Patents

Literature

456results about How to "Increase melt viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

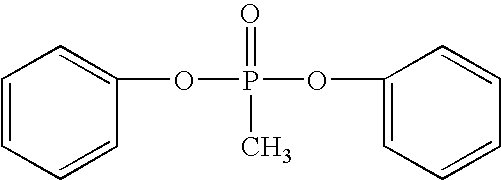

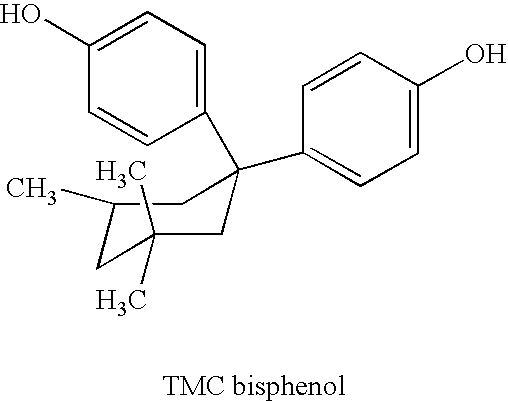

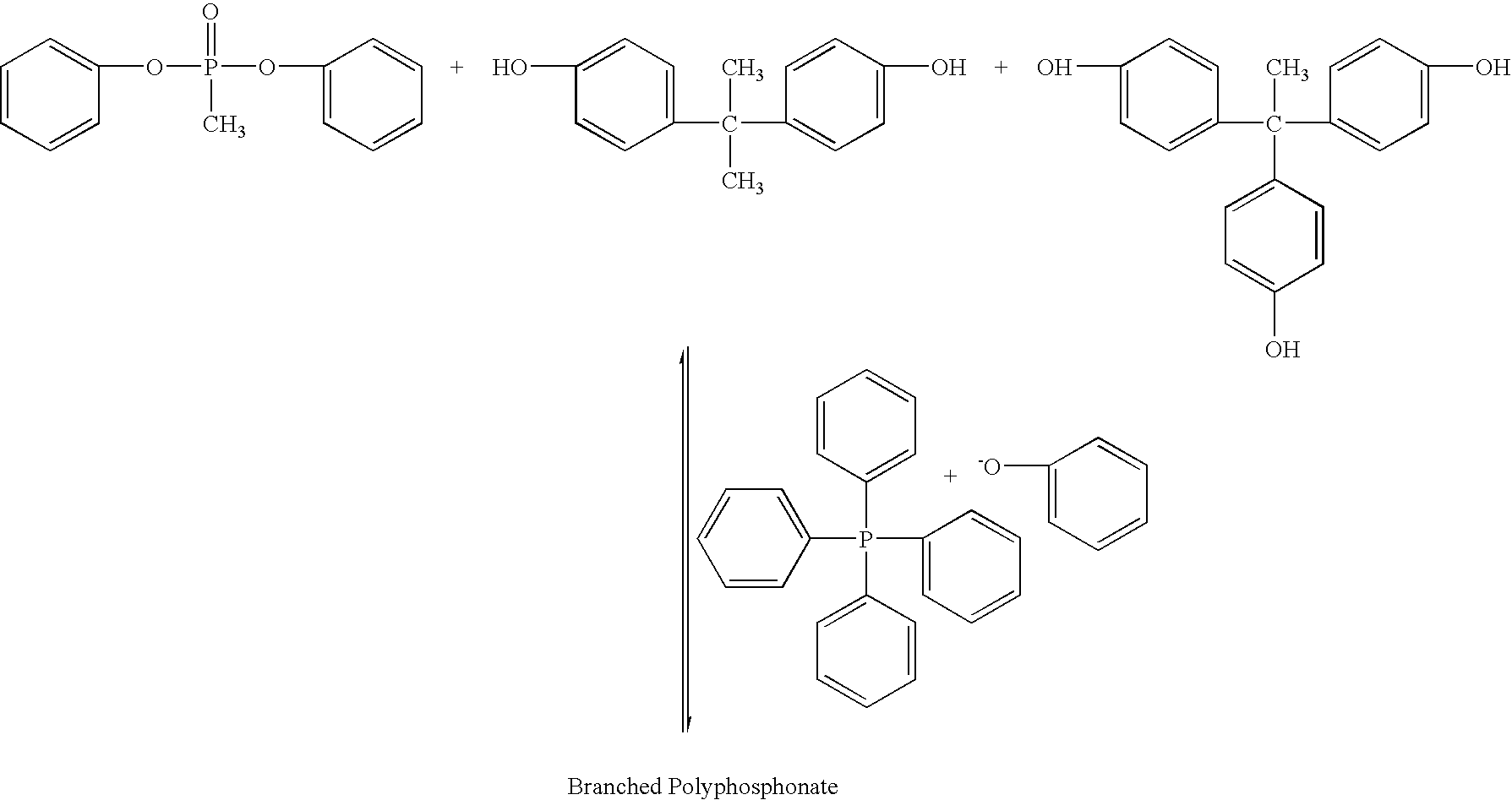

Branched polyphosphonates that exhibit an advantageous combination of properties, and methods related thereto

Disclosed are branched polyphosphonates produced via a superior transesterification process, and methods related thereto. These branched polyphosphonates exhibit a unique and advantageous combination of properties, such as outstanding fire resistance, improved heat stability, improved toughness, and superior processing characteristics. Also disclosed are polymer compositions that comprise these branched polyphosphonates and at least one other polymer, wherein the resulting polymer compositions exhibit flame retardant properties. Further disclosed are articles of manufacture produced from these polymers, such as fibers, films, coated substrates, moldings, foams, fiber-reinforced articles, or any combination thereof; these articles may be coated with a moisture barrier to enhance their moisture resistance properties.

Owner:FRX POLYMERS LLC

Molding composition based on polyetheramides

ActiveUS20050014842A1Increase melt viscosityAdequate long-lasting flexibilityBiocideOrganic active ingredientsEtherDicarboxylic acid

A composition suitable for molding is provided having the following components: I. from 97 to 80 parts by weight of a polyetheramide, having units based on one or more linear aliphatic diamines having from 6 to 14 carbon atoms, one or more linear aliphatic or aromatic dicarboxylic acids having from 6 to 14 carbon atoms, and one or more polyetherdiamines having at least 3 carbon atoms per ether oxygen and having primary amino groups at the chain ends, II. from 3 to 20 parts by weight of a rubber containing one or more functional groups; and where the total of the parts by weight of I and II is 100; and moldings produced therefrom.

Owner:EVONIK OPERATIONS GMBH

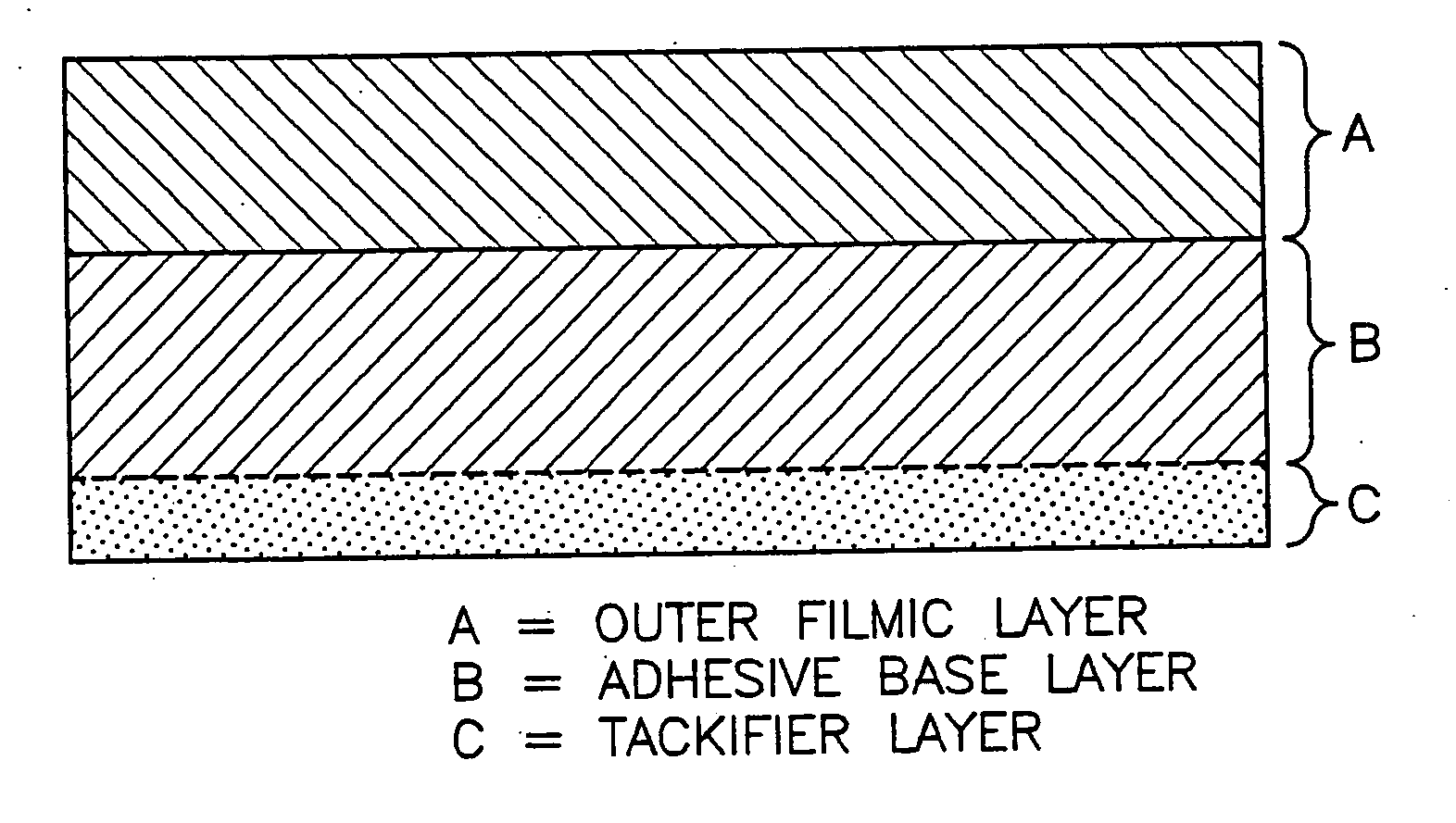

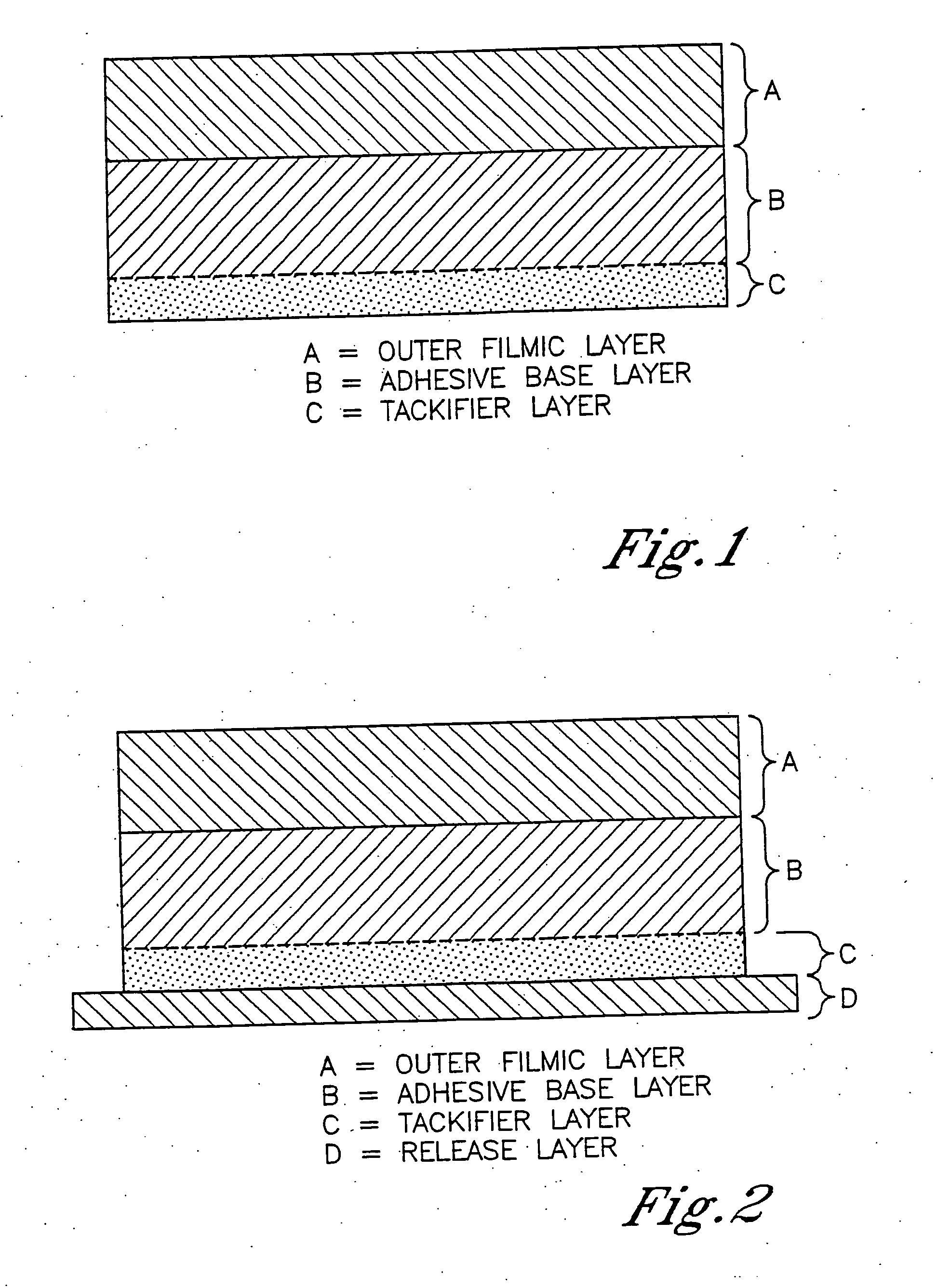

Pressure sensitive adhesive (PSA) laminates

InactiveUS20070231571A1High cohesive strength polymerImprove cohesive strengthFlat articlesThin material handlingTackifierPolymer

A PSA laminate is provided comprising at least one non-adhesive laminate and at least one tackifier layer; wherein the non-adhesive laminate comprises at least one facestock layer and at least one adhesive base layer; wherein the facestock layer comprises at least one facestock material; wherein the adhesive base layer comprises at least one adhesive base polymer; wherein the tackifier layer comprises at least one tackifier; wherein the tackifier composition is not a PSA; and wherein the tackifier layer is applied to the adhesive base layer side of the non-adhesive laminate to produce the PSA laminate. Processes for producing the PSA laminate are also provided as well as articles comprises the PSA laminates.

Owner:EASTMAN CHEM CO

Methods for converting linear polyesters to macrocyclic oligoester compositions and macrocyclic oligoesters

InactiveUS6525164B2Low viscosityCost-effectivePreparation by ester-hydroxy reactionOrganic compound preparationPolyesterDicarboxylic acid

Owner:LIQUID THERMO PLASTICS

Melt-fabricable core/shell perfluoropolymer

InactiveUS7763680B2High viscosityIncrease in critical shear rateFibre treatmentCoatingsPolymer sciencePolymer

Owner:THE CHEMOURS CO FC LLC

Molding composition based on polyetheramides

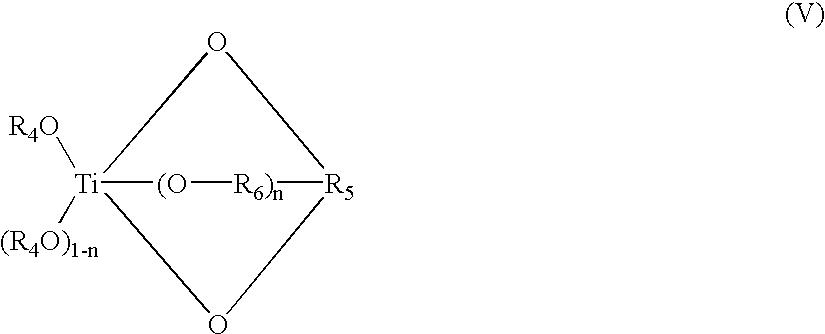

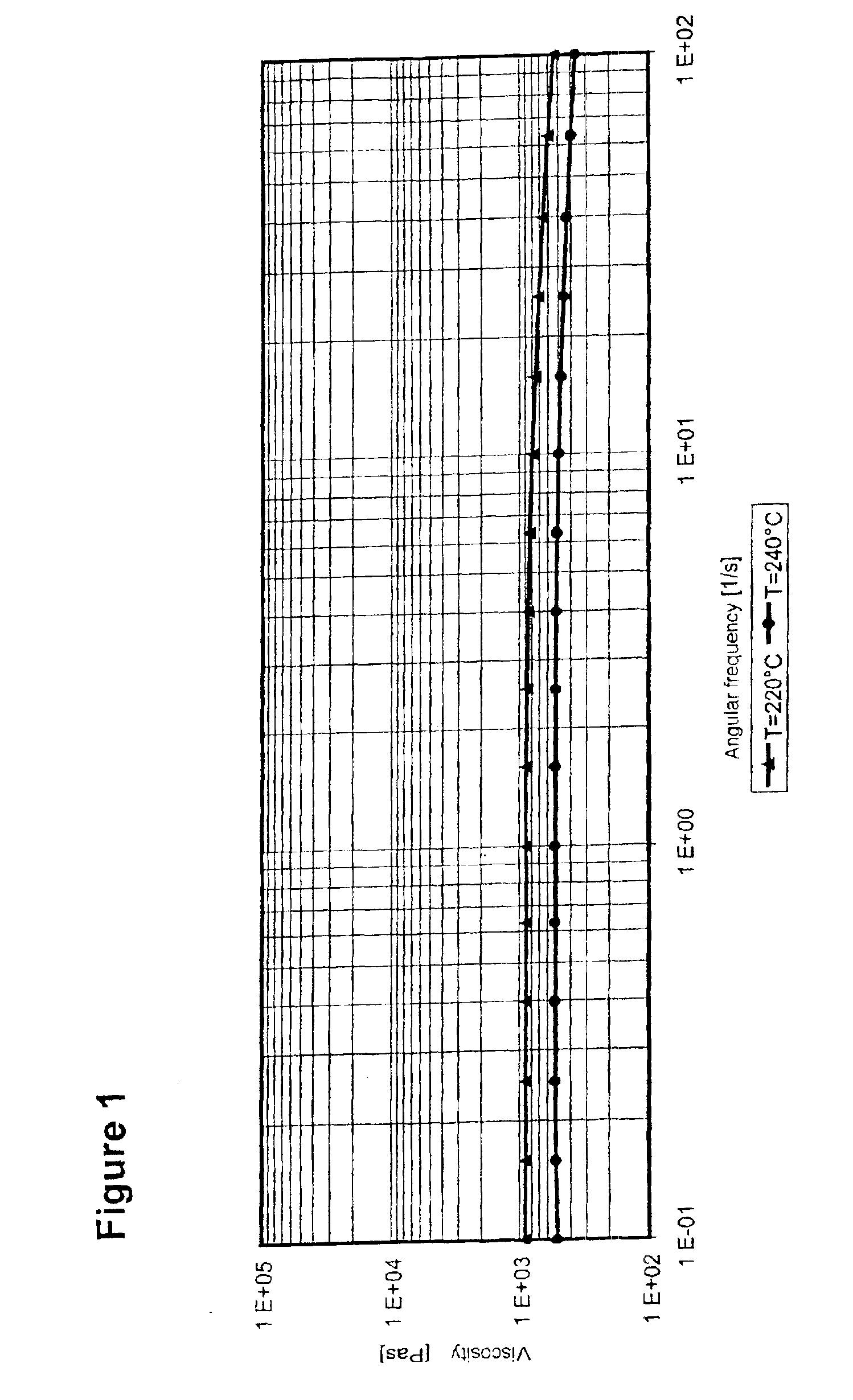

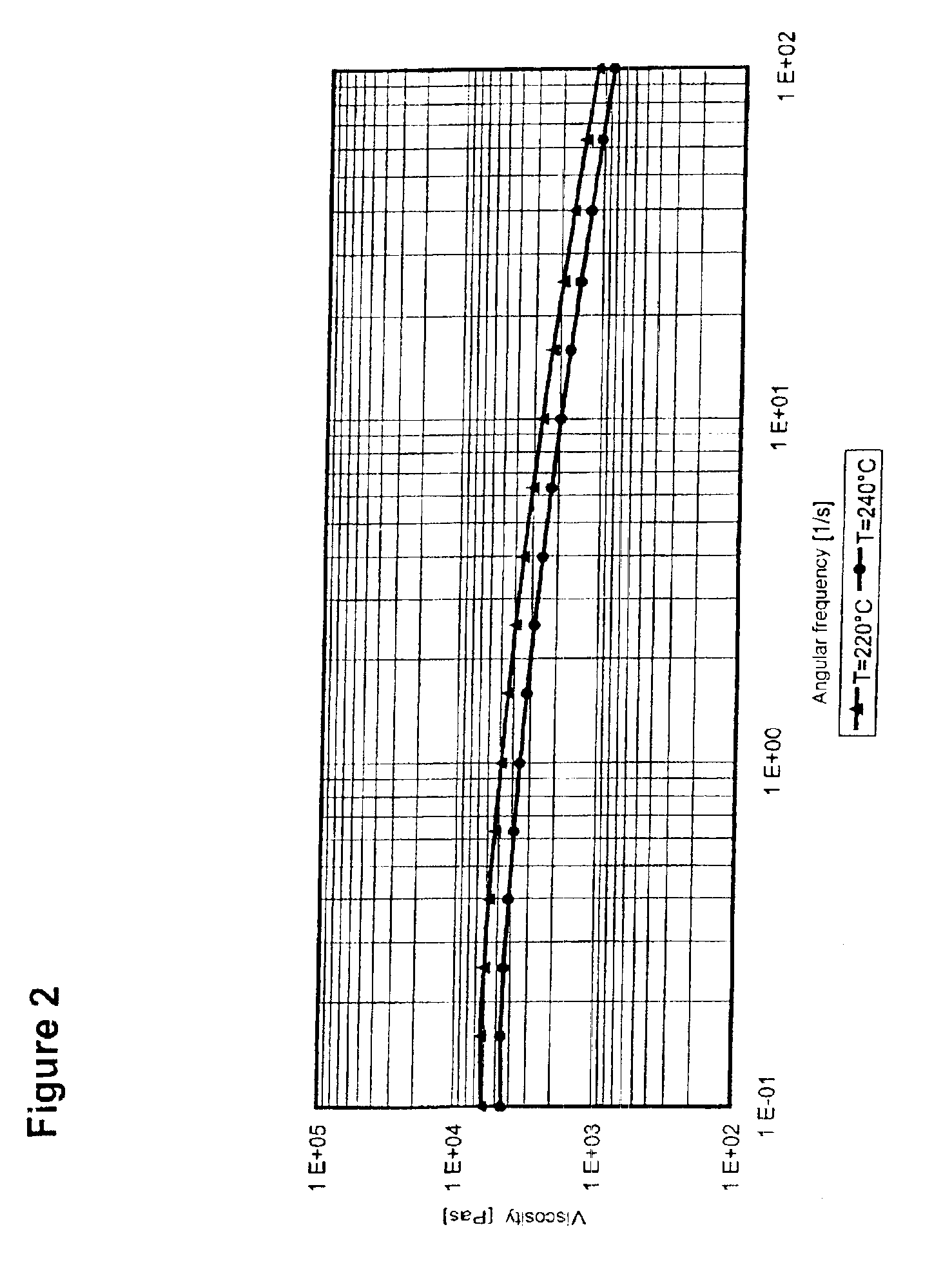

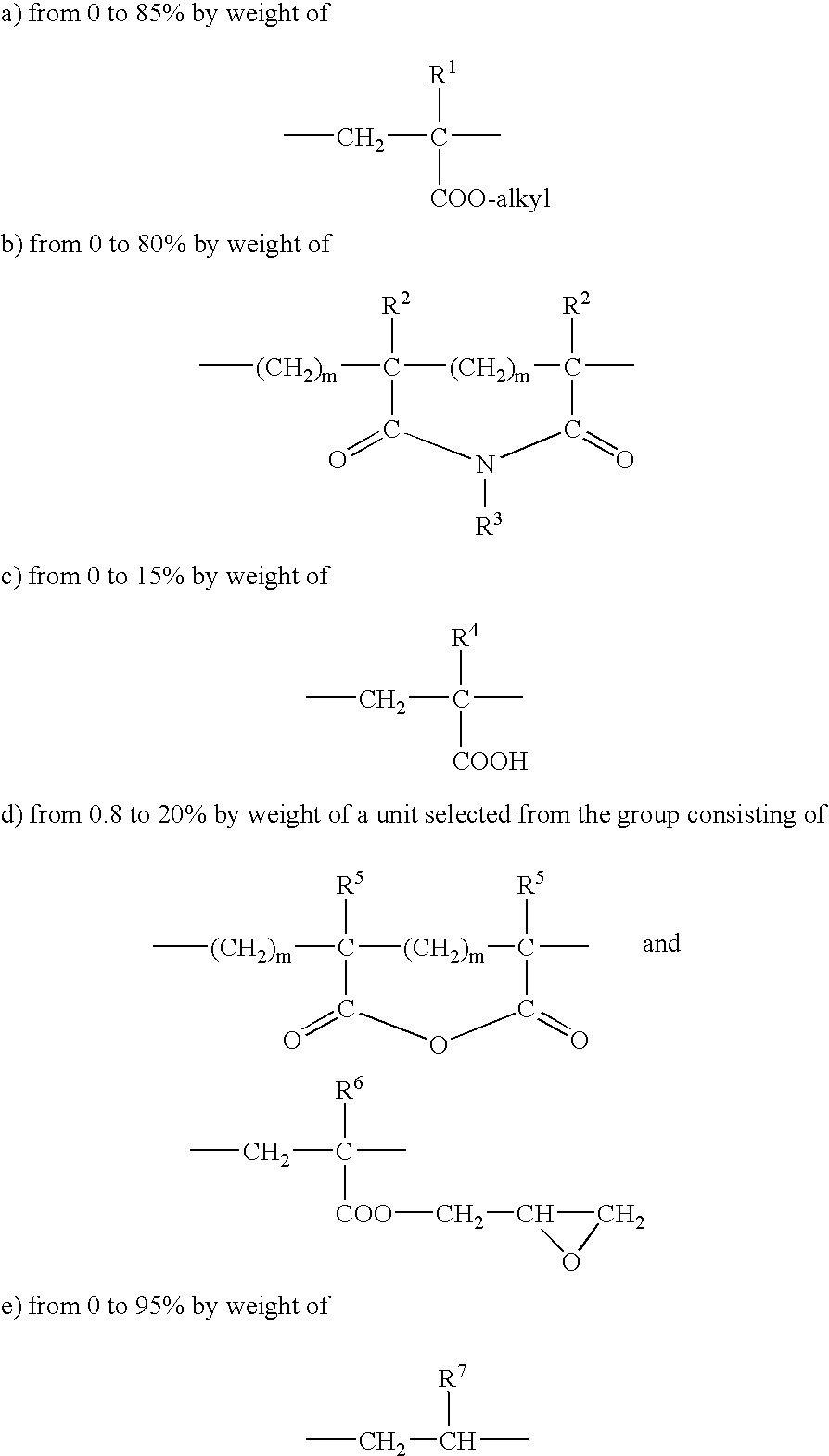

InactiveUS6884485B2Increase melt viscosityEasy extrusionEnvelopes/bags making machineryBottlesPolymer scienceDicarboxylic acid

A molding composition containing the following components:I. from 99.9 to 95 parts by weight of a polyetheramide obtained from 1) a linear aliphatic diamine having from 6 to 12 carbon atoms, 2) a linear aliphatic or aromatic dicarboxylic acid having from 6 to 12 carbon atoms, and 3) a polyetherdiamine having at least 3 carbon atoms per ethereal oxygen atom and having a primary amino group at an end of the chain, andII. from 0.1 to 5 parts by weight of a copolymer which contains from 0.8 to 20% by weight of an anhydride or an epoxide in copolymerized form,wherein the total amount of I. and II. is 100 parts by weight, is suitable for the extrusion of flexible pipes, and also for the production of flexible blow-molded articles.

Owner:EVONIK DEGUSSA GMBH

Low cost, high performance, rodent resistant, flexible reinforcement for communications cable

InactiveUS6897382B2Low costImprove performancePlastic/resin/waxes insulatorsPower cables with screens/conductive layersTelecommunicationsCopper

A low cost, high performance flexible, rodent resistant reinforcement member that can be used for both optical and copper communications cable. The reinforcement members made according to the preferred process are more rigid than known reinforcement members, but are less rigid than glass pultruded rods. Communications cables utilizing these members are lightweight and exhibit an improved combination of strength and flexibility compared to traditional communications cables. Further, these communication cables may then be installed into underground ducts using more economical and faster installation techniques.

Owner:NEPTCO JV LLC

Method for a layer-wise manufacturing of a three-dimensional object

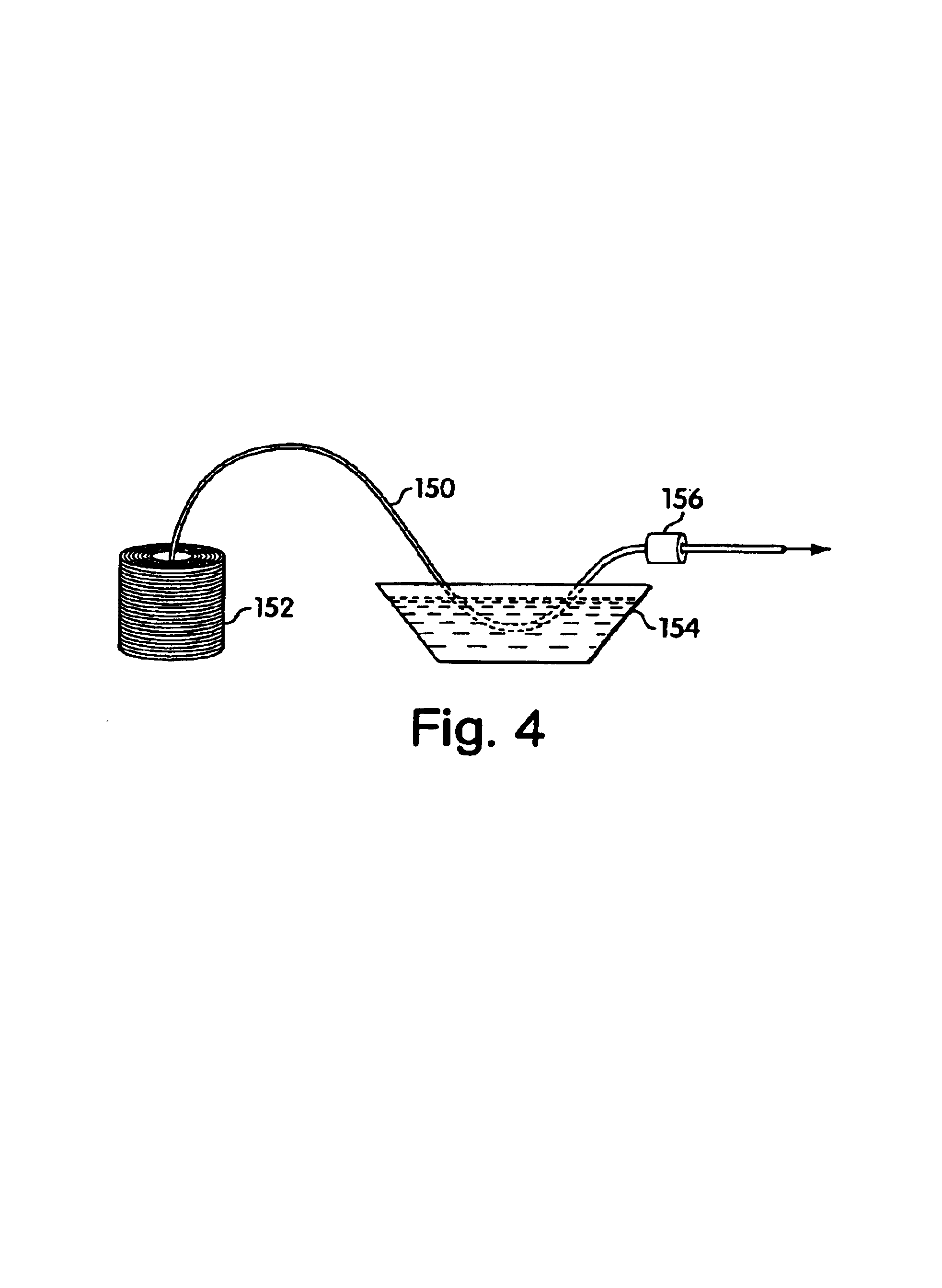

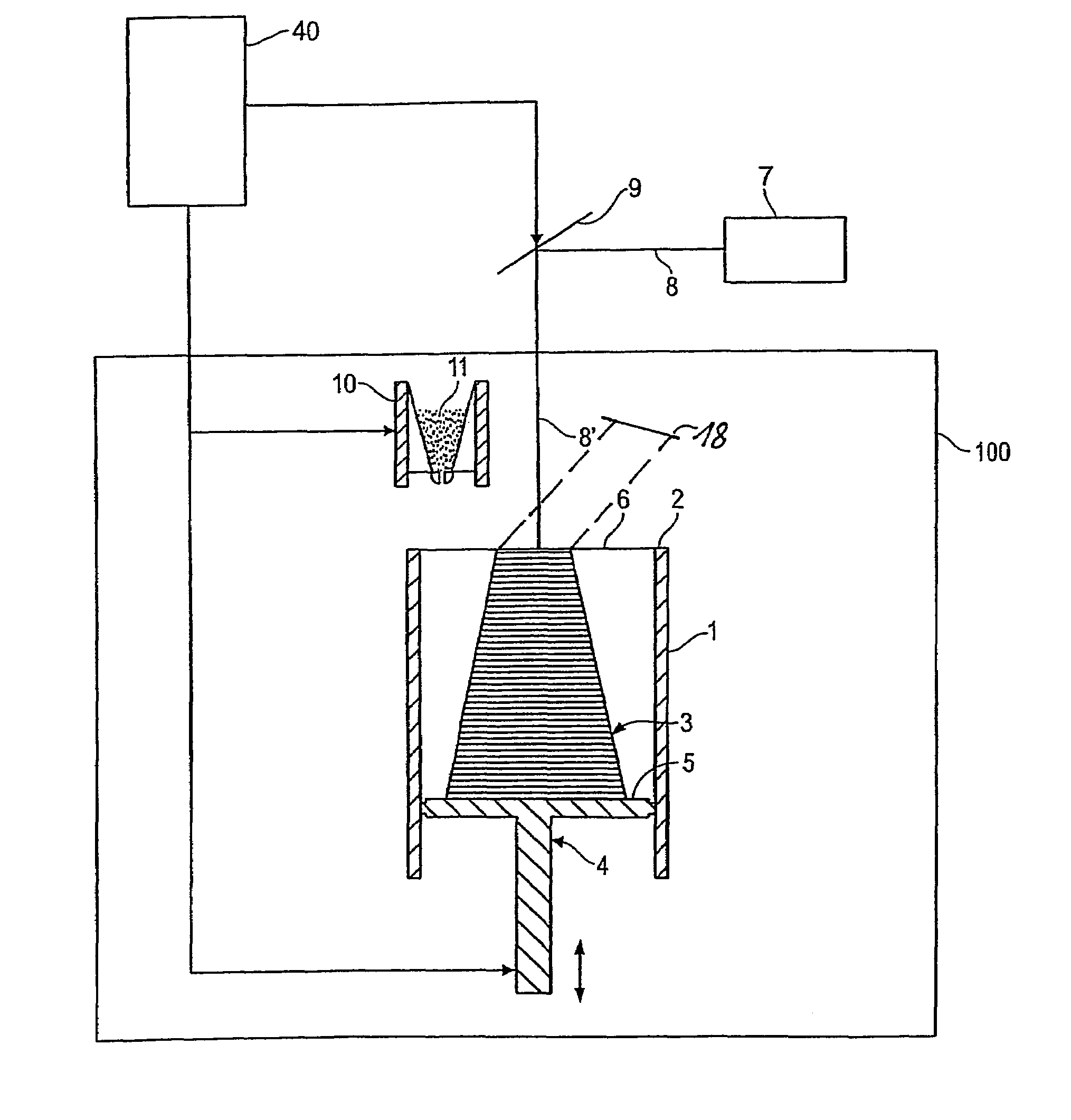

ActiveUS9011982B2Shorten the durationShorten the timeAdditive manufacturing apparatusPretreated surfacesParticle beamElectromagnetic radiation

A method for a layer-wise manufacturing of a three-dimensional object has a first step of providing a layer of a material in powder form or a liquid material on a support or a layer that has already been solidified at selected positions previously and a second step of directing a focussed photon or particle beam (8′) selectively at selected positions of the layer. In the second step, the photon or particle beam is selected such that it brings about a change of the absorption of the material when hitting the layer. After the termination of the second step, a third step is carried out, in which the layer is irradiated by means of electromagnetic radiation (18′) such that the material is homogenously solidified at those positions of the layer that correspond to the cross-section of the object to be formed.

Owner:EOS ELECTRO OPTICAL SYST

Macrocyclic polyester oligomers as carriers and/or flow modifier additives for thermoplastics

InactiveUS20070216067A1High trafficReduce molding pressureMaterial nanotechnologyThermoplasticPolyester

Concentrates of a carbon-based filler—such as carbon nanotubes, exfoliated graphite, and the like—and a macrocyclic polyester oligomer (also referred to herein as macrocyclic oligoester or MPO) are presented. When mixed with polymer, the MPO can act as a flow modifier, as well as a carrier for the carbon-based filler, allowing enhanced processability of the polymer-filler composite without adversely affecting the properties of the composite.

Owner:CYCLICS CORP

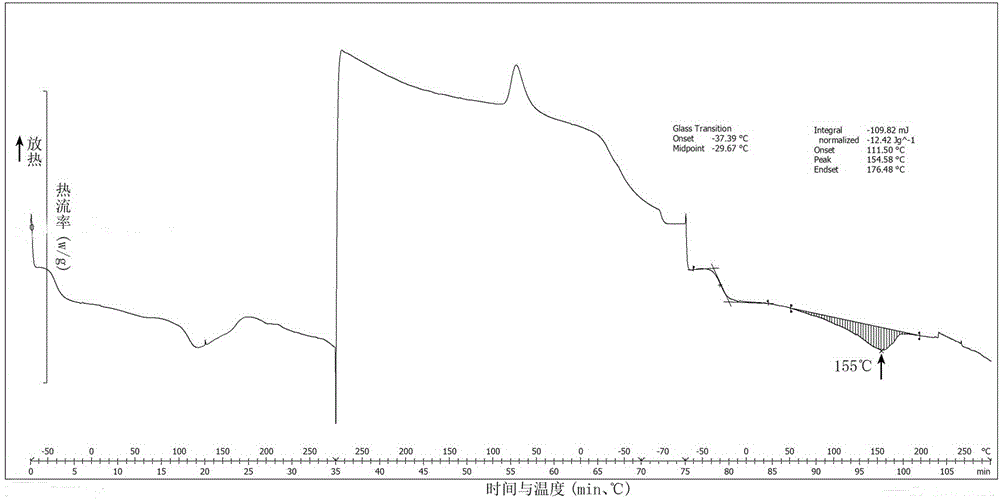

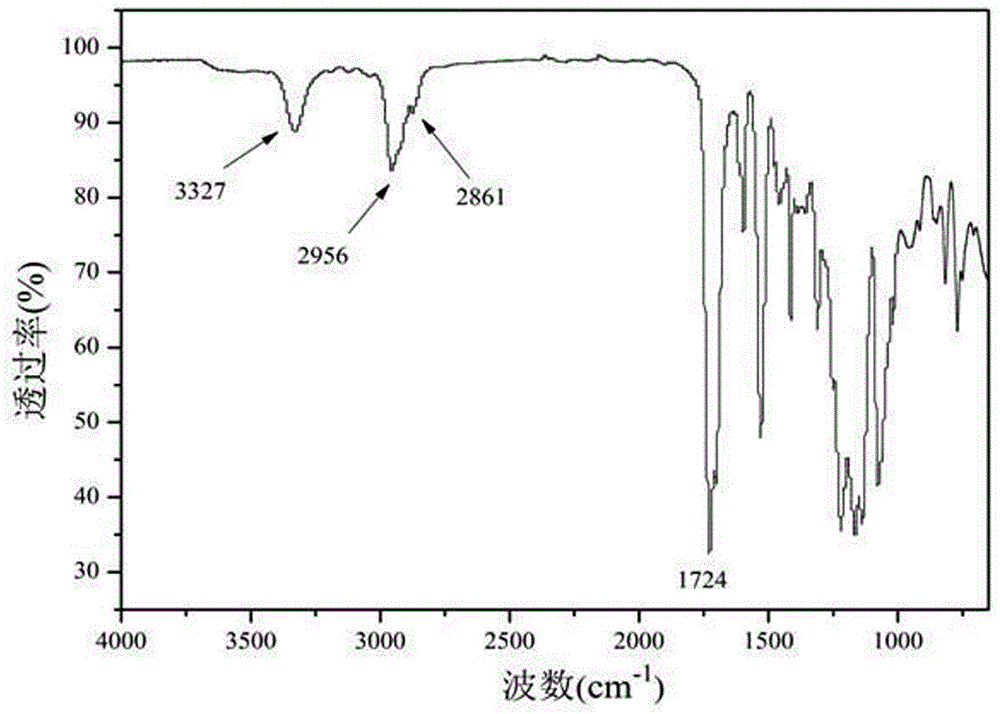

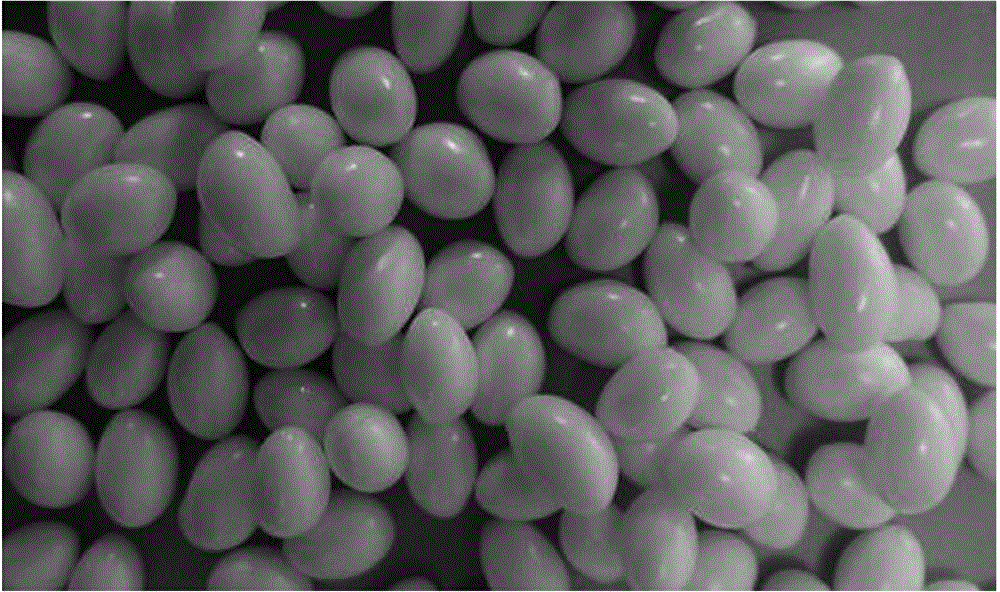

Preparation method of thermoplastic polyurethane beads and bead molding technology

The present invention discloses a preparation method of thermoplastic polyurethane beads and a bead molding technology. High foaming thermoplastic polyurethanes (TPU) beads are obtained through: melting and granulating TPU, melt viscosity modifiers, fillers and age resisters to prepare TPU co-blending granules; using clean, cheap, environmentally-friendly CO2 and / or N2 as foaming agents; and performing medium-temperature and high-pressure soakage, dissolution equilibrium, pressure relief and pre-foaming, saturated steam secondary foaming and other techniques. The obtained high foaming TPU beads are small in shrinkage ratio and smooth in surface. The invention further discloses the bead molding technology which uses a water vapor assisted mould pressing technology to prepare molded bodies of the TPU foaming beads, the prepared molded bodies of the TPU foaming beads are low in density, small in shrinkage ratio and uniform in surface texture, and also have an unique property of TPU resin. The TPU beads can be widely applied in the fields of vibration-absorptive materials, packaging materials, toys for children, sporting goods, aviation models, heat insulating materials, automotive interior materials, etc.

Owner:CHANGZHOU SHUNXIANG NEW MATERIAL TECH CO LTD

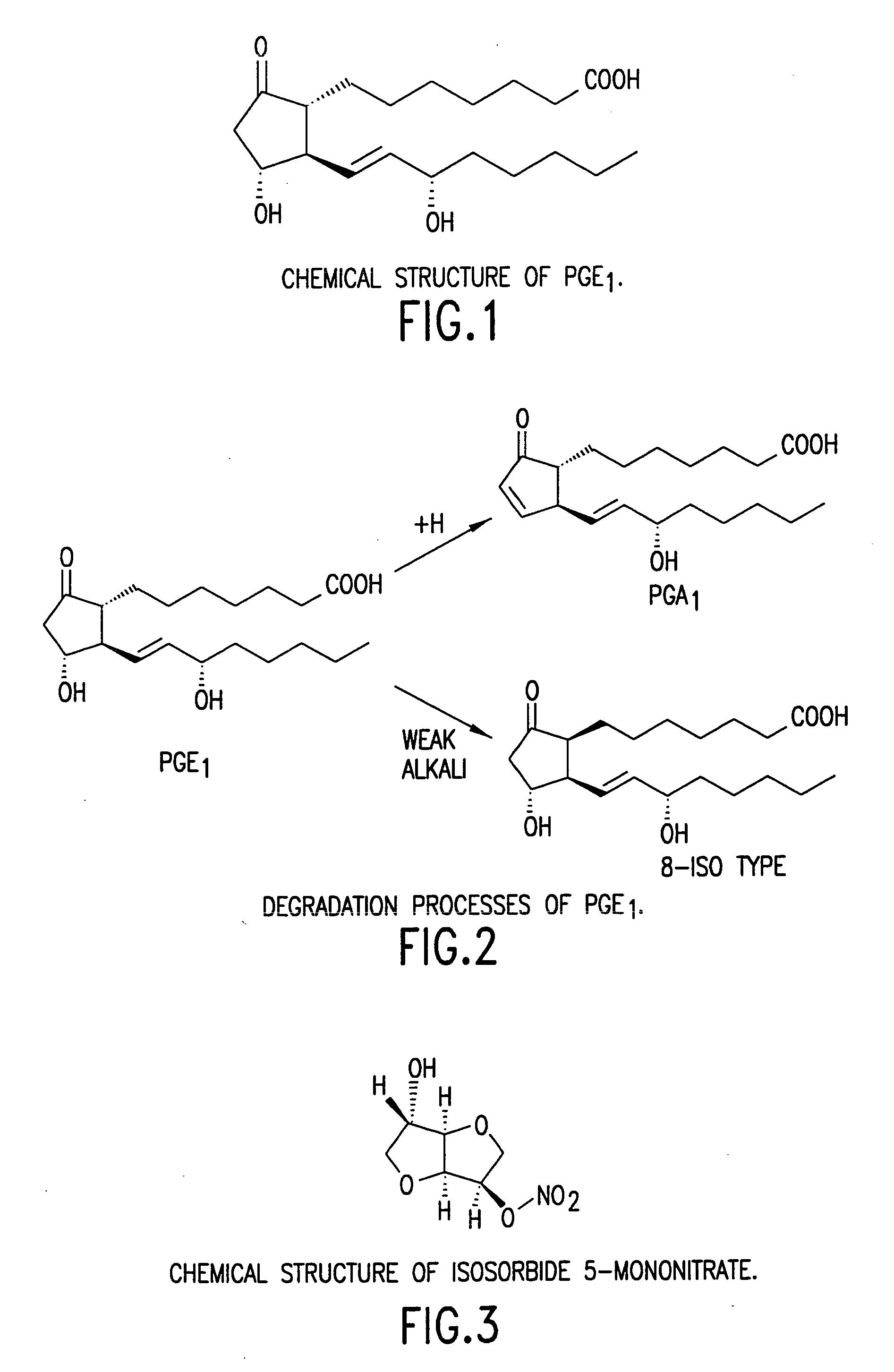

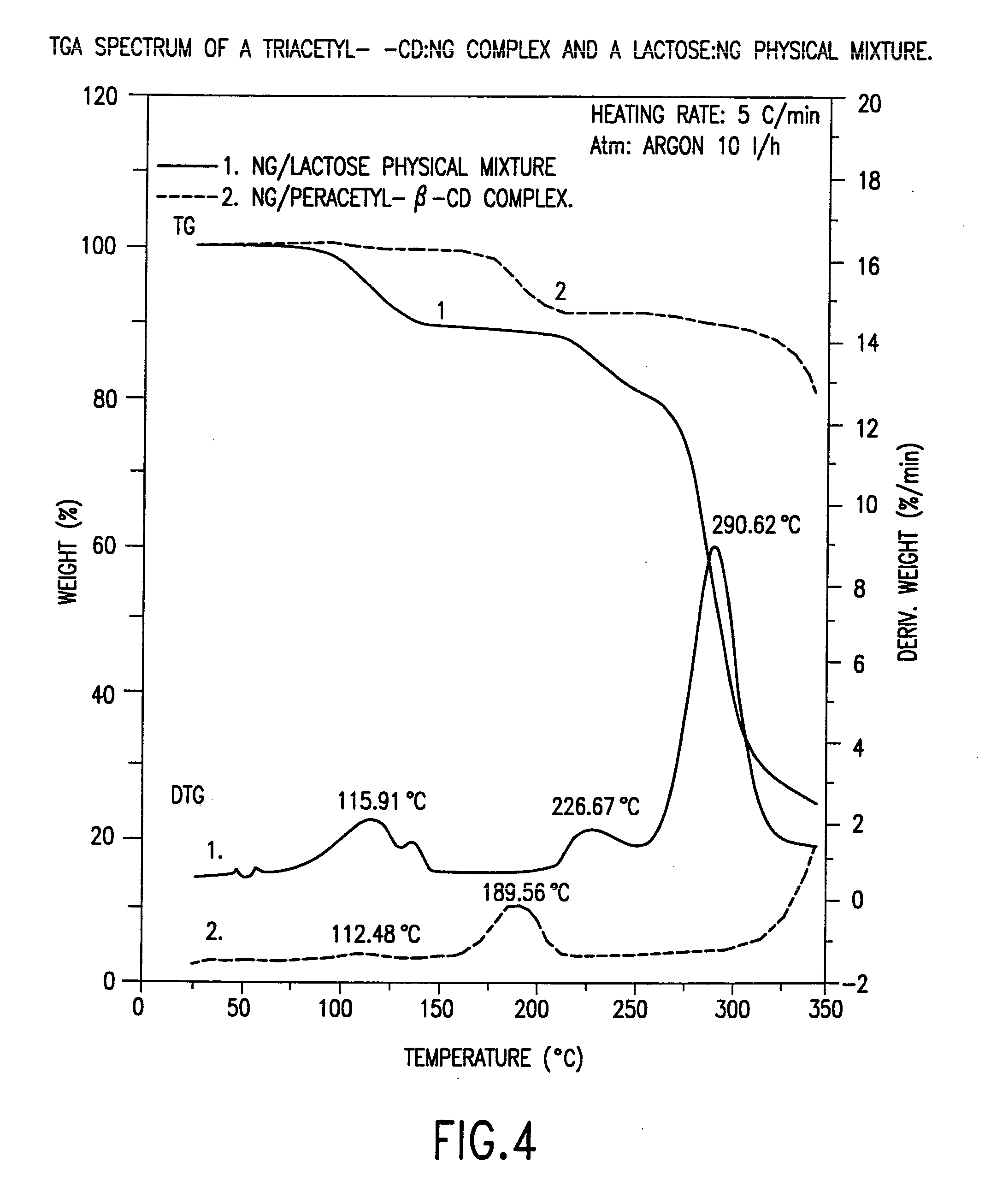

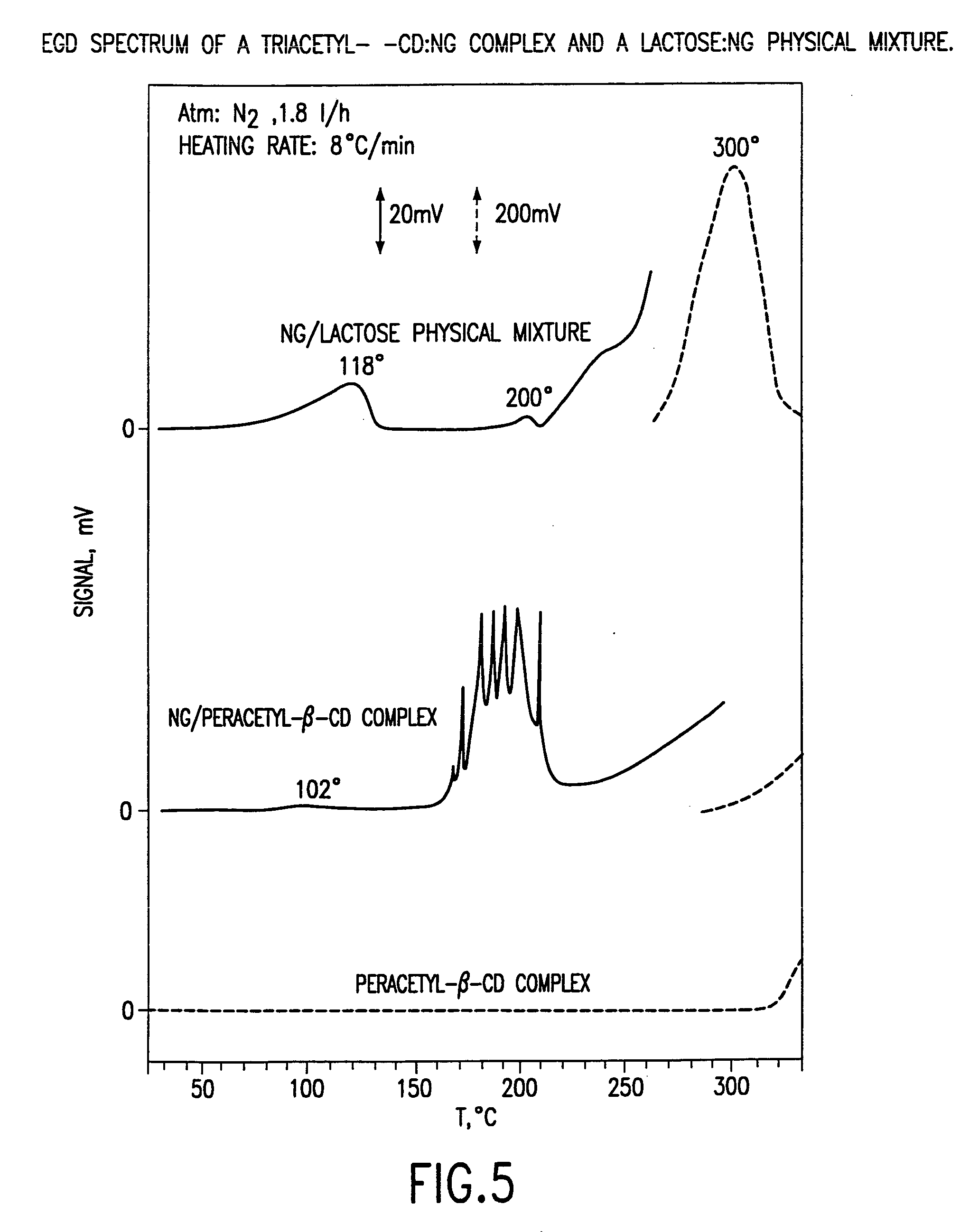

Acylated cyclodextrin: guest molecule inclusion complexes

InactiveUS20020025946A1Improve processing efficiencyImprove stabilityBiocideOrganic chemistryCyclodextrinAqueous medium

The present invention is directed to a method of making an inclusion complex comprising an acylated cyclodextrin host molecule and a guest molecule, wherein the method comprises the steps of: a)contacting the acylated cyclodextrin host molecule and the guest molecule to form an inclusion complex; and b) precipitating the inclusion complex in an aqueous medium. The present invention is further directed to an inclusion complex comprising an acylated cyclodextrin host molecule and a guest molecule, wherein the guest molecule comprises from about 2% (wt.) to about 15% (wt.) of the inclusion complex. Moreover, the present invention relates to a composition comprising a polymer and an inclusion complex, wherein the inclusion complex comprises an acylated cyclodextrin host molecule and a guest molecule and medical devices and solid pharmaceutical compositions comprised thereof.

Owner:EASTMAN CHEM CO

Thermoplastic resin composition and engineering plastic composition

InactiveUS20050159533A1Improve liquidityImprove melt fluiditySpecial tyresEngineering plasticTape recorder

Owner:MITSUBISHI CHEM CORP

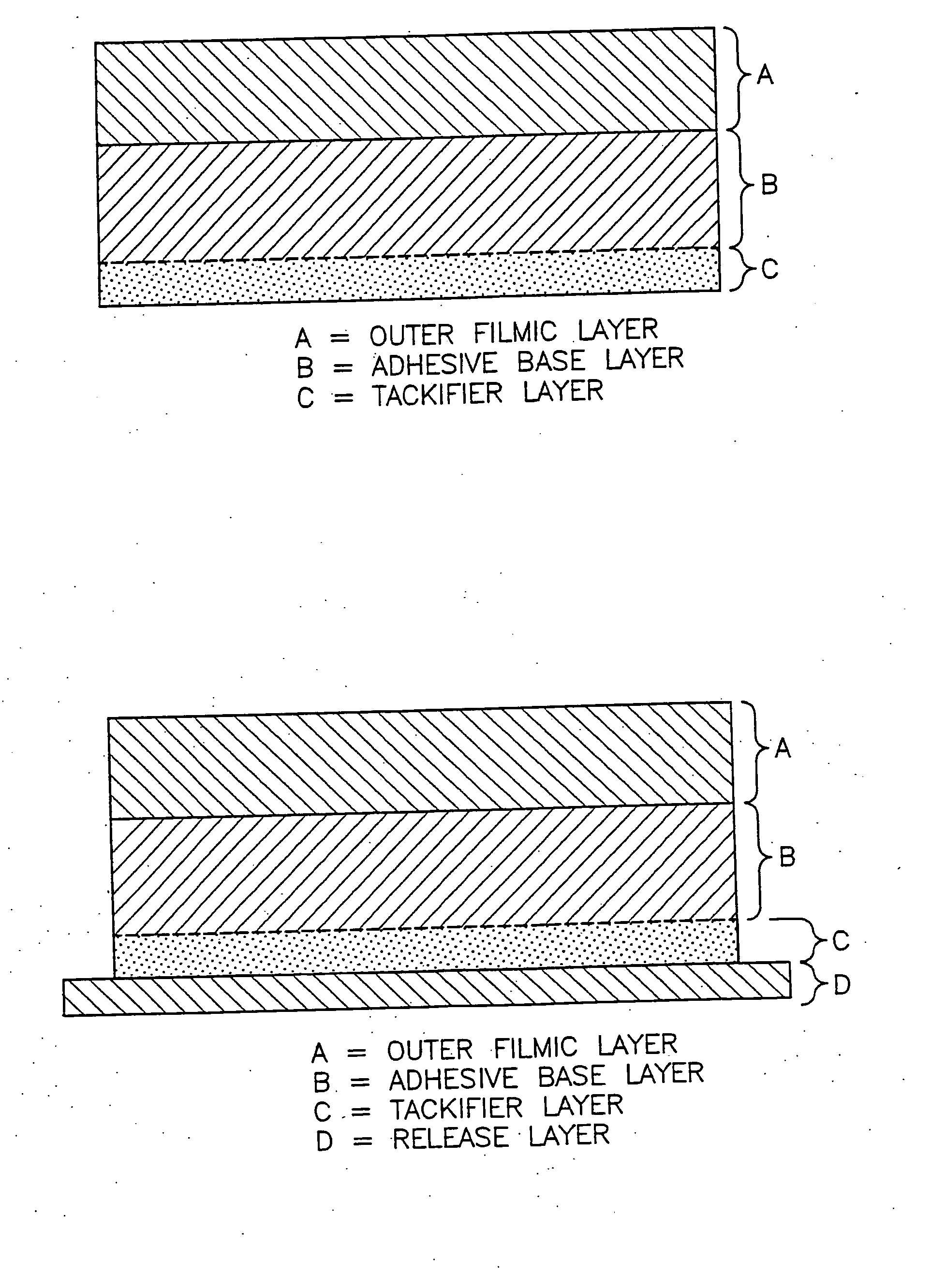

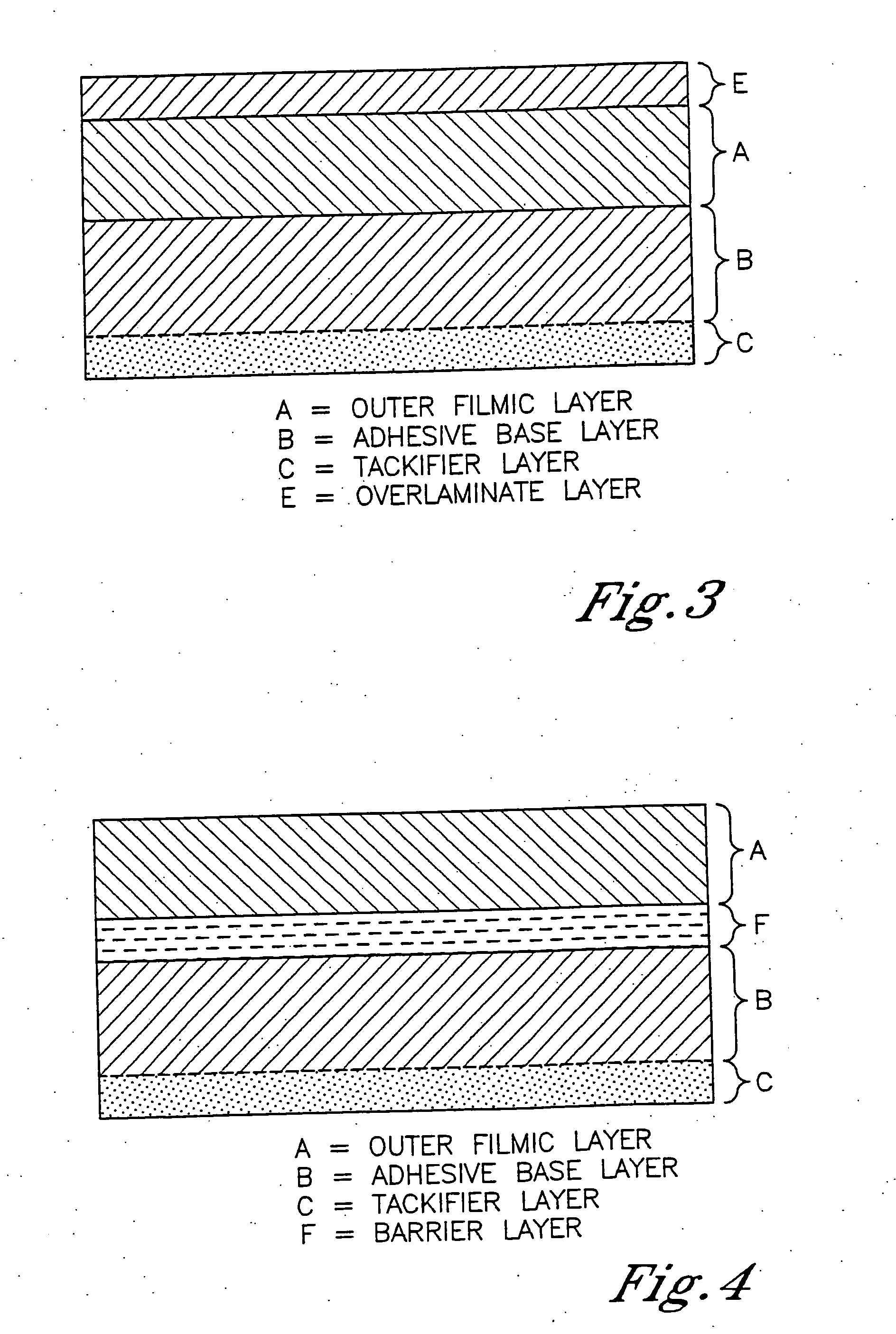

Pressure sensitive adhesives (PSA) laminates

InactiveUS20060263596A1High cohesive strength polymerHigh cohesive strengthAdhesive articlesSynthetic resin layered productsPressure sensitivePolymer

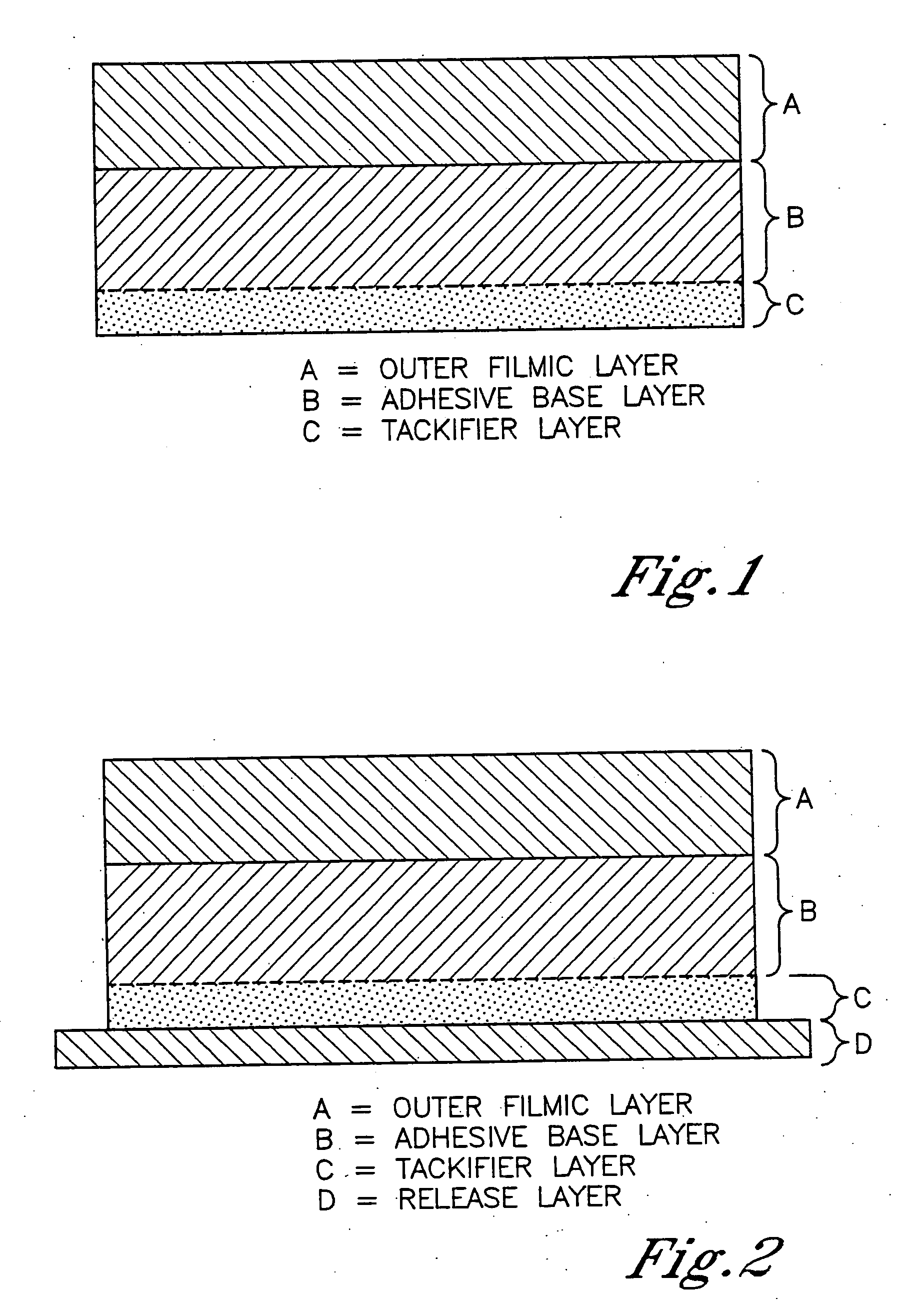

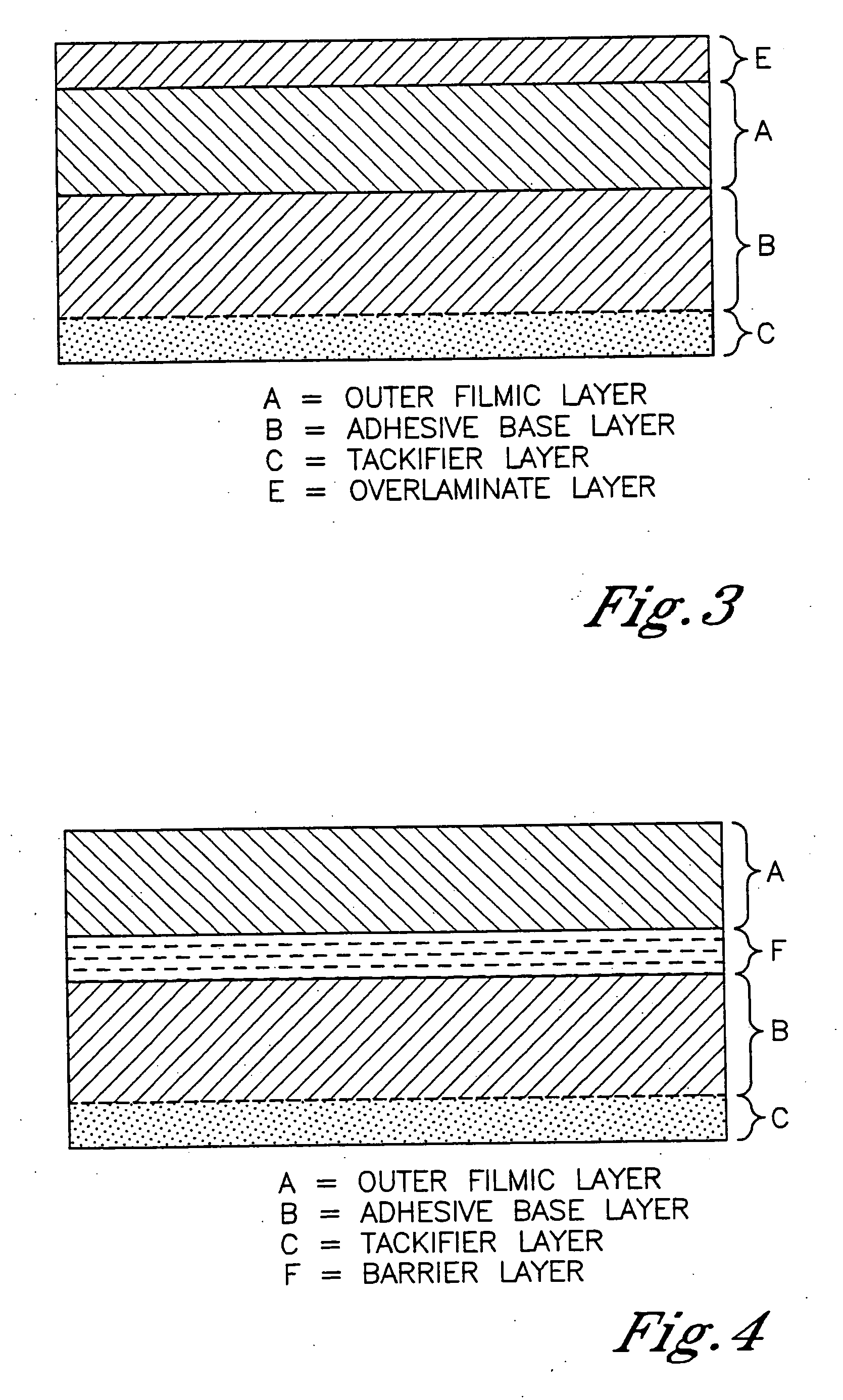

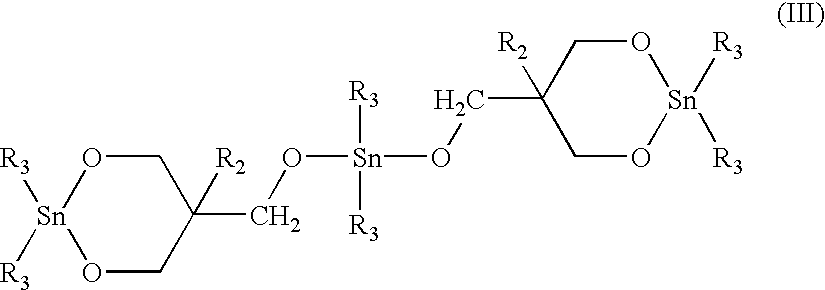

A PSA laminate is provided comprising: a) at least one outer filmic layer (A) comprising at least one filmic polymer; b) at least one adhesive base layer (B) comprising at least one adhesive base polymer; and c) at least one tackifier layer (C) comprising at least one tackifier and at least one polymer; wherein the pressure sensitive adhesive laminate is obtainable by co-extruding the outer filmic layer (A) with the adhesive base layer (B) to produce a non-adhesive laminate and applying the tackifier layer (C) to the adhesive base layer side of the non-adhesive laminate to produce the PSA laminate. Processes for producing the PSA laminate, and articles comprising the PSA laminate are also provided.

Owner:EASTMAN CHEM CO

Acylated cyclodextrin: guest molecule inclusion complexes

InactiveUS20040063663A1Inhibited DiffusionLow process temperatureBiocidePowder deliveryCyclodextrinAqueous medium

Owner:BUCHANAN CHARLES M +4

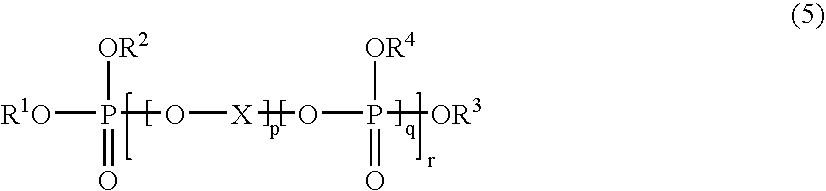

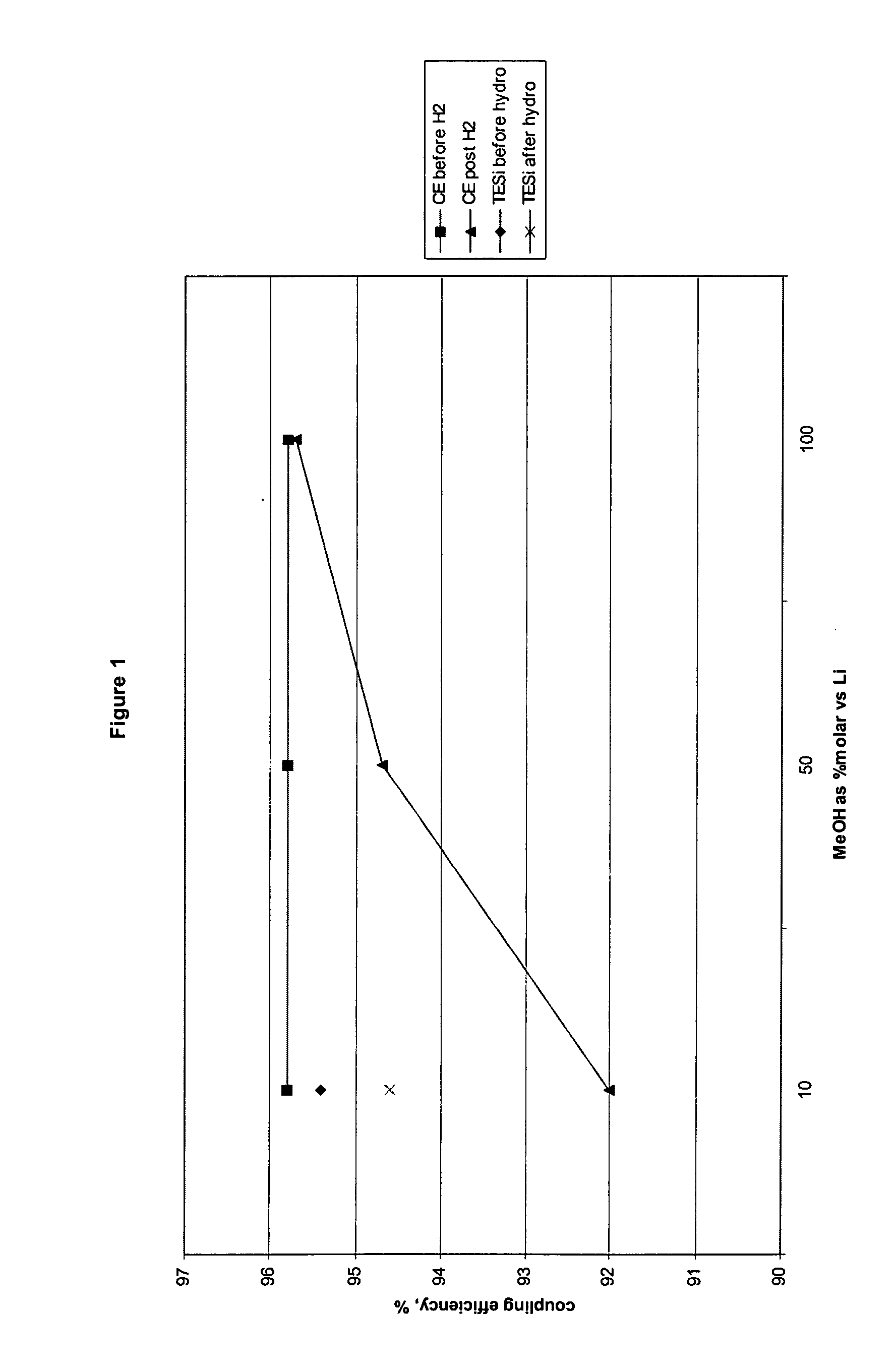

Process for preparing block copolymer and resulting composition

Lithium-terminated polymers of one or more conjugated dienes and of one or more mono alkenyl arenes are coupled by reaction with an alkoxy silane coupling agent having the formula Rx—Si—(OR′)y, where x is 0 or 1, x+y=4, R and R′ are the same or different, R is selected from aryl hydrocarbon radicals, linear alkyl hydrocarbon radicals and branched alkyl hydrocarbon radicals, and R′ is selected from linear and branched alkyl hydrocarbon radicals, such that the resulting polymer composition contains less than about ten weight percent of uncoupled polymer diblock. The polymer compositions are subsequently selectively hydrogenated, and are useful in a variety of compounds and end use applications.

Owner:KRATON POLYMERS US LLC

Glaze for fast-fired crystal glaze ceramic tile, and preparation method and applications of ceramic tile

ActiveCN104829268AReduce granularity requirementsSimple manufacturing processManufacturing technologyBrick

The invention provides a glaze for fast-fired crystal glaze ceramic tile and a preparation method and applications of ceramic tile. The glaze comprises basic crystal glaze and a color developing agent, wherein the basic crystal glaze comprises the following raw materials: zinc oxide, titanium dioxide, quartz, cryolite, zinc phosphate, kaolin, and lead frit. A proper amount of zinc phosphate is introduced into the glaze to avoid the raw material frit treatment, which is carried out to ensure the residual amount of nucleating agent, the requirements on the glaze granularity are reduced, the manufacture technologies of crystal glaze and ceramic tiles are simplified, and the technical difficulties that the crystal glaze sintering technology is complicated, the crystal patterns are difficult to control, and the production cost is high are solved. Moreover, the addition amount of quartz and lead frit is precisely controlled to obtain crystal glaze art ceramic tiles which have the advantages of good crystallization effect, strong three-dimensional effect, and good artistic effect. The provided preparation method has the advantages of simpleness, lower sintering temperature, shorter period, and suitability for massive industrial production.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK +1

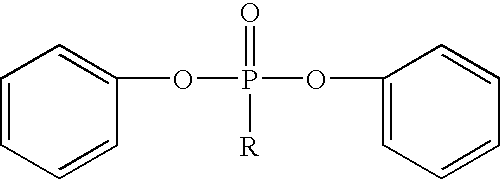

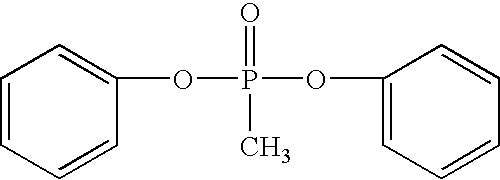

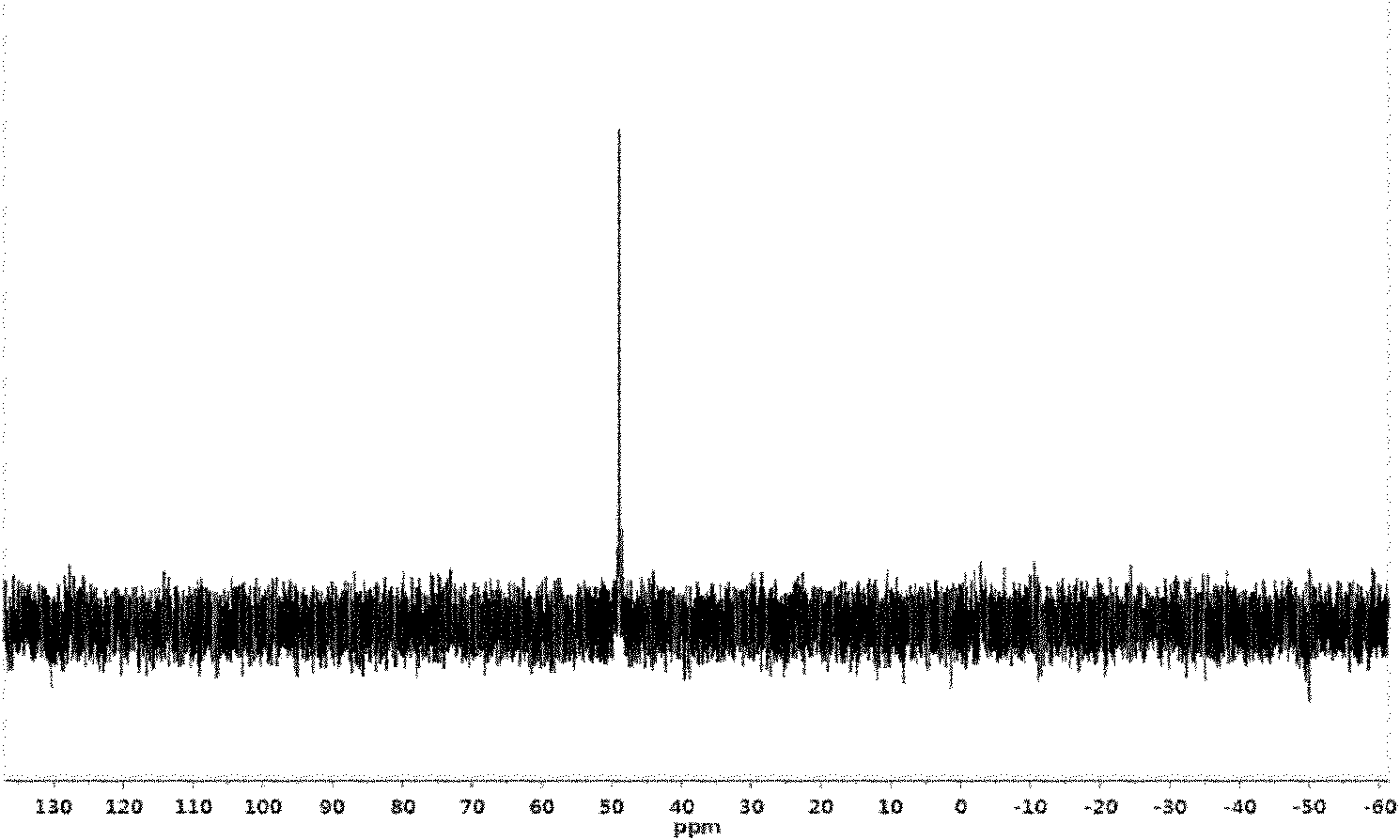

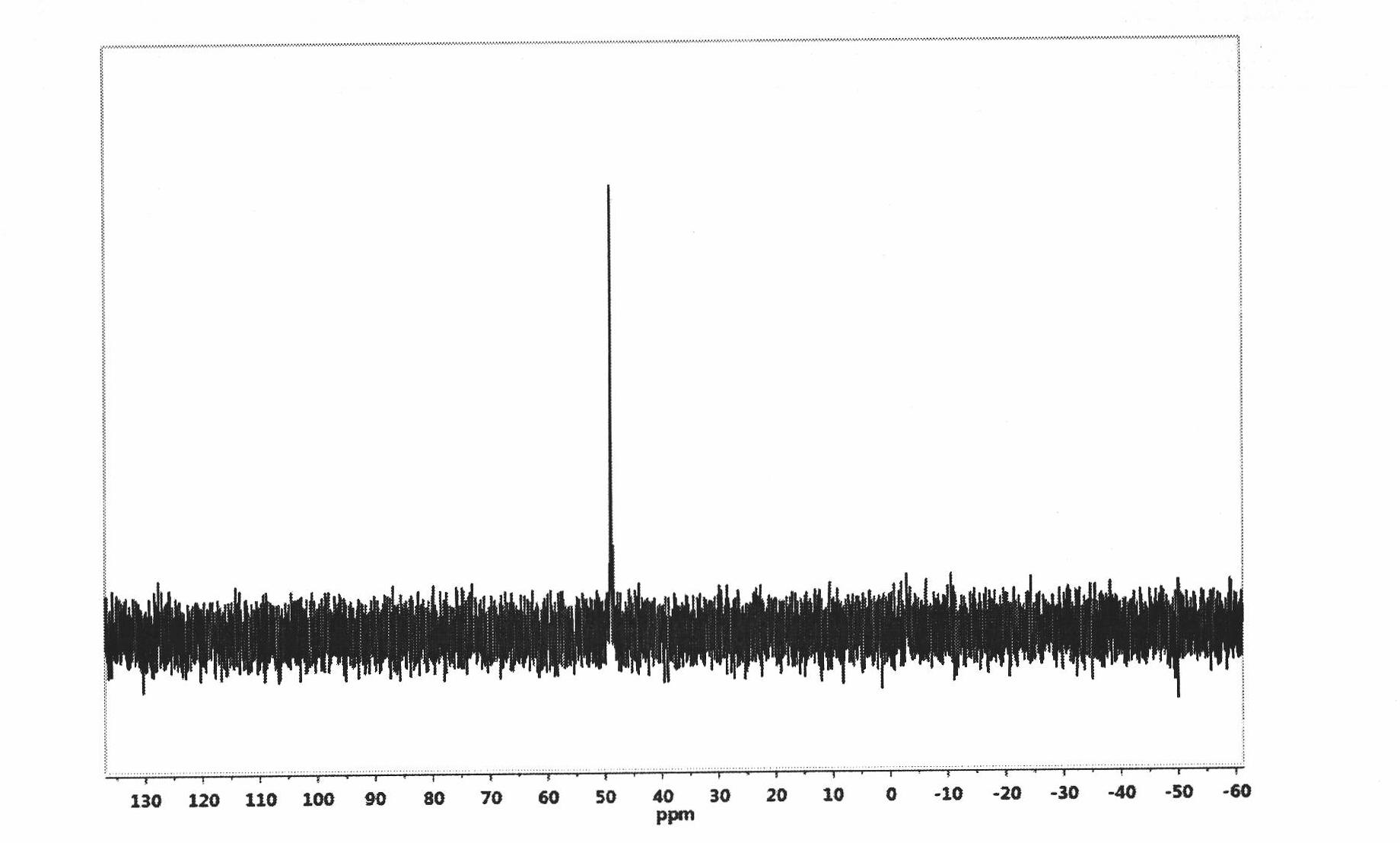

Insoluble and Branched Polyphosphonates and Methods Related Thereto

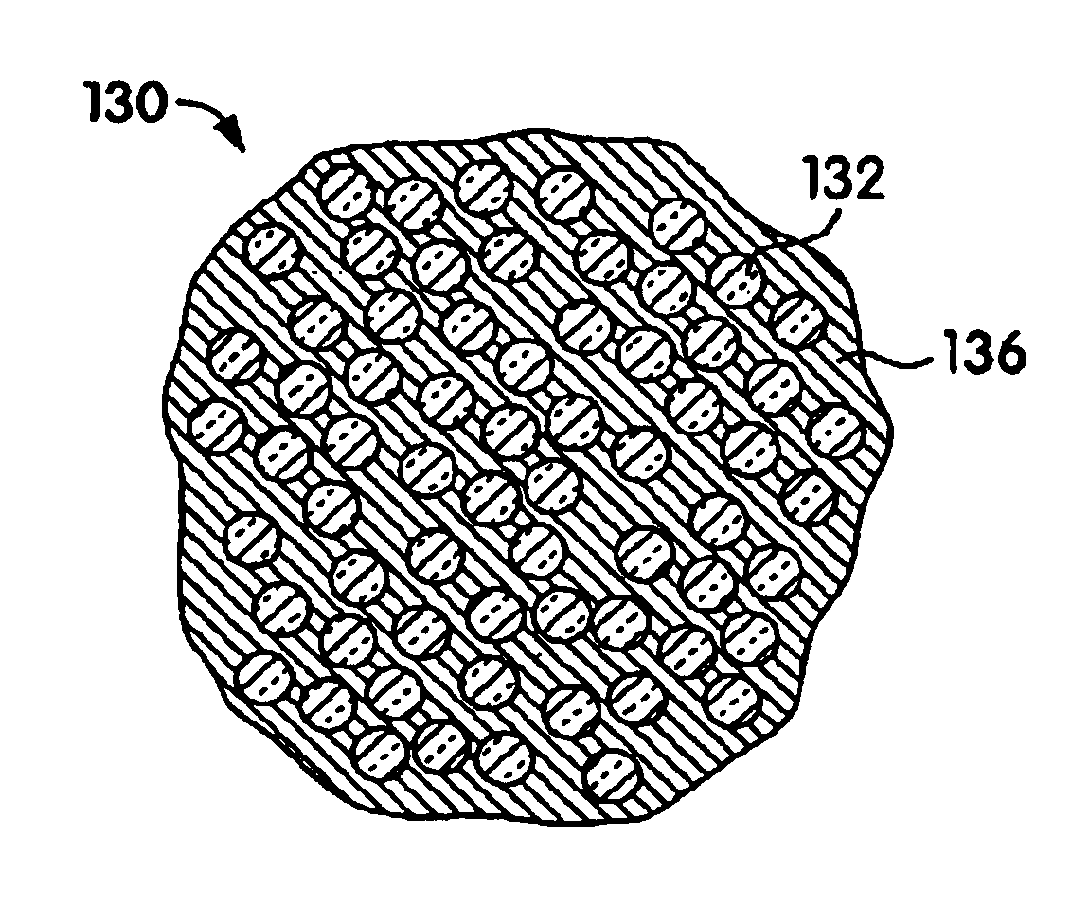

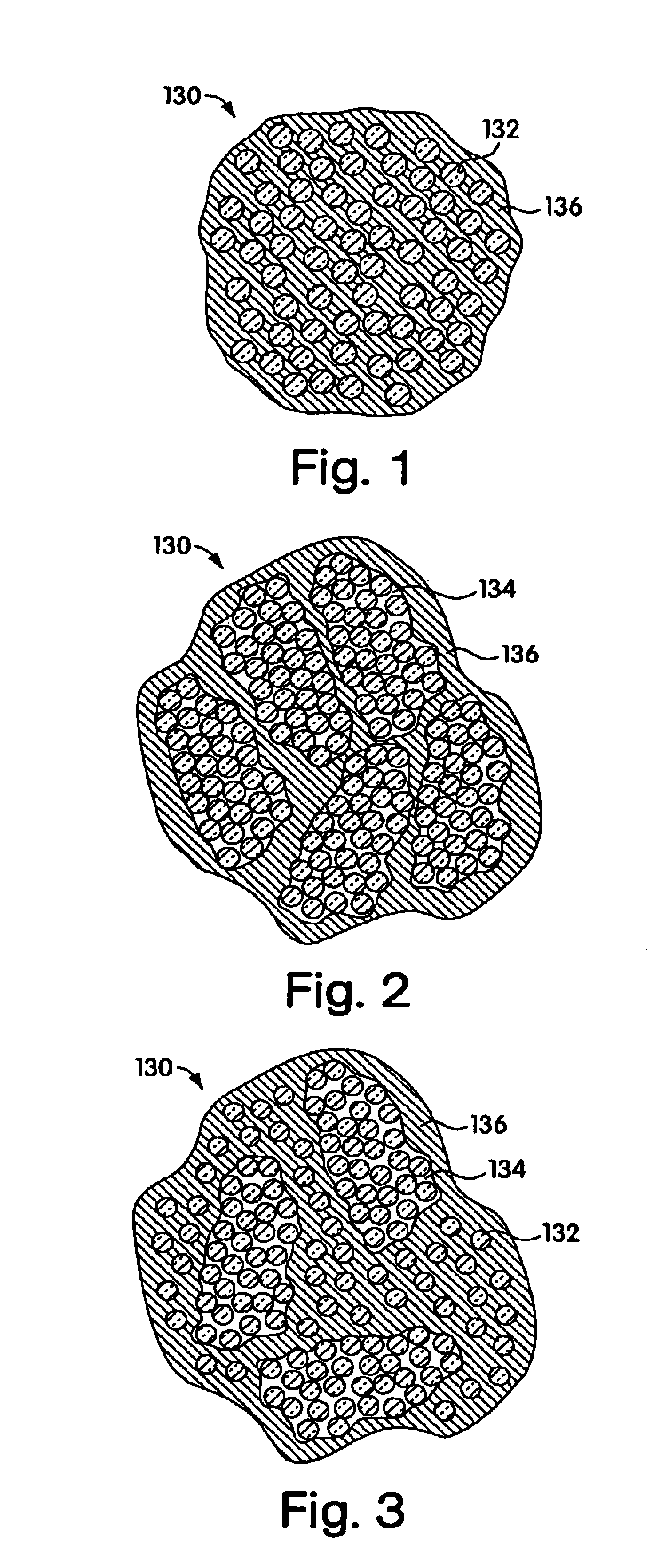

InactiveUS20090032770A1Increase melt viscosityLiquid crystal compositionsPolymer scienceTransesterification

Insoluble polyphosphonates produced via a transesterification process, methods for preparing such insoluble polyphosphonates and polymer compositions and articles of manufacture including such insoluble polyphosphonates are described herein.

Owner:FRX POLYMERS LLC

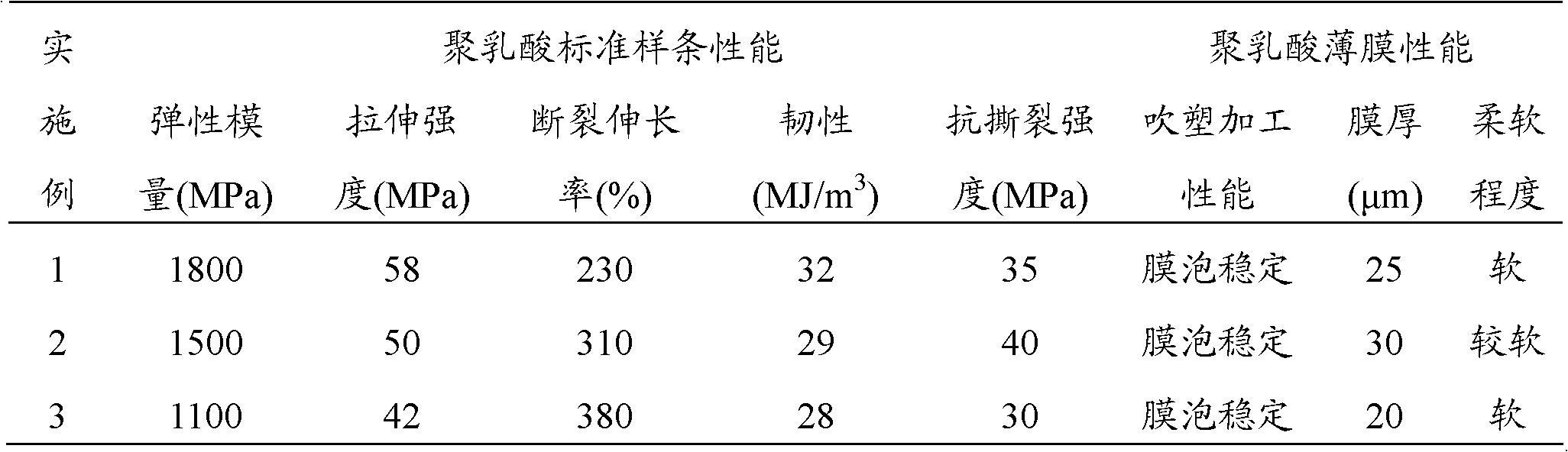

Polylactic acid composition and polylactic acid product

InactiveCN102618003AGood comprehensive mechanical propertiesImprove blow molding processabilityPlasticizerPolylactic acid

The invention provides a polylactic acid composition and a polylactic acid product. The polylactic acid composition comprises the following components by weight percent: 50 to 80 percent of polylactic acid, 0 to 35 percent of adipic acid-polybutylene terephthalate, 0 to 35 percent of poly(butylene succinate), 0.05 to 0.5 percent of peroxide, 0.05 to 0.5 percent of chain extendor and 3 to 15 percent of plasticizer, wherein the content of the adipic acid-polybutylene terephthalate and the content of the poly(butylene succinate) are not 0 percent. The mechanical properties such as melt strength, elongation at break, tenacity and anti-tear strength of the polylactic acid composition provided by the invention are improved, so that the polylactic acid composition with better comprehensive mechanical properties can be obtained, and the polylactic acid composition has more stable processability and better film forming stability.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Biodegradable branched aromatic polyester-aliphatic polyester multi-block polymer

The invention relates to a biodegradable branched aromatic polyester-aliphatic polyester multi-block polymer and a preparation method thereof. By combining excellent biological degradability of aliphatic polyester, excellent mechanical property, thermal performance and stability of aromatic polyester and improved physical and mechanical performances of branched aliphatic polyester, the invention provides the biodegradable branched aromatic polyester-aliphatic polyester multi-block polymer. The multi-block polymer is a branched multi-block copolymer comprising an chain segment I and a chain segment II, or a branched multi-block polymer comprising the chain segment I and a chain segment III, or a branched multi-block polymer comprising the chain segment I, the chain segment II and a chain segment III. According to the multi-block polymer, the defects of the aliphatic polyester in performance are overcome; and the multi-block polymer has the advantages of high viscosity of fused mass, high strength of the fused mass, excellent stability and the like.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

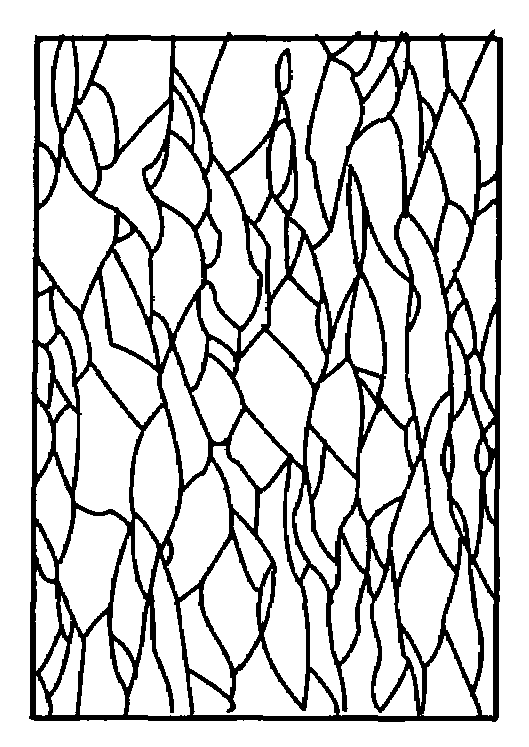

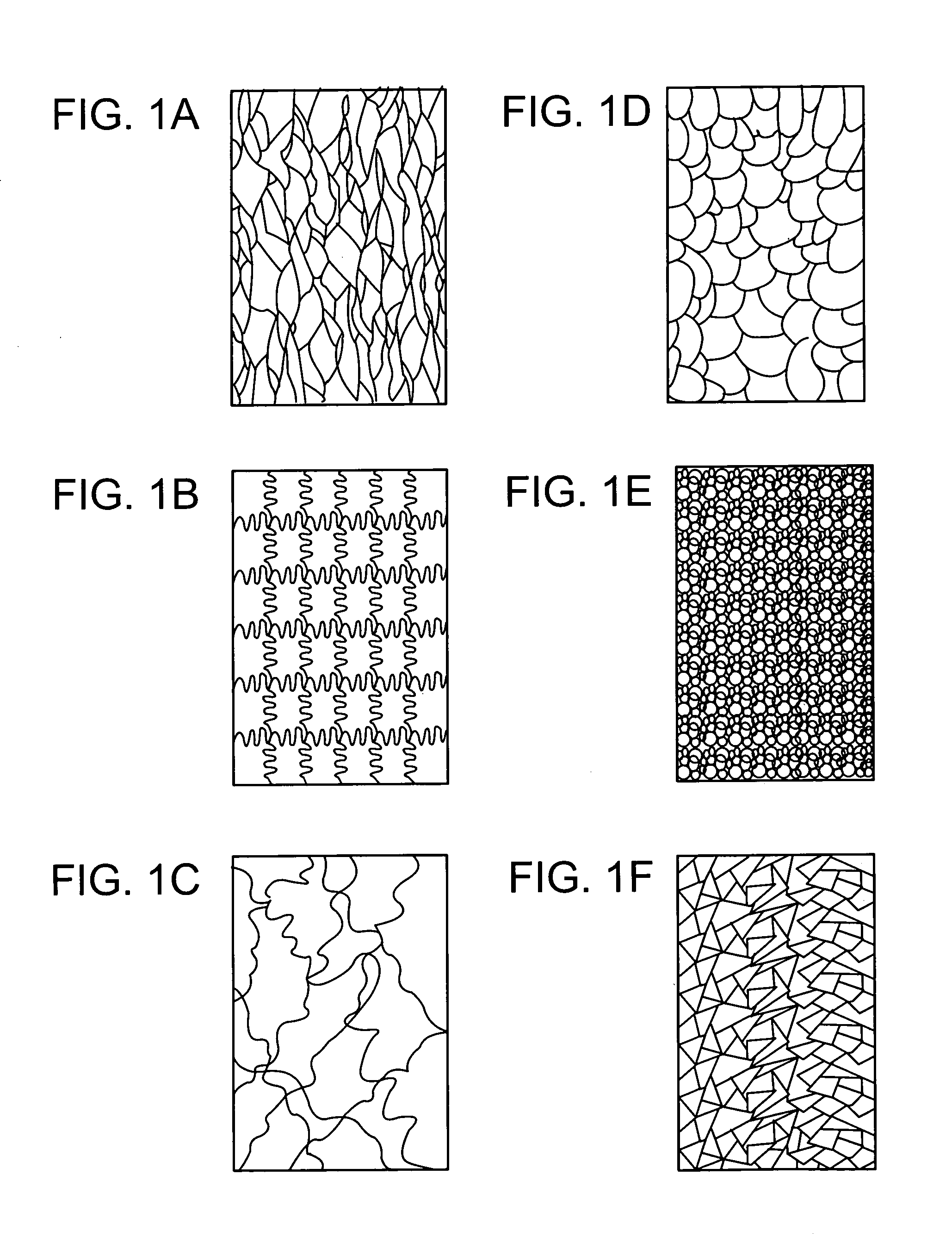

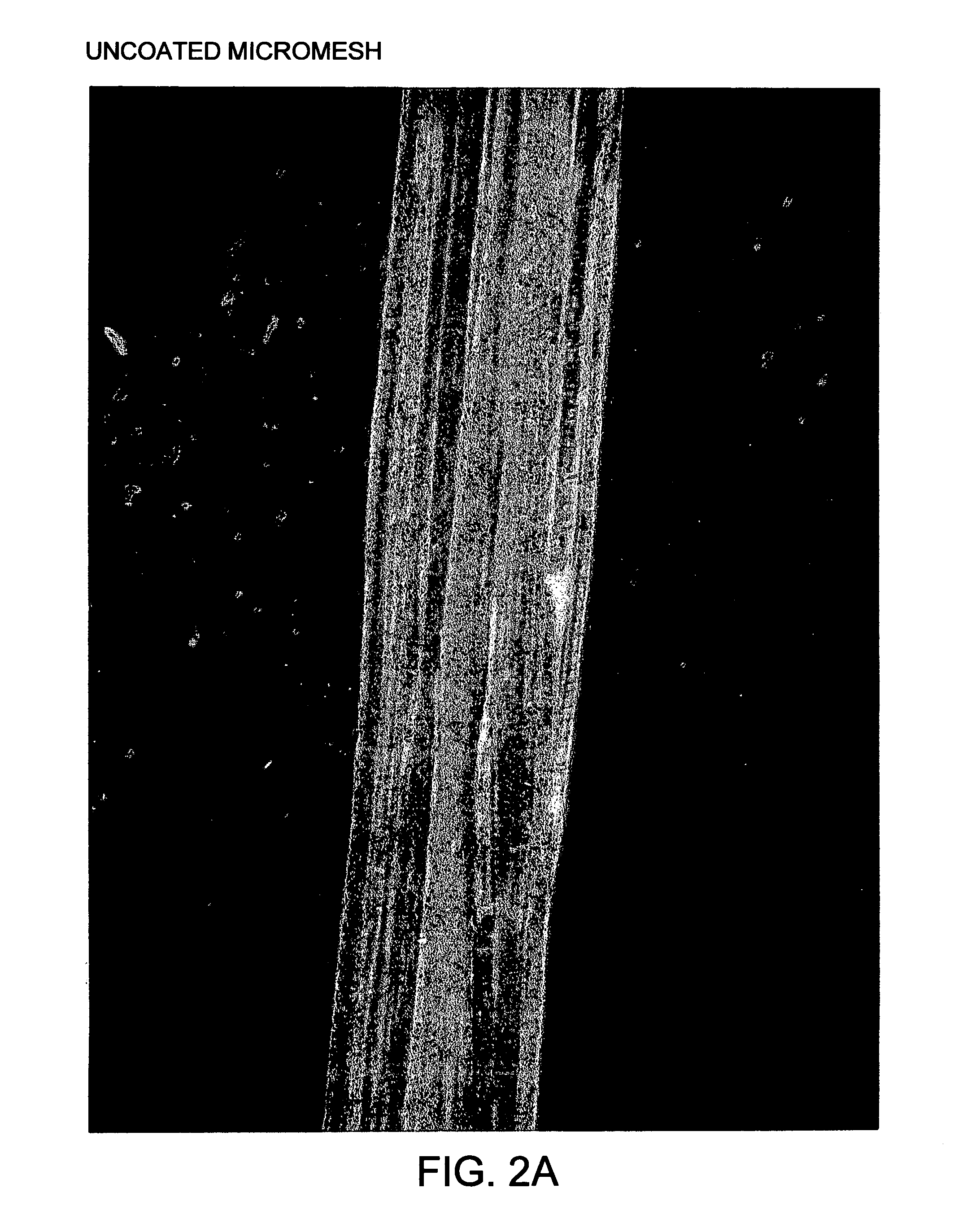

Micromesh interproximal devices

InactiveUS7025986B2Avoid physical damageAvoid damageBiocideCosmetic preparationsMedicineUltimate tensile strength

A shred resistant, ultra-high molecular weight polyethylene, micromesh interproximal device produced by fibrillating and slitting stretched polyethylene film having a tensile-strength from between about 0.7 GPa and about 5 GPa, where said polyethylene has an intrinsic viscosity of from between about 5 and about 50 dl / g and wherein said resultant micromesh tape is coated with an oral care substance at from between about 10 and about 120 mg / yd.

Owner:WHITEHILL ORAL TECH

Fluoropolymer composition

InactiveUS20070117929A1Increase melt viscosityImprove the extrusion effectTetrafluoroethyleneMolten state

A melt-mixed composition of non-melt flowable polytetrafluoroethylene (PTFE) and melt-fabricable perfluoropolymer is provided that exhibits thixotropy at increasing shear rate in the molten state and high elongation at break even at PTFE concentrations well above 4 wt %, based on the combined weight of the PTFE and the perfluoropolymer, e.g. at least 200% up to at least 30 wt % PTFE, the composition also exhibiting the structure of a dispersion of submicrometer-size particles of the PTFE in a continuous phase of the melt-fabricable perfluoropolymer.

Owner:EI DU PONT DE NEMOURS & CO

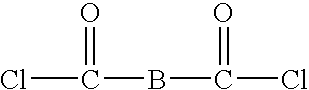

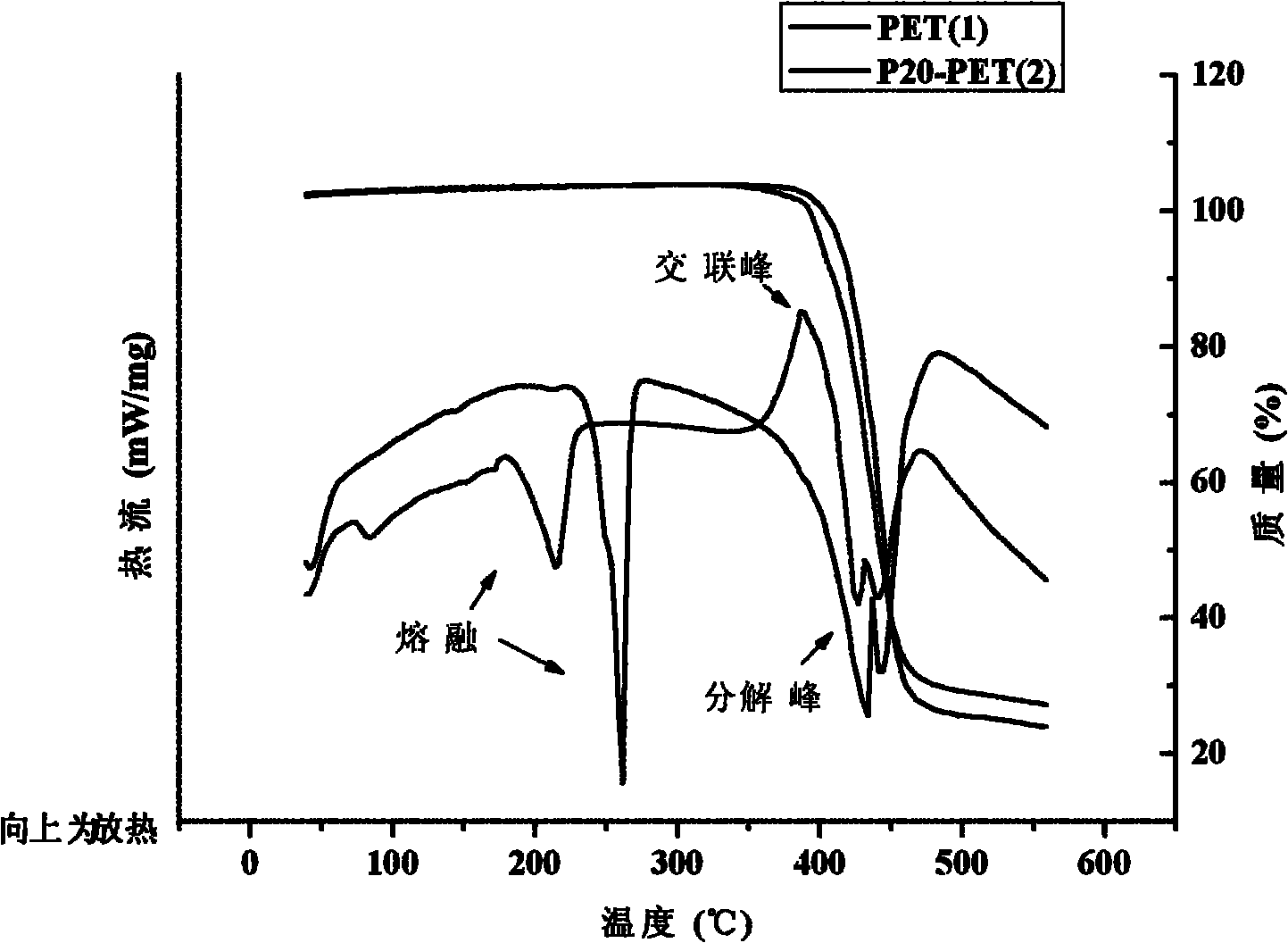

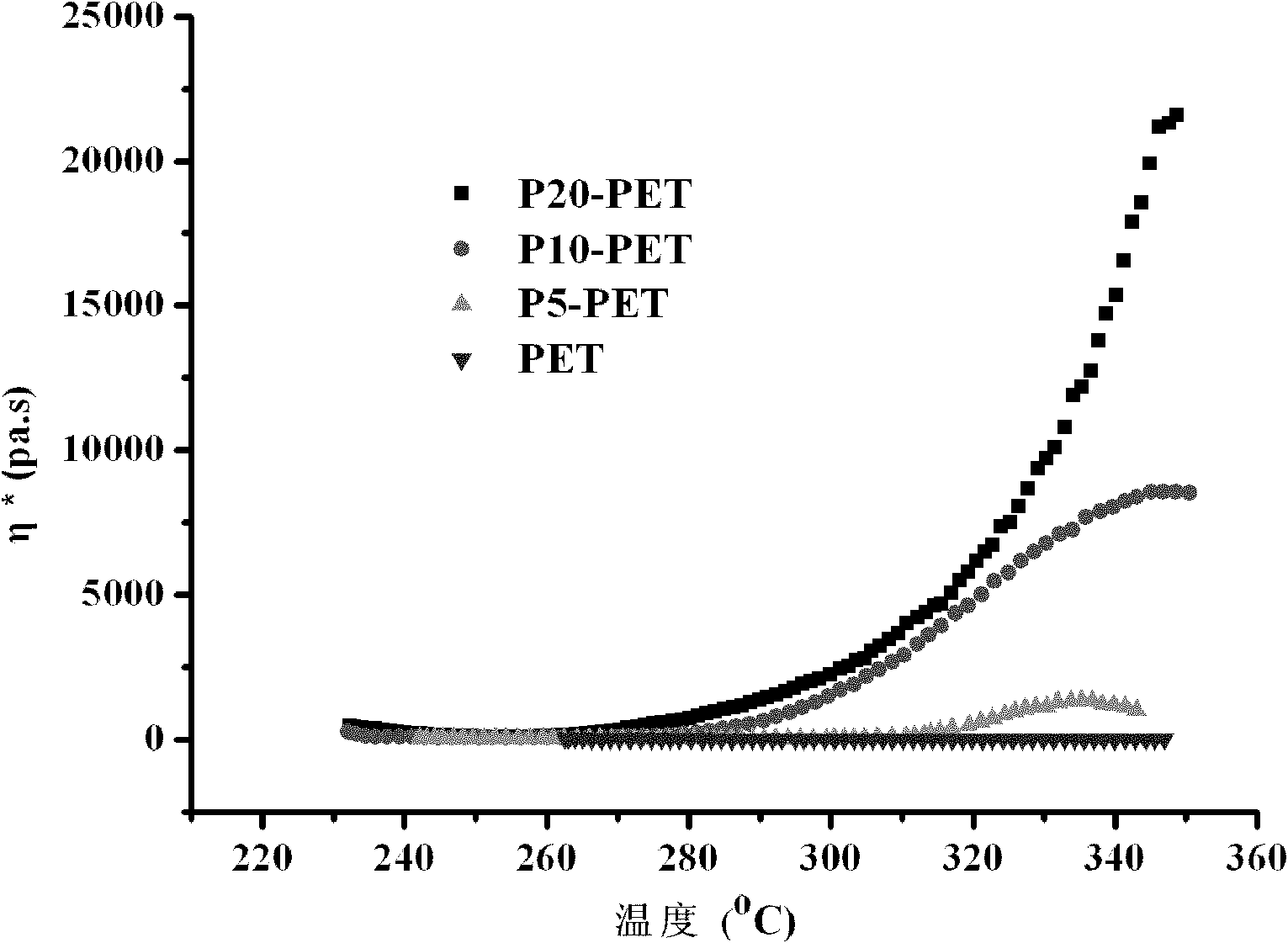

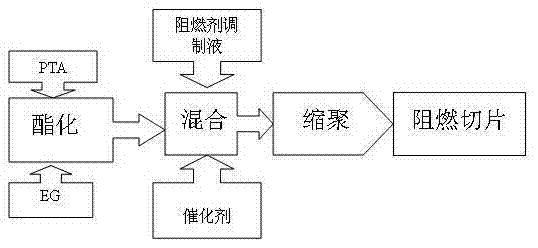

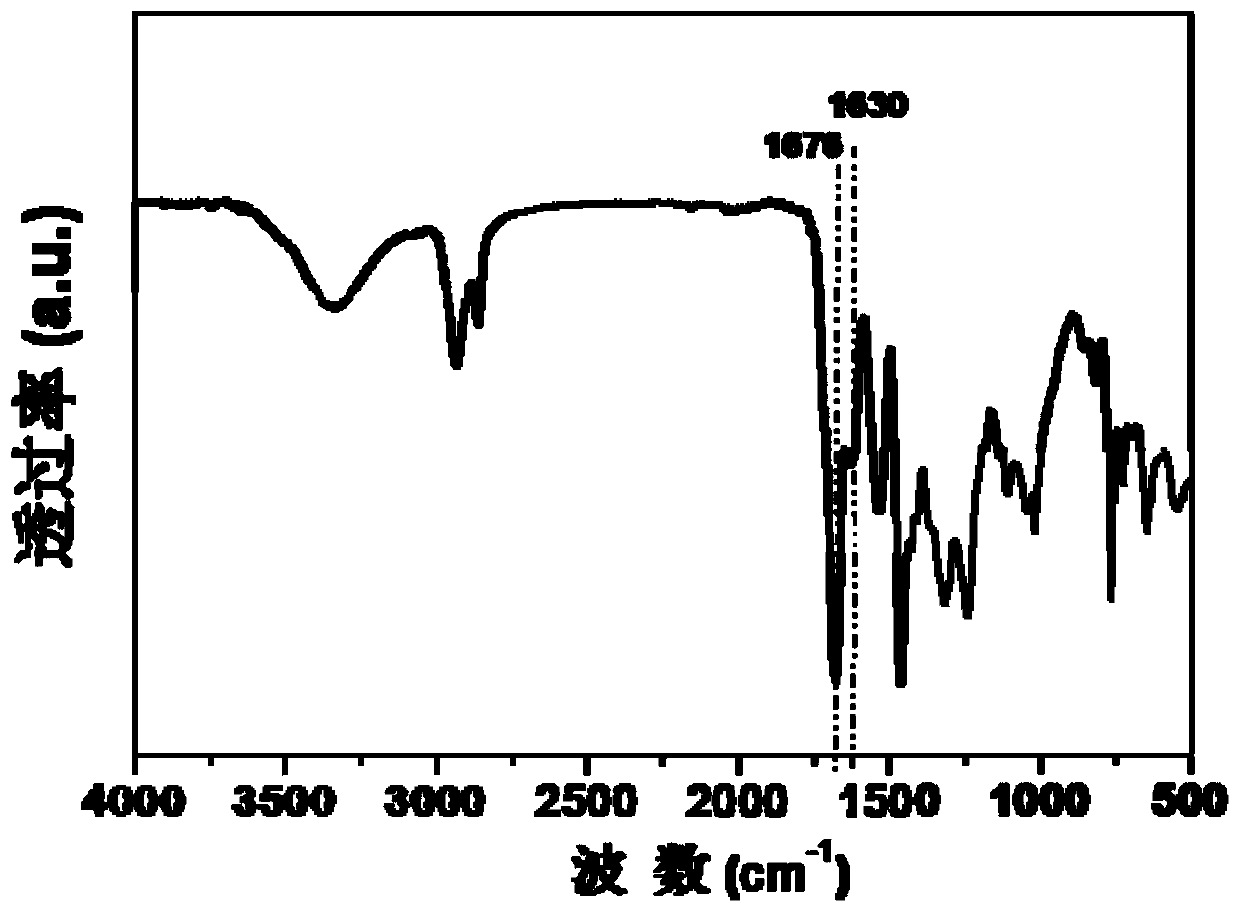

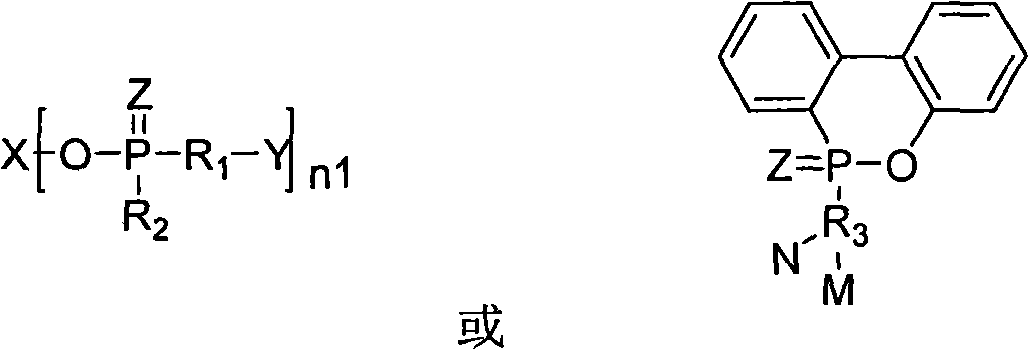

High-temperature self-crosslinking flame-retardant anti-dripping copolyester and preparation method thereof

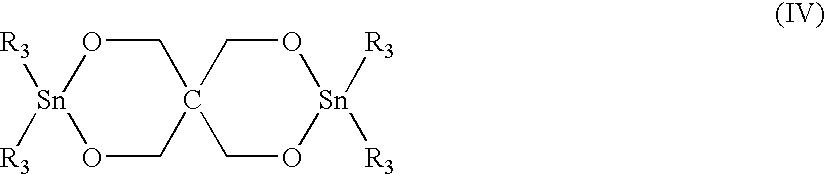

The invention discloses a high-temperature self-crosslinking flame-retardant anti-dripping copolyester which is prepared by introducing a structural unit shown as IV in the specification or introducing structural units shown as III and IV in the specification by random copolymerization on the basis of structural units of synthetic polyester shown as I and II in the specification, and the intrinsic viscosity [eta] of the prepared high-temperature self-crosslinking copolyester is 0.25-1.25dL / g. The invention also discloses the preparation method of the high-temperature self-crosslinking copolyester. Because the crosslinking group introduced in the invention is a high-temperature self-crosslinking group, on the premise of not affecting the preparation and forming of the polyester, self-crosslinking can be realized at higher temperature, and the melt viscosity of the polyester is improved through the char formation effect and stable chemical crosslinking of the self-crosslinking group, thereby performing combined action with the phosphorus-containing flame-retardant structural unit IV and endowing the polyester with better flame-retardant and anti-dripping properties.

Owner:SICHUAN UNIV

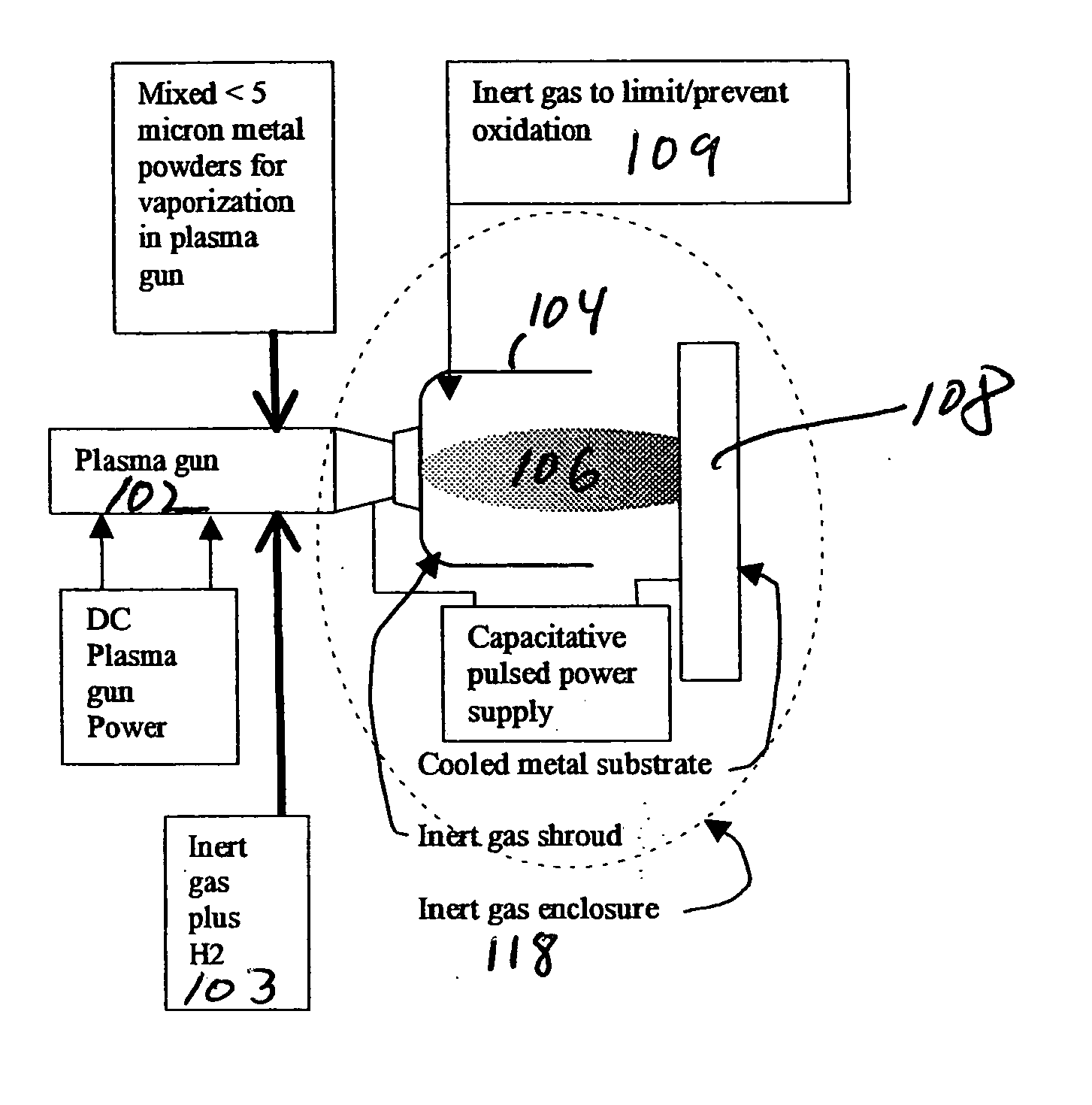

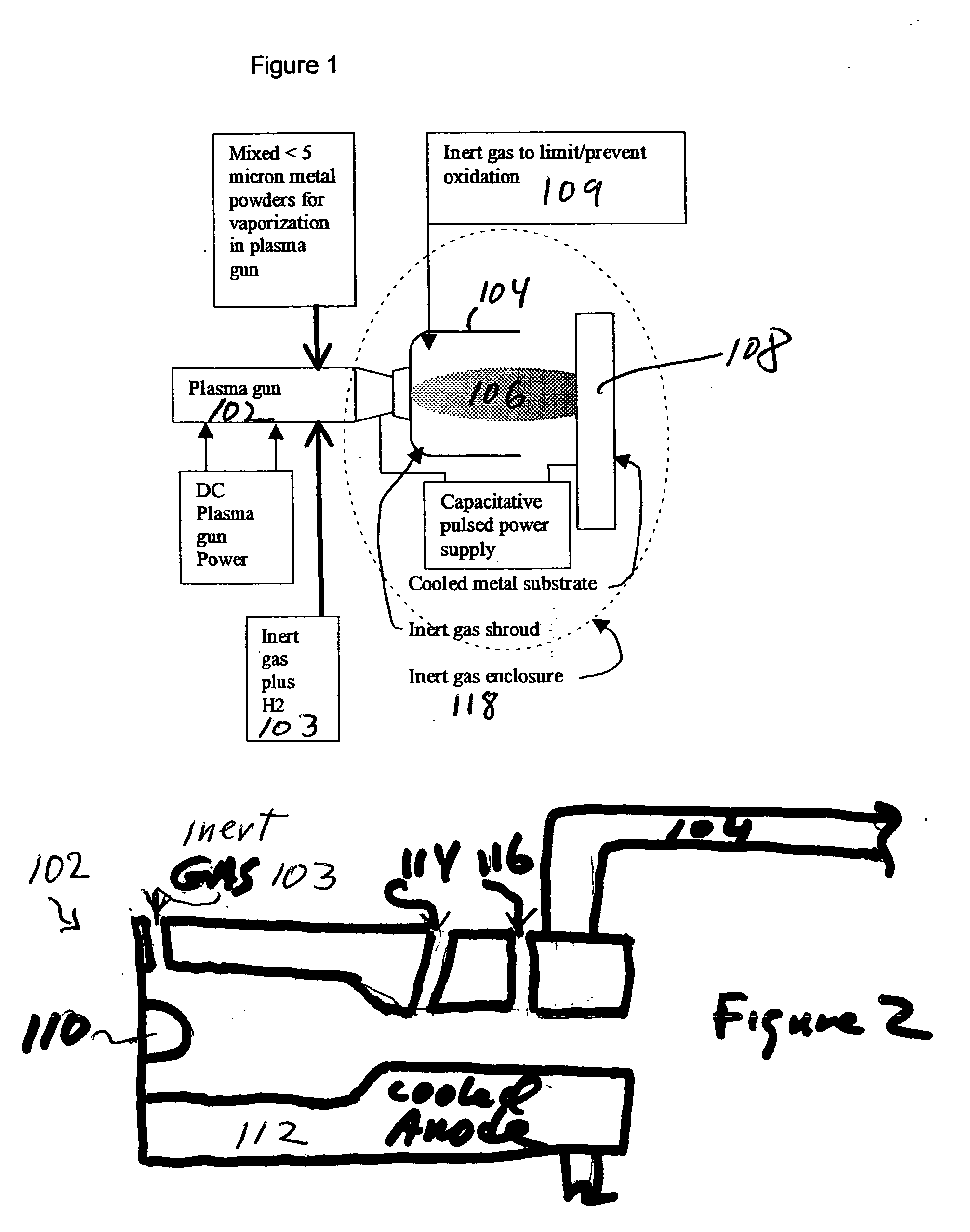

Amorphous metal deposition and new aluminum-based amorphous metals

InactiveUS20050123686A1Improve toughnessIncrease impactLiquid surface applicatorsMolten spray coatingHigh densityMetal alloy

Methods for applying an amorphous metal alloy to a substrate, comprising the steps of vaporizing an amorphous metal alloy composition, in a plasma spray gun to form a metal alloy vapor plasma plume, directing the metal alloy vapor plume onto a cooled substrate, maintained and condensing and rapidly solidifying the amorphous metal alloy composition vapor on the substrate, to form an amorphous metal layer deposit of high density and strength.

Owner:MYRICK JAMES J

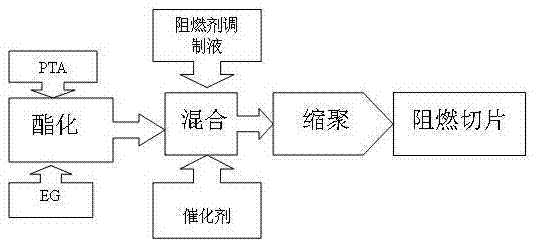

Method for producing phosphorus copolymerized flame-retarding terylene high-strength industrial yarns

ActiveCN102199807ADoes not affect the molecular skeleton structureImprove hydrolytic stabilityArtificial filament heat treatmentMonocomponent copolyesters artificial filamentYarnHigh intensity

The invention discloses a method for producing phosphorus copolymerized flame-retarding terylene high-strength industrial yarns, which is characterized by comprising the following steps: pumping ethylene glycol (EG) and purified terephthalic acid (PTA) into a pulping kettle according to a molar ratio of 1.15 for pulping; after uniform pulping, transferring the uniform pulp into an esterification kettle for esterification; after the esterification is accomplished, adding blended liquid of a flame retardant, uniformly mixing, and adding the mixture into a polymerization kettle; after the polymerization is accomplished, discharging and cutting to obtain flame-retarding polyester chips with a viscosity of 0.61; feeding the prepared flame-retarding polyester chips into a solid-phase polymerization system, and improving the viscosity to 0.90 to 1.10; and melting at a high temperature into molten spinning solution in a screw extruder, spinning by a spinning component, drawing, and thermally setting to obtain phosphorus copolymerized flame-retarding terylene high-strength industrial yarns. In the invention, a copolymerized flame-retarding modification process is used for flame-retarding modification of the polyester, and the obtained terylene industrial yarns have high strength and a permanent flame-retarding property.

Owner:ZHEJIANG GUXIANDAO POLYESTER DOPE DYED YARN CO LTD

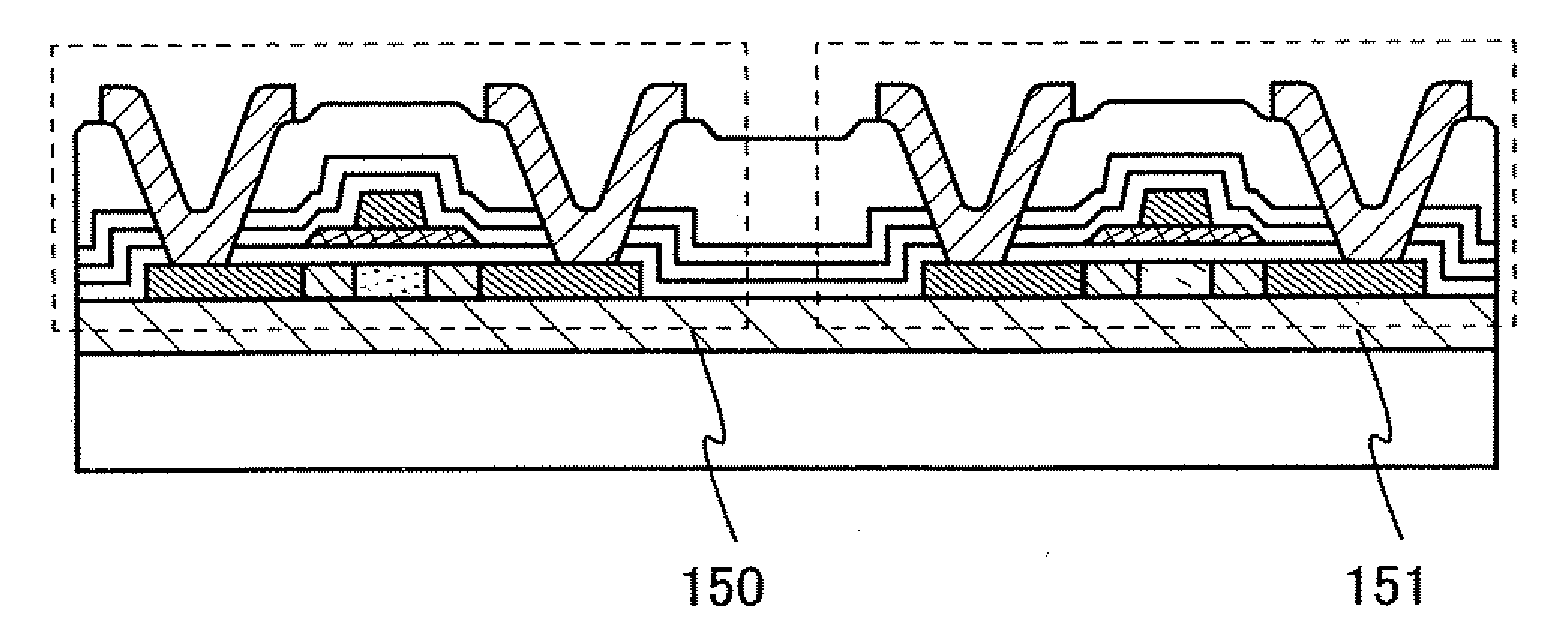

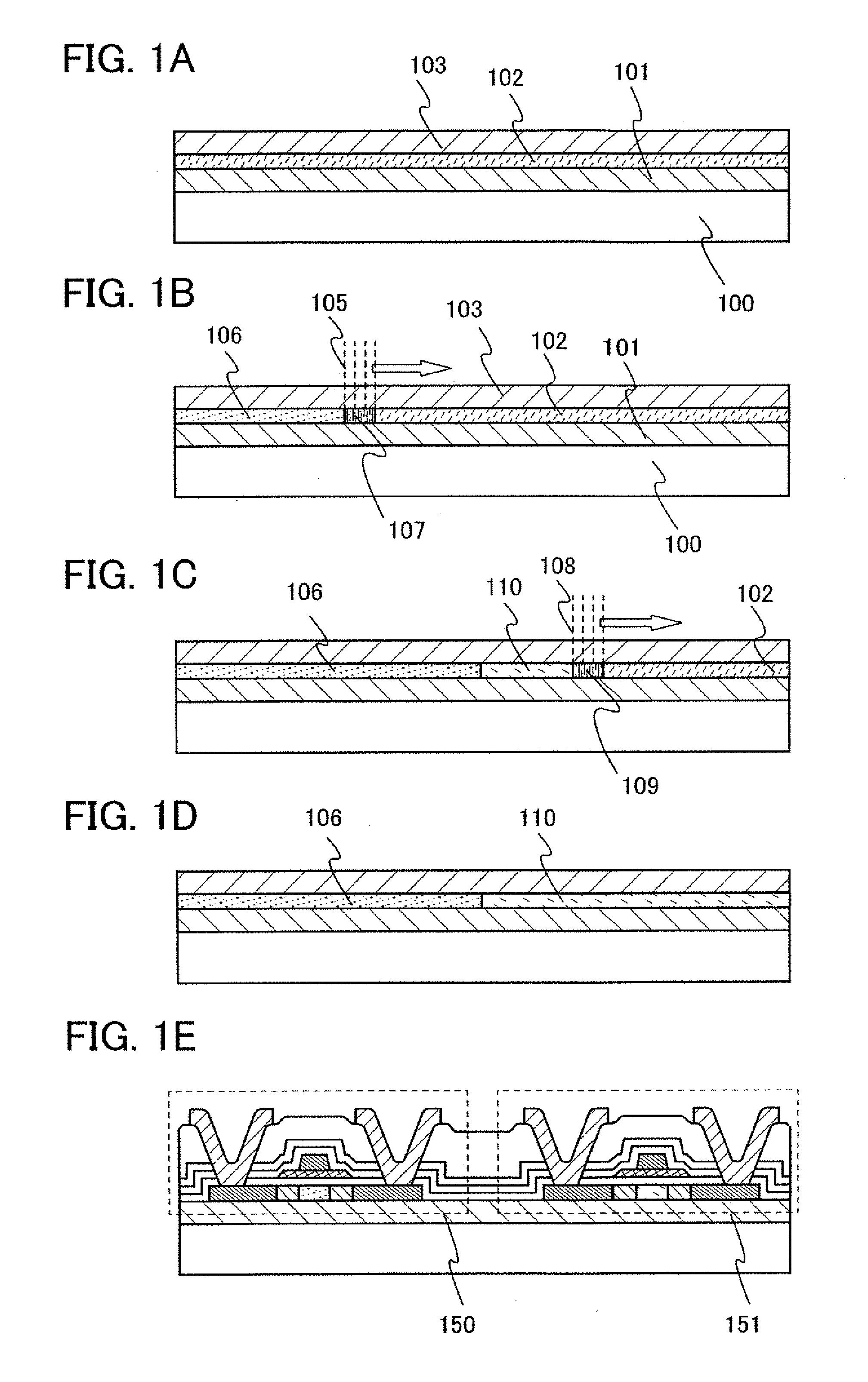

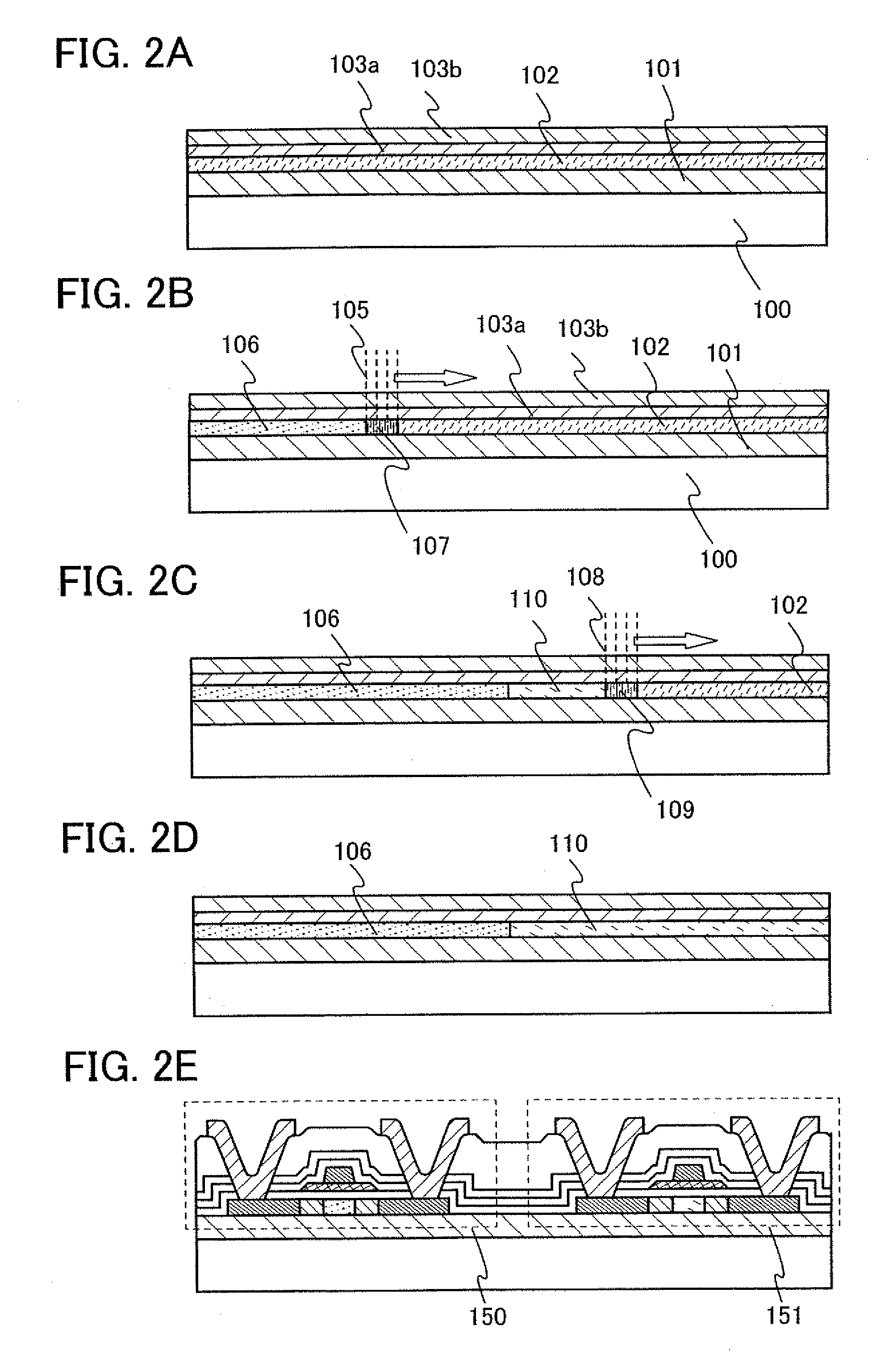

Manufacturing method of semiconductor device

InactiveUS20080213984A1Increase melt viscositySuppress turbulenceSolid-state devicesSemiconductor/solid-state device manufacturingCrystal planeP channel

A cap film is formed over semiconductor films formed over an insulating substrate; the semiconductor films are irradiated with a laser beam which is capable of completely melting the semiconductor film in a film-thickness direction to completely melt the semiconductor film. By controlling the laser beam, a crystalline semiconductor films are formed over the substrate, in each of which orientations of crystal planes are controlled. In addition, an n-channel thin film transistor is formed using a crystalline region in which crystal planes are oriented along {001} and a p-channel thin film transistor is formed using a crystalline region in which crystal planes are oriented along {211} or {101}.

Owner:SEMICON ENERGY LAB CO LTD

Polyvinyl butyral foamed material

The invention discloses a polyvinyl butyral foamed material, which belongs to the field of high molecular materials. Recycled waste and used polyvinyl butyral is taken as a main raw material; rubber or an elastomer is taken as a main auxiliary material; a foaming agent, a foaming auxiliary agent, a plasticizing agent, a foamed hole nucleating agent, a foamed hole regulating agent, a crosslinking agent, a filler and the like are taken as the auxiliary materials; all the materials are mixed in a high-speed mixing machine at high speed, melted and blended in an extruding machine or an enclosed mixing machine, and formed through compression molding foaming in a flat-plate vulcanizing machine to obtain a polymer foamed material. The foamed material has excellent performance of an elastomer foamed material, has excellent cohesive property, is easy to process, and can be changed from wastes to valuables.

Owner:LUOHE IRON HORSE RUBBER PROD CO LTD

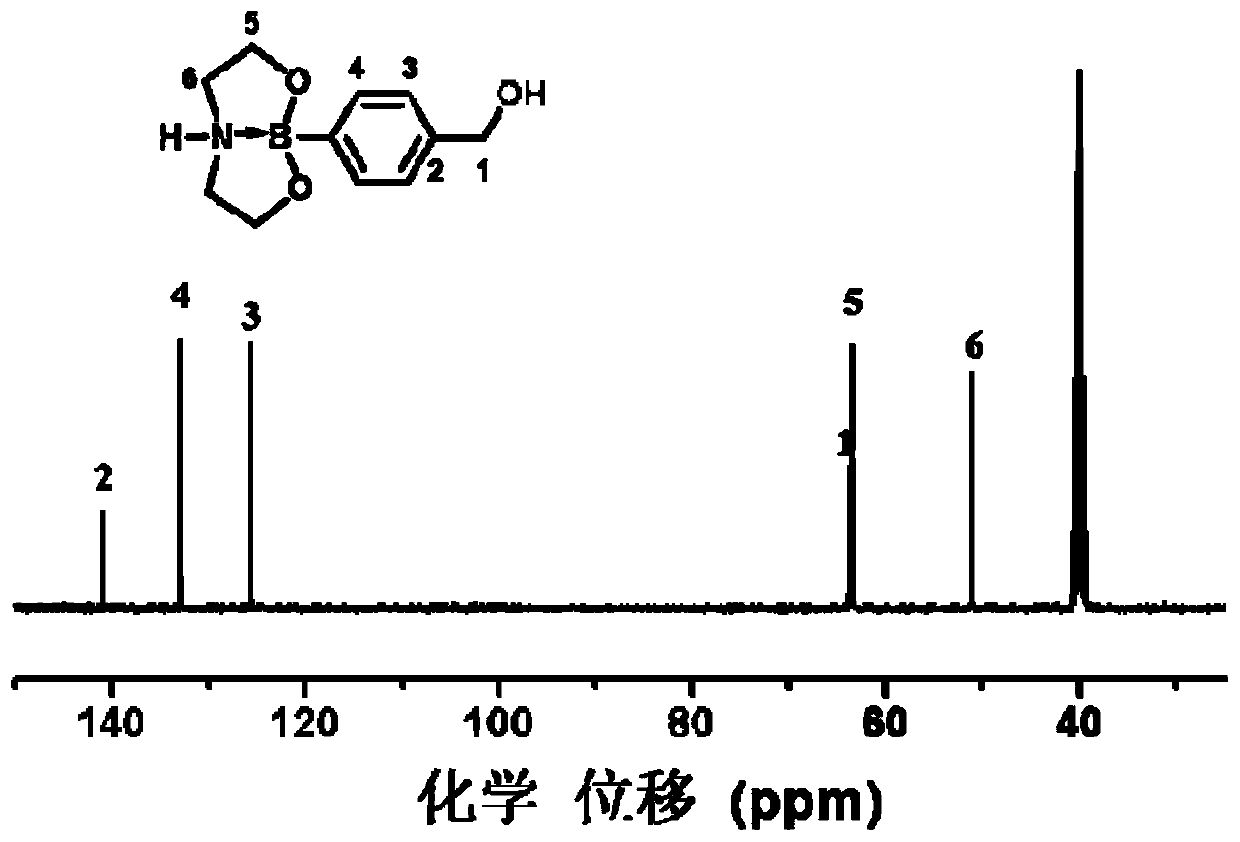

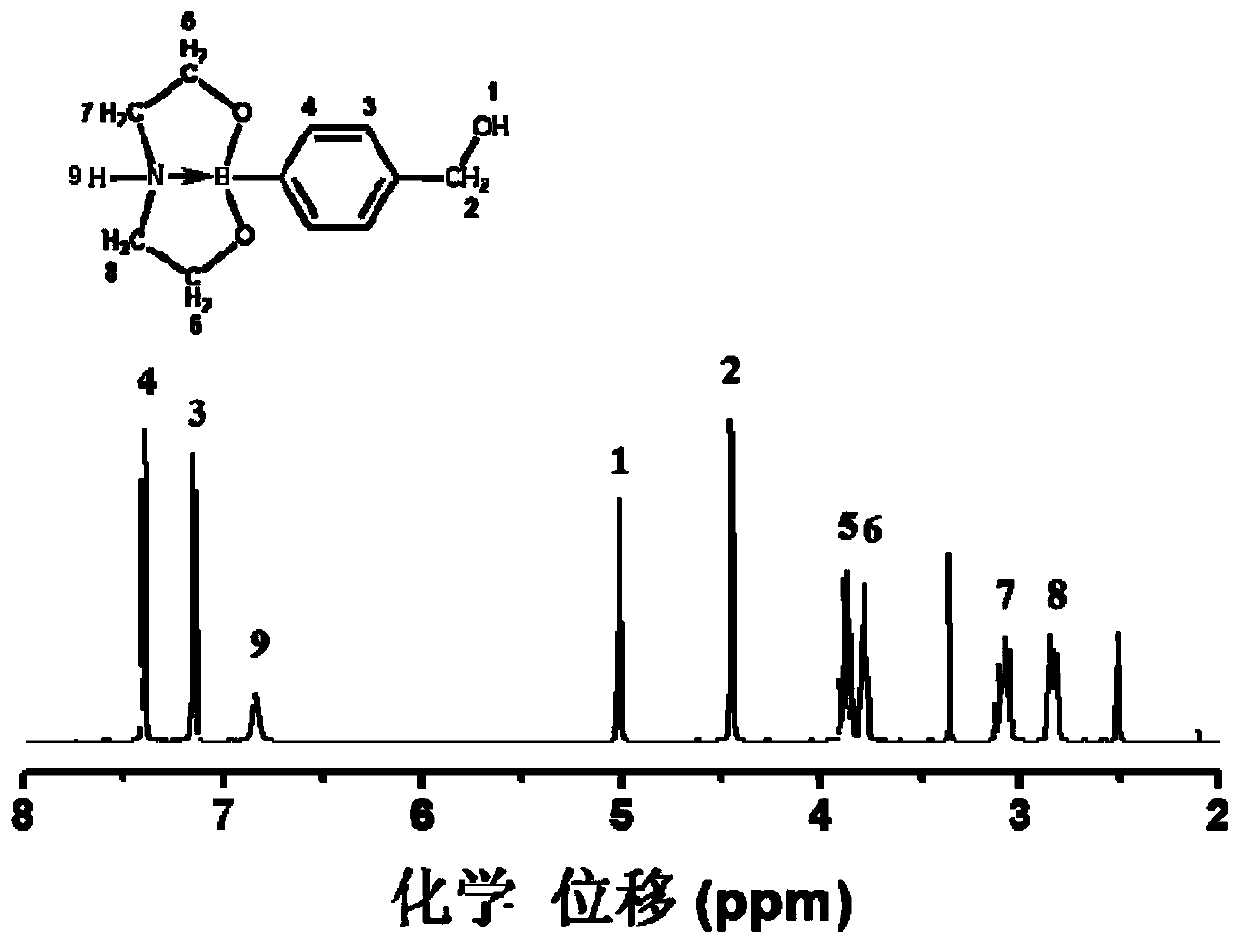

Renewable polyurea-urethane based on dynamic covalent crosslinking of stable borate bonds, and preparation method and application thereof

ActiveCN109897148AImprove stabilityEfficient recyclingPolyureas/polyurethane adhesivesGroup 3/13 element organic compoundsOrganic solventHydrogen

The invention discloses a renewable polyurea-urethane based on dynamic covalent crosslinking of stable borate bonds, and a preparation method and an application thereof. The preparation method comprises the following steps: dissolving an cyclic borate compound and an isocyanate compound which are coordinated in nitrogen and boron in an organic solvent according to a molar ratio of active hydrogento an isocyanate group: 1:(0.8-1.5), performing sufficient stirring to form a uniform solution, and completely reacting the uniform solution at a preset temperature to prepare a PUU resin gel, whereinthe isocyanate compound is one or a mixture of two or more of difunctional or / and trifunctional isocyanate compounds; the organic solvent is one or a mixture of two or more of strong polar solvents.The PUU of the present invention has the advantages of high strength, excellent mechanical properties, repairability and remoldability, and can be recycled many times.

Owner:XI AN JIAOTONG UNIV

Core/shell polymer

InactiveUS20070117935A1Increase melt viscosityGood extrudabilityFibre treatmentCoatingsPolymer chemistryPolymer

Owner:THE CHEMOURS CO FC LLC

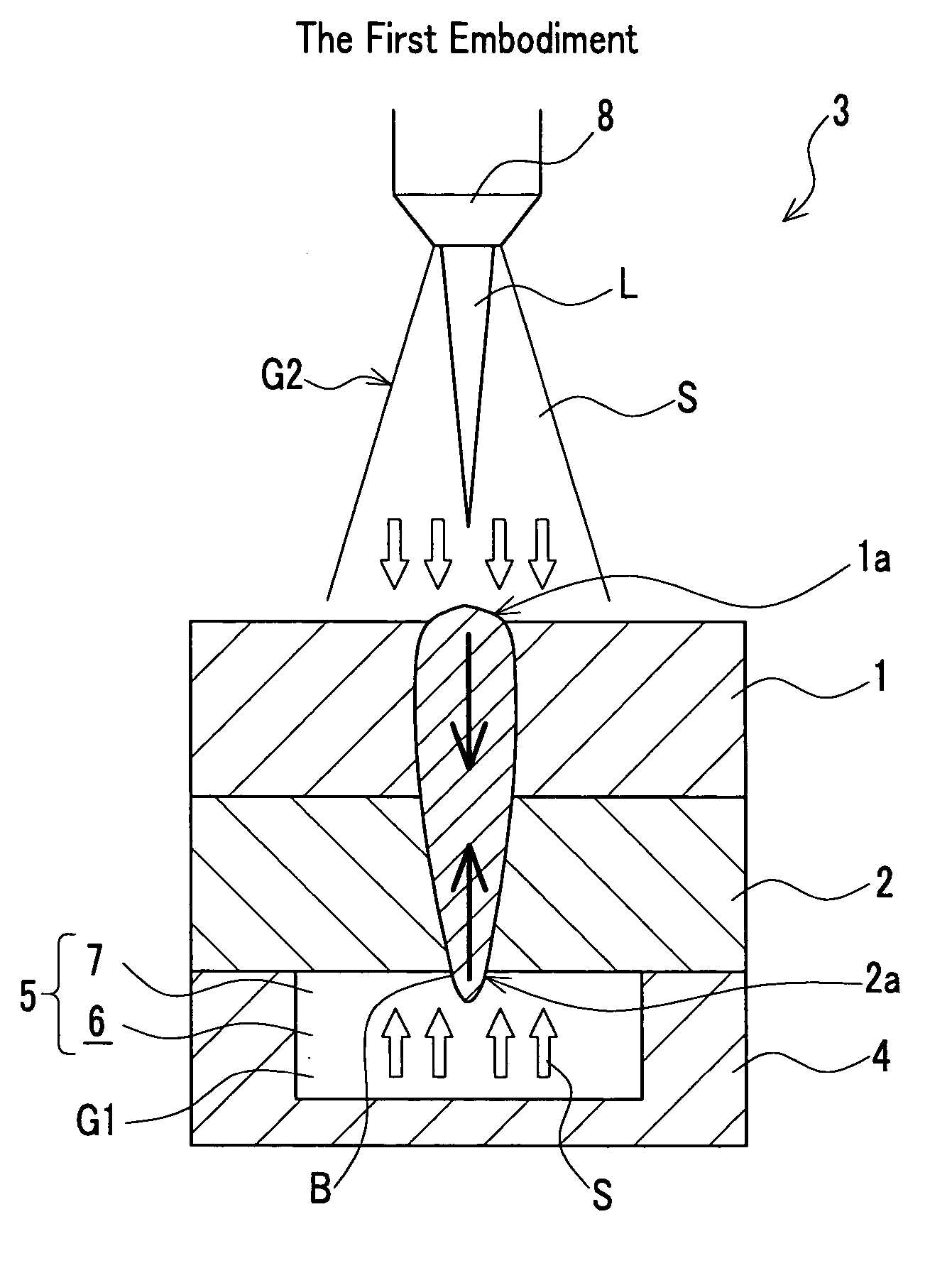

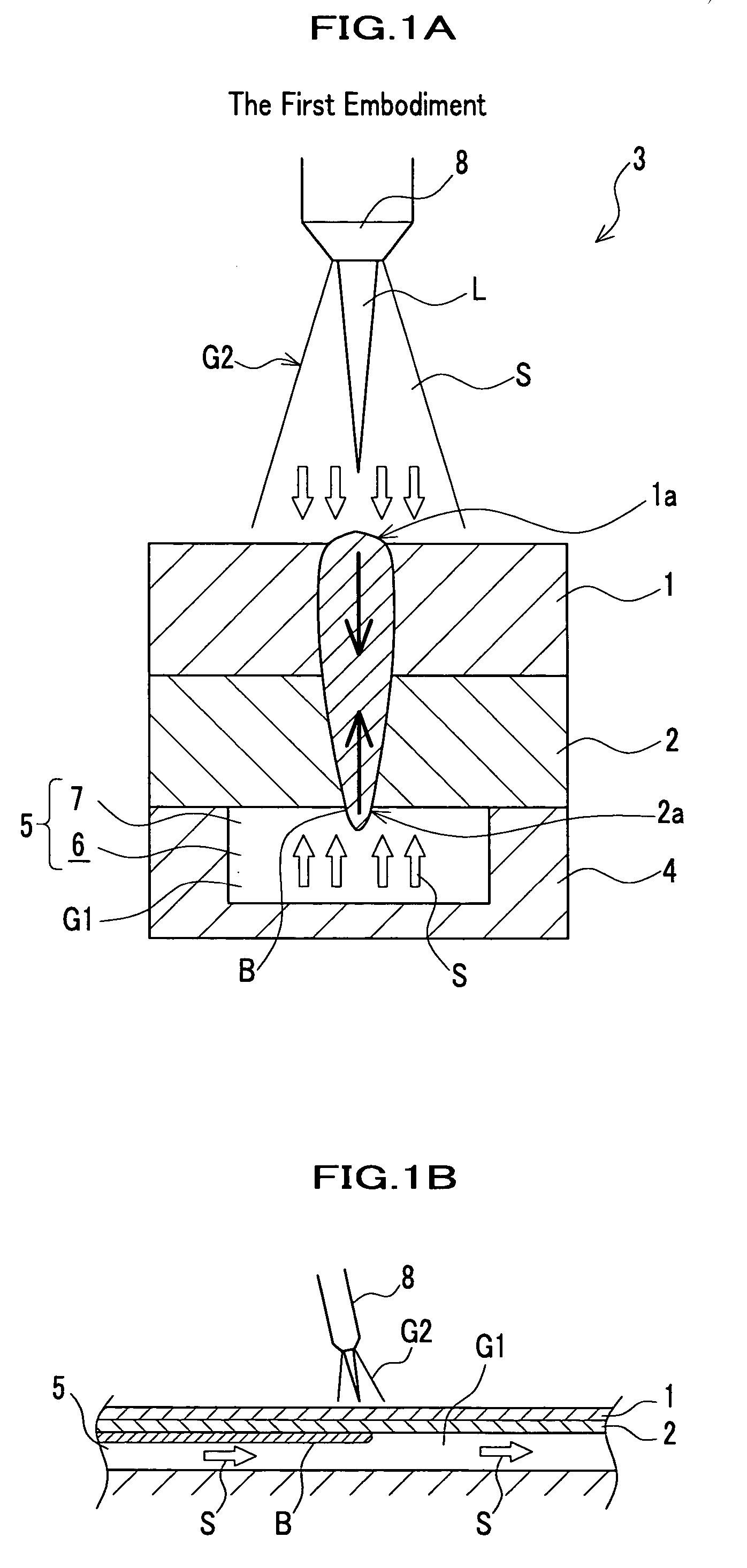

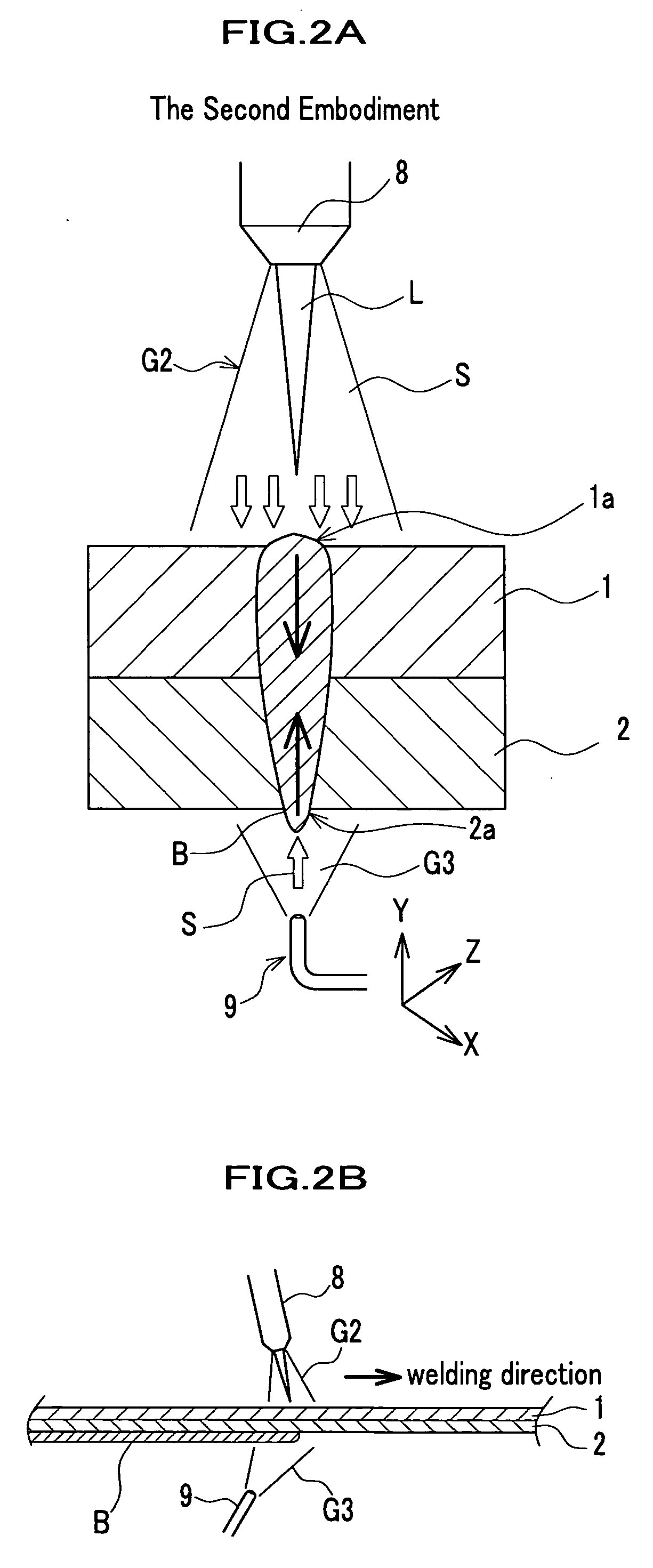

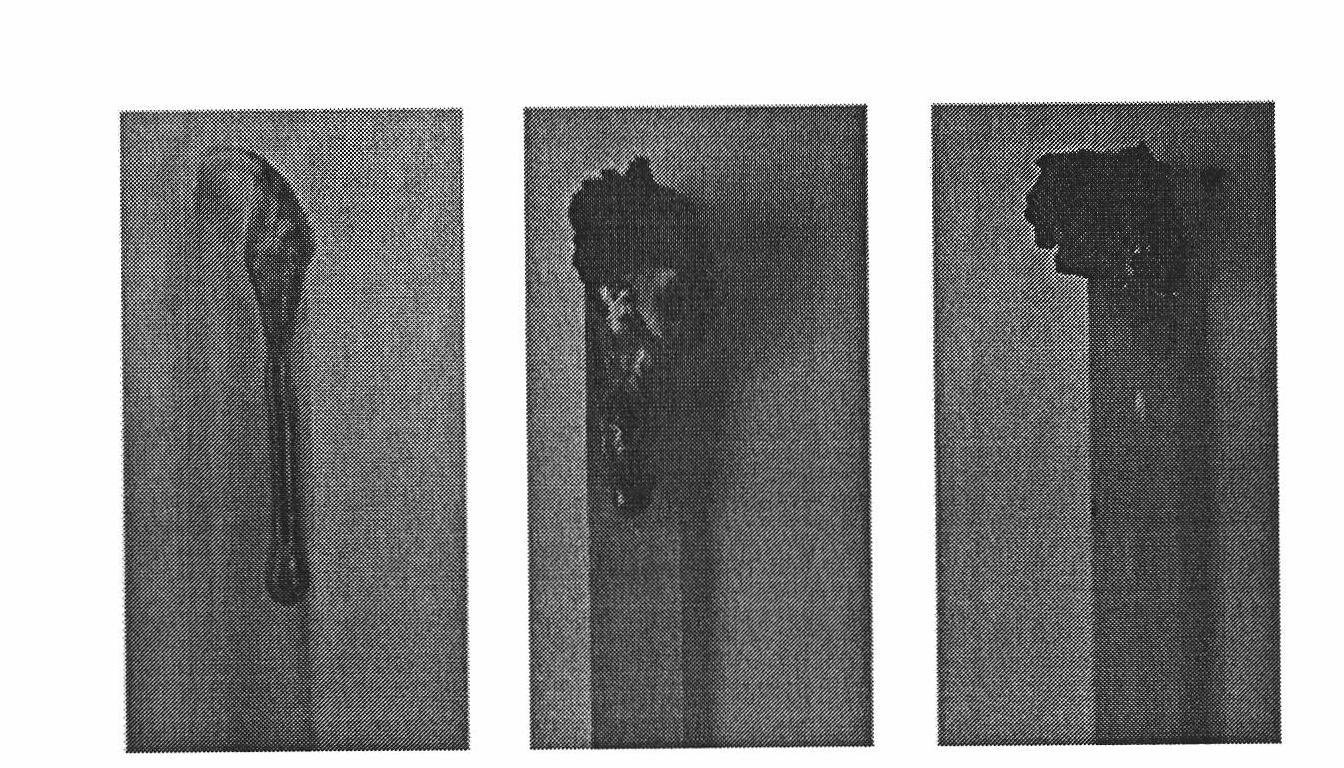

Through weld for aluminum or aluminum alloy base metals by using high-density energy beams

InactiveUS20040084425A1Avoid formingHigh bonding strengthElectron beam welding apparatusWelding/soldering/cutting articlesHigh energyShielding gas

This invention provides a new through weld method to carry out welding of a base metal made of aluminum or that of aluminum alloy using high energy beams wherein a shield gas ambience (an inert gas ambience) to cover a welding site in a submerged-scar is formed, even a shield gas ambience (an inert gas ambience) to cover a welding site irradiated by the high energy beams. Since the former shield gas ambience to cover the submerged-scar pushes the keyhole against the gravity and / or the gas pressure force of the latter shield gas supplied to the laser irradiation side, then the forming of hang down of beads and the resultant projection of the welding base metal are prevented.

Owner:HONDA MOTOR CO LTD

Droplet-resistant flame-retardant polyester, nanometer compound material thereof and method for preparing same

The invention discloses droplet-resistant flame-retardant polyester. The flame-retardant polyester is prepared by random copolymerization of a branched monomer, terephthalic acid or dimethyl terephthalate, ethylene glycol and flame-retardant monomer, wherein the branched monomer is an aliphatic compound or aromatic compound having three or more functional groups; and the flame-retardant monomers adopts any of the following structures. The invention also discloses a method for preparing the droplet-resistant flame-retardant polyester, a nanometer compound material containing the droplet-resistant flame-retardant polyester and a method for preparing the nanometer compound material. Because the droplet-resistant flame-retardant polyester provided by the invention simultaneously contains the branched monomer and the fire retardant having the droplet-resistant effect, the melt viscosity of the droplet-resistant flame-retardant polyester at the high temperature is greatly improved, the sensitivity of the droplet-resistant flame-retardant polyester to temperature is lowered, and the droplet-resistant effect is good; because of the nanometer effect and the blocking effect, the nanometer compound material shows better droplet-resistant effect; and the polyester and the nanometer compound material can be directly used as raw materials for preparing fibers, engineering plastics, films and the like.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com