Method for extracting potassium chloride from sintering dust in iron and steel enterprises

A potassium chloride, enterprise technology, applied in the direction of alkali metal chloride, etc., can solve the problems of long operation process, low recovery rate, secondary pollution, etc., and achieve the effects of being conducive to recovery, less impurity metal elements, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

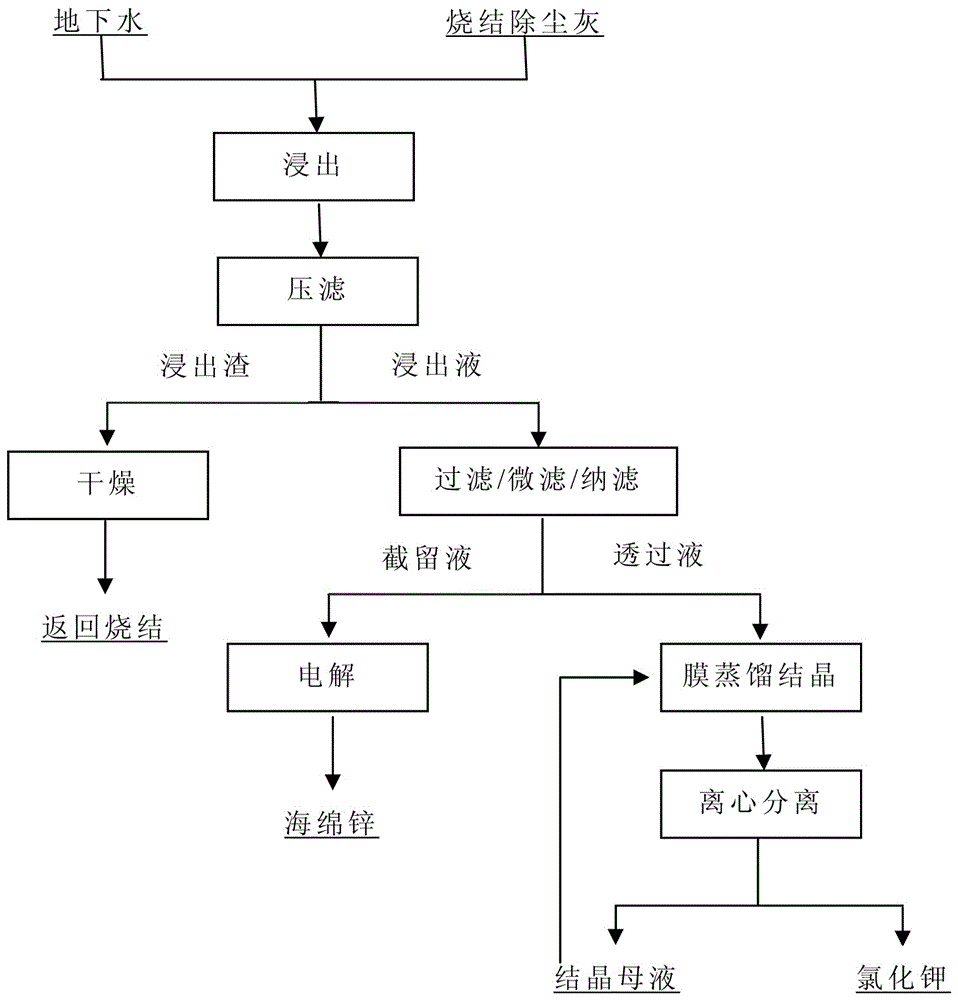

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0020] refer to figure 1 As shown, the invention discloses a method for extracting potassium chloride from sintering dust of iron and steel enterprises, comprising the following steps

[0021] a) Leaching: Fully stir groundwater with a liquid-solid ratio of 3:1-2:1 and sintering dust for 0.5-1h under normal temperature and pressure conditions, and the leaching rate can reach more than 95%. After the leaching is completed, the formed slurry sent to the mechanical filter press unit.

[0022] b) Mechanical filter press: The mechanical press filter unit separates the slurry from solid to liquid, the leached residue is dried and then returned to the sintering process, the leachate is leached again, and the leachate enters the membrane impurity removal unit, and the leachate contains a small amount of impurity metal ions, such as Fe 3+ , Ca 2+ , Mg 2+ , Zn 2+ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com