Patents

Literature

2553 results about "Ultraviolet resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultraviolet resistance is the ability of a material, often a polymer, to withstand the degradation that can be caused by exposure to ultraviolet light.

High-temperature thermal-insulation anticorrosive nano coating and its preparing method

InactiveCN1709988AImprove Radiation PerformanceGood heat insulationAlkali metal silicate coatingsPolymer scienceThermal insulation

The invention discloses a kind of new industry dope. It comprises such materials as 95 - 105 weight shares of Component A, and 1 - 3 weight shares of Component B; thereinto, Component A is made from following weight percents of materials: cementing agent 30-60%, pigment 12 - 30%, filling agent 10 - 30%, auxiliary agent 0.1 - 5%, compound nanometer dispersing agent 5 - 15% and solvent 10 - 25%; Component B is comprised of catalyzed membrane forming agent - nanometer Sb2O3 and mixed organic solvent carriers. The invention firstly brings nanometer Sb2O3 into high temperature heat preservation dope as catalyzer in dope membrane forming process. The dope of the invention has following advantages: it has high temperature heat preservation and heavy anticorrosion performances, and the coat has good acid resistance, alkali resistance, salt mist resistance, oil resistance, chemical reagent resistance, waiting resistance and ultraviolet resistance; it has excellent fire protection and waterproof performance; the clinging strength of smearing membrane is good, membrane forming speed is fast, and performance is stable.

Owner:孙启明

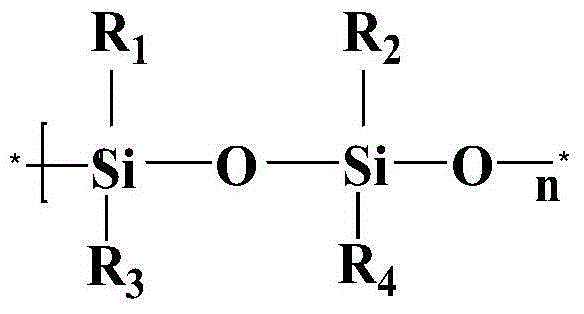

Curable polysiloxane composition, and polysiloxane cured product, optical member, member for aerospace industry, semiconductor light-emitting device, illuminating device and image display device using the same

ActiveUS20110098420A1Improve heat resistanceImprove light resistanceSemiconductor/solid-state device detailsSolid-state devicesHeat resistanceLight emitting device

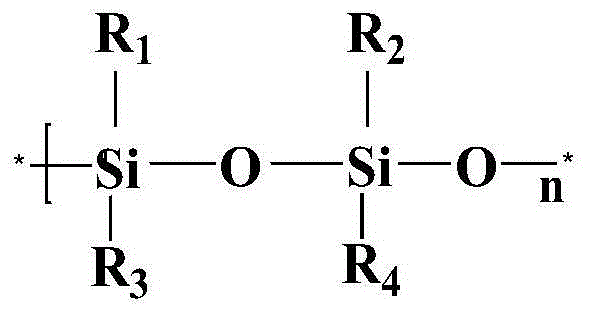

The present invention provides a curable polysiloxane composition which is excellent in light resistance (particularly ultraviolet resistance) and adhesion and has a sufficient heat resistance / hydrothermal resistance and film-forming property and which generates little foaming at curing and does not generate cracks, peeling, coloring, and foaming even when used for a long period of time. A curable polysiloxane composition which comprises a specific hydrosilyl group-containing polysiloxane compound, a specific polysiloxane compound comprising two or more silanol groups in one molecule, and a dehydrogenative condensation reaction catalyst.

Owner:MITSUBISHI CHEM CORP

Preparation method of functional fabric

InactiveCN104805680AOvercome strong adsorptionDestruction of the entangled bonded statePhysical treatmentEcological environmentProcess equipment

The invention relates to a preparation method of a functional fabric, and belongs to the technical field of textile materials. Functional nanoparticles are compounded on the surface of the fabric through the preparation of the functional nanoparticles and the preparation of the functional fabric. The existence of vinyl polysiloxane overcomes high adsorption capacity of functional nanoparticle aggregate, so that the uniformly dispersed functional nanoparticles are firmly adhered to the surface of the fabric, and the fabric has multiple functions of ultraviolet resistance, super-hydrophobicity, pollution resistance, antibacterial property, health and the like through the synergistic effect of the vinyl polysiloxane and the functional nanoparticles. According to the preparation method of the functional fabric disclosed by the invention, the vinyl polysiloxane is efficiently utilized, the productive value of the vinyl polysiloxane is improved, and the application of the vinyl polysiloxane to other fields is developed; moreover, the whole process is simple in equipment, relatively low in cost and free of pollution to ecological environment, and has a great application prospect.

Owner:WUHAN TEXTILE UNIV

Ceramic composite material for optical conversion and use thereof

ActiveUS20060124951A1Improve thermal stabilitySolid-state devicesLuminescent compositionsCeramic compositeHeat resistance

A ceramic composite material for light conversion, which is a solidified body comprising two or more matrix phases with respective components being two or more oxides selected from the group consisting of metal oxides and complex oxides each produced from two or more metal oxides, wherein at least one of the matrix phases is a phosphor phase containing an activated oxide. The solidified body is preferably obtained by the unidirectional solidification method. The ceramic composite material for light conversion is excellent in brightness, light-mixing property, heat resistance and ultraviolet light resistance.

Owner:UBE IND LTD

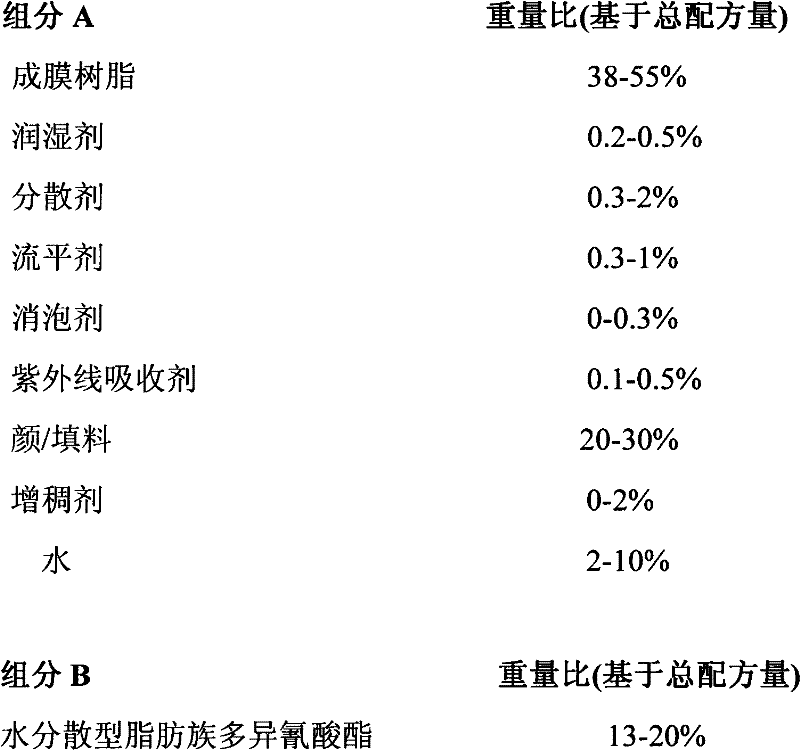

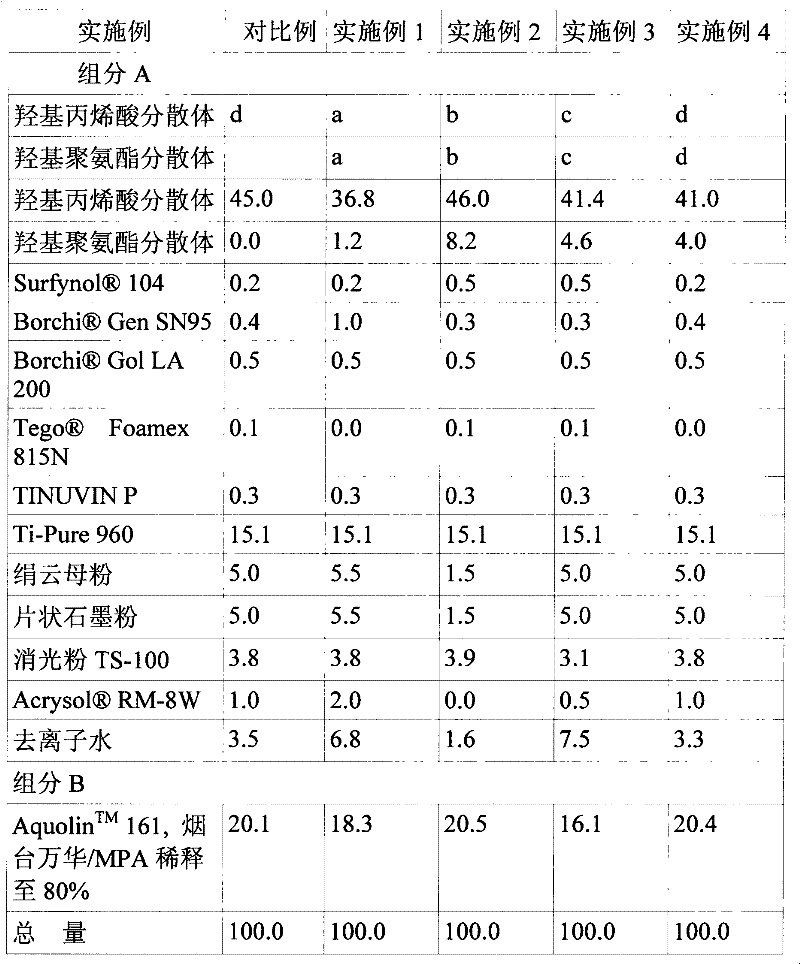

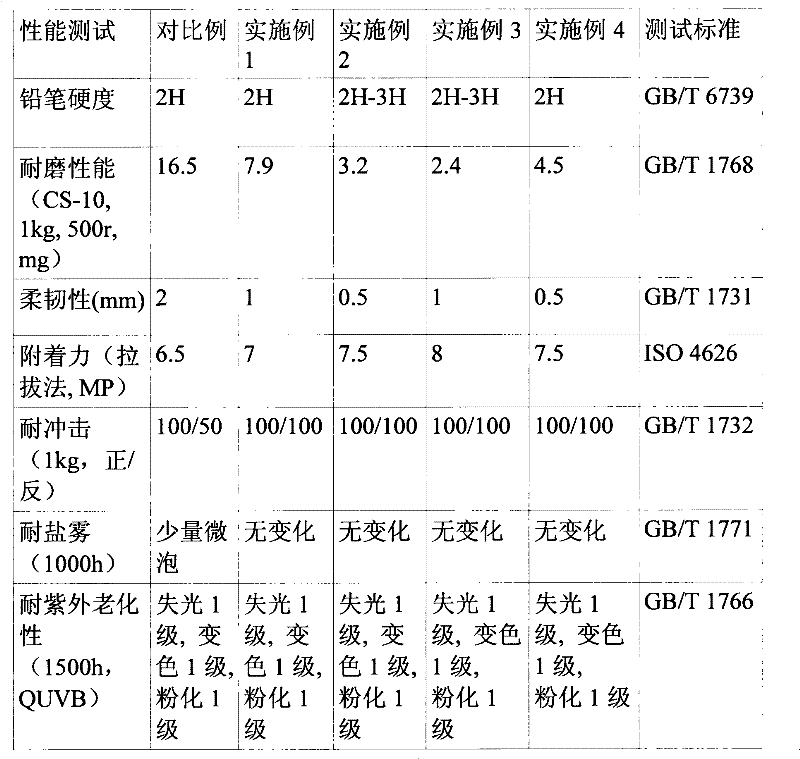

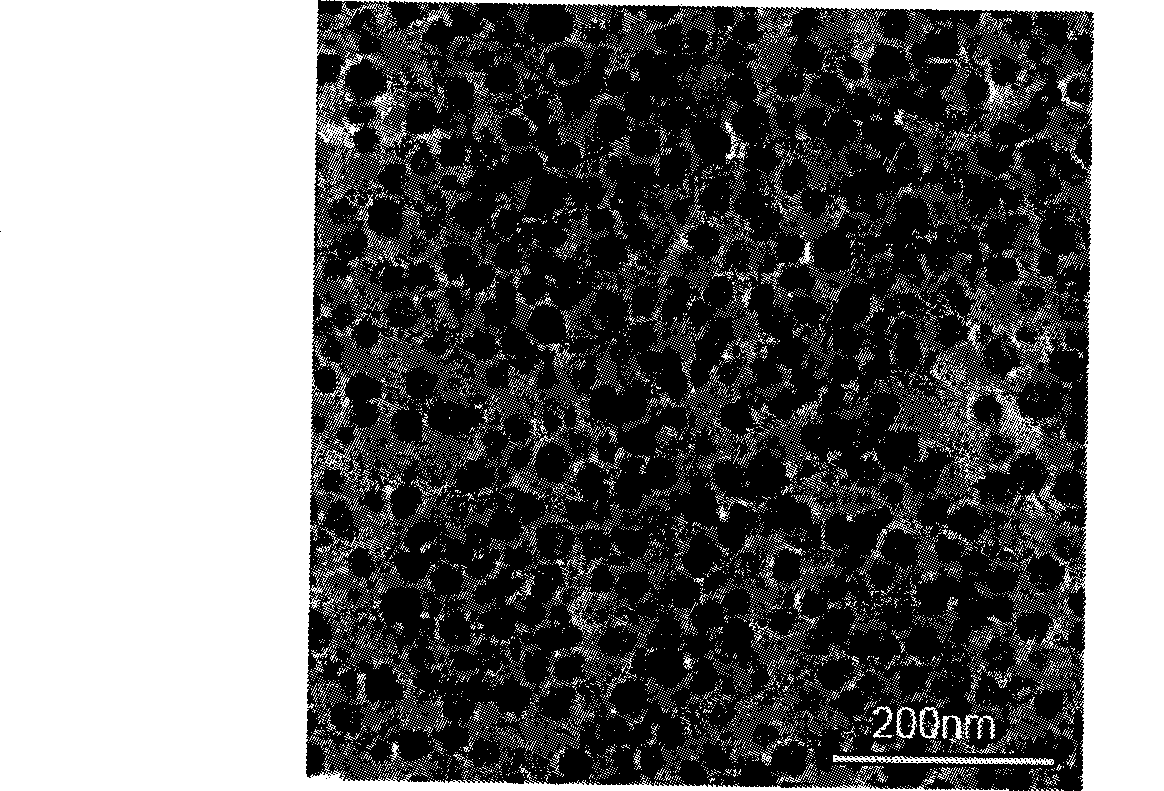

Water-based coating and preparation method and application thereof

ActiveCN102533078AGood UV aging resistanceImprove wear resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsWater basedPolyurethane dispersion

The invention discloses a water-based coating and a preparation method and an application thereof. The water-based coating belongs to a water-based two-component polyurethane coating for a wind turbine blade, and can be taken as priming paint and finishing paint. Film forming resin consists of a hydroxyl acrylic acid dispersion and a hydroxyl polyurethane dispersion; due to the adoption of a acrylic acid structure and a polyurethane structure, excellent ultraviolet ray resistance and high wear resistance can be provided respectively; and water-dispersible aliphatic diisocyanate is taken as a curing agent. The coating has excellent adhesive ability on the wind turbine blade, has excellent tolerance, and can be used for effectively prolonging the service life of wind power equipment.

Owner:WANHUA CHEM GUANGDONG +2

Light curing nano composite coating

The invention relates to a photo-cured nanometer composite material which consists of 0 to 64 weight percent of film forming substance, 1 to 60 weight percent of inorganic nanometer particles, 1 to 56 weight percent of active thinner, 1 to 9.3 weight percent of evocating agent, 0 to 8 weight percent of coating additive and 0 to 31 weight percent of solvent. The manufacturing method comprises the following steps: (1) the prepared photo-cured nanometer composite material is counted by 100 weight percent; according to the proportion, each composition is weighed; (2) through a sol-gel method, a mechanical dispersion method or the combination of two methods, the inorganic nanometer particles are introduced to the active thinner to obtain a mixed master material; and (3) the mixed master material, an oligomer, the evocating agent, the coating additive and the solvent are mixed and evenly stirred to prepare the photocuring nanometer composite material. The photocuring nanometer composite material has the characteristics of high content of nanometer particles, good levelling performance, high transparency, good lustrousness, high adhesive force with a polymer substrate, high rigidity, scratching resistance, ultraviolet resistance and the like.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

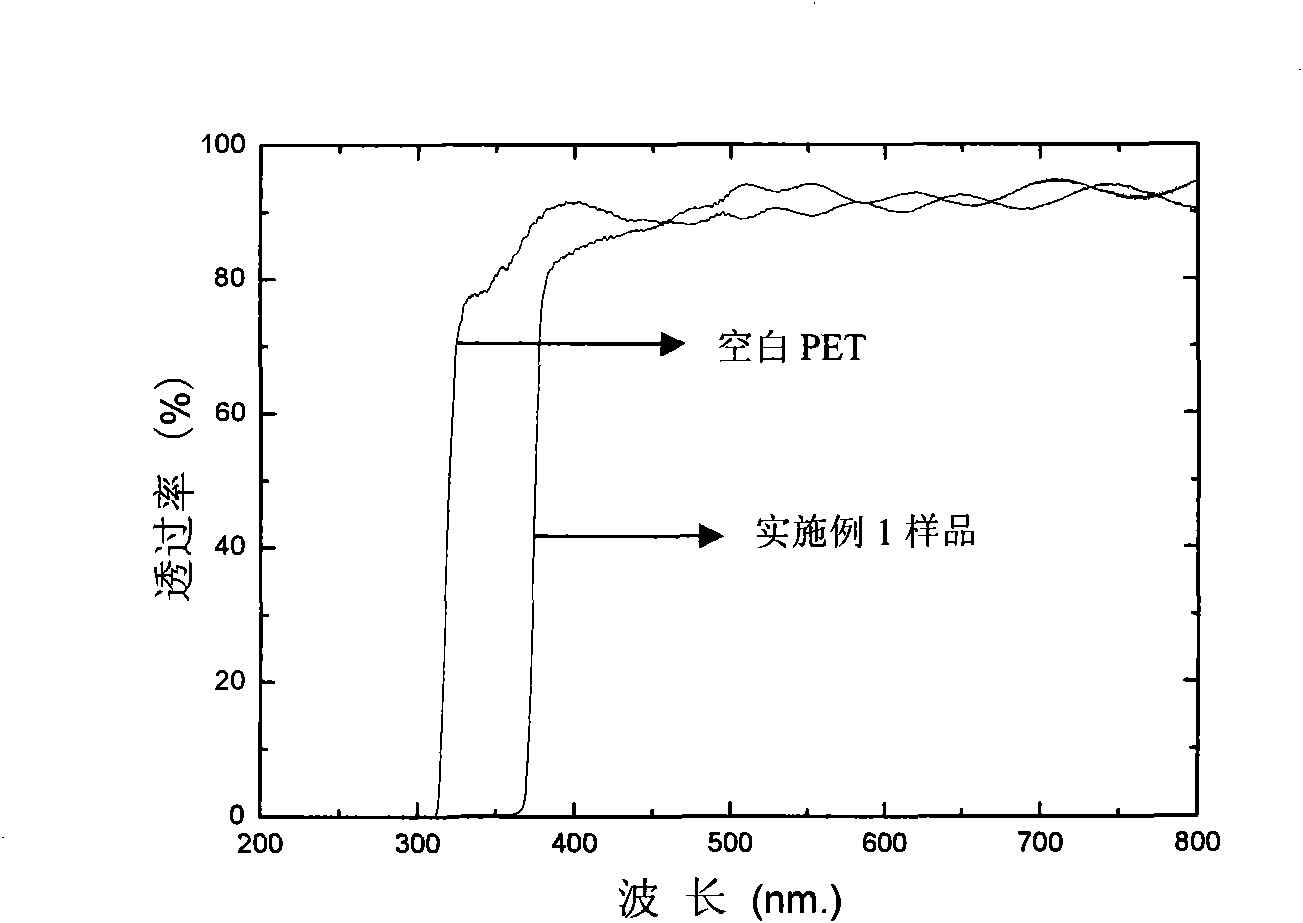

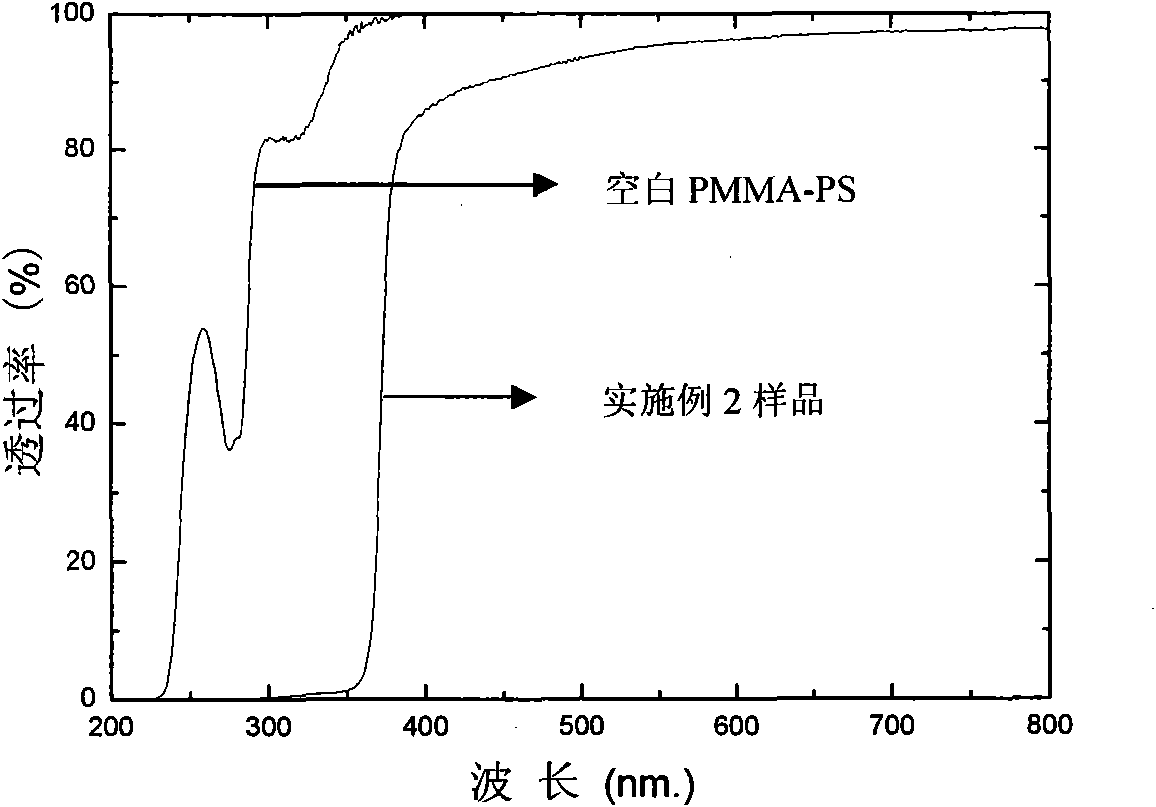

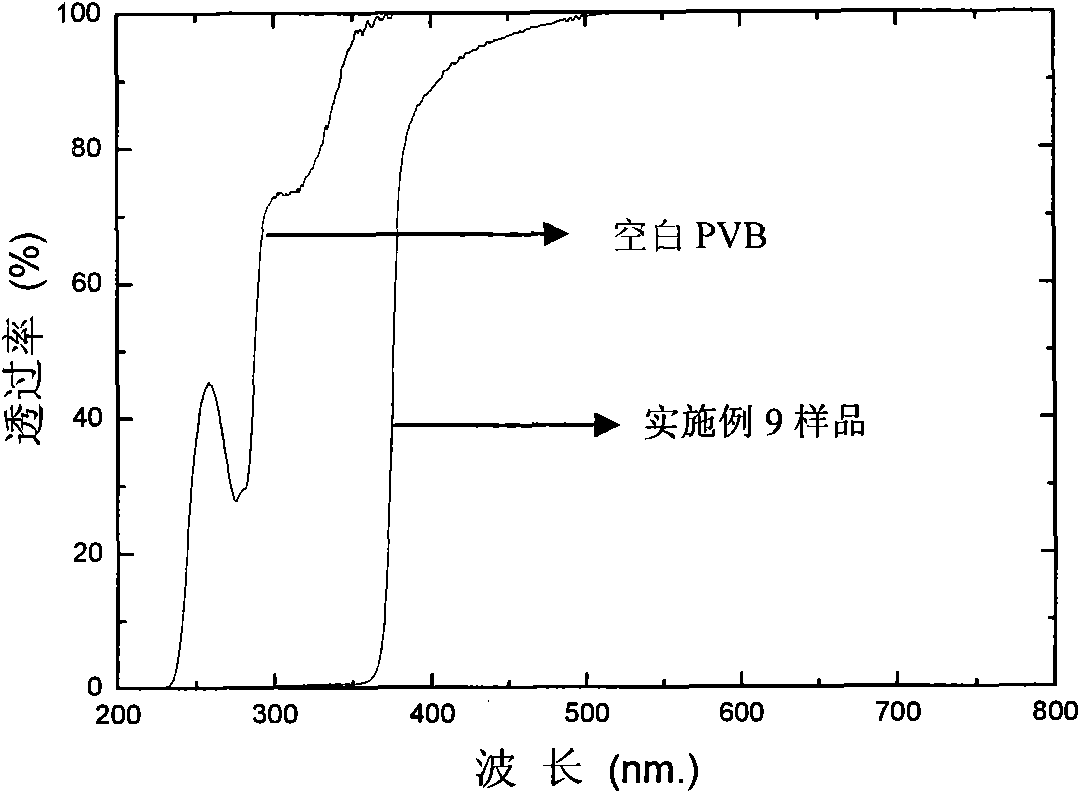

Highly-transparent ultraviolet-resistant energy-saving film and preparation method thereof

The invention relates to a highly-transparent ultraviolet-resistant energy-saving film and a preparation method thereof, belonging to the field of composite films synthesized by compounding polymer and inorganic nano-particles and aiming at overcoming the defects that the prior film has low visible light transmission and high production cost. The highly-transparent ultraviolet-resistant energy-saving film comprises the following components by the weight percent: 50-99.8 of organic polymer, 0.2-50 of metal-oxide nano-particles and 0-39.9 of polymer auxiliary agent. The highly-transparent ultraviolet-resistant energy-saving film is prepared by a solution mixing method or a solution-melting mixing method; with the solution mixing method, the organic polymer and the metal-oxide nano-particles are dispersed in dispersing medium to prepare film preparing stock solution, and the film preparing stock solution is used for preparing the energy-saving film on a substrate; with the solution-melting mixing method, the mixture of the organic polymer and the metal-oxide nano-particles is dried to prepare master batch, and the master bath is mixed with the organic polymer and the polymer auxiliary agent to prepare the energy-saving film. The highly-transparent ultraviolet-resistant energy-saving film has high visible light transmission, good ultraviolet resistance and energy-saving effect, simple preparation process and low cost, thereby being suitable for industrial production.

Owner:BEIJING UNIV OF CHEM TECH +1

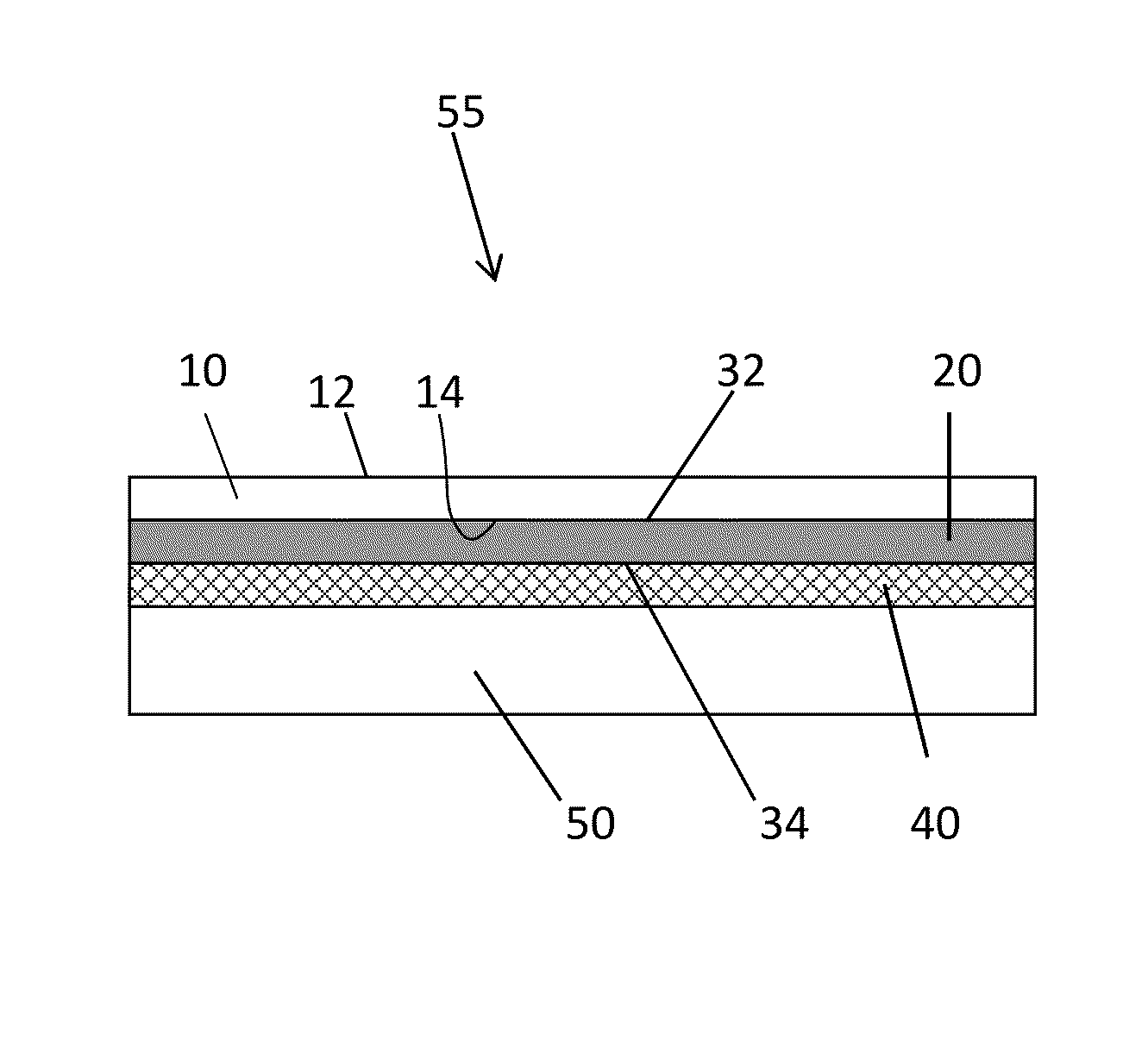

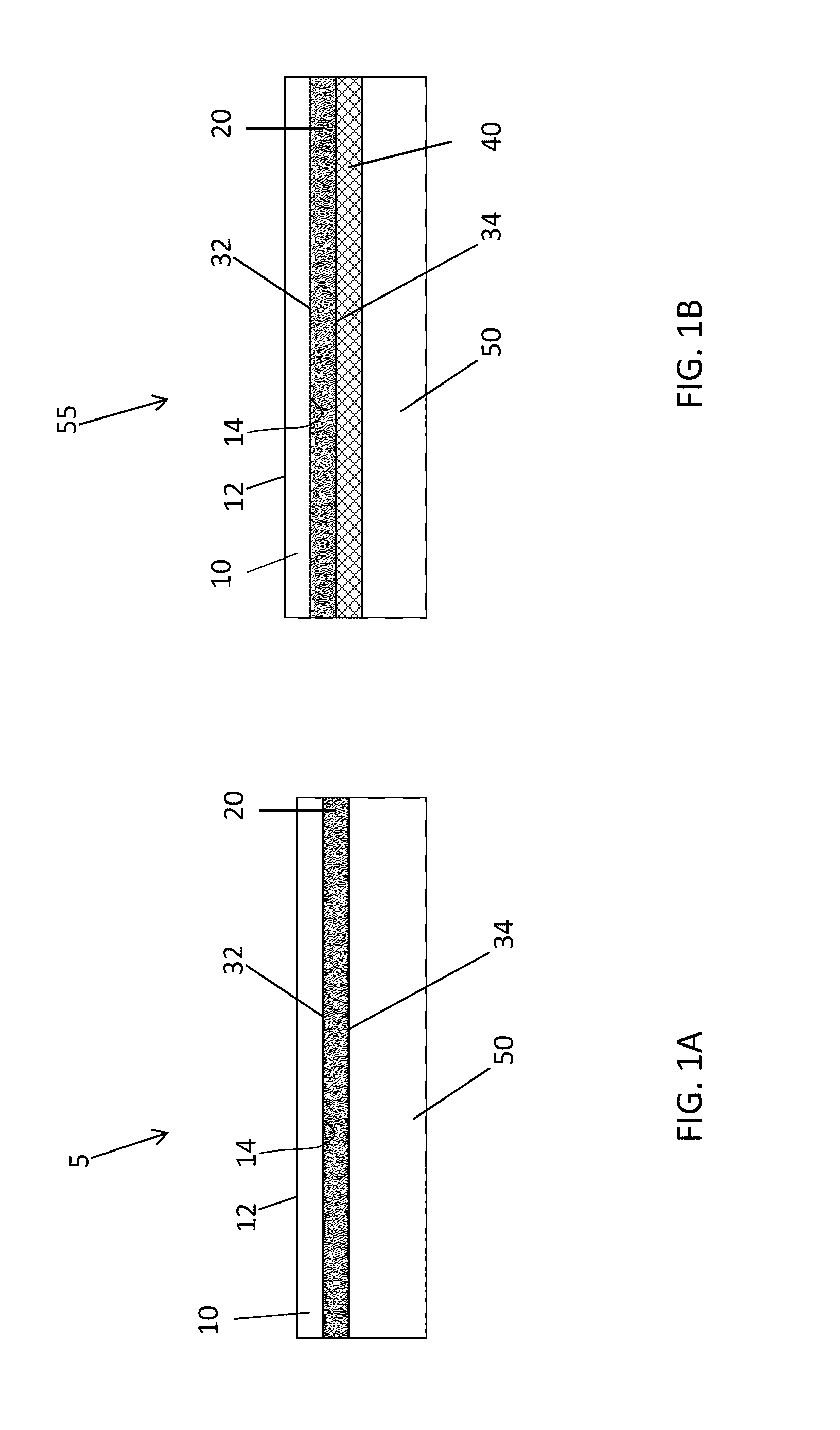

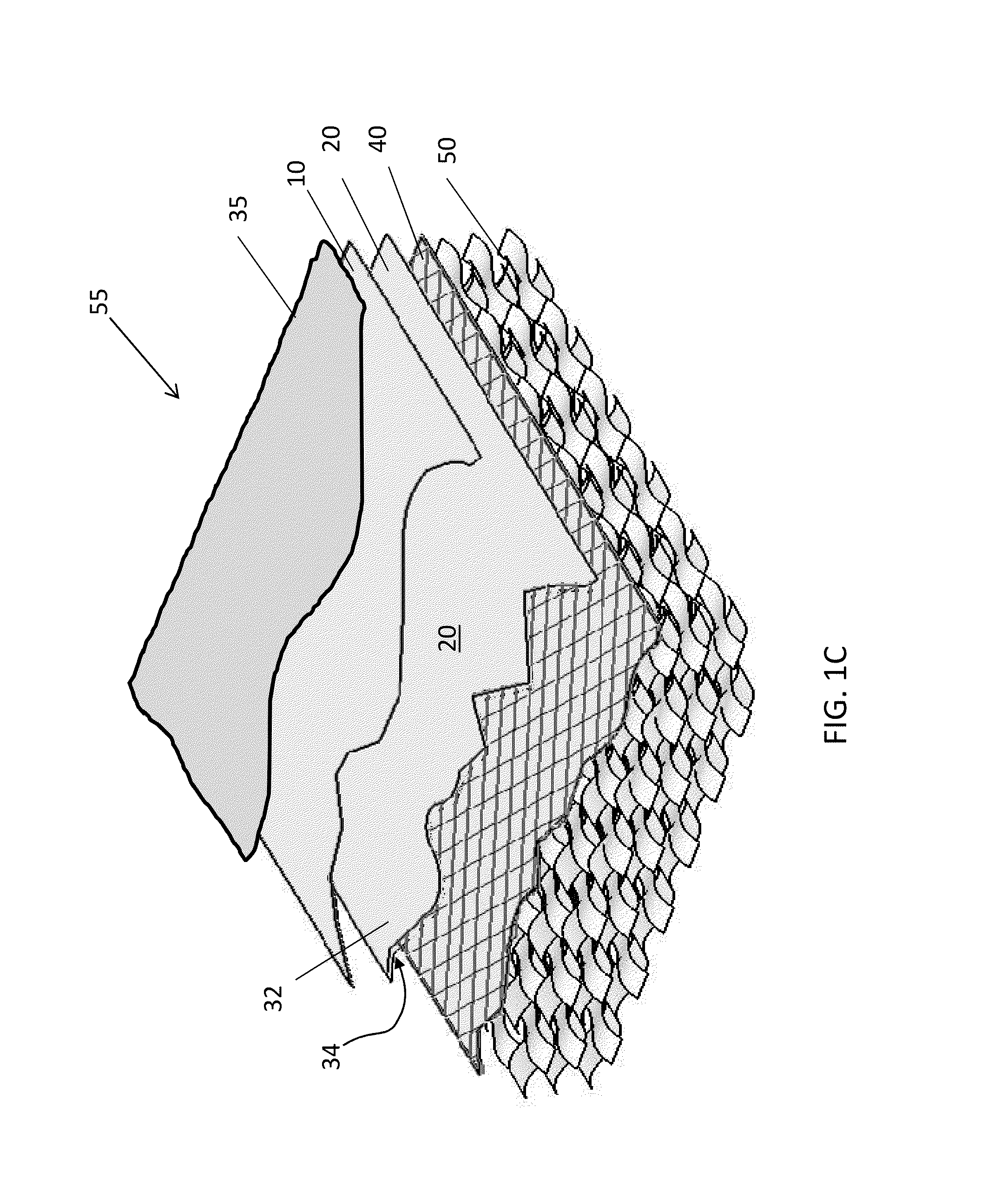

Nanoreinforced films and laminates for aerospace structures

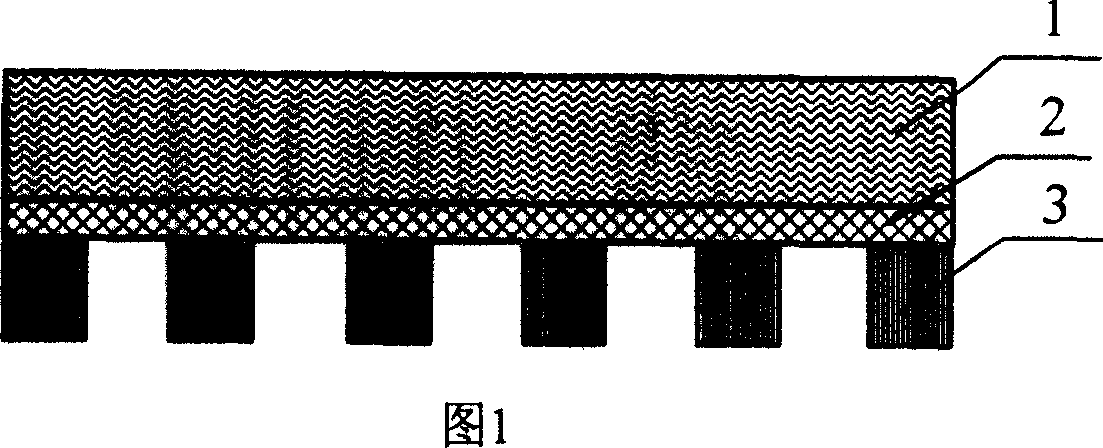

ActiveUS20140011414A1Improved ultraviolet resistance and resistance to microcrackingMaterial nanotechnologyWarp knittingPolymer resinNanofiber

A composite laminate for use on an external part of an aerospace vehicle has improved ultraviolet resistance and resistance to microcracking from thermal cycling. The laminate comprises a nanoreinforcement film, a support veil, and a composite layer. The laminate also can have a lightning strike protection layer and an external paint and primer. The nanoreinforcement film can comprise carbon nanomaterial and a polymer resin, and the composite layer has one or more layers of a reinforcement and a polymer resin. The carbon nanomaterial can be carbon nanofibers, and the nanoreinforcement film can have an areal weight of less than about 100 g / m2. The carbon nanomaterial can also comprise carbon nanofibers and carbon nanotubes.

Owner:ROHR INC +1

Ethylene-vinyl acetate copolymer packaging thin film

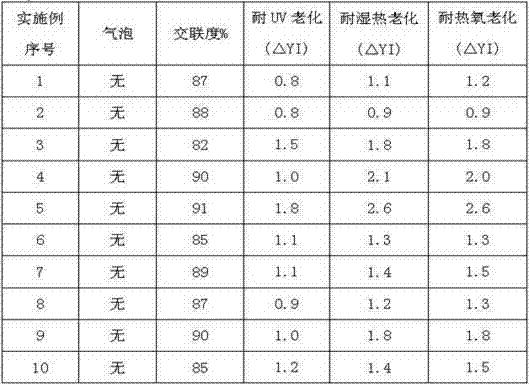

InactiveCN102391568AEnhanced network structureImprove moisture resistancePhotovoltaic energy generationSemiconductor devicesPolymer scienceNetwork structure

The invention discloses an ethylene-vinyl acetate copolymer packaging thin film, which is used for packaging solar cell components. The thin film is prepared from the following raw materials in part by weight: 100 parts of an ethylene-vinyl acetate copolymer, 0.1 to 2.0 parts of crosslinking agent, 0.1 to 10.0 parts of aid crosslinking agent and a proper amount of aid. The ethylene-vinyl acetate copolymer contains 25 to 33 percent of vinylacetate, and the ratio of the amount of the aid crosslinking agent and the crosslinking agent is 1:10 to 10:1. In the invention, the introduction of the aid improves the network structure of crosslinked resin, improves crosslinking efficiency, greatly reduces the dosage and residue of the crosslinking agent greatly and avoids aging phenomenon caused by residual crosslinking agent, and the prepared thin film has higher dampness and heat resistance, high ultraviolet resistance, high thermal-oxidative aging resistance and the like and has long service life.

Owner:DONGFANG TURBINE CO LTD

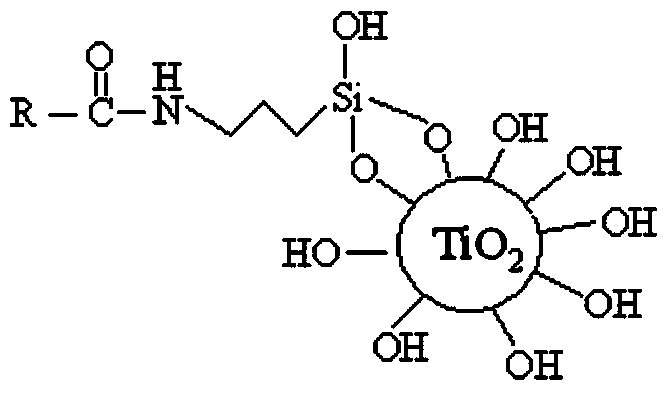

Method for finishing wool fabric by compositing chitosan/TiO2

ActiveCN103981694AImprove the efficiency of grafting reactionGood antibacterialLiquid/gas/vapor removalUltrasonic/sonic fibre treatmentCooking & bakingPollution

The invention provides a method for finishing wool fabric by compositing chitosan / TiO2, which comprises the following steps: A)pretreating fabric; B)preparing composite finishing liquor, taking butyl titanate and dissolving in ethanol, adding diethanolamine, uniformly stirring and adding mixed liquor mixed by ethanol and water, heating, stirring under a backflow state to form nano TiO2 sol; adding chitosan, citric acid and sodium hypophosphate in the nano TiO2 sol, uniformly stirring to obtain the composite finishing liquor; C)finishing wool fabric, placing wool fabric in the composite finishing liquor, dipping and padding twice, wherein mangle expression is 85% and padding temperature is 50-65%; D)predrying; E)baking; F)washing; and G)drying. According to the finishing method, chitosan and nano TiO2 sol are employed as the composite finishing liquor, the finished wool fabric has good antibiosis, shrinkproof, ultraviolet resistance and anti-insolation performances; the finishing method generates no pollution on human body and environment, and the finished wool fabric has good hand feeling.

Owner:ZHEJIANG ZHONGXIN DYEING & FINISHING CO LTD

Cellulose/titanium dioxide/silica aerogel and preparation method thereof

ActiveCN103203206AGood biocompatibilityGood flexibilityColloidal chemistry detailsThermal insulationSilica gel

The invention relates to a cellulose / titanium dioxide / silica aerogel and a preparation method thereof. The method comprises the steps such as cellulose sol preparation, nano-grade titanium dioxide surface loading, silica surface coating, curing, aging, hydrophobizing, bonding forming, drying treatment, and the like. According to the invention, nano-grade cellulose is adopted as a core, and is loaded with nano-grade titanium dioxide; a silica layer is coated; and the steps such as curing, aging, hydrophobizing, bonding forming, drying treatment, and the like are carried out, such that the cellulose / titanium dioxide / silica aerogel is obtained. The aerogel has the performances such as flexibility, high strength, bacterium resistance, ultraviolet resistance, odor-removing function, warm-keeping function, thermal insulation, and sound insulation. The aerogel can be widely applied in the fields such as thermal underwear, body armor, insulation materials, pressure-resistant materials, special coatings, aerospace materials, and the like.

Owner:SHANDONG CAYON TESTING TECH

Multifunctional knitting sportswear face fabric and manufacture method thereof

InactiveCN1920144ASatisfy moisture absorption and quick dryingMeet antistaticWeft knittingLiquid/gas/vapor textile treatmentEngineeringPolypropylene

The invention relates to a multifunctional knitting exercise clothes and relative production, wherein it uses four machines to prepare the face fabric with inner layer, middle connecting layer and outer layer; the outer layer is the polyester filament yarn of 75D / 100F and C-O shaped section and porous structure; the middle connecting layer is polypropylene or polyester filament yarn; the inner layer is the polyester filament yarn with ultraviolet resistance, at 75D / 72F + type or Y-shaped, H-shaped, and five-pointed star shape, which is treated with semi delustring. Said material is treated with alkali reduction before doping, and to be softened after doping. The invention and quickly adsorb the sweaty and release the sweaty outside the fabric, to avoid skin cancer, etc.

Owner:河南纺织高等专科学校

High-reflectivity photovoltaic module packaging film and application thereof

ActiveCN104497899AImproves UV resistanceIncrease usageNon-macromolecular adhesive additivesFilm/foil adhesivesHigh reflectivityReflective layer

The invention discloses a high-reflectivity photovoltaic module packaging film. The high-reflectivity photovoltaic module packaging film with a surface pre-crosslinked structure is prepared by the following steps: pre-mixing transparent resin with a high-reflectivity additive and other functional accessories, carrying out melting extrusion, film casting and surface pre-crosslinking treatment, and coiling. By adding the high-reflectivity additive, the ultraviolet-resistance performance of the film can be improved, and meanwhile, the utilization rate of a module on sunlight is enhanced, and therefore the effects of improving the service life and photoelectric conversion efficiency of the module are achieved; meanwhile, by virtue of the surface pre-crosslinked structure, the high-reflectivity layer film can be effectively prevented from overflowing during a photovoltaic module laminating process and the appearance of the module is effectively improved; the packaging film is universal for various laminating processes.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

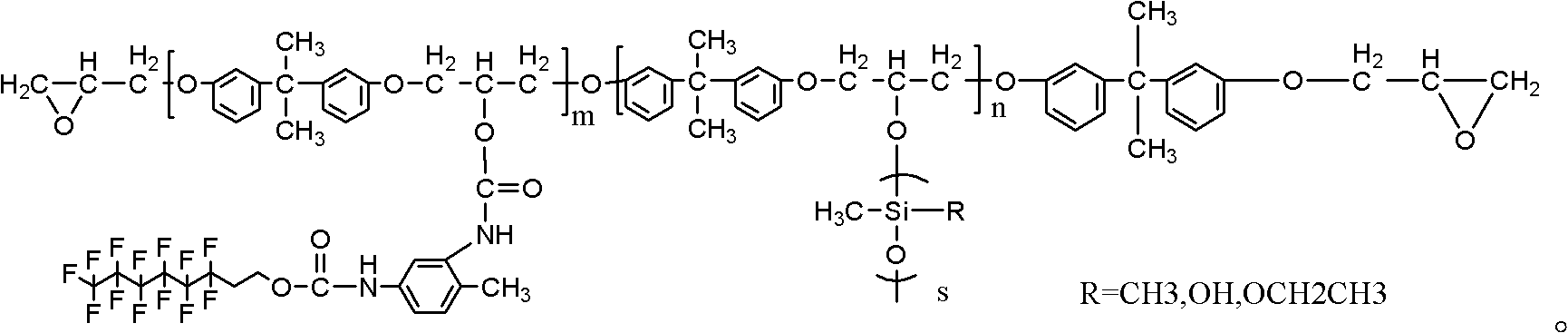

High-voltage power transmission line ice-covering-proof paint and preparation method thereof

InactiveCN102146249AImprove thermal conductivityImprove hydrophobicityEpoxy resin coatingsTransformerLow temperature curing

The invention discloses high-voltage power transmission line ice-covering-proof paint and a preparation method thereof. The preparation method comprises the following steps: using toluene diisocynate, tridecafluoro-octanol, butyl acetate, organosilicon modified epoxy resin, epoxy resin curing agent, organic solvent, nanographite and carbon nanotubes as raw materials to react and ensure that long-carbon-chain fluoro-alcohol is grafted in the molecular chain of epoxy resin, and adding nanographite and carbon nanotubes in the modified epoxy resin to prepare the paint with good hydrophobicity and thermal conductivity. The paint is mainly used in the coating of the high-voltage power transmission line and the coatings of equipment such as the insulator and the transformer case; and the paint has high coating adhesion, is ice-covering-proof and environmental friendly, has the advantages of corrosion resistance, ultraviolet resistance and aging resistance, and no pollution. Compared with the traditional acrylic paint, the paint has the advantages of simple preparation technology and excellent room temperature curing performance and low temperature curing performance, and is convenient to construct and operate.

Owner:甘肃省电力公司检修公司 +1

Spraying quick-setting rubber asphalt waterproof coating material

ActiveCN103627258AWith anti-adhesive effectImprove adhesionConjugated diene hydrocarbon coatingsNatural rubber coatingsComposite constructionWater based

The invention relates to a spraying quick-setting rubber asphalt waterproof coating material. A special technology is adopted for preparation of the spraying quick-setting rubber asphalt waterproof coating material. The spraying quick-setting rubber asphalt waterproof coating material is a water-based spraying paint prepared according to a ratio, and a preparation method of the spraying quick-setting rubber asphalt waterproof coating material comprises following steps: a liquid rubber asphalt latex emulsion is prepared by mixing superfine, suspended and micro-emulsion modified emulsified asphalt with high-molecular polymer rubber latex; and the liquid rubber asphalt latex emulsion is mixed with a coagulant. Cold spraying construction is adopted for preparation of the spraying quick-setting rubber asphalt waterproof coating material; elastic coating film elongation is more than 1000%; restoration ratio is more than 95%. The spraying quick-setting rubber asphalt waterproof coating material possesses ultraviolet resistance, high construction efficiency, high bonding strength, excellent high-temperature resistance, excellent low temperature flexibility, and better quick setting effect; and is capable of forming films in 3 seconds. The spraying quick-setting rubber asphalt waterproof coating material is water based; is friendly to the environment; possesses no toxicity, and excellent endurance; is quick and convenient for construction; and is a novel environmental friendly waterproof paint with a wide application range. The spraying quick-setting rubber asphalt waterproof coating material is mainly used for various waterproof and anticorrosion projects. The spraying quick-setting rubber asphalt waterproof coating material is used for individual construction of waterproof projects, for composite construction of waterproof projects together with waterproof roll, and for individual construction of anticorrosion projects.

Owner:SHANDONG NORTH CHUANGXIN WATERPROOF SCI & TECH GRP CO LTD

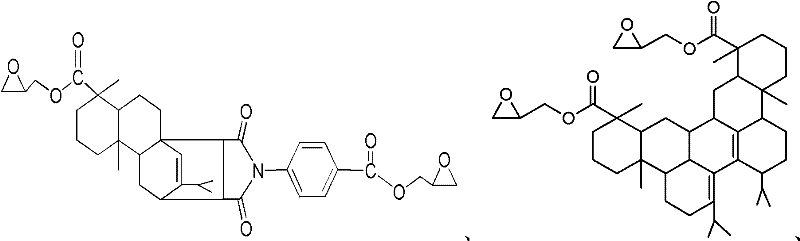

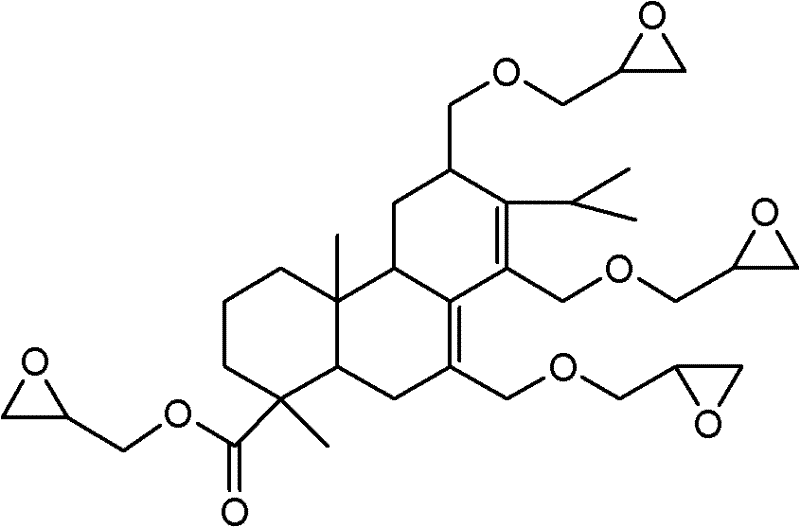

Full-biobased epoxy resin composition and condensate

ActiveCN102206324AGood environmental benefitsImprove flexibilityPlastic/resin/waxes insulatorsEpoxy resin adhesivesAging resistanceResin coating

The invention discloses a full-biobased epoxy resin condensate. The condensate is prepared by the following components in part by weight: 100 parts of abietyl-based epoxy resin base material, 50 to 300 parts of tung oil anhydride and 1 to 15 parts of catalyst, has the characteristics of higher mechanical property, high ultraviolet resistance, high aging resistance and the like and is particularlysuitable for preparing biobased composite material matrix resin and outdoor electric insulation materials. The invention also discloses a preparation method for the full-biobased epoxy resin condensate. The preparation method has a simple preparation process, is high in operability and process controllability and is easy to implement industrially. The invention also discloses a full-biobased epoxy resin composition and application thereof. The full-biobased epoxy resin composition is suitable for preparing a weather resistant epoxy adhesive, epoxy resin paint and an epoxy resin coating and has a good application prospect.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Preparation process, product and application of new plastic

ActiveCN101982495AImprove thermal stabilityImprove toughnessInsulated cablesInsulated conductorsTemperature controlHigh resistance

The invention provides a process for preparing a new plastic, which comprises the following steps: (1) preparing raw materials; (2) weighing and proportioning the raw materials; (3) mixing PVC powder, stabilizers, packing, plasticizers and other additives, then carrying out high-speed kneading on the obtained mixture, and preplasticizing the mixture so as to obtain a pre-plasticized mixture; (4) mixing the pre-plasticized mixture with TPU particles, carrying out banbury mixing on the obtained mixture under the condition of gradient temperature control so as to obtain colloidal products; (5) carrying out double-screw granulation on the obtained colloidal products; and (6) carrying out sorting, dehydration and packing on the granular products obtained in step 5 so as to obtain the new plastic. The process is simple, the conditions of the process are easy to control, and the process is suitable for large-scale production. The invention also provides a new plastic, which has the characteristics of high resistance to wear and scrape, high elasticity, easy recovery, high flame retardance, ultraviolet resistance, freezing damage (caused by low temperature in the north) resistance, environmental protection, soft handfeel and stick resistance, and the like; and the new plastic can be applicable to wire and cable compound.

Owner:GUANGDONG OMG TRANSMITTING TECH CO

Water-based polyurethane paint containing polyether glycol/nano TiO2 hybrid material

ActiveCN104403548AGood thermal propertiesImprove mechanical propertiesPolyurea/polyurethane coatingsWater basedOrganometallic catalysis

The invention belongs to the technical field of water-based polyurethane paints, and discloses a water-based polyurethane paint containing a polyether glycol / nano TiO2 hybrid material, and a preparation method and application thereof. The paint comprises the following components in parts by mass: 25-75 parts of polyether glycol / nano titanium dioxide hybrid material, 15-65 parts of diisocyanate, 100 parts of polyether glycol, 8-16 parts of polyhydroxy-carboxylic acid, 0.05-0.5 part of organo-metallic catalyst, 0.5-10 parts of crosslinking agent, 6.2-12.4 parts of neutralizer, 1-8 parts of chain extender and 0.2-2.0 parts of defoaming agent. The paint enhances the compatibility between the nano titanium dioxide and polyurethane base, has the advantages of favorable thermal properties, favorable mechanical properties, favorable wear resistance and excellent ultraviolet resistance, and can be widely used in the fields of architectural paints, automobile paints, wood paints, electrodeposition paints, paper conditioning paints, glass fiber paints, electrophoretic paints and the like.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Weaving process of hemp textile product

InactiveCN101838876AHigh degree of automationEasy windingFabric breaking/softeningBiochemical fibre treatmentYarnEngineering

The invention discloses a weaving process of a hemp textile product, which comprises the process steps of winding, warping and weaving. Blended yarns bended by hemp fibers and cotton fibers are weaved by warps and wefts in the process, wherein the rotary speed of a grooved drum is 600 plus or minus 5r / min, and the ratio of hemp fibers to cotton fibers is 35:65. The process also comprises processing steps of refining, singeing, softening, drying and calendering. The hemp textile product produced by the invention has less filoplume, biodegradability, and excellent moisture absorbance and sweat release properties, keeps the natural antimicrobial and health-care functions of hemp, has good soft and comfortable properties, excellent ultraviolet resistance, radiation resistance and antibacterial properties, excellent high-temperature resistance and unique odor absorption and waste discharging properties; and the hemp textile product feels soft and comfortable compared with other hemp products, and is a new-generation environment-protection product.

Owner:SUNVIM GROUP

Anticorrosive waterproof nano industrial coating and its preparing method

InactiveCN1709994ASignificant heavy-duty anti-corrosion performanceSignificant coating acid resistanceCoatingsUltravioletSolvent

The invention discloses a kind of new industry dope. It comprises of two kinds of materials of following weight shares: Component A 95 - 105 and Component B 2 - 8 shares; thereinto, Component A is made from such materials as membrane forming object, pigment, filling agent, auxiliary agent, compound nanometer dispersing agent and solvent; Component B is made from nanometer Sb2O3 and mixed organic solvent carriers. The dope of the invention has following advantages: at room temperature, it has prominent heavy anticorrosion performance, and has excellent performances of acid resistance, alkali resistance, salt mist resistance, oil resistance, chemical reagent resistance, waiting resistance and ultraviolet resistance; it also has excellent fire protection and waterproof performance; the clinging strength of smearing membrane is good, membrane forming speed is fast, and performance is stable.

Owner:王继征

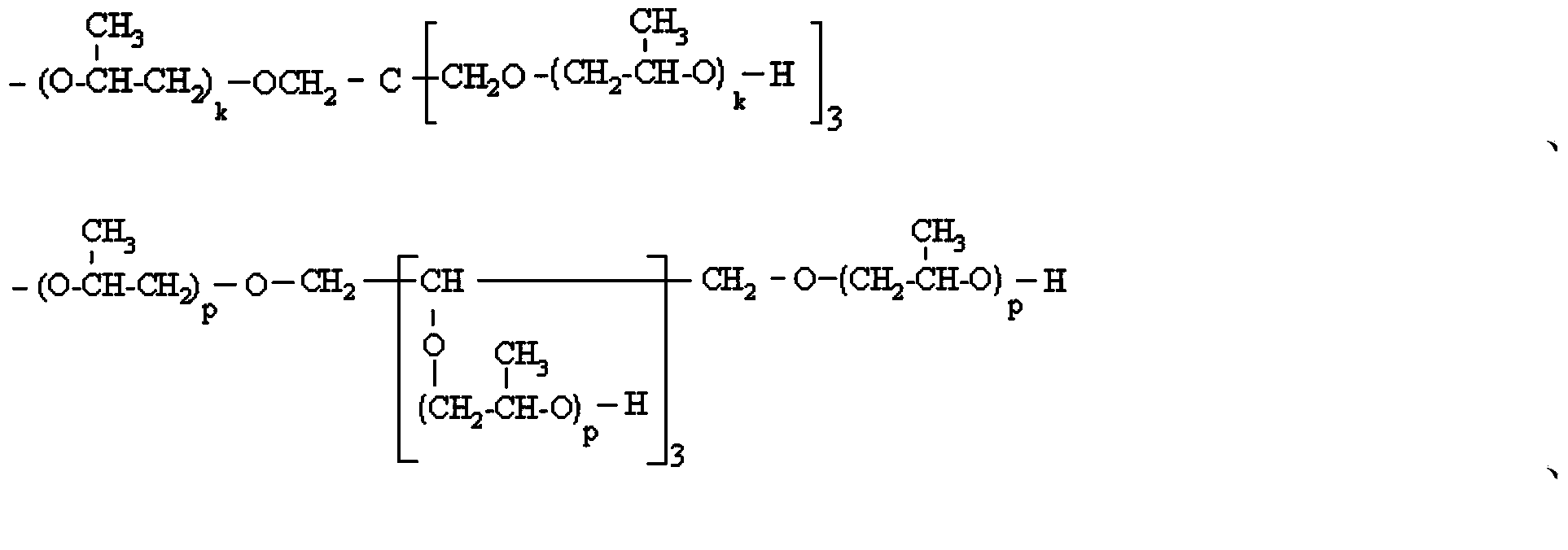

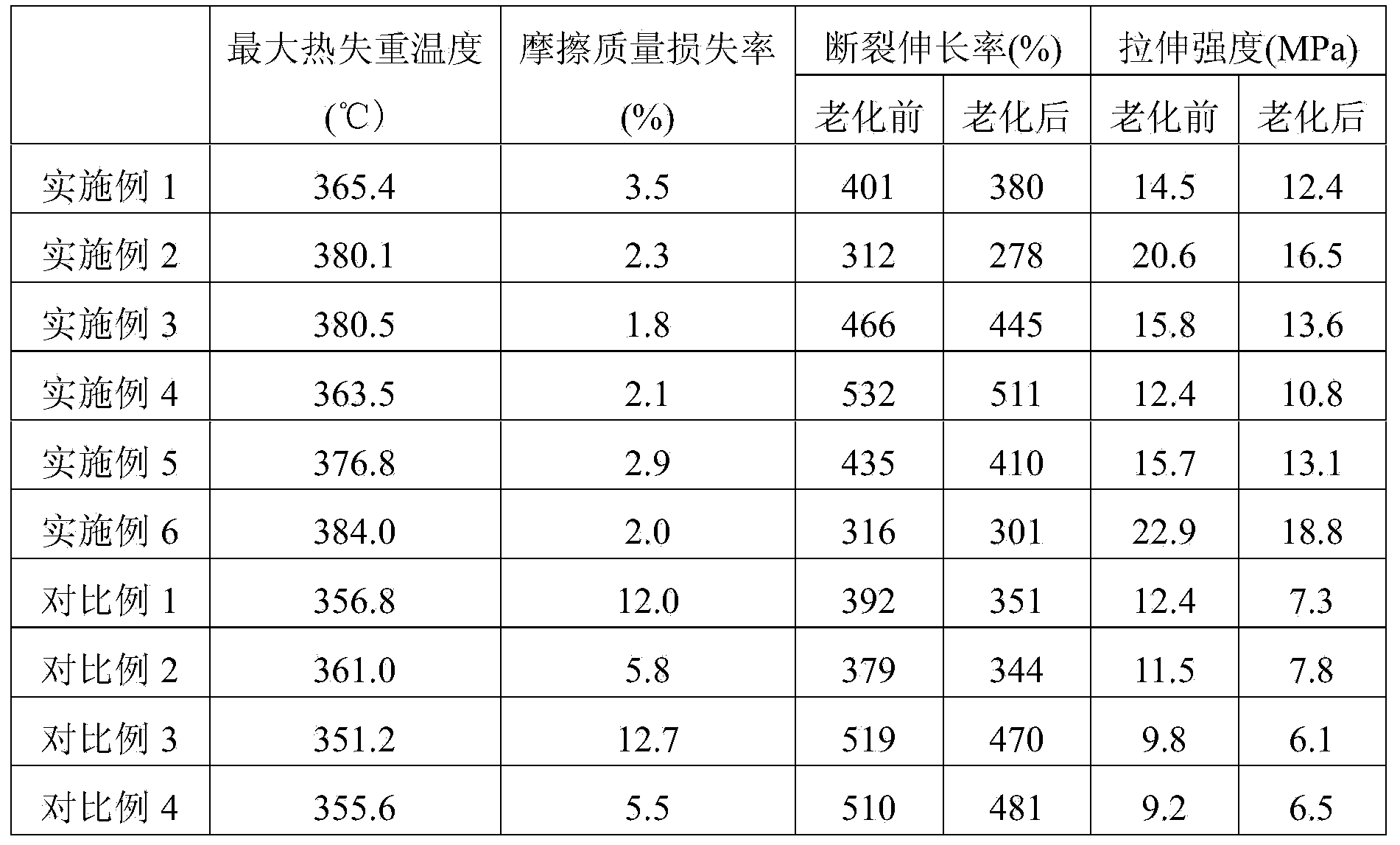

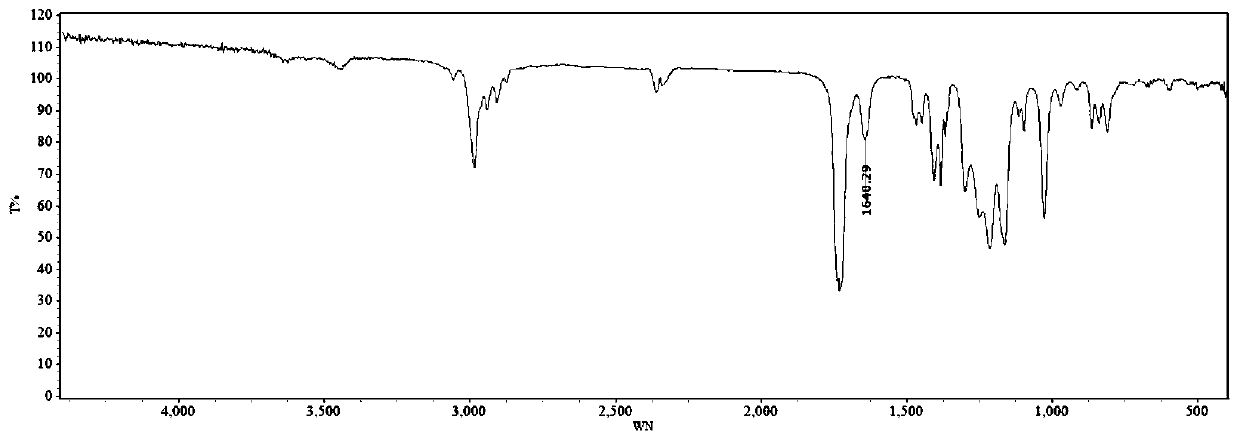

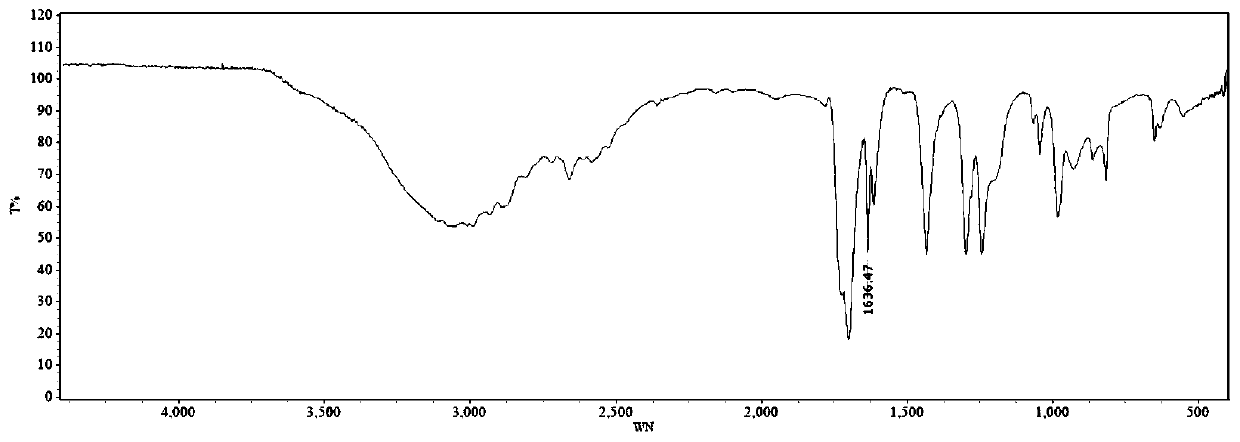

Water-dispersible polyaspartic ester resin, preparation method of waterborne polyurea coating and application

ActiveCN109761834ASmall particle sizeLow viscosityOrganic compound preparationAmino-carboxyl compound preparationWater dispersibleAging resistance

The invention relates to polyaspartic ester resin and in particular relates to water-dispersible polyaspartic ester resin, a preparation method of waterborne polyurea coating and application. Water-dispersible polyaspartic ester is obtained by carrying out Michael addition reaction on unsaturated binary carboxylate, unsaturated monocarboxylic acid and a primary amino compound under the action of acatalyst and a neutralizing agent; a coating film of the double-component waterborne polyurea coating is obtained by utilizing a water dispersion body of the water-dispersible polyaspartic ester; theperformance keeps main properties of solvent type polyurea coating, such as rapid curing at room temperature, high glossiness, high transparency, good water resistance, corrosion resistance, ultraviolet resistance and ageing resistance.

Owner:郁维铭 +1

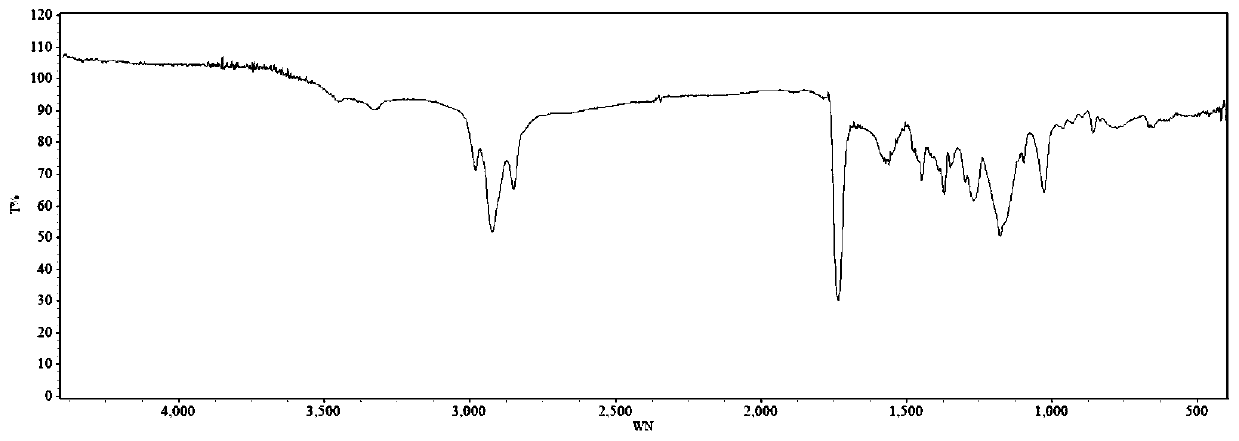

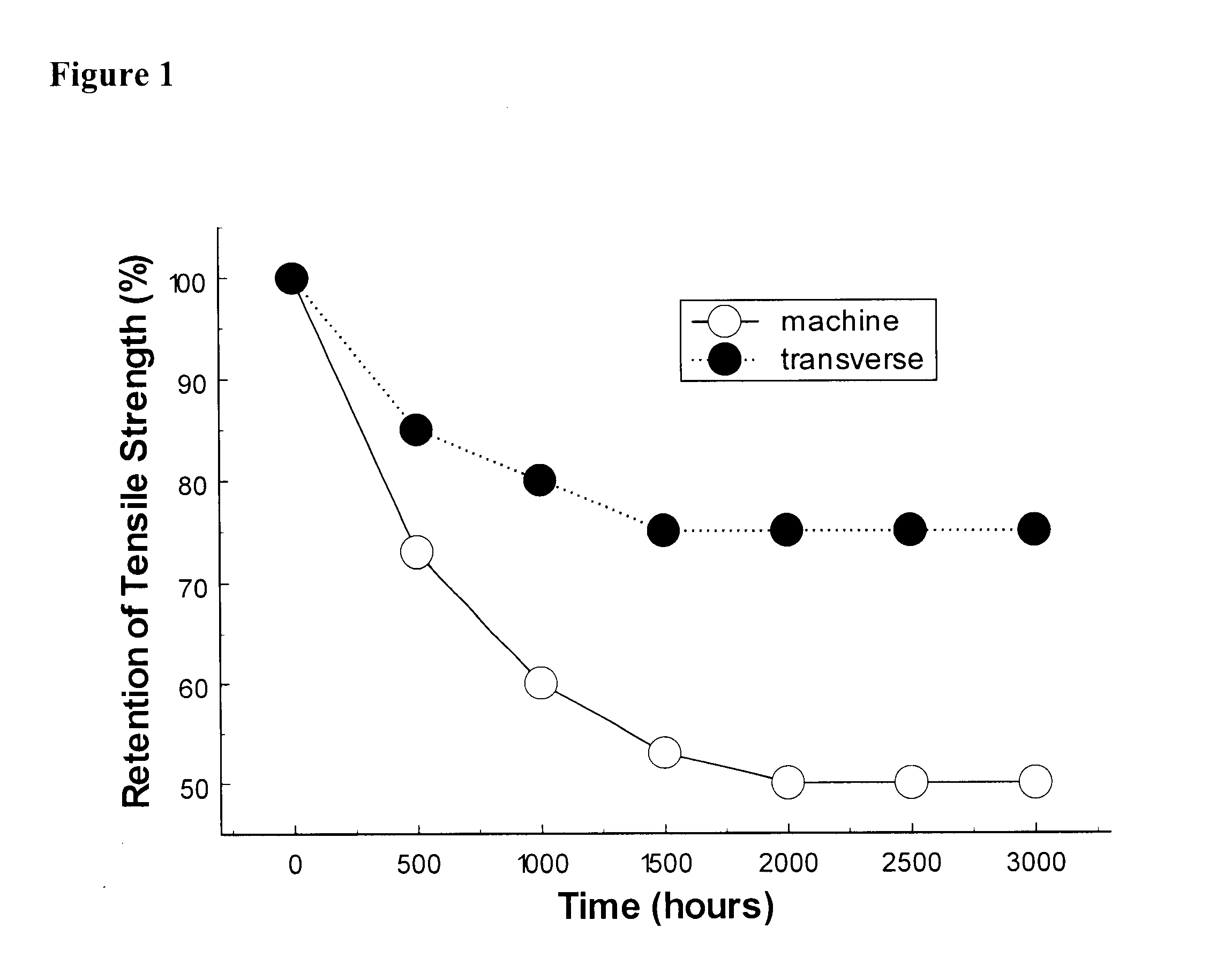

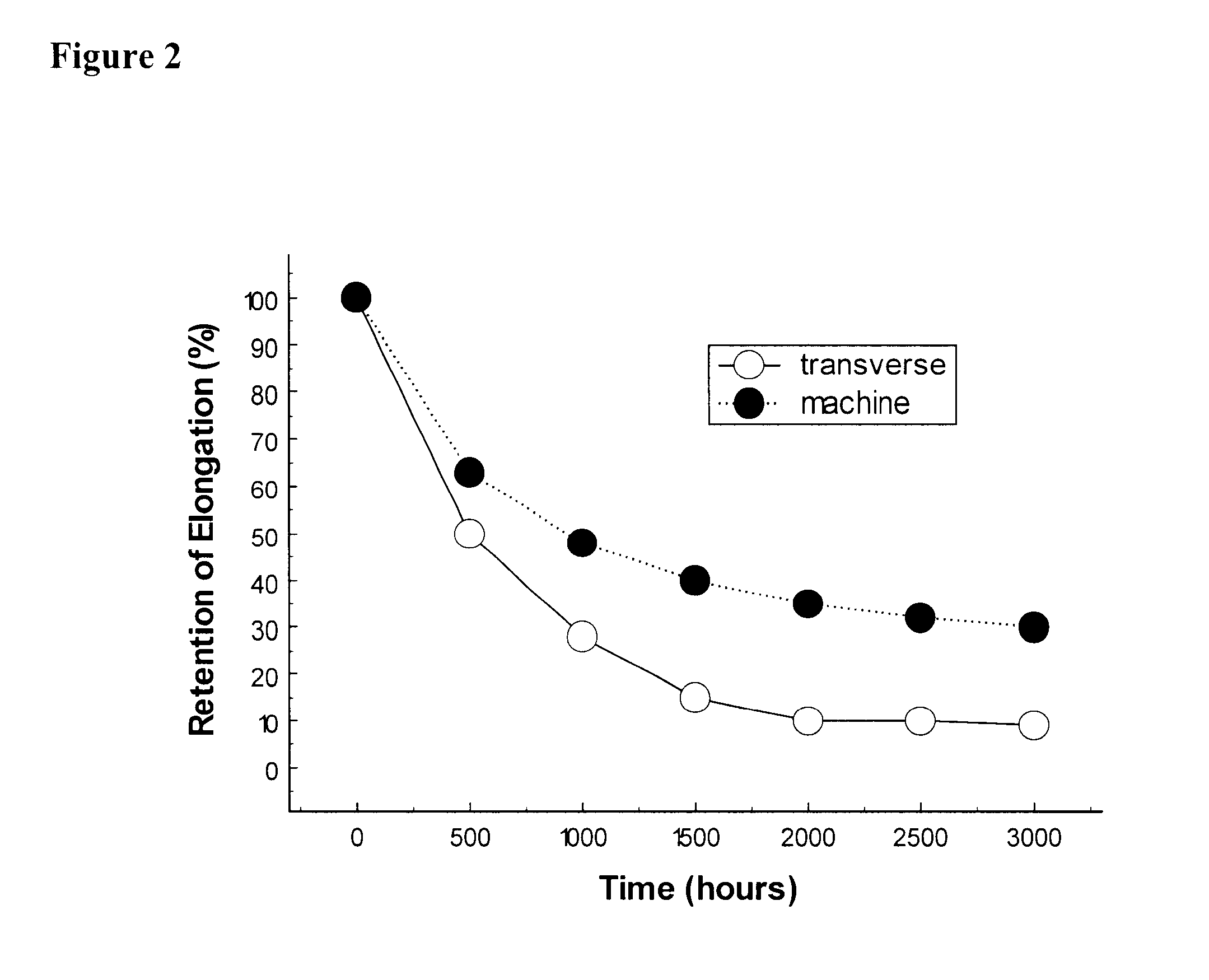

Poly (chlorotrifluoroethylene/vinylidenefluoride/vinylester) copolymers with excellent long-term ultraviolet light resistance

A composition containing a non-flammable chlorofluoro-olefin copolymer having a crystallinity index less than about 10% and a weight-average molecular weight greater than about 1,000,000 daltons, wherein the copolymer has at least two comonomer units of the formula:wherein each X is independently selected from H, Cl and F; Y is selected from H, Cl, F, O(CZ2)nCZ3, (CZ2)nCZ3, (OCZ2CZ2)nCZ3 and (O(CZ2)n)nCZ3, wherein each n is independently from about 1 to about 12 and each Z is independently selected from H, Cl and F; and A is selected from H, Cl and F, provided that for at least one comonomer unit, at least one of A, Y, either X or any Z is Cl. Substrates coated with the copolymer compositions are also disclosed.

Owner:ALLIEDSIGNAL INC

Multifunctional green environmental protection type nanometer paint

The multifunctional green nano paint consists of mainly: quaternary methacrylic acid-butyl acrylate-styrene-methyl methacrylate copolymer emulsion 20-65 wt%; nano titania 0.3-5 wt%; nano zinc oxide 0.2-3 wt%; silica 0.3-3 wt%; nano calcium carbonate 0.5-5 wt%; deionized water 3-12 wt%; superfine talcum powder 1-3 wt%; superfine calcium carbonate 3-15 wt%; titanium white3-25 wt%; and assistants including dispersant, wetter, rheologic agent, thickener, color paste, defoaming agent, etc. 2-12 wt%. The paint of the present invention features no toxicity, no pollution, wash resistance, scratching resistance, ultraviolet resistance, ageing resistance, waterproofing and mould proofing as well as self-cleaning function, so that the paint may be used wide in the decoration of inner and outer walls and the anticorrosive treatment of metal material surface.

Owner:王崇高

Aqueous fluorine-containing acrylate modified polyurethane coating, preparation method and application thereof

The present invention belongs to the field of polymer material synthesis, relates to aqueous polyurethane acrylate emulsion modification, and especially to an aqueous fluorine-containing acrylate modified polyurethane coating, a preparation method and an application thereof. The preparation method comprises: dissolving polyether polyol in an N-methyl pyrrolidone solution of dimethylol propionic acid; adding diisocyanate in a dropwise manner; adopting dibutyltin dilaurate as a catalyst, and adding hydroxyethyl methacrylate to carry out end capping; adding triethylamine to form a salt, then adding deionized water to prepare an aqueous polyurethane acrylate prepolymer emulsion; and finally adding hexafluorobutyl acrylate and azodiisobutyronitrile to prepare the aqueous fluorine-containing acrylate modified polyurethane coating. The synthesized emulsion of the present invention has the following advantages that: dispersion is uniform; stability is good; water resistance and mechanical property of the cured film are substantially improved; elasticity and mechanical property of polyurethane are provided; ultraviolet resistance, nuclear radiation resistance, flexibility, excellent surface properties, water resistance and corrosion resistance of the fluorine-containing material are provided; and the coating can be adopted as coatings for building and furniture.

Owner:BOMEX CHEM SHANGHAI

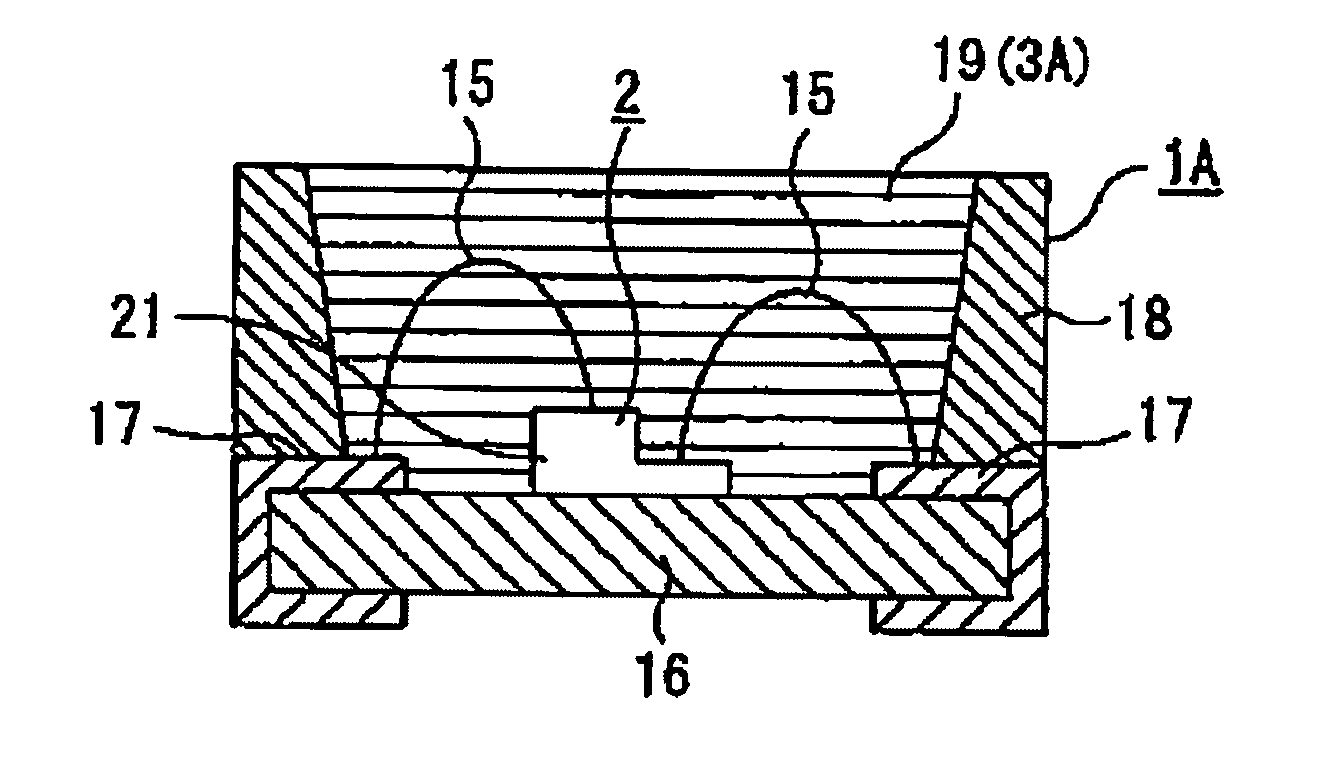

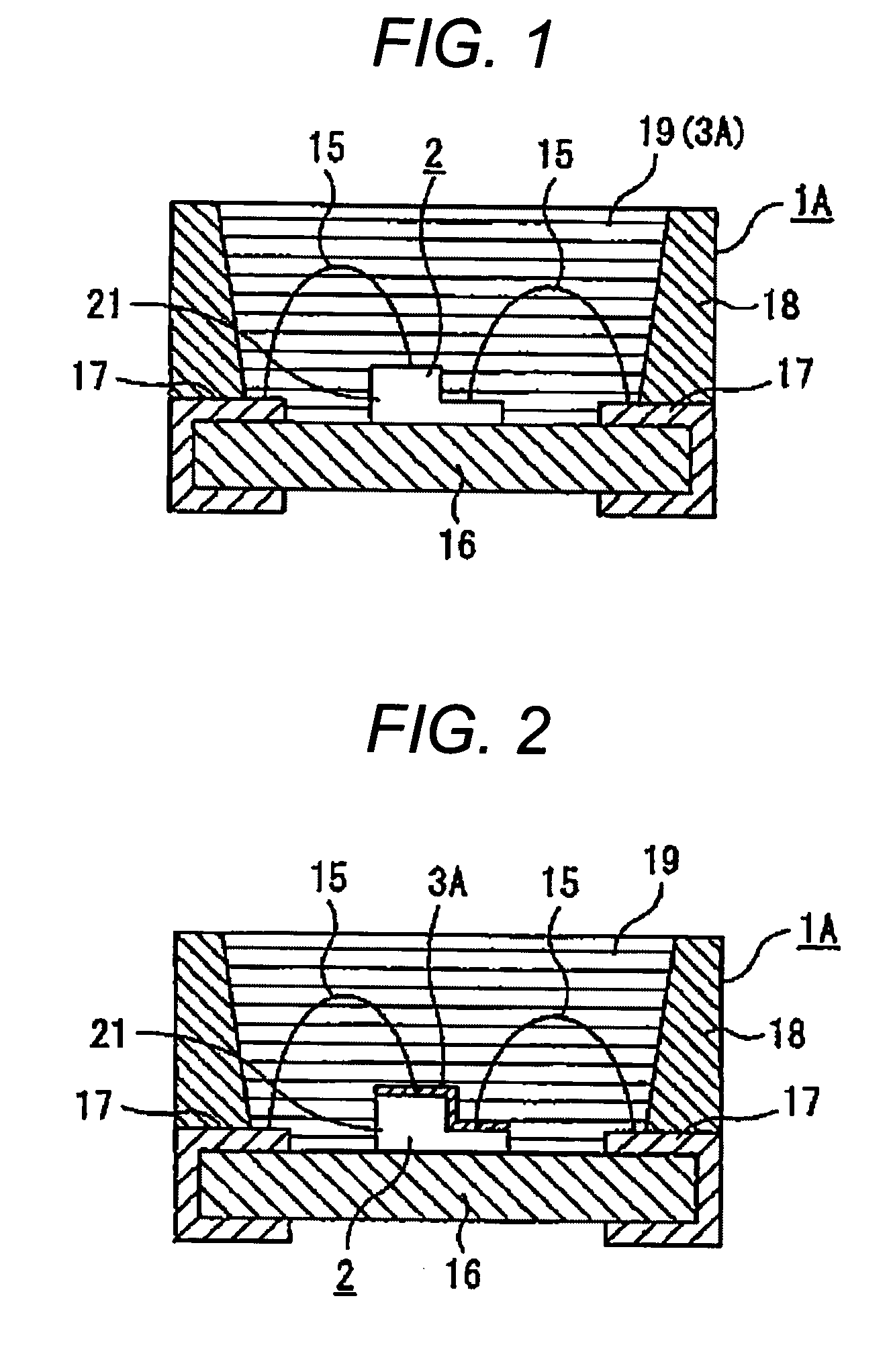

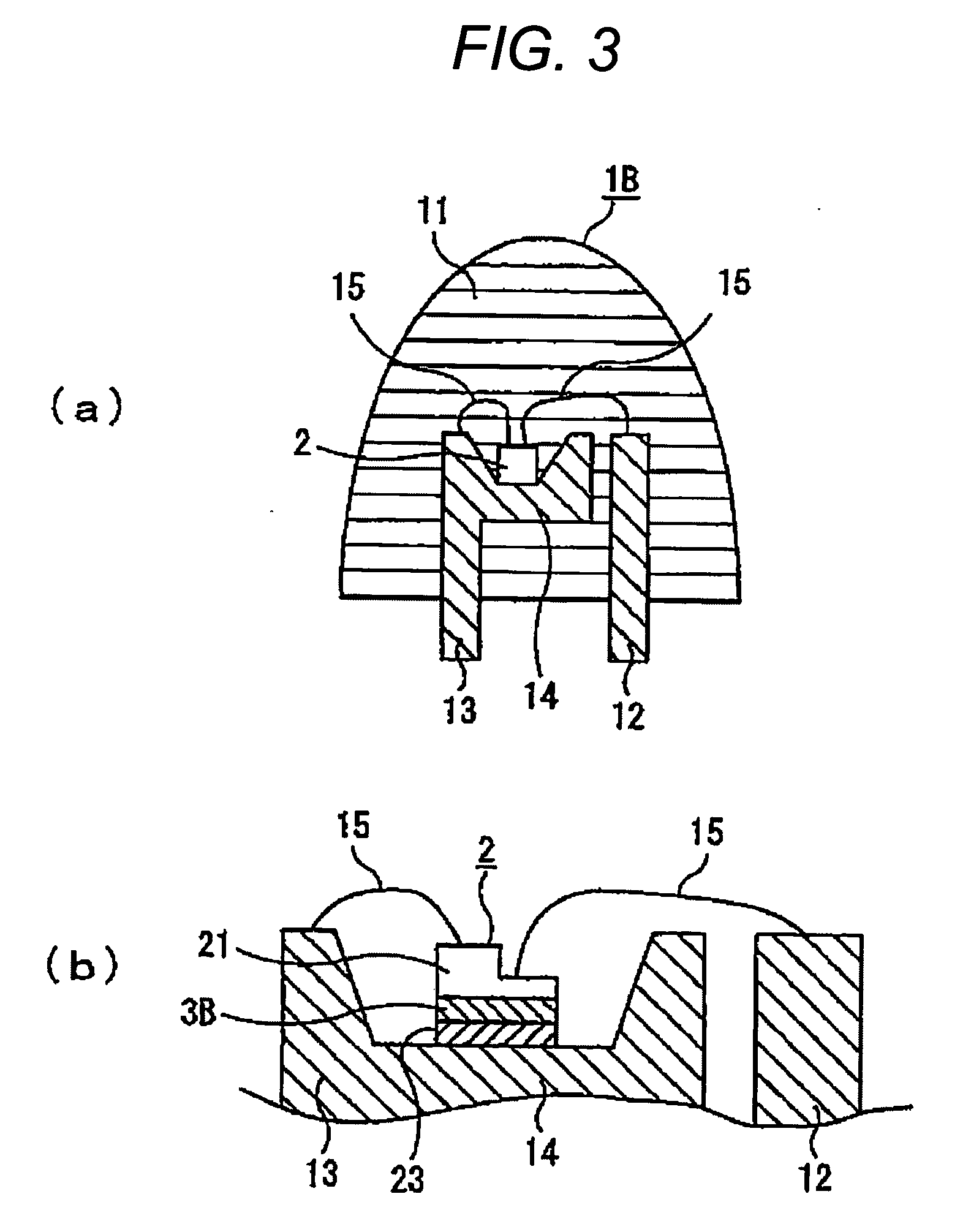

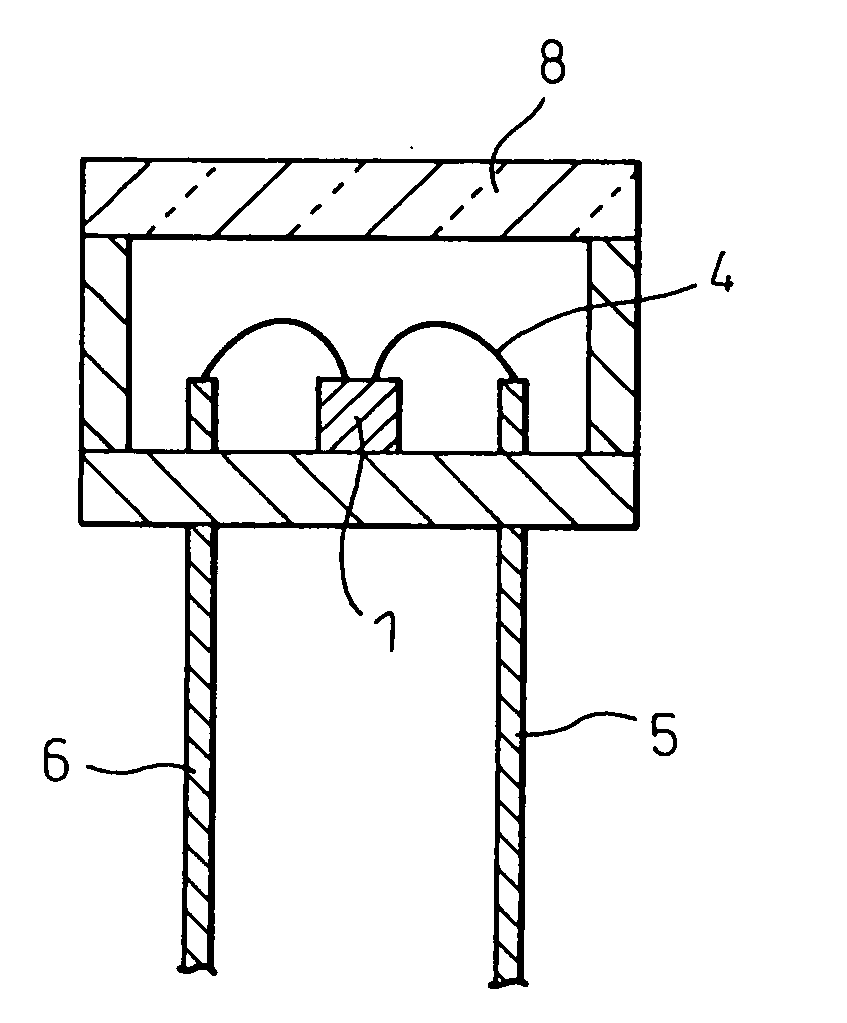

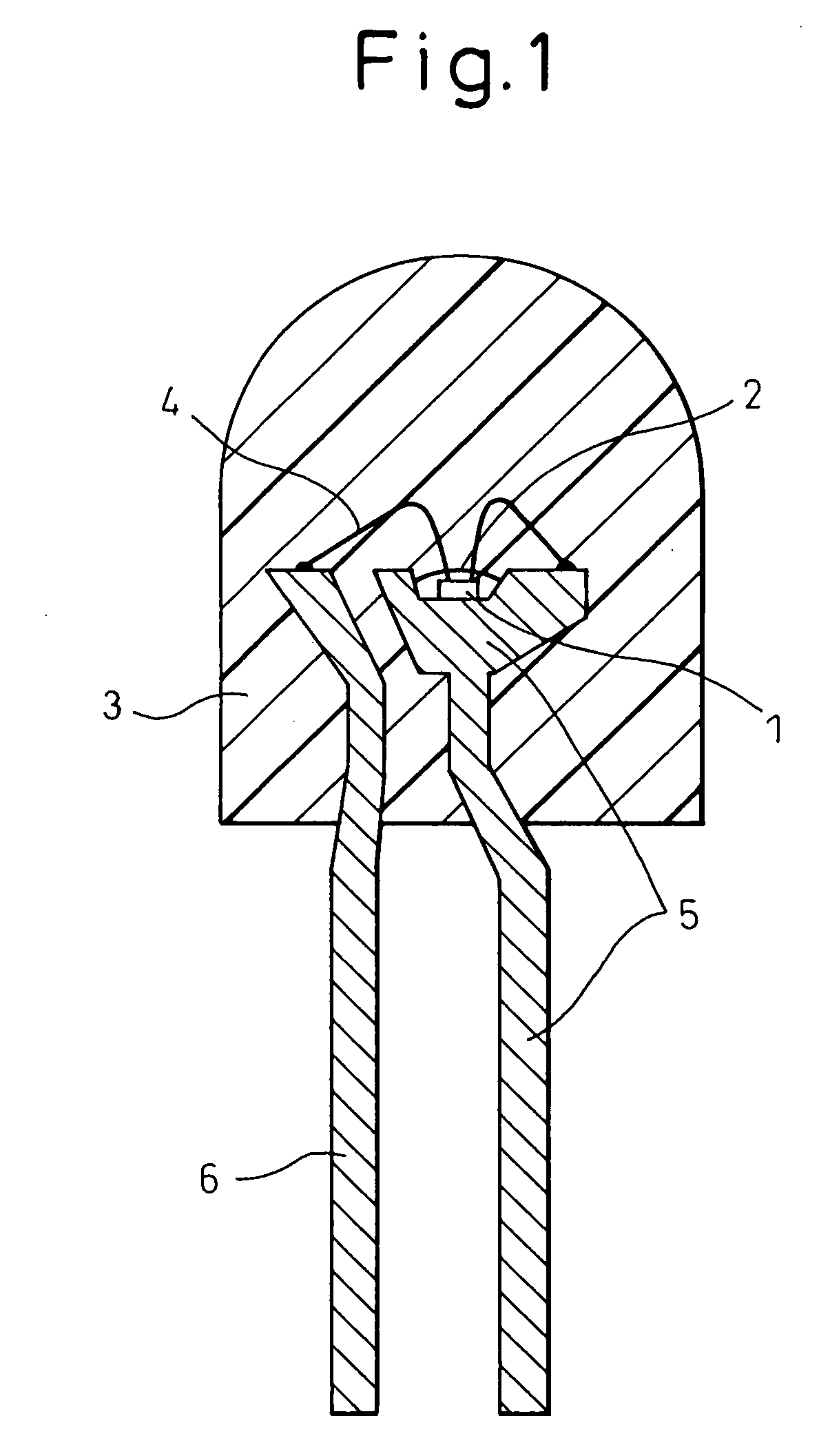

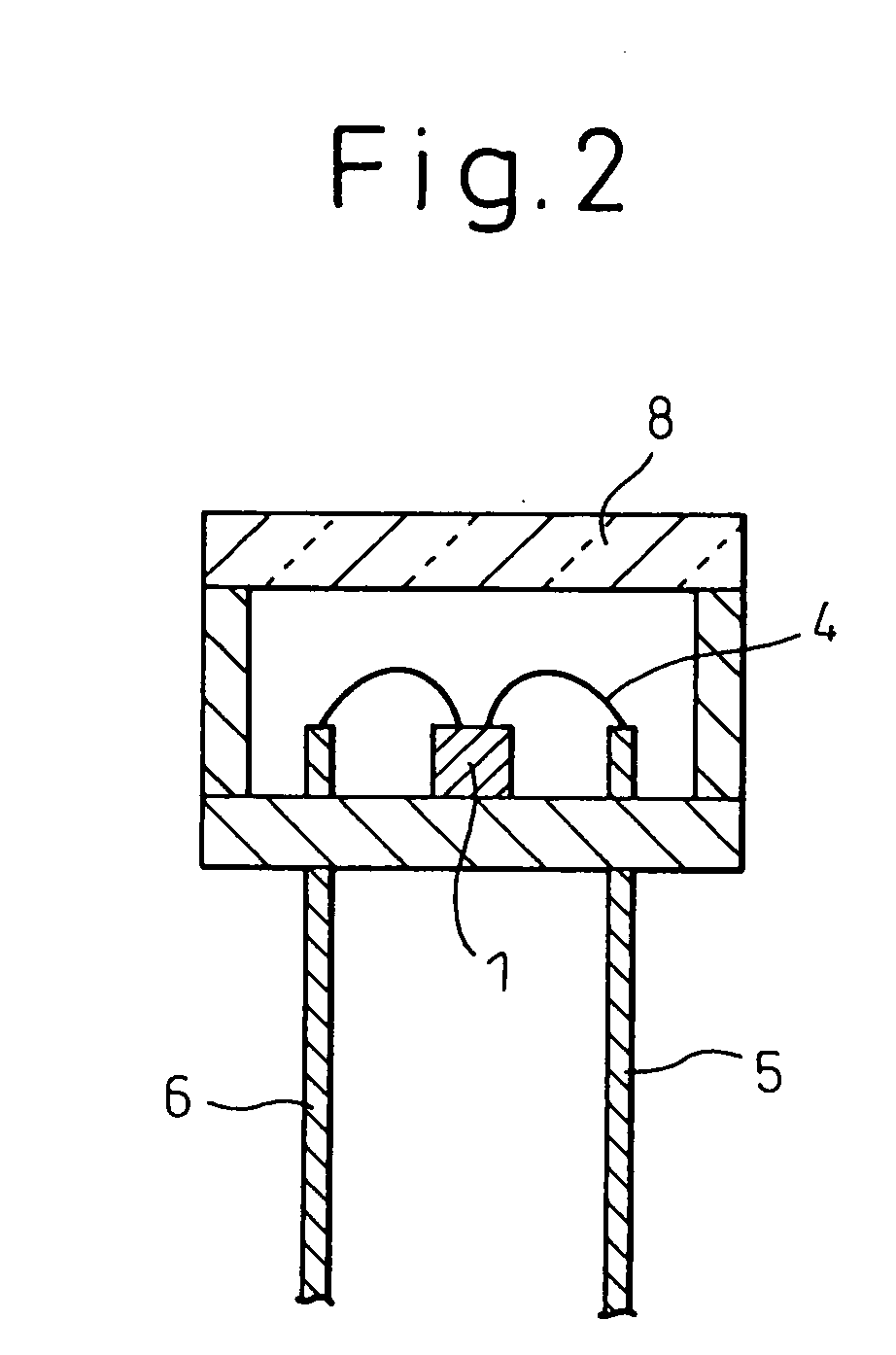

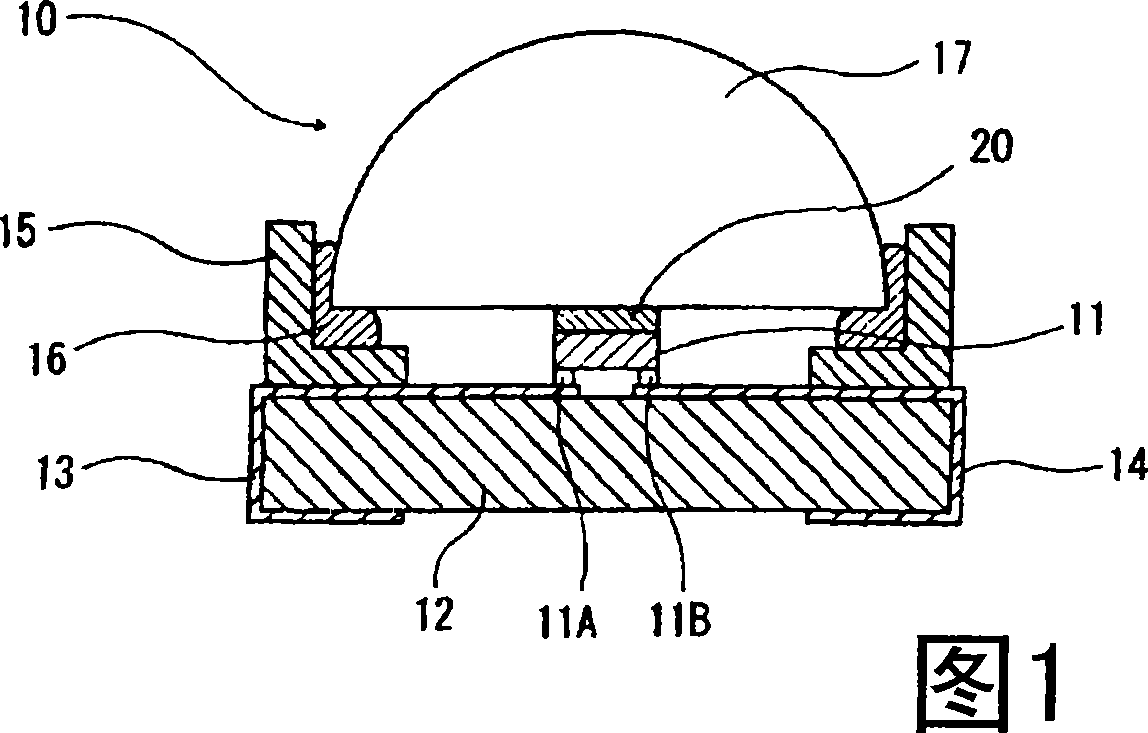

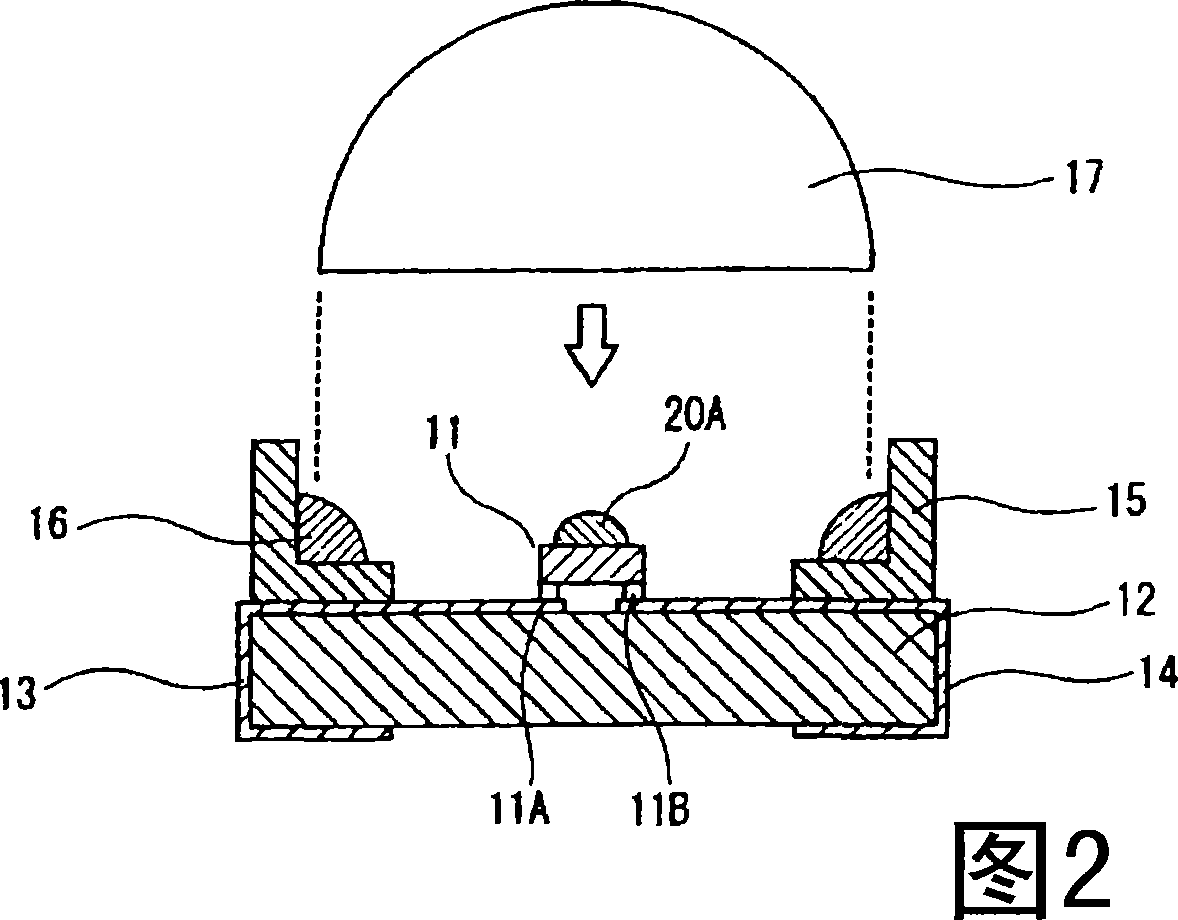

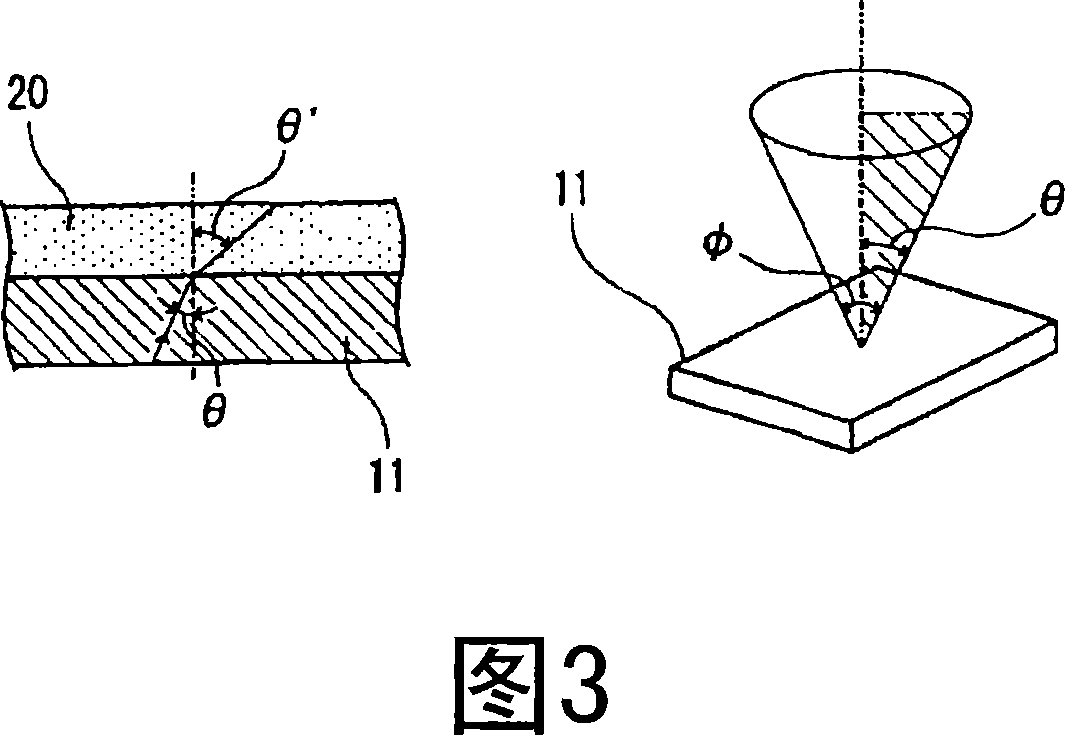

Ultraviolet ray emitting element package

The present invention provides an ultraviolet ray emitting element package that has a novel structure and is equipped with a condenser lens, for a high taking-out efficiency of ultraviolet ray and stable output. The ultraviolet ray emitting element package includes a condenser lens, and an ultraviolet ray emitting element positioned at the center on the bottom surface side thereof, away from the bottom surface of the lens. A refractive index difference buffering material having ultraviolet resistance is filled at least in the gap between the ultraviolet ray emitting element and the bottom surface of the condenser lens. A silicon resin or fluorine resin is used as the refractive index difference buffering material.

Owner:USHIO DENKI KK

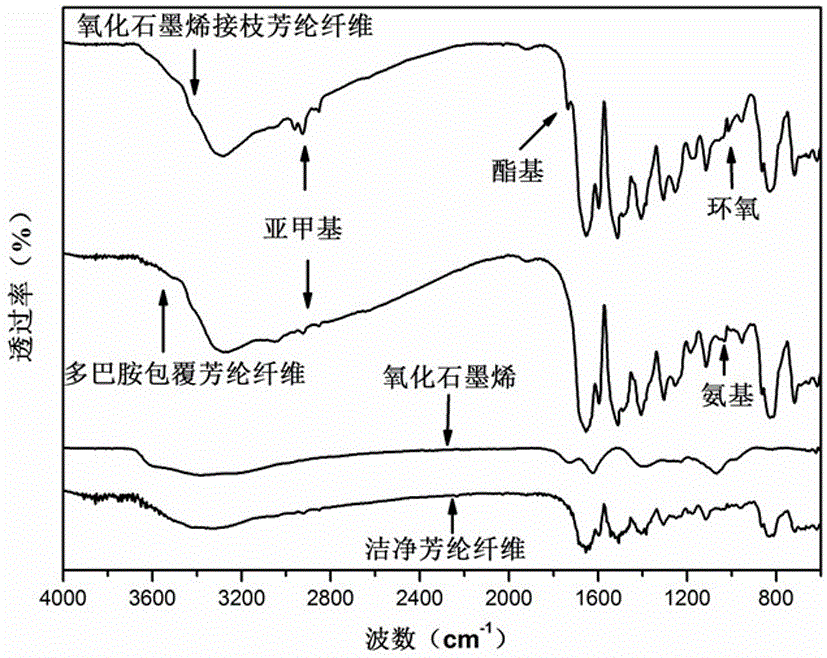

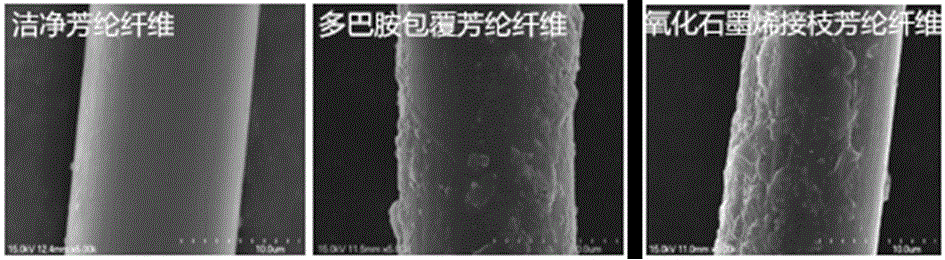

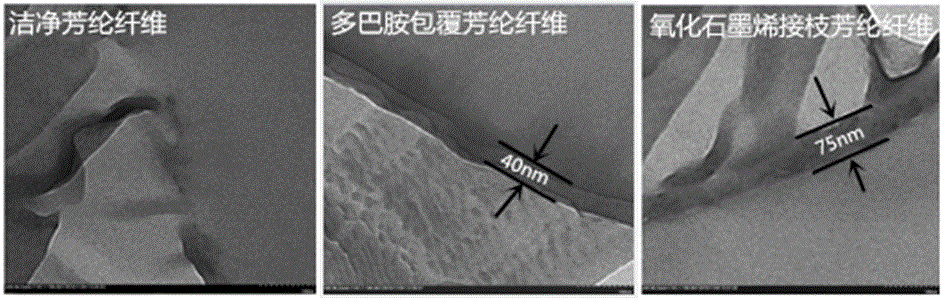

Surface modified aramid fiber and preparation method thereof

ActiveCN105603717AFacilitate graftingOutstanding UV resistancePhysical treatmentLight resistant fibresGraphenePre treatment

The invention discloses a surface modified aramid fiber and a preparation method thereof. Clean aramid fiber which is cleaned is dipped into a dopamine solution under a weak basicity condition to obtain a dopamine wrapped aramid fiber; through an esterification reaction and pi-pi interaction between oxidized graphene and the dopamine wrapped aramid fiber, a high-grafting-ratio oxidized graphene layer is formed on the surface of the aramid fiber, so that the surface modified aramid fiber is obtained. The surface modified aramid fiber has excellent ultraviolet resistance and is provided with a lot of active groups, in this way, the surface activity of the aramid fiber is obviously improved, and conditions are provided for further modification and application of the fiber. Meanwhile, in the process of modifying the aramid fiber, it is not needed to pretreat the aramid fiber, the preparation process is environmentally friendly, the operation technology is simple and controllable, and the surface modified aramid fiber is suitable for large-scale industrialized production.

Owner:SUZHOU UNIV

Colorful mortar for wall face

InactiveCN101508542AImprove water retentionImprove the lubrication effectCelluloseWeather resistance

The invention provides color mortar for wall facings, which is characterized in that the color mortar consists of the following raw materials in percentage by weight: 20 to 25 percent of cement, 50 to 60 percent of quartz sand, 10 to 20 percent of ground limestone, 2 to 4 percent of emulsion powder, 0.3 to 0.5 percent of lignocellulose, 0.3 to 0.5 percent of thixotropic lubricant, 0.15 to 0.2 percent of cellulose ether and 1 to 5 percent of inorganic pigment. The color mortar has the advantages of good weather resistance, firm and durable color and luster, good ultraviolet resistance, good binding force with various non-polar bottom layer materials, difficult cracking, and good hydrophobicity.

Owner:上海英硕聚合材料股份有限公司

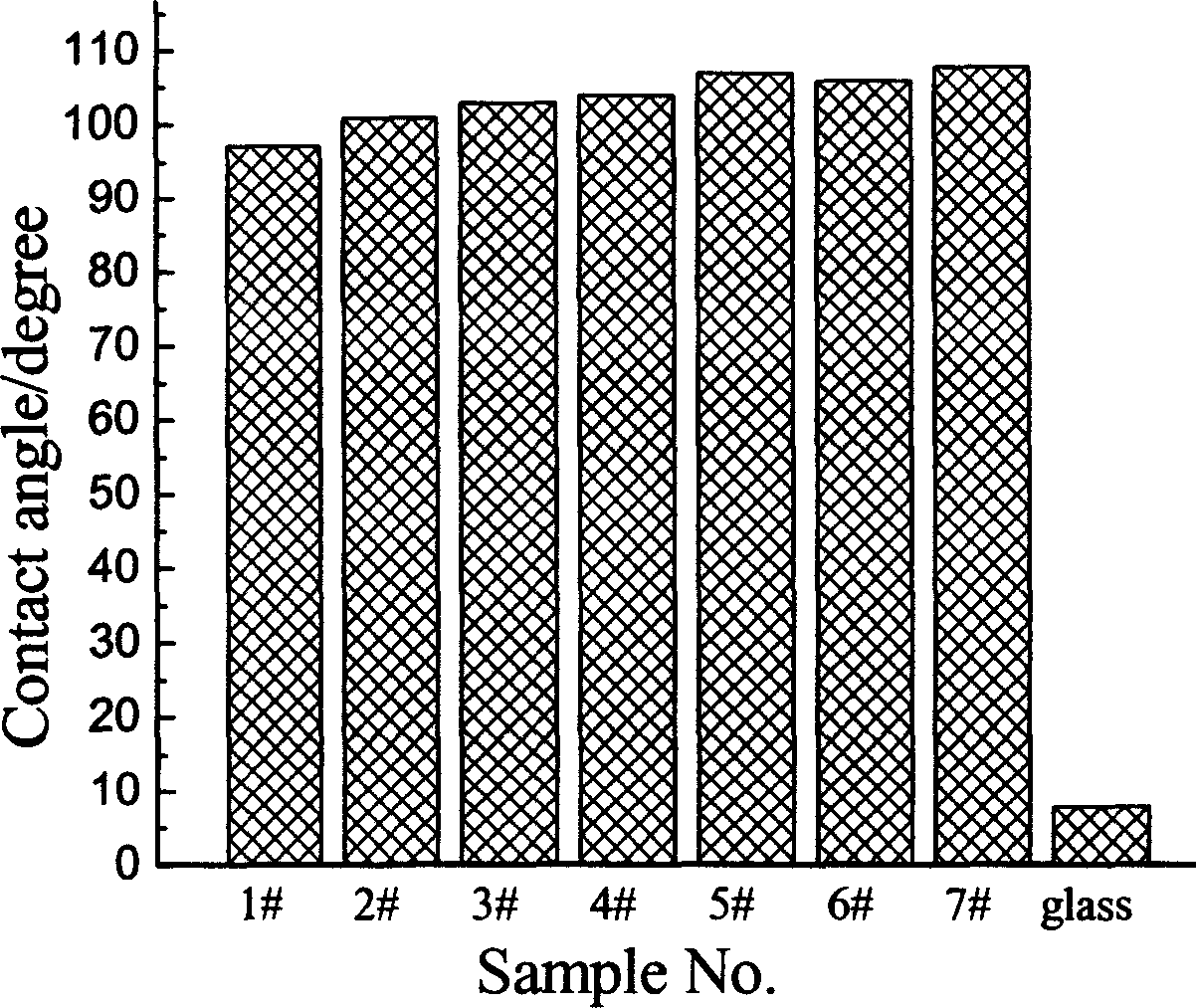

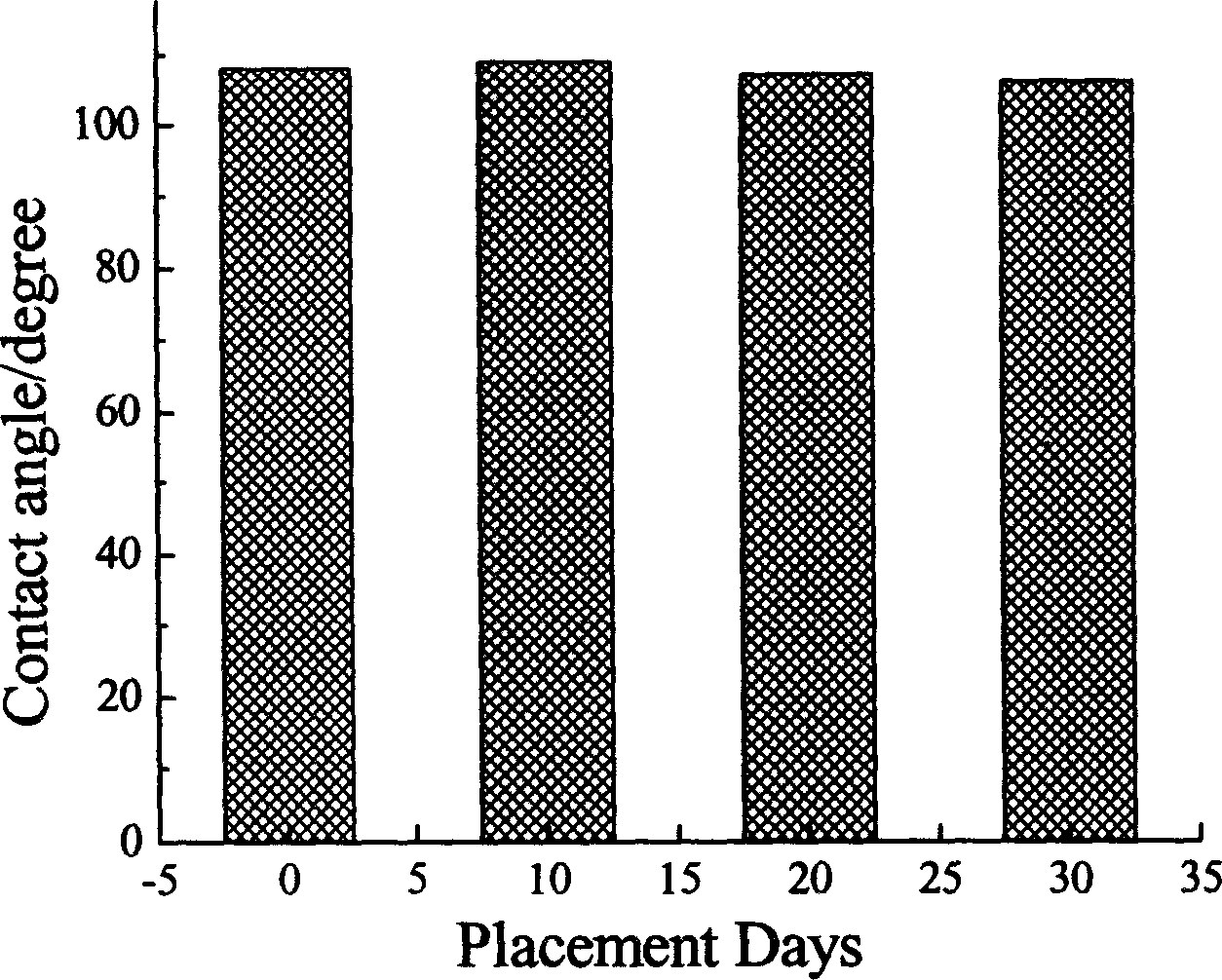

Hydrophobic and ultraviolet radiation proof transparent film and preparation thereof

InactiveCN1594646AImprove hydrophobicityThe cutoff wavelength increasesVacuum evaporation coatingSputtering coatingRadio frequency magnetron sputteringUltraviolet

The invention relates to a nitrogen doped titanium dioxide film of hydrophobicity and ultraviolet resistance, and its preparation. The character of film lies in that nitrogen exists in titanium dioxide crystal lattice in substitution and clearance mode, still a portion of Ti exist in Ti<3+> ion mode. film crystallization may be red schorl, anatase and amorphism. Titanium dioxide film prepared using direct current and radio-frequency magnetron sputtering method has good hydrophobic effect. Contact angle of film to distilled water is 97-110 DEG, ultraviolet cut-off wavelength is above 390nm, and visible light average transmittance is 70%-80%. Hydrophobicity of film is not influenced by film exposition time in air. The invention is easily operated, and the film thickness and composition can be controlled. Nitrogen doped hydrophobic film can be prepared for sample of different specification, material quality, and shape.

Owner:WUHAN UNIV OF TECH

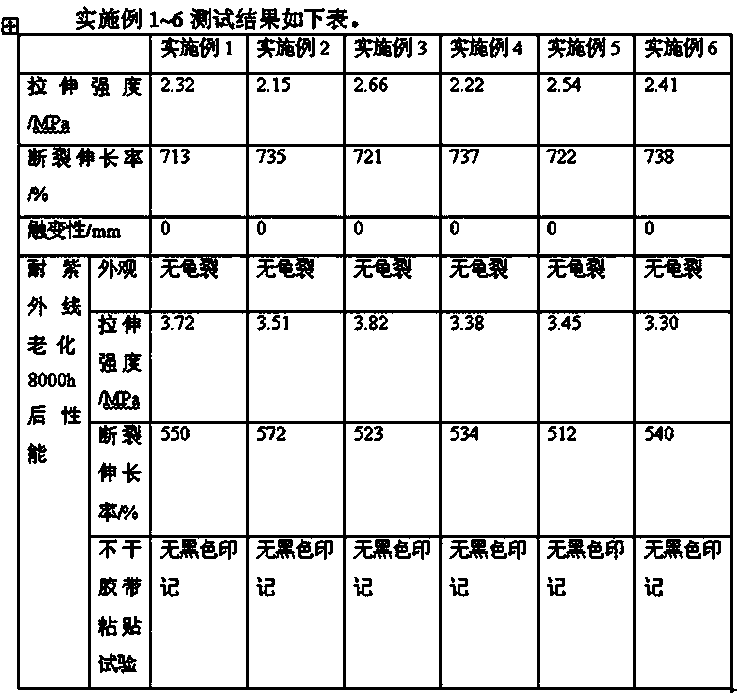

One-component moisture-cured polyurethane sealant with excellent ultraviolet resistance

ActiveCN103834345AImproves UV resistanceIncrease elasticityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAntioxidantUltraviolet

A one-component moisture-cured polyurethane sealant with excellent ultraviolet resistance belongs to the technical field of one-component moisture-cured polyurethane sealants, mainly solves the problems of photooxidation aging phenomenon, mechanical properties decreasing, sealant surface cracking, yellowing of white sealants and black water flowing of black sealants for the reason of rain erosion of one-component moisture-cured polyurethane sealants in the prior art under the effects of long-term irradiation of ultraviolet ray in natural light, and is mainly characterized by including 8 to 20 parts of a polyurethane prepolymer (I), 20 to 30 parts of a polyurethane prepolymer (II), 0.5 to 2 parts of a water absorption stabilizer, 0.1 to 0.7 part of a silane coupling agent, 0.1 to 1 part of a light stabilizer, 0.1 to 1 part of an antioxidant, 28 to 50 parts of a polyurethane-use filler, 1 to 4 parts of carbon black, 1 to 35 parts of a thixotropic agent and 0.4-2 parts of a catalyst. The one-component moisture-cured polyurethane sealant has the advantages of no cracking after placing in an ultraviolet aging box for 8000h, no black mark after pasting with a non-setting adhesive tape, good elasticity maintainence and less than 30% of decrease of the elongation at break, and is suitable for auto-body exterior caulking.

Owner:HUBEI HUITIAN NEW MATERIALS STOCK CO LTD

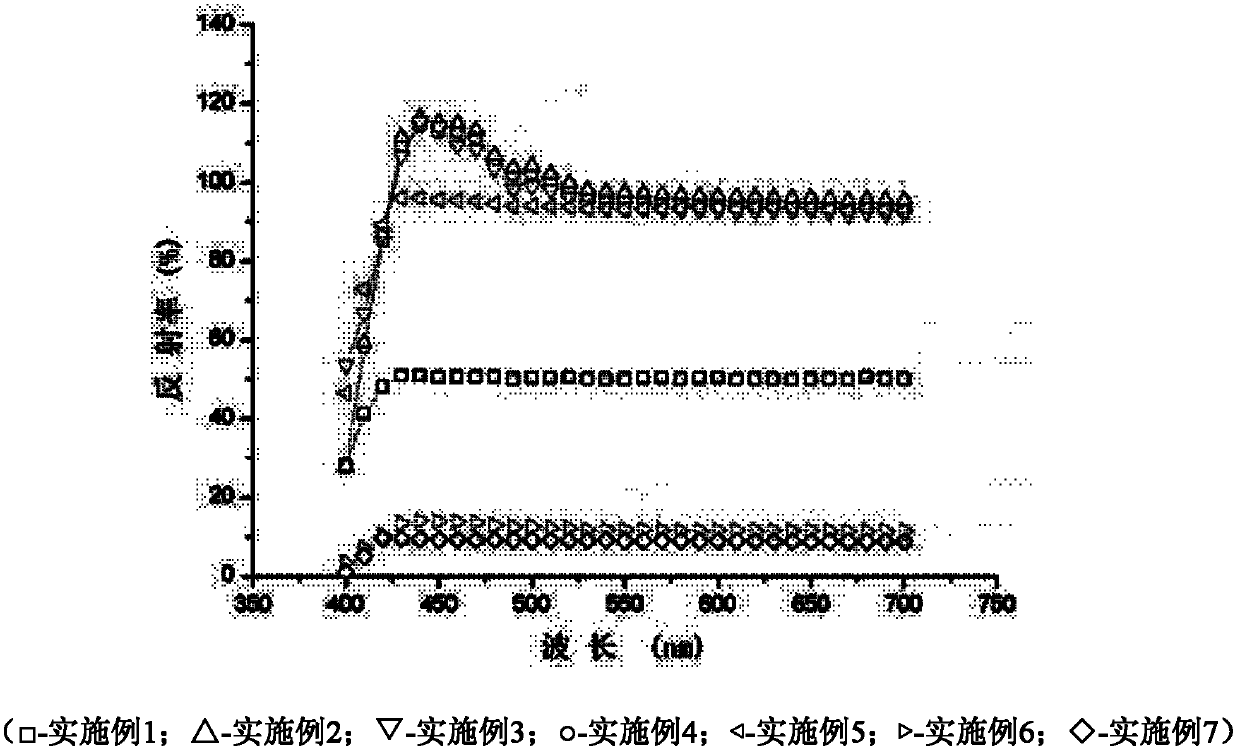

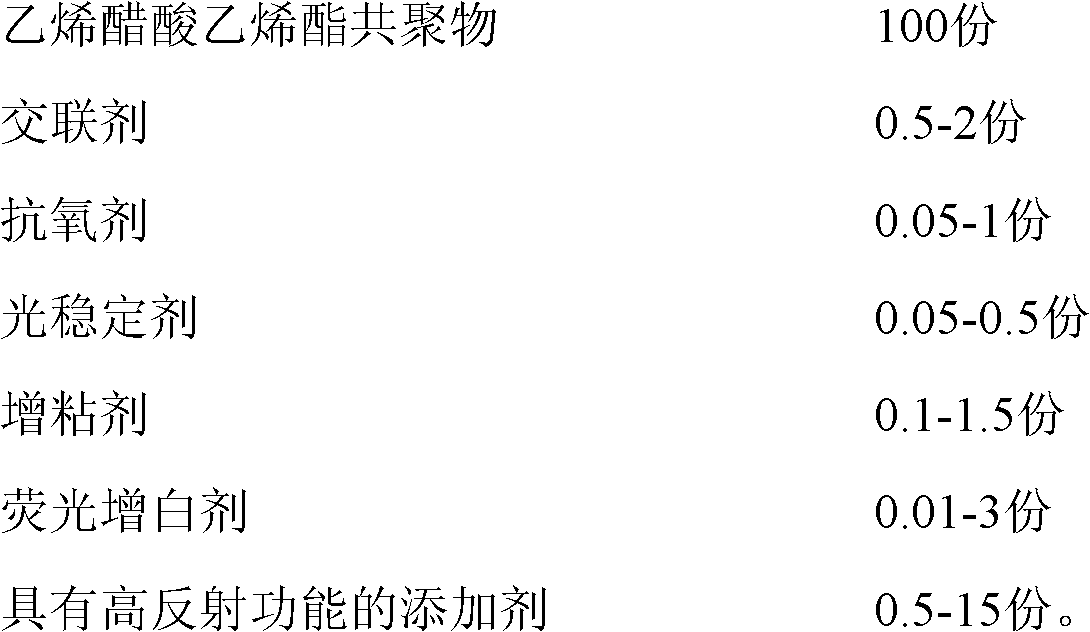

Preparing method of high reflectance rate ethylene-vinyl-acetate copolymer composition

InactiveCN102533163AImproves UV resistanceIncrease profitNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer scienceWhitening Agents

The invention discloses a preparing method of high reflectance rate ethylene-vinyl-acetate copolymer composition, which is characterized by containing the following components by weight proportion: 100 parts of ethylene-vinyl-acetate copolymer, 0.5-2 parts of cross-linking agent, 0.05-1 part of antioxidant, 0.05-0.5 part of light stabilizer, 0.1-1.5 parts of tackifier, 0.01-3 parts of fluorescent whitening agent and 0.5-15 parts of additive with a high reflection function. The ethylene-vinyl-acetate copolymer and the other functional additives are performed with premixing, fusing extruding and tape casting or calendaring for film forming, and finally are wound up to manufacture a high reflection rate ethylene vinyl acetate copolymer (EVA) packaging glue film. The preparing method of high reflectance rate ethylene-vinyl-acetate copolymer composition does not add organic ultraviolet absorber, thereby reducing yellowing effect on the glue film caused by the ultraviolet absorber. In addition, the preparing method of high reflectance rate ethylene-vinyl-acetate copolymer composition improves yellowing resistance and ultraviolet radiation resistance of the glue film by adding fluorescent whitening agent and high reflection additive. Simultaneously, reused ratio of light rays is increased, and finally long period service life of a photovoltaic assembly can be prolonged and photoelectric conversion efficiency of the photovoltaic assembly can be improved.

Owner:GUANGZHOU LUSHAN NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com