Inorganic nano composite anti-doodling resin and preparation method thereof

An anti-graffiti resin, inorganic nano technology, applied in anti-corrosion coatings, anti-fouling/underwater coatings, coatings, etc., can solve the problems of loss of anti-graffiti effect, decline of anti-graffiti performance, etc., and achieve better modification effect and improvement Weather resistance, uniform distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

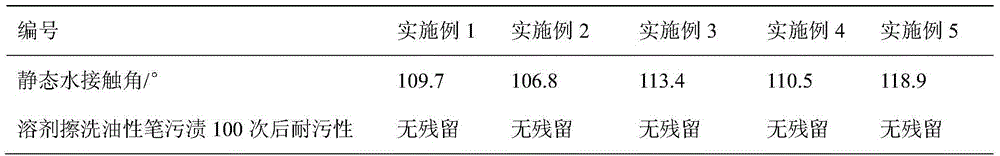

Examples

Embodiment 1

[0033] (1) Mix nano-silica with a particle size of 10nm, ethanol, water and γ-methacryloxypropyltrimethoxysilane in a mass ratio of 1:20:5:0.5, and reflux in a water bath at 55°C After reacting for 8 hours, the temperature was lowered to room temperature after the reaction was stopped, and the product was centrifuged and washed to obtain C=C modified silane coupling agent-modified inorganic nanoparticles.

[0034] (2) Dissolve 0.15 parts of 2,2'-azobisisobutyronitrile in 9 parts of butyl acetate, and preheat to 60°C to obtain the first solution.

[0035] (3) 5 parts of silane coupling agent modified inorganic nanoparticles, 10 parts of [N-methyl perfluorohexanesulfonamido] ethyl methacrylate, 20 parts of methyl methacrylate, 10 parts Glycidyl methacrylate, 0.3 parts of dodecyl mercaptan and 0.3 parts of 2,2'-azobisisobutyronitrile were dissolved in 18 parts of butyl acetate to obtain a second solution.

[0036] (4) Add the second solution obtained in step (3) to the first sol...

Embodiment 2

[0038] (1) Mix nano-silica with a particle size of 50nm, ethanol, water and γ-methacryloxypropyltrimethoxysilane in a mass ratio of 1:40:10:2.5, and reflux in a water bath at 55°C After reacting for 12 hours, the temperature was lowered to room temperature after the reaction was stopped, and the product was centrifuged and washed to obtain C=C modified silane coupling agent-modified inorganic nanoparticles.

[0039] (2) Dissolve 0.15 parts of 2,2'-azobisisobutyronitrile in 9 parts of ethylene glycol ethyl ether acetate, and preheat to 60°C to obtain the first solution.

[0040] (3) 5 parts of silane coupling agent modified inorganic nanoparticles, 10 parts of [N-methyl perfluorobutanesulfonamido] ethyl methacrylate, 20 parts of methyl acrylate, 10 parts of methyl Glycidyl acrylate, 0.3 parts of dodecyl mercaptan and 0.3 parts of 2,2'-azobisisobutyronitrile were dissolved in 18 parts of ethylene glycol ether acetate to obtain a second solution.

[0041] (4) Add the second solu...

Embodiment 3

[0043] (1) Mix nano-silica with a particle size of 100nm, ethanol, water, and γ-methacryloxypropyltrimethoxysilane in a mass ratio of 1:50:12:3.5, and reflux in a water bath at 55°C After reacting for 16 hours, the temperature was lowered to room temperature after the reaction was stopped, and the product was centrifuged and washed to obtain C=C modified silane coupling agent-modified inorganic nanoparticles.

[0044] (2) Dissolve 0.3 parts of benzoyl peroxide in 12 parts of methyl ethyl ketone, and preheat to 75° C. to obtain the first solution.

[0045] (3) 10 parts of silane coupling agent modified inorganic nanoparticles, 20 parts of [N-methyl perfluorohexanesulfonamido] ethyl acrylate, 40 parts of octadecyl acrylate, 20 parts of acrylic acid shrink Glycerides, 0.8 parts of octadecyl mercaptan and 0.6 parts of benzoyl peroxide were dissolved in 24 parts of methyl ethyl ketone to obtain a second solution.

[0046] (4) Add the second solution obtained in step (3) to the fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com