Preparation method of super hydrophobic and oleophobic film for dual-bionic film with photothermal effects

A photothermal effect, super-hydrophobic technology, applied in chemical instruments and methods, pervaporation, membrane technology, etc., can solve the problems of poor anti-organic pollution effect of super-hydrophobic membrane, low flux of coating modified membrane, complicated preparation process, etc. , to avoid the pore size and porosity greatly decreased, easy to operate, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A method for preparing a superhydrophobic and oleophobic membrane for double biomimetic membrane distillation with photothermal effect, the steps are as follows:

[0029] ① Dopamine modification: dopamine concentration 10.6mM, CuSO 4 Concentration 5mM, H 2 o 2 The concentration is 19.6mM, the buffer is Tris-HCl buffer with pH=8.50, the water bath shaker is used to control the temperature at about 25°C during modification, the shaker speed is 50-300r / min, and the coating time is 0.5h-2h .

[0030] ②Silver deposition: silver nitrate (AgNO 3 ) process the film described in step ①, and deposit a layer of evenly distributed nano-silver spheres on its surface, so that the film has a photothermal effect.

[0031] ③ Fluorination treatment: use 10 mM low surface energy fluoride perfluorodecyl mercaptan to treat the membrane described in step ② for 1-24 hours.

[0032] Apply the superhydrophobic and oleophobic membrane with photothermal effect to direct contact membrane dist...

Embodiment 1

[0034] A method for preparing a superhydrophobic and oleophobic membrane for double biomimetic membrane distillation with photothermal effect, the steps are as follows:

[0035] (1) Dopamine modification: place PVDF treated with absolute ethanol in a medium containing 10.6mM DA, 5mM CuSO 4 and 19.6mM H 2 o 2 In the Tris-HCl buffer solution, the pH value of the buffer solution is 8.50, shake the reaction for 30min in a water bath shaker with a temperature of 25°C and a rotation speed of 200r / min, then rinse with a large amount of deionized water, and dry in a vacuum oven at 45°C Dry polymerized dopamine-modified PVDF.

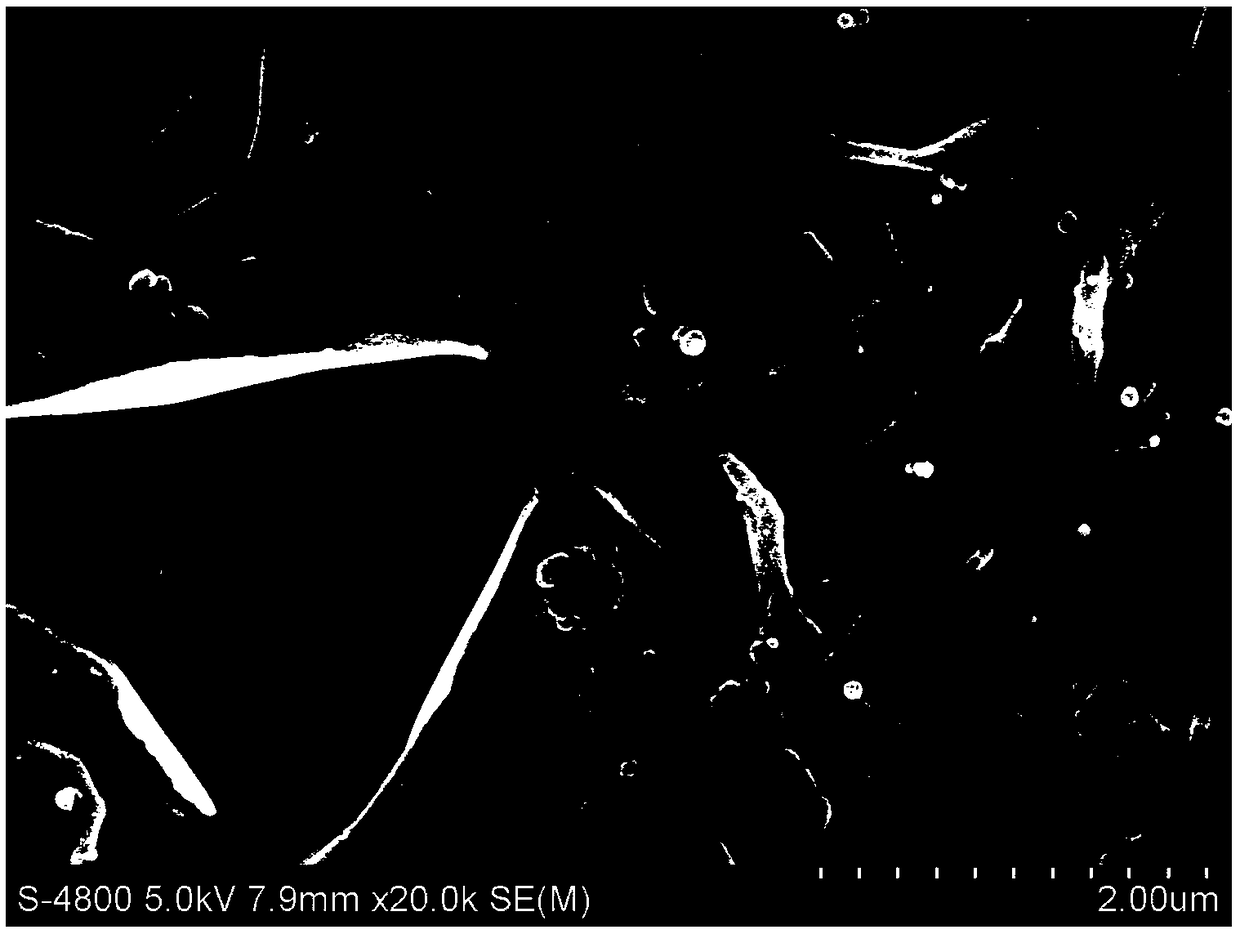

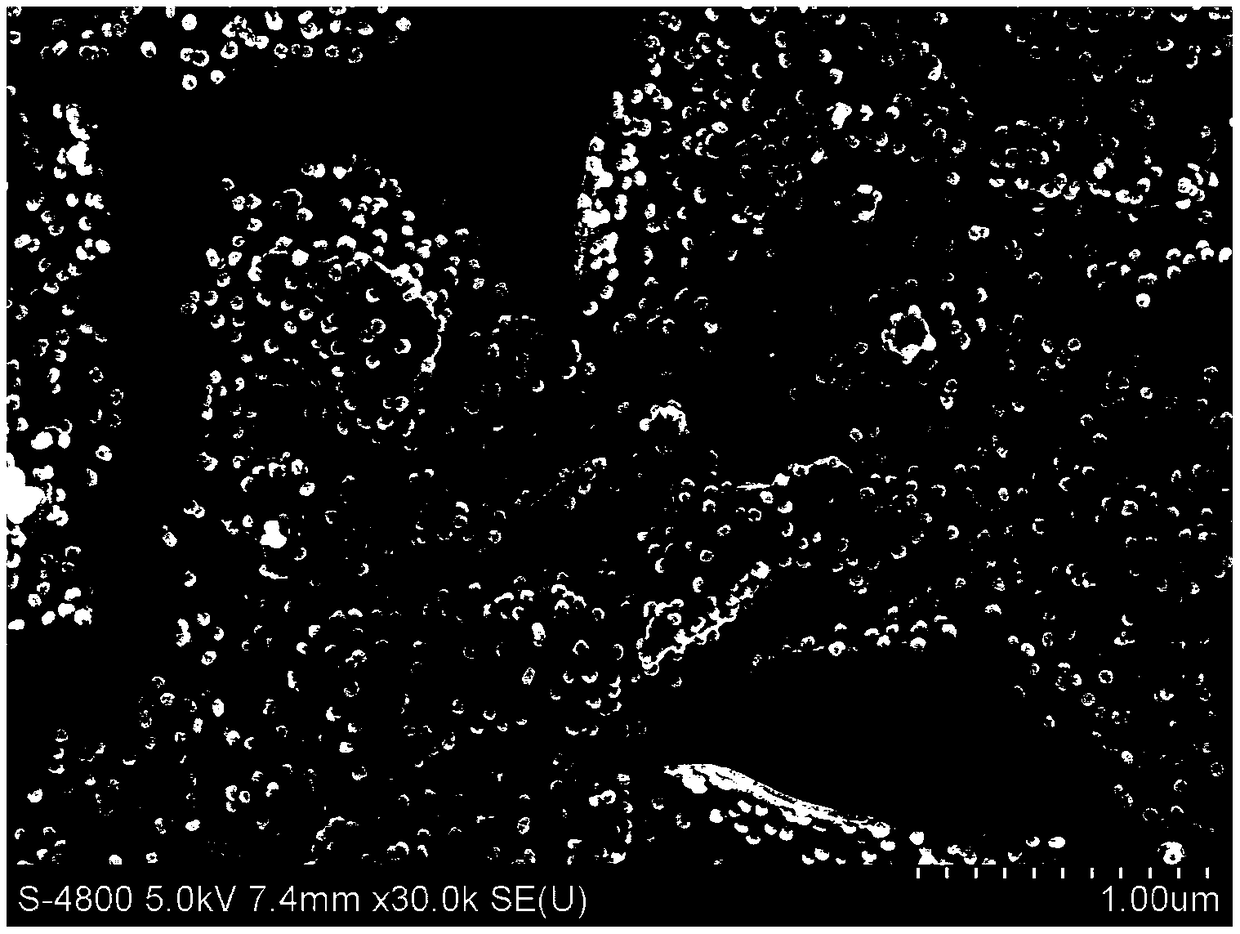

[0036] (2) Silver deposition: Put the polymerized dopamine-modified PVDF in 300mM silver nitrate solution, shield it with aluminum foil, react at 30°C for 6h, and dry it in a vacuum oven at 45°C to obtain a PVDF film with a micro-nano layered structure.

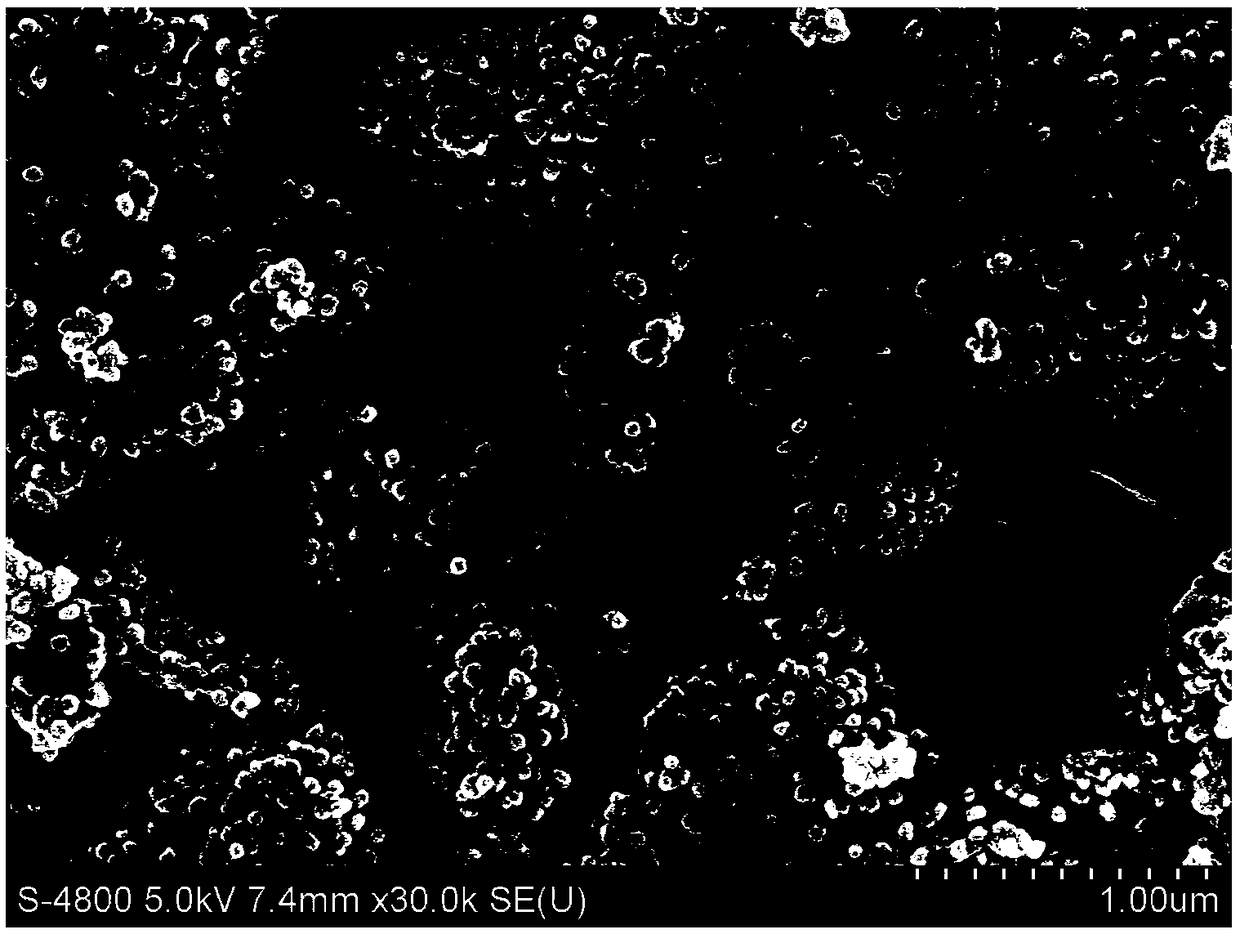

[0037] (3) Fluorination treatment: Submerge the PVDF deposited with nano-silver particles in 10m perfluor...

Embodiment 2

[0057] A method for preparing a superhydrophobic and oleophobic membrane for double biomimetic membrane distillation with photothermal effect, the steps are as follows:

[0058] (1) Soak the polypropylene (PP) hollow fiber membrane in isopropanol for 1 hour, and dry it at 45°C for later use. Contains 10.6mM DA, 5mM CuSO 4 , 19.6mM H 2 o 2 After the Tris-HCl buffer (pH=8.50) is prepared, put it into the dry polypropylene hollow fiber membrane immediately, shake it in a water bath shaker at 25°C and 200r / min for 1h, take it out, and rinse it with a large amount of deionized water ,drying.

[0059] (2) Treat the above-mentioned PP hollow fiber membrane with 300mM silver nitrate solution for 3 hours at 30°C and avoid light, then treat it with 50mM perfluorodecyl mercaptan for 24 hours, and dry it.

[0060] (3) The contact angle of the modified PP hollow fiber membrane is measured, and the water contact angle can reach 163.5°, and the pore size is about 0.2 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com