Patents

Literature

1181 results about "Semipermeable membrane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Semipermeable membrane is a type of biological or synthetic, polymeric membrane that will allow certain molecules or ions to pass through it by diffusion—or occasionally by more specialized processes of facilitated diffusion, passive transport or active transport. The rate of passage depends on the pressure, concentration, and temperature of the molecules or solutes on either side, as well as the permeability of the membrane to each solute. Depending on the membrane and the solute, permeability may depend on solute size, solubility, properties, or chemistry. How the membrane is constructed to be selective in its permeability will determine the rate and the permeability. Many natural and synthetic materials thicker than a membrane are also semipermeable. One example of this is the thin film on the inside of the egg. Note that a semipermeable membrane is not the same as a selectively permeable membrane. Semipermeable membrane describes a membrane that allows some particles to pass through (by size), whereas the selectively permeable membrane "chooses" what passes through (size is not a factor).

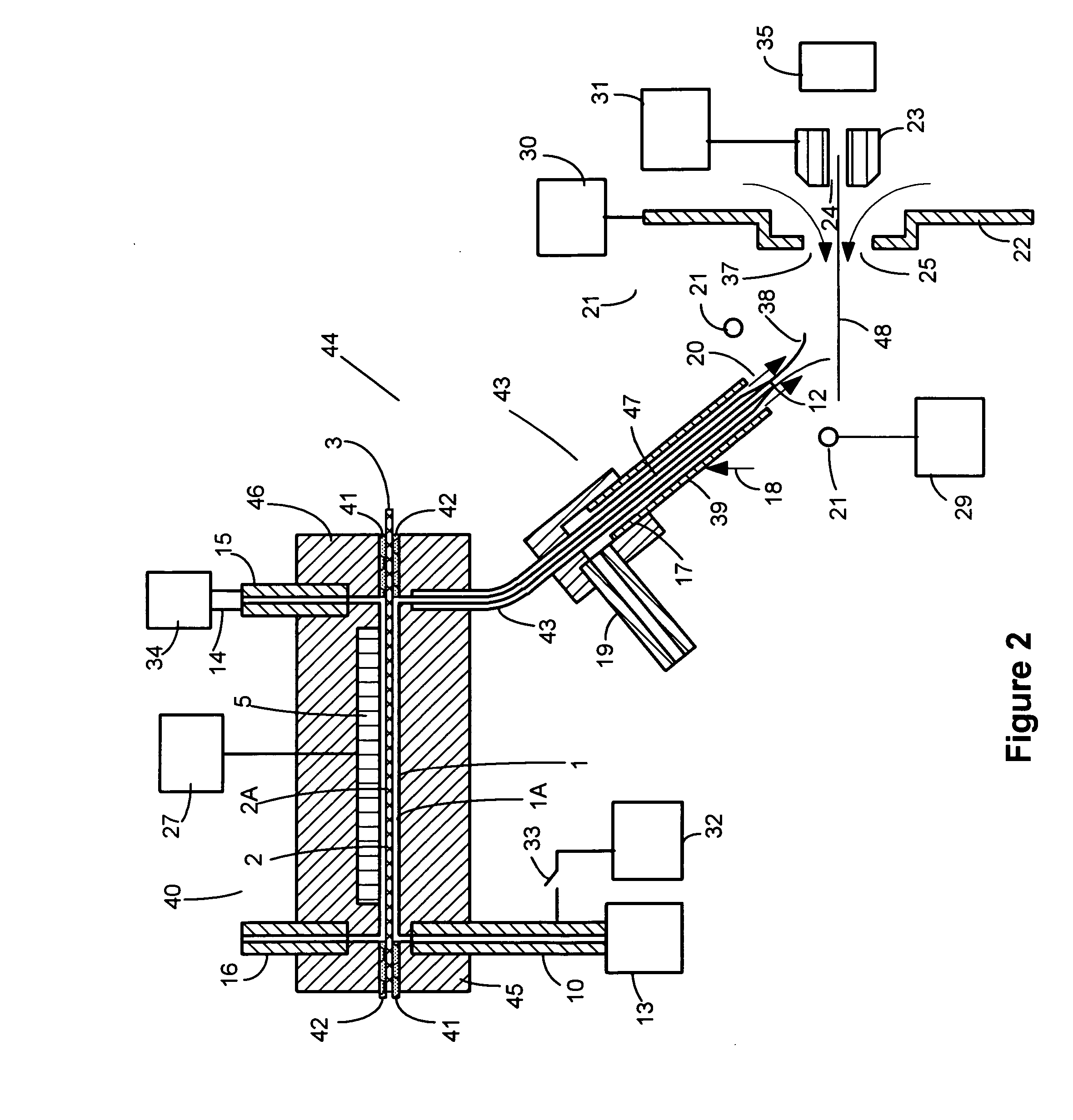

Methods and implantable devices and systems for long term delivery of a pharmaceutical agent

InactiveUS6436091B1Improve delivery rateMedical devicesPharmaceutical delivery mechanismSemipermeable membraneImplanted device

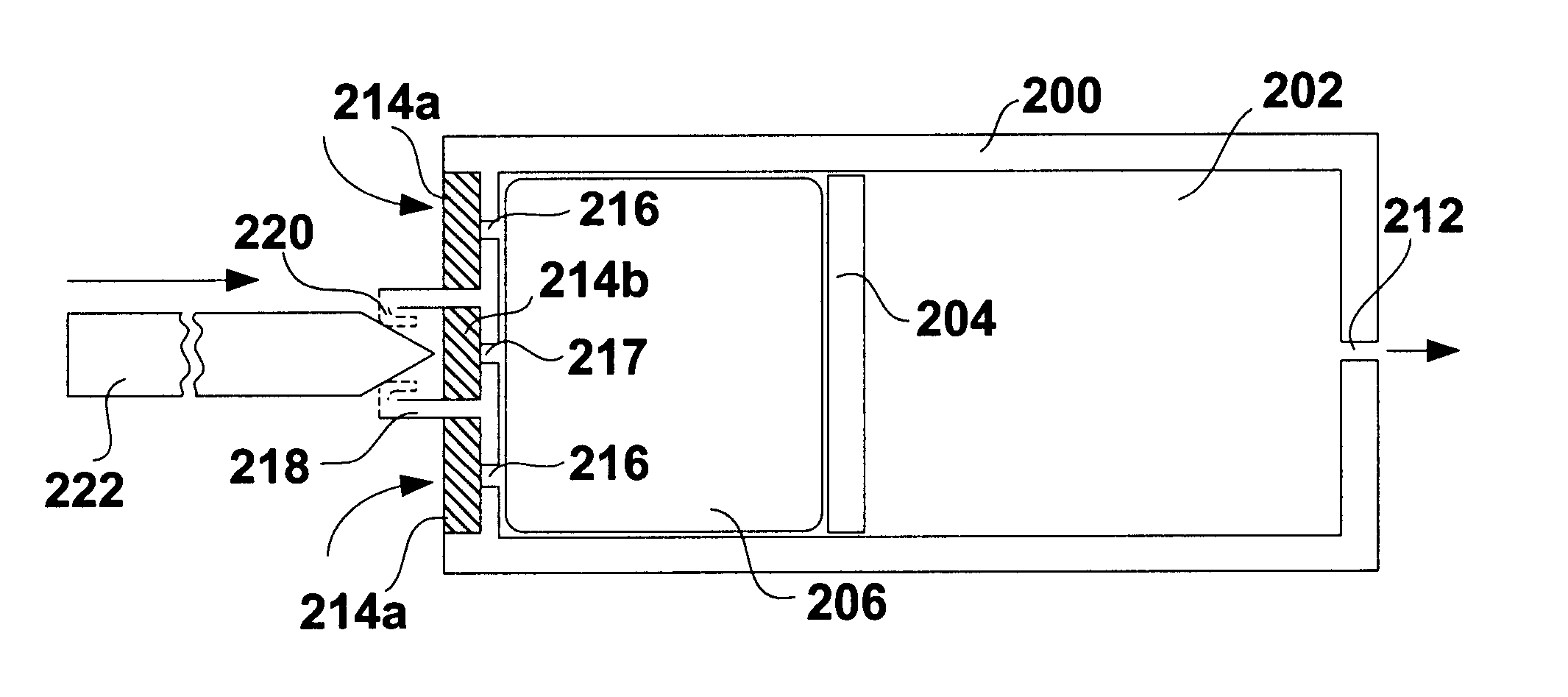

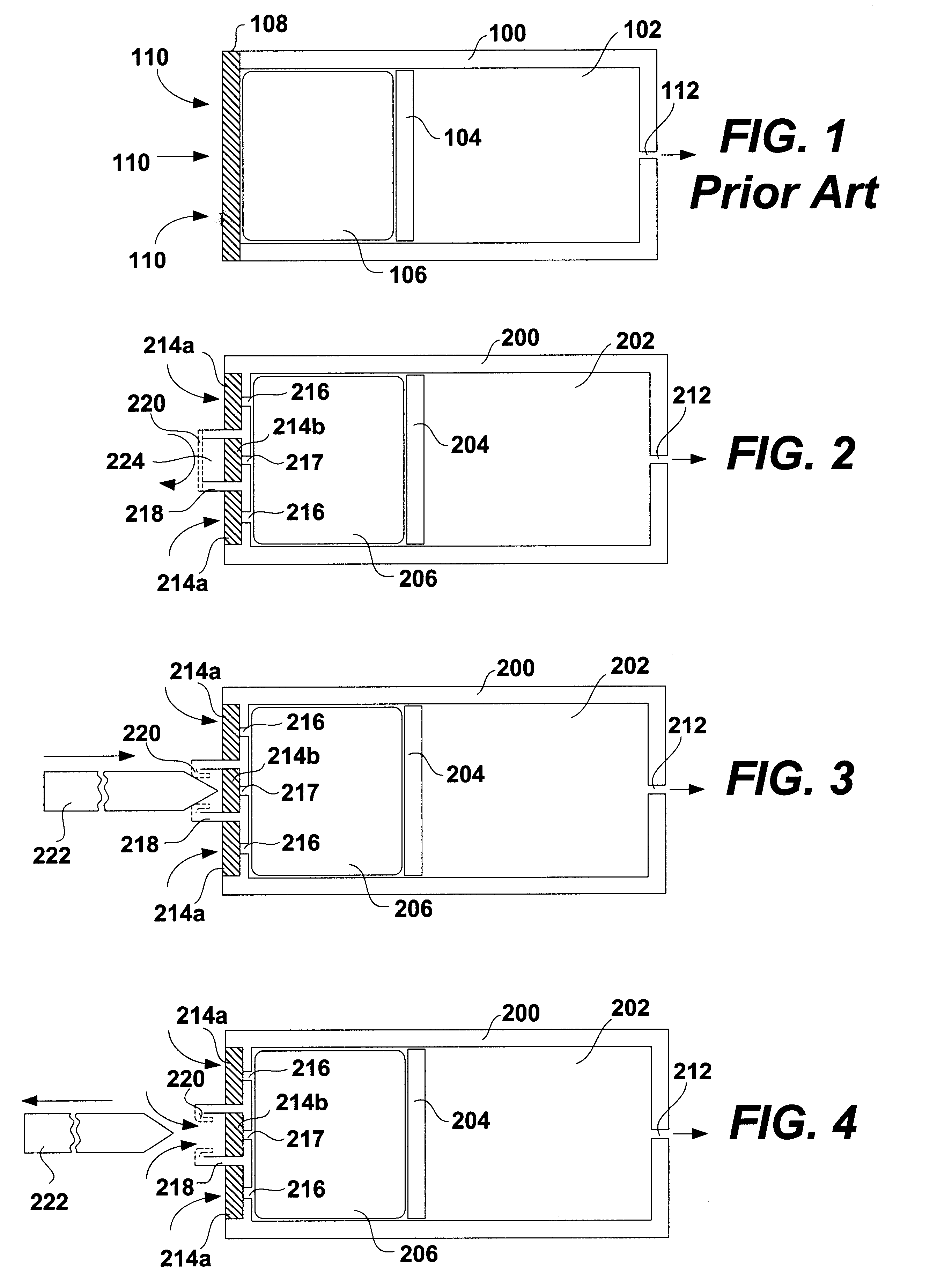

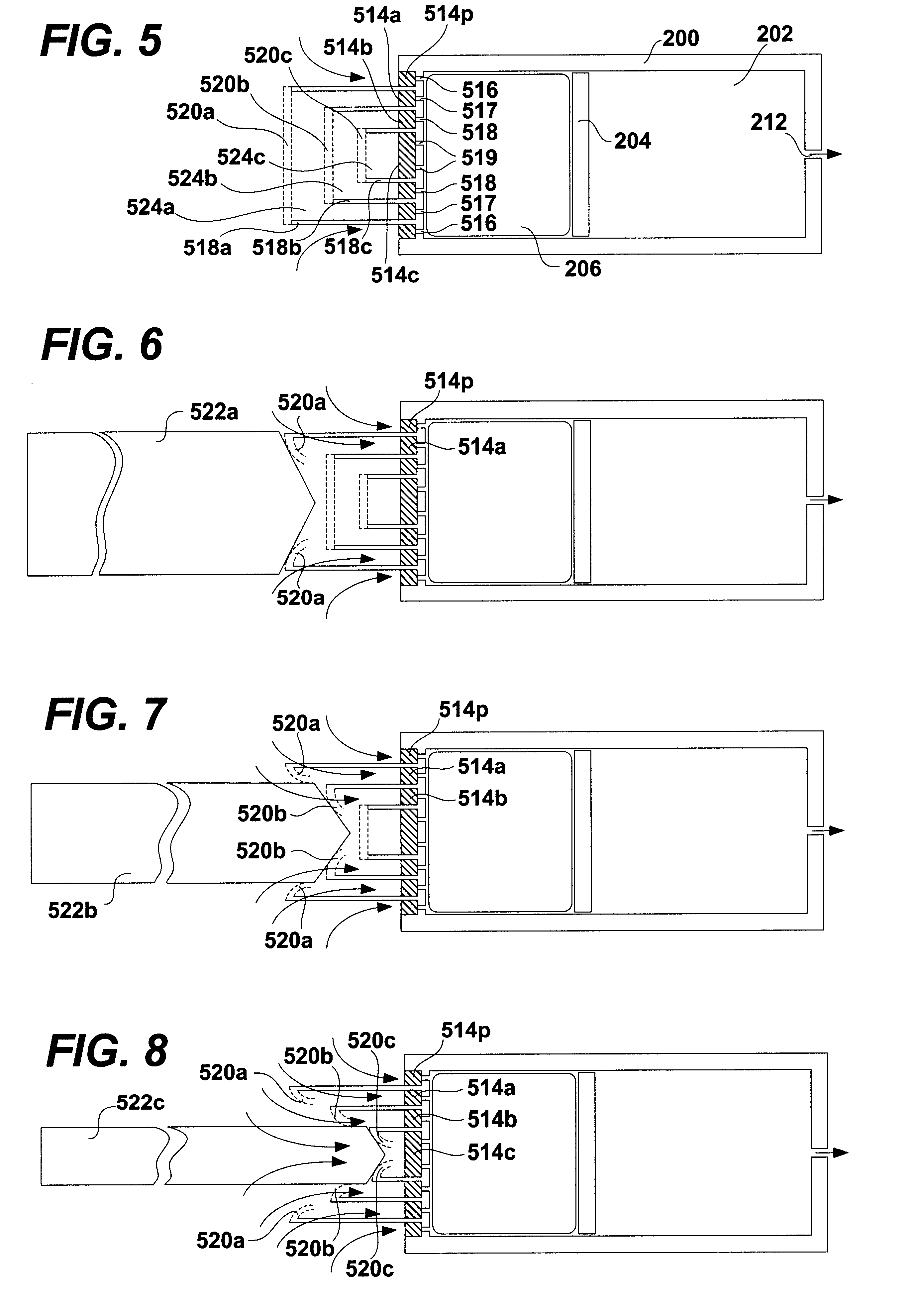

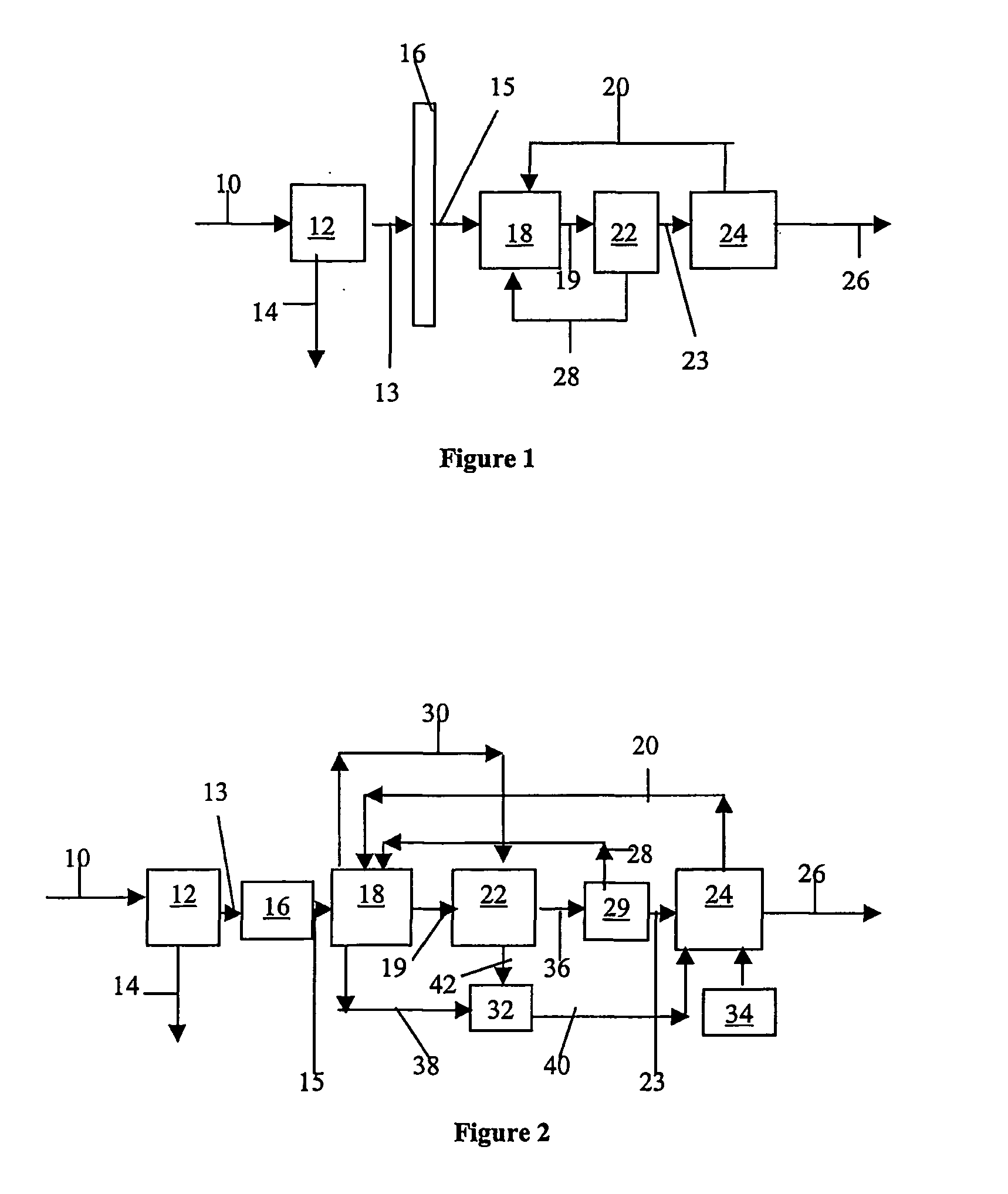

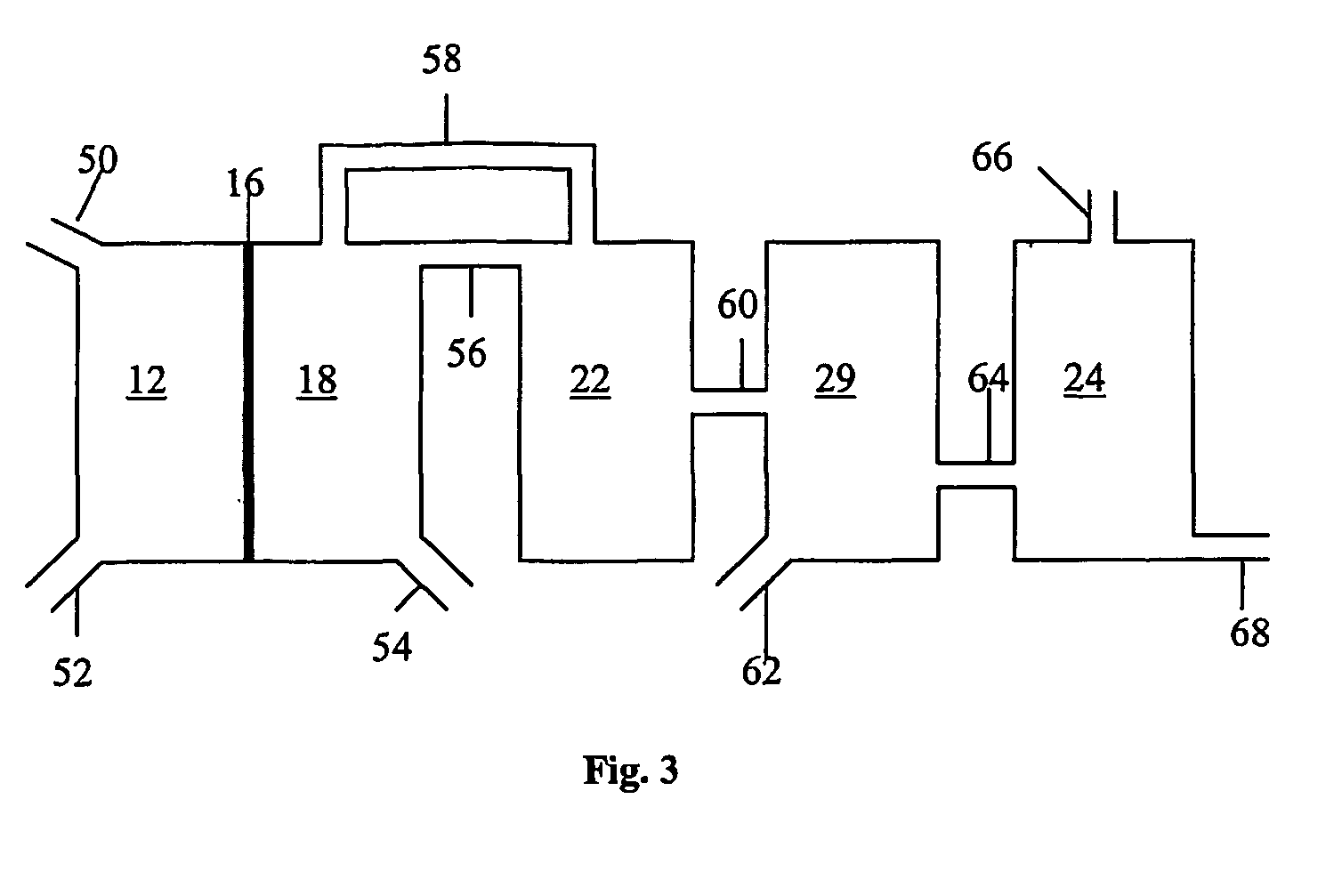

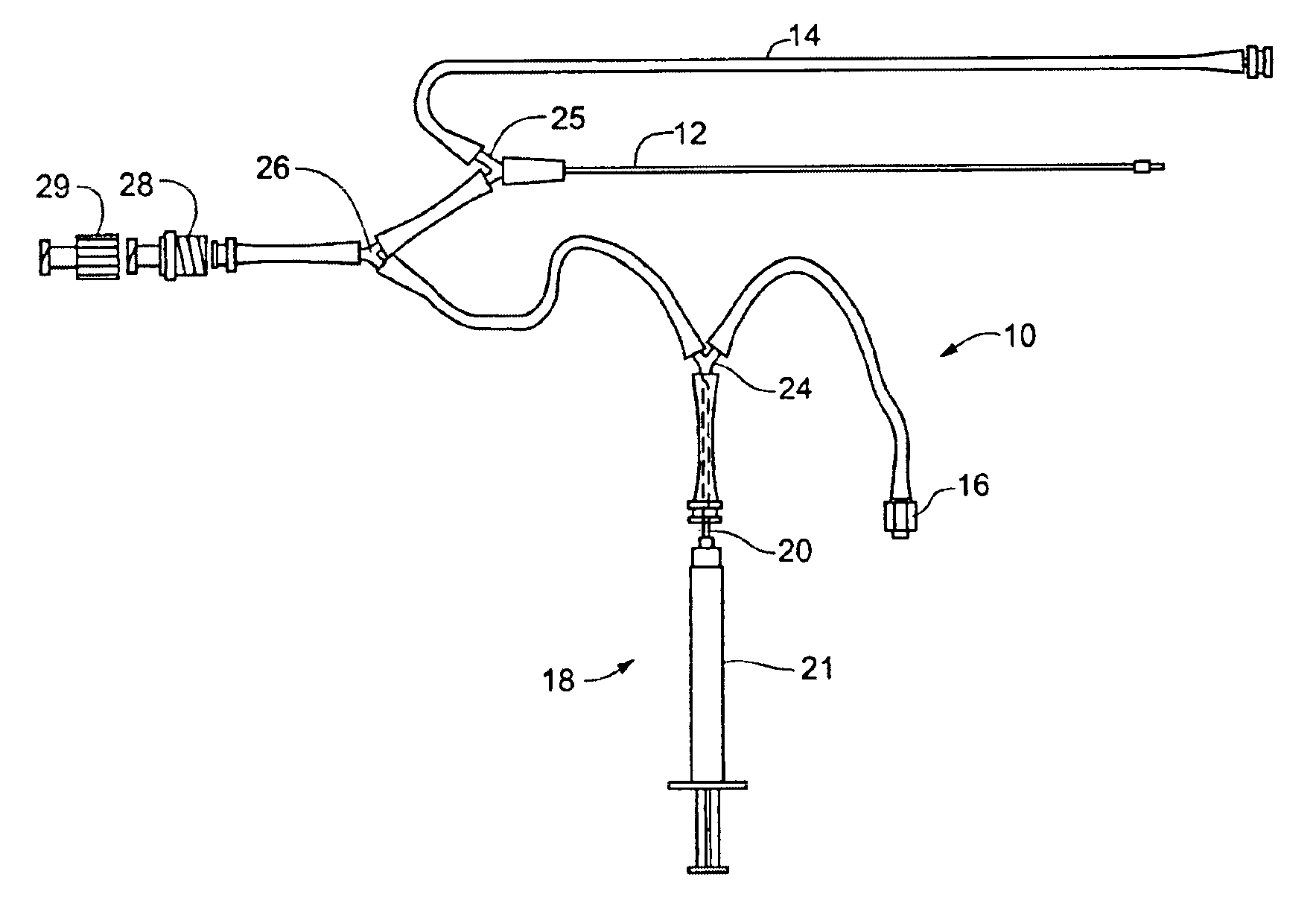

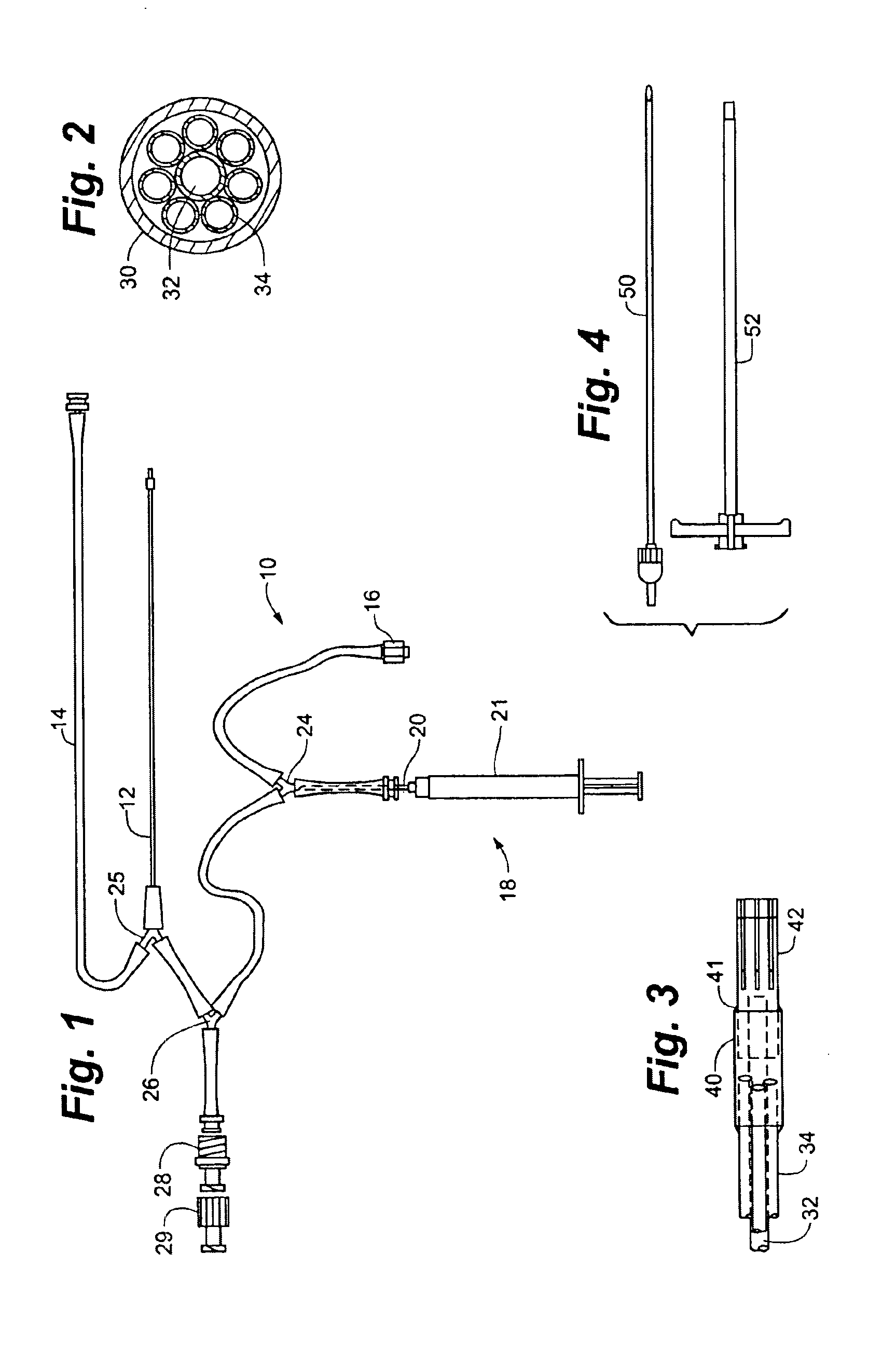

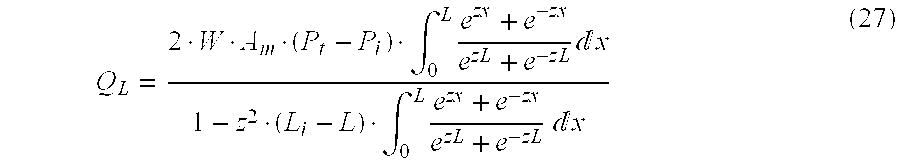

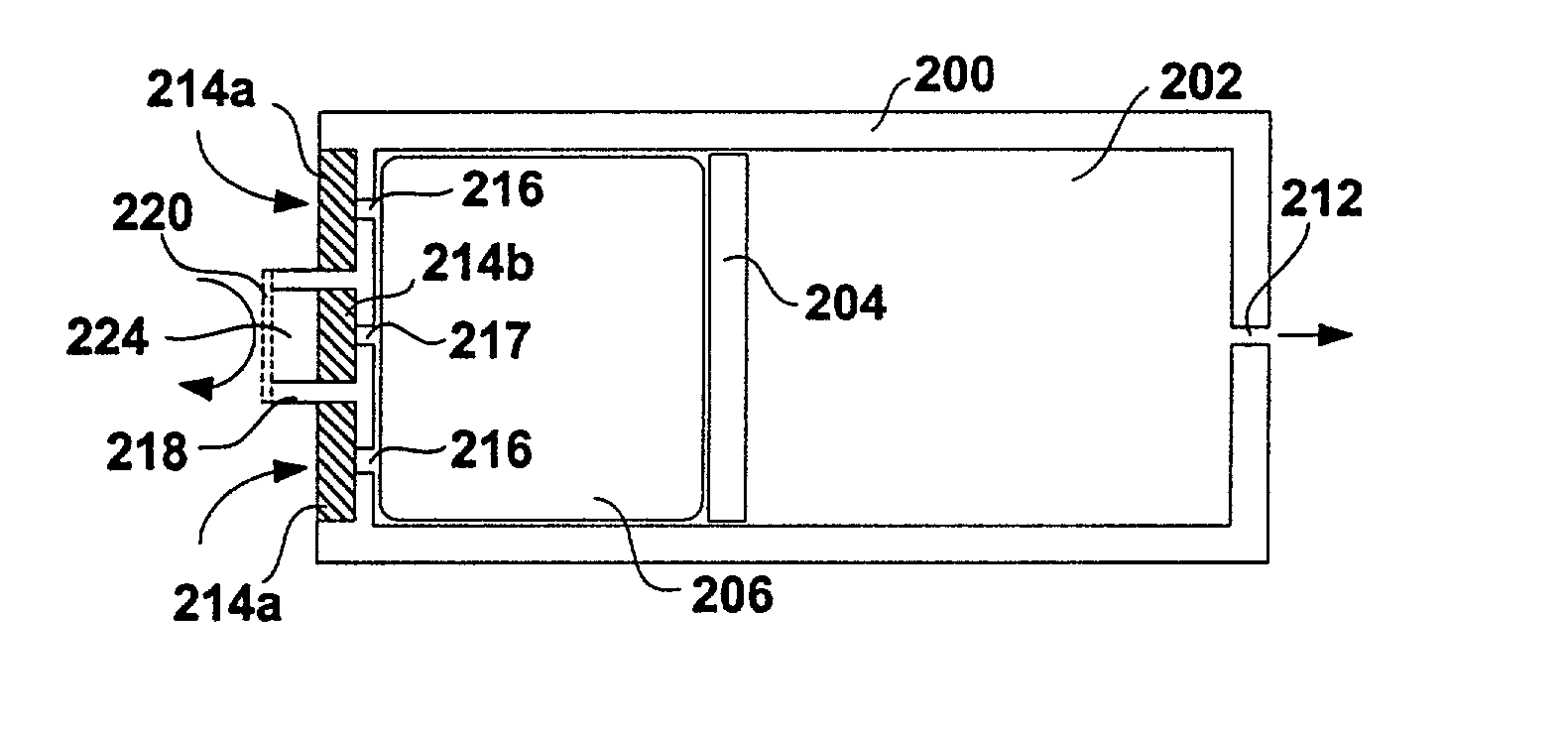

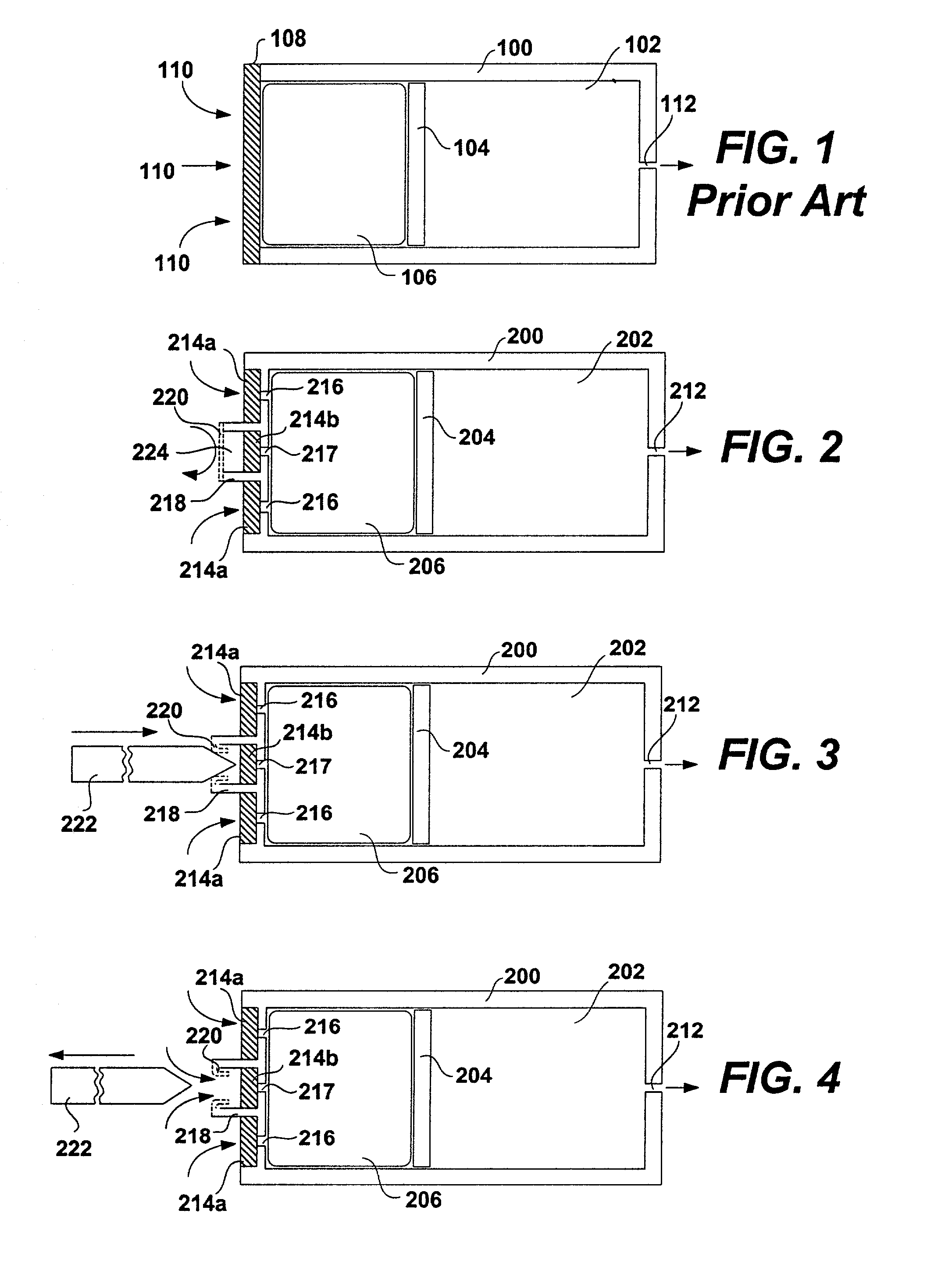

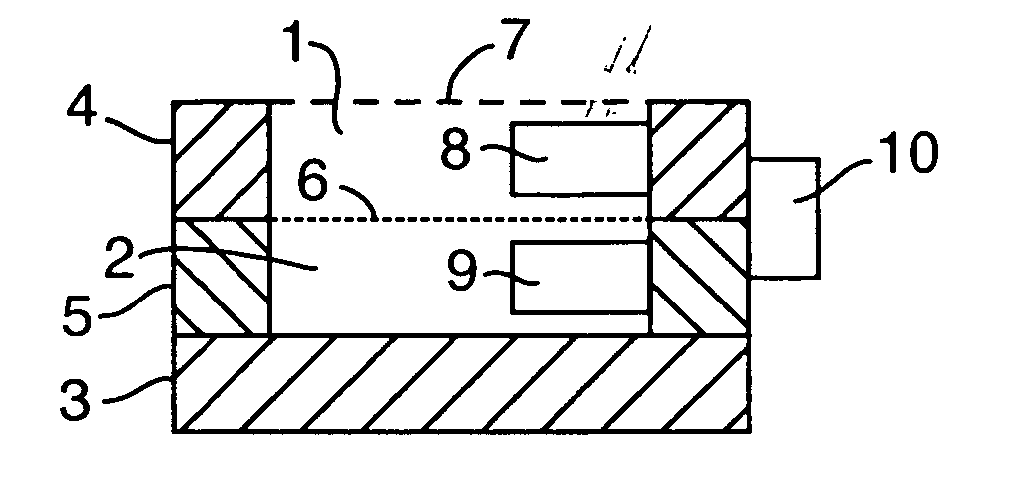

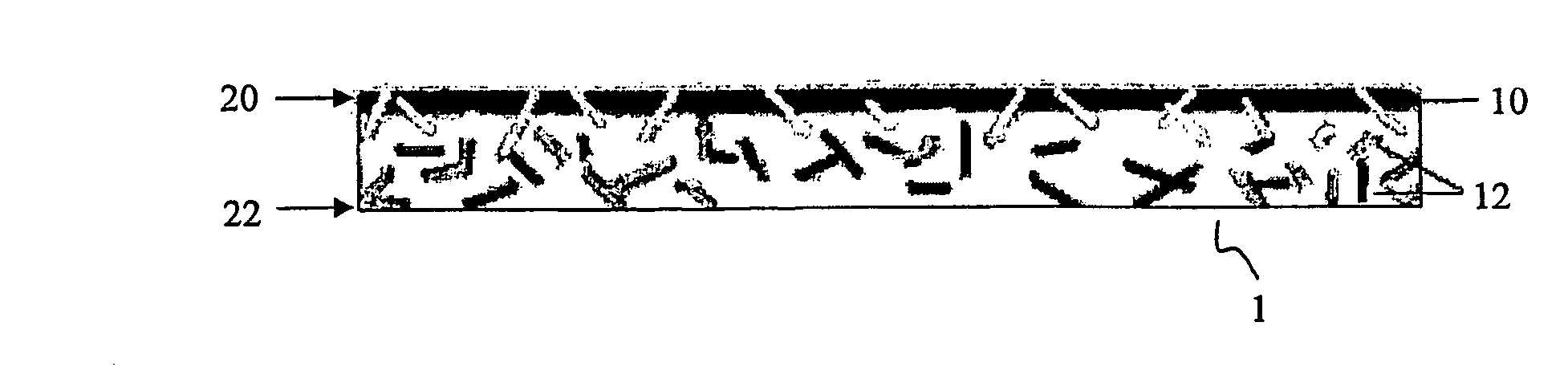

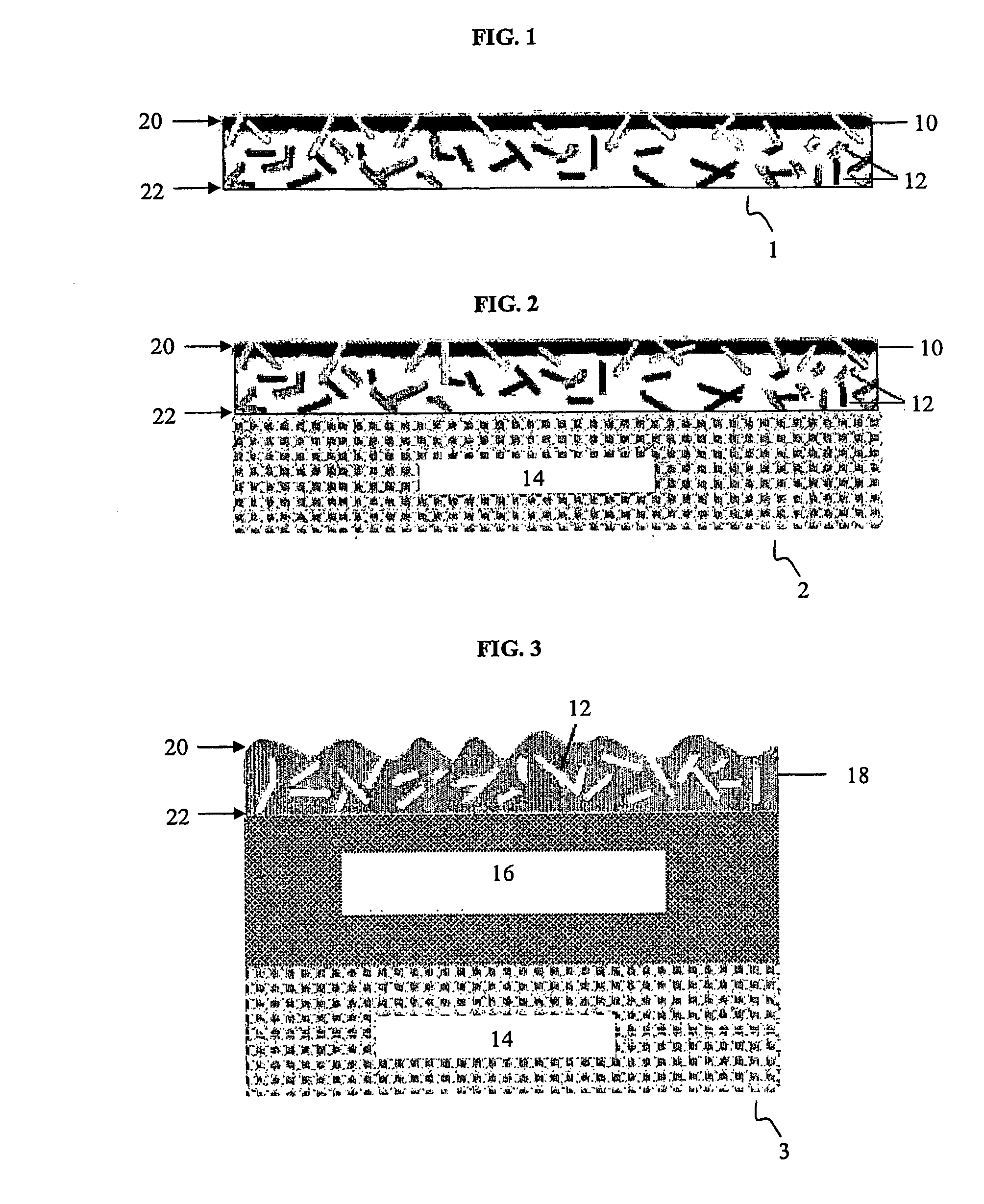

Implantable devices and osmotic pump and catheter systems for delivering a pharmaceutical agent to a patient at selectable rates include an impermeable pump housing and a moveable partition disposed within the housing, the partition dividing the housing into an osmotic driving compartment having an open end and a pharmaceutical agent compartment having a delivery orifice. A plurality of semi permeable membranes may be disposed in the open end of the osmotic driving compartment and a number of impermeable barriers may seal selected ones of the plurality of semi permeable membranes from the patient until breached. Breaching one or more of the impermeable barriers increases the surface area of semi permeable membrane exposed to the patient and controllably increases the delivery rate of the pharmaceutical agent through the delivery orifice and catheter. Each of the plurality of semi permeable membranes may have a selected surface area, composition and / or thickness, to allow a fine-grained control over the infusion rate while the pump is implanted in the patient.

Owner:MICROSOLUTIONS

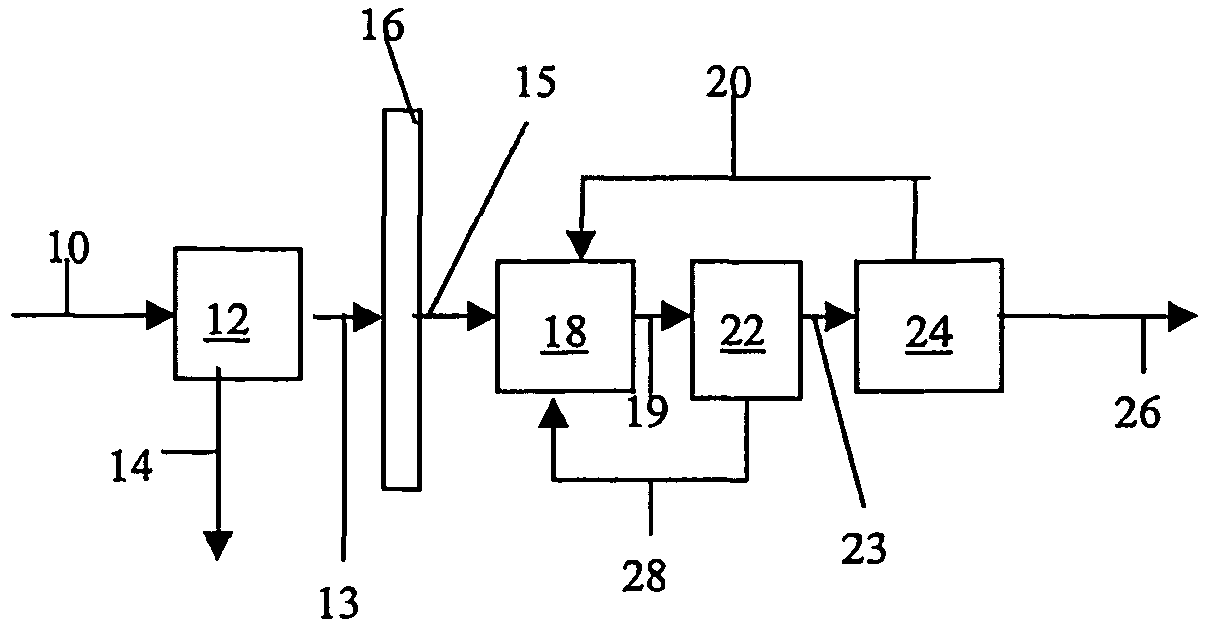

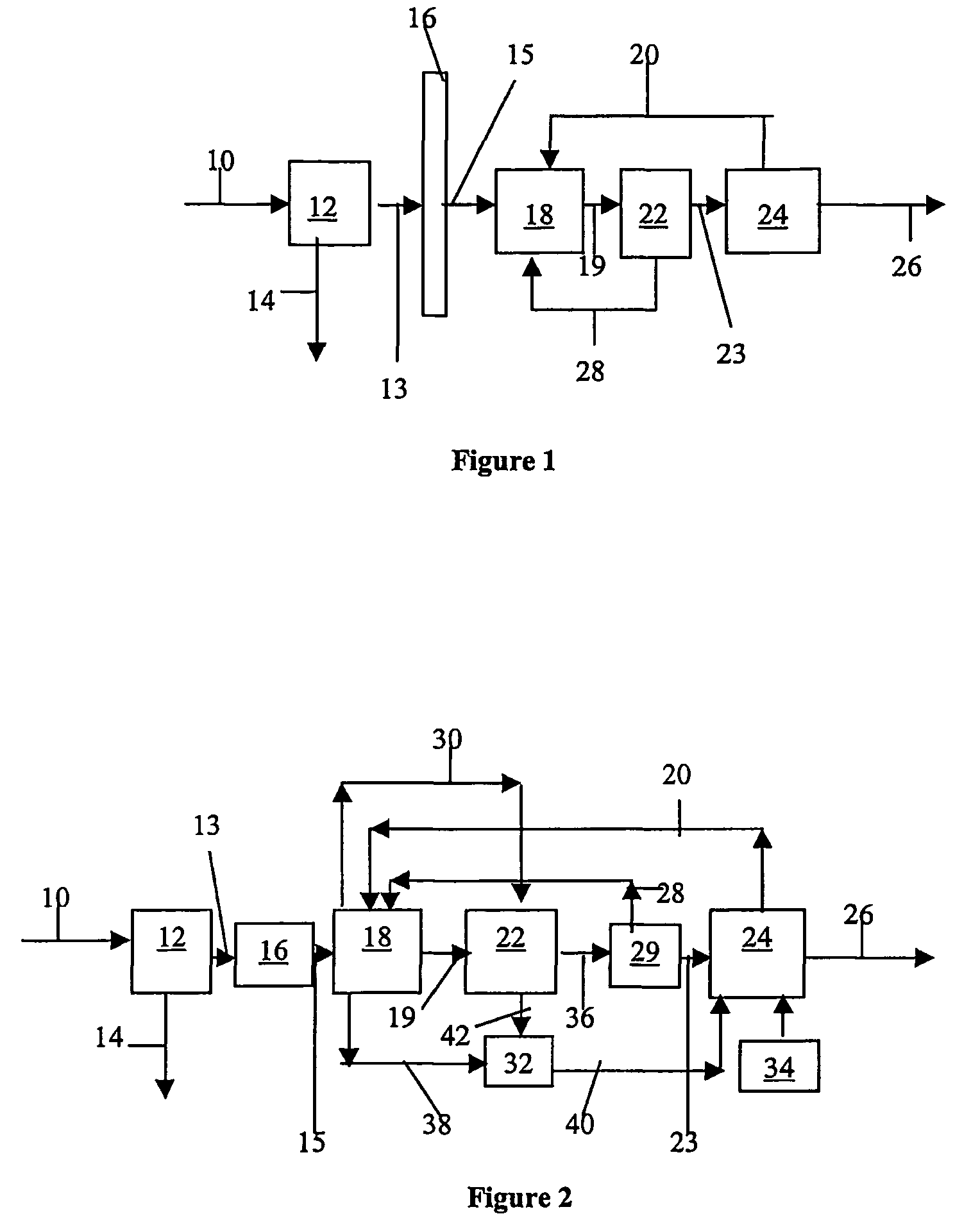

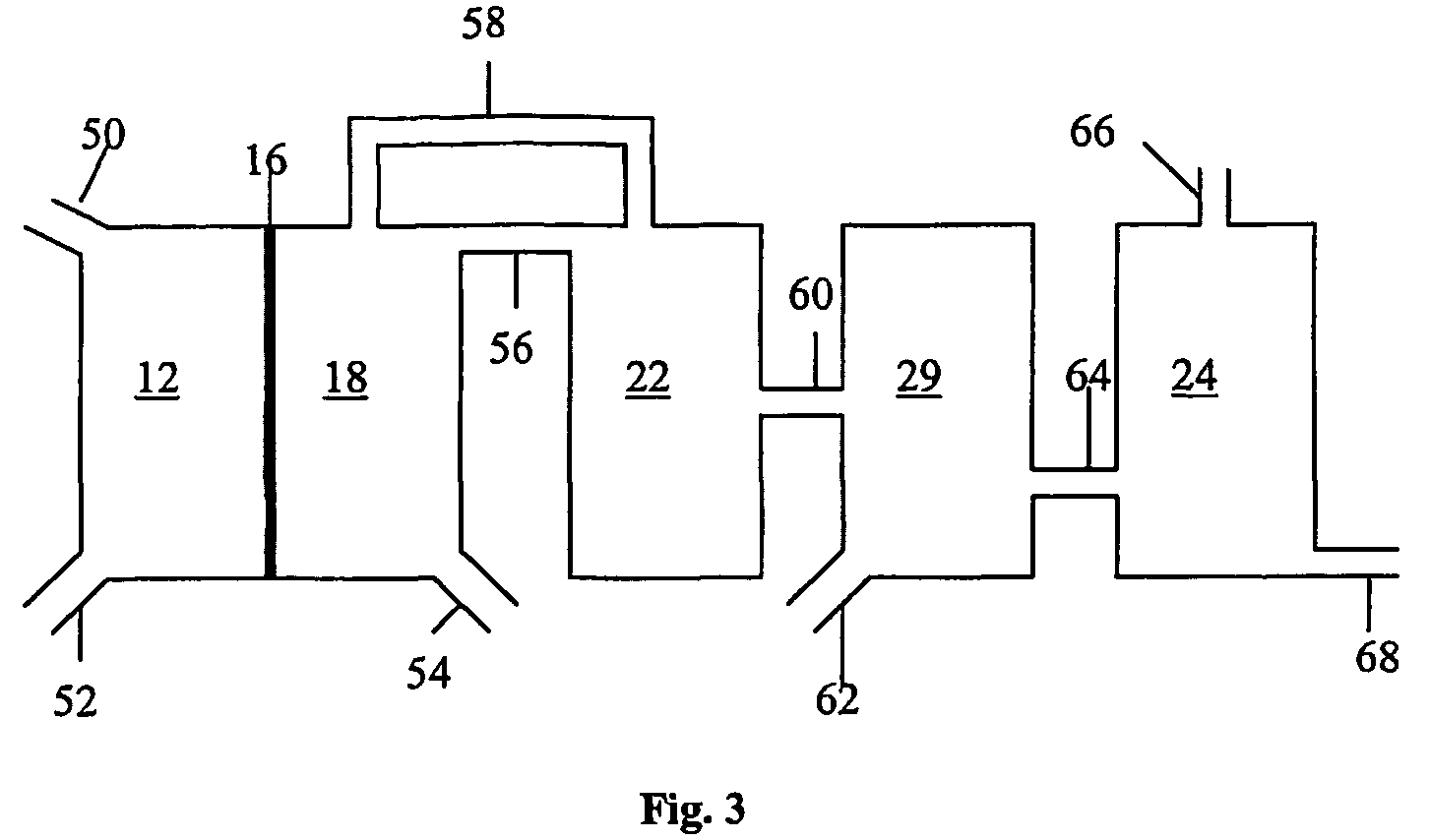

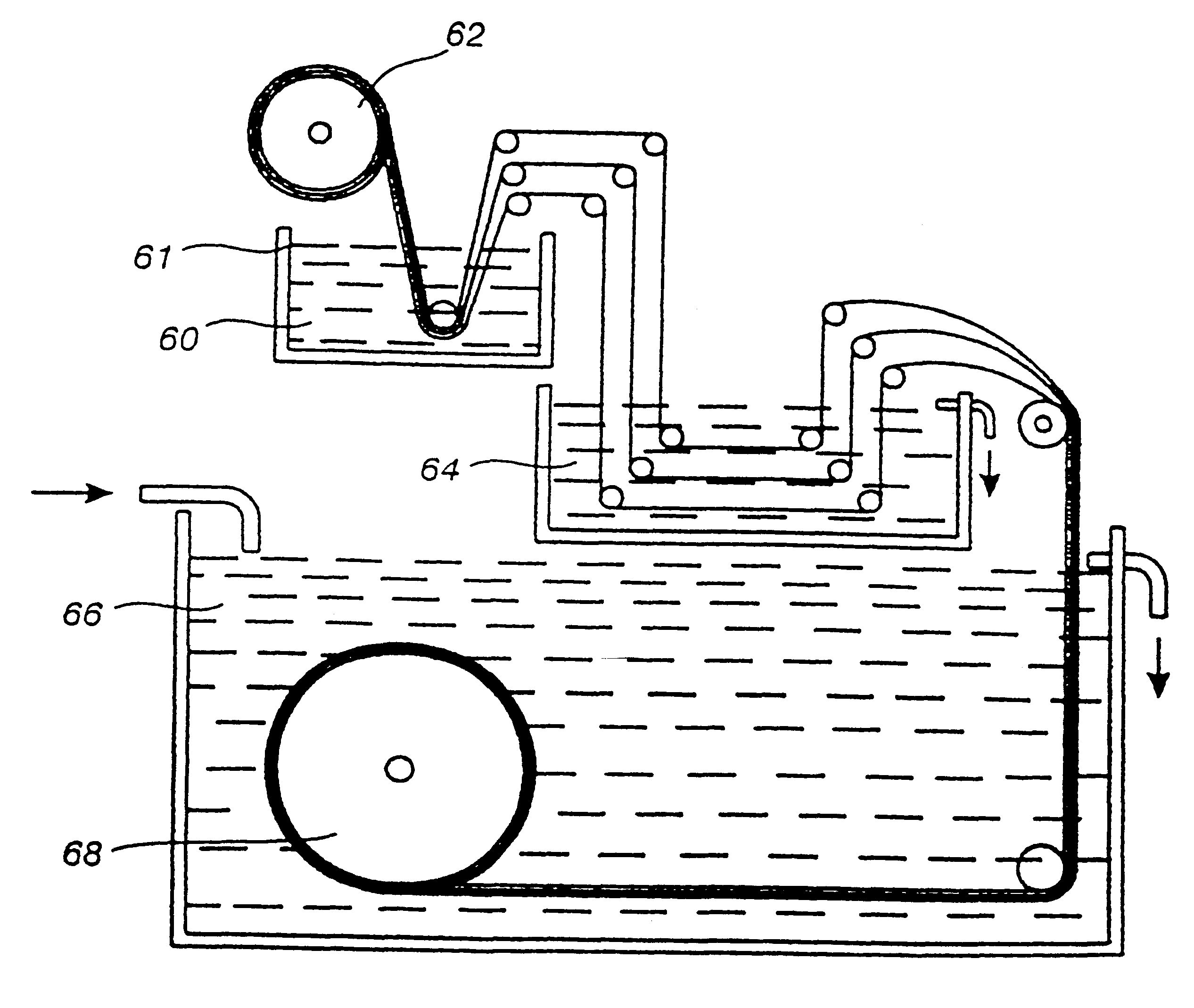

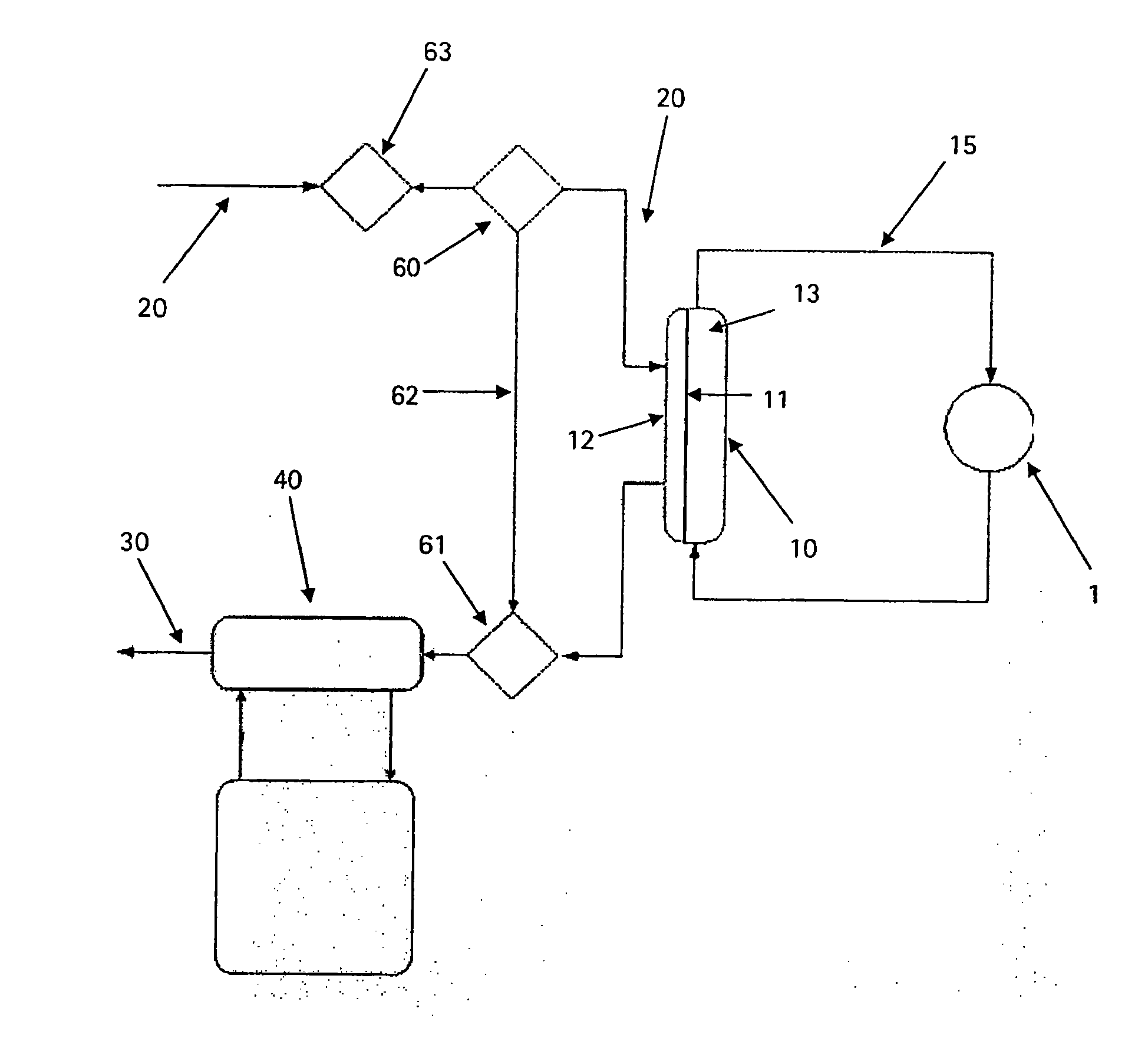

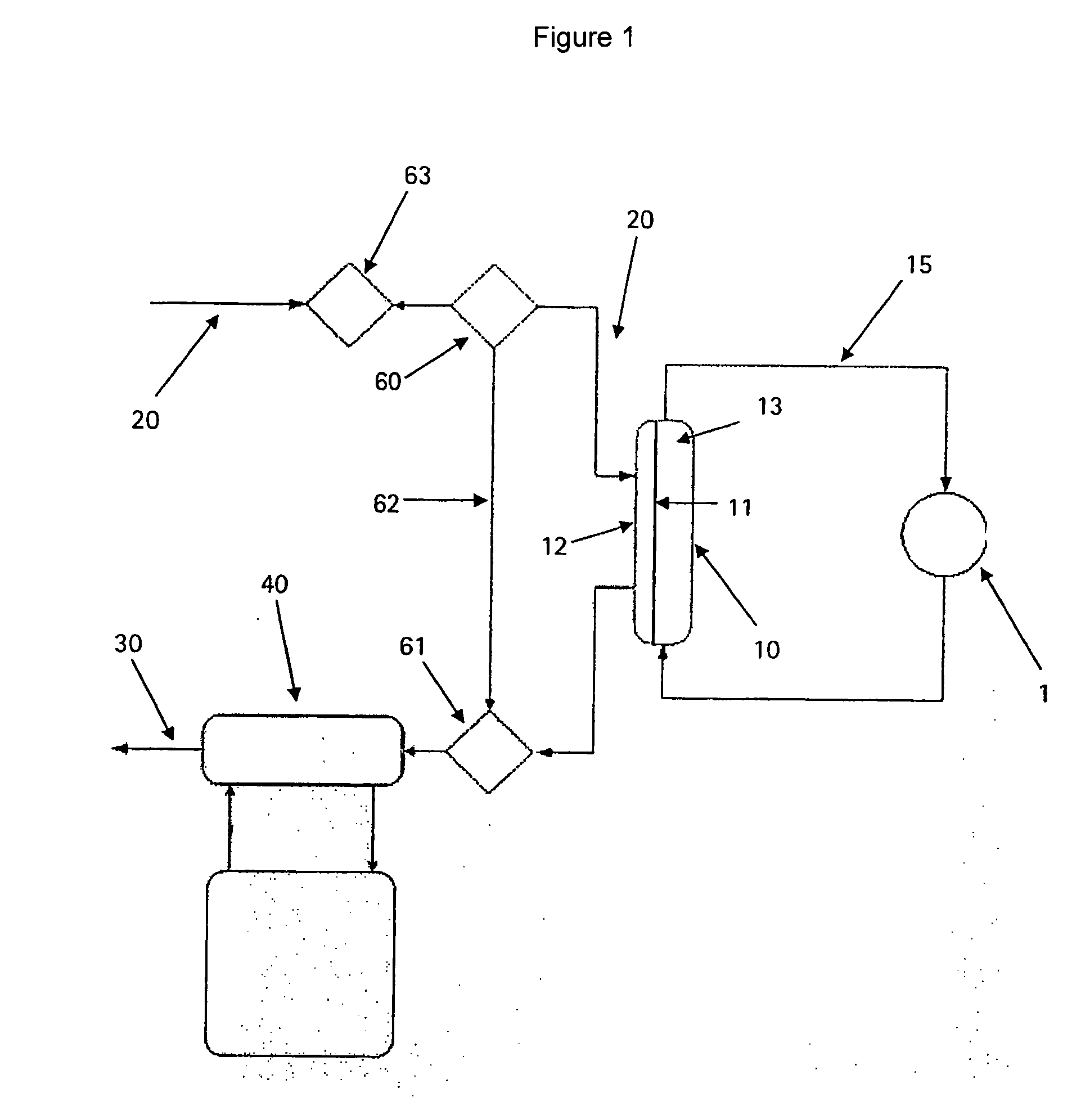

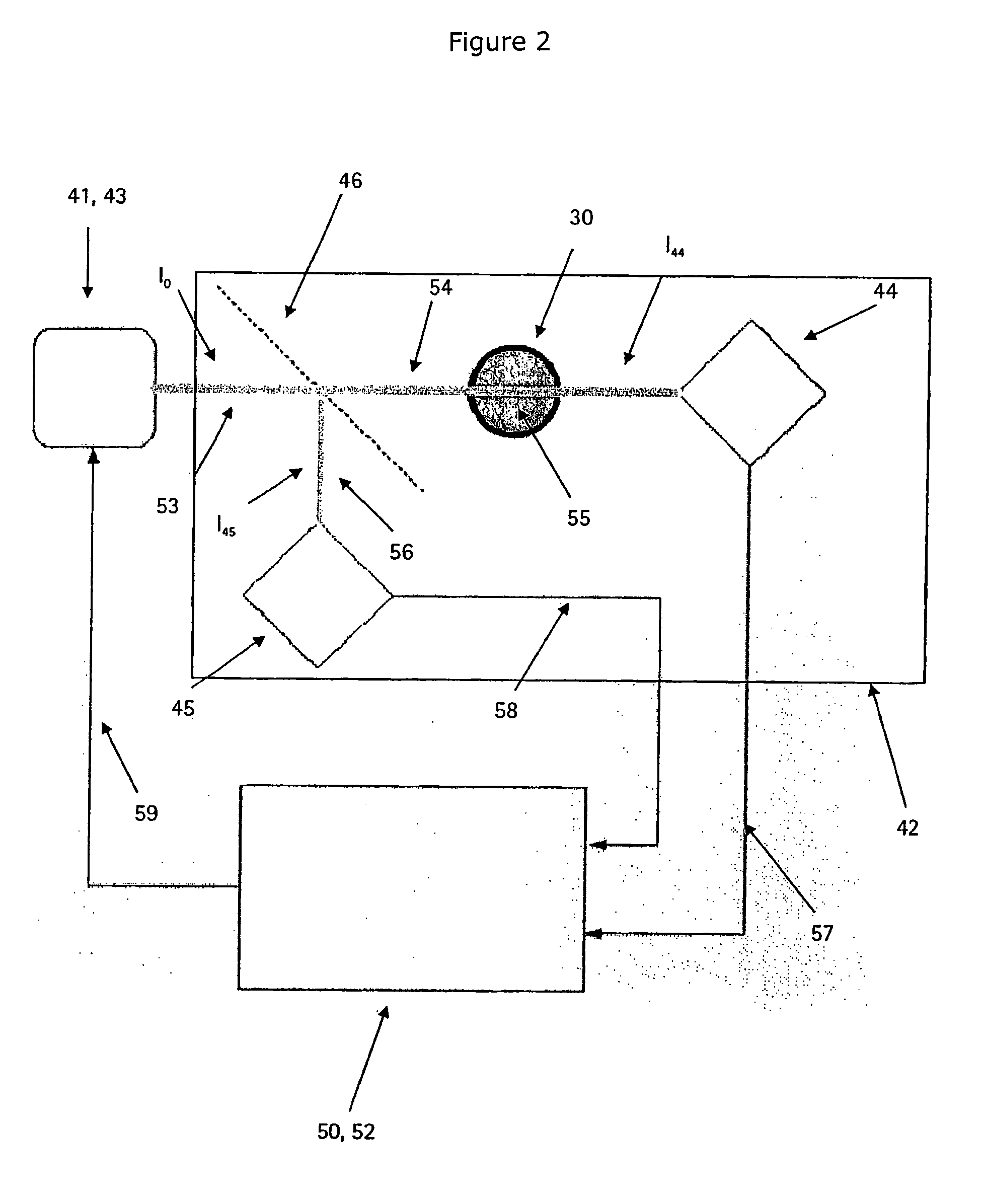

Osmotic desalination process

InactiveUS20050145568A1High yieldImprove concentrationSolvent extractionGeneral water supply conservationPresent methodDesalination

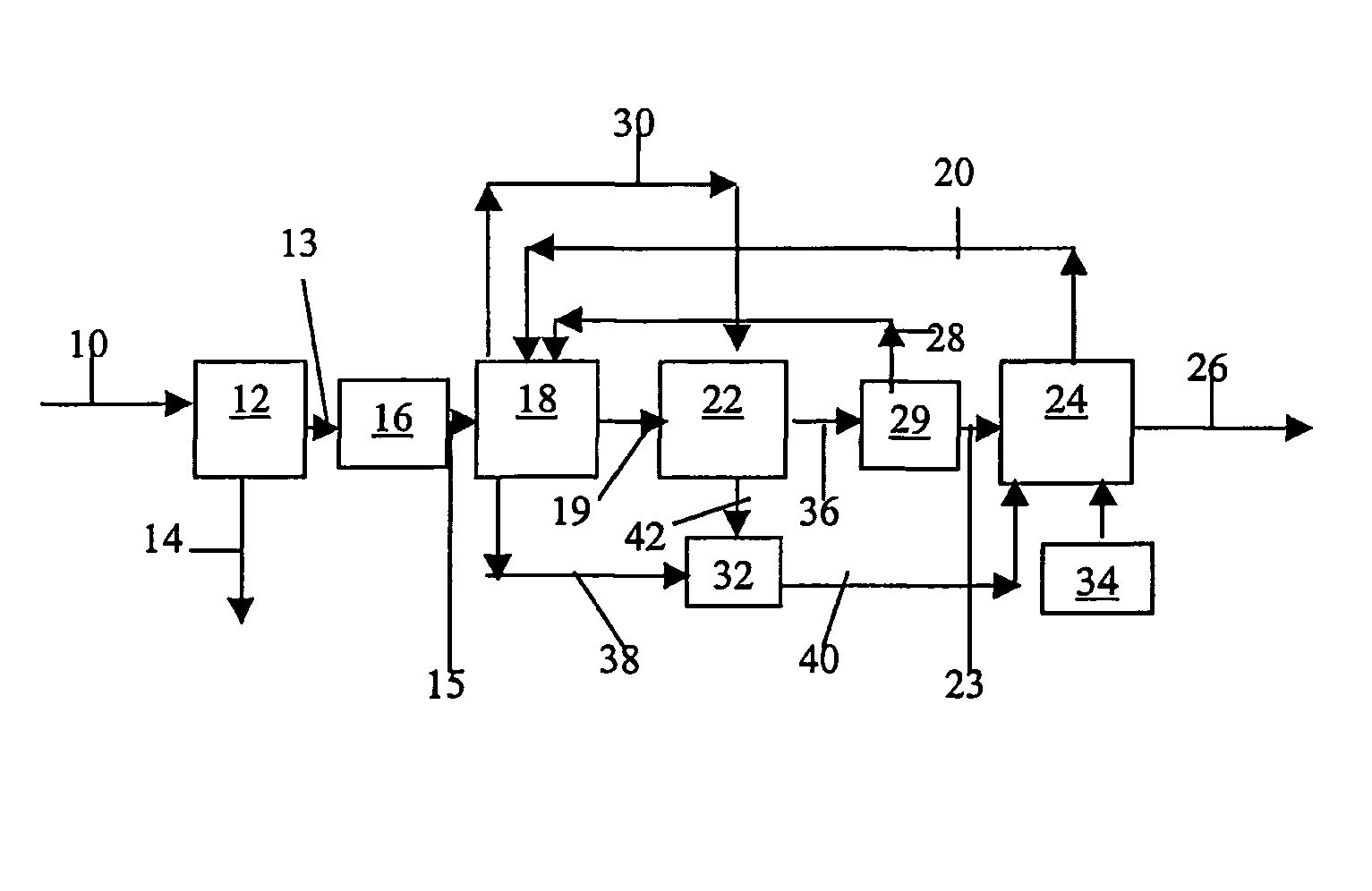

An energy efficient desalination process that does not produce waste products involves the extraction of water from a first solution, such as seawater, by using a second concentrated solution to draw the water from the first solution across a semi-permeable membrane. By manipulating the equilibrium of the soluble and insoluble species of solute within the second solution in favor of the soluble species of the solute, a saturated second solution can be used to generate osmotic pressure on the first solution. Also, by adjusting the equilibrium in favor of the less soluble species after the water has been drawn from the first solution, a portion of the solute can easily be precipitated out. Heating the second solution decomposes the solute into its constituent gasses. The constituent gasses and precipitated solute may be recycled through the process to affect the changes in equilibrium and eliminate waste products. Additionally, by using the waste steam from industrial sources and a heat pump to effectively distribute heat through the present method, the present method exhibits greater energy efficiency than prior art methods.

Owner:YALE UNIV

Flat capacitor for an implantable medical device

InactiveUS6699265B1Liquid electrolytic capacitorsCapacitor terminalsCapacitanceSemipermeable membrane

One embodiment includes a capacitor having a first anode stack having a first number of anode foils, a second anode stack having a second number of anode foils, where the first number of anode foils is different than the second number of anode foils. Another aspect provides a capacitor having a case having a curved interior surface, and first, second, and third capacitor modules that confront the curved interior surface of the case. One aspect provides a capacitor having one or more anodes and a cathode structure comprising a plurality of integrally connected cathode plates, the cathode structure having a serpentine shape, interweaving under and over each of the one or more anodes. One aspect provides a feedthrough assembly having an electrically conductive member dimensioned to extend at least partially through a feedthrough hole of a case of the capacitor, the conductive member having a passage therethrough. One aspect provides a capacitor having a first stack of capacitive elements a second stack of capacitive elements, wherein the first and second stacks are enclosed in separate compartments of a capacitor case that electrically isolate the electrolytes of each stack from one another. One aspect provides a capacitor case including a portion having opposing interior and exterior surfaces, with the portion having a hole; and a semi-permeable membrane adjacent the hole to regulate passage of fluids through the hole.

Owner:CARDIAC PACEMAKERS INC

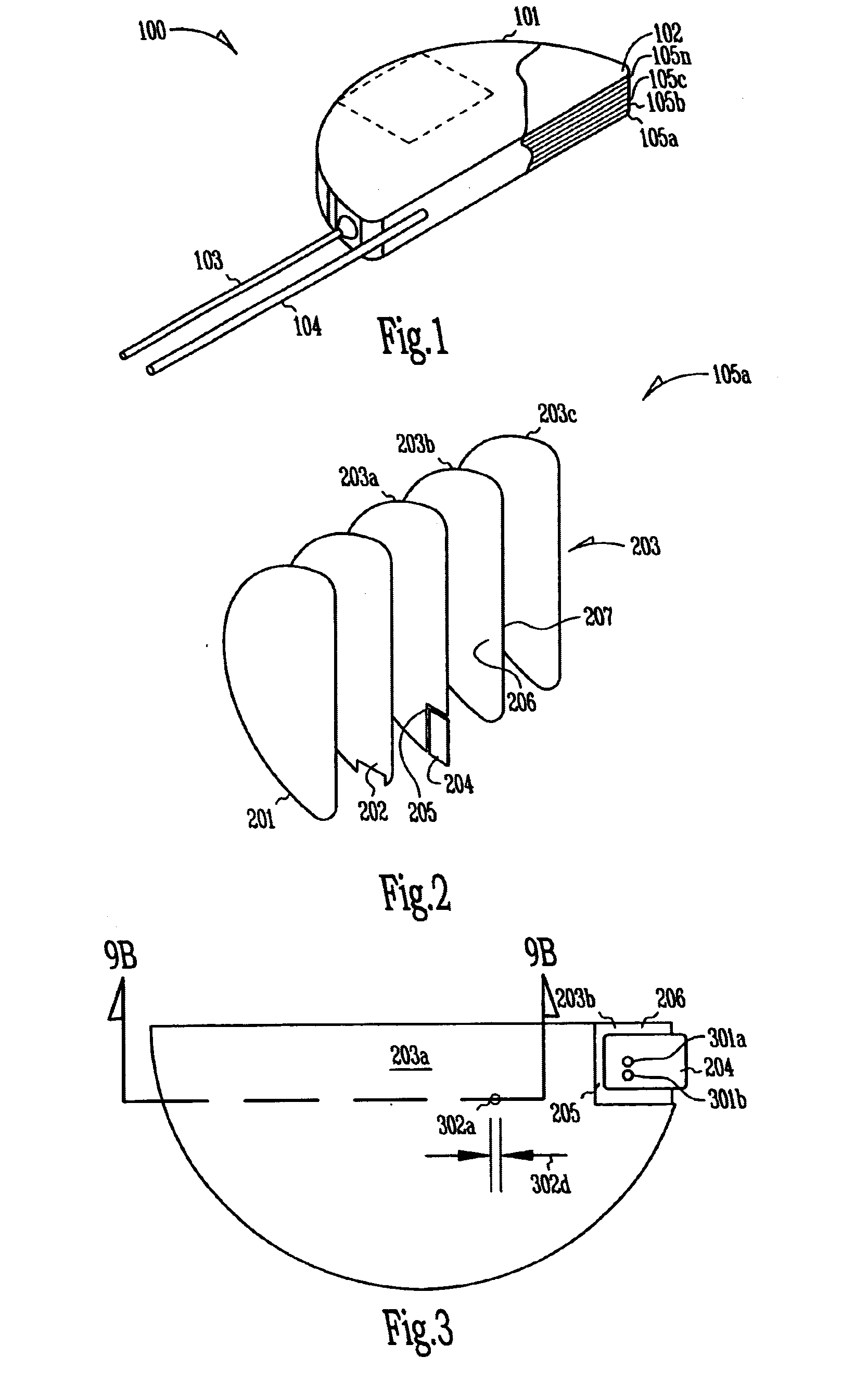

System for treating tissue swelling

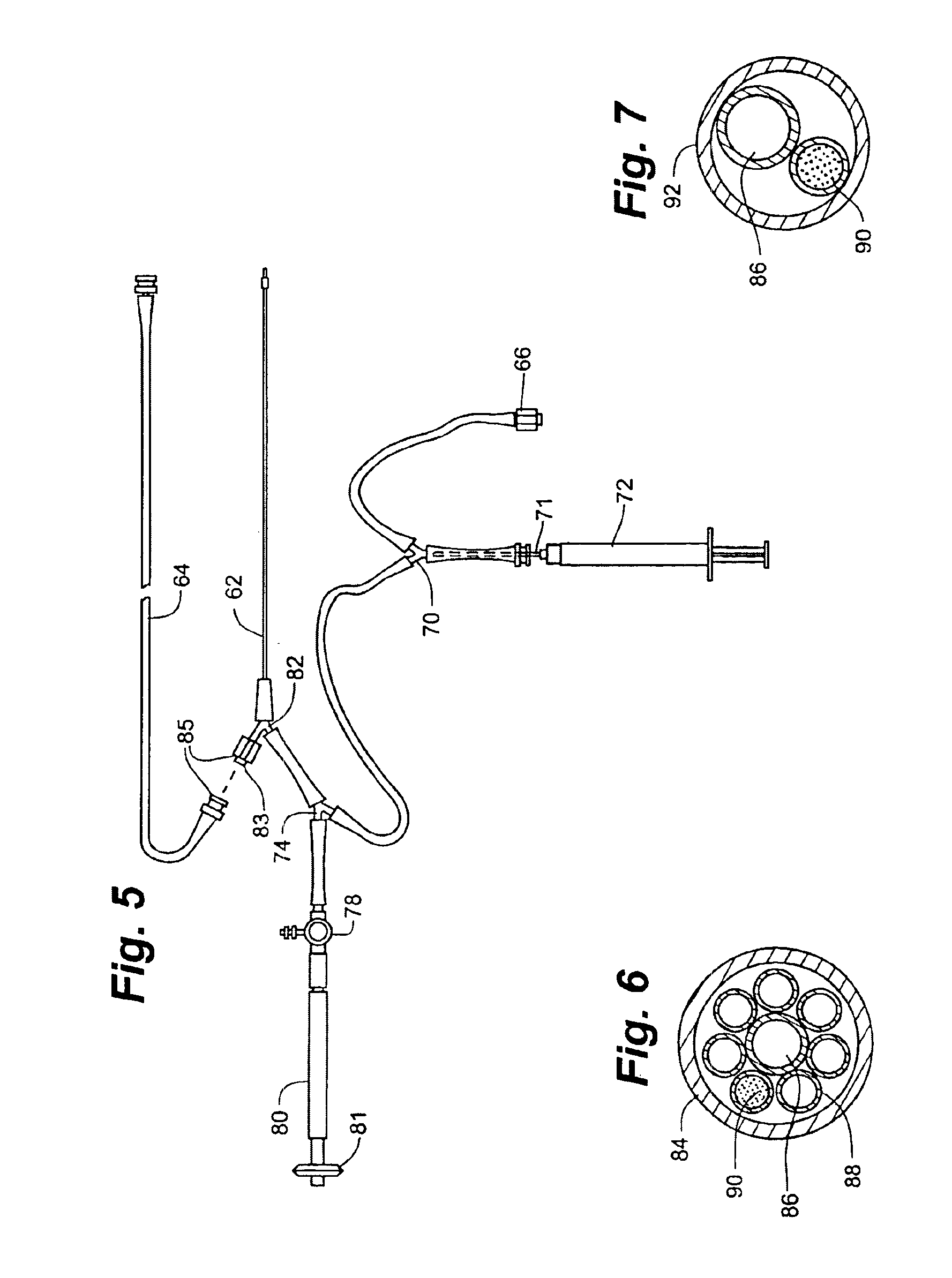

A system and method for performing site specific therapy to alleviate tissue swelling, involving the placement and use of recovery catheters having semipermeable membranes adapted to recover bulk fluid or fluid components from a tissue site. Fluid recovery can be accomplished by the delivery of a hydratable medium to the membranes, under conditions suitable to permit fluid or components to pass through the membranes in order to hydrate the medium, which is then removed from the tissue site. The method and system can also include the use of components for monitoring the progress of the system, and components for introducing a recovery catheter to a tissue site.

Owner:TWIN STAR MEDICAL

Osmotic pump drug delivery systems and methods

InactiveUS6471688B1Avoid mixingMedical devicesPharmaceutical delivery mechanismTreatment effectAnalgesics effects

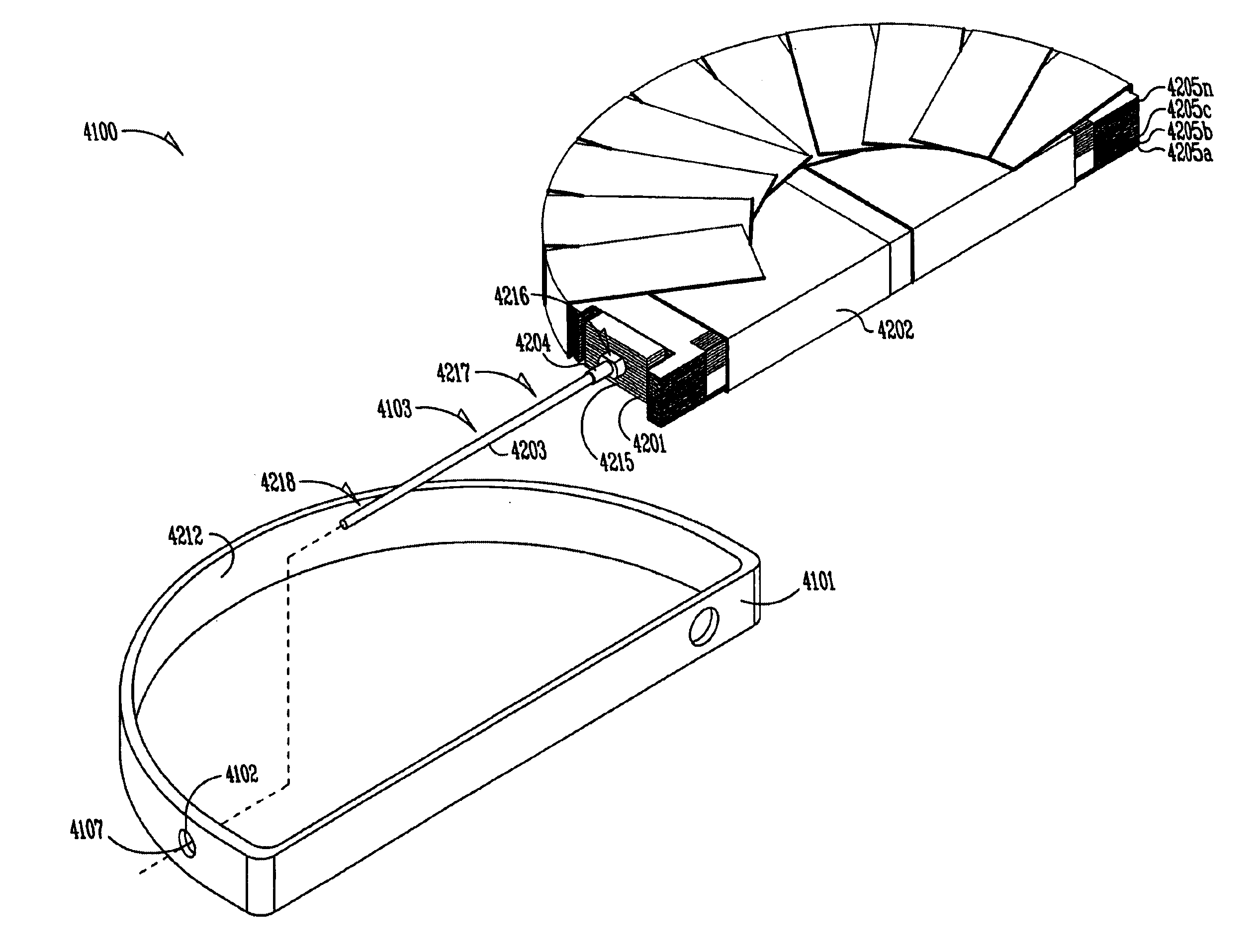

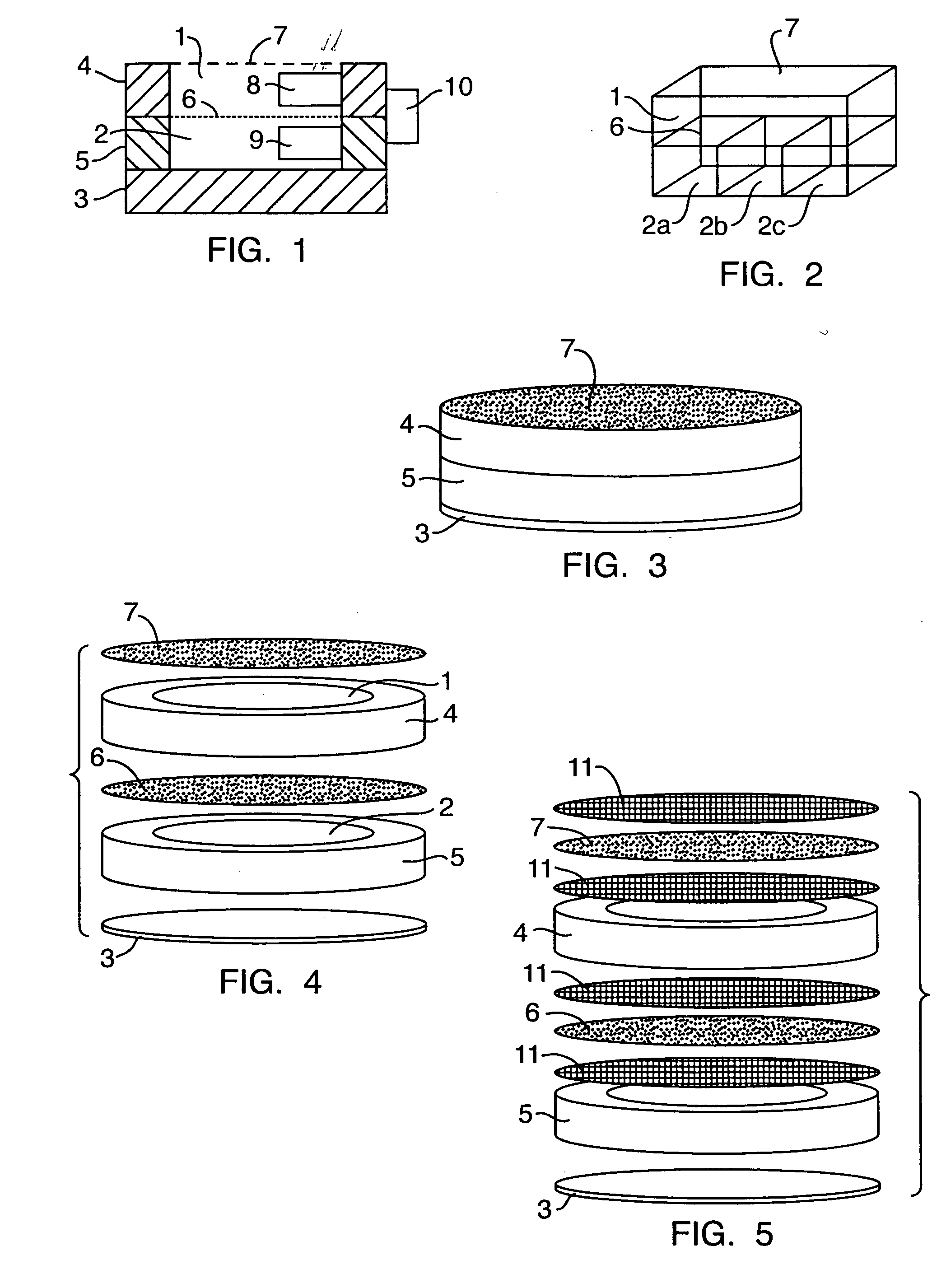

Implantable osmotic pump devices and systems include multiple osmotic pumps and / or semipermeable membranes to extend the useful life cycle and functionality of the drug delivery system. Use of an implantable system including multiple implantable osmotic pumps allows different drugs to be administered from the same implanted system. One or more of the semipermeable membranes of the system may be initially sealed by an overlying impermeable membrane upon implantation of the system into the patient. When the patient develops a tolerance to a first drug or to a first dose of the first drug, the impermeable membrane may be breached, to expose the underlying semipermeable membrane to the osmotic pressure of the patient at the implant site. This causes the infusion rate to increase, thereby providing the patient with the needed relief and / or other desired therapeutic effect. In the case of a multiple pump system, breaching an impermeable membrane may cause the infusion of a second drug. The second drug may potentiate a therapeutic effect (such as an analgesic effect) of the first drug, as is the case with Sufentanil and Clonidine.

Owner:MICROSOLUTIONS

Porous substrates, articles, systems and compositions comprising nanofibers and methods of their use and production

Porous nanofiber bearing substrate materials are provided having enhanced surface area for a variety of applications including as electrical substrates, semipermeable membranes and barriers, structural lattices for tissue culturing and for composite materials, and the like.

Owner:ONED MATERIAL INC

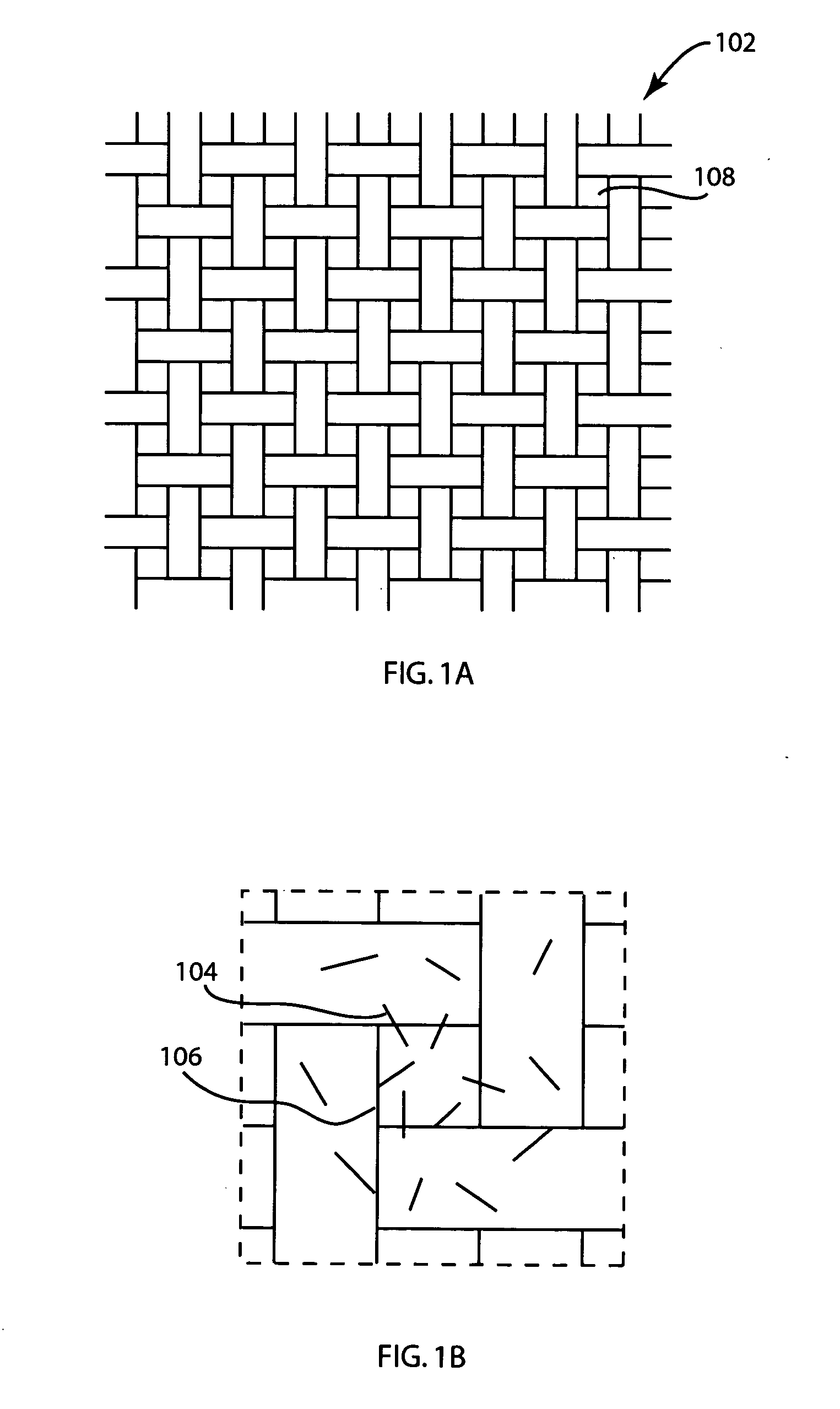

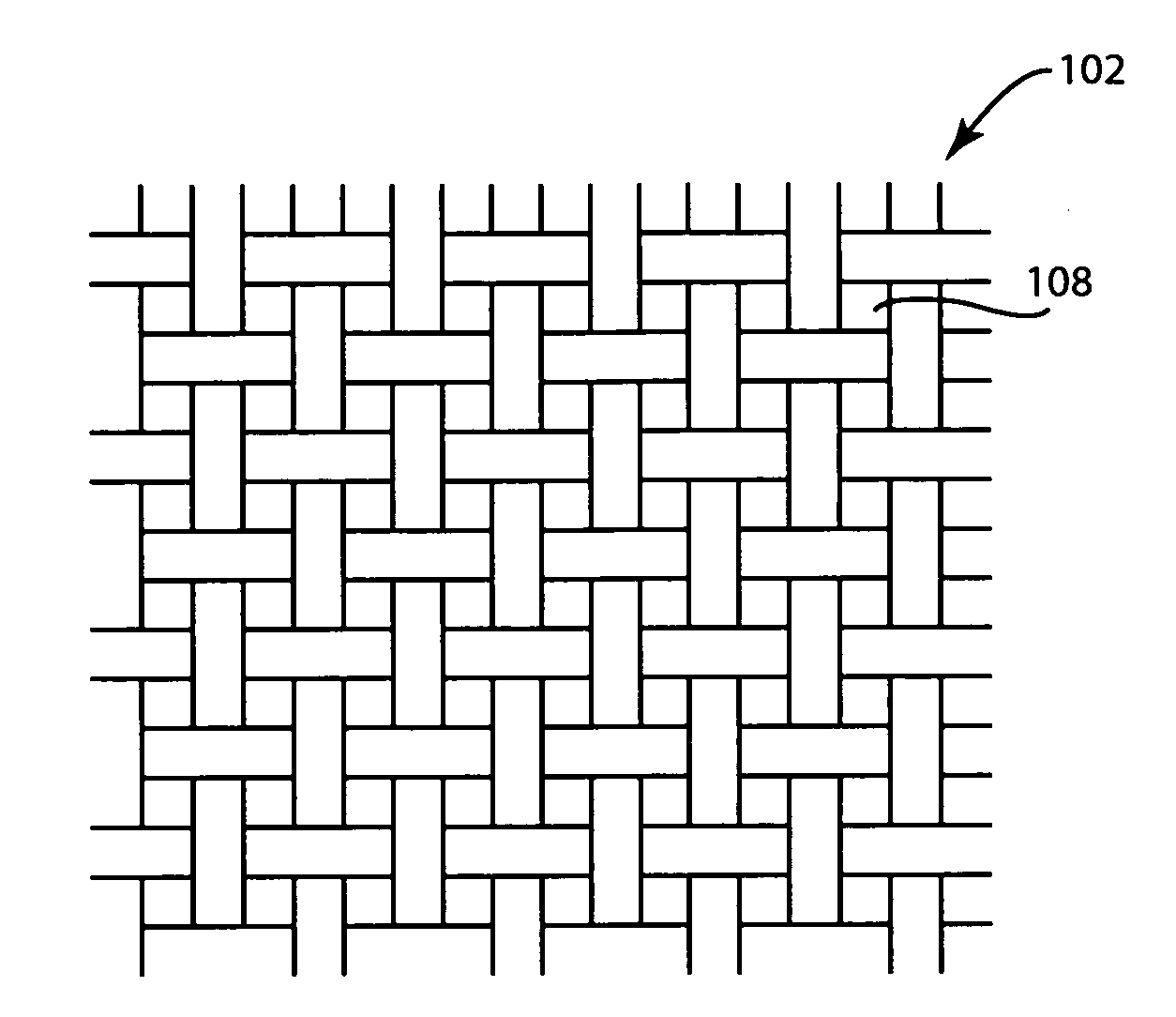

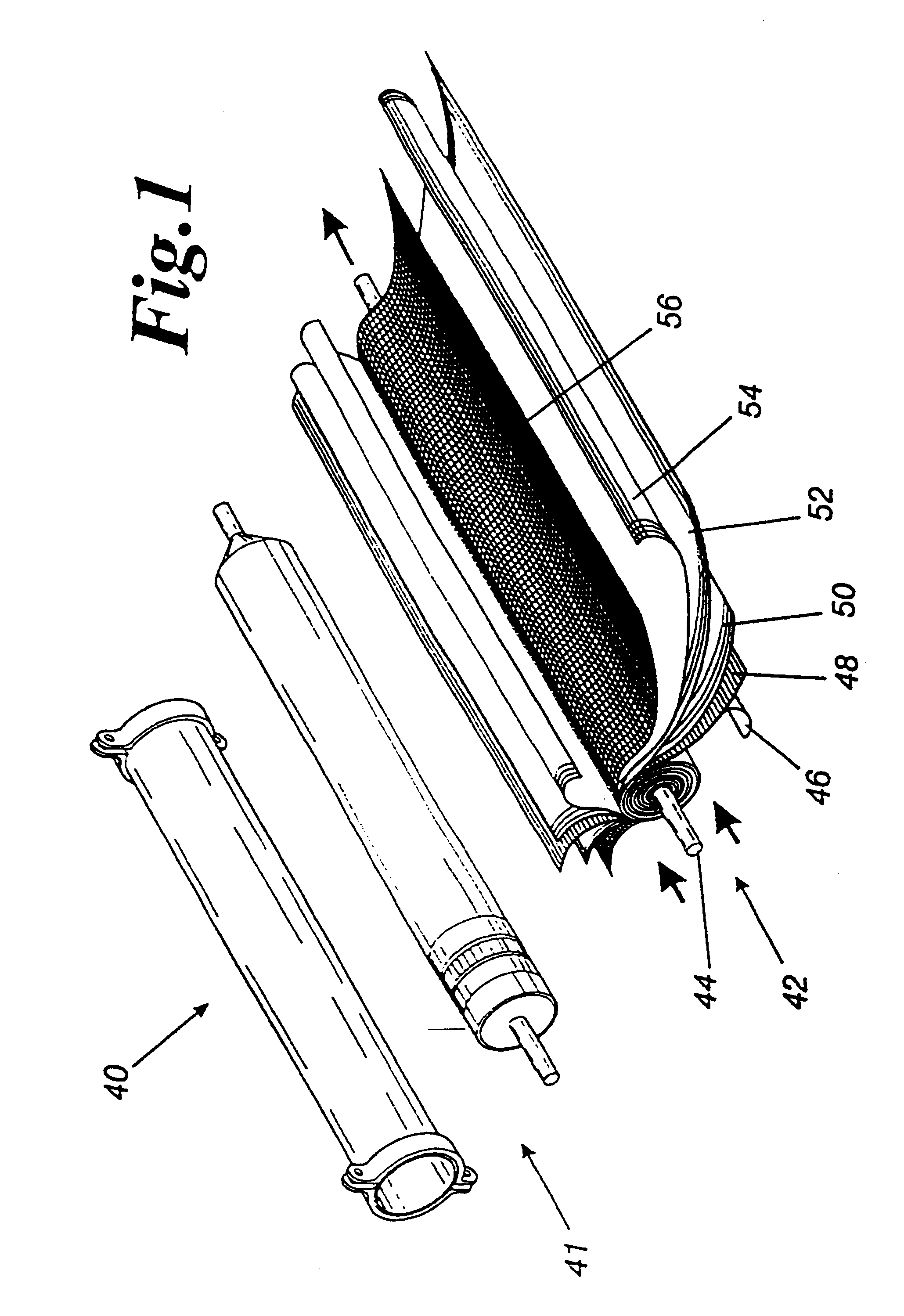

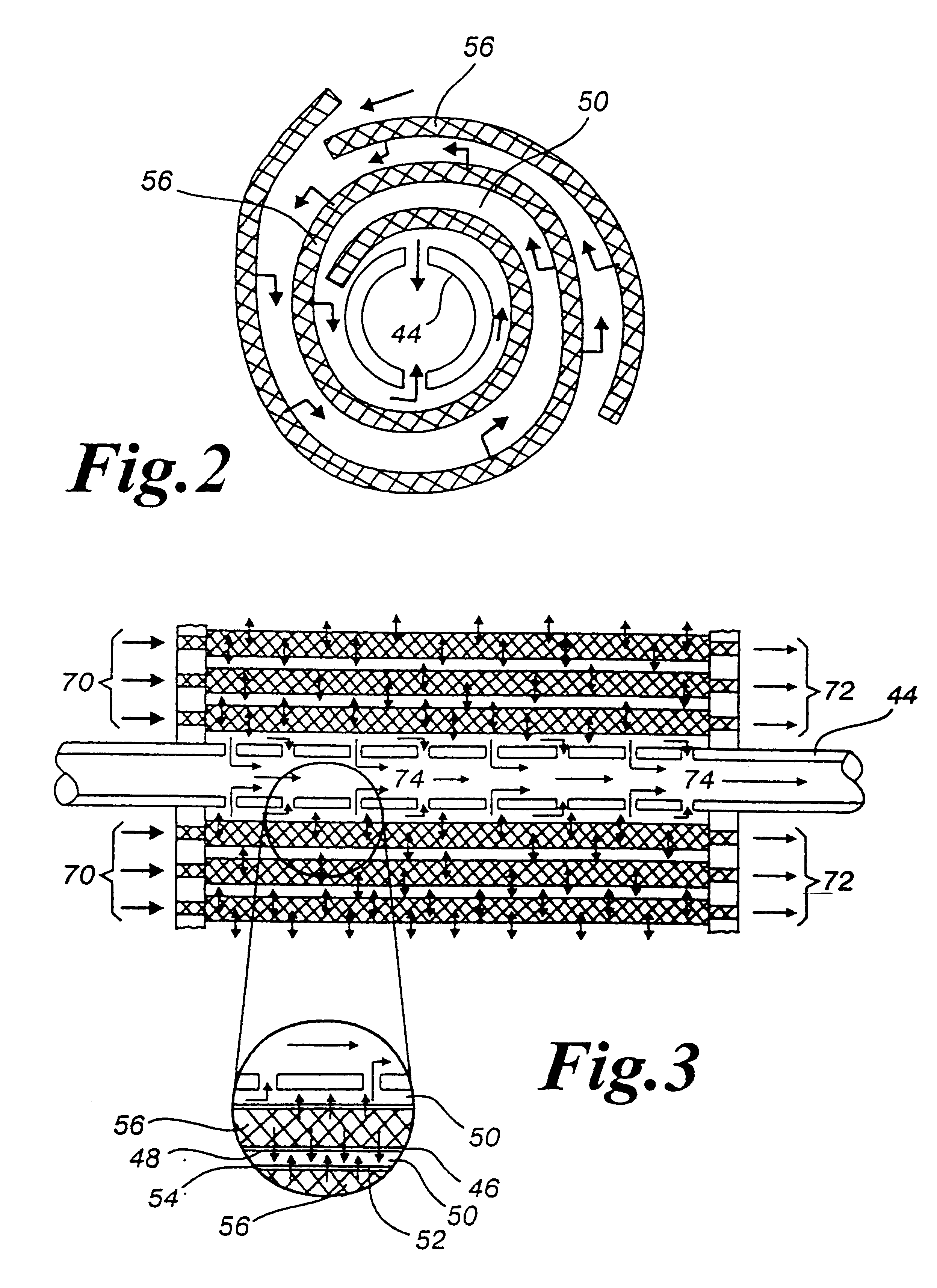

Cross flow filtration materials and cartridges

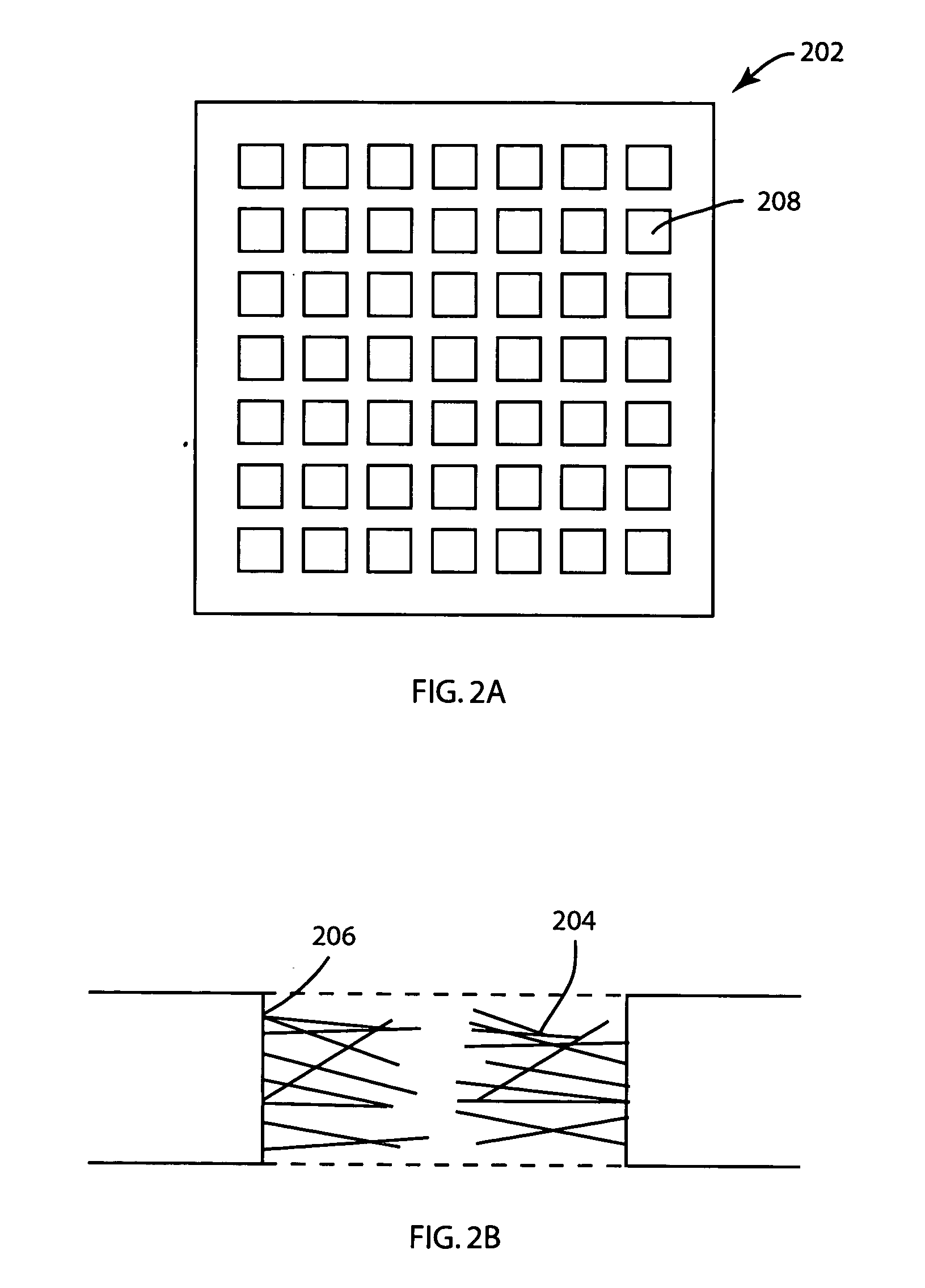

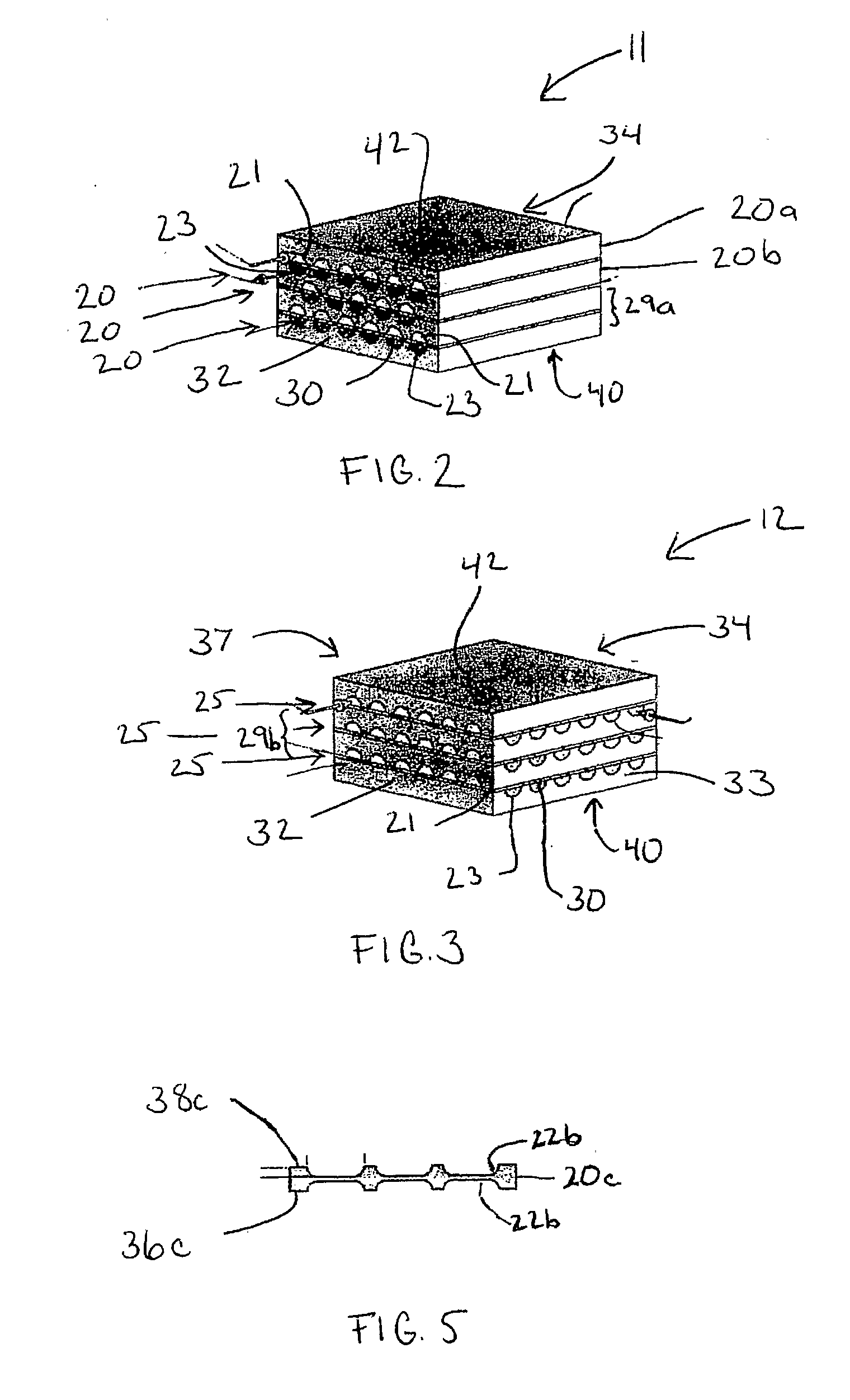

InactiveUS7048855B2Reduced operating requirementsAvoid problemsSemi-permeable membranesOther chemical processesFiberCross-flow filtration

Cross flow filtration cartridges are made using semipermeable membrane of sheet formation that was cast upon an integral polymeric fibrous support material which exhibits excellent permeate flow in the plane thereof and serves as both backing material and permeate carrier. A fibrous support having a thickness between about 0.4 mm and about 2 mm and at least one surface region with a mean pore size no greater than about 300 microns has a semipermeable membrane cast in situ thereupon from a liquid solution. After gelling to form a polymeric semipermeable membrane, the product is spirally wound about a porous tube in association with feed-passageway-providing sheet material, but in the absence of any separate permeate carrier, to form an effective cross-flow filtration cartridge wherein the feed flow may be spiral and the permeate discharge through one of the side edges.

Owner:GE OSMONICS INC

Methods and implantable devices and systems for long term delivery of a pharmaceutical agent

InactiveUS20040111080A1Improve delivery ratePharmaceutical delivery mechanismMedical devicesSemipermeable membraneImplanted device

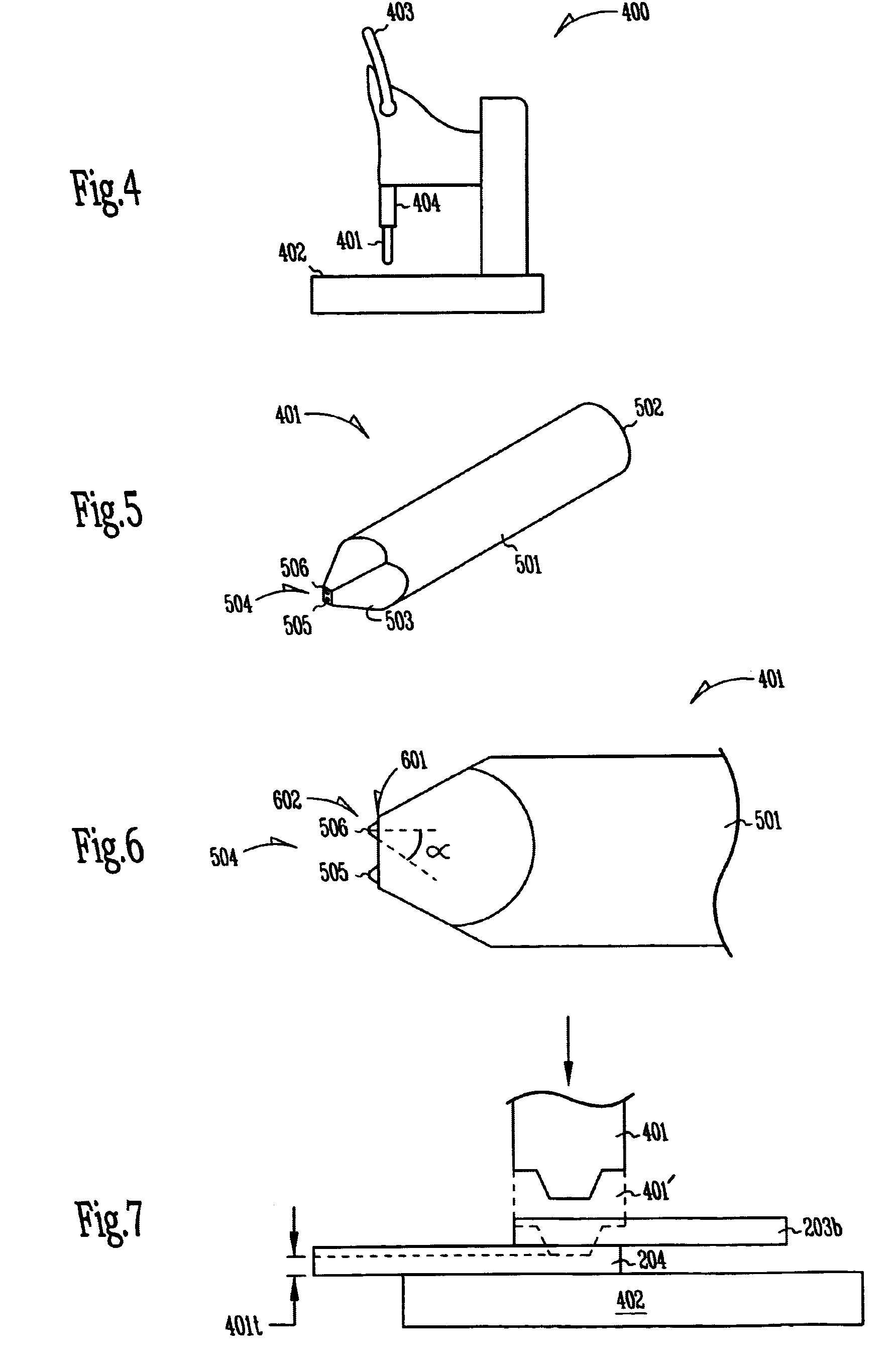

Implantable devices and osmotic pump and catheter systems for delivering a pharmaceutical agent to a patient at selectable rates include an impermeable pump housing and a moveable partition disposed within the housing, the partition dividing the housing into an osmotic driving compartment having an open end and a pharmaceutical agent compartment having a delivery orifice. A plurality of semi permeable membranes may be disposed in the open end of the osmotic driving compartment and a number of impermeable barriers may seal selected ones of the plurality of semi permeable membranes from the patient until breached. Breaching one or more of the impermeable barriers increases the surface area of semi permeable membrane exposed to the patient and controllably increases the delivery rate of the pharmaceutical agent through the delivery orifice and catheter. Each of the plurality of semi permeable membranes may have a selected surface area, composition and / or thickness, to allow a fine-grained control over the infusion rate while the pump is implanted in the patient.

Owner:MICROSOLUTIONS

Method and device for monitoring analyte concentration by use of differential osmotic pressure measurement

InactiveUS20050154272A1Reduce decreaseSurface/boundary effectEndoradiosondesConcentrations glucoseBlood or Tissue

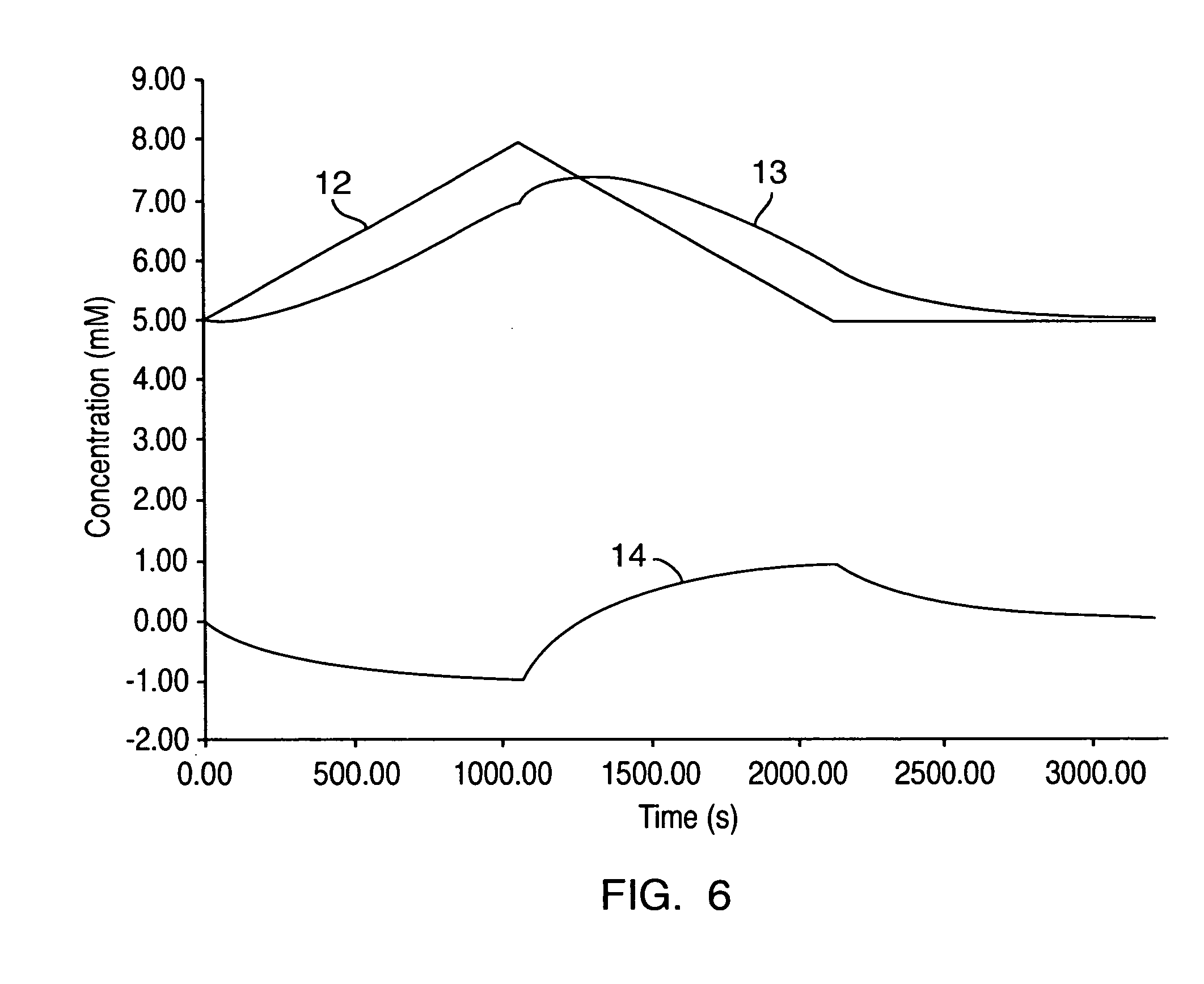

A method is provided for the determination of the concentration of compounds in body tissue and fluids. The method utilises two compartments containing reference solutions, which are separated from the sample by two different semi-permeable membranes, in a serial manner, whereby a difference in osmotic pressure occurs in the two compartments due to compounds, which can permeate one of the membranes, but not the other. The difference in osmotic pressure reflects the concentration of these compounds. The method is especially suited for analysis of the concentration of glucose in blood or tissue of diabetic patients, where a device is implanted underneath the skin of the patient and where the method is carried out by using the implanted device.

Owner:DANFOSS AS

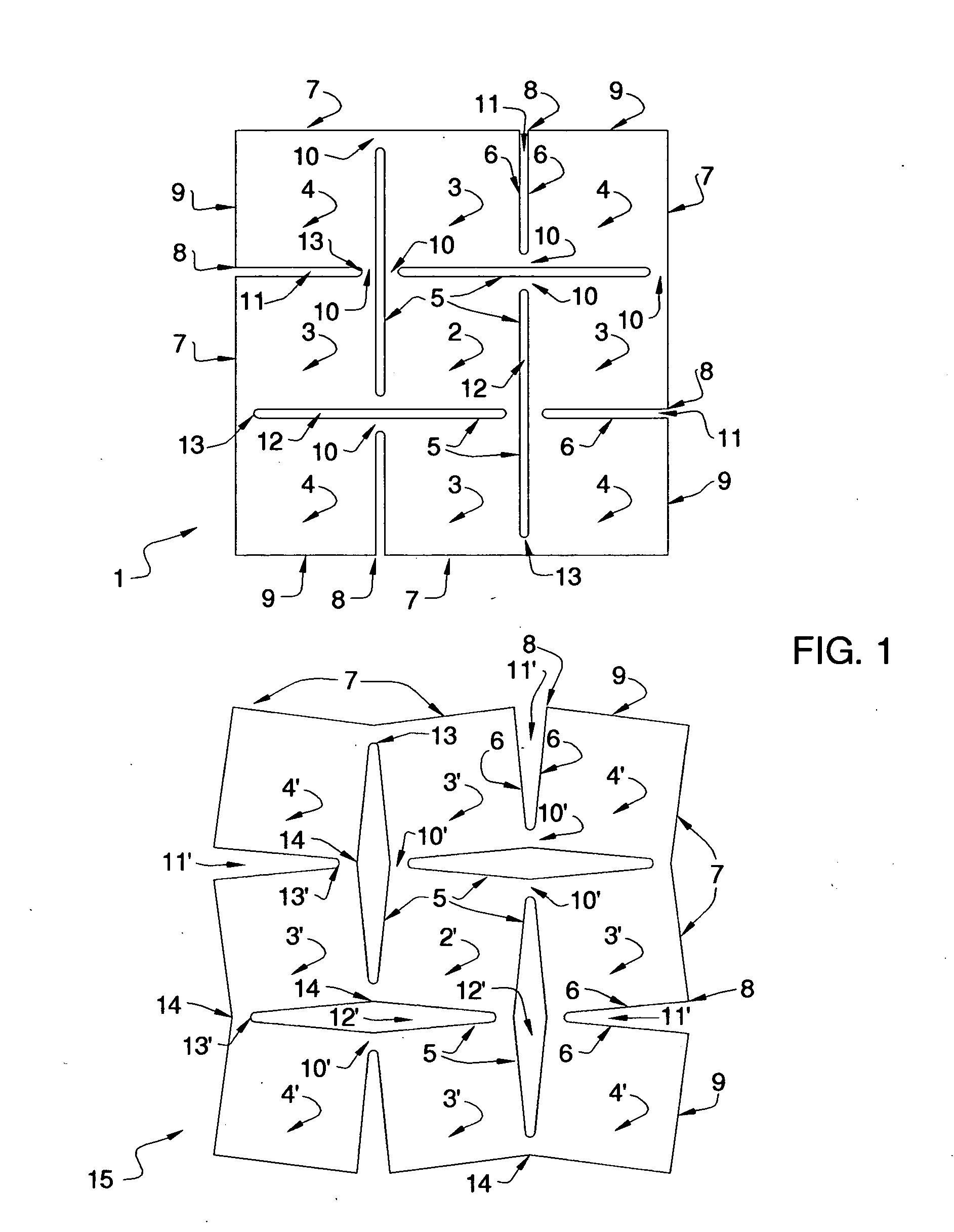

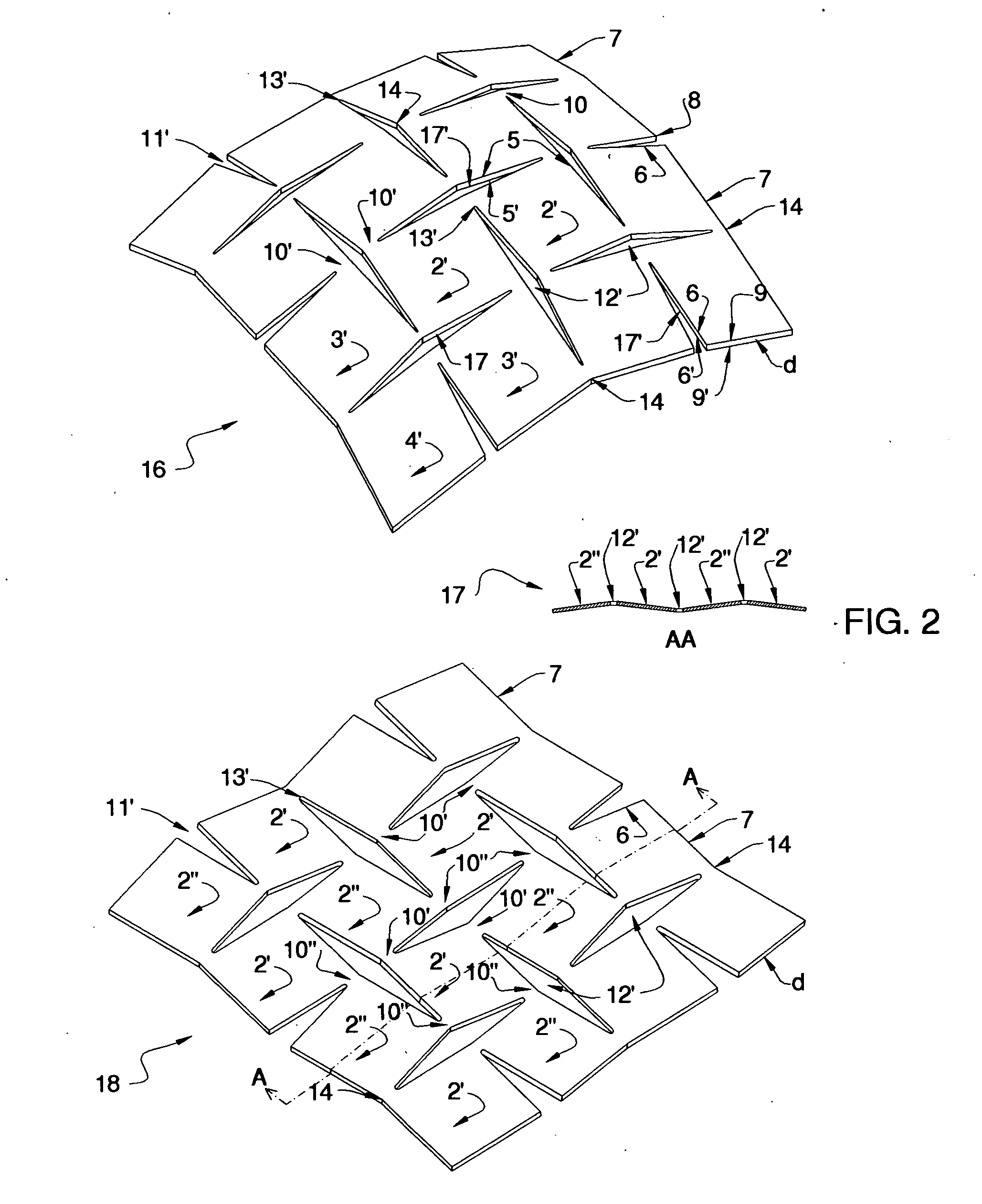

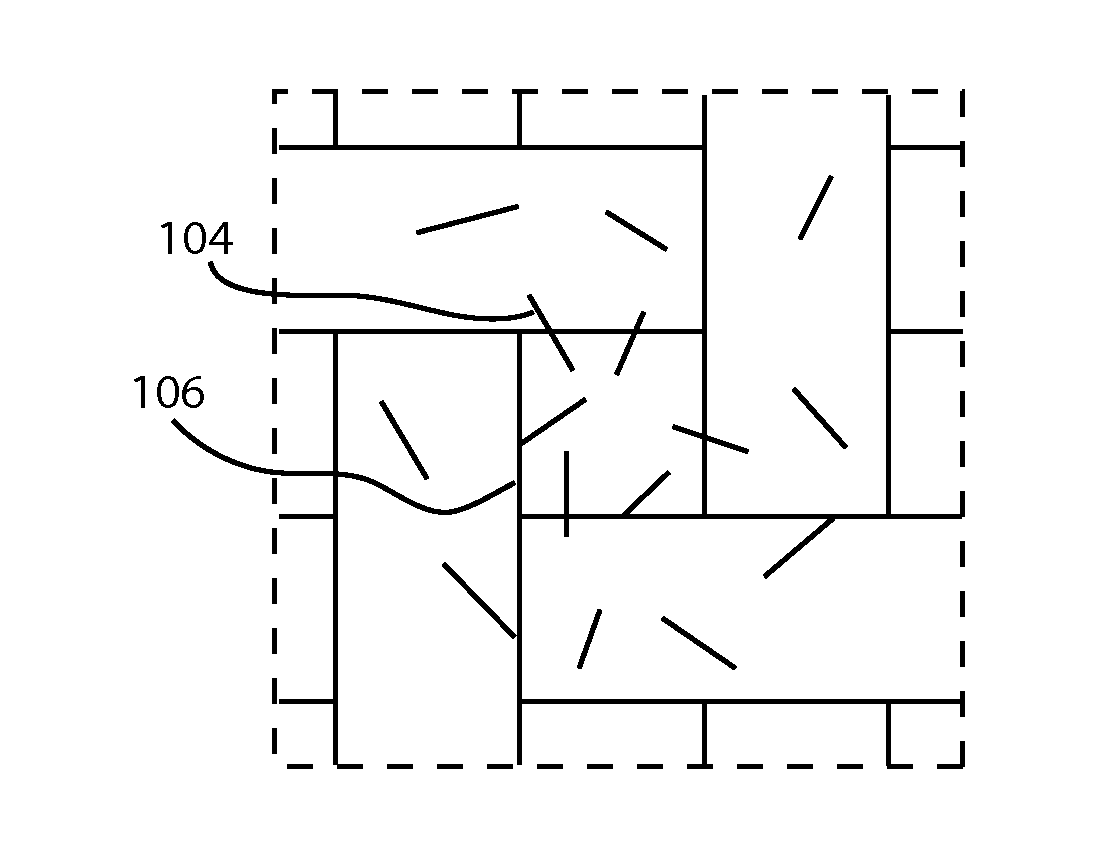

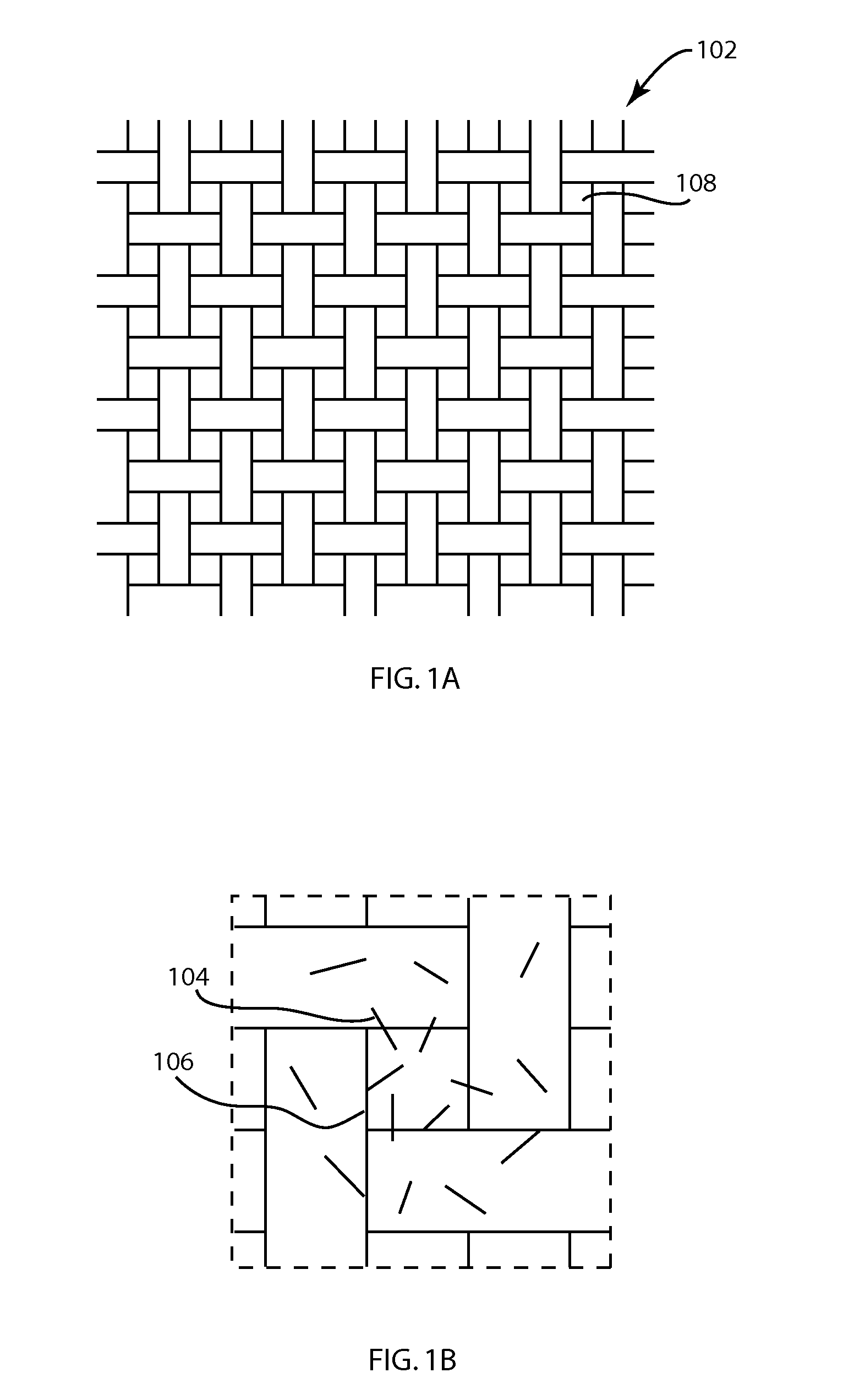

Multi-directional and variably expanded sheet material surfaces

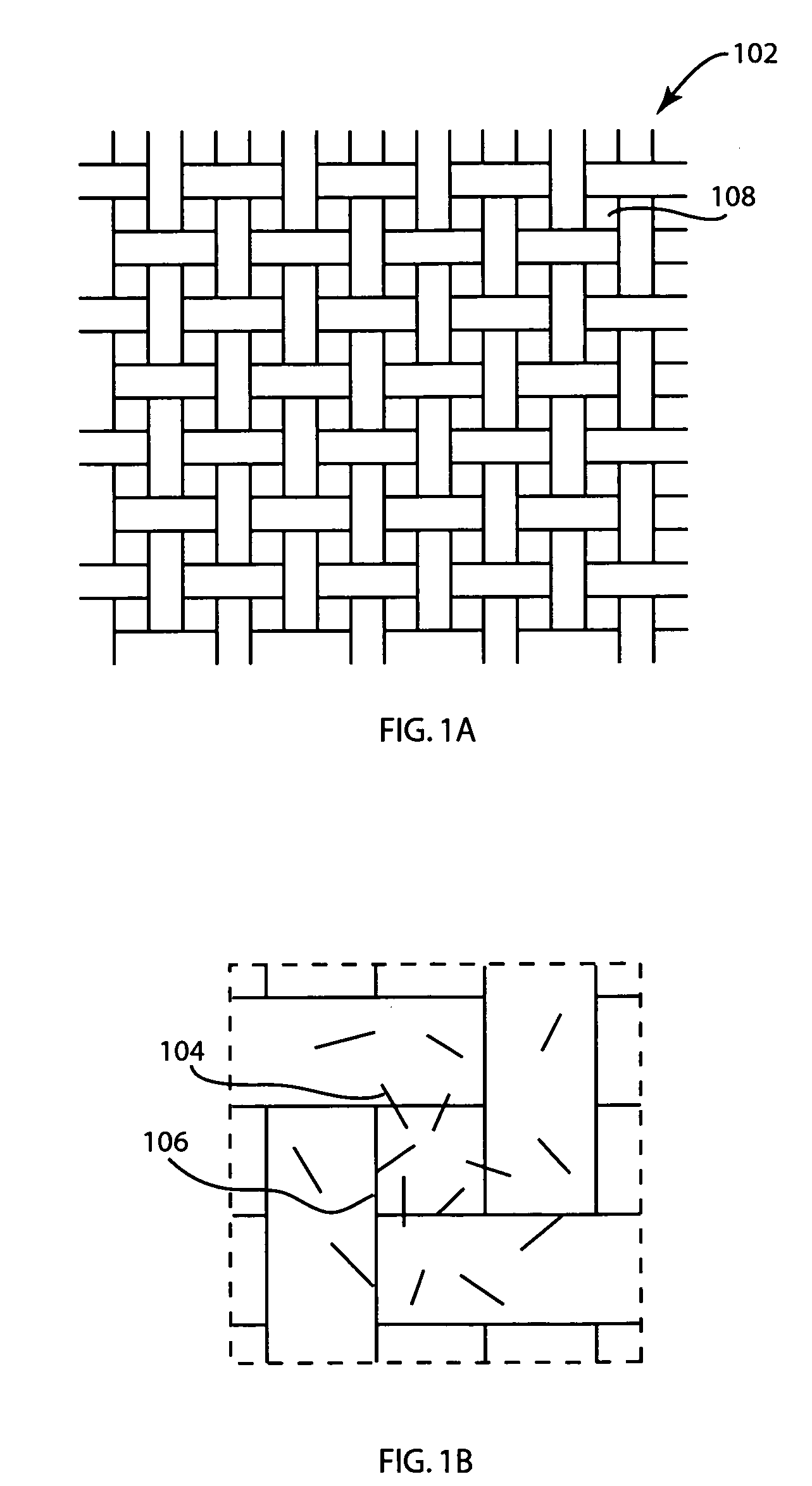

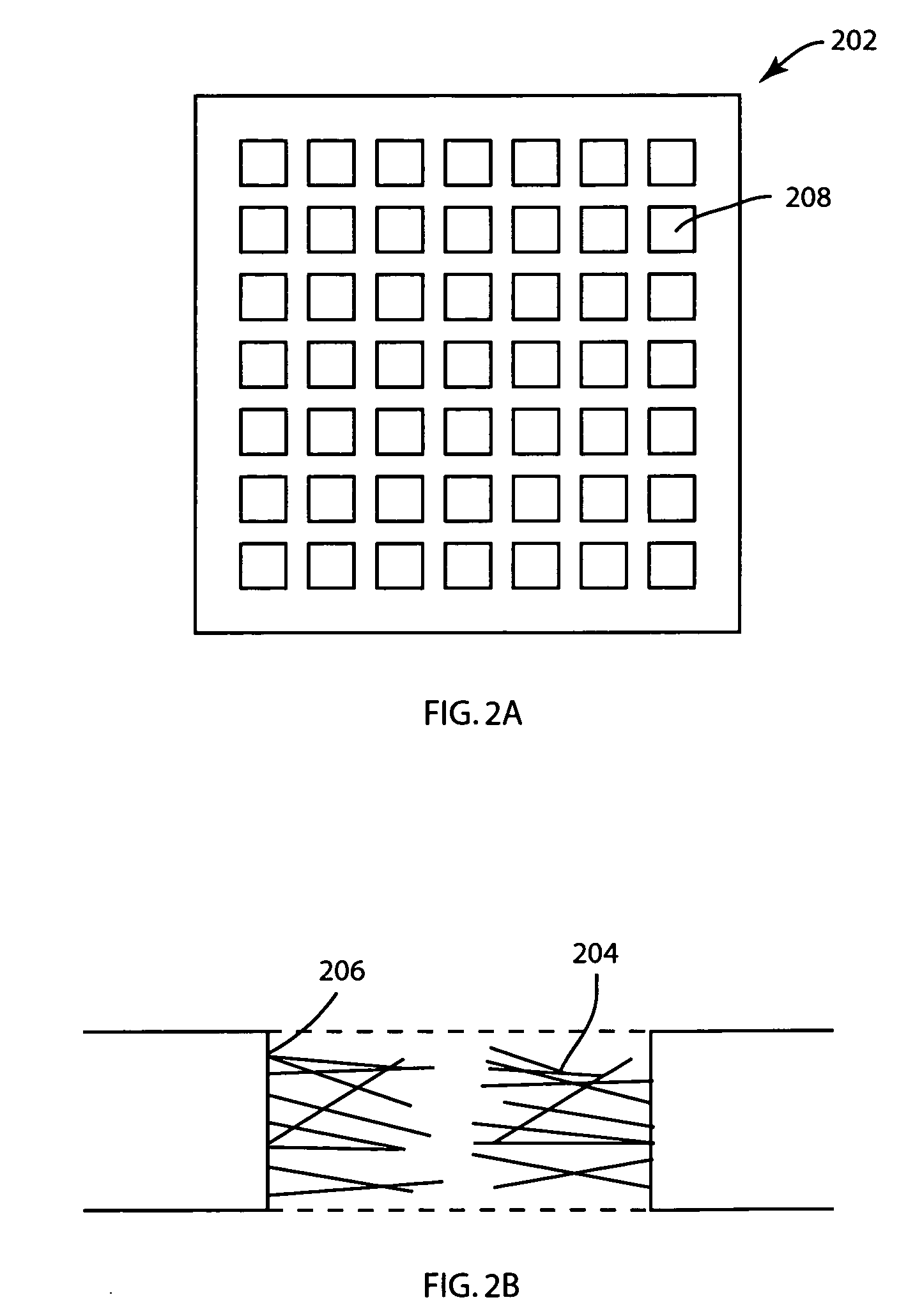

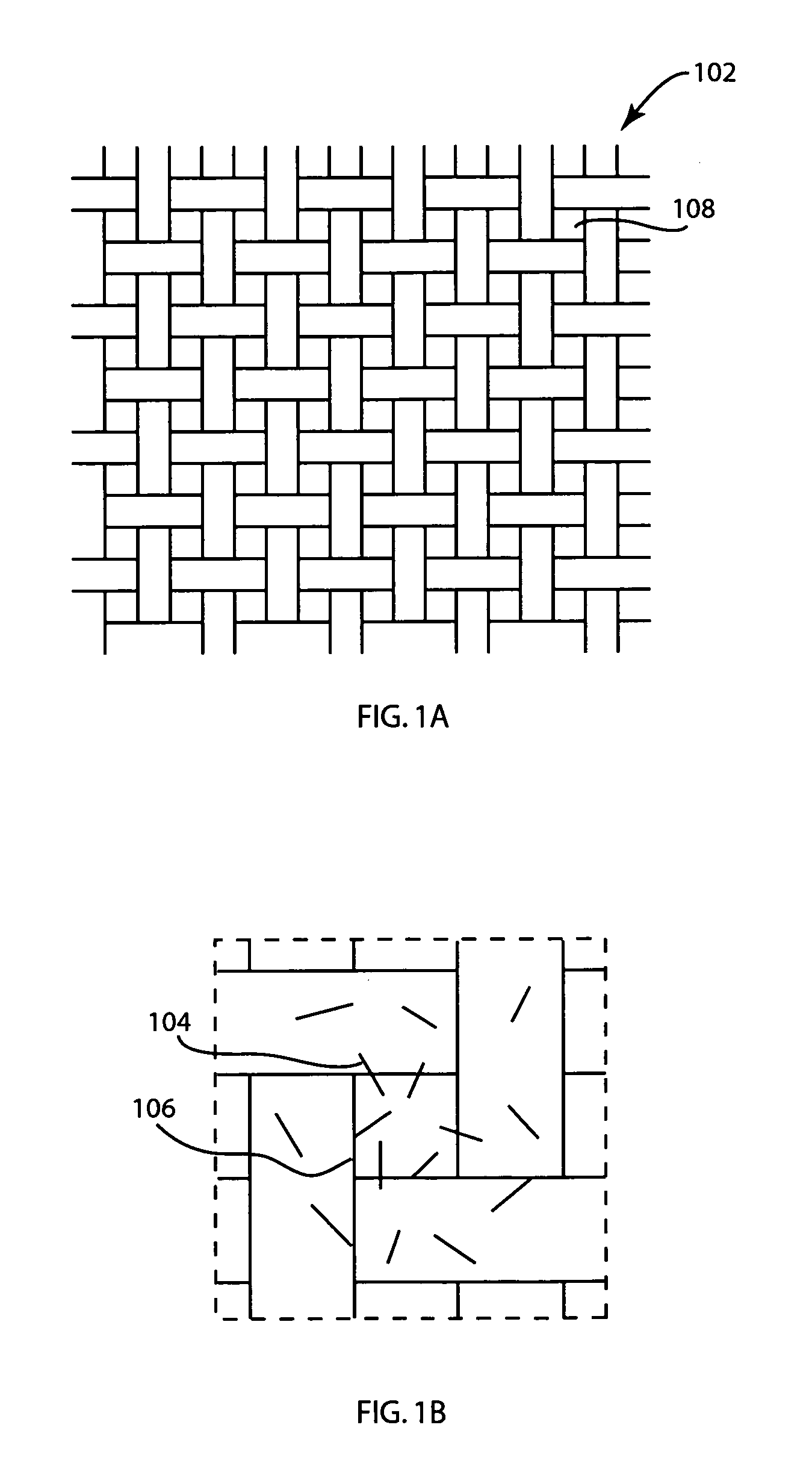

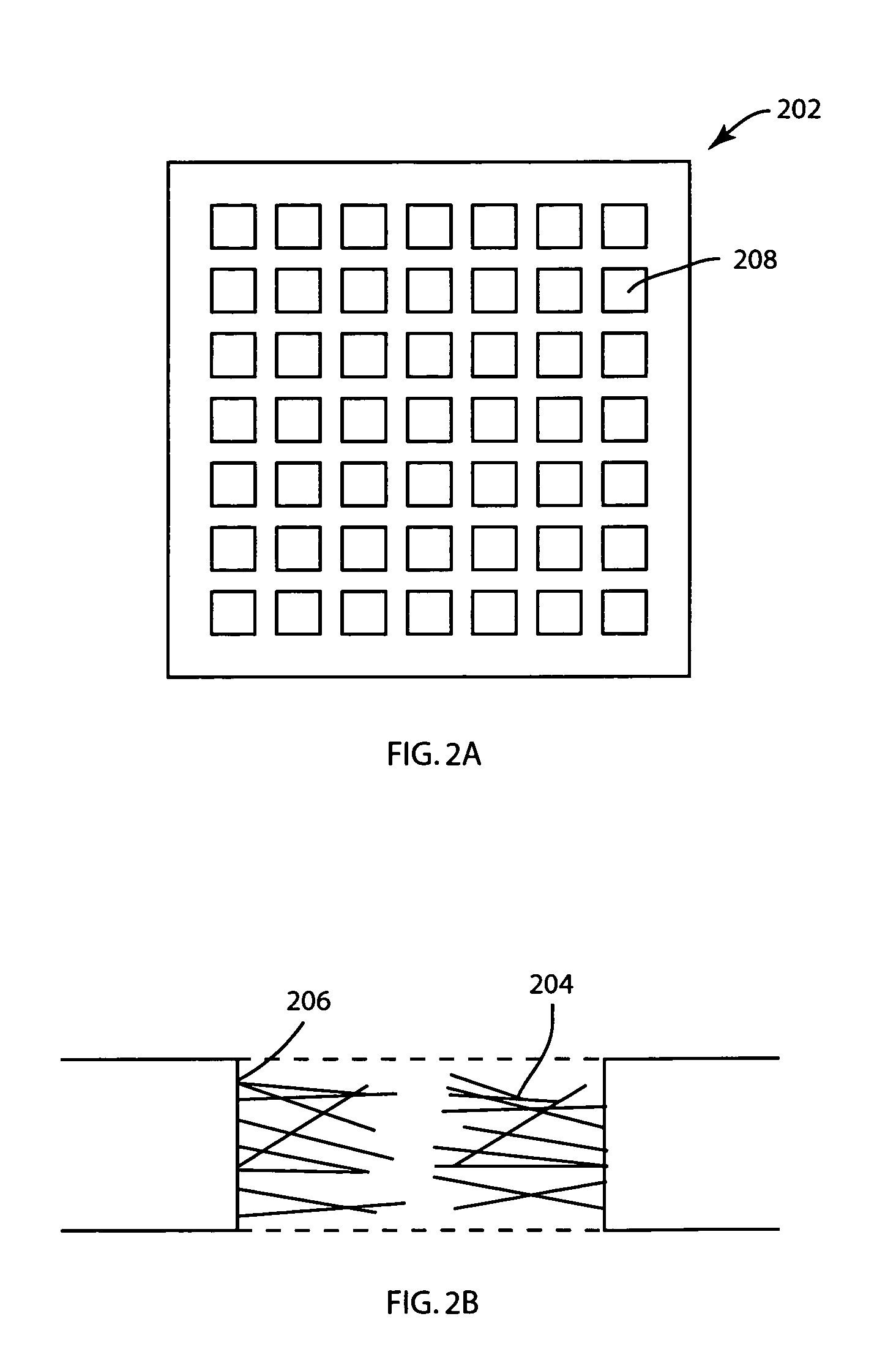

ActiveUS20070122590A1Efficient use ofIncrease surface areaPaper/cardboard articlesFloorsLaser cuttingNanoscopic scale

Expandable surfaces made from sheet materials with slits distributed on the surface of sheet material where the surfaces expand by application of force along or / and across the surface of sheet material. The unexpanded surfaces are flat sheets, or closed surfaces like cylinders, spheres, tubes, or custom-designed organic shapes marked with pre-formed or post-formed slit designs. The expanded surfaces can be single units or modules which can be attached to one another through various means. The sheet materials range from hard surfaces like metals, to softer materials like papers and plastics, or pliable materials like fabrics, rubbers, synthetic surfaces or bio-surfaces. The slits are arranged in patterns ranging from periodic, non-periodic to irregular designs. The slits can be straight, bent, curved or irregularly shaped with even or uneven spacing. Slitting can be achieved by digital cutting or punching devices like laser-cutting, water-jet cutting, digital punching, automated dies, etc. or pre-formed when casting the sheet material. Force can be applied manually with tools or through the use of machines and special set-ups. Applications range from architectural surfaces, walls, ceilings, panel systems, structures and sculpture. On a smaller scale, applications include containers, packaging material, fabrics and human wear. On micro- to nano-scale, applications range from expandable surfaces for gauzes, band-aids, stent designs, skin grafts, semi-permeable membranes and micro-filters for various industries including purification of fluids and chemical substances.

Owner:LALVANI HARESH

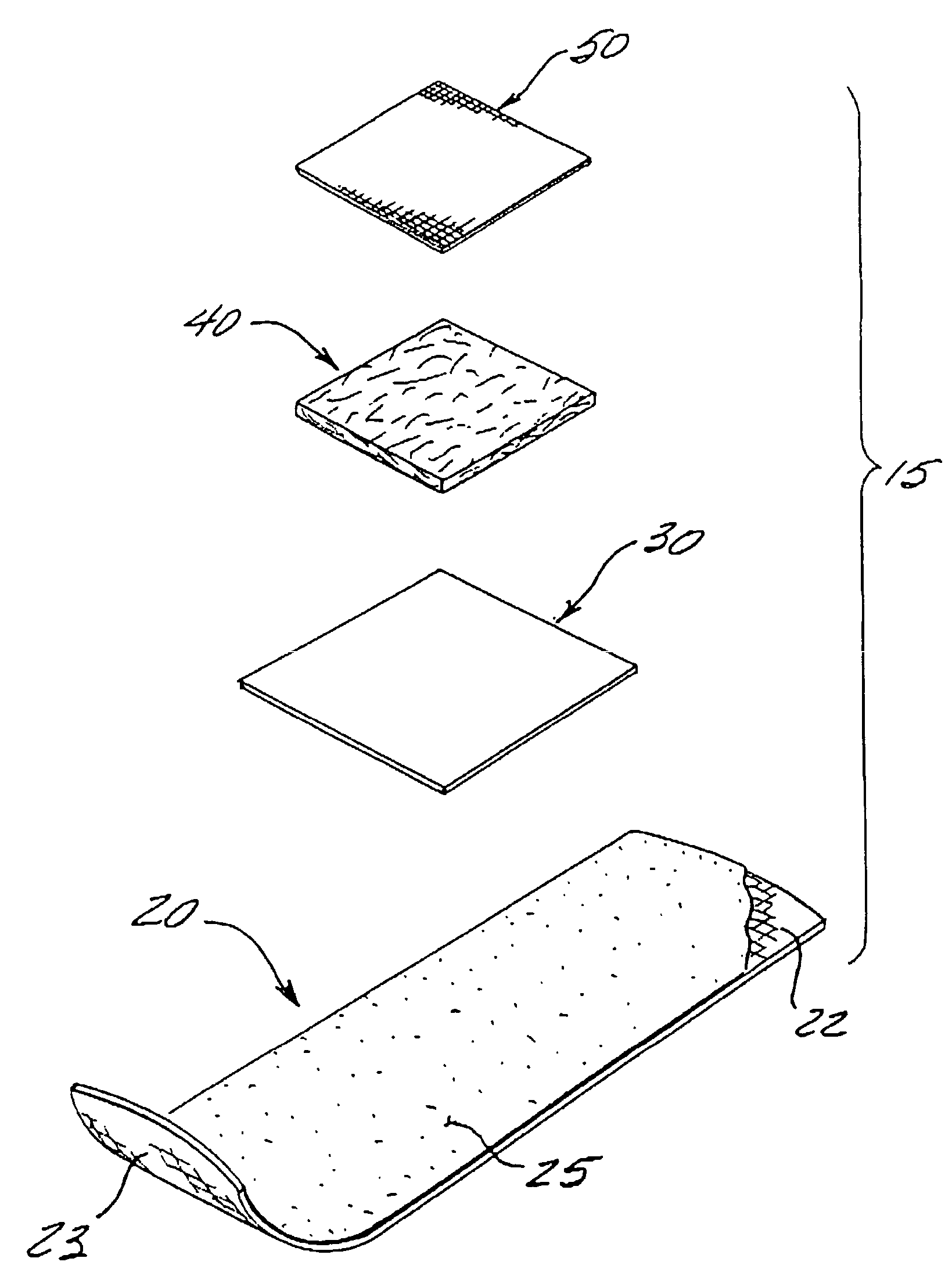

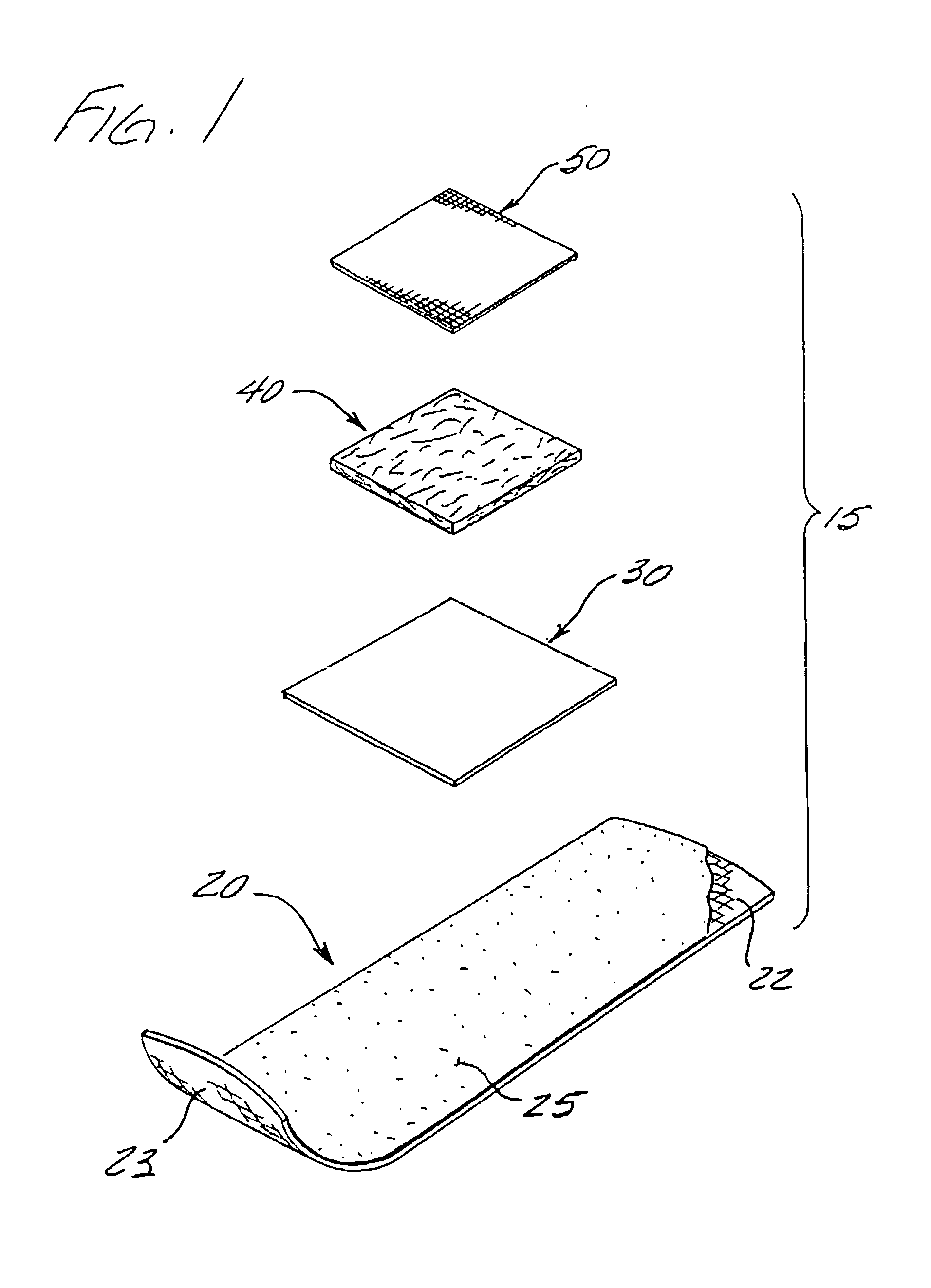

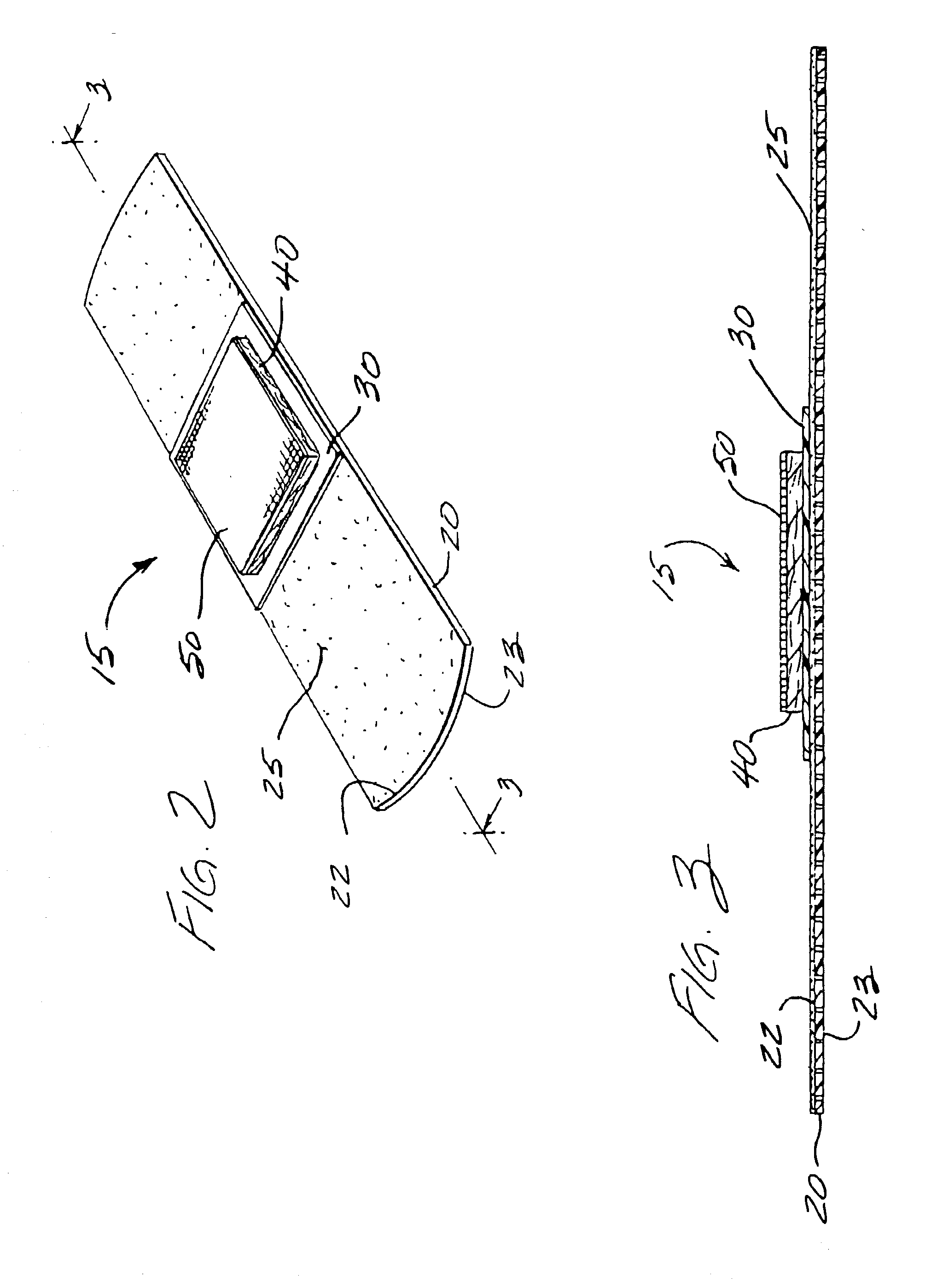

Adhesive bandage having a selectively placed layer

InactiveUS20040002676A1Good recovery environmentReduce the possibilityAdhesive dressingsAbsorbent padsCushioningContact pad

An adhesive bandage having a backing material; a selectively placed layer; an adhesive; and a wound-contacting pad is disclosed. The selectively placed layer, which may be a semi-permeable film or a wound-cushioning material, has at least one dimension which is less than the corresponding dimension of the backing material. The bandage is cost efficient and comfortable to wear.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

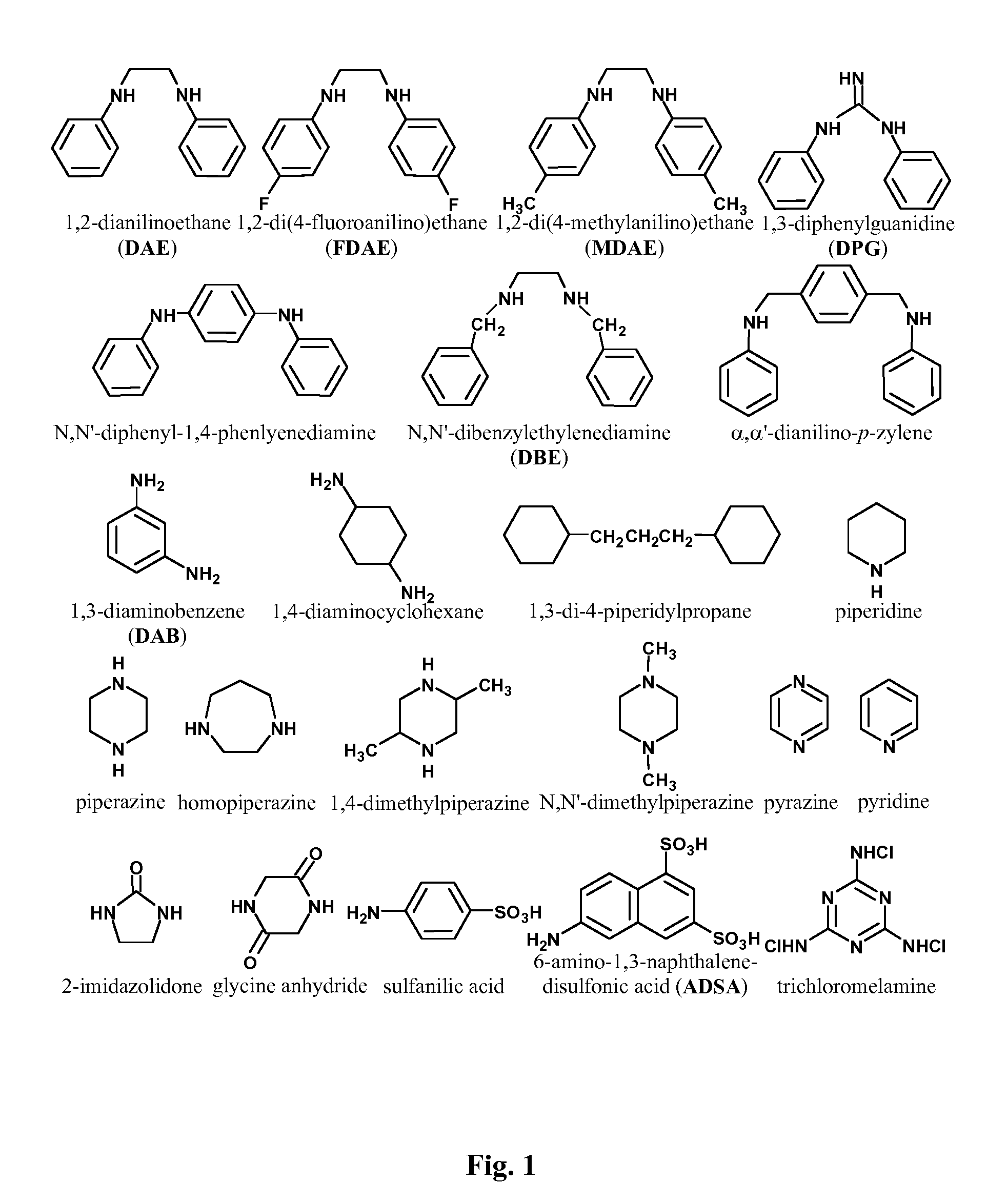

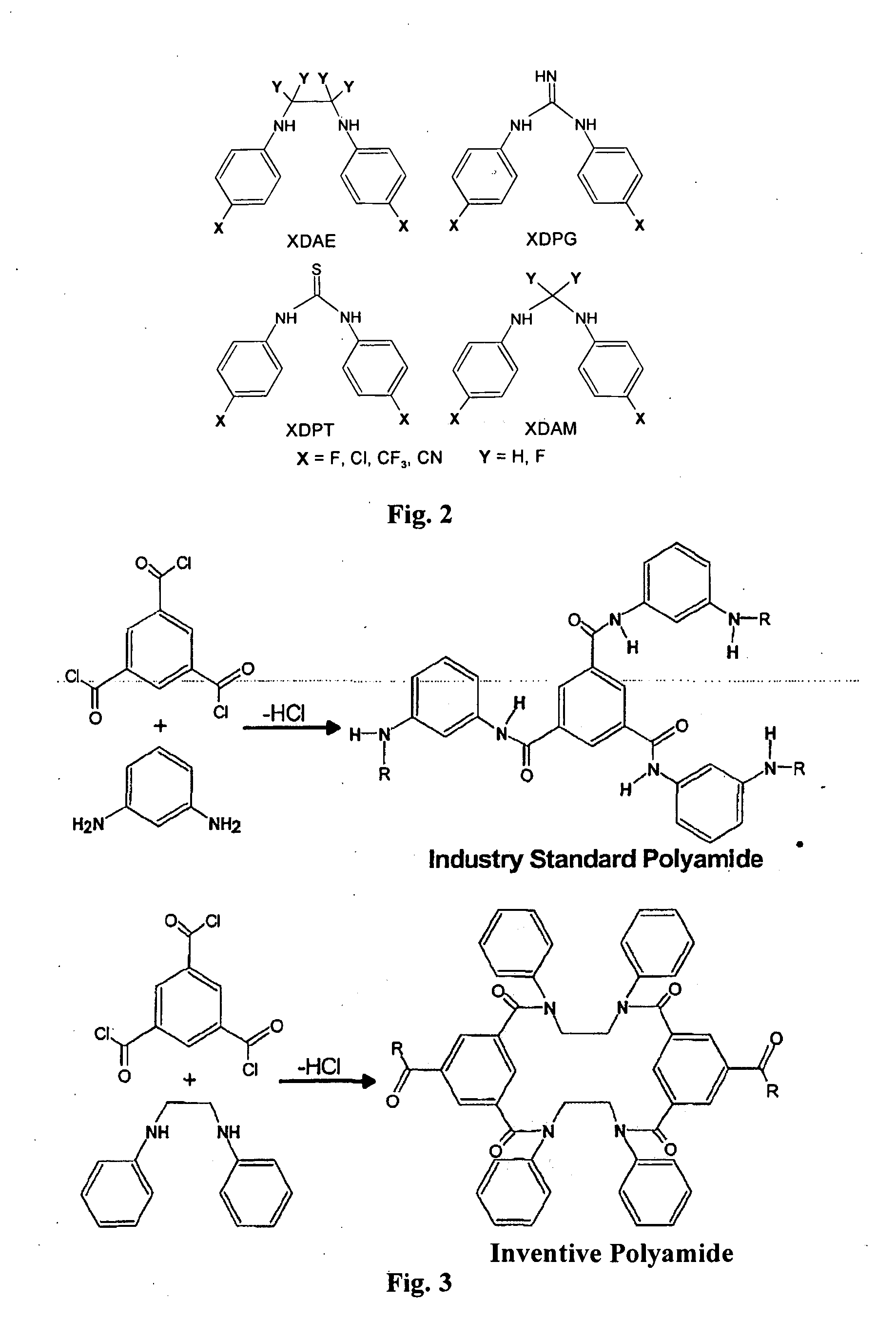

Composite semipermeable membrane, processfor producing the same, and method of purifying water with the same

InactiveUS6406626B1Semi-permeable membranesWater/sewage treatment bu osmosis/dialysisPurification methodsHigh rate

The present invention relates to a composite semipermeable membrane which is characterized in that it is a composite semipermeable membrane in which there is formed by polycondensation on top of a microporous support membrane a crosslinked polyamide ultra-thin membrane layer from polyfunctional amine, polyfunctional acid halide and polyfunctional acid anhydride halide, and the flow of water permeate at an operating pressure of 0.3 MPa, a temperature of 25° C. and a pH of 6.5 lies in the range from 0.8 to 4.0 m3 / m2.day and, furthermore, the percentage humic acid removal is at least 98%; a method for the production thereof; and a water purification method employing same. With the composite semipermeable membrane obtained by means of the present invention it is possible, in particular, to recover drinking water at a high rate by permitting passage of silica and preventing deposition thereof at the membrane surface while selectively separating / removing the pollutants and trace quantities of harmful materials and their precursors, etc, contained in the raw water in water treatment plants.

Owner:TORAY IND INC

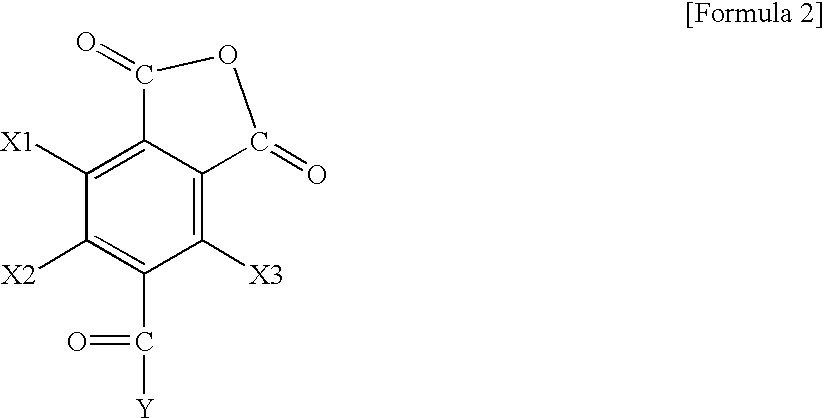

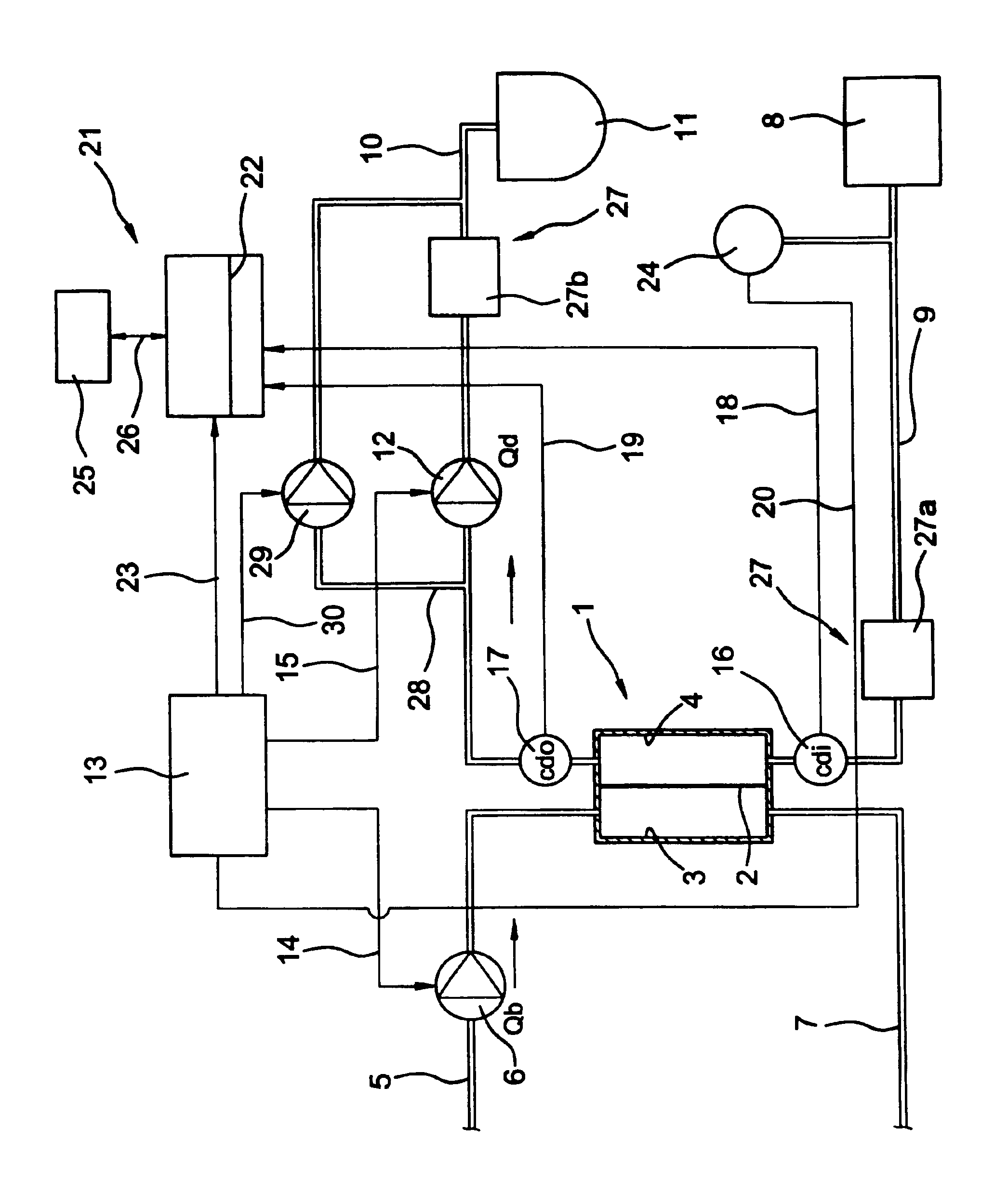

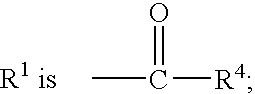

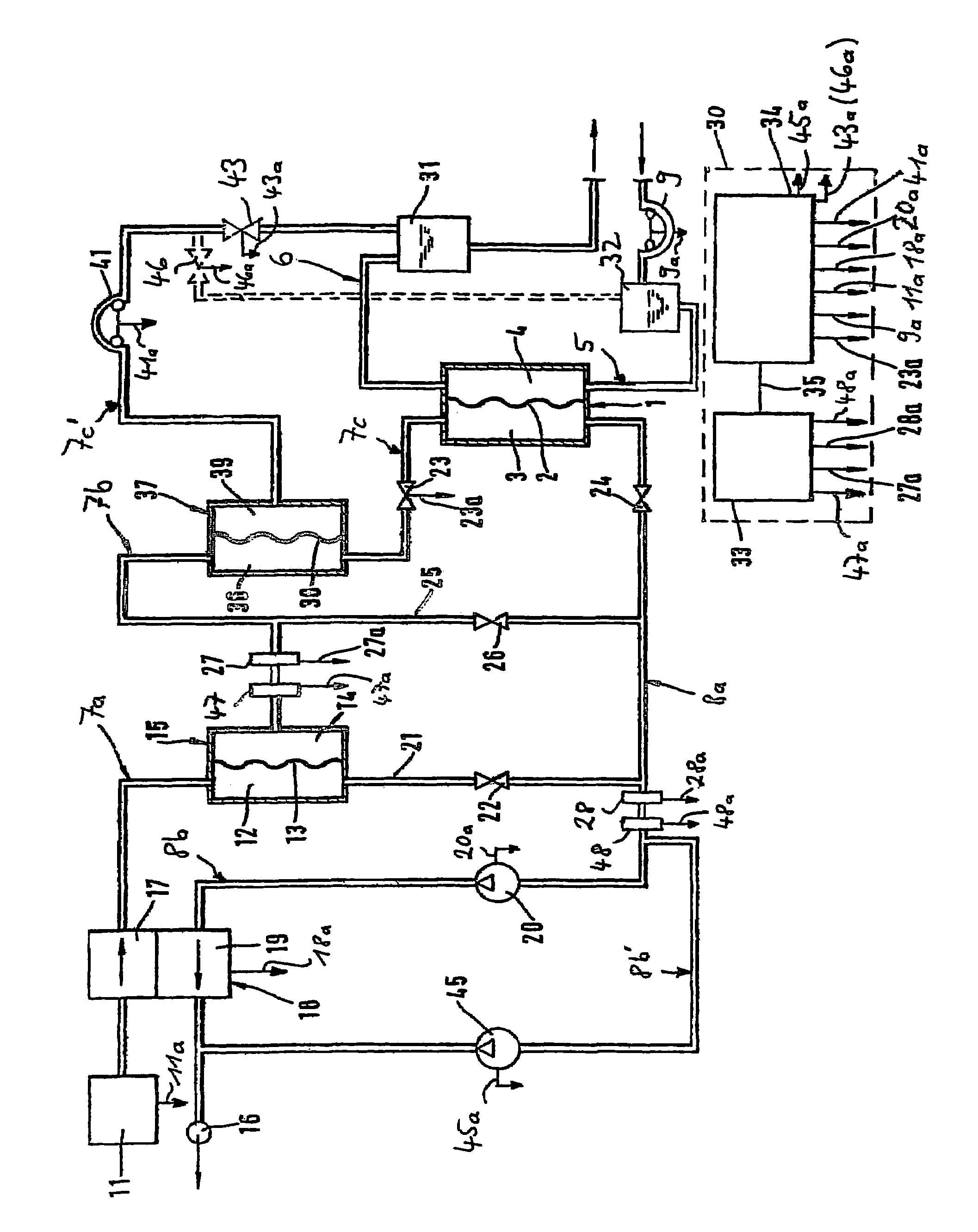

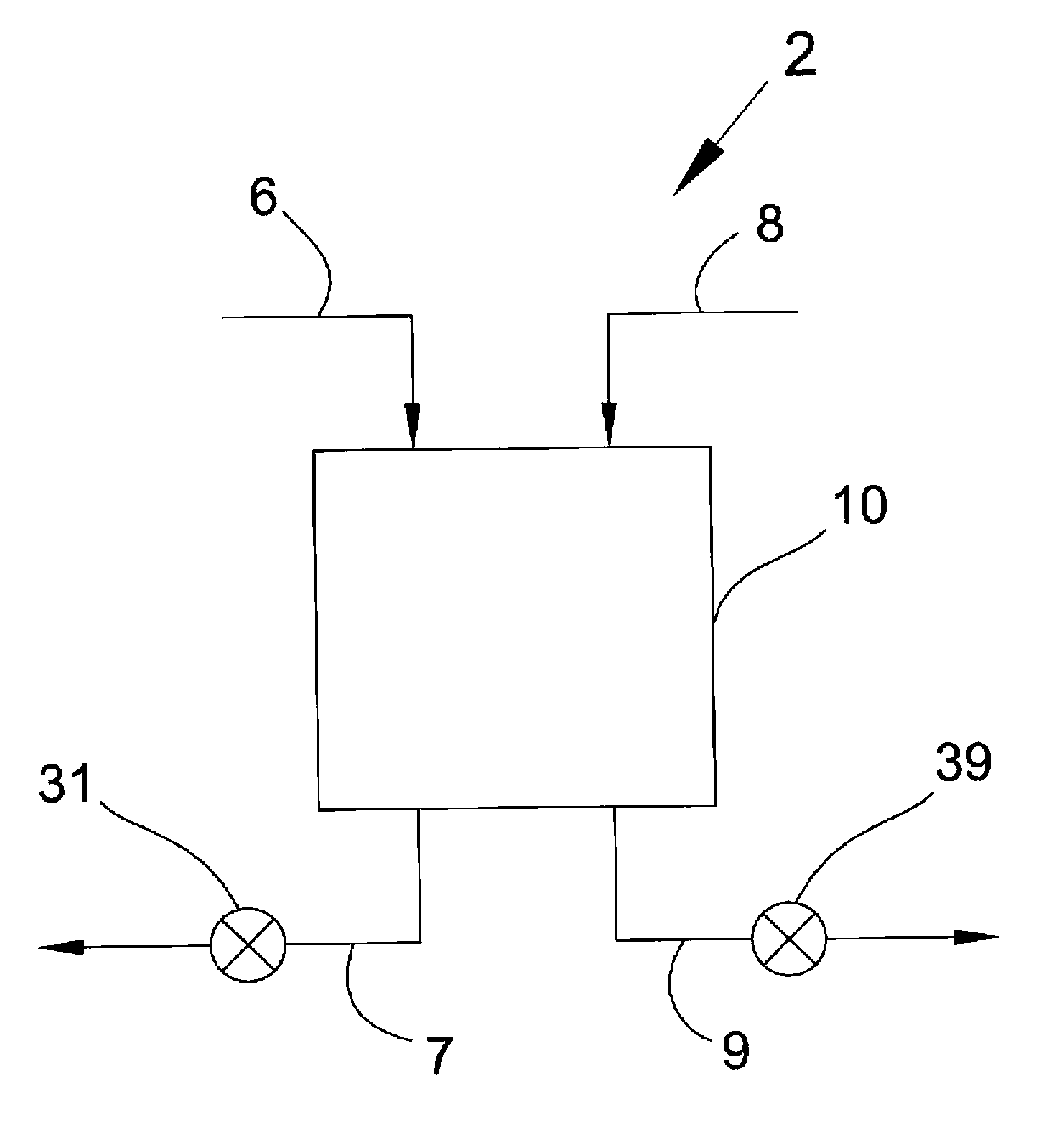

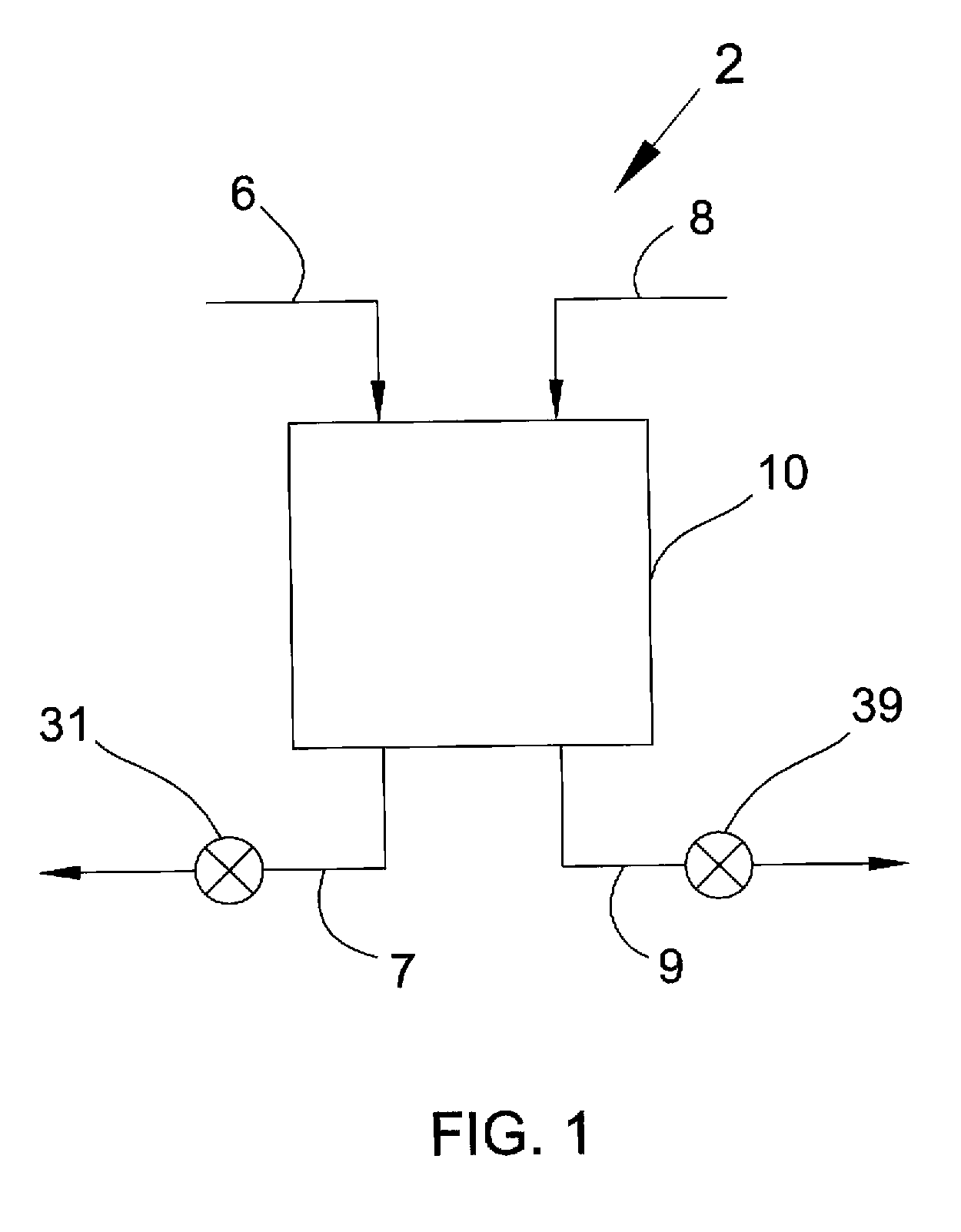

Method of determining the efficiency of a dialyzer of a dialysis machine and a dialysis machine for carrying out this method

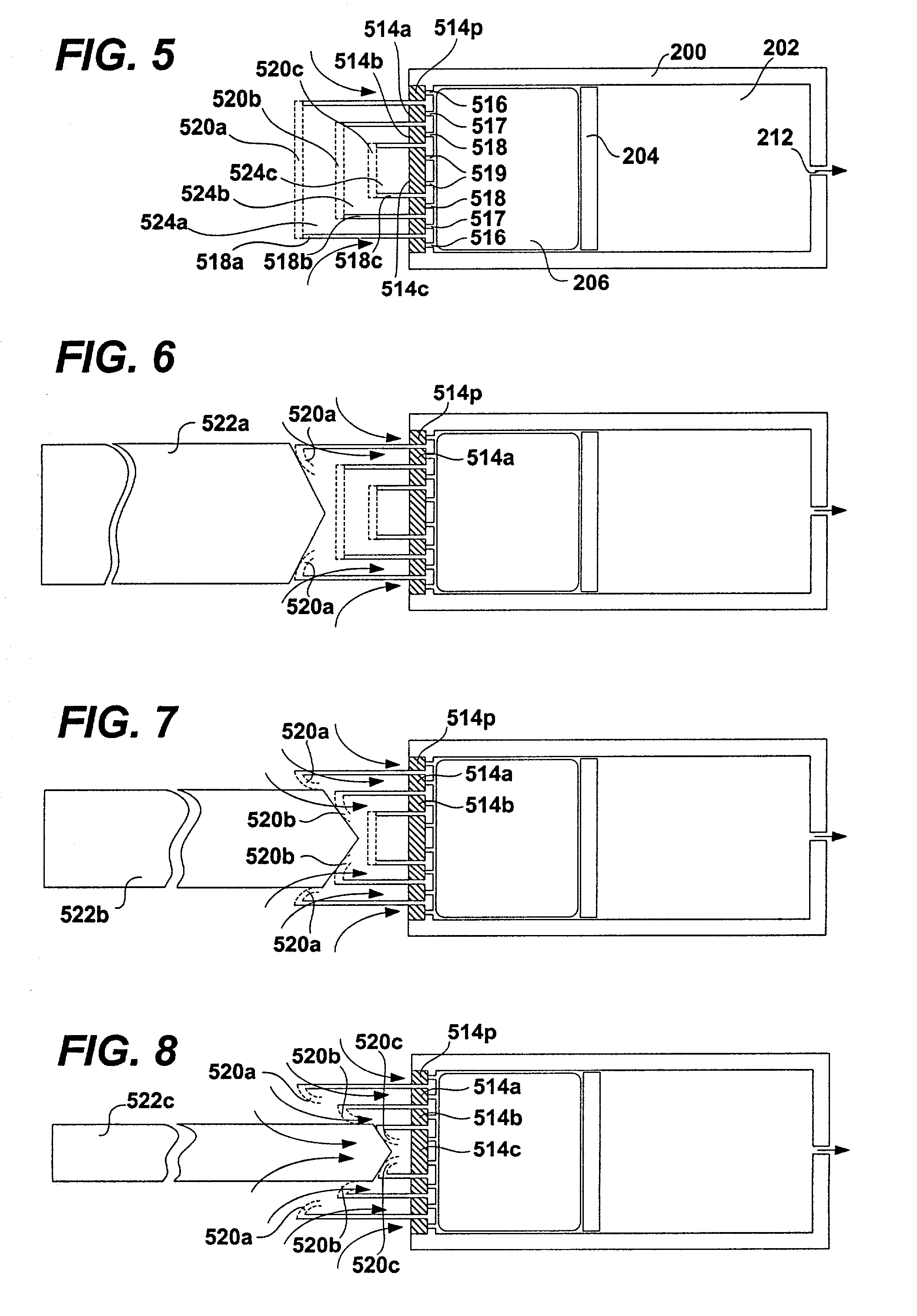

InactiveUS6860866B1Accurate efficiencyEasy to monitorSolvent extractionHaemofiltrationSemipermeable membraneDialysis fluid

A method and a device for determining the efficiency of a dialyzer of a dialysis machine during a dialysis treatment wherein the dialyzer is divided by a semipermeable membrane into a blood chamber and a dialysis fluid chamber and wherein the blood flows at a predetermined flow rate through the blood chamber and dialysis fluid flows at a predetermined flow rate through the dialysis fluid chamber. In use, the dialysance or clearance for a predetermined dialysis fluid flow rate and / or blood flow rate is measured, and then the dialysance or clearance for any dialysis fluid flow rate and blood flow rate is calculated.

Owner:FRESENIUS MEDICAL CARE DEUTSCHLAND GMBH

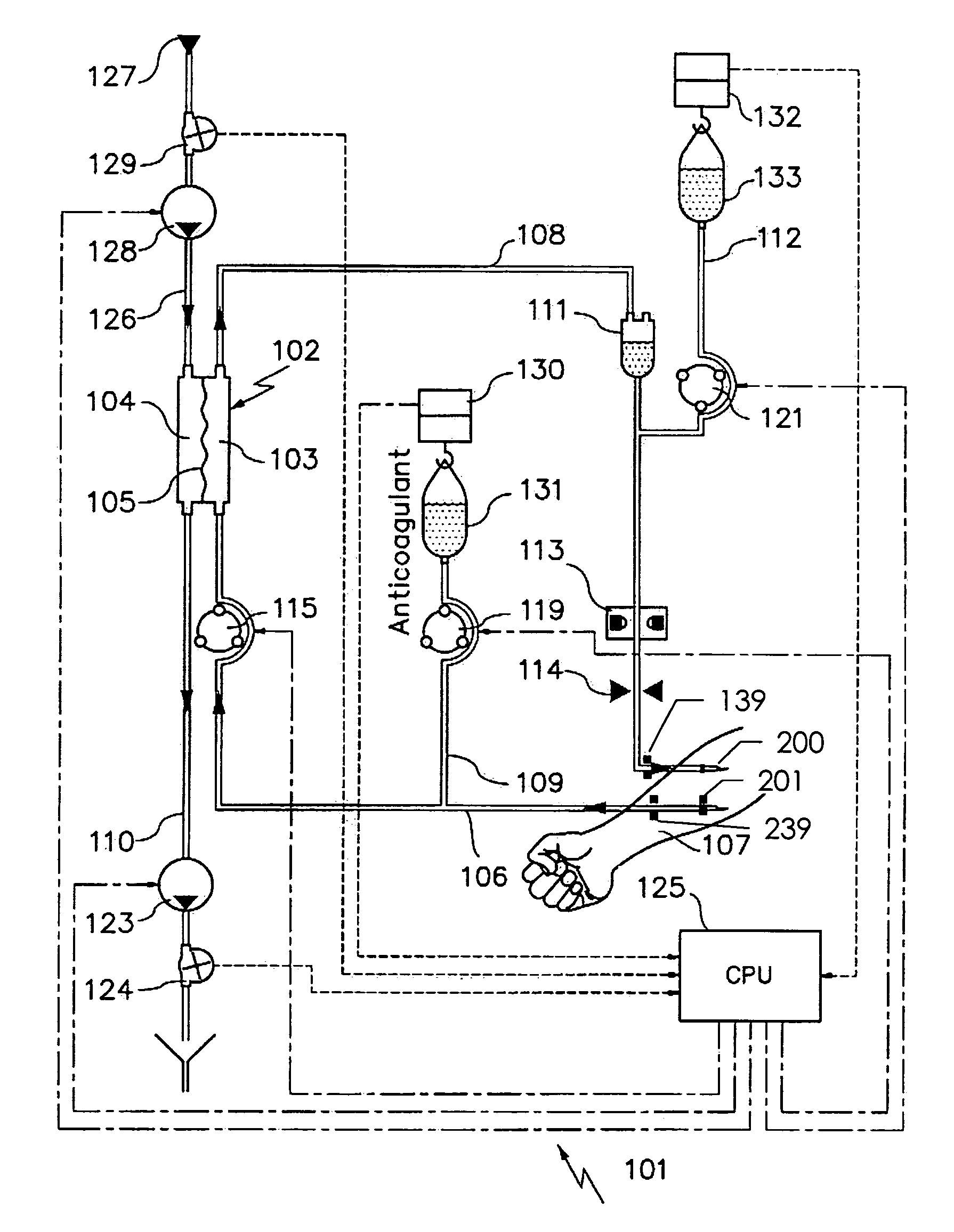

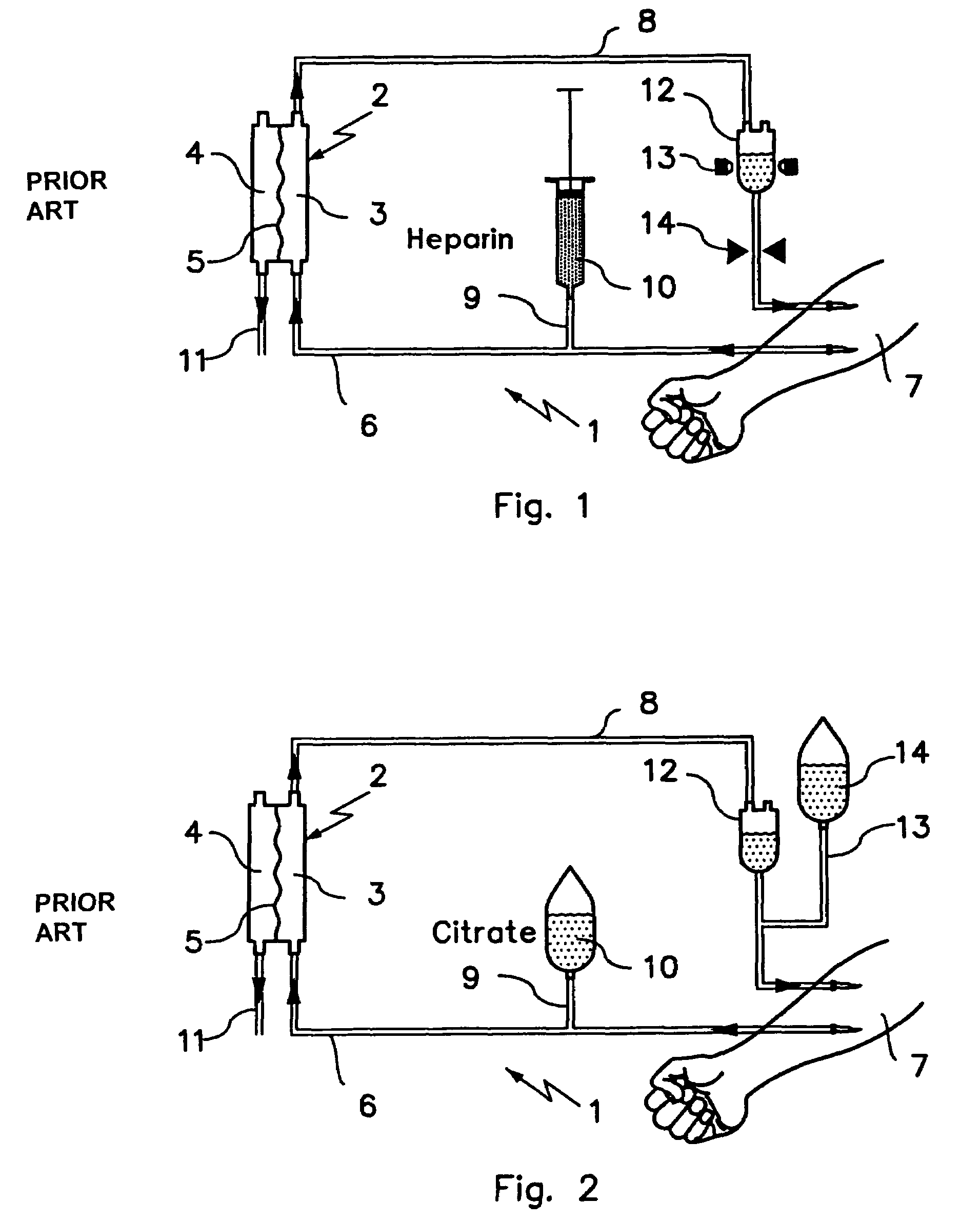

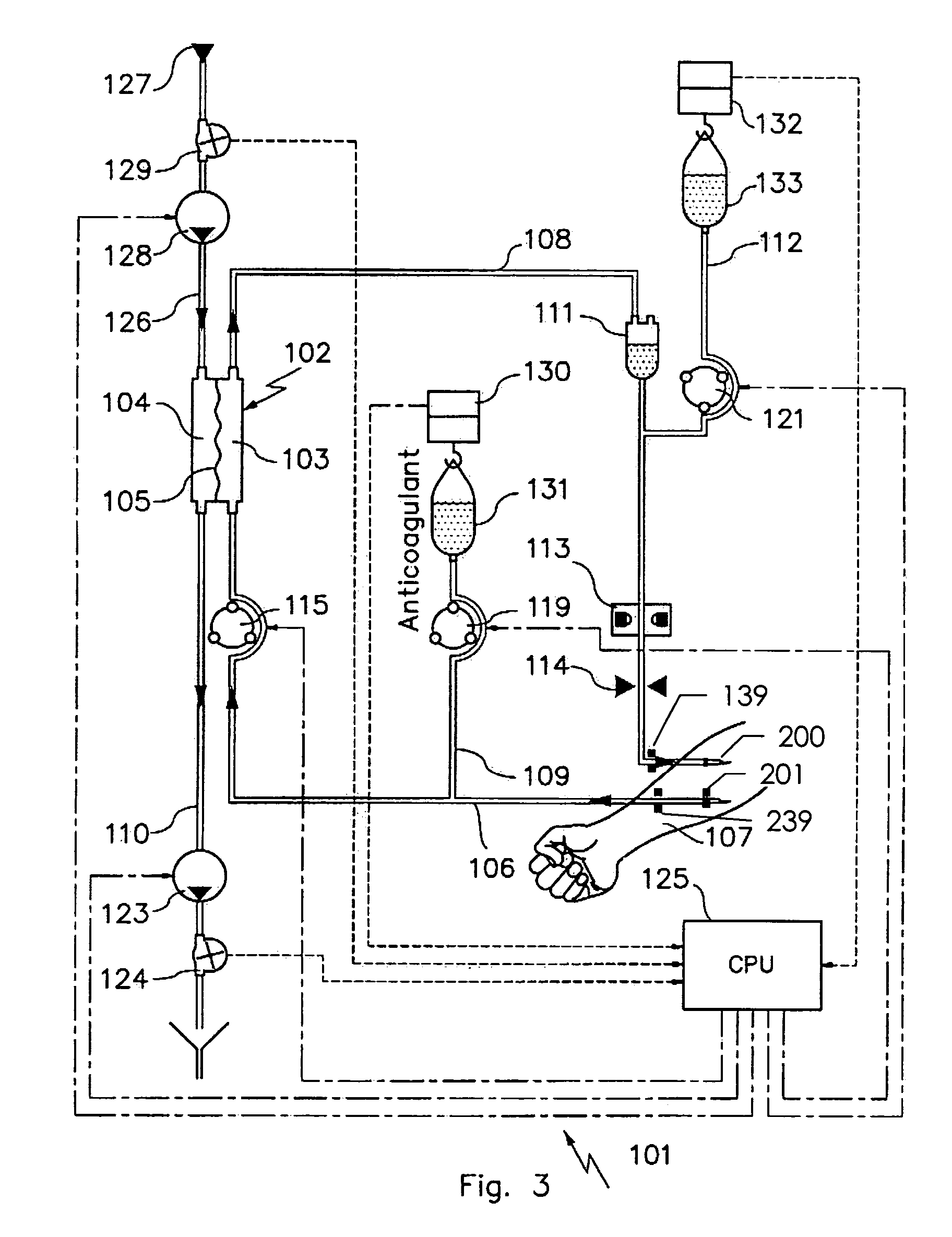

Device and process for extracorporeal treatment by citrate anticoagulant

ActiveUS7351218B2Inhibit blood coagulationSimple structureOther blood circulation devicesHaemofiltrationExtracorporeal circulationVein

A device for treating blood by extracorporeal circulation comprising a filter having a first chamber and a second chamber separated by a semi-permeable membrane. The device has an arterial line connected to the first chamber of the filter, a venous line issuing from the first chamber of the filter, a channel used for pre-infusion of a substance for regional anticoagulation and linked to the arterial line, a purge channel issuing from the second chamber of the filter, and an air separator on the venous line. The device also includes a line for post-infusion of a solution at least partially re-establishing the ionic equilibrium of the blood downstream of the air separator, the post-infusion line being configured immediately upstream of an air detector.

Owner:GAMBRO LUNDIA AB

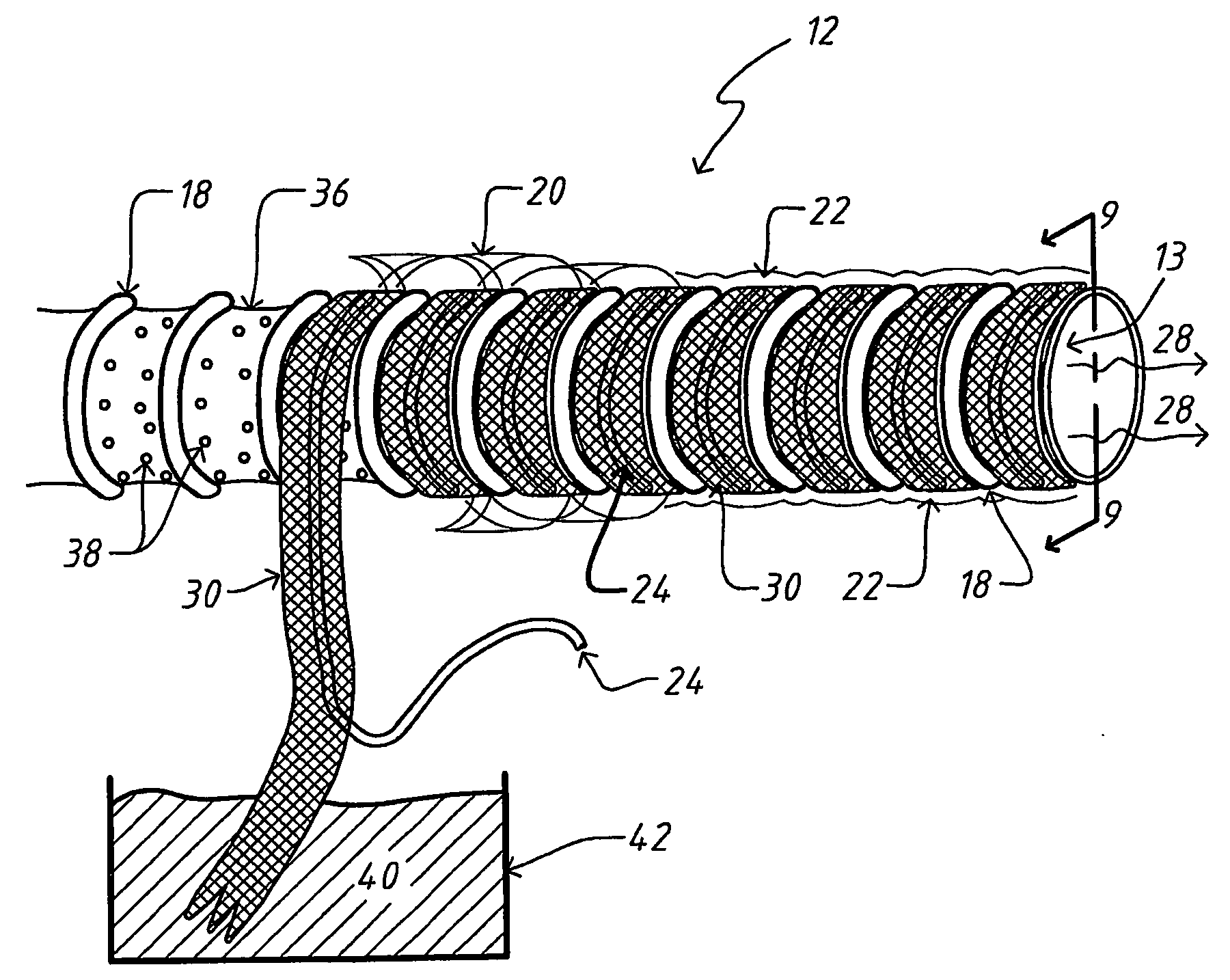

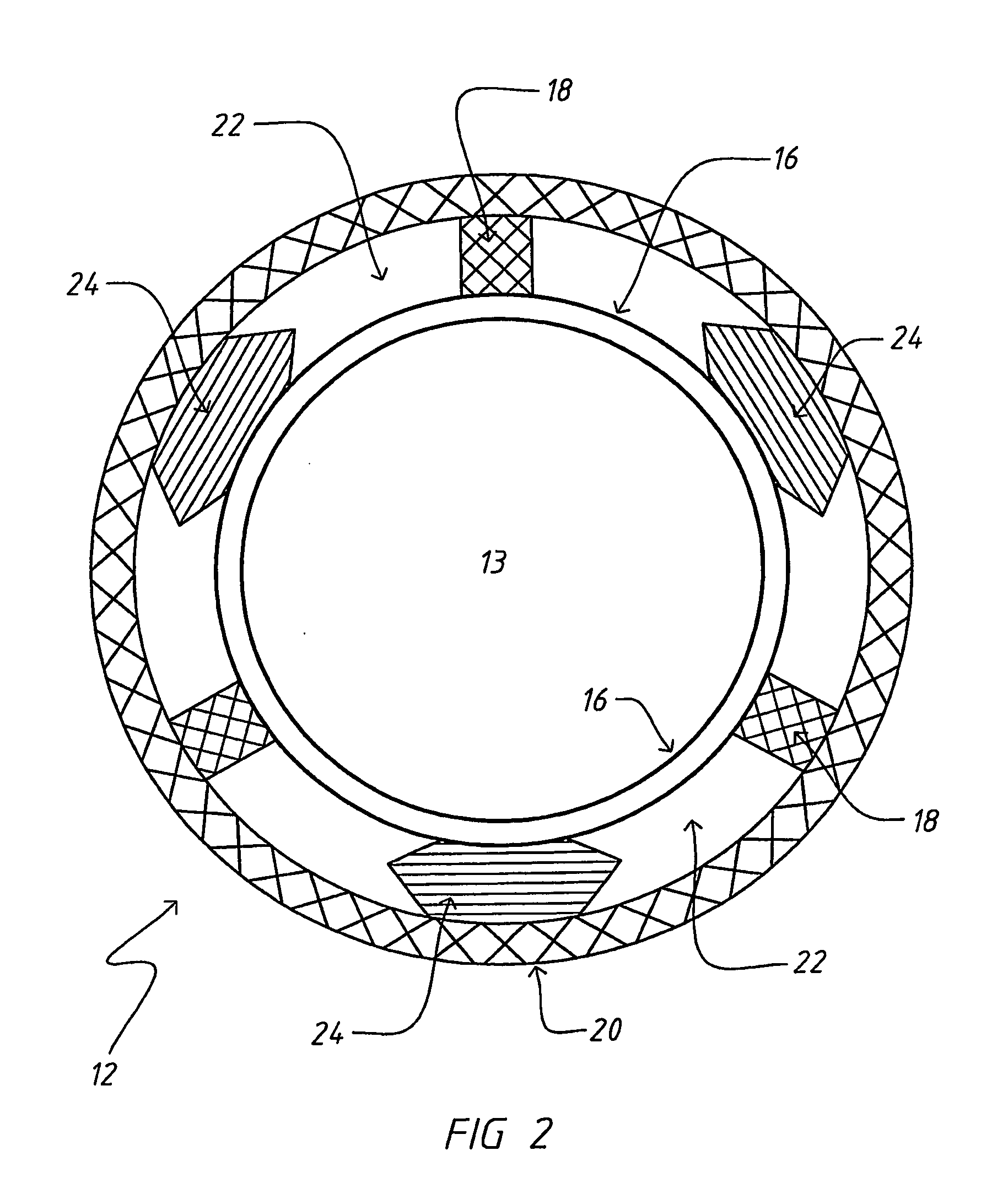

Humidification arrangement for a respiratory apparatus

InactiveUS20100083965A1Increase vaporization rateRespiratory masksMedical devicesWater channelSemipermeable membrane

A humidifying apparatus utilizing a semi-permeable membrane portion within a gas conduit where the direction of gas flow within a central lumen is given by an arrow. The humidification apparatus has a helical configuration for the semi-permeable membrane portion, a structural reinforcing member or members, a water channel and a heating element. The helical configuration of an outer wall may be similar to conventional conduits that are in common use in respiratory apparatus. Thus the humidification apparatus may be readily substituted into existing respiratory device by exchanging the gas conduit.

Owner:RESMED LTD

Porous substrates, articles, systems and compositions comprising nanofibers and methods of their use and production

ActiveUS20090143227A1High densityHigh productMaterial nanotechnologyPolycrystalline material growthPorous substrateNanofiber

Porous and / or curved nanofiber bearing substrate materials are provided having enhanced surface area for a variety of applications including as electrical substrates, semipermeable membranes and barriers, structural lattices for tissue culturing and for composite materials, production of long unbranched nanofibers, and the like.

Owner:ONED MATERIAL INC

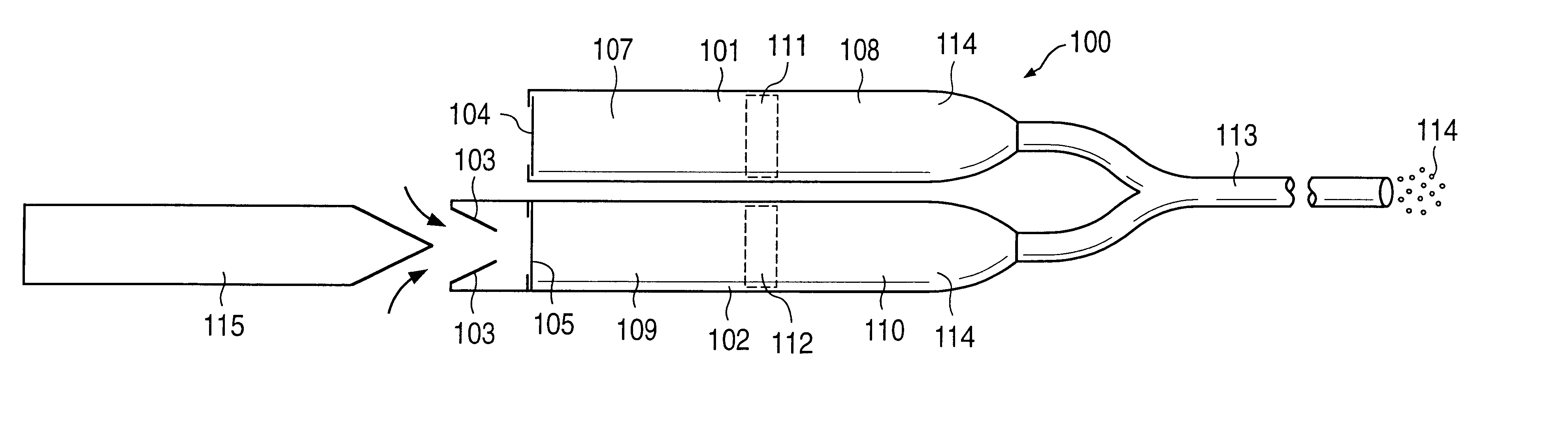

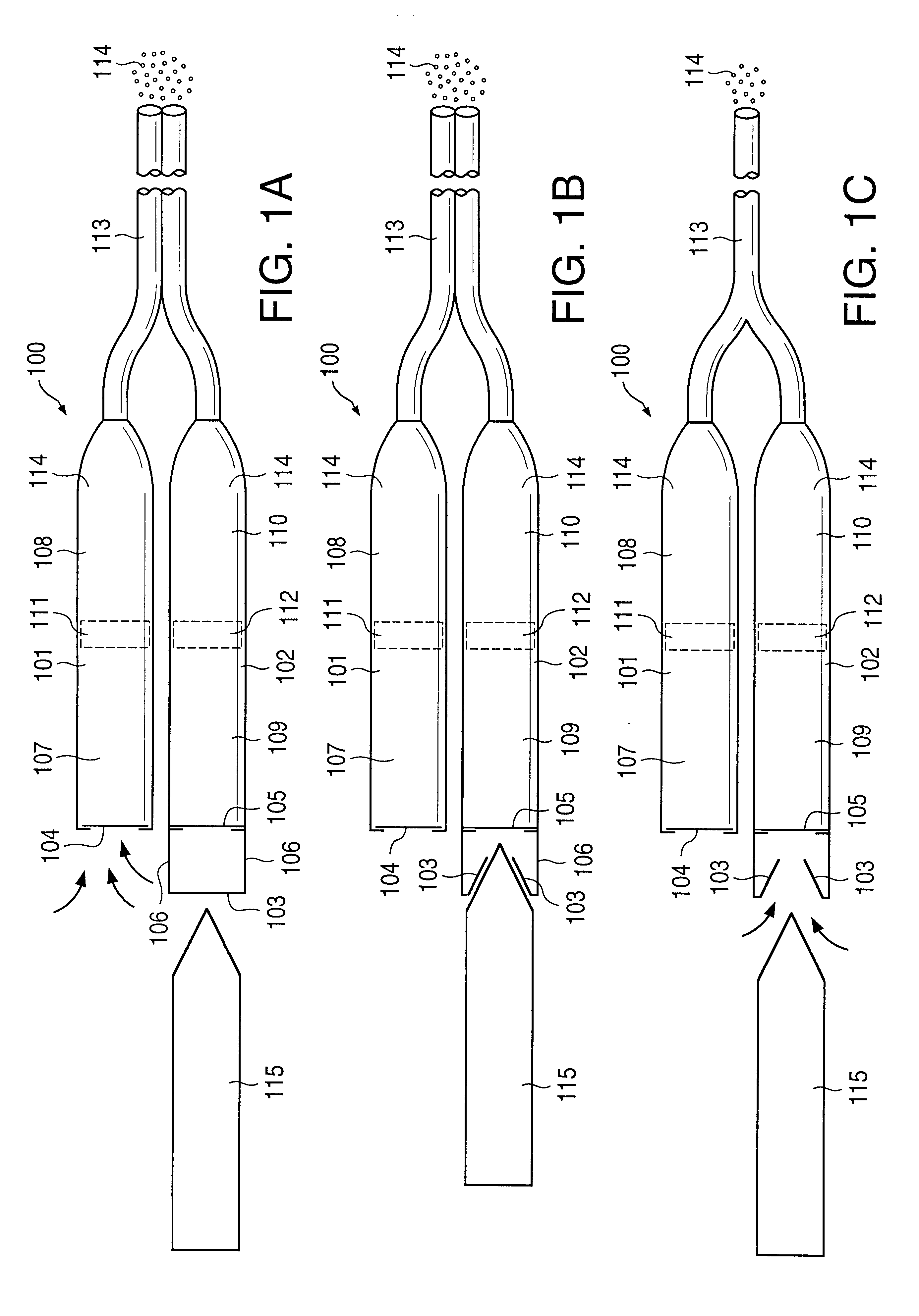

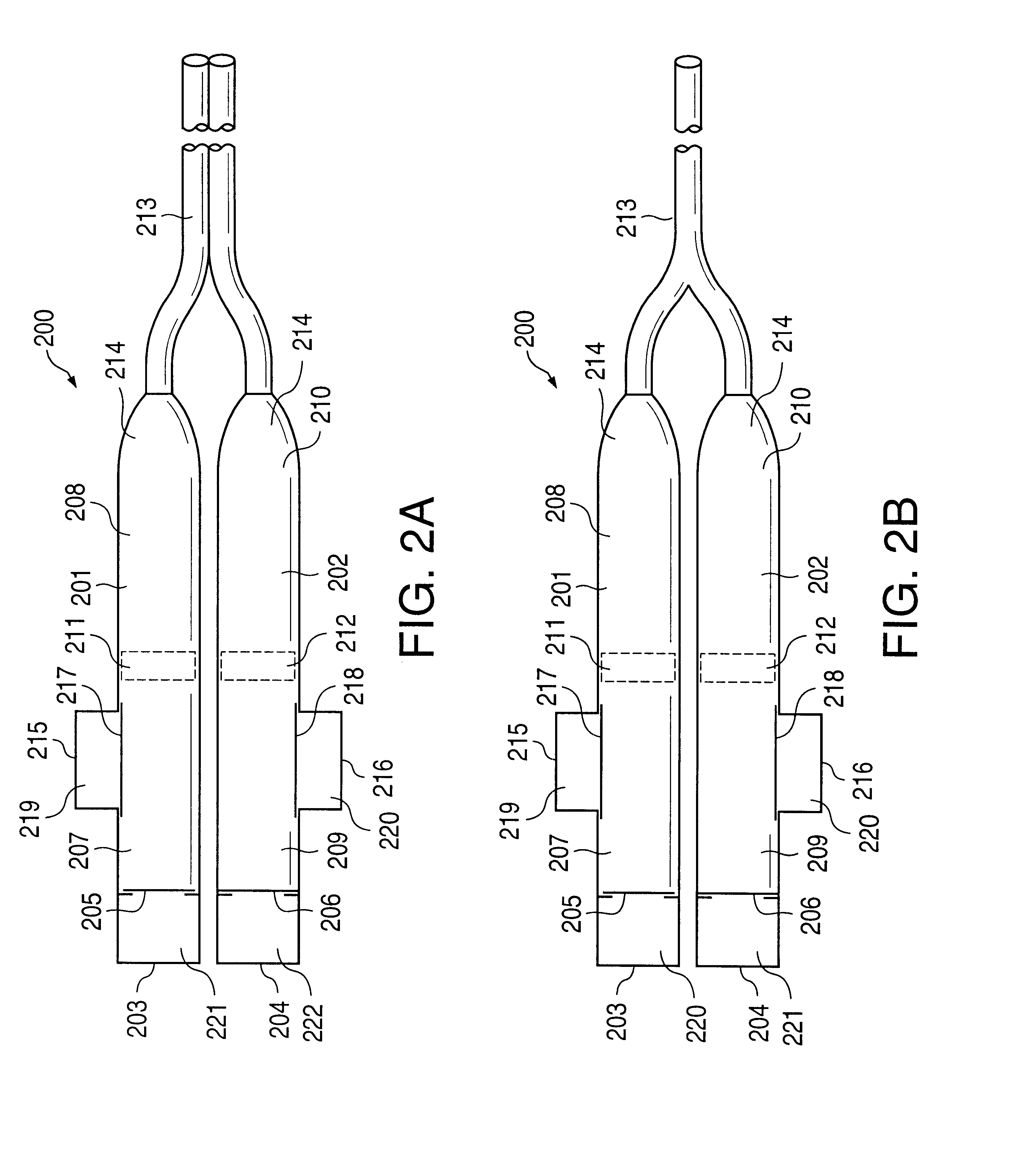

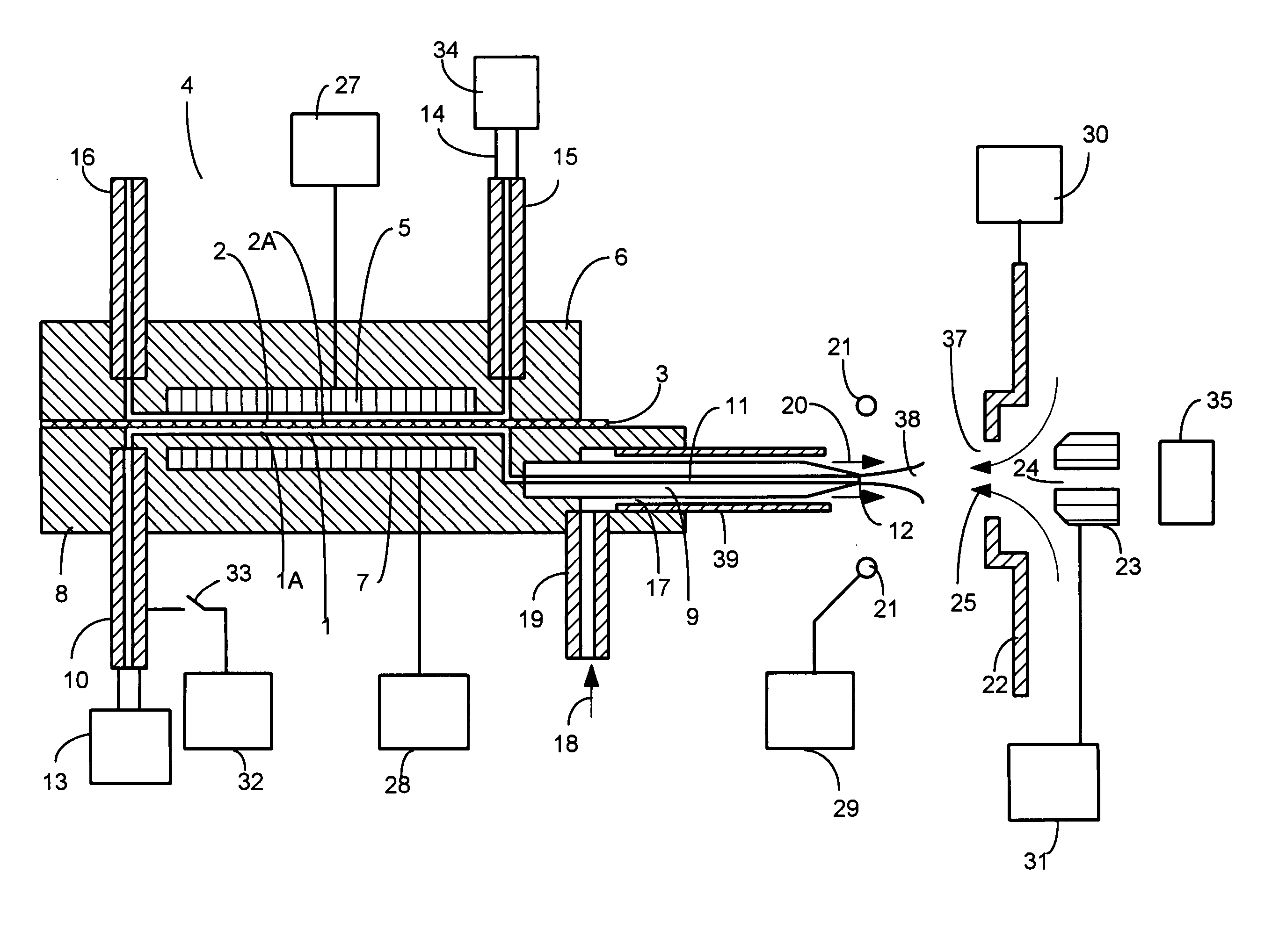

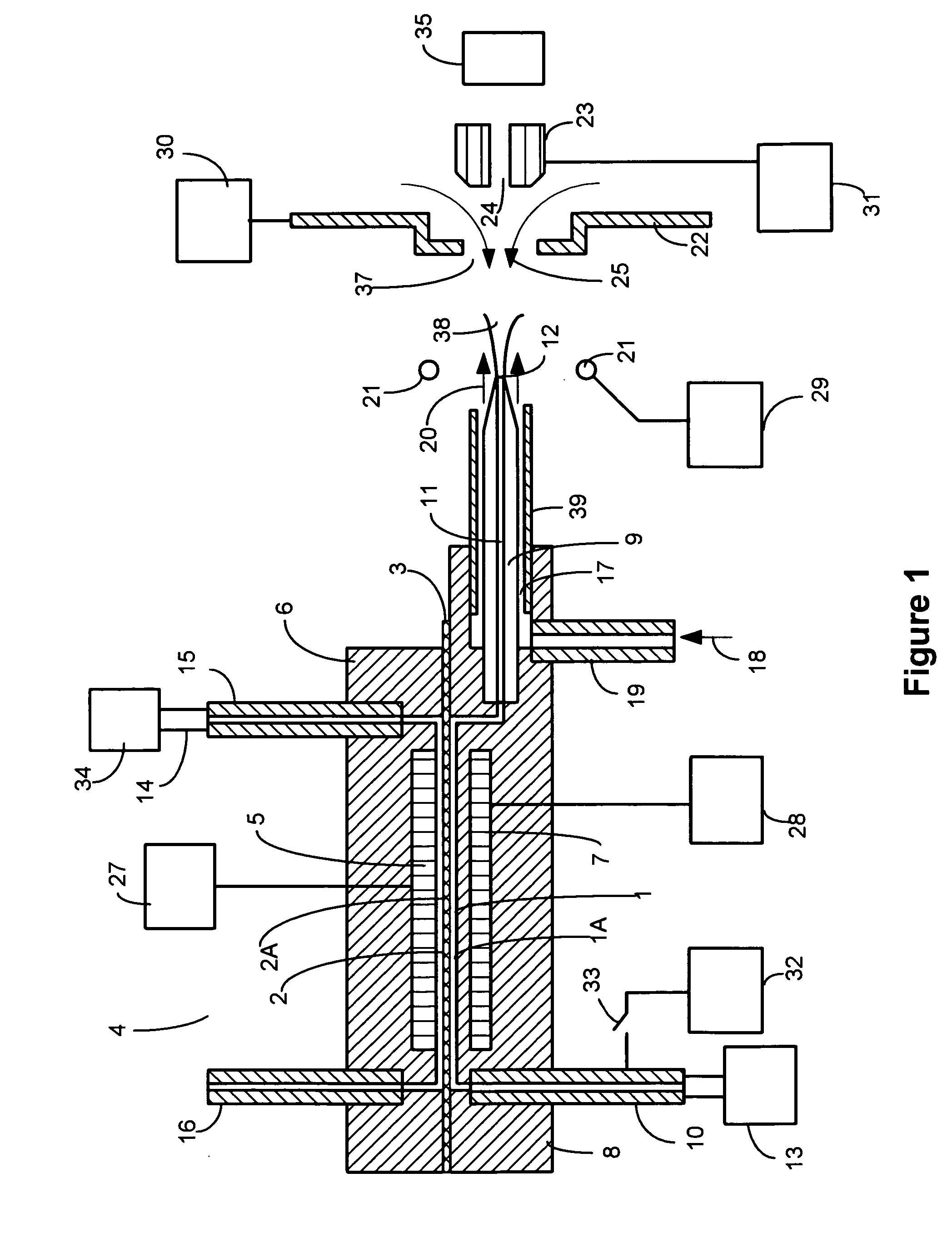

Charged droplet sprayers

ActiveUS20050258360A1Improve performanceOptimize charged droplet spray performanceMembranesSemi-permeable membranesSprayerElectric field

Charged droplet spray is formed from a solution with all or a portion of the charged droplet spray current generated from reduction or oxidation (redox) reactions occurring on surfaces removed from the first or sample solution flow path. In one embodiment of the invention, two solution flow channels are separated by a semipermeable membrane. A first or sample solution flowing through the first solution flow channel exchanges cation or anion charged species through the semipermeable membrane with a second solution or gas flowing through the second flow channel. Charge exchange is driven by the electric field applied at the charged droplet sprayer sample solution outlet. Redox reactions occur at an electrode surface in contact with the second solution. The invention increases the control and range of the Electrospray ionization process during ES / MS operation. Alternative embodiments of the invention provide for conducting redox reactions on conductive surfaces removed from the first or sample solution flow path but not separated by semipermeable membranes.

Owner:PERKINELMER U S LLC

High titer production of poly (α 1,3 glucan)

A process for enzymatic preparation of poly (α1, 3 glucan) from sucrose is disclosed. The glucosyltransferase enzyme (gtfJ) from Streptococcus salivarius is used to convert sucrose to fructose and poly (α1, 3 glucan). Application of semi-permeable membranes to continuously remove fructose, a by-product of the gtf enzyme, thus increasing the poly (α1, 3 glucan) liter, is disclosed.

Owner:NUTRITION & BIOSCIENCES USA 4 INC

Aqueous liquid laundry detergent compositions with visible beads

InactiveUS7169741B2Inorganic/elemental detergent compounding agentsOrganic detergent compounding agentsLiquid coreSemipermeable membrane

Disclosed are aqueous liquid laundry detergent compositions which are in the form of an externally structured aqueous liquid matrix having dispersed therein a plurality of visibly distinct beads. Such beads are prepared so as to be in the form of a liquid core surrounded by a semi-permeable membrane formed by interaction of a cationic polymeric material with an anionic polymeric material. Such beads are stable in the aqueous liquid detergent compositions herein yet disintegrate substantially upon their introduction via the composition into agitated dilute aqueous laundering liquors.

Owner:THE PROCTER & GAMBLE COMPANY

Haemodialysis device

A blood purification device has a blood purification element divided into two chambers by a semipermeable membrane, with a first chamber as part of a dialysis fluid loop and a second chamber as part of an extracorporeal blood loop. By virtue of an analysis unit operatively connected to a sensor in the dialysis fluid loop, the device provides simple and uncomplicated determination of the blood purification performance of the blood purification element for a second material by derivation from a previously established blood purification performance for a first material. In this way, the device also determines the blood concentration of the second material during the blood treatment through measurements in the dialysis fluid without intervention in the treatment sequence.

Owner:FRESENIUS MEDICAL CARE DEUTSCHLAND GMBH

Osmotic desalination process

InactiveUS7560029B2High yieldImprove concentrationSolvent extractionGeneral water supply conservationPresent methodDesalination

An energy efficient desalination process that does not produce waste products involves the extraction of water from a first solution, such as seawater, by using a second concentrated solution to draw the water from the first solution across a semi-permeable membrane. By manipulating the equilibrium of the soluble and insoluble species of solute within the second solution in favor of the soluble species of the solute, a saturated second solution can be used to generate osmotic pressure on the first solution. Also, by adjusting the equilibrium in favor of the less soluble species after the water has been drawn from the first solution, a portion of the solute can easily be precipitated out. Heating the second solution decomposes the solute into its constituent gasses. The constituent gasses and precipitated solute may be recycled through the process to affect the changes in equilibrium and eliminate waste products. Additionally, by using the waste steam from industrial sources and a heat pump to effectively distribute heat through the present method, the present method exhibits greater energy efficiency than prior art methods.

Owner:YALE UNIV

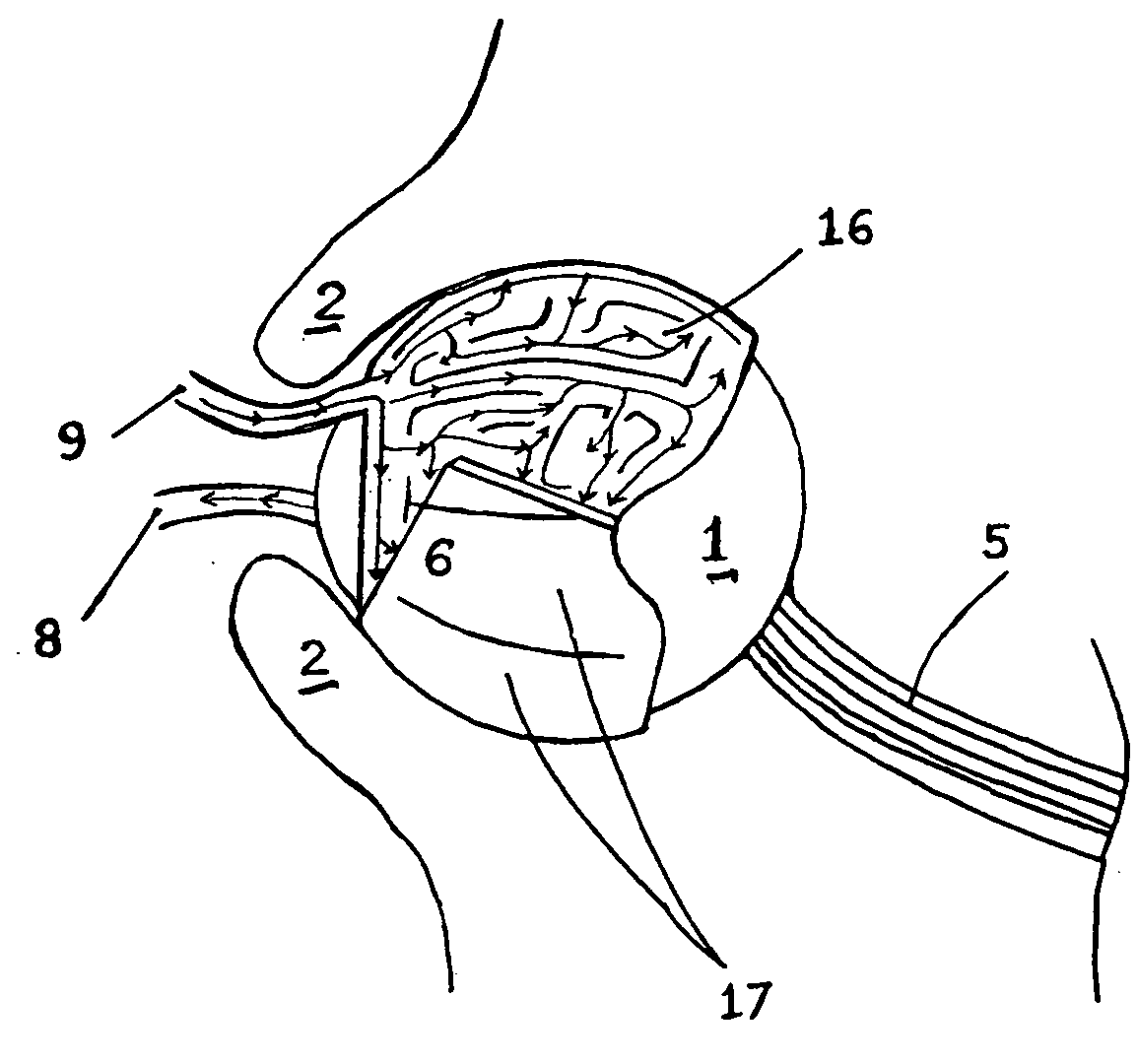

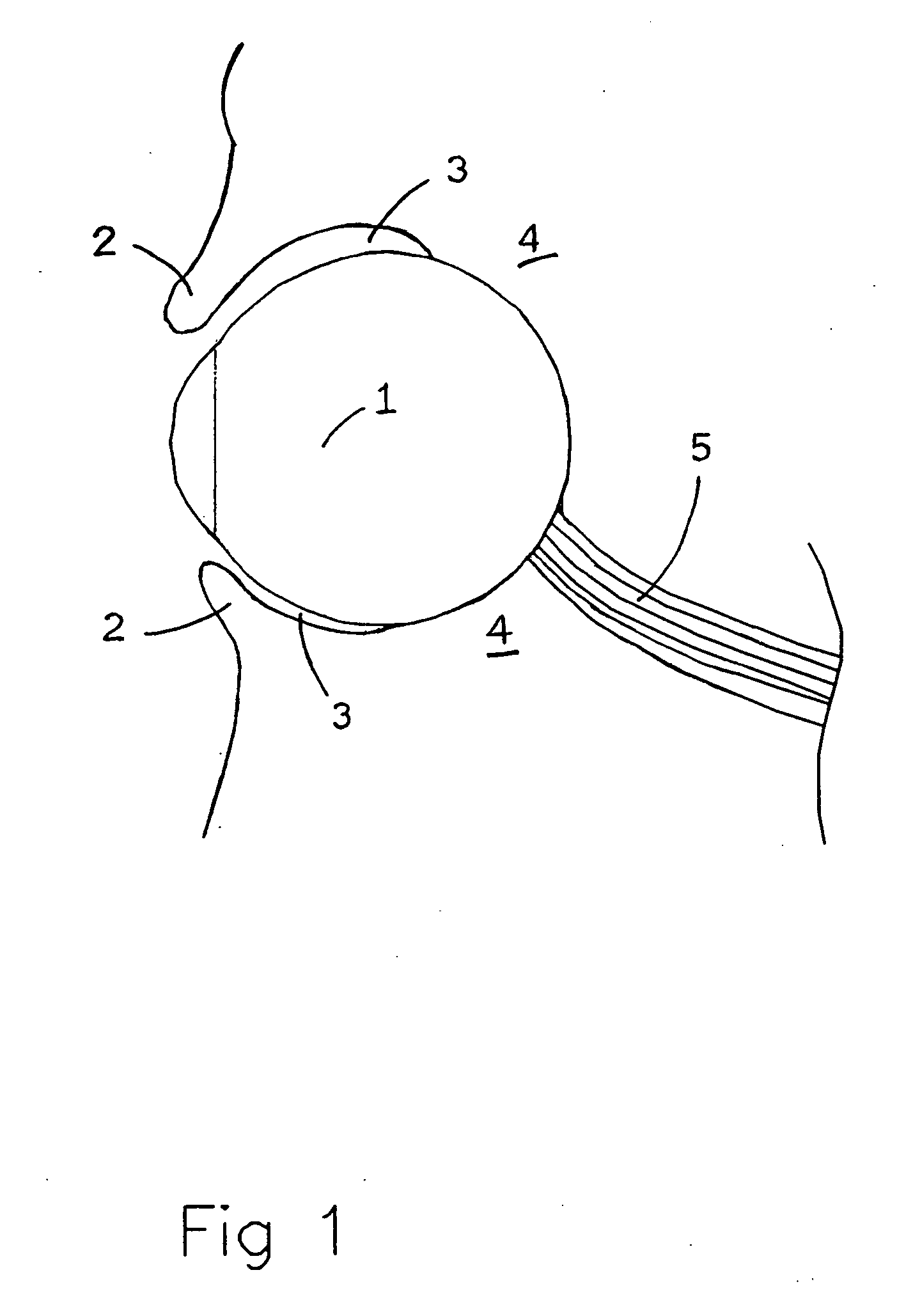

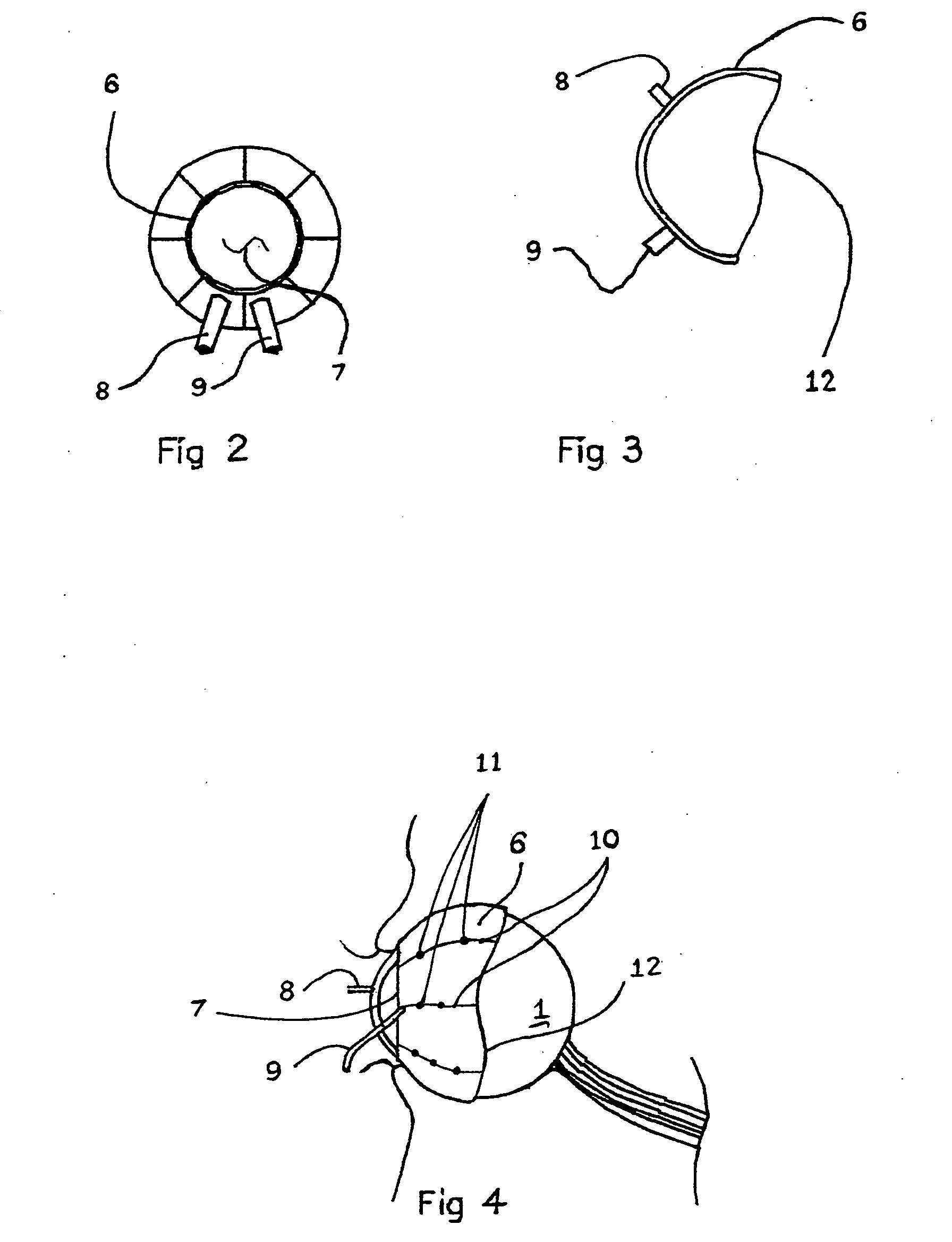

Medical device and method for temperature control and treatment of the eye and surrounding tissues

ActiveUS20060136022A1Easily penetrate sclera of eyeImprove the level ofEye surgerySurgeryDiseaseIntraocular pressure

The invention provides a medical device having a thermister for temperature measurement, irrigation / aspiration ports for fluid exchange and application of therapeutic modalities, a pressure manometer for pressure measurement, and an external system for control of temperature, pressure, and flow rate. When applied to the eye and orbit, this device can be used in hypothermia or hyperthermia applications, the control of intraocular pressure (IOP), and the application of treatment modalities. Methods of using the device in treating patients suffering from central retinal artery occlusion, anterior optic nerve disease, pathology of the choroid and retina including the macula, inflammation of the eye including the vitreous and anterior segment, glaucoma, inflammation and / or infections of the anterior and / or posterior segment of the eye, treatment before / during / after surgery of the eye, and the application of treatment modalities through a semi-permeable membrane are described.

Owner:WONG JR EDWARD K +2

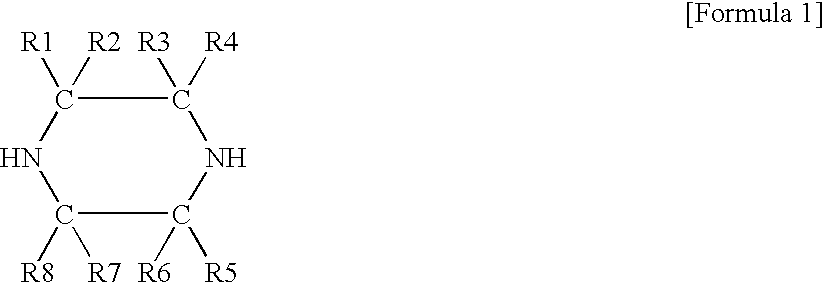

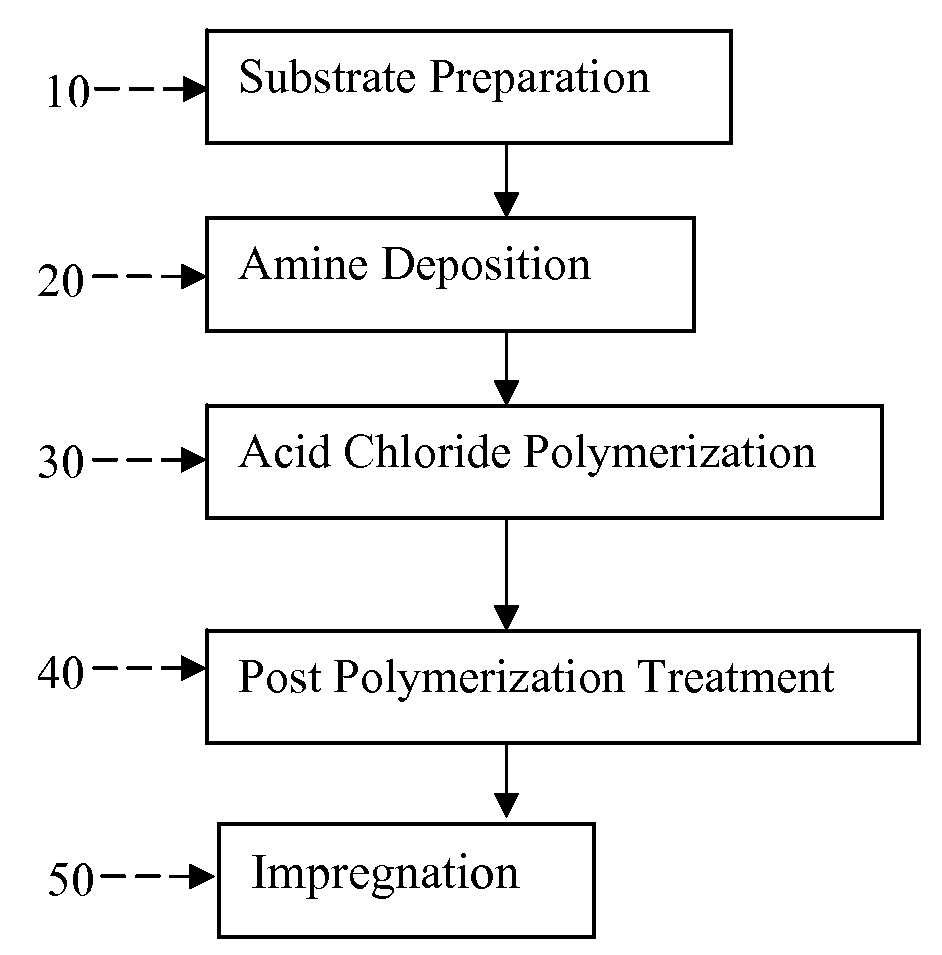

Semipermeable polymers and method for producing same

InactiveUS20100006495A1Suitable performanceMembranesSemi-permeable membranesCross-linkOrganic solvent

A polyamide membrane comprising reaction product of an anhydrous solution comprising an anhydrous solvent, at least one polyfunctional secondary amine and a pre-polymer deposition catalyst; and an anhydrous, organic solvent solution comprising a polyfunctional aromatic amine-reactive reactant comprising one ring. A composite semipermeable membrane comprising the polyamide membrane on a porous support.A method of making a composite semipermeable membrane by coating a porous support with an anhydrous solution comprising an anhydrous solvent, a polyfunctional secondary amine and a pre-polymer deposition catalyst, to form an activated pre-polymer layer on the porous support and contacting the activated pre-polymer layer with an anhydrous, organic solvent solution comprising a polyfunctional amine-reactive reactant to interfacially condense the amine-reactive reactant with the polyfunctional secondary amine, thereby forming a cross-linked, interfacial polyamide layer on the porous support. A method of impregnating a composite semipermeable membrane with nanoparticles selected from heavy metals and / or oxides of heavy metals.

Owner:ELTRON RES

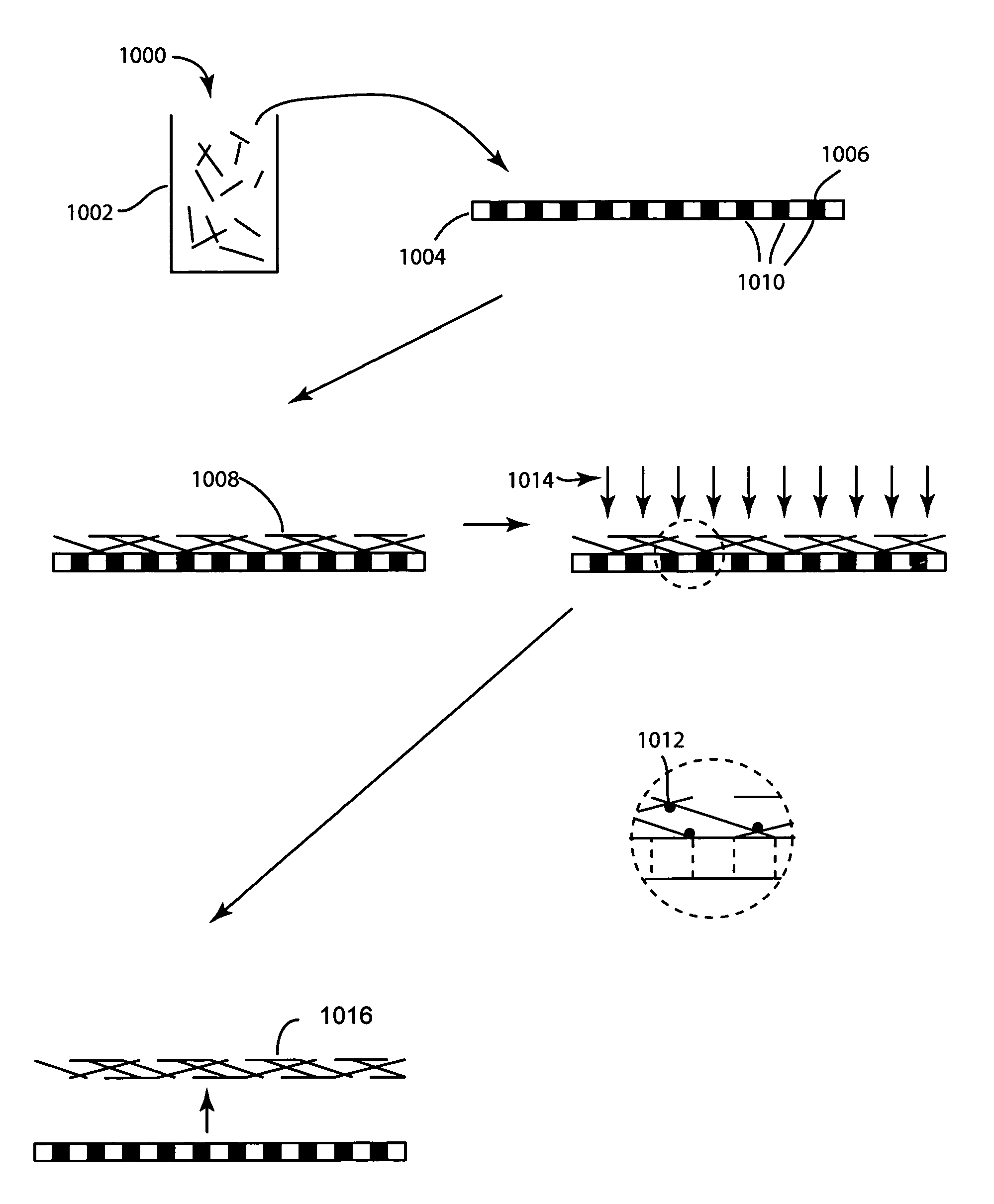

Porous Substrates, Articles, Systems and Compositions Comprising Nanofibers and Methods of Their Use and Production

InactiveUS20100173070A1High densityHigh productMaterial nanotechnologyComponent separationPorous substrateNanowire

Porous and / or curved nanofiber bearing substrate materials are provided having enhanced surface area for a variety of applications including as electrical substrates, semipermeable membranes and barriers, structural lattices for tissue culturing and for composite materials, production of long unbranched nanofibers, and the like. A method of producing nanofibers is disclosed including providing a plurality of microparticles or nanoparticles such as carbon black particles having a catalyst material deposited thereon, and synthesizing a plurality of nanofibers from the catalyst material on the microparticles or nanoparticles. Compositions including carbon black particles having nanowires deposited thereon are further disclosed.

Owner:ONED MATERIAL INC

Mecs Diayzer

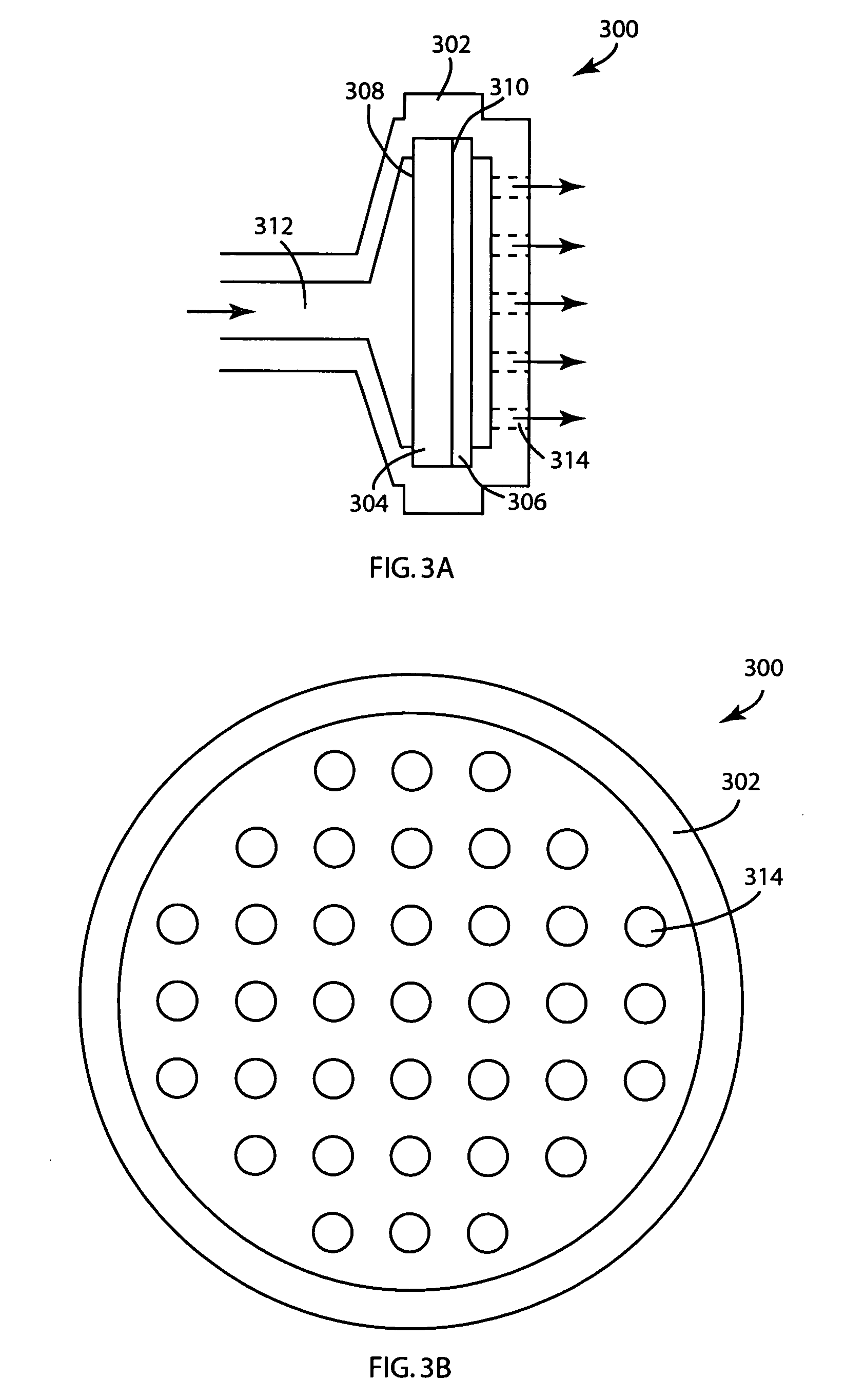

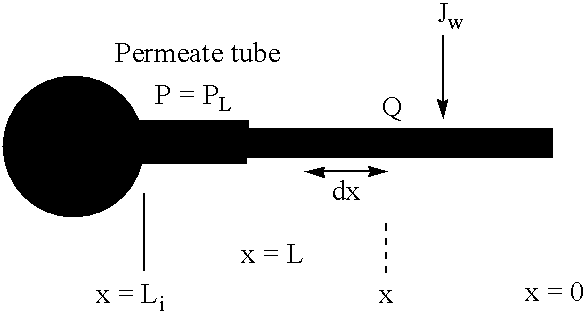

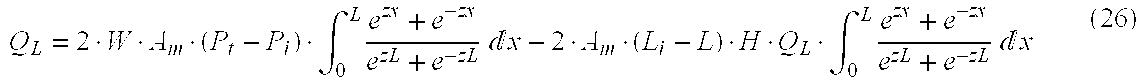

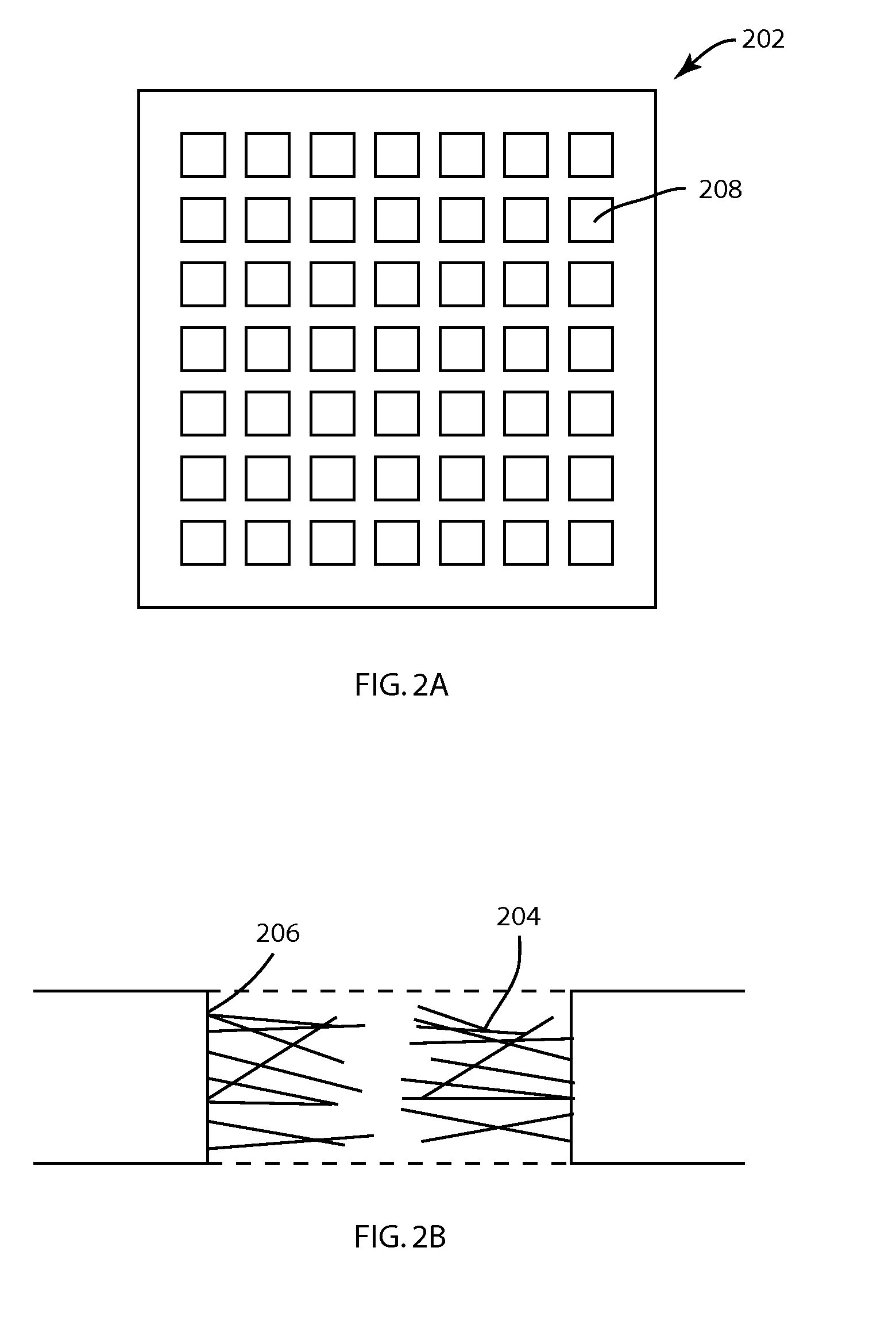

ActiveUS20080093298A1Enhanced mass transferImprove mass transfer efficiencyMembranesSolvent extractionDialysis membranesHaemodialysis machine

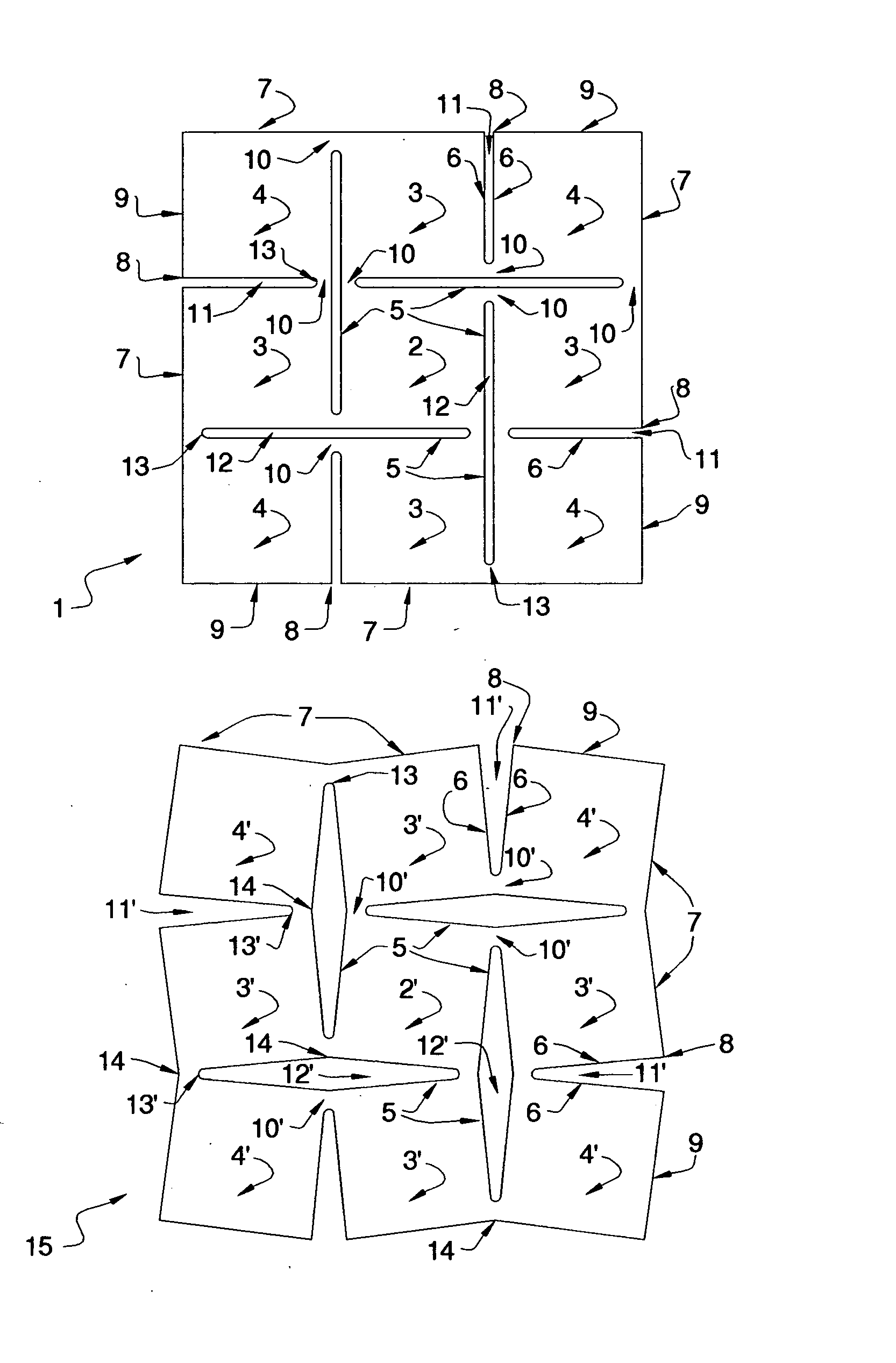

The present invention is related to hemodialysis, and more particularly, to a dialyser with improved efficiency of mass transfer across a dialysis membrane utilizing microchannel separation provided in accordance with embodiments of the present invention. In accordance with an embodiment, a dialyzer is provided comprising a plurality of semipermeable membrane sheets and a plurality of flow separators. The membrane sheets and flow are arranged in alternating configuration and coupled into a laminae stack defining a plurality of parallel microchannel layers. Each microchannel layer comprises a plurality of first microchannels and a plurality of second microchannels. The first and second microchannels of each microchannel layer are in fluid communication with each other via one of the plurality of membrane sheets therebetween. The MECS dialyzer is characterized as having a high surface to volume ratio and a high mass transfer coefficient.

Owner:OUTSET MEDICAL

Antimicrobial semi-permeable membranes

Cast semi-permeable membranes made from synthetic polymer used in reverse osmosis, ultrafiltration and microfiltration are treated with a non-leaching antimicrobial agent to prevent its bio-fouling and bacterial breakthrough. The semi-permeable membranes include a polymeric material and a non-leaching antimicrobial agent that is incorporated into and homogeneously distributed throughout the polymeric material. The polymeric material, in the case of one membrane, may be cellulose acetate. In the case of thin film composite polyamide membranes, the antimicrobial agent is incorporated in a microporous polysulfone layer that is sandwiched between a reinforcing fabric and an ultrathin polyamide material. The invention also includes a treatment of flat and hollow fiber semipermeable membranes made with polysulfones and polyvinylidene fluoride.

Owner:MICROBAN PROD CO INC

Porous substrates, articles, systems and compositions comprising nanofibers and methods of their use and production

ActiveUS7553371B2High densityHigh productMaterial nanotechnologyPolycrystalline material growthPorous substrateSemipermeable membrane

Porous and / or curved nanofiber bearing substrate materials are provided having enhanced surface area for a variety of applications including as electrical substrates, semipermeable membranes and barriers, structural lattices for tissue culturing and for composite materials, production of long unbranched nanofibers, and the like.

Owner:ONED MATERIAL INC

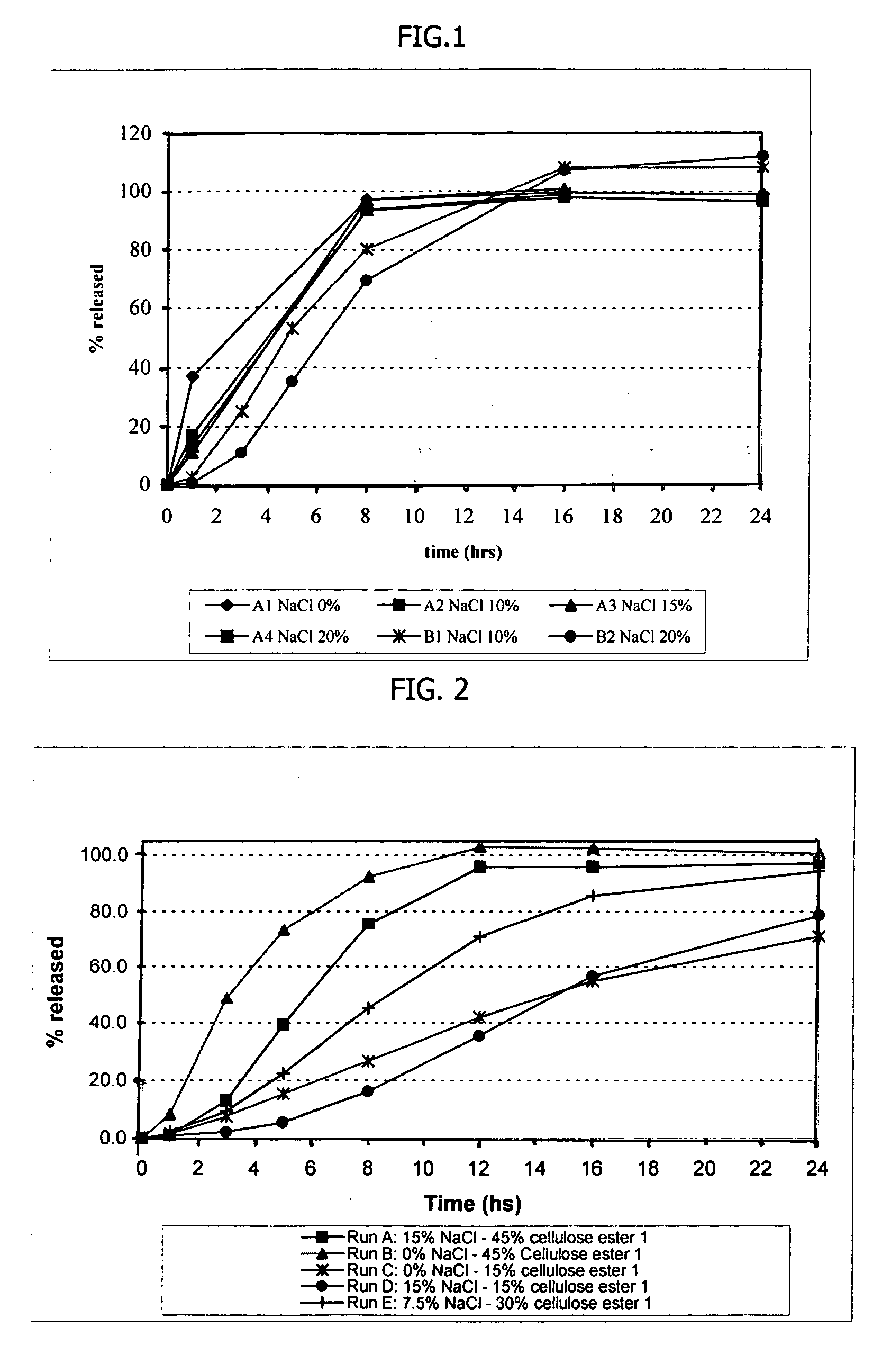

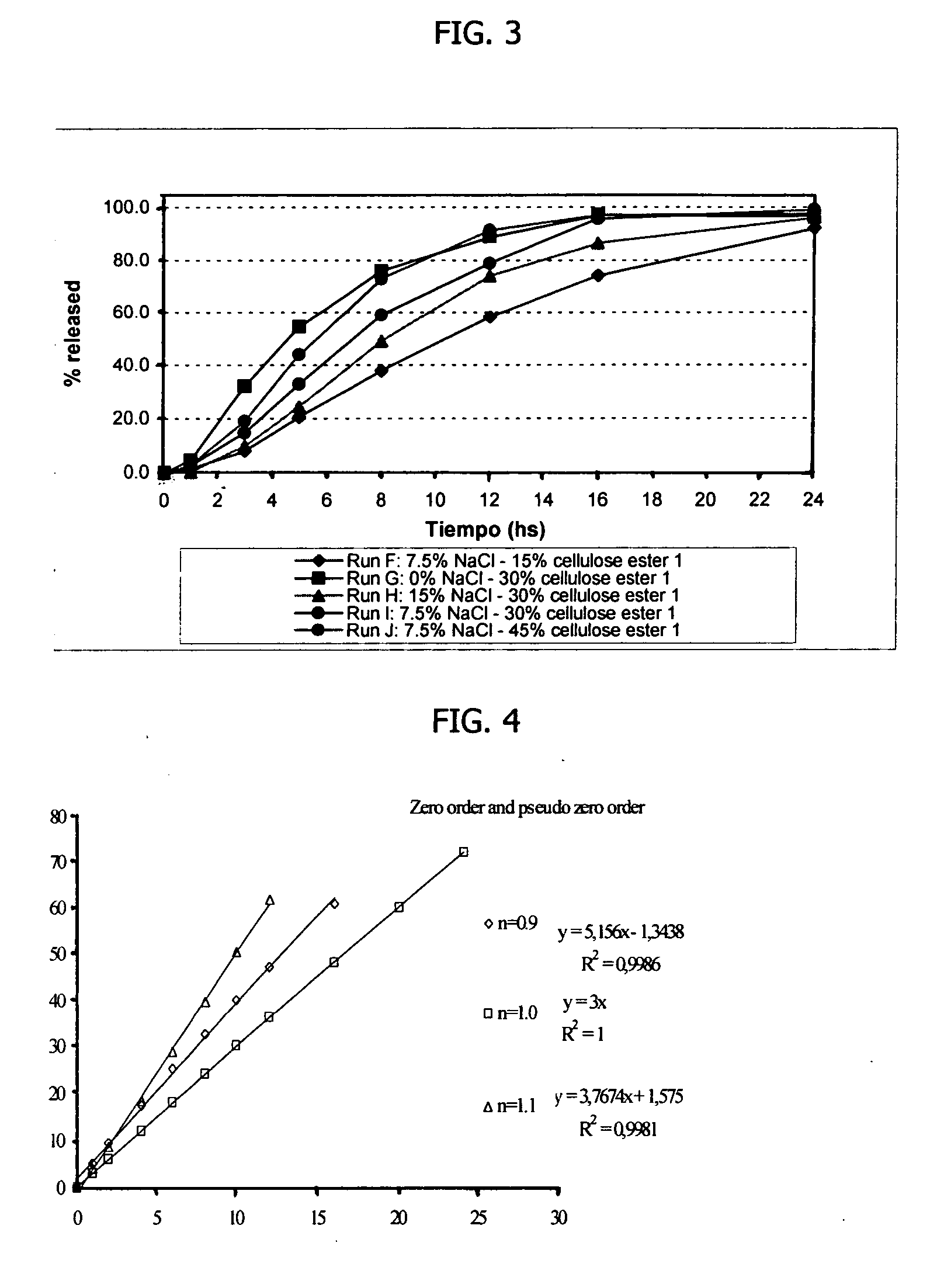

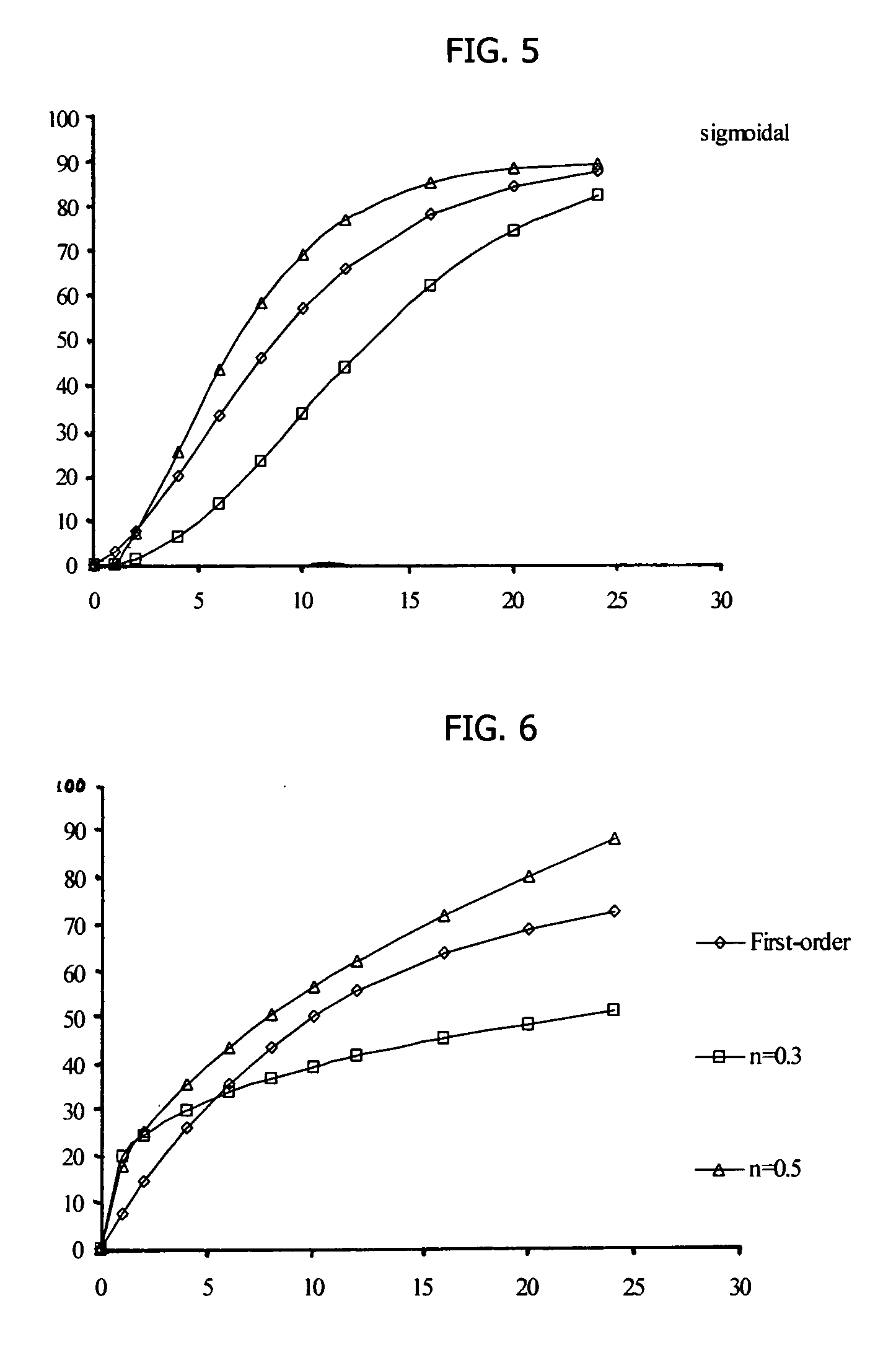

Osmotic device containing amantadine and an osmotic salt

The osmotic devices of the present invention contain a unitary core comprising a salt of amantadine and an osmotic salt, wherein the two salts have an ion in common. The release rate of the amantadine is modified from a first order release profile to a zero order, pseudo-zero order or sigmoidal release profile by increasing the amount of the osmotic salt in the core of the device. The osmotic device includes a semipermeable membrane having a controlled porosity that can be adapted as needed to cooperate with the osmotic salt in providing a predetermined drug release profile. The osmotic salt need not be coated and it is in admixture with the amantadine salt.

Owner:OSMOTICA KERESKEDELMI & SZOLGALTATO

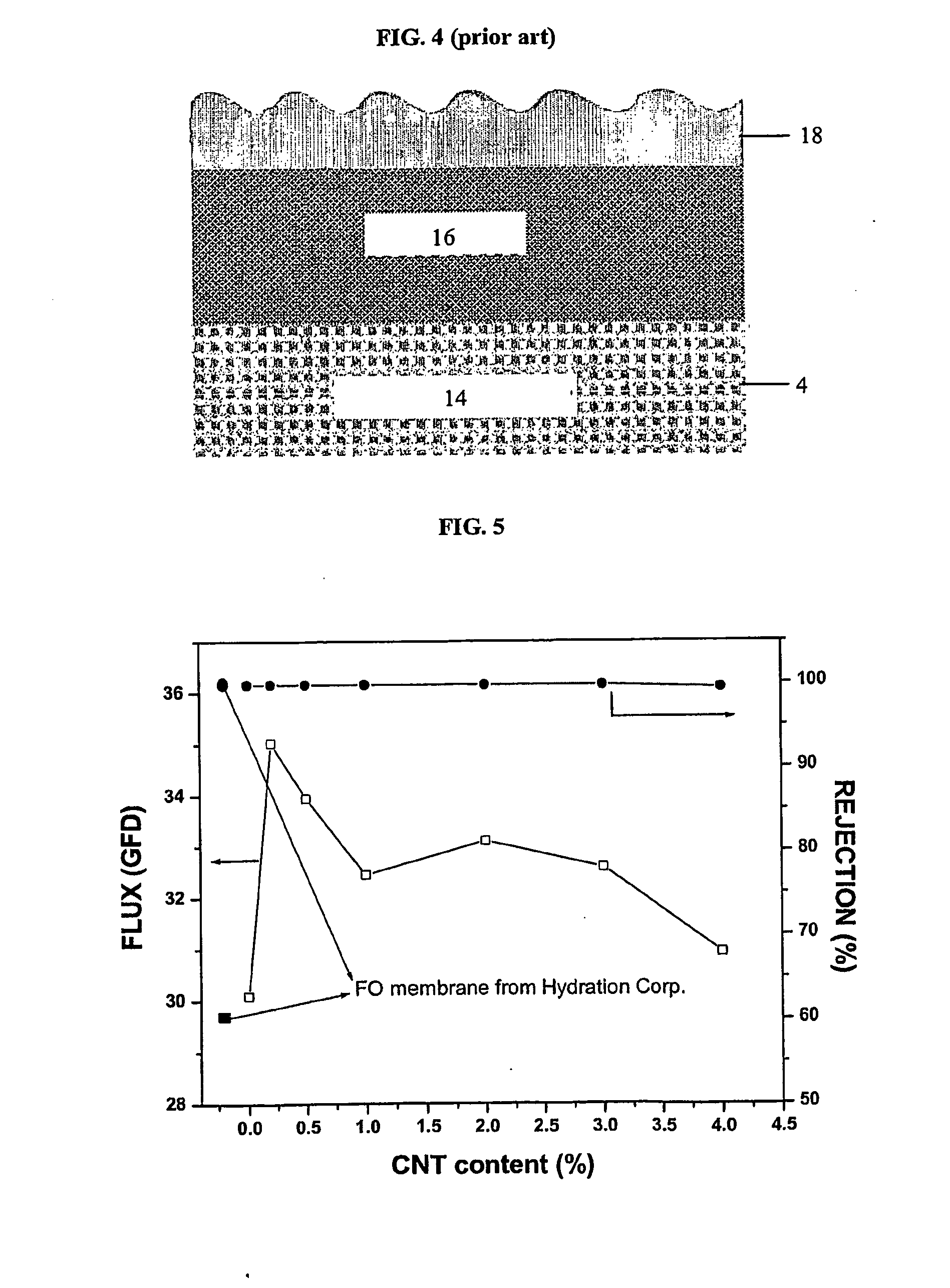

Polymeric membranes incorporating nanotubes

InactiveUS20100206811A1Inhibition formationMaterial nanotechnologyMembranesSemipermeable membraneNanotube

The present invention relates to semipermeable membranes with nanotubes dispersed therein, and the methods of preparing the same.

Owner:NAT UNIV OF SINGAPORE

Apparatus for the extracorporeal treatment of blood

ActiveUS20110309019A1Improve performanceEasy temperature controlSemi-permeable membranesSolvent extractionMeasurement deviceSemipermeable membrane

Apparatus and methods for the extracorporeal treatment of blood are described. The apparatus includes a dialyzer which is separated into a first and second chamber by a semipermeable membrane, wherein the first chamber is disposed in a dialysis fluid path and the second chamber can be connected to the blood circulation of a patient by way of a blood inflow conduit and a blood outflow conduit, a feed for fresh dialysis fluid, a discharge for spent dialysis fluid, a measuring device disposed within the discharge for determining the absorption of the spent dialysis fluid flowing through the discharge, wherein the measuring device has at least one radiation source for substantially monochromatic electromagnetic radiation, and a detector system for detecting the intensity of the electromagnetic radiation, wherein means are provided to compensate for changes that occur in the intensity of the electromagnetic radiation of the radiation source and / or the sensitivity of the detector system.

Owner:B BRAUN AVITUM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com