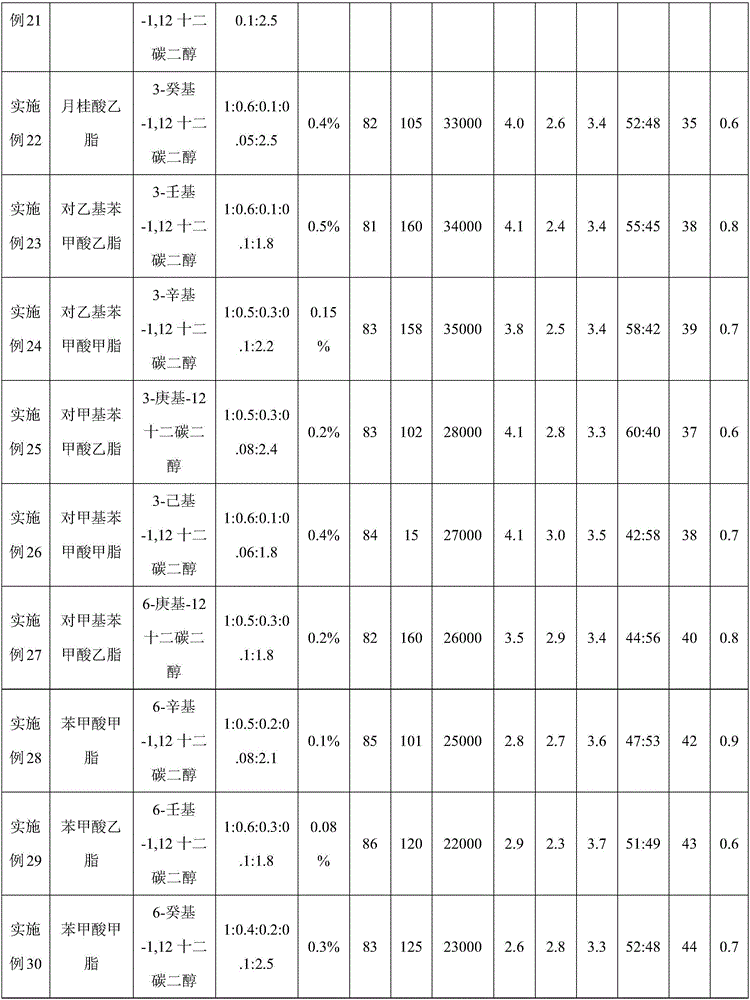

Patents

Literature

3564 results about "Diethylene glycol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Diethylene glycol (DEG) is an organic compound with the formula (HOCH₂CH₂)₂O. It is a colorless, practically odorless, poisonous, and hygroscopic liquid with a sweetish taste. It is miscible in water, alcohol, ether, acetone, and ethylene glycol. DEG is a widely used solvent. It can be a contaminant in consumer products; this has resulted in numerous epidemics of poisoning since the early 20th century.

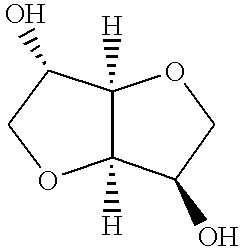

Polyesters including isosorbide as a comonomer blended with other thermoplastic polymers

A polymer blend including a polyester and another thermoplastic polymer. The polyester includes terephthaloyl moieties and, optionally, other aromatic diacid moieties; and ethylene glycol moieties; optionally diethylene glycol moieties; isosorbide moieties; and, optionally one or more other diol moieties. The polyester has an inherent viscosity of at least about 0.35 dL / g.

Owner:EI DU PONT DE NEMOURS & CO

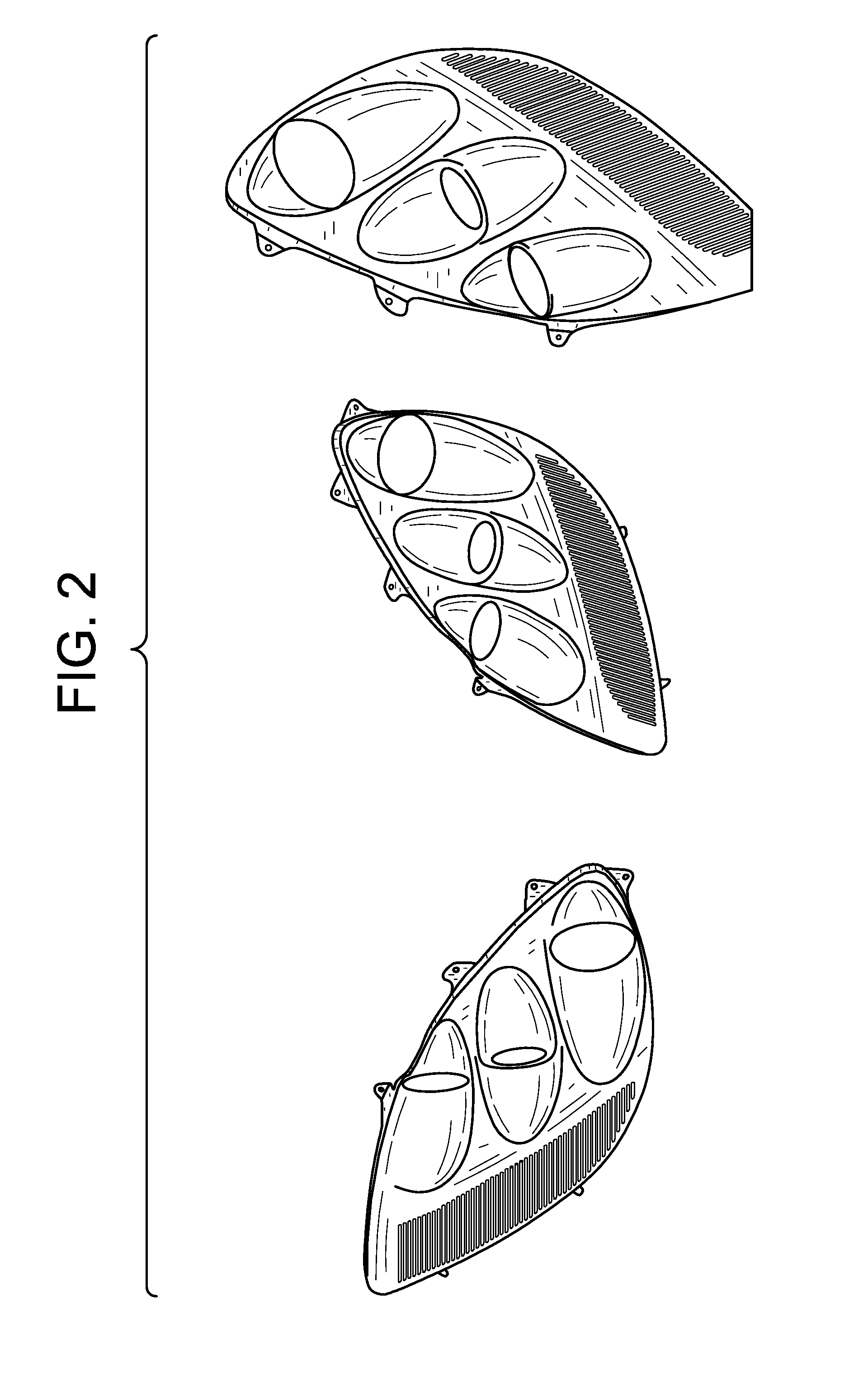

Articles derived from compositions containing modified polybutylene terephthalate (PBT) random copolymers derived from polyethylene terephthalate (PET)

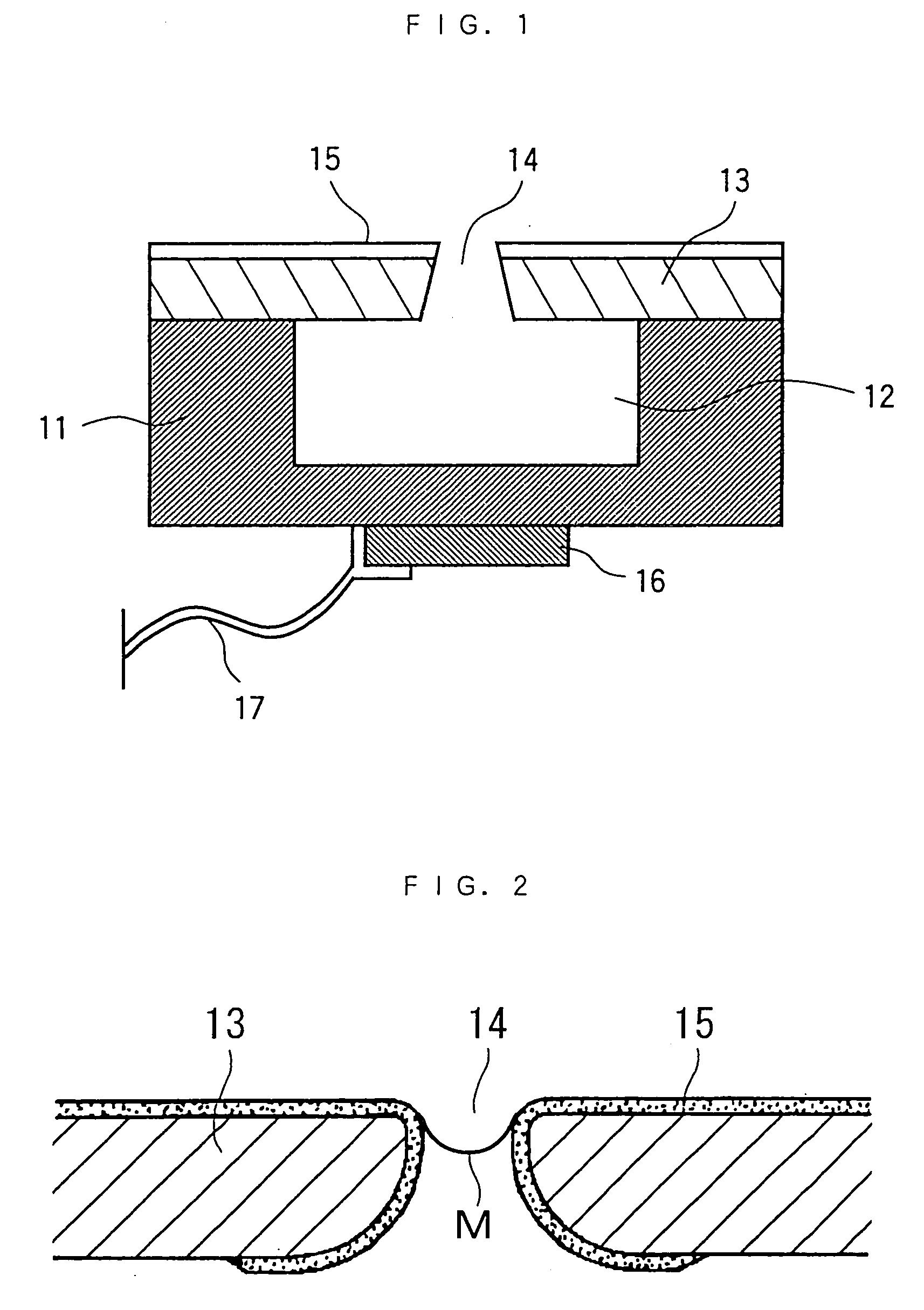

ActiveUS20070275242A1Useful performance propertyPlastic recyclingSpecial tyresPolytetramethylene terephthalatePolyethylene terephthalate glycol

Compositions of matter including articles derived from (a) from 5 to 99.99 wt % of a modified polybutylene terephthalate random copolymer that (1) is derived from polyethylene terephthalate and (2) contains a at least one residue derived from polyethylene terephthalate selected from the group consisting of antimony, germanium, diethylene glycol groups, isophthalic acid groups, cis isomer of cyclohexane dimethanol, trans isomer of cyclohexane dimethanol, sodium benzoate, alkali salts, napthalane dicarboxylic acids, 1,3-propane diols, cobalt, cobalt-containing compounds, and combinations thereof, and (b) from 0.01 to 95 wt. % of a member selected from the group consisting of (1) fillers, (2) a carboxy reactive component, (3) polyethyelene terephthalate, (4) a component including a polycarbonate and an impact modifier. The articles may be derived from various conversion processes, e.g., injection molding processes, extrusion processes, thermoforming processes, melt-blown process.

Owner:SHPP GLOBAL TECH BV

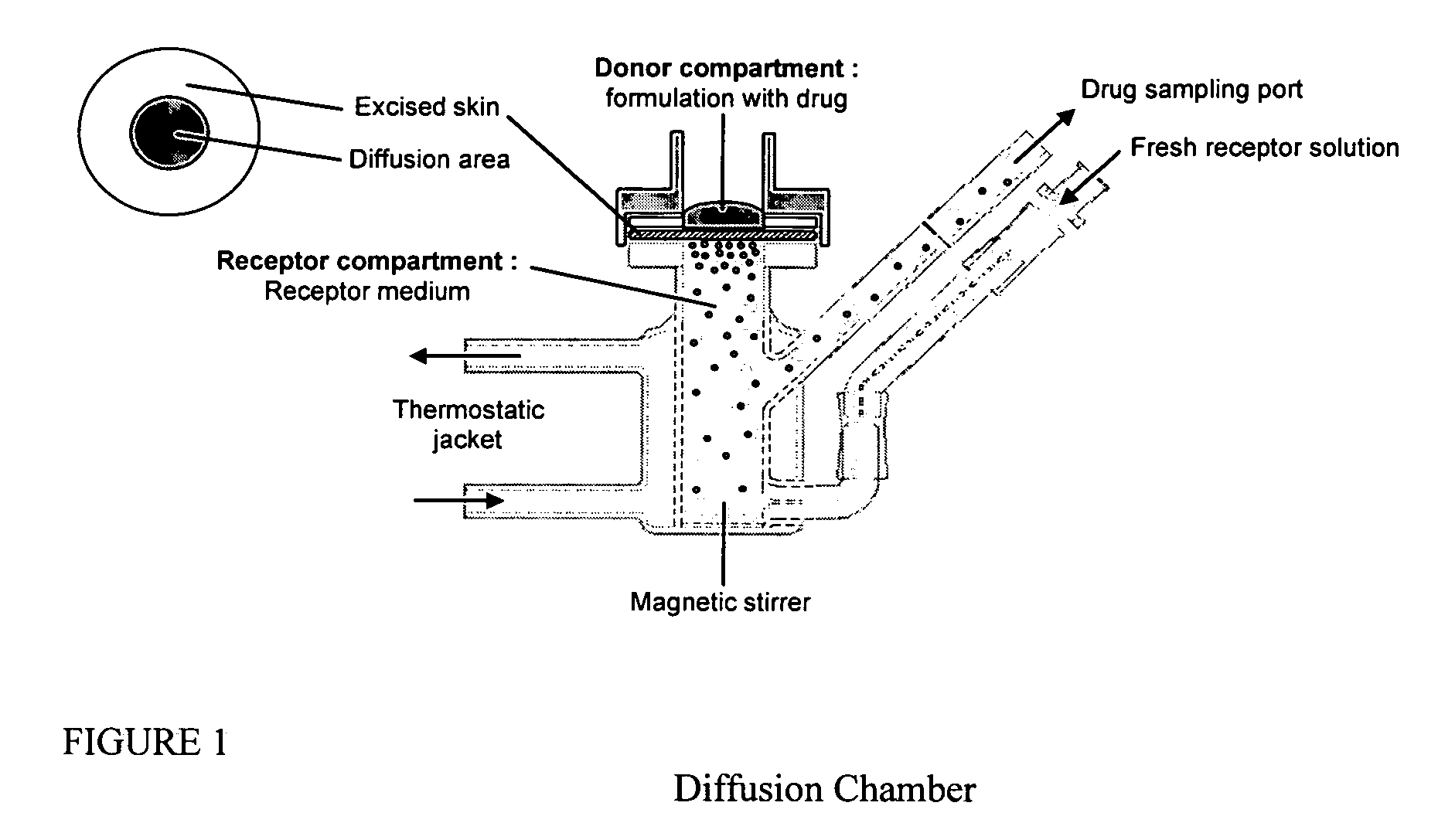

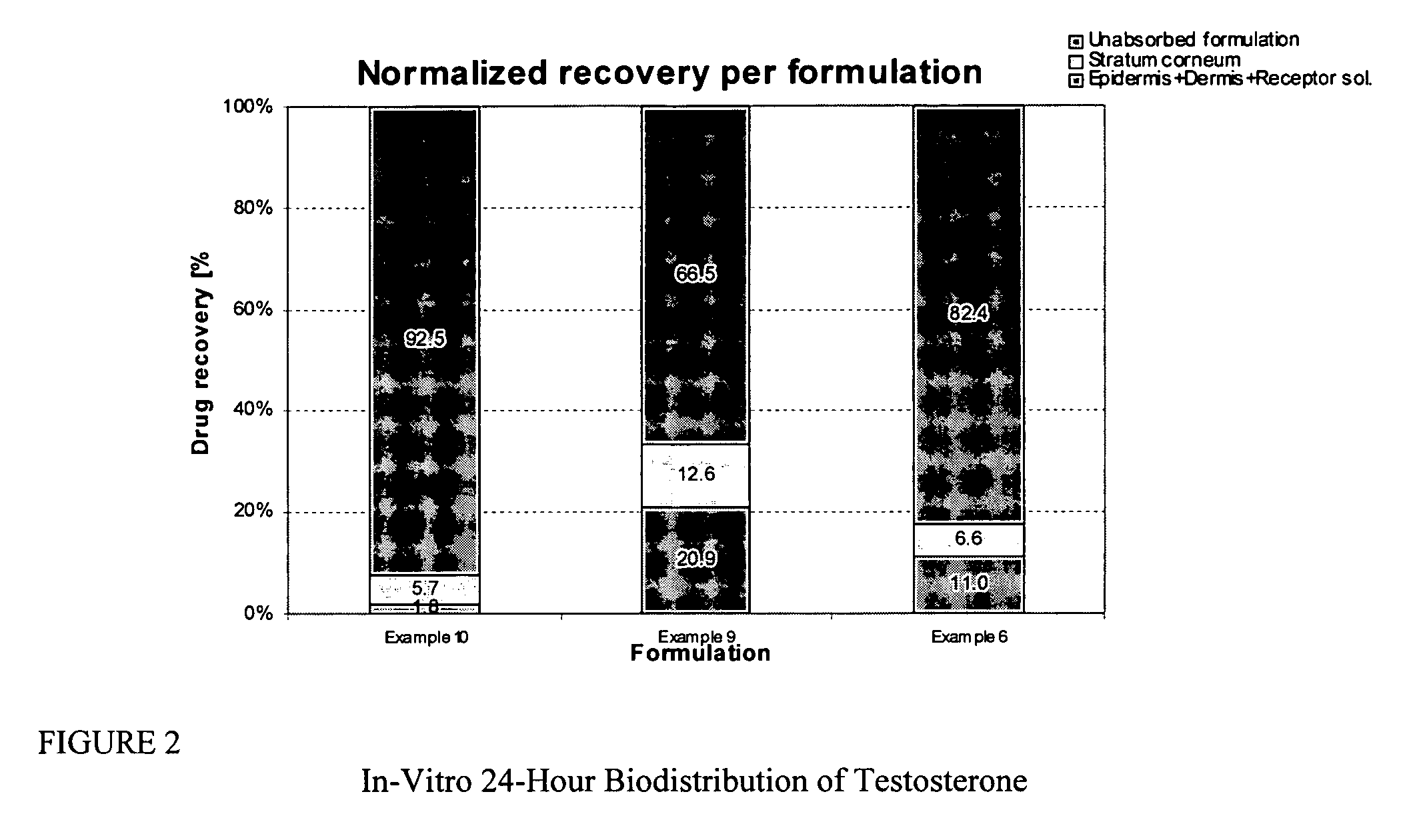

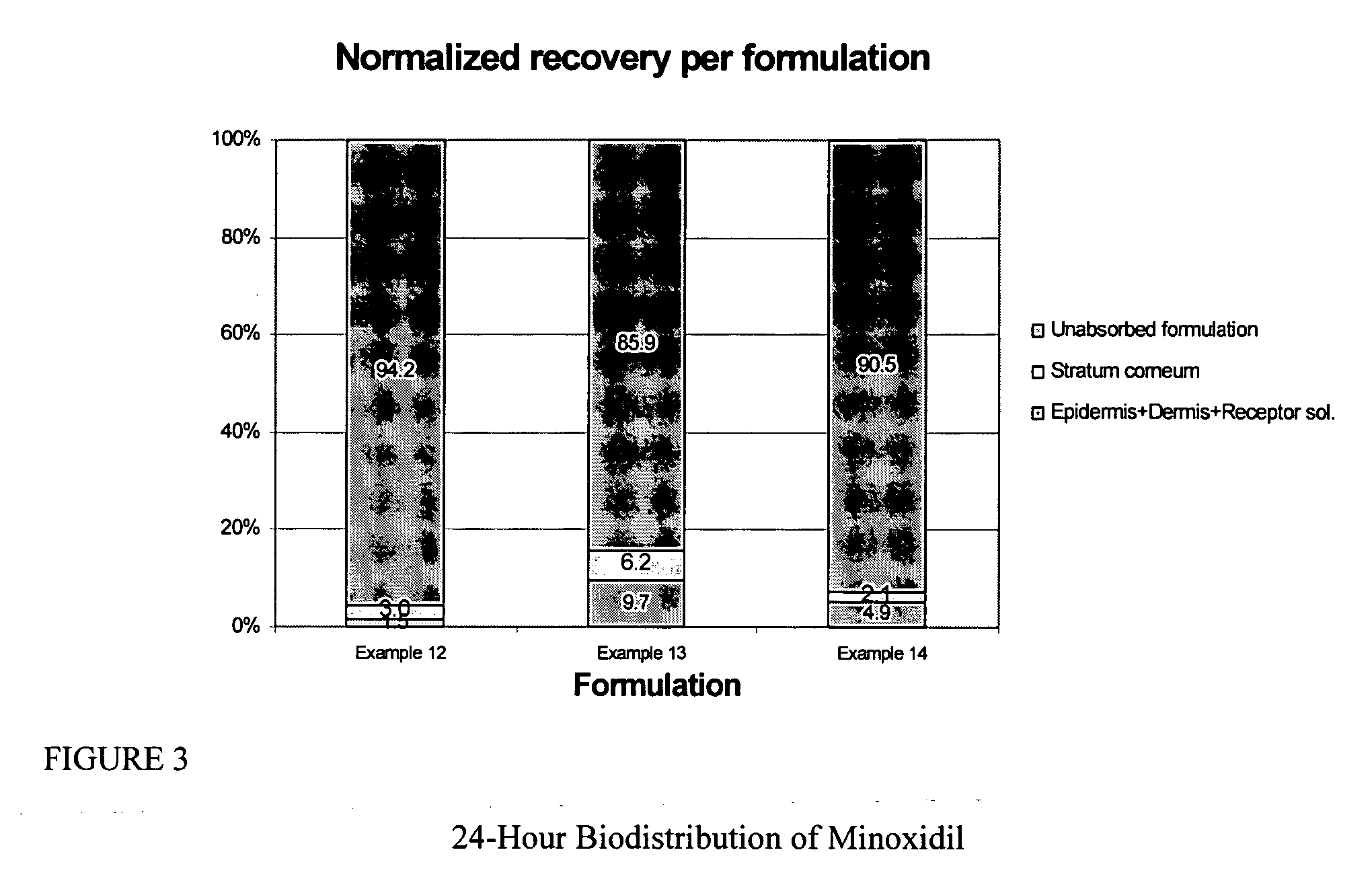

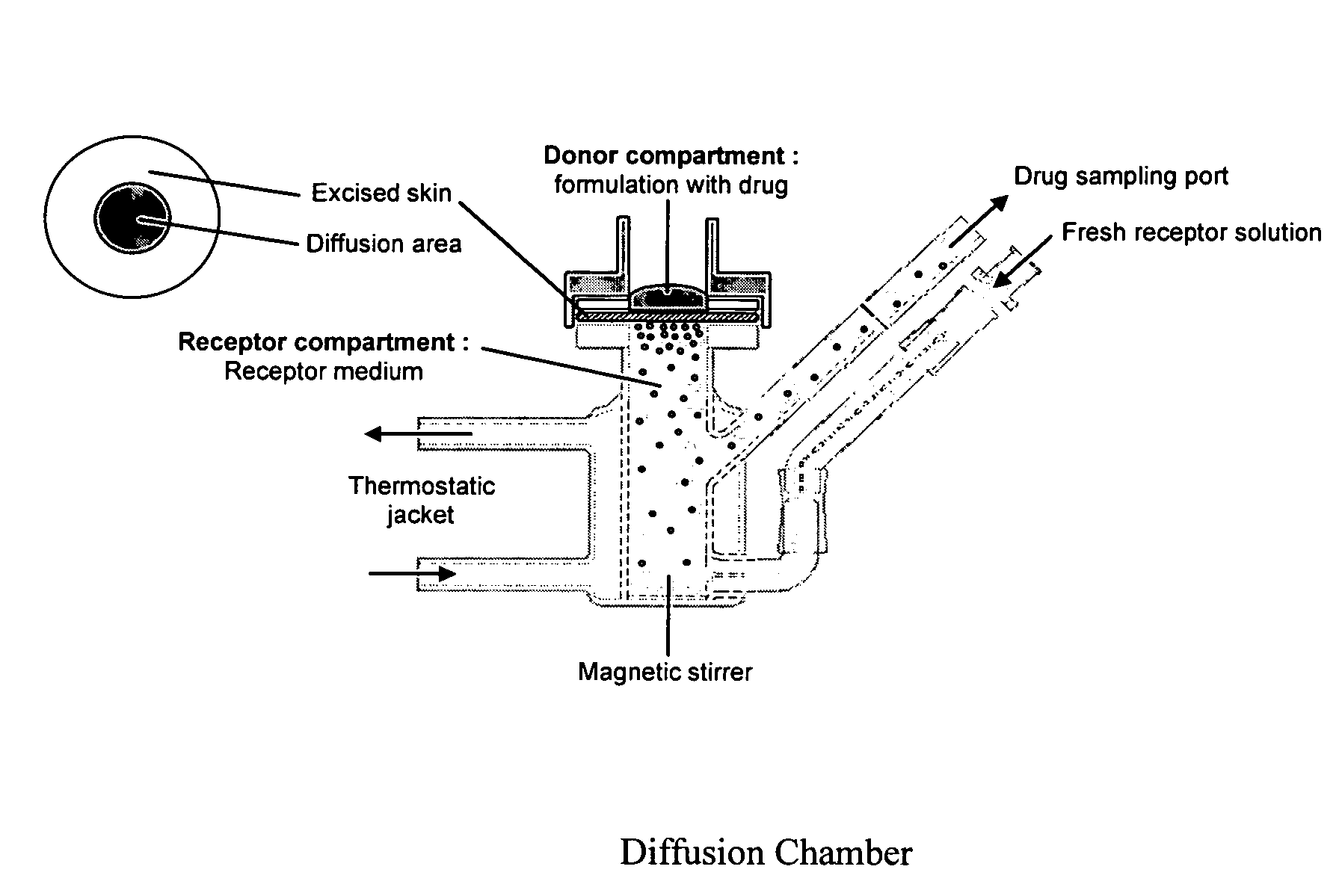

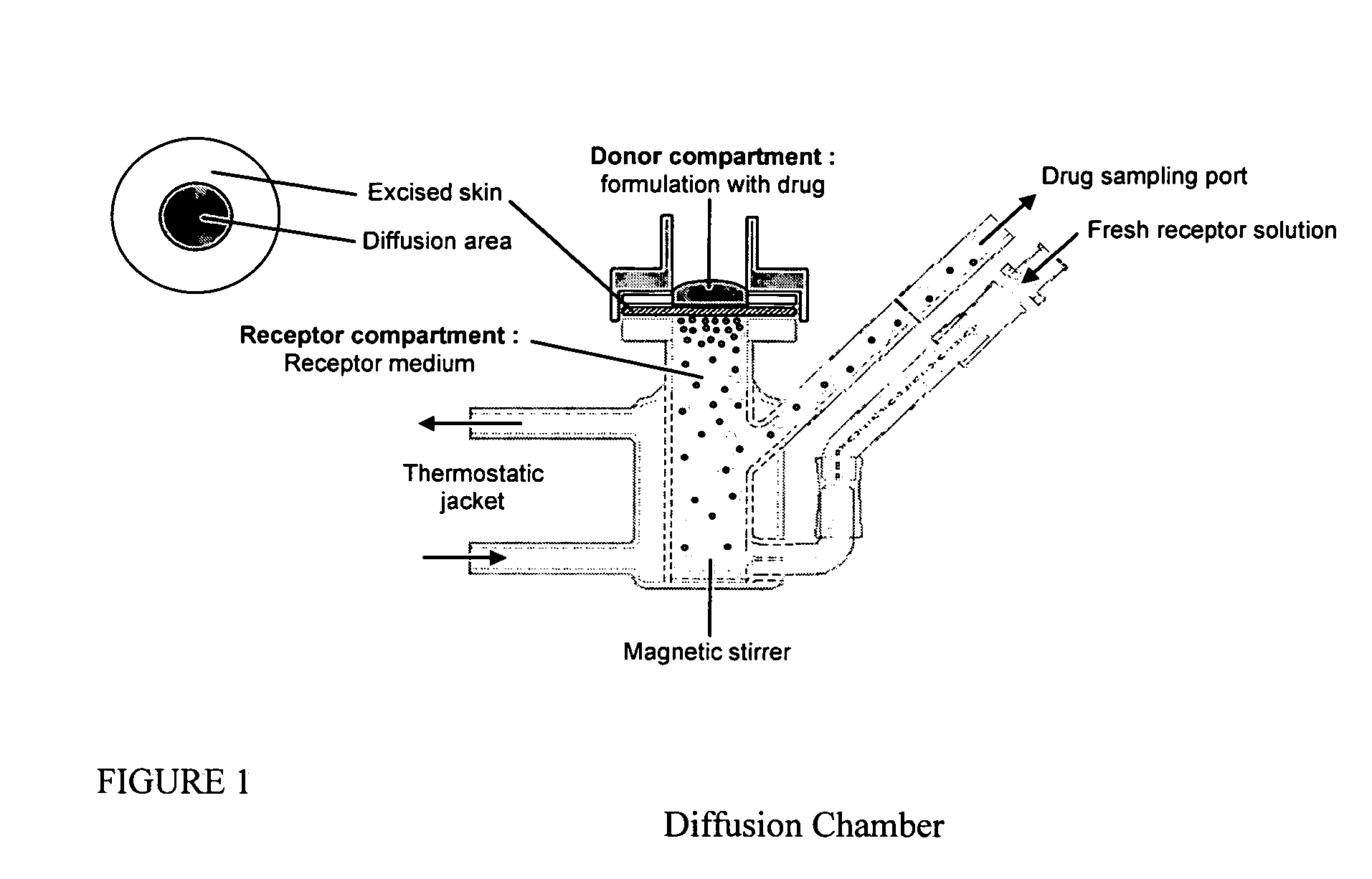

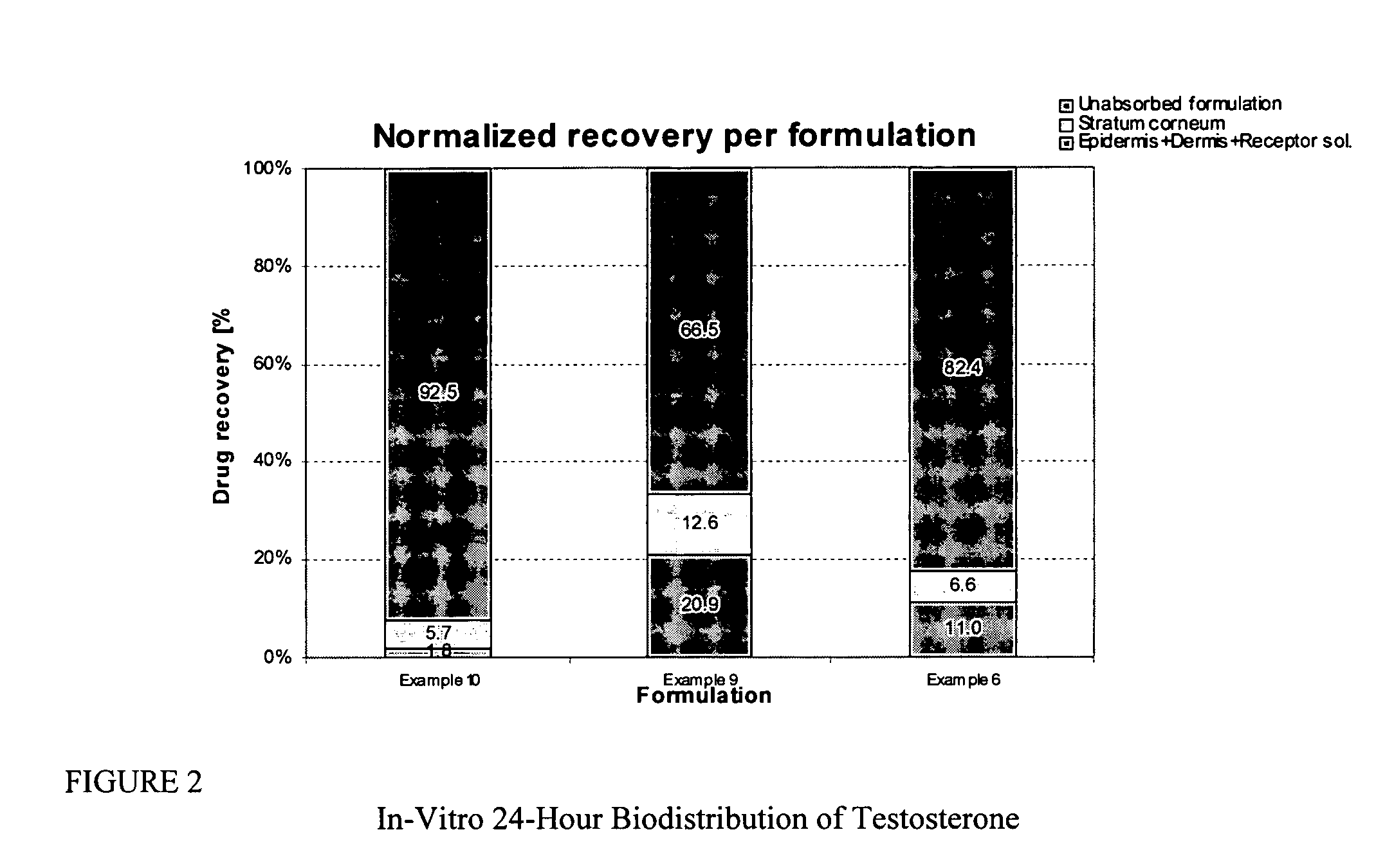

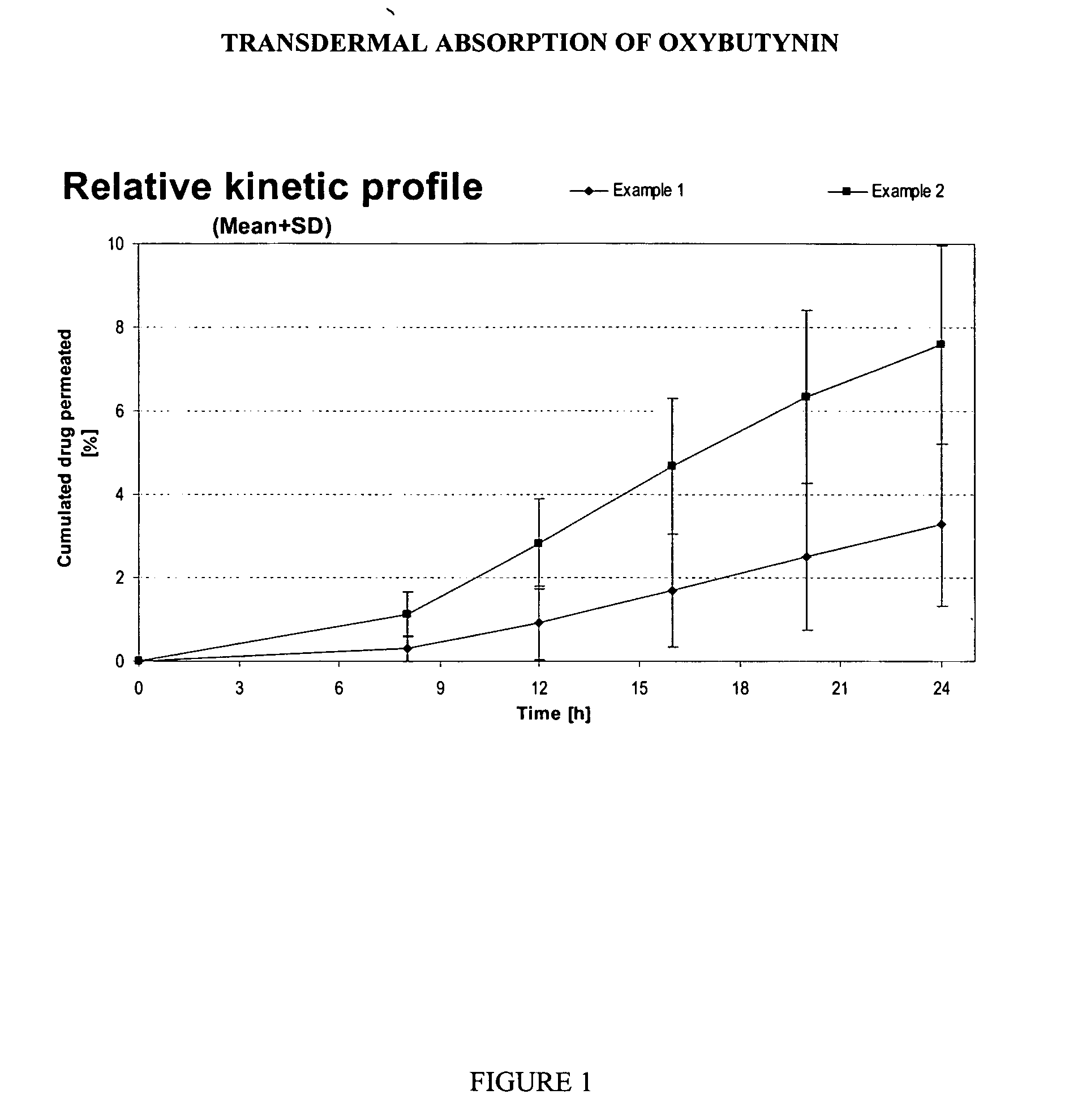

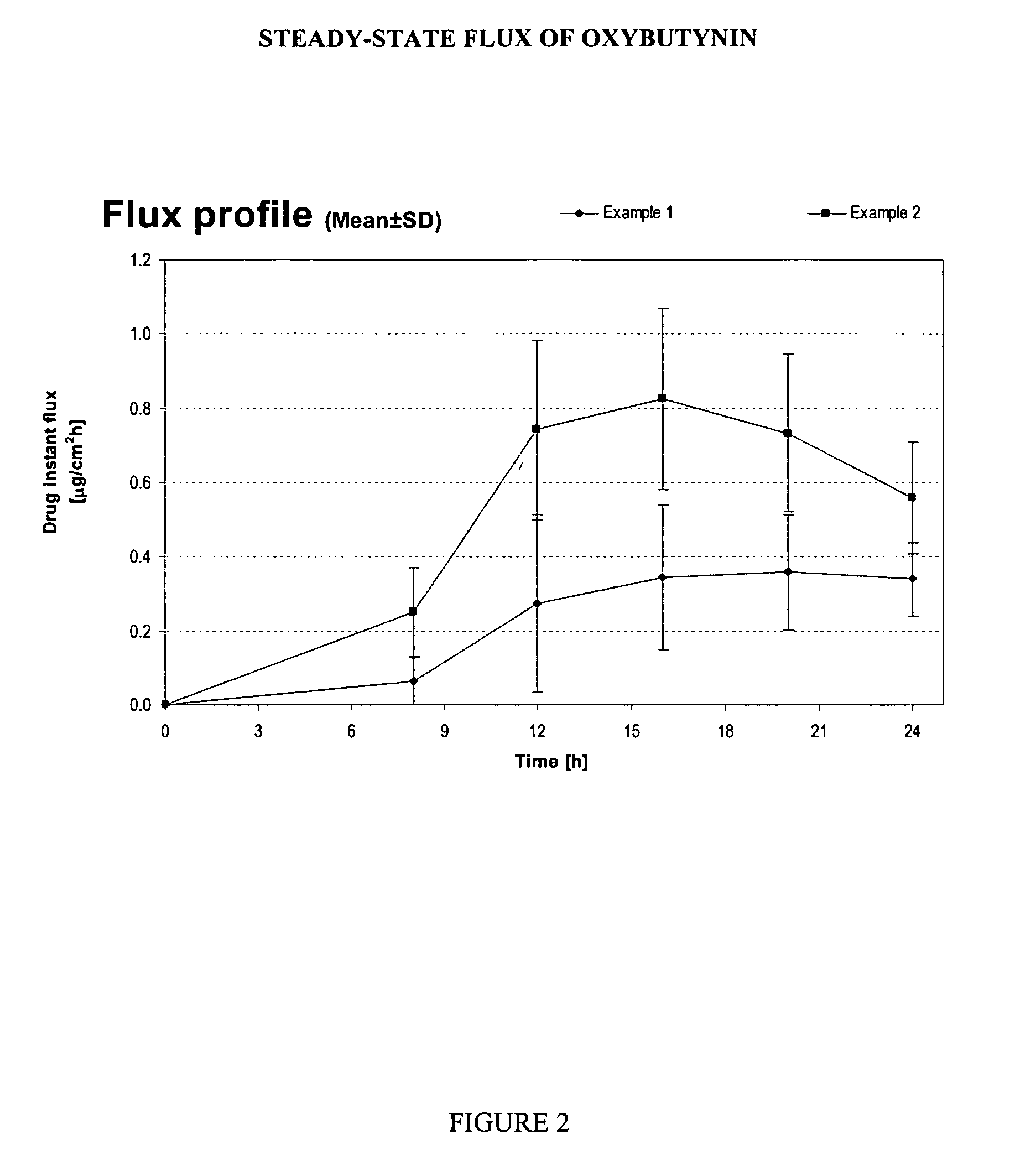

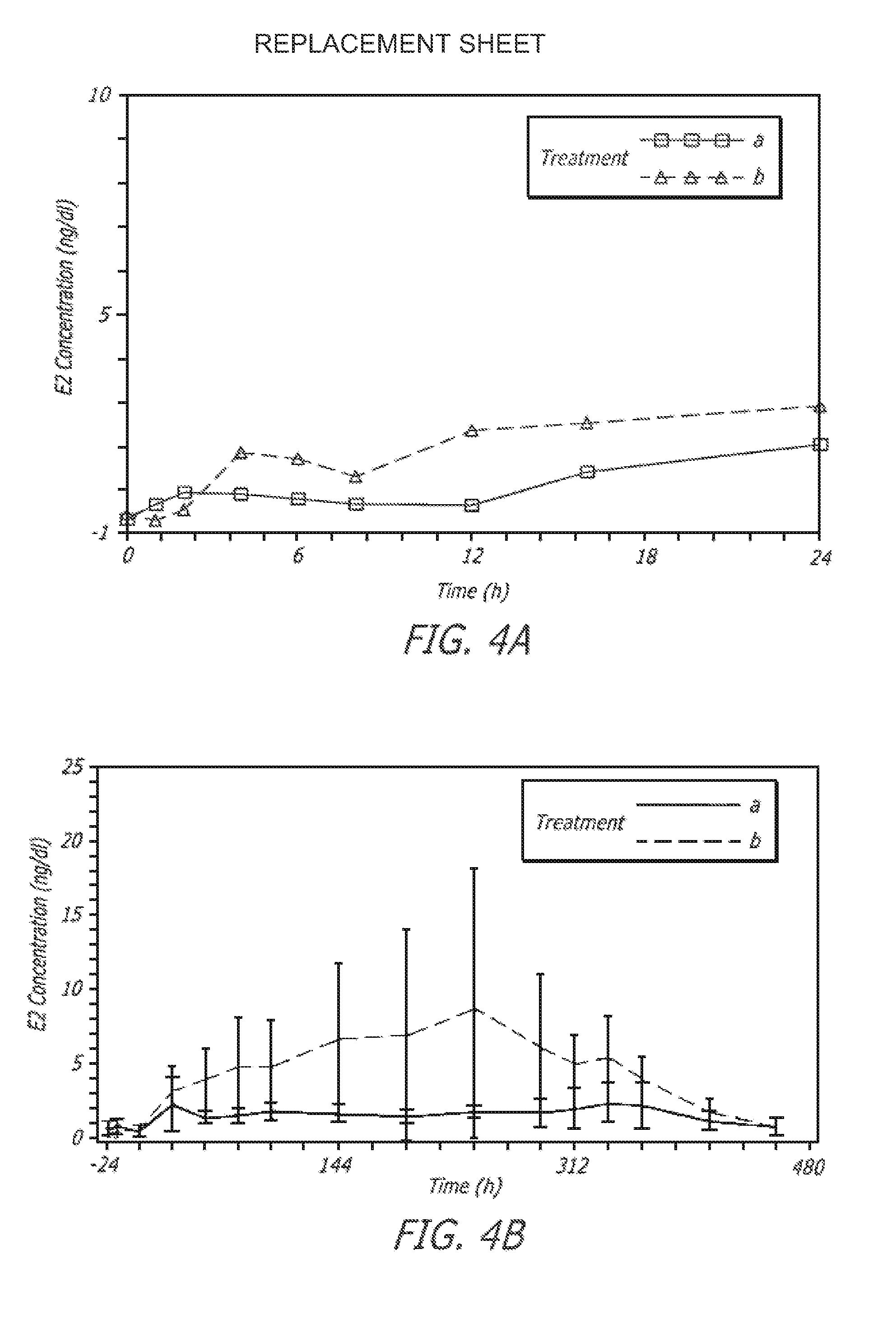

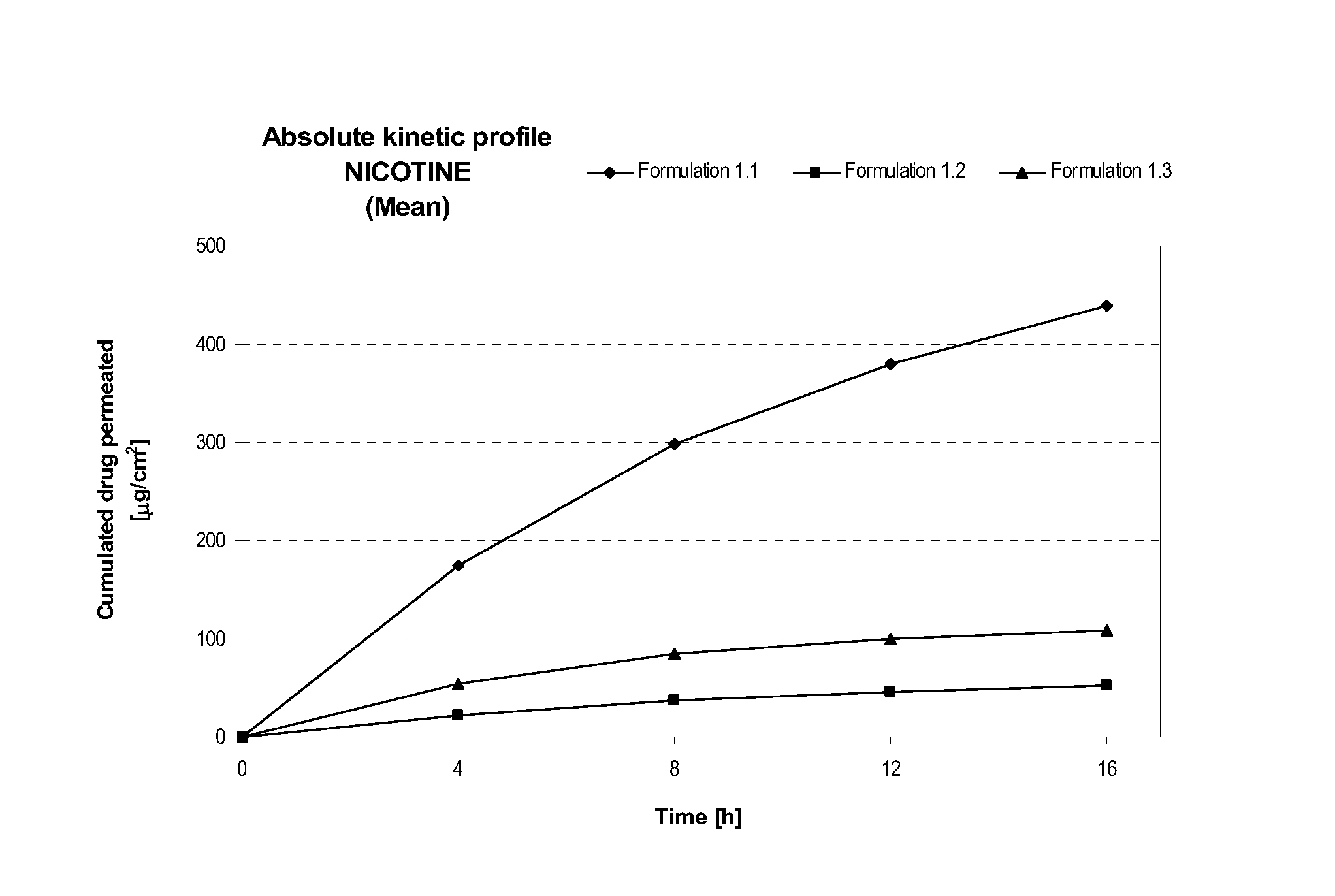

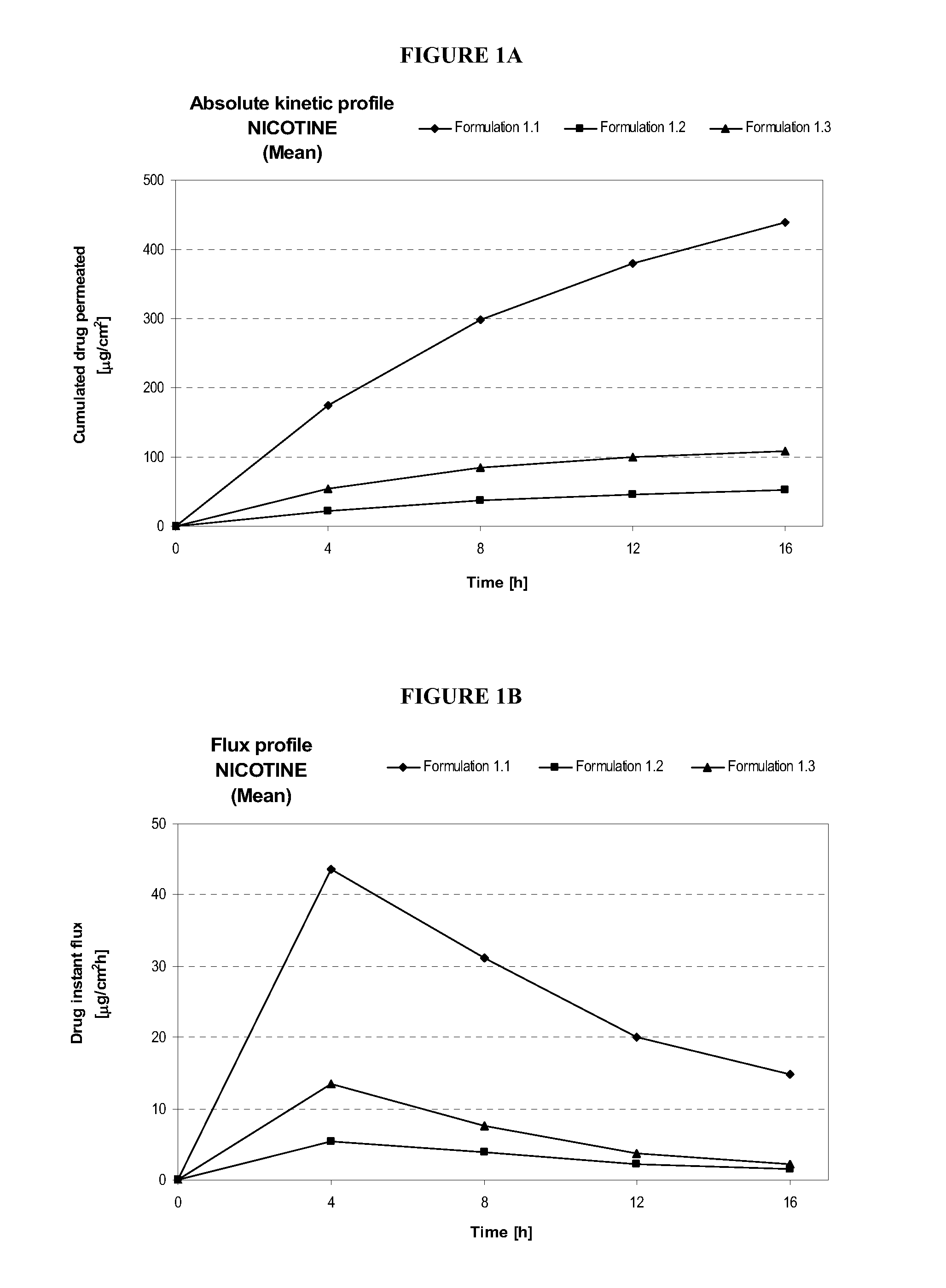

Transdermal pharmaceutical formulation for minimizing skin residues

InactiveUS20060153905A1Reduce transferLoss of therapyOrganic active ingredientsNervous disorderActive agentBULK ACTIVE INGREDIENT

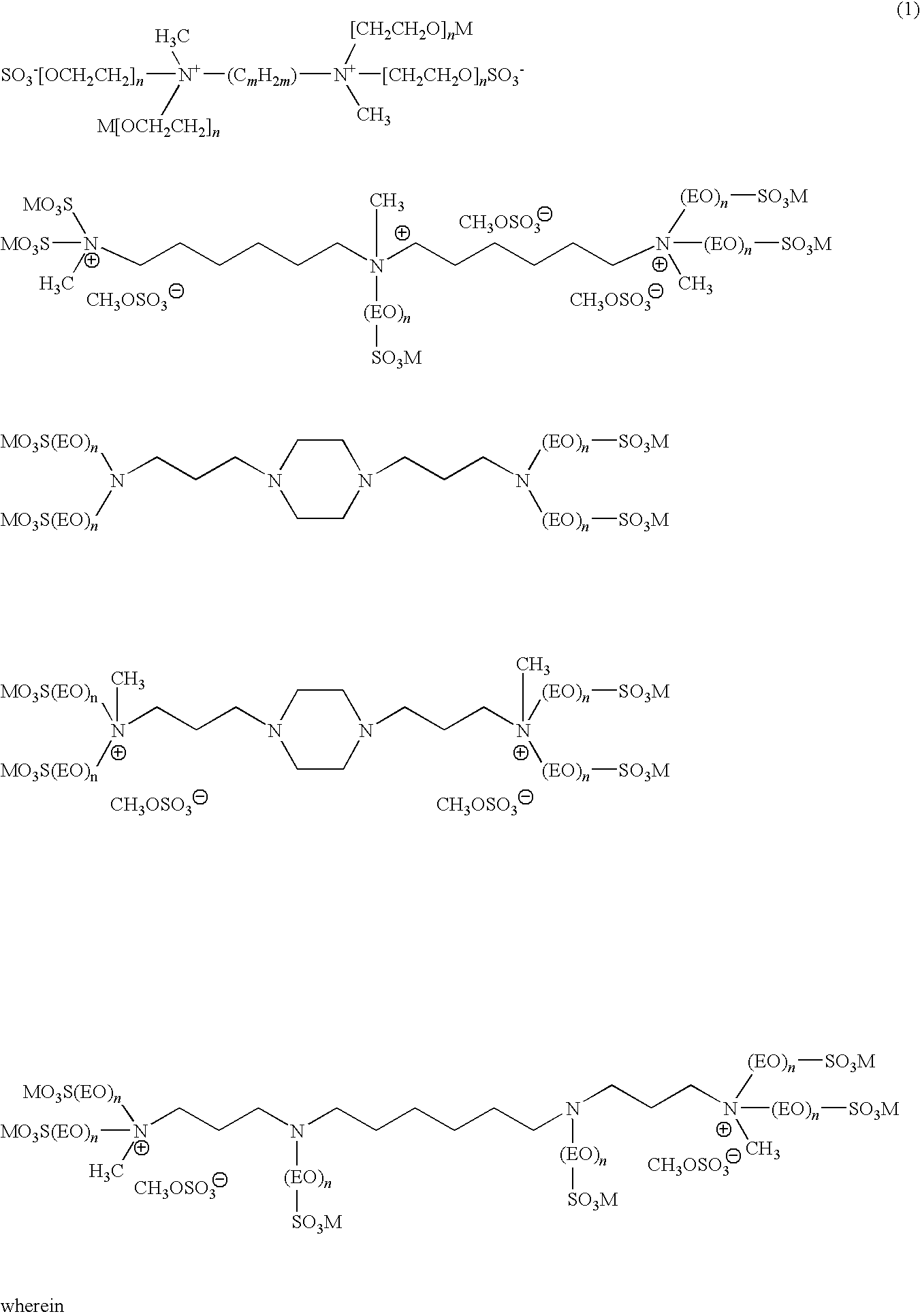

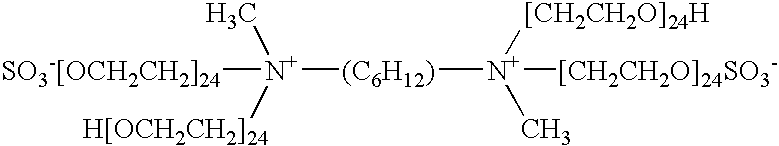

This invention relates to novel transdermal or transmucosal pharmaceutical formulation which reduces the occurrences of contamination of other individuals and the transference to clothing of the user. The novel formulation includes at least one pharmacologically active ingredient, and a solvent system having a monoalkylether of diethylene glycol and a glycol present in specified ratios, and a mixture of water and alcohol. The invention also relates to a method for inhibiting or delaying crystallization of an active agent in a pharmaceutical formulation.

Owner:ANTARES PHARMA IPL

Ink for ink jet recording, ink set for ink jet recording, method for ink jet recording, ink cartridge for ink jet recording, ink jet recording apparatus and recorded article

InactiveUS20030107632A1Excellent ejection stabilityGood storage stabilityMeasurement apparatus componentsInksImaging qualityEngineering

An ink for ink jet recording and an ink jet recording method which realize an image quality of laser printer on a plain paper in a one-pass printing mode under conditions of a volume of an ink droplet ejected being 5 to 43 Pico liter, a velocity of an ink droplet being 6 to 20 m / sec, frequency of 1 kHz and resolution of 300 dpi or more. The ink for ink jet recording is a penetrating type ink which comprises (1) at least one humectant selected from glycerin, 1,3-butandiol, triethyleneglycol, 1,6-hexanediol, propyleneglycol, 1,5-pentanediol, diethyleneglycol, dipropyleneglycol, trimethylolpropane and trimethylolethane, (2) colorant contained in the amount of 6 % by weight or more, (3) a polyol having 8 to 11 carbon atoms and glycolether, and an anionic surfactants or non-ionic surfactants, the ink has viscosity of 5 mPa.s or more at 25° C. and a surface tension of 40 mN / m or less.

Owner:RICOH KK

Transdermal pharmaceutical formulation for minimizing skin residues

InactiveUS7335379B2Reducing and preventing transferMinimize contaminationOrganic active ingredientsNervous disorderAlcoholActive agent

This invention relates to novel transdermal or transmucosal pharmaceutical formulation which reduces the occurrences of contamination of other individuals and the transference to clothing of the user. The novel formulation includes at least one pharmacologically active ingredient, and a solvent system having a monoalkylether of diethylene glycol and a glycol present in specified ratios, and a mixture of water and alcohol. The invention also relates to a method for inhibiting or delaying crystallization of an active agent in a pharmaceutical formulation.

Owner:ANTARES PHARMA IPL

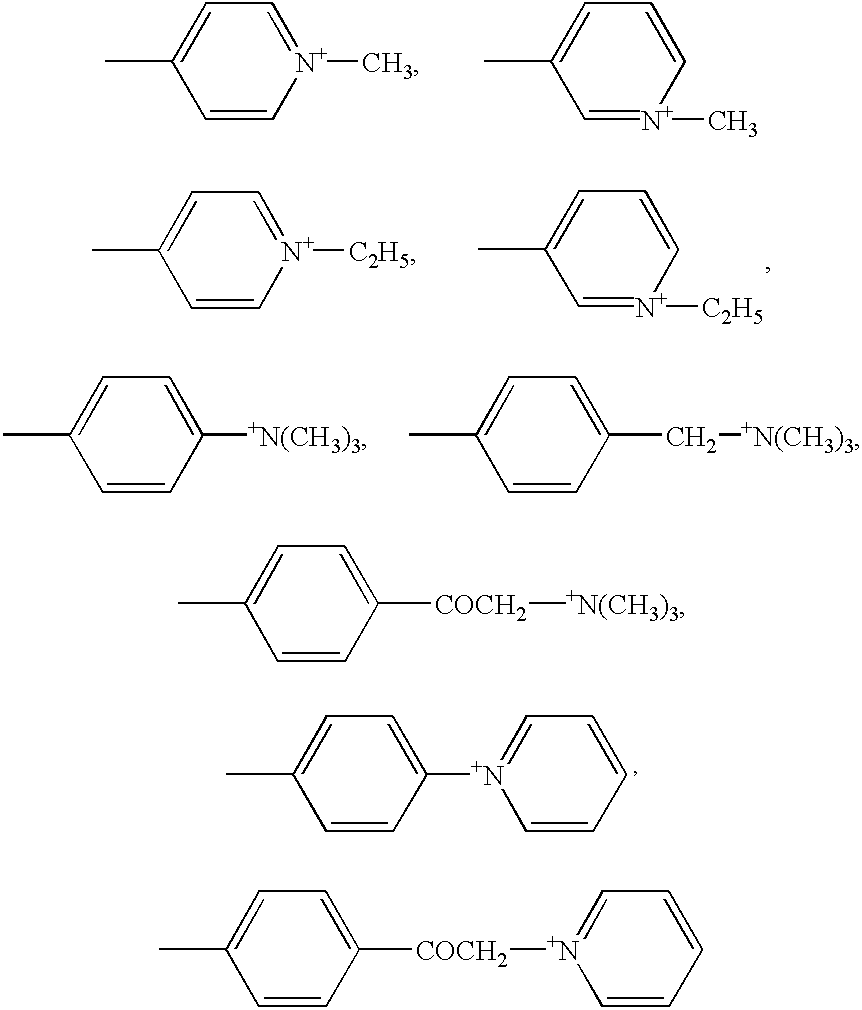

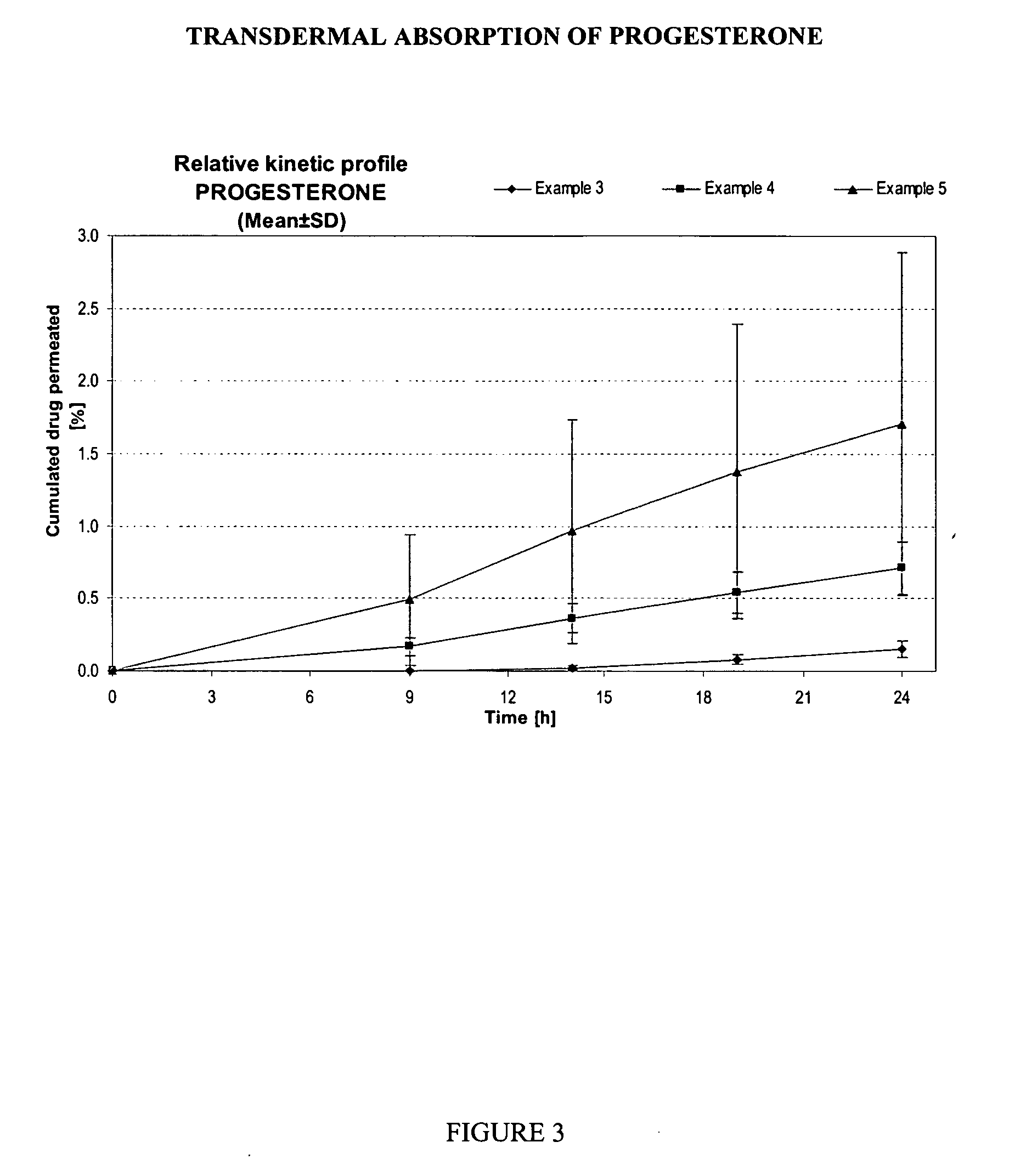

Permeation enhancer comprising genus Curcuma or germacrone for transdermal and topical administration of active agents

InactiveUS20050244522A1Increase permeationImprove permeabilityBiocideOrganic active ingredientsTetraglycolGermacrone

A formulation, method and system for the topical, transdermal or transmucosal administration of a therapeutically effective active agent. Particularly, the invention provides a formulation, system and method for enhancing the permeation or penetration of active agents across the dermal or mucosal surfaces of a mammalian subject. The formulation includes a plant extract of the genus Curcuma of the family Zingiberaceae, a germacrone, or a natural or synthetic constituent thereof, which has been found to increase penetration of the active agent across the dermal or mucosal surface. If desired, a secondary permeation enhancer of a polyalcohol, a monoalkyl ether of diethylene glycol, a tetraglycol, or a mixture thereof can be used for certain active agents for optimal permeation enhancement.

Owner:ANTARES PHARMA IPL

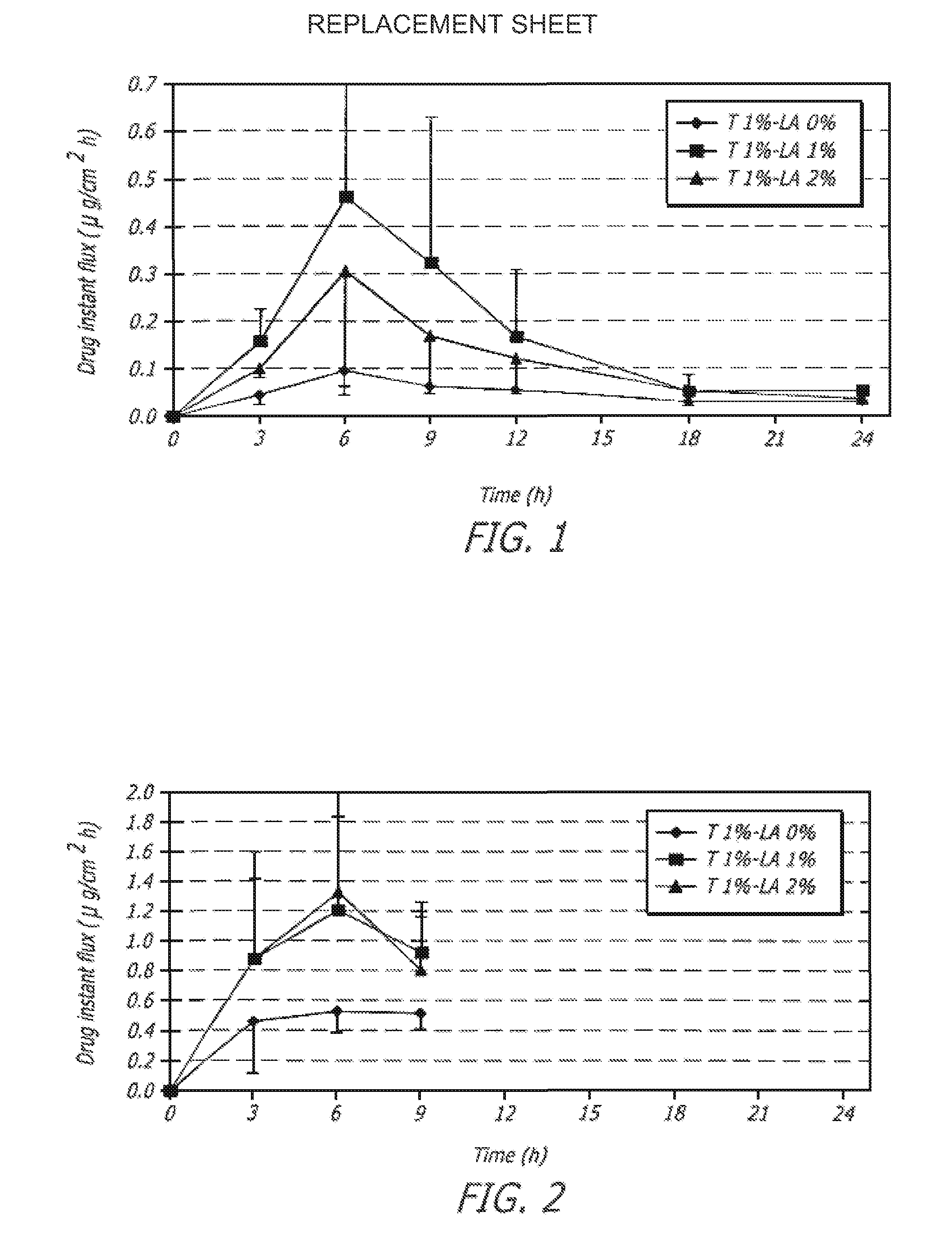

Transdermal delivery systems for active agents

InactiveUS20110195114A1Avoid potential undesirable odor and irritation effectsEasy to useAntibacterial agentsBiocideIrritationPatient compliance

A delivery vehicle for topical pharmaceutical formulations that include a C2 to C4 alkanol, a polyalcohol, and a monoalkyl ether of diethylene glycol present in relative amounts sufficient to provide permeation enhancement of an active agent through mammalian dermal or mucosal surfaces. Preferably, the delivery vehicle as well as the formulations that contain it are substantially free of long-chain fatty alcohols, long-chain fatty acids and long-chain fatty esters in order to avoid potential undesirable odor and irritation effects caused by such compounds during use of the formulation. Without these additives, use of the formulations is facilitated and patient compliance is greater

Owner:ANTARES PHARMA IPL

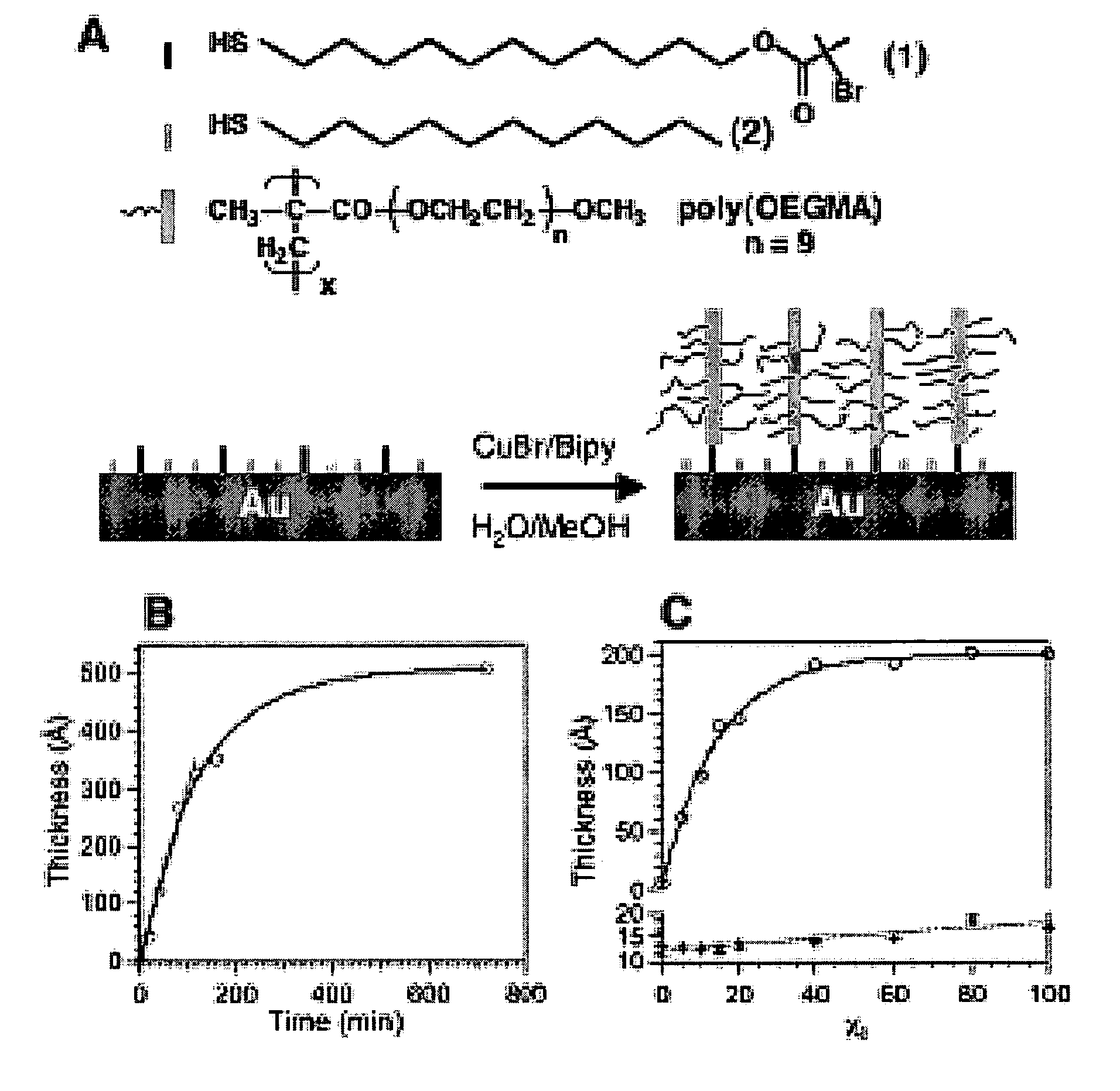

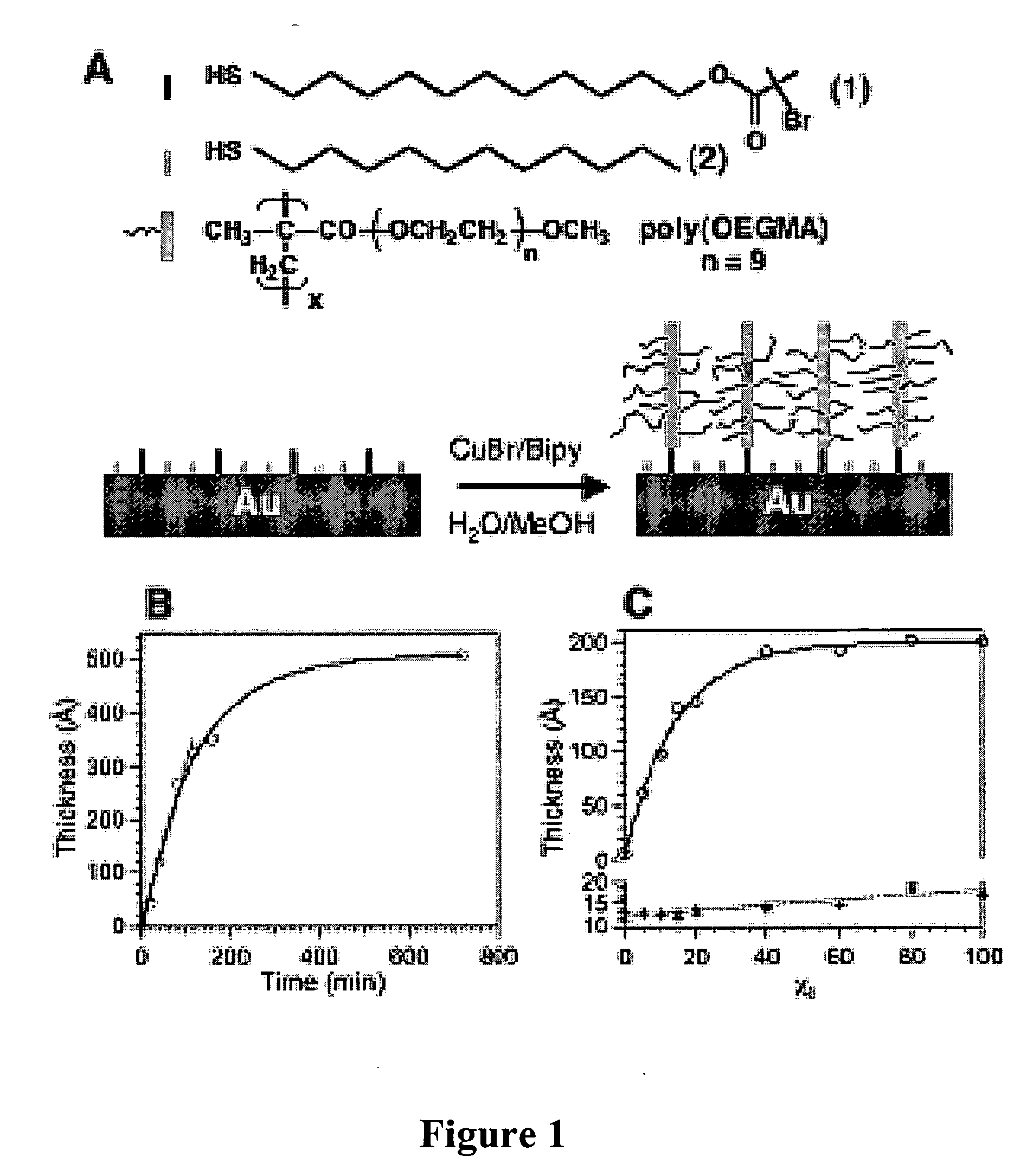

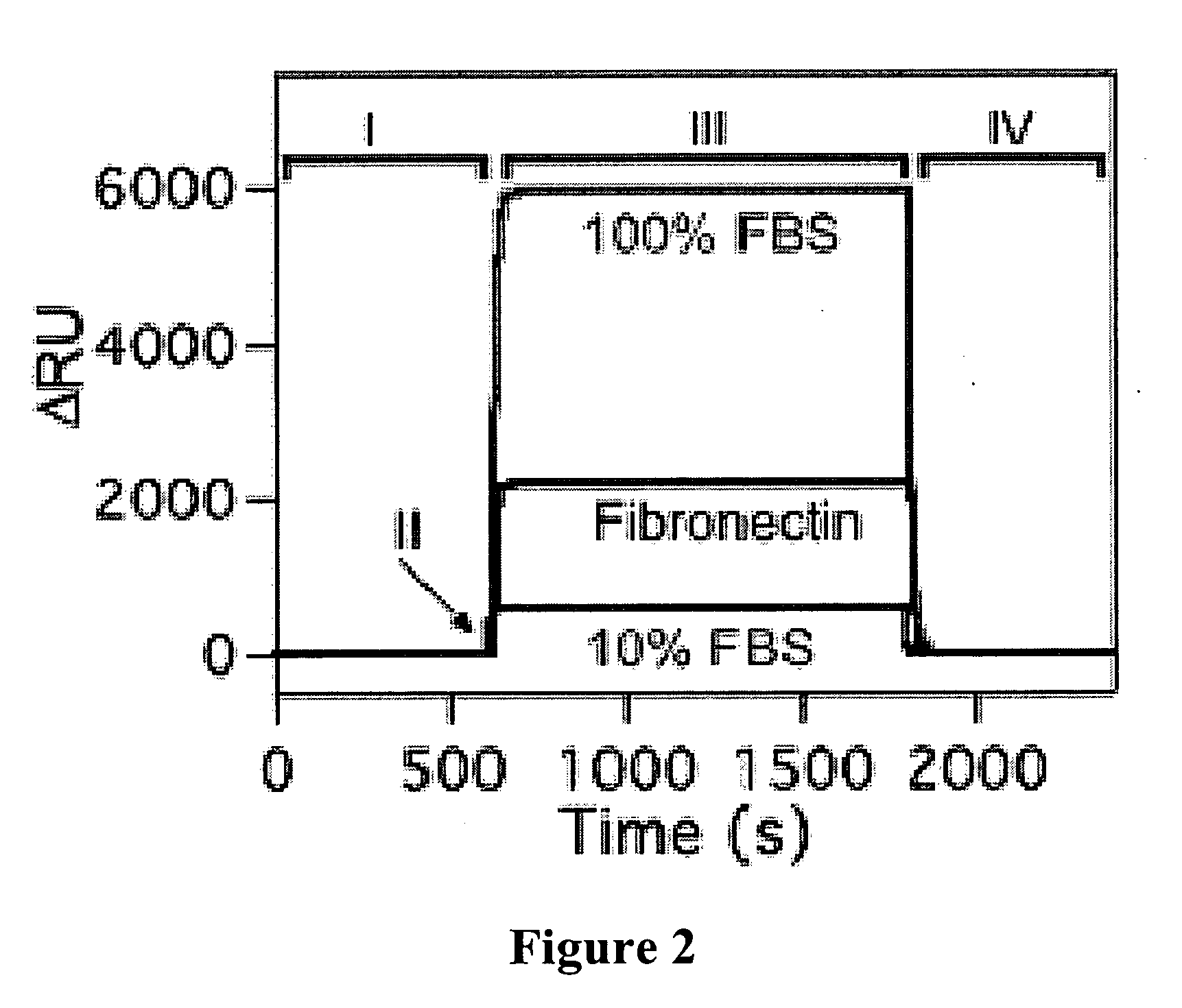

Tunable nonfouling surface of oligoethylene glycol

An article having a nonfouling surface thereon is comprises: (a) a substrate having a surface portion; (b) a linking layer on the surface portion; and (c) a polymer layer formed on the linking layer, preferably by the process of surface-initiated polymerization of monomeric units thereon, with each of the monomeric units comprising a monomer core group having at least one protein-resistant head group coupled thereto, to thereby form a brush molecule on the surface portion. The brush molecule comprising a stem formed from the polymerization of the monomer core groups, and a plurality of branches formed from the hydrophilic head group projecting from the stem. Methods of making and using such articles, are also described.

Owner:DUKE UNIV

Polymeric films

ActiveUS20090312462A1Excellent oxygen barrier propertiesSuitable for usePaper coatingDomestic articlesMolten statePolymer science

A polymer composition and its use for thin film packaging applications including on a dry basis: a) from 45 to 90% by weight of starch; b) from 0.1 to 15% by weight of a water soluble polymer selected from polyvinyl alcohol, polyvinylacetate, and copolymers of ethylene and vinyl alcohol which have a melting point compatible with the molten state of the starch component; and c) from 5 to 45% by weight of one or more plasticizers having a molecular weight in the range of 50-6000, more preferably 50-2500 and more preferably still 100-400 and desirably selected from the group consisting of sorbitol, glycerol, maltitol, xylitol, mannitol, erythritol, glycerol trioleate, tributyl citrate, acetyl tri-ethyl citrate, glyceryl triacetate, 2,2,4-trimethyl-1,3-pentanediol diisobutyrate, polyethylene oxide, ethylene glycol, diethylene glycol or polyethylene glycol.

Owner:PLANTIC TECH

Oily ink composition for ink-jet recording, and ink-jet recording method

InactiveUS7156909B2Quality improvementHigh glossMeasurement apparatus componentsDuplicating/marking methodsOrganic solventDiethylene glycol

An oil based ink composition for ink jet recording containing, as an organic solvent, a mixture of a diethylene glycol compound that is liquid at ordinary temperature under atmospheric pressure and a dipropylene glycol compound that is liquid at ordinary temperature under atmospheric pressure at a diethylene glycol compound to dipropylene glycol compound weight ratio of 20:80 to 80:20, and an ink jet recording method using the oil based ink composition are disclosed. The oil based ink composition for ink jet recording provides high quality images with high gloss, excellent abrasion resistance and water resistance, and freedom from blur or bleeding.

Owner:THE INCTEC INC +1

Topical skin care formulations

InactiveUS20110044920A1Improve visual appearanceExtended maintenance periodCosmetic preparationsBiocideCaprylyl GlycolStearic acid

Disclosed is a topical skin care composition that includes water, silymarin, hydrolyzed algin, palmitoyl tripeptide 8, ceramide 2, pomegranate extract comprising pomegranate sterols, glycerin, disodium EDTA, caprylic / capric triglyceride, shea butter, C12-15 alcohols benzoate, dimethicone, glyceryl stearate and PEG 100 stearate, cetyl alcohol, stearyl alcohol, stearic acid, butylene glycol, caprylyl glycol, and (s) a mixture of acrylamide / sodium acryloyldimethyl taurate copolymer, isohexadecane, and polysorbate 80.

Owner:MARY KAY INC

Materials composites of a moulded article of transparent or translucent dyeable plastics moulding compounds

InactiveUS20070128442A1Large flow lengthPerfect purityLayered productsThin material handlingPolymer scienceStearic acid

The present invention relates to materials composites of a moulded article of at least one transparent or translucent dyeable plastics moulding compound which moulded article is bonded to at least one transparent or translucent surface layer and / or to decorative films, functional films or coats or rubbers or other plastics, wherein the plastics moulding compound used for the manufacture of the moulded article, the surface layer or the other plastics contains in an amount of 0.01 to 5.0% by weight, preferably 0.01 to 2.0% by weight, each related to the total weight of the moulding compound, at least one lubricant selected from the group consisting of sorbitan esters, sebacic acid esters, dodecanedioic acid esters, docosanoic acid esters, glycerine, glycol, diethylene glycol, stearoyl amide, stearyl stearate, ethylene bissteroyl amide, octane pyrrolidone, and from the group consisting of non-polar paraffin oils and of tetracosanes, and wherein a permanent adhesion to the other plastics layers and / or sheets or coats or rubbers or other plastics is achieved.

Owner:EMS CHEM AG

Conductive composition, conductive film, and process for the formation of the film

ActiveUS20050116203A1Conductive materialNon-conductive material with dispersed conductive materialParticulatesSilver carbonate

A conductive composition capable of producing a conductive paint with excellent flexibility and a high conductivity comparable to that of metallic silver, without using high temperatures as film forming conditions. The conductive composition includes a particulate silver compound and a binder, and optionally a reducing agent and a binder. Silver oxide, silver carbonate and silver acetate and the like are used as the particulate silver compound. Ethylene glycol, diethylene glycol, and ethylene glycol diacetate and the like are used as the reducing agent, and a fine powder of a thermosetting resin such as a polyvalent phenol compound, phenol resin, alkyd resin or polyester resin, or a thermoplastic resin such as a styrene resin or polyethylene terephthalate, with an average particle diameter from 20 nm to 5 μm is used as the binder. Furthermore, the average particle diameter of the particulate silver compound is preferably from 0.01 to 10 μm.

Owner:THE FUJIKURA CABLE WORKS LTD +1

Ink jet black ink, ink set, ink jet recording method, ink cartridge, recording unit, and ink jet recording apparatus

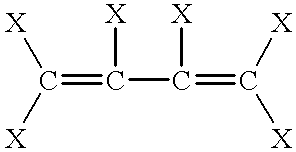

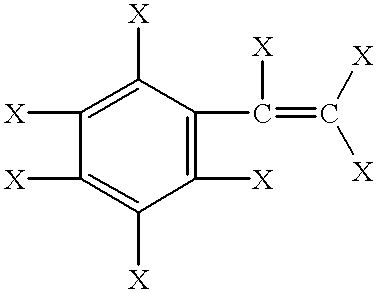

InactiveUS7247196B2Good colorHigh dye concentrationMeasurement apparatus componentsDuplicating/marking methodsDecompositionDiethylene glycol

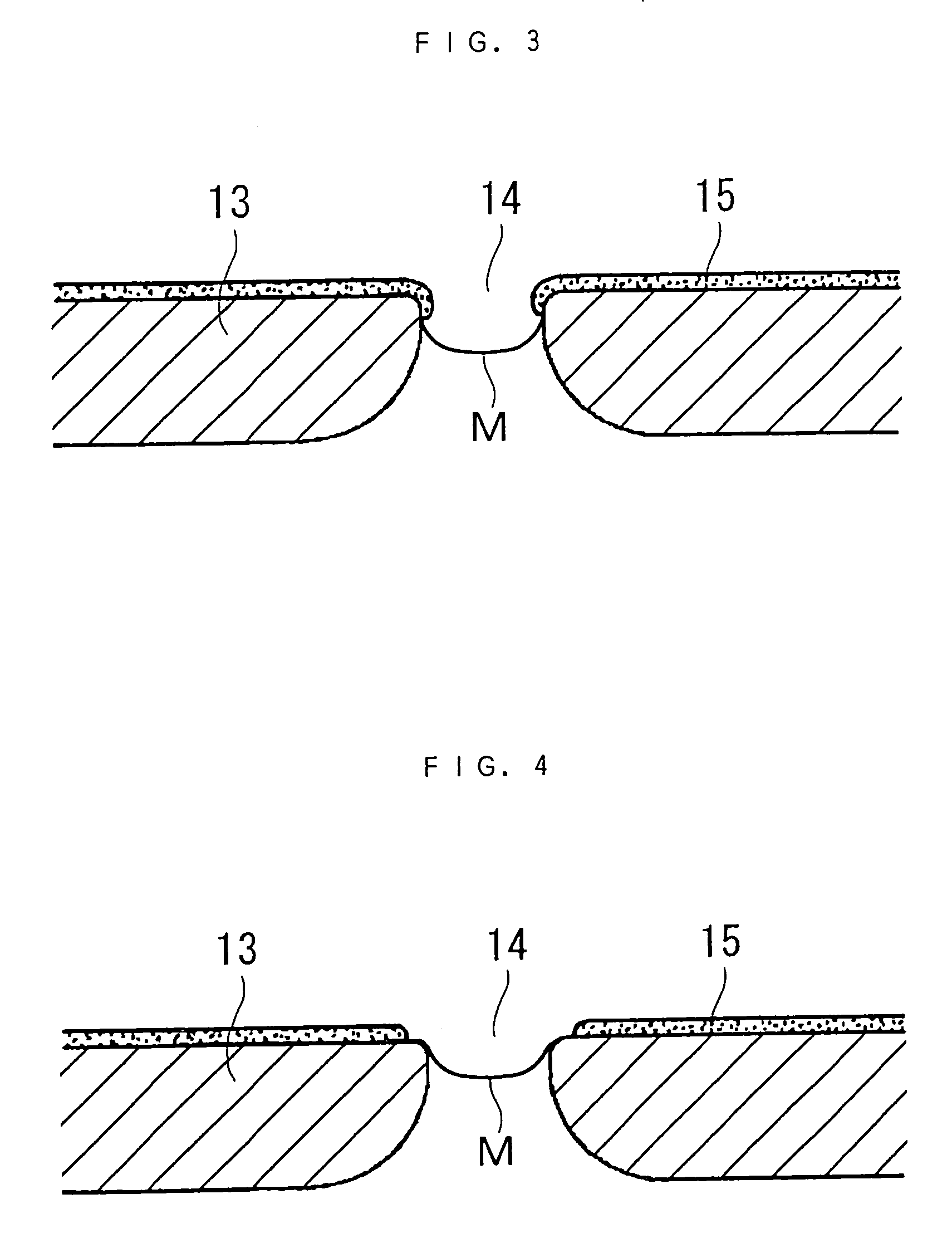

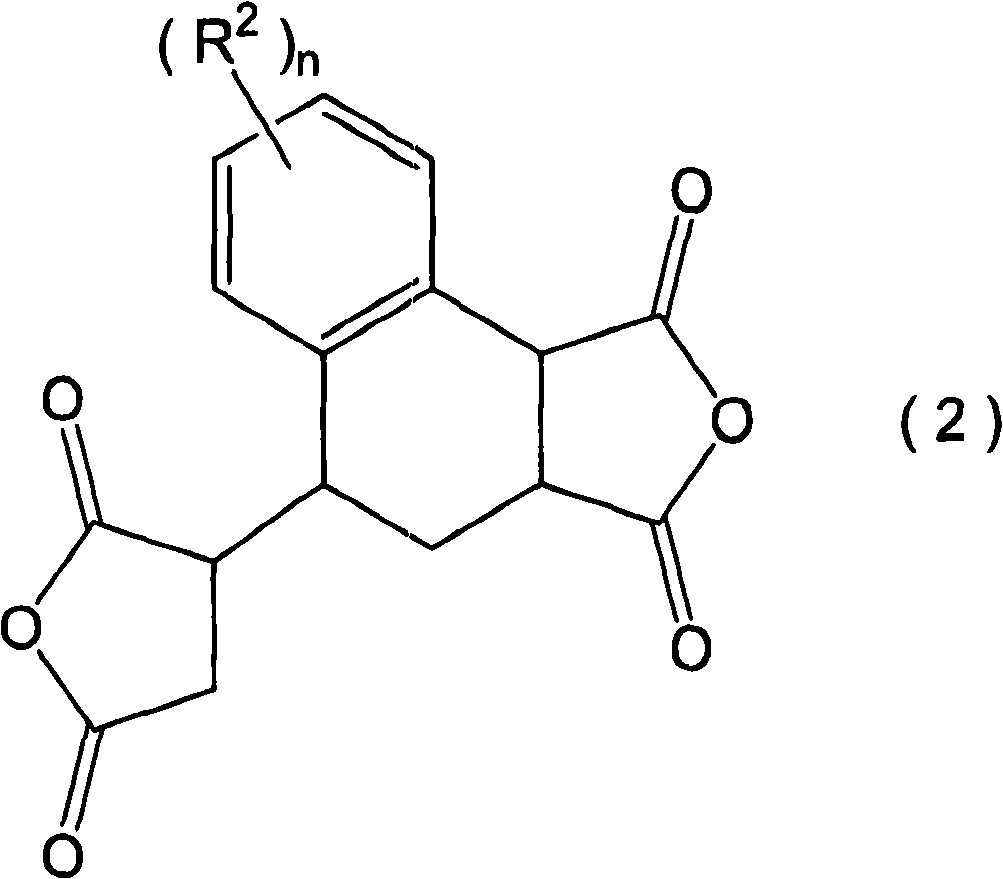

To provide an ink jet black ink which has a favorable tint for ink jet black ink, provides high ozone fastness, a high image density, and high sticking recovery property, and is capable of suppressing the decomposition of a compound represented by the following general formula (I) or a salt thereof at the time of storage for a long time period. The ink jet black ink is an ink jet black ink comprising at least a compound represented by the following general formula (I) or a salt thereof as a coloring material, and ethylene glycol or diethylene glycol, wherein the content of ethylene glycol or diethylene glycol is 15 mass % or more and 30 mass % or less with respect to the total mass of the ink jet black ink.General formula (I)

Owner:CANON KK

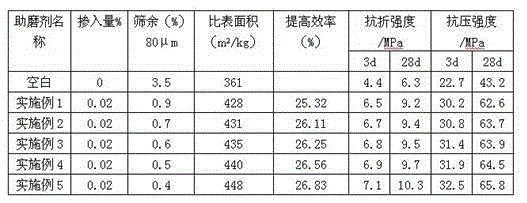

Silicate cement grinding aid and preparation method thereof

The invention discloses a silicate cement grinding aid and a preparation method thereof. The silicate cement grinding aid is prepared from the following main raw materials by weight: 3-6 parts of sodium hexametaphosphate, 2-5 parts of aluminum sulfate, 5-8 parts of tetra sodium salt of amino trimethylene phosphonic acid (ATMP.Na4), 4-6 parts of ethylene diamine tetra (methylene phosphonic acid) sodium, 38-45 parts of polymeric alkylol amine, 34-42 parts of triisopropanolamine, 8-12 parts of waste engine oil, 2-5 parts of sodium alpha-olefin sulfonate, 10-16 parts of sorbitol, 15-20 parts of diethylene glycol, 8-13 parts of polypropylene wax, 6-10 parts of oxidized polyethlene wax, 4-8 parts of lignite wax, 20-30 parts of odium thiosulfate, 12-18 parts of sodium thiosulfate and 15-20 parts of quicklime powder. The prepared silicate cement grinding aid has the advantages that the quality is stable, the effect is remarkable, the adding amount is small, the use is simple, and the adding is more convenient and reliable to control.

Owner:王金奎

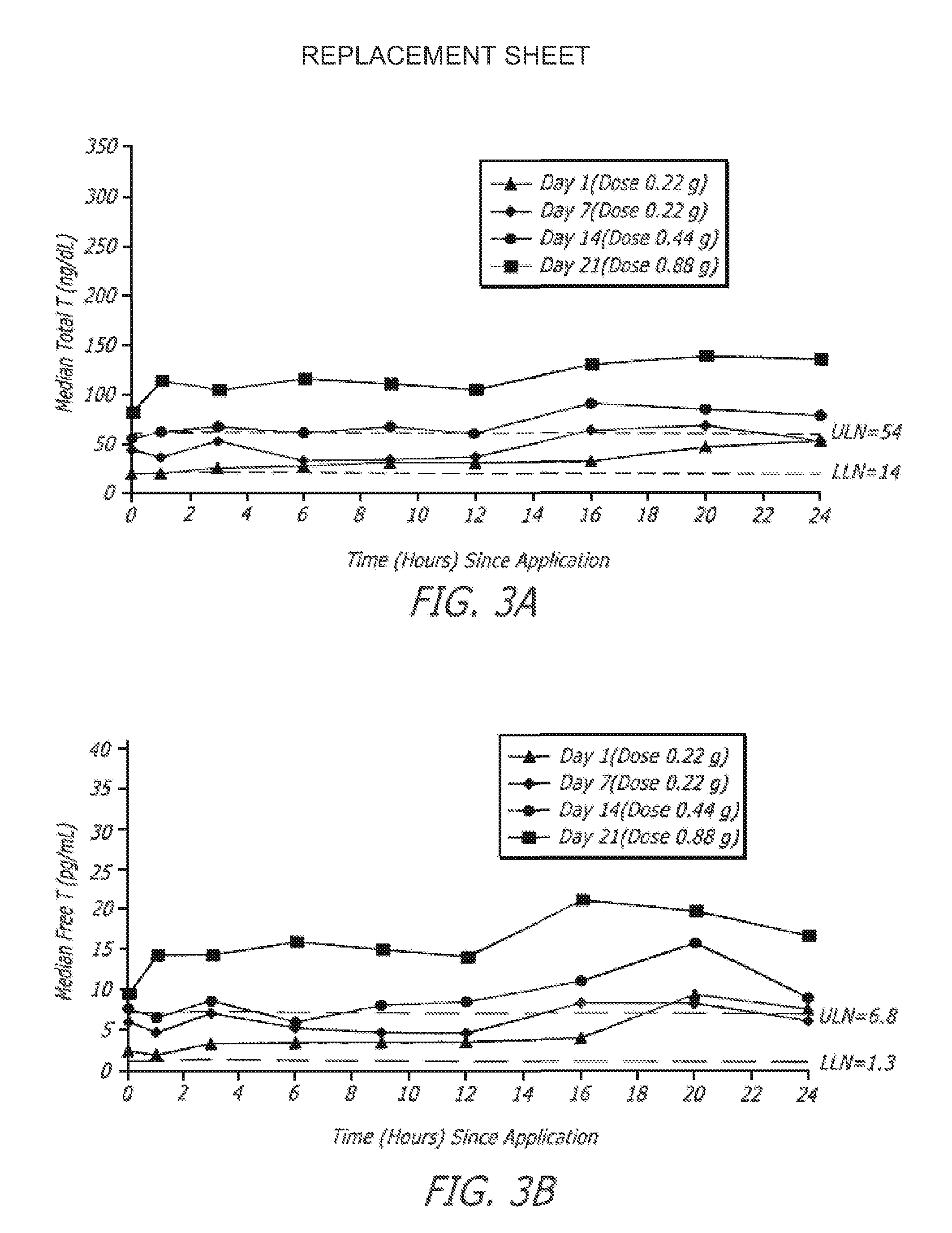

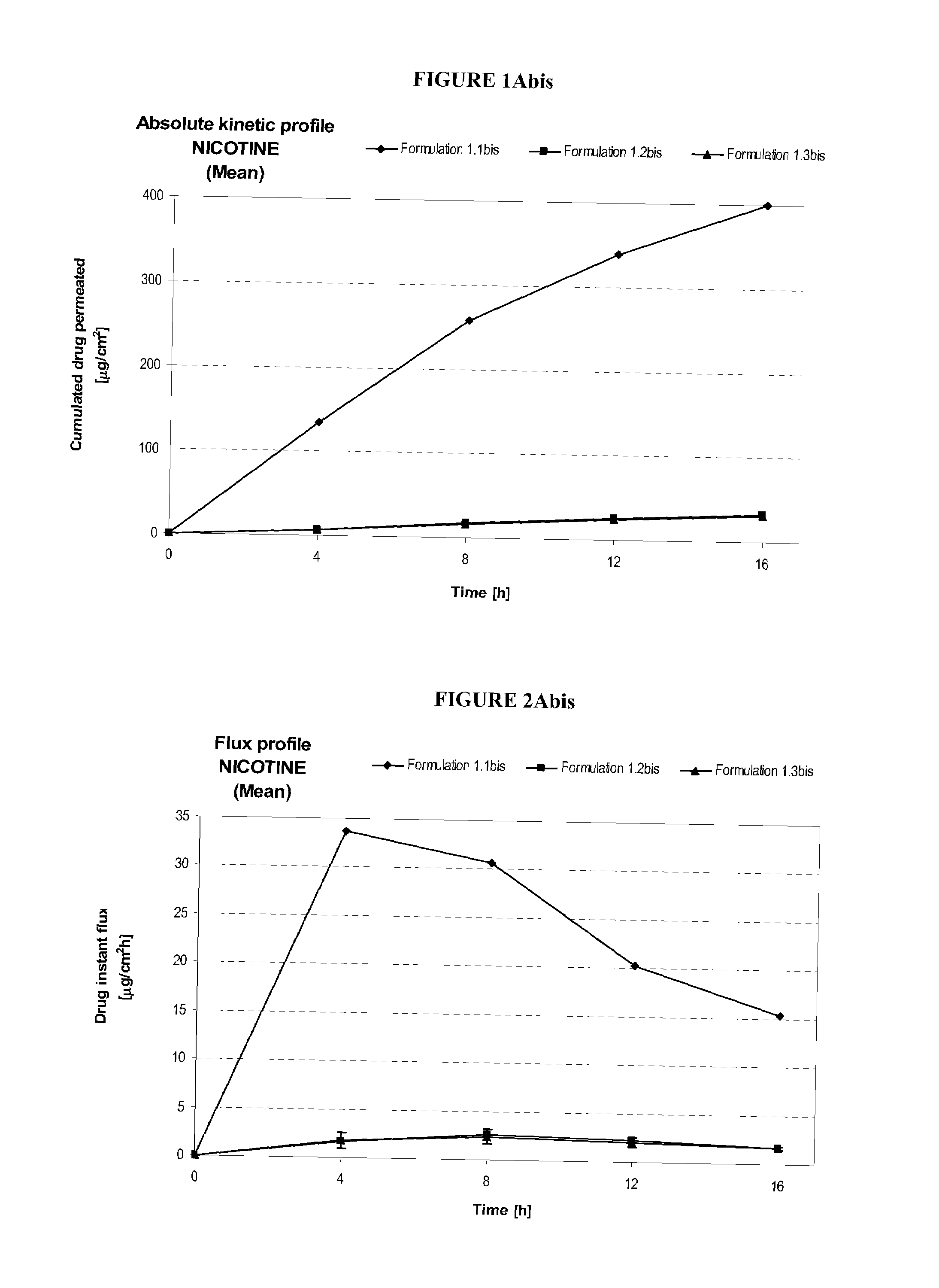

Pharmaceutical compositions of nicotine and methods of use thereof

The present invention comprises non occlusive compositions for transdermal delivery of nicotine, and more particularly pharmaceutically acceptable salts thereof, and methods of making same. The composition may, for example, be a gel suitable for transdermal or transmucosal applications. The compositions of the present invention typically comprise a mixture of water and alcohol, and a solvent system having a mono alkyl ether of diethylene glycol and a glycol present in specified ratios and in specific amounts, wherein the pH of the gel is usually between a pH of 5.5 and 7. The compositions may include further components, for example, the hydroalcoholic vehicle may further comprise additional penetration enhancer(s), buffering agent(s), antioxidant(s), stabilizer(s) and / or gelling agent(s). The invention also relates to a method for the sustained delivery of nicotine pharmaceutically acceptable salts to treat a variety of conditions and disorders.

Owner:ANTARES PHARMA IPL

Water-soluble, liquid-containing pouch

InactiveUS7563757B2Aqueous liquid non-soap compositionsDetergent compounding agentsPolyvinyl alcohol1,3-Propanediol

The present invention relates to water-soluble pouch which contains a liquid detergent composition, wherein the pouch is a water-soluble film, the film material comprising a polyvinyl alcohol, and wherein the liquid detergent composition also comprises a plasticizer, wherein the plasticizer is selected from the group consisting of glycerol, ethylene glycol, diethylene glycol, triethylene glycol, 2-methyl-1,3-propane diol, sorbitol, methanol, diglycerol, 1,4-butane diol, urea and mixtures thereof, and wherein the liquid detergent composition further comprises a viscosity modifier, preferably a hydrogenated castor oil.

Owner:PROCTER & GAMBLE CO

Liquid benzoate ester compositions and aqueous polymer compositions containing same as plasticizers

Owner:EASTMAN SPECIALITIES HLDG CORP

Articles derived from compositions containing modified polybutylene terephthalate (PBT) random copolymers derived from polyethylene terephthalate (PET)

Compositions of matter including articles derived from (a) from 5 to 99.99 wt % of a modified polybutylene terephthalate random copolymer that (1) is derived from polyethylene terephthalate and (2) contains a at least one residue derived from polyethylene terephthalate selected from the group consisting of antimony, germanium, diethylene glycol groups, isophthalic acid groups, cis isomer of cyclohexane dimethanol, trans isomer of cyclohexane dimethanol, sodium benzoate, alkali salts, napthalane dicarboxylic acids, 1,3-propane diols, cobalt, cobalt-containing compounds, and combinations thereof, and (b) from 0.01 to 95 wt. % of a member selected from the group consisting of (1) fillers, (2) a carboxy reactive component, (3) polyethyelene terephthalate, (4) a component including a polycarbonate and an impact modifier. The articles may be derived from various conversion processes, e.g., injection molding processes, extrusion processes, thermoforming processes, melt-blown process.

Owner:SHPP GLOBAL TECH BV

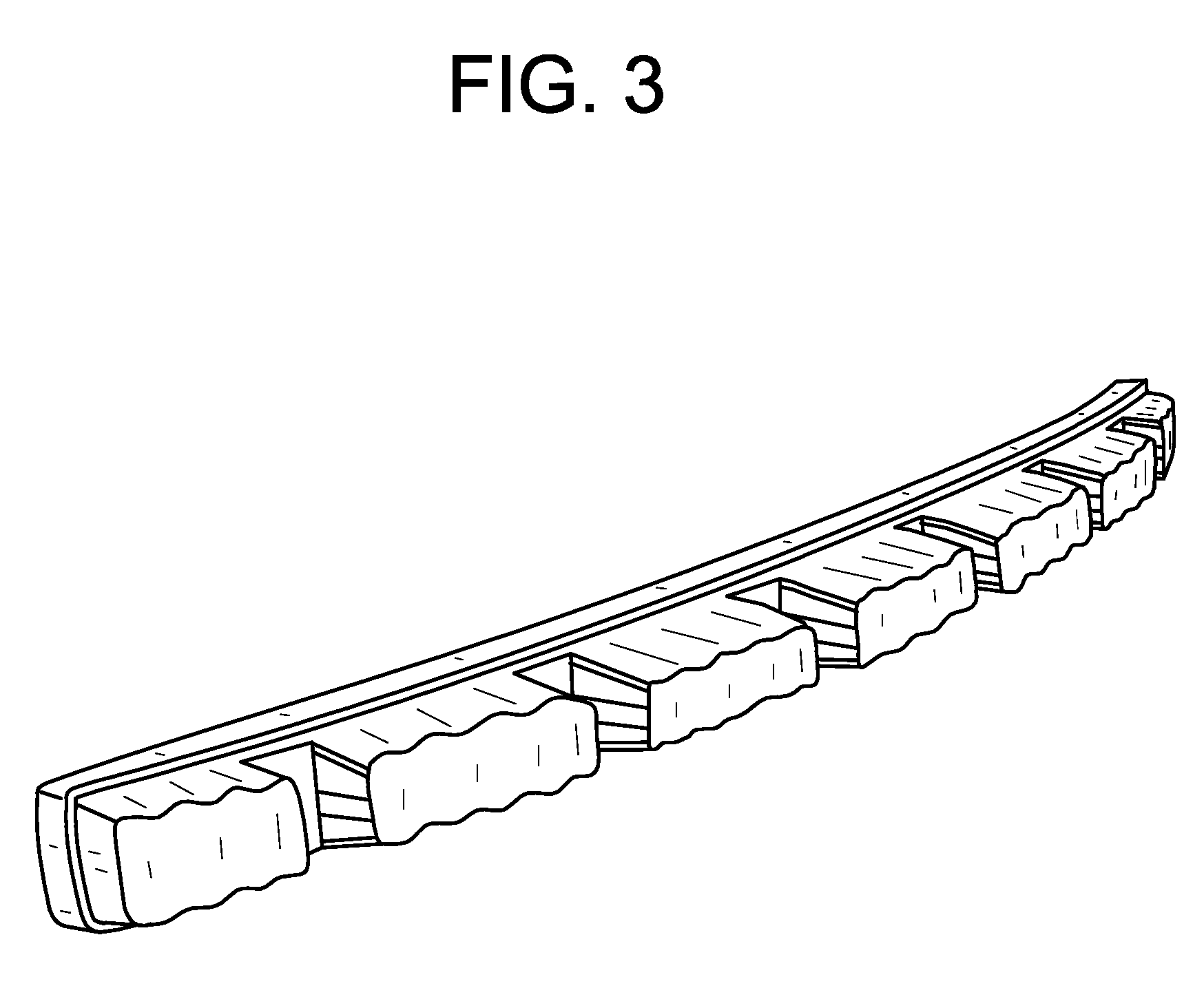

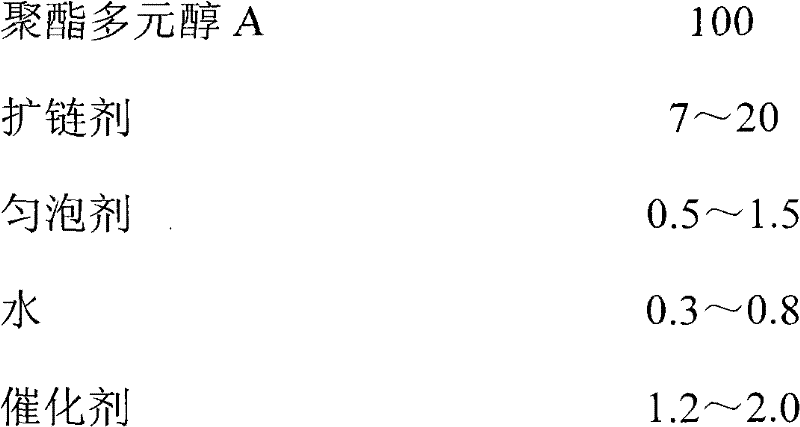

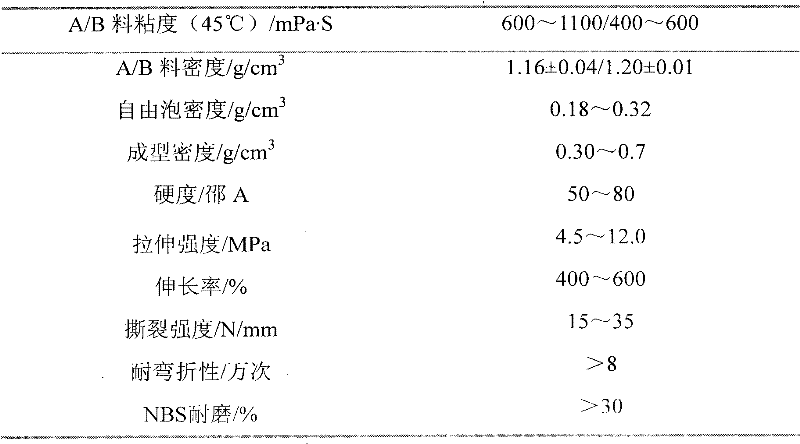

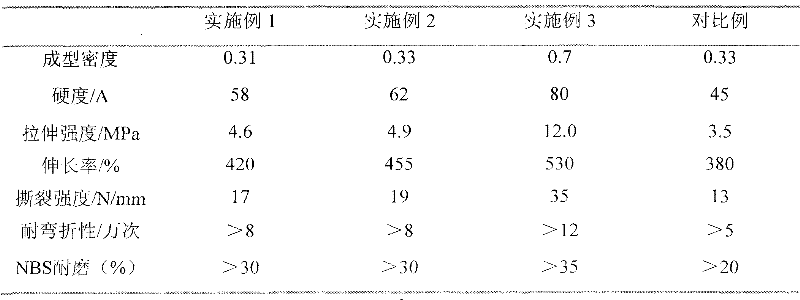

Microcellular polyurethane elastomer and preparation method thereof

The invention discloses a microcellular polyurethane elastomer and a preparation method thereof. The elastomer contains two components, i.e., a polyol component and a prepolymer component, wherein the polyol component comprises polyester polyol, a chain extender, a foam stabilizer, water, a catalyst and the like; and the prepolymer component comprises polyester polyol, isocyanate and the like. The polyester polyol in the polyol component is prepared from a mixture of aromatic dibasic acid and aliphatic diacid and a mixture of diethylene glycol and other dihydric alcohols by means of polycondensation reaction. Compared with common microcellular polyester-type elastomers, the prepared elastomer has higher hardness and mechanical properties as well as better abrasive and bending resistances, besides, the flowability of materials is good. The material can be used in the fields like soles, solid tires, buffer blocks and the like. The preparation method is simple and feasible.

Owner:LIMING RES INST OF CHEM IND

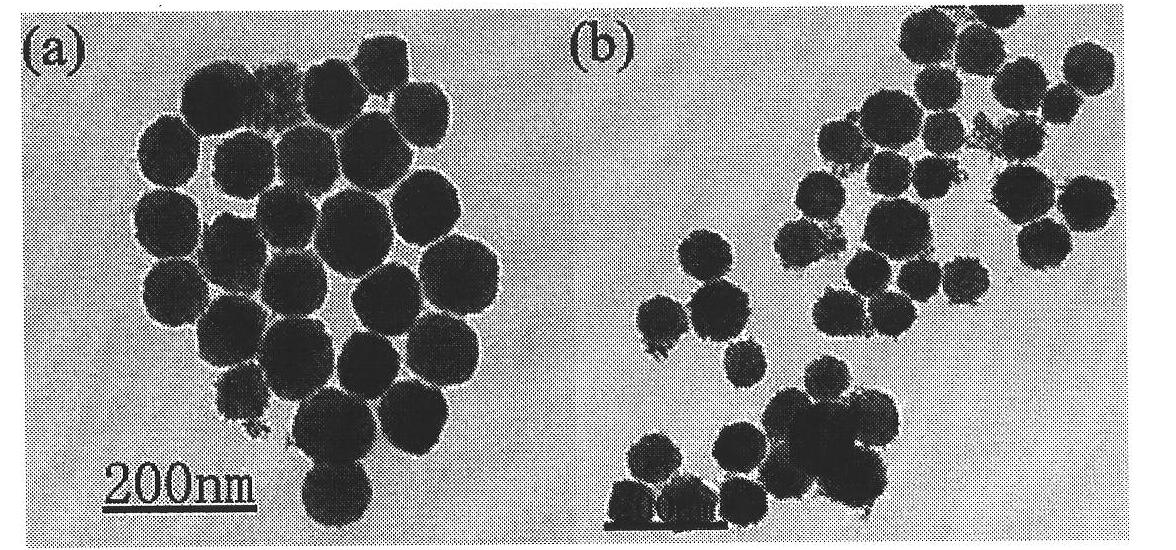

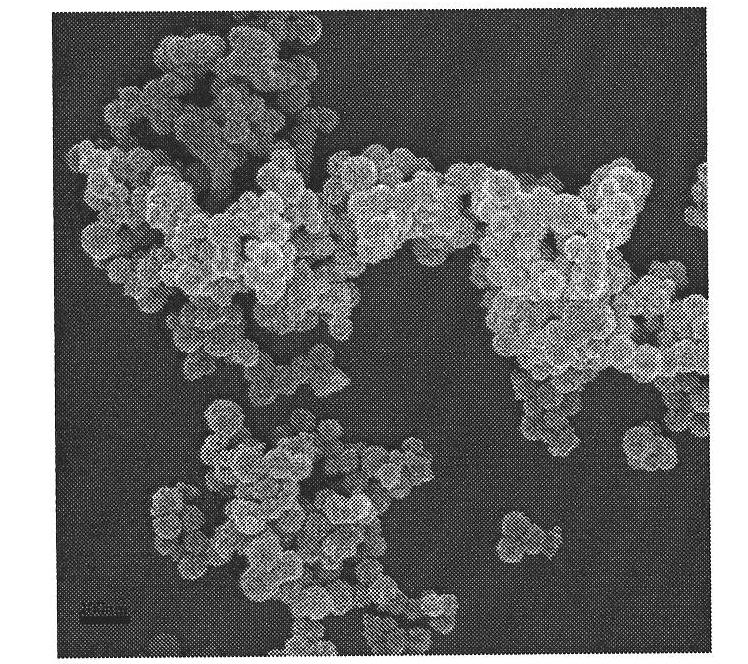

Preparation method of cerium oxide nanoballs

InactiveCN101792171AGood dispersionSmall particle sizeNanostructure manufactureRare earth metal compoundsSolventSolvothermal reaction

The invention relates to a preparation method of cerium oxide nanoballs, and belongs to the technical field of the preparation processes of the inorganic nanomaterials. The key points of the method of the invention include: stirring and mixing cerium salt and a certain amount of surfactant at room temperature, dissolving the mixture in a mixed solution of water and an organic solvent and ultrasonically processing the mixture for 5 to 10 minutes, wherein the cerium salt is optimally cerium nitrate; the surfactant is most preferably polyvinylpyrrolidone; and the belonged organic solvent is most preferably diglycol; then transferring the mixed solution into a high pressure reaction kettle to perform a solvothermal reaction; heating the mixed solution to perform reaction for 24 to 28 hours at the temperature of 100 to 200 DEG C so as to obtain the cerium oxide nanoball sol; evaporating the sol at the temperature of 1500 o 180 DEG C to dryness; and forging the obtained powder for 1 to 4 hours at the temperature of 400 to 600 DEG C; and finally obtaining the cerium oxide nanoballs in the shape of yellow solid powder. The nanoballs have a particle size ranging from 30 to 160nm and high performance and can be applied in fields of ultraviolet light shielding, mechanical polishing and automobile exhaust catalyzation and the like.

Owner:SHANGHAI UNIV

Low viscosity hair care composition

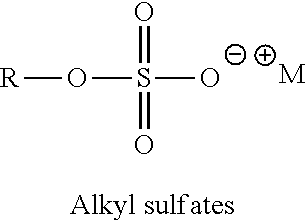

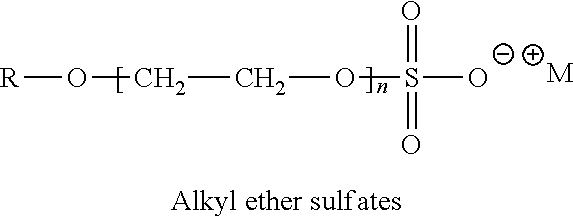

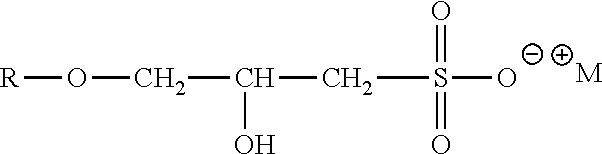

ActiveUS20180110707A1Stable concentrated hair care compositionCosmetic preparationsHair cosmeticsSulfateDiethylene glycol

The invention relates stable, low viscosity hair care compositions having high surfactant content comprising linear sulfates (with alkyl tail of C12 and above) and branched sulfates (with alkyl tail of C12 and above), a water-miscible solvent such as dipropylene glycol or glycerin. Suitable compositions have a ratio of (Linear anionic surfactant / Branched anionic surfactant) / Miscible solvent from about 0.2 to about 5 and a viscosity of less than about 500 cP at 26.5° C.

Owner:THE PROCTER & GAMBLE COMPANY

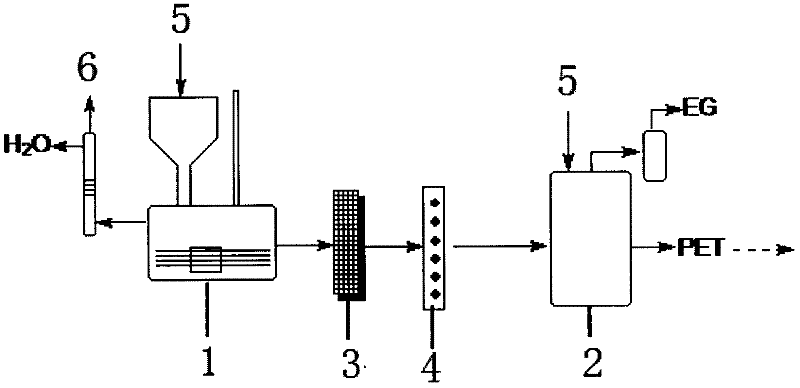

Regenerated terylene filament and preparation method thereof

ActiveCN102505175AAvoid pollutionAvoid exhaustionPlastic recyclingMonocomponent copolyesters artificial filamentPolyesterEnvironmental resistance

The invention provides regenerated terylene filament, which has higher mechanical properties and is prepared by depolymerizing waste polyester with polyol as a solvent. The PET (Polyethyleneglycol Terephthalate) granules are depolymerized in a homogeneous state by optimizing the solvent, pressure, temperature, time, catalyst and parameter conditions as well as controlling the pressure and temperature, so as to improve the depolymerization reaction rate. A composite catalyst is adopted, thus the ratio of the solvent to waste polyester is strictly controlled, the polyol consumption is reduced, the process economy is improved, the generation of diethylene glycol is reduced, and the quality and spinnability of the regenerated polyester are improved. The depolymerization rate of the polyester and the mechanical properties of the regenerated terylene filament are improved by adding a third component, thus the mechanical properties of the prepared regenerated terylene filament achieve the properties of the conventional terylene filament. The preparation method is simple, economical and environmentally friendly and is suitable for industrial production.

Owner:江苏芮邦科技有限公司

Filament low-melting-point polyester fiber and preparation method thereof

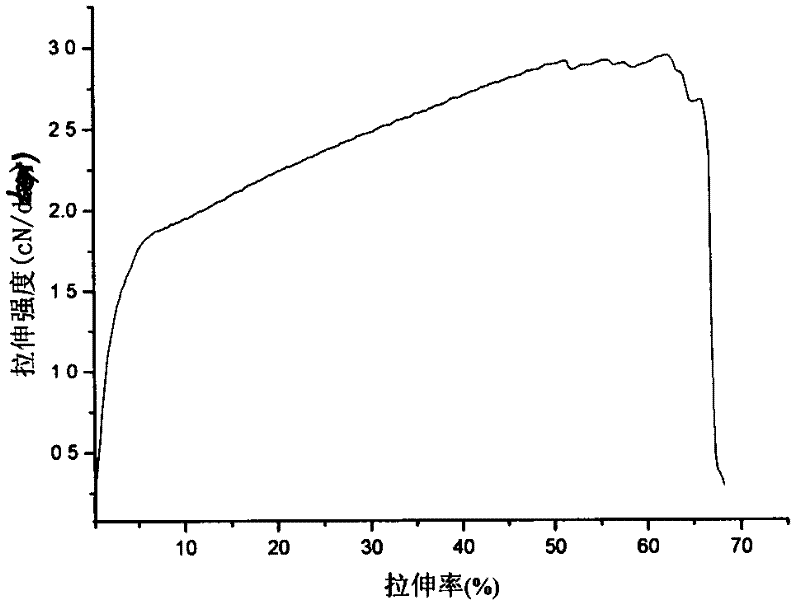

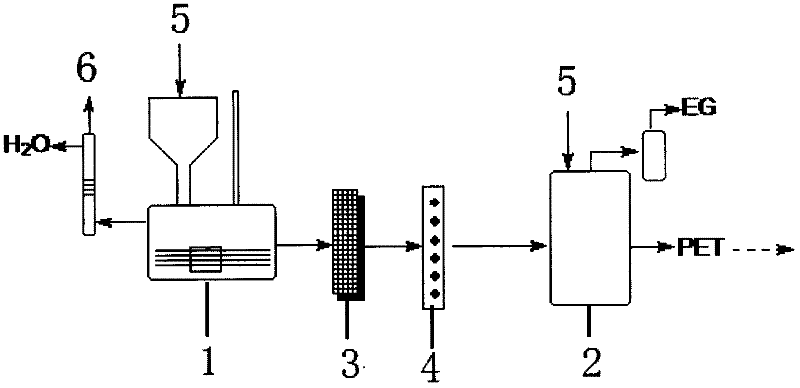

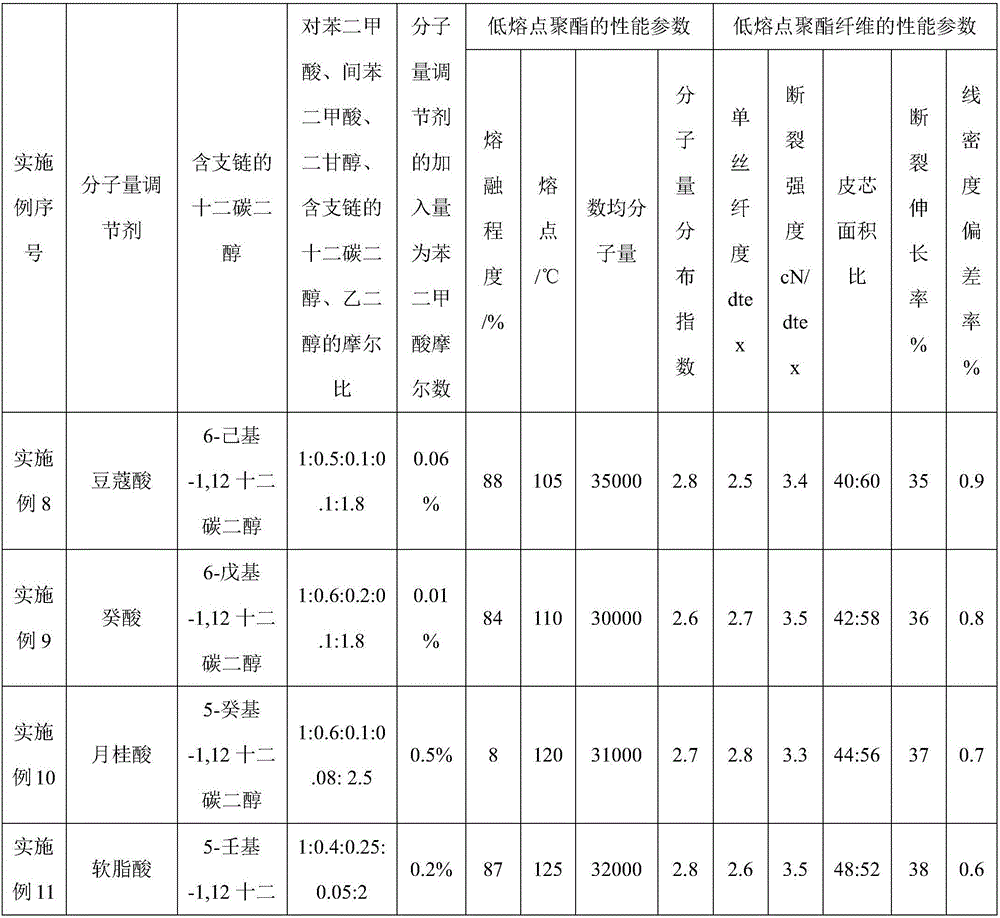

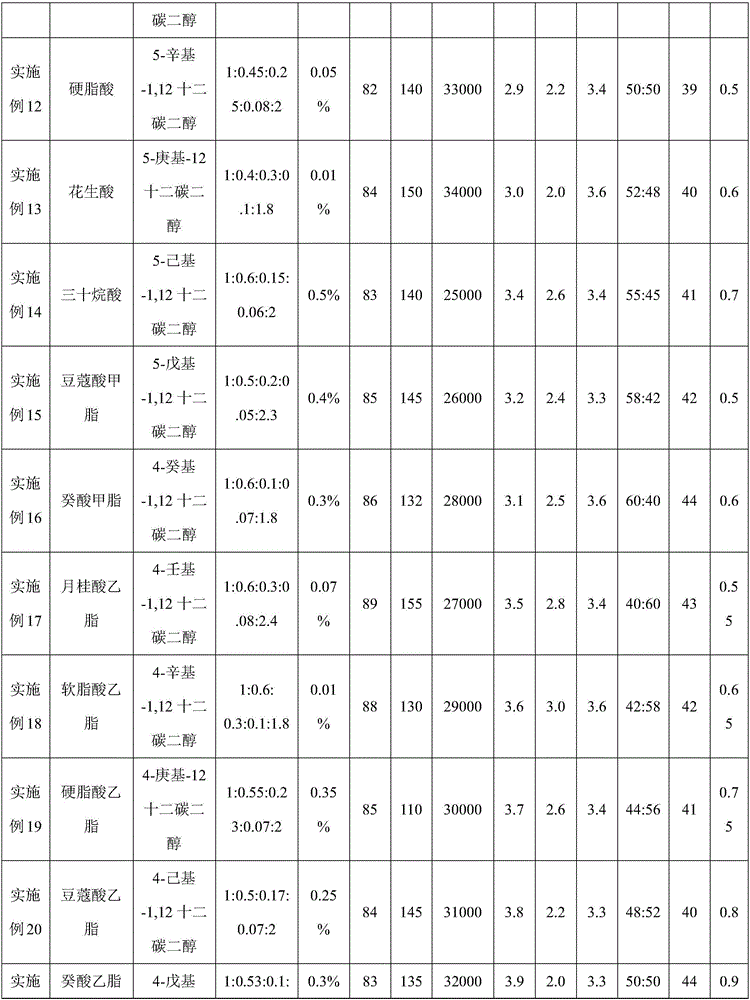

ActiveCN106757518AImprove fitImprove stabilityFilament/thread formingConjugated synthetic polymer artificial filamentsPolymer sciencePolyethylene terephthalate

The invention relates to a filament low-melting-point polyester fiber and a preparation method thereof. The filament low-melting-point polyester fiber is in a skin-core structure, a skin layer is made of low-melting-point polyester; a core layer is made of PET (polyethylene terephthalate); the low-melting-point polyester consists of a terephthalic acid chain segment, an isophthalic acid chain segment, an ethylene glycol chain segment, a diethylene glycol chain segment, a molecular weight modifier chain segment and a 1, 12-Dodecanediol chain segment containing branched chains; a molecular weight modifier corresponding to the molecular weight modifier chain segment is specifically a monoacid series or a diacid series; the preparation method of the filament low-melting-point polyester fiber comprises the following steps: polymerization of the low-melting-point polyester and skin-core composite spinning, so as to obtain the filament low-melting-point polyester fiber. The prepared filament low-melting-point polyester fiber has the advantages that the initial melting point is reduced, the melting speed is increased, the polyester fiber is immediately melted at the corresponding temperature, and the melting effect is good.

Owner:扬州富威尔复合材料有限公司

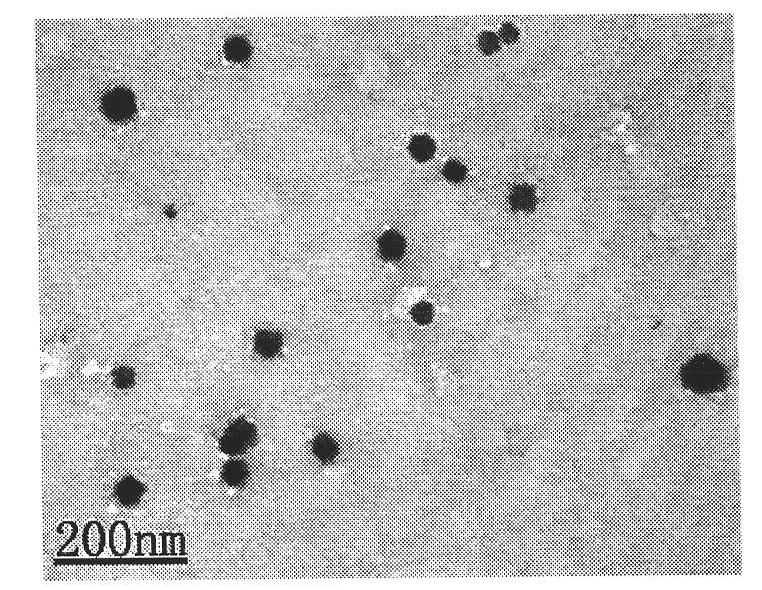

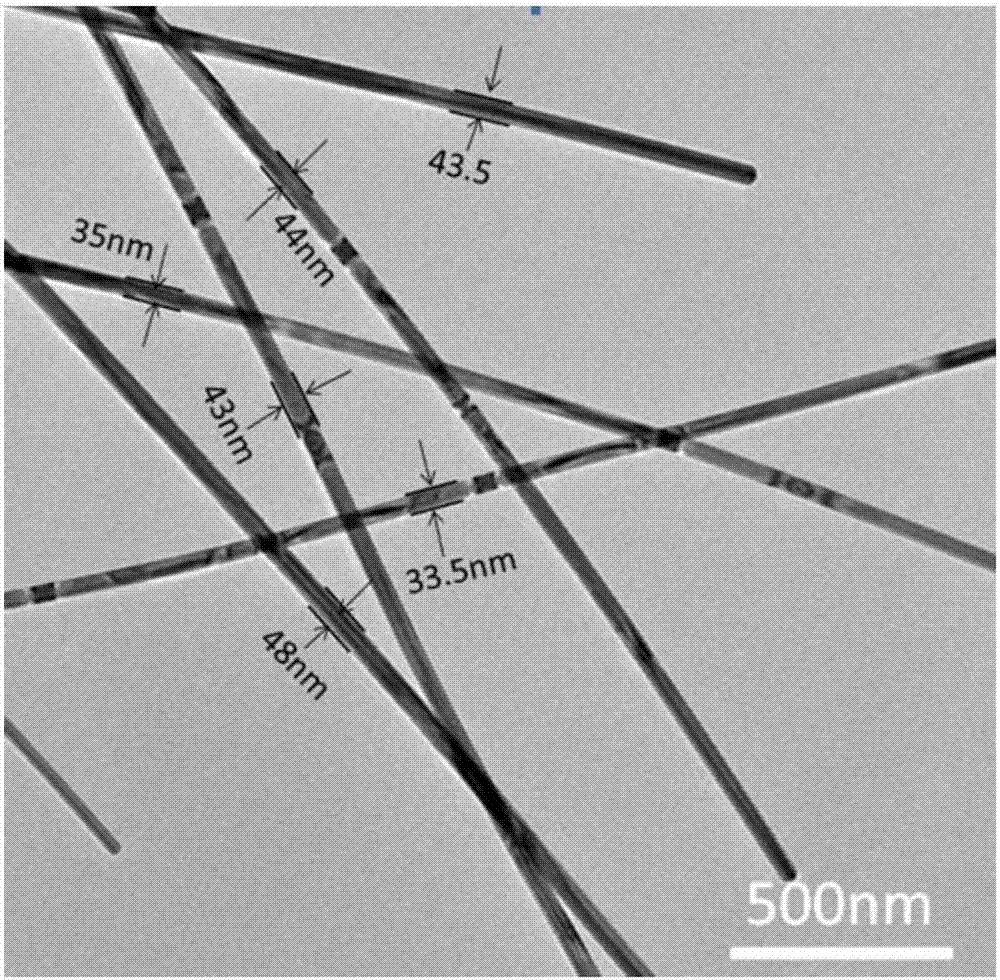

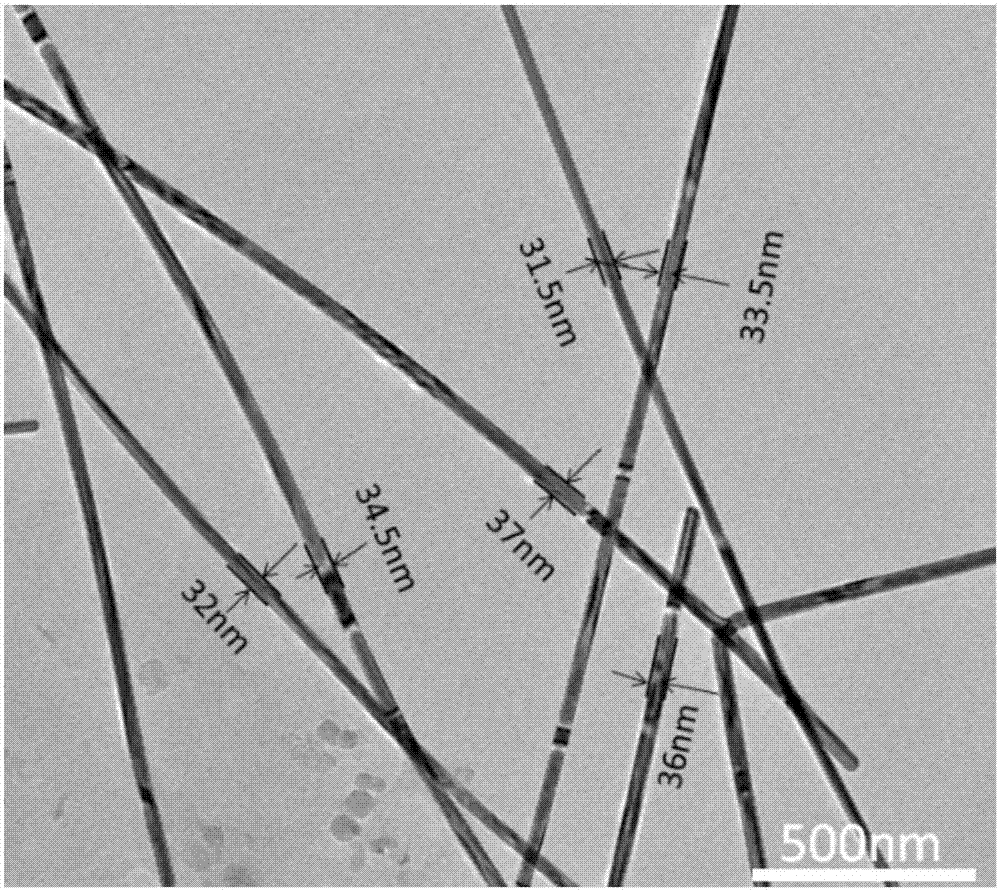

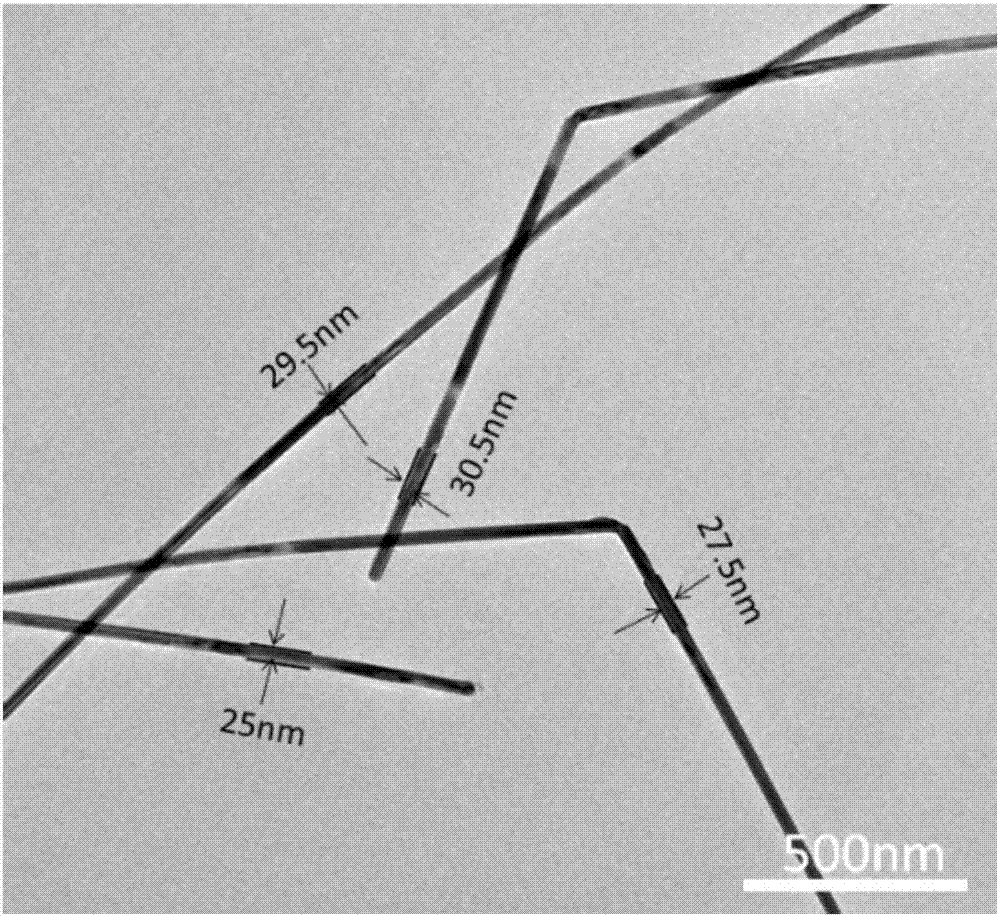

Method for preparing silver nanowires with smaller diameter through mixing polyhydric alcohols

ActiveCN106938341ASave powerAchieve purificationMaterial nanotechnologyTransportation and packagingPolyolAlcohol

The invention discloses a method for preparing silver nanowires with smaller diameters through mixing polyhydric alcohol, in which, silver nanowires with different diameters, different lengths and smaller diameters can be obtained by regulating the volume ratio, reaction temperature, and reaction time of ethanediol and diethylene glycol. The beneficial effects of the invention are: (1) the silver nanowires with different diameters and different lengths can be obtained, and the diameters of the silver nanowires may be controlled to be 40 nm or lower, even may be reduced to about 20 nm; (2) the reaction condition is not required to be accurately controlled, the uniformity of the diameters of the silver nanowires is easily controlled, the purity is relatively high, and can be prepared in a large scale; and (3) no expensive experiment apparatus is needed and the preparing cost is low.

Owner:NORTHWEST UNIV

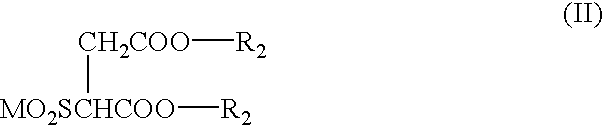

Liquid crystal alignment agent and liquid crystal display unit

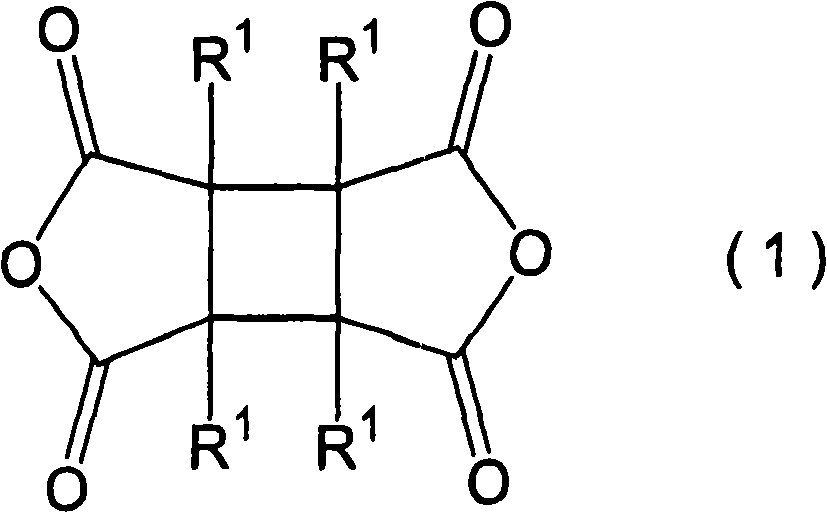

The present invention relates to an aligning agent for liquid crystal containing at least a polymer and solvent selected from polyamic acid and polyimide gained by dewatering closed-loop, the solvent contains: (A) a first solvent containing compound with formula (I); (B) a second solvent selected from at least one of N-methyl-2-pyrrolidone, gamma-butyrolactone, 1,3-dimethyl-2-imidazolone, N, N-dimethylformamide and N, N- dimethylacetylamide; and (C) a third solvent selected from at least one of butyl cellosolve, diacetone alcohol, carbonic sub-propyl ester, diethylene glycol diethyl aether and ethyl-3- oxethyl propionic ether. (In formula (I) the R respectively represents alkyl with 3 to 10 carbon atoms).

Owner:JSR CORPORATIOON

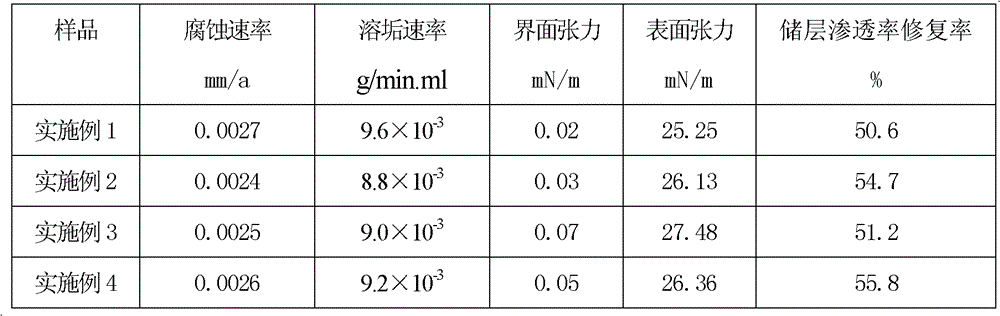

Blocking remover of gas well shaft

The invention relates to a blocking remover of a gas well shaft. The blocking remover comprises, by weight, 5-25% of an alcohol ether compound, 0.5-10% of a dispersant, 1-10% of a cleaning agent, and 0.5-5% of chelating agent, with the balance being a nitrogen-containing polar solvent, wherein the nitrogen-containing polar solvent is one selected from N,N dimethyl formamide, N,N dimethyl acetamide, and N-methyl pyrrolidone, the alcohol ether compound is one selected from glycol-ether, glycol-propyl ether, glycol-butyl ether, and diglycol-ether, the disperant whose micelle particle size is from 20nm to 100nm is a middle-phase microemulsion-type dispersant mixed by kerosene, water, a surfactant and a cosurfactant, the cleaning agent is one selected from allene diamine, acetonitrile and pentylamine, and the chelating agent is one selected from sodium citrate and EDTA. The blocking remover has the advantages that corrosivity is weak, that the speed of dissolving blockage is fast, that the product performance is stable in high temperatures, and that the blocking remover can reduce damages caused by water locking and fouling in areas close to gas wells, and can recover the permeability of storing layers.

Owner:PETROCHINA CO LTD

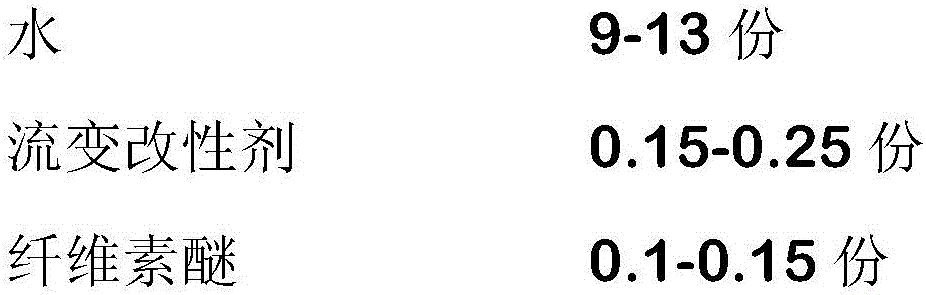

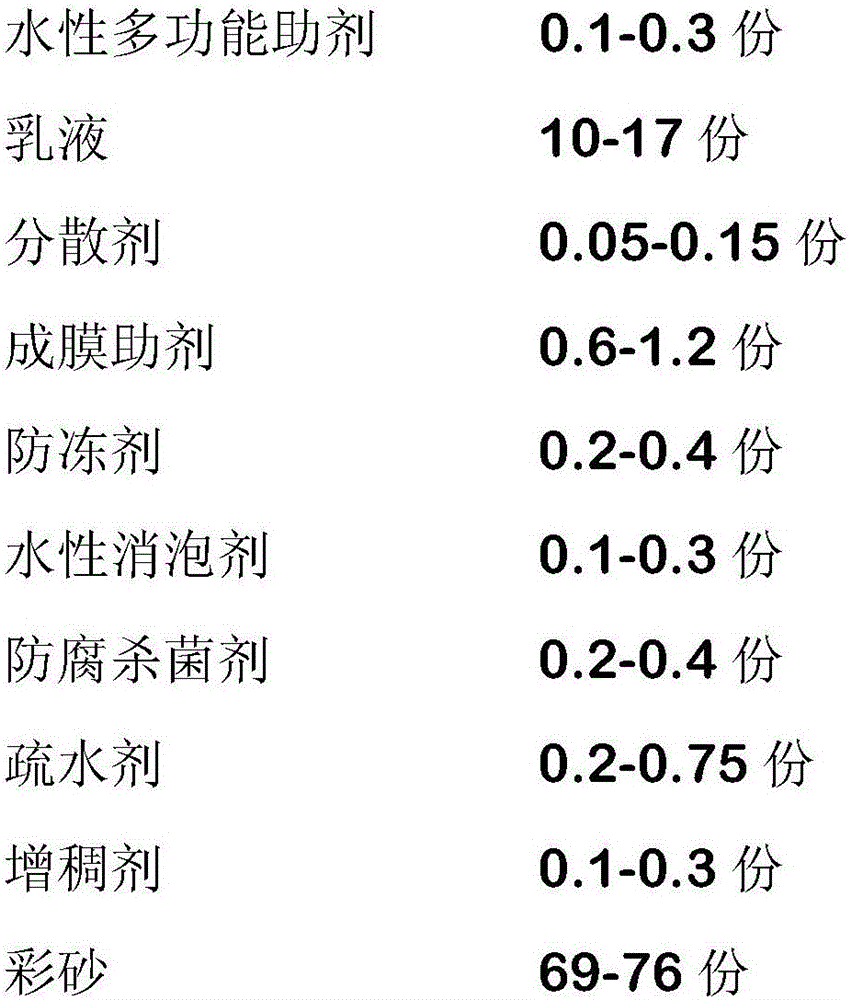

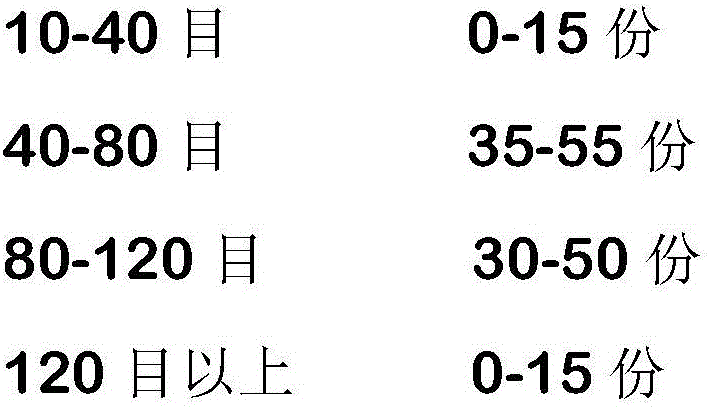

Real-stone paint and preparation method thereof

ActiveCN106590268AFast film formationImprove water resistanceAntifouling/underwater paintsPaints with biocidesCellulosePolymer science

The invention relates to real-stone paint and a preparation method thereof and belongs to the technical field of building decorative materials. Firstly, an inorganic mineral rheological agent and a nonionic water-soluble cellulose ether are combined, so that the two components have the synergistic effect of guaranteeing viscosity of the real-stone paint and excellent constructability, and on the basis hereinabove, the usage amount of cellulose ether, which has water retention effect, in the real-stone paint is reduced, so that a paint film is reduced in the water retention effect and moisture volatilization is improved; secondly, alcohol ester-12 is combined with any one of four film forming additives, comprising ethylene glycol monobutyl ether, propylene glycol butyl ether, diethylene glycol butyl ether and benzyl alcohol, which have high volatile speed, thus accelerating film forming. For solving of a problem of poor antifouling performance of the real-stone paint, through reasonable combination of particle size of color sands and usage of a hydrophobic agent, the real-stone paint can form a compact film and a nano hydrophobic coating layer, which is completely composed of nano hydrophobic particles, is formed on the surface of the paint film, so that the paint film is reduced in surface energy and water absorbency, and is improved in antifouling performance.

Owner:BEIJING SATELLITE MFG FACTORY

Water-soluble, liquid-containing pouch

InactiveUS20060276364A1Aqueous liquid non-soap compositionsDetergent compounding agentsPolyvinyl alcohol1,3-Propanediol

The present invention relates to water-soluble pouch which contains a liquid detergent composition, wherein the pouch is a water-soluble film, the film material comprising a polyvinyl alcohol, and wherein the liquid detergent composition also comprises a plasticizer, wherein the plasticizer is selected from the group consisting of glycerol, ethylene glycol, diethylene glycol, triethylene glycol, 2-methyl-1,3-propane diol, sorbitol, methanol, diglycerol, 1,4-butane diol, urea and mixtures thereof, and wherein the liquid detergent composition further comprises a viscosity modifier, preferably a hydrogenated castor oil.

Owner:THE PROCTER & GAMBLE COMPANY

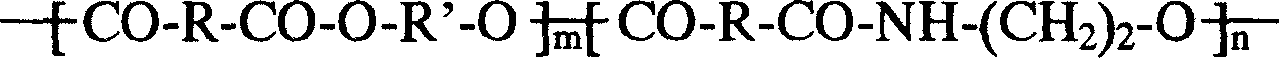

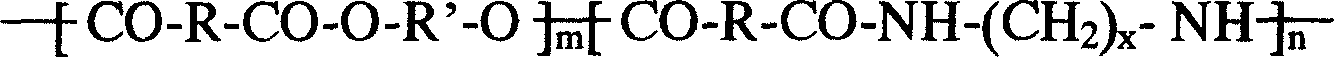

Degradable unsaturated polyesteramide resin and synthesis method thereof

The invention adopts a melt polycondensation method. A few of monomers of C2-5 aliphatic dibasic alcohol, diethylene glycol, polyglycol, fumaric acid, maleic anhydride, lactic acid, glycolic acid, ethanolamine, C2 to C12 aliphatic diamine, glutamic acid, lysine, glycine, etc. are taken as basic materials to be synthesized to obtain non toxic unsaturated polyester-amide resin with adjustable degradation rate and lower cost; wherein, the partial fumaric acid or maleic anhydride can be replaced with phthalic anhydride, isophthalic acid, or adipic acid. The resin yearns for being used as matrix resin of medical bone internal fixation material, tissue engineering scaffold material, bone tissue temporary substitutes, environmental protection type bonding agent, environmental protection type fiberglass reinforced plastics, environmental protection type coating material, disposable tableware, packing material, shopping bags, disposable bags, drug coating or capsule, drug delivery (controlled-release) material, agricultural mulching films, etc., and can be recovered to be utilized.

Owner:HUNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com