Patents

Literature

1215results about How to "Fast film formation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-temperature thermal-insulation anticorrosive nano coating and its preparing method

InactiveCN1709988AImprove Radiation PerformanceGood heat insulationAlkali metal silicate coatingsPolymer scienceThermal insulation

The invention discloses a kind of new industry dope. It comprises such materials as 95 - 105 weight shares of Component A, and 1 - 3 weight shares of Component B; thereinto, Component A is made from following weight percents of materials: cementing agent 30-60%, pigment 12 - 30%, filling agent 10 - 30%, auxiliary agent 0.1 - 5%, compound nanometer dispersing agent 5 - 15% and solvent 10 - 25%; Component B is comprised of catalyzed membrane forming agent - nanometer Sb2O3 and mixed organic solvent carriers. The invention firstly brings nanometer Sb2O3 into high temperature heat preservation dope as catalyzer in dope membrane forming process. The dope of the invention has following advantages: it has high temperature heat preservation and heavy anticorrosion performances, and the coat has good acid resistance, alkali resistance, salt mist resistance, oil resistance, chemical reagent resistance, waiting resistance and ultraviolet resistance; it has excellent fire protection and waterproof performance; the clinging strength of smearing membrane is good, membrane forming speed is fast, and performance is stable.

Owner:孙启明

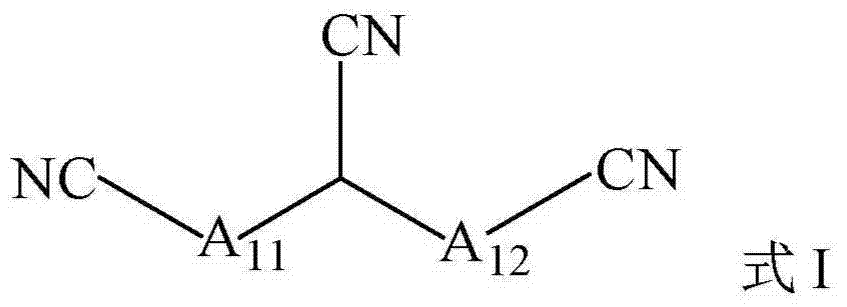

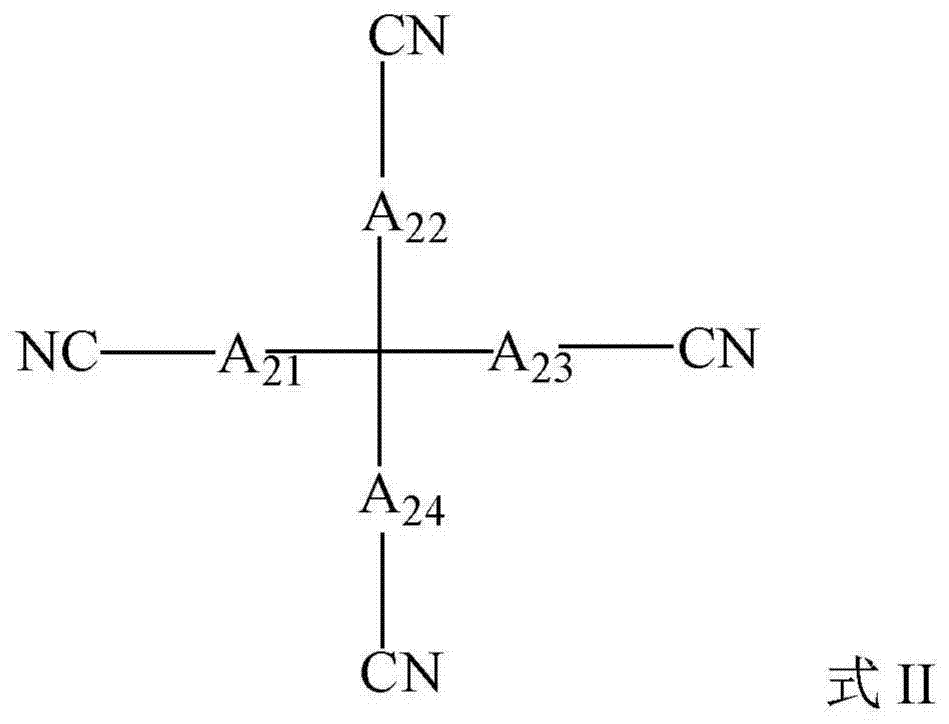

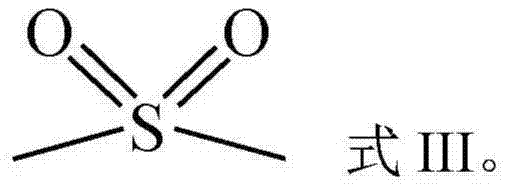

Electrolyte additive and application thereof in lithium ion battery

ActiveCN104766995AImprove cycle lifeImprove featuresLi-accumulatorsOrganic electrolytesHigh temperature storageSulfur

The invention discloses an electrolyte additive and an application thereof in a lithium ion battery. The electrolyte additive comprises a polynitrile-based compound and a compound comprising a sulfur bond and an oxygen bond. When the electrolyte additive is applied to the lithium ion battery, good cycle life, good low-temperature discharging property and good high-temperature storage property of the lithium ion battery under the high voltage still can be maintained.

Owner:CONTEMPORARY AMPEREX TECH CO

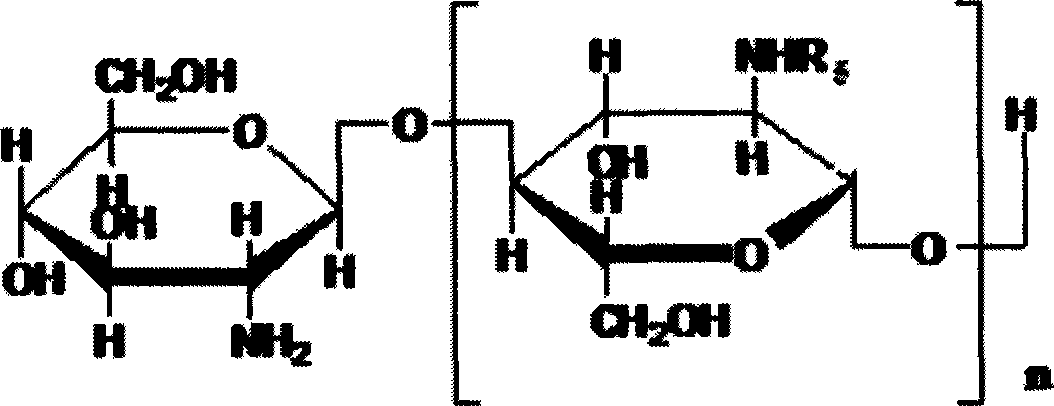

Preparation of chitosan-polyurethane ion complex elastomer material

The invention discloses a preparation method of chitosan-polyurethane ionic compound elastomeric material, which comprises the following steps: polyisocyanates reacts with polymer polylol and then reacts with diol or diamine, organic solvent and ionization reagent are added in the reactants to react with water for generating anionic waterborne polyurethane and further performs the ionic recombination reaction with cationic chitosan water solution to obtain the microemulsion or latex of chitosan-polyurethane ion composite, and finally the microemulsion or latex of chitosan-polyurethane ion composite is dried and solidified to obtain the chitosan-polyurethane ionic compoundelastomeric material. The chitosan-polyurethane ionic compoundelastomeric material has the advantages of good mechanical property, easy processing, good oil-water resistance property, good cohesive property with parent metal, controllable performance, good biocompatibility, biodegradable property, high biological activity, good blood contact property, good bacteriostatic property, good antibacterial property, and the like, can be applied in fields of mechanical industry, building industry, sport, medical treatment, and the like, and especially has wider purpose in aspects of life science research, medical materials and medical appliances.

Owner:NANJING UNIV

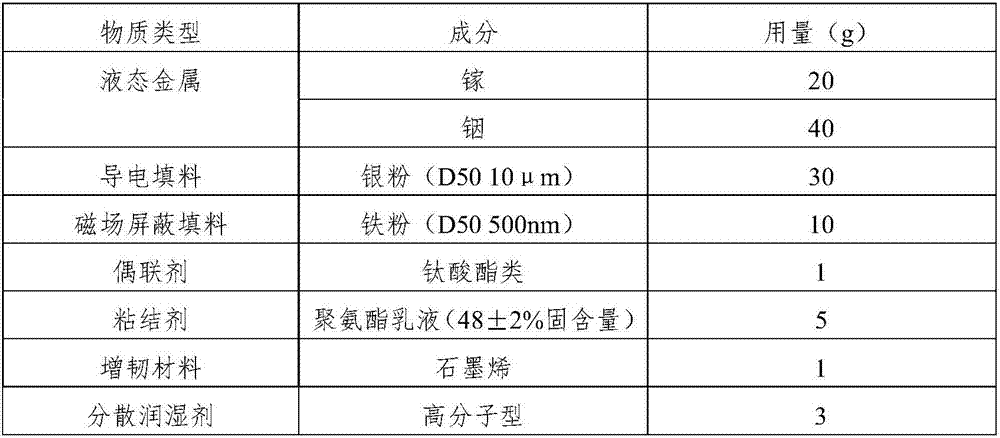

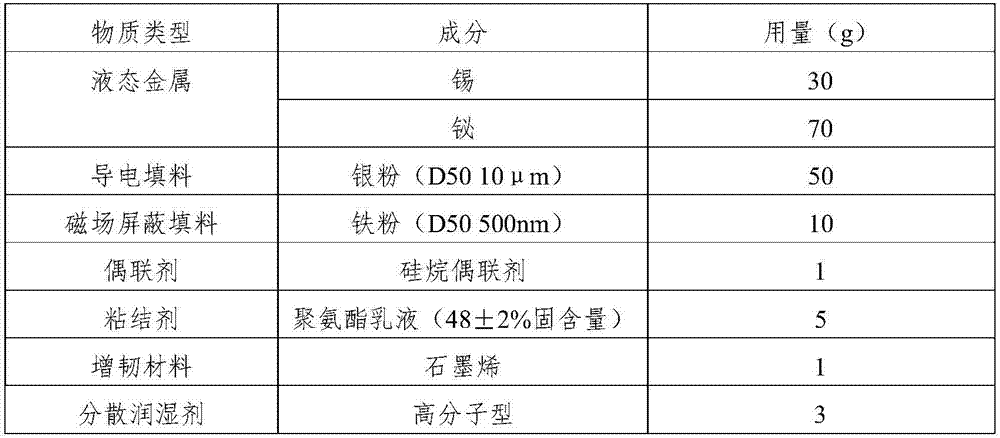

Electromagnetic shielding coating material and preparation method thereof

ActiveCN107573745AGood compatibilityImprove dispersion stabilityMagnetic/electric field screeningElectrically-conductive paintsHazardous substanceLiquid metal

The invention provides an electromagnetic shielding coating material. The electromagnetic shielding coating material comprises 40-70% of liquid metal, 10-40% of a conductive filler, 5-15% of a magnetic shielding filler, 0.5-2% of a coupling agent, 1-10% of a binder, 0.5-2% of a toughening material and 0.5-2% of a wetting dispersing agent, wherein the liquid metal is low-melting-point metal with the melting point of 300 DEG C or below or a conductive nanofluid formed by mixing low-melting-point metal nanoparticles with a fluid dispersant. For the first time, the concept of taking the liquid metal as a conductive auxiliary binder and a conductive auxiliary flow aid is put forward and implemented, and the liquid metal replaces a non-conductive solvent and a non-conductive binder to form the electromagnetic shielding coating material system. Besides, the electromagnetic shielding coating material neither contains any toxic or harmful substances nor produce any volatile organics, is high infilm forming speed, has the characteristics of being safe and environmentally friendly, convenient to construct and low in cost, and can be widely applied to a plurality of fields including militaryscience, electronics, aerospace, buildings and the like.

Owner:BEIJING DREAM INK TECH CO LTD

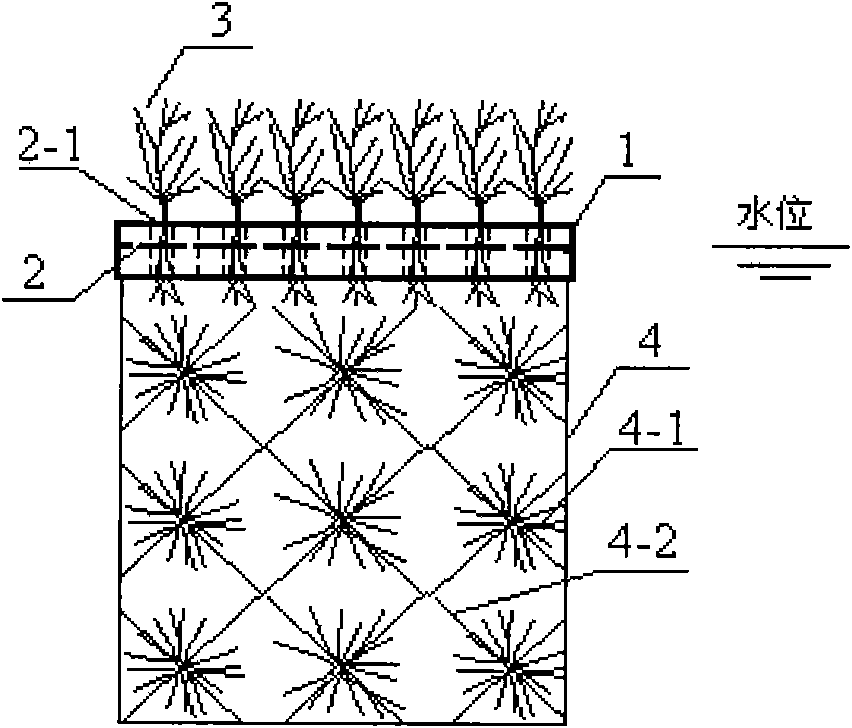

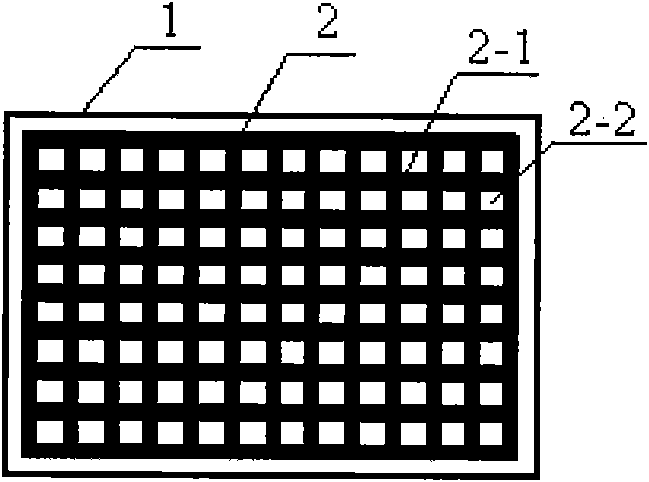

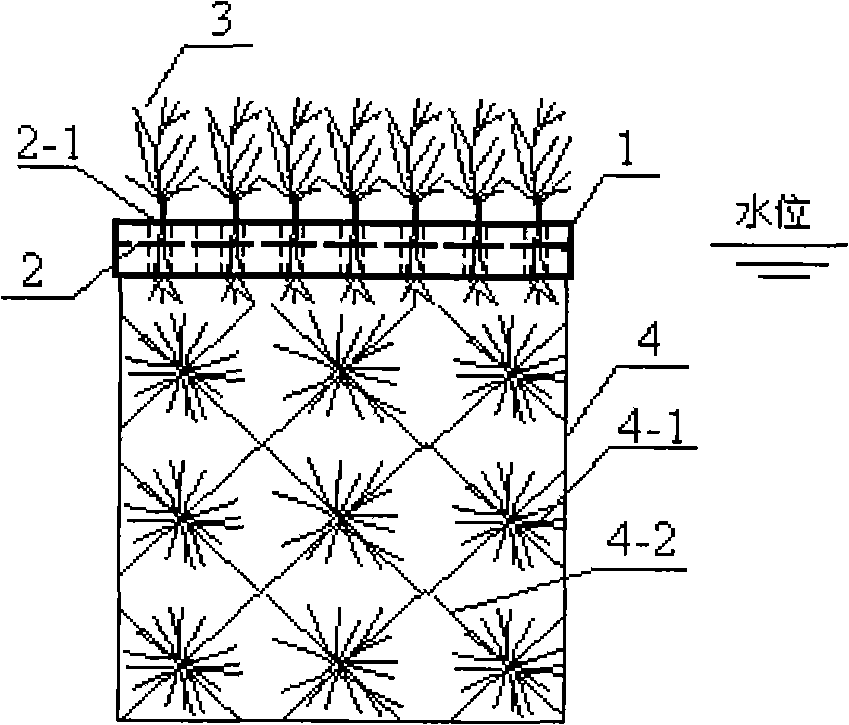

Combined type ecological floating bed water purifying device

InactiveCN101851024AFavorable for attachment growthAvoid the disadvantages of churnBiological water/sewage treatmentEutrophicationWater quality

The invention relates to a combined type ecological floating bed water purifying device used for in-situ purification treatment of polluted water in rivers and lakes. A floating body frame of a floating bed is provided with a grid-like bamboo charcoal floating bed main board made of bamboo charcoal pieces which are processed intensely by a compound enzyme biological promoter before being used, and when the bamboo charcoal pieces are used, the bamboo charcoal pieces can quite well adsorb nitrogen and phosphorus in the water and effectively promote the attached growth of indigenous microorganisms in the water; grid holes on the bamboo charcoal floating bed main board are used as planting holes of plants, and various aquatic plants or economic plants with water purification function can be mixedly planted; and biological fillers are arranged on the lower part of the floating bed, and biomass-based materials which are natural vegetable fibers are used by biofilm formation of microorganisms. The device can greatly improve the capability of removing nitrogen, phosphorus and organic matters from the eutrophication water of the ecological floating bed device and has the characteristics of simple structure, convenient mounting and control, high water flow impact resistance and the like, so that the device is quite suitable to be used for the in-situ purification treatment of water in natural rives, lakes and reservoirs and scenic water.

Owner:TONGJI UNIV

Silane modified polyurethane glass primer and preparation method thereof

ActiveCN102516921AFast film formationIncrease the density of crosslinksNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesSolventChemistry

The invention discloses a silane modified polyurethane glass primer and a preparation method thereof. The glass primer is prepared from the following raw materials by weight: 20 to 60 parts of silane-terminated polyurethane perpolymer, 30 to 65 parts of a solvent, 1 to 3 parts of a water-removing additive, 2 to 10 parts of carbon black, 1 to 2 parts of an anti-settling agent, 2 to 5 parts of a cross-linking promoter and 0.05 to 0.2 part of a catalyst A, wherein, raw materials for the silane-terminated polyurethane perpolymer comprise, by weight, 15 to 25 parts of polyether polyol, 12 to 24 parts of diisocyanate, 0.01 to 0.05 part of dibutyltin dilaurate or stannous octoate, 30 to 60 parts of ethyl acetate and 12 to 22 parts of an end-capping reagent. According to the invention, disadvantages of the prior art are overcome; when the silane modified polyurethane glass primer is used at normal temperature for 40 min in the air, the phenomenon of obvious thickening does not appear, and a film is not formed on the surface of the glass primer; the glass primer facilitates construction and is simple to use, and when used, the glass primer is directly poured into a container and then is directly used for brush coating within 40 min.

Owner:SHANDONG NORTH MODERN CHEM IND

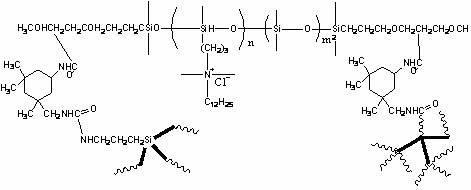

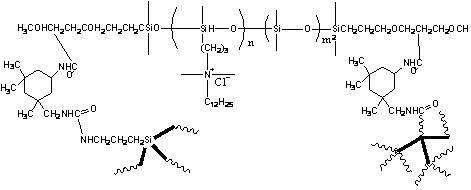

Quaternary ammonium salt modified organosilicon polyurethane ocean antifouling paint and preparation method and application thereof

ActiveCN102220080AInhibition of adsorptionReduce usageAntifouling/underwater paintsPaints with biocidesDisiloxaneQuaternary ammonium cation

The invention discloses a quaternary ammonium salt modified organosilicon polyurethane ocean antifouling paint, the structure is shown as the formula (1); in the formula, an organosilicon soft segment containing quaternary ammonium salt side chain is an isocyanate hard segment; the quaternary ammonium salt modified organosilicon polyurethane ocean antifouling paint is prepared by the following steps: preparing 2,4,6-tri(3- chlorine propyl group)-2,4,6- trimethyl-ring trisiloxane; preparing 1,3-bi(3-(1-methoxy group-2-hydroxy propyl group) propyl group)-tetramethyl disiloxane; preparing 1,3-bi(3-(1-methoxy group-2-hydroxy propyl group) propyl group)-tetramethyl disiloxane; preparing dihydroxy ended chloropropylated polysiloxane; preparing polysiloxane compound containing the quaternary ammonium salt and hydroxyl; mixing the compound with the isocyanate, and adding gamma-aminopropyl triethoxy silane for chain extension to obtain a prepolymer, and the prepolymer being crosslinked and condensed in air. In the invention, the double effect of low surface energy and poison killing are achieved, so as to suppress the adsorption of marine organisms and kill bacteria adsorbed on the surface of a ship body through the quaternary ammonium salt.

Owner:ZHEJIANG UNIV

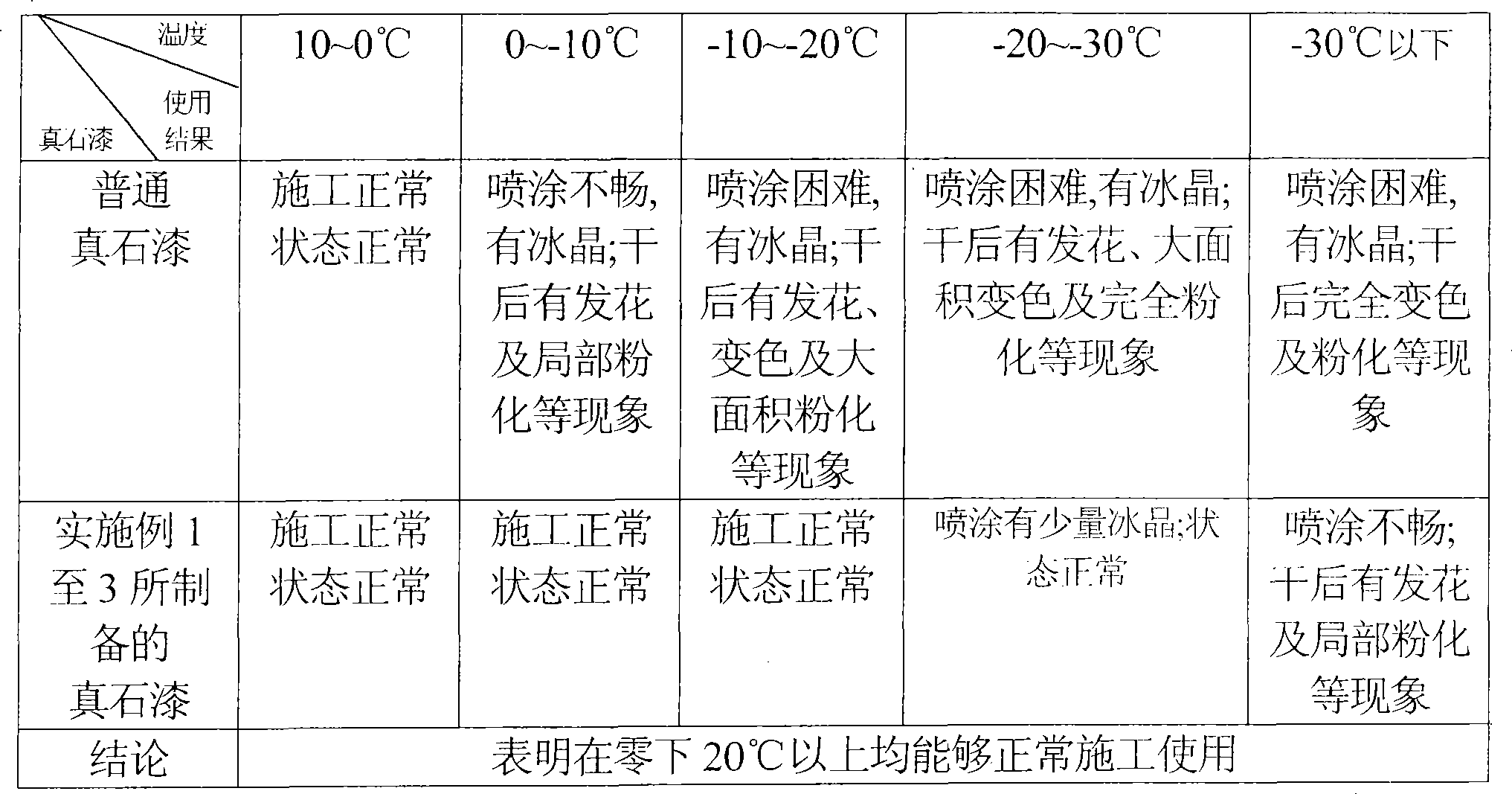

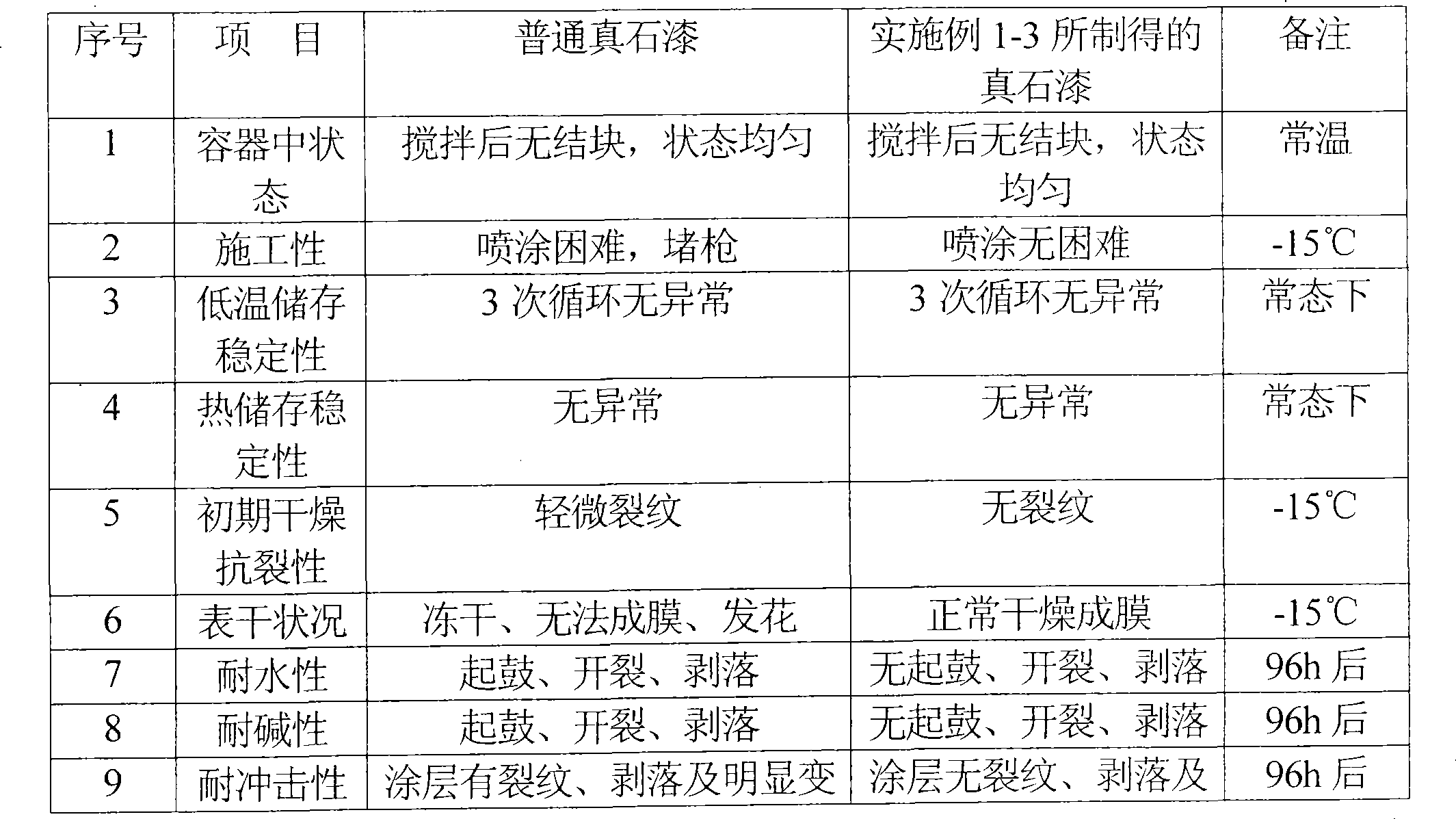

Environment friendly antifreezing stone-like paint and preparation thereof

The invention discloses an environment freeze protection stone paint, which comprises the following raw material components according to the parts by weight: 0.1-5 of fibrin aqueous solution of 1-4% concentration, 0.8-1.2 of glycol, 50-70 of colored sand of 41-80 mesh, 5-25 of colored sand of 81-120, 17-23 of KE025 acrylic emulsion, 0.6-0.9 of alcohol ester-12 addition agent, 0.02-0.06 of foam killer, 0.01-0.1 of thickness agent and 0.02-0.06 of neutralizing agent. Meanwhile, the invention also discloses a preparation method for the stone paint. The stone paint has the environment and freeze protection performance, provides powerful guarantee for being suitable for winter construction, in particular to various severe conditions of winter construction in the northern area of our country.

Owner:许军 +1

Anticorrosive waterproof nano industrial coating and its preparing method

InactiveCN1709994ASignificant heavy-duty anti-corrosion performanceSignificant coating acid resistanceCoatingsUltravioletSolvent

The invention discloses a kind of new industry dope. It comprises of two kinds of materials of following weight shares: Component A 95 - 105 and Component B 2 - 8 shares; thereinto, Component A is made from such materials as membrane forming object, pigment, filling agent, auxiliary agent, compound nanometer dispersing agent and solvent; Component B is made from nanometer Sb2O3 and mixed organic solvent carriers. The dope of the invention has following advantages: at room temperature, it has prominent heavy anticorrosion performance, and has excellent performances of acid resistance, alkali resistance, salt mist resistance, oil resistance, chemical reagent resistance, waiting resistance and ultraviolet resistance; it also has excellent fire protection and waterproof performance; the clinging strength of smearing membrane is good, membrane forming speed is fast, and performance is stable.

Owner:王继征

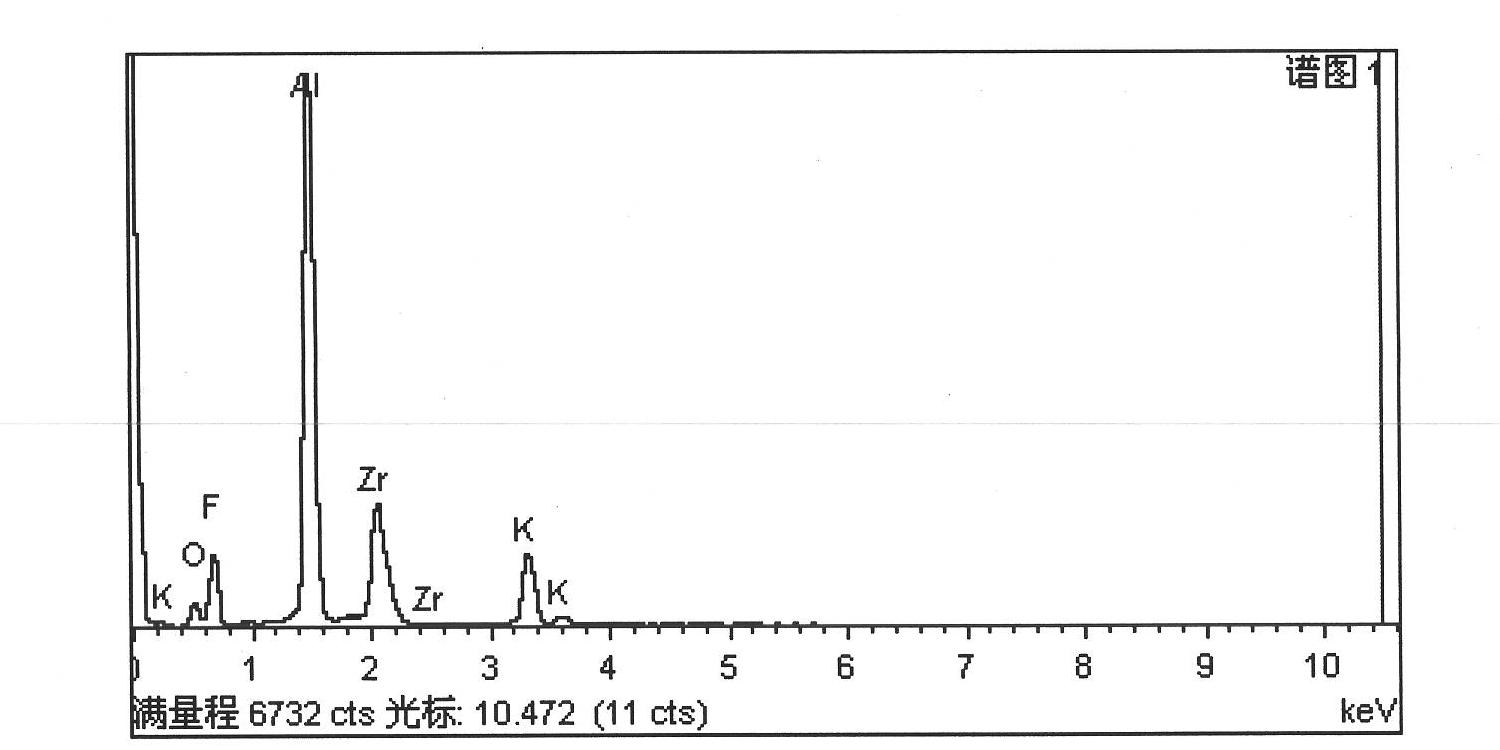

Rare-earth modified Ti-Zr chemical passivation solution for surface treatment of aluminium profiles and using method of rare-earth modified Ti-Zr chemical passivation solution

ActiveCN103103512AImprove compactnessImprove performanceMetallic material coating processesCerium nitratePotassium fluoride

The invention discloses a rare-earth modified Ti-Zr chemical passivation solution for surface treatment of aluminium profiles and a using method of the rare-earth modified Ti-Zr chemical passivation solution. The rare-earth modified Ti-Zr chemical passivation solution is characterized in that the passivation solution is a main salt for auxiliary film-formation, which takes rare-earth compounds as a Ti-Zr passivation treatment solution, and a passivation film is light yellow in appearance and has field judgement property on the quality of a formed film. A formula of the rare-earth modified Ti-Zr chemical passivation solution is as follows: each litre of solution contains 0.5g.L<-1>-10g.L<-1> of potassium fluotitanate (hexafluorotitanic acid), 0.5g.L<-1>-10g.L<-1> of potassium fluozirconate (fluozirconic acid), 0.5g.L<-1>-5g.L<-1> of cerium nitrate (ceric sulfate and ammonium ceric nitrate), 2g.L<-1>-10g.L<-1> of potassium nitrate, 0.5g.L<-1>-3g.L<-1> of sodium fluoride (potassium fluoride), 0.5g.L<-1>-1g.L<-1> of sodium dodecyl benzene sulfonate or OP-10, 0.2mL-5mL.L<-1> of nitric acid and 1g.L<-1>-5g.L<-1> of boric acid. The using method of the rare-earth modified Ti-Zr chemical passivation solution comprises the following steps of: (1) clearing dirt, such as dirt attached to an aluminium alloy; (2) pretreating the surface of the aluminium alloy; (3) carrying out passivating treatment on the surface of the aluminium alloy by using the rare-earth modified Ti-Zr chemical passivation solution; and (4) washing the aluminium alloy by using water and drying the aluminium alloy. The rare-earth modified Ti-Zr chemical passivation solution disclosed by the invention has the advantages of light yellow appearance, high film formation speed, simple process, uniformity in film layer, strong corrosion resistance, low environment pollution and the like.

Owner:GUANGDONG XINGFA ALUMINUM

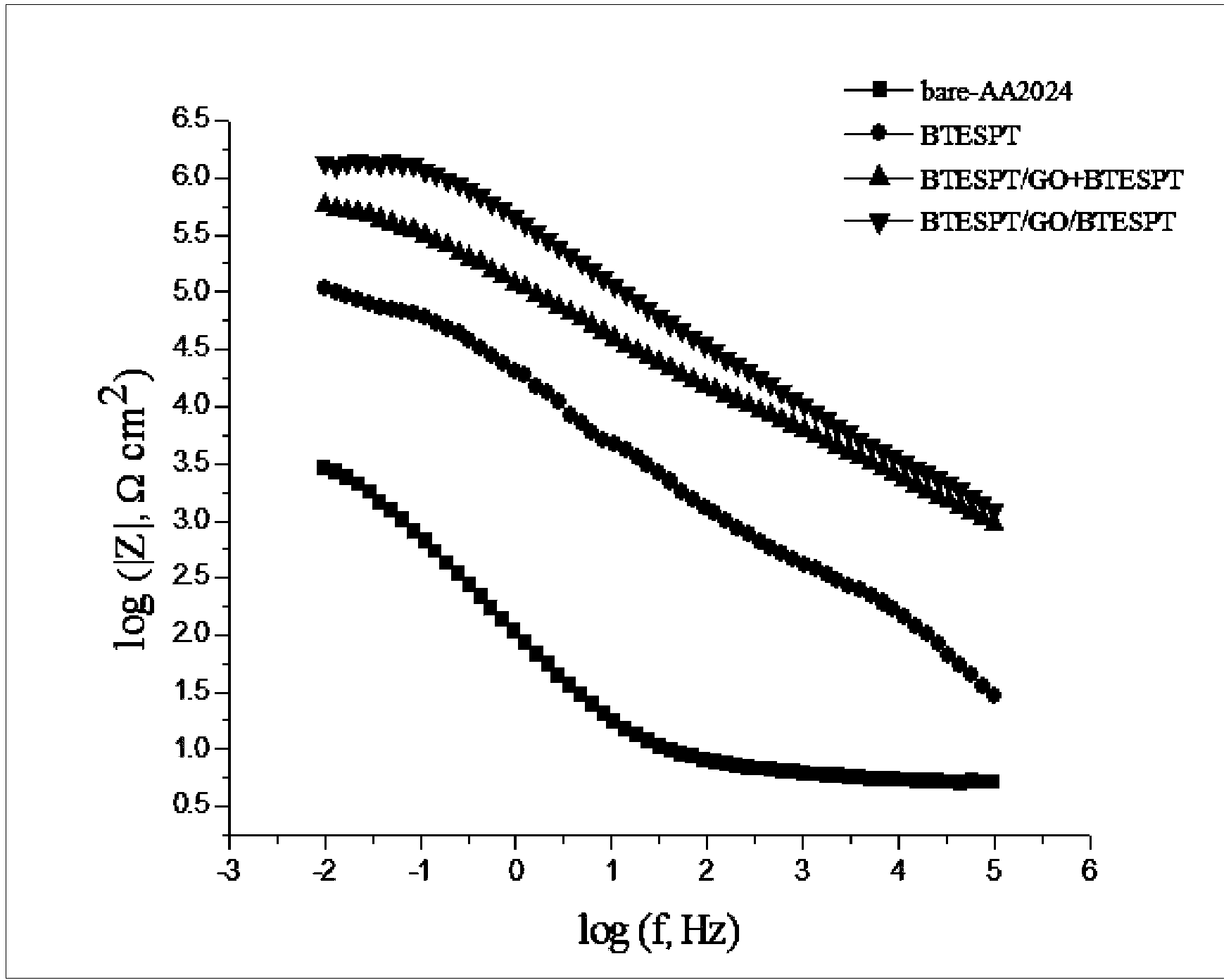

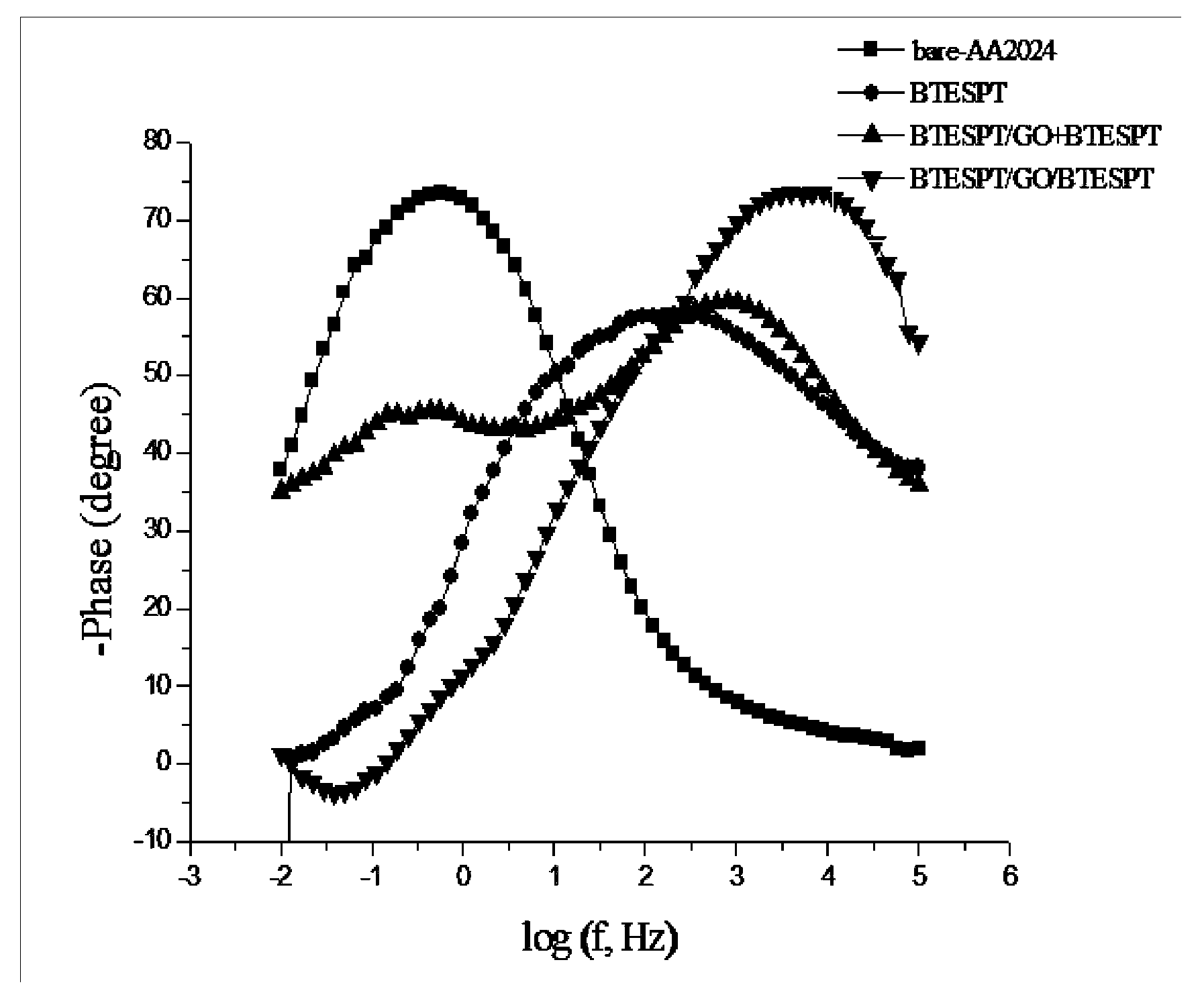

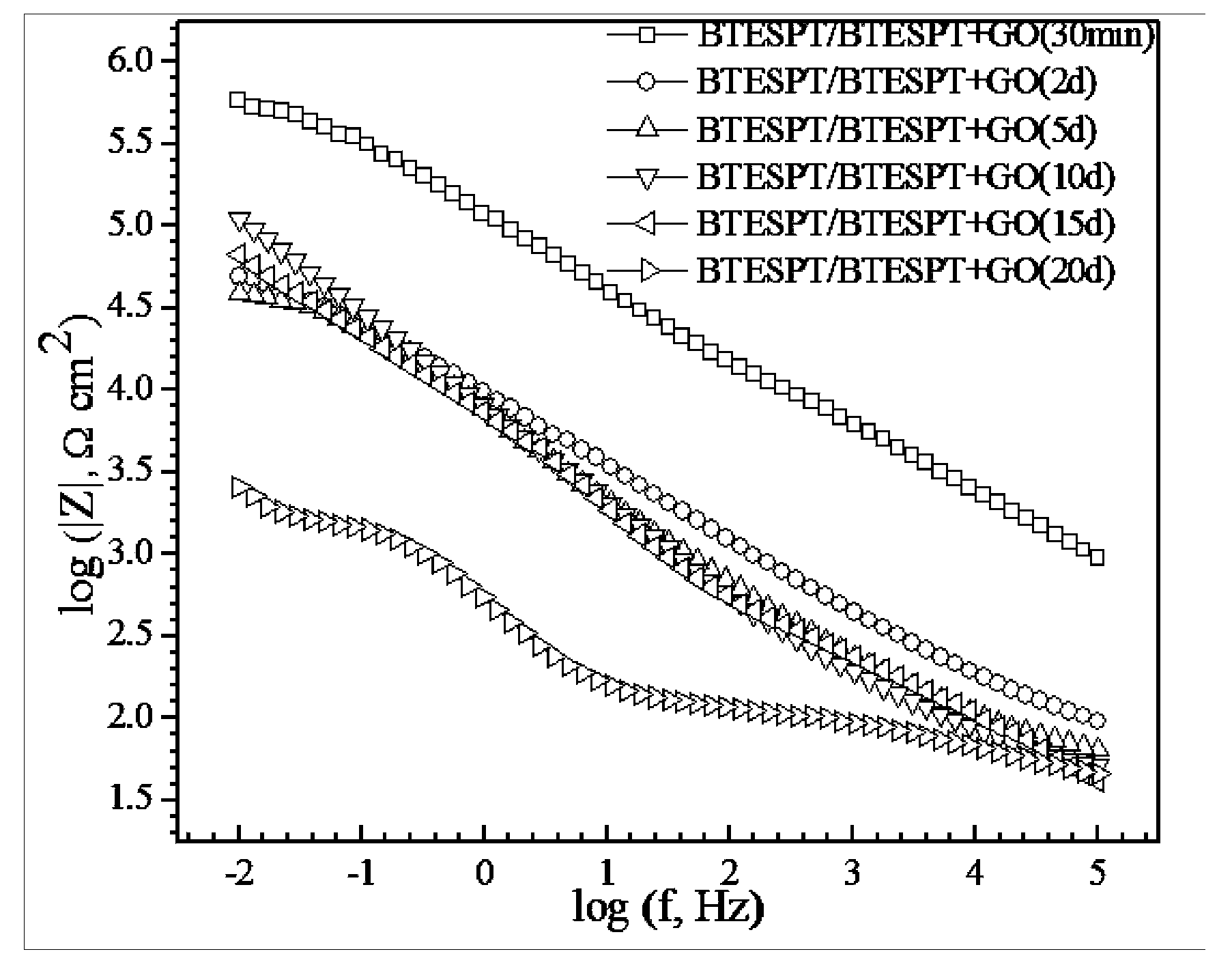

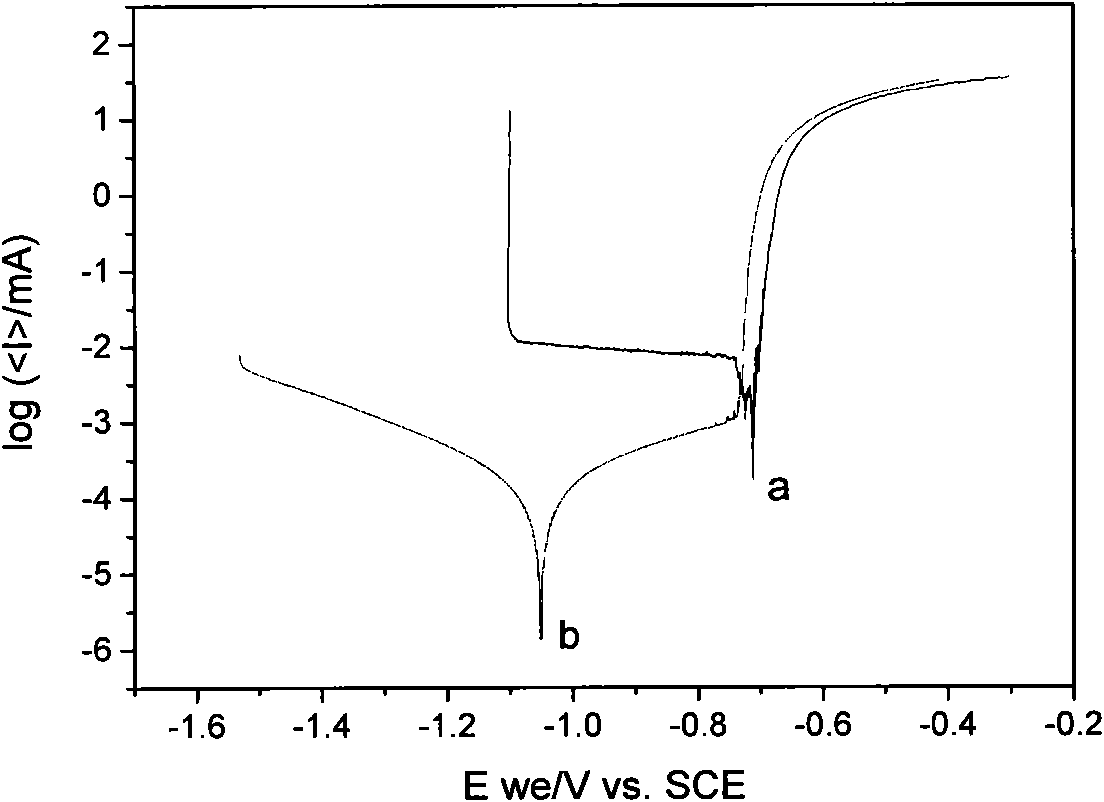

Preparation method of graphene composite anticorrosive coating

ActiveCN104231703ASimple manufacturing processFast film formationAnti-corrosive paintsElectrolytic organic material coatingPower flowDip-coating

The invention discloses a preparation method of a graphene composite anticorrosive coating. The preparation method comprises the following steps: (1) preparing an organic coating solution with a plurality of hydroxyls or amino groups; (2) preparing an oxidized graphene or modified graphene solution; (3) performing metal surface pretreatment; (4) performing electrodeposition to form an organic coating film; and (5) preparing the graphene composite anticorrosive coating. The method is simple and feasible in technology, the film forming speed is obviously improved, and the prepared coating is more compact and uniform; compared with a plain sample, the low-frequency impedance modulus value of the prepared composite coating is improved to 10<6.2> from 10<3.5> by performing electrochemical testing in 3.5wt% NaCl neutral electrolyte solution, the self-corrosion current is also remarkably reduced, and longer effective prevention effect on a matrix can be achieved. Compared with the conventional dip-coating method, the preparation method has lower requirement on the flatness of a metal surface, and controllable preparation can be effectively realized; the prepared coating is non-toxic and environment-friendly, controllable in thickness, and more compact and uniform, and more durable and stable protection effect on the metal matrix can be achieved.

Owner:OCEAN UNIV OF CHINA

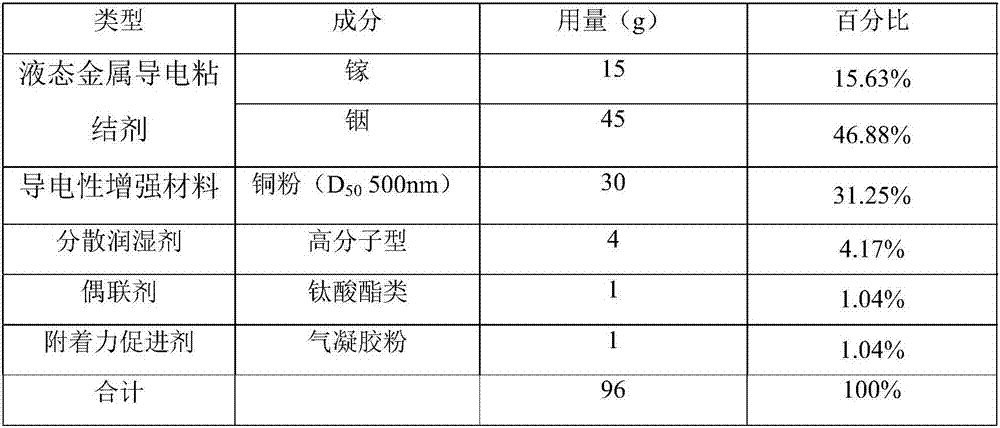

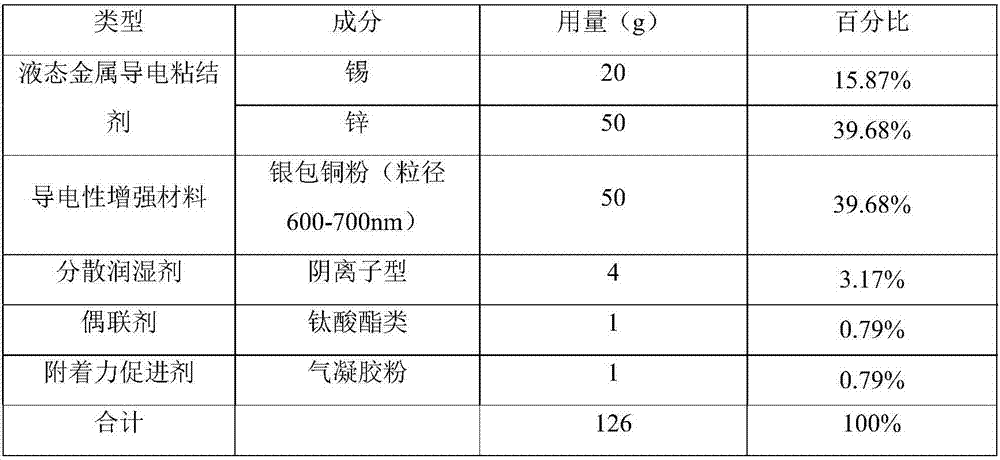

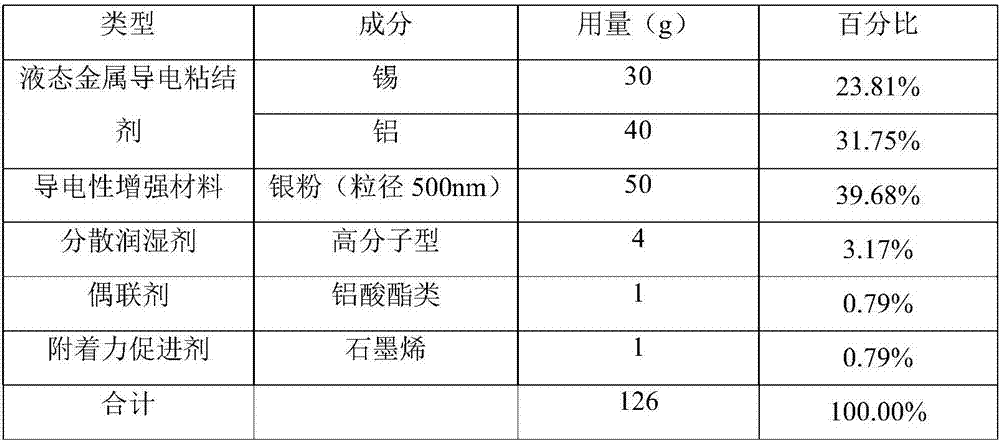

Low cost recyclable conductive paste and preparation method thereof

ActiveCN107578838AGood compatibilityImprove dispersion stabilityConductive layers on insulating-supportsMetal/alloy conductorsDispersion stabilityLiquid metal

The invention provides a low cost recyclable conductive paste. By weight percentage, 45-80% liquid metal conductive binder, 12-50% conductive reinforced material, 1-5% dispersant wetting agent, 0.5-2%coupling agent and 0.5-2% clunging promoter are comprised, wherein the liquid metal is a low melting point metal or alloy with a melting point below 300 DEG C or conductive nano-fluids formed throughmixing low melting point metal nano particles with fluid dispersant. The low cost recyclable conductive paste is advantaged in that the liquid metal conductive binder is utilized to replace a non-conductive high-molecular binder and solvent, under the synergism effect of small amount of coupling agent and the dispersant wetting agent, through adding small amount of the conductive reinforced filling material to realize uniform and stable dispersion, the low cost conductive paste with high compatibility and high dispersion stability is formed, and volume resistivity reaches 3*10<-5> Omega*cm.

Owner:BEIJING DREAM INK TECH CO LTD

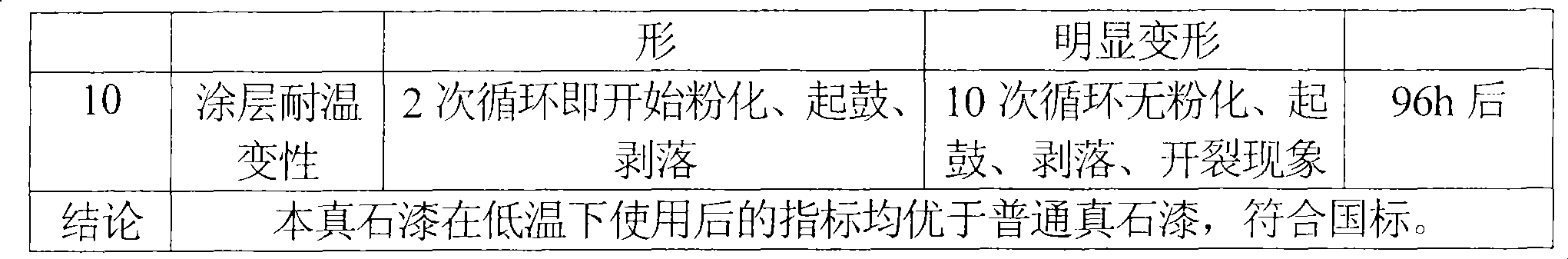

Organosilicon type marine antifouling paint binder and preparation method and application thereof

ActiveCN102212306AInhibition of adsorptionReduce usageAntifouling/underwater paintsPaints with biocidesQuaternary ammonium cationSide chain

The invention discloses organosilicon type marine antifouling paint binder. The structure of the paint binder is shown in the formula (1), wherein the paint binder is an organosilicon-polyurethane compound with bactericide side chain and R represents CH2CH3. The preparation method comprises the following preparation steps: 1) using chloropropylmethyldimethoxysilane and dimethyldimethoxysilicane to react and obtain chloropropyl-containing polysiloxane; 2) using chloropropyl-containing polysiloxane, tertiary amine and hydroxyl-containing tertiary amine to perform reflux reaction and generate polysiloxane with quaternary ammonium salt and hydroxyl; and 3) mixing isocyanate, butyltin dilaurate and polysiloxane with quaternary ammonium salt and hydroxyl with solvent, adding gamma-aminopropyltriethoxysilane to extend the chain and obtain prepolymer with the crosslinked group -Si(OCH2CH3), and using the prepolymer to perform crosslinking and condensation in the air and obtain the finished product. The organosilicon type binder has low surface energy performance and very good hydrophobicity; and the molecular chain has environmentally-friendly bactericide, thus the binder has very good bactericidal effect and marine antifouling effect.

Owner:ZHEJIANG UNIV

Environment-friendly type composite pre-film reagent used for recirculated cooling water system pre-film processing and method of use thereof

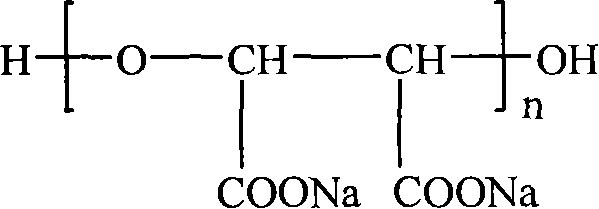

InactiveCN101182643AReduce total usageUse low concentrationScale removal and water softeningLiquid wasteTricarboxylic acid

The invention belongs to the circulating cooling water treatment technical field, and refers in detail to an environment-protecting composite pretreatment filming agent used for the pre-treatment filming in a circulating cooling water system and a use method thereof. The environment-protecting composite pretreatment filming agent comprises the main components of 2-phosphonobutane- 1, 2, 4-tricarboxylic acid and sodium of polyepoxysuecinic acid as well as a proper amount of carboxylic acid copolymer, benzotriazole, sodium molybdate, zinc sulphate and so on. When used, the composite pre-treatment filming agent is added into the circulating cooling water directly, and a corrosion-resistant protecting film is formed after 48 years of operation, the corrosion resistance of which to the standard copper sulphate drip solution is far better than the traditional phosphor-zinc pretreatment filming agent. The total phosphor content of the environment-protecting composite pretreatment filming agent is less than 7.5mg / l, and the water pH value does not have to be adjusted. After the pretreatment filming, the water is clear and transparent, and the normal operation can be started without replacing the water. Thus, not only the water to be replaced is saved, but also the chemical base investment expense during the normal operation after the water replacement is reduced. Meanwhile, no waste liquor of pretreatment filming is discharged, so the invention belongs to the environment-friendly pretreatment filming method.

Owner:TONGJI UNIV

Oxidized graphene film, graphene film, preparation method and application thereof

The invention provides an oxidized graphene film, a graphene film, a preparation method and application thereof. The preparation method of the oxidized graphene film comprises: 1) preparing an aqueous solution or organic solvent solution of graphite oxide from graphite by a conventional method; 2) adding an organic solvent or water into the aqueous solution or organic solvent solution of graphite oxide, conducting a first ultrasonic treatment and a first centrifugal treatment, taking the solid, then adding a mixed solvent consisting of water and the organic solvent into the solid, carrying out a second ultrasonic treatment and a second centrifugal treatment, and taking the supernatant, i.e. an oxidized graphene solution; and 3) employing a Langmuir-Blodgett method to add the oxidized graphene solution dropwisely on a water surface so as to form the oxidized graphene film on a water-air interface, and then transferring the oxidized graphene film to a substrate.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

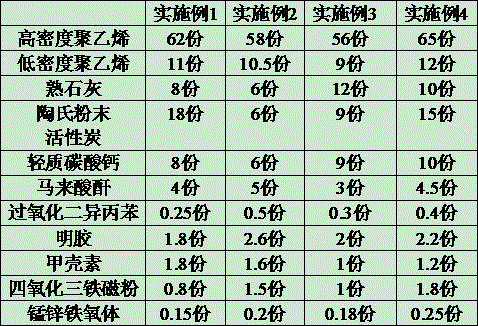

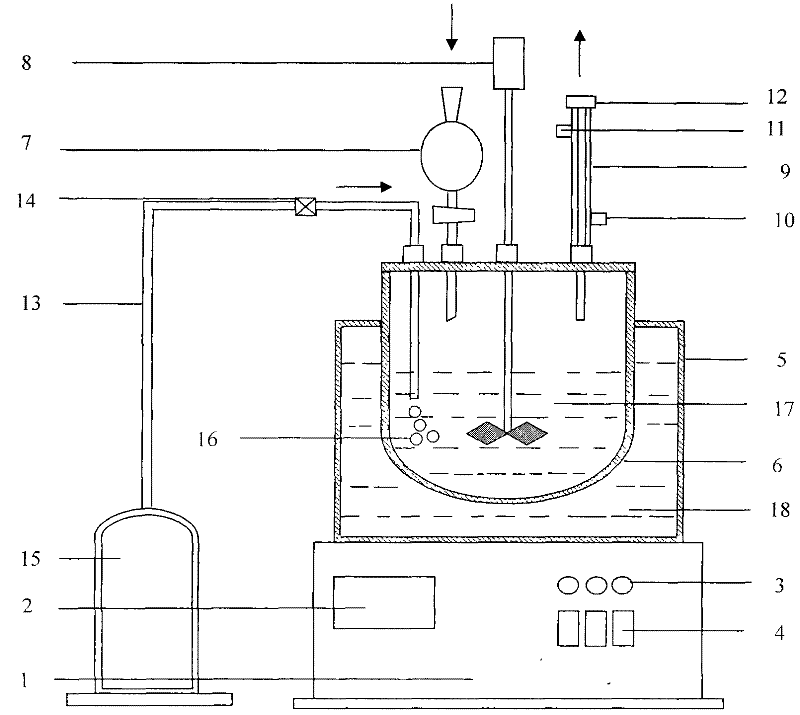

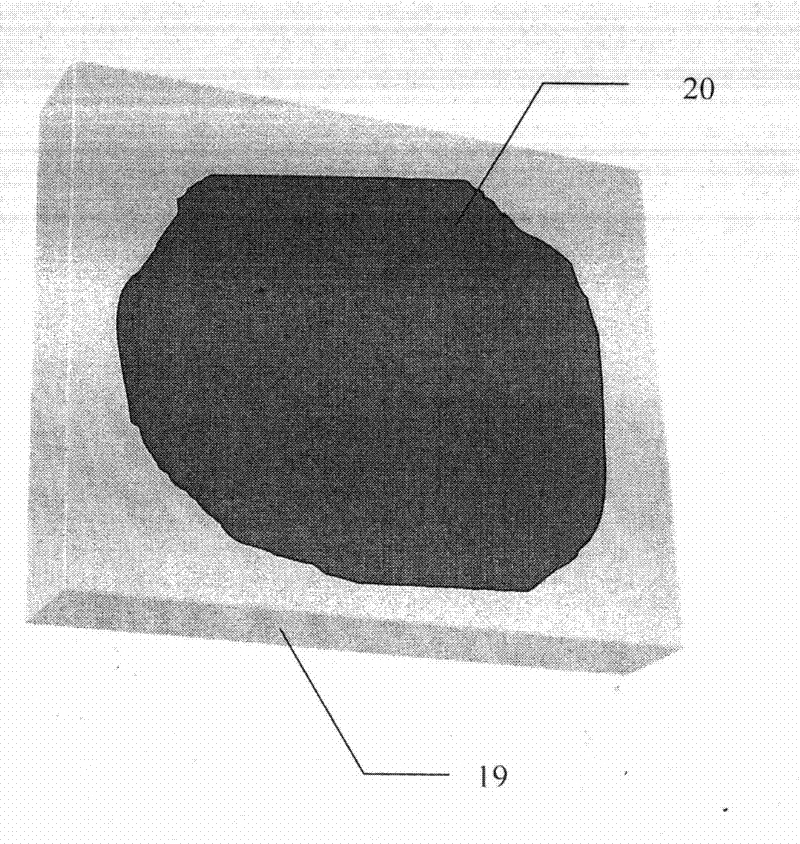

Hydrophilic carrier for microbial biofilm formation

InactiveCN105621595ANot easy to fall offPromote sheddingTreatment with microorganism supports/carriersLow-density polyethyleneMicrobial Biofilms

The invention discloses a hydrophilic carrier for microbial biofilm formation. The hydrophilic carrier comprises a hollow short tube, and a first concentric ring and a second concentric ring which are sequentially concentrically arranged outside the hollow short tube, wherein the surface of the outermost second concentric ring is toothed; and the microbial filler is composed of the following components in parts by weight: high-density polyethylene, low-density polyethylene, white lime, Dow powder activated carbon, light calcium carbonate, maleic anhydride, dicumyl peroxide, gelatin, chitin, ferroferric oxide magnetic powder and manganese-zinc ferrite. The density of the microbial filler is 0.96-0.98 g / cm<3>. The hydrophilic carrier for microbial biofilm formation prolongs the contact time between microbes and organic matters, so that the organic matters are degraded quickly and thoroughly; and the biological oxidation can restore the surface adsorption capacity of the activated carbon.

Owner:KOOVINE ENVIRONMENTAL PROTECTION TECH CO LTD

Process for preparing carbon nano tube film through electrophoresis deposition

InactiveCN1570220AShort preparation cycleControl thicknessElectrophoretic coatingsHigh volume manufacturingElectrophoresis

A method for electrophoretic deposition preparation of the carbon nanotube film belongs to the field of the nano materials technology. The preparing method comprises the following steps: purification treatment and face finish for the carbon nanotube, the formation of the carbon nanotube stable suspension, electrophoretic deposition for the carbon nanotube film, film drying, and second electrophoretic deposition. The invention has the advantages of simple production equipment, rapid film forming speed, controllable film thickness, and unlimited substrate shape.

Owner:TSINGHUA UNIV

Aqueous asphalt-based epoxy resin waterproof material composition and preparation process thereof

ActiveCN102464890AImprove stabilityGood high and low temperature resistanceBuilding insulationsEpoxyEmulsion

The invention provides a high-performance aqueous asphalt-based epoxy resin waterproof material composition and a preparation process thereof. The composition comprises 45 to 55% of emulsified asphalt, 25 to 35% of cationic SBR latex, 10 to 20% of epoxy resin emulsion, 2 to 8% of epoxy resin curing agent emulsion and 0.05 to 0.15% of an antifoaming agent. A waterproof material provided in the invention has the following advantages: (1) the waterproof material has excellent resistance to high and low temperature and excellent toughness, and the material does not flow at a high temperature more than 140 DEG C, is not crisp at a low temperature of -20 DEG C and has great adhesion stress; (2) the waterproof material is environment friendly, the preparation process is simple, and a system is stable; (3) construction performance is good, and surface film formation is fast.

Owner:CHINA PETROLEUM & CHEM CORP +1

Quick preparation method for graphene oxide film

The invention relates to a quick preparation method for a graphene oxide film, which comprises the following steps: taking crystalline flake graphite powder as a raw material, taking a piece of plain glass as a film-forming carrier, taking sulfuric acid, sodium nitrate, potassium permanganate and hydrogen peroxide as materials used in a preparation process, taking deionized water as a solvent and taking nitrogen as a protection gas; firstly, preparing a graphene oxide solution in a four-hole boiling flask and using a salpeter solution to flocculate the graphene oxide solution; and then forming a film on the plain glass; and vacuum-drying the film, thereby acquiring the graphene oxide film. The graphene oxide film is 1-2 mu m in thickness and has high strength and excellent toughness as well as excellent breaking strength resistance. The quick preparation method has the advantages that the process flow is short, the speed is high, the operation is simple and the mass production can be realized. The prepared film can be applied to carriers of paper battery and fuel battery catalysts. The quick preparation method is an ideal method for quickly preparing the graphene oxide film.

Owner:TAIYUAN UNIV OF TECH

Solid-liquid interface self-assembly preparation method for graphene oxide film

The invention relates to a solid-liquid interface self-assembly preparation method for a graphene oxide film, which comprises the following steps: adding graphite oxide into solvent to carry out ultrasound with the ultrasonic power of 20-300W; after aluminum or aluminum alloy is carried out natural oxidation layer removal preprocessing, placing the aluminum or the aluminum alloy into acid electrolyte; applying voltage to carry out first anodic oxidation processing; soaking in a mixing solution of phosphoric acid and chromic acid to remove a first anodic oxidation film so as to retain a highlysequential shell-shaped convex-concave structure on the surface of the metal aluminum; carrying out second anodic oxidation under the same condition with the first anodic oxidation; adopting a concaveposition as an initial forming locus of a hole and forming a highly sequential hole array so as to acquire a porous anodic aluminum oxide solid film attached to a matrix of the aluminum; soaking theanodic aluminum oxide film into a prepared soluble graphene oxide film solution; standing and then taking out to air or dry to obtain the graphene oxide film. The preparation method for the graphene oxide film has simple operation, high film forming speed and adjustable thickness and size of the film.

Owner:SHENZHEN CTRUST TESTING TECH CO LTD

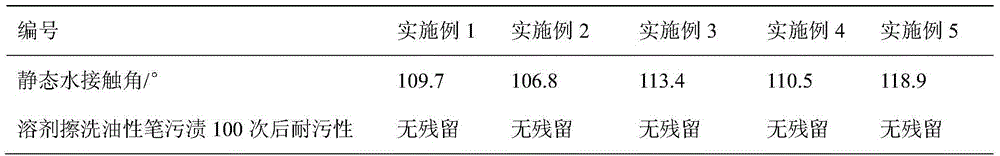

Inorganic nano composite anti-doodling resin and preparation method thereof

ActiveCN104558447AEasy to modifyGood weather resistanceAntifouling/underwater paintsPaints with biocidesRadical polymerizationWeather resistance

The invention discloses an inorganic nano composite anti-doodling resin and a preparation method thereof. Silane-coupling-agent-modified inorganic nanoparticles, fluorine-containing acrylate monomer, alkyl acrylate monomer and hydroxyalkyl acrylate monomer are subjected to free-radical polymerization reaction to obtain the inorganic nano composite anti-doodling resin. The film formed by the inorganic nano composite anti-doodling resin has the advantages of excellent weather resistance, excellent scratch resistance, excellent chemical corrosion resistance, excellent ultraviolet resistance, excellent wear resistance, low surface energy, excellent pollution resistance and excellent anti-doodling performance, thereby implementing the long-term anti-doodling action. The invention relates to the field of an anti-doodling resin and a preparation method thereof.

Owner:HANGZHOU JIHUA POLYMER MATERIAL CO LTD

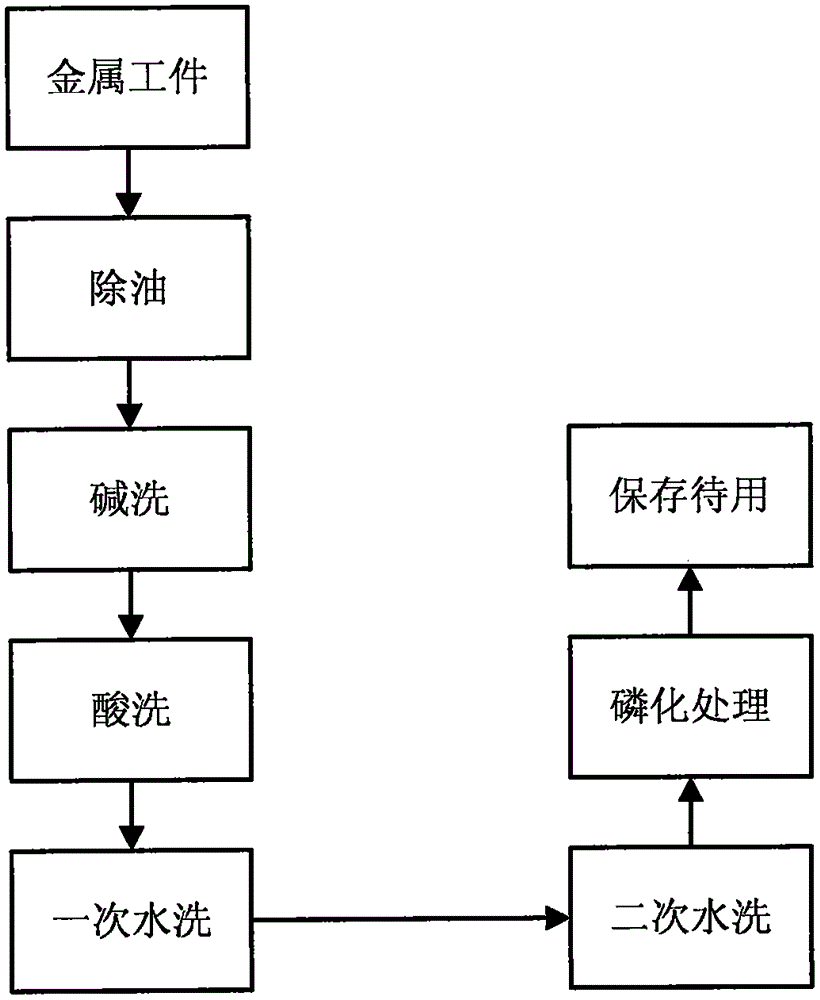

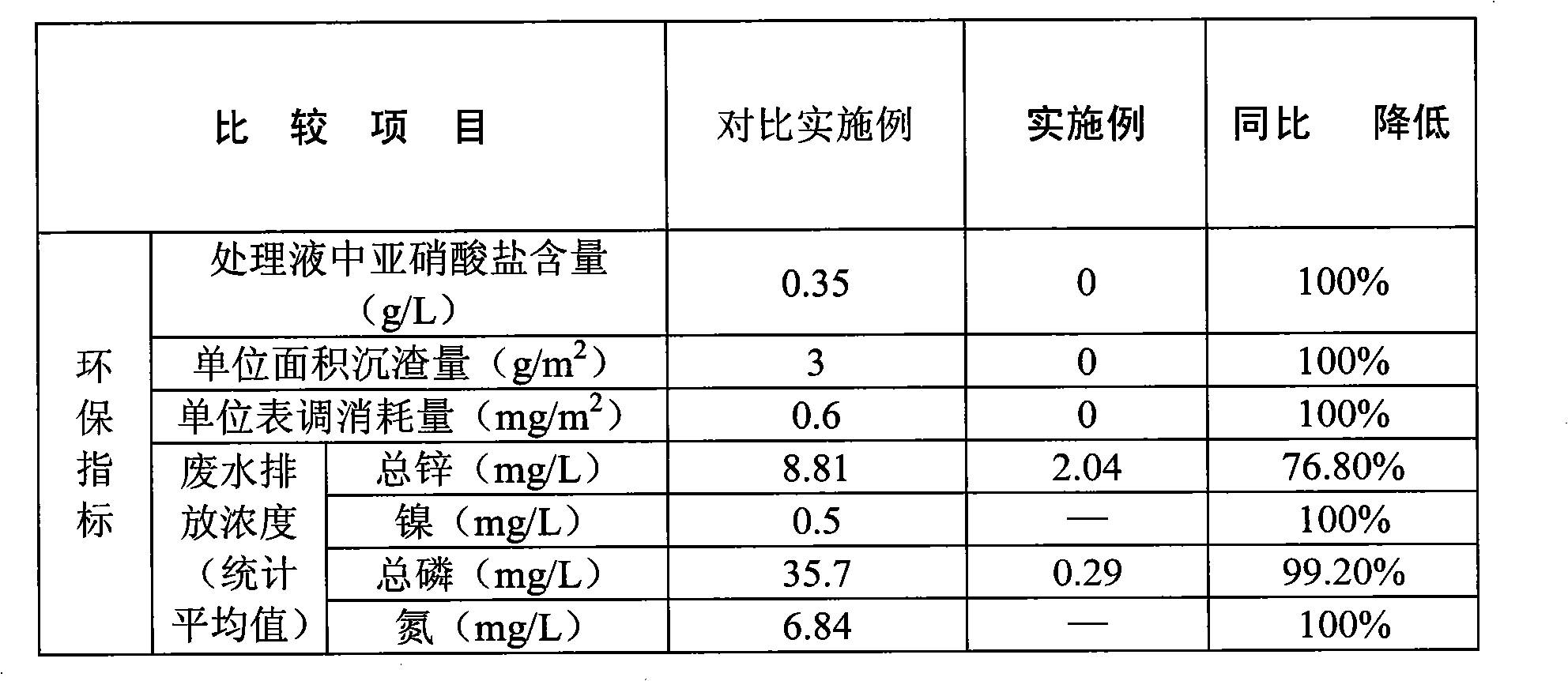

Before-coating metal surface treatment method

ActiveCN105369271AImprove permeabilityFast film formationMetallic material coating processesNonferrous metalAcid washing

The invention discloses a before-coating metal surface treatment method. The before-coating metal surface treatment method comprises such steps as oil removal, alkali washing, acid washing, two times of water washing and phosphorization. Adopted environment-friendly alkaline cleaning liquid has the technical effects of energy conservation and environmental protection, and has an excellent cleaning effect on both black metal and nonferrous metal; adopted phosphorization liquid has such advantages as quick film formation, strong paint film bonding force, good corrosion resistance, capability of operating through brushing or spraying, simple operation and low cost; the prepared phosphorization liquid reduces phosphorization liquid sediments, and guarantees the quality of phosphorized film; and the film layers are uniform and exquisite, so that the metal surface treatment method can realize the before-coating metal surface treatment more environment-friendly and more efficiently, and has active effects on the coating process and the coating quality.

Owner:苏州天成涂装系统股份有限公司

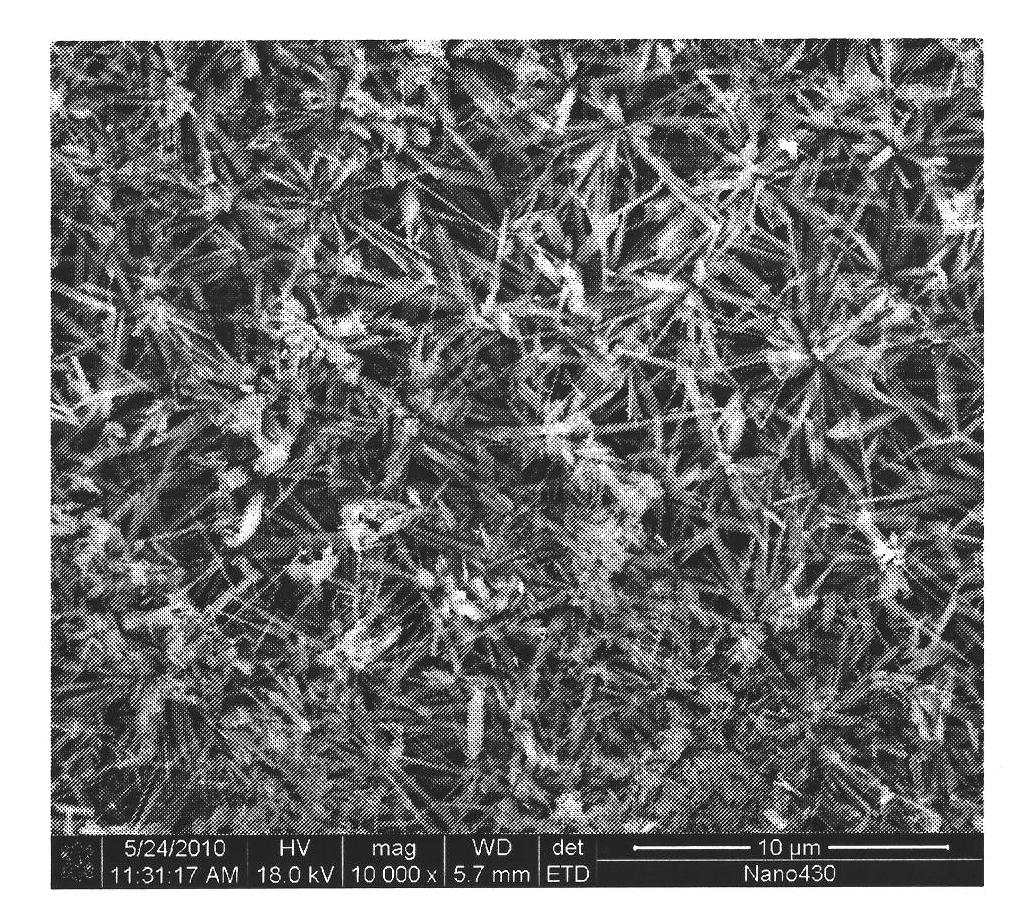

Treating fluid for preparing zirconium-containing coloring passive film on surface of aluminum alloy and treating method thereof

InactiveCN101985750AHigh bonding strengthImprove the protective effectMetallic material coating processesPotassium fluorideCompound (substance)

The invention discloses a treating fluid for preparing a zirconium-containing coloring passive film on the surface of an aluminum alloy and a treating method thereof. The zirconium chemical passive treating fluid comprises the following main components of: potassium fluoride, a pH value regulator, fluorozirconate and / or potassium fluozirconate; and the pH value of the treating fluid is between 2.5 and 4.5, and the film can be formed within 3 to 10 minutes. The color of the passive layer prepared by the method is black gray; the film layer is tightly combined with a substrate; and the film layer has high strength and high corrosion resistance. The method is simple in operating process, and a coating does not contain hexavalent chromium which is harmful to the environment and human bodies.

Owner:SOUTH CHINA UNIV OF TECH

Aluminum alloy surface rare earth chemical conversion treatment method

InactiveCN101260521AEasy to operateGolden colorMetallic material coating processesCleaning using liquidsCeriumAccelerant

The invention discloses a method for treating the rare earth chemical conversion on the surface of aluminium alloy. The method comprises a pretreatment procedure on the surface of the aluminium alloy, the preparation of rare earth chemical conversion treating liquid and the treatment of rare earth chemical conversion. The rare earth chemical conversion treating liquid consists of 10 to 30g / L cerium salt, 1 to 5g / L oxidant solution, 0 to 5x10<-2> mol / L film forming accelerant and 1 to 3g / L film forming surface morphology truing agent; the PH value of the treating liquid is 1 to 3; the cerium salt is selected form one or two of hydrous cerium chloride and hydrous cerous nitrate; the film forming accelerant is one or a plurality of transitional metal free ions; the film forming process is completed in 5 to 15 minutes. The method for treating a coating by conversion has high combining intensity with a substrate, good protective performance and simple structure; the coating contains no hexavalent chrome or trivalent chromium which is harmful to the environment and human body.

Owner:SOUTH CHINA UNIV OF TECH

Prepn and application in industrial effluent treatment of biomembrane carrier

InactiveCN101066802AFast fixationPromote growthTreatment with aerobic and anaerobic processesSustainable biological treatmentEpoxyElectrolytic agent

The present invention relates to one kind of functional biological carbon fiber and its preparation process and application as biomembrane carrier. The biomembrane carrier is prepared with polyacrylonitrile carbon fiber, and through electrochemical surface treatment in 5-20 % concentration ammonium bicarbonate electrolyte to increase the surface acid oxygen containing functional groups and raise wettability, and gluing with water soluble epoxy resin in the amount 0.5-2 %. The biomembrane carrier can fix nitrobacteria, sulfate reducing bacteria and anaerobic methanogen. It may be used in treating high concentration acrylon waste water, and can eliminate sulfate, COD and ammonia nitrogen effectively. In addition, the biomembrane carrier is easy to regenerate and has no secondary pollution.

Owner:BEIJING UNIV OF CHEM TECH

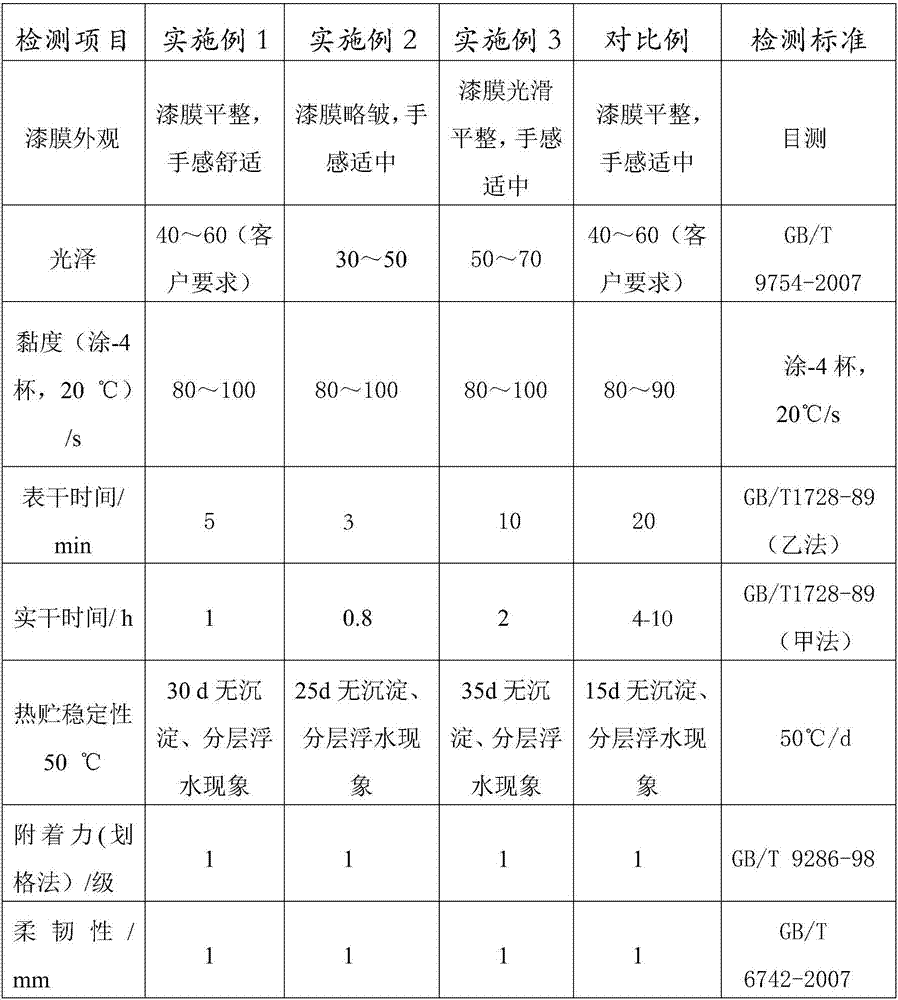

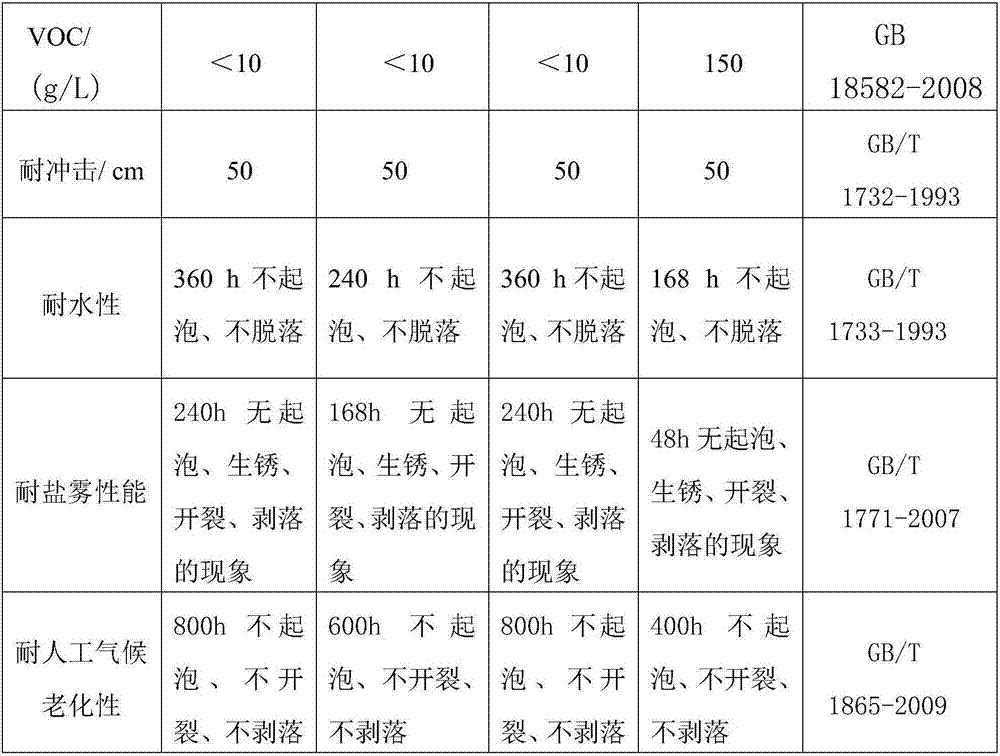

Water-based single-component primer-topcoat paint and preparation method thereof

InactiveCN107057533AFast film formationSimple internal structureAnti-corrosive paintsEmulsion paintsWater basedEpoxy

The invention discloses water-based single-component primer-topcoat paint and a preparation method thereof and relates to the technical field of anti-corrosion coatings. The water-based single-component primer-topcoat paint is prepared by mixing and stirring the following components in parts by weight: 400-600 parts of a water-based epoxy resin-modified acrylic emulsion, 1-3 parts of a pH modifier, 30-80 parts of an environment-friendly cosolvent, 5-20 parts of a dispersing agent, 0.5-3 parts of an antifoaming agent, 2-3 parts of a flatting agent, 3-5 parts of a base material wetting agent, 5-20 parts of a flash-rust inhibitor, 10-20 parts of a thickener, 20-40 parts of an anti-settling agent, 50 parts of a pigment, 70-150 parts of a rust protection filler and 150-250 parts of deionized water. The water-based single-component primer-topcoat paint has the characteristics of being high in drying speed, high in anticorrosion property, low in VOC (volatile organic compound), simple in construction and operation and high in one-time film-forming property.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Surface pretreatment agent before metal coating and preparation method and use method thereof

InactiveCN101660153AImprove densification performanceTightly boundMetallic material coating processesWater solubleFilm-forming agent

The invention discloses a surface pretreatment agent before metal coating, consisting of components with the following weight ratio: 15-19 portions of film-forming agents; 15-19 portions of coupling agents; 18-23 portions of water-soluble F-containing complex compounds; and 85-90 portions of water. A method for preparing the surface pretreatment agent before metal coating is as follows: firstly wetting the film-forming agents sufficiently with water; and then adding the coupling agents, the F-containing complex compounds or the salts thereof, and the balance of water to be evenly mixed; the method for using the surface pretreatment agent before metal coating comprises the following steps of: firstly using water to dilute the surface pretreatment agent before metal coating until the pH value thereof is 4.5-6; spraying or infiltrating the surface of the treated metal with the treatment time of 30s-90s; and by adopting the technical scheme, the film can be tightly combined with the coating on the metal surface, forms a middle layer with very strong combination force between the metal and the coating, has very good combination force both with the metal surface and the coating, and cancompletely replace the phosphating agent.

Owner:安徽天航机电有限公司

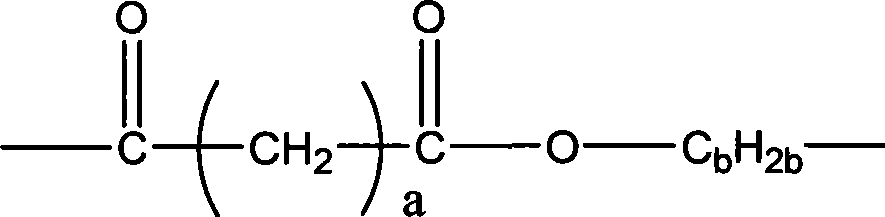

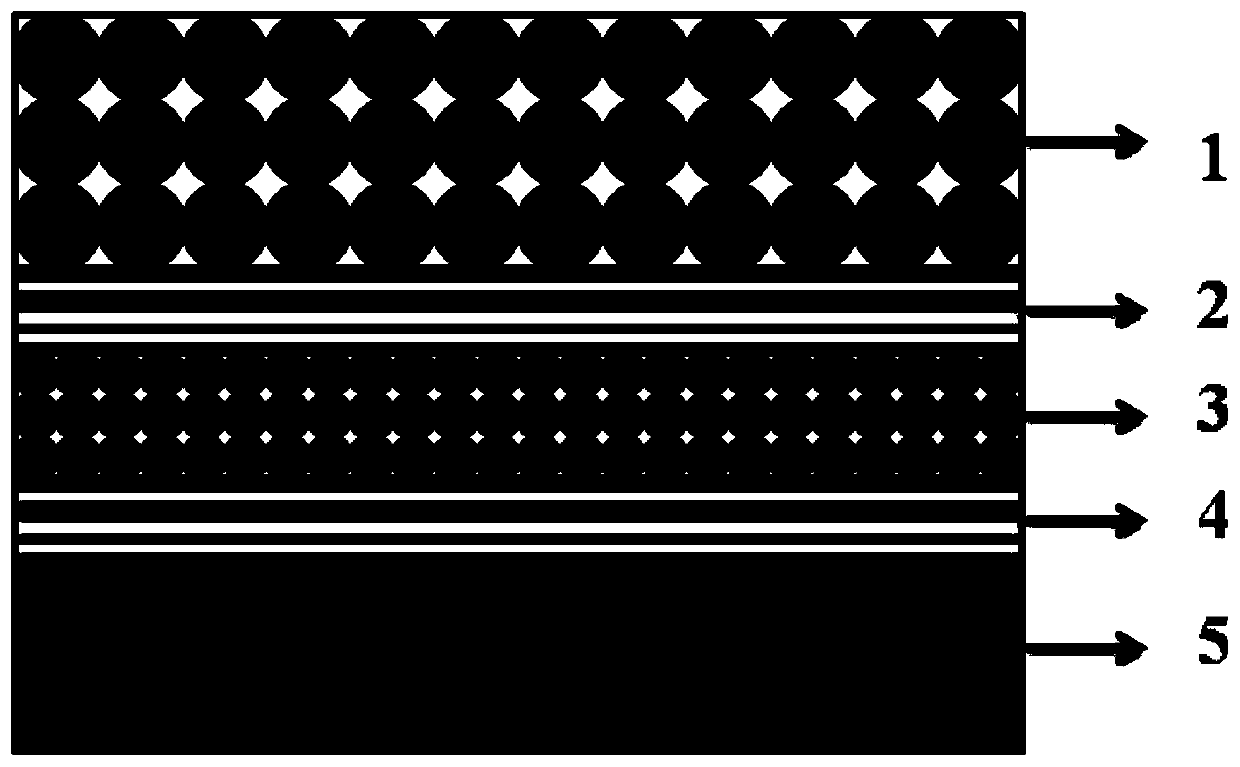

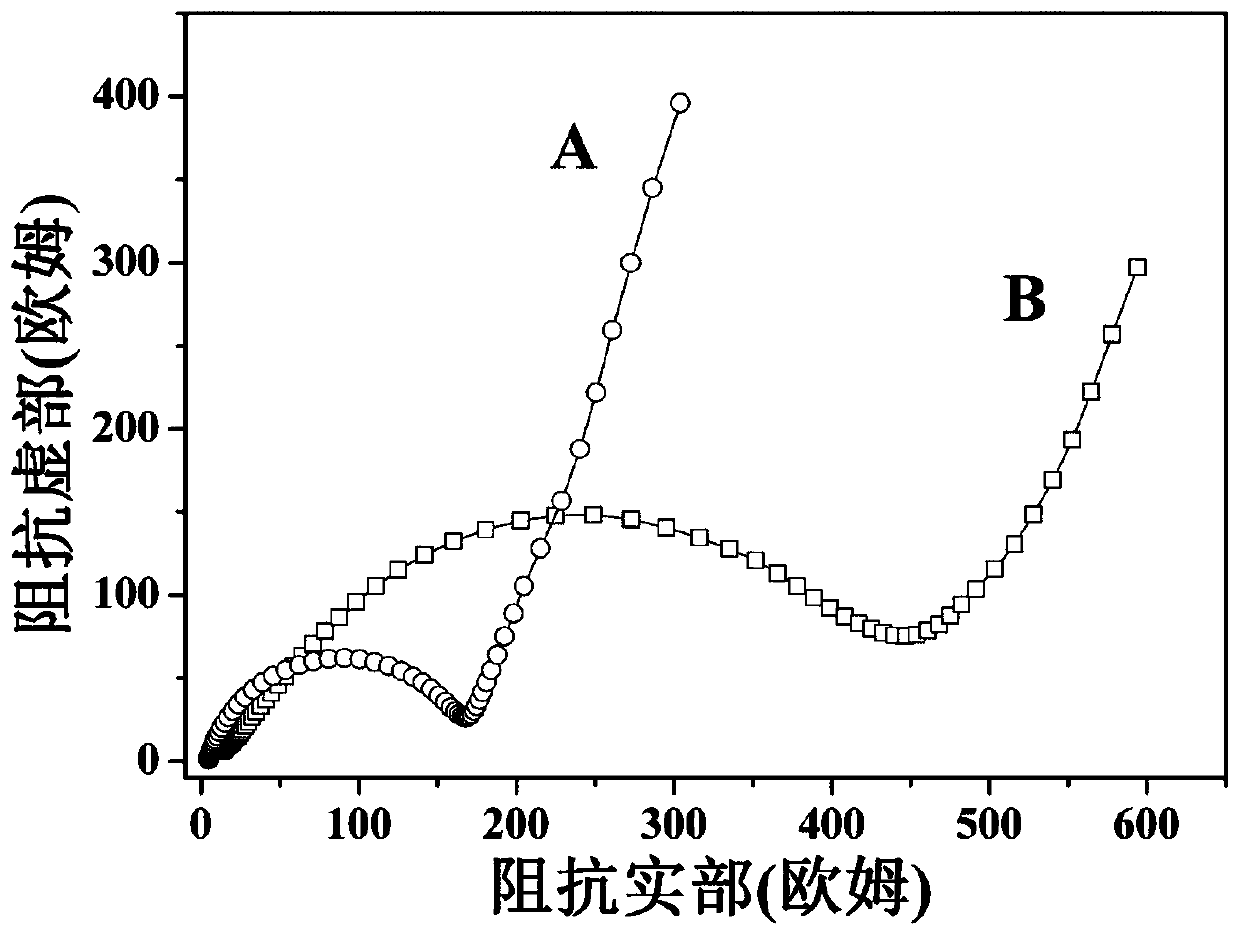

Buffer layer for sulfide solid-state battery, preparation method of buffer layer, and solid-state battery

ActiveCN110034275AFast film formationIncrease relative volatilityFinal product manufactureSecondary cellsSolid state electrolyteElectrical battery

The invention provides a buffer layer for a sulfide solid-state battery. The buffer layer comprises a polymer material and ethylene carbonate, and is formed in situ on an electrode plate through a buffer layer solution; and due to the existence of a polymer, poor physical contact between an electrode and an electrolyte caused by volume deformation of a positive electrode material in a charging / discharging process can be improved. The buffer layer is existent between the positive electrode and the solid electrolyte of the solid-state battery and between the negative electrode and the solid-state electrolyte, so that the solid-solid interface impedance can be reduced; and meanwhile, good ionic conductivity of the buffer layer can improve the lithium ion transmission capacity. The sulfide composite positive electrode in the solid-state battery provided by the invention contains the polymer material, and the existence of the polymer can improve the poor physical contact between the electrode and the electrolyte caused by the volume deformation of the positive electrode material in the charging / discharging process; and meanwhile, the solid-state battery contains the buffer layer, so that the solid-state battery has low interface resistance and high ionic conductivity, and is excellent in capacity and cycling performance.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

Sputtering target and process for producing the same

ActiveCN101189358AImprove featuresInhibit deteriorationVacuum evaporation coatingSputtering coatingRefractive indexRecording layer

A sputtering target, which contains Al2O3: 0.2 to 3.0 atomic%, MgO and / or SiO2: 1 to 27 atomic%, and the balance is ZnO, which has low refractive index and low volume resistance. A method for manufacturing a sputtering target, the sputtering target has low refractive index and low volume resistance, wherein the raw material Al2O3 powder and ZnO powder are pre-mixed and pre-calcined, and then the calcined Al2O3-ZnO mixed powder Mix MgO and / or SiO2 powder in and sinter. The present invention provides a target for forming an optical thin film that does not contain sulfur, has low volume resistance, can realize DC sputtering, and has a low refractive index, and a manufacturing method thereof. Since it has a high transmittance and is composed of a non-sulfide system, it is useful for the formation of a thin film for an optical information recording medium that is less prone to degradation of the adjacent reflective layer and recording layer. Improvement in the characteristics of the optical information recording medium, reduction in equipment cost, and significant improvement in throughput through an increase in film formation speed can be achieved.

Owner:JX NIPPON MINING & METALS CO LTD

High-strength antibacterial aluminum alloy for aluminum alloy ladder and preparation method thereof

ActiveCN107201469AHigh hardnessImprove toughnessAnodisationMicro arc oxidationPlasma electrolytic oxidation

The invention relates to the technical field of aluminum alloy ladder preparation, and particularly relates to high-strength antibacterial aluminum alloy for an aluminum alloy ladder and a preparation method thereof. The aluminum alloy comprises a high-strength aluminum alloy matrix and a micro-arc oxidation film, wherein the micro-arc oxidation film is arranged on the surface of the aluminum alloy matrix, the weight of a hole sealing agent on the micro-arc oxidation film is 0.15 g / cm<2> to 0.90 g / cm<2>, and the hole sealing agent covers at least 92% of micropores in the micro-arc oxidation film. The preparation method comprises the steps of smelting metal, modifying, refining and degassing, pouring and forming and performing quenching treatment, aging treatment, micro-arc oxidation and hole sealing treatment, wherein in the step of modifying, nanometer modificators are uniformly dispersed into liquid alloy obtained by smelting; in the step of refining and degassing, 0.23% to 0.38% of hexachloroethane is added to the modified liquid alloy so as to refine and degas; and the aging treatment is divided into four-stage aging treatment. The aluminum alloy prepared by adopting the preparation method has the characteristics of high hardness, high strength, wear resistance, corrosion resistance, good anti-cracking performance, good antibacterial effect, difficulty in aging and deformation and long service life.

Owner:浙江洋铭实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com