Electric wheel hub

A technology of electric wheel hub and wheel hub, applied in the direction of wheel hub, electric components, electrical components, etc., can solve the problems of bloated wheel shape, increase in size, and increase in volume, etc., to simplify the external structure of the wheel hub, compact internal structure, and small external volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

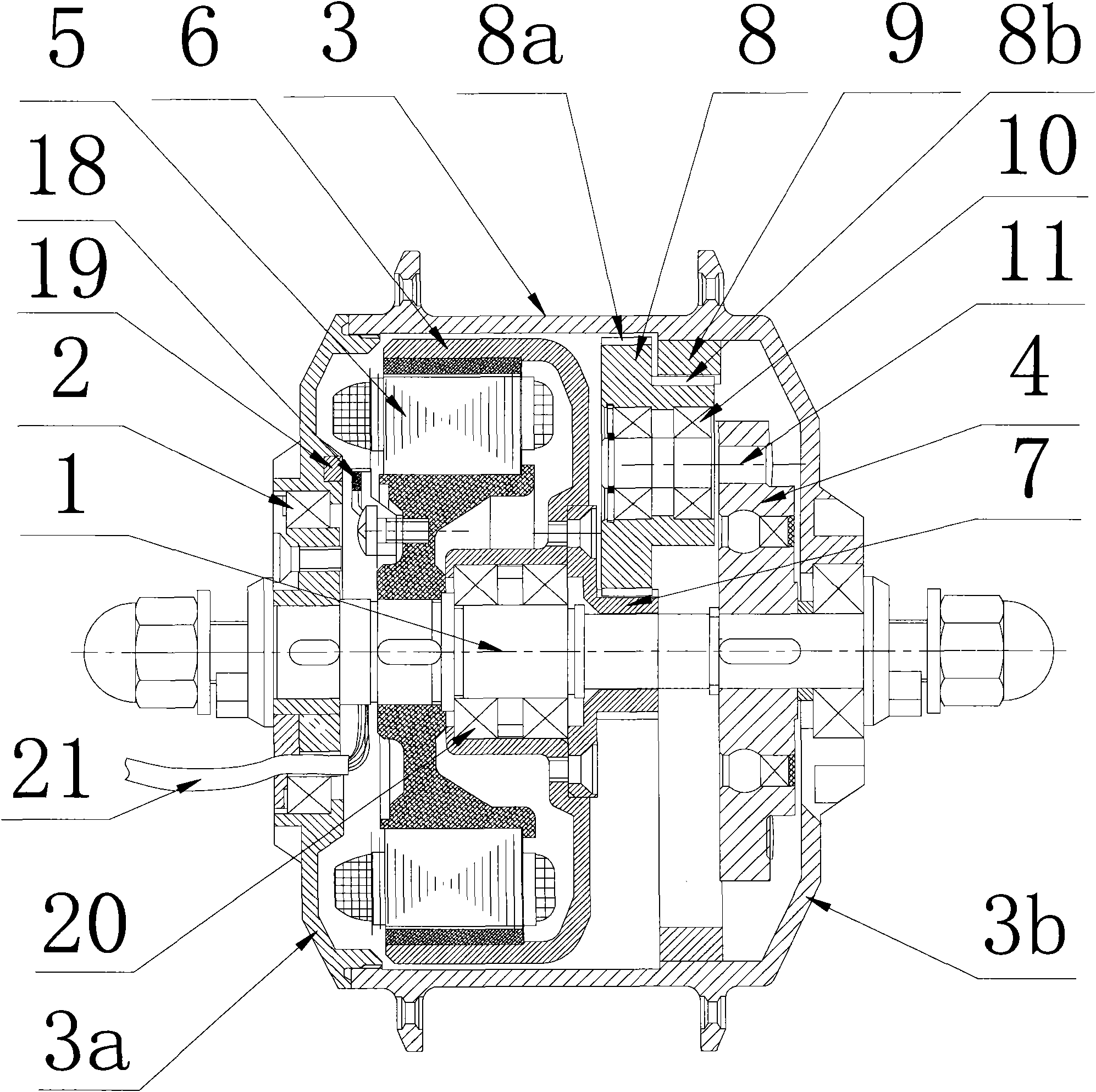

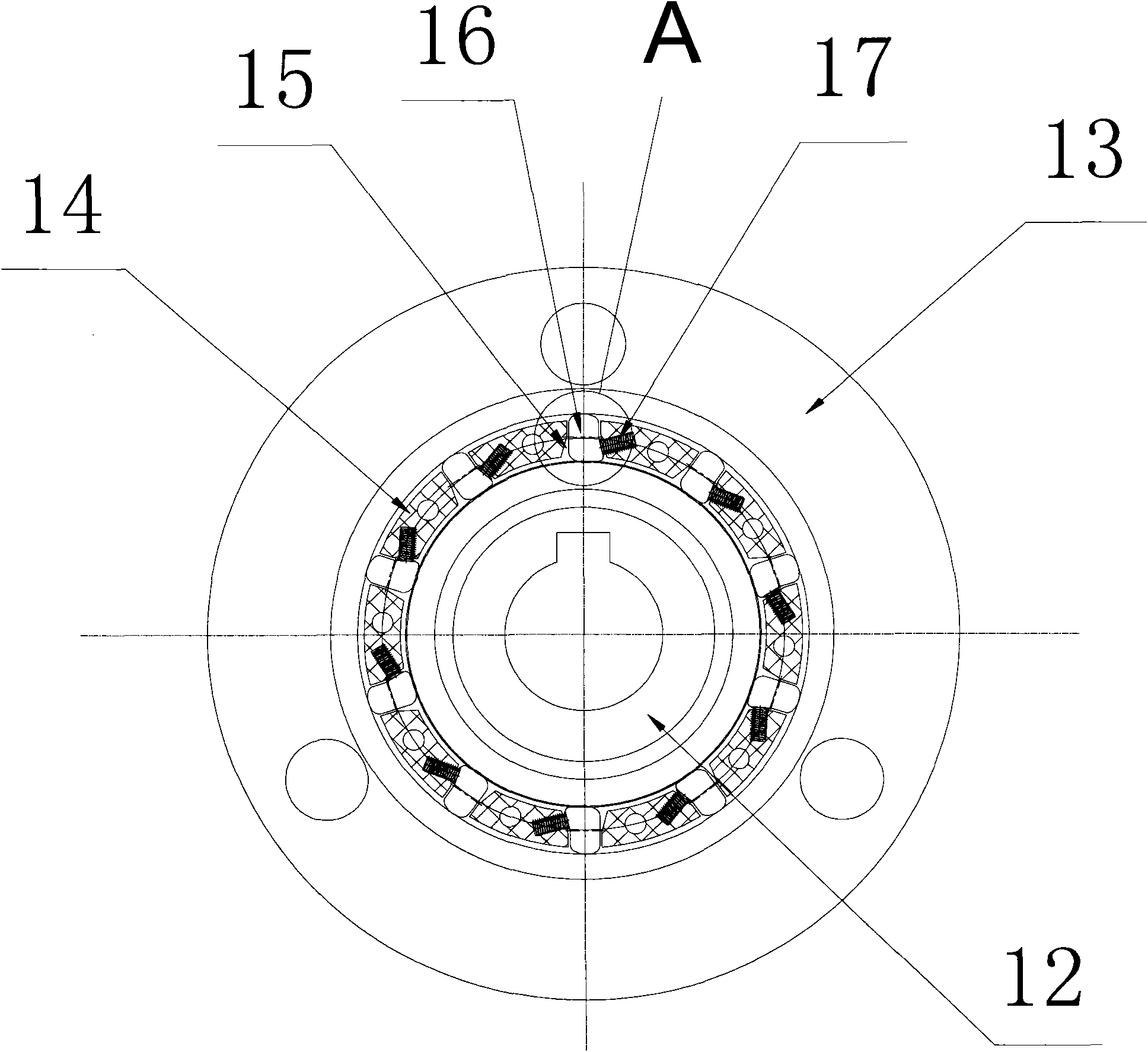

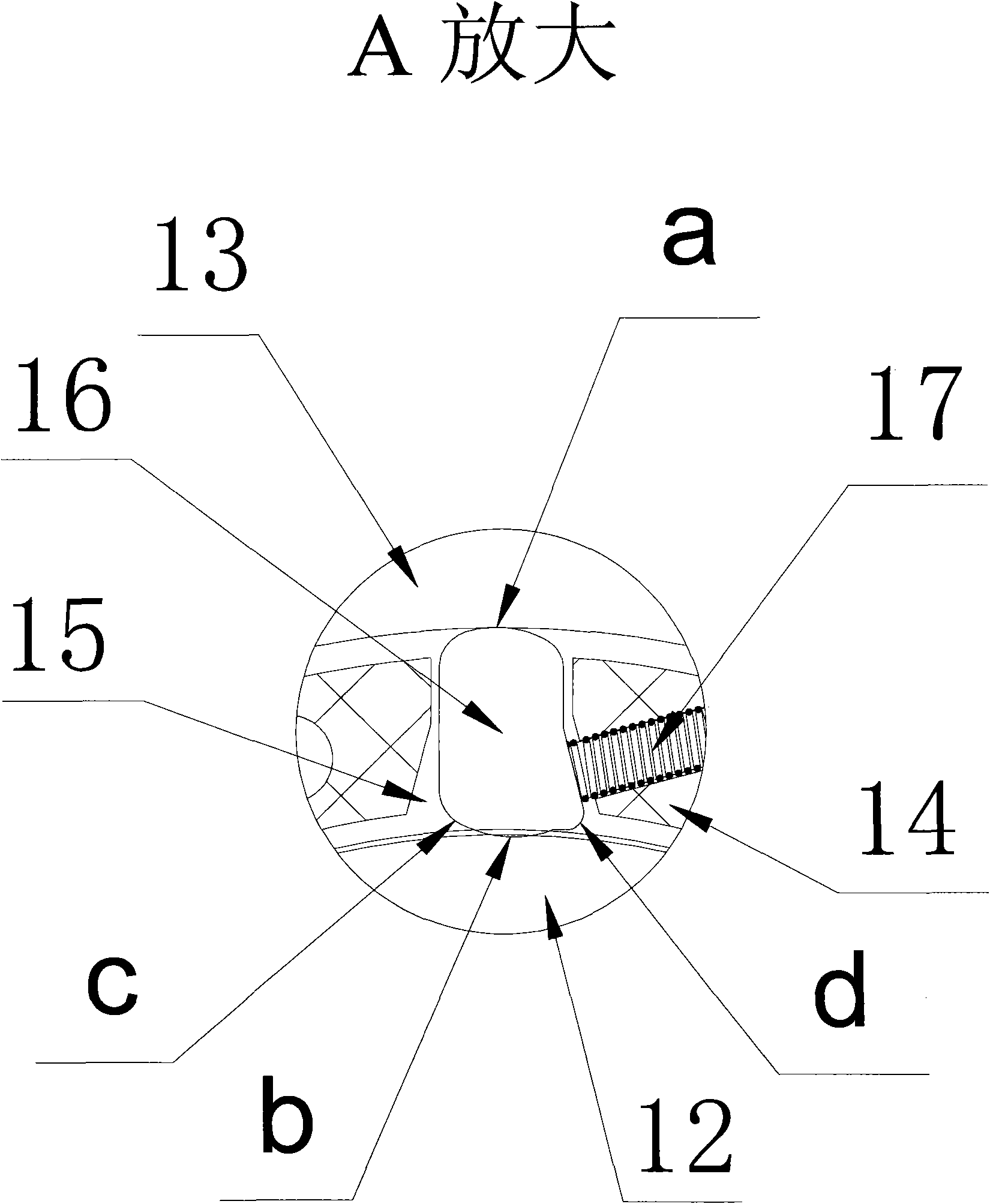

[0021] Embodiment 1: as figure 1 As shown, the electric hub provided in this embodiment includes a main shaft 1, on which a hub shell 3 is mounted, and the hub shell 3 is fixed by a left hub end cover 3a and a right hub cover 3b. and the hub cover 3a and the hub cover 3b are installed on the main shaft 1 through the hub shell bearing 2 respectively. A speed sensor, a motor and a planetary gear reduction mechanism are installed in the hub shell 3 from left to right. The motor adopts an outer stator inner rotor structure, the stator 5 is fixed on the main shaft 1, the rotor 6 is installed on the main shaft 1 through the two-stage rotor bearing 20, and the sun gear 7 sleeved on the main shaft 1 is fixed on the rotor 6 , the sun gear 7 meshes with three planetary gears 8 ( figure 1 Only one is shown in ), the planetary gears 8 are double gears, which are made of two coaxially integrated gears of the same size and the same modulus. The large gear 8a meshes with the sun gear 7, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com