Absorbent for selectively absorbing sulfur dioxide and application thereof

A sulfur dioxide and absorbent technology, which is applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problem that the absorption rate cannot be maintained at a high level for a long time, which is not conducive to the subsequent utilization of regenerated acid gas, and the increase in solvent circulation and other issues, to achieve the effect of being conducive to recycling, anti-oxidation ability, not easy to foam, and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

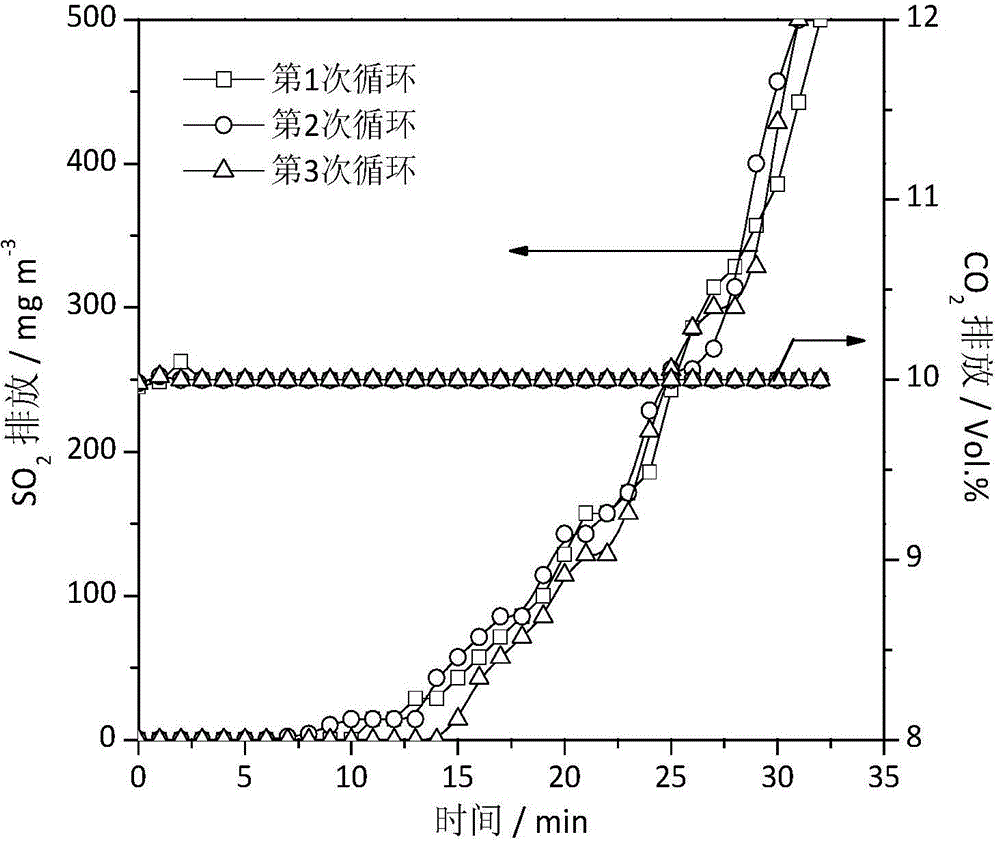

[0060] This embodiment provides a kind of SO of the present invention 2 Absorbent, and evaluate its selectivity and regeneration performance.

[0061] The composition of the absorbent is as follows:

[0062] N,N,N,N-Tetramethylethylenediamine, 10% by mass;

[0063] Piperazine, mass percent 15%;

[0064] The total molar ratio of sulfuric acid to N,N,N,N-tetramethylethylenediamine and piperazine is (0.5~0.6):1;

[0065] Hydroquinone, mass percent 0.2%;

[0066] Ethylenediamine, 5% by mass;

[0067] water, balance.

[0068] The SO 2 The initial pH value of the absorbent is 4.5-6.0.

[0069] Absorb SO 2 operating conditions:

[0070] Temperature: 50°C, Pressure: absolute pressure 0.1MPa,

[0071] Mixture composition: SO 2 2.0Vol% (volume percent, the same below), CO 2 10.0Vol%, O 2 3.0Vol%;

[0072] Volume flow rate 300mL / min;

[0073] Absorbent dosage 50mL.

[0074] Regenerated SO 2 operating conditions:

[0075] Temperature: 100°C, pressure: absolute pressure 0...

Embodiment 2

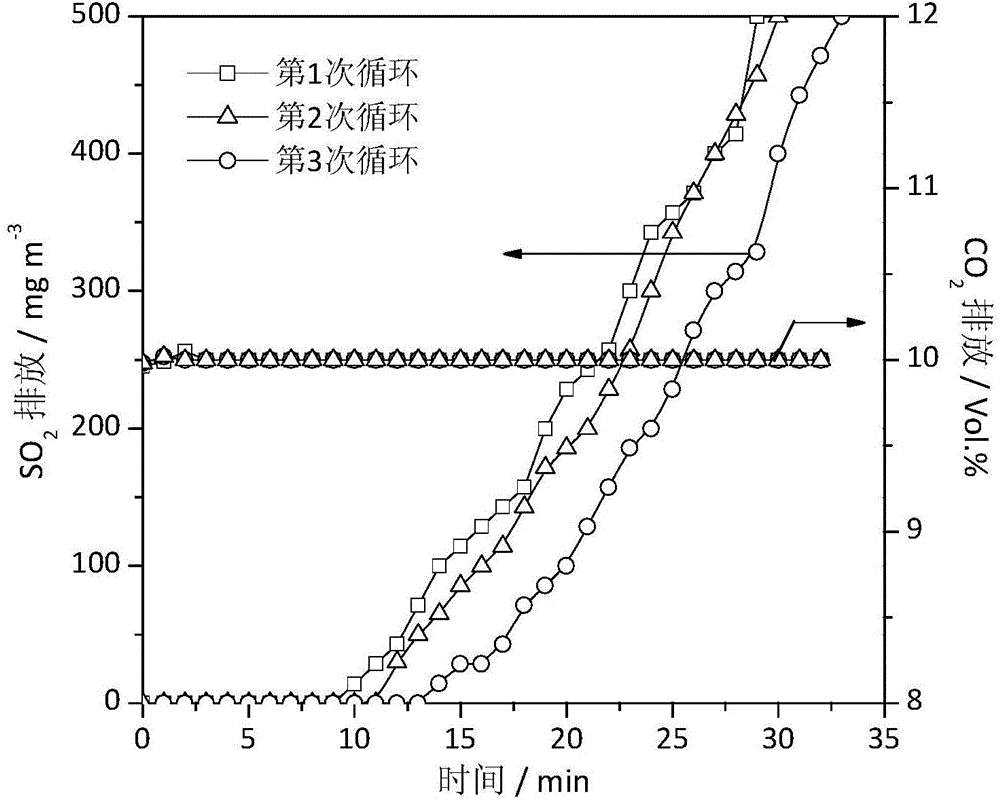

[0081] This embodiment provides a kind of SO of the present invention 2 Absorbent, and evaluate its selectivity and regeneration performance.

[0082] The composition of the absorbent is as follows:

[0083] N,N,N,N-Tetrahydroxyethylethylenediamine, 10% by mass;

[0084] Piperazine, 15% by mass

[0085] The total molar ratio of sulfuric acid to N,N,N,N-tetramethylethylenediamine and piperazine is (0.5~0.6):1;

[0086] Hydroquinone, mass percentage 0.1%;

[0087] Ethylenediamine, 3% by mass;

[0088] water, balance.

[0089] The SO 2 The initial pH value of the absorbent is 4.5-6.0.

[0090] Absorb SO 2 operating conditions:

[0091] Temperature: 60°C, Pressure: absolute pressure 0.1MPa,

[0092] Mixture composition: SO 2 2.0Vol% (volume percent, the same below), CO 2 10.0Vol%, O 2 3.0Vol%;

[0093] Volume flow rate 300mL / min,

[0094] Absorbent dosage 50mL.

[0095] Regenerated SO 2 Operating conditions:

[0096] Temperature: 100°C, pressure: absolute pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com