Patents

Literature

1948results about How to "Simple internal structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

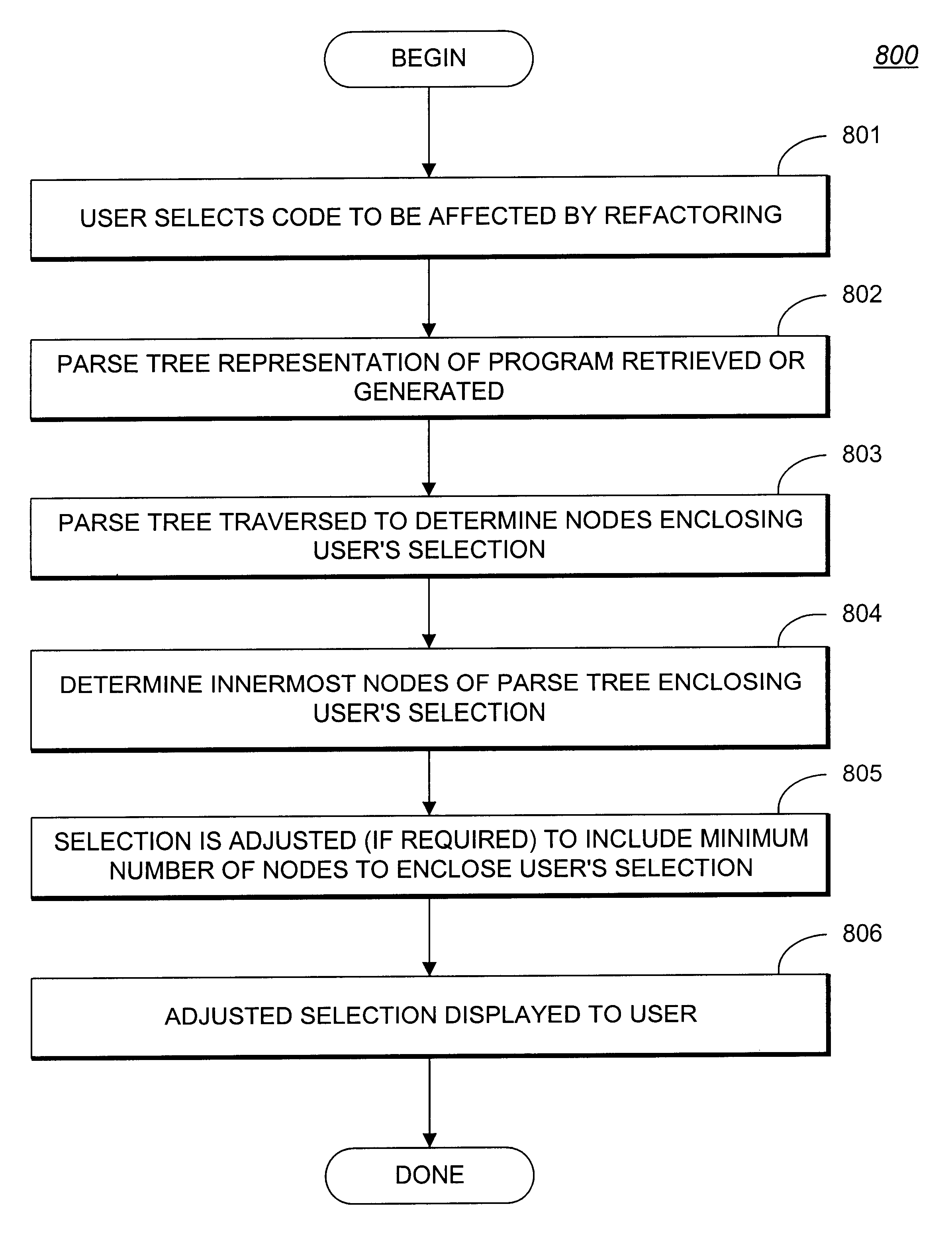

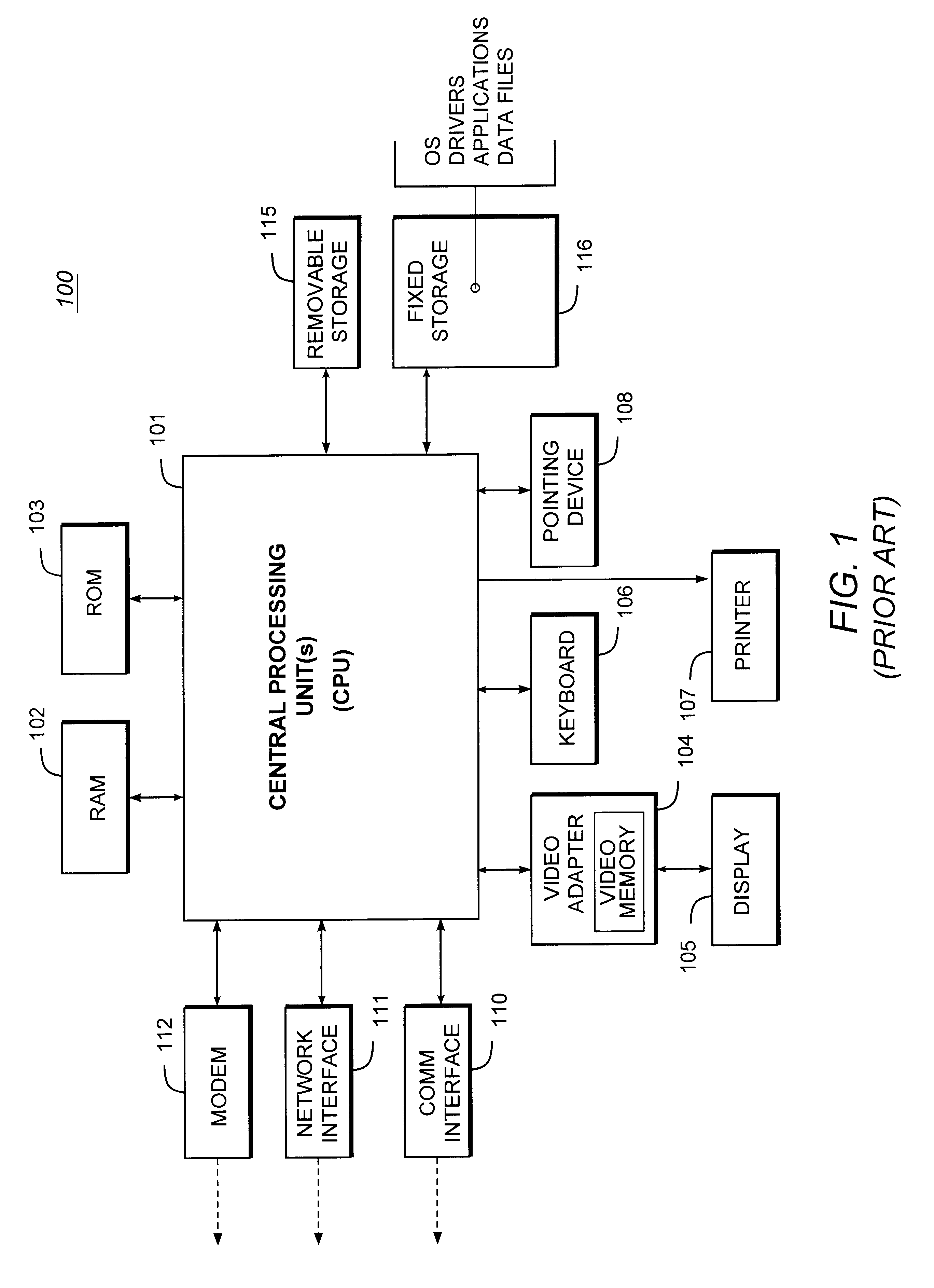

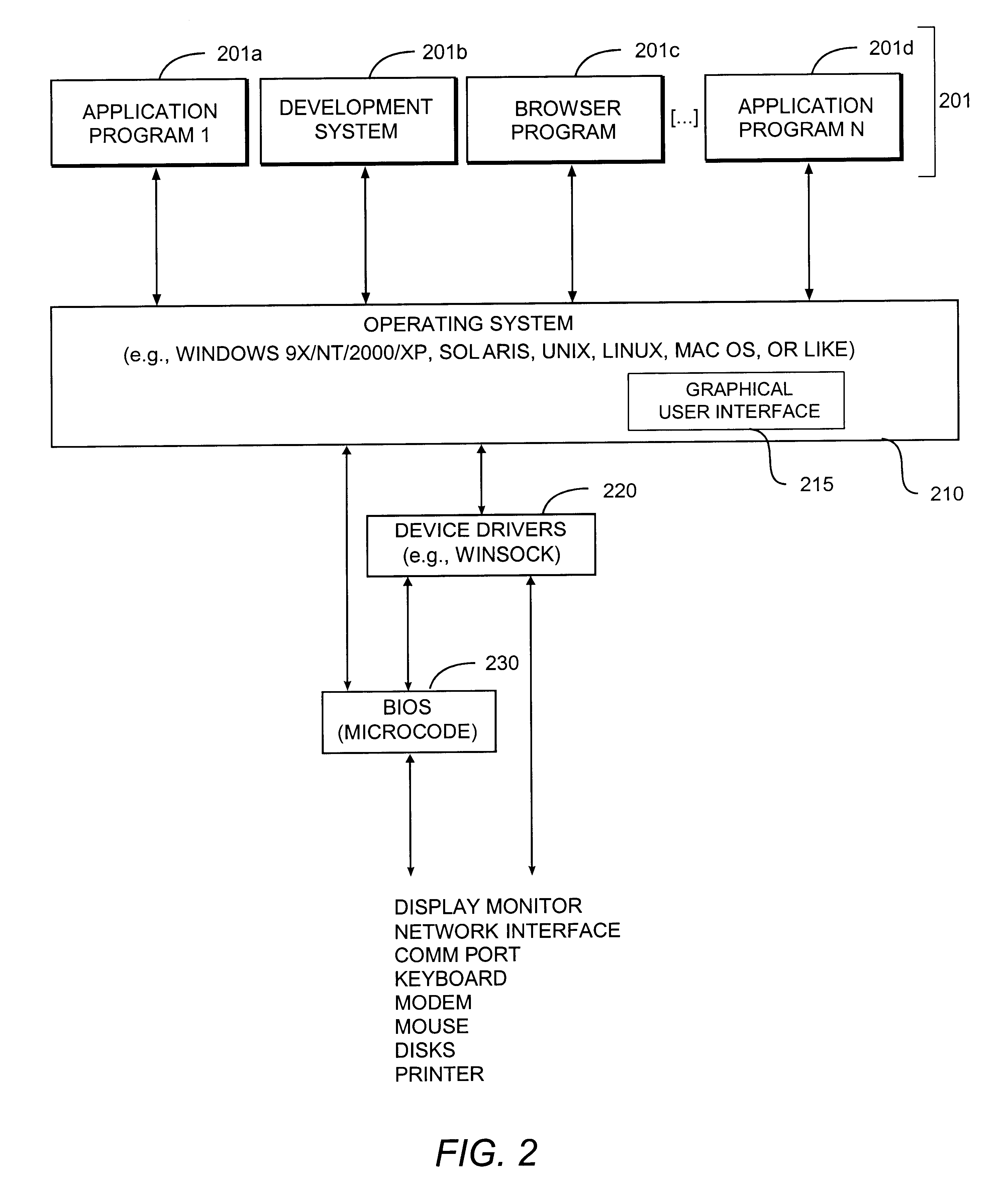

System and methodology providing automated selection adjustment for refactoring

InactiveUS6807548B1Simple internal structureSimplifying additionData processing applicationsCode refactoringUser inputSource code

A system providing methods for adjusting a user's selection of source code of a program to correspond with a parsed version of the program is described. The method commences with user input of a selection of source code of a program for performing an operation such as a refactoring. The user's selection is compared with a parsed version of the program. If the user's selection does not correspond with the parsed version of the program, the user's selection is adjusted to achieve correspondence with the parsed version of the program.

Owner:CODEGEAR

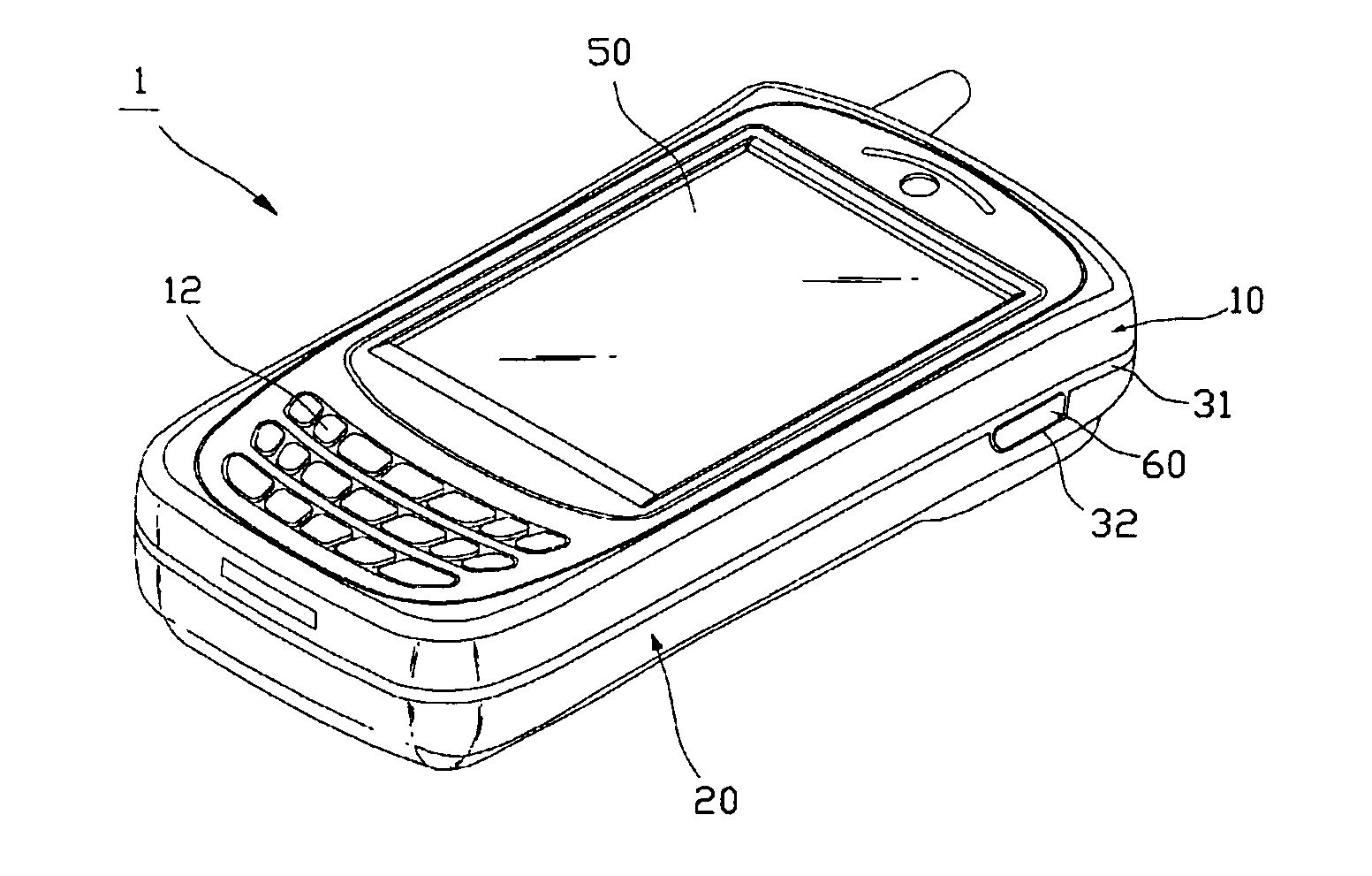

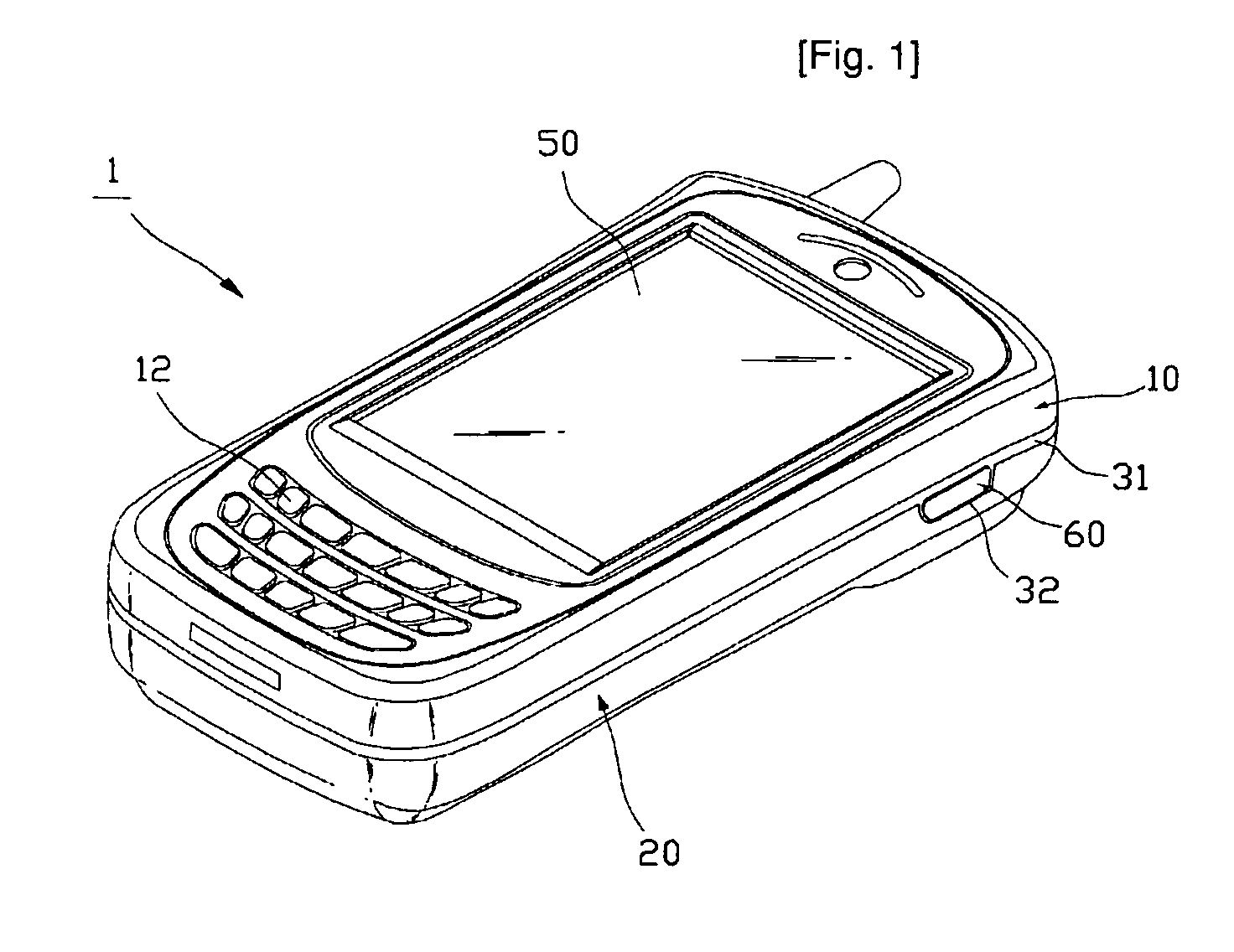

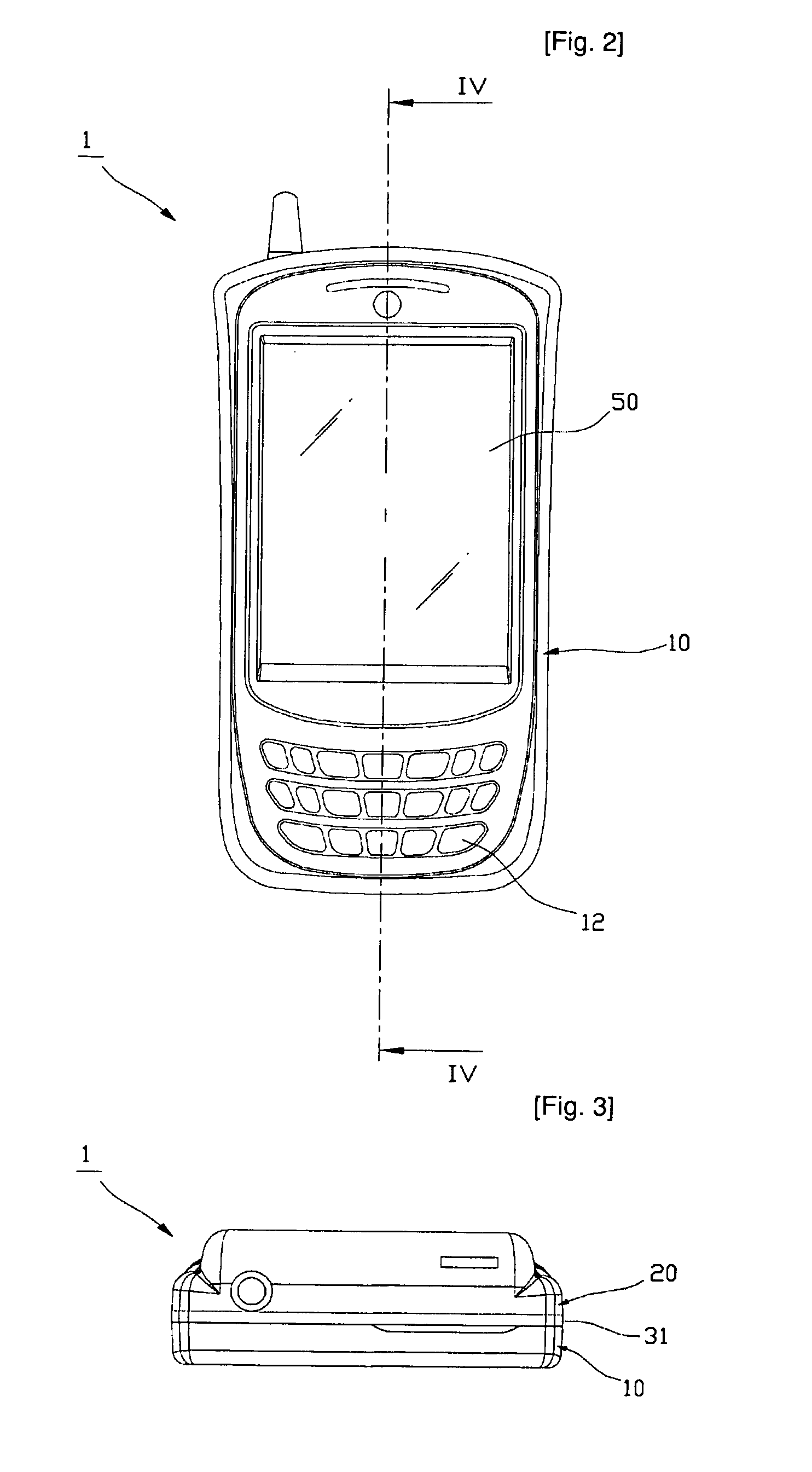

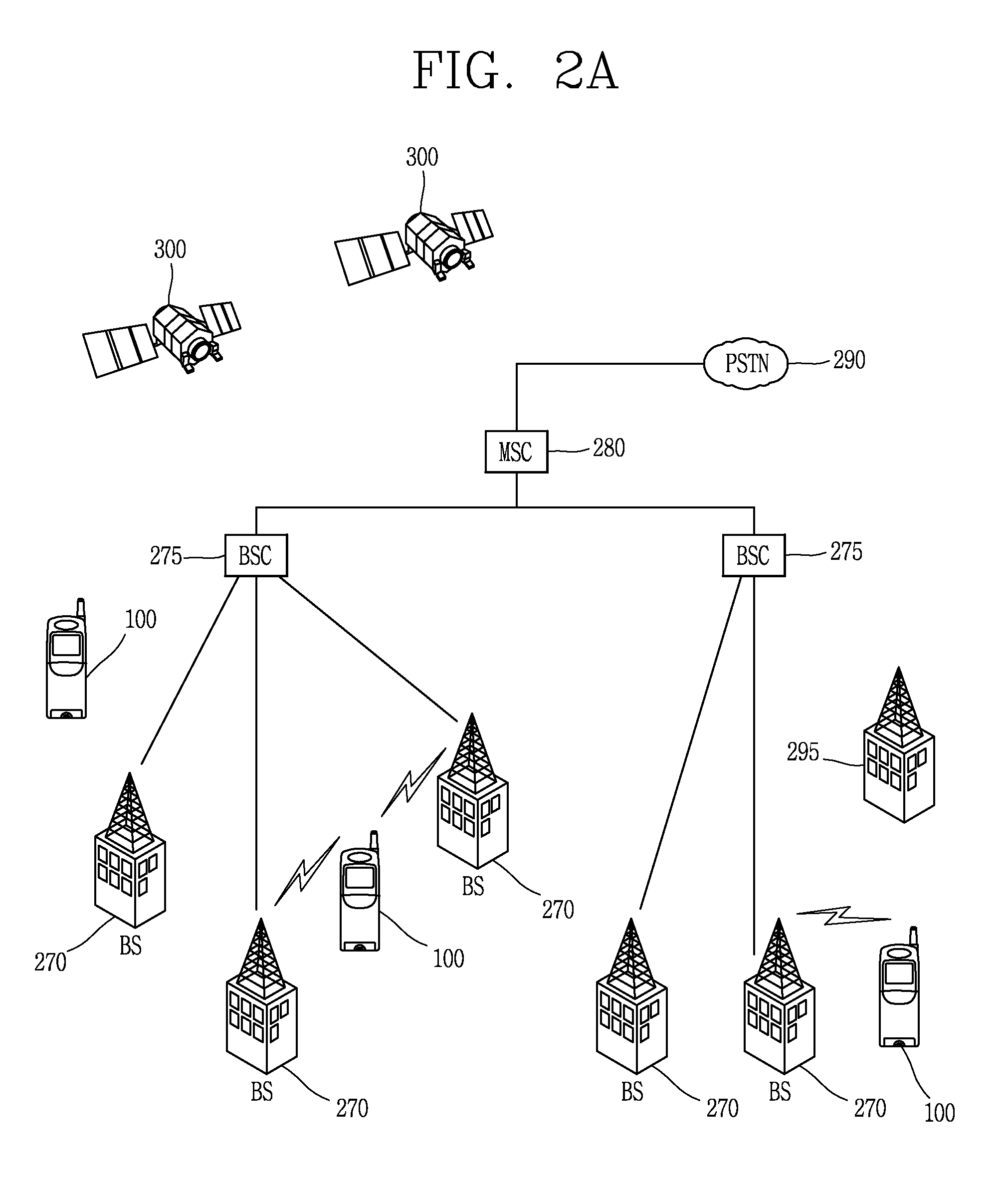

Mobile terminal

ActiveUS20090291709A1Simple structureSimplify the assembly processDigital data processing detailsDigital computer detailsEngineeringSynthetic resin

A mobile terminal includes an upper casing having at least one exposure opening formed by penetrating a predetermined area thereof, a lower casing coupled to the upper casing to face each other and having an accommodation space formed therein and capable of accommodating an internal part assembly including a printed circuit board, and a middle frame arranged between the upper casing and the lower casing and coupled to the upper casing and the lower casing, and supporting installation parts electrically connected to the internal part assembly and installed such that at least part thereof is exposed to the outside through the exposure opening. A resin mold waterproof ring which is injection molded of synthetic resin having elasticity to have a predetermined width along at least part of an edge portion of the middle frame is integrally coupled to the middle frame and, when the upper casing, the lower casing, and the middle frame are coupled one another, the resin mold waterproof ring is pressed by the upper casing and the lower casing to seal a gap between the upper casing and the lower casing.

Owner:BLUEBIRD

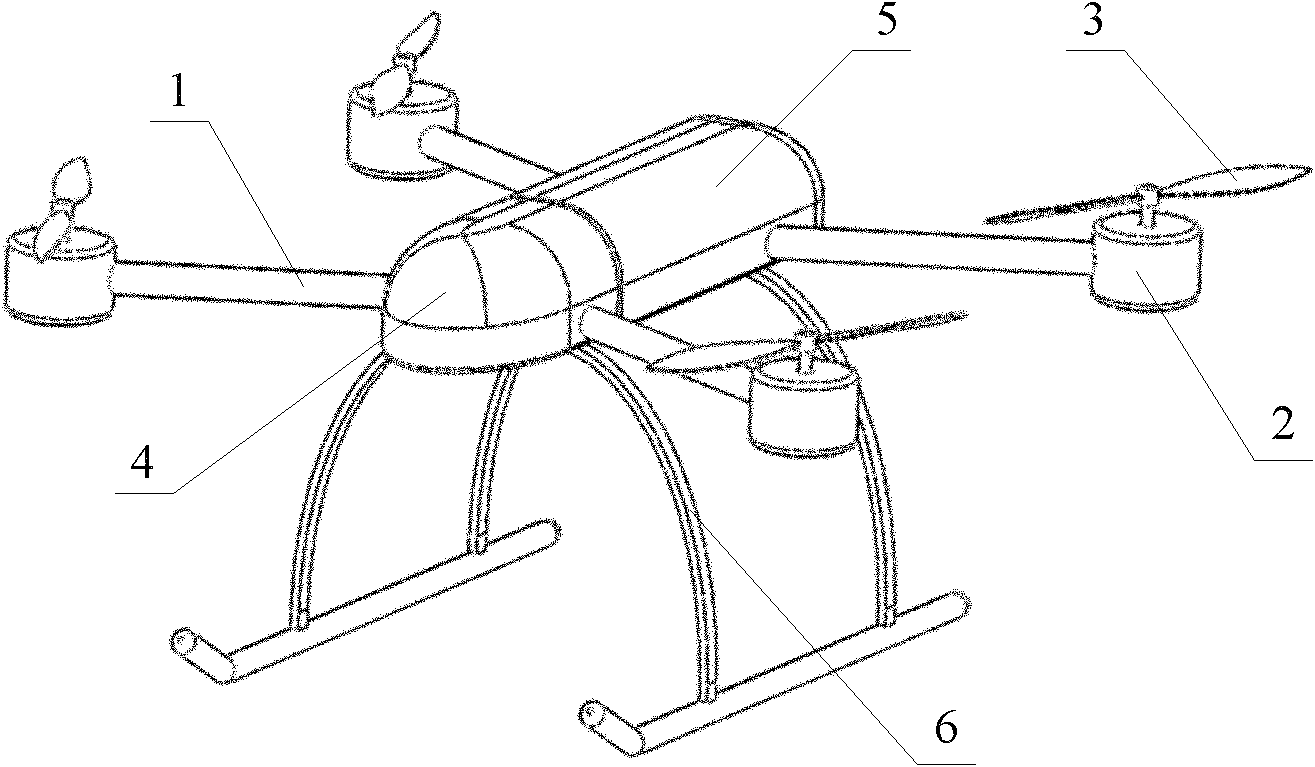

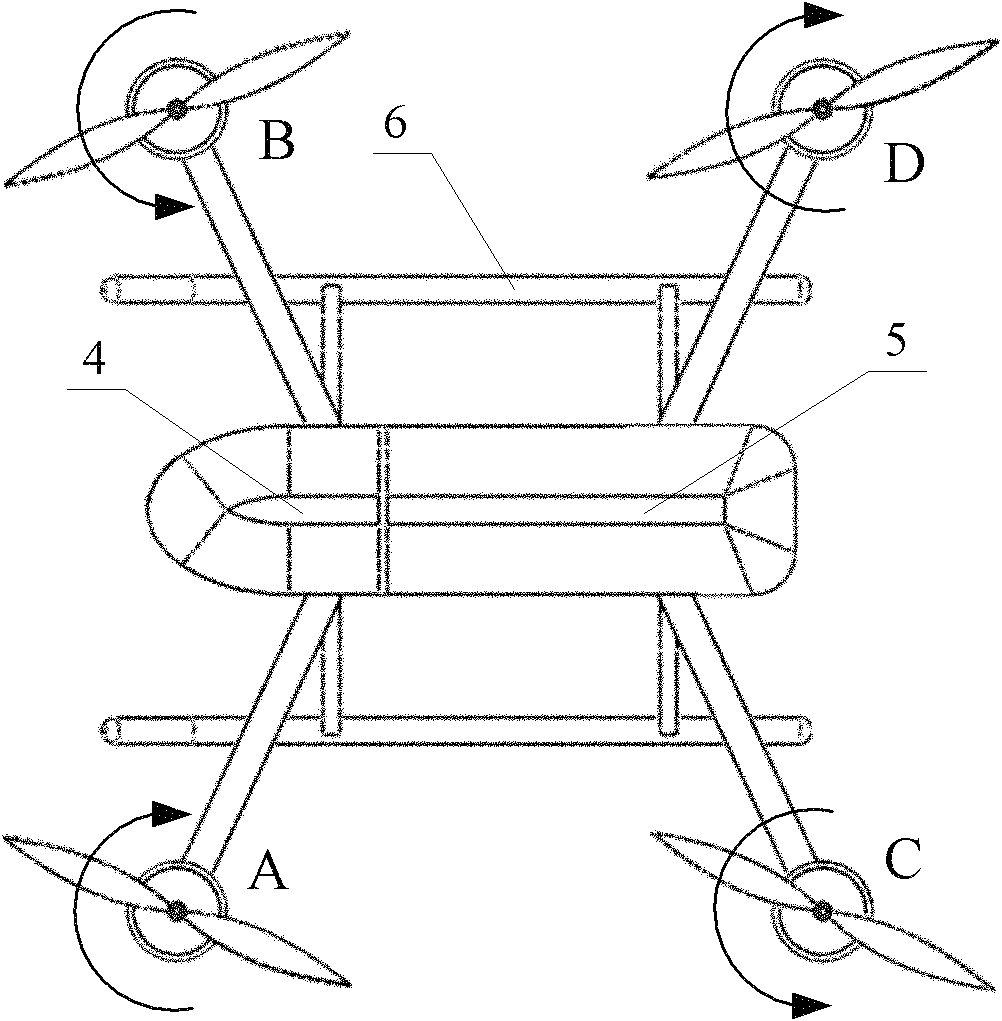

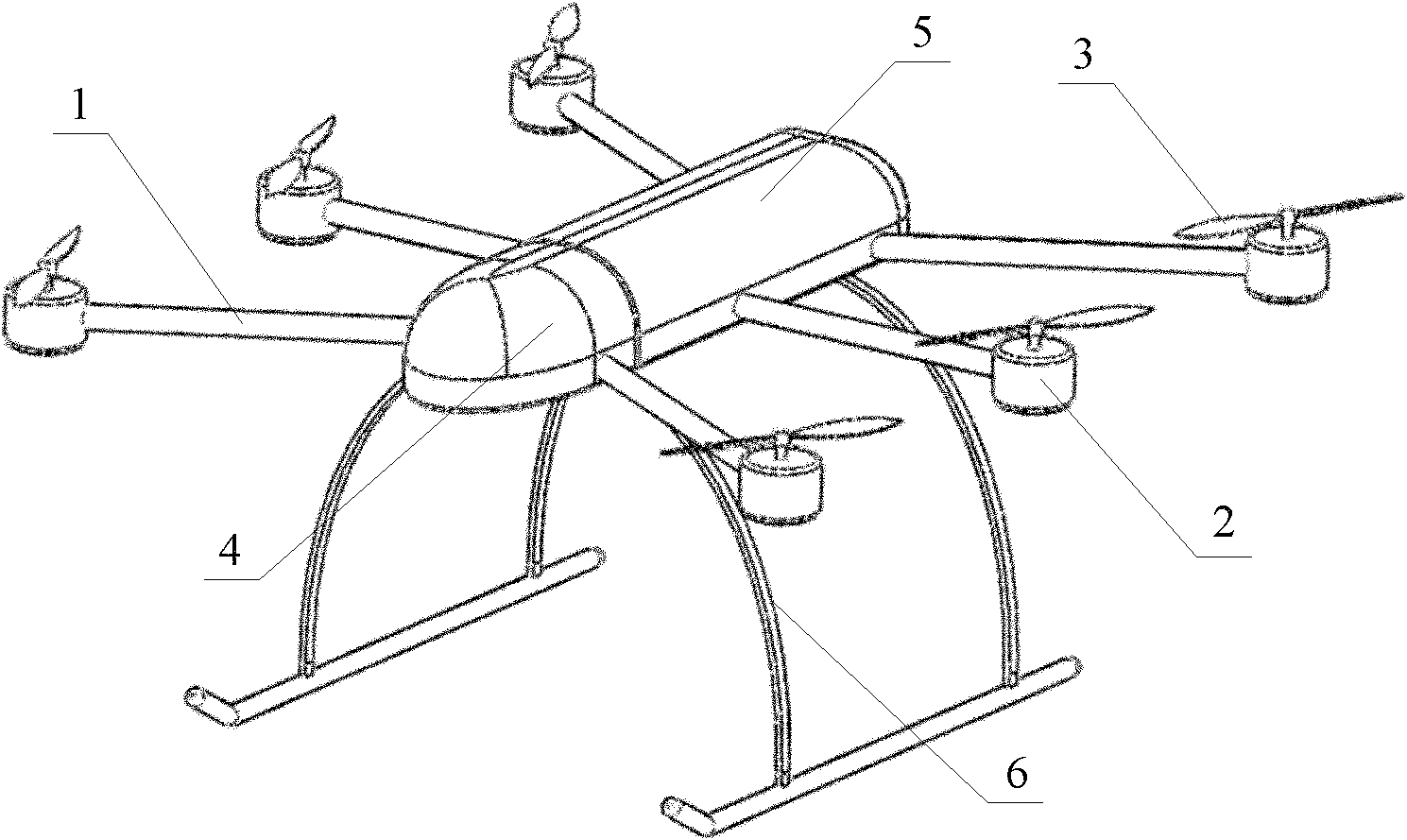

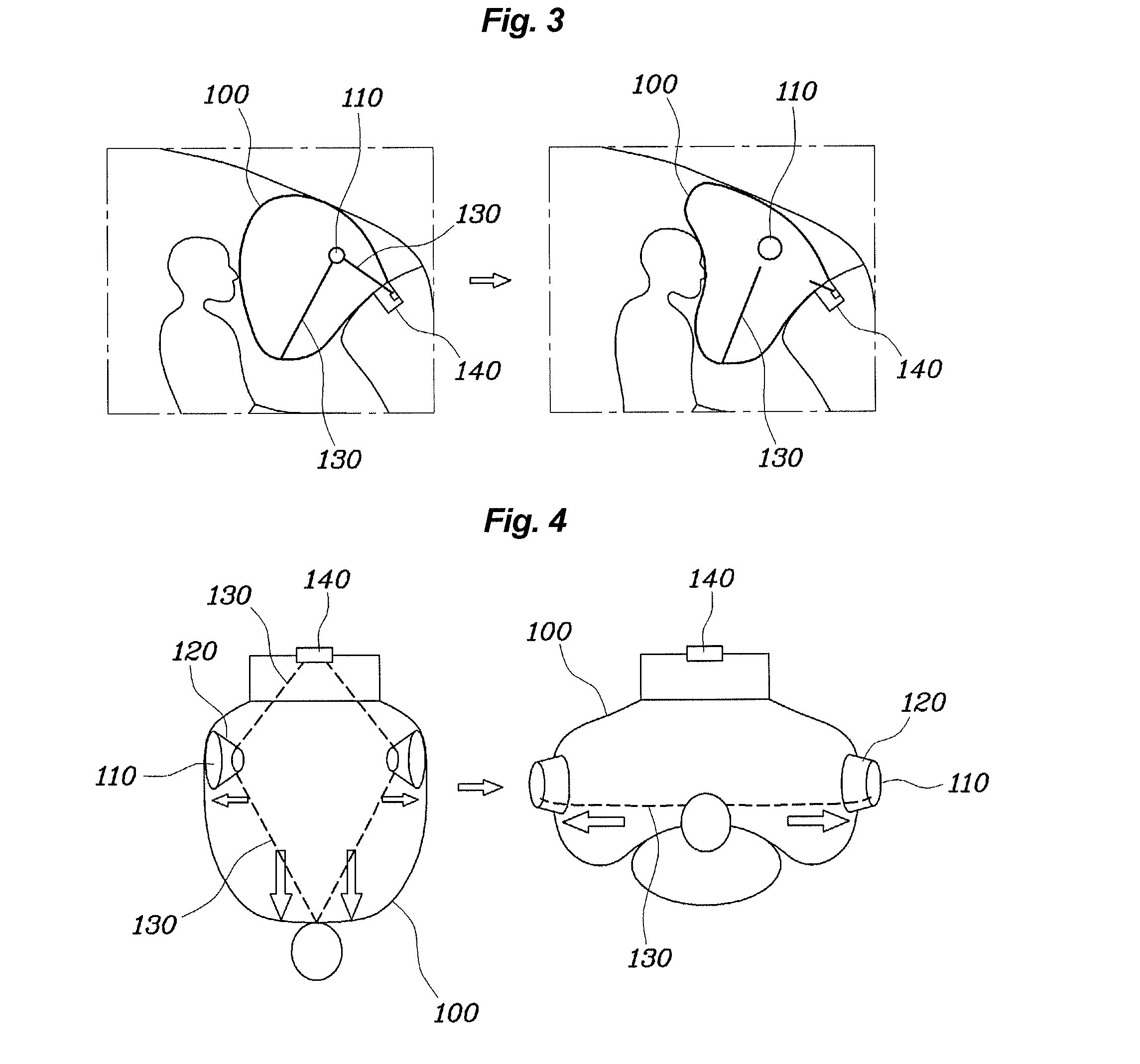

Unmanned air vehicle with multiple rotary wings in plane-symmetry layout

InactiveCN102126554AEasy to identifyEasy to operateRotocraftAircraft indicatorsFlight vehicleElectric machinery

The invention discloses an unmanned air vehicle with multiple rotary wings in a plane-symmetry layout, comprising a body, rotary wing assemblies and undercarriage, wherein, the number of the rotary wing assemblies is an even number more than or equal to 4; each rotary wing assembly comprises a rotary wing support arm, a rotary wing motor and a rotary wing, the rotary wing motor is fixed at the outer end of the rotary wing support arm; the rotary wing is arranged on a rotation shaft of the rotary wing motor and is driven by the rotary wing motor; the longitudinal symmetrical planes of the all rotary wing assemblies relative to the body are distributed in a bilateral symmetry mode, and are fixedly connected with the two sides of the body through the inner ends of the rotary wing support arms; an equipment compartment and a power source compartment separated front and back are arranged in the body, the equipment compartment comprises a navigation component, a flight control component and a communication component; the power source compartment comprises a battery for providing power to the electronic equipment of the whole air vehicle; the undercarriage is fixedly connected at the lower part of the body; and the flight control component is provided with a flight control computer with the functions of fault diagnosis of the multiple rotary wings and fault-tolerant flight control. The unmanned air vehicle has the advantages of novel appearance layout, concise internal structure, reliable system control and better engineering application value, and is easy for engineering implementation.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

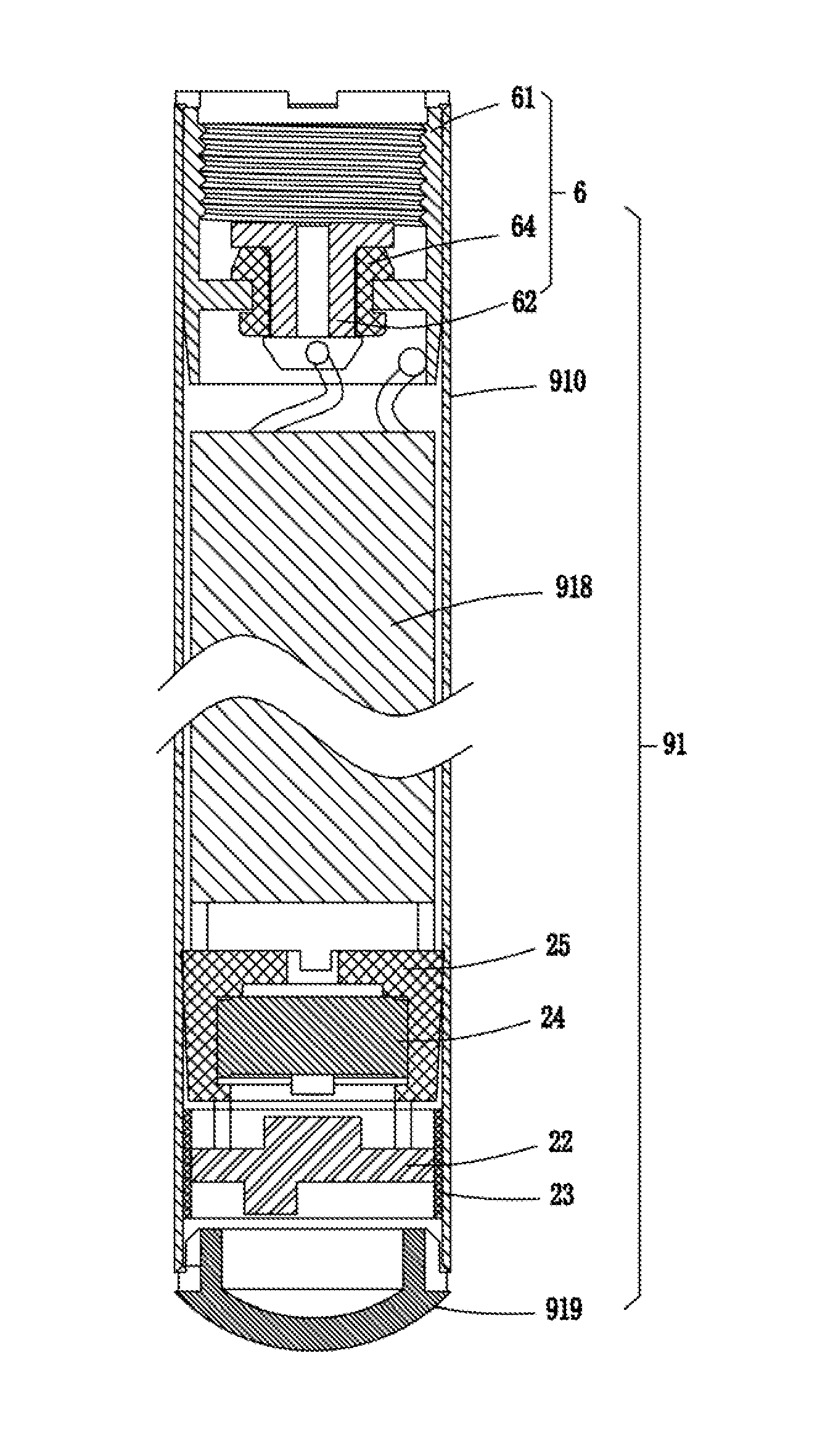

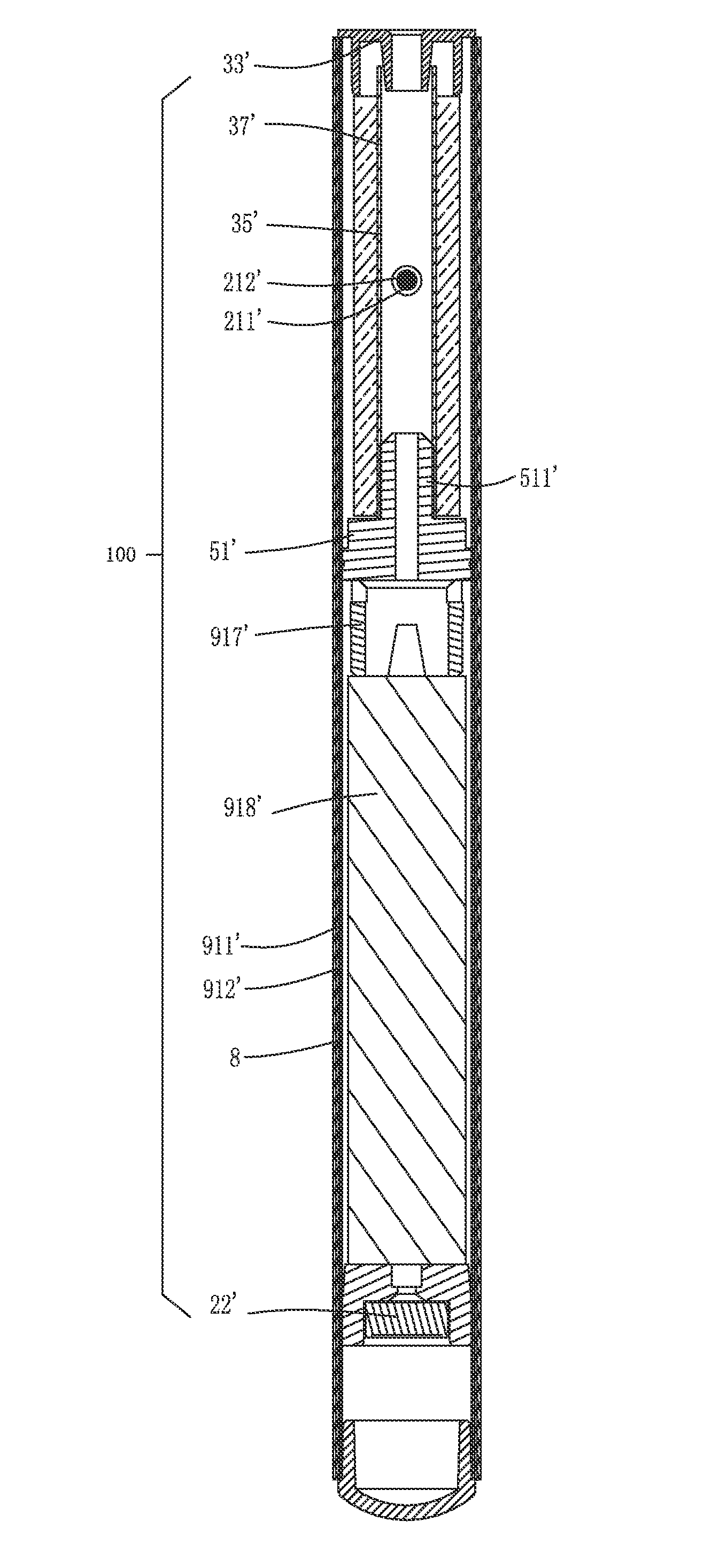

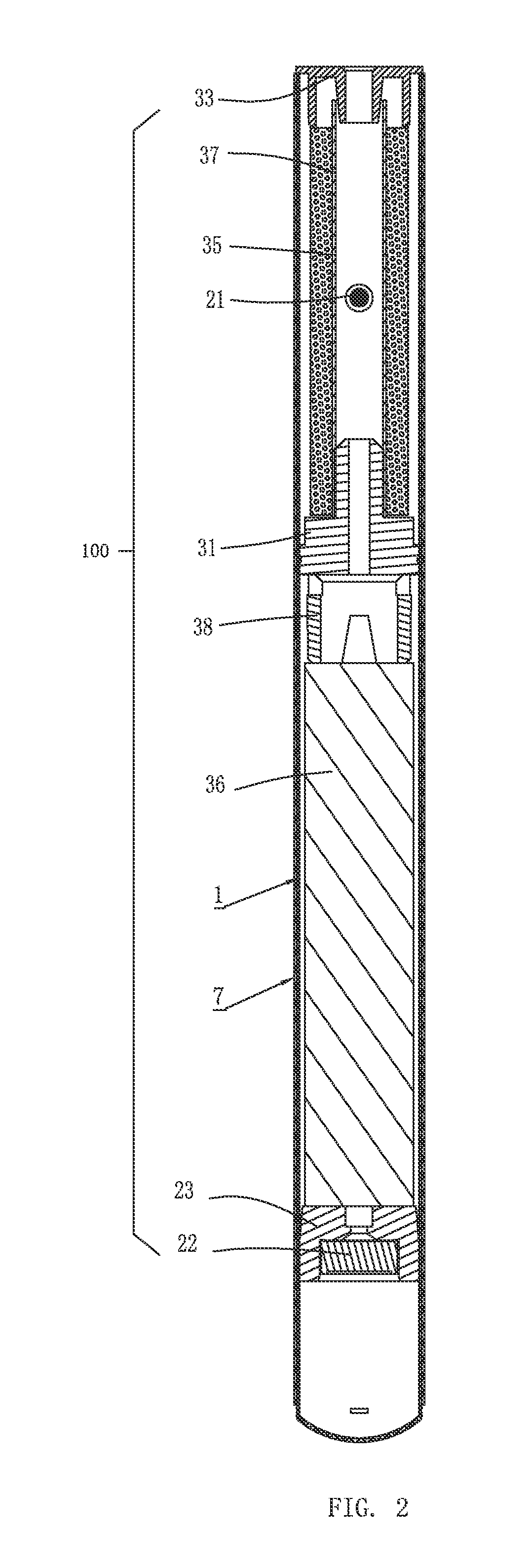

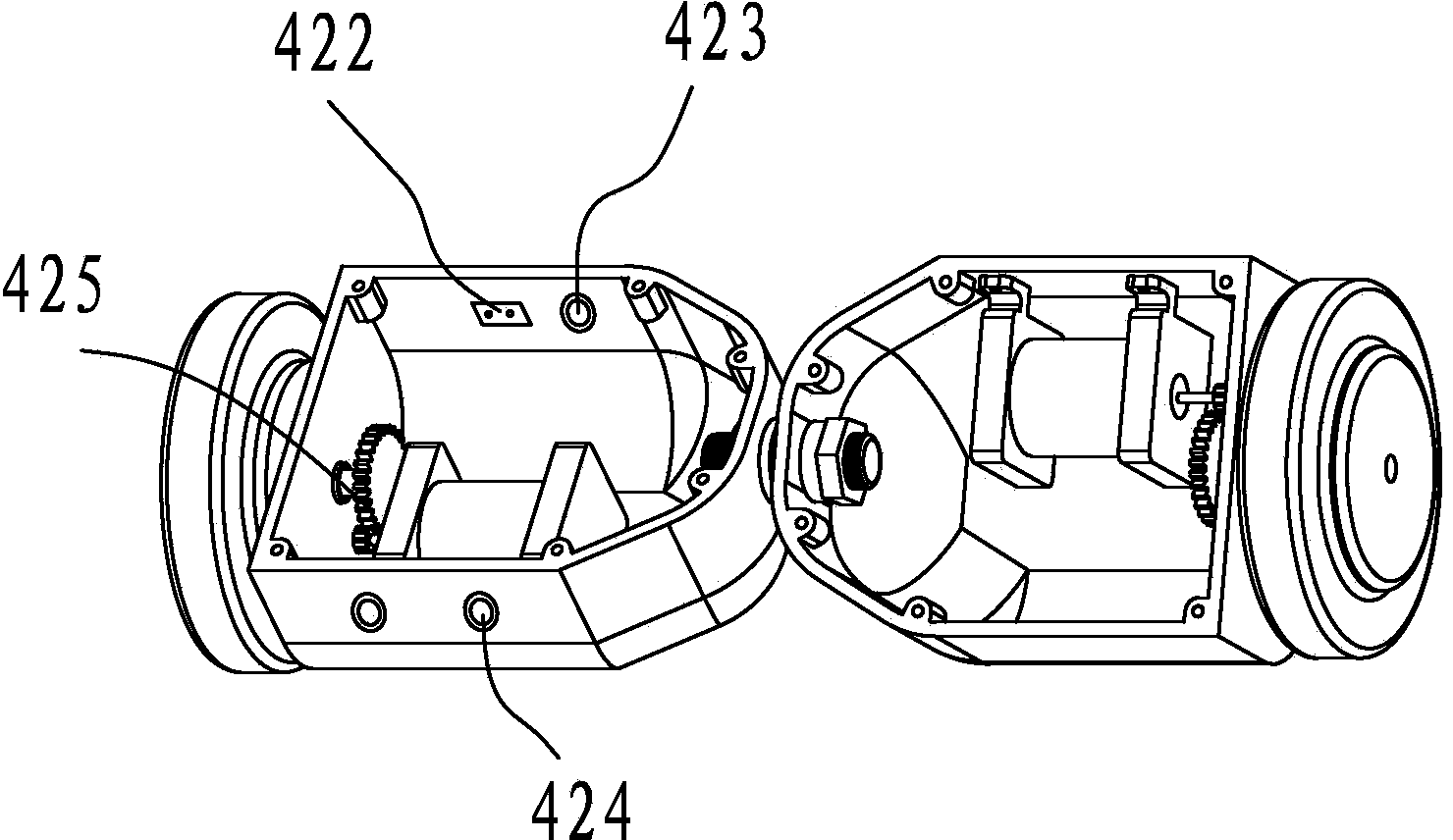

Electronic cigarette

InactiveUS20160113325A1Quickly and conveniently assembledEasy to operateTobacco pipesTobacco devicesElectrical batteryEngineering

An electronic cigarette comprising a housing and, arranged within the housing, an atomizer apparatus and a power supply control apparatus used for providing power supply to the atomizer apparatus and for controlling the working of same. The power supply control apparatus comprises a battery, a microphone, and a control panel. The microphone and the control panel are both arranged at one end of the battery. The microphone is adjacent to the battery. The control panel is arranged in proximity to an opening end of the housing and is adjacent to the microphone. The microphone and the control panel are insulated and separated from each other. The electronic cigarette is structurally simple and is easy and convenient to assemble.

Owner:KIMREE HI TECH

Electronic cigarette

InactiveUS20150128970A1Feel goodIncrease flexibilityTobacco pipesTobacco devicesSoft layerElectronic cigarette

The invention is related to an electronic cigarette, including an outer shell; at least two soft layers are fitted around the outer shell and wrap the outer shell therein; the outer shell therein has a liquid storage component, an atomizer and a power supply; one end of the outer shell is set with a mouthpiece cover; the outer shell therein is further set with an liquid isolation component; the liquid storage component is disposed in a closed space enclosed by the mouthpiece cover, part of the outer shell and the liquid isolation component; inner wall of the liquid storage component is set with a conduit supporting the liquid storage component, the conduit is respectively communicated with the mouthpiece cover and the liquid isolation component; the atomizer is fixedly supported in the conduit. The electronic cigarette offers favorable feeling to touch and mouth, a simple structure, and quick and convenient assembly.

Owner:KIMREE HI TECH

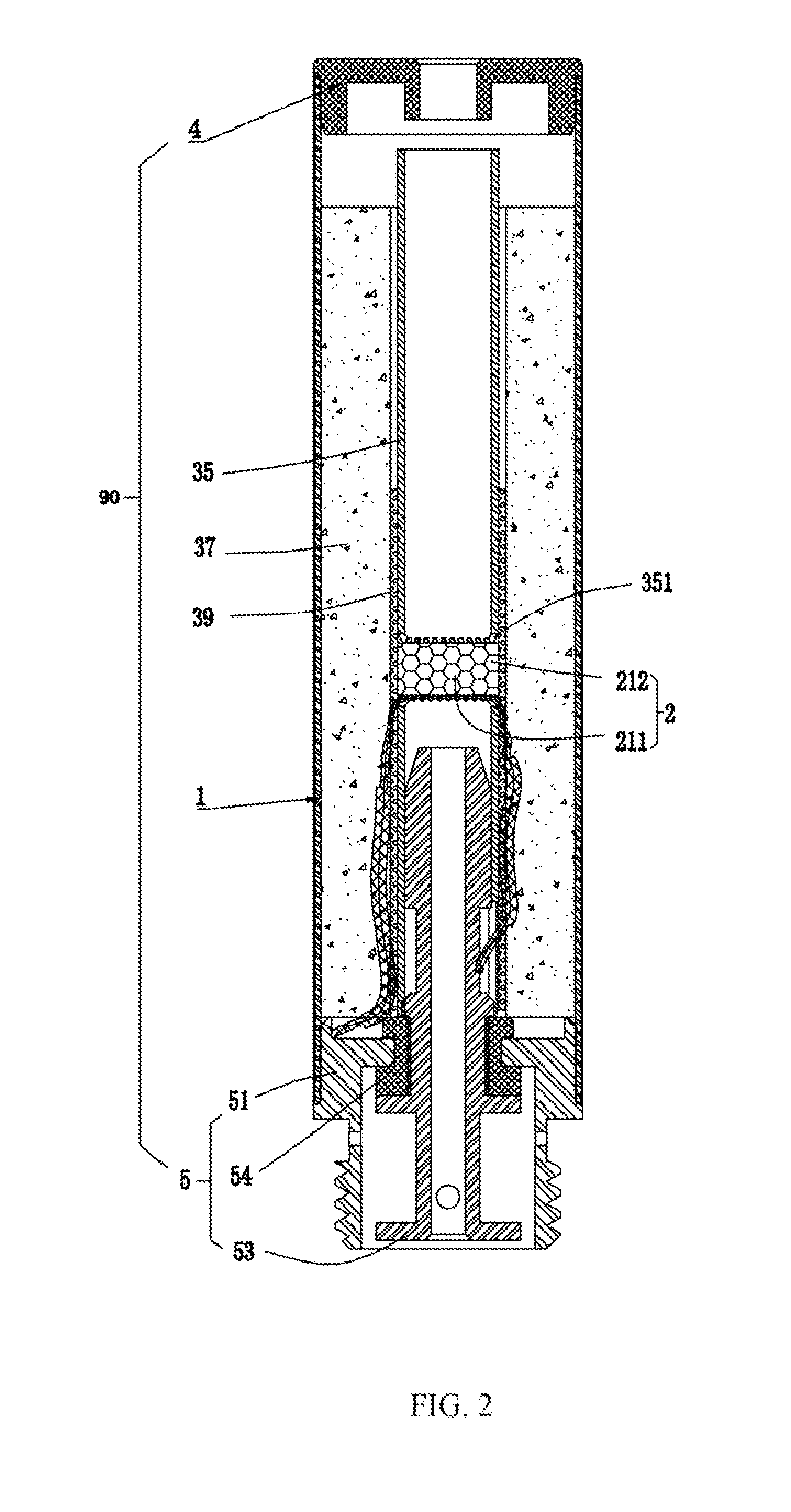

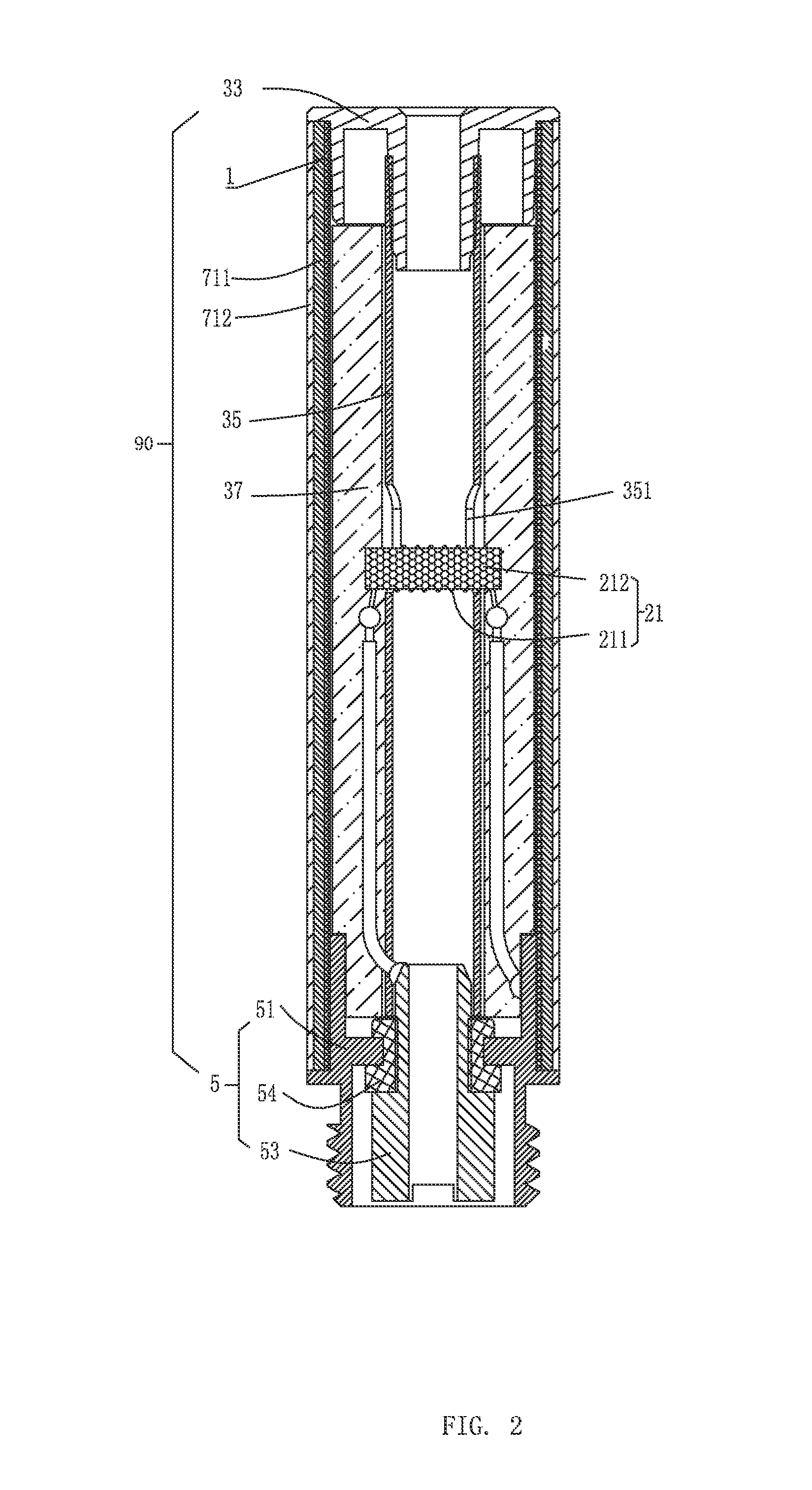

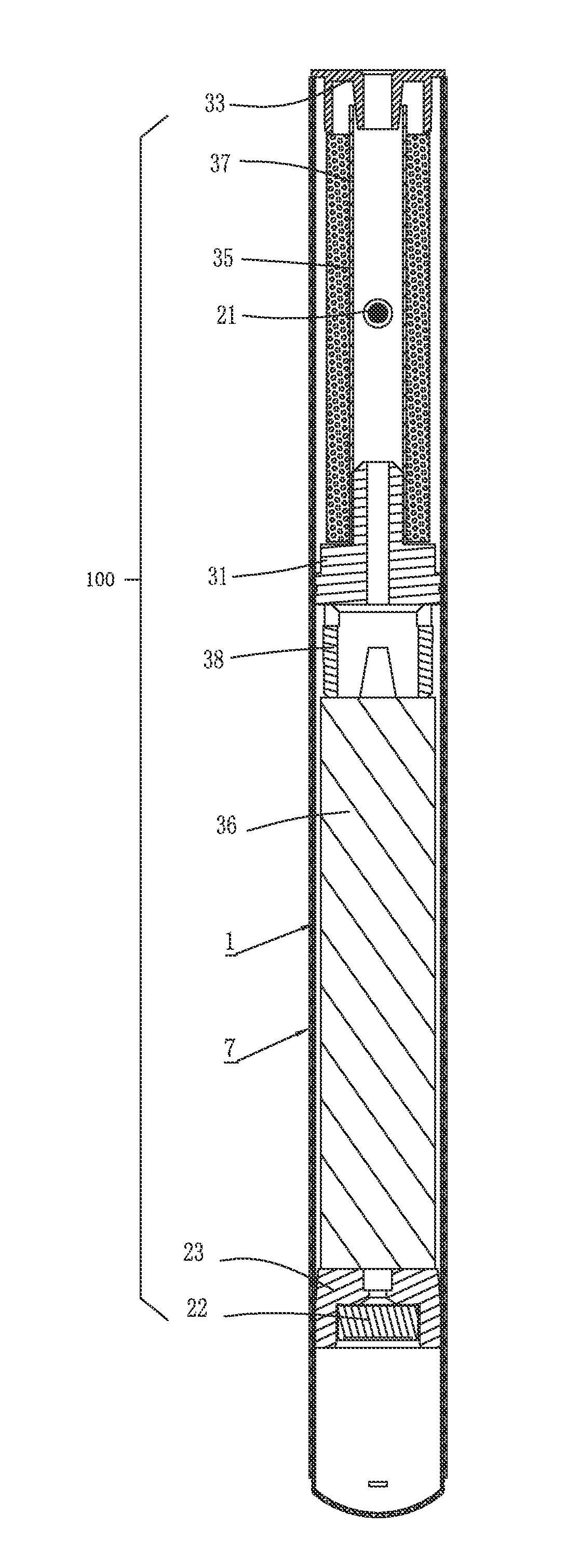

Electronic cigarette

InactiveUS20150181941A1Simple structureQuickly and conveniently assembledTobacco pipesTobacco devicesElectronic cigaretteWaste management

An electronic cigarette comprising a cylindrical housing (1), a mouthpiece cover (33) arranged at one end of the housing, and a bottom cover arranged at the other end of the housing, where the bottom cover and the housing are integrally formed. The housing has arranged therein a liquid storage component (37), an atomizer (21), and a storage power supply (36). The housing also has arranged therein a liquid partitioning component (31). The liquid storage component is accommodated and fixed within a closed space defined and formed jointly by the mouthpiece cover, a portion of the housing, and the liquid partitioning component. The liquid storage component has arranged on the inner wall thereof a conduit (35) used for supporting the liquid storage component. The conduit is in communication respectively with the mouthpiece cover and with the liquid partitioning component. The atomizer is supported and fixed on the conduit. This electronic cigarette is capable of preventing the bottom cover from falling off of the housing, also is structurally simple, and is easy and convenient to assemble and disassemble.

Owner:KIMREE HI TECH

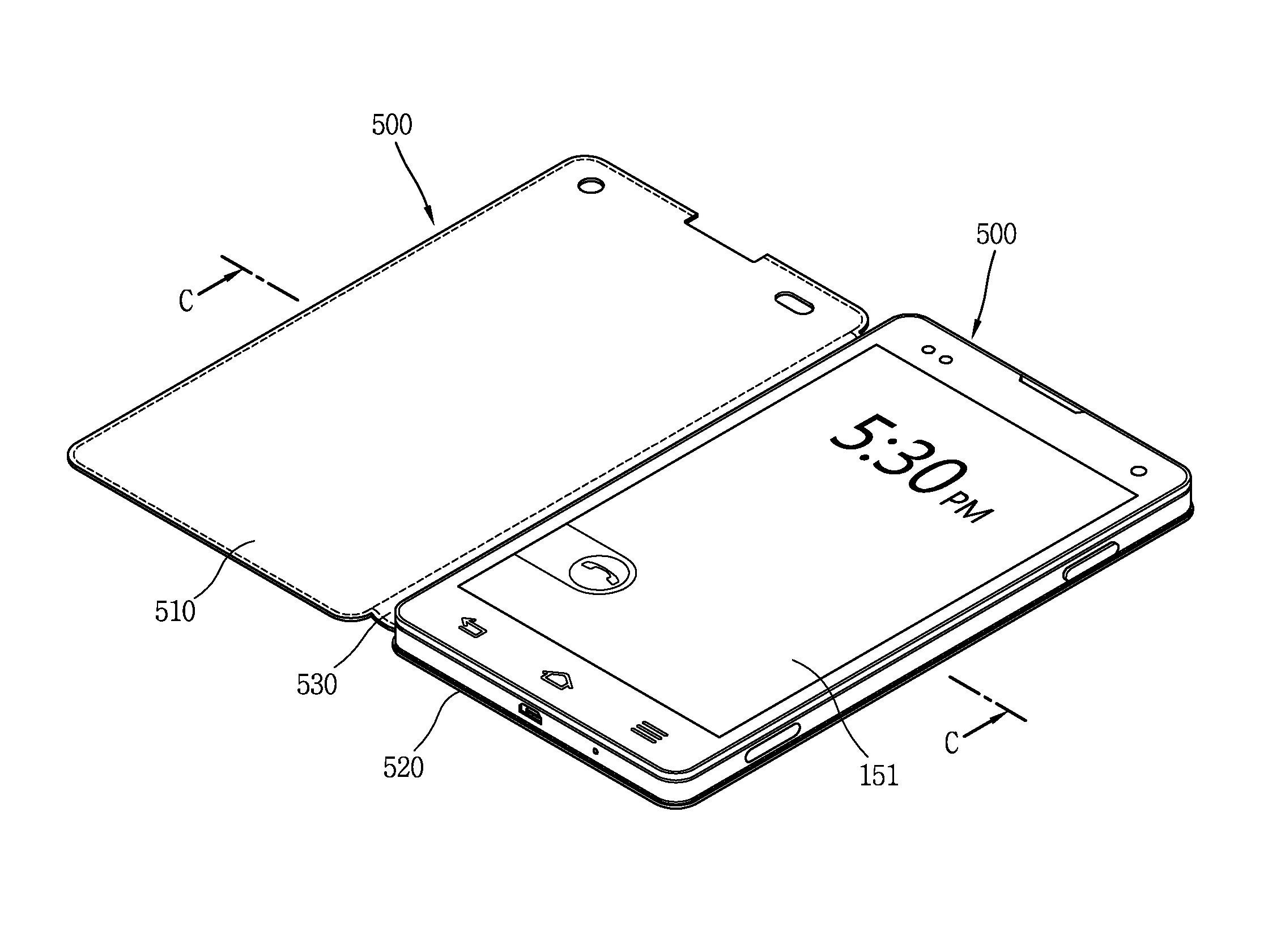

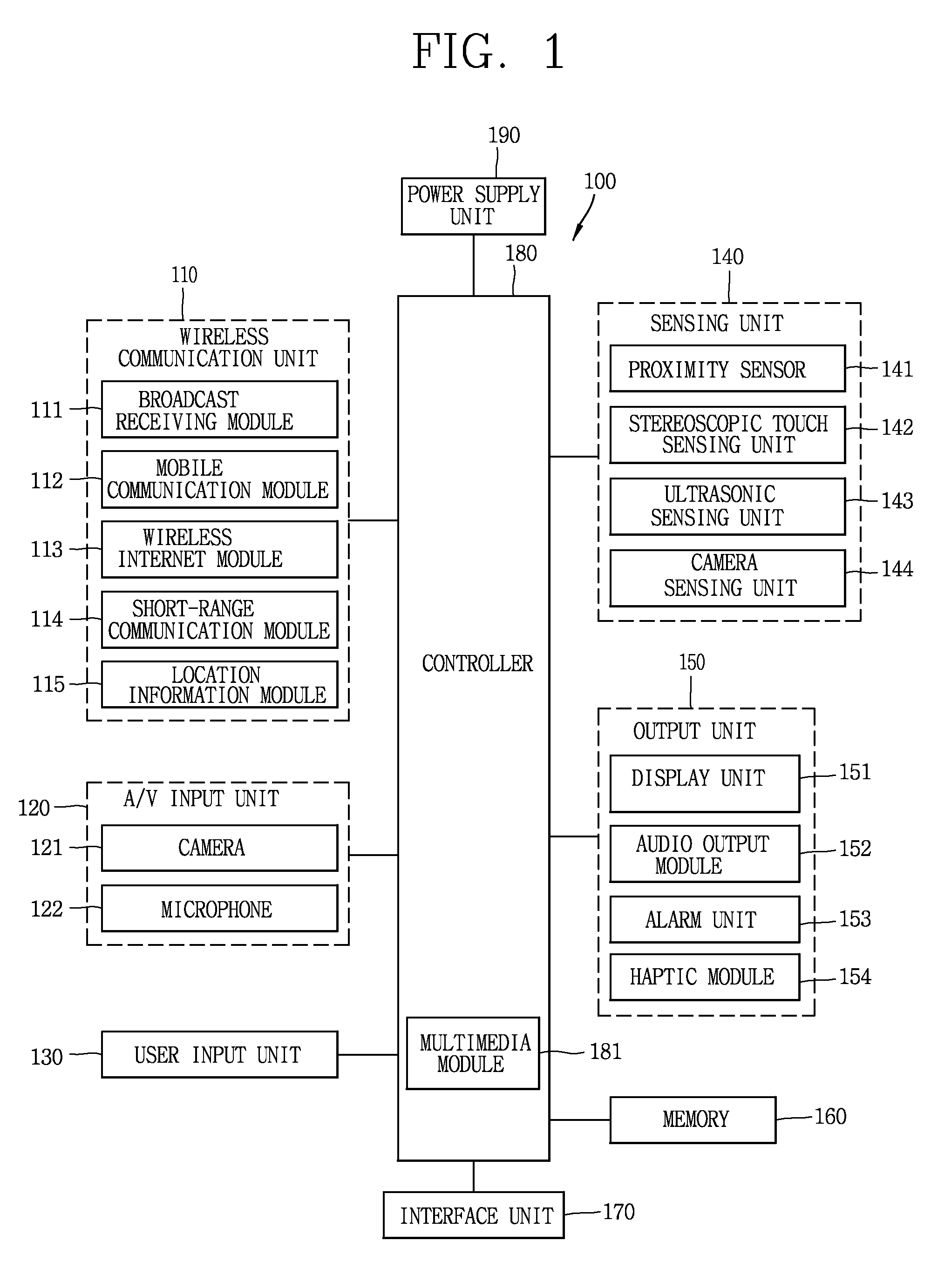

Mobile terminal

ActiveUS9159260B2Easy to useSimple terminal structureStatic indicating devicesDigital data processing detailsDisplay deviceMobile end

A mobile terminal includes a terminal body including a display unit formed on one surface thereof, a cover coupled to the terminal body such that it can be converted into a closed state in which the display is covered and an opened state in which the display unit is exposed, a signal generating unit configured to generate a state signal according to the closed state and the opened state, and a controller configured to control the display unit such that the display unit is activated in the opened state on the basis of the state signal.

Owner:LG ELECTRONICS INC

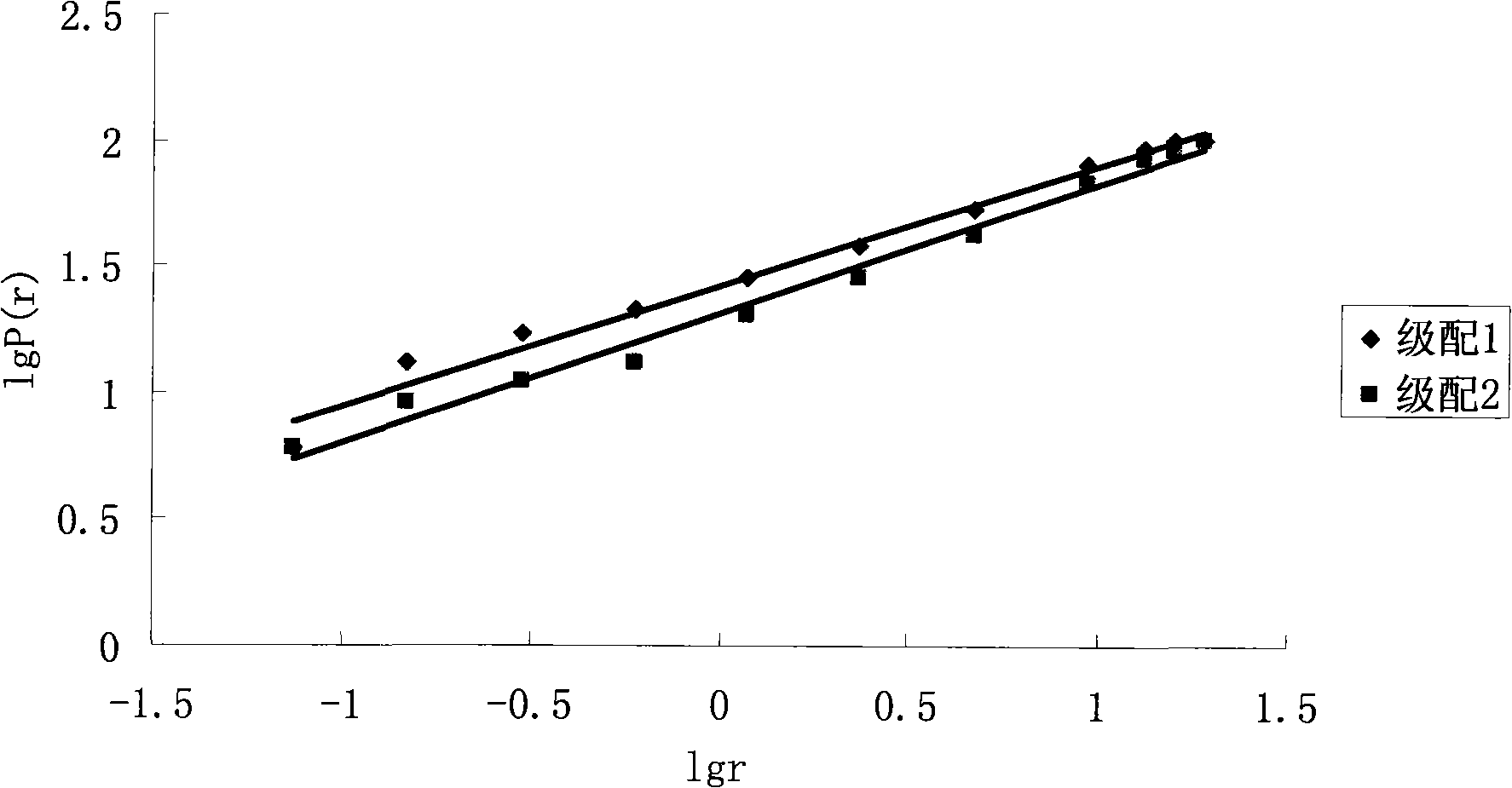

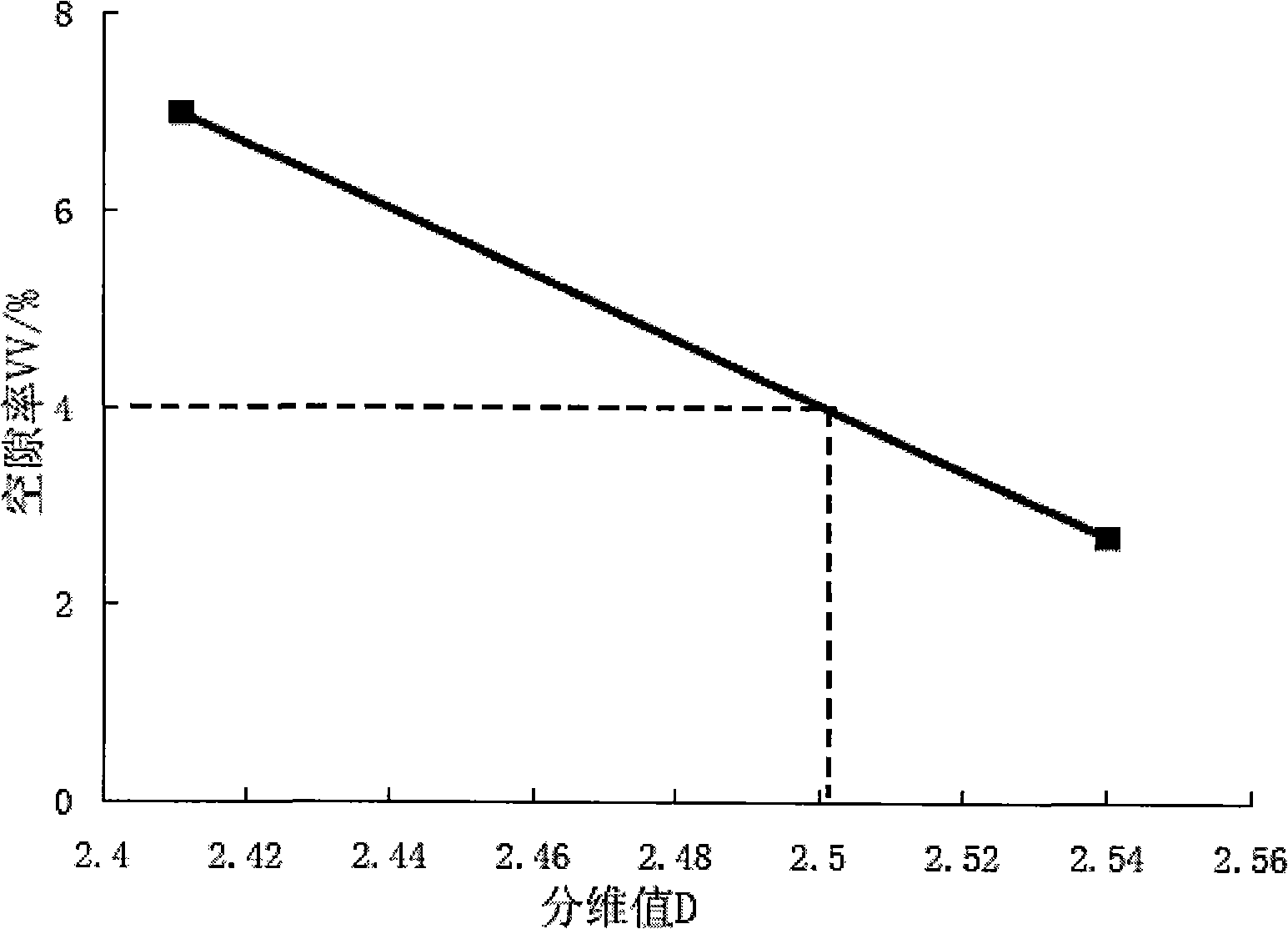

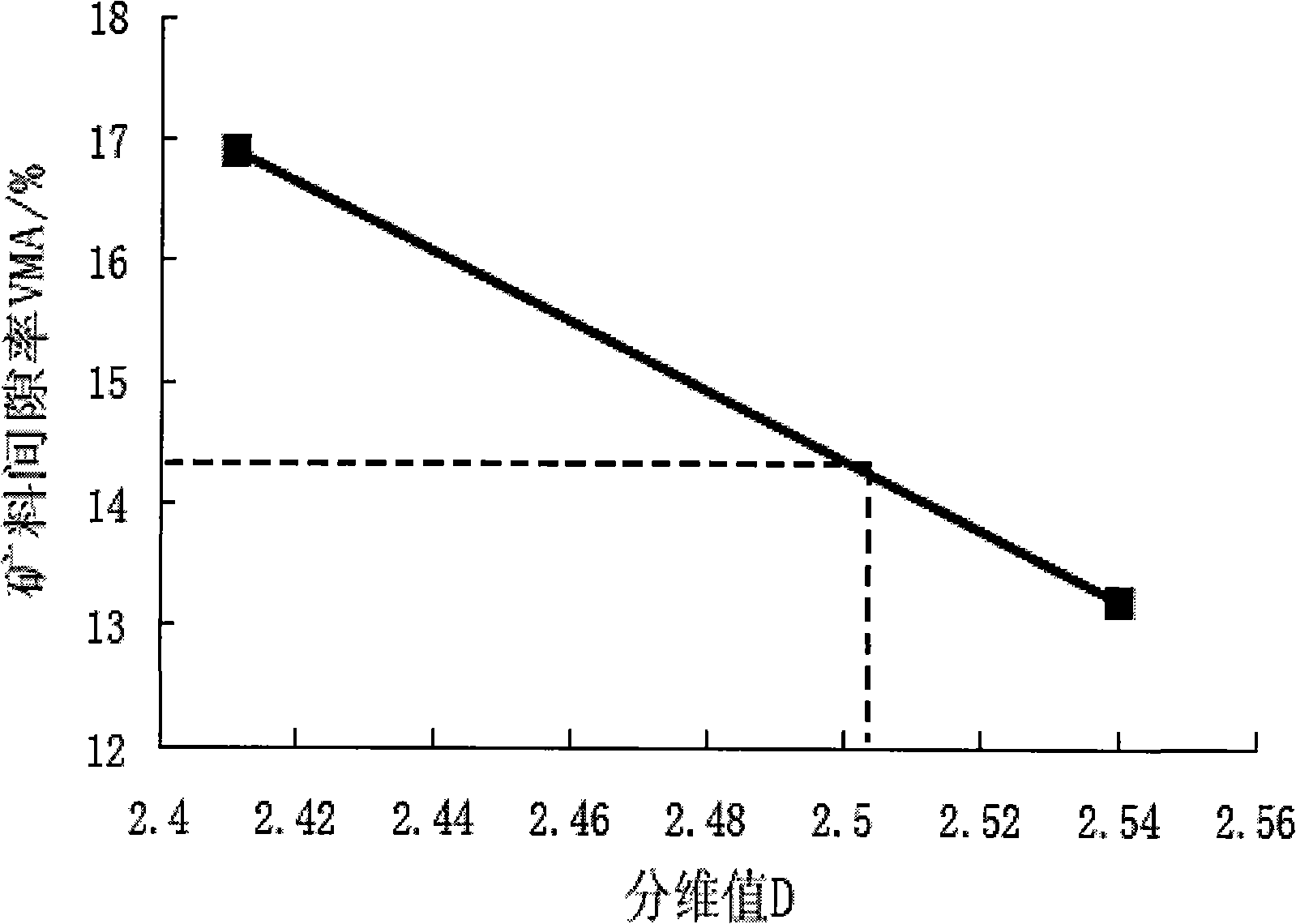

Asphalt mixture mixing proportion design method based on inert solid fractal distribution characteristic

InactiveCN101318794AImprove road performanceSimple internal structureSolid waste managementCeramic shaping apparatusMathematical modelTest sample

The invention relates to a method of designing a mixed ratio for a bitumen mixture based on fractal and distributional features of ore materials. The method comprises the following steps: (1) mathematical models for particle diameter distribution and mass distribution of the ore materials are set up respectively; (2) the type and the grading limit of the bitumen mixture are determined; (3) raw materials are selected and checked; (4) graduations of two arbitrary groups of the ore materials are determined and corresponding fractal dimension values(D) are worked out; (5) the use level of the bitumen is worked out; (6) the bitumen mixture is prepared by stirring; (7) a Marshall test sample is made, the relative density of the bulk volume of the test sample is determined, the theoretical maximum relative density is determined, and the volume index is worked out; (8) relationship curves between the fractal dimension values(D) and the volume indexes are drawn; (9) the graduation of the ore materials and the optimum use level of the bitumen are determined; (10) the road performance of the bitumen mixture is tested; and (11) the construction mixed ratio of the bitumen mixture is determined. The invention utilizes the fractal theory to set up the mathematical models, and in the process of designing the mixed ratio of the bitumen mixture, the optimum bitumen use level and the optimum graduation of the ore materials meeting and regulating all design rules of the bitumen mixture can be quickly determined.

Owner:LANZHOU JIAOTONG UNIV

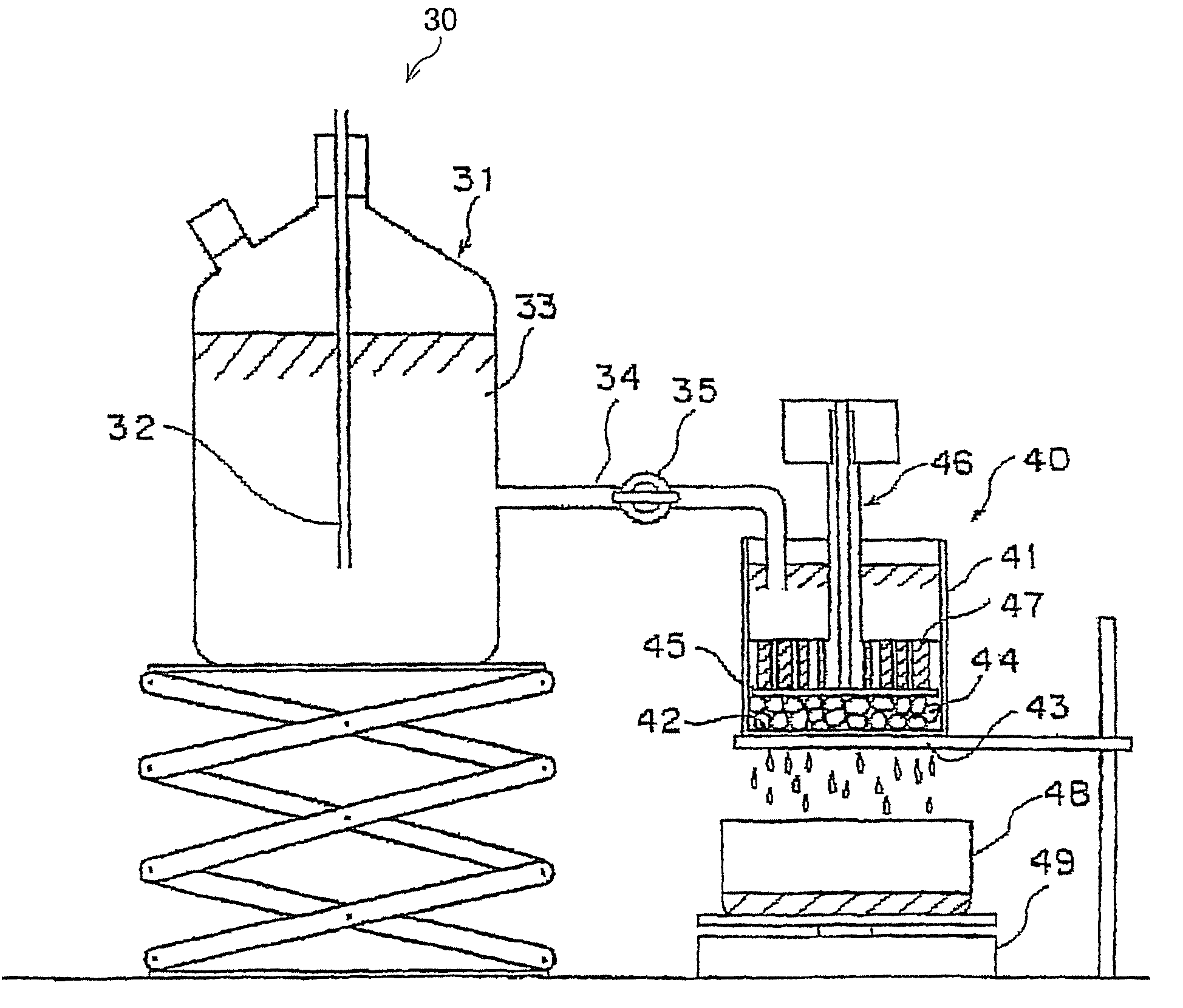

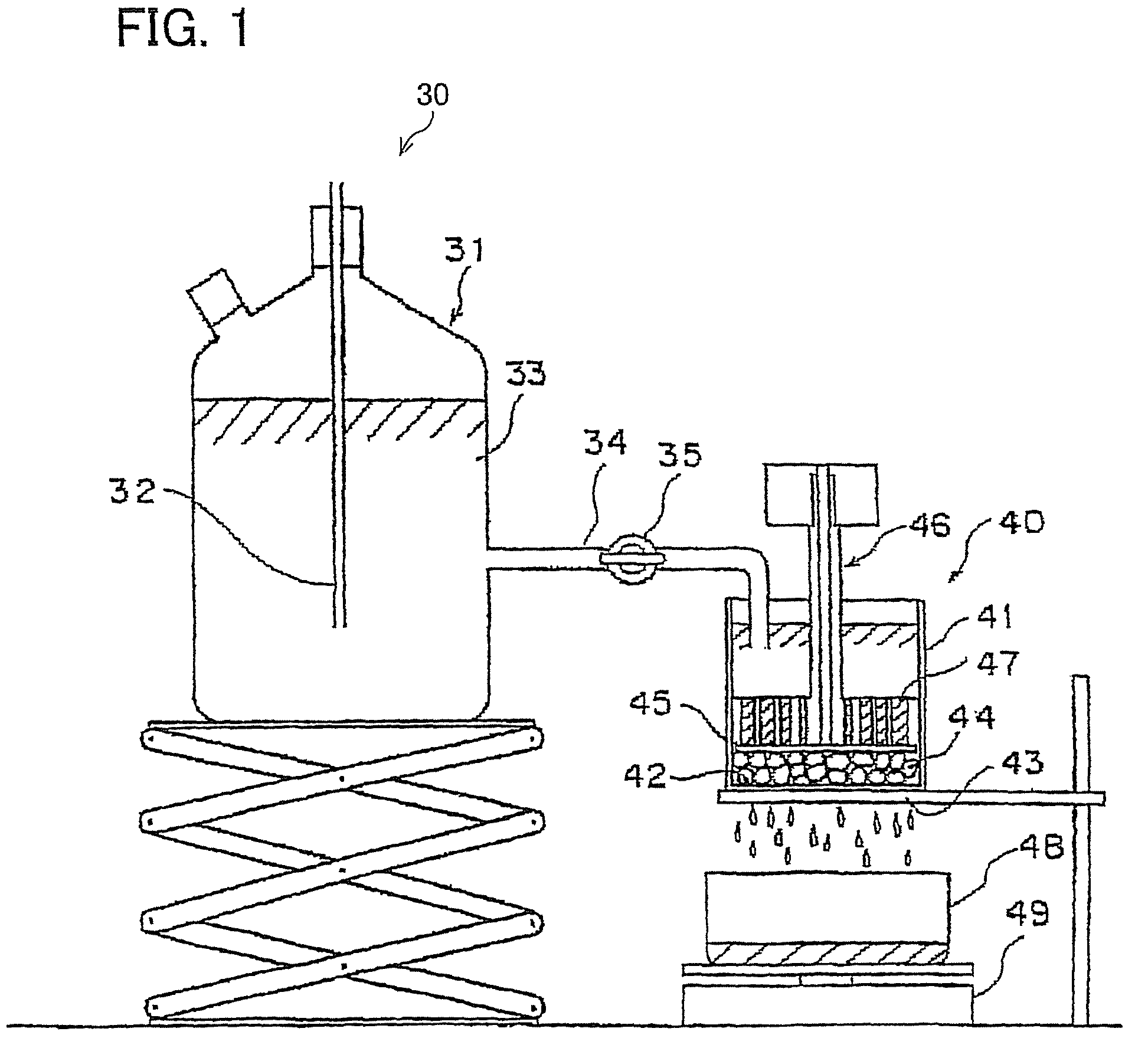

Water absorbing resin with improved internal structure and manufacturing method therefor

ActiveUS8383746B2Simple internal structureConvenient timeAbsorbent padsThin material handlingAfter treatmentPolymer science

According to the present invention, the manufacturing method for the water absorbing resin involves the step of polymerizing a water-soluble unsaturated monomer, 0.06 of 5 mol % of which is composed of an internal crosslinking agent; and the step of drying a water-containing gel which has a thermally decomposing radical initiator content index of 40 to 100 at 100 to 250° C. The water absorbing resin of the present invention contains a water-soluble unsaturated monomer as a repeat unit for a major chain, 90 mol % of the monomer being composed of an acrylic acid and / or salt thereof, the resin having an internal crosslinking structure and exhibiting a weight-average molecular weight Mw of 360,000 to 1,000,000 daltons and an intrinsic viscosity IV of 2.1 to 6.0 dL / g where the weight-average molecular weight Mw and the intrinsic viscosity IV are measured after treatment under set 2 of hydrolysis conditions.

Owner:NIPPON SHOKUBAI CO LTD

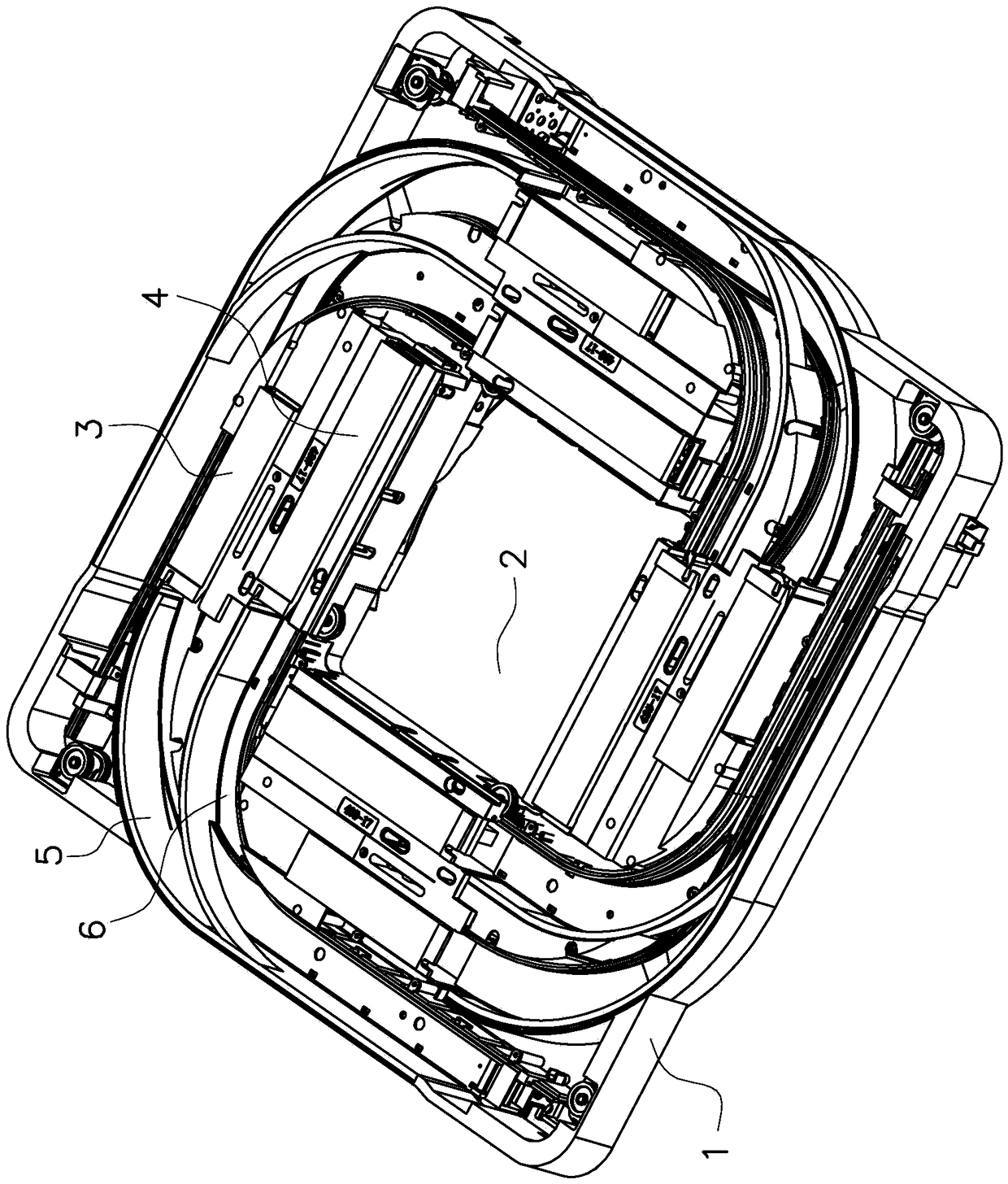

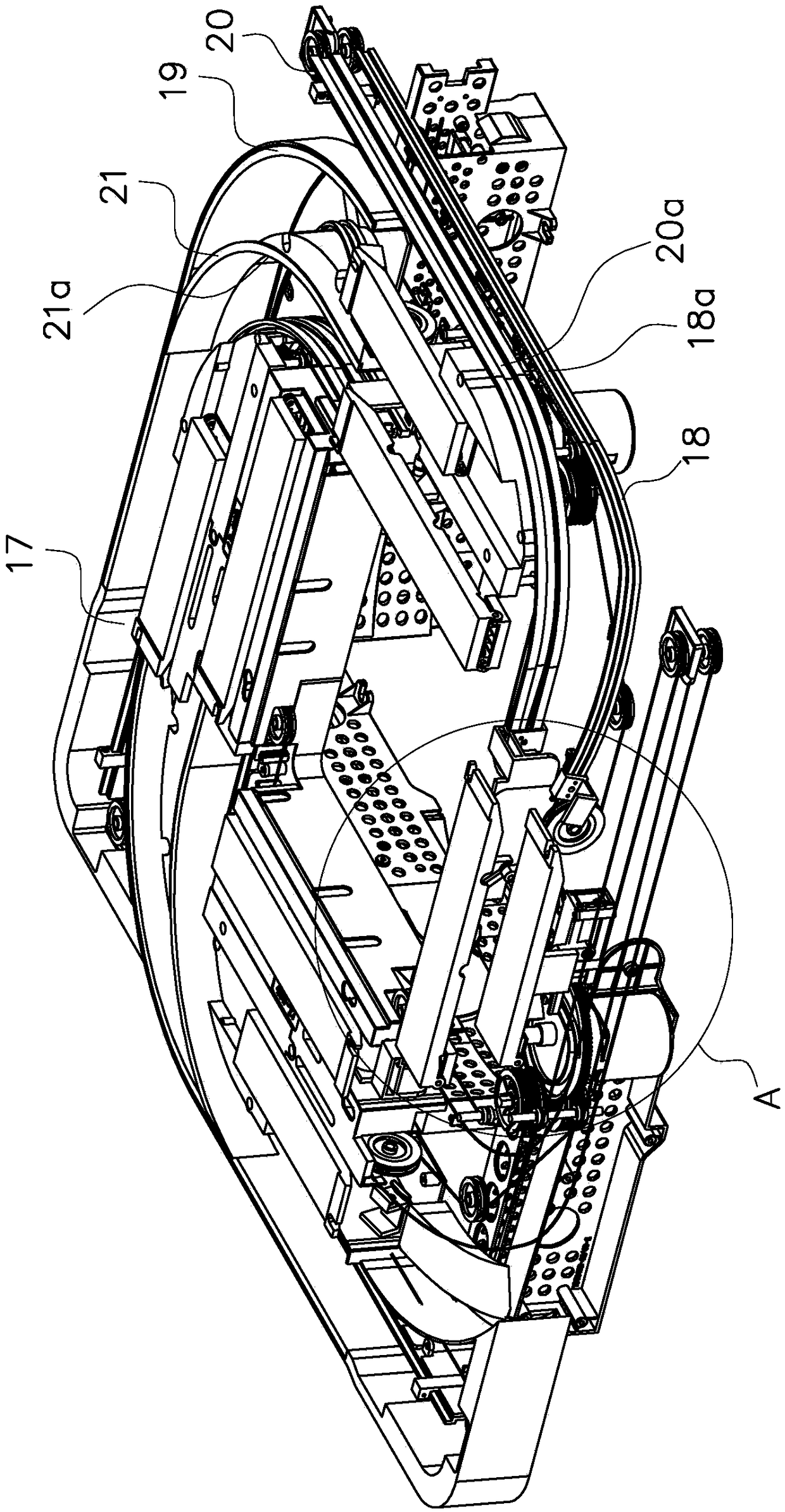

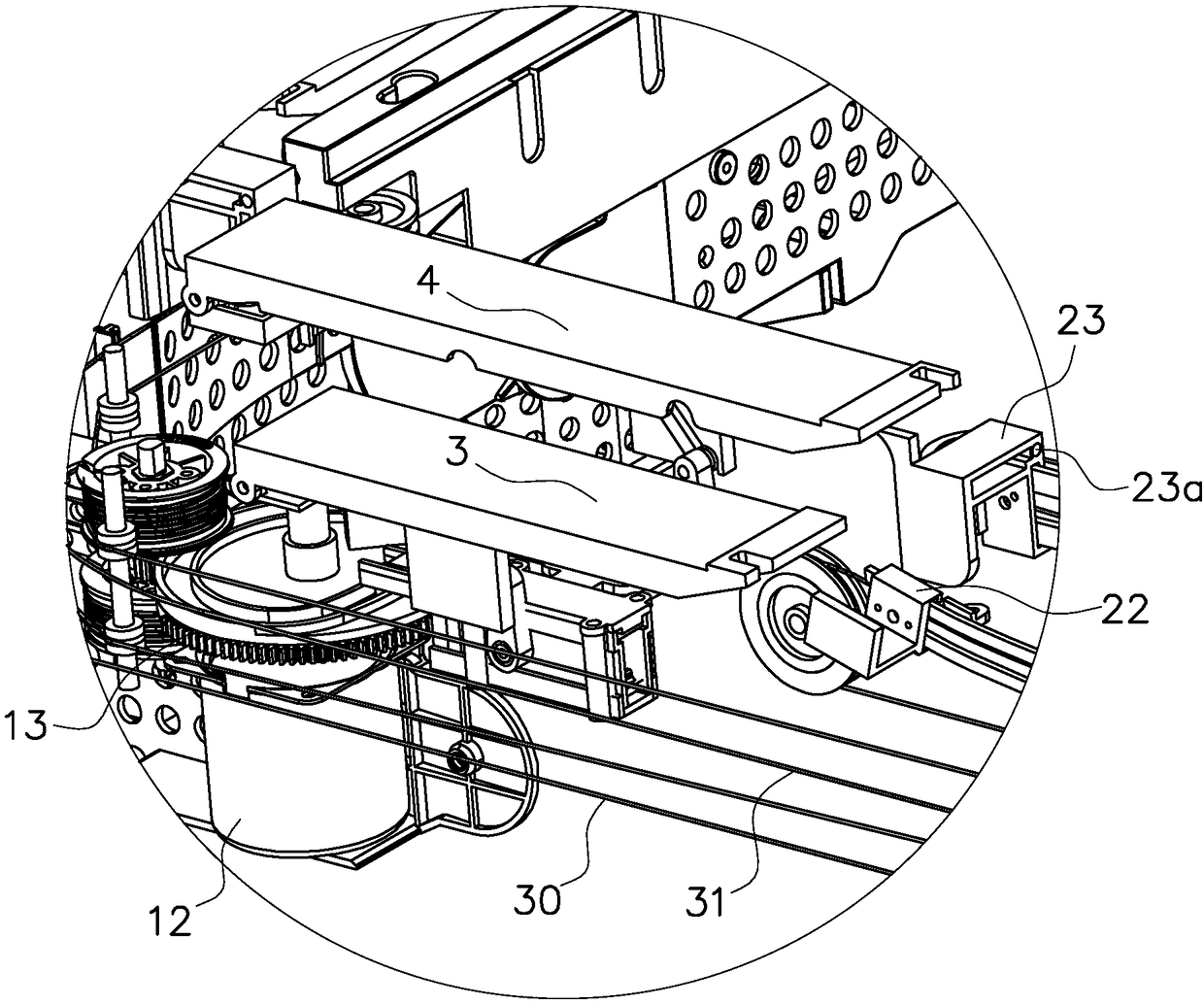

Tile delivery mechanism of eight-outlet automatic mahjong machine

The invention discloses a tile delivery mechanism of an eight-outlet automatic mahjong machine. The mahjong machine comprises a rack, a large plate is arranged in the rack, and each of four sides of the large plate is provided with two outlets; the tile delivery mechanism comprises initial tile delivery tracks arranged at the four sides of the large plate, and first and second tile delivery tracksboth arranged on four sides of the large plate; the initial ends of the first and second tile delivery tracks are connected with corresponding initial tile delivery tracks, and the tile delivery terminal ends of each pair of the first and second tile delivery tracks are arranged corresponding to two outlets at one corresponding side of the large plate; first tile pushing heads are slidably arranged in the initial tile delivery tracks and the first tile delivery tracks, and second tile pushing heads are slidably arranged in the initial tile delivery tracks and the second tile delivery tracks;and the rack is provided with a driving mechanism used for driving the first tile pushing heads and the second tile pushing heads to simultaneously depart from the initial tile delivery tracks and arrive at the corresponding tile delivery terminal ends. The tile delivery mechanism realizes tile sending and dividing at the same time, and saves the time for dividing tiles.

Owner:王彬

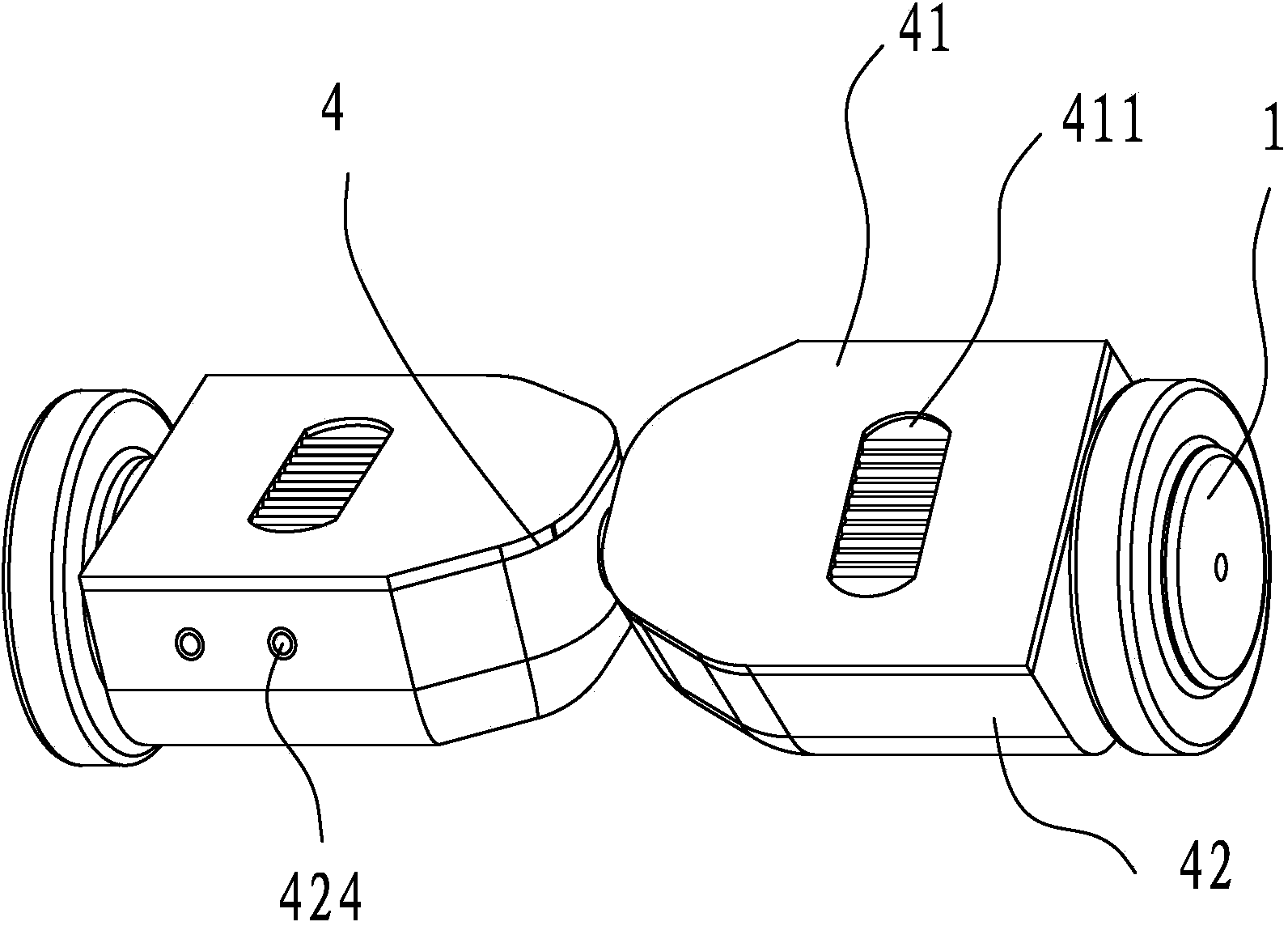

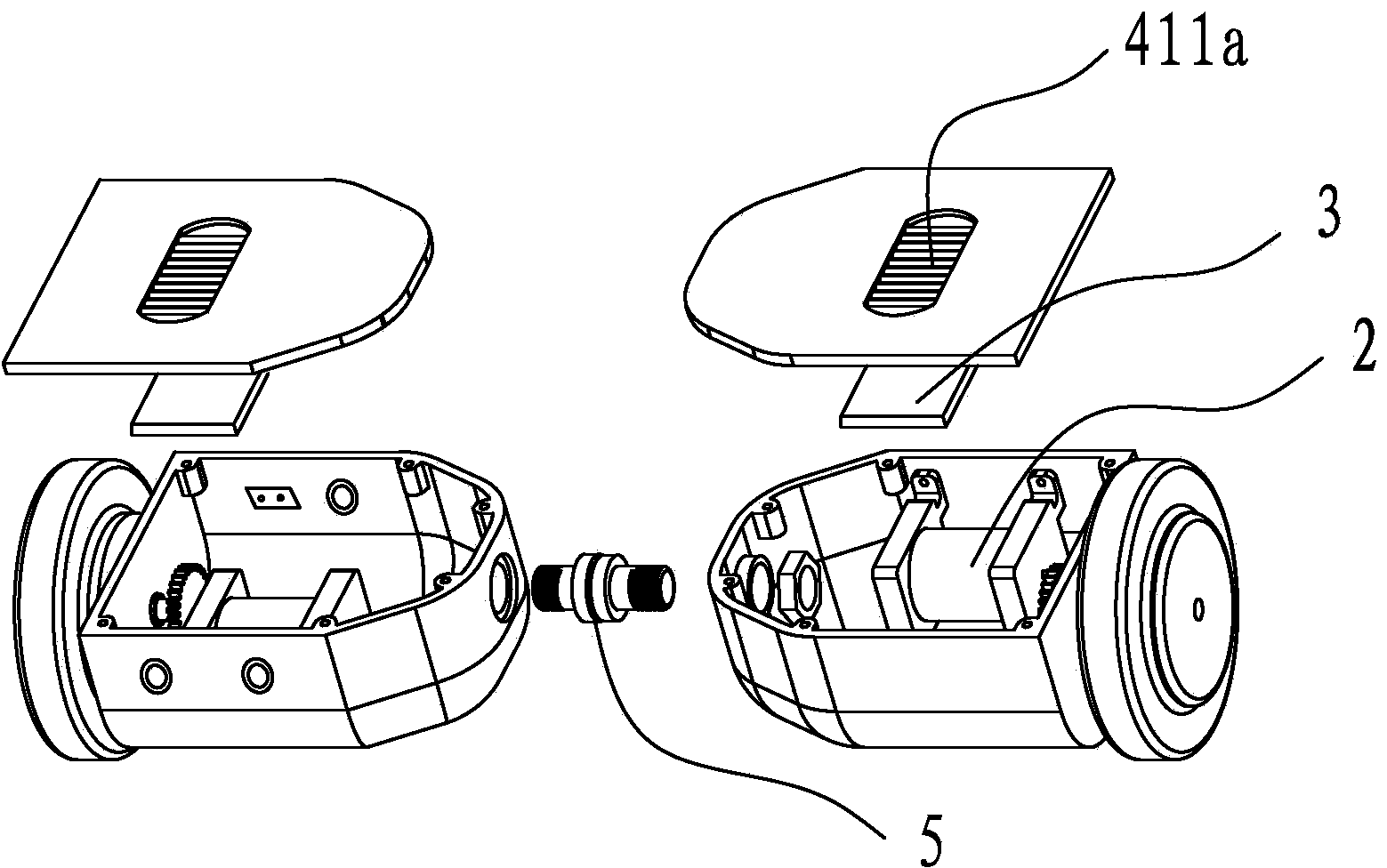

Steering control method for self-balancing two-wheeled vehicle

InactiveCN104163222ARealize the turning functionEasy to operateMotorcyclesRider propulsionVehicle frameGyroscope

The invention discloses a steering control method for a self-balancing two-wheeled vehicle. The two-wheeled vehicle comprises two separated split frames, a connecting shaft is arranged between the two split frames, and motors and gyroscopes capable of controlling the rotating speed of the motors are arranged in the split frames. The steering control method for the self-balancing two-wheeled vehicle comprises the following steps that firstly, the outer split frame needing to turn is treaded by the foot, and the inner split frame is kept horizontal. According to the split frame in the horizontal state, due to the fact that the gyroscope does not induct changes of the inclination angle, the motor does not rotate, the gyroscope at the bottom of an upper cover pedal inducts the changes of the inclination angle after inclination, signals are output to a circuit board to enable the motor to rotate, and therefore wheels are driven to rotate. Finally, one wheel does not rotate, the other wheel rotates, the two-wheeled vehicle turns and moves with the wheel which does not rotate as the center, the acceleration, speed reduction and turning functions can be achieved through foot treading, and the structure is simple.

Owner:重庆鹏得基业汽车部件有限公司

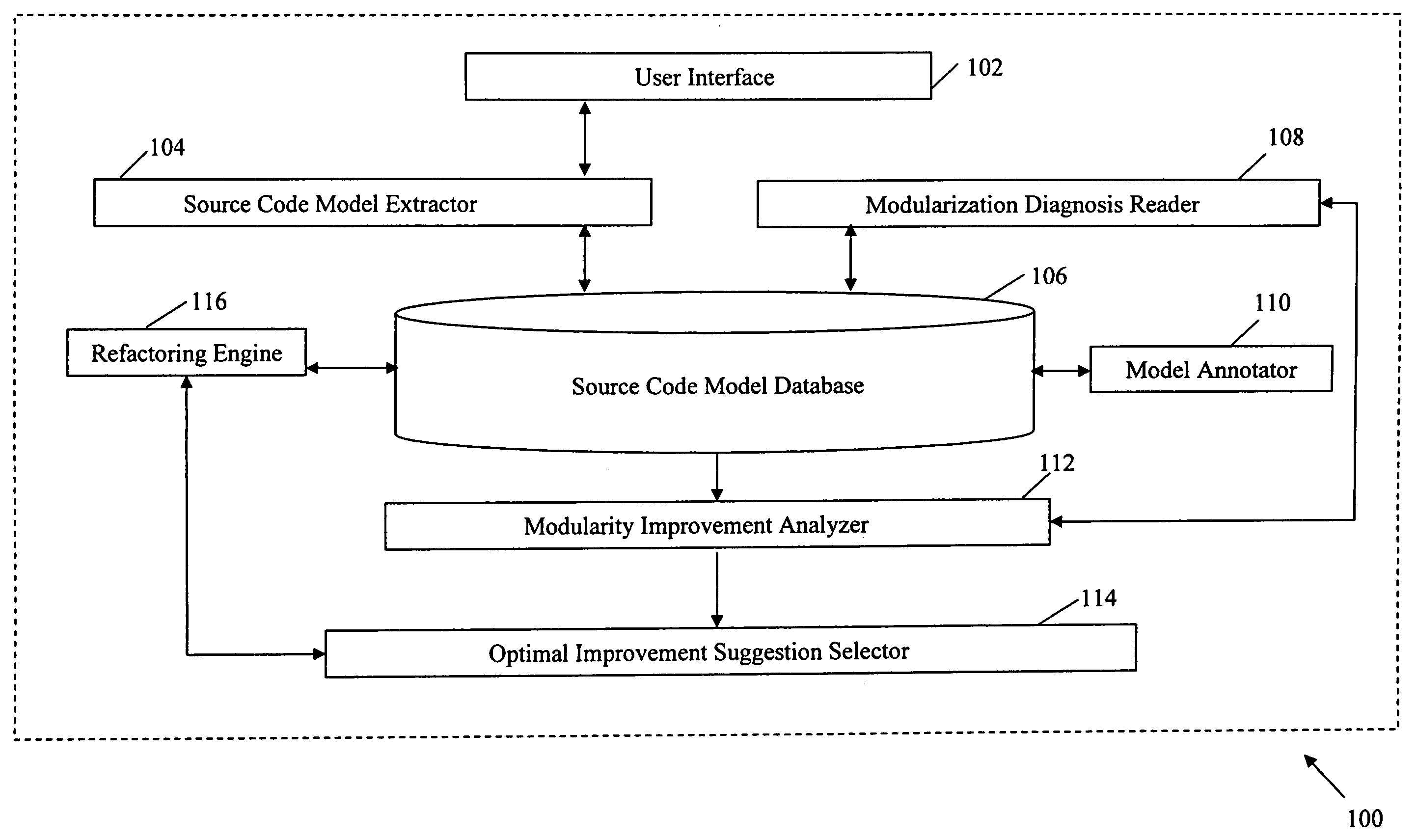

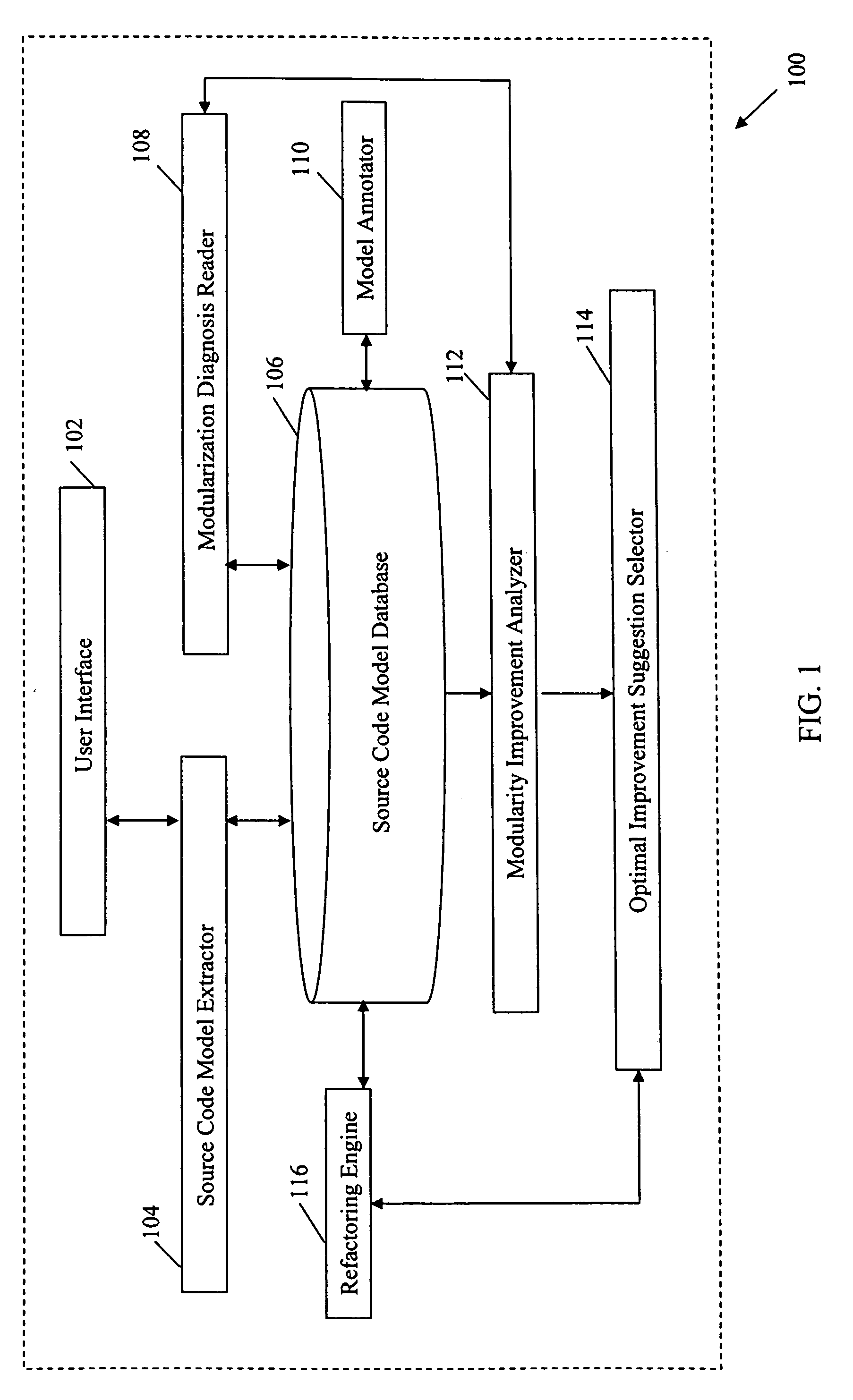

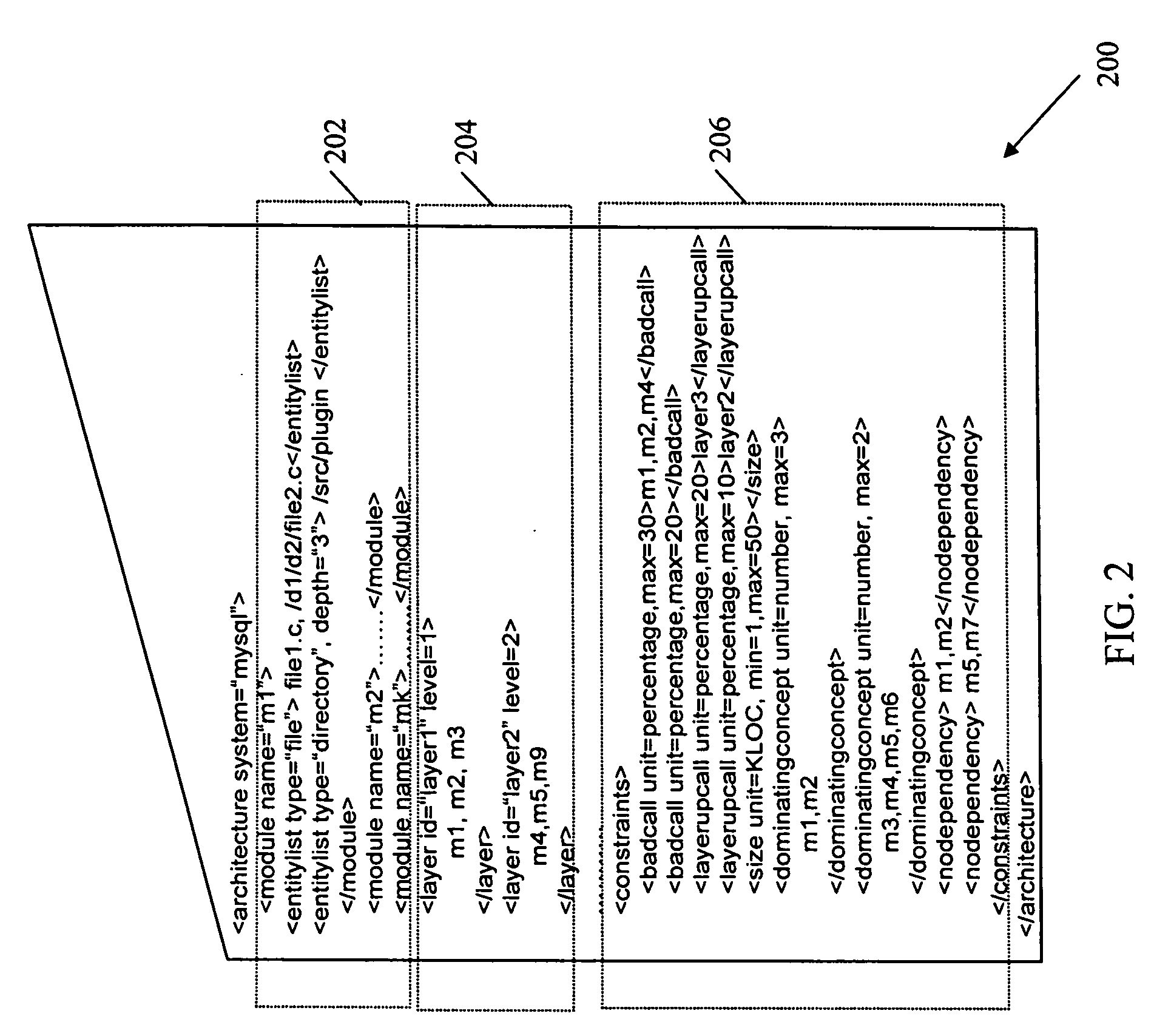

System and method for improving modularity of large legacy software systems

ActiveUS20100070948A1Evaluate effectAchieve modularityCode refactoringSpecific program execution arrangementsDiagnostic dataSoftware system

A system and method for improving modularity of a software source code is provided. The system comprises of a user interface for receiving source code; a source code model extractor for parsing and forming a model of the source code; a source code model database for storing the source code model, refactoring operators, and a record of refactoring changes; a modularity improvement analyzer for reading the source code model and modularity problem diagnosis data and generating a set of prescriptions; an optimal improvement suggestion selector for evaluating and selecting prescriptions; and a refactoring engine for receiving selected prescriptions and applying them on the source code.

Owner:INFOSYS LTD

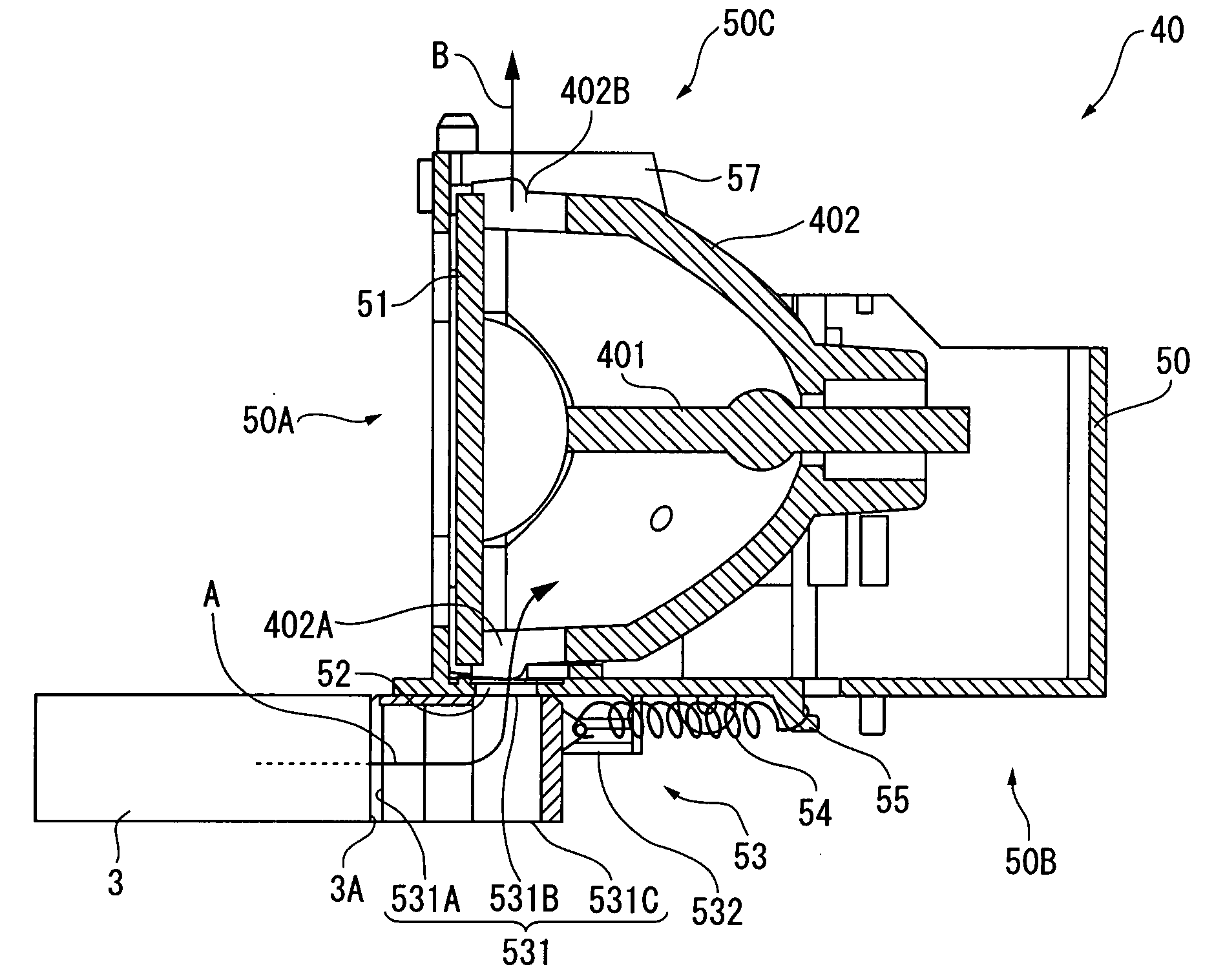

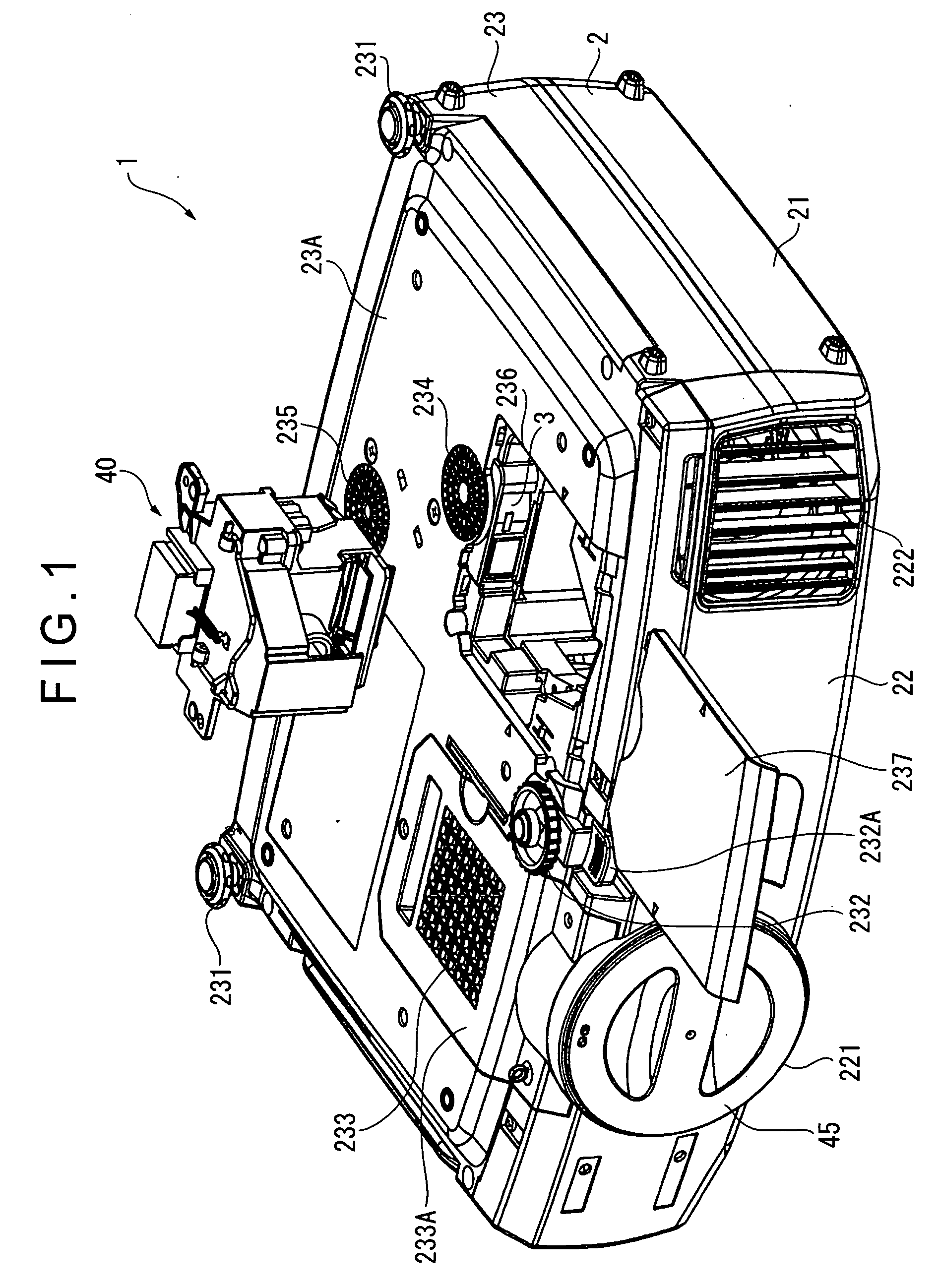

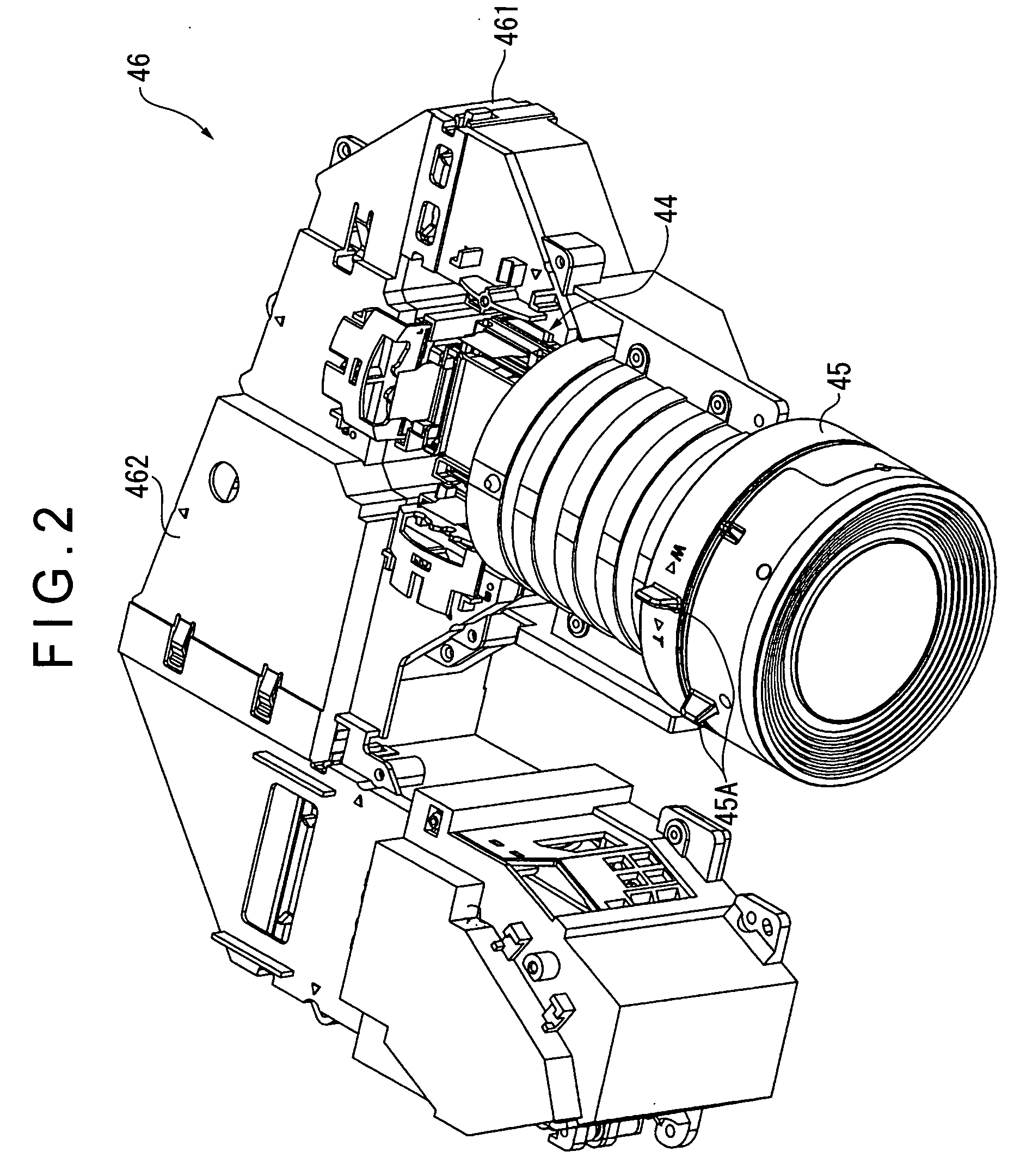

Light source and projector

InactiveUS20040228130A1Improve cooling effectReduce component countTelevision system detailsPoint-like light sourceLight irradiationOptoelectronics

A light source device (40) attached to an optical equipment provided with a light-source cooling fan (3) has a light source (401), a reflector (402), a light-transmissive component (51) that closes the light-irradiation side of the reflector (402) and a light source housing (50) that houses the above components. An opening (402A) for introducing a cooling air is formed on the reflector (402) and an opening (52) is formed on the light source housing (50) at a position corresponding to the light source housing (50). A duct (53) of which light-irradiation side is opened is provided on the opening (52). When the light source device (40) is attached to the optical equipment, the duct (53) protrudes toward the light-irradiation side to be connected with the fan (3). The opening (52) is opened in accordance therewith, so that the air from the fan (3) is introduced into the reflector (402).

Owner:SEIKO EPSON CORP

Recycled concrete and production technology thereof

The invention discloses a recycled concrete and a production technology thereof. The recycled concrete is prepared from, by weight, 100-112 parts of coarse aggregates, 68-75 parts of fine aggregates,27-33 parts of cement, 15-22 parts of a mineral admixture, 5-10 parts of fibers, 3-8 parts of rubber particles, 13-19 parts of water and 0.6-1.0 part of an admixture; the coarse aggregates include modified recycled coarse aggregates and ordinary coarse aggregates, and the recycled coarse aggregates are obtained by modifying waste concrete particles with a nano-material and silica sol as modifiers;and the fine aggregates include recycled fine aggregates and ordinary fine aggregates. The production technology improves the compressive strength, the flexural strength and the drying shrinkage of concrete, and improves the flexural property, the impermeability, the corrosion resistance, the impact resistance and the wear resistance of concrete. The preparation method of the recycled concrete includes the following steps: detection, metering, mixing, stirring and curing. The preparation method of the invention has the advantages of simple production process, safety in operation, and easinessin implementation.

Owner:四川衡鼎建材有限公司

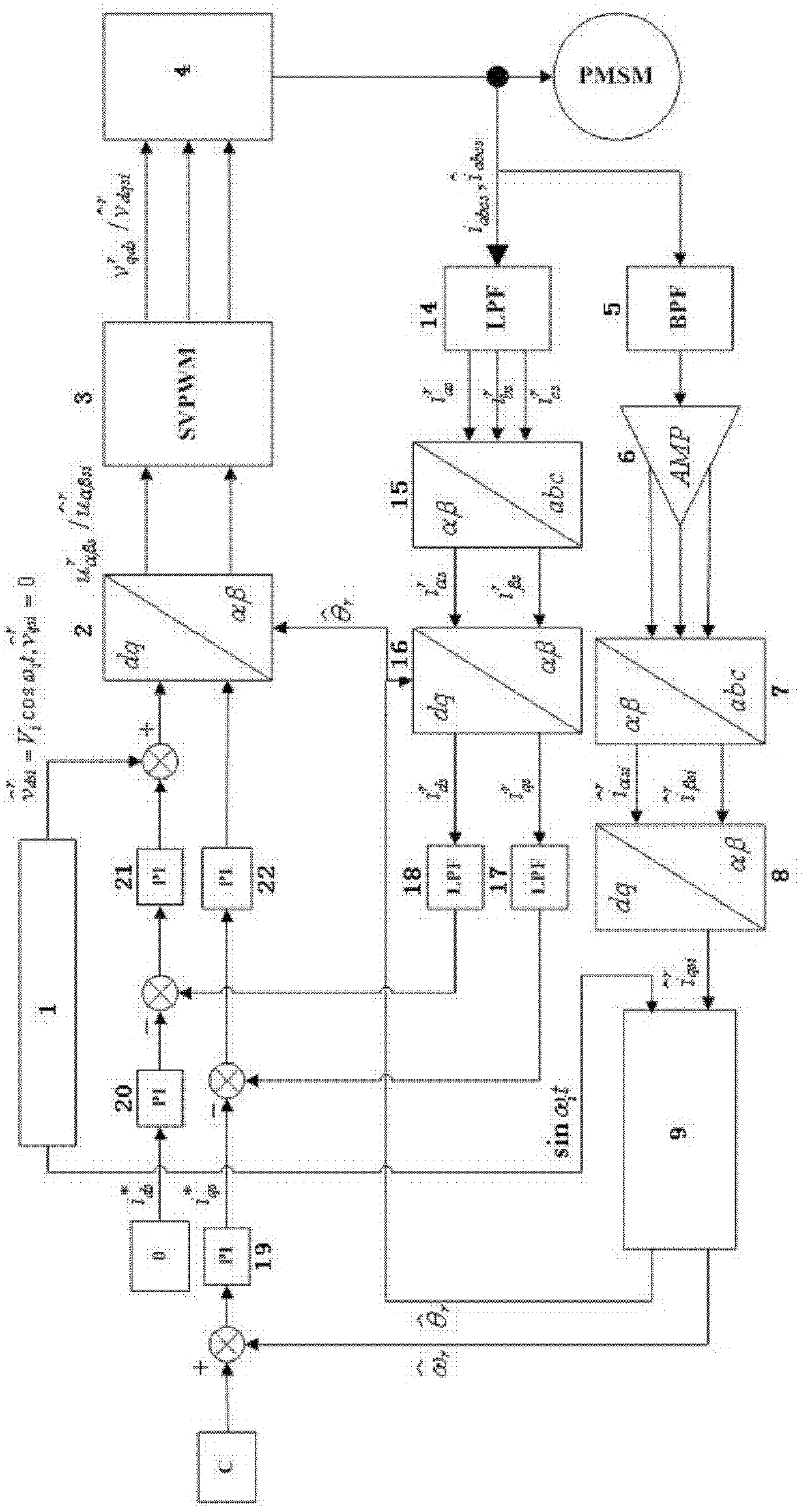

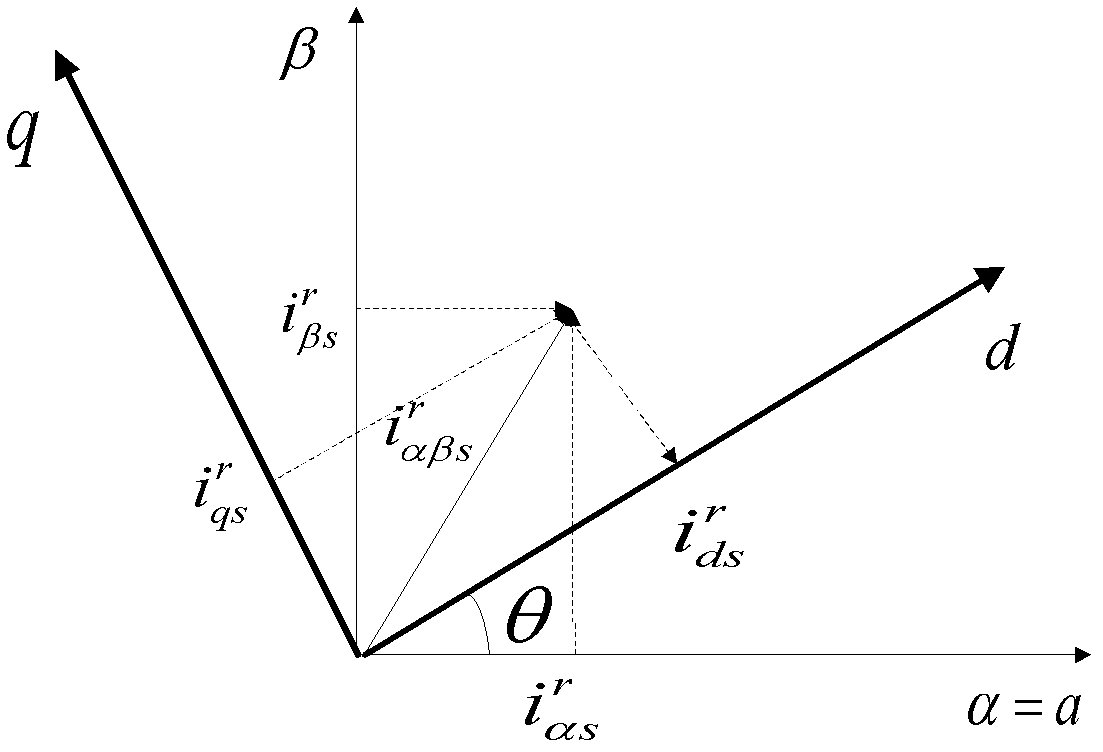

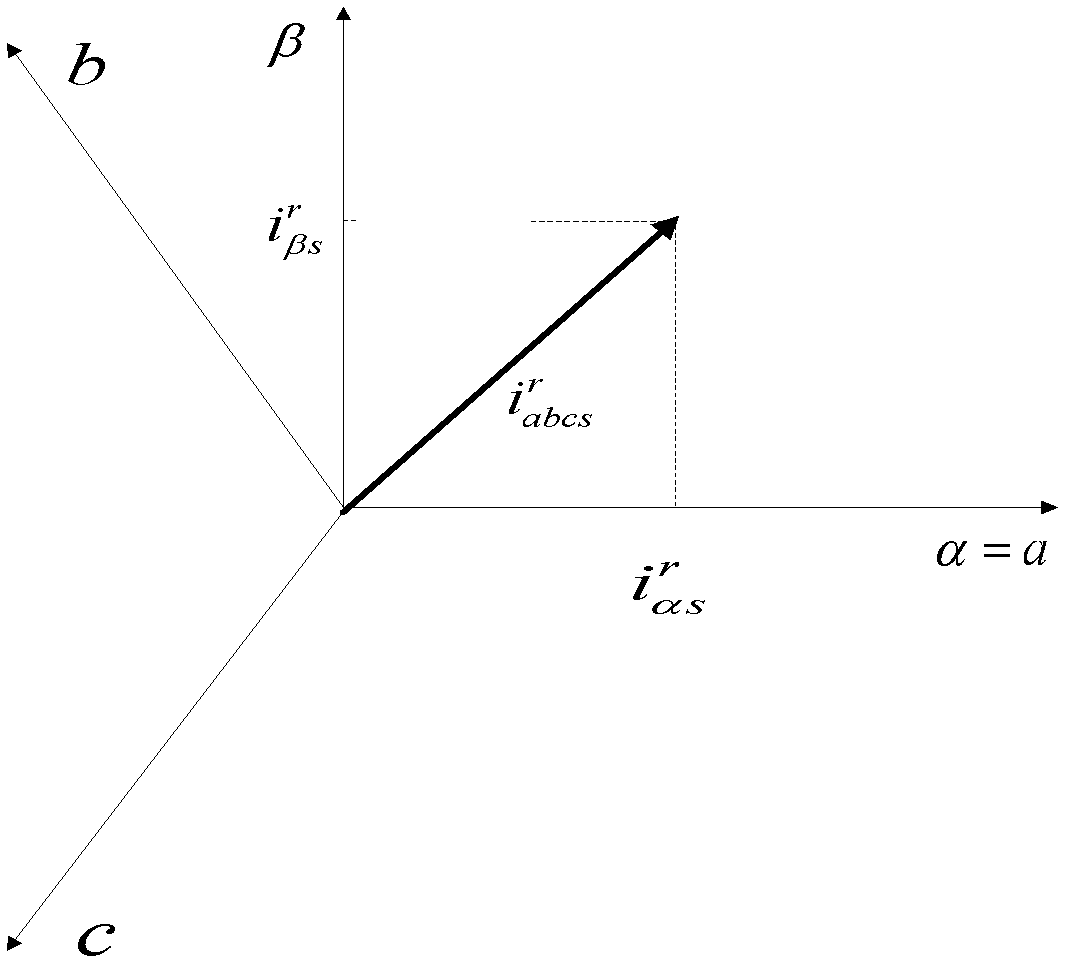

Motor control system and method without position sensor

ActiveCN102624322AImprove stabilitySimple internal structureElectronic commutation motor controlAC motor controlVoltage vectorBand-pass filter

The invention relates to a motor control system and method without a position sensor. According to the invention, internal signals of a motor can be detected without needing the position sensor. In the motor control system without the position sensor, a high-frequency voltage signal injection unit injects a high-frequency voltage signal to a d axis in a synchronically rotating d-q coordinate system; the voltage signal is obtained by a Park inverse transformation unit; a voltage vector on a static coordinate system generates a power device pulse width signal through a space vector pulse width modulation algorithm; a three-phase current signal and a high-frequency injection signal are generated according to the power device pulse width signal; the three-phase current signal is filtered by using a band-pass filter to reserve the high-frequency injection signal; the high-frequency injection signal is subjected to Clarke transformation and Park transformation in turn to obtain current; the current is subjected to signal processing through a rotor position observer unit to obtain position and speed of a rotor. According to the invention, internal structure of a motor system is simplified, cost for the motor control system is greatly reduced, and stability of the motor is improved.

Owner:HANGZHOU ZHOUJU ELECTRONICS TECHNOLOGICAL

Air mattress

ActiveUS7694372B1Improve environmental qualitySimple internal structureStuffed mattressesSpring mattressesEngineeringVertical motion

An air mattress includes an inflatable compartment having a length and width, when inflated, sufficient to support a human body; an internal, generally horizontal wall located between the top and bottom of the compartment and connected to and horizontally restraining the sides of the compartment; at least one internal, generally vertical member connected to and restraining the relative vertical movement of the top and bottom of the compartment; and wherein one of the internal, generally vertical member and the internal, generally horizontal wall possesses an opening that permits at least a portion of the other structure to pass therethrough without interruption.

Owner:BOYD DENNIS

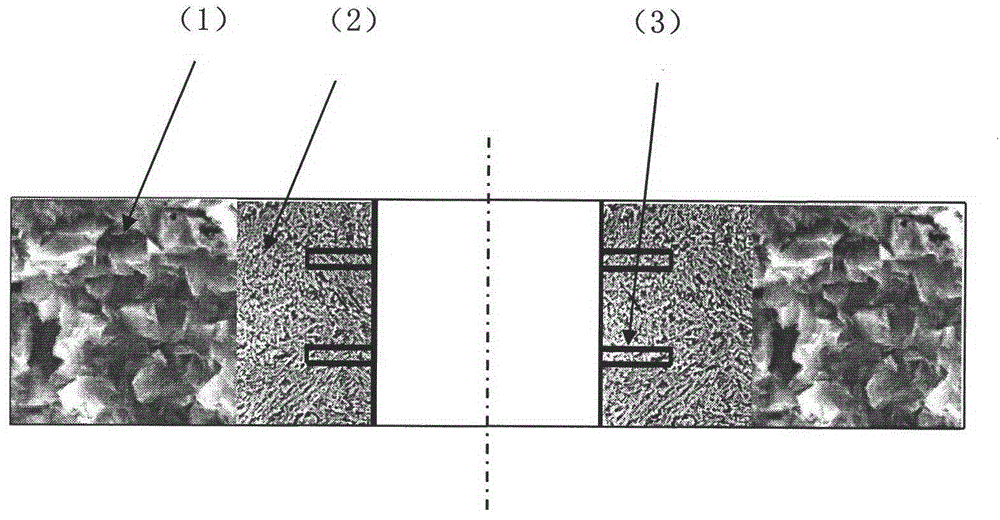

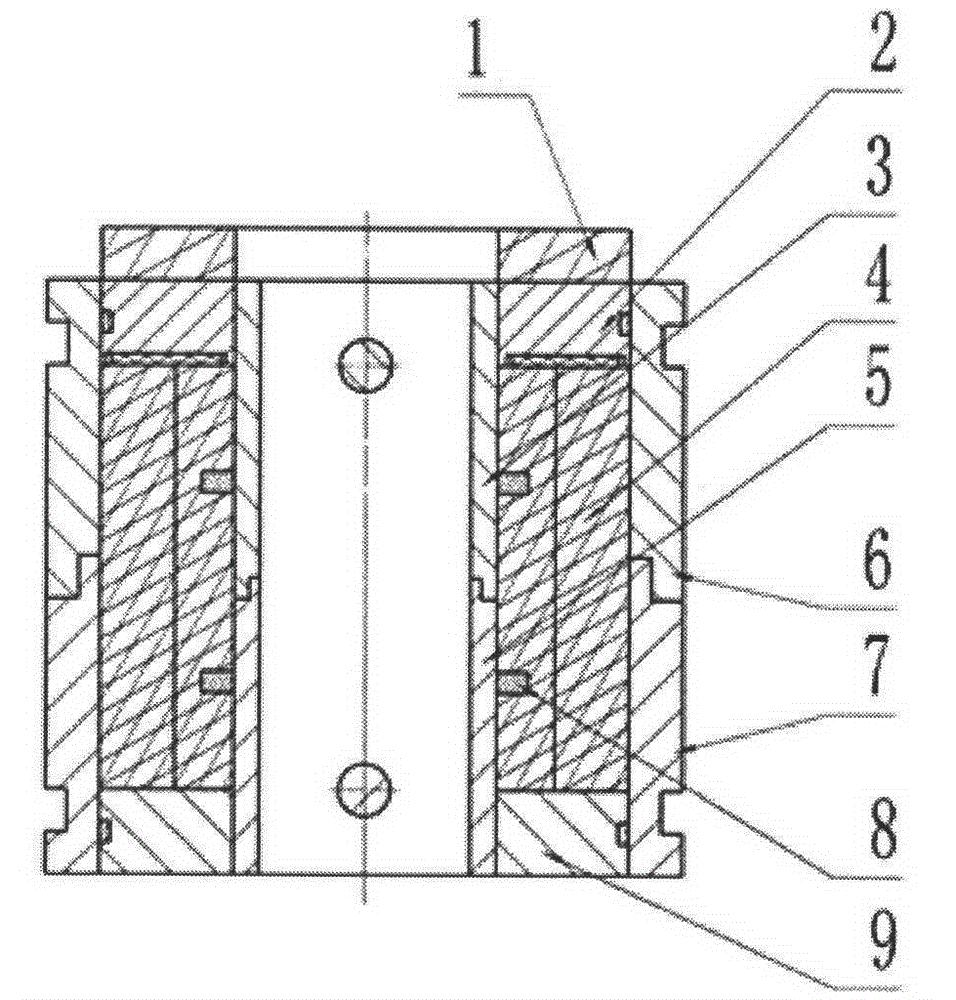

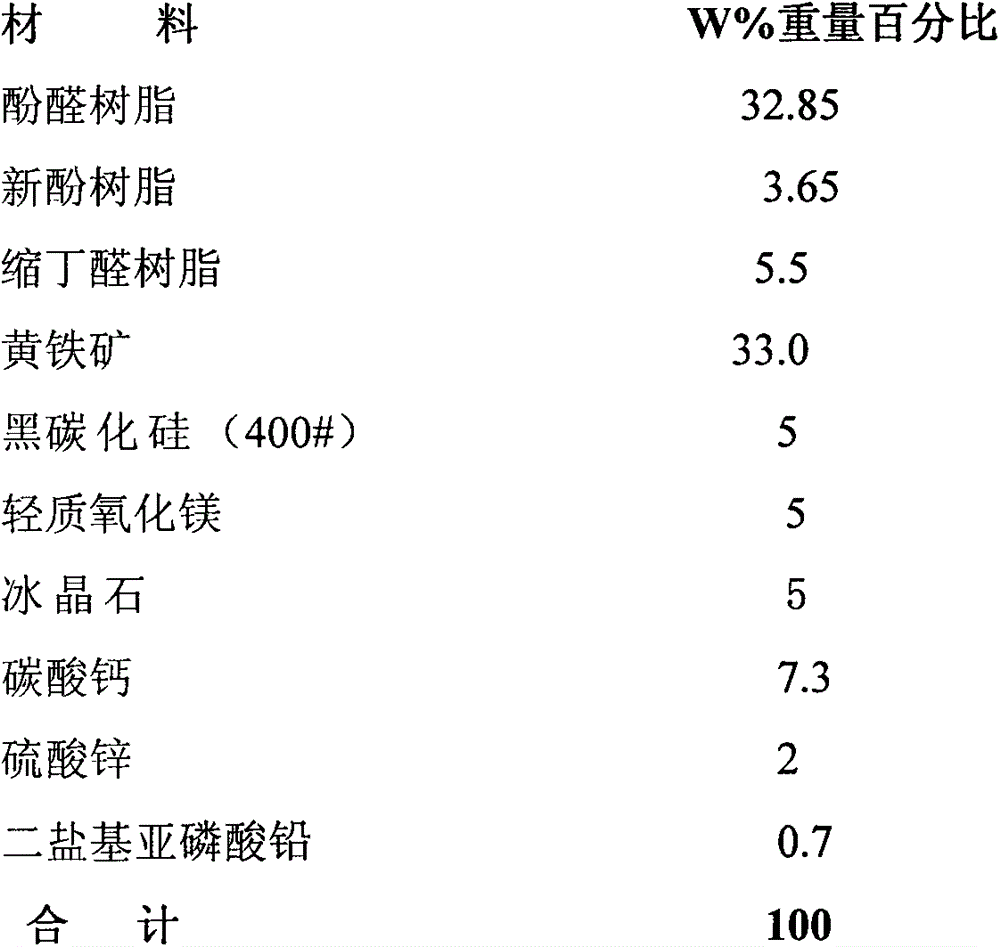

Large-standard high-speed resin heavy duty grinding wheel for grinding steel billet

ActiveCN104625978AHigh tensile and flexural strengthImprove the lubrication effectAbrasion apparatusGrinding devicesFiberMaximum diameter

The preparation method for the large-standard high-speed resin heavy duty grinding wheel for grinding a steel billet comprises the steps that a dedicated binding agent for a high-performance modified high polymer matrix phenolic resin grinding wheel is prepared by using phenolic resin, xylok resin, butyral resin, iron pyrite, cryolite, light magnesium oxide, barite, 400 # carborundum and calcium carbonate, dedicated formulas for a grinding layer and a core layer are separately designed by using grinding materials such as fused alumina zirconia, aluminium oxide sintered corundum, black silicon carbide, furfural, dibutyl ester, fibers and steel rings, and the large-standard high-speed resin heavy duty grinding wheel for grinding the steel billet is prepared by adopting a dual-phase reinforced composite technology and structure. According to the large-standard high-speed resin heavy duty grinding wheel for grinding the steel billet, the linear velocity is equal or greater than 90 m / s to 120 m / s, the maximum diameter is 925 mm, the thickness is 125 mm, and the tensile and breaking strength and the grinding efficiency of the grinding wheel are greatly improved. When the large-standard high-speed resin heavy duty grinding wheel for grinding the steel billet is under heavy duty, the adaptability of the condition of grinding range is wide, and the linear velocity is high. The grinding efficiency reaches a thickness of 1 cm at a time, the problems that an existing grinding wheel cannot adapt to a steel billet, and the heavy duty grinding of steel is difficult are solved well, and the increasing development requirements of the iron and steel industry are met.

Owner:江苏华东砂轮有限公司

Curing agent capable of rapidly curing sludge at room temperature and use method thereof

The invention discloses a curing agent capable of rapidly curing sludge at room temperature and a use method thereof. The curing agent is prepared from, by weight, 48%-70% of inorganic micro powder, 28%-50% of emulsion, 0.05%-1.8% of high-performance water-absorbent resin and 0.05%-0.5% of triethanolamine. The emulsion can react with the inorganic micro powder and activated silicon dioxide and aluminum oxide in the sludge to form a zeolite-like crystalline substance of a silicon (aluminum)-oxygen tetrahedron structure. The sludge curing agent is capable of improving the curing strength of the sludge and shortening the curing time, small in air shrinkage and good in water resistance, and dosing of materials can be particularly adjusted according to components of the sludge, so that curing of the sludge is not limited by time, the strength, the stability and the like meet the actual engineering requirements, the cost is low, pollution does not exist, and the curing agent can be widely applied and promoted.

Owner:GUANGZHOU INSTITUTE OF BUILDING SCIENCE CO LTD

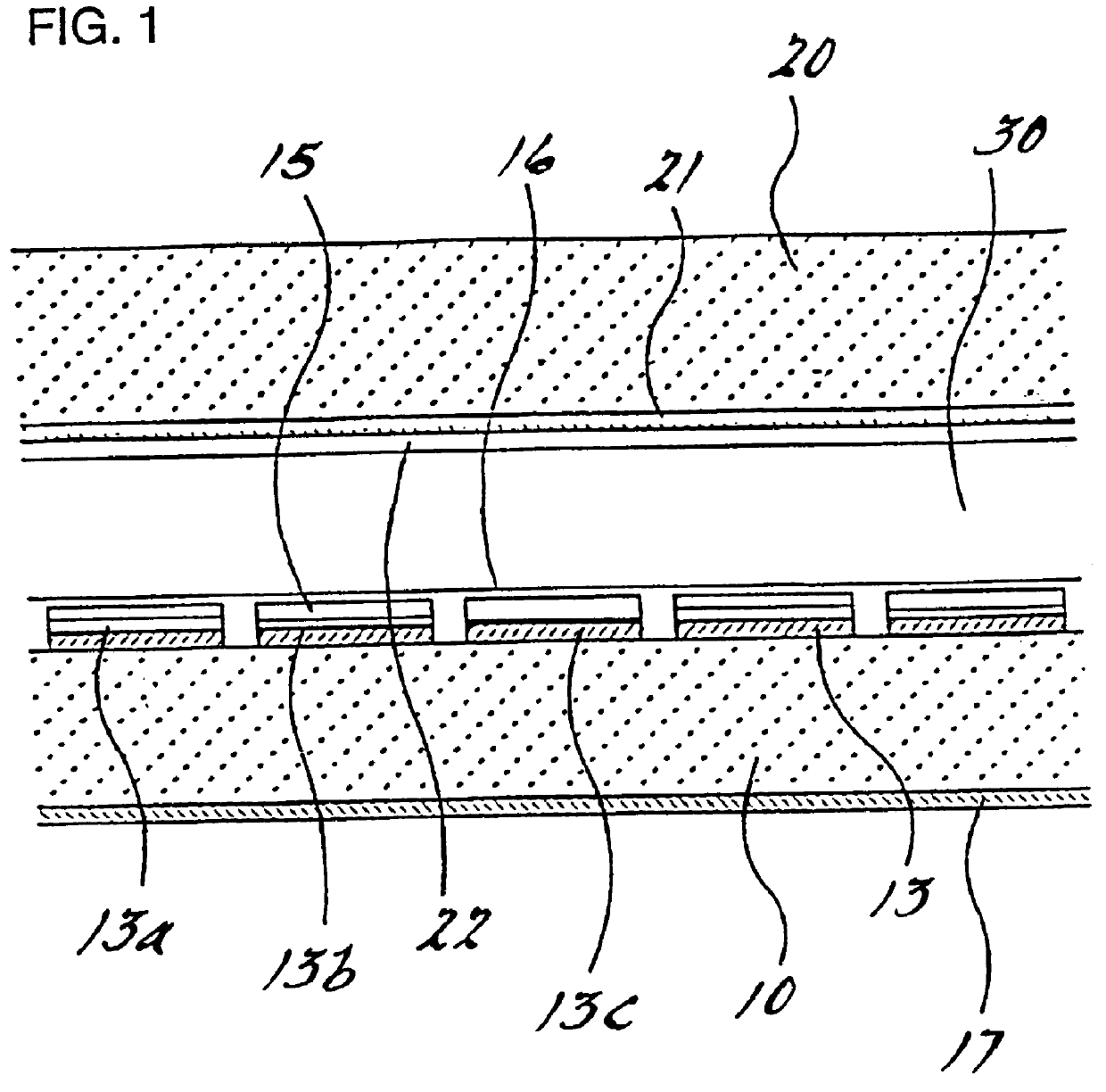

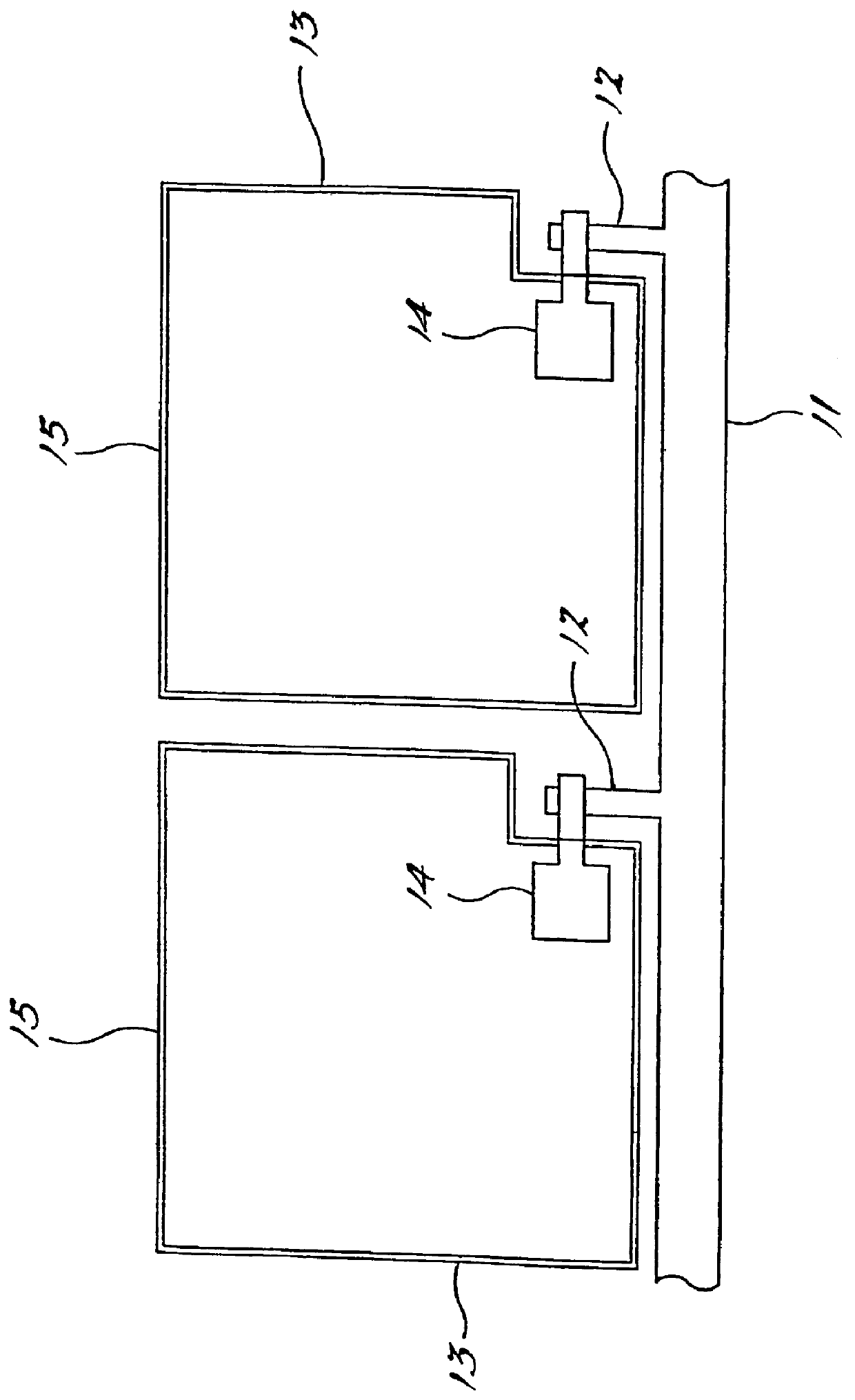

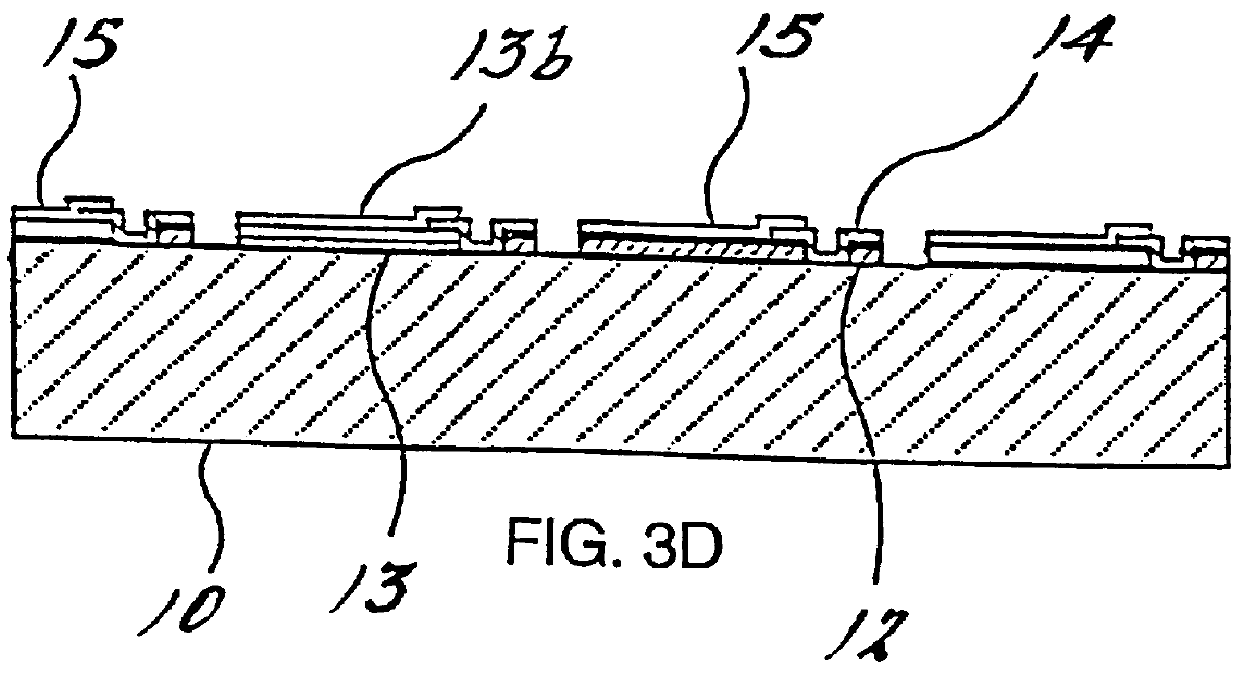

Liquid-crystal display unit, and process for manufacturing the same

InactiveUS6104459AExpansion quantityEasy to manufactureNon-linear opticsLiquid-crystal displayEngineering

PCT No. PCT / JP97 / 02426 Sec. 371 Date Mar. 10, 1998 Sec. 102(e) Date Mar. 10, 1998 PCT Filed Jul. 11, 1997 PCT Pub. No. WO98 / 02775 PCT Pub. Date Jan. 22, 1998The present invention provides a liquid-crystal display device and a process for manufacturing the same, wherein the unit achieves an inhibition of reduction in the displaying brightness even when used for a color reflection-type liquid-crystal display device, and a restriction of variation in the color tone which varies depending on the quantity of incident light. For each of the pixel regions, a pixel reflective layer 13 is formed with Ta. On the surface of each of a plurality of the pixel regions, three anodic oxide films 13a, 13b and 13c are formed with mutually different thicknesses. The thicknesses of the anodic oxide films are determined such that light reflected by the pixel reflective layer 13 is colored into three different colors.

Owner:SEIKO EPSON CORP

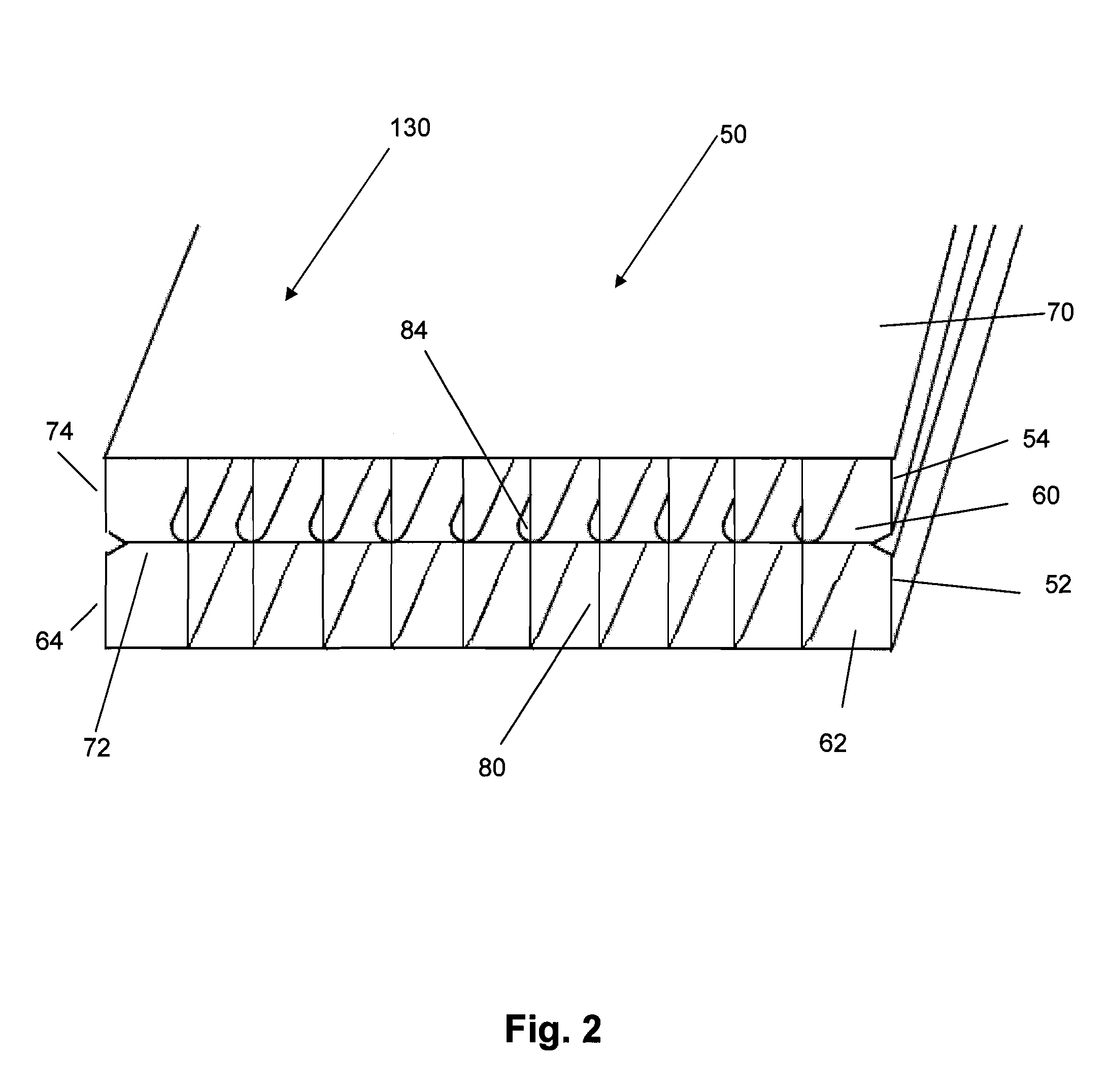

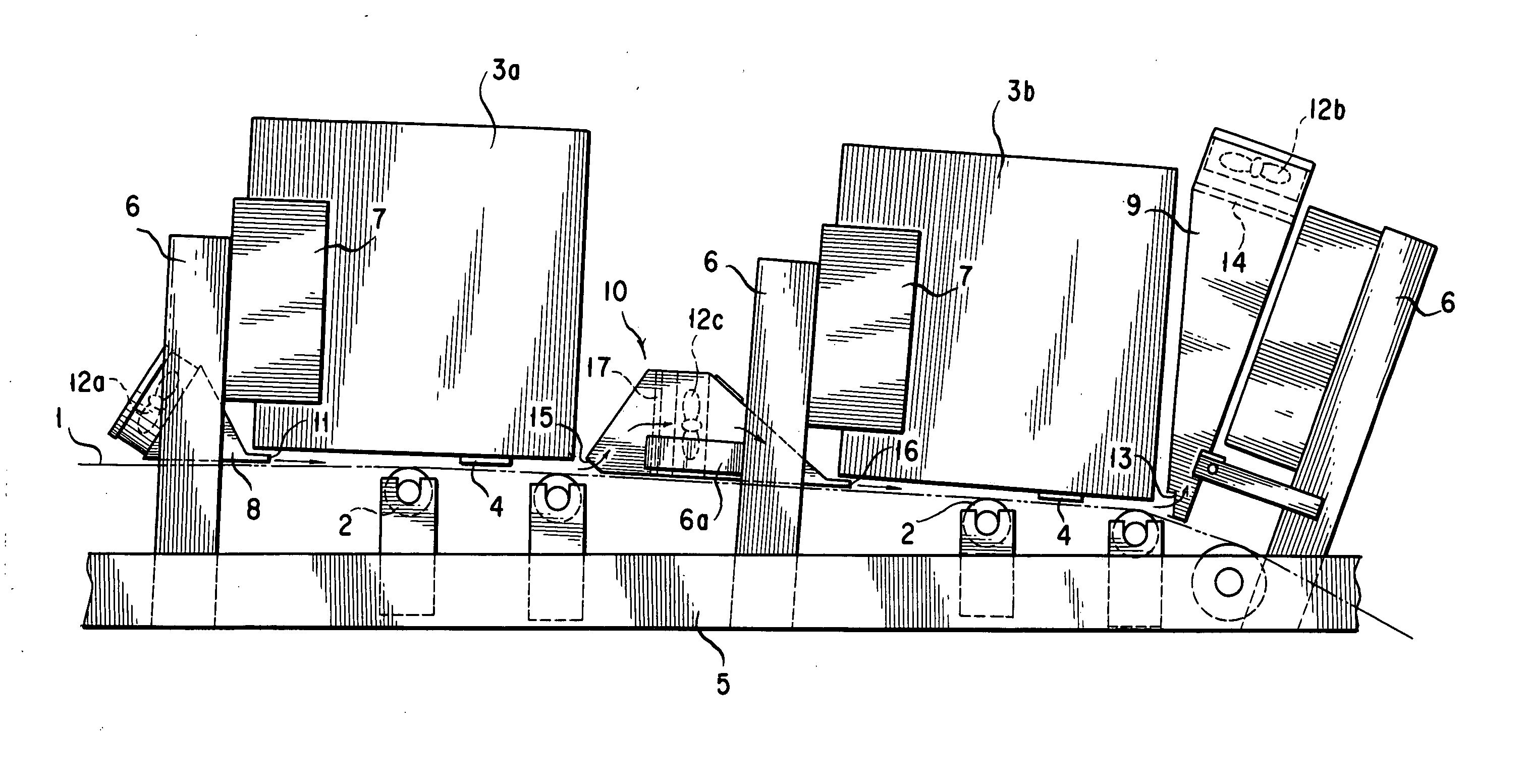

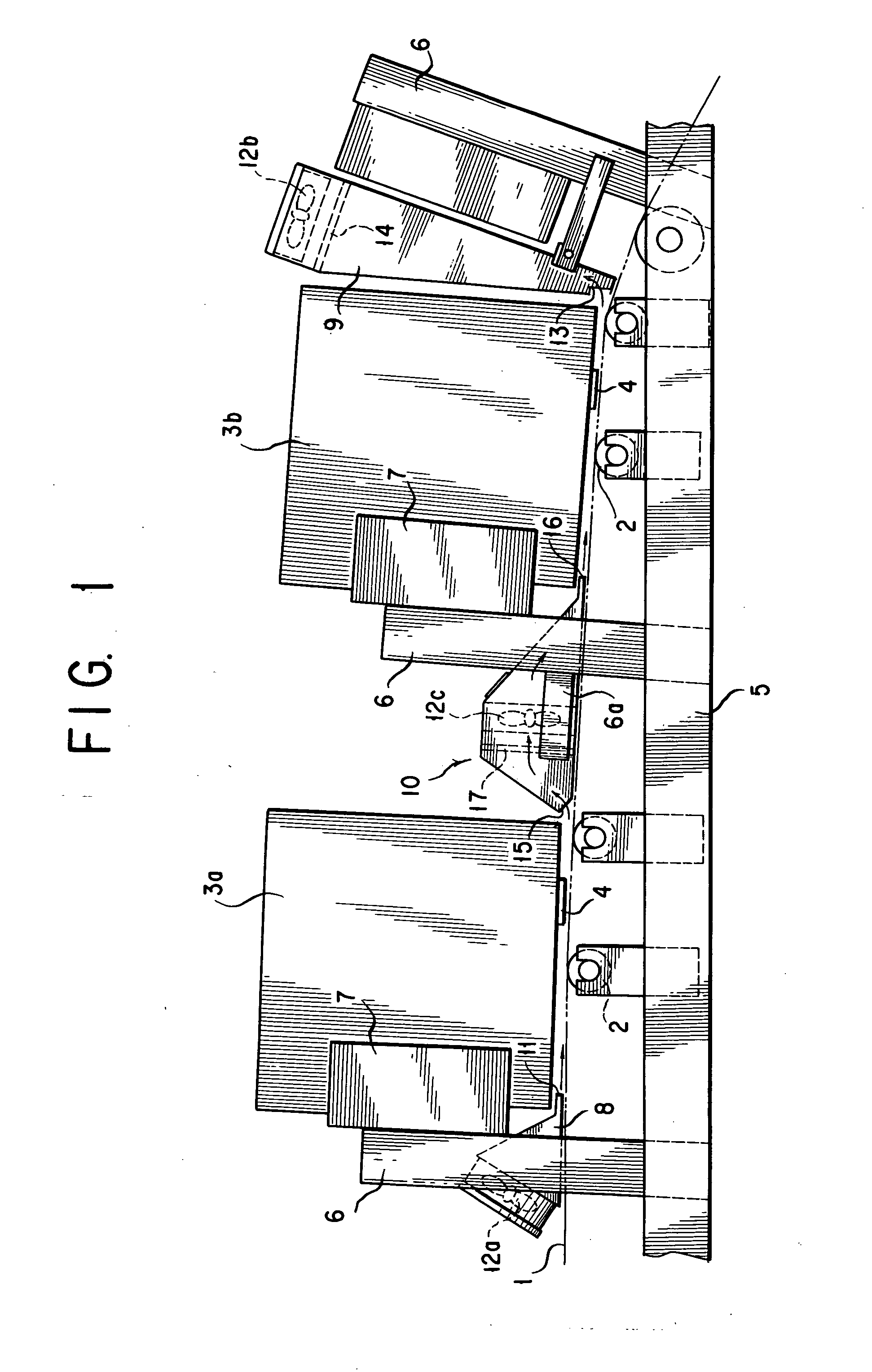

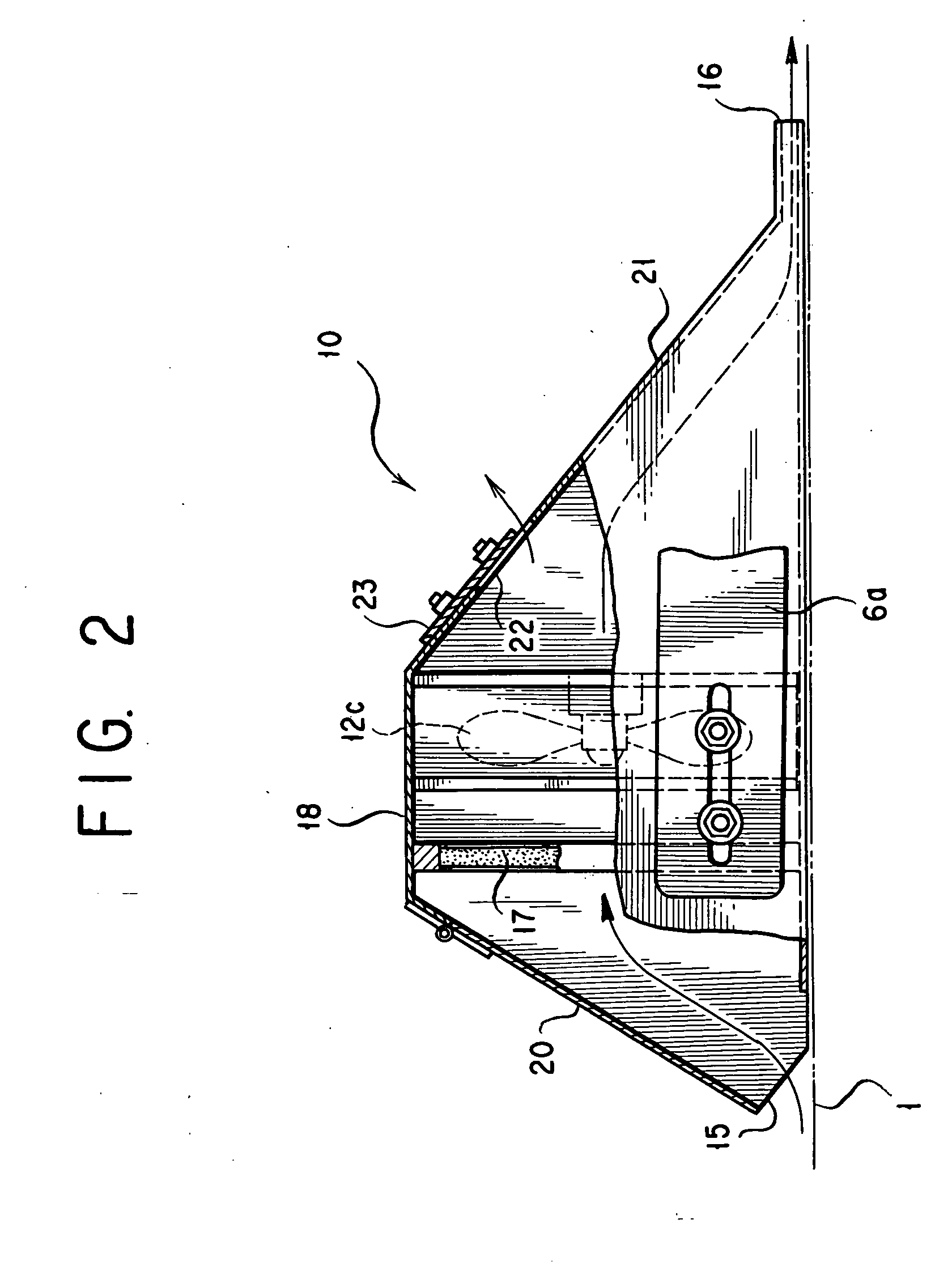

Inkjet recording apparatus

ActiveUS20070109348A1Efficient removalEfficient collectionPower drive mechanismsAir blastWaste management

An inkjet recording apparatus having a plurality of inkjet heads arranged along a paper conveyance line is disclosed, which is capable of collecting an ink mist efficiently without making the inkjet heads intricate in makeup. To this end, an air suction and blast unit is disposed in a space between the upstream and downstream inkjet heads which are successive and includes a housing, an air suction port provided at one side of the housing, an air blast nozzle provided at the other side of the housing, a fan provided between the air suction port and the air blast nozzle in the housing for creating an air flow flowing from the air suction port to the air blast nozzle and a mist filter in the housing for catching an ink mist in the air flow created by the fan, wherein the air suction port is opposed from a downstream side to a gap between an under surface of the upstream inkjet head and the paper conveyance line while the air blast nozzle is opposed from an upstream side to a gap between the downstream inkjet head and the paper conveyance line.

Owner:MIYAKOSHI PRINTING MACHINERY

Building staircase multifunctional electric meter

InactiveCN105675979AImprove the defense levelSimple internal structureCharacter and pattern recognitionElectrical measurementsSampling circuitsElectric energy

The invention relates to a building staircase multifunctional electric meter, which comprises a current transformer, a sampling circuit, a voltage sampling circuit, a person trajectory analysis device and an MSP430 single chip microcomputer, wherein the current transformer and the sampling circuit are used for sampling current signals in an AC line; the voltage sampling circuit is used for sampling voltage signals in the AC line; the person trajectory analysis device is used for determining whether the action trajectory of a person target in the staircase is suspicious; and the MSP430 single chip microcomputer is connected with the current transformer and the sampling circuit, the voltage sampling circuit and the person trajectory analysis device respectively for determining active power and reactive power in the AC line based on the sampled current signals and the sampled voltage signals and determining whether the person target is an escaped convict based on output of the person trajectory analysis device. Thus, the building security efficiency is improved while the electric energy outputted by the AC line can be accurately detected.

Owner:WUXI ZHIGURUITUO TECH SERVICE CO LTD

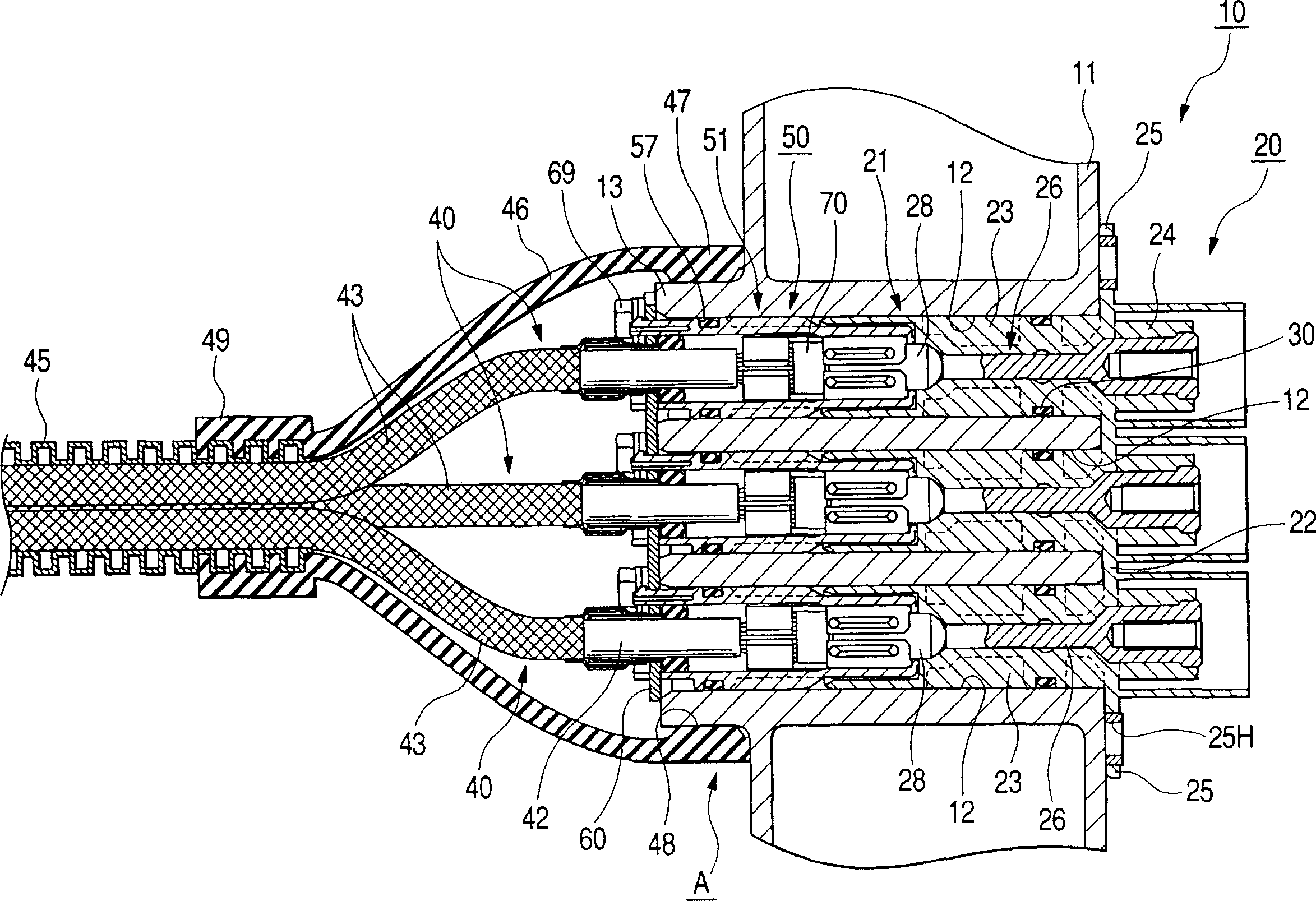

Connecting structure for electric wire to shield case of apparatus

InactiveCN1551455AEffective protectionReduce in quantityVehicle connectorsWindingsElectric wireElectrical wiring

Owner:株式会社自动车电网络技术研究所 +3

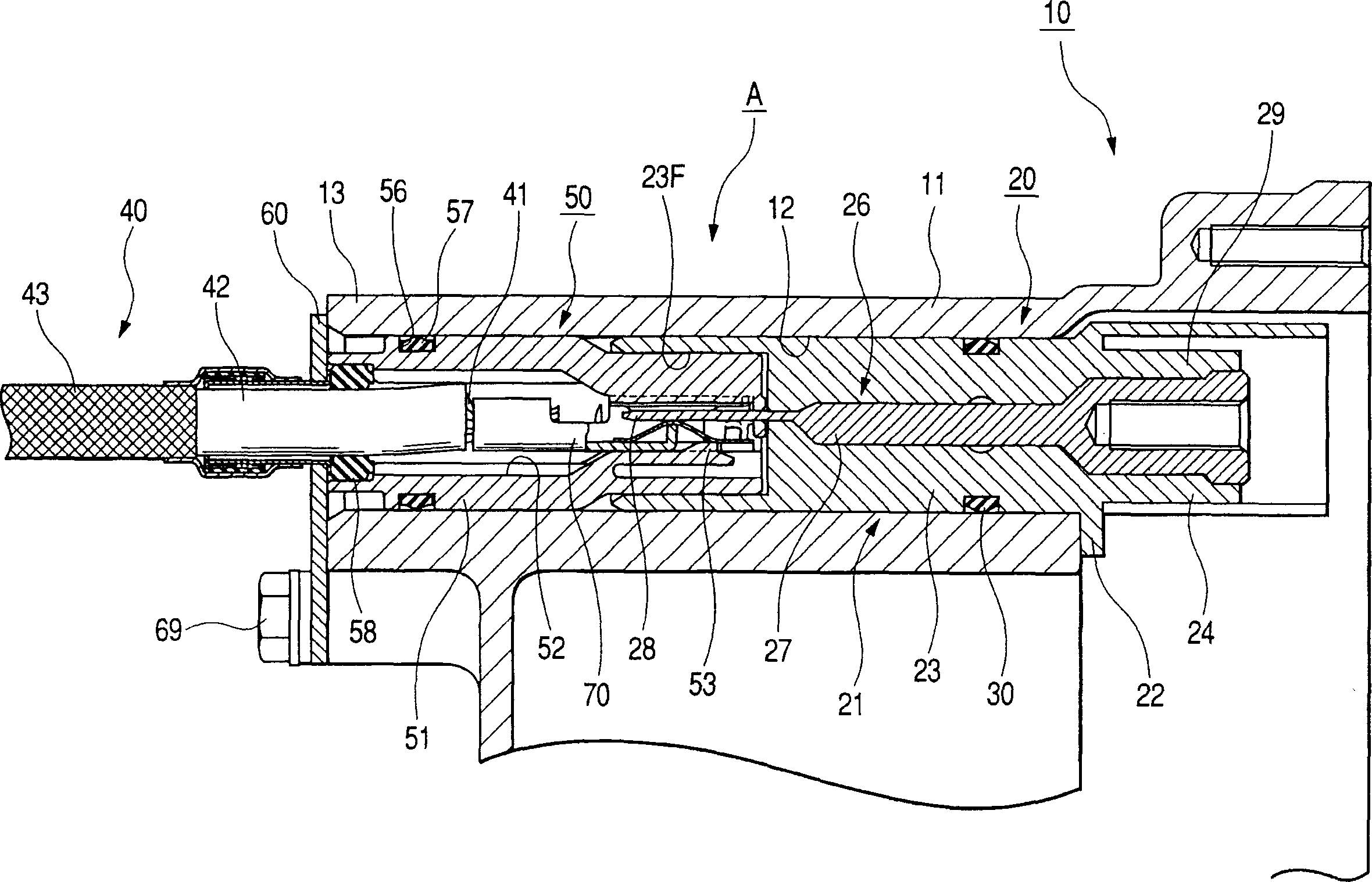

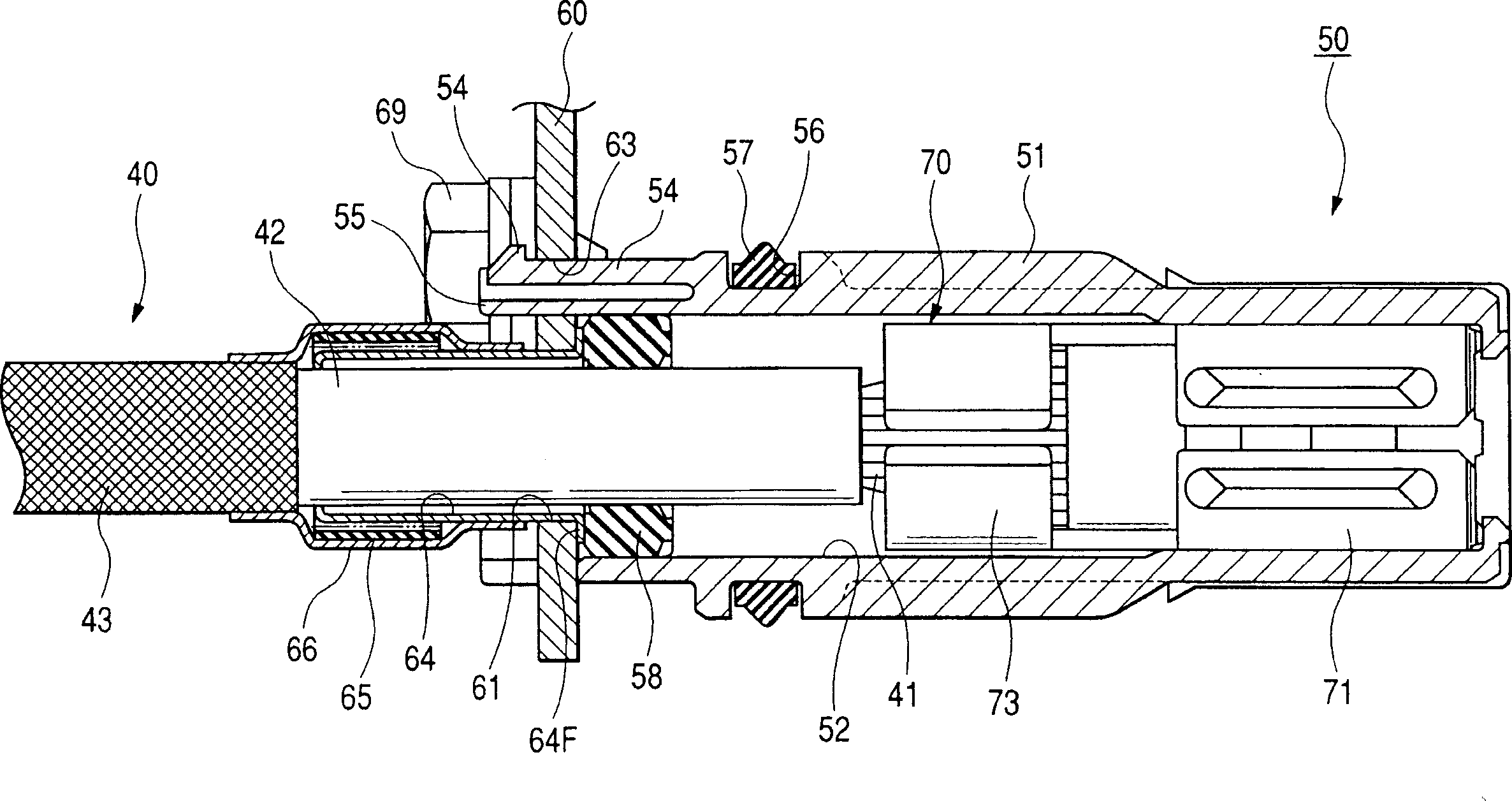

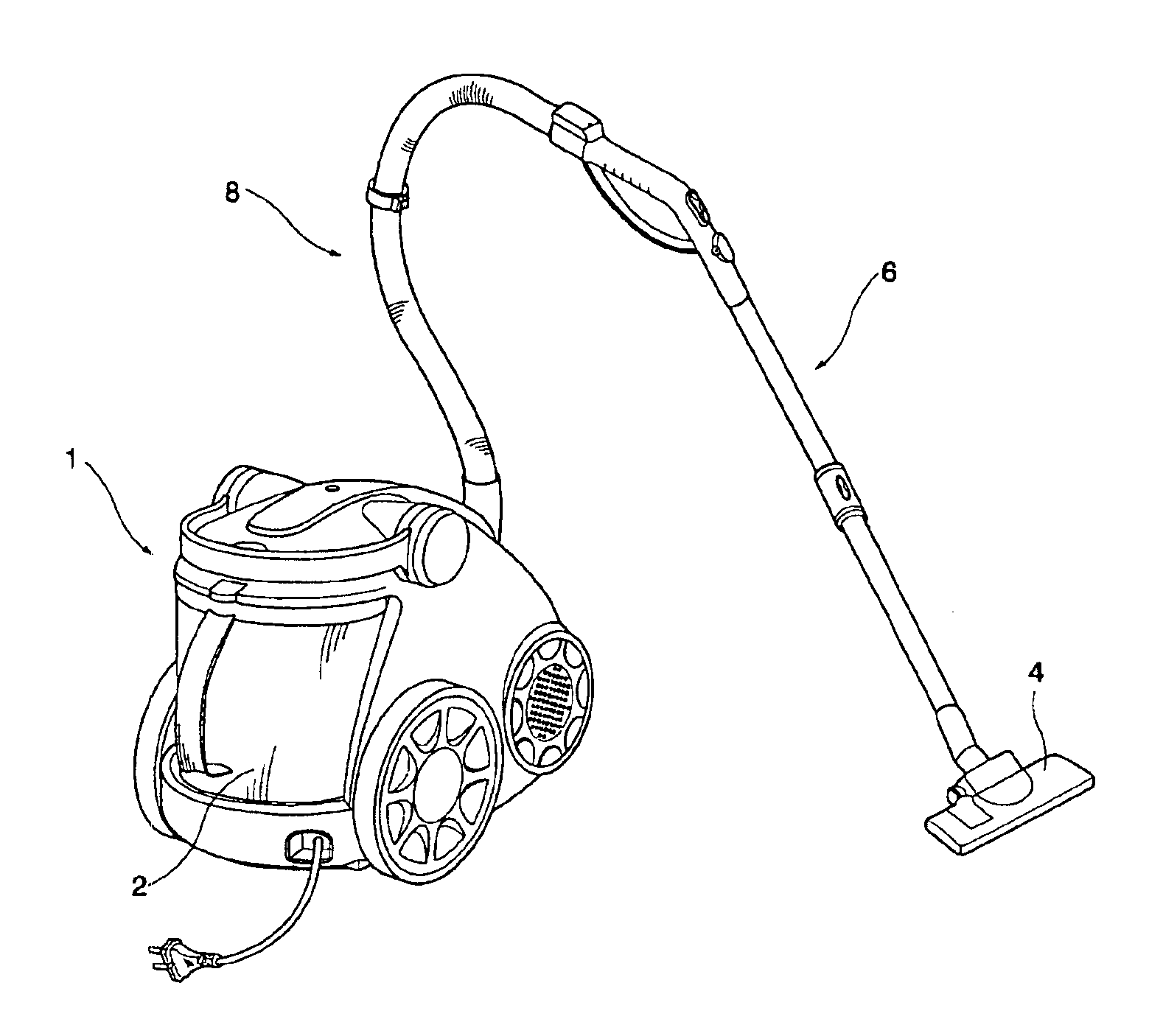

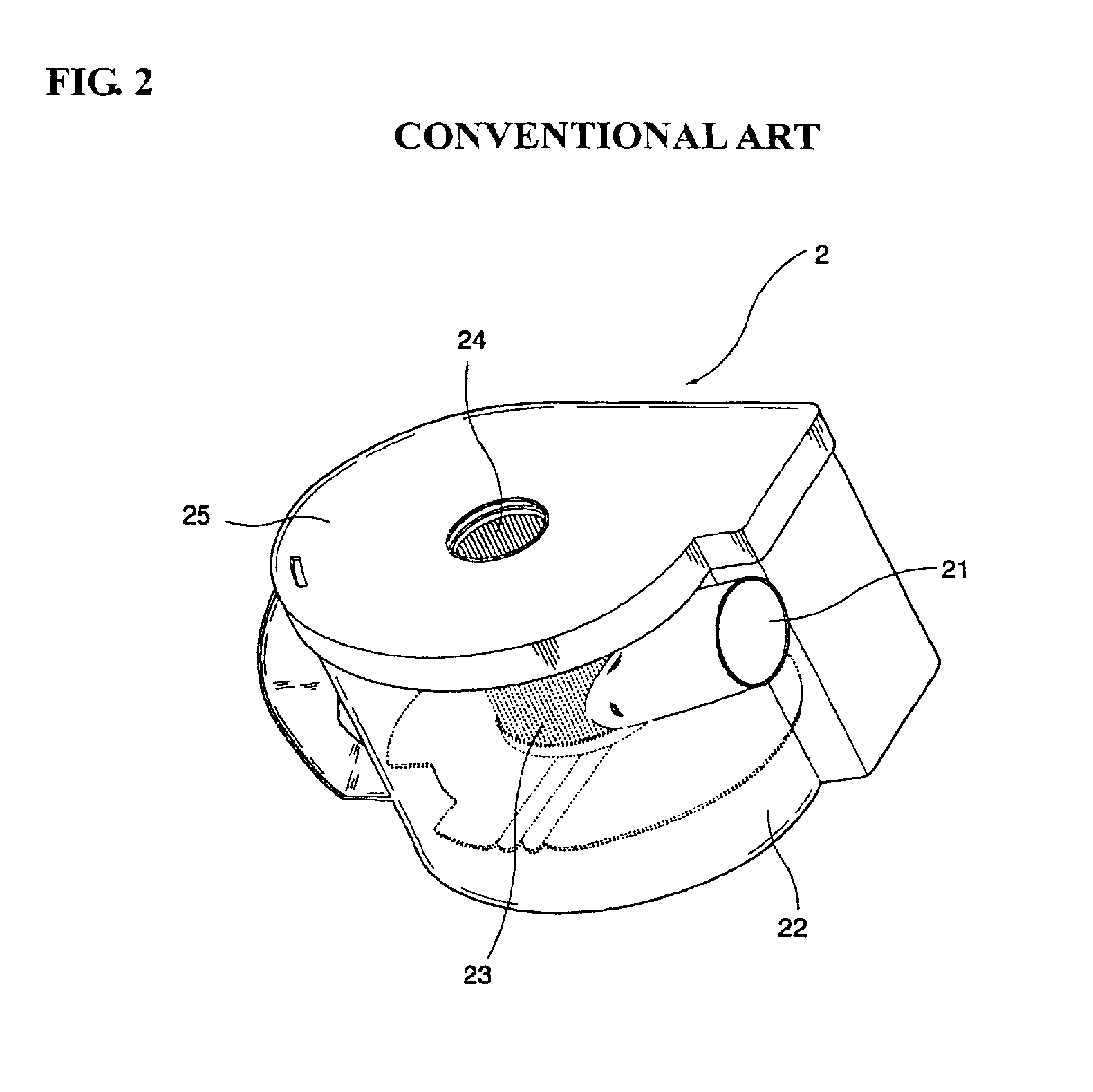

Dust collection unit for use in vacuum cleaner and main body of vacuum cleaner having the same

InactiveUS6901625B2Simple internal structureCleaning filter meansCombination devicesForeign matterEngineering

The present invention relates to a dust collection unit for use in a vacuum cleaner. According to the present invention, there is provided a dust collection unit for use in a vacuum cleaner which comprises a cylindrical casing in which air introduced through an inlet port is formed into spiral flow and of which an upper end is open; a cover for opening and closing the upper end of the casing; a filter which is installed on a bottom surface of the cover and formed in the shape of a cylinder having a predetermined length and by which fine foreign substances can be filtered out when the air is introduced from the exterior thereof, and through which the air is discharged downwardly; and an exhaust duct which comes into close contact with a bottom surface of the filter and including an exhaust port on a side surface of the casing to discharge the air from the filter to the exterior of the casing. It is preferred that the exhaust port of the casing be formed at a lower portion of the side surface of the casing.

Owner:LG ELECTRONICS INC

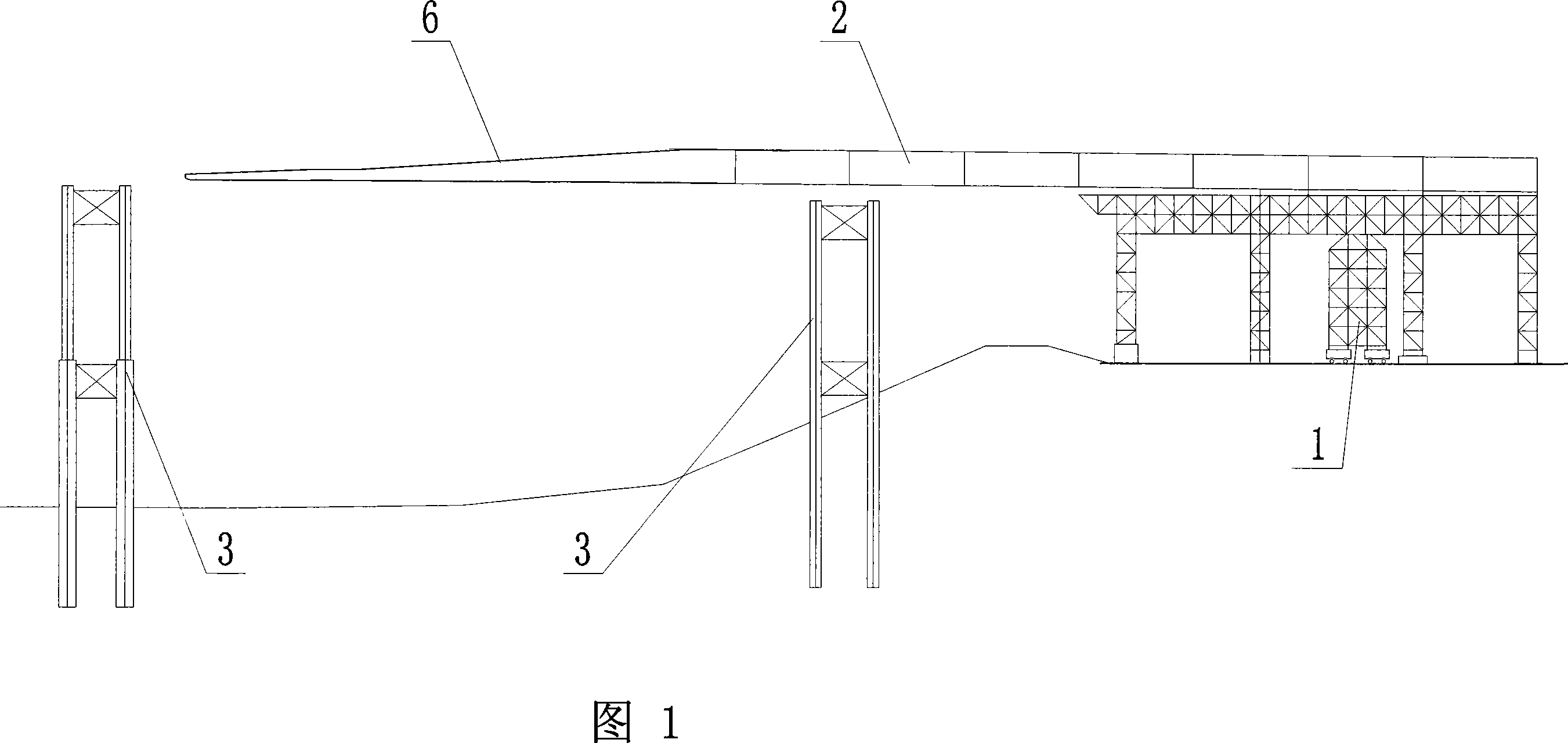

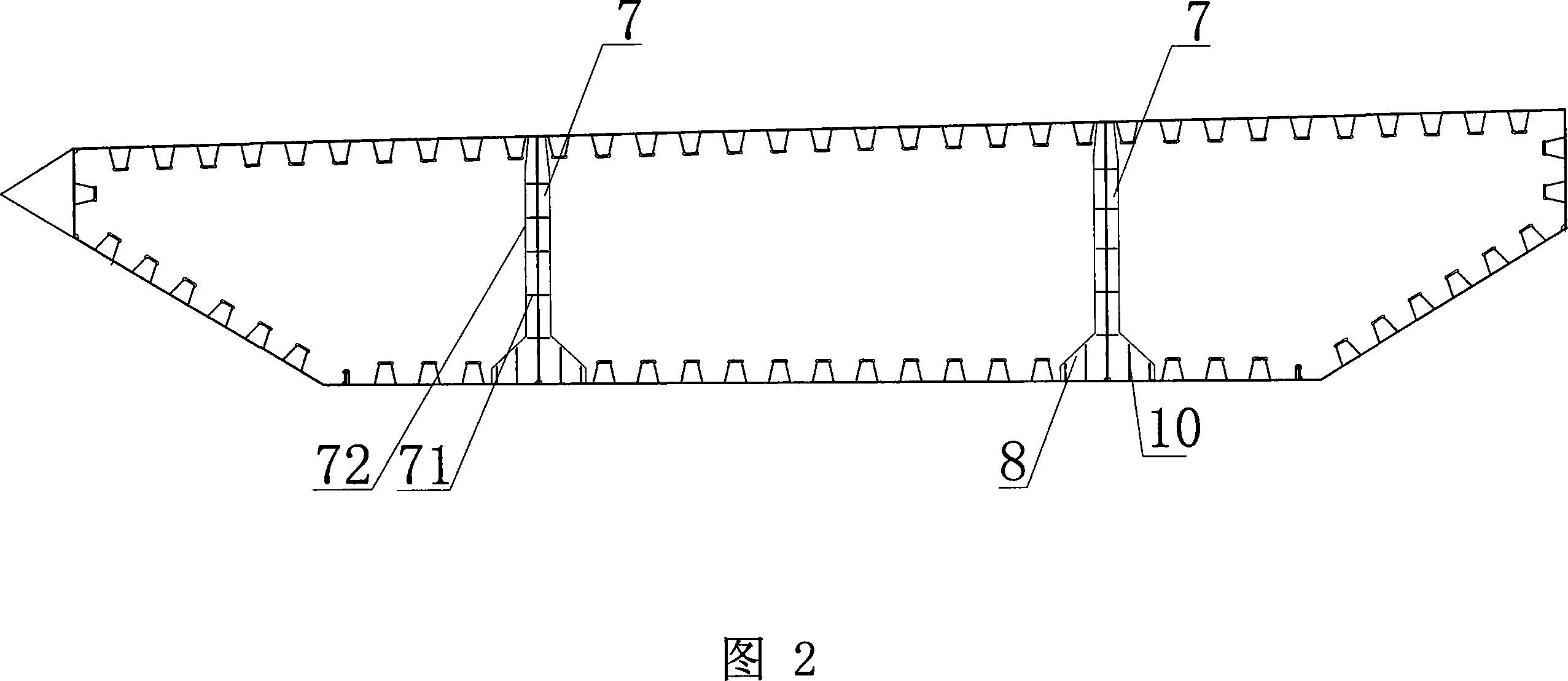

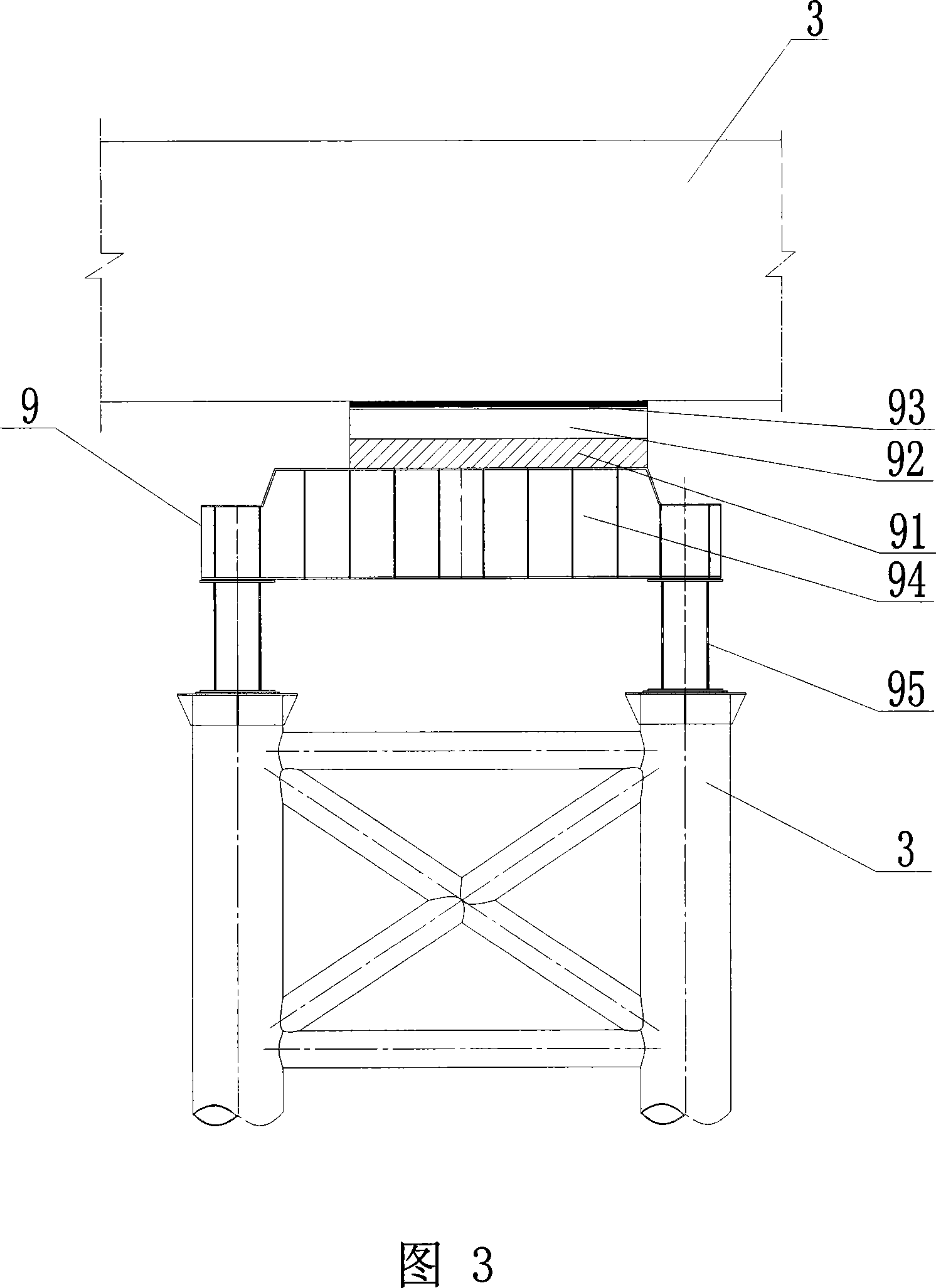

Steel box beam erection method for self-anchored suspension bridge

InactiveCN101078198ASave manpower and costImprove efficiencyBridge erection/assemblyEngineeringSteel box girder

The invention discloses a method for steel-box beam erection applied in self-anchored suspension bridge. Procedures comprise that (1) the support for steel-box beam is set on bank or in no-navigation area and steel-box beam is preassembled with dividing segments on the support for steel-box beam; (2) temporary piers for steel-box beam, which satisfy waterway grade, are set in the waterway suspended by the suspension bridge; (3)preassembled steel-box beam is pushed forwards by pushing or dragging method so that the steel-box beam moves to temporary piers for steel-box beam from the support for steel-box beam and the steel-box beam is supported by temporary piers; then the steel-box beam is preassembled in dividing segments and it is pushed or dragged continuously so that preassembled steel-box beam moves forwards and it passes through temporary piers for steel-box beam on waterway in turn to achieve the opposite bank. The invention is provided with simple construction and it can be applied in waterway with busy suspension and higher waterway grade.

Owner:HUNAN PROVINCIAL COMM PLANNING SURVEY & DESIGN INST CO LTD

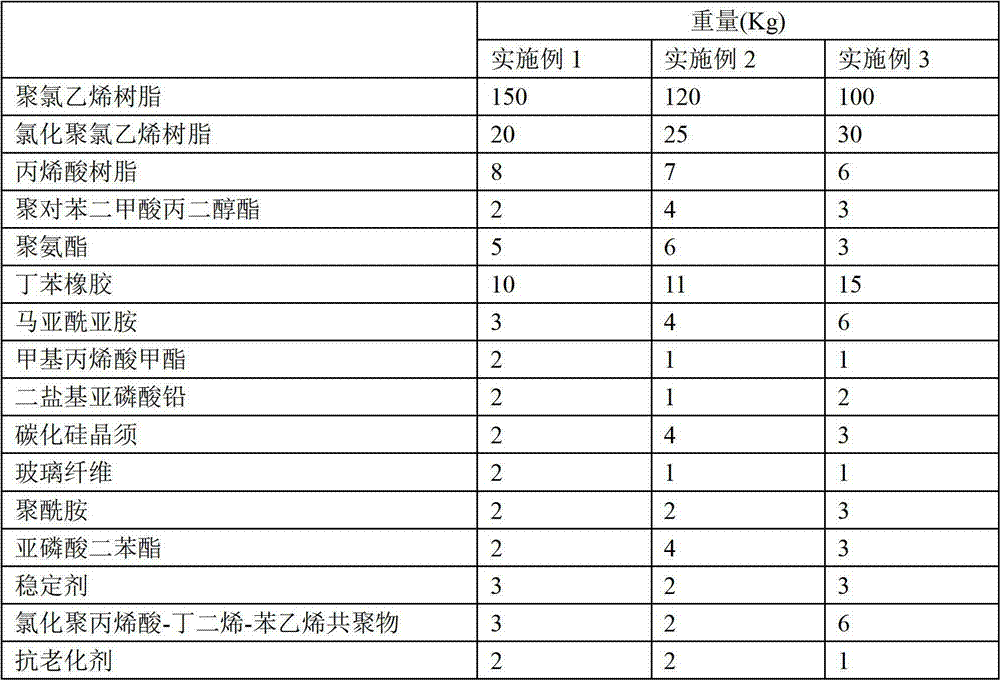

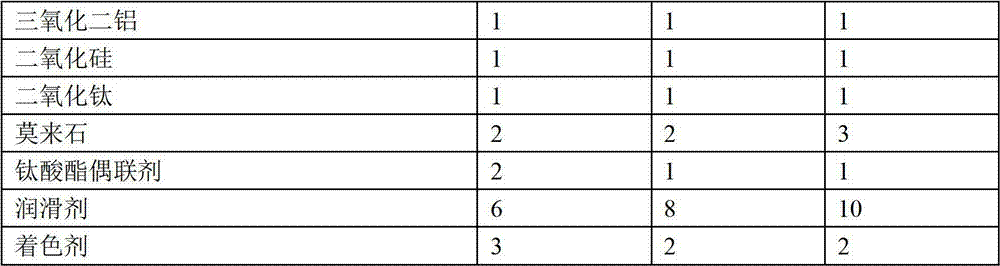

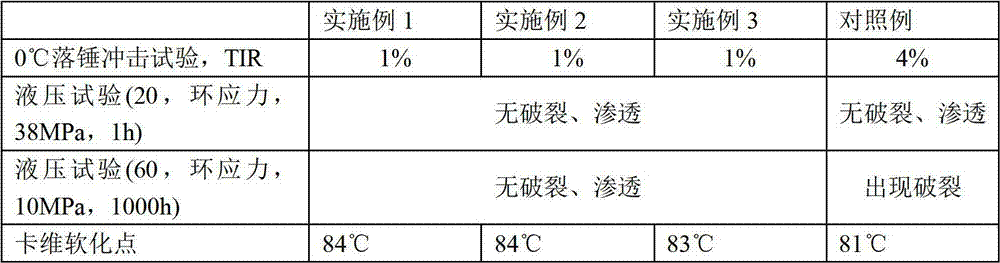

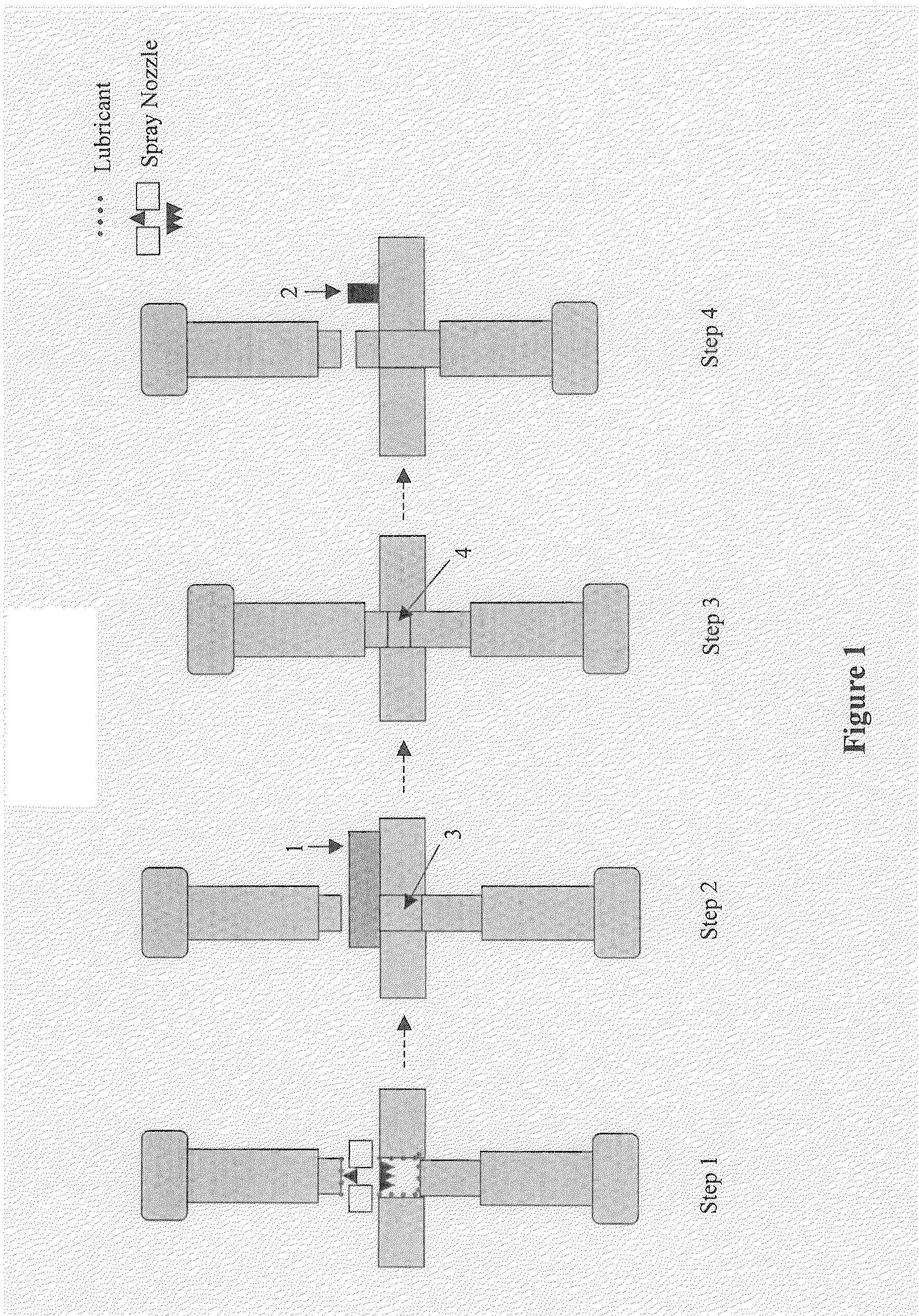

High-toughness polyvinyl chloride tube

InactiveCN102850696AStrengthen the structureImprove toughnessRigid pipesHigh polymerStyrene-butadiene

The invention provides a high-toughness polyvinyl chloride tube, belonging to the technical field of high polymer materials. The high-toughness polyvinyl chloride tube is prepared from the following components in parts by weight: 100-150 parts of polyvinyl chloride resin, 20-30 parts of chlorinated polyvinyl chloride resin, 6-8 parts of acrylic resin, 2-4 parts of polytrimethylene terephthalate, 3-6 parts of polyurethane, 10-15 parts of styrene-butadiene rubber, 3-6 parts of maleimide, 1-2 parts of methyl methacrylate, 1-2 parts of dibasic lead phosphite, 2-4 parts of silicon carbide whisker, 1-2 parts of glass fiber, 2-3 parts of polyamide, 2-4 parts of diphenyl phosphite, 2-3 parts of stabilizer, 2-6 parts of chlorinated polyacrylic acid-butadiene-styrene copolymer, 1-2 parts of antiaging agent, 1 part of aluminum oxide, 1 part of silicon dioxide, 1 part of titanium dioxide, 2-3 parts of mullite, 1-2 parts of titanate coupling agent, 6-10 parts of lubricant and 2-3 parts of colorant. The prepared polyvinyl chloride tube has the characteristics of high toughness and high mechanical strength, and is superior to like products in the market.

Owner:WUJIANG HUACHENG COMPOSITE MATERIAL SCI & TECH

Tablets and Preparation Thereof

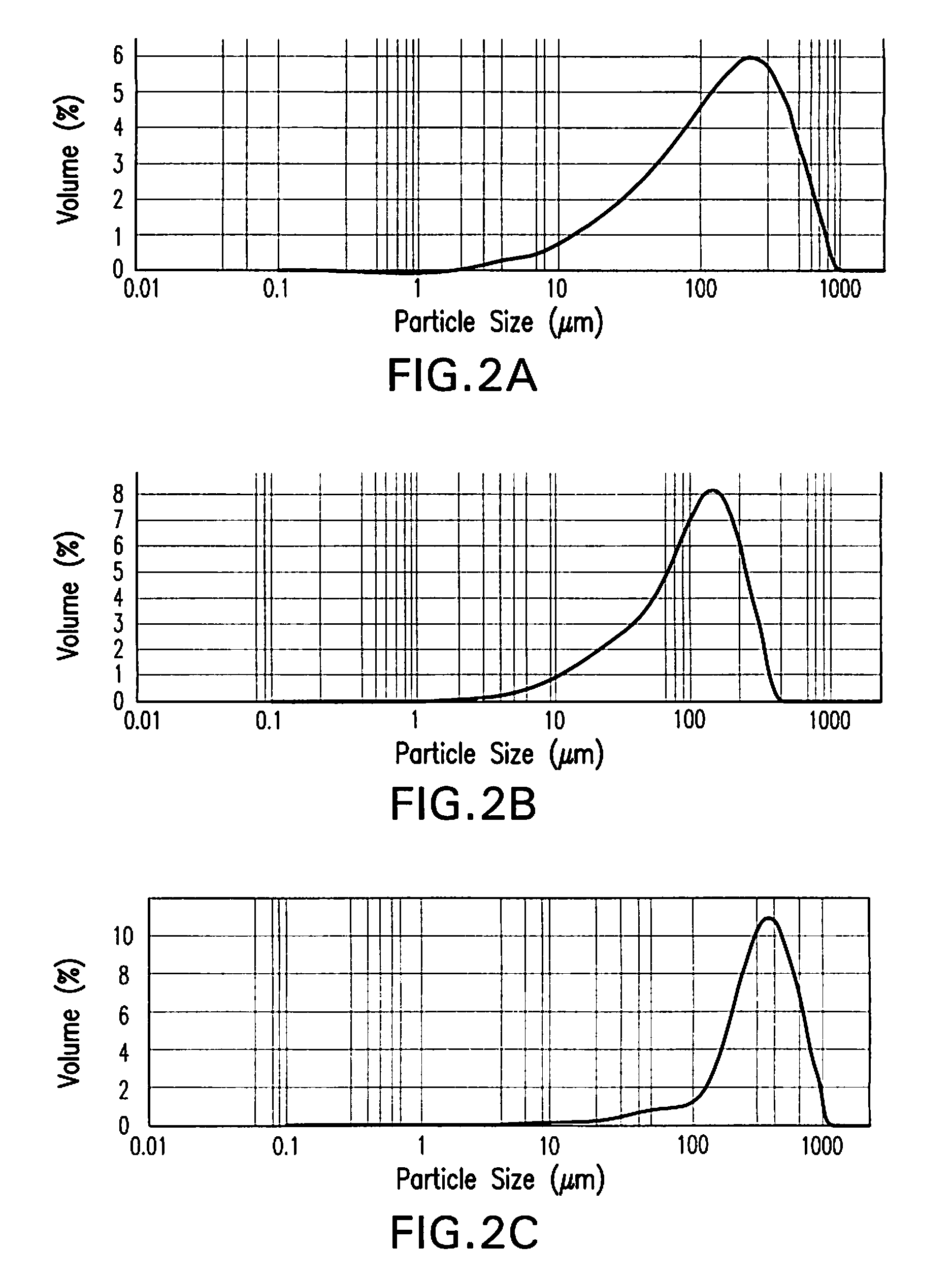

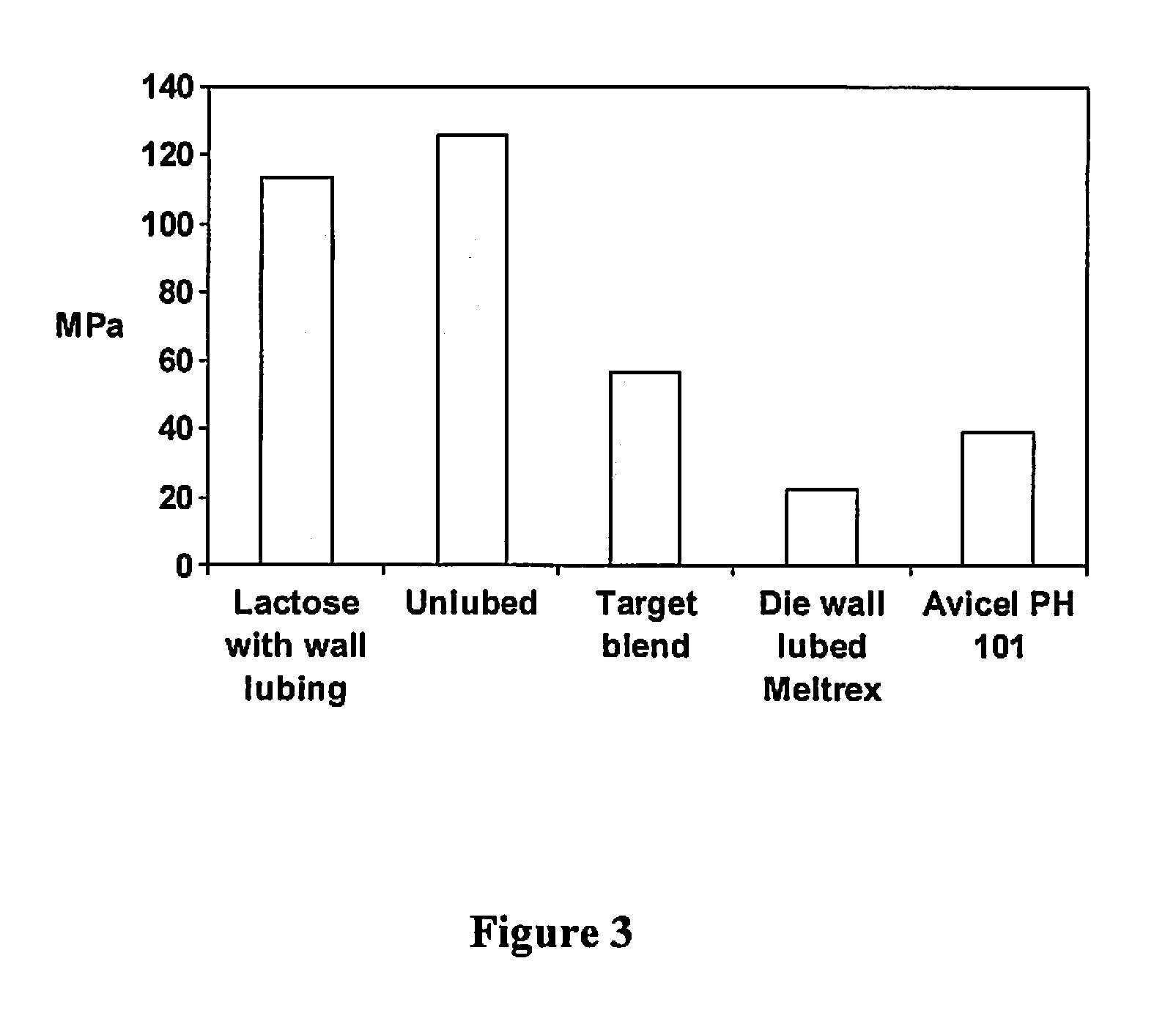

InactiveUS20100021540A1Less internal fractureReduced internal structural failureBiocideOrganic active ingredientsBiomedical engineeringLubricant

The present invention features processes of making tablets having reduced internal fractures. In one aspect, the processes comprise the steps of (1) compressing a pre-tabletting material in a die to form a tablet, where an internal surface of the die is lubricated with at least one lubricant and the pre-tabletting material comprises at least one therapeutic agent and at least one pharmaceutically acceptable polymer; and (2) ejecting said tablet from said die. In another aspect, the processes employ a granular or powdery pre-tabletting material which comprises at least one therapeutic agent and at least one pharmaceutically acceptable polymer, wherein 90% of the particles in the pre-tabletting material are smaller than 400 μm.

Owner:ABBVIE INC

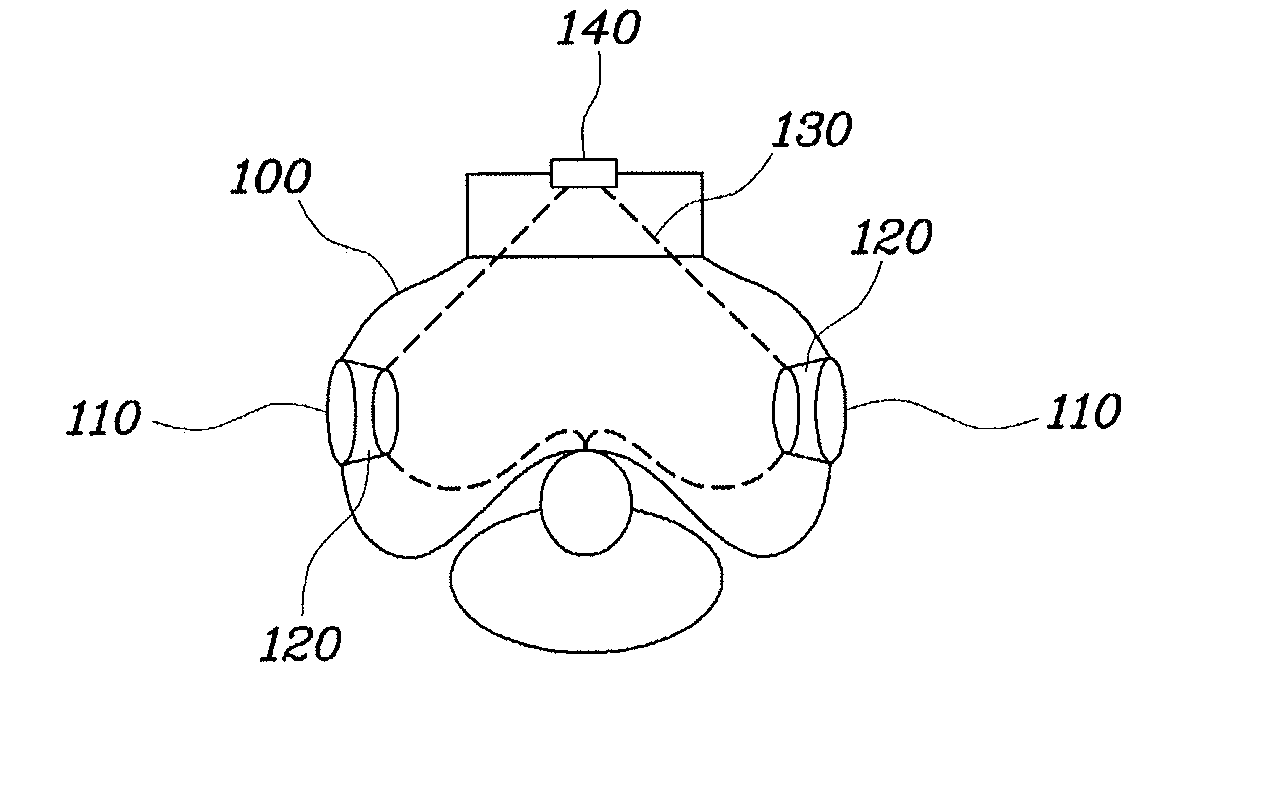

Airbag for vehicle

InactiveUS20130147171A1Reduce numberReduce riskPedestrian/occupant safety arrangementCushionEngineering

An airbag apparatus for a vehicle, may include an integrated vent formed in an airbag cushion, a tube provided on the airbag cushion and communicating with the integrated vent, wherein an inner diameter of the tube varies while gas may be discharged through the tube, so that a rate at which gas may be discharged from the airbag cushion may be adjusted according to a point of time of deployment of the airbag cushion, and a tether wrapped around the tube, the tether being connected to inner surface of the airbag cushion such that opposite ends of the tether may be pulled away from each other when the airbag cushion deploys, so that in a predetermined time period of the deployment of the airbag cushion, the tether contracts the tube, and after the predetermined time period, the tether snaps, thus releasing the tube.

Owner:HYUNDAI MOTOR CO LTD

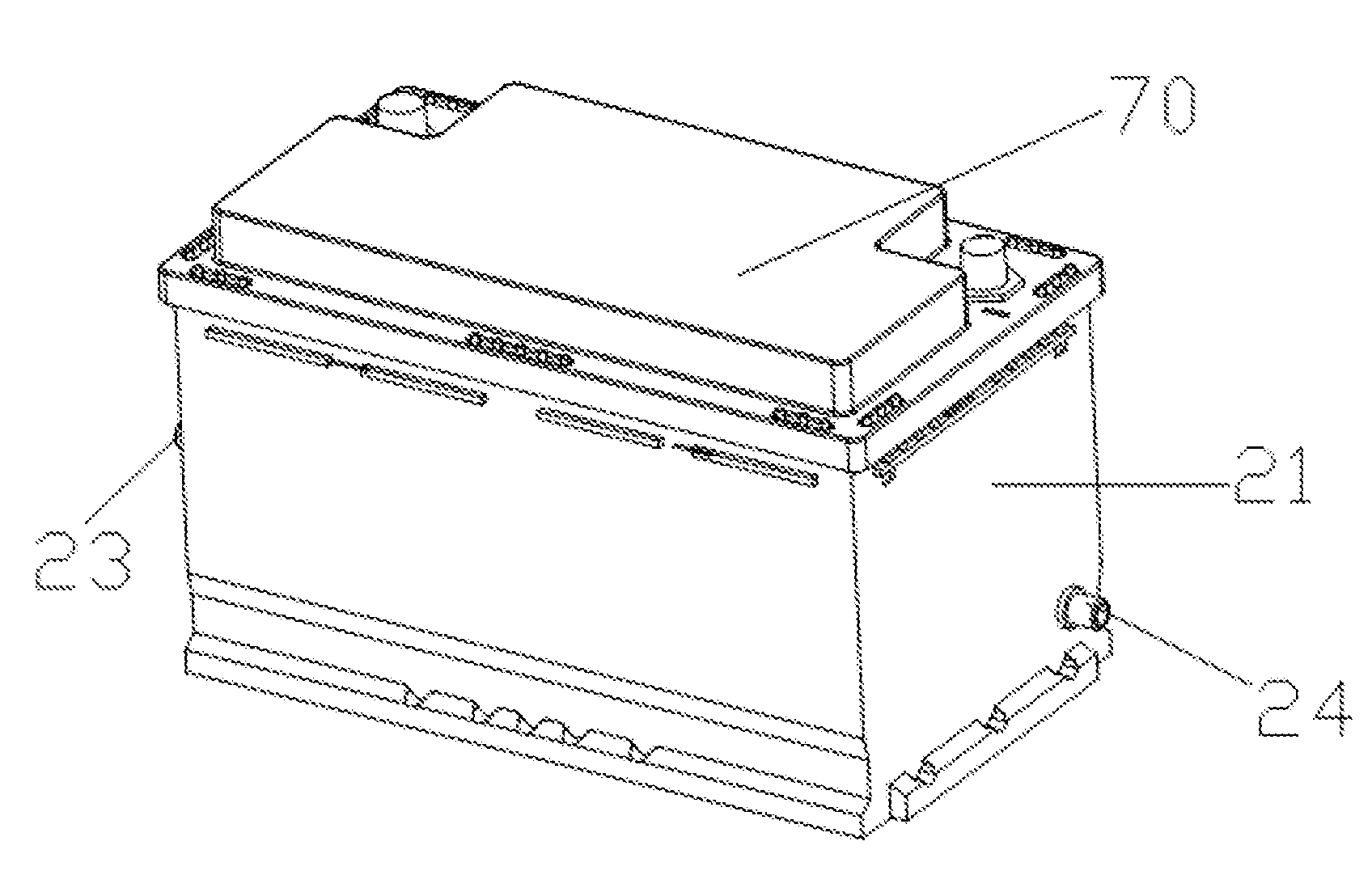

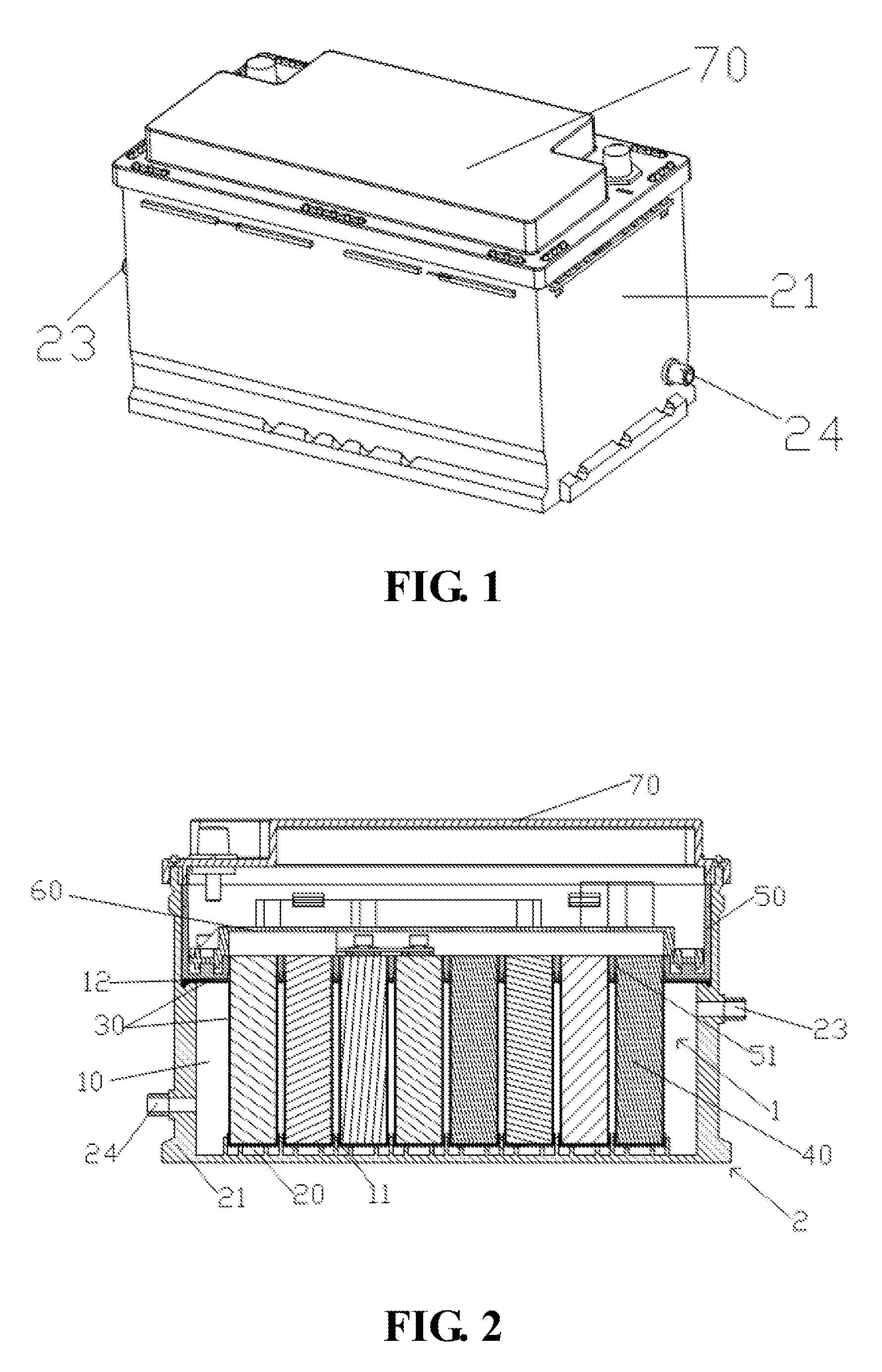

Oil-cooled lithium battery module

InactiveUS20130260195A1Internal structure be simplifyCost reductionCell temperature controlCell lids/coversTop capOil temperature

This invention belongs to the category of the lithium battery technology, specially, it relates to an oil-cooled lithium battery module comprising of an oil cooling system and a lithium battery module, wherein the lithium battery module immerged in the oil cooling system and composed of a battery base, a battery core within a core rubber sleeve as well as a press plate, a PCB support plate and a top cap which are disposed in sequence at the front end of the battery core. The top cap is sealingly connected with the battery base, which houses the core rubber sleeve. In comparison with the prior art, the oil cooling system in the present invention controls the oil temperature to ensure that the battery core can run under normal ambient temperature.

Owner:NINGDE AMPEREX TECH

Solid aluminum alloy conductor and preparation method thereof

ActiveCN103146960AUp to conductor cross sectionAchieve the required electricalCable/conductor manufactureRare-earth elementElectrical conductor

The invention provides a solid aluminum alloy conductor and a preparation method thereof. The solid aluminum alloy conductor contains by weigh 0.40-1.00% of iron, 0.05-0.20% of copper, 0.05-0.10% of silicon, 0.02-0.12% of zinc, 0.01-0.05% of magnesium, 0.02-0.12% of rare earth element and the balance of aluminum and unavoidable impurities. The method comprises steps of: completely melting an aluminum ingot; adding a magnesium ingot with a special tool; after melting, sequentially adding manganese aluminum alloy, zinc aluminum alloy, copper aluminum alloy, iron aluminum alloy, silicon aluminum alloy and rare earth aluminum alloy of different weights; fully mixing, refining and conducting ladle analysis; after qualification of all components, casting and rolling into a required aluminum alloy rod; conducting aging treatment; extruding the required solid core conductor according to the requirements; conducting special heat treatment to reach corresponding performance indicators, so as to meet the need to substitute a traditional copper core electrical wire of electrical wire materials.

Owner:ANHUI NANYANG NEW MATERIAL TECH CO LTD

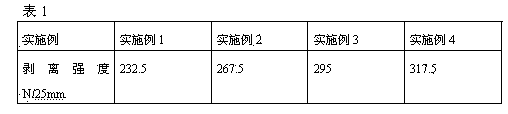

High peel strength acrylate adhesive

InactiveCN103834307AImprove toughness and strengthHigh peel strengthOrganic non-macromolecular adhesiveEpoxyElastomer

The invention discloses a high peel strength acrylate adhesive which belongs to the technical field of two-component acrylate adhesives, and mainly solves the problems that second generation acrylate structural adhesives in the prior art are poor in toughness, and have the peel strength of only 50-100N / 25mm. The high peel strength acrylate adhesive is mainly characterized by including a main agent component which comprises 25 to 60 parts of acrylate monomers containing at least one vinyl, 0 to 25 parts of methacrylic acid, 0 to 25 parts of an elastomer, 5 to 15 parts of epoxy resin, 0.5 to 8 parts of an initiator and 0.1 to 5 parts of a stabilizer; and a curing agent component which comprises 25 to 60 parts of the acrylic monomers containing at least 1 vinyl, 0 to 25 parts of the methacrylic acid, 0 to 25 parts of the elastomer and 1-10 parts of an accelerant. The high peel strength acrylate adhesive is characterized by significantly improving the toughness and the peel strength of the adhesive, the peel strength can reach 200-300N / 25mm, and the high peel strength acrylate adhesive is mainly used as a high peel strength acrylate adhesive.

Owner:HUBEI HUITIAN NEW MATERIALS STOCK CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com