Patents

Literature

969 results about "Membrane distillation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

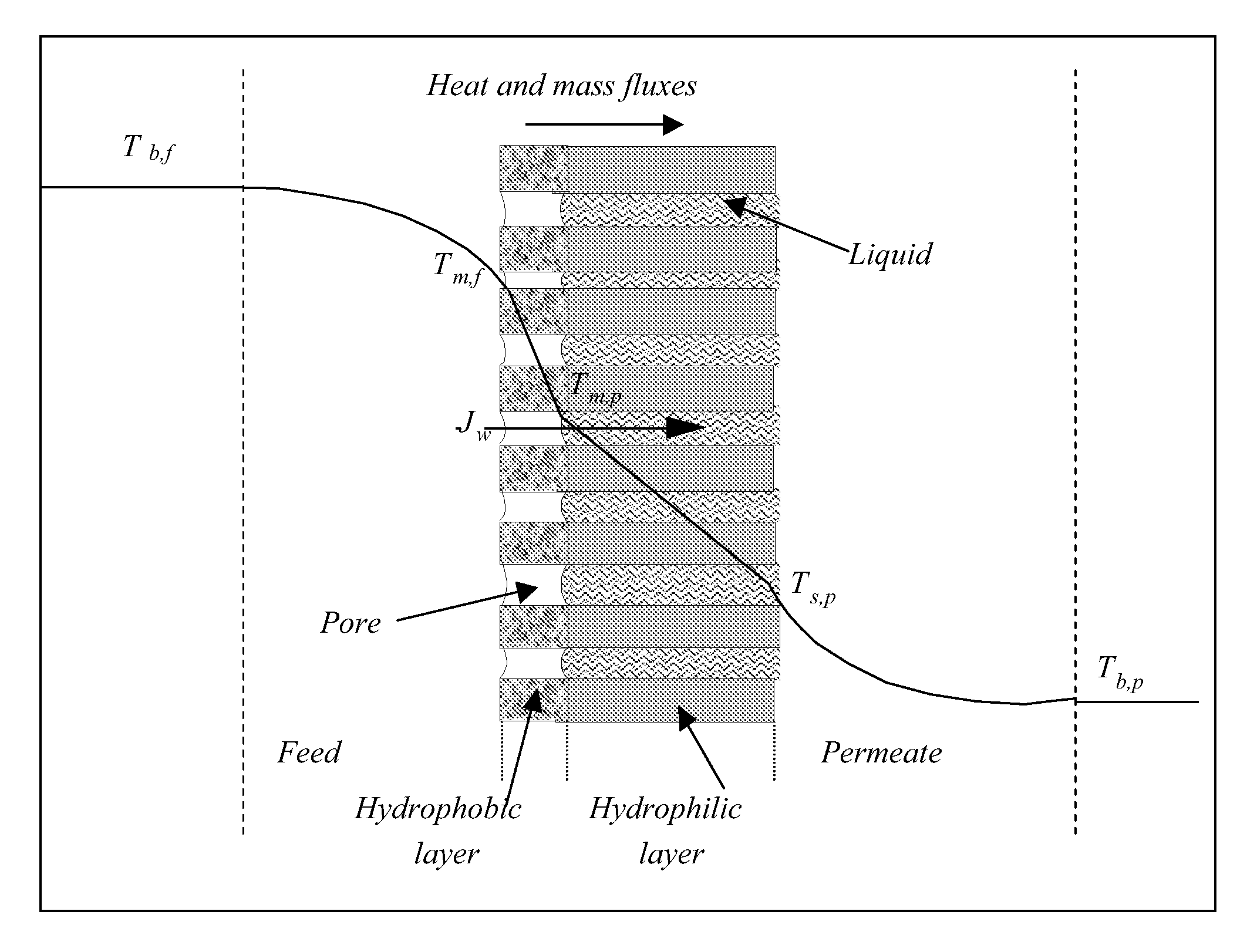

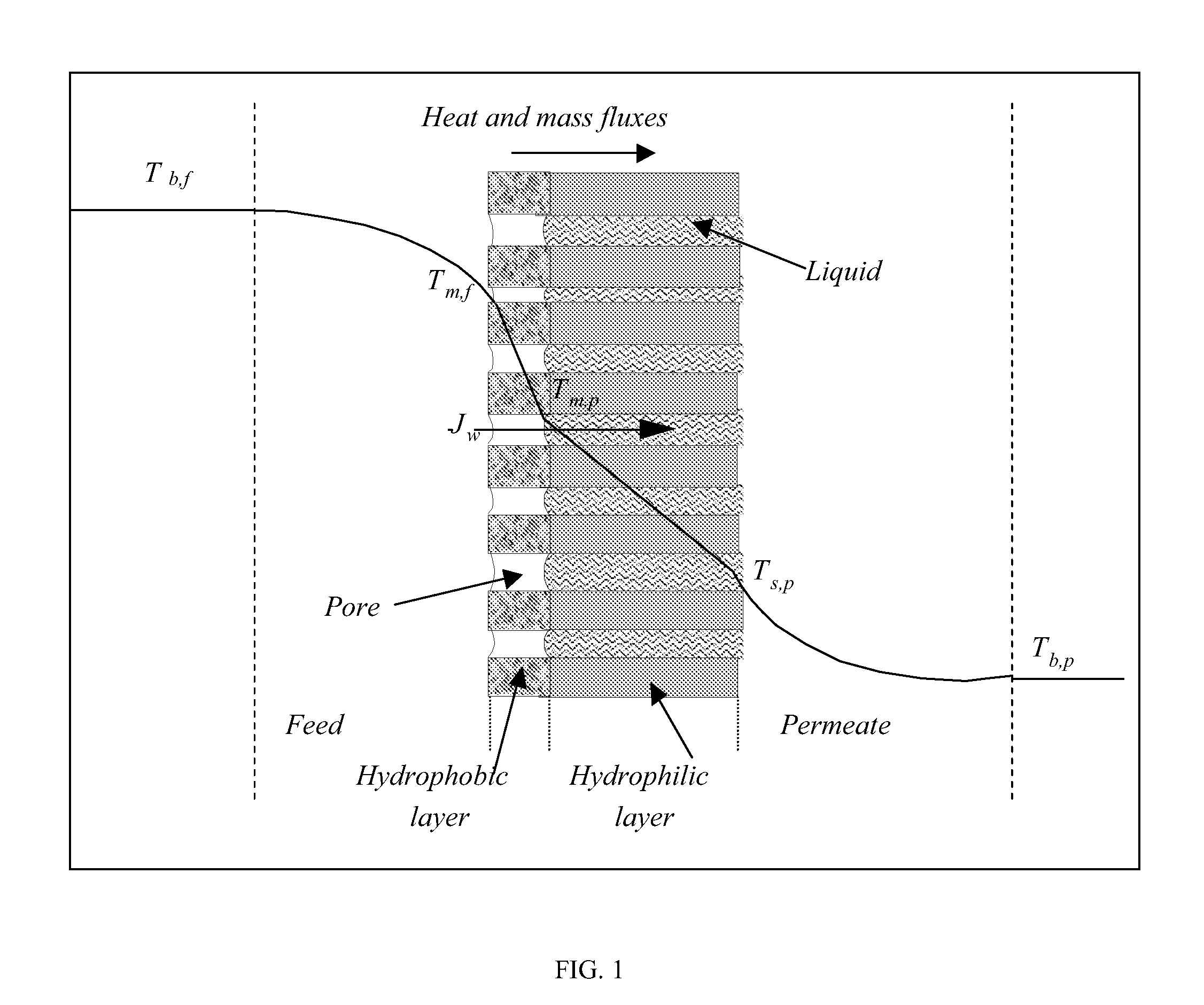

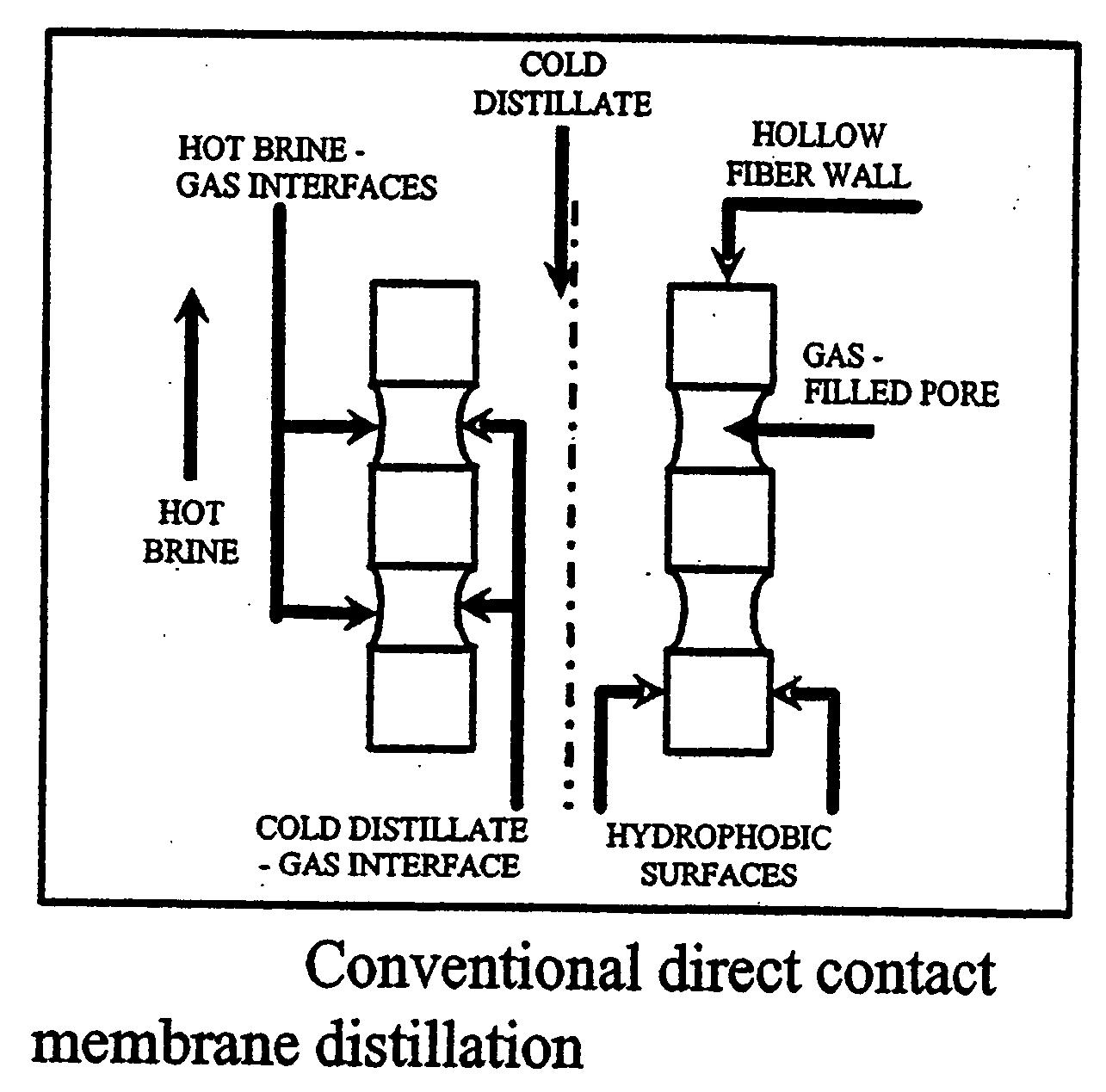

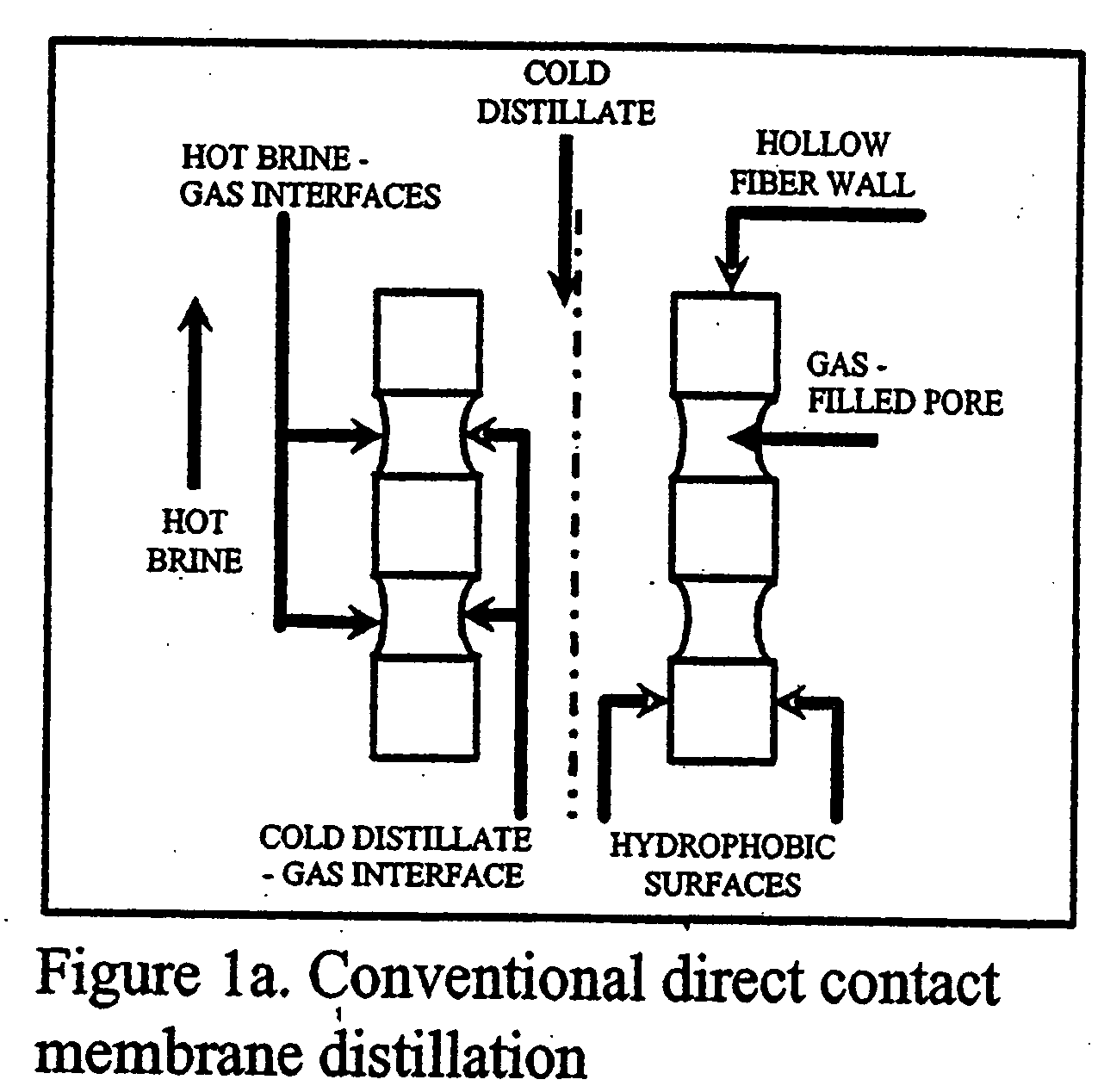

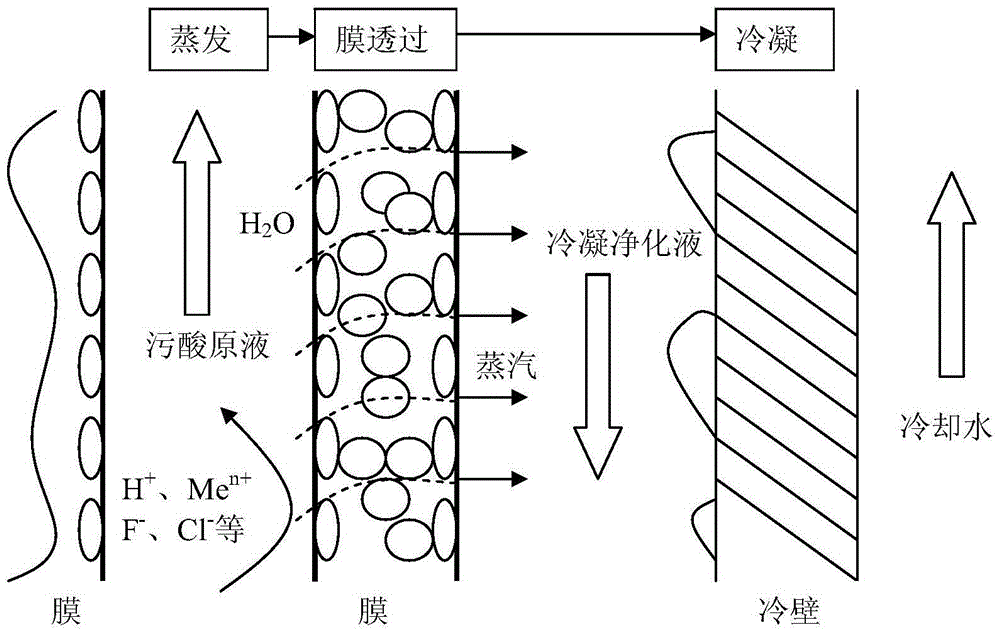

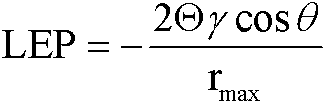

Membrane distillation (MD) is a thermally driven separation process in which separation is driven by phase change. A hydrophobic membrane presents a barrier for the liquid phase, allowing the vapour phase (e.g. water vapour) to pass through the membrane's pores. The driving force of the process is a partial vapour pressure difference commonly triggered by a temperature difference.

Composite membranes for membrane distillation and related methods of manufacture

ActiveUS20110031100A1Maximizing porosityThickness minimizationMembranesVacuum distillation separationPolymer scienceHydrophilic polymers

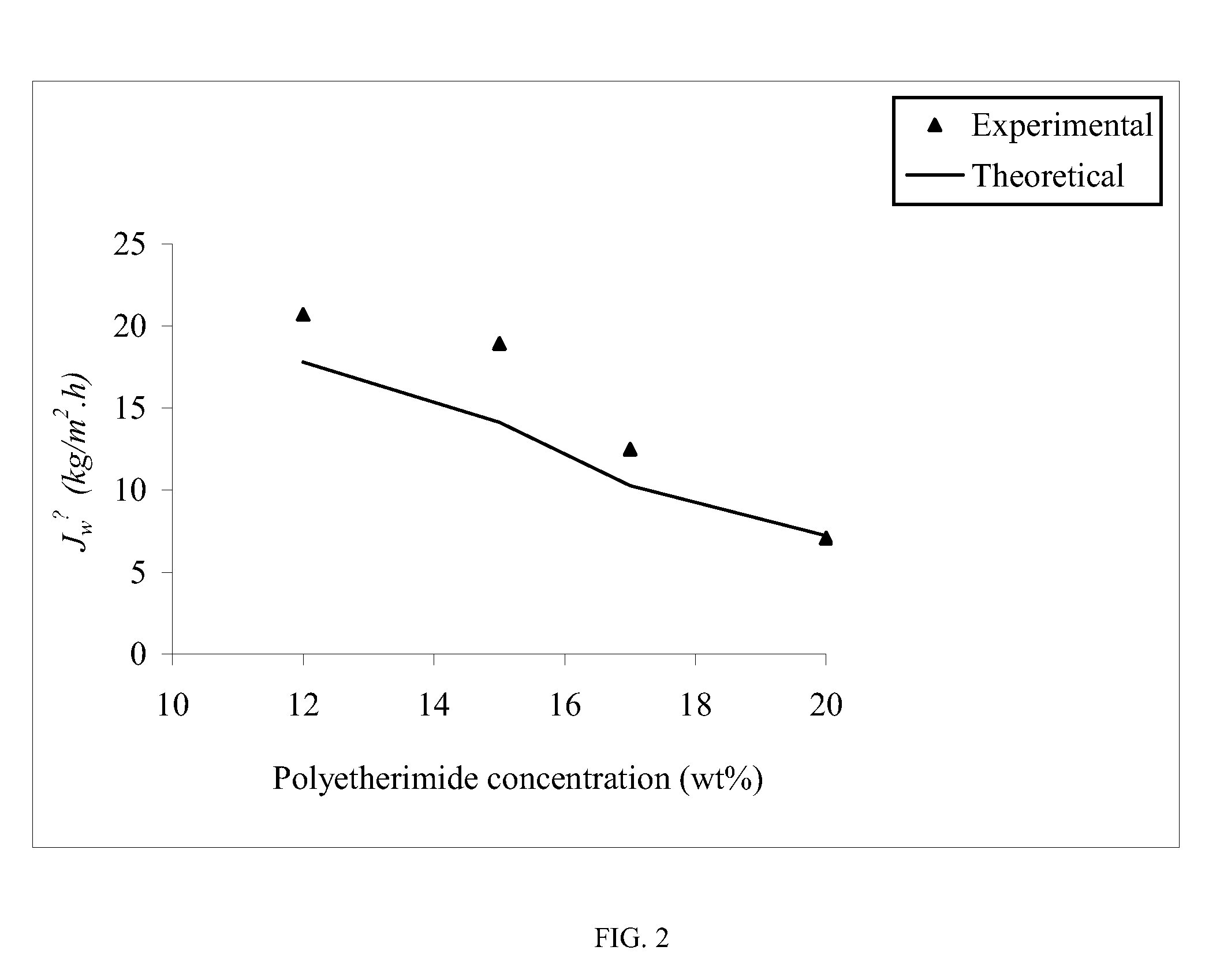

The present invention provides composite membranes for membrane distillation and related methods of manufacture. In particular, there is provided a composite hydrophilic / hydrophobic membrane comprising a hydrophilic polymer layer and a hydrophobic polymer layer comprising fluorinated surface-modifying macromolecules, wherein said composite membrane has a high vapour flux. Also provided herein are methods of manufacturing and optimizing the composite membranes and a membrane distillation system comprising the composite membranes.

Owner:MEMBRANE DISTILLATION DESALINATION LTD

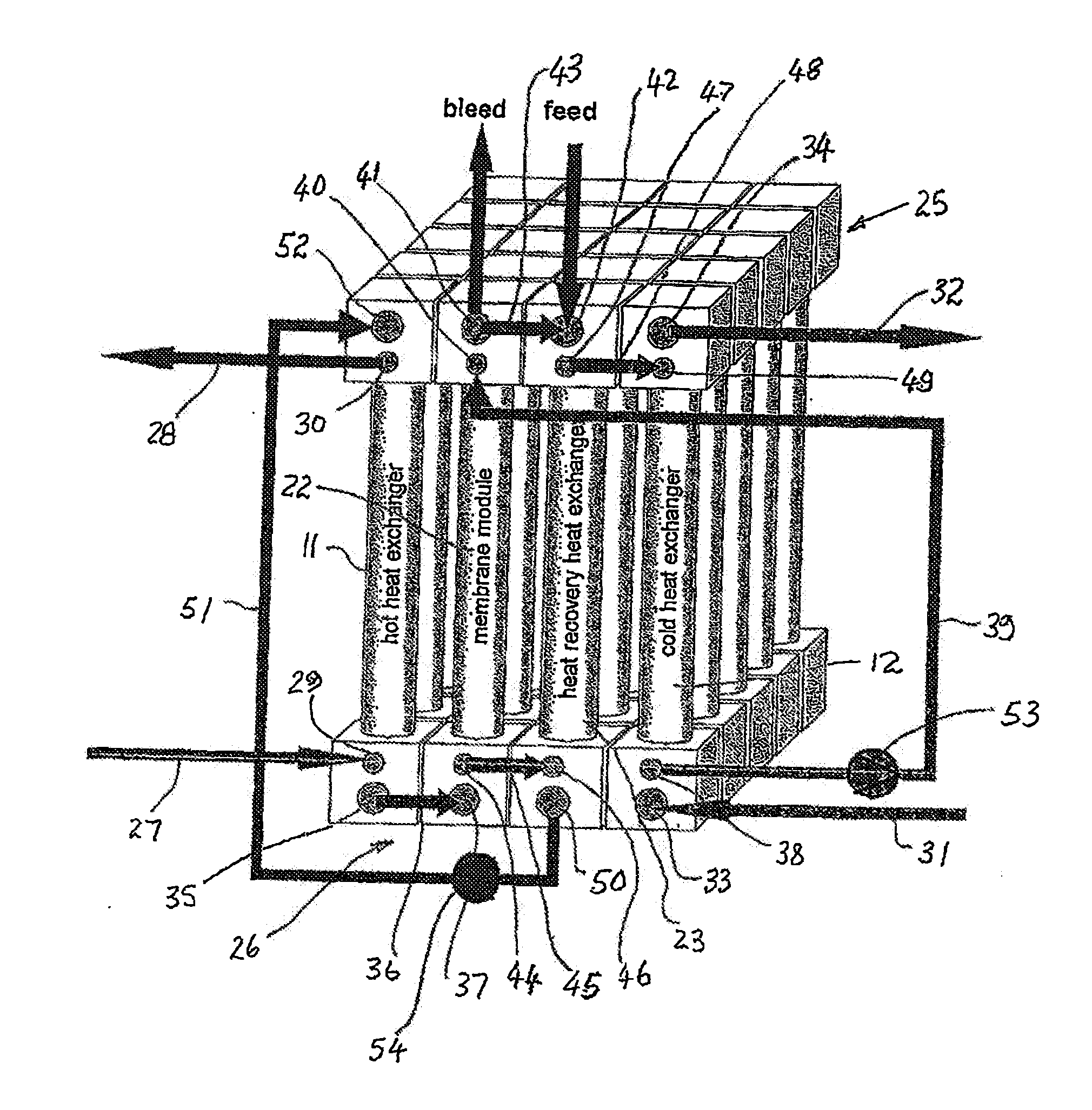

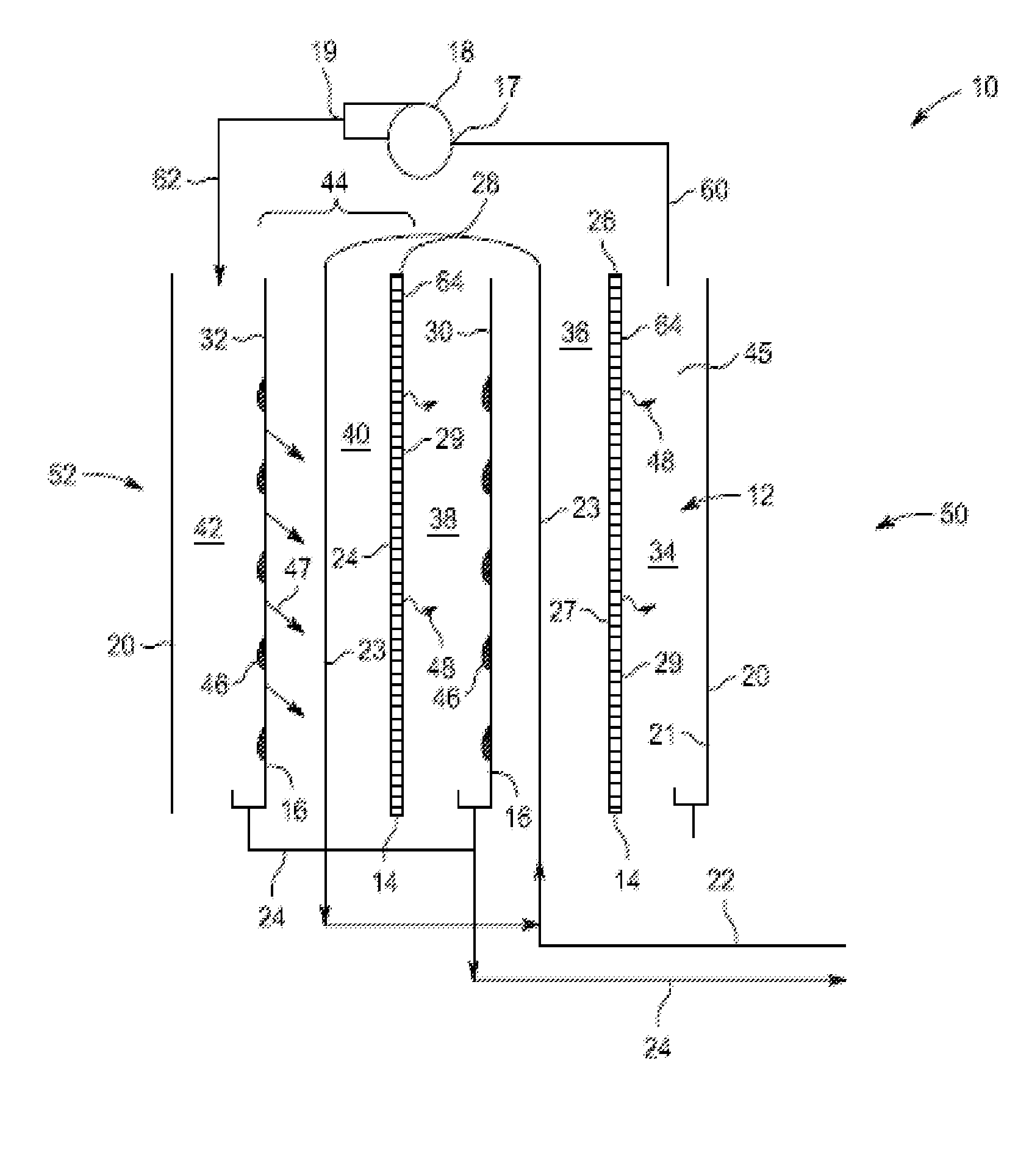

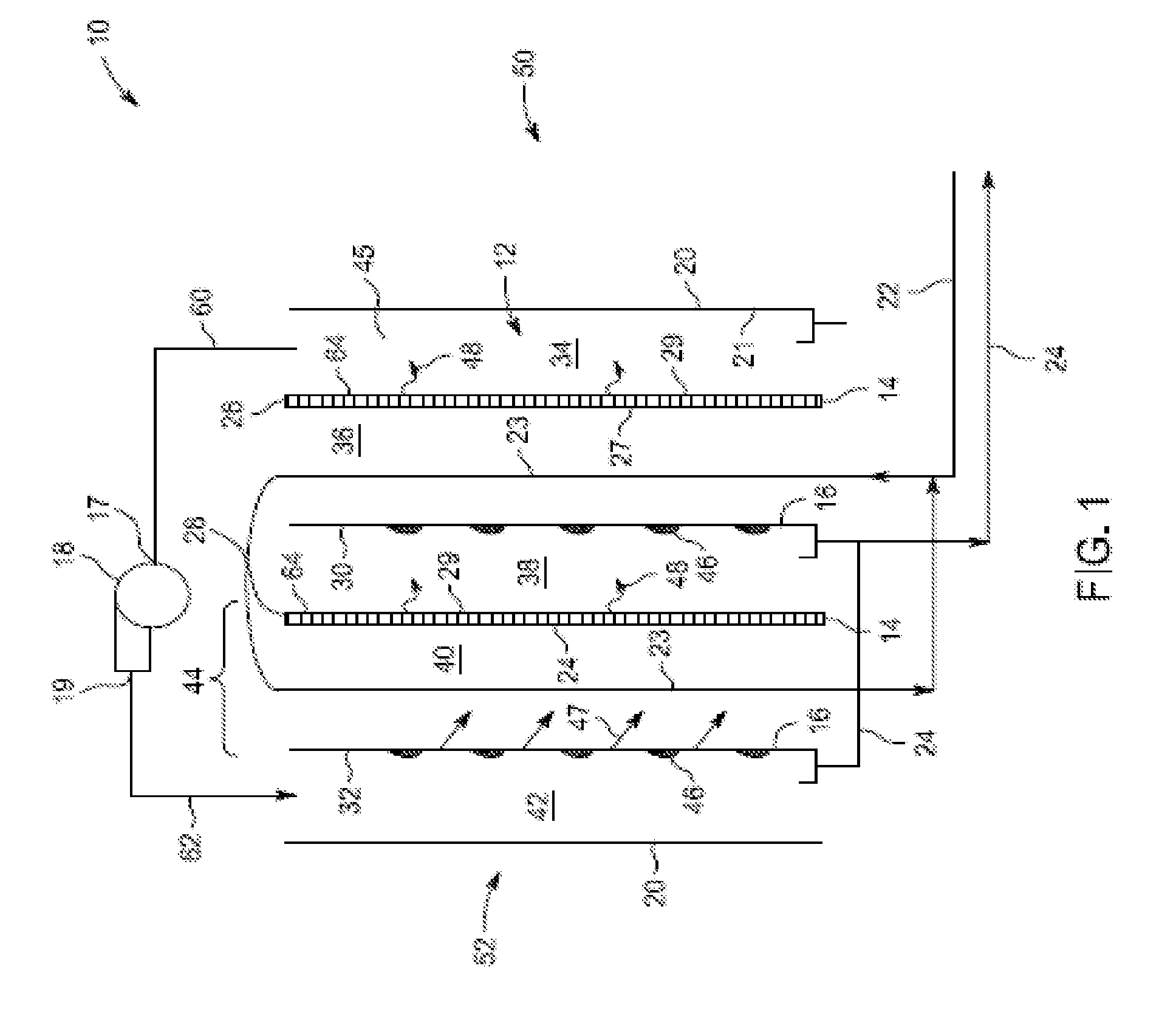

Membrane-assisted fluid separation apparatus and method

InactiveUS7459084B2Easy to disassembleReduce complexityMembranesGeneral water supply conservationFiberHigh concentration

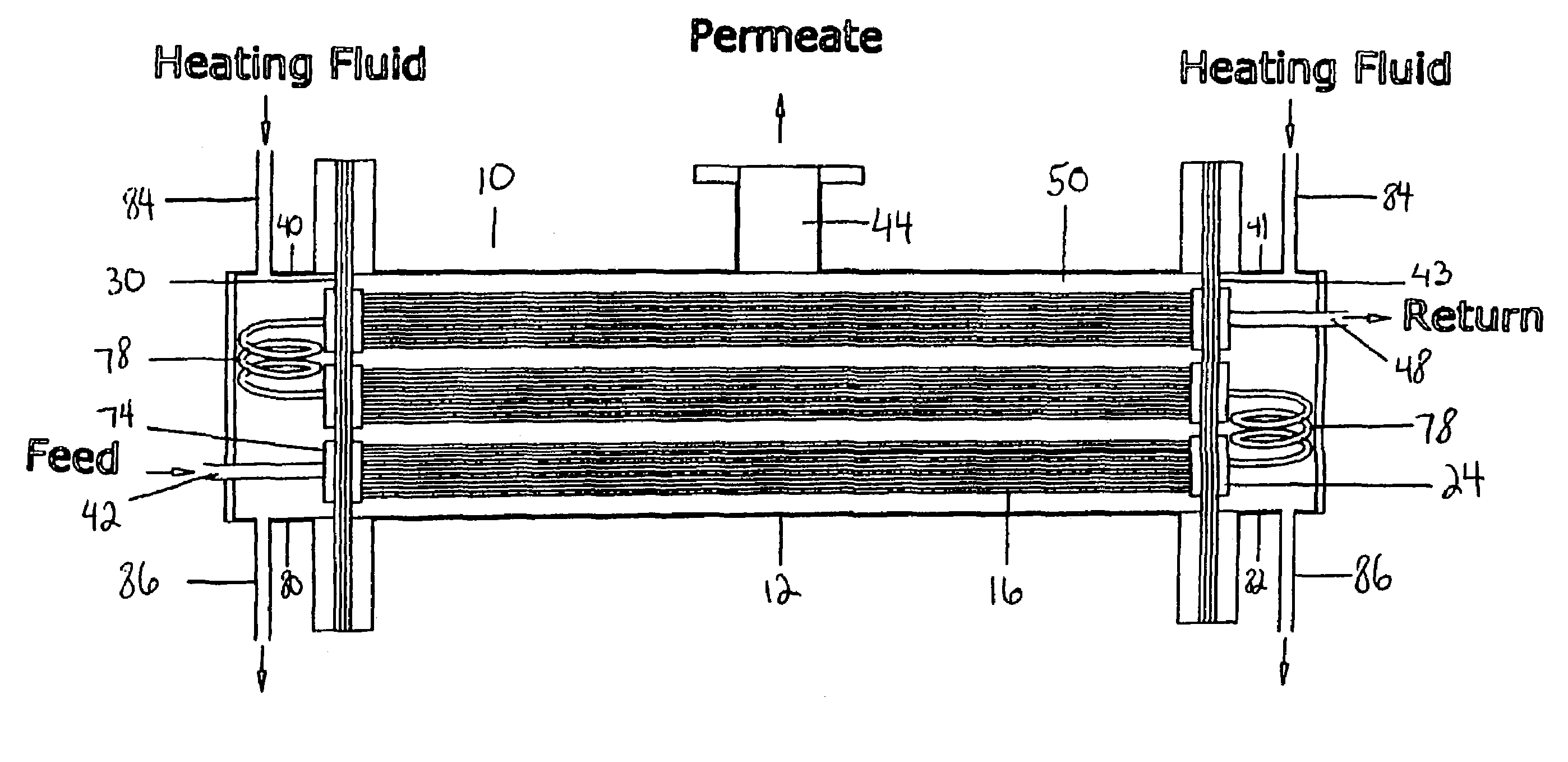

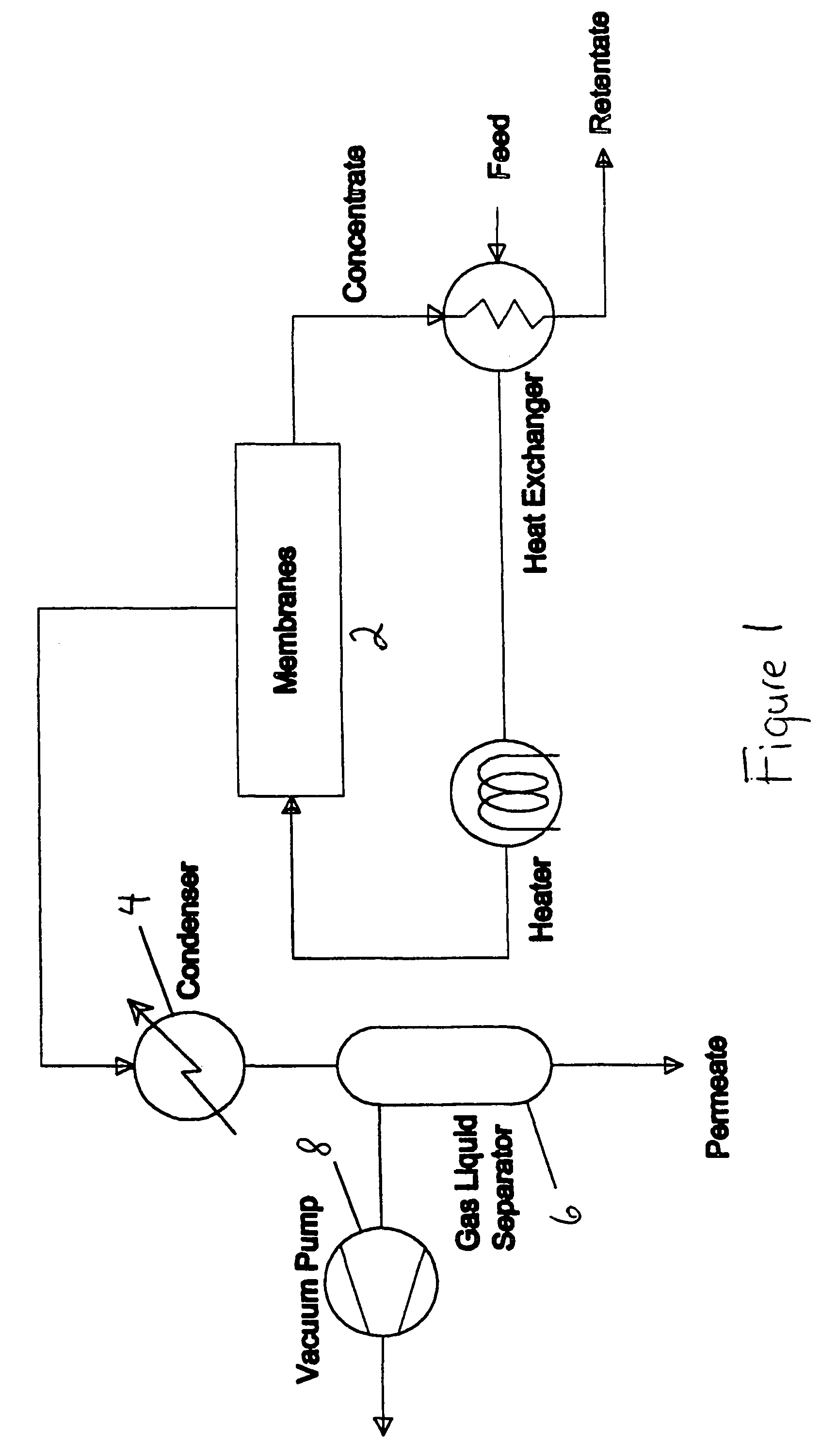

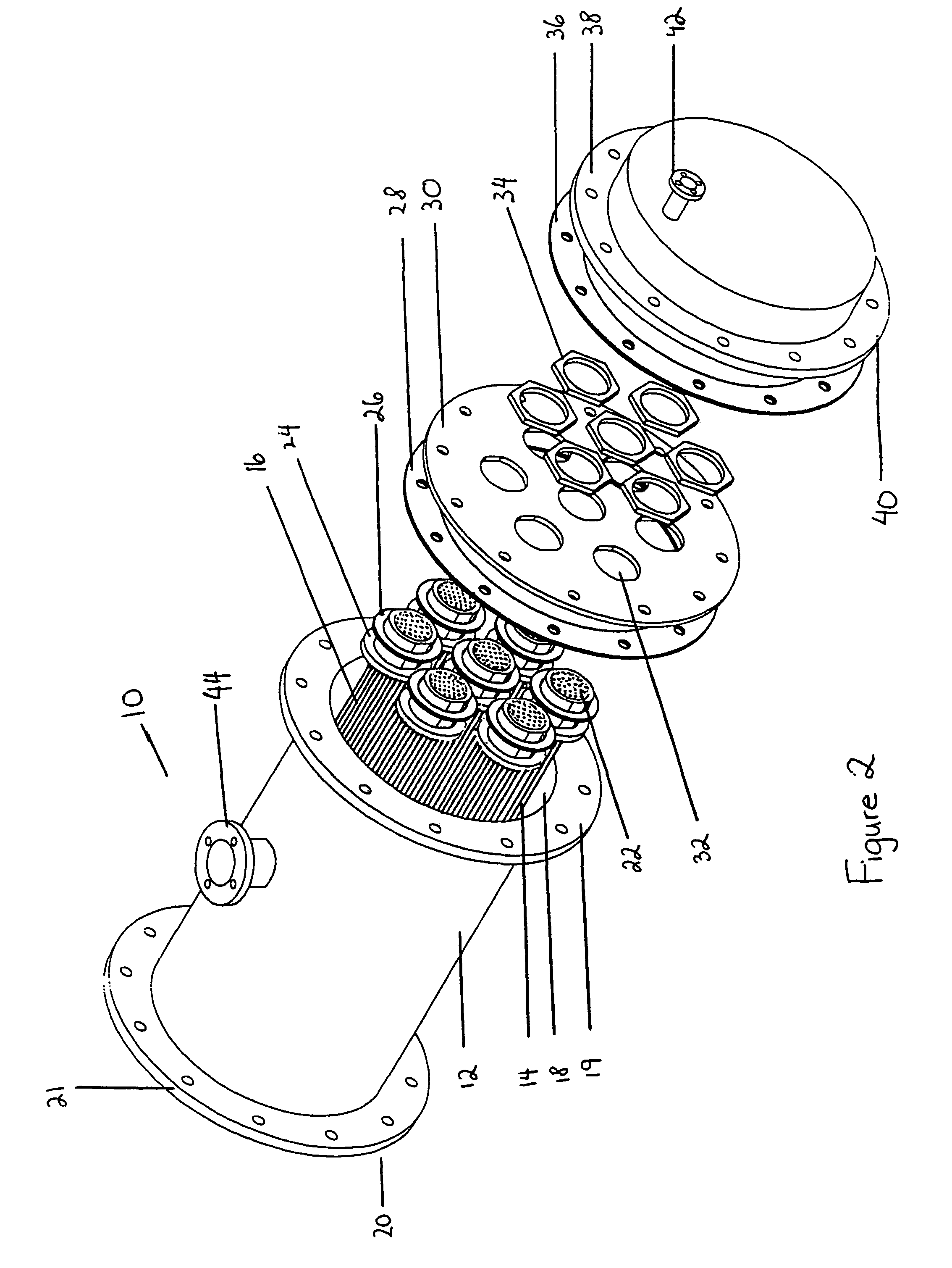

This present invention relates to a fluid separation module adapted to separate a given fluid mixture into permeate and retentate portions using bundles of hollow fiber membranes. The membranes may be composed of different kinds of membranes depending on the application being used to separate the fluid mixture. The fluid separation module may be used to separate fluid mixtures by a number of different processes, including but not limited to, pervaporation, vapour permeation, membrane distillation (both vacuum membrane distillation and direct contact membrane distillation), ultra filtration, microfiltration, nanofiltration, reverse osmosis, membrane stripping and gas separation. The present invention also provides an internal heat recovery process applied in association with those fluid separation applications where separation takes place by evaporation through the membrane of a large portion of the feed into permeate. Desalination and contaminated water purification by means of vacuum membrane distillation are just two examples where the internal heat recovery process may be applied. In these two examples, large portions of the feed are separated by membranes into a high purity water permeate stream by evaporation through the membranes and into a retentate stream containing a higher concentration of dissolved components than present in the feed. In this process the permeate vapour that is extracted from the fluid separation module is compressed by an external compressor to increase the temperature of the vapour higher than the temperature of the feed entering the separation module. Heat from the permeate vapour at the elevated temperature is transferred back to the incoming feed fluid mixture entering the fluid separation module in a condenser / heat exchange.

Owner:LOEB INVESTORS CO 166 LP +1

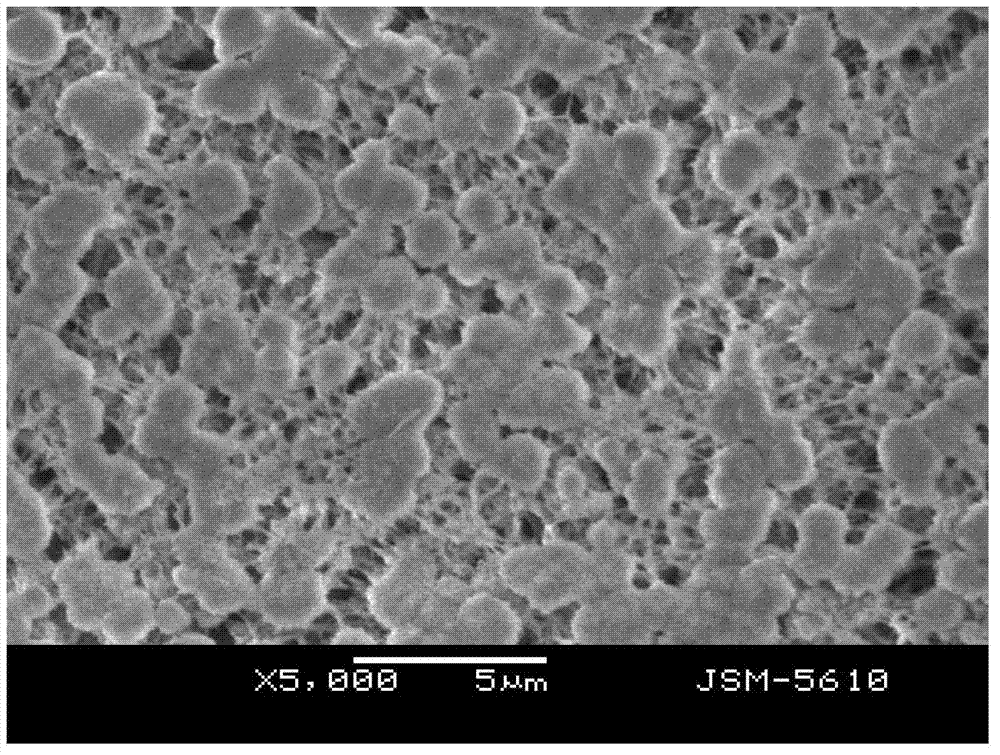

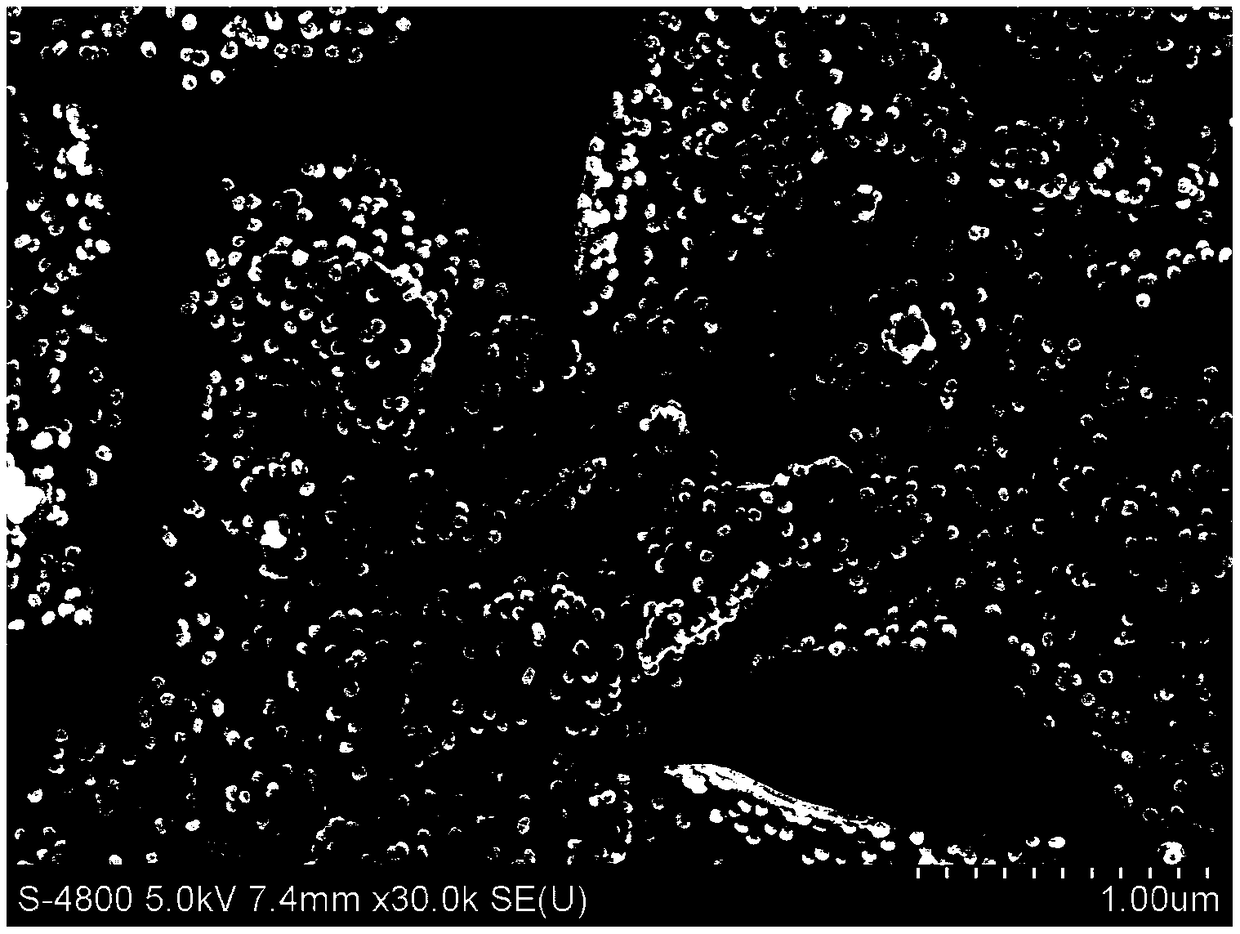

Preparation method of electrostatic spinning hydrophobic nanofiber porous membrane for membrane distillation

The invention relates to a preparation method of an electrostatic spinning hydrophobic nanofiber porous membrane for membrane distillation. The method comprises the following steps of: dissolving a hydrophobic functional polymer material in the solvent to get a 1-35wt% polymer spinning solution, performing electrostatic spinning to get a hydrophobic nanofiber porous membrane, and further performing thermal treatment, thereby obtaining the electrostatic spinning hydrophobic nanofiber porous membrane for membrane distillation. The preparation method provided by the invention is simple and practicable, and can be used for conveniently and accurately controlling the thickness and uniformity of the nanofiber membrane and realizing operations of mass production more easily; the high-hydrophobicity nanofiber porous membrane prepared by the preparation method can be used for signally improving the defects of the conventional membrane for membrane distillation that the water flux is low and the membrane pores get wet easily, so that the membrane distillation technology can compete with a reverse osmosis technology in the seawater desalination field.

Owner:DONGHUA UNIV

Devices and methods using direct contact membrane distillation and vacuum membrane distillation

ActiveUS20060076294A1Eliminate pore wettingReduce lossesGeneral water supply conservationSolid sorbent liquid separationFiberHollow fibre membrane

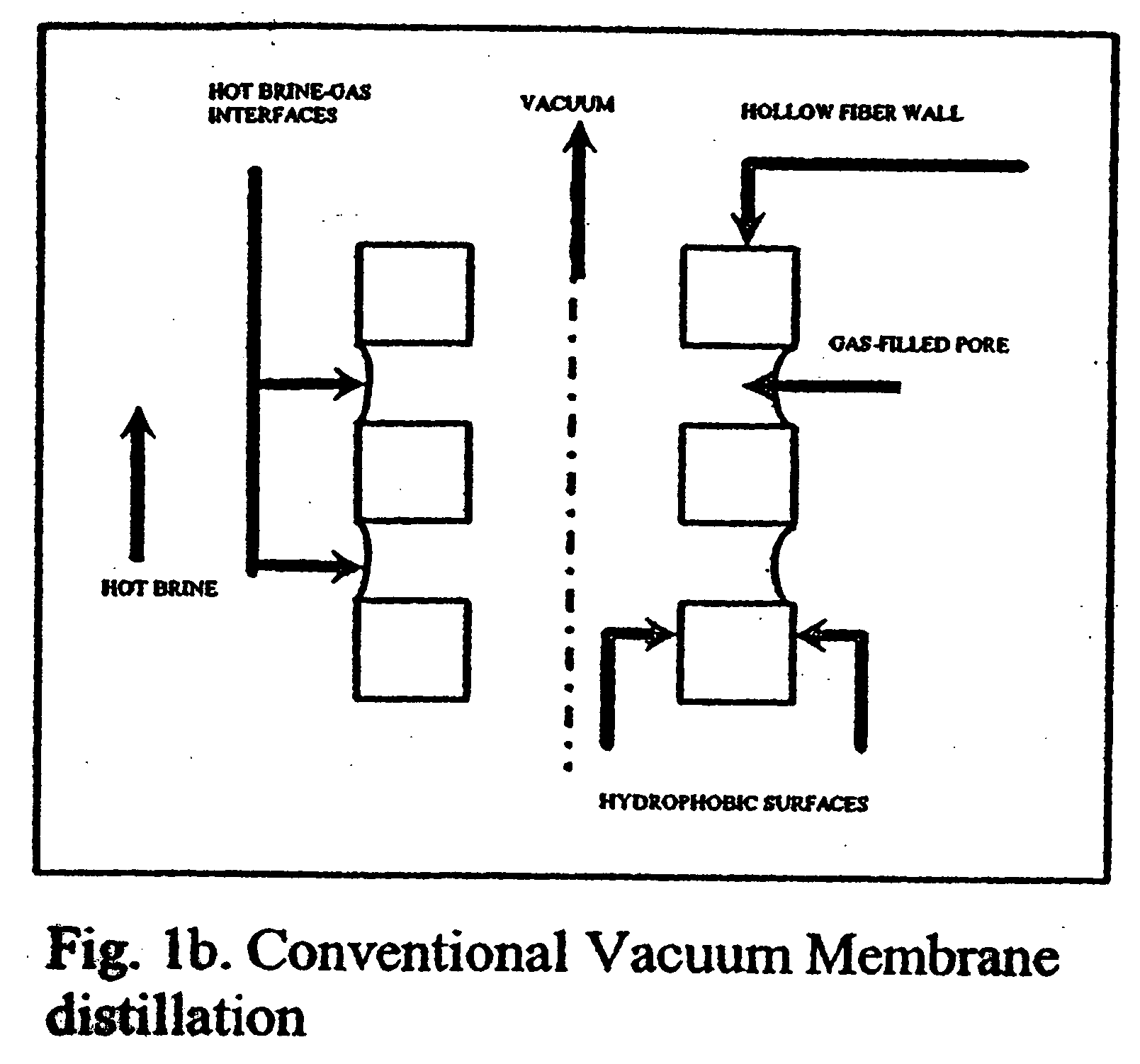

DCMD and VMD systems and methods for use in desalination applications are provided. The DCMD and VMD systems employ coated porous hydrophobic hollow fiber membranes. The coatings advantageously function to essentially eliminate pore wetting of the membrane, while permitting substantially unimpeded water vapor permeance through the fiber walls. The DCMD and VMD membranes are characterized by larger fiber bore diameters and wall thicknesses. The membranes substantially reduce the loss of brine sensible heat, e.g., heat loss via conductive heat flux through the membrane wall and the vapor space and, in exemplary embodiments, the brine-side heat transfer coefficient is dramatically enhanced by horizontal / vertical cross flow of brine over the outside surface of the coated fibers. Superior water vapor fluxes are achieved with the systems and methods.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

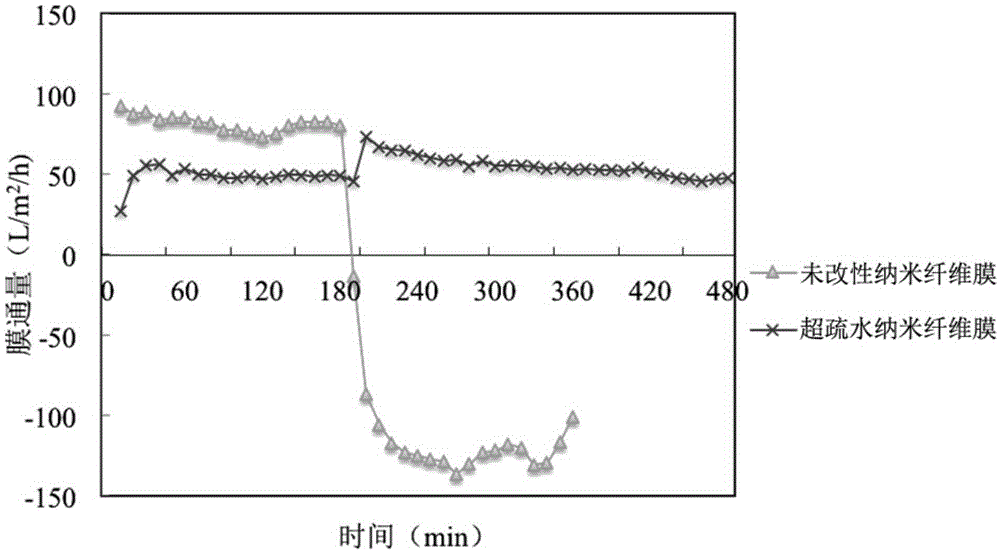

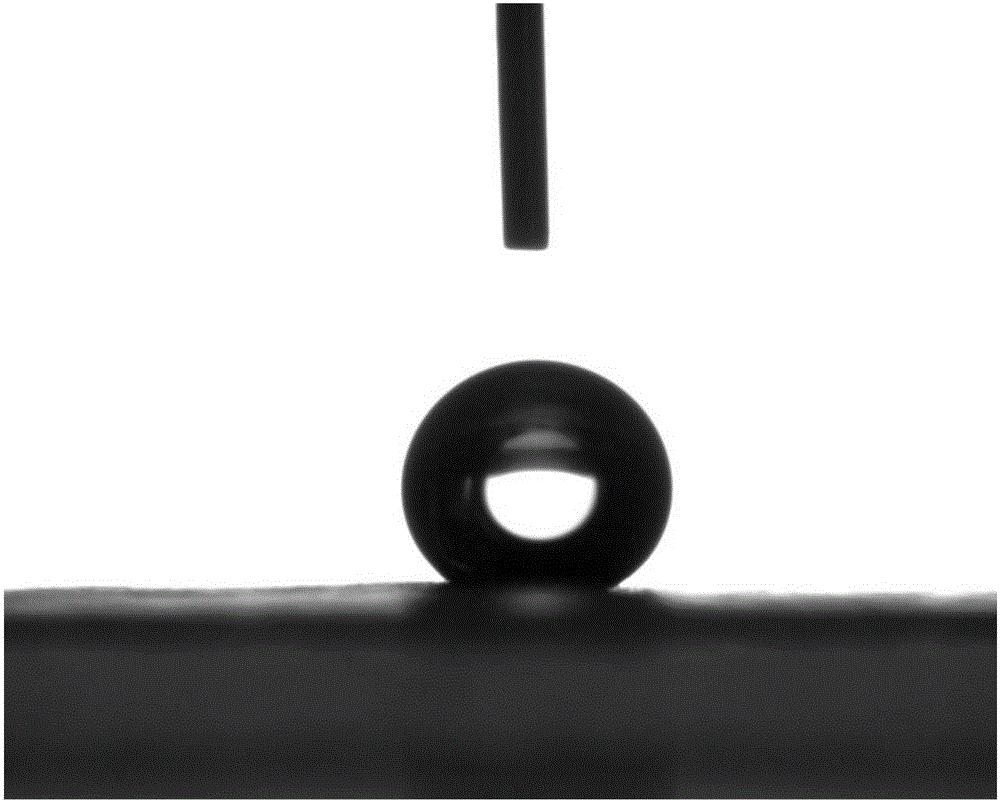

Preparation method and application of super-hydrophobic membrane

The invention provides a preparation method of a super-hydrophobic membrane. The preparation method comprises steps as follows: hydrophobic organic polymer materials and nano granules are dissolved in an organic solvent, the mixture is stirred and left to stand, and an electrostatic spinning solution is prepared; high-pressure electrostatic spinning parameters are set, electrostatic spinning membrane preparation is performed, and a nanofiber membrane is obtained and subjected to thermal treatment; TiO2 is prepared, the surface of the nanofiber membrane is covered with TiO2, and thermal treatment, water-bath heating, washing and ultraviolet radiation treatment are performed; silane solutions are prepared, the nanofiber membrane surface covered with TiO2 is covered with the silane solutions, thermal treatment, washing and airing are performed, and the super-hydrophobic membrane is obtained. The invention further provides an application of the super-hydrophobic membrane in the membrane distillation process. By means of the method, the super-hydrophobic nanofiber membrane is prepared. The membrane simultaneously has super-hydrophobicity and high throughput performance, the wet resistance of the membrane is effectively improved, and the service life of the membrane is prolonged.

Owner:SHANGHAI JIAO TONG UNIV

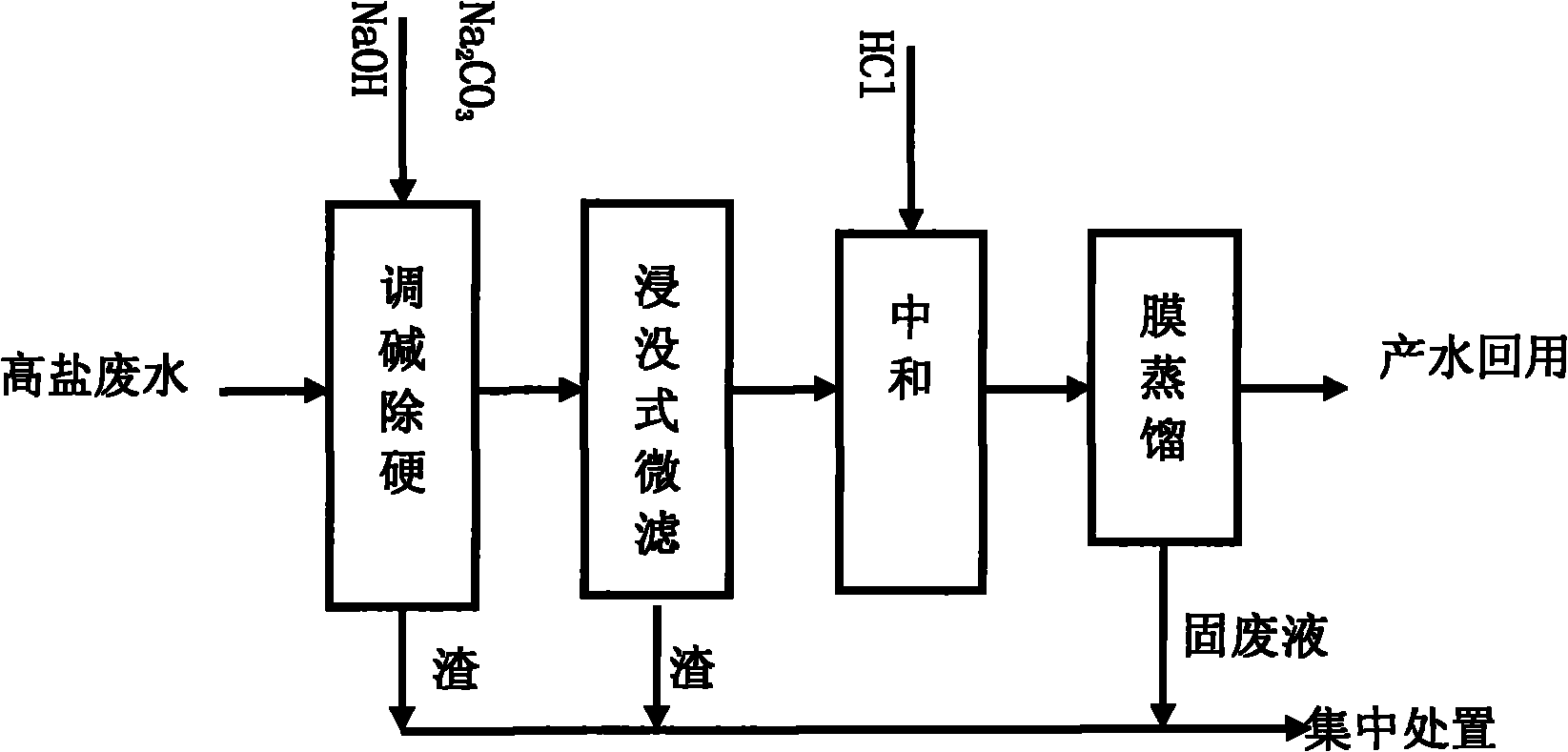

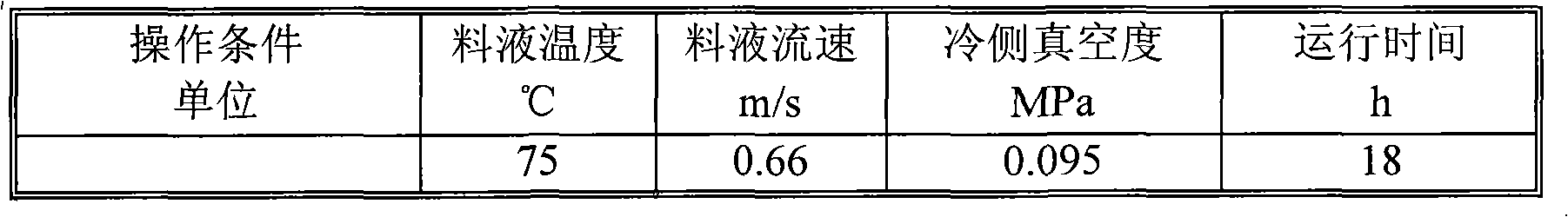

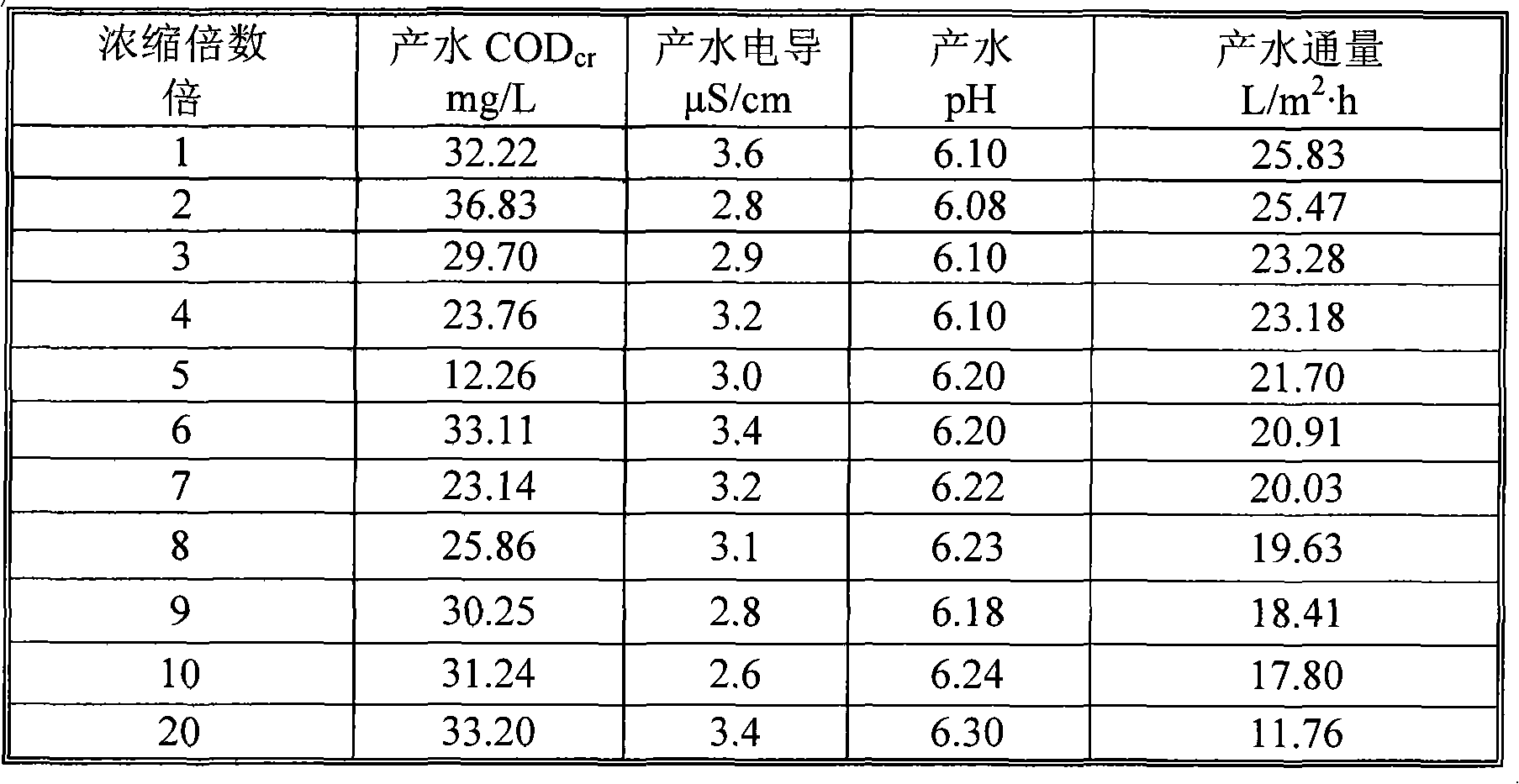

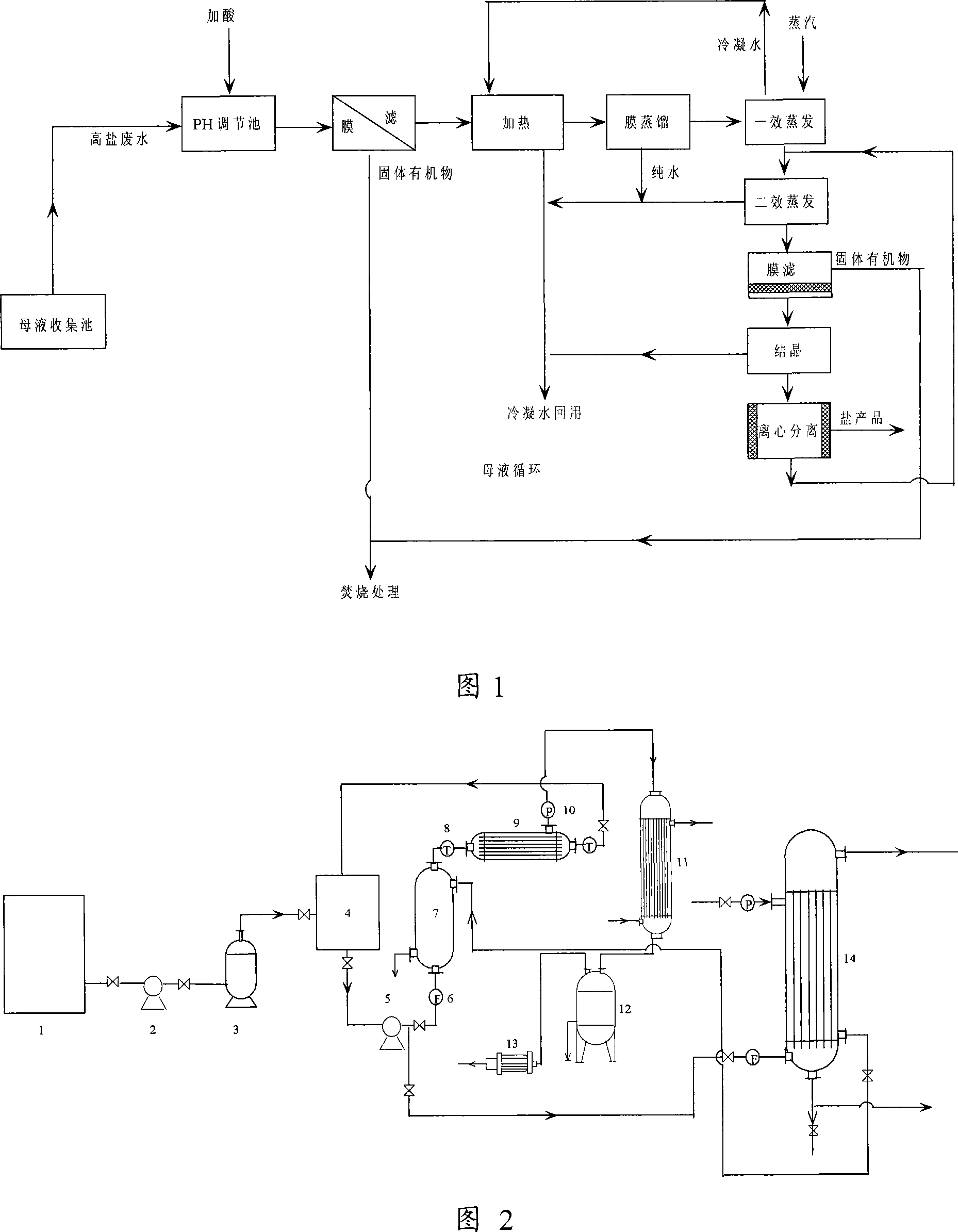

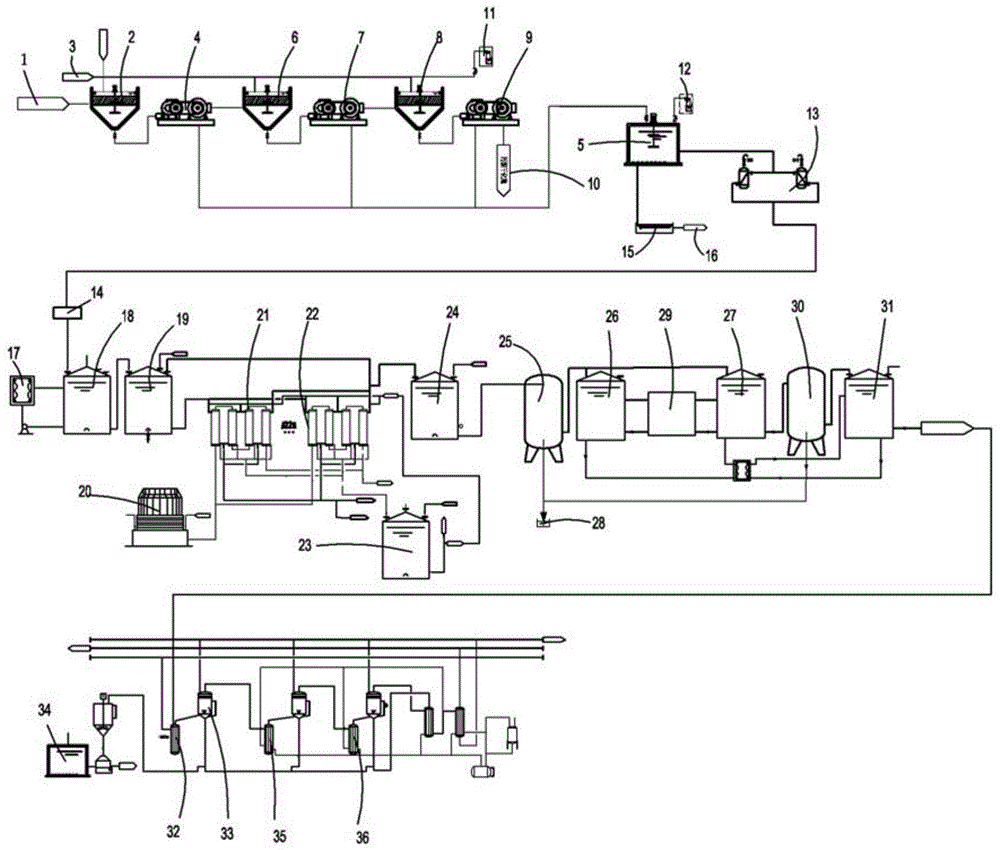

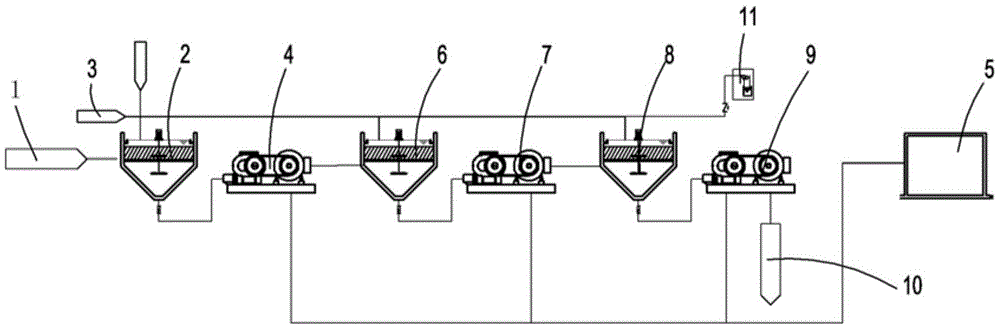

Method for treating high salinity wastewater

ActiveCN101928087AHigh hardnessHardness removalWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentWastewaterWater quality

The invention relates to a method for treating high salinity wastewater. The invention uses treatment processes of alkali regulation and hardness removal, immersed microfiltration, neutralization and membrane distillation, aiming at the high salinity wastewater in petrifaction enterprises. The immersed microfiltration solves the problems of easy blocking, rapid flux decline rate and the like of a membrane; and the alkali regulation and hardness removal effectively removes the hardness in wastewater, reduces membrane pollution, improves the concentration multiple of the membrane distillation, lowers the load of evaporation and improves the processing effect and the operation stability of the membrane distillation. The method of the invention has wide applicability, simple device, convenient operation, stable operation and the like, and water produced by membrane distillation is good in water quality and can be directly reused for production.

Owner:CHINA PETROLEUM & CHEM CORP +1

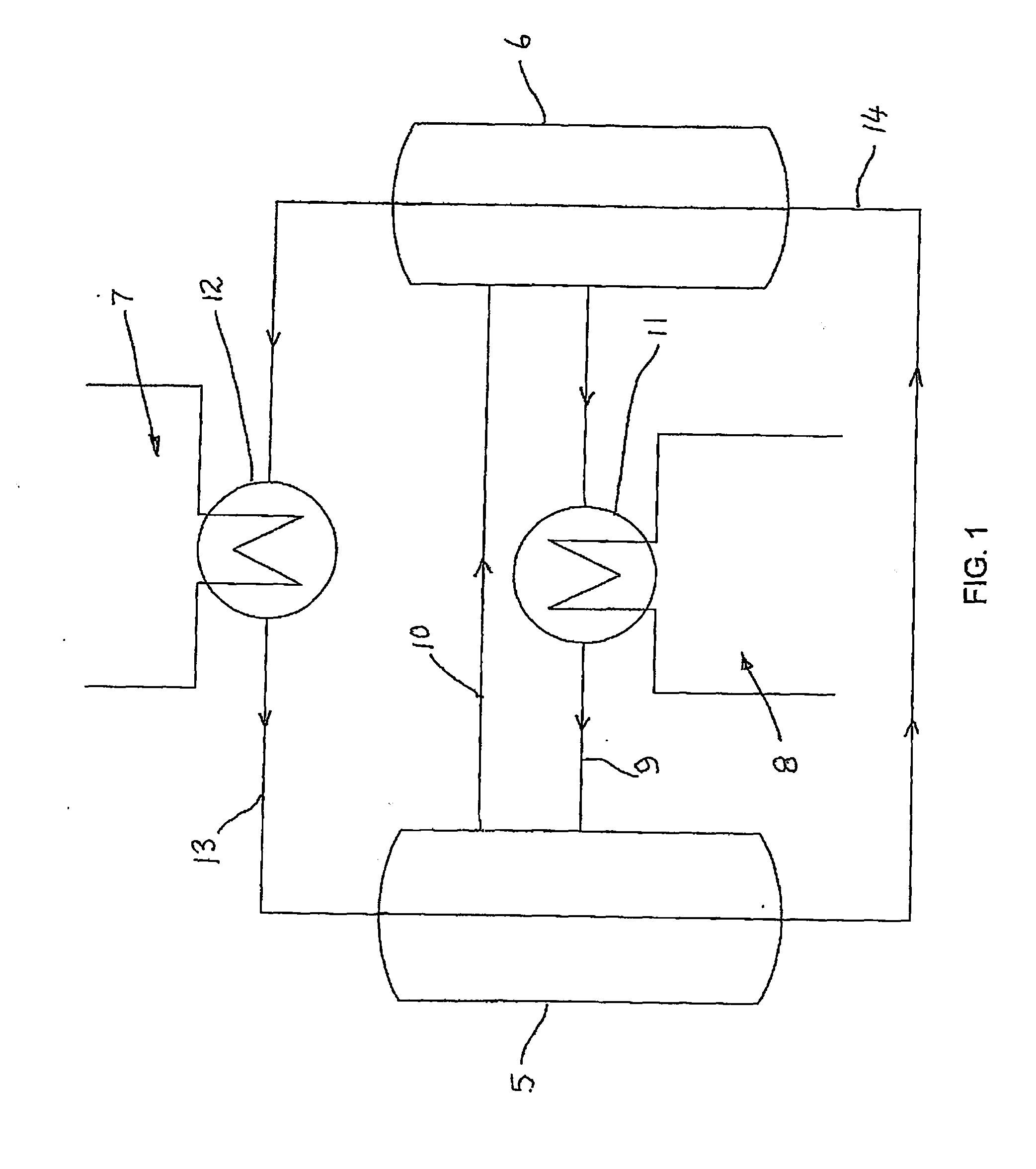

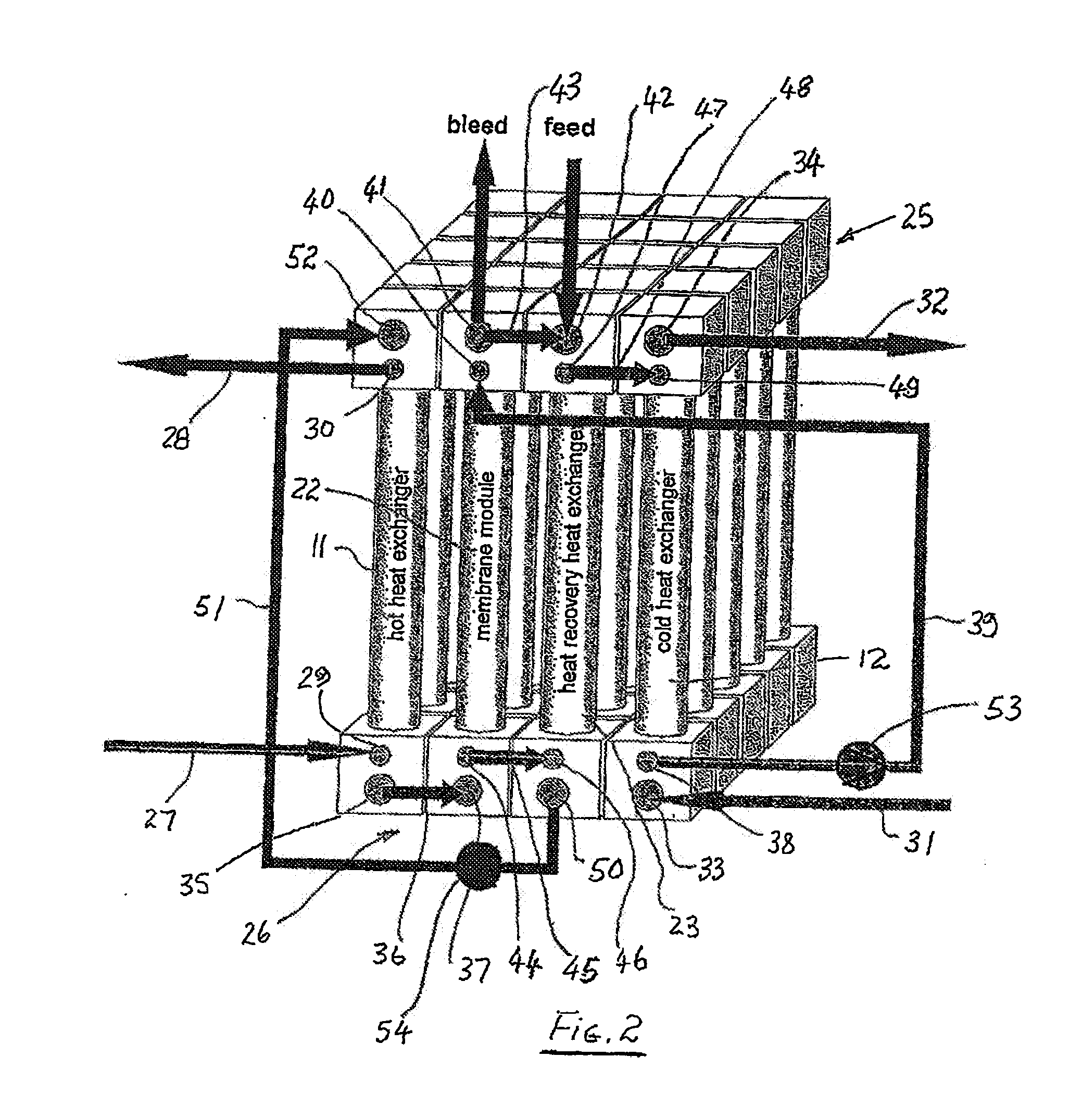

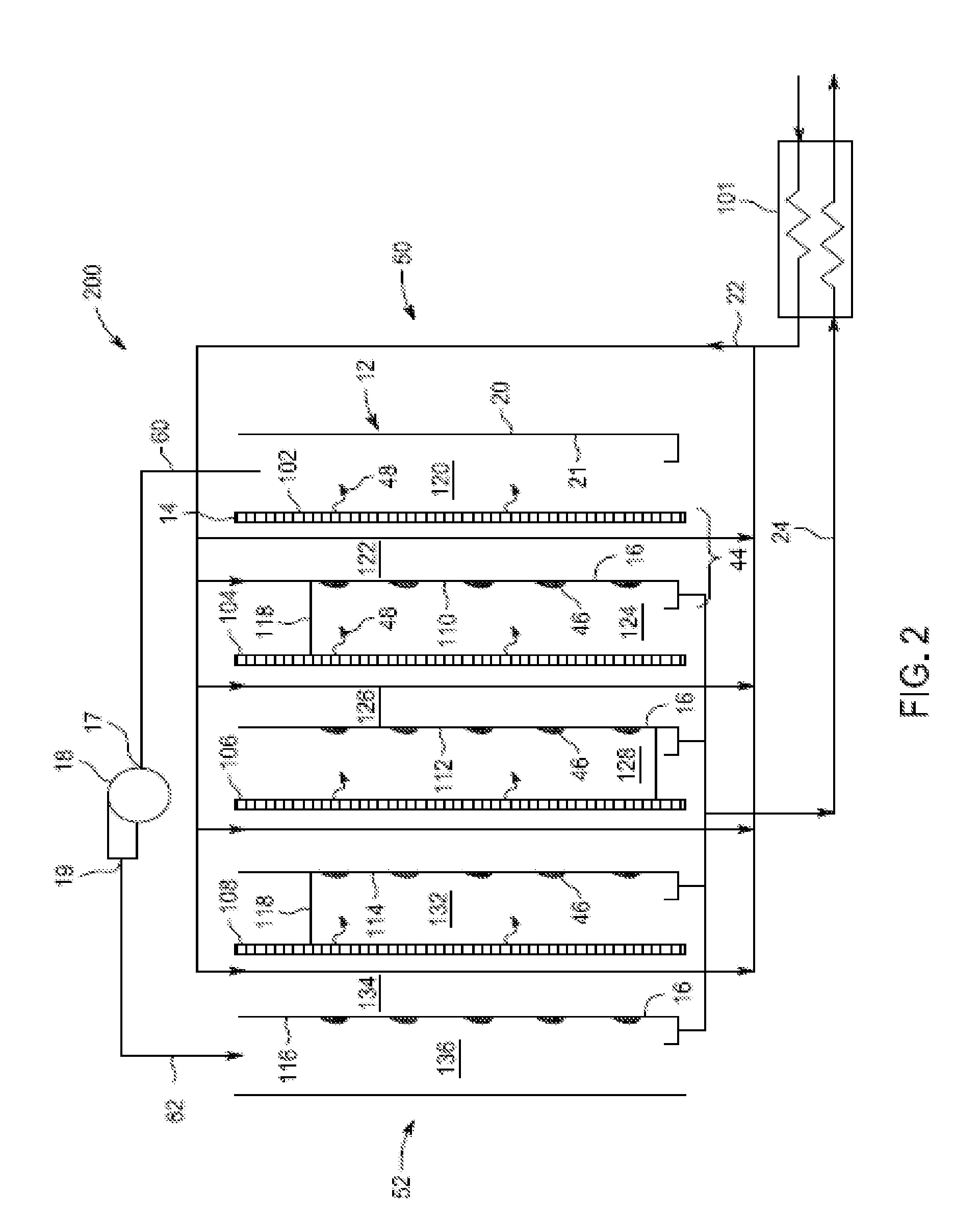

Block Configuration for Large Scale Membrane Distillation

InactiveUS20110132826A1Compact designMembranesGeneral water supply conservationComputer moduleMembrane distillation

Embodiments of the present invention seek to provide a membrane distillation system having compact design and simplified connection system for fluid flow paths used in the system. According to one aspect, a membrane distillation system includes at least one membrane module and at least one like configured heat exchanger module, the modules being supported and connected to like configured manifold devices for providing fluid communication between said modules.

Owner:SIEMENS IND INC

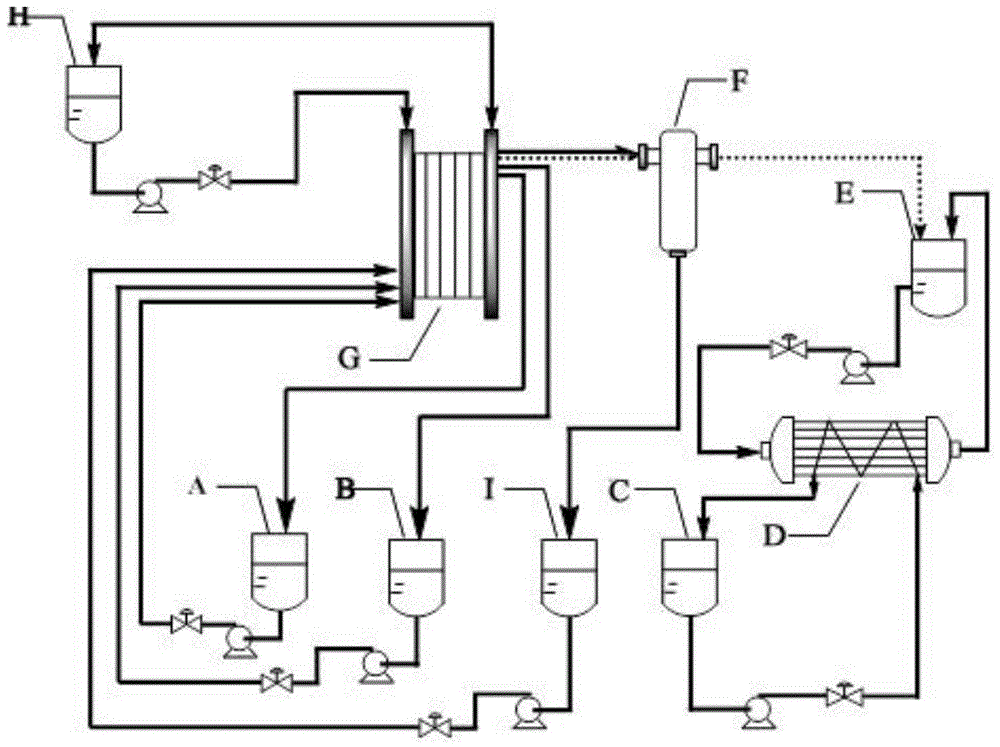

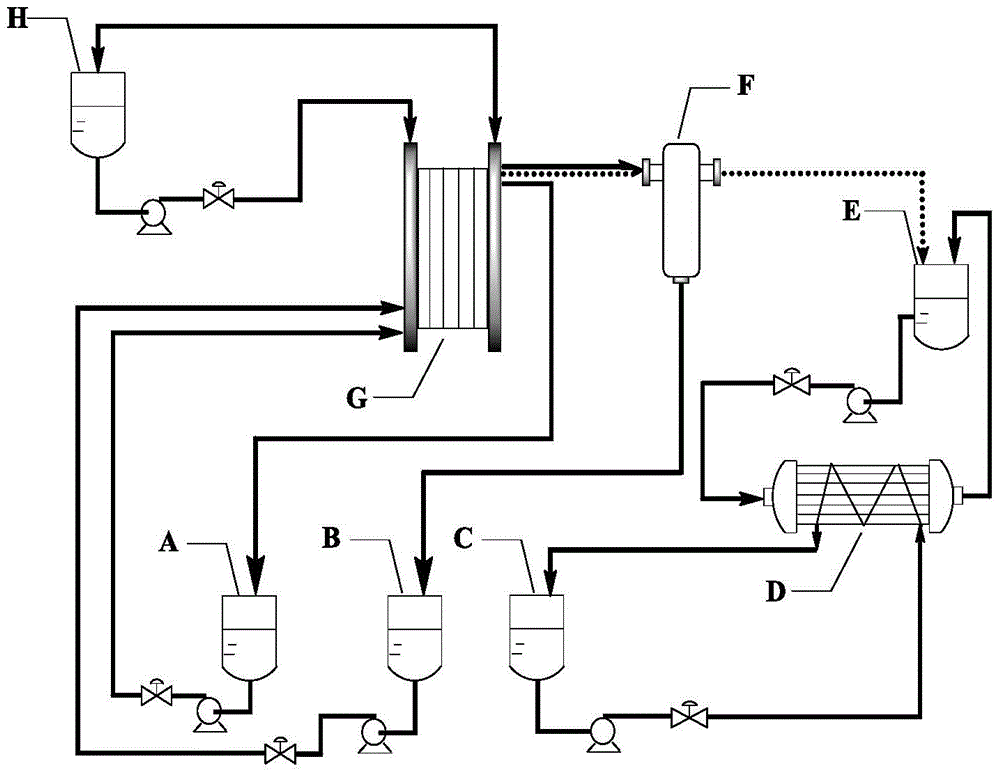

Waste water treatment method and device based on forward osmosis and membrane distillation

InactiveCN103073146AReduced operating temperature rangeLow costSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisSalt contentWater concentration

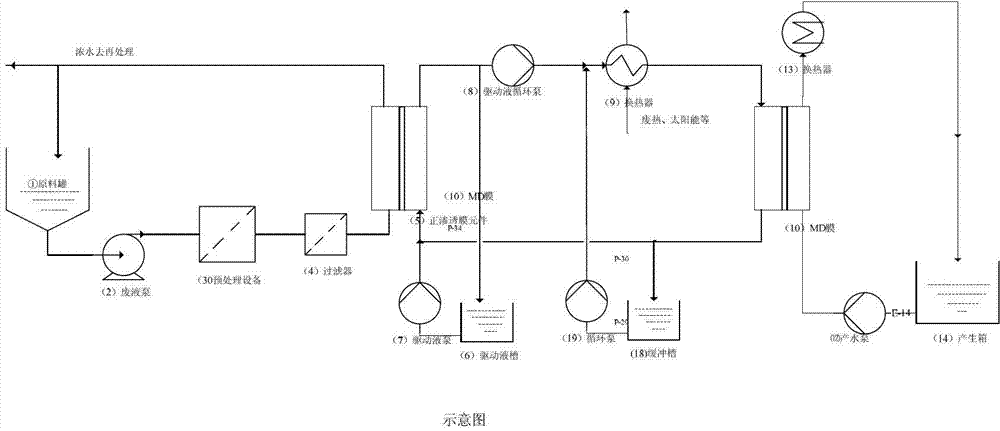

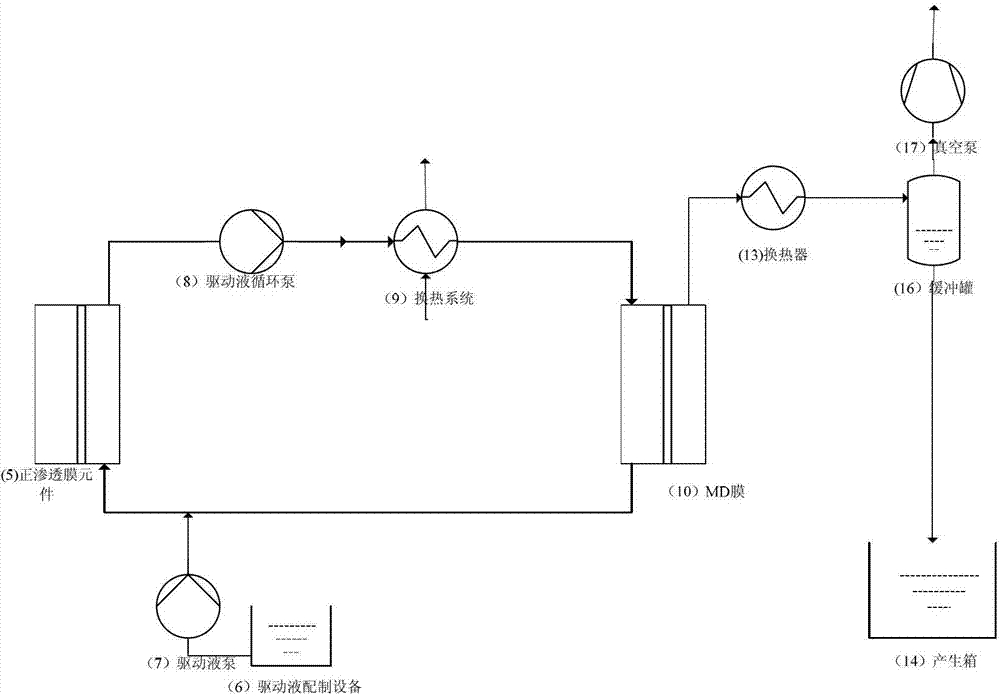

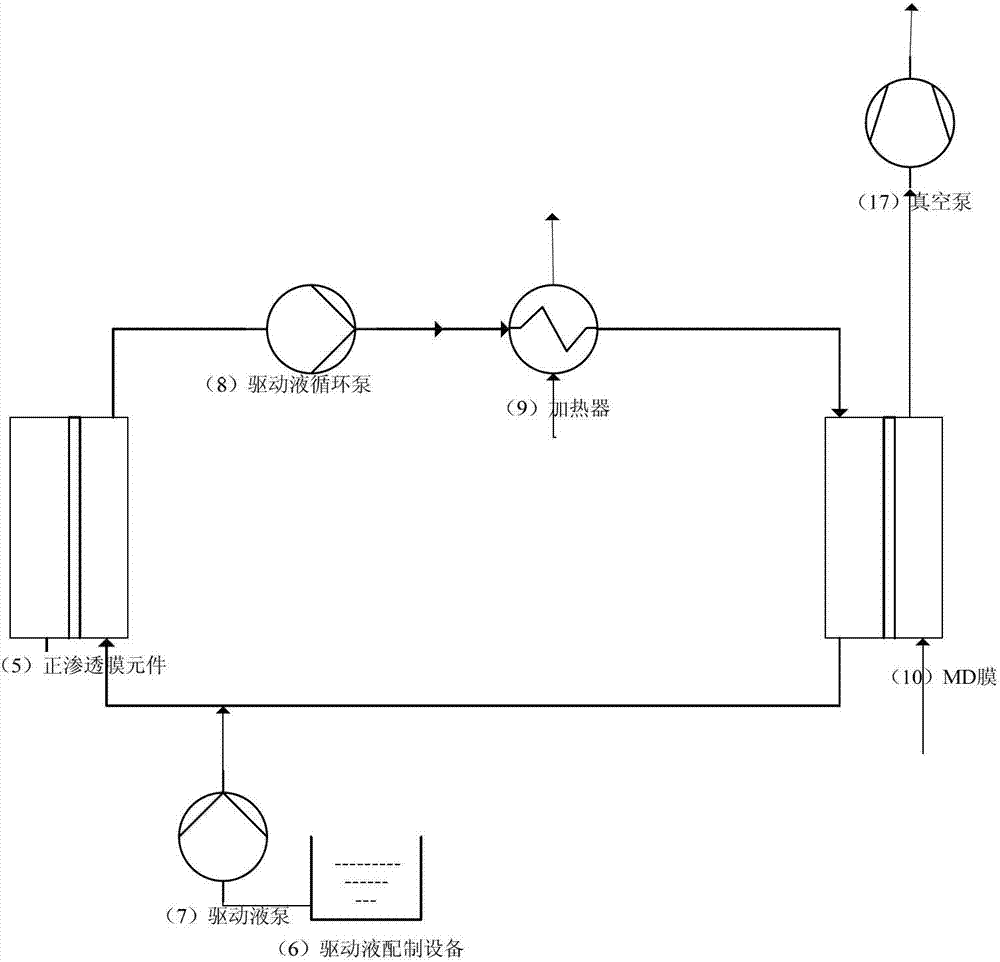

The invention belongs to the field of sewage treatment, and particularly relates to a waste water treatment method and device based on forward osmosis and membrane distillation. The waste water treatment method based on the forward osmosis and membrane distillation comprises a waste water concentration process and a drive liquid circulation process, wherein the waste water concentration process adopts a forward osmosis technology to concentrate waste water with high salt content and high chemical oxide demand (COD) concentration through drive liquid so as to obtain the concentrated waste water and diluted drive liquid; the drive liquid circulation process adopts a membrane distillation technology to dehydrate the diluted drive liquid so as to obtain the purified water and renewable drive liquid; and the renewable drive liquid is repeatedly used for the waste water concentration process so as to continuously concentrate the waste water. Due to the adoption of the method and device for treating the waste water with high salt content and high COD concentration, the waste water of different sources and fields can be treated, and the advantages such as wide applicability for waste water, stability in running and low treatment cost can be realized.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

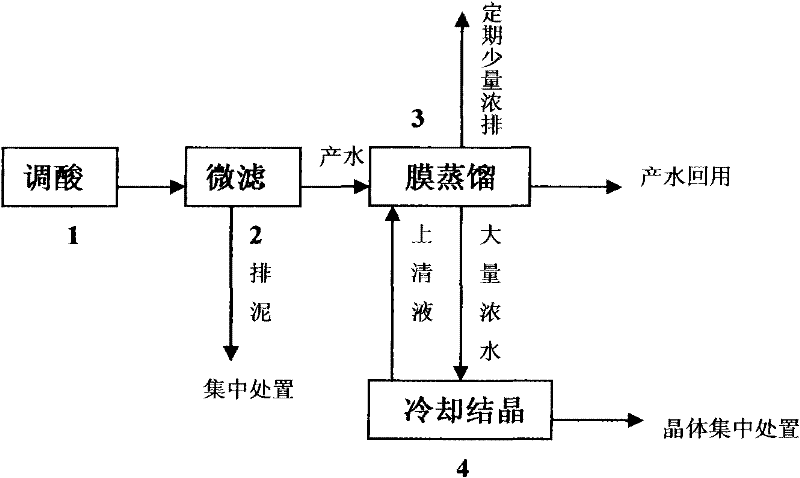

A method for the treatment and reuse of ammonia-nitrogen-containing high-salt catalyst wastewater

ActiveCN102295378ATake advantage of highly concentrated processingHigh salt contentWater contaminantsWater/sewage treatment bu osmosis/dialysisSocial benefitsSeparation technology

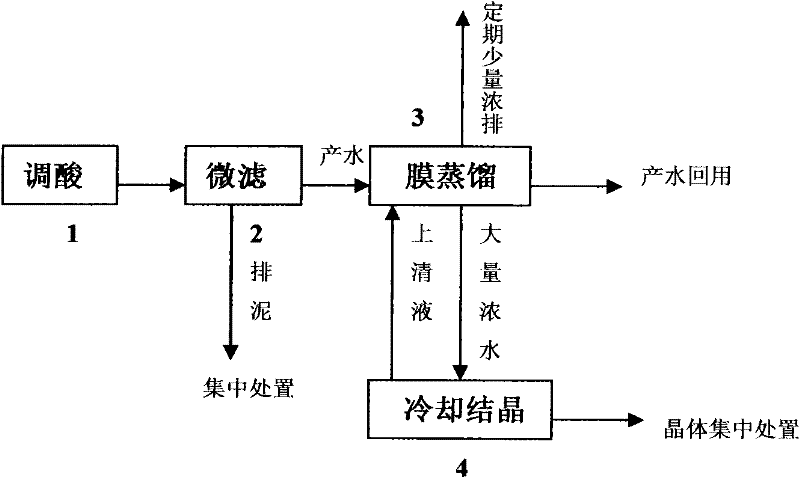

The invention relates to a recycling method for treating ammonia nitrogen containing high-salt catalyst wastewater by adopting a membrane separation technology. The process flow of 'acid regulation, micro-filtration, membrane distillation, cooling and crystallization' is adopted in the method. By adopting the process flow, salts, ammonia nitrogen and metal ions in the wastewater can be effectively removed, and deep treatment and recycle of the ammonia nitrogen containing high-salt catalyst wastewater are realized. The process flow makes full use of the technical advantages of membrane distillation, solves the problem that the discharge of high salts, ammonia nitrogen and metal ions of the ammonia nitrogen containing high-salt catalyst wastewater does not reach the standards, and realizes recycle of the produced water. After the ammonia nitrogen containing high-salt catalyst wastewater is treated by the process flow, the reclamation rate of the wastewater is more than 90 percent, and high recycle of the ammonia nitrogen containing high-salt catalyst wastewater is realized; and the method accords with the development strategies of energy conservation and emission reduction, and has remarkable social benefit and economic benefit.

Owner:CHINA PETROLEUM & CHEM CORP +1

Recycling method of high brine waste water based on forward osmosis

InactiveCN103304088AWide applicabilityGuaranteed long-term stable operationSemi-permeable membranesMultistage water/sewage treatmentWater basedWastewater

The invention discloses a recycling method of high brine waste water based on forward osmosis. The method comprises the following steps: firstly, concentrating high brine waste pretreated through a forward osmosis membrane element, wherein water in waste water enters into a driving liquid from a raw material side of a forward osmosis membrane; and then, concentrating, dehydrating and regenerating the diluted driving liquid obtained through one or more of a membrane distillation membrane element, a membrane distillation evaporation assembly or a low temperature multi-effect evaporation assembly, wherein regenerated driving liquid is recycled in the process of returning to forward osmosis. The method is widely applicable for the type of waste water, and has the advantages of long-term stable operation and low treatment cost.

Owner:何涛 +1

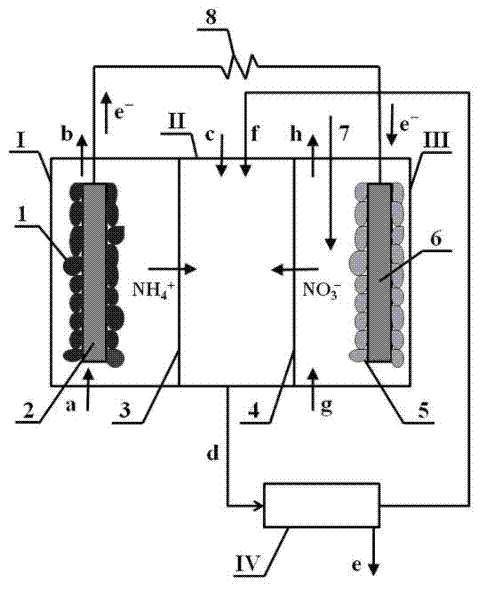

Nitrogen-containing sewage treatment process and device for synchronously producing electricity and recovering nitrogen element

InactiveCN102372398ARealize resource processingSimple structureFinal product manufactureBiochemical fuel cellsAnaerobic decompositionHigh concentration

The invention belongs to the technical field of water treatment, and in particular relates to a nitrogen-containing sewage treatment process and device for synchronously producing electricity and recovering a nitrogen element. The device comprises a bioelectrochemical system and a membrane distillation system, wherein the bioelectrochemical system comprises six parts, namely a positive electrode chamber, a positive membrane, a recovery chamber, a negative membrane, a negative electrode chamber, an outer circuit. The process comprises the following steps: entering nitrogen-containing sewage into the positive electrode chamber, carrying out microorganism anaerobic decomposition on pollutants and transferring electrons to a positive electrode, and further transferring the electrons to a negative electrode through the outer circuit so as to achieve electricity production; entering the nitrogen-containing sewage into the negative chamber for aerobic treatment, thus converting ammonia nitrogen into nitrate nitrogen; respectively entering ammonium radical in the positive electrode chamber and nitrate radical in the negative electrode chamber into the recovery chamber through the positivemembrane and the negative membrane under the driving of potential difference; and treating water in the recovery chamber with the membrane distillation system, and refluxing percolate to the recoverychamber, wherein a concentrated liquid is a solution containing high-concentration ammonium nitrate and the like, thereby achieving the recovery of the nitrogen element. The process provided by the invention is simple and has high efficiency and good economic benefits; and the treatment device is simple in structure, and is convenient for practical application.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

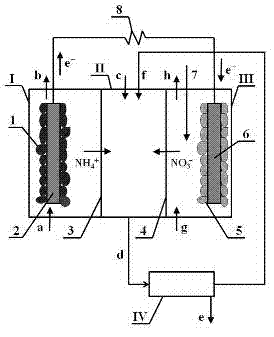

High-salt epoxy resin production waste-water film integrated salt recovery and biochemical treatment method

InactiveCN1850635ASolve the problem of high salinity alkaline wastewaterAdvanced technologySemi-permeable membranesMembranesHigh concentrationEpoxy

The invention discloses a membrane-process integration salt recovering and biochemical processing method for waste water from high-salinity epoxy resin production, purifying and splitting waste water, i.e. processing the washing waste waters of different salinities and concentrations, respectively: concentrating little amounts of waste water with high salinity and high concentration by membrance distillation integration technique and screening out salt; preprocessing large amounts of rinsing waste water with low salinity and low concentration of organic matters and then processing in a two-stage biochemical processing system, to meet the specified effluent standard. And it largely solves the problem of serious inhibition of high-salinity organic waste water to the biotreatment and adopts salt recovering and water recycling processes, and large amounts of waste heat can serve as a heat source of membrane distillation and the afterheat of the waste water can be used by the membrane distillation.

Owner:ZHEJIANG UNIV

Preparation method for microporous membrane having multi-scale gradient micro-structure surface

ActiveCN103611437APlay the role of inner support reinforcementControllable areaSemi-permeable membranesMicro structureUltrafiltration

The present invention relates to a preparation method for a microporous membrane having a multi-scale gradient micro-structure surface. The method comprises: fixing a screen mesh on the upper surface of a rough flexible substrate, coating a polymer solution layer with a thickness of 50-500 mum on the upper surface of the screen mesh at a constant speed, curing, washing, and carrying out simple mechanical peeling to remove the rough flexible substrate to obtain the microporous membrane having the multi-scale gradient micro-structure surface. According to the present invention, the process of the method is simple, the membrane area can be controlled, continuous production can be achieved, mechanical properties of the membrane are high, and the membrane has super-hydrophobic or super-hydrophilic property, wherein the super-hydrophobic membrane has super-lipophilic property, and the super-hydrophilic membrane has super-oleophobic property under water and has super-hydrophobic property under oil; and the obtained membrane can be adopted to effectively separate various oil and water mixtures including nano-scale oil water emulsions, and can further be used in fields of self-cleaning ultrafiltration / microfiltration membrane sewage treatments, medical sterilization, food turbidity removal, sterilization, material separation, membrane distillation, and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

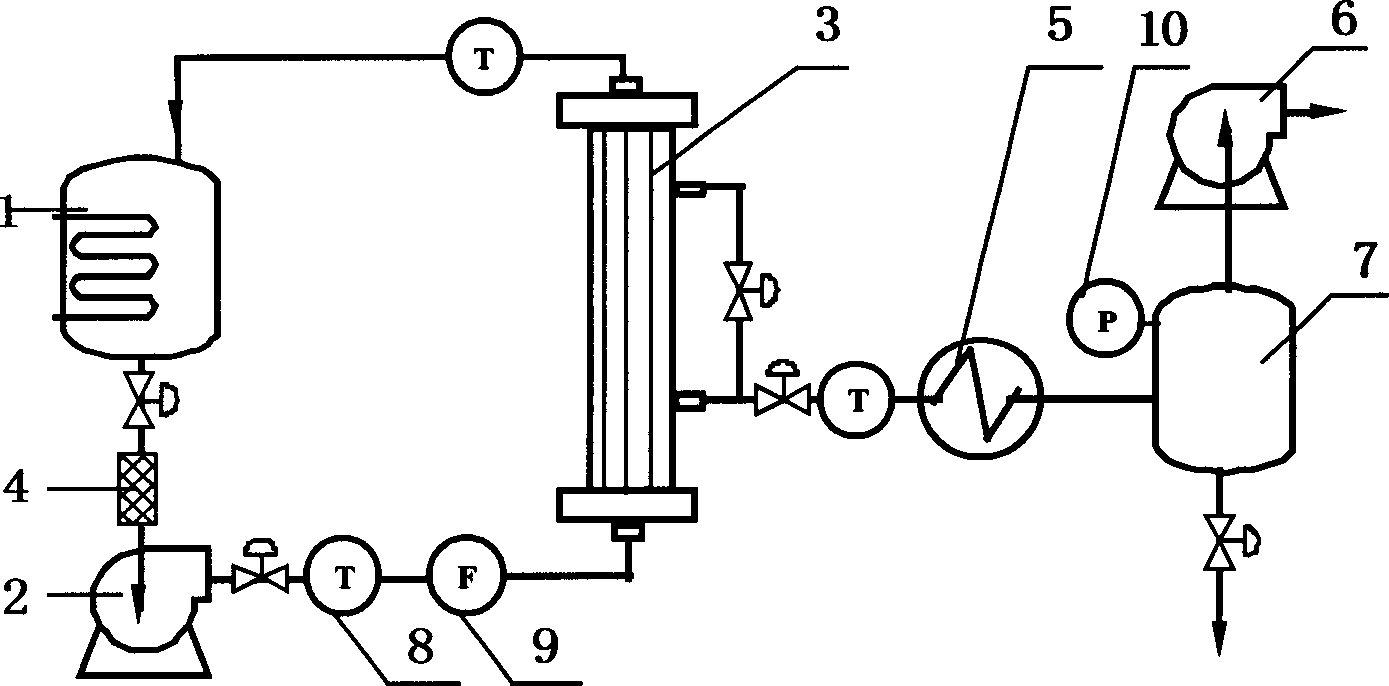

Method for treating epoxy resin waste-water with high alkalinity, high salt and high content of organics

InactiveCN101117258ASolve the problem of continuous operationRealize comprehensive utilizationWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentEpoxyFiltration

The invention discloses a disposal method of epoxy resin waste water with high alkalinity, high salt content and high organic content, the steps of which is as follows: (1) neutralization, membrane filtration; (2) membrane distillation; (3) evaporation and concentration; (4) crystallization. The invention solves the problem that the traditional biological treatment method can hardly dispose waste water with high alkalinity and high salt content (under the condition of high salt content and high alkalinity, biological bacterium is hard to survive). The invention has the advantages of advanced technologies, compact equipments, a small floor space and good water quality of effluents. The invention can effectively save energy and operating cost by utilizing afterheat of wastewater and low energy heat source generated during the process. Moreover, the invention can lower operating cost and create economic performances by recovering sodium chloride, byproducts during the process of manufacture.

Owner:ZHEJIANG UNIV +1

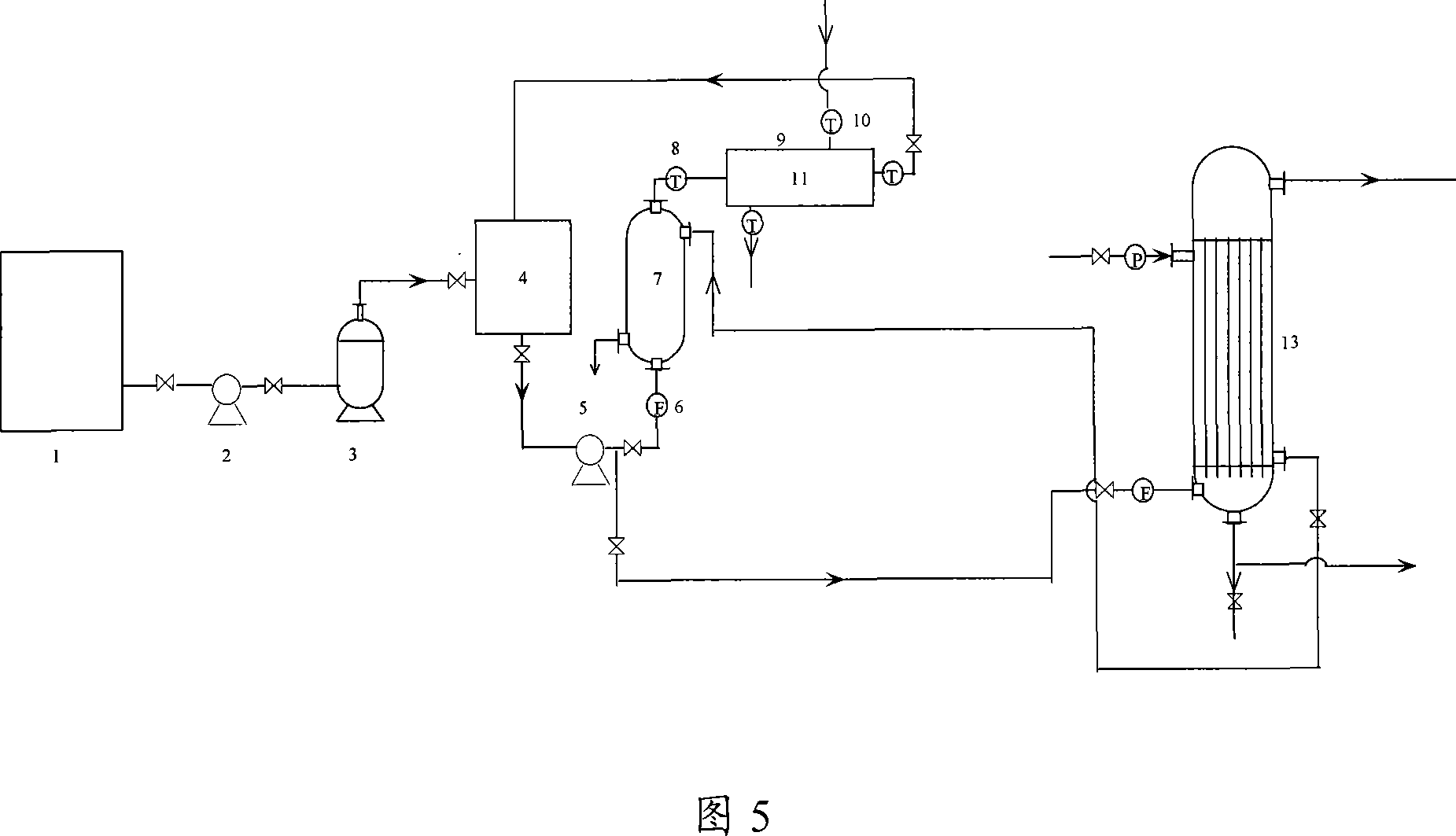

Method for treating high-salt water by air stripping type membrane distillation

ActiveCN101659451AReduce concentration polarizationIncreased turbulenceWater/sewage treatment bu osmosis/dialysisEnergy based wastewater treatmentHigh concentrationConcentration polarization

The invention provides a method for treating high-salt water by air stripping type membrane distillation. In the method, an air compressor is arranged in the system, a hydrothermal circulation pump and the air compressor jointly generate a gas-liquid two phase flow on a high-temperature side of a hydrophobic membrane, an electromagnetic valve is arranged on an air pipe, and pulse air intake is formed by the intermittent opening and closing of the electromagnetic valve. The method can effectively control membrane pollution and ensures the stable and high-efficiency operation of a membrane distillation device. The method has the main advantages of effectively relieving the concentration polarization of membrane distillation and preventing the formation of a gel layer due to the scraping effect of air bubbles on membrane surfaces in the gas-liquid two phase flow, and improving the turbulence scale of the membrane surfaces, increasing the membrane surface flow rate, reducing the concentration of membrane surface salt solution and increasing membrane permeation flux due to the adoption of pulse air intake. Air passing through a membrane component can be used for cooling membrane distillation penetrating fluid. The method of the invention can treat salt water with an extremely high concentration.

Owner:GO HIGHER ENVIRONMENT GRP CO LTD

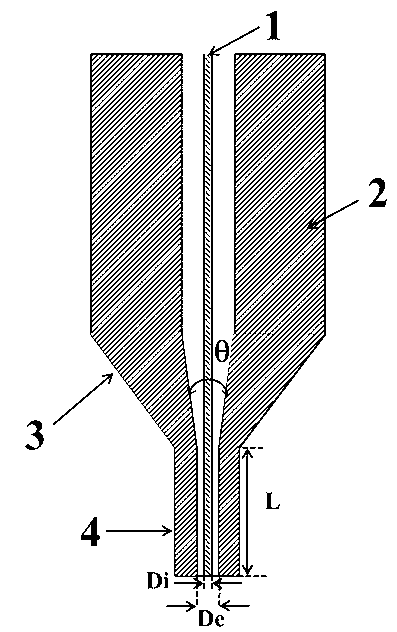

Preparation method of teflon hollow fiber membrane for membrane distillation

InactiveCN102941025ALow costAvoid loss of product water qualitySemi-permeable membranesIndustrial effluentPhysical chemistry

The invention discloses a preparation method of a teflon hollow fiber membrane for membrane distillation, which comprises the following steps of: mixing teflon dispersion powder and a extruding-aid agent, pressing a blank, extruding the blank into a teflon hollow tube through a pushing and pressing machine with a cone mould and a mouth mould, and performing longitudinal stretch, sintering and heat setting on the teflon hollow tube in a drying oven to obtain the teflon hollow fiber membrane. The processed teflon hollow fiber membrane is in an asymmetric structure, the mean pore size of an outer layer is 0.10-1.0 micrometer, the mean pore size of an inner layer is 5.0-20 micrometers, the wall thickness is 0.1-0.5 millimeter, the bubble point pressure is 0.5-2.0 kgf / square centimeter, and the water resistance pressure is 1.5-6kgf / square micrometer. The invention is mainly used for the membrane distillation separation process, and can be applied to the fields of sea water desalination, industrial wastewater treatment, cryoconcentration of food and biological products, and the like.

Owner:ZHEJIANG SCI-TECH UNIV

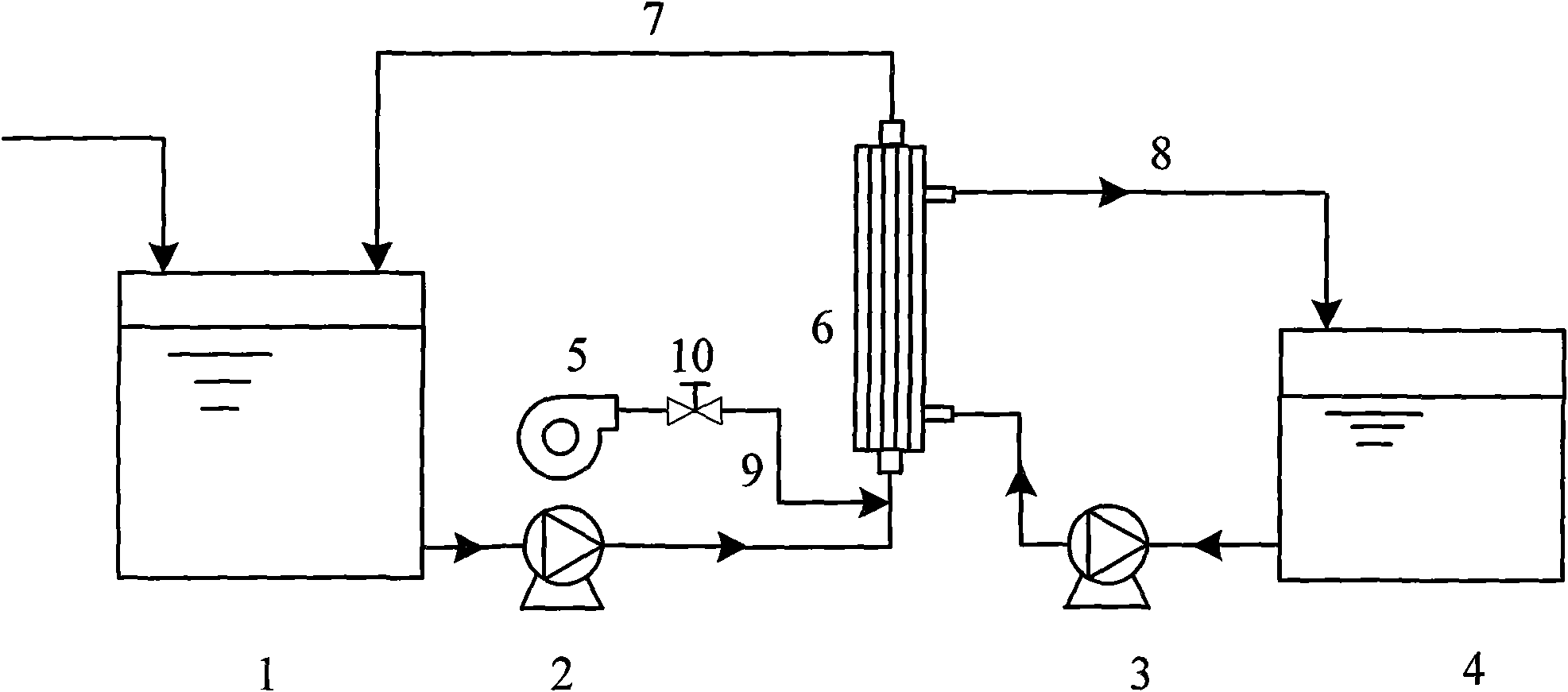

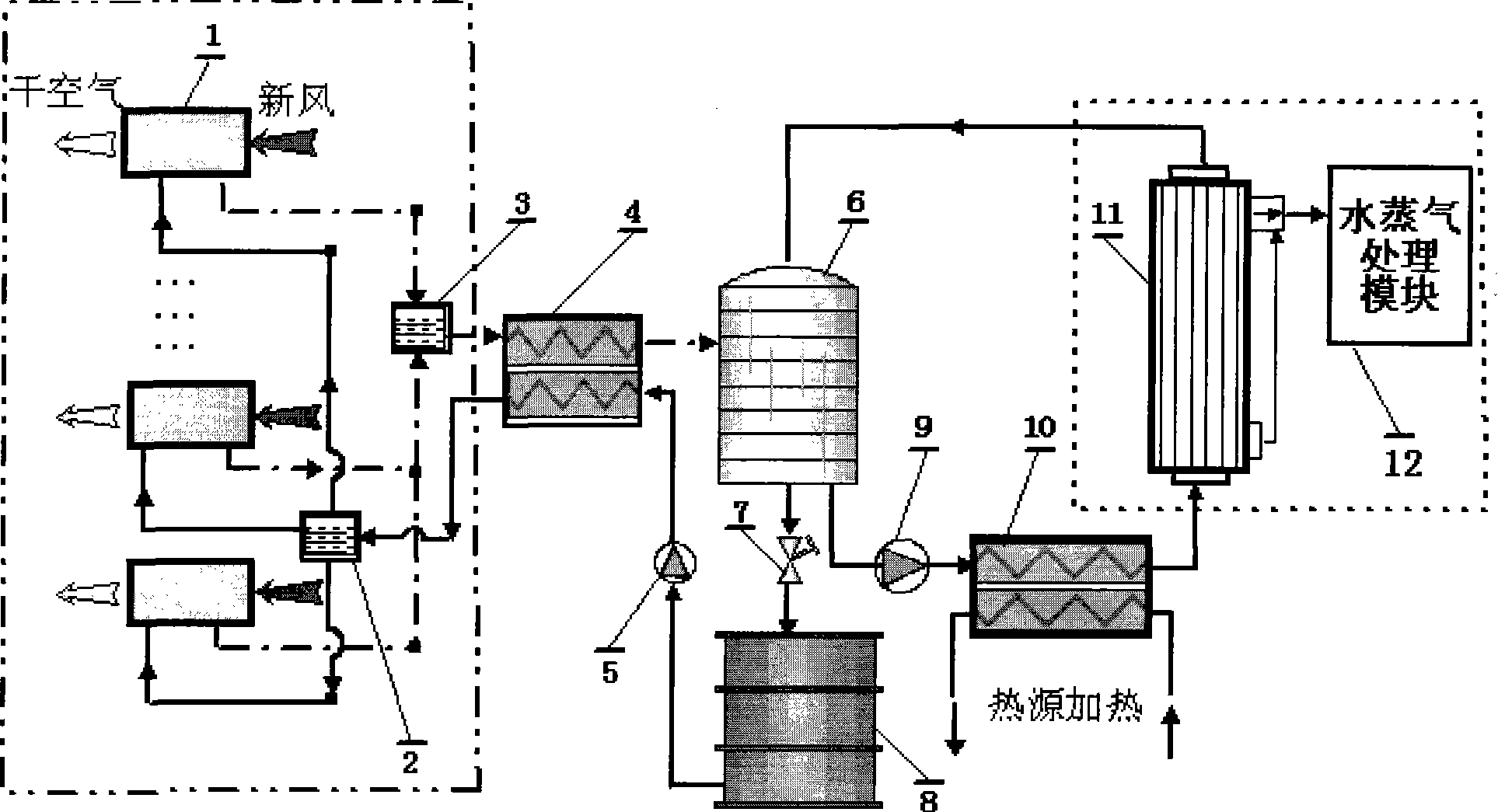

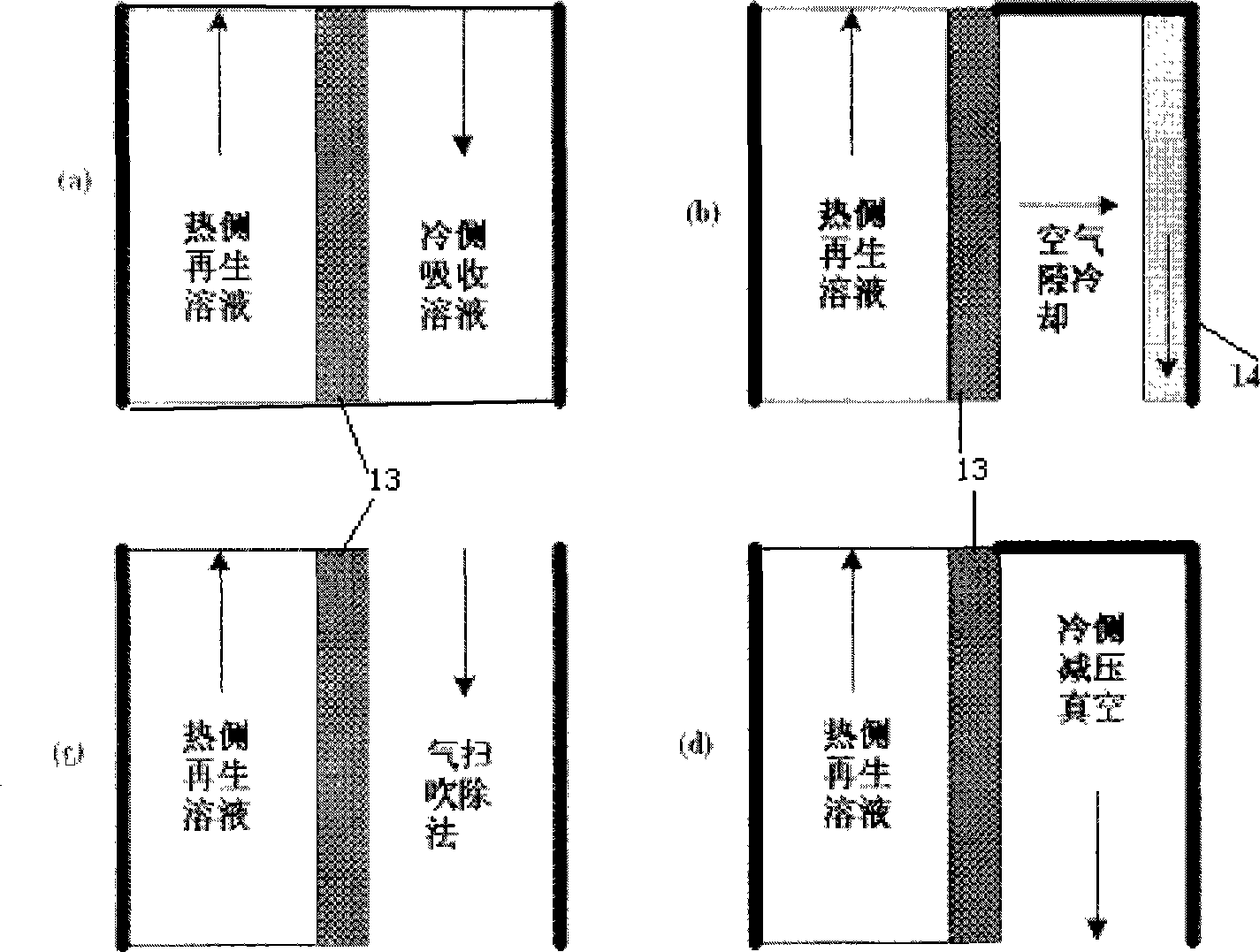

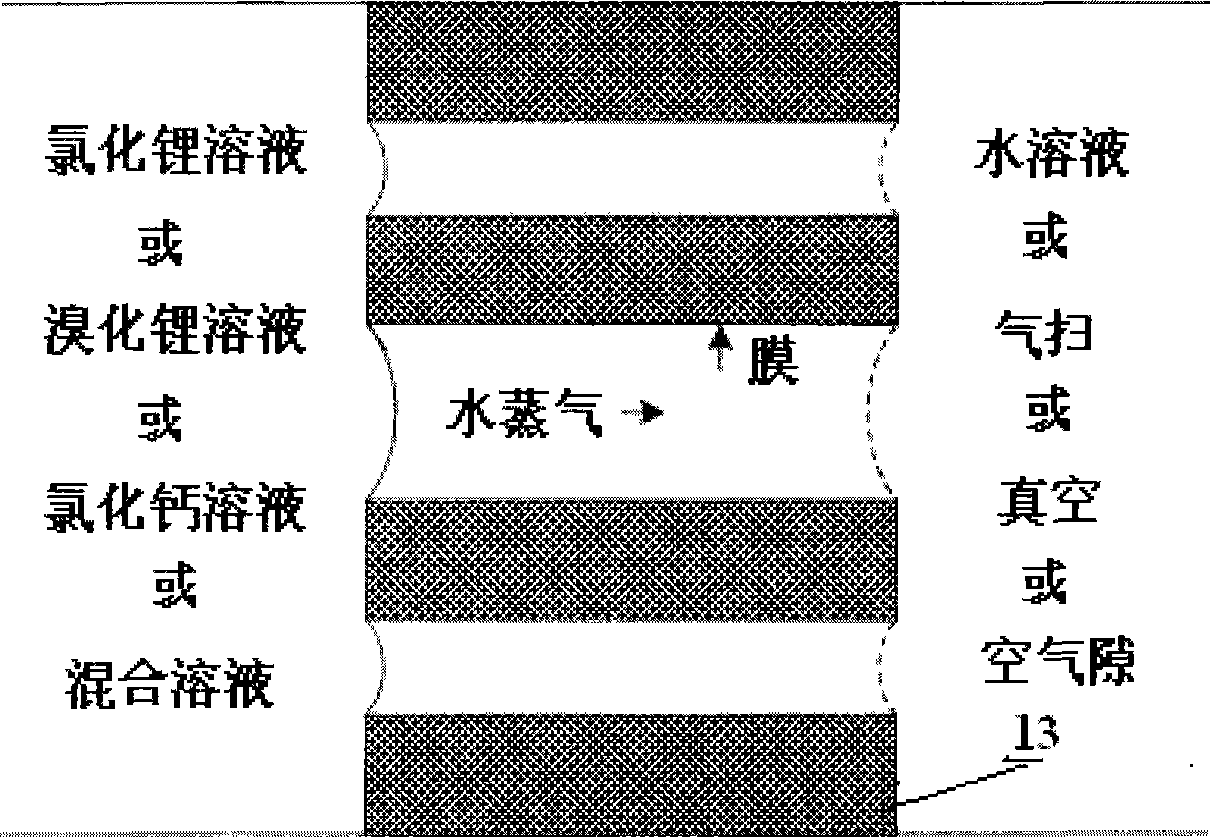

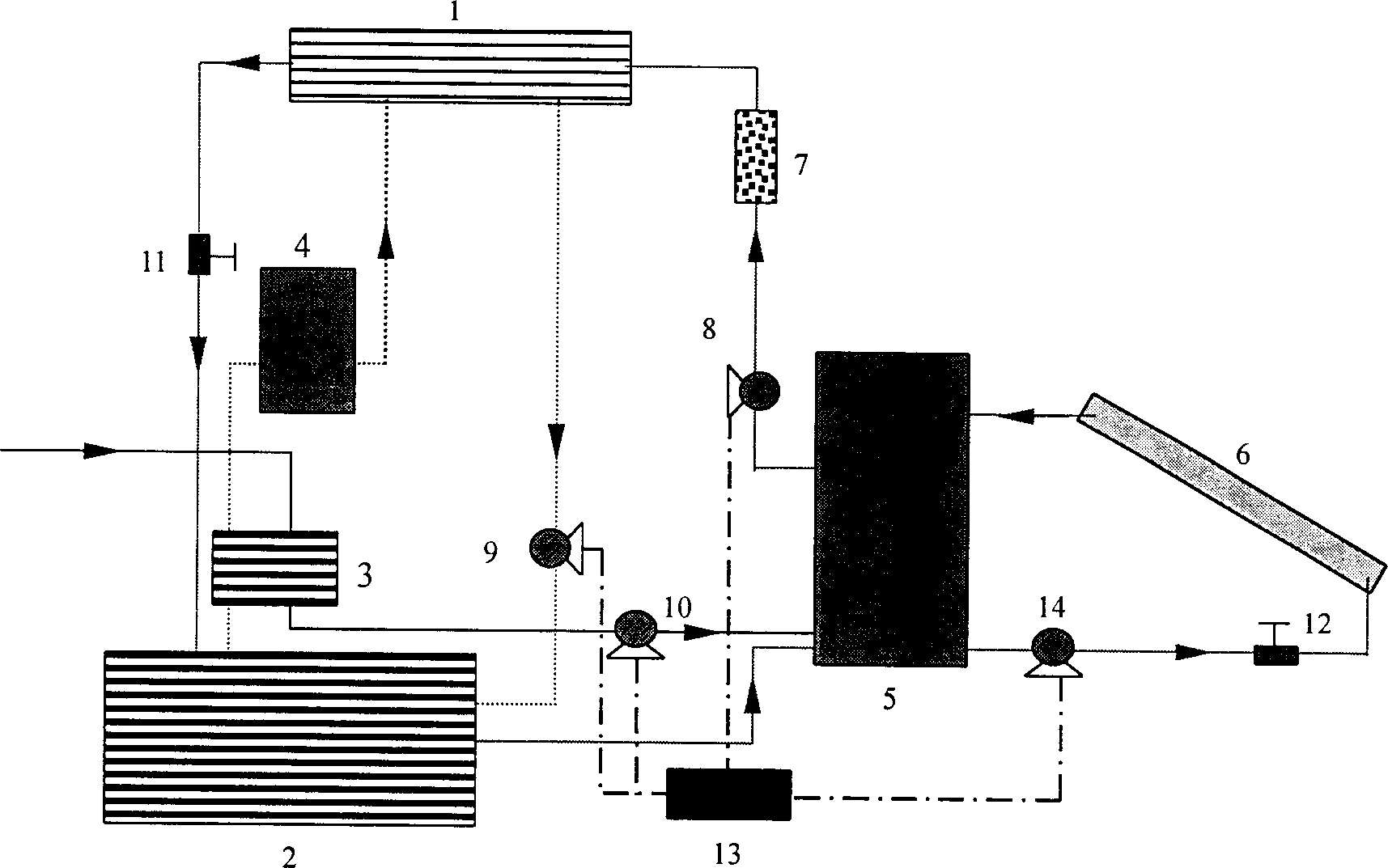

Solution regenerative device of solution dehumidifying air-conditioning system

InactiveCN101435608AWide choiceEasy to combineLighting and heating apparatusDispersed particle separationThermal energyWater vapor

The invention relates to a solution regeneration unit for a solution dehumidification air-conditioning system based on the membrane distillation technology, which mainly comprises a diluted solution reservoir, a concentrated solution reservoir, a solution heating device, a regenerative circulating pump, a water vapor treatment module and a membrane distillation component. By utilization of the characteristic in the membrane distillation technology that the temperature of driving heat source is low, the heat source temperature required by the solution regeneration process is greatly reduced, and the available temperature difference range of heat energy is increased; meanwhile, by utilization of the large contact area provided by a membrane component under unit volume and the expandability of the membrane component, the volume and the weight of a solution regeneration system are greatly reduced. Compared with the prior packed tower solution regeneration unit, the solution regeneration unit has low operating temperature and the heat energy during the operating process is only used for transmembrane latent heat transfer of water vapor, so that the energy consumption is small.

Owner:XI AN JIAOTONG UNIV

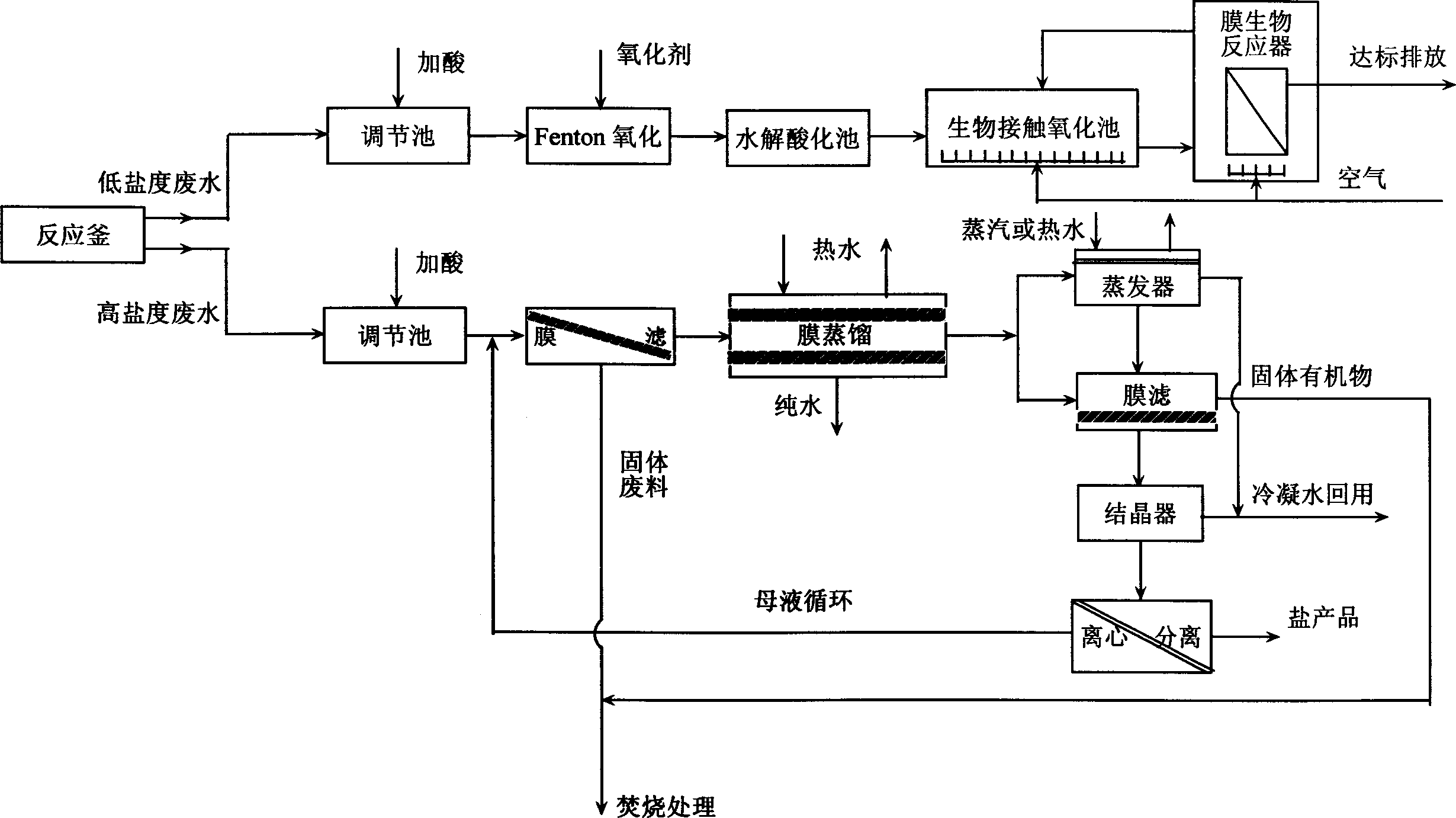

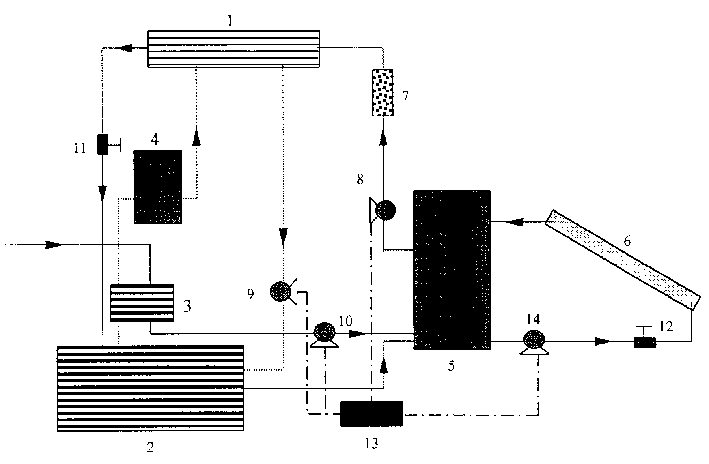

Energy-saving pressure-reduction distillation device and method

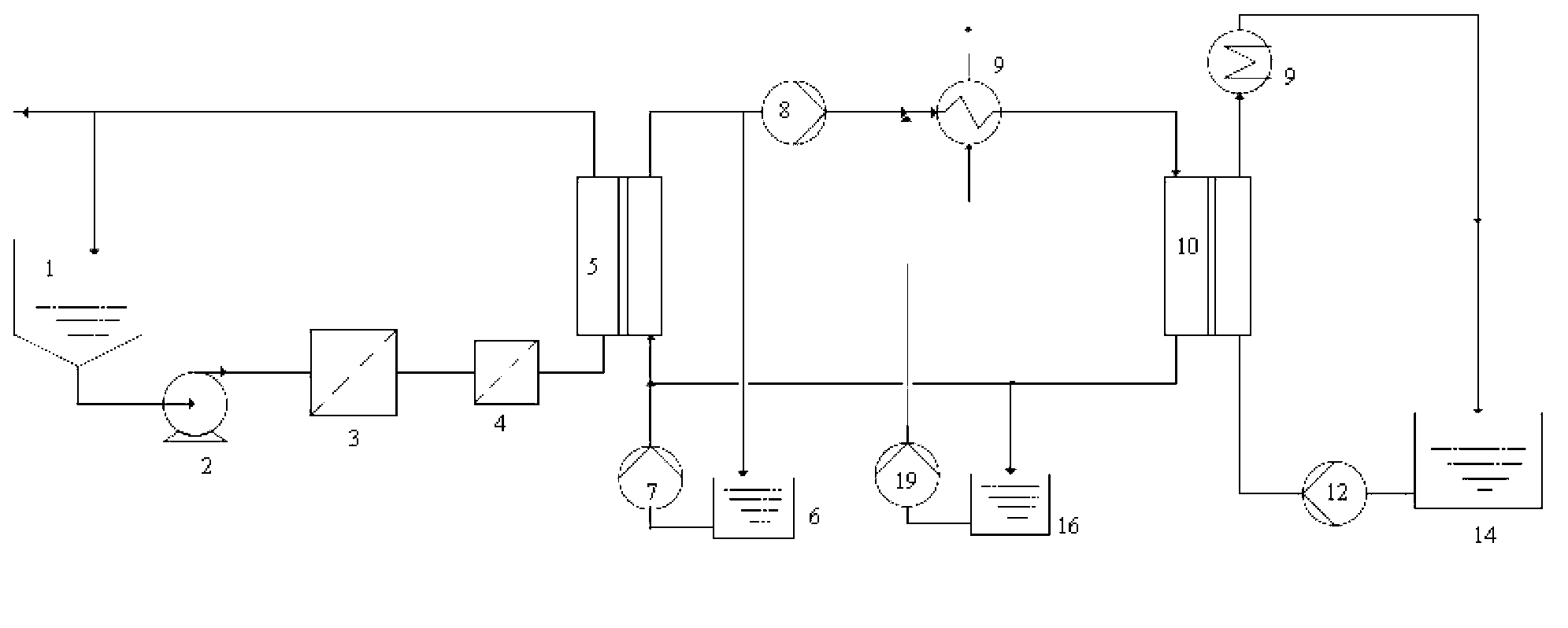

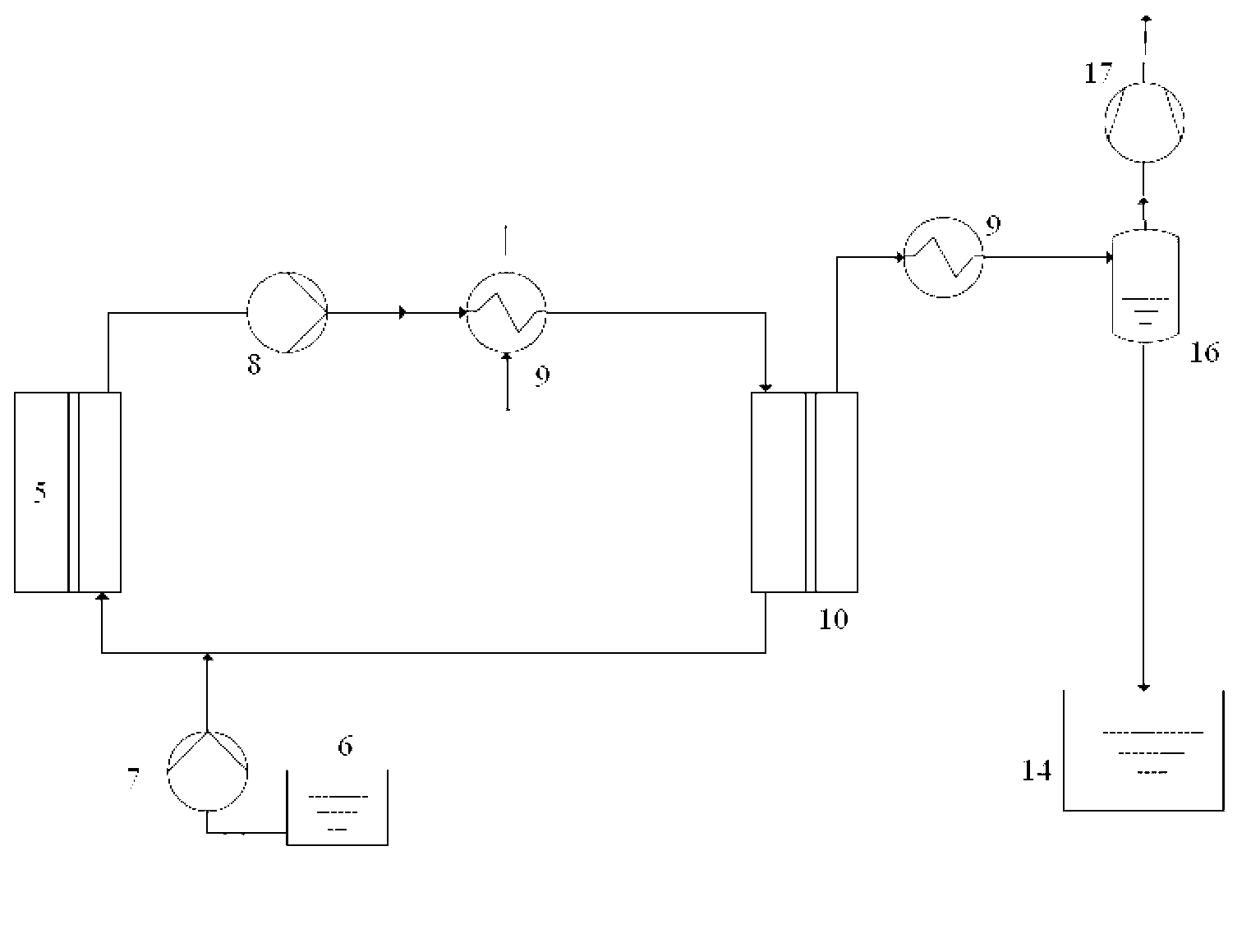

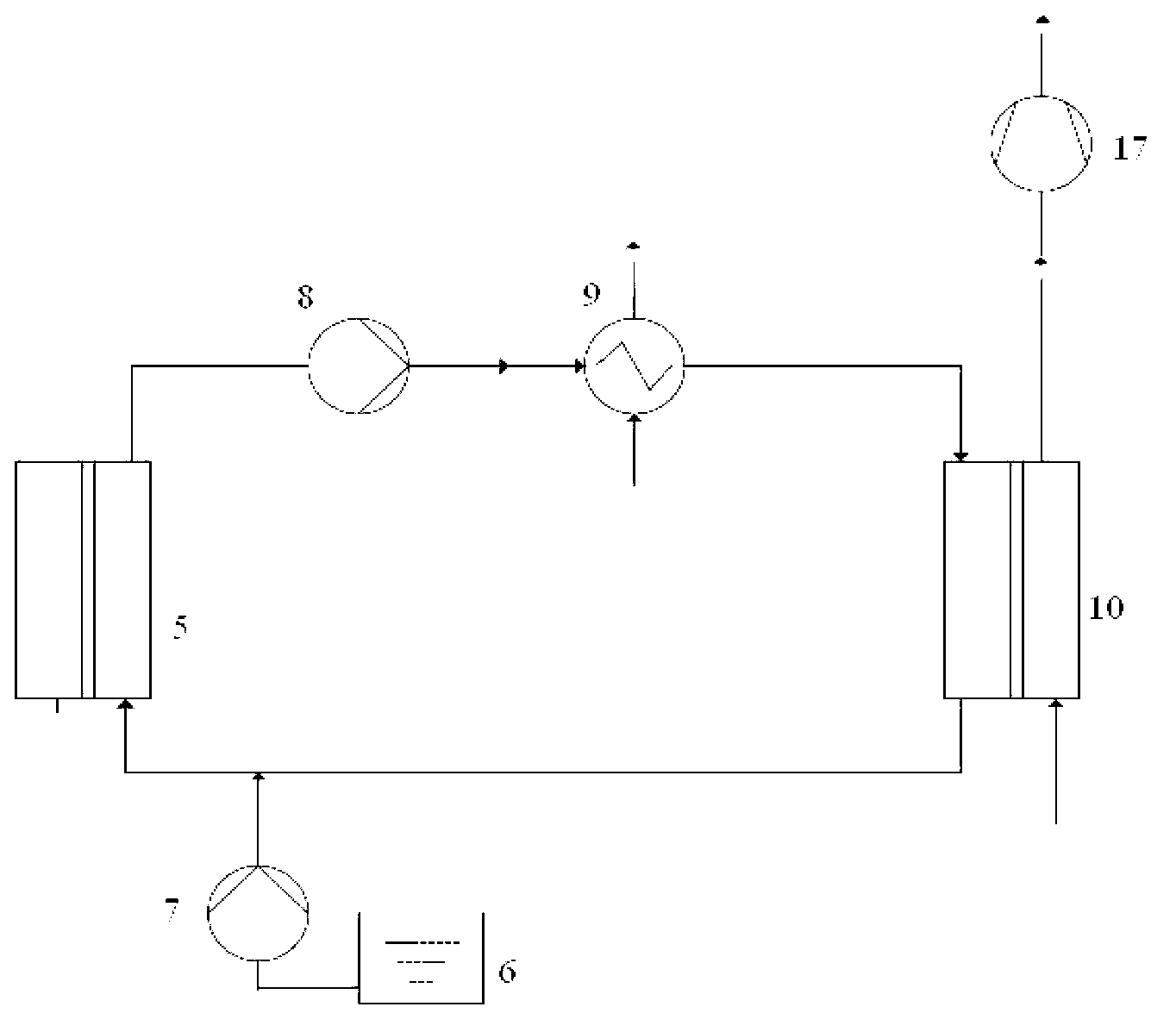

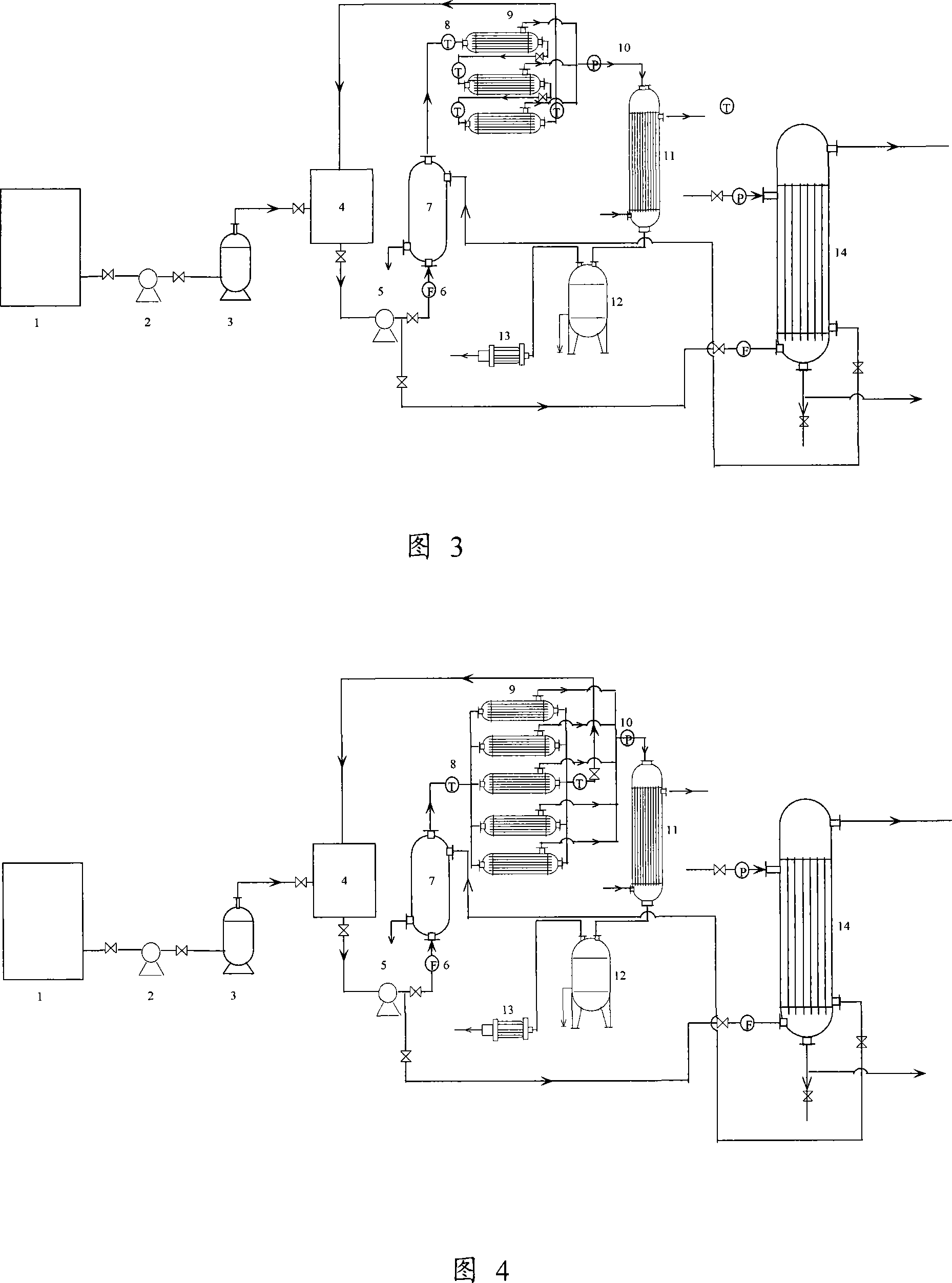

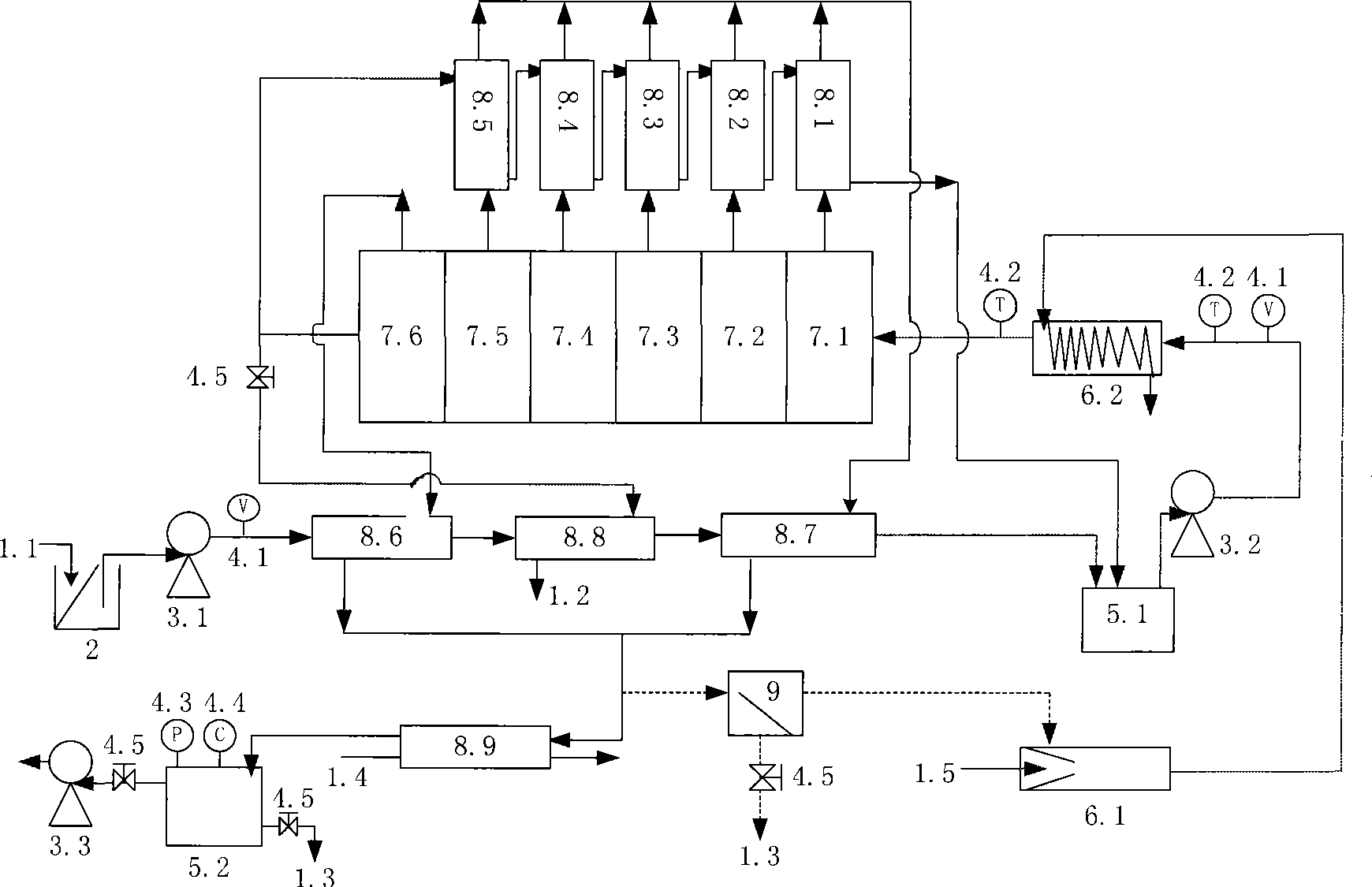

The invention relates to a vacuum membrane distillation (VMD) device and a method used for carrying out heat recovery effectively, comprising a membrane distillation system, a heat recovery system, a heating equipment, a vacuum equipment, a liquid circulation system, a pre-disposal system, system control and detection. The vacuum membrane distillation (VMD) device and the method can utilize low-temperature heat source, and have high heat utilization ratio, high desalinization ratio and wide application range.

Owner:海之凰(南通)环境科技发展有限公司

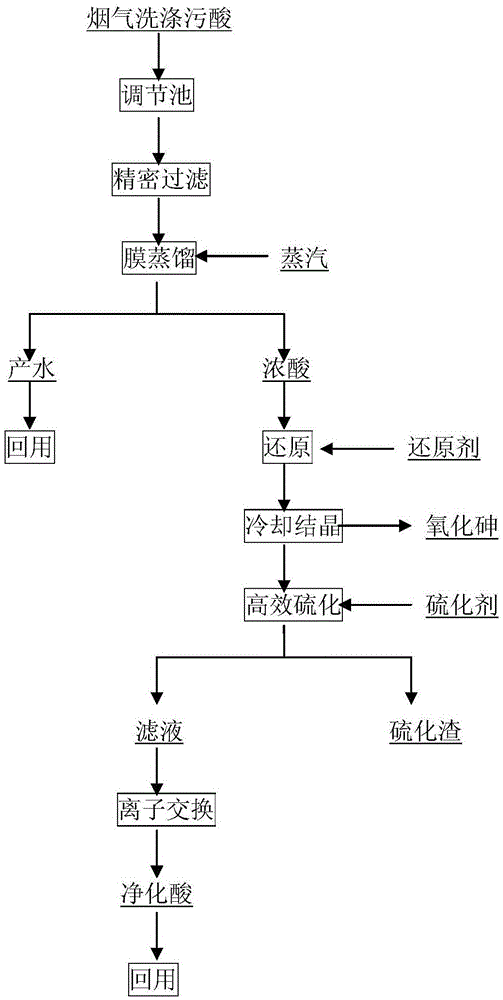

Method for purifying and recycling high arsenic polluted acid wastewater

ActiveCN105540973AEfficient separationQuality improvementWater contaminantsTreatment involving filtrationDistillationIon exchange

The invention provides a method for purifying and recycling high arsenic polluted acid wastewater. A main technique process comprises steps: filtering polluted acid, performing acid concentrating by membrane distillation and recycling condensed water, performing reduction on the concentrated acid, and then cooling to separate out arsenic trioxide, then sulfidizing to perform deep arsenic and heavy metal removing, and finally, removing fluorine and chlorine by ion exchange to obtain acid with low impurity and recycling for a system. The processing method effectively combines a traditional distillation technology and a membrane technology and can realize high quality recycle of purified water without affecting a smoke washing effect. The concentrated acid subjected to membrane distillation is subjected to efficient sulfidizing and then subjected to fluorine and chloride removing by ion exchange, thus providing guarantee for recycle of the concentrated acid. Enriching and concentrating of arsenic can be realized, the arsenic is reduced by a reducing agent, liquid is cooled and crystallized after reducing, 60 percent to 70 percent of arsenic is finally removed in a form of As2O3 from the polluted acid, the effective opening of the arsenic in a smelting system is realized, dosage of a subsequent sulfidizing or neutralizing agent can be greatly reduced, operation cost is reduced, an arsenic filter cake and waste residue are reduced, and secondary pollution risk to the environment is reduced.

Owner:CENT SOUTH UNIV +1

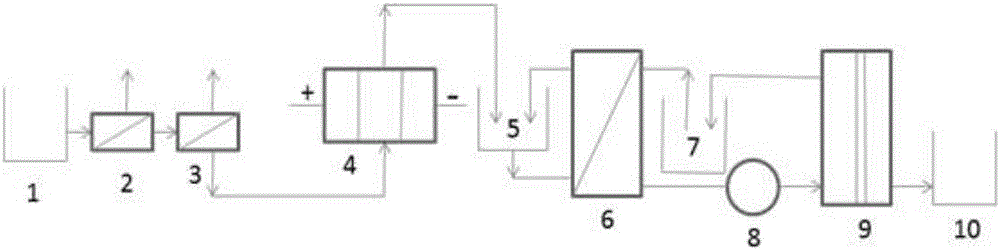

Device and method for treating high-salinity wastewater with forward osmosis technique

InactiveCN105712560AReduce saltPure waterWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentPotential differenceWastewater

The invention relates to a device and a method for treating high-salt wastewater by forward osmosis technology, belonging to the technical field of water treatment. The pretreated high-salt wastewater first passes through the fresh water chamber of the electrodialyzer, and the ions in the wastewater migrate to the concentrated water chamber under the driving force of the concentration difference and the potential difference, so that the salt content in the wastewater is reduced to a level suitable for forward osmosis. Conditions of technical processing. Then it is further concentrated through the forward osmosis membrane element, the water in the wastewater enters the draw liquid side from the raw material liquid side of the forward osmosis membrane, and then the obtained diluted draw liquid is concentrated, dehydrated and regenerated through the membrane distillation membrane module, and the concentrated draw The liquid is recycled in the forward osmosis process, and very pure product water is obtained. The method has wide applicability to high-salt wastewater, and has the advantages of long-term stable operation and high economic benefits.

Owner:BEIJING E & E TECH

Method and device for preparing methionine and recovering by-product-carbon dioxide

ActiveCN105671587ARealize cleaner productionReduce energy consumptionElectrolysis componentsElectrolytic organic productionHydantoin derivativesCo2 absorption

The invention discloses a method for preparing methionine and recovering a by-product-carbon dioxide. The method comprises the steps that a methionine salt and carbonate mixed solution obtained by hydrolyzing methylmercapto-ethyl hydantoin with alkali is filtered through a microporous membrane, and then filtrate is delivered to a bipolar membrane electrodialysis system to be subjected to electrodialysis treatment, so that acid liquor A and alkali liquor A are obtained; the alkali liquor A is treated continuously and cyclically, and the acid liquor A is subjected to gas-liquid separation, so that gaseous carbon dioxide and acid liquor B are obtained; the acid liquor B is delivered back into the bipolar membrane electrodialysis system to be subjected to cyclic treatment till the pH value of the acid liquor B is 3.8-4.5, the reaction is completed, a methionine solution is prepared, and the methionine is prepared through concentration and crystallization of the methionine solution; the gaseous carbon dioxide is introduced into an absorption cell, and carbon dioxide on the upper portion of the absorption cell absorbs mother liquor, is subjected to membrane distillation and concentration and then is circulated back to the absorption cell; carbonate crystals are grown at the bottom of the absorption cell and guided out from the bottom of the absorption cell; and carbonate is recovered through solid-liquid separation. According to the method for preparing the methionine and recovering the by-product-carbon dioxide, the gaseous carbon dioxide is recycled, so that carbon emission is reduced, and energy resources are saved through the membrane distillation technique.

Owner:浙江佰辰低碳科技有限公司

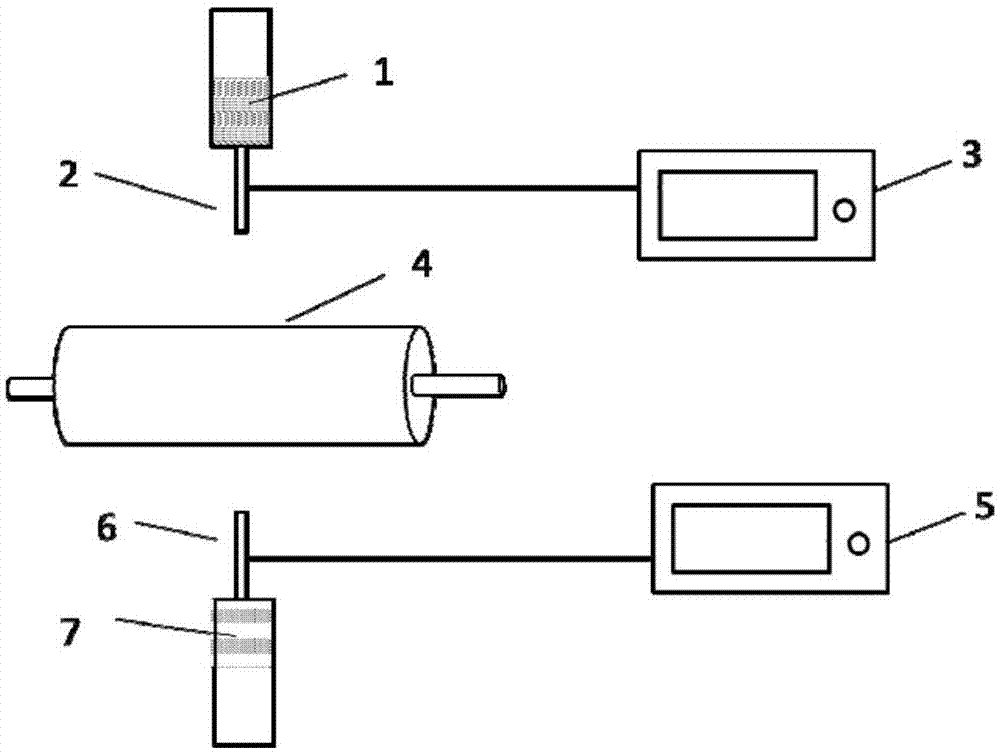

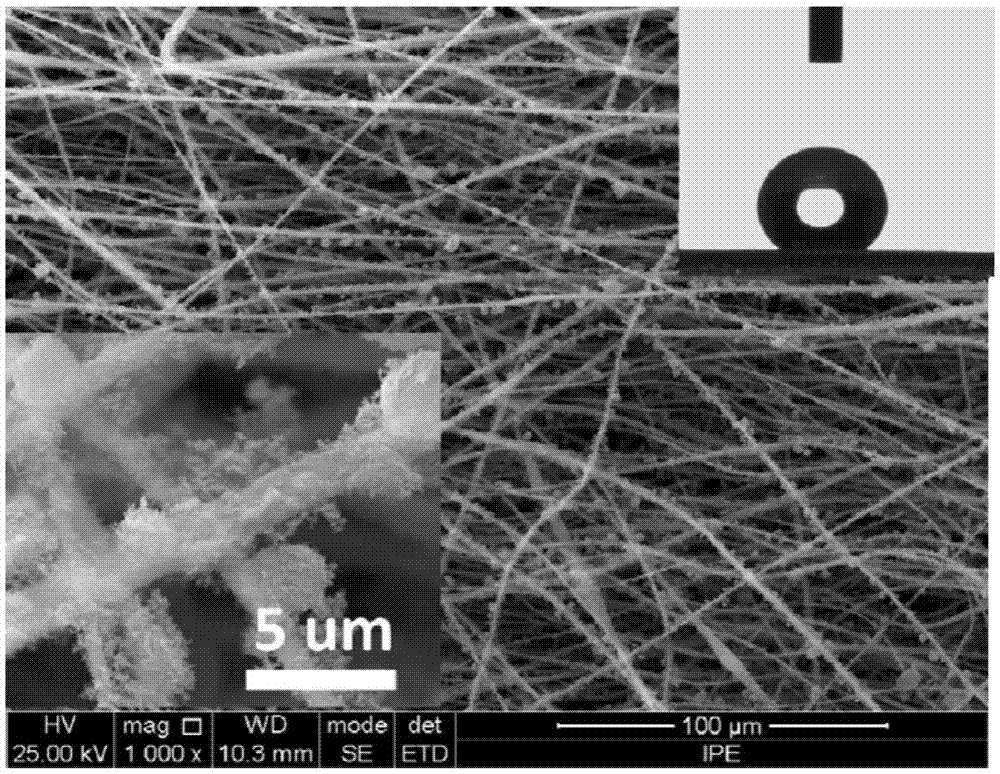

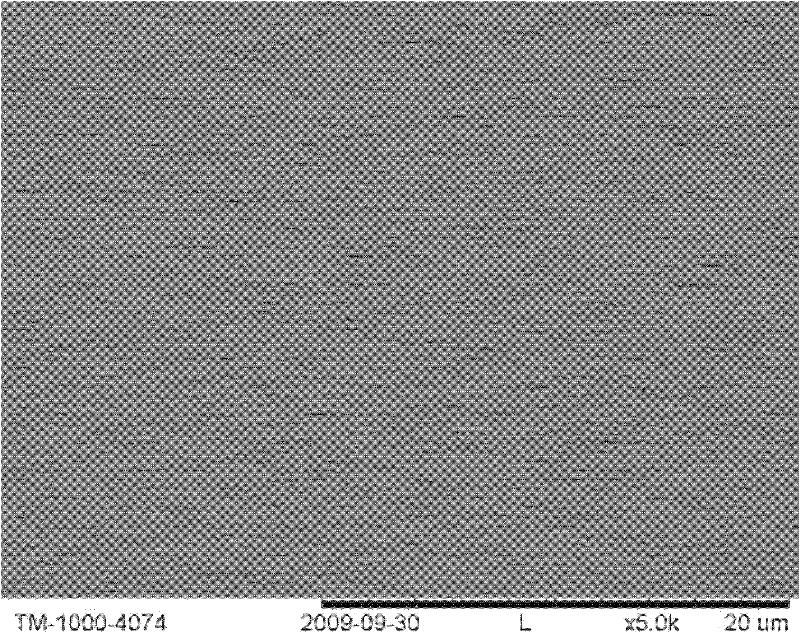

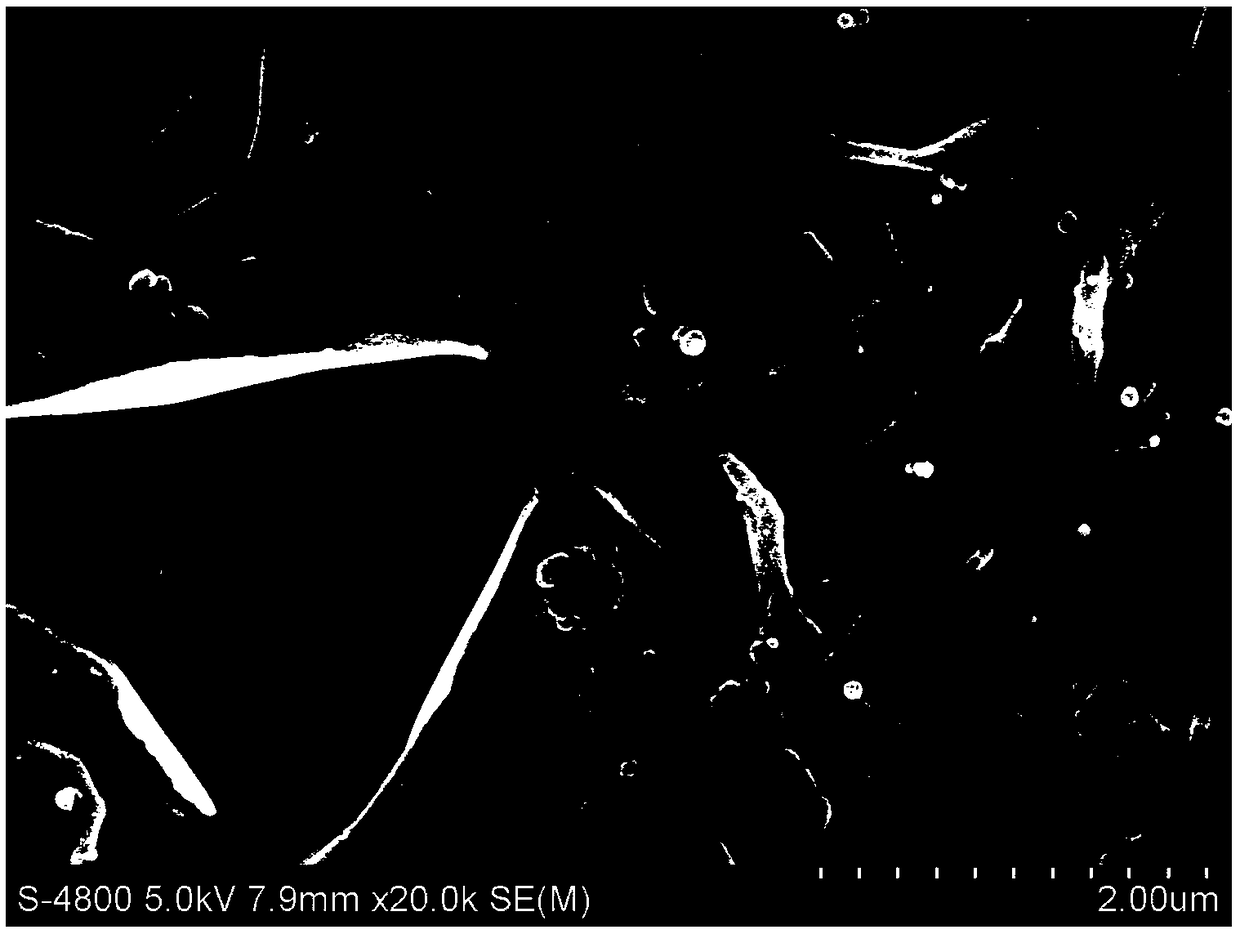

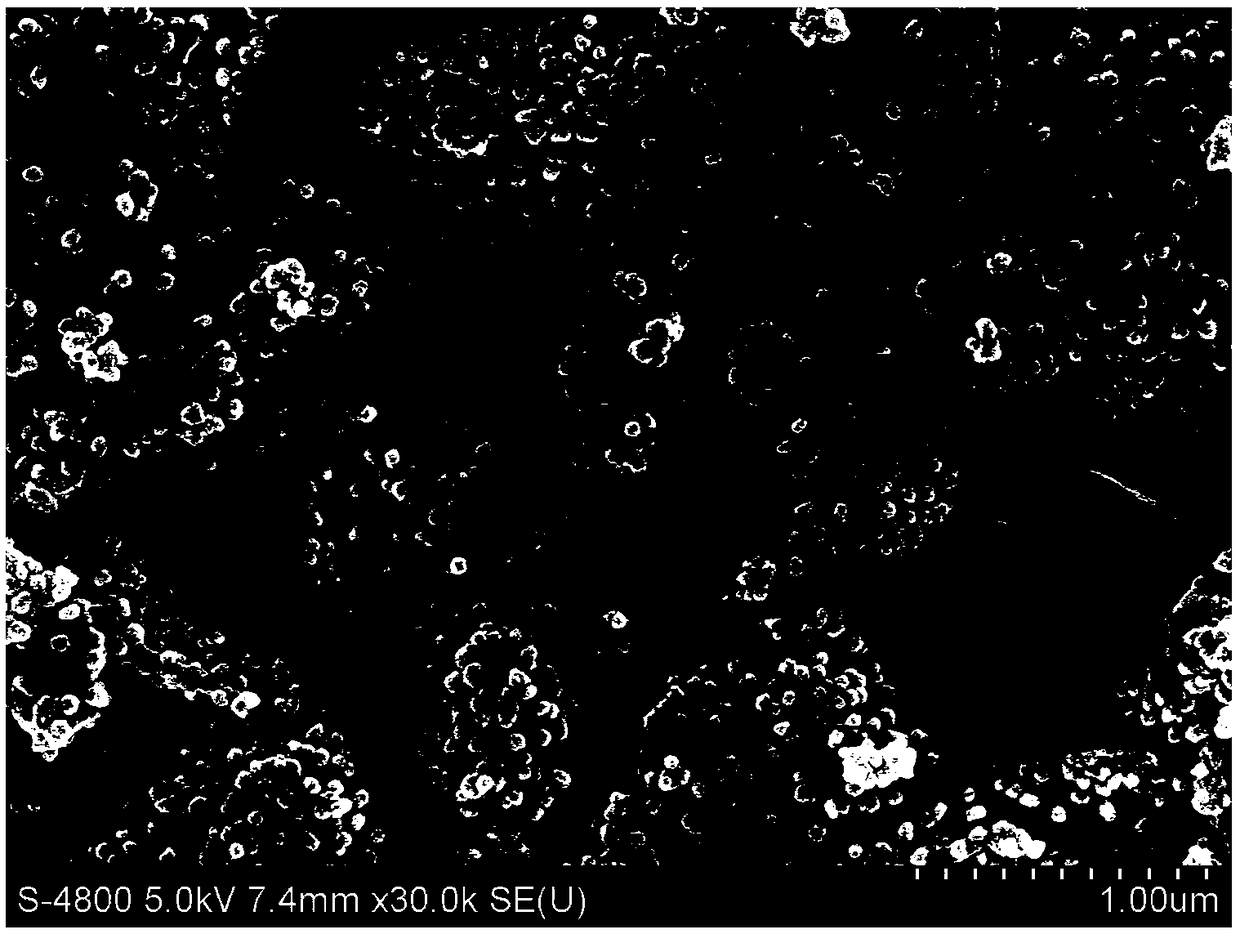

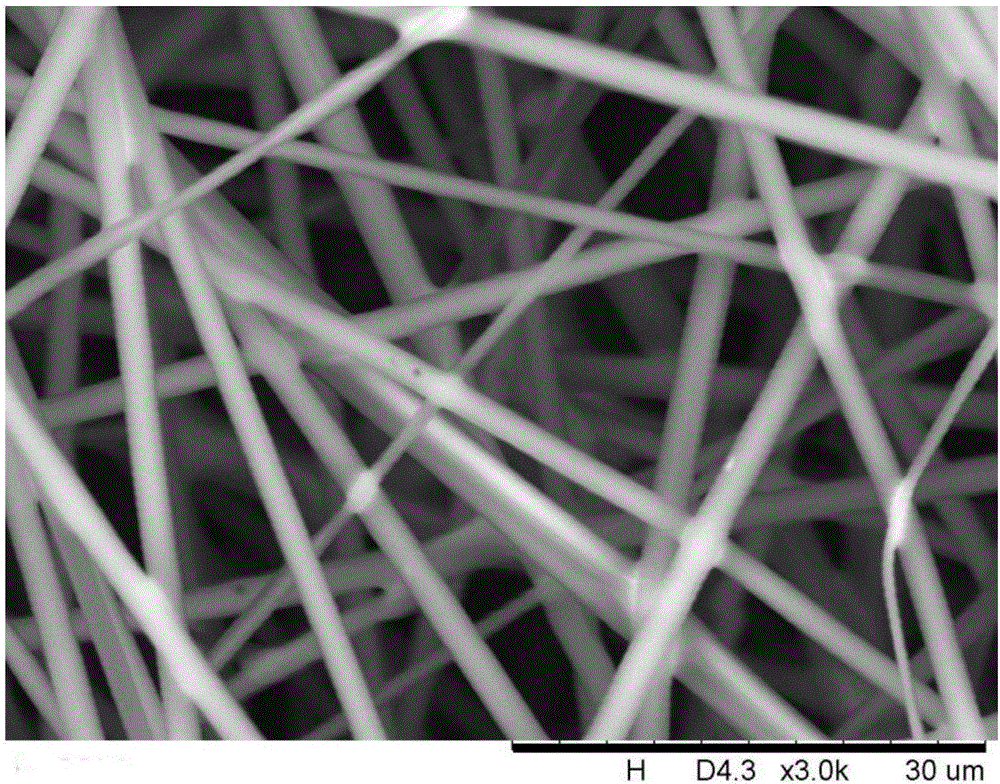

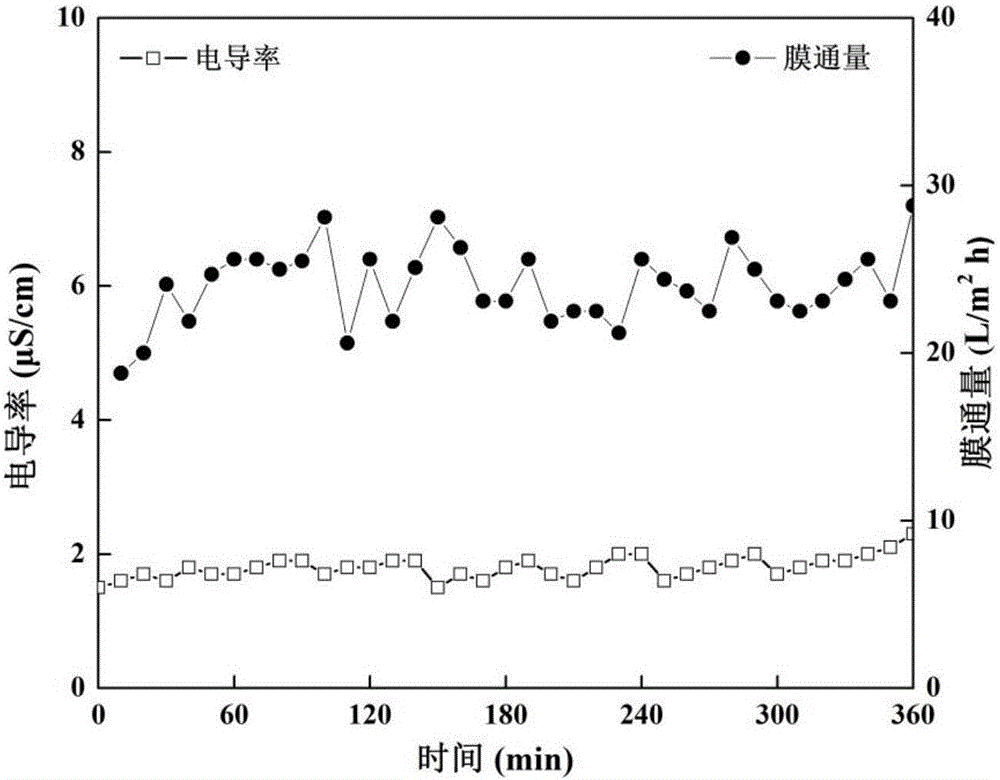

Nanofiber membrane for membrane distillation and preparation method of nanofiber membrane

ActiveCN106868712AHigh porosityStable super hydrophobic performanceElectro-spinningNon-woven fabricsPorosityNanofiber

The invention provides a nanofiber membrane for membrane distillation and a preparation method of the nanofiber membrane. The nanofiber membrane consists of nanofibers and nano branch structures distributed on the nanofibers. According to the method, a spraying (or atomizing) technology and an electrostatic spinning technology can be simply implemented synchronously, and the nanofiber membrane with superhydrophobic property for membrane distillation is prepared in a combined manner. The preparation method is simple, the process is easy to control, complicated preparation steps and expensive post treatment equipment are not required, the prepared nanofiber membrane is high in porosity, the surface of the membrane has uniform and excellent super-hydrophobicity, the plane, which is formed by the nanofibers, of each layer in the nanofiber membrane has the super-hydrophobicity, and therefore, the wetting resistance of the membrane can be greatly improved. The problems of low membrane flux and easiness in wetting are solved effectively.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Membrane distillation type water treating apparatus using solar energy or afterheat

InactiveCN1396120AGeneral water supply conservationWater/sewage treatment bu osmosis/dialysisThermal energyMembrane distillation

A membrane distillation apparatus using solar energy or afterheat to treat water is composed of membrane assembly, solar heat or afterheat collector, more than one circulating pumps and its driver, and pipeline. Its advantages are no need of electric energy, and continuous treatment of water.

Owner:TSINGHUA UNIV

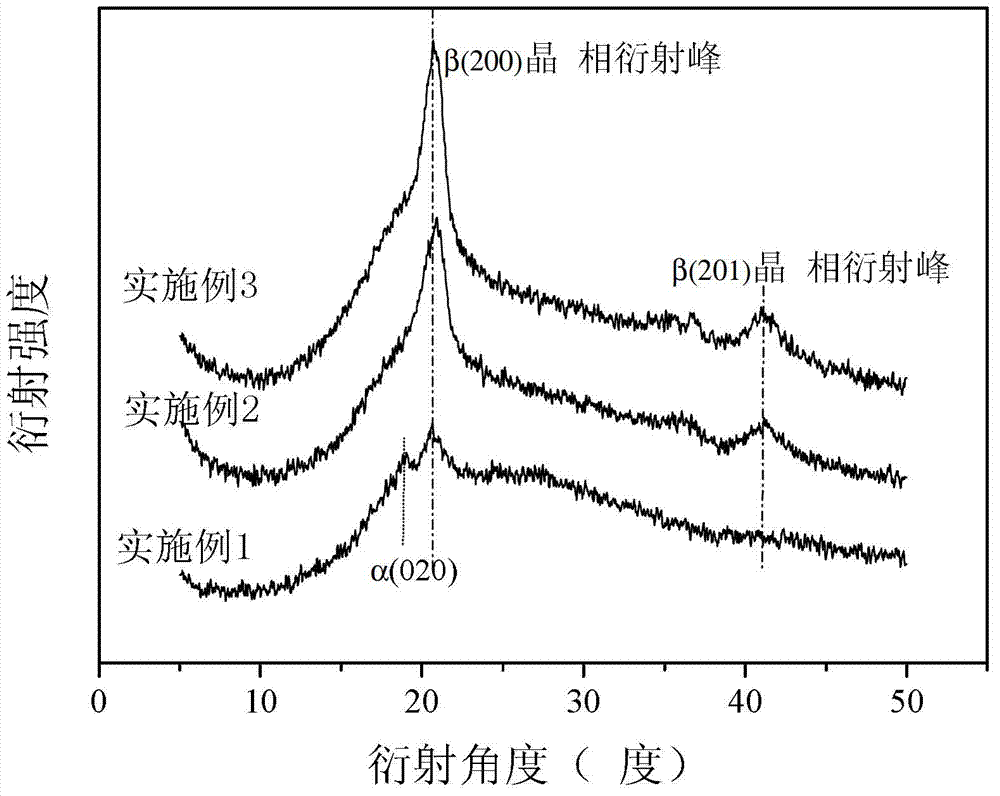

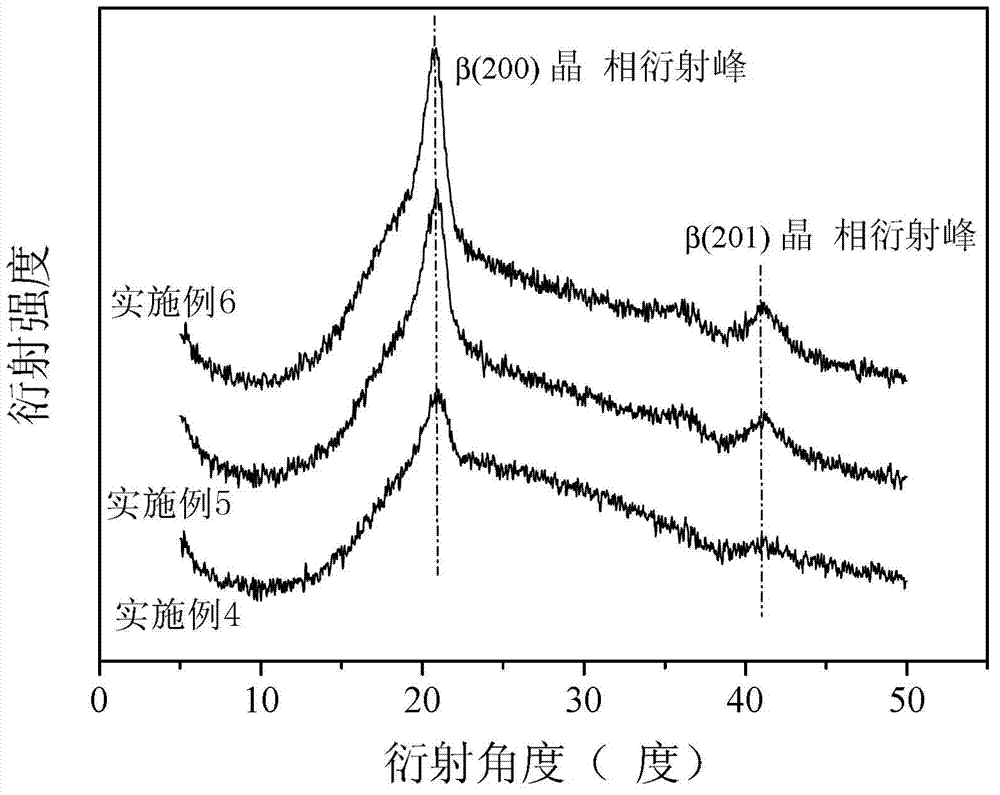

Preparation method and product of hydrophobic PVDF (Polyvinylidene Fluoride) microporous membrane with beta crystalline phase structure

InactiveCN102755841AImprove hydrophobicitySimple preparation processSemi-permeable membranesCrystallographyOrganic solvent

The invention discloses a preparation method of a hydrophobic PVDF (Polyvinylidene Fluoride) microporous membrane with a beta crystalline phase structure. The preparation method comprises the following steps of: dissolving ionic liquid and polyvinylidene fluoride into an organic solvent I and stirring for at least 8 hours to prepare uniform membrane formation solution; defoaming the membrane formation solution, scraping a primary flat plate liquid membrane of 150-250 mum on a flat plate carrier, remaining in air for 30-50 seconds and soaking the primary flat plate liquid membrane into a solidification bath to cure and form a membrane; and soaking the membrane formed by curing and membrane formation in de-ionized water to prepare the hydrophobic PVDF microporous membrane with the beta crystalline phase structure. The invention also discloses the hydrophobic PVDF microporous membrane with the beta crystalline phase structure prepared by the method. The preparation method of the hydrophobic PVDF microporous membrane with the beta crystalline phase structure has the advantages of simple process and low preparation cost; and the prepared PVDF microporous membrane has strong hydrophobicity and has excellent application value in the aspects of membrane distillation, oil / water separation and the like.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

Hydrophobically modified distillation membrane material of high throughout and high salt rejection rate and application thereof

InactiveCN102228801AImprove throughputHigh Salt RejectionEnergy based wastewater treatmentWater/sewage treatment by heatingProtein solutionFruit juice

The invention discloses a hydrophobically modified distillation membrane material of high throughout and high salt rejection rate and its application. For the material of the invention, ultrafiltration or microfiltration membrane materials are employed as the basic membrane material, the surface of which is subjected to cleaning and etching pretreatment by means of drying and plasmas. Then the surface of the basic membrane material is modified with a modification material by gas phase, liquid phase or plasma modification, thus obtaining the hydrophobically modified distillation membrane material of high throughout and high salt rejection rate. The invention discloses a novel hollow fiber membrane material with hydrophobic surface modification, and the membrane material is characterized by high throughout, high salt rejection rate and high stability. The distillation membrane material provided in the invention can be used for direct contact membrane distillation or sweeping gas membrane distillation or vacuum membrane distillation, and is applicable to the treatment of seawater, reverse osmosis concentrated wastewater and industrial wastewater, and the concentration of biomass solution, protein solution and fruit juice.

Owner:何涛 +1

Method for synergistic treatment and harmless cyclic utilization of refuse fly ash by using cement kiln

ActiveCN105478438AIncrease temperatureAvoid foulingSolid waste disposalSnow meltingMembrane distillation

The invention relates to a method for synergistic treatment and harmless cyclic utilization of refuse fly ash by using a cement kiln. The method for synergistic treatment and harmless cyclic utilization of refuse fly ash by using thecement kiln comprises a three-stage washing desalination technology, a technology of removing heavy metals by coagulation and sedimentation, a membrane distillation concentration technology, a technology of removing slight trace carnallite and a triple-effect evaporation crystallization technology, wherein the three-stage washing desalination technology can remove heavy metals and chloride ions in the fly ash, and the fly ash which contains water and dioxin and the fly ash which contains less than 1% of chlorine ions enter the cement kiln and are incinerated at the temperature of above 1400 DEG C to turn into cement raw materials, and the dioxin is split at the temperature of above 800 DEG C; the technology of removing the heavy metals by coagulation and sedimentation can remove multiple metal ions in the fly ash, and precipitates are dried in advance and then enter the cement kiln to be incinerated; the membrane distillation concentration technology can remove the rest of chloride ions in a solution, and generated distilled water can be recycled; the technology of removing the slight trace carnallite can remove the slight trace carnallite, and heat energy can be recycled; and the triple-effect evaporation crystallization technologyevaporates and separates high salt content concentrated liquid to obtain industrial salt which is used for a paper making technology, snow-melting agents and chloro-alkali industries.

Owner:HUZHOU SENNUO MEMBRANE TECH ENG

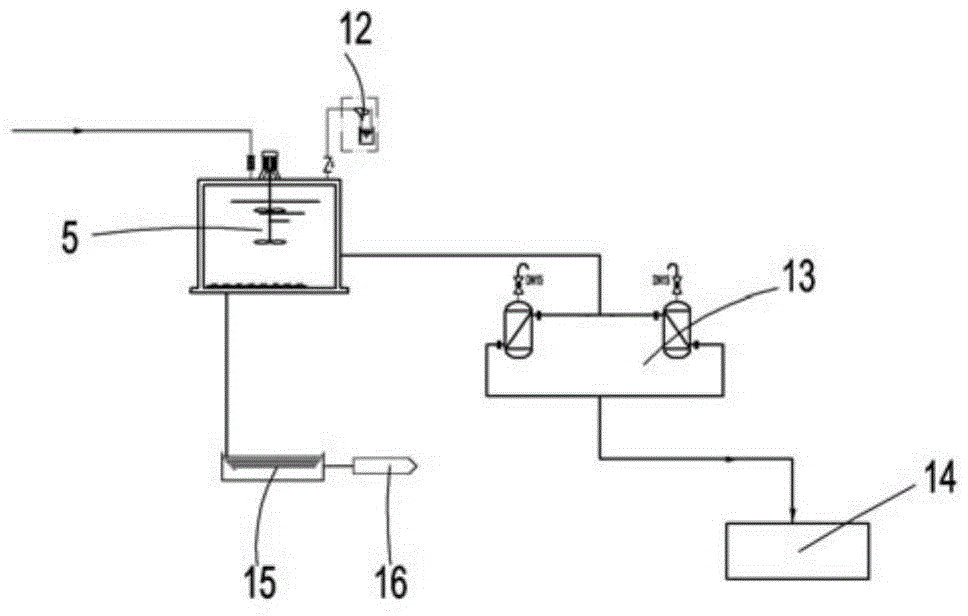

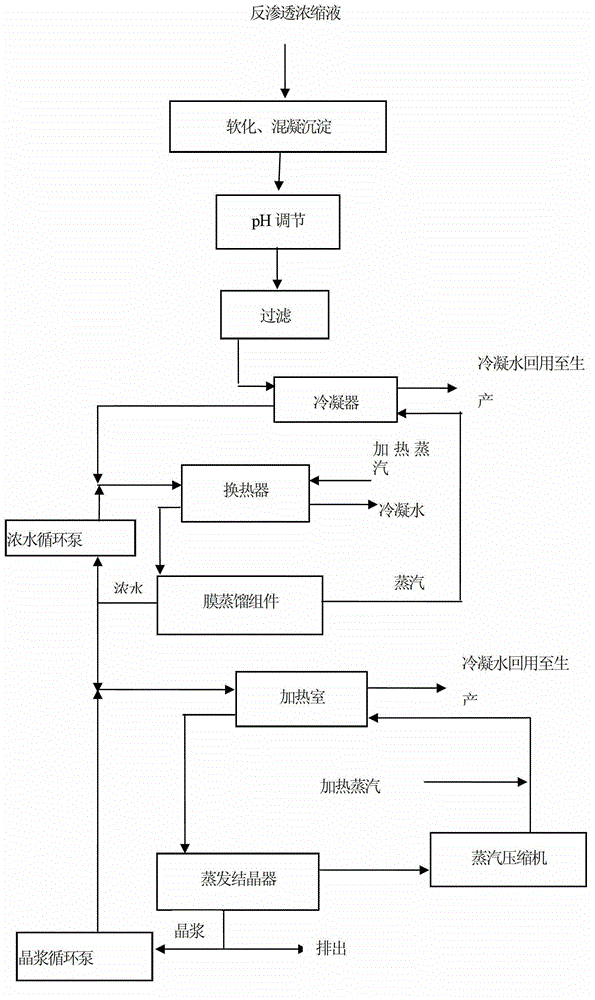

Zero discharge method of stainless steel cold rolling acidic waste water concentrated liquid

InactiveCN104058536AAchieving zero emissionsImprove economyGeneral water supply conservationWaste water treatment from metallurgical processInorganic saltsSocial benefits

The invention provides a zero discharge method of stainless steel cold rolling acidic waste water concentrated liquid, which orderly comprises the following steps: (1) softening, and coagulating sedimentation; (2) pH adjustment; (3) filtration; (4) membrane distillation, that is, heating the waste water concentrated liquid treated in step (3) to 55-75 DEG C, allowing the waste water concentrated liquid to enter a membrane distillation assembly, wherein the obtained condensed water can be recycled for production; (5) evaporative crystallization, that is, allowing the concentrated liquid discharged after membrane distillation treatment in step (4) to enter an evaporating crystallizer for evaporative crystallization to obtain crystal slurry, heating the crystal slurry in a heating chamber to 95-100 DEG C, allowing the heated crystal slurry to enter a crystallization chamber, boiling the crystal slurry to allow the solution to reach a saturation state, and discharging the generated crystals. The zero discharge method of the invention carries out membrane distillation and evaporative crystallization treatment of concentrated liquid generated by reverse osmosis desalination treatment of stainless steel cold rolling waste water, recycles obtained pure water for production, converts inorganic salt in the concentrated liquid into solids, realizes zero discharge of waste water, and has good social benefit and environment benefit.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Preparation method of super hydrophobic and oleophobic film for dual-bionic film with photothermal effects

ActiveCN108722200ASimple processEasy to operateWater/sewage treatment bu osmosis/dialysisDistillationDistillationMembrane distillation

The invention discloses a preparation method of a super hydrophobic and oleophobic film for a dual-bionic film with photothermal effects and used in the field of membrane distillation. According to the method, a porous film substrate is put into a buffer solution containing dopamine so as to obtain a polymerized dopamine modified film material; then, silver nitrate solution is used for treating the film material with the dopamine coating; a rough structure is built; finally, a low-surface-energy substance is used for performing fluorination treatment; the material surface energy is reduced; the super hydrophobic and oleophobic separation film with the micro nanometer delamination structure and the photothermal effects can be obtained. The method is mainly used for solving the problems of low film flux, serious film pollution phenomenon and the like in the film distillation field. The operation is simple; the realization is easy; the structure of the film material cannot be damaged; inaddition, the film flux can be improved; the film pollution phenomenon can be avoided; practical application value is realized.

Owner:TIANJIN UNIV

Vapor compression membrane distillation system and method

A desalination system wherein a latent heat of condensation produced by the temperature gradient across a membrane distillation (MD) module is transferred directly to a latent heat of vaporization during desalination of a liquid flow stream. The desalination system comprises the MD module disposed within an object and configured to receive an input feed stream for desalination and produce an output flow stream of a product. The system also comprises a vapor compressor in fluidic communication with the MD module and configured to introduce a hot steam to a high temperature side of the MD module and extract a cool steam, having a temperature less than the hot steam, from a low temperature side of the MD module, thereby creating a temperature gradient across of the MD module. A desalination method is also presented.

Owner:BL TECH INC

Super-hydrophobic electrostatic spinning polydimethylsiloxane membrane and preparation method and application thereof

InactiveCN106334462AEasy to prepareThe preparation process is simple and controllableSemi-permeable membranesMembranesParticulatesOrganic solvent

The invention discloses a preparation method of a super-hydrophobic electrostatic spinning polydimethylsiloxane membrane. The preparation method comprises the steps that a substrate organic polymer material is dissolved in an organic solvent, and an electrostatic spinning base solution is prepared through high-temperature stirring; the functional organic polymer material and nano particulate matter are dissolved in the electrostatic spinning base solution prepared in the step 1, and an electrostatic spinning solution is prepared through high-temperature stirring and high-temperature standing; the parameters of an electrostatic spinning correlated instrument and environmental parameters are set, electrostatic spinning membrane forming is performed by using the electrostatic spinning solution to obtain the electrostatic spinning polydimethylsiloxane membrane; the electrostatic spinning polydimethylsiloxane membrane is subjected to heat treatment and standing cooling. The invention further provides the super-hydrophobic electrostatic spinning polydimethylsiloxane membrane and application of the super-hydrophobic electrostatic spinning polydimethylsiloxane membrane in a membrane distillation process. The preparation method is simple, a preparation process is easy to control, the preparation cost is low, the preparation time is shorter, the water contact angle of the membrane is large, and the membrane can be directly applied to the membrane distillation process and is high in flux and long in service life.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com