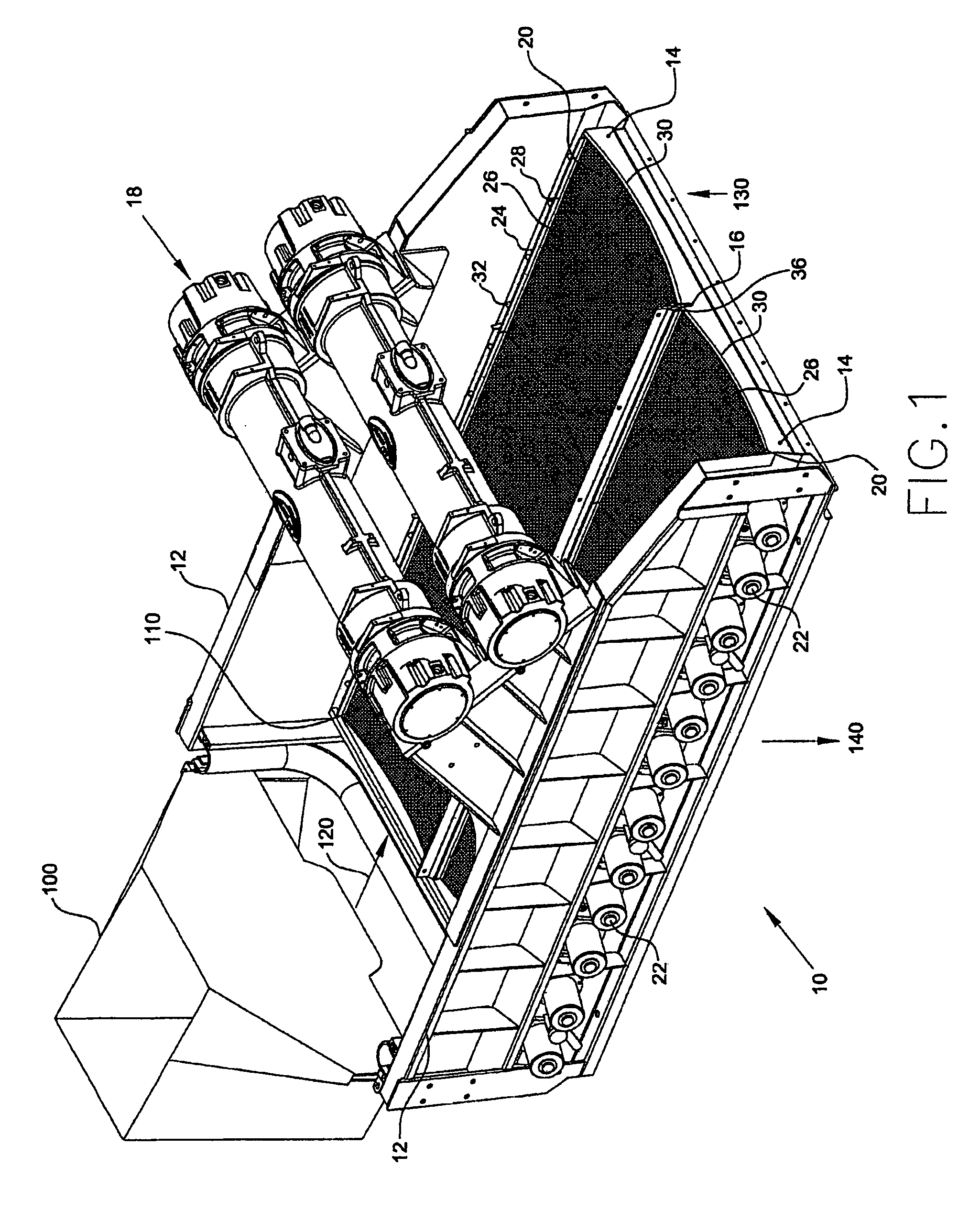

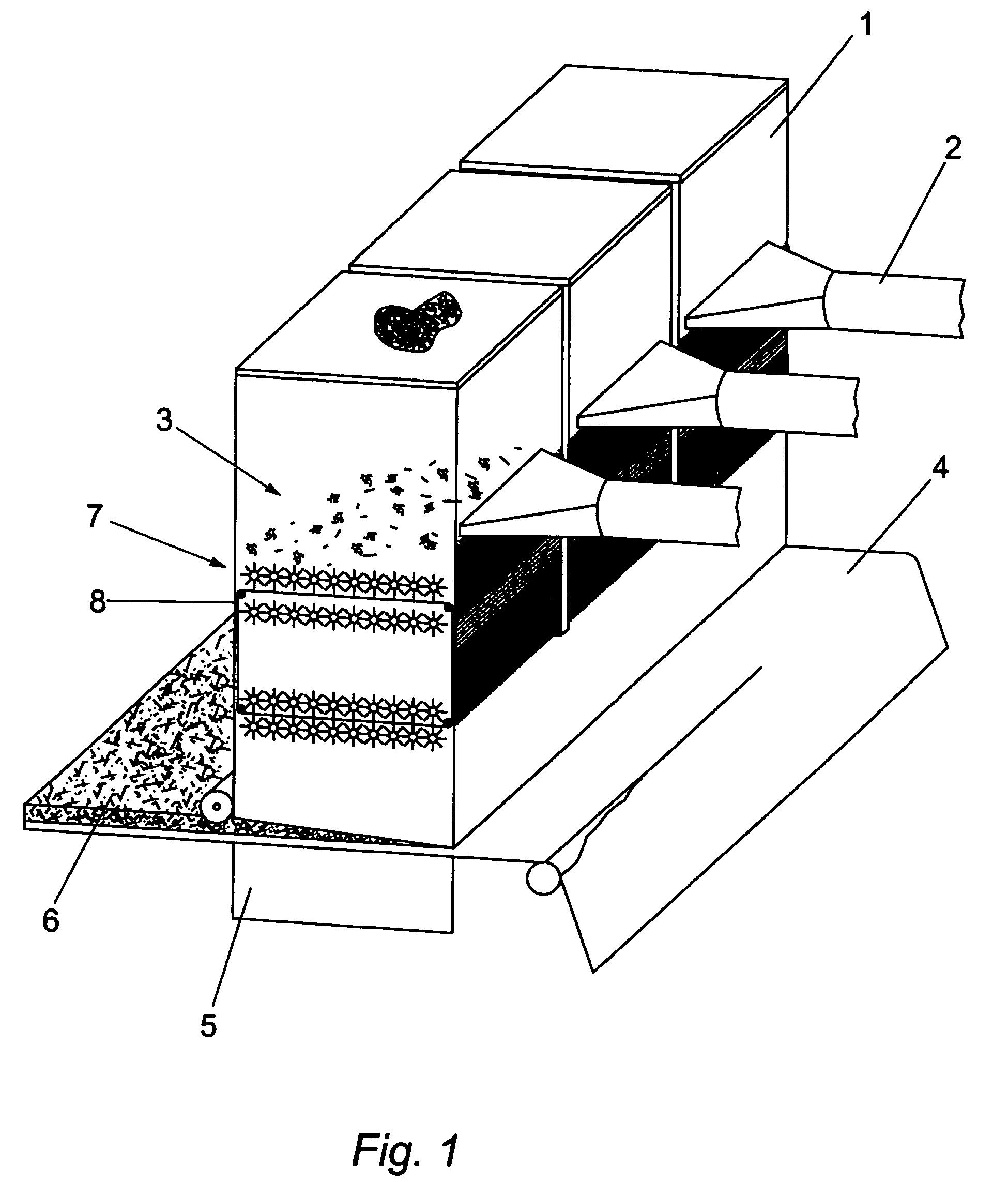

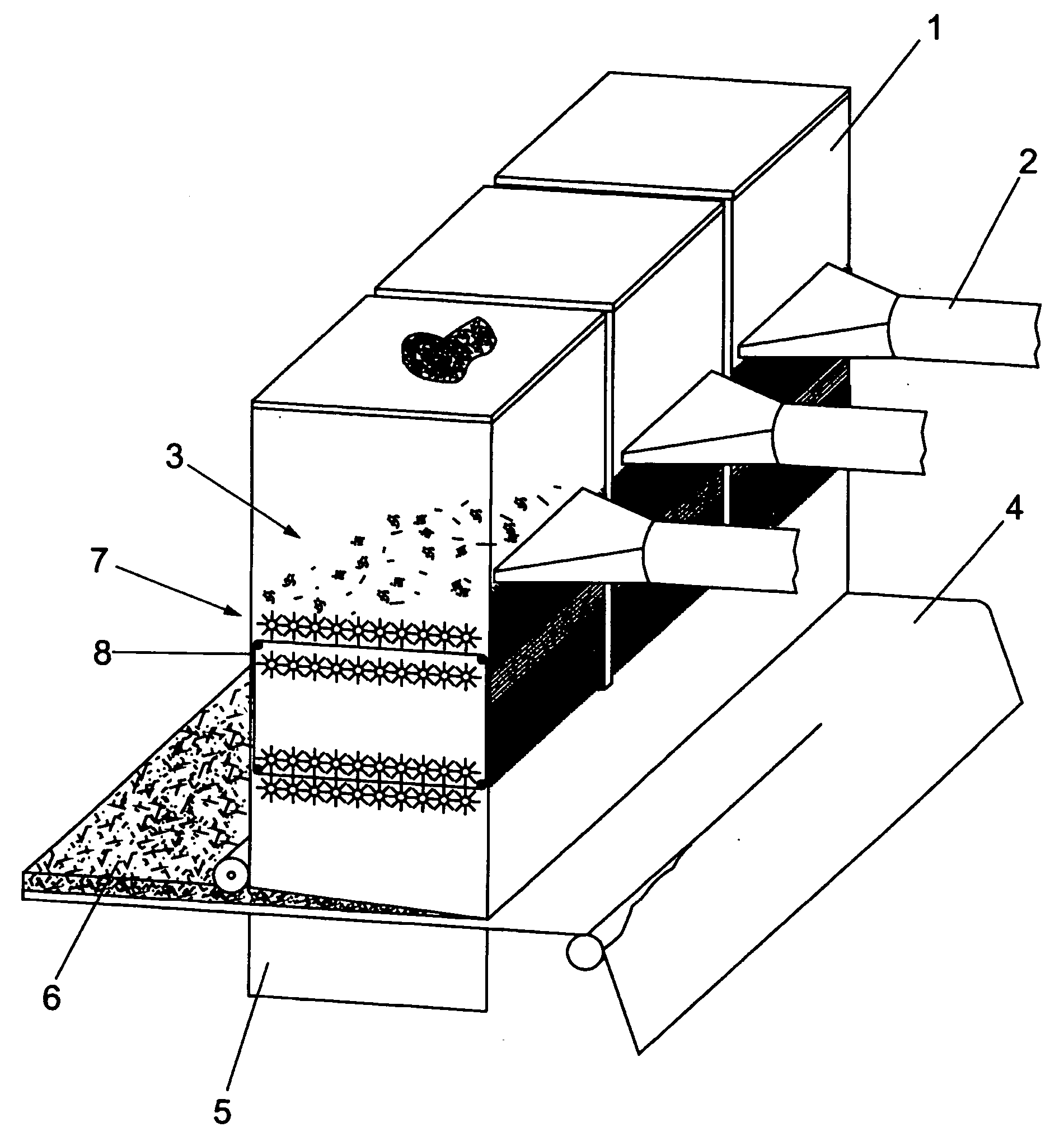

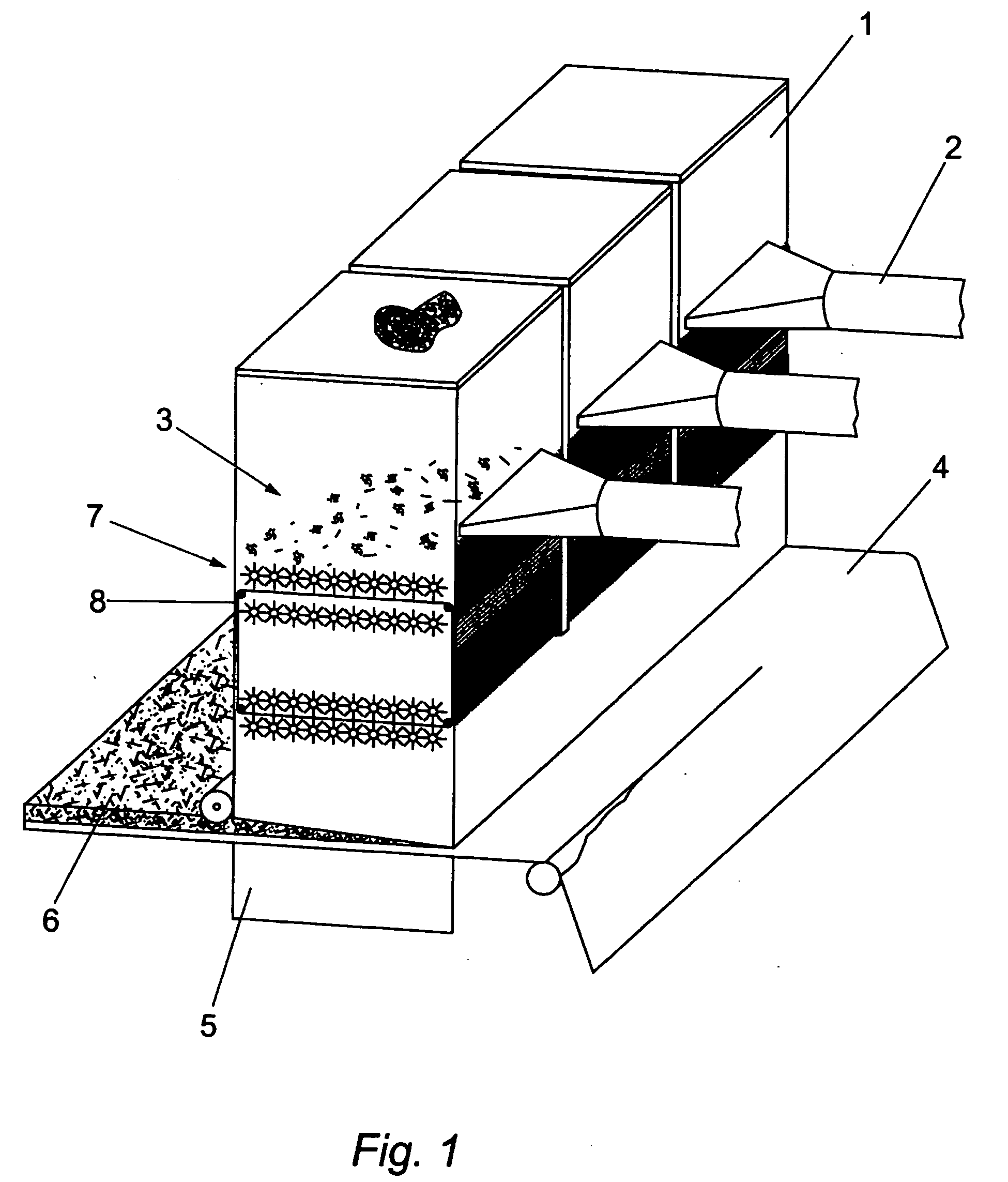

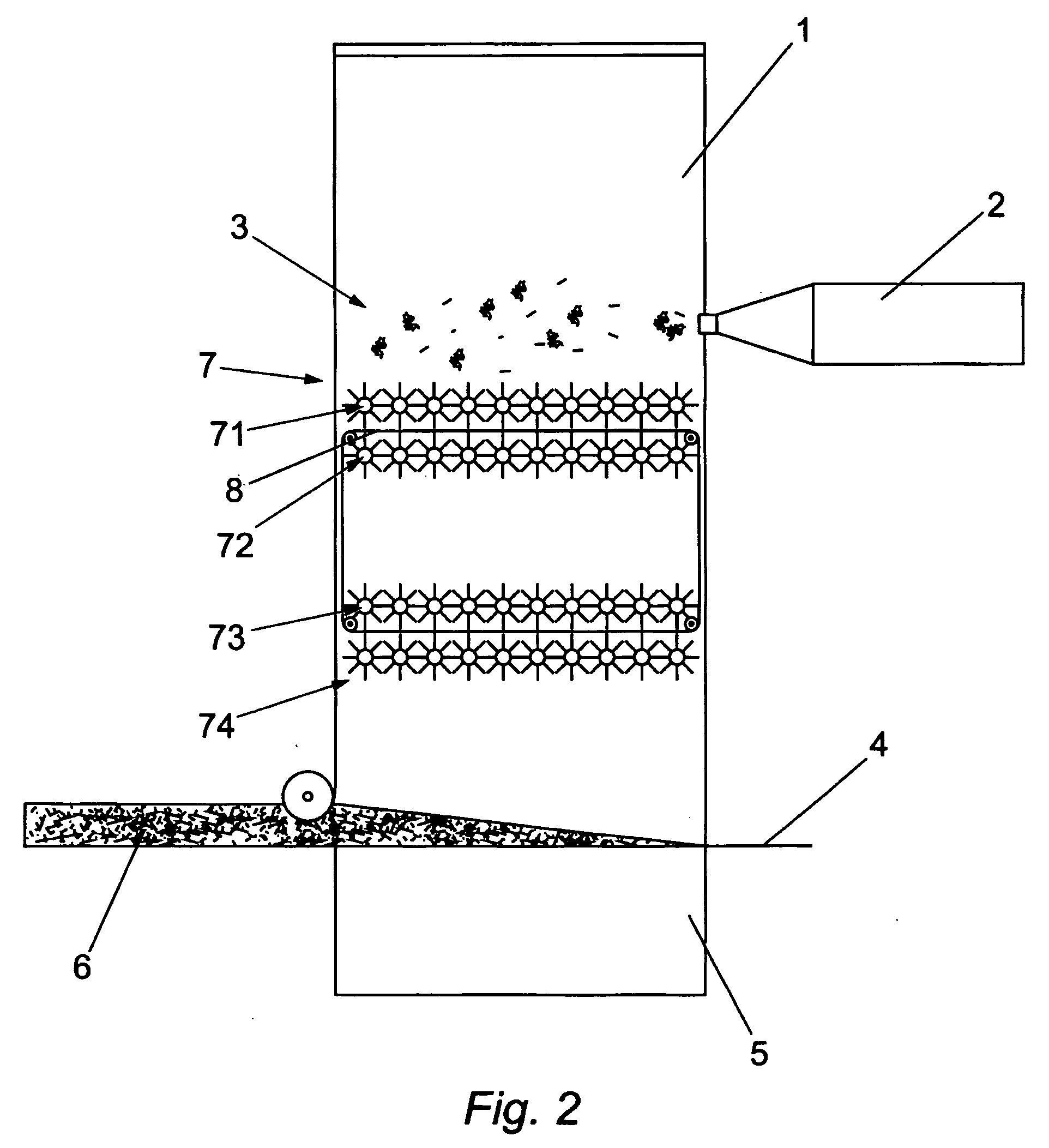

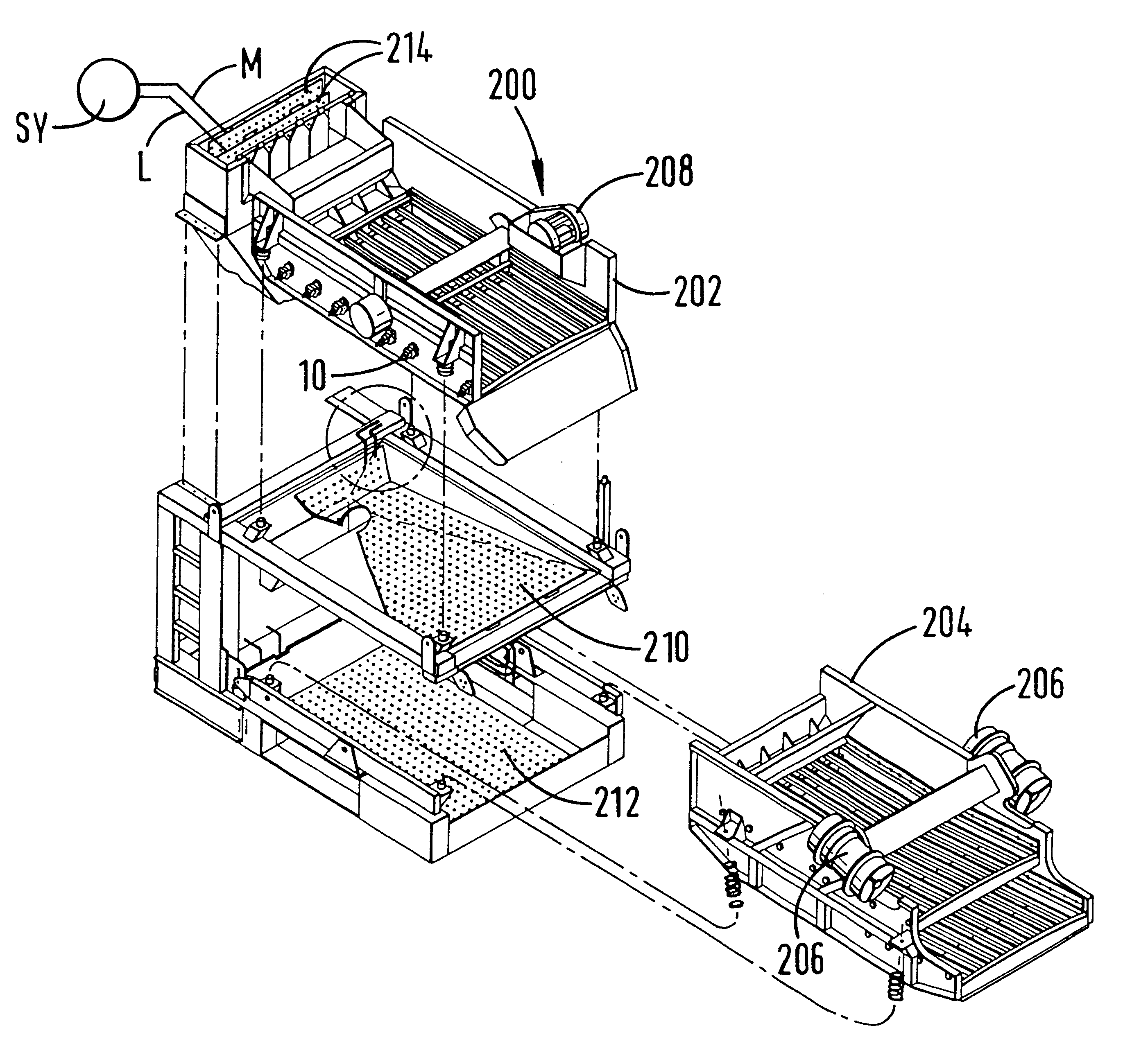

Fiber distribution device for dry forming a fibrous product and method

A forming box for use in dry forming of a mat of fibrous material, and a forming method. The forming box comprises a housing with an open bottom providing direct access for fibers onto an underlying forming wire and a vacuum box underneath said forming wire; an inlet for supplying fiber material into the inside of the housing; and a number of fiber separating rollers in one or more rows in the housing between the fiber inlet and the housing bottom. An endless belt screen is provided inside the housing having an upper run between two rows of spike rollers and a lower run closer to the open bottom of the forming box. Fiber clumps captured on the lower run of the belt screen are conveyed above fiber separating rollers and are released from the upper run of the belt screen into contact with the fiber separating rollers.

Owner:FORMFIBER DENMARK APS

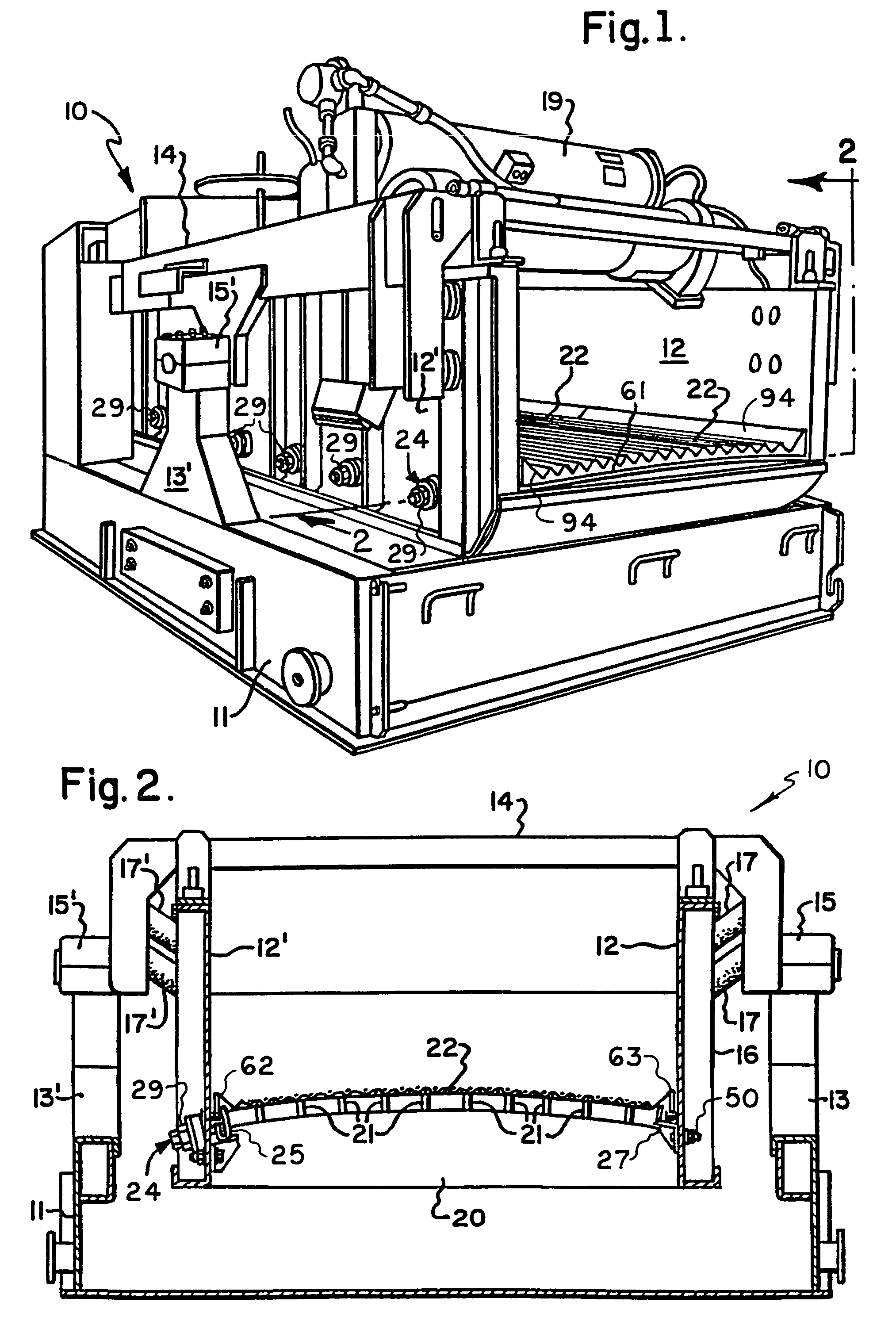

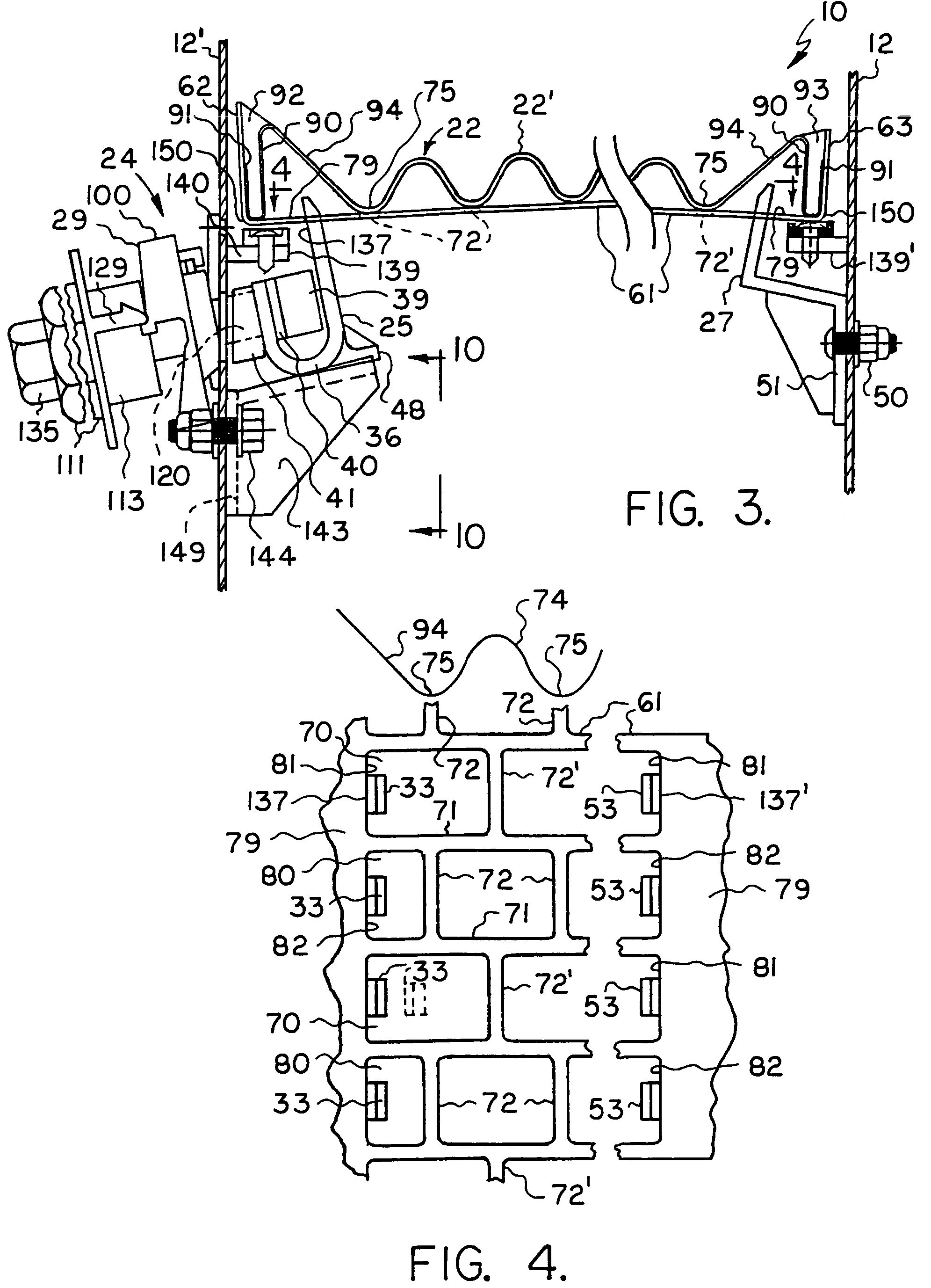

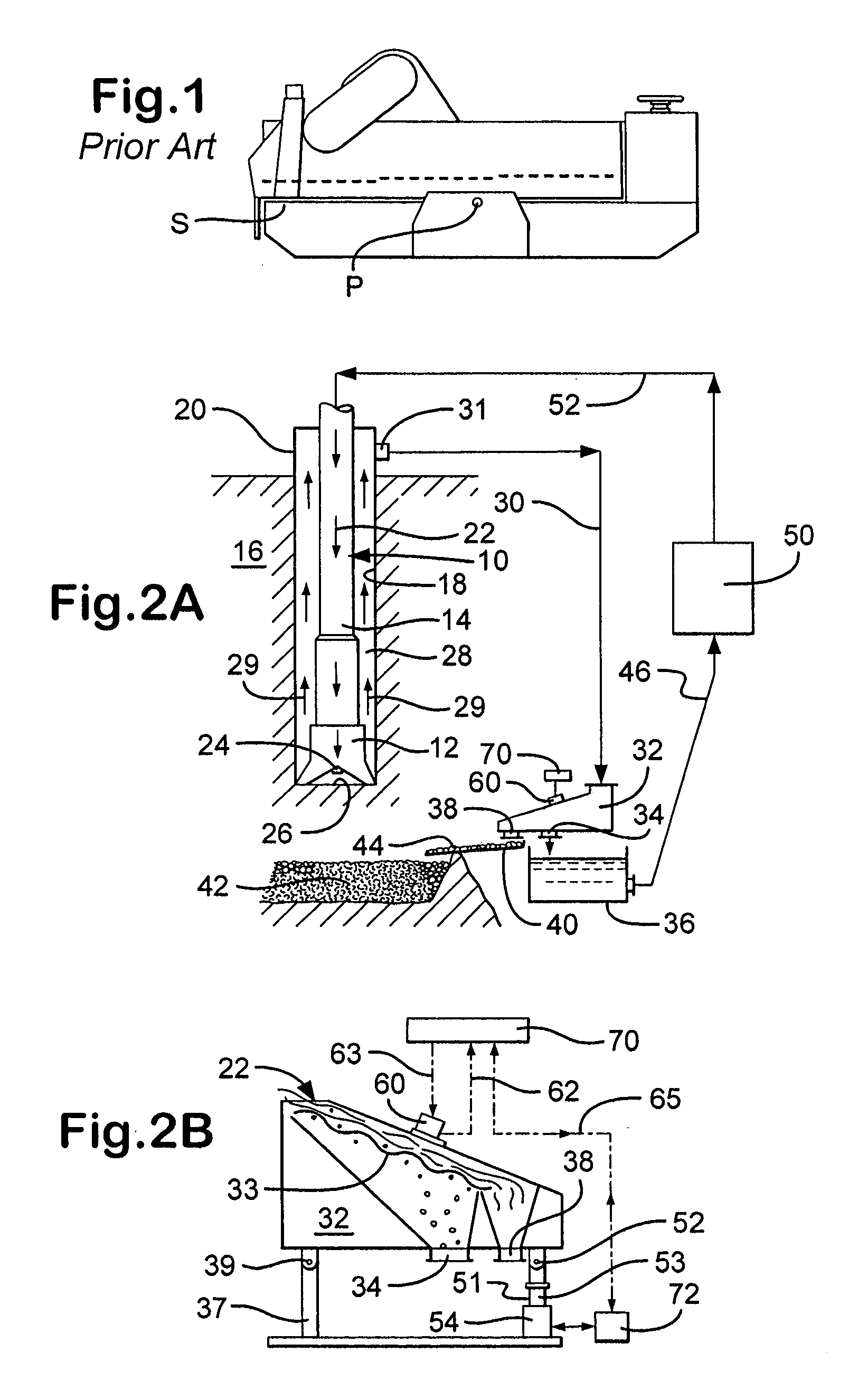

Method and apparatus for screening

ActiveUS20090321328A1Simple processQuick installationSievingScreeningEngineeringMechanical engineering

A screening machine includes wall members, screen assembly guide members, a screen assembly and a compression assembly. The screen assembly includes a frame with a plurality of side members and a screen supported by the frame. The compression assembly is attached to at least one wall member and forms the screen assembly into a concave shape.

Owner:DERRICK CORP

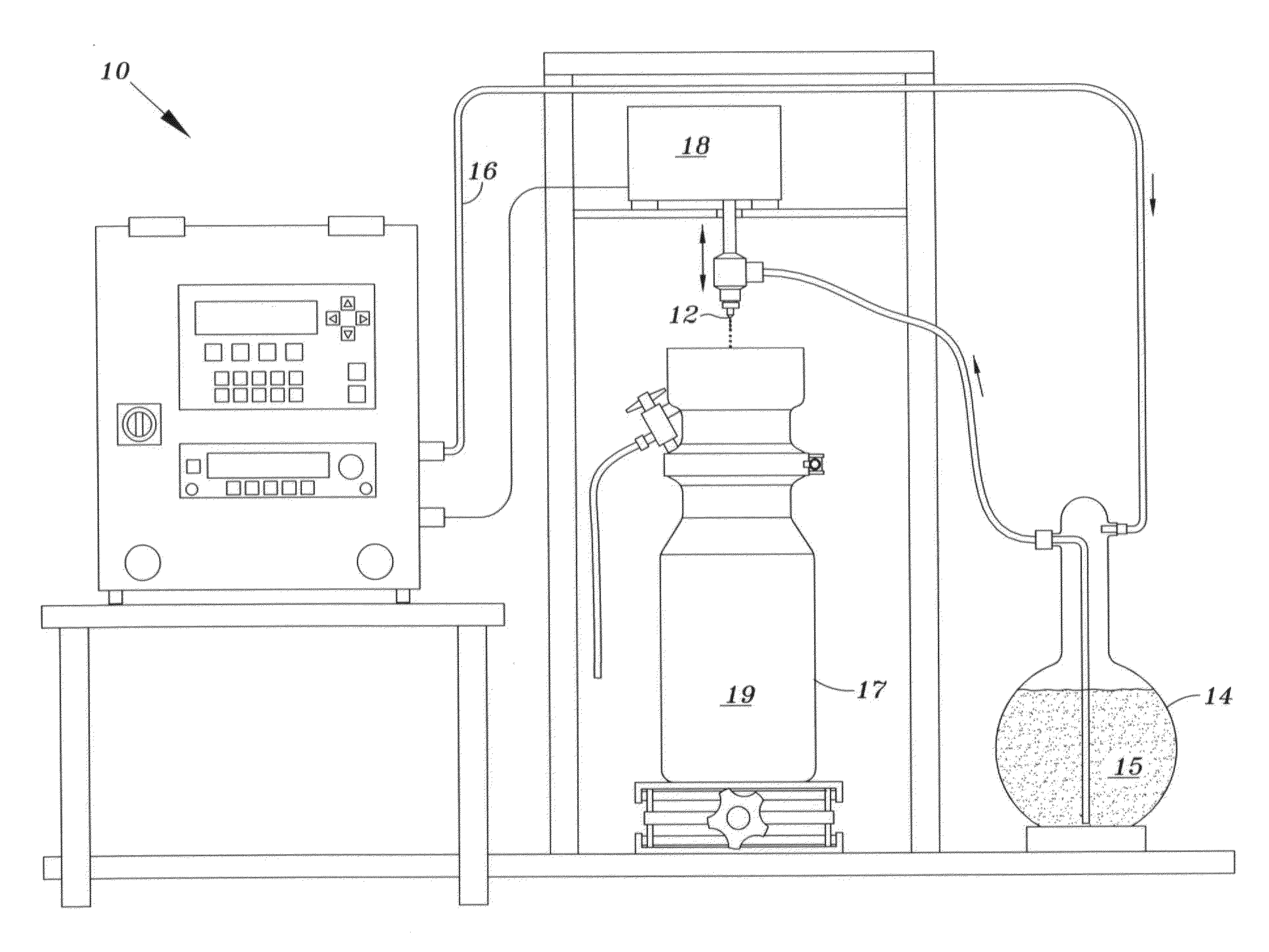

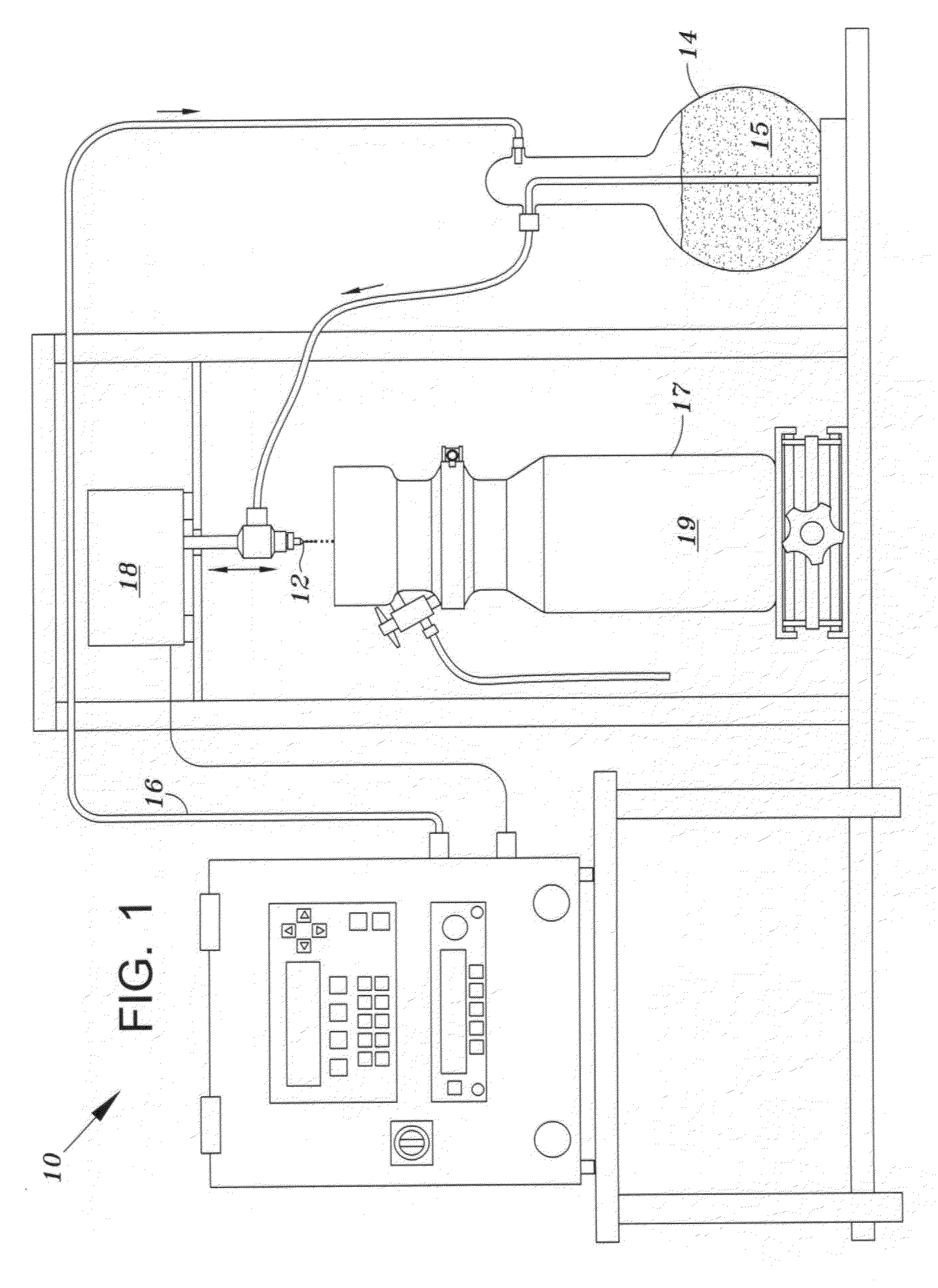

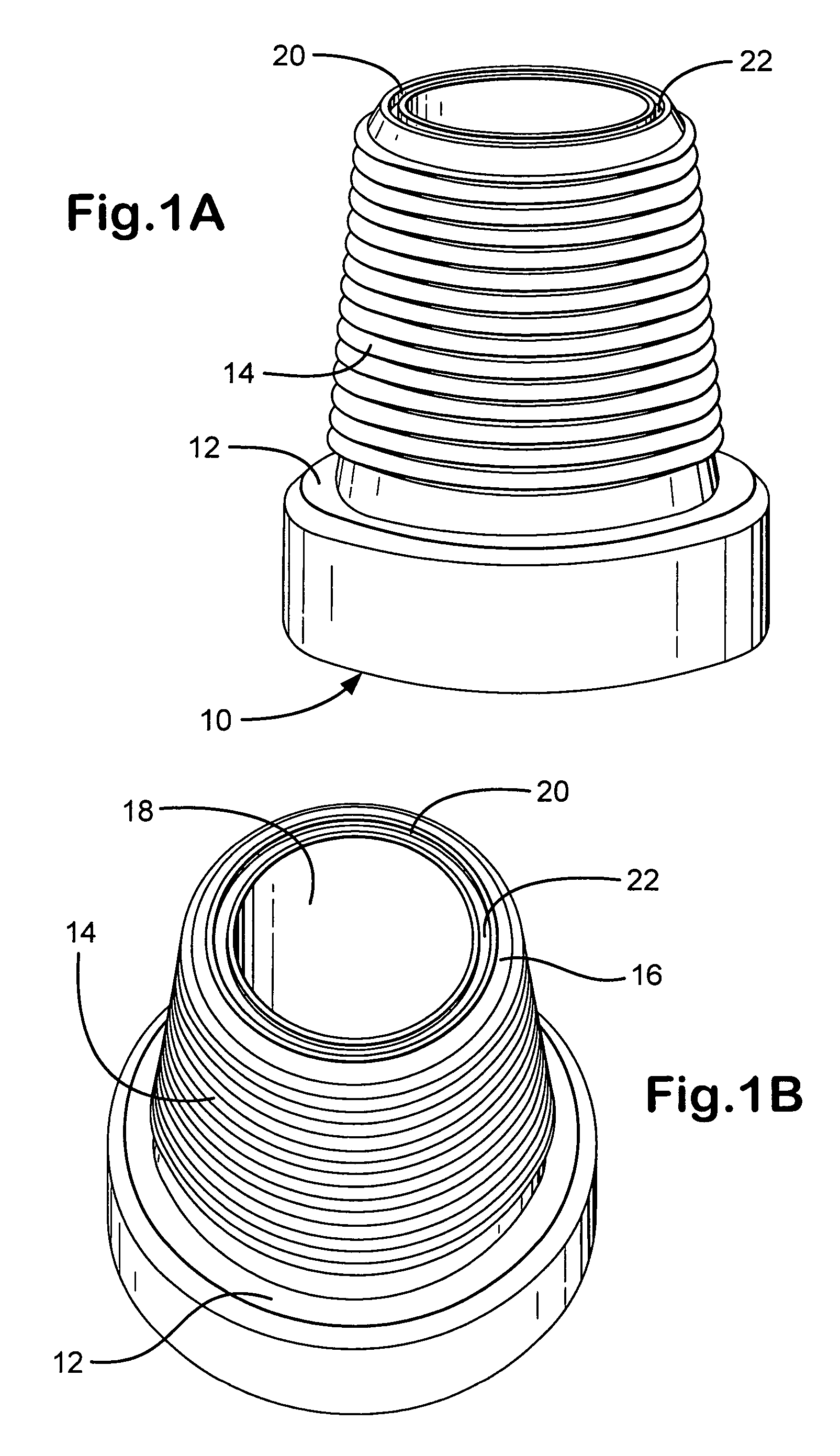

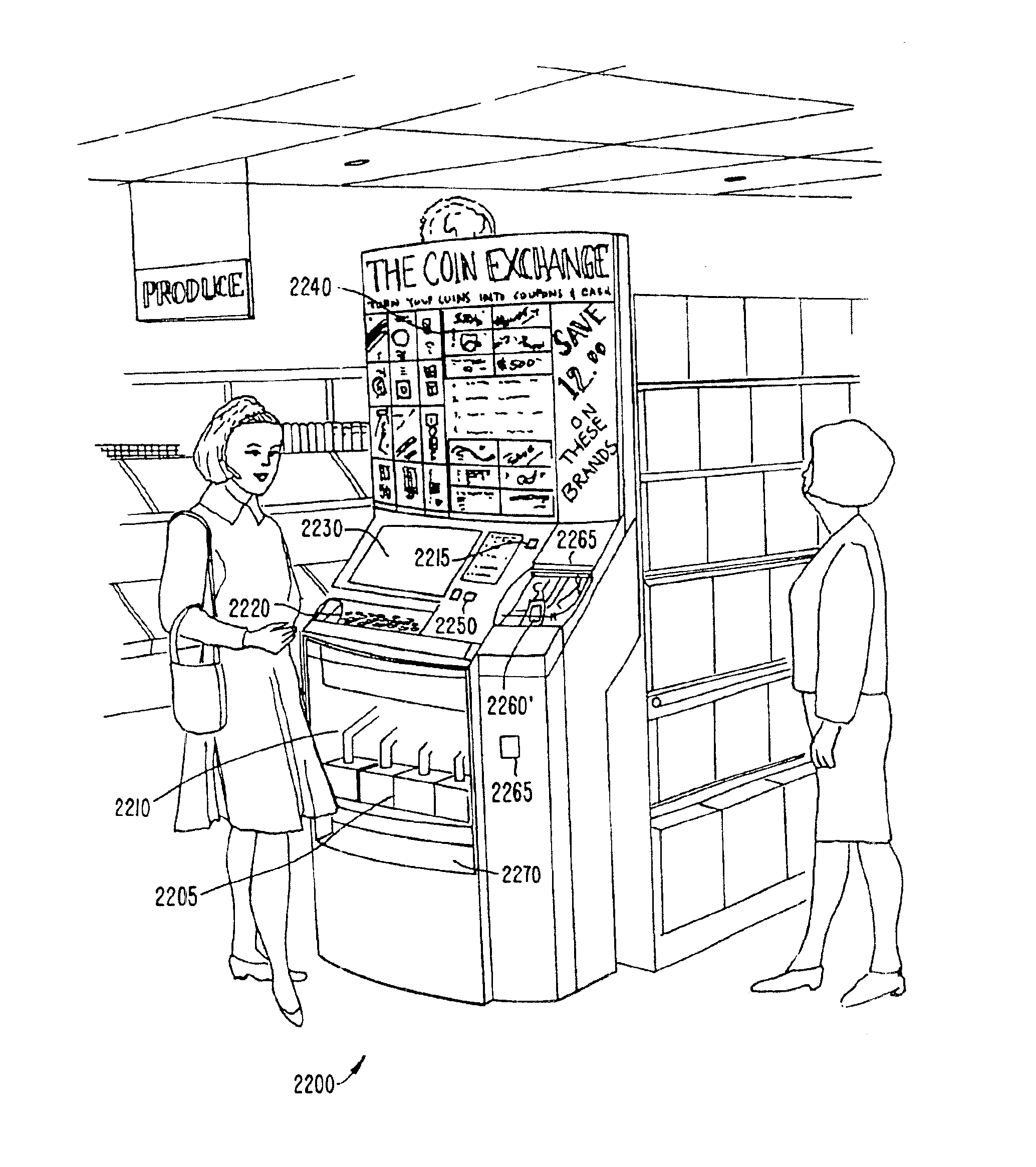

Method and apparatus for conditioning coins prior to discrimination

Methods and systems for cleaning coins and issuing a redeemable voucher for same. In one embodiment, an apparatus for issuing a redeemable voucher includes a coin input region configured to receive a plurality of coins, and a user interface configured to receive a request for a redeemable voucher. The apparatus can further include a debris separation device having a first opening configured to receive the plurality of coins from the coin input region, and at least a first wall forming an interior surface and an exterior surface. The first wall of the debris separation device includes at least one second opening smaller than the first opening and sized to prevent passage therethrough of the smallest coin of the plurality of coins. A driver can be configured to move the debris separation device and agitate the plurality of coins.

Owner:COINSTAR LLC

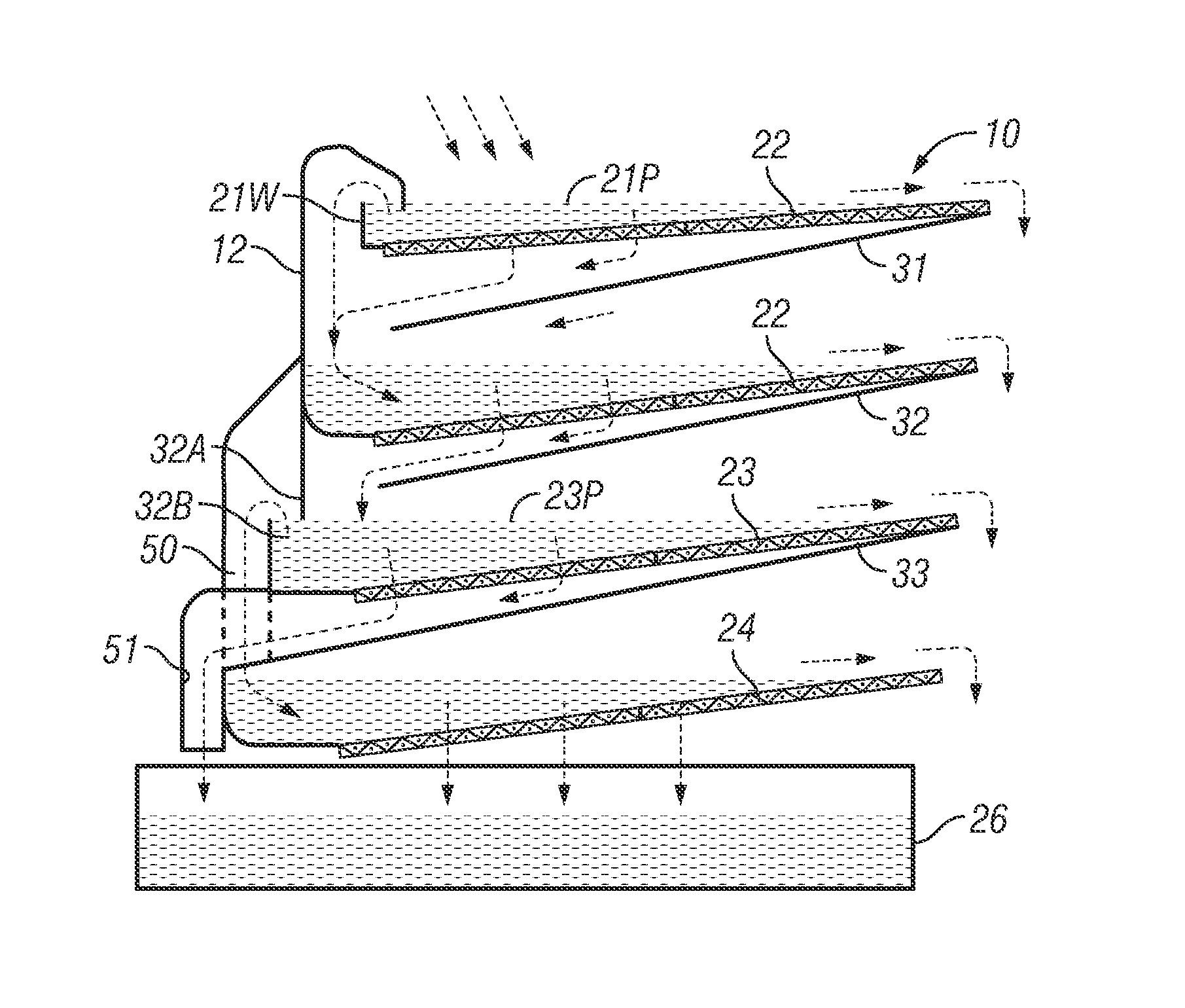

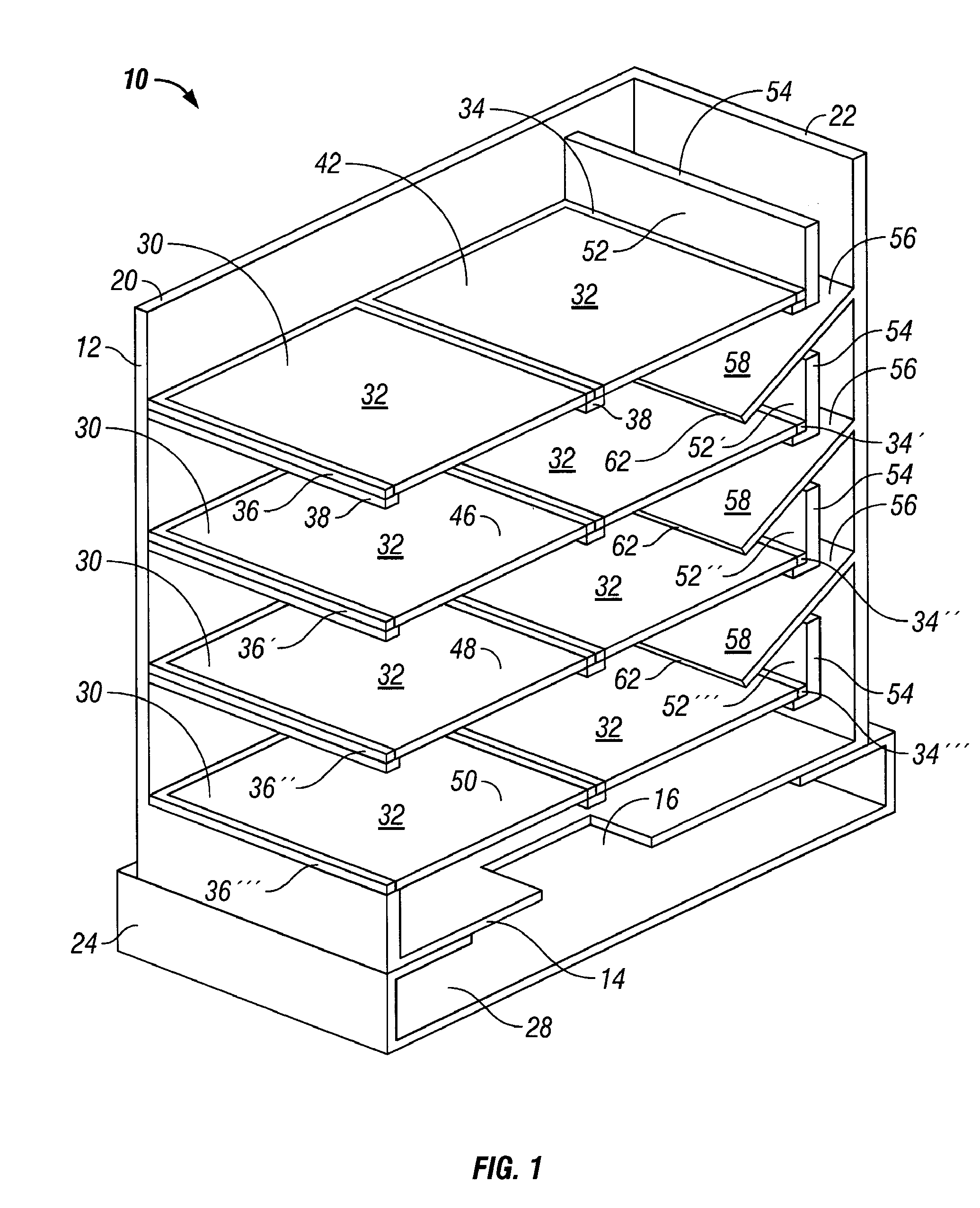

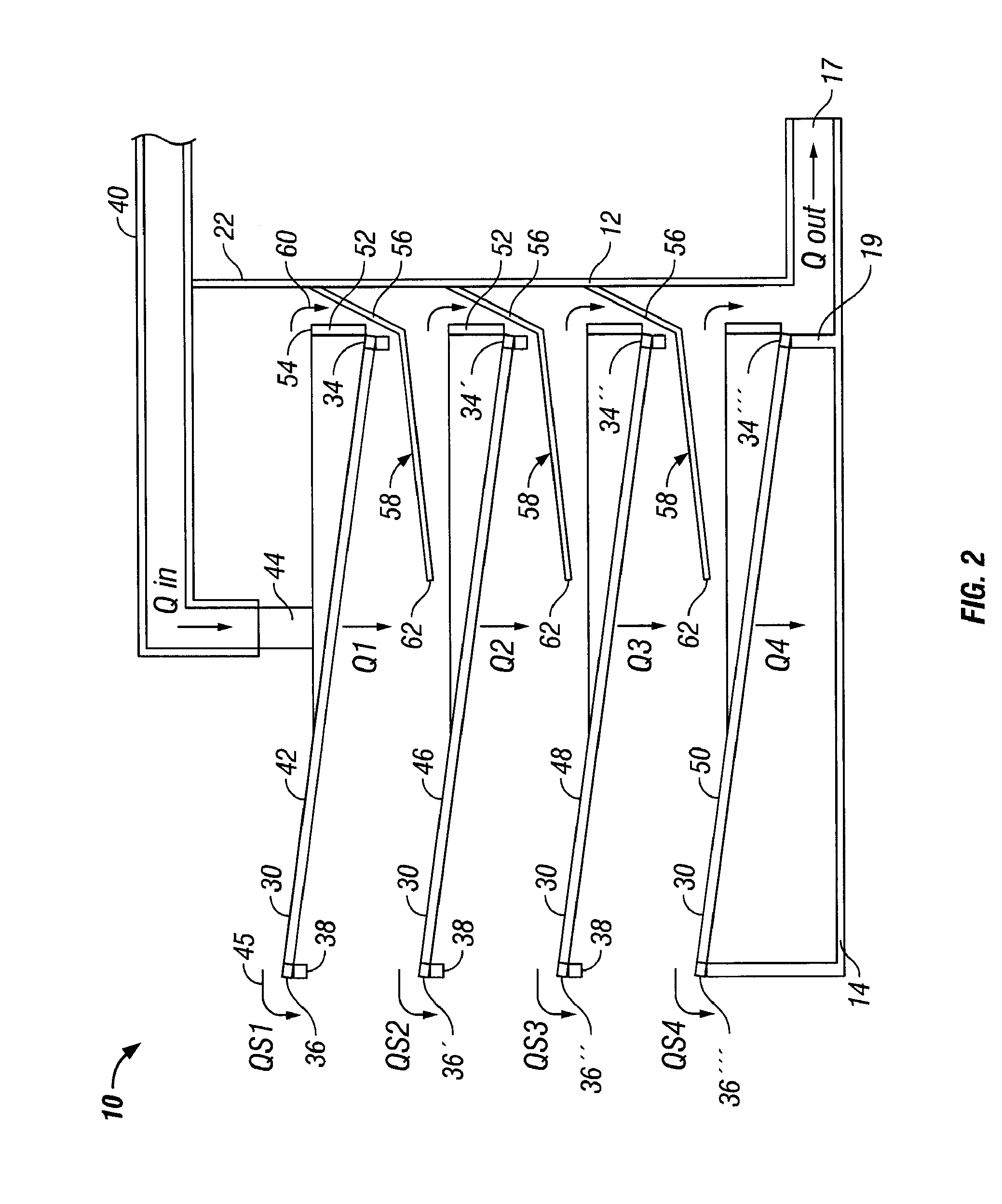

Fluid flow diffusers and vibratory separators

A vibratory separator including basket apparatus for holding screening apparatus, at least one upper screen apparatus in the basket, the at least one upper screen apparatus having a fluid exit end, at least one lower screen apparatus in the basket below the at least one upper screen apparatus, fluid flowable from the at least one upper screen apparatus down onto the at least one lower screen apparatus, flow diffusion apparatus mounted below the fluid exit end of the at least one upper screen apparatus and above the at least one lower screen apparatus, so that fluid flowing down from the at least one upper screen apparatus flows onto the flow diffusion apparatus and is diffused thereby, and vibrator apparatus for vibrating the basket and the screen apparatus therein.

Owner:VARCO I P INC

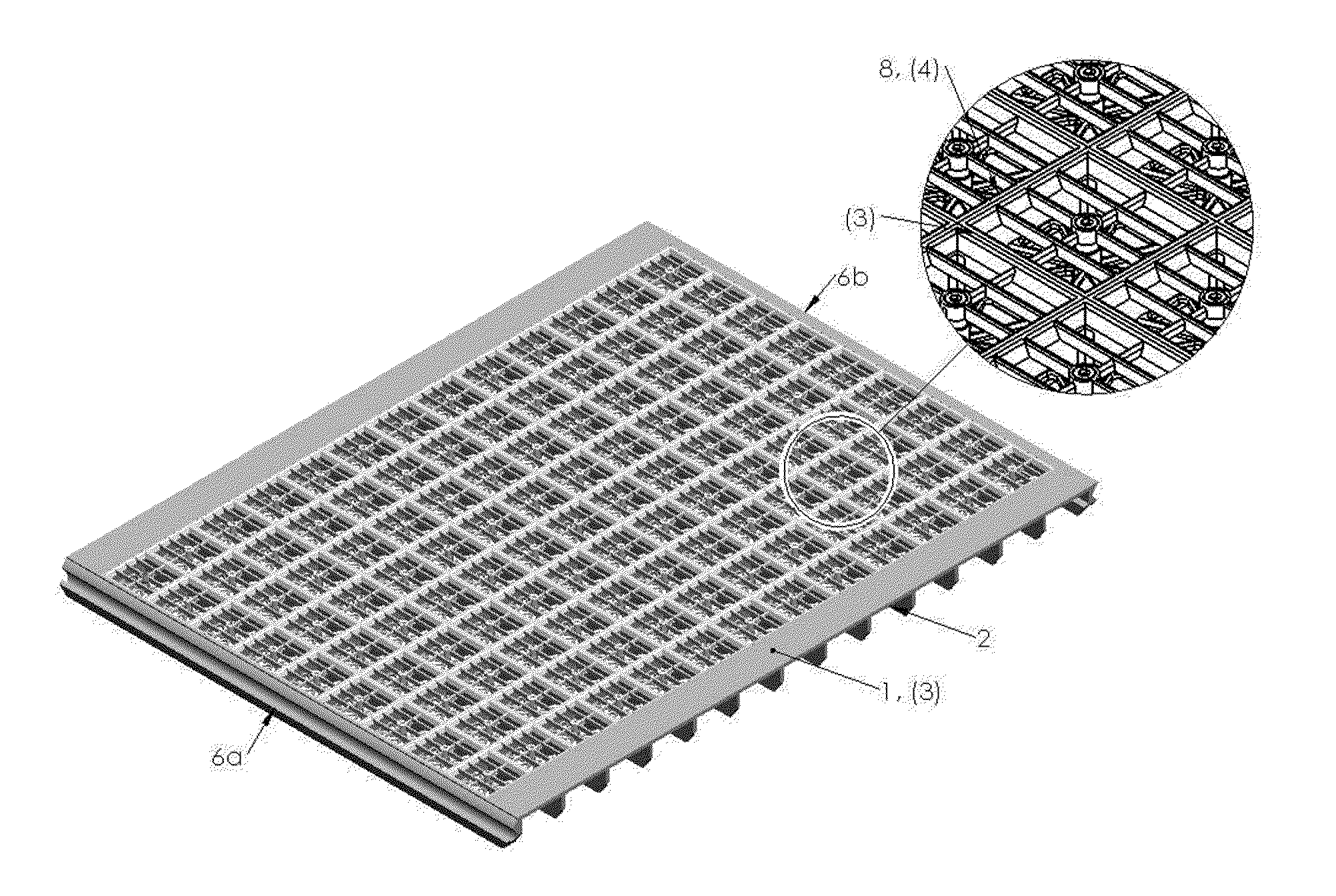

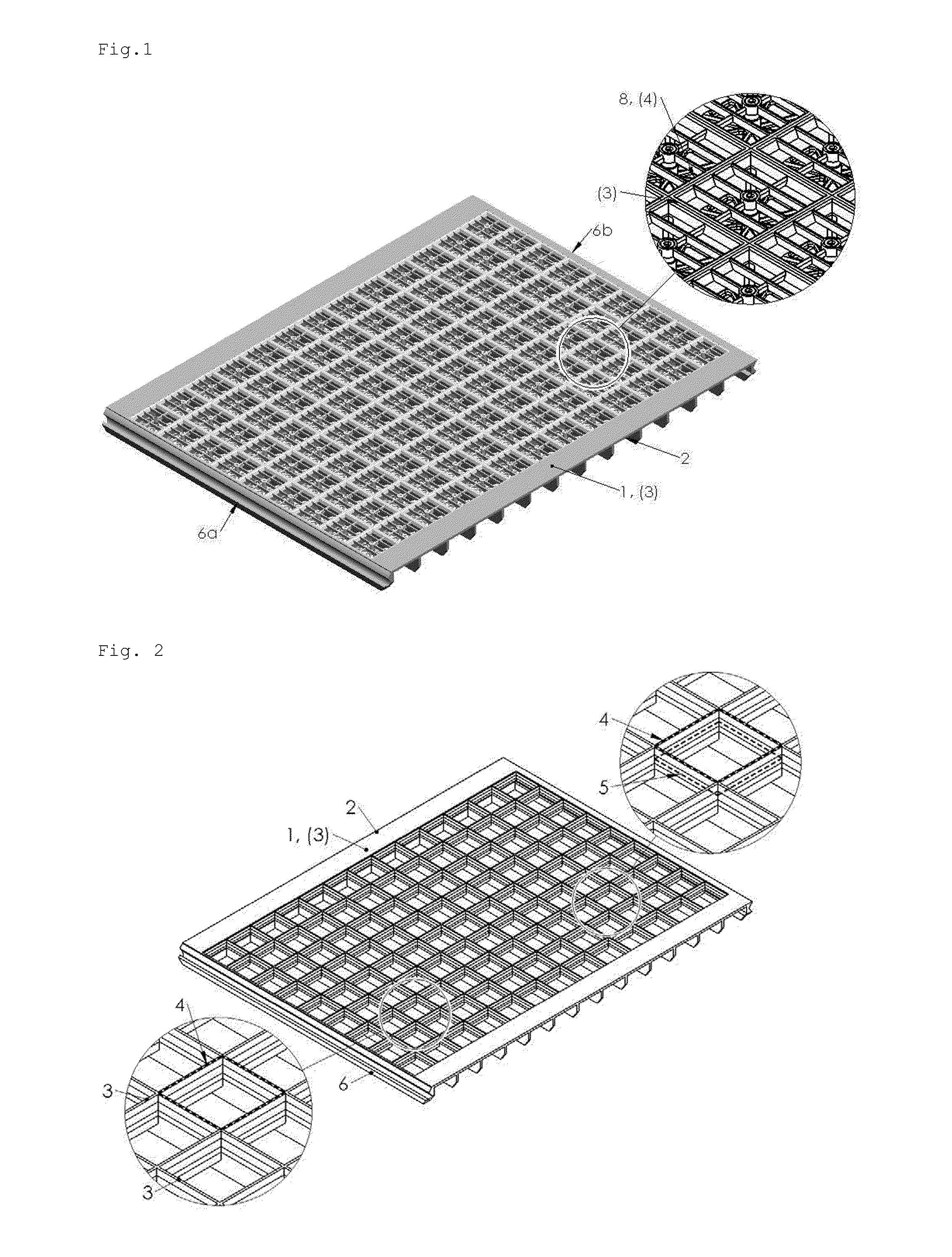

Shaker screen filter for a drilling fluid shaker

ActiveUS20110094950A1Shorten the timeReduce frictionSievingSnap-action fastenersLocking mechanismEngineering

An improved shaker screen filter for a well fluid shale shaker includes a main frame arranged for being arranged in the well fluid shale shaker for screening, preferably under vibration, of drilling mud, wherein the mainframe is subdivided into a plurality of smaller cell frames, one or more cell plug filters with one or more layers of screen cloths on top of at least one support cloth or support layer, wherein each of the cell plug filter includes a cell plug filter frame arranged to be held in each of the cell corresponding frames of the main frame, wherein at least one of the cell plug filter frame includes a locking mechanism arranged for locking the cell plug filter frame, upon desire, in a preferred position in the cell frame, correspondingly releasing the cell plug filter frame from the cell frame.

Owner:OPTIPRO

Shale shaker

A shale shaker for separating solids from solids laden drilling fluid is disclosed as having a basket with a scalping screen deck, at least one first screen deck and at least one second screen deck. The basket further may have a flow tray arranged between said scalping screen deck and at least one first screen deck, and a plurality of first ducts and a plurality of second ducts, the plurality of first ducts for directing solids laden drilling fluid to the at least one first screen deck. The second plurality of second ducts are for directing solids laden drilling fluid to said second screen deck.

Owner:NAT OILWELL VARCO LP

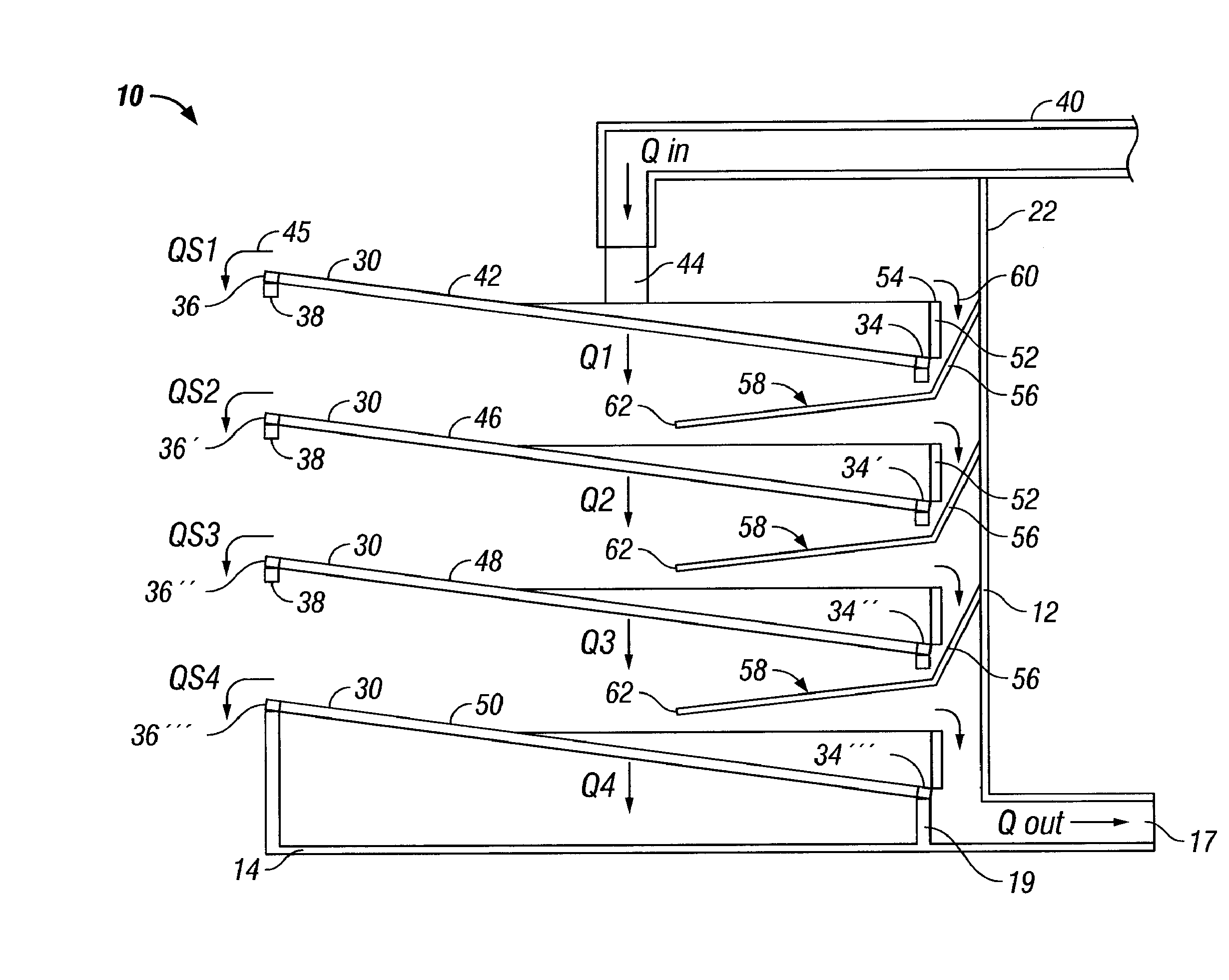

Vibratory Separator

An apparatus for separating solids from a drilling fluid that includes a basket having two opposed spaced-apart side walls having first ends and second ends, the first ends spaced apart by an end wall connected to each of the side walls, the basket further including a bottom wall through which a fluid outlet passage is defined, a plurality of screening surfaces having a front edge and a back edge and positioned within the basket between the side walls with each screening surface spaced apart vertically from adjacent screening surfaces and the back edge spaced apart from the end wall of the basket, wherein the back edge of each screening surface is lower than the front edge of the corresponding screening surface, a plurality of weirs, each weir retained along the back edge of a corresponding screening surface and spaced apart from the end wall to define a fluid passage between each weir and the end wall, wherein each weir has a top edge extending to a weir height above the back edge of the corresponding screening surface and the top edge is lower than the front edge of the corresponding screening surface, at least one flow director catching unseparated drilling fluid in the fluid passage and directing the unseparated drilling fluid onto a lower screen, and wherein fluid in the fluid passage between the lowermost screen and the end wall is directed to a spillover fluid outlet is disclosed.

Owner:MI

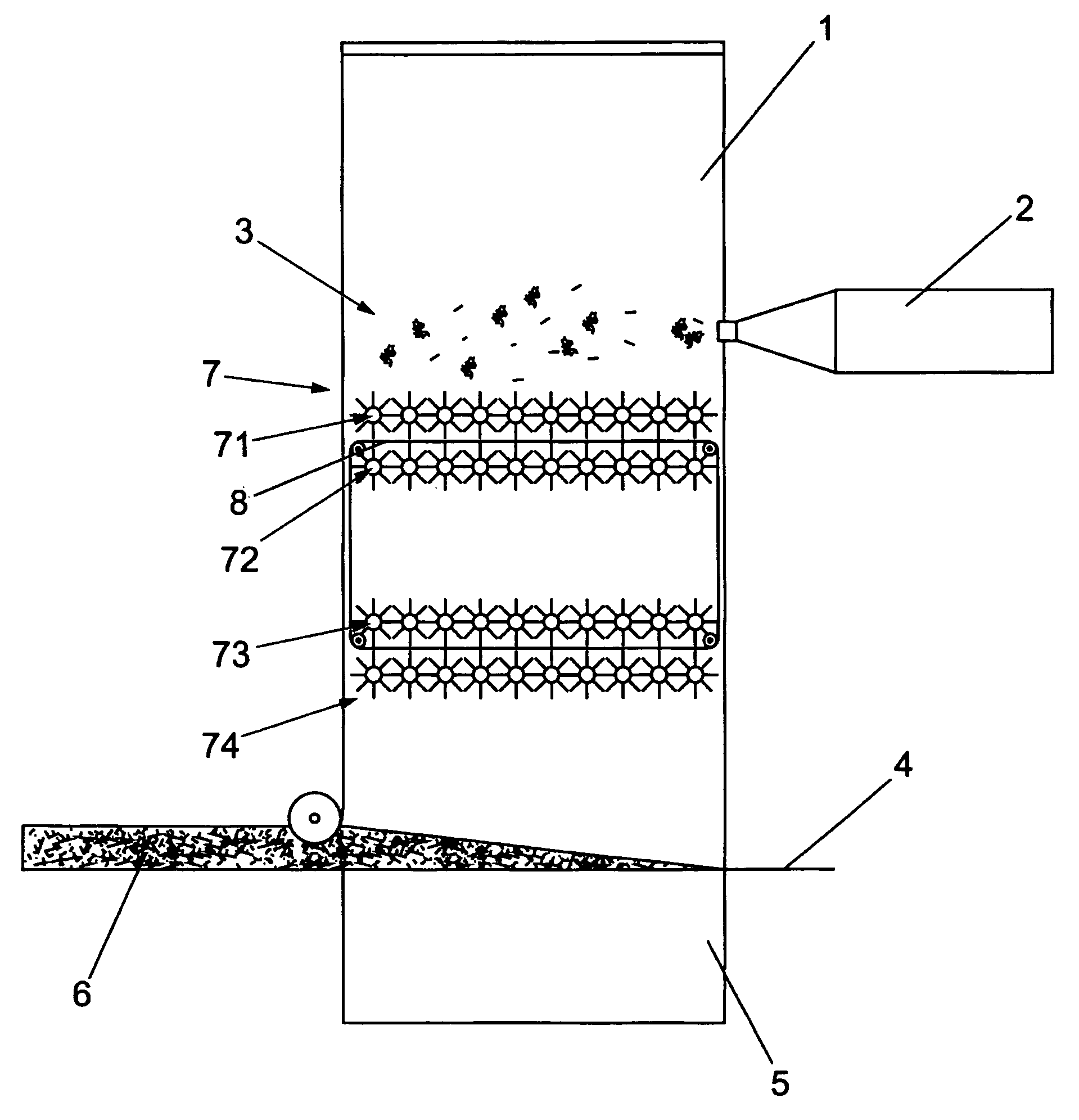

Air flow screening device for micron-sized powder materials

The invention relates to an air flow screening device for micron-sized powder materials, belonging to the screening technical field of powder engineering. The device is formed by improving the existing boiling dryer as follows: a front exhaust main pipe of the existing dryer is divided into a front exhaust main pipe and a back exhaust main pipe, a sieve plate mesh box with a sieve inside is added between the front exhaust main pipe and the back exhaust main pipe to increase the space dimensions of a fluid bed so as to increase the area of the sieve, so that the effective drift diameter of the sieve is increased, and the pore diameter of the sieve can be changed; a blowback device is added to prevent the sieve from being clogged; a circulating device is added to circulate the powder back to the main cavity of the fluid bed; and a pneumatic transmitting and discharging device is added on the basis of the original exhaust system. The device overcomes the defects that the existing boiling dryer can be only used for millimeter-sized particle materials due to the small sieve area and large meshes of the existing boiling dryer and powder materials are piled on the sieve and clog the sieve to block or even disable the air exhaust so as to affect the normal operation of the air jet screening when a small-pore sieve is used in the existing boiling drier. And the invention is applicable to the screening of powder materials.

Owner:YUNNAN GUZHIJI NUTRIMENT CO LTD

Vibratory separator with material heater

A vibratory separator apparatus for separating components from a fluid material stream fed to the vibratory separator apparatus, the vibratory separator apparatus, in certain aspects, having separator apparatus for separating components of the fluid material stream, and heating apparatus for heating the fluid material stream. A screening system with a screen mounting basket, at least one screen mounted on the basket, and heating apparatus for heating the at least one screen. Methods are disclosed for using such apparatuses and systems

Owner:VARCO I P INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com