Patents

Literature

102results about How to "Good for recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyvinyl butyral foamed material

The invention discloses a polyvinyl butyral foamed material, which belongs to the field of high molecular materials. Recycled waste and used polyvinyl butyral is taken as a main raw material; rubber or an elastomer is taken as a main auxiliary material; a foaming agent, a foaming auxiliary agent, a plasticizing agent, a foamed hole nucleating agent, a foamed hole regulating agent, a crosslinking agent, a filler and the like are taken as the auxiliary materials; all the materials are mixed in a high-speed mixing machine at high speed, melted and blended in an extruding machine or an enclosed mixing machine, and formed through compression molding foaming in a flat-plate vulcanizing machine to obtain a polymer foamed material. The foamed material has excellent performance of an elastomer foamed material, has excellent cohesive property, is easy to process, and can be changed from wastes to valuables.

Owner:LUOHE IRON HORSE RUBBER PROD CO LTD

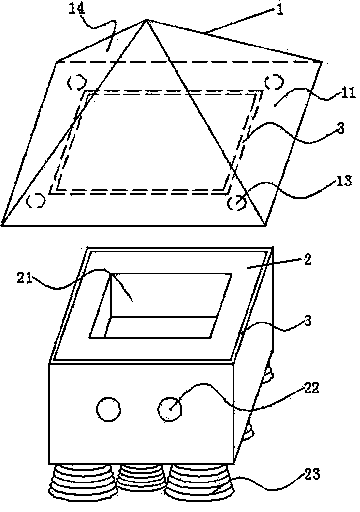

Extreme low-altitude drop device

InactiveCN103448911AAvoid the effects of turbulent airflowGood for recyclingParachutesLaunching weaponsTerrainCushion

The invention discloses an extreme low-altitude drop device which comprises a top cover and a cushion connected with the top cover. The top cover is intermeshed and fixed with the cushion through zippers, and a fin extends out of the top cover along the external contour of the cushion. Air accumulating holes are formed in the fin, and a speed reducing umbrella which is fitted with an edge of the fin to seal and fix is arranged around the fin. A zipper is arranged on the other surface of the top cover, and air accumulating holes are formed in the periphery of the zipper. The whole cushion is in a hollow structure, a concave-inward material groove is formed in the top surface of the cushion, intermeshed zippers are arranged on the surrounding edges of the cushion, and a shock absorption device is arranged on the bottom surface of the cushion. The extreme low-altitude drop device can effectively realize extreme low-altitude air drop under harsh environmental conditions such as high wind, rainfall, complex terrain conditions and the like, can avoid the influence of disturbance airflow, can realize fixed point precise air drop to fill the domestic blank in the field, and is also beneficial to recovery for secondary utilization after air drop.

Owner:JINLING INST OF TECH

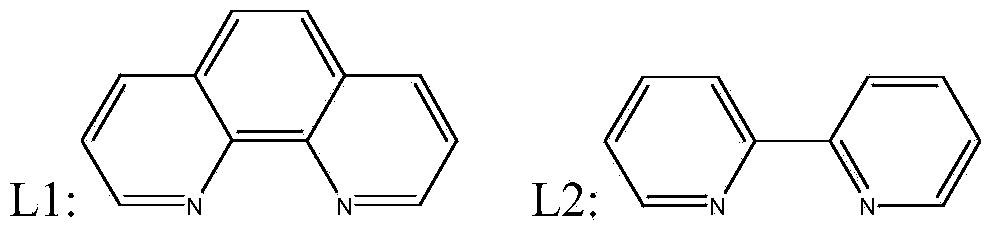

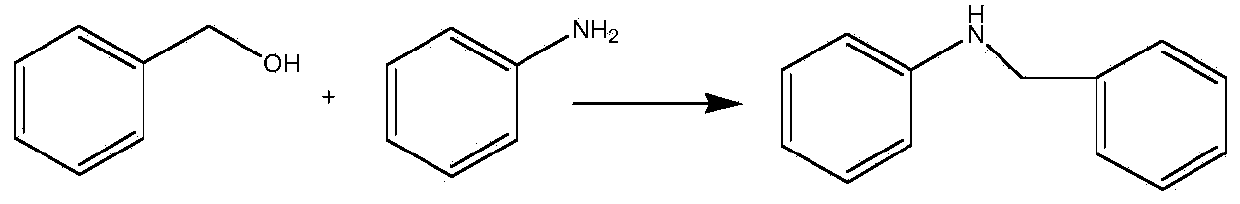

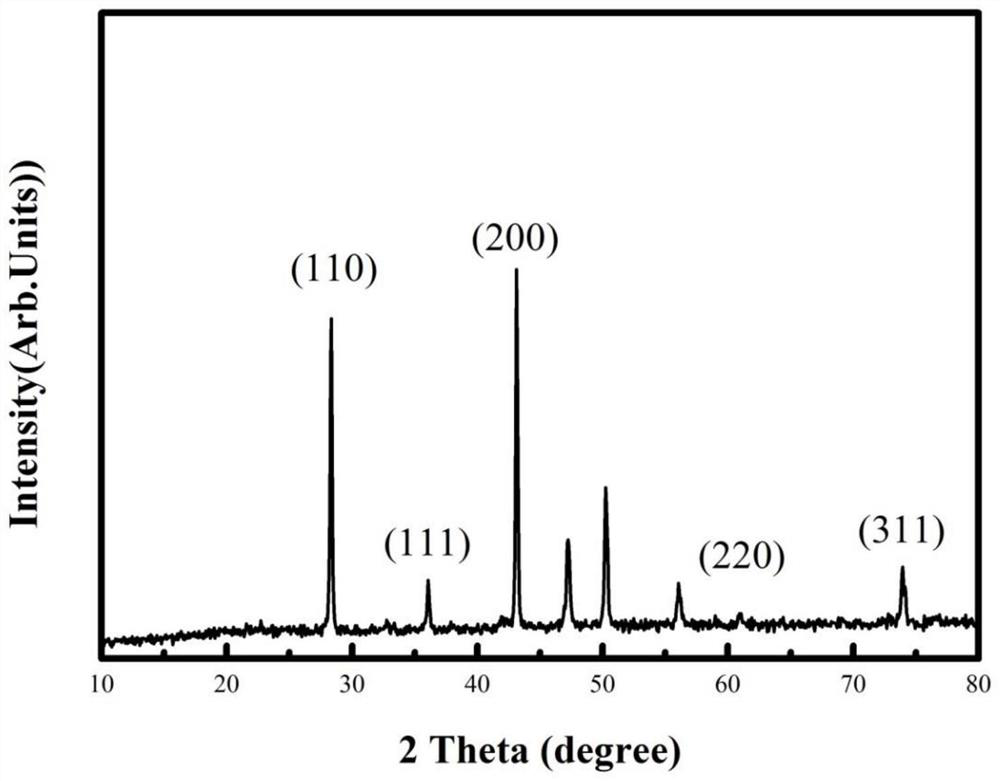

Preparation method of nanocrystalline metal catalyst loaded with carbon and nitrogen materials

InactiveCN104069882AHigh catalyst activityGood for recyclingPhysical/chemical process catalystsOrganic compound preparationOrganic compoundOrganic solvent

The invention relates to a preparation method of a nanocrystalline metal catalyst loaded with carbon and nitrogen materials. The preparation method is characterized by comprising the following steps: stirring metal compound and nitrogen-containing ligand in an organic solvent for carrying out coordinating reaction; adding a carrier, heating and stirring; removing the organic solvent; carrying out vacuum drying and finally carrying out calcination under inert gas to obtain the nanocrystalline metal catalyst loaded with the carbon and nitrogen materials. By coordinating metal salt and organic compound, the formation and dispersion of nano metal particles are facilitated; the multi-phase catalyst obtained through calcination has enhanced activity, and is convenient to recycle for repeated use. The preparation method of the catalyst is simple and convenient, raw materials are easily available, and therefore, the method is suitable for industrial production.

Owner:NANJING UNIV OF TECH

Production method for alumina

InactiveCN1876569AReduce the liquid-solid ratioGood for recyclingAlkali metal oxidesFiltration separationL&D processSeed crystal

The invention provides the preparing method of aluminum oxide, comprising preparing ore pulp, digest, diluting ore pulp, separating and washing red mud, disassembling seed crystal, separating and washing aluminum hydroxide, calcining aluminum hydroxide, evaporating mother liquid and causticizing soda solution. The invention adopts pressing filter to replace hydro-separator at the course of separating and washing red mud. The method is in favor of the reclamation of Na2O and Al2O3, and the invention has the advantages of saving cost, short process flow and little apparatus.

Owner:娄进

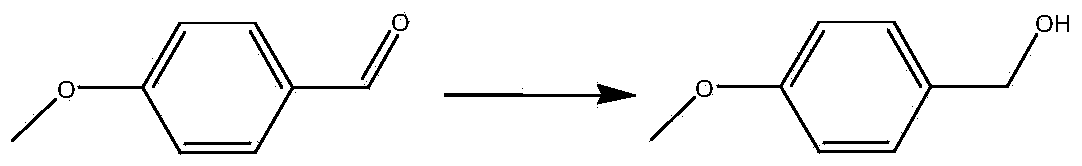

Integrated membrane processing technology for purifying and regenerating spent lubrication oil

ActiveCN103289807AAvoid accelerated oil deteriorationGood for recyclingLubricant compositionChemistryLubrication

The invention belongs to the domain of the technical field of petrochemical engineering and environment protection, and particularly relates to a membrane processing technology for purifying and regenerating spent lubrication oil. The technology comprises the following steps of (1) natural settlement treatment; (2) extraction treatment by adopting a polar organic solvent; (3) oiling agent separation; (4) heating and warming; (5) filtering treatment of a metal filter; (6) filtering treatment of a metal film; (7) clay adsorption and edulcoration treatment; (8) filtering carclazyte by frame filtering; (9) adding an additive to allocate, so as to obtain the regenerated lubrication oil product. By utilizing the technology, the purifying and regenerating quality performance of the spent lubrication oil is equal to that of the regenerated lubrication oil of a new lubrication oil product. Thus, the technology is wide in application range on the spent lubrication oil, simple in flow, and reliable in technique, has actual popularization and application value, and can generate obvious social, economic and environmental benefits.

Owner:湖北中硕环保有限公司

Preparation method of Au-Pd/TiO2 NBs photocatalyst

ActiveCN104492431AGood for recyclingAvoid water pollutionWater/sewage treatment by irradiationWater contaminantsPhotocatalytic degradationIon

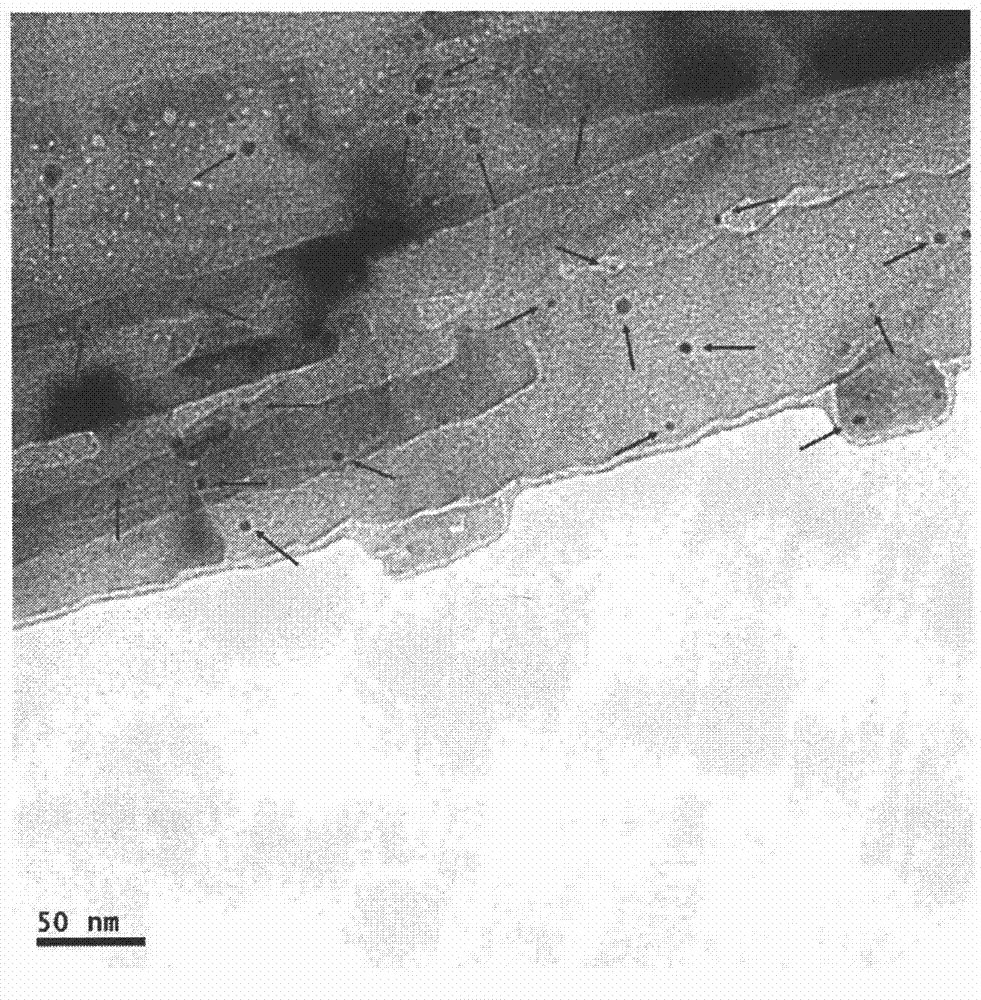

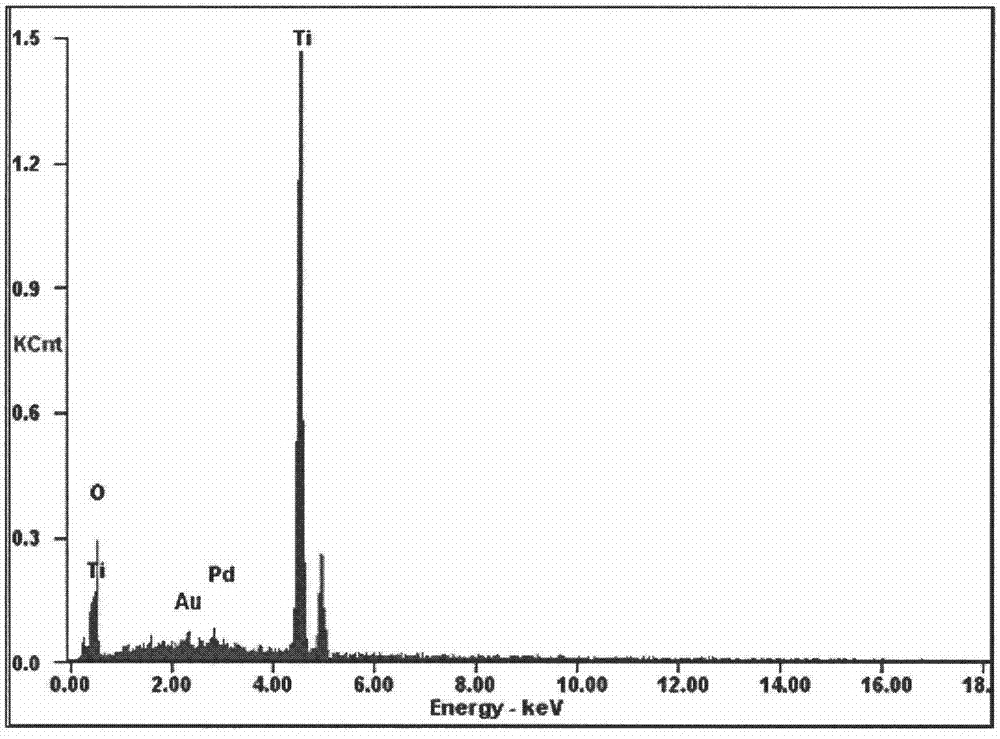

The invention discloses a preparation method of an Au-Pd / TiO2 NBs photocatalyst, which comprises the following steps: with a titanium sheet as a matrix, performing anodic oxidation treatment on the titanium sheet to prepare TiO2NBs; before anodic oxidation, performing ultrasonic cleaning of the titanium sheet in ethanol and acetone respectively, performing acid pickling, washing with deionized water and drying, wherein a two-electrode system is adopted for the anodic oxidation; calcining in air; modifying the TiO2NBs prepared in the step I with Au-Pd bimetallic nanoparticles; adopting a three-electrode system in which chloroauric acid and a palladium chloride aqueous solution are used as Au and Pd sources; and depositing Au and Pd in turn and drying. The photocatalyst prepared by the method disclosed by the invention is fixed on the titanium matrix, the water body pollution caused by non-thorough recovery is avoided, a contactable surface area is larger, the contact reaction between organic pollutant molecules and the photocatalyst is facilitated, the photocatalytic degradation property of the photocatalyst is remarkably promoted, reaction conditions are mild, and the process flow is simple and easy to control.

Owner:QINGDAO AGRI UNIV

Hierarchical alpha-Fe2O3/TiO2 hollow sphere dual-functional photocatalyst and application thereof

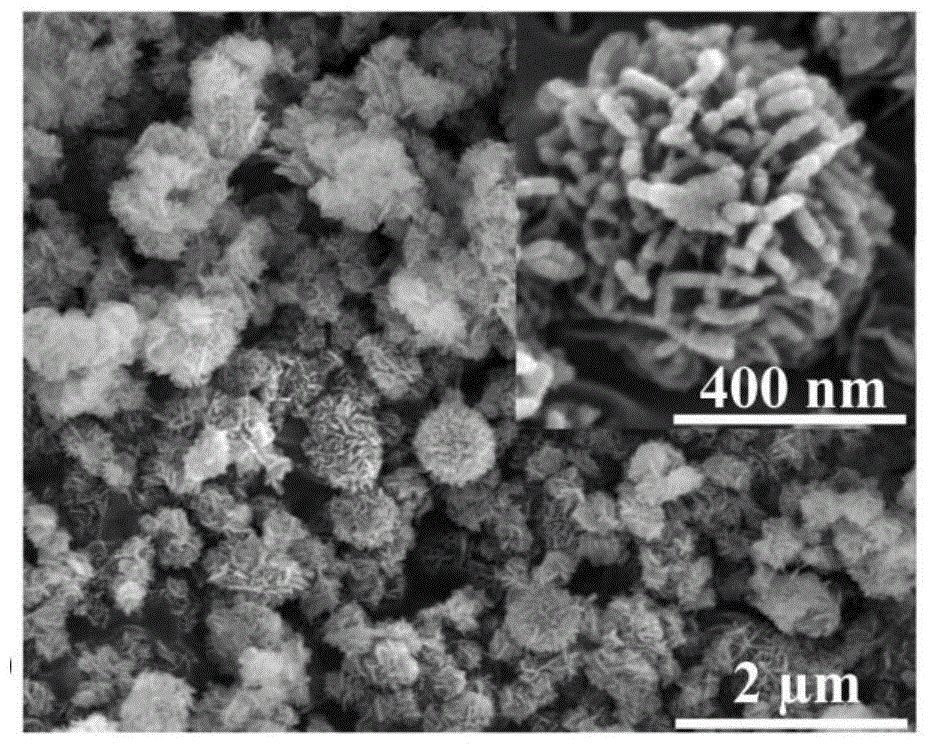

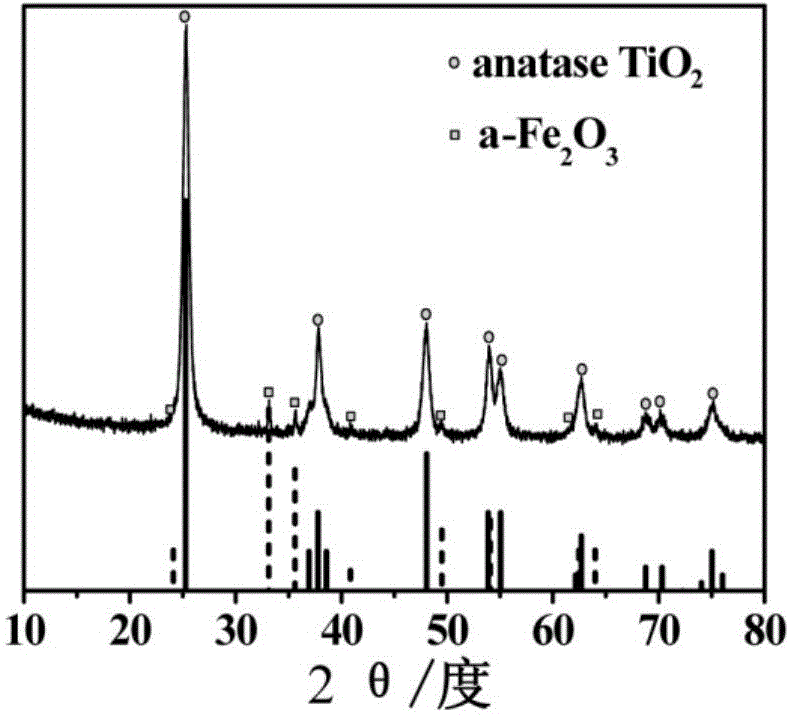

ActiveCN104437495AImprove adsorption capacityEasy to recycleWater/sewage treatment by irradiationOther chemical processesPhotocatalytic reactionSulfate

The invention provides a hierarchical alpha-Fe2O3 / TiO2 hollow sphere difunctional photocatalyst. The alpha-Fe2O3 / TiO2 hollow sphere difunctional photocatalyst with a hierarchical structure is prepared by virtue of hydrothermal reaction from FeOOH as a substrate, and butyl titanate, titanium tetrachloride, titanyl sulfate or isopropyl titanate as a titanium source; next, the alpha-Fe2O3 / TiO2 hollow sphere difunctional photocatalyst is dispersed in water containing heavy metal ions and adsorption and light-catalyzed reaction are performed under the irradiation of simulated sunlight. The invention also provides new application of the hierarchical alpha-Fe2O3 / TiO2 hollow sphere difunctional photocatalyst in treating of heavy metal ion pollution in the water.

Owner:HEBEI UNIV OF TECH

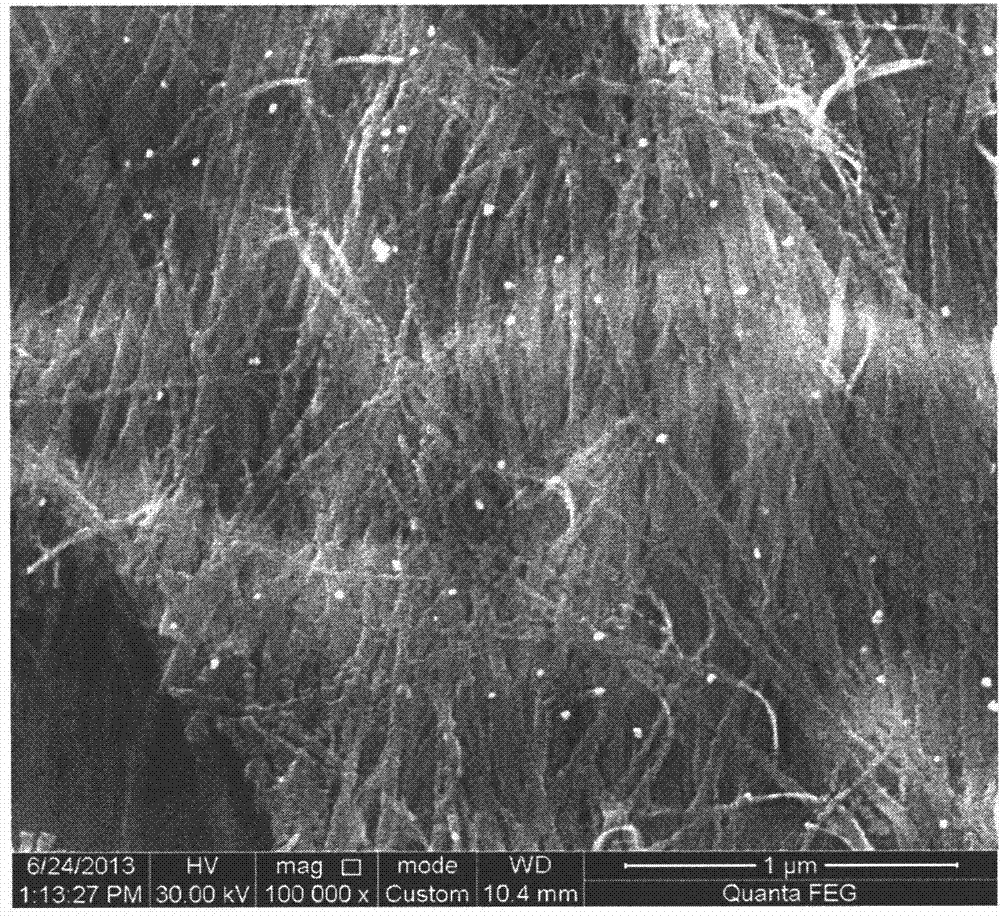

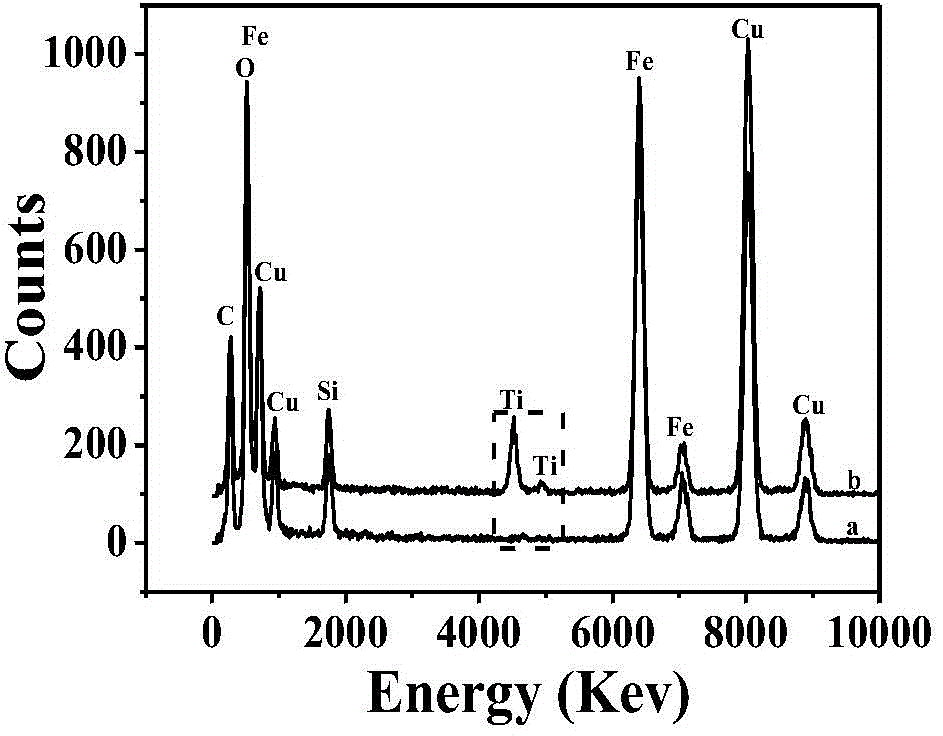

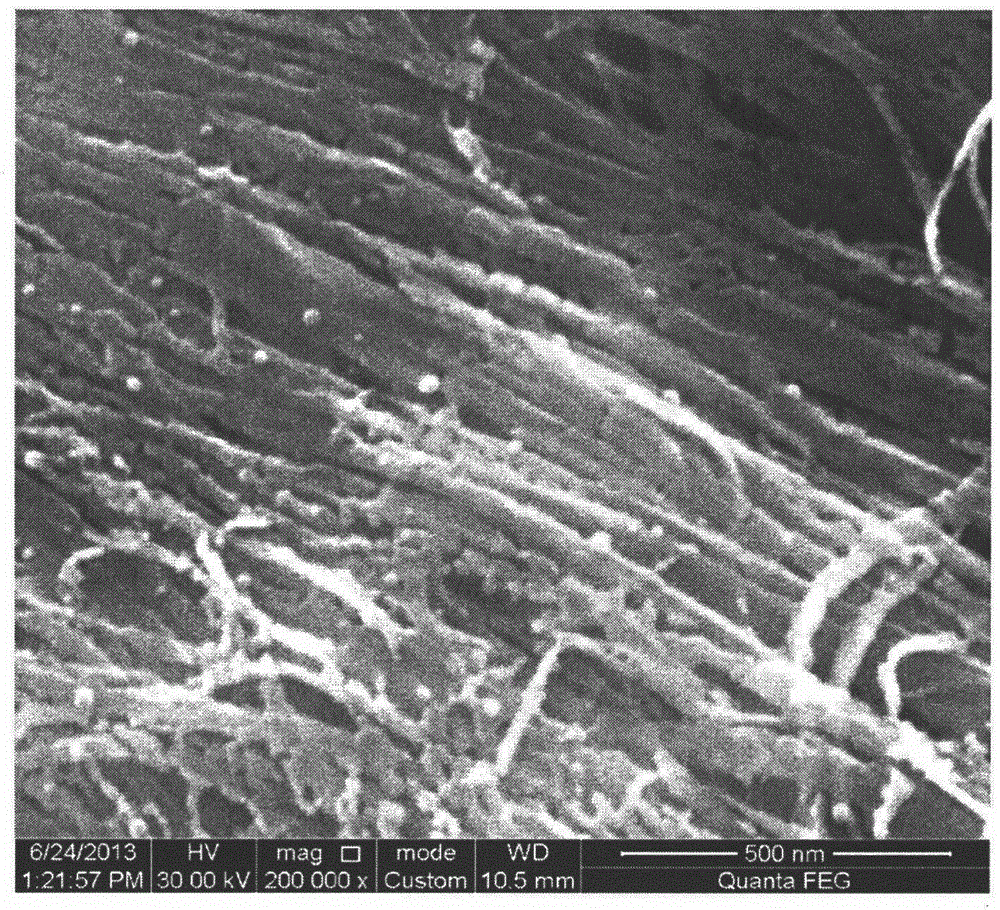

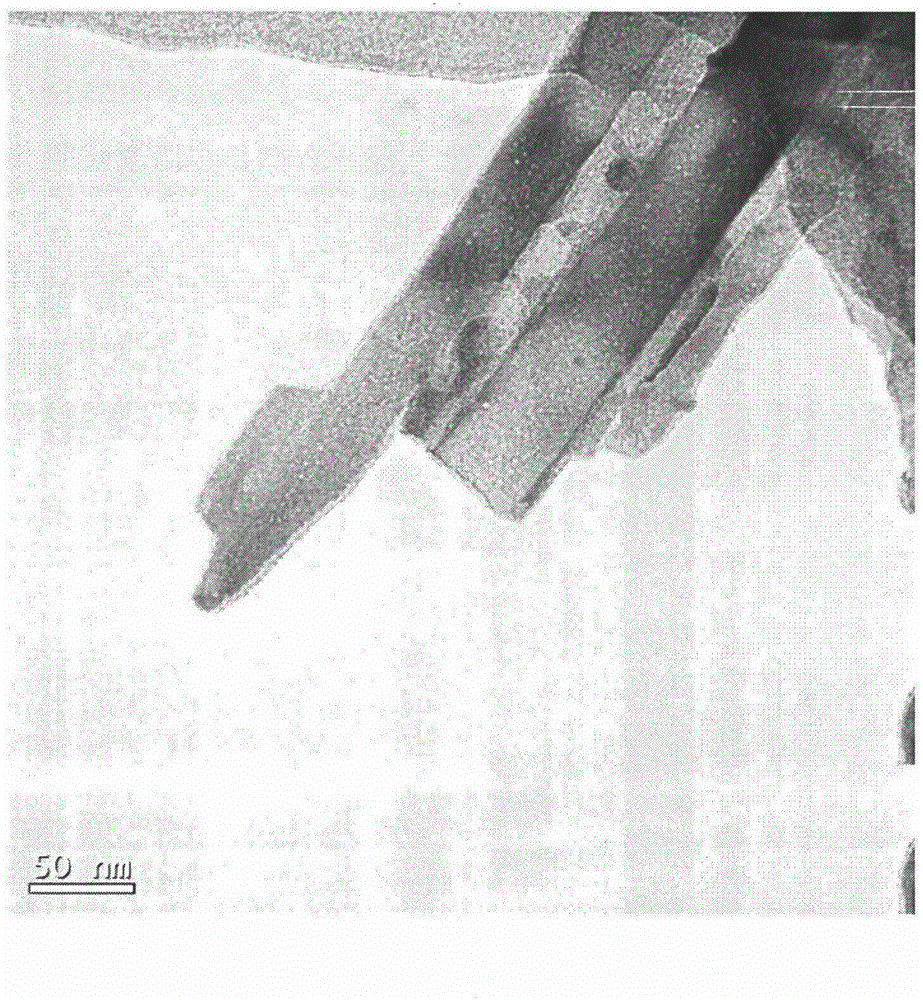

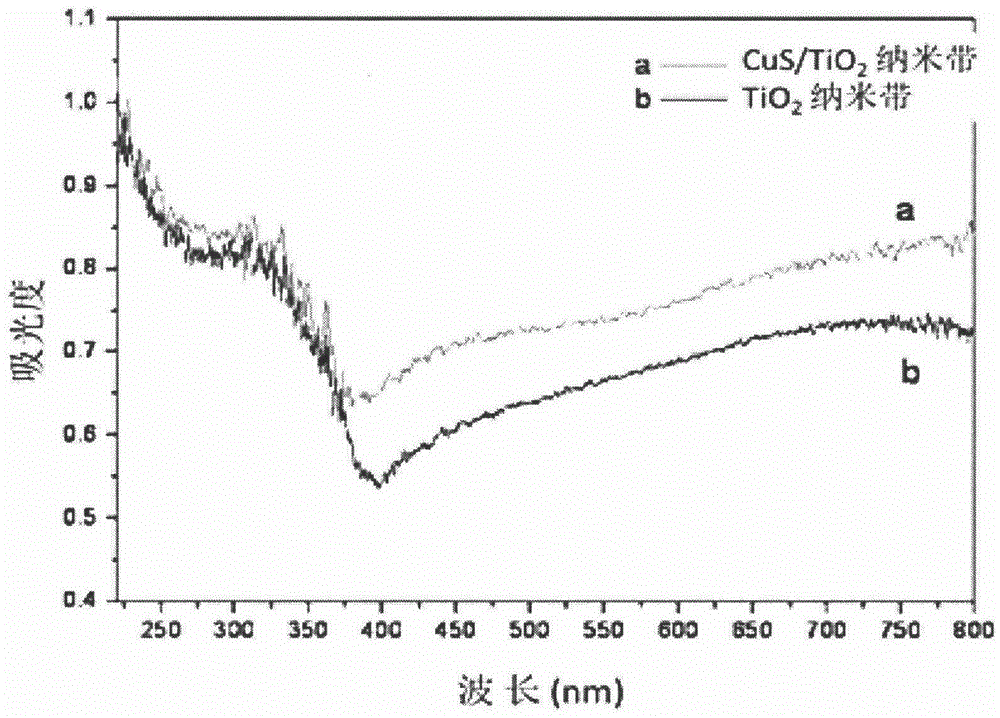

Preparation method and use method of CuS modified immobilized TiO2 nanoribbon photocatalyst

ActiveCN104437551AGuaranteed uniformityGood for recyclingPhysical/chemical process catalystsChemistryPre treatment

The invention discloses a preparation method and use method of a CuS modified immobilized TiO2 nanoribbon photocatalyst. The preparation method of the CuS modified immobilized TiO2 nanoribbon photocatalyst is characterized by comprising the following specific steps: (1) pretreating a titanium sheet; (2) anodizing the titanium sheet electrochemically to prepare an immobilized nanoribbon; and (3) preparing a CuS modified immobilized TiO2 nanoribbon by adopting the successive ionic layer adsorption and reaction process. The CuS modified immobilized TiO2 nano photocatalyst prepared by adopting the preparation method can absorb visible light, can promote the separation of photo-generated electrons from holes to have high photocatalytic efficiency and can be used for effectively removing organic contaminants in environment to avoid causing nano pollution.

Owner:QINGDAO AGRI UNIV

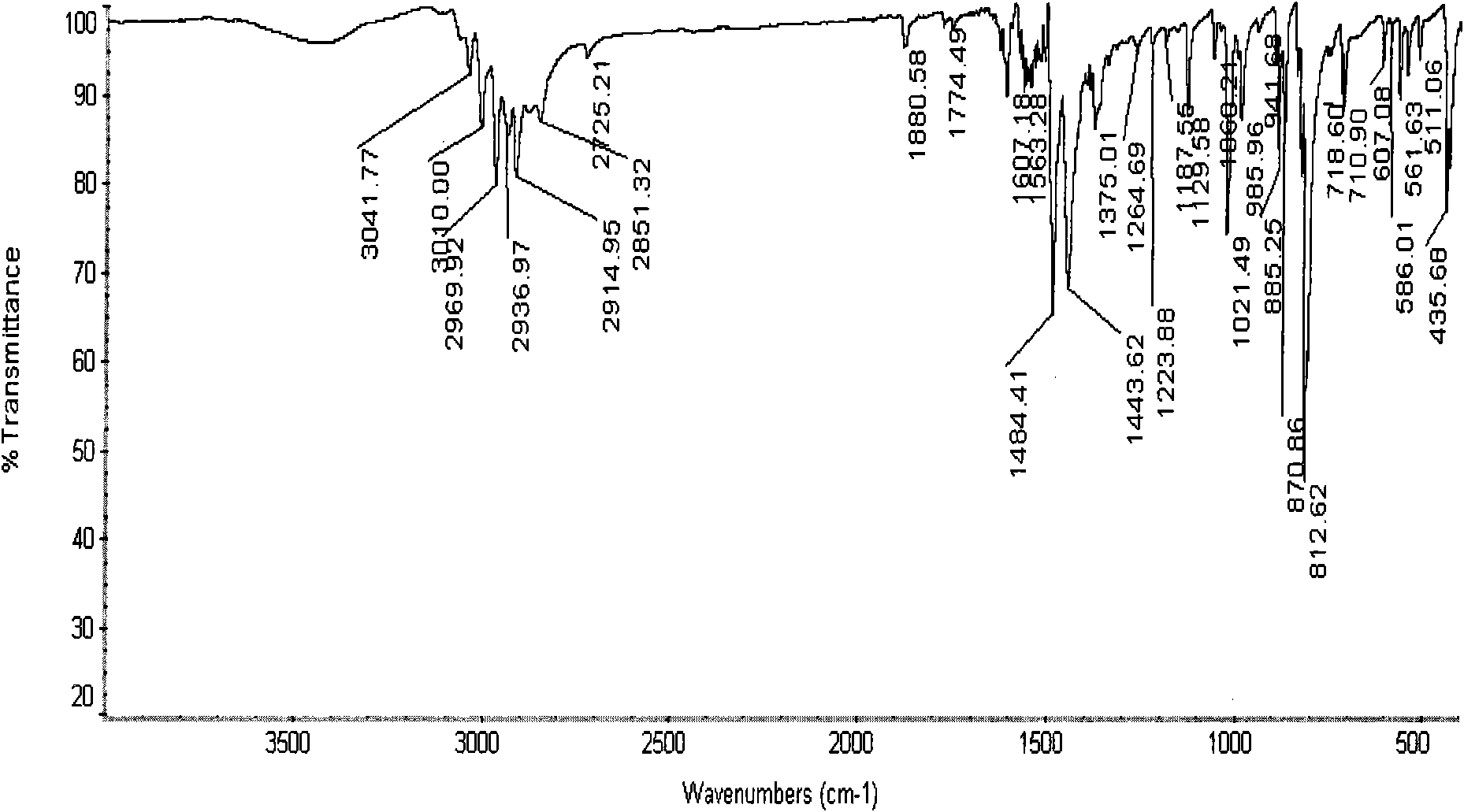

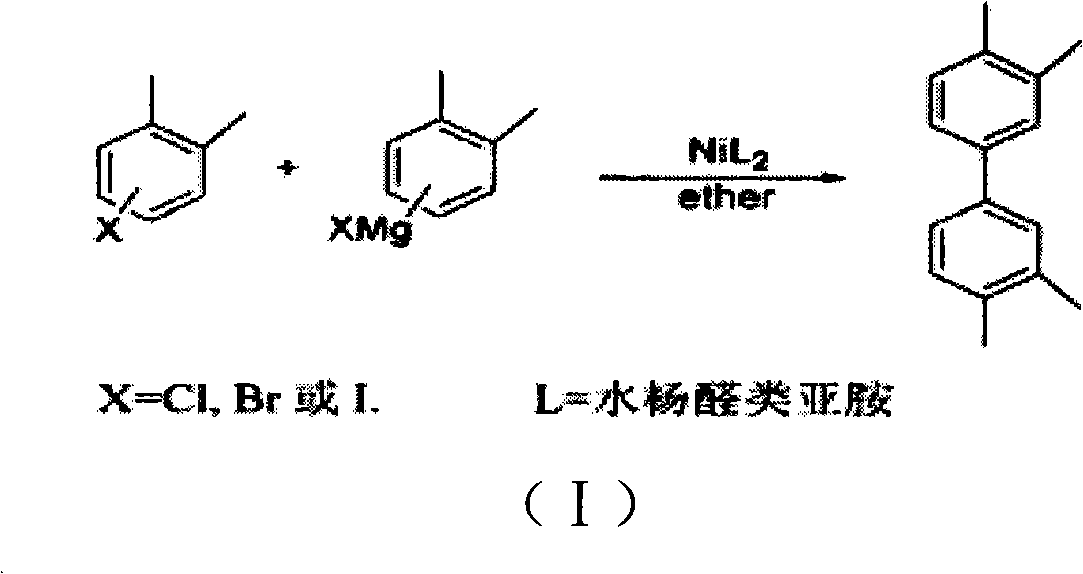

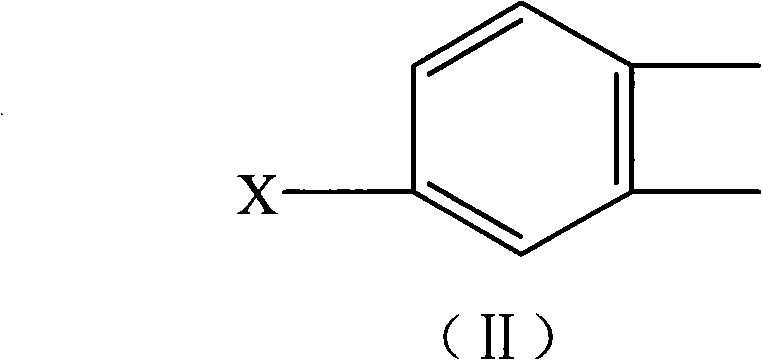

Tetramethylbiphenyl preparation method

InactiveCN101638354AEasy to follow upGood for recyclingHydrocarbon from halogen organic compoundsSolventPalladium

Owner:BYD CO LTD

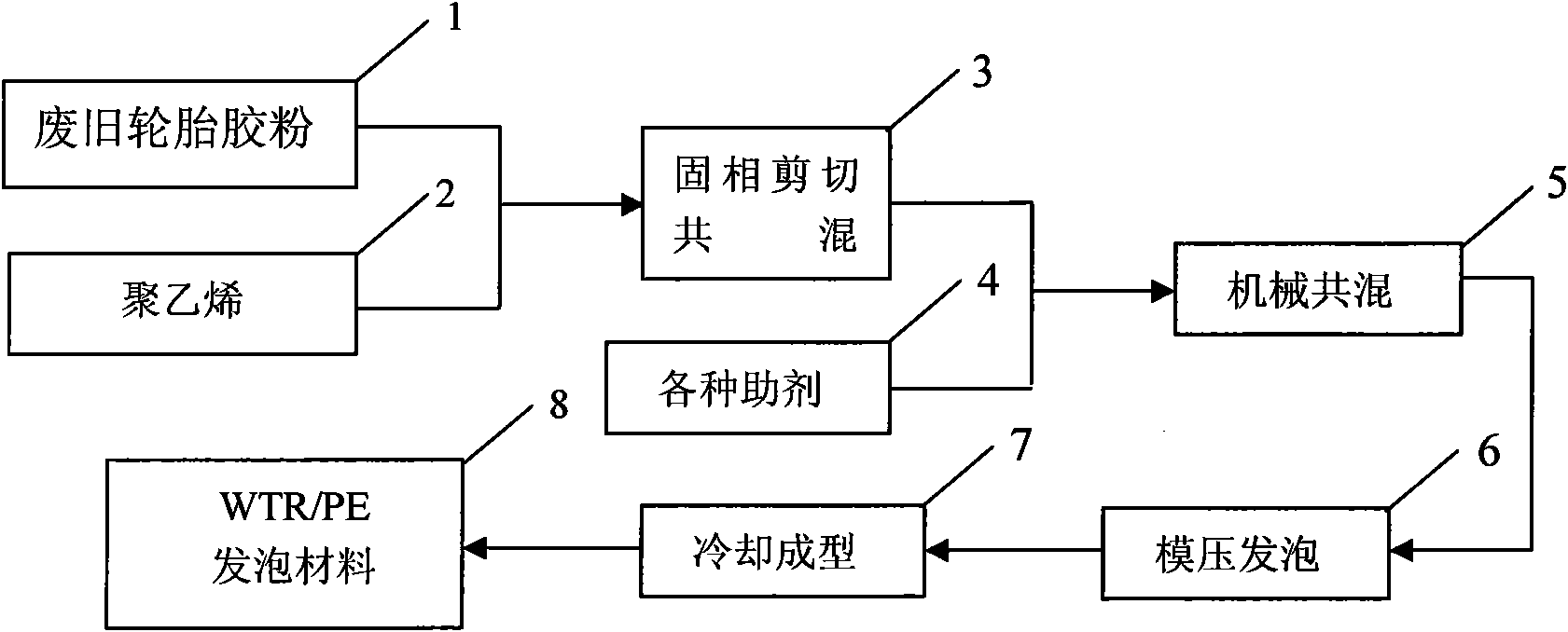

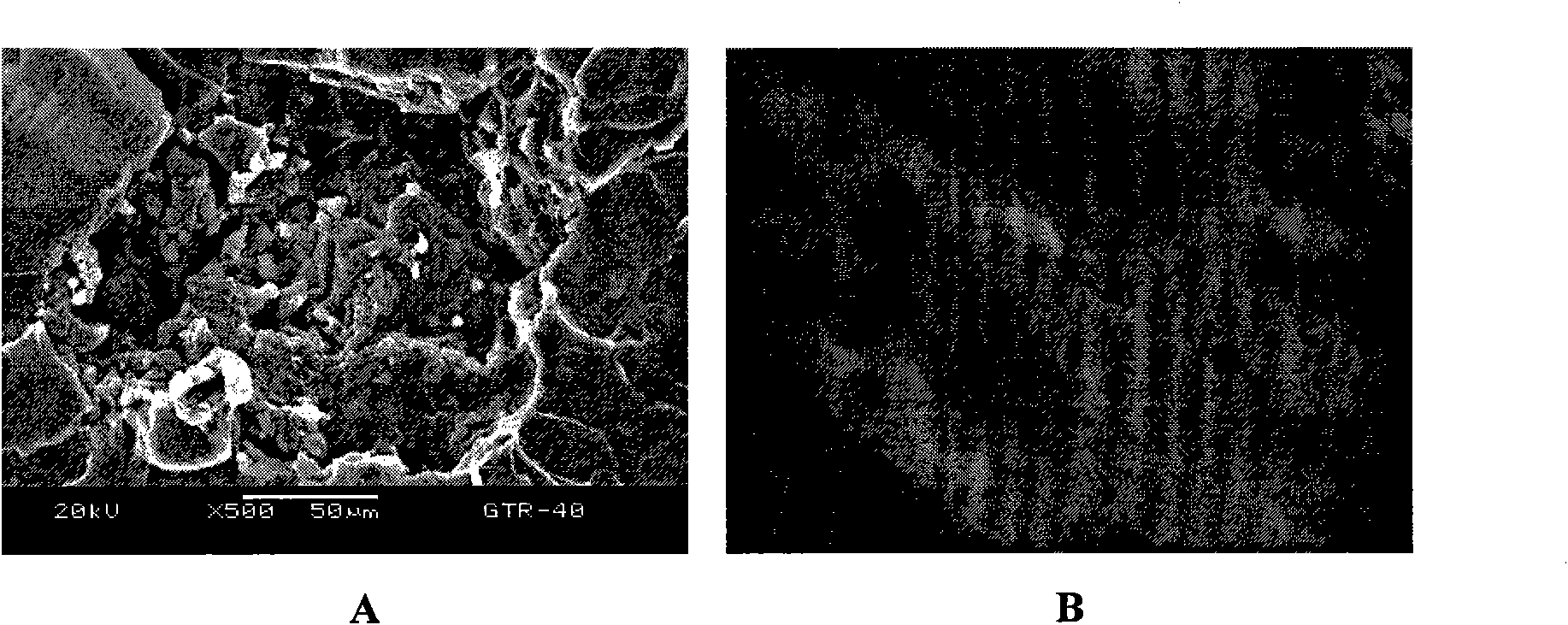

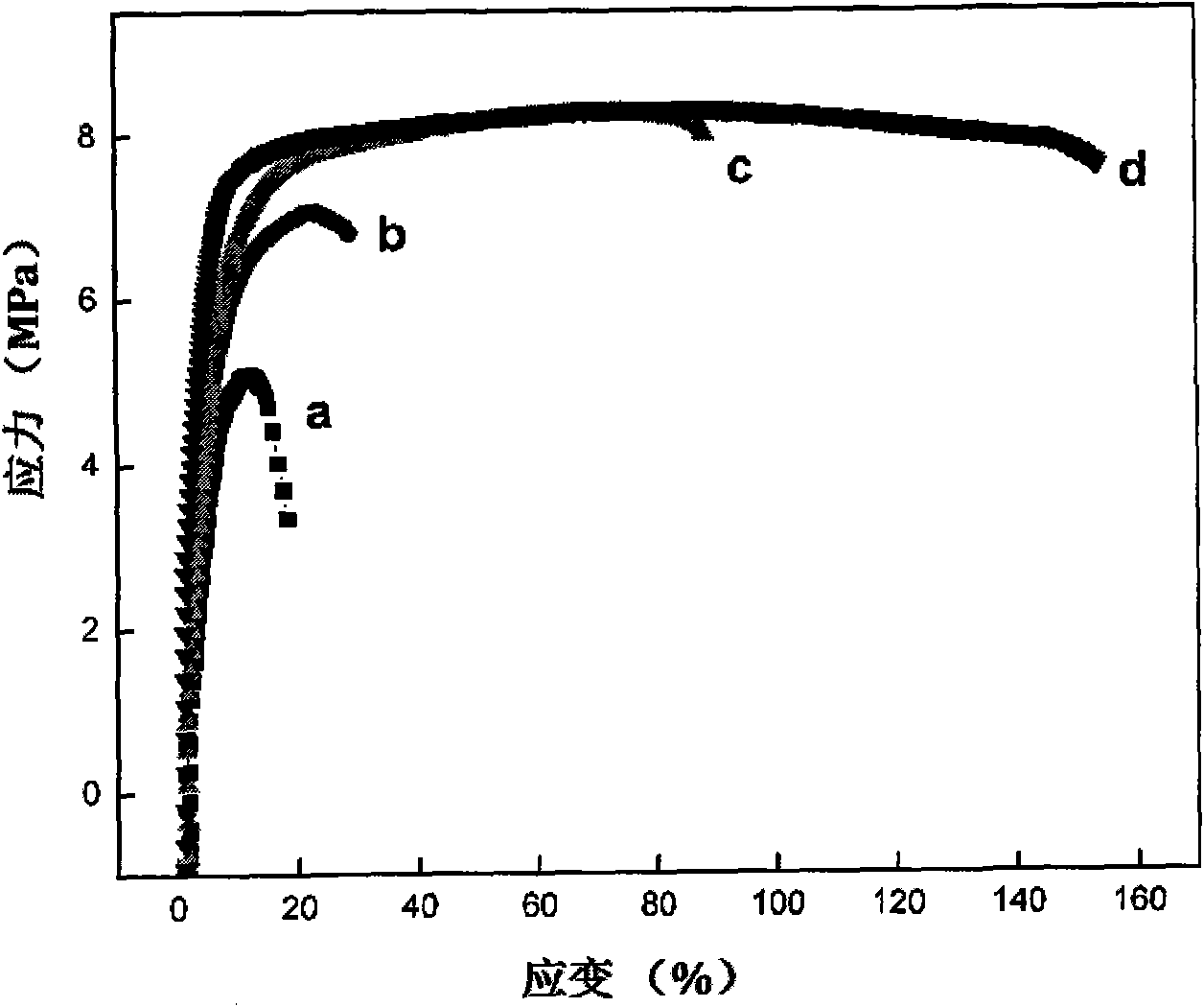

Preparation method of waste tire rubber/polyethylene foam material

InactiveCN101870169AGood for recyclingImproved compatibility and interfacial interactionsWaste tiresOxide

The invention discloses a preparation method of waste tire rubber / polyethylene foam material, which is characterized in that: 20 to 40 weight parts of waste tire rubber and 100 weight parts of polyethylene are added into a dynamic chemical reactor (ZL95111258.9) to be milled at room temperature so that part of the waste tire rubber (WTR) is desulfurized and the surface thereof is activated; simultaneously, the WTR and the PE are mixed at high efficiency to obtain the WTR / PE composite powder which is uniformly mixed with the average grain size of 10 to 100mu m; the composite powder is added into a mixer, then is sequentially added with 1 to 5 weight parts of foaming agent, 1 to 3 weight parts of cross linker, 0.5 to 2 weight parts of antioxidant, 0.5 to 4 weight parts of zinc oxide and 0.5 to 2 weight parts of lubricant to be melted and mixed to obtain the mixture of the waste tire rubber / polyethylene foam material; and then the mixture is put into a plate rheometer to be stamped, foamed and formed to obtain the waste tire rubber / polyethylene foam material. The foam material has the advantages of environmental protection, low energy consumption, high production efficiency and relative lower production cost.

Owner:SICHUAN UNIV

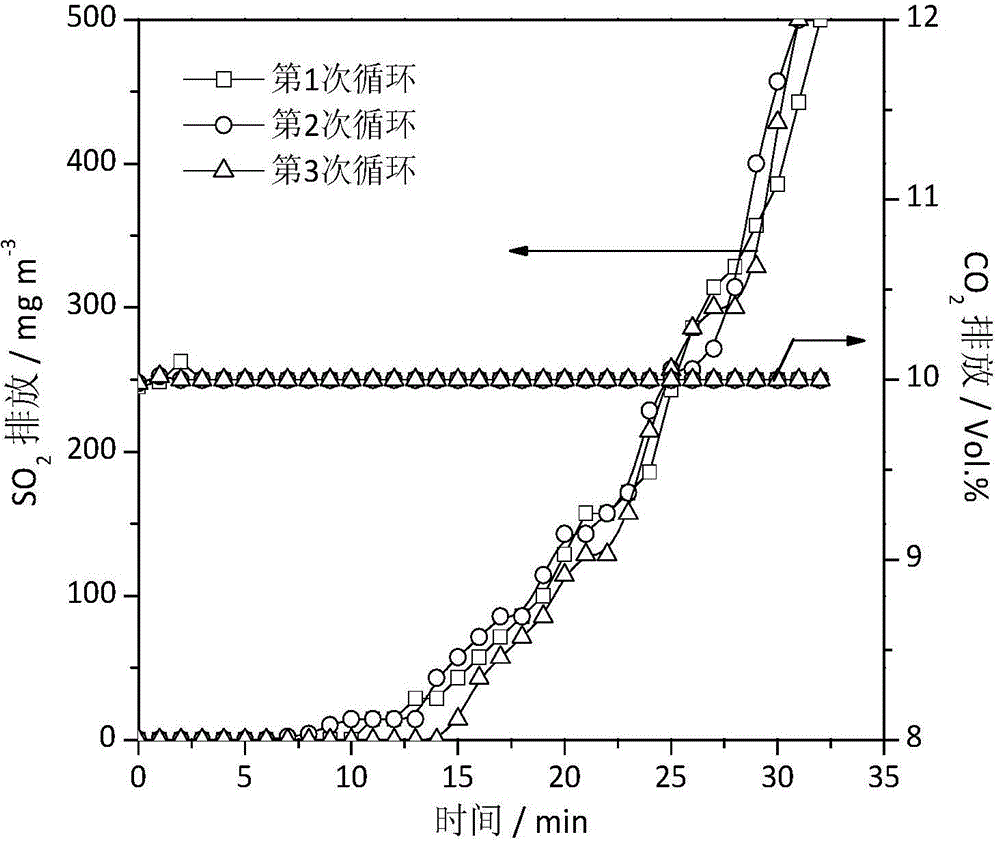

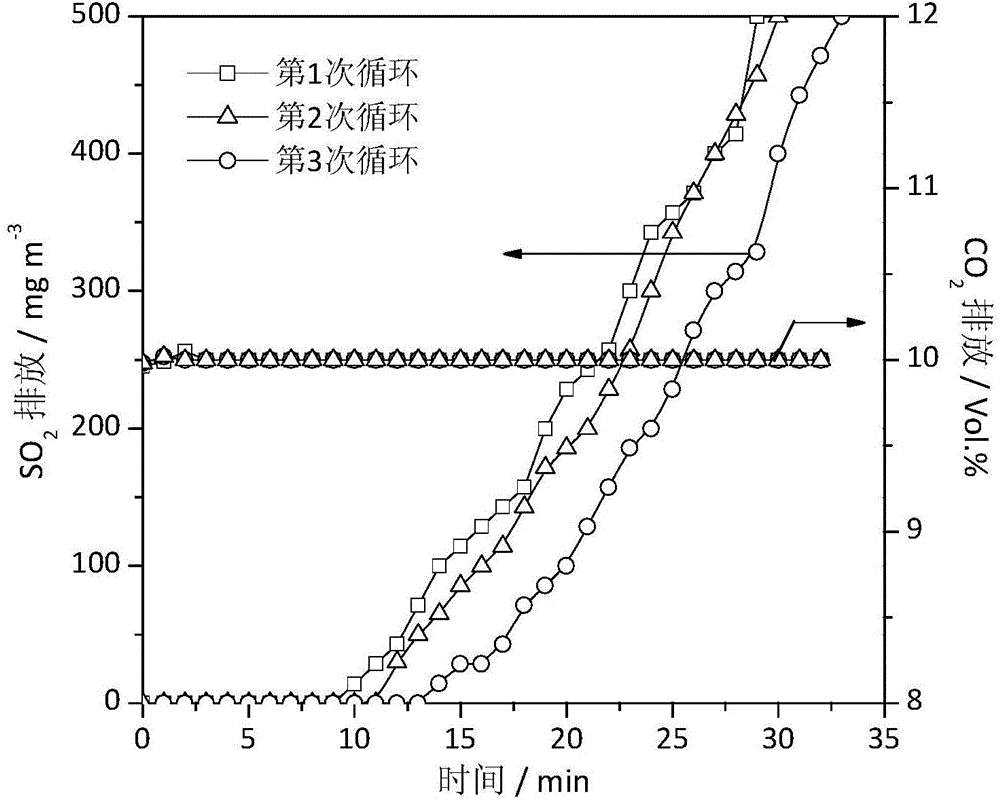

Absorbent for selectively absorbing sulfur dioxide and application thereof

InactiveCN105983310AGood for recyclingLow viscosityDispersed particle separationExhaust gasAbsorption rate

The invention discloses an absorbent for selectively absorbing sulfur dioxide and an application thereof, which belong to the technical fields of environmental protection and gas purification. The absorbent comprises the following components by mass percentage: 5-80% of organic multi-amine; inorganic strong acid, wherein the mol ratio of the inorganic strong acid to the organic multi-amine is (0.3-1.2):1; 0.01-1.00%of an antioxidant, 0.01-8.00% of a desulfuration activator, and the balance of water; and the pH value of the absorbent is 4.0-6.5. The SO2 absorbent has high absorptivity and selectivity on SO2, SO2 can be absorbed from a mixing gas containing SO2 and CO2, but CO2 is not absorbed, the initial absorption rate can reach 100%, the absorption rate can still reach more than 99% in 30 minutes, and the absorbent is suitable for purifying the industrial exhaust gas containing SO2, especially the exhaust gas of a sulfur recovery device. The SO2 absorbent has good renewable performance and stability, and is in favor of cyclic utilization of the absorbent.

Owner:PETROCHINA CO LTD

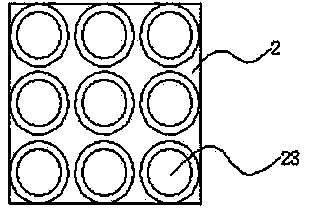

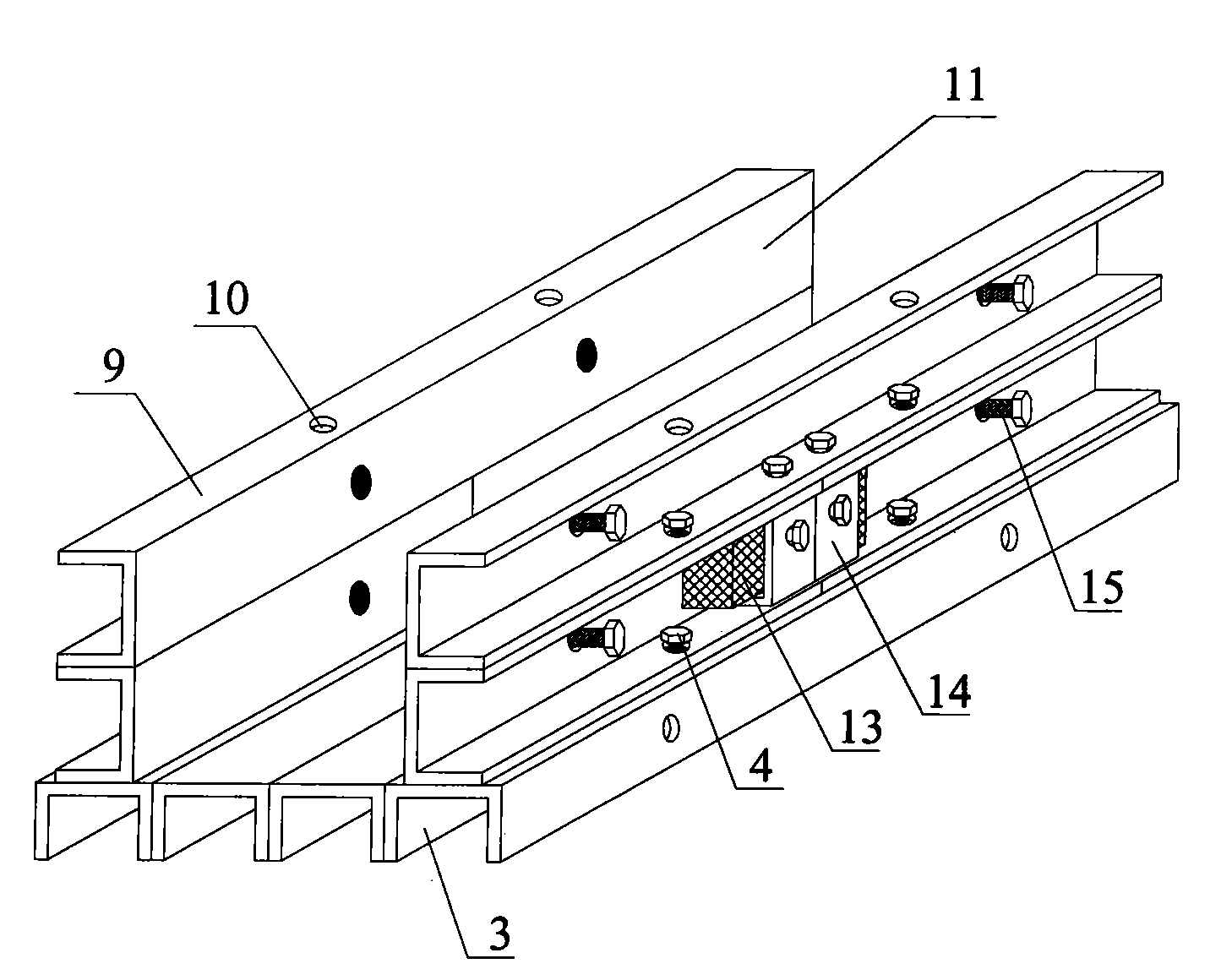

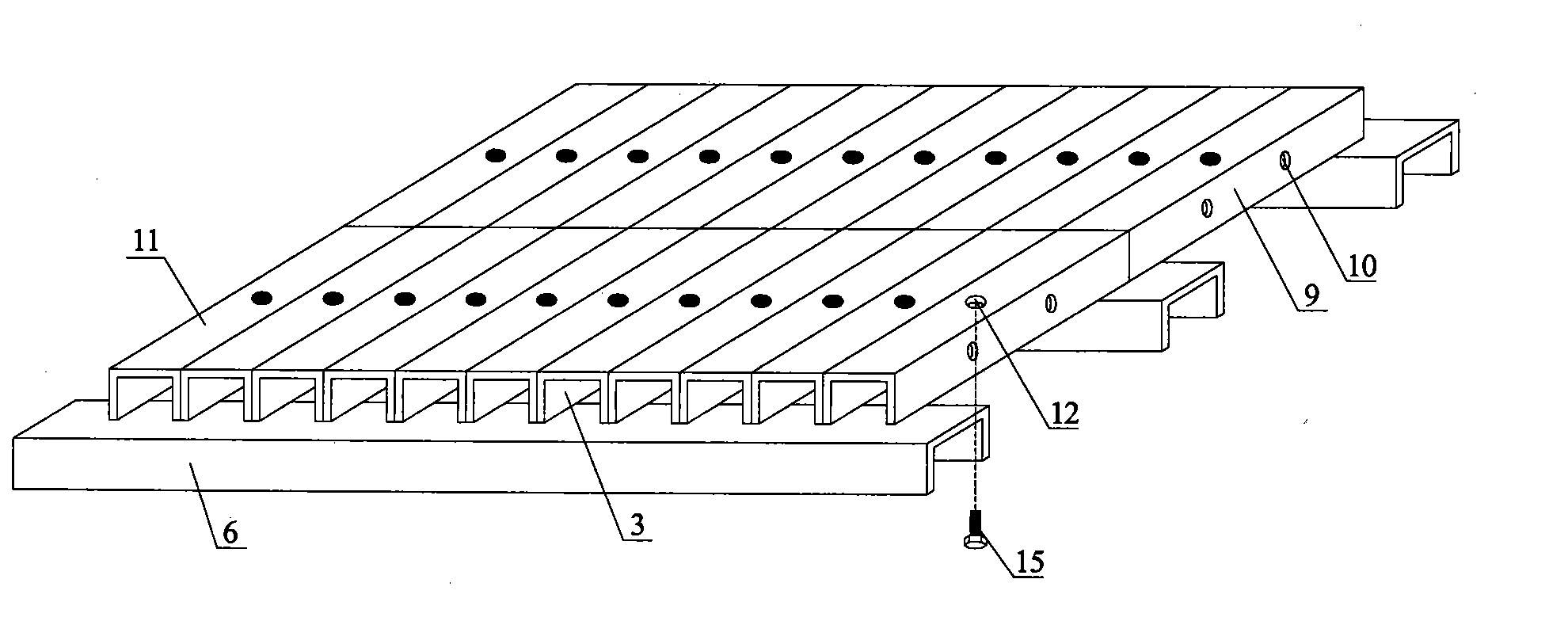

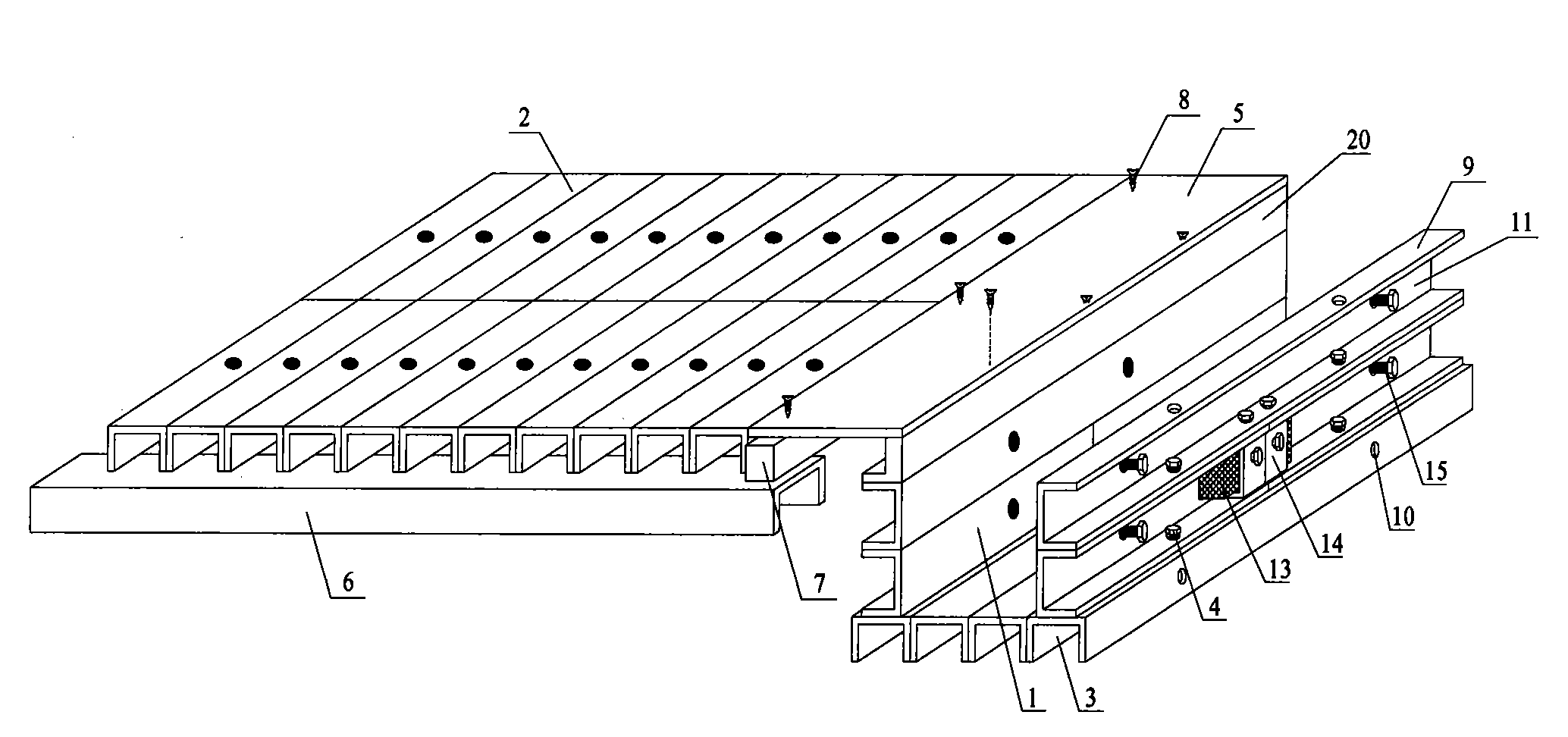

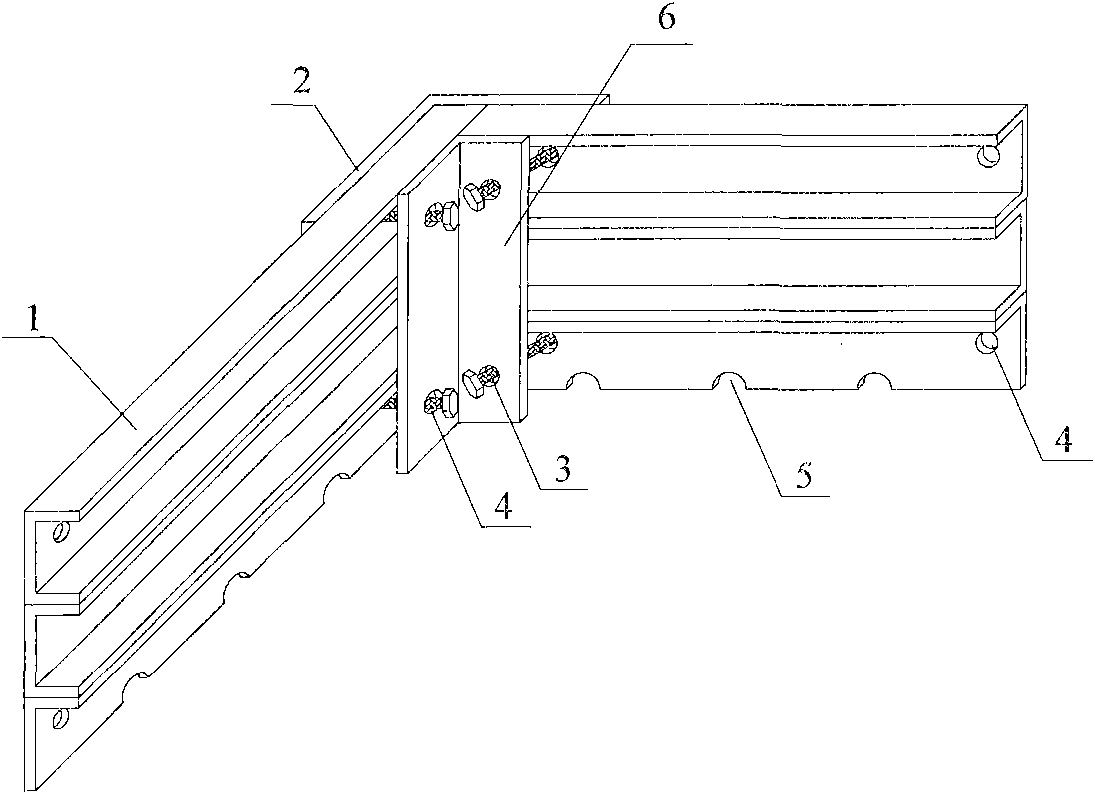

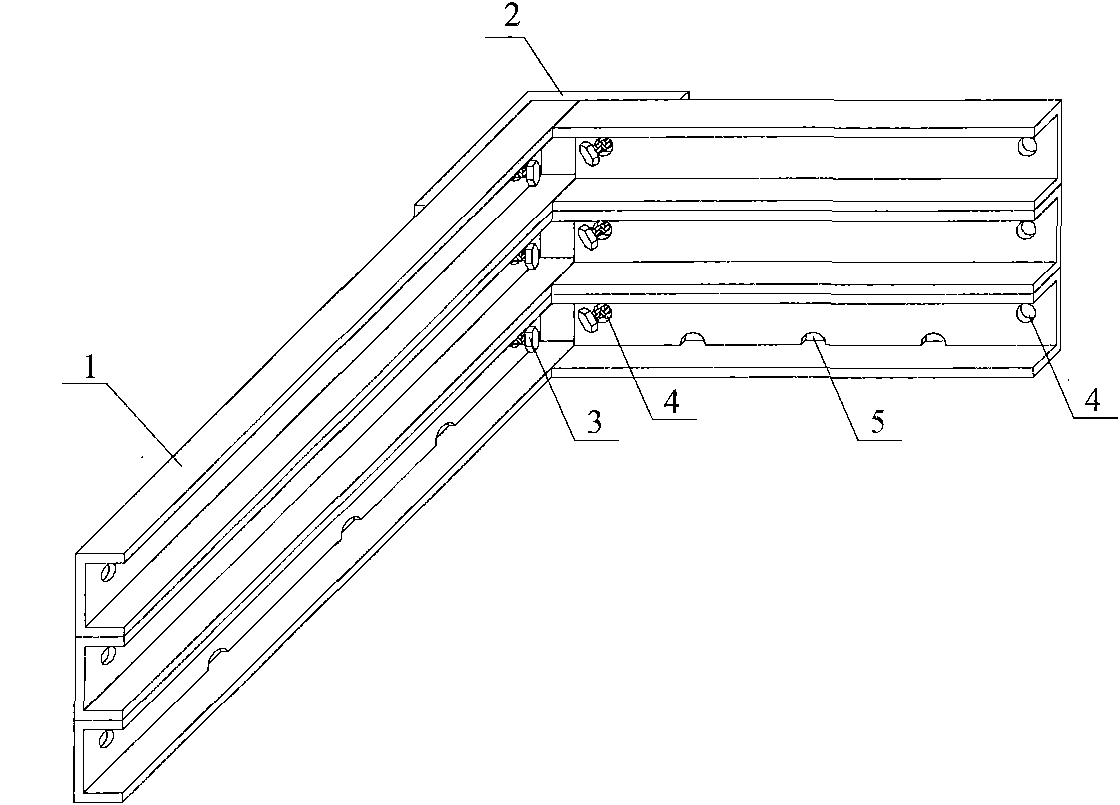

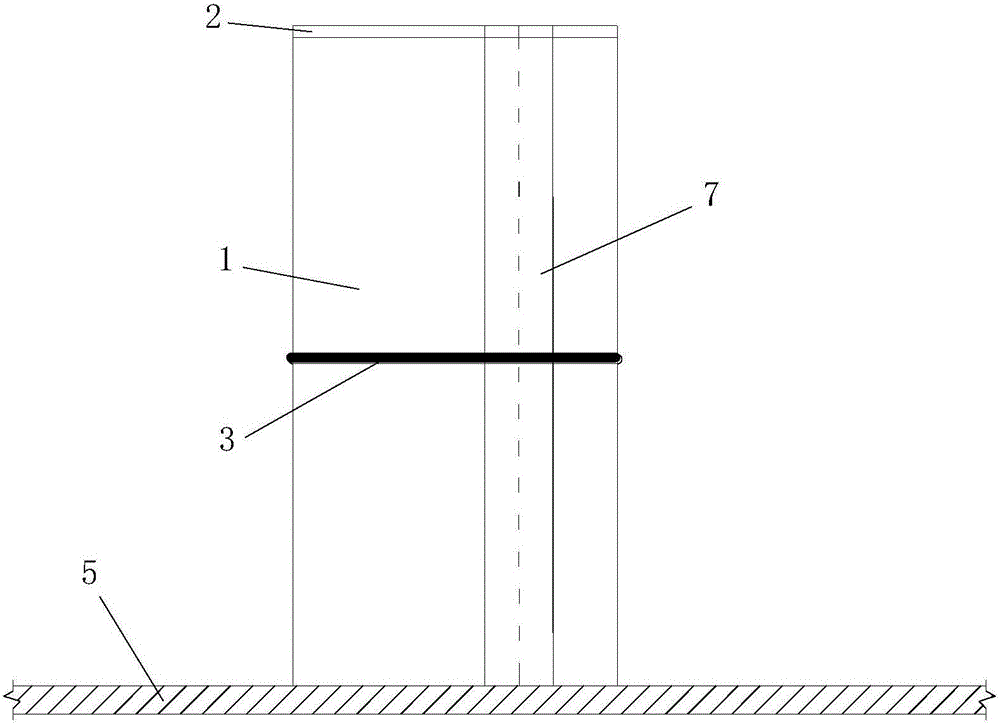

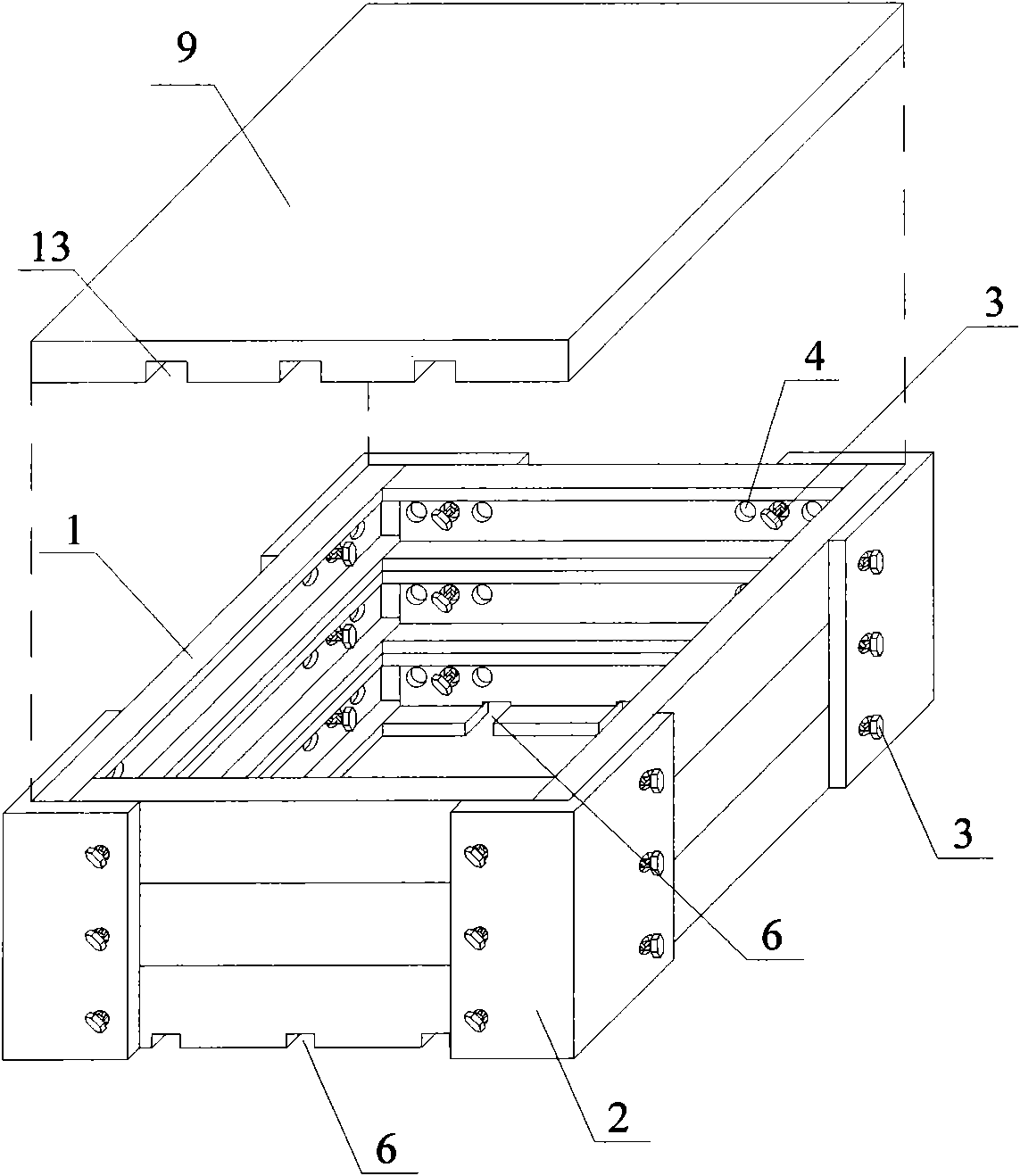

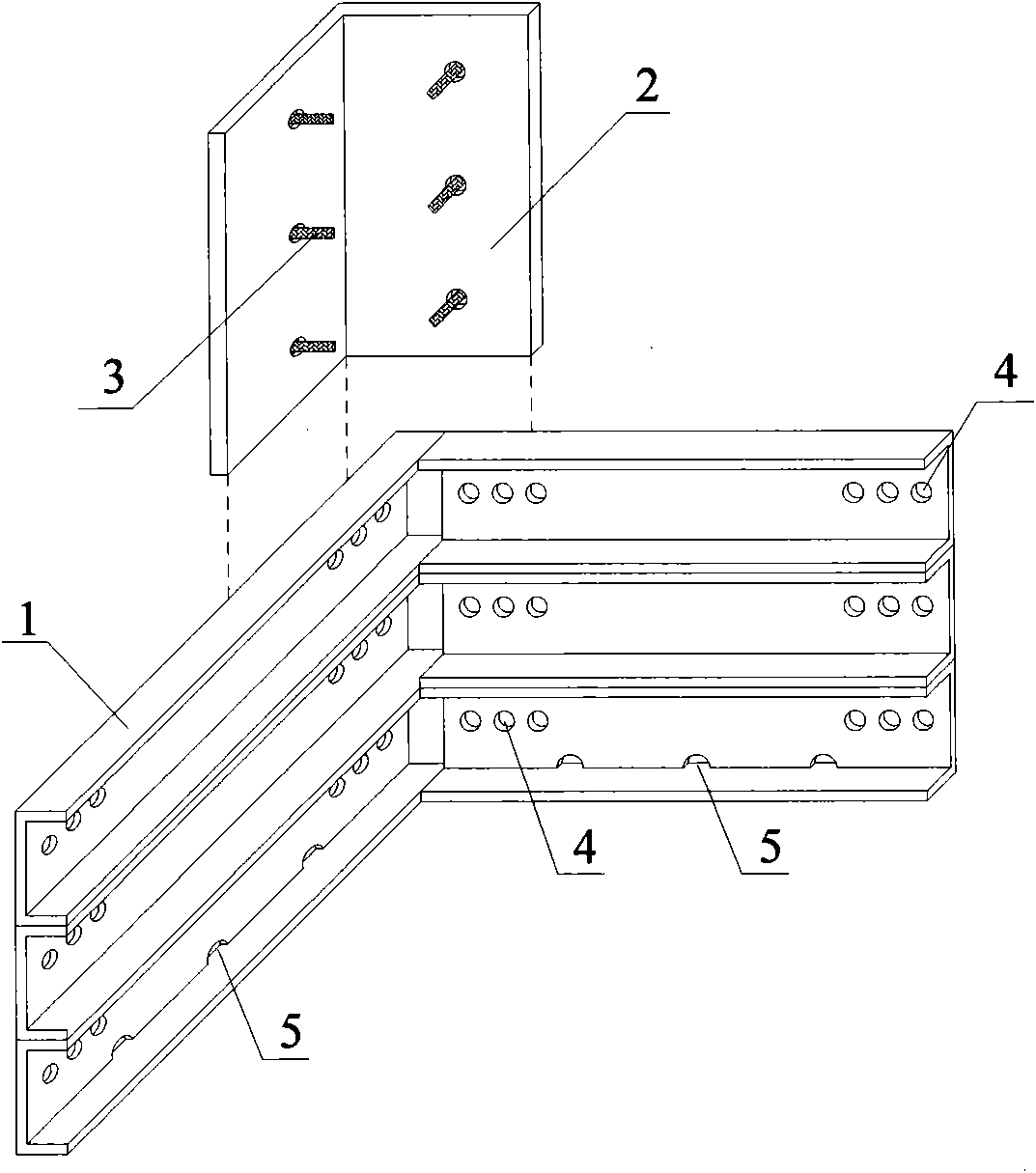

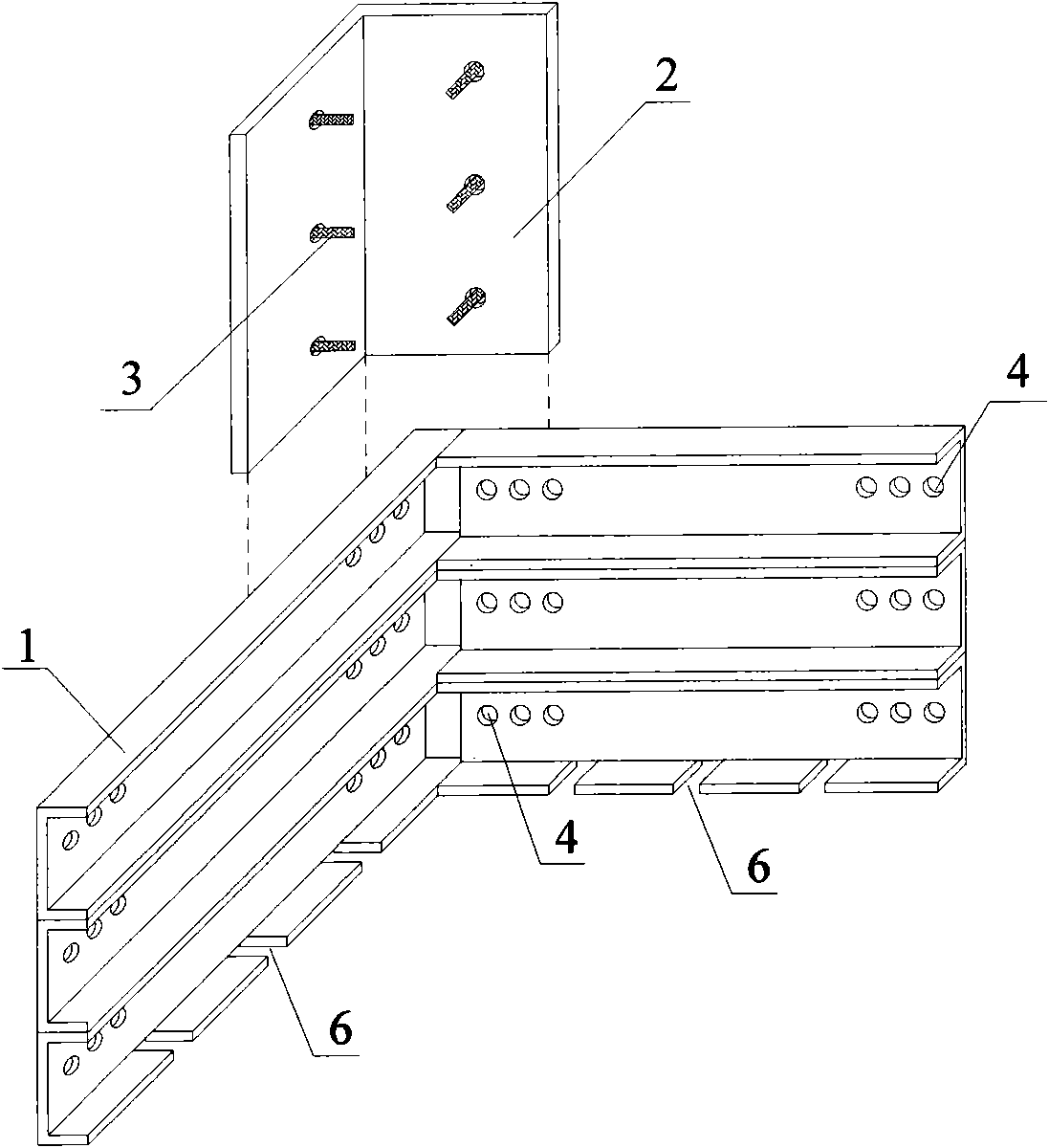

Beam and slab integrally casted building template

ActiveCN102116080ALight weightIncrease flexibilityAuxillary members of forms/shuttering/falseworksForming/stuttering elementsBearing capacity

The invention discloses a beam and slab integrally casted building template. The template comprises a beam template (1) and a slab template (2), wherein both the beam template (1) and the slab template (2) are formed by assembling a plurality of groove-shaped modules (3) which are connected with each other; the groove-shaped modules (3) are connected with each other via bolts (4) or plugs; the bottom of the slab template (2) is supported by support beams (6); a cover plate (5) is arranged at the joint of the slab template (2) and the beam template (1); a filler strip (7) is arranged on a support beam (6) at the bottom of the slab template (2); a backing plate (20) is arranged at the top of the beam template (1); one end of the cover plate (5) is supported on the filler strip (7) and the other end of the cover plate is supported on the backing plate (20); and the cover plate (5) and the filler strip (7) or the backing plate (20) are connected with screws (8), bolts or plugs. The template is convenient to assemble, has high rigidity and bearing capacity, is easy to dismantle and can solve the problem of insufficient modules when the template is assembled.

Owner:吴充

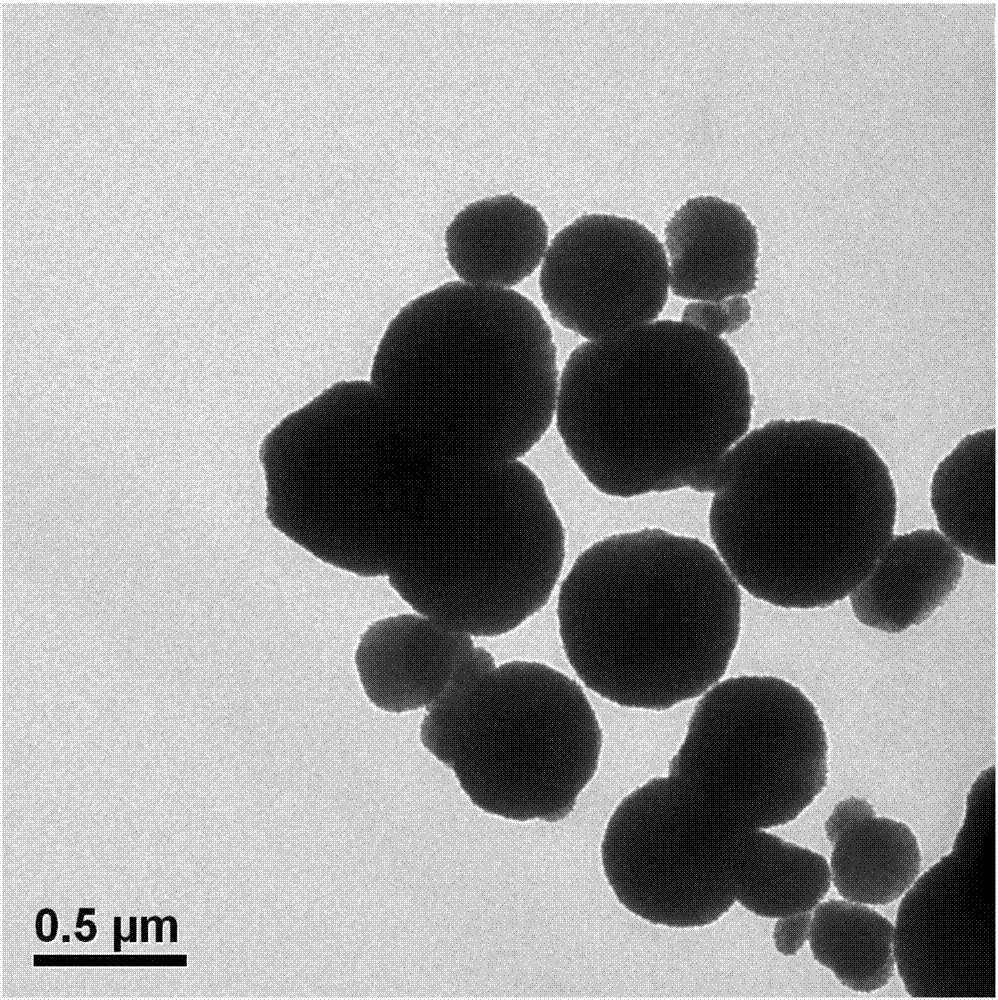

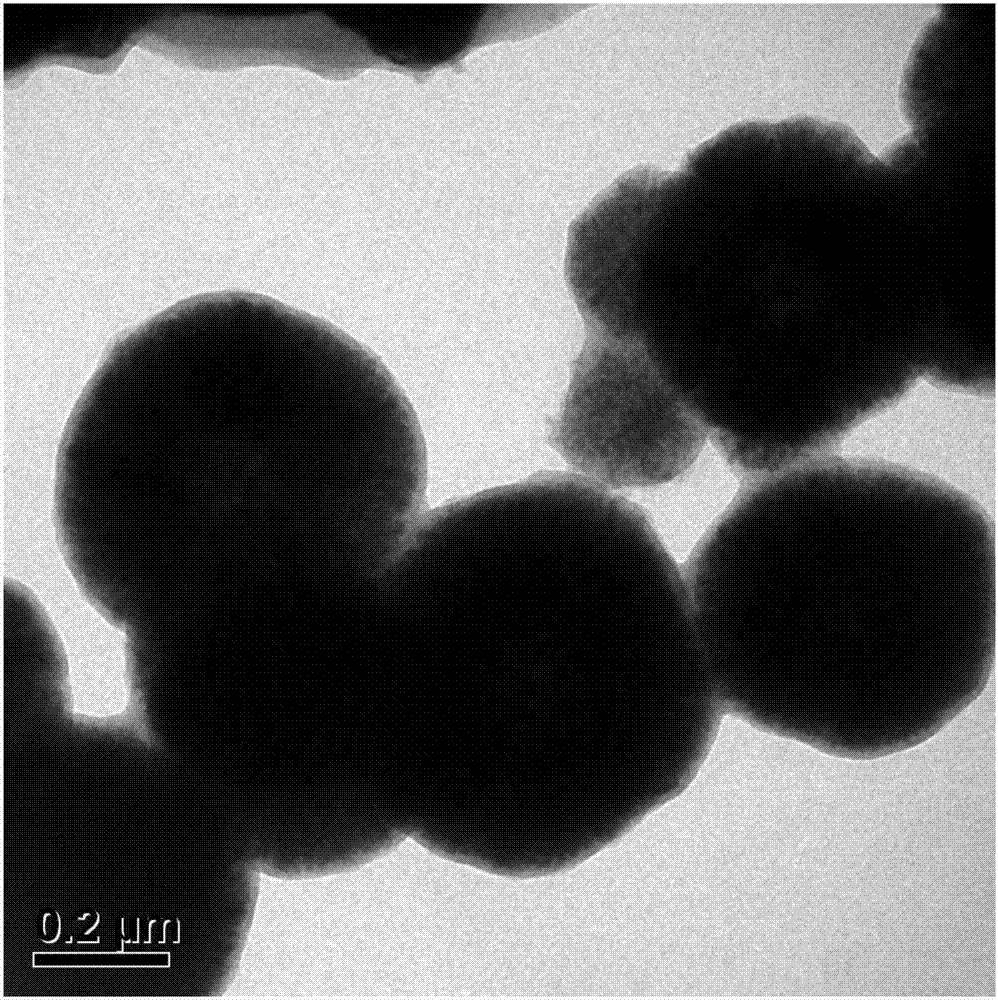

Preparation method of hydrophobic magnetic composite material

The invention relates to a preparation method of a hydrophobic magnetic composite material. The preparation method comprises the following steps of 1) preparing Fe3O4 nanoparticles; 2) dispersing the Fe3O4 nanoparticles in the step 1) in water for hydrothermal reaction with glucose to obtain Fe3O4 / C powder; 3) dispersing the Fe3O4 / C powder in the step 2) in isopropyl alcohol, and adding 3-aminopropyltriethoxysilane for surface modification to obtain an intermediate product; 4) preparing nanoparticle colloid by a sodium citrate method; and 5) dispersing the intermediate product in the step 3) in the water, adding gold nanoparticle colloid for continuous ultrasound under an ultrasound state, performing cleaning, dispersing the gold nanoparticle colloid in n-hexane, adding 1H, 1H, 2H, 2H-perfluorooctyl trichlorosilane for hydrophobic processing, and performing separation and drying to obtain the hydrophobic Fe3O4 / C / Au magnetic composite material. The Fe3O4 / C / Au magnetic composite material prepared by the method is stable in structure and has hydrophobicity.

Owner:ZHEJIANG UNIV

Synthesis process of graft copolymerized fiber slurry of collagen and acrylonitrile

InactiveCN101747479AReduce the introduction of impuritiesGood for recyclingMonocomponent protein artificial filamentMonocomponent synthetic polymer artificial filamentSolventAmount of substance

The invention relates to a synthesis process of graft copolymerized fiber slurry of collagen and acrylonitrile, the process comprises the steps of using a redox initiation system for carrying out graft copolymerization on a framework compound of the collagen and a first polymer monomer of the acrylonitrile or the first polymer monomer of the acrylonitrile and a second polymer monomer in concentrated zinc chloride water solution, wherein the redox initiation system is an organic substance, and the organic substance consists of an oxidant of organic peroxo acid and a reducing agent of glucose. Compared with the prior art, the synthesis process can greatly reduce the introduction of impurities in the zinc chloride solvent, be conductive to the recycling of the zinc chloride solvent, reduce the cost and reduce the environmental pollution.

Owner:SHANGHAI ZHENGJIA MILKFIBER SCI & TECH

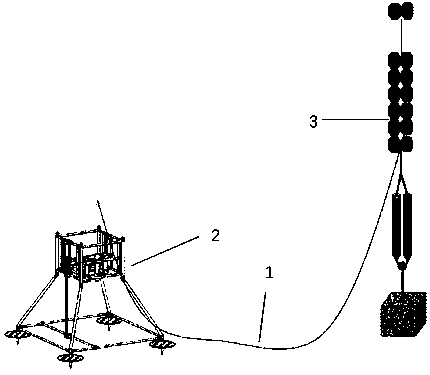

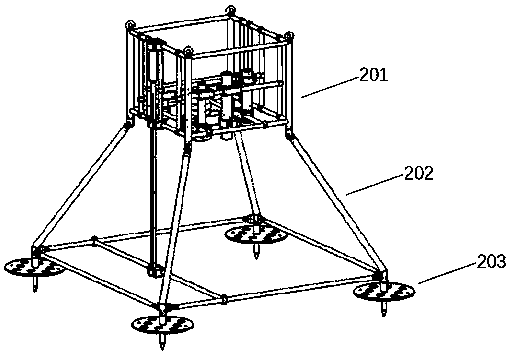

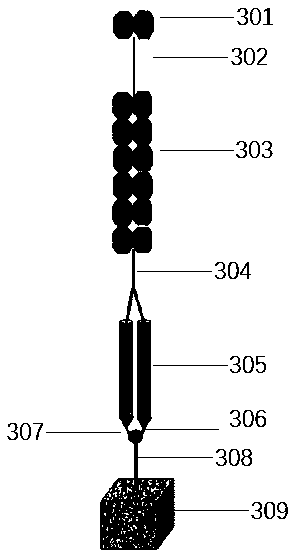

Seabed boundary layer observation device and laying and recovering method thereof

ActiveCN111351528AImprove accuracyGood for recyclingMeasurement apparatus componentsVessel partsObservation dataGeotechnical engineering

The invention relates to the technical field of ocean survey, and especially relates to a seabed boundary layer observation device and a laying and recovering method thereof. The split design of an observation platform and a recovery device is adopted, and a floating body material with a huge size is separated from observation equipment, so that the influence of the floating body material on key parameters such as ocean current is avoided, and the accuracy of observation data is greatly improved; the observation platform on the seabed is recovered by using a connecting cable, so enough tensioncan be provided, and the situation that the observation platform sinks into sediments and cannot be smoothly separated from the seabed is avoided; due to the chained design of the recovery device, after the recovery device floats up to the water surface, recycling of a large scientific investigation ship is better facilitated; and the laying and recovering method is set according to the characteristics of the device, is stable and reliable, is suitable for various ships, and has a good popularization prospect.

Owner:OCEAN UNIV OF CHINA

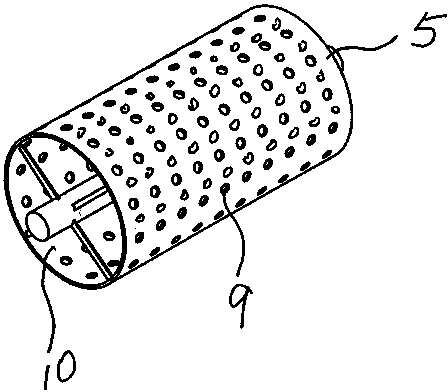

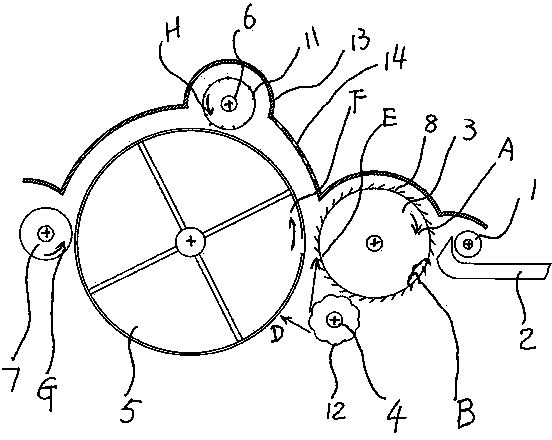

Cashmere carding short fiber extracting device

The invention belongs to the technical field of cashmere machines and discloses a cashmere carding short fiber extracting device. The cashmere carding short fiber extracting device is mainly characterized by comprising a cotton feeding mechanism, a cashmere carding roller, an airflow wool stripping roller, an airflow stripping roller and a short fiber stripping roller, wherein the cotton feeding mechanism is fixed to a machine frame and provided with a cashmere feeding conveying pressing roller; the peripheral face of the cashmere carding roller is coated with metal needle cloth and the cashmere carding roller rotates in the clockwise direction A; the peripheral face of the airflow stripping roller is of a mesh structure and the two ends of the airflow stripping roller are open; the airflow stripping roller and the cotton feeding mechanism are arranged at the two sides of the cashmere carding roller respectively, and the airflow wool stripping roller is fixed to the lower side of the cashmere carding roller and located on the lower side of the airflow stripping roller. According to the cashmere carding short fiber extracting device, short cashmere in tailing materials can be separated from attached wool and skin impurities to the maximum degree, and the short cashmere is fully used.

Owner:HEBEI YUTENG CASHMERE PROD

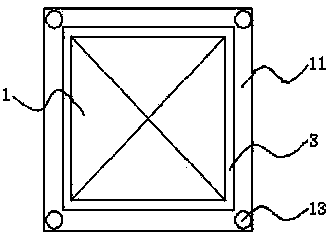

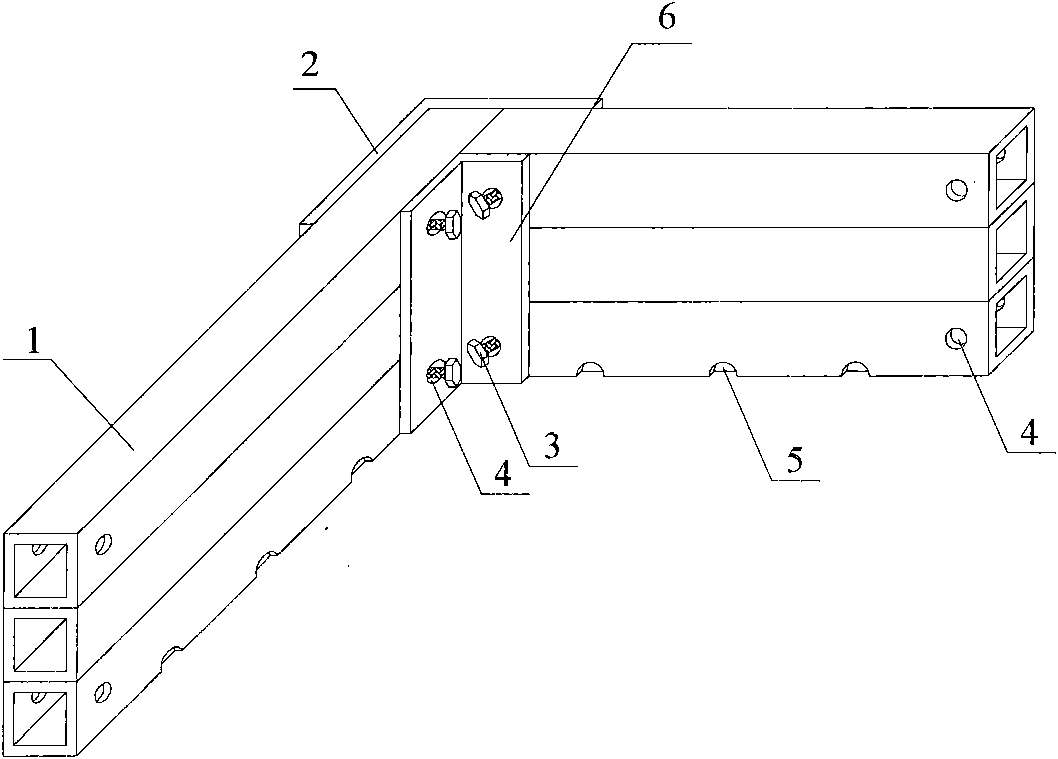

Hollow slab template for buildings

InactiveCN101906875ALight weightIncrease flexibilityForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksFloor slabHollow core

The invention discloses a hollow slab template for buildings, which comprises modules (1), corner moulds (2), connecting pieces such as bolts (3) or pins, and a prefabricated baseplate (9), wherein the bottom module (1) of the hollow slab template is provided with two or more holes or nicks (5). When the hollow slab template is assembled, the modules (1) are arranged in order; and because the end parts of the modules (1) and the corner moulds (2) are provided with corresponding holes (4), the modules (1) and the corner moulds (2) are connected at the holes (4) through the connecting pieces such as the bolts (3) or pins to form the hollow slab template. During instruction, supporting ribs (10) can be implanted into the holes or nicks (5) of the bottom module (1); and after the hollow slab template is detached, the prefabricated baseplate (9) is put on the supporting ribs (10) to form an integral hollow slab. The hollow slab template for the buildings has the advantages of high rigidity, high bearing capacity, simple construction process, mechanical production and convenient control of construction quality.

Owner:吴方伯

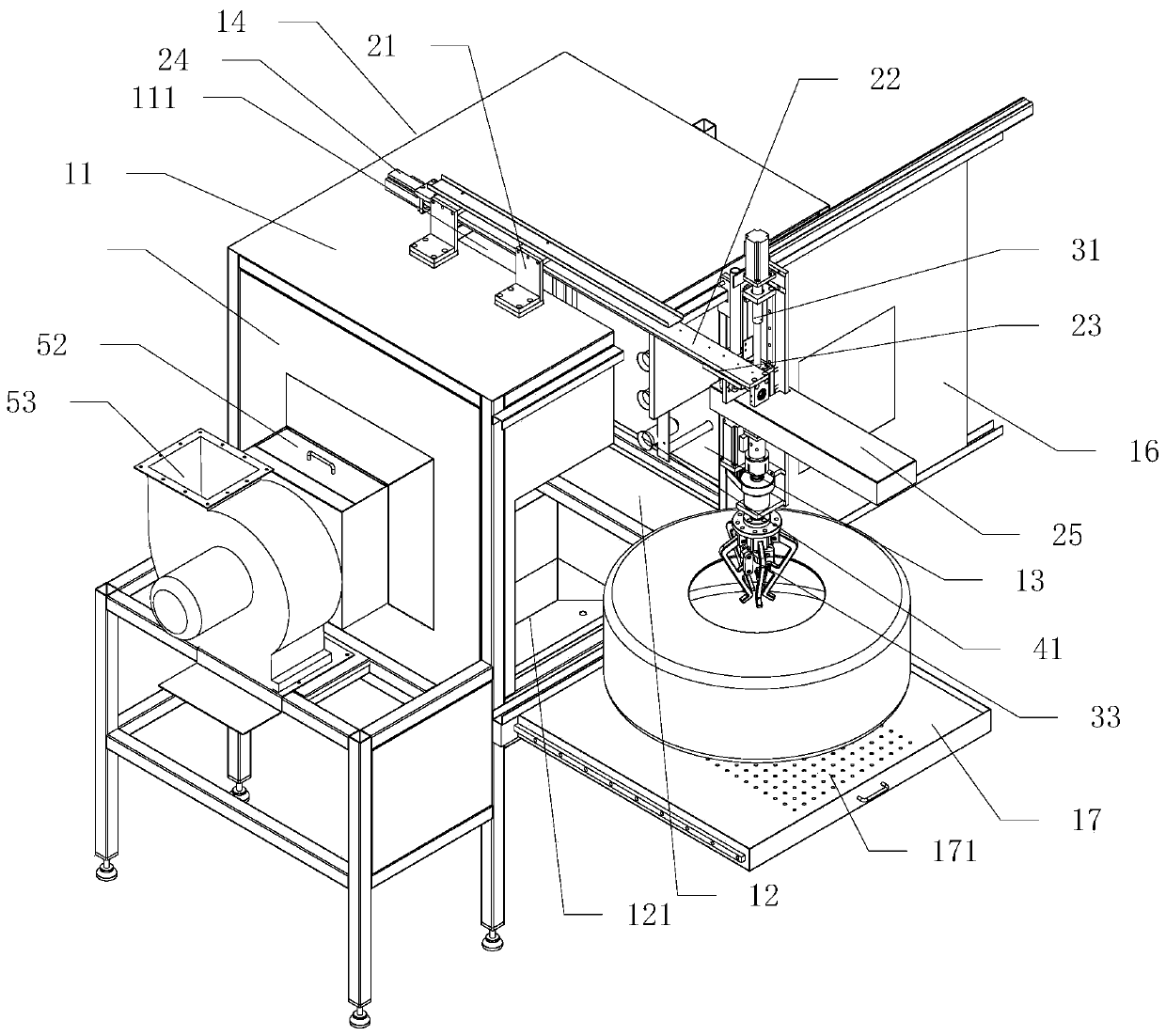

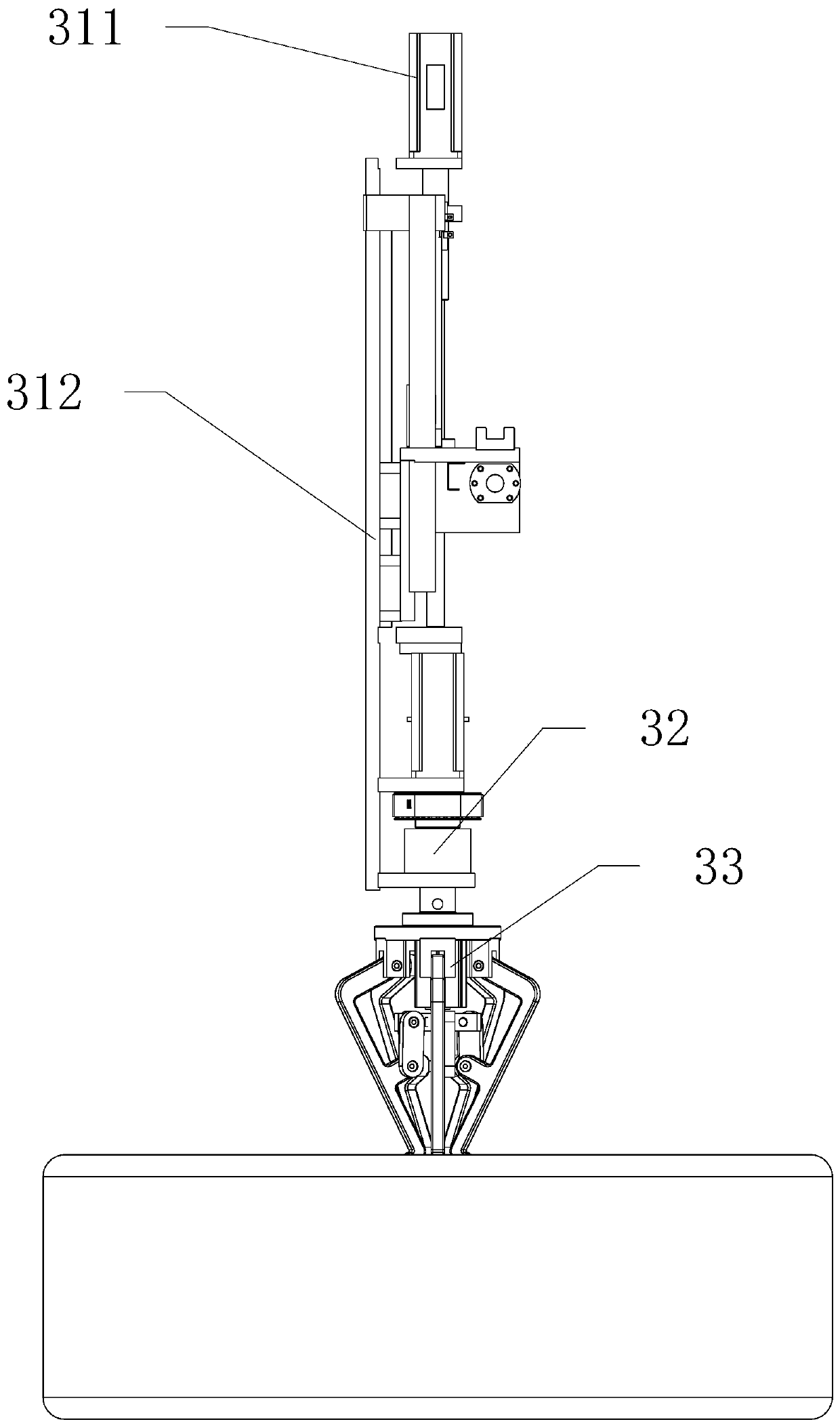

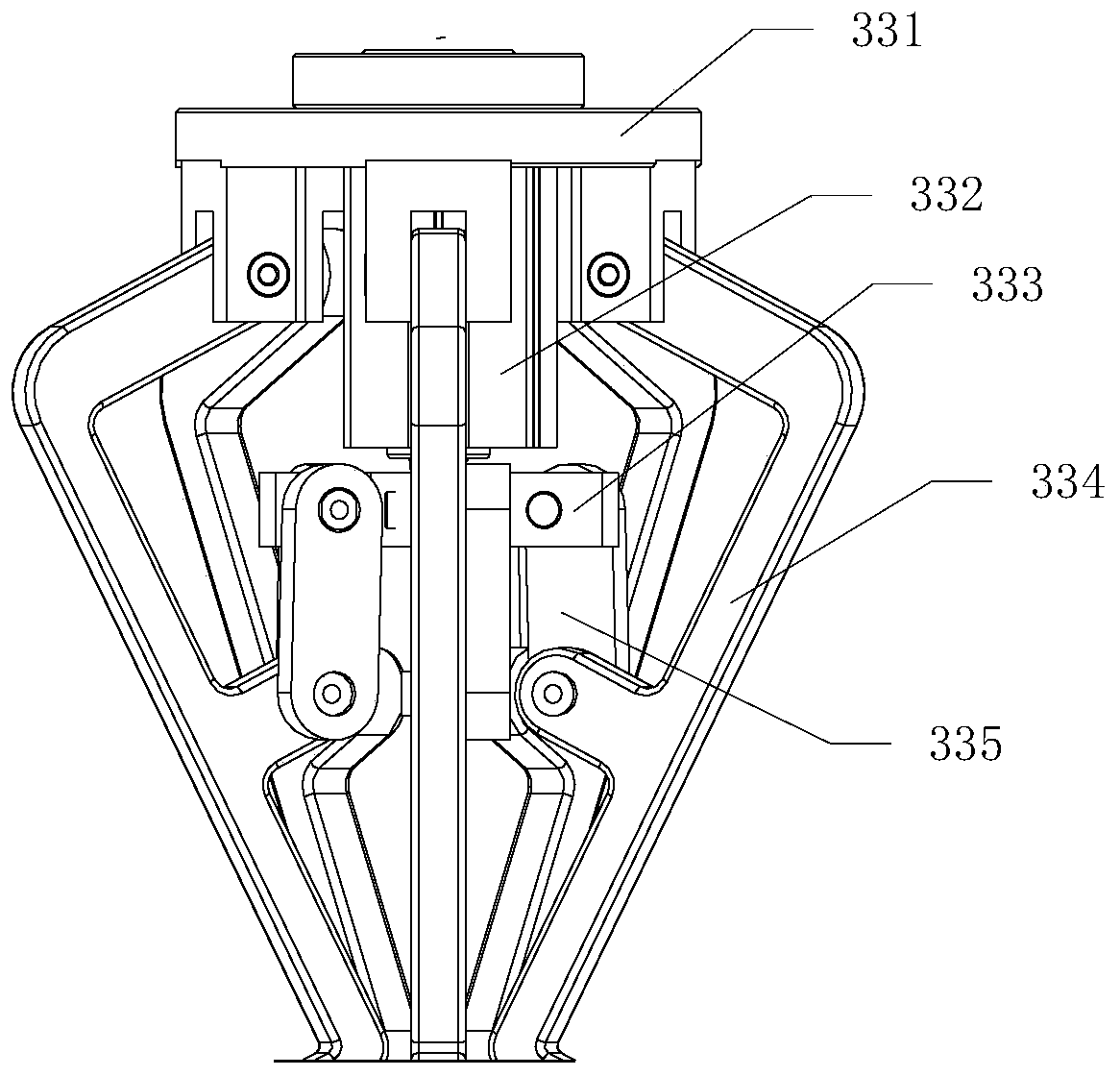

Tire bladder spray machine

PendingCN110000042AGood for recyclingRealize automatic sprayingSpray boothsSpray nozzleMechanical engineering

The invention belongs to the technical field of equipment for tire production, and particularly relates to a tire bladder spray machine. The tire bladder spray machine comprises a spraying room, a horizontal mechanism arranged above the spraying room, a supporting hook mechanism arranged on the horizontal mechanism, a spray nozzle system arranged on one side of the spraying room and a filtering and exhausting system arranged on the other side of the spraying room. According to the technical scheme, the automatic spraying of the tire bladder is realized through the arrangement of the spraying room, the horizontal mechanism, the supporting hook mechanism, the spray nozzle system and the filtering and exhausting system, the supporting hook mechanism is used in hoisting a tire bladder, the surface of the tire bladder is prevented from contacting as contacting can cause damage, the spraying process is controlled in the relatively closed spraying room, the external environment cannot be influenced, and recycling of spraying oil is facilitated; and problems of the safety, the environmental protection and energy saving in the tire bladder spraying process are completely solved.

Owner:SUZHOU UNIV OF SCI & TECH

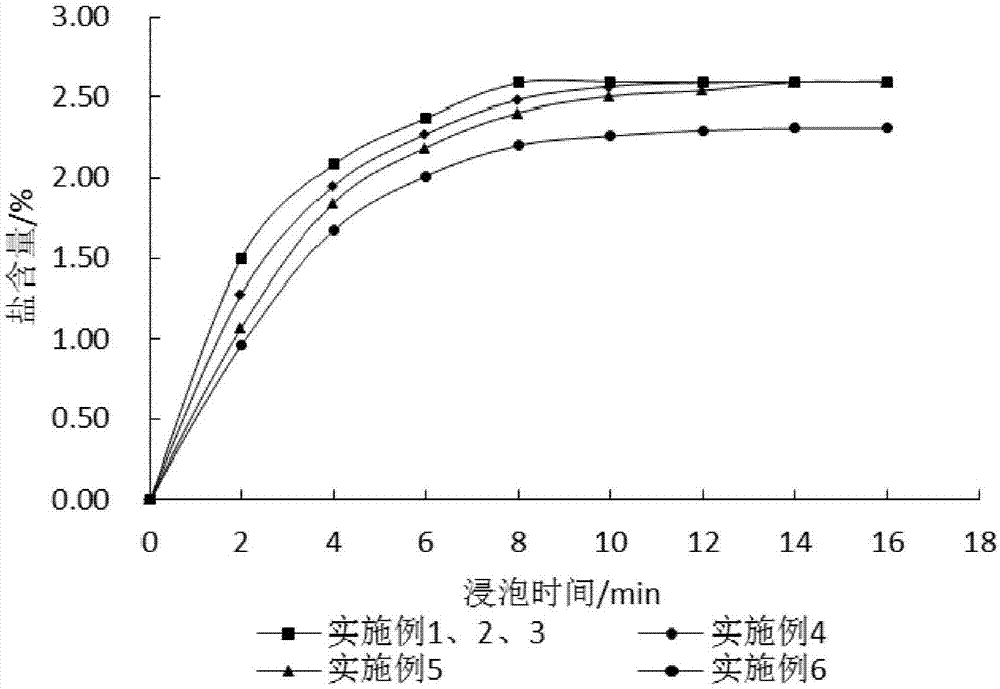

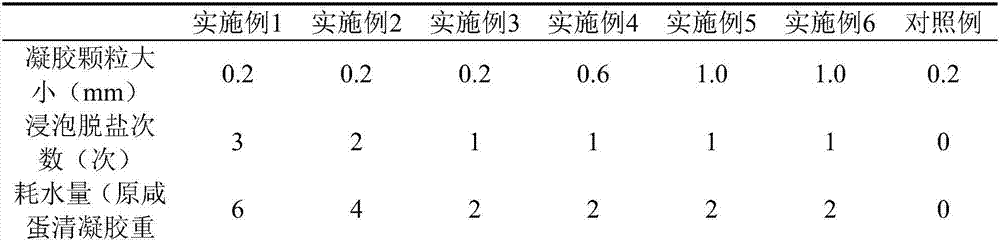

Desalting method for salted egg white

The invention discloses a desalting method for salted egg white and belongs to the technical field of deep-processing of poultry egg by-products. The desalting method includes the steps of: 1) performing thermal treatment to the salted egg white at 80-100 DEG C for 10-40 min to form gel; 2) with a stirrer, crushing the salted egg white gel into granules being 0.2-1.0 mm in size; 3) placing the salted egg white gel granules in a dehydrator with a filter bag so as to rapidly remove a part of water and salt in the gel granules through centrifugation; 4) soaking the dehydrated salted egg white gel granules in water, after soaking balance is rapidly reached, placing the gel granules into the dehydrator with the filter bag for performing centrifugation, and repeating the step 4) for 1-2 times to obtain desalted salted egg white gel granules. The desalting method has simple process and low demand on equipment, wherein water consumption is only 2-6 times of the weight of the salted egg white gel. The method is not less than 80% in desalting rate and is not less than 86% in protein retention rate.

Owner:SOUTH CHINA UNIV OF TECH +1

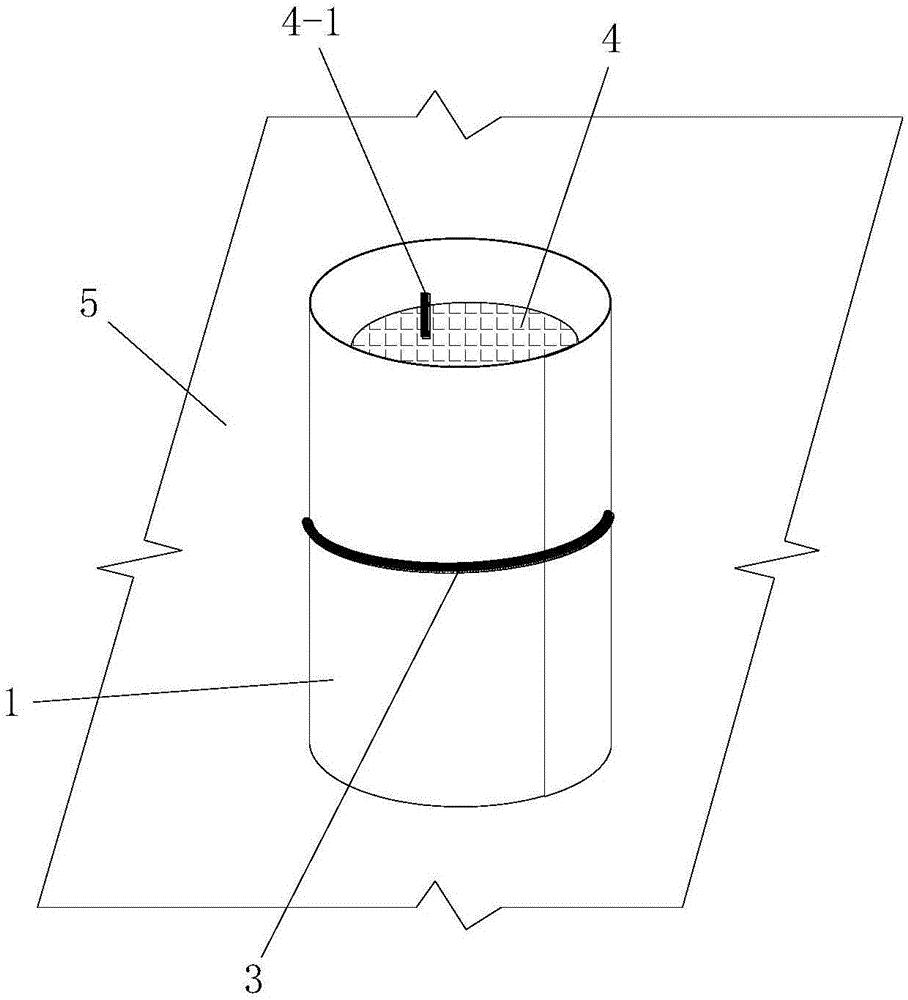

Inflatable adjustable type construction mold for reserved hole in concrete structure plate, and construction method

InactiveCN106049862ASimple structureEasy to processForms/shuttering/falseworksStructural engineeringBuilding construction

The invention discloses an inflatable adjustable type construction mold for a reserved hole in a concrete structure plate, and a construction method. The mold comprises a cylinder formed by rolling of a rectangular iron sheet, a circular cover plate for plugging an upper end opening of the cylinder, and an inflatable air bag placed in the cylinder, wherein the cylinder is vertically arranged, and the outer diameter of the cylinder is the same as the hole diameter of the reserved hole needing to be constructed in the concrete structure plate; the inflatable air bag is a cylindrical air bag, and the inflatable air bag and the cylinder are coaxially arranged; and the bottom of the cylinder is supported on a shaping template of the concrete structure plate, the cylinder and the circular cover plate form an outer sleeve, and an outer sleeve fixing piece for fixing the outer sleeve is arranged on the shaping template. The construction method comprises the following steps of I, erecting the shaping template; II, performing measurement and paying-off; III, mounting the mold; IV, casting concrete; and V, dismantling the mold. The inflatable adjustable type construction mold disclosed by the invention is reasonable in design, simple and convenient to mount and dismantle, and good in use effects; after concrete is finally coagulated, the mold is dismantled, so that the quality of the constructed and shaped reserved hole can be effectively guaranteed, and the accuracy of the position of the reserved hole can be guaranteed.

Owner:THE TENTH CONSTR OF SHANXI CONSTR ENG GROUP OPERATE FUNCTION

Anode slurry binding agent used for lithium ion batteries

InactiveCN106571469AImprove adhesionGood effectCell electrodesSecondary cells servicing/maintenancePolyvinyl alcoholSlurry

The invention belongs to the technical field of lithium ion battery manufacturing, and discloses an anode slurry binding agent used for lithium ion batteries. The anode slurry binding agent is prepared from raw materials including polyvinyl alcohol, polyacrylic acid, sodium carboxymethylcellulose, sodium alginate, and a binding agent additive; the binding agent additive is prepared from polyvinylidene fluoride, Ketjen black, and polymethyl acrylate. The anode slurry binding agent possesses excellent binding performance, is capable of realizing better and more uniform binding of anode active materials, is suitable for batteries with requirements on higher cycling performance, and is capable of improving safety performance of anode slurry, realizing automatic stop of exothermic reaction of assembled lithium ion batteries at high temperature, and ensuring the safety of lithium ion batteries in applications.

Owner:长兴天晟能源科技有限公司

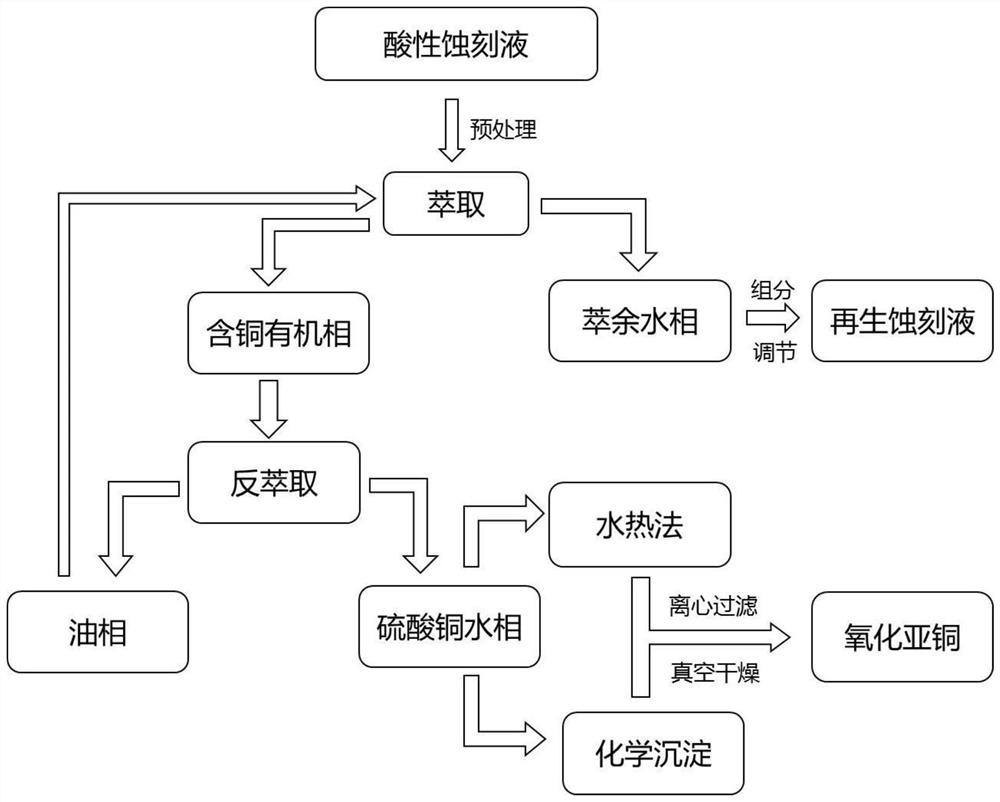

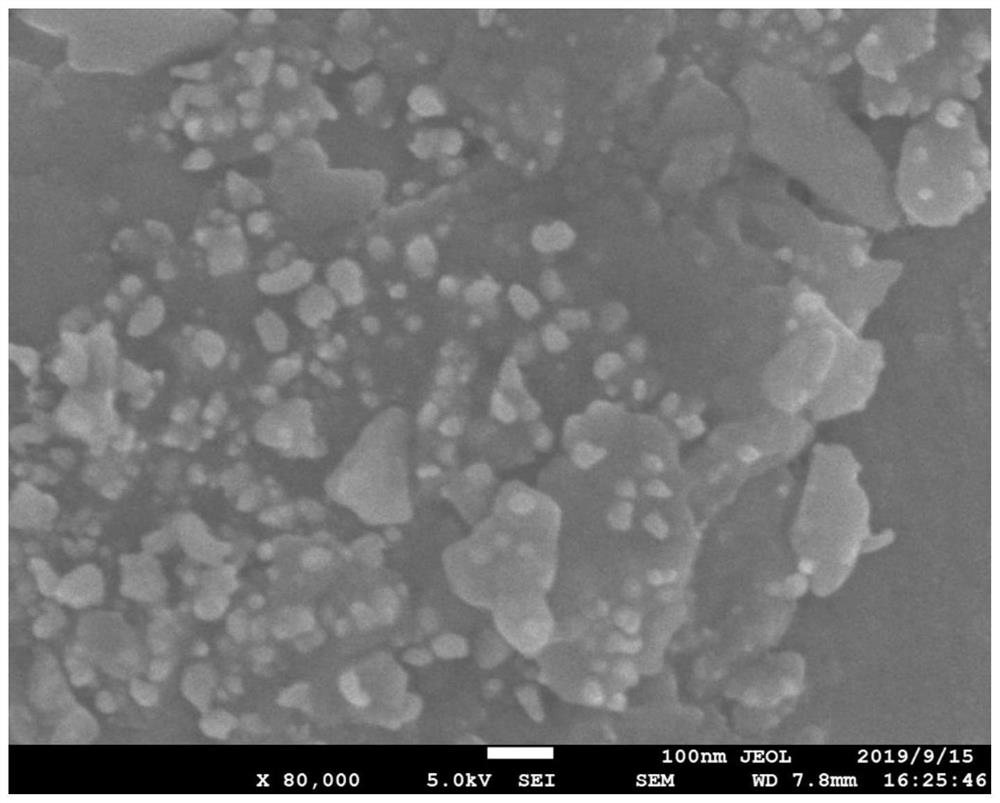

Method for recovering copper from acidic copper-containing etching solution and preparing cuprous oxide

InactiveCN111635994AEasy to handleAvoid pollutionRotary drum furnacesCrucible furnacesPhysical chemistrySulfuric acid

The invention discloses a method for recovering copper from an acidic copper-containing etching solution and preparing cuprous oxide. The method comprises the following steps of: S1, filtering the acidic copper-containing etching solution to obtain a crude copper-containing solution; S2, adjusting the pH of the crude copper-containing solution to 2-4, adding an extractant, mixing and stirring, standing for layering, wherein the upper layer is a primary copper-containing organic phase, and the lower layer is a primary water phase; recovering the primary water phase for an etching production line; S3, washing the copper-containing organic phase with deionized water, and separating to obtain a secondary copper-containing organic phase and a primary washing water phase; S4, adding sulfuric acid into the secondary copper-containing organic phase, fully stirring, standing for layering, wherein the upper layer is an extractant-containing organic phase, and the lower layer is a CuSO 4-containing water phase; S5, adding the primary washing water phase into the extractant-containing organic phase, washing, standing for layering to obtain a pure extractant organic phase for use in the step S2; and S6, preparing cuprous oxide from the CuSO 4-containing water phase by a hydrothermal method or a chemical precipitation method.

Owner:SICHUAN UNIV

NiMoW/MCM-41 composite catalyst for hydrodeoxygenation of octanoic acid and preparation and application thereof

InactiveCN110227536AGood catalytic activityImprove stabilityMolecular sieve catalystsHydrocarbonsTungstenNickel

The invention relates to a NiMoW / MCM-41 composite catalyst for hydrodeoxygenation of octanoic acid, a preparation and an application thereof. The NiMoW / MCM-41 composite catalyst comprises MCM-41 molecular sieve and active metal elements such as nickel, molybdenum and tungsten supported on the molecular sieve, wherein the loading amount of tungsten is 1wt%-15wt% of the mass of the carrier, and theratio of the loading amount of other metals to the mass of tungsten is 1:5-1:1. As that catalyst is prepared by adopting a co-impregnation method, the preparation method is simple, the reproducibilityis good, and the catalyst has high activity and stability; when the catalyst is used for hydrodeoxygenation of octanoic acid, under the conditions of 270 DEG C, hydrogen initial pressure of 3MPa andreaction time of 7h, the conversion of octanoic acid is 97.1%, and the selectivity of octane in the product distribution is 72.0% and the practical meaning is obtained.

Owner:SOUTHEAST UNIV

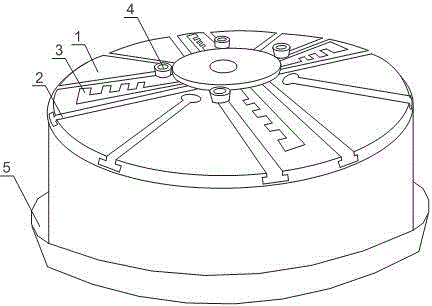

Lathe turntable with oil collecting function

InactiveCN104416371AEasy to cleanGood for recyclingLarge fixed membersPositioning apparatusScrapMachine tool

The invention discloses a lathe turntable with an oil collecting function. The lathe turntable comprises a workbench and a rotating shaft, wherein the rotating shaft is arranged at the center of the workbench; the workbench is provided with multiple groups of combined grooves; each combined groove comprises three T-shaped grooves and a tooth-shaped groove which are sequentially arranged; the directions of the T-shaped grooves and the tooth-shaped grooves are superposed with the radial direction of the workbench; the lathe turntable also comprises press bolts slidably arranged on the combined grooves and multiple shock absorbers arranged at the lower part of the workbench; a scrap baffle is arranged at the periphery of the workbench; an oil collecting groove is formed between the bottom of the scrap baffle and the bottom of the workbench. Sweeps intercepted by the scrap baffle and engine oil or other liquid substances left on the workbench can be intensively collected by the oil collecting groove formed between the bottom of the scrap baffle and the bottom of the workbench, so that the turntable can be conveniently cleaned, wastes can be favorably recycled, the production cost is lowered, and the working strength of working personnel in a process of lathe cleaning can be alleviated.

Owner:张丹

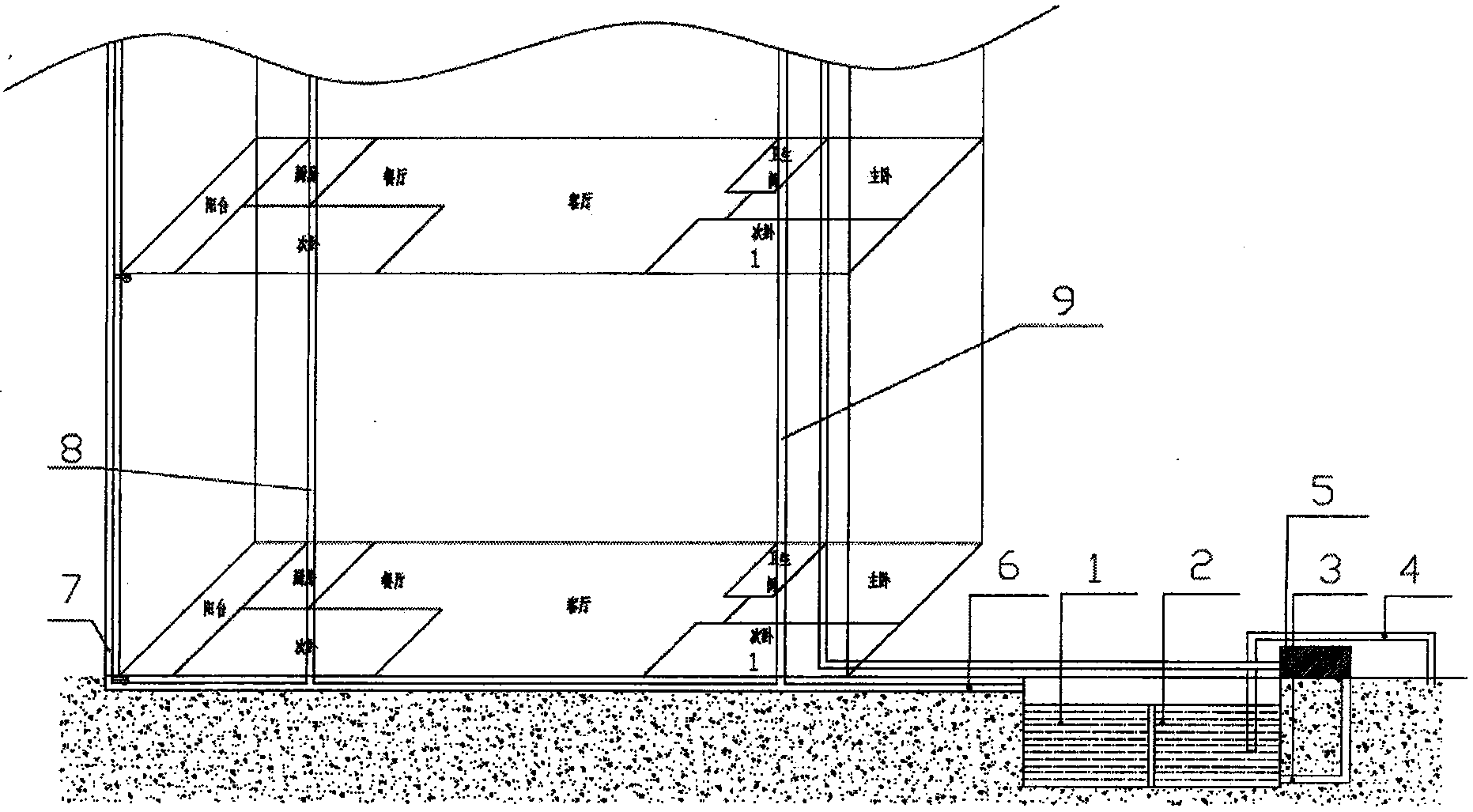

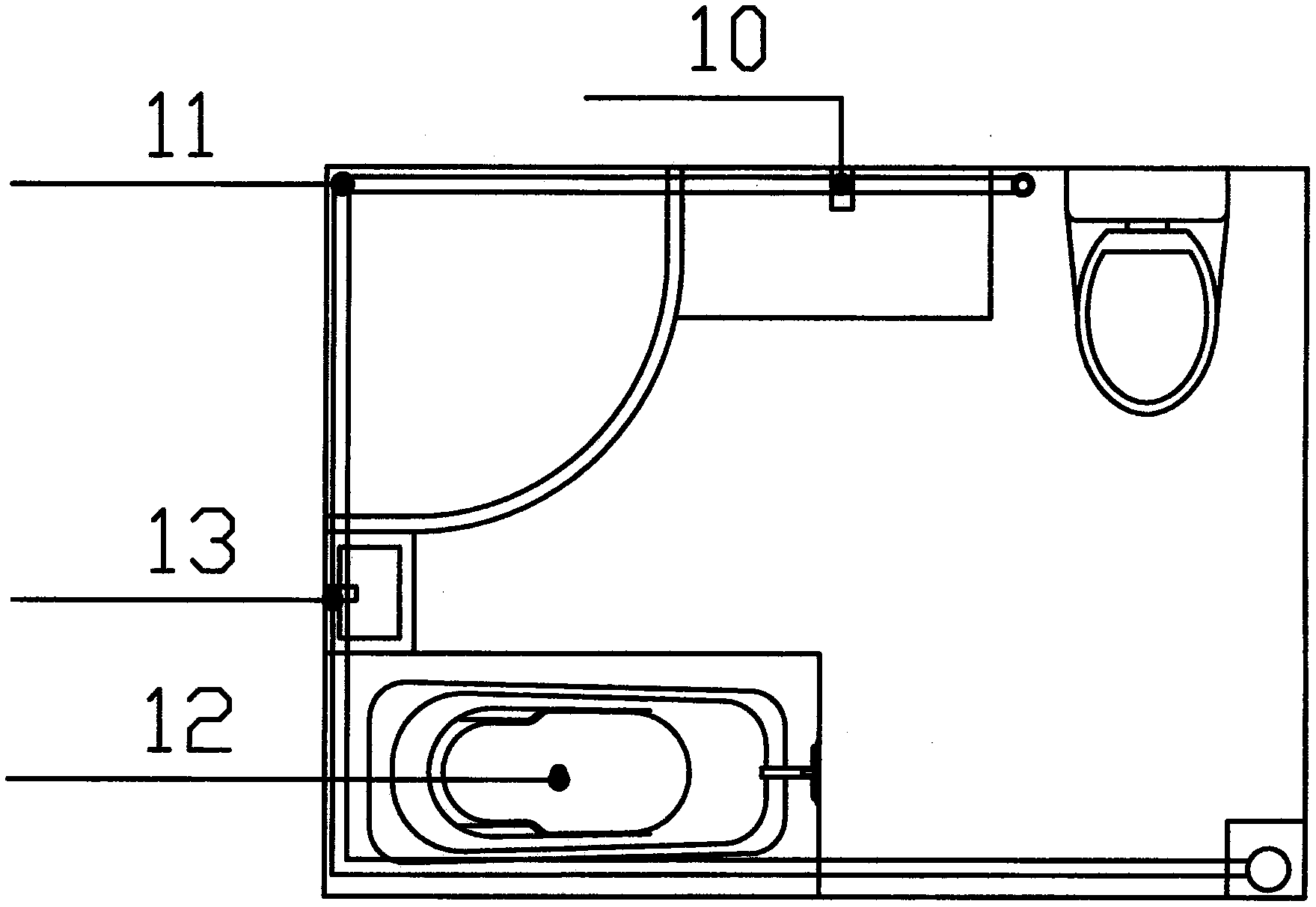

Device for recycling rainwater and domestic water in whole building

InactiveCN104047329AGood for recyclingSave tap water, that is, drinking water resourcesDomestic plumbingWater supply installationPipingWater delivery

The invention discloses a device for recycling rainwater and domestic water in a whole building. The device comprises a sewage treatment tank, a clear water reservoir, a water inlet pipe, a tap water supply pipeline and a booster pump, wherein the sewage treatment tank is connected with a rainwater pipe, a kitchen wastewater pipe and a toilet sewage pipe which are arranged in the building through a sewage main pipe; the clear water reservoir is connected with the sewage treatment tank through a purification device; one end of the water inlet pipe is communicated with the bottom side of the clear water reservoir, and the other end of the water inlet pipe is connected with a water suction hole of the booster pump; a water outlet is connected with a water delivery main pipe; the water delivery main pipe is connected with a toilet water container at each floor; the tap water supply pipeline is also connected with the clear water reservoir. The device for recycling rainwater and domestic water in the whole building is beneficial for recycling water resources, and saving tap water, namely a drinking water resource.

Owner:贺清集团有限公司

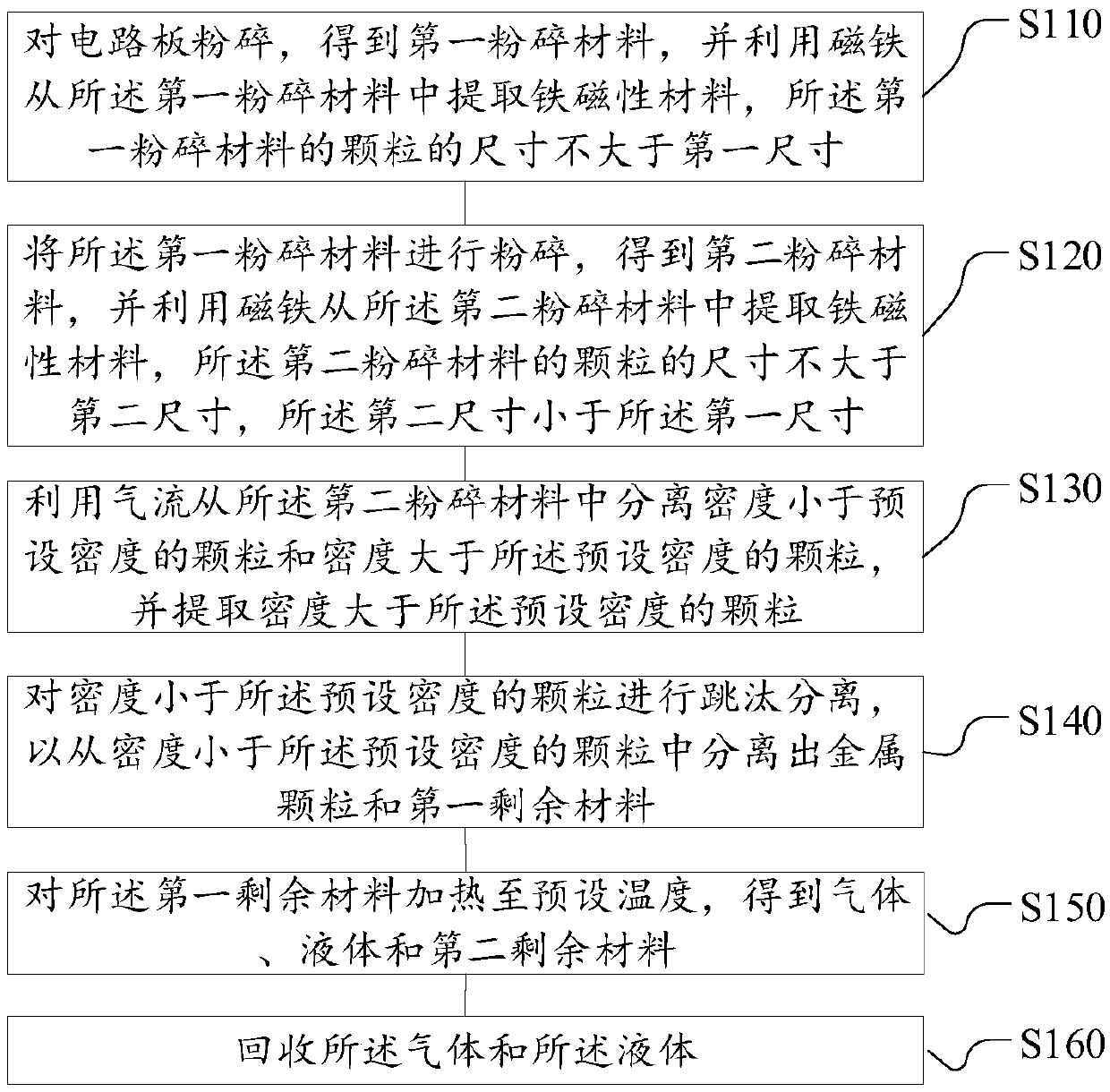

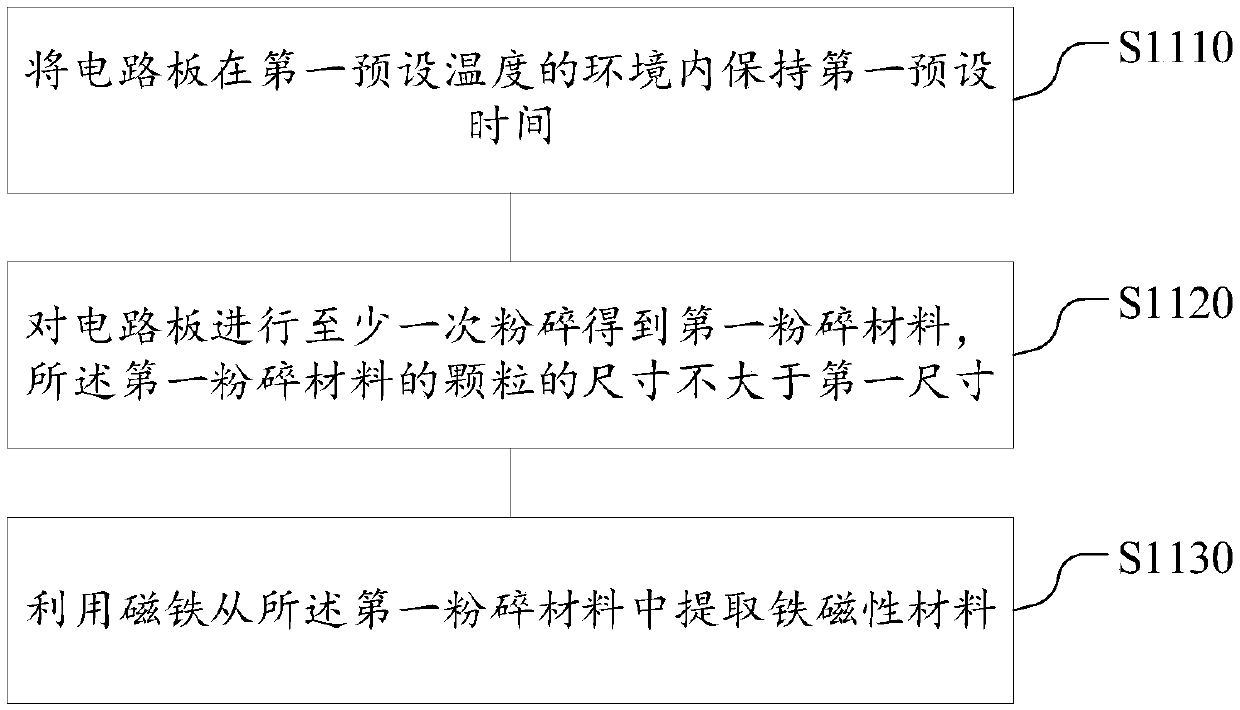

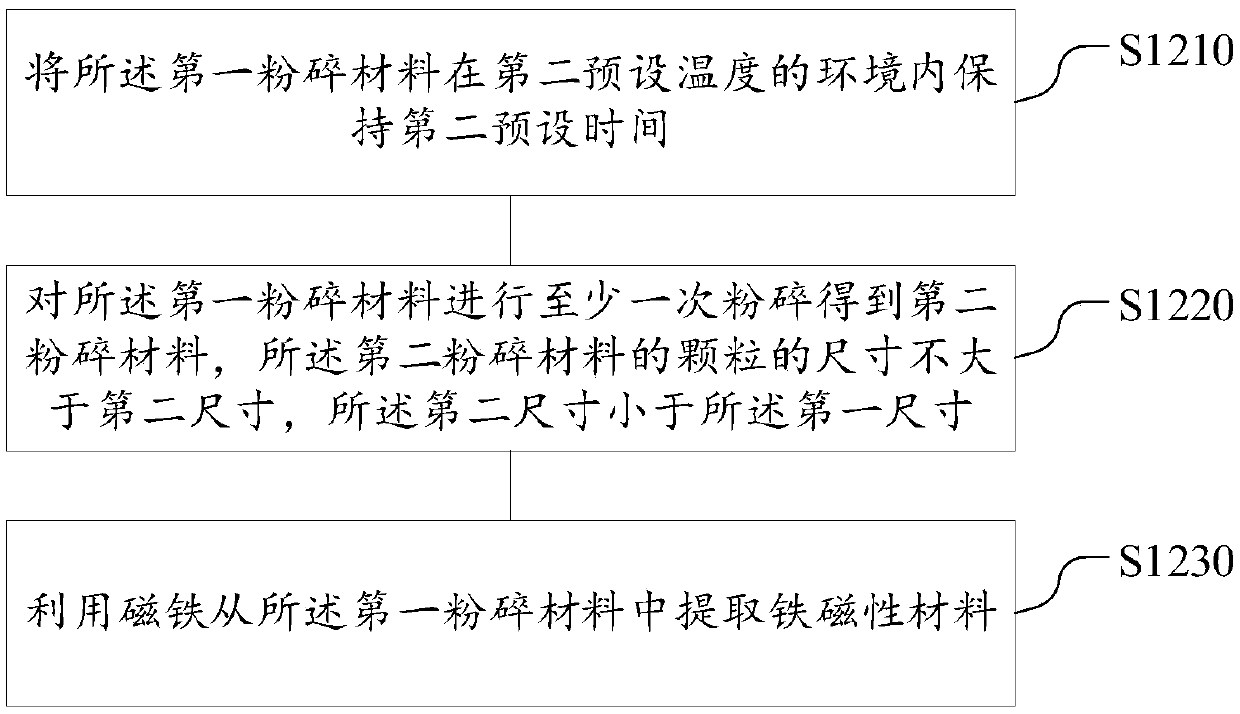

Circuit board recovery method

The invention provides a circuit board recovery method, and relates to the technical field of circuit board recovery. The method comprises the steps of crushing circuit boards so as to obtain first crushing materials, and extracting ferromagnetic materials from the first crushing materials by utilizing a magnet, wherein the particle size of the first crushing materials is not larger than the firstsize; crushing the first crushing materials so as to obtain second crushing materials, and extracting ferromagnetic materials from the second crushing materials by utilizing the magnet, wherein the particle size of the second crushing materials is not larger than the second size; extracting particles of which the density is larger than the preset density with particles of which the air separationdensity is less than the preset density and particles of which the density is larger than the preset density; jigging and separating the particles of which the density is less than the preset density, and separating metal particles and first surplus materials from the particles of which the density is less than the preset density; and heating the first surplus materials to the preset temperatureso as to obtain gas, liquid and second surplus materials, and recovering the gas and the liquid. According to the circuit board recovery method disclosed by the invention, the waste of resources and environmental pollution can be avoided.

Owner:CHINA ENFI ENGINEERING CORPORATION

Method for catalytic synthesis of glycine in homogeneous system

ActiveCN108558687AHigh catalytic efficiencyGood for recyclingOrganic compound preparationAmino-carboxyl compound preparationSolventCatalytic efficiency

The invention discloses a method for catalytic synthesis of glycine in a homogeneous system. Chloroacetic acid and ammonia gas are used as raw materials, an ammonolysis reaction is carried out in thepresence of a substituted pyridine catalyst and a solvent, and glycine and ammonium chloride are obtained from the reaction liquid obtained through the ammonolysis reaction after filtrating, washing and other operations. In the method provided by the invention, the reaction system adopts a homogeneous system of alcohol and uses substituted pyridine as a catalyst, so that the problems of low catalytic efficiency of urotropine, easy loss of catalyst, serious side reactions and the like can be effectively solved; and the method has the advantages of high conversion rate, easy purification of products, difficult loss of the catalyst and recycle utilization, reduces the production cost, reduces pollution, and has a high practical value.

Owner:SICHUAN FOURSTAR BIOTECH RANDD CORP

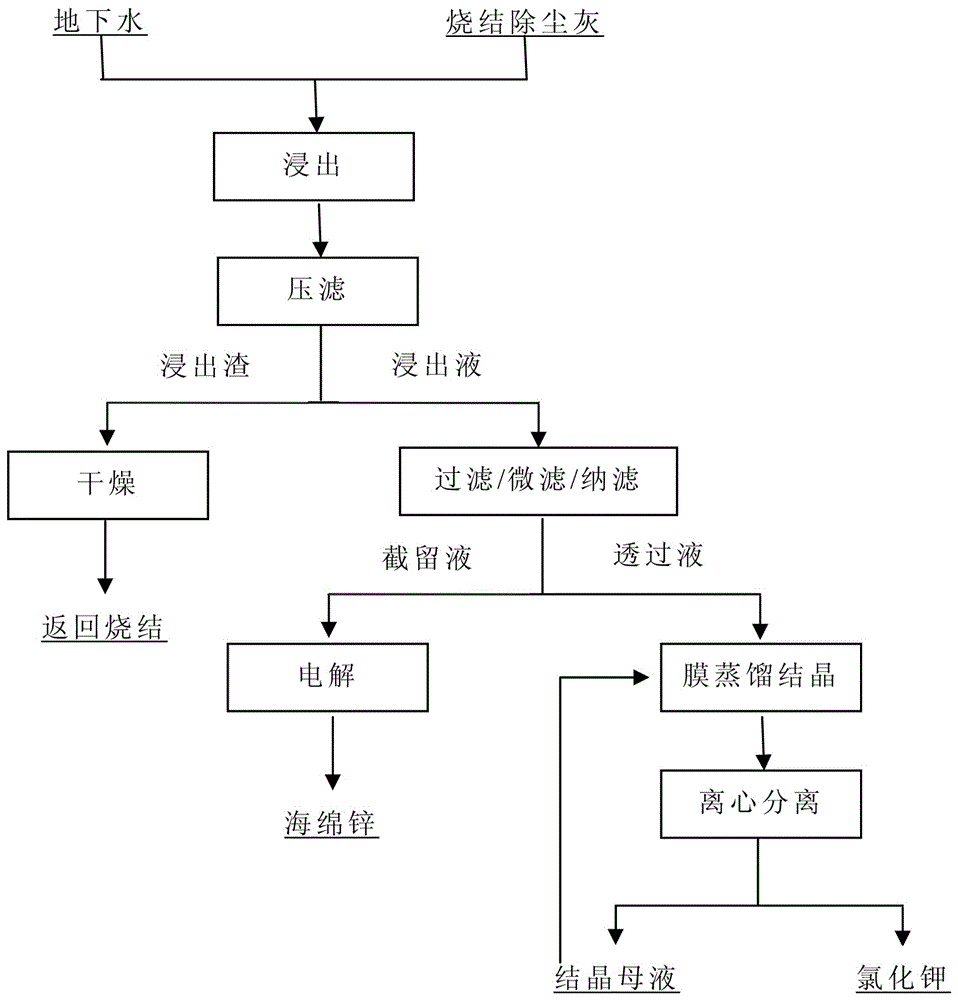

Method for extracting potassium chloride from sintering dust in iron and steel enterprises

The invention discloses a method for extracting potassium chloride from sintering dust in iron and steel enterprises. The method comprises the following steps: fully stirring a leaching solution and sintering dust under normal temperature and normal pressure conditions for 0.5-1 hour, conveying the formed slurry to a mechanical filter pressing unit after completion of leaching, performing solid-liquid separation on the slurry through the mechanical filter pressing unit, drying the leaching residues, returning to a sintering process, leaching the leaching solution again, allowing the leaching solution to enter a membrane process impurity removal unit, conveying the leaching solution to a quartz sand filter through a pump, filtering to remove particles in the liquid, performing micro-filtration treatment, and removing colloid in the liquid; finally, realizing separation of multivalent metallic impurities and potassium through nanofiltration, so as to obtain a refined potassium-containing pregnant solution, allowing the refined potassium-containing pregnant solution to enter a membrane distillation and crystallization unit, concentrating the potassium-containing pregnant solution by utilizing a low-temperature heat source of the iron and steel enterprises, cooling, so as to obtain a potassium chloride crystal. The method disclosed by the invention is simple in process, high in degree of automation and low in energy consumption, wastewater emission is avoided, and comprehensive utilization of harmful solid wastes in the iron and steel enterprises is realized.

Owner:WUHAN GREAT SEA HI TECH

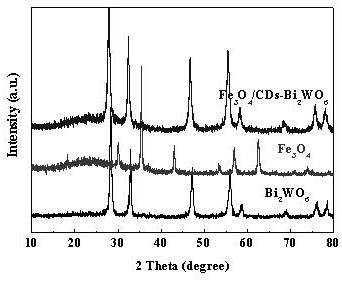

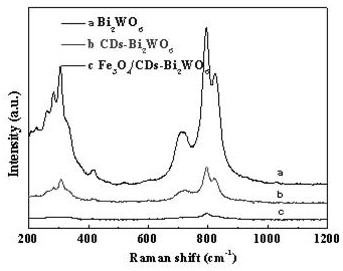

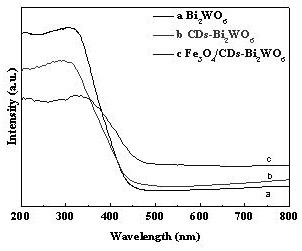

Preparation method and application of corncob biomass carbon dot composite Bi2WO6 photocatalyst based on magnetic Fe3O4 modification

PendingCN112108150AGood for recyclingAvoid wastingWater/sewage treatment by irradiationWater treatment compoundsPhotocatalytic degradationPhoto catalysis

The invention belongs to the technical field of chemical preparation of environmental materials, and particularly relates to a preparation method and application of a corncob biomass carbon dot composite Bi2WO6 photocatalyst based on magnetic Fe3O4 modification. The method comprises the following steps: step 1, treating a corncob precursor; step 2, preparing biomass carbon dots (CDs); step 3, preparing Bi2WO6; step 4, preparing Fe3O4; step 5, preparing CDs / Bi2WO6; and step 6, adding the CDs / Bi2WO6 obtained in the step 5 into the Fe3O4 nanosphere precursor solution obtained in the step 4, conducting heating in a polytetrafluoroethylene reaction kettle, washing the obtained product with ethanol and deionized water, and conducting drying for later use. The magnetic Fe3O4 modified corncob biomass carbon dot composite Bi2WO6 photocatalyst prepared by the method is used for photocatalytic degradation of tetracycline. The corncobs are applied to preparation of biomass carbon dots, so that waste is turned into wealth; and Fe3O4 is used as a composite material to prepare the composite photocatalyst, so that the catalyst can be recycled and reused, and the waste of resources is avoided. Thephotocatalyst has excellent photocatalytic activity and stability.

Owner:TONGHUA NORMAL UNIV

Hollow floorslab template for building

InactiveCN102003068ALight weightIncrease flexibilityForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksFloor slabHollow core

The invention discloses a hollow floorslab template for building, which comprises modules (1), angle molds (2), bolts (3) or latches, and a prefabricated bottom plate (9), wherein one or more holes (4) are arranged on the end parts of each module (1); four or more than four bolts (3) or latches are arranged on the angle molds (2); and the modules (1) and the angle molds (2) are connected in the position of the holes (4) through the bolts (3) or the latches. The hollow floorslab template comprises two or more than two modules (1) which are connected through the angle molds (2), and when in construction, the prefabricated bottom plate (9) is arranged on the top of the top-layer module to form the integral hollow floorslab template after the multiple modules (1) are connected with the angle molds (2) . The hollow floorslab template for the building has the advantages of large rigidity, high bearing capacity, long service life, simple construction procedures, and convenience in mold disassembly; and the modules (1) can be produced in a mechanized way, and the control of the construction quality is convenient.

Owner:吴方伯

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com