Patents

Literature

16678 results about "Mechanical equipment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

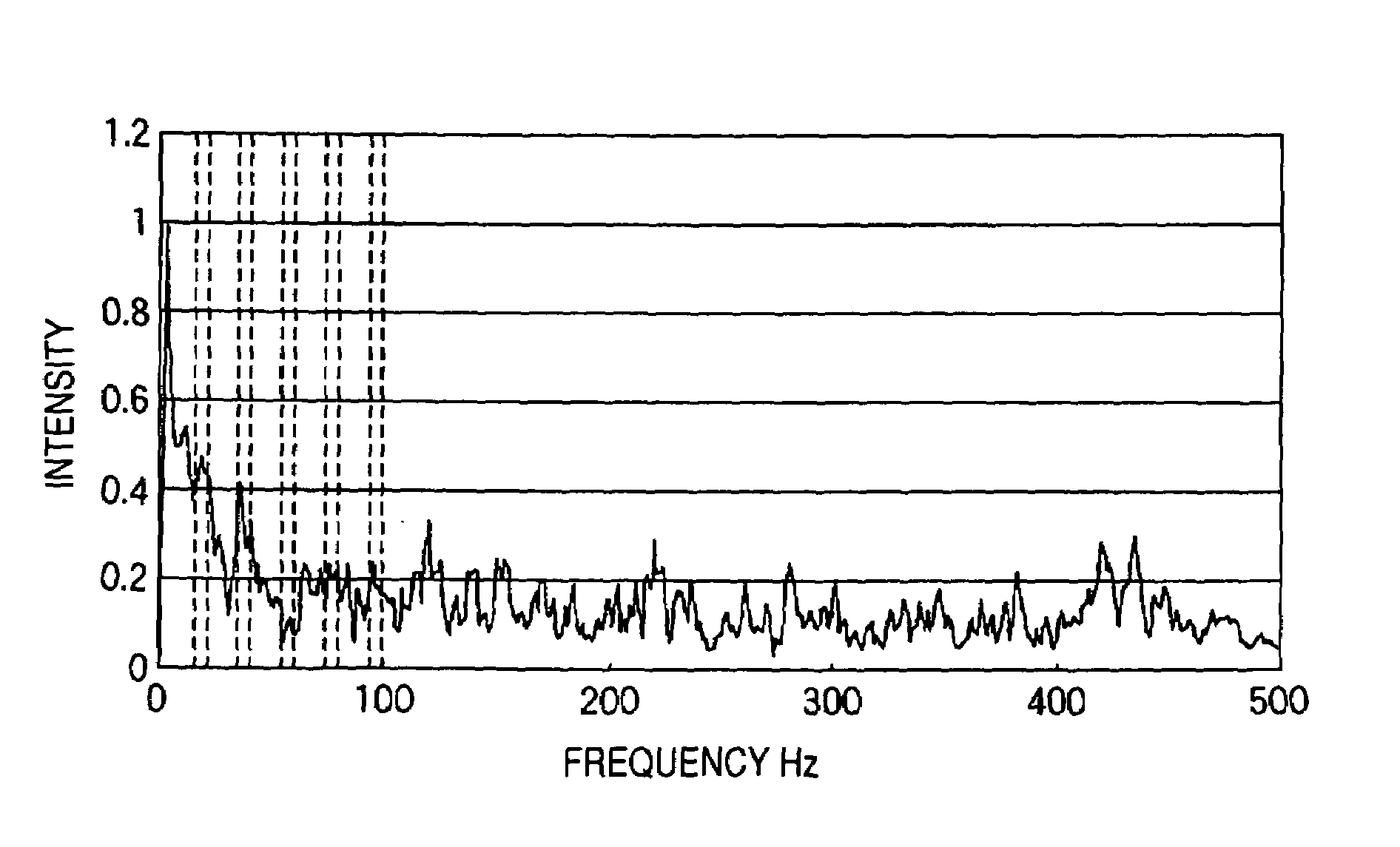

Abnormality Diagnosing System For Mechanical Equipment

ActiveUS20080033695A1Accurate detectionAvoid noisy signalsVibration measurement in solidsMachine part testingDifferential coefficientMoving average

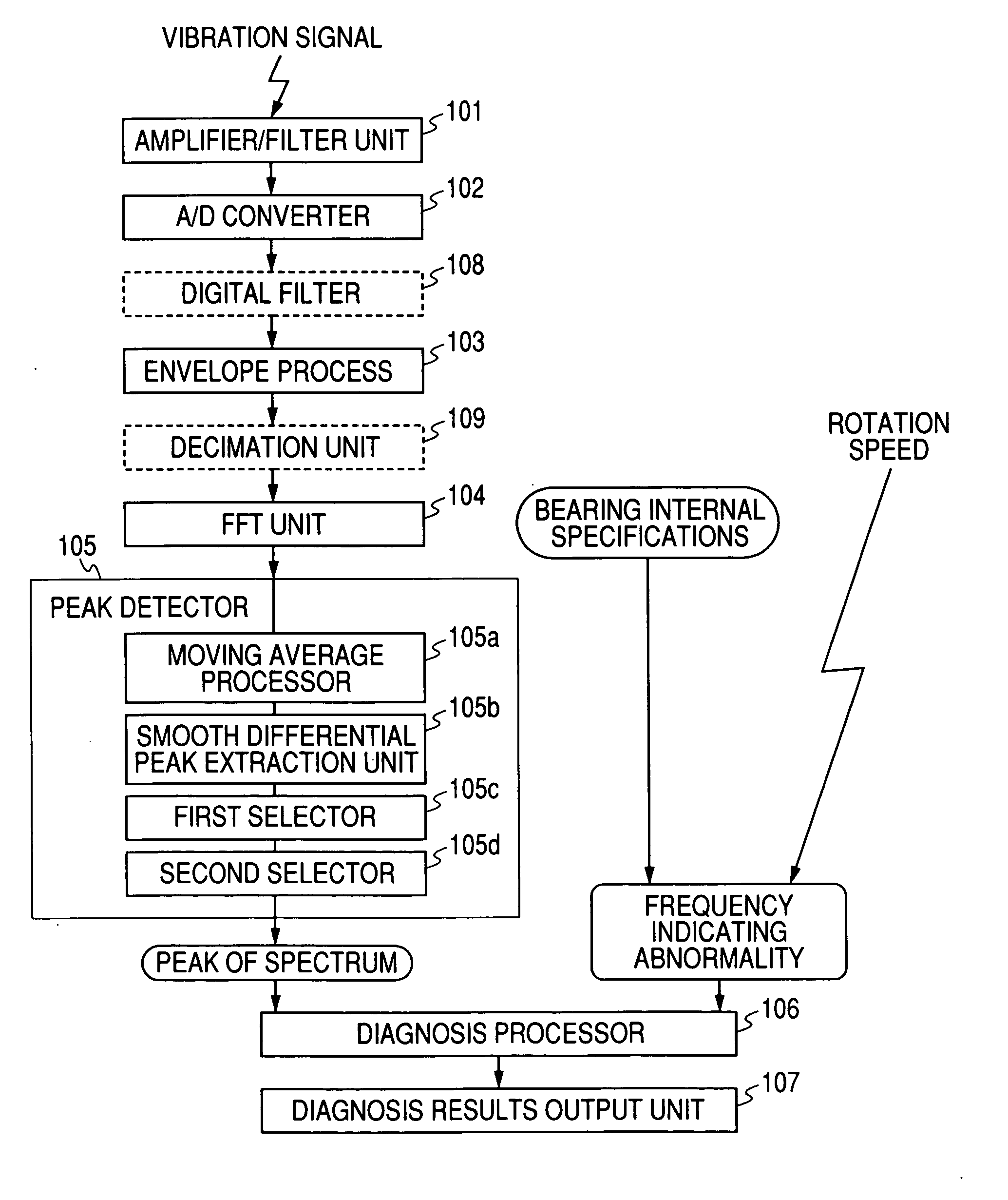

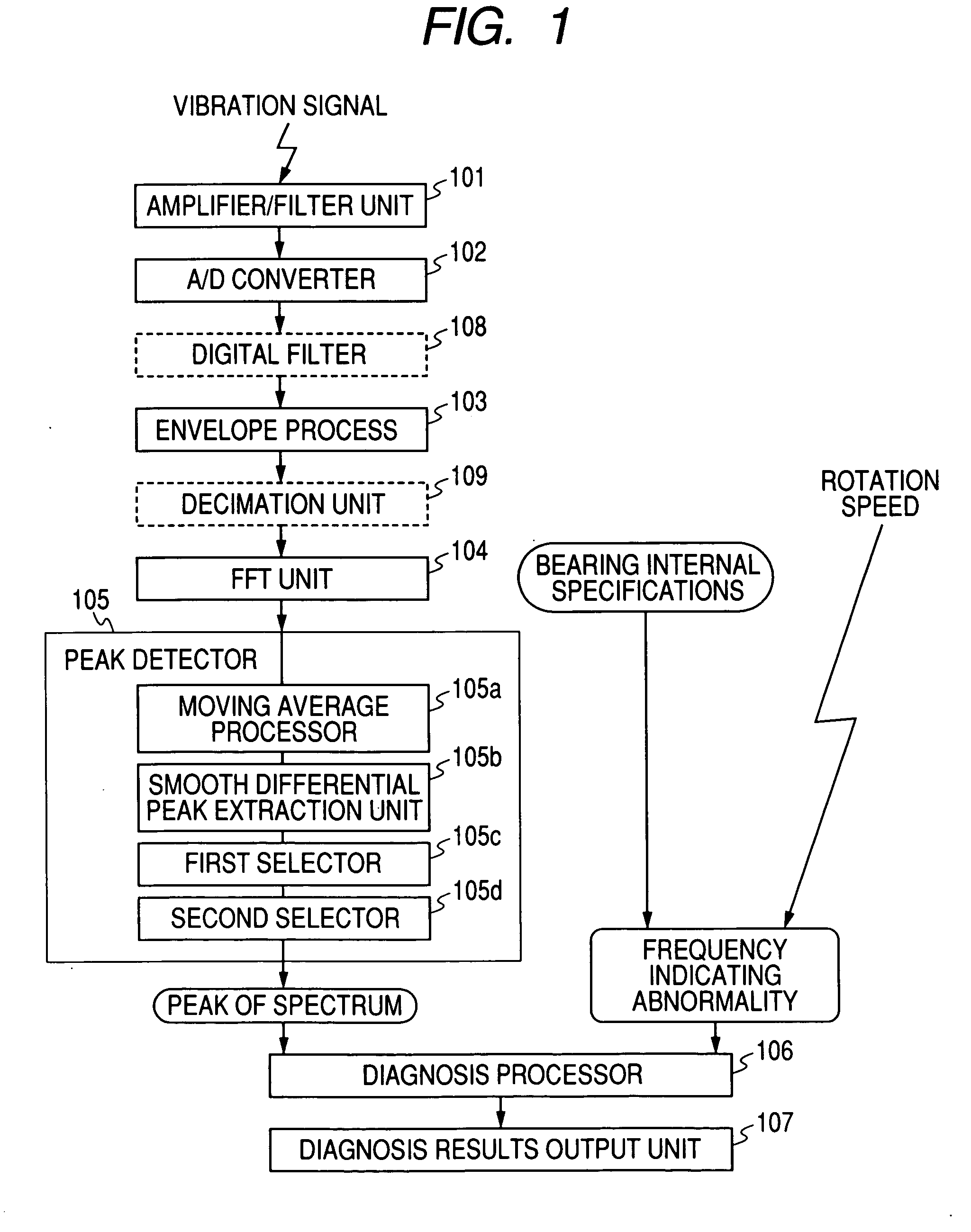

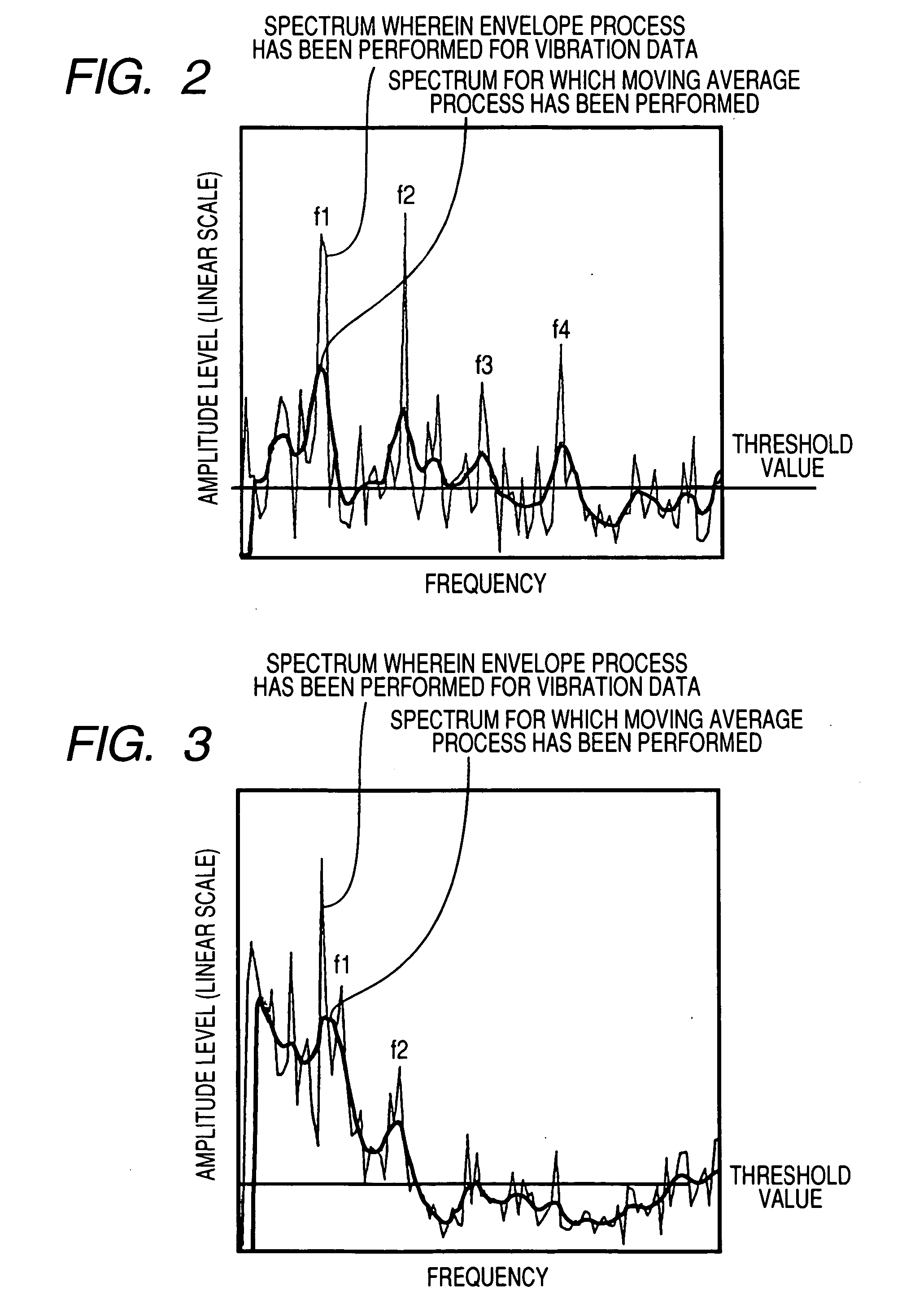

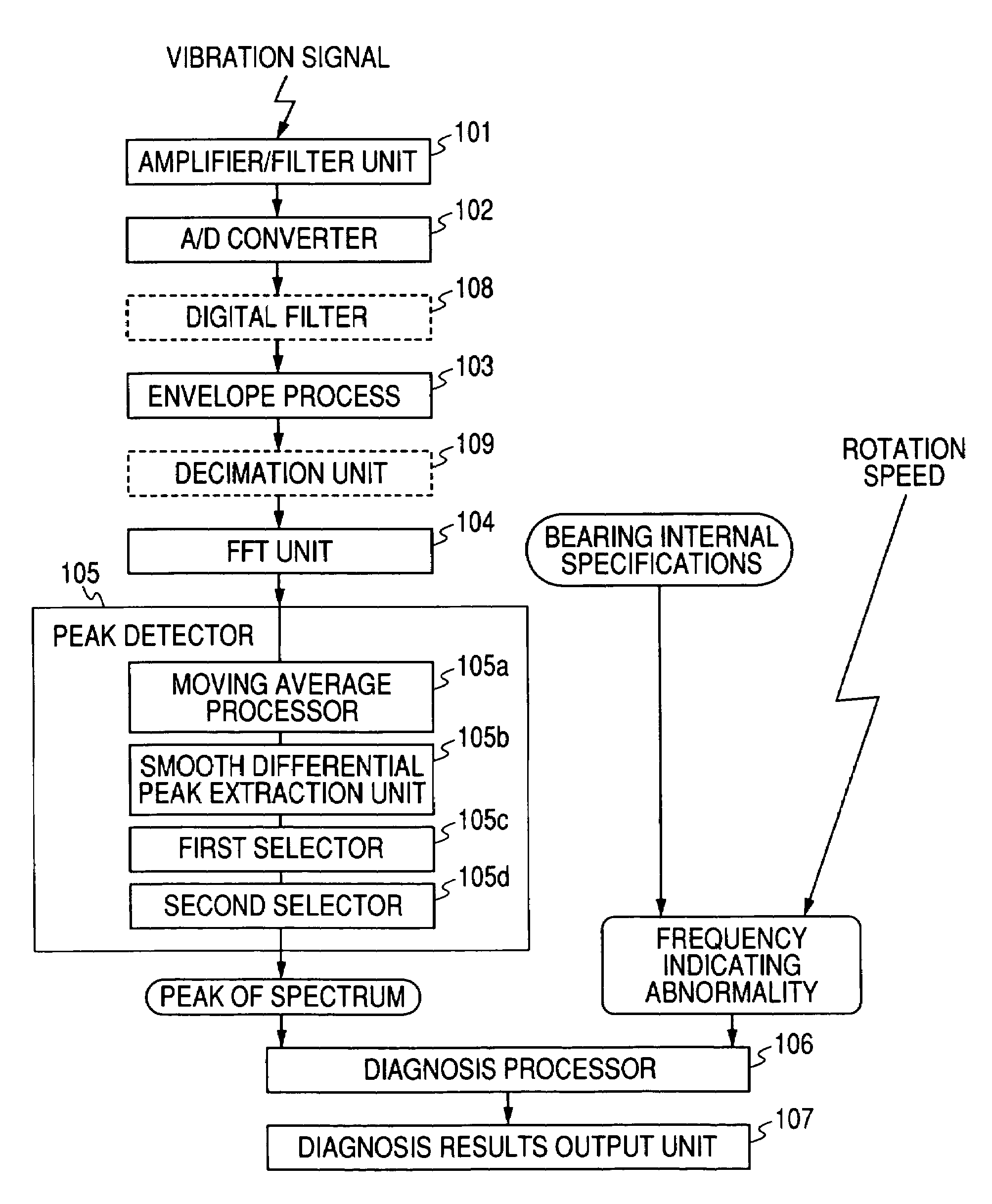

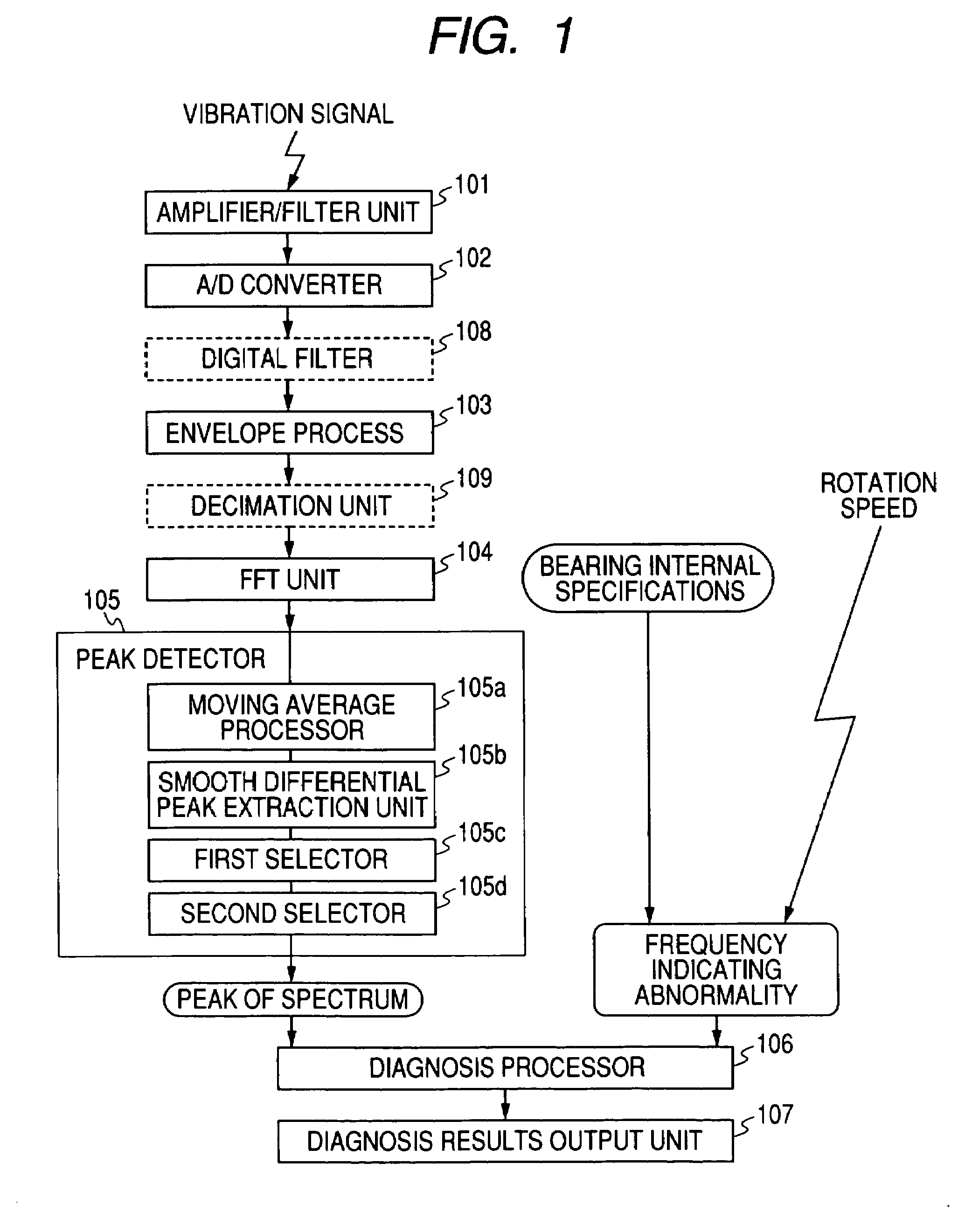

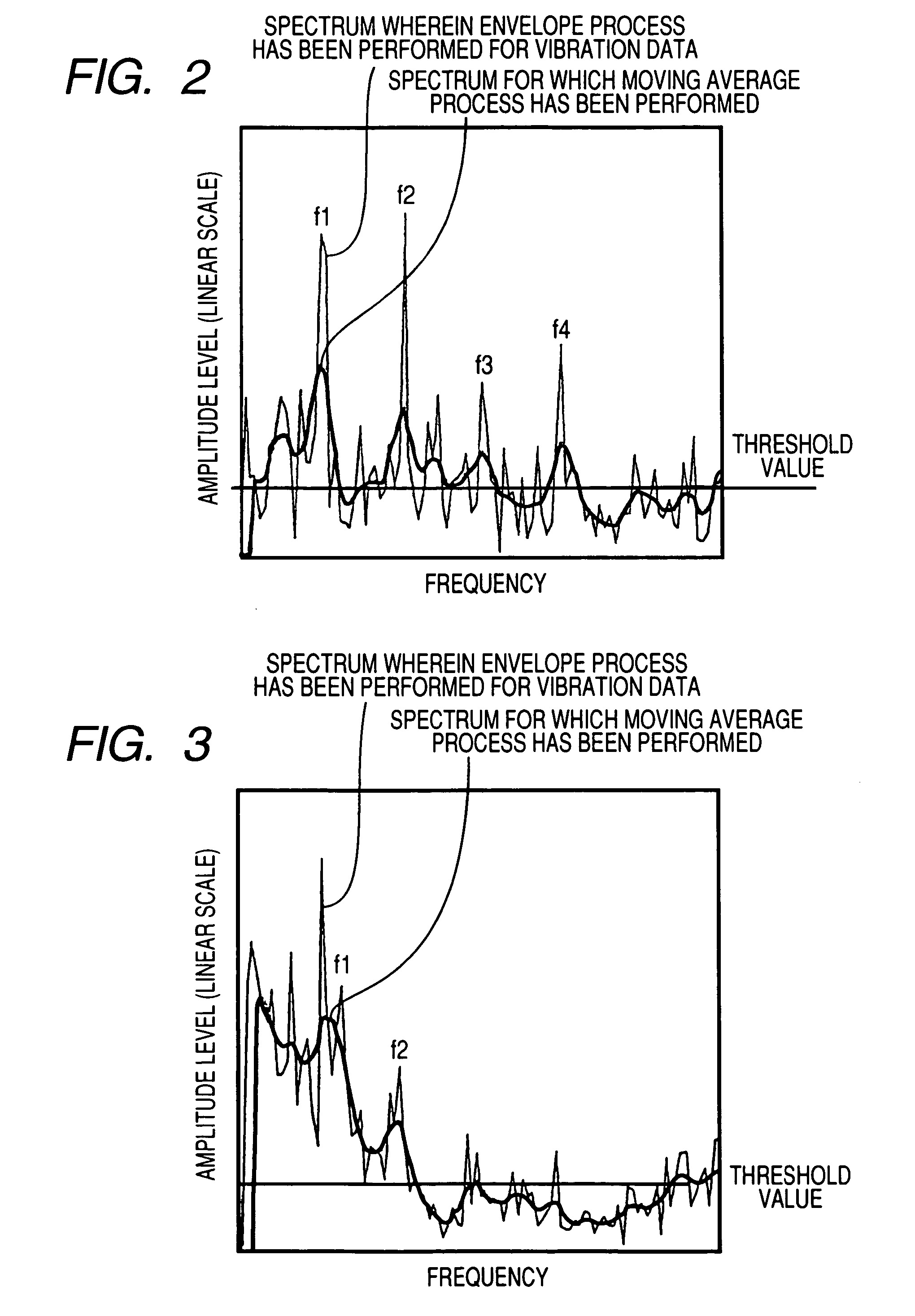

Provided are an envelope processor 103, for obtaining an envelope for a detected signal; a FFT unit 104, for converting the envelope into a frequency spectrum; a peak detector 105, for smoothing the frequency spectrum by calculating a moving average, for further performing smoothing and differentiation for the spectrum, and detecting, as peaks, frequency points at which a sign of a differential coefficient is changed from positive to negative, for extracting peaks having a predetermined threshold value or greater, and for sorting the extracted peaks and detecting upper peaks; and a diagnosis processor T, for diagnosing an abnormality based on the detected peaks.

Owner:NSK LTD

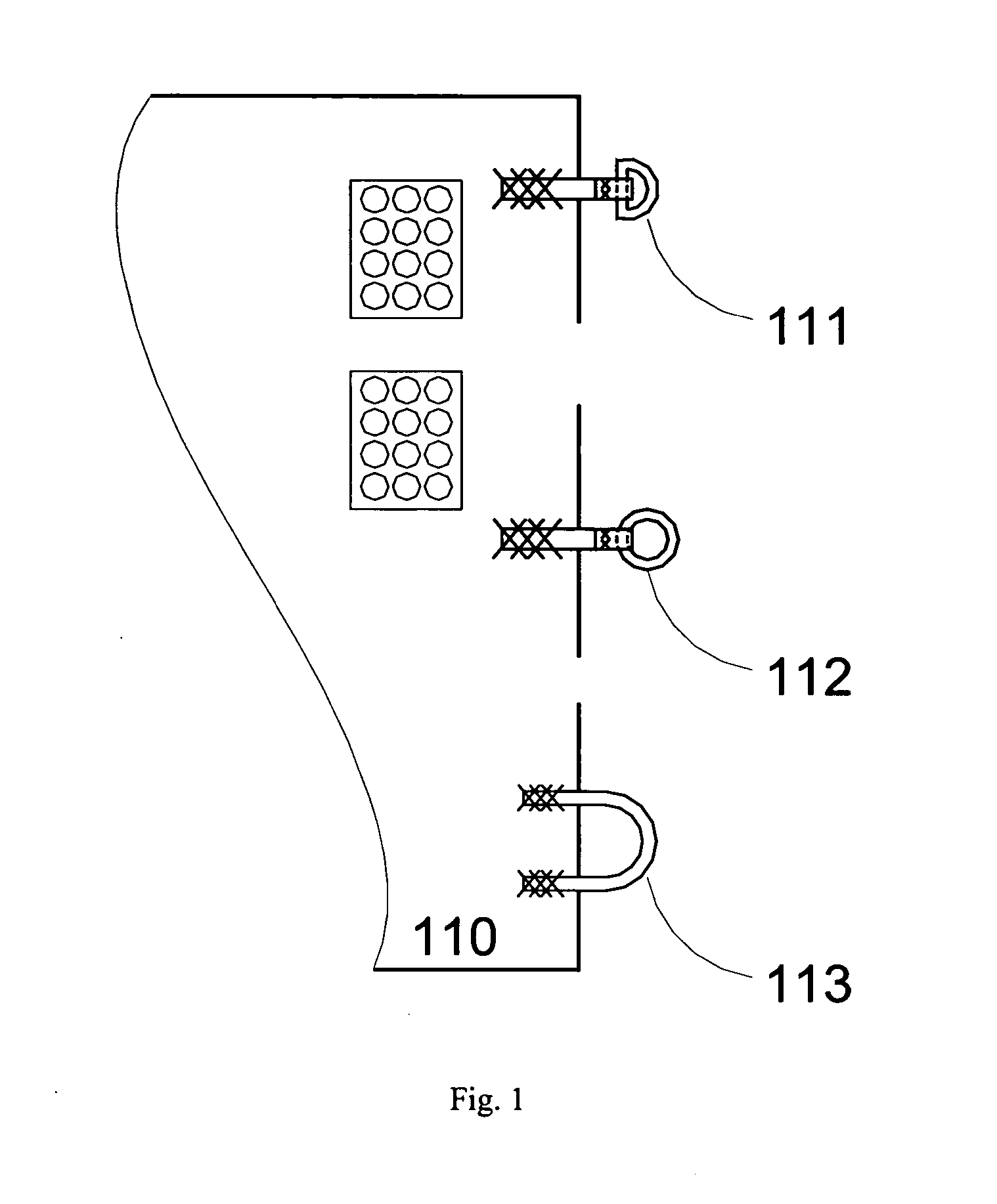

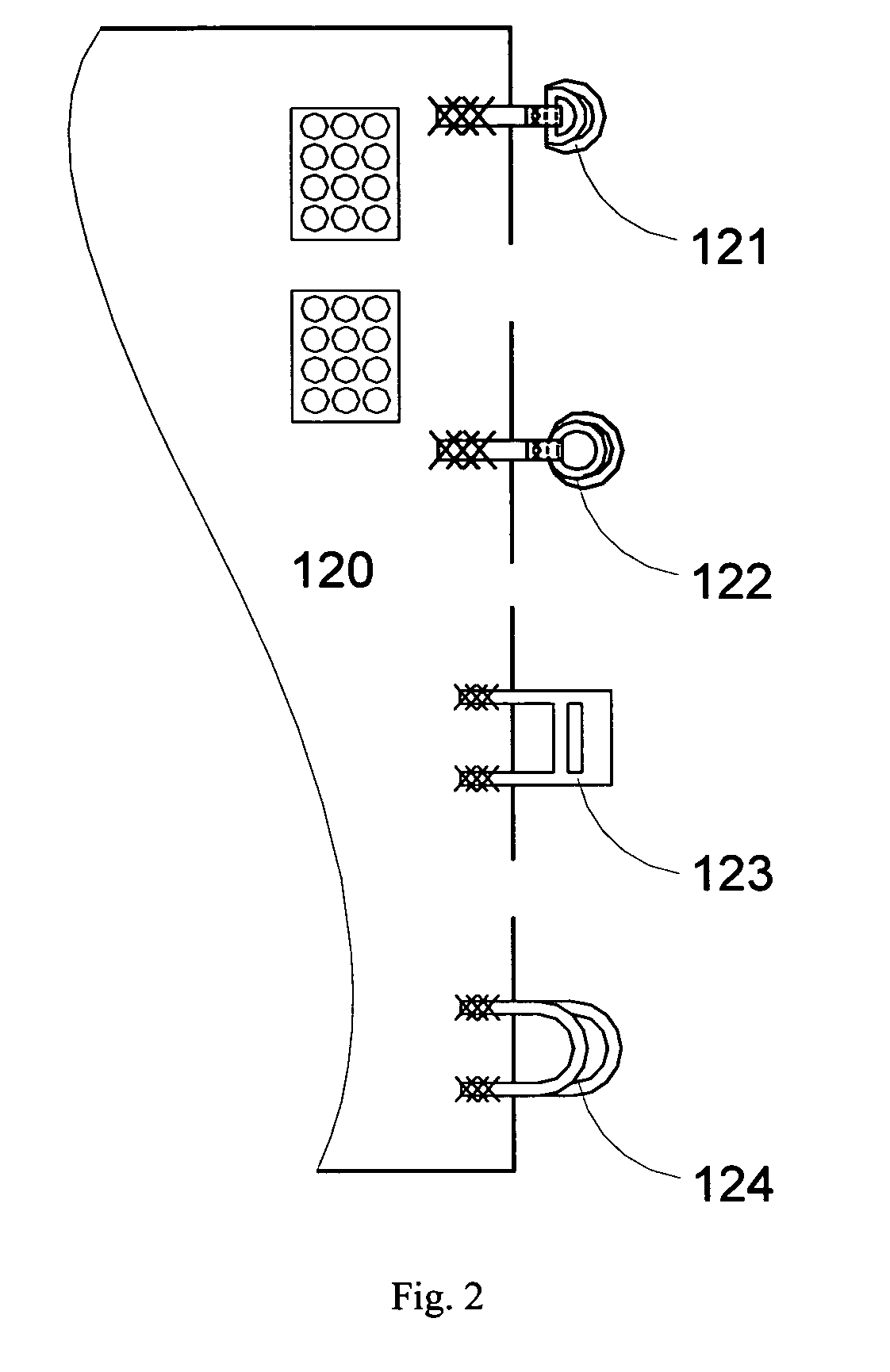

Portable solar panel with attachment points

InactiveUS20060225781A1High solar efficiencyBatteries circuit arrangementsPV power plantsStrappingEngineering

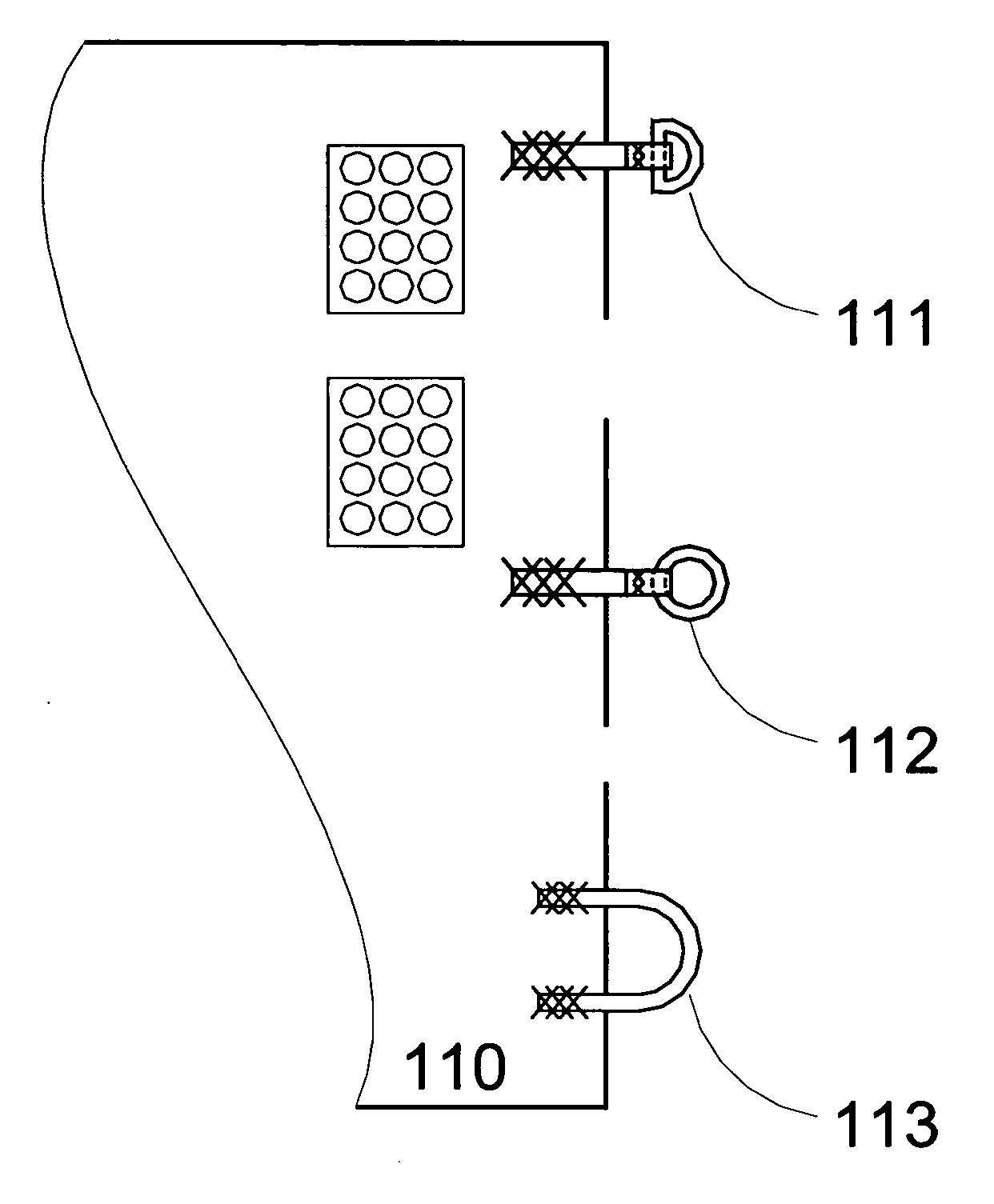

The present invention discloses a portable solar tarp or a field portable battery charger employing a solar tarp, utilizing flexible solar panels, solar fabric, or solar film. Around the perimeter of the solar tarp is a series of attachment points for straps. The attachment points can be grommets, loops, buckles, hooks, buttons, or grab loops and lines, and to which connected various straps (webbing, line, cord, or cable). The present invention further discloses a versatile, adjustable strapping system utilizing straps, buckles, and hooks. The present invention strapping system can attach almost any object to nearly any other object, such as back packs, luggage, vehicles, boats, permanent and portable shelters and buildings, mechanical equipment, and natural objects such as trees, rocks. The solar panel according to the present invention can have the photovoltaic cells wired individually, or in a single line, because when parts of the photovoltaic system is subjected to shade, or if due to space constraint, parts of the photovoltaic system is covered or folded away, the remaining photovoltaic cells with useable energy are still able to function at peak capacity, since the covered cells will not become an energy drain upon the remaining cells. Further, the photovoltaic system is able to harness all available energy, regardless of the required or desired voltage and / or amperage for the system, thus converting any and all available energy into a useable current to either recharge batteries, or power a load.

Owner:LOCHER STEVE

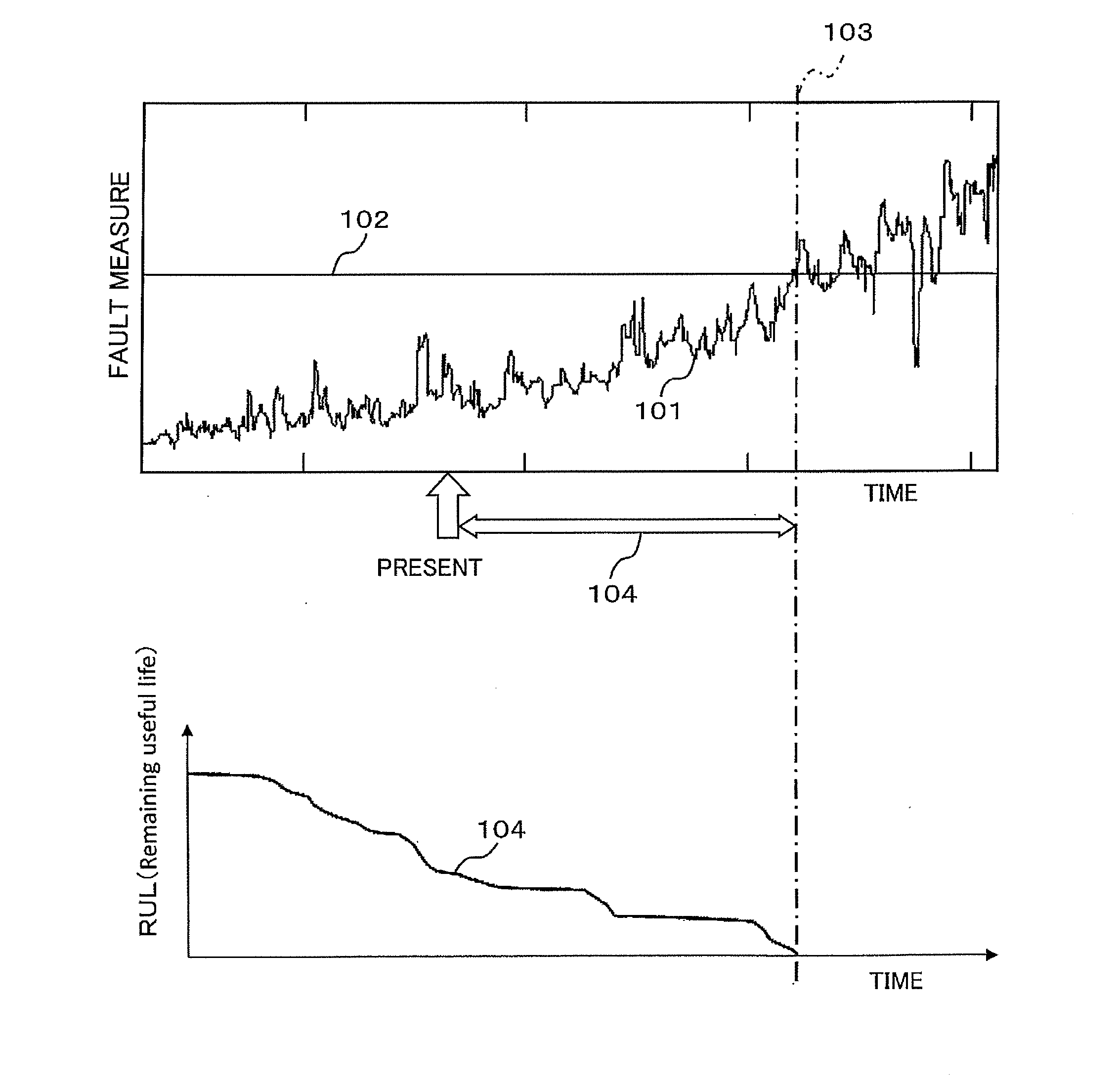

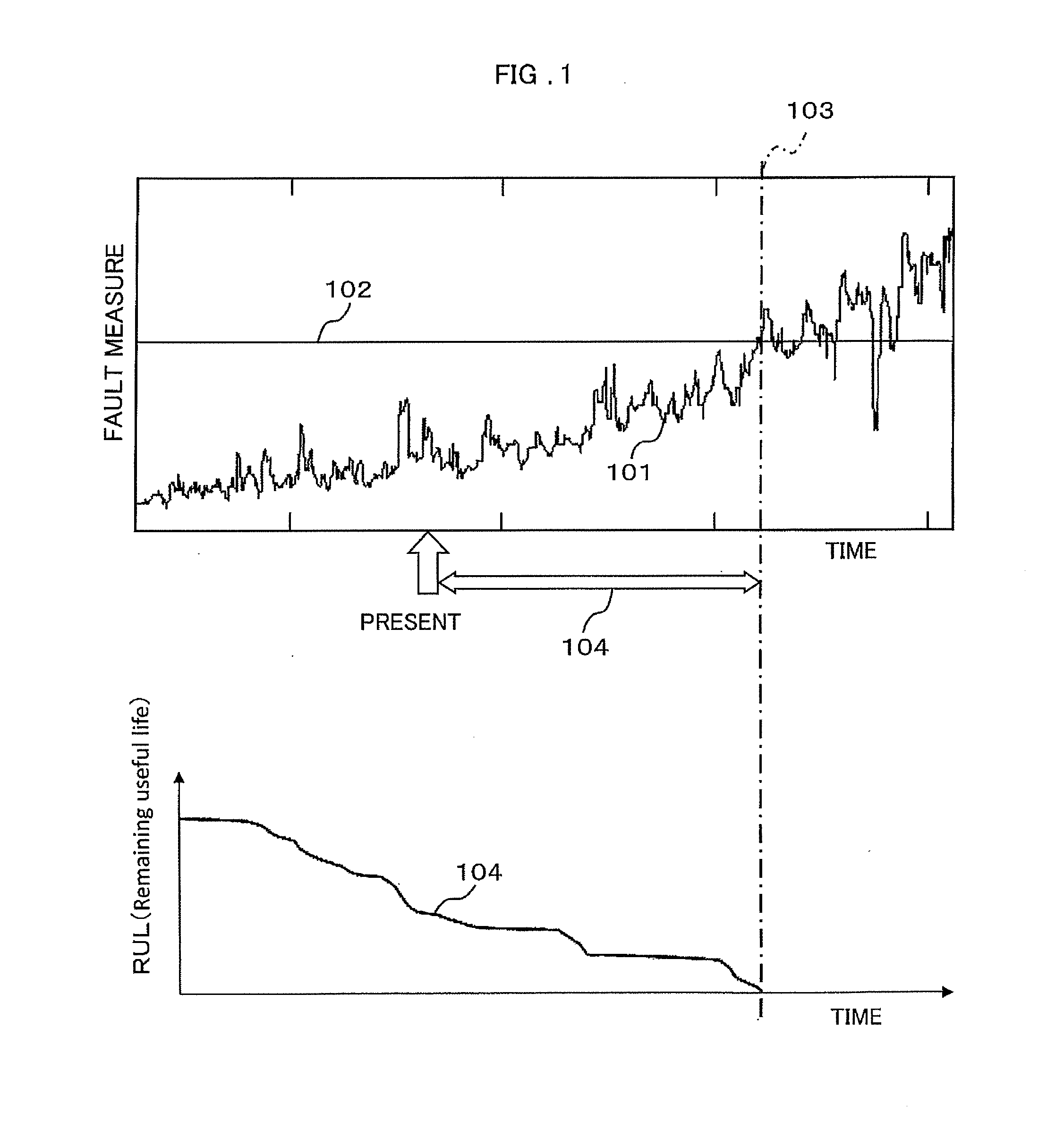

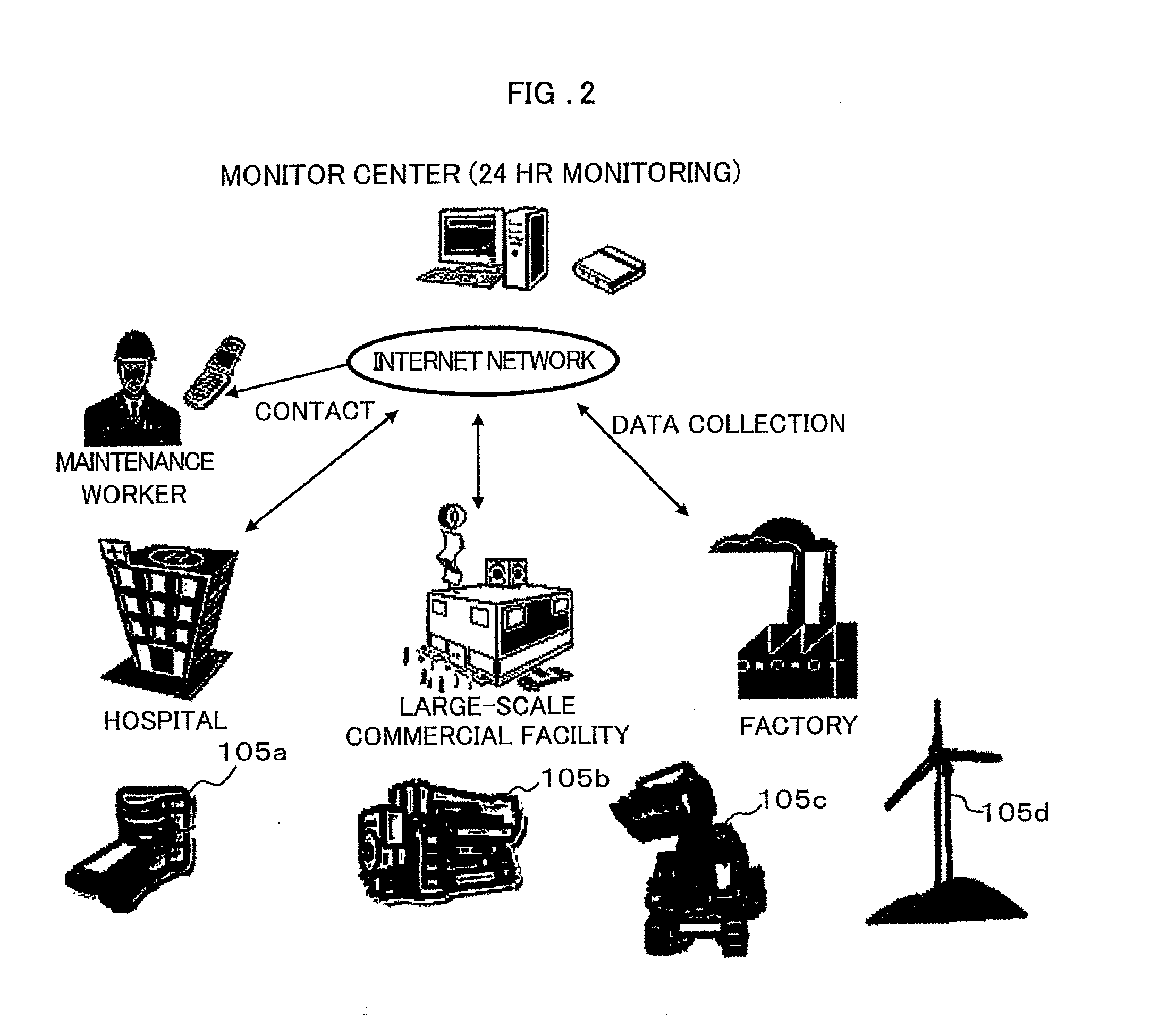

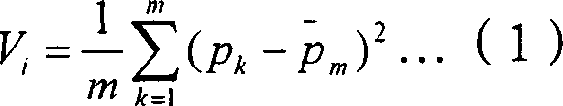

Health management system, fault diagnosis system, health management method, and fault diagnosis method

ActiveUS20150160098A1Easy to identifyTesting/monitoring control systemsStructural/machines measurementLearning dataMechanical equipment

An objective is to identify the health state of mechanical equipment and provide information usable for determining maintenance work timing or the like. A health management system includes a time-series data acquisition unit configured to acquire multi-dimensional sensor data and environmental data from mechanical equipment; a first discrimination unit configured to quantify the equipment state of the mechanical equipment by a statistical method using normal data as learning data; a second discrimination unit configured to quantify the health state indicating the performance or quality of the mechanical equipment by a statistical method using normal data; and an output unit configured to display and / or output to the outside the quantified equipment state and health state.

Owner:HIATACHI POWER SOLUTIONS CO LTD +1

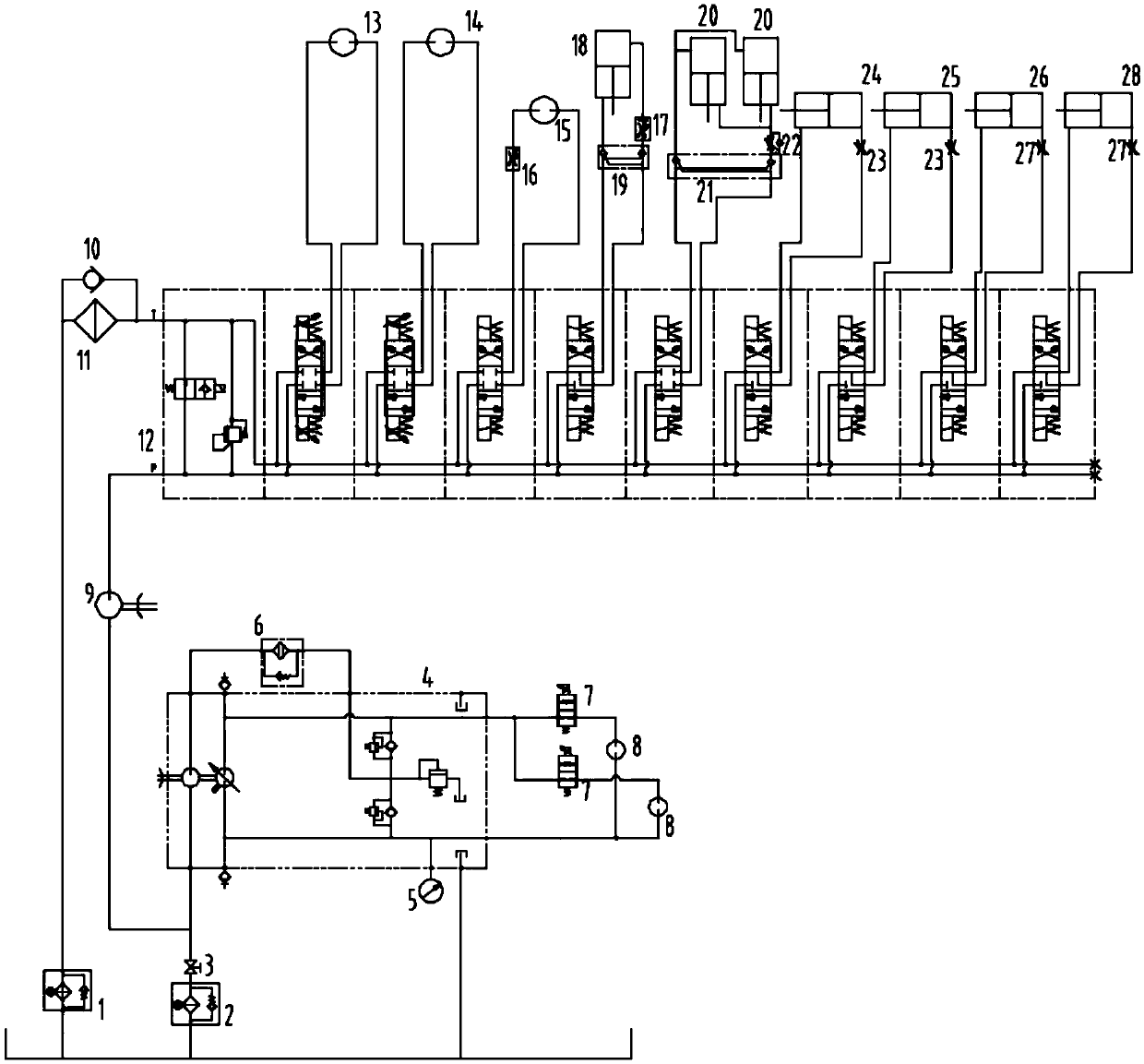

Hydraulic system of orchard picking equipment

PendingCN109515177AMeet actual job needsGuaranteed uptimeConveyorsPicking devicesHydraulic cylinderMechanical equipment

The invention belongs to the field of orchard mechanical equipment and particularly relates to a hydraulic system of orchard picking equipment. Power is provided for an up-installed conveying system and a chassis steering system simultaneously through a constant displacement pump. Flow input of a stacking conveying belt motor and a main conveying belt motor is controlled through a proportional multi-way valve. Control over the extending-and-contracting movement speed of a hydraulic cylinder is achieved through a speed regulation valve. Functions such as automatic conveying of fruit picking andautomatic cartoning of fruits are achieved. Problems that labor capacity of pure manual picking is large, picking efficiency is low and the picking cost is high are solved. The characteristics that fruit harvesting is strong in seasonality and short in harvesting time are met.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

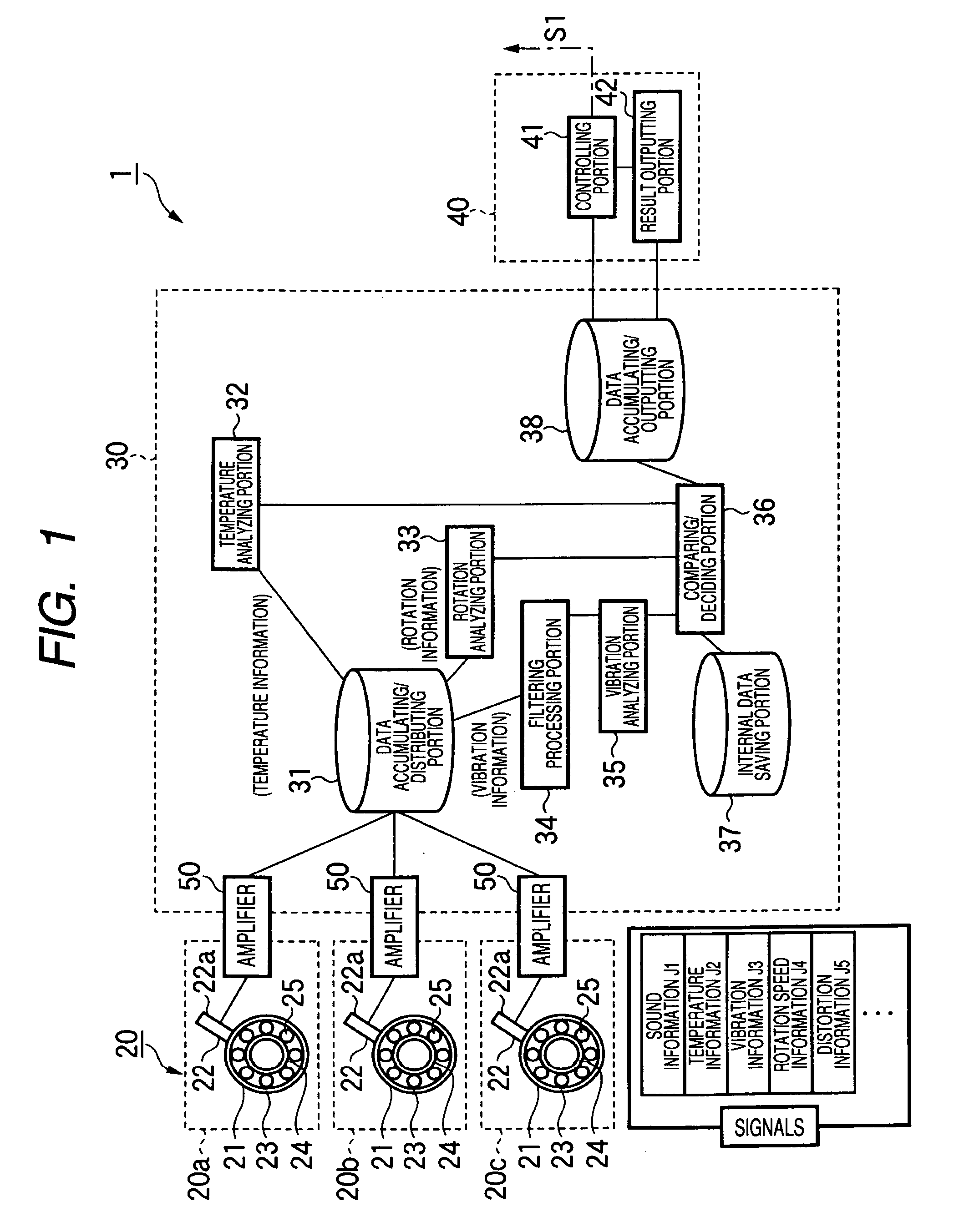

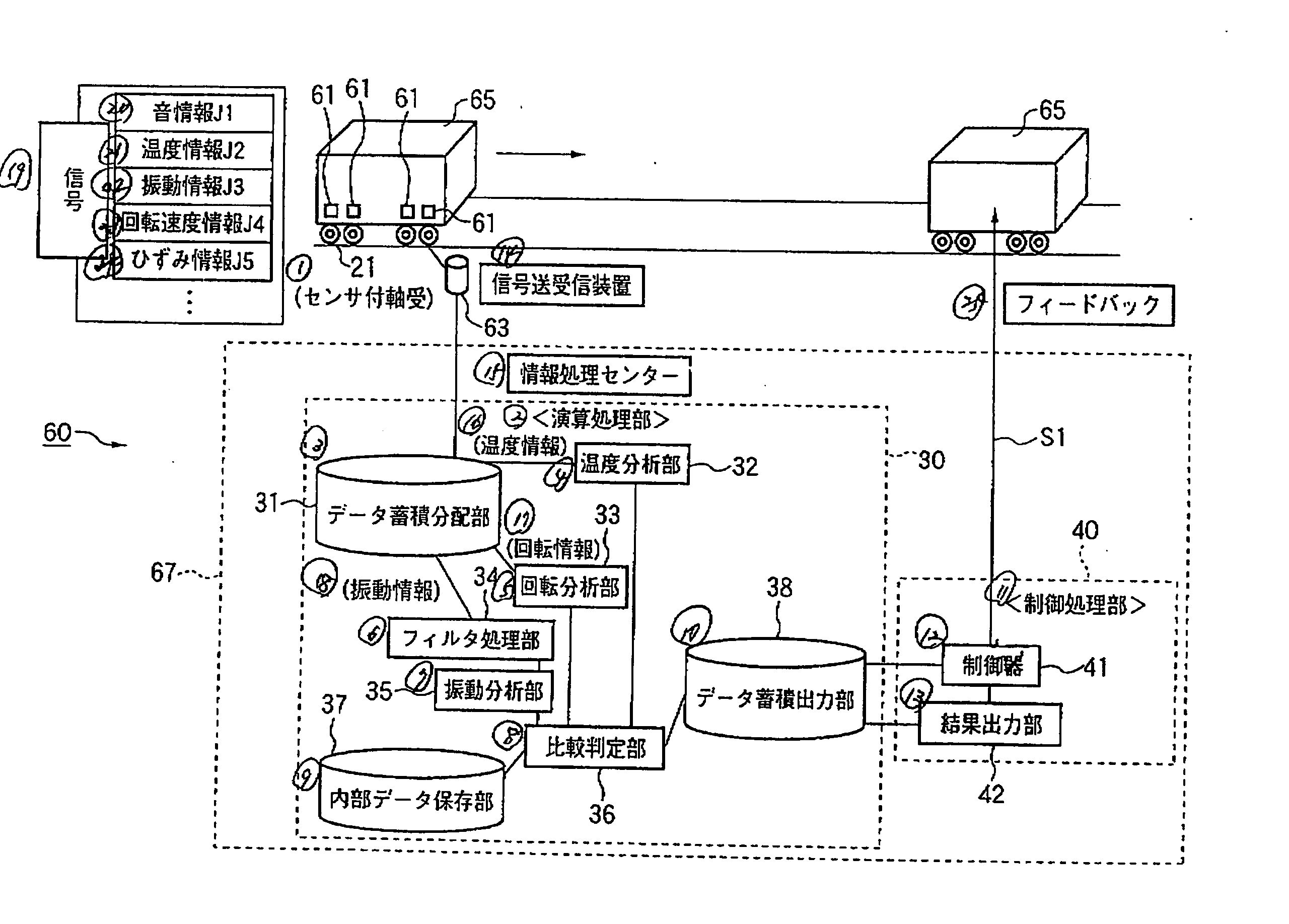

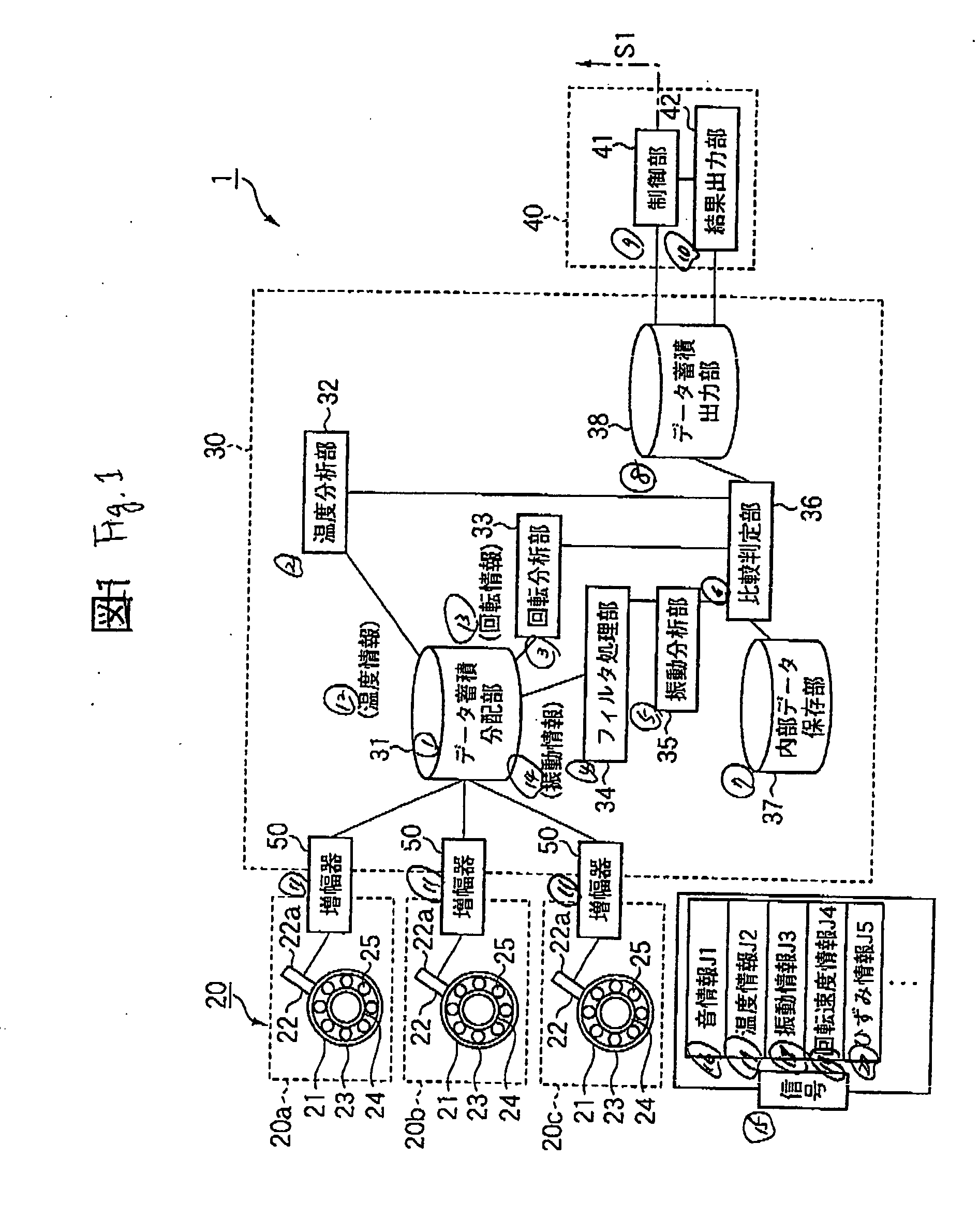

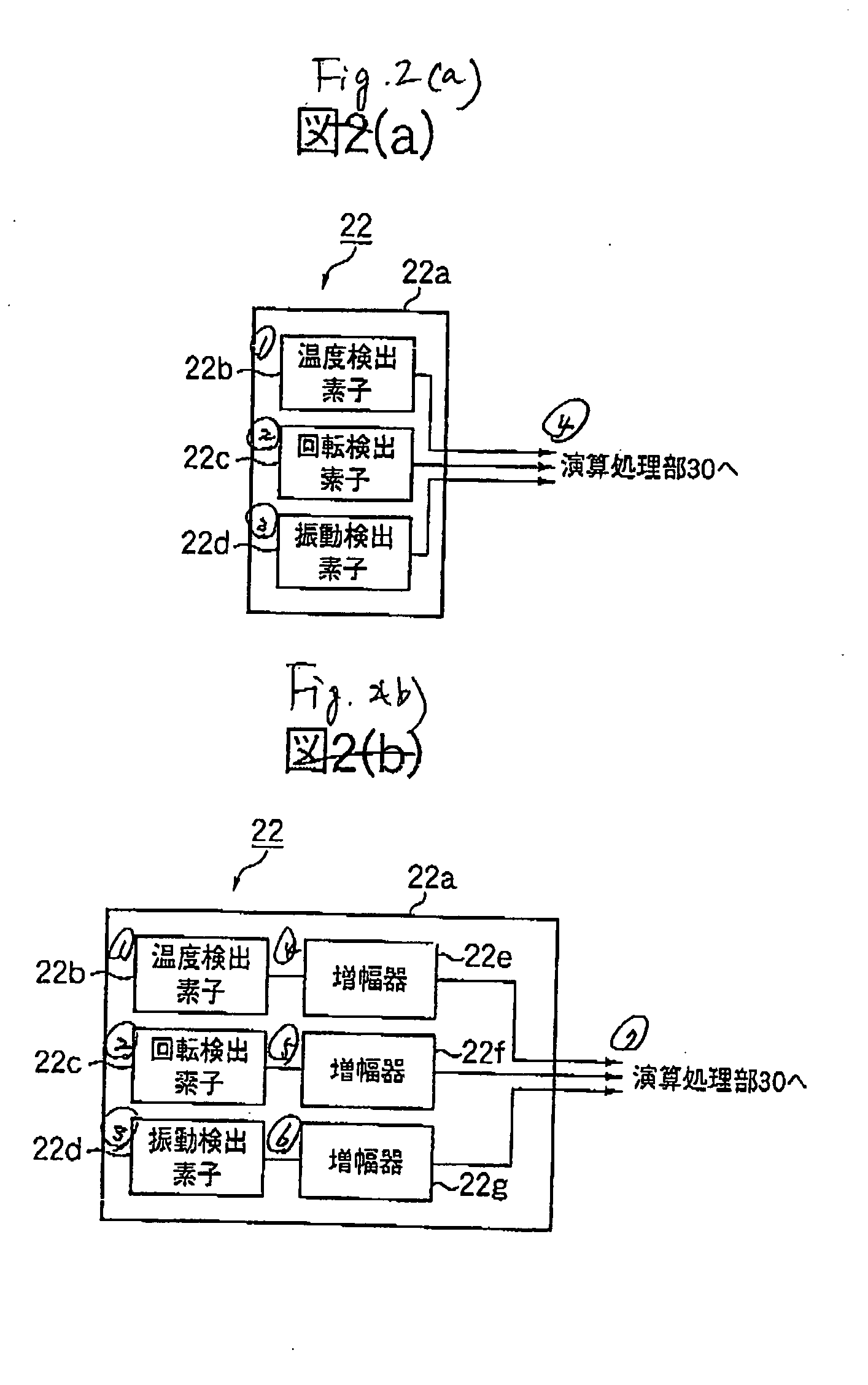

Method and device for monitoring status of mechanical equipment and abnormality diagnosing device

An abnormality-diagnosing device is used to diagnose if a bearing device used on the axle of a railway vehicle is normal. The abnormality-diagnosing device comprises a detection processing part, an operation processing part, a result output part and a control processing part, wherein, the detection processing part outputs the signal generated by the bearing device, which is regarded as an electric signal, the operation processing part conducts an abnormality diagnosis on the bearing device according to the output of the detection processing part, the result output part outputs the judgement result of the operation processing part, and according to the judgement result, the control processing part returns a control signal to the control system of the railway vehicle.

Owner:NSK LTD

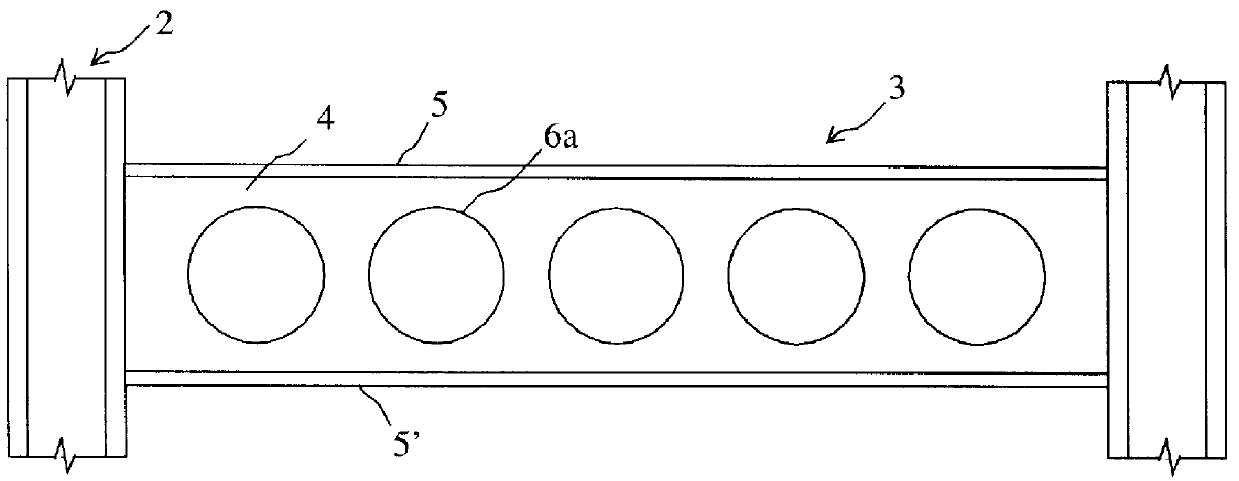

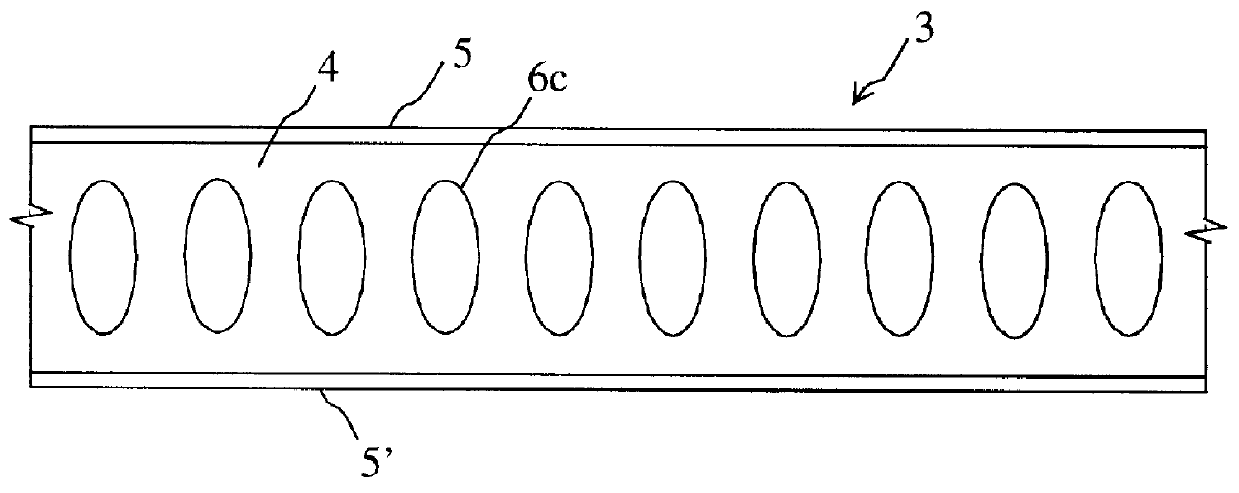

Moment-resistant structure, sustainer and method of resisting episodic loads

The present invention relates to a moment-resistant structure, sustainer, and method of construction for deformably resisting episodic loads, particularly those of high intensity. The episodic loads may be due to earthquake, impact, or other intense episodic sources. The structure and sustainer may be in buildings, bridges, or other civil works, land vehicles, watercraft, aircraft, spacecraft, machinery, or other structural systems or apparati. Deformation capacity is enhanced by the use of multiple dissipative zones. Dissipative zones that function in a manner similar to plastic hinges are determined by one or more voids that are located in the web of a sustainer. The one or more voids are of a size, shape, and configuration to assure that the dissipative zones deform inelastically when a critical stress, i.e., a maximum allowable demand, is reached, thereby developing the action of a structural fuse, preventing the occurrence of stress and strain demands sufficient to cause fracture of the connection welds or adjacent heat-affected zones, i.e., preventing the stress and strain demands from exceeding the strength capacity of the connection welds or adjacent heat-affected zones. The sustainers may be removably connected to the remainder of the structure, facilitating their replacement after inelastic deformation. The structure, sustainer, and method of construction may be utilized in new construction and in the rehabilitation of existing construction. Mechanical equipment and utilities may pass through the voids.

Owner:ASCHHEIM MARK AMOS

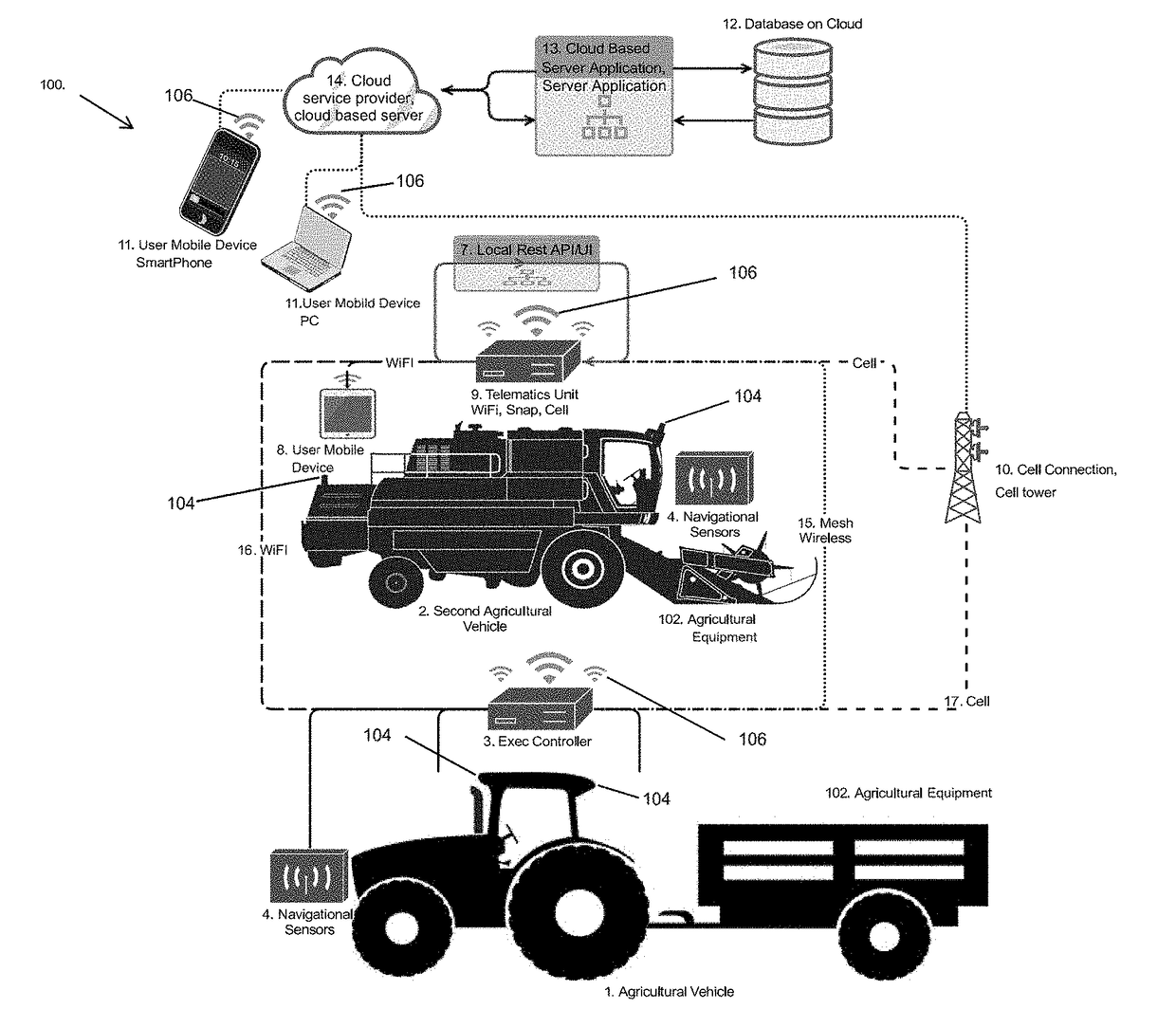

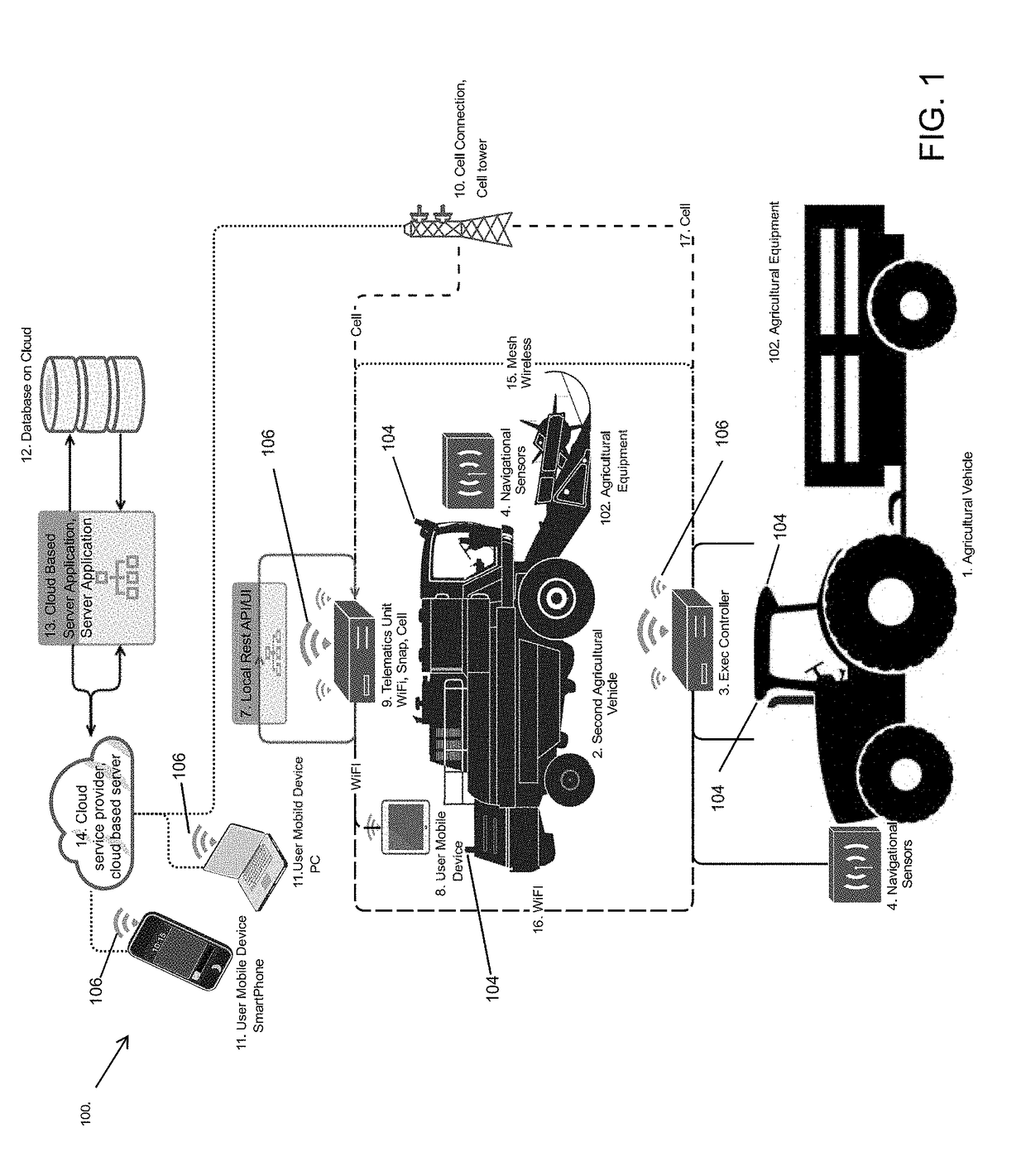

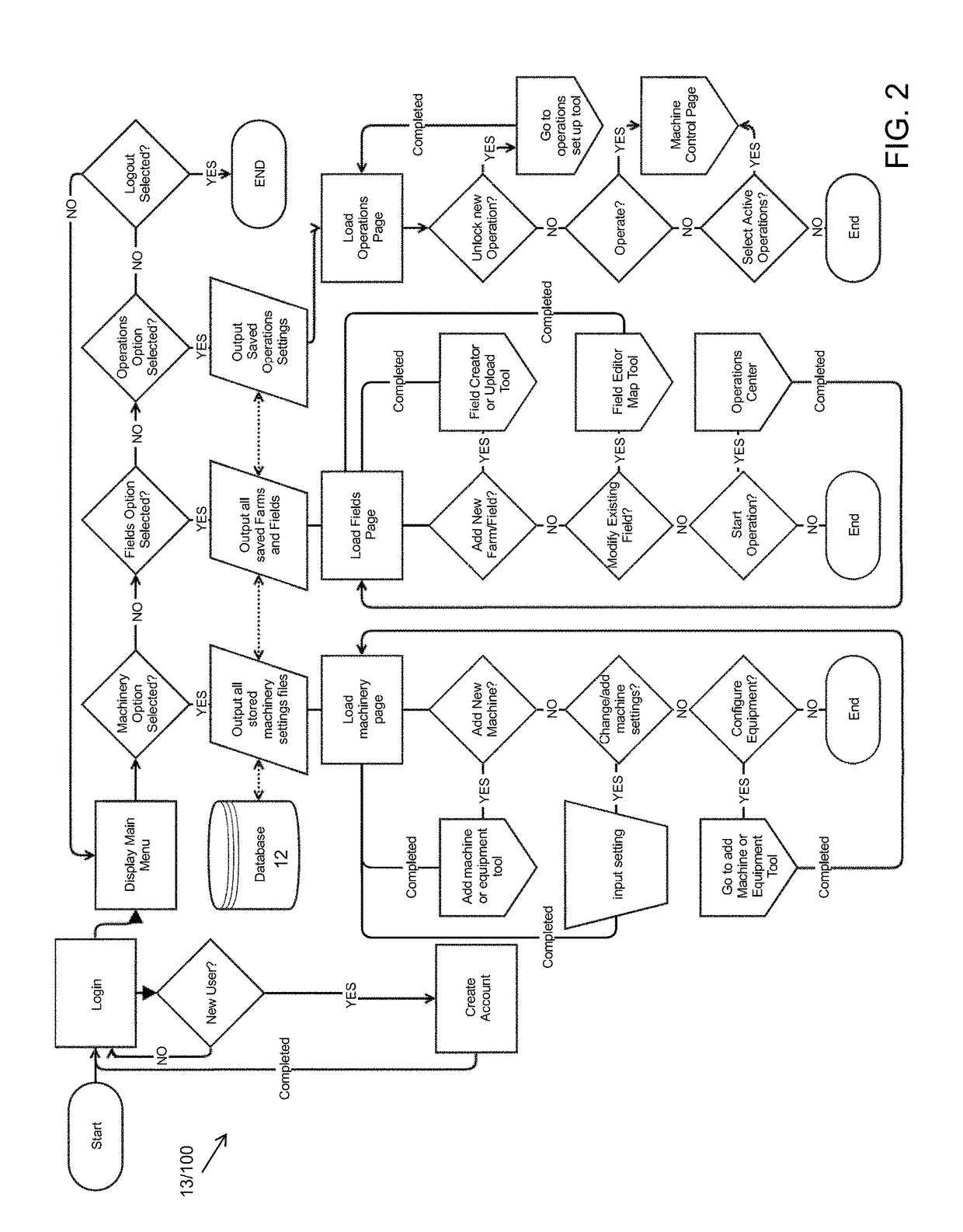

System and method for autonomous control of agricultural machinery and equipment

ActiveUS20180024549A1Directional communicationService provisioningAutonomous decision making processAutomatic controlProgram planning

A system and method of controlling agriculture equipment which combines geographical coordinates, machine settings, machine position, path plans, user input, and equipment parameters to generate executable commands based of a variety of different in-field agricultural operation objectives for a vehicle equipped with an automatic or electronically controlled locomotion systems capable of reading and executing the commands.

Owner:RAVEN INDUSTRIES INC

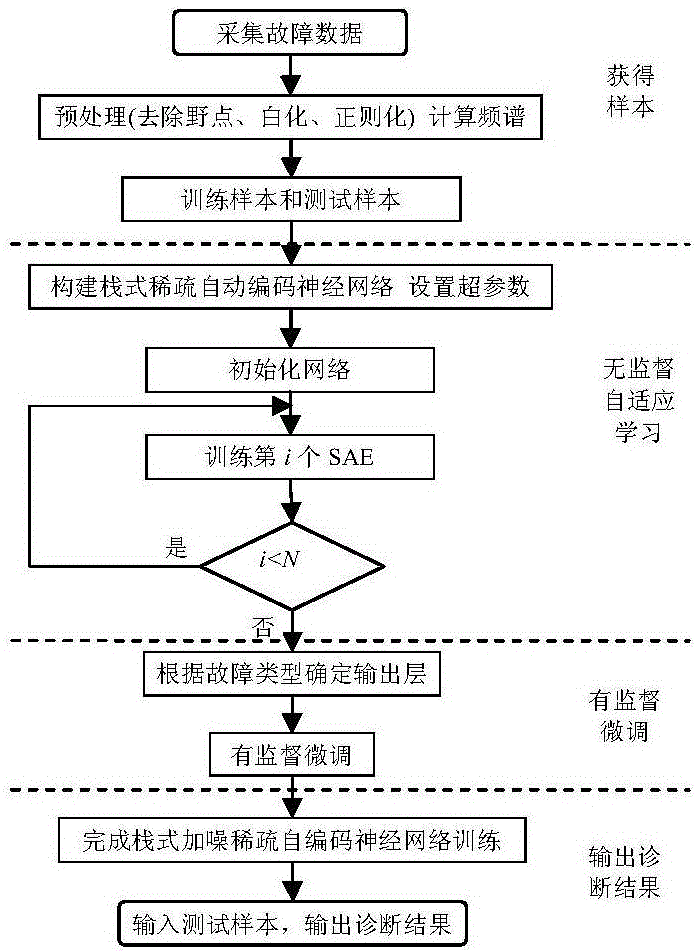

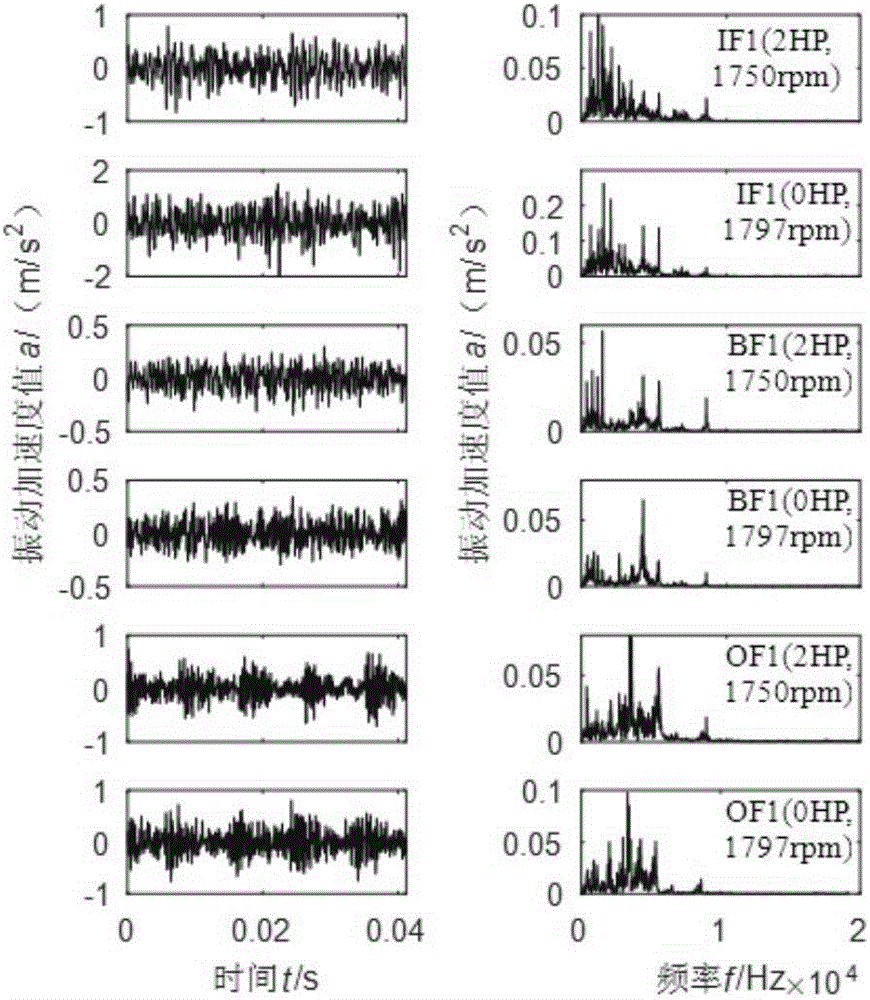

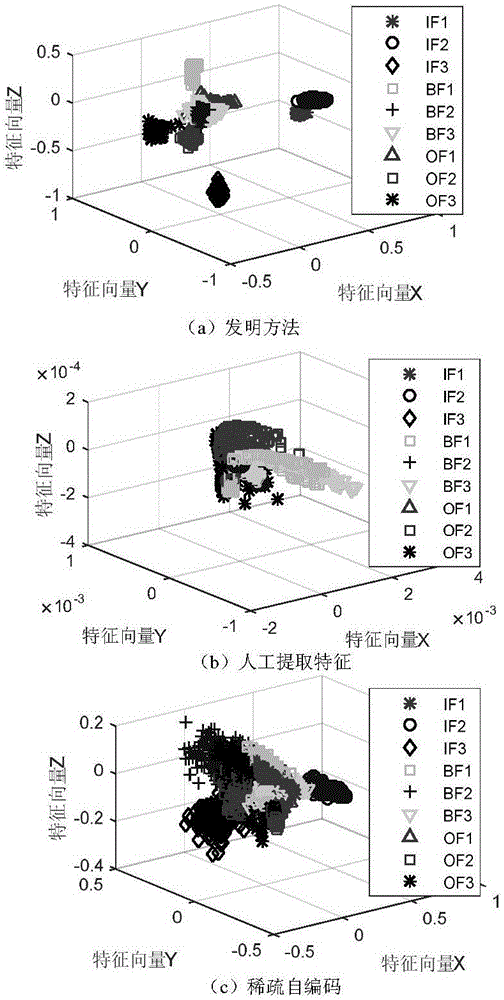

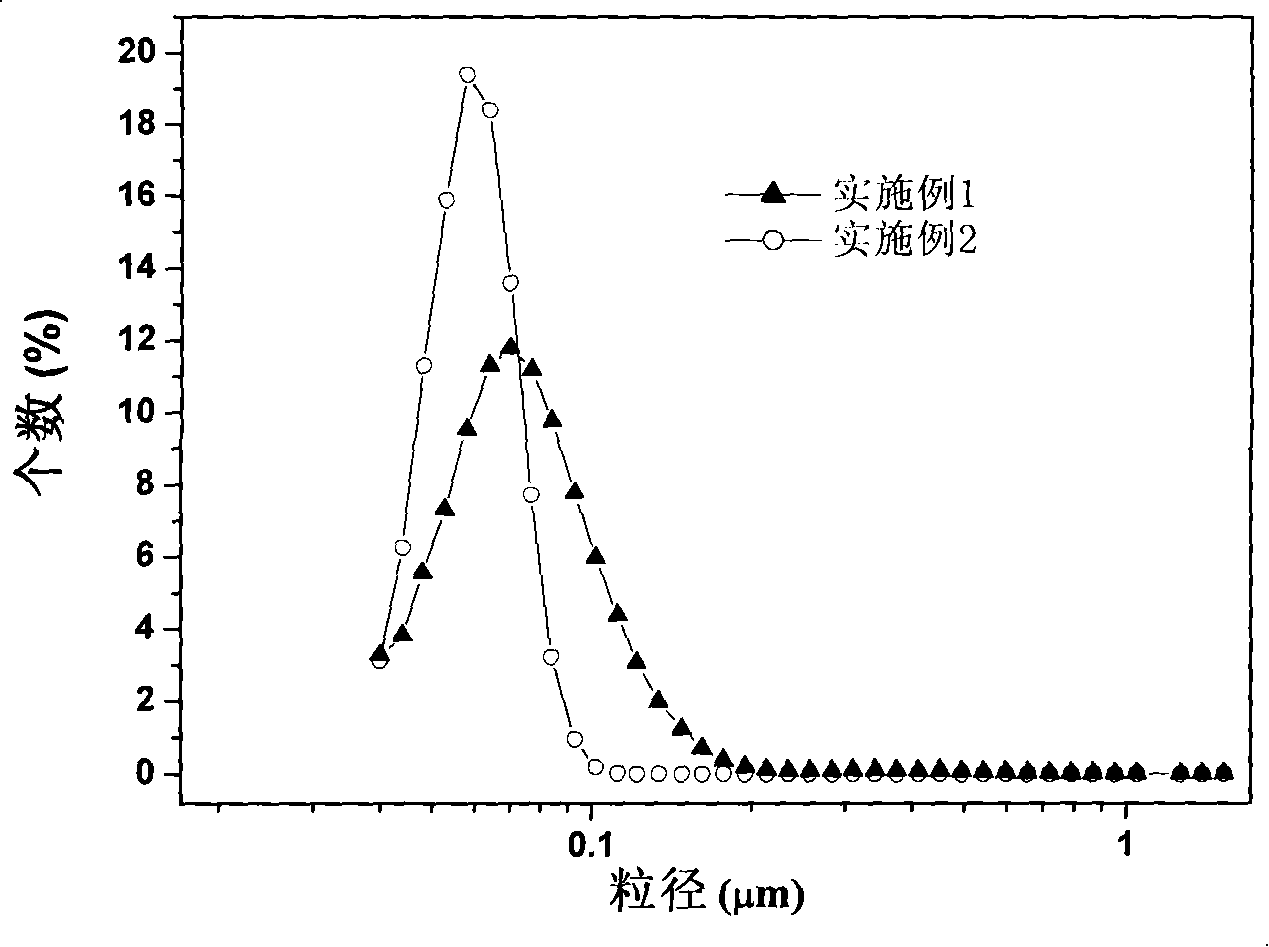

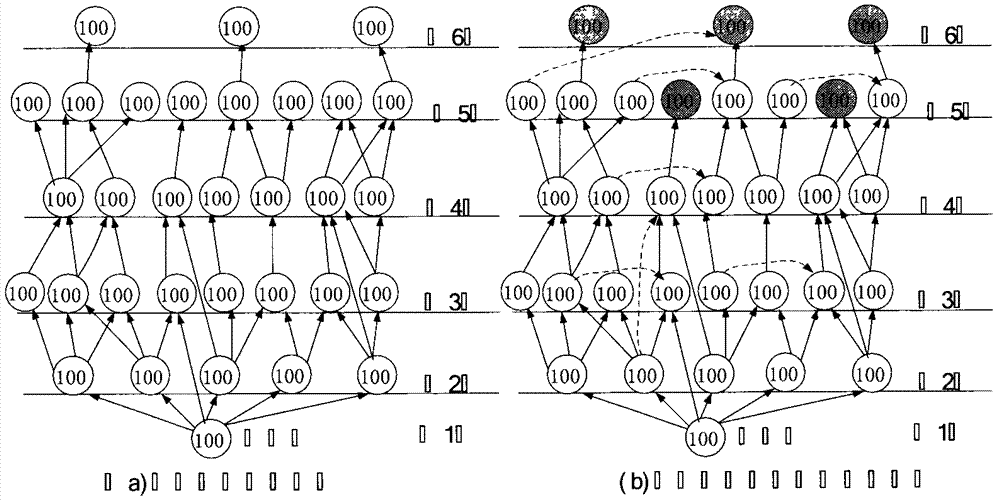

Adaptive extraction and diagnosis method for degree features of mechanical fault through stack-type sparse automatic coding depth neural network

InactiveCN106323636AImprove robustnessRealize intelligent diagnosis of fault levelMachine bearings testingNeural learning methodsAdaptive learningFeature extraction

The invention relates to an adaptive extraction and diagnosis method for degree features of a mechanical fault through a stack-type sparse automatic coding depth neural network, and belongs to the technical field of mechanical equipment state monitoring and reliability evaluation. The method aims at a problem of intelligent diagnosis of the degree of the mechanical fault, and comprises the steps: carrying out the stacking of sparse automatic coding, adding a classification layer, and constructing the stack-type sparse automatic coding depth neural network which integrates the adaptive learning and extraction of the degree features of the fault and fault recognition; employing the advantage that the sparse automatic coding can automatically learn the internal features of data, and adding noise coding to be integrated in the sparse automatic coding for improving the robustness of feature learning; carrying out the layer-by-layer no-supervision adaptive learning and supervision fine tuning of the original input complex data through multilayer sparse automatic coding, completing the automatic extraction and expression of the degree features of the mechanical fault and achieving the intelligent diagnosis of the degree of the fault. The method is used for the diagnosis of the degree of faults of rolling bearings under different work conditions, and obtains a good effect of feature extraction and diagnosis.

Owner:CHONGQING JIAOTONG UNIVERSITY

Method and device for monitoring status of mechanical equipment and abnormality diagnosing device

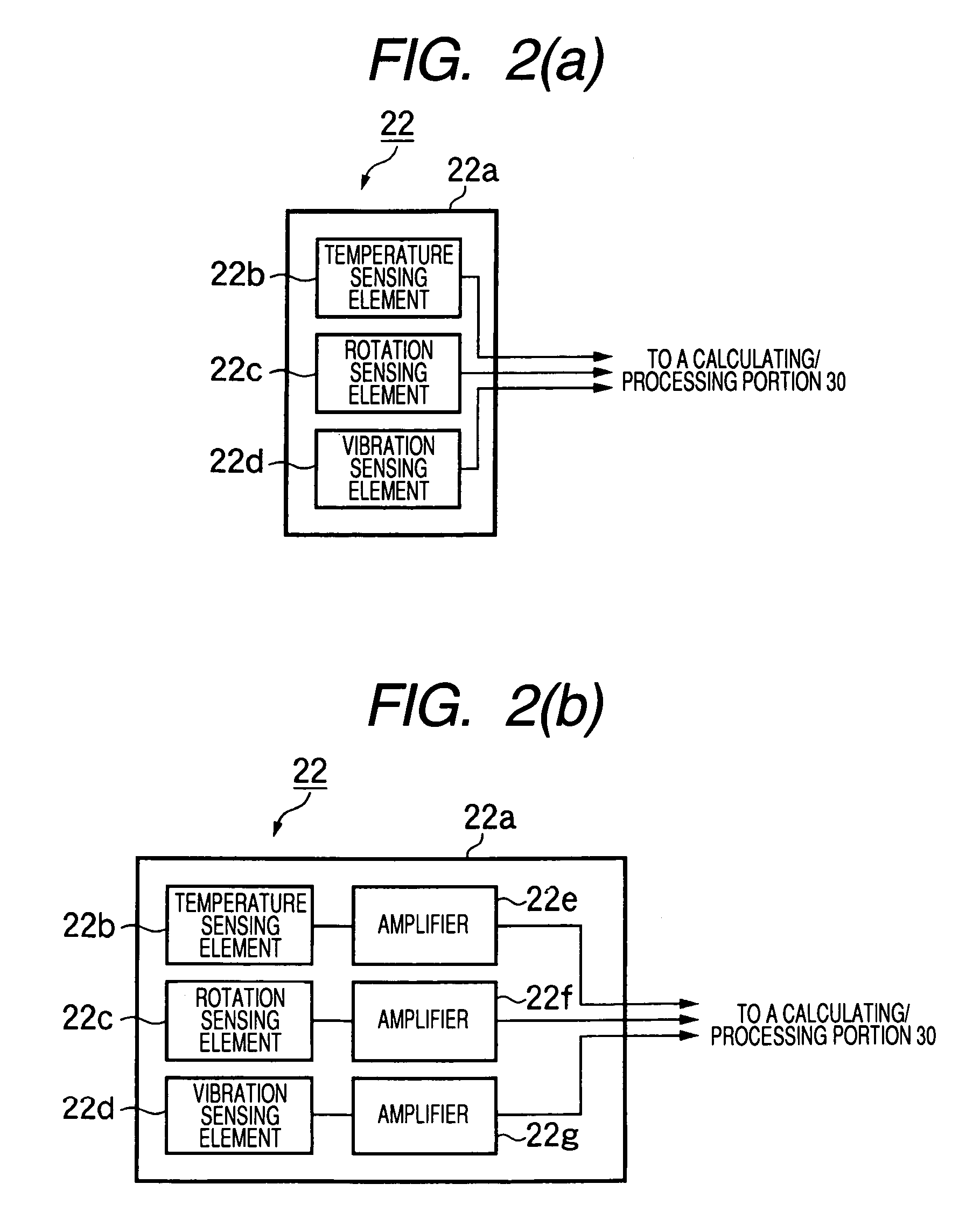

An abnormality diagnosis system for diagnosing a presence or absence of an abnormality of a bearing unit for a railway vehicle axle, comprises a sensing / processing portion for outputting a signal generated from the bearing unit as an electric signal, a calculating / processing portion for making an abnormality diagnosis of the bearing unit based on an output of the sensing / processing portion, a result outputting portion for outputting a decision result of the calculating / processing portion, and a controlling / processing portion for feeding back a control signal to a control system of the railway vehicle based on the decision result.

Owner:NSK LTD

Abnormality diagnosing system for mechanical equipment

ActiveUS7640139B2Vibration measurement in solidsMachine part testingDifferential coefficientMoving average

Provided are an envelope processor 103, for obtaining an envelope for a detected signal; a FFT unit 104, for converting the envelope into a frequency spectrum; a peak detector 105, for smoothing the frequency spectrum by calculating a moving average, for further performing smoothing and differentiation for the spectrum, and detecting, as peaks, frequency points at which a sign of a differential coefficient is changed from positive to negative, for extracting peaks having a predetermined threshold value or greater, and for sorting the extracted peaks and detecting upper peaks; and a diagnosis processor T, for diagnosing an abnormality based on the detected peaks.

Owner:NSK LTD

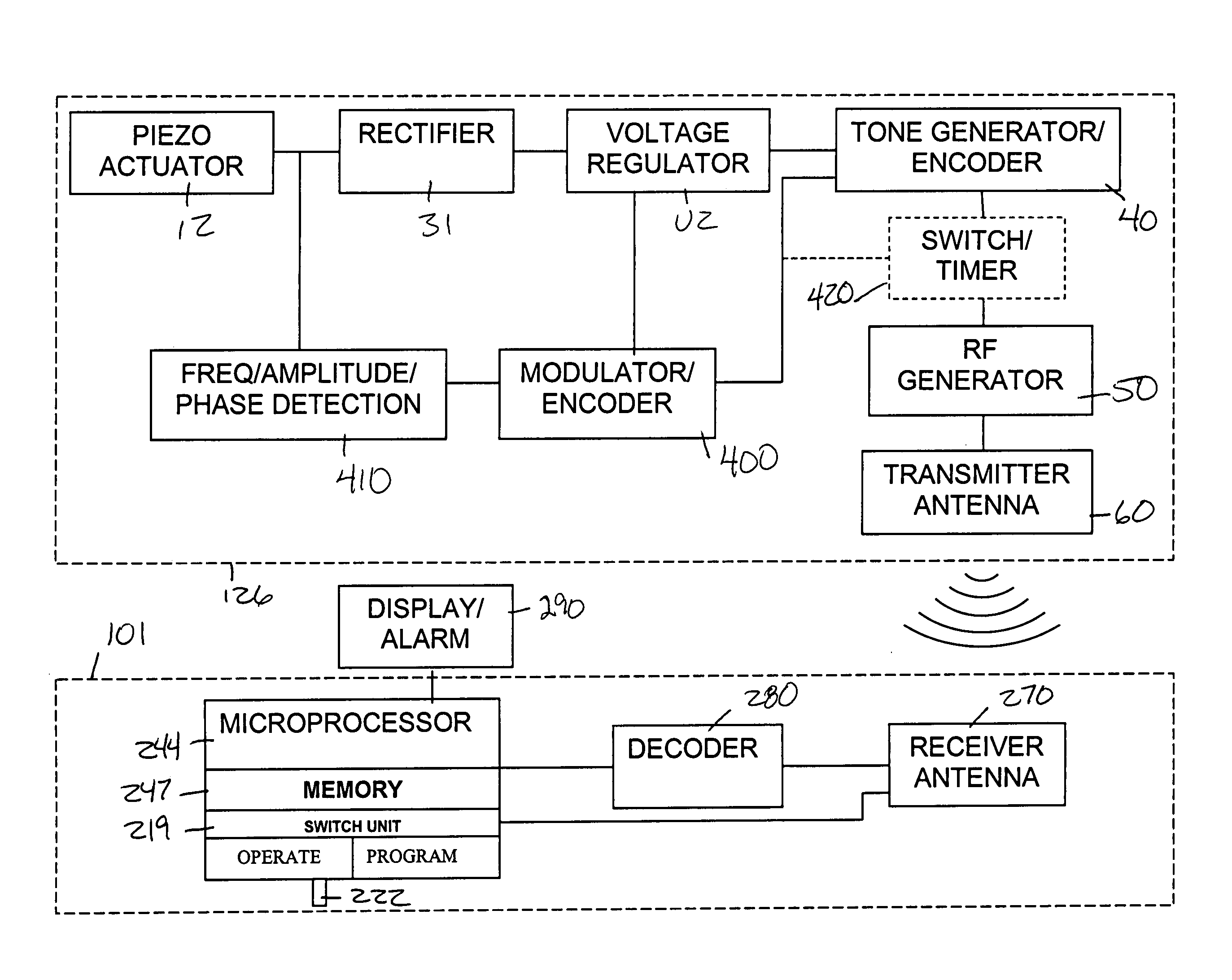

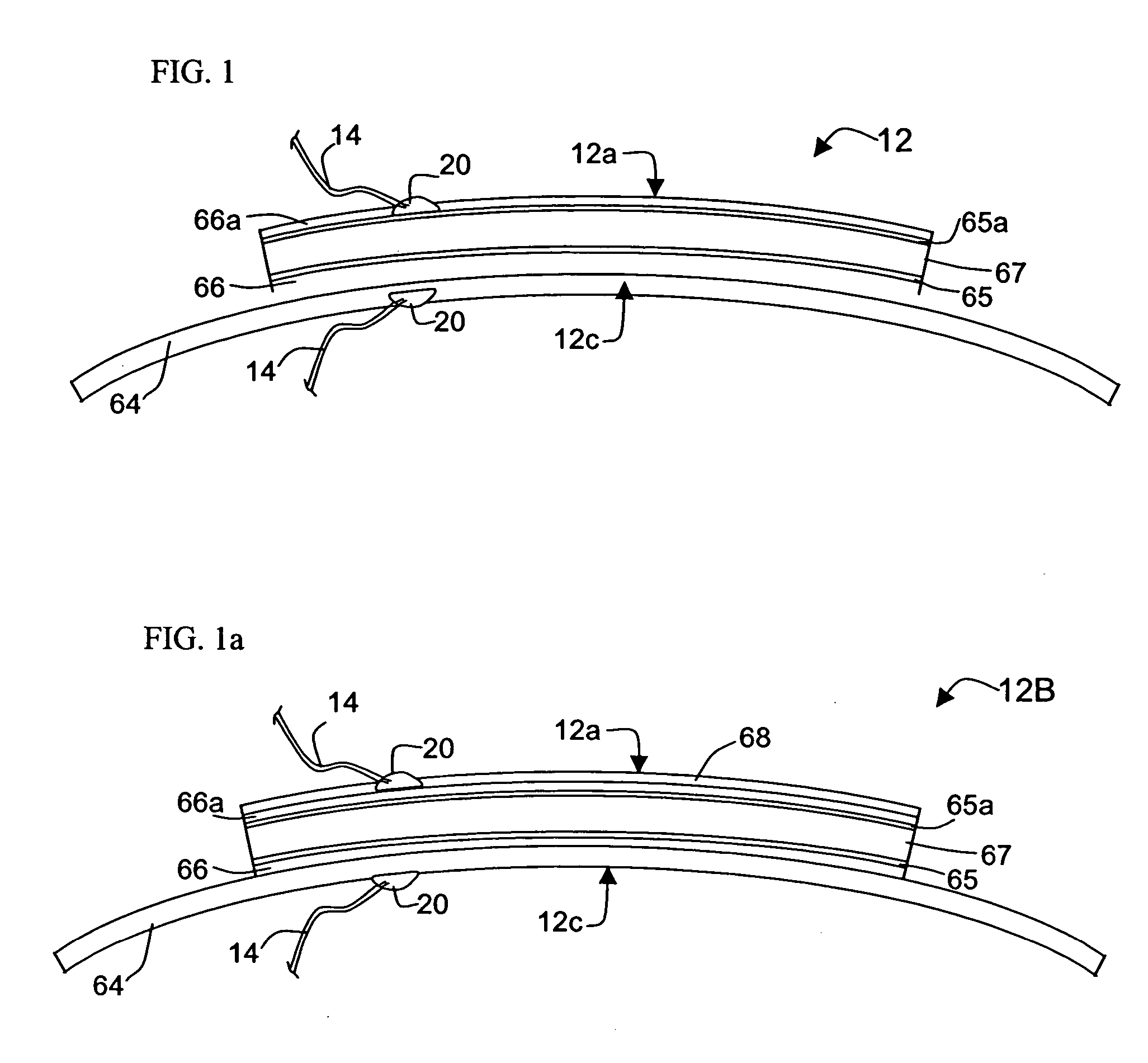

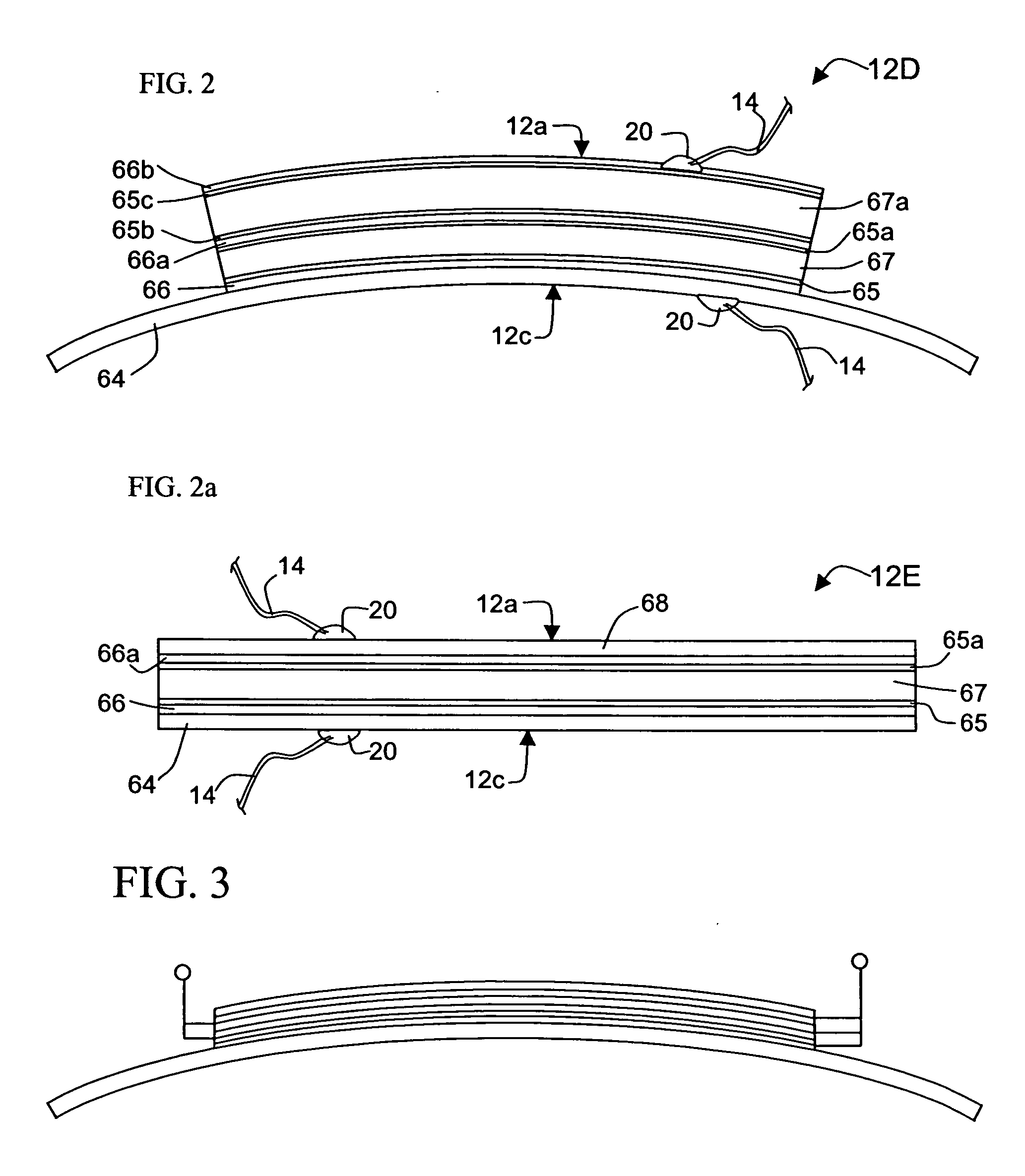

Self-powered vibration monitoring system

InactiveUS20050087019A1Sufficient magnitudeEasy to useSubsonic/sonic/ultrasonic wave measurementMaterial analysis using acoustic emission techniquesElectricityMonitoring system

A system for monitoring the vibration of electrical and mechanical equipment. More particularly, the present invention relates to a self-powered vibration monitoring device and system that generates an electrical signal that not only powers the device(s), but also is indicative of the frequency and / or amplitude of vibration of the equipment to which it is attached. The power is preferably generated through a piezoelectric element and is sent through signal generation circuitry coupled to a transmitter for sending RF signals indicative of the vibrational status of the equipment to one or more receivers for further display or processing.

Owner:FACE BRADBURY R

Method and device for monitoring status of mechanical equipment and abnormality diagnosing device

InactiveUS20060167659A1Diagnose abnormalityMachine part testingEngine fuctionsMonitoring statusControl system

An abnormality diagnosis system for diagnosing a presence or absence of an abnormality of a bearing unit for a railway vehicle axle, comprises a sensing / processing portion for outputting a signal generated from the bearing unit as an electric signal, a calculating / processing portion for making an abnormality diagnosis of the bearing unit based on an output of the sensing / processing portion, a result outputting portion for outputting a decision result of the calculating / processing portion, and a controlling / processing portion for feeding back a control signal to a control system of the railway vehicle based on the decision result.

Owner:NSK LTD

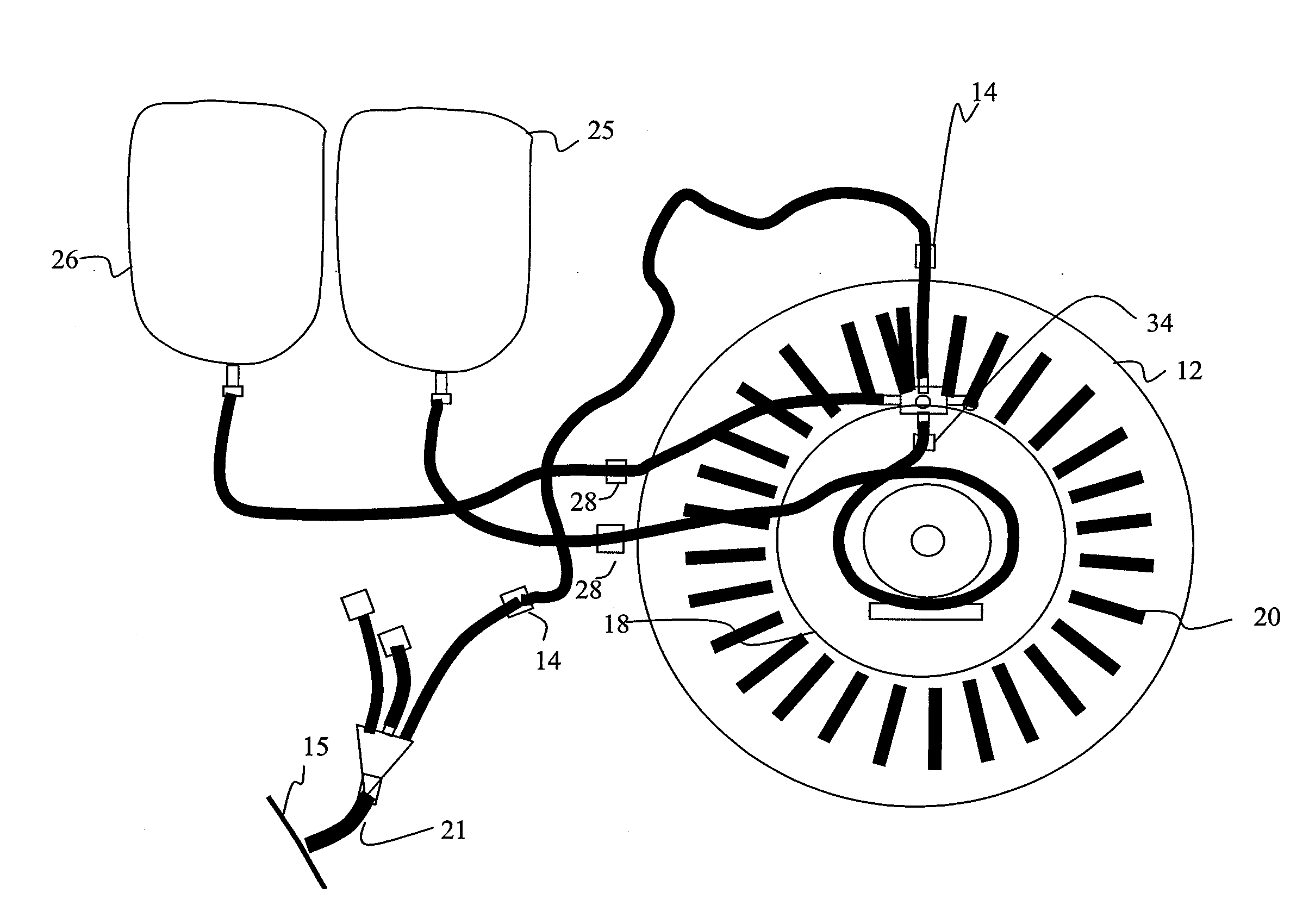

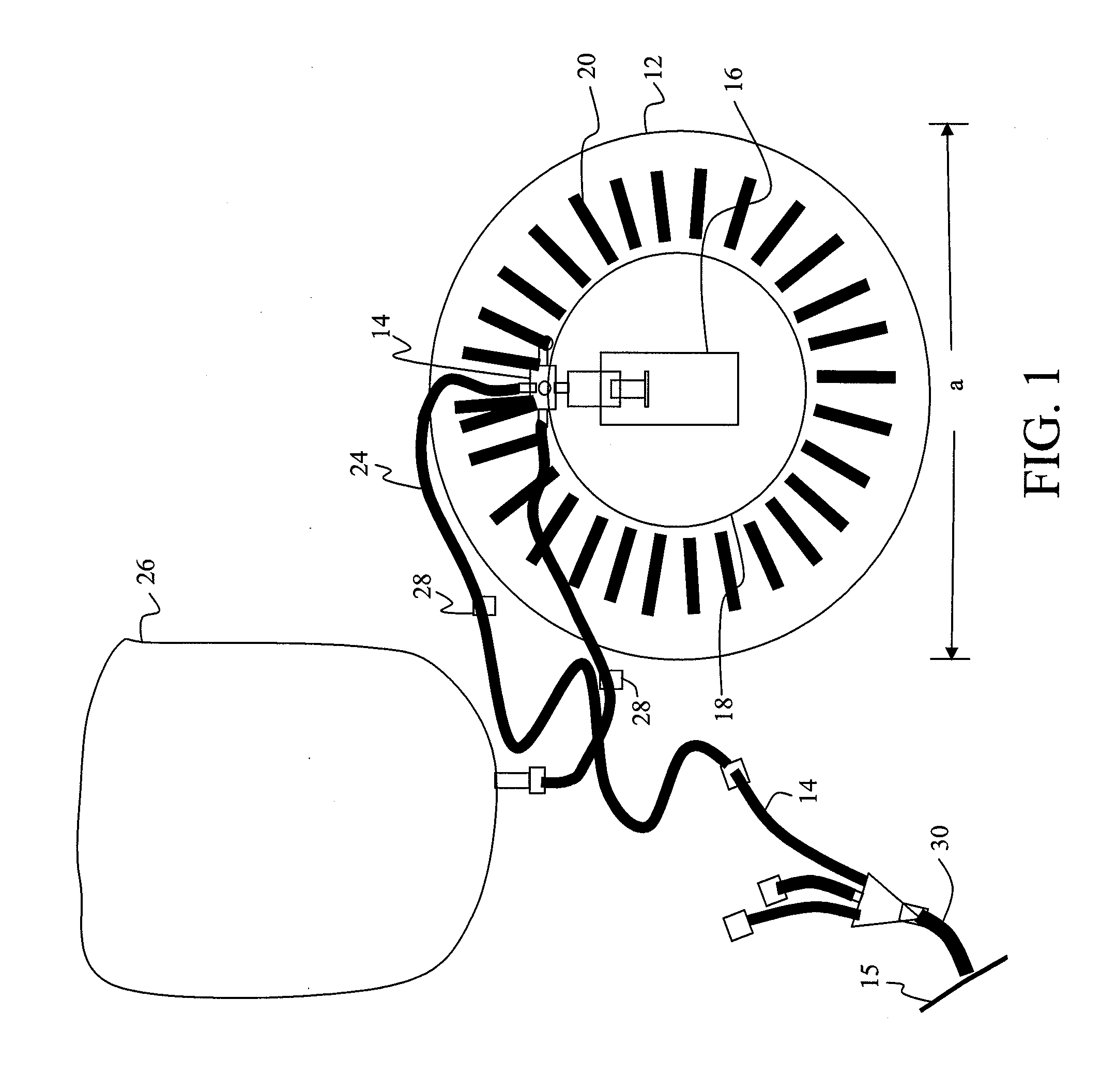

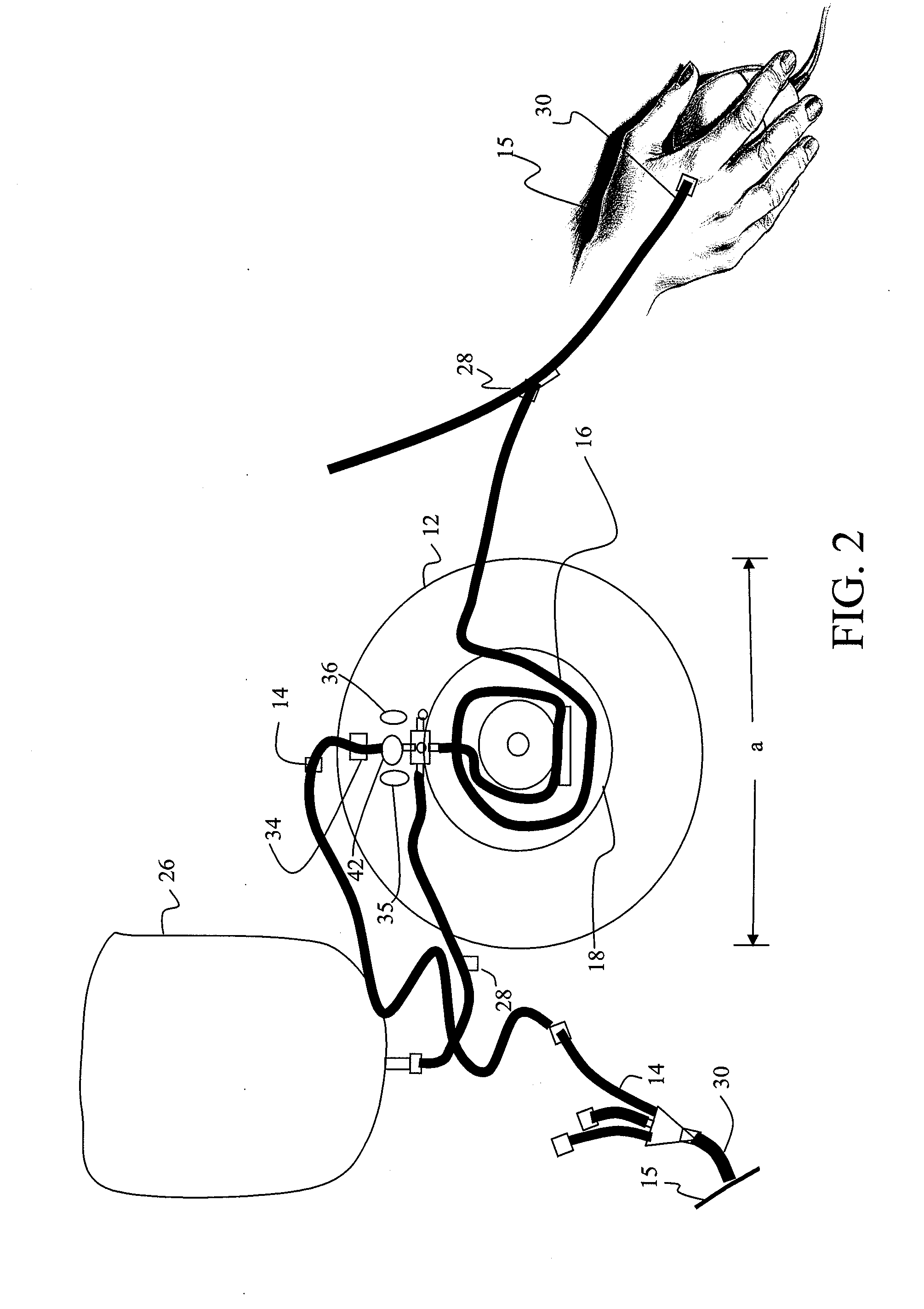

Wearable Automated Blood Sampling and Monitoring System

A wearable blood chemistry monitoring device is disclosed which comprises a wearable automated blood chemistry monitoring device comprising (A) a mini pump which can be, for example a peristaltic pump or syringe pump; (B) a portable form factor mechanical apparatus which preferably includes a rotatable disc with a hole which fits over the pump; (C) at least one measurement element for measuring at least one blood parameter, preferably on the disc, and preferably a series of glucose strips arranged radially in a spoke-like pattern on the disc; (D) a catheter connected to the pump via a tube; (E) a computerized device adapted to automatically measure blood analytes and blood parameters; (F) a belt adapted to hold the housing, a waste bag, and a flush solution bag; wherein the pump and disk are arranged in the housing so that a hole in a disk fits over the pump.

Owner:GLUCON

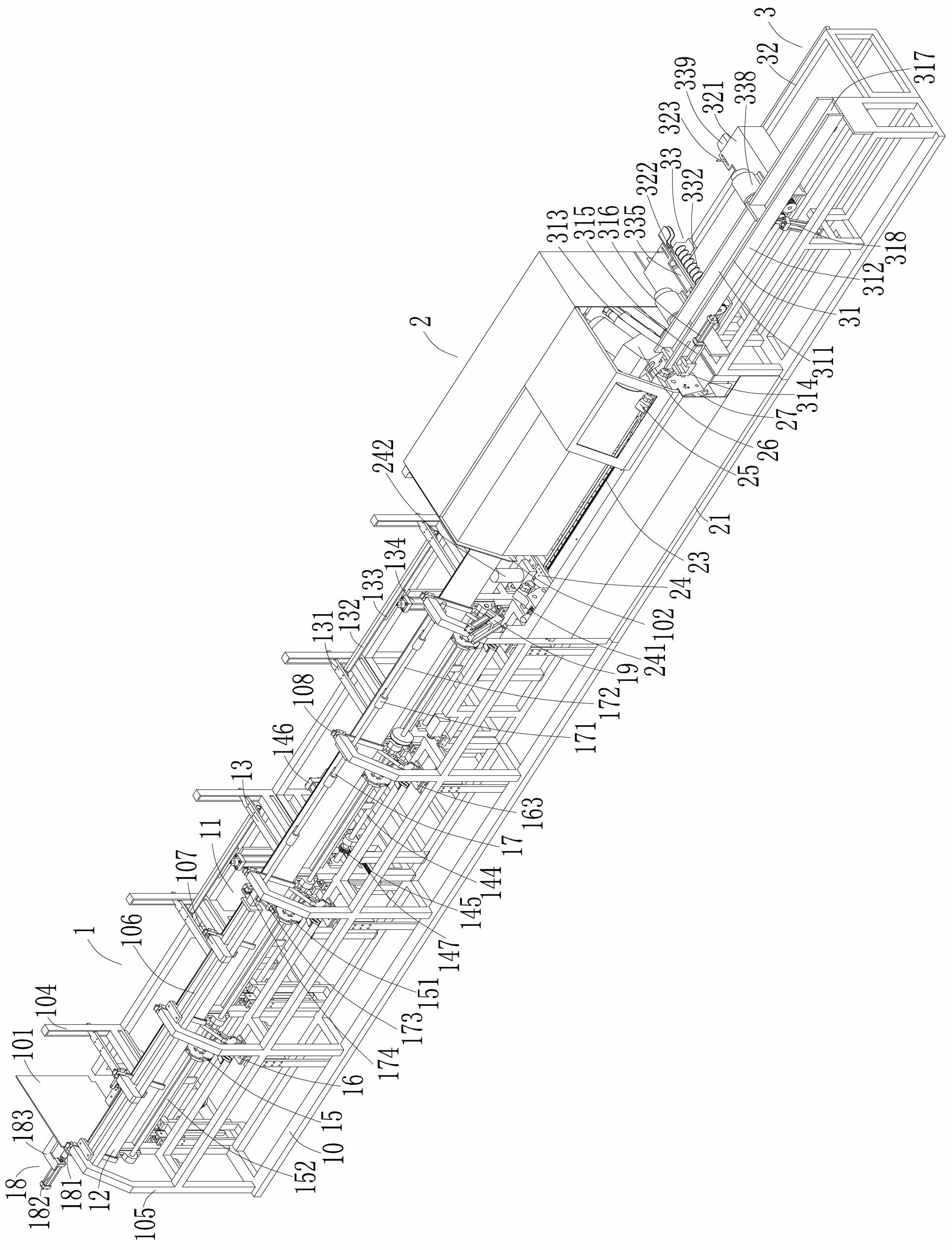

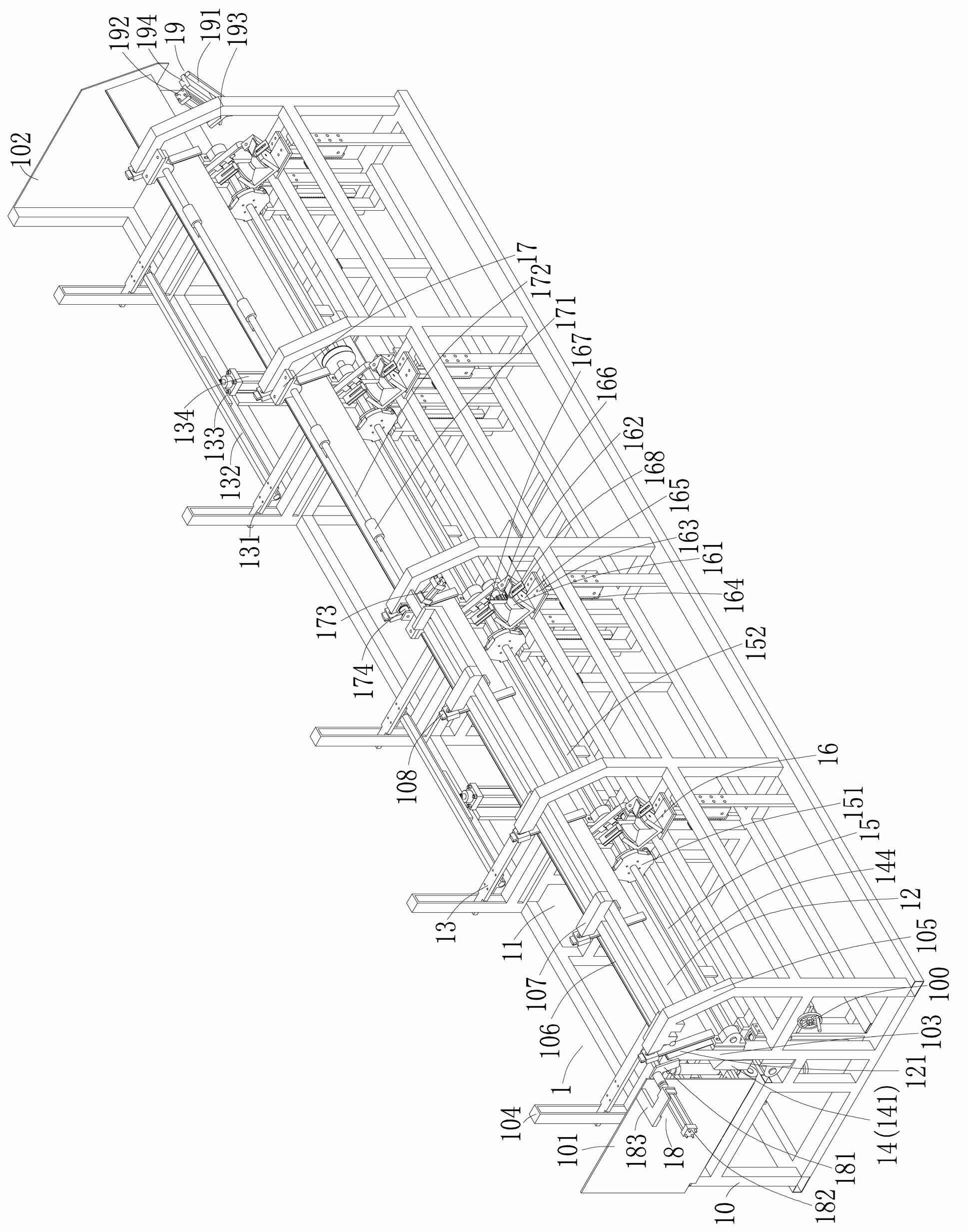

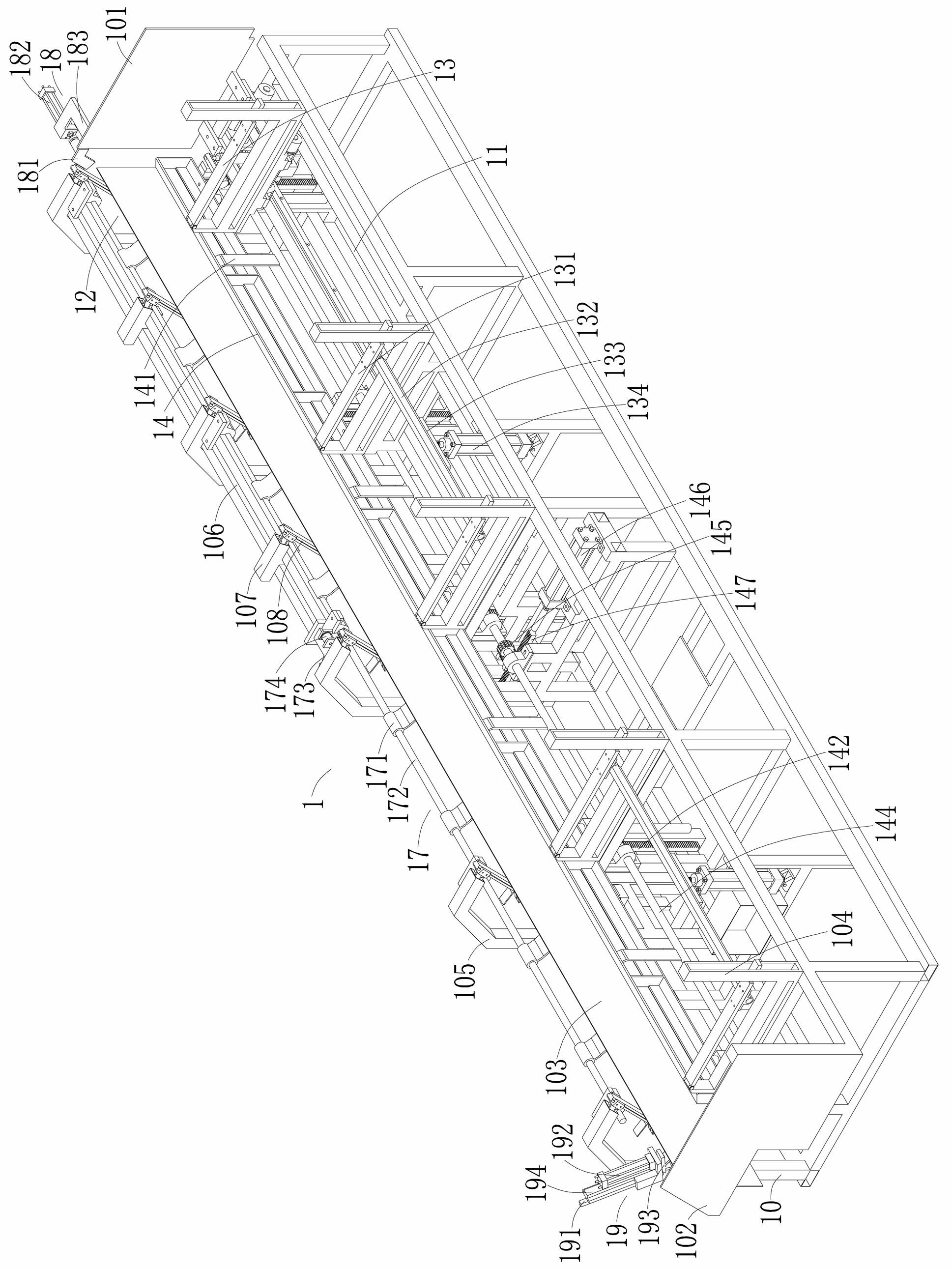

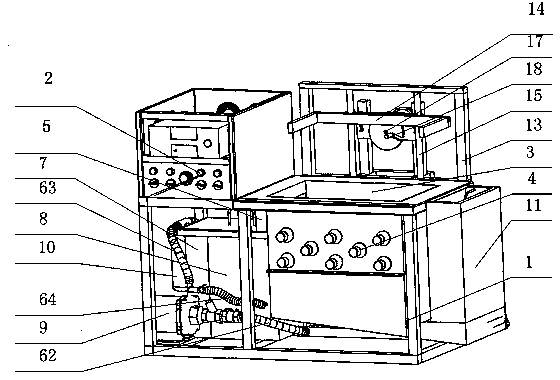

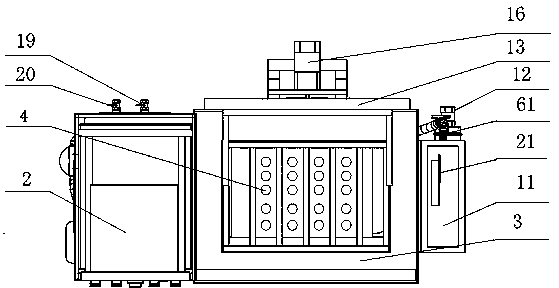

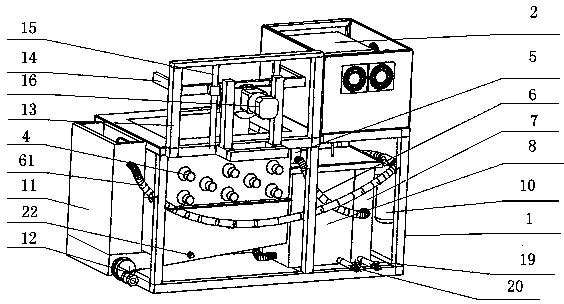

Full-automatic feeding, cutting and receiving equipment and processing method thereof

ActiveCN102145453AAffect normal workIncrease stiffnessOther manufacturing equipments/toolsPositioning apparatusLeveling mechanismMechanical equipment

The invention relates to the field of production machining mechanical equipment and discloses full-automatic feeding, cutting and receiving equipment. A material slot of a feeding device of the full-automatic feeding, cutting and receiving equipment is provided with a shifting mechanism consisting of a shifting fork and a shifting rod. The end of the shifting mechanism, which corresponds to a rear baffle plate of the feeding device, is provided with a leveling mechanism. A feeding bracket at the side of an unloading mechanism, which is correspondingly connected with a tube cutting device, is provided with a clamping mechanism. A lower roller and a side roller which are connected are arranged in the unloading mechanism. A split clamp of the tube cutting device is arranged on a tube cutting bracket through a trapezoid block. A recovery device consists of a recovery mechanism and a return mechanism, wherein the recovery mechanism is arranged at one side of the split clamp in a leveling mode; and the return mechanism is arranged on a recovery bracket at the rear end of the recovery mechanism. A brush wheel is arranged in the return mechanism. A machining method of the equipment comprises the steps of adding, aligning, feeding, cutting and receiving. The full-automatic feeding, cutting and receiving equipment is smooth to feed materials and is clear to separate the materials, so that resource waste is avoided, the machining procedures of the engineering are reduced, the cutting quality is improved, both manpower and material resources are saved and the production efficiency is improved.

Owner:东莞市机信机械有限公司

Nylon modified plastic

The invention discloses a nylon modified plastic which comprises the following raw materials in parts by weight: (1) 20-80 parts of nylon resin; and (2) one or more of 15-45 parts of reinforcer, 5-20 parts of toughener or 9-15 parts of compound flame retardant, wherein the nylon resin is prepared from pentamethylene diamine and aliphatic dibasic acid used as raw materials, and at least one of the pentamethylene diamine and the aliphatic dibasic acid is prepared through a biological method. The nylon modified particle prepared by the invention has excellent properties of reinforcing, toughening, flame retardance and the like, can be further used in the fields of automobile industry, electronic / electric apparatus industry, mechanical equipment and the like, and has wide industrial application prospects.

Owner:CATHAY R&D CENT CO LTD +1

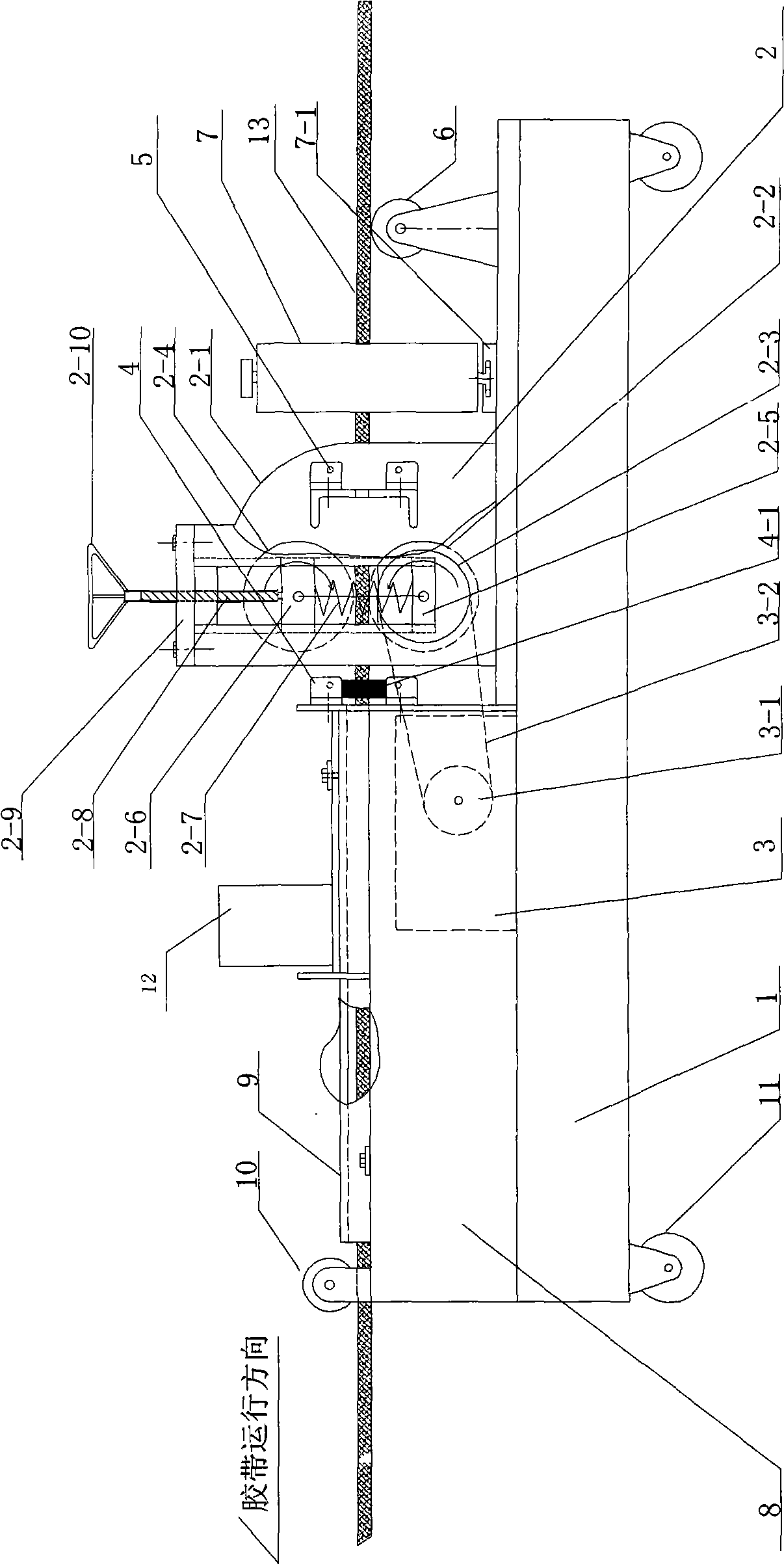

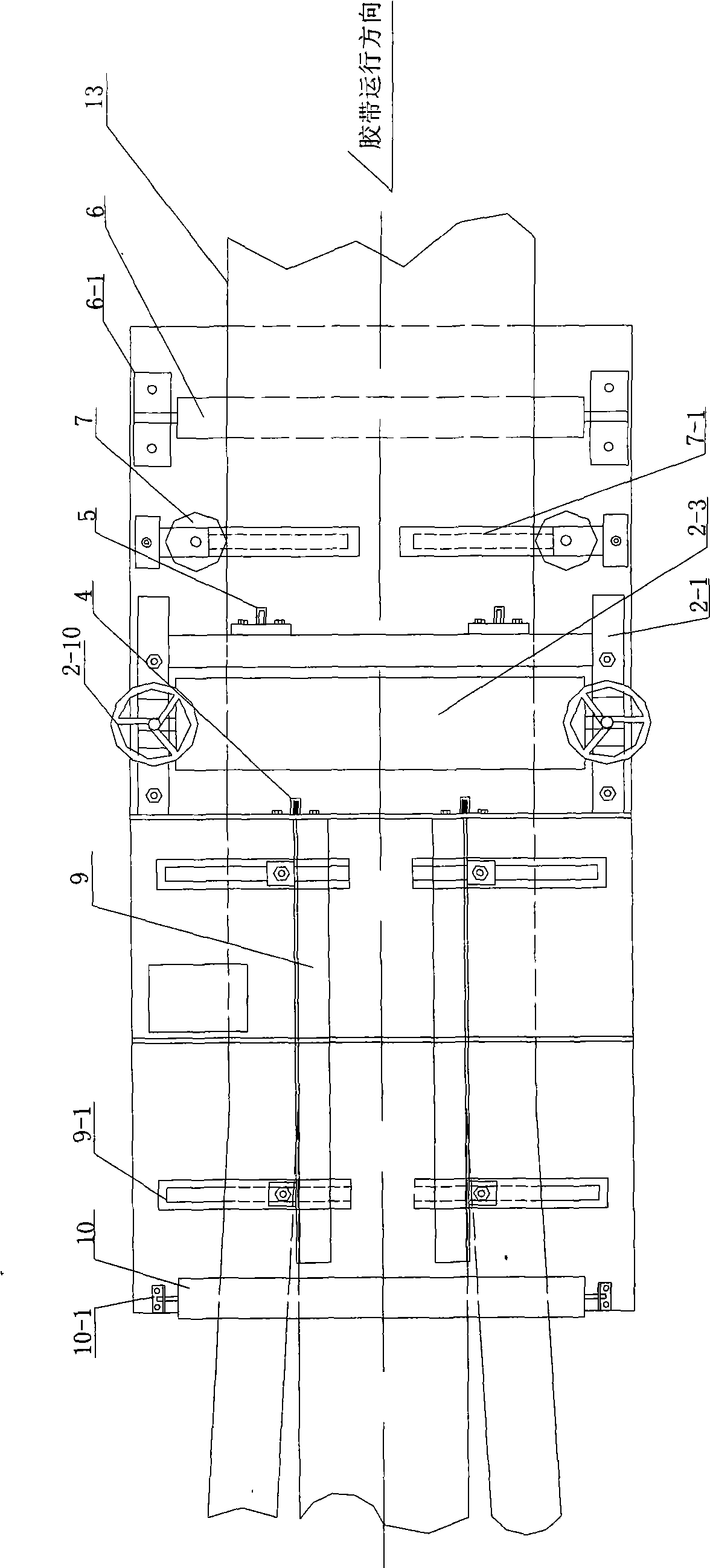

Cutting trimming device of conveyer belt

InactiveCN101508119ARealize comprehensive utilizationSave resourcesMetal working apparatusWebs handlingElectric machineryMechanical equipment

The invention relates to mining mechanical equipment, in particular to a conveyor belt cutting and dressing machine, which consists of a pedestal, a drive device, a conveyor belt device, a main tool post, an auxiliary tool post, a carrier roller, a guide wheel, a saddle, a guide groove, a belt hold roller and an electric control box; the drive device consists of an electric motor and a gear box; the conveyor belt device consists of an upright post bracket, a conveyor belt driving roller, a conveyor belt pressing roller and a feed screw nut; the gear box and the conveyor belt driving roller are connected through chains; the front end and the rear end of the drive device are provided with the main tool post and the auxiliary tool post; the tool posts are provided with cutting knives or saw bits driven by a small-power motor; the rear end of the auxiliary tool post is provided with the guide wheel; the rear end of the guide wheel is provided with the carrier roller; the saddle is arranged on the pedestal; the guide groove and the belt hold roller are arranged on the saddle; and a road wheel is arranged at the bottom of the pedestal. The mining mechanical equipment is used for the trimming, the reshaping and the width modification of the conveyor belt, realizes the waste utilization, saves energy resources, reduces the cost and labor intensity, improves the production efficiency, and has a simple structure and convenient operation.

Owner:兖矿能源集团股份有限公司

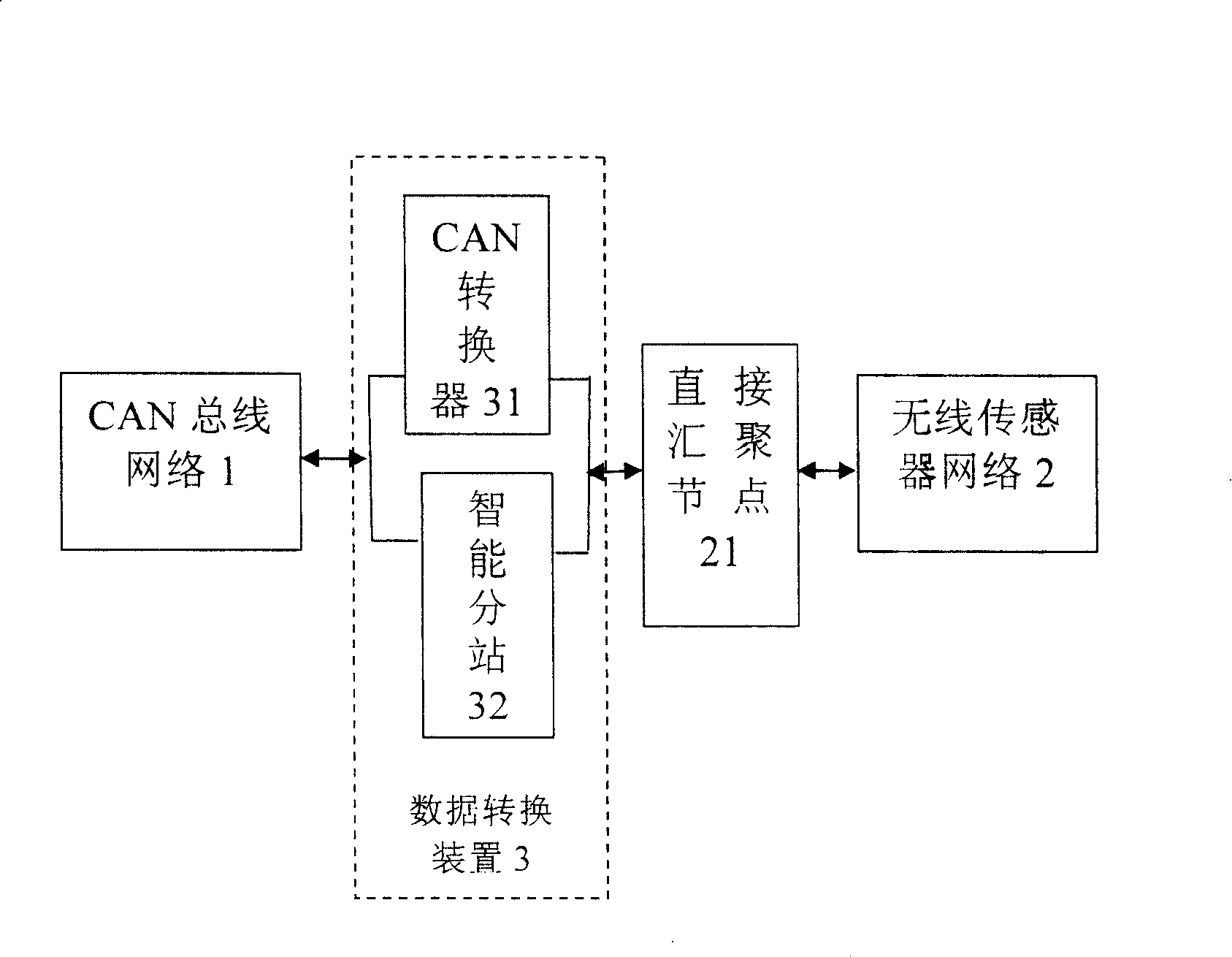

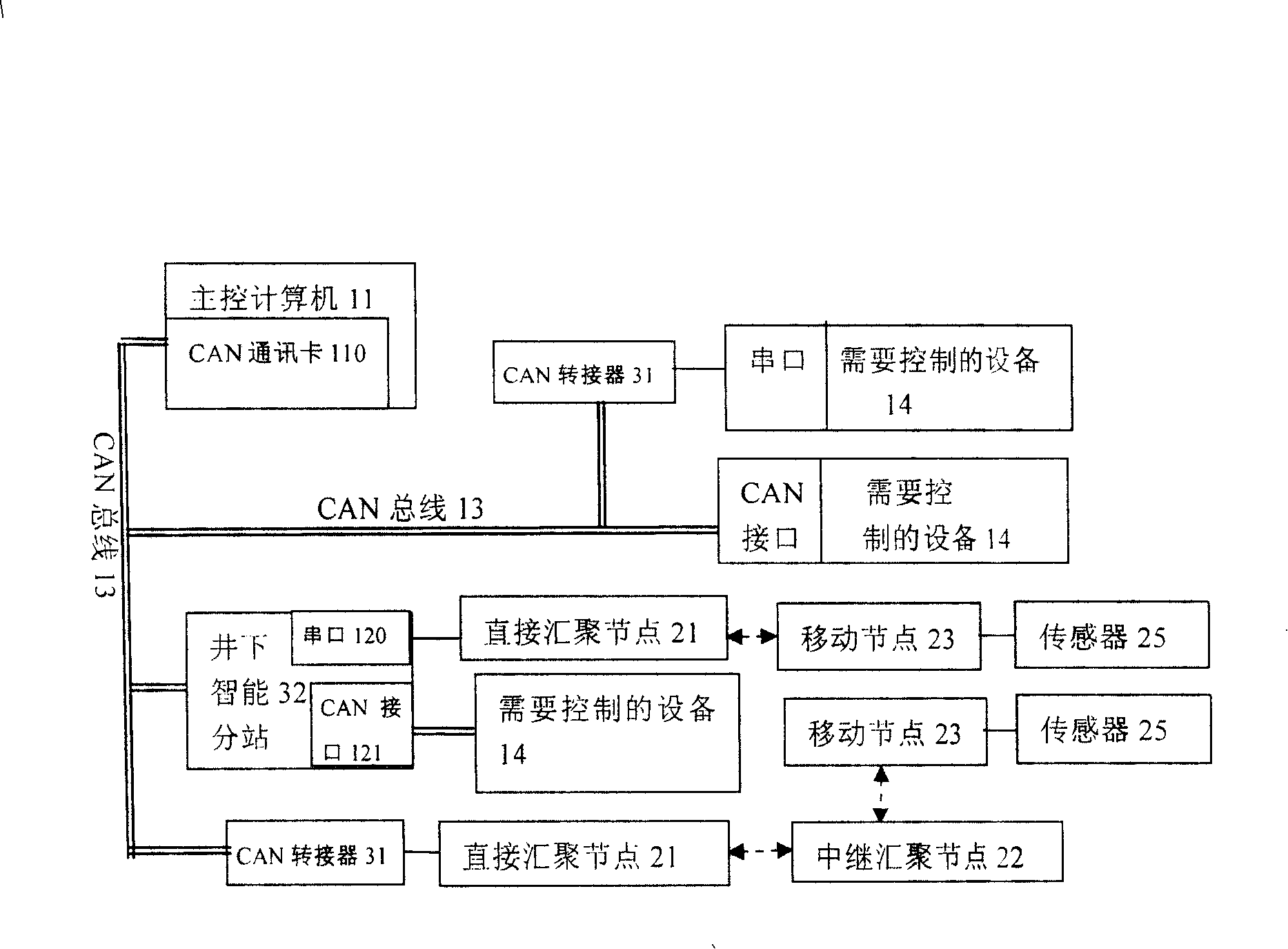

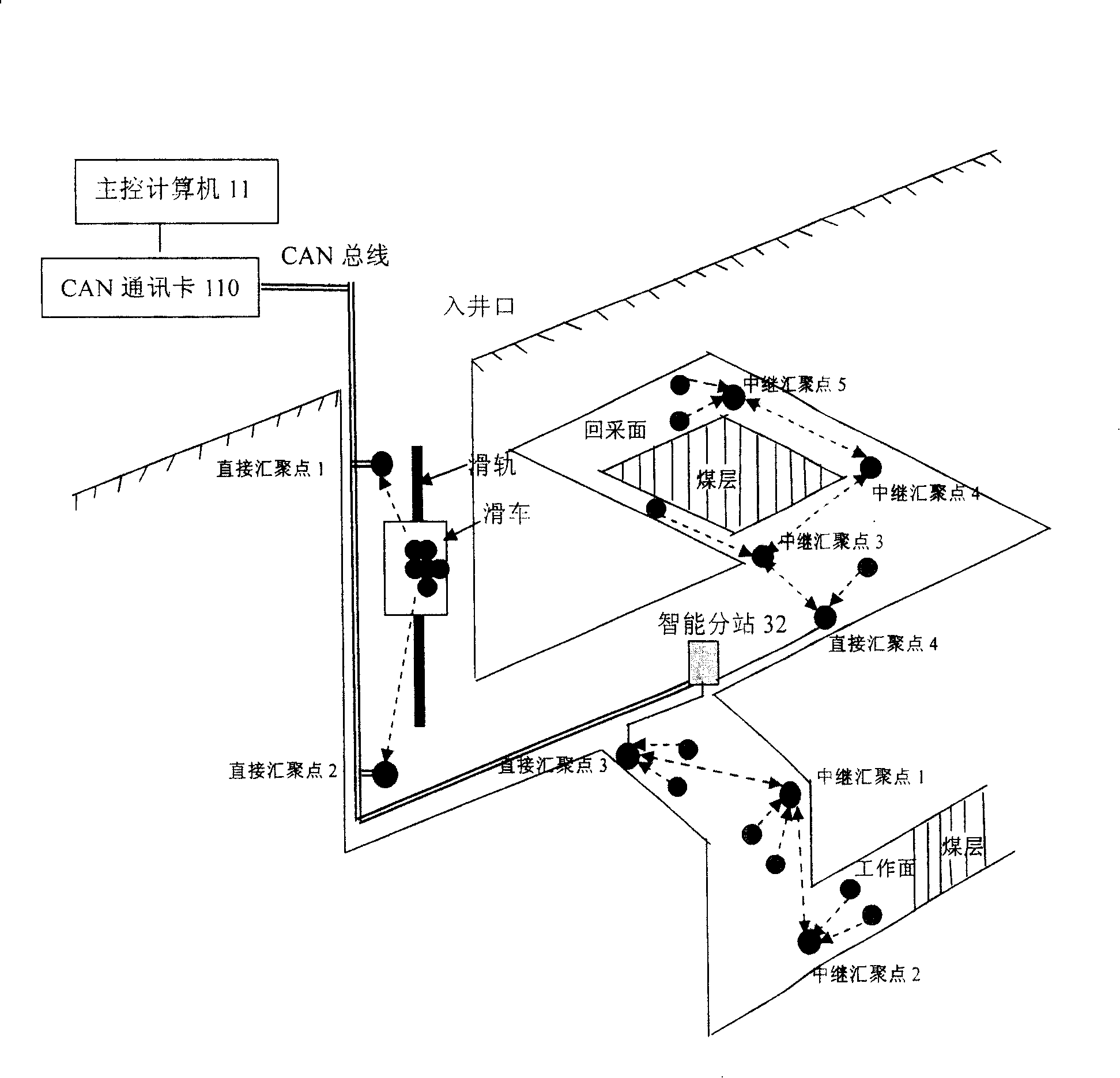

Coal mine down-hole personnel positioning and mash gas concentration dynamic monitoring method and system

InactiveCN101240717AReduce usageReduce investmentMining devicesTransmission systemsNetwork connectionDynamic monitoring

The present invention discloses methods and system for coal mine downhole personnel locating and mash gas concentration dynamic monitoring, the system includes: CAN bus network, wireless sensor network and data conversion device. CAN network connects with wireless transducing network connections by data switching device, and by using wireless sensor network self-organizing, multi- skip, data acquisition and processing, and wireless communicating characteristic, the invention designs a system about out-in well personnel work attendance and moving vehicle zone location in coal mine well, and a system for monitoring gas dynamic concentration. The system and method overcome the current deficiency of operating gas monitoring system and personnel position location system respectively, not only personnel zone location and dynamic gas testing is realized, but also allocation is obtained about personnel arrangement and moving mechanical equipment before the accident, this provides reliable data for rescuing miner and avoiding second disaster.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

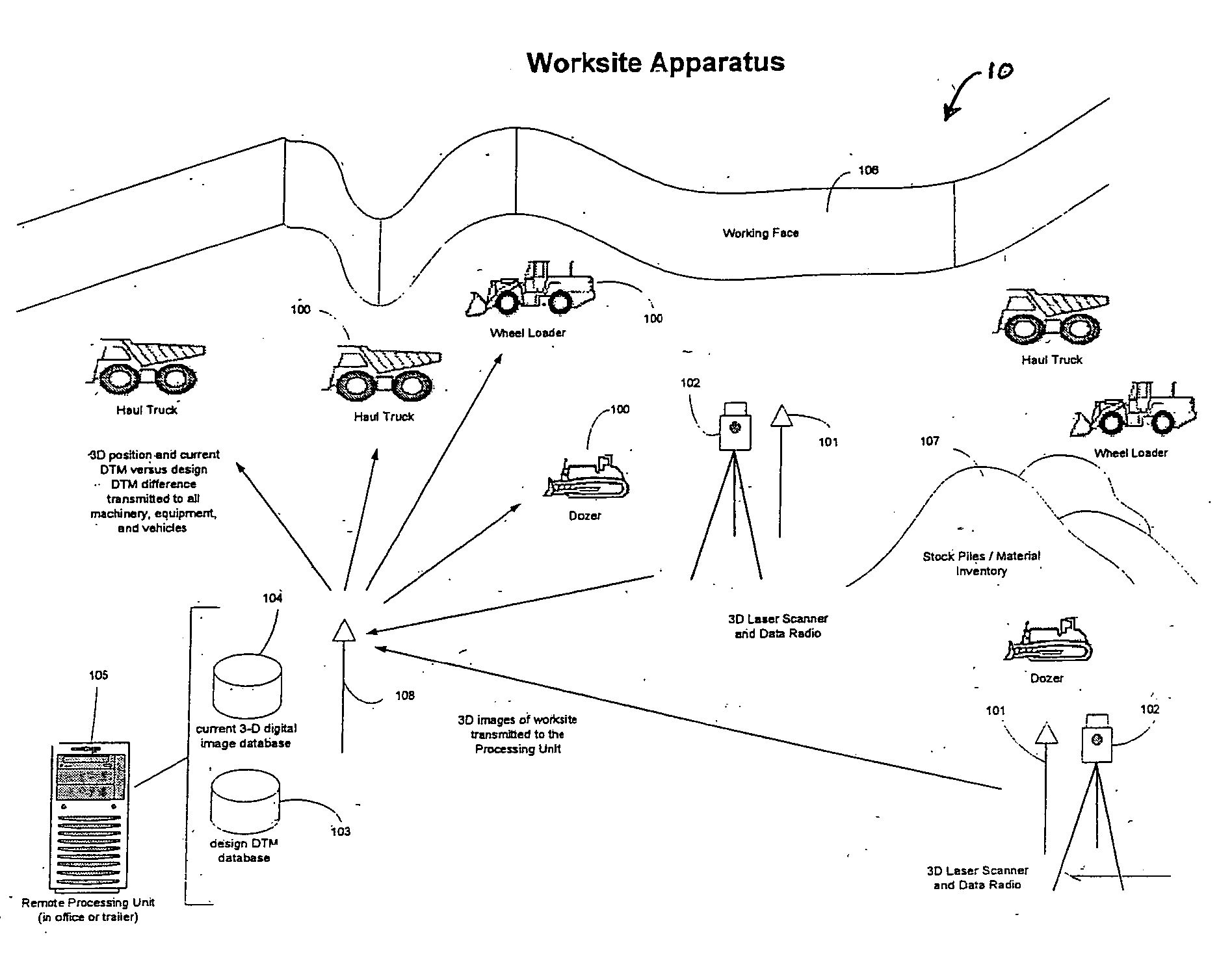

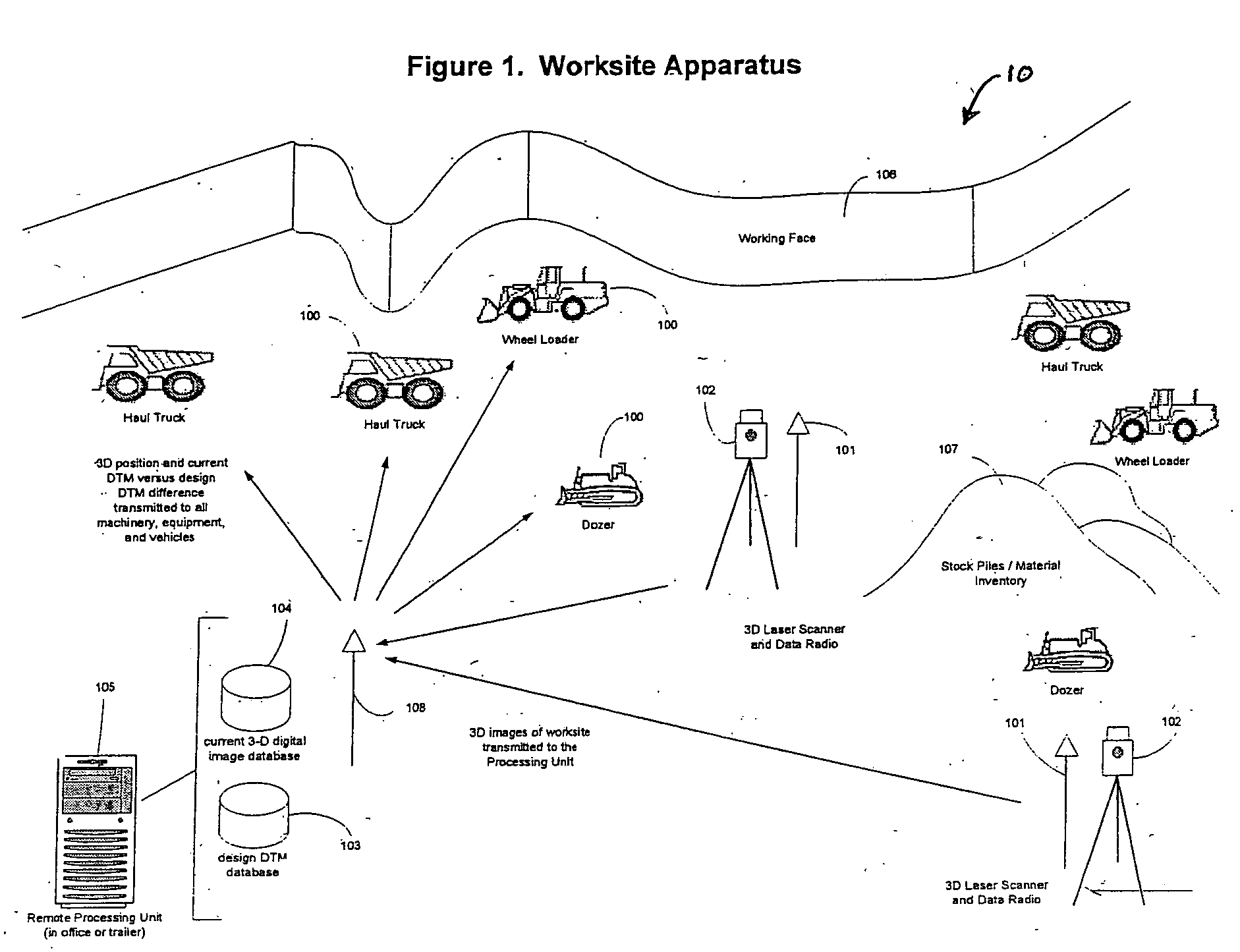

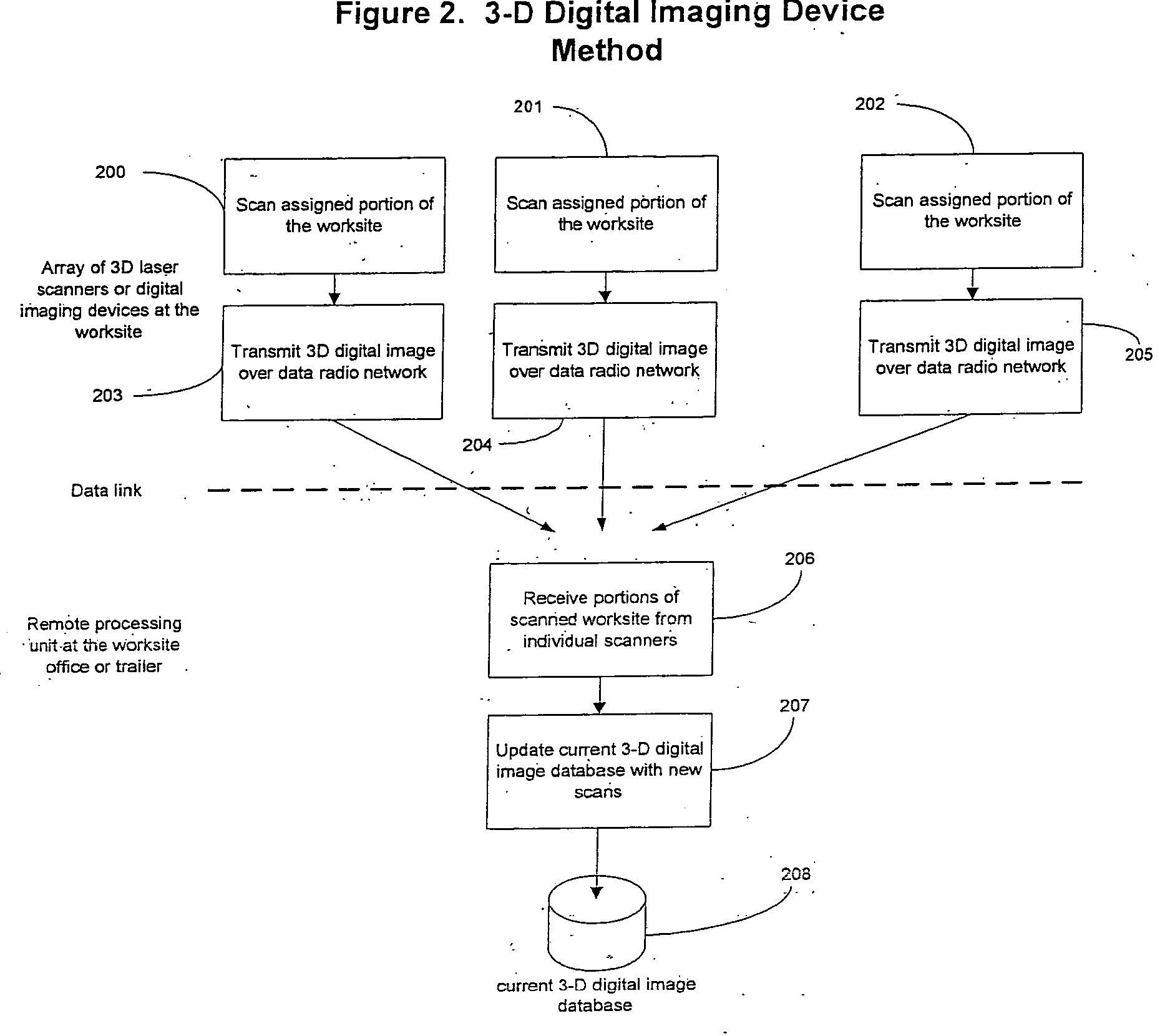

Method and apparatus for machine guidance at a work site

InactiveUS20050283294A1Advanced technologyAnalogue computers for trafficComputations using stochastic pulse trainsTerrainDigital imaging

A method and apparatus for providing machine guidance of all types of earthmoving machinery, other heavy equipment, and work site vehicles. The method and apparatus is applicable to any industrial work site such as a construction site, open pit mine, quarry operation, or landfill. The machinery, equipment, or vehicle is not required to be equipped with a positional receiver of any kind. The position of all machinery, equipment, and vehicles is performed by employing an array of 3D laser scanners (or any 3D digital imaging devices) positioned throughout the work site. 3D images of the work site are transmitted from the laser scanners to a remote processing unit via a data link or network. The processing unit analyzes the images and determines the position of the machinery, equipment and vehicles. The positions are transmitted to the machinery, equipment, and vehicles via the data link or network. The current Digital Terrain Model (DTM) of the work site is captured and stored in real time in the form of a 3-D digital image, as a by-product of scanning the work site and determining the position of the work site machinery, equipment, and vehicles. The remote processing unit compares the current DTM to the work site's design DTM and transmits the difference to the required machinery, equipment, and vehicles for feedback to their operators in real time.

Owner:LEHMAN ALLEN A JR +2

Ultrasonic cleaner

ActiveCN103878143AConsistent cleanlinessReduce replacement cycleCleaning using liquidsFiltrationWater storage tank

The invention discloses an ultrasonic cleaner and belongs to the field of mechanical equipment cleaning. The ultrasonic cleaner solves the problems that cleaning fluid in an existing ultrasonic cleaner cannot remove impurities in time, and the cleaning fluid is wasted. The ultrasonic cleaner comprises a rack (1), an ultrasonic generator (2), a cleaning tank (3) and ultrasonic vibrators (4). A water circulation device is arranged on the outer side of the cleaning tank (3) and comprises an overflow tank (5) arranged on one side of the cleaning tank (3). The water circulation device further comprises the overflow tank, an oil contamination tank (7), a water storage tank (8), a water pump (9), a filter (10) and a water injection tank (11). The bottom of the water injection tank (11) is communicated with the cleaning tank (3). The bottom of the cleaning tank (3) is an inclined plane. The ultrasonic cleaner integrates the functions of heating, ultrasonic waves, circulating filtration, oil-water separation and article movement, the cleaning speed is high, and the cleaning effect is good; besides, the ultrasonic cleaner is multifunctional, low in energy consumption and capable of prolonging the replacement cycle of the cleaning fluid and reducing environmental pollution, thereby being wide in application range.

Owner:台州鸿辰机械制造有限公司

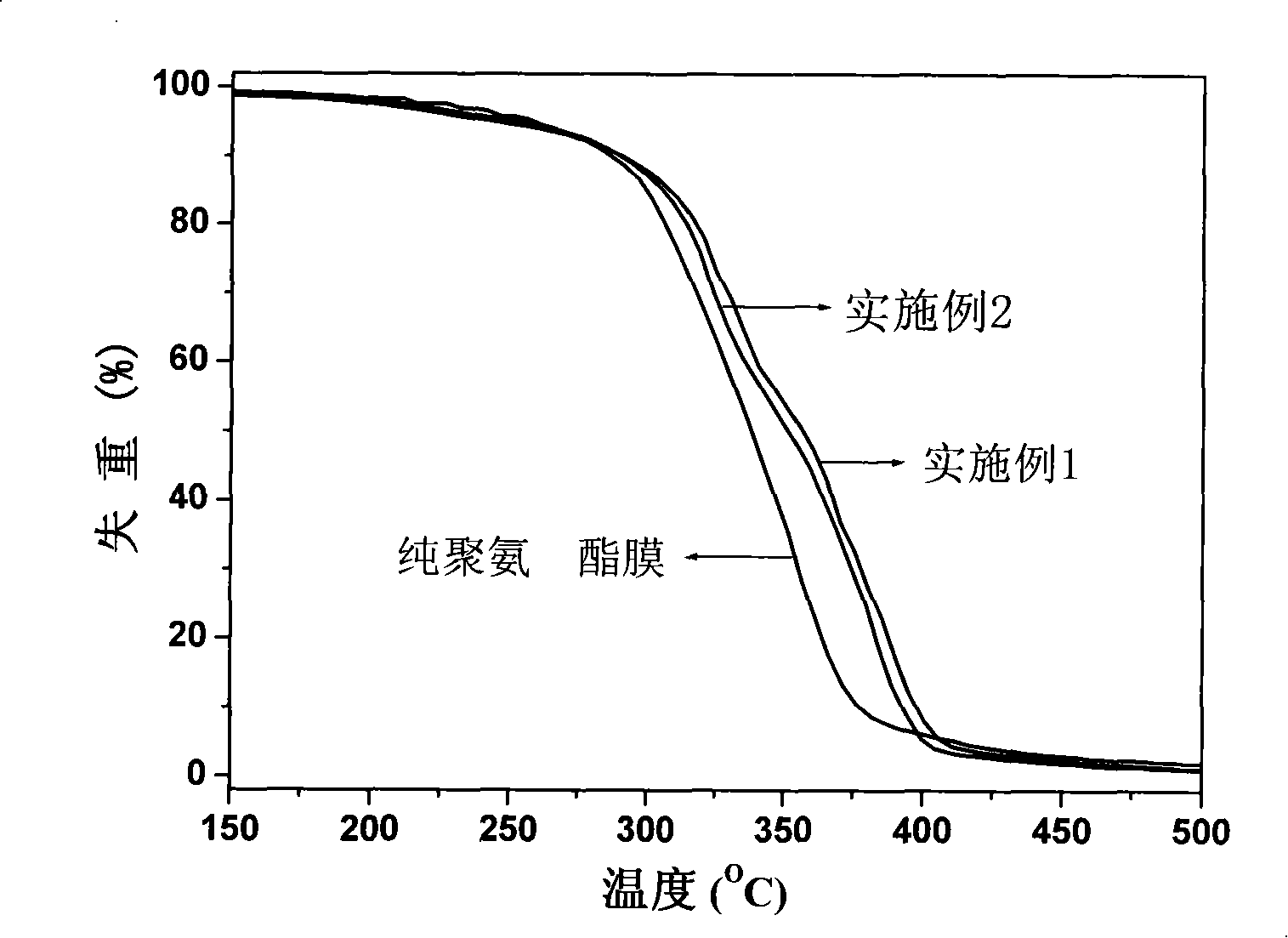

POSS/polyurethane aqueous composite paint and preparation method thereof

ActiveCN101250375ANo subsidenceEasy to storePolyurea/polyurethane coatingsEmulsion paintsPolyurethane dispersionHeat resistance

The invention relates to a POSS / polyurethane water compound paint and the process for preparation, the water compound paint is prepared by the following process, firstly, preparing POSS which is not capped with a hydrolysis method, secondly, adopting silane coupling agent KH-550 to cap and get a POSS which contains amido group, and finally, chemically compounding POSS and water polyurethane dispersion to prepare a POSS / polyurethane water compound paint. The water compound paint of the invention has the advantages of excellent indoor temperature storage property, degree of hardness and waterproof property, and fire-resisting property and anti-ultraviolet light property are excellent. The process for preparation of the invention has the advantages of convenient and simple technique, high film coating quality, low production cost and extend application prospect and the like, which has no pollution to environment, the water paint is a new generation environmental-friendly high-performance chemical product, which can be applied in the fields such as automobile coating, wood coating, construction, office furniture, leather, textile finishing, pigment printing and mechanical equipment.

Owner:SUZHOU JIREN HIGH TECH MATERIAL CO LTD

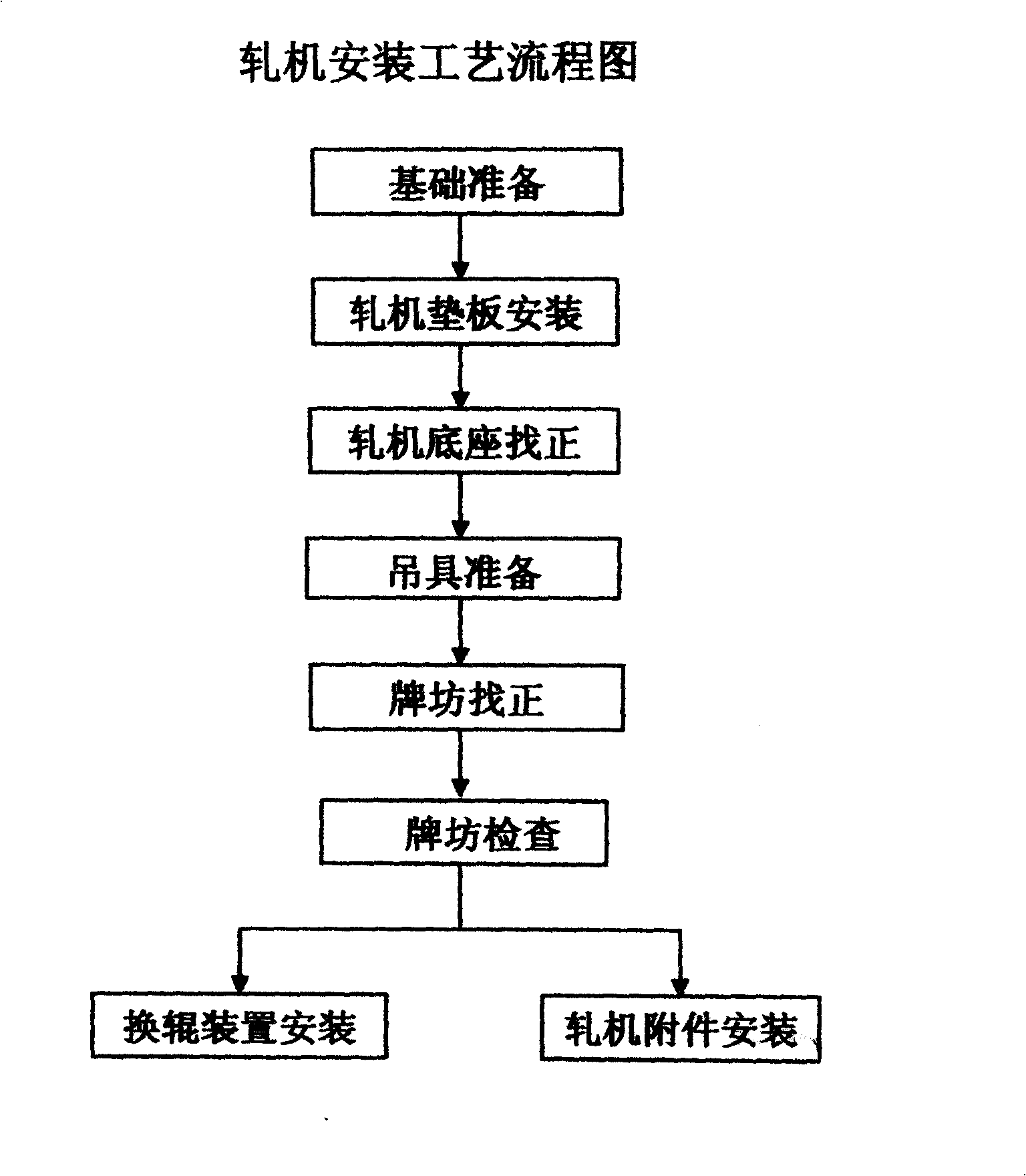

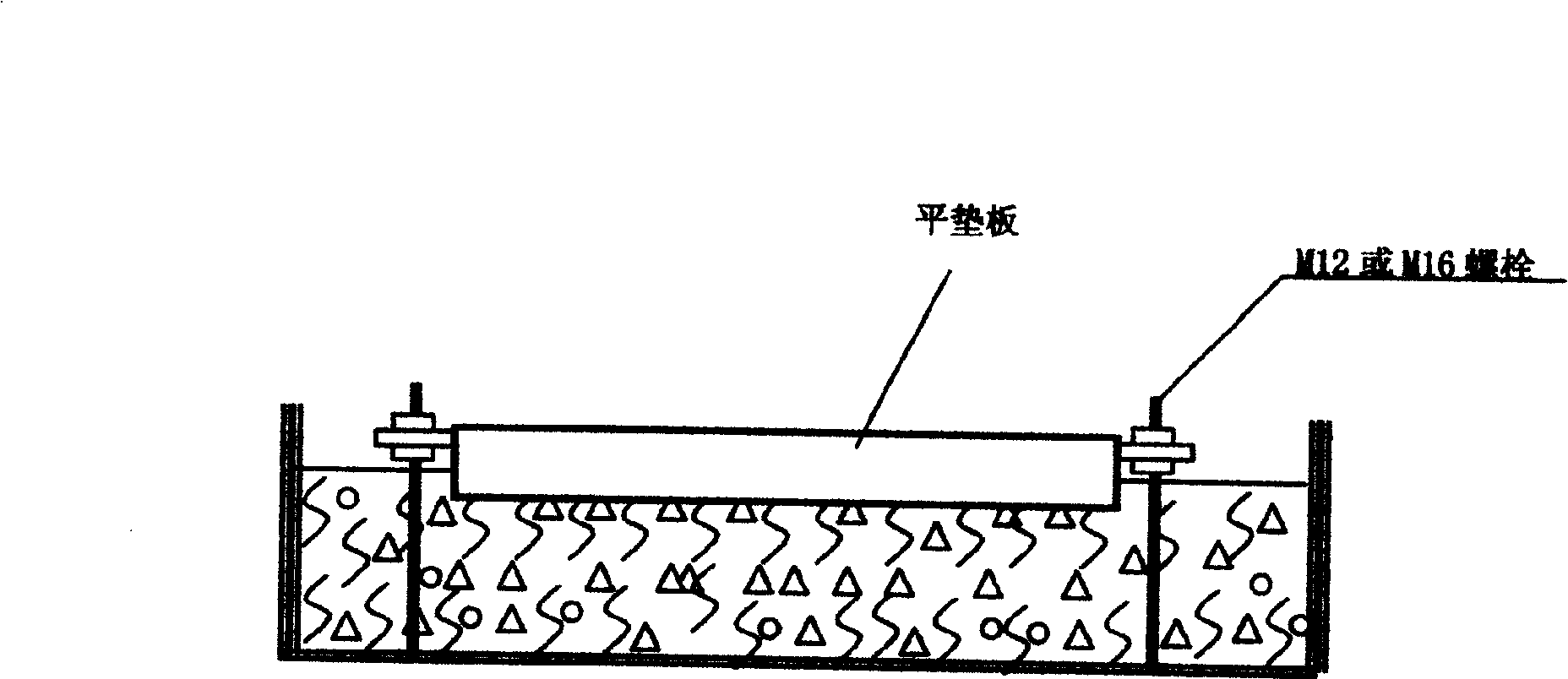

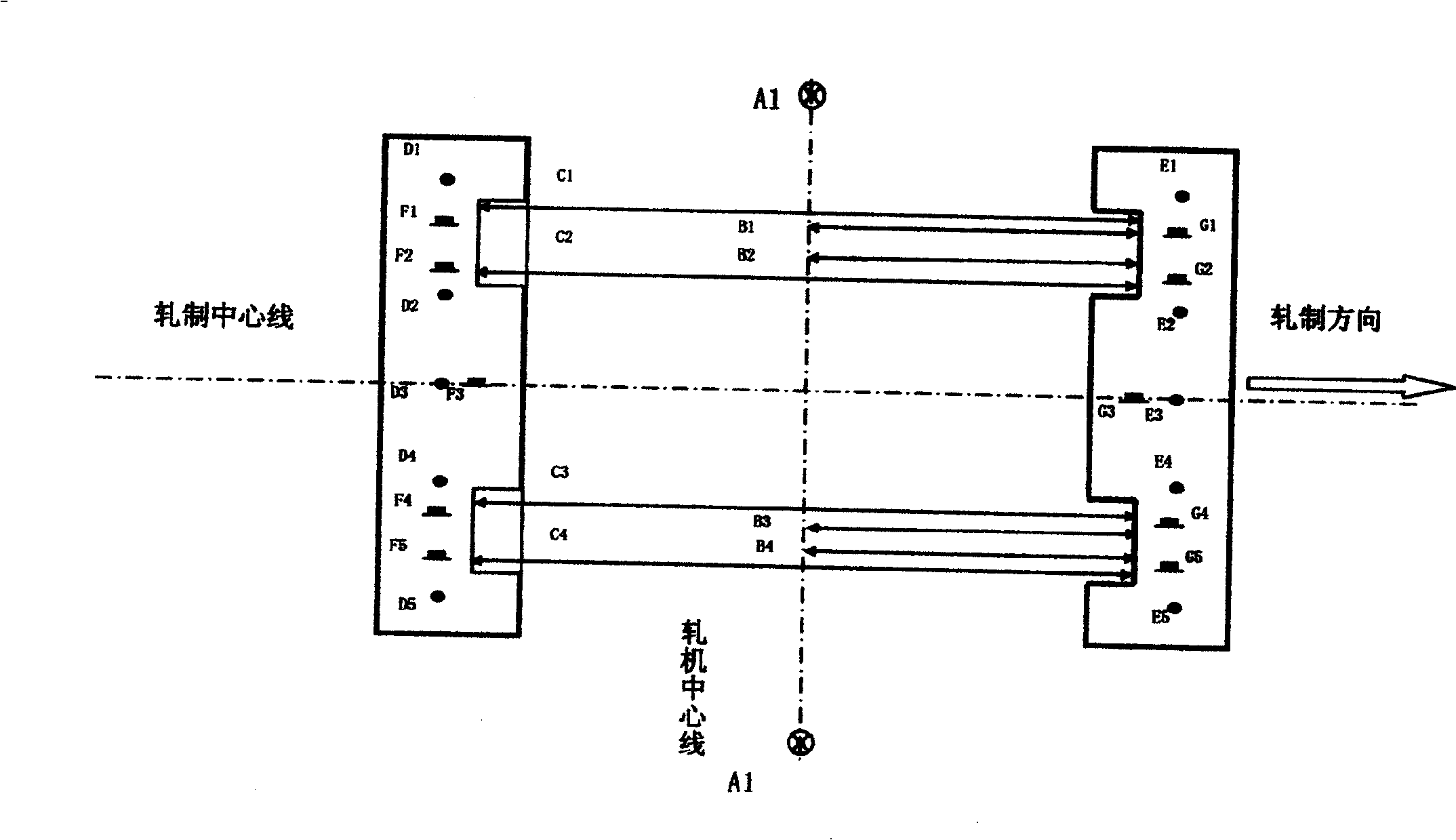

Method for mounting large-sized rolling mills

InactiveCN101275400AReduce loosenessAvoid damageFoundation engineeringBuilding material handlingStrip millMechanical equipment

The invention relates to an installation of metallurgy industry rolling mills, pinch pass mill, burnishing machines and the like large-scale mechanical equipment, especially to an installation method of a large-scale rolling mill, which is characterized in that the installation of a large-scale rolling mill is realized by the process steps of base preparation, rolling mills bearing plate installation, rolling mills motherboard transverse alignment, sling preparation, memorial archway transverse alignment, memorial archway check-up, roll-changer installation and rolling mill accessory installation. The invention satisfies all requirement of different construction sites, effectively resolves hanging difficult problem, saves work efficiency about 6-7 times, ensures installation quality, uses hydraulic bolt stretchers to avoid bolt up force moment from macrolesion bolt, and adopts small fastening force moment to allow rolling mills subbase to become flexible. Work difference bands are used to control the roll changing transmission device central line and the rolling mill central line to ensure installation quality. According to combination of calculation and on-site practicality, the invention not only can be used for rolling mills installation, but also can spread in mechanical equipment installation with common advising signification.

Owner:ANGANG CONSTR CONSORTIUM

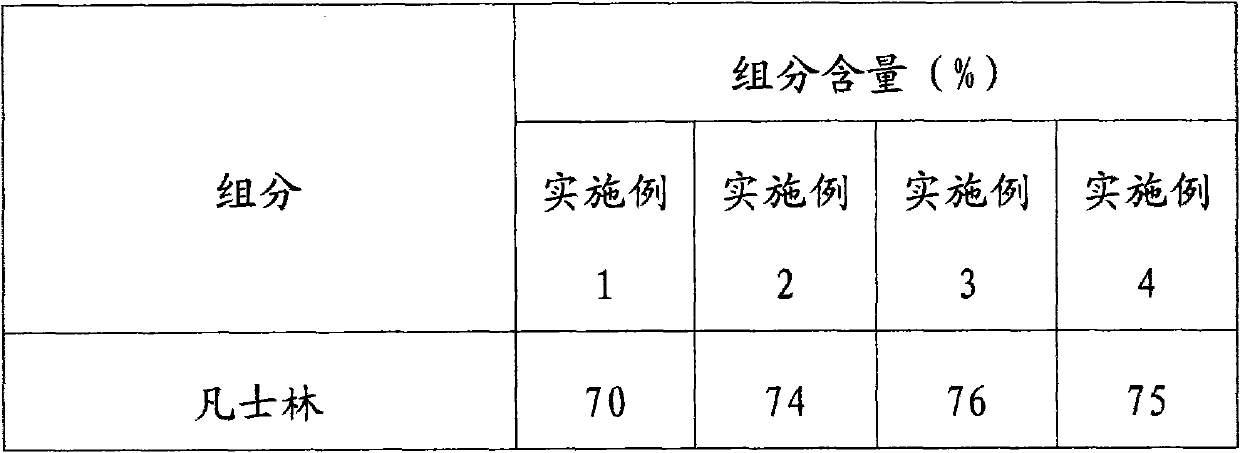

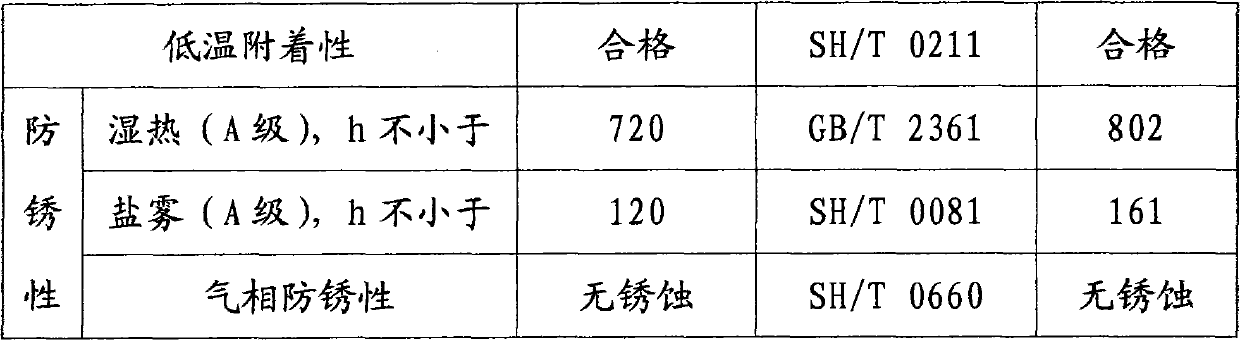

Lipid type antirust oil with gaseous phase antirust function

The invention discloses a lipid type antirust oil with gaseous phase antirust function; the composition of the lipid type antirust oil in weight percent is as follows: 70-90% of base lipid, 4-15% of antirust agent, 1-5% of gaseous phase antirust agent and 5-10% of oil film modifying agent; the inventive antirust oil has long protection period, sun and rain exposure resistance, non-leakage at hightemperature, non-cracking at low temperature, transparent and soft oil film, good paintability, and easy removal, and is mainly applied for antirusting for various metalwares, precise instruments, mechanical equipments, metal rotation sequence of workshops in machining industry, etc.

Owner:天津蓝星清洗有限公司

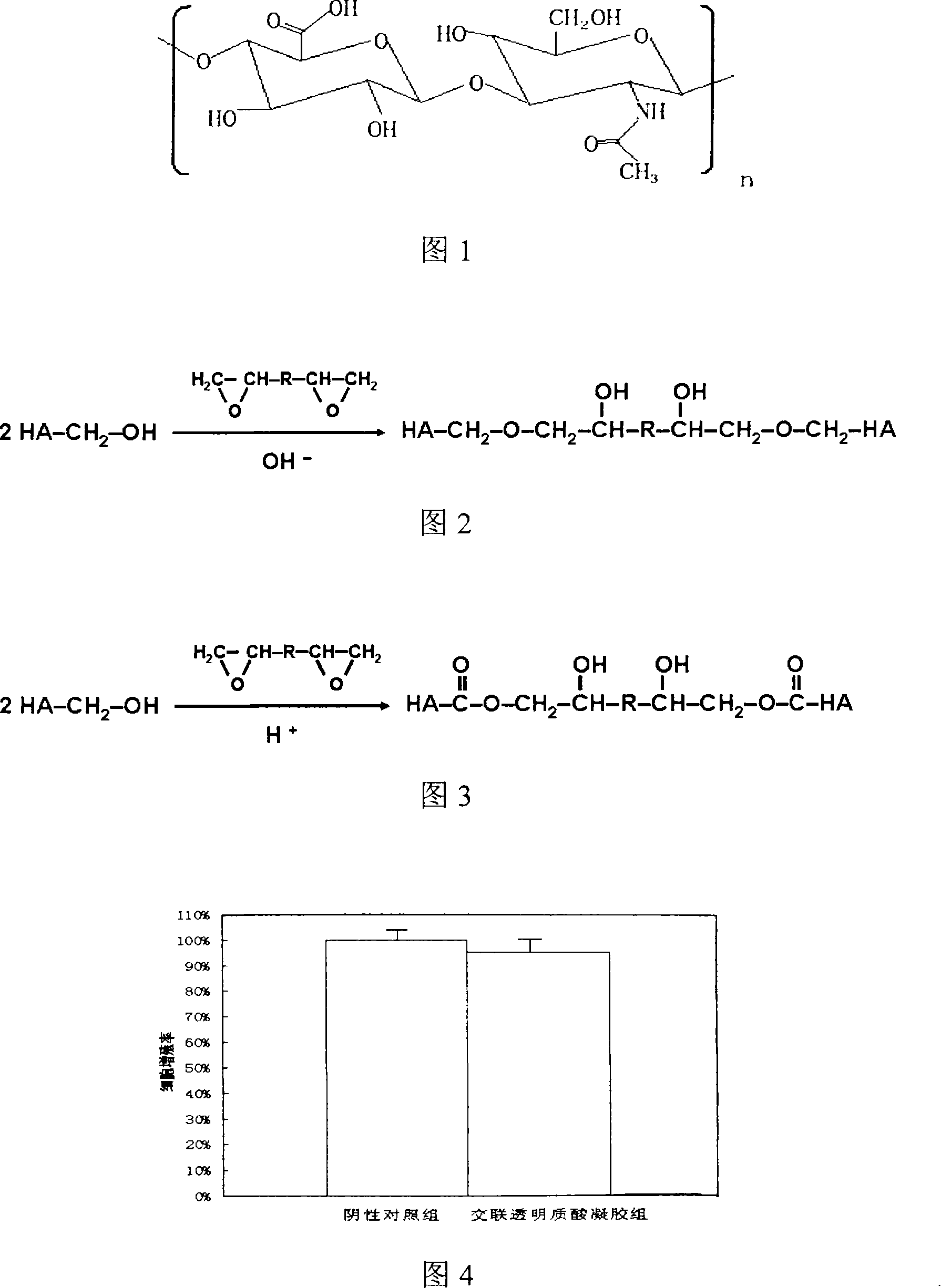

Method for preparing crosslinked hyaluronic acid microgel for tissue filling

The invention relates to a preparation method of cross-linking hyaluronic acid microgel for tissue filler; wherein, the monolithic gel is generated by the cross-linking reaction of the hyaluronic acid and the di-epoxide in the certain mold and processed by acid solution; the purification and dialysis by physiological balanced solution are processed; the microgel is made by extrusion of mechanical equipment. The cross-linking hyaluronic acid microgel has the advantages of (1) specific physical properties that the storage modulus (G') is 500-2000Pa, the loss modulus (G'') is 50-200Pa, the phase angle (Delta) is below 20 and the complex viscosity (Eta*) is 10-3500Pa x s as described by the dynamic viscoelasticity at frequency of 0.05-10Hz, (2) good stability that the performance of gel is independent of high pressure-high temperature treatment and the enzymolysis-resistant performance is excellent, (3) injectable property that the size of fine particle is 50-1000Mum, (4) good biocompatibility of no cytotoxicity, (5) biodegradability of being fully degraded by hyaluronidase, and (6) being suitable for tissue filler and bio-medical treatment.

Owner:SHANGHAI QISHENG BIOLOGICAL PREPARATION CO LTD

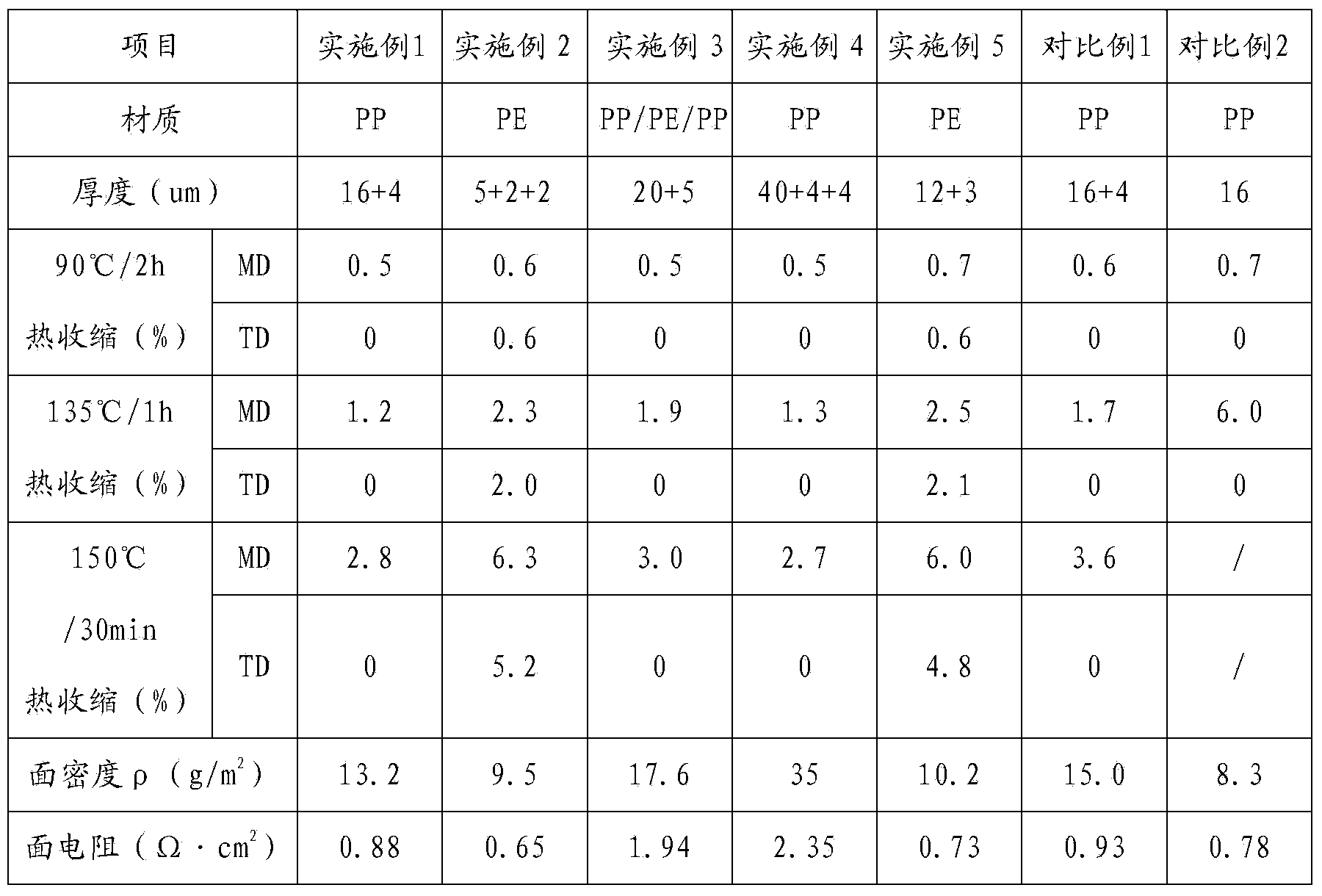

Water-based ceramic coating lithium ion battery diaphragm and processing method thereof

The invention discloses a water-based ceramic coating lithium ion battery diaphragm. The water-based ceramic coating lithium ion battery diaphragm comprises a polyolefin porous membrane and a coating which coats one or both sides of the polyolefin porous membrane, wherein the coating is 2-8 microns in thickness, and consists of 20-60 percent by weight of base material and 40-80 percent of water; the base material comprises 0.1-5 parts by weight of a water-soluble high polymer thickener, 0.1-5 parts of a water-based dispenser, 0.1-10 parts of a water-based adhesive and 80-99.7 parts of boehmite particles. The invention further discloses a processing method of the ceramic coating lithium ion battery diaphragm. The processing method has the advantages of slight wear to mechanical equipment, uniform and consistent coating thickness and contribution to continuous and stable large-scale production.

Owner:SHENZHEN SENIOR TECH MATERIAL

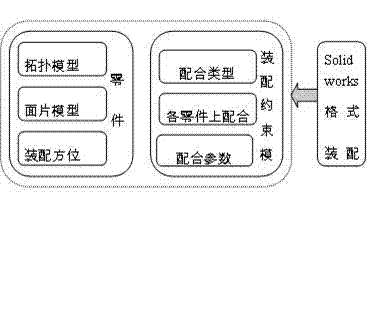

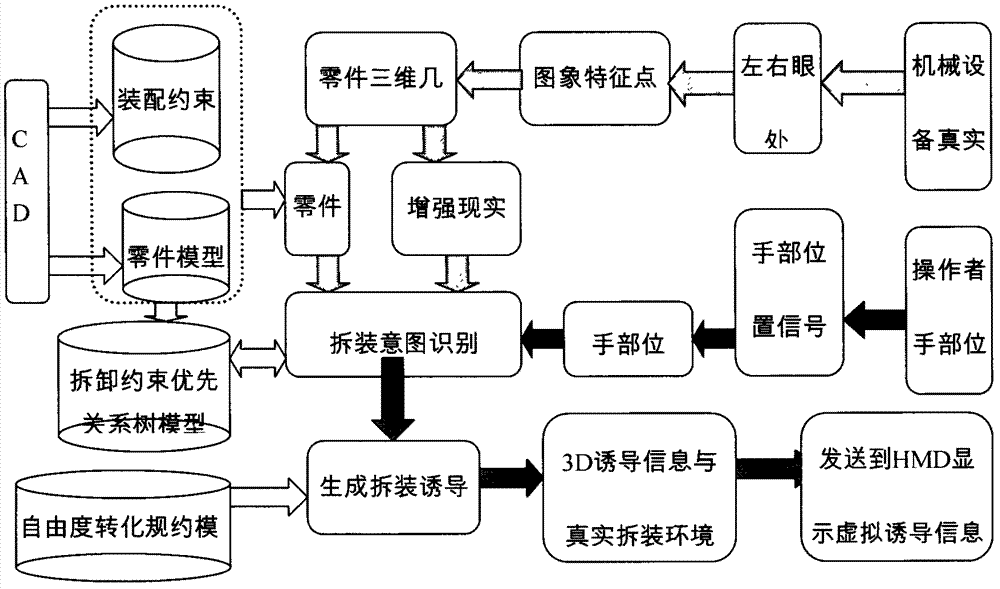

Induction method of three-dimensional (3D) online induction system for mechanical equipment dismounting

InactiveCN102789514AAugmented reality inductionImprove high universalityInput/output for user-computer interactionGraph readingInduction motor3d design

The invention discloses an induction method of a three-dimensional (3D) online induction system for mechanical equipment dismounting. The induction system comprise an eyeglass-type augmented reality helmet, a hand position tracking device and a computer, wherein the augmented reality helmet is provided with two display screens and two cameras; and wireless communication can be realized among the augmented reality helmet, the hand position tracking device and the computer. An induction method for realizing the three-dimensional online induction system for mechanical equipment dismounting comprises the following steps of: 1, transforming a virtual assembly model; 2, initializing the induction system; 3, recognizing the dismounting purpose; 4, generating induction information; 5, overlapping the induction information; and 6, repeating the steps 3-5 until the online product induction is finished. The method disclosed by the invention has the characteristics of accurate induction information, strong universal capability and convenience in carrying, and can be used for realizing the 3D online induction driven by requirements of operators, current situations of tasks and dismounting history and realizing the integration of product 3D design and dismounting induction.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

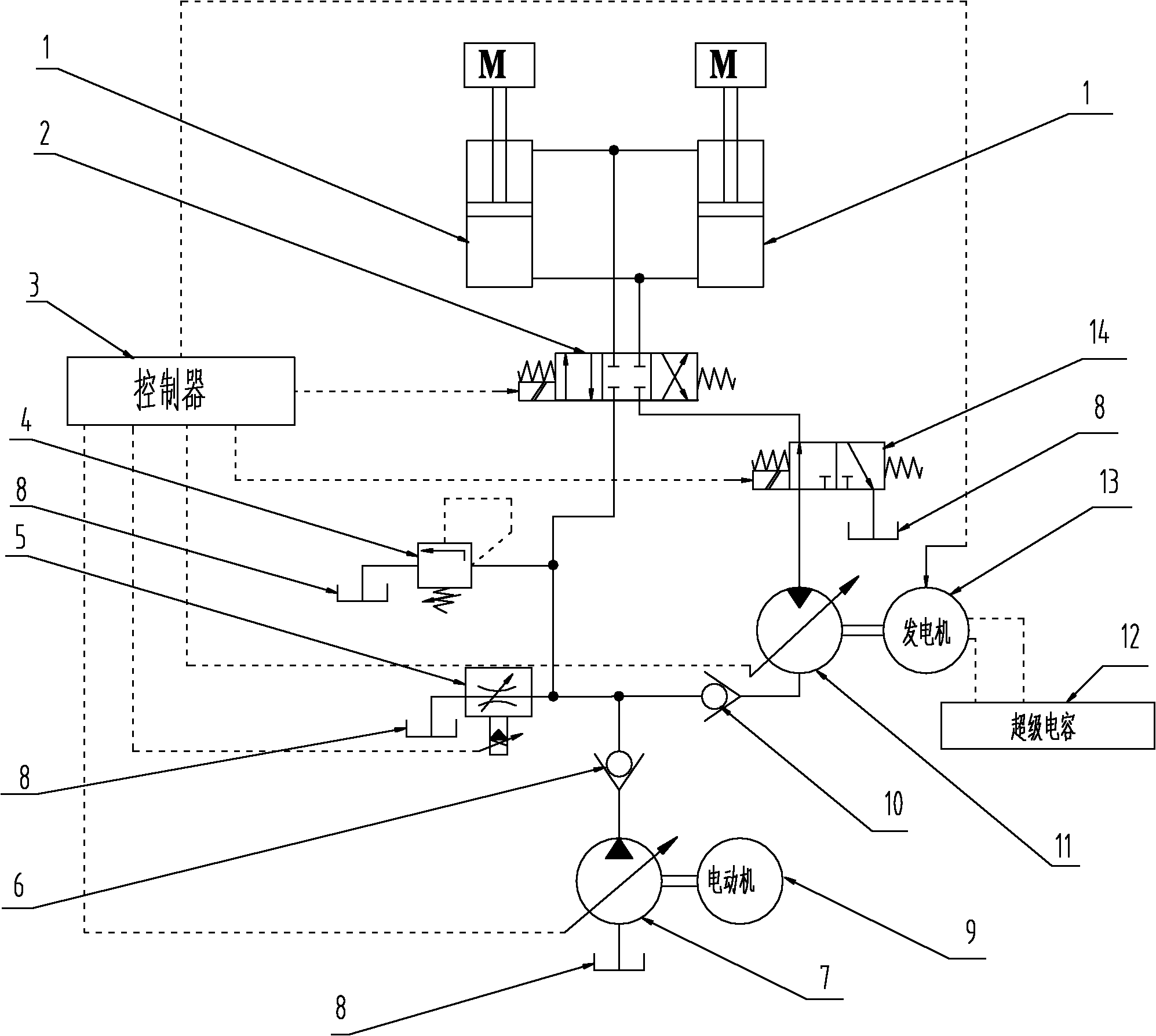

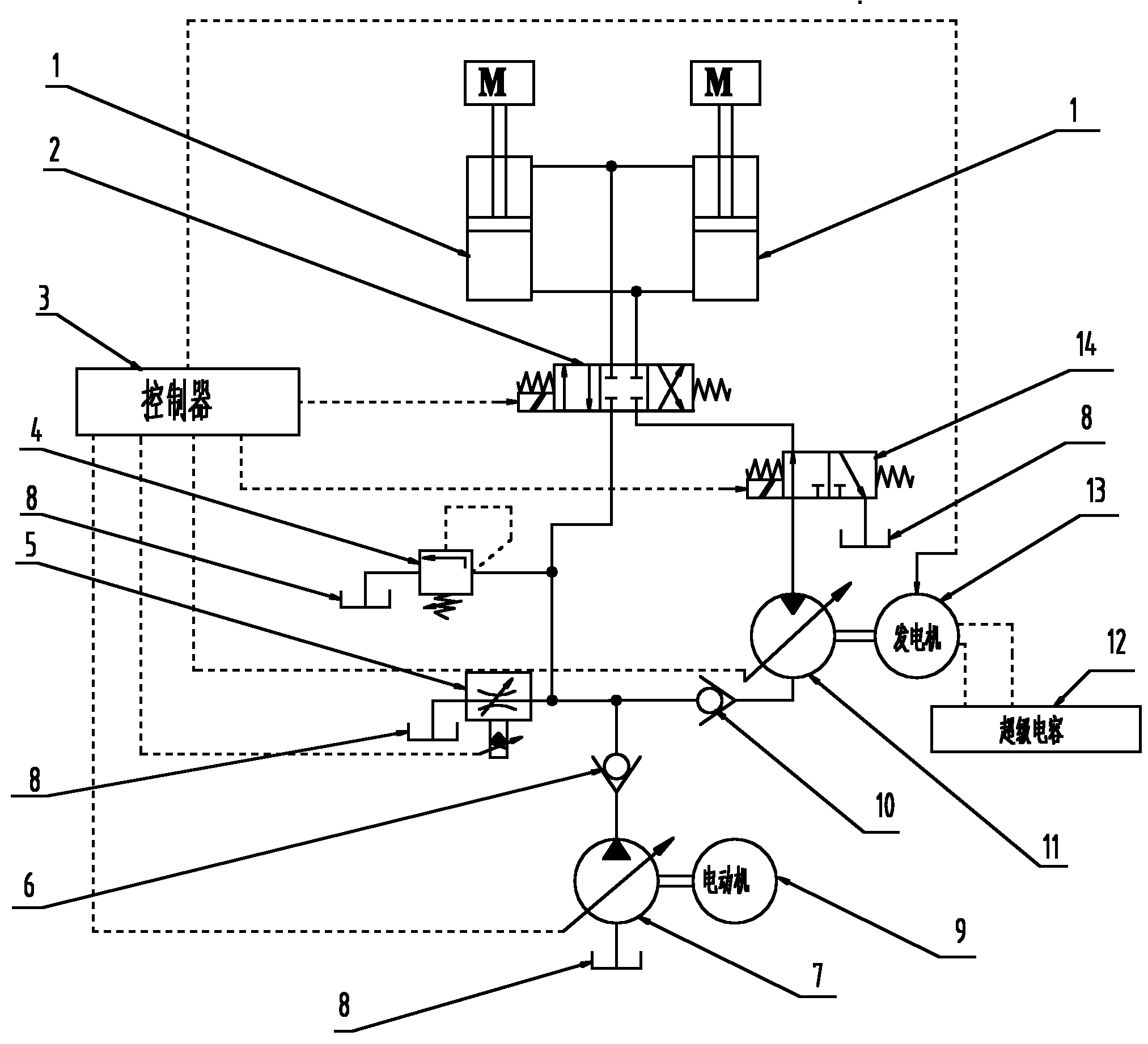

Movable arm flow re-generation system with potential energy recovery device for excavator

InactiveCN102182730AExtended service lifeReduce energy consumptionFluid-pressure actuator componentsMechanical equipmentExcavator

The invention discloses a movable arm flow re-generation system with a potential energy recovery device for an excavator, and belongs to the technical field of engineering mechanical equipment. The system comprises a movable arm hydraulic cylinder, a three-position four-way servo valve, a controller, an overflow valve, an electromagnetic flow valve, a one-way valve, a variable output pump, an oil tank and an engine; the controller is electrically connected with the servo valve, the electromagnetic flow valve and the variable output pump; the three-position four-way servo valve is sequentially connected with a reversing valve and a hydraulic motor; the hydraulic motor is axially connected with a power generator; an output end of the power generator is electrically connected with a super capacitor; the outlet pressure of the hydraulic motor is controlled by the electromagnetic flow valve through the one-way valve of the motor; the reversing valve is connected with the oil tank; and the controller is electrically connected with the reversing valve, the power generator and the hydraulic motor. By the system, the optimal energy-saving state of the excavator can be realized during the falling of a movable arm, the energy consumption of the hydraulic system is reduced, the utilization ratio of the energy is improved, and the service life of the excavator is prolonged.

Owner:四川升腾元创机电技术研究有限公司

Low-temperature high-strength, high-toughness steel and preparing method therefor

InactiveCN101024870AHigh strengthGuaranteed toughnessHeat treatment process controlLift systemThermal treatment

The invention relates to a low-temperature, high-intensity, high-toughness steel and the making method thereof, applicable to the environment down to -60 deg.C, adopting low-carbon Cr-Ni-Si-Mn-Mo-V alloy, and its chemical composition includes in mass percent (mass%): C: 0.16-0.24,Si:1.0-1.4, Mn:1.10-1.50,Cr:0.80-1.20,Ni:1.00- 1.40,Mo:0.20-0.40,V:0.05-0.20,S=<0.035,P=<0.035,Cu =<0.050, and the rest Fe. And its making method comprises: (1) smelting; (2) forging: heating at 1280-1320deg.C, where initial forging temperature: 1100-1250deg.C, final forging temperature >=850deg.C; annealing after forging, where heating temperature: 700+-30deg.C, and tapping temperature =<300deg.C; (3) thermal treatment: normalizing: air cooling at 930-950deg.C; tempering: air cooling at 790-720deg.C; quenching: oil cooling at 900-930deg.C; and tempering: air cooling at 200-260deg.C; (4) supersonic crack detection and magnetic particle crack detection. And it is especially applied to the materials for flying rings, hocks, pin shafts, etc, in the lifting systems of mechanical facilities.

Owner:RG PETRO MACHINERY GROUP

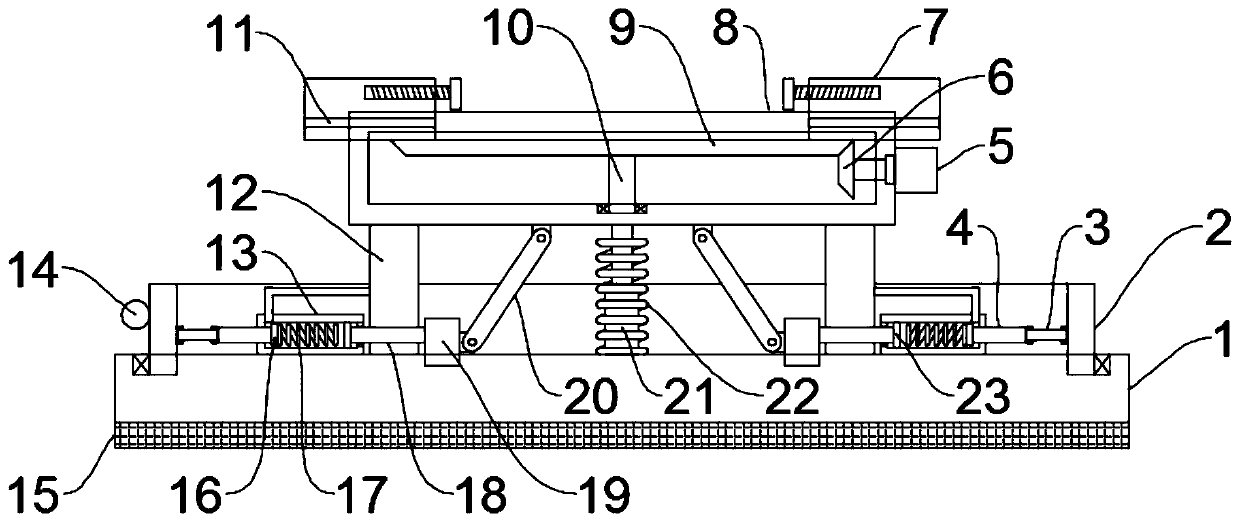

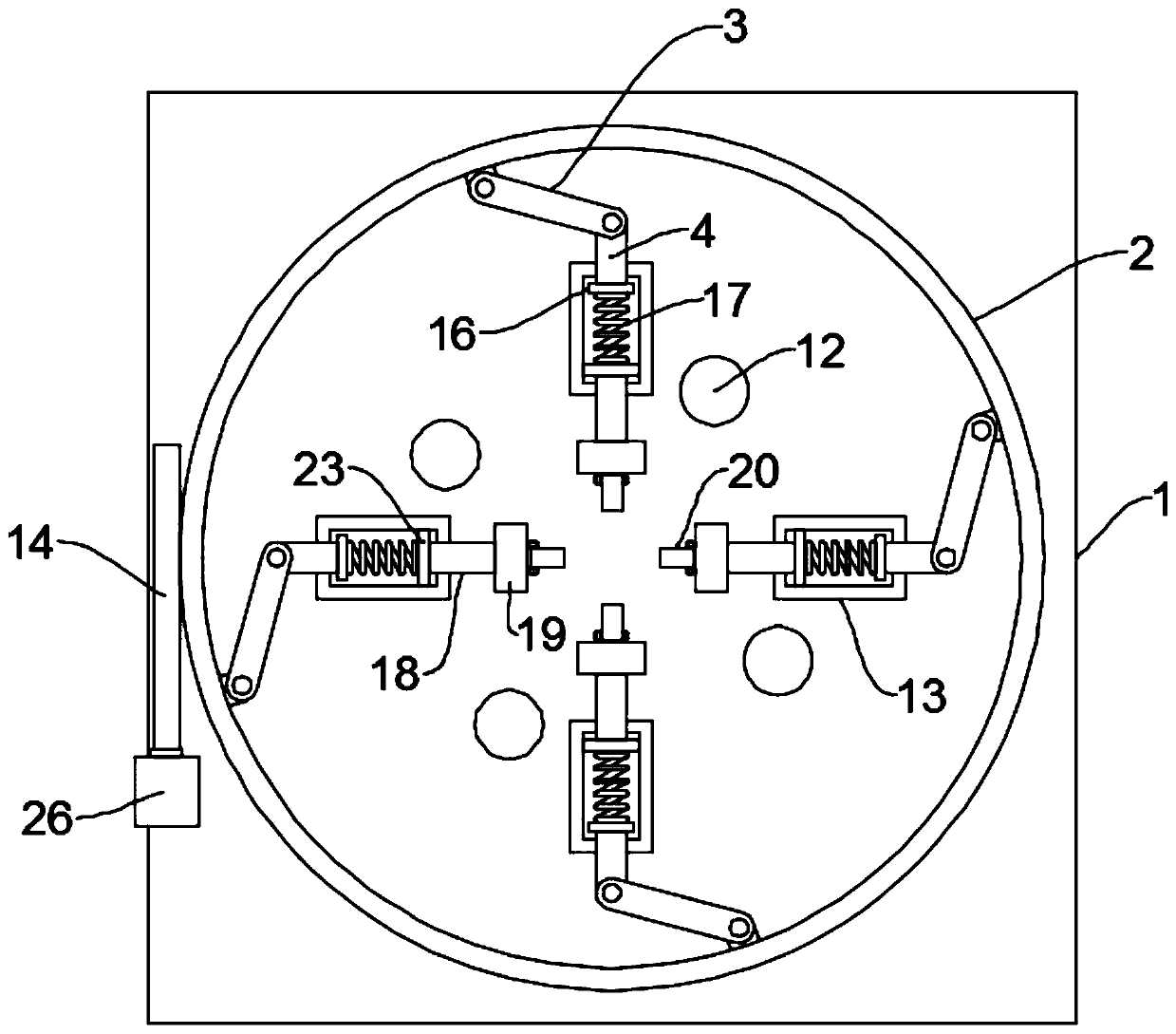

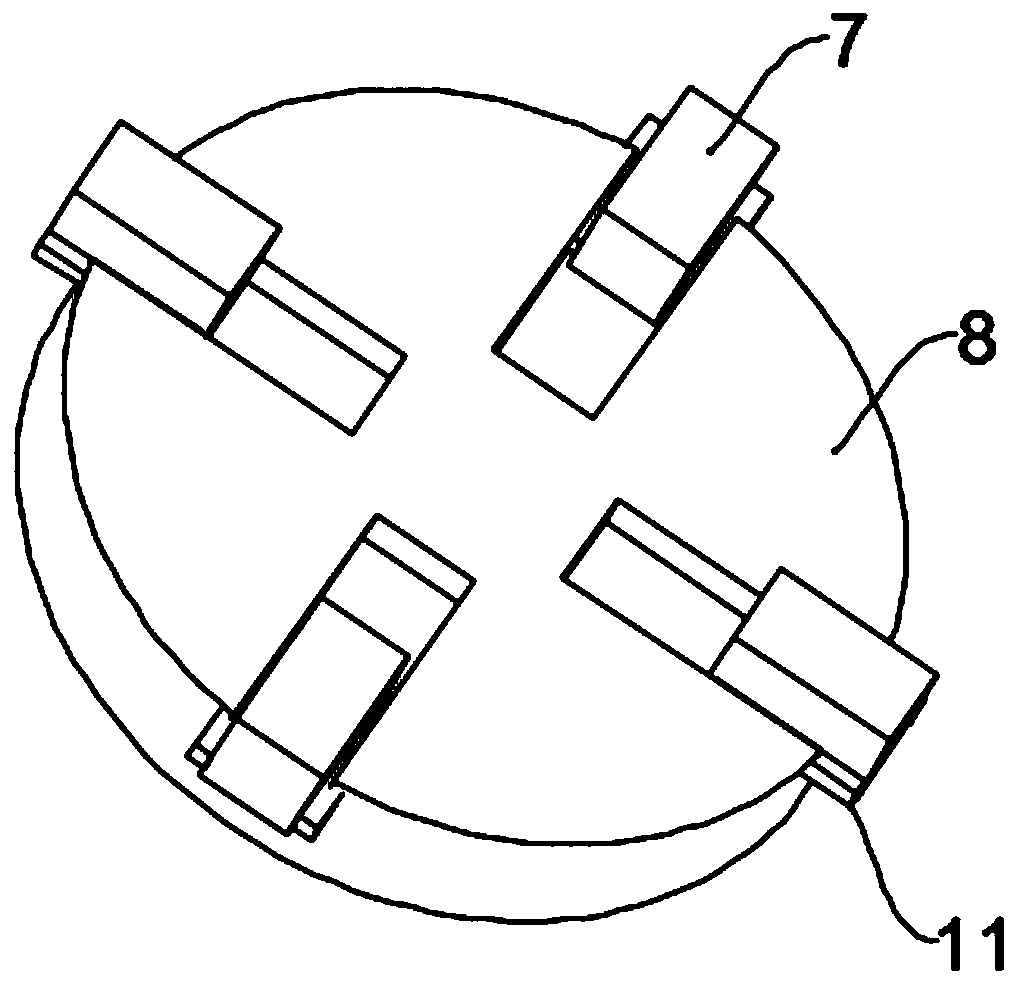

Efficient damping device for mechanical equipment

ActiveCN110486416AAdjust the amount of initial compressionAdjust the cushion strengthSpringsNon-rotating vibration suppressionMechanical equipmentEngineering

The invention discloses an efficient damping device for mechanical equipment. The efficient damping device comprises a base, a mounting seat for mounting the mechanical equipment and a damping mechanism, wherein the mounting seat is arranged above the base; the damping mechanism is connected between the mounting seat and the base and comprises a telescopic rod, a first spring, a worm, a worm wheelring, a first connecting rod, an adjusting rod, a plurality of cylinder blocks, an adjusting plate, a second spring, a piston, a piston rod, a movable block and a second connecting rod; air sacs aremounted on the upper surface, on one side of each of the cylinder blocks, of the base; and a mounting mechanism is arranged on the mounting seat and comprises a first stepping motor, a first bevel gear, a second bevel gear and a clamping positioning block. The efficient damping device is provided with the damping mechanism to realize efficient damping and adjust the initial compression amount andthe buffering strength of the second spring so as to be adapted to different buffering demands of mechanical equipment with different weight; the air sacs are arranged to improve the buffering effect;and the mounting mechanism is arranged to quickly clamp and position the mechanical equipment.

Owner:SUZHOU LAIJIN ELECTROMECHANICAL AUTOMATION CO LTD

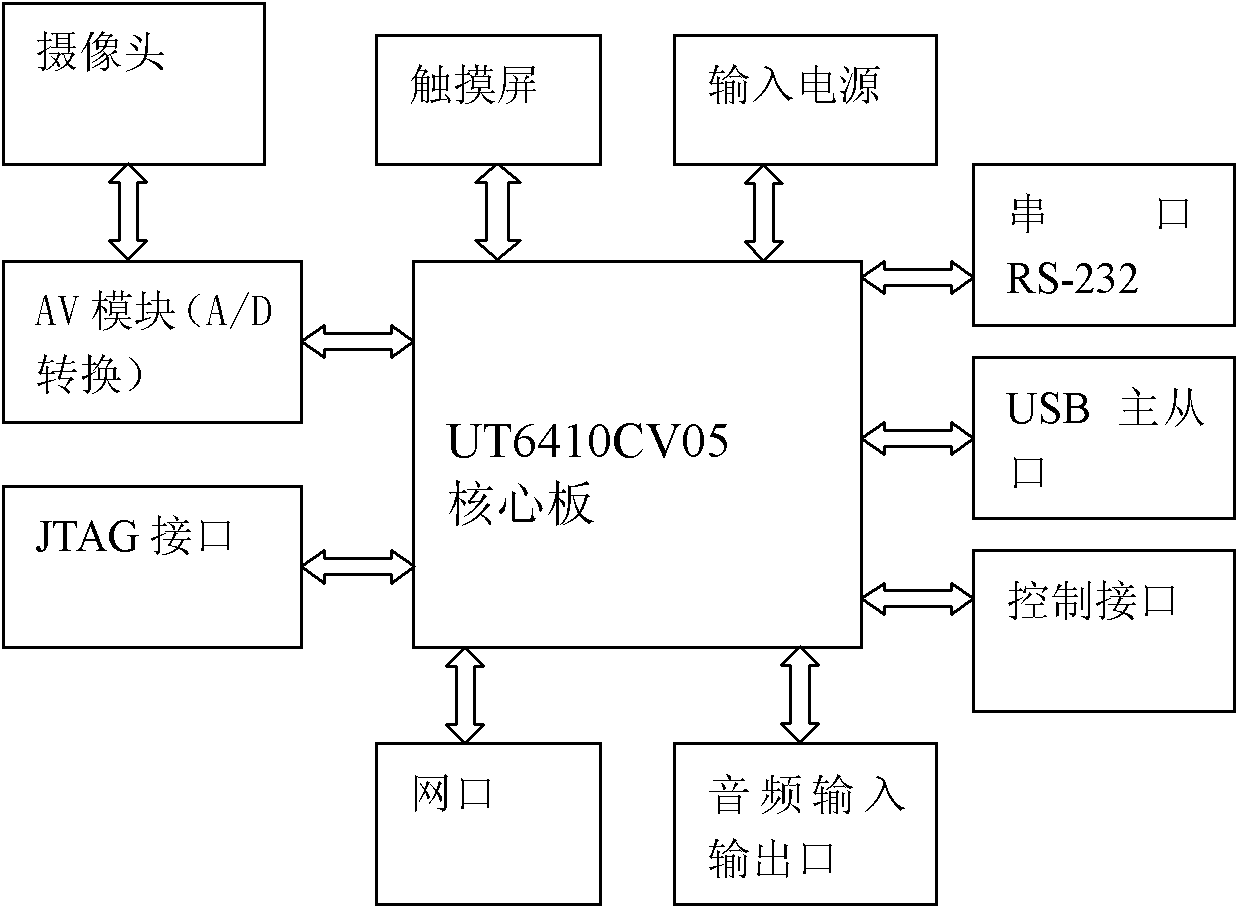

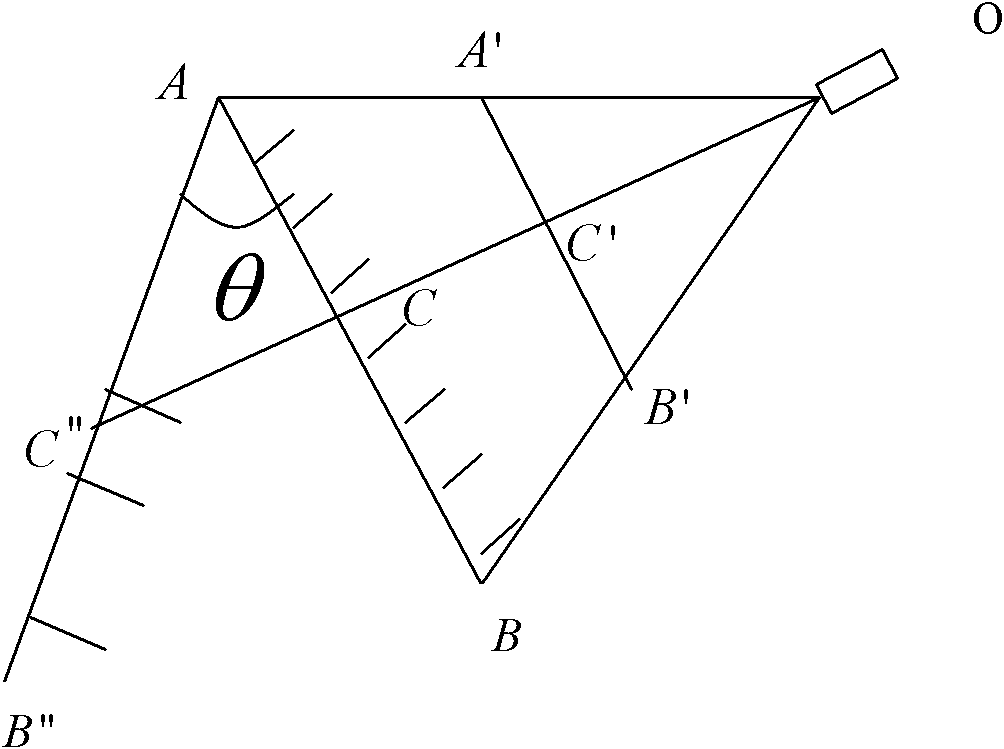

Machine-vision based liquid level detection device and method

InactiveCN102147281AFast operationStrong real-timeMachines/enginesLevel indicatorsMicrocontrollerData set

The invention discloses a machine-vision based liquid level detection device and method. In the method, algorithm processing is carried out on a field liquid level image acquired by using an infrared camera to obtain real-time liquid level height information so as to obtain the instant height of the liquid level. In order to obtain the height information of the liquid level accurately and efficiently, five self-designed algorithms including a cameral distortion correction algorithm, a self-adaptation detection coordinate setting algorithm, a liquid level line segmentation algorithm, a data filter algorithm and a data setting algorithm are used in the machine-vision based liquid level detection device; and meanwhile, in order to implement the algorithms effectively, a calibration manner is introduced in the invention and is applied to a target tracking process of a camera. In the invention, a single-chip microcomputer of an ARM (Advanced RISC (Reduced Instruction Set Computer) Machine) series is used as a main processor. By adoption of self-adaptation coordination setting, the device is not only suitable for open type and / or closed type liquid level detection environments but also suitable for mechanical equipment positioning and product counting, and has a very broad application prospect.

Owner:HUNAN UNIV

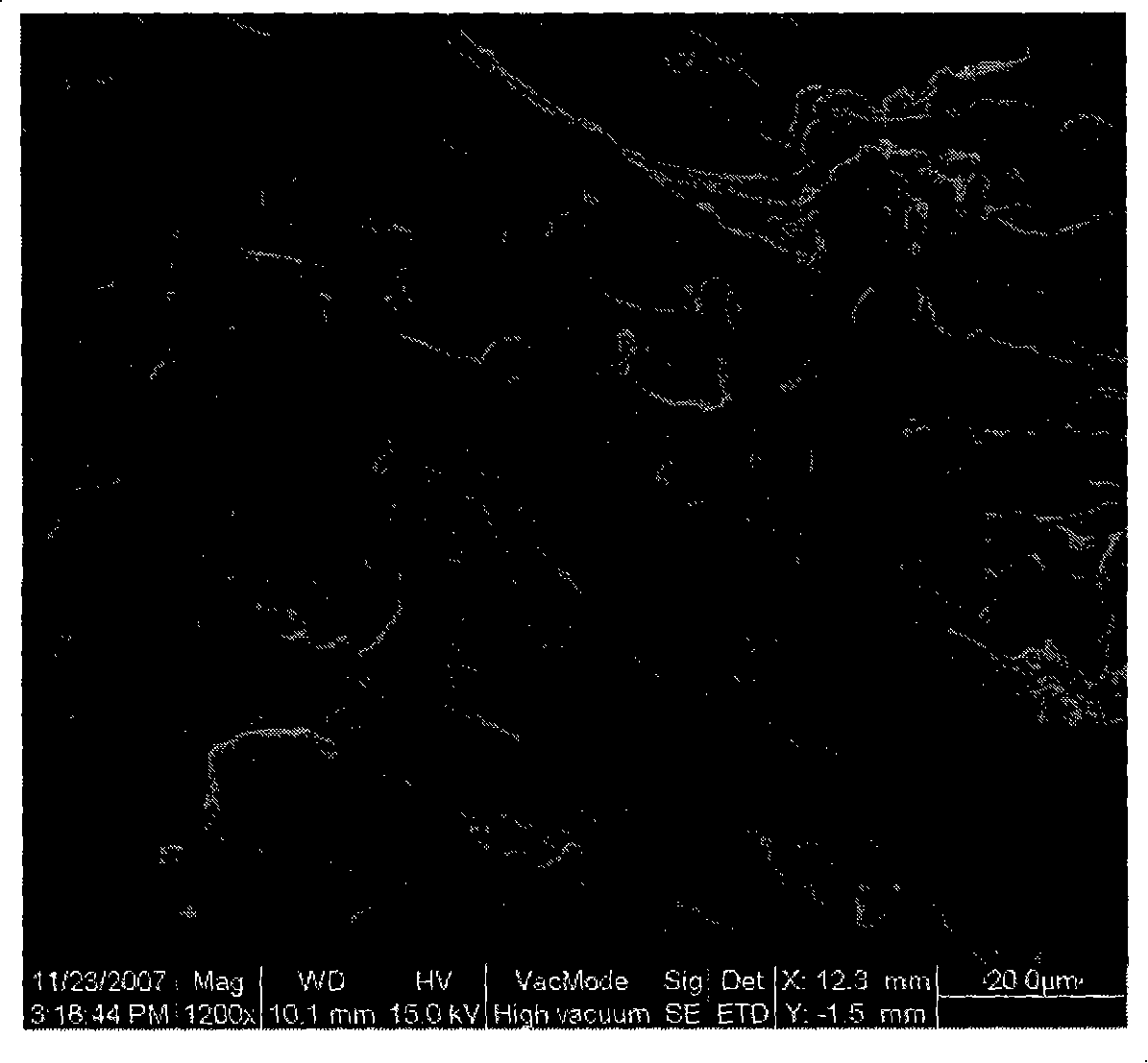

Nano hollow silica dioxide micro-sphere/polyurethane composite aqueous paint and preparation method thereof

InactiveCN101250374AIncrease the degree of cross-linkingExcellent thermodynamic propertiesPolyurea/polyurethane coatingsEmulsion paintsMechanical equipmentSilicon dioxide

The invention belongs to the technical filed of water paint, which particularly relates to nanometer hollow silica sphere / polyurethane compound water paint and the process for preparation thereof. The water compound paint is chemically compounded by hollow SiO2 sphere, whose dimension is 50-250 nanometers, isocyanate terminated polyurethane prepolymer, catalyst and other auxiliary agents. Indoor temperature storage stability of the compound water paint is excellent, nanometer hollow SiO2 sphere and water polyurethane have excellent compatibility, hardness and compatibility of the water compound coating layer are greatly improved, and fire-resisting property and ultraviolet resistant performance are excellent. The process for preparation of the invention has the advantages of convenient and simple technique, high film coating quality, low production cost and extensive application prospect and the like, which has no pollution to environment, the water paint is a new generation environmental-friendly high-performance chemical product, which can be applied in the fields such as automobile coating, wood coating, construction, office furniture, leather, textile finishing, pigment printing and mechanical equipment.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com