Patents

Literature

935 results about "Hydrophobic effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The hydrophobic effect is the observed tendency of nonpolar substances to aggregate in an aqueous solution and exclude water molecules. The word hydrophobic literally means "water-fearing", and it describes the segregation of water and nonpolar substances, which maximizes hydrogen bonding between molecules of water and minimizes the area of contact between water and nonpolar molecules. In terms of thermodynamics, the hydrophobic effect is the free energy change of water surrounding a solute. A positive free energy change of the surrounding solvent indicates hydrophobicity, whereas a negative free energy change implies hydrophilicity.

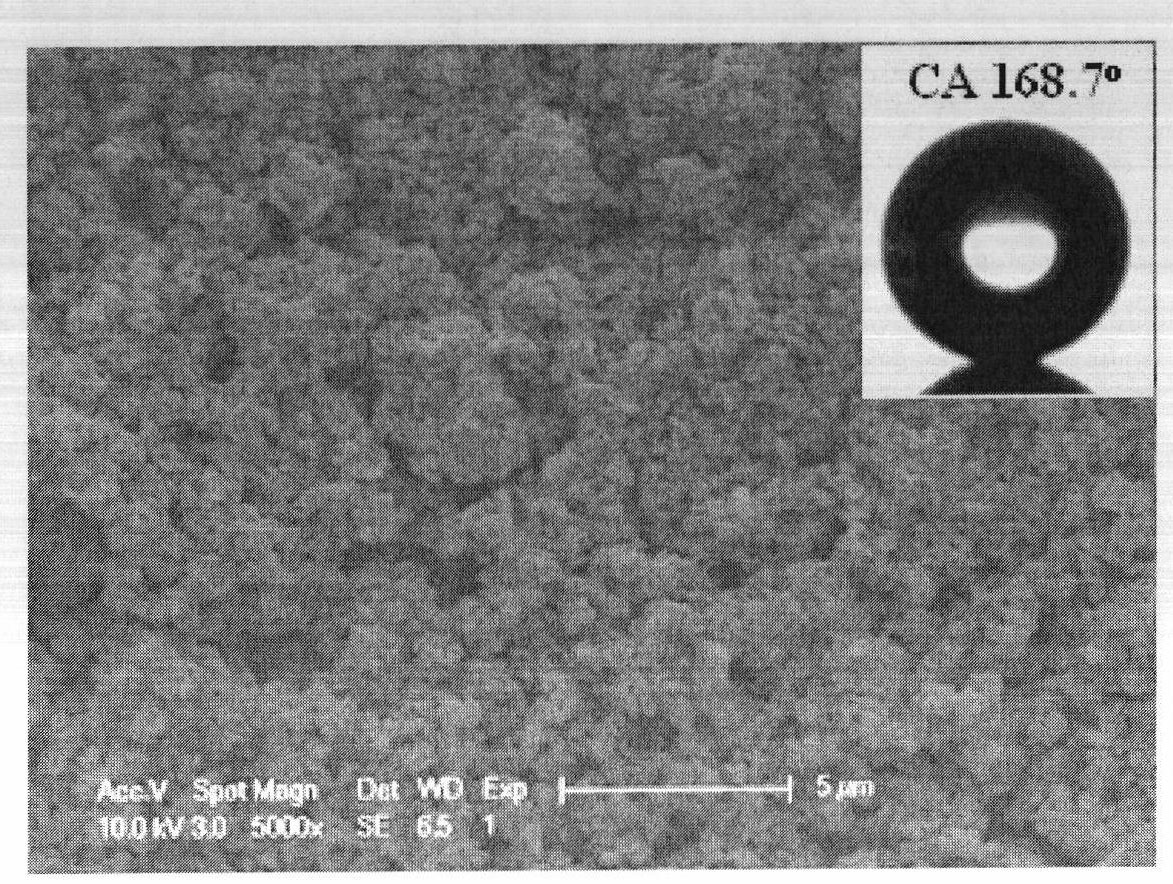

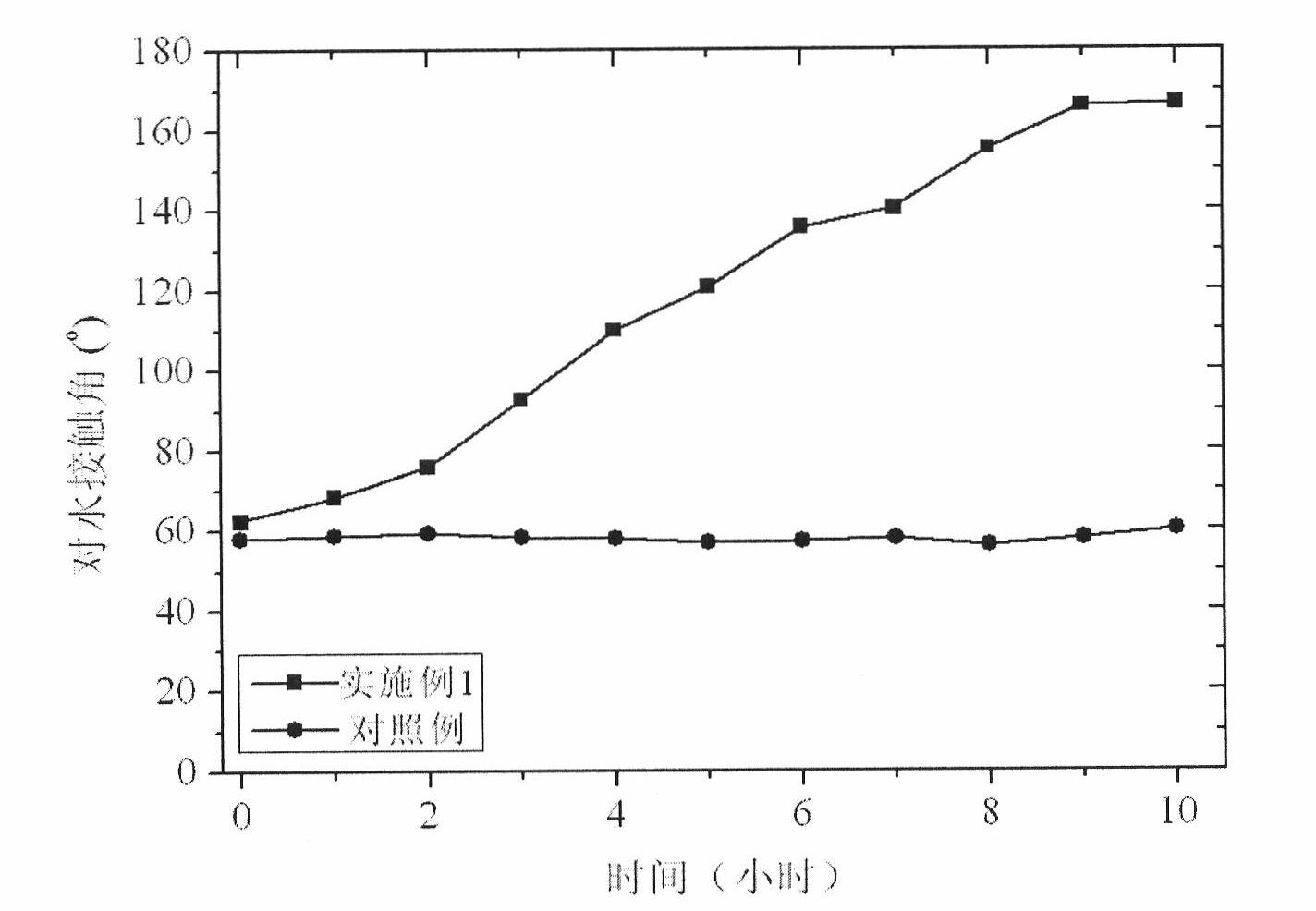

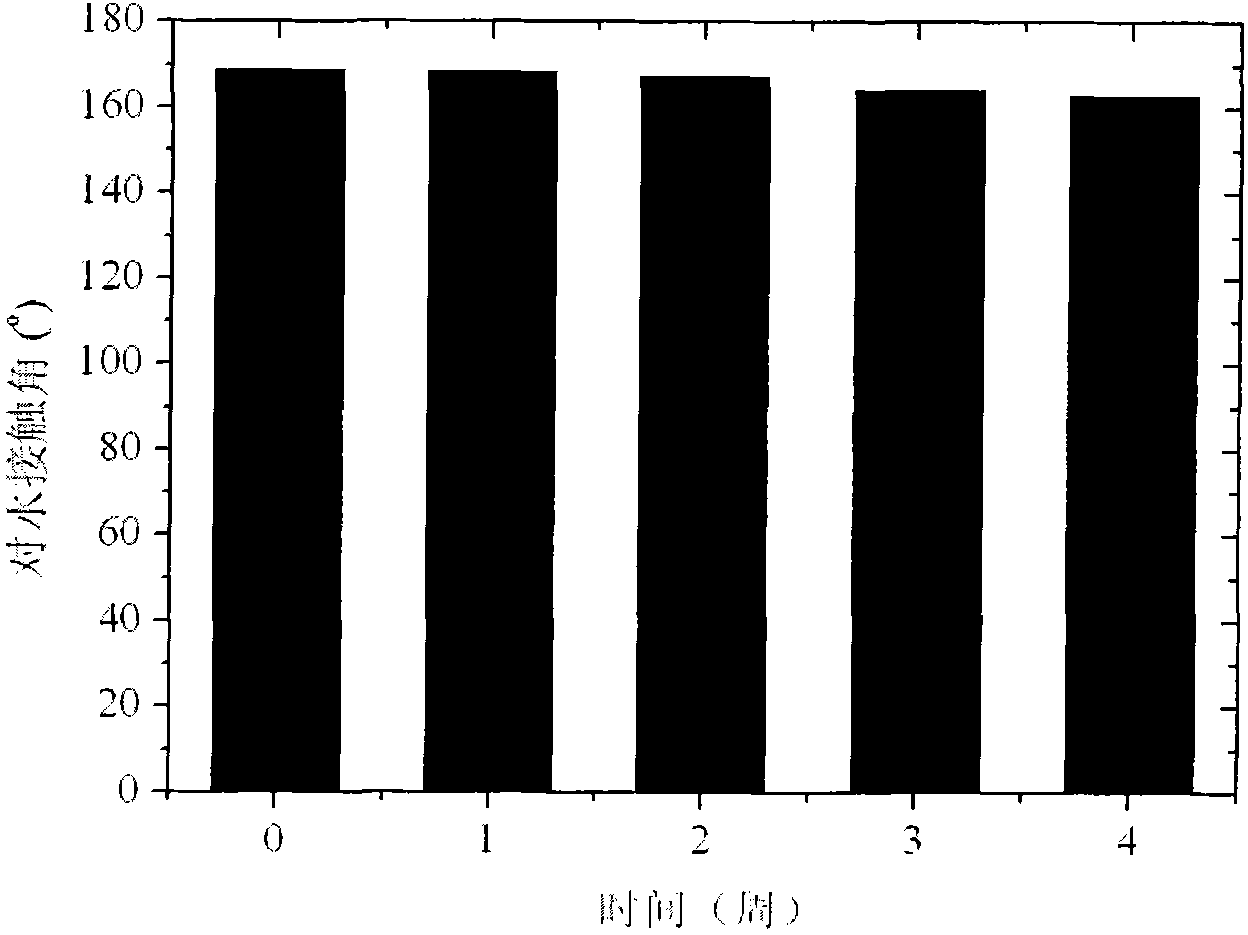

High-durability super-hydrophobic self-cleaning coating material and preparation method thereof

InactiveCN101962514AHas the following advantages: (1) cleanlinessHas the following advantages: (1) has the functionAntifouling/underwater paintsPaints with biocidesDouble bondDimethyl siloxane

The invention belongs to the technical field of a new chemical material, and in particular relates to a high-durability super-hydrophobic self-cleaning coating material and a preparation method thereof. The coating material of the invention is prepared by curing and drying nanoparticles with photo-catalytic activity, a low-surface-free-energy polymer and a cross-linking agent at the room temperature, wherein the low-surface-free-energy polymer consists of one or more of polysiloxane fluoride, dimethyl silicone polymer and polyphenylene methyl siloxane, which contain active groups, such as hydroxyl alkoxy group, carbon-carbon double bond, silanol group, siloxy group, and the like; the cross-linking agent is hydrogen-containing silicone oil or aminosilane; and the mass content of the photo-catalytic nanoparticles in the coating ranges from 10 to 60 percent. The coating is formed into a micro-nanostructure by nanoparticle self-organization; a super-hydrophobic self-cleaning coating with lotus effect is prepared from the coating and a cross-linked filming matrix with low surface energy; the persistence of a lotus-shaped super-hydrophobic characteristic of the coating is realized by using the photo-catalytic decomposition characteristic of an organic pollutant for the nanoparticles; and thus the material is suitable for large-area construction and has high weathering resistance andprominent self-cleaning characteristic.

Owner:FUDAN UNIV

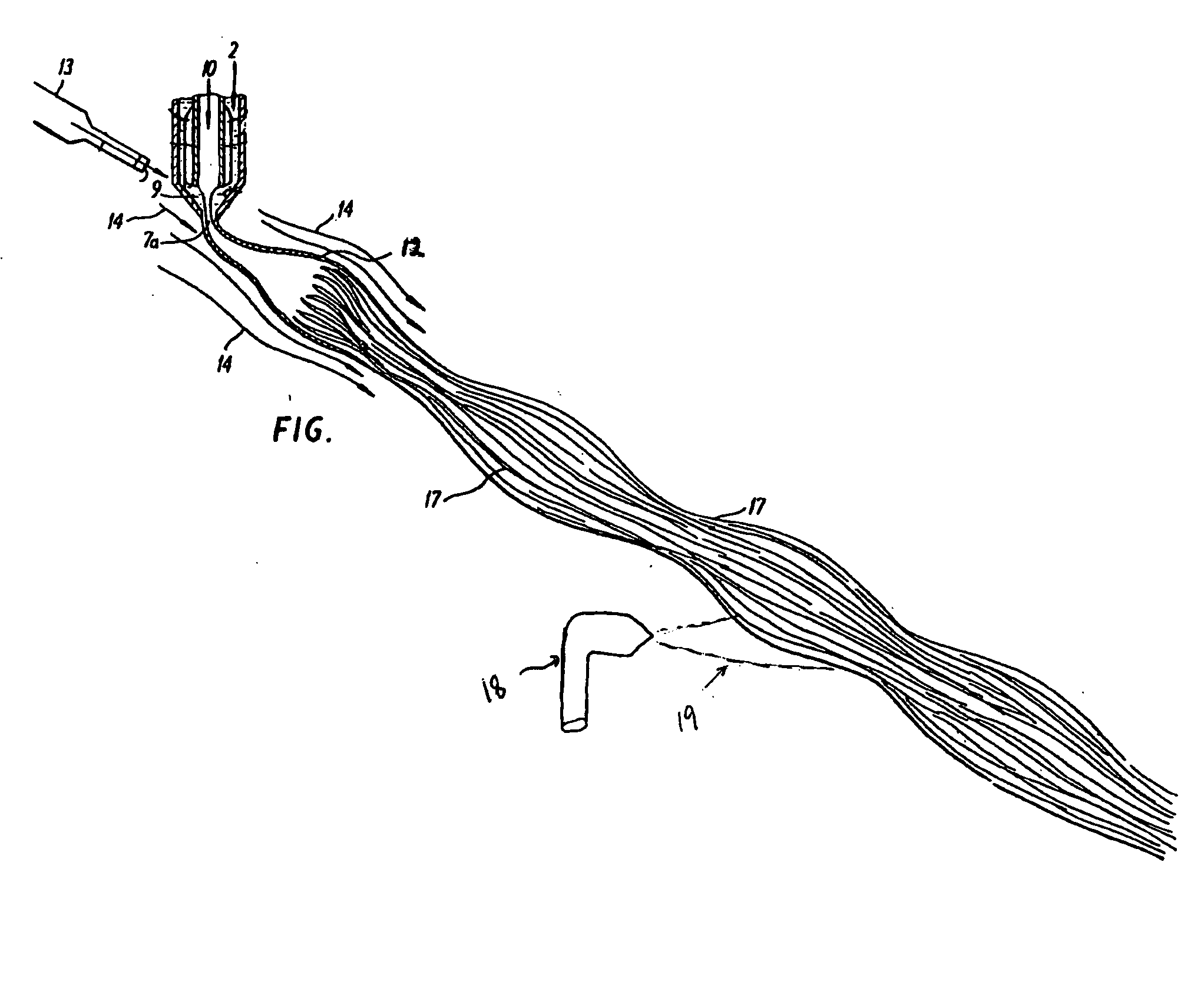

Coated nanofiber webs

ActiveUS20050008776A1Liquid surface applicatorsSynthetic resin layered productsPlasticizerNanoparticle

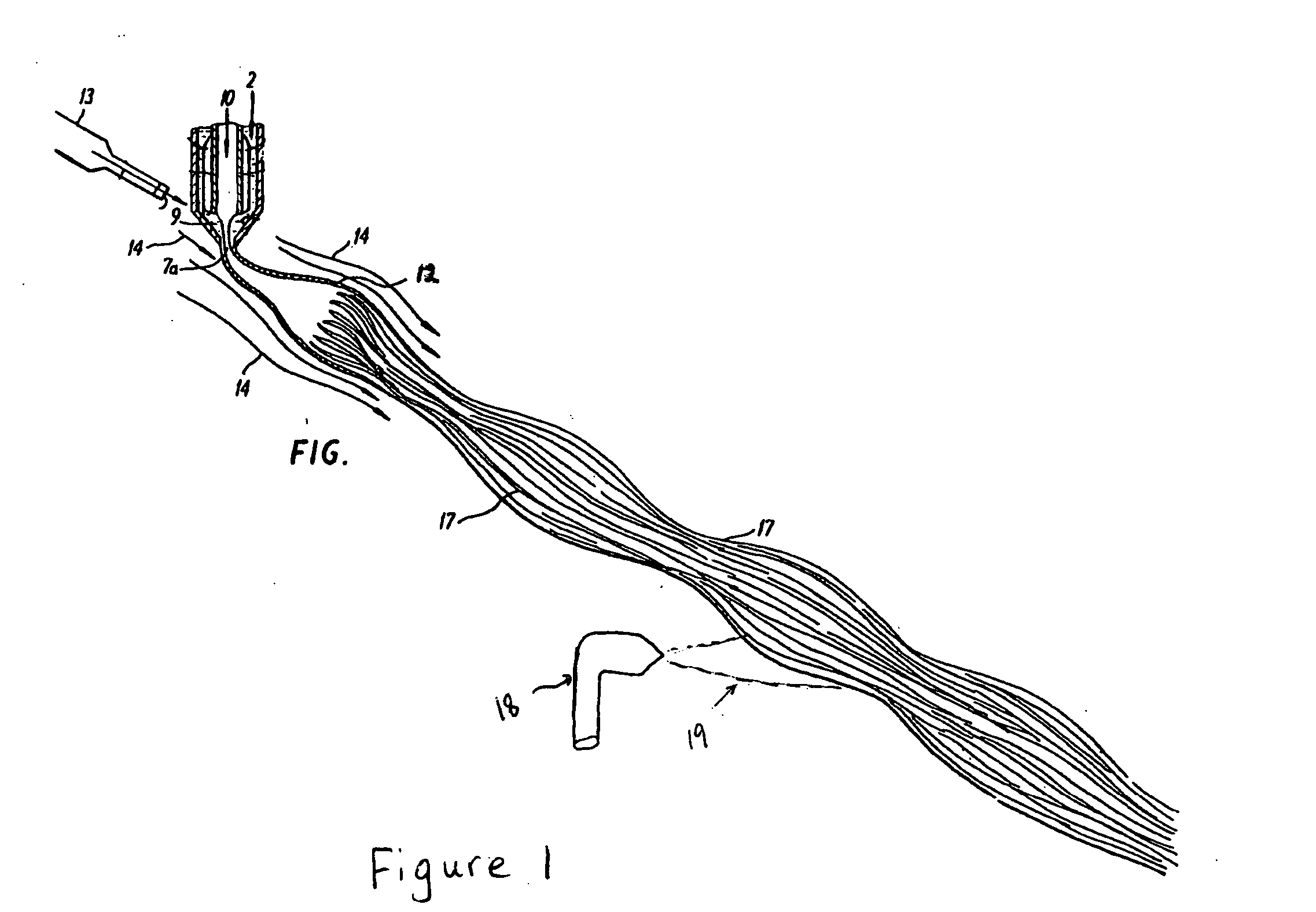

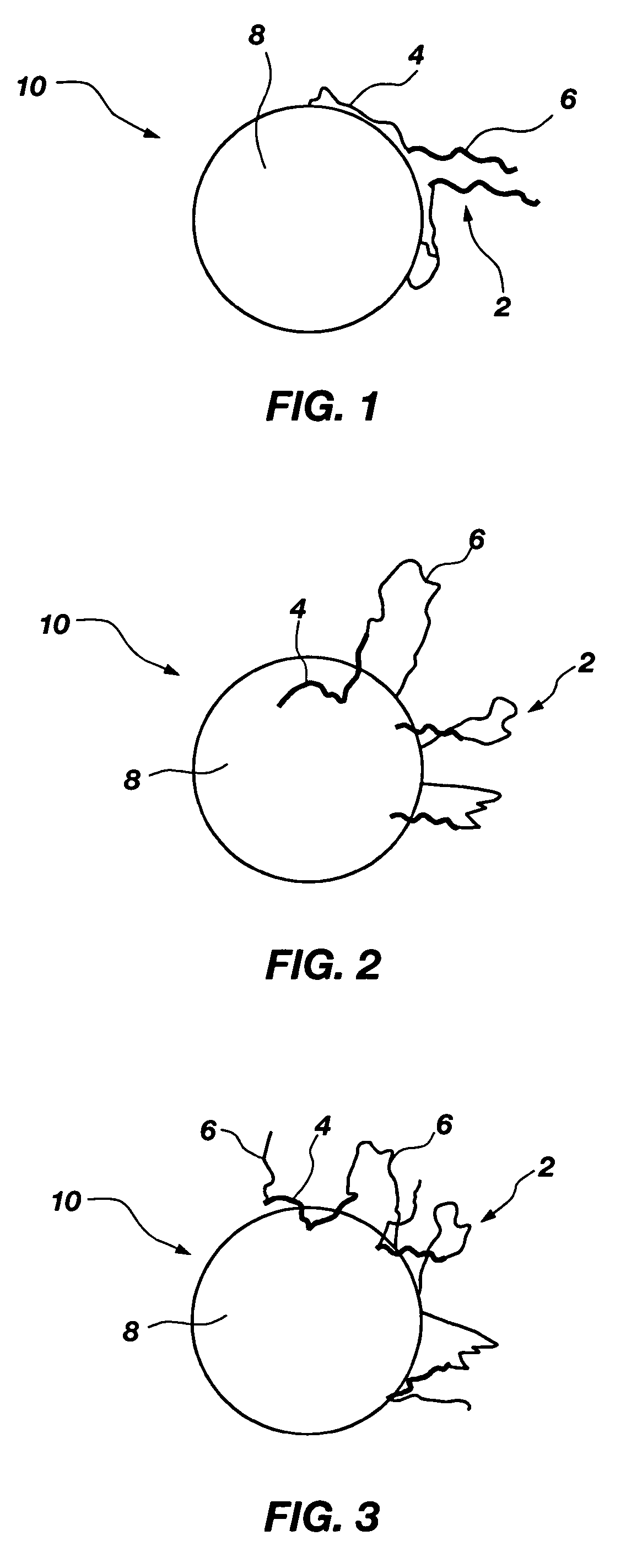

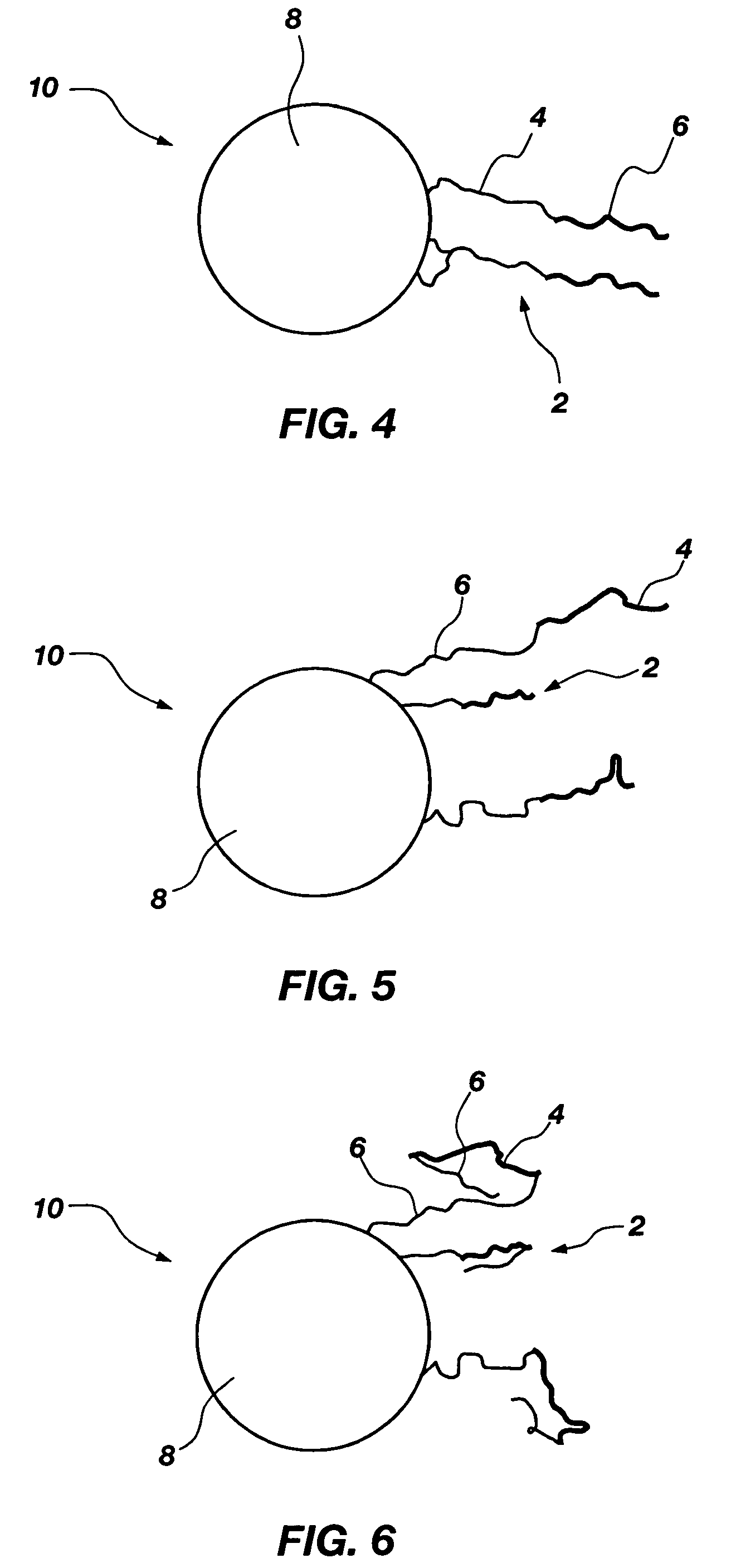

The present invention is directed to a method of forming nonwoven webs comprising coated fibers. The method of forming the nonwoven web generally comprises the steps of forming fibers from a melt fibrillation process, forming at least one fluid stream containing a coating substance, applying the coating substance onto the surface of the fiber, and depositing the coated fibers on a surface to form a web. Typically, the fibers are coated in flight. Preferably, the melt fibrillation process to form the fibers is a melt film fibrillation process. A melt film fibrillation process generally includes the steps of providing a polymeric melt, utilizing a central fluid stream to form an elongated hollow polymeric film tube, and using air to form multiple nanofibers from the hollow tube. The nonwoven web may comprise a layer having a significant number of nanofibers with diameters less than one micron. The layer may comprise two or more pluralities of fiber diameter distributions wherein at least one plurality has an average fiber diameter of less than about one micron. The coating substance can be selected from the group consisting of lotions, powders, surfactants, softeners, nanoparticles, creams, gels, conducting fluids, hydrophilic agents, hydrophobic agents, hygroscopic agents, emollients, plasticizers, absorbent gelling material, antimicrobial agents, and combinations thereof. A preferred coating substance is a surfactant. Another preferred coating substance is a hydrophilic or hydrophobic substance. The present invention is also directed to a nonwoven web comprising a layer having a significant number of nanofibers with diameters less than one micron and a coating substance is applied to a surface of said nanofibers

Owner:THE PROCTER & GAMBLE COMPANY

Wiping sheet

InactiveUS6013349AImprove bending resistancePromote recoveryCleaning machinesCleaning equipmentPolymer scienceNonwoven fabric

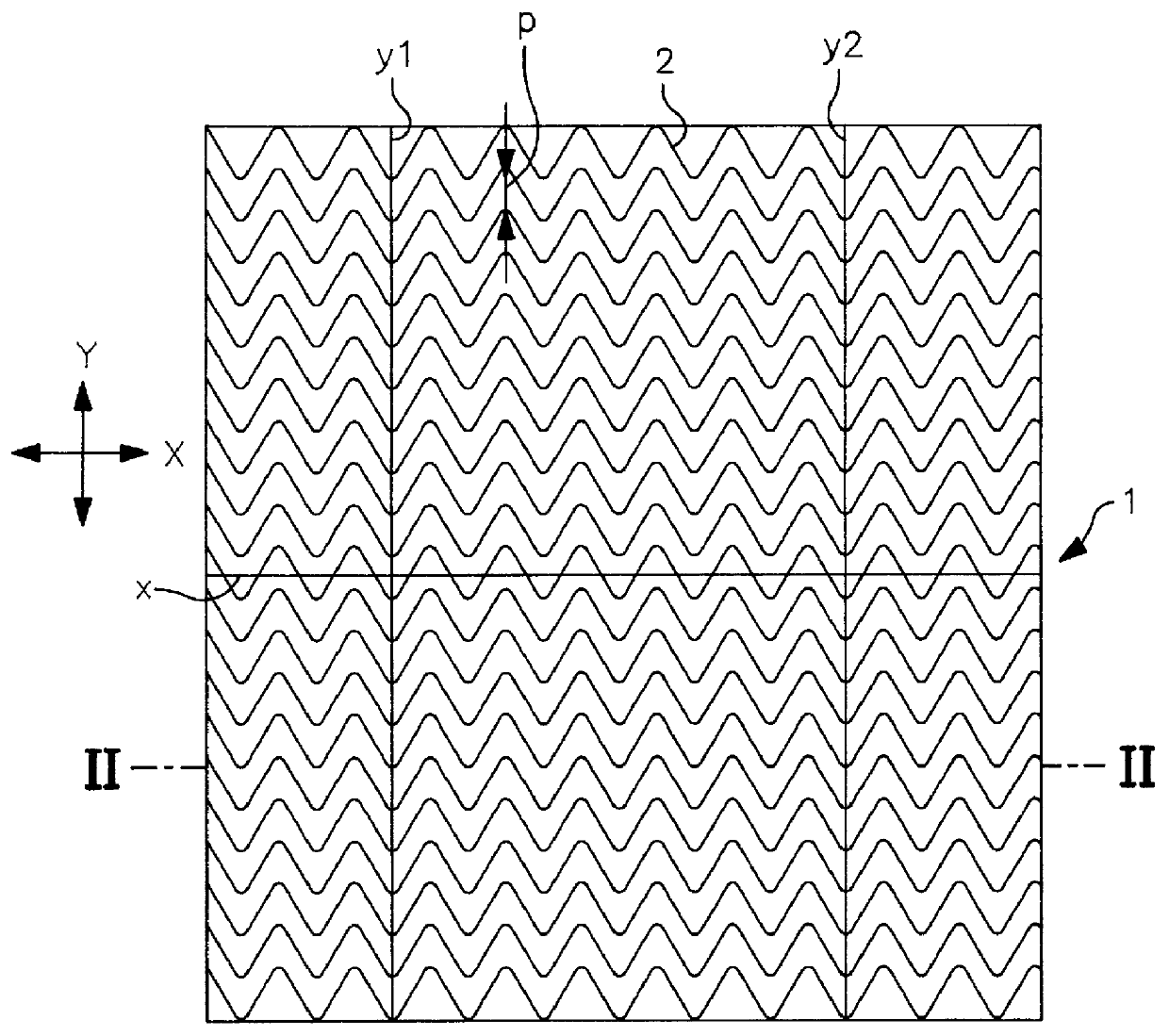

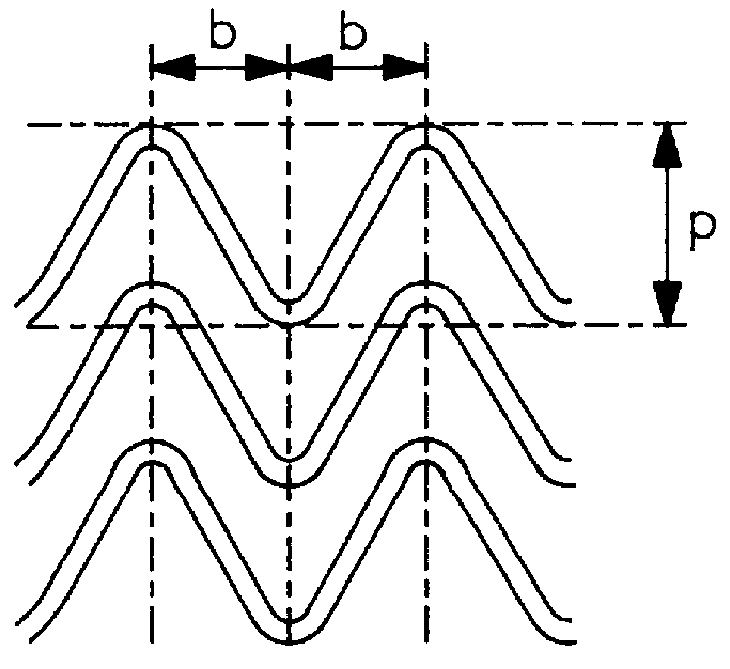

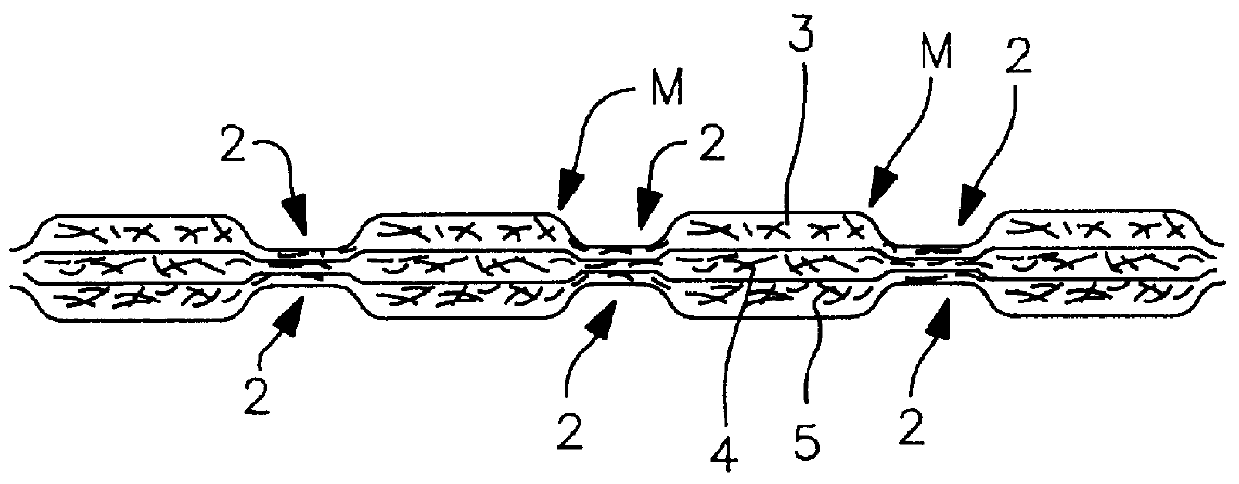

An absorbent core 4 composed of a nonwoven fabric containing an absorbent fiber at 20% by weight or more to 80% by weight or less and a hydrophobic fiber at 20% by weight or more to 80% by weight or less is interposed between a top sheet 3 and a bottom sheet 5, both the sheets being composed of a nonwoven fabric containing an absorbent fiber, such as rayon, at 30% by weight or more to 70% by weight or less and a hydrophobic fiber at 30% by weight or more to 70% by weight or less. Then, the top sheet 3, the absorbent core 4 and the bottom sheet 5 are bonded together on bonding lines 2. These individual layers are water retentive because of the absorbent fiber therein, and the resulting sheet has good slip properties because of the hydrophobic fiber contained therein. The absorbent core 4 works to enhance the bending resistance.

Owner:UNI CHARM CORP

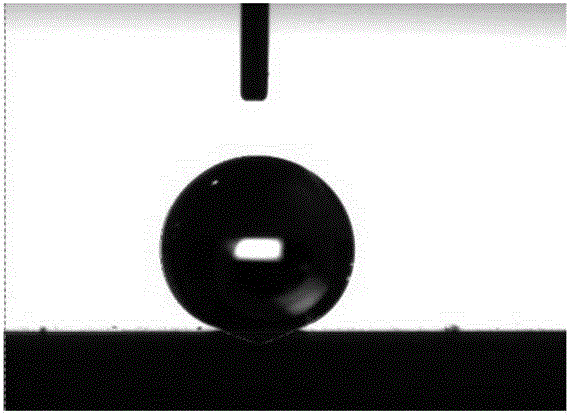

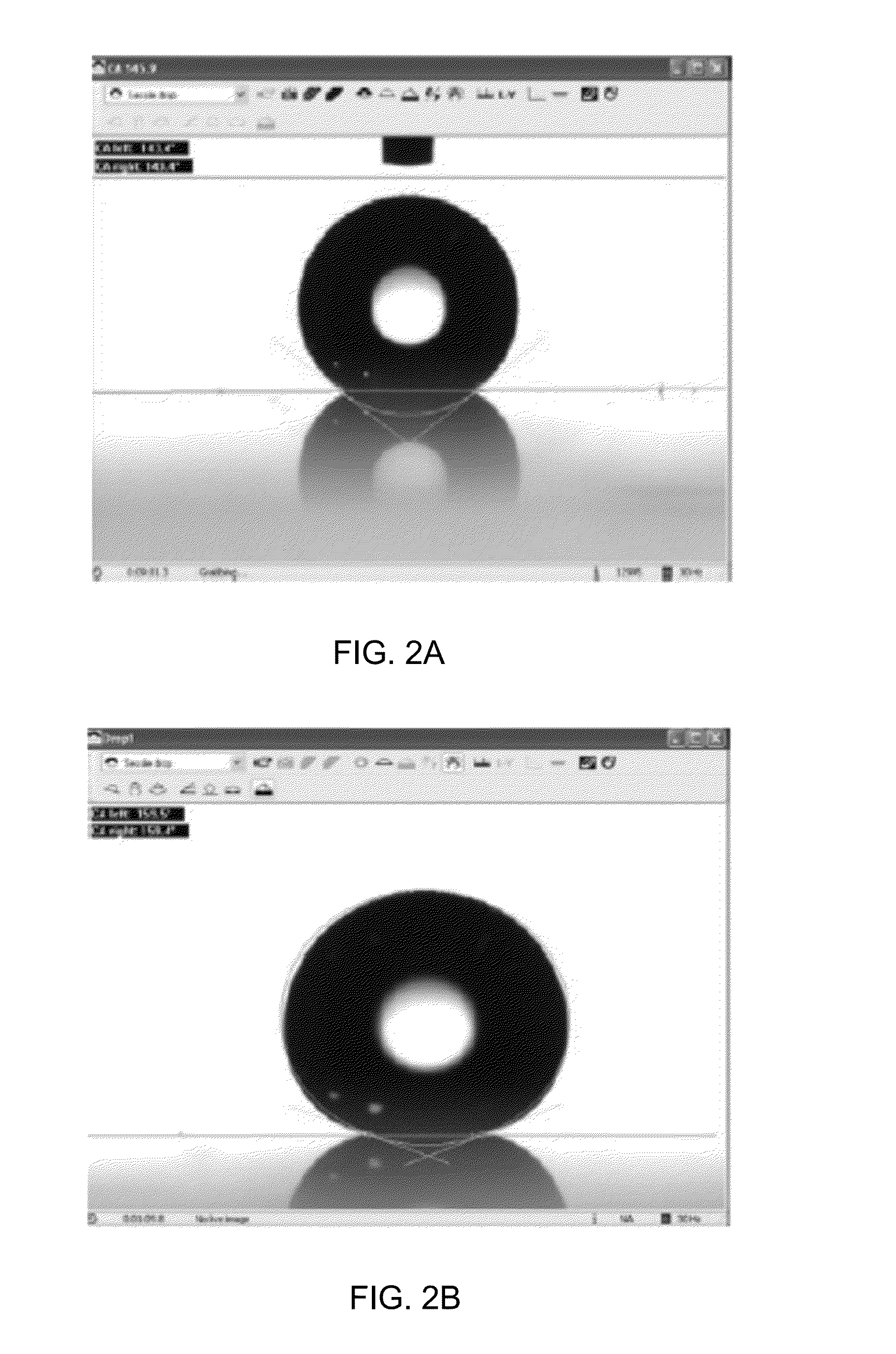

Hydrophobic self-cleaning coating composition

InactiveUS20080250978A1Efficient use ofSolve the lack of resistanceSemiconductor/solid-state device manufacturingMixingWater basedMineral spirit

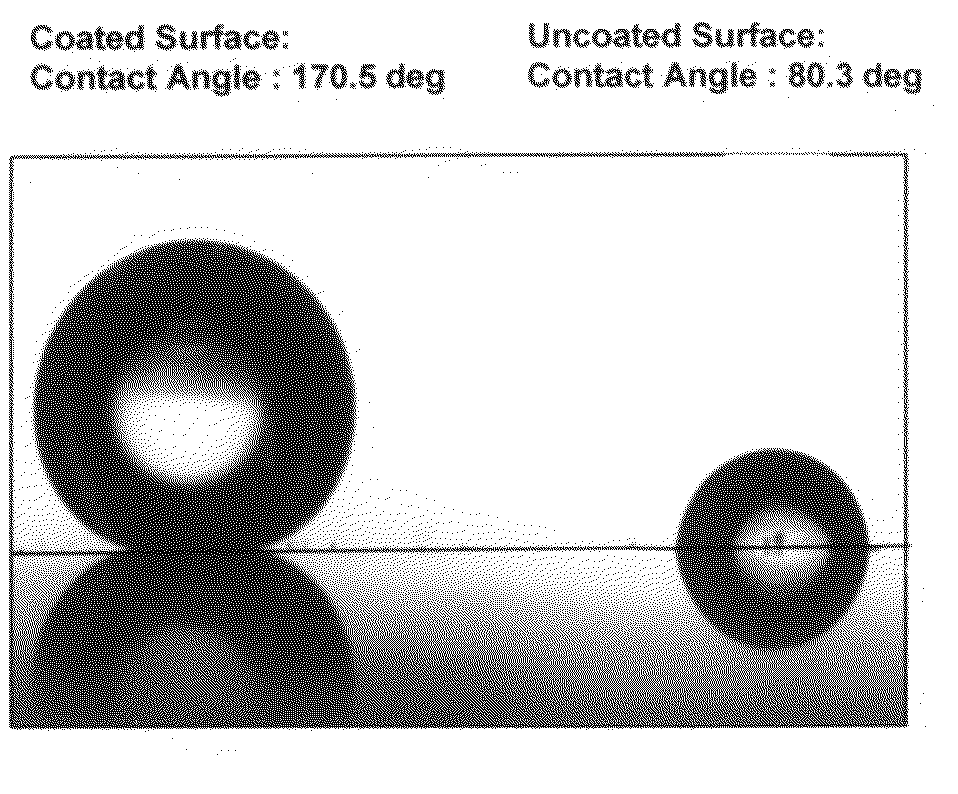

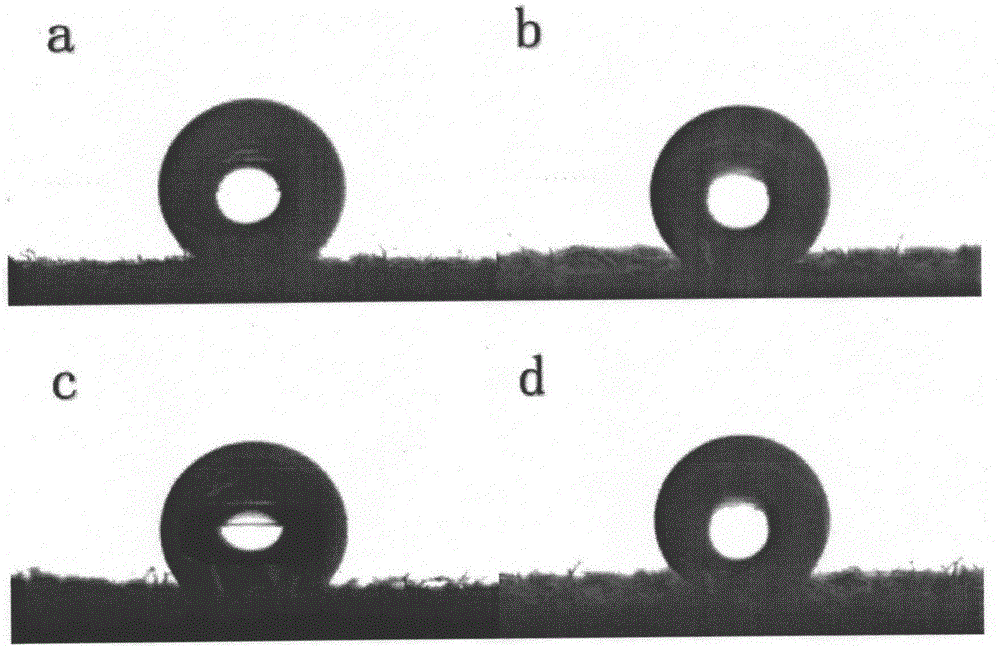

The present invention provides a water based, low VOC super hydrophobic coating composition that can be used to make wet and dry dirt repellent surfaces to keep the surfaces clean for a reasonable period of time. The coating utilizes hydrophobic nanoparticles dispersed in water. This treatment produces a virtually transparent coating releasing very little or no VOC compounds whereas previous coatings of comparable hydrophobicity release up to 99 percent VOC compounds. The coating can be applied by a simple, single application method and the super hydrophobic property can be achieved by drying at room temperature for 5 to 10 minutes. A preferred coating can be easily removed and renewed when desired. The aqueous hydrophobic self cleaning coating composition that can be applied by conventional methods such as by spraying the composition onto a surface creating a wet and dry dirt repellent coating on the surface. The hydrophobic self cleaning coatings are used on exterior automotive and boat surfaces, and in many other applications, to produce a self cleaning surface, reduce adherence of dirt and contaminants to a treated surface, and reduce drag in some applications providing an energy savings. The coating solves the problem of poor resistance to UV light, opaque appearance, and / or abrasion found in previous coatings of similar nature. A preferred coating has good resistance to UV light and some resistance to abrasion. Clear, nearly transparent and translucent coatings are produced as compared to conventional coatings of comparable hydrophobicity which are typically white or opaque. The coating can be applied by a single and easy spraying method and the super hydrophobic property can be achieved by drying the film by evaporation of the solvent wetting solution and water based carrier at ambient temperature for 5 to 10 minutes. Embodiments of the hydrophobic self-cleaning coating composition can be produced resulting in a clear coating or in some cases a translucent dirt repellant film or coating on painted material, plastic, metal, glass, ceramic, fiberglass or a polymer substrate. The coating typically utilizes hydrophobic nanoparticles of fumed silica and / or titania wetted by a hydrophilic solvent such as acetone for no VOC applications, or with mineral spirits, alcohol or a light distillate if VOC are not a consideration, together with a selected surfactant typically having an HLB value in a range of from 9 to 13.At least one preferred coating composition comprising an effective amount of a treated fumed silica wetted with a solvent and dispersed in water, upon drying, resulted in a coated surface providing a contact angle of at least 165 degrees and a surface energy below 12 dynes / centimeter as compared to water having a contact angle of from 65 to 80 degrees on a noncoated surface. The composition imparts a degree of hydrophobicity to a surface so that the surface will have a tilt angle of sliding of less than 2 degrees as compared to water on a noncoated surface having a tilt angle of sliding of 90 degrees or higher. The coating composition is removed by washing with a detergent or applying pressure to the coating wiping same from the treated surface. Exposure to water in the form of rain or snow does not remove the coating composition.

Owner:ASHLAND LICENSING & INTPROP LLC

Hydrophobic self-cleaning coating compositions

InactiveUS20090018249A1Reduce icingInexpensive comparedOther chemical processesSpecial tyresEvaporationSolvent

A hydrophobic self cleaning coating composition that can be applied by conventional methods such as by spraying the composition onto a surface forming creating a wet and dry dirt repellent coating on the surface. The coating utilizes hydrophobic nanoparticles of fumed silica and / or titania in a solvent which evaporates at ambient temperature. The coating solves the problem of poor resistance to UV light, opaque appearance, and / or abrasion found in previous coatings of similar nature. Virtually transparent coating are produced as compared to conventional coatings of comparable hydrophobicity which are typically white or opaque. The coating can be applied by a single and easy spraying method and the super hydrophobic property can be achieved by drying the film by evaporation of the solvent at ambient temperature for 5 to 10 minutes. Embodiments of the hydrophobic self-cleaning coating composition can be produced resulting in a clear coating or in some cases a translucent dirt repellant film or coating on painted material, plastic, metal, glass, ceramic, fiberglass or a polymer substrate. One preferred coating composition utilizing an effective amount of a treated fumed silica in a solvent forms a coated surface providing a contact angle of at least 165 degrees as compared to water having a contact angle of from 10 to 15 degrees on a noncoated surface. The self-cleaning coating composition imparts a degree of hydrophobicity to a surface so that the treated surface will have a tilt angle of sliding of less than 2 degrees as compared to water on a noncoated surface having a tilt angle of sliding of 90 degrees or higher.

Owner:ASHLAND LICENSING & INTPROP LLC

Hydrophobic self-cleaning coating compositions

InactiveUS20080221009A1Not to damageEfficient use ofNon-ionic surface-active compoundsNon-surface-active detergent compositionsEvaporationEngineering

A super hydrophobic self cleaning coating composition that can be applied by conventional methods such as by spraying the composition onto a surface creating a wet and dry dirt repellent coating on the surface. The super hydrophobic self cleaning coatings are used on exterior automotive and boat surfaces, and in many other applications, to produce a self cleaning surface, reduce adherence of dirt and contaminants to a treated surface, and reduce drag in some applications providing an energy savings. The coating utilizes a blend of organic and / or inorganic polymers with hydrophobic nanoparticles of fumed silica and / or titania in a volatile solvent which evaporates at ambient temperature. The coating solves the problem of poor resistance to UV light, opaque appearance, and / or some abrasion resistance not found in previous coatings of similar nature. A preferred coating has good resistance to UV light and some resistance to abrasion. Clear, nearly transparent and translucent coatings are produced as compared to conventional coatings of comparable hydrophobicity which are typically white or opaque. The coating can be applied by a single and easy spraying method and the super hydrophobic property can be achieved by drying the film by evaporation of the solvent at ambient temperature for 5 to 10 minutes. Embodiments of the super hydrophobic self-cleaning coating composition result in a clear coating or in some cases a translucent dirt repellant film for coating on painted material, plastic, metal, glass, ceramic, fiberglass or a polymer substrate. The coating utilizes a blend of organic and / or inorganic polymers with hydrophobic nanoparticles of fumed silica and / or titania in a volatile solvent. At least one preferred coating composition comprising an effective amount of a treated fumed silica in a solvent resulting in a coated surface providing a contact angle of at least 165 degrees as compared to water having a contact angle of from 10 to 15 degrees on a noncoated surface. The composition imparts a degree of hydrophobicity to a surface so that the surface will have a tilt angle of sliding of less than 2 degrees as compared to water on a noncoated surface having a tilt angle of sliding of 90 degrees or higher. The coating composition is removed by washing with a detergent or applying pressure to the coating wiping same from the treated surface. Exposure to water in the form of rain or snow does not remove the coating composition.

Owner:ASHLAND LICENSING & INTPROP LLC

Water based hydrophobic self-cleaning coating compositions

InactiveUS20090064894A1Efficient use ofWater-repelling agents additionSemiconductor/solid-state device manufacturingWater basedHydrophobic silica

A coating composition comprising hydrophobic particles having an average size of between 7 nm and 4,000 nm and a wetting agent for promoting dispersion of the hydrophobic particles in water. The hydrophobic particles may be oxides, such as silica, titania, or zinc oxide. In one embodiment, the hydrophobic particles comprise fumed silica. The coating composition may be brushed, spin coated, or dipped onto a surface. In one embodiment, once the coating composition dries, the coating formed thereby is characterized by a contact angle formed with a water droplet in excess of 165 degrees. A method of making a coating composition comprising providing hydrophobic particles having an average size of between 7 nm and 4,000 nm, mixing a wetting agent with the hydrophobic particles to form a paste, and dispersing the paste in water by mixing to form a mixture.

Owner:VALVOLINE LICENSING & INTPROP LLC

Pigment dispersions that exhibit variable particle size or variable viscosity

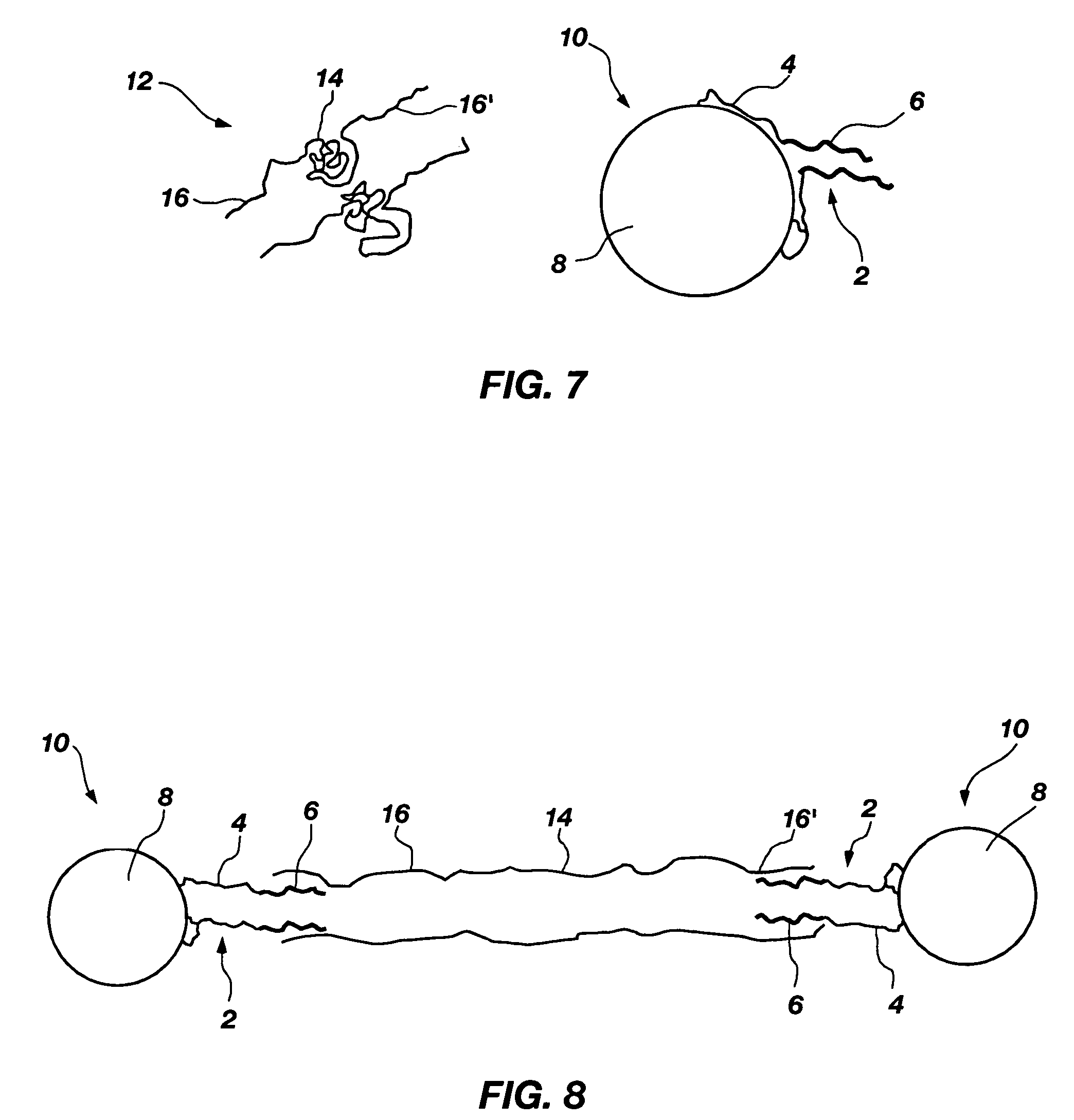

An inkjet ink including a polymer-attached pigment formulated to exhibit a compact configuration and an elongated configuration, which provides the polymer-attached pigment with a variable particle size. The polymer-attached pigment may include a pigment having at least one polymer attached to its surface. The at least one polymer may be formed from a hydrophobic segment and a hydrophilic segment, where the hydrophilic segment is soluble in an aqueous environment and the hydrophobic segment is insoluble in the aqueous environment. The polymer-attached pigment may be dispersed in an ink vehicle to provide a low viscosity inkjet ink. The inkjet ink may optionally include at least one binder formed from a hydrophobic segment and two hydrophilic segments. A method of producing a printed image having good durability and gloss is also disclosed.

Owner:HEWLETT PACKARD DEV CO LP

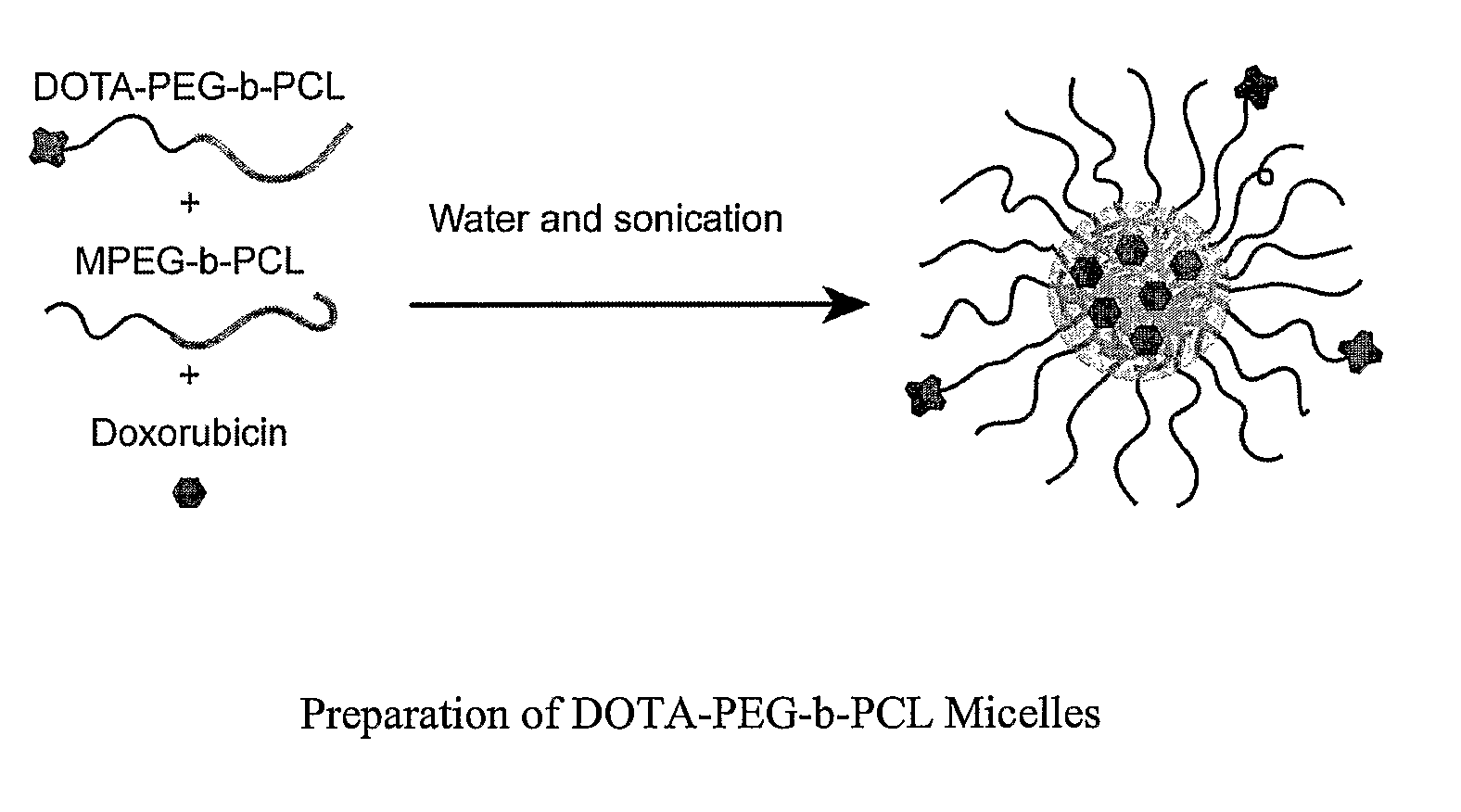

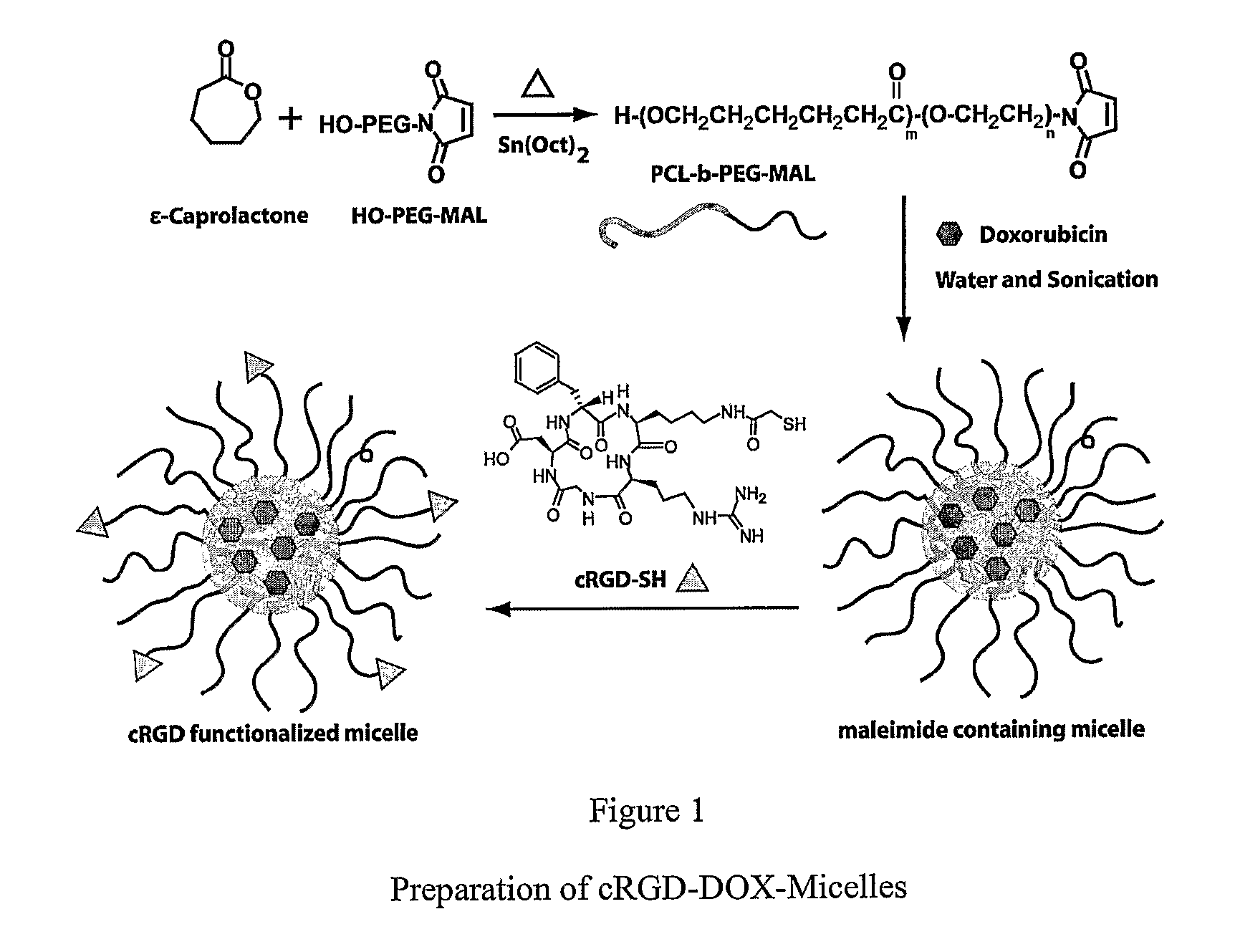

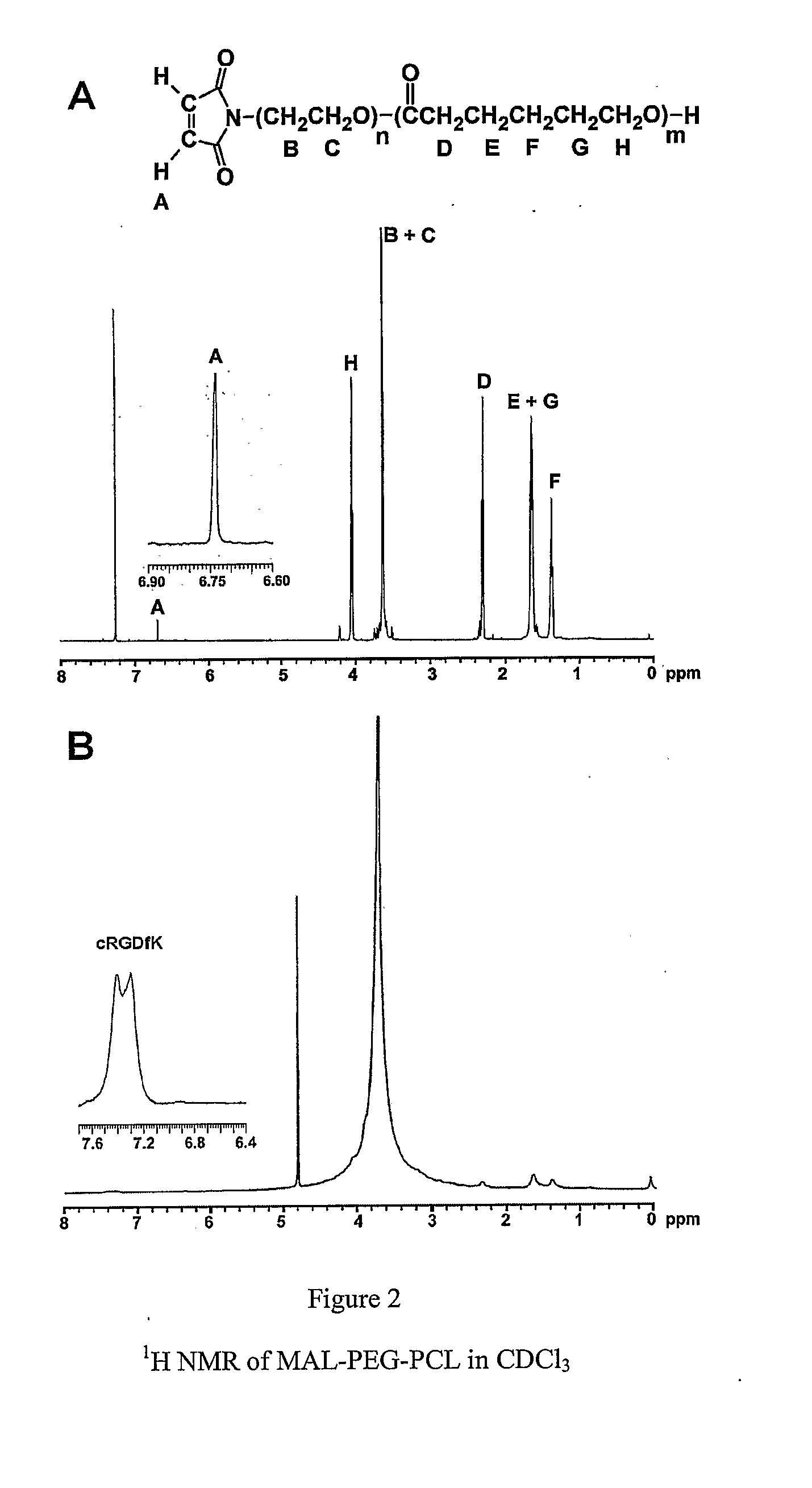

Hybrid block copolymer micelles with mixed stereochemistry for encapsulation of hydrophobic agents

Owner:INTEZYNE TECH INC

Biological implants of semipermeable amphiphilic membranes

An implantable biological device including a semipermeable membrane formed into a geometric shape capable of encapsulating biological cells and capable of immunoisolating the biological cells upon introduction into the body, the semipermeable membrane including an amphiphilic copolymer network having hydrophobic segments and hydrophilic segments, wherein the hydrophobic segments include polyolefins terminated with radicals selected from the group consisting of acryloyl groups, methacryloyl groups and mixtures thereof and wherein the hydrophilic segments include polyacrylates. Also provided is a method of encapsulating and immunoisolating cells using the semipermeable membrane and method of treating ailments using the implantable biological device.

Owner:THE UNIVERSITY OF AKRON

Method for preparing white carbon black by utilizing silicon tetrachloride

The invention discloses a method for preparing white carbon black by utilizing silicon tetrachloride. The method comprises the following steps: mixing deionized water and low molecular fatty alcohol at the molar ratio of 1:4-4:4, and adding a proper amount of surfactant; slowly adding a certain amount of the silicon tetrachloride at the room temperature; and obtaining the white carbon black through the steps of preparing reaction solution, curing the reaction solution, sedimentation and abstersion, pulpifying and spray drying, wherein the concentration of the silicon tetrachloride is controlled to be 0.2-1.0 mol.1-1, and modifiers such as 0.01-0.1mol.1-1 of Hexamethyl disilazane and the like can be added in the preparation process of the hydrophobic white carbon black. The grain diameter of the prepared white carbon black is 50-350nm and the specific surface area is 100-300m<2>.g-1; and the method has high economic value and the prepared white carbon black has good hydrophobic effect.

Owner:HENAN UNIV OF SCI & TECH

Preparation method for super-hydrophobic silica particle and super-hydrophobic coating

InactiveCN106587075ASimple manufacturing processExcellent superhydrophobic propertiesSilicaPolyurea/polyurethane coatingsHydrophobic silicaUltrasonic nebulization

The invention provides a preparation method for super-hydrophobic silica particles and super-hydrophobic coatings. The method includes the following steps that in step S1, nanometer silica particles and silane modifiers are dispersed in a solvent to form a mixed solution, wherein weight ratio for nanometer silica particles and silane modifiers and the solvent is 1:0.05-0.5:3-20; the PH value of the mixed solution is adjusted to 2.0-5.0 by hydrochloric acid, and then the mixed solution is stirred for 2 to 24 hours at the temperature from 0 DEG C to 50 DEG C; the PH value of the mixed solution is adjusted to 6.0-7.5 by ammonia water, and then the mixed solution is stirred for 0.5 to 3 hours; a dispersion solution of modified nanometer silica particles is achieved; in step S2 the dispersion solution is dispersed into droplets by an ultrasonic nebulization technology and is dried at the temperature from 80 DEG C to 120 DEG C; the super-hydrophobic silica particles are achieved. With the preparation method for super-hydrophobic silica particles and super-hydrophobic coatings, the super-hydrophobic silica particles and the super-hydrophobic coatings are achieved, and have the advantages of being good in super-hydrophobic effect and simple in manufacturing process.

Owner:THE HONG KONG POLYTECHNIC UNIV

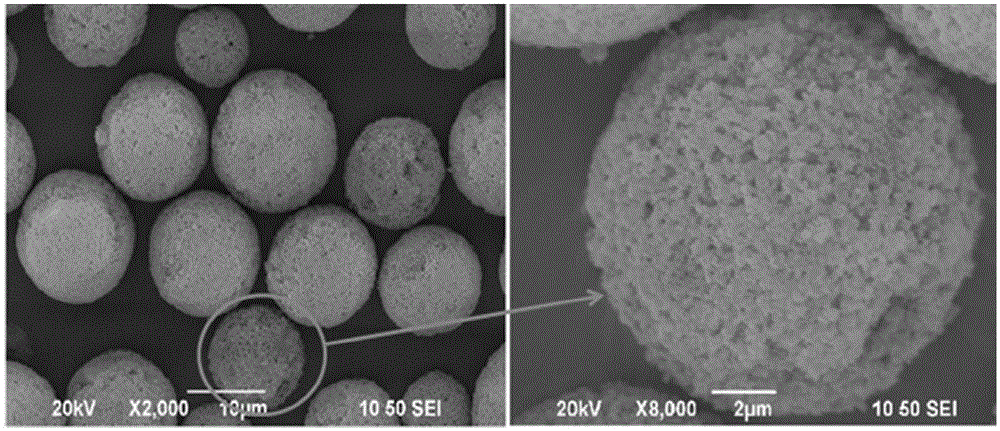

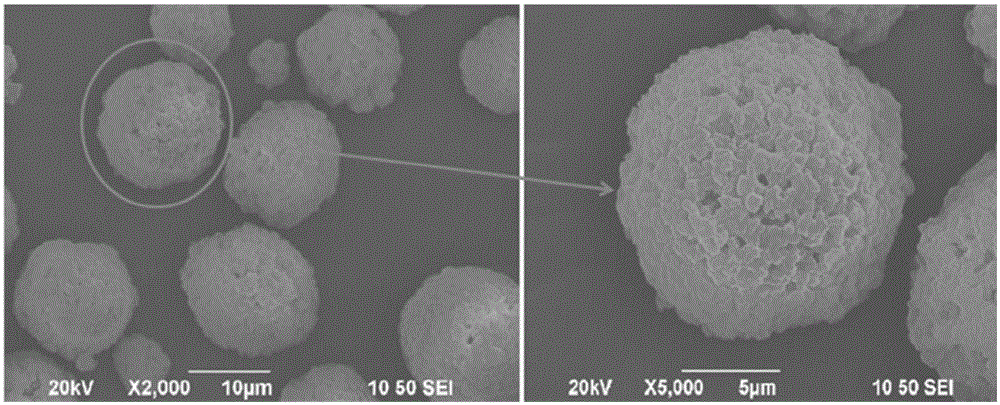

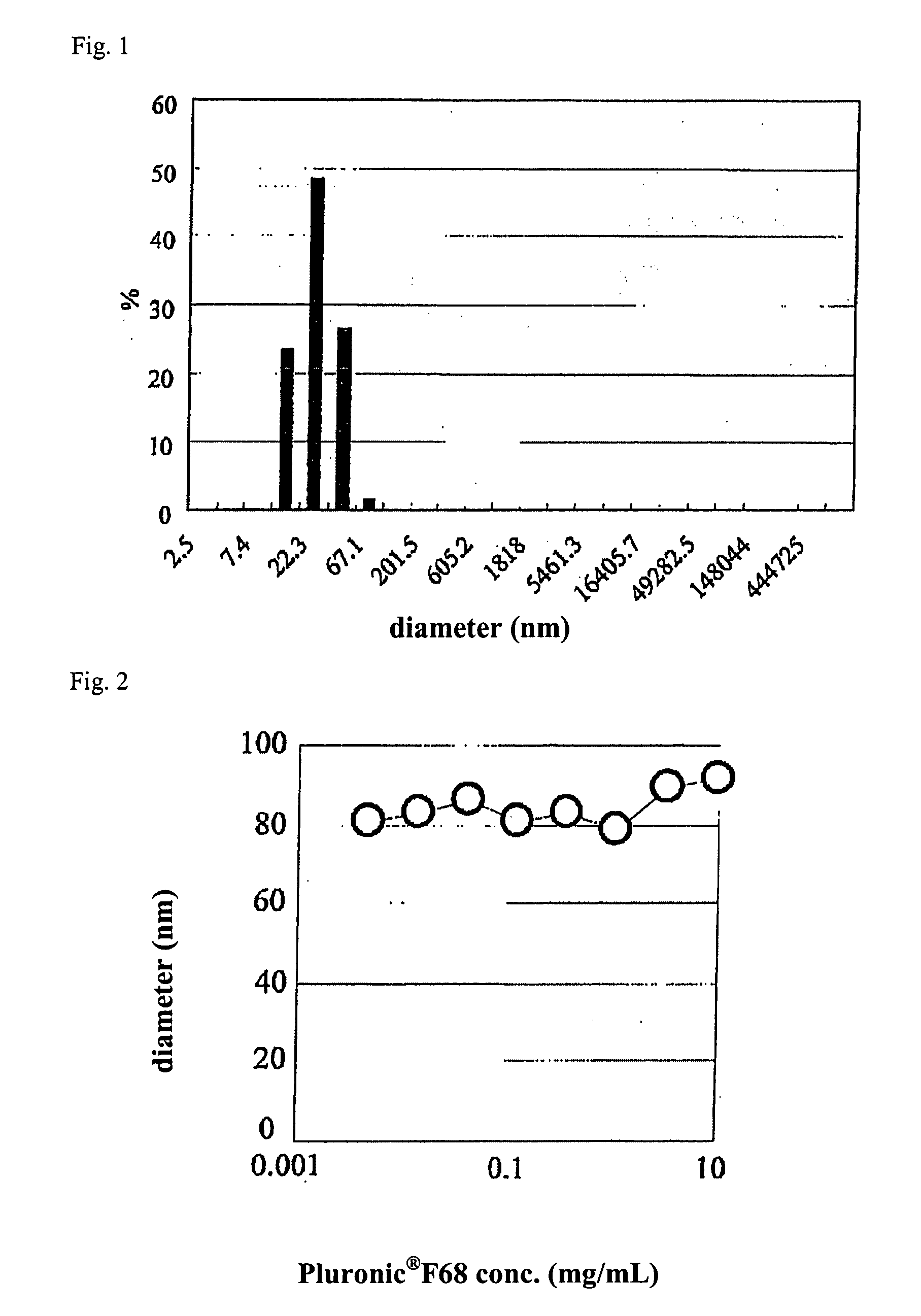

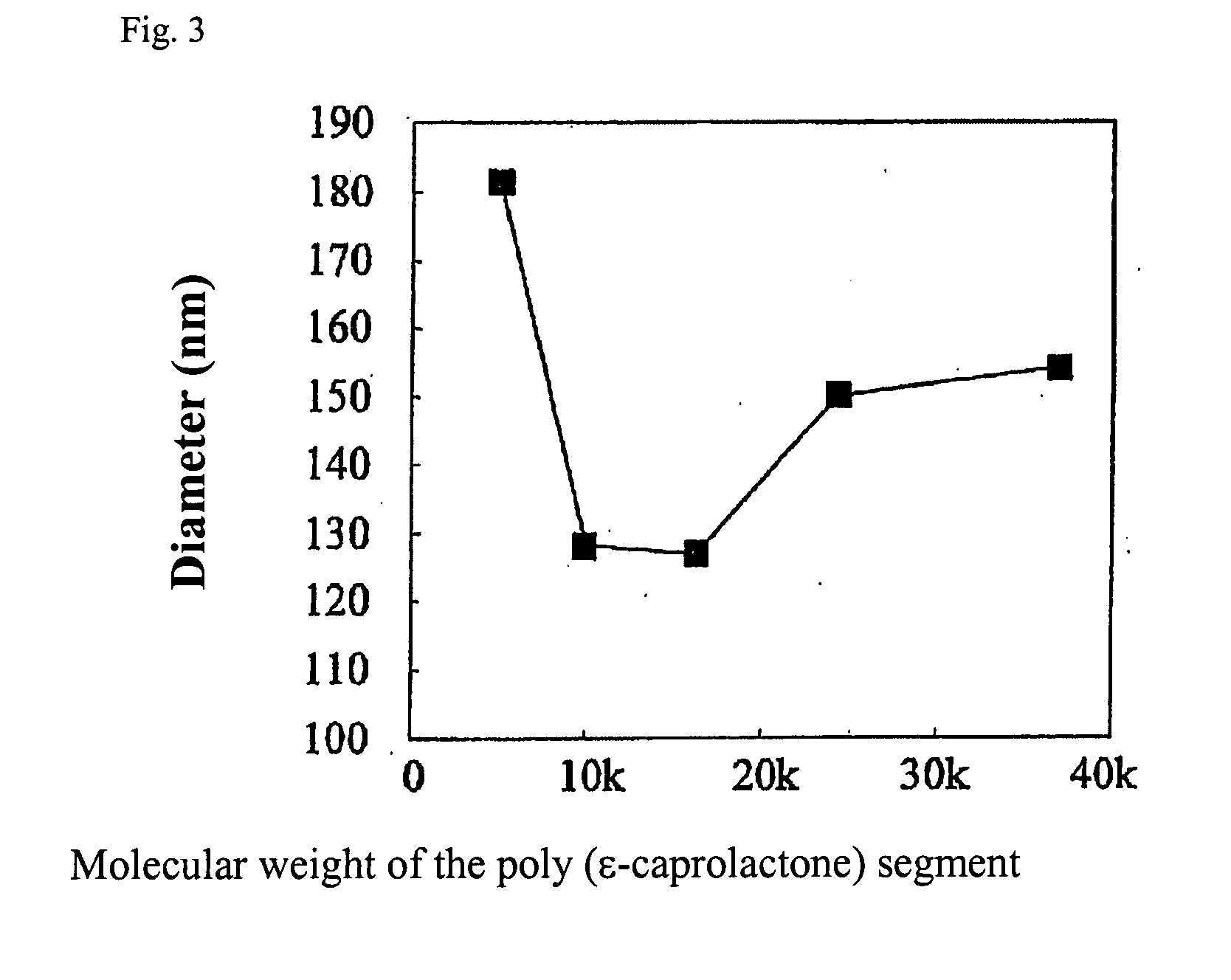

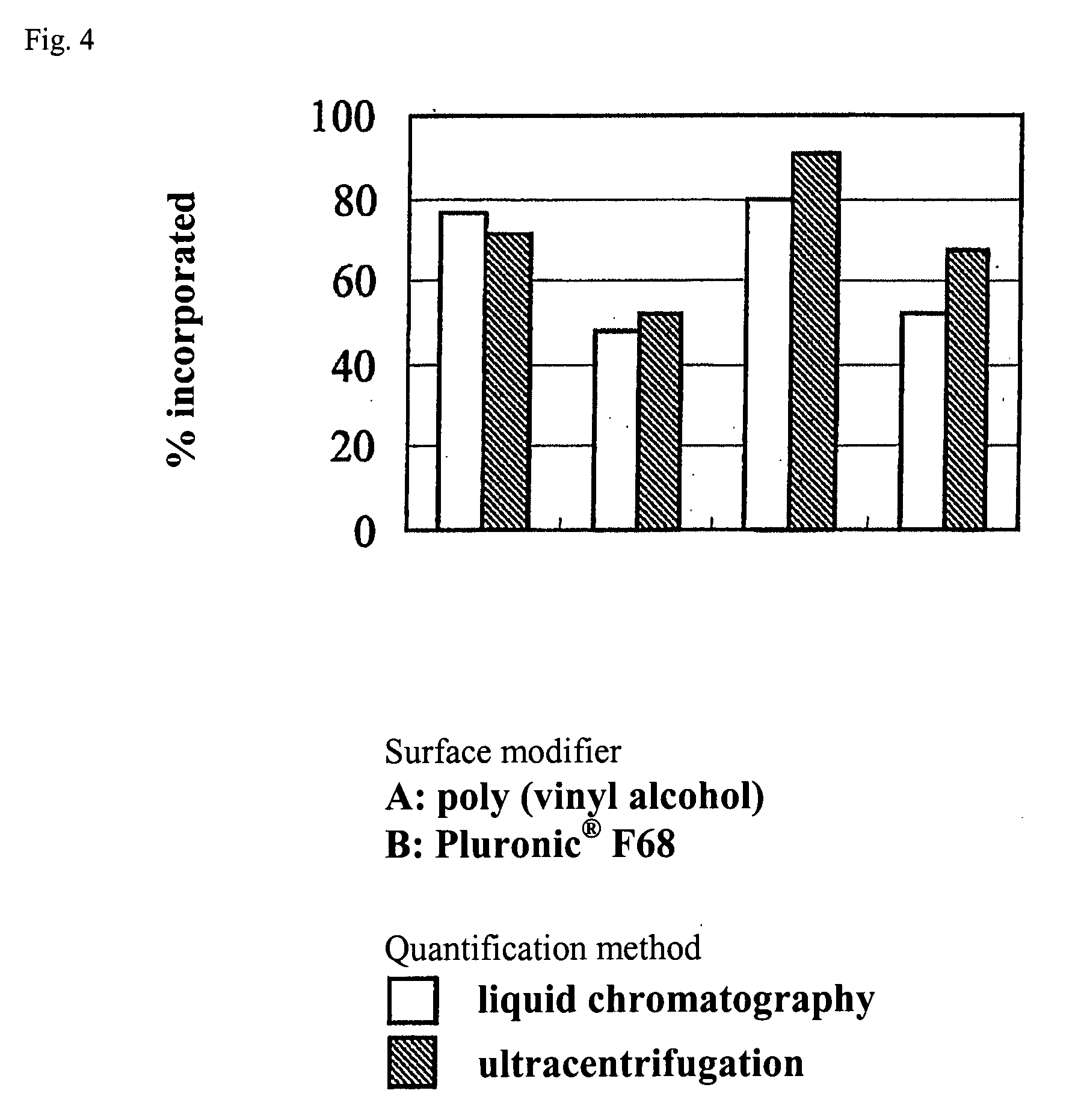

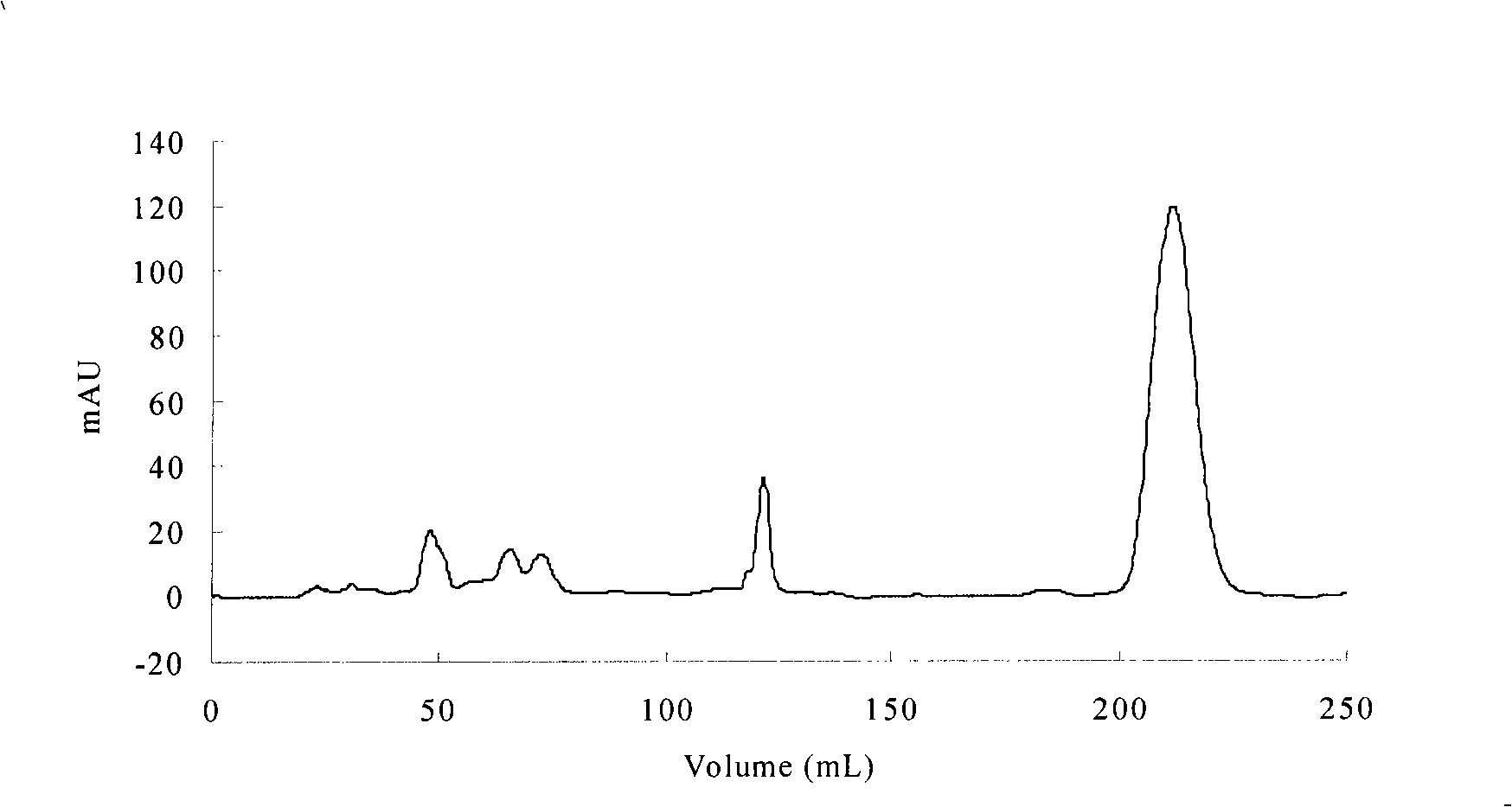

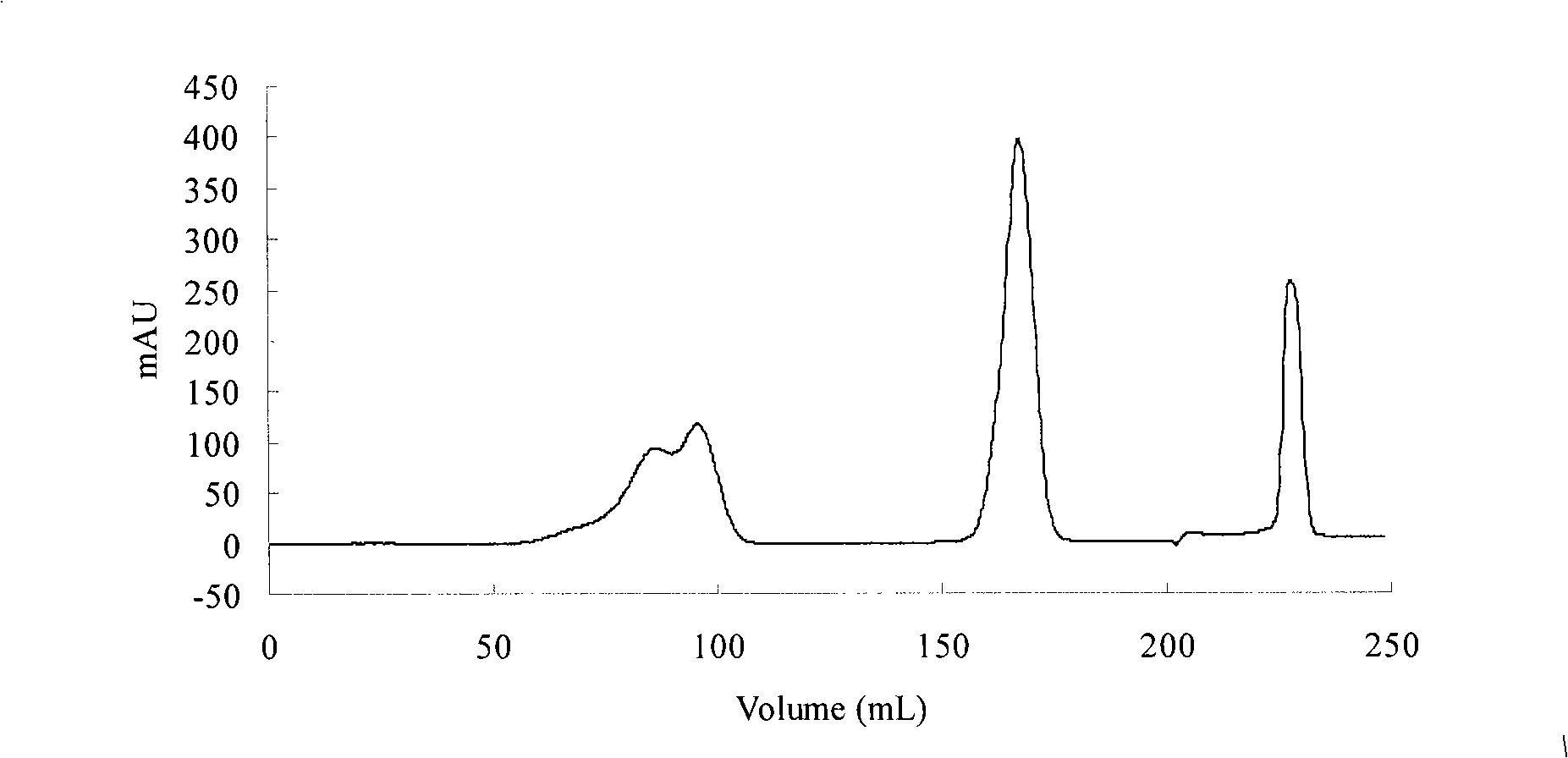

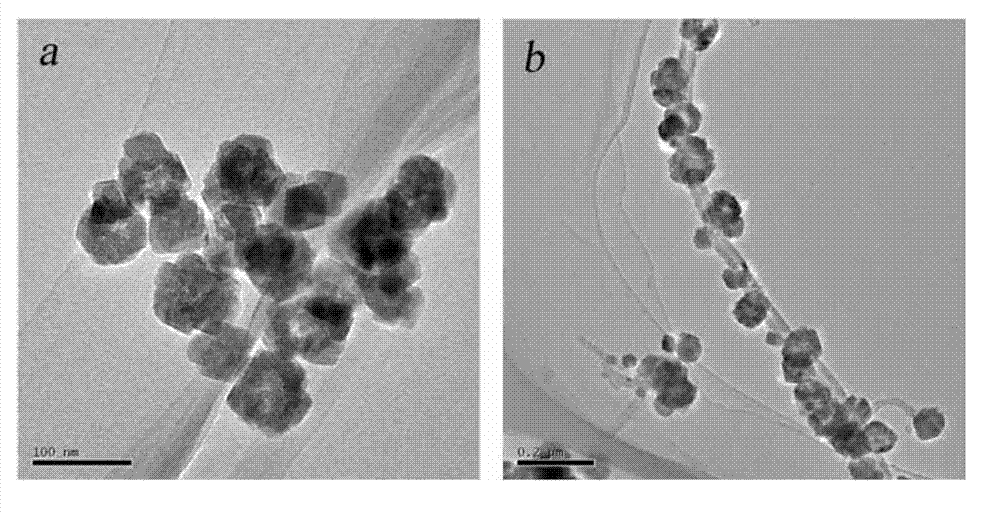

Fine Particle and Pharmaceutical Preparation

A fine particle comprising an amphiphilic polymer, further comprising an inner nucleus of hydrophilic segment of amphiphilic polymer, and a hydrophobic outer layer of hydrophobic segment of amphiphilic polymer, and having a surface modifier bonded to the hydrophobic outer layer.A fine particle of the invention effectively enclose protein, peptide drug, nucleic acid medicine of hydrophilic property and large molecular weight in the inner nucleus of hydrophilic segment of amphiphilic polymer, and are preferable for stabilizing in the body and promoting absorption.

Owner:TORAY IND INC

Method for separating and purifying sea-mussel mucin by using mixing adsorption chromatography

ActiveCN101348520AOvercoming the problem of low yieldHigh yieldPeptide preparation methodsAnimals/human peptidesHigh concentrationChromatographic separation

The invention relates to a method for separating and purifying mussel mucin by using a mixed adsorption chromatography. Mussel mucin contains a group of L-3,4- -Dihydroxyphenylalanine (L-DOPA), a phenohydroxyl group thereof can act as the supplier for hydrogen bond, the benzene ring thereof can generate a hydrophobic effect, and the lysine thereof with strong positive charges is capable of forming a static bond. On the basis of the properties of mussel mucin, a mixed adsorption chromatography (i.e. the adsorption chromatography based on three principles of adsorption with hydrogen bond, adsorption with hydrophobic effect, and static adsorption) is adopted to overcome the problem of low yielding rate of mussel mucin in the prior art for separating and purifying mussel mucin. An strong acid extraction is adopted to eliminate small-molecular compounds from a desalting column, an argar medium with high concentration and high cross-linking degree to separate and purify mussel mucin, and an acetic acid-urea- polyacrylamide gel electrophoresis is used to differentiate mussel mucin through specific chromogenesis with nitro blue tetrazolium. Three principles adopted with one separation medium to separate mussel mucin achieve high selectivity, simplify the purification technology, and decrease production cost.

Owner:JIANGYIN USUN BIOCHEMICAL TECH CO LTD

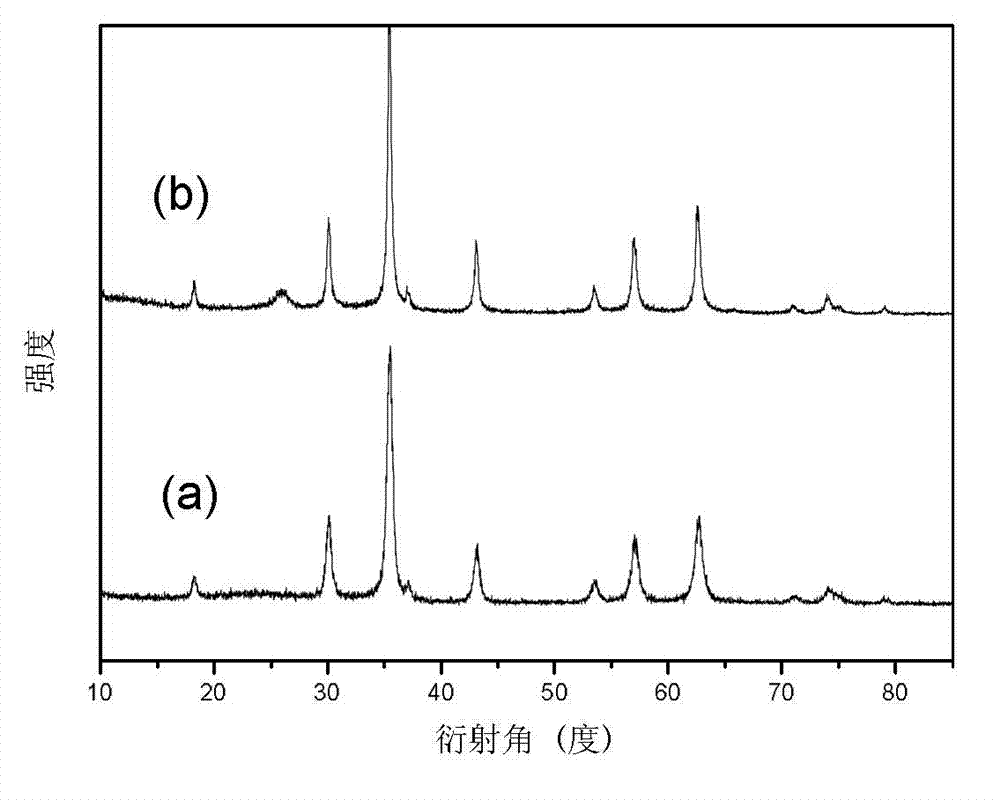

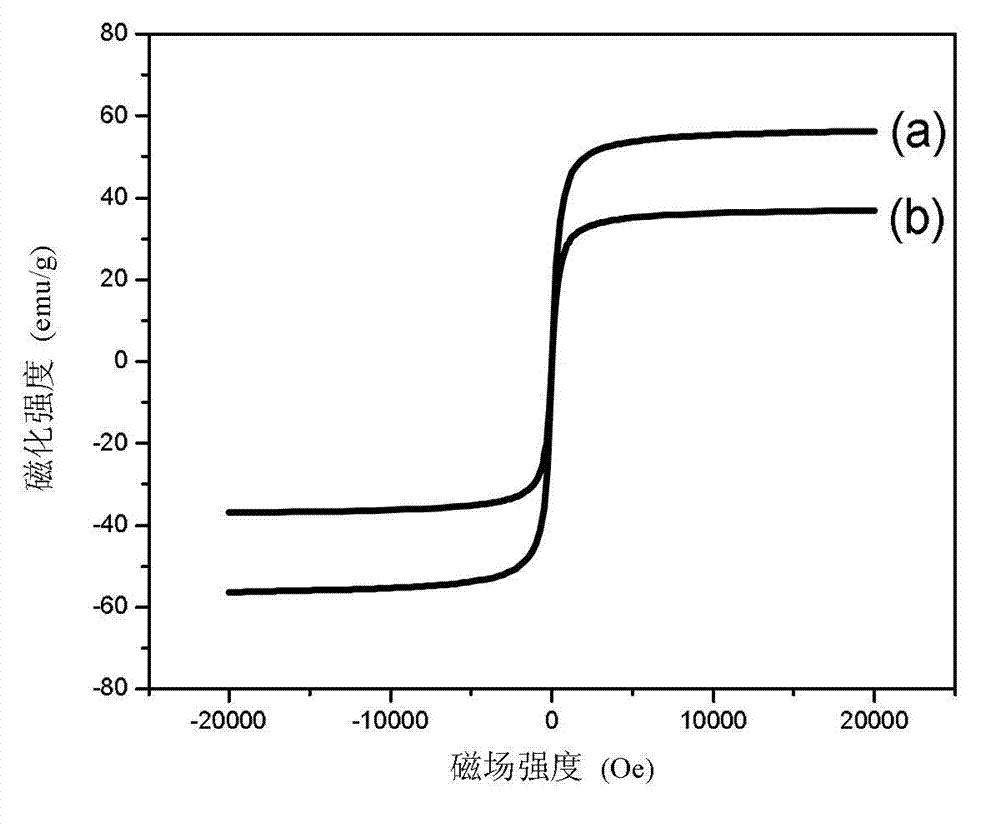

Magnetic carbon nanotube composite material and preparation method and application thereof

InactiveCN103041773AImprove bindingEasy to separateIon-exchange process apparatusComponent separationSorbentHexamethylenediamine

The invention discloses a magnetic carbon nanotube composite material and a preparation method and an application thereof. The preparation method comprises the following steps: adding FeCl3.6H2O to an ethylene glycol solution; then adding anhydrous sodium acetate and polyethylene glycol; adding a carboxylated multiwalled carbon nanotube; performing ultrasonic dispersion; adding hexamethylenediamine or ethanediamine; heating to 200-300 DEG C for reaction for 8-24h; and washing and performing vacuum drying to prepare the amino-modified magnetic Fe3O4-carbon nanotube composite material. The amino-modified magnetic Fe3O4-carbon nanotube composite material prepared by the invention is of nanoscale and superparamagnetism, can be stably dispersed in solutions, and can be quickly separated and enriched through a simple action of a magnetic field. As an adsorbent, the material is large in superficial area and has various active groups on the surface. The material can adsorb pigments from complex substrates through pi-pi electron interaction and hydrophobic effect of the carbon nanotube and can adsorb compounds such as organic acids and phenols through weak anion exchange effect of amino groups on the surfaces of magnetic nanoparticles.

Owner:TIANJIN UNIV

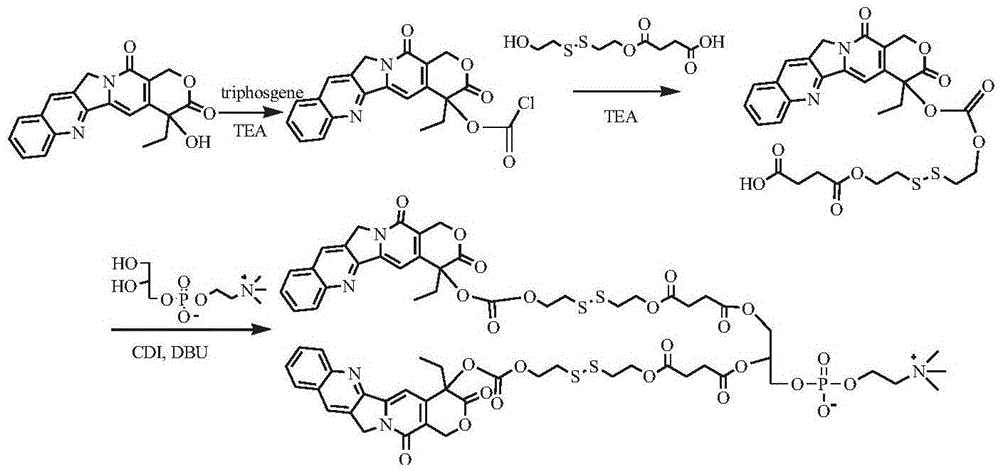

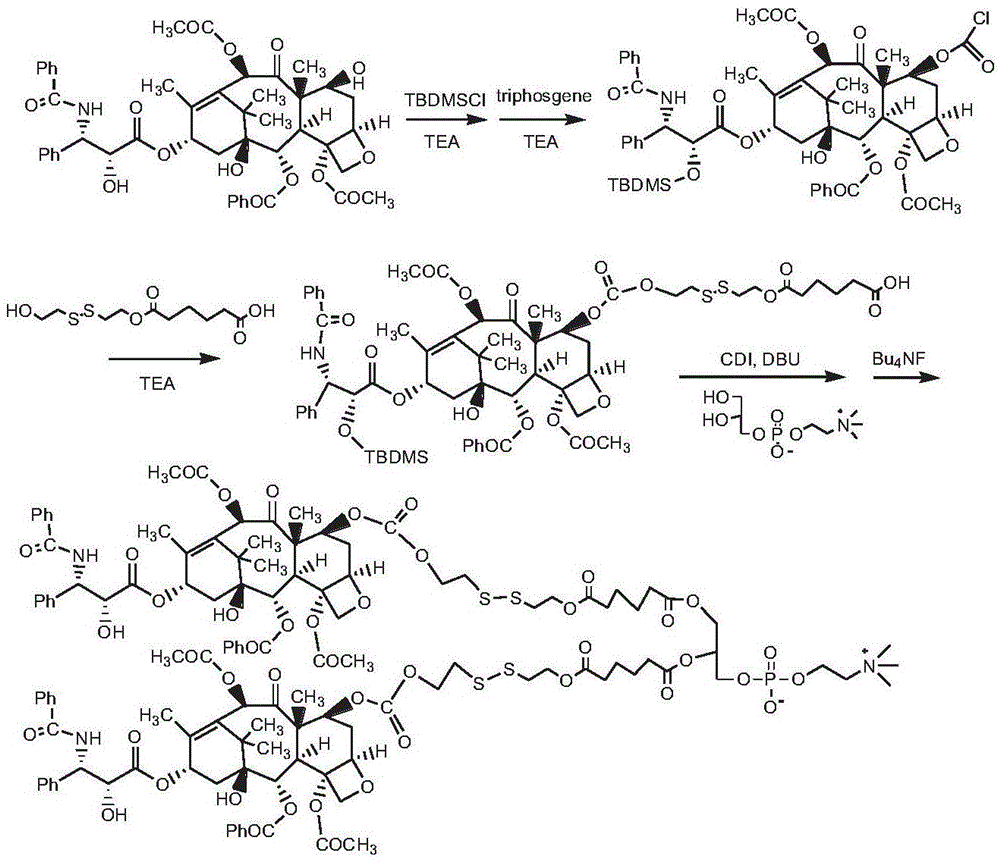

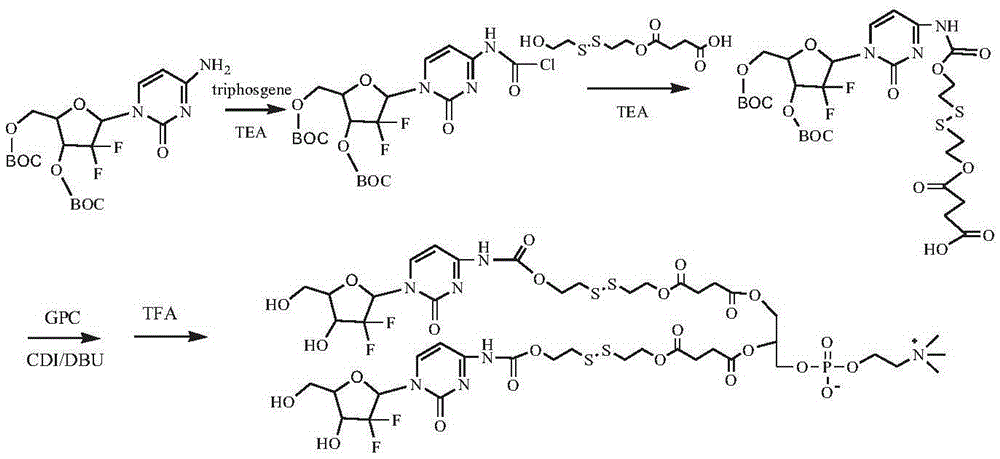

Quick release type medicine phosphatide compound and medicine composition thereof

InactiveCN105457038AEnhance hydrophobic lipophilic effectImprove hydrophobicityHeavy metal active ingredientsDipeptide ingredientsPharmacodynamic StudyHydrophobic effect

The invention discloses a quick release type medicine phosphatide compound and a medicine composition thereof. In the compound, a medicine Y1 and a medicine Y2 are connected with a quick release type hydrophobic spacer arm and an enhancement type hydrophobic spacer arm through chemical bonds, the two spacer arms are cooperated to enhance the hydrophobic effect to form hydrophobic lipotropy chains, the two hydrophobic chains are connected with a phospholipid hydrophilic head to form an amphipathic molecule. The medicine composition is the quick release type medicine phosphatide compound or a combined medicine composition of the compound and a carrier acceptable in pharmacodynamics. The quick release type medicine phosphatide compound and lipidosome nano particles thereof can be used as a liquid preparation, a solid preparation, a semi-solid preparation, a sterilization preparation and a sterile preparation, are low in toxicity and can be used for efficiently treating various tumor diseases.

Owner:SOUTHEAST UNIV

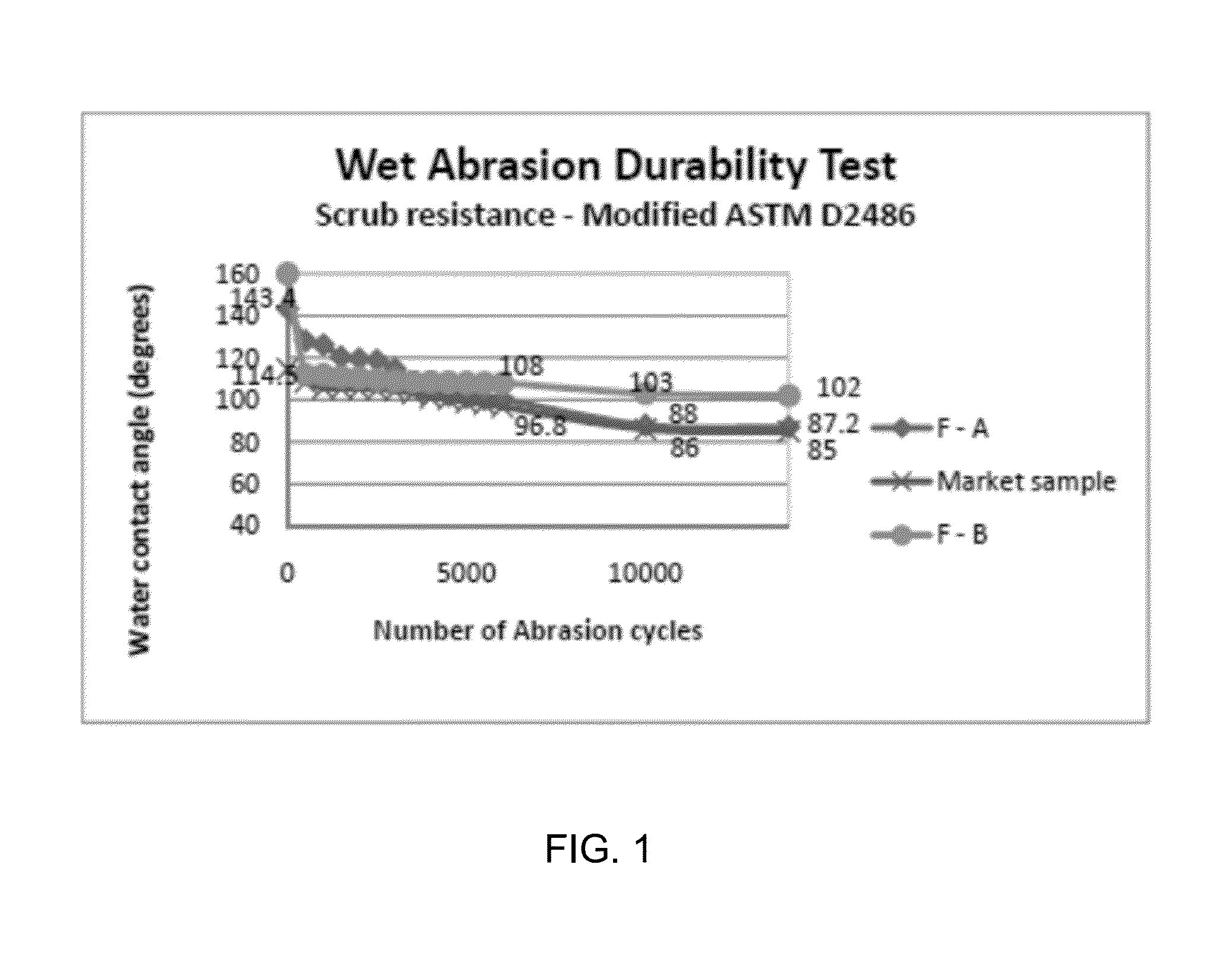

Super hydrophobic coating

InactiveUS20140208978A1Increase contact angleWater rolling effectMaterial nanotechnologyOther chemical processesRoom temperatureSports equipment

A super hydrophobic coating composition that is a highly durable super hydrophobic transparent coating for glass, metal, and plastic, and automobile painted surfaces that is manually dispensable and may be easily applied to many substrates is provided. Moreover, the inventive super hydrophobic coating is user friendly as coating takes place at room temperature, and can be applied by a normal hand spray method. Embodiments of the coating dry within 30 minutes, and generate a super hydrophobic effect for ready use. The coating is useful to repel water droplets, dew drops, and dust particles in various applications such as solar panels, wind turbines surfaces, house hold components, metal coated furniture, marine equipment parts, marine sports equipment like speed boat screens, automobile wind shields, automobile plastic components, auto bodies and aerospace applications.

Owner:ILLINOIS TOOL WORKS INC

Common carrier material for targeting anticancer drug and gene and preparation and application

InactiveCN102949727AGood biocompatibilityEnhanced Osmotic Retention EffectGenetic material ingredientsInorganic non-active ingredientsTumor targetingResponse control

The invention relates to a common carrier material based on graphene oxide for a targeting anticancer drug and a gene and application and application. Folic acid, lactobionic acid and other tumor cell targeting or liver targeting molecules and part of amino groups of soluble chitosan are connected by amide bonds to prepare a conjugate, the conjugate is then connected with graphene oxide, quaternization is performed by using an epoxy compound with a quaternary ammonium group, and gene molecules are loaded by the quaternizationquaternized part of the chitosan through electrostatic attraction; and then the anticancer drug is loaded by pi-pi conjugates, hydrogen bonds and hydrophobic effects in a non-covalent bond method. By adopting the targeting performance of targeting molecules and effects of graphene oxide of a particular size to enhance penetration and retention in tumor tissues and combining the performance of the graphene oxide for pH response control release of the loaded drug, the drug can be realized released in a tumor cell, an intelligent delivery system for the common carrier of the tumor targeting or liver targeting anticancer drug and the gene is synthesized from the perspective of synergetic medication, and a theoretical basis and a method basis are provided for combined therapy of tumor.

Owner:TIANJIN MEDICAL UNIV

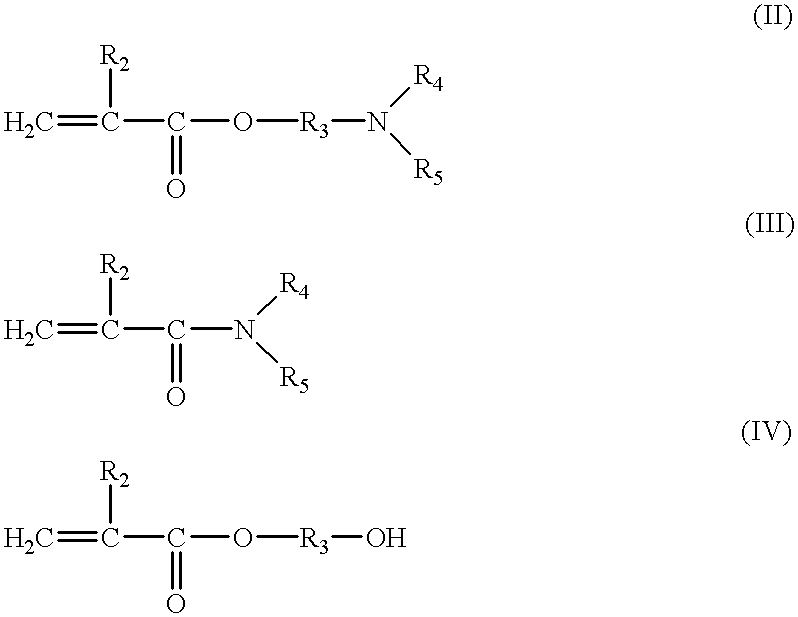

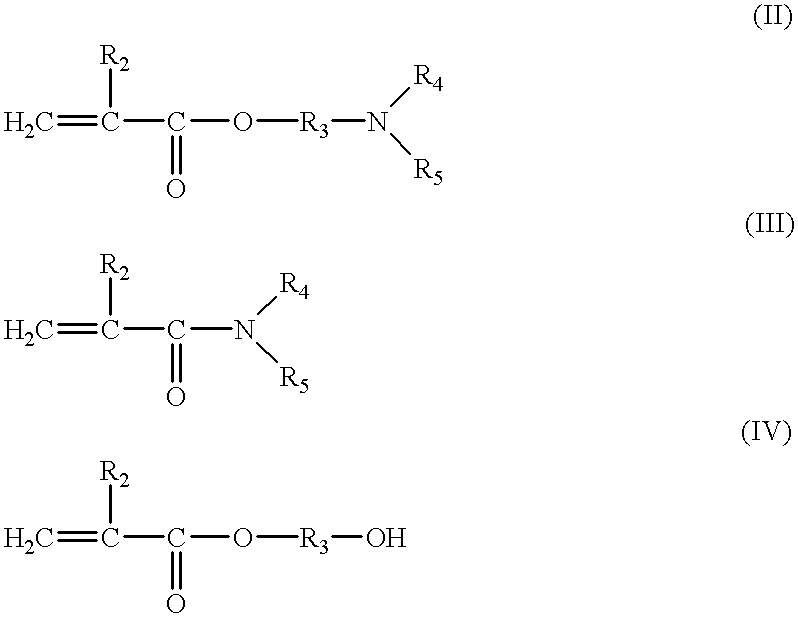

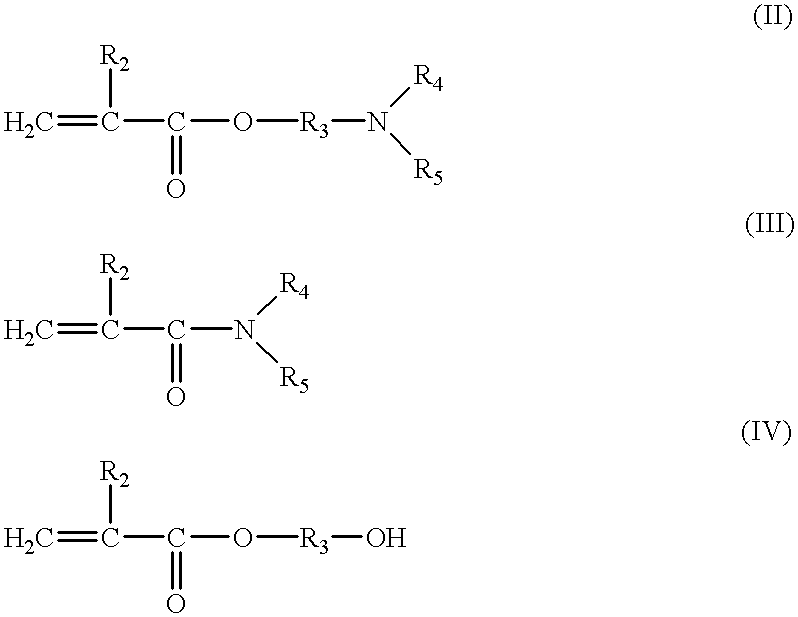

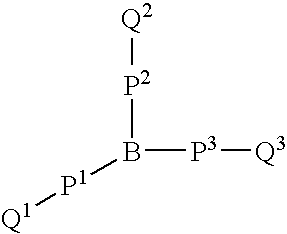

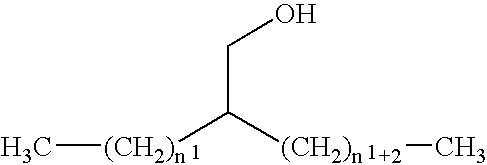

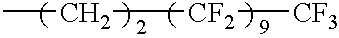

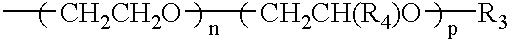

Associative thickener combinations

ActiveUS20070155880A1Good viscosity stabilityGreat effective hydrophobicityEmulsion paintsViscosityPolymer chemistry

A method for improving the viscosity stability of an aqueous composition having a latex polymer and associative thickeners with at least one hydrophilic segment and at least two hydrophobic segments is provided. The associative thickeners are chosen such that one associative thickener has a lower molecular weight than the other associative thickener.

Owner:ROHM & HAAS CO

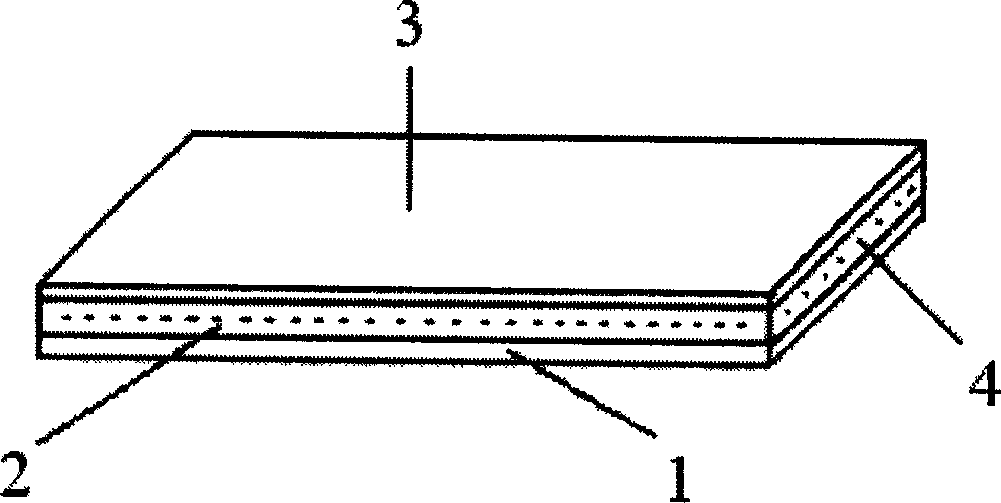

Waterproof and breathable film and preparation method thereof

ActiveCN103290615AAdvantages of waterproof and breathable functionReduce voidsSynthetic resin layered productsNon-woven fabricsElectrospinningPerspiration

The invention belongs to the technical field of high polymer materials, and relates to a waterproof and breathable film and a preparation method thereof. The waterproof and breathable film comprises a hydrophilic film and a hydrophobic film. The prepared waterproof and breathable film comprises two layers of non-woven fabrics, wherein one layer is the hydrophilic film, the other layer is the hydrophobic film, the hydrophilic film layer can keep water on the hydrophilic film layer for a period, rather than, the water rapidly flows to the hydrophobic film layer, so that wetting is realized, and the hydrophobic effect is better. The obtained film has waterproof and breathable performance and can be applied to fields such as clothes, sports shoes and the like, which have requirements for ventilation, perspiration and water drainage; and simultaneously, fiber gaps of a filter film prepared with an electrostatic spinning method are small, and the film has better advantages in the waterproof function.

Owner:HEFEI GENIUS NEW MATERIALS

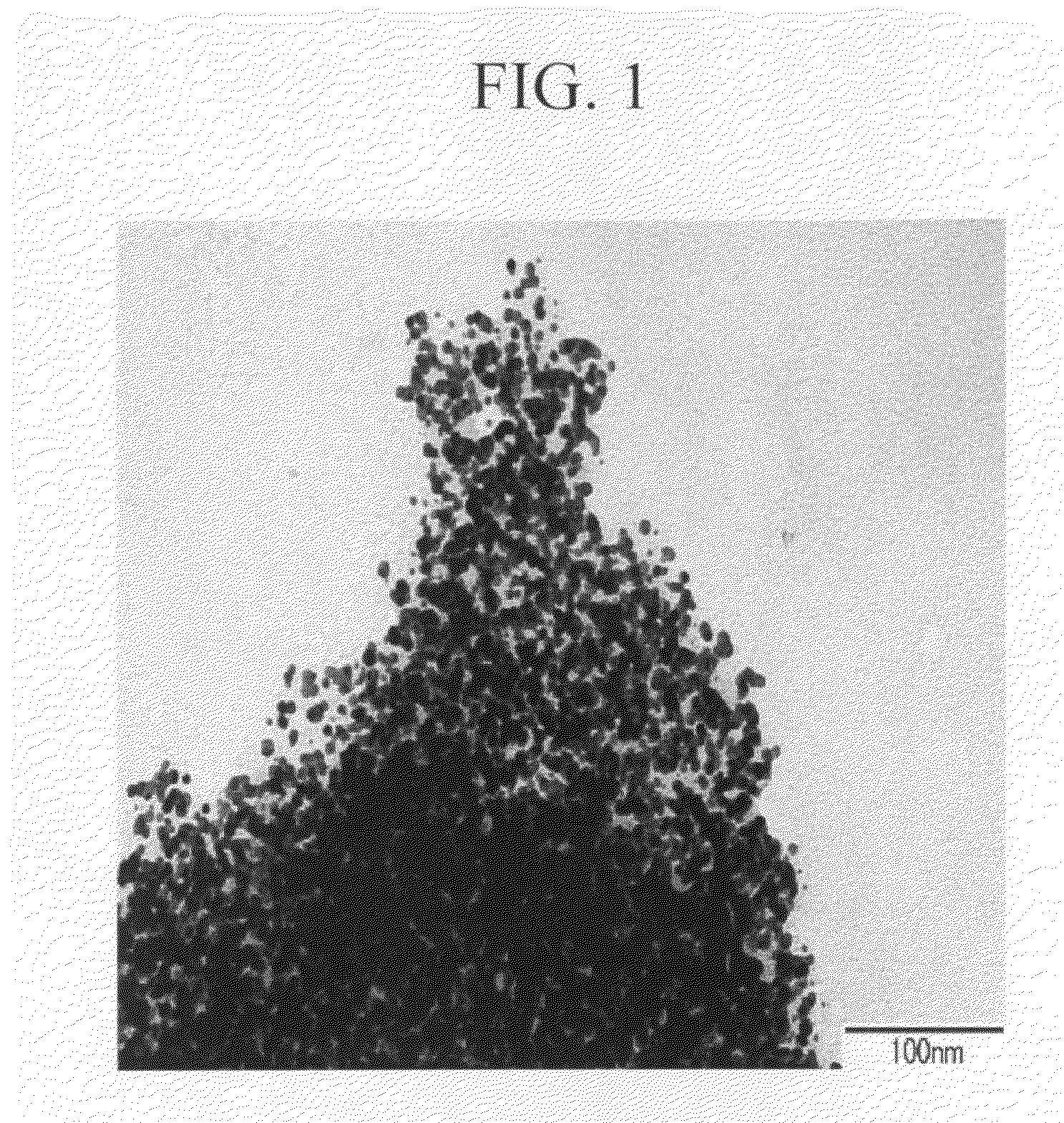

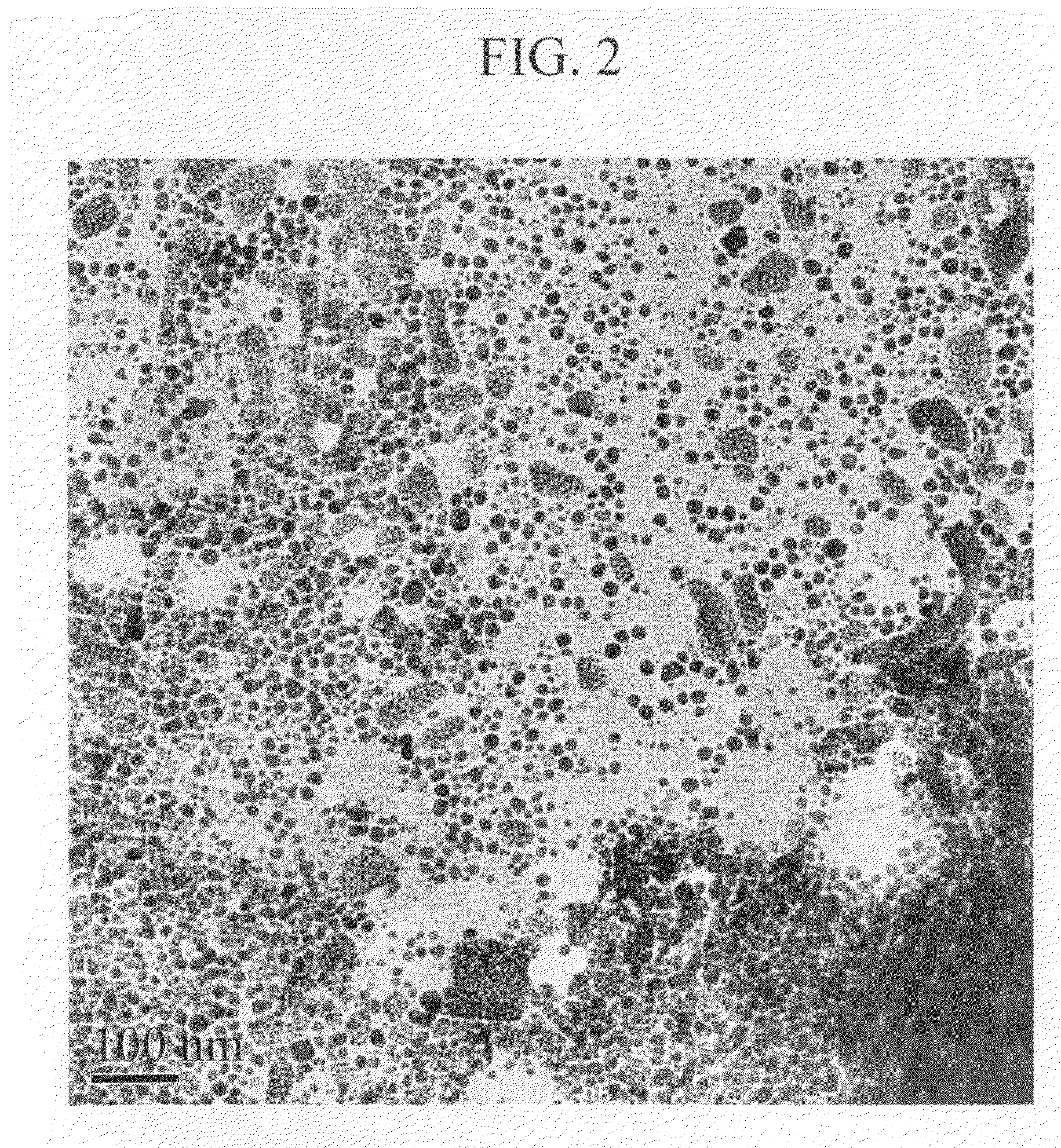

Metal nanoparticle dispersion and production process of the same

InactiveUS20090198009A1Superior self-assembling abilityStable dispersed stateMaterial nanotechnologyConductive materialPolymer scienceNanometre

A metal nanoparticle dispersion comprising: a dispersion of a polymer compound (X), which comprises a polyalkyleneimine chain (a), a hydrophilic segment (b) and a hydrophobic segment (c), and metal nanoparticles (Y).

Owner:DAINIPPON INK & CHEM INC

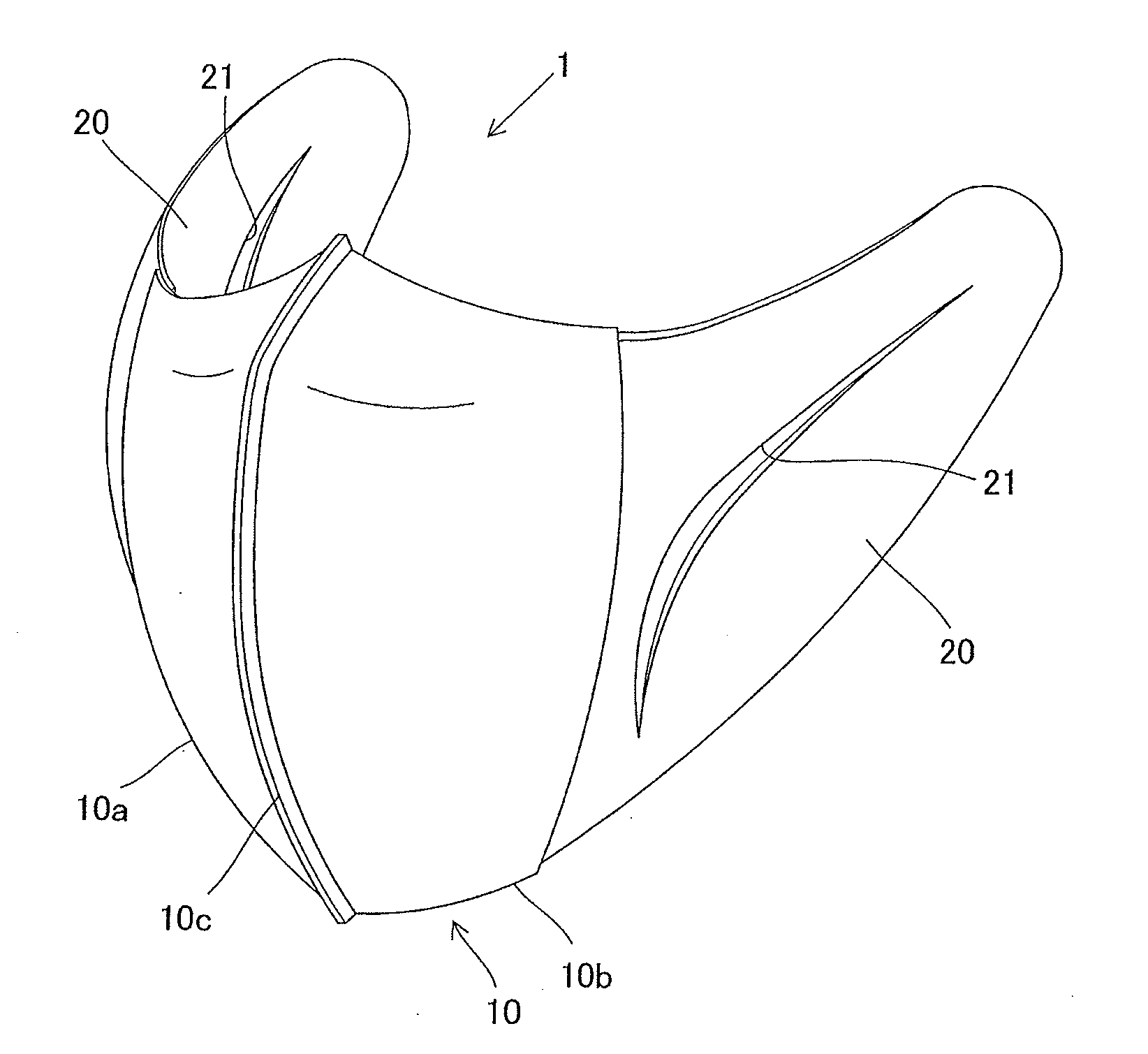

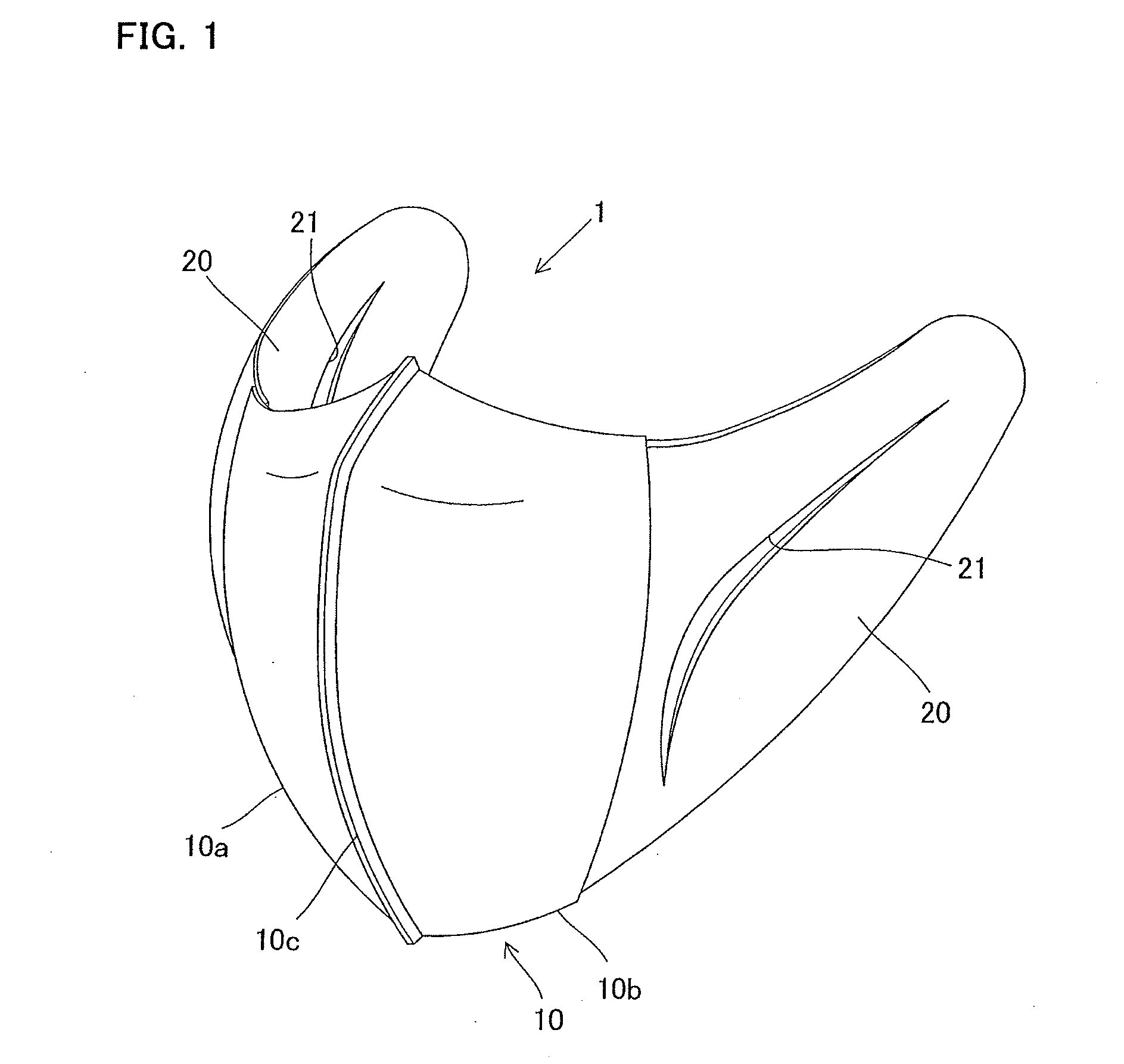

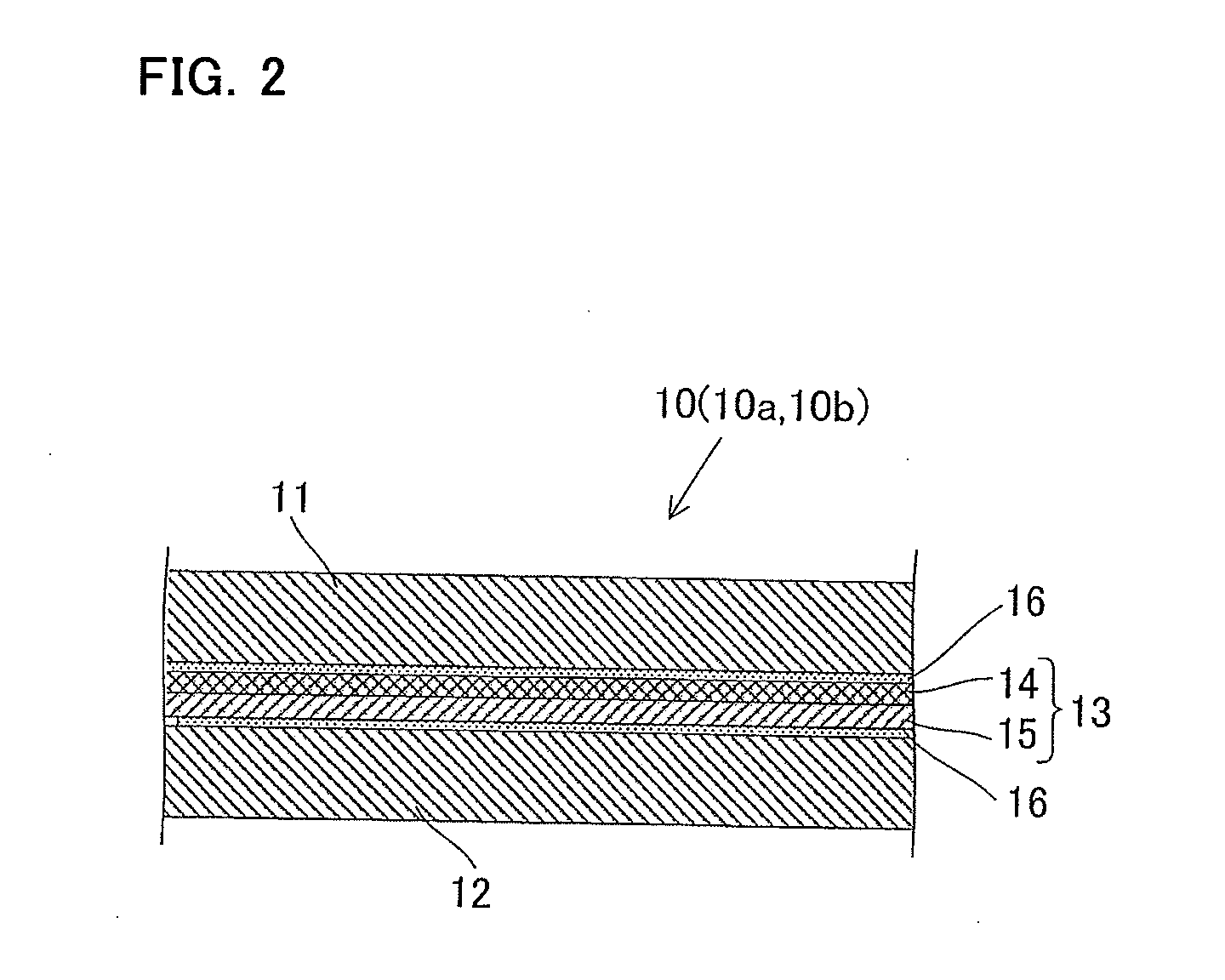

Face mask

InactiveUS20120180800A1High antibacterial and antiviral effectImprove efficiencyGarment special featuresBreathing filtersPolyolefinFiber diameter

A mask has a mask body and a pair of ear straps. The mask body includes an outer layer sheet and an intermediate layer sheet. The outer layer sheet is formed of hydrophobic fibers. The intermediate layer sheet is laid on the outer layer sheet so as to be located on a wearer's side of the outer layer sheet when the mask is worn. The intermediate layer sheet includes a first fiber layer which is formed of polyolefin fibers containing an inorganic antimicrobial agent and a second fiber layer which is formed of polyolefin fibers and has a larger fiber diameter than the first fiber layer. The fiber diameter of the first fiber layer is within a range of 0.5 to 2.8 μm and the ratio of a particle diameter of the inorganic antimicrobial agent with respect to the fiber diameter is within the range of 0.1 to 6.0.

Owner:UNI CHARM CORP

Emergency wound dressing and its preparation method

InactiveCN1830409AImprove breathabilityGood moisture permeabilityAdhesive dressingsAbsorbent padsWound dressingInter layer

A dressing for the first aid to wound is a composite non-woven cloth consisting of an internal layer made of the mixture of chitosan fibers and alginate fibers, a middle layer made of the hydroscopic fibers mixed with high-hydroscopicity resin, and an external layer made of hydrophobic fibers. Its preparing process is also disclosed.

Owner:SANITARY EQUIP INST ACAD OF MILITARY MEDICAL SCI PLA

Dual Function Polymer Micelles

Owner:CASE WESTERN RESERVE UNIV

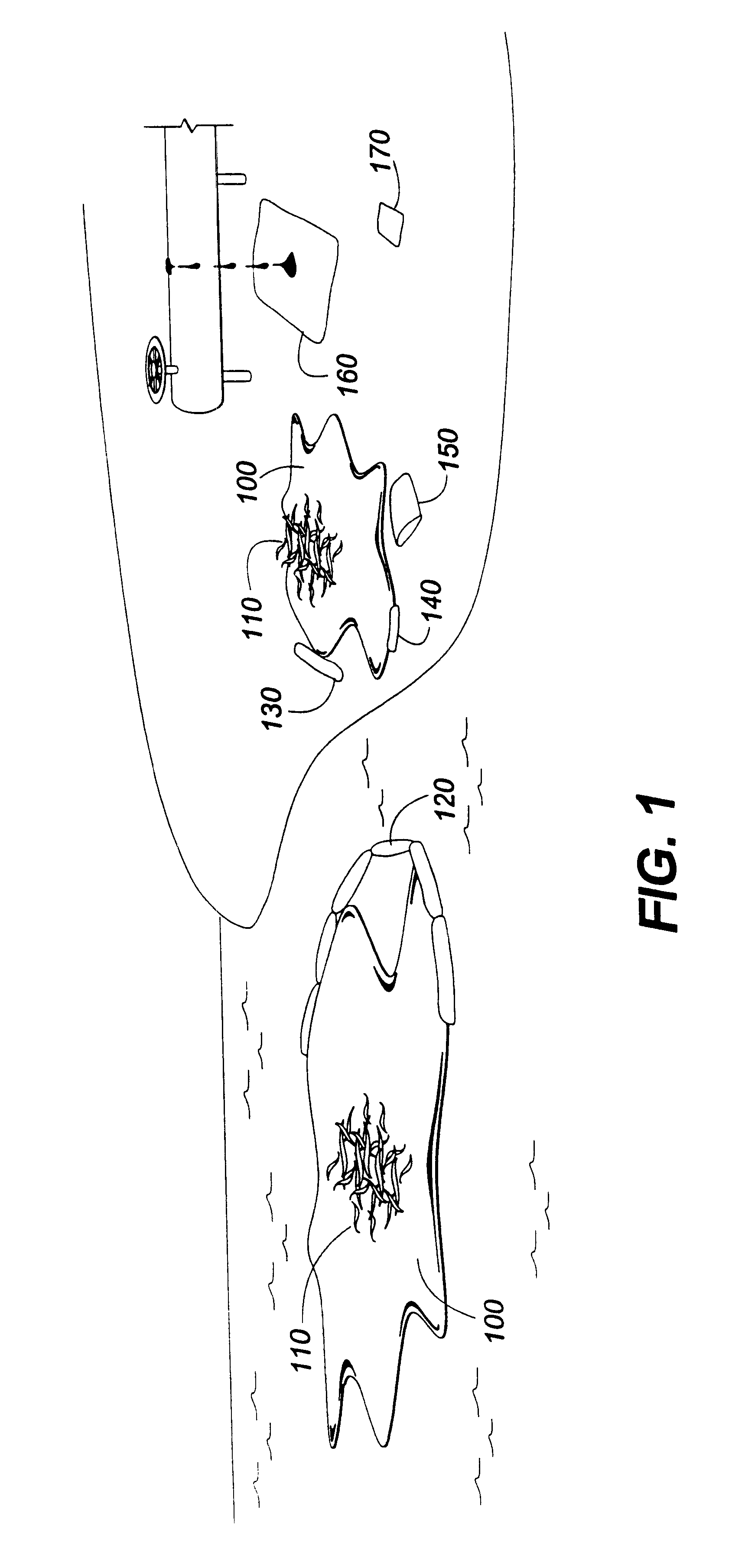

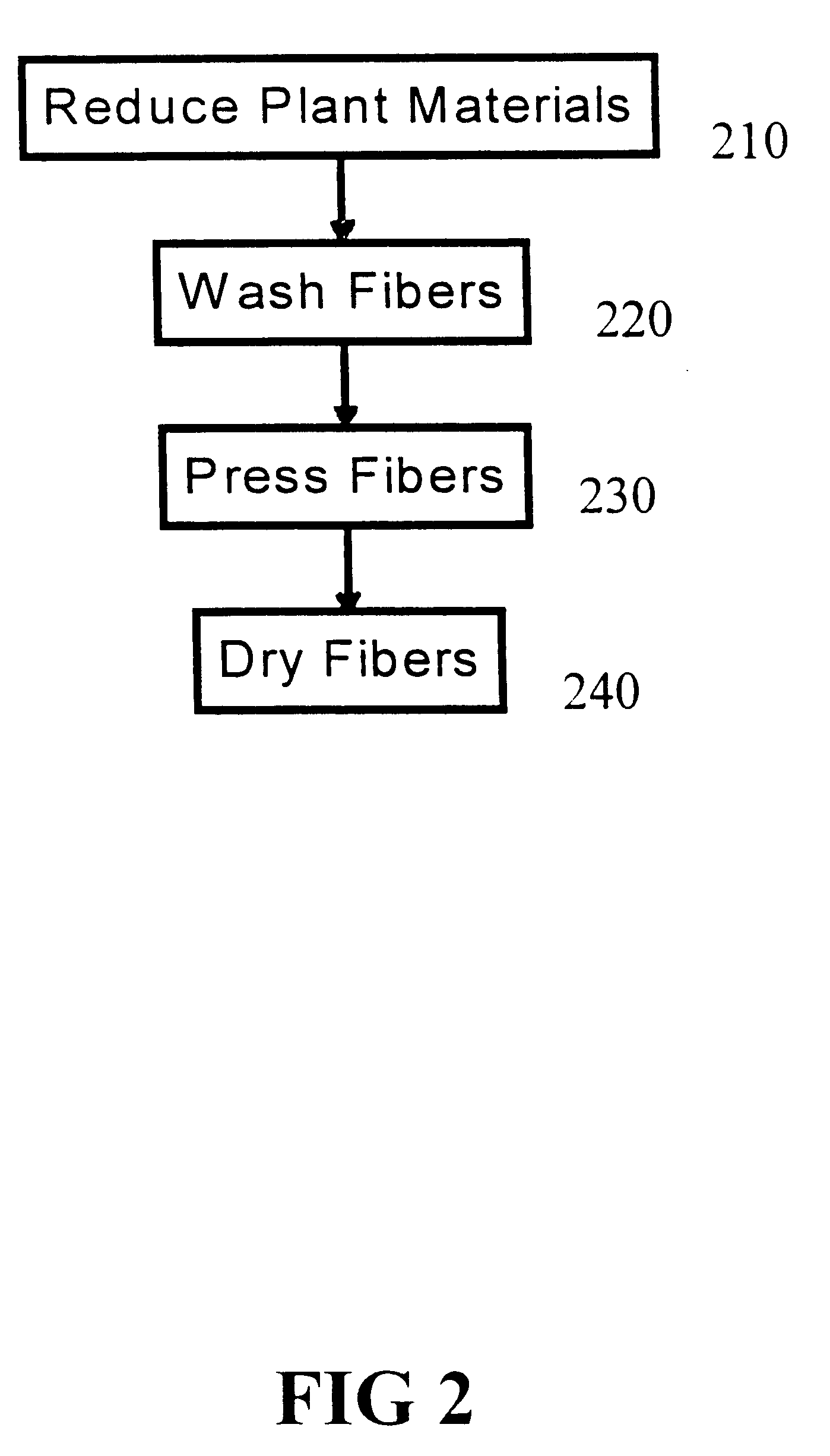

Process for sorbing liquids using tropical fibers

InactiveUS6506307B1Minimizing useImprove hydrophobic absorptivityOther chemical processesIon-exchanger regenerationFiberTropical plants

A process is described for sorbing hydrophobic liquids using a plurality of dried, washed fibers originating from a tropical plant material having naturally hydrophobic fibers. The dried, washed fibers have been washed sufficiently to extract a substantial portion of natural liquids therefrom, thereby improving their hydrophobic absorptive properties. The dried, washed fibers are applied in communication with a body containing the hydrophobic liquid whereupon they sorb the hydrophobic liquid from the body.

Owner:JOSEPHINE VALLEY

Composition in the form of a water-in-oil emulsion stabilized with a 2-acrylamido-2-methylpropanesulphonic acid (CO) polymer containing hydrophobic grafts

A composition, in the form of a water-in-oil emulsion, is characterized in that it contains at least one amphiphilic polymer or copolymer of 2-acrylamido-2-methylpropanesulphonic acid bearing hydrophobic grafts chosen from hydrocarbon-based radicals containing from 6 to 30 carbon atoms, oxyalkylenated hydrocarbon-based radicals comprising a hydrocarbon-based group containing from 6 to 30 carbon atoms and at least one oxyalkylene unit, and mixtures thereof.

Owner:LOREAL SA

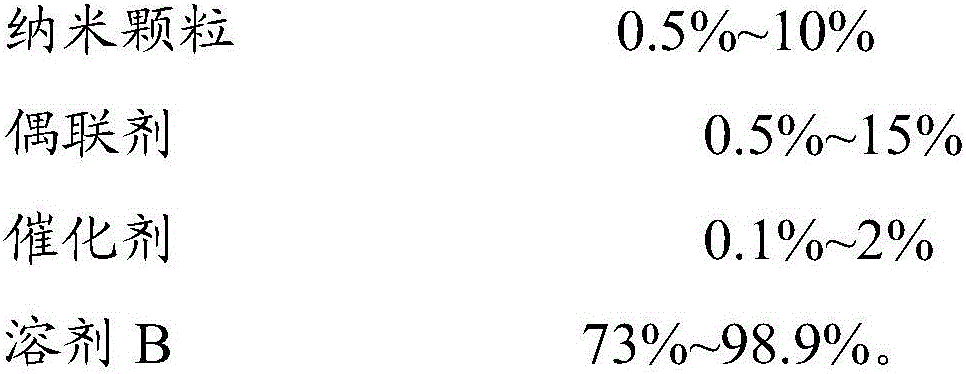

Super-hydrophobic fabric and preparation method thereof

ActiveCN105780468AImprove wear resistanceMaintain superhydrophobic effectLiquid repellent fibresVegetal fibresNanoparticleWear resistant

The invention discloses a super-hydrophobic fabric and a preparation method thereof and belongs to the technical field of super-hydrophobicity. The super-hydrophobic fabric comprises a fabric body, wherein a coupling agent wear-resistant layer is stuck to the surface of the fabric body, a super-hydrophobic layer is stuck to the surface of the coupling agent wear-resistant layer, the coupling agent wear-resistant layer contains a coupling agent A, and the super-hydrophobic layer is a coupling agent B modified nanoparticle layer. The super-hydrophobic fabric disclosed by the invention contains the coupling agent wear-resistant layer and the super-hydrophobic layer, and the coupling agent wear-resistant layer can be used for improving the wear resistance of the super-hydrophobic layer, so that the super-hydrophobic fabric can keep a super-hydrophobic effect in a long-acting manner.

Owner:BEIJING NEATRITION TECH CO LTD

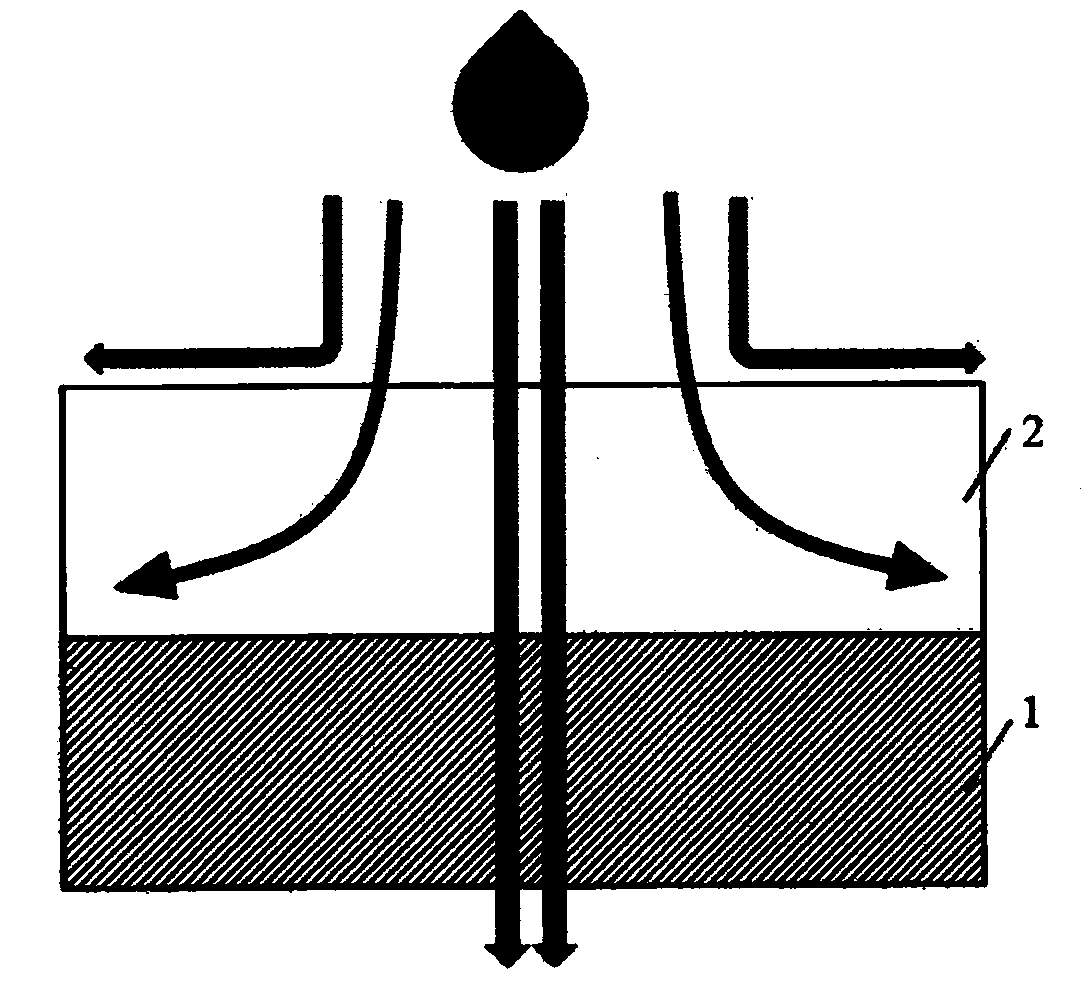

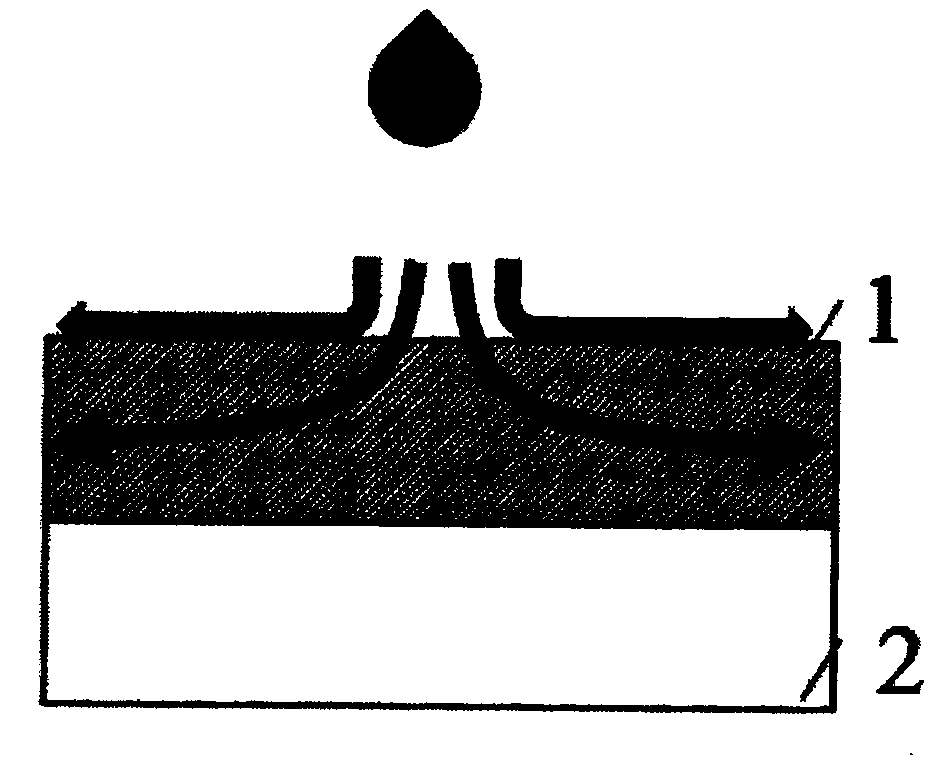

Nonwoven composite material with oriented water guide function, and manufacturing method thereof

ActiveCN105369476AGood orientationRealize directional water guideNon-woven fabricsFiberHydrophobic effect

The invention provides a nonwoven composite material with an oriented water guide function, and a manufacturing method thereof. The nonwoven composite material with an oriented water guide function is characterized by comprising a hydrophilic layer, a water repellent layer, and a mixed layer between the hydrophilic layer and the water repellent layer. The hydrophilic layer is formed by hydrophilic fibers. The water repellent layer is formed by hydrophobic fibers. The mixed layer is formed by the hydrophilic fibers and the hydrophobic fibers. Part or all hydrophilic fibers in the hydrophilic layer and part or all hydrophobic fibers in the water repellent layer are arranged along a certain direction, and arraying directions of the hydrophilic fibers and the hydrophobic fibers are the same. A horizontal surface and a vertical surface have the oriented water guide function at the same time, and oriented water guide effect is excellent.

Owner:南京锦琪昶新材料有限公司

Method for performing anticorrosive hydrophobic modification on surface of aluminum alloy

InactiveCN101885934ACoating thickness is thinImprove adhesionAnti-corrosive paintsMetallic material coating processesSpray coatingLayer thickness

The invention discloses a method for performing anticorrosive hydrophobic modification on the surface of an aluminum alloy, which belongs to the technical field of corrosion prevention. The method specifically comprises the following steps of: (1) performing surface degreasing and oil removing on an aluminum alloy material by using conventional alkaline degreasing solution first, performing surface activation treatment by using reductive acidic cleaning solution, and then performing inactivation and sealing treatments on the activated surface; (2) preparing a composition with a hydrophobic effect, wherein the composition consists of a first component and a second component in a weight ratio of 9-16:1, the first component is prepared from the following materials in percentage by weight: 35 to 60 percent of fluorocarbon resin, 10 to 40 percent of anticorrosive pigment, 1 to 8 percent of organosilicon compound, 0.5 to 5 percent of dispersing agent, 0.5 to 3 percent of anti-settle agent and 10 to 40 percent of organic solvent, and the second component is a fatty series / aromatic series curing agent; and (3) performing anticorrosive hydrophobic modification on the surface of the aluminum alloy, namely coating the composition with the hydrophobic effect in the step (2) on the surface of the aluminum alloy after treatment in a brush coating, spray coating or dip coating mode, and curing the surface for about 12 hours. The anticorrosive hydrophobic coating layer obtained on the surface of the aluminum alloy by using the technique of the invention has the advantages of thin coating layer thickness, high adhesive force, sea water corrosion resistance, surface super-hydrophobic property and the like.

Owner:BEIJING UNIV OF CHEM TECH

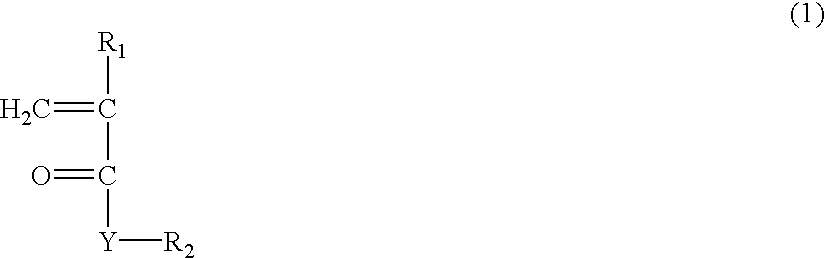

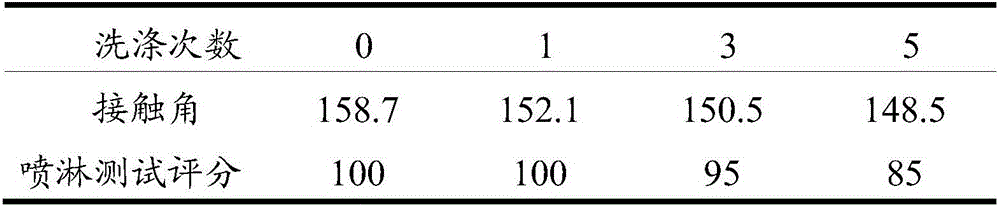

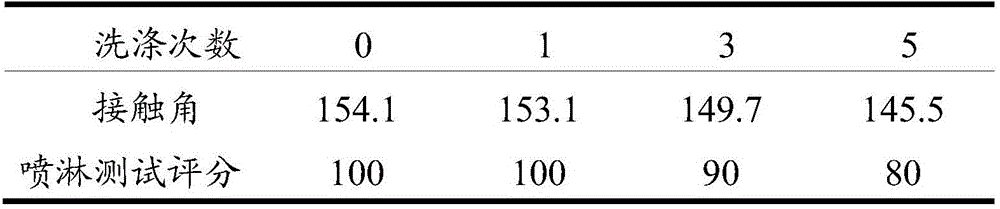

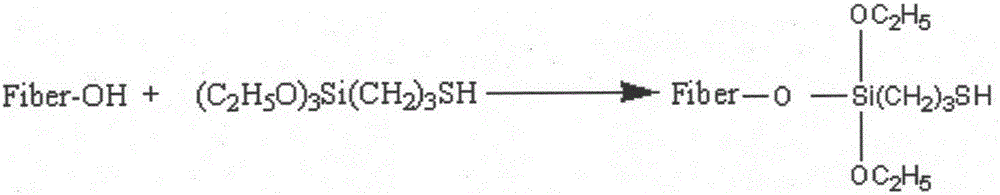

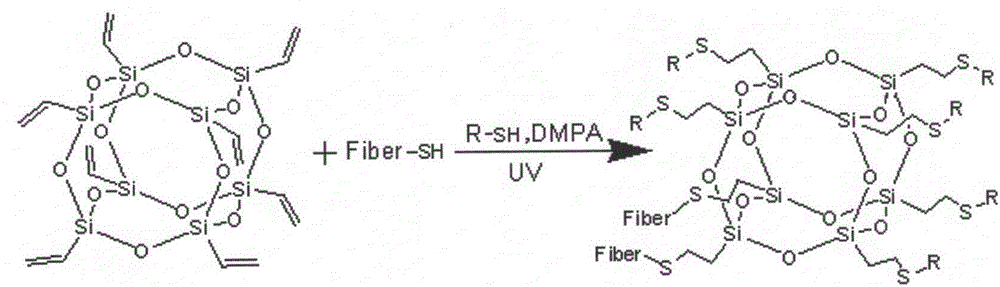

Ultraviolet curing reaction-based fluoride-free and water-repellent finishing method of cotton fabric

InactiveCN106637959AImprove water repellency durabilityHigh activityPhysical treatmentLiquid repellent fibresAcetic acidTriethoxysilane

The invention discloses an ultraviolet curing reaction-based fluoride-free and water-repellent finishing method of cotton fabric. The method comprises the steps of putting the cotton fabric into 3-mercaptopropyl triethoxysilane ethyl acetate solution and carrying out mercapto modification to obtain pretreated cotton fabric; dipping the cotton fabric subjected to mercapto modification into vinyl polyhedral oligomeric silsesquioxane solution, and obtaining the fluoride-free and water-repellent cotton fabric, which has a surface with an approximate super-hydrophobic effect, under the ultraviolet curing condition. The reaction is based on the principle of click chemistry, so that a static contact angle is basically remained unchanged after soaping treatment is carried out. Furthermore, according to a test method of AATCC 22-2005 waterproof spray test, the waterproof spray test score of the cotton fabric subjected to water-repellent finishing reaches 95. The ultraviolet curing reaction-based fluoride-free and water-repellent finishing method of the cotton fabric is simple in operation and high in efficiency, obvious in water-repellent effect under the condition that a finishing agent is fluoride-free, and high in finishing washing fastness.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com