Patents

Literature

32 results about "Shale shakers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

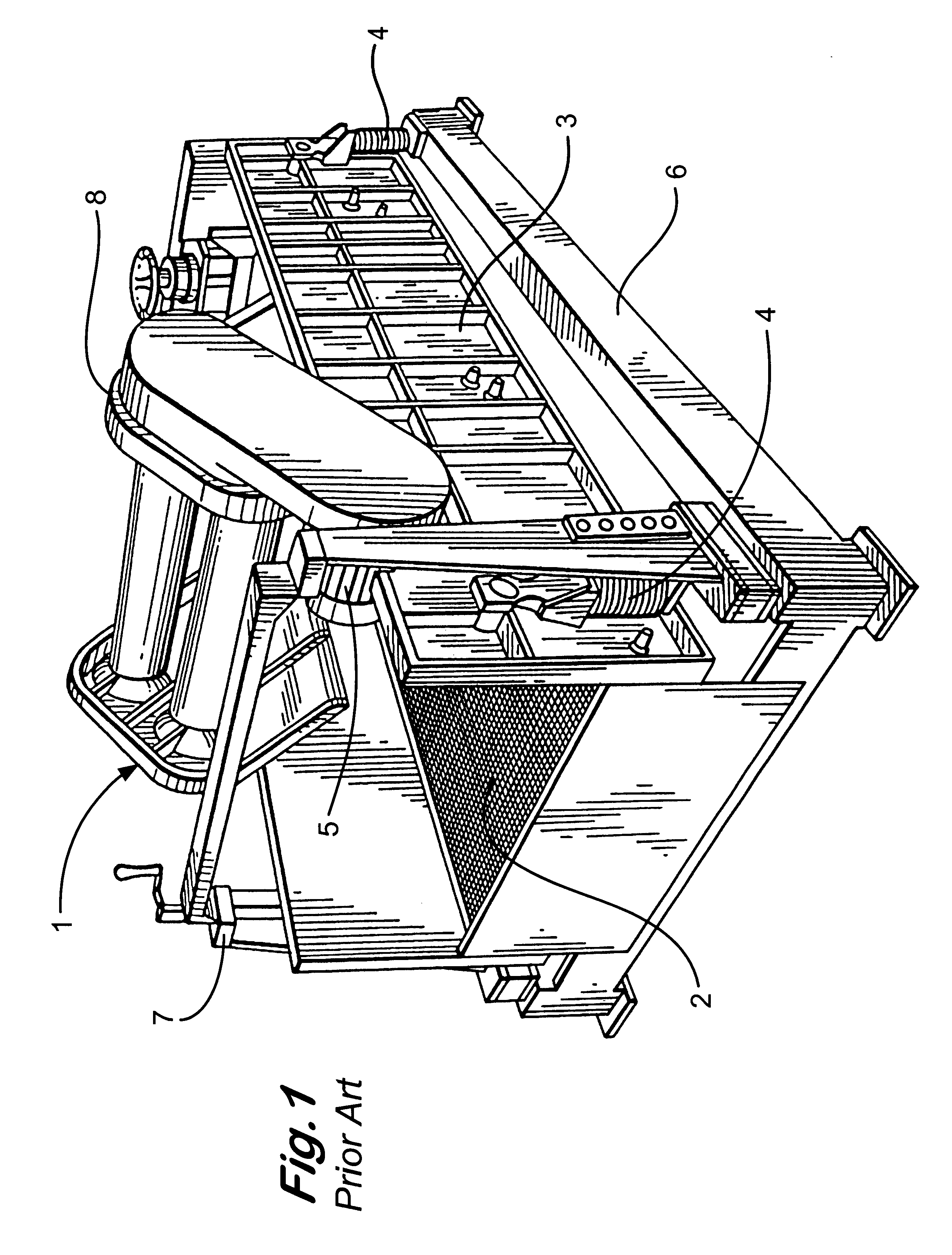

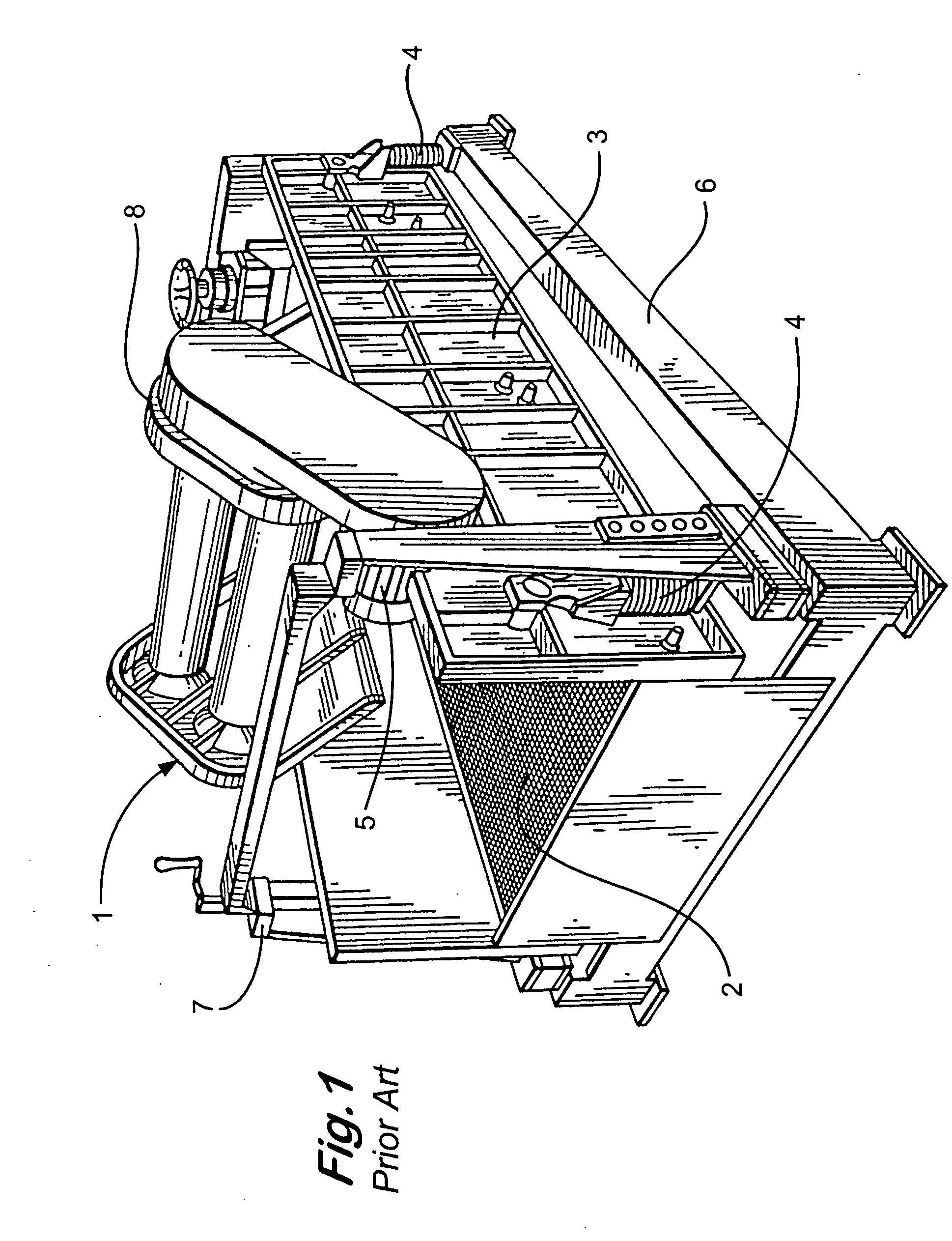

Shale shakers are components of drilling equipment used in many industries, such as coal cleaning, mining, oil and gas drilling. They are the first phase of a solids control system on a drilling rig, and are used to remove large solids (cuttings) from the drilling fluid ("mud").

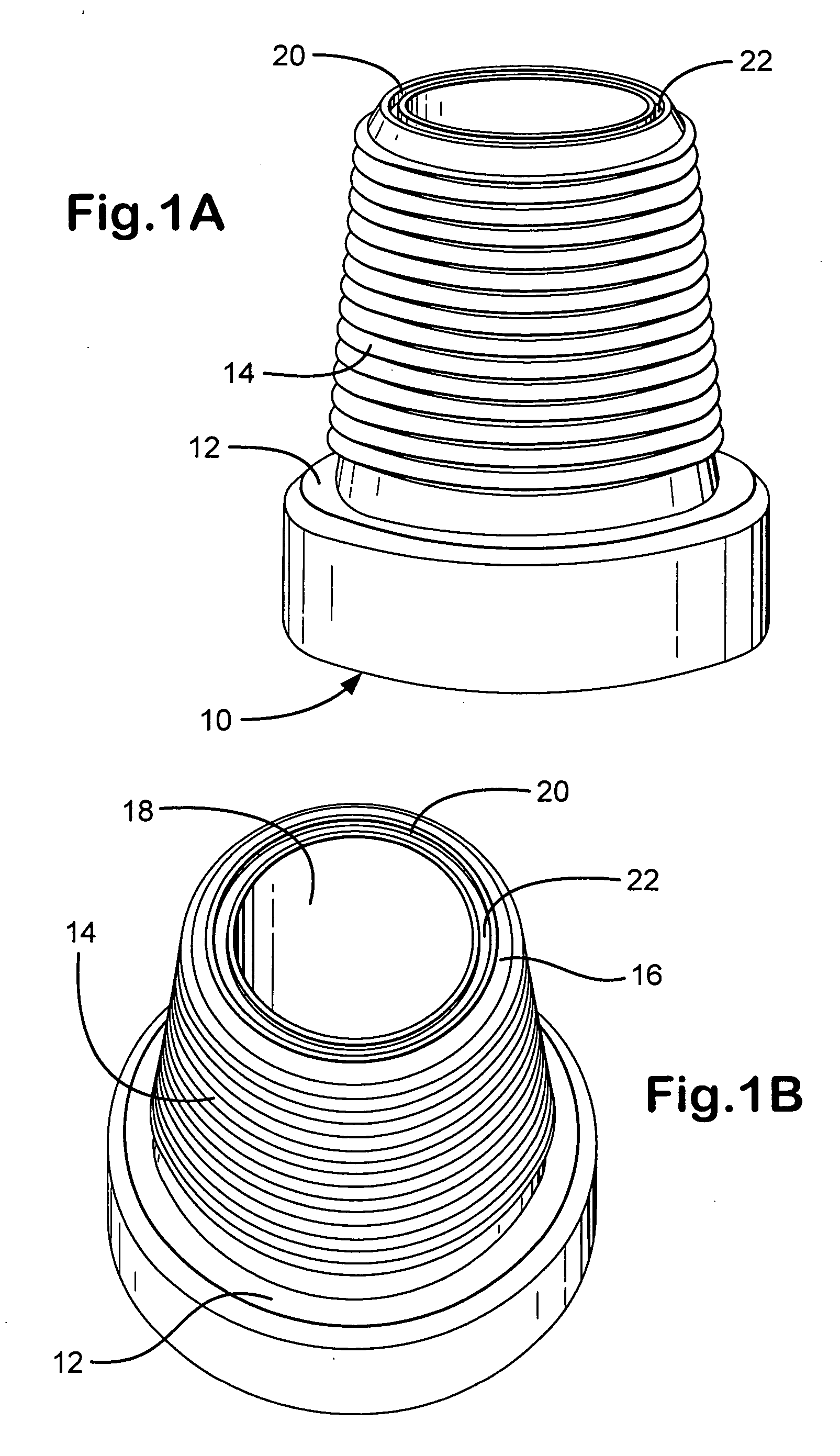

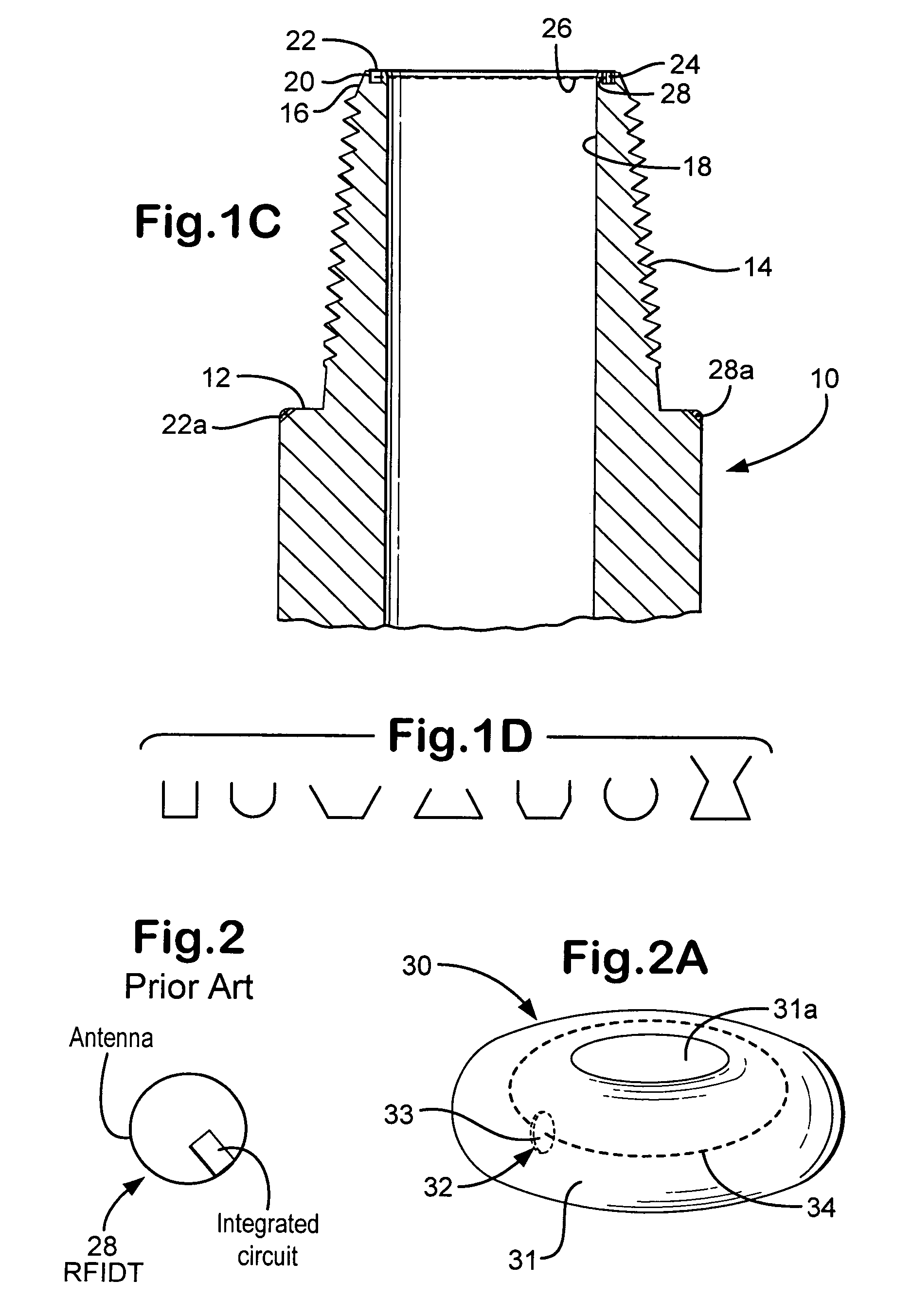

Shale shakers and screens with identification apparatuses

A screen apparatus, which in certain aspects is a screen apparatus having a support, screening material on the support, and energizable identification apparatus on (exteriorly, interiorly, and / or within) the support for identifying the screen apparatus; a vibratory separator with such a screen apparatus; and a vibratory separator or shaker with energizable identification apparatus.

Owner:VARCO I P INC

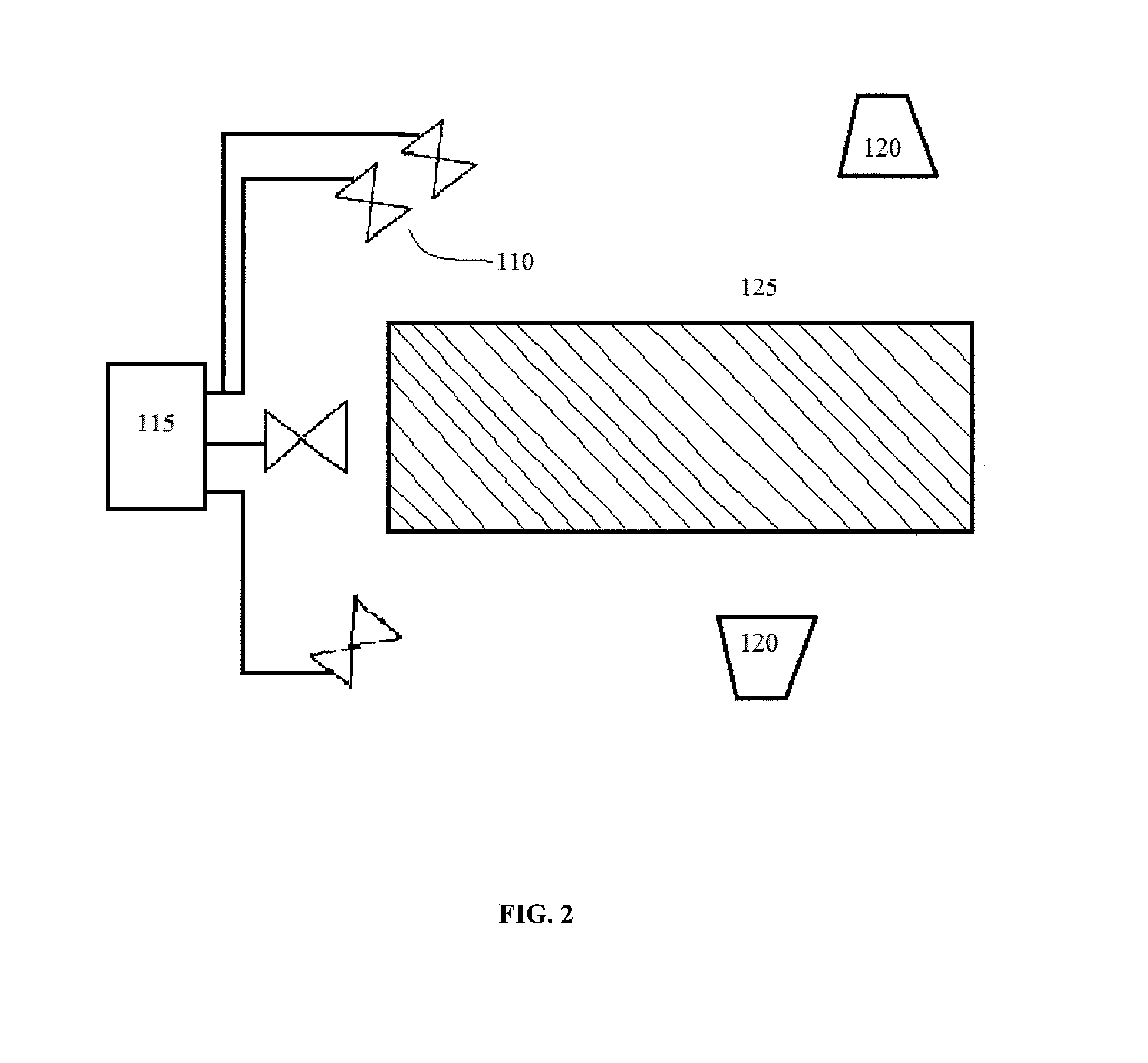

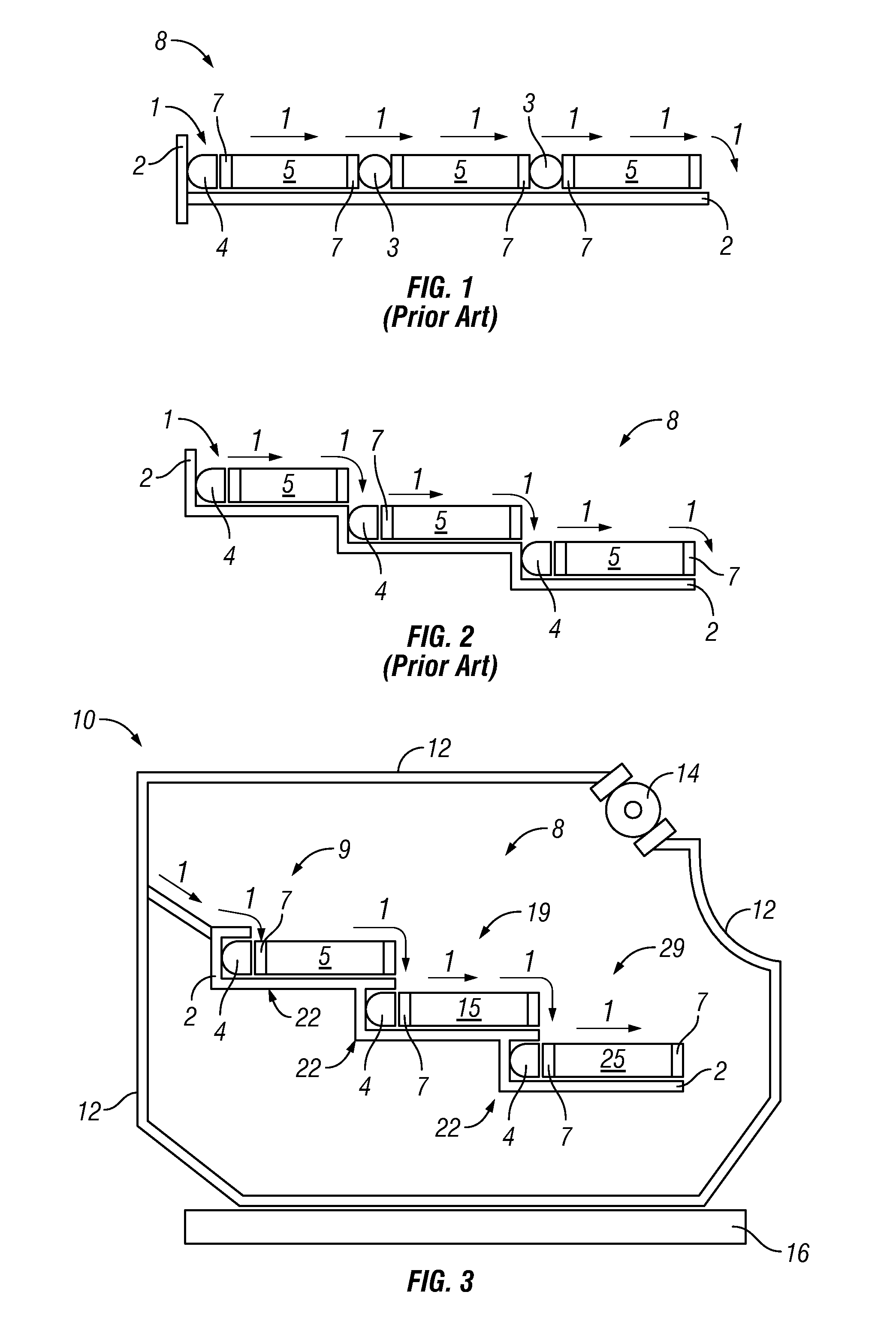

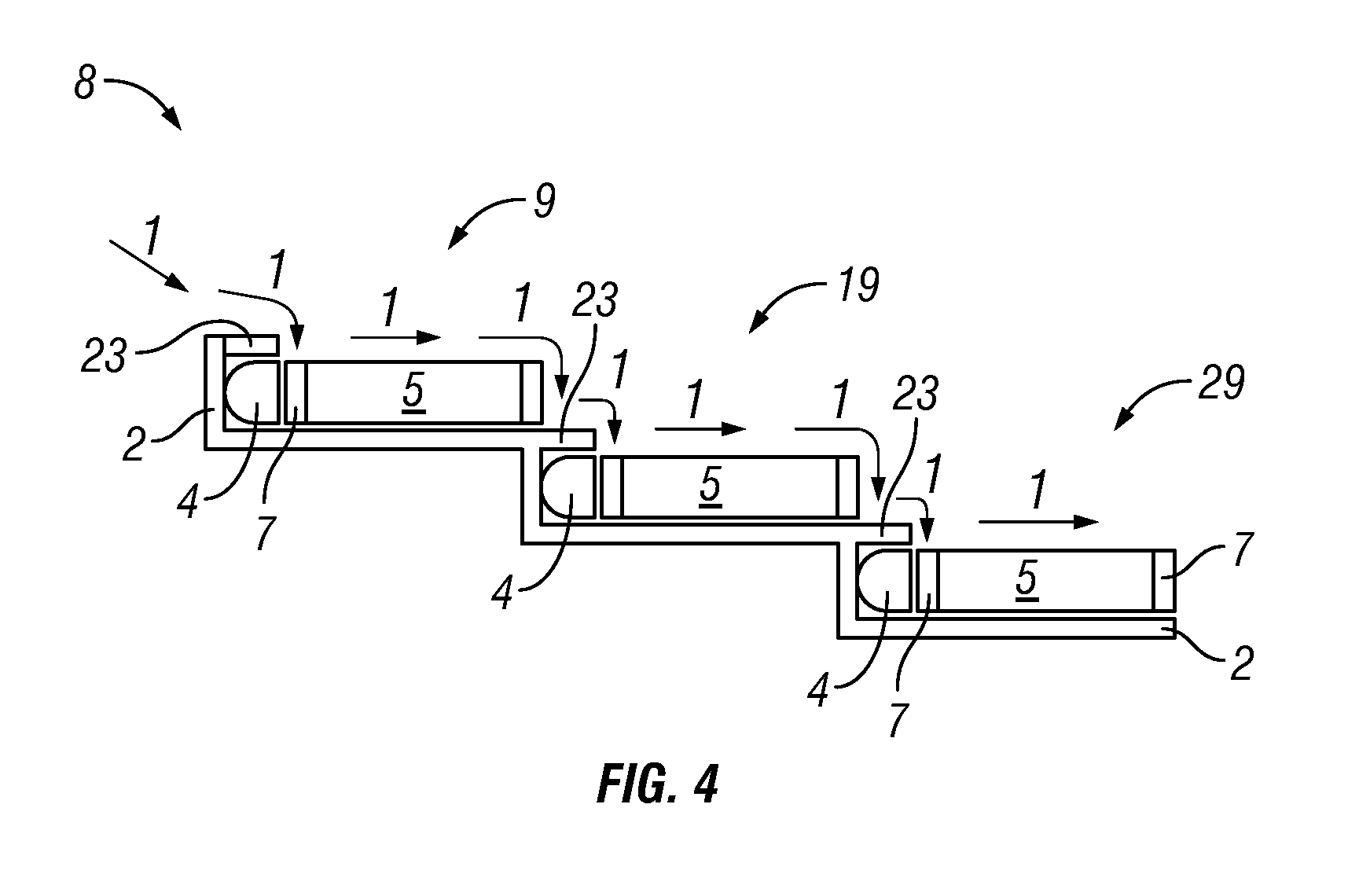

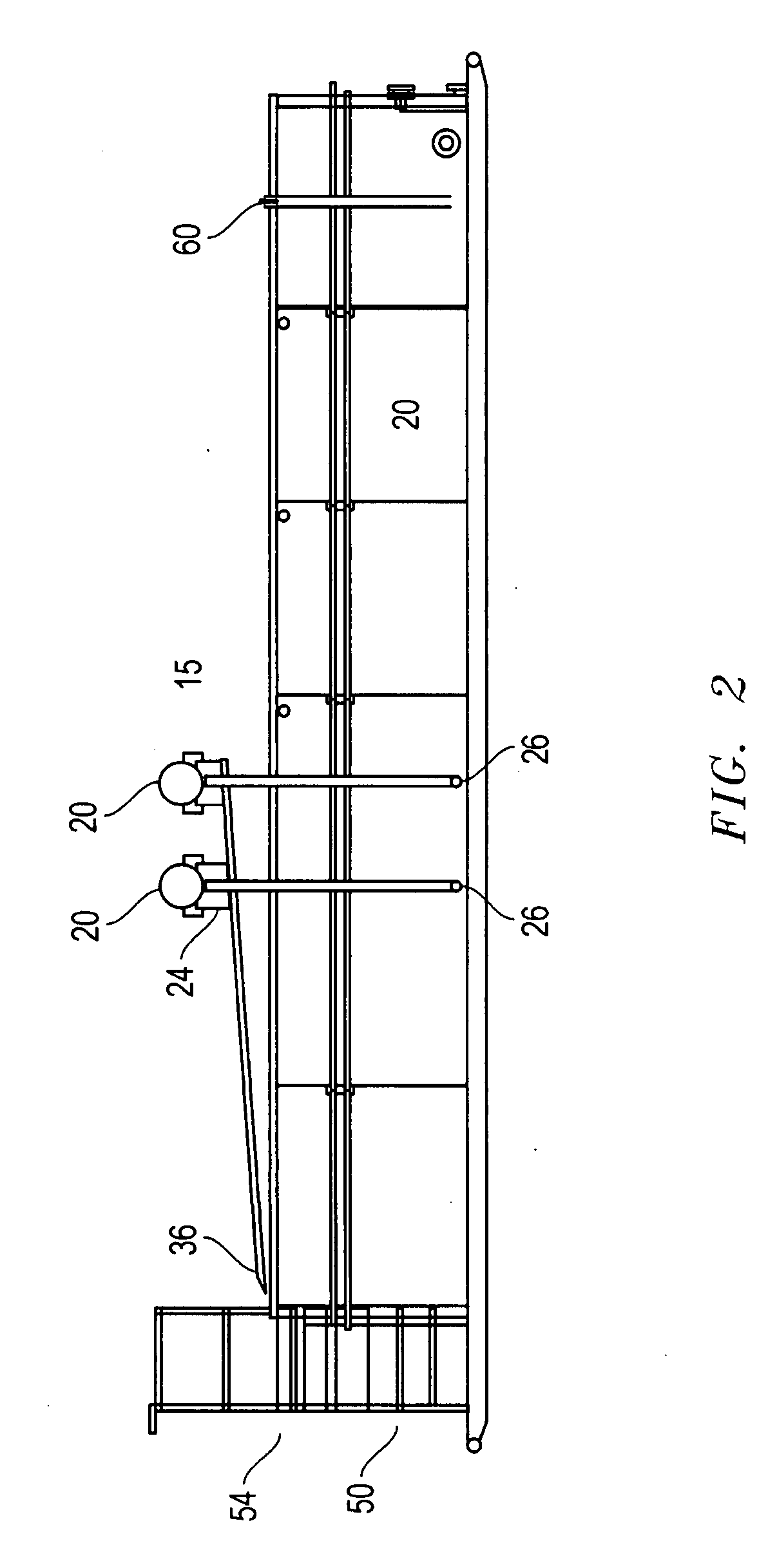

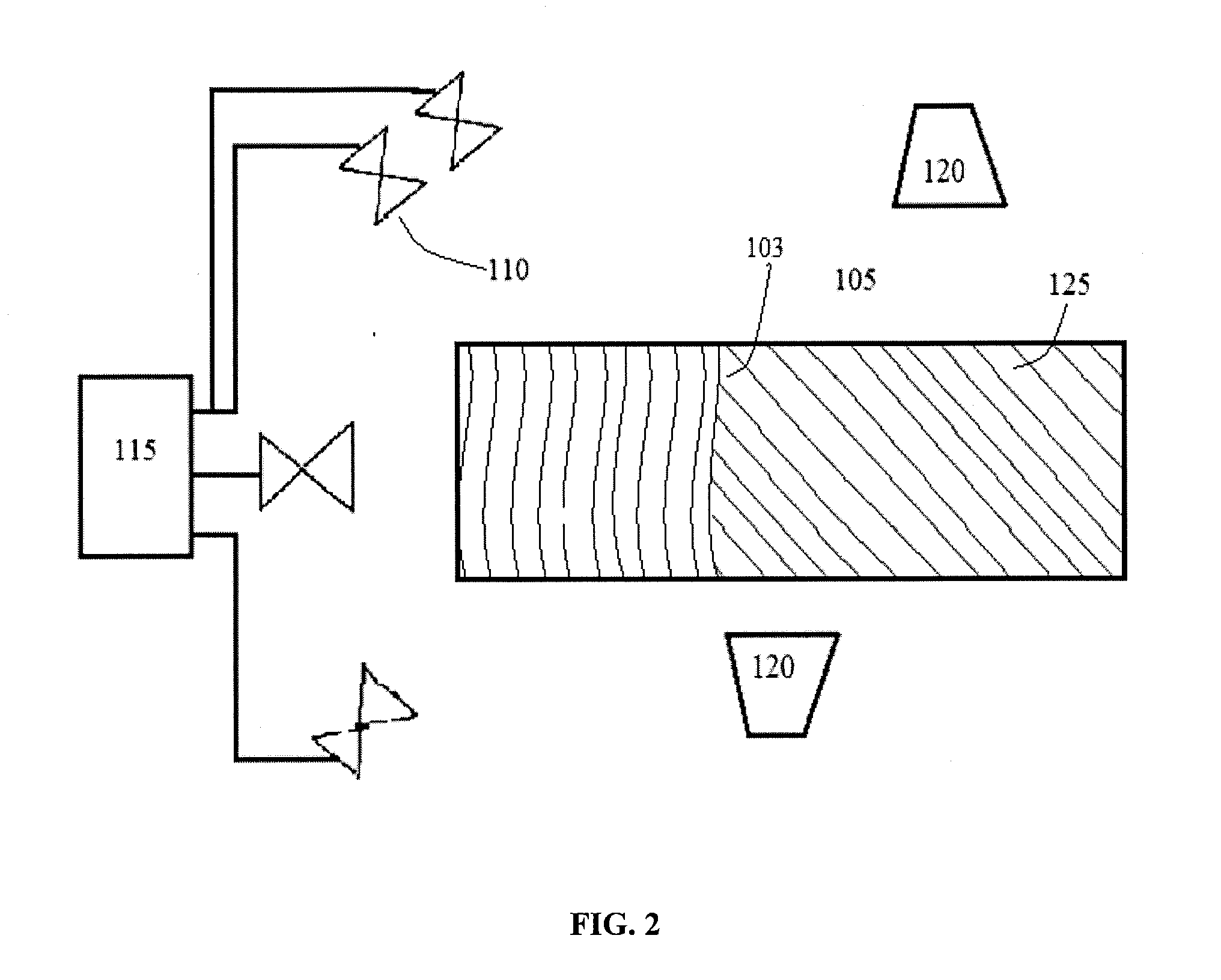

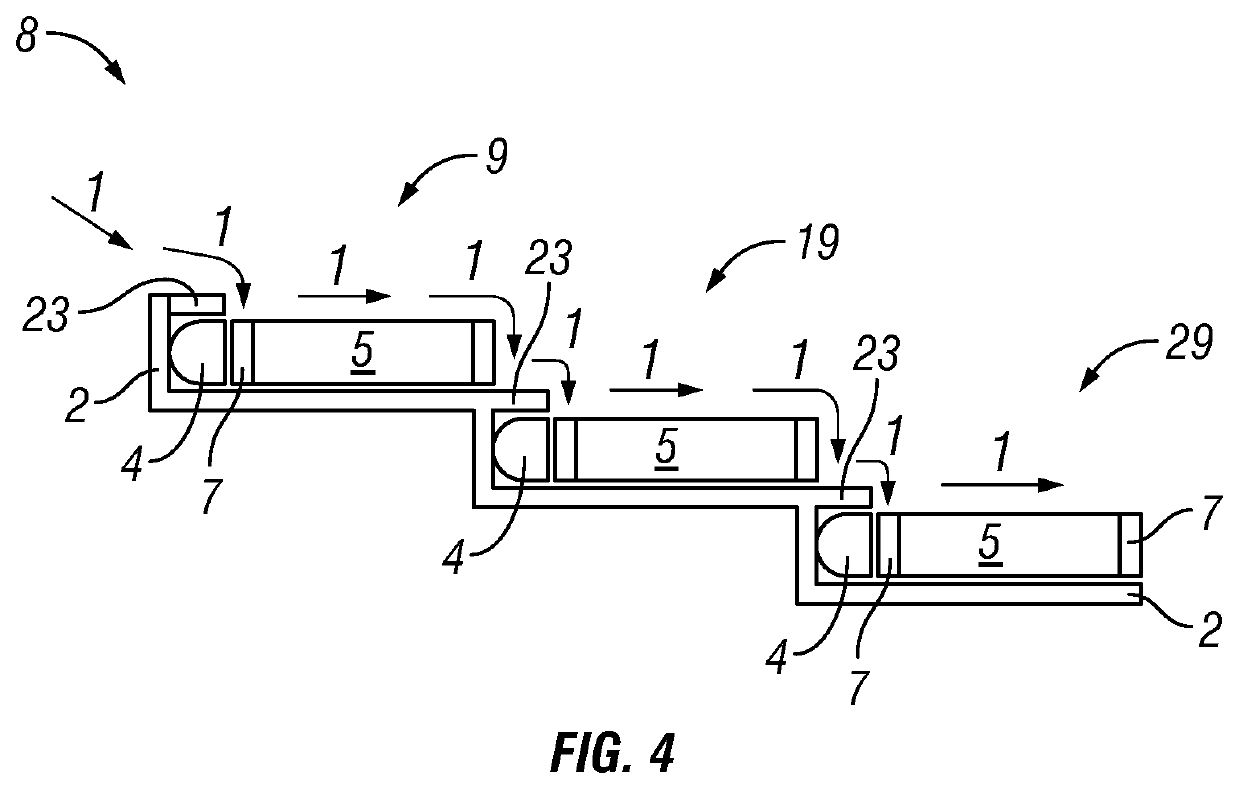

Shale Shakers with Selective Series/Parallel Flow Path Conversion

Methods and systems are disclosed employing a shale shaker for processing a mixture of drilling fluid and solids with multiple screen assemblies and conversion apparatus for switching flow to the screen assemblies between series flow and parallel flow; and in one aspect, a screen or screens for screening lost circulation material.

Owner:NAT OILWELL VARCO LP

Shale shakers and screens with identification apparatuses

A screen apparatus, which in certain aspects is a screen apparatus having a support, screening material on the support, and energizable identification apparatus on (exteriorly, interiorly, and / or within) the support for identifying the screen apparatus; a vibratory separator with such a screen apparatus; and a vibratory separator or shaker with energizable identification apparatus.

Owner:VARCO I P INC

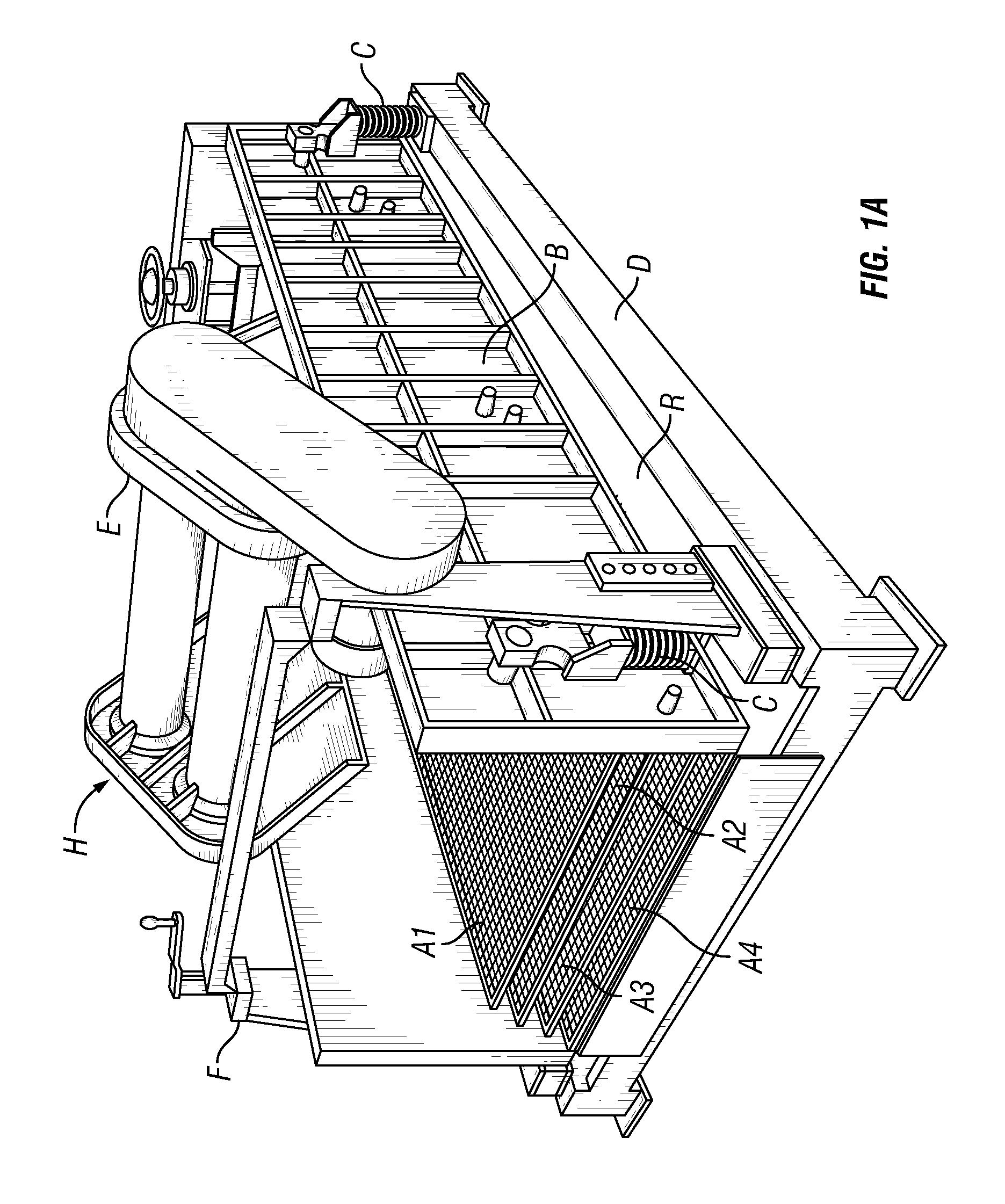

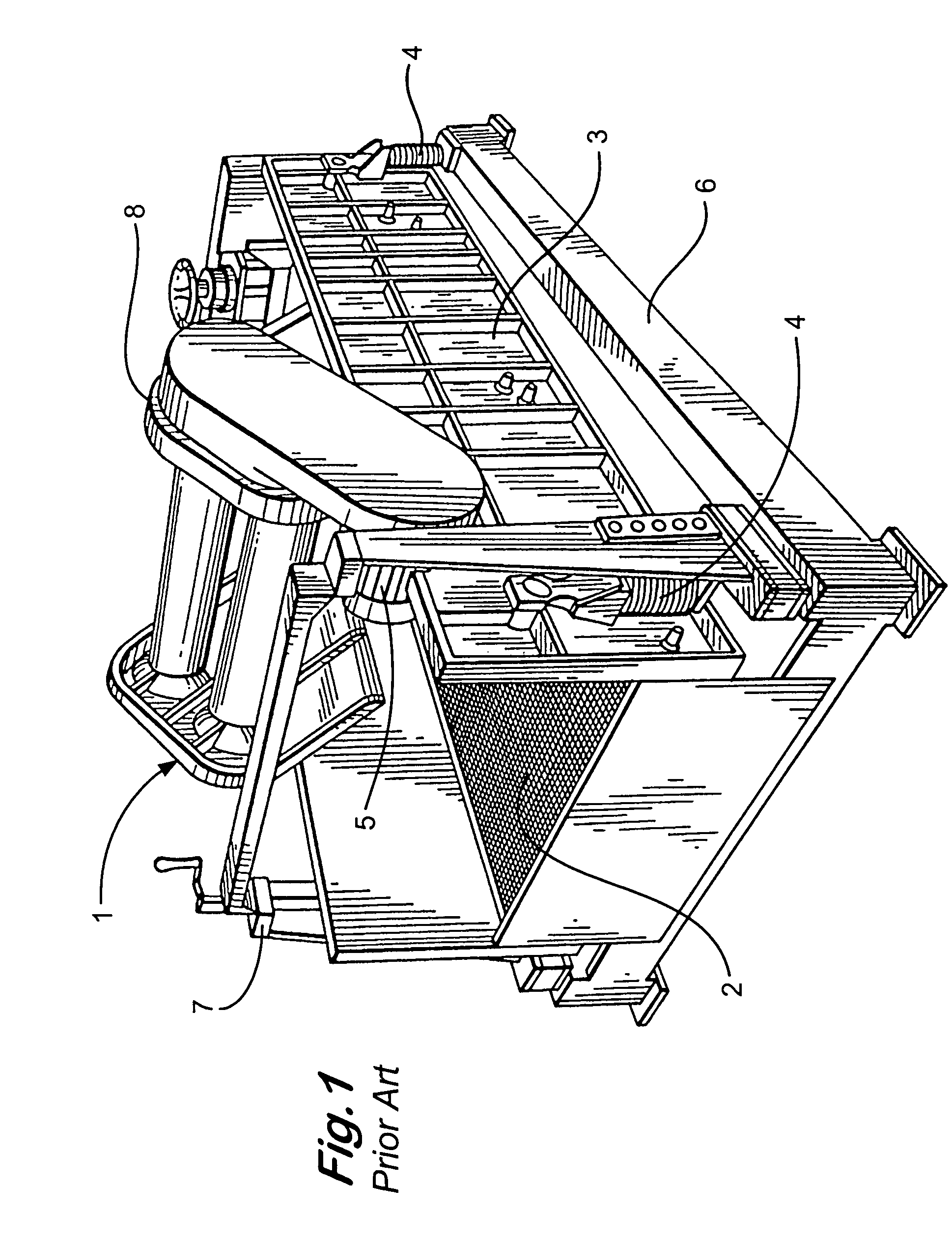

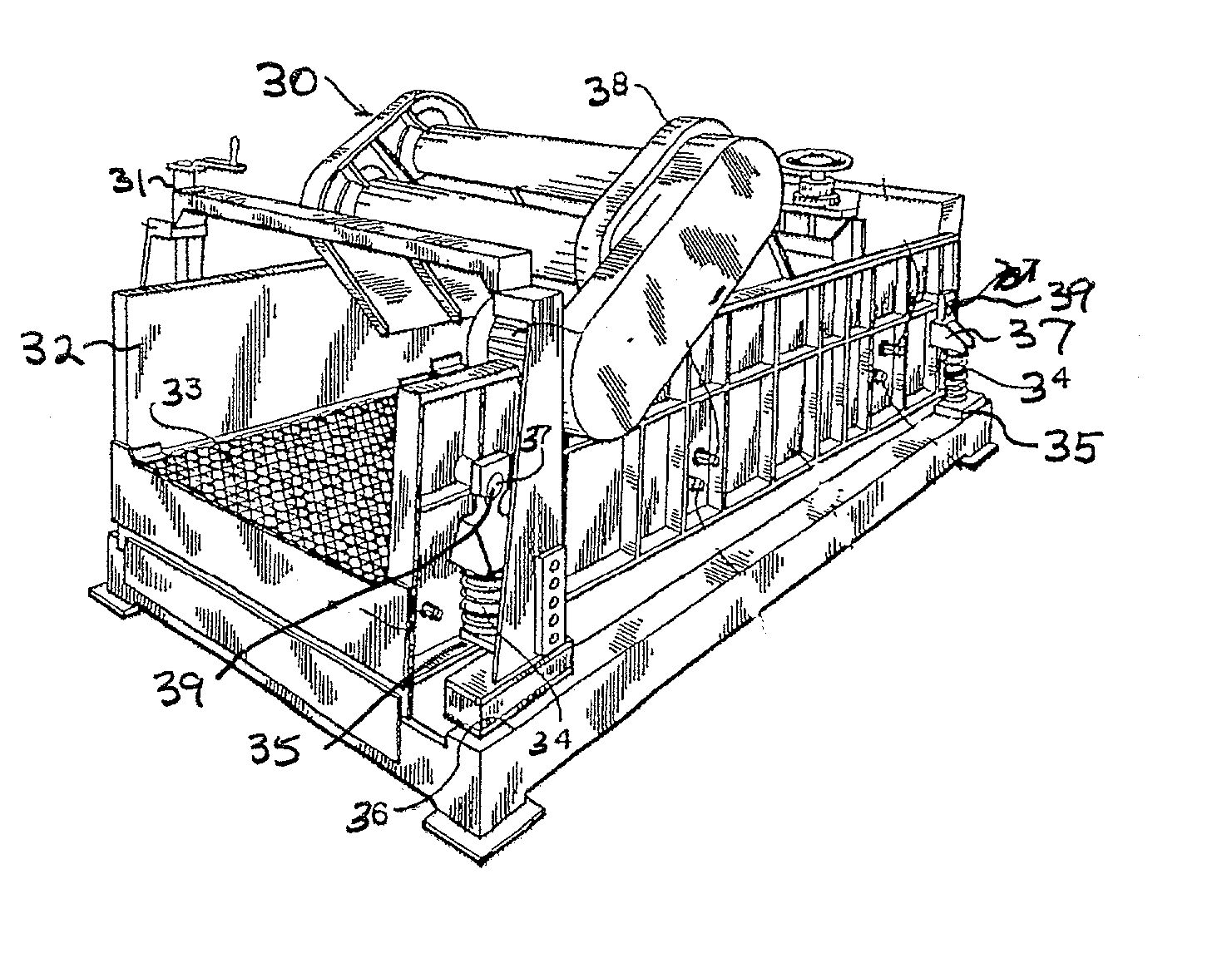

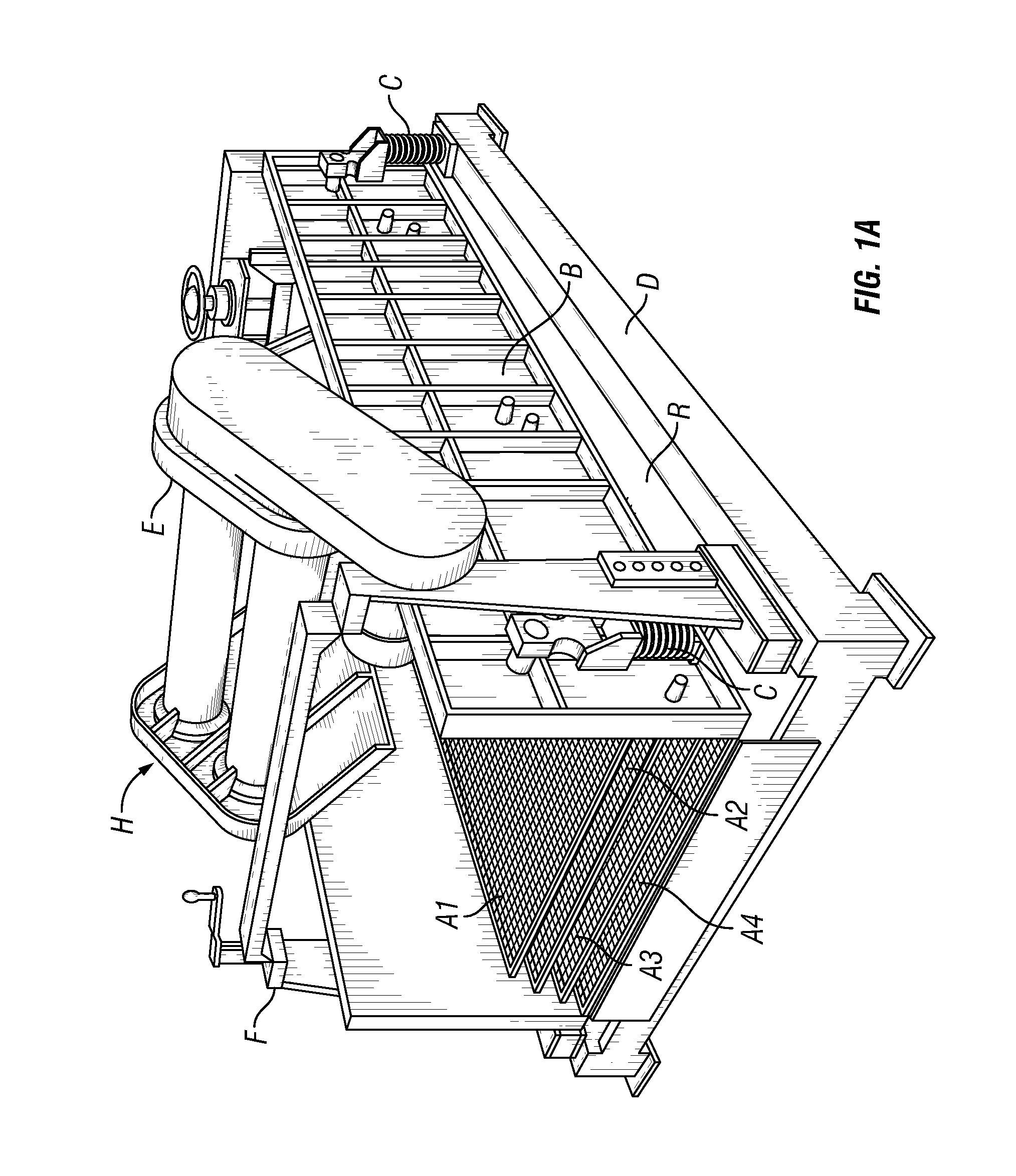

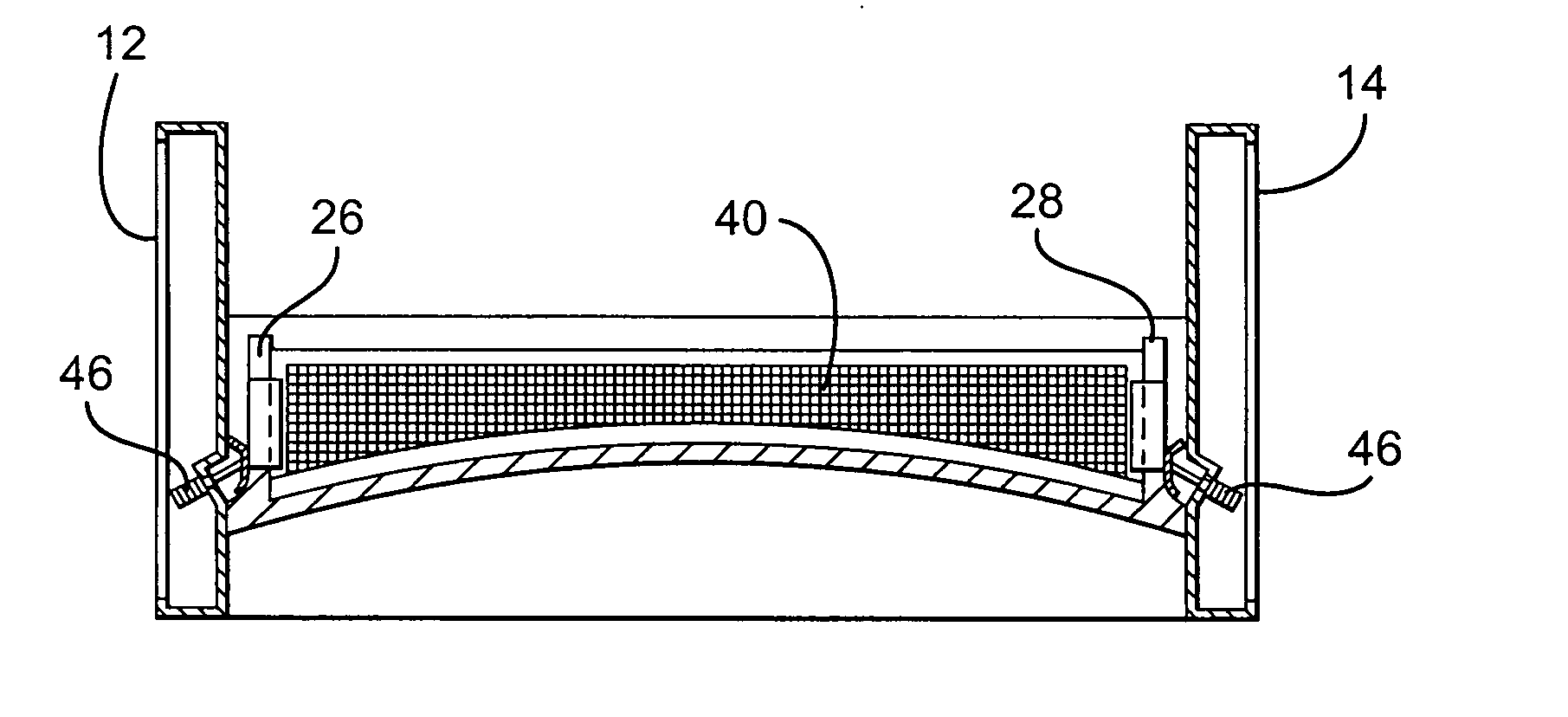

Screen basket and shale shakers

InactiveUS7216767B2Shorten the lengthAvailable screening areaSievingScreeningShale shakersEngineering

A screen mounting basket for a vibratory separator for separating components of material introduced into the basket, the vibratory separator including a collection receptacle beneath the basket, the basket including two opposed spaced-apart side walls having first ends and second ends, the first ends spaced-apart by spaced-apart end walls connected to each of the side walls, a basket bottom between the two spaced-apart side walls, at least one screen assembly positioned vertically in the basket for interceptions material introduced into the basket and for screening said material, and the at least one screen assembly extending from one side wall of the basket to the other.

Owner:VARCO I P INC

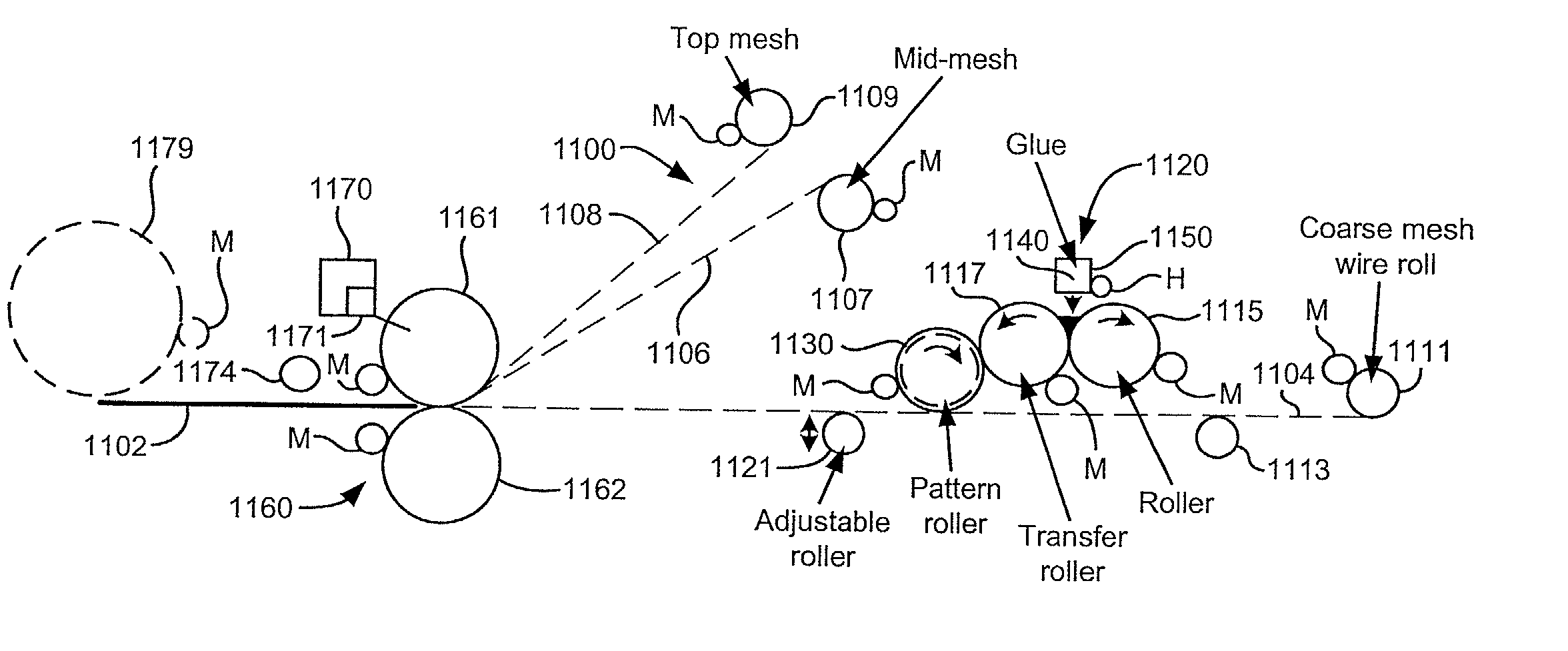

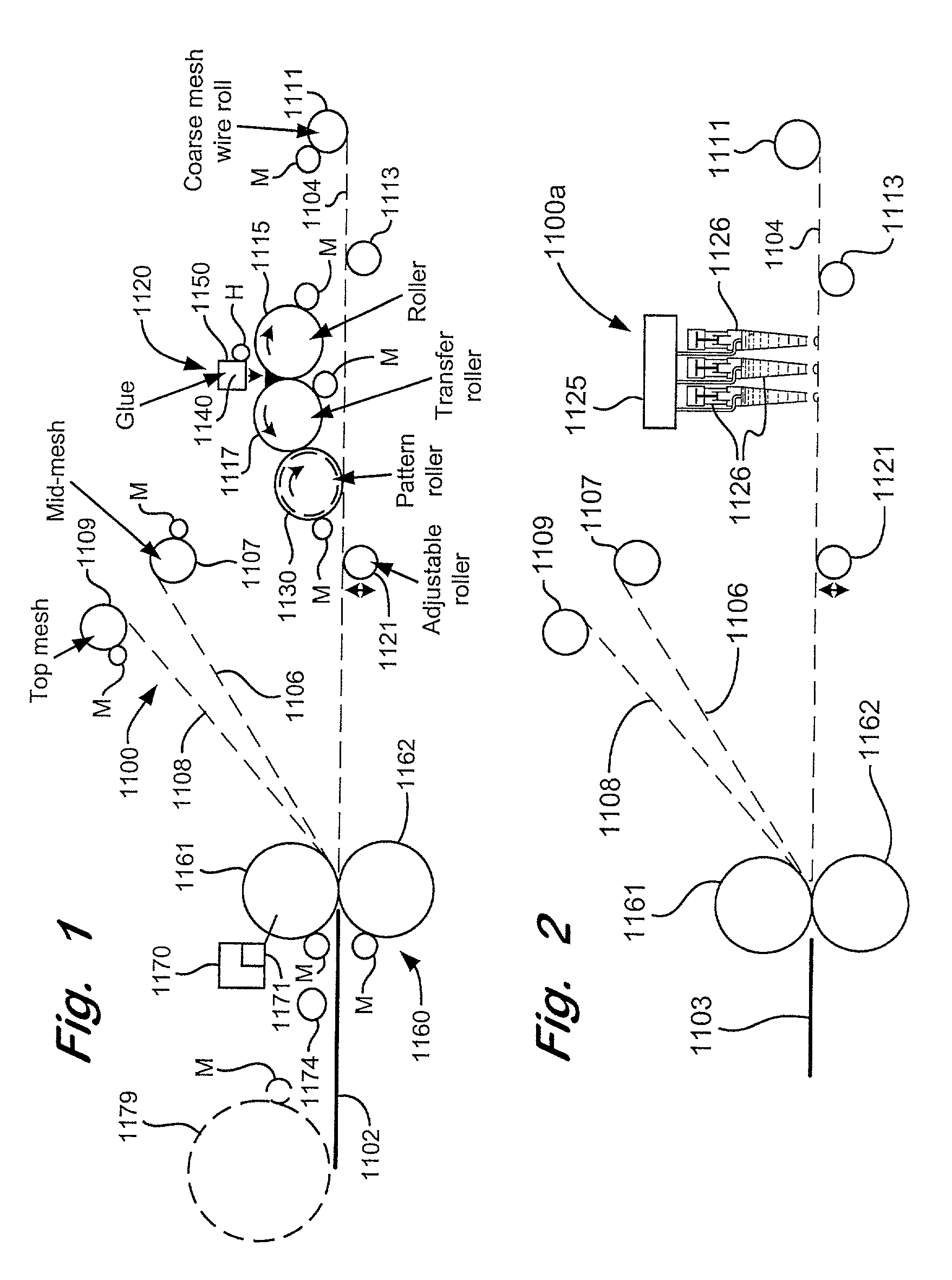

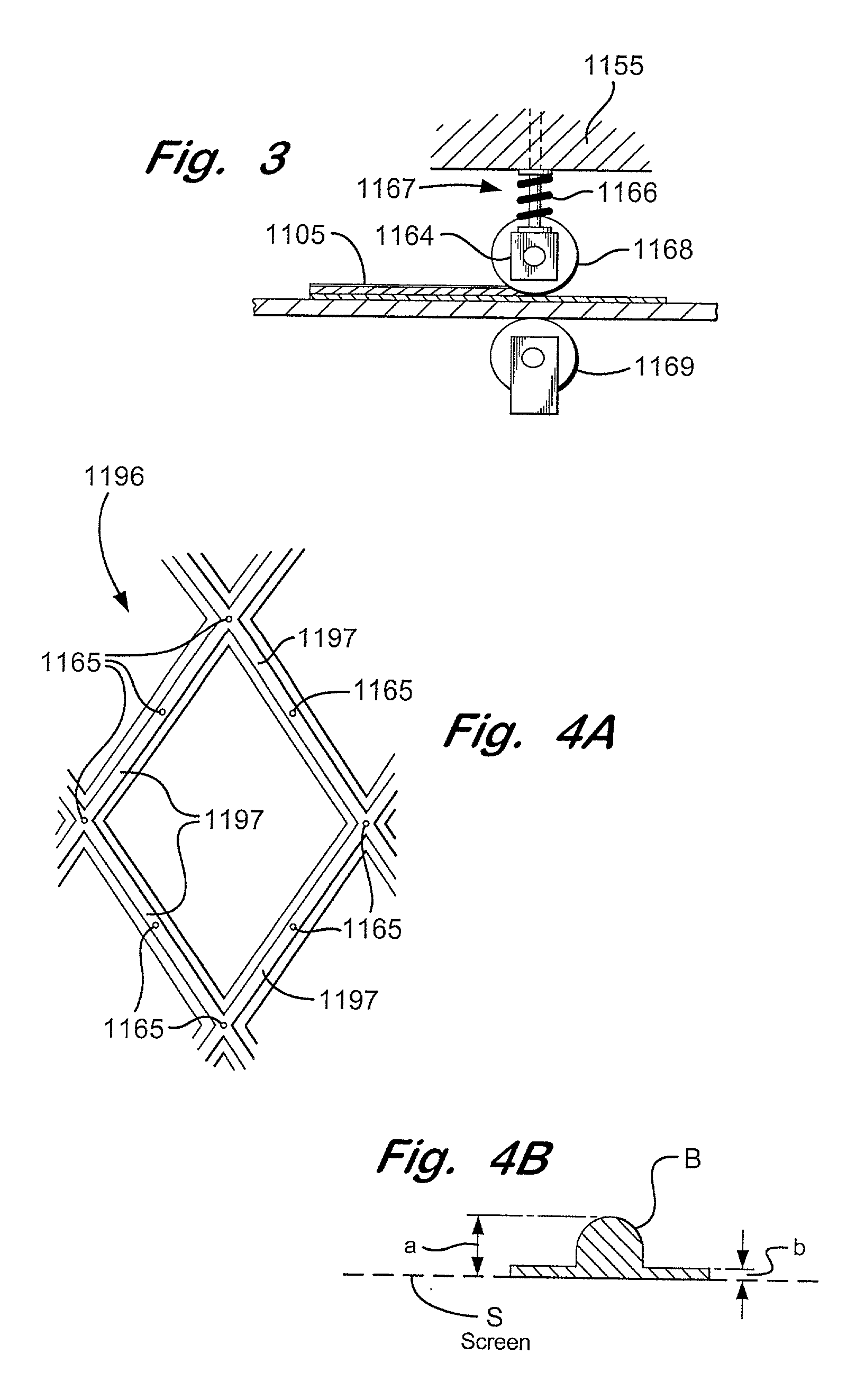

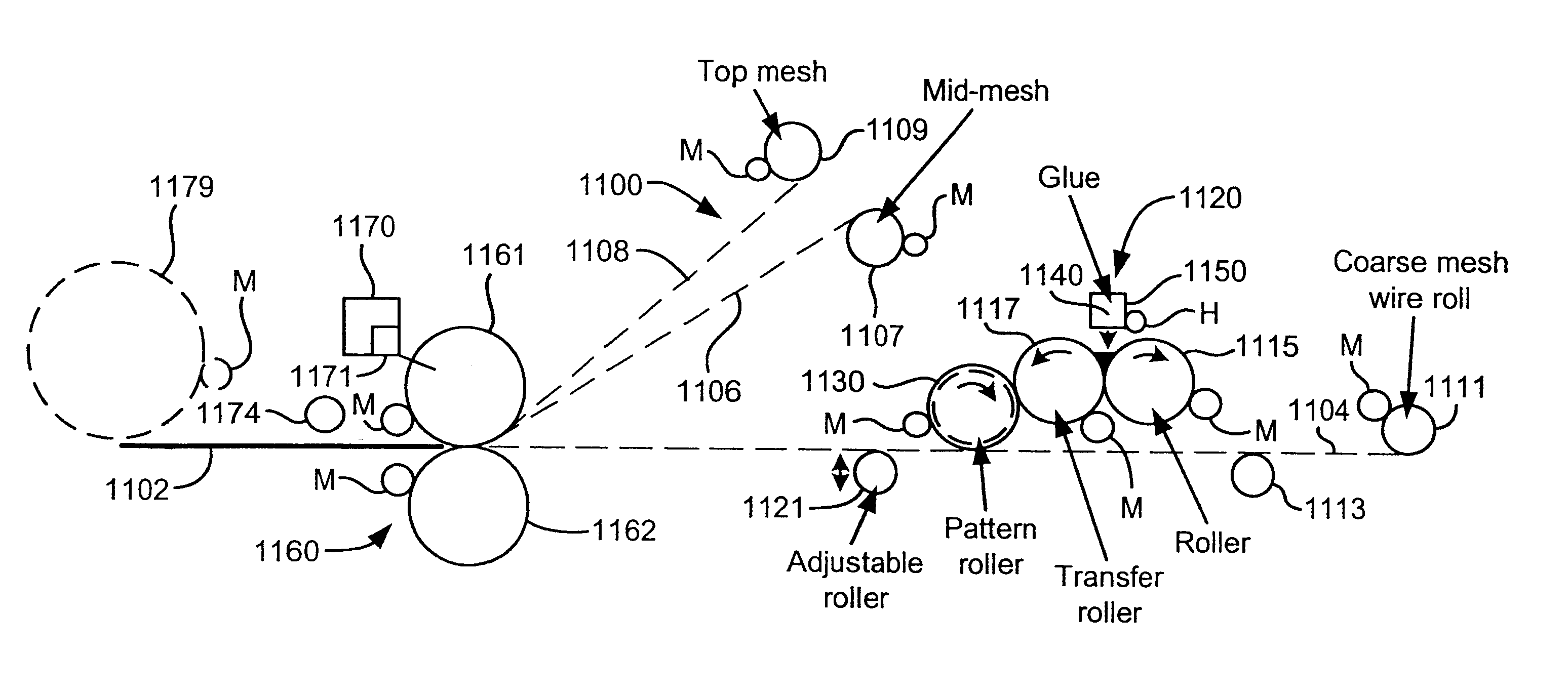

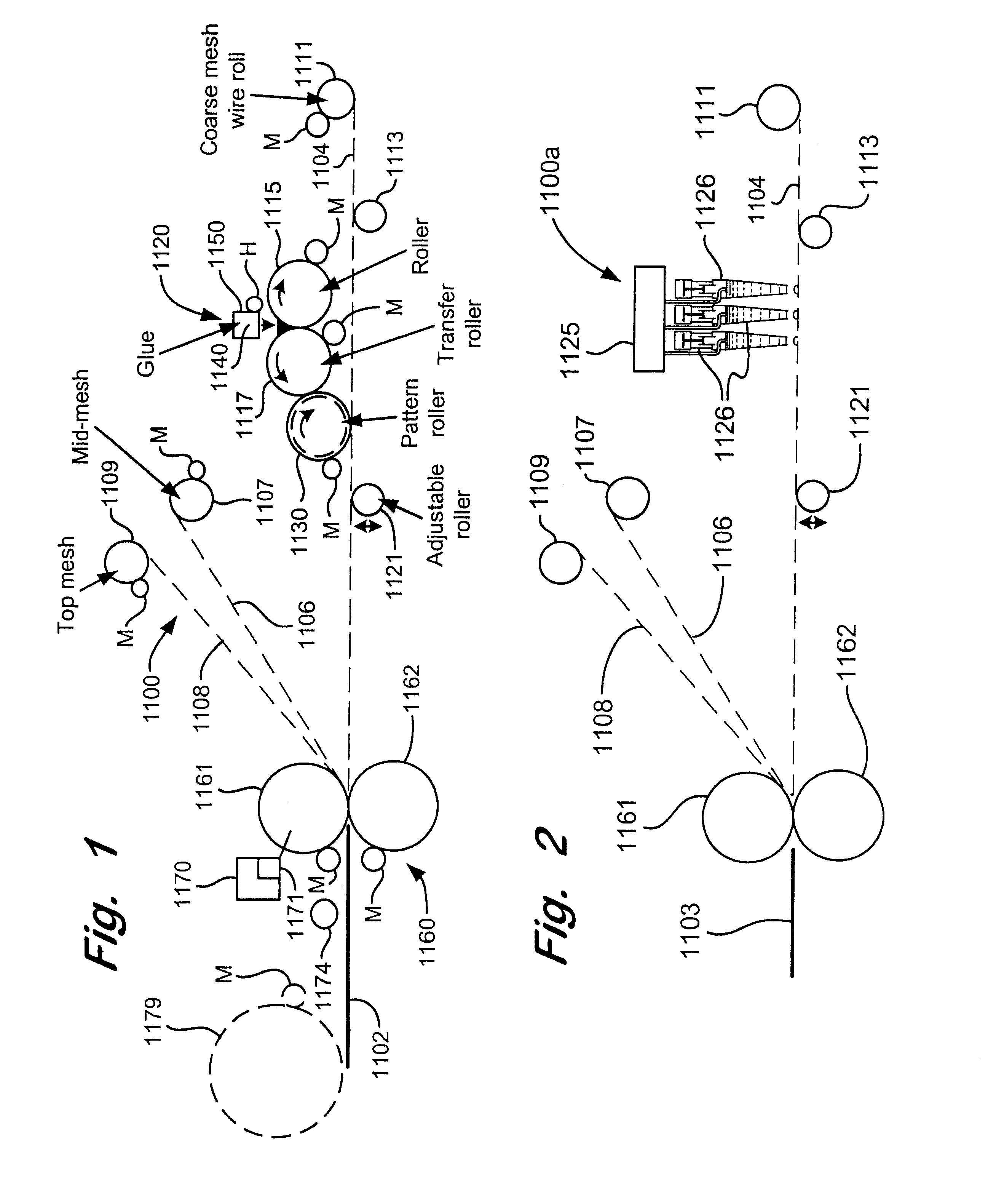

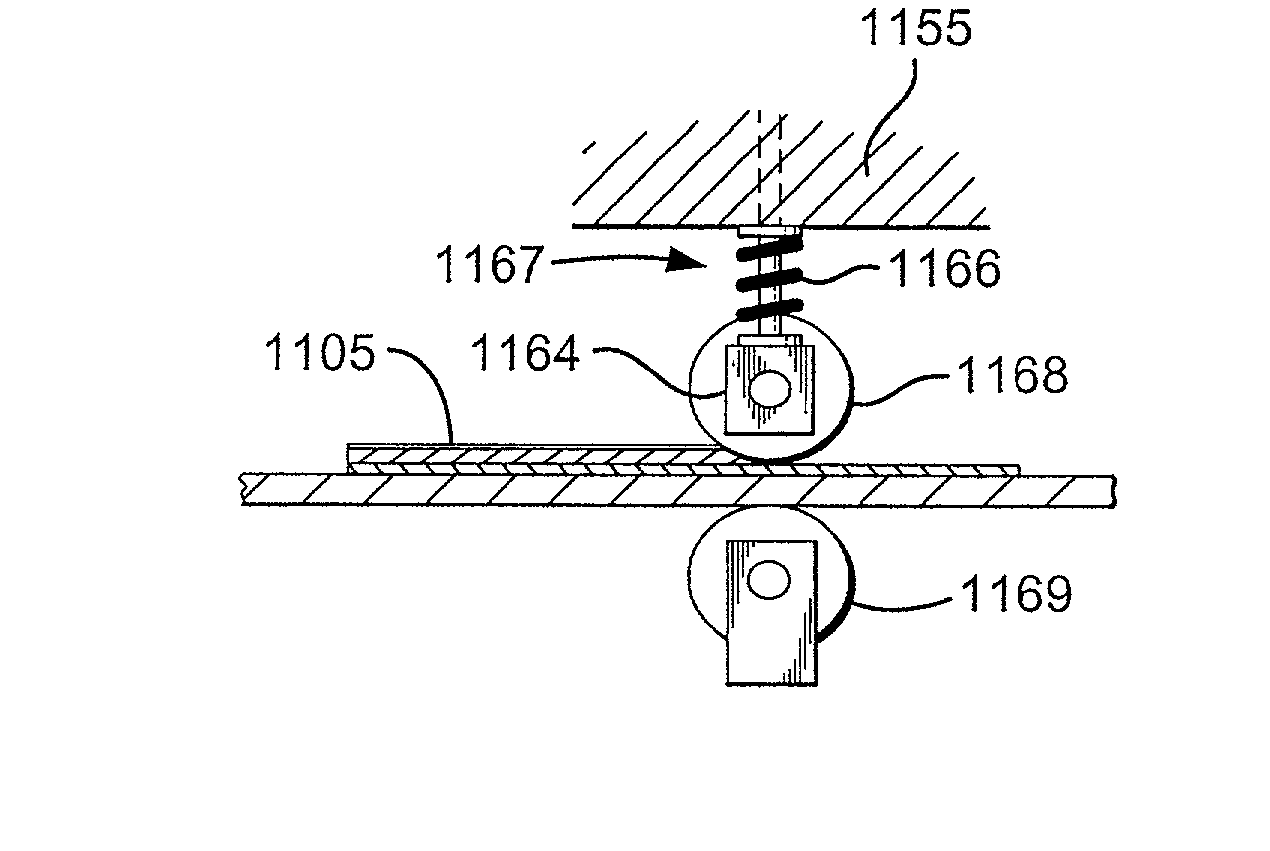

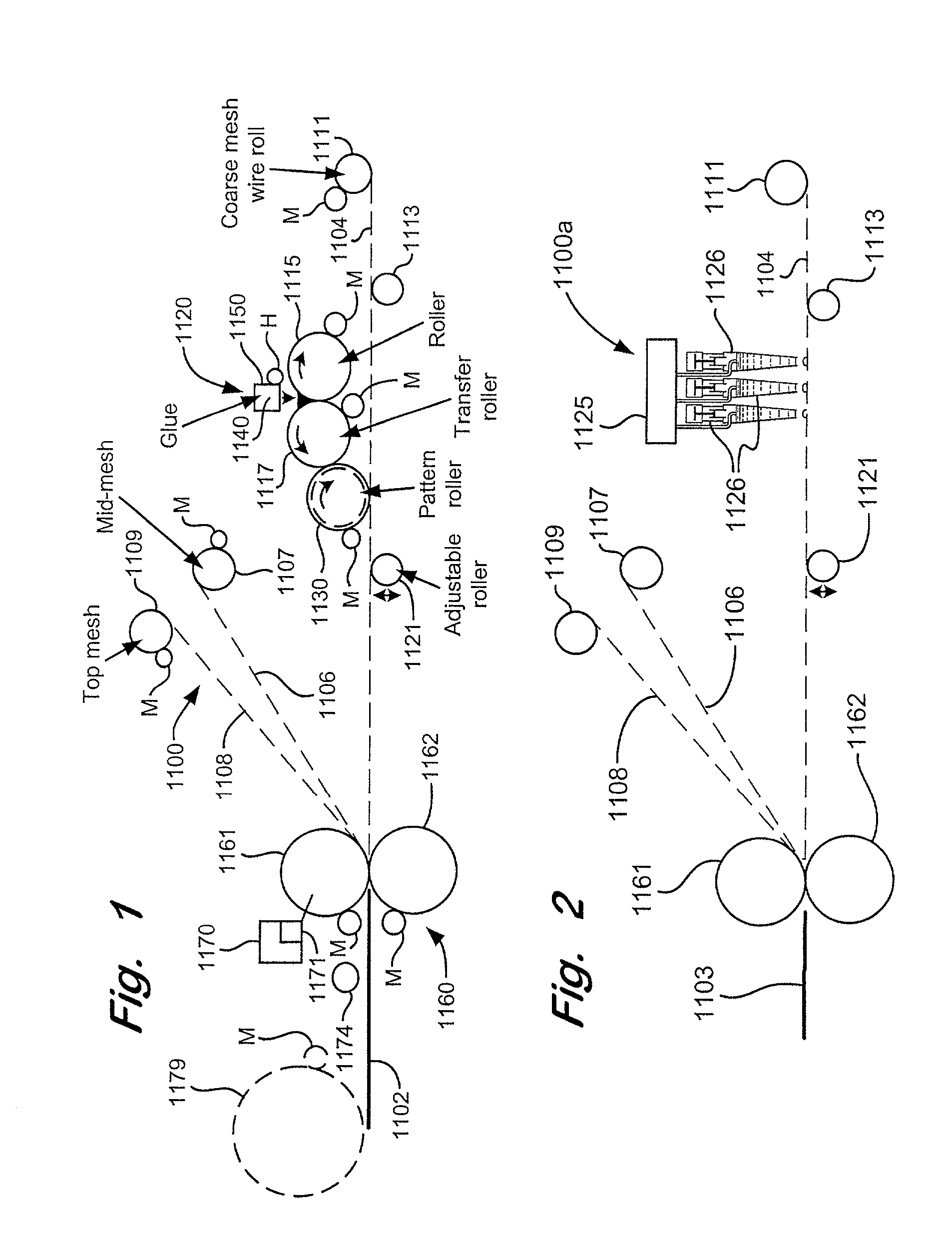

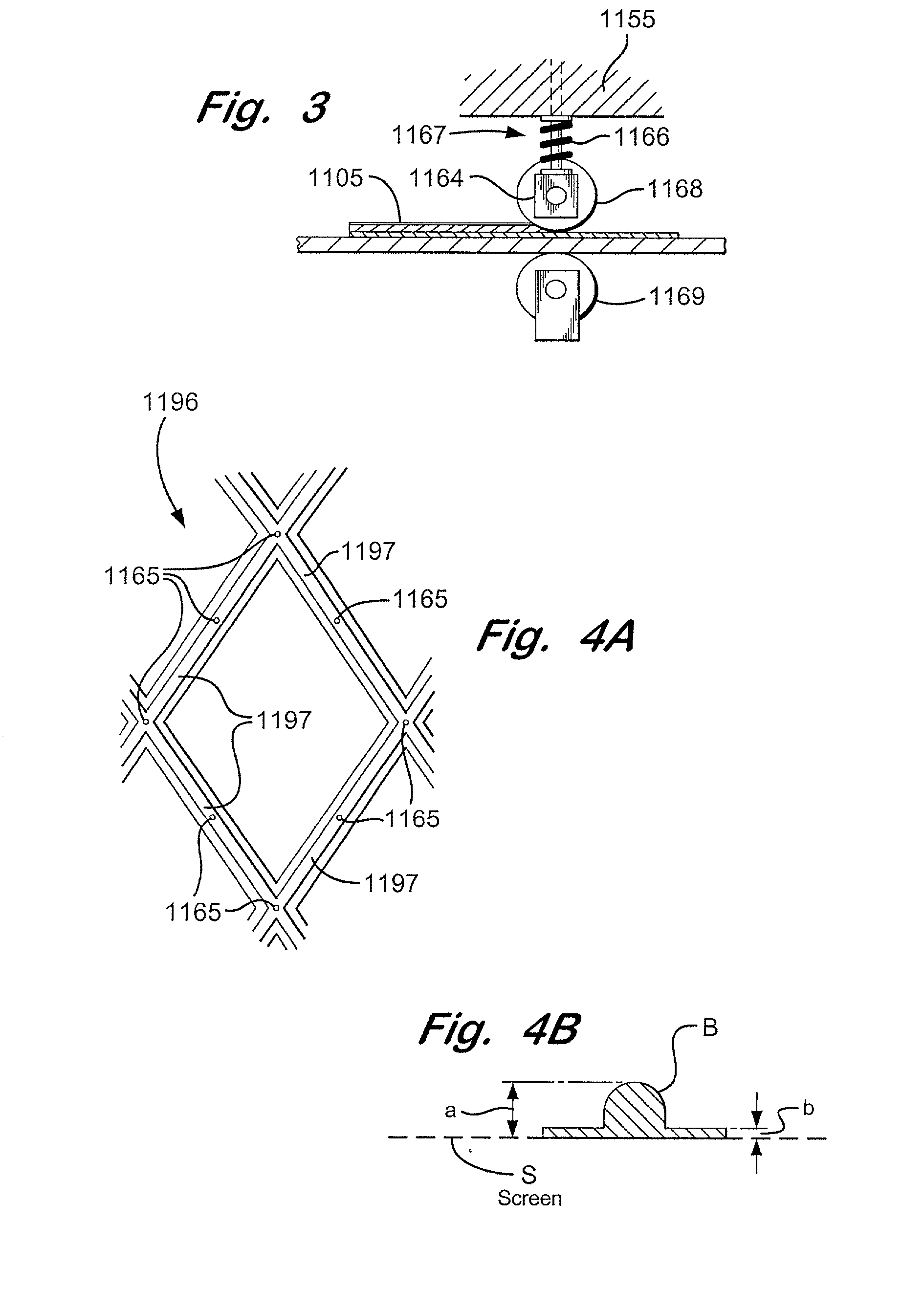

Glued screens for shale shakers

Screens and screen assemblies for a vibratory separator or shale shaker, such screens and screen assemblies made by a method including applying glue in a glue pattern to at least one layer of screening material, said applying done by powered moving mechanical glue application apparatus; in one aspect moving with powered mechanical screen movement apparatus the at least one layer of screening material beneath the powered moving mechanical glue application apparatus; in one aspect, using hot melt moisture-curing glue, and in one aspect facilitating the cure of moisture-curing glue by applying moisture to it.

Owner:VARCO I P INC

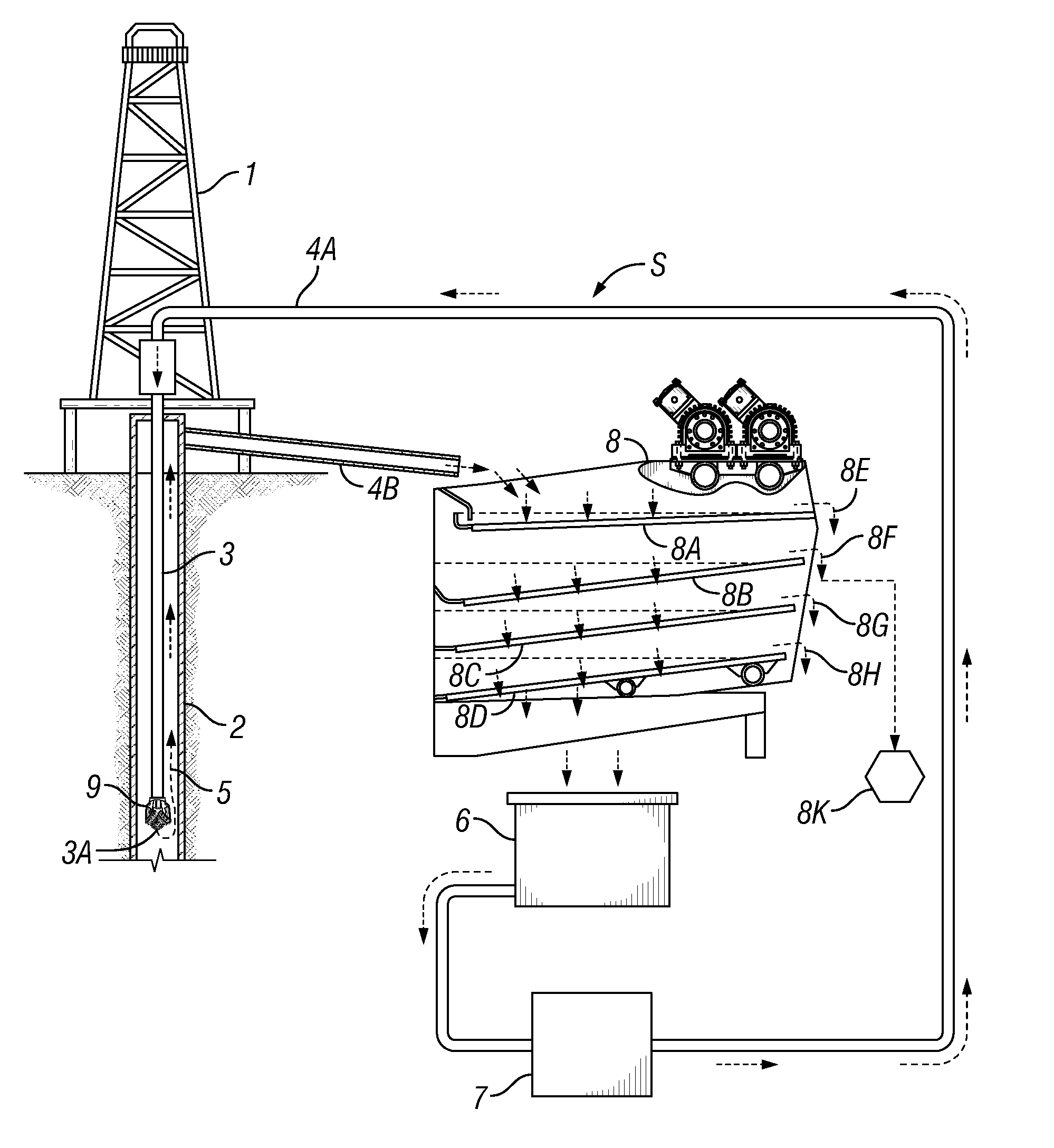

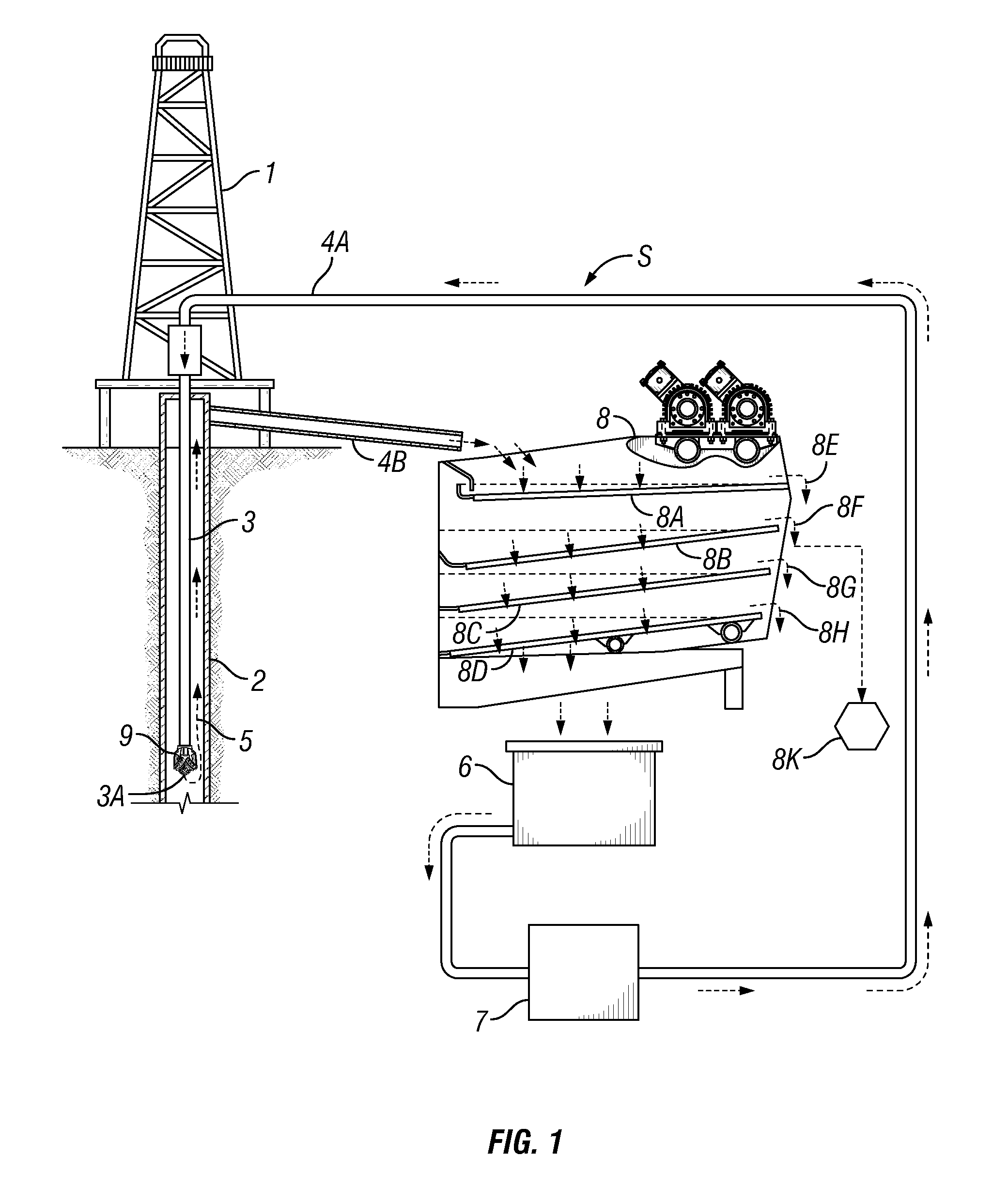

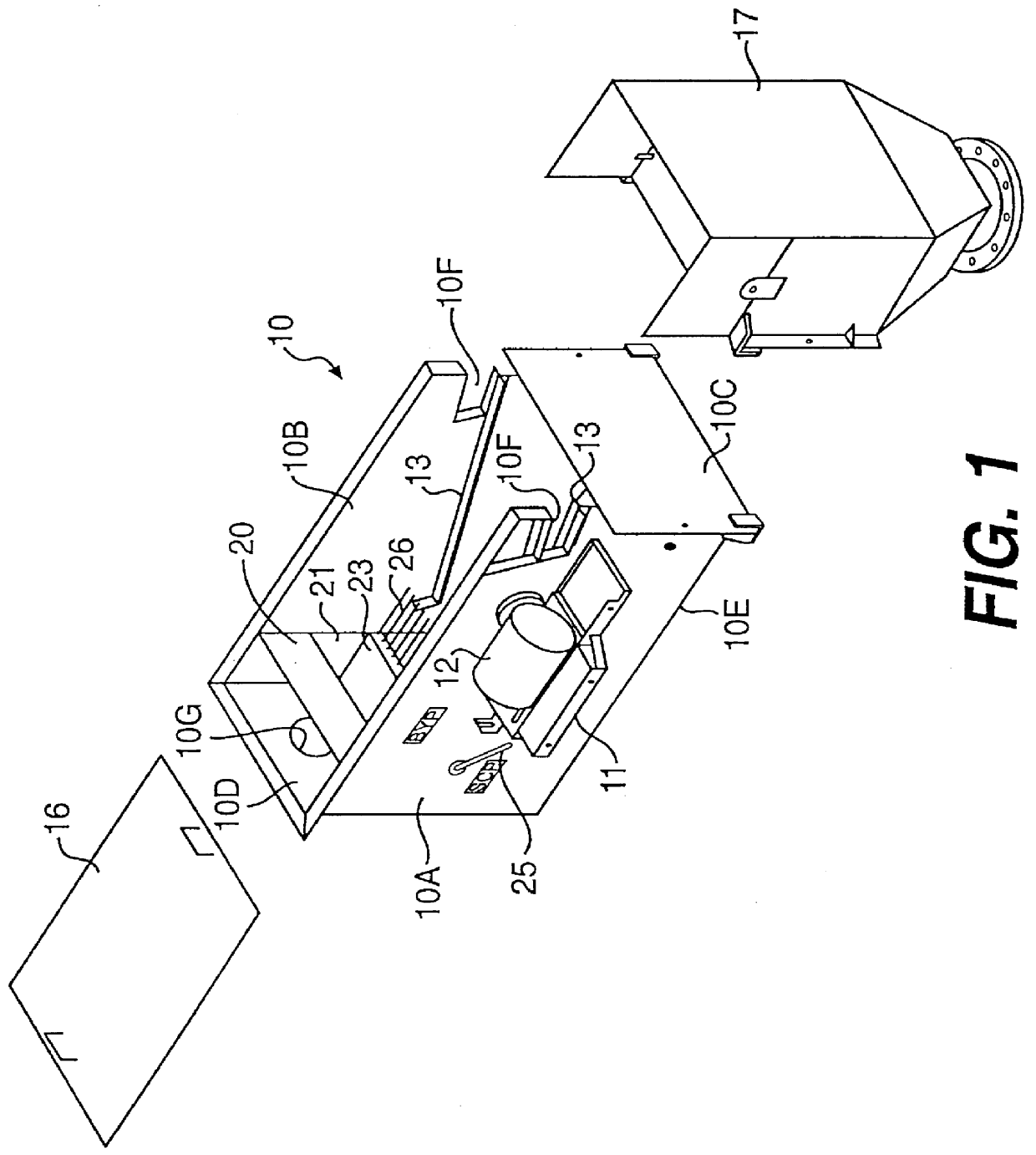

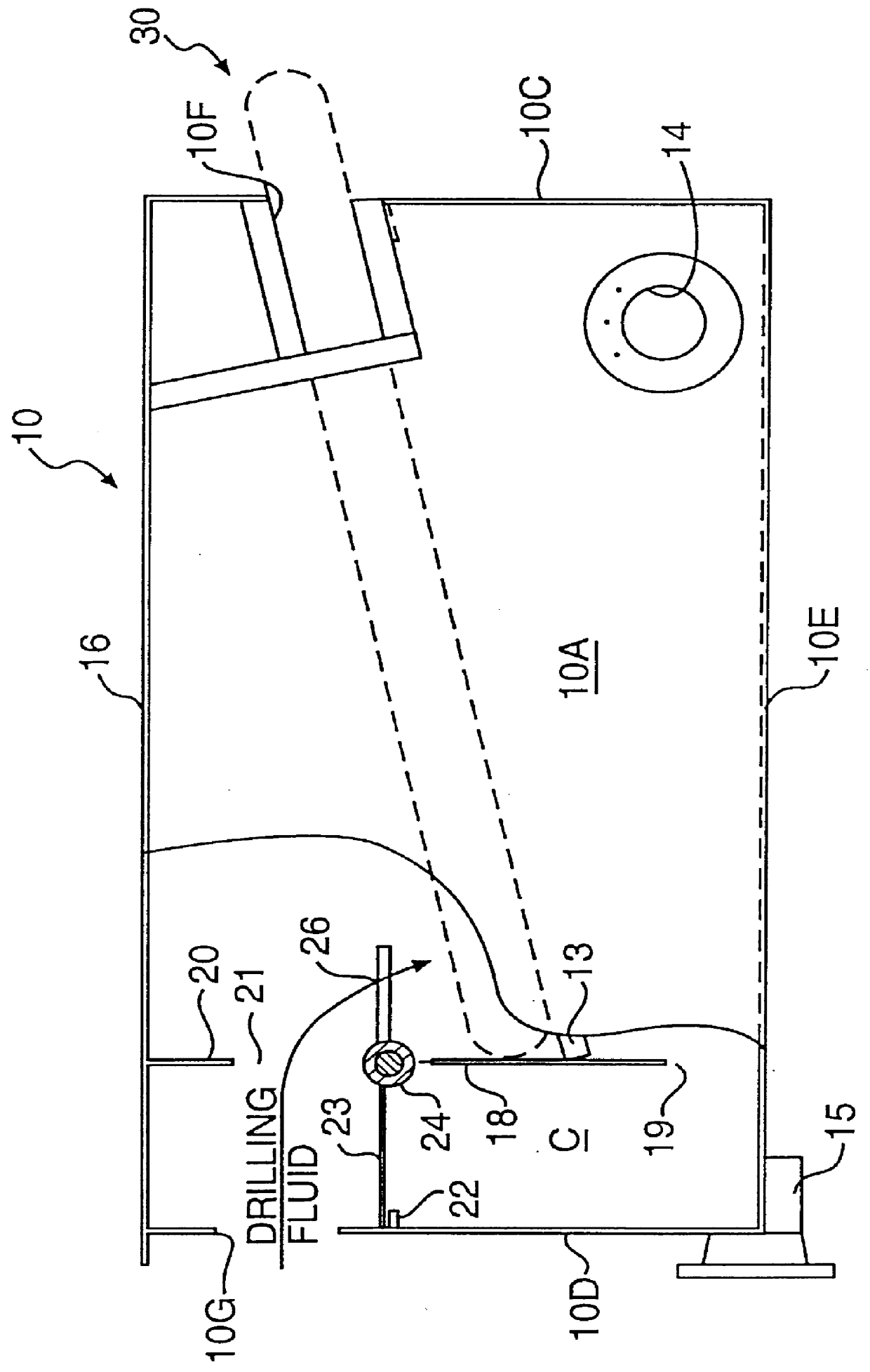

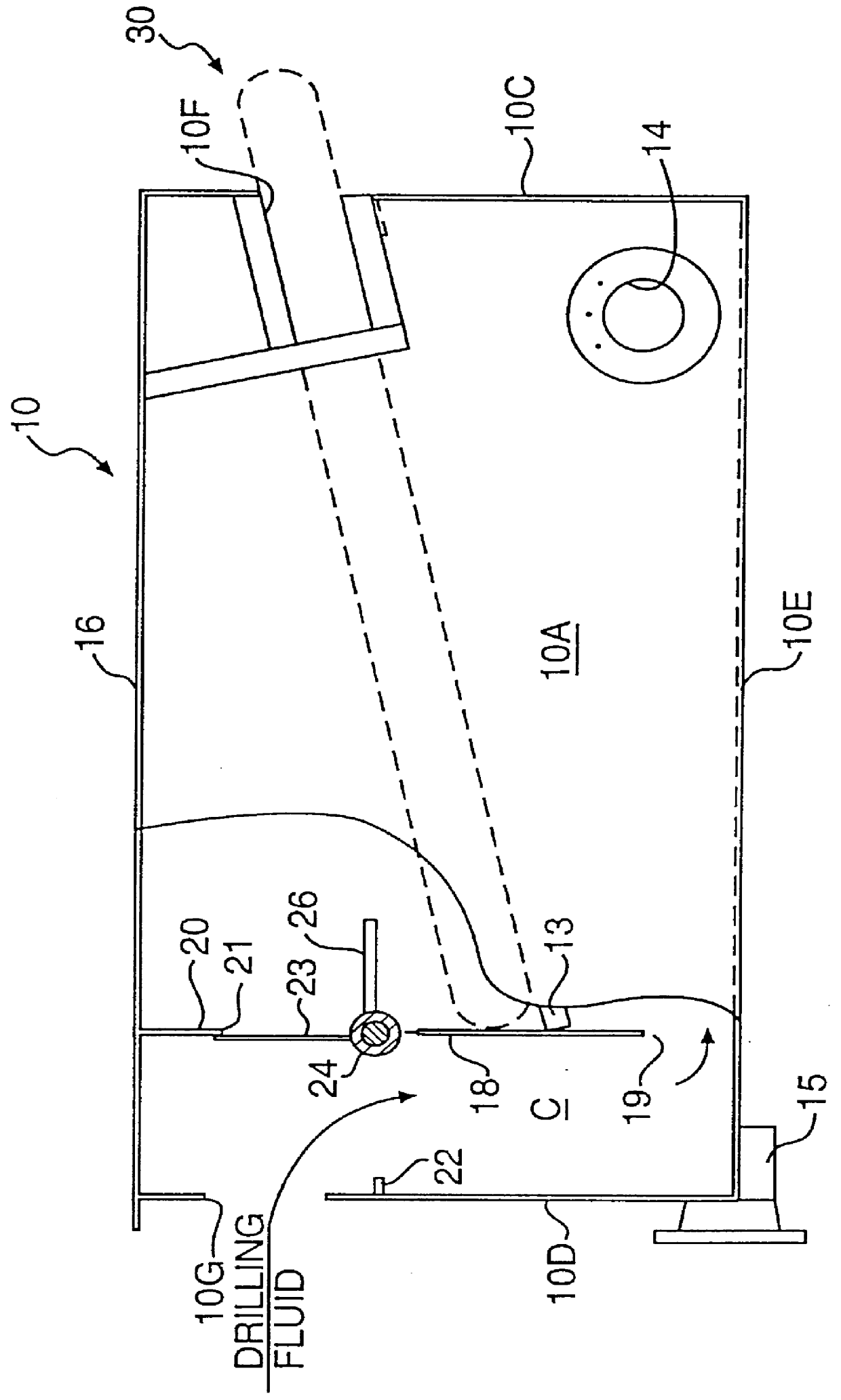

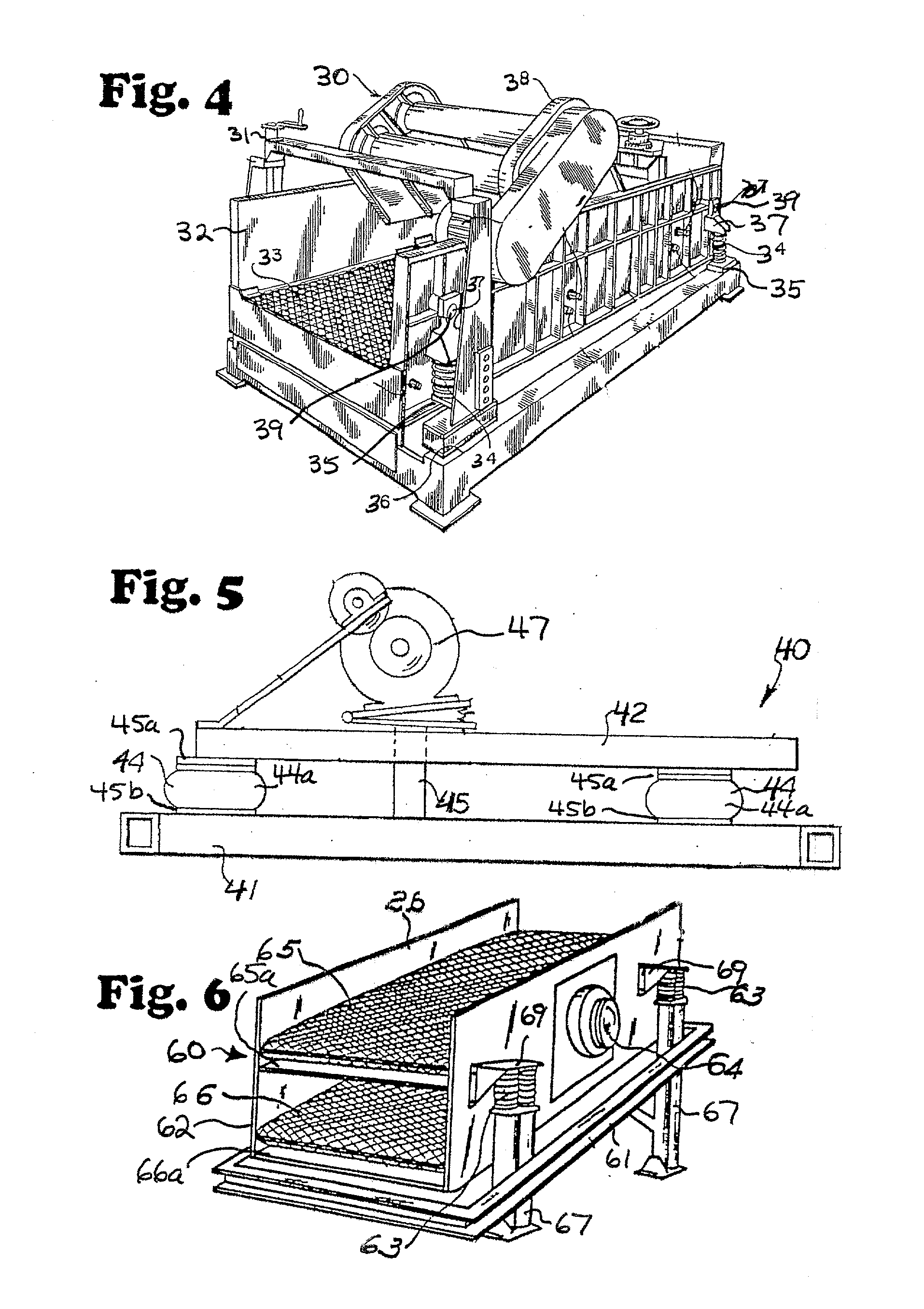

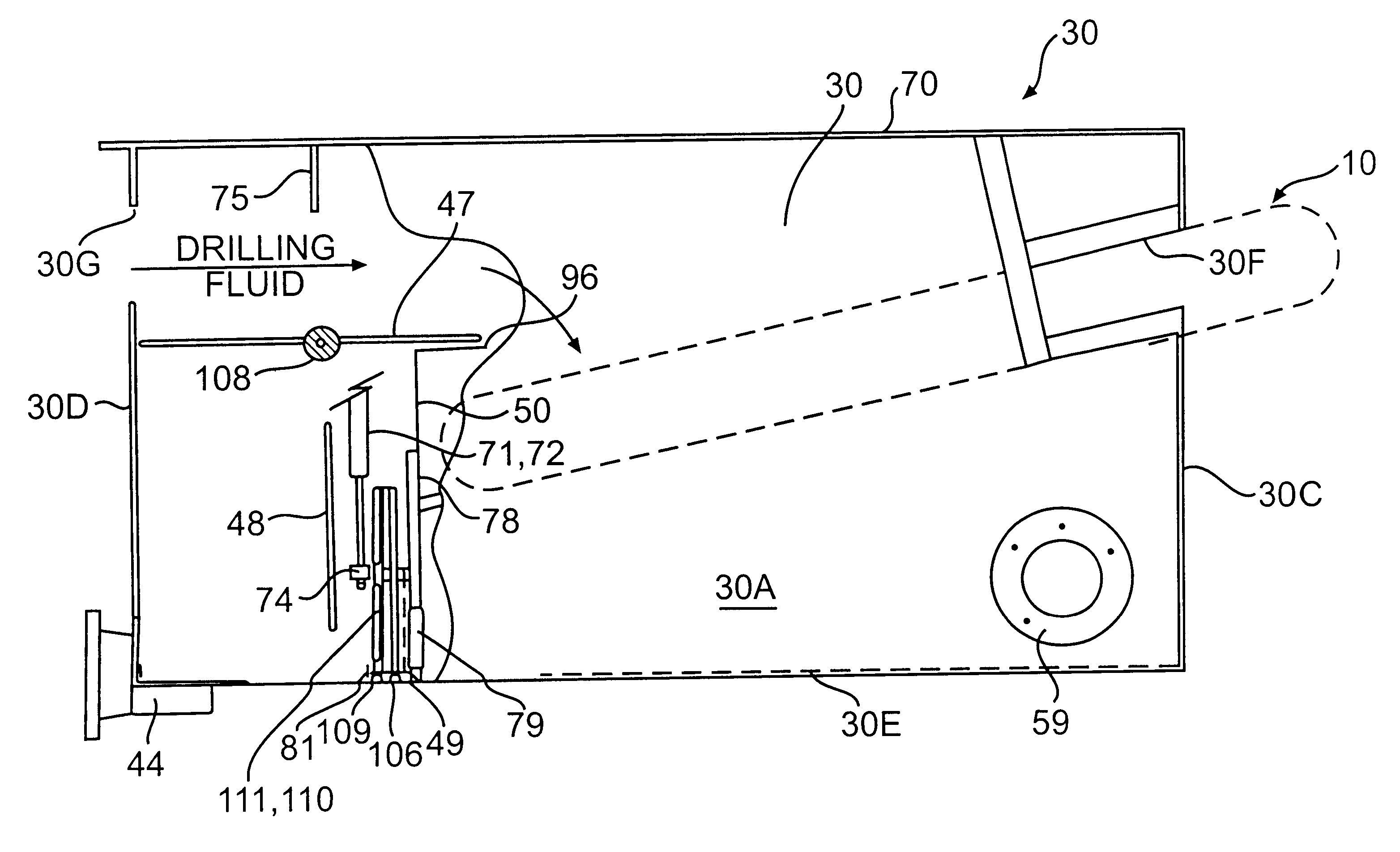

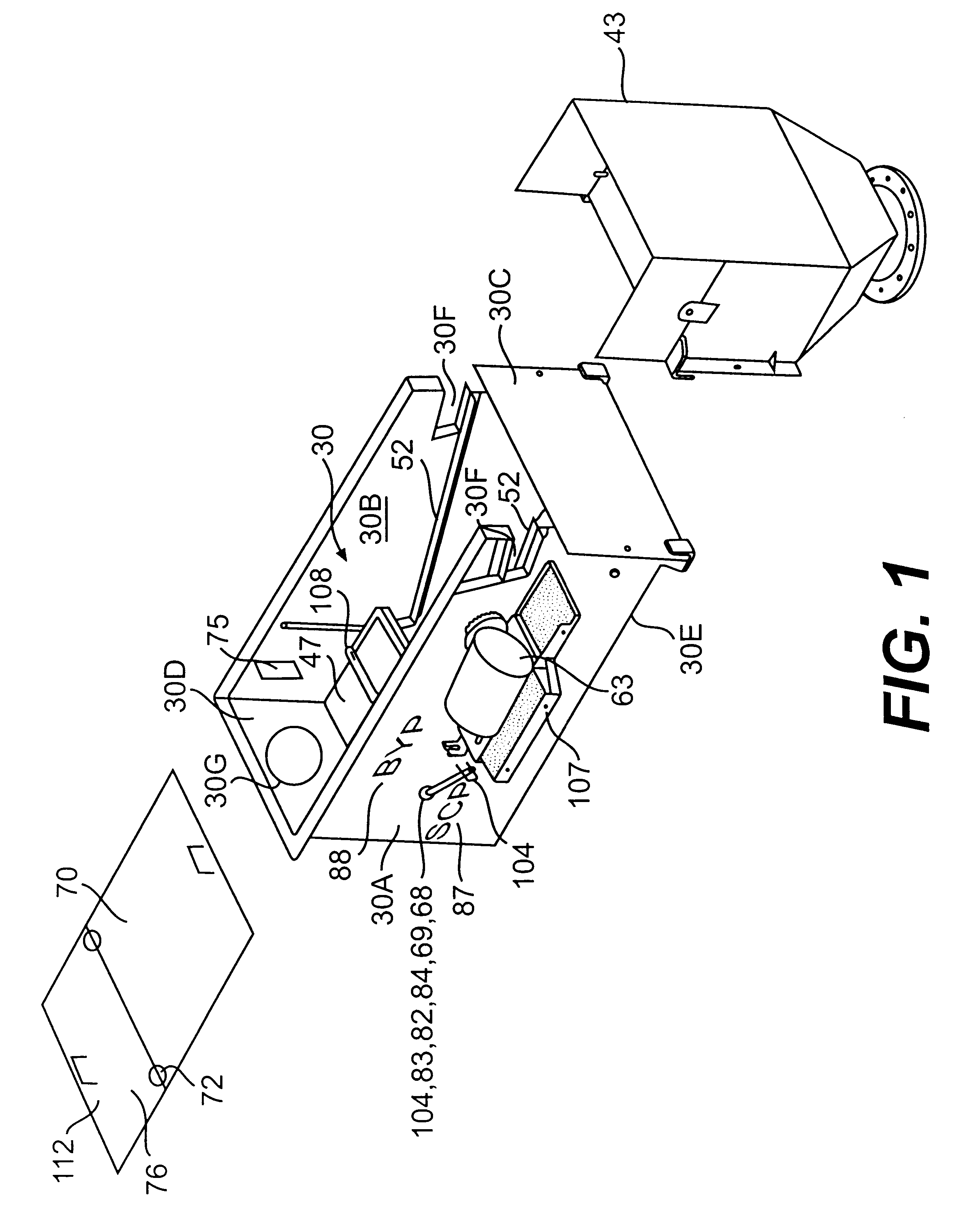

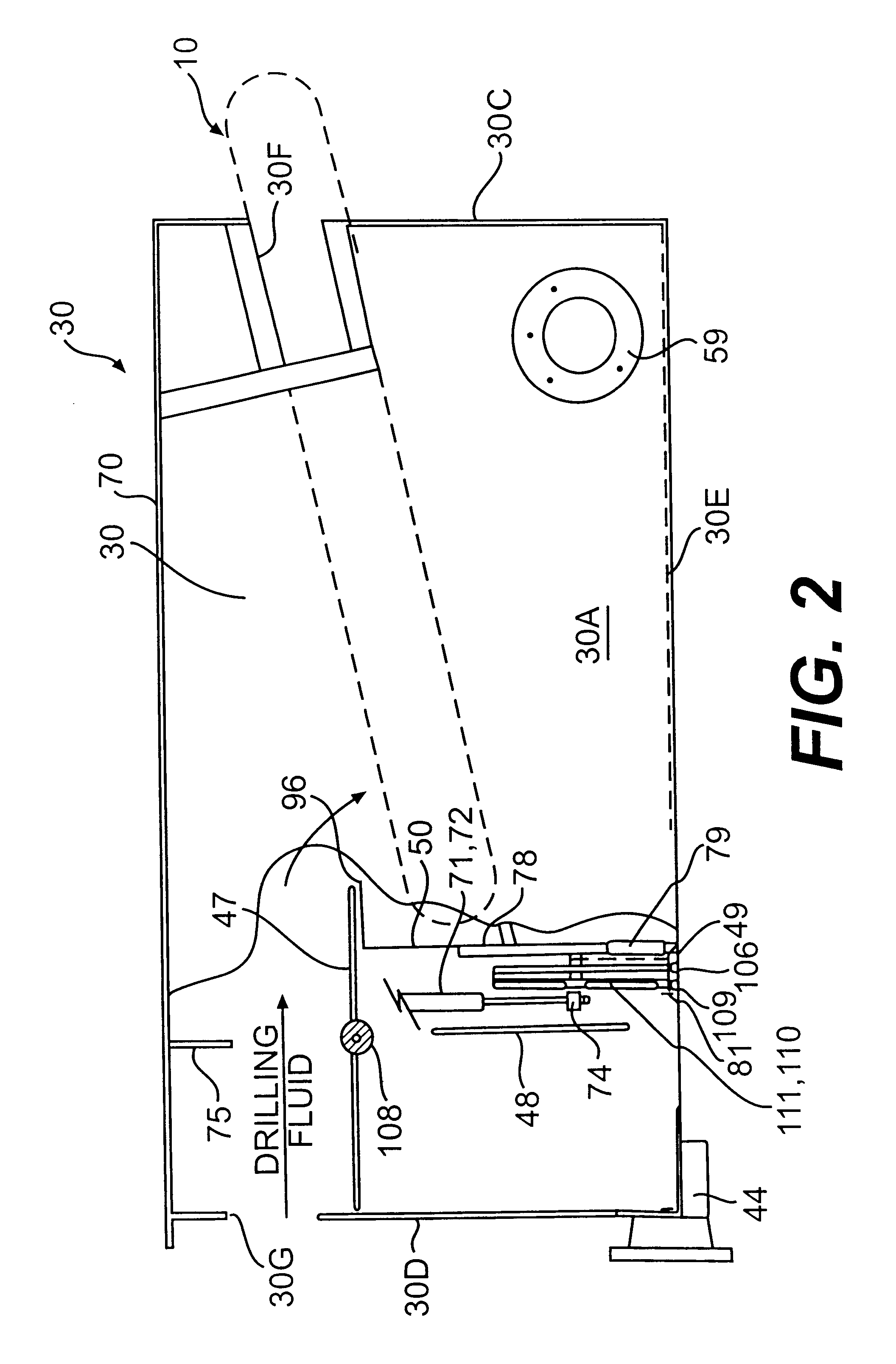

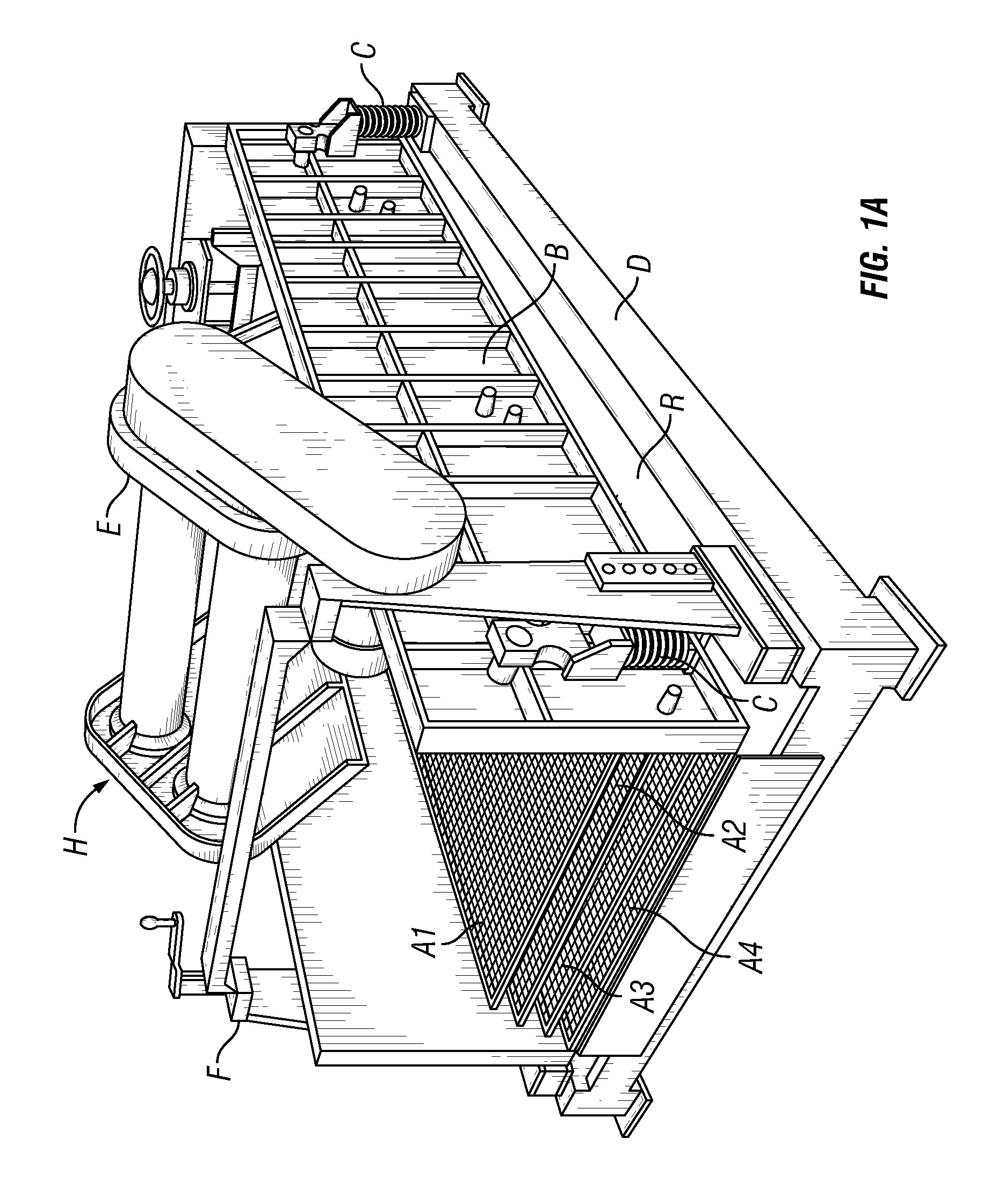

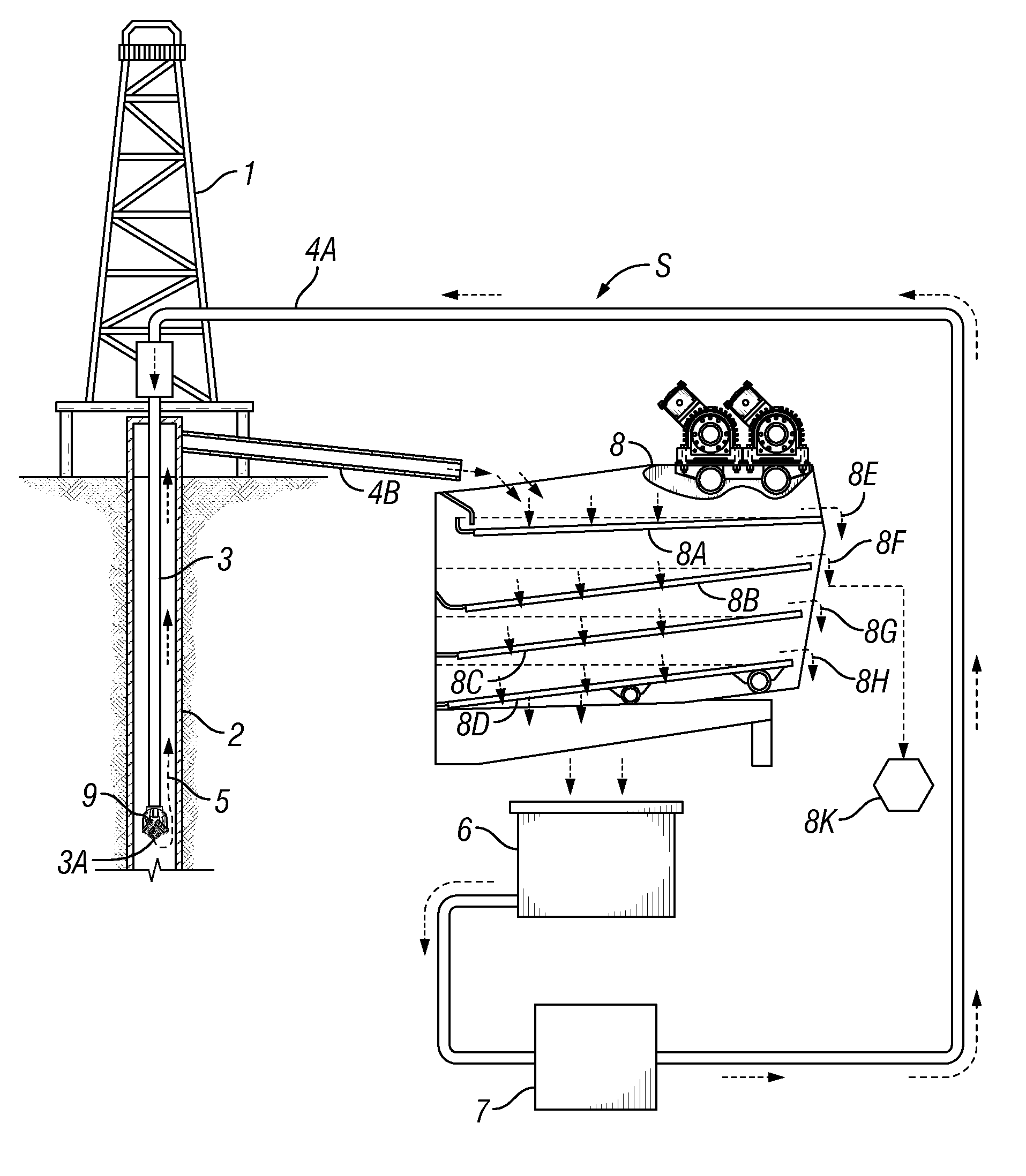

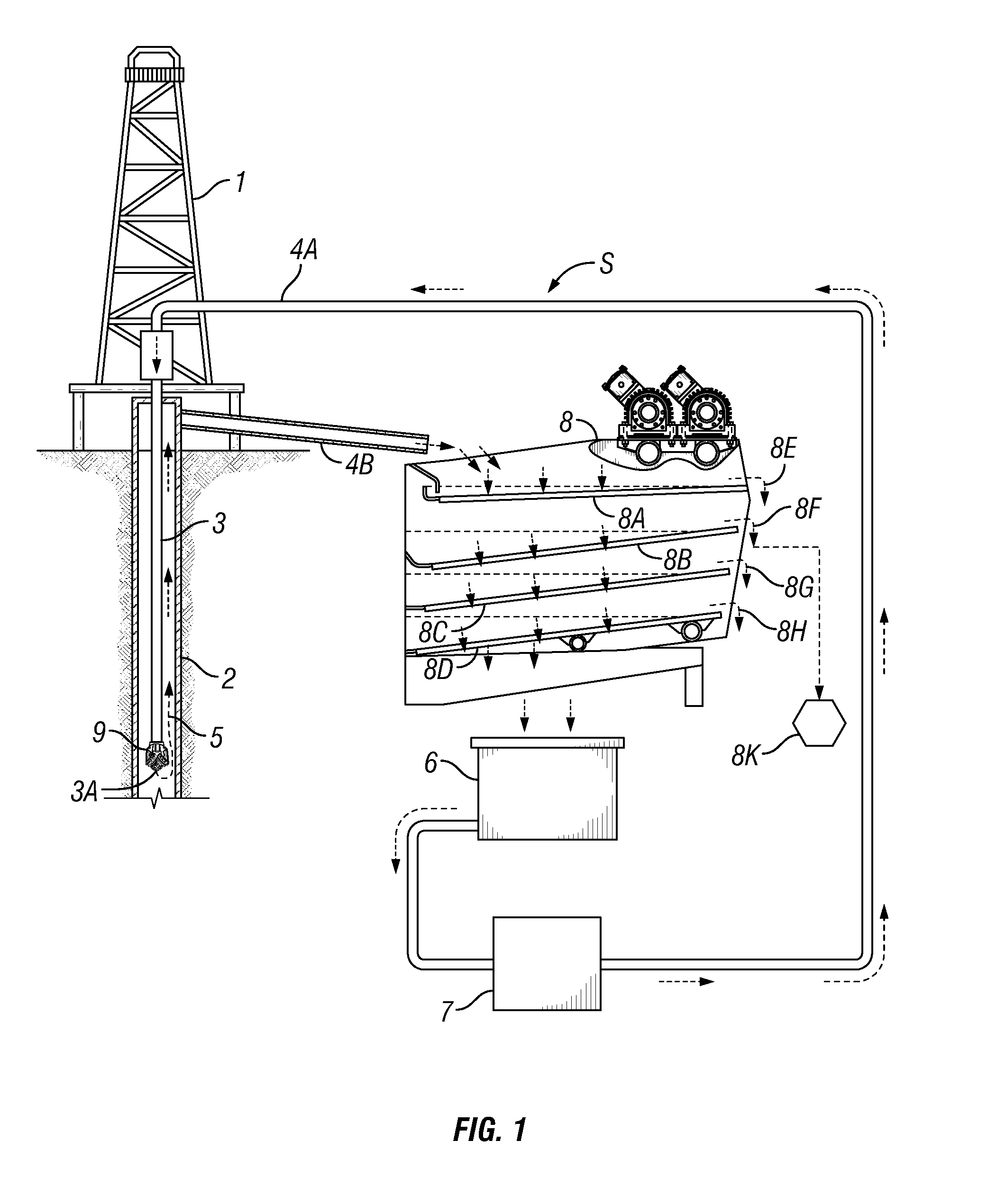

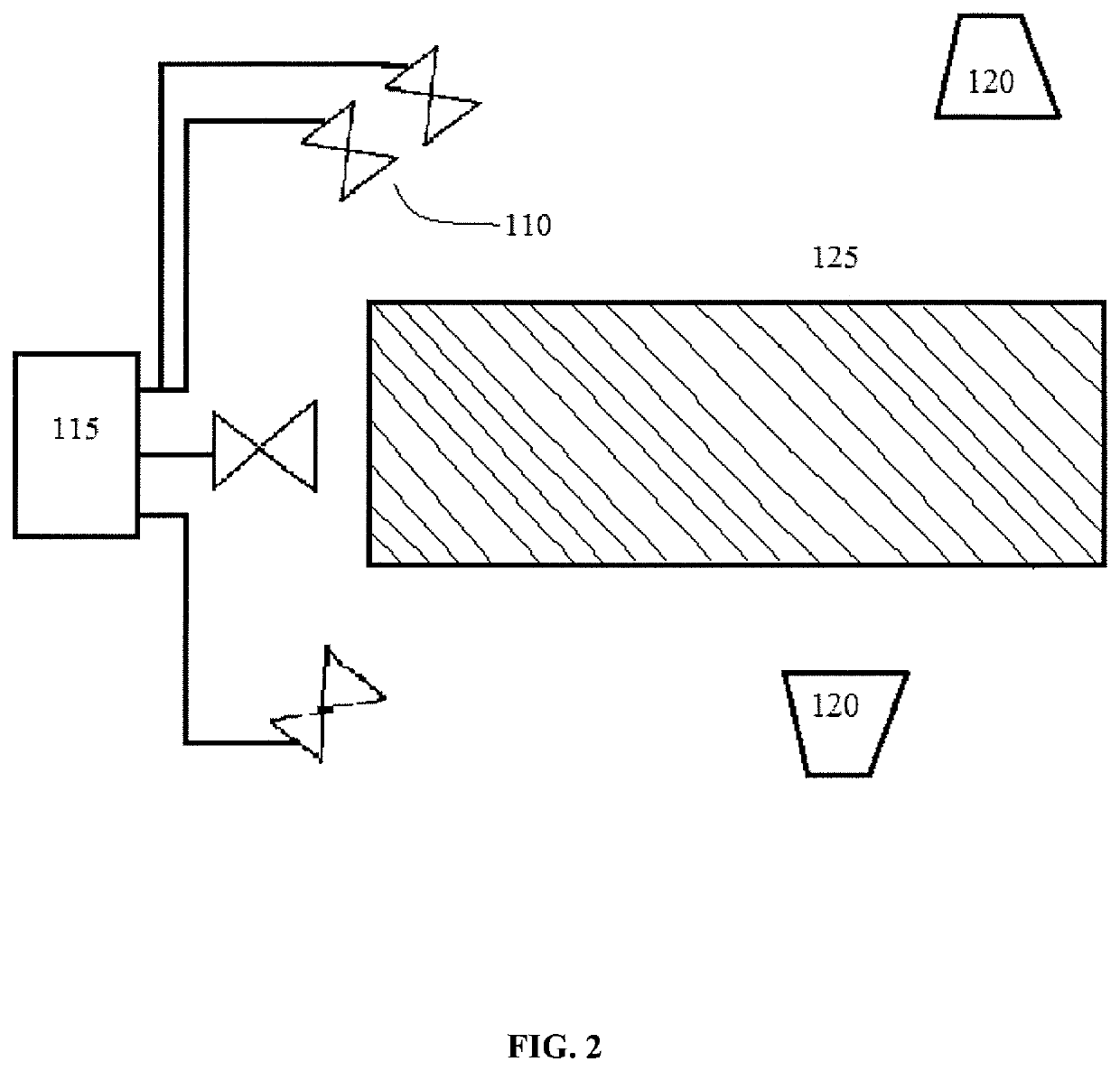

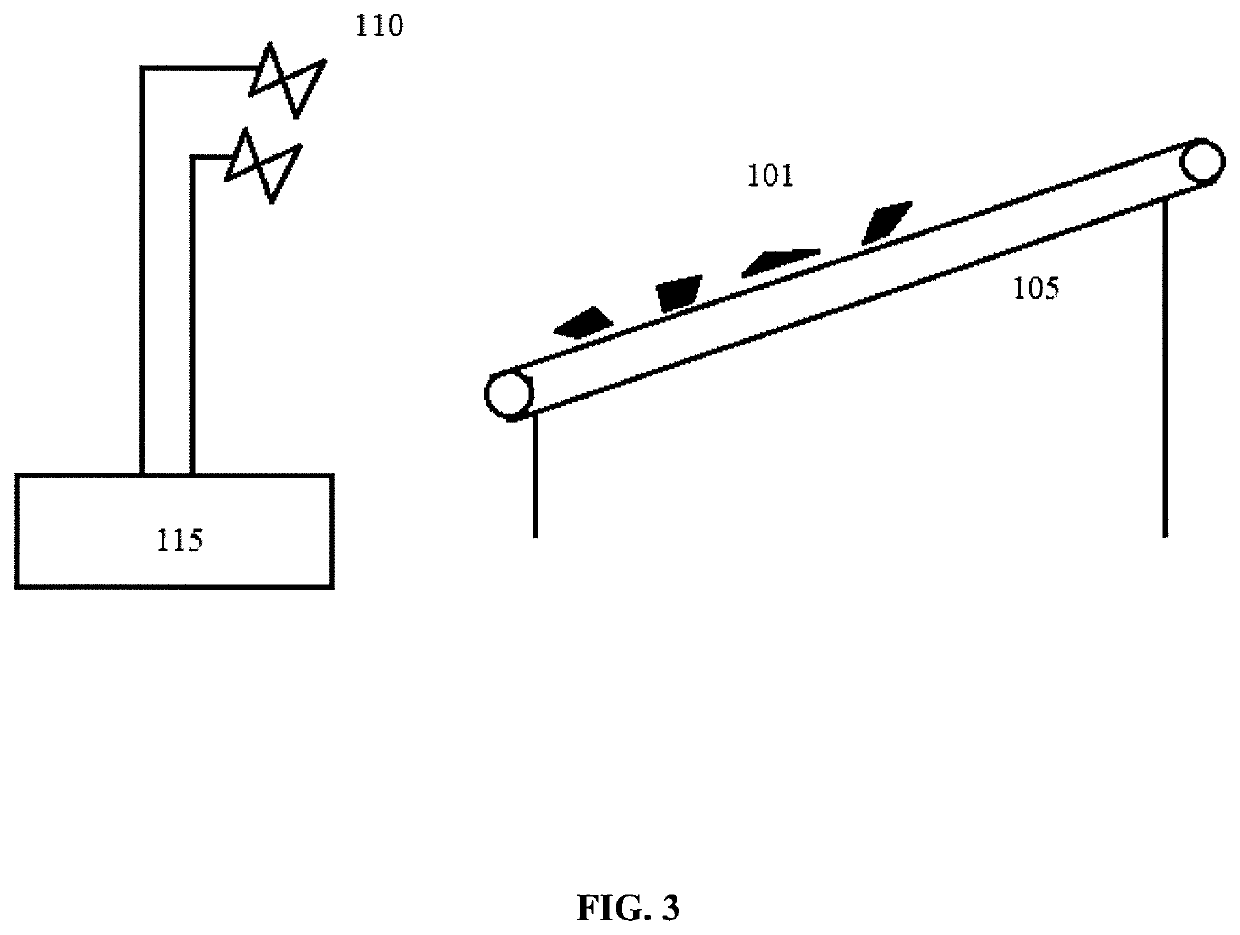

Bypass diverter box for drilling mud separation unit

A bypass diverter box disposed upstream from conventional solids control equipment of a mud system of a drilling rig contains a drilling mud separation unit having a continuous-loop scalper screen that is driven in a continuous loop to separate, convey and discharge large amounts of gumbo, heavy clays and drill solids at the end of the separation unit. The flow divider box is a box-like housing with a verter plate, upper and lower baffle plates and a grate that allows drilling fluid or drilling mud to be selectively directed to the mud separation unit to be separated prior to passing to the conventional downstream solids control equipment or allows the fluid to bypass the separation unit and flow directly to the conventional solids control equipment. The bypass diverter box baffle plates, diverter plate and grate, and selective utilization of the mud separation unit removes large amounts of gumbo, heavy clays and drill solids from the drilling mud and allows high flow rates to be easily processed by shale shakers and other conventional downstream solids control equipment of the mud system and compliments the drilling operations with respect to changes in the lithology, geological formations, or loss of returns in relation to the gallons pumped or folume of drilling fluid or drilling mud entering the bypass diverter box.

Owner:TUBOSCOPE NU TECGNT

Shale shakers

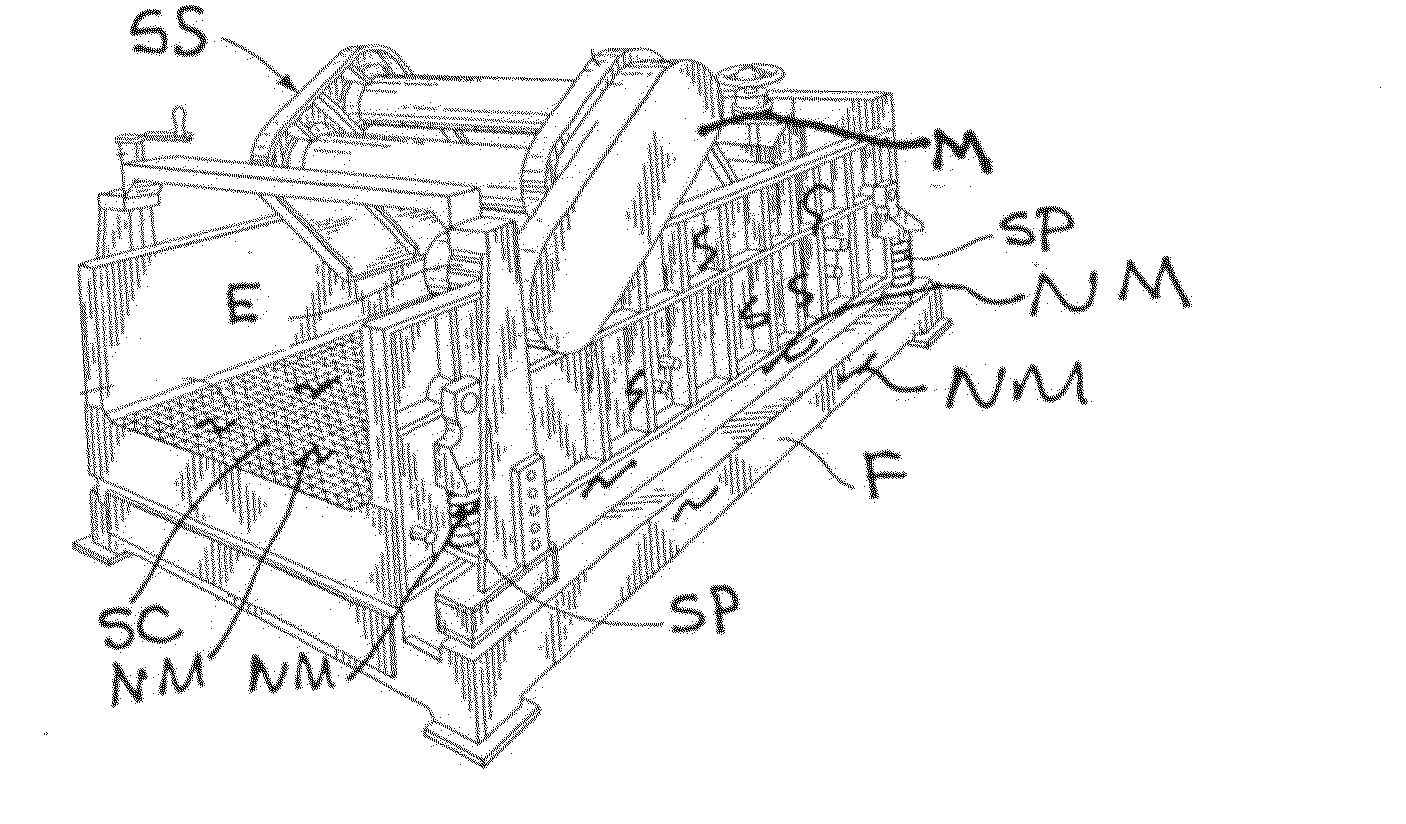

A shale shaker or vibratory separator which, in one aspect, has a base, vibration isolation apparatus on the base, a basket, mount apparatus for mounting the basket on the base, and at least one of the base, basket, and the mount apparatus made of, encased in, or coated with composite material which, in certain aspects, is all or part flexible composite material; and methods of using such separators and shakers.

Owner:VARCO I P INC

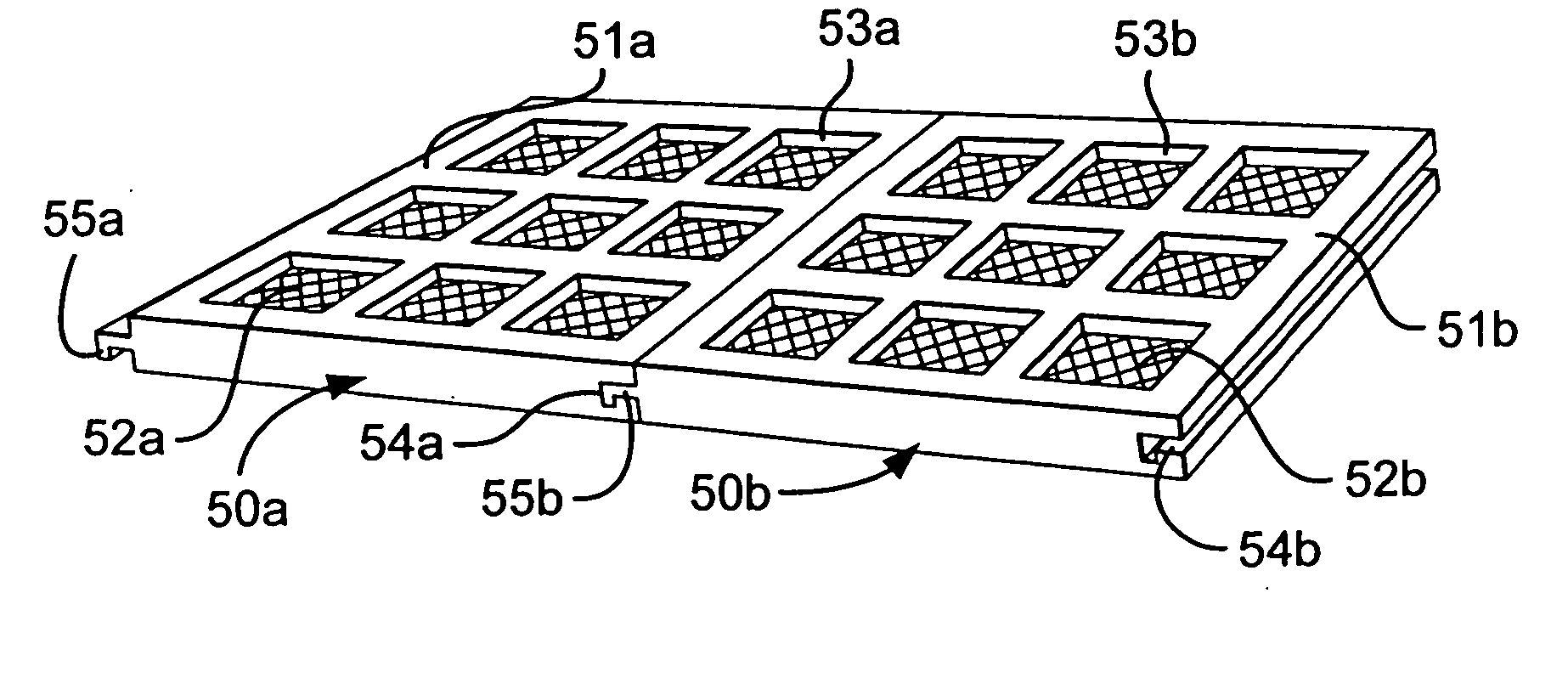

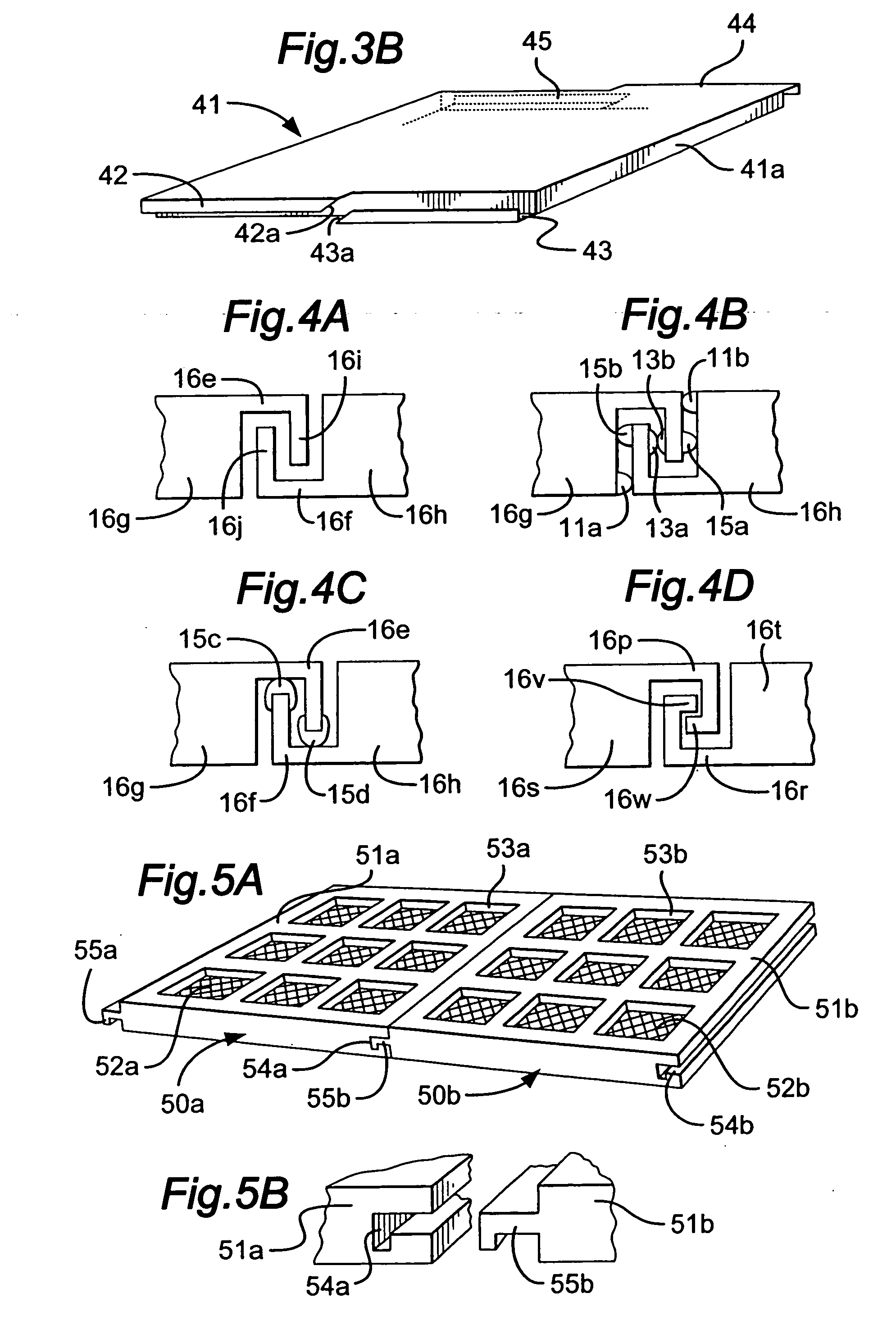

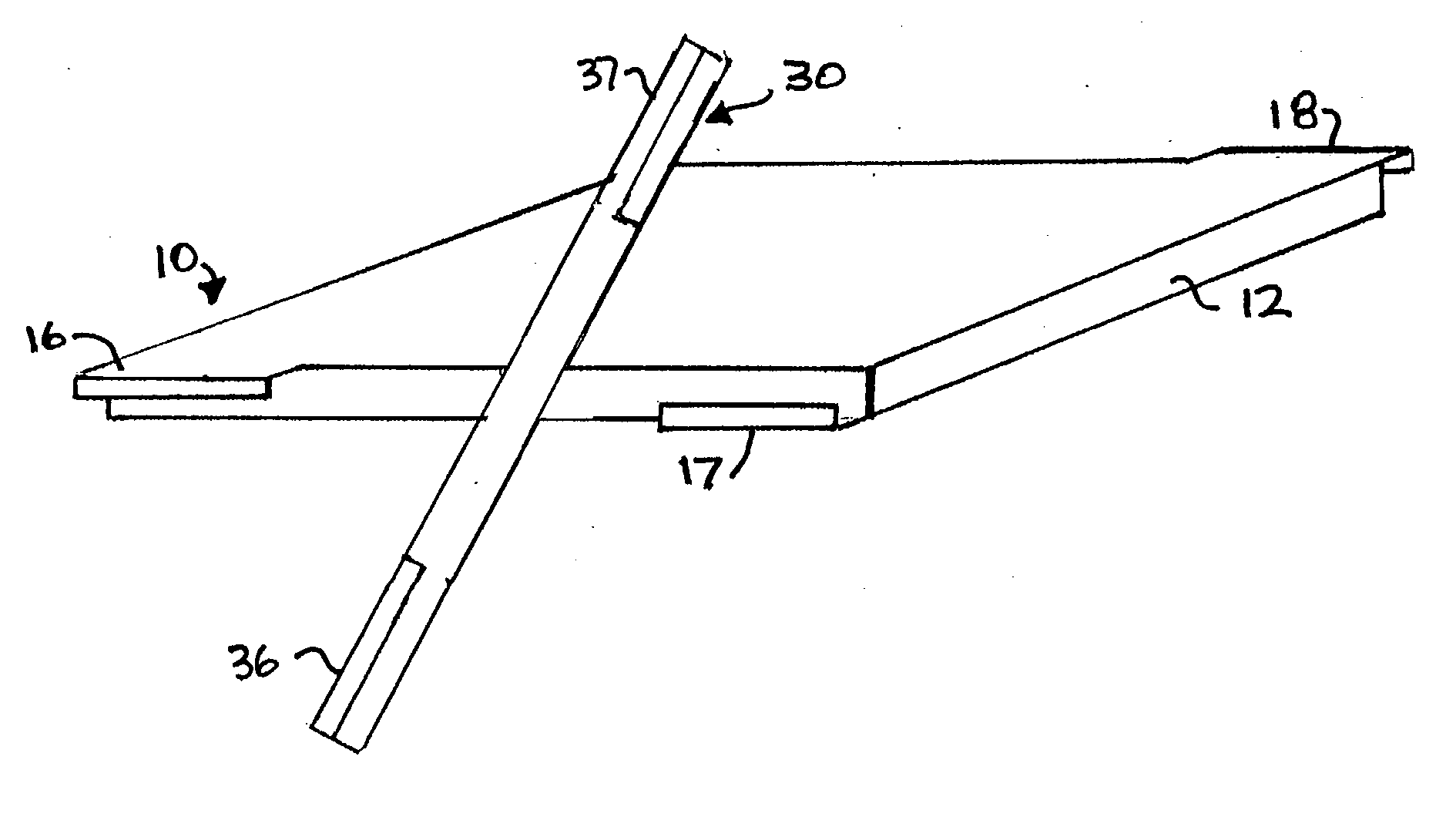

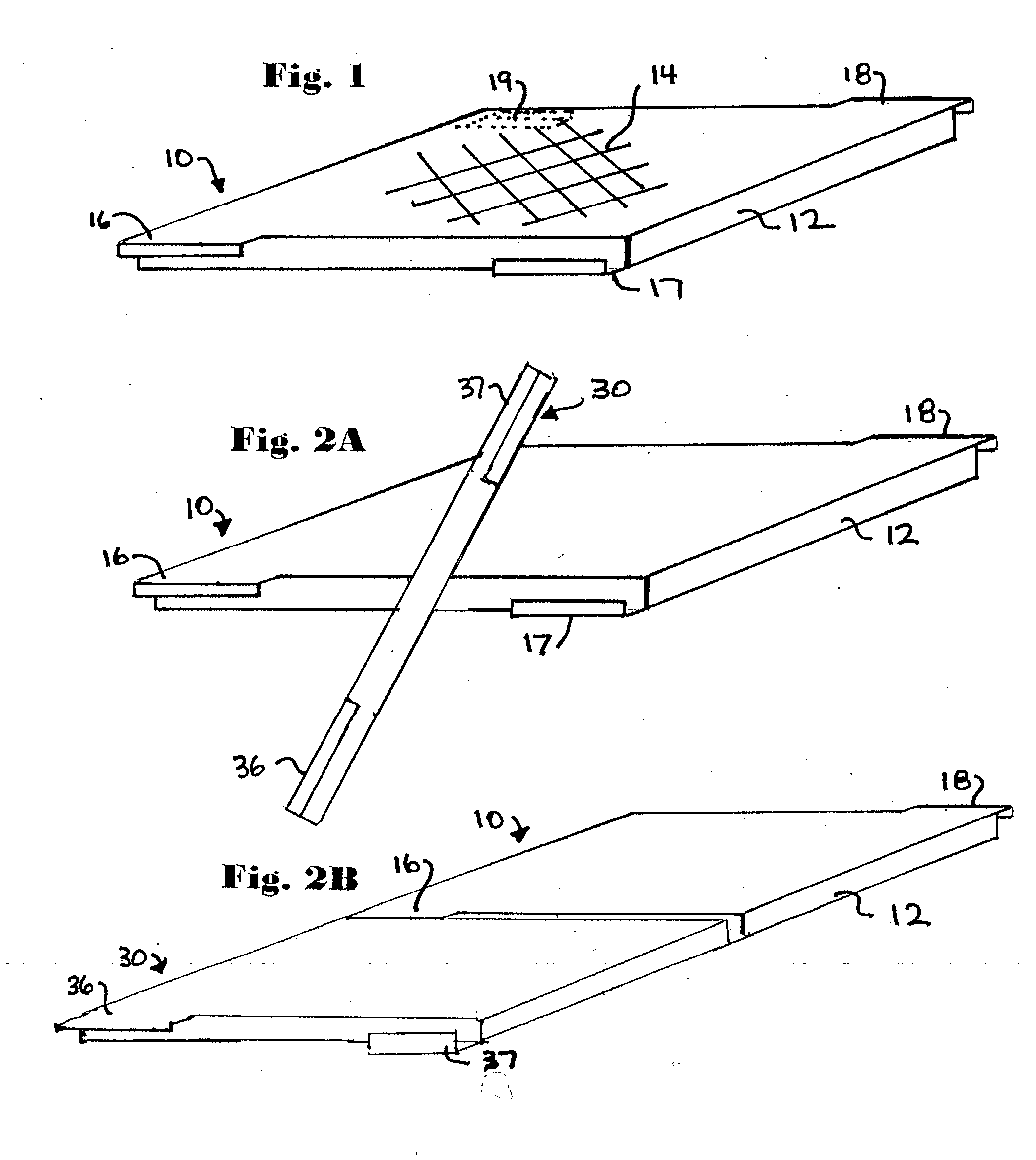

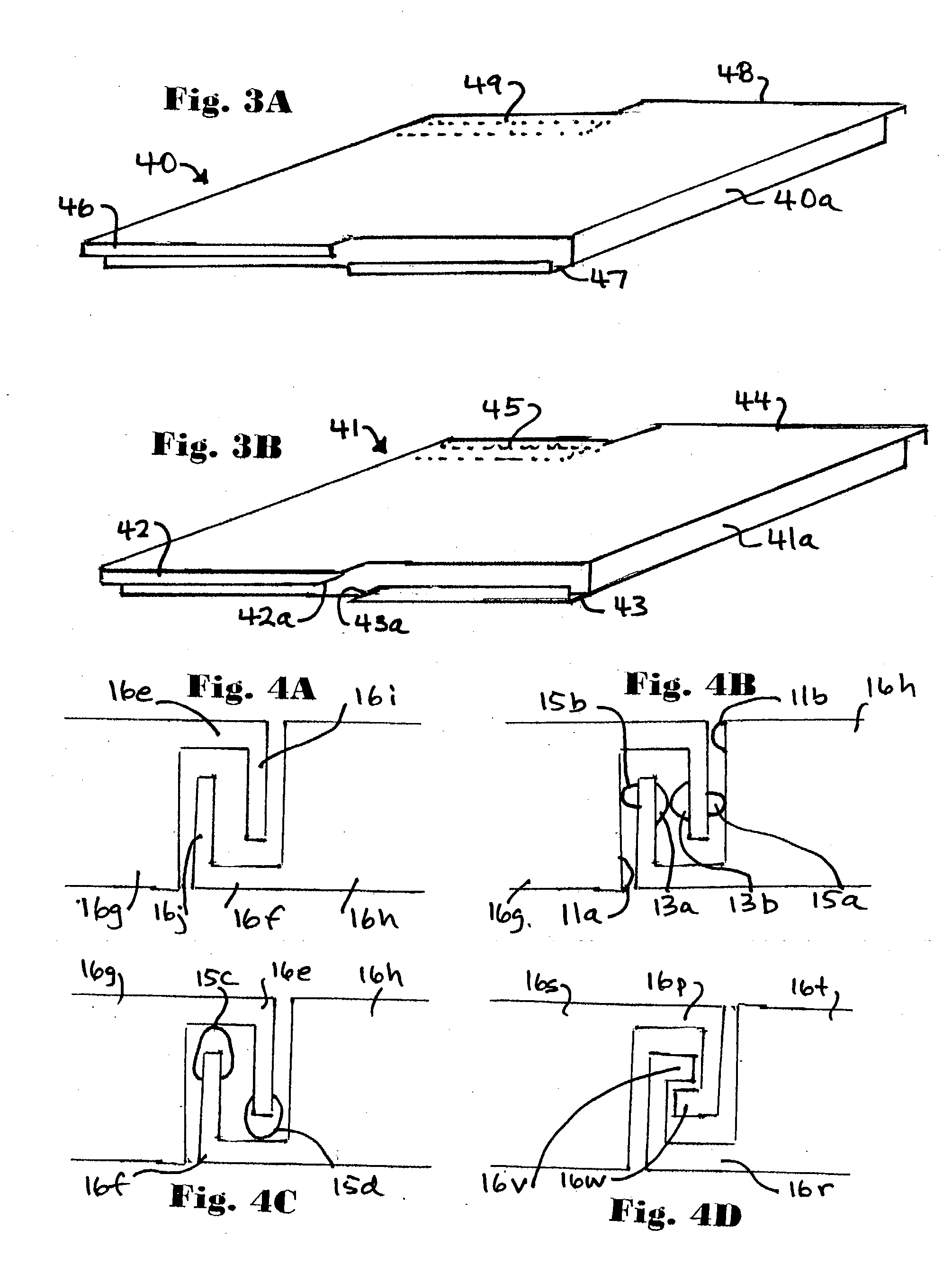

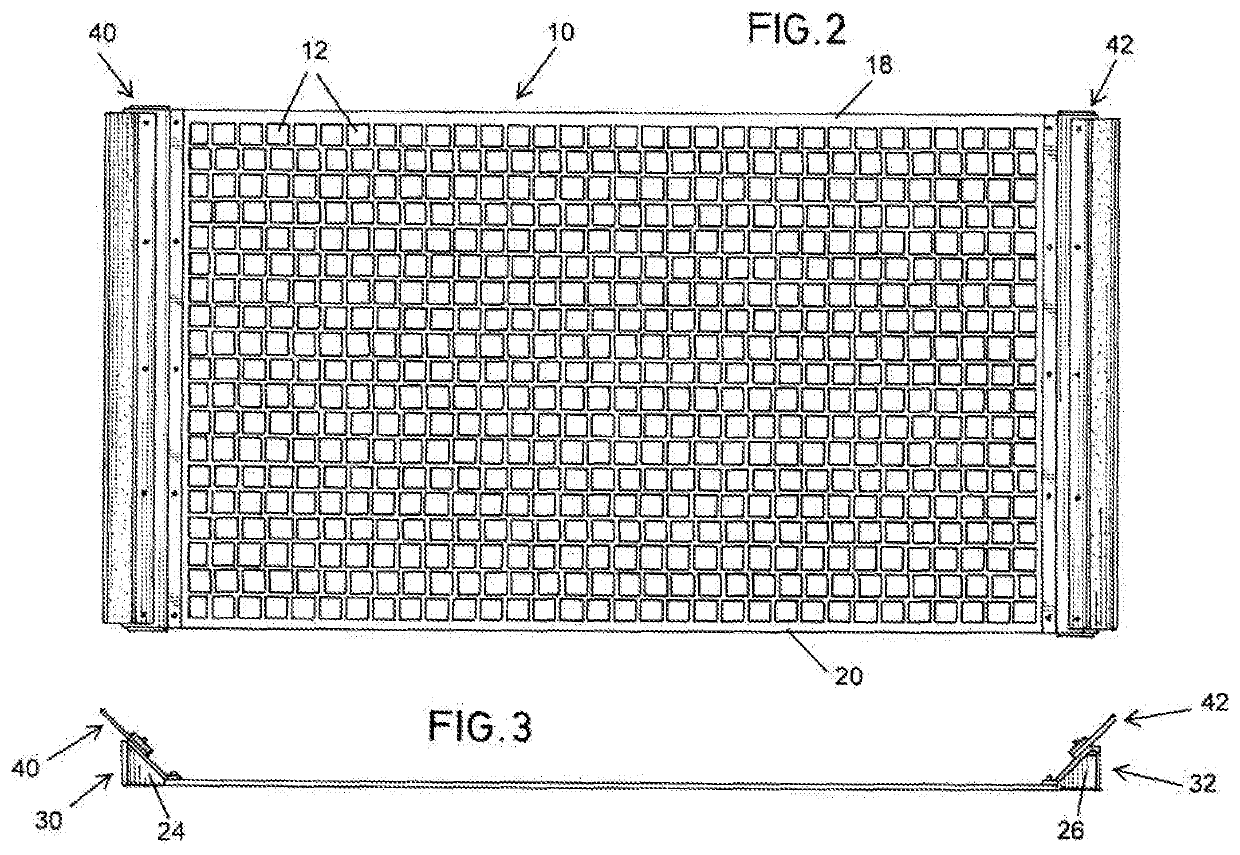

Interlocking screens for vibratory separators

InactiveUS7063214B2Easy to disassembleImprove stabilitySievingScreeningShale shakersMechanical engineering

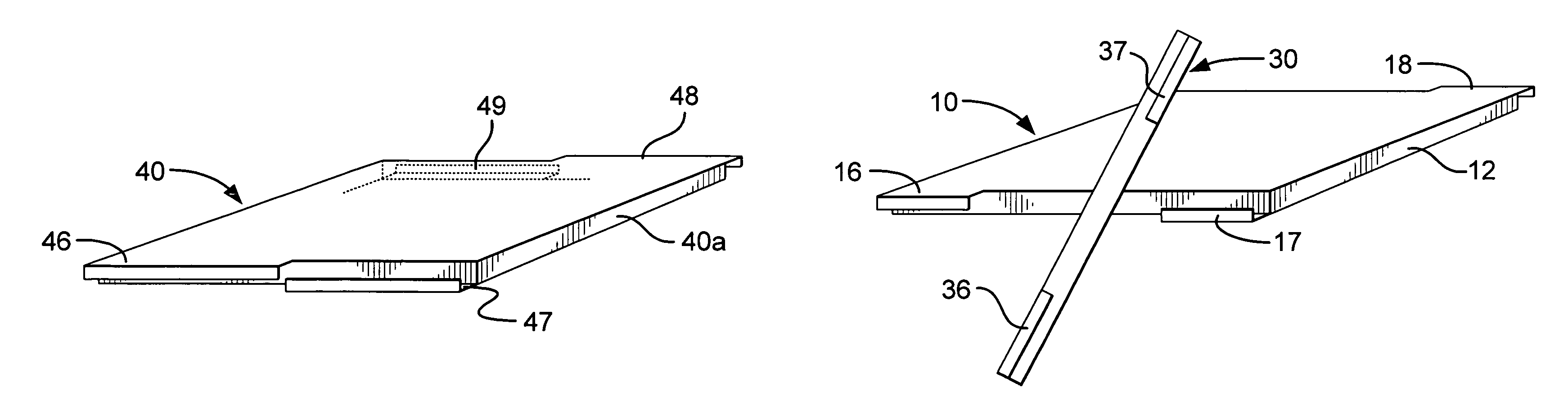

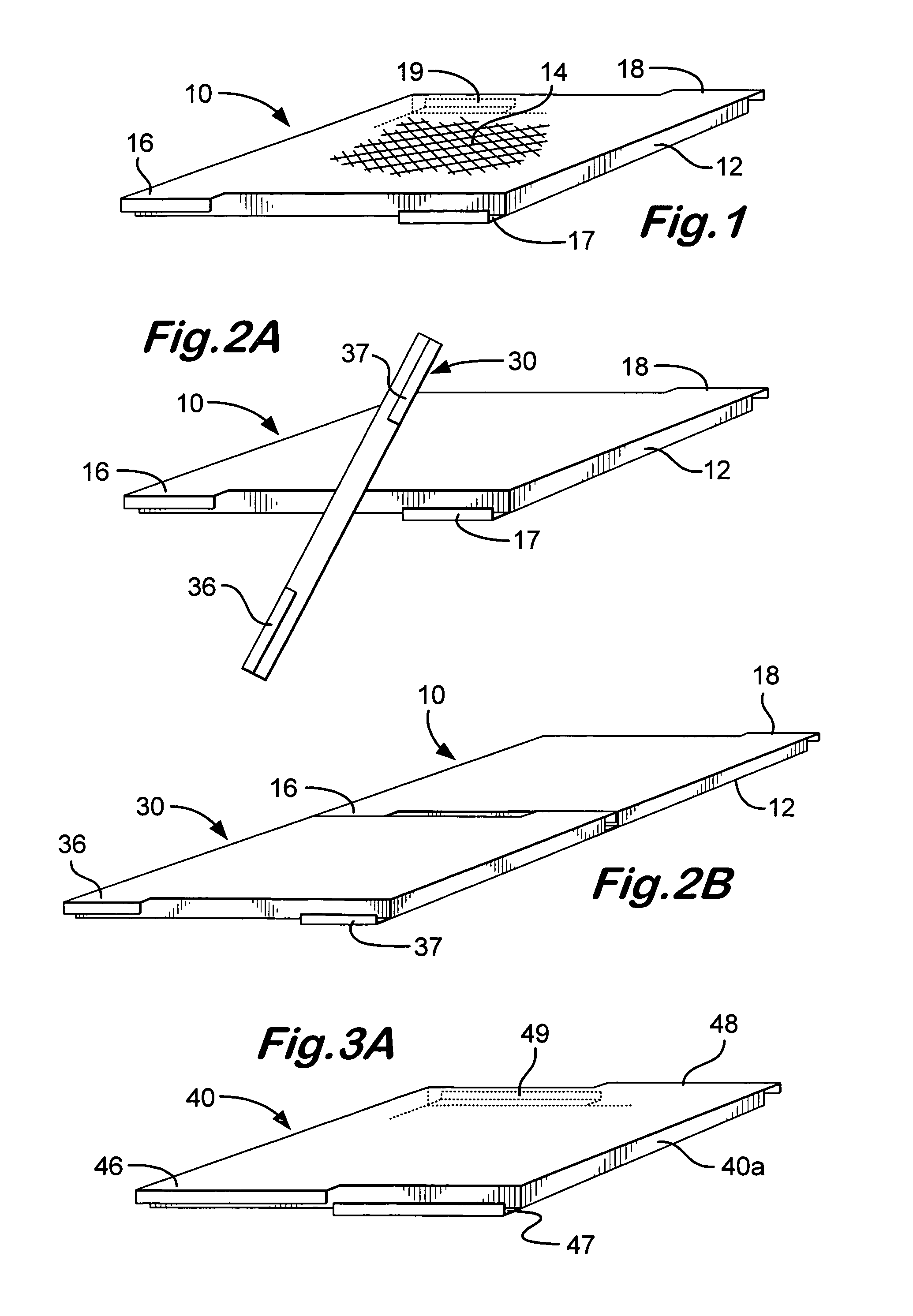

Interconnectible screen assemblies for vibratory separators or shale shakers and methods for manipulating such screen assemblies which, in certain aspects, include a first screen assembly and a second screen assembly positioning at least a portion of the first screen assembly with respect to screen assembly holding apparatus, connecting a second screen assembly to the first screen assembly, and moving the first screen assembly and the second screen assembly together with respect to the screen assembly holding apparatus.

Owner:VARCO I P INC

Connected screens for vibratory separators

Interconnectible screen assemblies for vibratory separators or shale shakers and methods for manipulating such screen assemblies which, in certain aspects, include a first screen assembly and a second screen assembly positioning at least a portion of the first screen assembly with respect to the second screen assembly, releasably connecting the second screen assembly to the first screen assembly, and moving the first screen assembly and the second screen assembly together.

Owner:VARCO I P INC

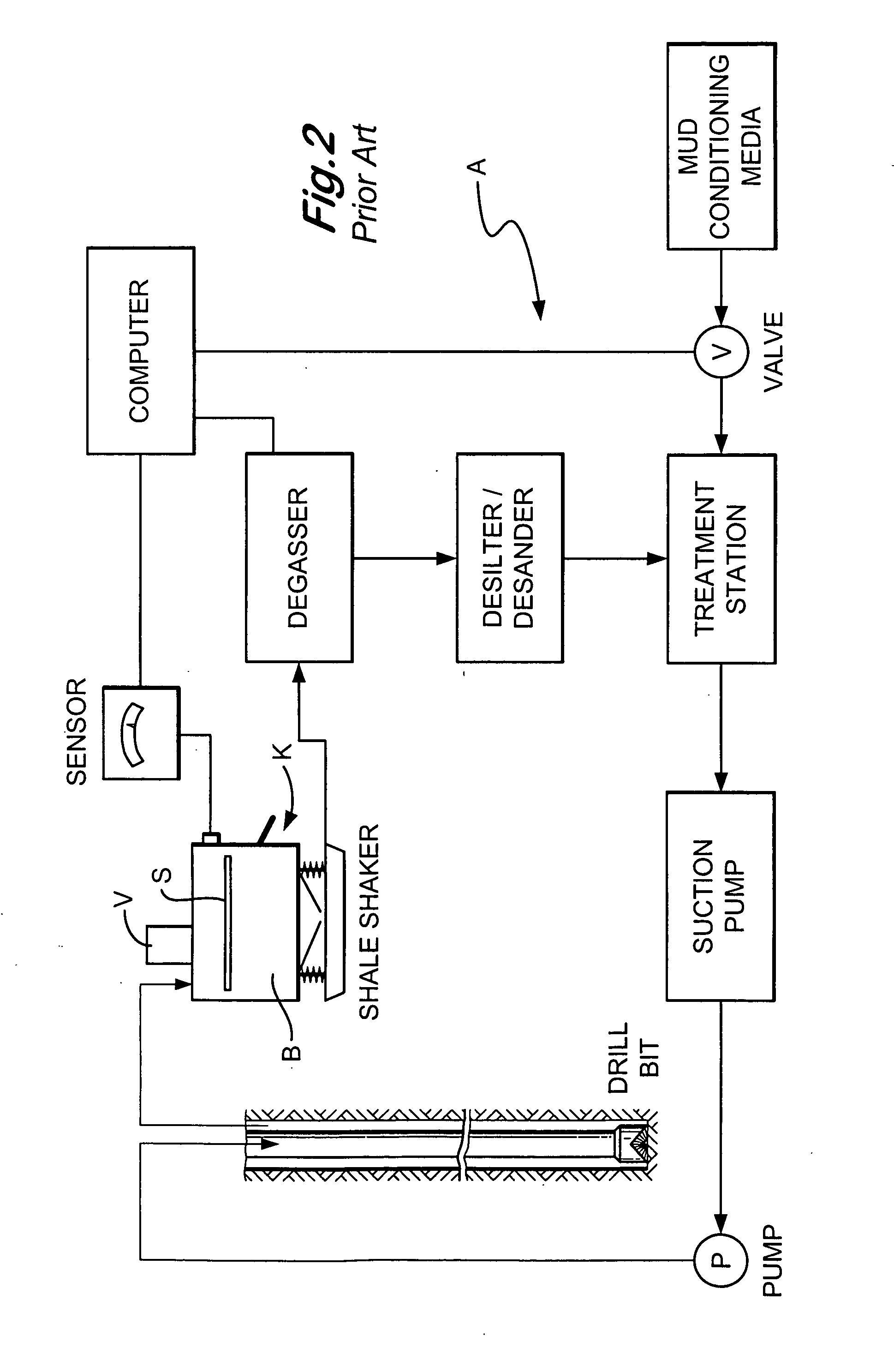

Weir box for drilling mud separation unit

InactiveUS6244362B1Settling tanks feed/dischargeLoose filtering material filtersLithologyShale shakers

A weir box disposed upstream from conventional solids control equipment of a mud system of a drilling rig contains a drilling mud separation unit having a continuous-loop scalper screen that is driven in a continuous loop to separate, convey and discharge large amounts of gumbo, heavy clays and drill solids at the end of the separation unit. The flow divider box is a box-like housing with a diverter plate, weir baffle plates and a sliding gate that allows drilling fluid or drilling mud to be selectively directed to the mud separation unit to be separated prior to passing to the conventional downstream solids control equipment or allows the fluid to bypass the separation unit and flow directly to the conventional solids control equipment. The sliding gate is adjustable to selectively control or meter the flow rate and to create a hydrostatic head upstream from the conventional solids control equipment. The weir box baffle plates, sliding gate, and selective utilization of the mud separation unit allows the operator to produce an increased hydrostatic head, which enables high flow rates to be easily processed by shale shakers and other conventional downstream solids control equipment of the mud system and to compliment the drilling operation with respect to changes in the lithology, geological formations, or loss of returns in relation to the gallons pumped or volume of drilling fluid or drilling mud entering the weir box.

Owner:WILLIAMS J TERRELL

Interlocking screens for vibratory separators

InactiveUS20040149632A1Improve stabilitySimple structureSievingScreeningShale shakersMechanical engineering

Interconnectible screen assemblies for vibratory separators or shale shakers and methods for manipulating such screen assemblies which, in certain aspects, include a first screen assembly and a second screen assembly positioning at least a portion of the first screen assembly with respect to screen assembly holding apparatus, connecting a second screen assembly to the first screen assembly, and moving the first screen assembly and the second screen assembly together with respect to the screen assembly holding apparatus.

Owner:VARCO I P INC

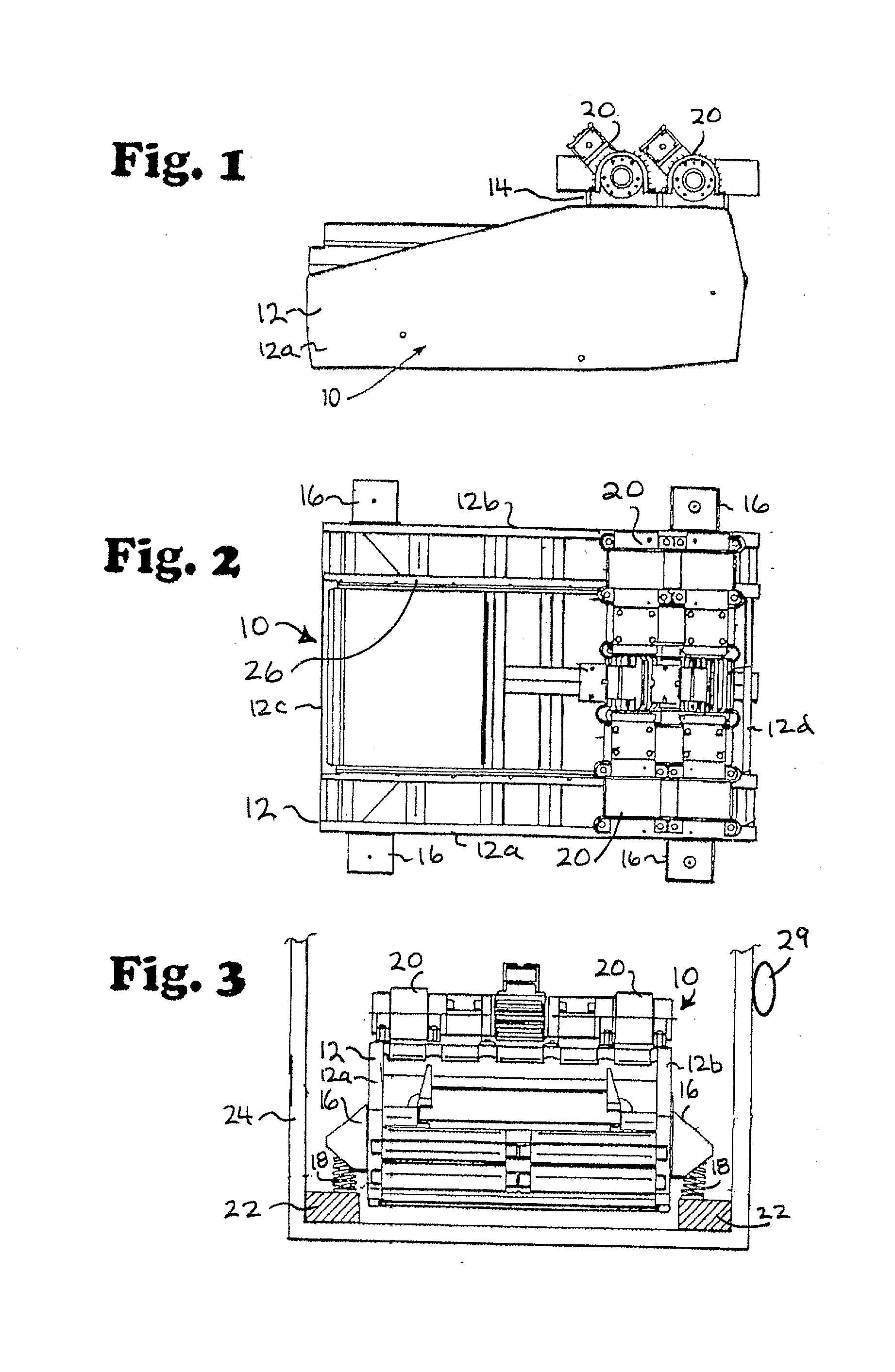

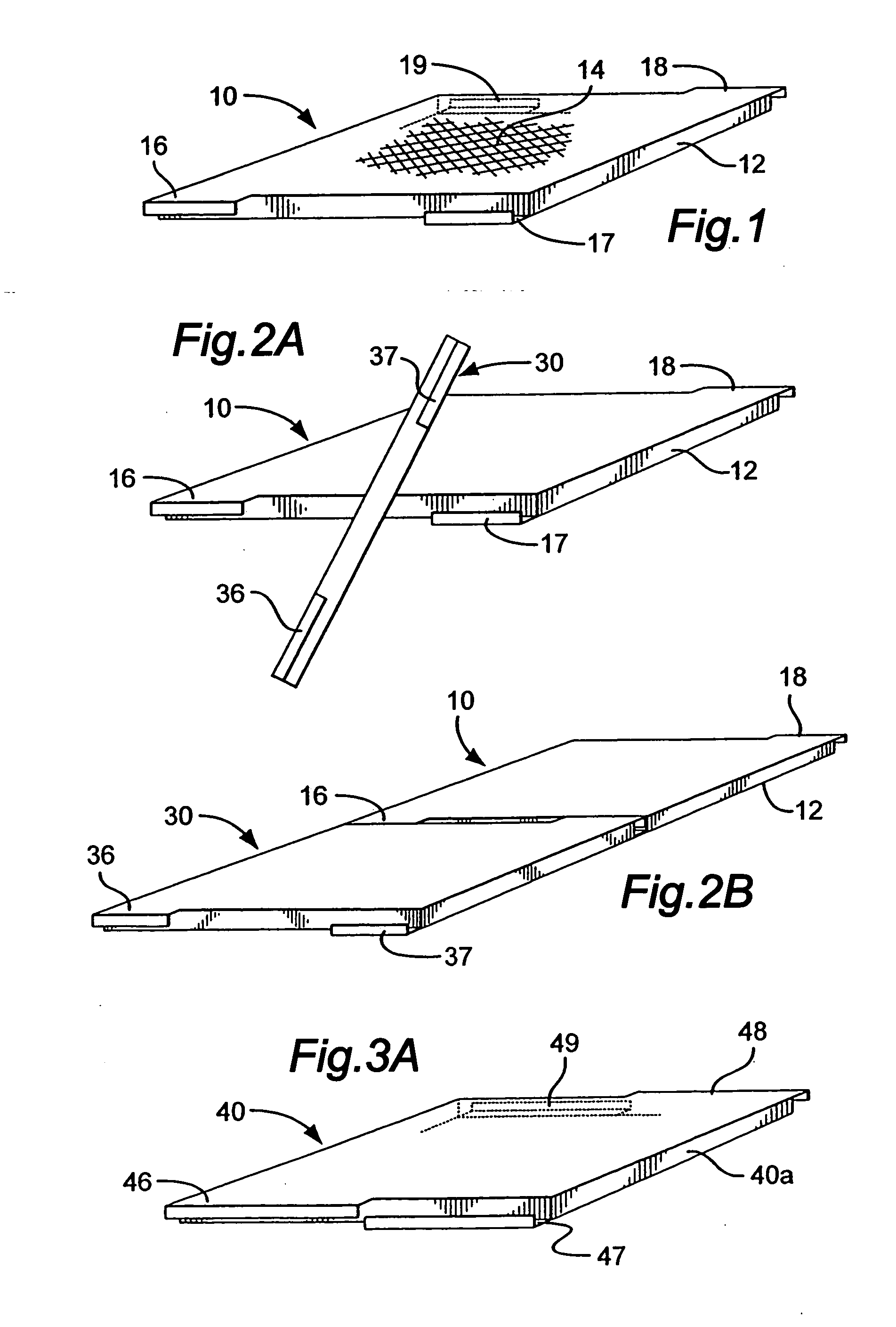

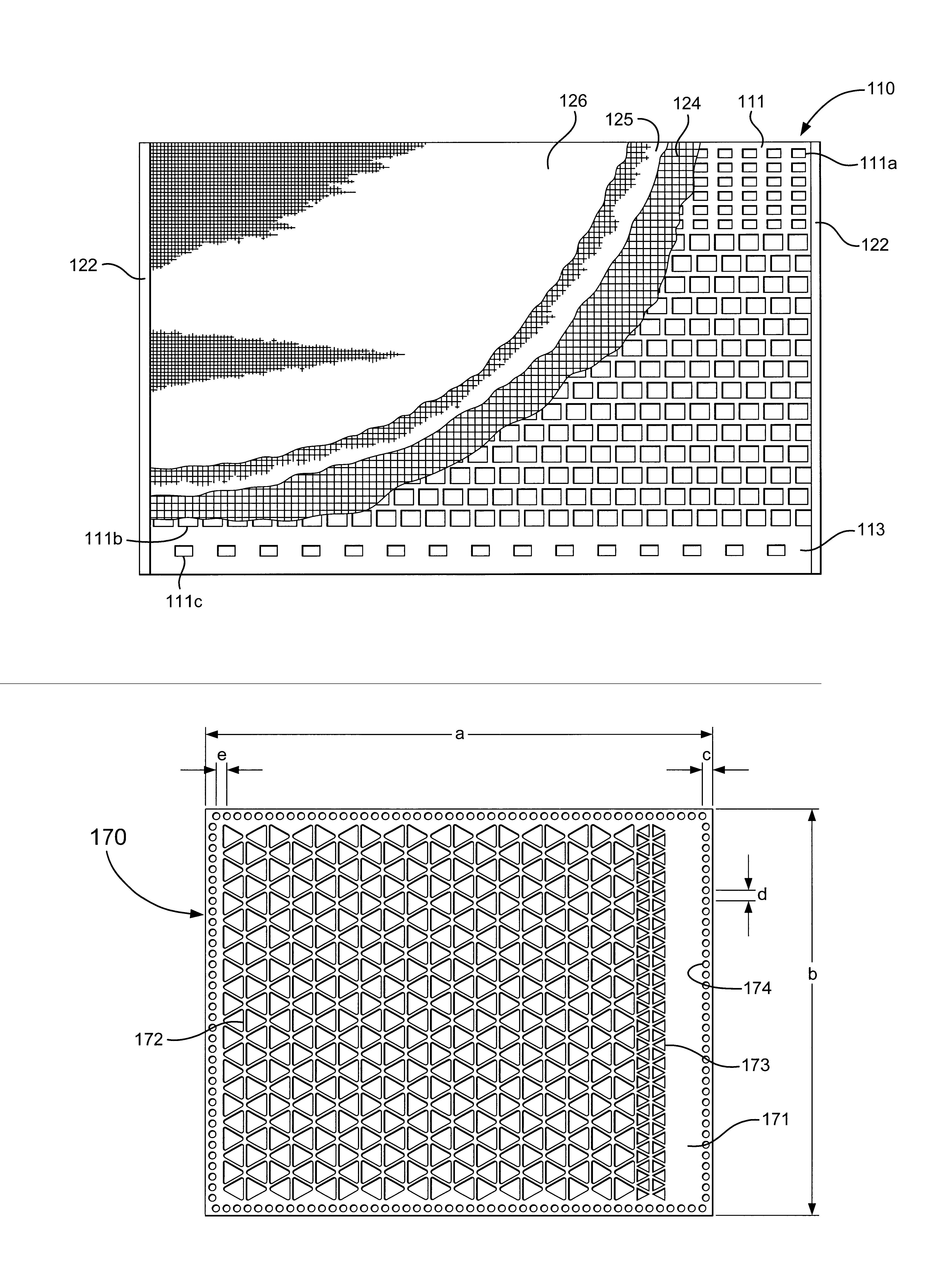

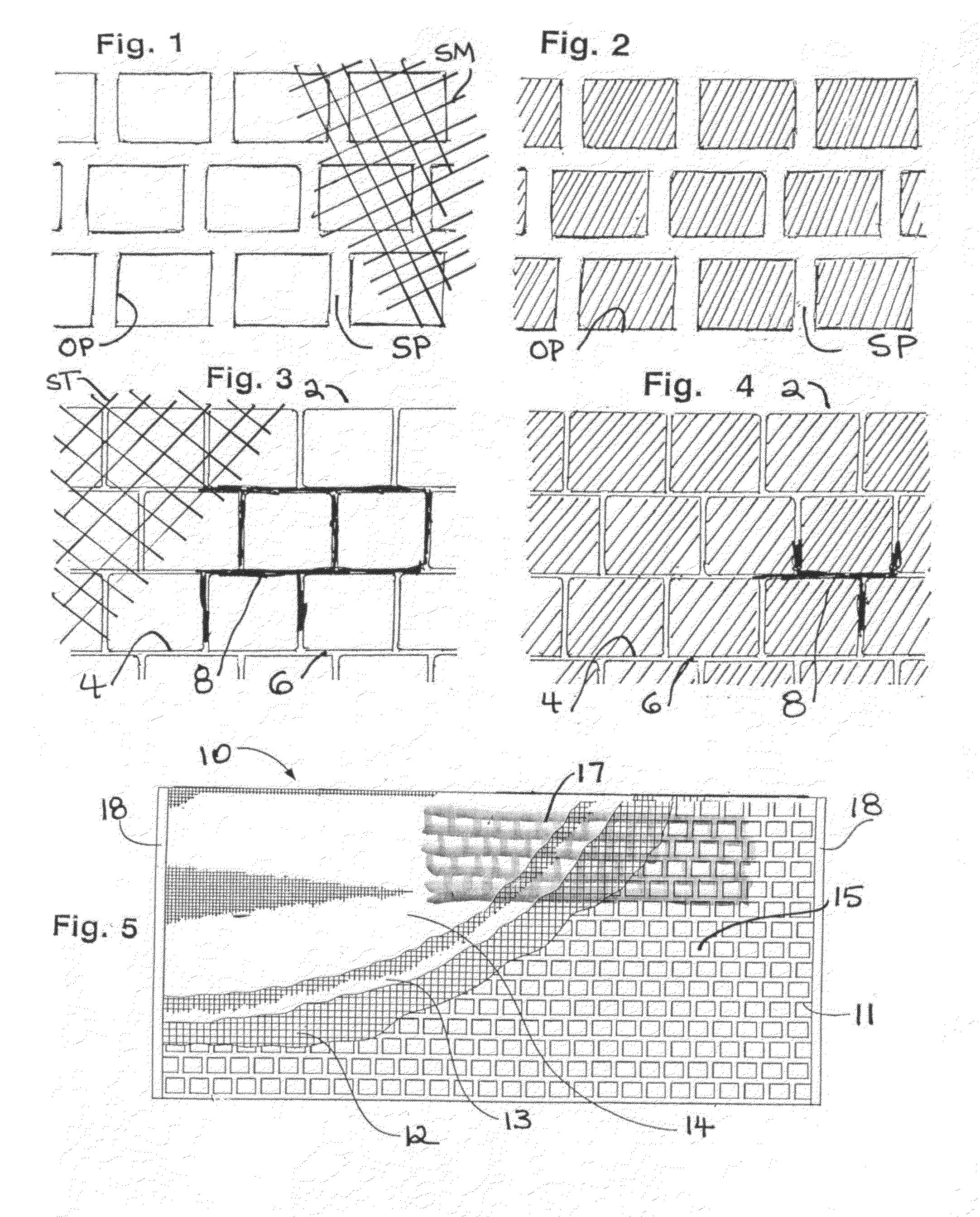

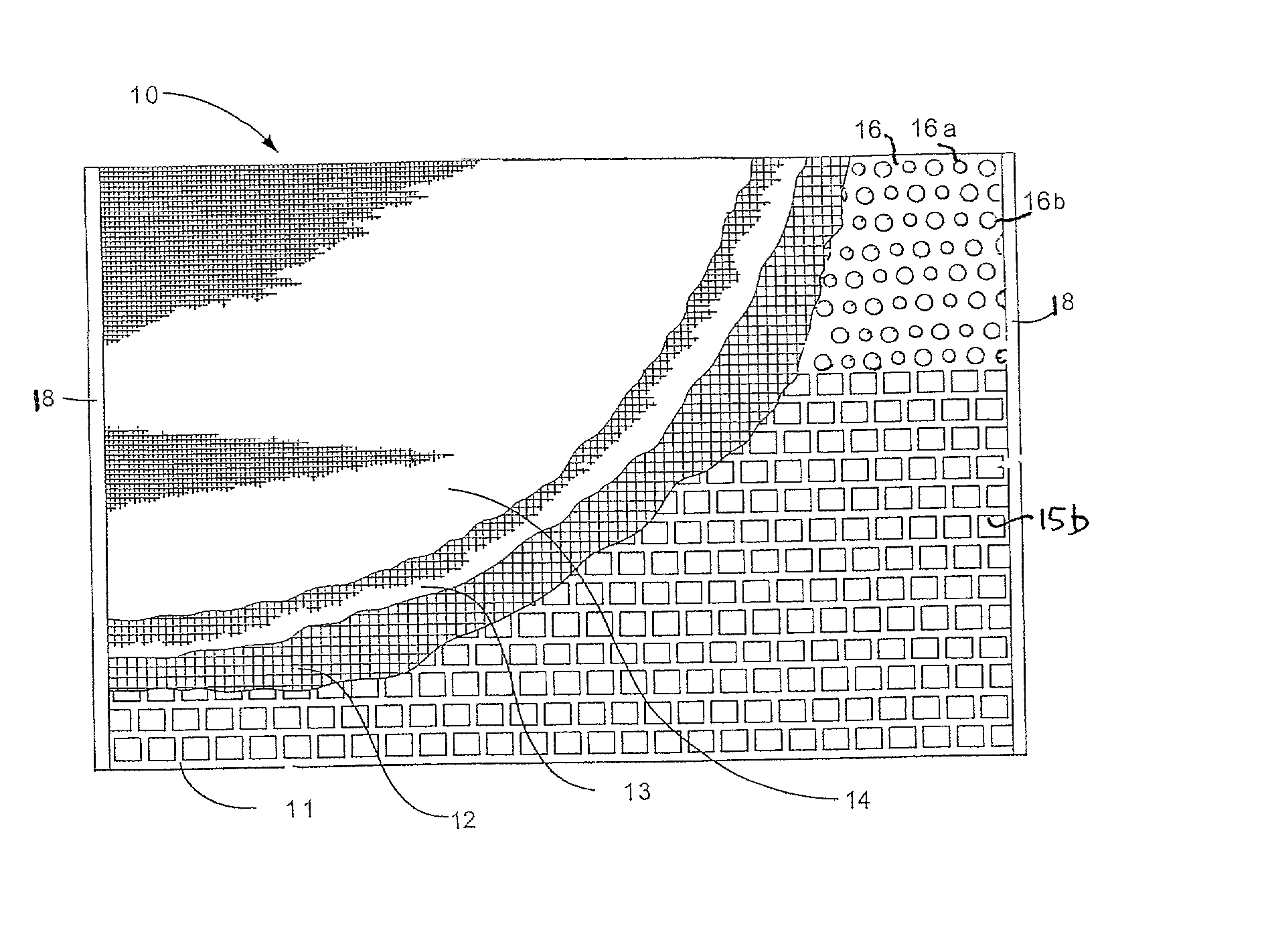

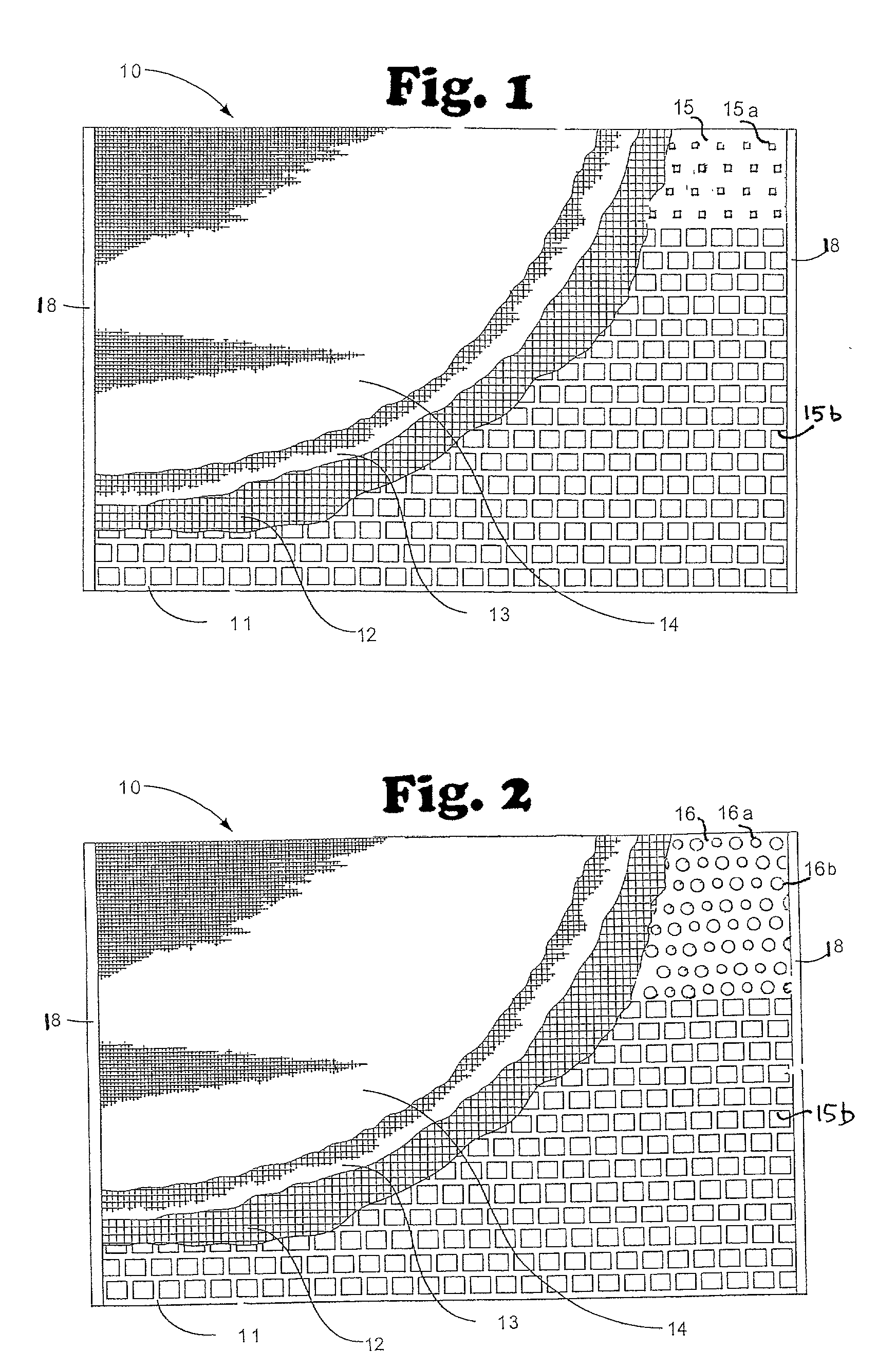

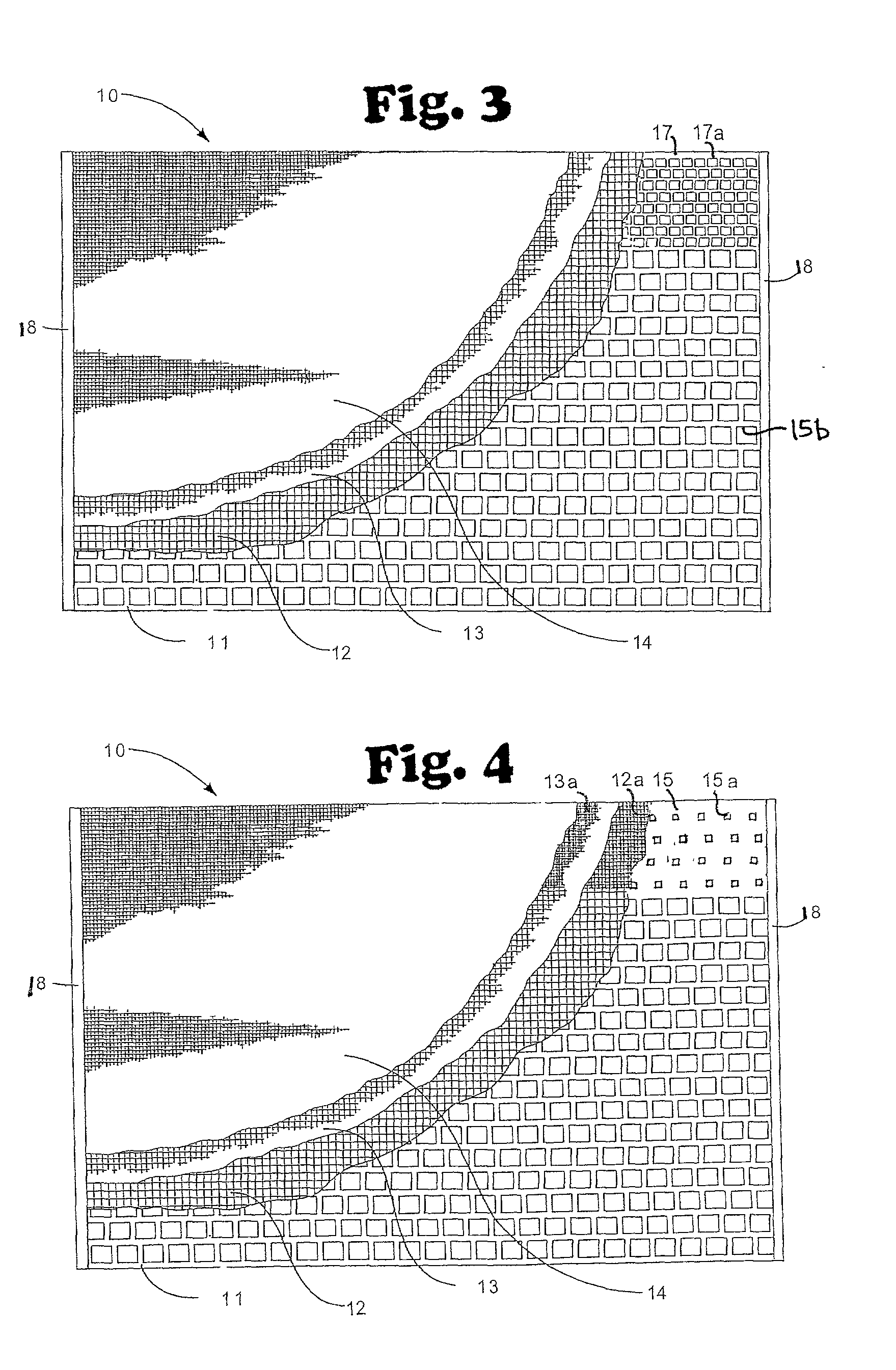

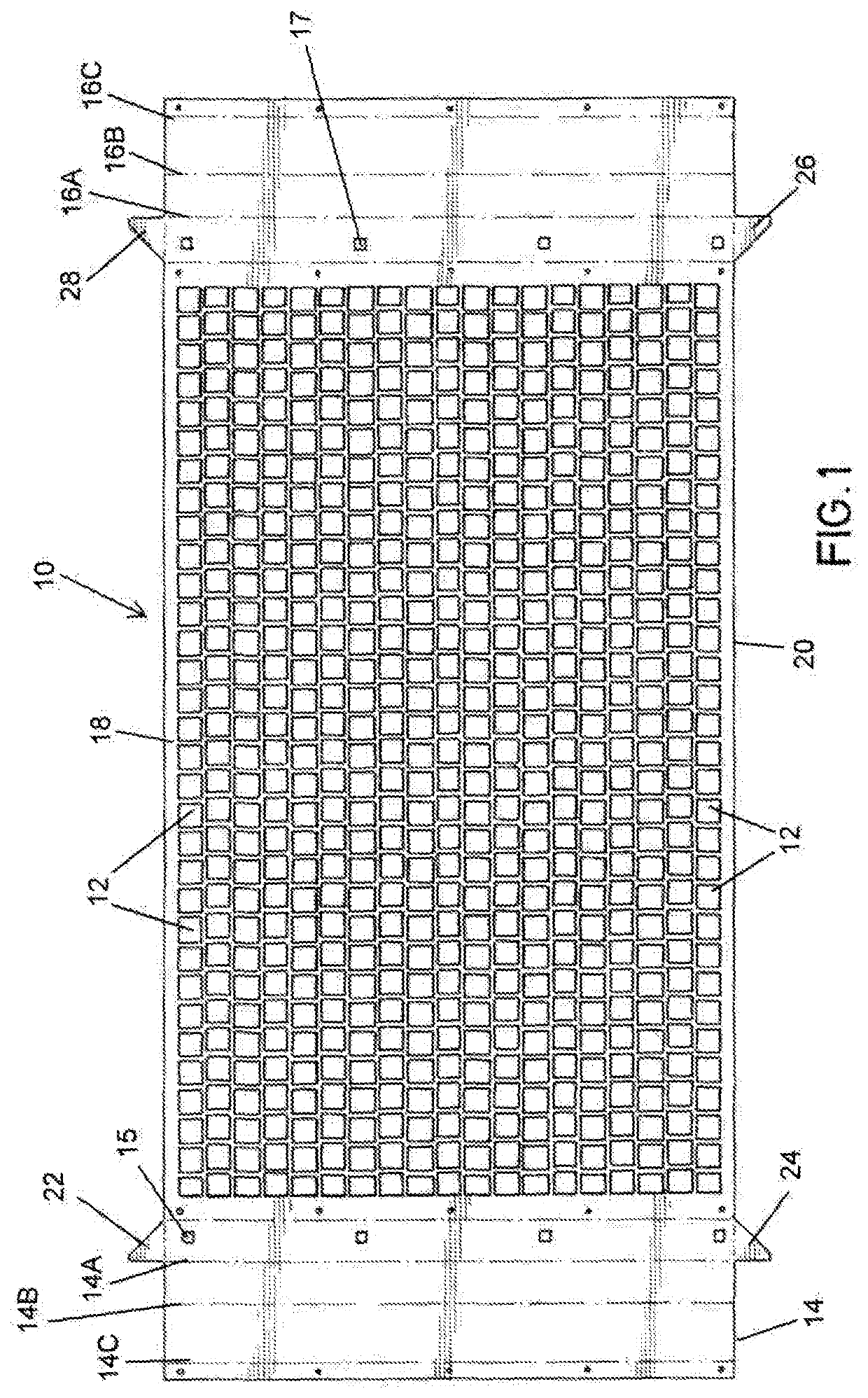

Screen support and screens for shale shakers

InactiveUS6601709B2Efficient introductionGuaranteed effective sizeSievingScreeningShale shakersBiomedical engineering

A support for a screen assembly for a vibratory separator, a screen assembly with such a support, a vibratory separator with one or more such screen assemblies, and a method of using such a screen assembly, such a support having a body, a first series of holes through the body each hole having a first opening size as viewed from above, a second series of holes through the body each hole with a second opening size as viewed from above, the second series of holes at a selected area of the body and the support positionable in a vibratory separator so that the selected area is adjacent a selected location with respect to the vibratory separator, and the second opening size smaller than the first opening size and / or the second series of holes with holes spaced apart differently than the holes of the first series of holes; and in one aspect, a plastic grid with such hole series for fusing together layers of screening material.

Owner:VARCO I P INC

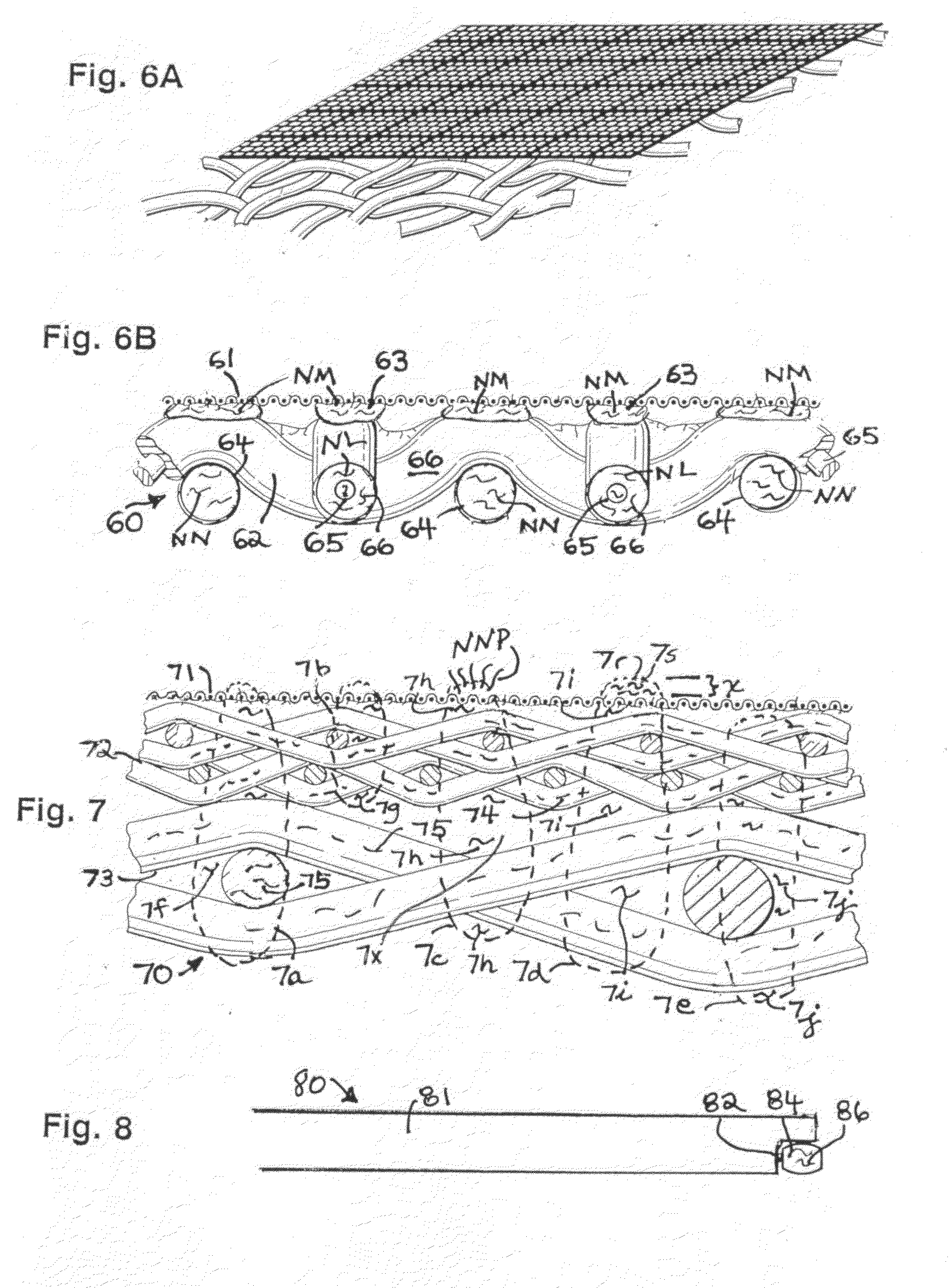

Nanostrong vibratory screens & separators

InactiveUS20130277281A1Sacrificing needed strengthLarge openingMaterial nanotechnologySievingShale shakersSubject matter

Vibratory separators, shale shakers, screens, and screen assemblies, and screening material with nanomaterial thereon and / or therein for strengthening, conductivity enhancement, or both, and methods of using such things. This abstract is provided to comply with the rules requiring an abstract which will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure and is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims, 37 C.F.R. 1.72(b).

Owner:MCCLUNG III GUY L

Screen basket for shale shakers

InactiveUS6371301B1Increasing available screening areaShorten the lengthSievingScreeningShale shakersEngineering

Owner:TUBOSCOPE IP

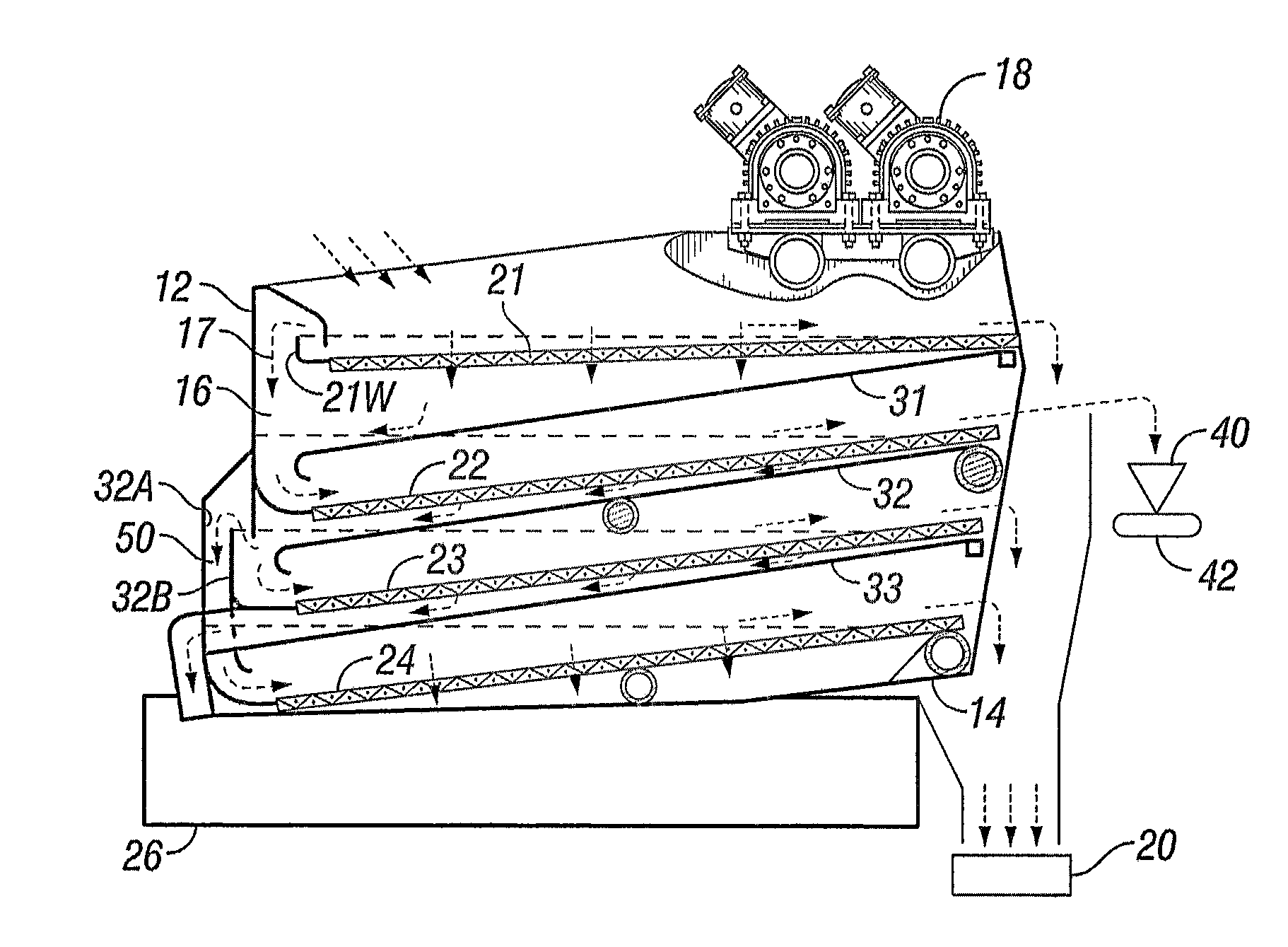

Shale shakers with selective series/parallel flow path conversion

Methods and systems are disclosed employing a shale shaker for processing a mixture of drilling fluid and solids with multiple screen assemblies and conversion apparatus for switching flow to the screen assemblies between series flow and parallel flow; and in one aspect, a screen or screens for screening lost circulation material.

Owner:NAT OILWELL VARCO LP

Screen support and screens for shale shakers

InactiveUS20020139724A1Efficient introductionGuaranteed effective sizeSievingScreeningShale shakersBiomedical engineering

A support for a screen assembly for a vibratory separator, a screen assembly with such a support, a vibratory separator with one or more such screen assemblies, and a method of using such a screen assembly, such a support having a body, a first series of holes through the body each hole having a first opening size as viewed from above, a second series of holes through the body each hole with a second opening size as viewed from above, the second series of holes at a selected area of the body and the support positionable in a vibratory separator so that the selected area is adjacent a selected location with respect to the vibratory separator, and the second opening size smaller than the first opening size and / or the second series of holes with holes spaced apart differently than the holes of the first series of holes; and in one aspect, a plastic grid with such hole series for fusing together layers of screening material.

Owner:VARCO I P INC

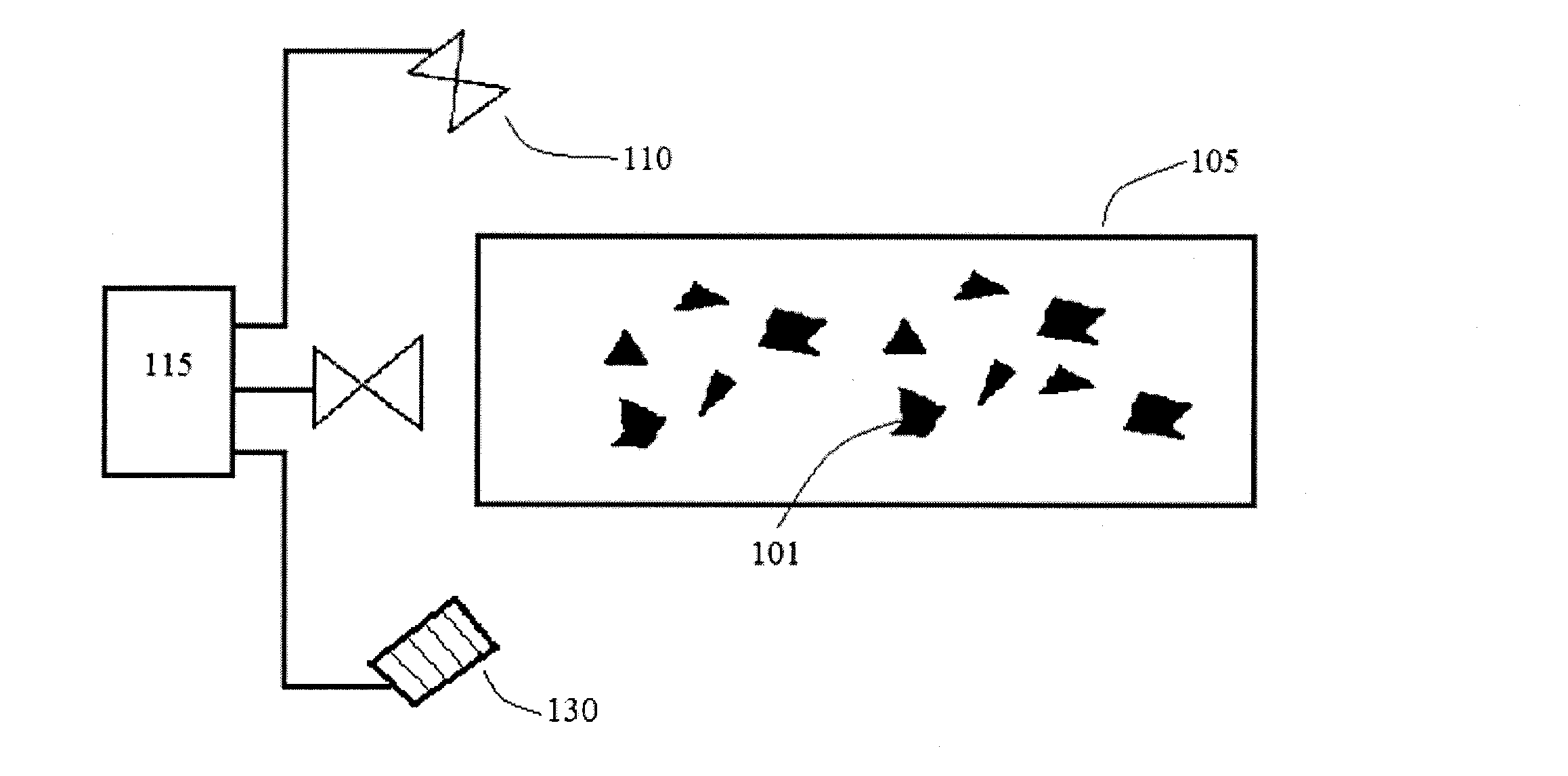

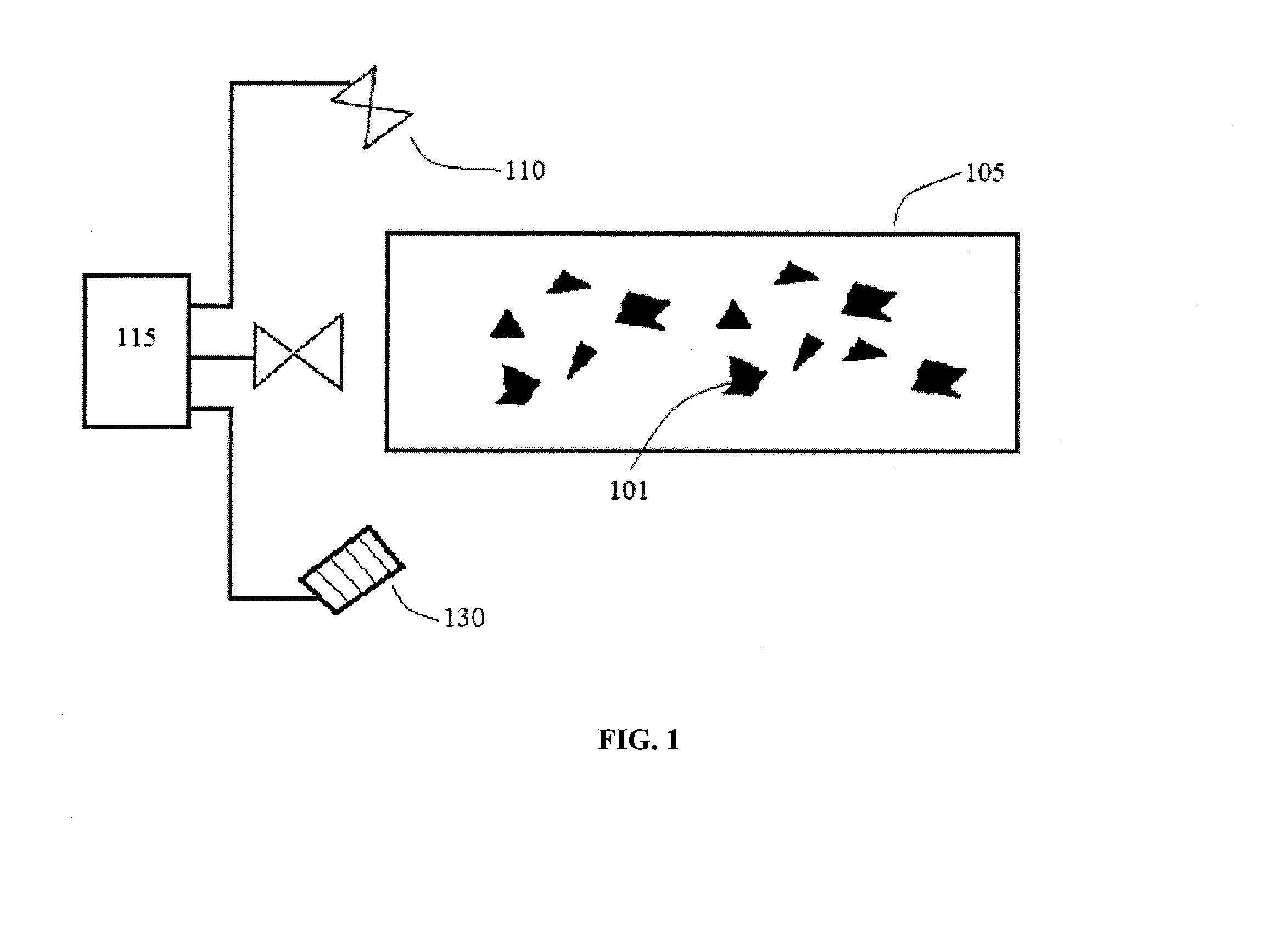

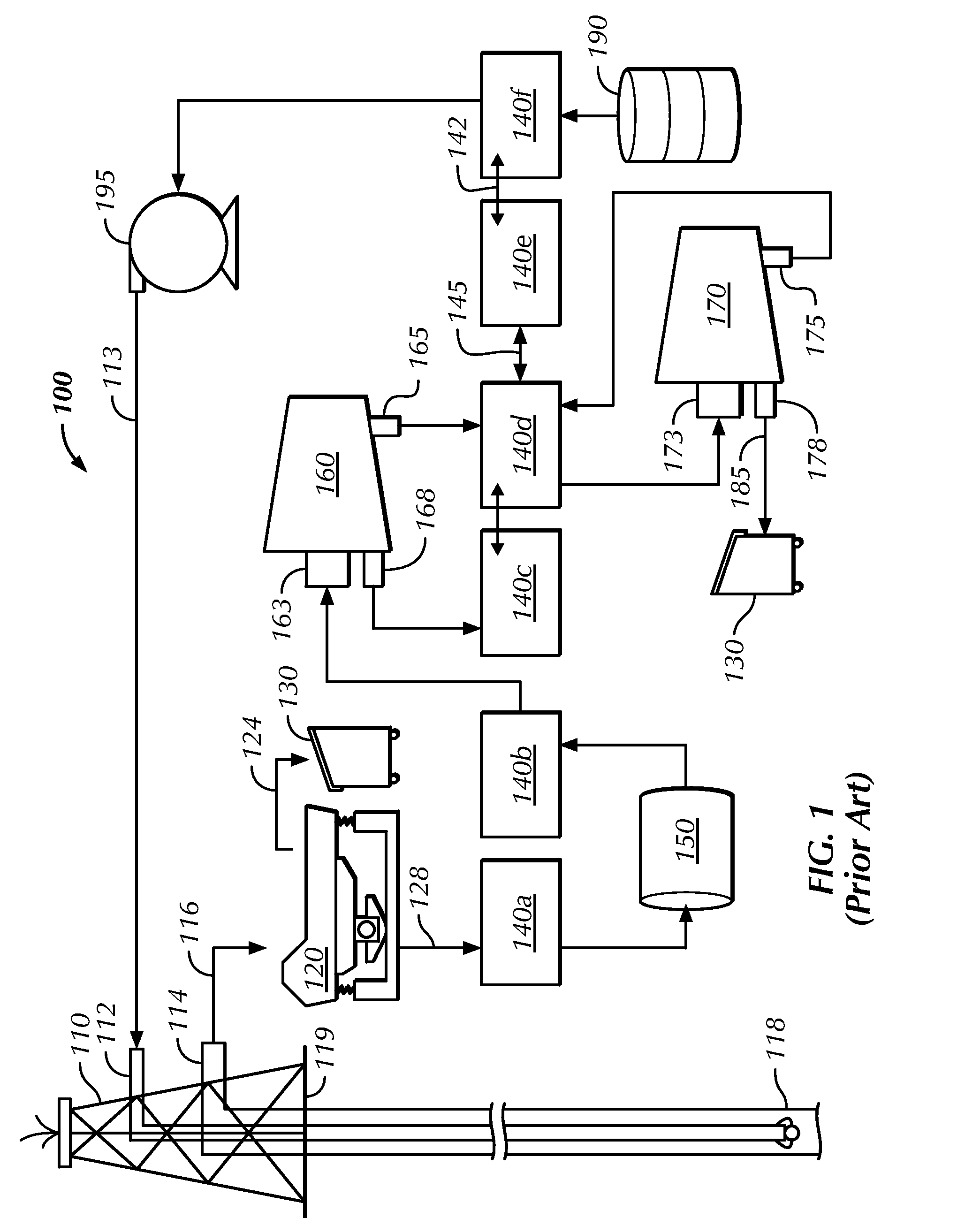

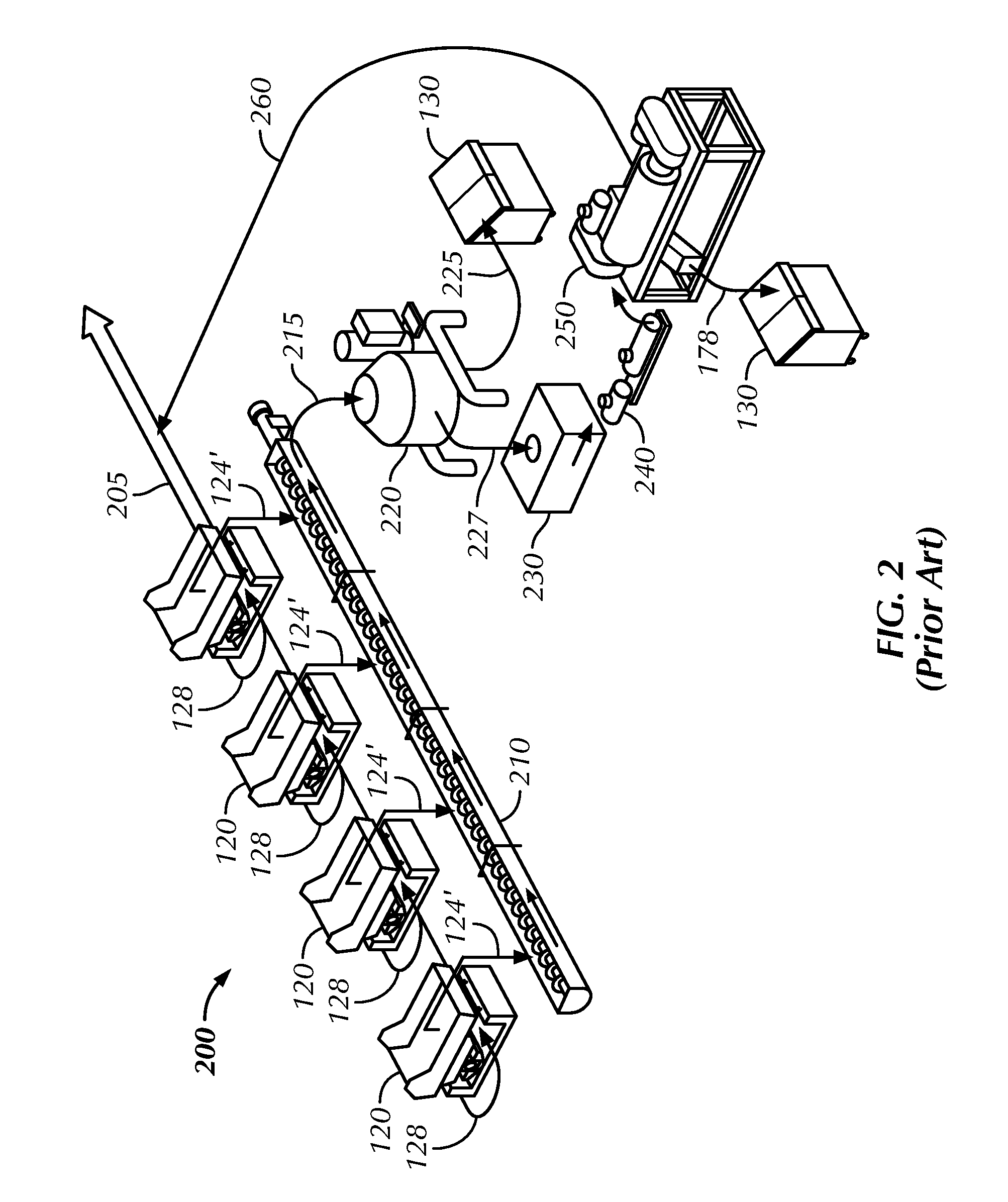

System and method for estimating cutting volumes on shale shakers

A system for monitoring the volume of cuttings exiting a shaker table is disclosed. The system comprises a shaker table configured to be adjusted based on information compiled by a processor and at least one camera configured to monitor said shaker table. The camera may be operably connected to the processor. The processor may be configured to identify drill cuttings and estimate the volume of the cuttings exiting the shaker table using machine vision techniques.

Owner:HELMERICH & PAYNE TECH LLC

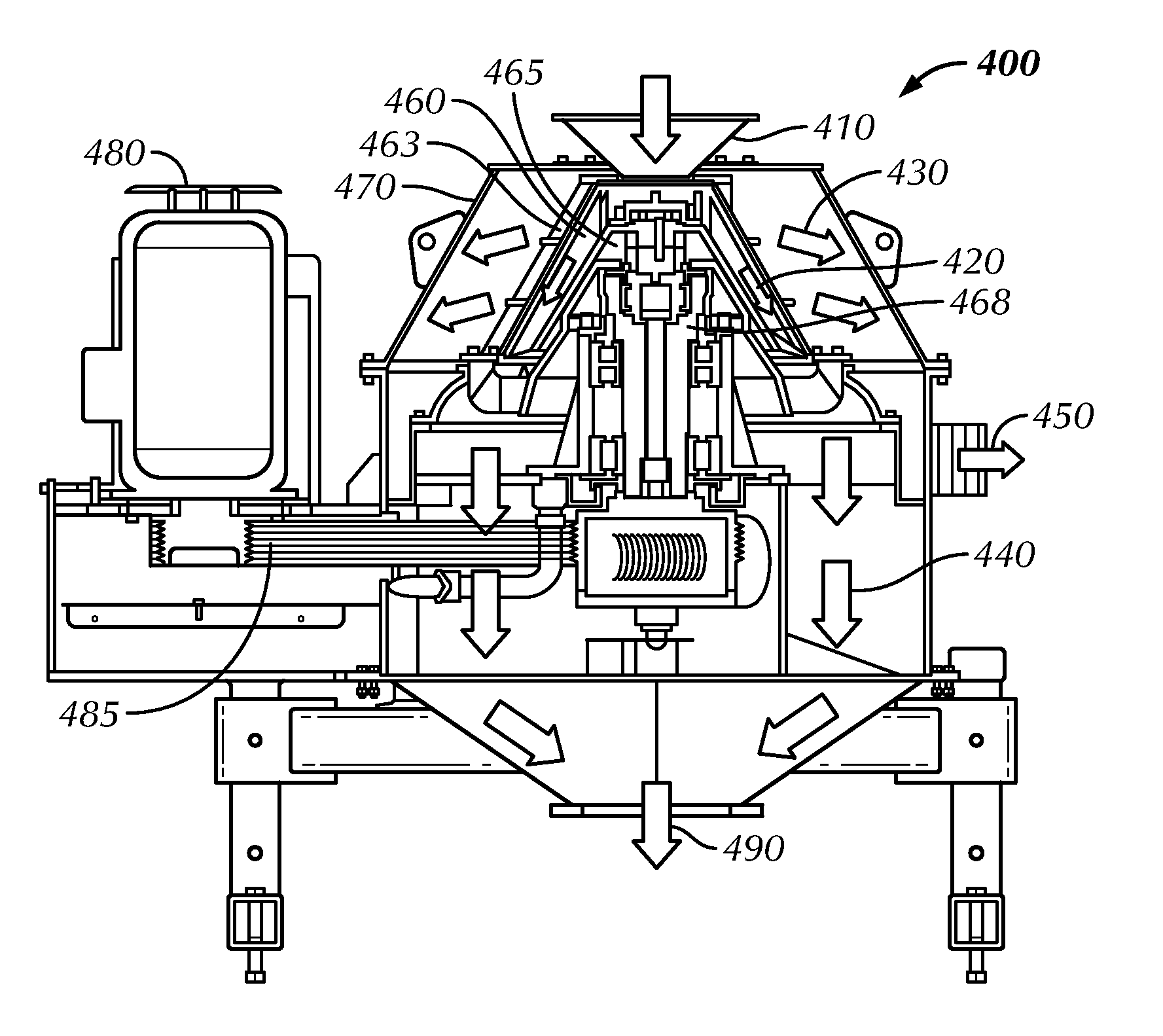

Method of Solids Control and Fluid Recovery in Drilling Operations

A method of processing mud laden cuttings from a rig's wellbore comprising collecting the cuttings from a plurality of shale shakers into a hopper, feeding the collected cuttings to an improved vertical dryer, continually recirculating the fluids from the dryer until ready for further processing, mixing the fluids with flocculates and diluting them before processing through high speed centrifuge and barite recovery centrifuges.

Owner:HURST JASON

Glued screens for shale shakers

Screens and screen assemblies for a vibratory separator or shale shaker, such screens and screen assemblies made by a method including applying glue in a glue pattern to at least one layer of screening material, said applying done by powered moving mechanical glue application apparatus; in one aspect moving with powered mechanical screen movement apparatus the at least one layer of screening material beneath the powered moving mechanical glue application apparatus; in one aspect, using hot melt moisture-curing glue, and in one aspect facilitating the cure of moisture-curing glue by applying moisture to it.

Owner:VARCO I P INC

Shale shakers with selective series/parallel flow path conversion

Methods and systems are disclosed employing a shale shaker for processing a mixture of drilling fluid and solids with multiple screen assemblies and conversion apparatus for switching flow to the screen assemblies between series flow and parallel flow; and in one aspect, a screen or screens for screening lost circulation material.

Owner:NAT OILWELL VARCO LP

Screen basket and shale shakers

InactiveUS20050199532A1Increasing available screening areaShorten the lengthSievingScreeningShale shakersEngineering

A screen mounting basket for a vibratory separator for separating components of material introduced into the basket, the vibratory separator including a collection receptacle beneath the basket, the basket including two opposed spaced-apart side walls having first ends and second ends, the first ends spaced-apart by spaced-apart end walls connected to each of the side walls, a basket bottom between the two spaced-apart side walls, at least one screen assembly positioned vertically in the basket for interceptions material introduced into the basket and for screening said material, and the at least one screen assembly extending from one side wall of the basket to the other.

Owner:VARCO I P INC

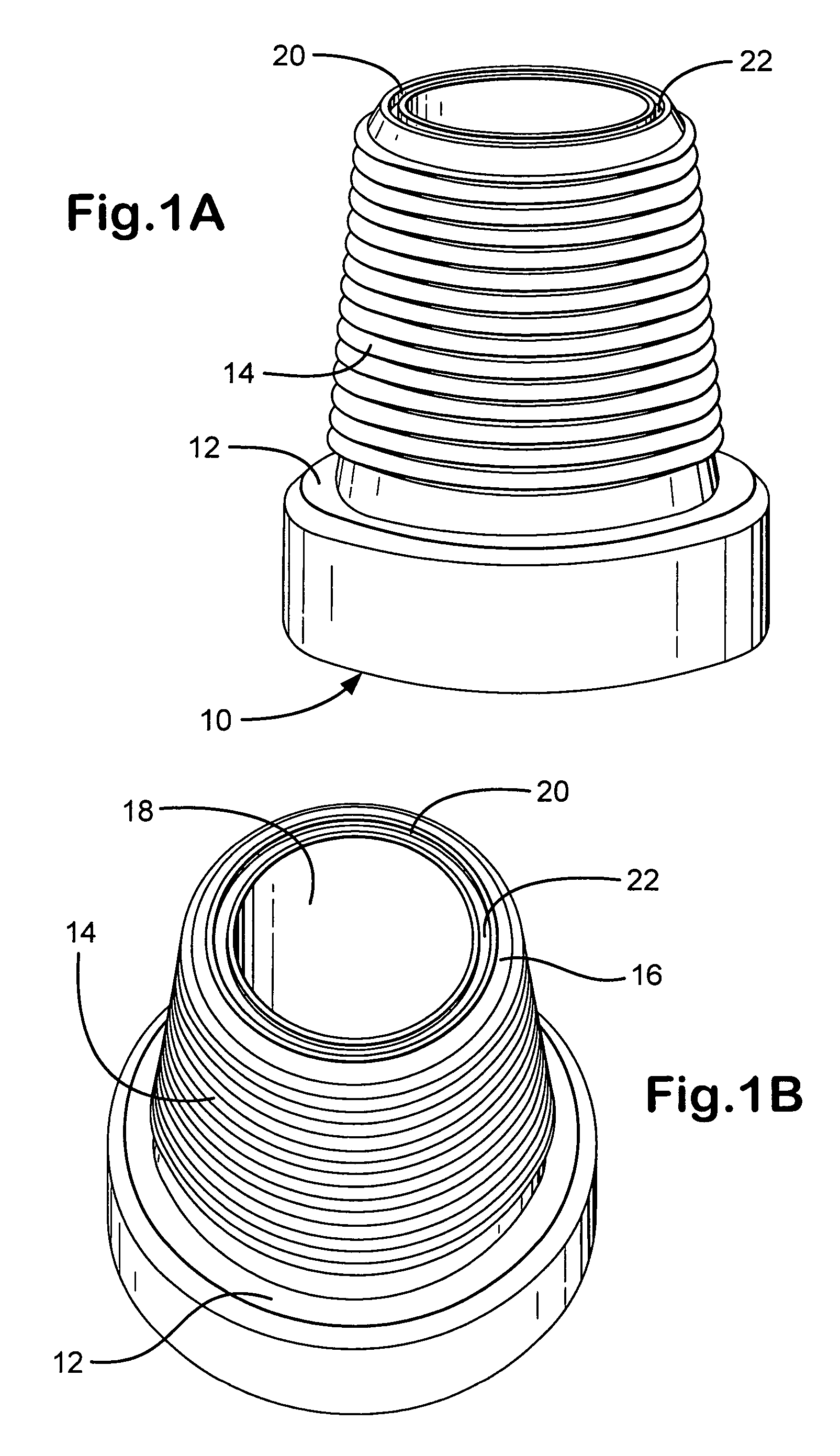

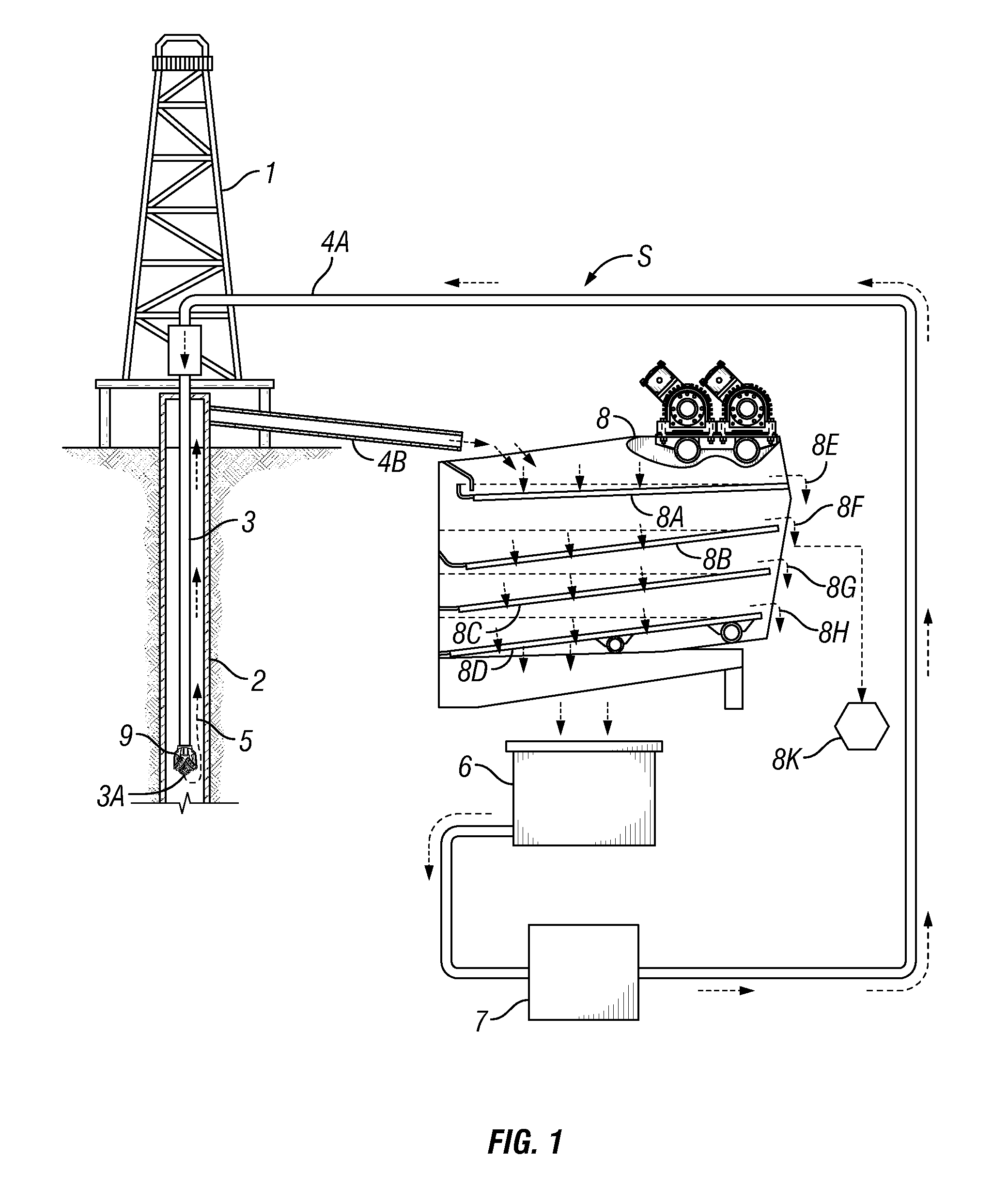

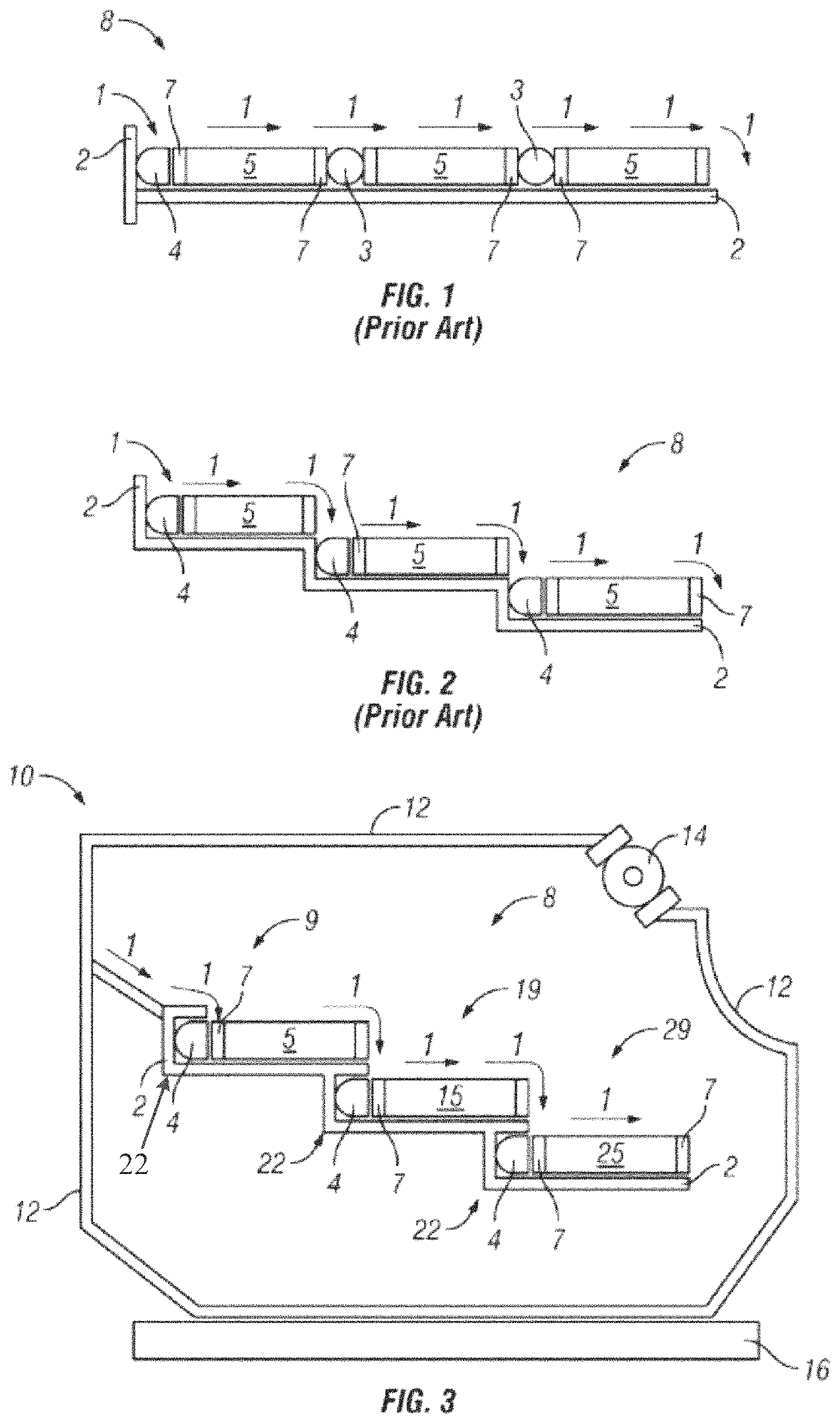

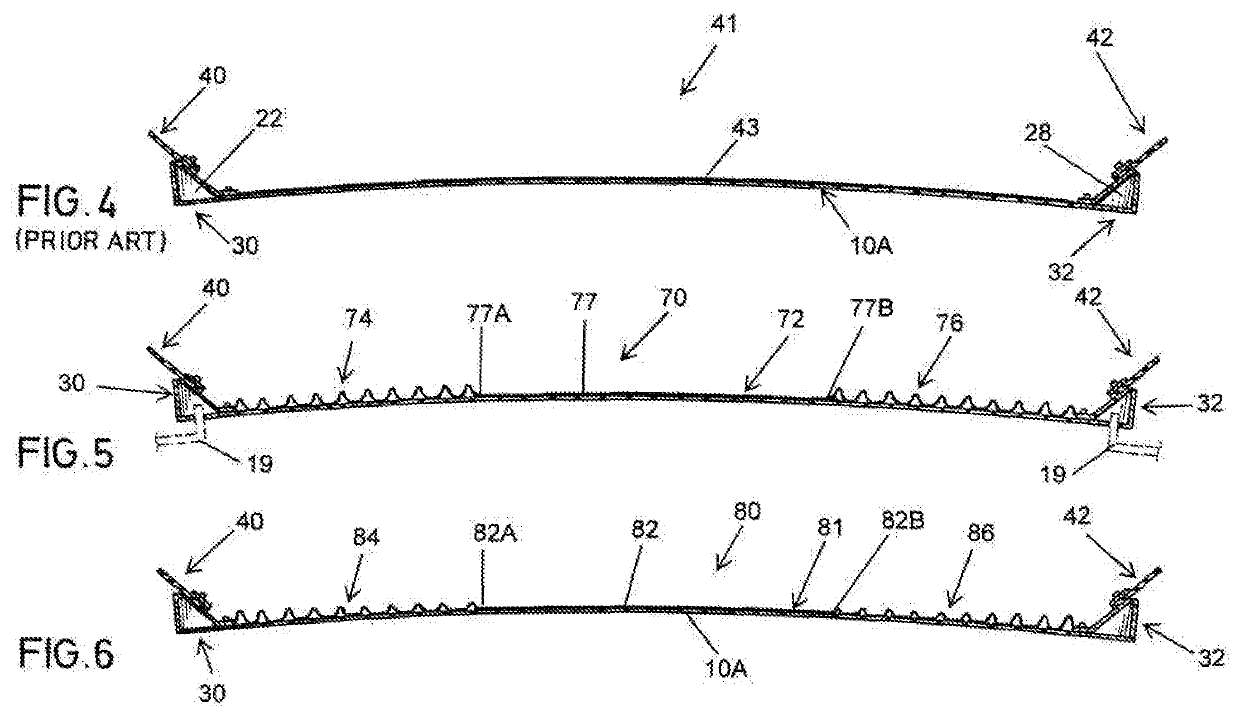

Shale shaker with stair-stepped arrangement of screens and methods of using same, and methods of retrofitting shale shakers

ActiveUS20160319616A1Reduce and eliminate solidReduce and eliminate exposureFlushingMoving filtering element filtersShale shakersEngineering

A shale shaker that includes a base, a basket, a vibrator interconnected with the basket, and two shaker screens releasably mounted on the basket, with the first shaker screen having a discharge end, with the second screen having a first end with a seal abutted thereto, with the second screen positioned such that the seal is positioned below the first shaker screen, and positioned so that discharge from the first screen will not discharge onto the seal.

Owner:ELGIN SEPARATION SOLUTIONS IND LLC

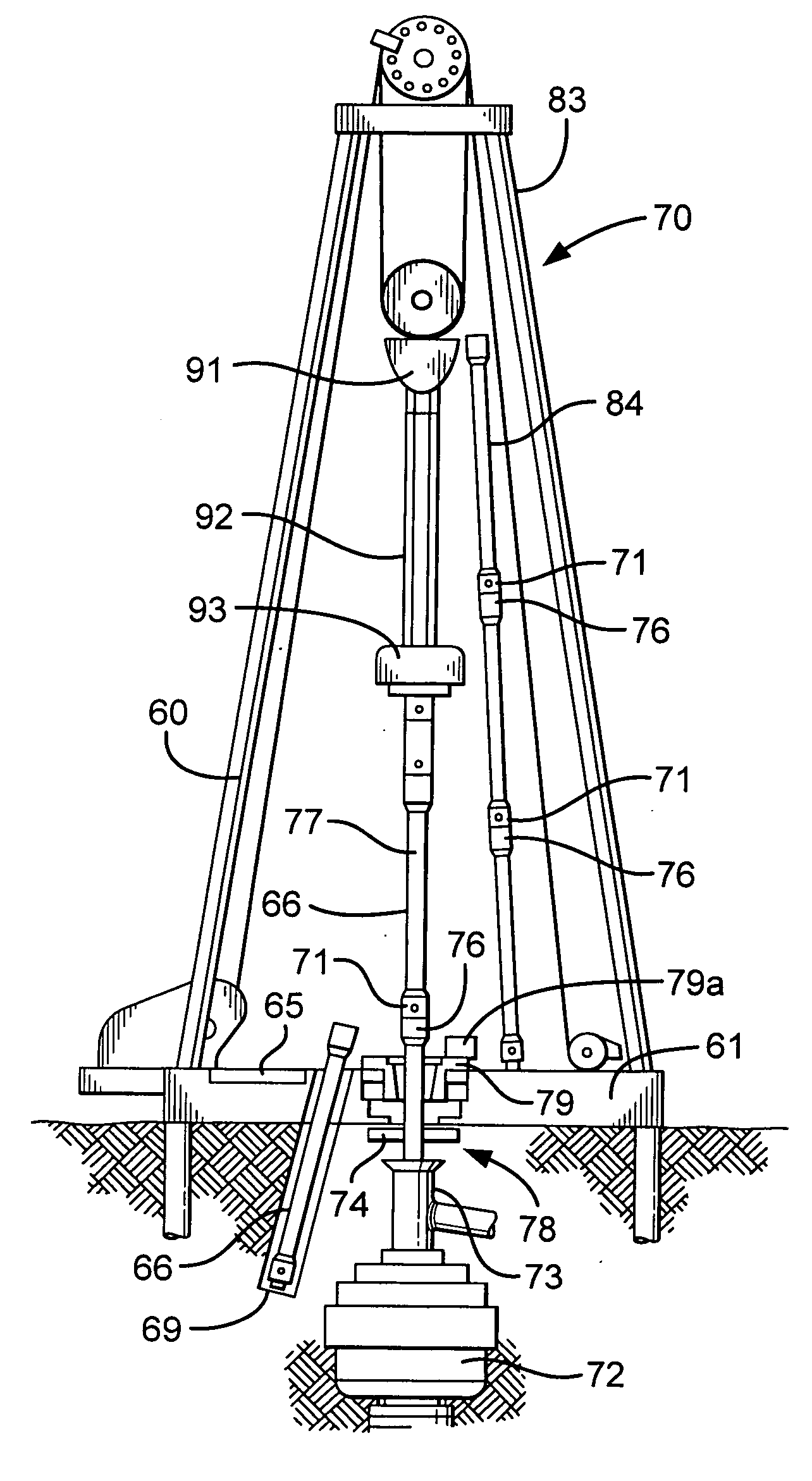

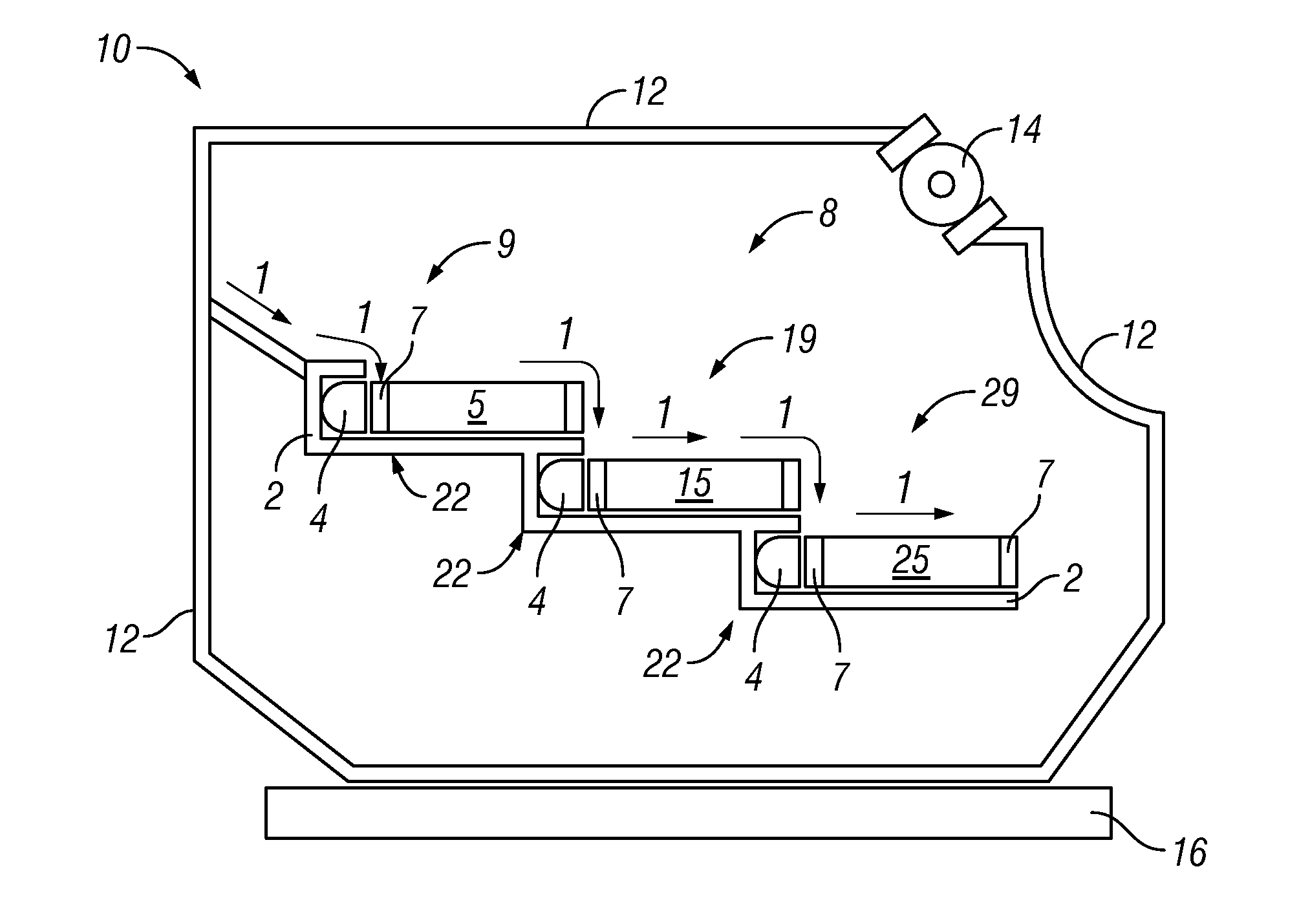

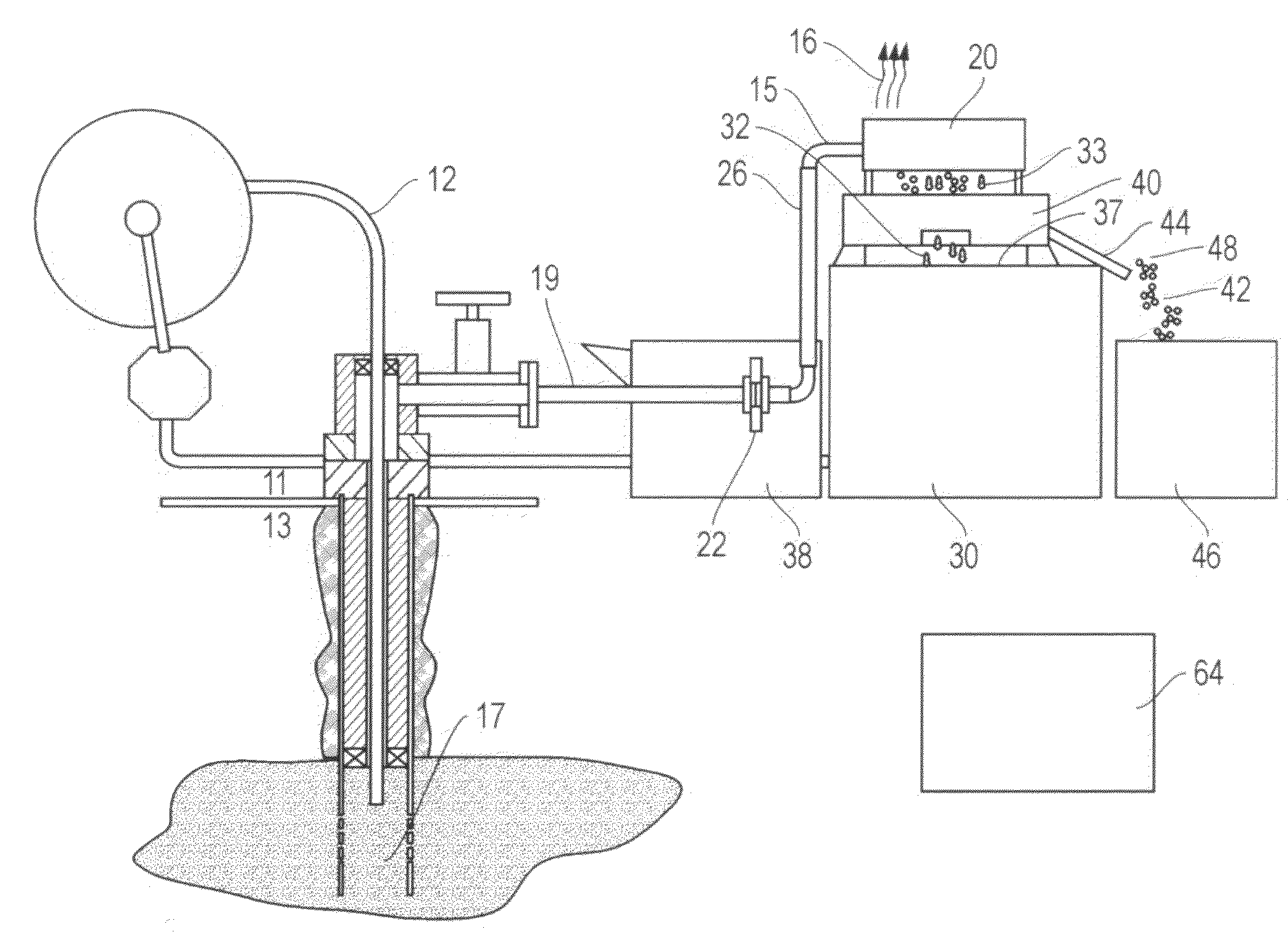

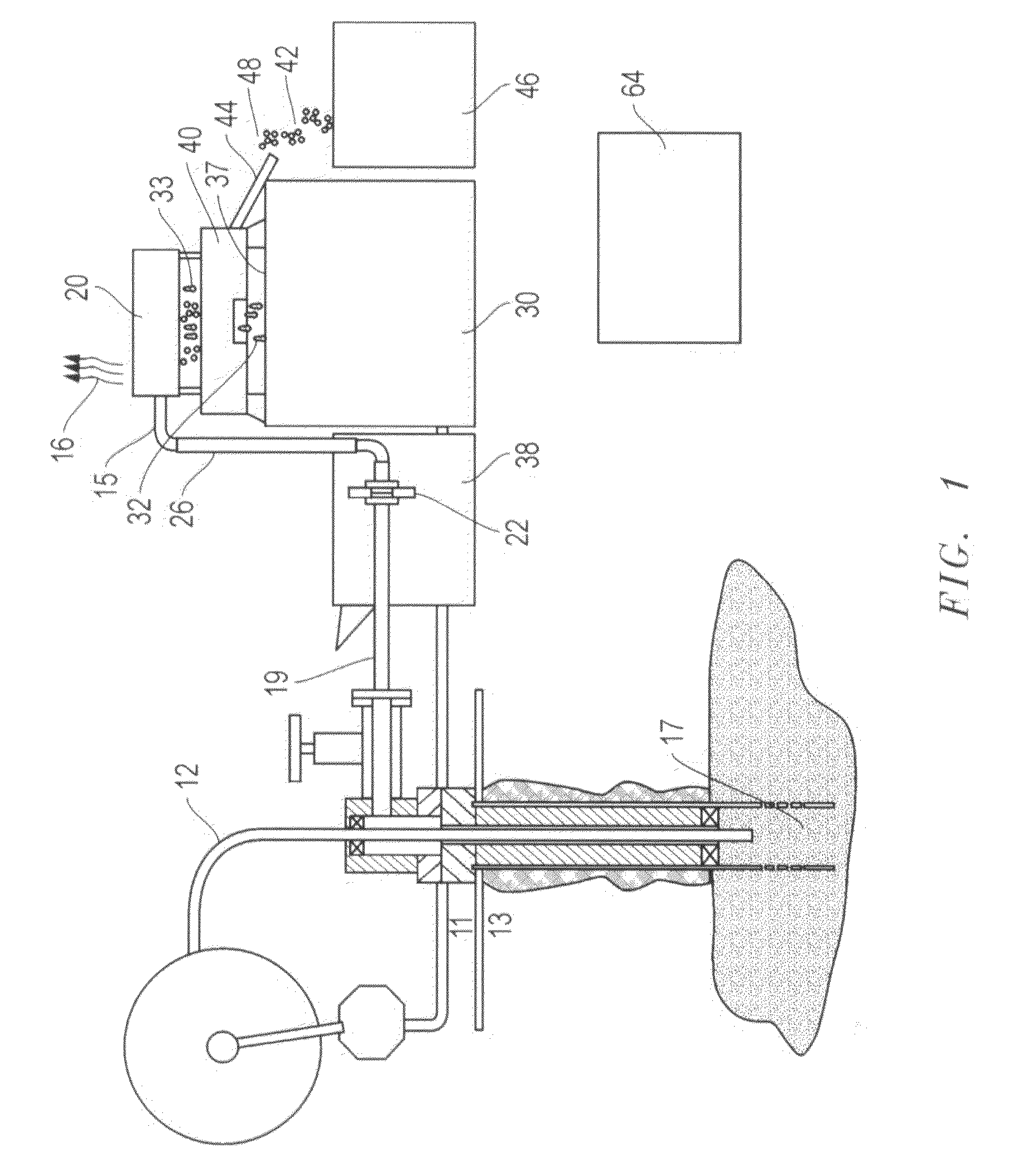

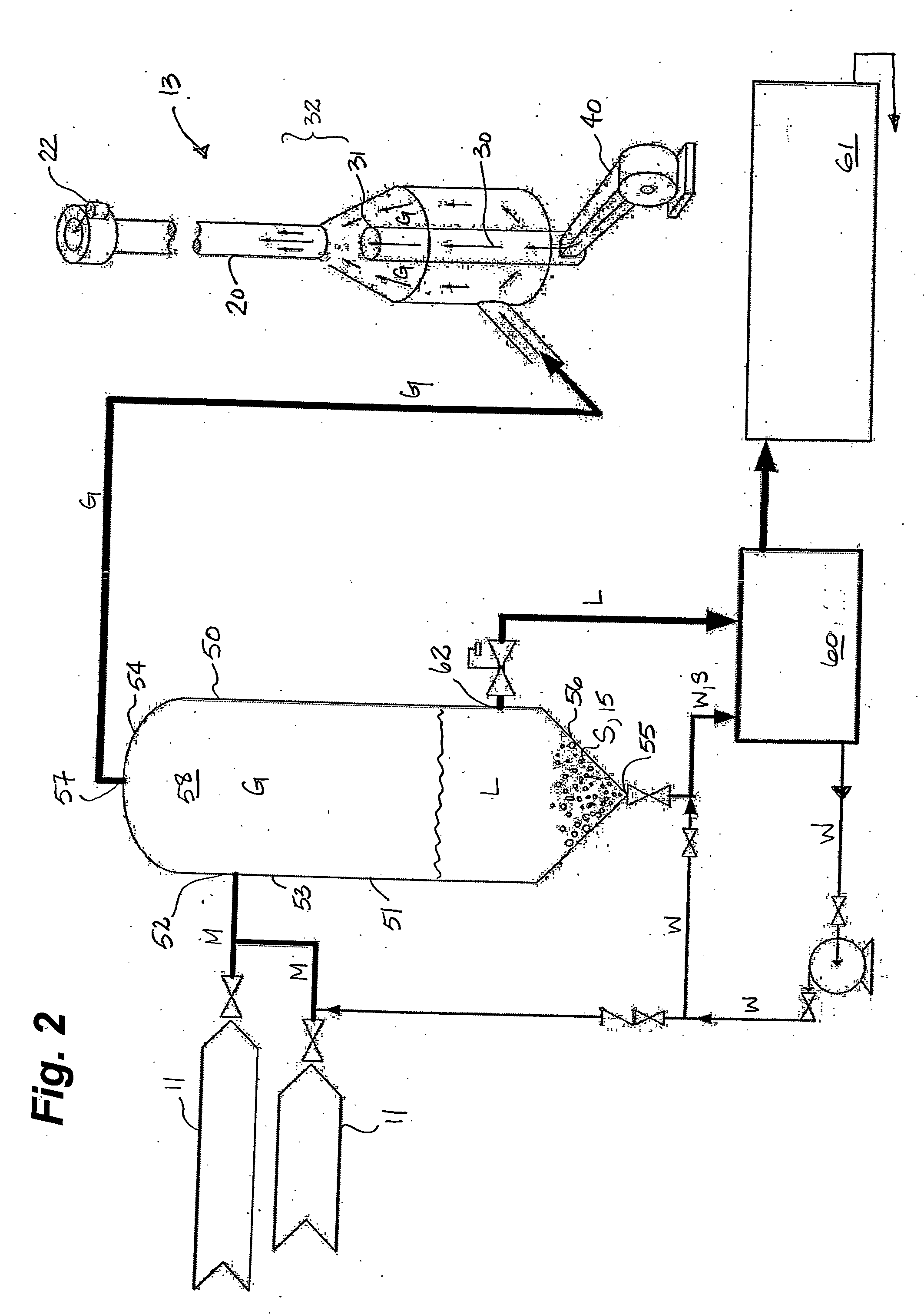

System and method for separating, monitoring and sampling coiled tubing flow back returns

InactiveUS20080236822A1Quickly and safely identifyMinimize hazardDrilling rodsFluid removalShale shakersCoiled tubing

The invention relates to a system and method for separating, and safely monitoring and sampling flow back fluid returns from coiled tubing operations in oil and natural gas wells. The system comprises a flow back tank; one or more gas diffusers; one or more shale shakers; and a chute, which diverts flow from the gas diffusers to a sampling site positioned near the perimeter of the flow back tank. The system also has a volume level indicator on or near the perimeter of the flow back tank. The method comprises piping fluid returns from a wellbore, separating the trapped gases from the fluid returns, directing the degassed fluids to a shale shaker to separate the solids and directing the separated solids and liquids into separate tanks for analysis and reconditioning, if necessary. Cleaned liquids may be recirculated back to the wellbore.

Owner:TETRA TECH INC

Methods and machines for making glued shale shaker screens

Methods for making screen assemblies and screens for a vibratory separator or shale shaker, such methods including applying glue in a glue pattern to at least one layer of screening material, said applying done by powered moving mechanical glue application apparatus; in one aspect moving with powered mechanical screen movement apparatus the at least one layer of screening material beneath the powered moving mechanical glue application apparatus; in one aspect, using hot melt moisture-curing glue, and in one aspect facilitating the cure of moisture-curing glue by applying moisture to it.

Owner:VARCO I P INC

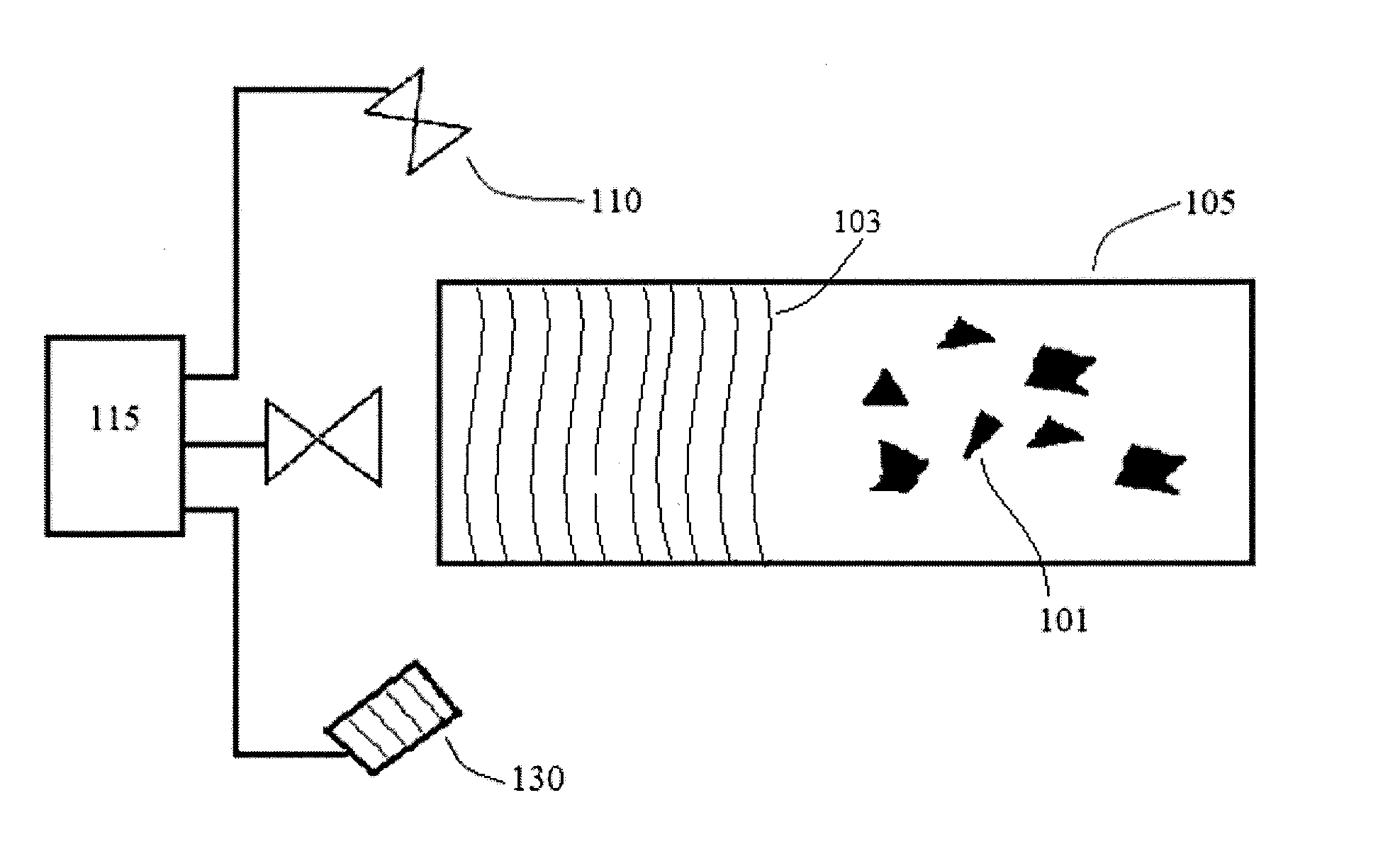

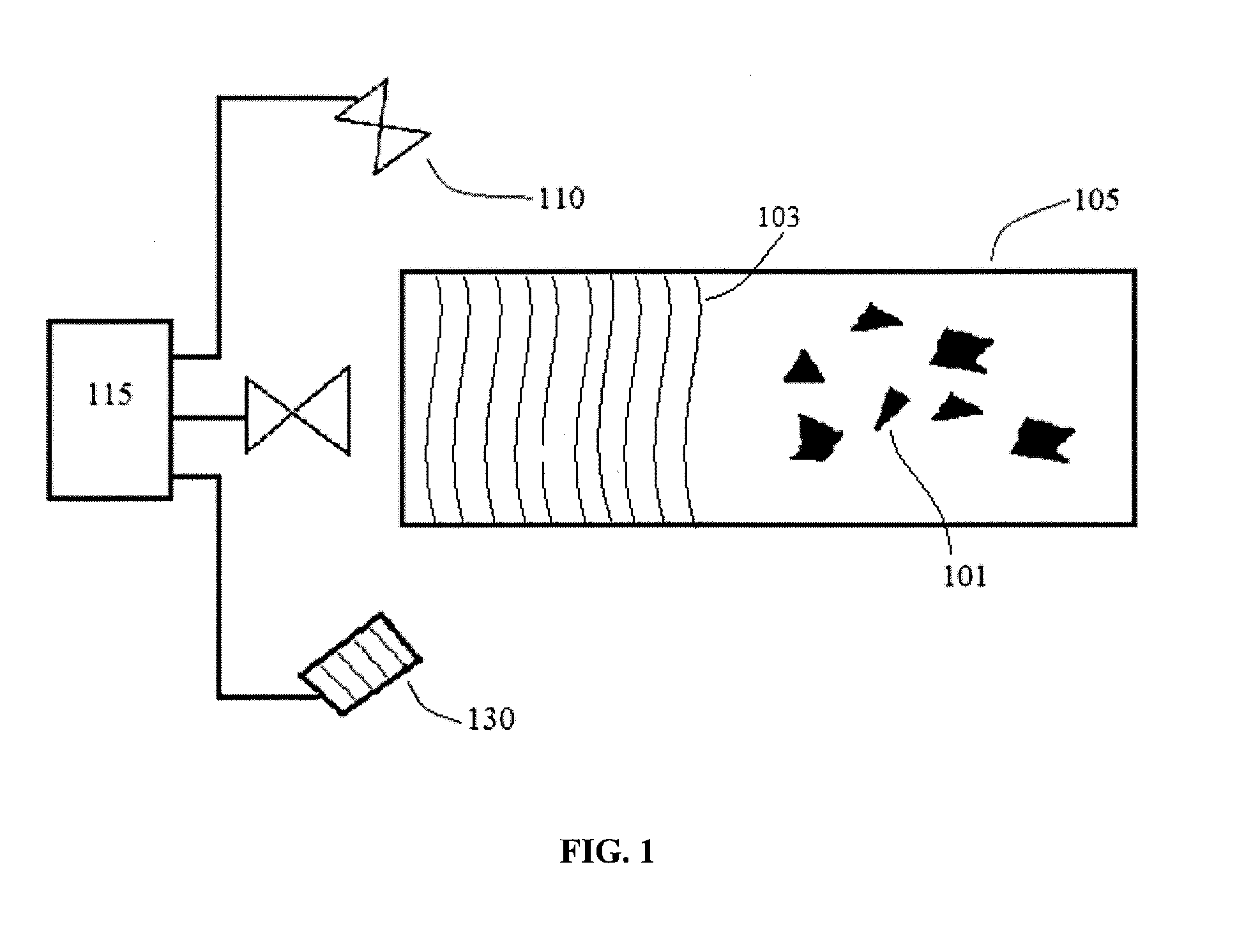

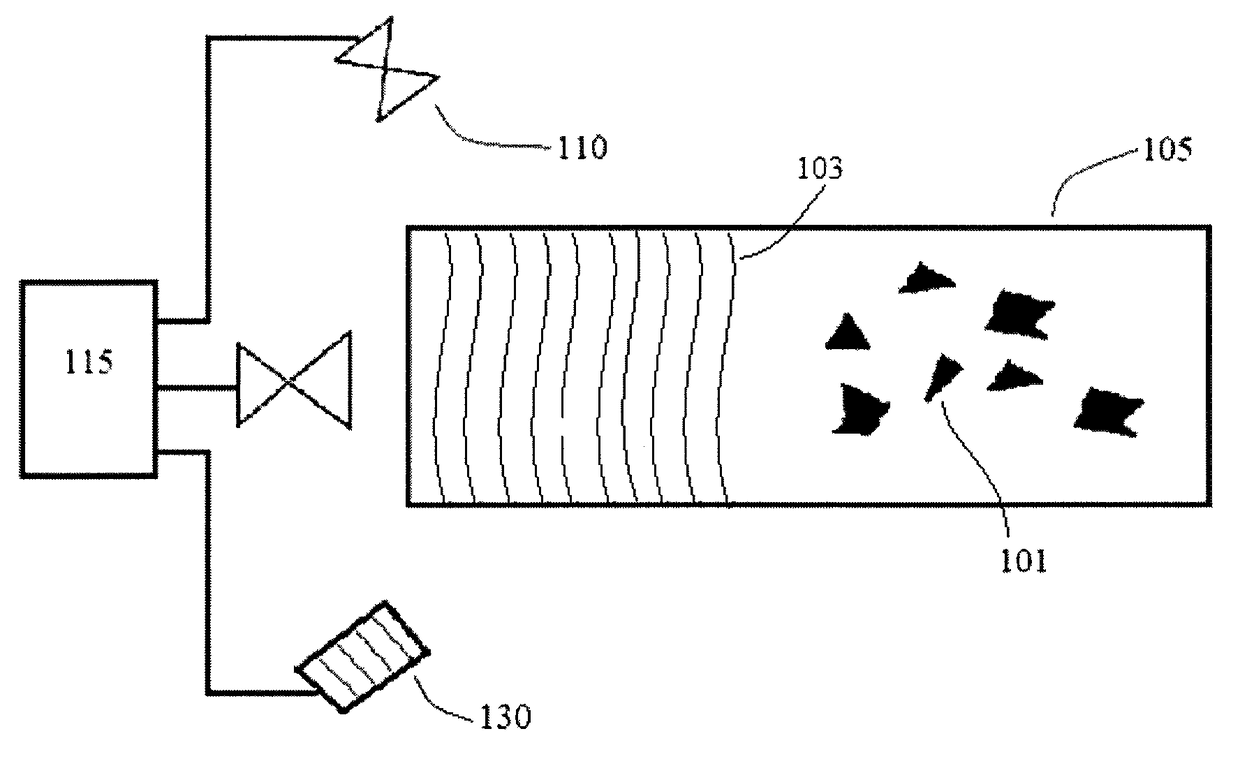

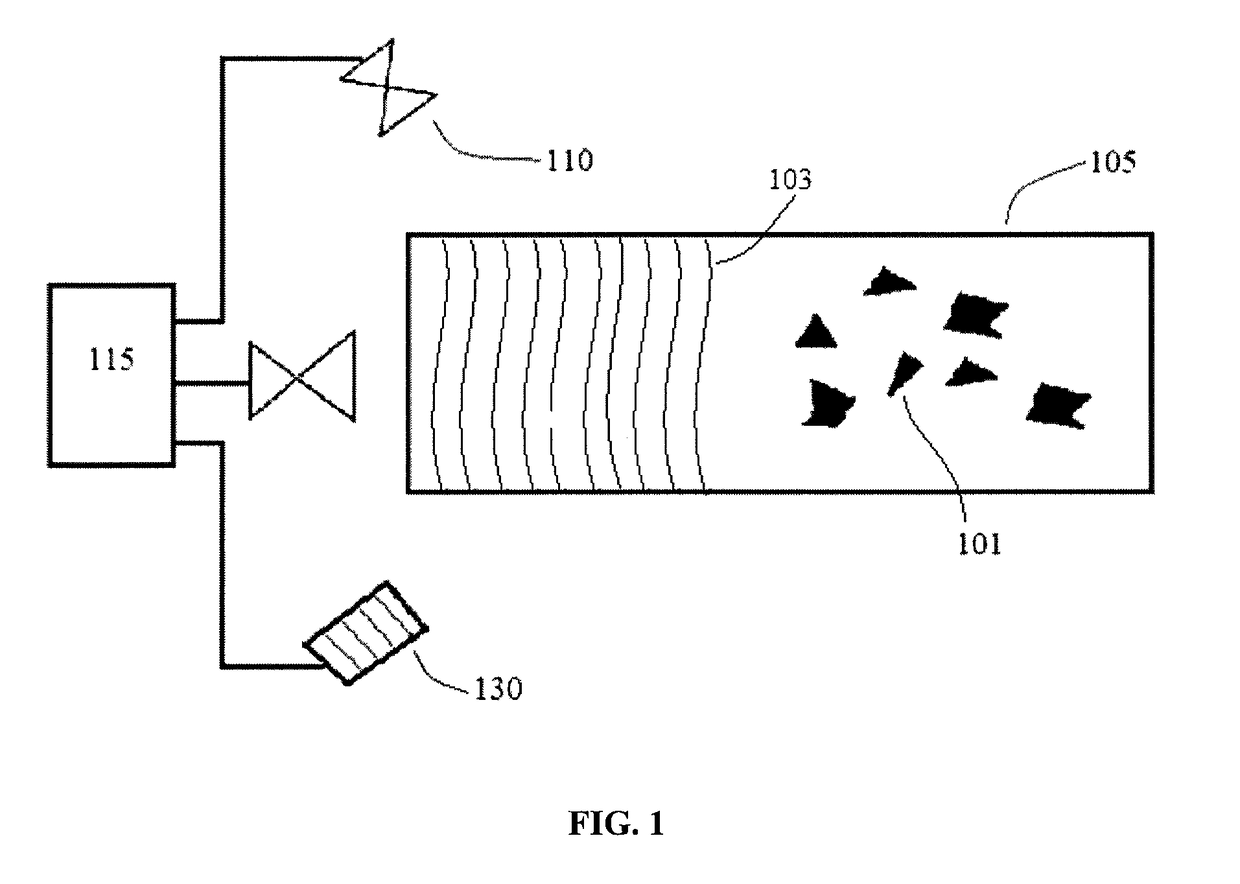

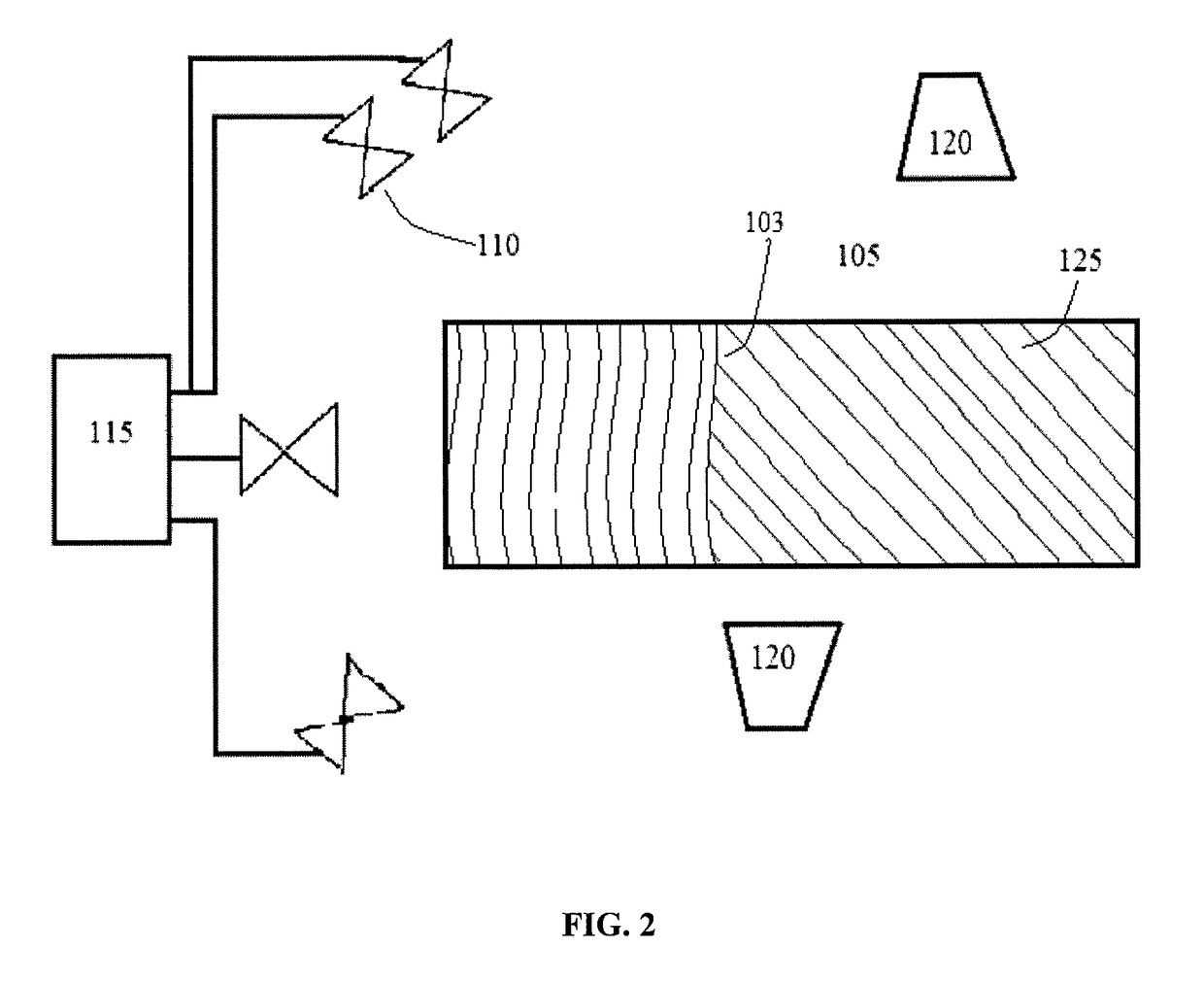

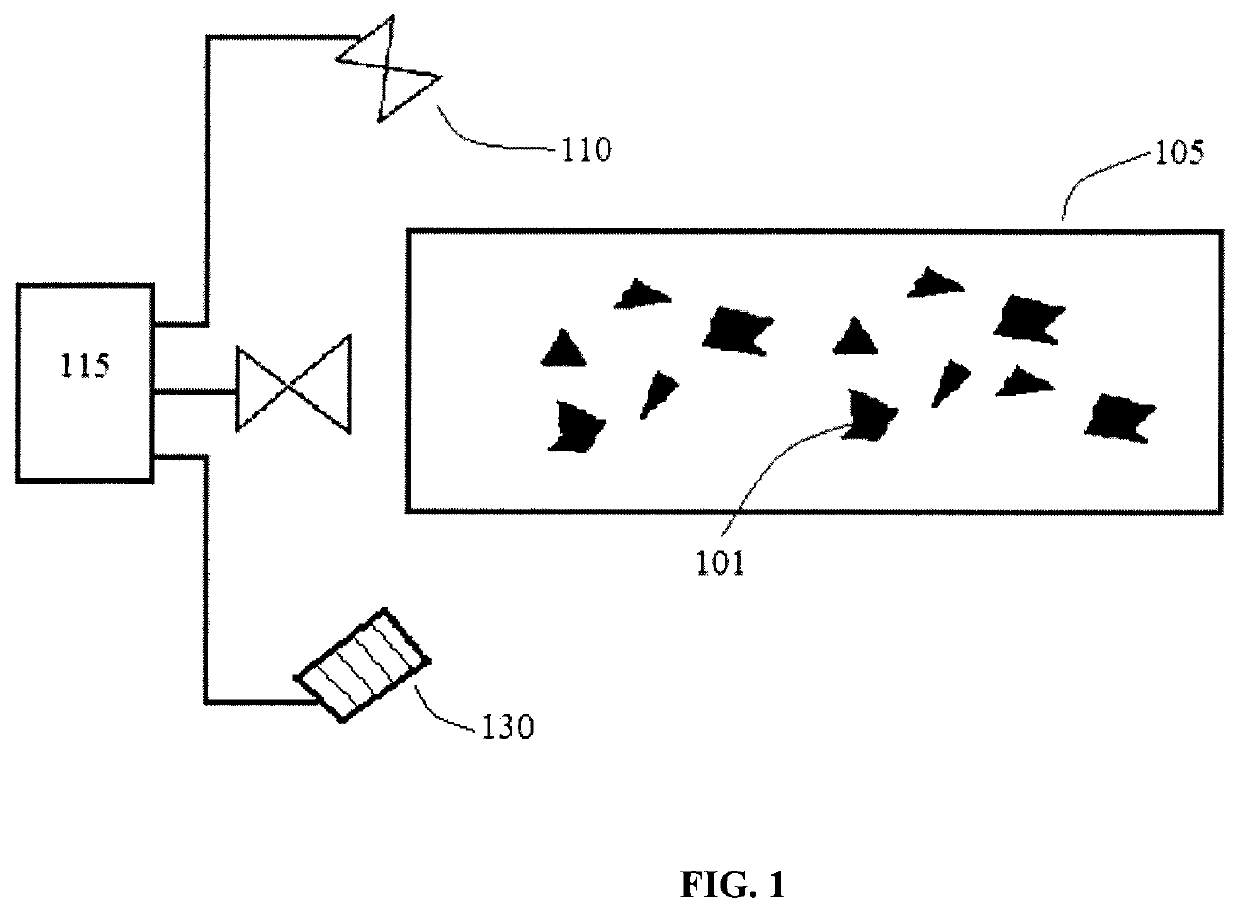

System and method for measuring fluid front position on shale shakers

ActiveUS20170056929A1Maximize efficiencyMaximize lifespanSievingTelevision system detailsShale shakersMachine vision

Owner:HELMERICH & PAYNE TECH LLC

Shale shaker with stair-stepped arrangements of screens and methods of using same, and methods of retrofitting shale shakers

ActiveUS10711545B2Reduce and eliminate solidReduce and eliminate exposureFlushingShale shakersClassical mechanics

A shale shaker that includes a base, a basket, a vibrator interconnected with the basket, and two shaker screens releasably mounted on the basket, with the first shaker screen having a discharge end, with the second screen having a first end with a seal abutted thereto, with the second screen positioned such that the seal is positioned below the first shaker screen, and positioned so that discharge from the first screen will not discharge onto the seal.

Owner:ELGIN SEPARATION SOLUTIONS IND LLC

System and method for measuring fluid front position on shale shakers

A system for monitoring the fluid front on a shaker table is disclosed. The system comprises a shaker table or shaker table screen configured to be adjusted based on information compiled by a processor and at least one camera configured to monitor said shaker table. The camera may be operably connected to a processor. The processor may be configured to perform detection and localization of the fluid front on the shaker table using machine vision techniques.

Owner:HELMERICH & PAYNE TECH LLC

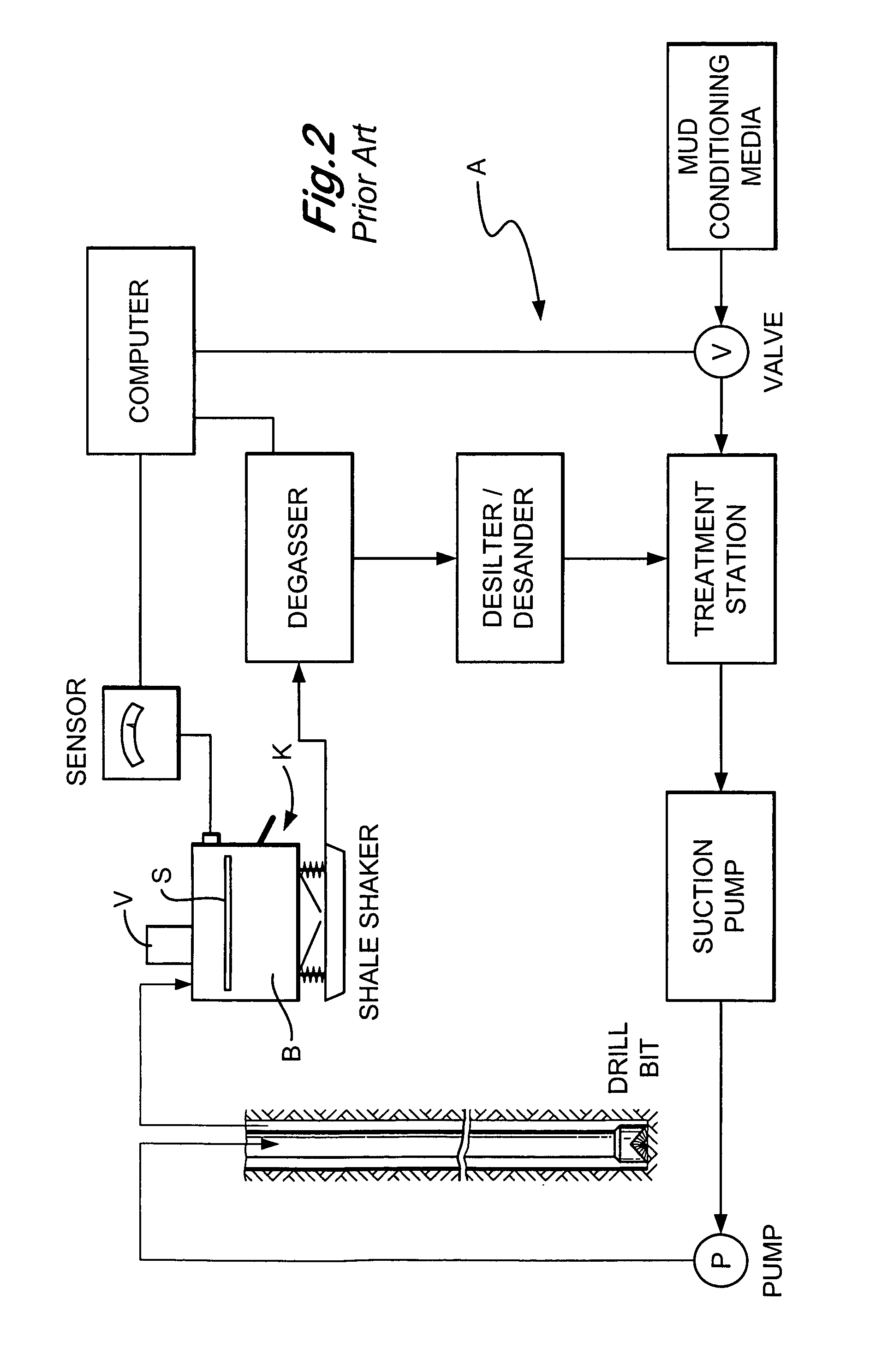

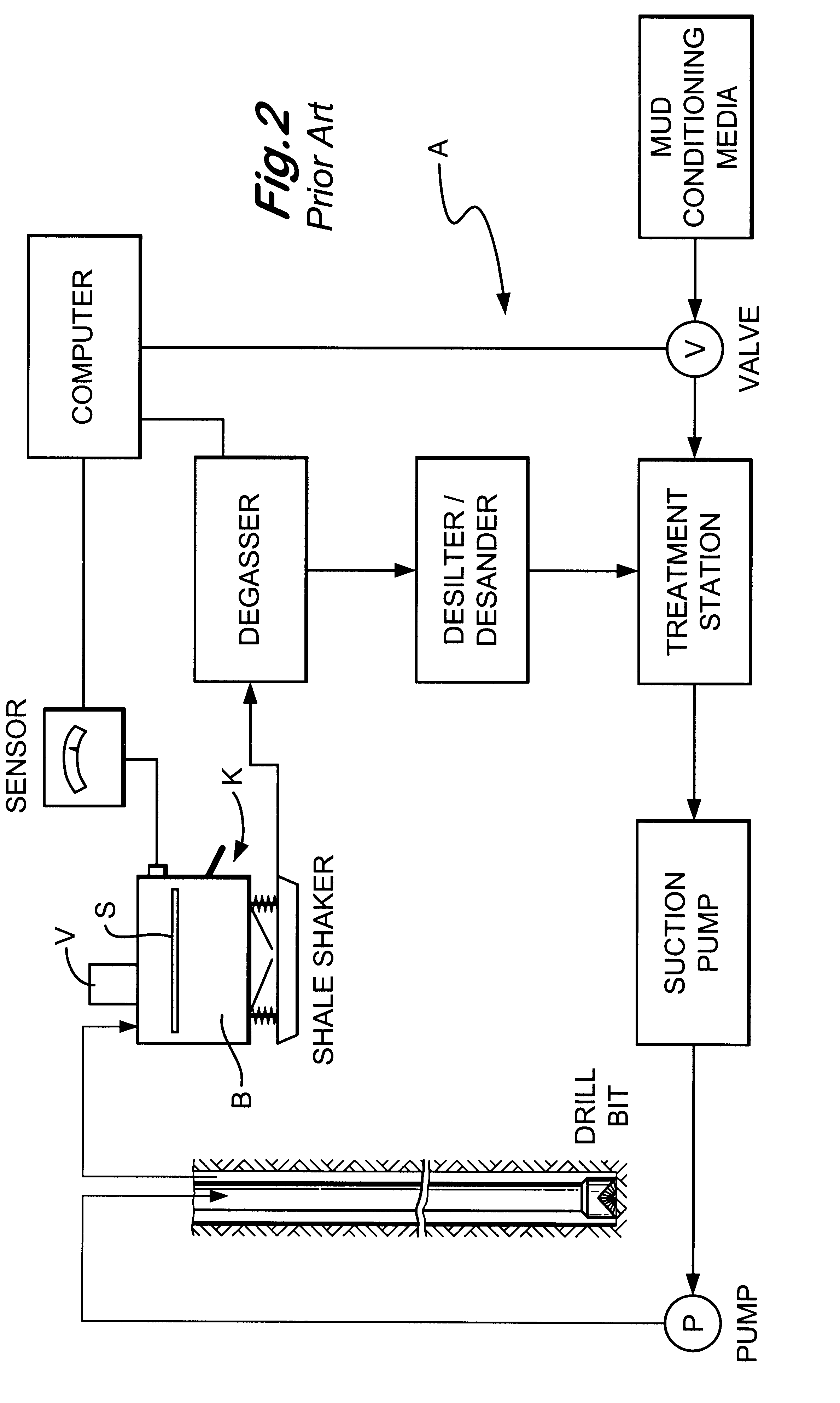

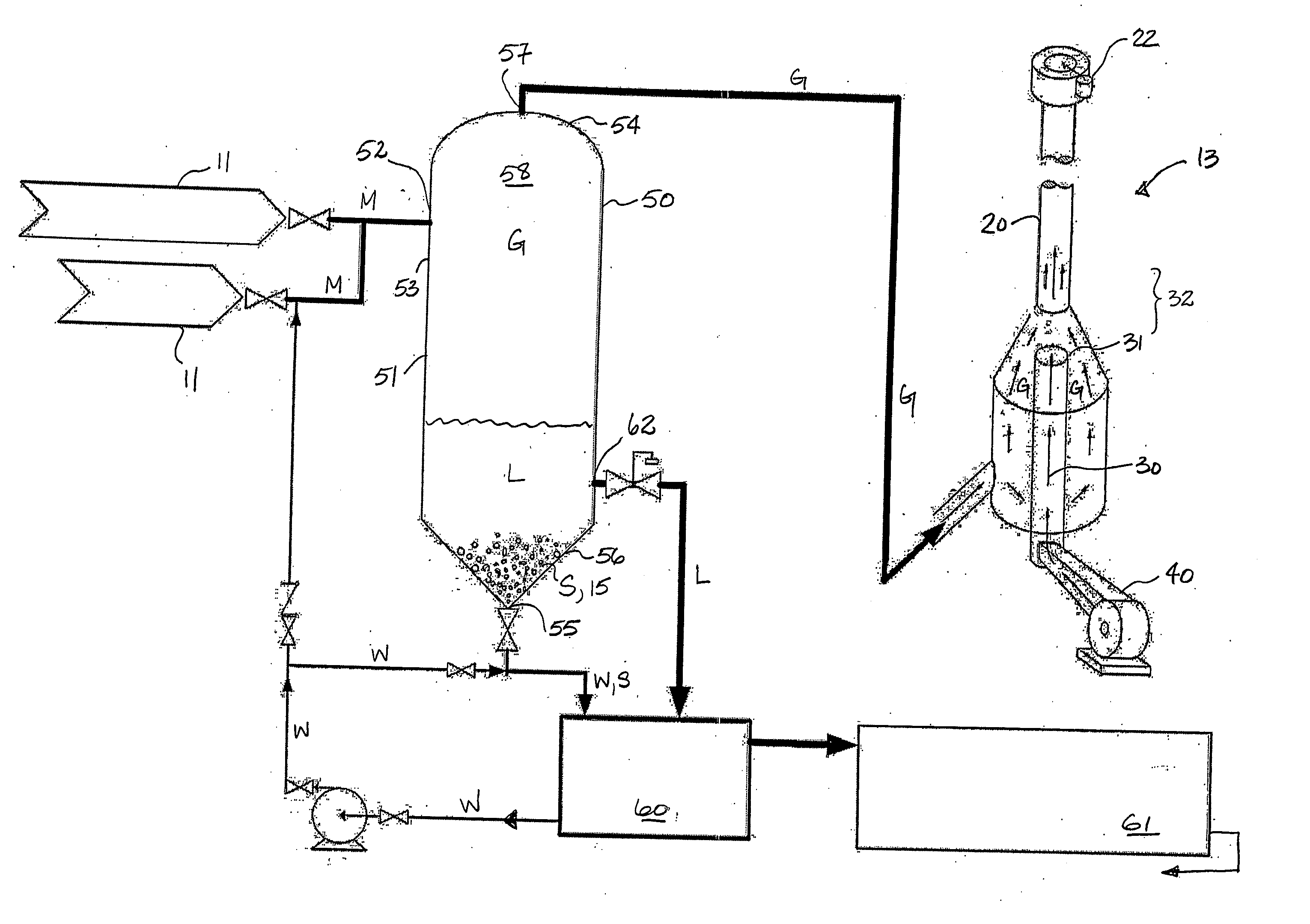

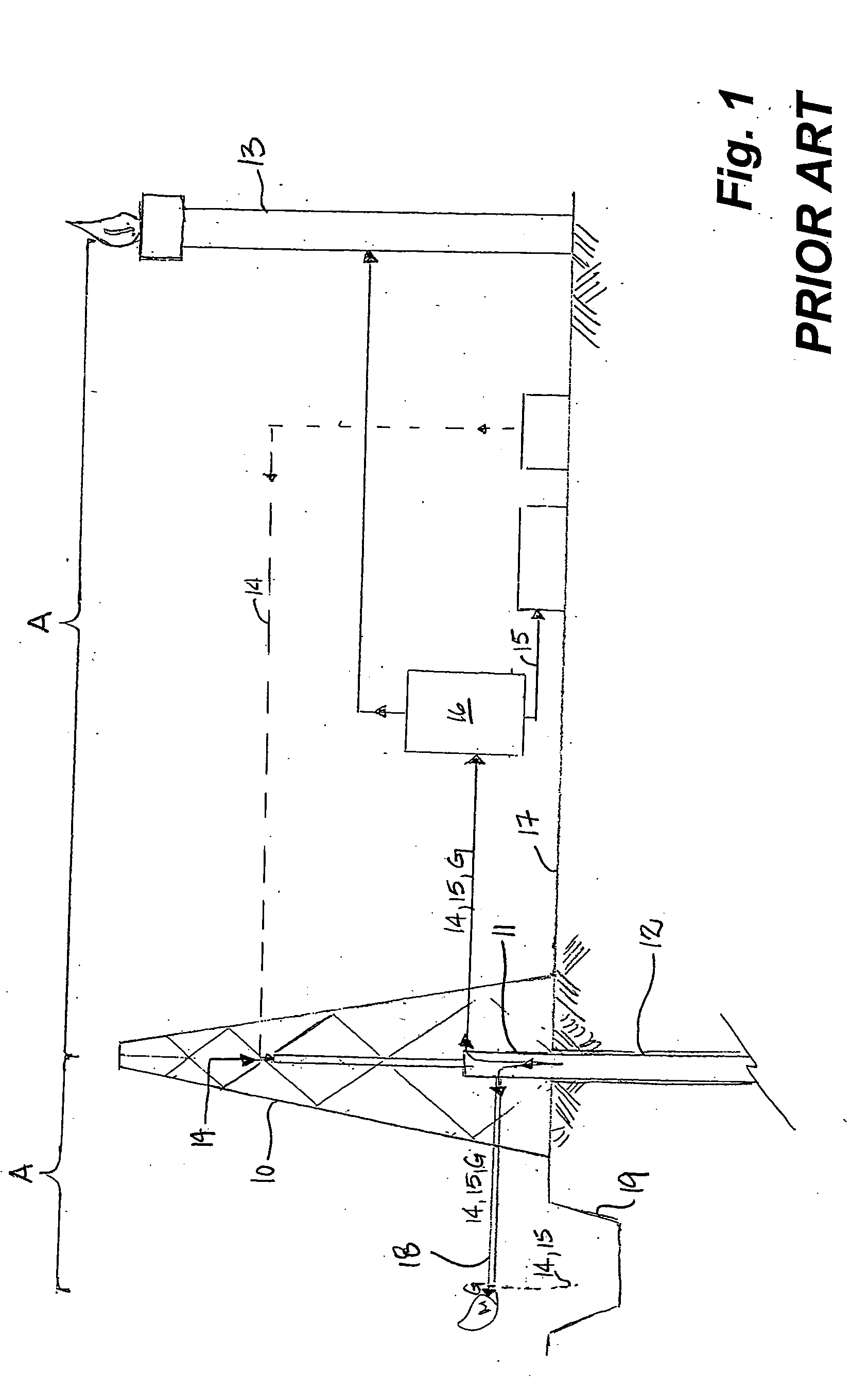

Separation of evolved gases from drilling fluids in a drilling operation

InactiveUS20050269137A1Minimizes drilling interruptionAvoid evolutionDrilling rodsConstructionsDegasserShale shakers

A fluid handling system for drilling cuttings utilizes a constant and gravity managed liquid level between a substantially atmospheric separator and a shale shaker to maximize fluid residence time within the separator and ensure substantially all of the gas entrained in the cuttings is evolved and passed to a flare thus preventing evolution of the gas at the shale shaker. Solids from the separator are combined with liquid recirculation from and returning to the shale shaker. Optionally, a vacuum degasser is positioned between the separator and the shale shaker and separated gases are passed from the degasser to the flare. This method and system is particularly applicable to balanced, underbalanced and air drilling operations where the flow of gas is intermittent and unpredictable.

Owner:SWARTOUT MATT

System and method for estimating cutting volumes on shale shakers

ActiveUS10954729B2Improve performanceImprove securitySurveyImage analysisShale shakersMachine vision

Owner:HELMERICH & PAYNE TECH LLC

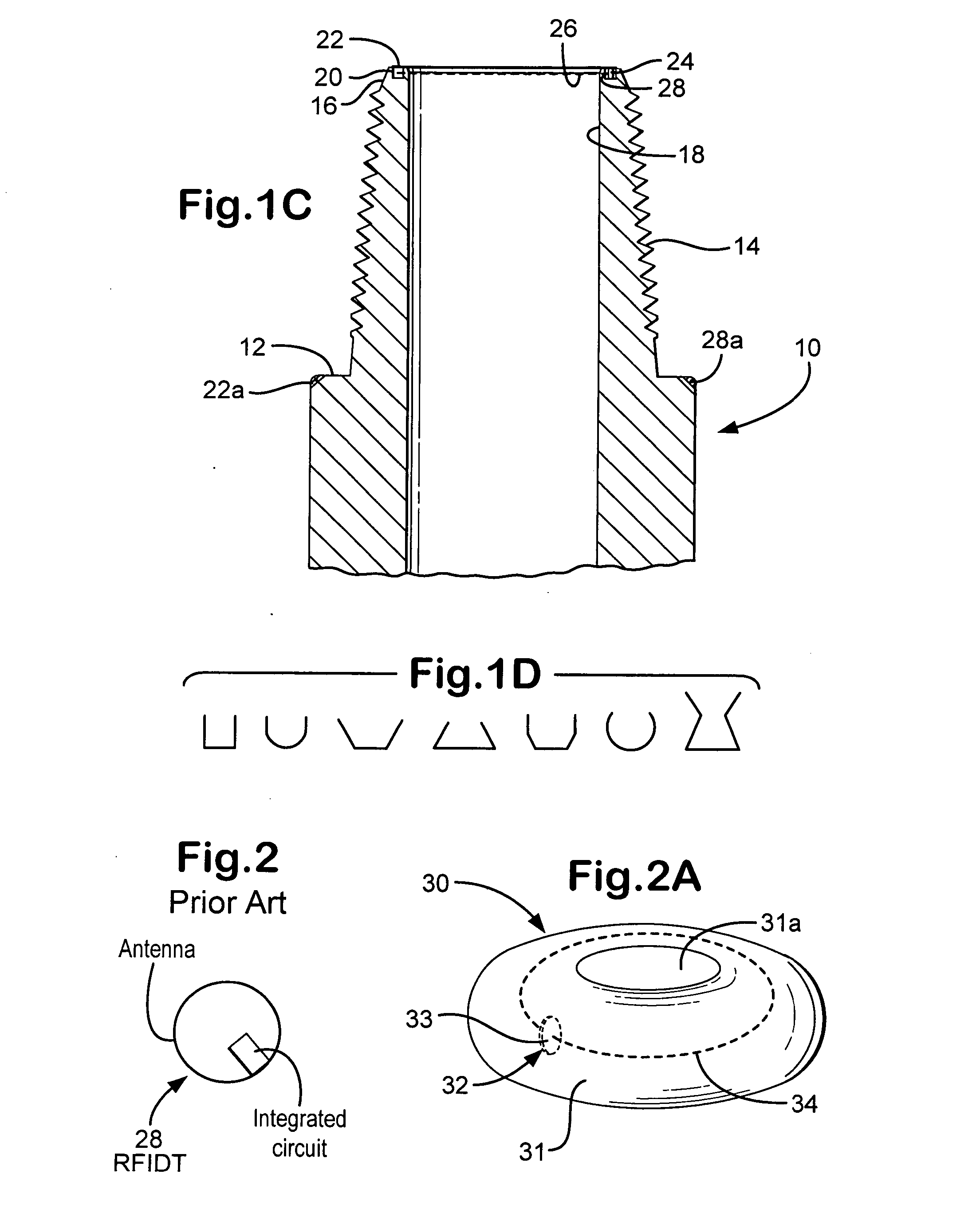

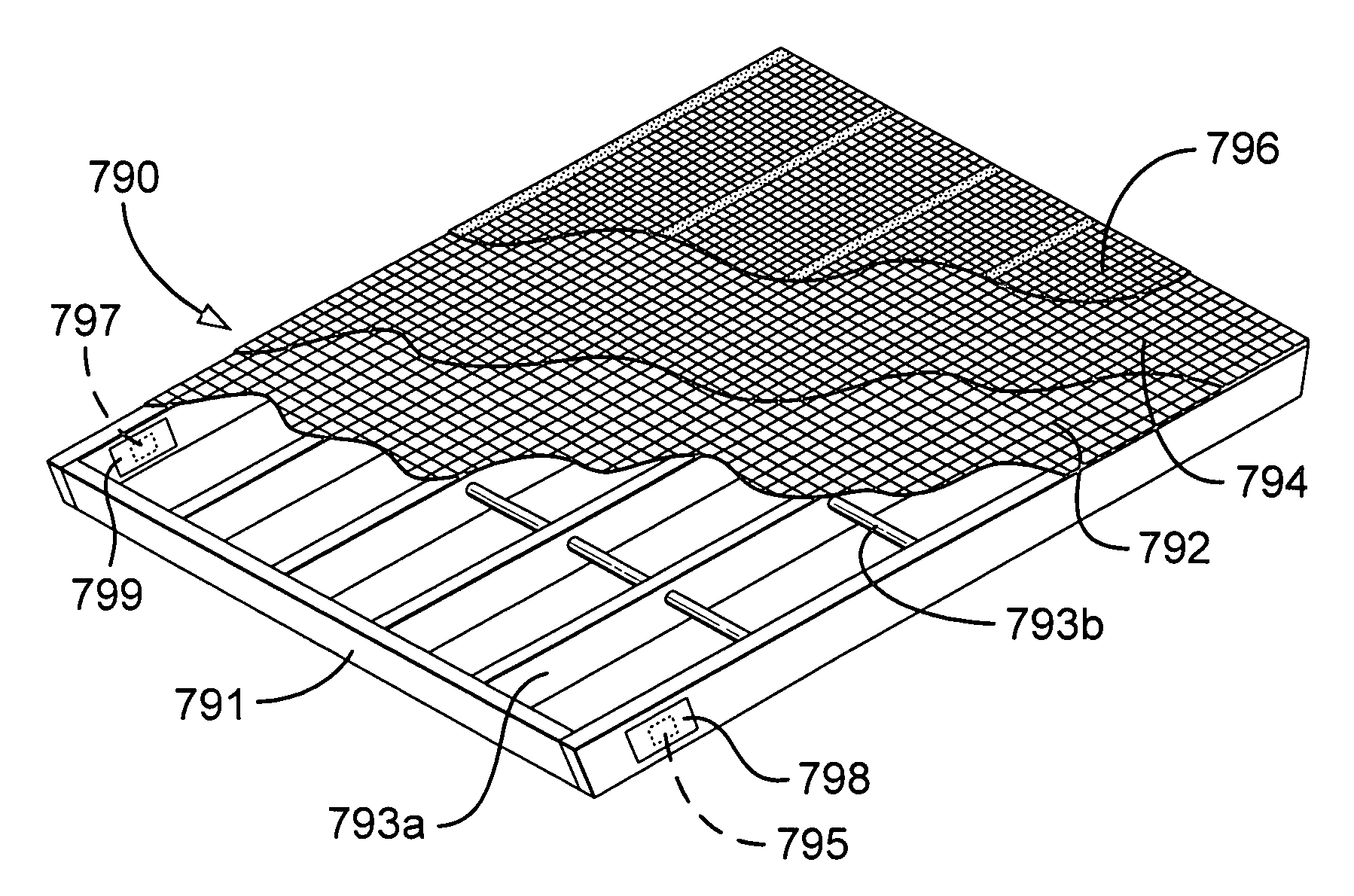

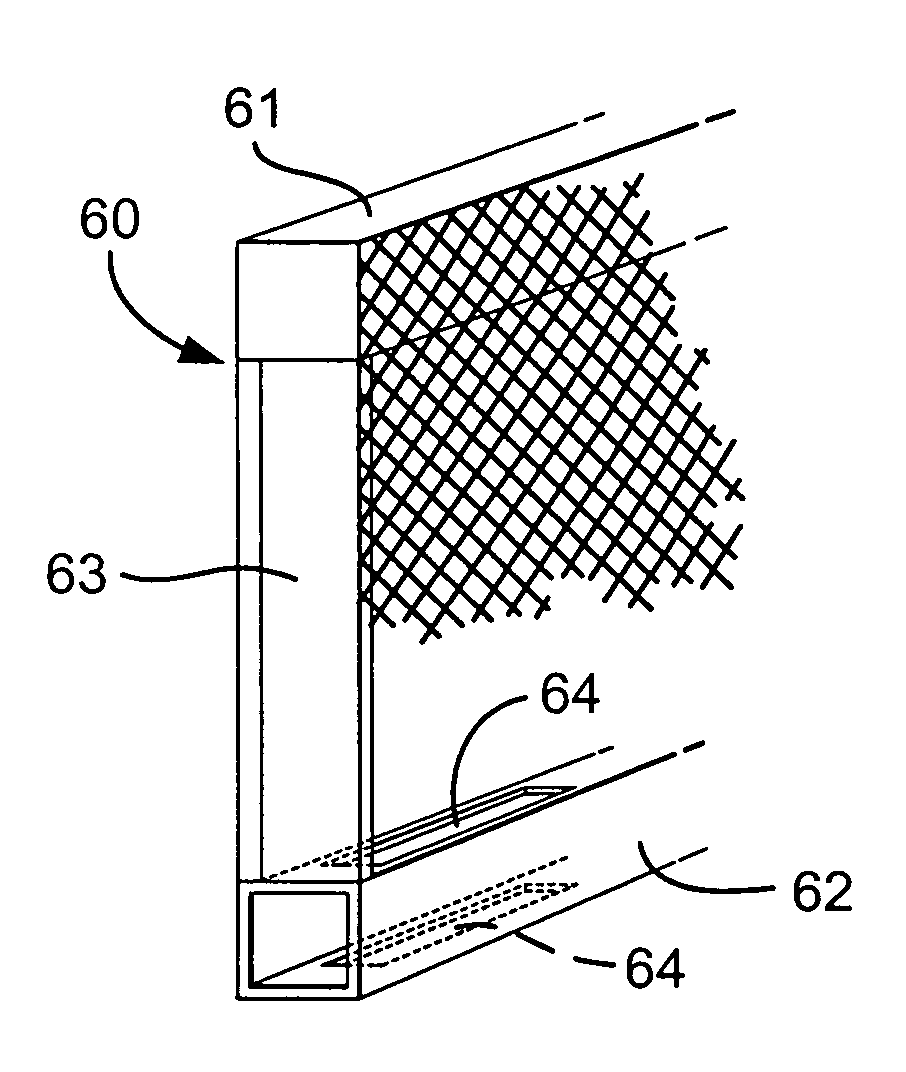

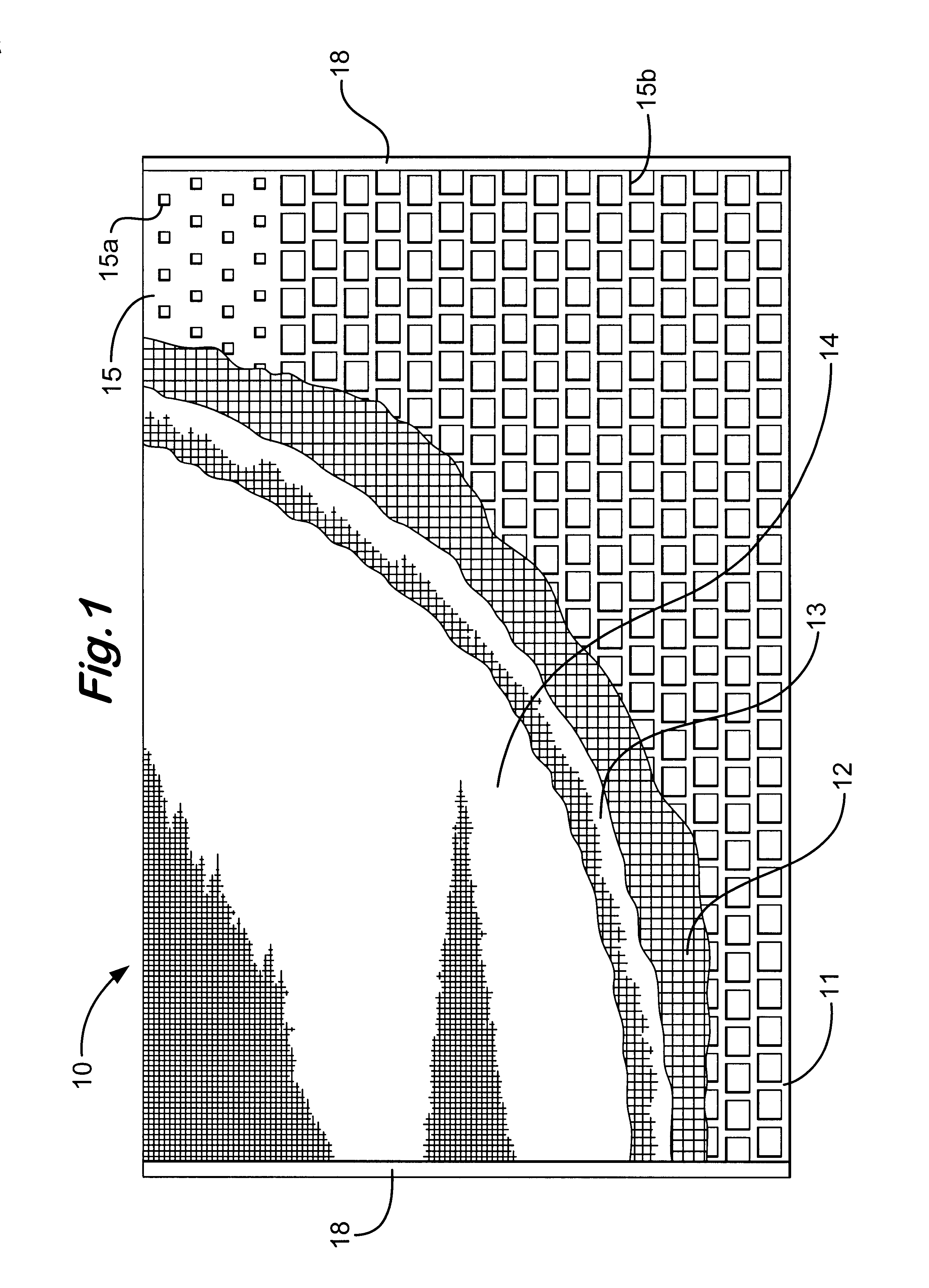

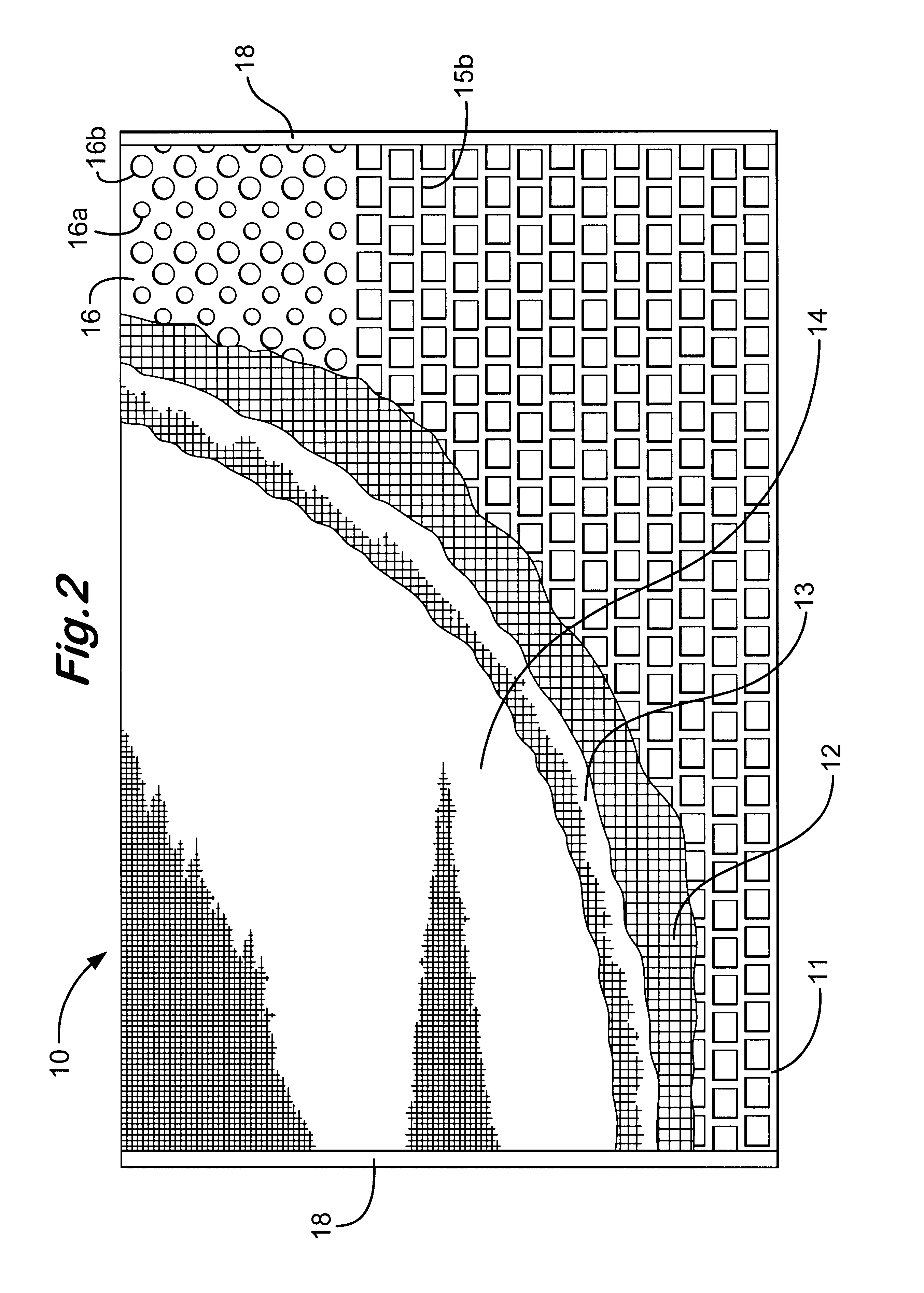

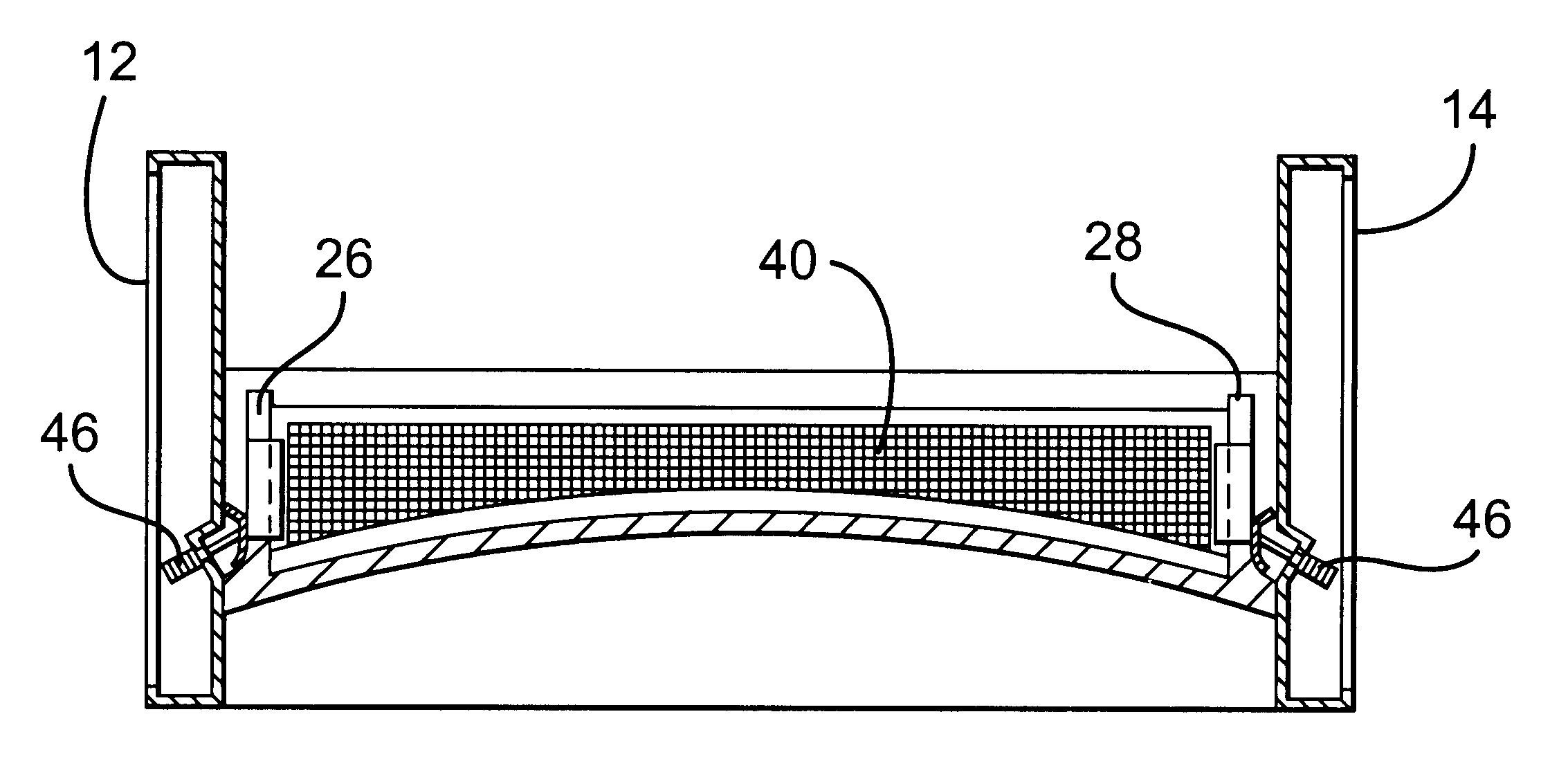

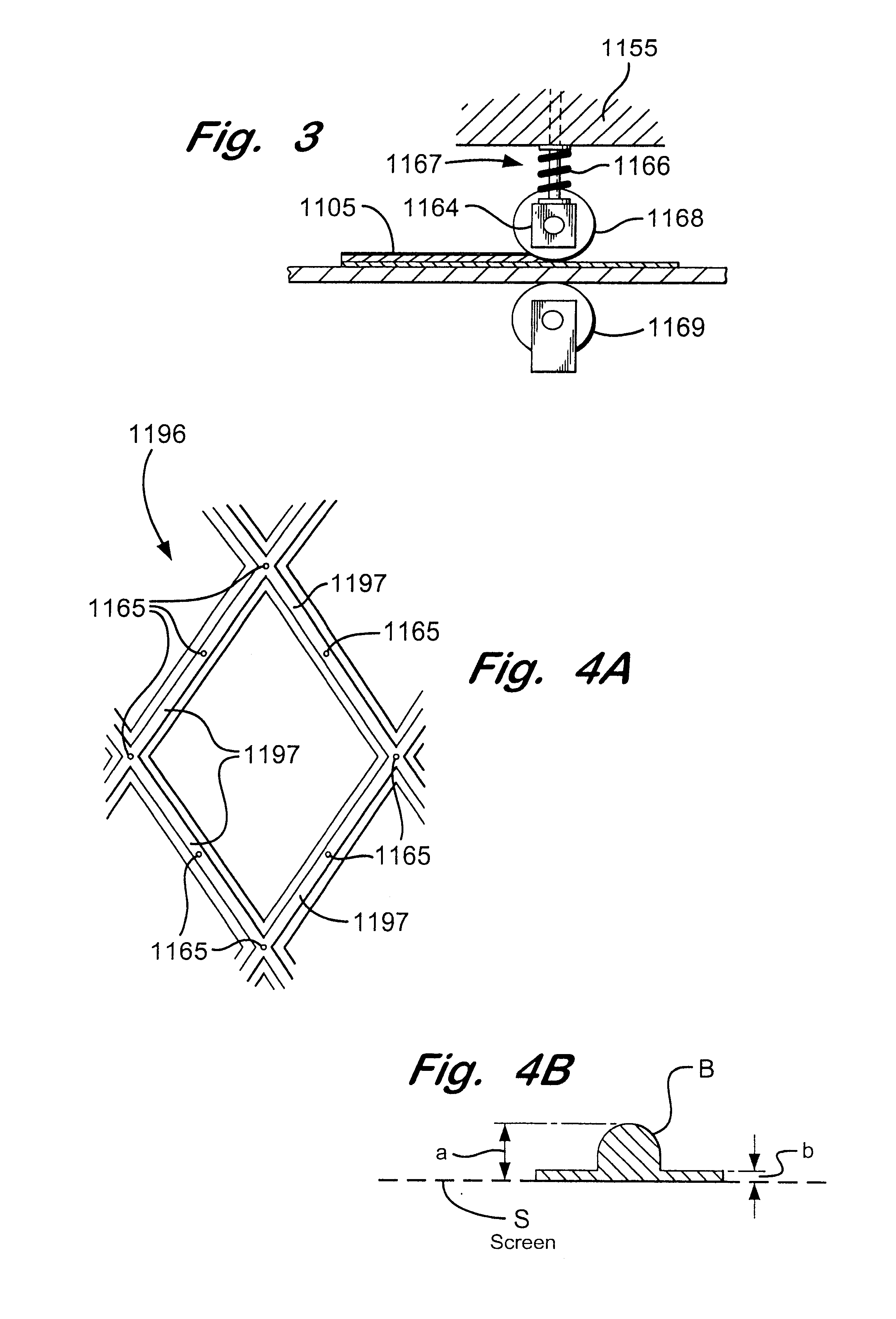

Screening Material and Screen Assembly

A screen assembly for use in vibratory separators, e.g., shale shakers. The screen assembly has a support with first and second sides, and support surfaces bounded by and connected to at least a portion of the first and second sides. Overlying and adhered to at least portions of the support surfaces is a screen which has alternating planar and undulating portions of screening material.

Owner:STROX SYST LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com