Ultraviolet aging-resistant compound modified asphalt and preparation method thereof

A compound modified asphalt anti-ultraviolet aging technology, which is applied in the field of road asphalt modification, can solve the problems of unreasonable ratio of rubber powder and furfural oil extraction, affect the anti-ultraviolet performance of asphalt, and insufficient swelling of rubber powder, etc. Effects of UV performance, photooxidation resistance, excited state energy, and UV aging resistance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0032] In the following specific examples, the base asphalt is 70#A grade road petroleum asphalt. The waste rubber powder is waste rubber tire tread rubber powder, the carbon black content is between 28-58wt%, and the particle size is between 45-80 mesh. The molecular weight of the styrene-butadiene-styrene block copolymer (SBS) is between 100,000 and 300,000, and the type is linear, star or mixed (linear and star in any proportion mix). The rock asphalt is natural asphalt with a bitumen content of 80-95wt%, and trichlorethylene insoluble matter is less than 20wt%.

[0033] The swelling agent is furfural extracted oil after dewaxing treatment, which is rich in aromatic components, and the content of the aromatic components is between 68wt% and 78wt%.

[0034] The activator is 2,2-bis(6-tert-butyl-p-phenol) disulfide,

[0035] Described plasticizer is diethylene glycol dibenzoate.

[0036] The stabilizer is several compositions of sulfur, zinc oxide, stearamide, dithiol ben...

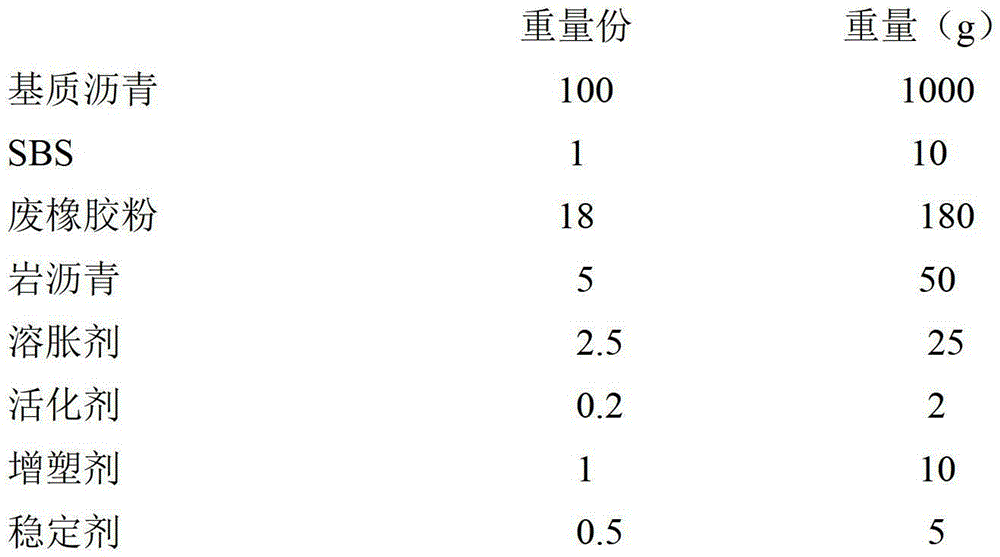

specific Embodiment 1

[0037] A kind of anti-ultraviolet aging composite modified asphalt, it is based on 100 parts by weight of matrix asphalt, plus SBS, waste rubber powder, rock asphalt, swelling agent, activator, plasticizer, stabilizer, these raw materials are in steps, by Prepared by processes such as swelling, shearing, and stirring development, the following is added based on 100 parts of base asphalt, and the parts of each component are as follows:

[0038]

[0039] The preparation method is as follows: first, swell waste rubber powder, take 180g waste rubber powder with a high-temperature resistant container with a cover, add 25g swelling agent, 2g activator, 10g plasticizer, preheat (the preheating temperature is 160°C) and put Stir and mix the rubber powder and various additives evenly, then put the lid on and put it in an oven for 2 hours at 180°C to obtain swollen waste rubber powder; the second step is to prepare modified asphalt, heating 1000g of base asphalt to 140°C, Add 10g of ...

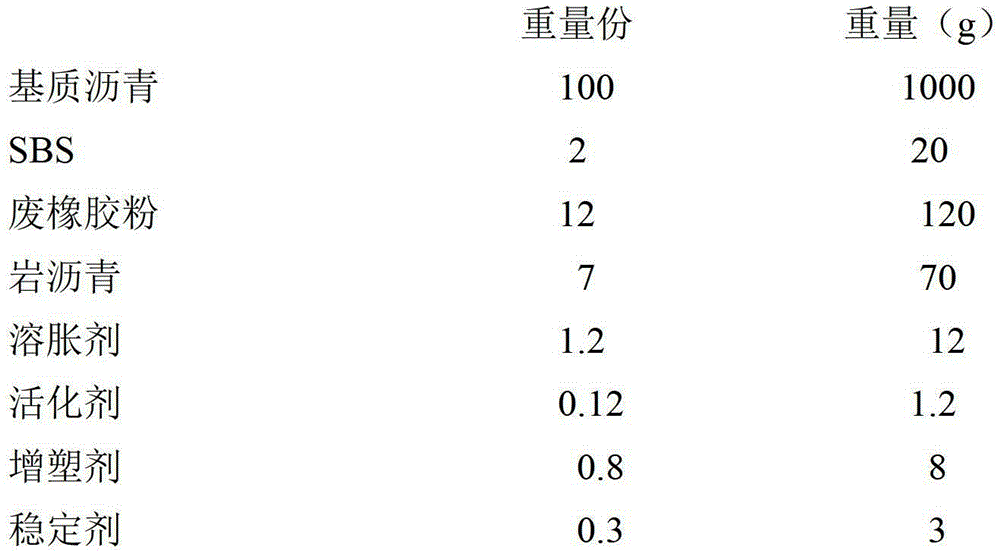

specific Embodiment 2

[0042] A kind of anti-ultraviolet aging composite modified asphalt, it is based on 100 parts by weight of matrix asphalt, plus SBS, waste rubber powder, rock asphalt, swelling agent, activator, plasticizer, stabilizer, these raw materials are in steps, by Prepared by processes such as swelling, shearing, and stirring development, the following is added based on 100 parts of base asphalt, and the parts of each component are as follows:

[0043]

[0044] The preparation method is as follows (the second method): at first swell the waste rubber powder, get 120g waste rubber powder with a high temperature resistant container with a cover, add 12g swelling agent, 1.2g activator, 8g plasticizer, preheat (the preheating temperature 158°C), mix the rubber powder and various additives evenly, then add 240g of base asphalt (160°C), mix evenly, then cover and put it in an oven for 2 hours at 180°C to obtain swollen waste rubber powder; the second step is to prepare modified asphalt, he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com