Patents

Literature

403results about How to "Small inner diameter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

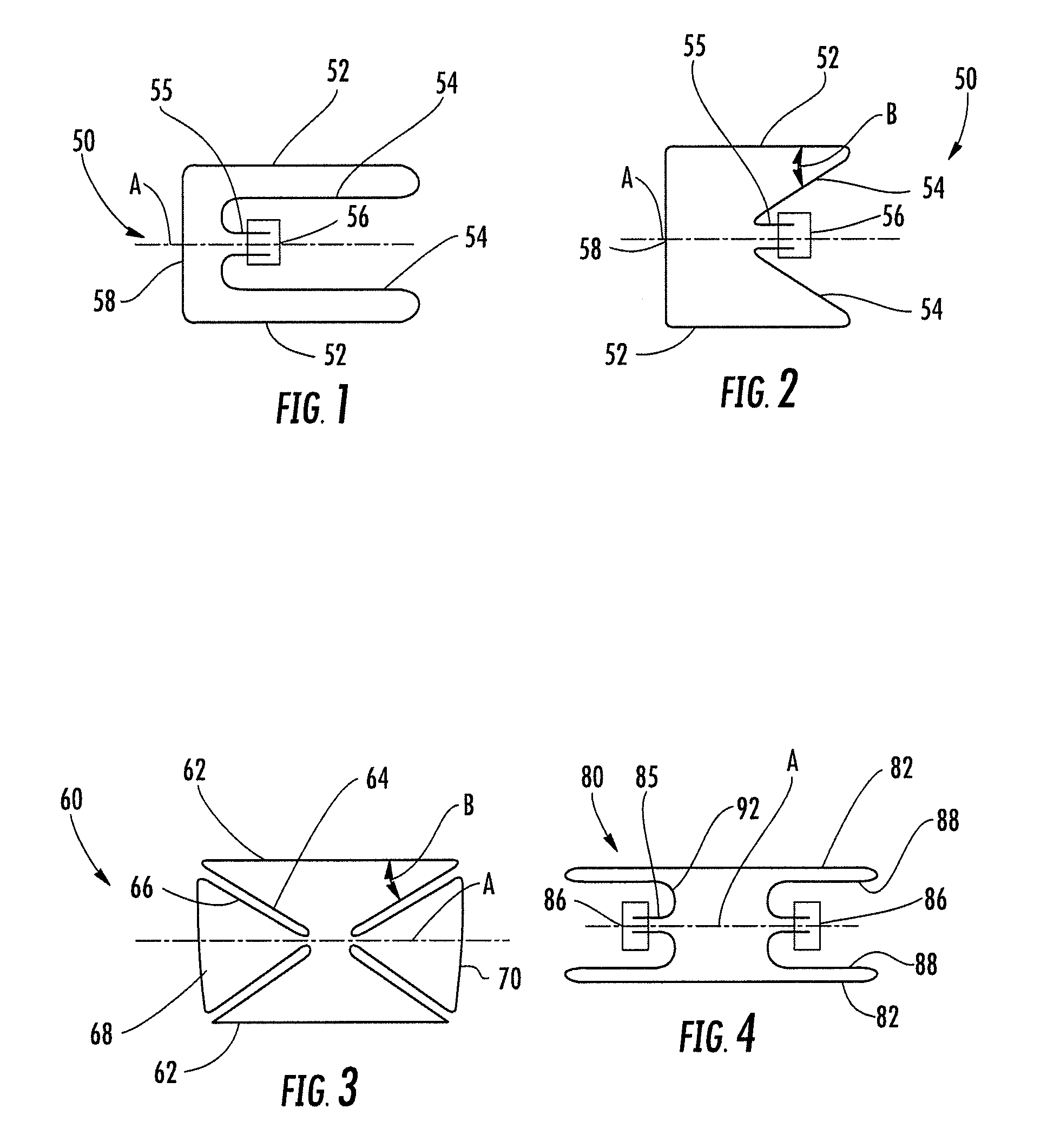

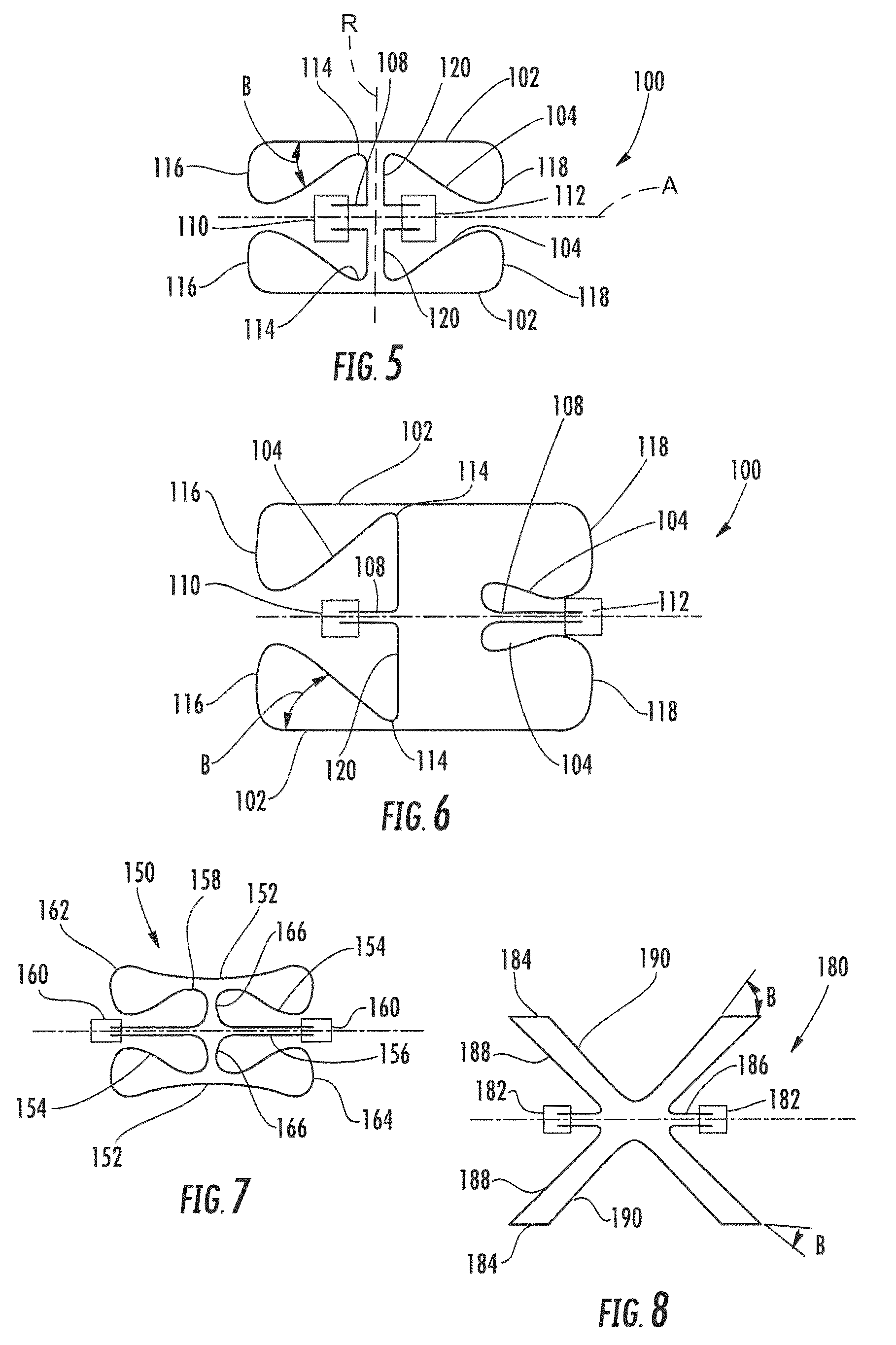

Multi-layered medical device for treating a target site and associated method

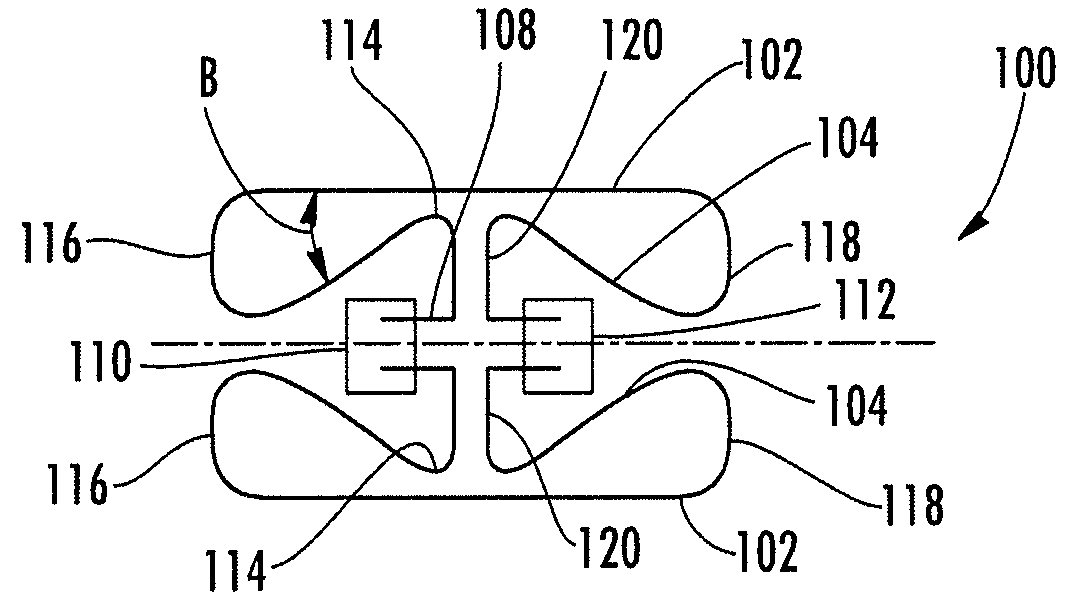

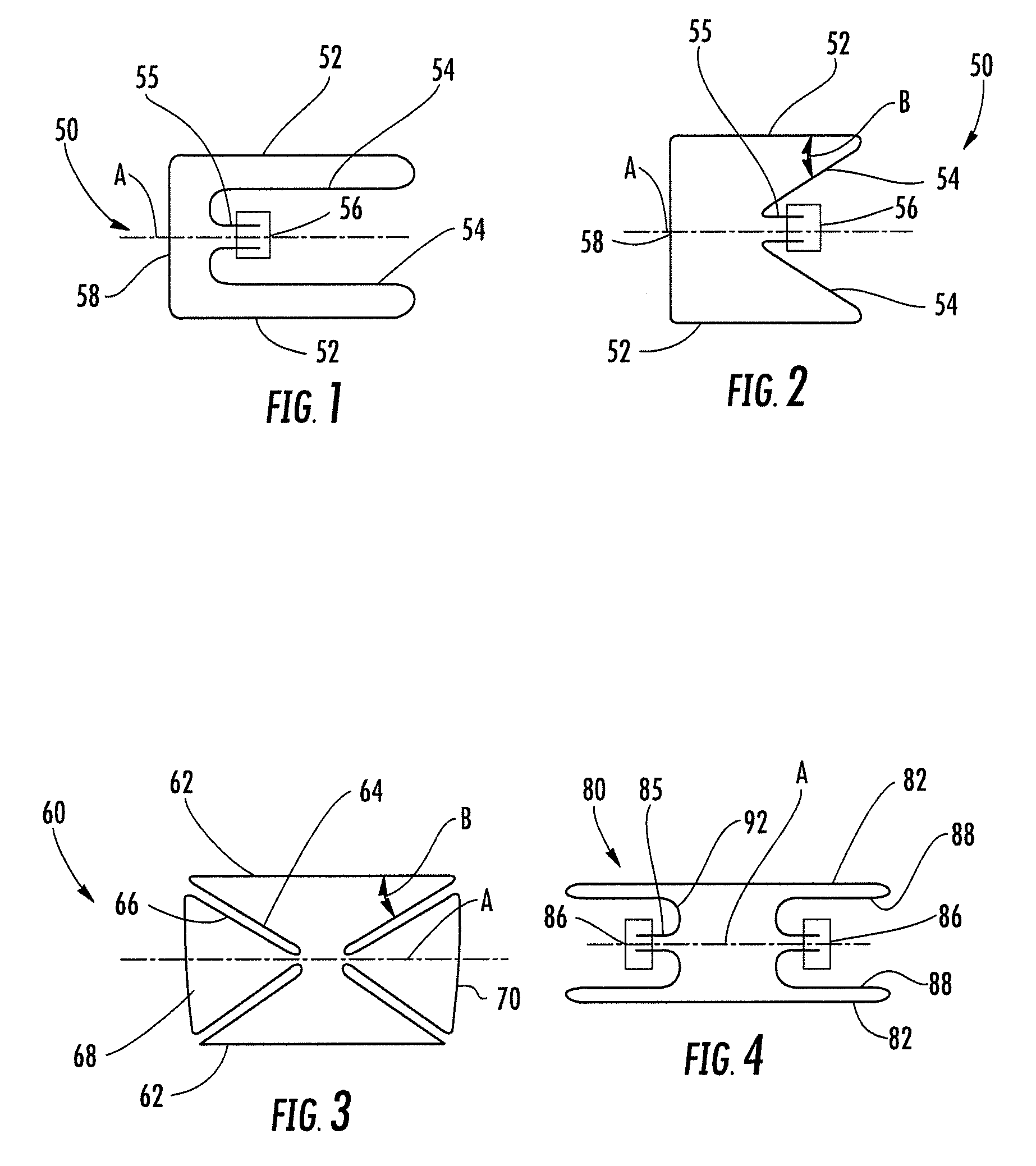

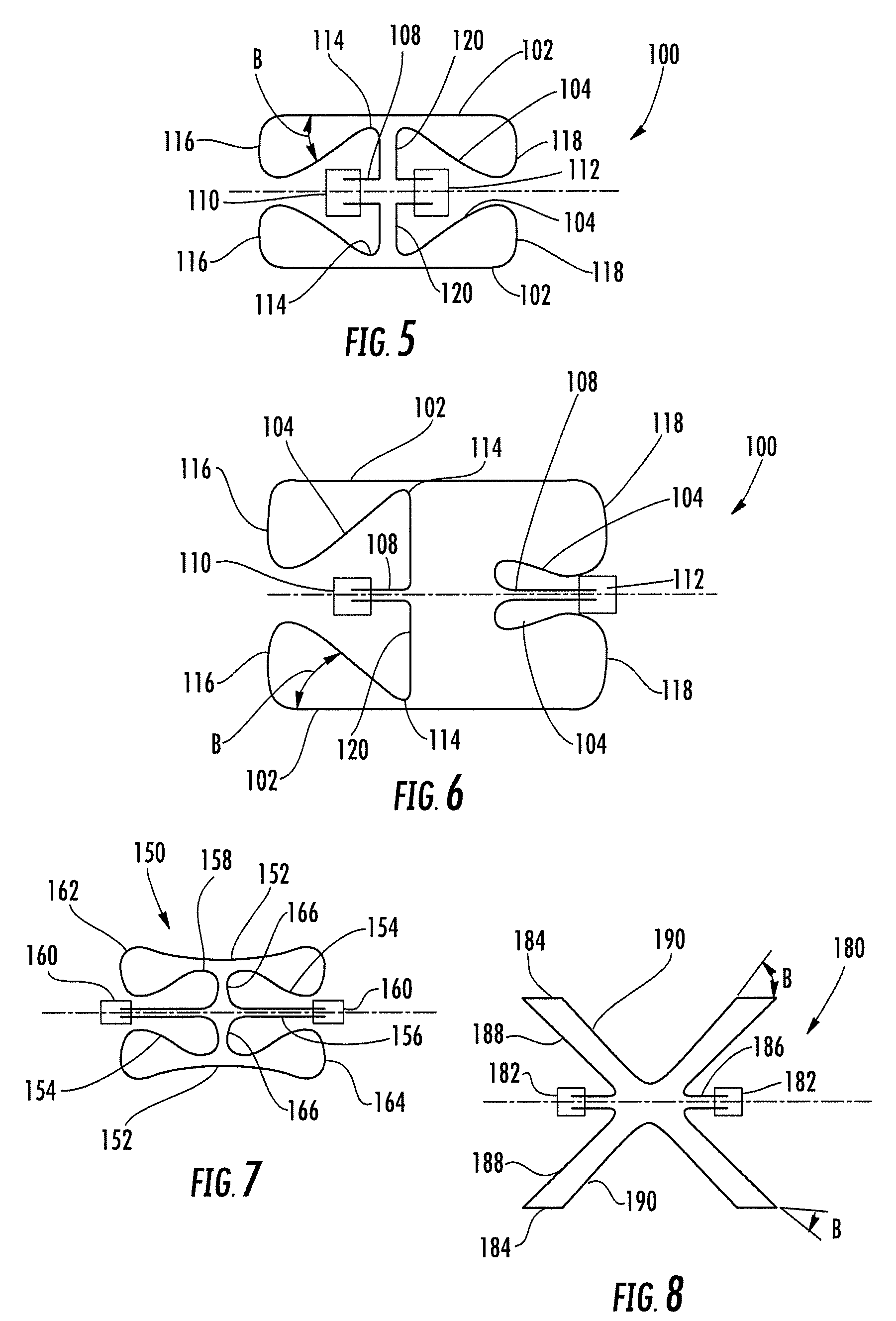

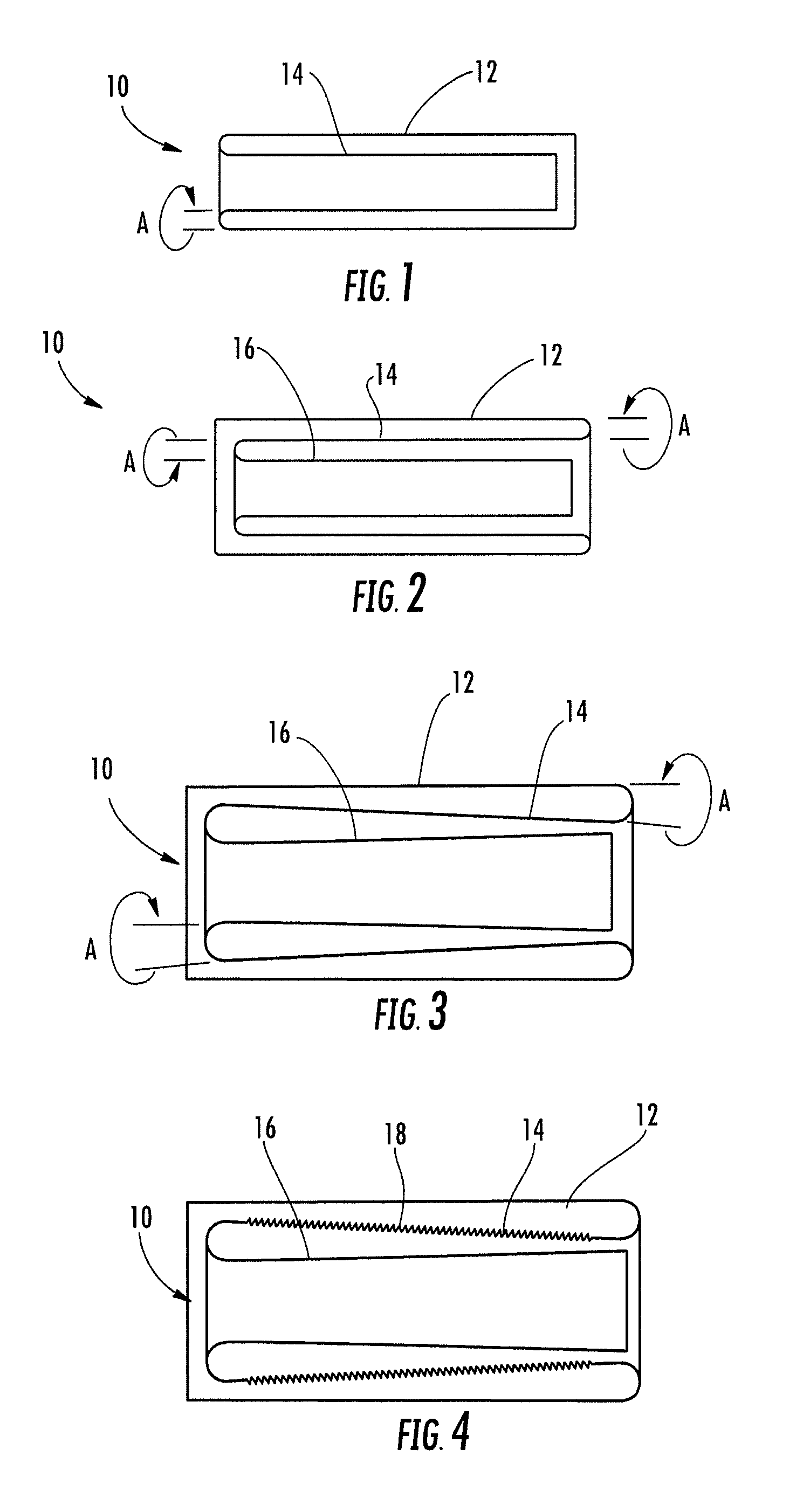

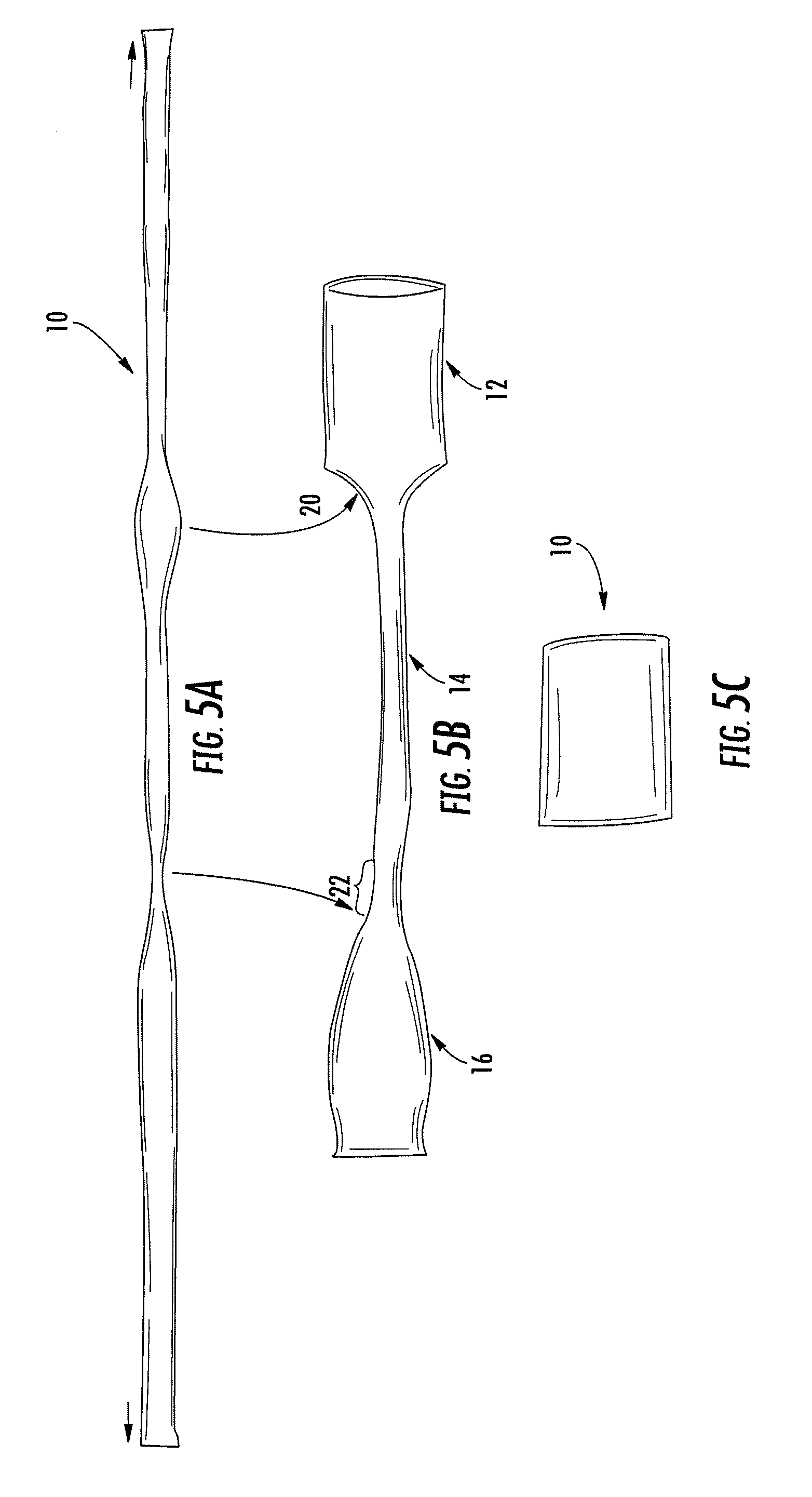

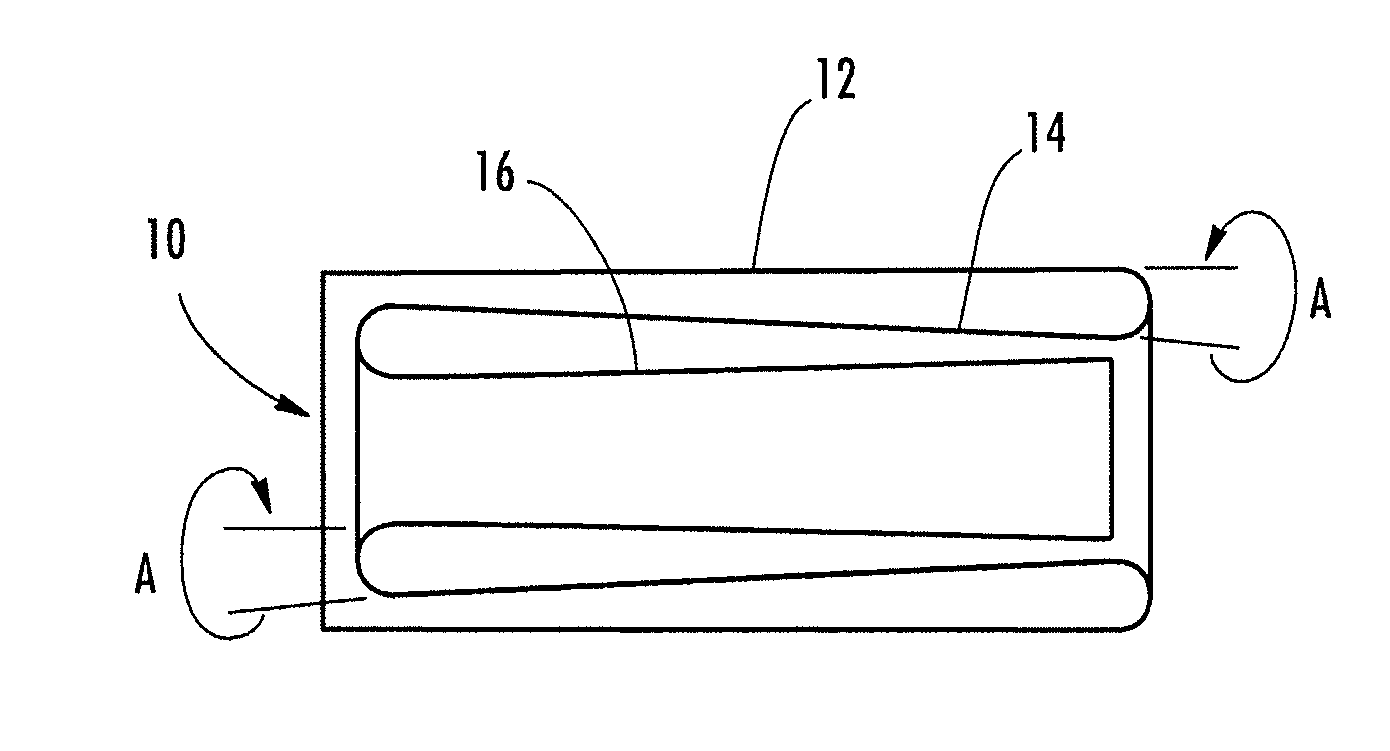

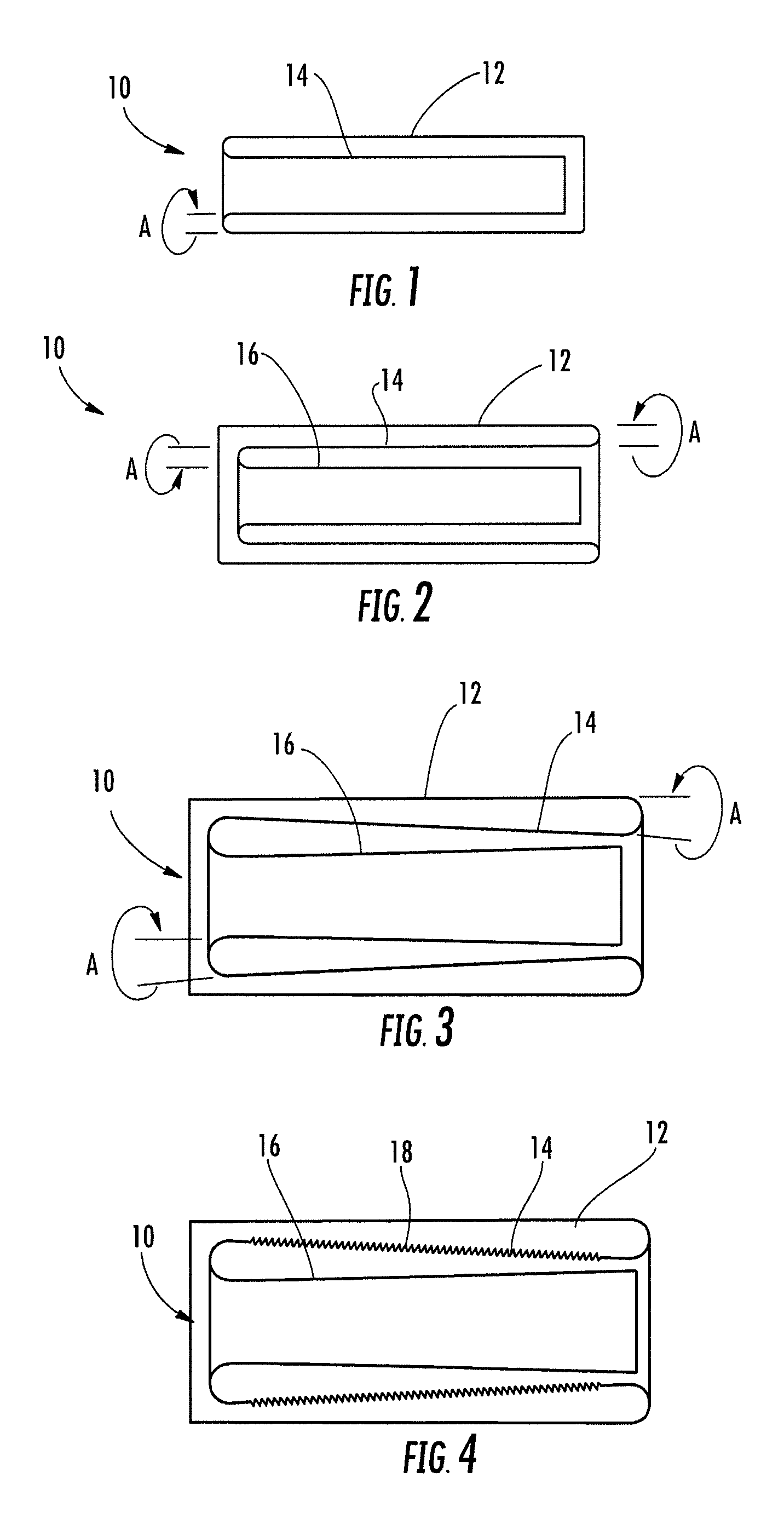

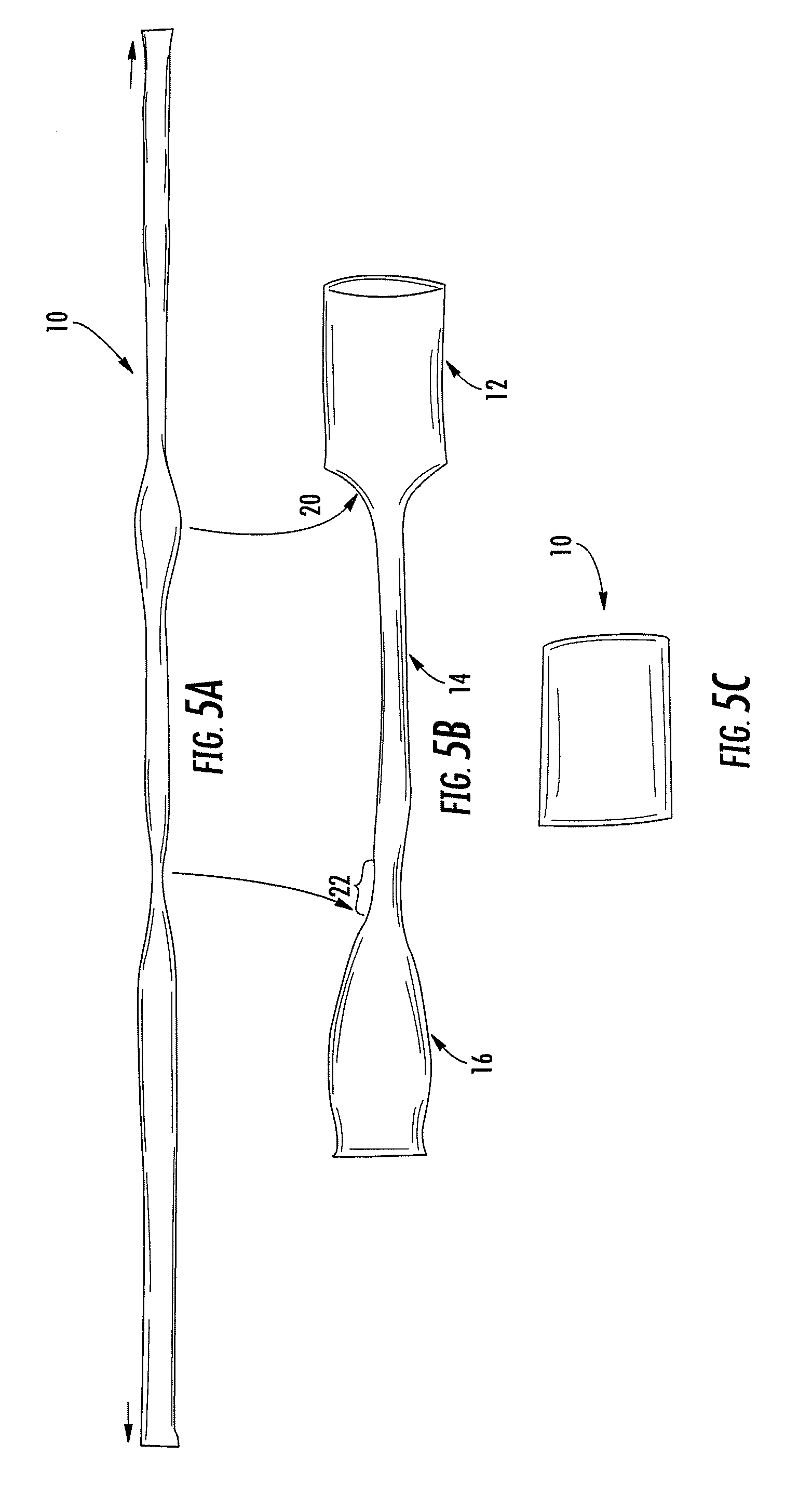

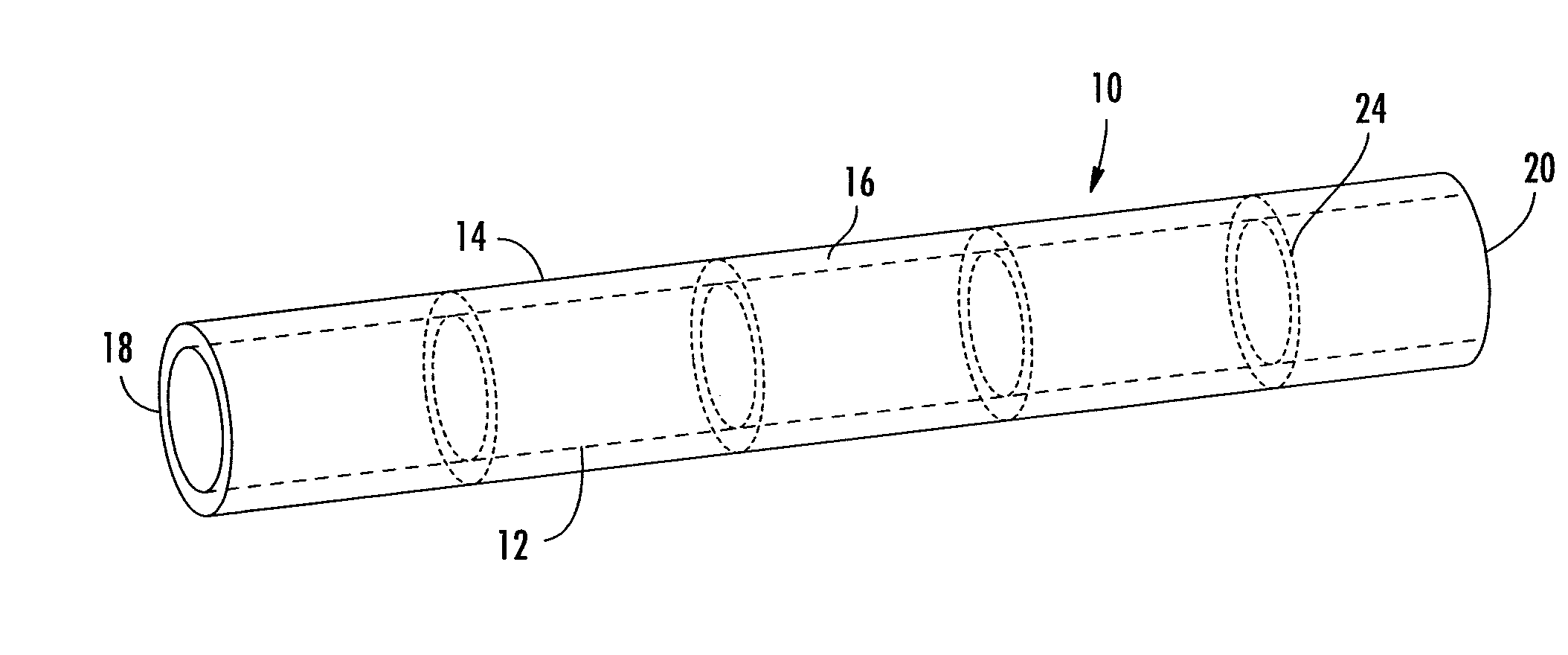

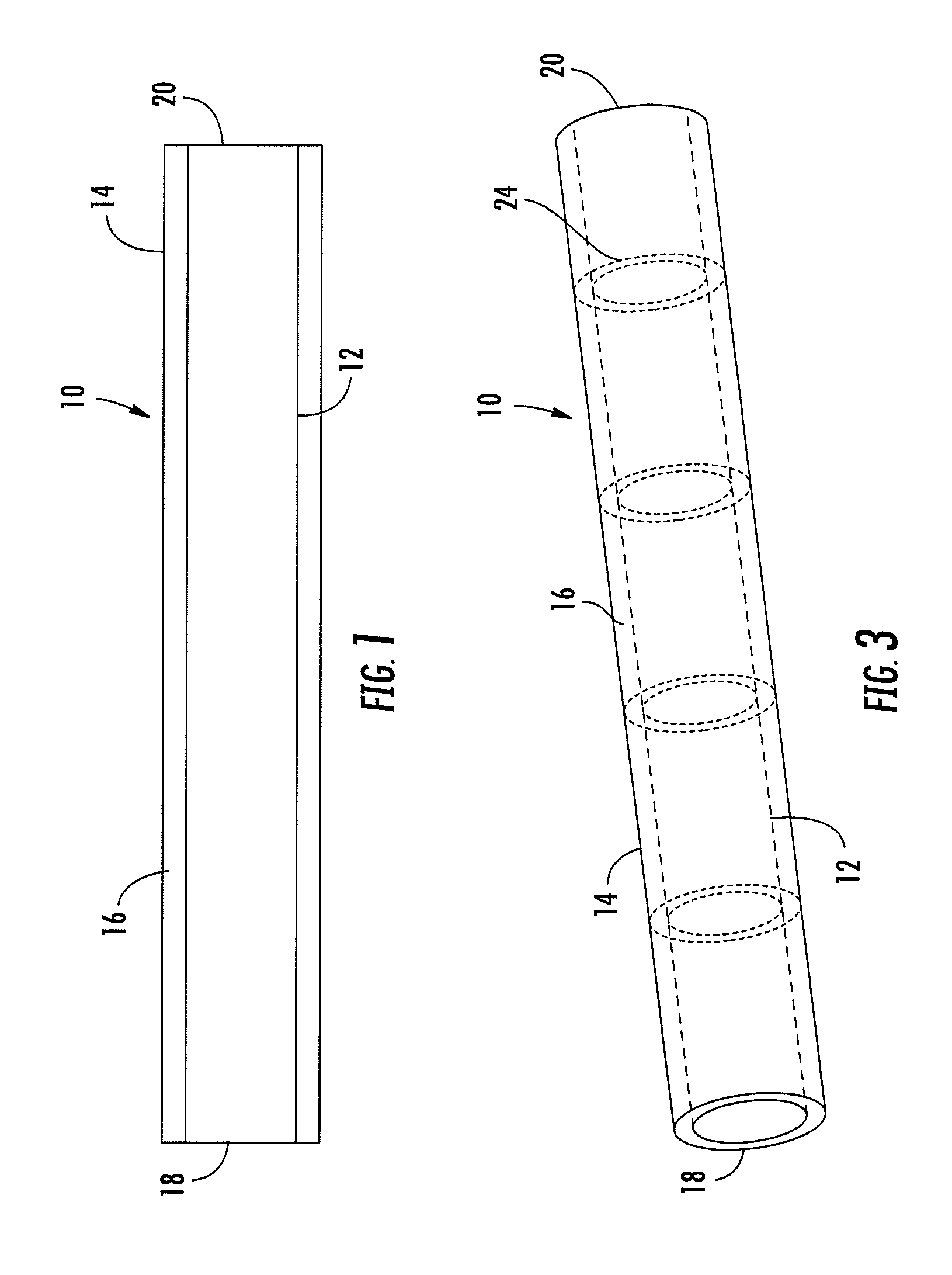

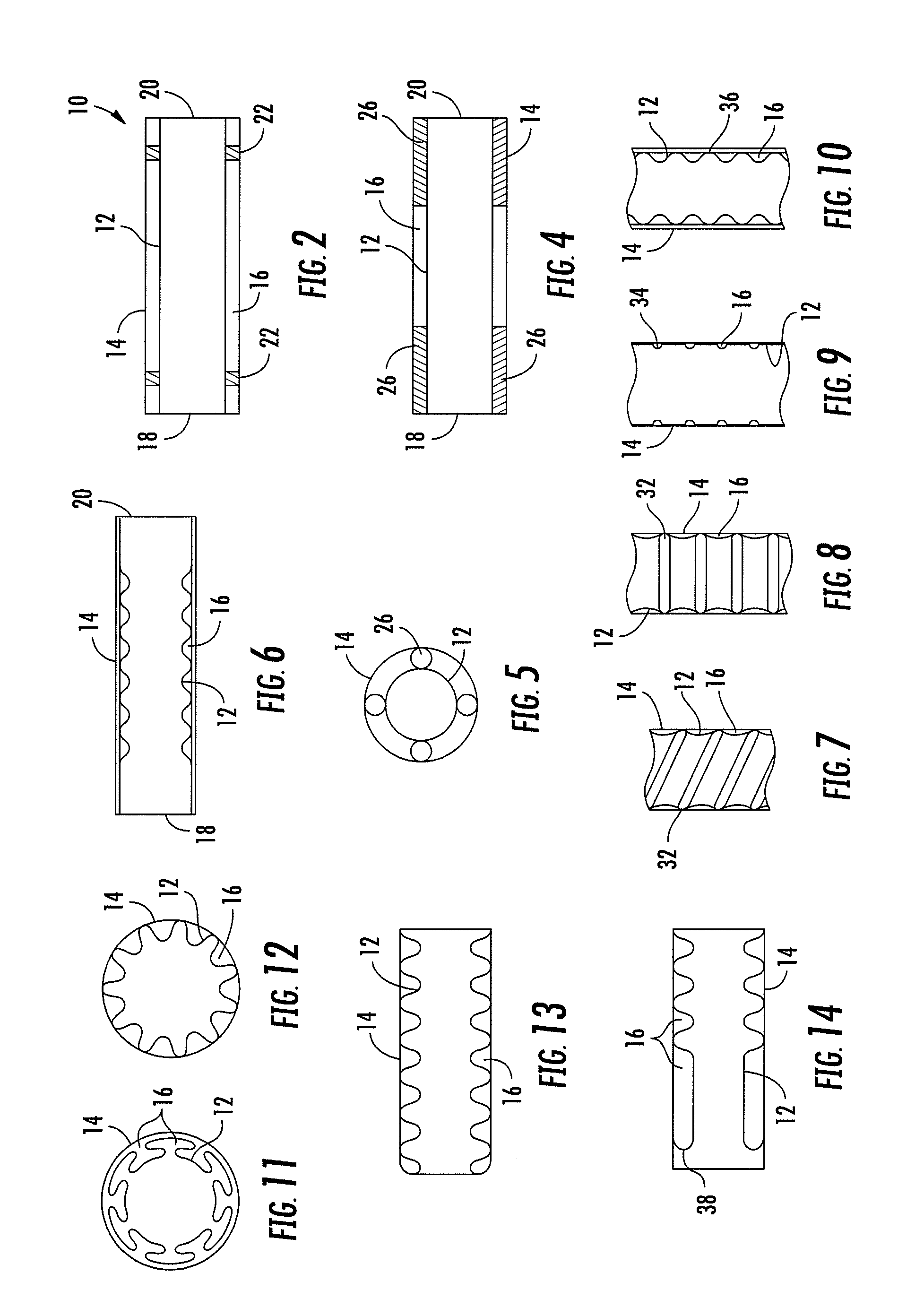

Embodiments of the present invention provide medical devices and methods for treating a target site within the body, such as for treating vascular abnormalities. For example, one embodiment provides an occlusion device including an occlusive material having proximal and distal ends and a central axis extending therebetween. The occlusive material has a preset, overlapping configuration including at least three inverted overlapping layers folded over one another, wherein the at least three inverted overlapping layers are aligned with the central axis within about 45 degrees or less and are configured to be separated and disposed within a catheter in a non-overlapping configuration and return to the preset, overlapping configuration when deployed from the catheter.

Owner:ST JUDE MEDICAL CARDILOGY DIV INC

Multi-layered medical device for treating a target site and associated method

Embodiments of the present invention provide medical devices and methods for treating a target site within the body, such as for treating vascular abnormalities. For example, one embodiment provides a stent graft including an occlusive material having a preset, overlapping configuration comprising at least three inverted overlapping layers that are folded over one another. The at least three inverted overlapping layers are configured to be separated and disposed within a catheter in a non-overlapping configuration and return to the preset, overlapping configuration when deployed from the catheter.

Owner:ST JUDE MEDICAL CARDILOGY DIV INC

Multi-layered medical device for treating a target site and associated method

Owner:ST JUDE MEDICAL CARDILOGY DIV INC

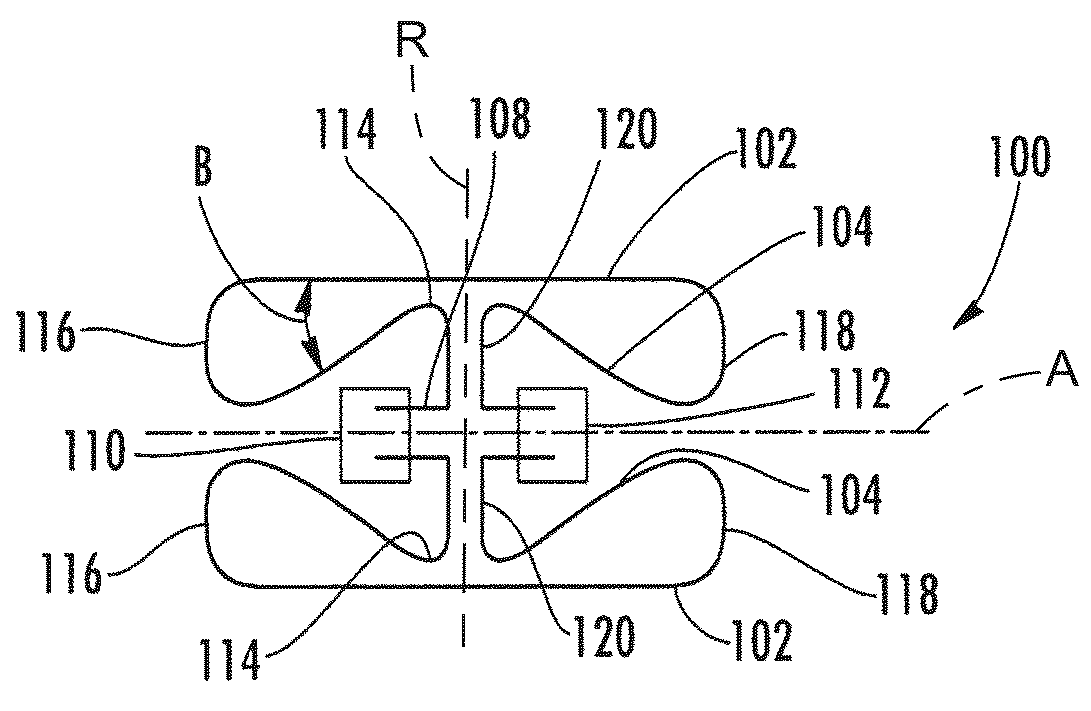

Multi-layer device with gap for treating a target site and associated method

ActiveUS20100106235A1Promote thrombosisEfficient exclusionStentsBlood vesselsLayered structureBiomedical engineering

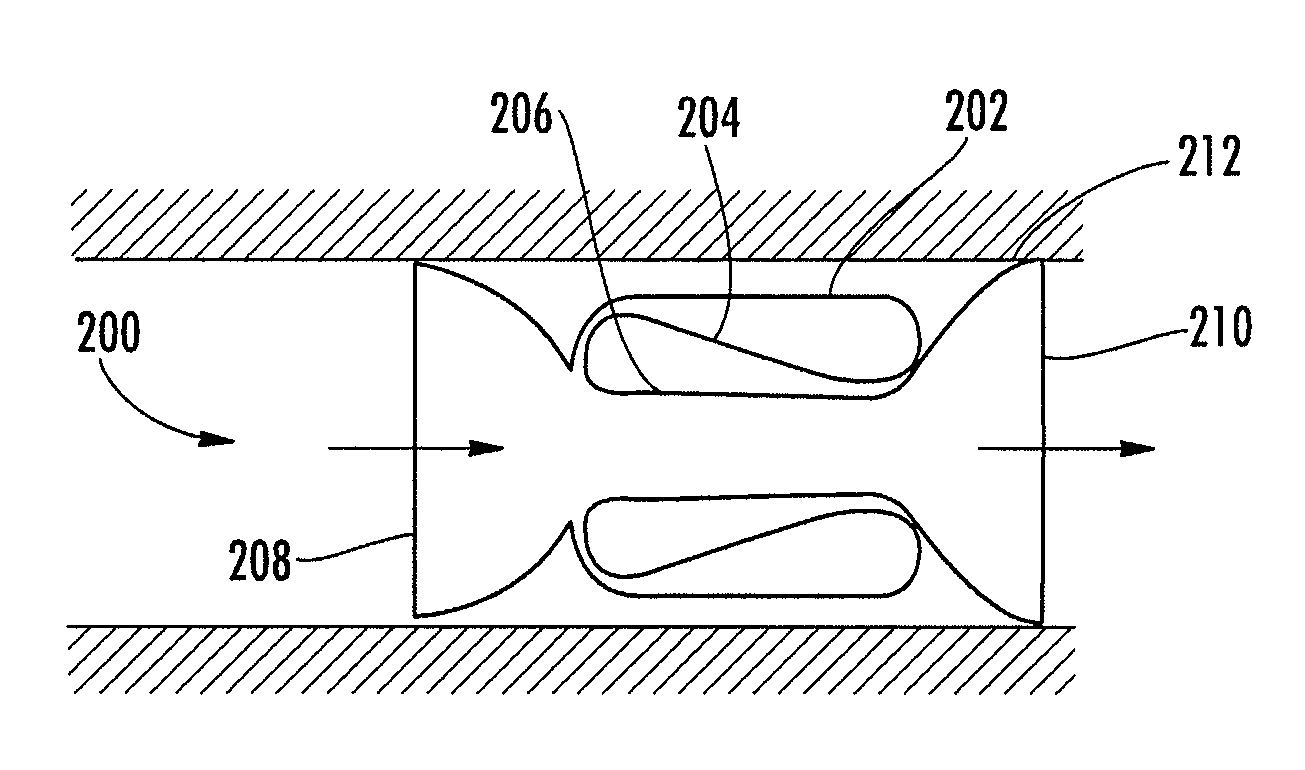

Embodiments of the present invention provide medical devices and methods for treating a target site within the body. For example, a medical device includes a multi-layered structure comprising an inner layer disposed within an outer layer, wherein each of the inner and outer layers has respective inner and outer surfaces. The multi-layered structure further comprises at least offset located between the inner and outer layers or formed in the inner and / or outer layers to define at least one gap therebetween such that a majority of the outer surface of the inner layer is spaced apart from the inner surface of the outer layer. The multi-layered structure is configured to be deployed within a lumen such that at least a portion of the outer layer is configured to engage the lumen and the at least one gap is configured to promote thrombosis between the inner and outer layers.

Owner:ST JUDE MEDICAL CARDILOGY DIV INC

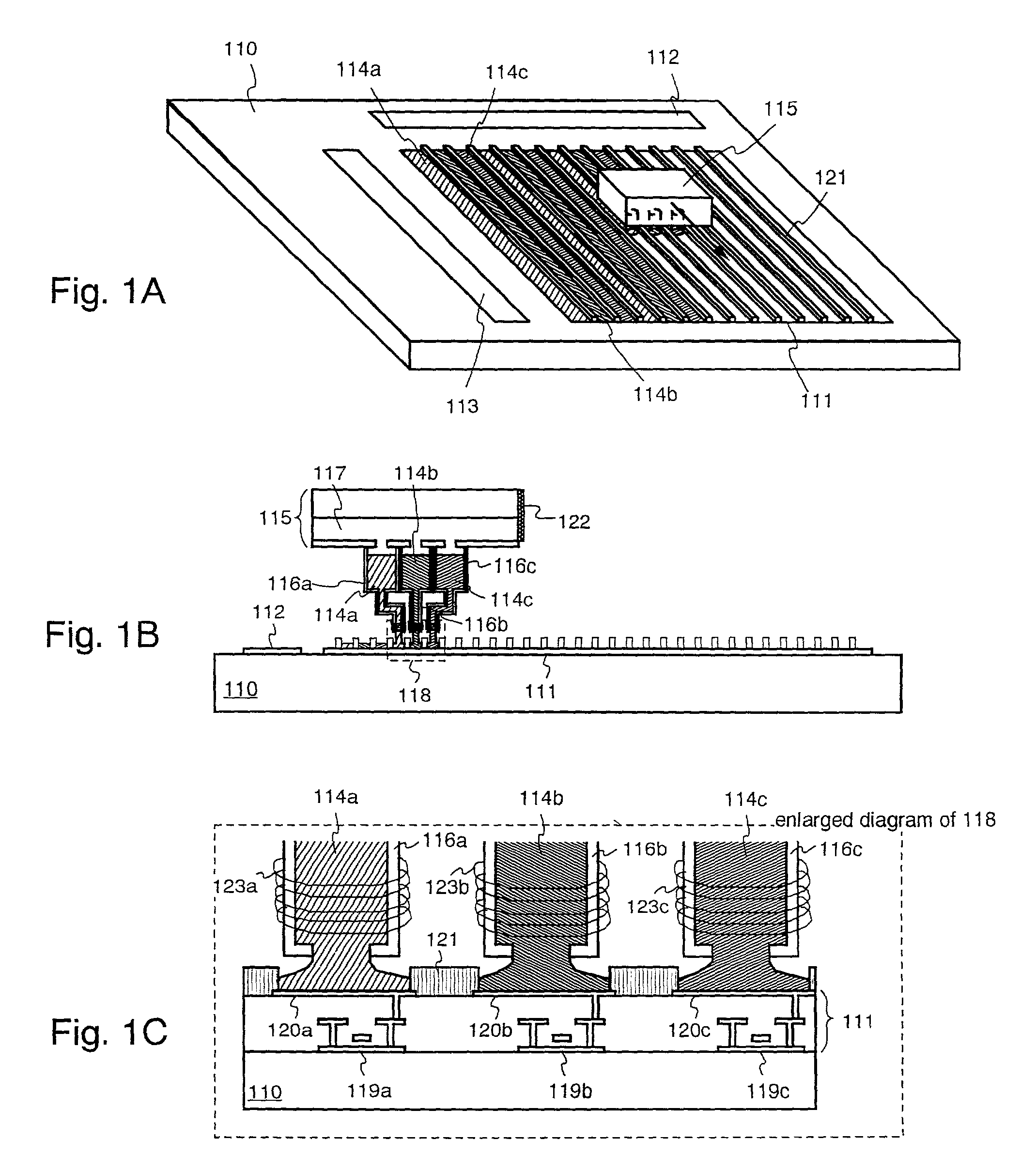

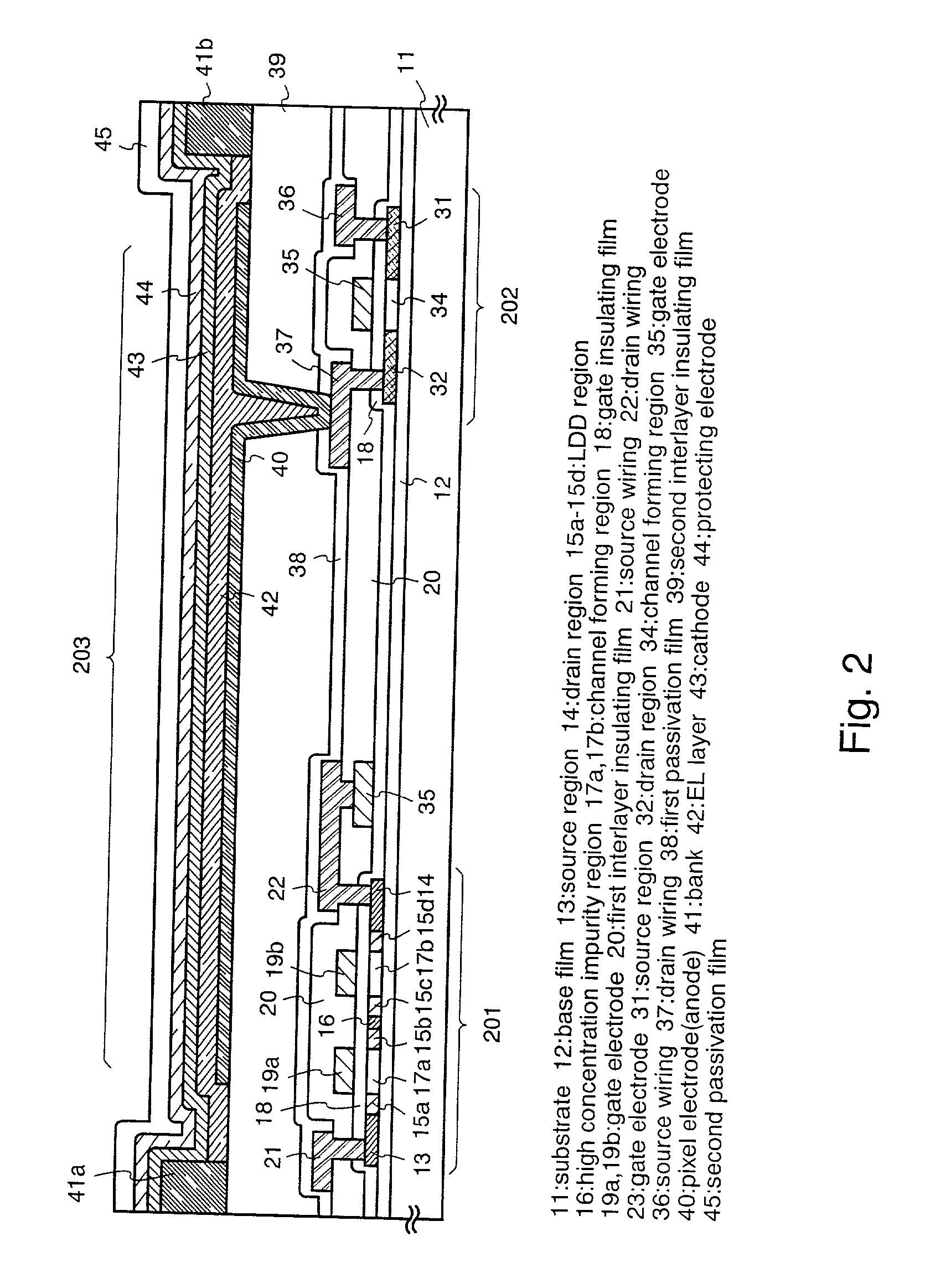

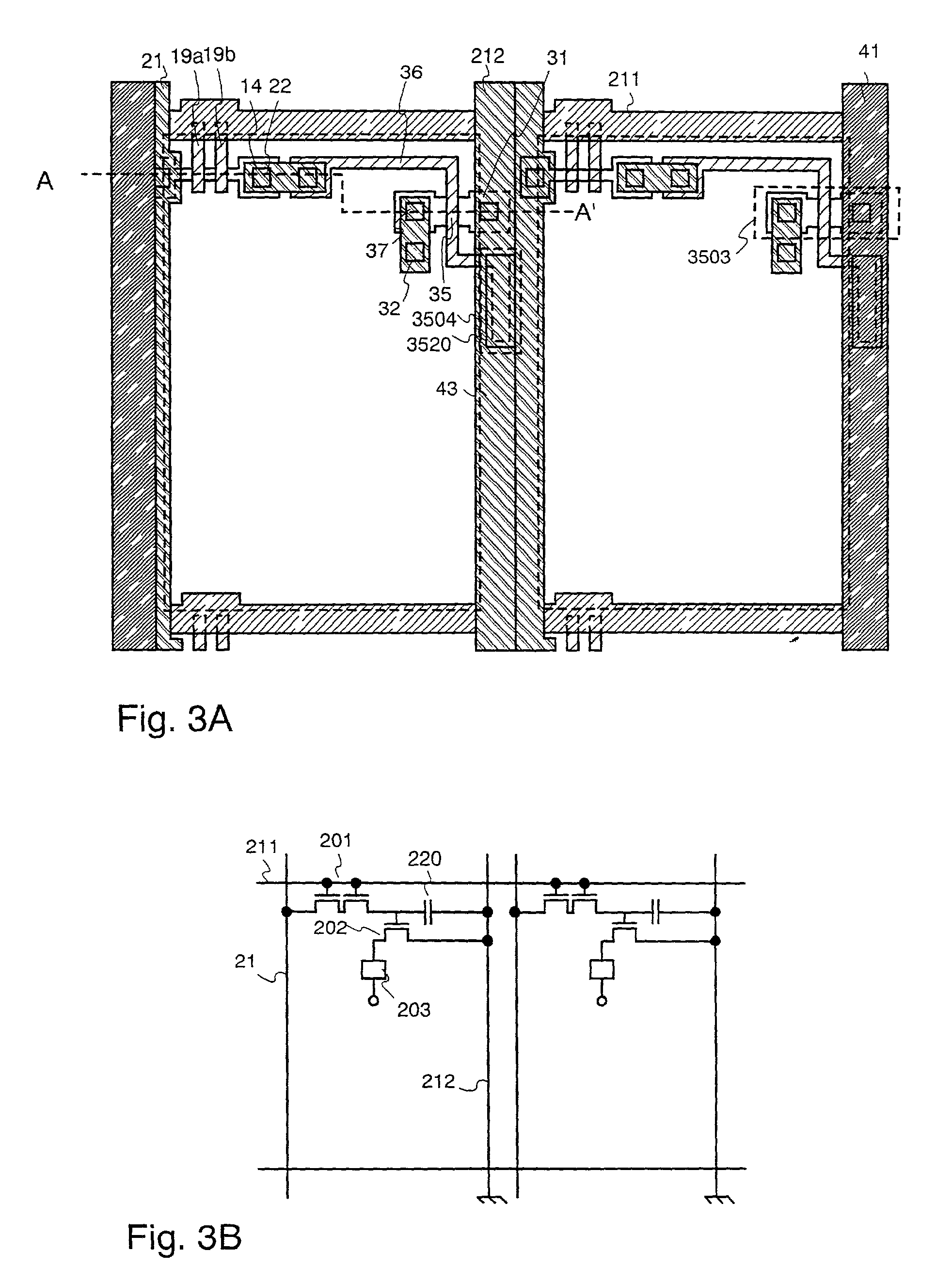

Thin film formation apparatus and method of manufacturing self-light-emitting device using thin film formation apparatus

InactiveUS20010023661A1Solve the real problemLarge diameterFuel elementsSolid-state devicesEngineeringLight emitting device

A means of effectively applying an organic EL material application liquid with good application liquid cut-off is provided. A heater and an ultrasonic oscillator are formed in a thin film formation apparatus when applying the application liquid, and heat and ultrasonic oscillations are imparted to the application liquid. Defective application liquid cut-off and liquid clogging can thus be resolved.

Owner:SEMICON ENERGY LAB CO LTD

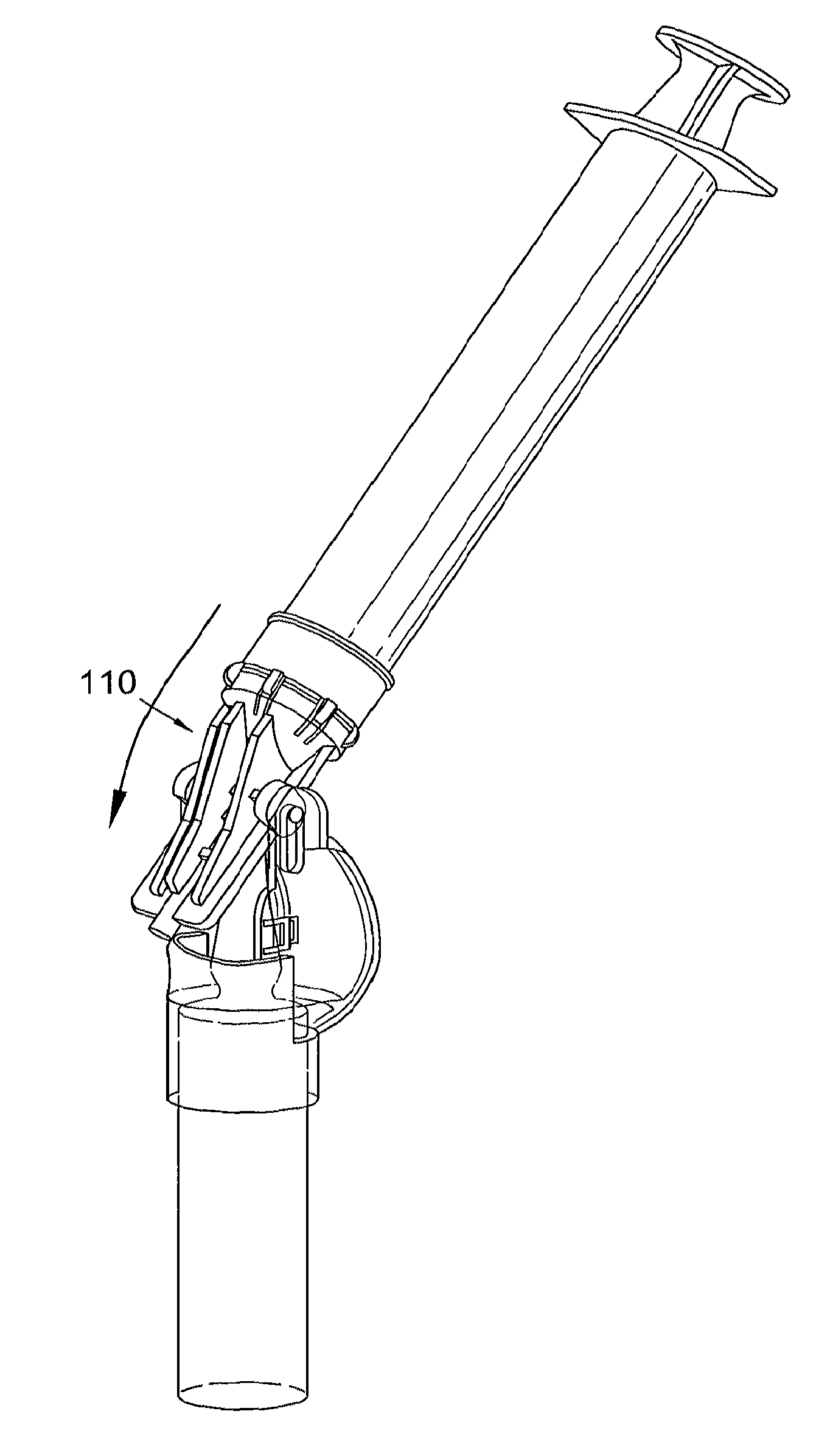

Apparatus and method

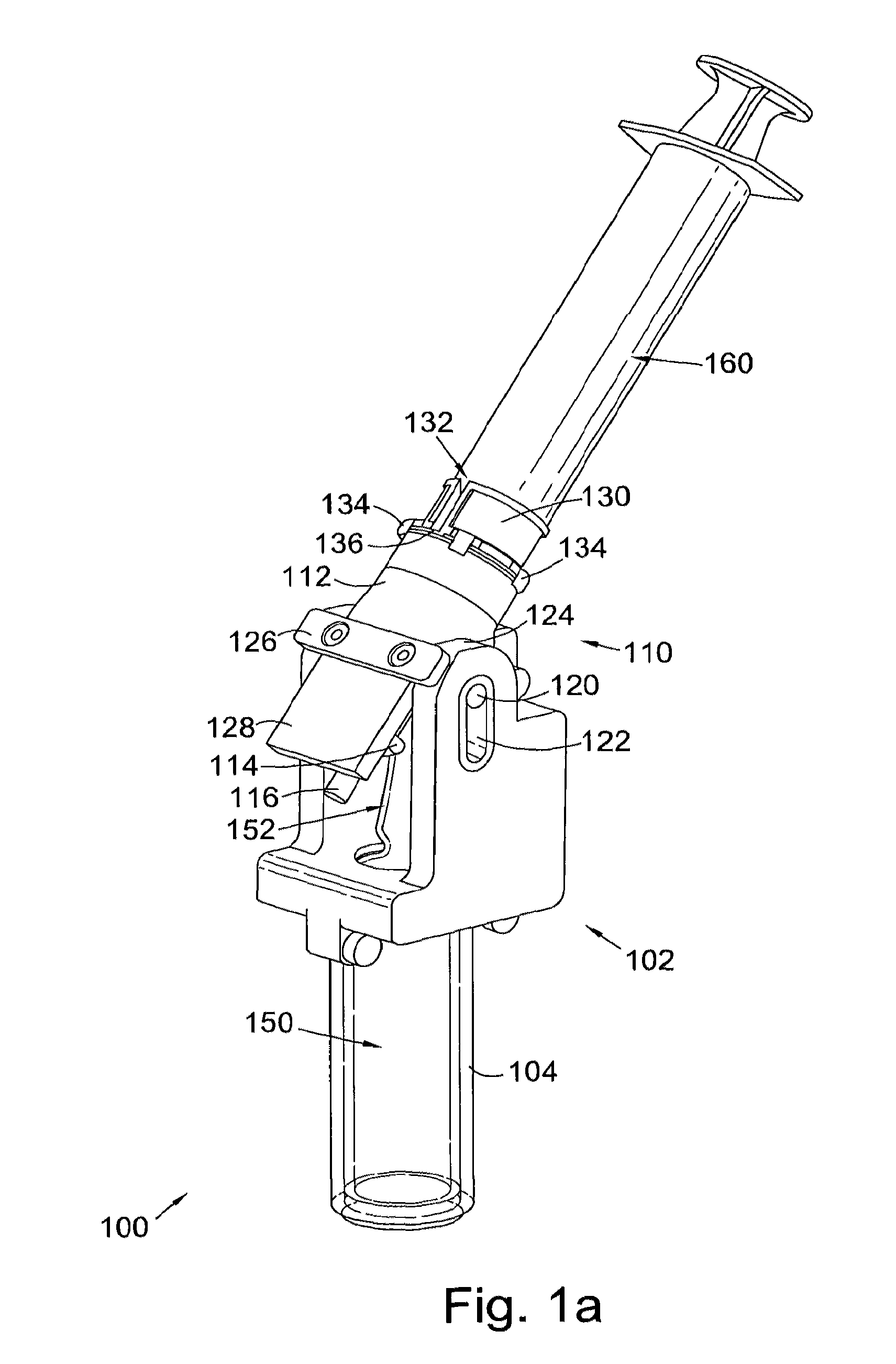

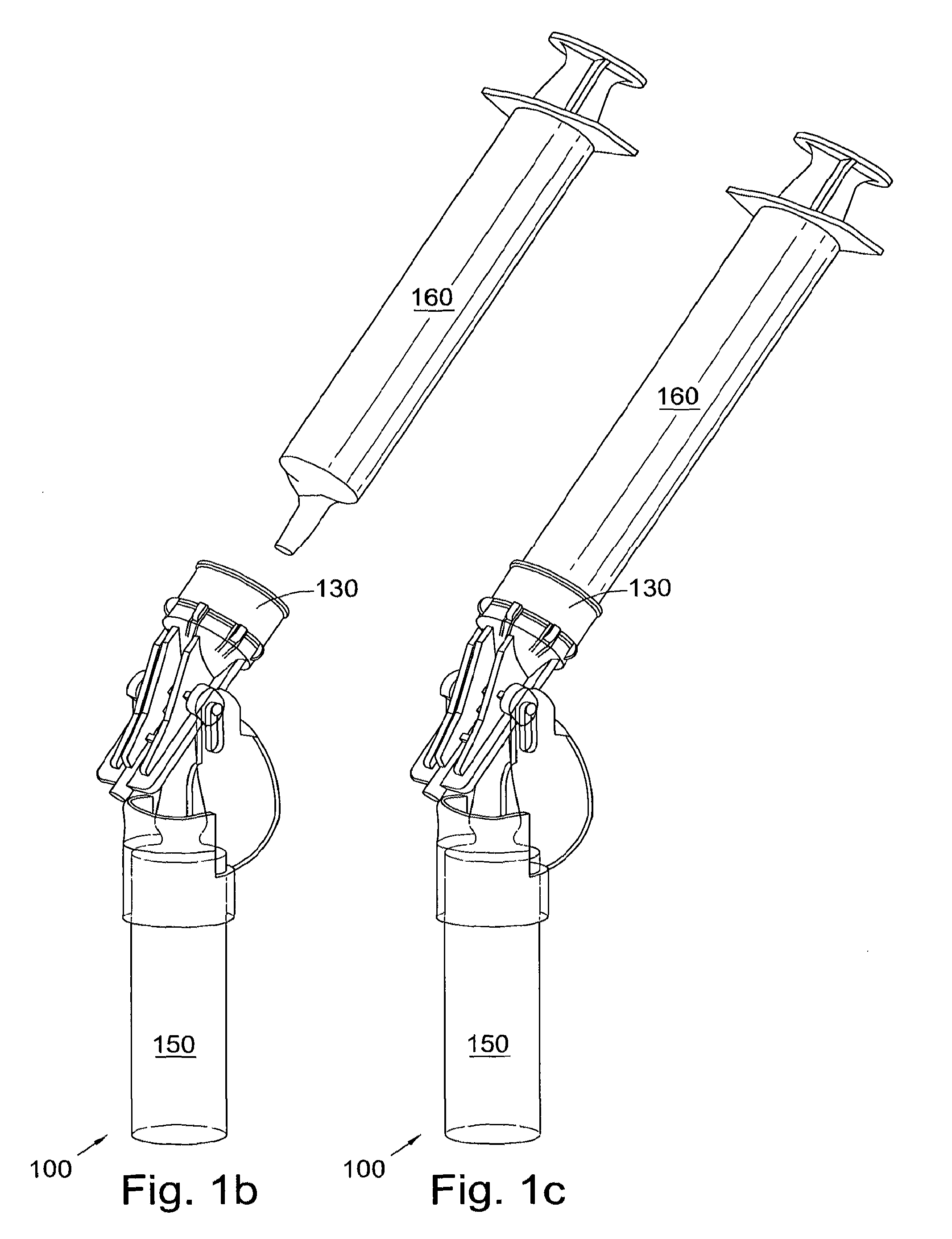

InactiveUS20120310203A1Limited spaceReduce the overall heightOpening closed containersBottle/container closureMedical deviceBiomedical engineering

This invention relates to medical devices for labelling a syringe filled from an ampoule, and to safer devices for filling a syringe from an ampoule, and to associated methods. We describe a device for attaching to an ampoule to label a syringe filled from the ampoule, the device comprising: an ampoule-mounting portion for mounting the device to a filled ampoule; a syringe-fitting portion to enable the device to be fitted onto said syringe; and a label holder to hold a label for contents of said ampoule; and wherein one of said syringe and said ampoule is detachable from said device; and wherein said label is configured such that in conjunction with a filling operation of said syringe and detachment of said one of said syringe and said ampoule from said device said syringe is labelled by said label.

Owner:CAMBRIDGE ENTERPRISE LTD

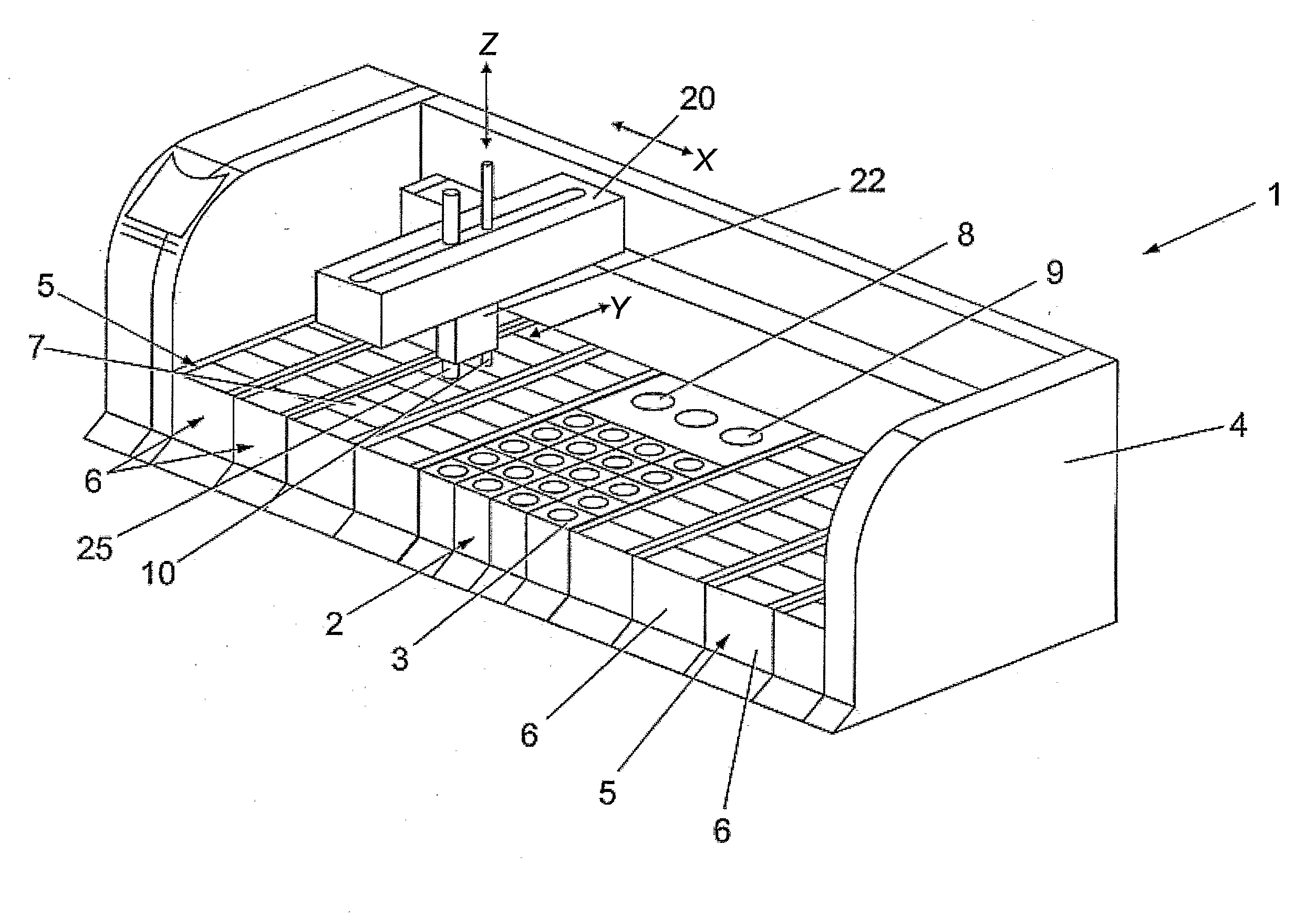

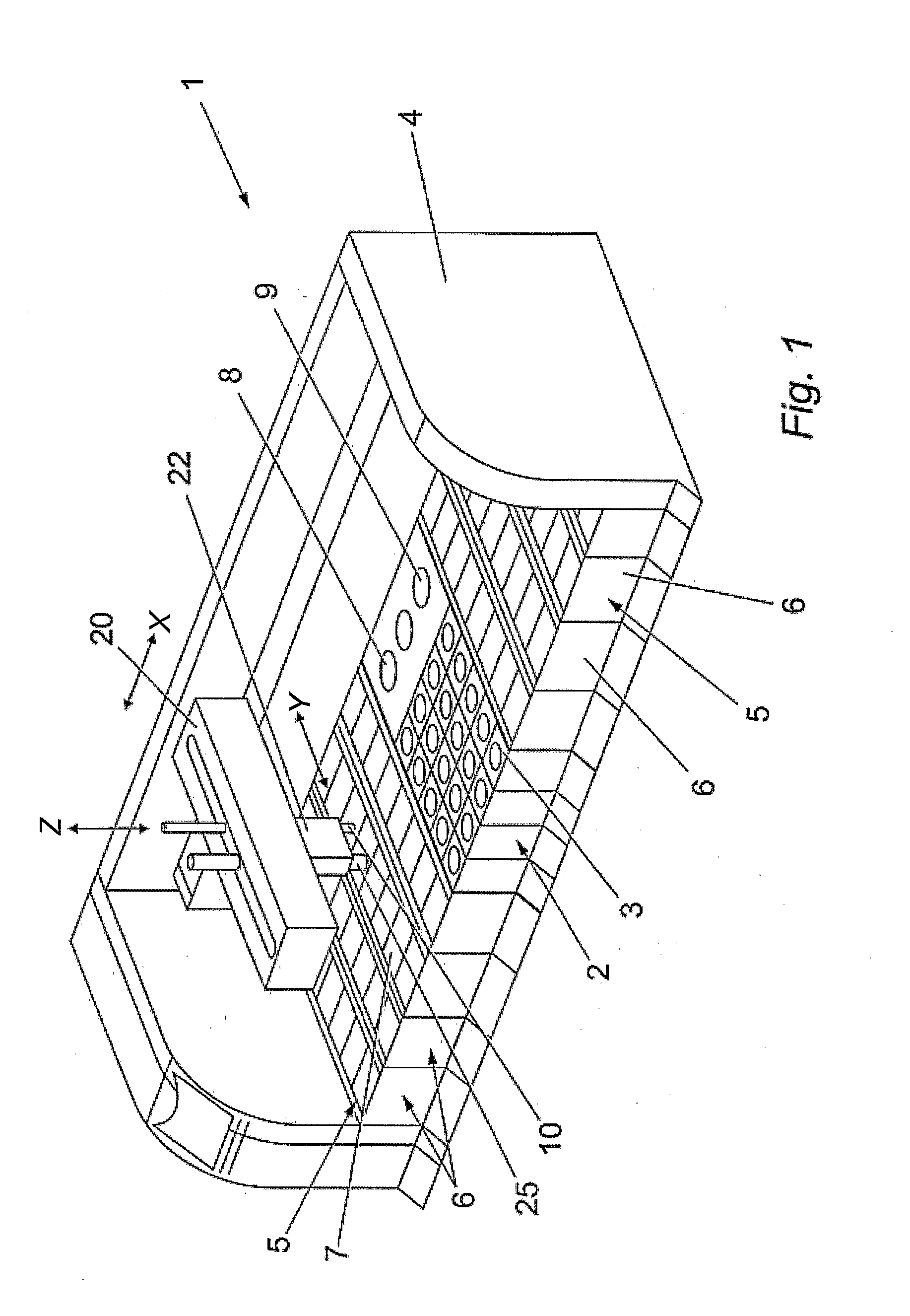

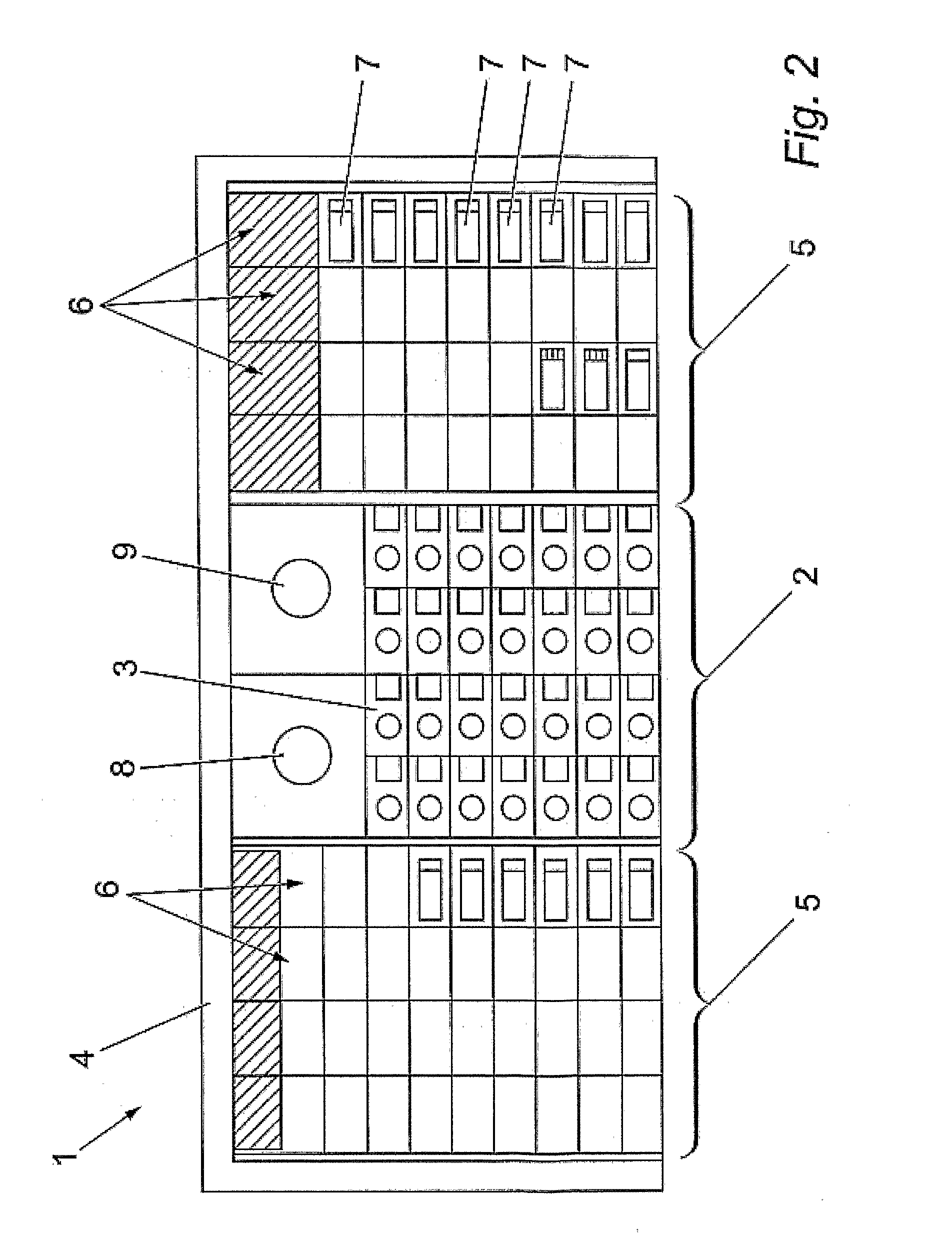

Reagent Delivery System, Dispensing Device and Container for a Biological Staining Apparatus

ActiveUS20090325309A1Allocation is accurateEliminate cross-contaminationAnalysis using chemical indicatorsTesting/calibration apparatusMicroscope slideStaining

The invention concerns reagent delivery system for an apparatus for processing of biological samples arranged on microscope slides, comprising a reagent section having one or more reagent containers; a slide section in which at least one microscope slide is arranged; a probe for dispensing a portion of reagent onto a predetermined microscope slide, and means for handling the probe. The probe comprises a continuous prove tubing element extending through a rigid probe member and connecting the probe tip to a pneumatic pressure regulation device. The reagent containers are adapted for cooperation with the probe tip. In this manner a high though-put and a very low carry over of fluid residues is achieved since there is no assembled parts making up the inside volume of the probe in which the fluid may be retained.

Owner:AGILENT TECH INC

Multi-layered medical device for treating a target site and associated method

Embodiments of the present invention provide medical devices and methods for treating a target site within the body, such as for treating vascular abnormalities. For example, one embodiment provides an occlusion device including an occlusive material having proximal and distal ends and a central axis extending therebetween. The occlusive material has a preset, overlapping configuration including at least three inverted overlapping layers folded over one another, wherein the at least three inverted overlapping layers are aligned with the central axis within about 45 degrees or less and are configured to be separated and disposed within a catheter in a non-overlapping configuration and return to the preset, overlapping configuration when deployed from the catheter.

Owner:ST JUDE MEDICAL CARDILOGY DIV INC

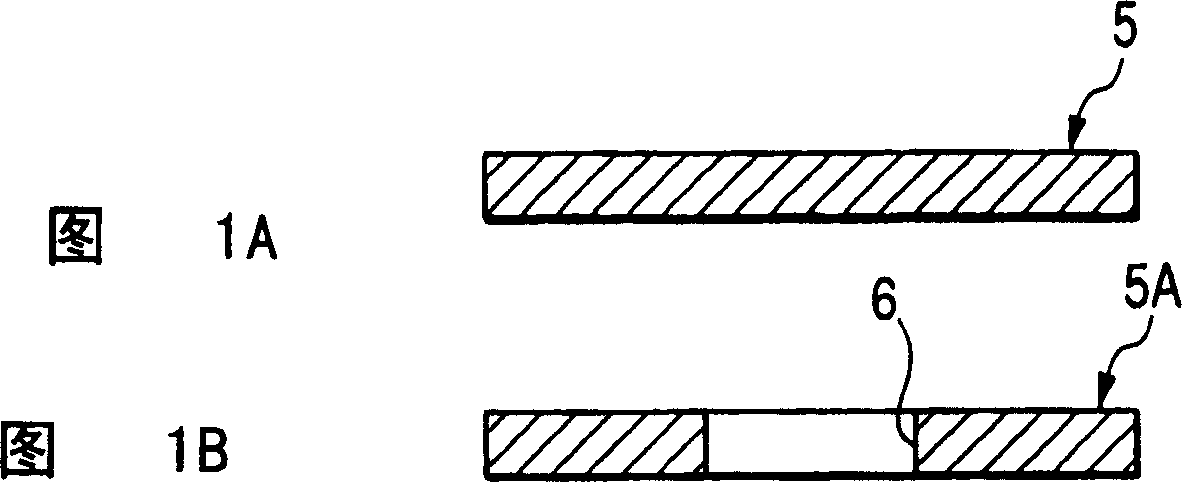

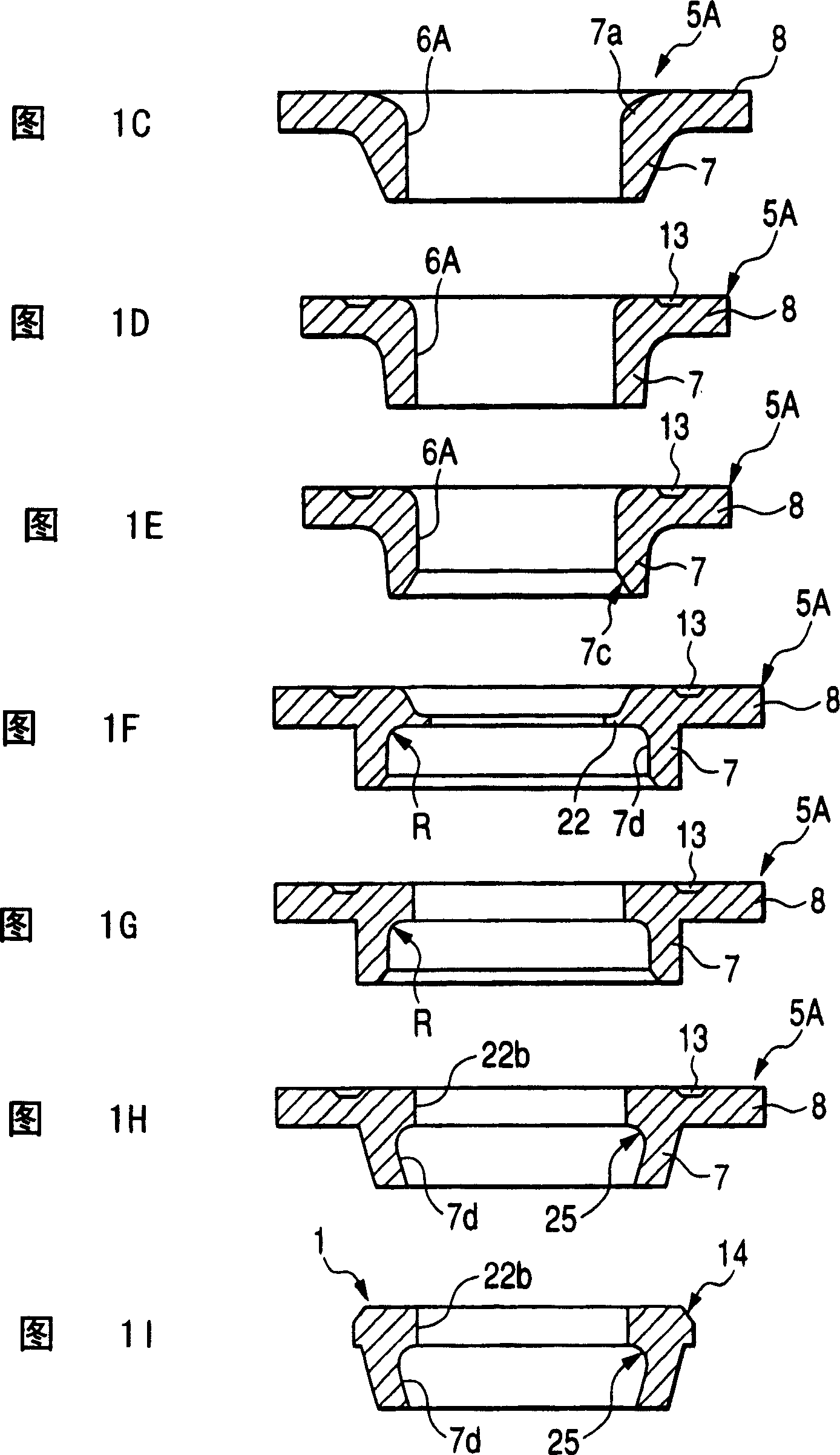

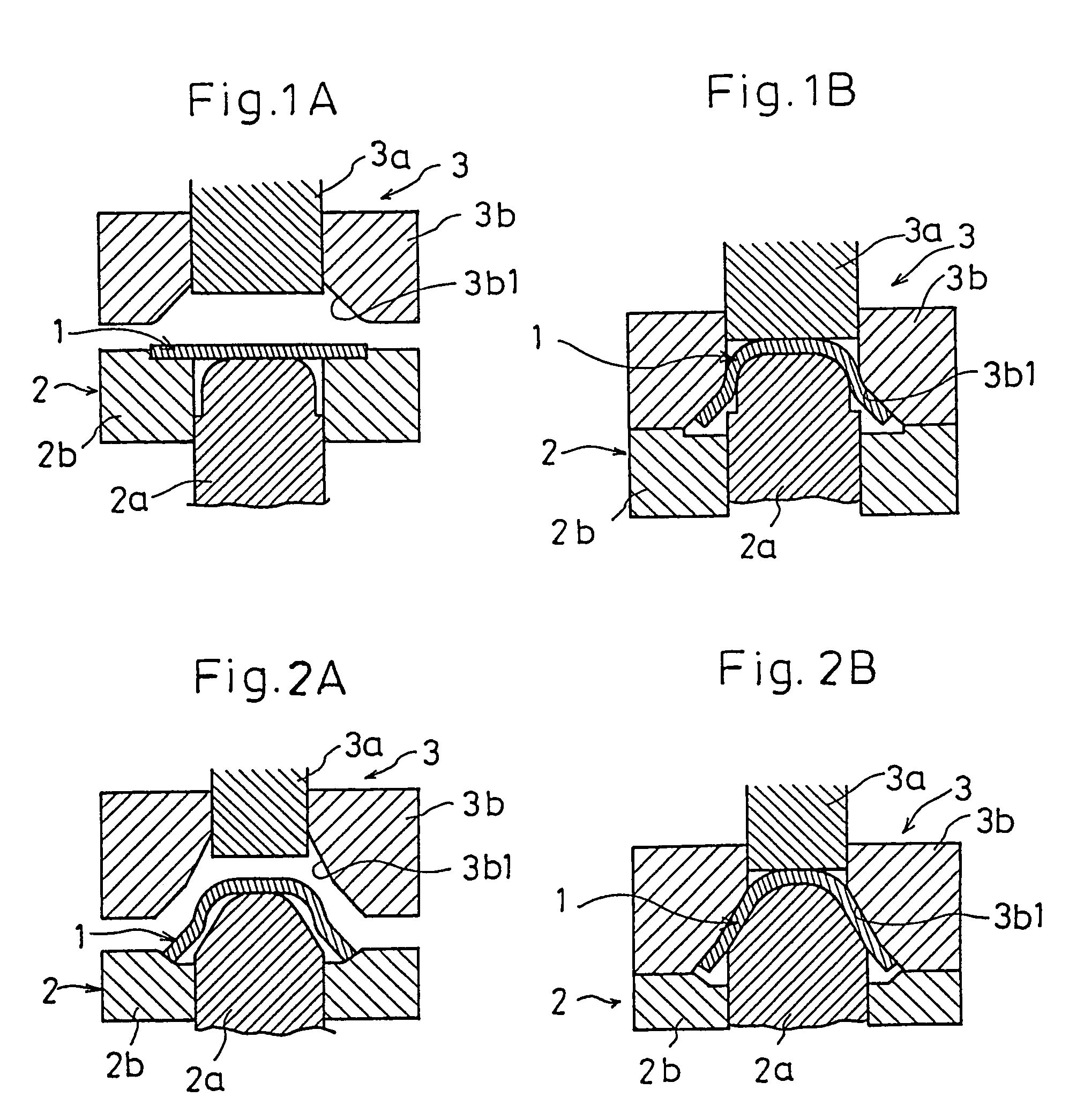

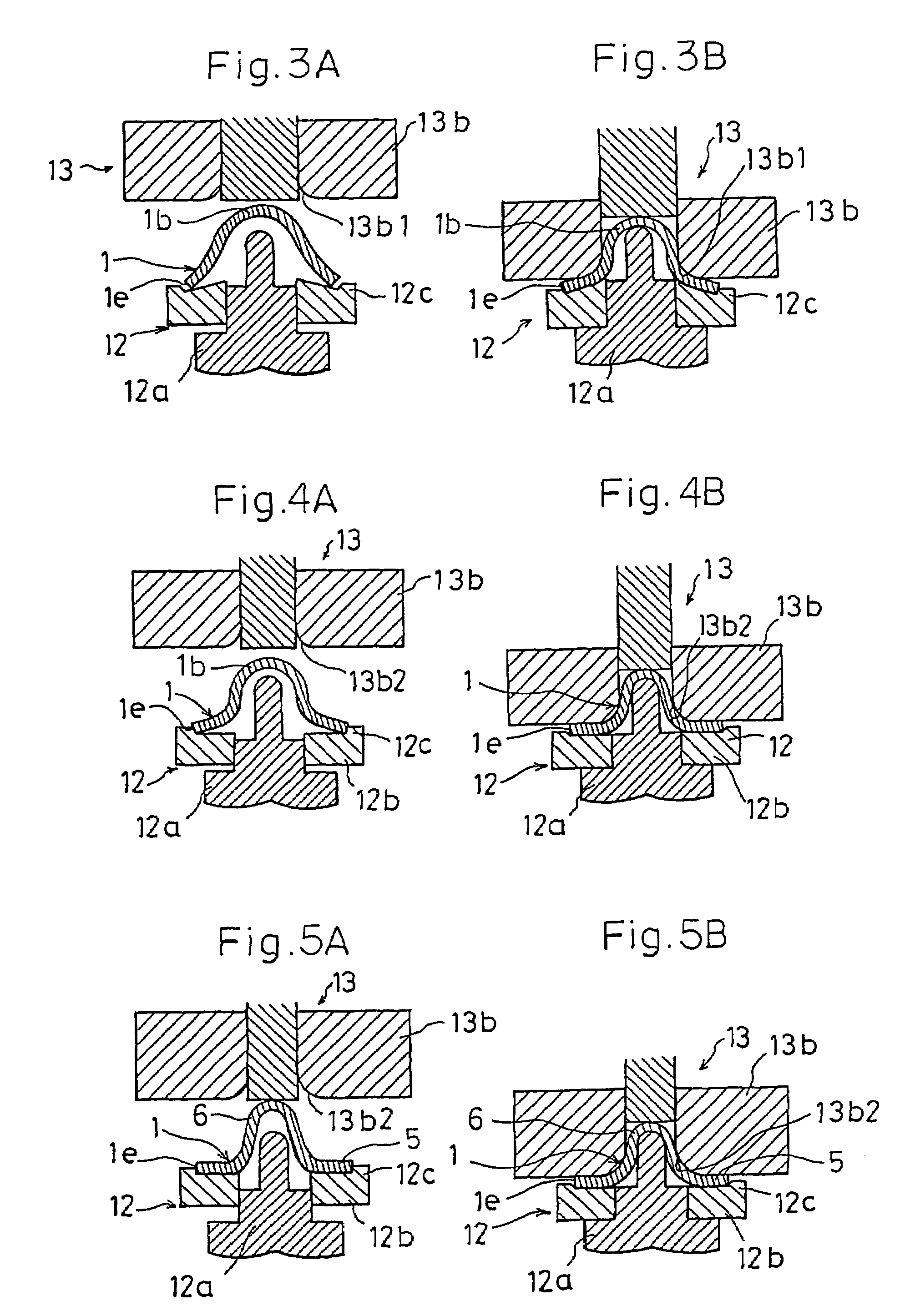

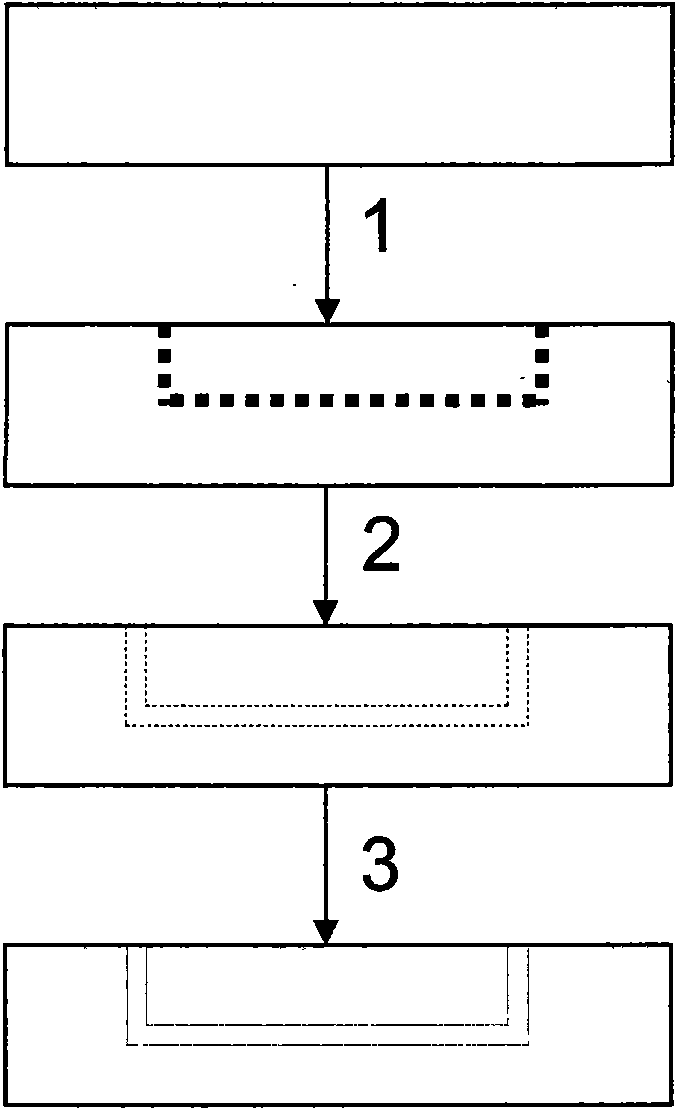

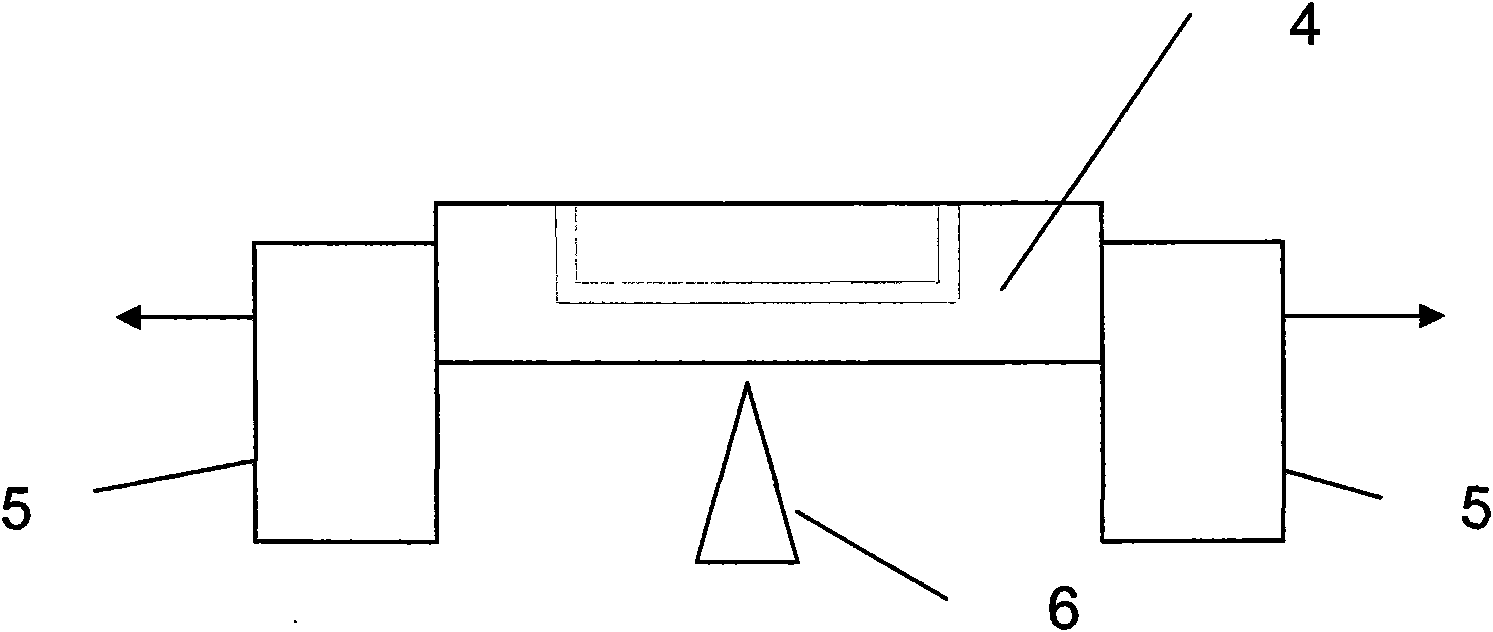

Annular component fabricating method, die for use in such fabricating method and annular component fabricated thereby

A method of fabricating an annular component part 1 is disclosed wherein press forming is carried out to prepare an annular body 5A having a cylindrical wall 7, having a root portion and a distal end, and an annular flange portion 8. The fabricating method comprises expanding an inner circumferential periphery 7d of the cylindrical wall 7 to an inner diameter corresponding to an inner diametric concave portion 25 formed on the inner circumferential periphery 7d and squeezing the cylindrical wall 7 in a tapered profile such that the inner diameter 7d of the cylindrical wall 7 gradually decreases. During inner diametric expanding operation, an annular shoulder 7e is formed on the inner circumferential periphery 7d of the cylindrical wall 7 and plays a role as an undercut of the annular component 1.

Owner:DENSO CORP

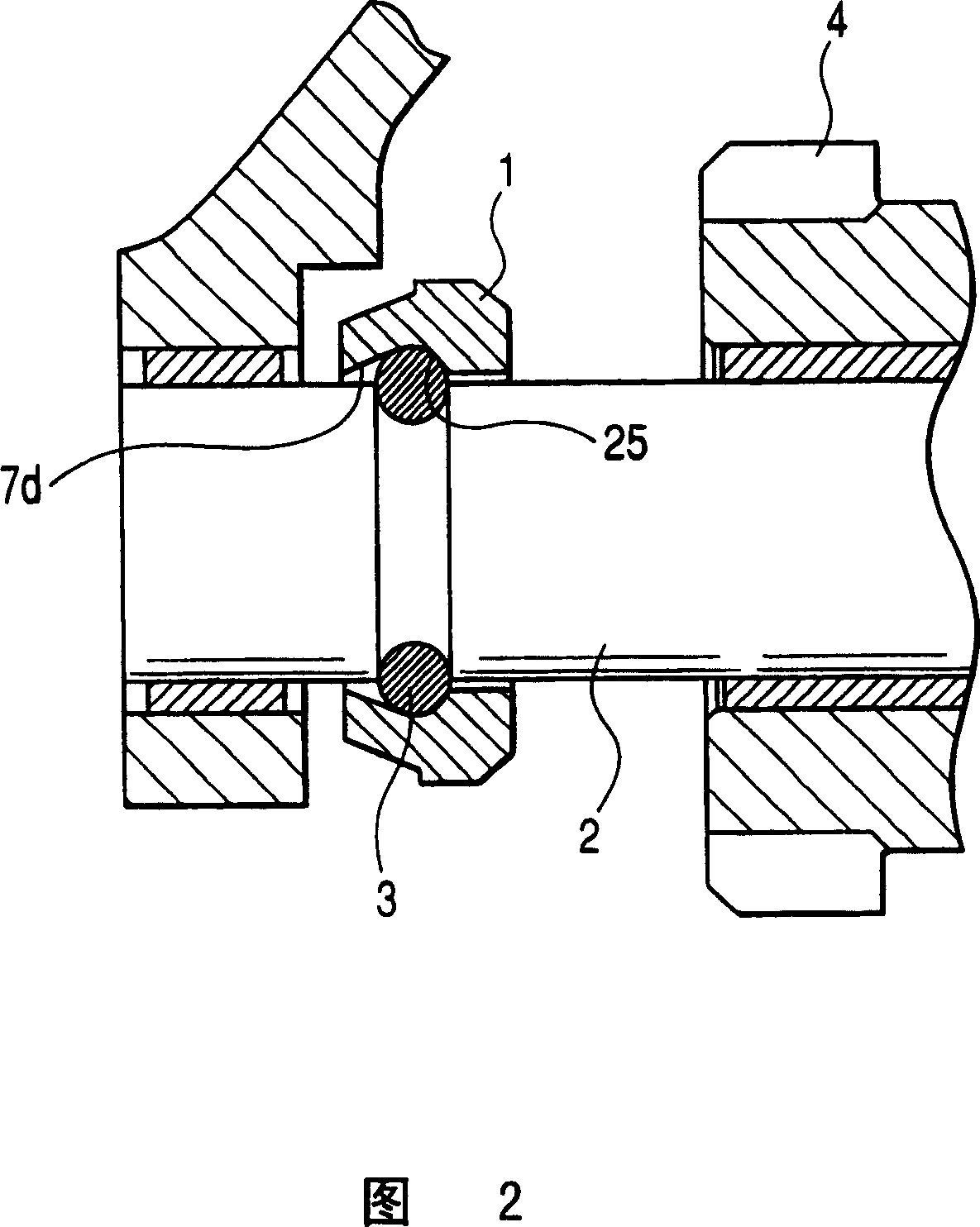

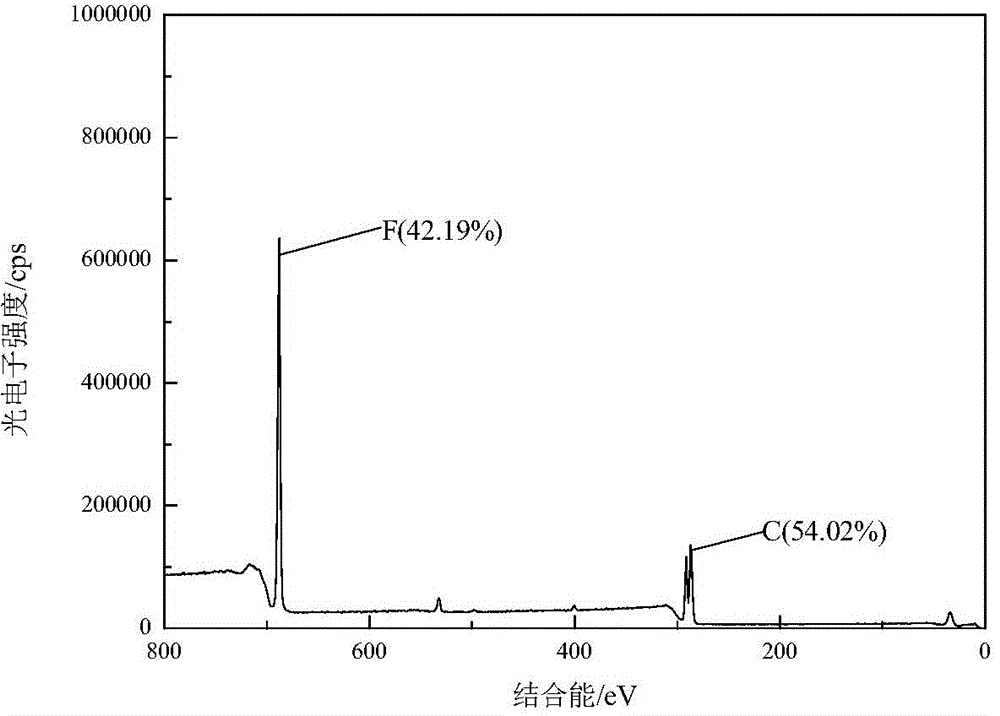

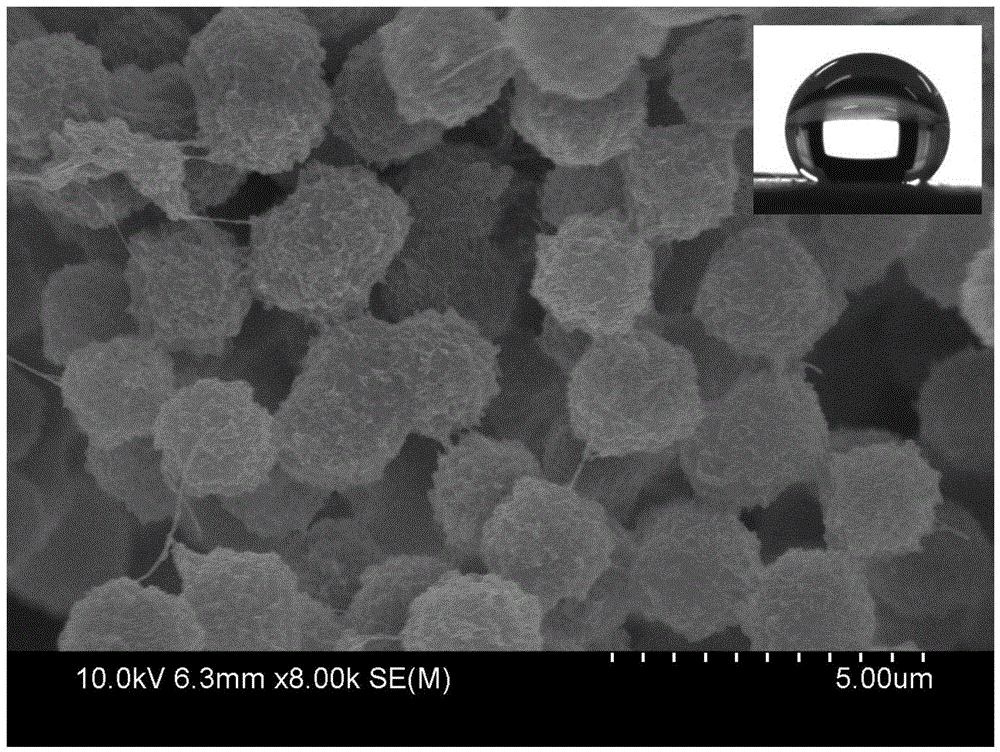

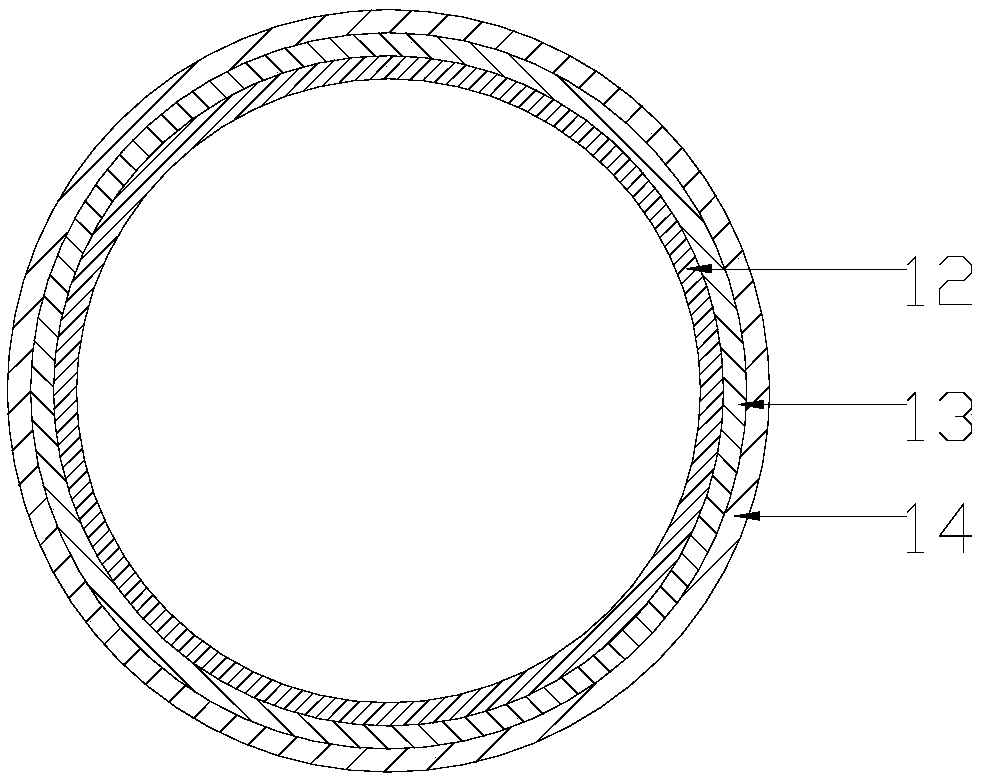

Production formula and method of PVDF (polyvinylidene fluoride)/carbon nano-tube super-hydrophobic film

InactiveCN104826503AImprove and modify pore structureImprove and modify distributionSemi-permeable membranesFiberHollow fibre

The invention discloses a production formula and method of a PVDF (polyvinylidene fluoride) / carbon nano-tube super-hydrophobic membrane. The formula includes, by weight, 5% to 30% of PVDF, 0.005% to 5% of carbon nano-tubes, and 67% to 91% of solvent. The production method includes: evenly dispersing the carbon nano-tubes in the solvent, adding the PVDF, and performing high-speed stirring at 50 DEG C to 100 DEG C to obtain casting solution; producing a flat membrane by scraping, or producing hollow fibers to obtain a primary membrane via a hollow spinneret; solidifying the primary membrane in the non-polar steam environment, and removing solvent residue by deionizing soaking so as to obtain the PVDF / carbon nano-tube super-hydrophobic membrane. The membrane produced by the formula and the method is rich in CNTs on surface and has super-hydrophobic surface and excellent permeability; the method is simple, and operability is high.

Owner:TIANJIN POLYTECHNIC UNIV

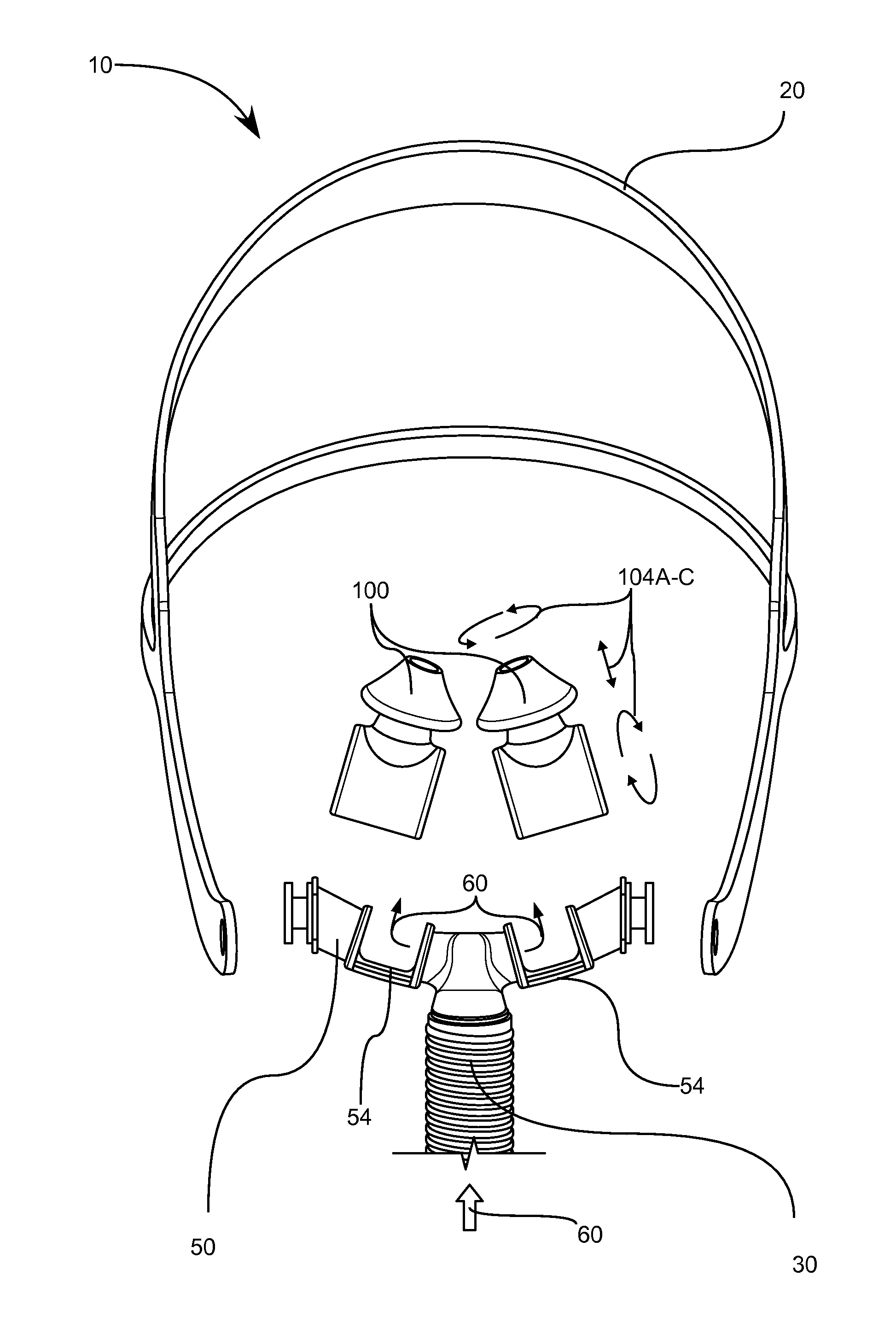

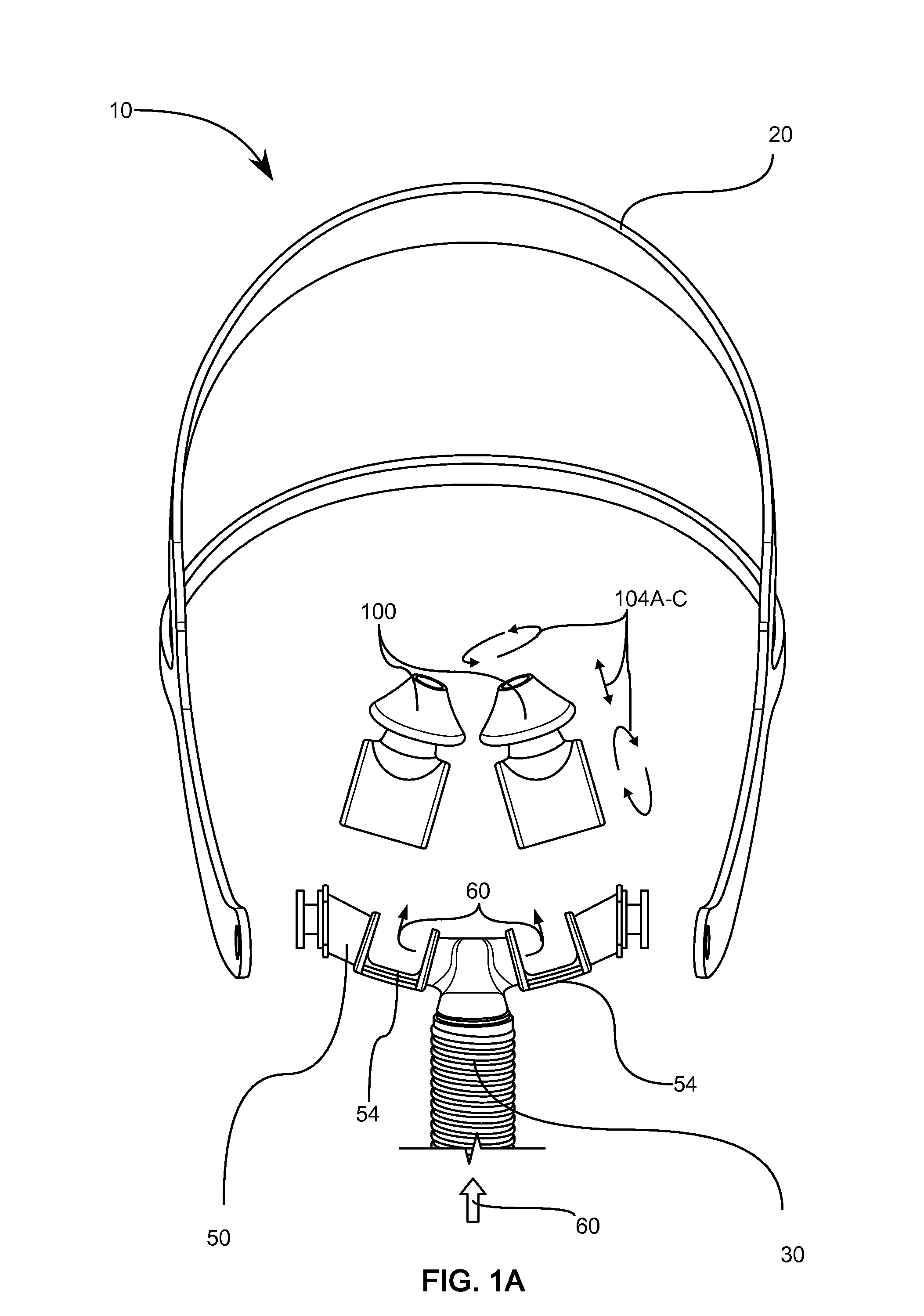

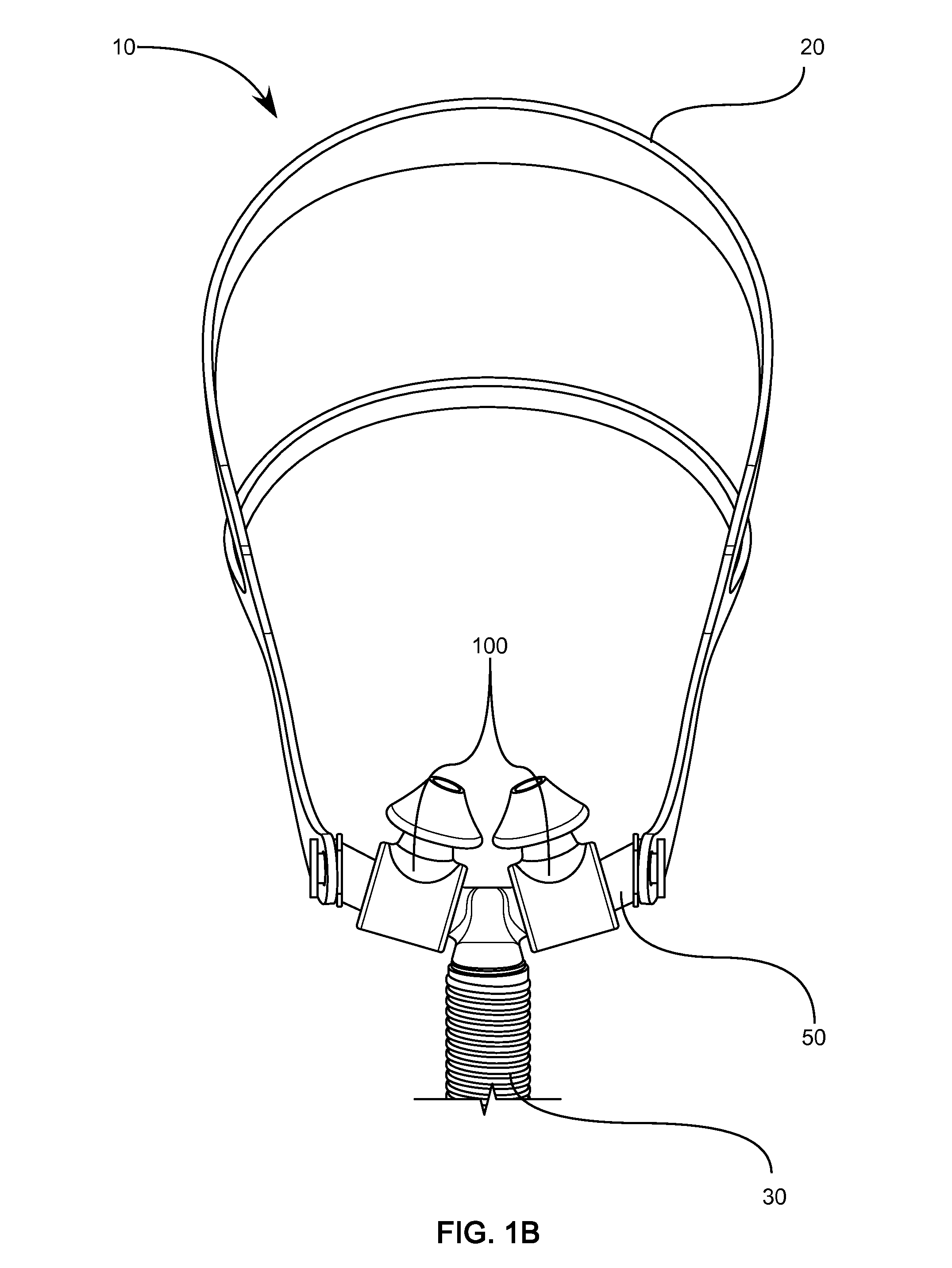

Adjustable positive airway pressure or ventilation system

ActiveUS20160015921A1Improve comfortReduce hardnessRespiratory masksBreathing masksPositive airway pressurePositive pressure

The present disclosure relates to a comfortable and adjustable nasal pillow configured to be part of a nasal pillow system that is part of a mask system used with a ventilation or PAP device. The nasal pillows are configured to have multiple degrees of freedom of rotation.

Owner:HUMAN DESIGN MEDICAL

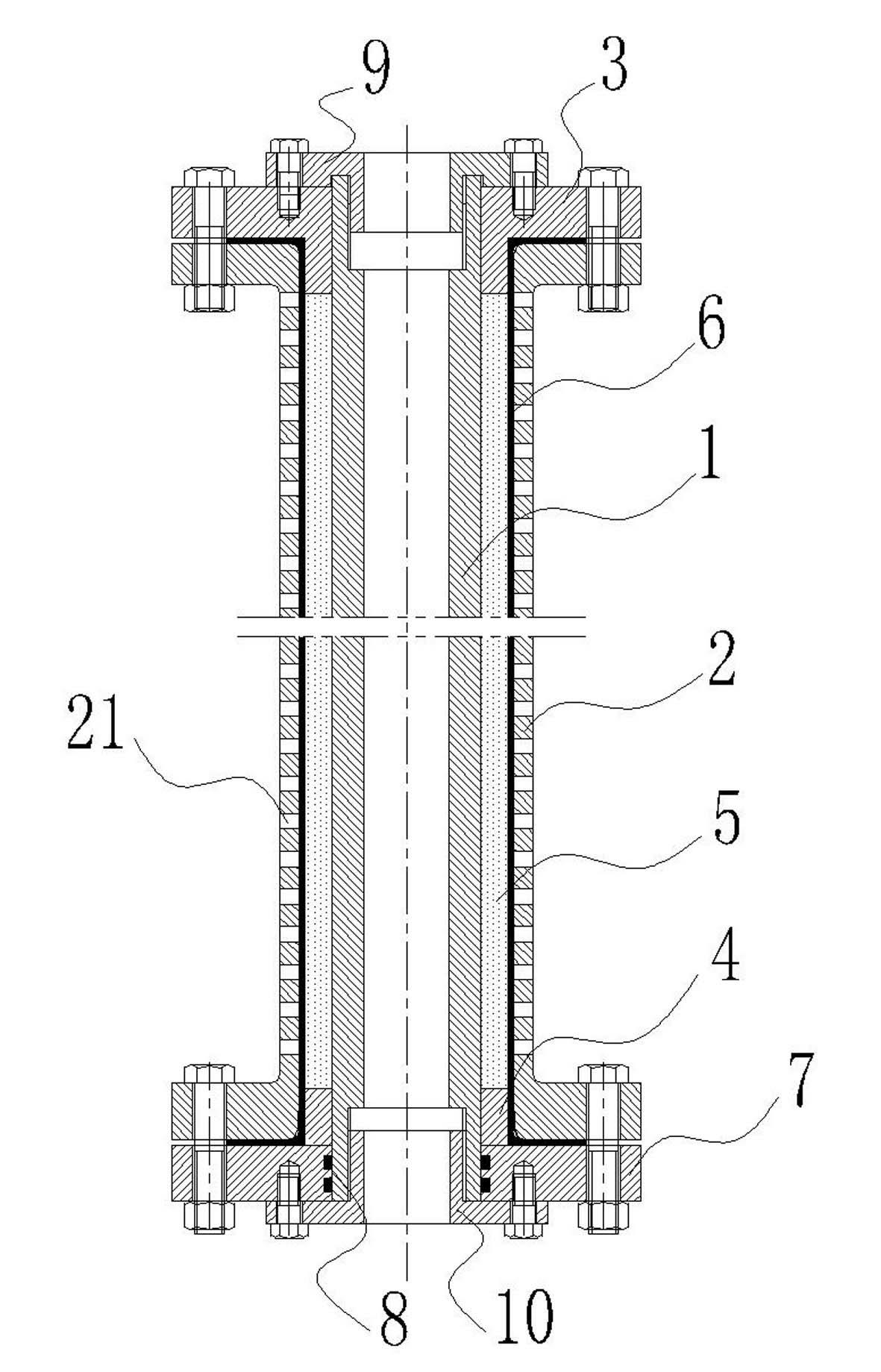

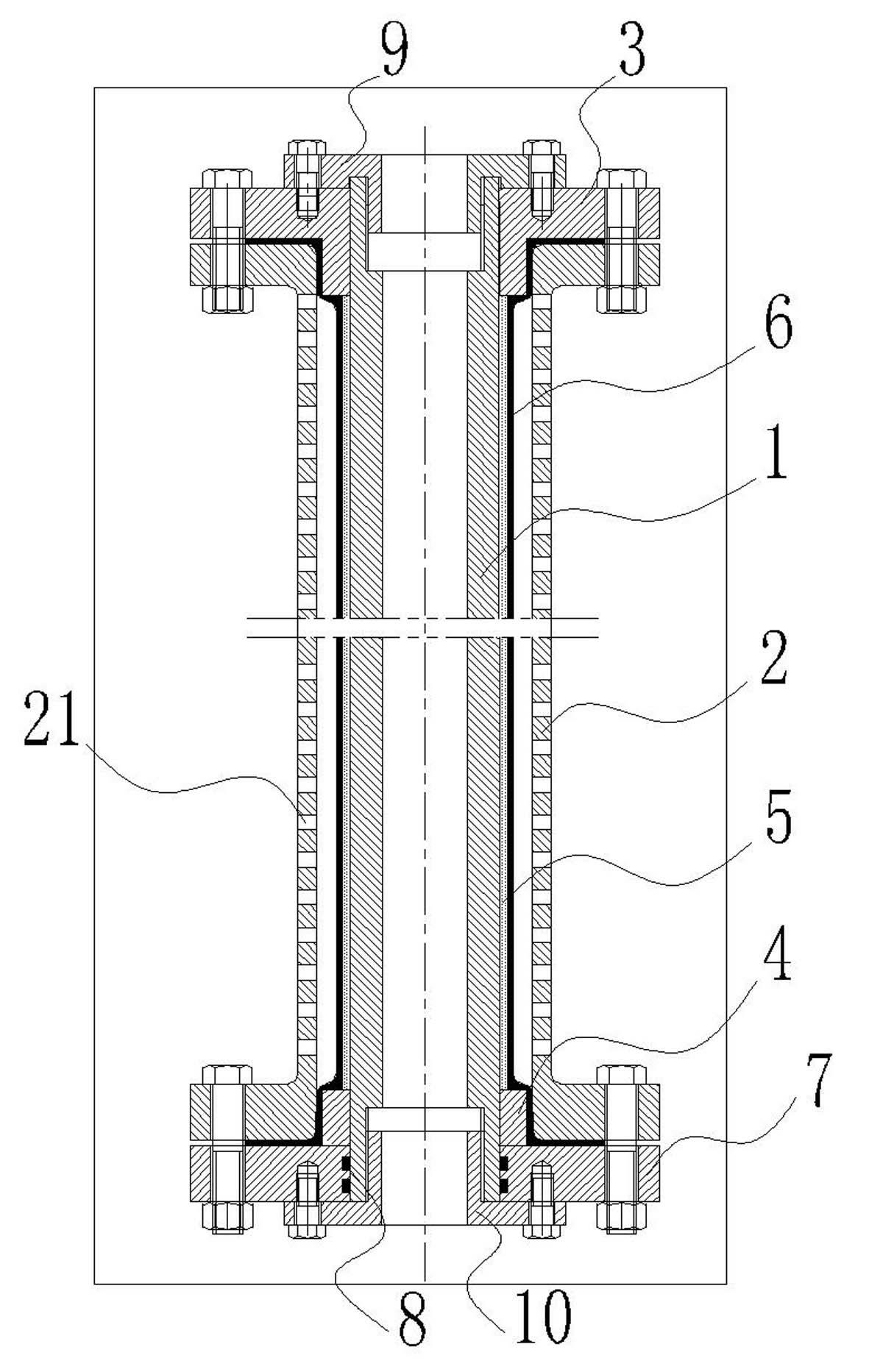

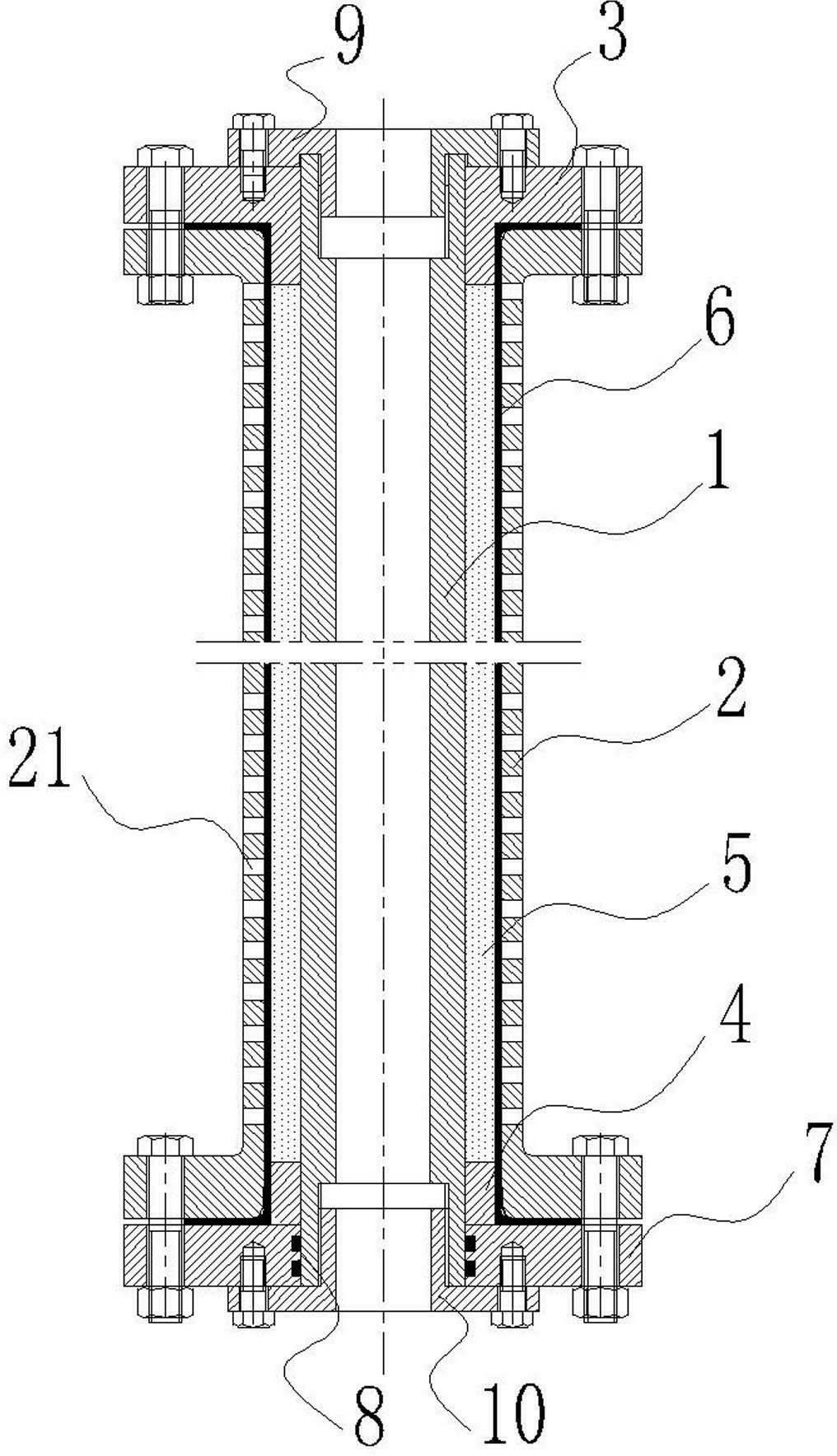

Polytetrafluoroethylene isostatic pressure molding device and pipeline lining method by aid of same

ActiveCN102632578AImprove product qualityHigh densityTubular articlesMoulding deviceComposite material

The invention discloses a lining molding device used on chemical equipment and a lining method, and provides a polytetrafluoroethylene isostatic pressure molding device and a lining method. The polytetrafluoroethylene isostatic pressure molding device is smart in conception and fine in performance, a pipe molded by the aid of the polytetrafluoroethylene isostatic pressure molding device is high in strength, and the polytetrafluoroethylene pipe can be tightly lined in a pipeline by the aid of the lining method, and the technical problems of low polytetrafluoroethylene lining density, poor tensile strength and permeation resistance and the like due to insufficient molding pressure of an existing polytetrafluoroethylene molded pipe of the prior are solved. The method includes integrally placing a mold below the liquid level of a high-pressure cabin of an isostatic pressure machine; pressurizing the high-pressure cabin to process pressure and leading a polytetrafluoroethylene blank to be in cold press molding; adopting an isostatic pressure process; sintering a blank part released from the mold, drawing down the blank part, and placing the blank part into the pipeline; realizing memory rebounding of a polytetrafluoroethylene pipe blank after heating; and leading the polytetrafluoroethylene pipe lining to be lined in the pipeline. The lining is fine in high-temperature resistance and high-pressure resistance, and full-vacuum service requirements under the condition with high temperature of 232 DEG C are met.

Owner:四达氟塑股份有限公司

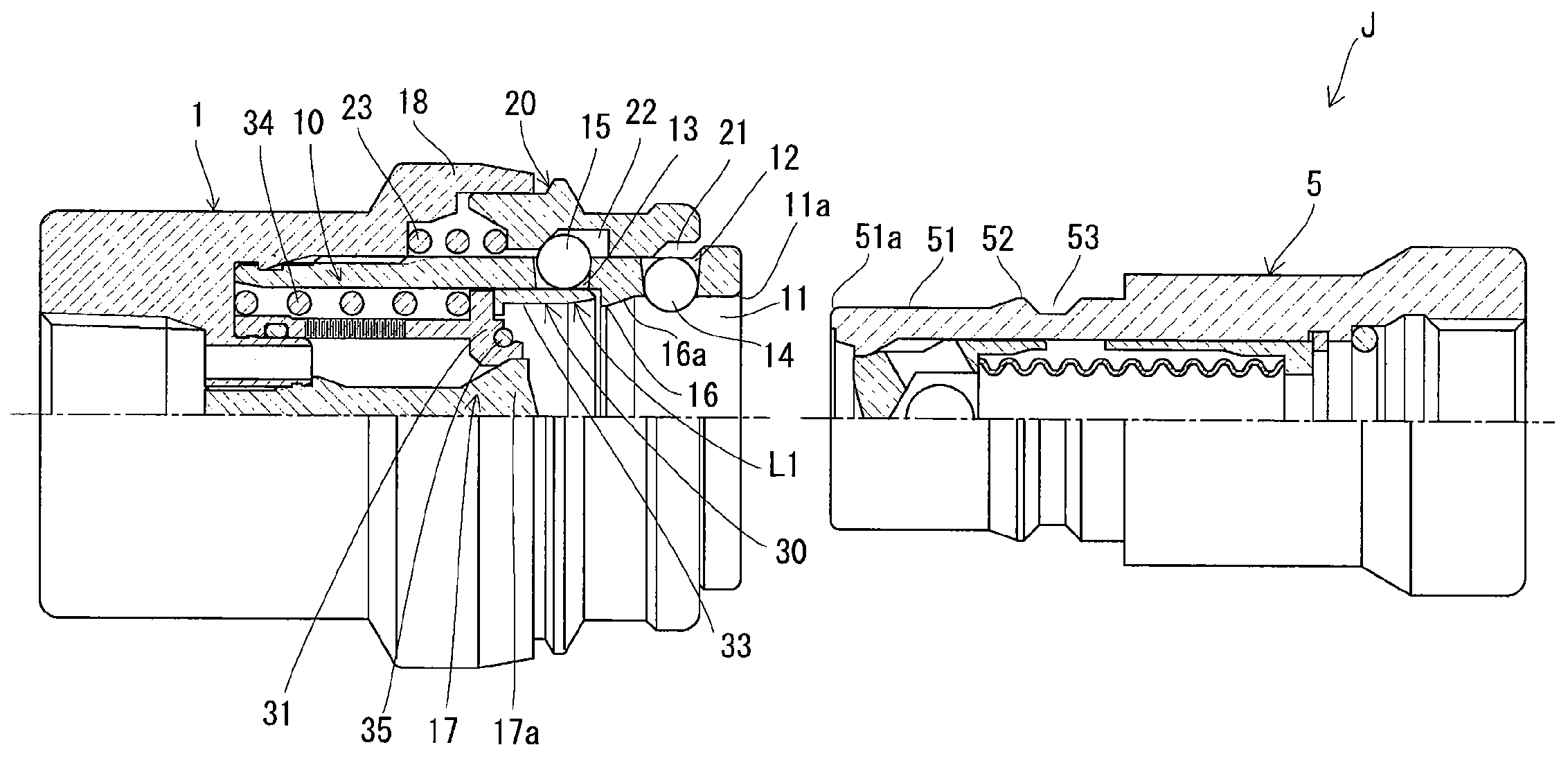

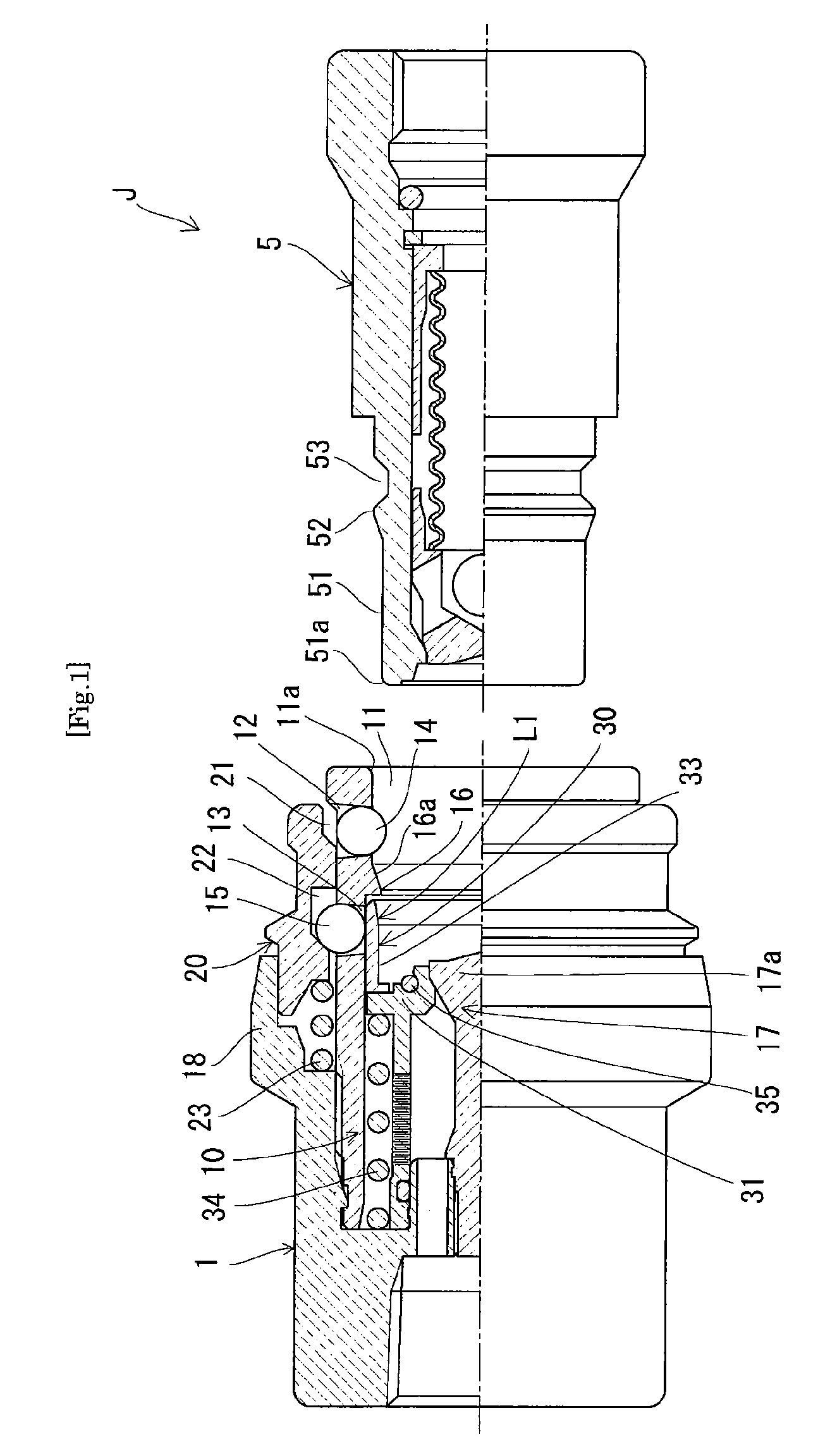

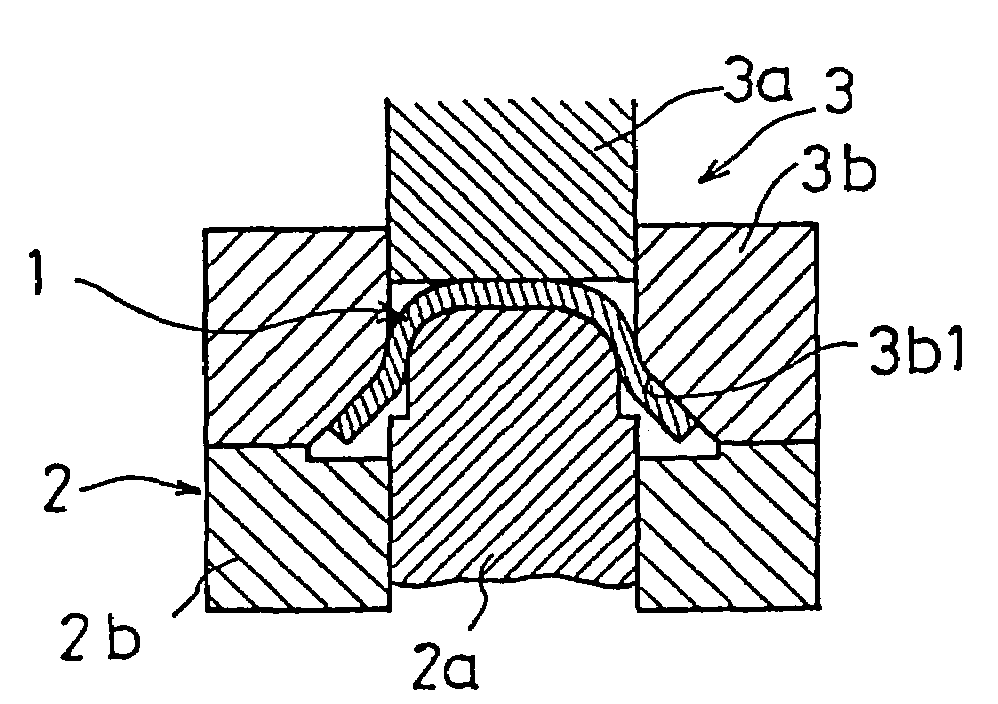

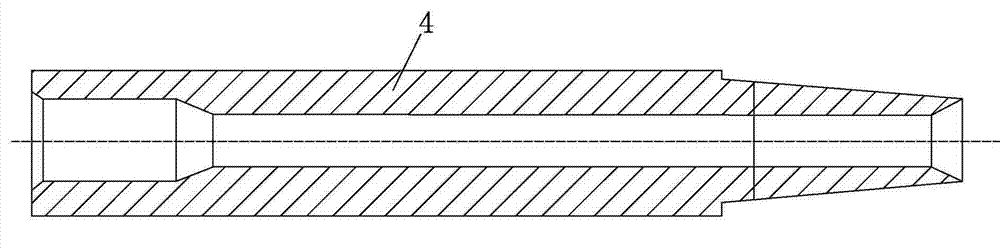

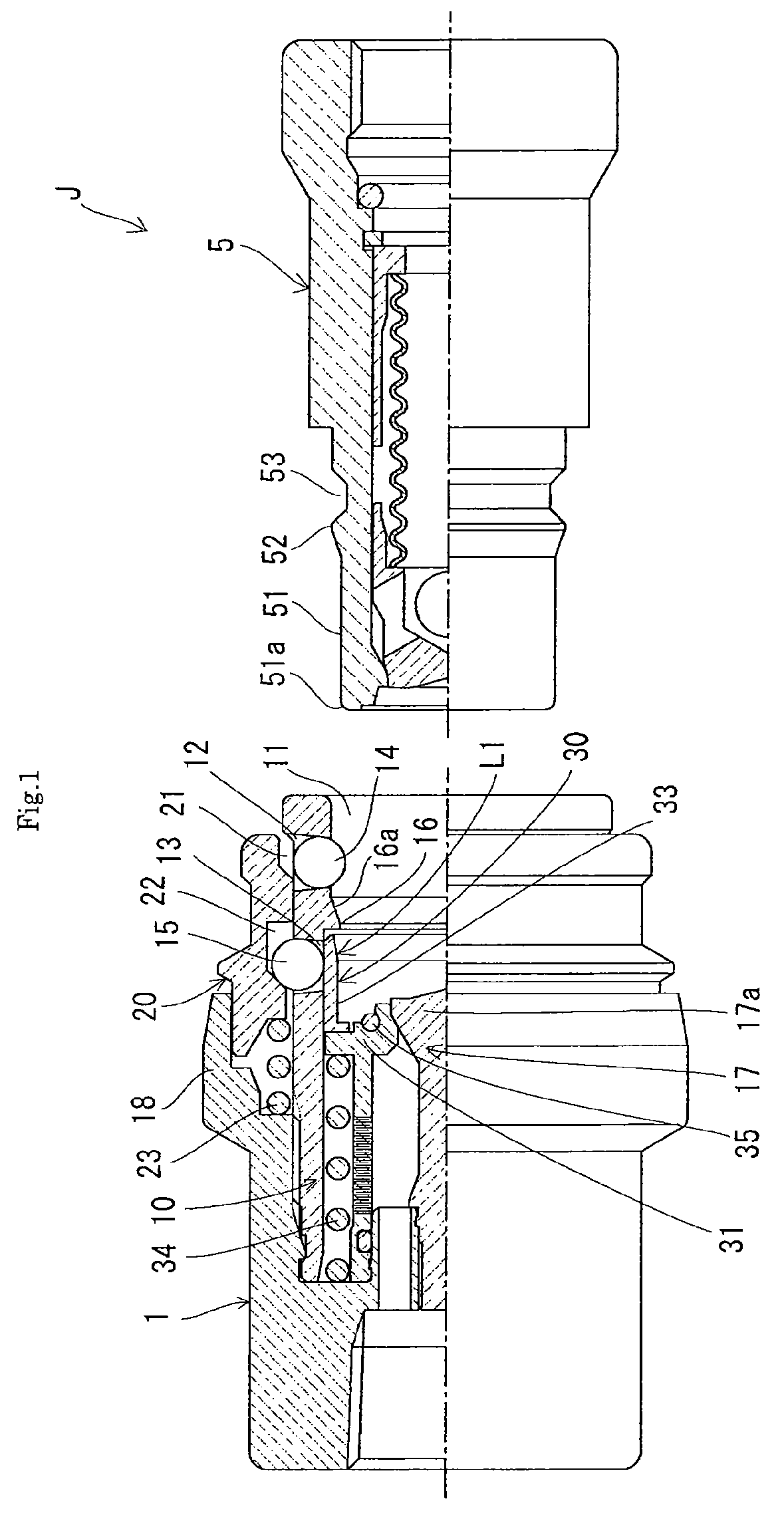

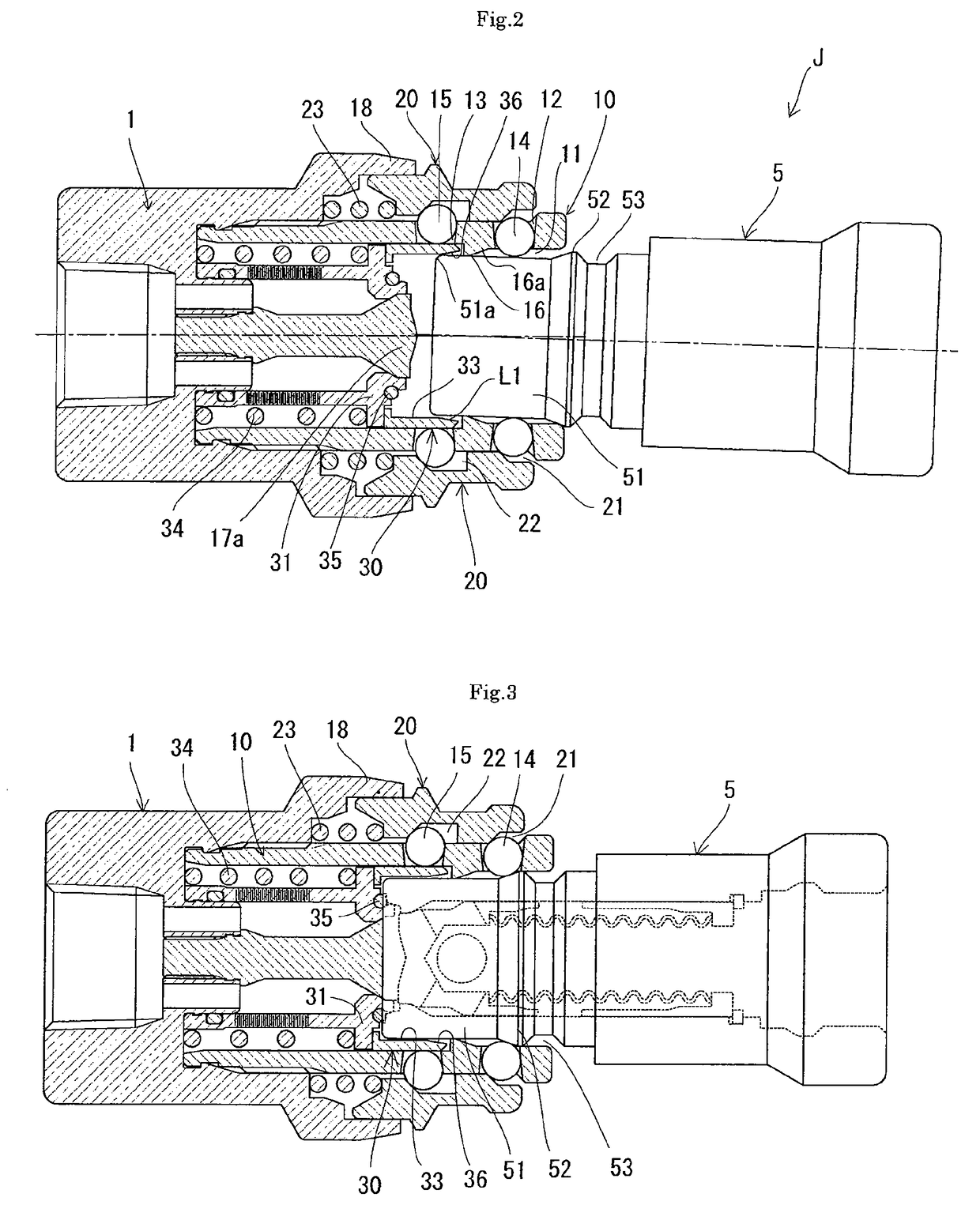

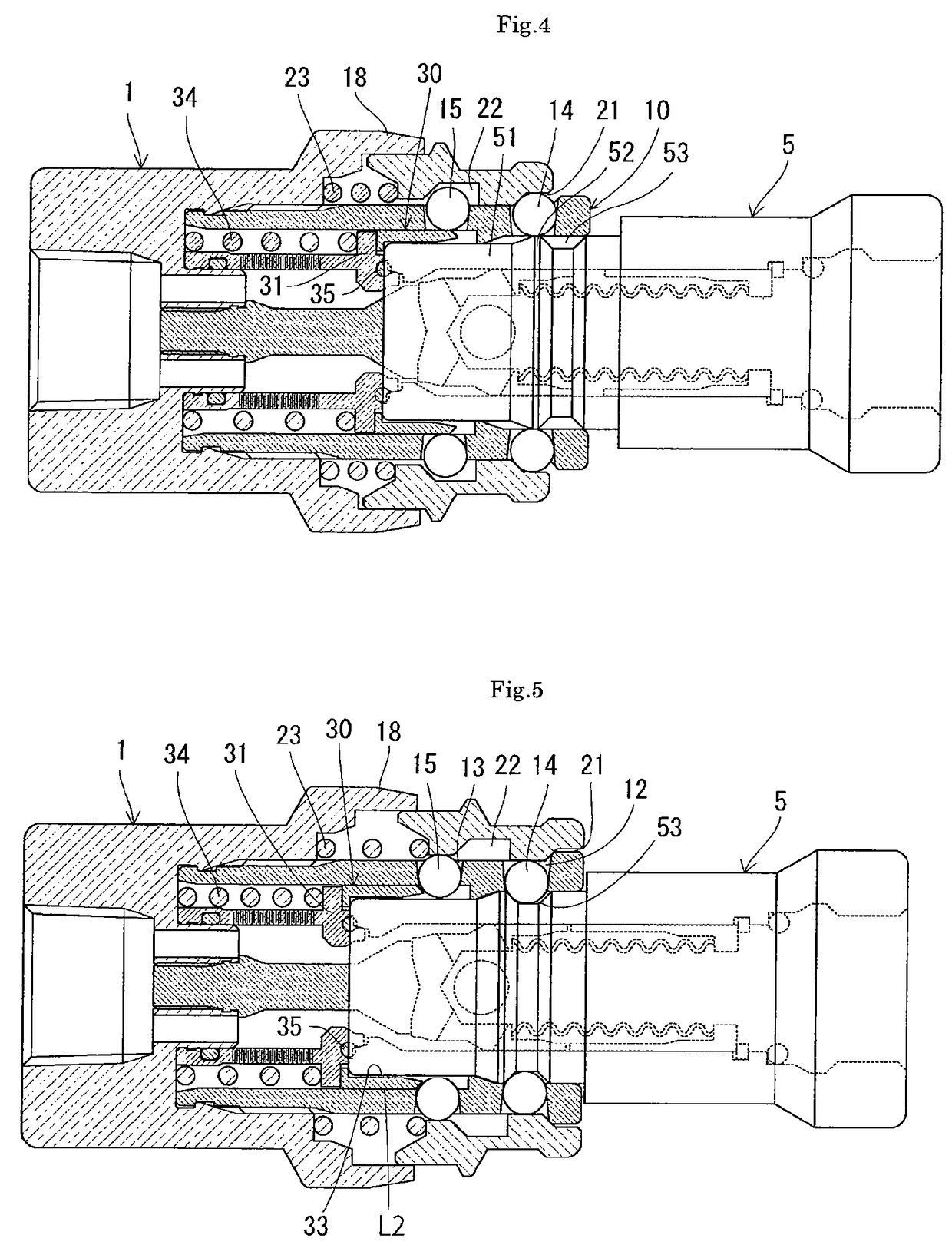

Socket for pipe joint and pipe joint

Owner:NITTO KOHKI CO LTD

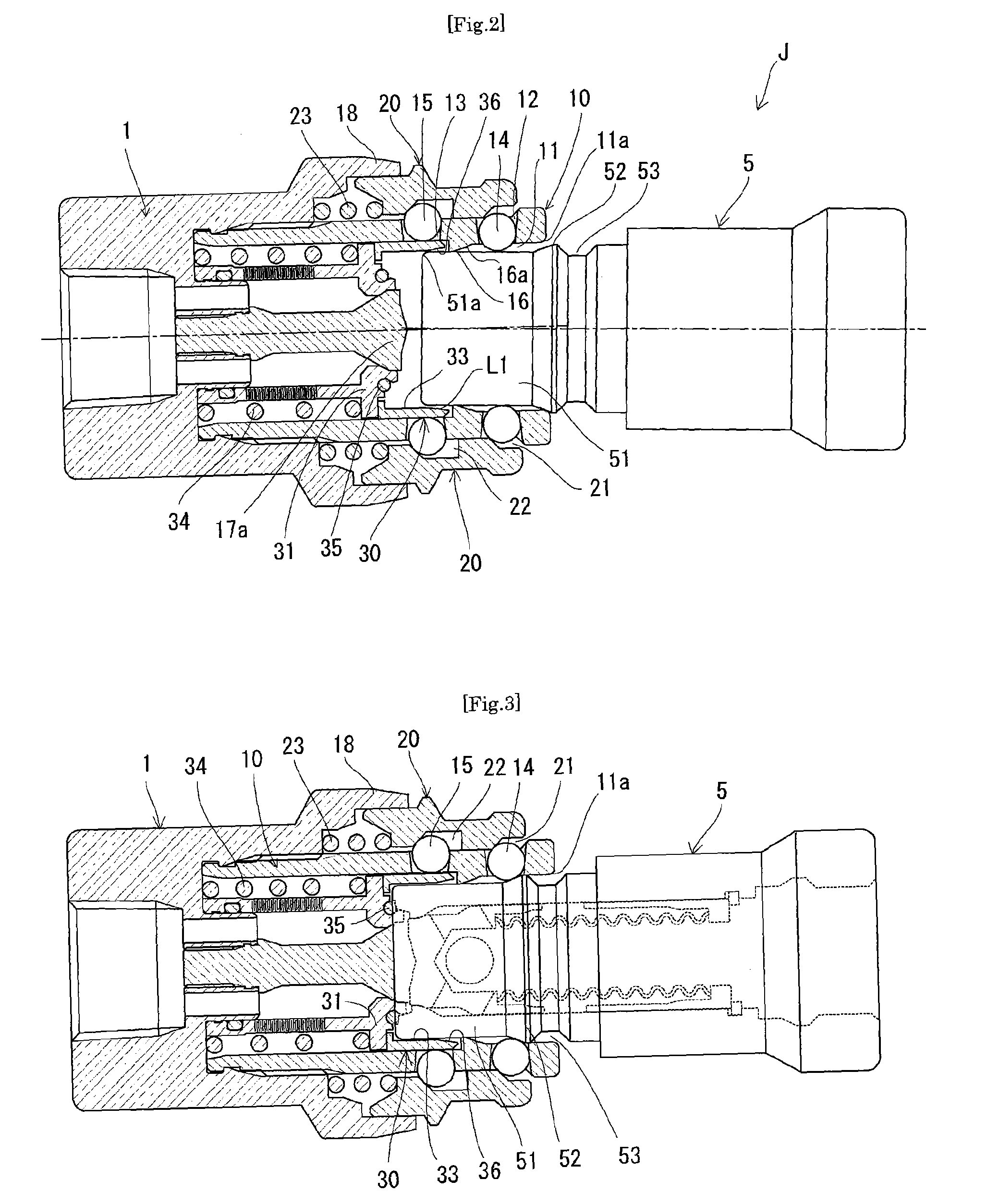

Method for cutting ultra-thin silicon wafer by superfine steel wire

The invention relates to a method for cutting ultra-thin silicon wafer by a superfine steel wire. The method comprises the following steps of: (1) forming slots in a man shaft; (2) sticking bars; (3) preparing a cooling liquid; (4) cutting; (5) unloading; (6) degumming and cleaning; and (7) detecting; the cooling liquid prepared in the step (3) is pure water and a water-based cutting fluid with concentration being 0.6%-2.0%; and during cutting in the step (4), cutting steel wires are 60 [mu]m diamond wires, diamond particles are particles with diameter being 6-8 [mu]m, tension is set to be 7-9 N, and slot pitch of the main shaft is 0.19-0.210 mm. According to the method, single crystal slicing yield is further reduced, slicing thickness is reduced, silicon loss is reduced and processing cost is reduced; and meanwhile, a wire braking rate can be reduced, yield is increased, and wire doubling is avoided.

Owner:SHANGHAI SHENHE THERMO MAGNETICS ELECTRONICS CO LTD

Surge protected coaxial termination

InactiveUS6944005B2Avoid damageAvoid reflectionsTwo pole connectionsCoupling device detailsCapacitanceElectrical conductor

A surge-protected coaxial termination includes a metallic outer body, a center conductor extending through a central bore of the outer body, and a spark gap created therebetween to discharge high-voltage power surges. A pair of dielectric support insulators support the center conductor on opposite sides of the spark gap. High impedance inductive zones surround the spark gap to form a T-network low pass filter that nullifies the additional capacitance of the spark gap. An axial, carbon composition resistor is disposed inside the outer body, and inside the dielectric insulator to absorb the RF signal, and prevent its reflection. The resistor extends co-axially with the center conductor, and one end of the resistor is electrically coupled thereto. A blocking chip capacitor extends radially from the opposite end of the resistor to the grounded outer body. The opposing second end of the resistive component may protrude from the metallic outer body and related dielectric material; the DC blocking capacitor preferably extends radially between the second end of the resistive component and the metallic outer body, or to a grounding post secured thereto.

Owner:PPC BROADBAND INC

Method of producing a rotary member made of a metallic plate

InactiveUS7490503B1Reduce thicknessDimensional precision can be increasedShaft and bearingsPortable liftingMechanical engineeringEngineering

The method according to the present invention comprises: a first curving step of curving a plate-like metallic blank (1) such that the blank (1) is convexed; a bending step of bending, with the outer peripheral edge portion (1e) of the blank (1) restrained from radially outwardly extending, the resulting arcuate portion (1b) of the curved blank (1) in the direction opposite to the convex direction thereof, so that a boss (6) is formed; and a second curving step of pushing the inner peripheral portion of a flat portion (5) of the blank (1) in the direction opposite to the boss projecting direction. Through the steps above-mentioned, the blank (1) is provided at the center thereof with the case-like boss (6) projecting in one direction from one lateral side of the blank (1) and at the outer periphery thereof with a peripheral wall (7) projecting in the same direction in which the boss (6) projects. Thus, with a small press machine, there can be securely formed, with high precision, a boss having a desired diameter and a desired projecting height, without the original thickness of the blank (1) decreased so much in the course of production steps.

Owner:KANEMITSU KK

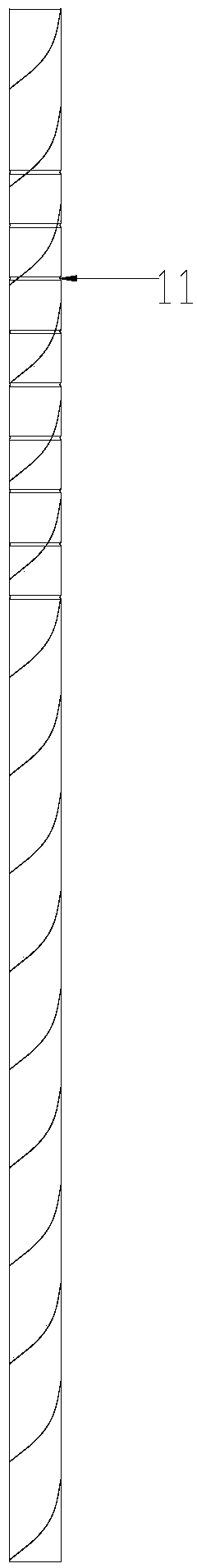

Paper straw with 90-degree elbow

PendingCN109431212ANot softenedFully bentSpecial paperPaper/cardboard articlesPulp and paper industryDrinking straw

The invention discloses a paper straw with a 90-degree elbow. The straw is formed by spirally overlapping and forming a paper strip body and cutting both ends, one end of the straw is uniformly pressed with 8-12 annular grooves, the paper strip body is composed of a first paper layer, a second paper layer and a third paper layer, it is ensured that the straw is not softened during use, a pluralityof the annular grooves with certain spacing are formed so that the straw fully bends to 90 degrees, the inner diameter of a straw bending zone is not significantly reduced, and the straw can be fullydegraded after use, do not cause white pollution, have low pressure on the environment, and can effectively replace plastic straws used in the market.

Owner:MENGTE COMMODITY CO LTD

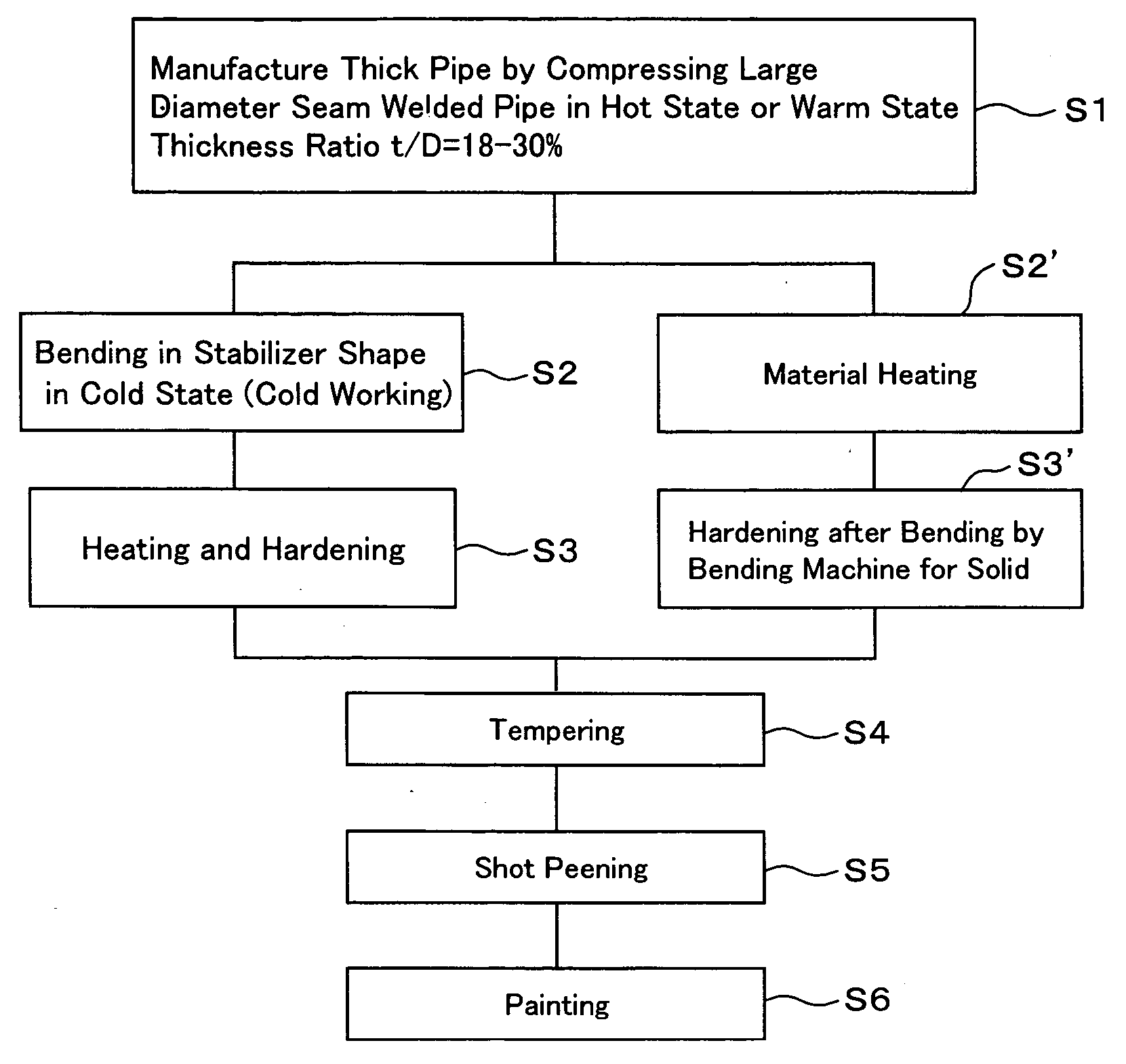

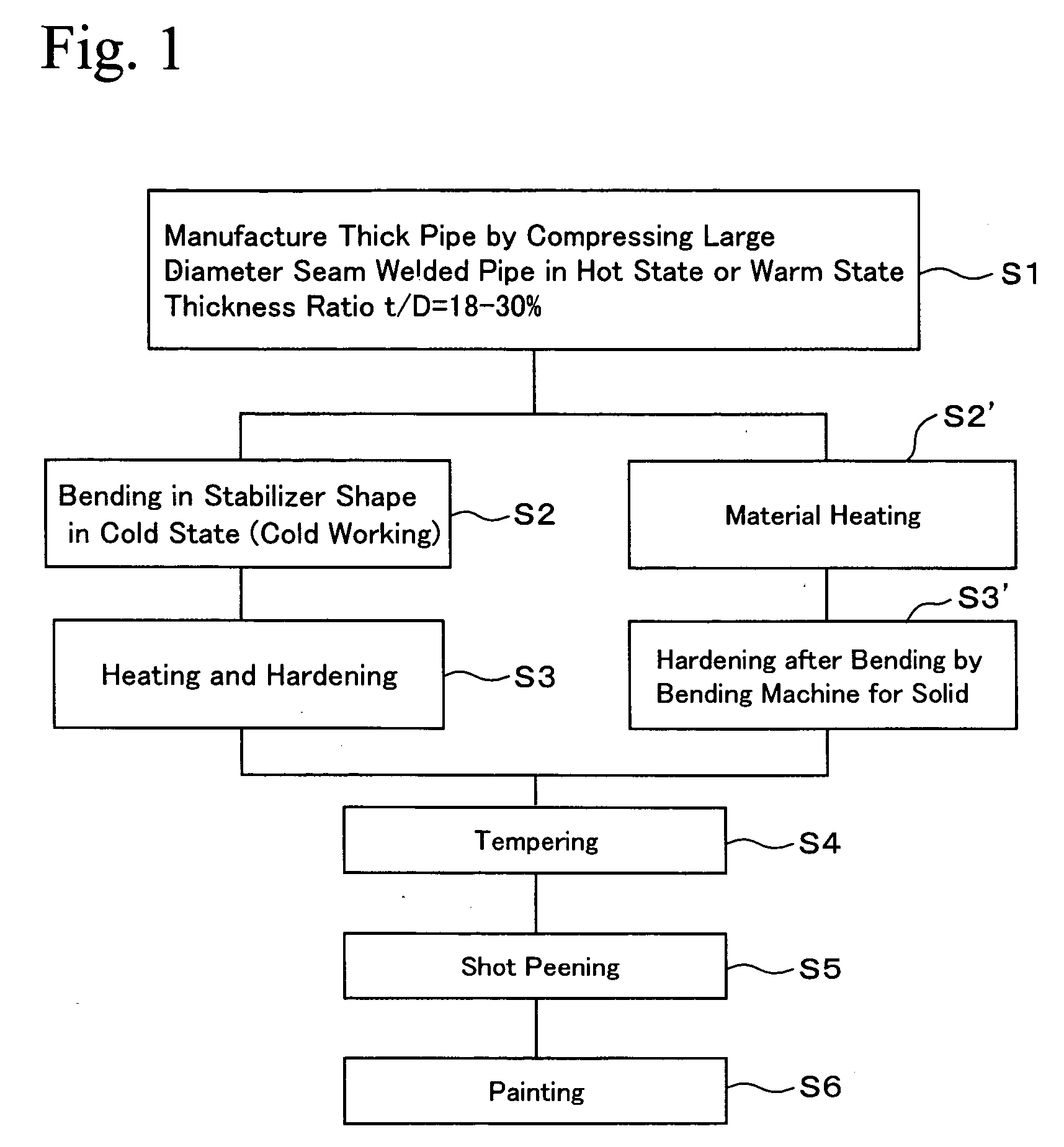

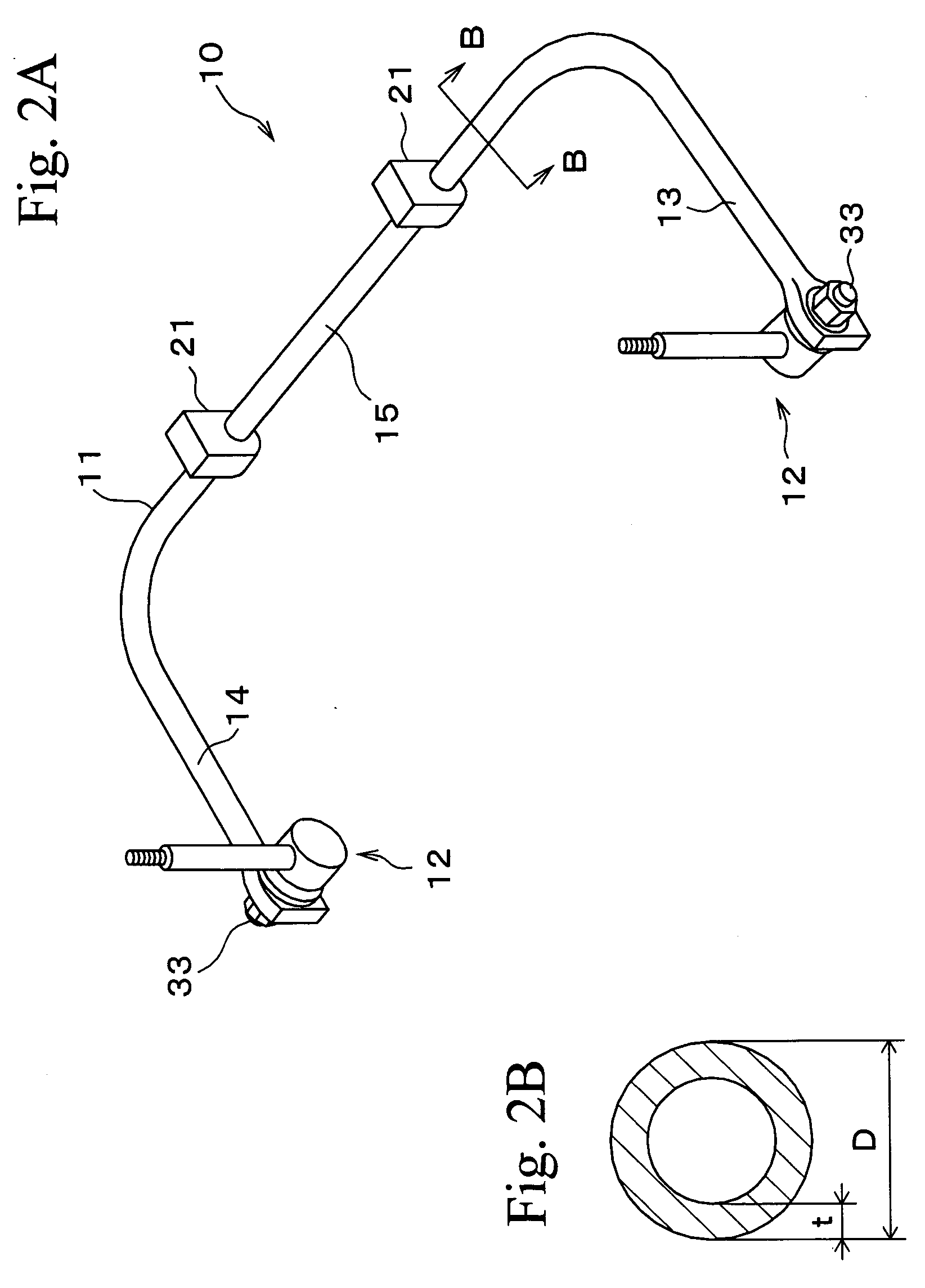

Hollow stabilizer and method of manufacturing the same

InactiveUS20060200990A1Wide range of choicesEasily correspondMetal-working apparatusFurnace typesBiomedical engineeringPeening

In a method of manufacturing a hollow stabilizer, a pipe compressing step of compressing an electroseamed pipe in a temperature range of a hot state or a warm state so as to make a rate of a thickness with respect to an outer diameter between 18 and 35% is performed, and a forming step of forming the compressed electroseamed pipe in a stabilizer shape in a cold state is executed. Next, a step of applying a heat treatment to a half-finished stabilizer is performed, a shot peening step of impacting a shot on the half-finished stabilizer is performed, and a step of coating the half-finished stabilizer is performed.

Owner:NHK SPRING CO LTD

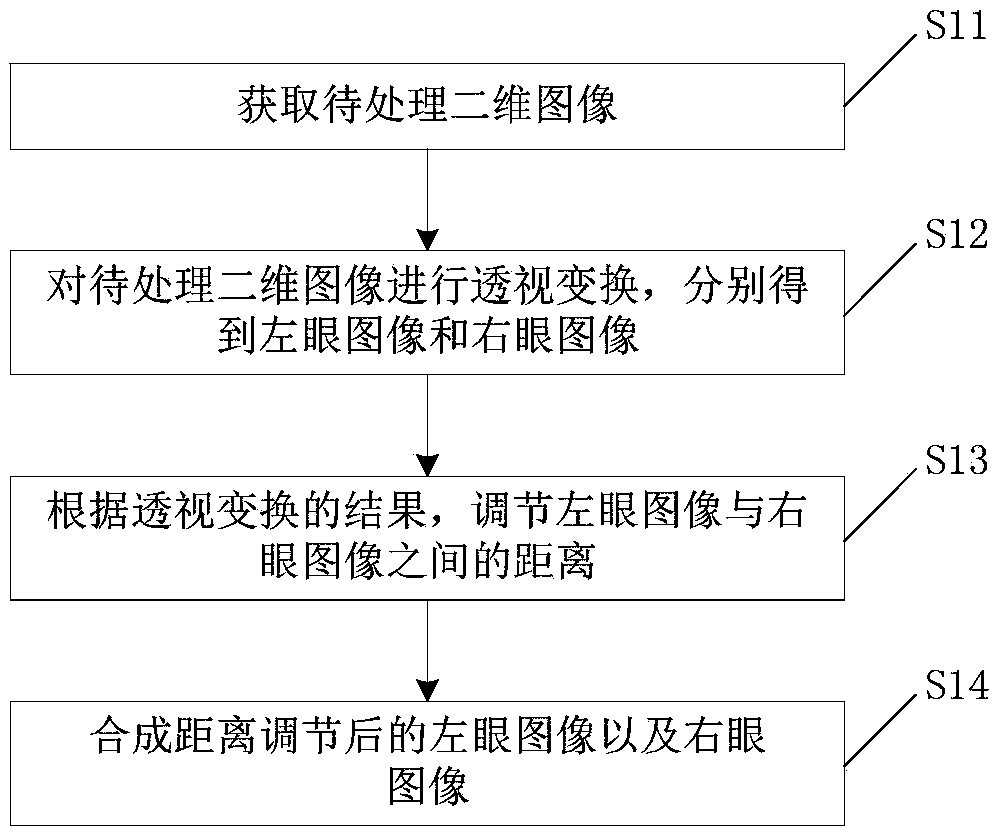

Method and device for converting two-dimensional image into three-dimensional image, and three-dimensional imaging system

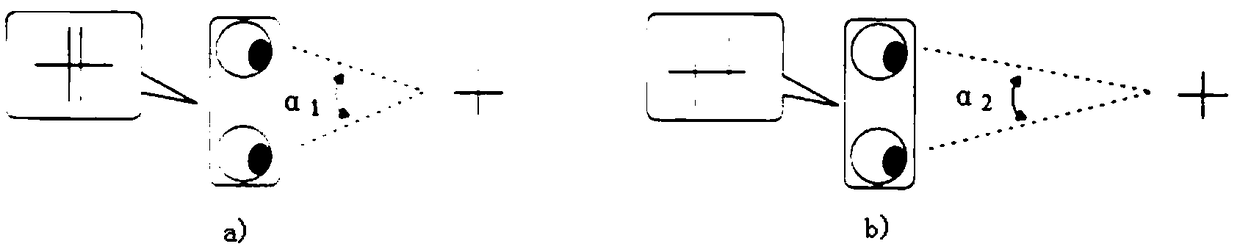

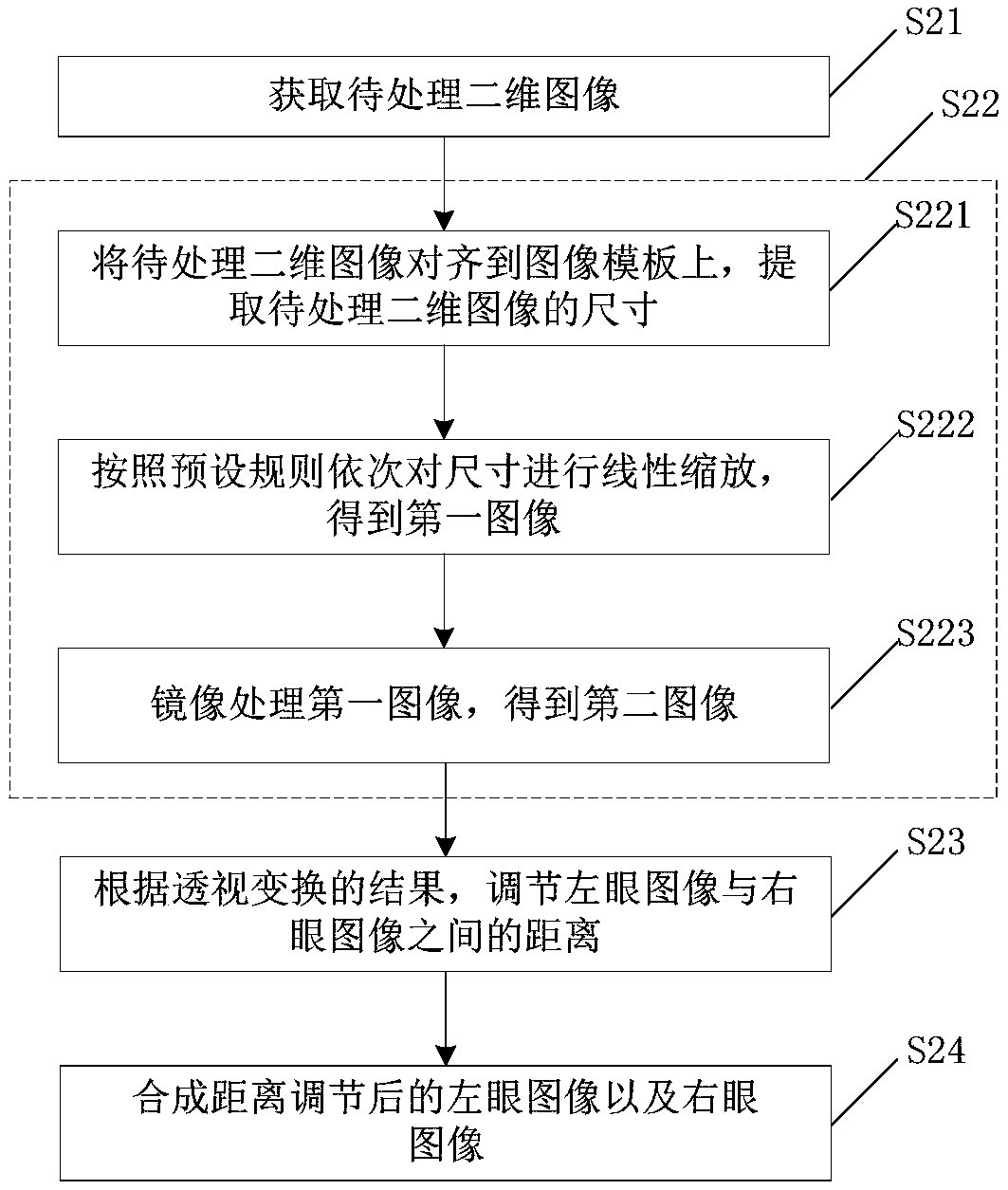

ActiveCN108712643AImprove conversion efficiencyAdjustable distanceTelevision system detailsGeometric image transformationImaging qualityPerspective transformation

The invention discloses a method and device for converting a two-dimensional image into a three-dimensional image, and a three-dimensional imaging system. The method for converting the two-dimensionalimage into the three-dimensional image comprises the following steps: obtaining a two-dimensional image to be processed; performing perspective transformation on the two-dimensional image to be processed to obtain a left eye image and a right eye image separately; adjusting the distance between the left eye image and the right eye image according to the result of the perspective transformation; and synthesizing the left eye image and the right eye image after distance adjusting. According to the embodiment of the invention, a binocular parallax image is created through performing perspectivetransformation on the two-dimensional image to be processed; and the distance adjusting is performed on the left eye image and the right eye image after perspective transformation to form the binocular parallax and create a convergence angle, so that the image observed by naked eyes lies at different depths and different stereoscopic effects can be seen. The image transformation is performed through the two-dimensional image, which does not relate to the resolution and clarity of the image; therefore, the image quality of the image of 3D imaging is the same as that of the original two-dimensional image, and the effect of 3D imaging is not affected.

Owner:STSIVITA MEDIKAL TECH KO LTD

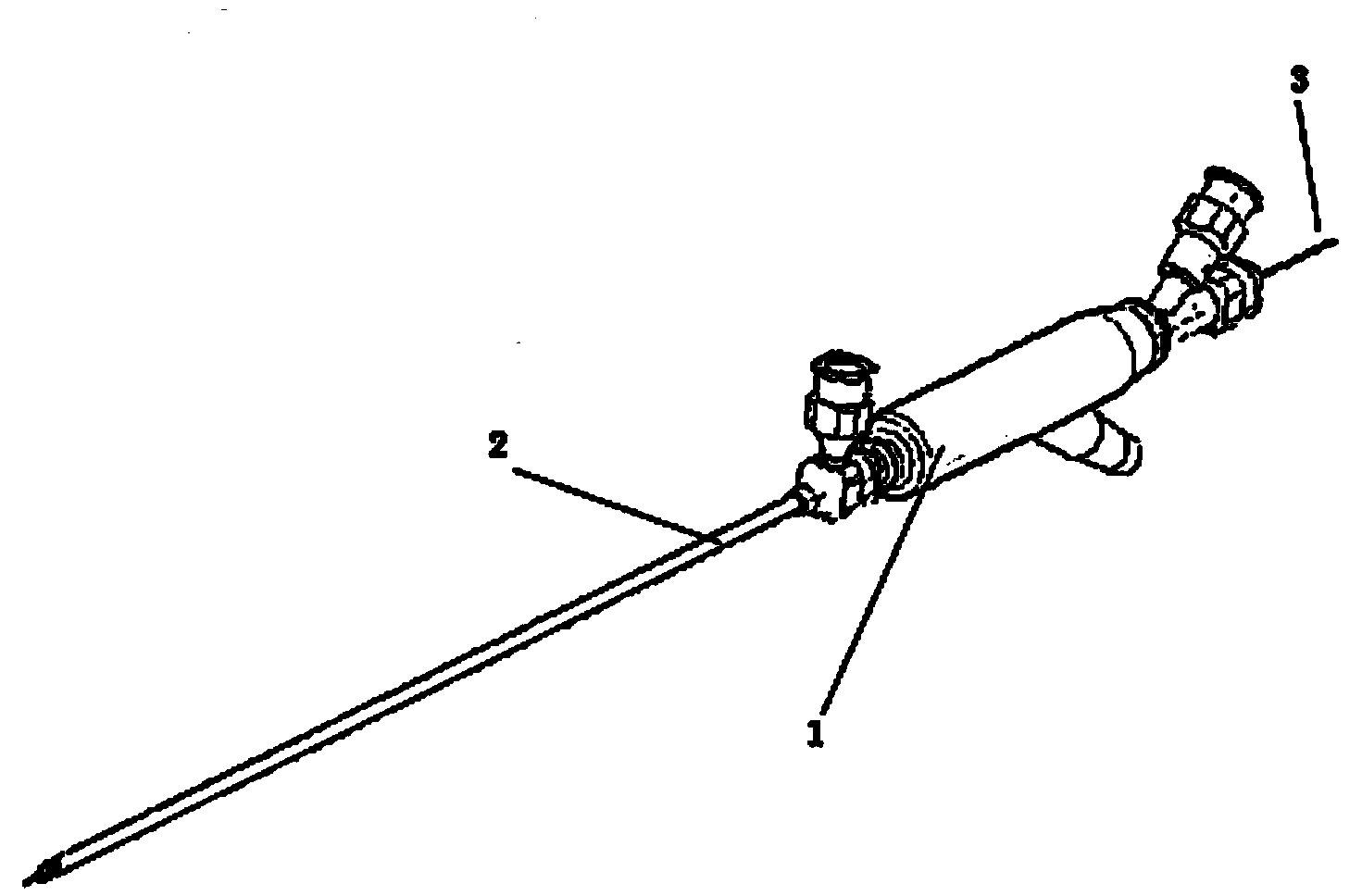

Plug-in coiled tubing induced-spraying device

InactiveCN102733787AAchieve multiple functionsSolve the problem of unsatisfactory liquid carrying effectFluid removalSealing/packingCoiled tubingEngineering

The invention discloses a plug-in coiled tubing induced-spraying device, which comprises an outer tubular column, a coiled tubing and a coiled tubing injector, wherein the coiled tubing is fed inside the outer tubular column through the coiled tubing injector; a locating seal working barrel is arranged in the outer tubular column; the periphery of the locating seal working barrel is matched with an inner periphery of the outer tubular column in a sealing way; an inserted sealing rod is arranged at the lower end of the coiled tubing; the inserted sealing rod is provided with a through hole communicated with the coiled tubing along the axial direction; and the inserted sealing rod is inserted into the seal work barrel when the coiled tubing injector feeds the coiled tubing downwards to a preset position in the outer tubular column, and the periphery of the inserted sealing rod is matched with the inner periphery of the locating seal working barrel in the sealing way. According to the device, the problems that water seepages at the stratum and the liquid carrying effect of a large-diameter tubular column is not ideal in a gas well test can be solved, and common gas lift induced spraying, production seeking and testing also can be carried out, so as to achieve the multifunctional purpose of the tubular column.

Owner:CHINA NAT OFFSHORE OIL CORP +1

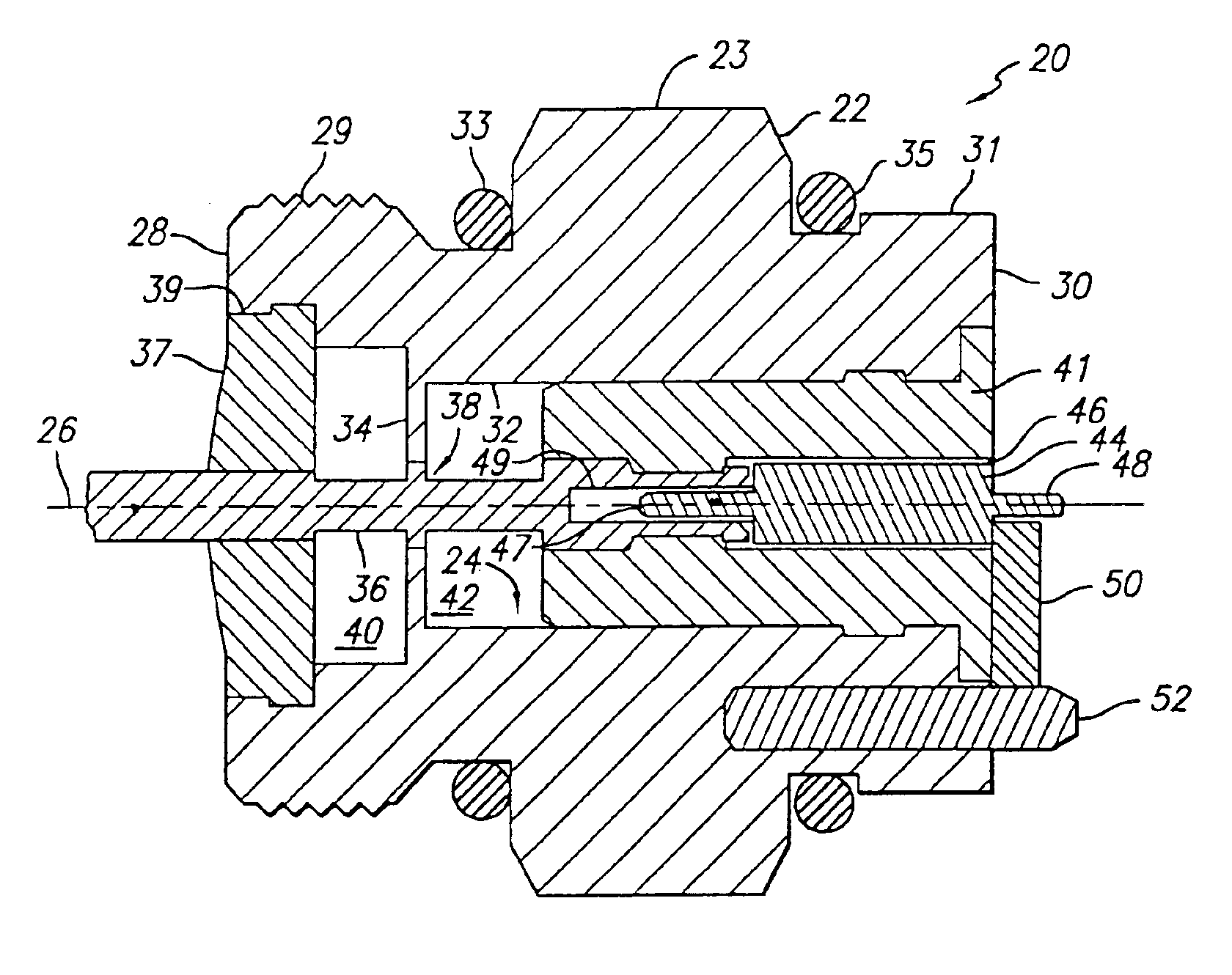

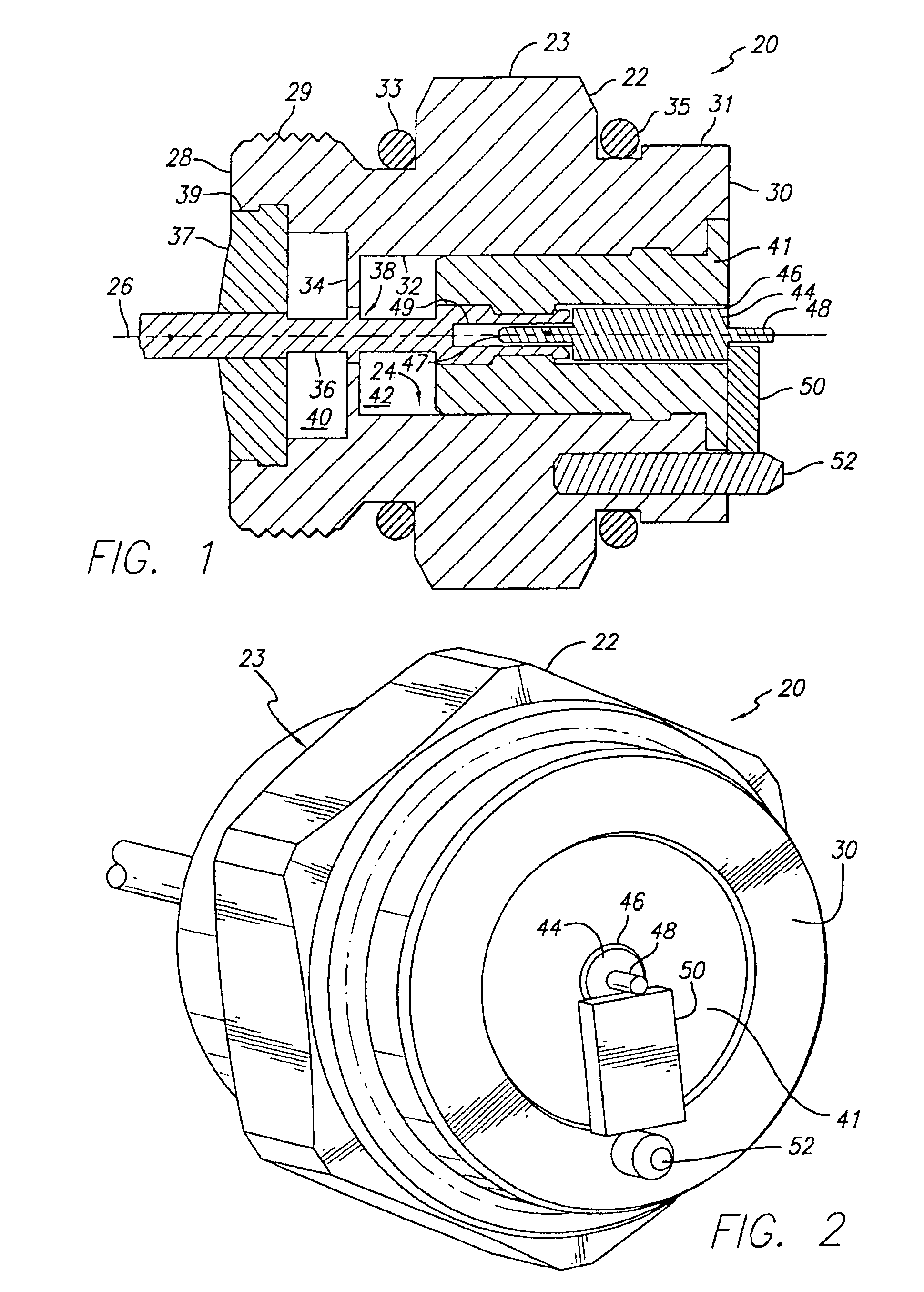

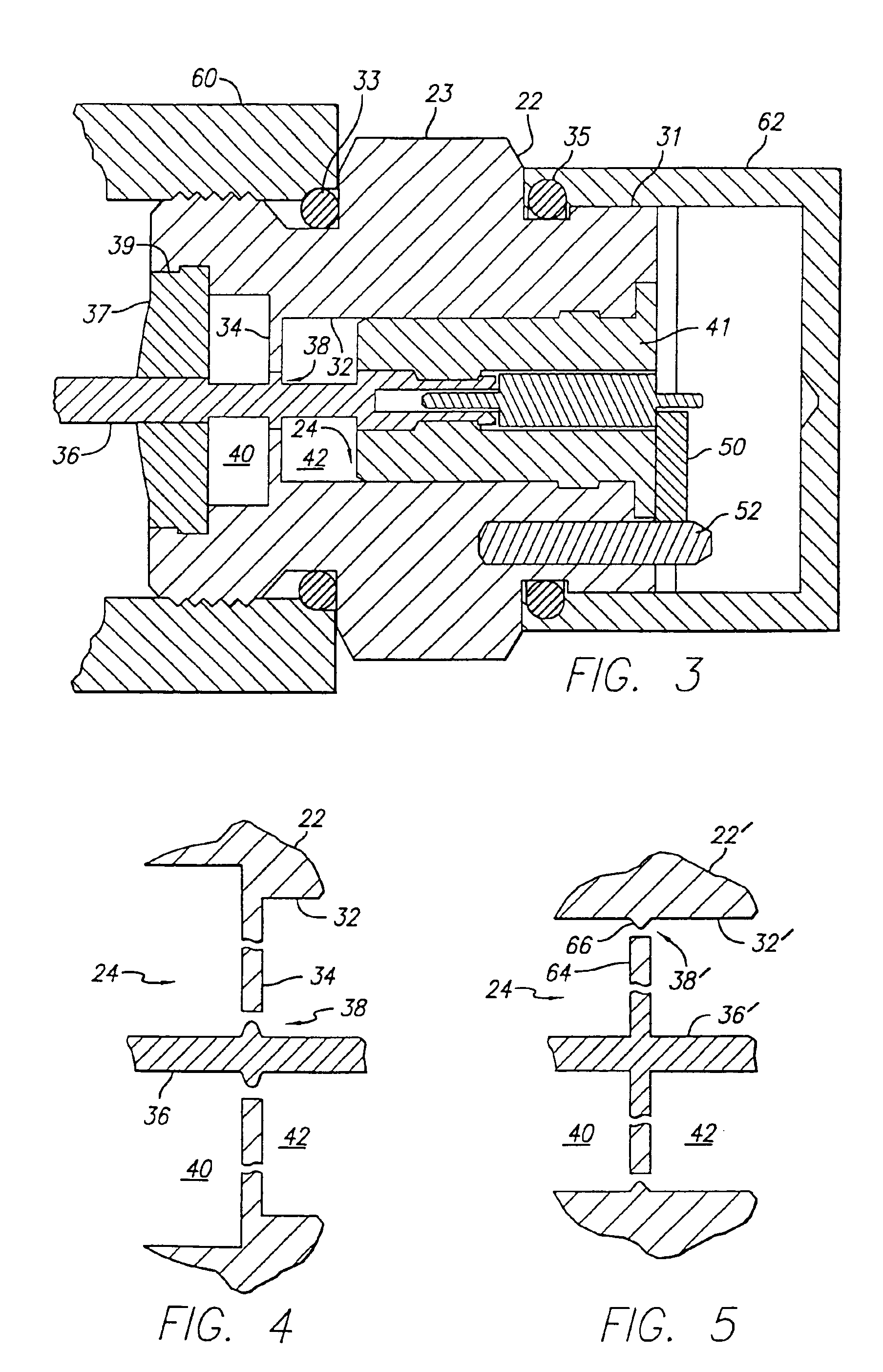

Socket for pipe joint and pipe joint

ActiveUS8469406B2Small inner diameterReduce the anglePipe elementsCouplingsEngineeringMechanical engineering

Owner:NITTO KOHKI CO LTD

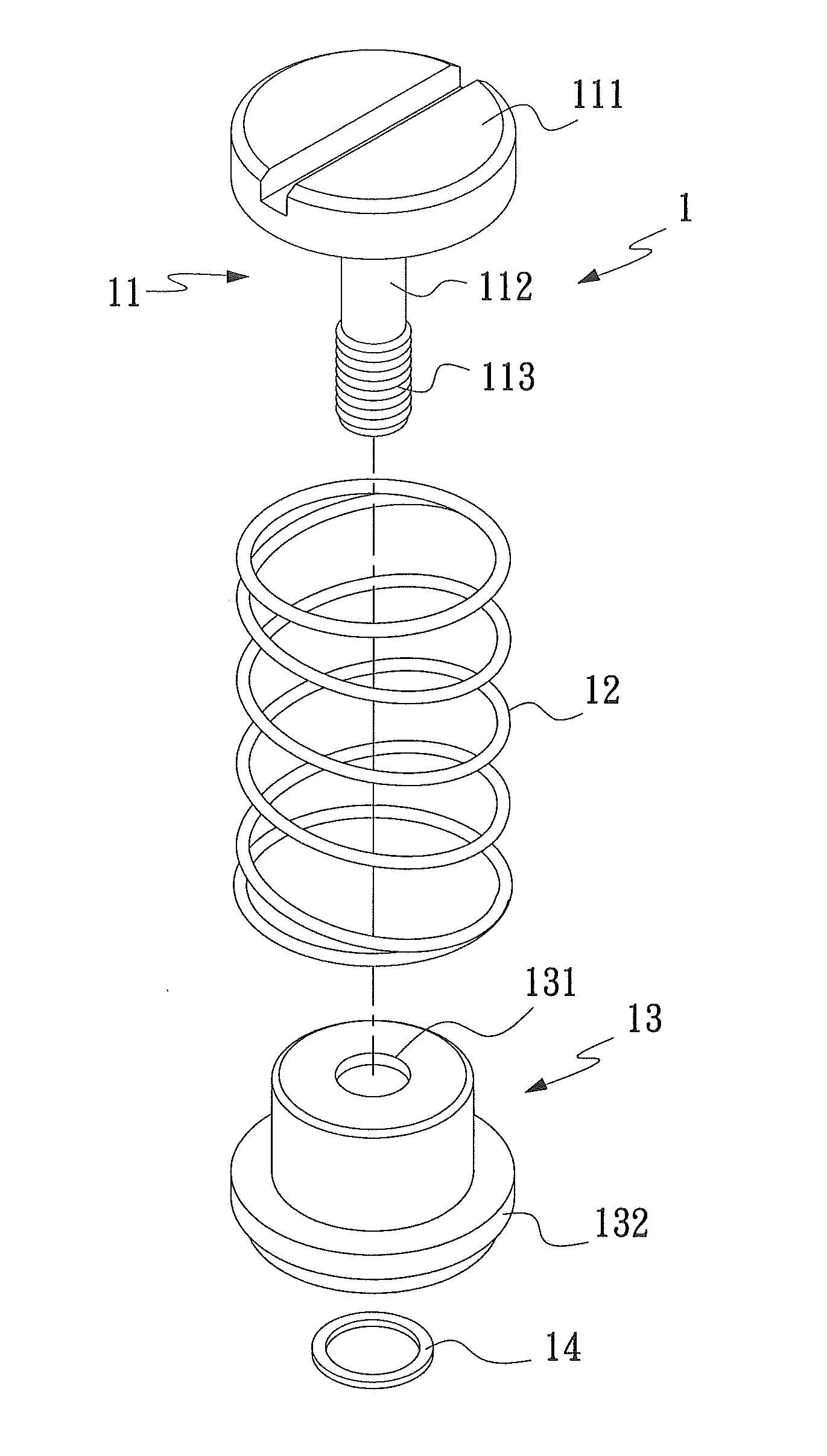

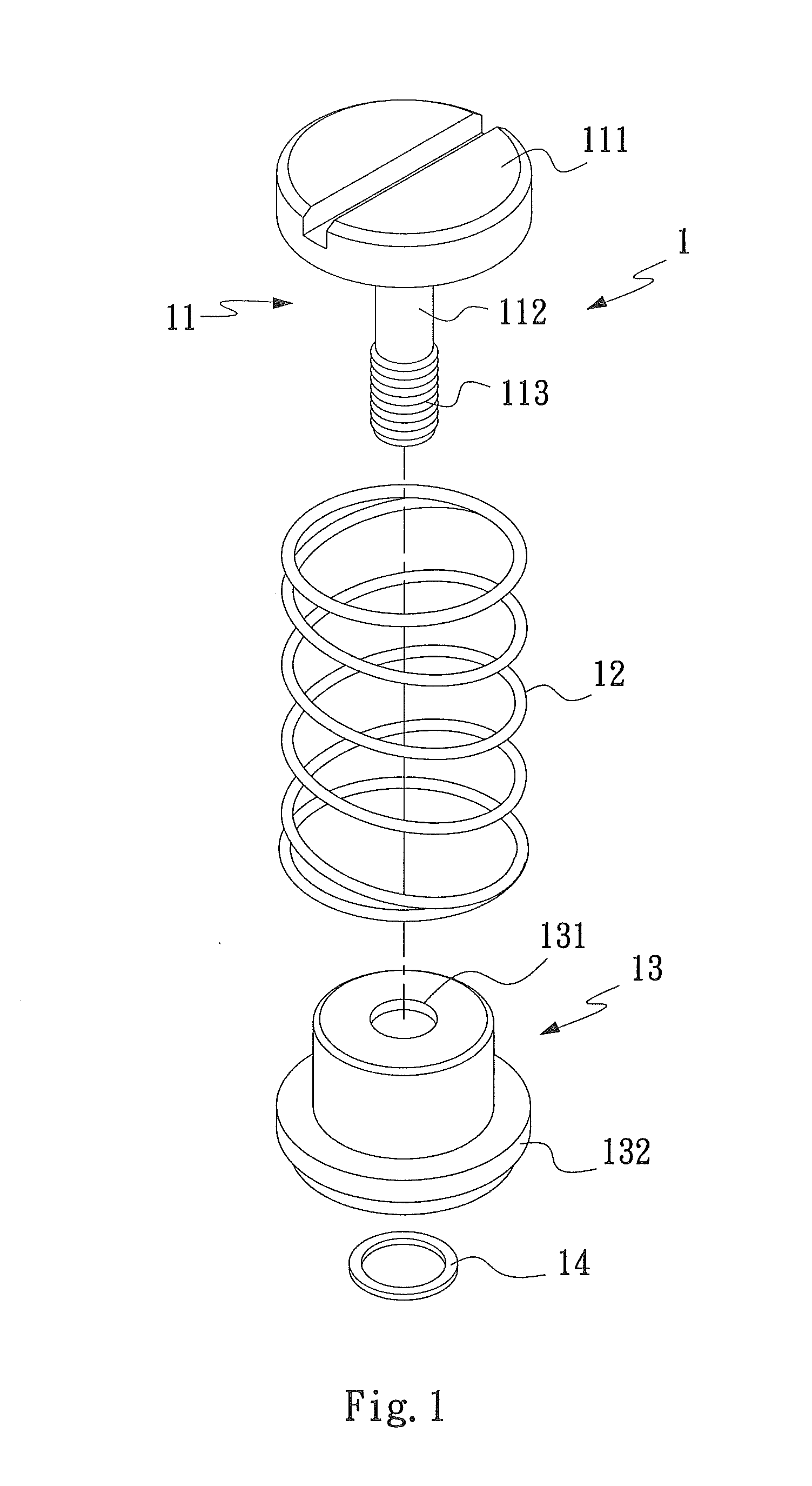

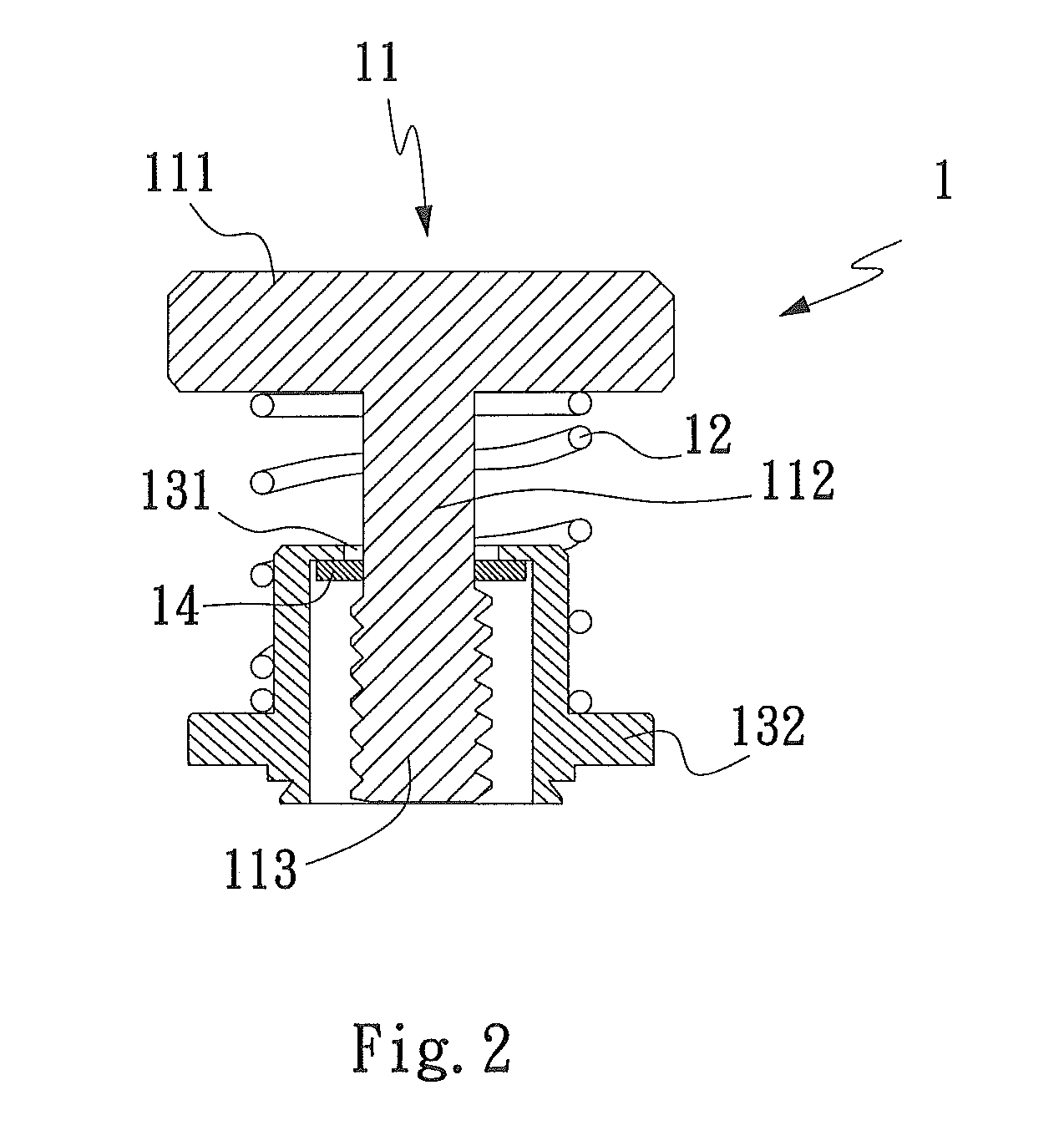

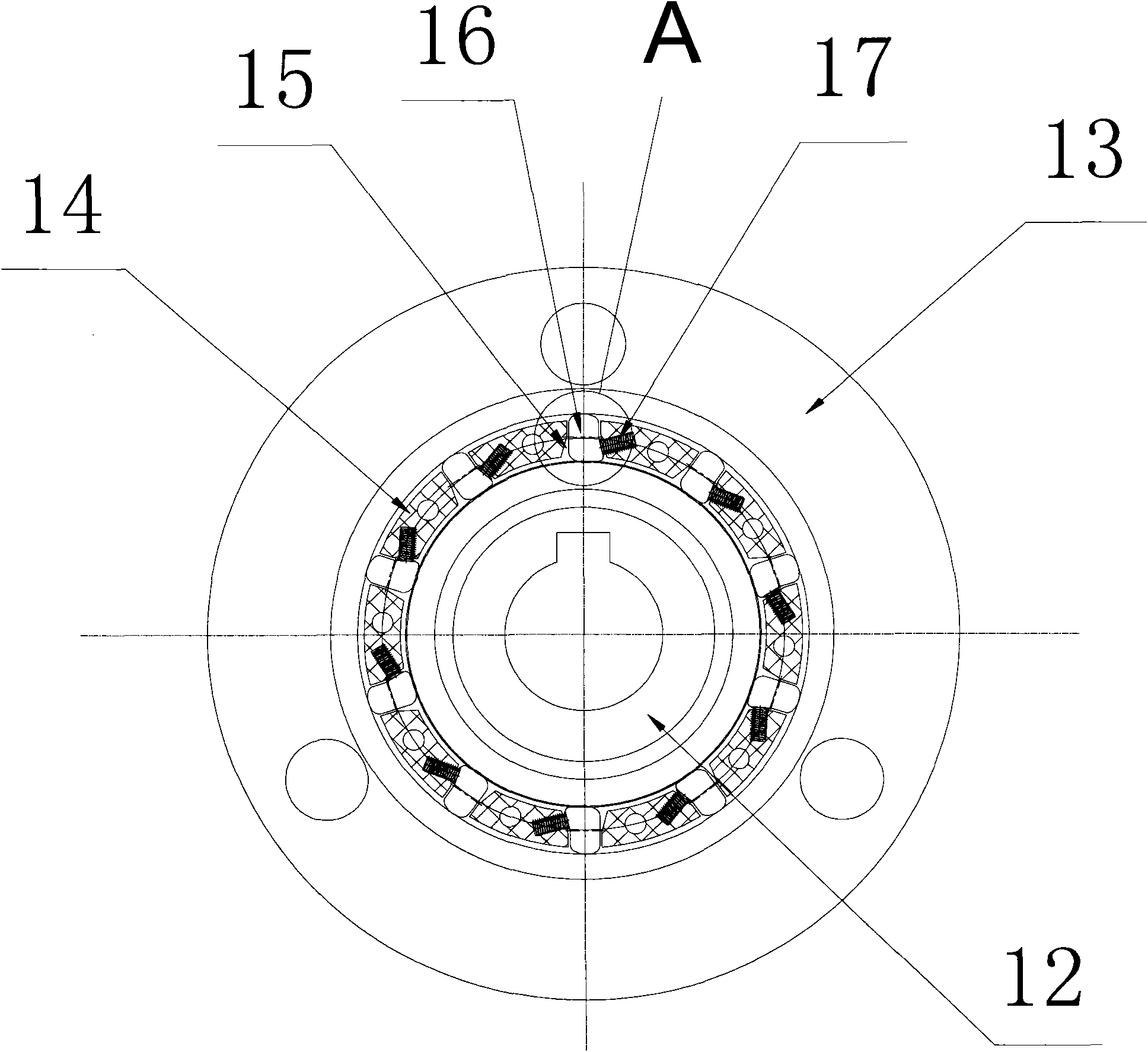

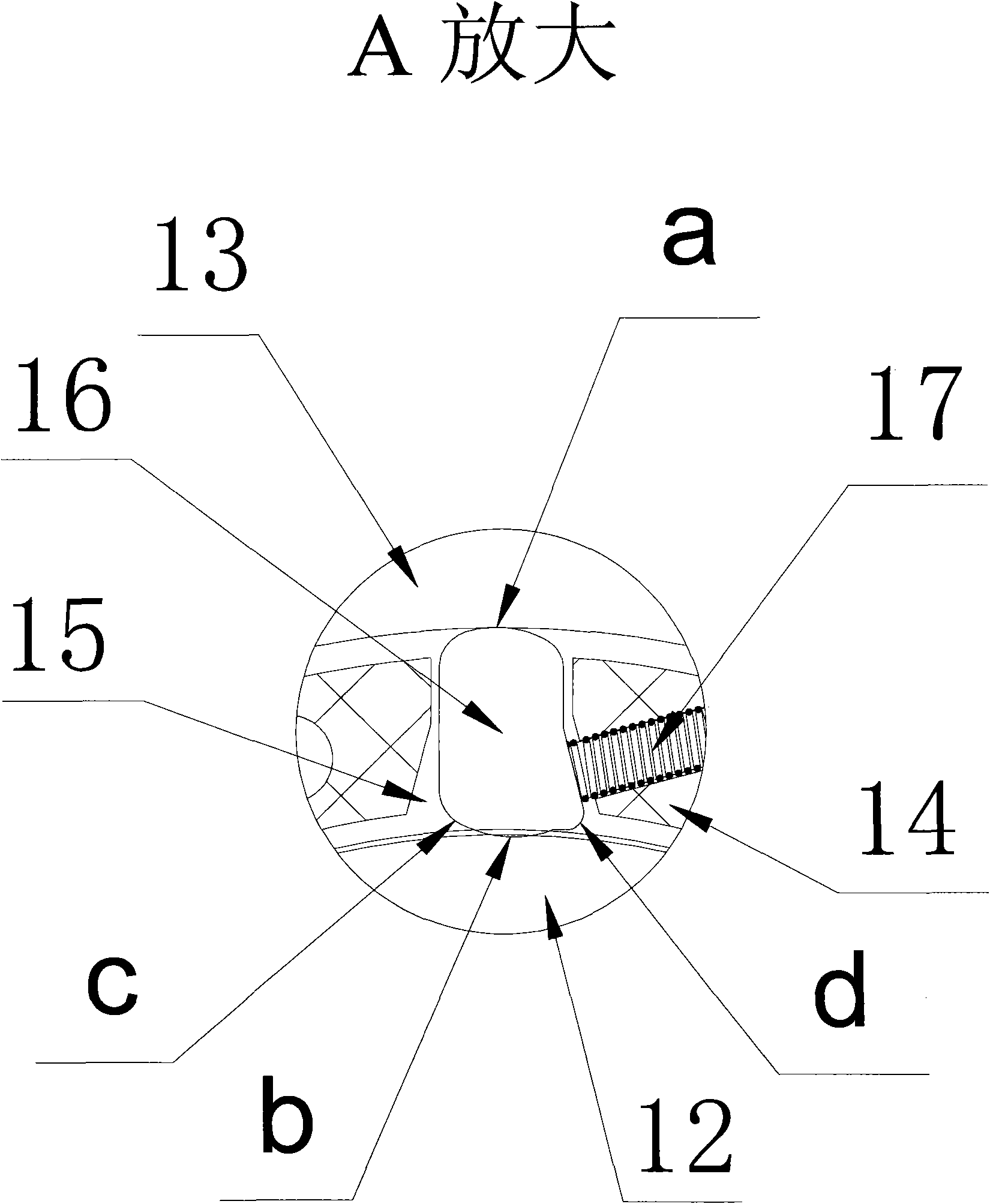

Method of assembling captive screw

InactiveUS20090313804A1Reduce manufacturing costStrong and reliable assemblyPinsNutsCoil springEngineering

A method for assembling captive screw includes the steps of providing an annular base and positioning an annular washer on a top of the annular base; providing a screw, a coil spring, and a sleeve; downward passing the screw through the coil spring and a top opening of the sleeve; and threading a threaded section of the screw through the annular washer, so that the annular washer is fitted around a shank of the screw to locate below the top opening of the sleeve and above the threaded section of the screw. An inner circumferential edge of the annular washer is not worn away by the threaded section of the screw threaded therethrough, enabling the annular washer to keep a small inner diameter for tightly fitting around the shank of the screw and ensuring reliable assembling of the sleeve to the screw.

Owner:FIVETECH TECH INC

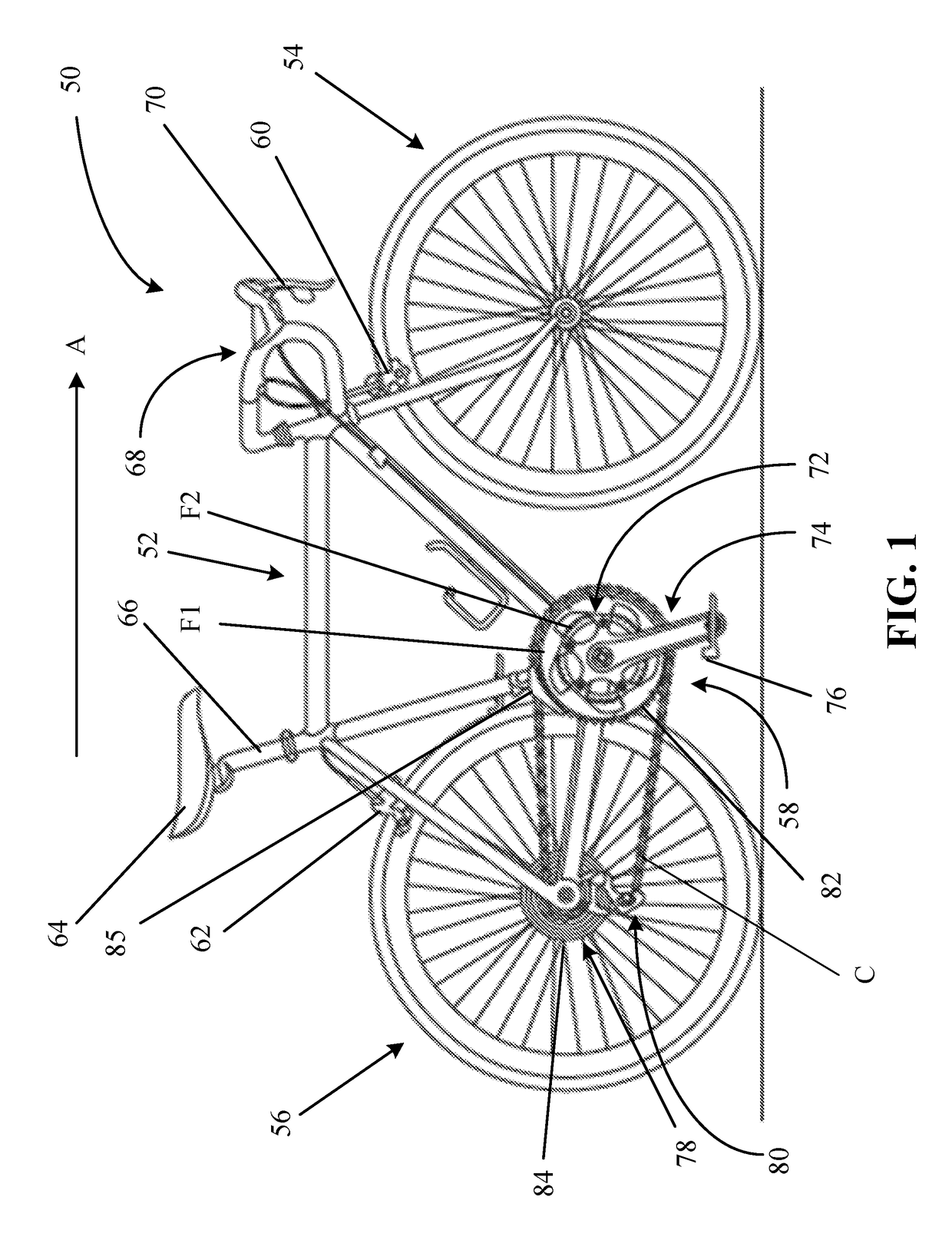

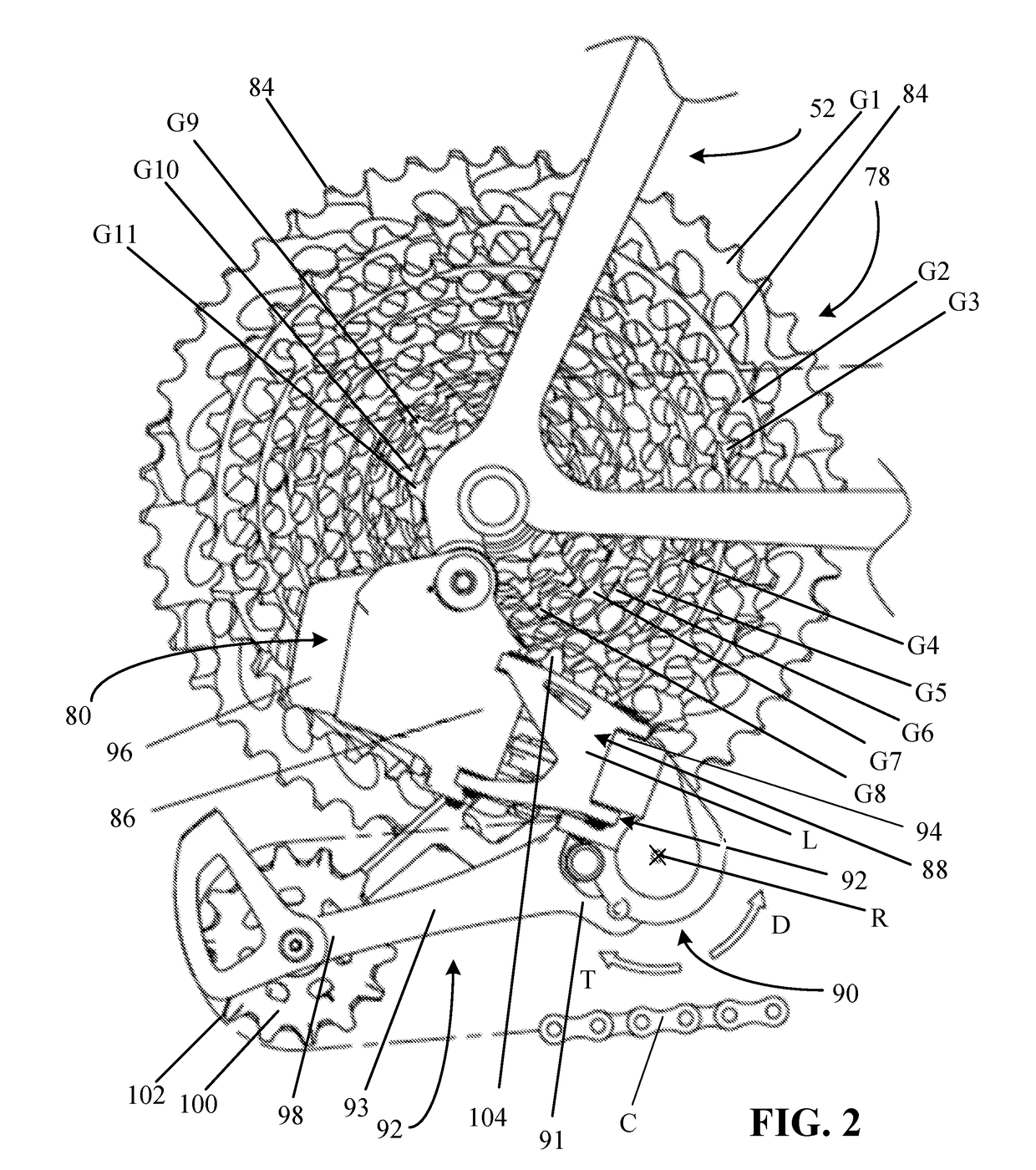

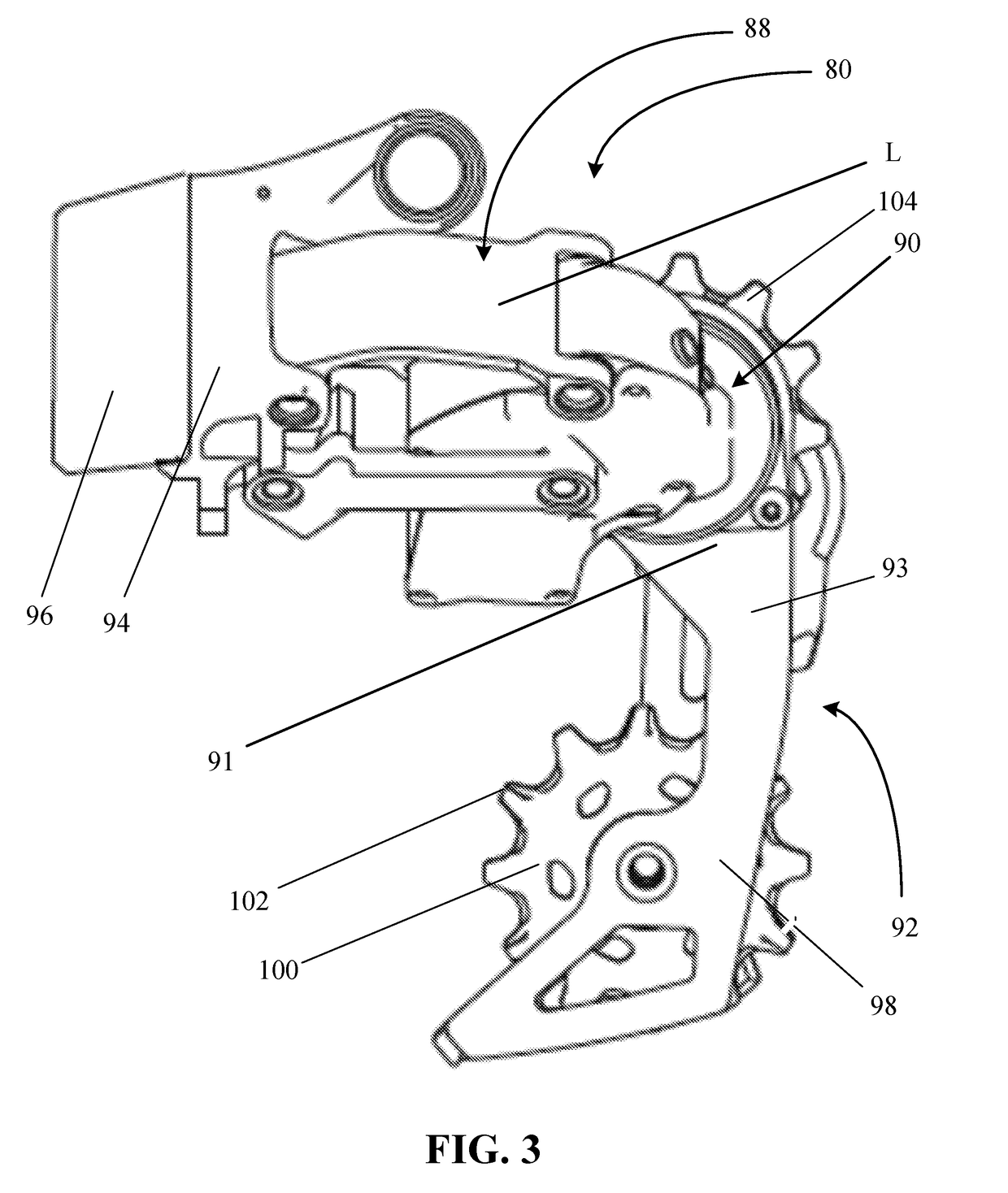

Damper for a bicycle component

A bicycle rear derailleur includes a movable member and a chain guide assembly rotatably connected to the movable member. The bicycle rear derailleur also includes a pivot member non-rotatably coupled to the chain guide assembly and having an outer annular surface, a biasing device configured to bias the chain guide assembly in a first rotational direction relative to the movable member, and a damper device disposed between the chain guide assembly and the movable member. The damper device is operable to apply a damping force to the chain guide assembly when the chain guide assembly rotates in a second rotational direction relative to the movable member. The damper device includes a friction device that is radially inner relative to the biasing device. The friction device includes a friction member having at least one friction surface biased against and in frictional engagement with the pivot member.

Owner:SRAM CORPORATION

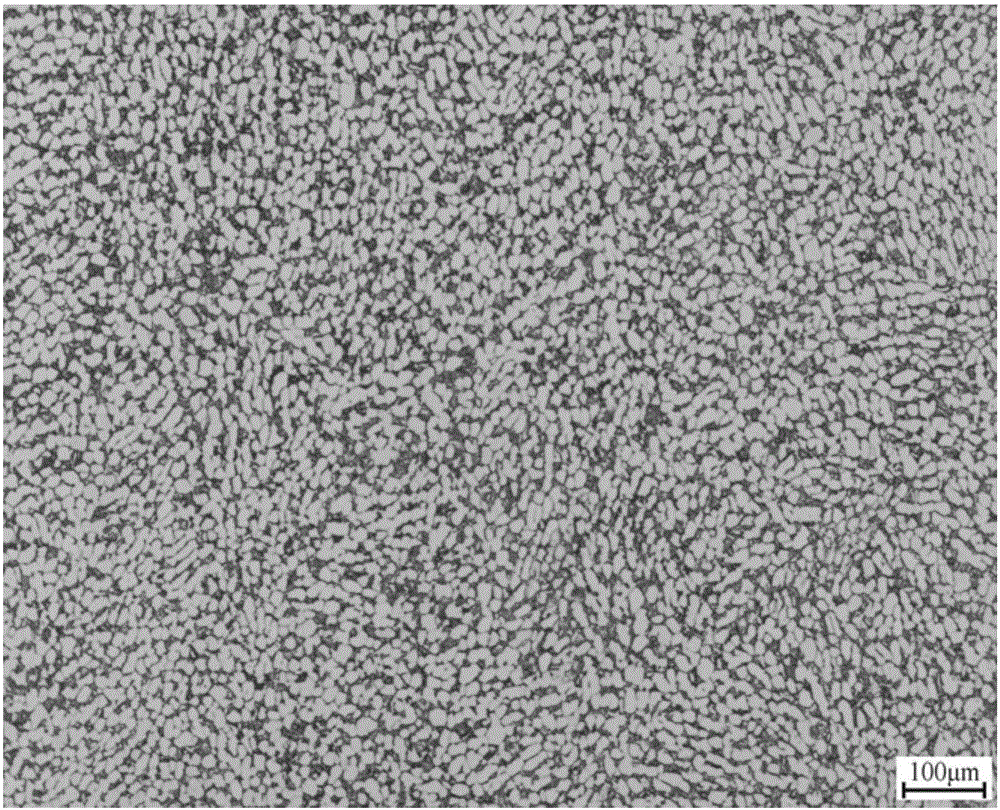

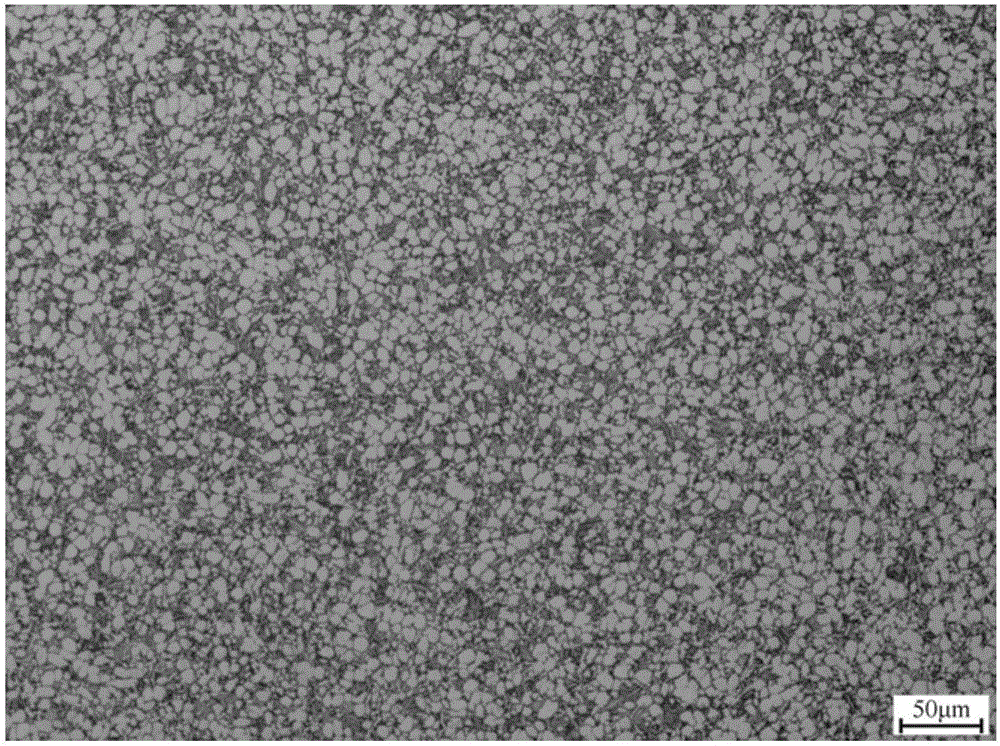

Preparation method for large-specification TC4 titanium alloy ring piece

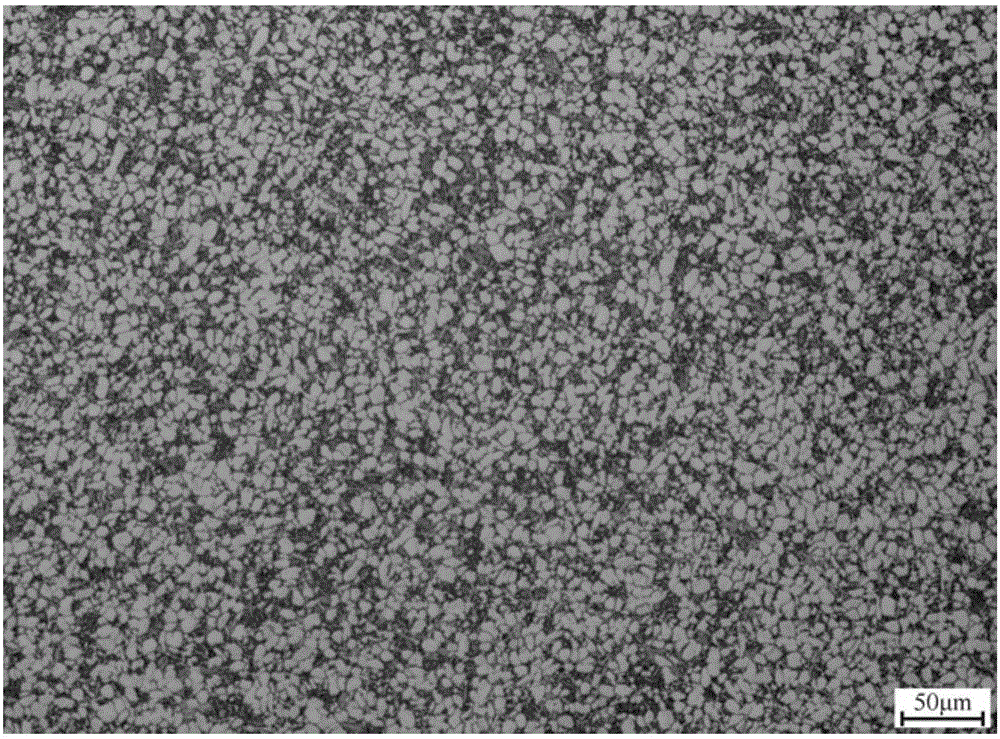

The invention provides a preparation method for a large-specification TC4 titanium alloy ring piece. The preparation method comprises the following steps that (1) TC4 titanium alloy blanks are heated to a technical temperature and subjected to heat insulation, and the forging operations of two-upsetting and two-drawing are conducted; (2) the TC4 titanium alloy blanks are heated to the technical temperature and subjected to heat insulation, the operations of upsetting and punching are conducted, and a TC4 titanium alloy circular blank is obtained; (3) the TC4 titanium alloy circular blank is heated to the technical temperature and subjected to heat-insulation and then the broaching operation is conducted; (4) the TC4 titanium alloy circular blank is heated to the technical temperature and subjected to heat-insulation, and rolling operation is conducted; (5) the TC4 titanium alloy circular blank is heated to the technical temperature and subjected to heat-insulation, and after the TC4 titanium alloy circular blank is reshaped, air cooling operation is conducted; and (6) the TC4 titanium alloy circular blank is subjected to annealing treatment, and the large-specification TC4 titanium alloy ring piece with the external diameter being 720mm-1300mm is obtained. The large-specification TC4 titanium alloy ring piece prepared through the method consists of the alpha equiaxed phase and the beta transformed tissue, the microstructure is uniform and small, and the large-specification TC4 titanium alloy ring piece does not have an original beta crystal boundary and has high strength and good plasticity.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

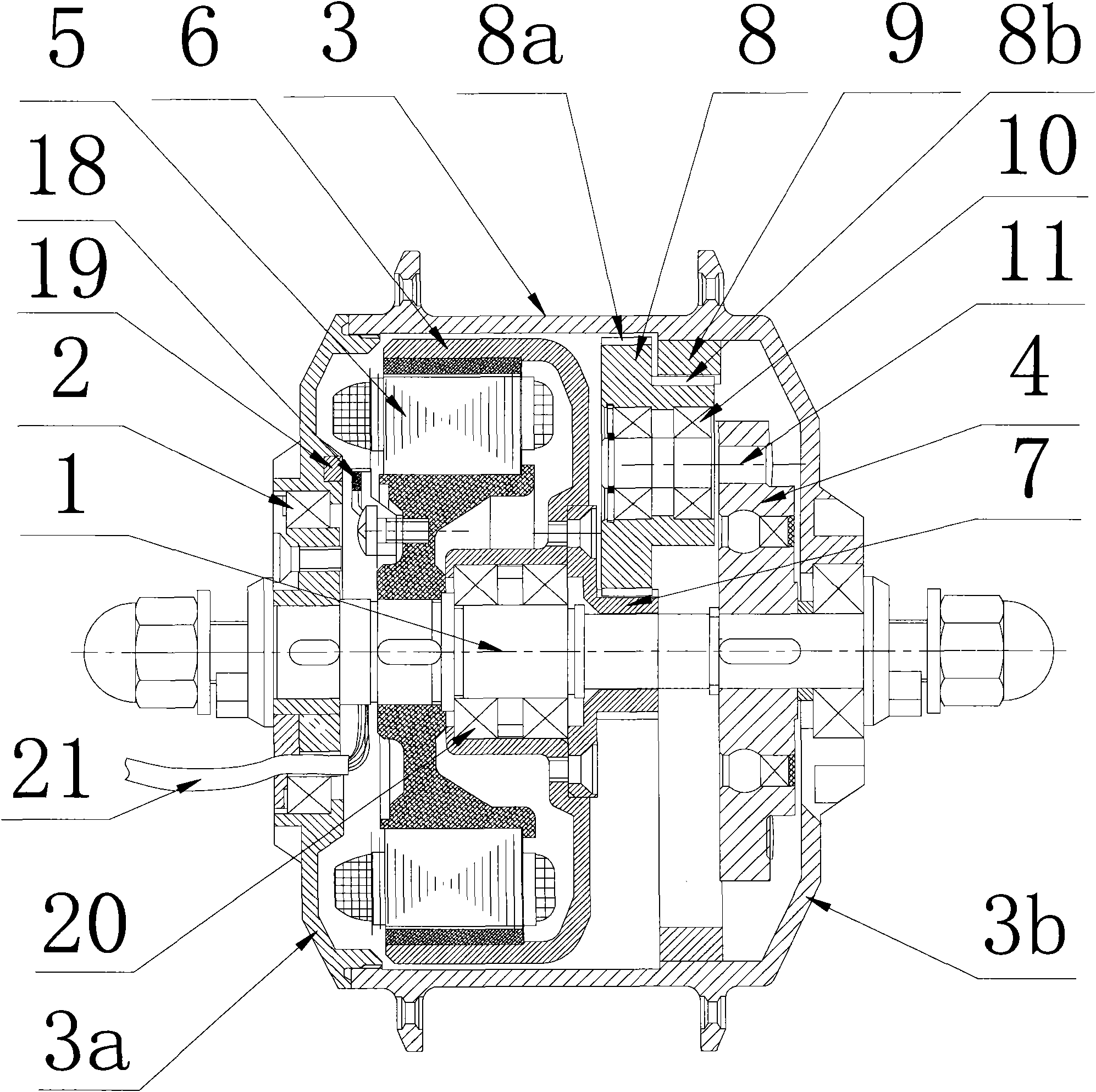

Electric wheel hub

InactiveCN101856949ACompact internal structureReduced external volumeHubsMechanical energy handlingGear wheelEngineering

The invention discloses an electric wheel hub, comprising a main shaft. A wheel hub casing is arranged on the main shaft through a wheel hub casing bearing; a motor, a planet wheel reducing gear and a clutch are arranged in the wheel hub casing; the motor uses a structure with an inner stator and an external rotor; a sun gear sleeved on the main shaft is fixed on the rotor and is meshed with a planet gear which is meshed with an inner gear ring fixed on the inner wall of the wheel hub casing; meanwhile, the planet gear is arranged on a planet shaft through a planet bearing; the planet shaft is fixed on the clutch which is fixed on the main shaft; and the planet gear adopts a duplicate gear which is formed by a bull gear and a pinion which are axially integrally formed, wherein the bull gear is meshed with the sun gear and the pinion is meshed with the inner gear ring. In the invention, the pinion of the duplicate gear is meshed with the inner gear ring, so that the inside diameter of the inner gear ring is reduced, the size of the wheel hub casing is correspondingly reduced, an internal structure of the whole electric wheel hub is more compact and the external volume is smaller.

Owner:SUZHOU SHENGYI MOTOR

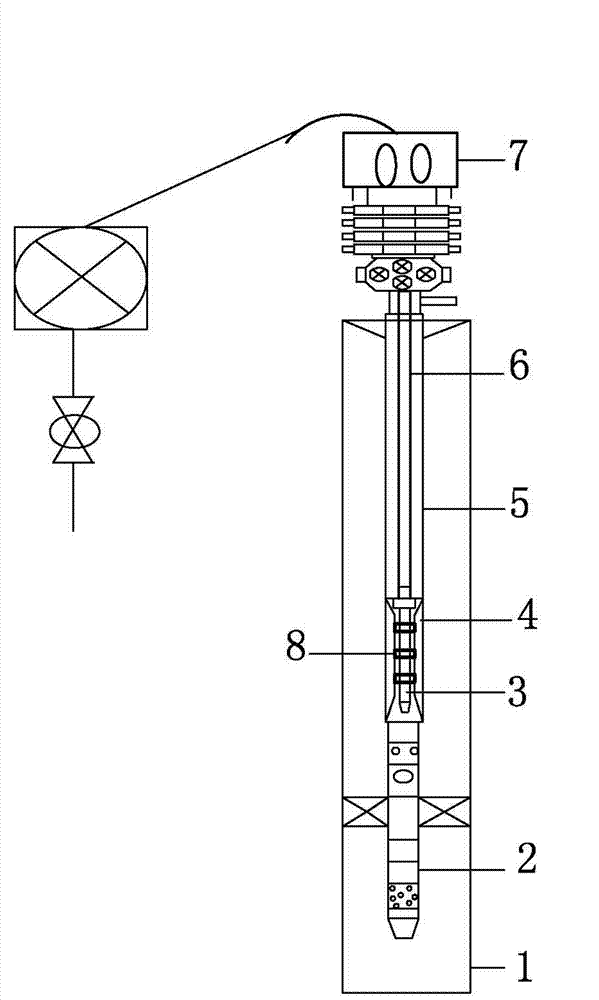

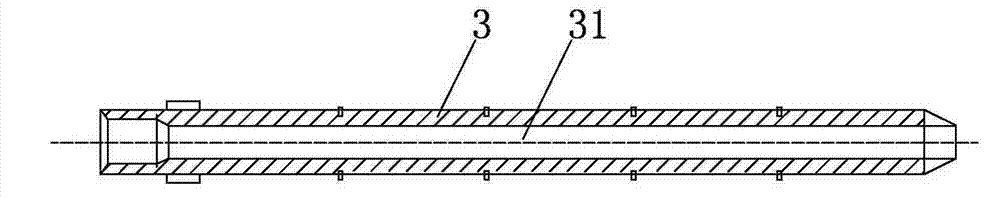

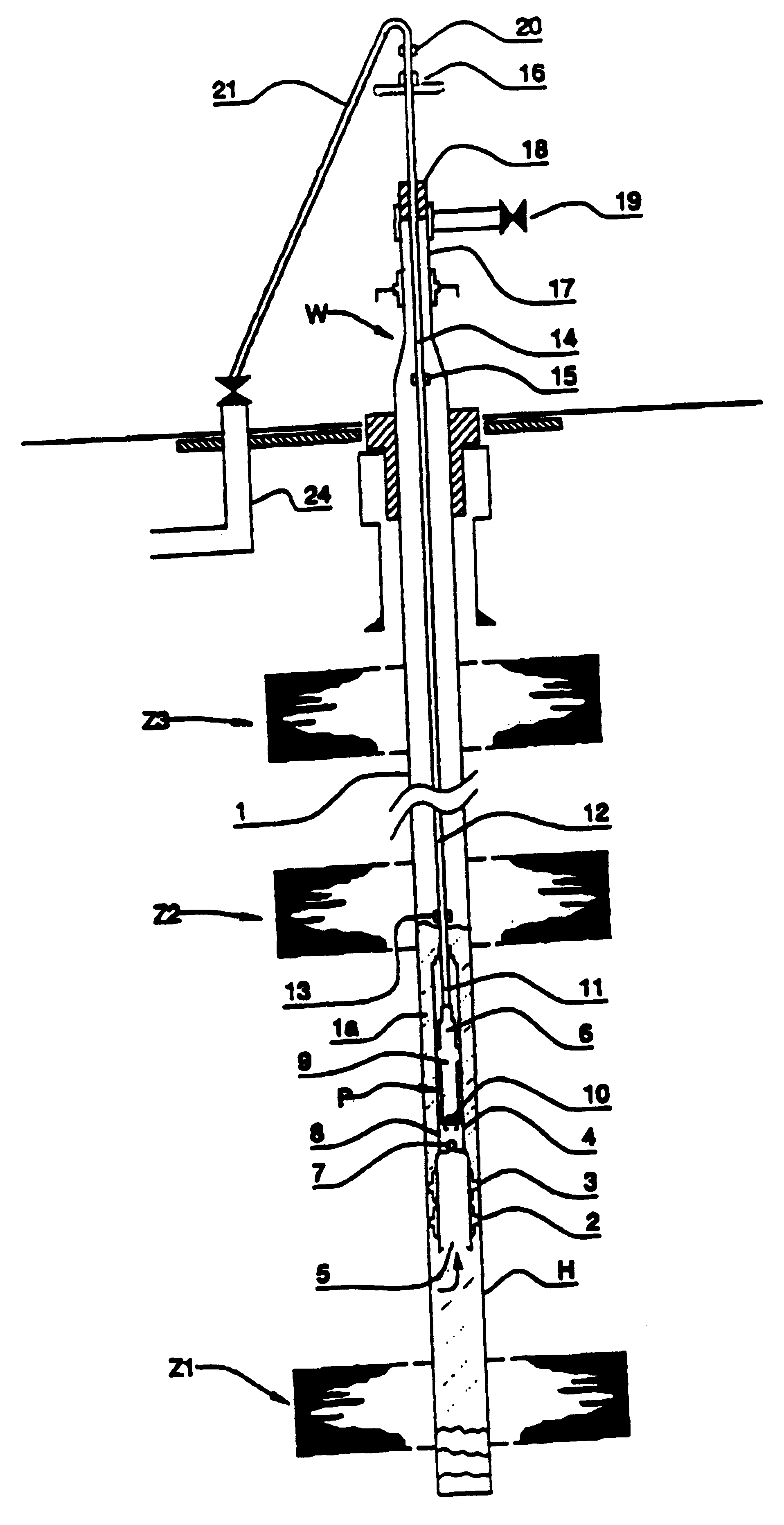

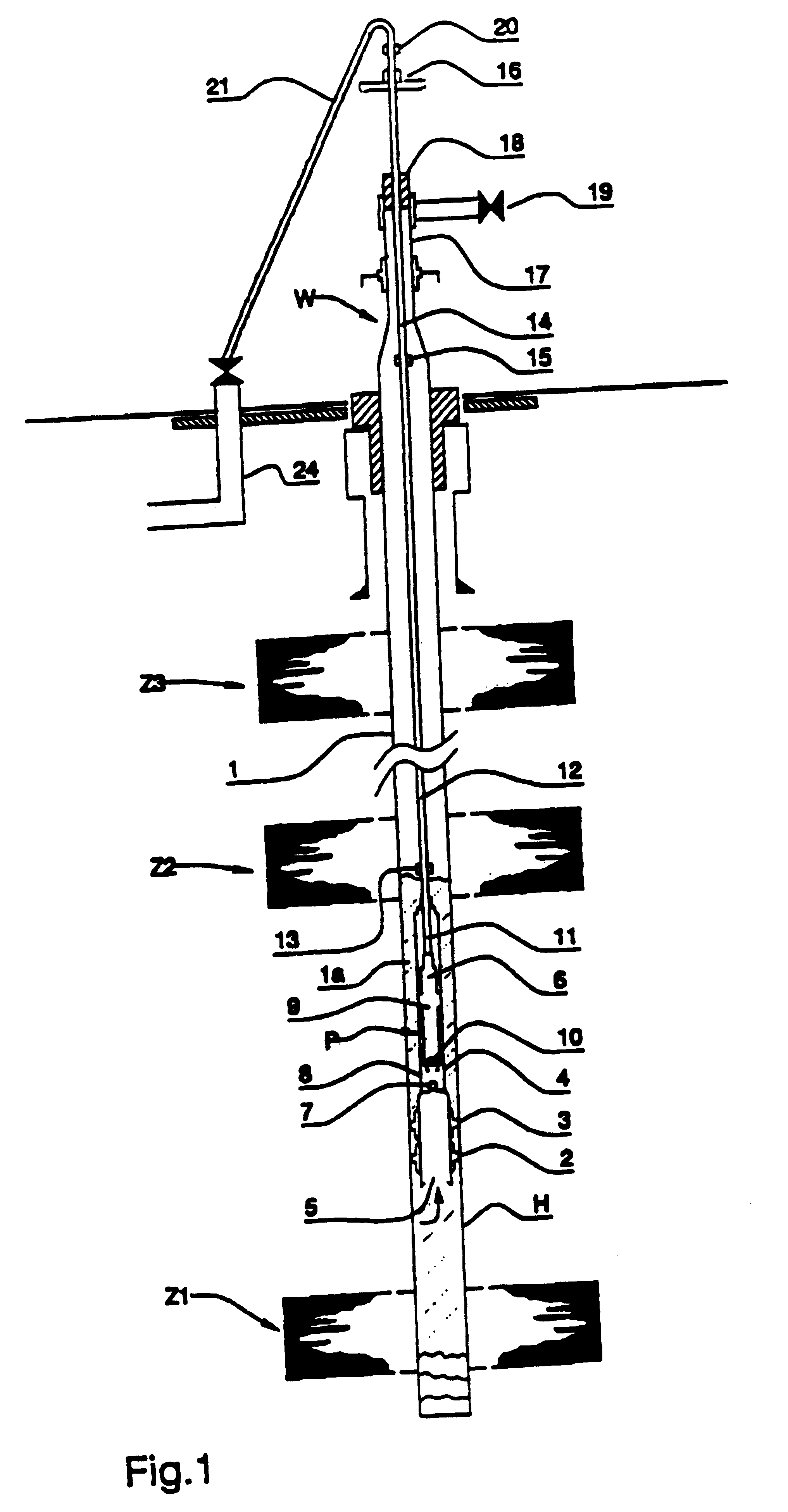

Assembly and method for the extraction of fluids from a drilled well within a geological formation

The present invention includes an assembly and method to pump fluids produced by a drilled well within a geological formation having a borehole wall fixed by casing. The invention includes a subsurface pump having a stationary member and a mobile member. A pump anchor fixes the pump to the well casing. A hollow continuous tube or coiled tubing extends within the well bore from the surface down to the lower portion of the well bore. The bottom end of the coiled tubing is connected to the mobile member of the pump. Preferably, the coiled tubing can be coiled and uncoiled from a reel located on the surface. A hollow polished rod has a bottom end coupled to a free top end of the coiled tubing. The hollow polished rod is connected to means to operate the hollow rod according to a selected movement, preferably reciprocating axial movement. The pumped fluids are recovered on the surface from the hollow polished rod and coiled tubing.

Owner:YPF SA

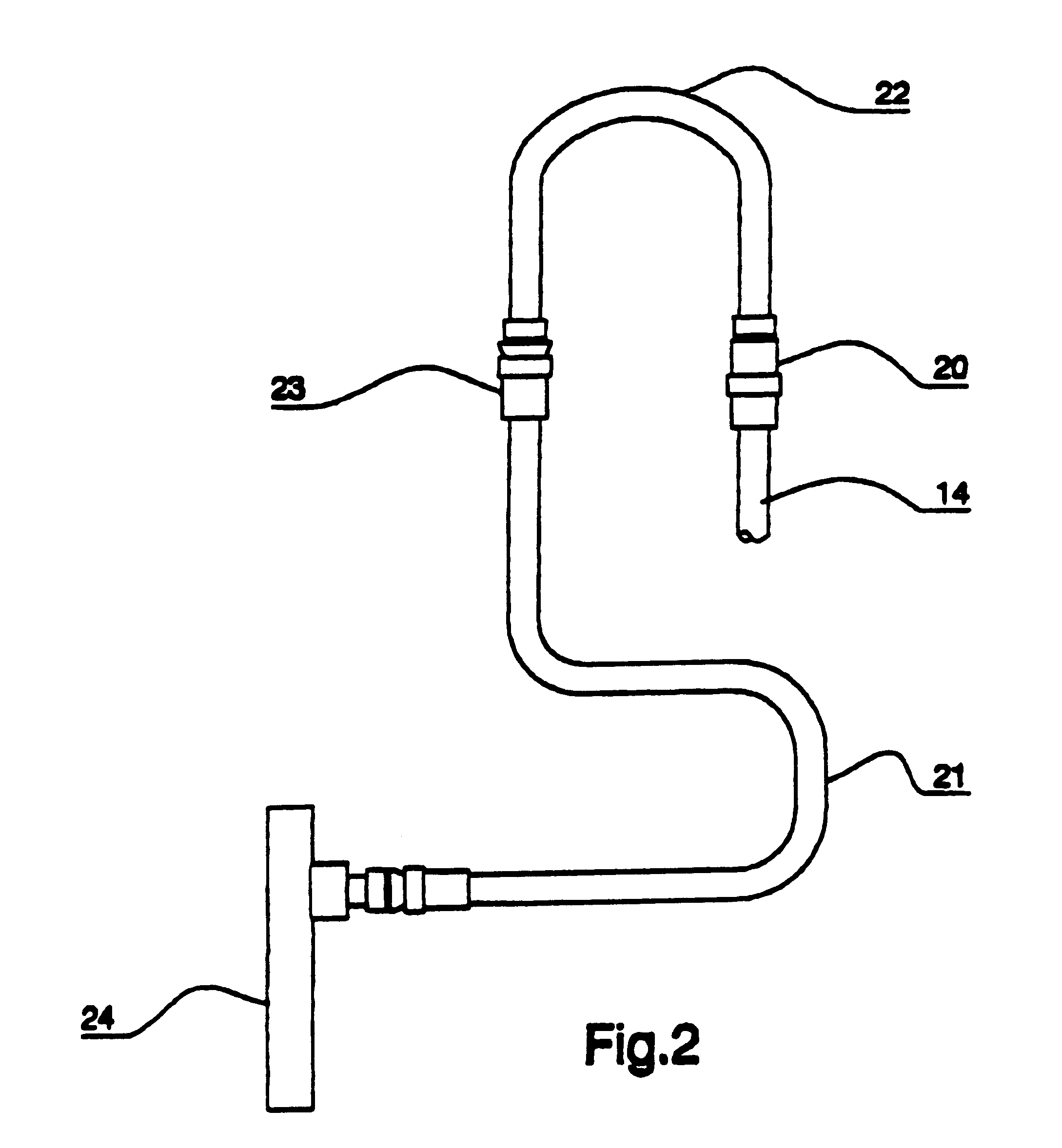

Gas generator

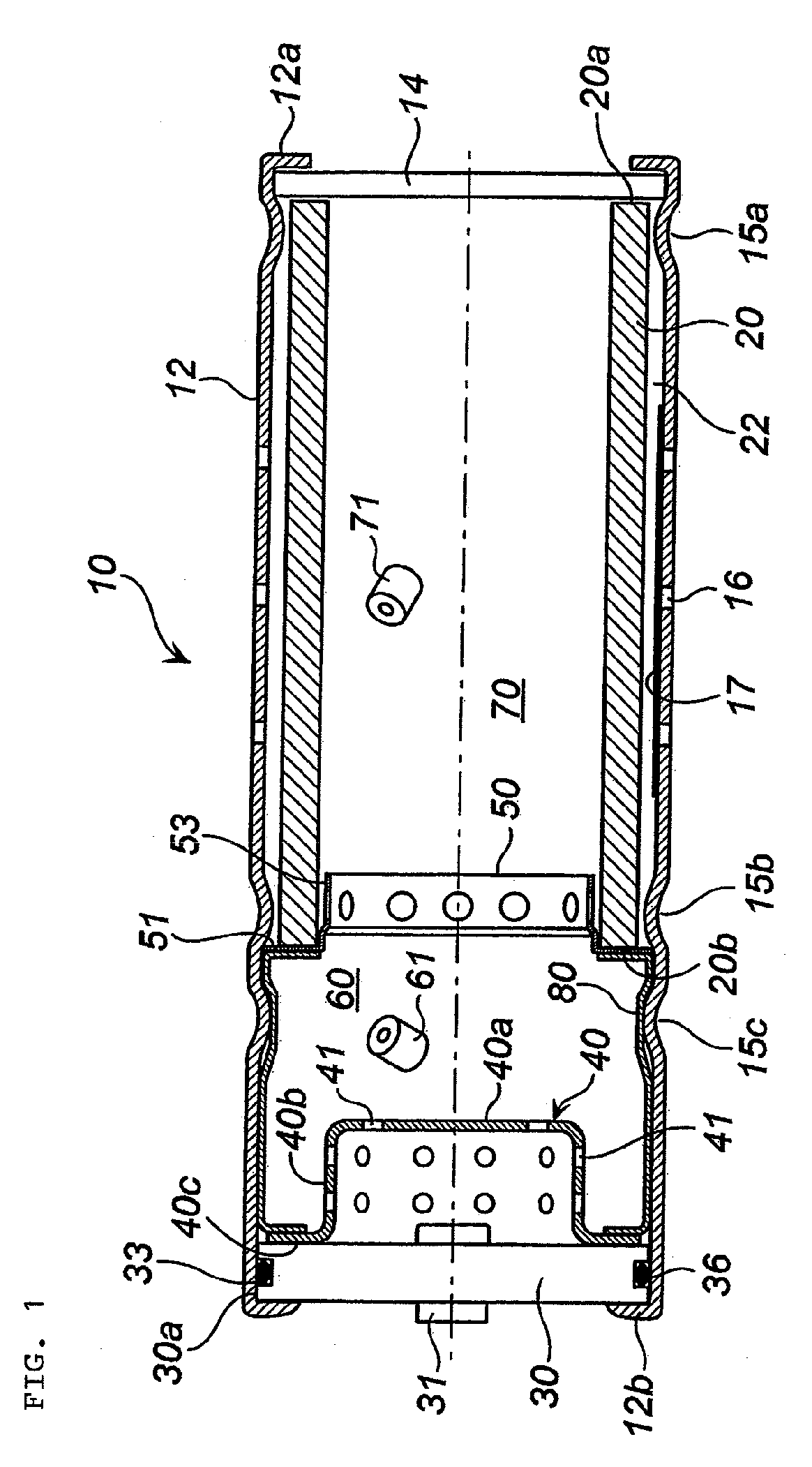

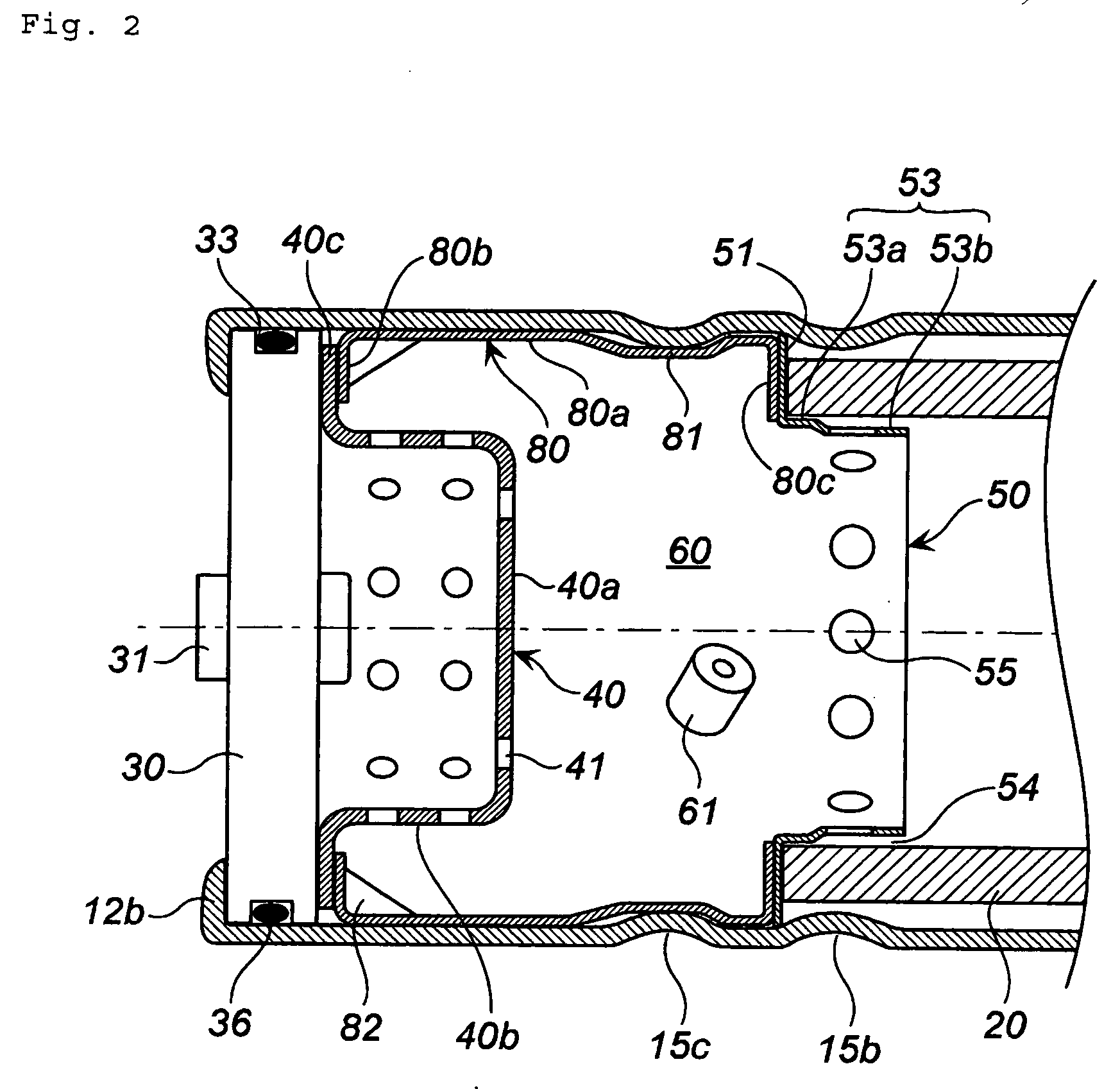

ActiveUS20090121464A1Small inner diameterPedestrian/occupant safety arrangementGas-discharge lampProduct gas

The present invention relates to a gas generator including:a cylindrical housing having a gas discharge port and being closed at both ends,an ignition device attached to one end of the cylindrical housing,a first gas generating agent chamber provided in the cylindrical housing at a position close to the ignition device and filled with a first gas generating agent,a cylindrical filter provided in a space axially adjacent to the first gas generating agent chamber,a second gas generating agent chamber provided inside the cylindrical filter and filled with a second gas generating agent, anda retainer disposed between the first gas generating agent chamber and the second gas generating agent chamber, the retainer having an annular flat surface and a annular circumferential wall surface that protrudes from an inner circumferential edge of the annular flat surface, the annular flat surface abutting against one end surface of the cylindrical filter and the annular circumferential wall surface abutting against a portion of an inner circumferential surface on one end side of the cylindrical filter,an inner diameter of the second gas generating agent chamber being smaller than an inner diameter of the first gas generating agent chamber.

Owner:DAICEL CHEM IND LTD

Method for preparing uniform three dimensional nanometer fluid passage by femto-second laser

InactiveCN101549852AUniform longitudinal shapeImprove taperNanostructure manufactureFemto second laserCompound (substance)

A method for preparing uniform three dimensional nanometer fluid passage by femto-second laser comprises the steps of irradiating transparent material by femto-second laser, chemical attacking and hot drawing. the three dimensional nanometer fluid passage prepared by the method in the invention achieves the advantages of uniform longitudinal appearance, good roundness of passage cross section, high smoothness of the passage inner wall and small passage inner diameter to nanometer scale.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

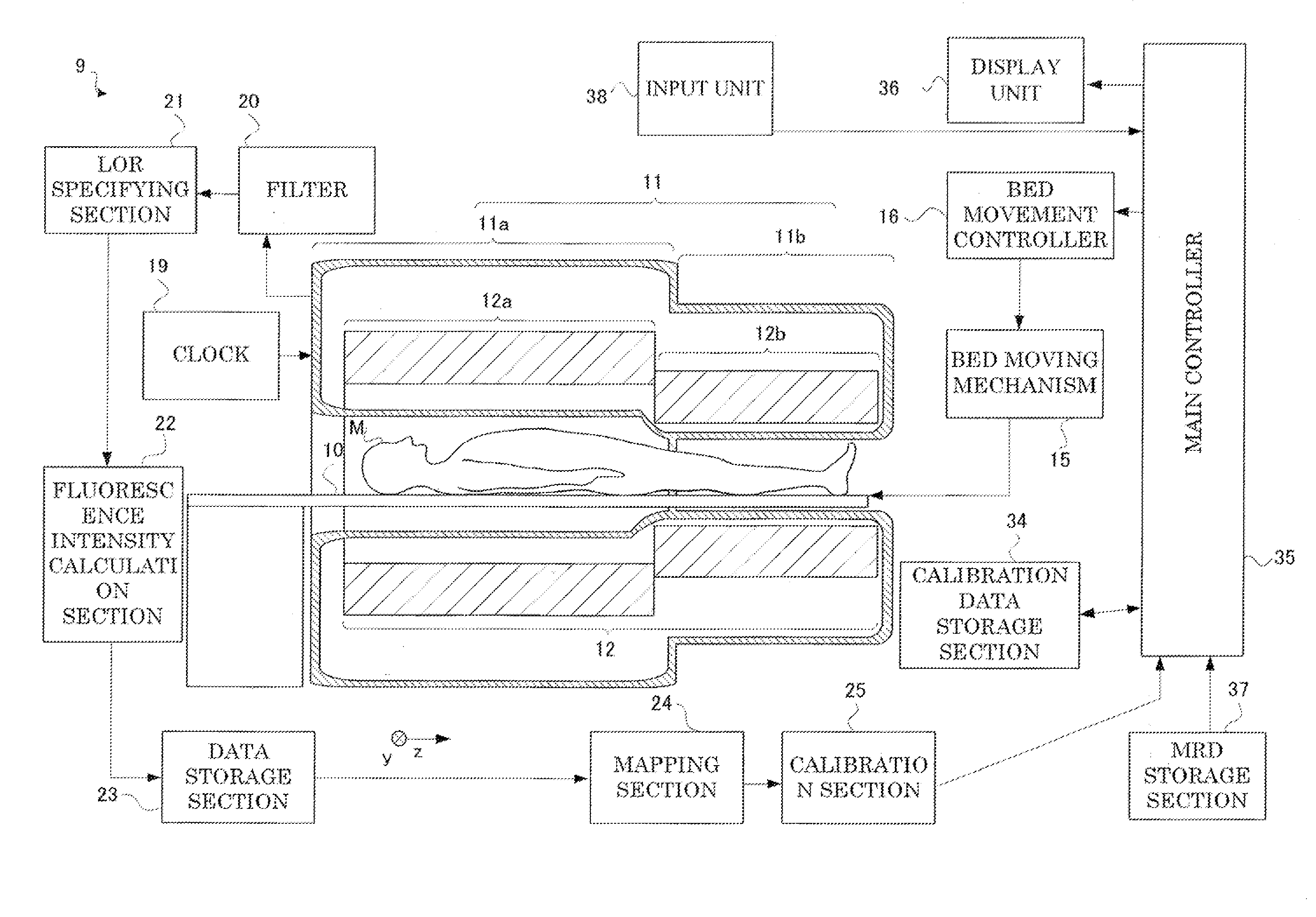

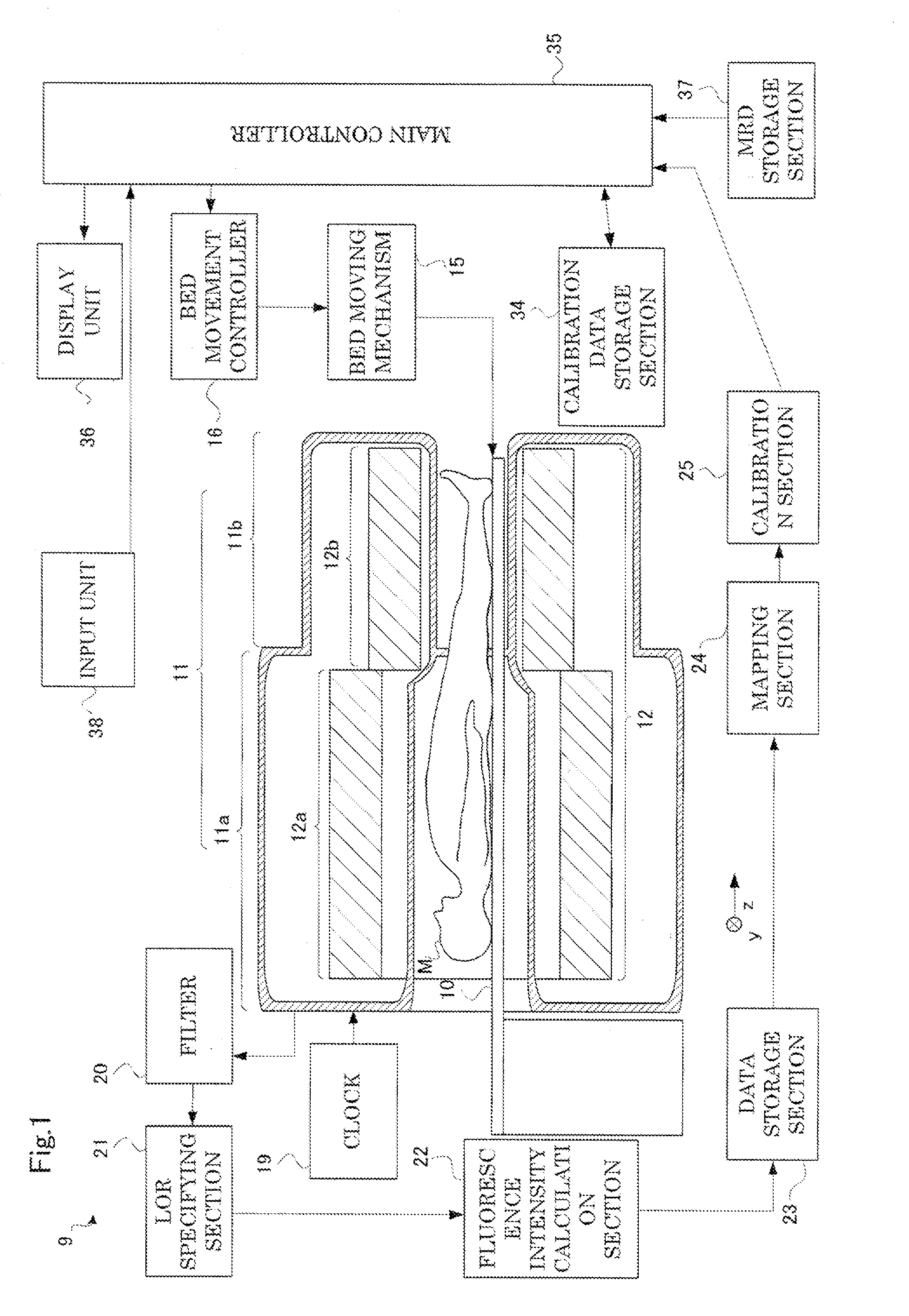

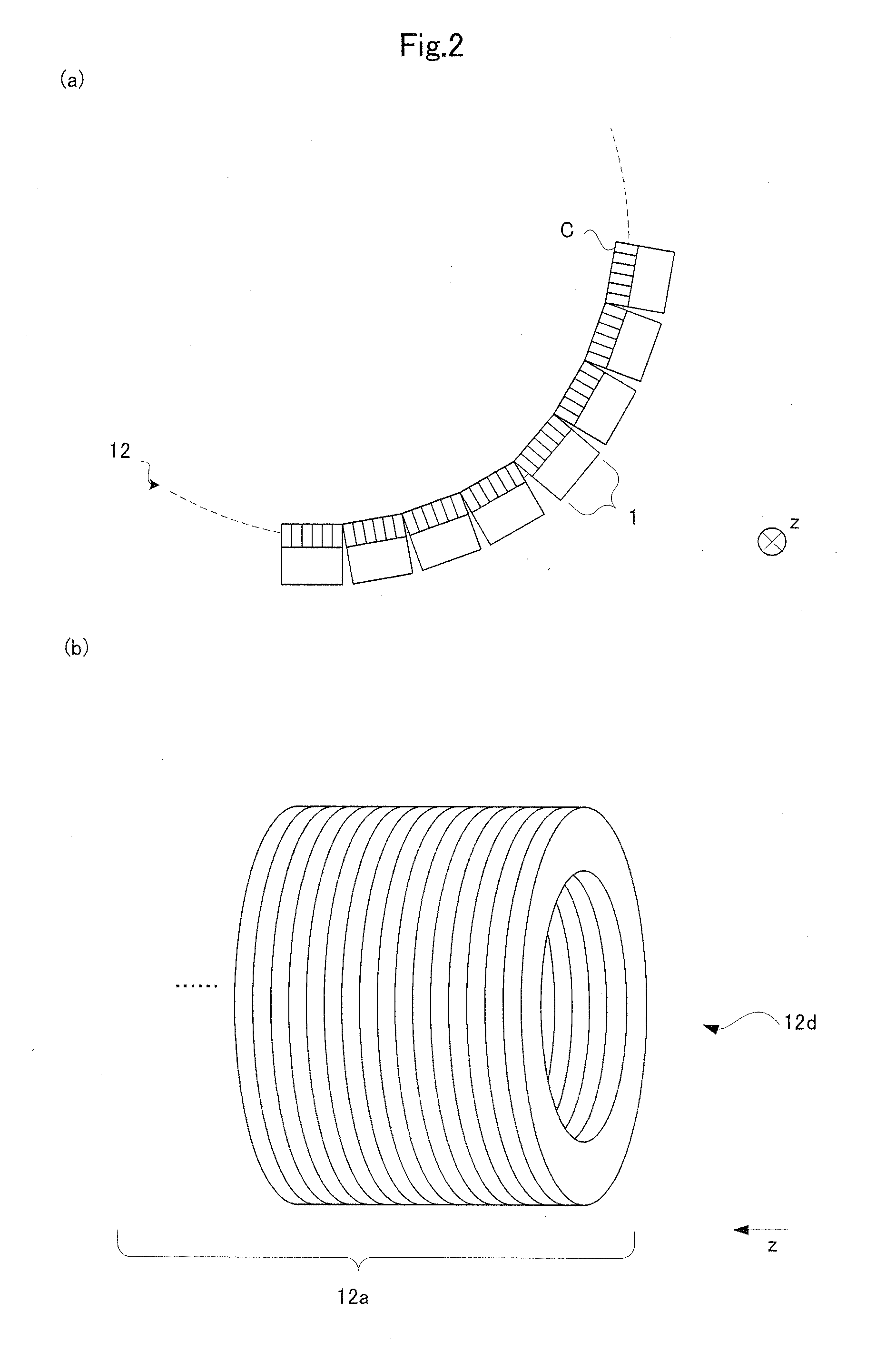

Radiation tomography apparatus

InactiveUS20120001077A1Low priceReduce the numberMaterial analysis by optical meansPatient positioning for diagnosticsImage resolutionTomography

This invention has one object is to provide radiation tomography apparatus that allows production with low price through suppression in number of radiation detectors to be mounted. One of the detector rings in this invention is a first detector ring having a sufficient internal diameter to introduce shoulders of the subject M, and the other is a second detector ring having a smaller internal diameter than the first detector ring. In so doing, the radiation detectors forming the detector ring may be suppressed in number, which may provide radiation tomography apparatus of low price. Moreover, a smaller diameter of the detector ring may result in improved spatial resolution and detection sensitivity of radiation.

Owner:SHIMADZU CORP

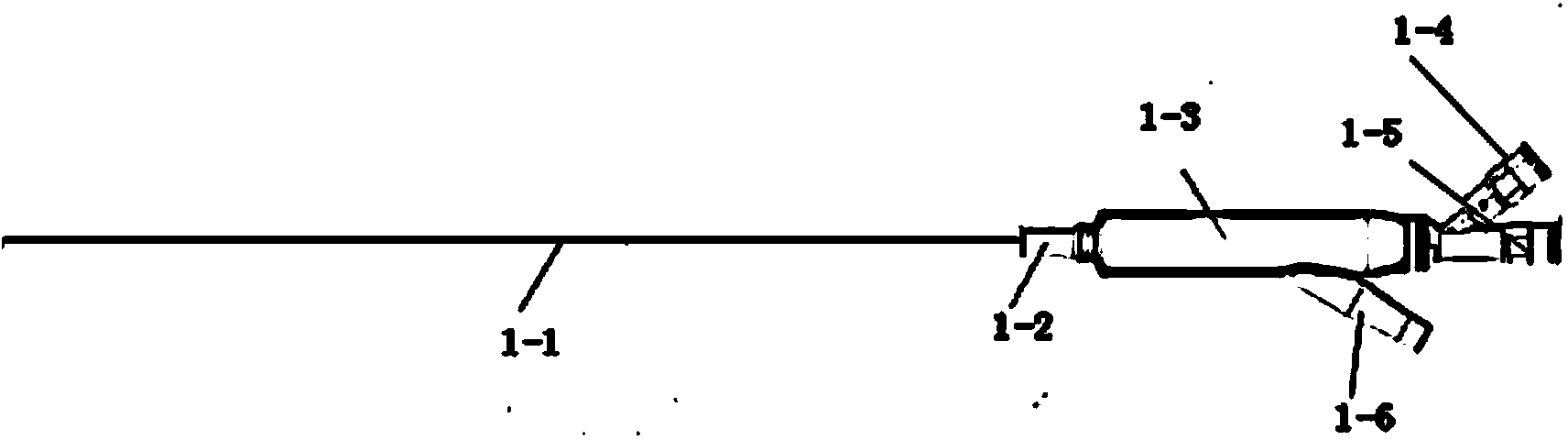

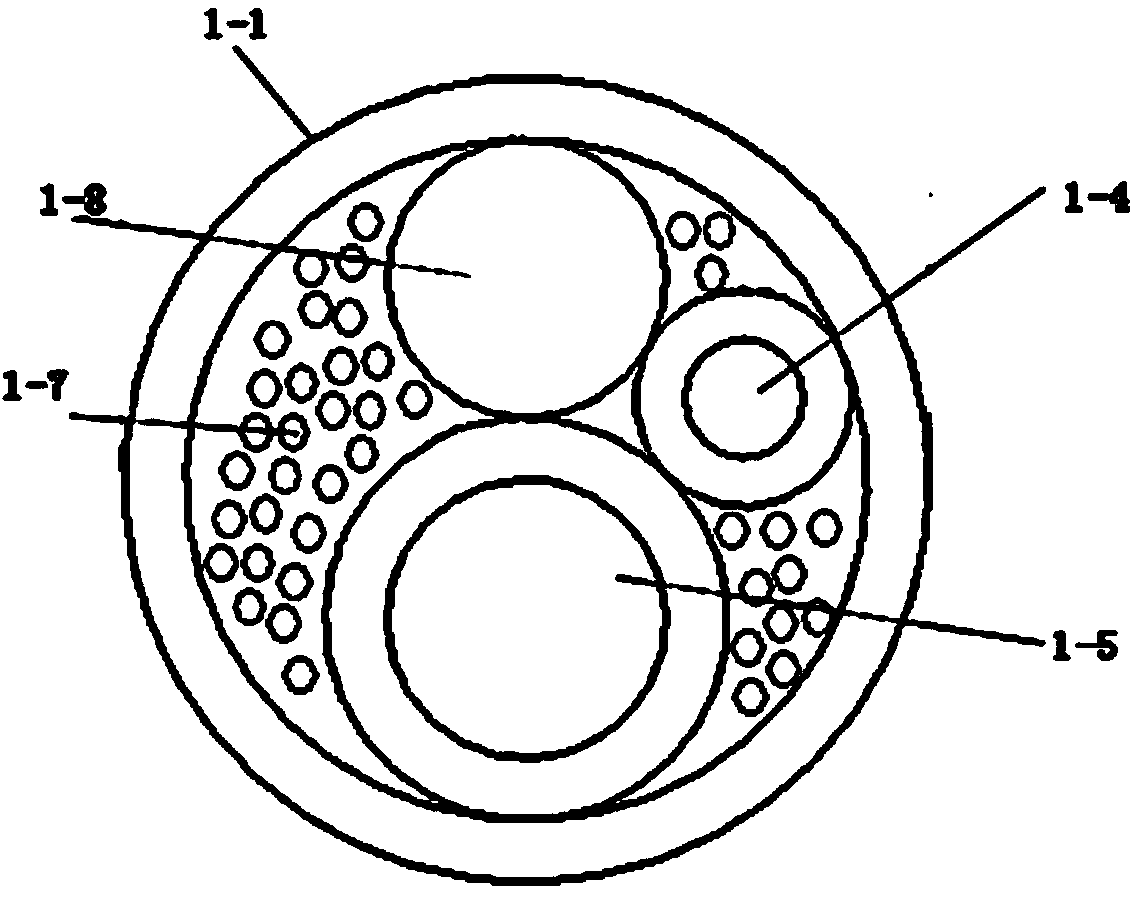

Endoscope component and medical equipment

ActiveCN103932656AReduce volumeSmall inner diameterSuture equipmentsInternal osteosythesisMedical equipmentLight guide

The invention discloses an endoscope component and medical equipment, and belongs to the technical field of medical treatment. The endoscope component comprises a work endoscope tube, an endoscope head, a handle and a light guide optical fiber. The work endoscope tube is provided with a liquid injection channel, an instrument channel and an imaging channel. The medical equipment comprises the endoscope component and a hollow needle-knife, and a liquid leading channel is formed between the inner wall of the hollow needle-knife and the outer wall of the work endoscope tube. The endoscope component comprises a small core optical imaging unit, and the size of the endoscope component is reduced; the liquid leading channel does not need to be arranged in the work endoscope tube, the inner diameter of the work endoscope tube is reduced, the inner diameter of the hollow needle-knife used in cooperation with the endoscope component is reduced, and injuries of a human body are reduced; the hollow needle-knife is used in cooperation with the endoscope component, so that blind operation of a needle-knife operation is changed to be visual operation, and the safety coefficient is improved.

Owner:乔晋琳

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com