Hydrophobic and ultraviolet radiation proof transparent film and preparation thereof

A transparent film and anti-ultraviolet technology, which is applied in the direction of sputtering plating, ion implantation plating, metal material coating technology, etc., can solve the problems of difficult film and poor physical and chemical properties of the film, and achieve the effect of preventing near ultraviolet rays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

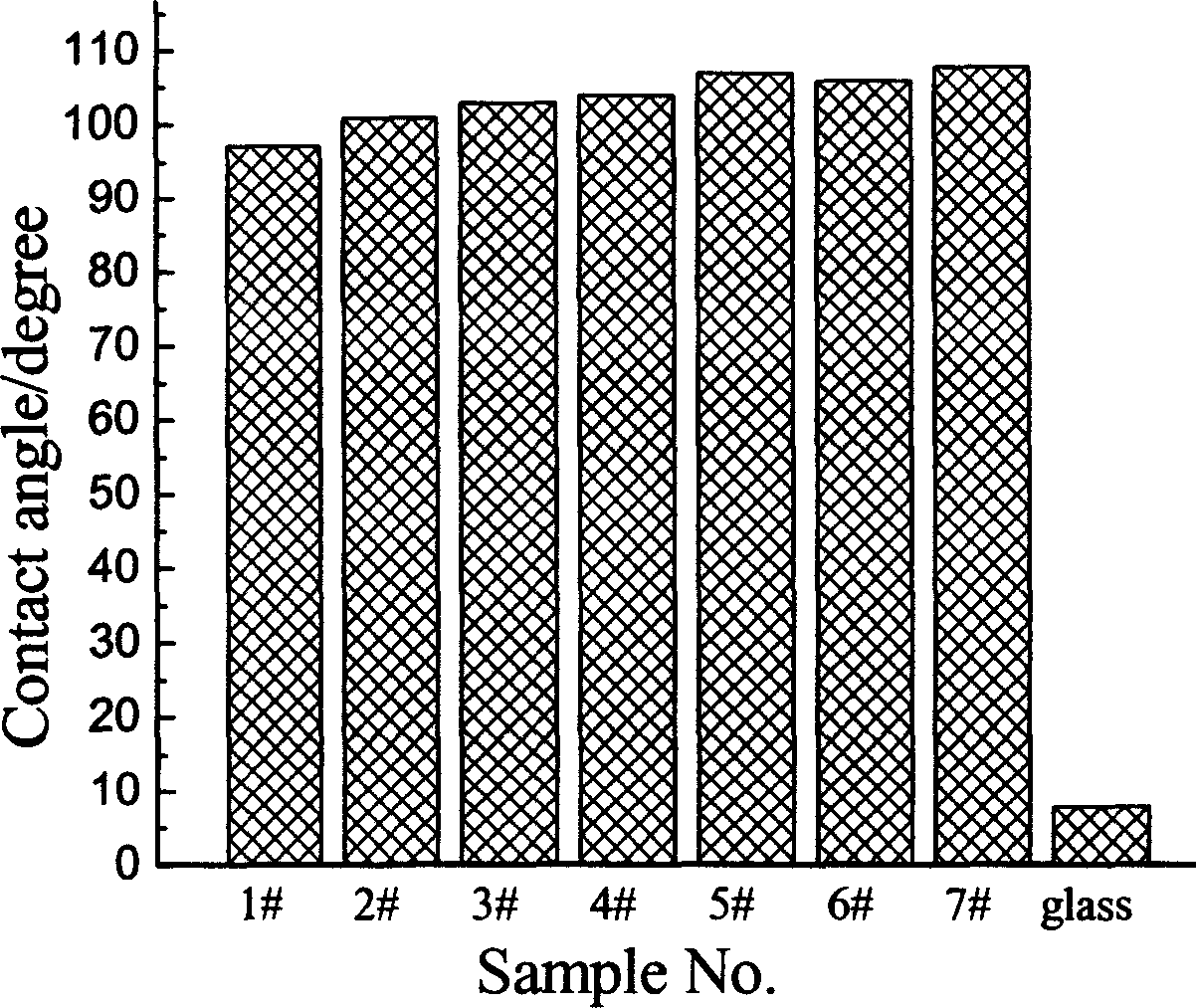

Embodiment 1

[0039] The carrier film is used as the substrate material, the sputtering cathode material is made of high-purity titanium target, and the background vacuum is 2.0×10 -3 Pa. DC reactive magnetron sputtering is selected here, and the sputtering conditions are specifically described as follows:

[0040] 1. Sputtering current: 0.3A.

[0041] 2. Sputtering voltage: 550V.

[0042] 3. Sputtering atmosphere: Ar (argon); working pressure: 0.8Pa.

[0043] 4. Reaction atmosphere: Oxygen-nitrogen mixed system; Working pressure: 0.8Pa, wherein the volume percentage of nitrogen is 80%.

[0044] 5. Substrate temperature: not heated.

[0045] 6. Bias applied to the substrate: 50V.

[0046] 7. Sputtering time: 60min.

[0047] 8. Distance from target to substrate: 15cm.

[0048] The sample number is 1#.

Embodiment 2、3 and 4

[0050] Except for the substrate temperature, other conditions are the same as in Example 1. Wherein the substrate temperature in Example 2 is 200°C, the substrate temperature in Example 3 is 350°C, and the substrate temperature in Example 4 is 400°C. The sample numbers are 2#, 3# and 4# respectively.

Embodiment 5,6

[0052] The sputtering process is the same as in Example 1, but the substrate is a quartz substrate. In order to obtain a good crystal form sample, the sample is sent into a closed container for heat treatment for 3 hours. Nitrogen is used as a protective atmosphere, and its pressure is 1.5Mpa. The heat treatment temperature of Example 5 is 600°C, and the heat treatment temperature of Example 6 is 700°C. The sample numbers are 5# and 6# respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com