Patents

Literature

6185 results about "Styrene-butadiene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

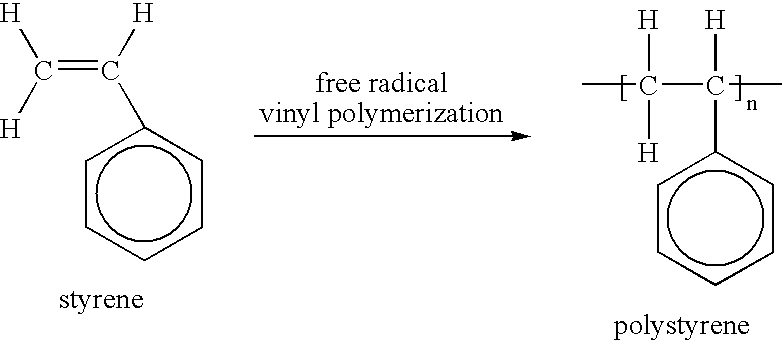

Styrene-butadiene or styrene-butadiene rubber (SBR) describe families of synthetic rubbers derived from styrene and butadiene (the version developed by Goodyear is called Neolite). These materials have good abrasion resistance and good aging stability when protected by additives. In 2012, more than 5.4 million tonnes of SBR were processed worldwide. About 50% of car tires are made from various types of SBR. The styrene/butadiene ratio influences the properties of the polymer: with high styrene content, the rubbers are harder and less rubbery. SBR is not to be confused with a thermoplastic elastomer made from the same monomers, styrene-butadiene block copolymer.

Lubricant additive

ActiveUS20120101017A1Good viscosity performanceIncrease VISolid-state devicesLiquid carbonaceous fuelsBase oilButadiene-styrene rubber

A hydrogenated styrene butadiene star copolymer is incorporated in a lubricant additive package. The star copolymer can include about 3 to 25% and about 97 to 75% butadiene. The star copolymer may further be incorporated in a lubricant additive in the amount of about 12 wt % of the star copolymer as compared to the base oil.

Owner:AFTON CHEMICAL

Integral gasketed filtration cassette article and method of making the same

InactiveUS20020139741A1Simple and efficient and economicalLow costSemi-permeable membranesFiltration separationEpoxyPolyester

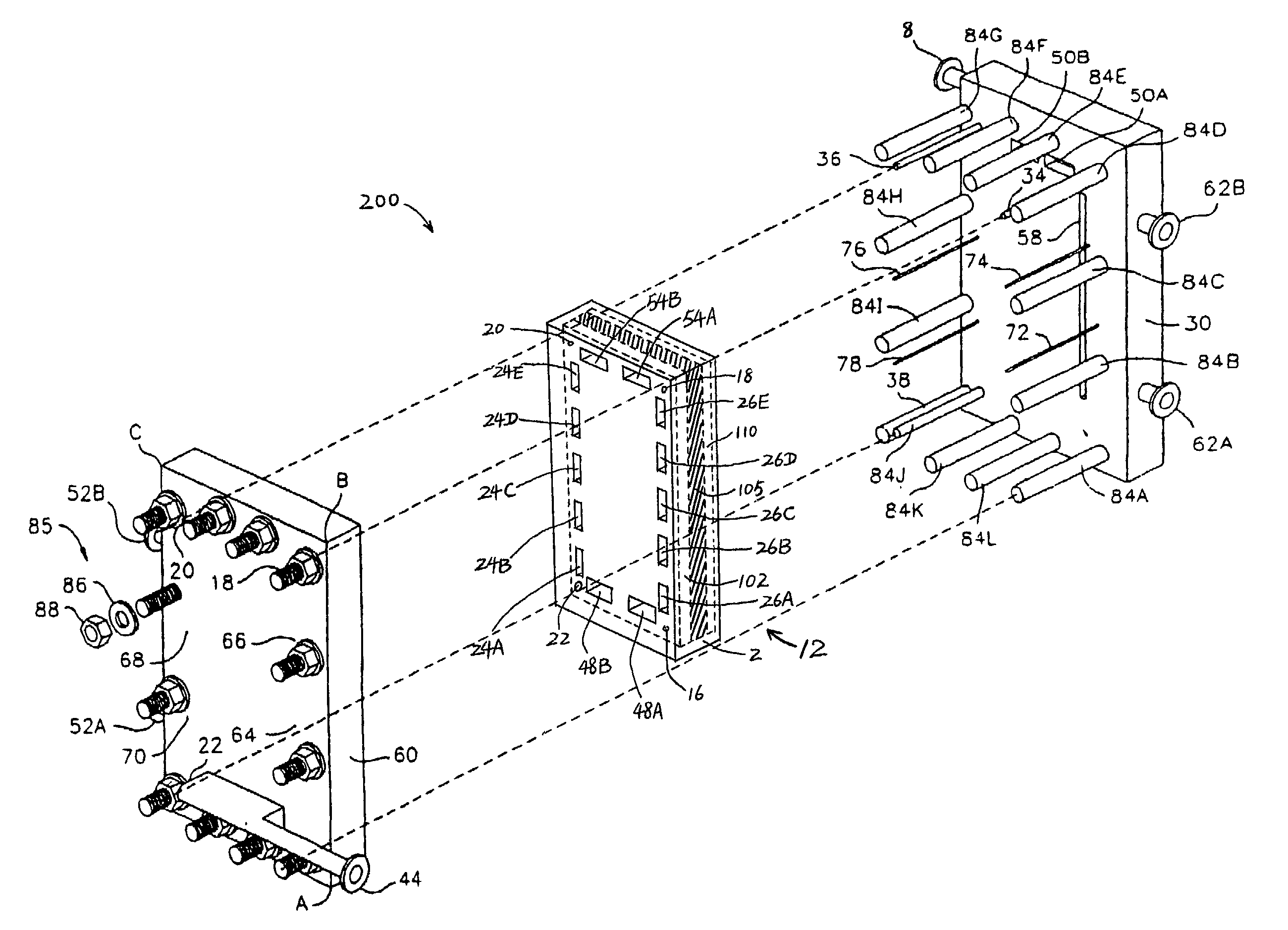

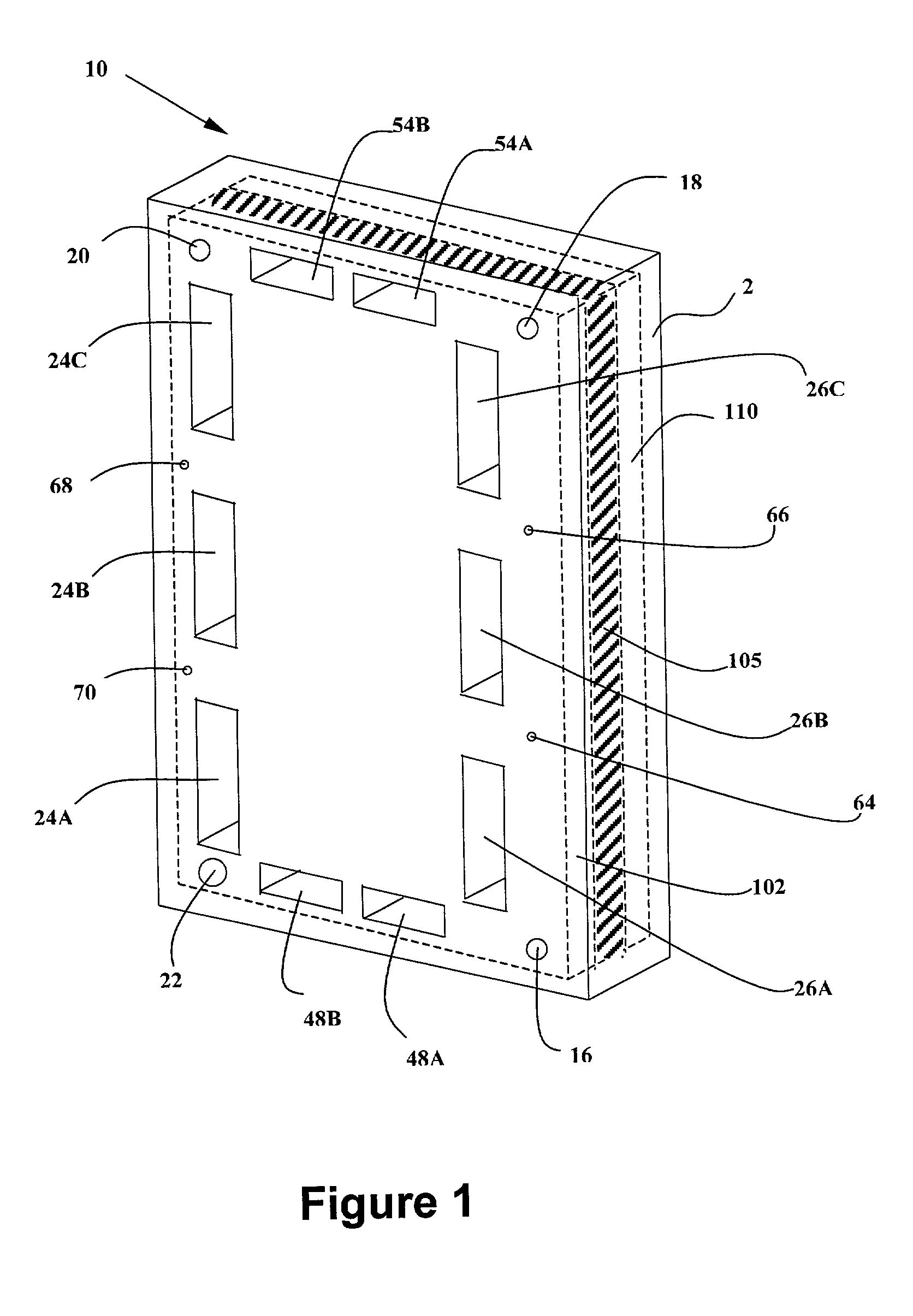

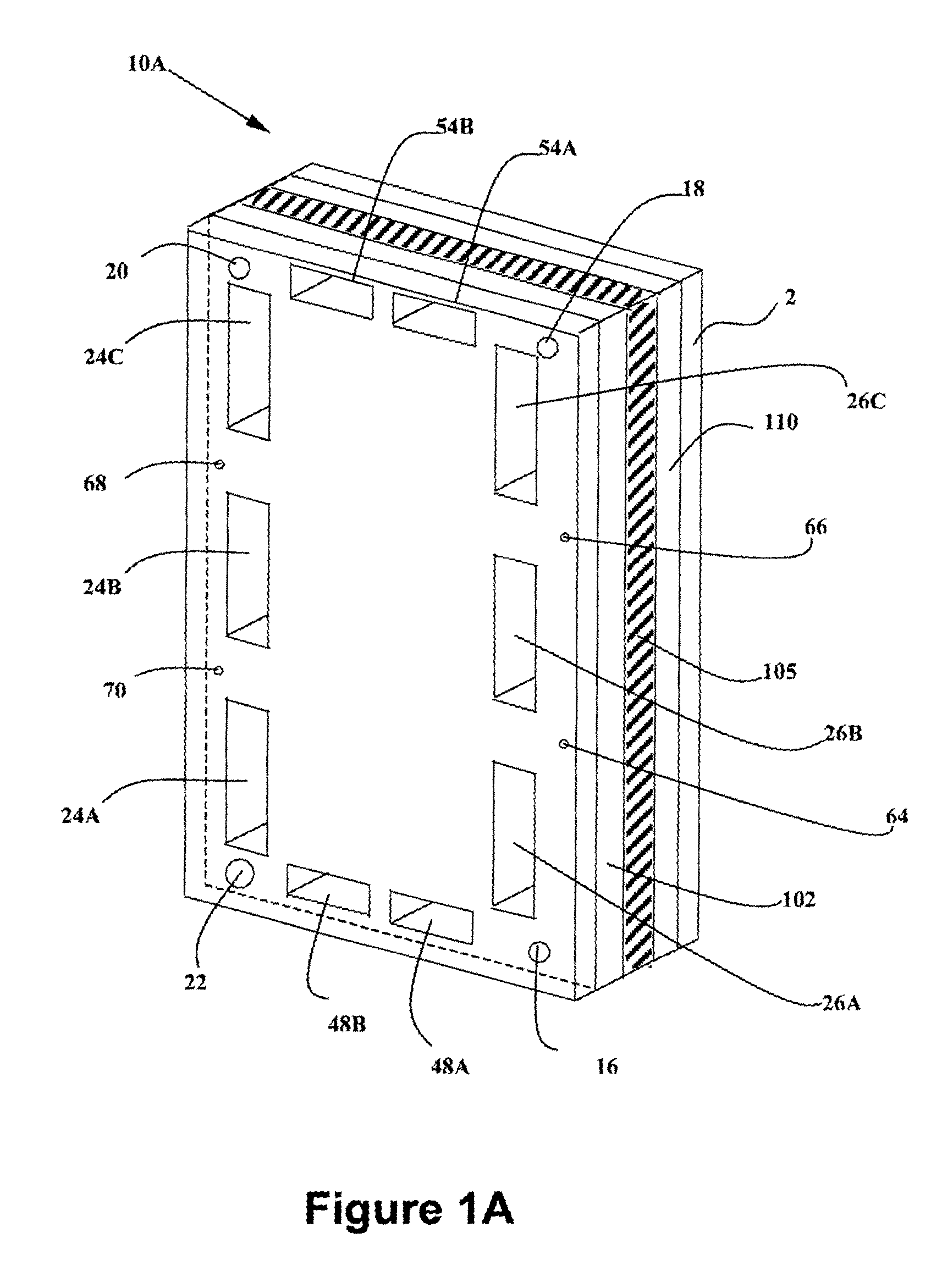

An integral gasketed filtration cassette structure of a type comprising a filtration cassette fully or partially overcoated by a gasket layer, forming a fluid-tight seal between the filtration cassette and the filtration cassette holder to which the filtration cassette is to be affixed. The filtration cassette comprises filter sheets arranged in a multilaminate, peripherally bonded array, wherein the filter sheets alternate with permeate and retentate sheets. The gasket layer comprises an elastomeric material with suitable hardness and temperature resistance for sealing, such as silicone, ethylenepropylenedienemonomer (EPDM), viton, polyurethane, polypropylene, polyethylene, polyvinylchloride, polyester, epoxy, ethylvinylacetate, bunnas, and styrene butadiene. The filtration cassettes and filter of the invention may be advantageously employed for dewatering of aqueous biomass suspensions, desalting of proteins, removal of secreted metabolites from cellular suspensions, and the like.

Owner:KOPF HENRY III

Ionomer/rubber/polyolefin blend and uses thereof

A thermoplastic ionomer blend or alloy exhibiting advantageous properties upon molding or extrusion and / or thermoforming, consisting essentially of the following components:A. about 15 to 85 parts by weight of a thermoplastic copolymer containing about 91 to 80 weight percent of alpha-olefin units and about 9 to 20 weight percent of alpha, beta-ethylenically unsaturated carboxylic acid units said carboxylic acid units being about 20 to 90 percent neutralized with metal ions, preferably zinc,B. about 10 to 80 parts by weight of a rubber, preferably a thermoplastic elastomer selected from the group consisting of (a) crosslinked ethylene-propylene-diene copolymers and equivalent polyolefin copolymers such as ethylene-butene, hexene, or octene, (b) acrylonitrile-butadiene copolymers, (c) styrene-butadiene copolymers, and (d) styrene acrylonitrile graft-crosslinked butadiene rubbers, andC. about 5 to 40 parts by weight of a thermoplastic polymer selected from the group consisting of polyethylene and polypropylene copolymers and homopolymers, the total number of parts being 100,and molded or extruded and / or thermoformed products produced from the same.

Owner:LYONDELLBASELL ADVANCED POLYMERS INC

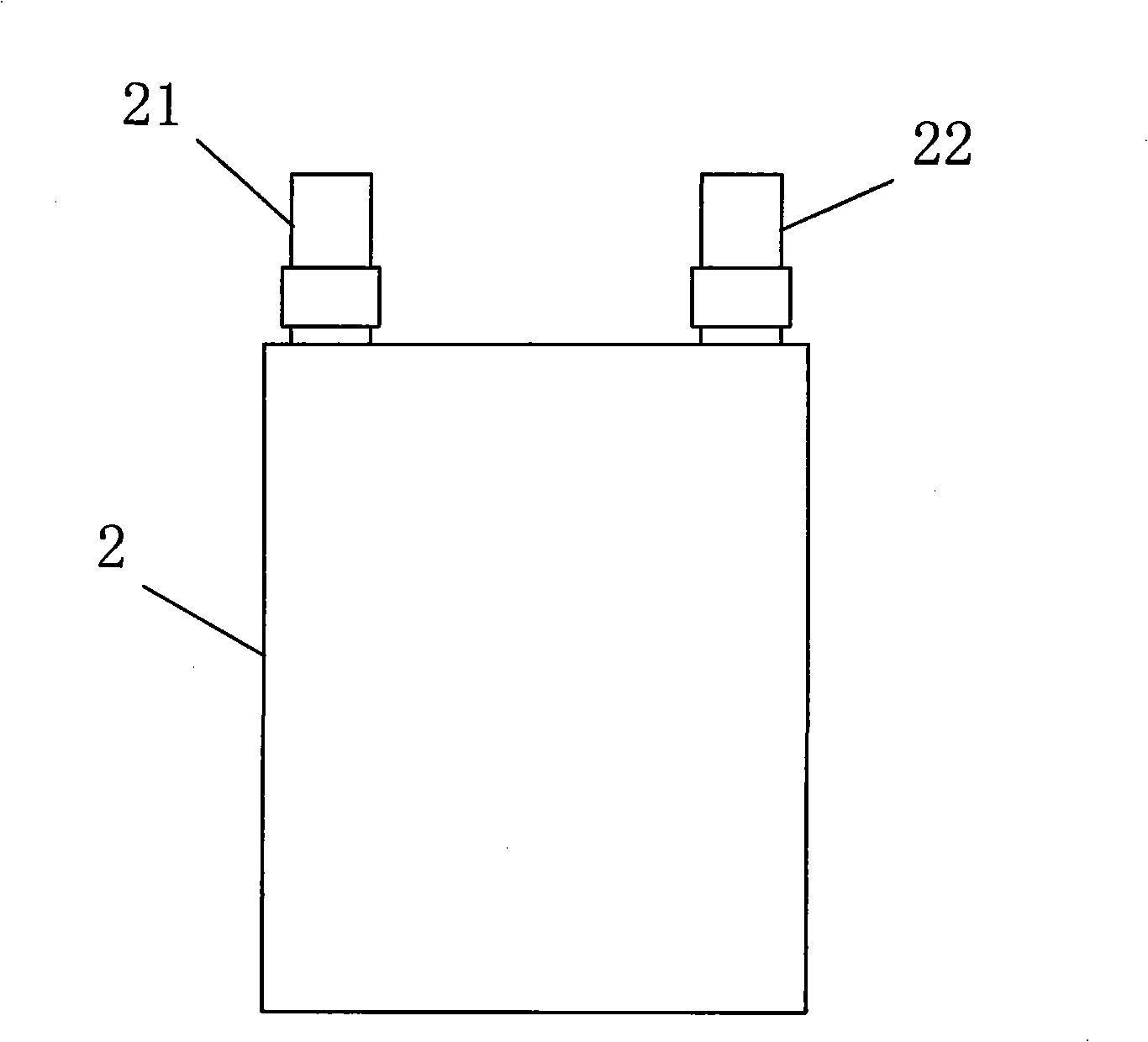

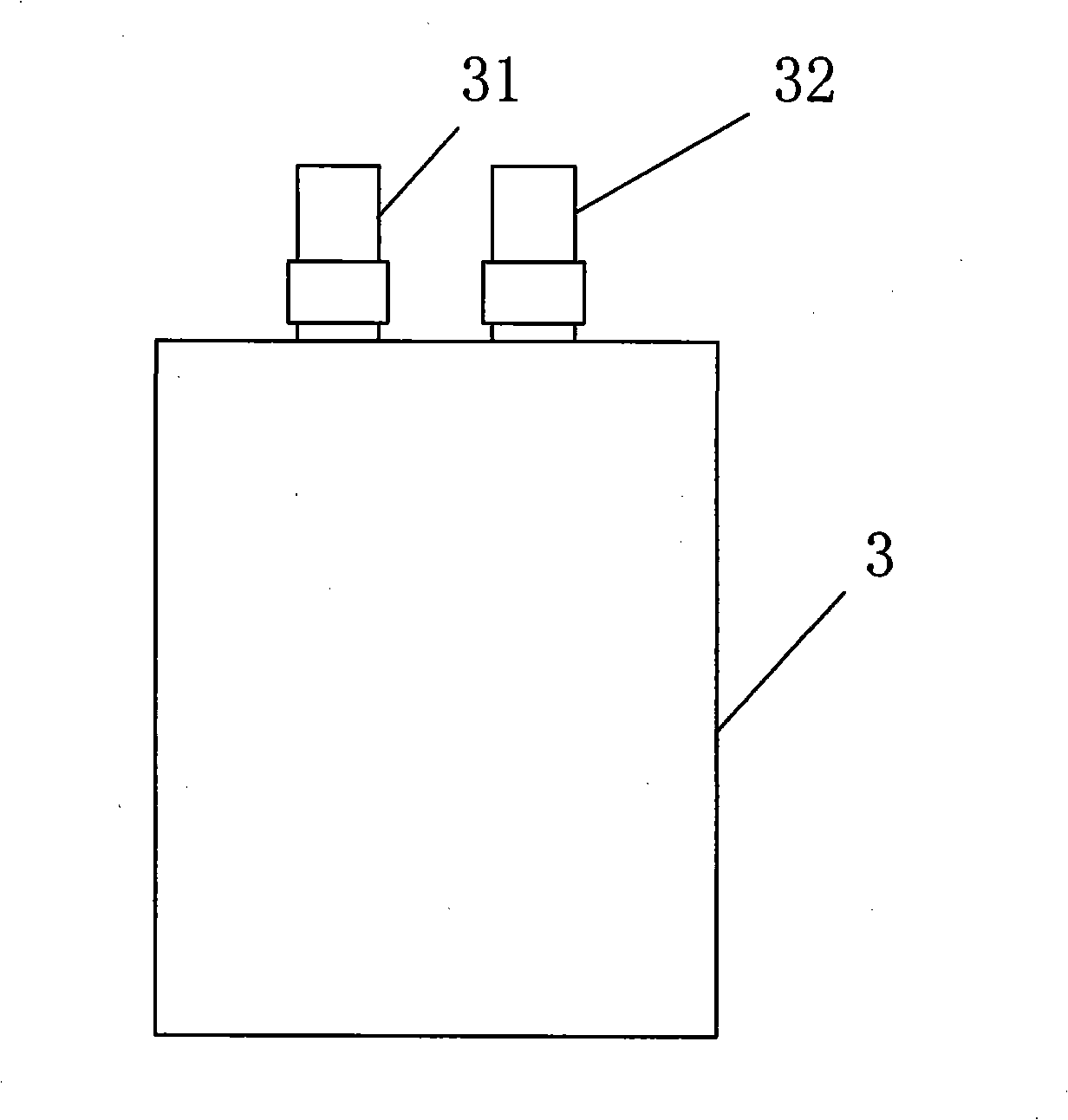

Large-capacity high power polymer ferric lithium phosphate power cell and preparation method thereof

InactiveCN101409369AImprove securityIncrease capacityElectrode manufacturing processesFinal product manufactureSlurryElectric vehicle

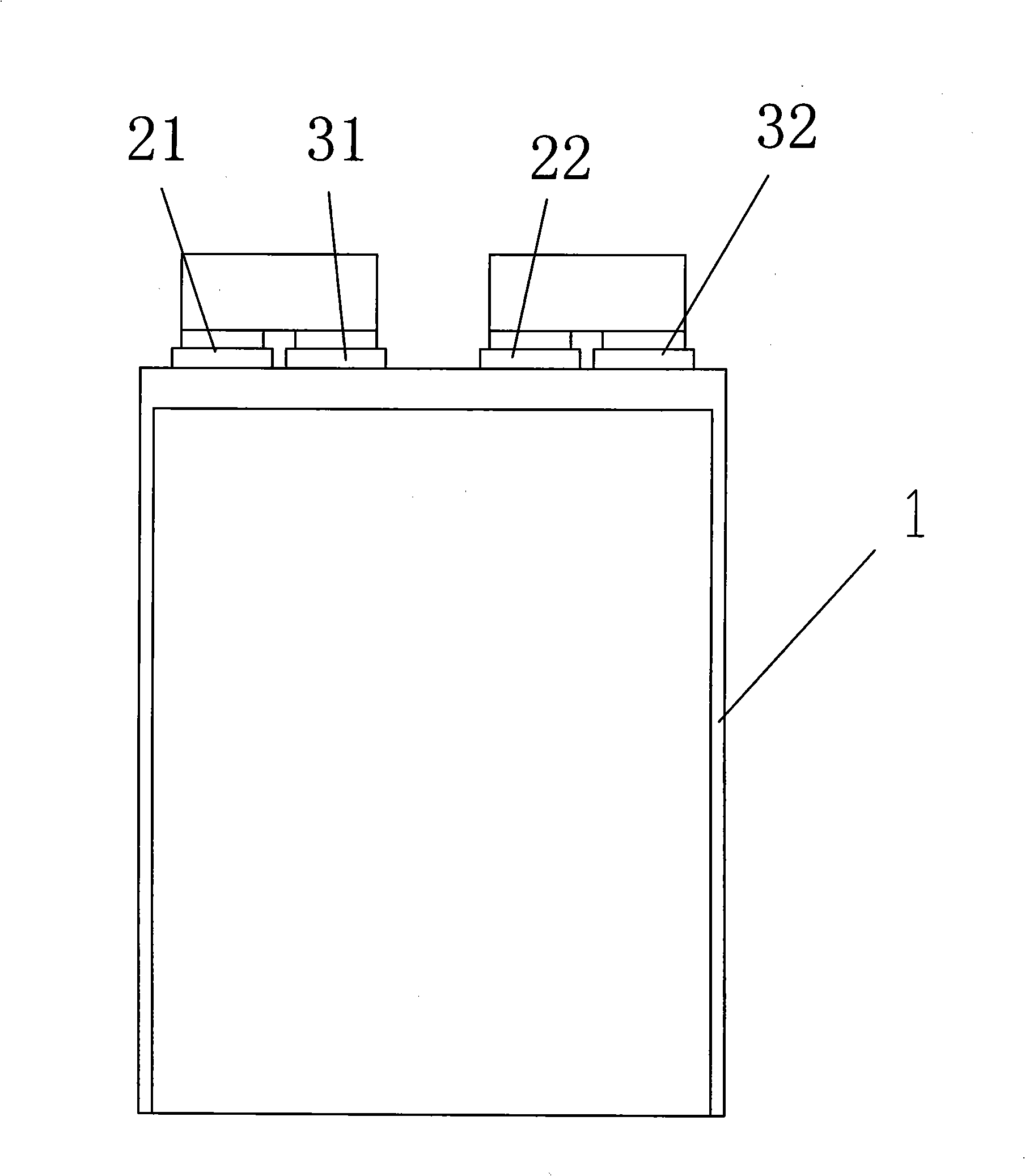

The invention discloses a large-capacity high-power polymer lithium iron phosphate power battery. The weight ratio of anode slurry is as follows: 81 to 85 percent of lithium iron phosphate, 1 to 5.5 percent of superconduction carbon, 0 to 2.5 percent of conductive carbon soot, 0 to 4 percent of conductive black lead, 0 to 2.5 percent of crystalline flake graphite, 0 to 2 percent of carbon nanometer tube as well as 6 to 7.5 percent of polyvinylidene fluoride; the weight ratio of cathode slurry is as follows: 89 to 91 percent of cathode material, 1 to 3.5 percent of superconduction carbon, 0 to 2 percent of conductive carbon soot, 0 to 4 percent of conductive black lead, 2.5 to 3.5 percent of styrene-butadiene rubber as well as 1.5 to 2 percent of sodium carboxymethyl cellulose; the steps for preparing the battery are as follows: preparing slurry, coating the anode and the cathode, rolling and pressing a polar plate, transversely and separately cutting the polar plate, baking the polar plate, welding the polar ears of the anode and the cathode, preparing a battery cell, putting the electric core into a shell and sealing, baking the electric core, injecting liquid into the battery as well as forming the battery and dividing the volume of the battery. The invention relates to a lithium-ion secondary battery which can provide drive energies for electric tools, electric bicycles, motor cars and electric vehicles.

Owner:MCNAIR TECH

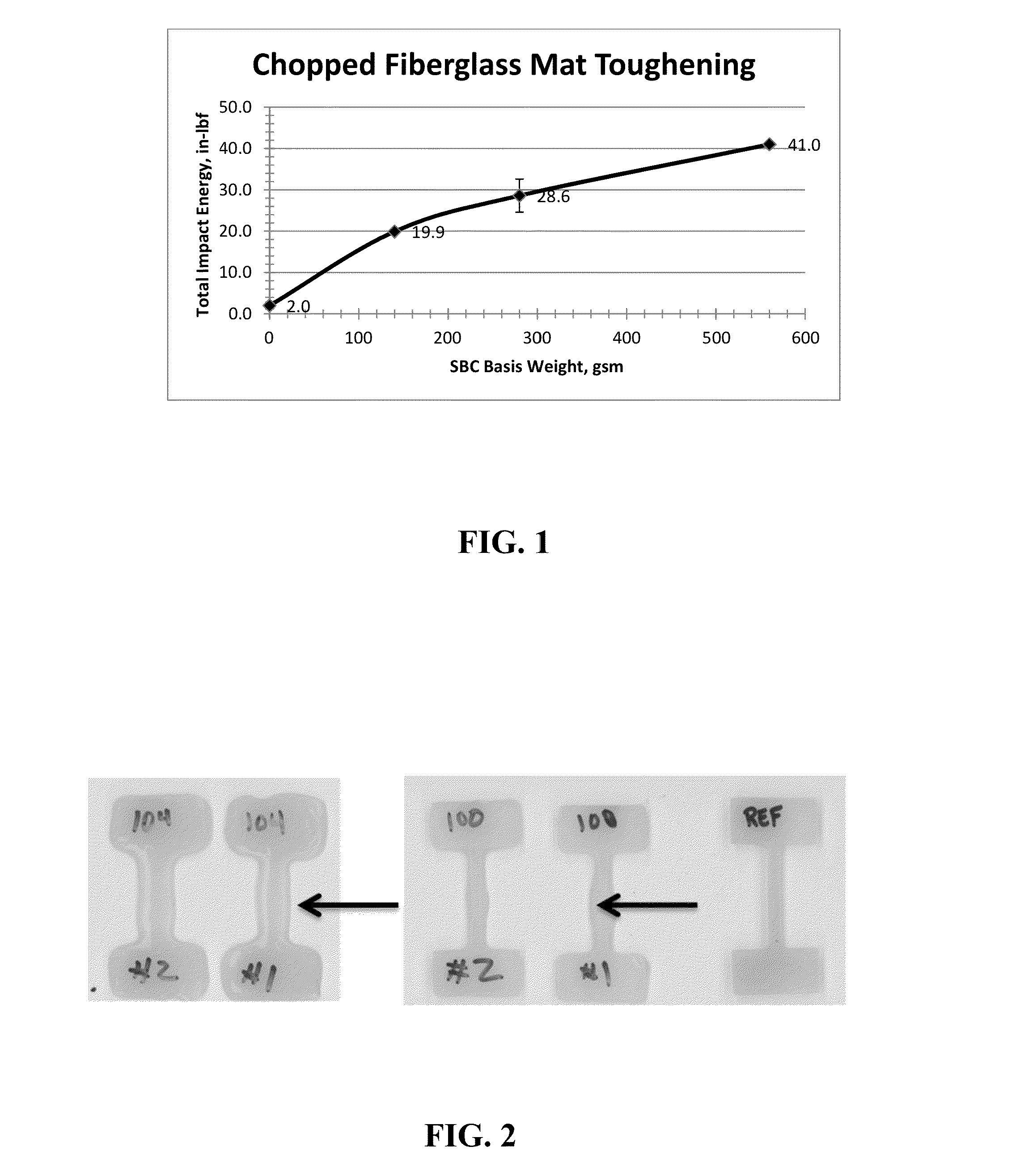

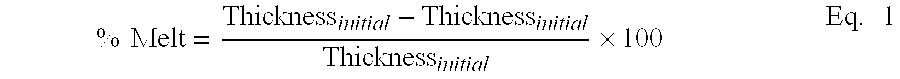

High flow, hydrogenated styrene-butadiene-styrene block copolymer and applications

The invention relates to unique applications for the novel high melt flow, low viscosity, selectively hydrogenated styrene-butadiene-styrene (hSBS) or selectively hydrogenated controlled distribution styrene-butadiene / styrene-styrene (hSBSS) block copolymers, wherein the melt flow rate of said block copolymer is at least 100 g / 10 min at 230° C. under 2.16 kg mass according to ASTM D1238. These block copolymers are novel and have the highest melt flow rate of any styrenic block copolymer also possessing high strength and elasticity. It has applications that prior to the present invention were not normally possible due to the normal low melt flow rate of styrenic block copolymers. The present invention also encompasses various fields of use such as a fiberglass hSBS or hSBSS reinforced mat, low viscosity hSBS or hSBSS coatings for industrial uses, hot melt adhesives prepared from hSBS or hSBSS blended with polyalpha-olefins, and elastic film, fiber, and nonwoven constructions using hSBS or hSBSS.

Owner:KRATON POLYMERS US LLC

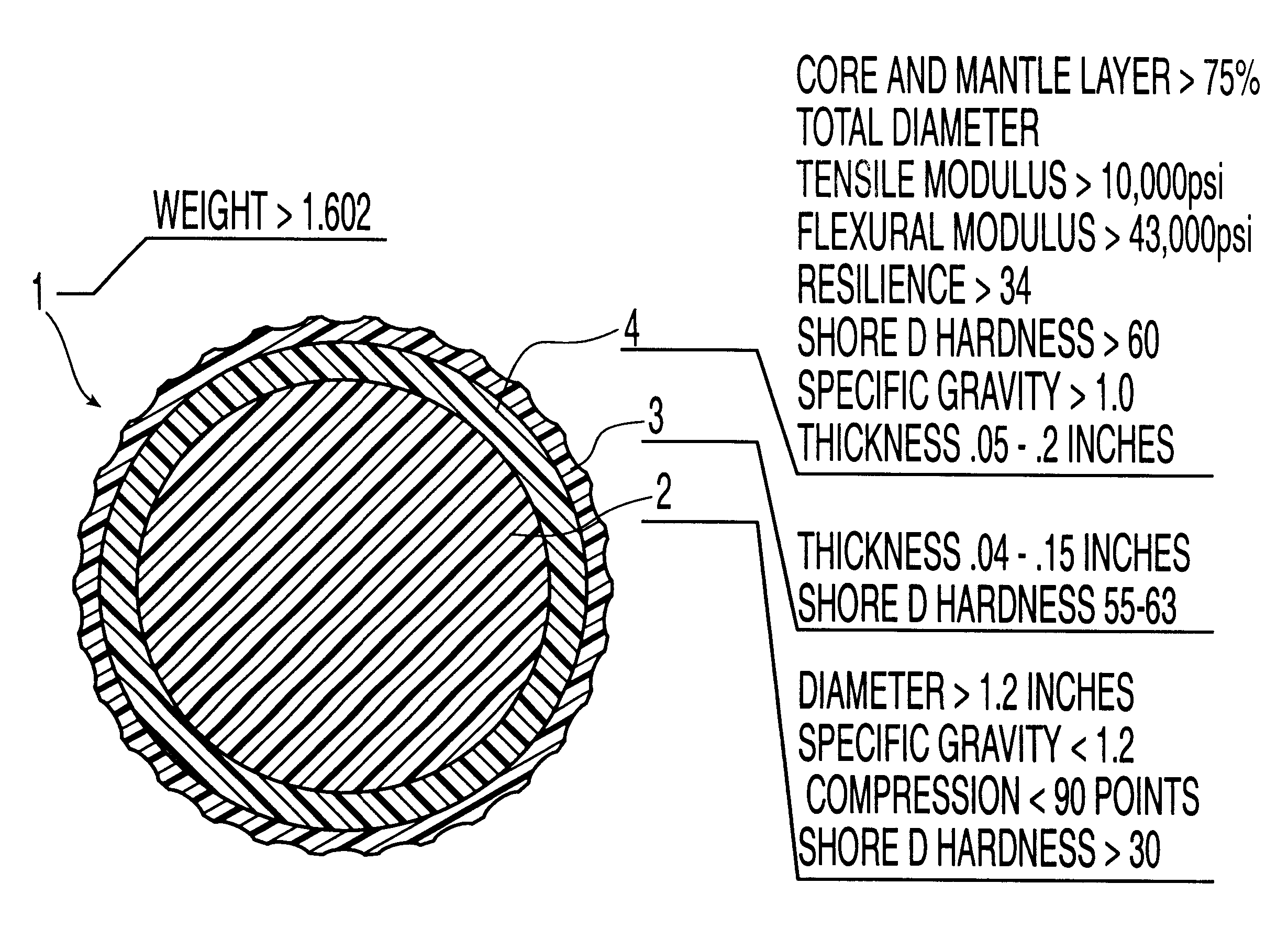

Multilayer golf ball

InactiveUS6315680B1Synthetic resin layered productsGolf ballsThermoplastic elastomerThermoplastic polyurethane

The present invention is directed towards a high-spin multi-layer golf ball which comprises a core with a Shore D hardness of preferably greater than about 30, and a mantle layer disposed between the core and a cover layer, wherein the mantle layer has a Shore D hardness greater than 60 and a resilience of greater than 34. Preferably, the mantle layer is comprised essentially of dynamically vulcanized thermoplastic elastomer, functionalized styrene-butadiene elastomer, thermoplastic polyurethane, metallocene polymer, thermoset materials or blends thereof. Preferably, the mantle layer has a specific gravity of greater than 1, and the core has a specific gravity of less than 1.2.

Owner:ACUSHNET CO

High-toughness photosensitive resin for 3D printing and preparation method thereof.

The invention provides a high-toughness photosensitive resin for 3D printing and a preparation method thereof. The photosensitive resin comprises a photosensitive resin (maleable photosensitive resin and rigid photosensitive resin), an active diluent, a light initiator and an additive. The method first synthesizes the toughness photosensitive resin (maleable polyurethane acrylate and epoxy modified polyurethane), and then the maleable photosensitive resin is mixed with the rigid photosensitive resin, active diluent, light initiator and additive. The maleable photosensitive resin is prepared from a polymer soft segment, which is a mixture of one or more selected from of polypropyleneoxide glycol ether, PTMG, hydroxyl-terminated polybutadiene, hydroxyl-terminated styrene butadiene rubber, hydroxyl-terminated butadiene acrylonitrile rubber and hydroxyl-terminated polysiloxane, and a polymer hard segment of toluene diisocyanate or isophorone diisocyanate, through hydroxyethyl acrylate or epoxypropanol termination. The photosensitive resin is applicable to DLP or SLA type 3D printers for modification of the existing 3D printing photosensitive resin, has excellent bending strength, and can directly print out elastic models.

Owner:QINGDAO UNIV OF SCI & TECH

Pneumatic tire having a component containing low PCA oil

There is disclosed a pneumatic tire having a component comprising a vulcanizable rubber composition comprising, based on 100 parts by weight of elastomer (phr), from about 40 to about 90 phr of a solution polymerized styrene-butadiene having a styrene content of greater than 38 percent by weight; from about 10 to about 60 phr of at least one additional elastomer; and from about 10 to about 70 phr of a process oil having a glass transition temperature of from about −80° C. to about −40° C. and a polycyclic aromatic content of less than 3 percent by weight as determined by the IP346 method.

Owner:THE GOODYEAR TIRE & RUBBER CO

Rubber composition for use in tires

ActiveUS20110144236A1Good dispersionImprove wet grip performanceSpecial tyresPolishing compositionsVitrificationPolymer science

A rubber composition for use in tires including from 60 to 120 parts by weight of a silica having a CTAB specific surface area of from 70 to 175 m2 / g and from 3 to 25 parts by weight of an aromatic modified terpene resin excluding terpene phenol resins per 100 parts by weight of a diene rubber including from 30 to 80 weight % of a terminal-modified styrene-butadiene rubber and from 10 to 50 weight % of a butadiene rubber. An average glass transition temperature of the diene rubber is −55° C. or lower and an average glass transition temperature of a component formed from the diene rubber, the aromatic modified terpene resin, and an optional plasticizer is −45° C. or lower.

Owner:YOKOHAMA RUBBER CO LTD

Pneumatic tire

The invention is directed to a pneumatic tire having a tread including a vulcanizable rubber composition including, expressed as parts by weight per 100 parts by weight of elastomer (phr),(A) 60 to 95 phr of solution-polymerized styrene-butadiene rubber with a bound styrene content of from 20 to 30 percent by weight, a vinyl 1,2 content of from 50 to 70 percent by weight based on the butadiene content, and a Tg of from about −40° C. to about −20° C.;(B) 5 to 15 phr of cis-1,4 polybutadiene having a Tg of from −95° C. to −105° C.;(C) 10 to 20 phr of 3,4-polyisoprene;(D) 30 to 70 phr of processing oil;(E) 10 to 30 phr of carbon black having an Iodine absorption ranging from 192 to 212 g / kg according to ASTM D-1510 and an oil absorption ranging from 126 to 142 cc / 100 g according to ASTM D-2414;(F) 90 to 110 phr of silica;(G) 0.5 to 20 phr of a sulfur containing organosilicon compound; and(H) 10 to 20 phr of resin.

Owner:THE GOODYEAR TIRE & RUBBER CO

Resin composition for wire and cable covering material

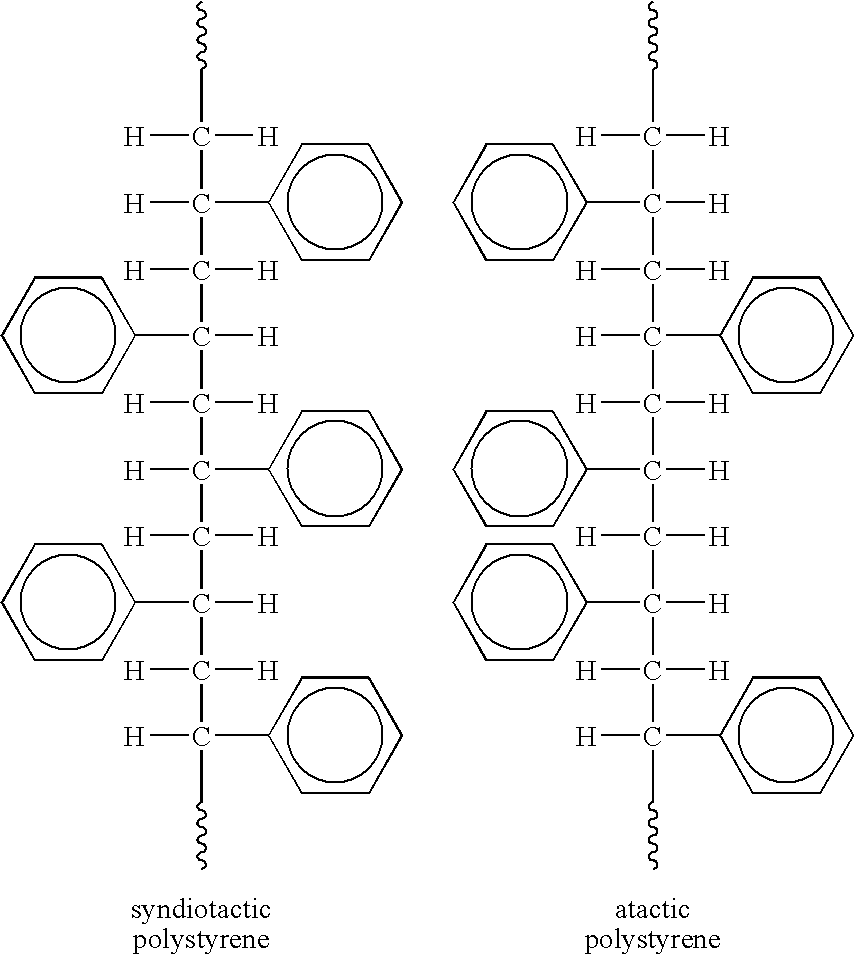

A flexible resin composition comprises poly(arylene ether) resin, syndiotactic polystyrene, olefin elastomer, hydrogenated styrene-butadiene copolymer, and a non-halogen fire retardant.

Owner:SABIC GLOBAL TECH BV

Rubber composition for tire and tire made therefrom

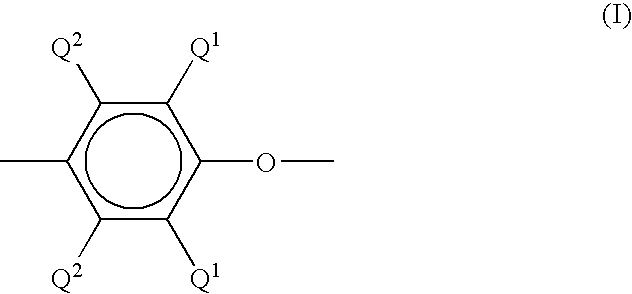

A rubber composition for tires which comprises 100 parts by mass of (A) copolymer (a) which is a styrene-butadiene copolymer having a weight-average molecular weight of 4.0×105 to 3.0×106; as obtained in accordance with gel permeation chromatography and expressed as the value of corresponding polystyrene, a content of the bound styrene St(a) of 10 to 50% by mass and a content of the vinyl unit in the butadiene portion of 20 to 70%; 10 to 200 parts by mass of (B) copolymer (b) which is a hydrogenated styrene-butadiene copolymer having a weight-average molecular weight of 5.0×103 to 2.0×105, as obtained in accordance with gel permeation chromatography and expressed as the value of corresponding polystyrene, a content of the bound styrene St(b) which is in the range of 25 to 70% by mass and satisfies a relation expressed by equation (I) and a fraction of hydrogenated double bond in the butadiene portion of 60% or greater and (C) at least one substance selected from resins providing tackiness to the rubber composition and liquid polymers having a weight-average molecular weight of 1,000 to 50,000. St(b)≧St(a)+10 (I)

Owner:BRIDGESTONE CORP

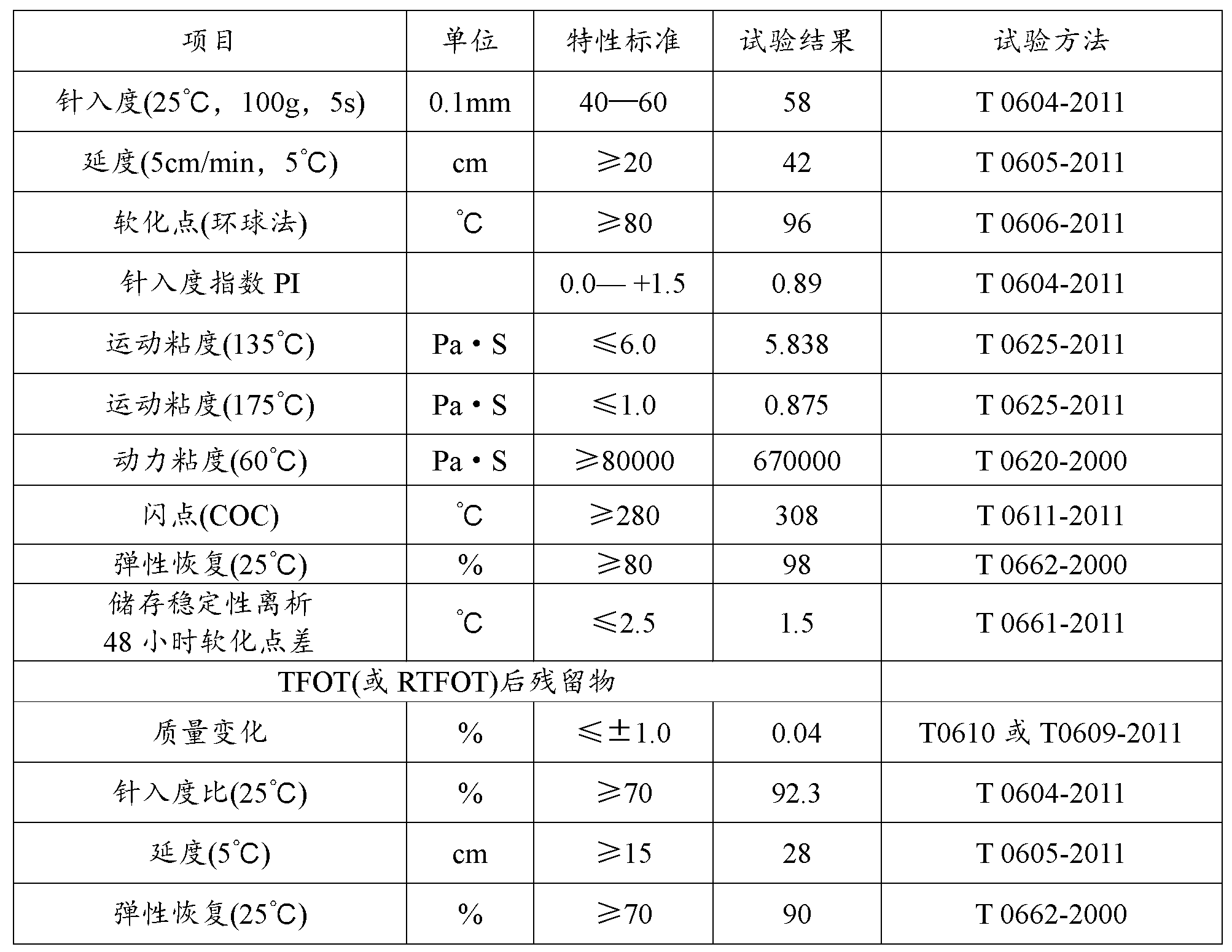

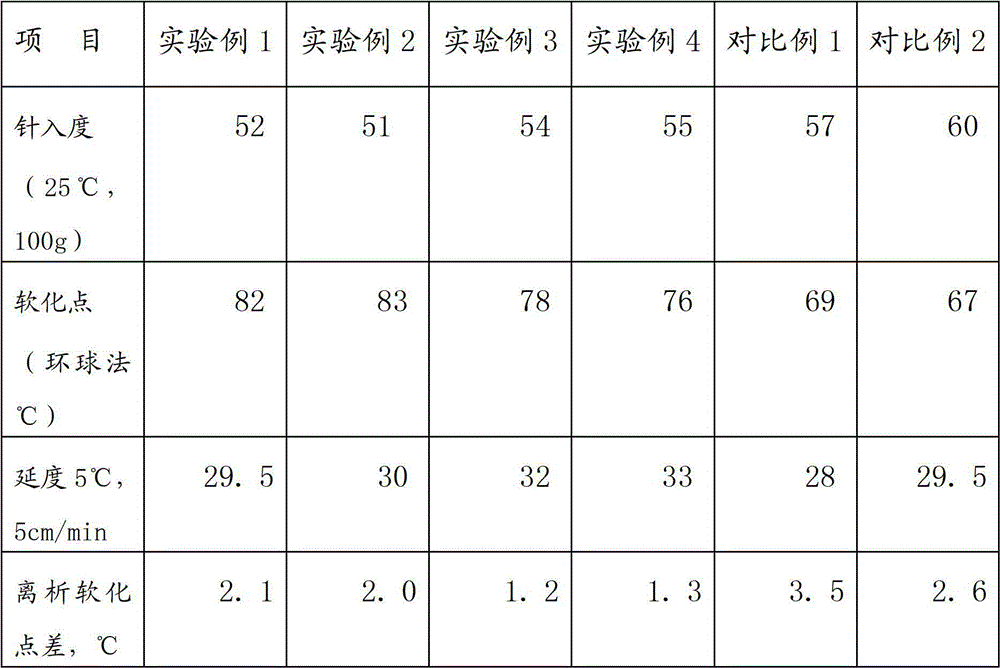

Asphalt modifier, modified asphalt and asphalt mixture

ActiveCN102838874AExcellent Adhesive PropertiesImprove low temperature 60°C viscosityIn situ pavingsBuilding insulationsRoad engineeringBridge deck

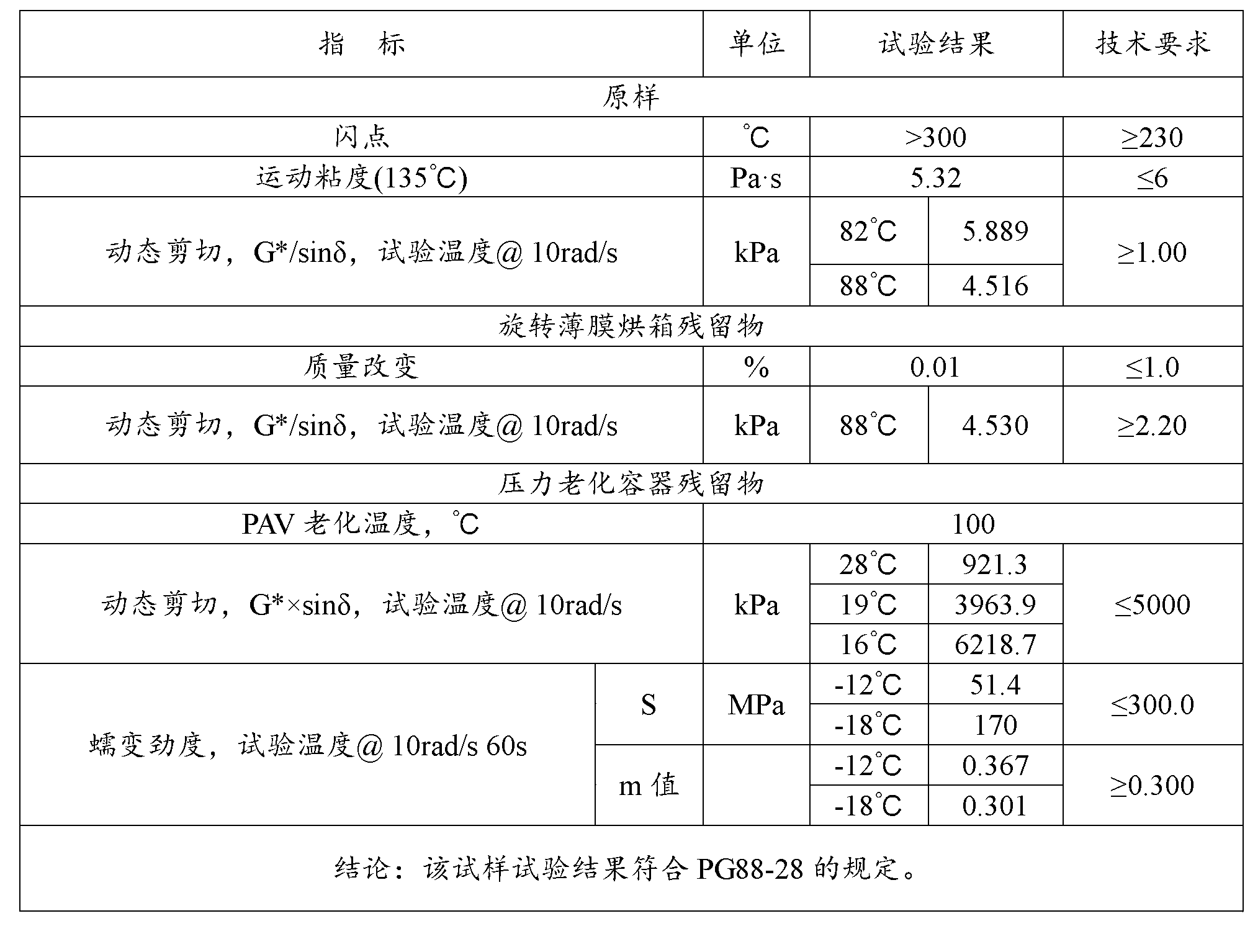

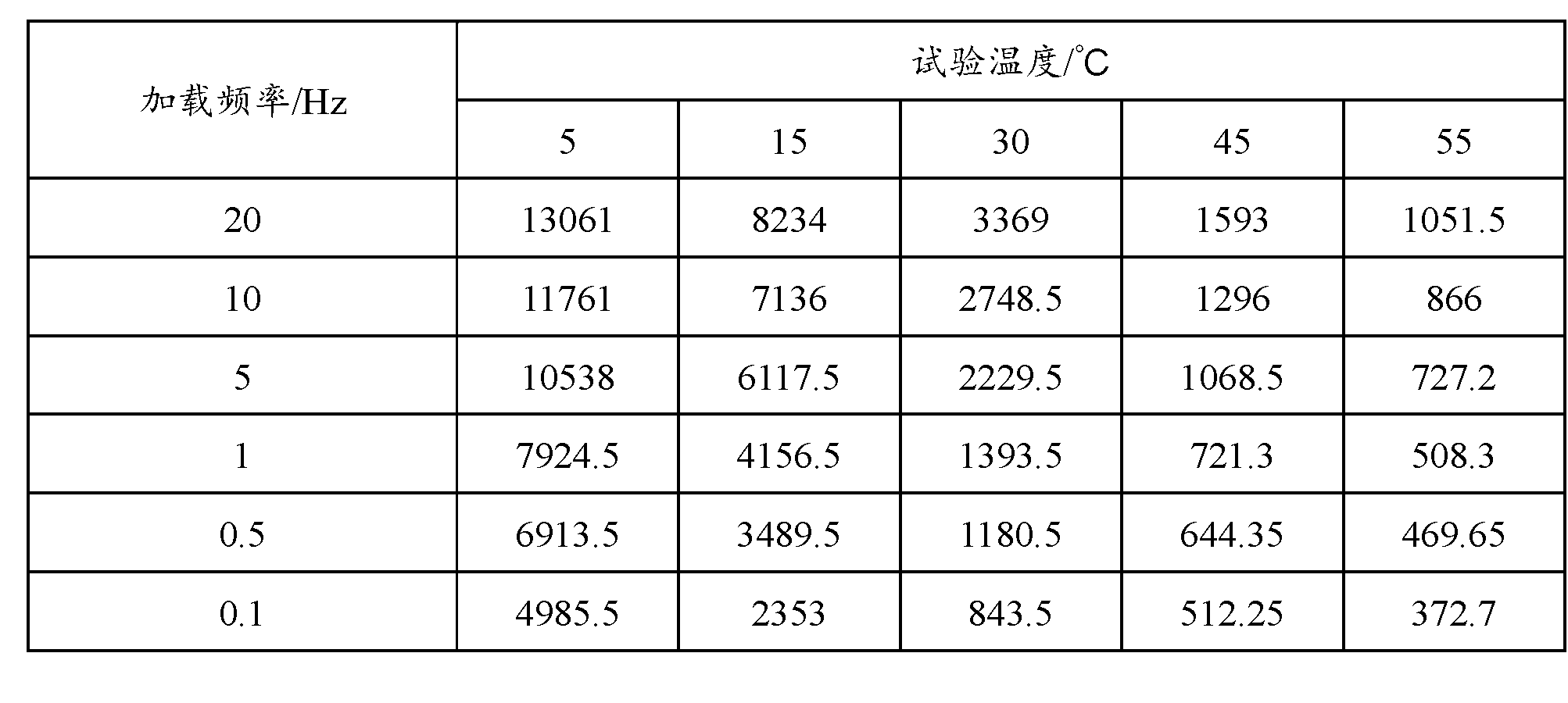

The invention belongs to the field of road engineering, and particularly relates to a hyperviscous and high-elastic asphalt modifier applicable to steel bridge deck pavement. The asphalt modifier comprises the following raw materials in parts by weight: 3-10 parts of junked tire rubber powder, 3-10 parts of polyethylene wastes, 3-8 parts of styrene-butadiene-styrene block copolymer, 1-5 parts of styrene-isoprene-styrene block copolymer, 1-5 parts of terpene resin, 5-10 parts of solvent naphtha, and 0.3-0.7 part of alcohol ether carboxylate adhesion agent. In addition, a modified asphalt and amodified asphalt mixture are prepared on the basis of the modifier, the 60 DEG C dynamic viscosity of the modified asphalt prepared by applying the modifier can reach more than 300000Pa.s, and the performance grading reaches PG 88-28; and the asphalt mixture has favorable water stability, higher dynamic modulus, higher track dynamic stability and low temperature failure strain, and can resist complicated mechanics and temperature environment of a steel bridge deck.

Owner:山东高速交通建设集团股份有限公司

Thermoplastic elastomer composition

InactiveUS20050288393A1Low costGood oil resistanceFilm/foil adhesivesCoatingsThermoplastic elastomerPolystyrene

A thermoplastic elastomer composition comprised of (a) a thermoplastic resin selected from the group consisting of polyphenylene ether, polypropylene, polyethylene, and polystyrene, (b) a block copolymer selected from the group consisting of styrene-ethylene butylene-styrene, styrene-ethylene propylene-styrene, hydrogenated polybutadiene, hydrogenated polyisoprene, hydrogenated styrene-isoprene random copolymer, styrene-ethylene propylene block copolymer, styrene-ethylene ethylene propylene-styrene and hydrogenated styrene-butadiene random copolymers, (c) a core-shell polymer comprised of a polymeric core and a polymeric shell with the proviso that the polymeric core and / or the polymeric shell may be crosslinked, and (d) an oil.

Owner:THE GOODYEAR TIRE & RUBBER CO

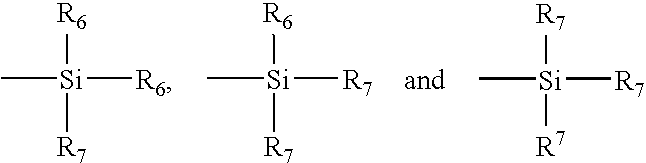

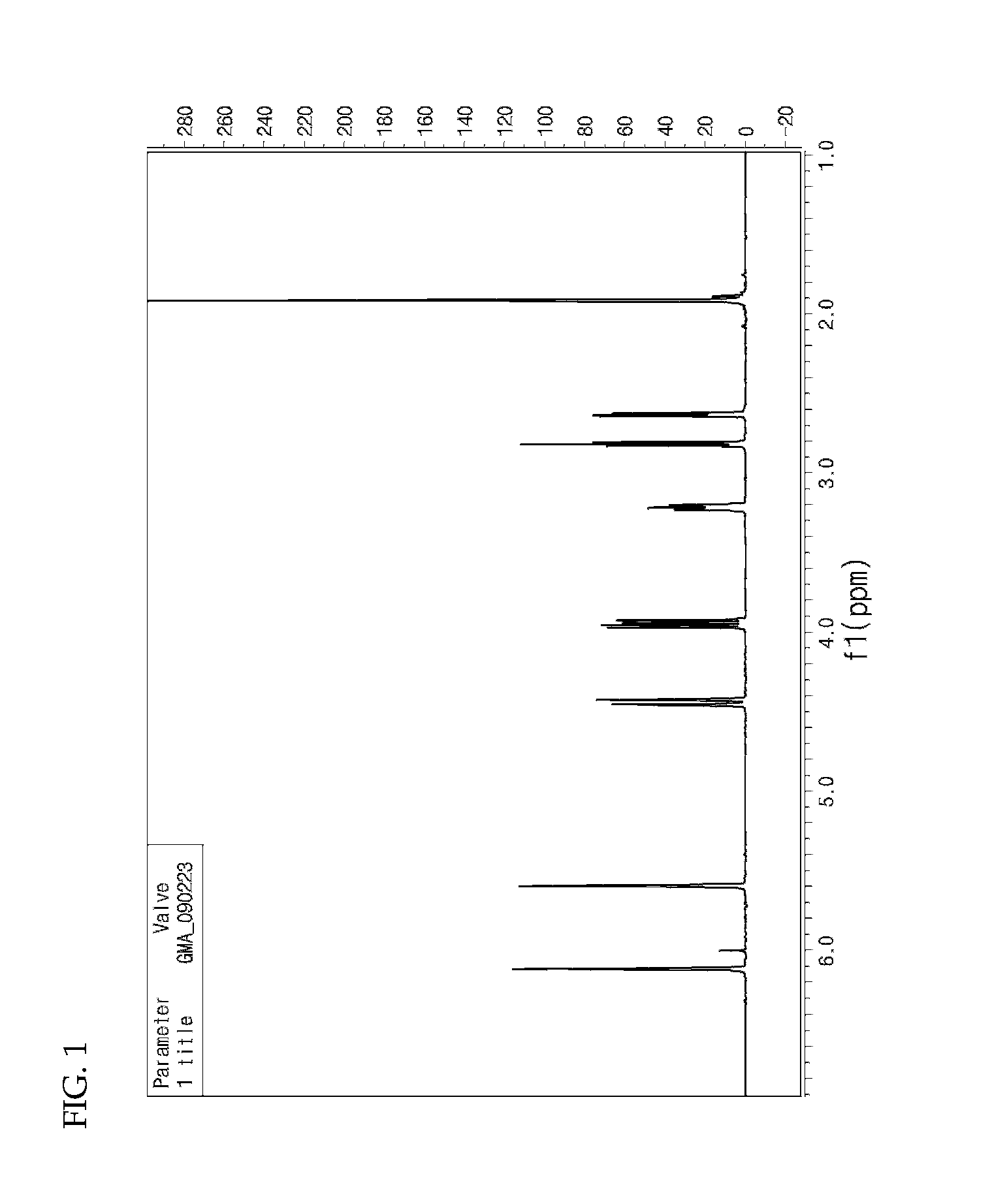

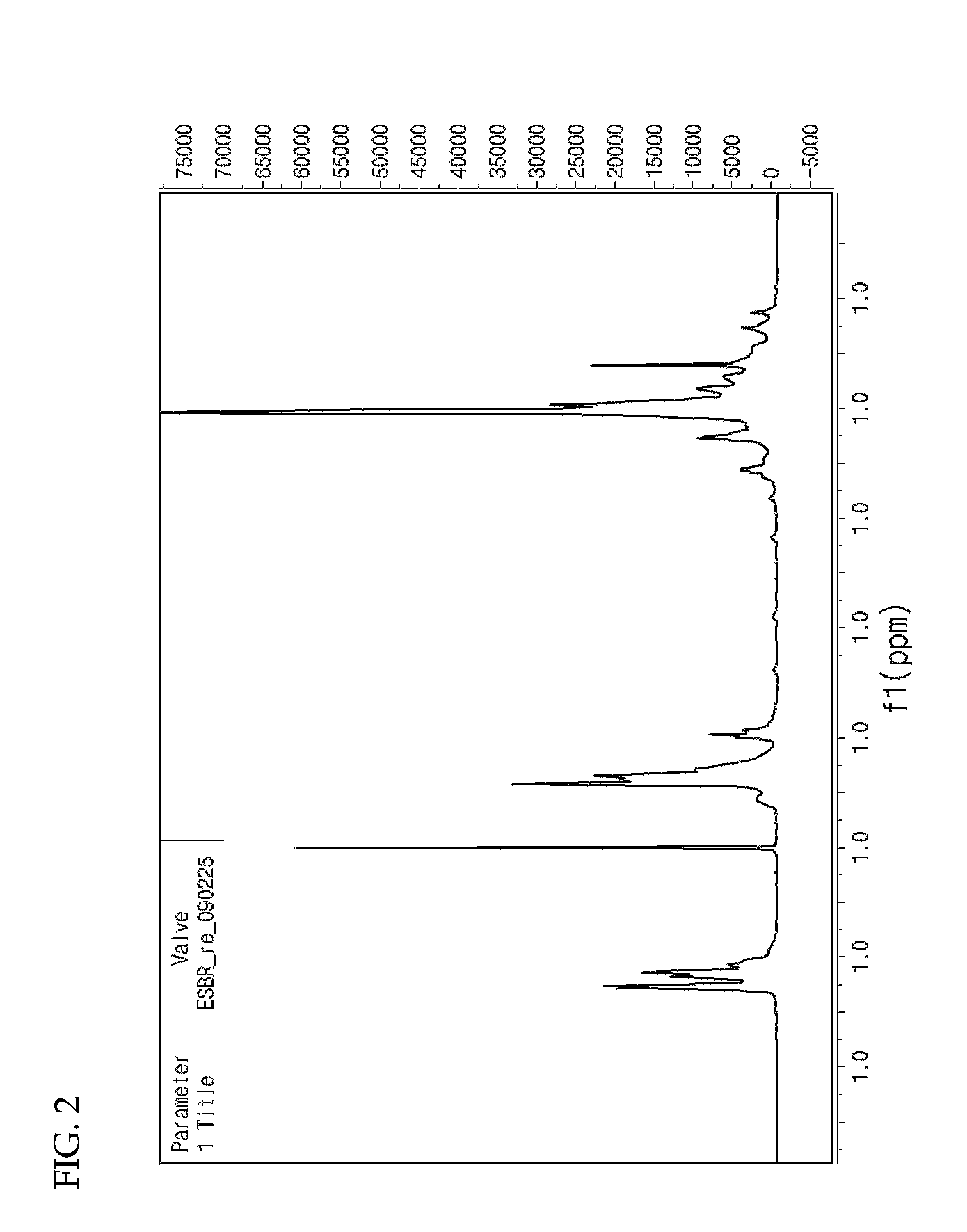

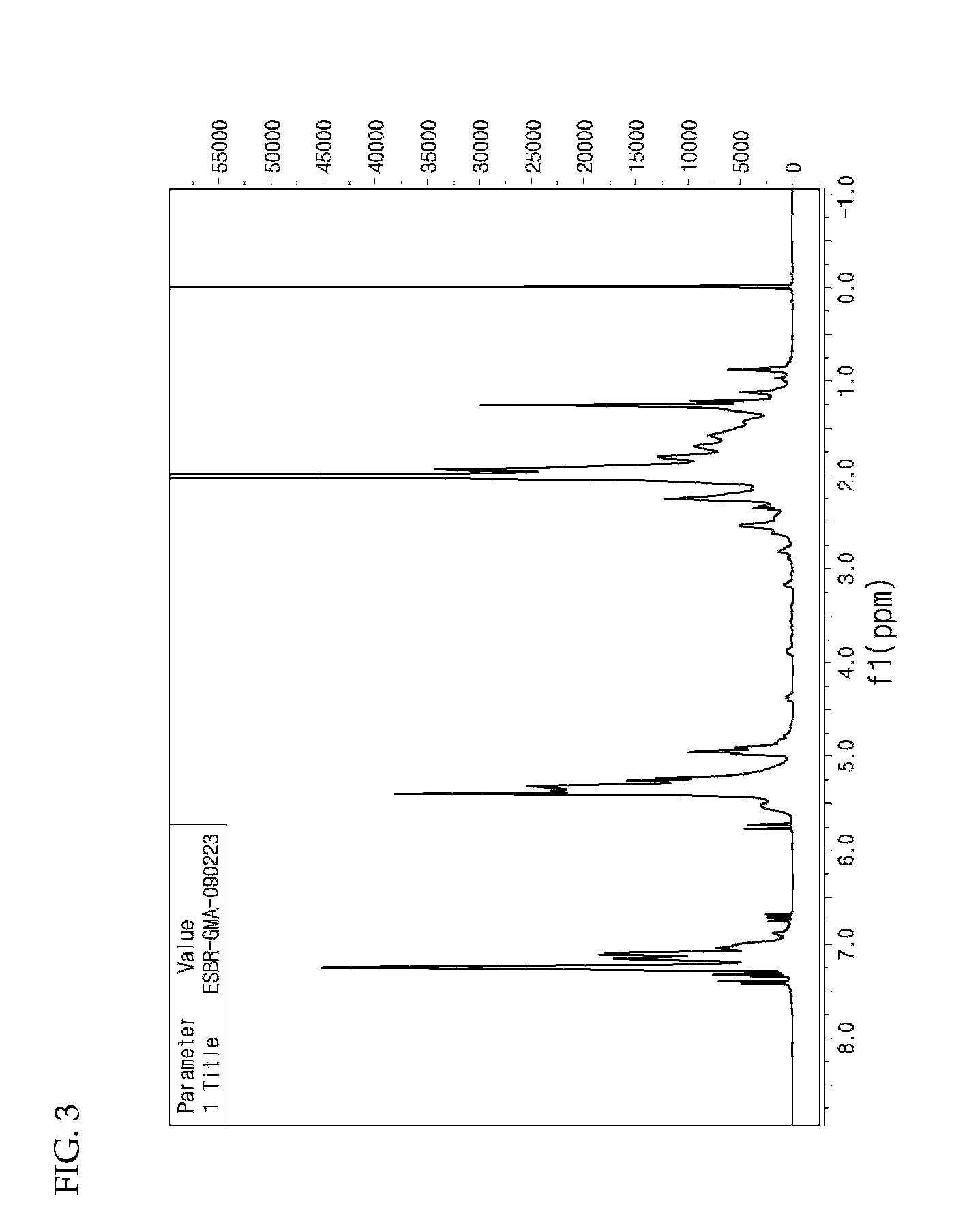

Functional styrene-butadiene copolymer

A functional styrene-butadiene copolymer is disclosed. More specifically, the copolymer is prepared by radical polymerization of a styrene monomer, a butadiene monomer and an epoxy acrylate monomer in an emulsion state and ring-opening of the resultant styrene-butadiene-epoxy acrylate copolymer. When blended with silica, the disclosed copolymer provides excellent wet stopping performance and superior wear resistance. Therefore, it can be usefully applied for industrial materials including fuel-efficient tires, snow tires, belts, hoses, etc.

Owner:KOREA KUMHO PETROCHEMICAL CO LTD

Lubricant additive

ActiveUS8999905B2Increase VISolid-state devicesLiquid carbonaceous fuelsBase oilButadiene-styrene rubber

A hydrogenated styrene butadiene star copolymer is incorporated in a lubricant additive package. The star copolymer can include about 3 to 25% and about 97 to 75% butadiene. The star copolymer may further be incorporated in a lubricant additive in the amount of about 12 wt % of the star copolymer as compared to the base oil.

Owner:AFTON CHEMICAL

Negative Electrode Material for Lithium Battery, and Lithium Battery

InactiveUS20070275302A1Lower electrode resistanceHigh electrode strengthNon-aqueous electrolyte accumulatorsElectrode carriers/collectorsCarboxymethyl celluloseCarbon fibers

The present invention relates to a negative electrode material for a lithium battery characterized by comprising a carbonaceous negative electrode active substance having a specific surface area of 1 m2 / g or more, a binder formed of styrene-butadiene rubber and a carbon fiber having a fiber diameter of 1 to 1,000 nm; and to a lithium battery using the negative electrode material, which has excellent characteristics, i.e., low electrode resistance, high electrode strength, excellent electrolytic solution permeability, high energy density, and good high-speed charging / discharging performance. The negative electrode material contains carbon fiber in the amount of 0.05 to 20 mass % and the binder formed of styrene-butadiene rubber in 0.1 to 6.0 mass %, and may further contain a thickner such as carboxymethyl cellulose in the amount of 0.3 to 3 mass %.

Owner:SHOWA DENKO KK +1

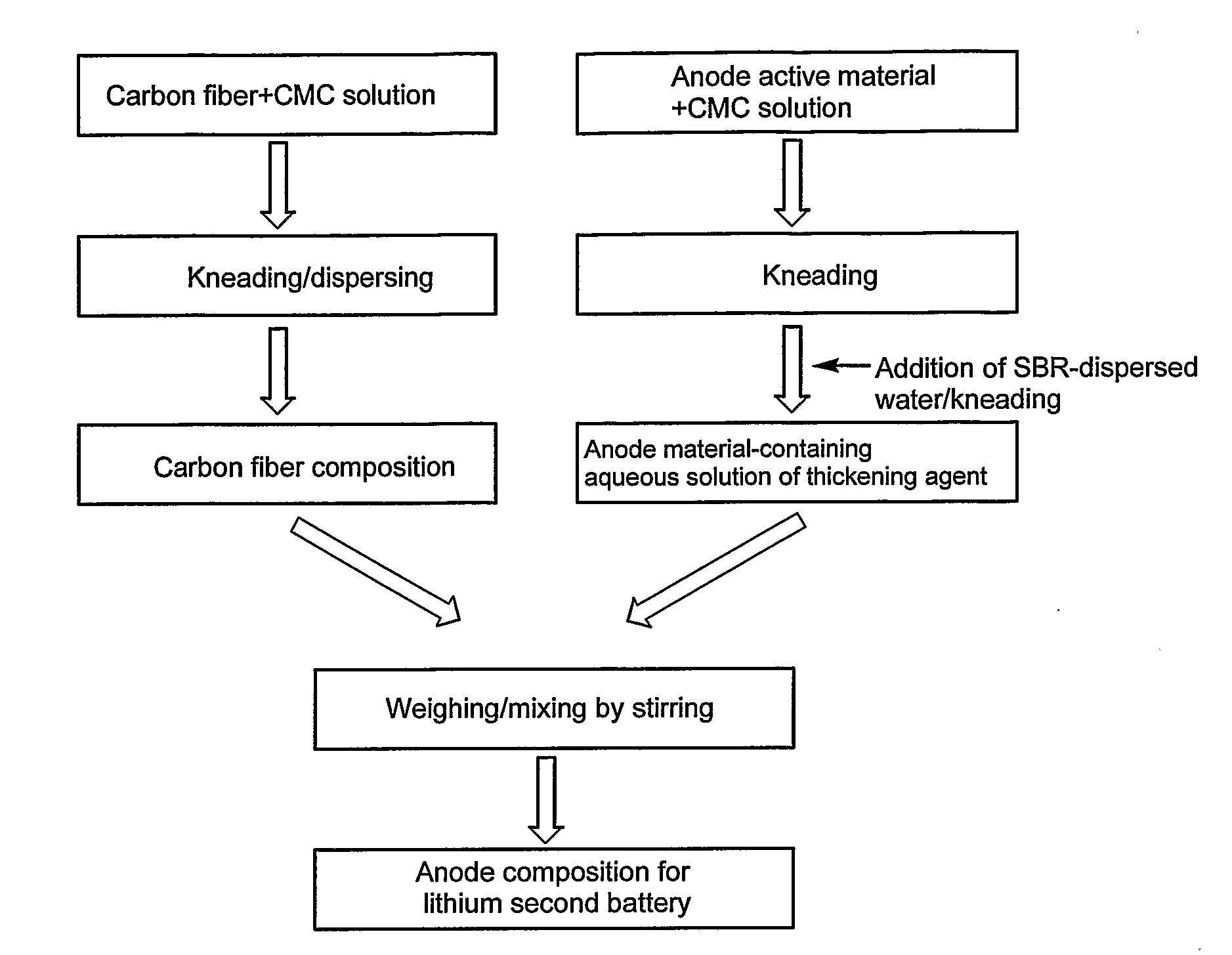

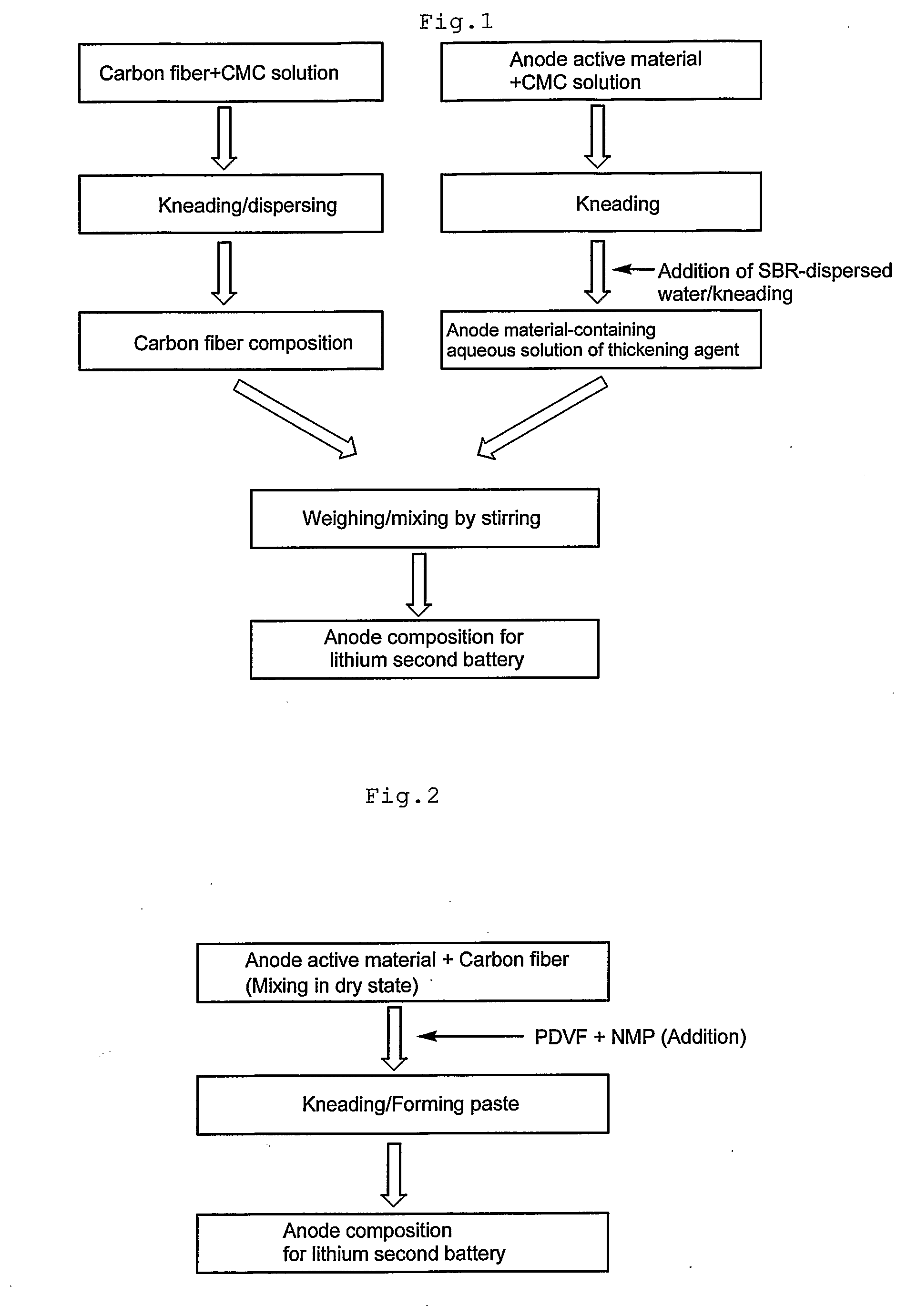

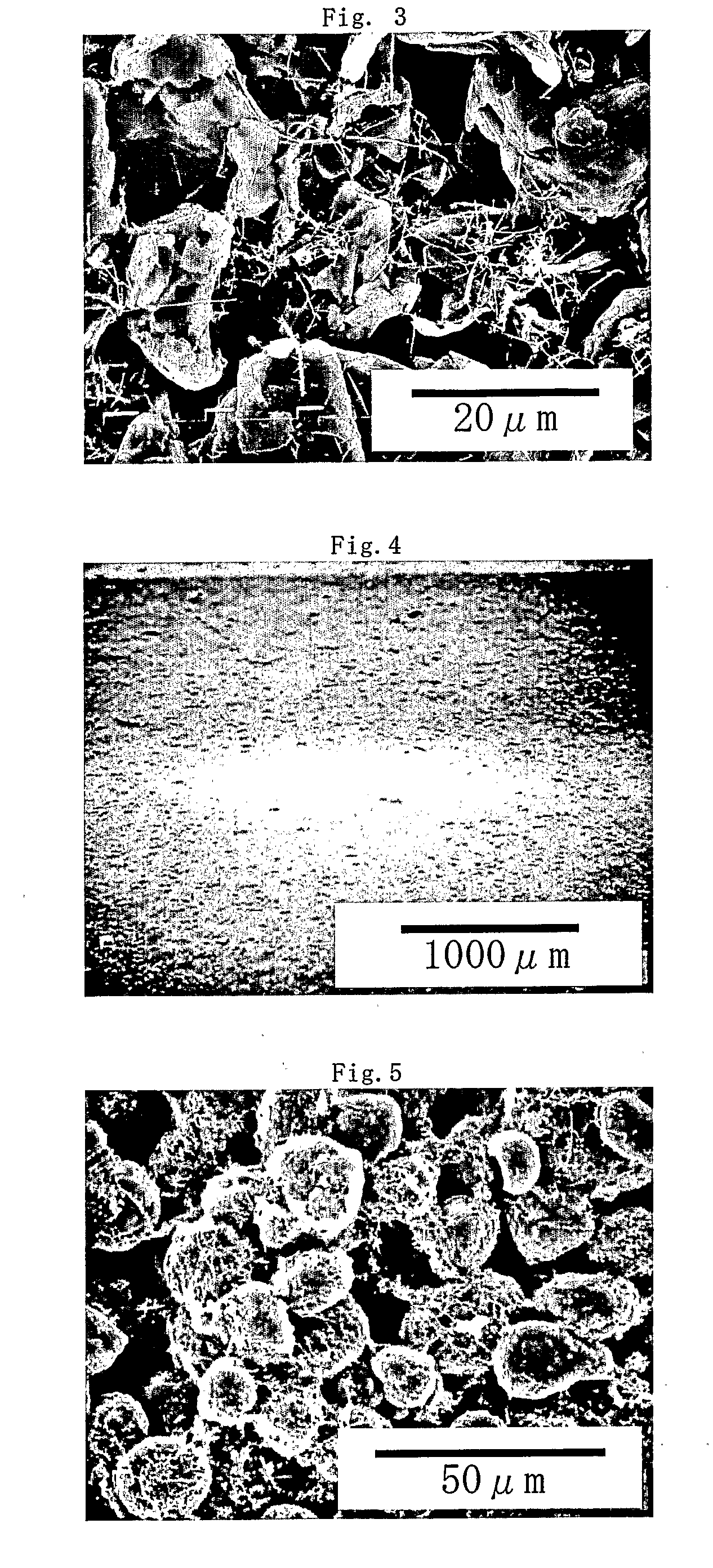

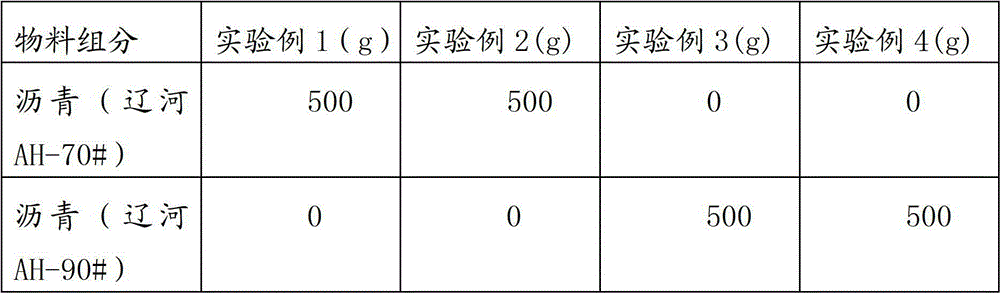

Method for producing anode for lithium secondary battery and anode composition, and lithium secondary battery

ActiveUS20090123850A1High capacity retentionImprove conductivityFinal product manufactureConductive materialFiberCarbon fibers

The invention relates to an anode for lithium secondary battery comprising vapor grown carbon fiber uniformly dispersed without forming an agglomerate of 10 μm or larger in an anode active material using natural graphite or artificial graphite, which anode is excellent in long cycle life and large current characteristics. Composition used for production for the anode can be produced, for example, by mixing a thickening agent solution containing an anode active material, a thickening agent aqueous solution and styrene butadiene rubber as binder with a composition containing carbon fiber dispersed in a thickening agent with a predetermined viscosity or by mixing an anode active material with vapor grown carbon fiber in dry state and then adding polyvinylidene difluoride thereto.

Owner:RESONAC CORP

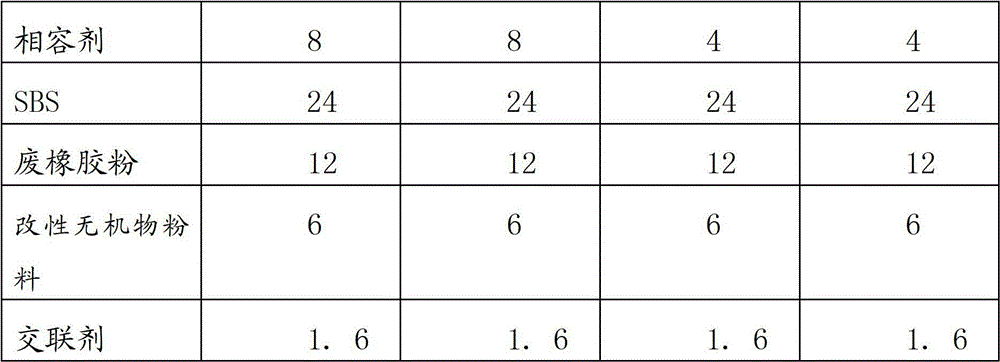

SBS (styrene-butadiene-styrene)/scrap rubber powder composite modified asphalt and preparation method thereof

InactiveCN102977621AImprove anti-aging propertiesReduce material costsBuilding insulationsHigh temperature storagePolymer science

The invention relates to an SBS (styrene-butadiene-styrene) / scrap rubber powder composite modified asphalt which comprises the following components in parts by weight: 75-96 parts of matrix asphalt, 0.5-12 parts of scrap rubber powder, 0.5-6 parts of SBS, 0.2-8 parts of modified inorganic substance powder, 0.1-8 parts of compatilizer and 0.1-3 parts of crosslinking agent. The preparation method comprises the following steps: preparing the scrap rubber powder; heating the matrix asphalt to 160-180 DEG C, adding the compatilizer while stirring, and evenly mixing; adding the SBS scrap rubber powder and modified inorganic substance powder, stirring at the speed of 1000-5000 rpm for 5-125 minutes while keeping the temperature, and adding the crosslinking agent; and quickly stirring for 20-300 minutes while keeping the temperature. The key technical indexes of the product are higher than those of the SBS modified asphalt; and the invention enhances the high / low-temperature properties and aging resistance, prolongs the high-temperature storage stabilization period, and completely satisfies the property requirements for national high-grade roads.

Owner:TIANJIN HI TECH ENVIRONMENT DEV CO LTD

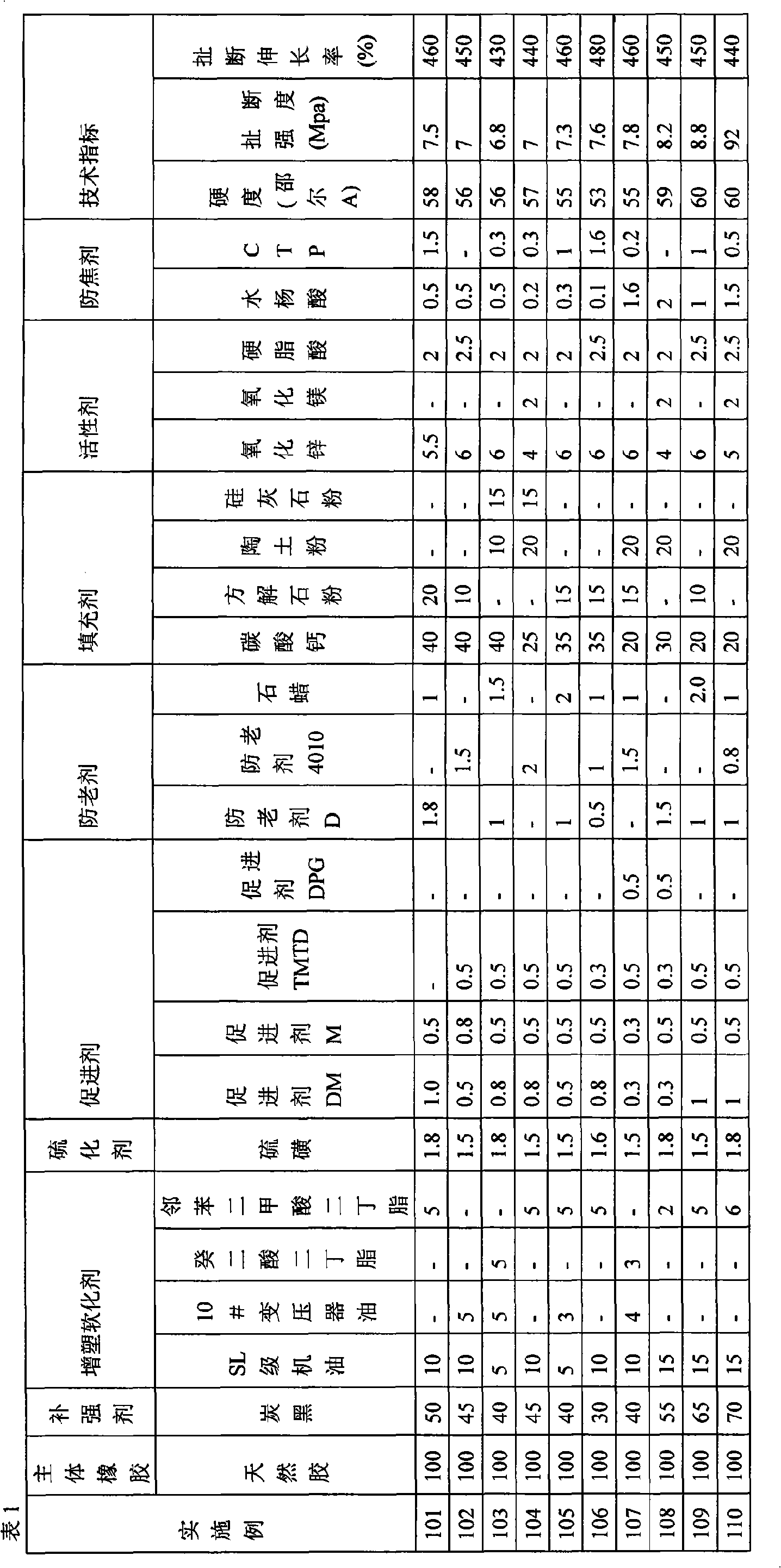

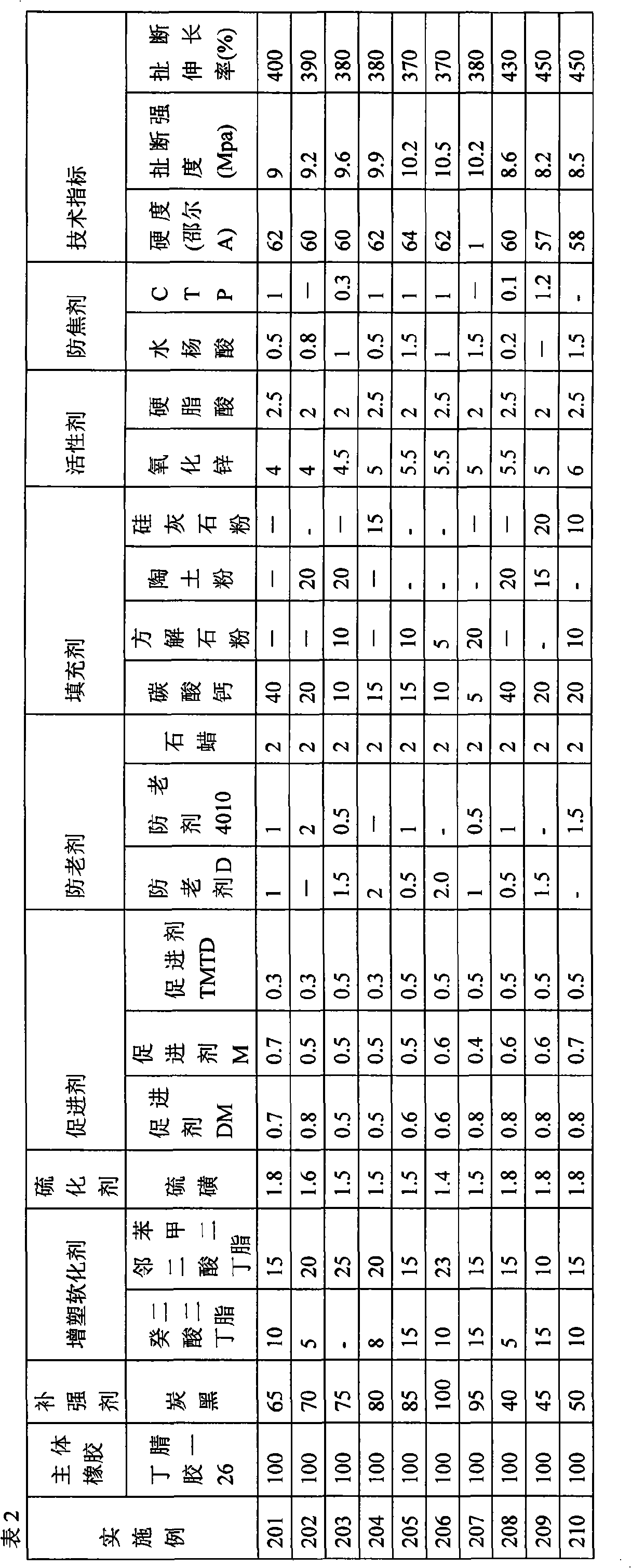

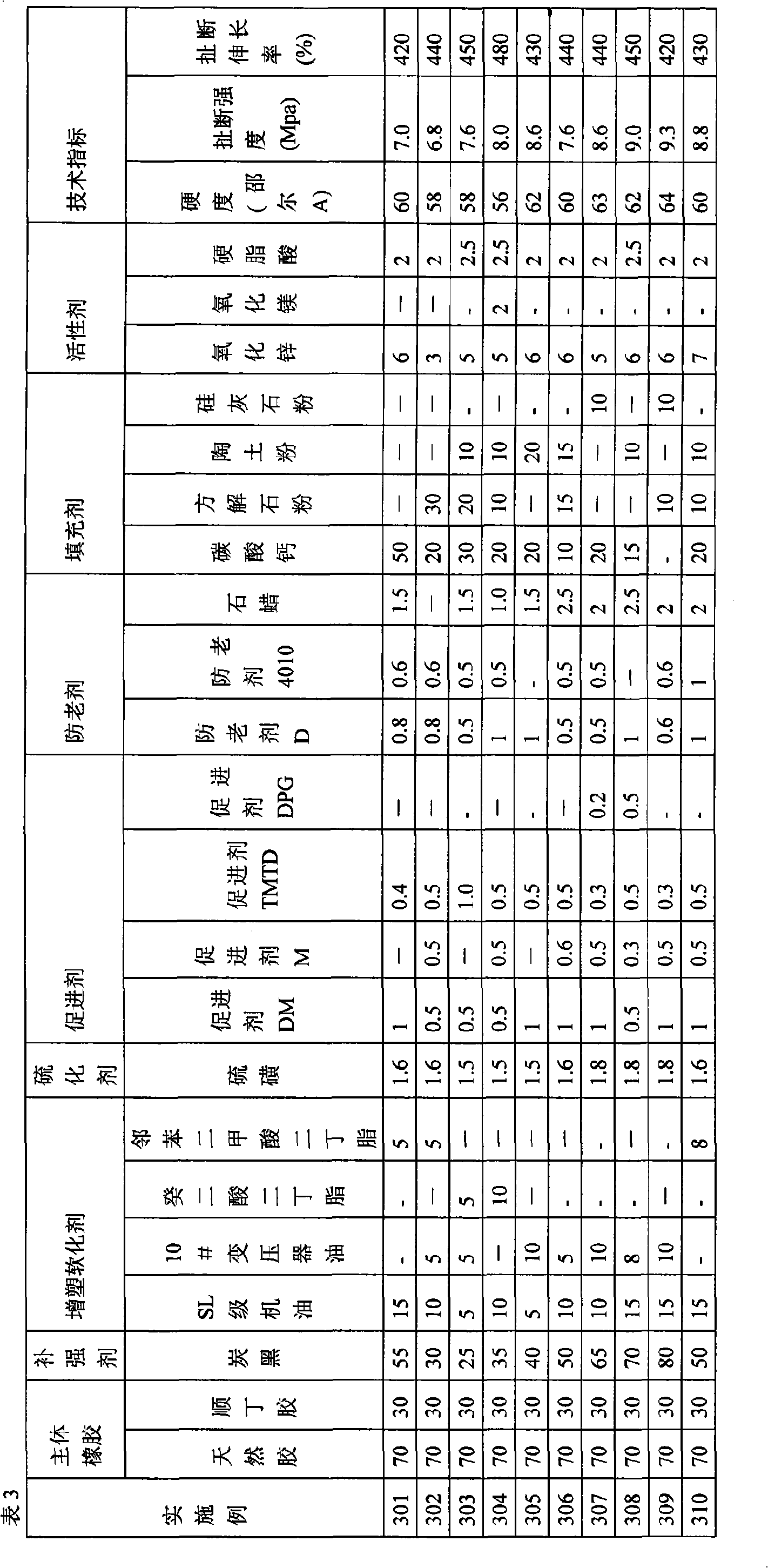

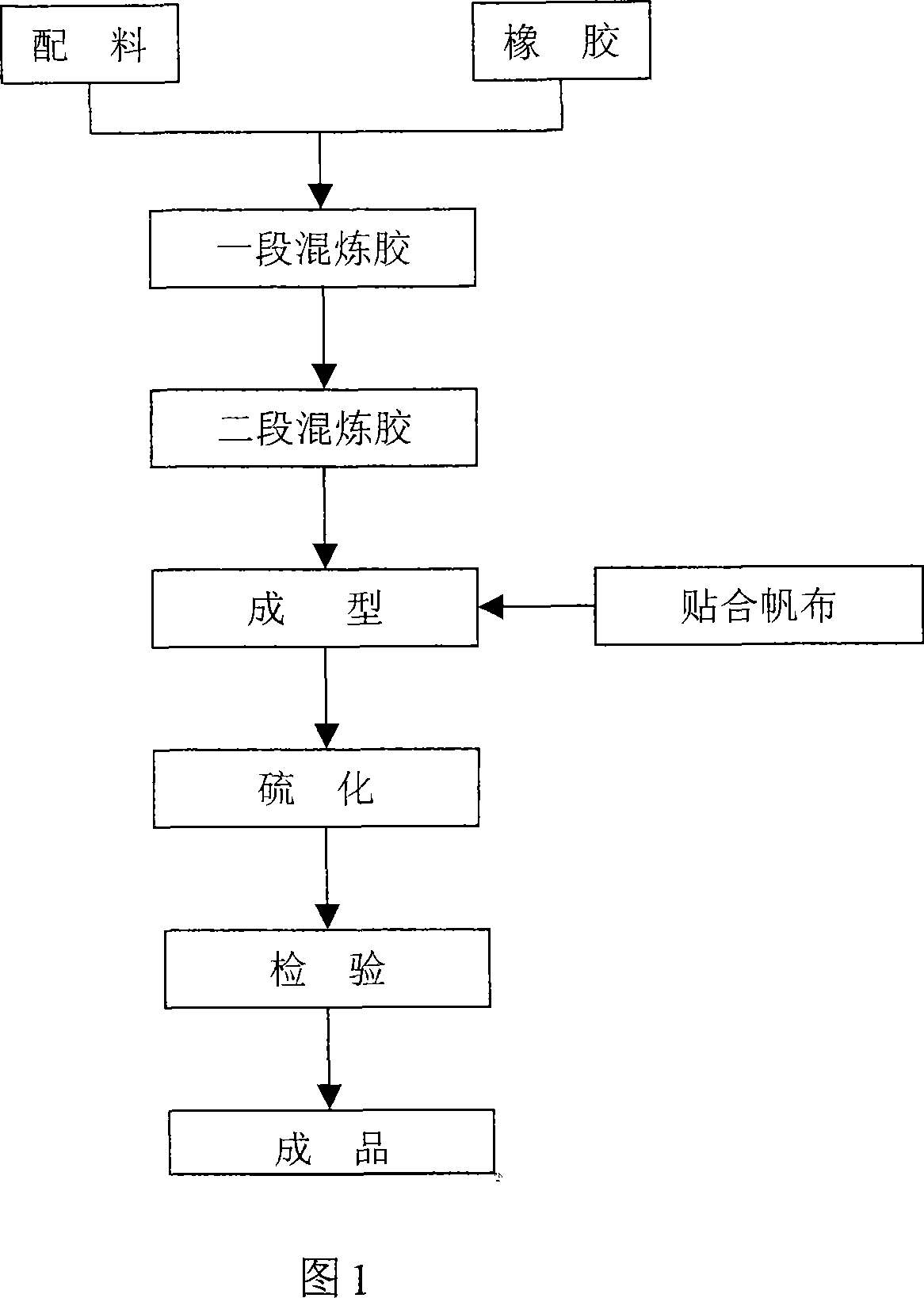

Sneaker sole material with high wear resistance and low hardness and preparation method thereof

The invention discloses a sneaker sole material with high wear resistance and low hardness and a preparation method thereof, particularly a method for preparing a sneaker sole material which is suitable for middle and high-grade sneaker soles with higher requirements on wear resistance and comfort. The sneaker sole material comprises the following components: butadiene rubber (BR), natural rubber (NR), styrene butadiene rubber (SBR), softening oil, a reinforcing agent, an activating agent, a coupling agent, a vulcanizer, a vulcanization accelerator, a tackifier and an anti-aging agent. A series of sole material with high wear resistance (DIN abrasion is less than or equal to 40mm<3>, and the length of grinding marks is 3.0 to 4.0mm) and low hardness (ShoreA 60-66) is prepared by screening the proportion of rubber composition, the coupling agent, the accelerator, and the activating agent and reasonably controlling a process on the basis of the rubber, the softening oil and the reinforcing agent. The material has the advantages that: (1) the total weight of a sneaker sole is expected to be reduced, namely the thickness of a rubber outer sole of a sneaker can be reduced under the condition that the material has the wearing life which is the same as that of the conventional sneaker sole, so that the total weight of the sole is reduced; (2) the humidity and slip resistance is improved, namely the hardness of the sole is lower and the sole is easy to distort under the condition of stress, so that the contact area of the sole and the ground is increased, and the aim of improving the humidity and slip resistance of the sole is fulfilled; and (3) the comfort is improved.

Owner:CHINA LEATHER & FOOTWEAR IND RES INST

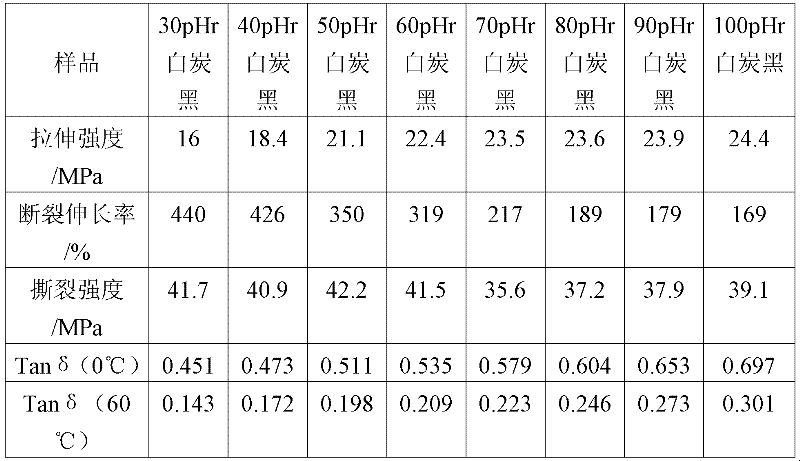

Preparation method of white carbon black modified styrene-butadiene rubber facing green tires and product thereof

ActiveCN102558627AEvenly dispersedImprove mechanical propertiesSpecial tyresRolling resistance optimizationFlocculationHydrogen

The invention provides a preparation method of white carbon black modified styrene-butadiene rubber facing green tires and a product thereof. White carbon black is used in the technical field of styrene-butadiene rubber modification, so as to provide guidance to the application of the white carbon black modified styrene-butadiene rubber in the tire industry. The styrene-butadiene rubber is characterized in that the styrene-butadiene rubber contains white carbon black of which the weight percentage to dry styrene-butadiene rubber latex is 30 percent to 100 percent. The preparation method comprises the steps that firstly, the white carbon black is mixed with water to obtain a white carbon black-water suspension; afterwards, the white carbon black-water suspension is subject to surface treatment, so as to enable the surface of the white carbon black to be organized; the pH (potential of hydrogen) value of the suspension is adjusted to be 9 to 12; and finally, the suspension is evenly mixed with the styrene-butadiene rubber latex to obtain liquid styrene-butadiene rubber sizing to which the white carbon black is added, and then the modified styrene-butadiene rubber containing the white carbon black is prepared by adopting an emulsion blending and flocculation process. The white carbon black modified styrene-butadiene rubber prepared by adopting the preparation method has the advantages that the white carbon black is evenly distributed in the styrene-butadiene rubber, and compared with pure styrene-butadiene rubber, the mechanical performance, the wet-skid resistant performanceand the rolling resistance of the white carbon black modified styrene-butadiene rubber are remarkably improved.

Owner:BEIJING UNIV OF CHEM TECH

Cold resistant rubber

The invention aims at providing a low-temperature resistant rubber which can be used for a long time in low temperature and has almost the same tensile strength and elongation at break and the same hardness at low temperature as at normal temperature. The low-temperature resistant rubber contains main body rubber, strengthening agent, plasticization softener and curing ingredient, and the weight ratio of main body rubber : strengthening agent : plastifying softener : curing ingredient is 100:10-350:5-75:0.5-3; the main body rubber is natural gum, styrene-butadiene-rubber, cis-butadiene rubber, butyl rubber, ethylene propylene diene rubber, butadiene nitrile rubber or the combination of natural gum and cis-butadiene rubber; the strengthening agent is black carbon or white carbon; the plastifying softener is machine oil, transformer oil, dibutyl sebacate, dibutyl phthalate or silicon oil; the curing ingredient is 2,5-dimethyl curing ingredient or sulphur.

Owner:南京固柏橡塑制品有限公司

Method for preparing low-contraction high-fluidity high-toughness polypropylene

InactiveCN101148528AInjection shrinkage reducedMeet the needs of industrial developmentElastomerPolyolefin

The present invention is one kind of low shrinkage high flowability and high toughness polypropylene composition and its preparation process and use. The polypropylene composition consists of high flowability polypropylene 35-65 weight portions, thermoplastic polyolefin elastomer 10-40 weight portions, toughening agent 6-20 weight portions, inorganic stuffing 10-25 weight portions, antioxidant 0.2-1.0 weight portion, weather resisting agent 0.2-1.0 weight portion and machining assistant 0.1-1.0 weight portion. The toughening agent is one or composition of ethylene-octene copolymer, ethylene propylene diene copolymer, styrene-butadiene-styrene block copolymer and hydrogenated styrene-butadiene-styrene block copolymer. The polypropylene composition is prepared through the following steps: 1. mixing all the materials and 0-50 wt% of inorganic stuffing for 3-8 min to obtain mixture; and 2. smelting and mixing the rest inorganic stuffing and mixture at 180-235 deg.c, and pelletizing.

Owner:SHANGHAI KINGFA SCI & TECH +1

Tearproof antiwear conveying belt

The present invention relates to one kind of tearproof antiwear conveying belt, and belongs to the field of rubber product technology. The tearproof antiwear conveying belt is produced through pre-pressing and mixing natural rubber, styrene butadiene rubber and cis-butadiene rubber inside a Banbury mixer; adding promoter, activator, leveler and antiaging agent before further mixing; adding reinforcing agent, softening agent and aramid fiber before further mixing to obtain mixed rubber; mixing for the second time and adding cross-linking agent inside a Banbury mixer after being set for some time; discharging batch to obtain mixed rubber; rolling to form rubber sheet; combining rubber sheet with tension element belt blank, rolling up and sulfurizing; and trimming to obtain the product. The tearproof antiwear conveying belt has excellent tearproof performance, excellent antiwear performance and long service life, and is suitable for use in mines.

Owner:WUXI BOTON CONVEYOR SOLUTION CO LTD

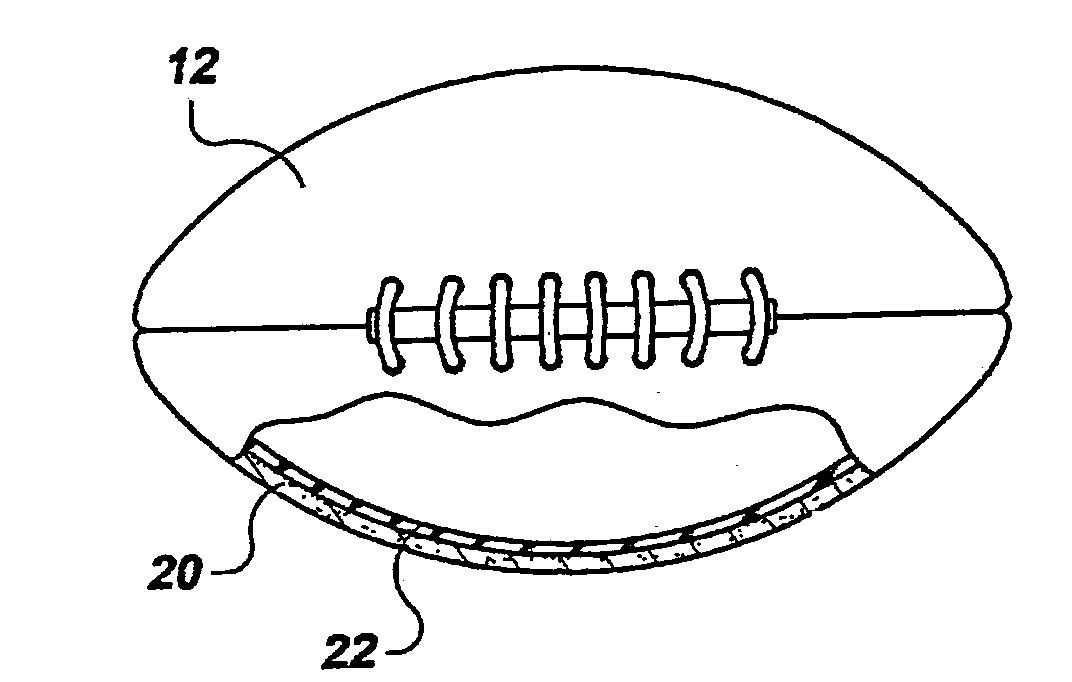

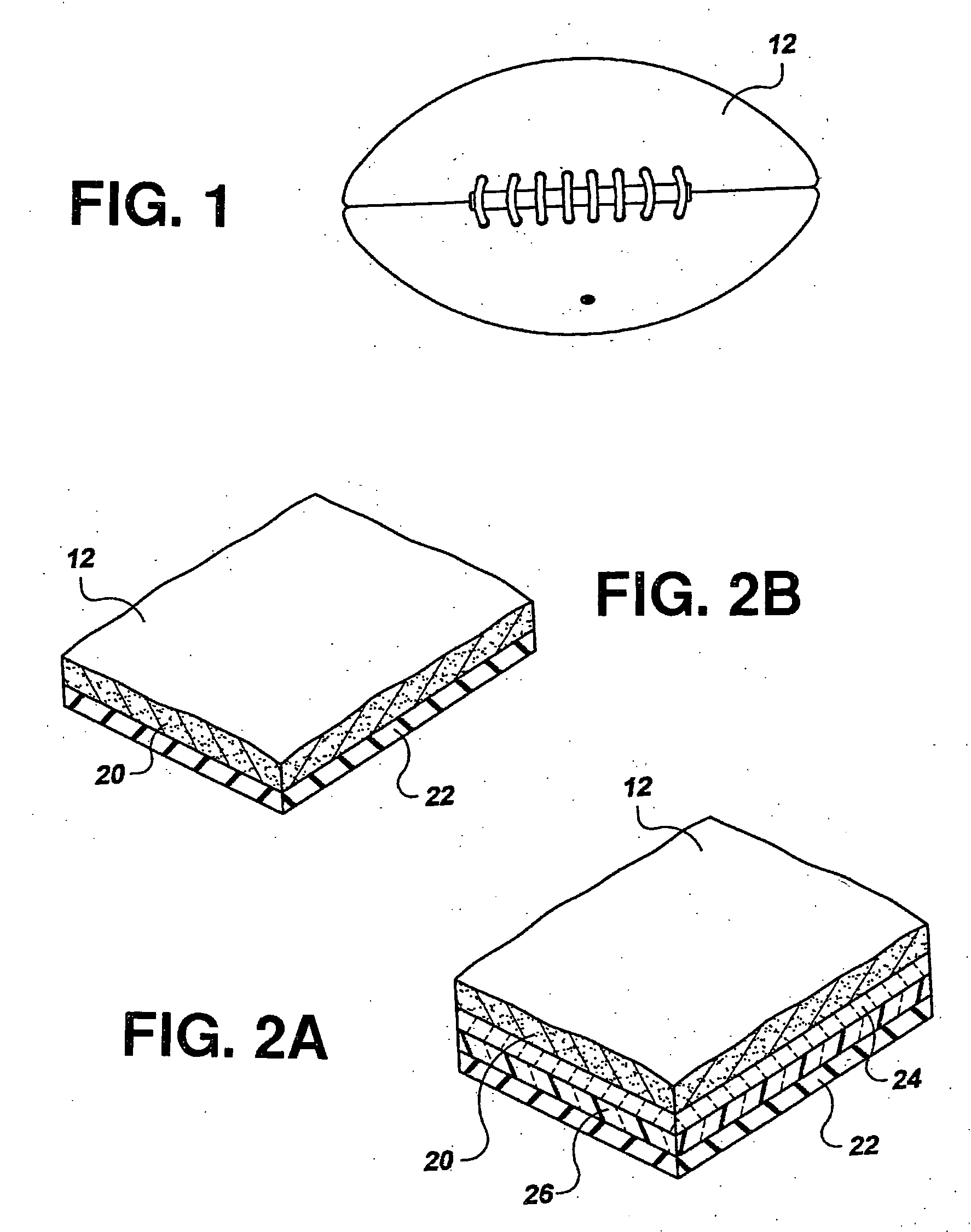

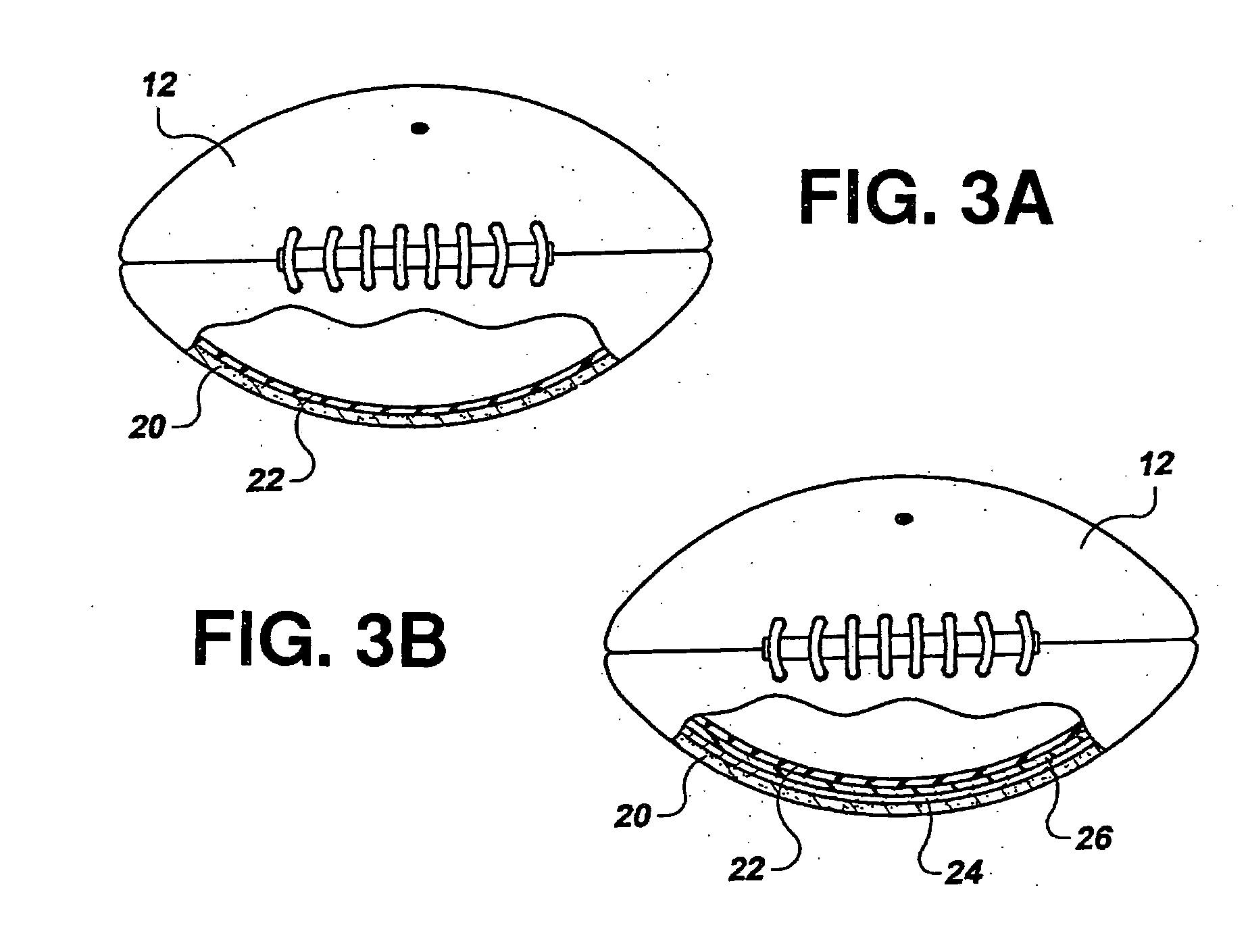

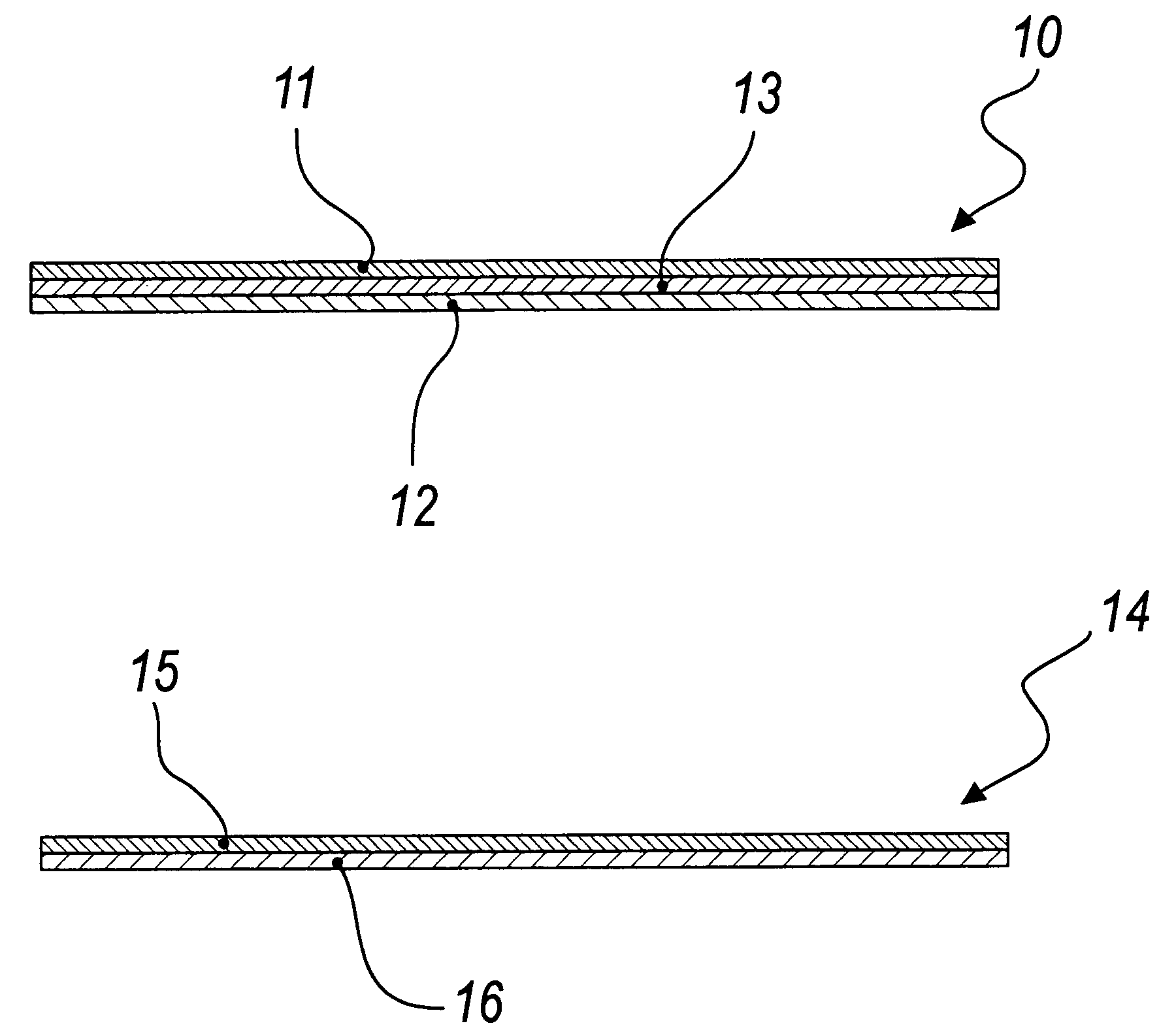

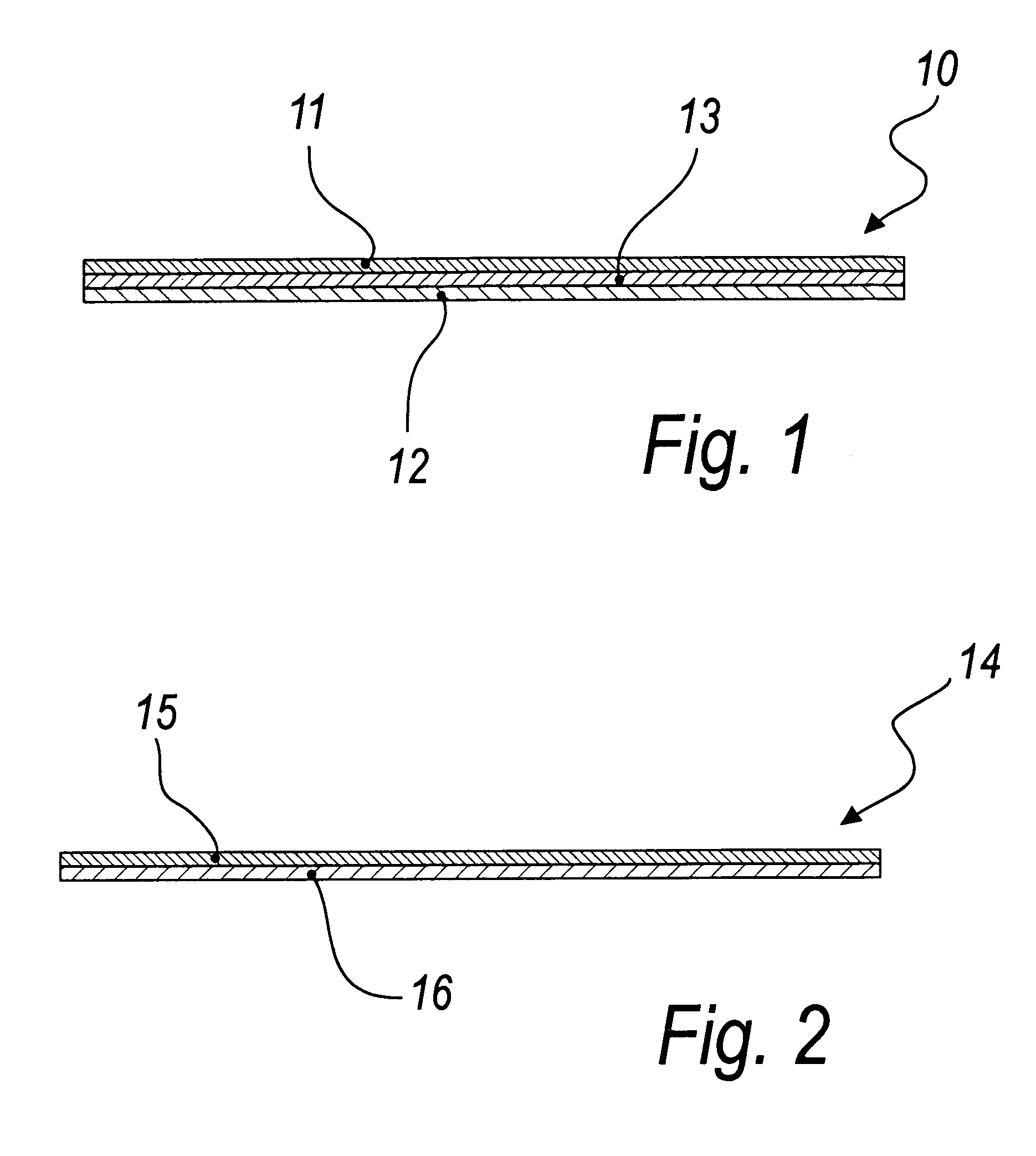

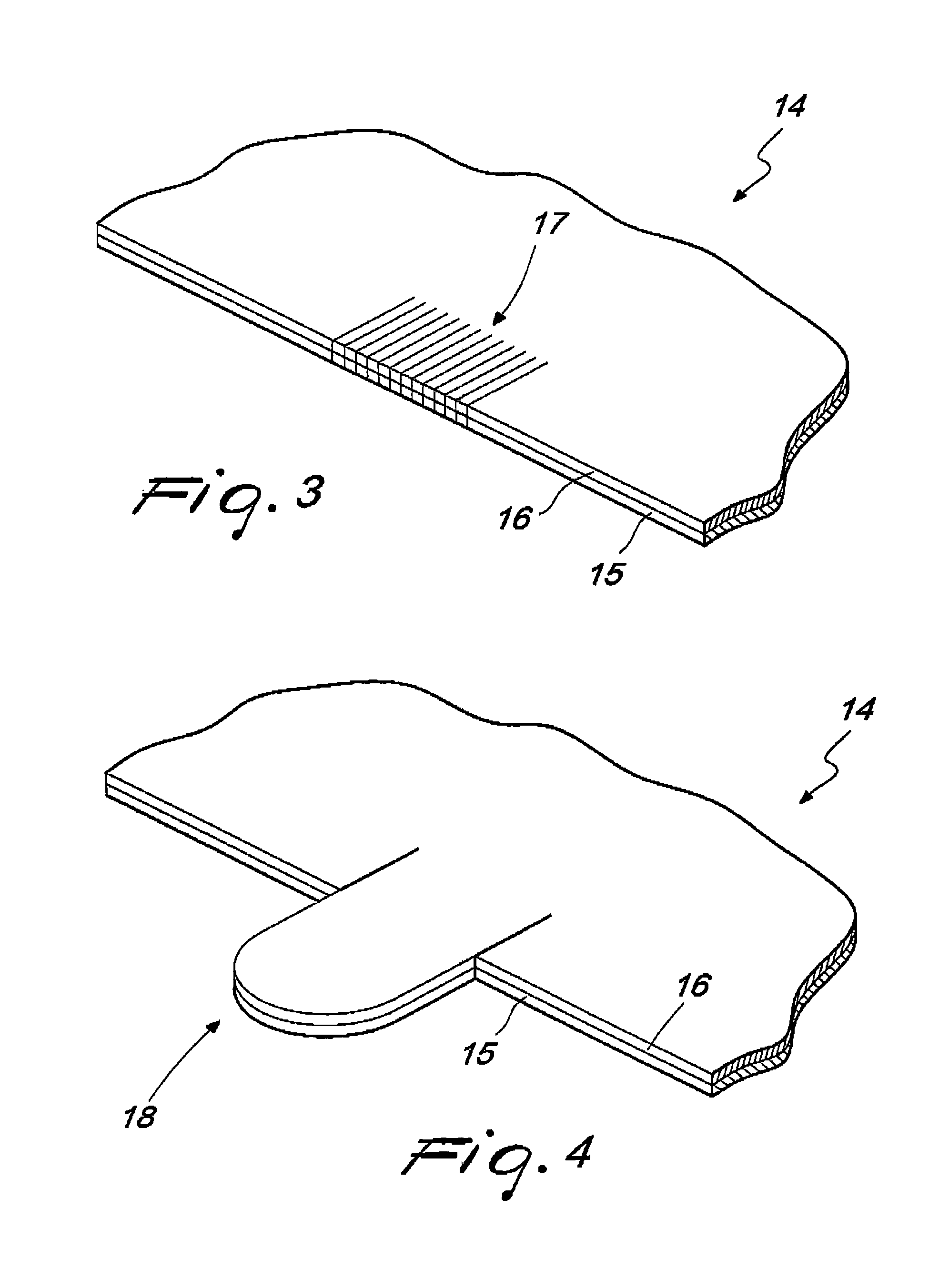

Football

InactiveUS20060293132A1Improved feel and playability characteristicHollow inflatable ballsEngineeringButadiene-styrene rubber

Disclosed is an inflatable sports ball with a plurality of layers. The sports ball may have an exterior layer, a padded layer, and a bladder. The padded layer may be configured to provide increased grip and feel characteristics for the user. The padded layer can be formed from a foamed styrene butadiene rubber. This disclosure is intended to apply to inflatable footballs, and the like.

Owner:SGG PATENTS +1

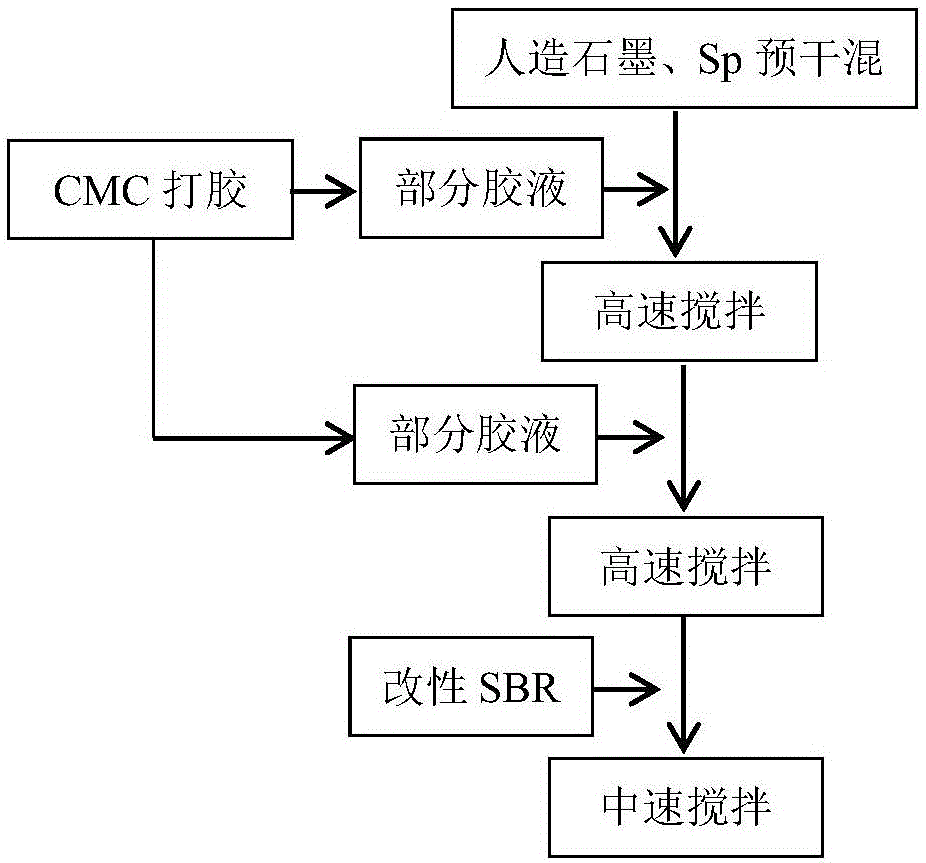

Preparation method of negative electrode slurry capable of reducing expansion of lithium ion battery

ActiveCN106159266AReduce bridgingChange structureCell electrodesSecondary cellsSlurrySodium-ion battery

The invention discloses a preparation method of negative electrode slurry capable of reducing the expansion of a lithium ion battery. The preparation method comprises the following steps of: carrying out dry blending on a negative electrode active substance and a conducting agent in advance; dissolving sodium carboxymethyl cellulose into de-ionized water to obtain a CMC (Carboxyl Methyl Cellulose) gel solution with the concentration of 1.0%-2.0%; adding one part of the CMC gel solution into a mixture of the negative electrode active substance and the conducting agent and stirring at a high speed for 0.5-1h; adding the balance of CMC gel solution and stirring at a high speed for 1-3h; adding a modified SBR (Styrene Butadiene Rubber) binding agent and stirring at a middle speed for 0.3-1h; and adjusting the viscosity. By adopting the method of carrying out the dry blending on artificial graphite and the conducting agent in advance, adding the glue solution by two times and utilizing modified SBR as the binding agent, a bridge phenomenon of the artificial graphite is reduced, a pole piece structure is changed, the binding force between grains is improved and the expansion of a negative electrode is reduced; meanwhile, the slurry sedimentation of the artificial graphite is inhibited. The preparation method of the negative electrode slurry capable of reducing the expansion of the lithium ion battery has important meanings on ternary lithium ion batteries and improvement of machinability, capacity and safety of high-capacity power batteries.

Owner:南京国轩新能源有限公司

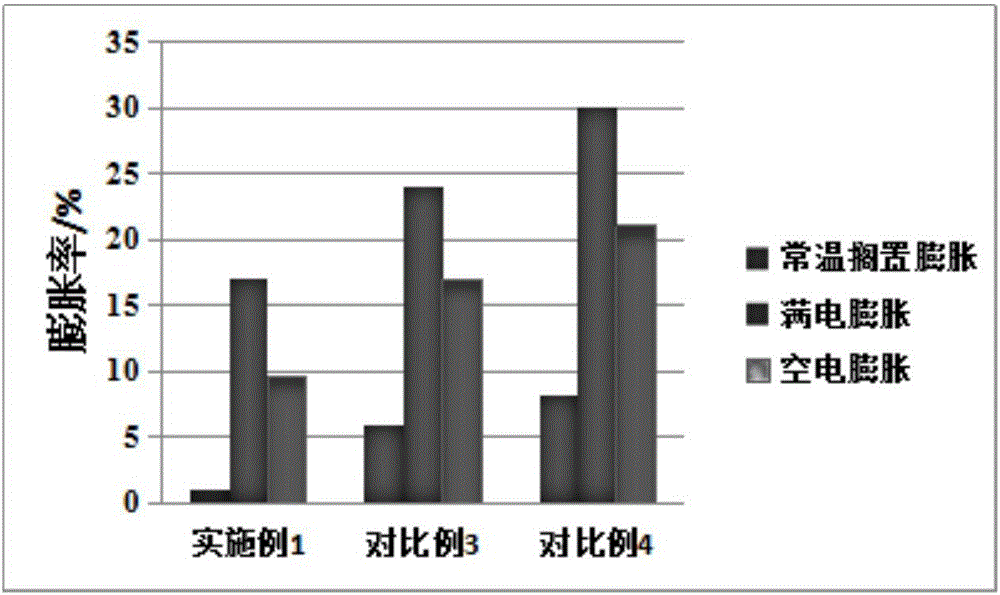

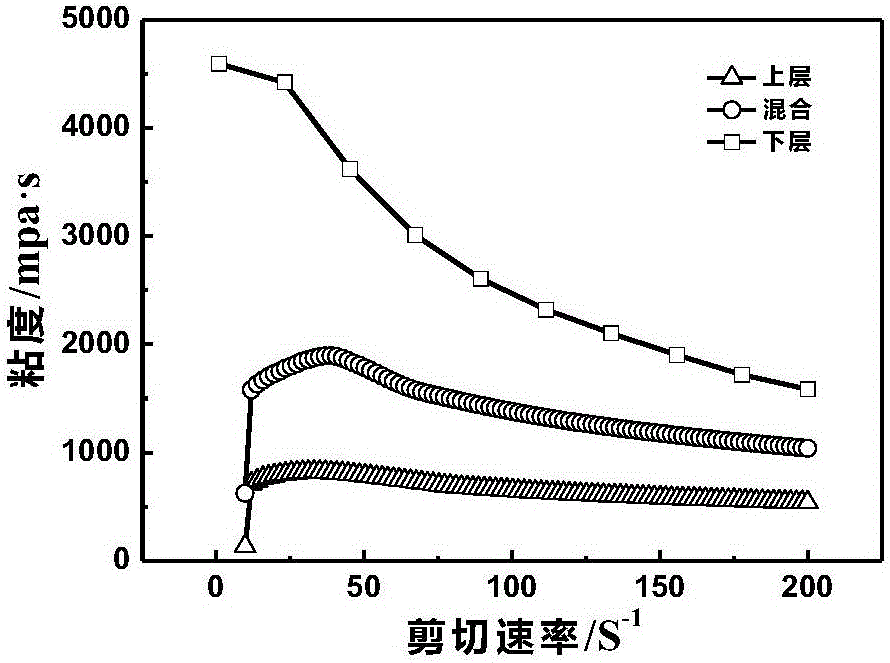

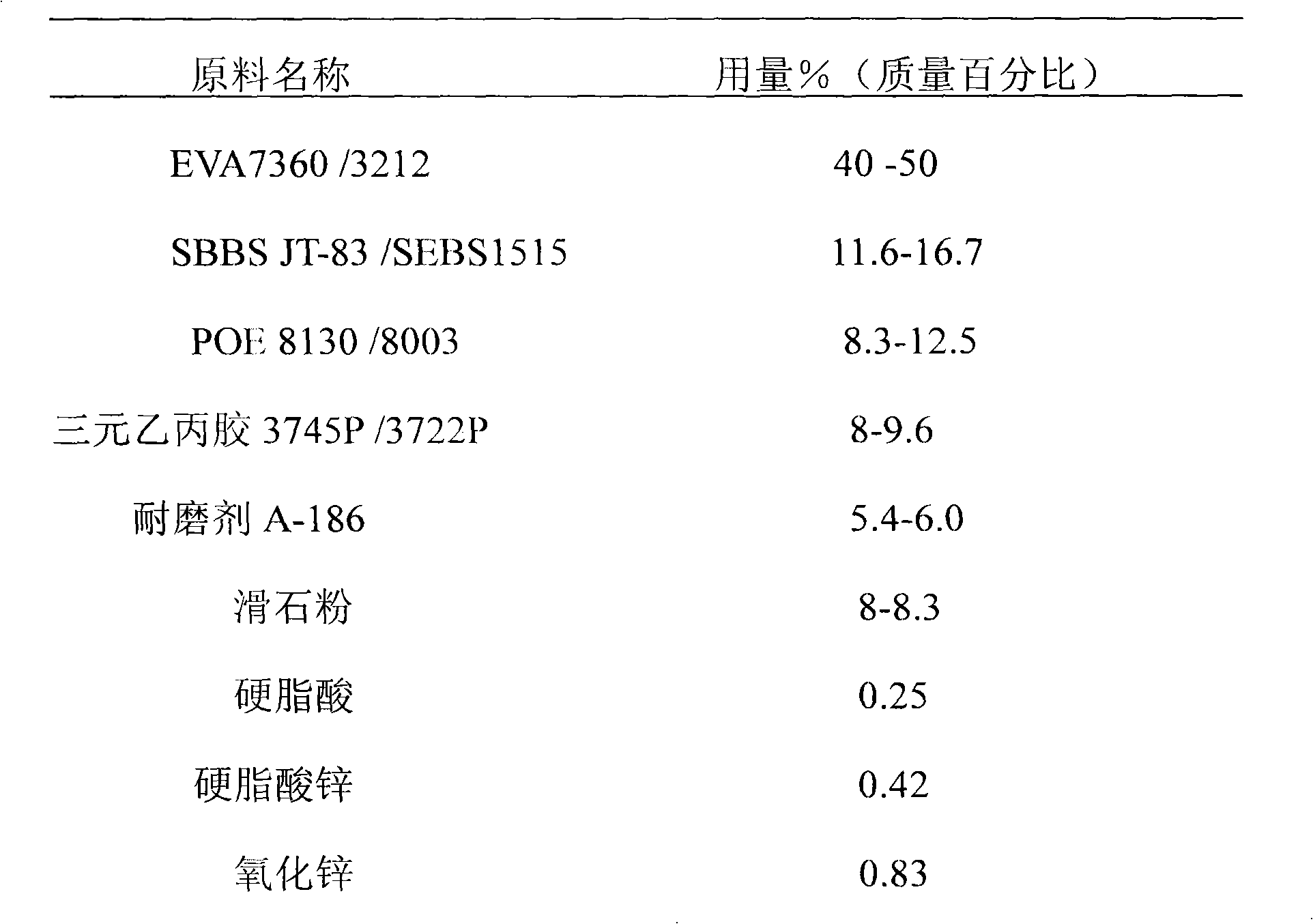

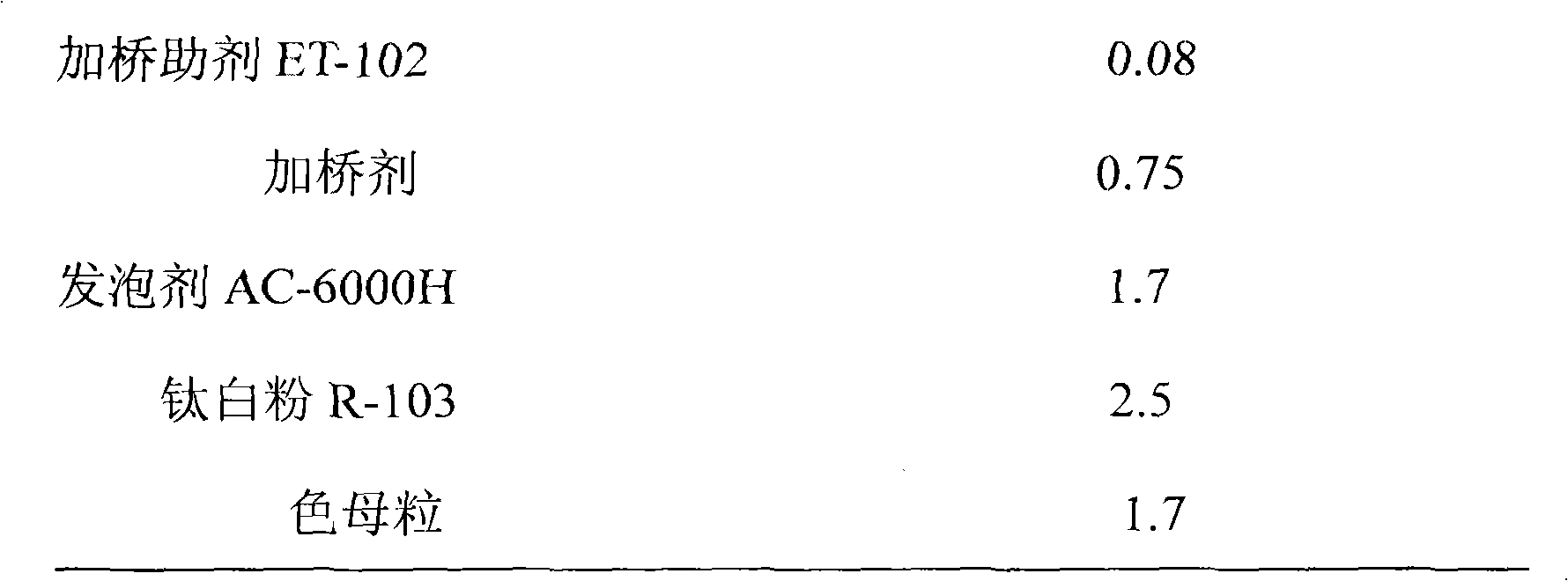

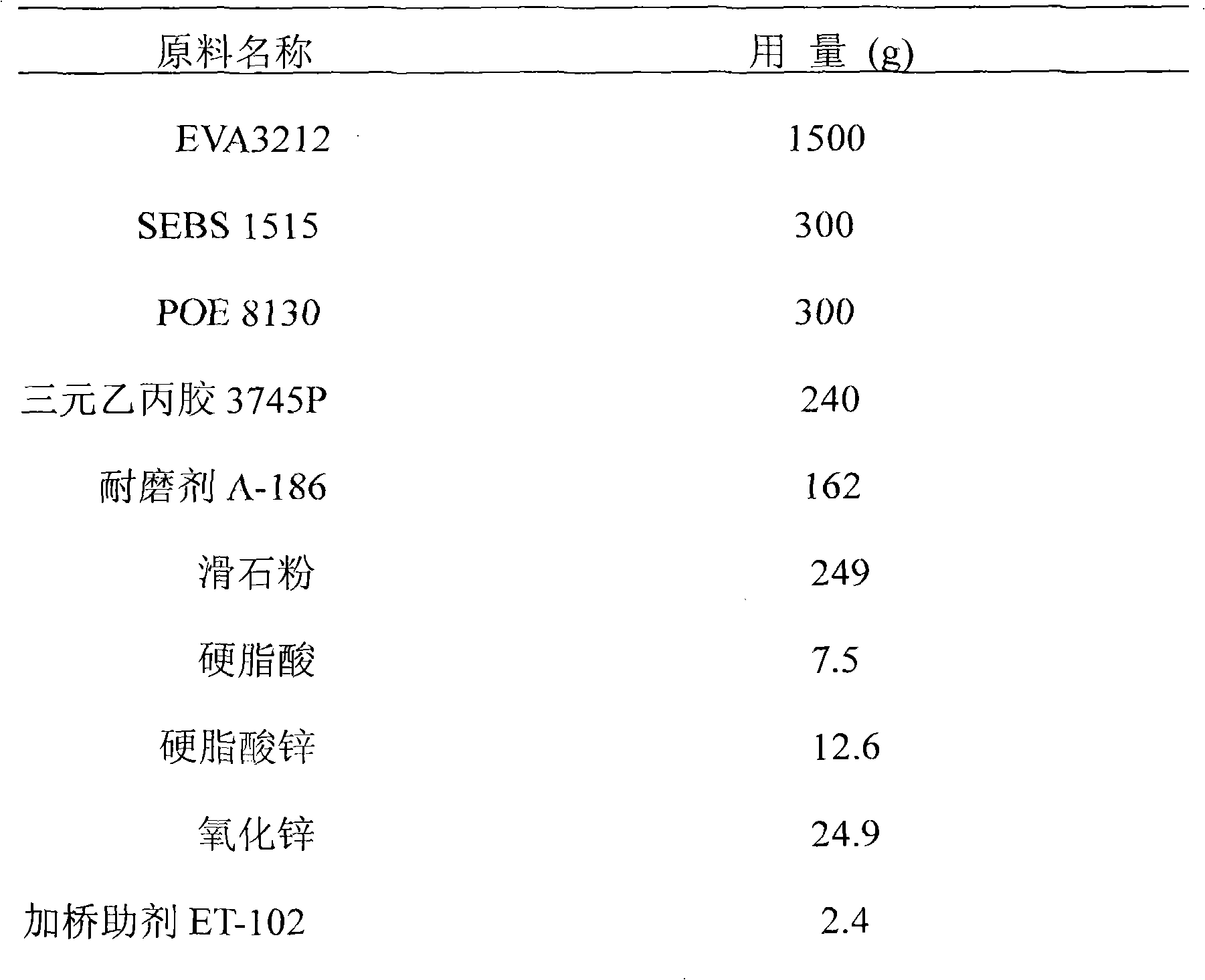

Formula of soles of PU-simulated foaming sneakers through injection and manufacturing method

The invention relates to a formula of soles of PU-simulated foaming sneakers through injection, which comprises the following raw materials in percentage by mass: 40 percent of 21 percent ethylene-vinyl acetate copolymer (EVA 7360), 16.7 percent of styrene butadiene copolymer SBBSJT-83, 12.5 percent of ethylene octylene copolymer POE8130, 8.3 percent of ethylene-propylene-diene copolymer 3745P, 65.9 percent of wear-resisting agent A-18, 8.3 percent of talcpowder, 0.25 percent of stearic acid, 0.42 percent of zinc stearate, 0.9 percent of zinc oxide, 0.08 percent of bridging auxiliary agent ET-102, 0.75 percent of bridging agent DCP, 1.7 percent of high-temperature foaming agent AC-6000H, 2.5 percent of titanium white powder R-103 and 1.7 percent of master batch. The preparation method comprises the steps of banburying, mixing, granulation, injection molding, physical property tests and the like. Thus, in the research and development and application, the PU-simulated foaming soles not only have the physical and chemical properties of no crease marks, high elasticity, low compression and wear resistance of PU soles, and but also have the advantages of low production cost, light specific gravity, good limited-slip properties, no hydrolysis and long service life.

Owner:泰亚投资集团有限公司

Package particularly for packaging food products

InactiveUS7128210B2Low costHigh yieldReady-for-oven doughsFlexible coversPlastic materialsCentral layer

A package particularly for packaging food products, comprising an inner package sheet, which individually wraps each product of the package and is composed of a coextruded film constituted by two outer layers of a styrene-butadiene copolymer resin and by a central layer chosen among polyethylene, polypropylene and other plastic material, and an outer package sheet, which wraps around a set of products contained in their respective inner packages and is composed of a high-barrier film coupled to a paper film.

Owner:ALCAN PACKAGING ITALIA SRL

Ultraviolet aging-resistant compound modified asphalt and preparation method thereof

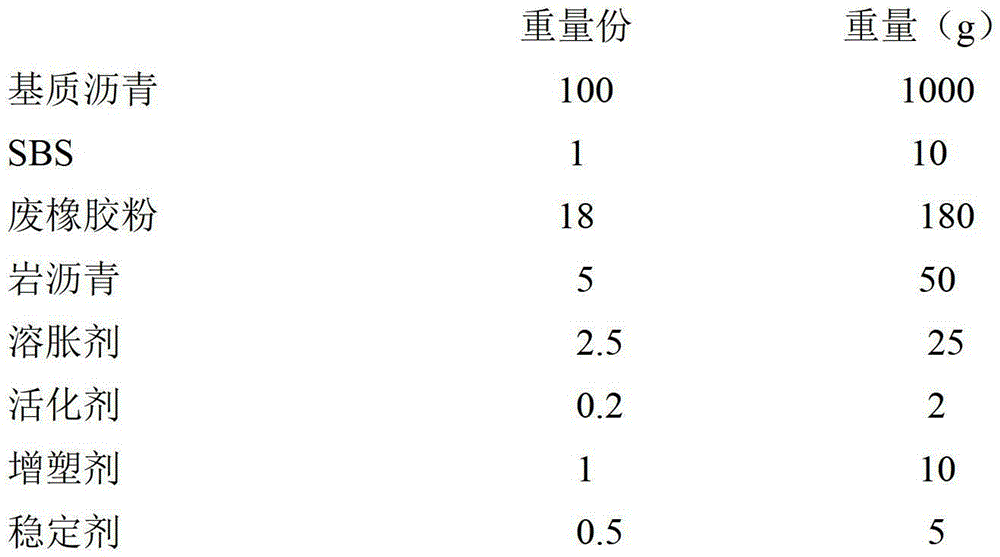

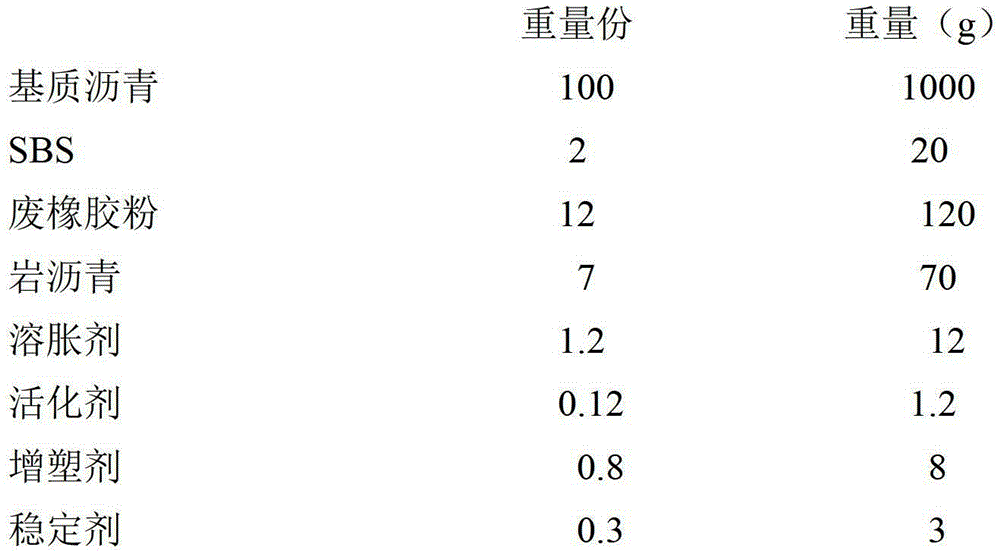

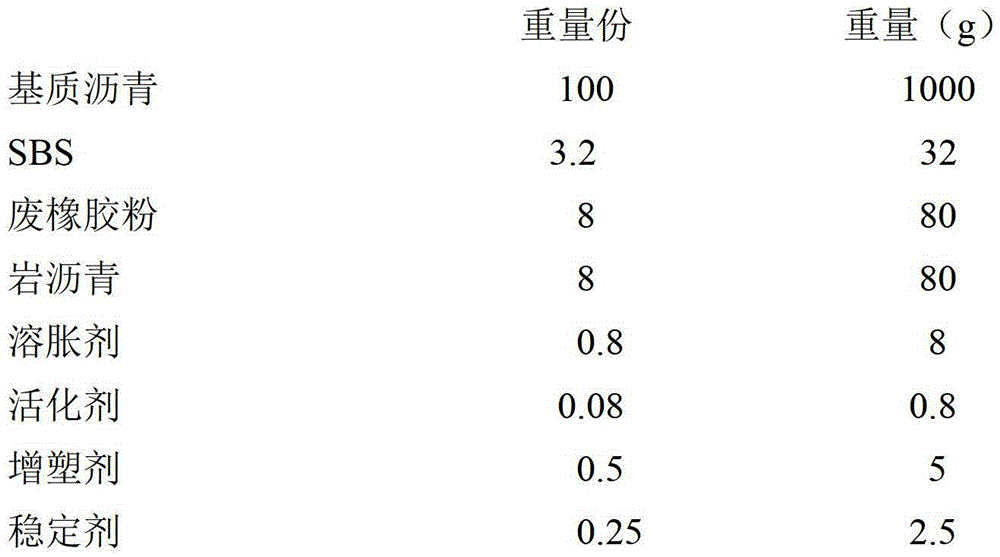

ActiveCN103146207AImprove anti-aging propertiesStop breakingTreatment with plural serial refining stagesBuilding insulationsPolymer modifiedPolymer science

The invention belongs to the technical field of road asphalt modification and relates to an ultraviolet aging-resistant compound modified asphalt, wherein on the basis of 100 parts by weight of matrix asphalt, in parts by weight, 1-6 parts of styrene-butadiene-styrene block copolymer, 3-18 parts of waste rubber powder, 5-10 parts of rock asphalt, 0.3-2.5 parts of sweller, 0.03-0.2 part of activator, 0.1-1 part of plasticizer and 0.2-0.5 part of stabilizer are further added, wherein the sweller is furfural extract oil which is subjected to dewaxing treatment previously; the furfural extract oil contains 60wt%-88wt% of aromatic components which contain 40-65wt% of heavy aromatic hydrocarbon; and the waste rubber powder is waste rubber tire tread rubber powder having the content of carbon black between 28wt% and 58wt% and the grain diameter between 45 and 80 meshes. The ultraviolet aging-resistant compound modified asphalt provided by the invention is up to the standard of the polymer modified asphalt in performance, and the ultraviolet aging resistance of the asphalt is improved to a large extent; and waste resources are utilized.

Owner:HUBEI GUOCHUANG HI TECH MATERIAL

Thermoplastic elastomer and its production method

The invention provides a high elasticity thermal plasticity elastic body and the method to make. The weight proportion of the elastic body includes: plasticity ingredient styrene-butadiene-styrene block copolymer 100, filling naphthenic oil or white oil 40-60, modification agent 0-110, stabilizing agent 2-10, lubricant 2-65, and other bulk agent 10-300. The invention has advantages of low compression deformation, strong flexing resistance and good resilience.

Owner:闫俊龙

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com