Patents

Literature

21923results about "Water/sewage treatment bu osmosis/dialysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

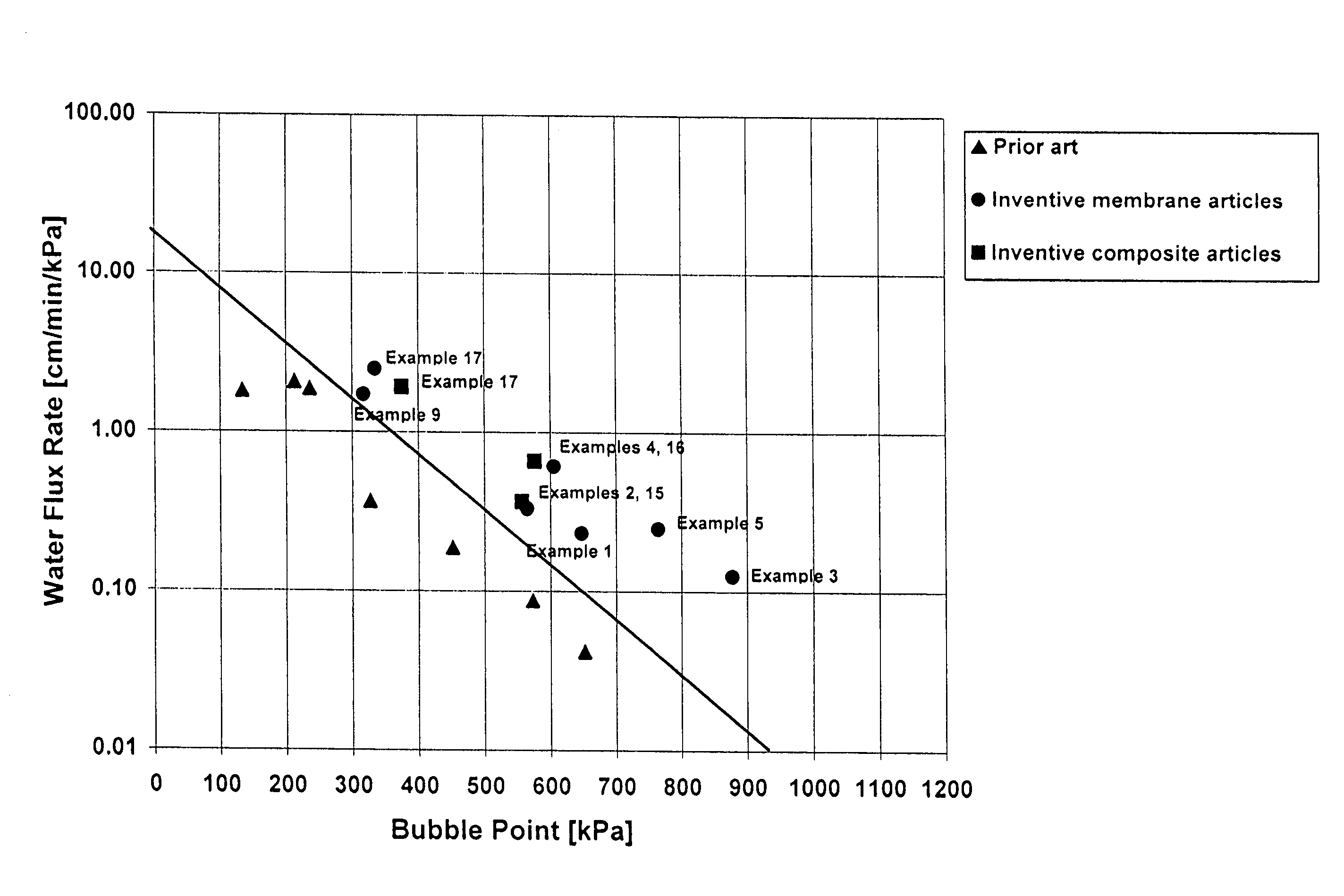

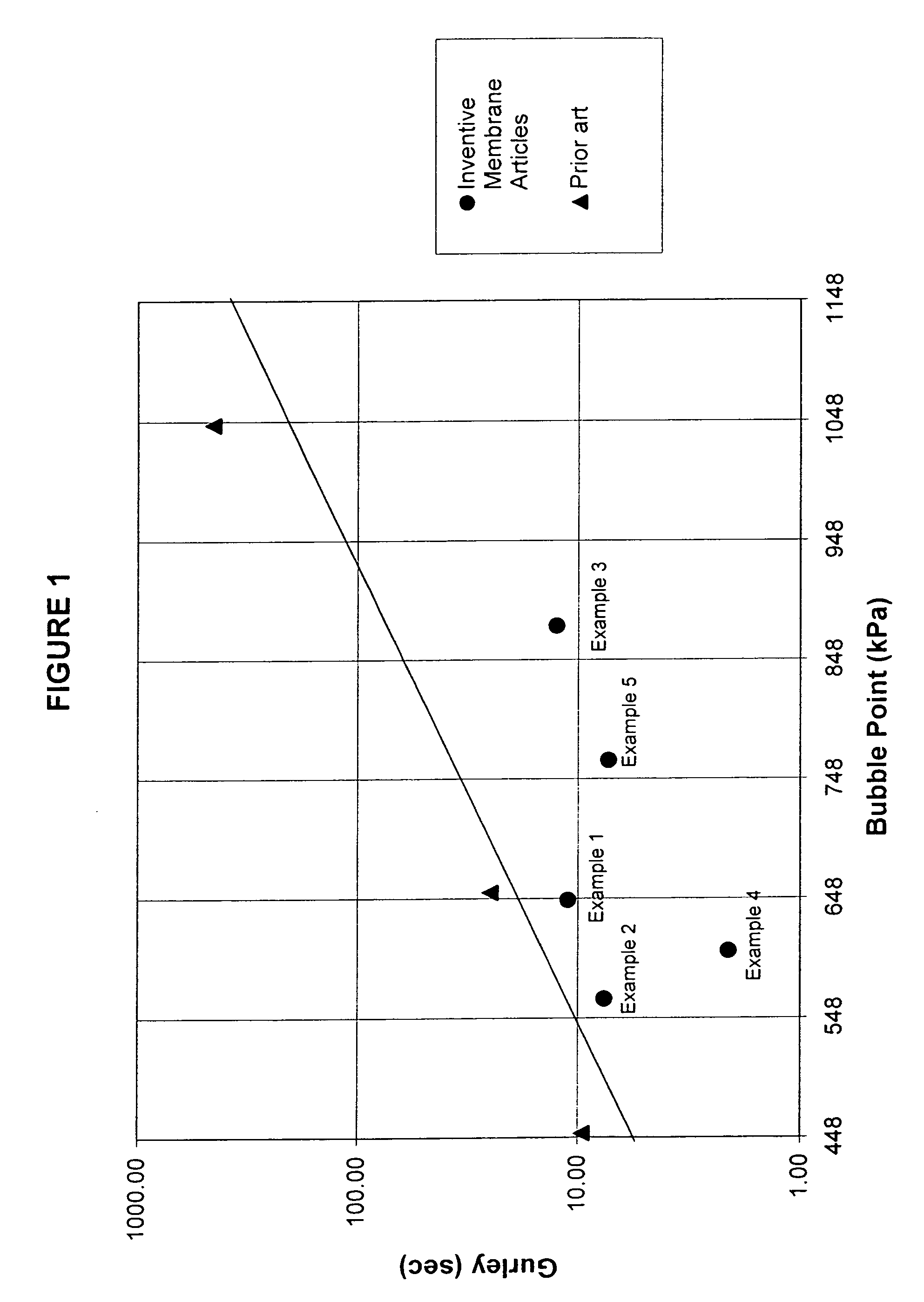

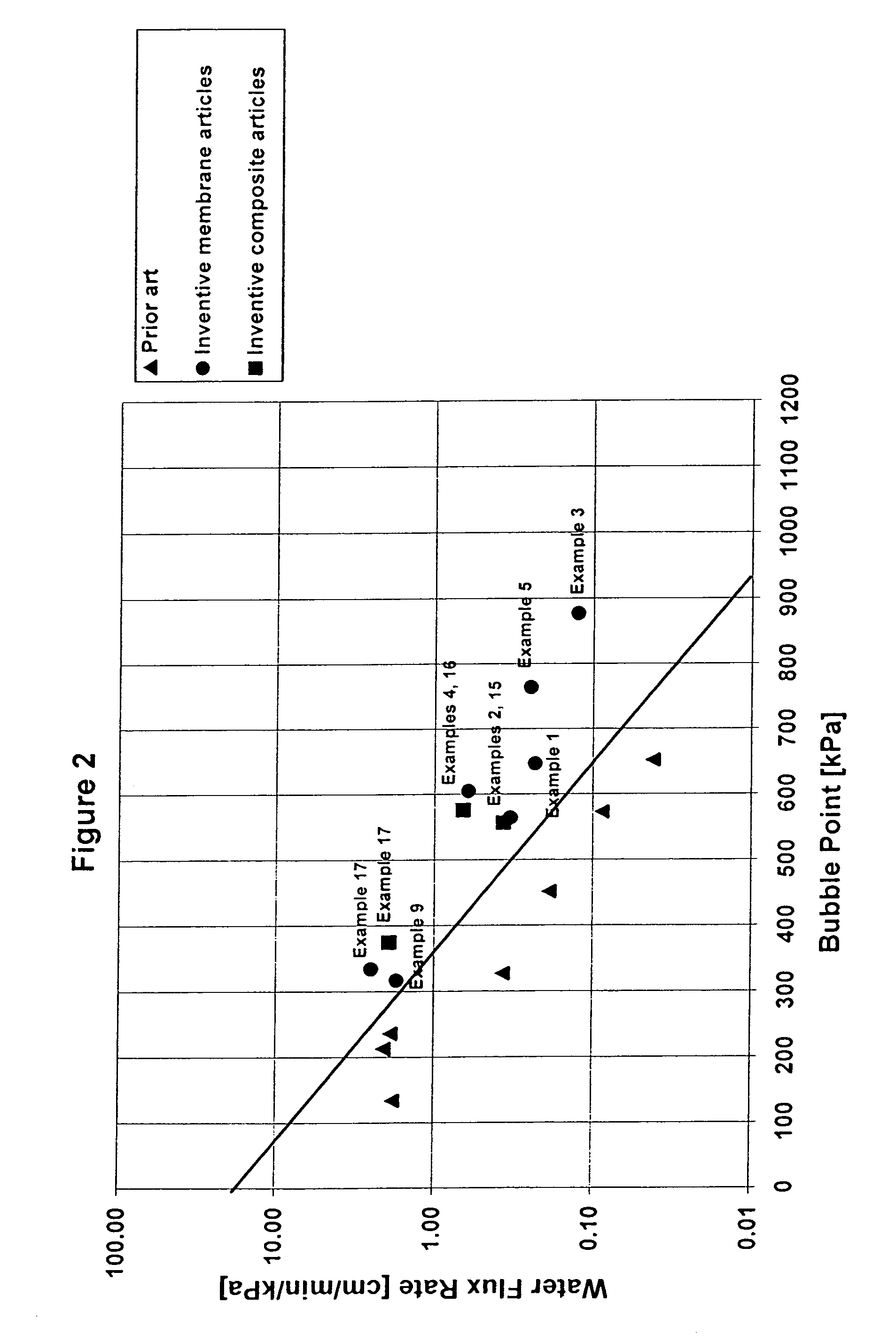

Porous PTFE materials and articles produced therefrom

ActiveUS7306729B2High strengthLower overall flow resistanceMembranesSemi-permeable membranesFlow resistivityFiltration

Novel porous PTFE membranes are described possessing a unique combination of high strength, low flow resistance, and small pore size. Additionally, unique constructions with superior filtration and venting properties incorporating porous PTFE membranes are described.

Owner:WL GORE & ASSOC INC

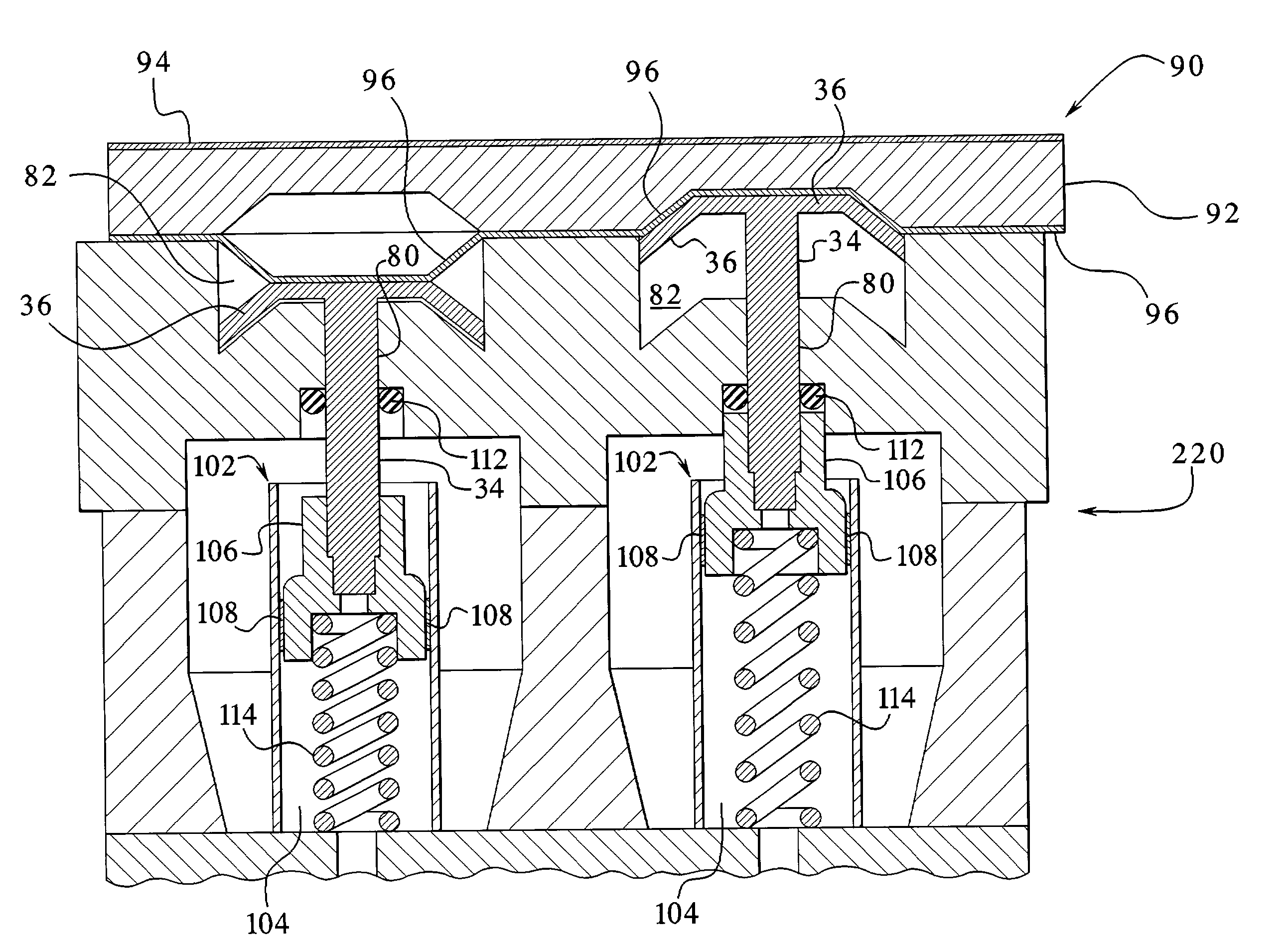

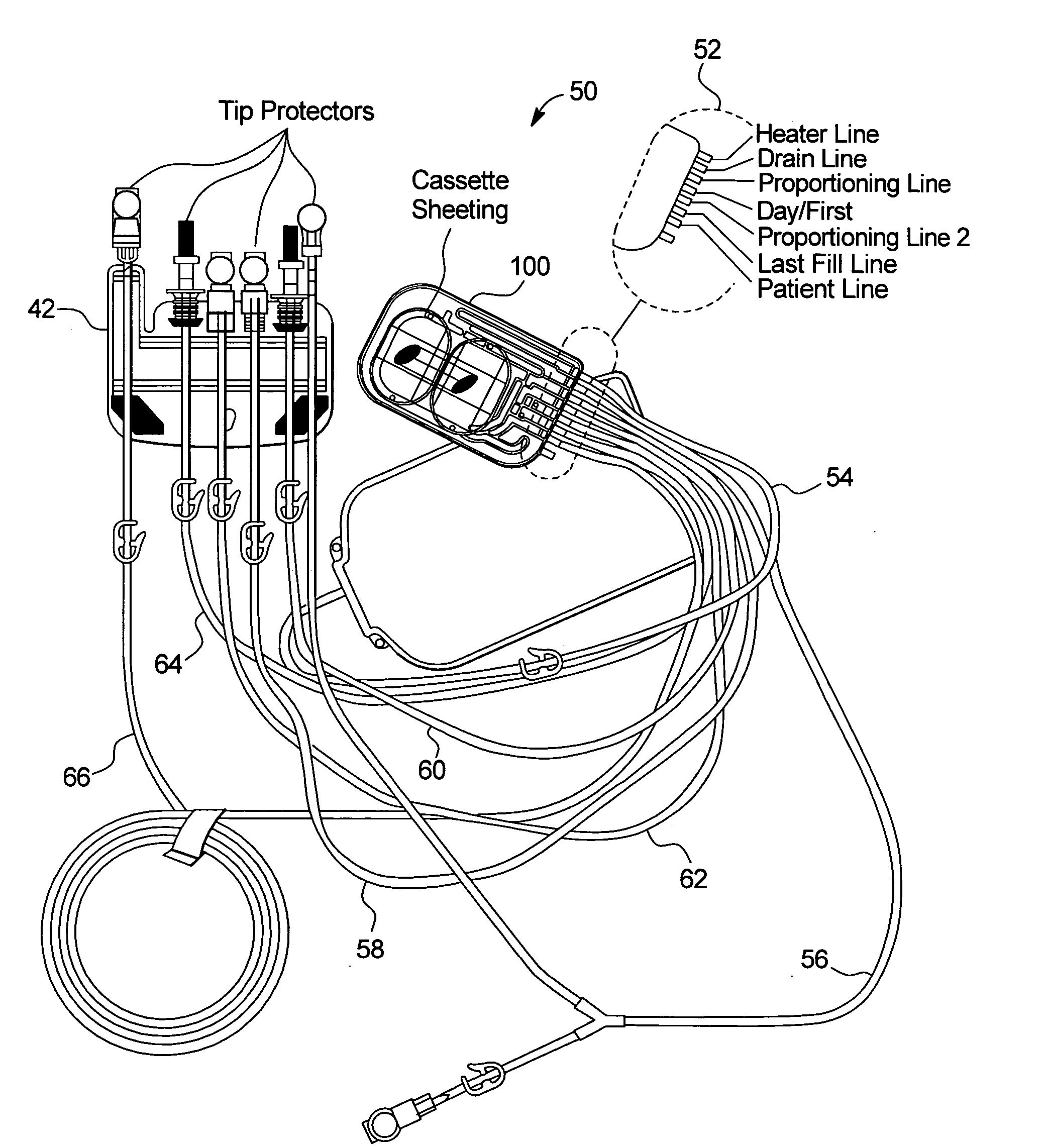

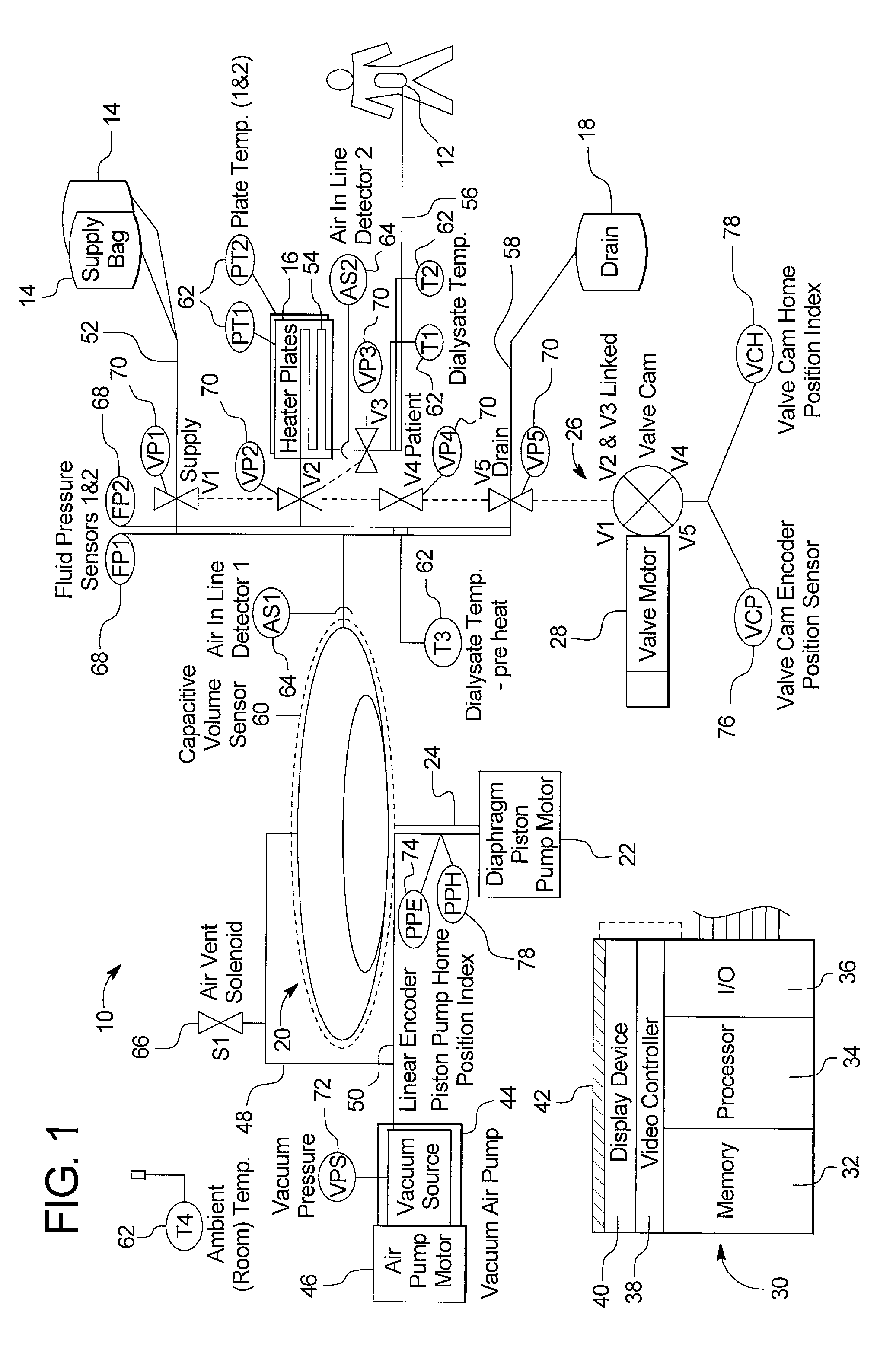

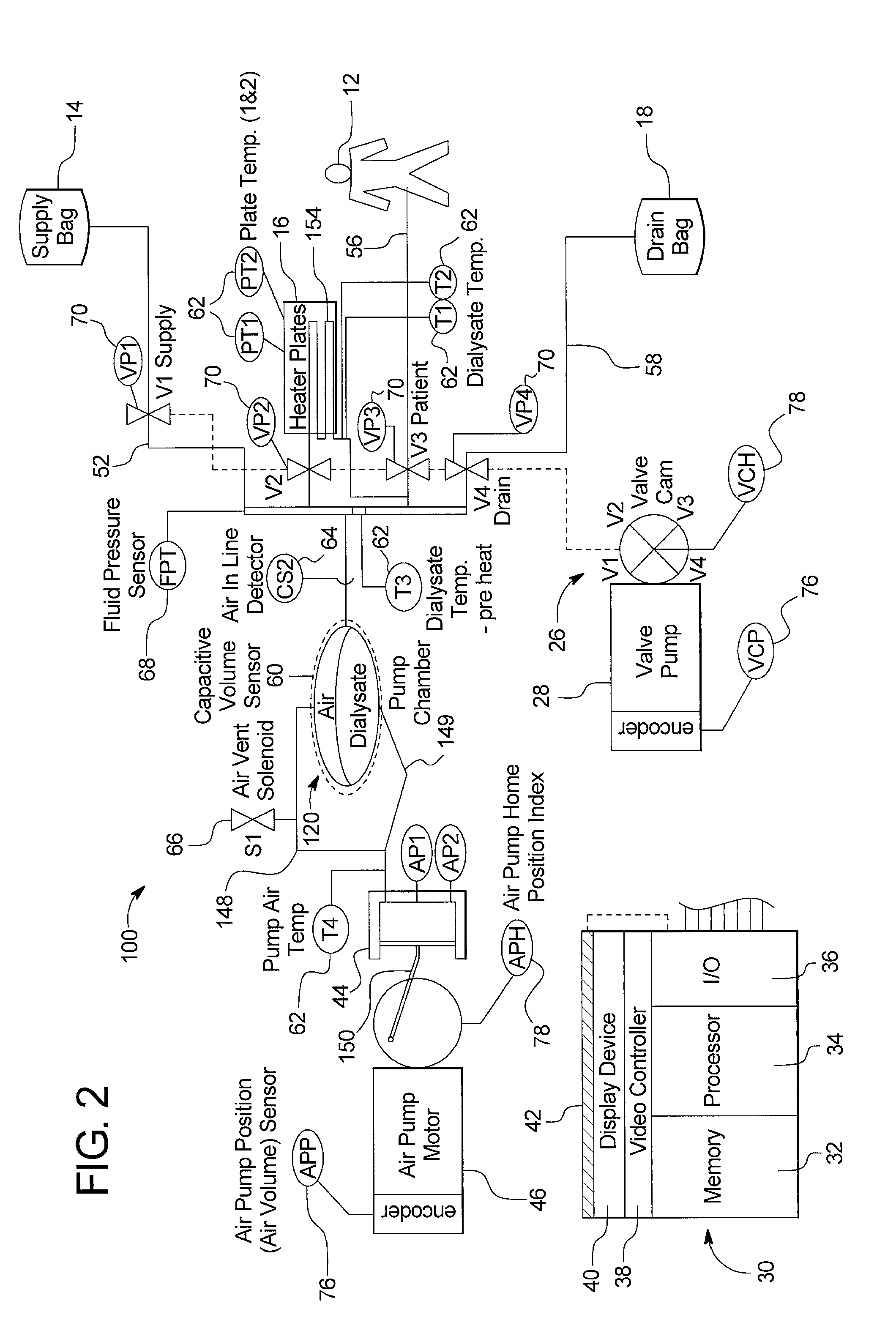

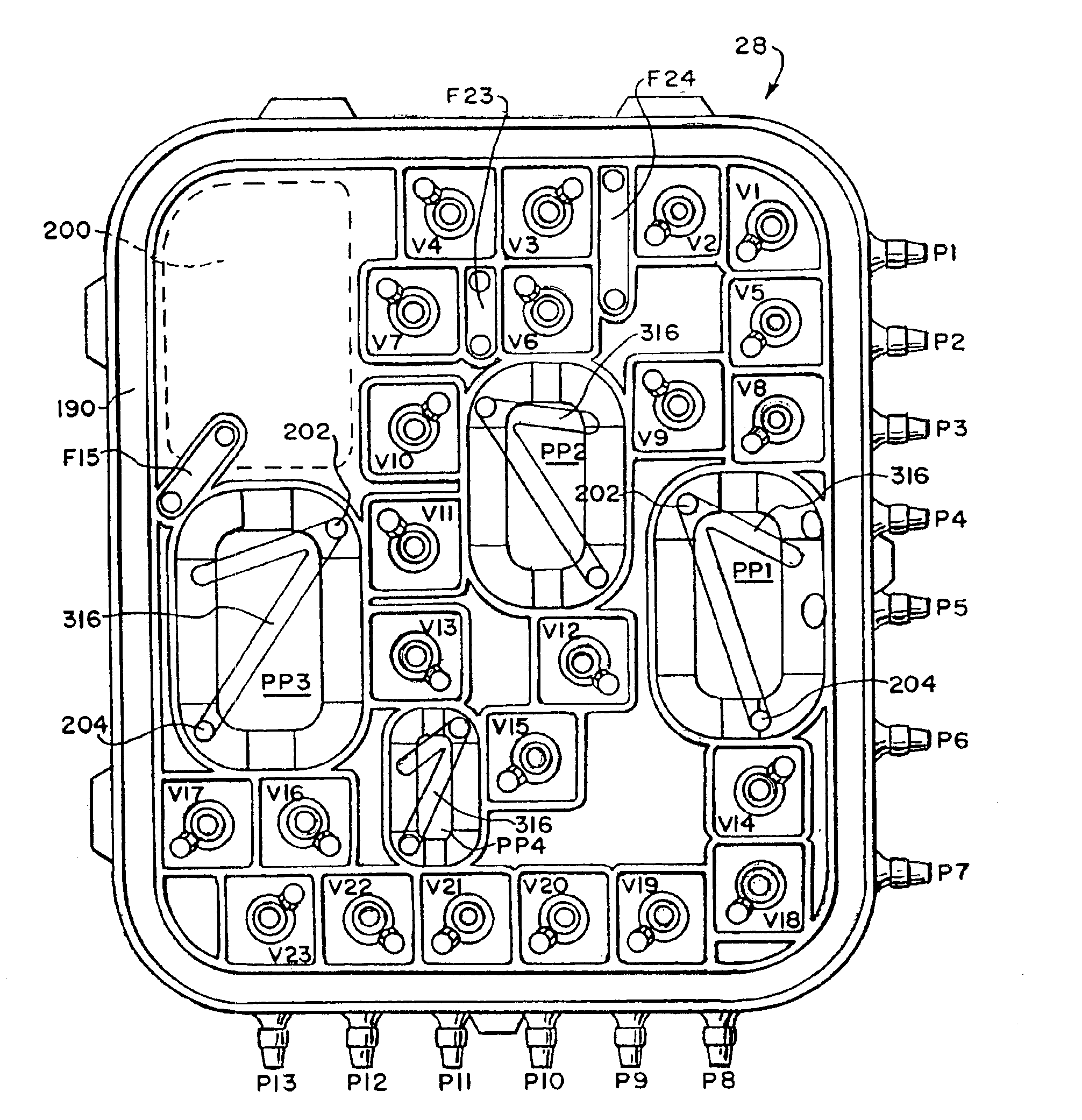

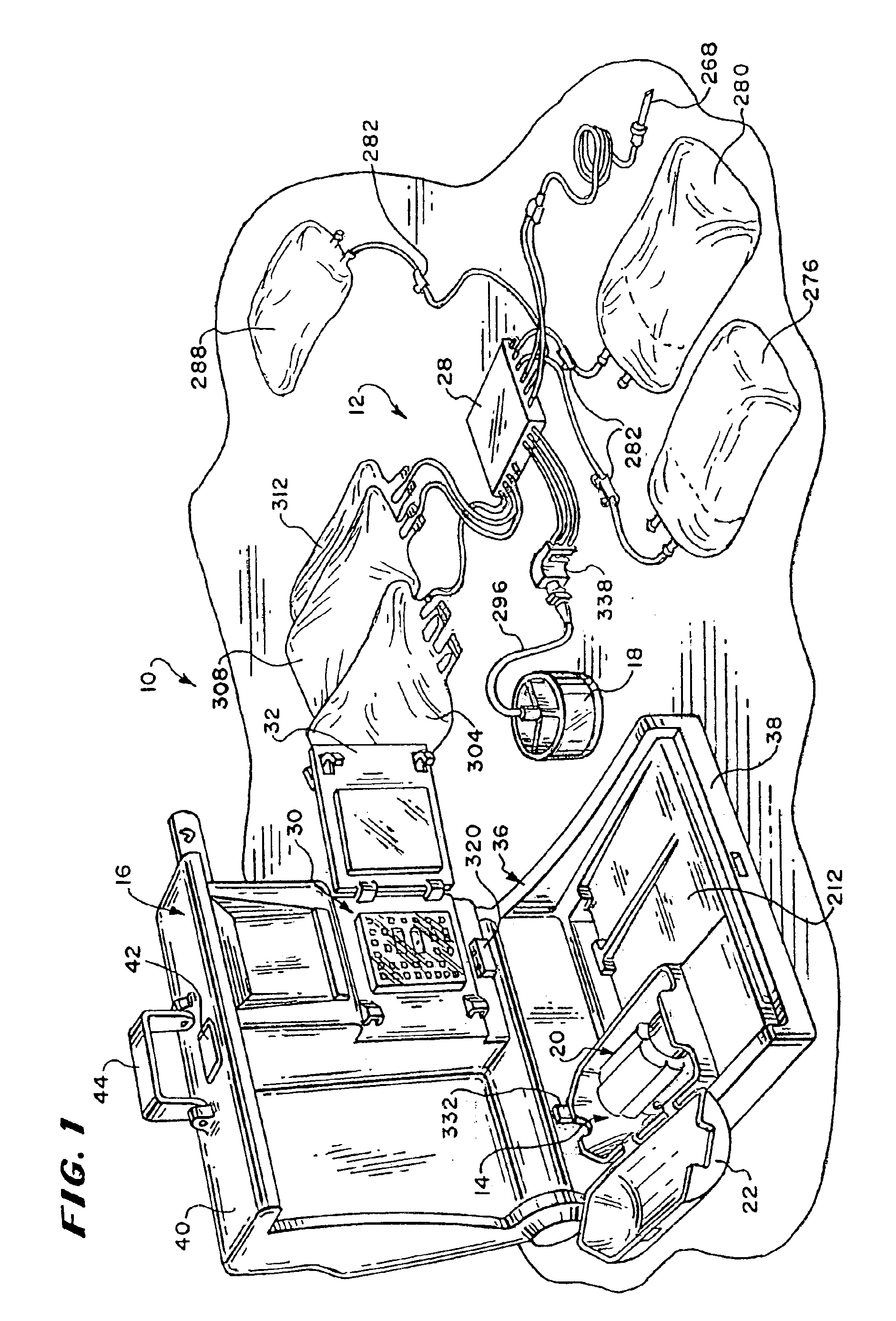

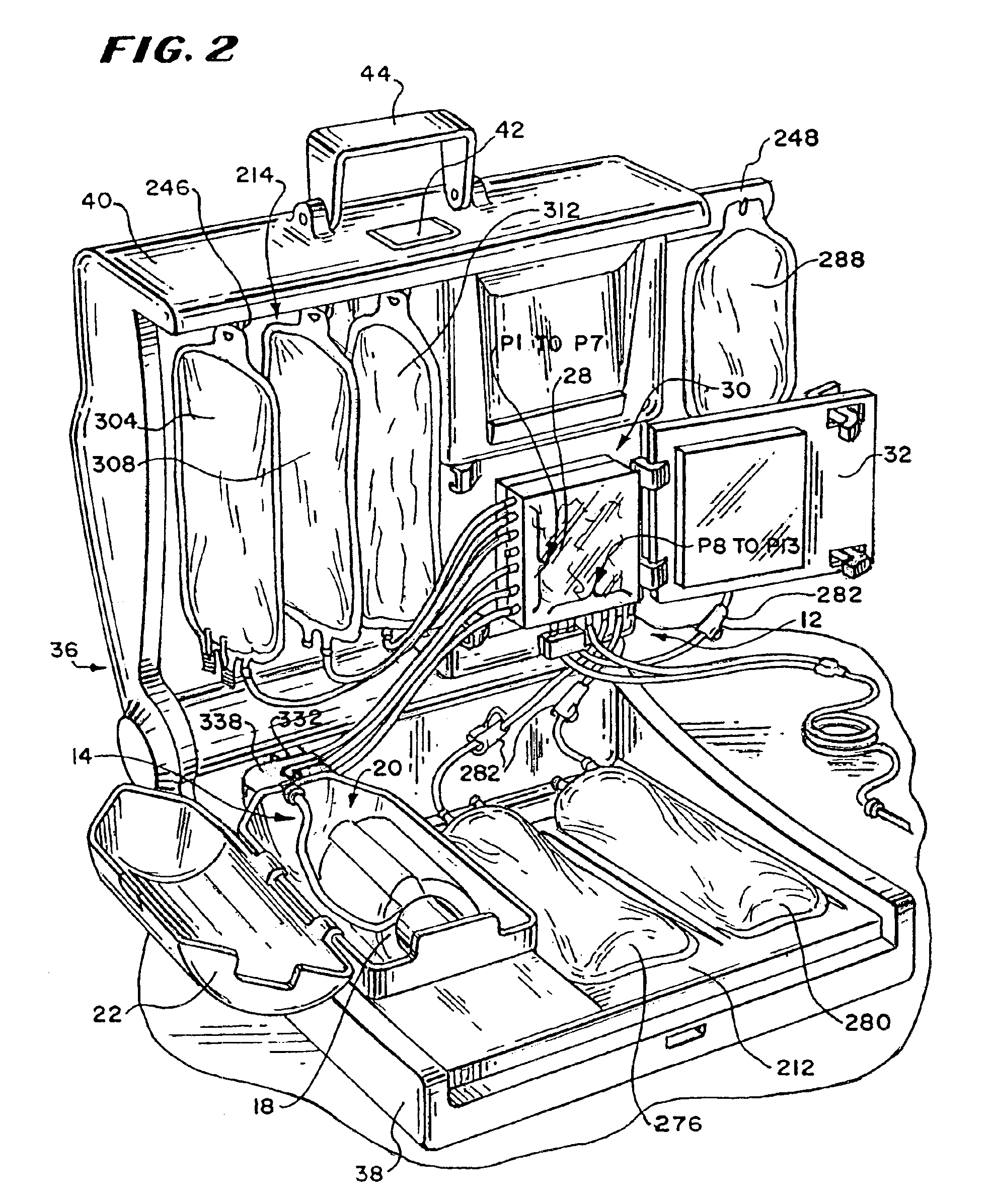

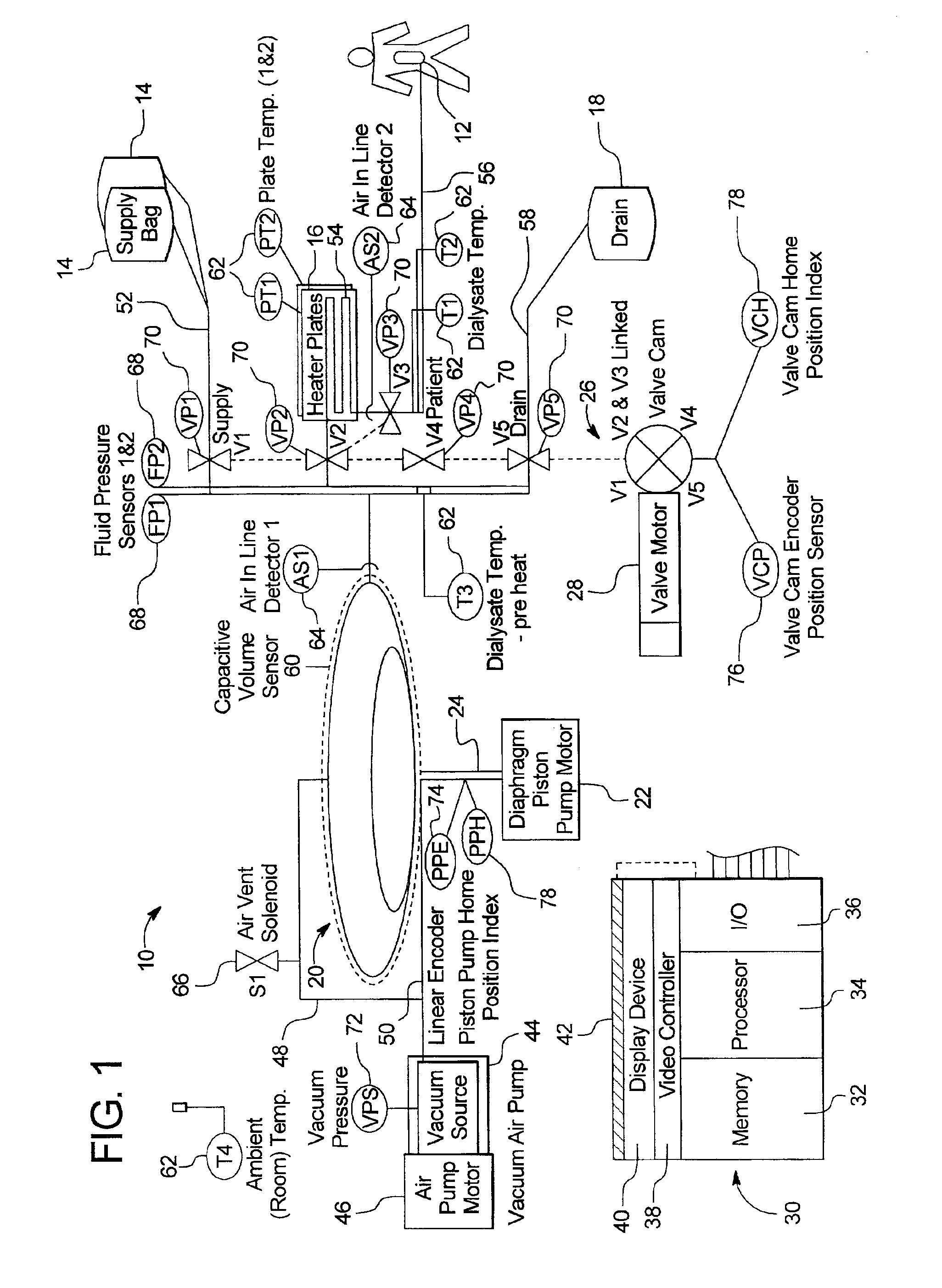

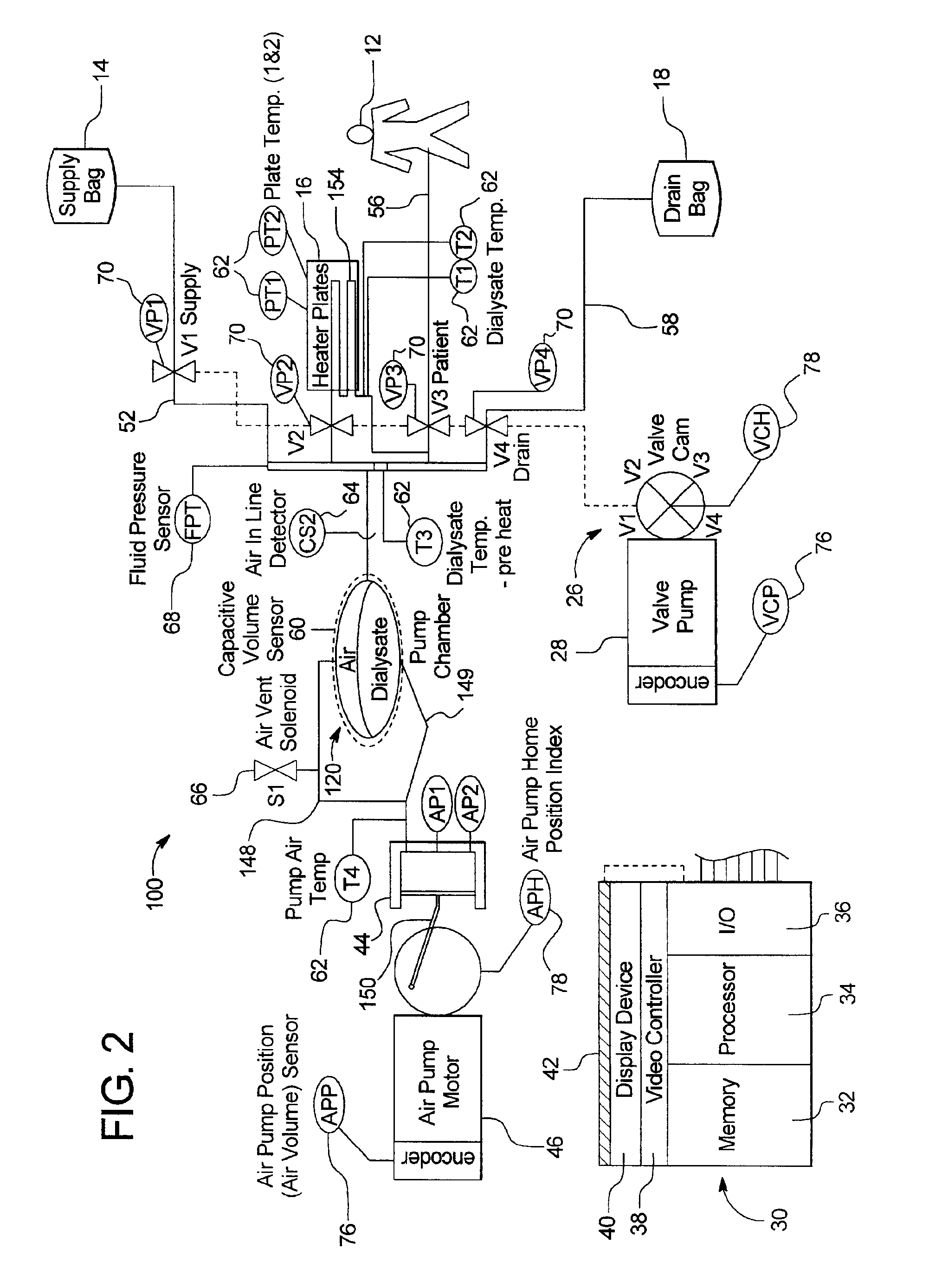

Systems, methods and apparatuses for pumping cassette-based therapies

InactiveUS7238164B2Simple materialSemi-permeable membranesSolvent extractionMultiplexingAir separation

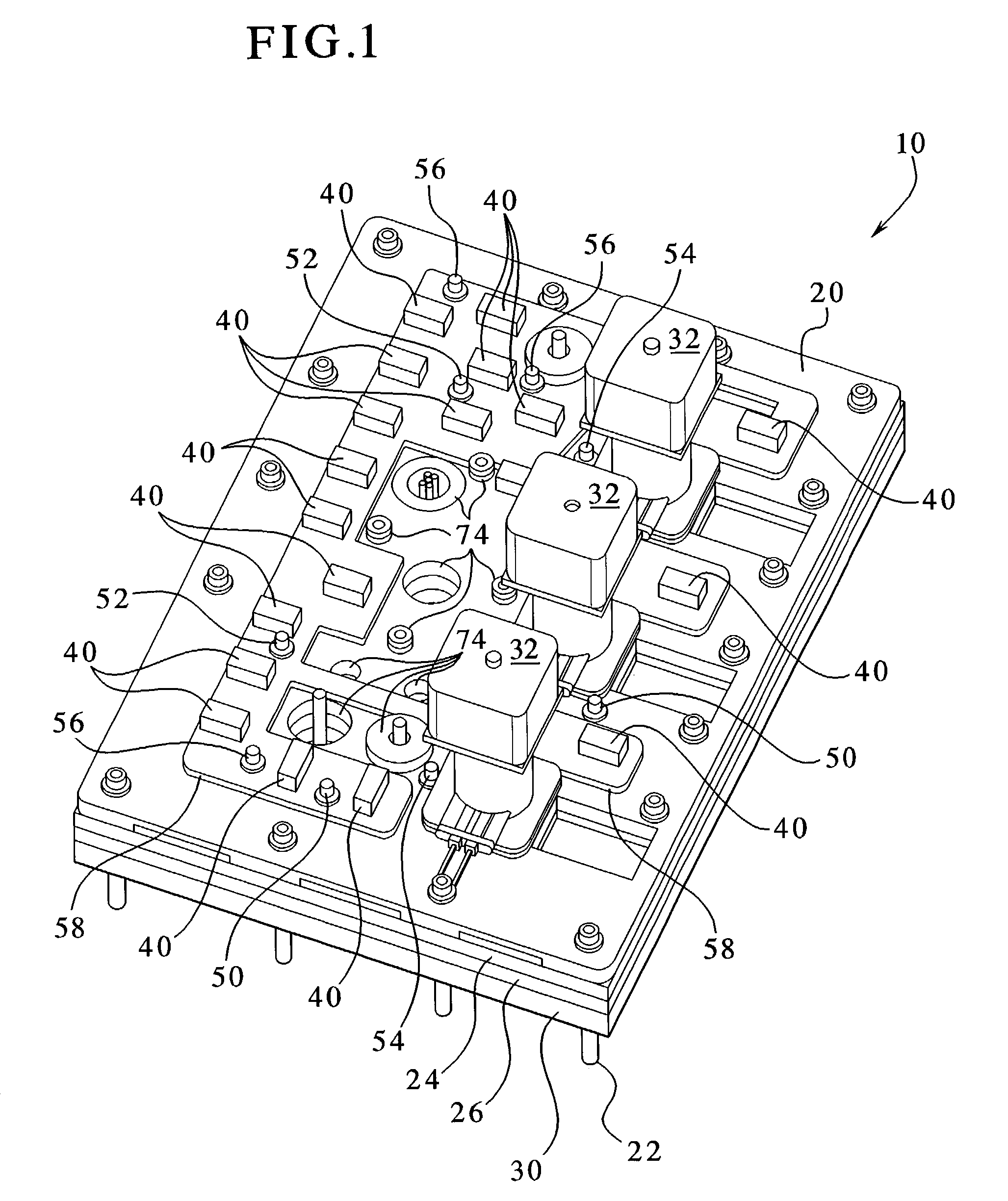

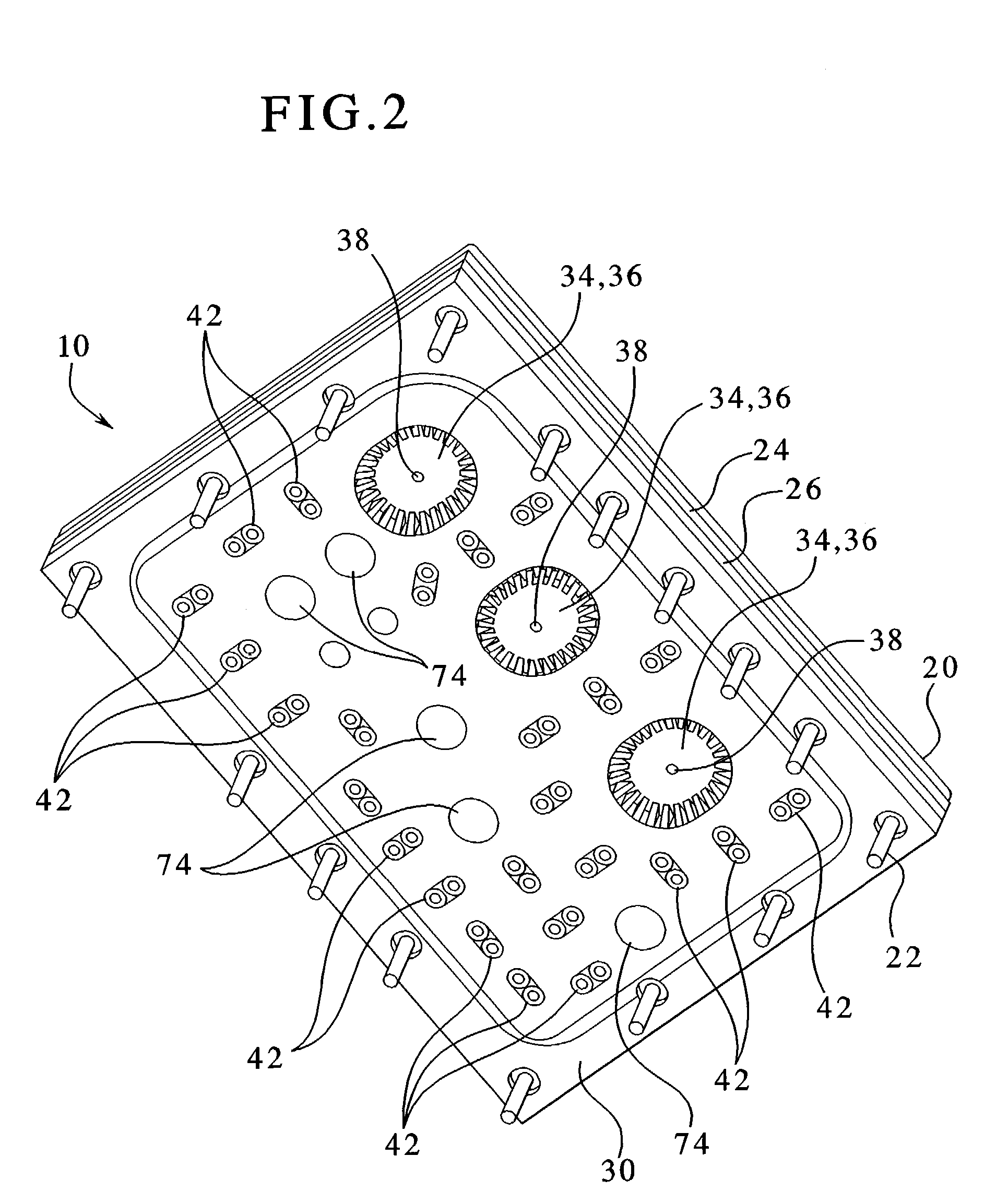

The present invention provides systems, methods and apparatuses for medical fluid delivery systems that employ a pumping cassette. In particular, the present invention provides systems, methods and apparatuses for cassette-based dialysis therapies including hemodialysis, hemofiltration, APD (including tidal modalities) and CFPD. The embodiments described include a combined pump / valve housing, a fail safe pump / valve arrangement, a cassette auto-alignment feature, a pumping membrane material, a multiplexing valve arrangement, an expert fluid pumping management system, an integral port vent and an in-line air separation chamber and combinations of each of these.

Owner:BAXTER INT INC +1

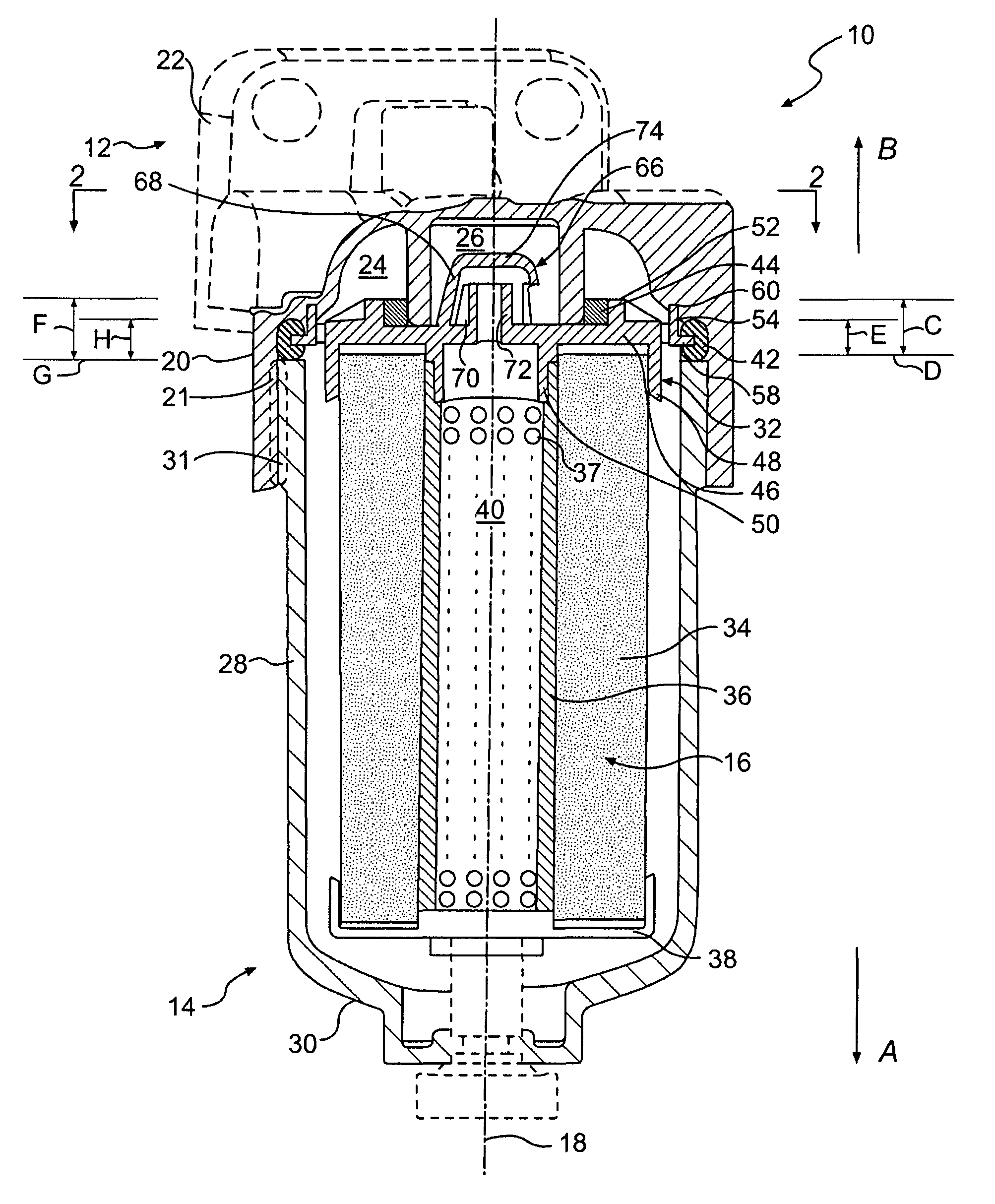

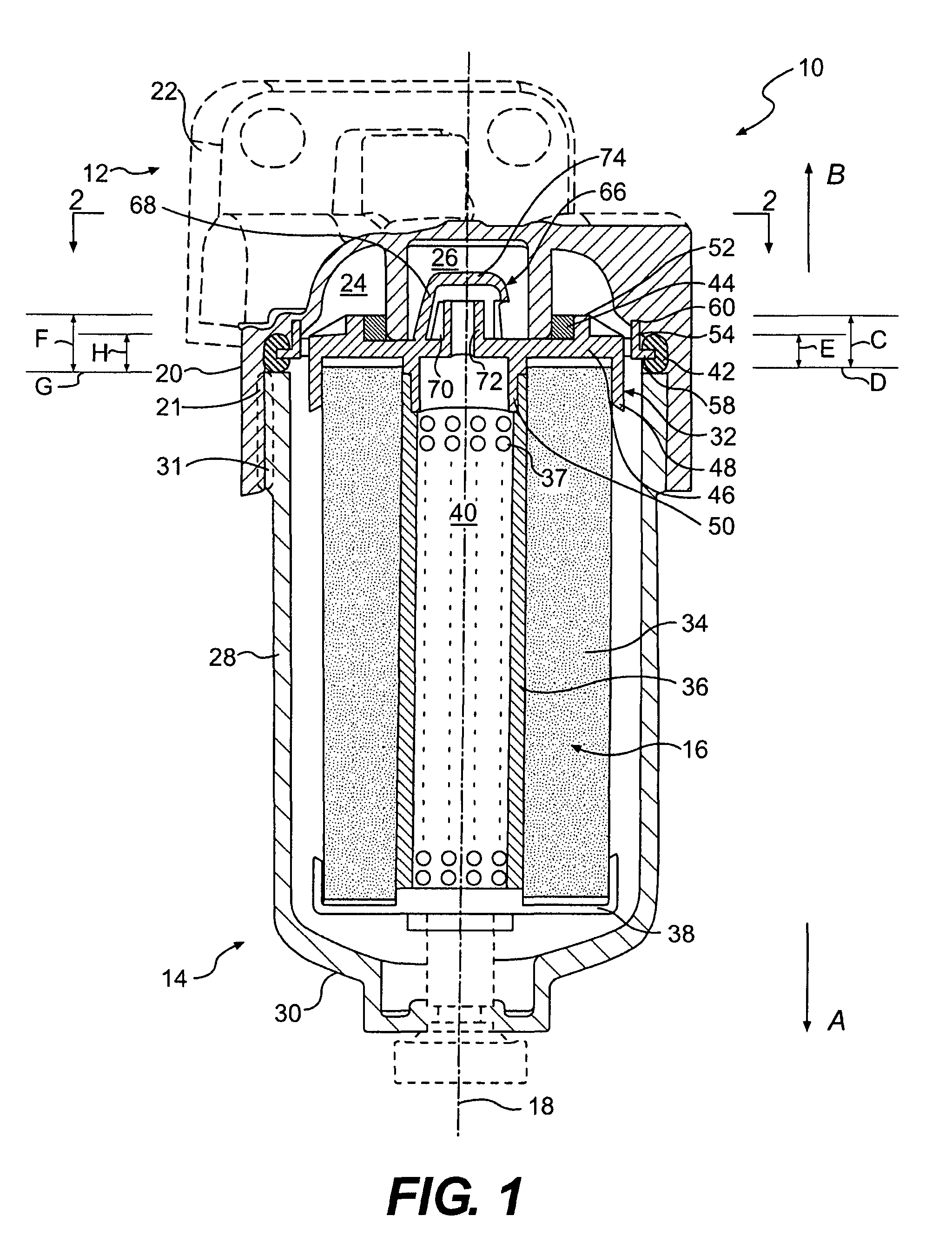

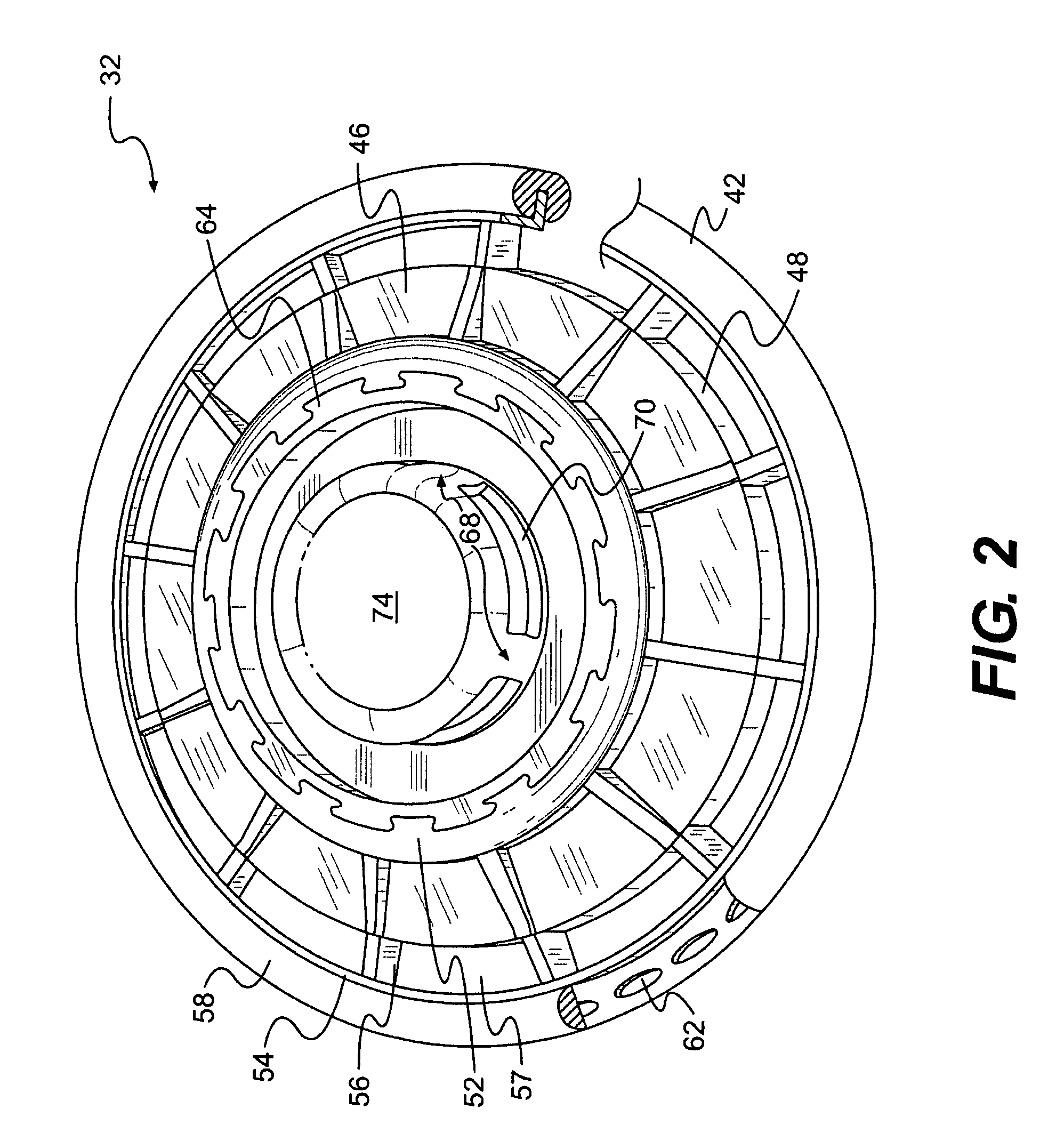

Fluid filter system

An endcap including a first plate member including a radial inner portion, a radial outer portion, and defining a longitudinal axis. The endcap also includes a flange disposed between the radial inner and outer portions of the first plate member and projecting axially along the longitudinal axis in a first direction. The endcap also includes a first seal member disposed adjacent the flange. The first seal includes a first portion thereof engaged with an axial facing surface of the first plate member and a second portion thereof engaged with a radially facing surface of the flange. The endcap further includes a second plate member disposed radially outward of the radial outer portion and a second seal member disposed adjacent the second plate member including at least a portion thereof axially spaced from the axially facing surface of the first plate member in a second direction along the longitudinal axis opposite the first direction.

Owner:DONALDSON CO INC +2

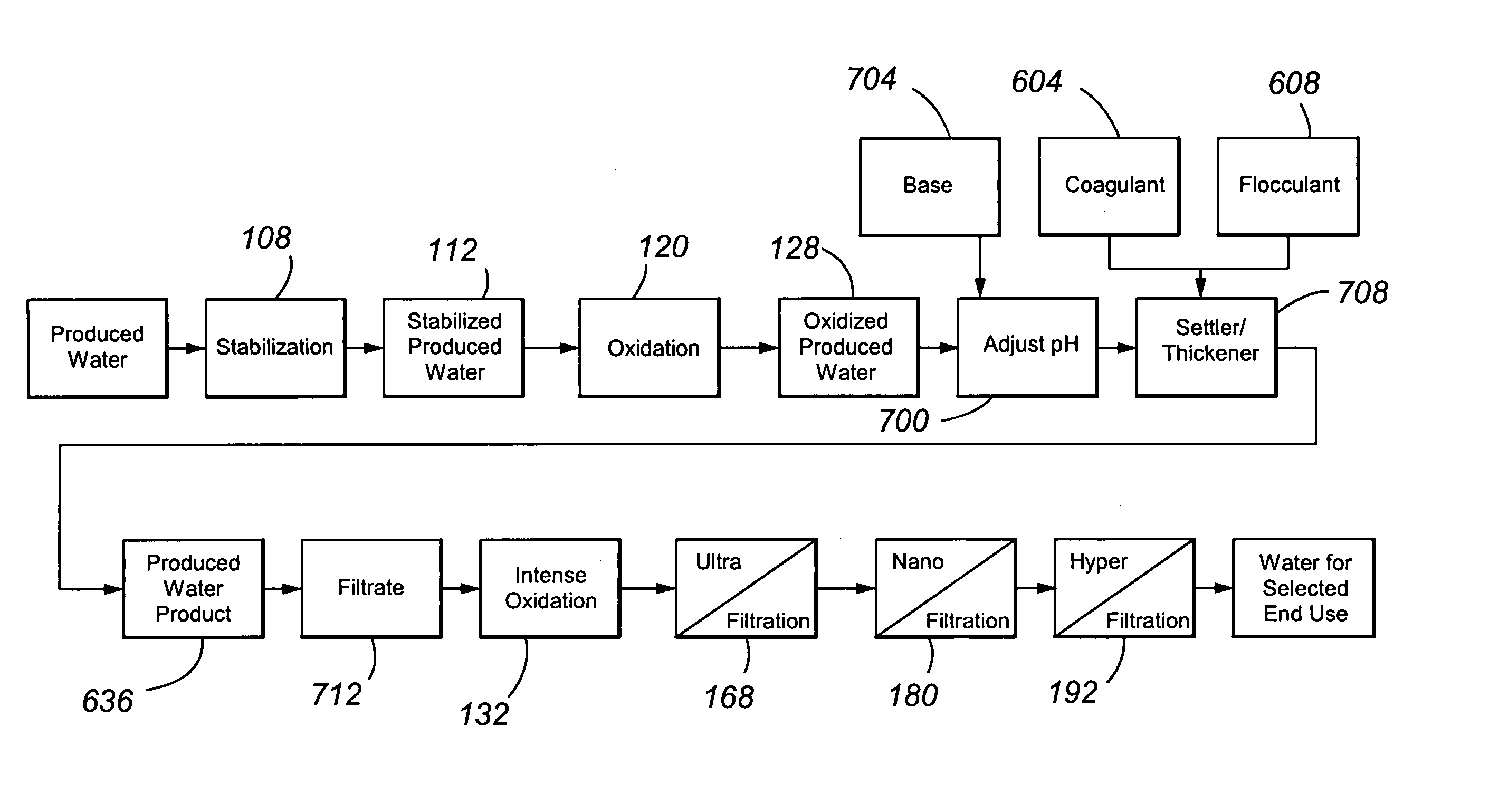

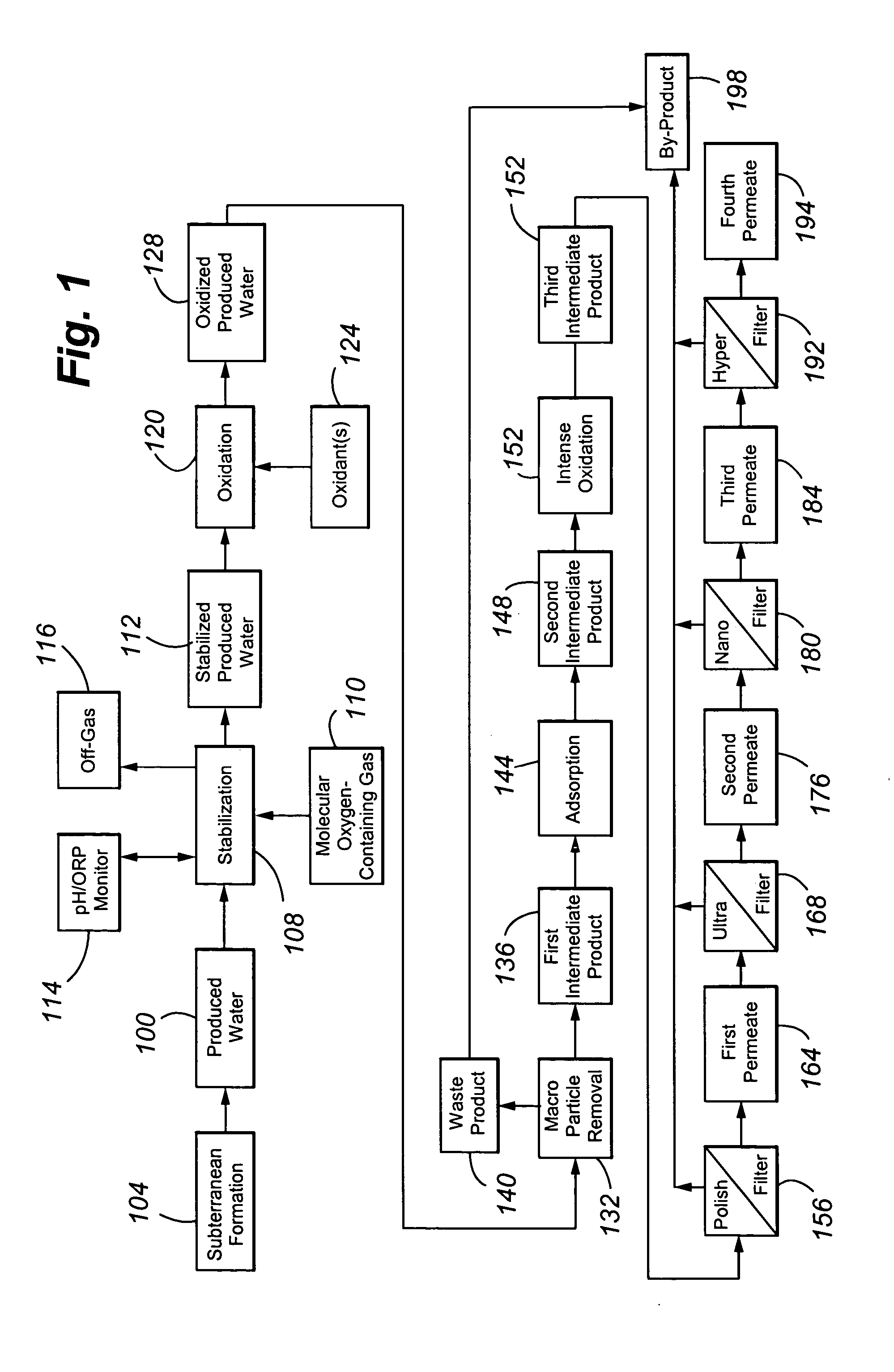

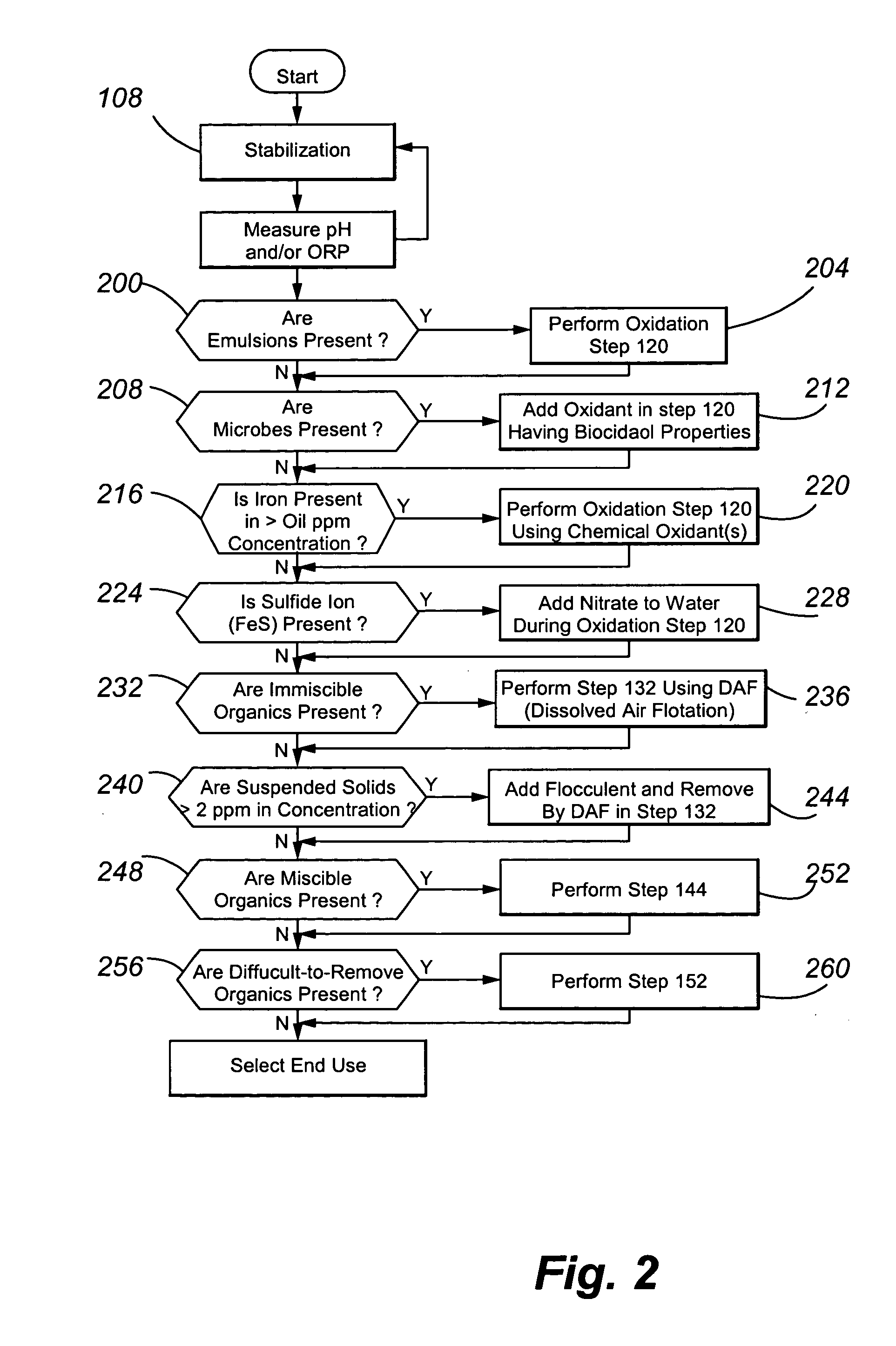

Treating produced waters

InactiveUS20070102359A1Complicate purificationIncrease ratingsUltrafiltrationTreatment involving filtrationEmulsionUnit operation

The present invention is directed to various sets of unit operations for treating aqueous effluents and logic for designing and effecting the treatment. The unit operations include stabilization of subterranean waters, sequential oxidation steps to alter selected target materials, oxidation to break up emulsions prior to removal of the emulsion components, and intense oxidation to break up difficult-to-remove organic target materials.

Owner:HW PROCESS TECH

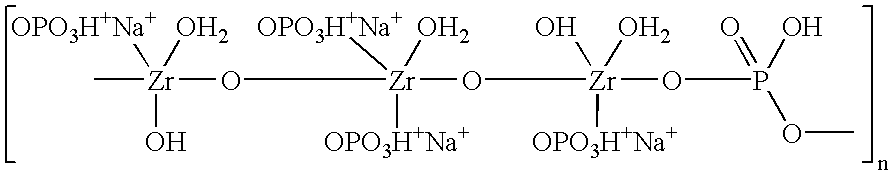

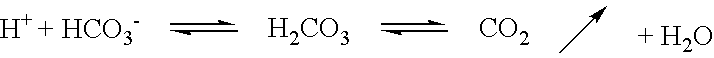

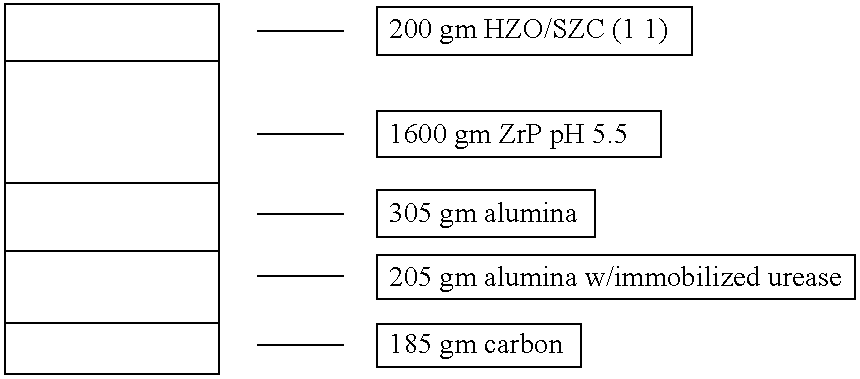

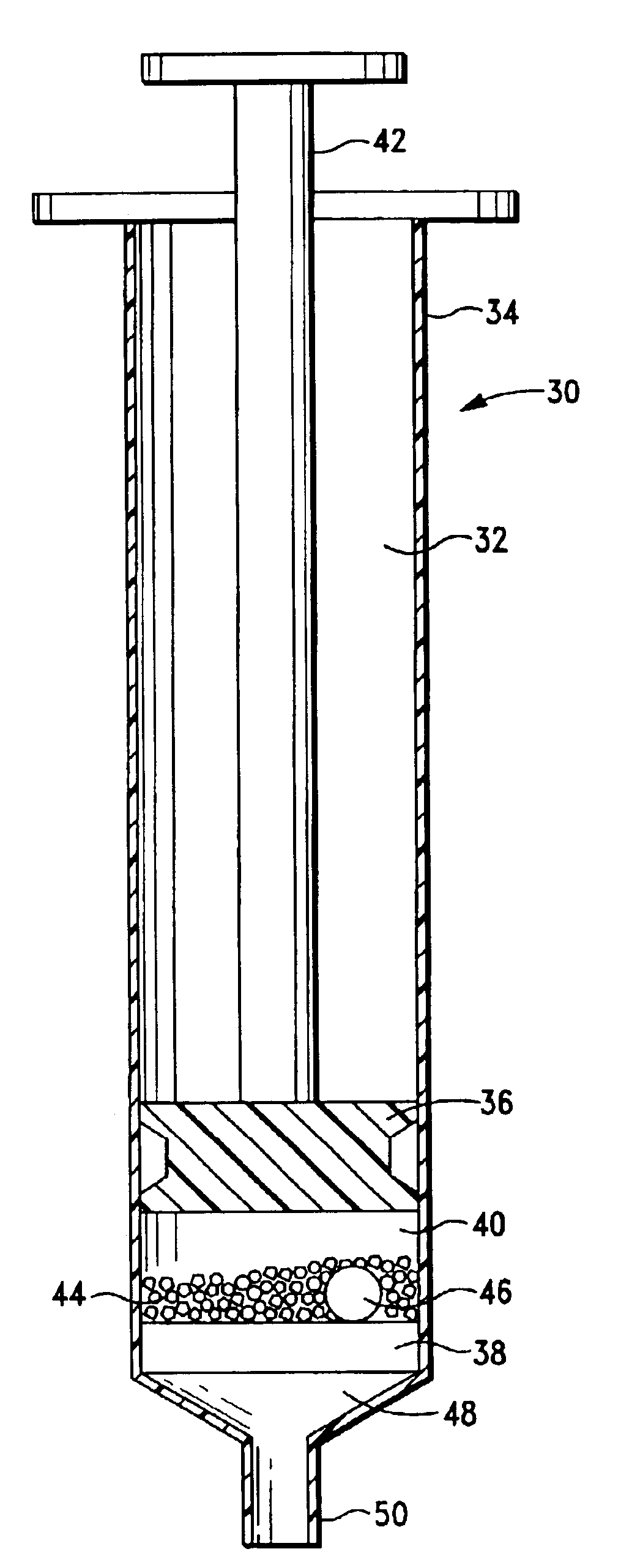

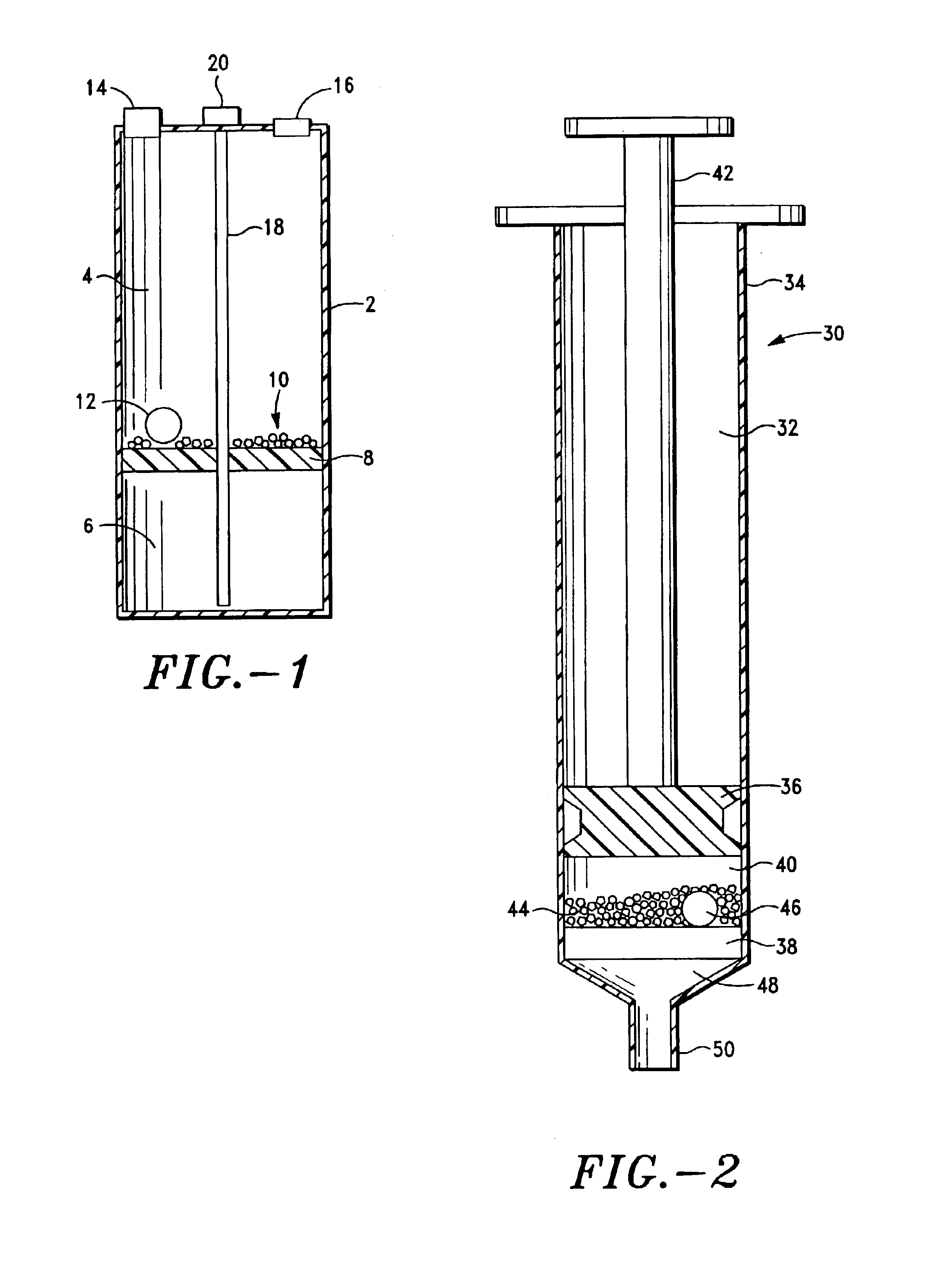

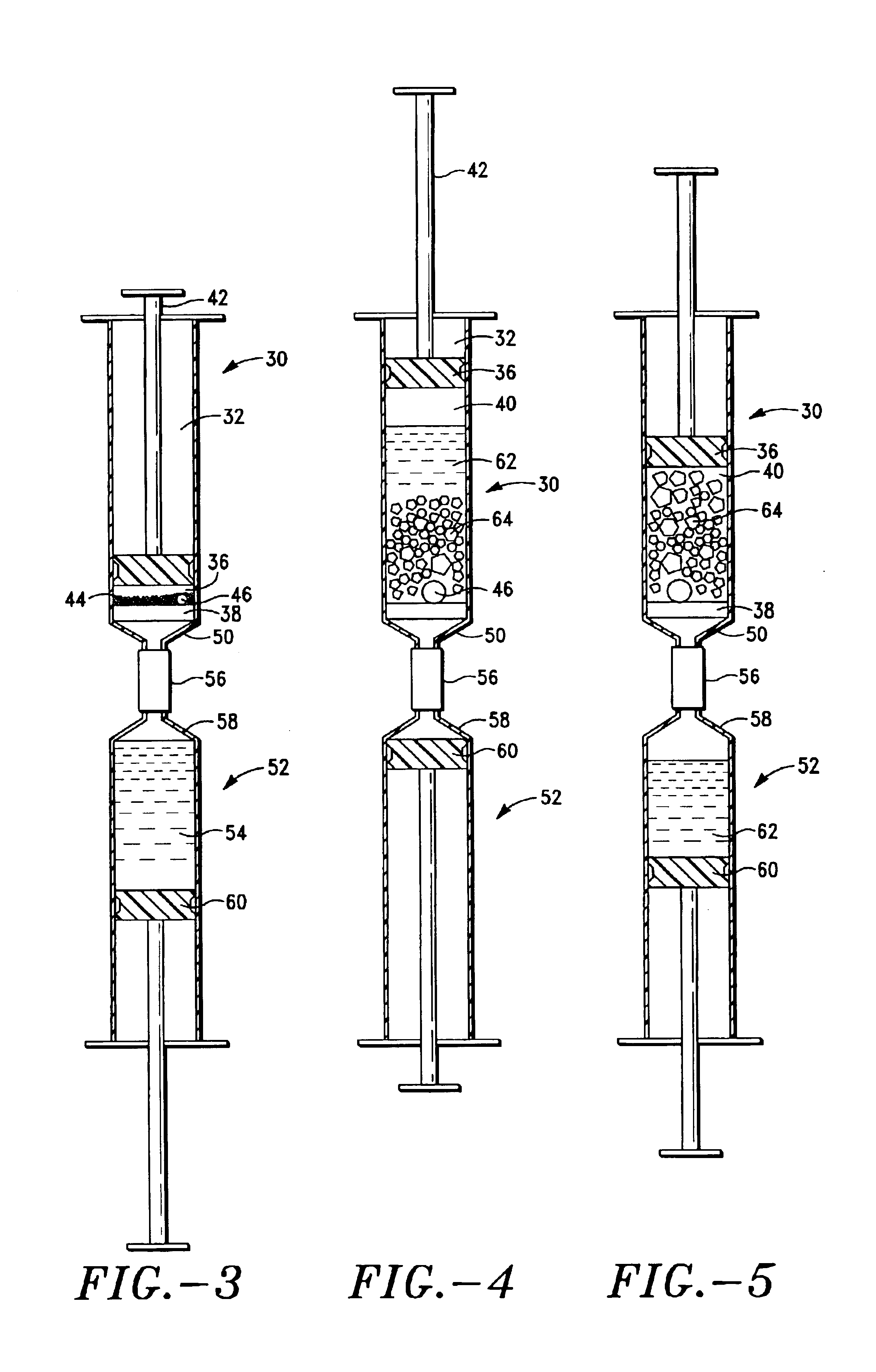

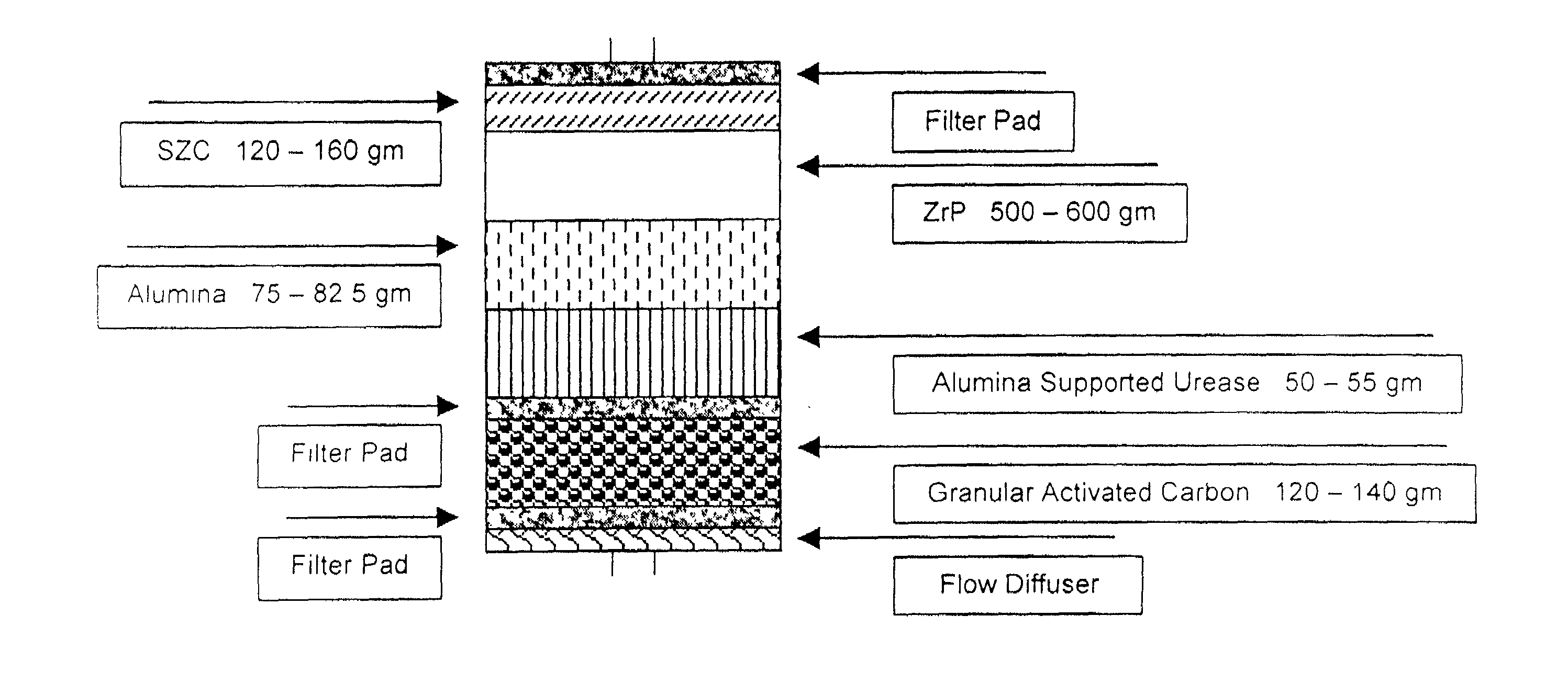

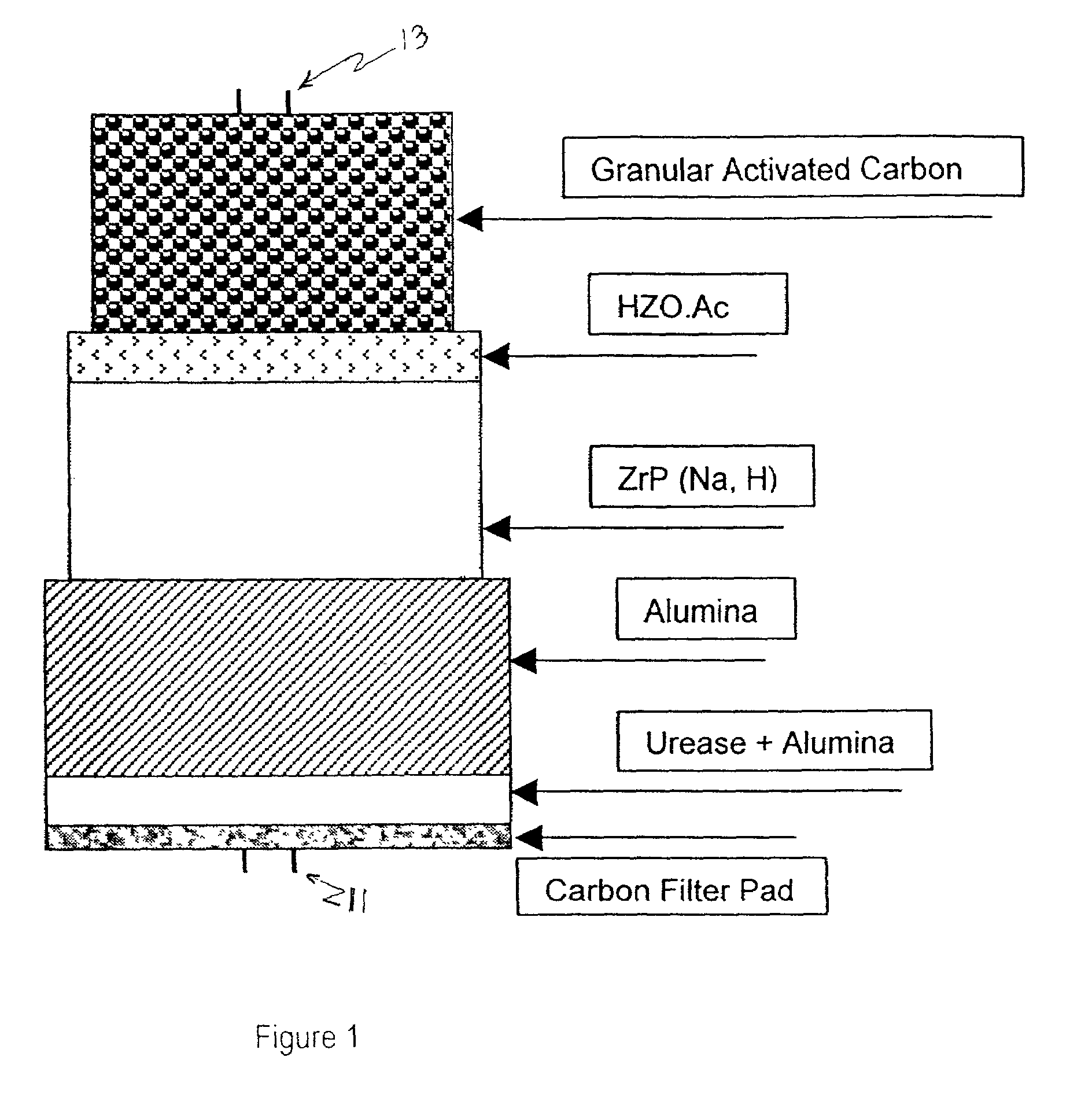

Cartridges useful in cleaning dialysis solutions

InactiveUS20020112609A1Avoid a lotSolve the blockageIsotope separationLoose filtering material filtersHemodialysis membraneChemistry

Owner:RENAL SOLUTIONS

Plasma concentrate apparatus and method

ActiveUS6905612B2Effective absorptionPromote absorptionMixing methodsDead animal preservationRed blood cellAbsorption of water

A plasma concentrator for producing plasma concentrate from a plasma from which erythrocytes have been substantially removed. The device comprises a concentrating chamber having an inlet port and an concentrate outlet, the concentrating chamber containing hydrogel beads and at least one inert agitator; and a concentrate chamber having an inlet communicating with the concentrator outlet through a filter, and having an plasma concentrate outlet port. A process for producing plasma concentrate from plasma from which erythrocytes have been substantially removed, comprising the steps of a) moving the plasma into a concentrating chamber containing hydrogel beads and an agitator to form a hydrogel bead-plasma mixture; b) causing the agitator to stir the hydrogel bead-plasma mixture, facilitating absorption of water by the beads from the plasma, until a hydrogel bead-plasma concentrate is formed; and c) separating the plasma concentrate from the hydrogel beads by passing the plasma concentrate through a filter. The concentrator can be one or more syringe devices coupled for multiple concentrations.

Owner:HANUMAN

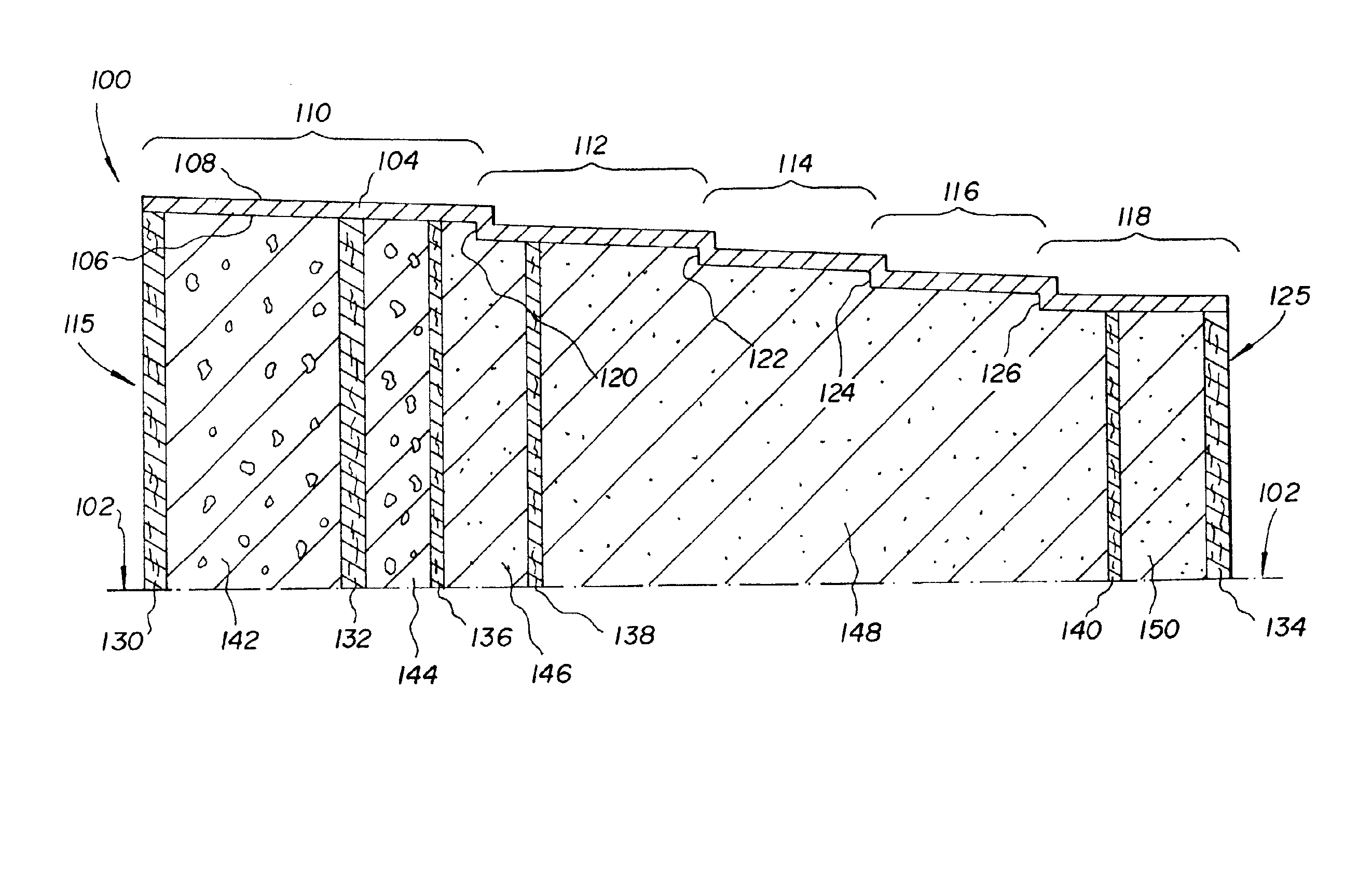

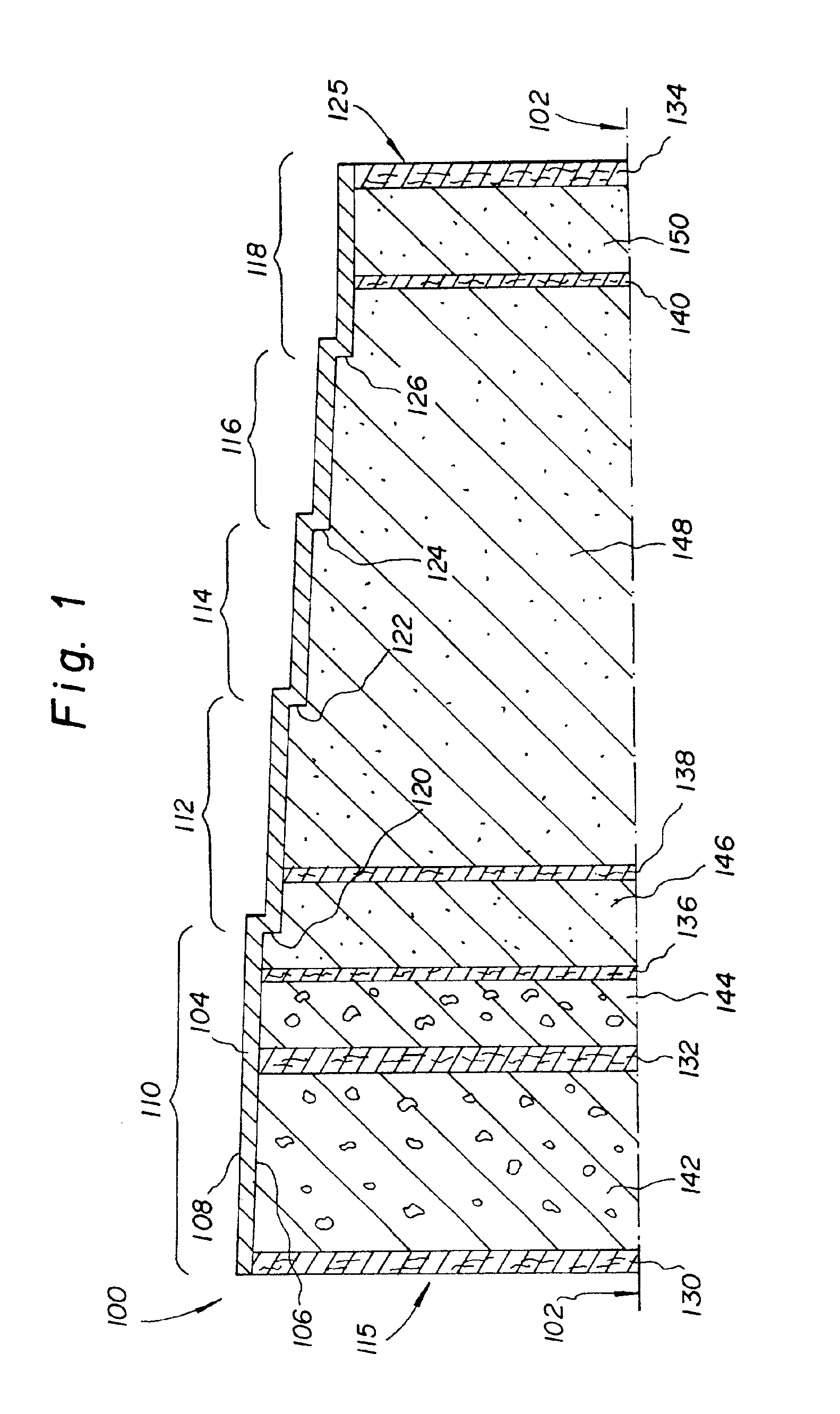

Filter cartridge assemblies and methods for filtering fluids

Filter cartridge assemblies and housings are provided and include a tubular housing having an inner wall, an outer wall, a first end, and a second end. The housings include inner walls with shoulders or other radially-inwardly extending flow directors at the intersections of adjacent sections of the tubular body. The assemblies include a plurality of filter media sections within the housing, and each of the plurality of filter media sections preferably has a different filter media composition. One or more of the filter media sections traverses one or more of the shoulders or other radially-inwardly extending flow directors such that the flow directors evenly direct the flow of fluid through the assembly. The assemblies find particular applicability in dialysis systems.

Owner:RENAL SOLUTIONS

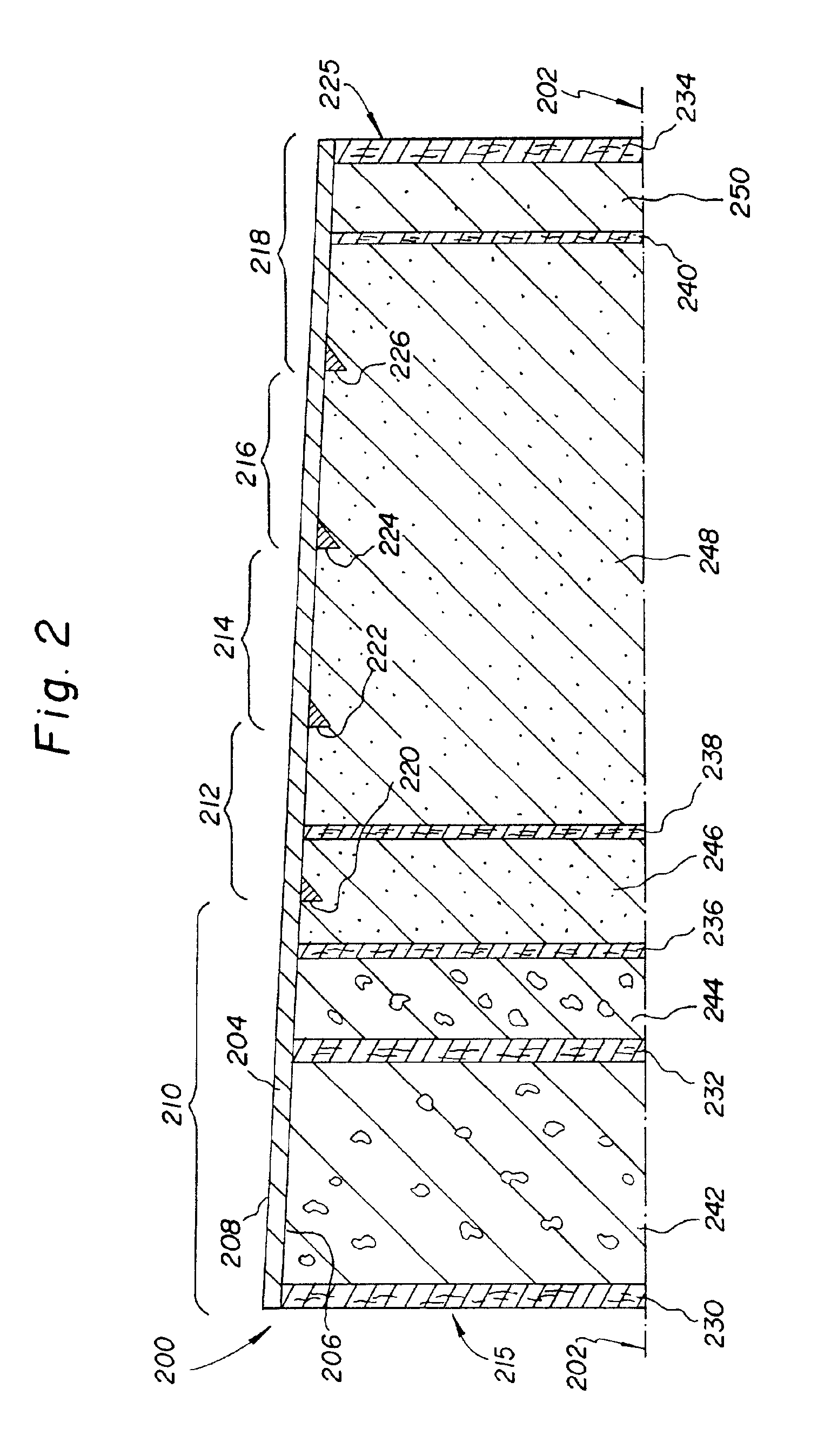

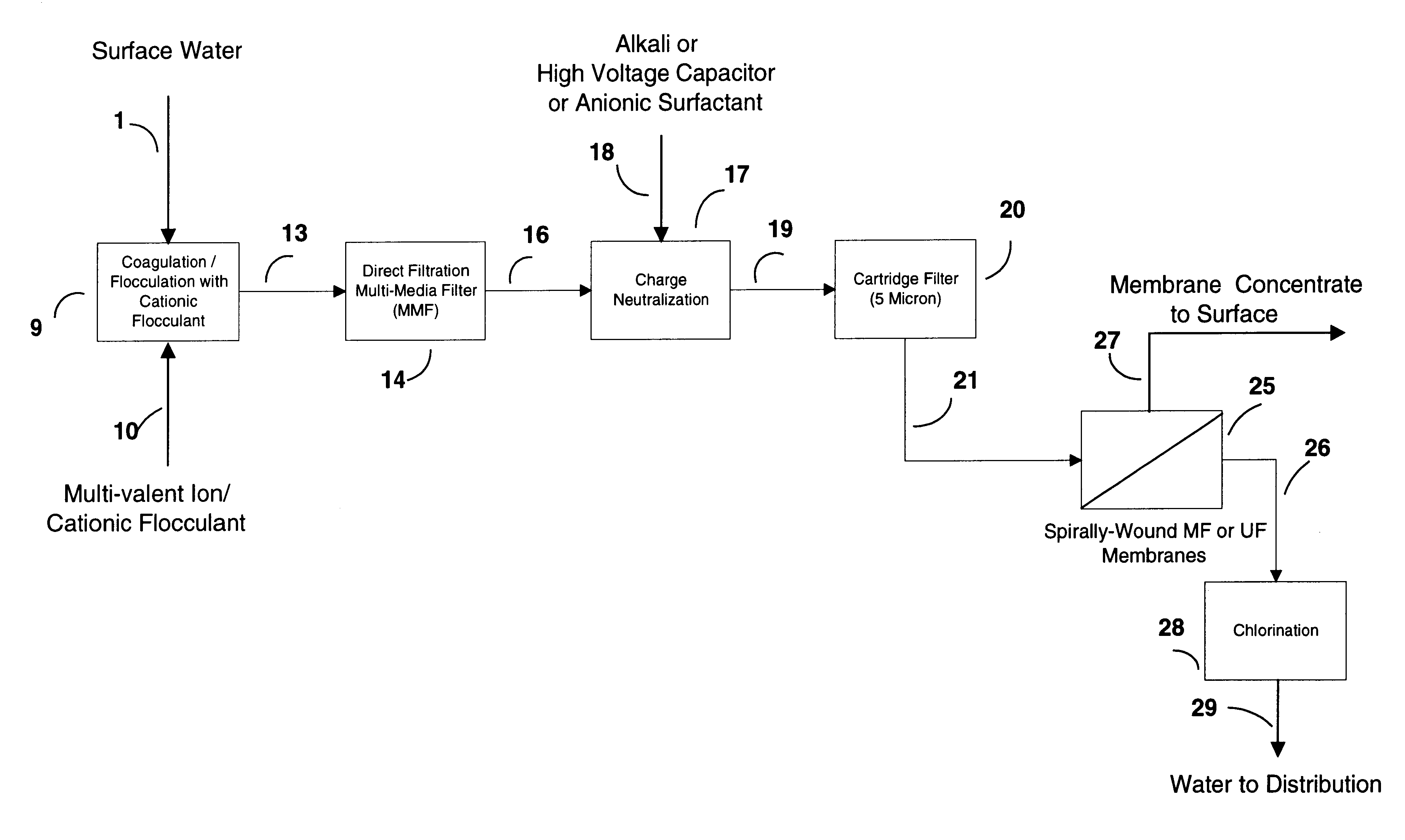

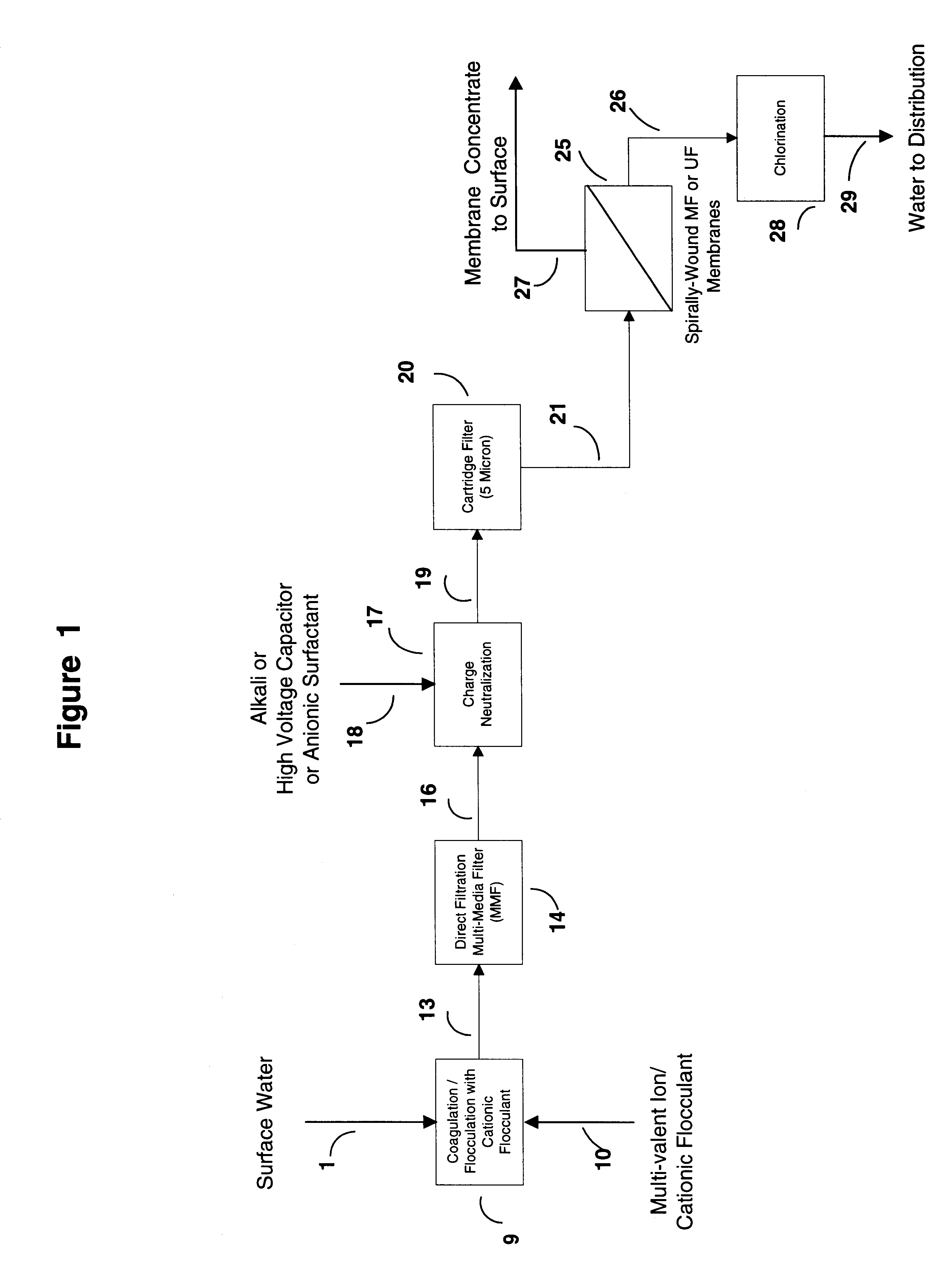

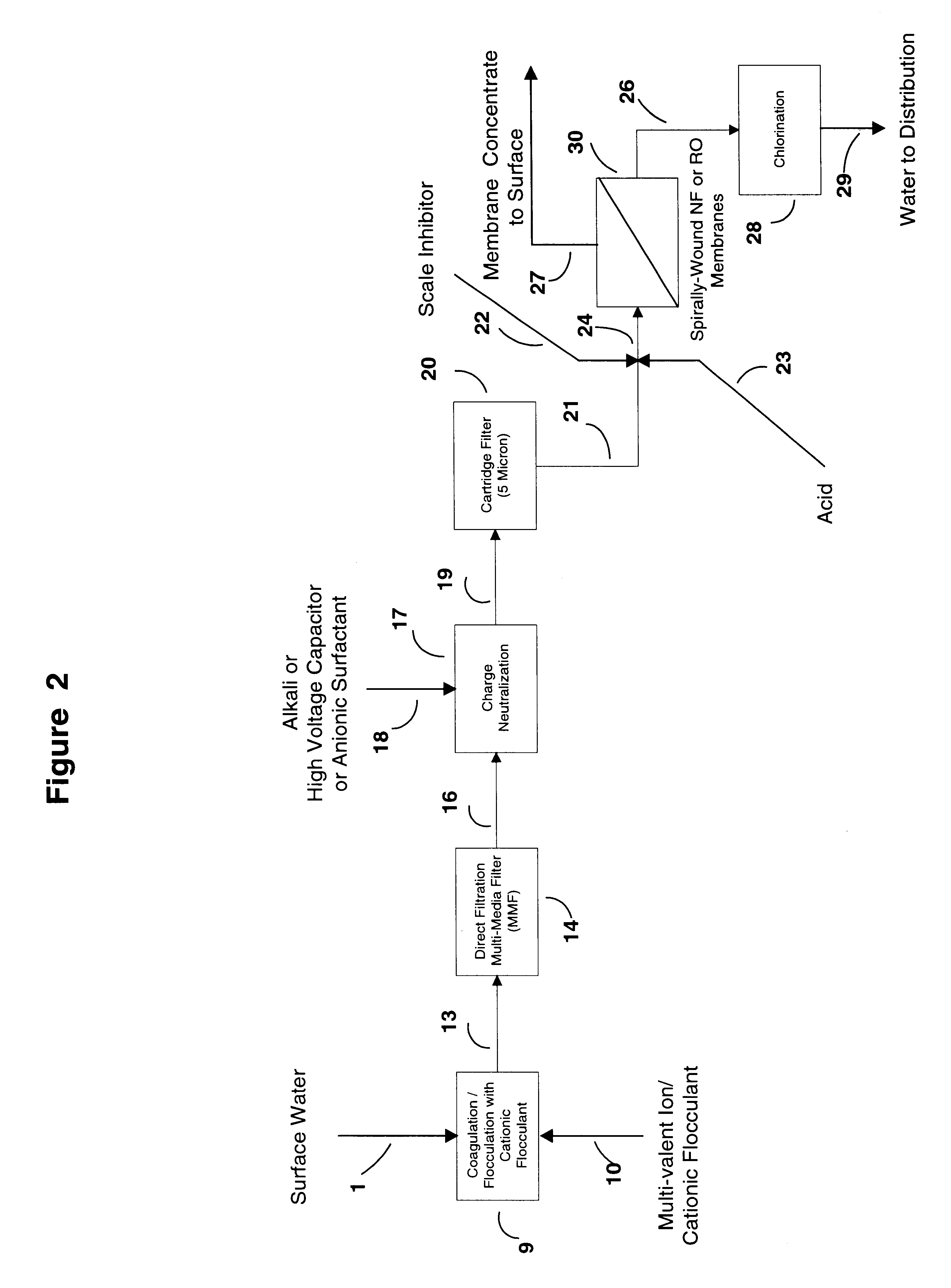

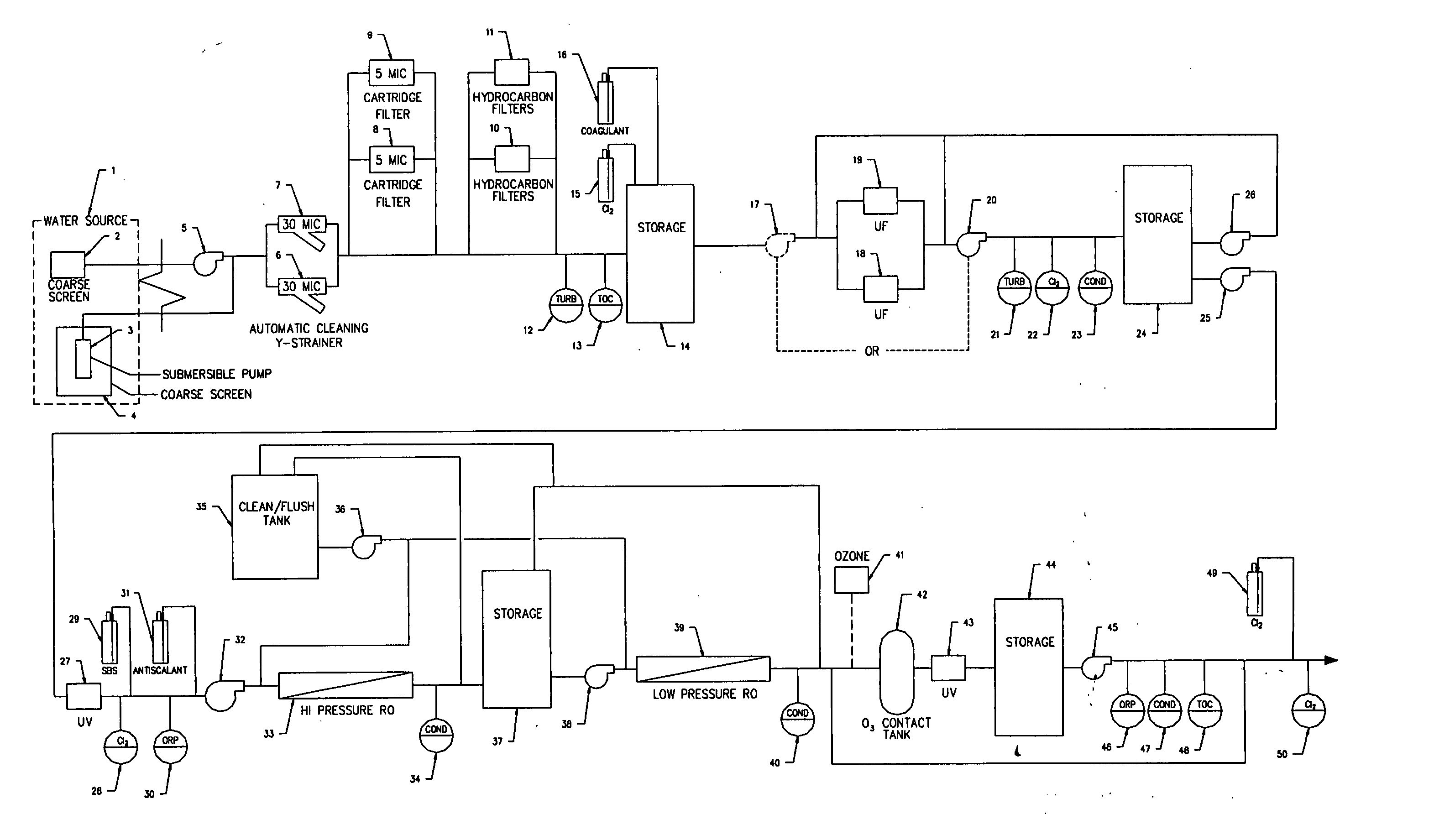

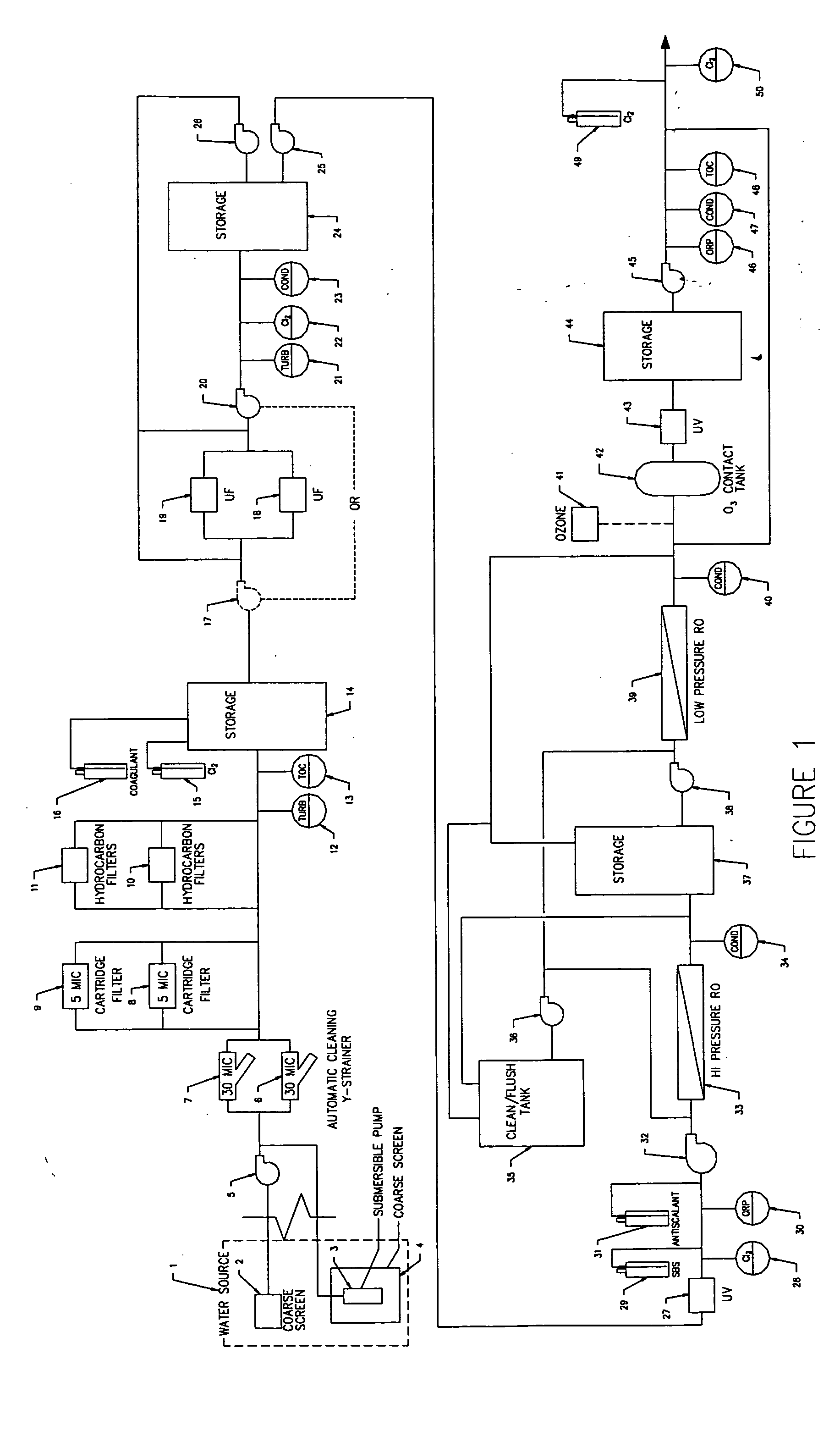

Water treatment process for membranes

InactiveUS6416668B1Effective and safe and reliable to produceCapital and operating costMembranesUltrafiltrationZeta potentialFiltration

This invention discloses a cost-effective process for separating contaminants and a wide-range of fouling material from surface water, ground water and from industrial effluents. Having undergone effective pre-treatment, the water can be purified further by using high-surface area spirally wound micro-filtration (MF), ultra-filtration (UF), nano-filtration (NF) or reverse osmosis (RO) membranes. High-quality potable water free from pathogen and other contaminants is thus produced at low-cost from the pre-treated surface water and ground-water. Conversely, pre-treated industrial effluents are further purified at a relatively low-cost using NF or RO membranes, thus producing water suitable for recycle or surface discharge. The process of this invention uses cationic inorganic and / or polymeric flocculants to coagulate and flocculate the water-borne colloidal matter (e.g. clays, iron hydroxides, naturally occurring matter (NOM's), etc.), followed by filtration using a multi-media filter, charge neutralization and reversal and final filtration using a 5-micron cartridge filter. These pre-treatment steps provides a good quality water having a low Silt Density Index and a significant negative zeta potential, thereby ensuring against irreversible chemical fouling of the spirally-wound membranes.

Owner:AL SAMADI RIAD A

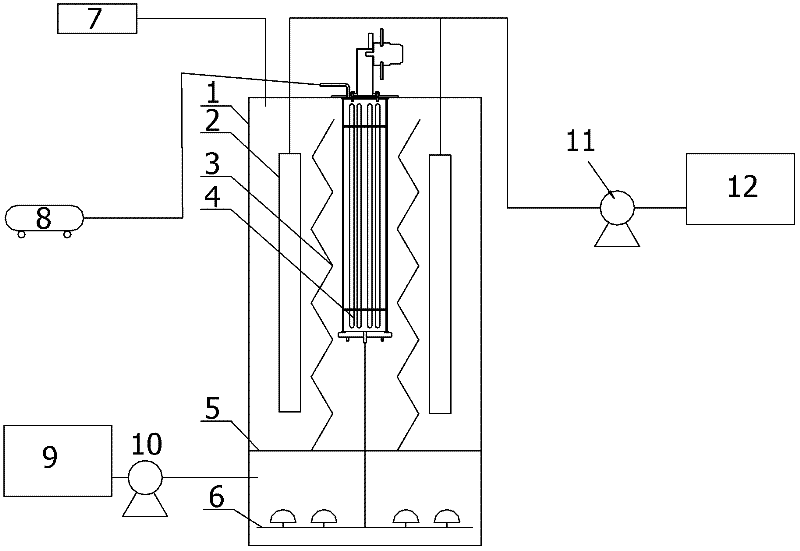

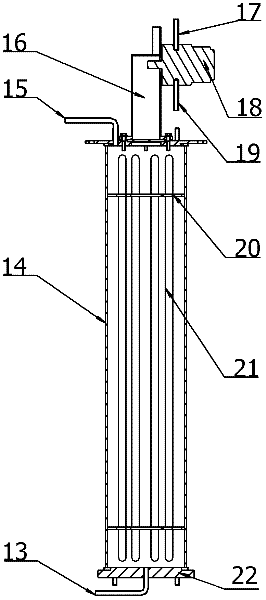

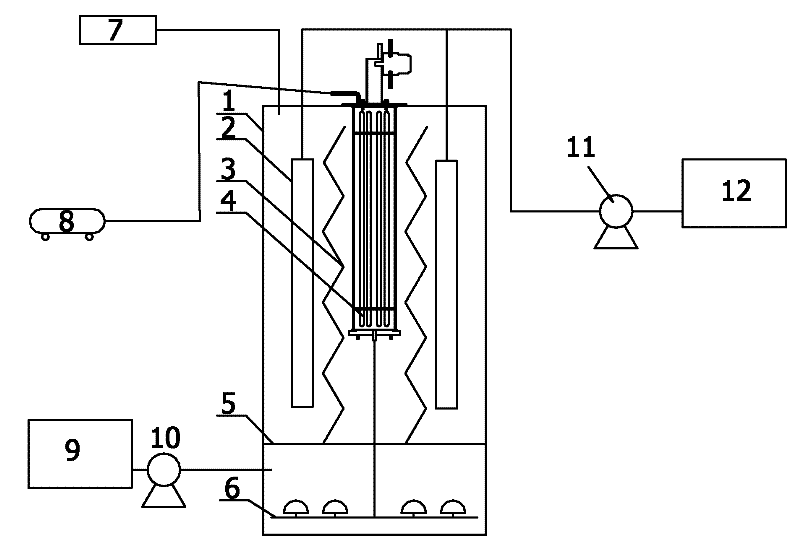

Industrial Wastewater Microwave Electrodeless UV Photocatalysis-Double Membrane Separation Coupling Treatment Device

InactiveCN102260003AAchieve coolingShort wavelengthWater/sewage treatment by irradiationWaste water treatment from animal husbandryIndustrial waste waterDecomposition

The present invention is an industrial waste water microwave electrodeless ultraviolet photocatalysis-dual membrane separation coupling treatment device, the device mainly consists of a reactor (1), a membrane separation system (2), a microwave electrodeless ultraviolet light source system (4), an aeration system, and an ozone tail gas decomposition device (7) connected to the reactor, and an inlet and outlet water system, wherein: the upper and lower parts of the reactor are respectively the reaction zone and the aeration zone, which are separated by a water distribution plate (5); the membrane separation system The microwave electrodeless ultraviolet light source system is located in the reaction zone and is separated by a corrugated partition (3); the aeration system is composed of a microporous aeration head (6) and a blower (8), and the microporous aeration head is located in the aeration At the bottom of the zone, the blower sends air to the aeration zone through the air duct. The invention has the characteristics of high reaction rate, complete degradation of organic matter, long-term operation and the like, and has strong operability and high safety. It is suitable for the treatment of refractory organic industrial wastewater, and it is also suitable for sterilization and disinfection in the field of water supply.

Owner:WUHAN TEXTILE UNIV

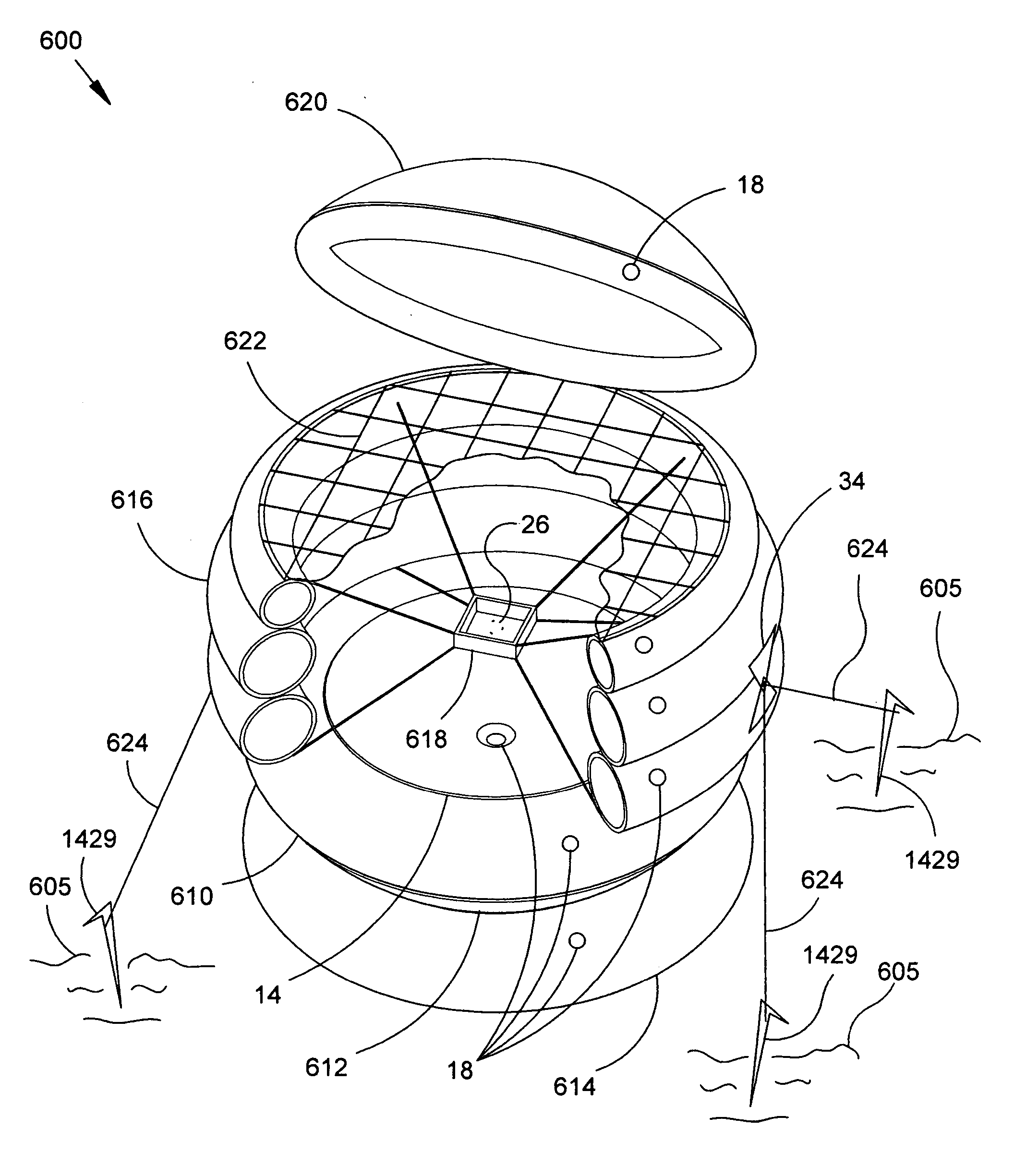

Multi-function field-deployable resource harnessing apparatus and methods of manufacture

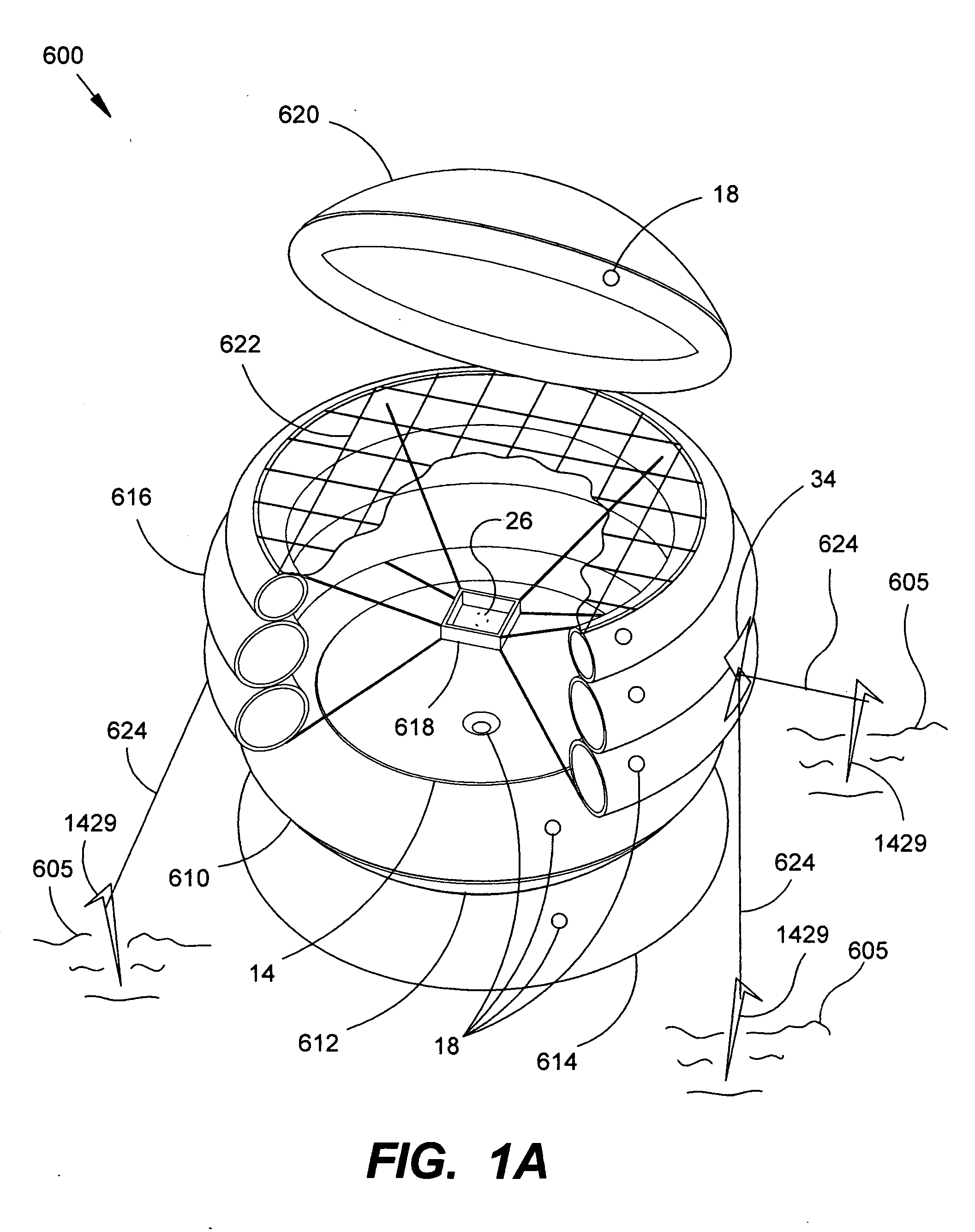

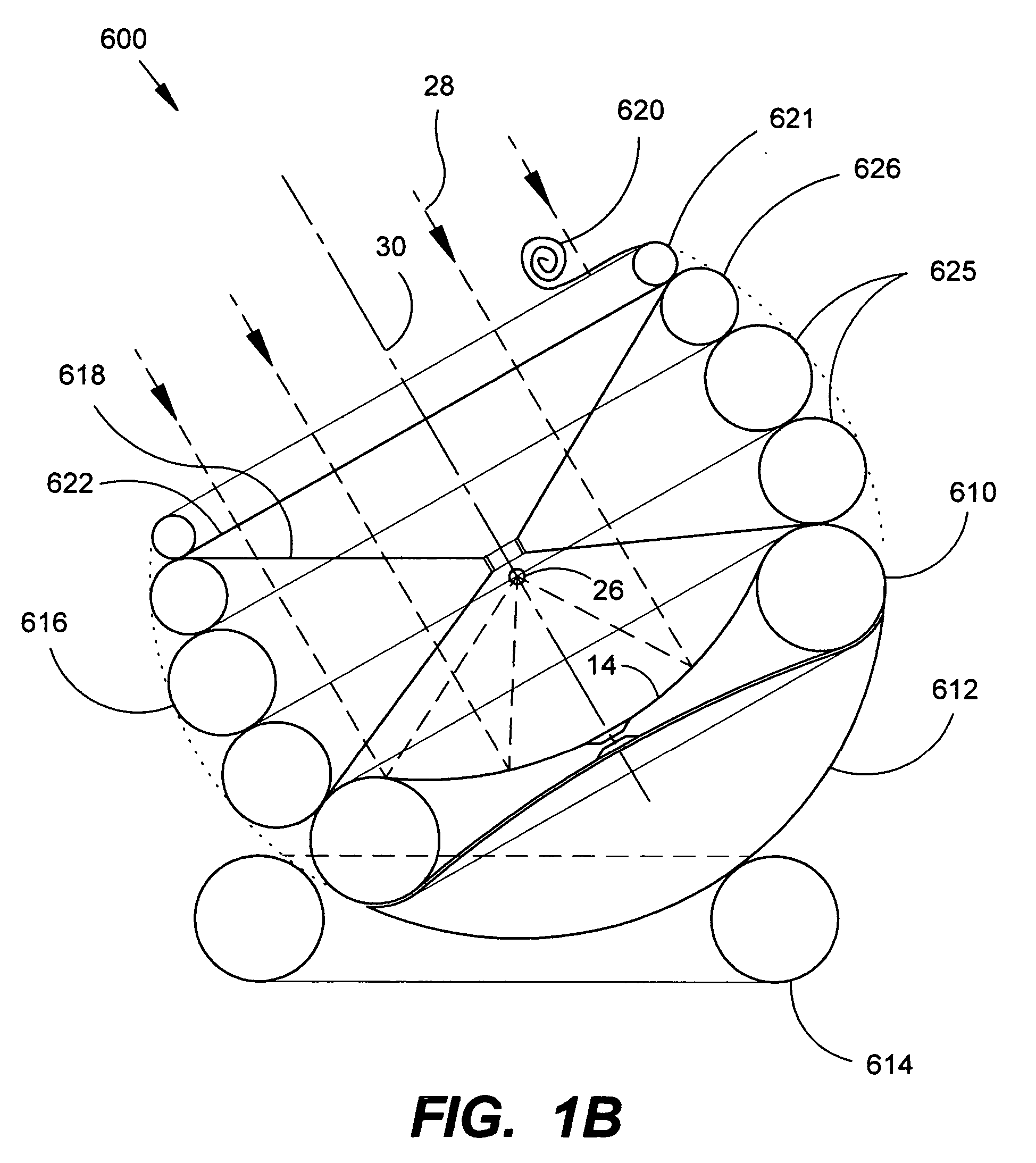

InactiveUS20060033674A1Solar heating energyGeneral water supply conservationLight signalMechanical engineering

A multi-function, field-deployable resource harnessing apparatus 600 having, in its embodiments, an inflatable reflector apparatus 610 comprising a least one manufactured parabolic mirror made from a pressure-deformable reflective covering of an inflatable ring for focusing electromagnetic energy from radio frequency radiation (RF) through the ultraviolet (UV) radiation including solar energy for (1) heating and cooking, (2) electrical power generation, (3) enhancing the transmission and reception of radio signals, (4) enhancing vision in low-light environments, and / or (5) projection of optical signals or images. The device also has non-electromagnetic uses, such as the collection and storage of water, harnessing of energy from a fluid stream, and / or harnessing wave energy. A first main embodiment of the inflatable reflector apparatus 610 generally utilizes two pressure-deformable membranes, at least one of which is reflective. A second main embodiment utilizes a reflective membrane and a transparent membrane. In addition to the reflector apparatus 610, the modular apparatus 600 typically further includes modular assemblies to increase versatility, facilitate use, and / or enhance safety such as, for example, a modular support and orienting assembly 612, a separate support ring 614, a safety shield or cage 616, a focal point support assembly 618, a safety cover 620, a safety net or mesh 622, and a stabilizing assembly 624. Portability is enhanced by complete collapsing of the inflatable device.

Owner:ESSIG JR JOHN R +1

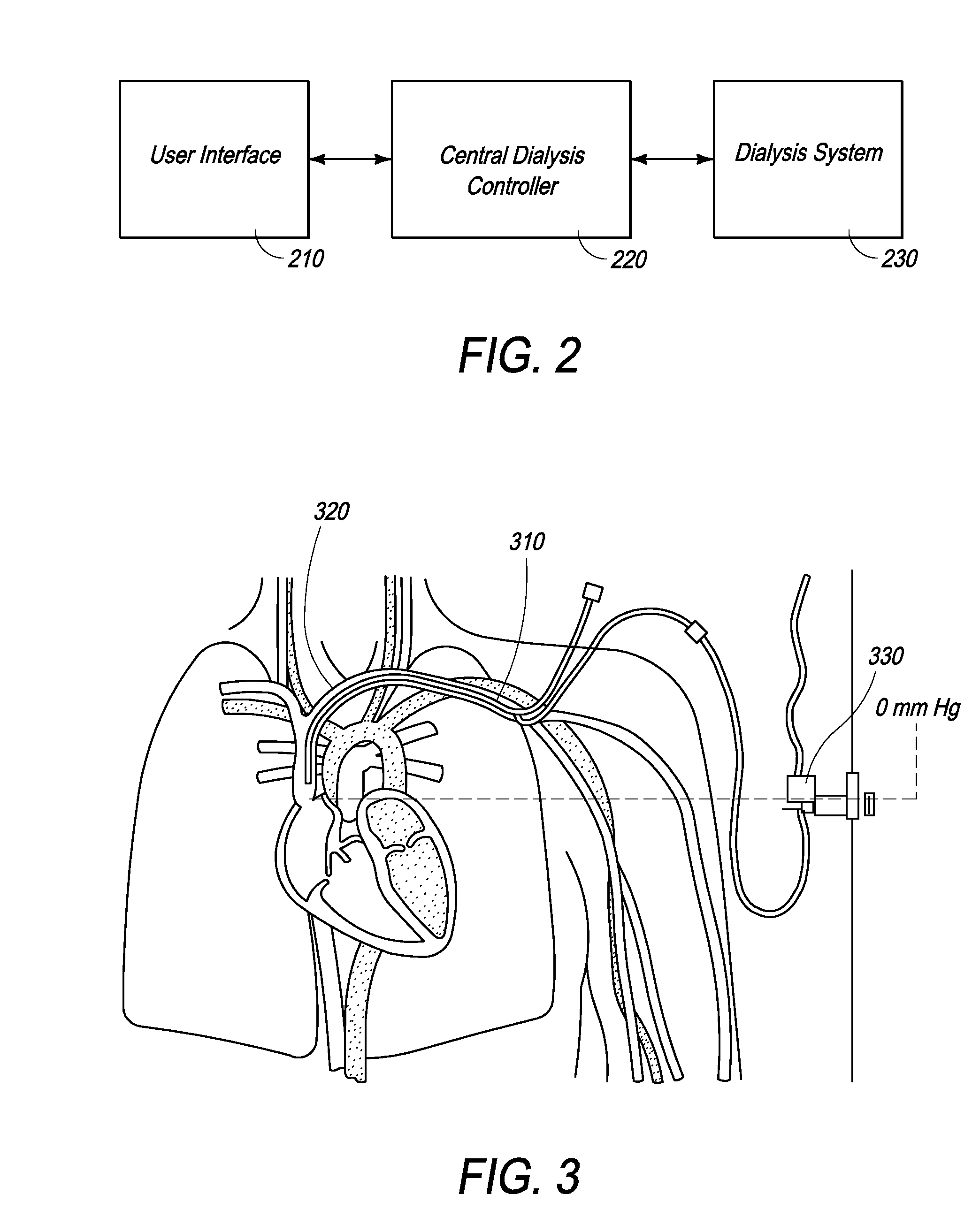

Blood treatment systems and methods

ActiveUS20100192686A1Increase pressureMechanical/radiation/invasive therapiesSolvent extractionBlood treatmentsGraphics

Dialysis systems comprising actuators that cooperate to perform dialysis functions and sensors that cooperate to monitor dialysis functions are disclosed. According to one aspect, such a hemodialysis system comprises a user interface model layer, a therapy layer, below the user interface model layer, and a machine layer below the therapy layer. The user interface model layer is configured to manage the state of a graphical user interface and receive inputs from a graphical user interface. The therapy layer is configured to run state machines that generate therapy commands based at least in part on the inputs from the graphical user interface. The machine layer is configured to provide commands for the actuators based on the therapy commands.

Owner:DEKA PROD LLP

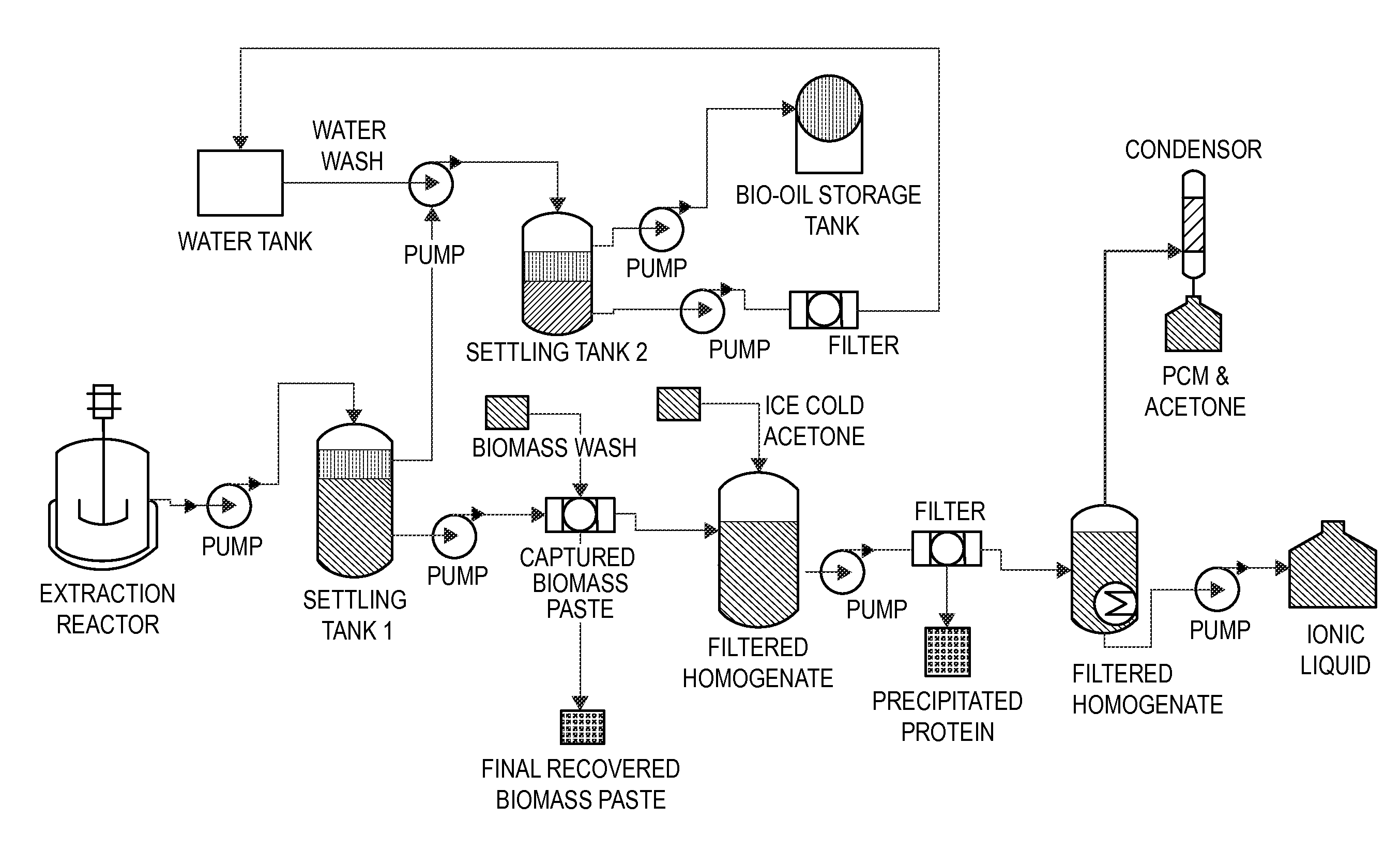

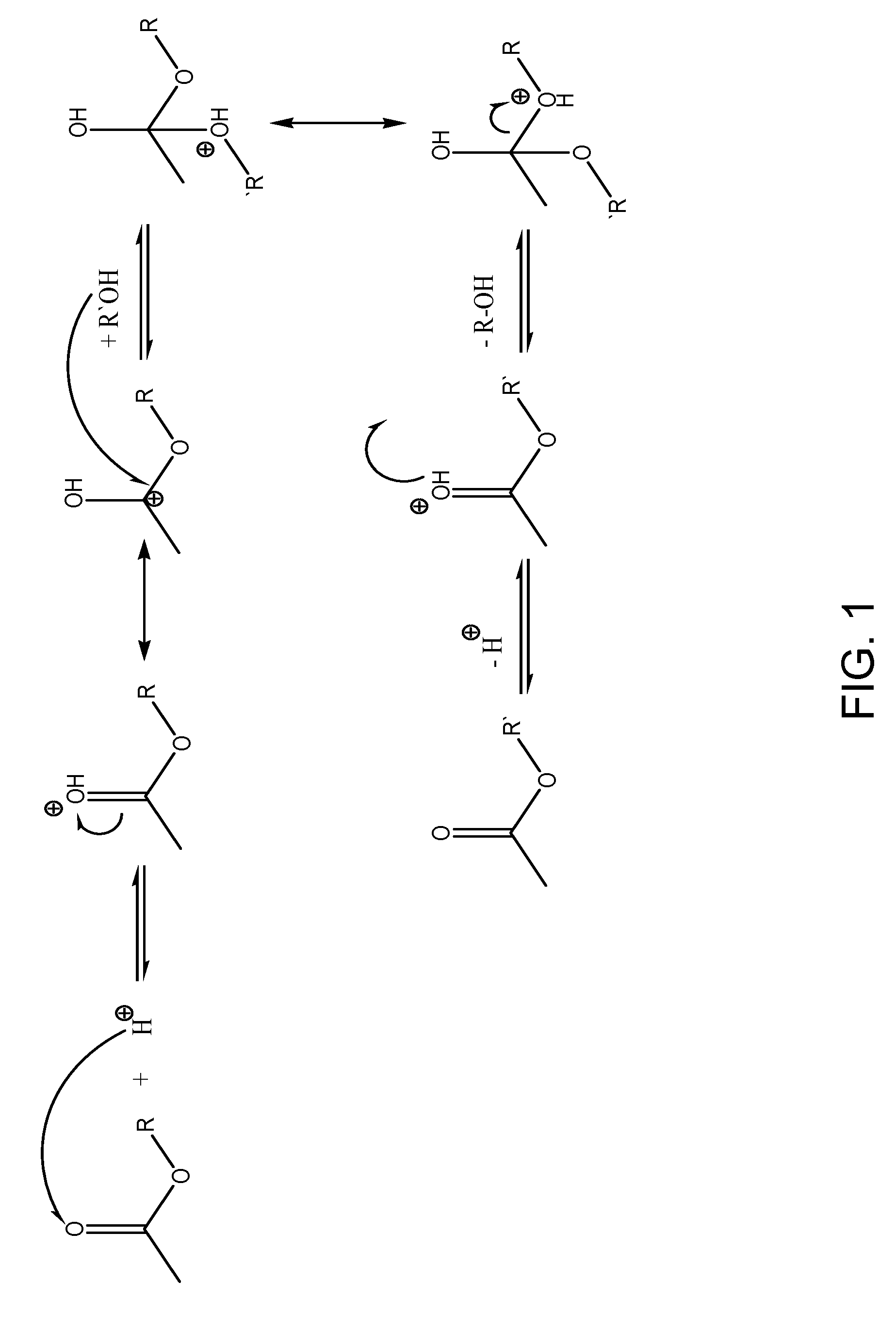

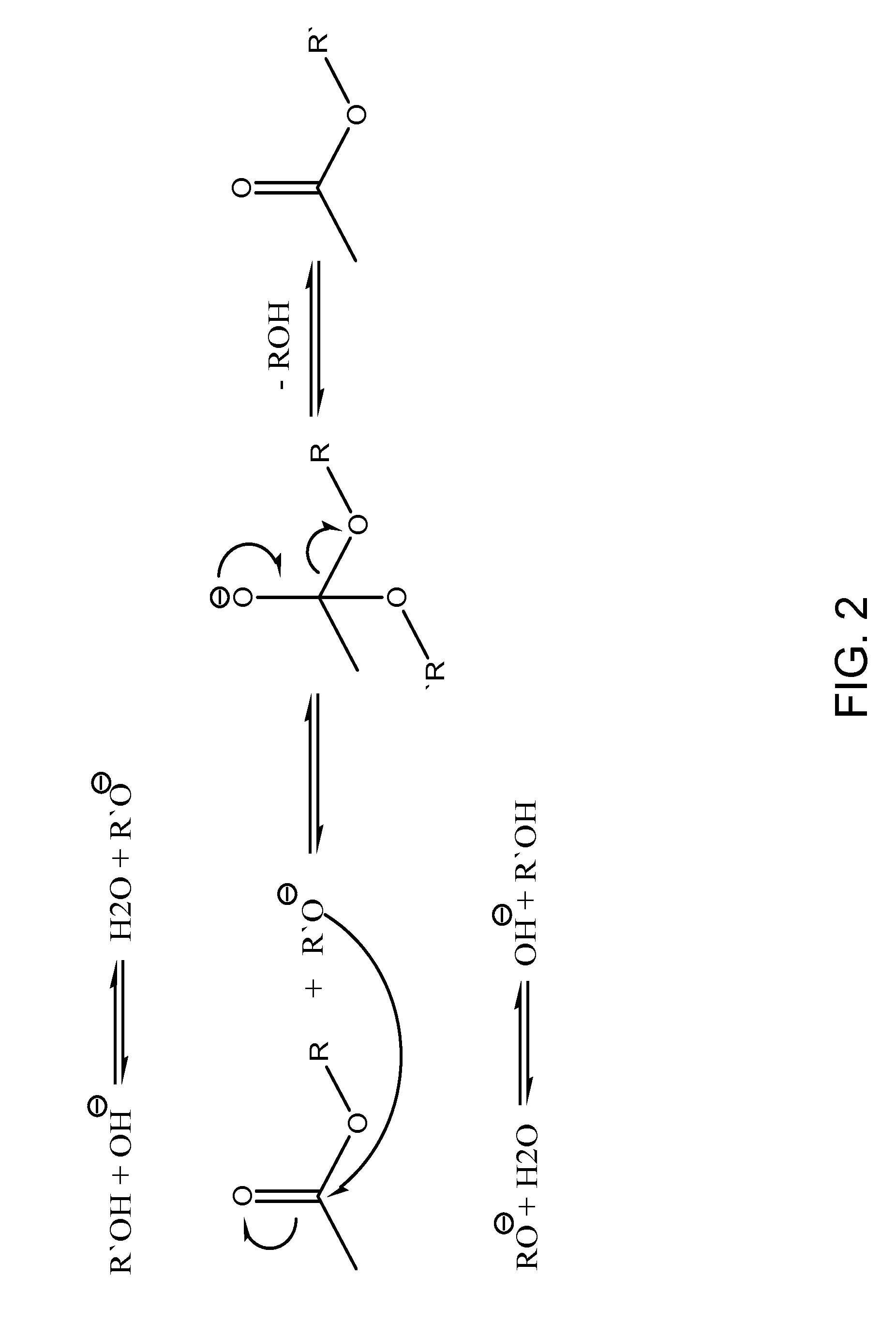

Methods and compositions for extraction and transesterification of biomass components

InactiveUS20090234146A1Fatty oils/acids recovery from wasteFatty acid esterificationTransesterificationBiofuel

Methods and compositions are disclosed for the direct transesterification and extraction of bio-lipids and bio-oils in the production of biofuel, particularly fatty acid methyl ester products.

Owner:UNIV OF HAWAII

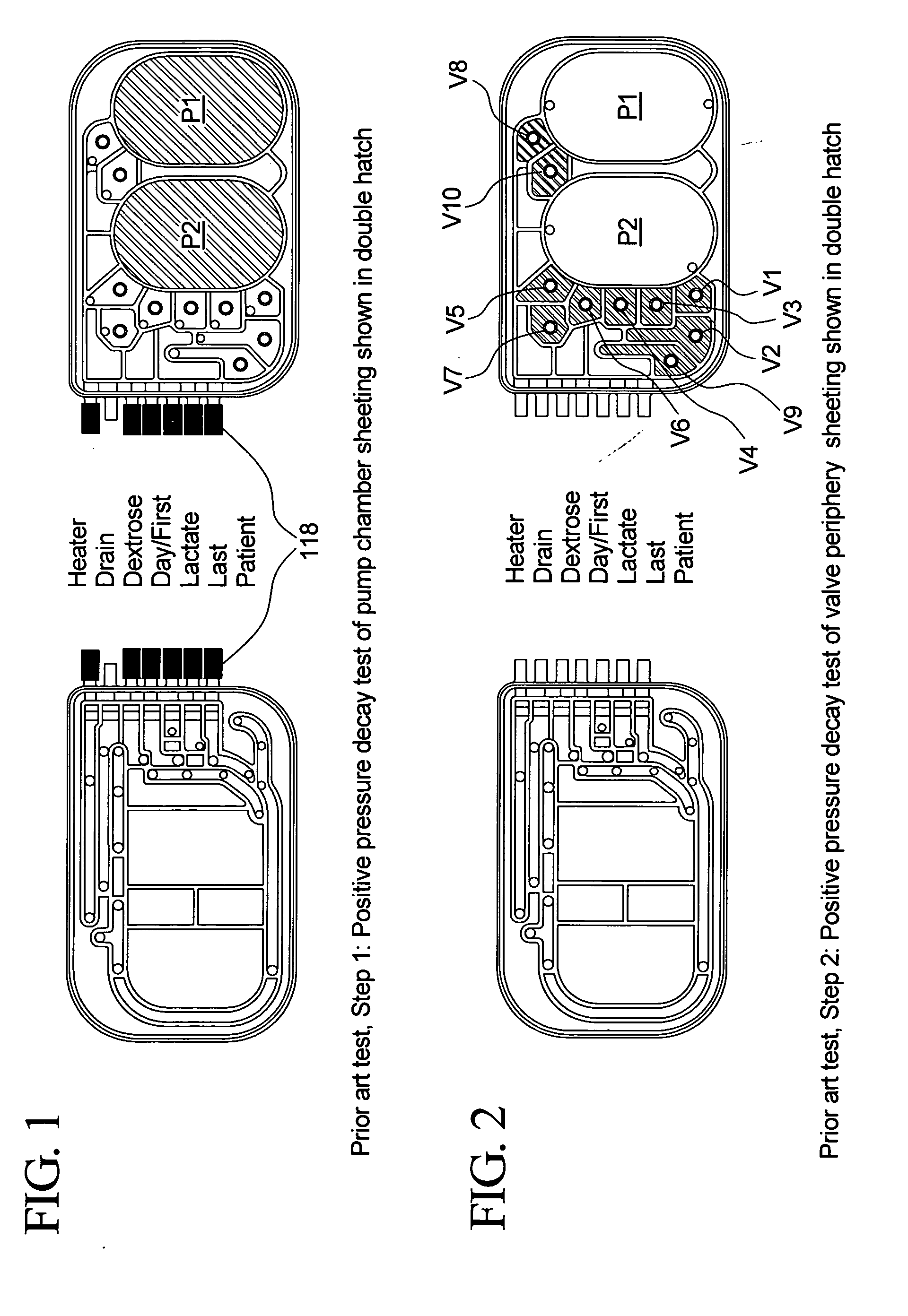

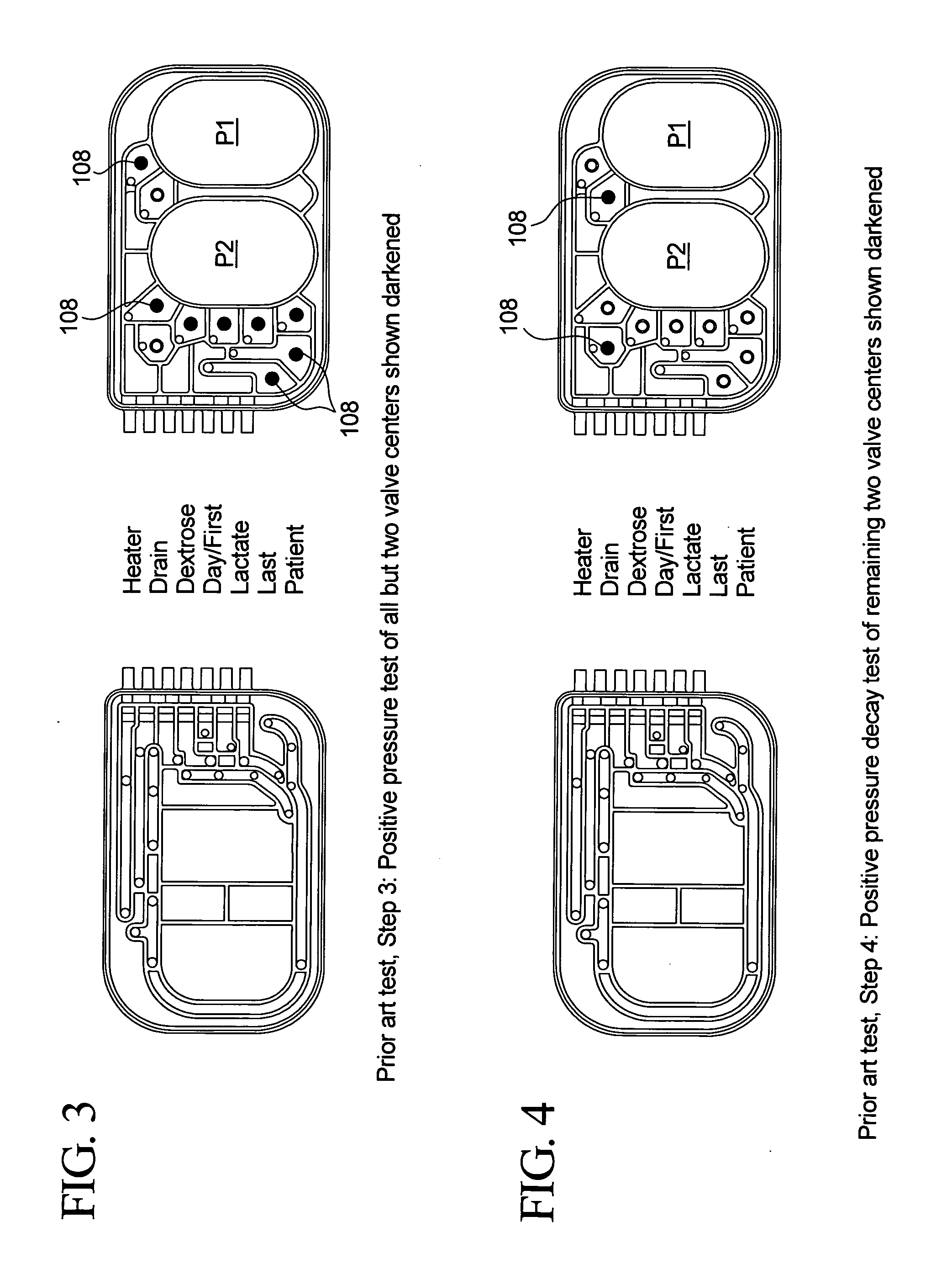

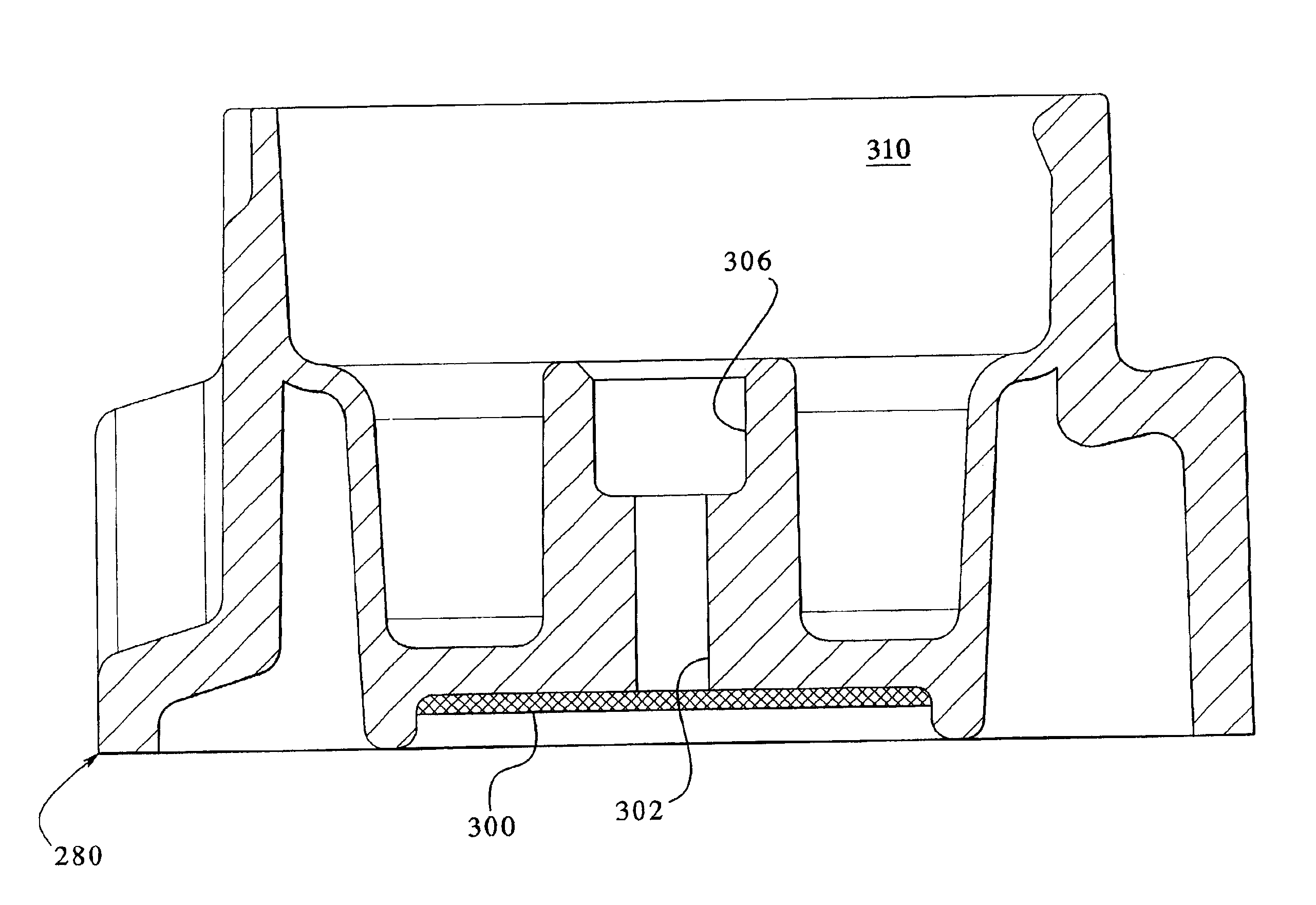

Priming, integrity and head height methods and apparatuses for medical fluid systems

ActiveUS20050126998A1Less timeLeakage is detectedDetection of fluid at leakage pointOther blood circulation devicesDelivery systemFluid system

Improved integrity test, priming sequence and bag height detection tests, apparatuses and methods for a medical fluid delivery system are provided. The integrity test includes a plurality of air pressure decay tests, using positive and negative pressure. The priming sequence includes pumping fluid through a portion of a patient line to be primed to overcome air in the line and other potential obstacles. The head height test measures a pressure build-up or drop-off within a pump chamber of a membrane pump. The measured pressure corresponds to a head height between a fluid supply and the pump or between the pump and a fluid drain. A determination is made whether the corresponding head height is acceptable.

Owner:BAXTER INT INC +1

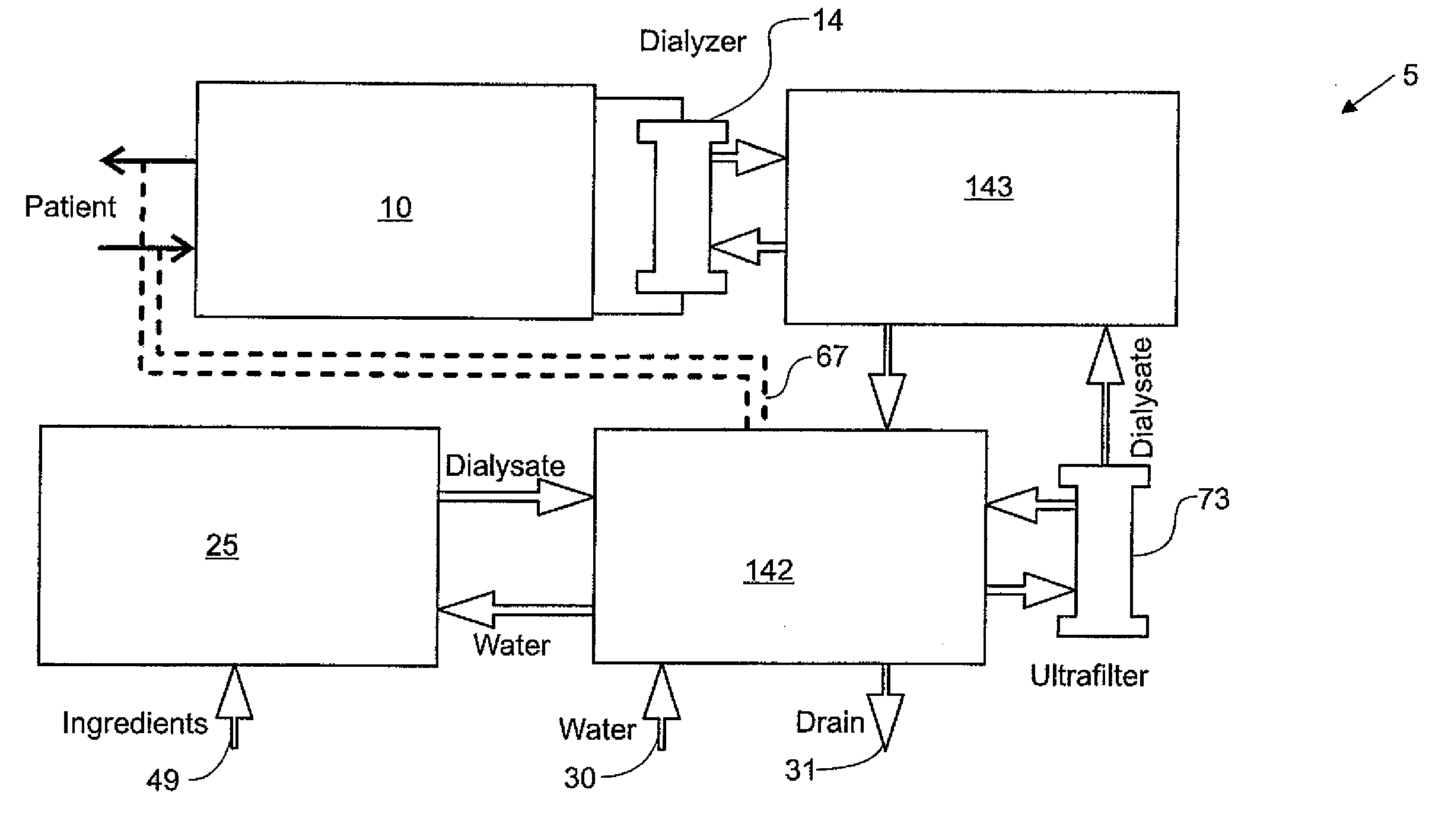

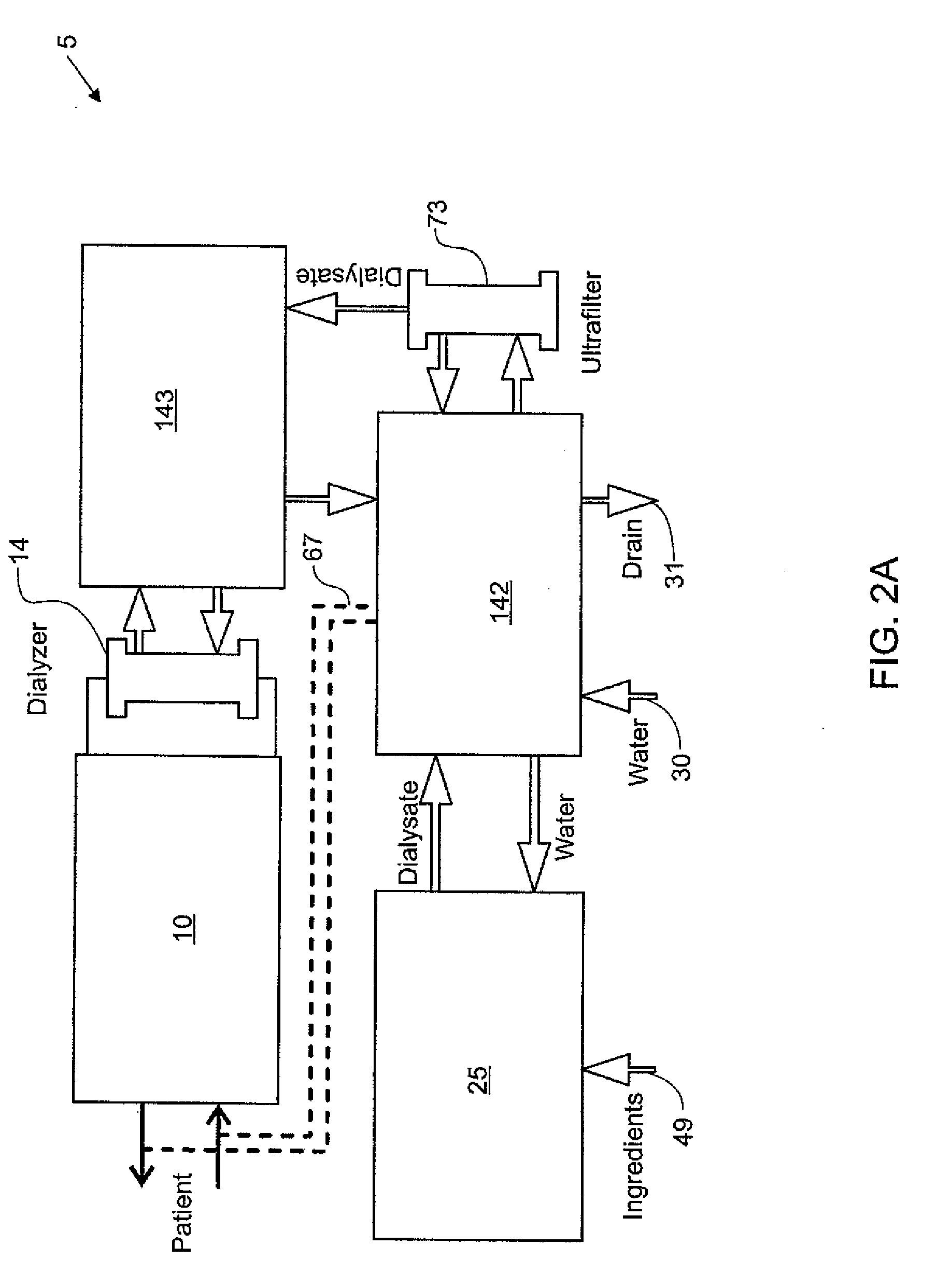

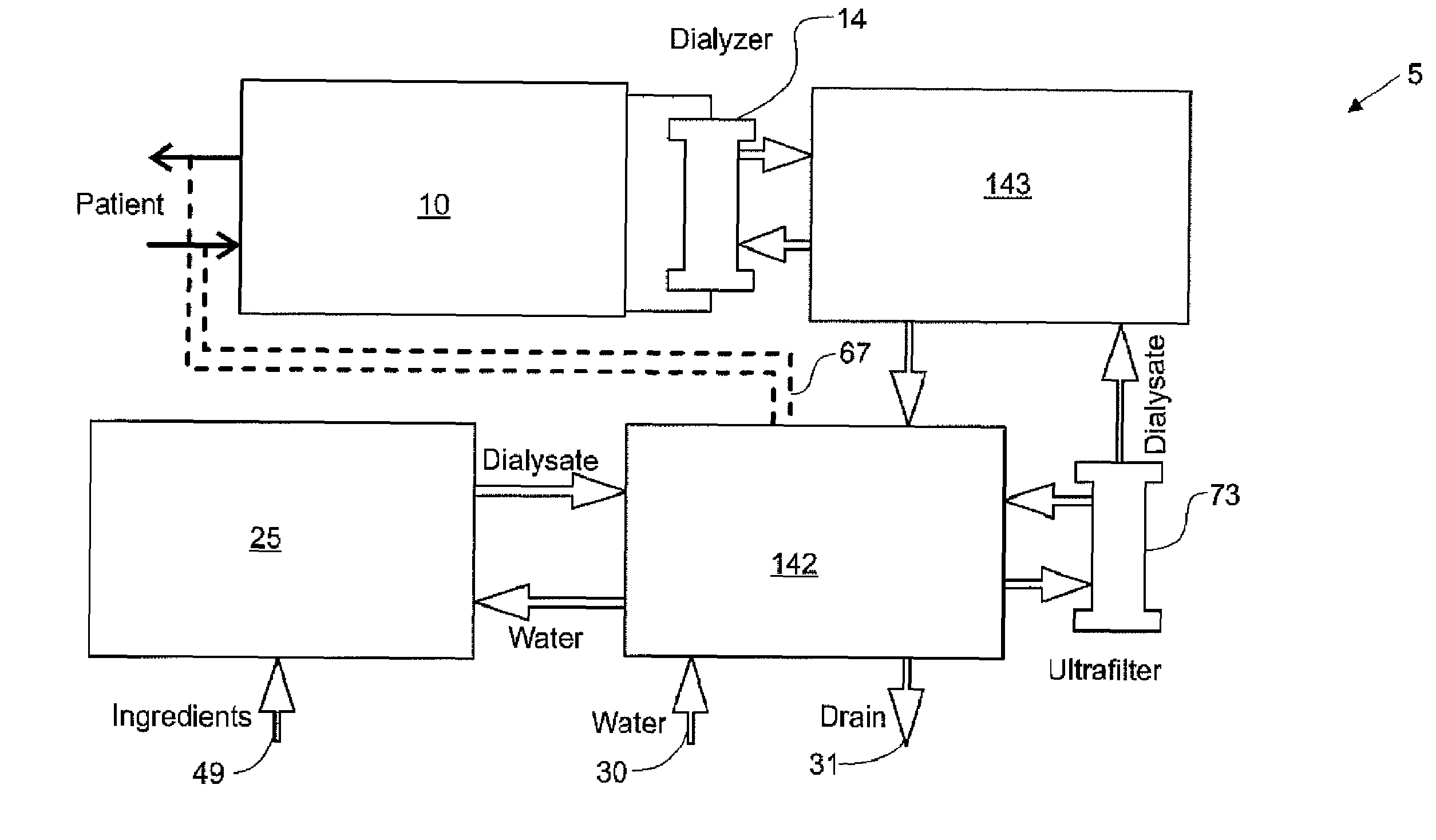

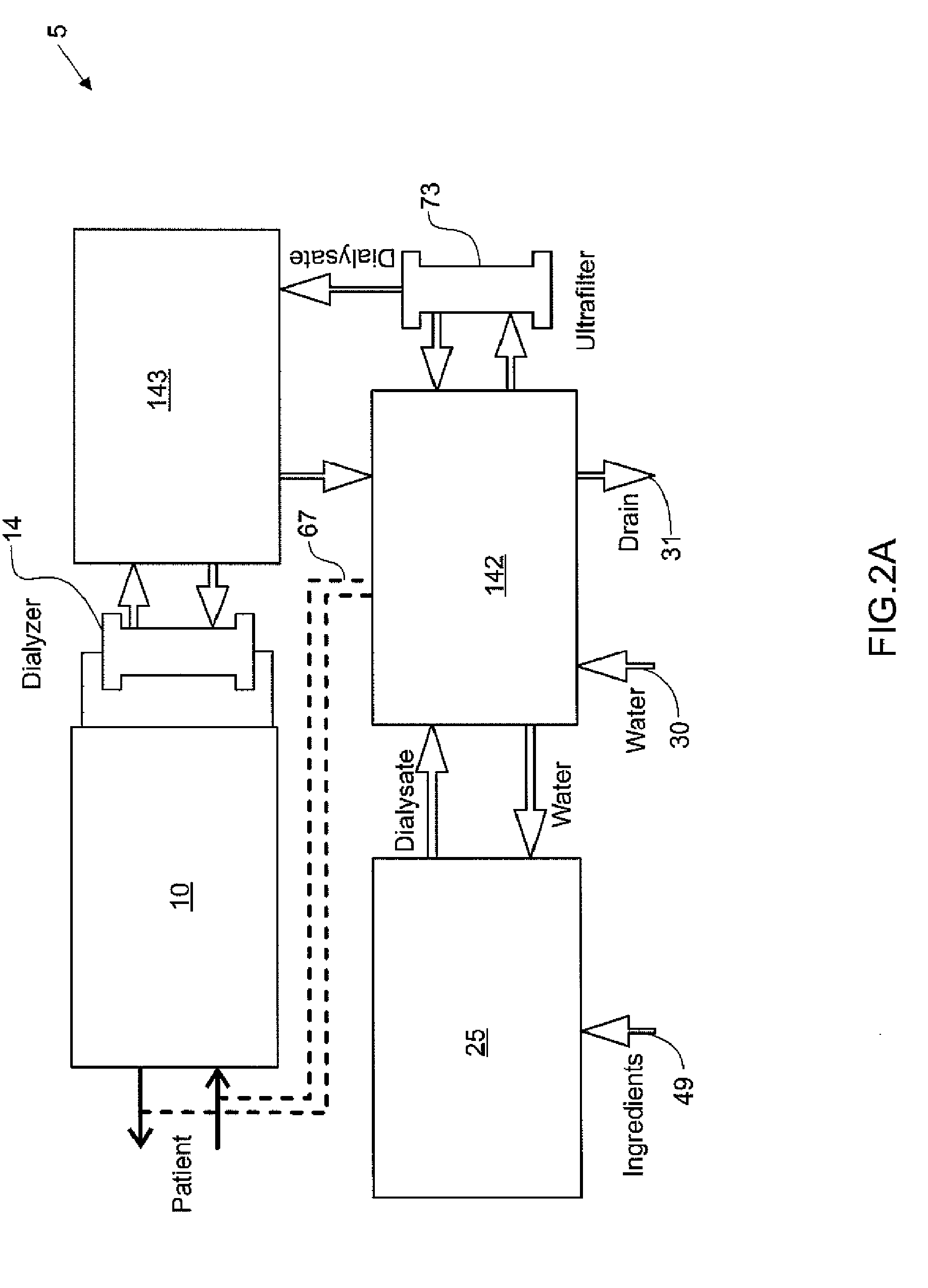

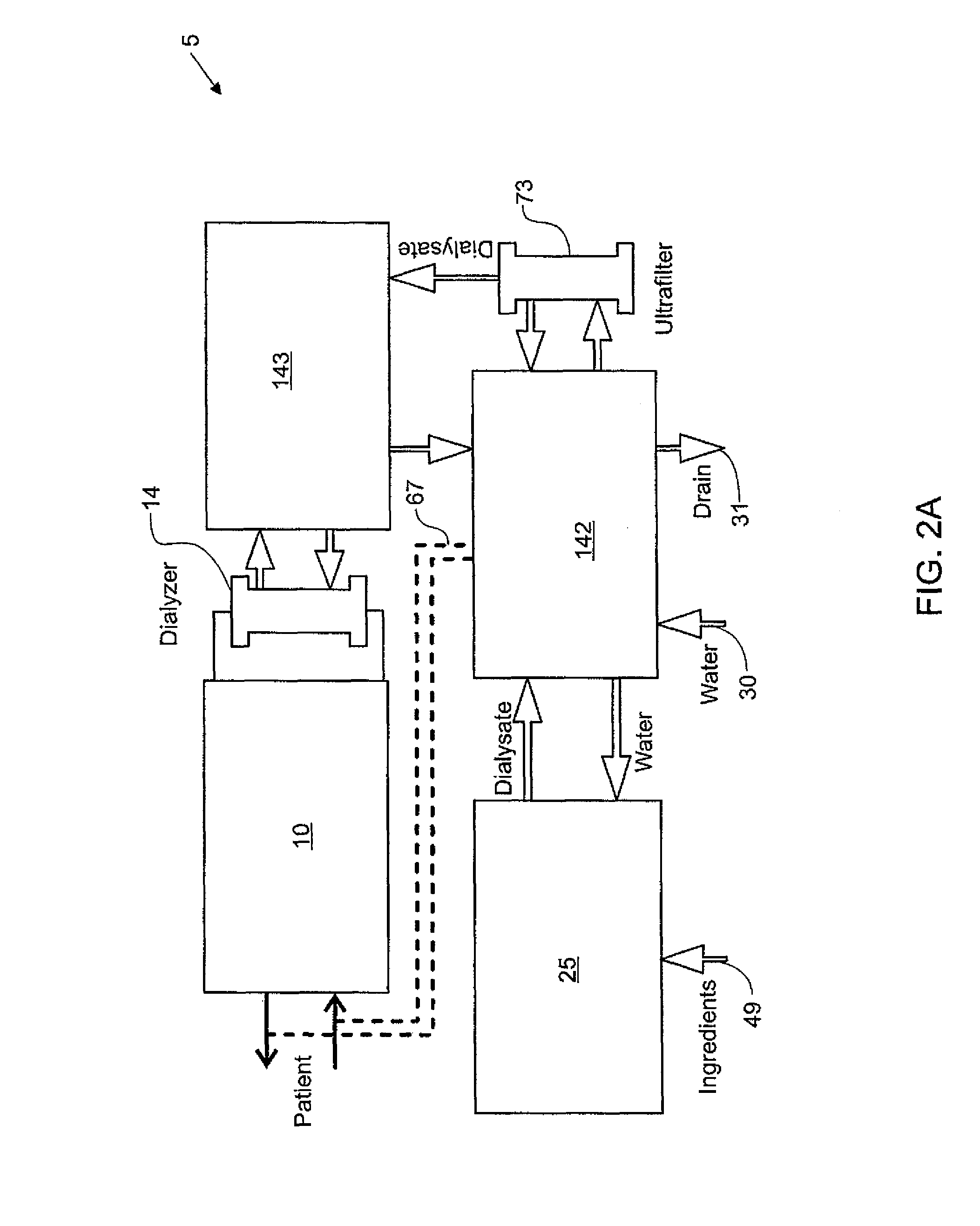

Hemodialysis systems and methods

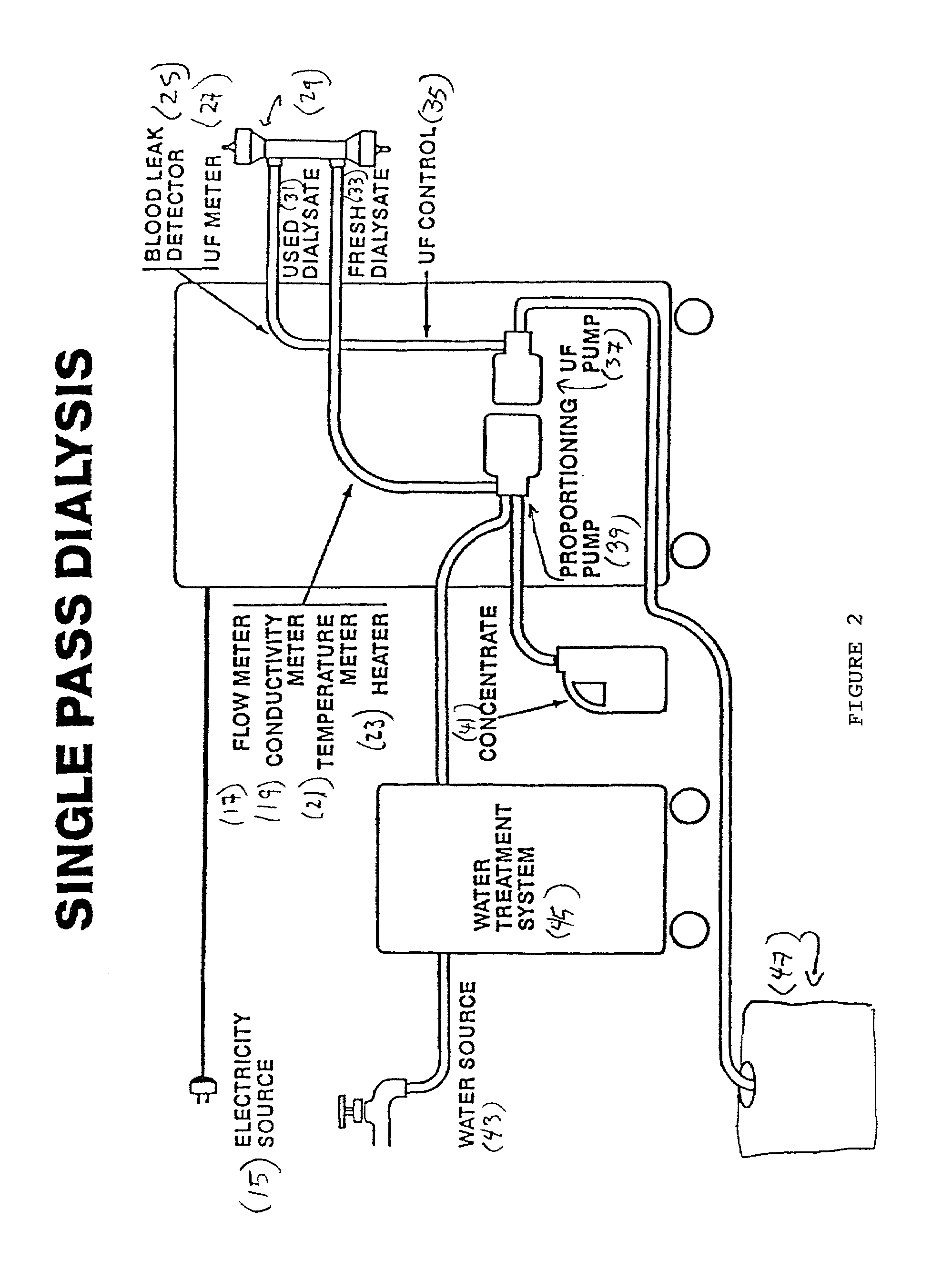

ActiveUS20090095679A1Mechanical/radiation/invasive therapiesSolvent extractionHaemodialysis machineDialysate flow

Hemodialysis dialysis systems are disclosed. Hemodialysis systems of the invention may include a dialysate flow path including a balancing circuit, a mixing circuit, and / or a directing circuit. The circuits may be defined within one or more cassettes. The fluid circuits may be at least partially isolated, spatially and / or thermally, from electrical components of the system. A gas supply may be provided in fluid communication with the dialysate flow path and / or the dialyzer to urge dialysate through the dialyzer and blood back to the patient. The hemodialysis systems may include fluid handling devices, actuated using a control fluid, optionally delivered using a detachable pump. Fluid handling devices may be generally rigid and of a spheroid shape, optionally with a diaphragm dividing the device into compartments.

Owner:DEKA PROD LLP

Cartridges useful in cleaning dialysis solutions

InactiveUS7033498B2Avoid a lotSolve the blockageZirconium compoundsLoose filtering material filtersMedicineHemodialysis membrane

Owner:RENAL SOLUTIONS

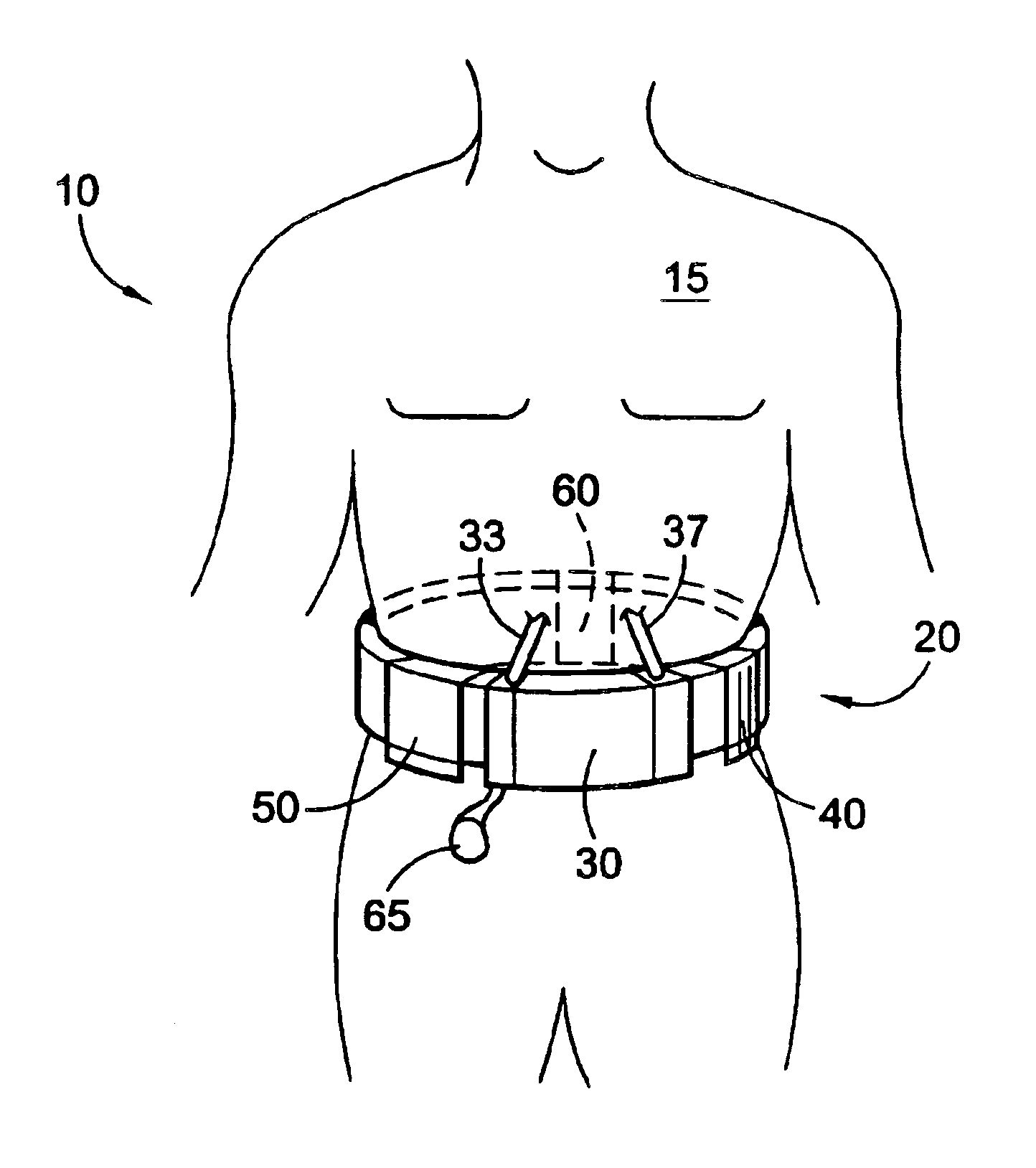

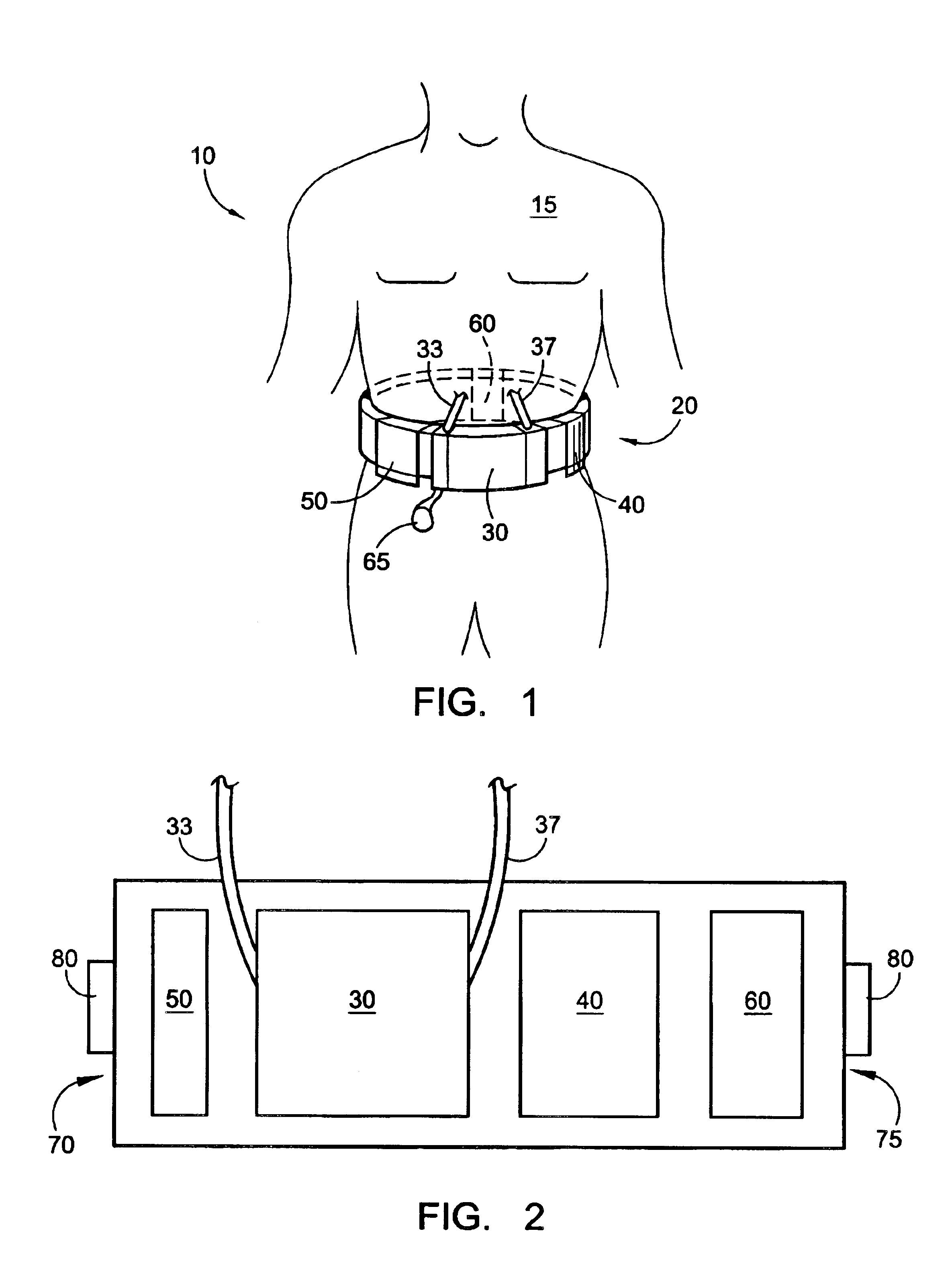

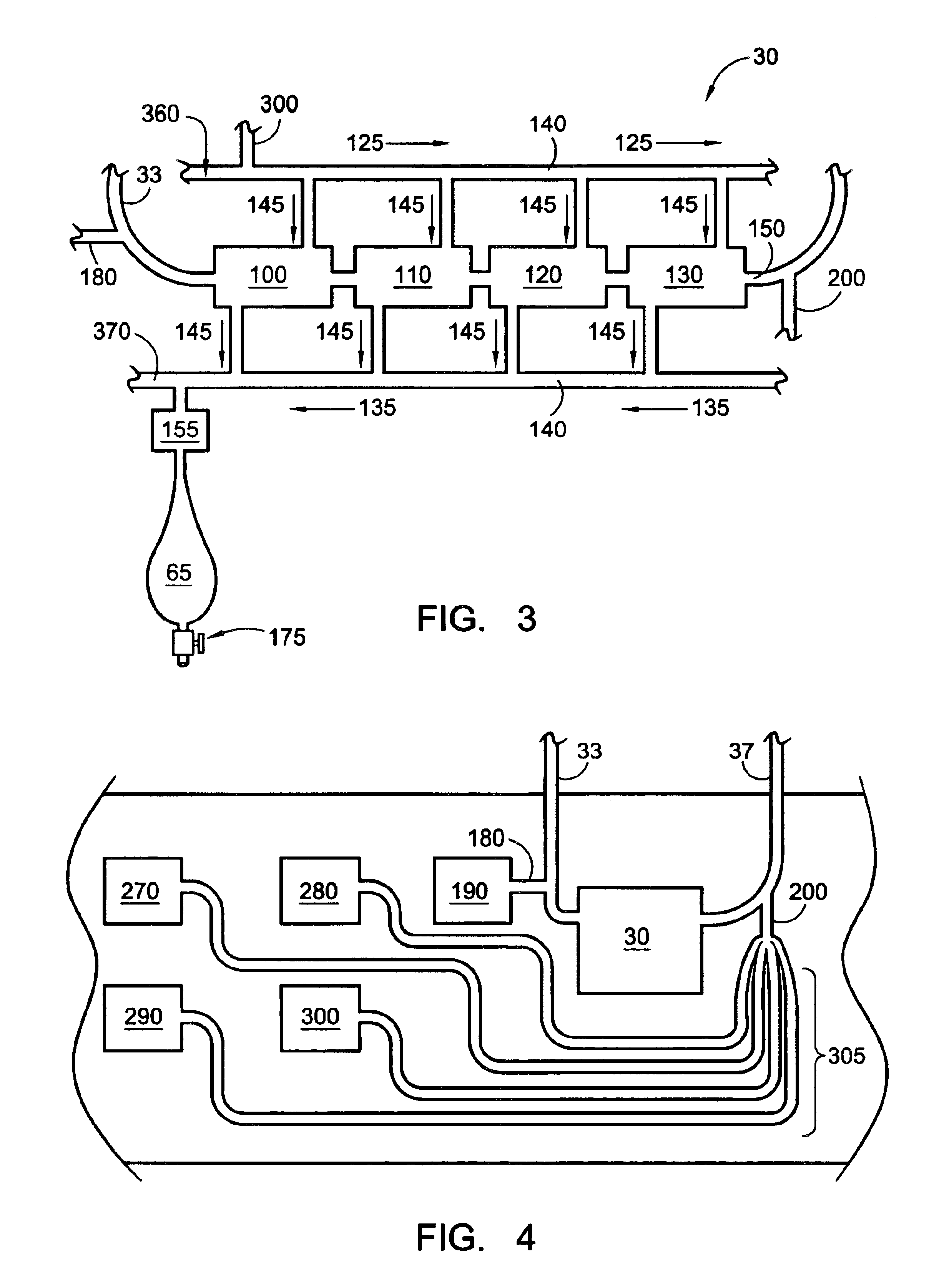

Wearable continuous renal replacement therapy device

A continuous renal replacement therapy device adapted to be worn on a portion of the body of a patient, including: a plurality of contoured dialyzers, which are connected in series and utilize dialysate to remove impurities from the blood of the patient; and a plurality of contoured sorbent device, which are connected in series and are for regenerating the spent dialysate.

Owner:FRESENIUS MEDICAL CARE HLDG INC

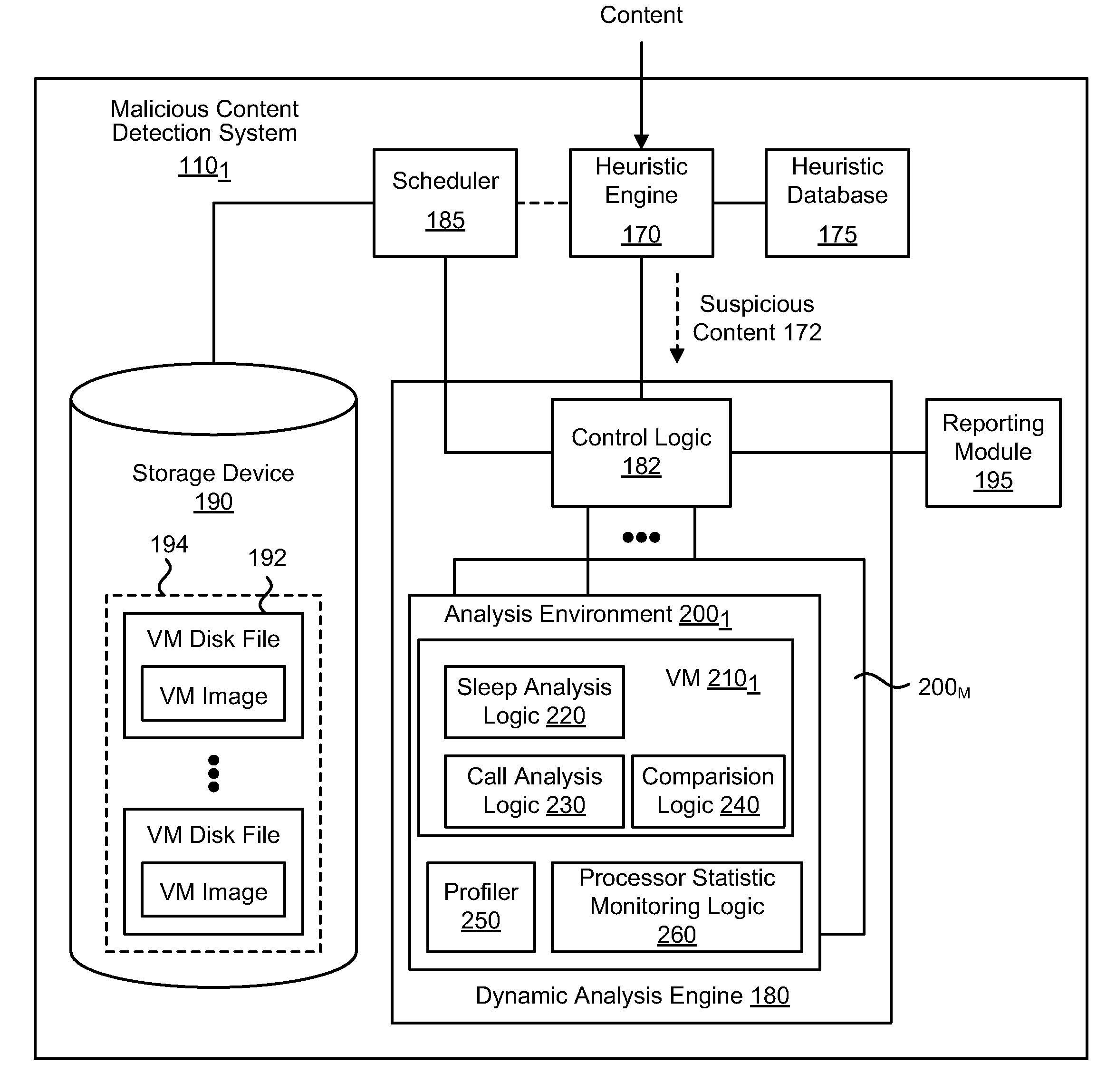

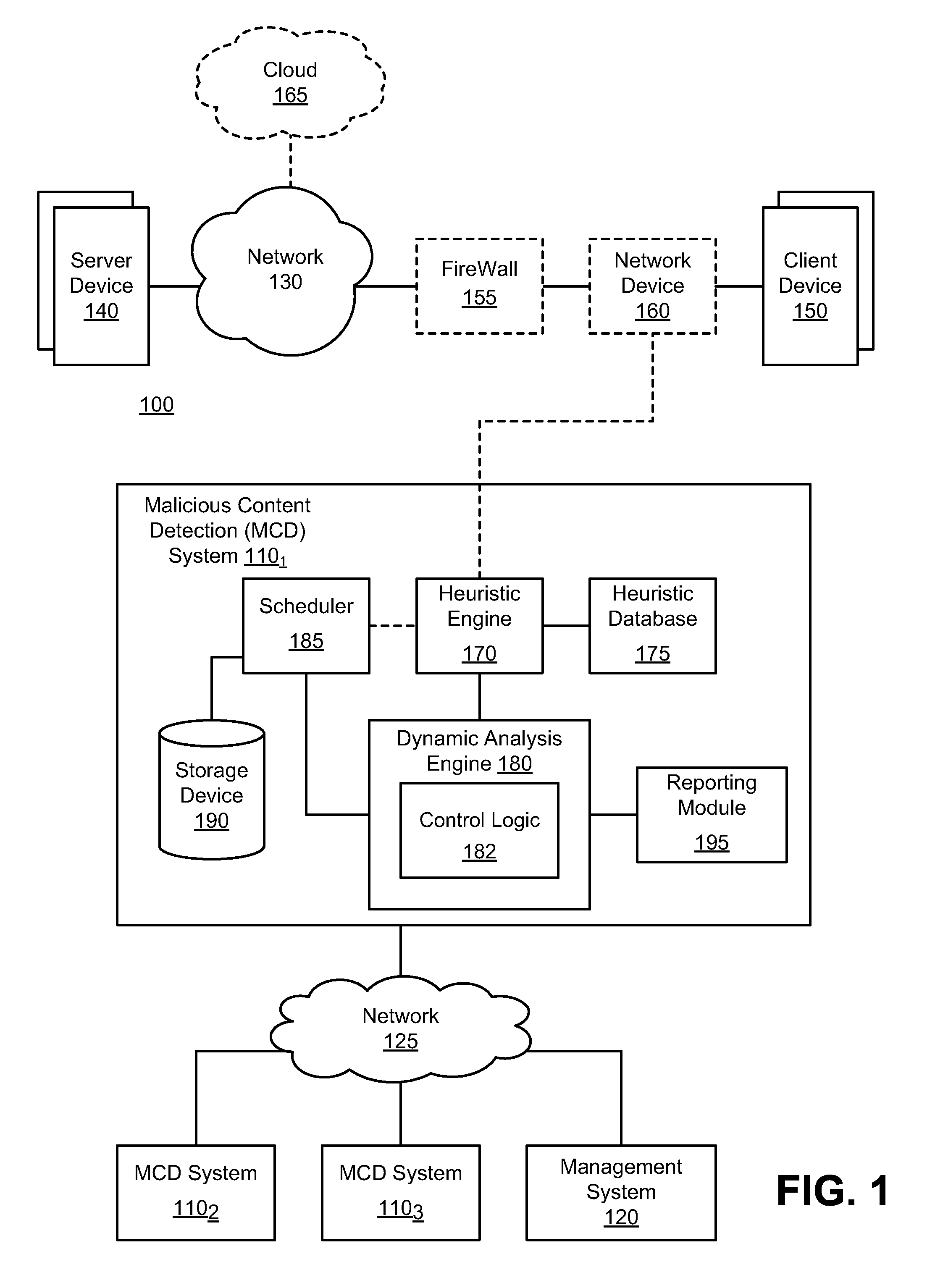

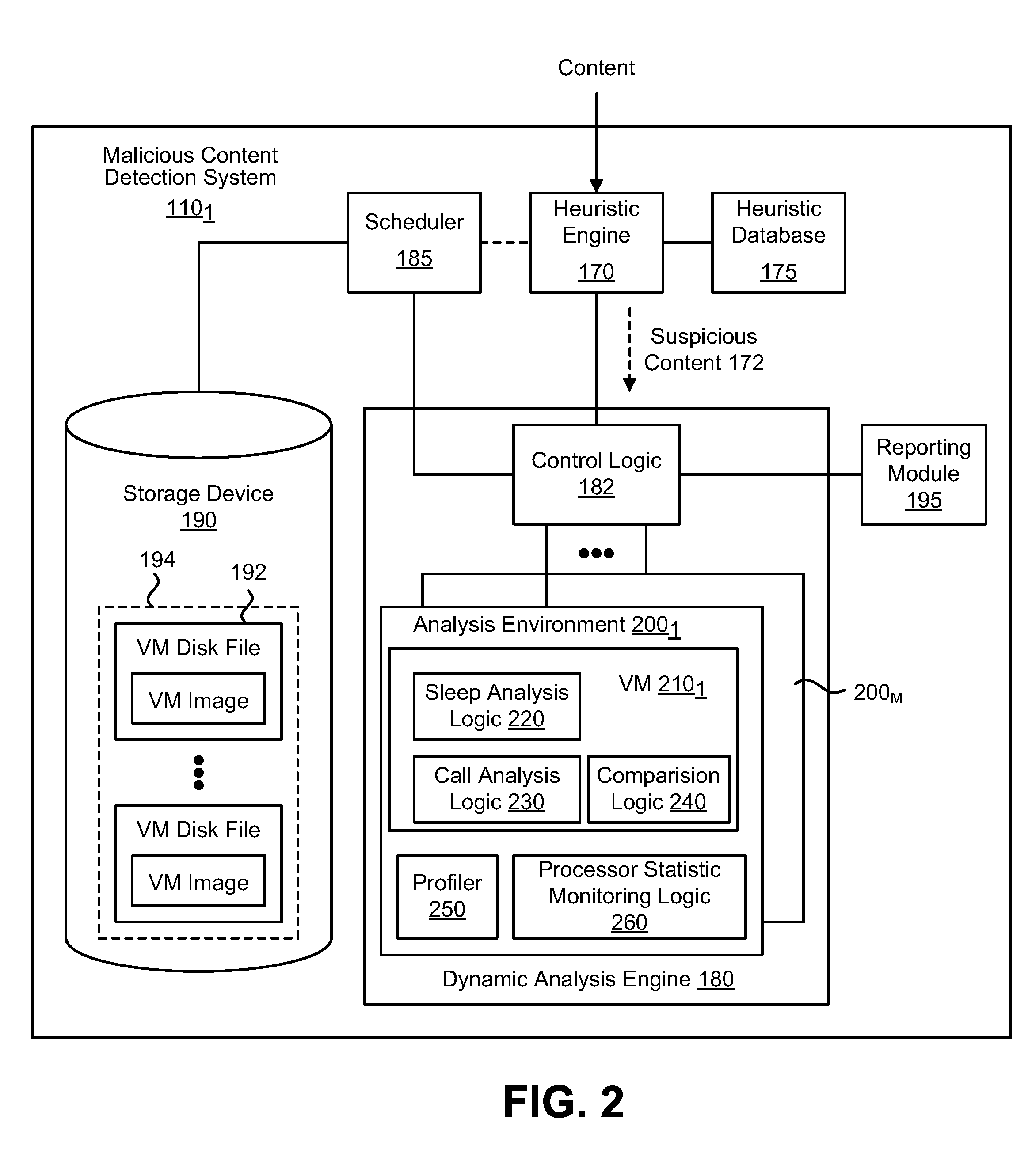

System and Method for Detecting Time-Bomb Malware

According to one embodiment, a system comprises one or more counters; comparison logic; and one or more hardware processors communicatively coupled to the one or more counters and the comparison logic. The one or more hardware processors are configured to instantiate one or more virtual machines that are adapted to analyze received content, where the one or more virtual machines are configured to monitor a delay caused by one or more events conducted during processing of the content and identify the content as including malware if the delay exceed a first time period.

Owner:FIREEYE SECURITY HLDG US LLC

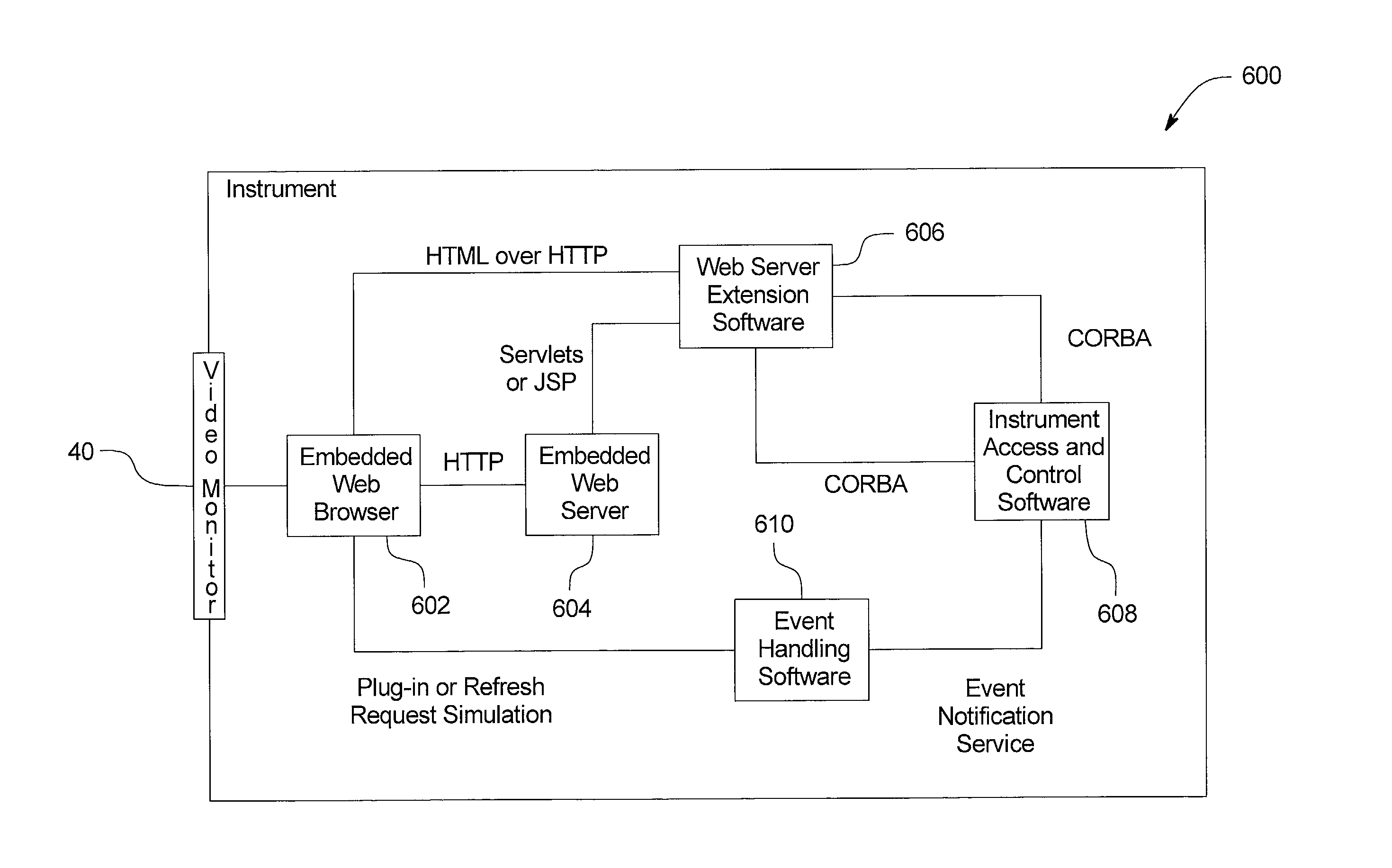

Graphical user interface for automated dialysis system

ActiveUS7033539B2Semi-permeable membranesMechanical/radiation/invasive therapiesGraphicsPeritoneal dialysis

A method, system and apparatus for performing peritoneal dialysis are provided. To this end, in part, a dialysis system is provided. The dialysis system includes a display device and a web browser and web server embedded in the dialysis system. The browser and the server operate with the display device to display a number of dialysis therapy set-up procedure screens that require operator input, and to display a number of dialysis treatment screens that graphically illustrate the progress of at least one step in the dialysis therapy in at least substantially real time.

Owner:BAXTER HEALTHCARE SA +1

Blood treatment systems and methods

ActiveUS8409441B2Increase pressureMechanical/radiation/invasive therapiesSolvent extractionBlood treatmentsGraphics

Dialysis systems comprising actuators that cooperate to perform dialysis functions and sensors that cooperate to monitor dialysis functions are disclosed. According to one aspect, such a hemodialysis system comprises a user interface model layer, a therapy layer, below the user interface model layer, and a machine layer below the therapy layer. The user interface model layer is configured to manage the state of a graphical user interface and receive inputs from a graphical user interface. The therapy layer is configured to run state machines that generate therapy commands based at least in part on the inputs from the graphical user interface. The machine layer is configured to provide commands for the actuators based on the therapy commands.

Owner:DEKA PROD LLP

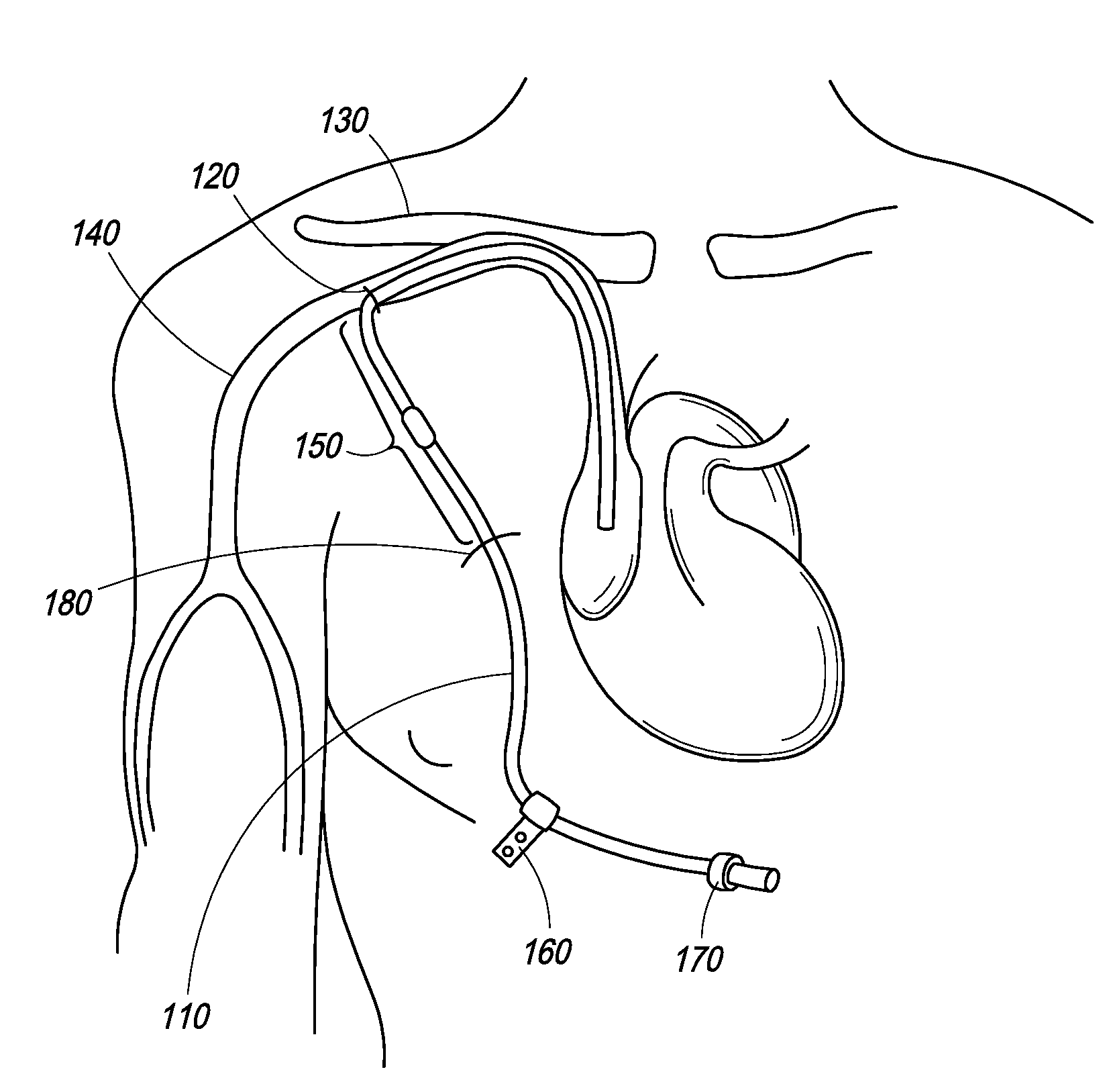

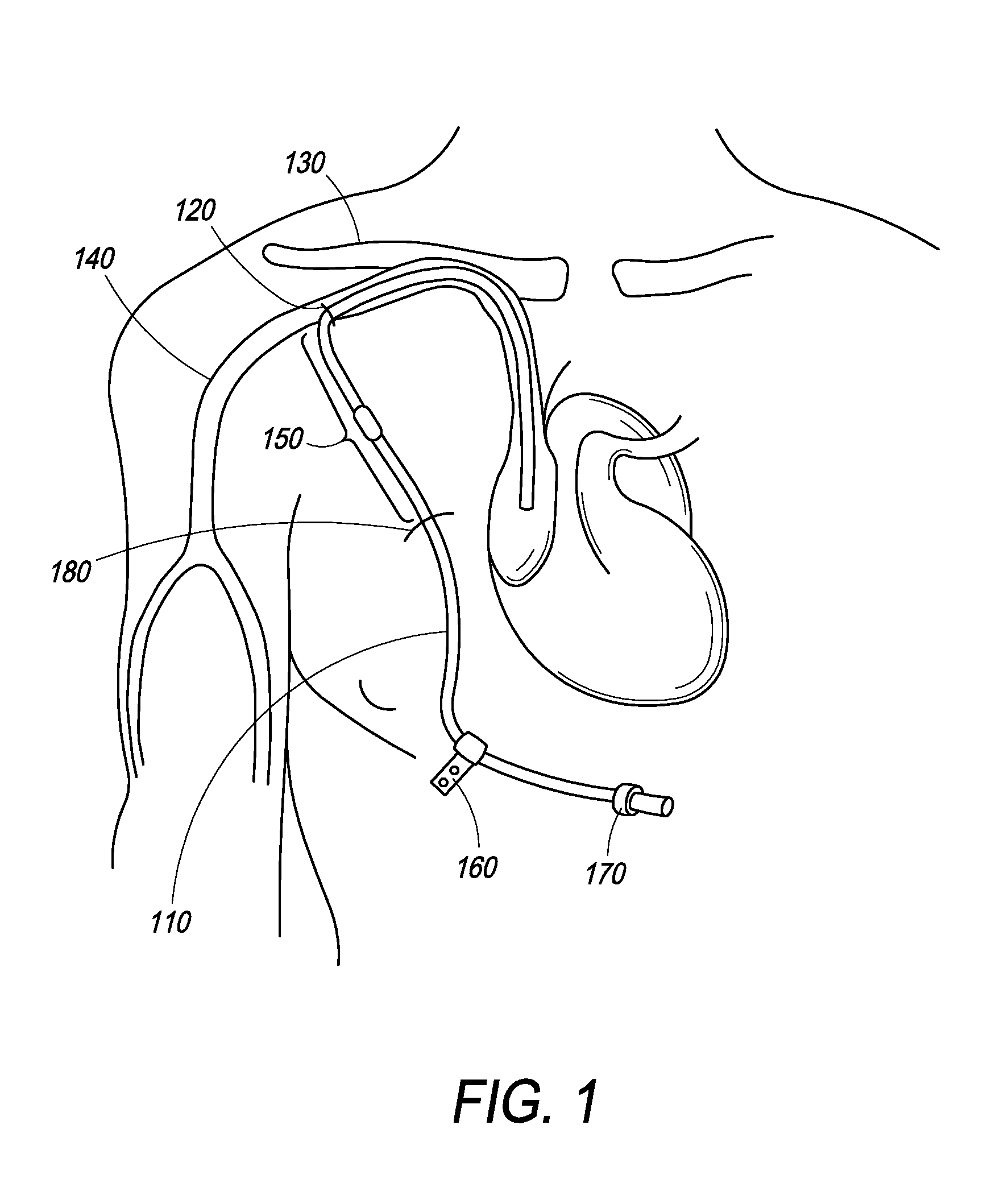

Methods and Systems for Controlling Ultrafiltration Using Central Venous Pressure Measurements

The volume of fluid removed from a patient during ultrafiltration is controlled automatically on the basis of central venous pressure (CVP) measurements. In one embodiment, a central venous catheter (CVC) is used for accessing blood during dialysis. A sensor located at the tip of the catheter or inside the dialysis machine is used to periodically measure CVP. CVP feedback data helps prevent the excessive removal of fluids from the patient.

Owner:FRESENIUS MEDICAL CARE HLDG INC

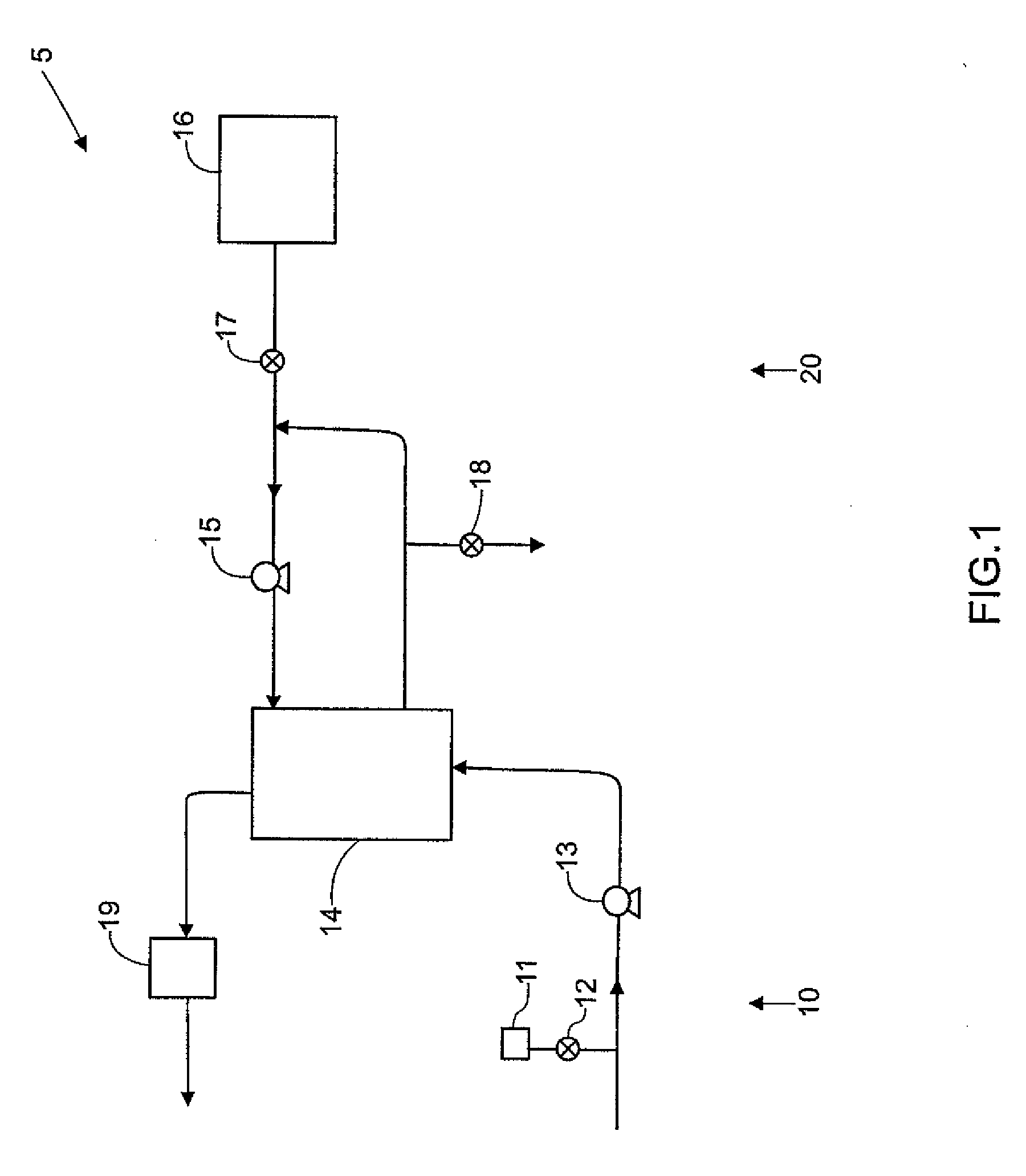

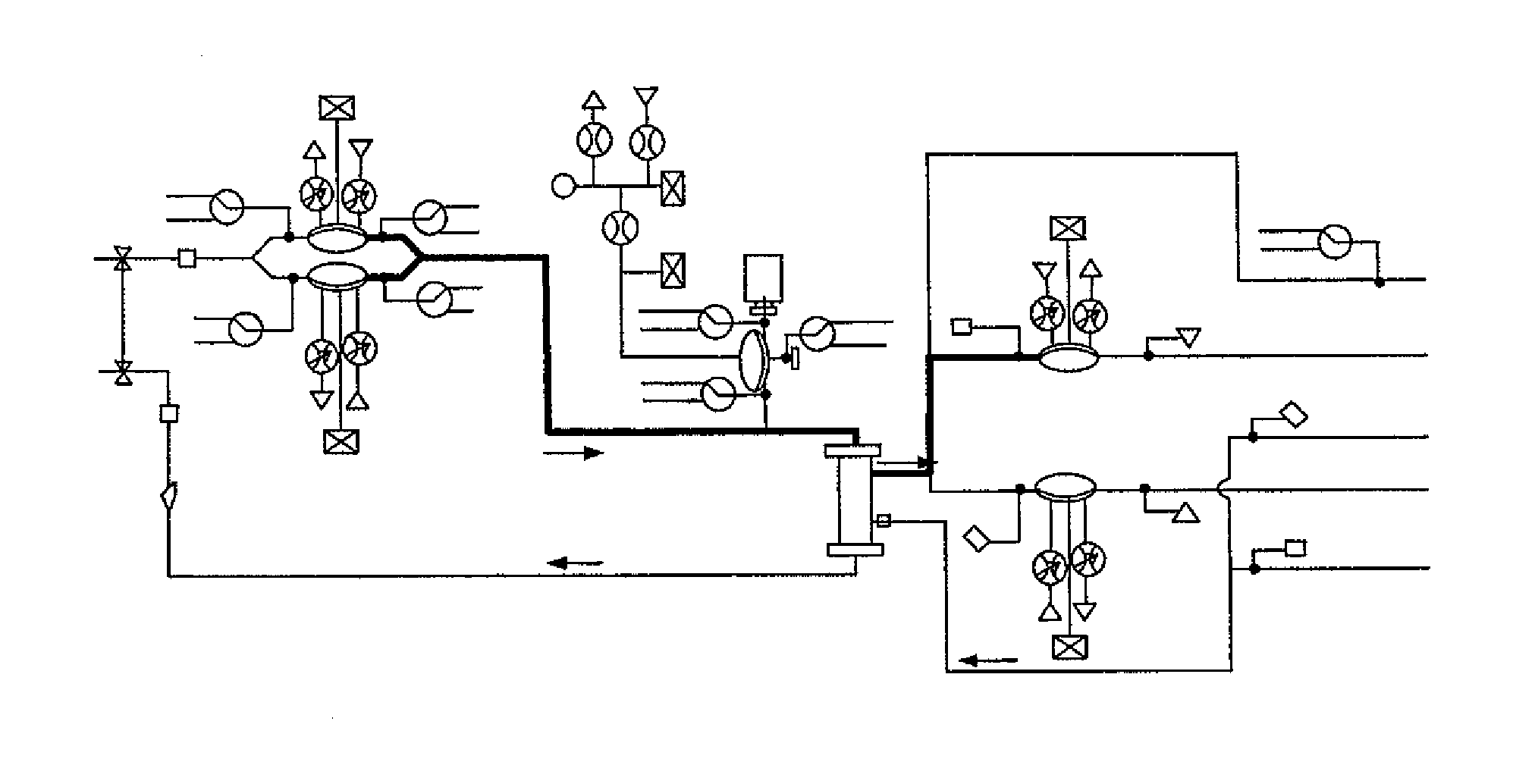

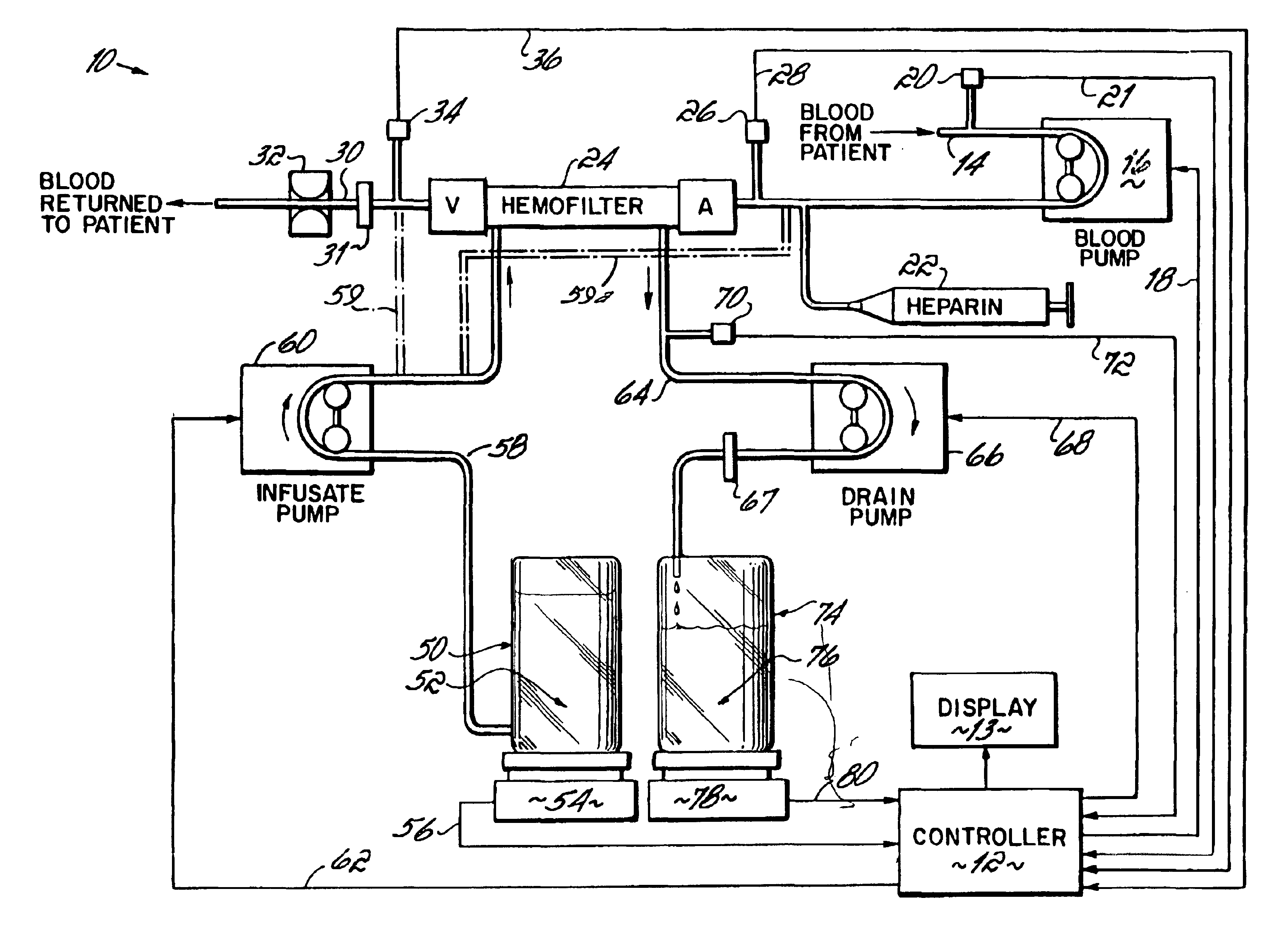

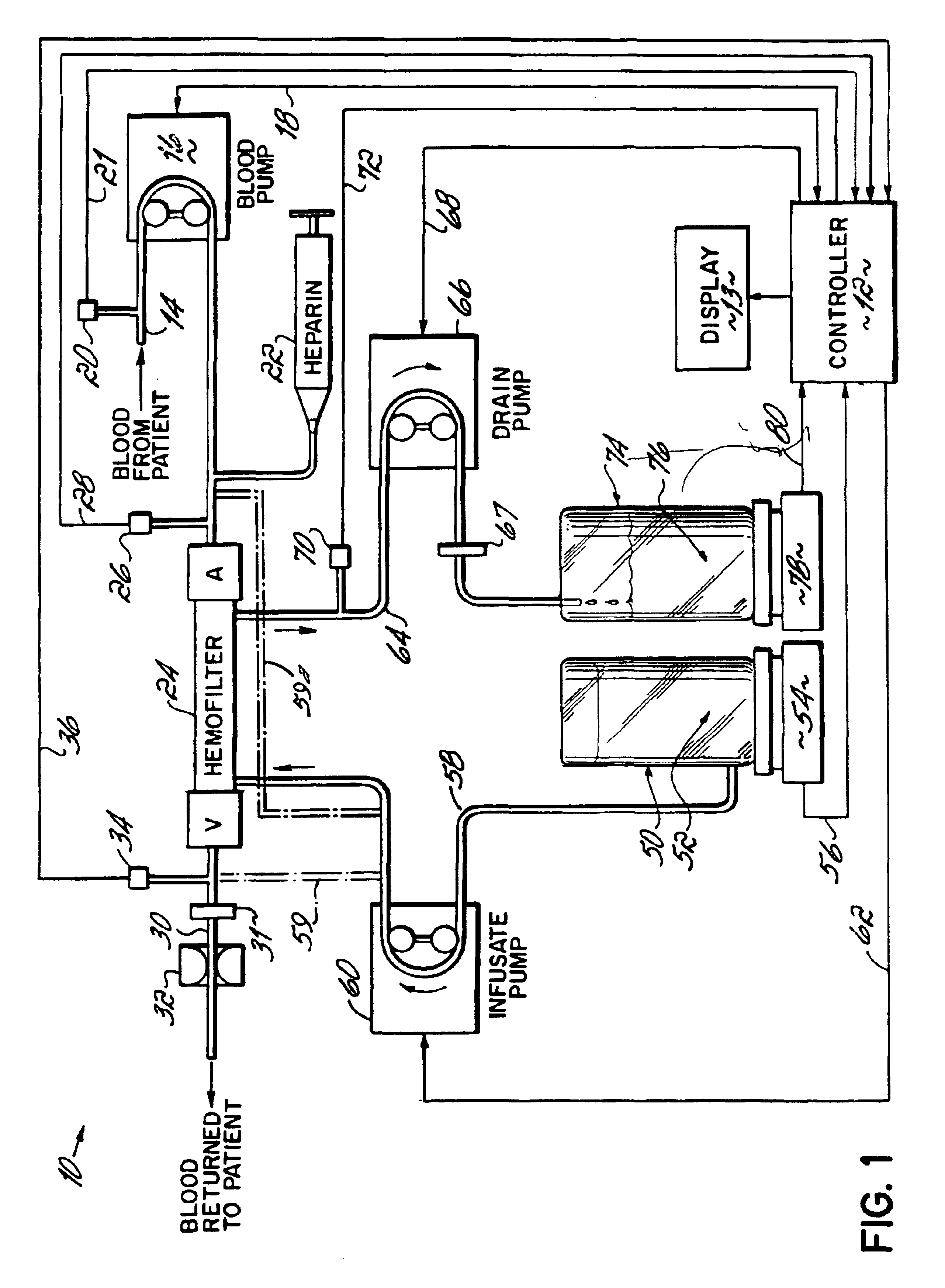

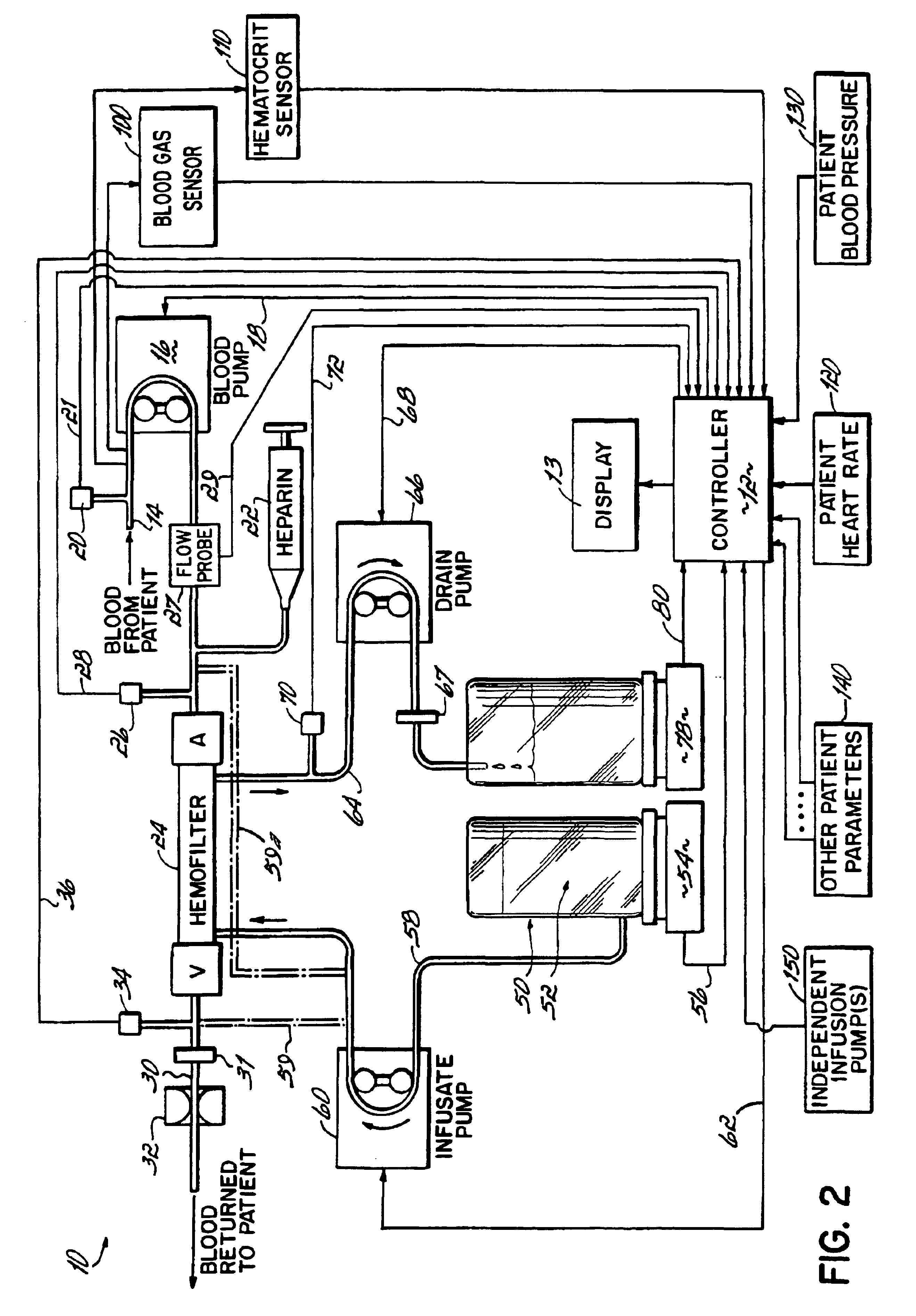

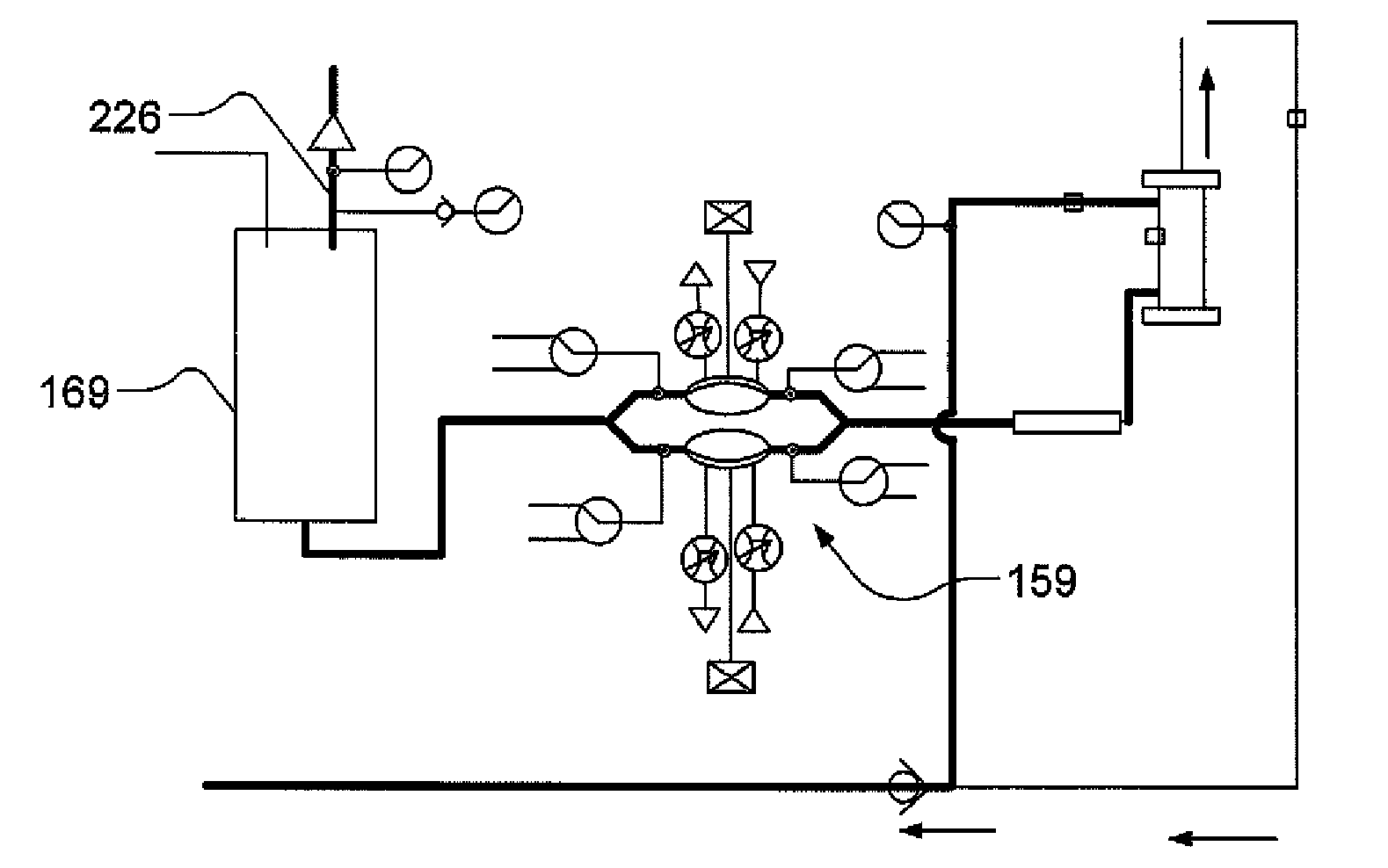

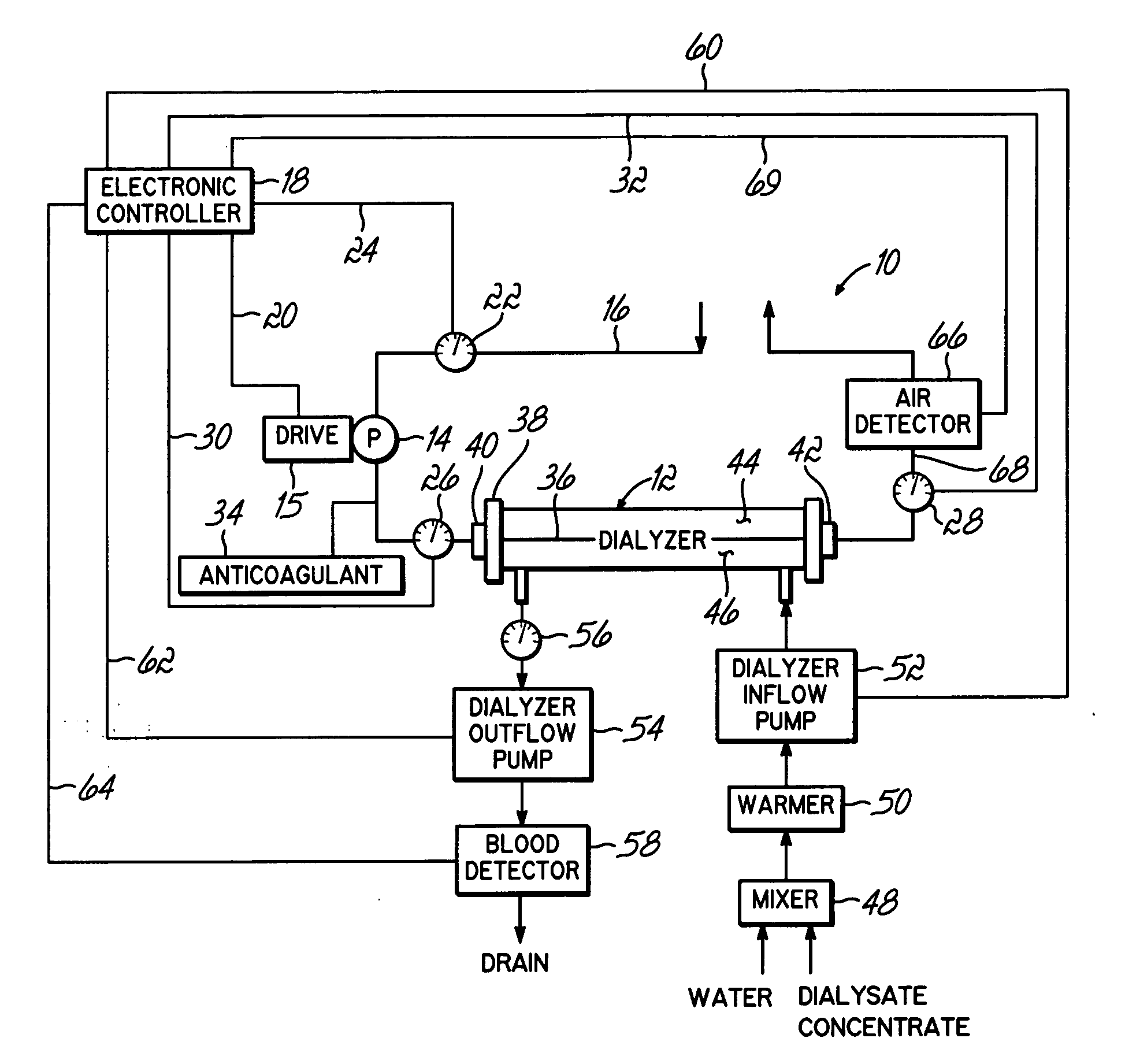

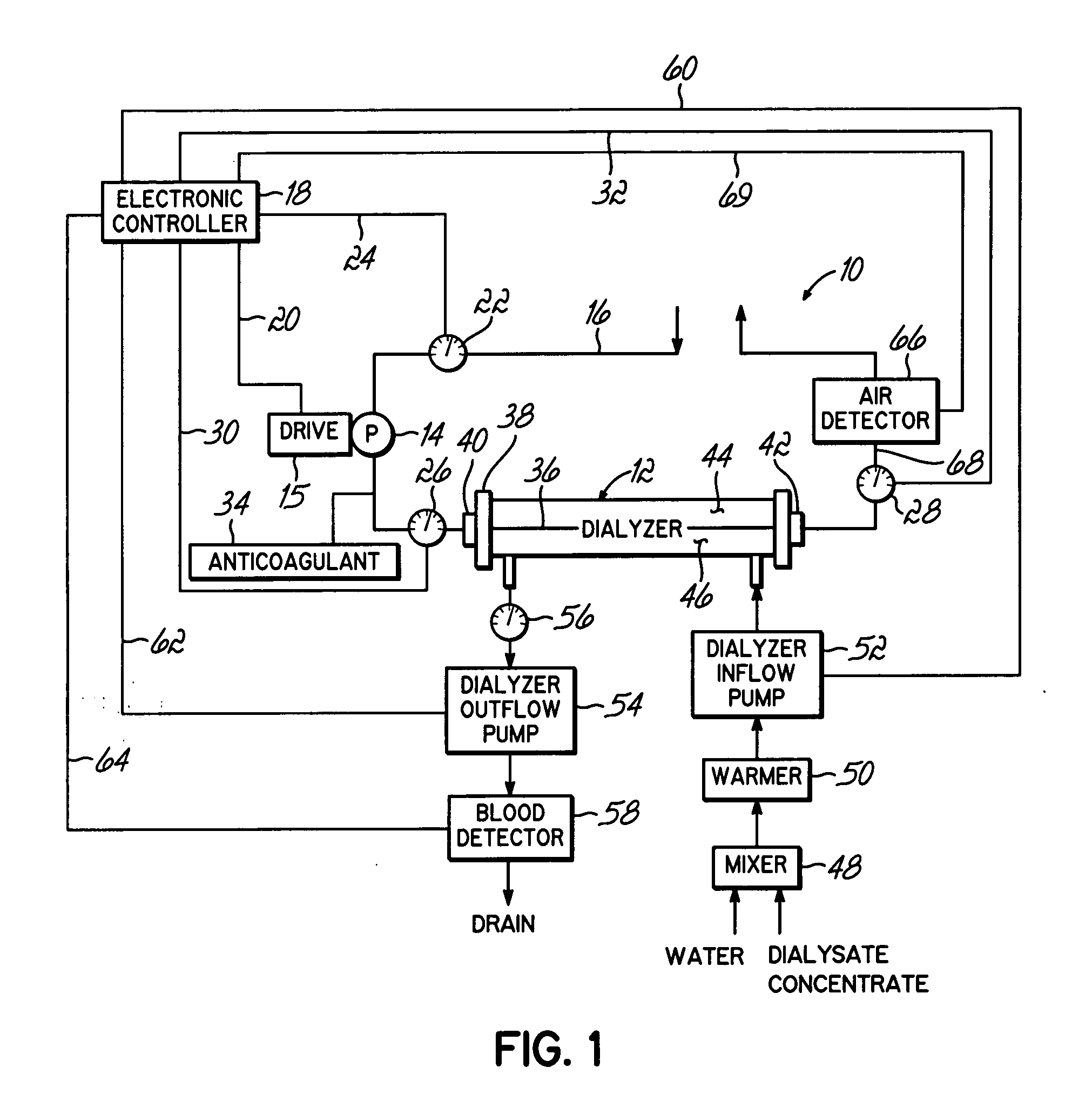

Hemofiltration system

InactiveUS6780322B1Reliable and long-term operationImprove accuracySolvent extractionUltrafiltrationMedicineTime changes

A multipurpose hemofiltration system (10) and method are disclosed for the removal of fluid and / or soluble waste from the blood of a patient. The system (10) continuously monitors the flow rates of drained fluid, blood, and infusate. When necessary, the pumping rates of the infusate, drained fluid and blood are adjusted to remove a preselected amount of fluid from the blood in a preselected time period. A supervisory controller (160) can monitor patient parameters, such as heart rate (120) and blood pressure (130), and adjust the pumping rates accordingly. The supervisory controller (160) uses fuzzy logic to make expert decisions, based upon a set of supervisory rules, to control each pumping rate to achieve a desired flow rate and to respond to fault conditions. An adaptive controller (162) corrects temporal variations in the flow rate based upon an adaptive law and a control law.

Owner:CHILDRENS HOSPITAL MEDICAL CENT CINCINNATI

Programmable, fluid pressure actuated blood processing systems and methods

InactiveUS6949079B1Solvent extractionOther blood circulation devicesBlood separation deviceEngineering

Owner:FENWAL

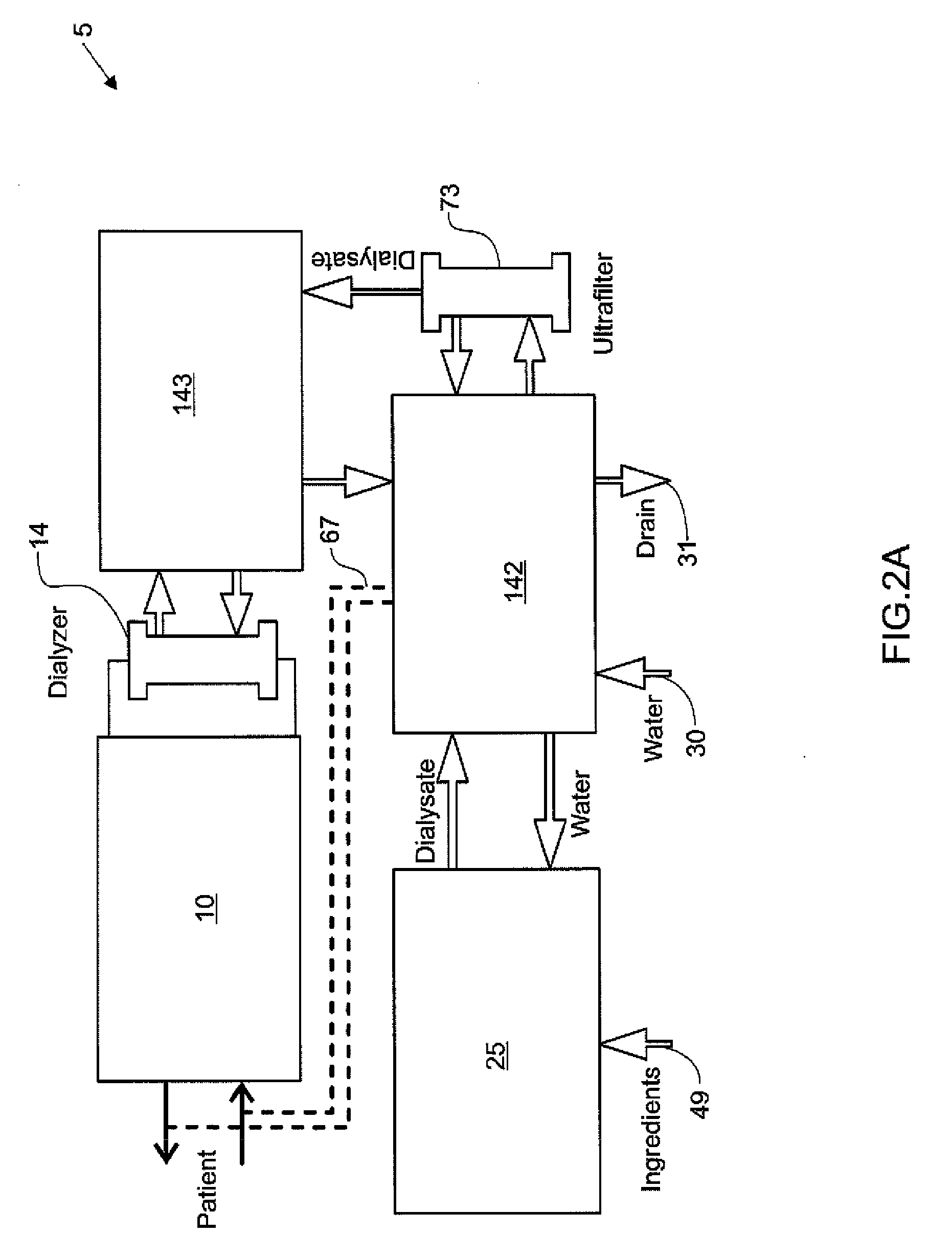

Hemodialysis systems and methods

The present invention generally relates to hemodialysis and similar dialysis systems, including a variety of systems and methods that would make hemodialysis more efficient, easier, and / or more affordable. One aspect of the invention is generally directed to new fluid circuits for fluid flow. In one set of embodiments, a hemodialysis system may include a blood flow path and a dialysate flow path, where the dialysate flow path includes one or more of a balancing circuit, a mixing circuit, and / or a directing circuit. Preparation of dialysate by the preparation circuit, in some instances, may be decoupled from patient dialysis. In some cases, the circuits are defined, at least partially, within one or more cassettes, optionally interconnected with conduits, pumps, or the like. In one embodiment, the fluid circuit and / or the various fluid flow paths may be at least partially isolated, spatially and / or thermally, from electrical components of the hemodialysis system. In some cases, a gas supply may be provided in fluid communication with the dialysate flow path and / or the dialyzer that, when activated, is able to urge dialysate to pass through the dialyzer and urge blood in the blood flow path back to the patient. Such a system may be useful, for example, in certain emergency situations (e.g., a power failure) where it is desirable to return as much blood to the patient as possible. The hemodialysis system may also include, in another aspect of the invention, one or more fluid handling devices, such as pumps, valves, mixers, or the like, which can be actuated using a control fluid, such as air. In some cases, the control fluid may be delivered to the fluid handling devices using an external pump or other device, which may be detachable in certain instances. In one embodiment, one or more of the fluid handling devices may be generally rigid (e.g., having a spheroid shape), optionally with a diaphragm contained within the device, dividing it into first and second compartments.

Owner:DEKA PROD LLP

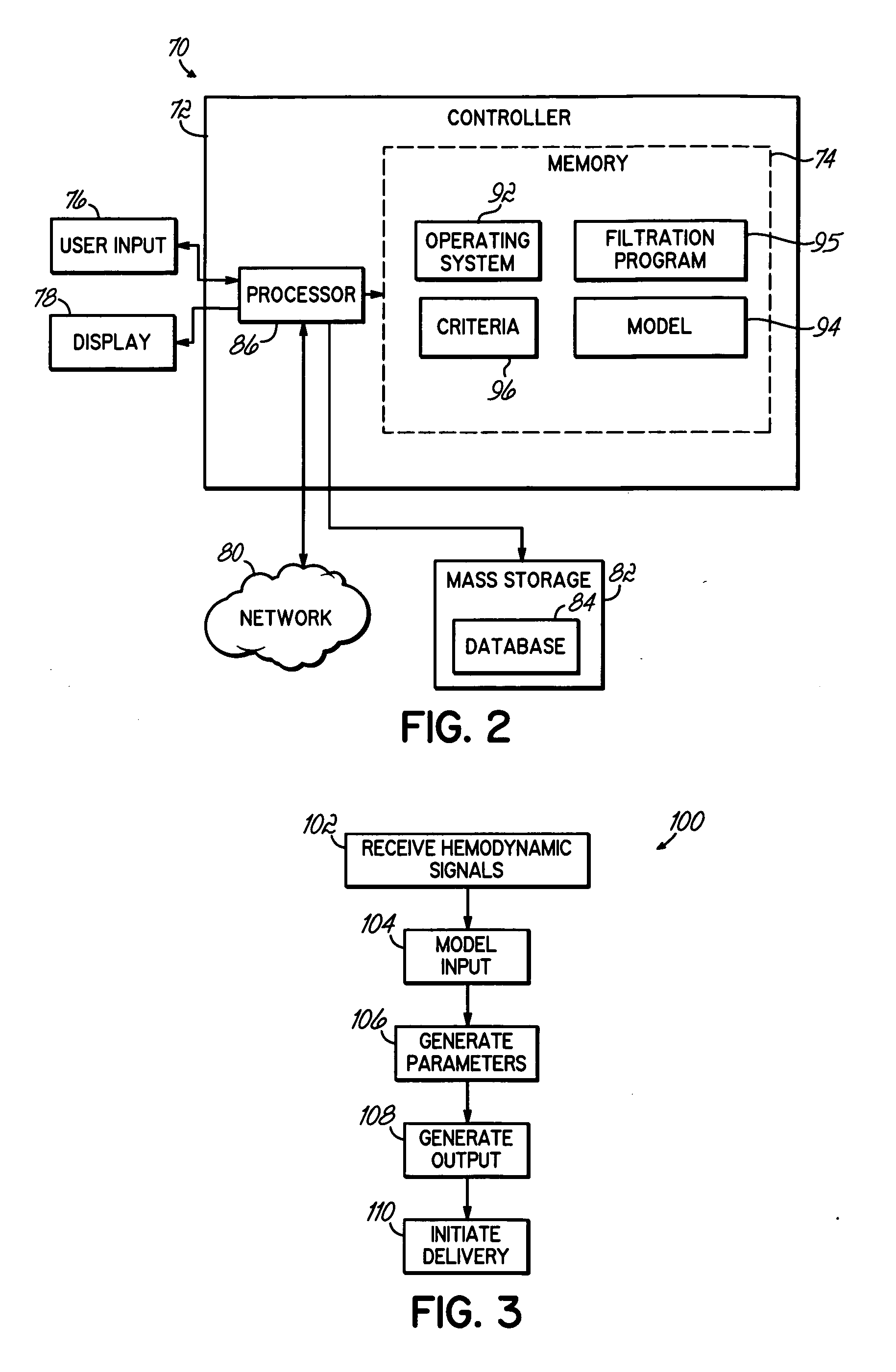

Extracorporeal renal replacement modeling system

InactiveUS20070215545A1AccuracyReduce decreaseSolvent extractionDialysis systemsUltrafiltrationMathematical model

A system, program product and method continuously optimize an ultrafiltration rate during an extracorporeal renal replacement process by modeling physiological and actual rate data. The system maps the sensed, physiological data to a mathematical model to assess the data in terms of the ultrafiltration rate. The model provides parameters used to predict where the treatment is headed based on current conditions. The system processes the parameters in terms of preset criteria to generate the optimized ultrafiltration rate. Where the system is networked, communication of the data may be accomplished using remote and online communication techniques.

Owner:CHILDRENS HOSPITAL MEDICAL CENT CINCINNATI

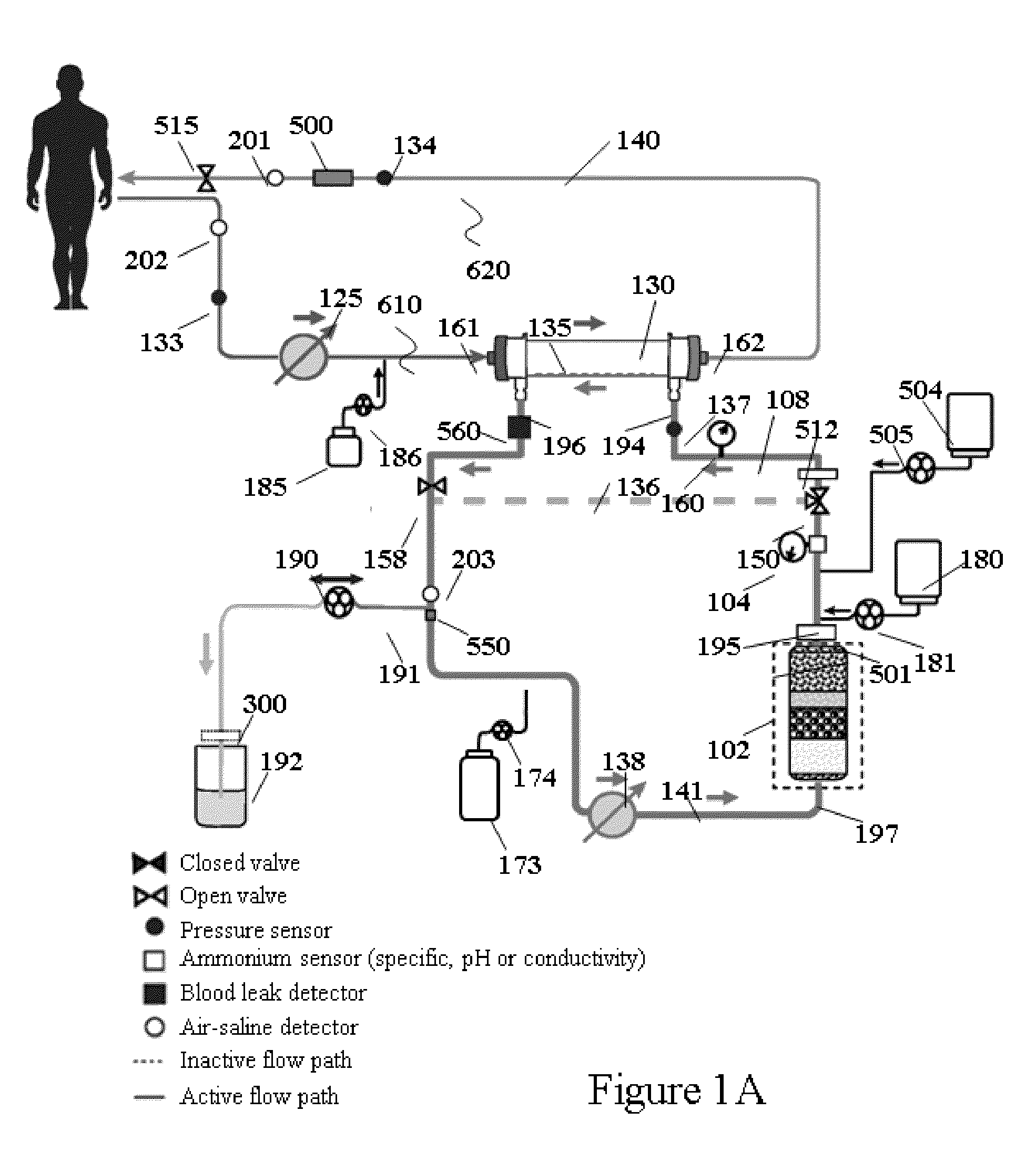

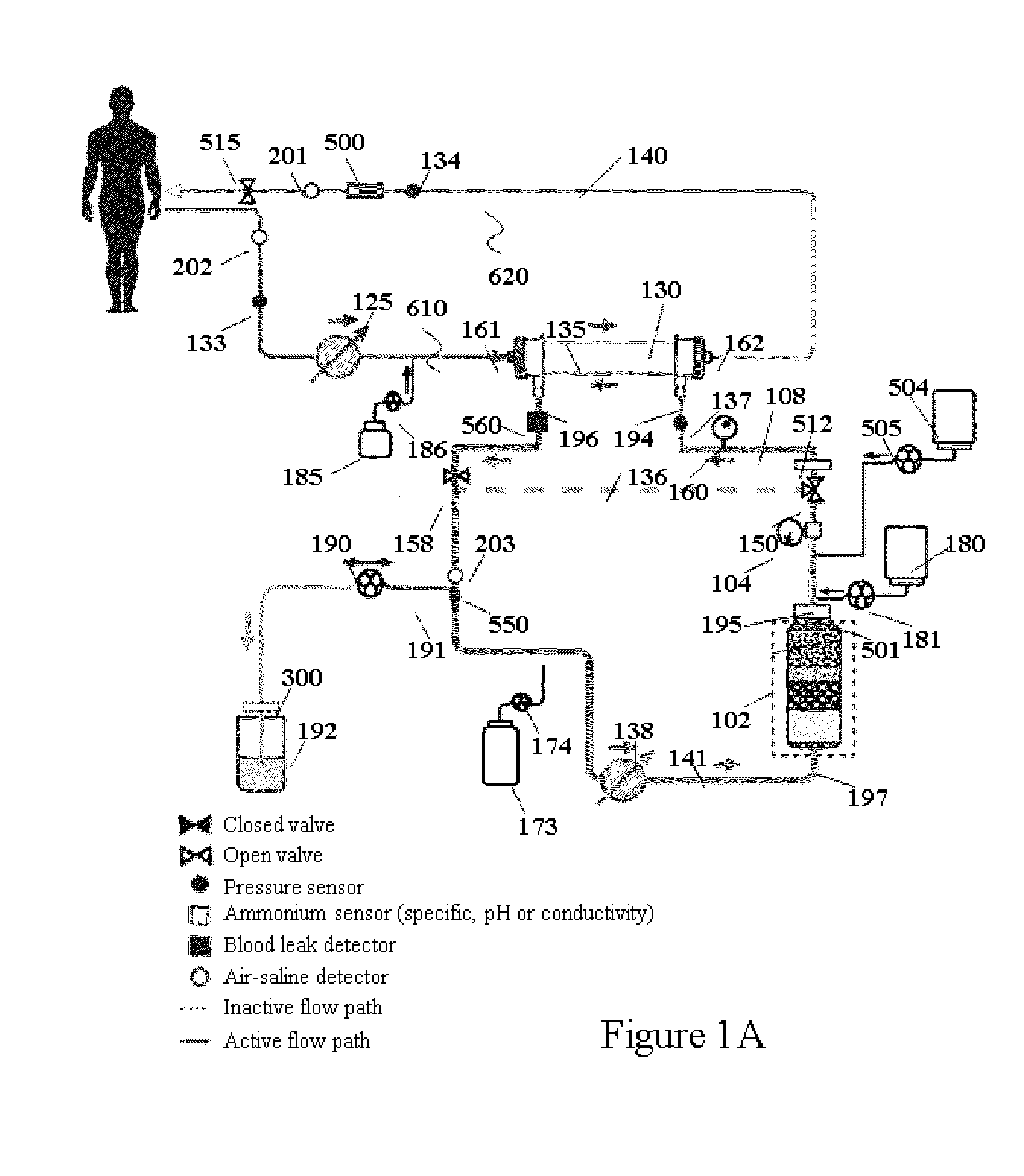

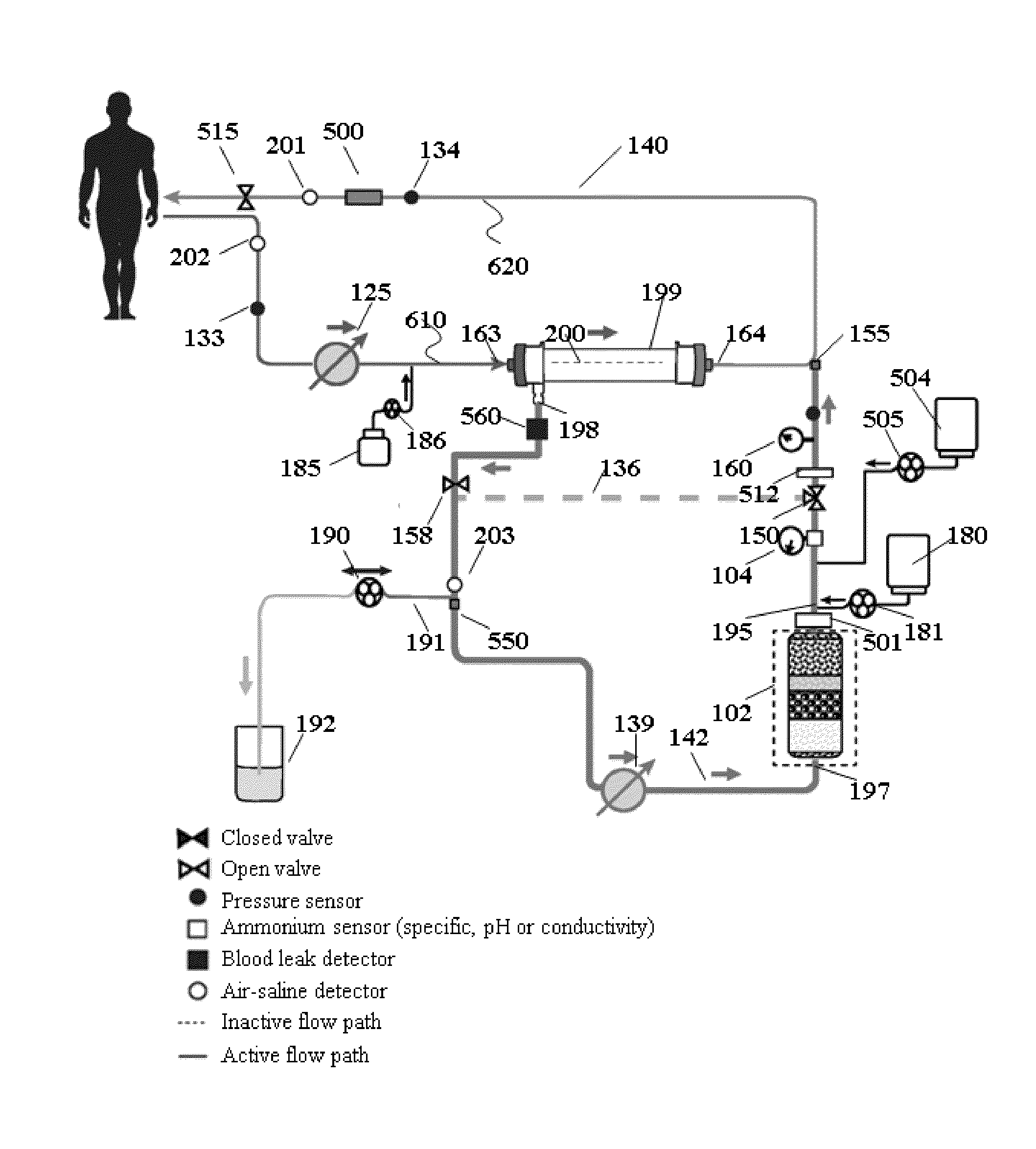

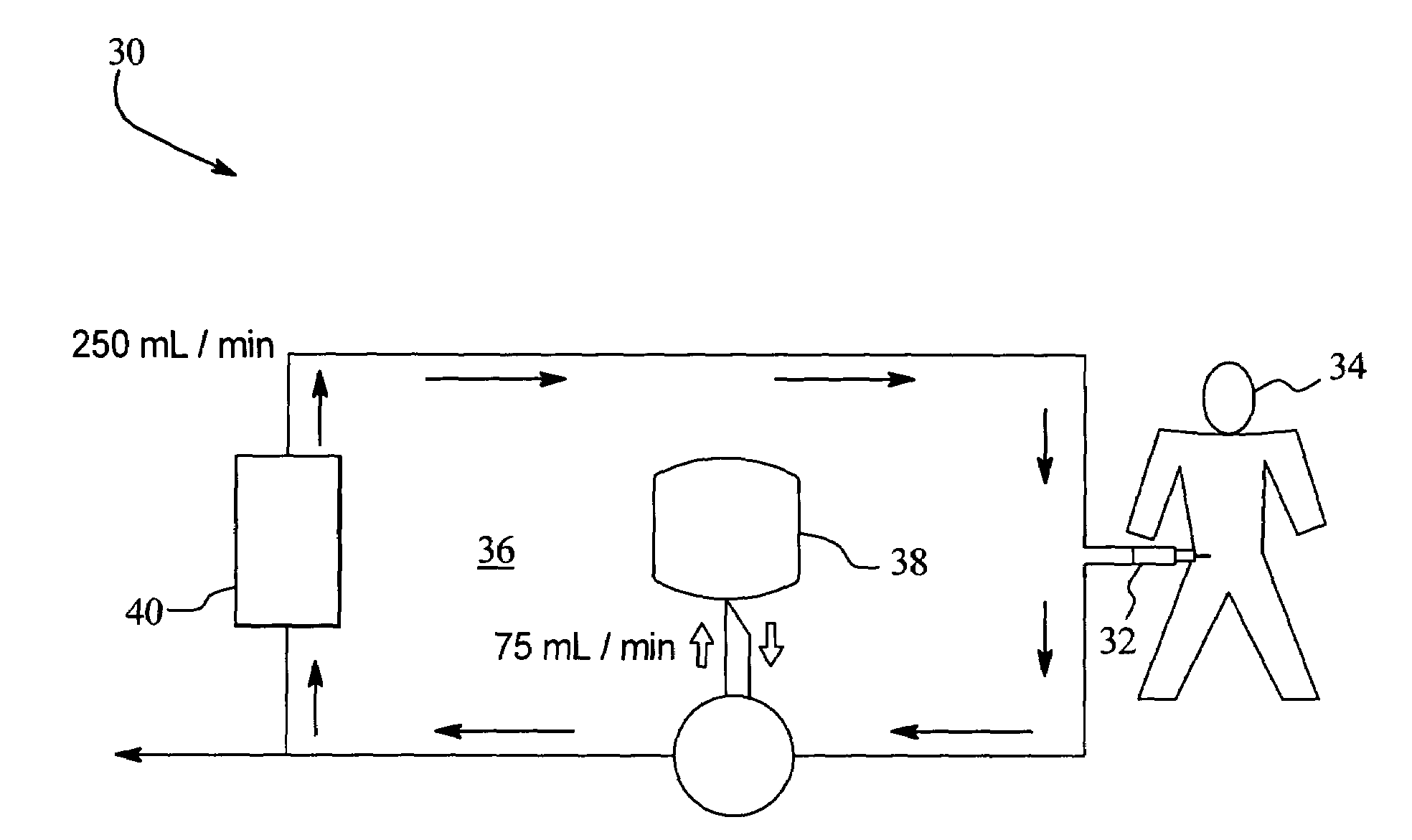

Hemodialysis system having a flow path with a controlled compliant volume

ActiveUS20130199998A1Enhanced convective clearanceReduce riskSemi-permeable membranesSolvent extractionDialysis membranesHaemodialysis machine

Systems and methods for the performance of kidney replacement therapy having or using a dialyzer, control components, sorbent cartridge and fluid reservoirs configured to be of a weight and size suitable to be worn or carried by an individual requiring treatment are disclosed. The system for performing kidney replacement therapy has a controlled compliance dialysis circuit, where a control pump controls the bi-directional movement of fluid across a dialysis membrane. The dialysis circuit and an extracorporeal circuit for circulating blood are in fluid communication through the dialysis membrane. The flux of fluid moving between the extracorporeal circuit and the dialysis circuit is modified by the rate at which the control pump is operating such that a rate of ultrafiltration and convective clearance can be controlled. The system provides for the monitoring of an inlet and outlet conductivity of the sorbent cartridge to provide a facility to quantify or monitor the removal of urea by the sorbent cartridge.

Owner:MOZARC MEDICAL US LLC

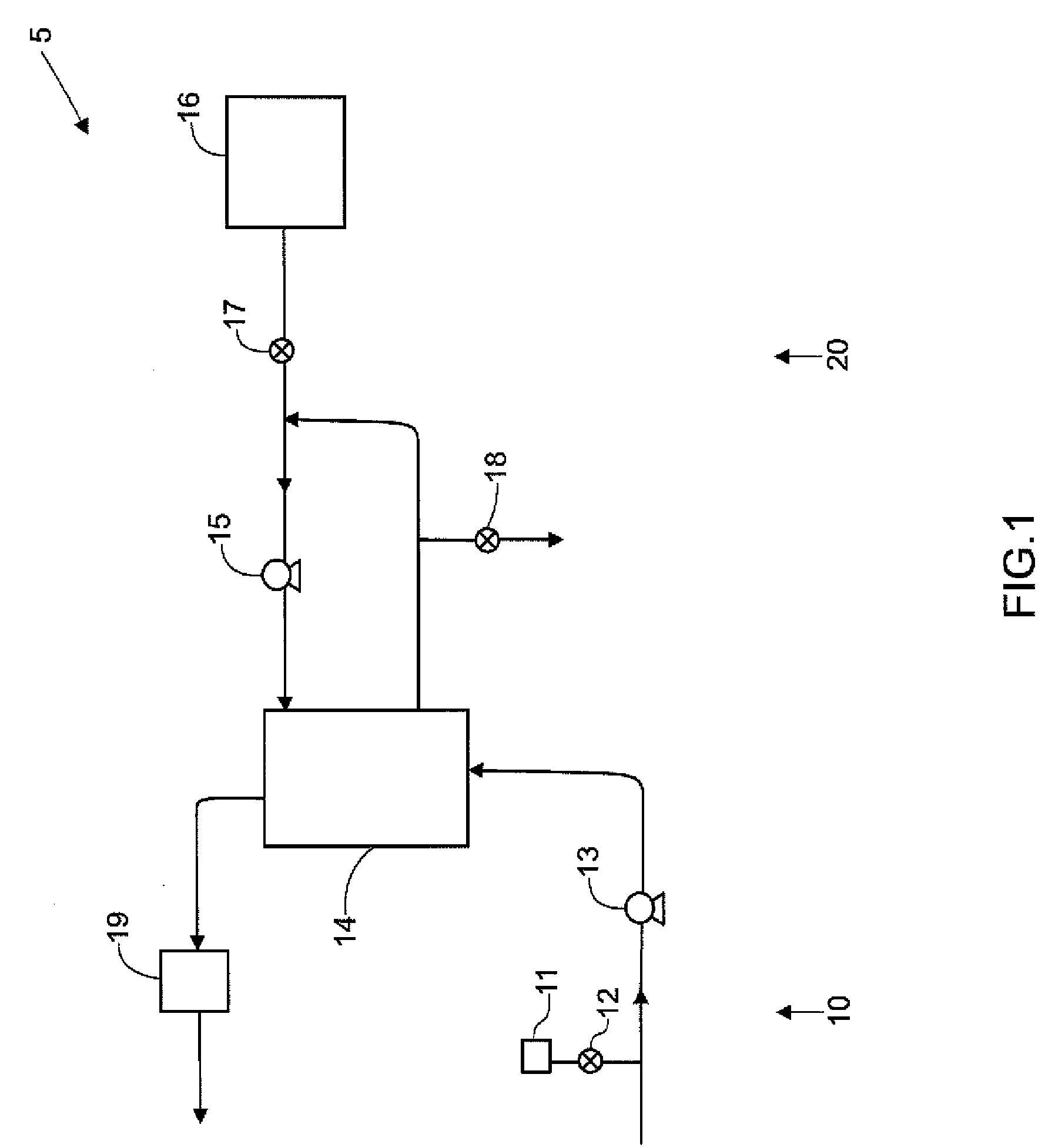

Filtration monitoring and control system

InactiveUS6077435AUseful controlAccurate CalibrationDispersed particle filtrationUltrafiltrationFouling indexFiltration

PCT No. PCT / AU96 / 00144 Sec. 371 Date Jan. 12, 1998 Sec. 102(e) Date Jan. 12, 1998 PCT Filed Mar. 15, 1996 PCT Pub. No. WO96 / 28236 PCT Pub. Date Sep. 19, 1996A method and apparatus for determining the fouling effect of a feedstream on a filter having known characteristics disclosed. The method comprises passing the feedstream through a filter (5) having known characteristics; determining the change in resistance to flow of the feedstream across the filter, either continuously or over a number of time intervals and from this data, calculating a feed fouling index (FFI) representative of the fouling characteristics of the feedstream with respect to the filter. A method and apparatus for monitoring the operation of a filtration system is also disclosed the method comprising sampling system parameter values at selected locations within the filtration system at a predetermined sampling rate; generating a parameter profile characteristic from the sampled parameter values at predetermined intervals of time; and analysing the parameter profile characteristic to determine correct operation of the filtration system. A further method and apparatus of monitoring and controlling a filtering system based on backwash efficiency is also disclosed, the method comprising determining resistance values of filtering elements used in the filtering system at predetermined times during the backwash cycle of the system by monitoring a number of operating parameters of the system; calculating a backwash efficiency value representative of the efficiency of the backwash cycle of the filtering system using the resistance values determined; and controlling the operation of the filtering system in dependence on the value of the backwash efficiency calculated.

Owner:EVOQUA WATER TECH LLC

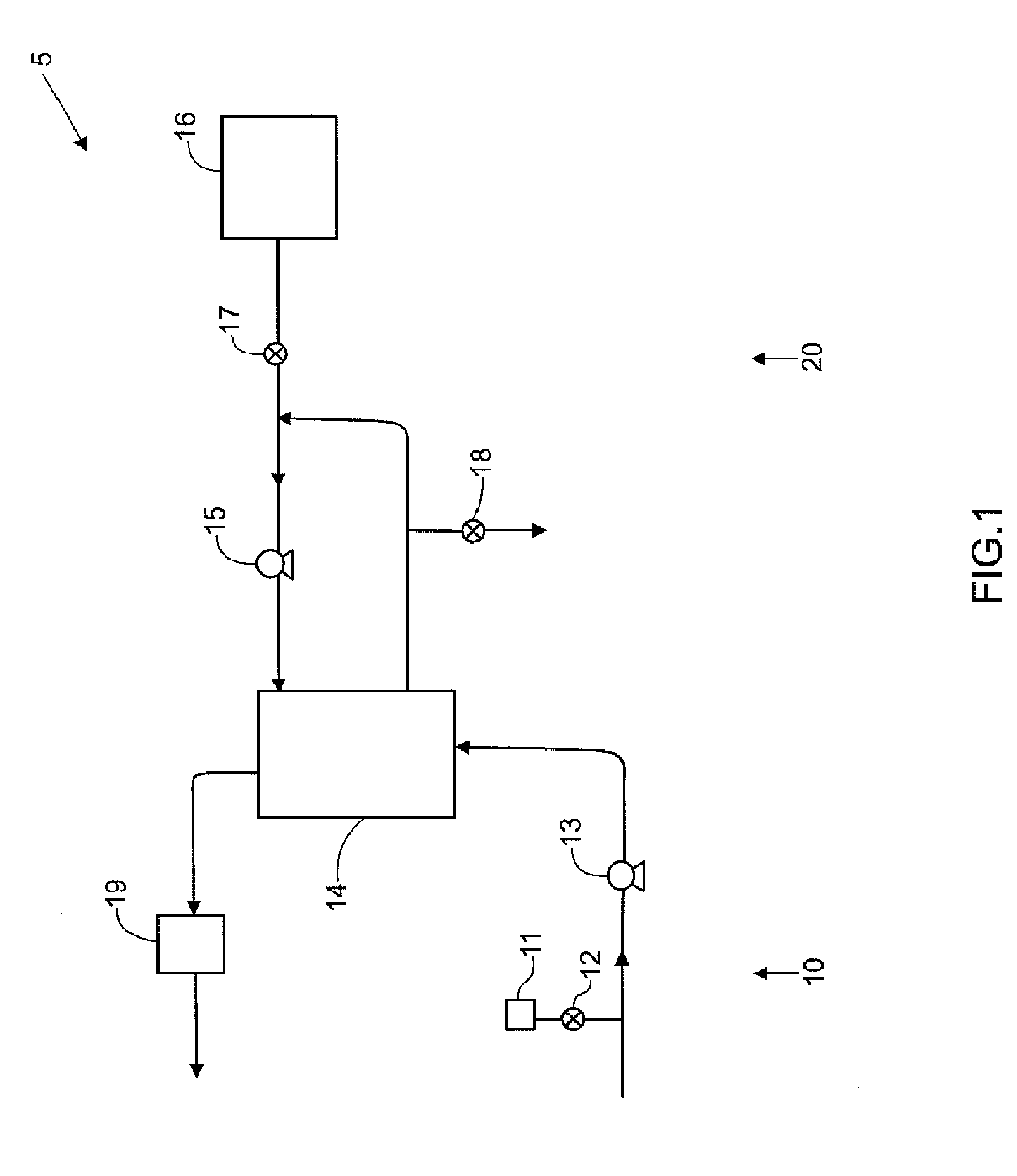

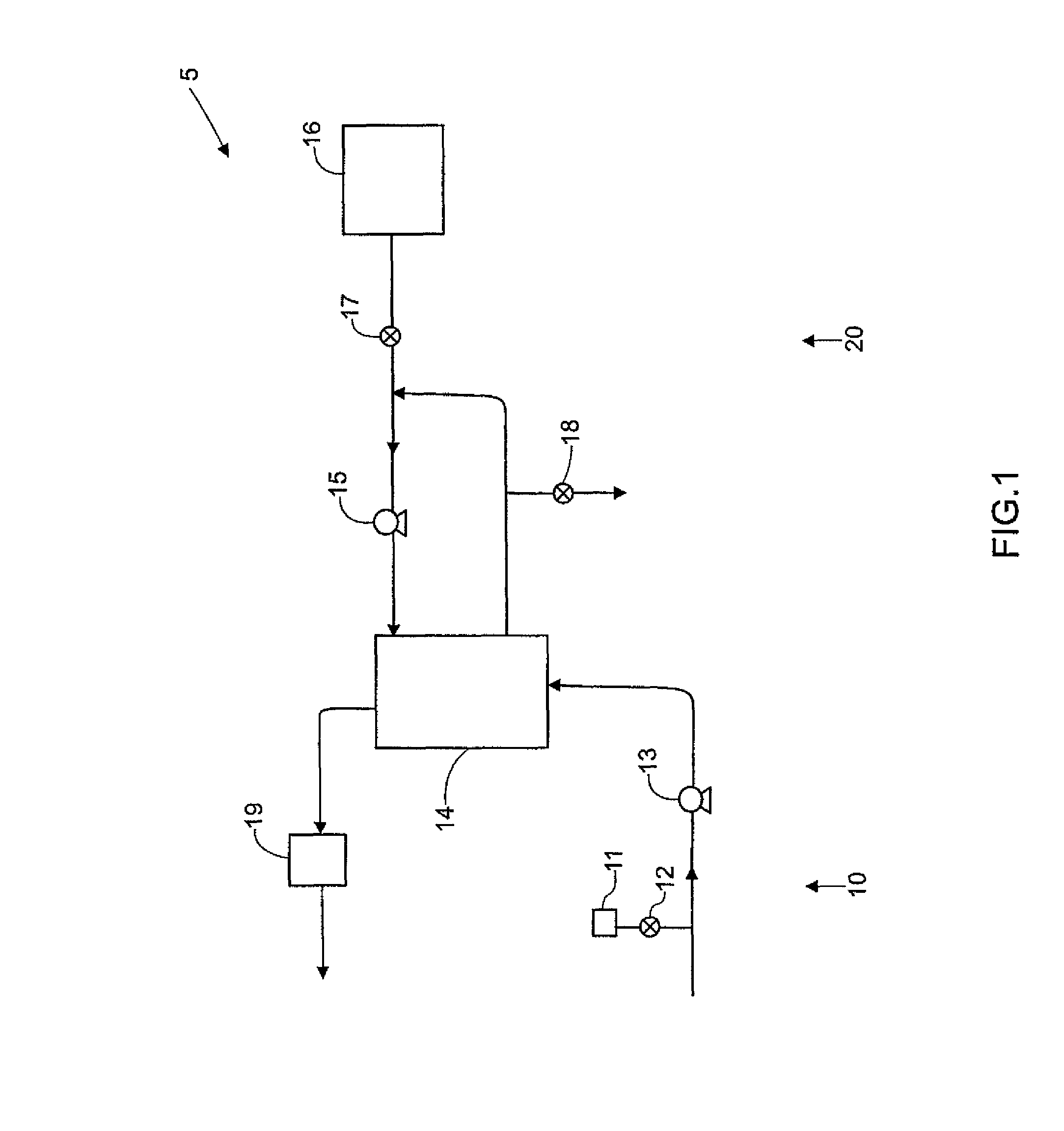

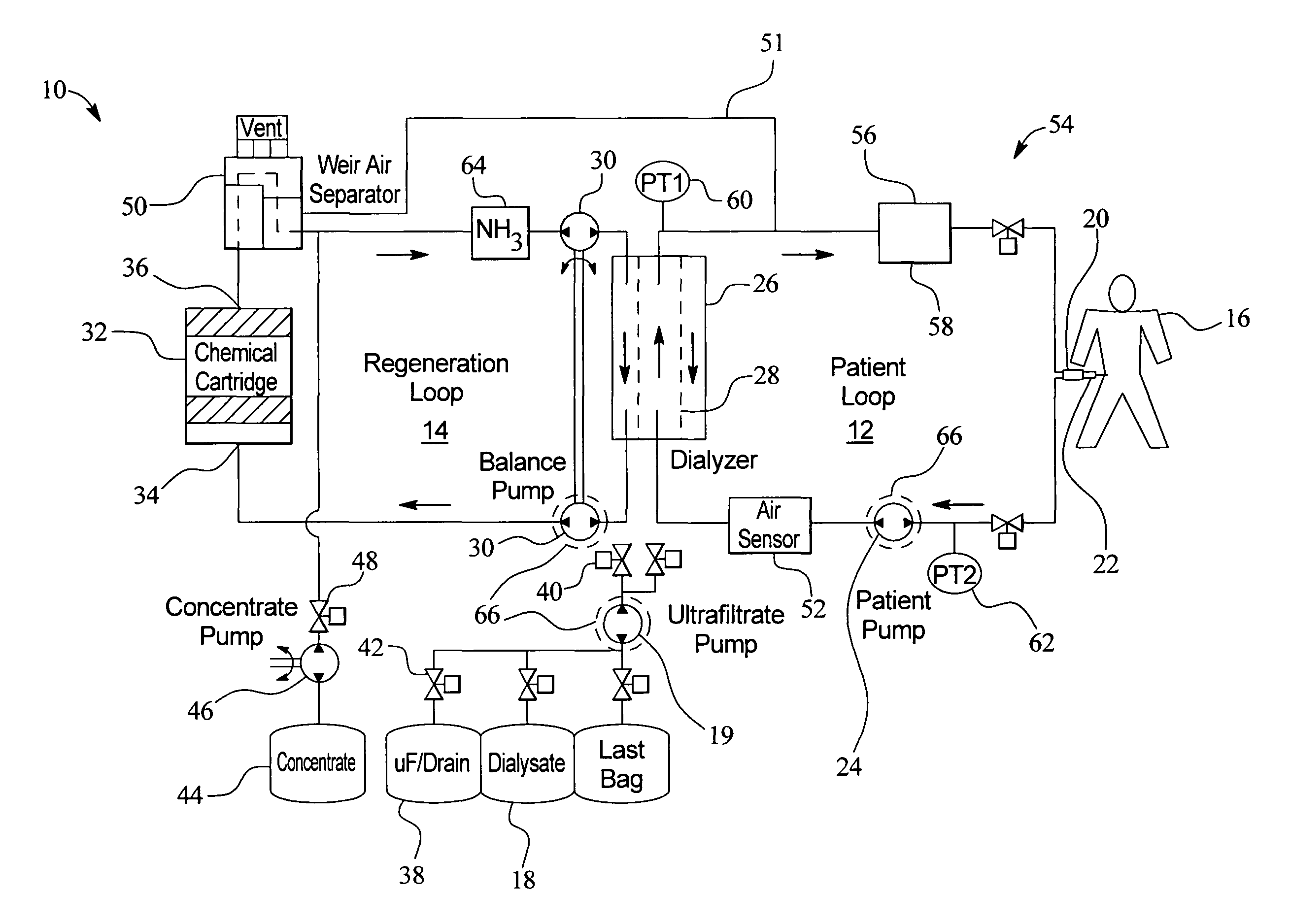

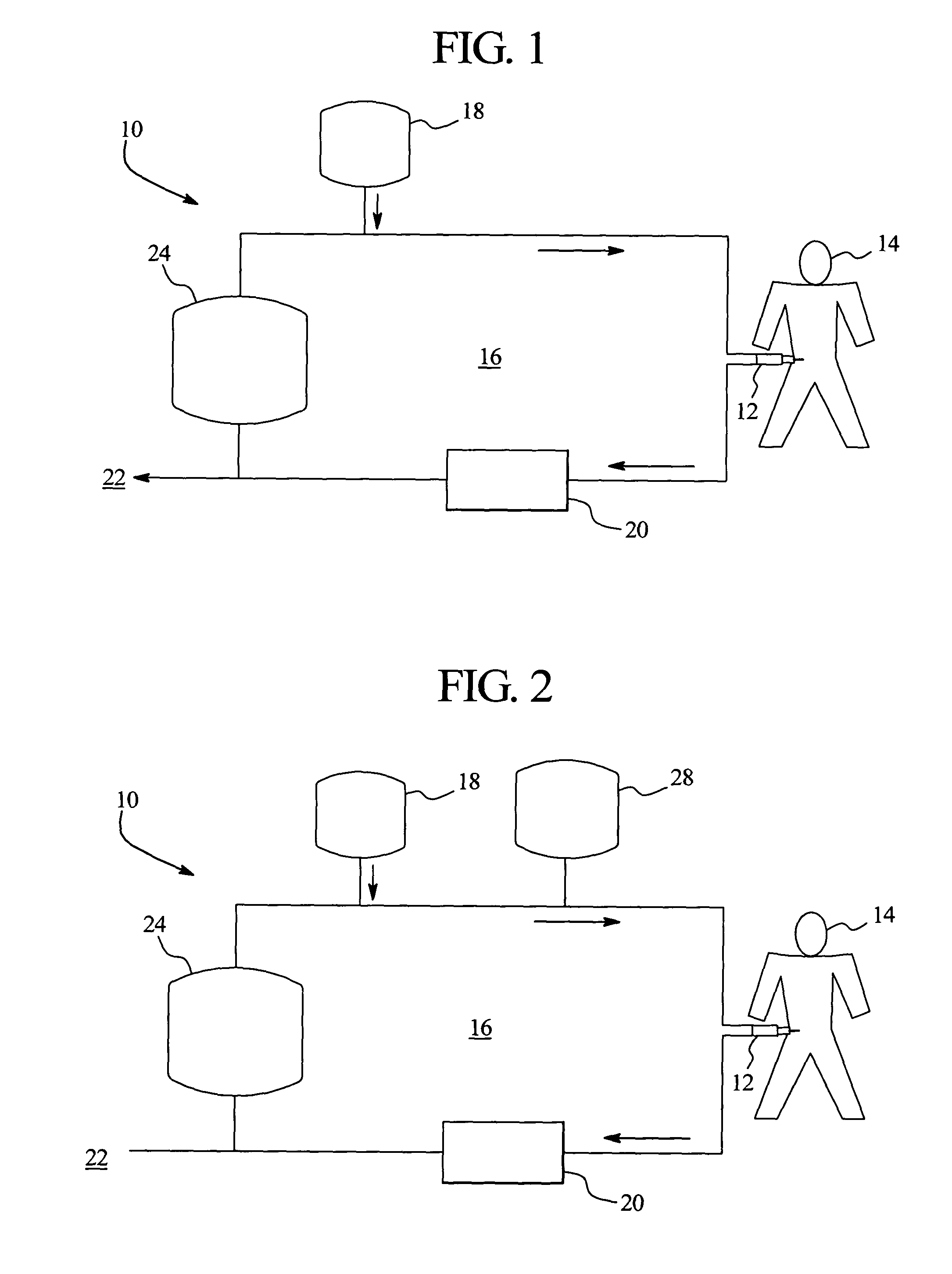

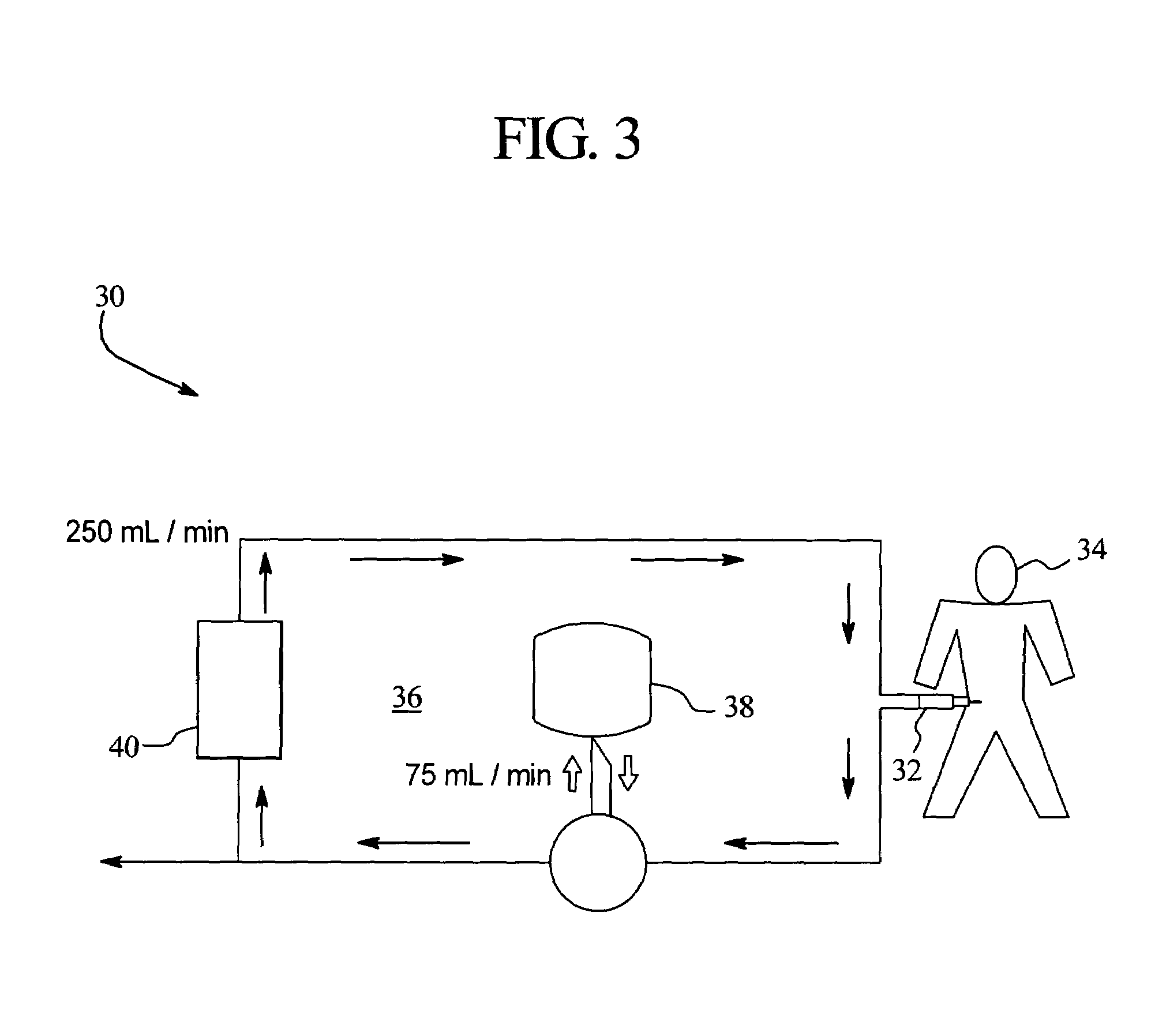

Systems and methods for performing peritoneal dialysis

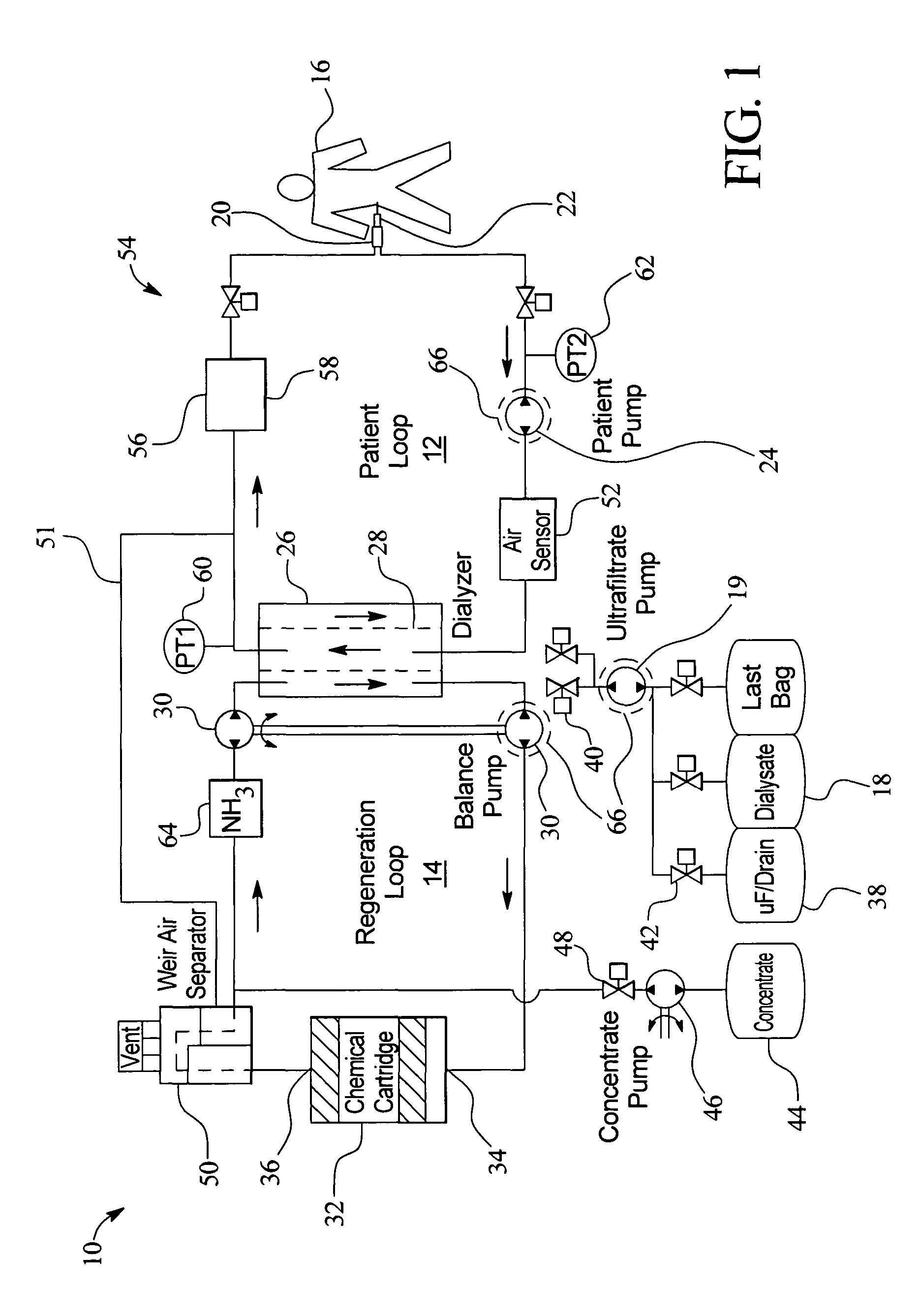

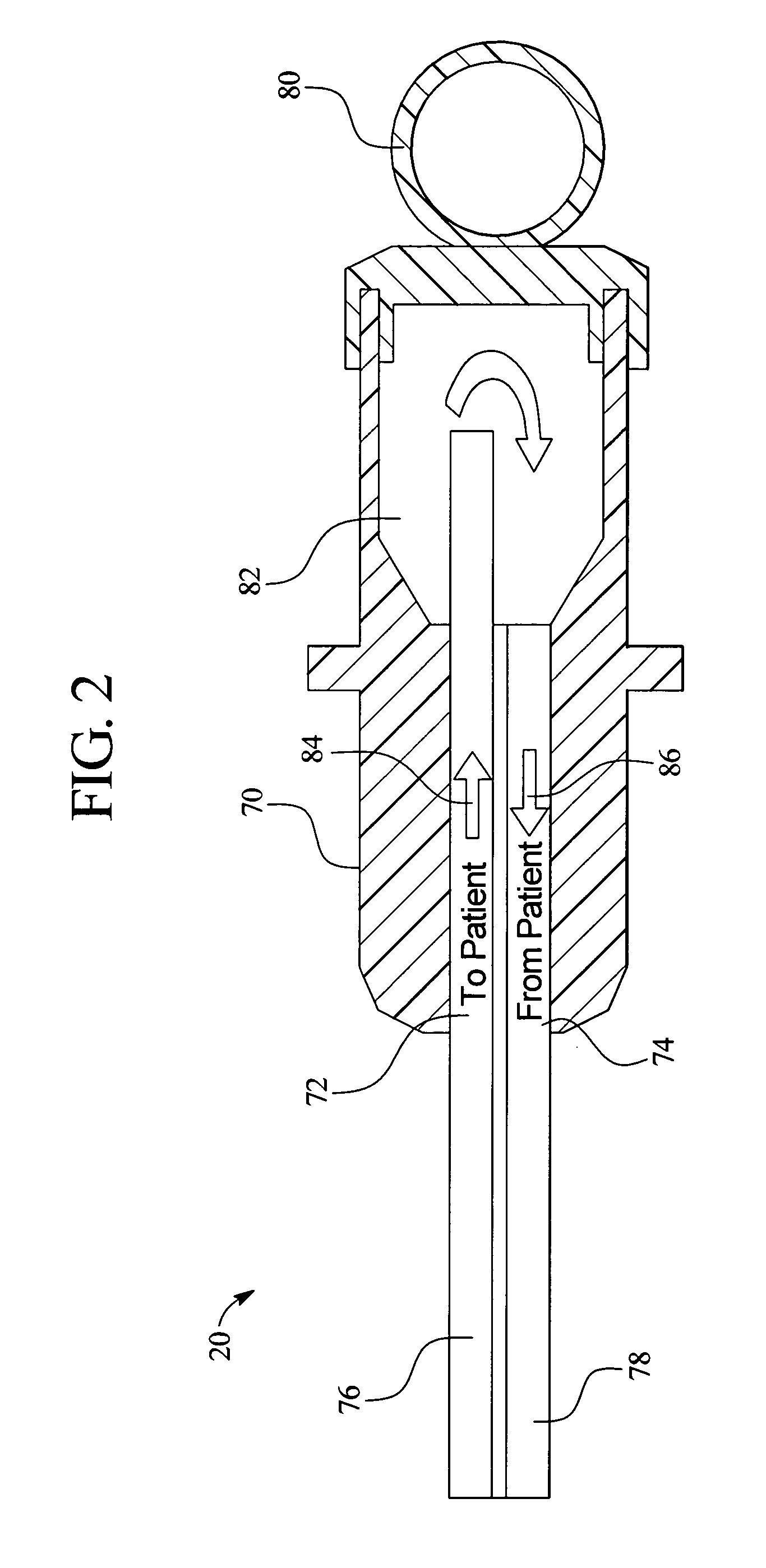

ActiveUS7867214B2Strengthen the systemImprove methodSolvent extractionIon-exchanger regenerationMetabolic wasteSorbent

In a peritoneal dialysis embodiment of the present invention, spent dialysate from the patient's peritoneal cavity passes, along a patient loop, through a dialyzer having a membrane that separates waste components from the spent dialysate, wherein the patient loop returns fresh dialysate to the patient's peritoneal cavity. The waste components are carried away in a second regeneration loop to a regeneration unit or sorbent cartridge, which absorbs the waste components. The regeneration unit removes undesirable components in the dialysate that were removed from the patient loop by the dialyzer, for example, excess water (ultrafiltrate or UF), toxins and metabolic wastes. Desirable components can be added to the dialysate by the system, such as glucose and electrolytes. The additives assist in maintaining the proper osmotic gradients in the patient to perform dialysis and provide the necessary compounds to the patient.

Owner:BAXTER INT INC

Water purifier and method of making and using the same

ActiveUS20050139530A1Fully removedGeneral water supply conservationTreatment involving filtrationHigh concentrationPurification methods

A method of producing safe drinking water from virtually any water source utilizing a water purification system is disclosed. The method includes a combination of water purification methods with a control system that evaluates water quality and functional processing parameters, such as pressure and flow. The control system determines what water processing methods to utilize and how most efficiently to operate them. The system is capable of treating highly contaminated water to the necessary degree to produce safe drinking water. Furthermore, the system regulates and cleans itself to maintain functionality despite receiving high concentrations of various contaminants from the feed water source.

Owner:HEISS CHRISTOPHER

Vented medical fluid tip protector methods

InactiveUS6929751B2Semi-permeable membranesSolvent extractionPeritoneal dialysisBiomedical engineering

A method, system and apparatus for performing peritoneal dialysis are provided. To this end, in part, a member for removably securing a medical fluid tube is provided. The member includes a body providing a first fluid pathway and an opening for removably receiving an end of the medical tube. The first fluid pathway is placed in fluid communication with a second fluid pathway defined by the tube when the end of the tube is removably receiving. The member further includes a filter so positioned and arranged so as to cause fluid flowing through the first fluid pathway to pass through the filter, the filter allowing air but not liquid to flow through the first fluid pathway.

Owner:BAXTER HEALTHCARE SA +1

Systems and methods for peritoneal dialysis

ActiveUS7208092B2Strengthen the systemImprove methodSemi-permeable membranesSolvent extractionContinuous flowIntensive care medicine

Systems and methods relating to dialysis therapy, particularly continuous flow dialysis therapy, are provided. The present invention includes a single closed fluid path along which a minimal amount of therapy fluid including dialysate is fed into, continuously circulated and cleaned such that a therapeutic effective amount of solutes, excess water and the like can be removed from the patient connected to the closed fluid loop during treatment.

Owner:BAXTER INT INC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com