Water-based ceramic coating lithium ion battery diaphragm and processing method thereof

A lithium-ion battery and ceramic coating technology, which is applied to battery pack parts, circuits, electrical components, etc., can solve the problems of unfavorable large-scale continuous production and difficulty in controlling the uniformity of coating thickness, and achieve continuous and stable large-scale Large-scale production, easy consistency control, and excellent affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

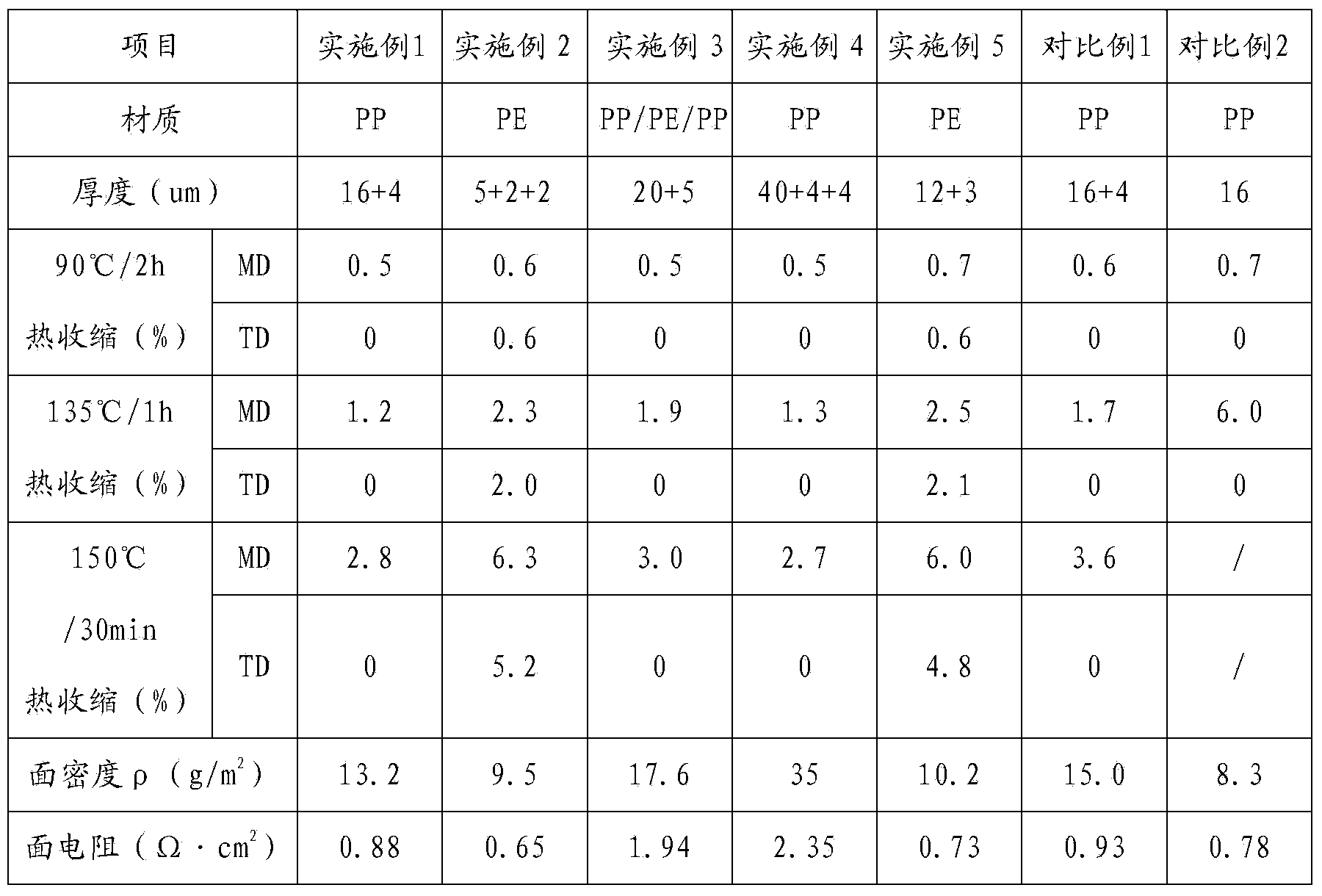

Embodiment 1

[0030] A water-based ceramic coating lithium-ion battery separator, comprising a polypropylene porous membrane and a water-based ceramic coating coated on one side of the polypropylene porous membrane, wherein the polypropylene porous membrane has a thickness of 16um, a porosity of 42%, and a coating thickness of It is 4um, and the coating slurry used for the coating consists of 20% base material and 80% water calculated by weight percentage; the base material includes 0.1% water-soluble polymer thickener hydroxyethyl cellulose, Water-based dispersant polyethylene glycol 0.1%, water-based adhesive styrene-butadiene latex 0.1%, D 50 0.2um, BET is 15m 2 / g platy boehmite particles 99.7%.

[0031] The method for preparing the polymer inorganic lithium-ion battery diaphragm; comprising the following preparation steps:

[0032] 1. Add the amount of water-soluble polymer thickener hydroxyethyl cellulose, water-based dispersant polyethylene glycol and deionized water into the pre-m...

Embodiment 2

[0037] A water-based ceramic coating lithium-ion battery separator, comprising a polyethylene porous membrane and a water-based ceramic coating coated on both sides of the polyethylene porous membrane, wherein the polyethylene porous membrane has a thickness of 5um and a porosity of 35%. The thickness of the layers is 2um, and the coating slurry used in the coating consists of 30% base material and 70% water calculated by weight percentage; the base material includes water-soluble polymer thickener carboxymethyl cellulose calculated by weight percentage Sodium 5%, water-based dispersant polyacrylic acid 5%, water-based adhesive polymethyl methacrylate 10%, D 50 4um, BET is 2m 2 / g platy boehmite particles 80%.

[0038] The method for preparing the water-based ceramic coating lithium-ion battery diaphragm is the same as that of Example 1, except that the dispersion speed is 9000 rpm, and the coating method is dip coating.

Embodiment 3

[0040] A water-based ceramic coating lithium-ion battery separator, comprising polypropylene / polyethylene / polypropylene composite porous film and a water-based ceramic coating coated on one side of the polypropylene / polyethylene / polypropylene composite porous film, wherein polypropylene / polypropylene The thickness of the polyethylene / polypropylene composite porous film is 20um, the porosity is 39%, and the coating thickness is 5um, and the coating film slurry used for the coating consists of base material 40% and water 60% calculated by weight percentage; the base material Including 0.2% water-soluble polymer thickener polyacrylamide, 0.2% water-based dispersant sodium polyacrylate, 2% water-based adhesive polyethylacrylate, D 50 0.6um, BET is 12m 2 / g platy boehmite particles 97.6%.

[0041]The method for preparing the water-based ceramic coating lithium-ion battery diaphragm is the same as that of Example 1, except that the dispersion speed is 5000 rpm, and the coating meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com