Shale shaker with stair-stepped arrangement of screens and methods of using same, and methods of retrofitting shale shakers

a technology of stair-stepped arrangement and shaker, which is applied in the direction of filtration separation, separation process, and well accessories, etc., can solve the problems of viscosity and gel problems, increased wear of mud pumps and other mechanical equipment used for drilling, and loss of circulation materials of drilling mud

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

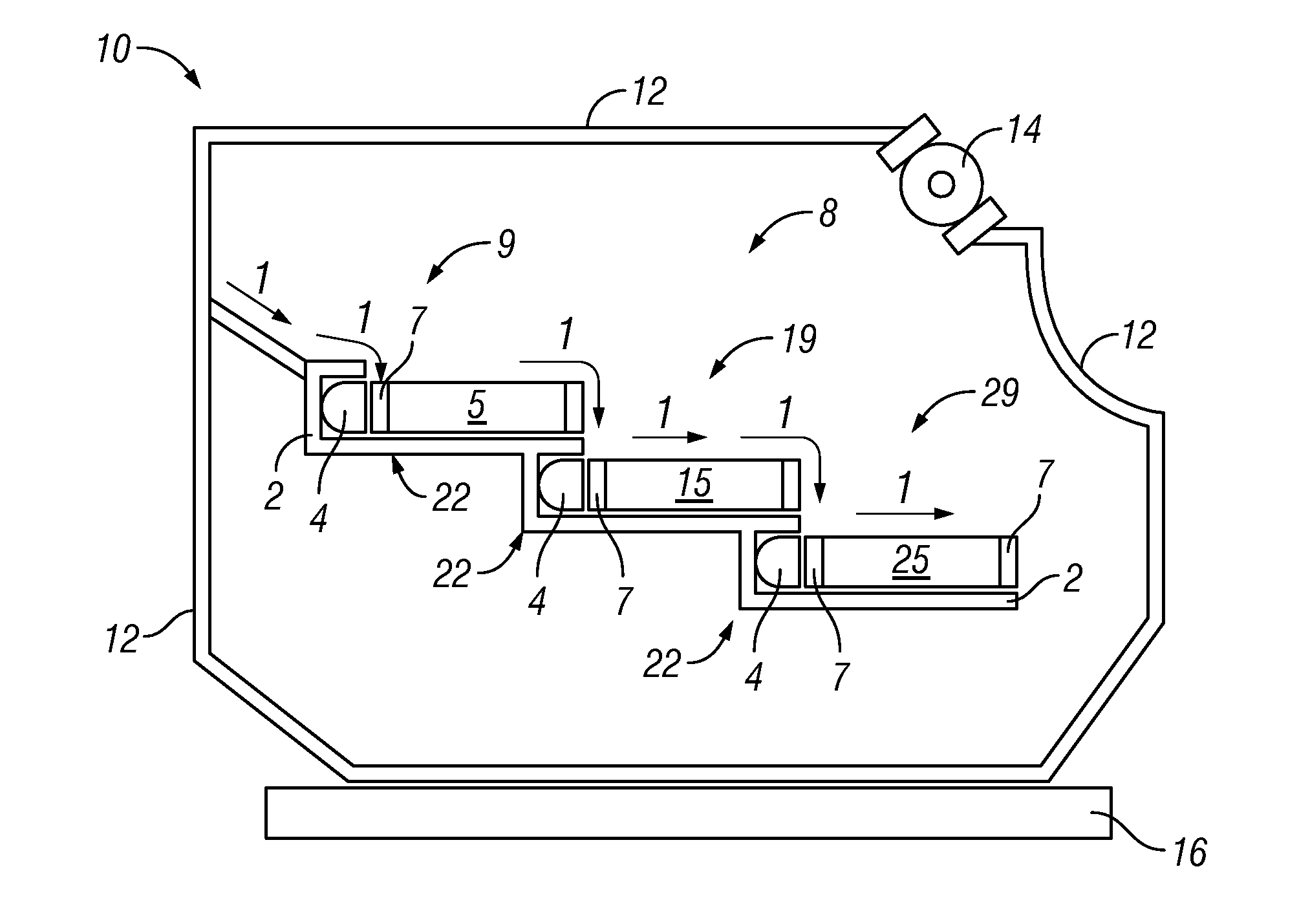

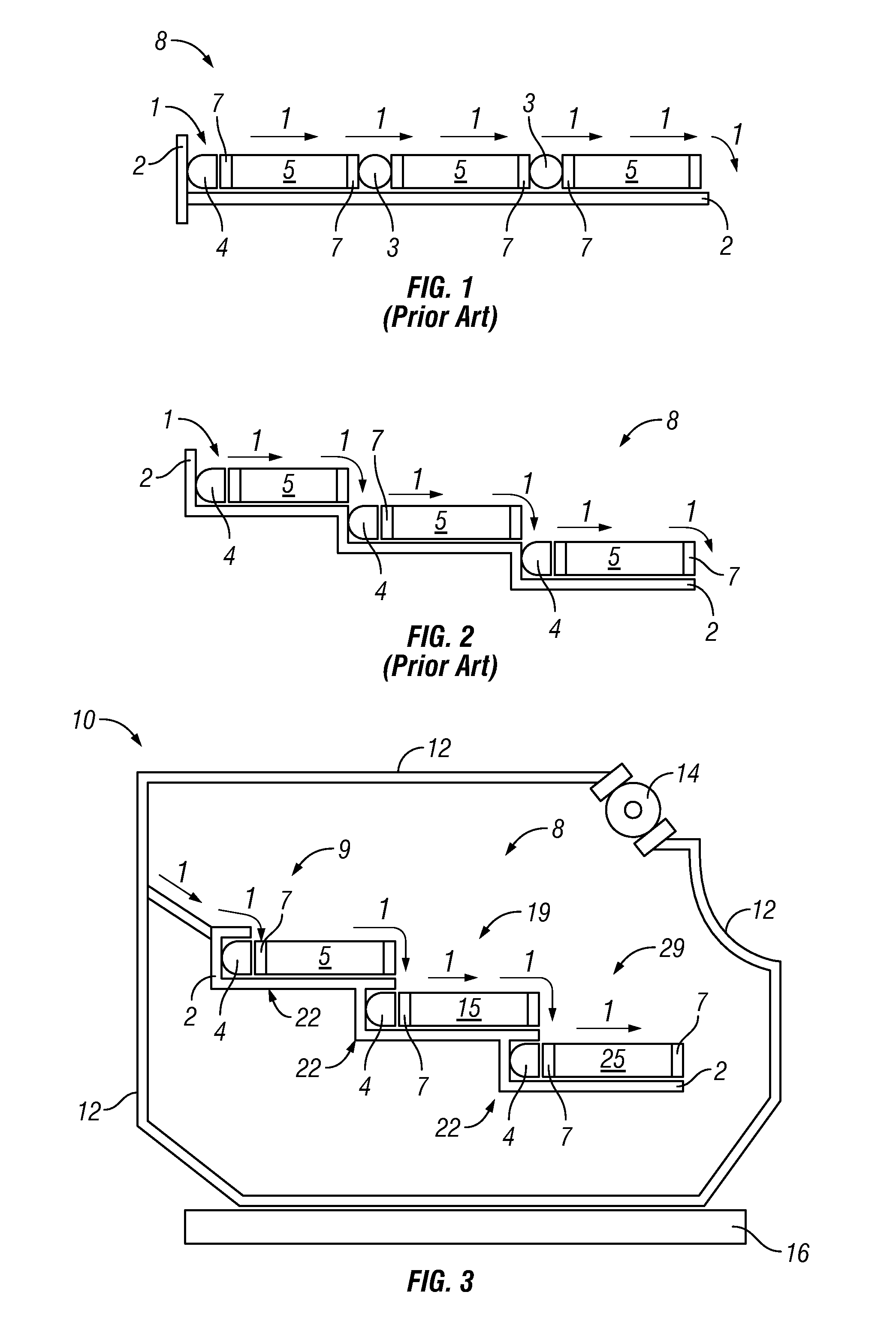

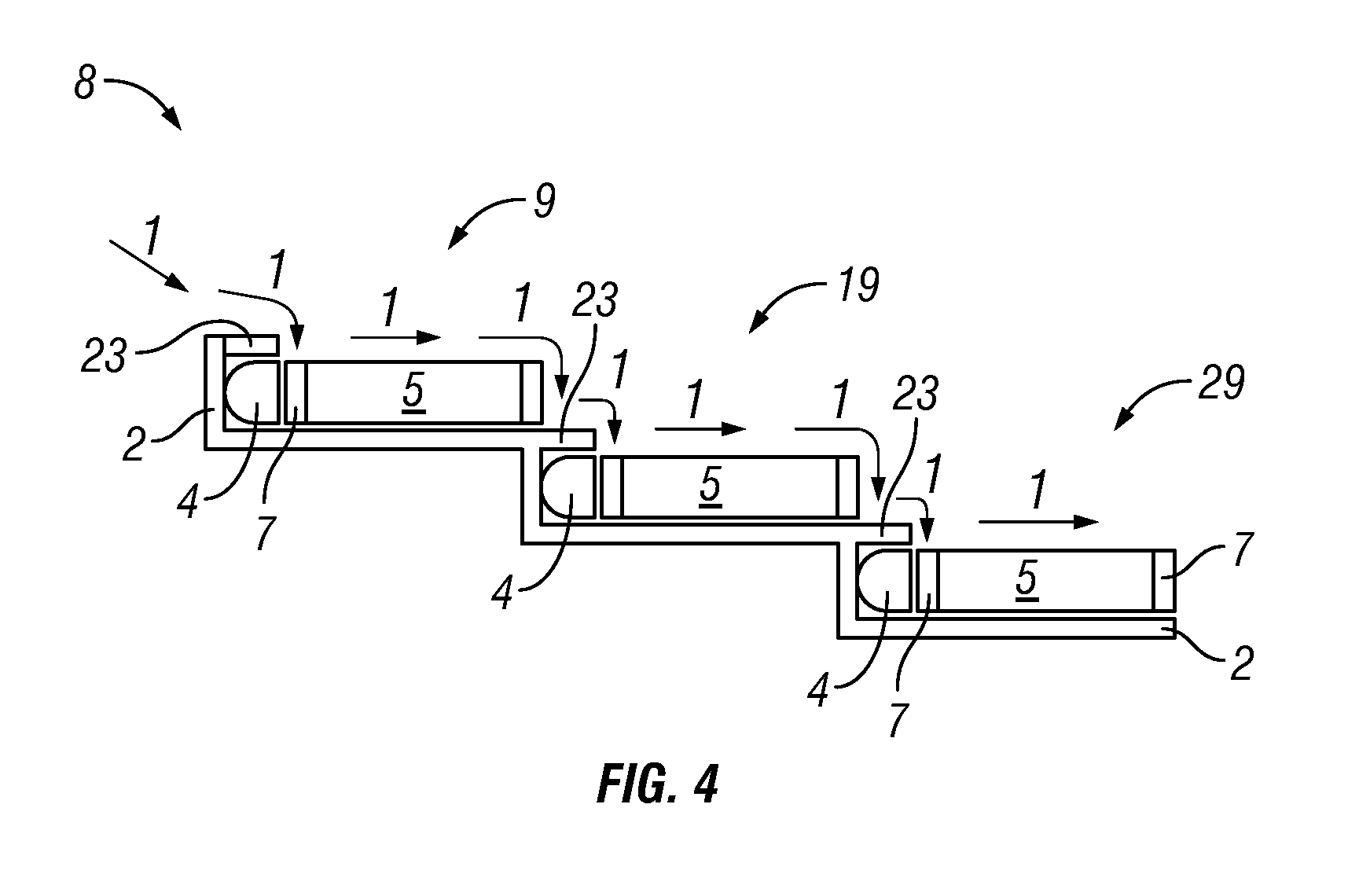

[0049]Prior to a discussion of the present invention, and in order to better understand how the present invention is an improvement over the prior art, reference will first be made to FIGS. 1 and 2 showing two prior art multi-screen deck arrangements commonly utilized in prior art shale shakers.

[0050]Referring first to FIG. 1, there is shown a common prior art multi-screen linear deck arrangement that is commonly utilized in shale shakers, showing deck 8 comprising three screen assemblies. Each screen assembly generally includes a screen 5 and a screen frame 7 around the screen 5. There are seals 3 interposed there between the screen assemblies, all supported by support frame 2. Vibration is utilized to urge the flow of solids containing fluids across screens 5 one screen at a time as shown by arrows 1 representing the flow. It should be understood that at each screen and depending upon the rating of the screen, a certain amount of fluids / solids pass through the screen, with a certa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| acidity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com