Patents

Literature

825results about "Capacitor terminals" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

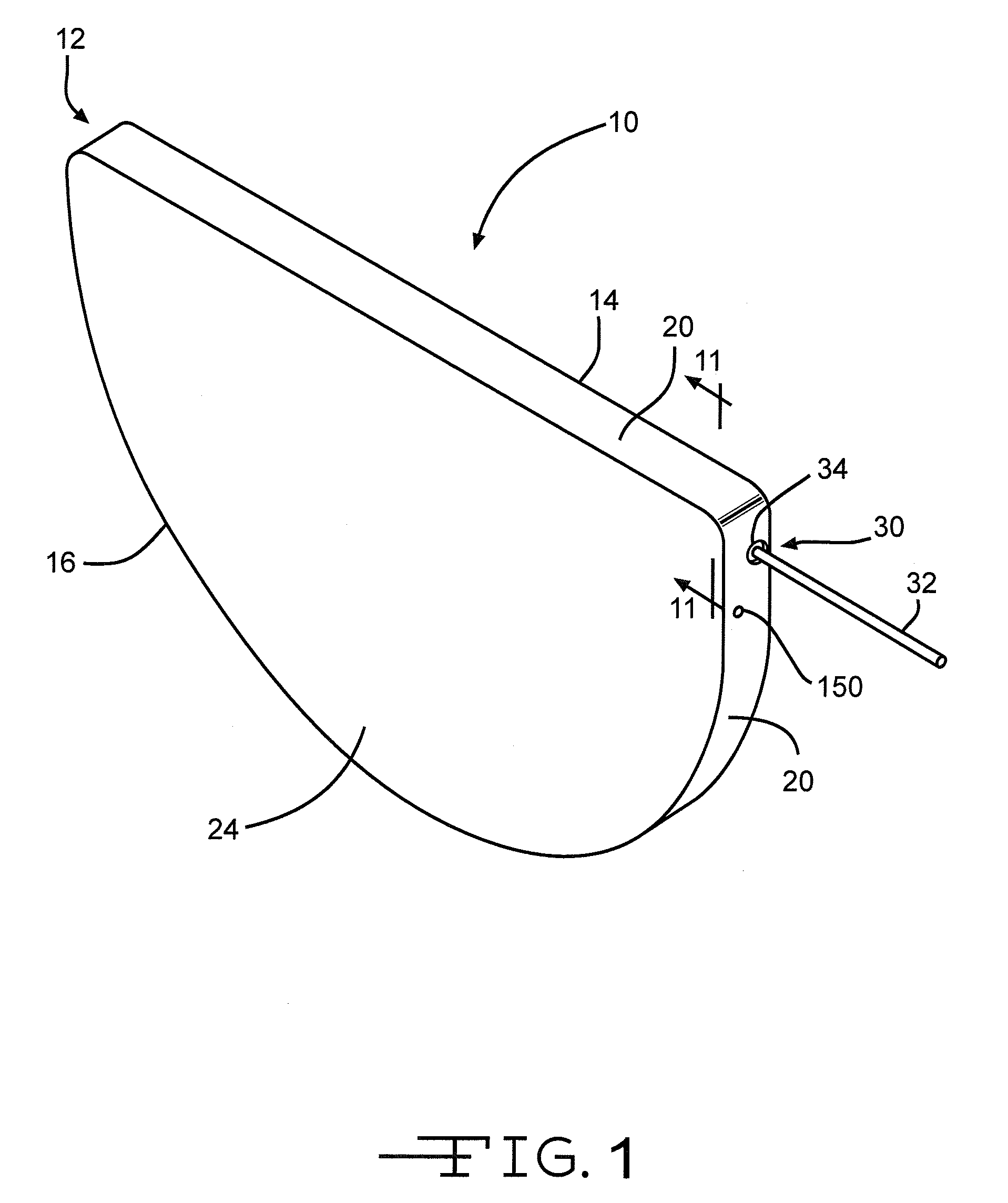

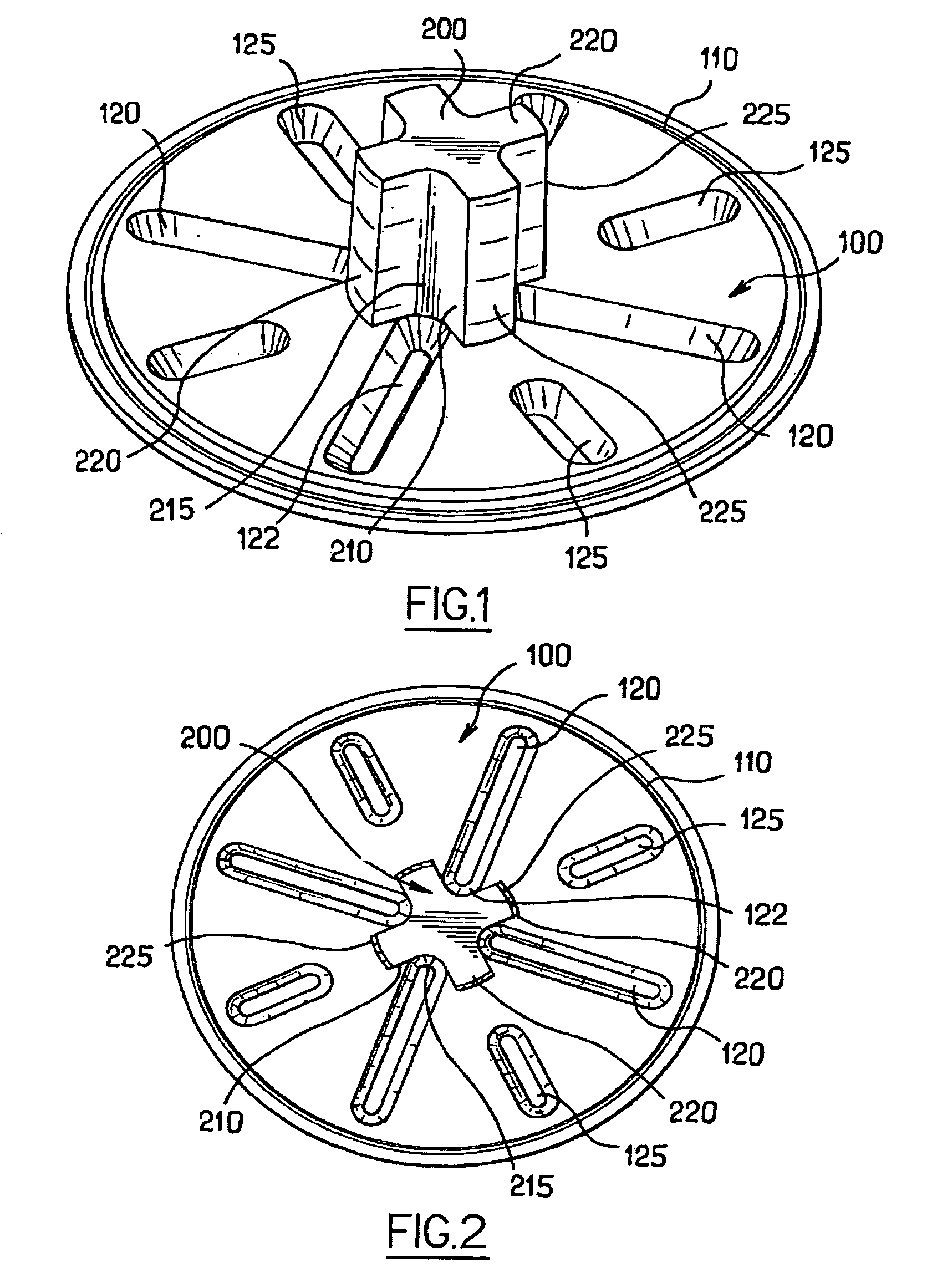

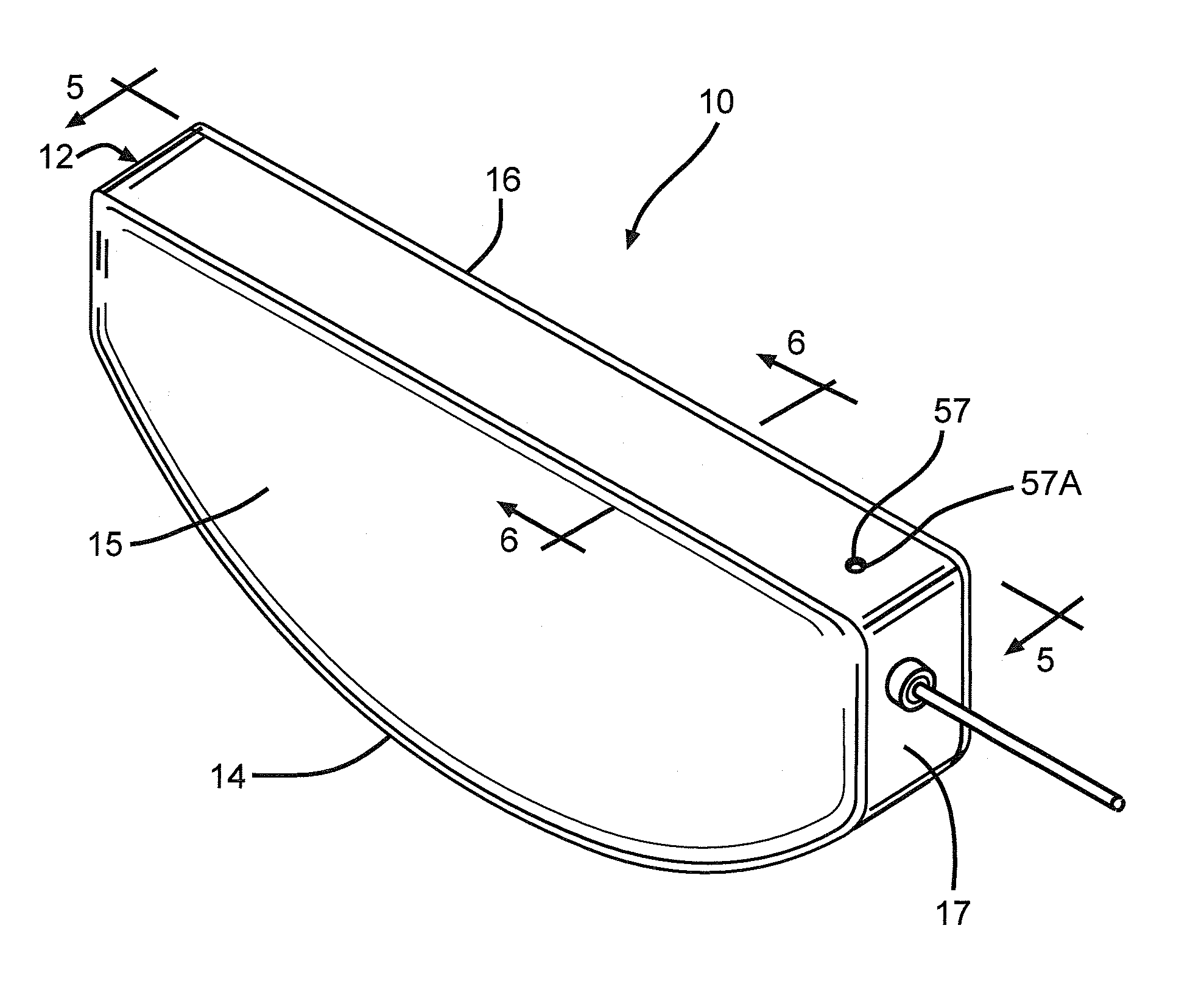

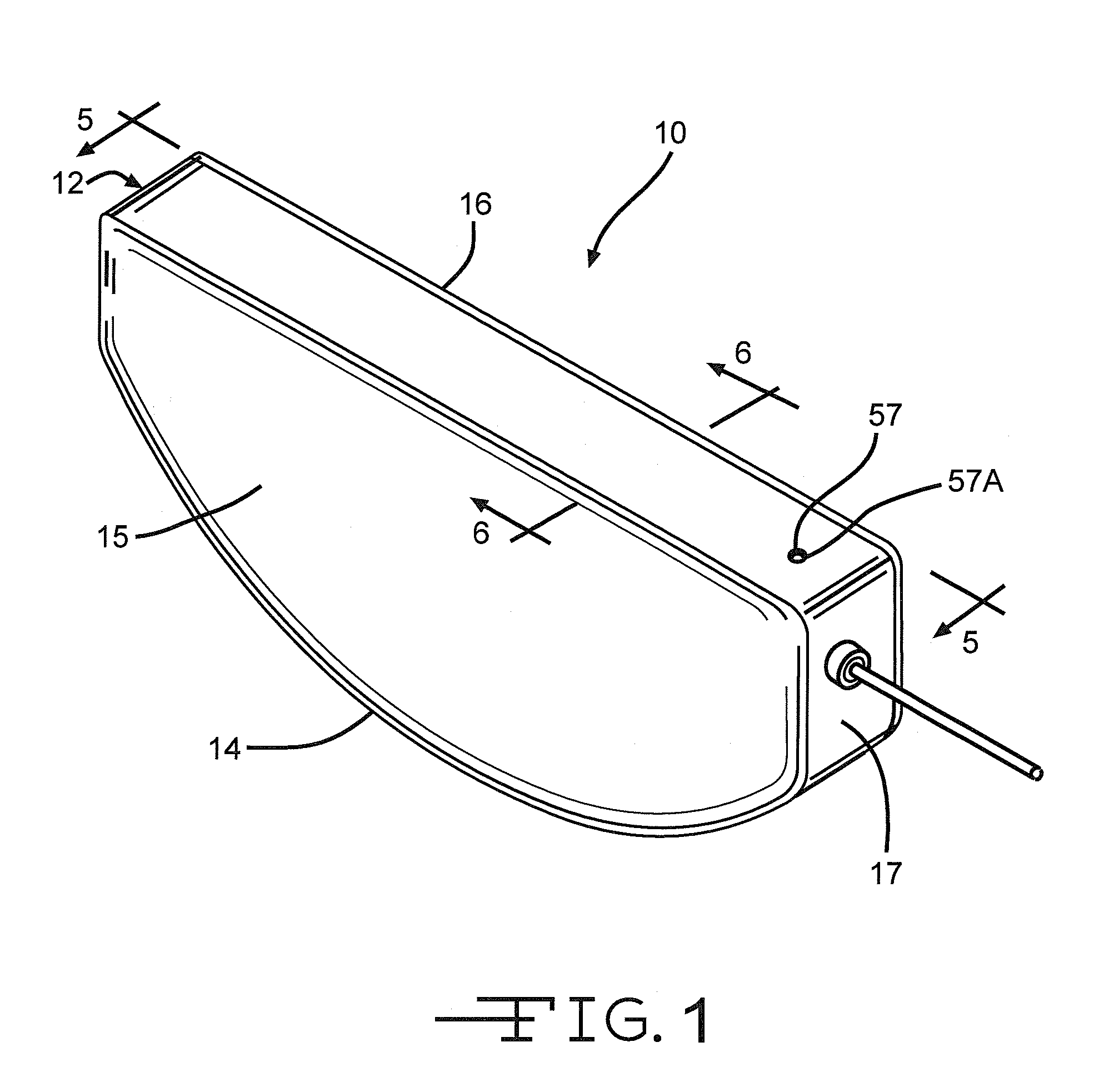

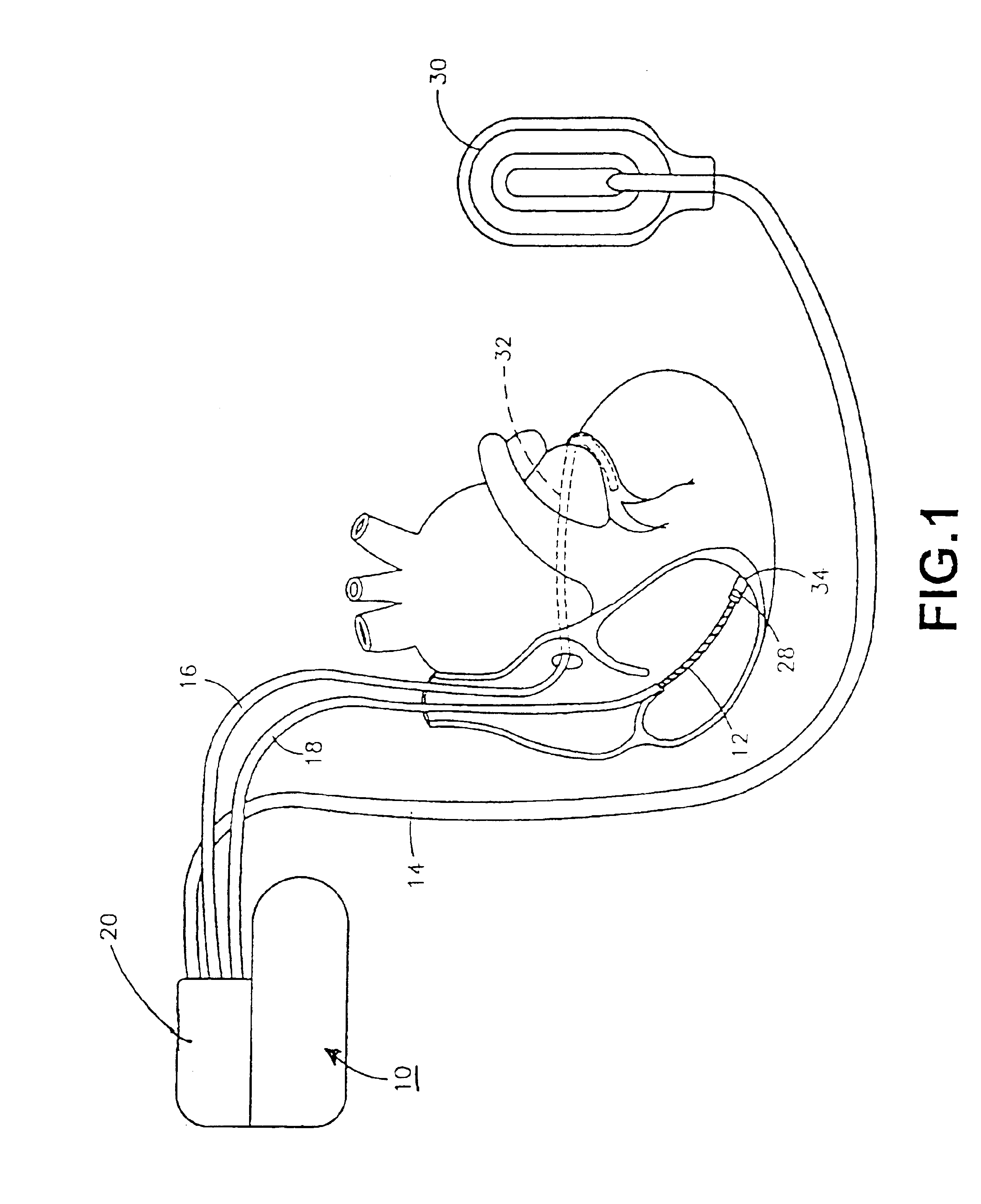

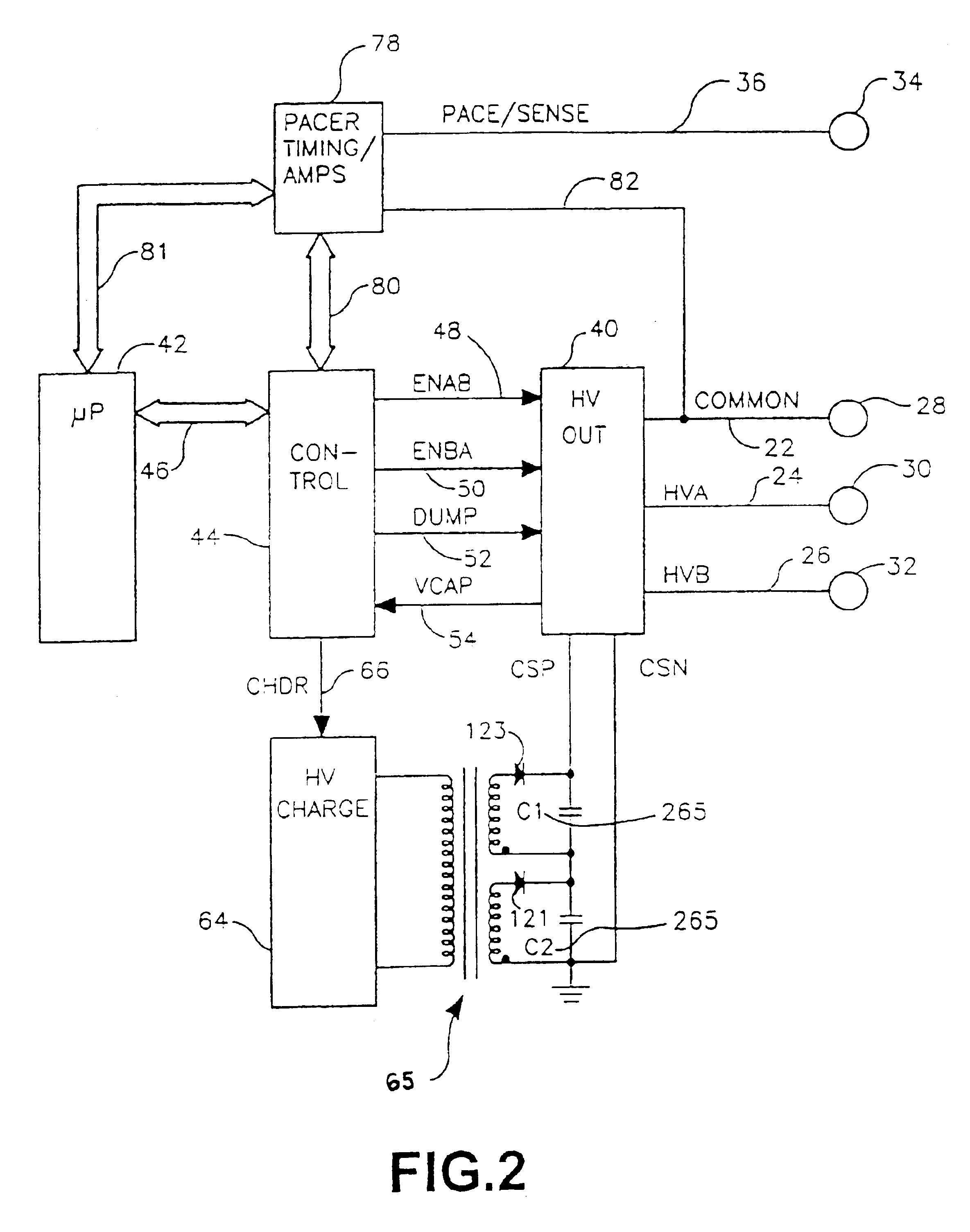

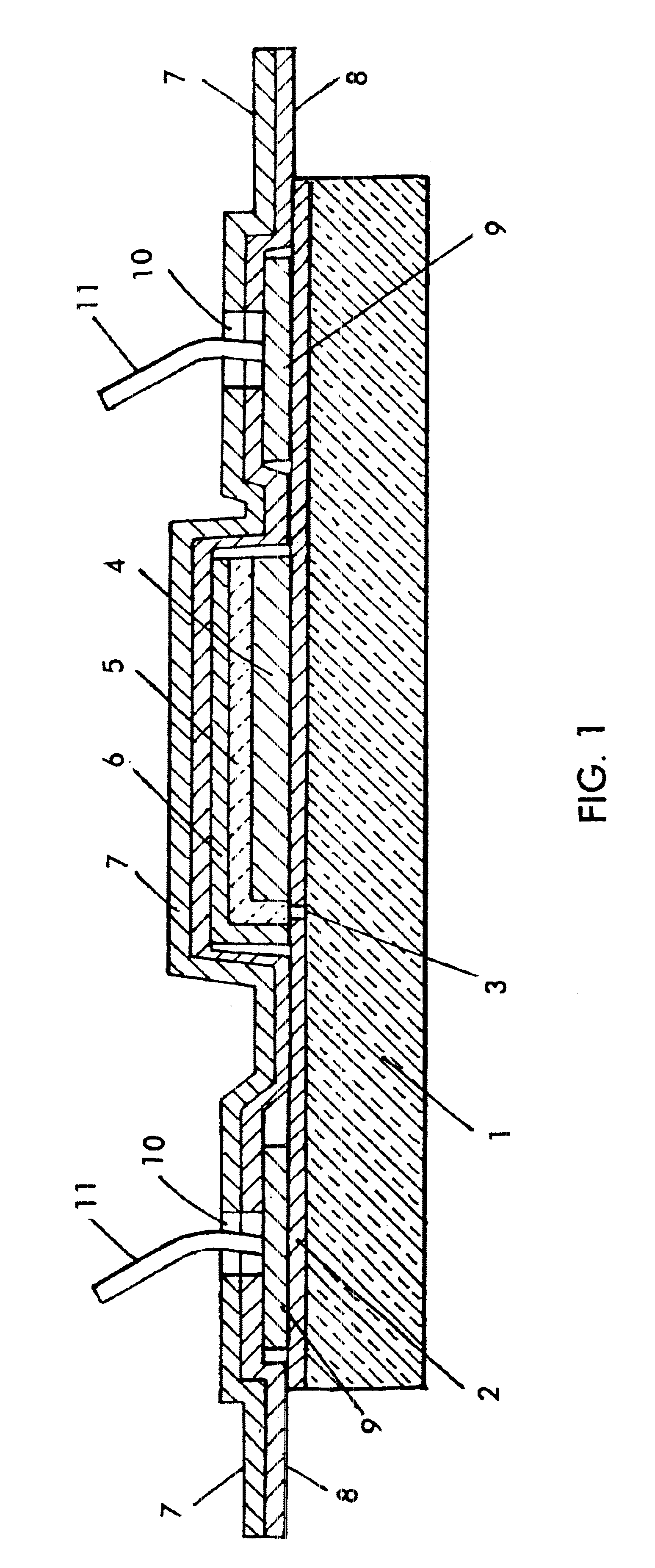

Flat capacitor for an implantable medical device

InactiveUS6699265B1Liquid electrolytic capacitorsCapacitor terminalsCapacitanceSemipermeable membrane

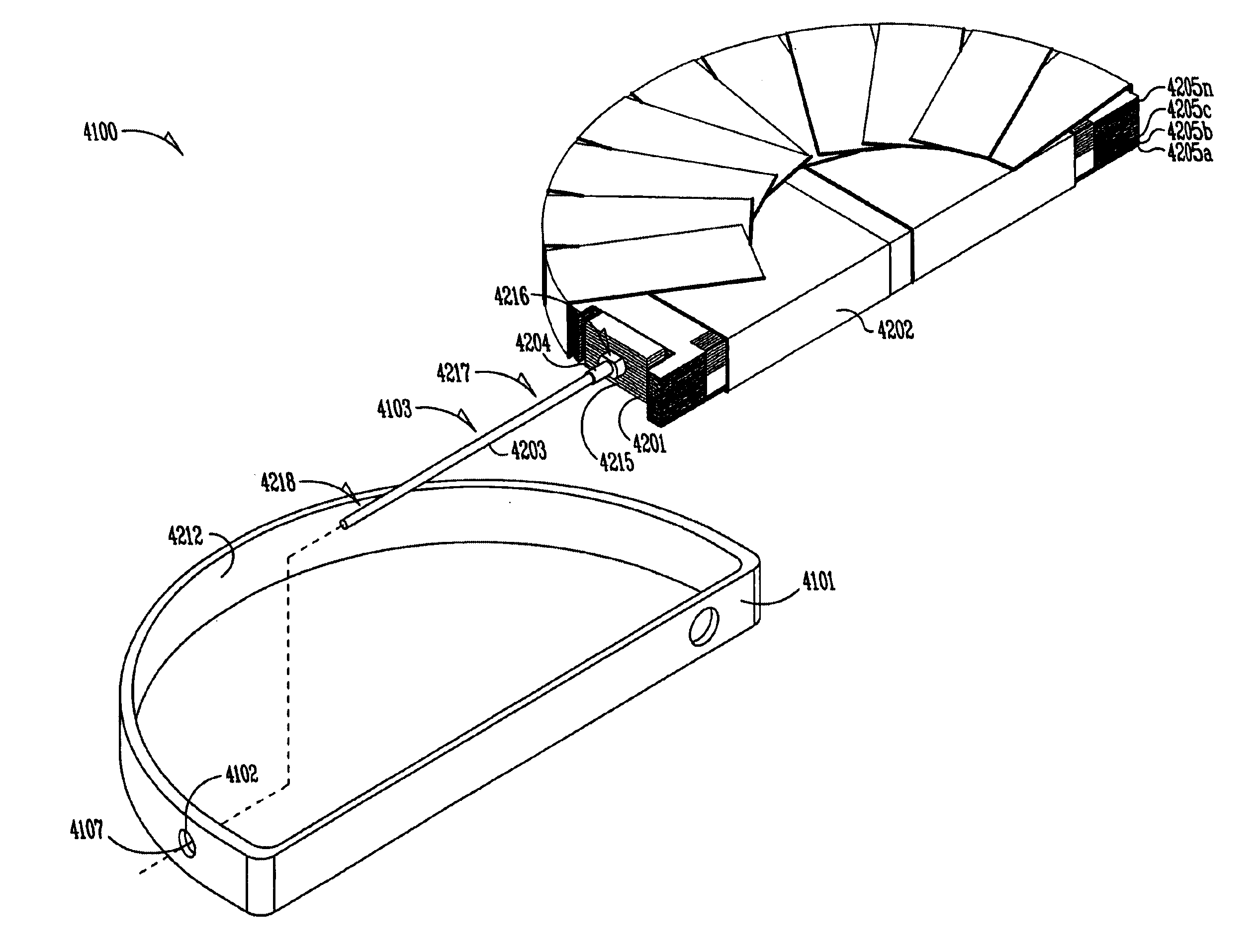

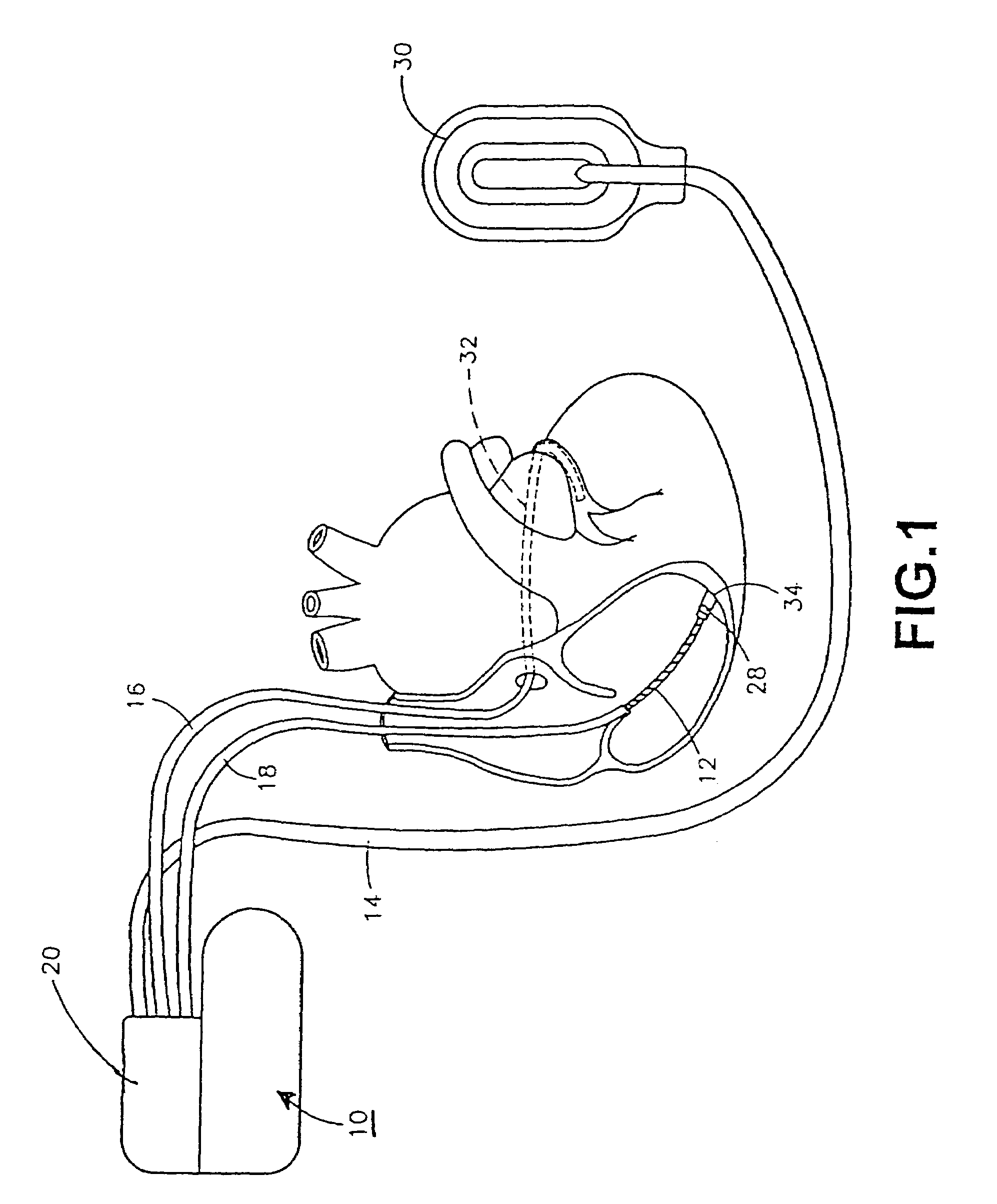

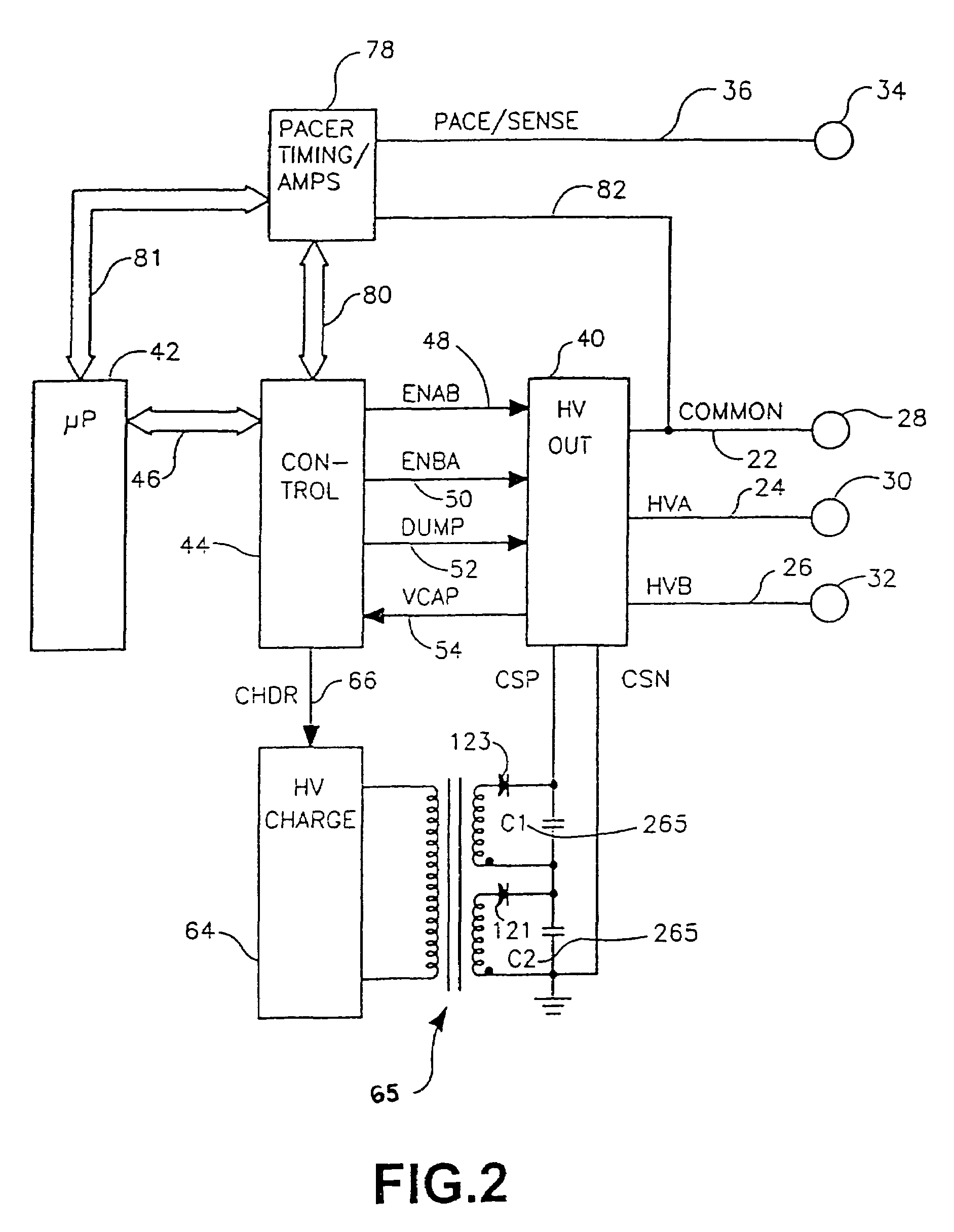

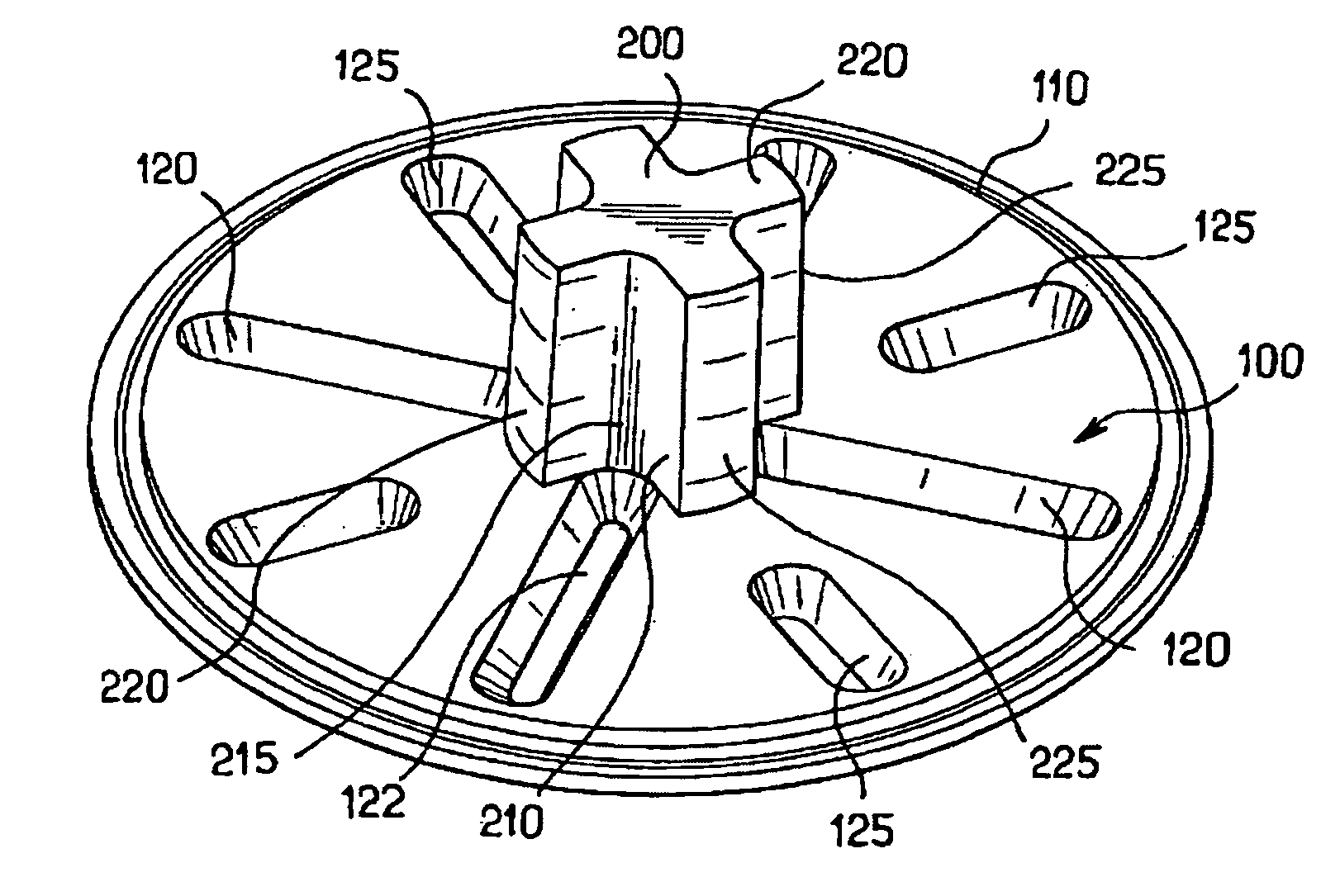

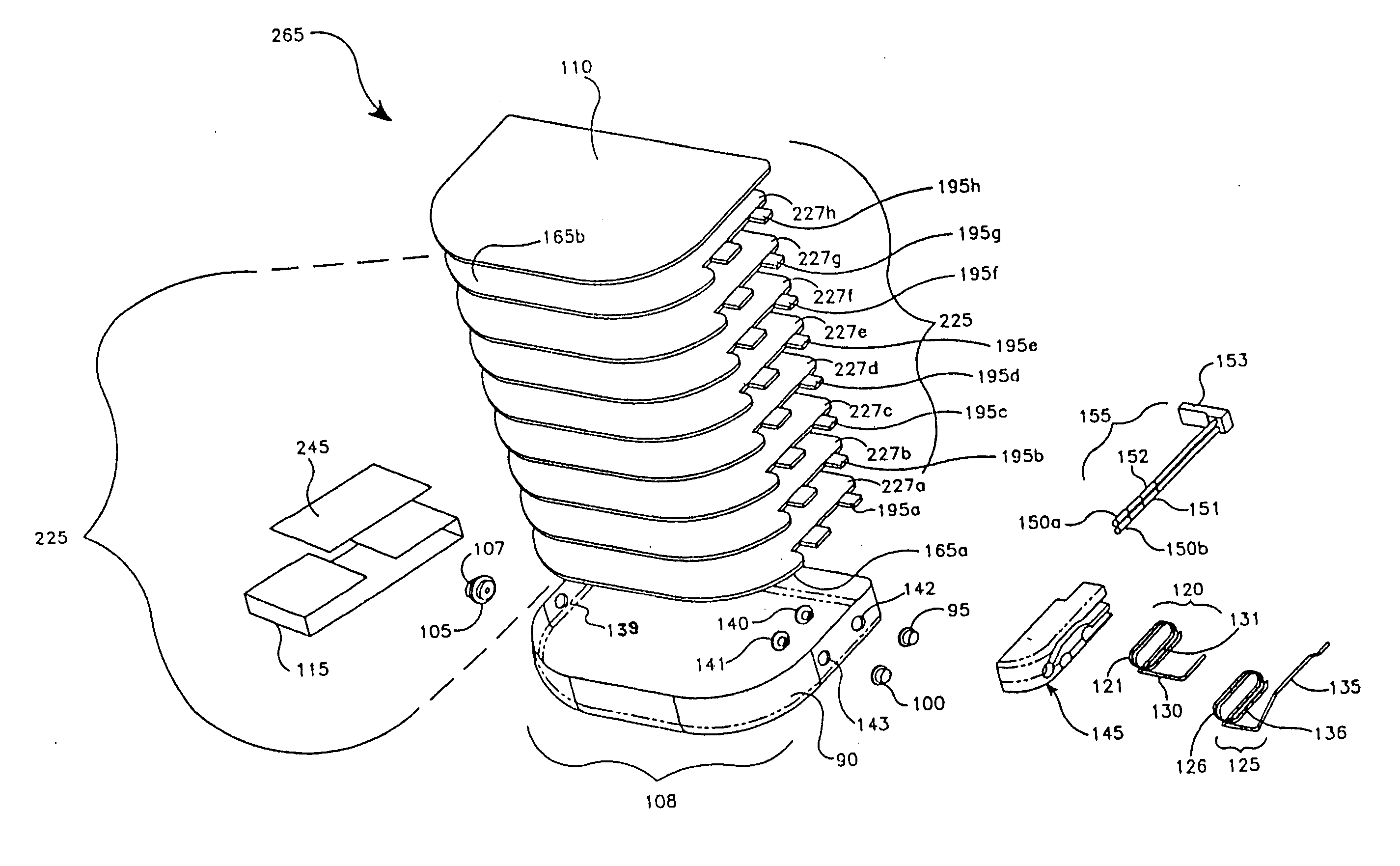

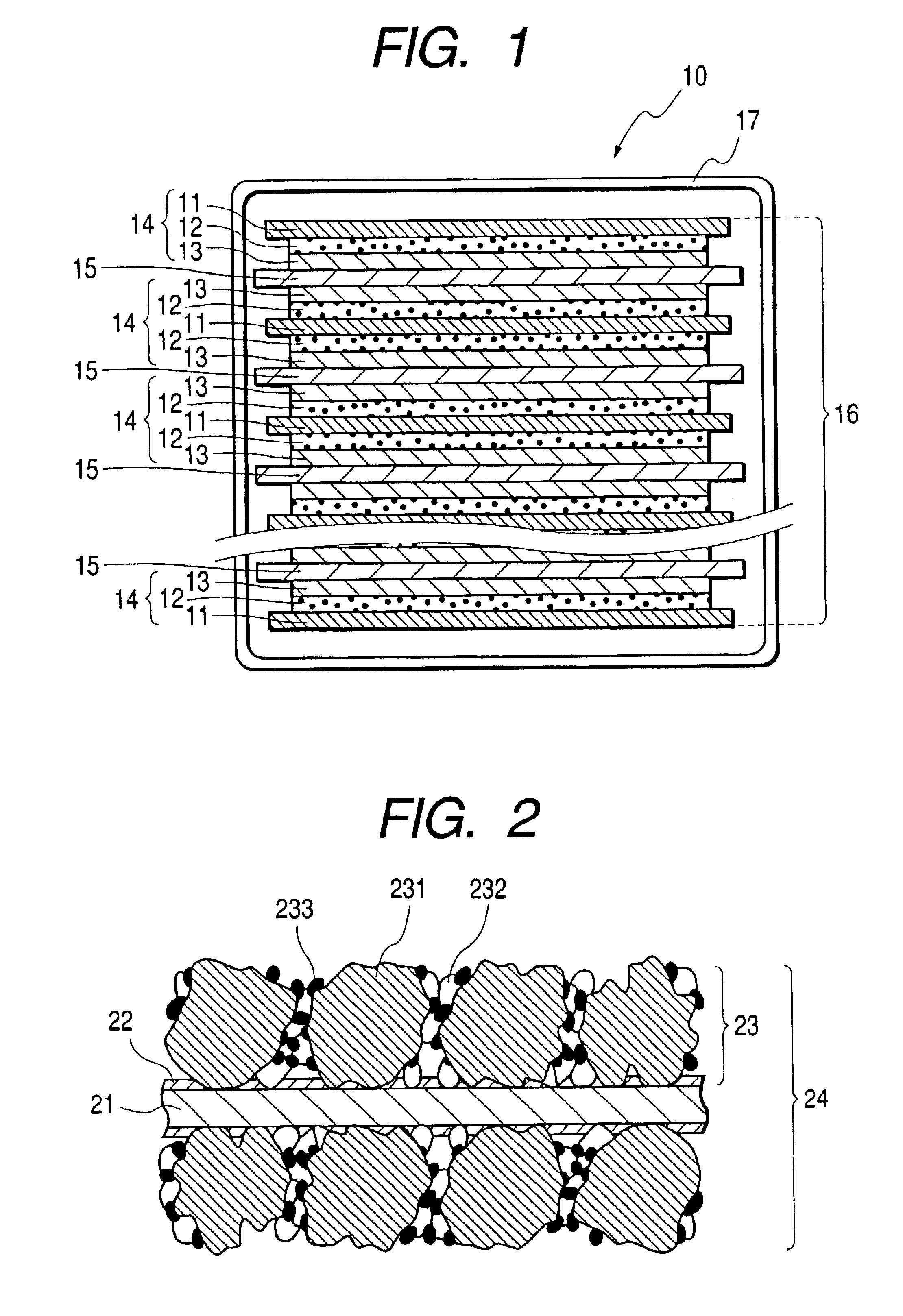

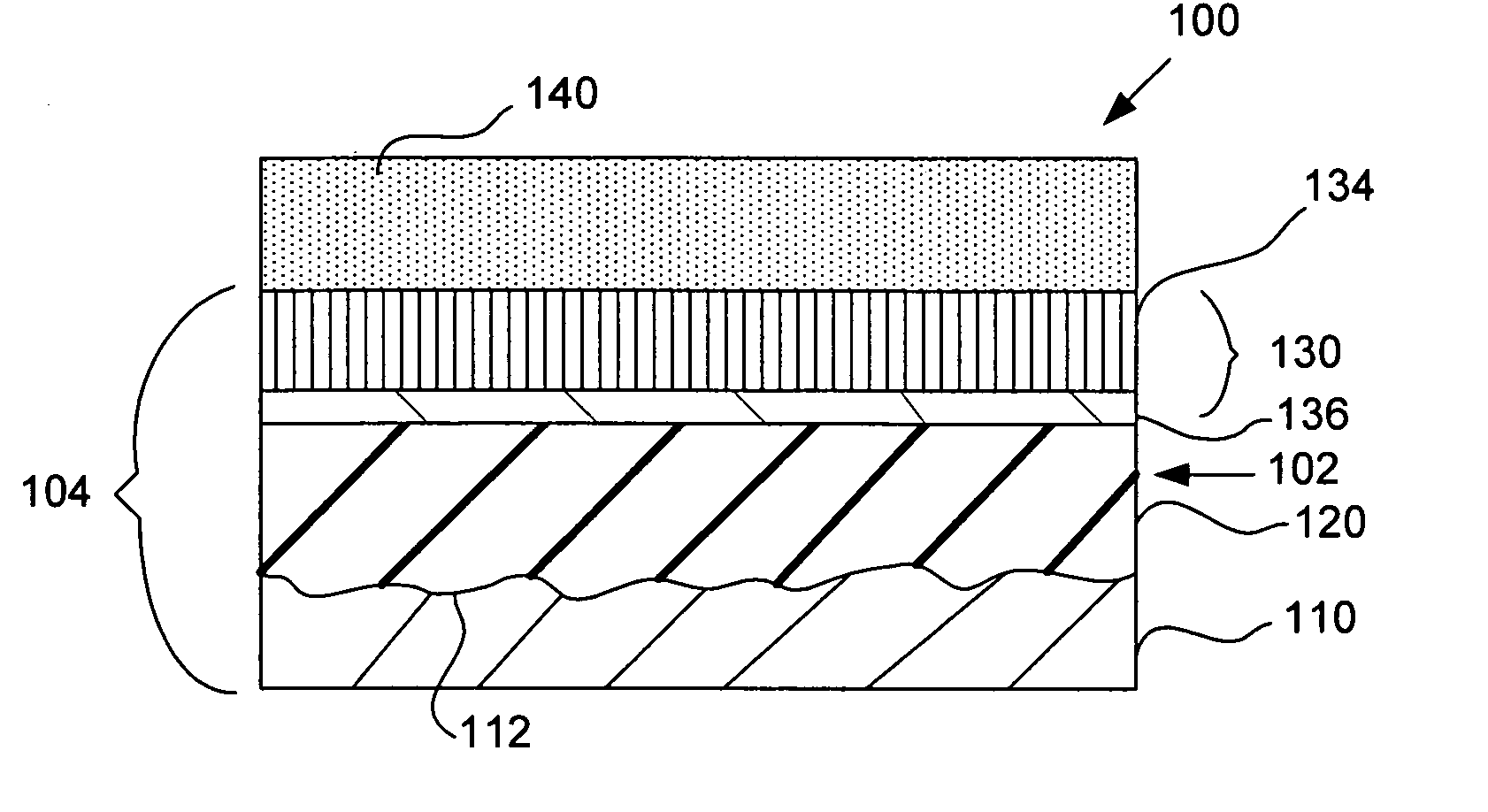

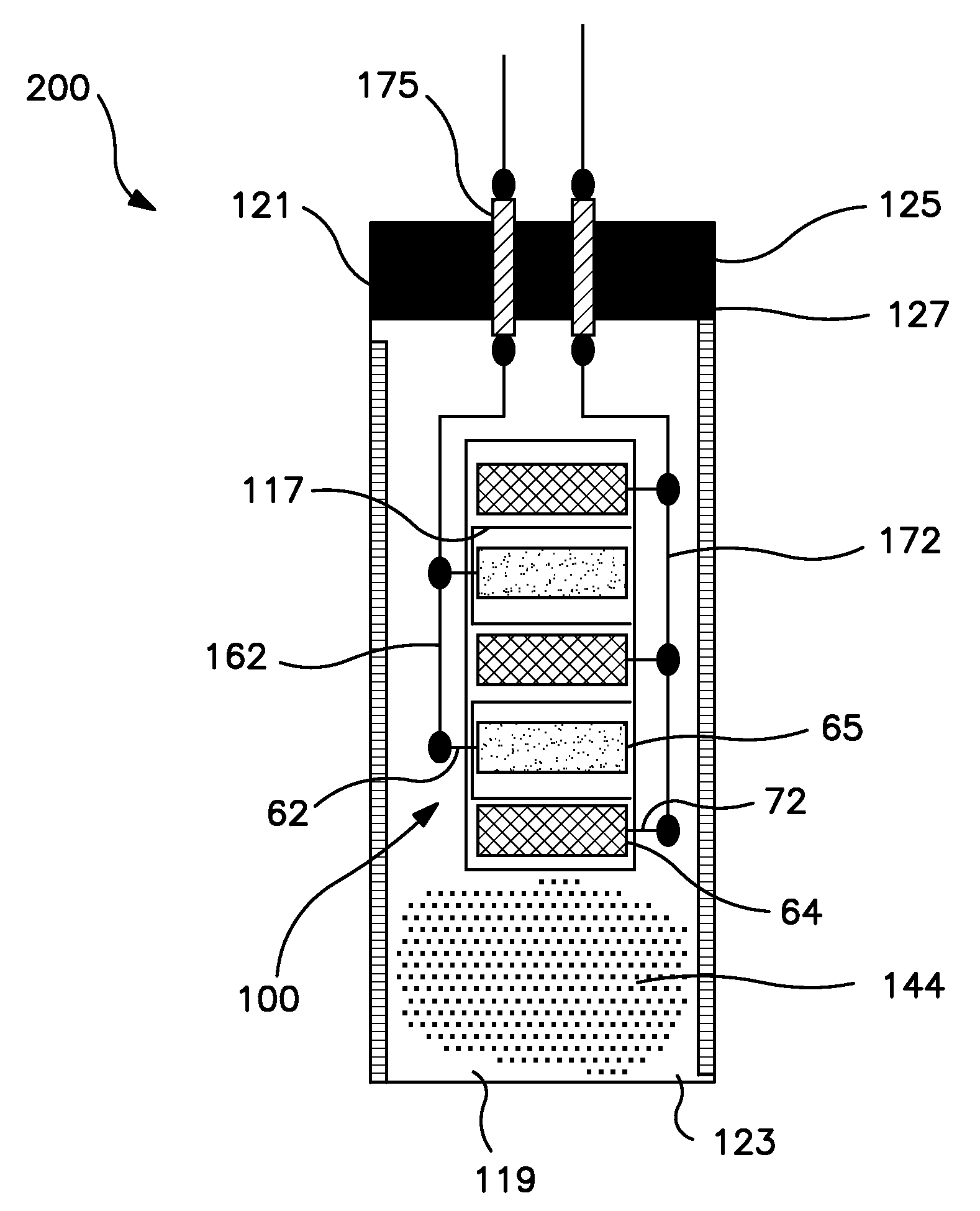

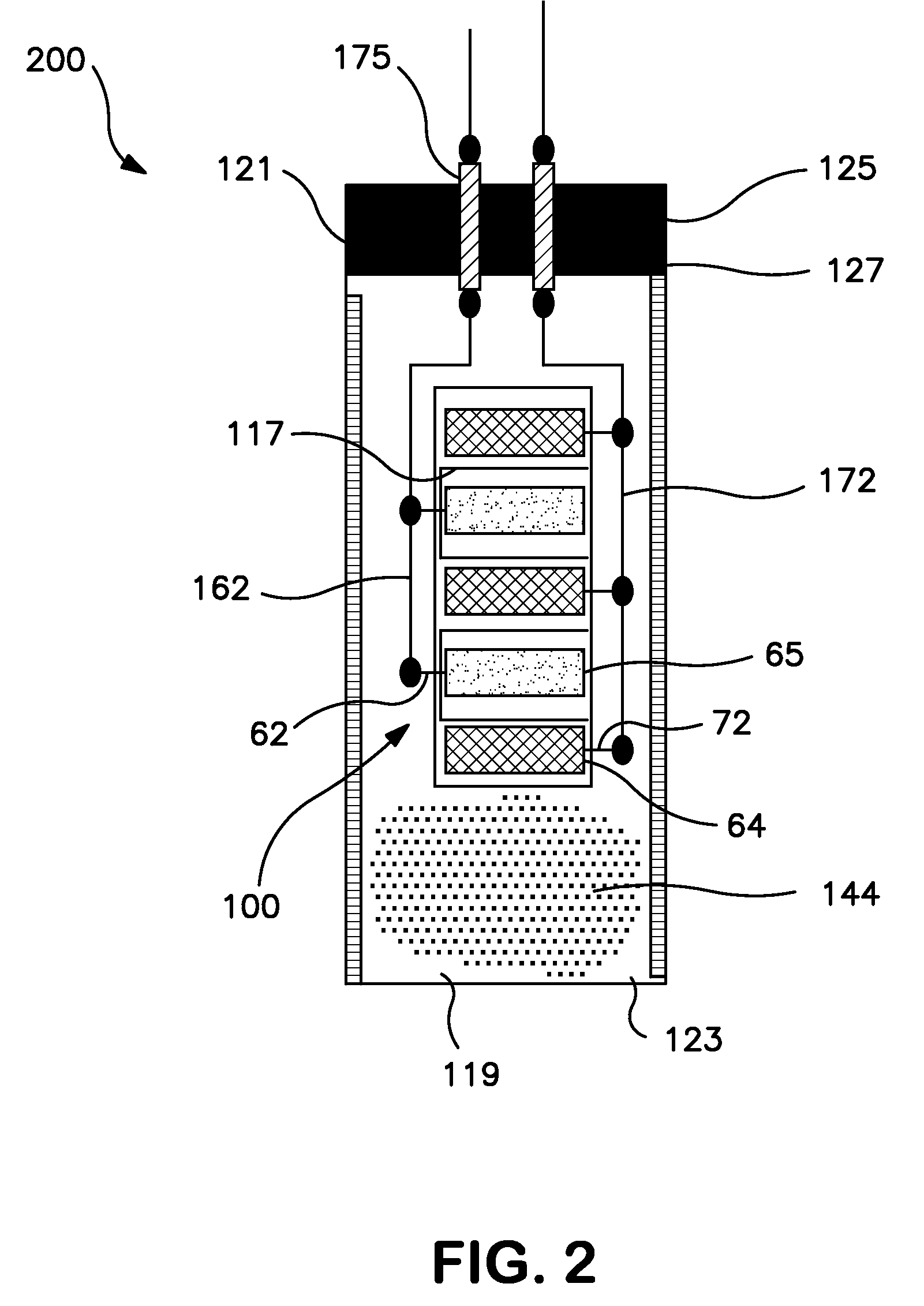

One embodiment includes a capacitor having a first anode stack having a first number of anode foils, a second anode stack having a second number of anode foils, where the first number of anode foils is different than the second number of anode foils. Another aspect provides a capacitor having a case having a curved interior surface, and first, second, and third capacitor modules that confront the curved interior surface of the case. One aspect provides a capacitor having one or more anodes and a cathode structure comprising a plurality of integrally connected cathode plates, the cathode structure having a serpentine shape, interweaving under and over each of the one or more anodes. One aspect provides a feedthrough assembly having an electrically conductive member dimensioned to extend at least partially through a feedthrough hole of a case of the capacitor, the conductive member having a passage therethrough. One aspect provides a capacitor having a first stack of capacitive elements a second stack of capacitive elements, wherein the first and second stacks are enclosed in separate compartments of a capacitor case that electrically isolate the electrolytes of each stack from one another. One aspect provides a capacitor case including a portion having opposing interior and exterior surfaces, with the portion having a hole; and a semi-permeable membrane adjacent the hole to regulate passage of fluids through the hole.

Owner:CARDIAC PACEMAKERS INC

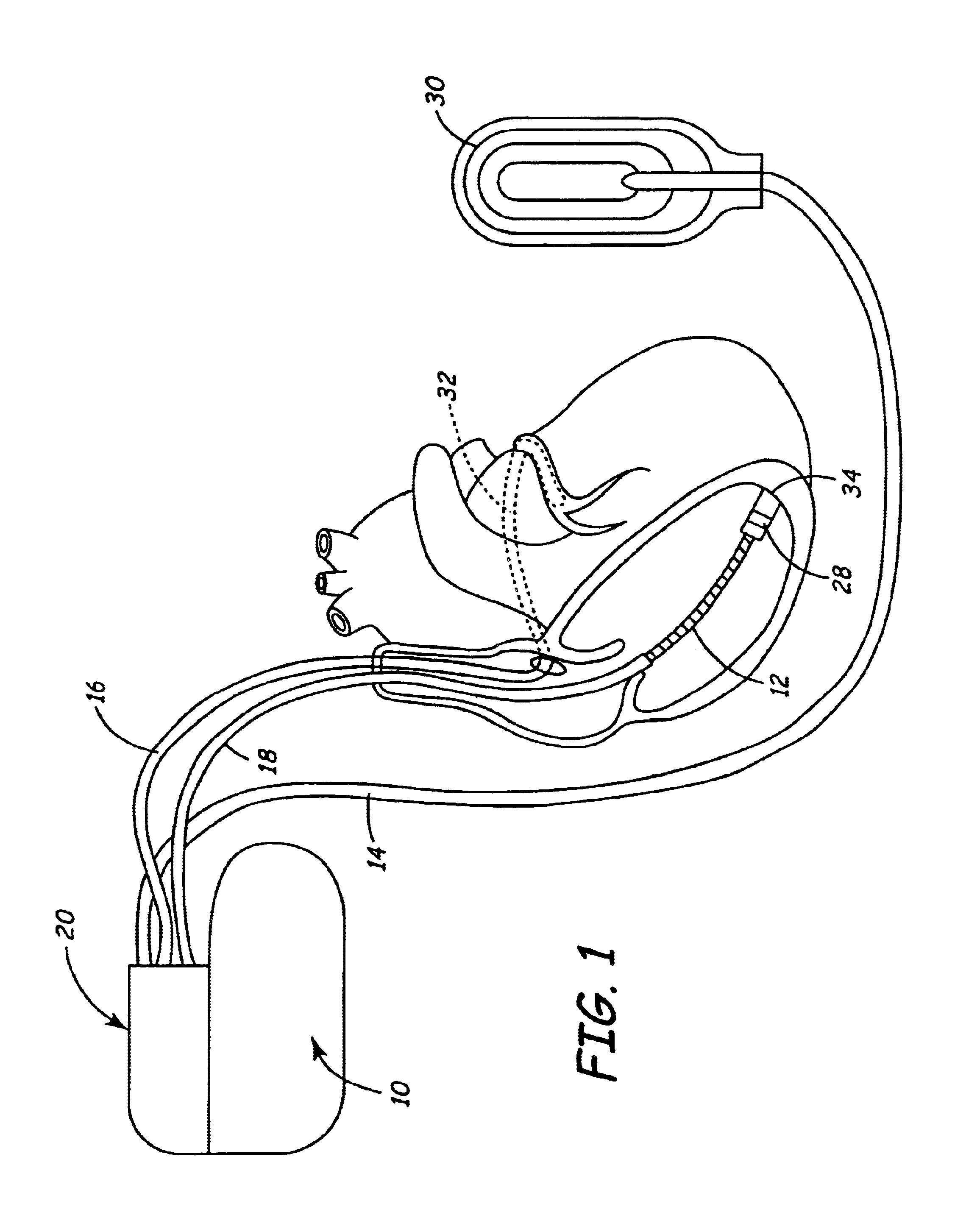

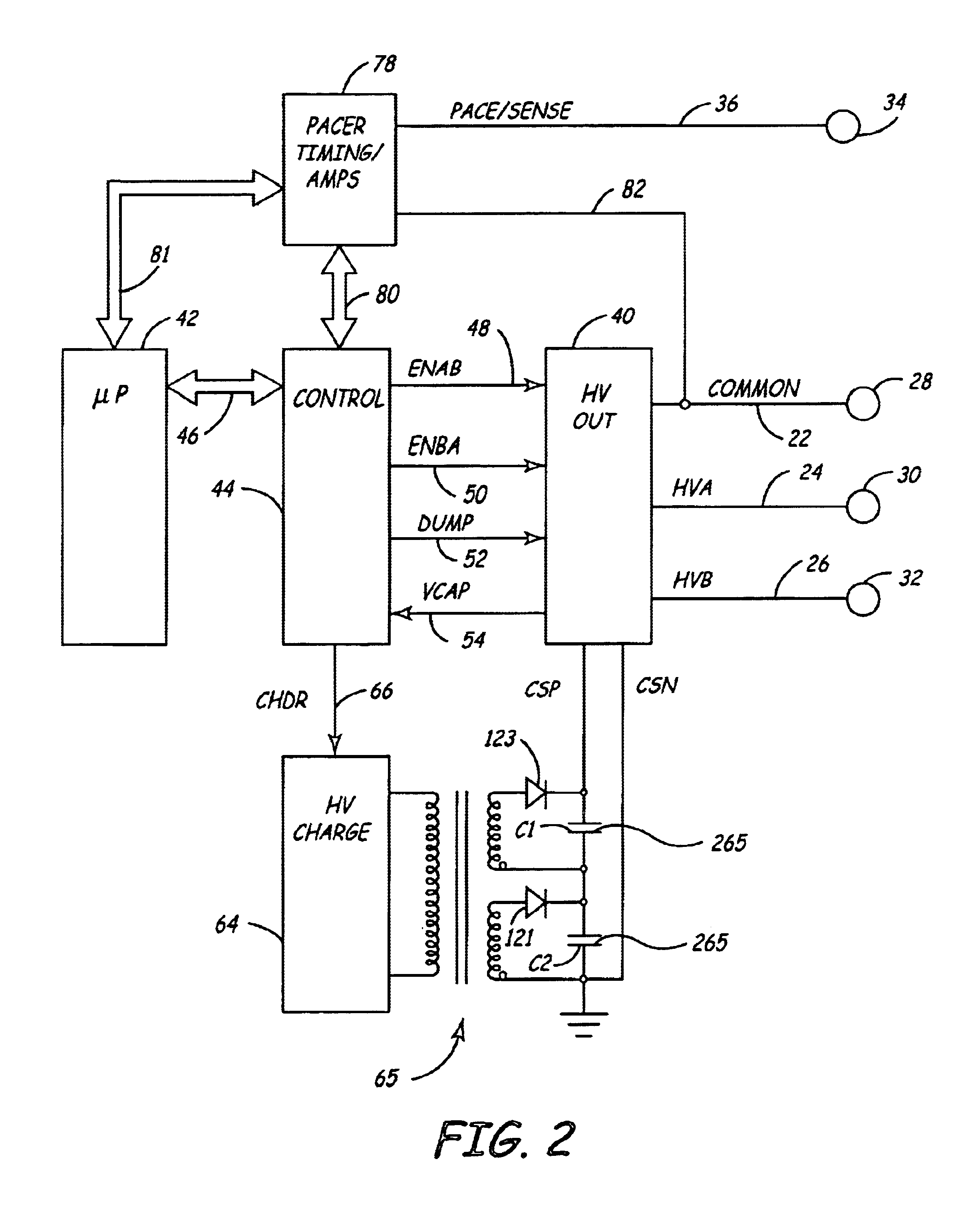

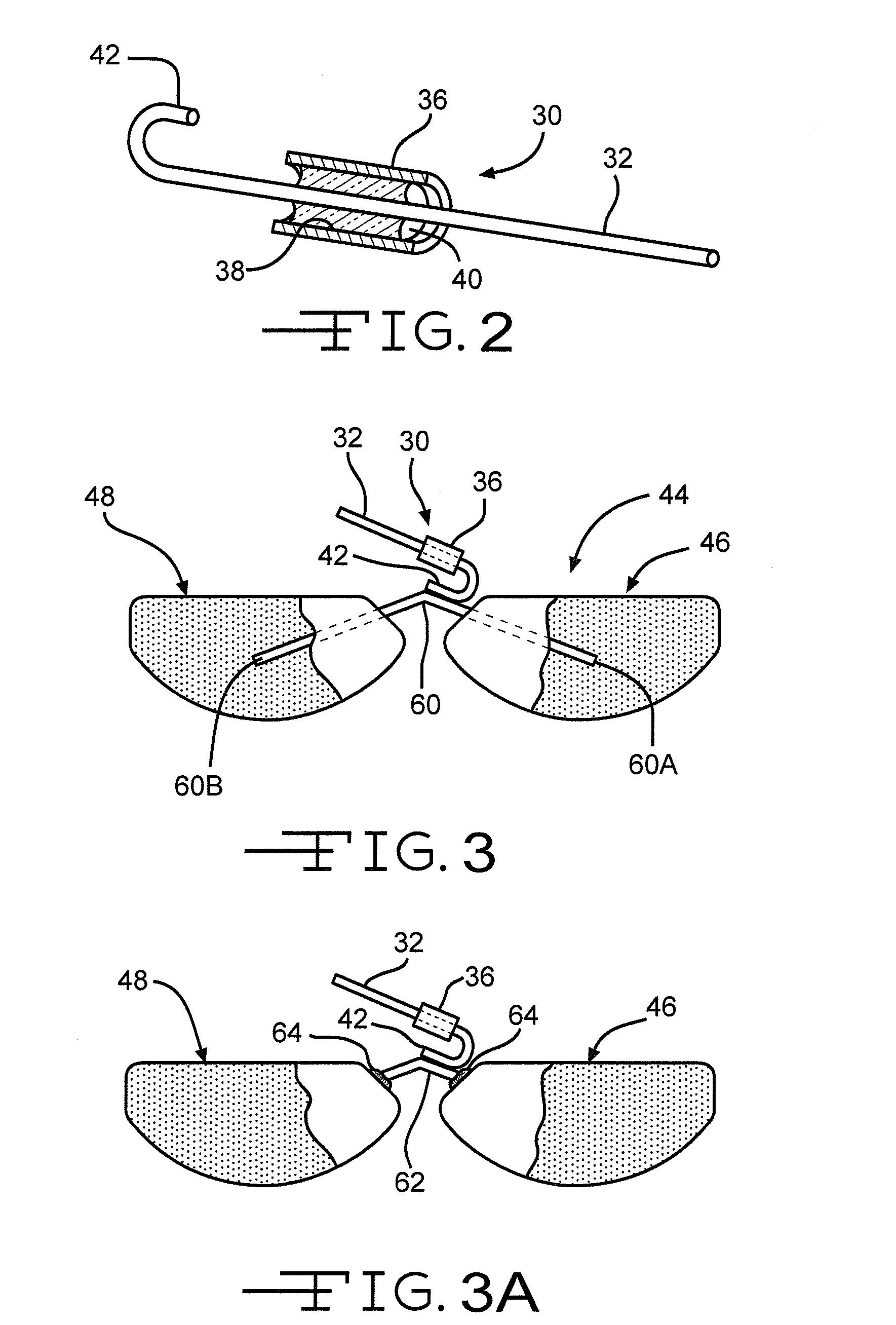

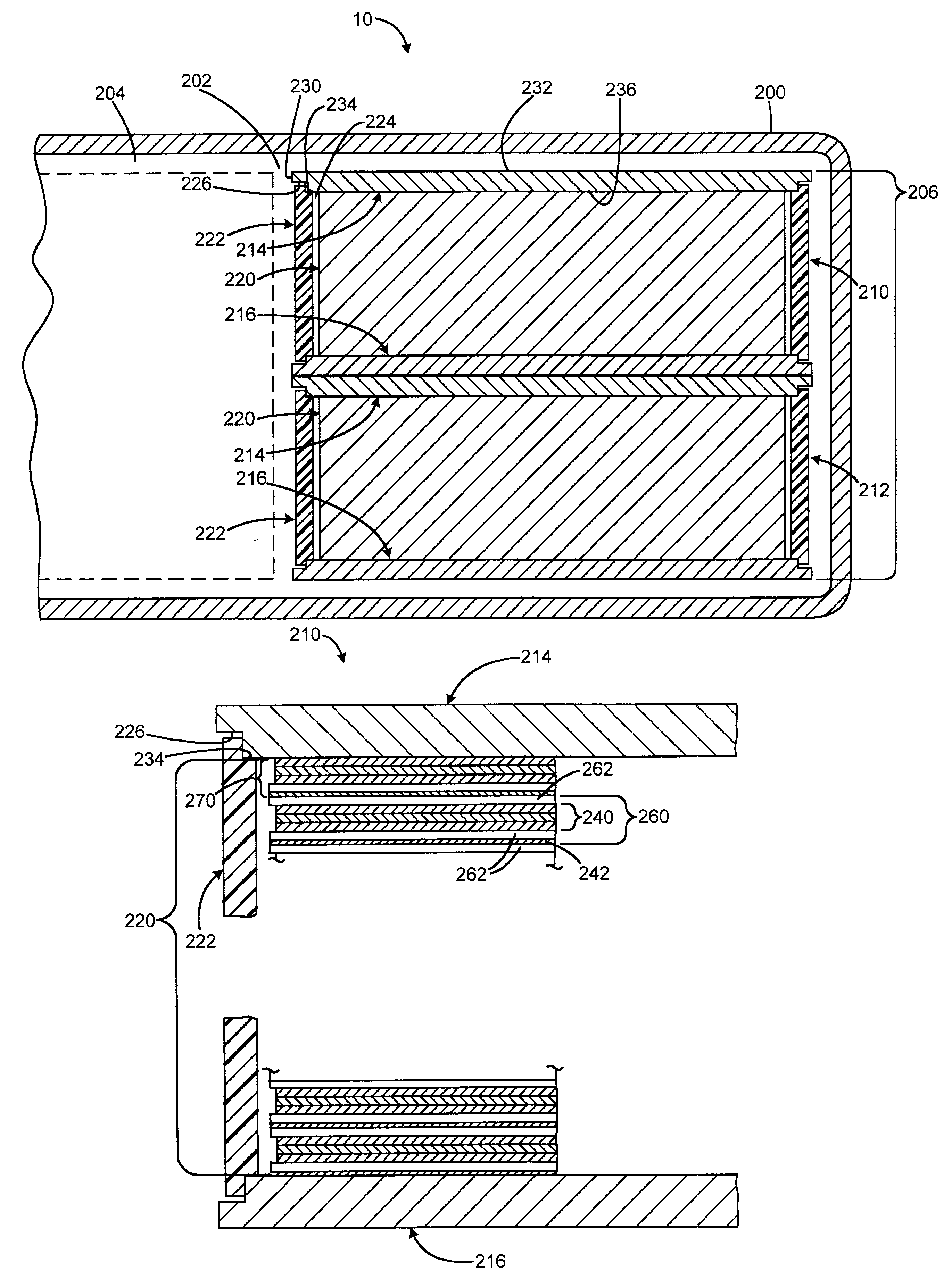

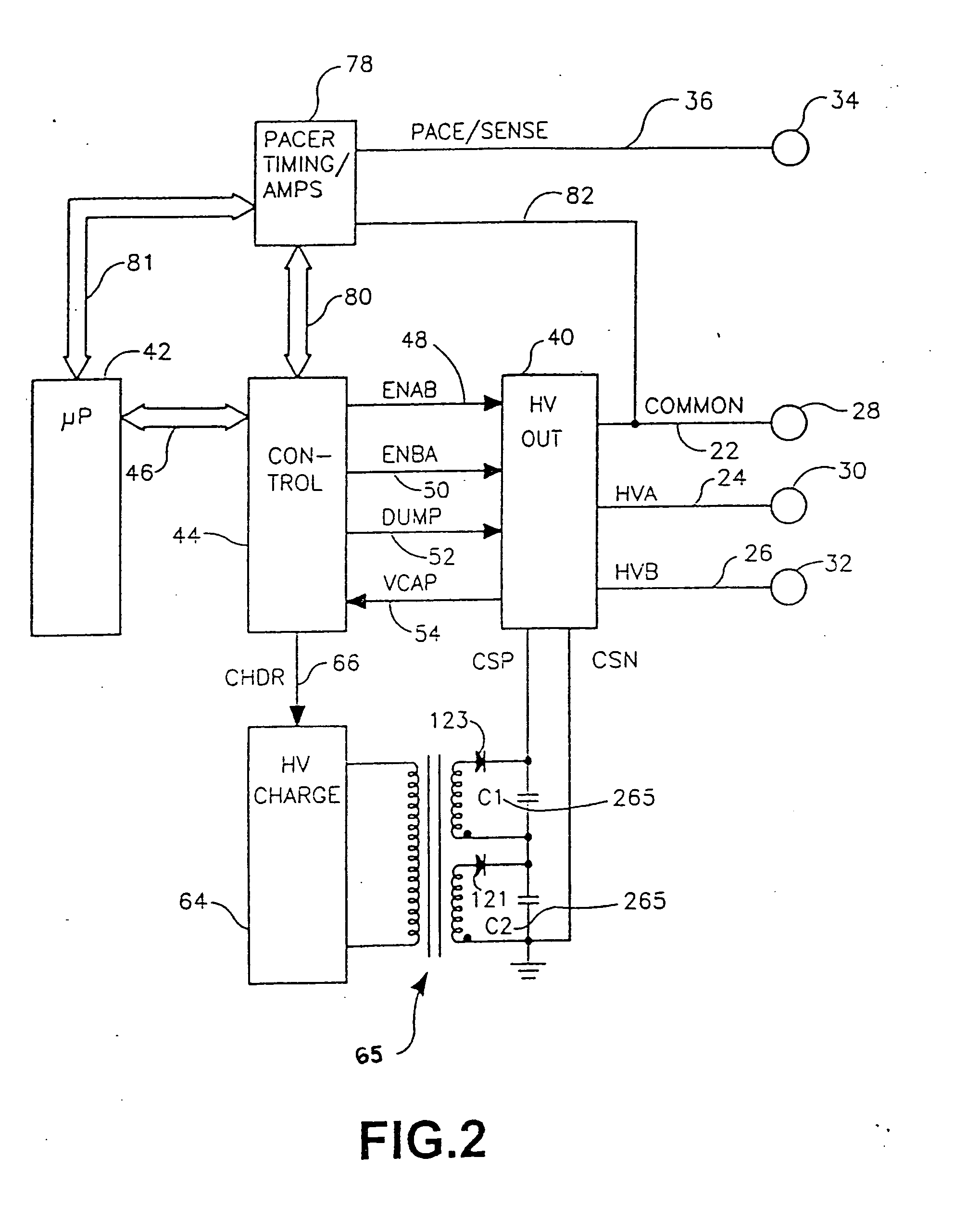

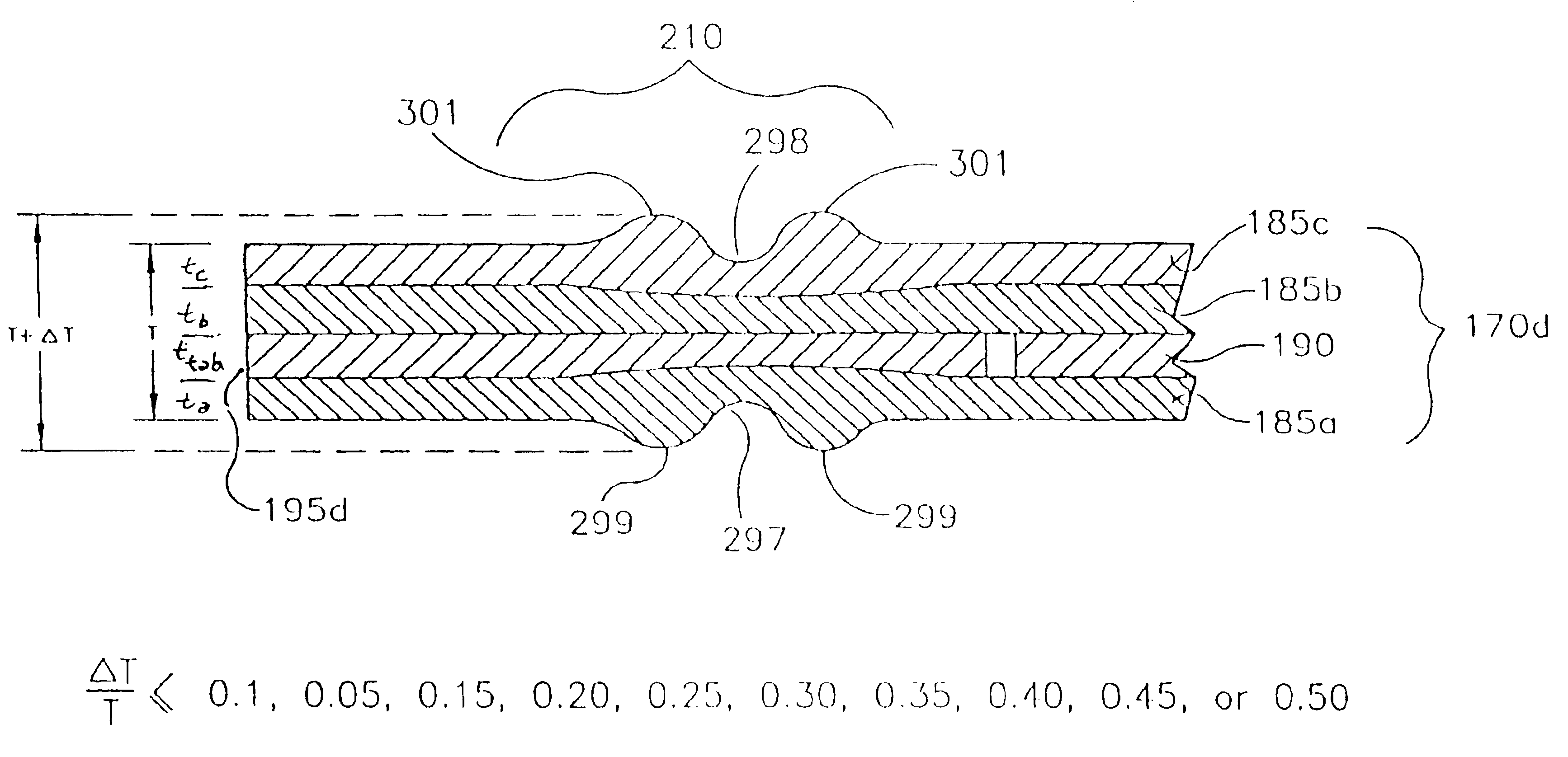

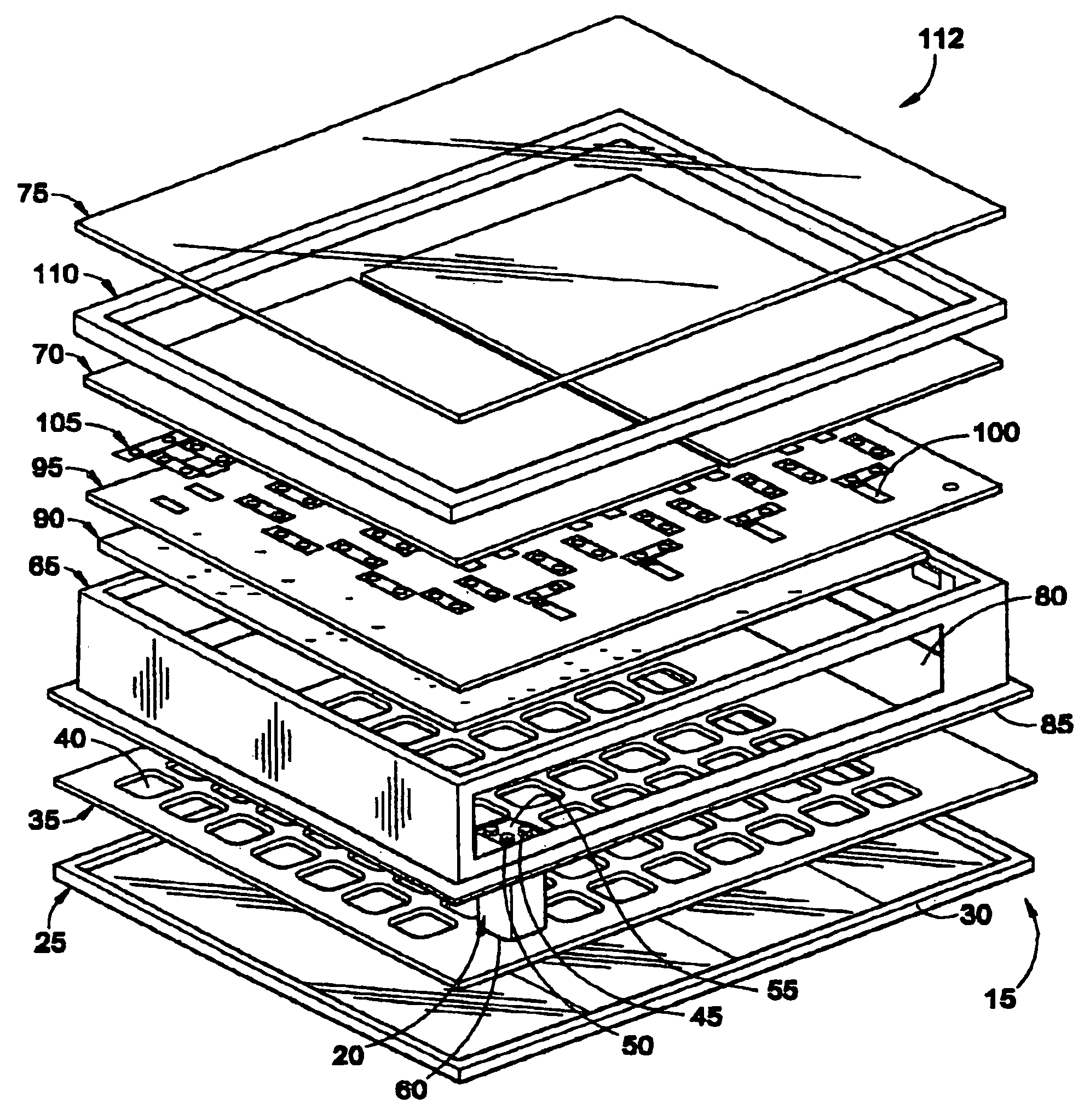

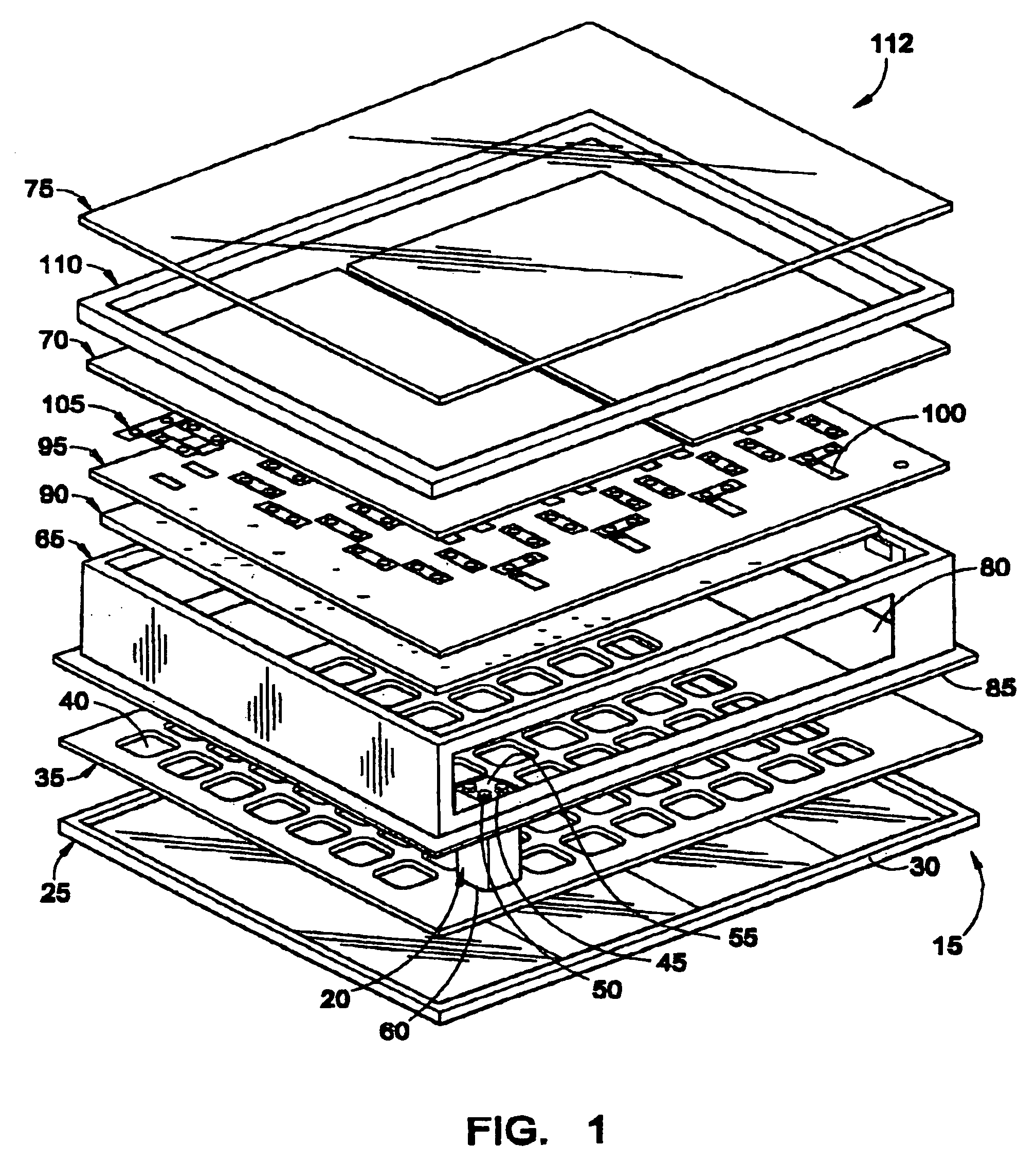

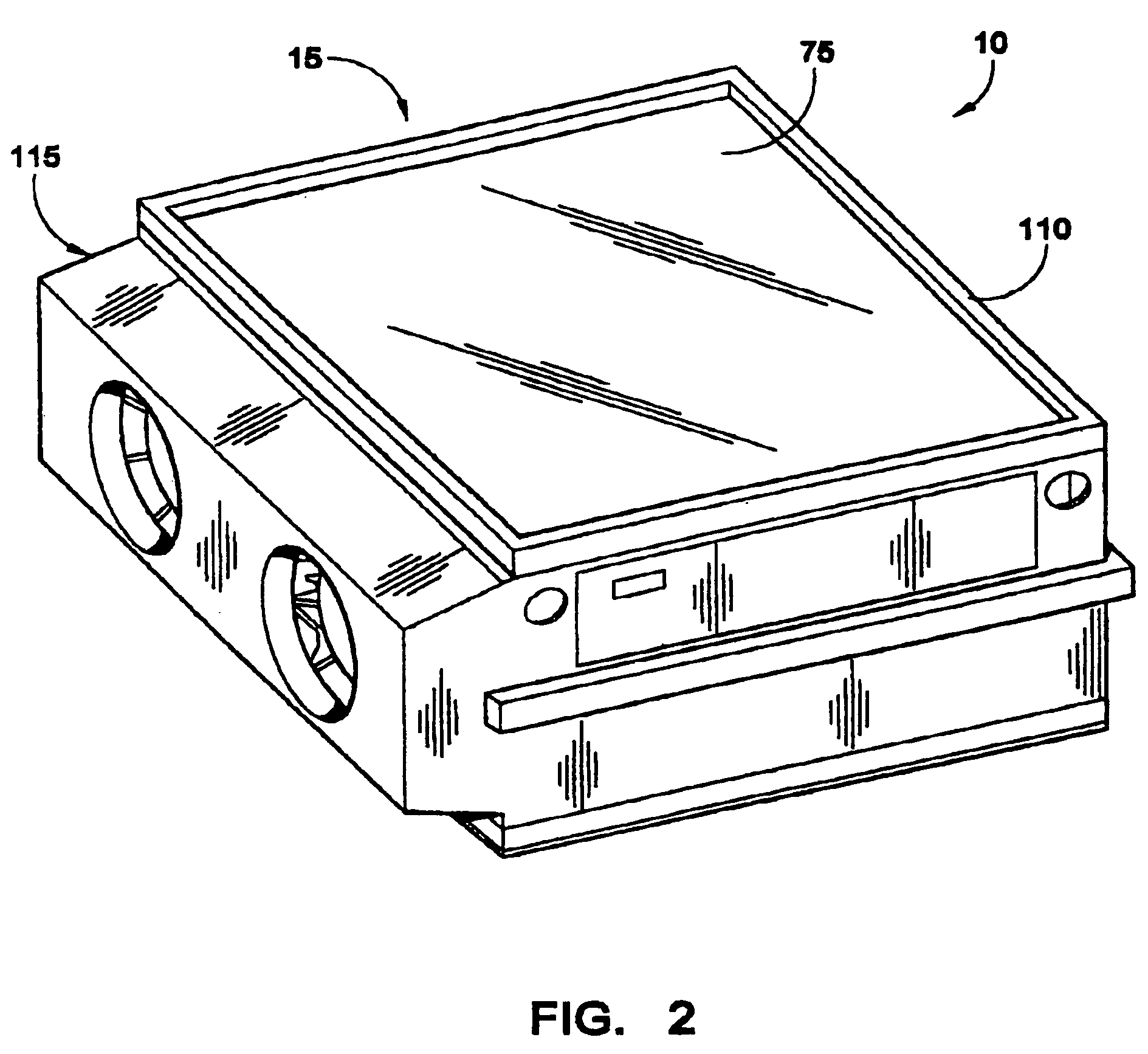

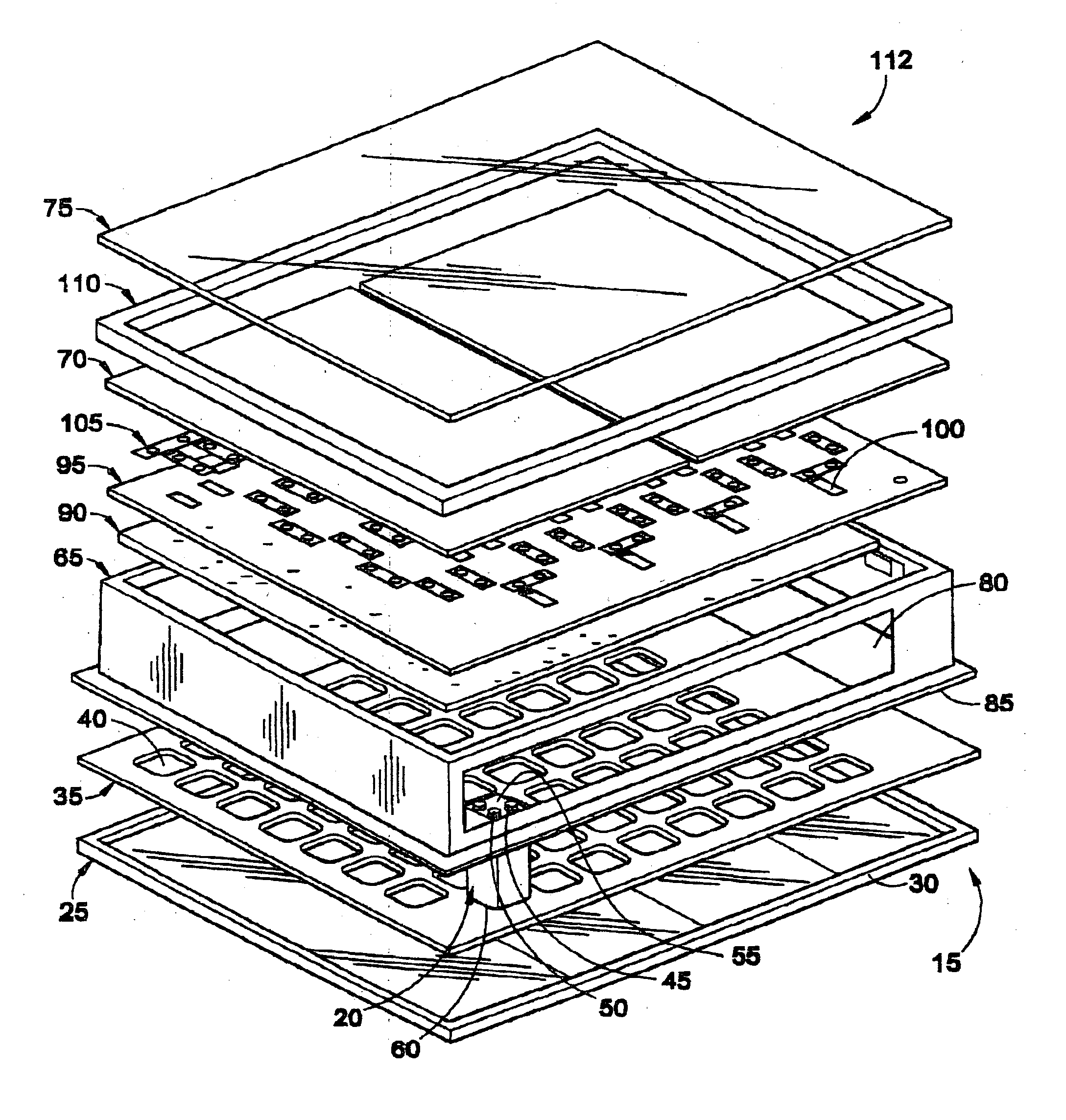

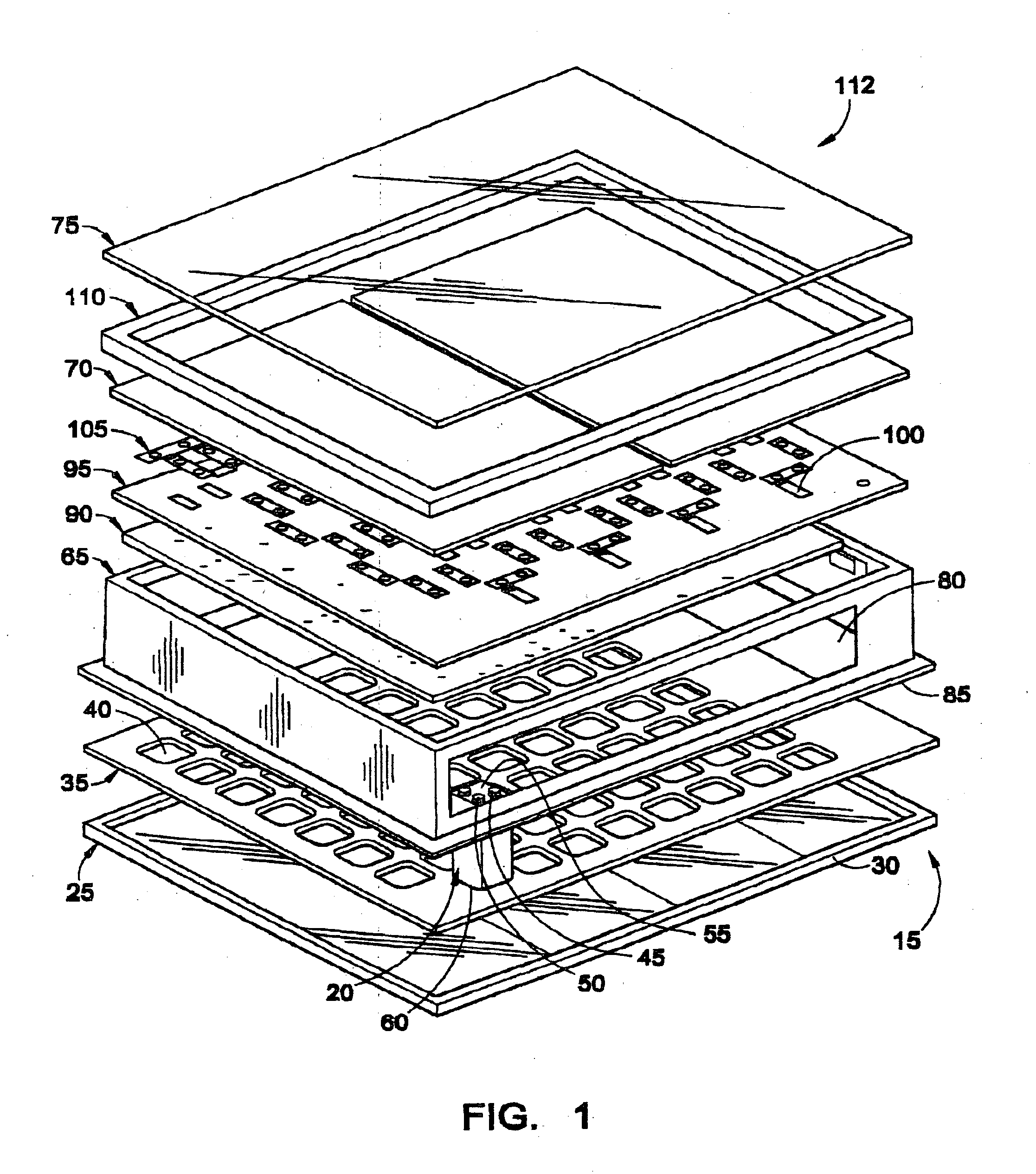

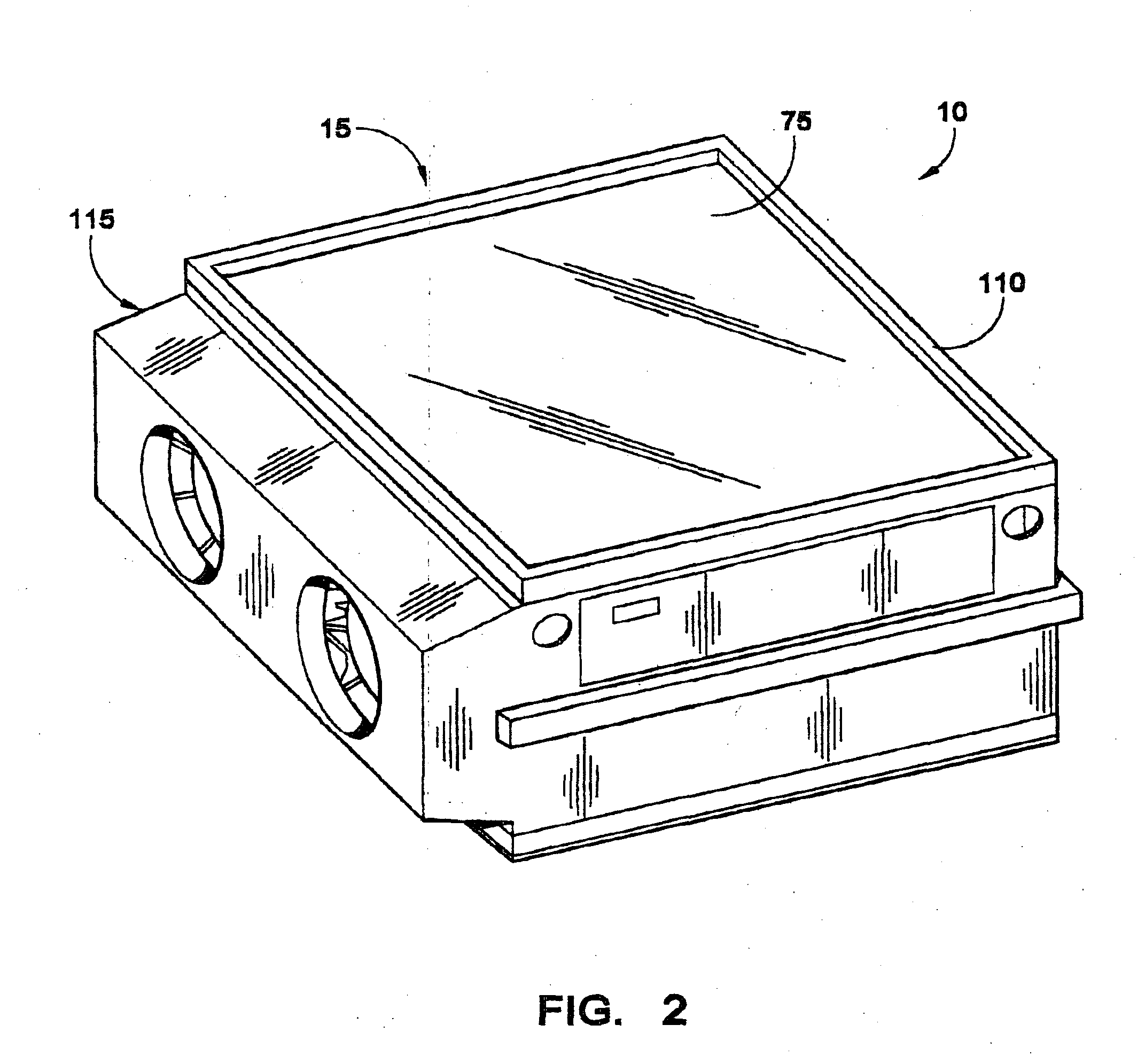

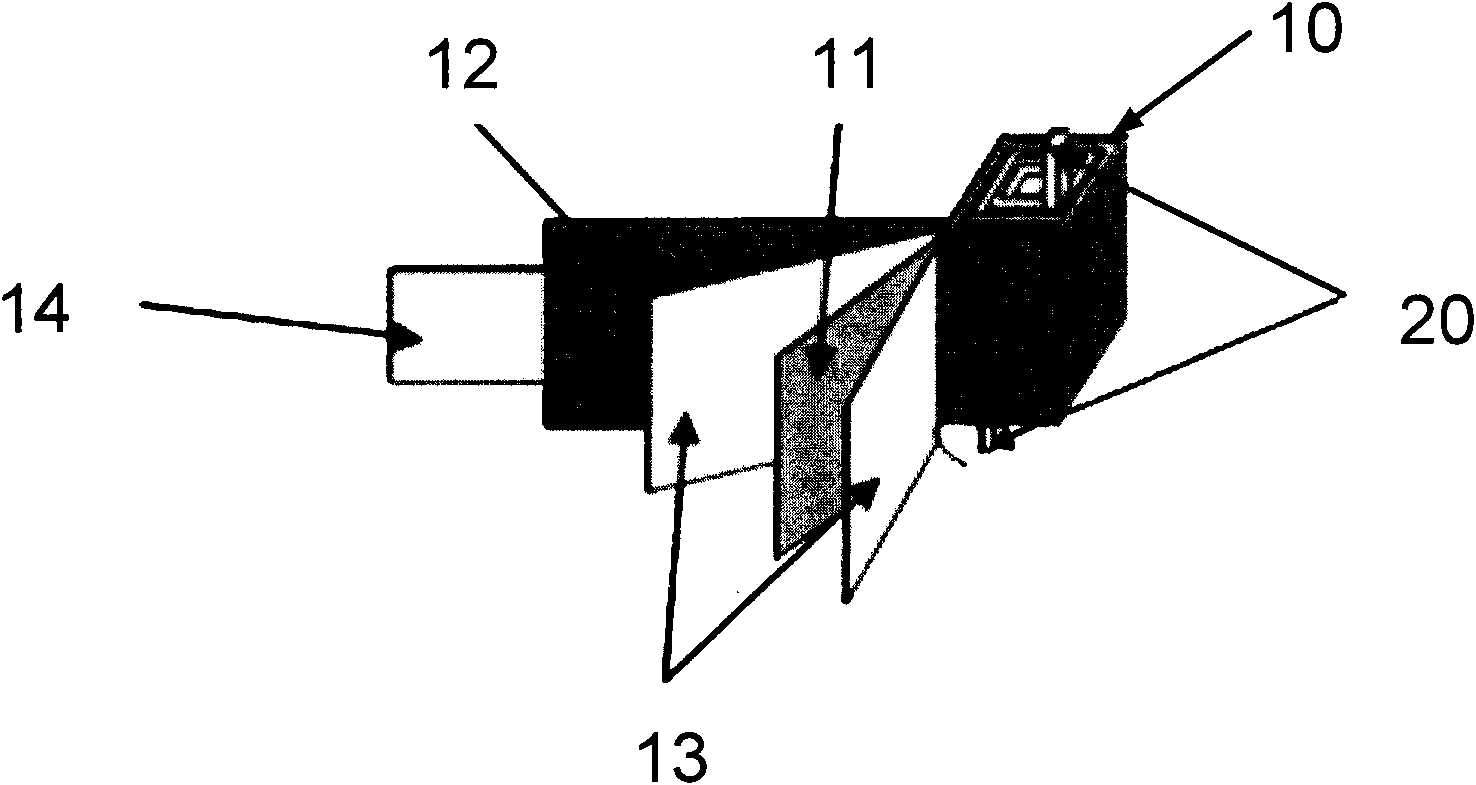

Implantable medical device having flat electrolytic capacitor fabricated with laser welded anode sheets

ActiveUS6922330B2Robust electrical and mechanical connectionMinimize damageLiquid electrolytic capacitorsCapacitor terminalsElectrolysisOptoelectronics

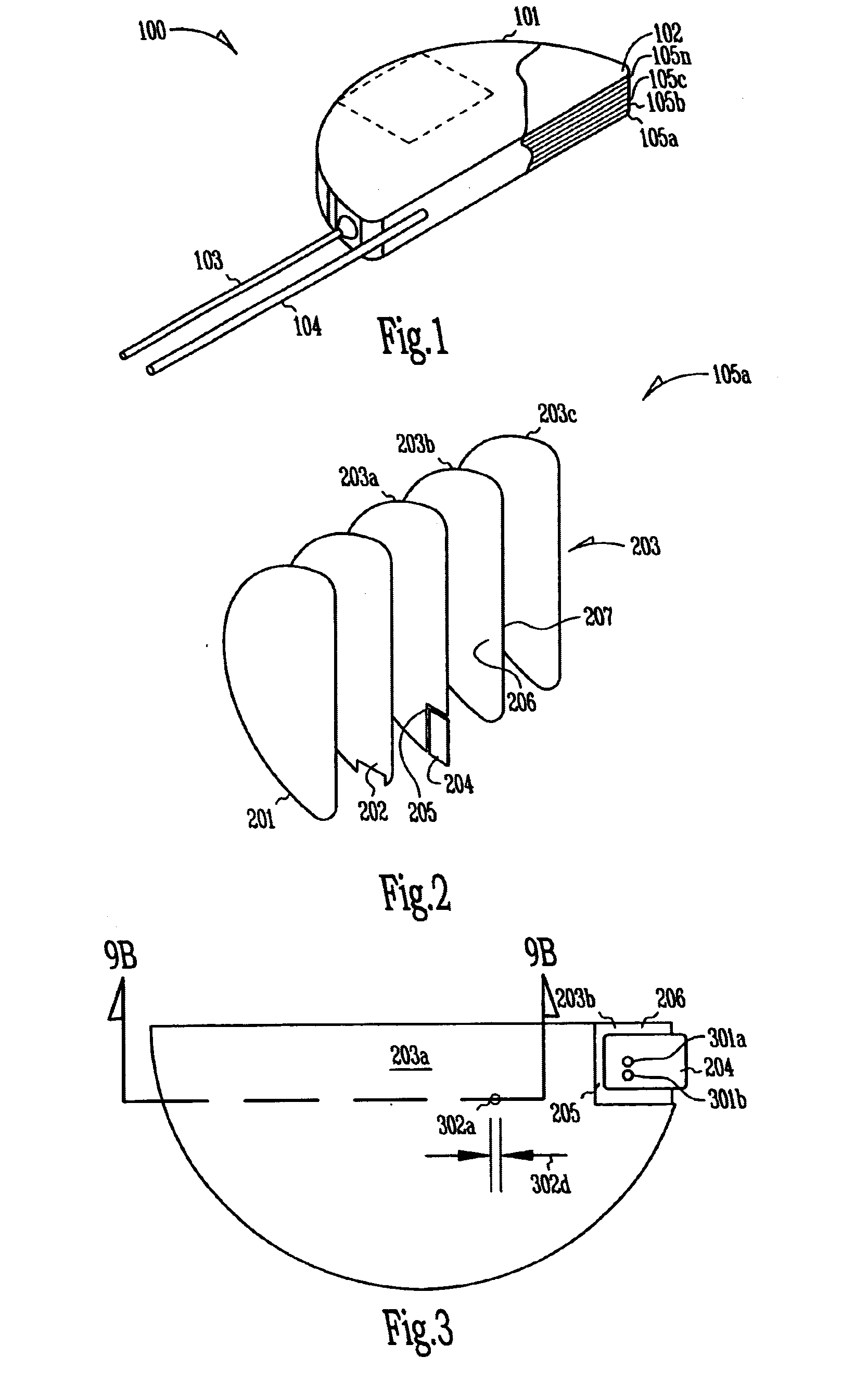

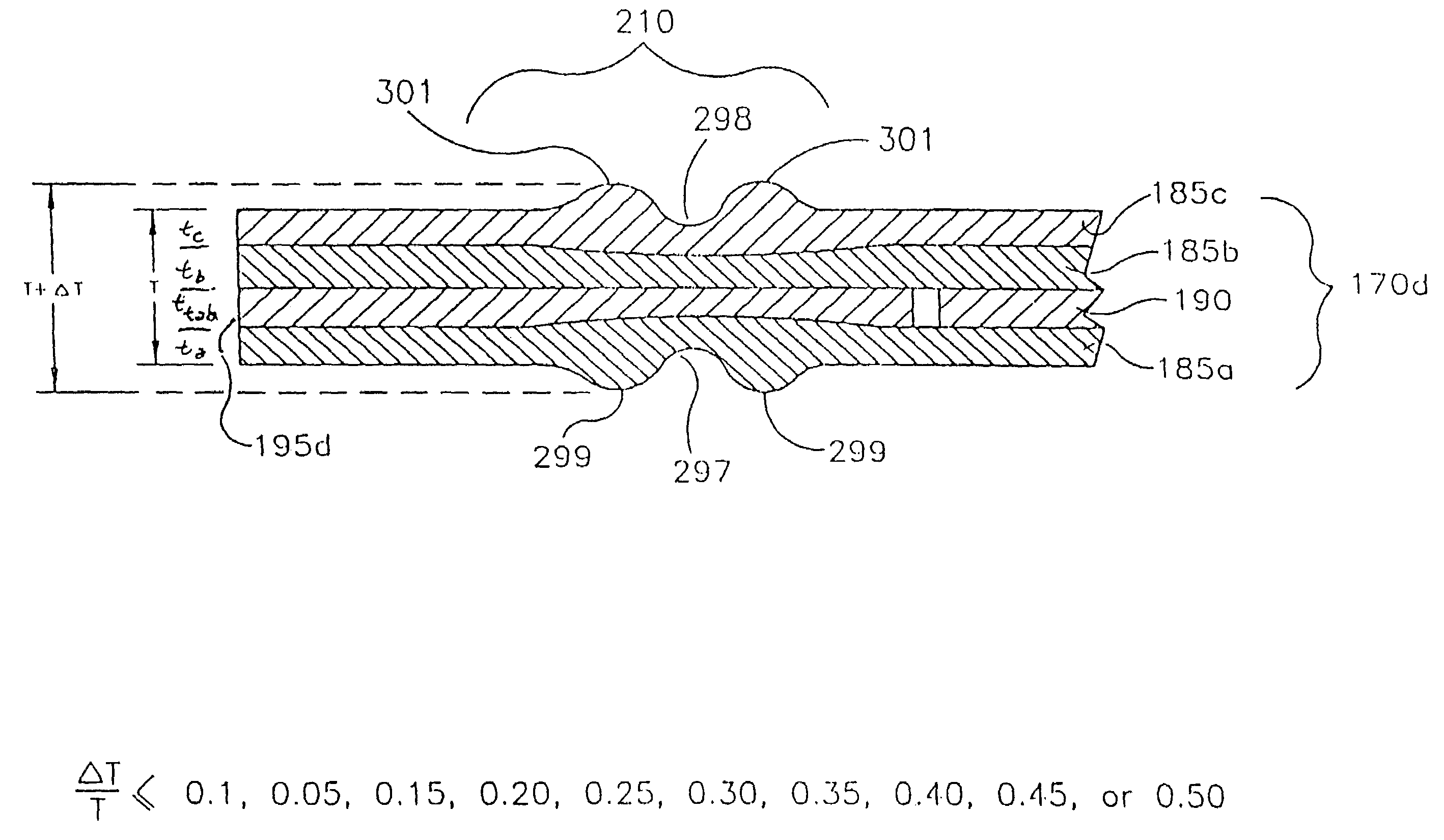

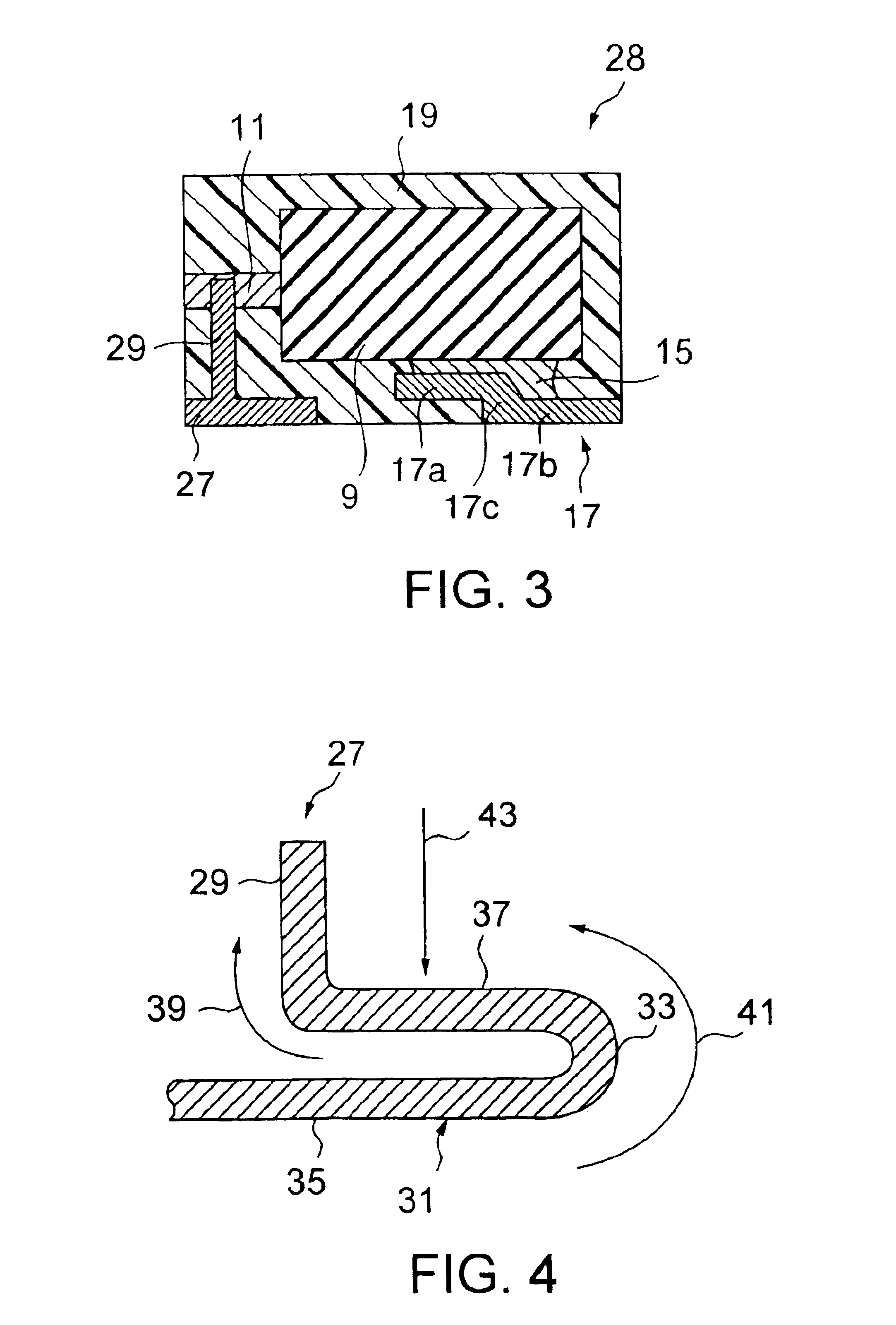

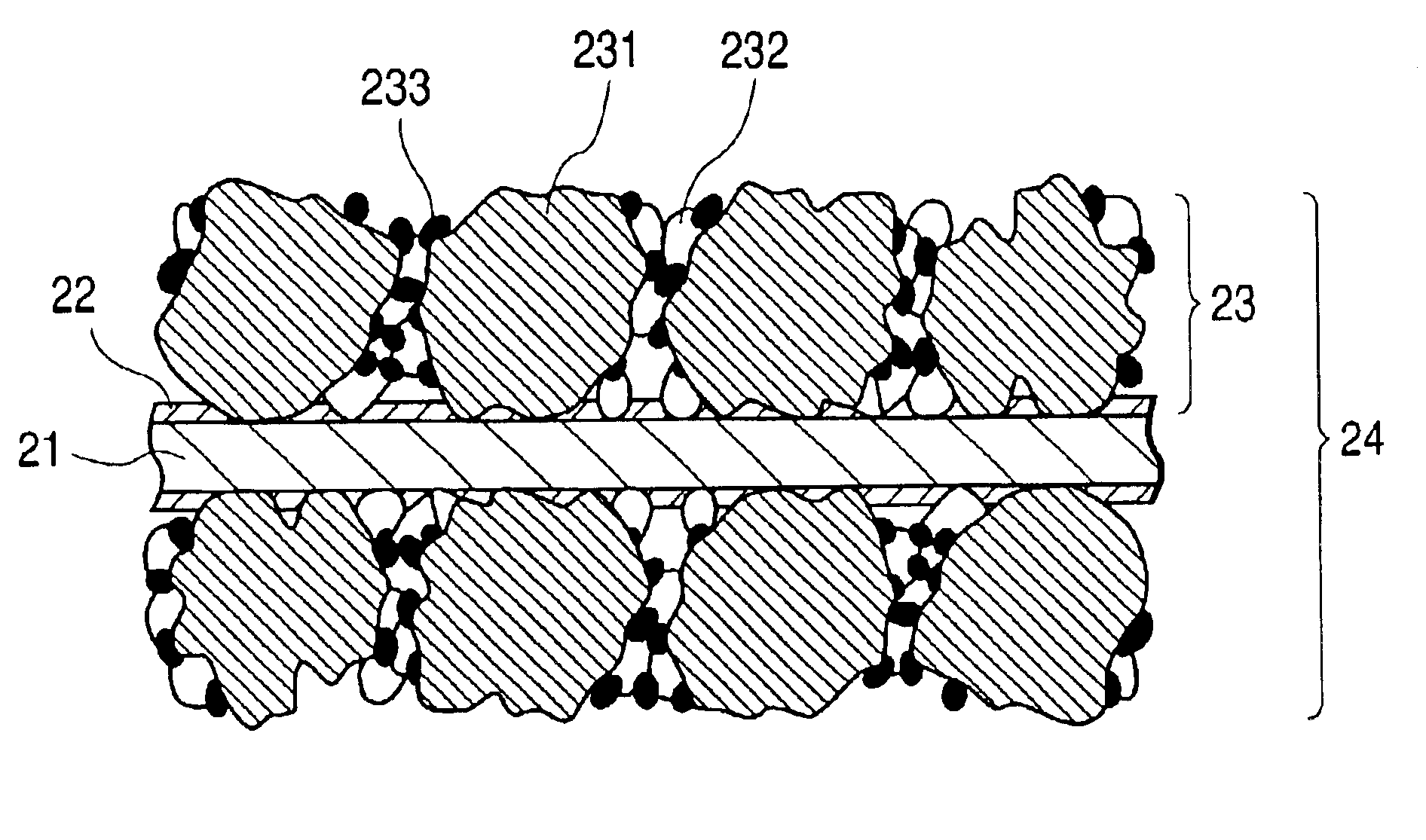

Implantable medical devices (IMDs) and components, including flat electrolytic capacitors and methods of making and using same, particularly an improved electrolytic capacitor fabricated of an electrode stack assembly comprising a plurality of capacitor layers stacked in registration upon one another. Each capacitor layer comprises a valve metal cathode layer having a cathode tab, a valve metal anode layer having an anode tab, and a separator layer located between the cathode layers. The anode layer is assembled from a plurality of valve metal anode sheets that are etched and anodized, stacked side-by-side, and electrically and mechanically joined together by laser weld beads. A valve metal anode tab having a thickness equal to one or more anode sheet is inserted into a tab notch in one or more stacked anode sheet and joined to the anode sheet stack by laser welding the tab and sheet edges together.

Owner:MEDTRONIC INC

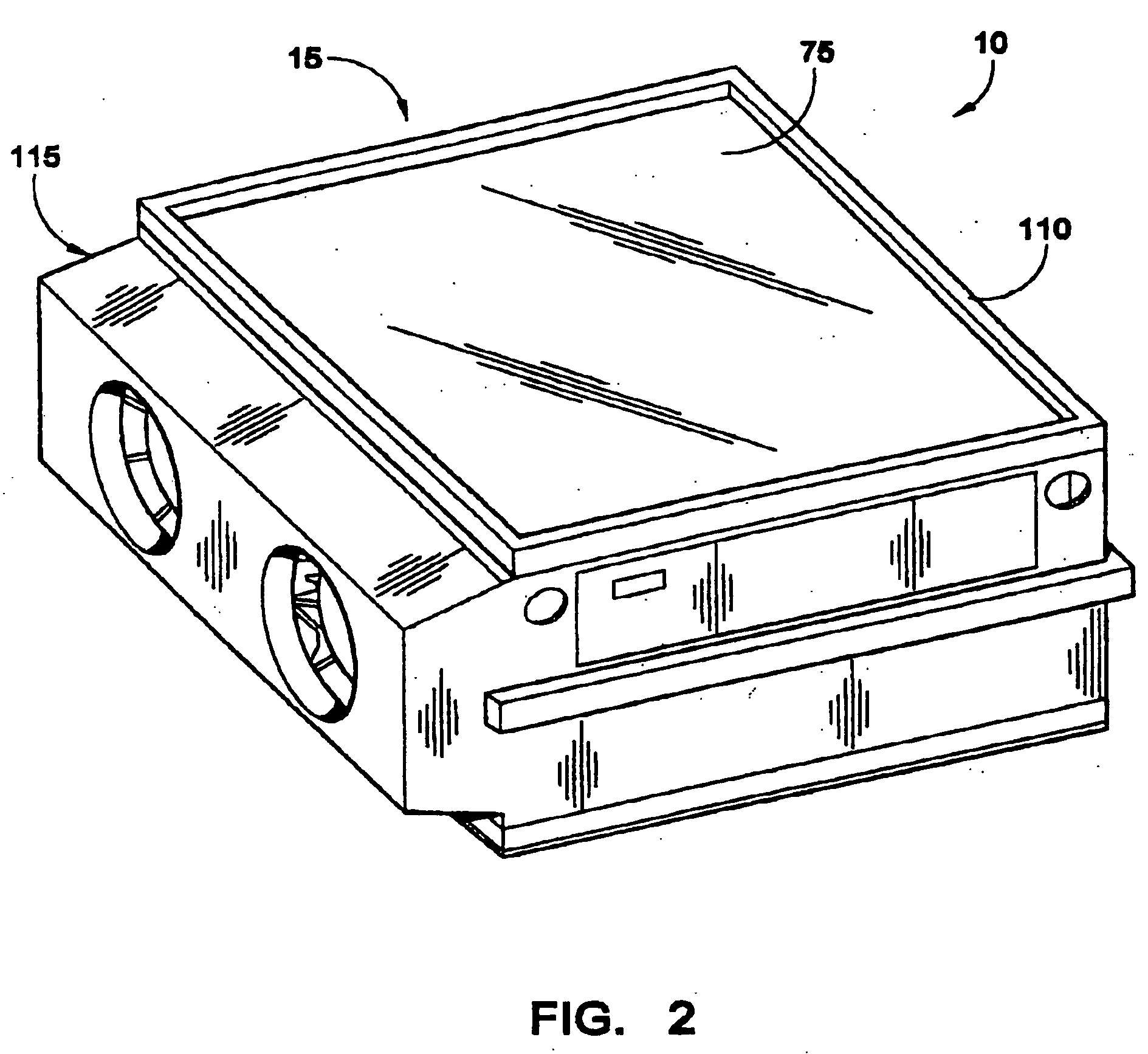

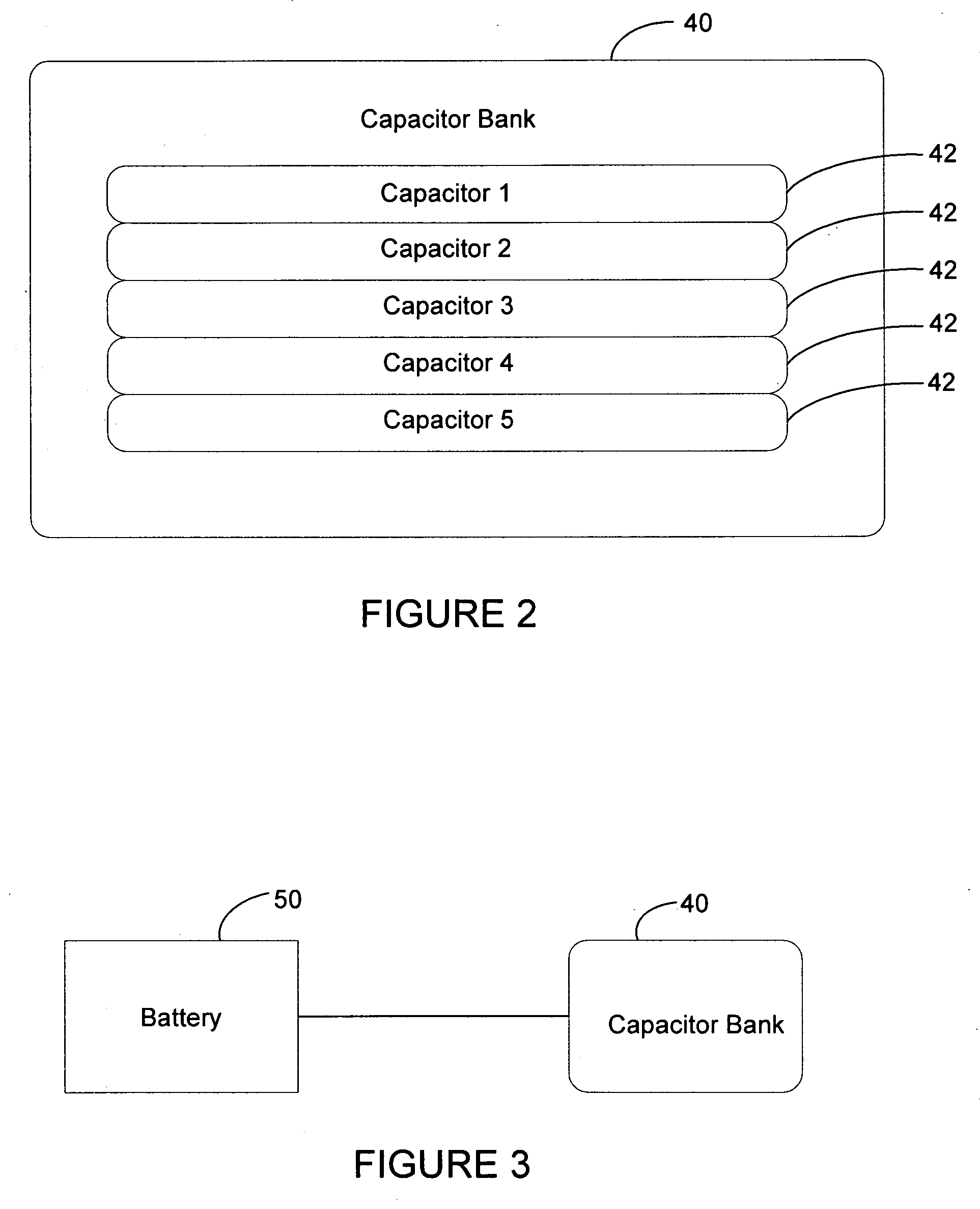

High-power ultracapacitor energy storage pack and method of use

InactiveUS20050041370A1Prolong lifeDischarge safetyCapacitor terminalsCapacitor housing/encapsulationElectrical batterySupercapacitor

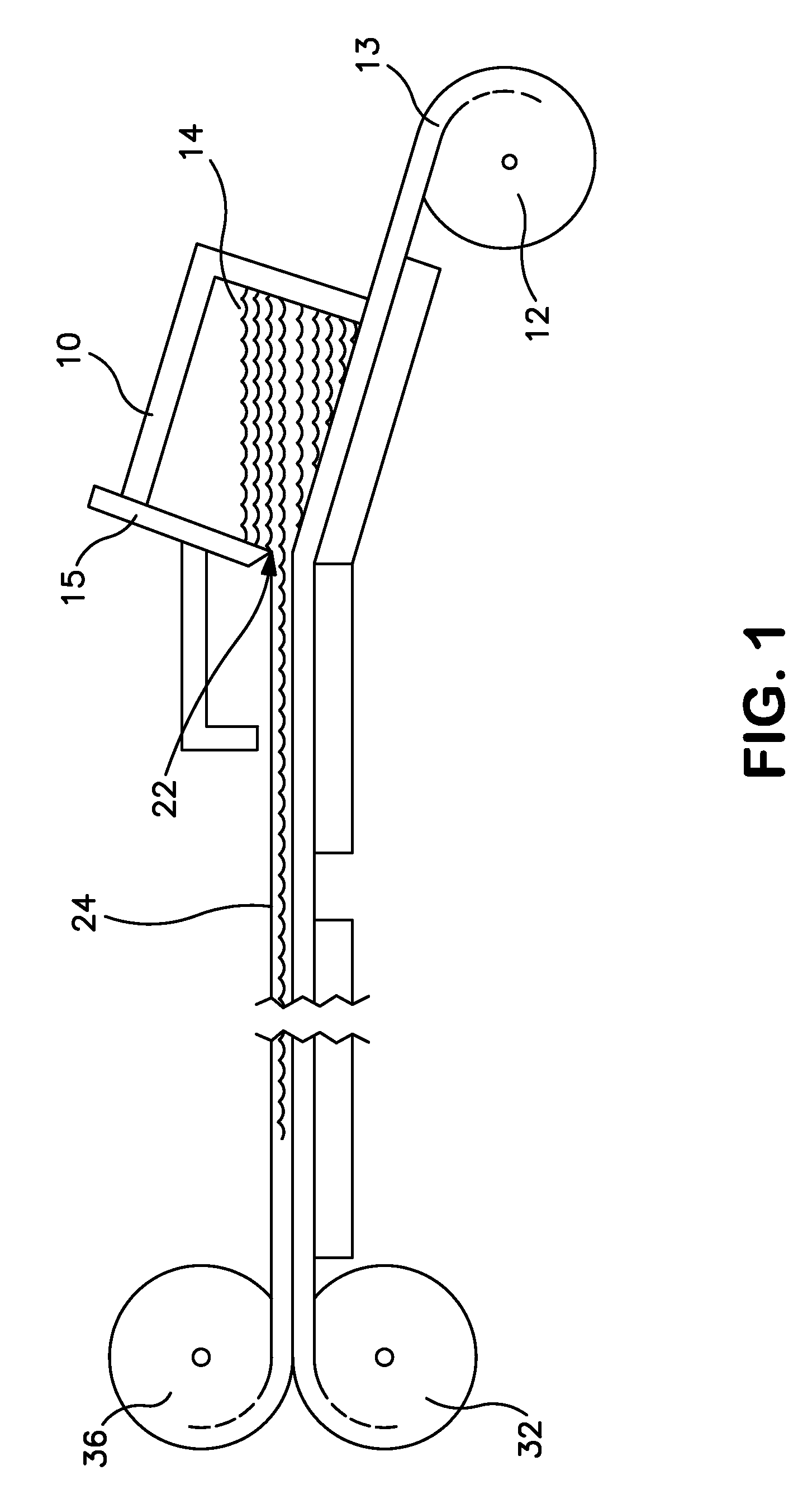

An ultracapacitor energy storage cell pack includes an ultracapacitor assembly having a plurality of series connected ultracapacitors and balancing resistors, each balancing resistor connected in parallel with each ultracapacitor to automatically balance each ultracapacitor over time, thereby automatically over time discharging the ultracapacitors of the ultracapacitor assembly; an enclosure to enclose and protect the ultracapacitor assembly; a controller for the ultracapacitor assembly; and one or more temperature sensors to monitor temperature of the ultracapacitor assembly and coupled to the controller.

Owner:SHEPPARD MULLIN RICHTER & HAMPTON

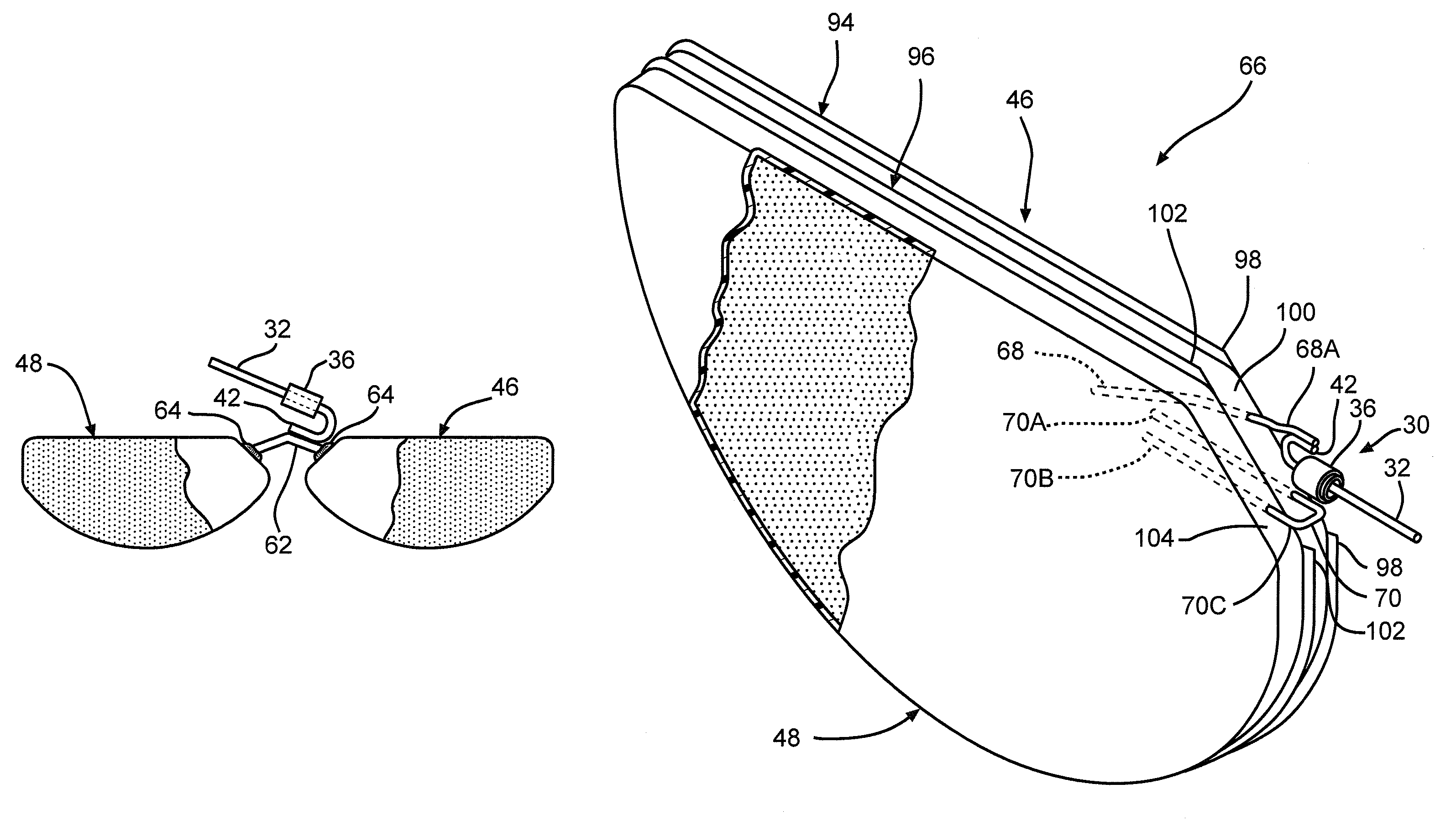

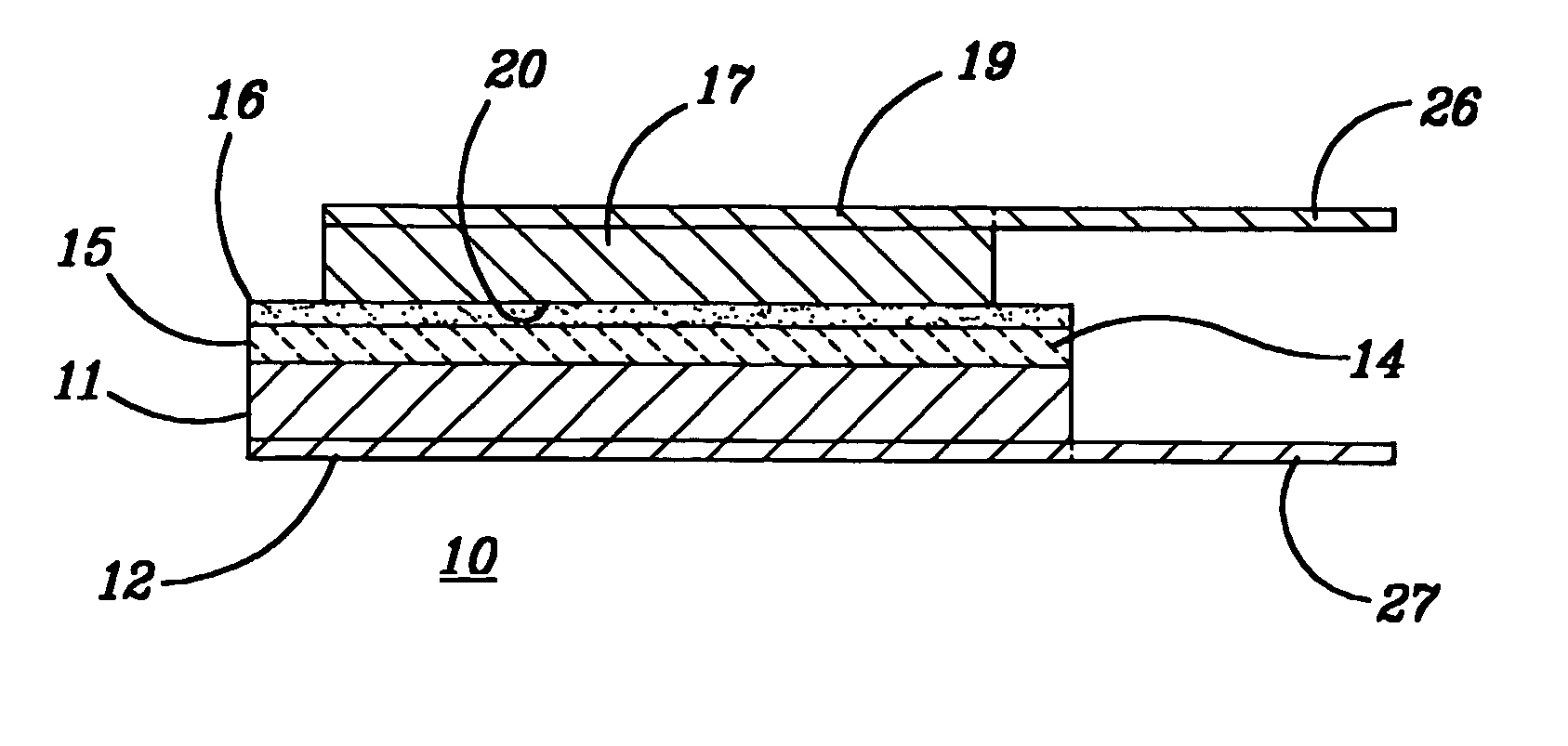

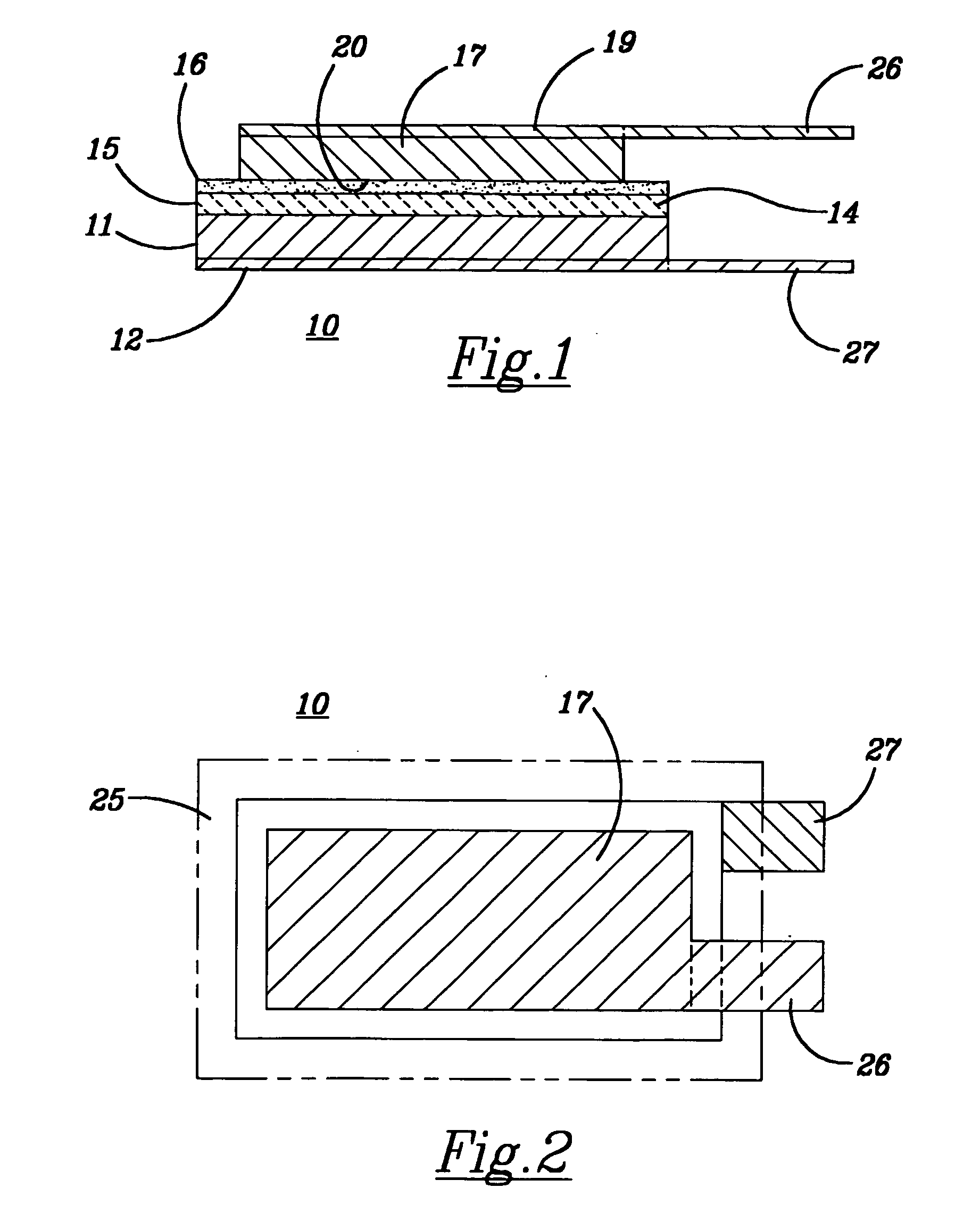

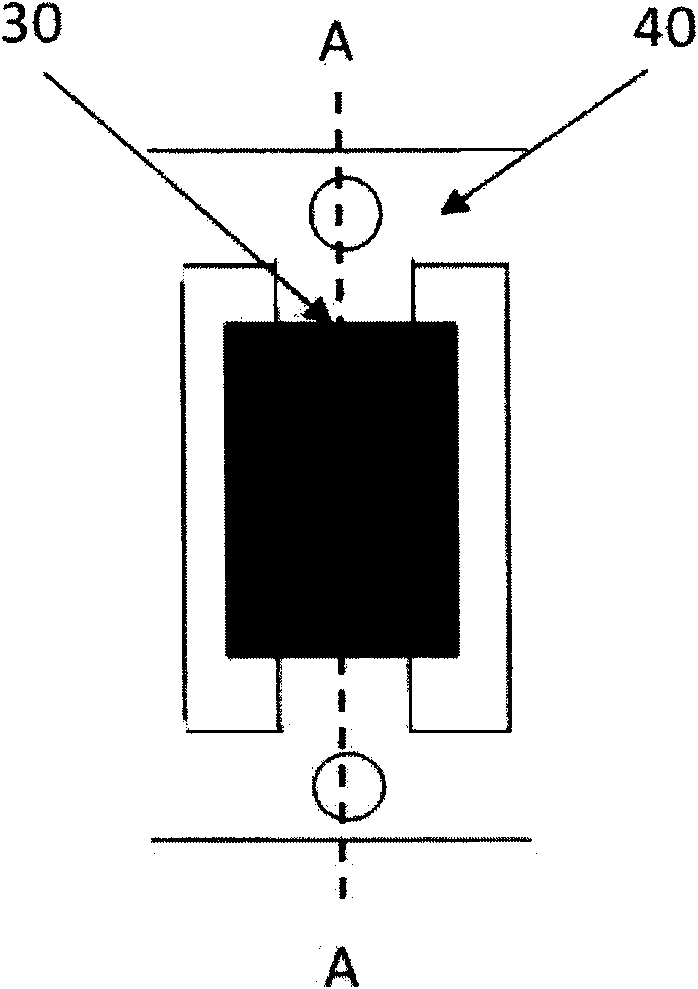

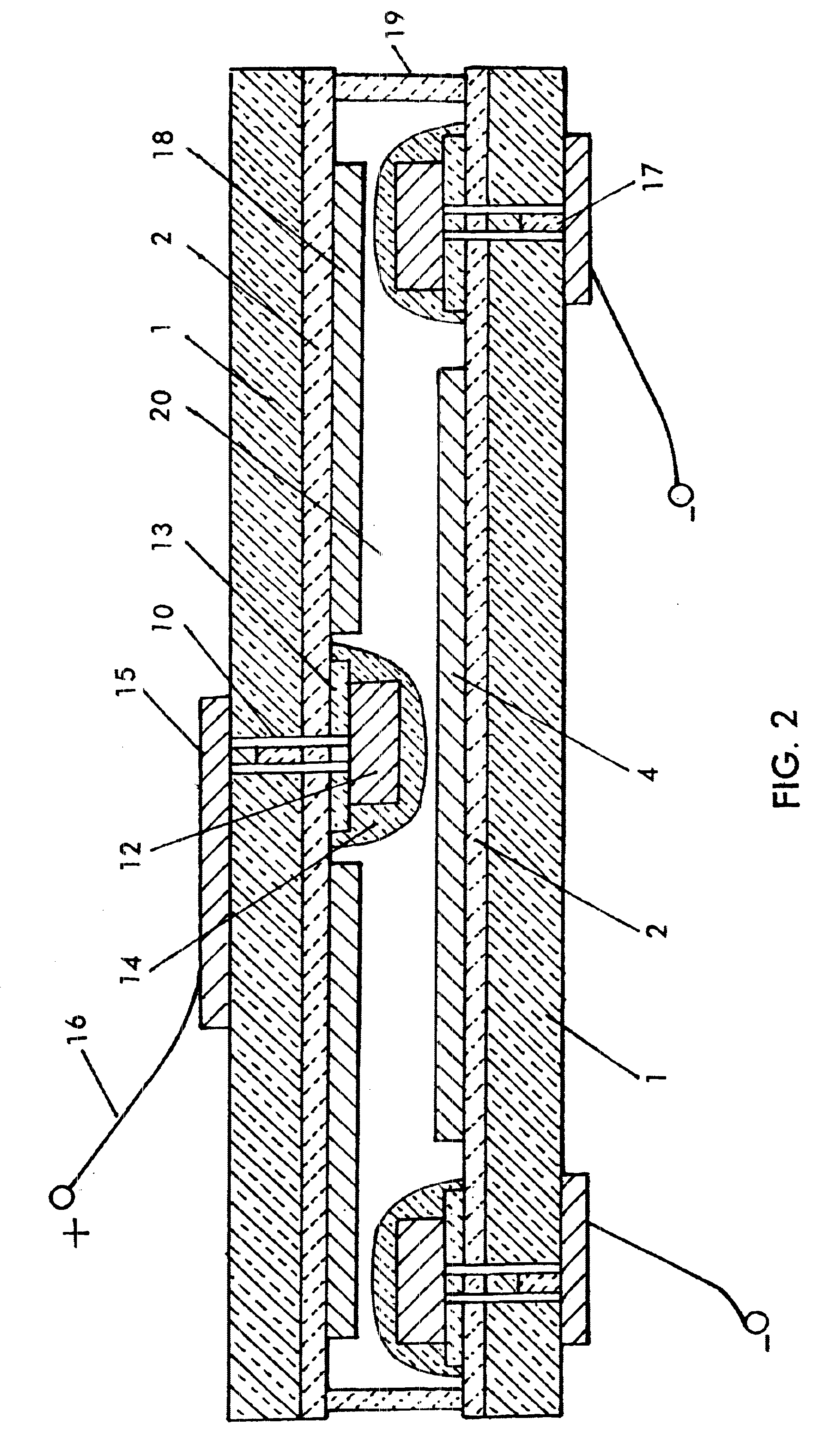

Dual anode capacitor with internally connected anodes

ActiveUS7483260B2Eliminate needAnti-noise capacitorsHybrid capacitor electrolytesCapacitorElectrolyte

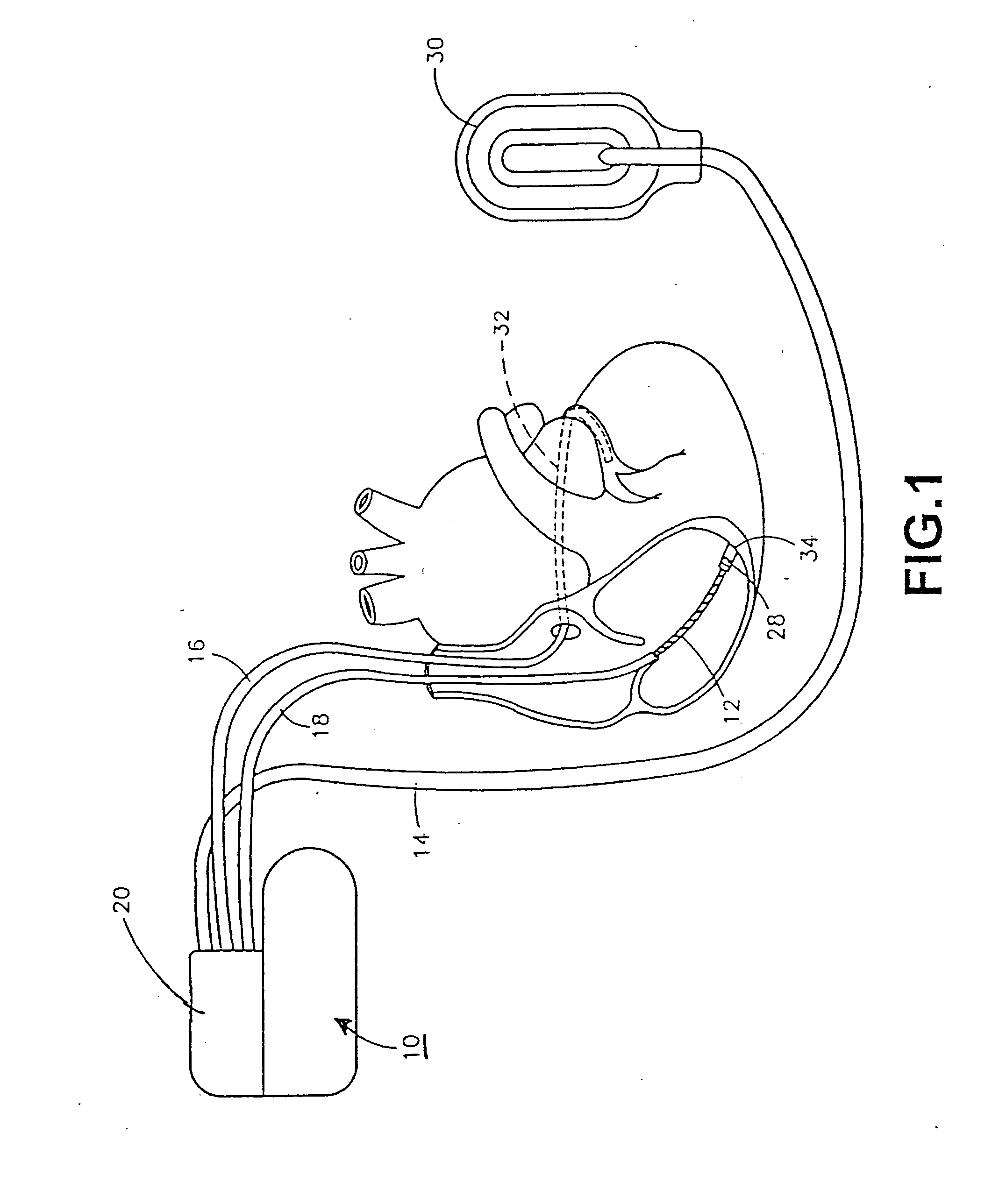

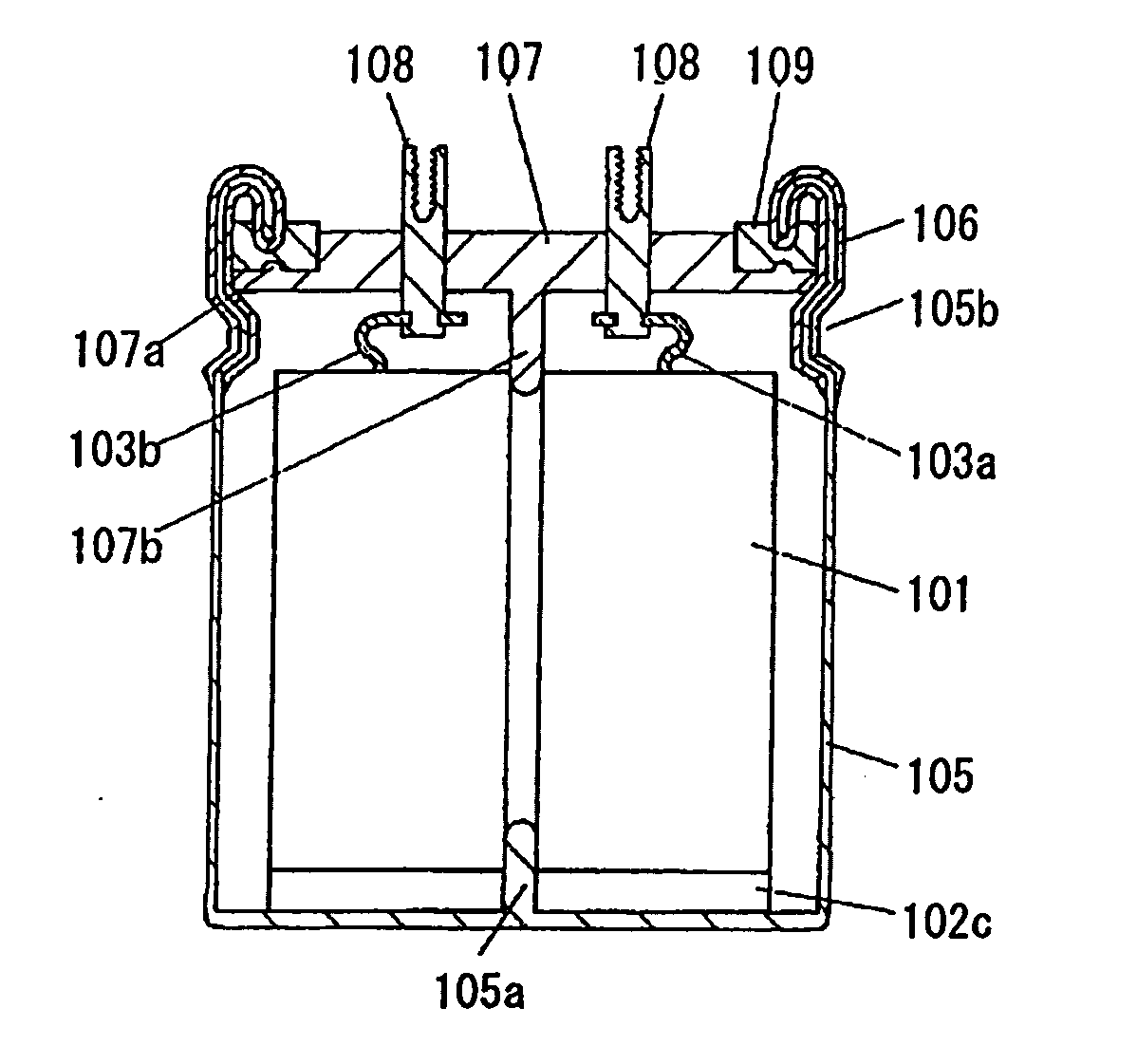

A capacitor a casing of first and second casing members, a feedthrough electrically insulated from the casing and extending there from, first and second anodes electrically connected to each other within the casing, a cathode, and an electrolyte is described. The first anode is electrically connected in parallel to the second anode by a first anode wire having opposite ends contacting the respective first and second anodes. A feedthrough wire extending outside the casing and electrically isolated there from is electrically connected to the first anode wire intermediate the first and second anodes. The cathode is disposed between the first and second anodes.

Owner:WILSON GREATBATCH LTD

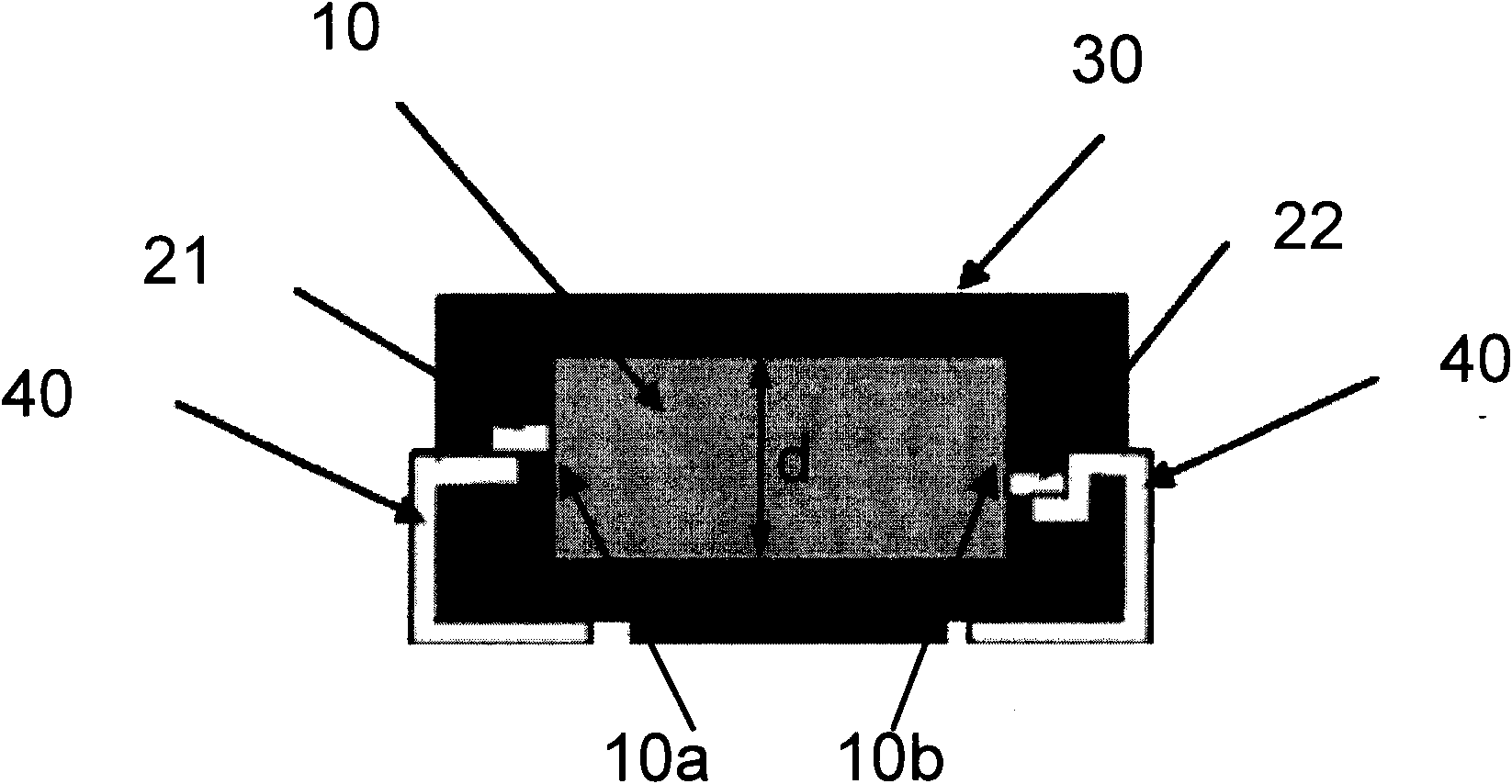

Implantable medical device having flat electrolytic capacitor with differing sized anode and cathode layers

InactiveUS7110240B2Area maximizationEasy to useAnti-noise capacitorsFeed-through capacitorsEngineeringMedical device

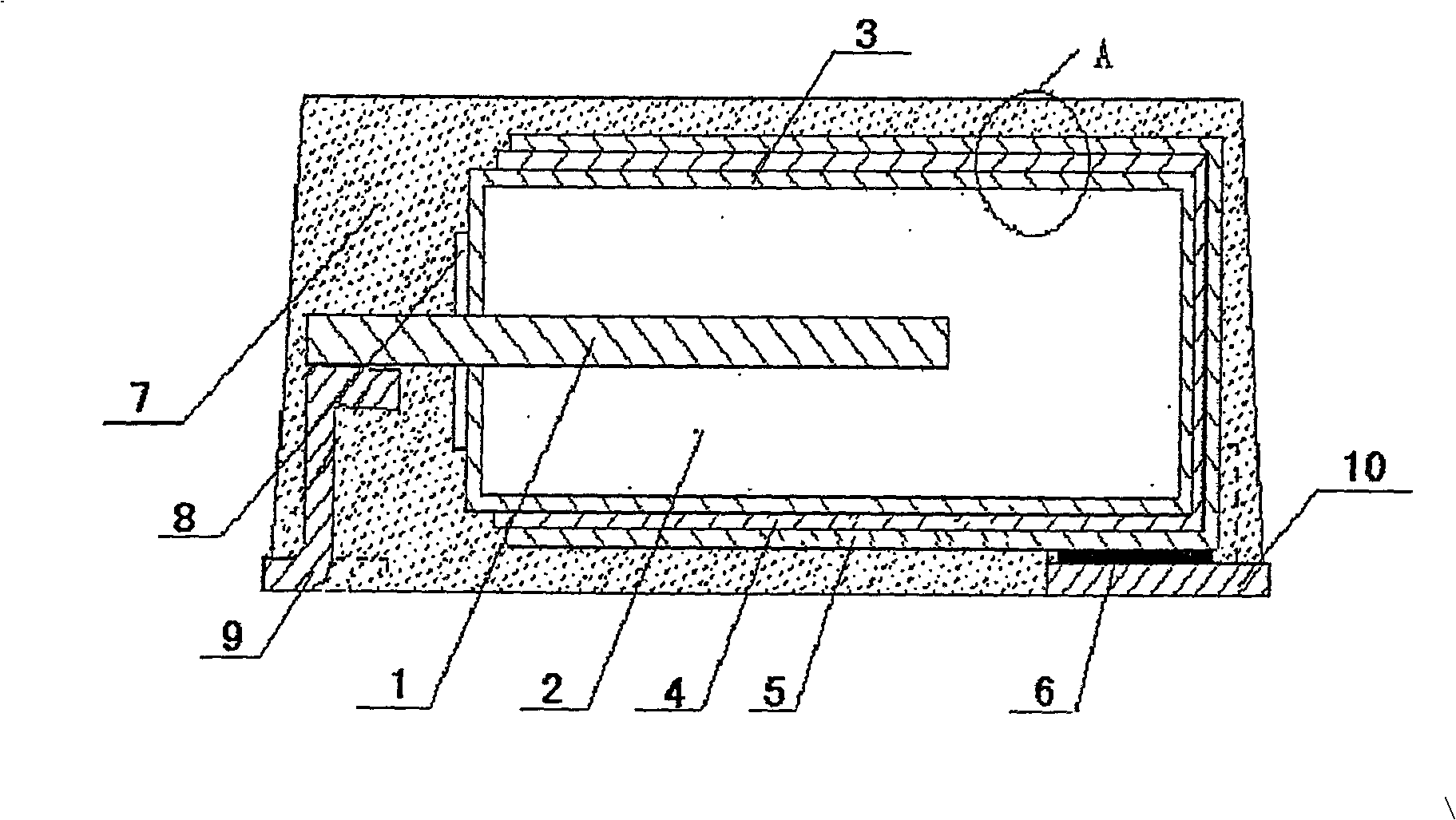

A capacitor is described. The capacitor includes a case chamber. An electrode stack assembly is disposed within the case chamber. The electrode stack assembly includes a layer. The layer includes an anode subassembly. The anode subassembly comprises at least one anode layer that has an anode edge disposed at a first distance from an interior wall of the case chamber. The layer also includes a capacitor layer. The capacitor layer includes a cathode edge disposed at a second distance from the wall interior. The second distance is greater than the first distance.

Owner:MEDTRONIC INC

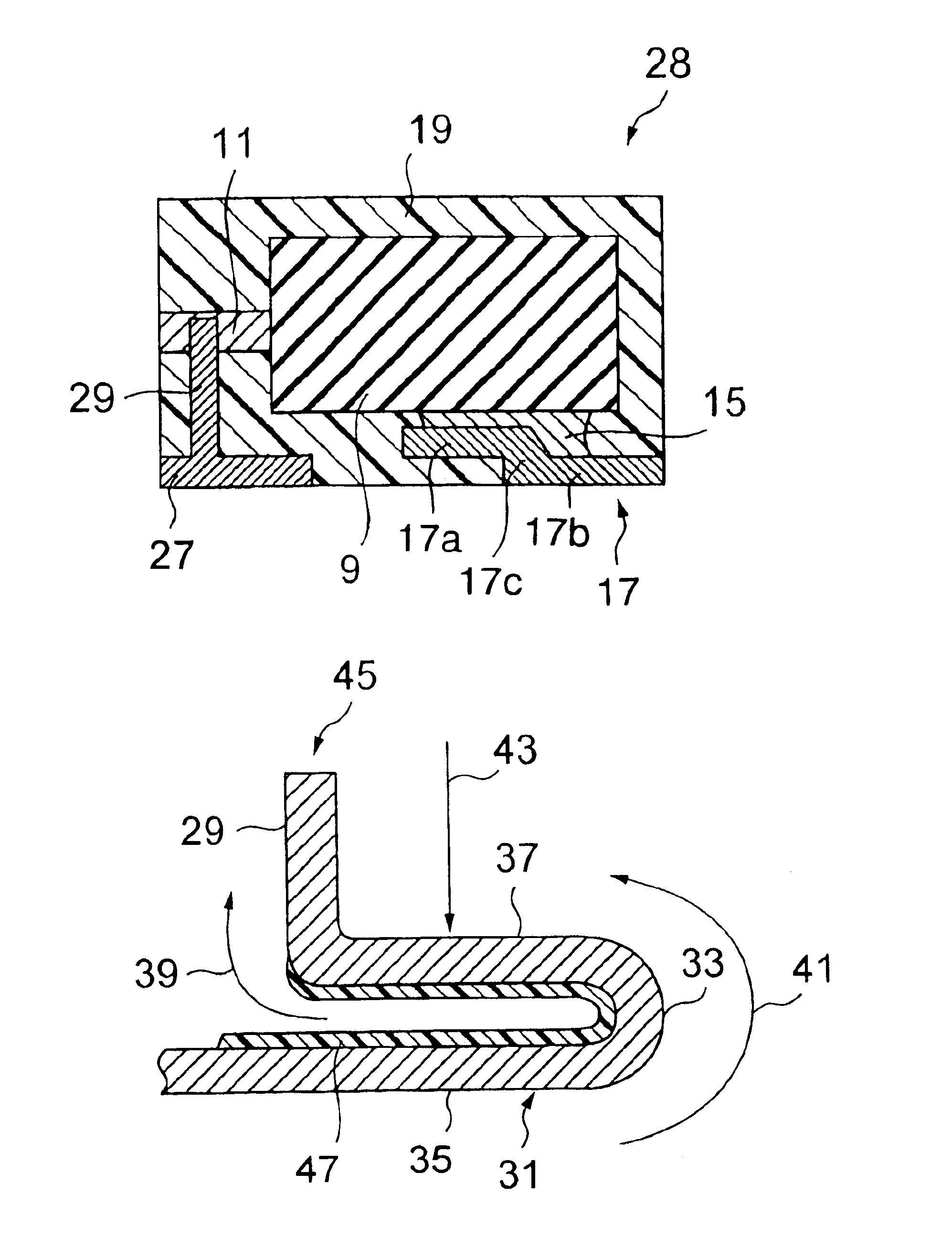

Supercapacitor cover with integrated center terminal

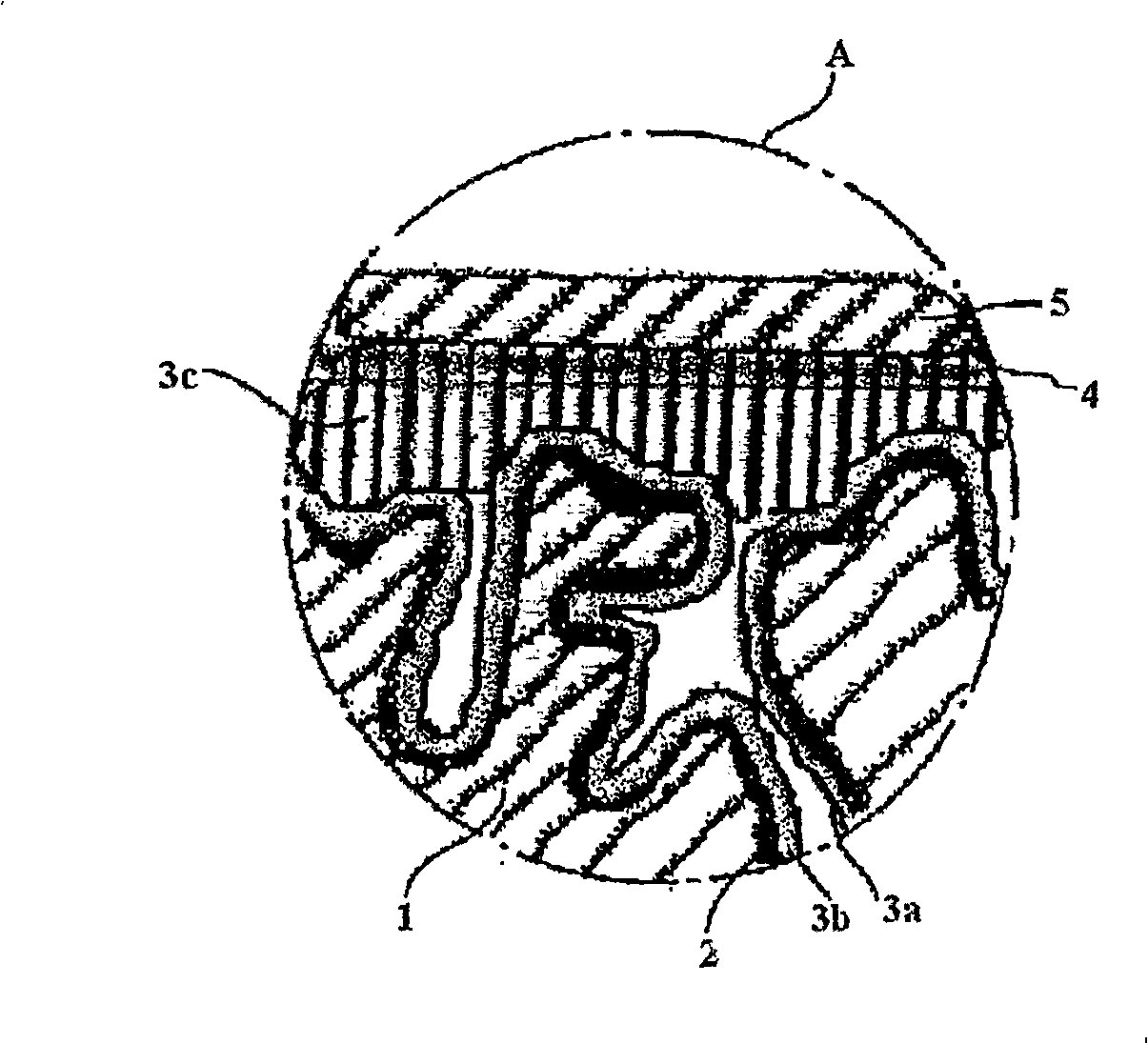

InactiveUS7911766B2Increase contactSolve the lack of spaceCapacitor terminalsDouble layer capacitorsSupercapacitorConductor Coil

An electric energy storage component having coil windings and at least one connector. A plate of the connector is in contact with the coil windings. The plate of the connector has a surface which is provided with a terminal wherein the shape thereof is essentially that of a revolution. The plate also forms a series of bosses extending in a raised manner along a surface of the plate opposite to that containing the terminal. The terminal has at least one inner recess and at least one boss which penetrates into the recess.

Owner:BLUE SOLUTIONS

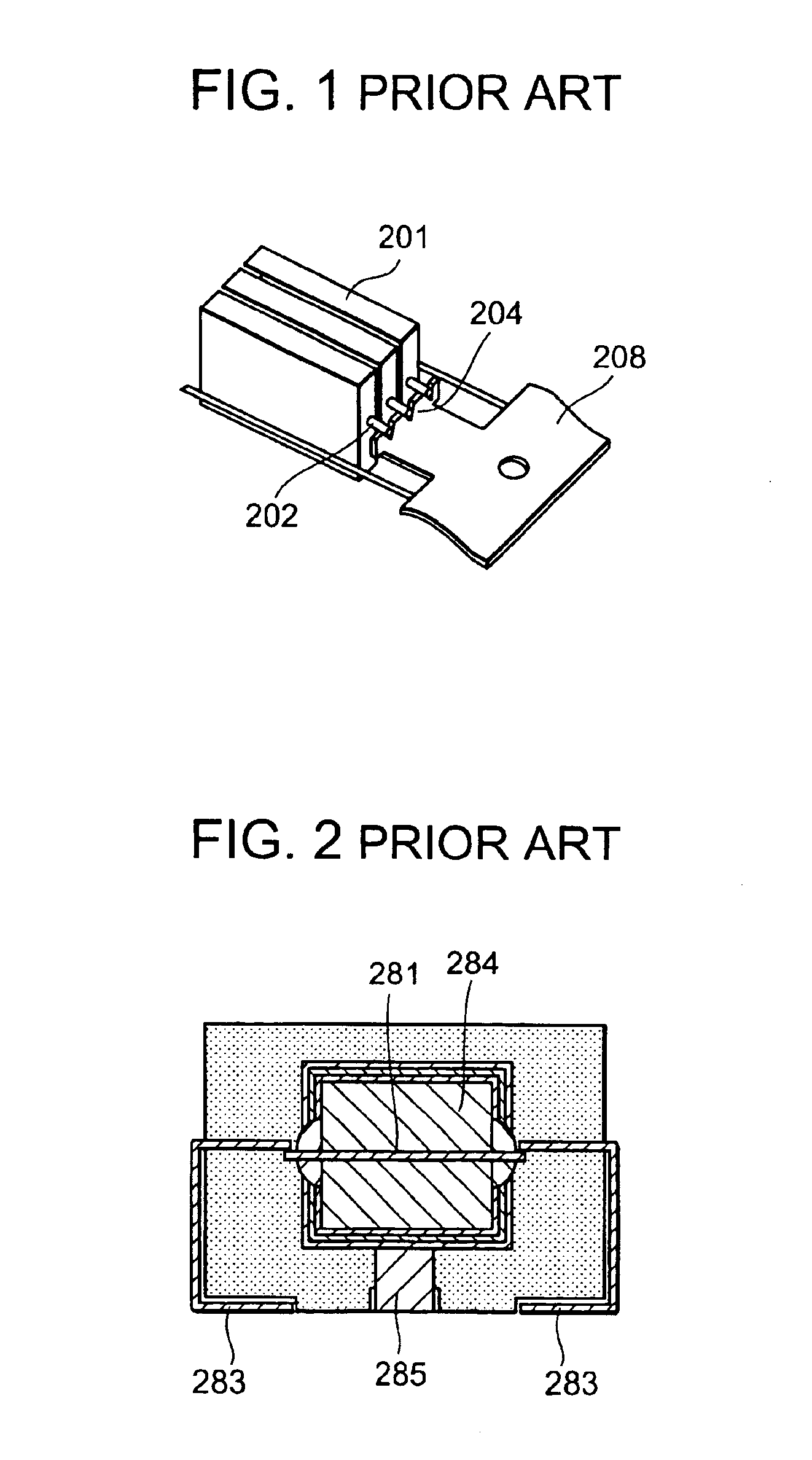

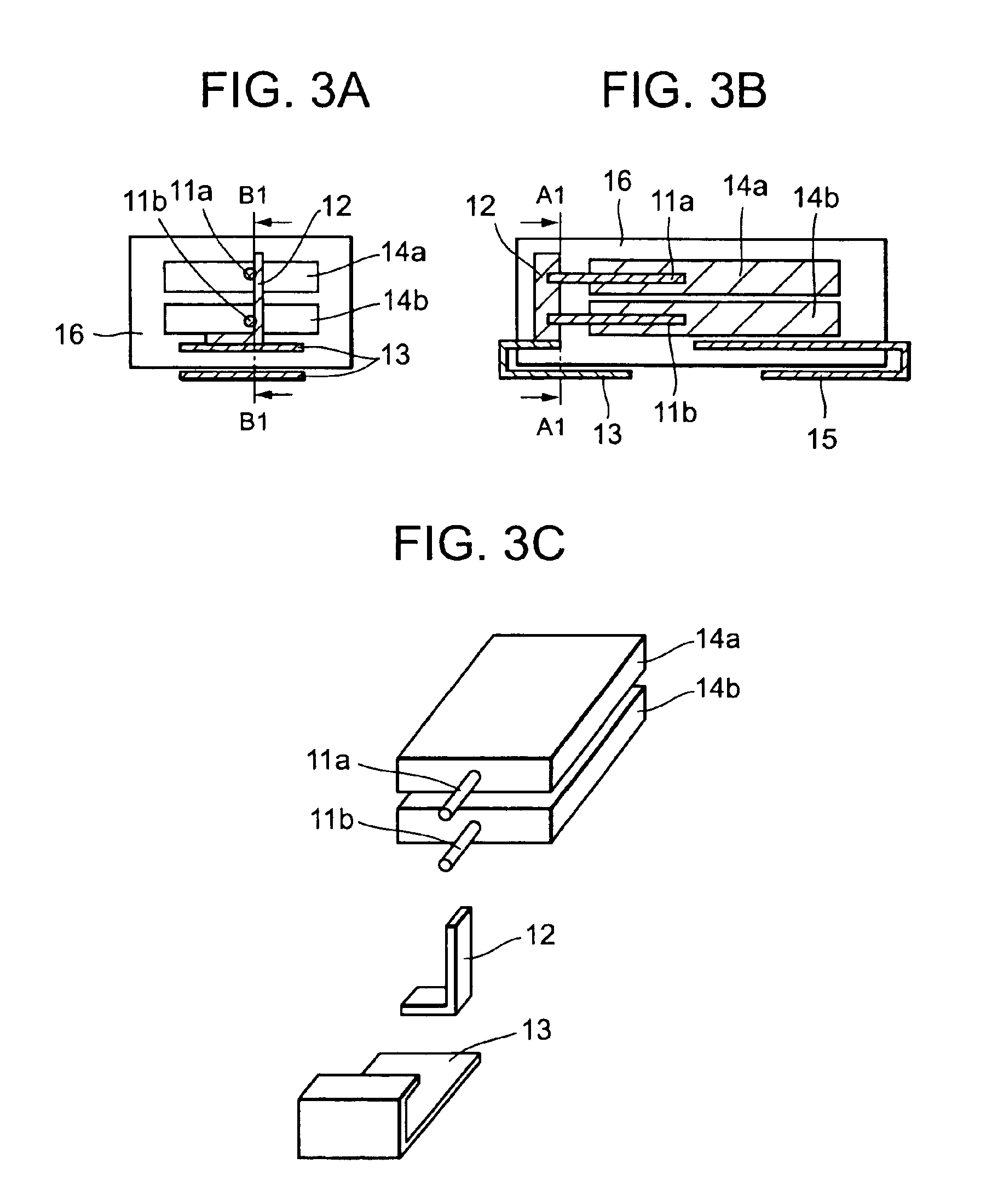

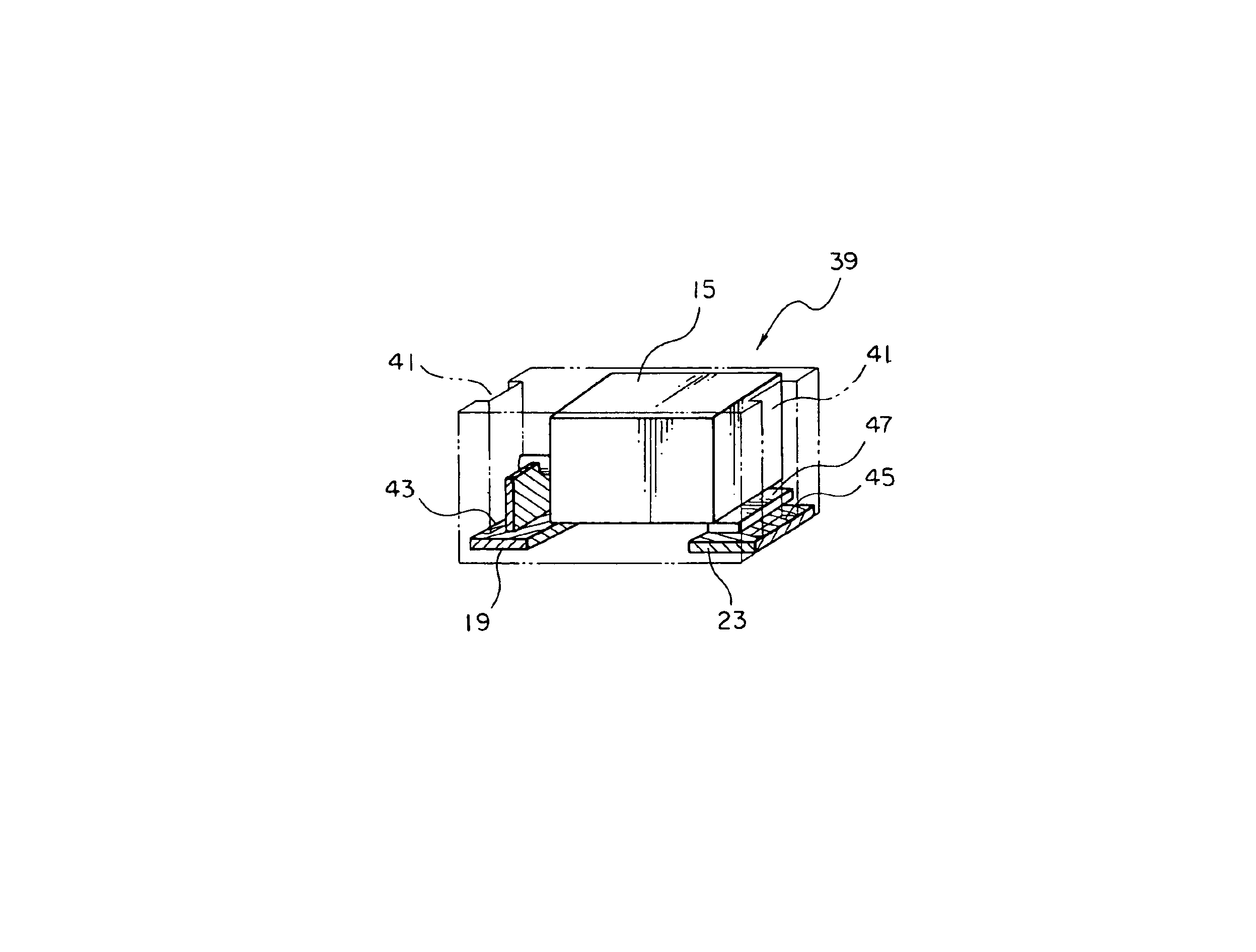

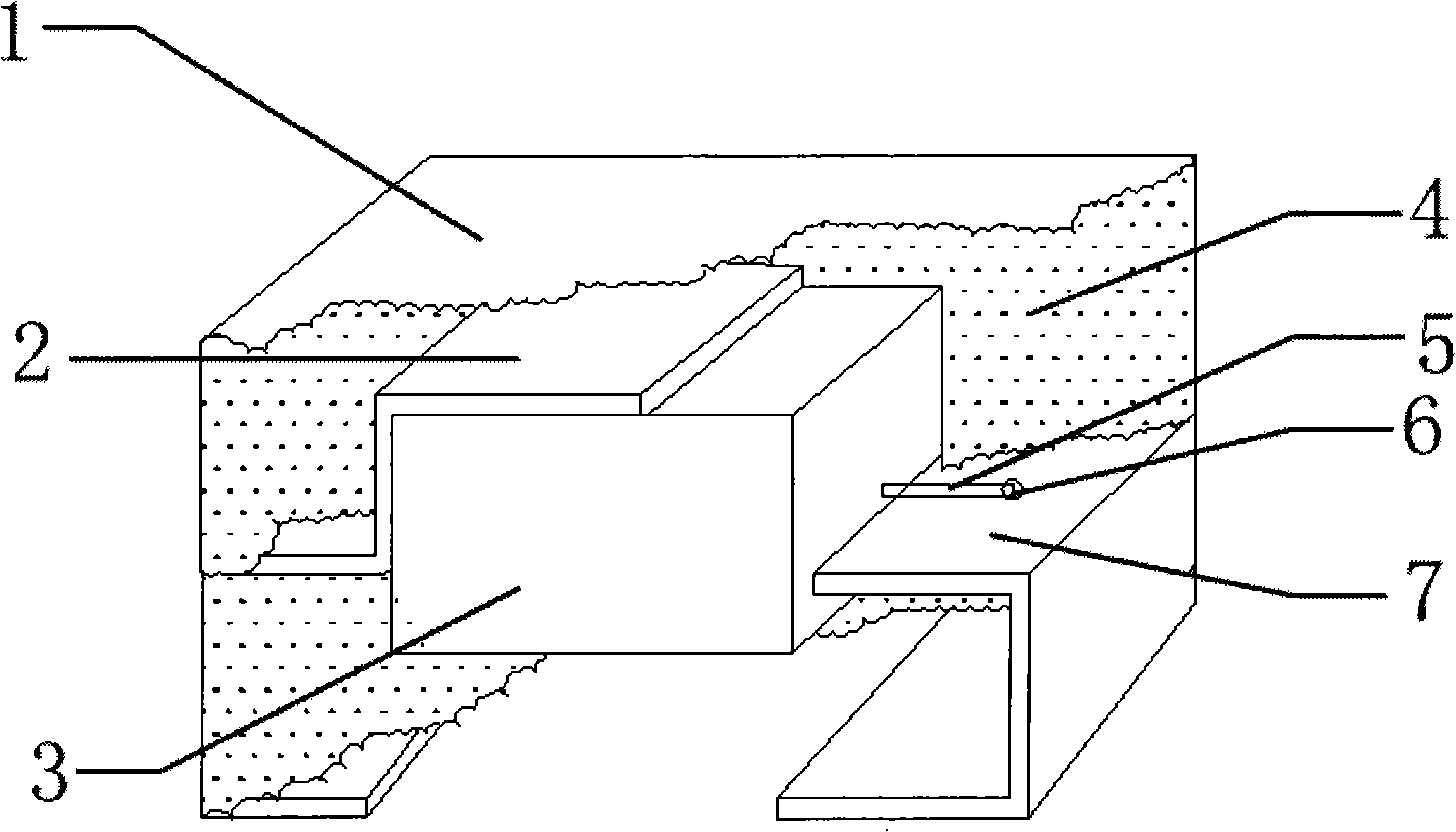

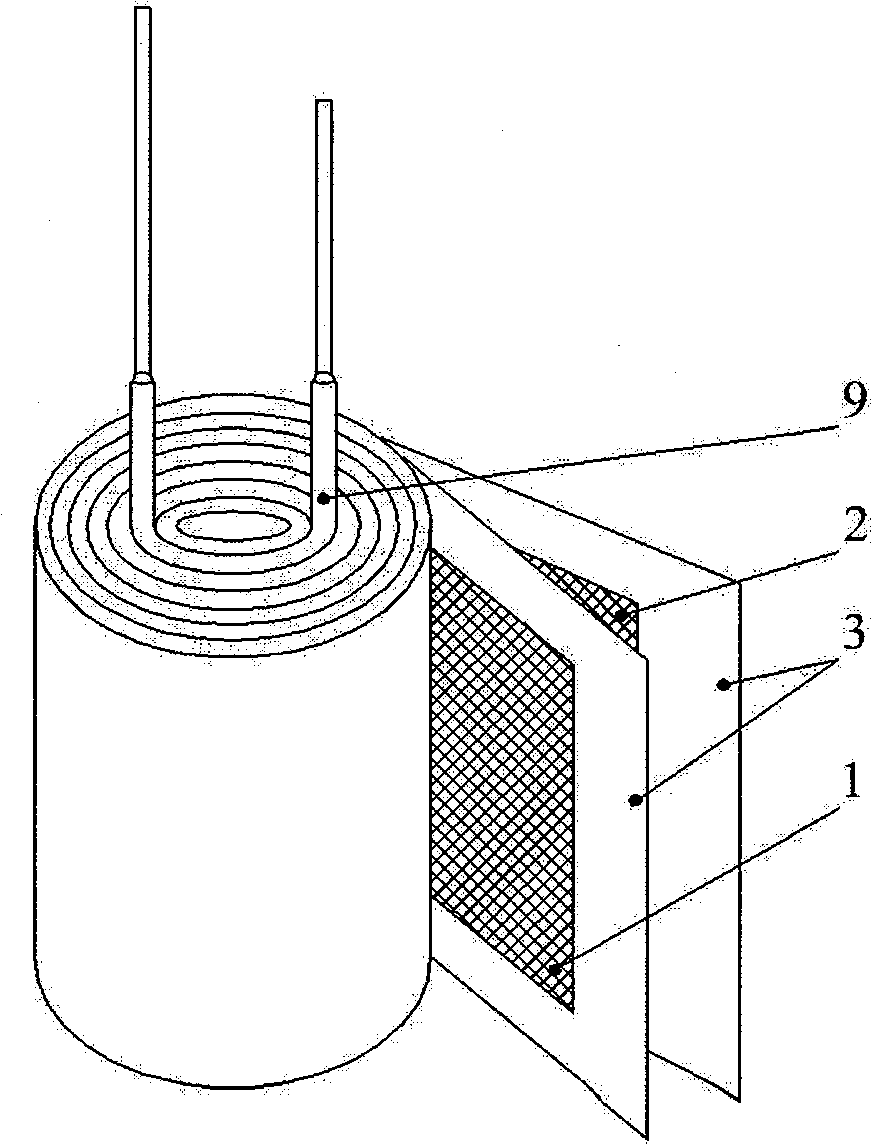

Solid electrolytic capacitor and method of manufacturing the same

ActiveUS6912117B2Low ESRLarge capacitySolid electrolytic capacitorsLiquid electrolytic capacitorsNiobiumMetal

A solid electrolytic capacitor having at least two capacitor elements using a valve action metal, such as tantalum or niobium, and laminated in a direction perpendicular to a mounting surface of a substrate. The capacitor elements have a width parallel to the mounting surface of the substrate greater than a thickness perpendicular to the mounting surface of the substrate, and an anode terminal is connected with anode leads led out to at least one side of an anode body made of the valve action metal generally in parallel to the mounting surface of the substrate. A cathode layer on a dielectric oxide film of the anode body is connected to a cathode terminal and is coated with exterior coating resin with a part of the anode terminal and a part of the cathode terminal exposed.

Owner:TOKIN CORP

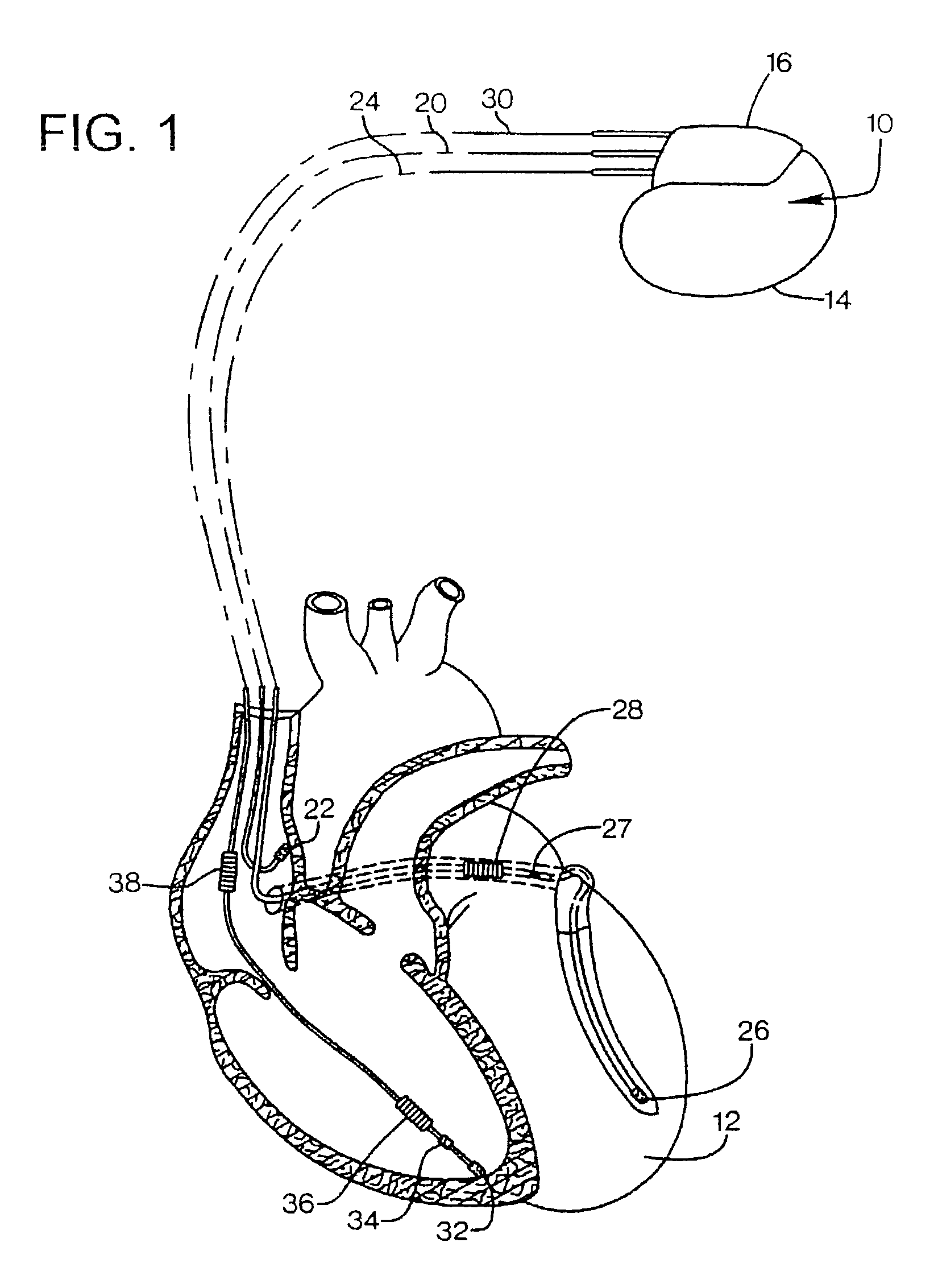

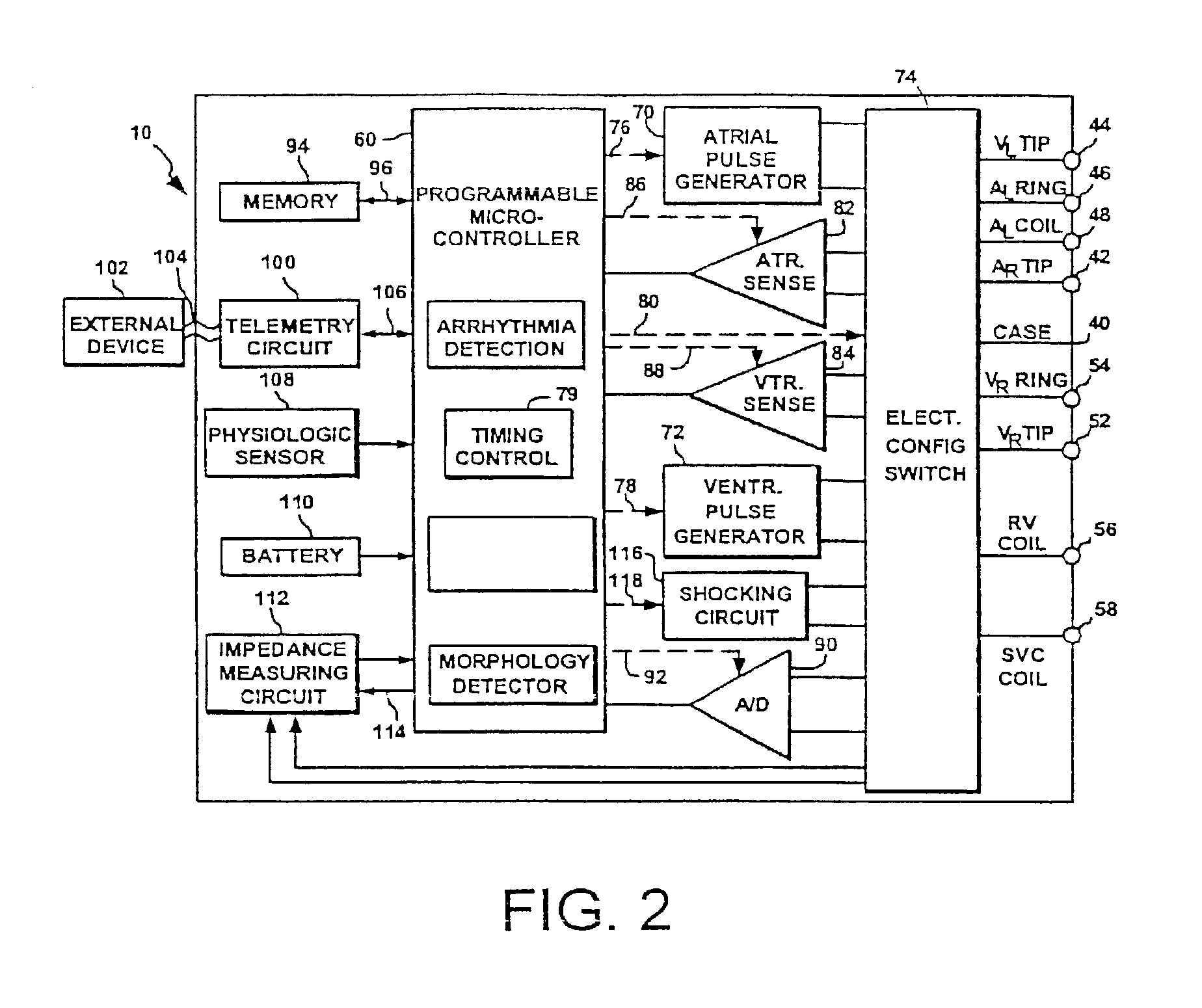

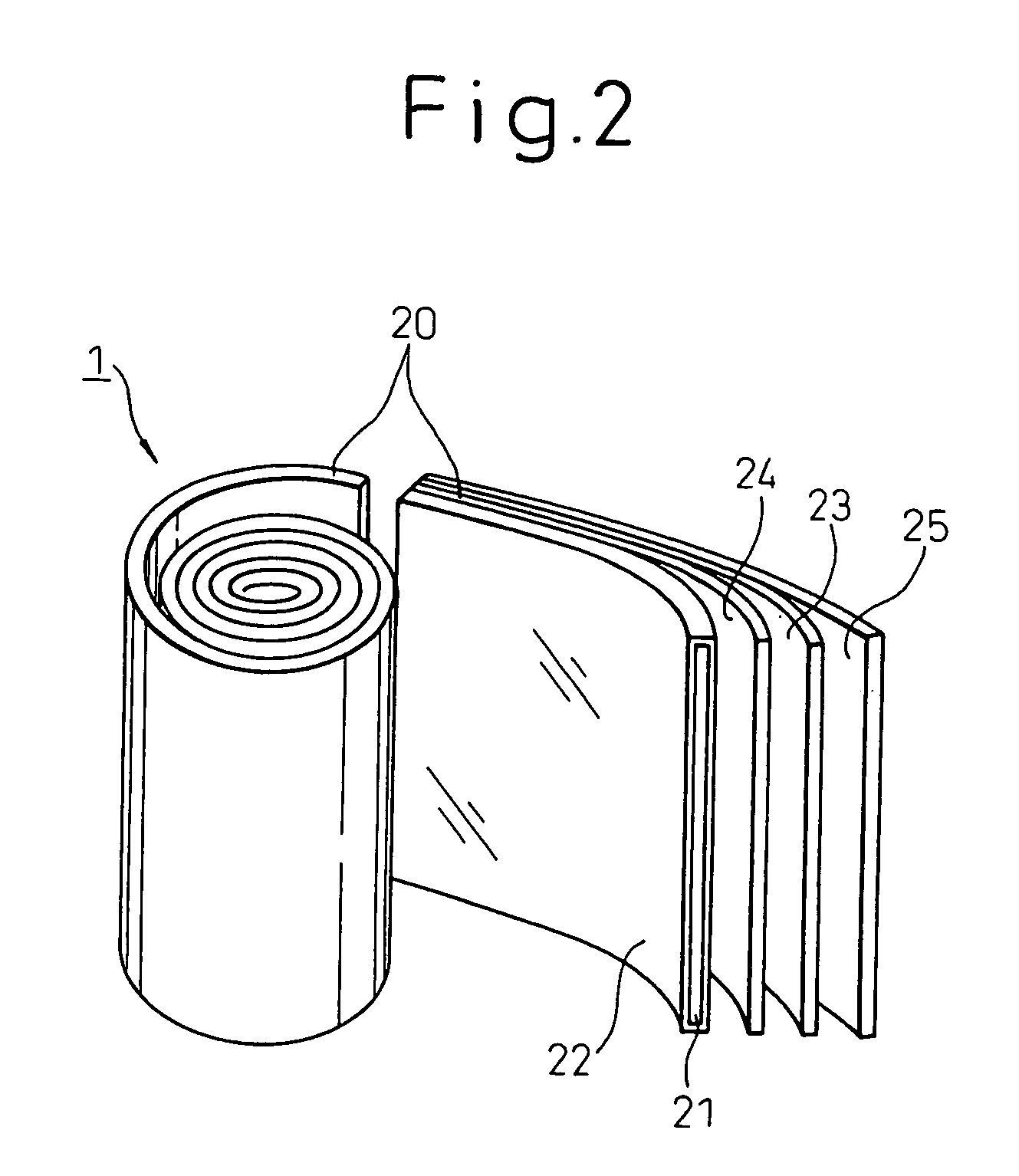

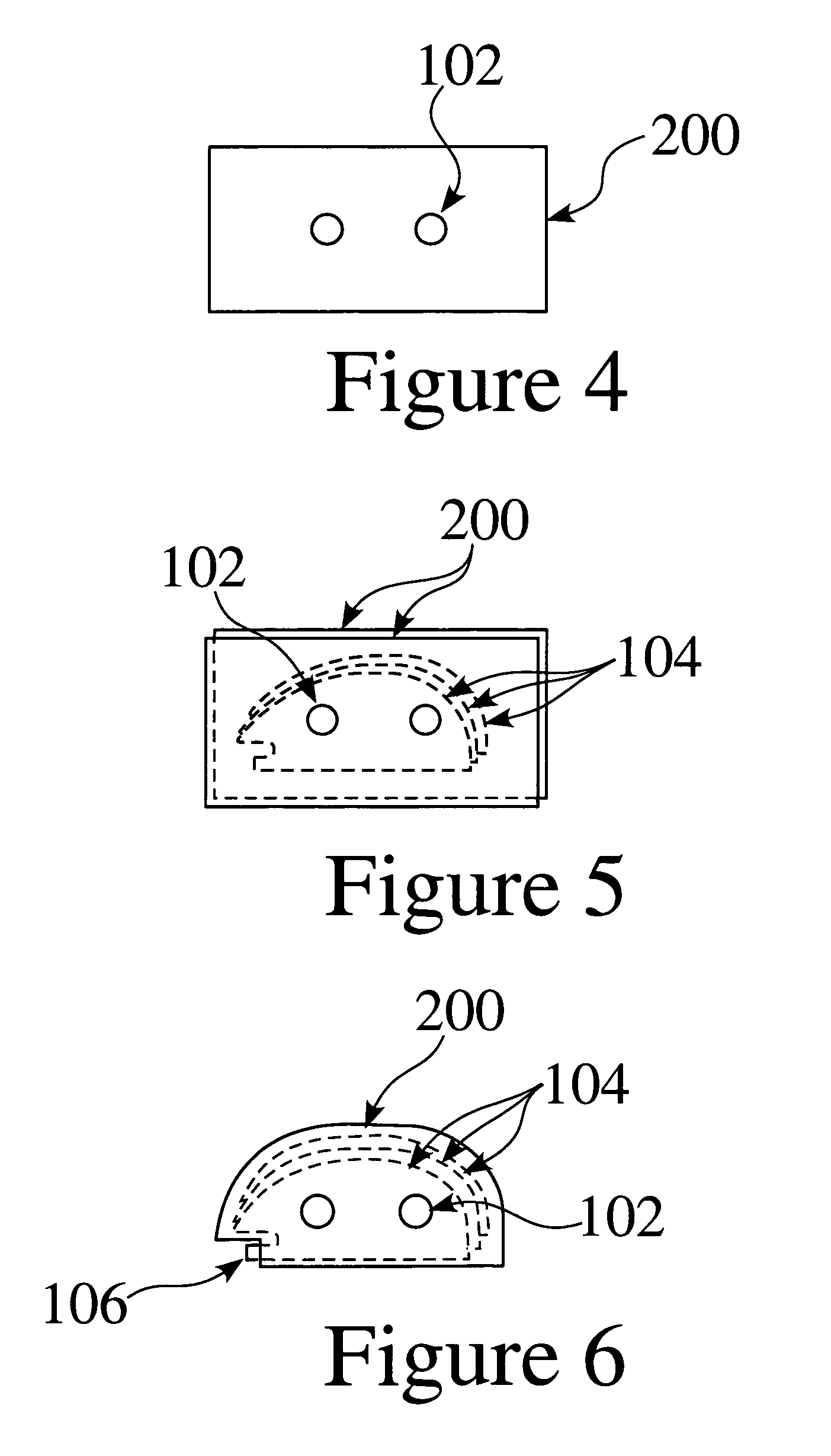

Stackable capacitor having opposed contacts for an implantable electronic medical device

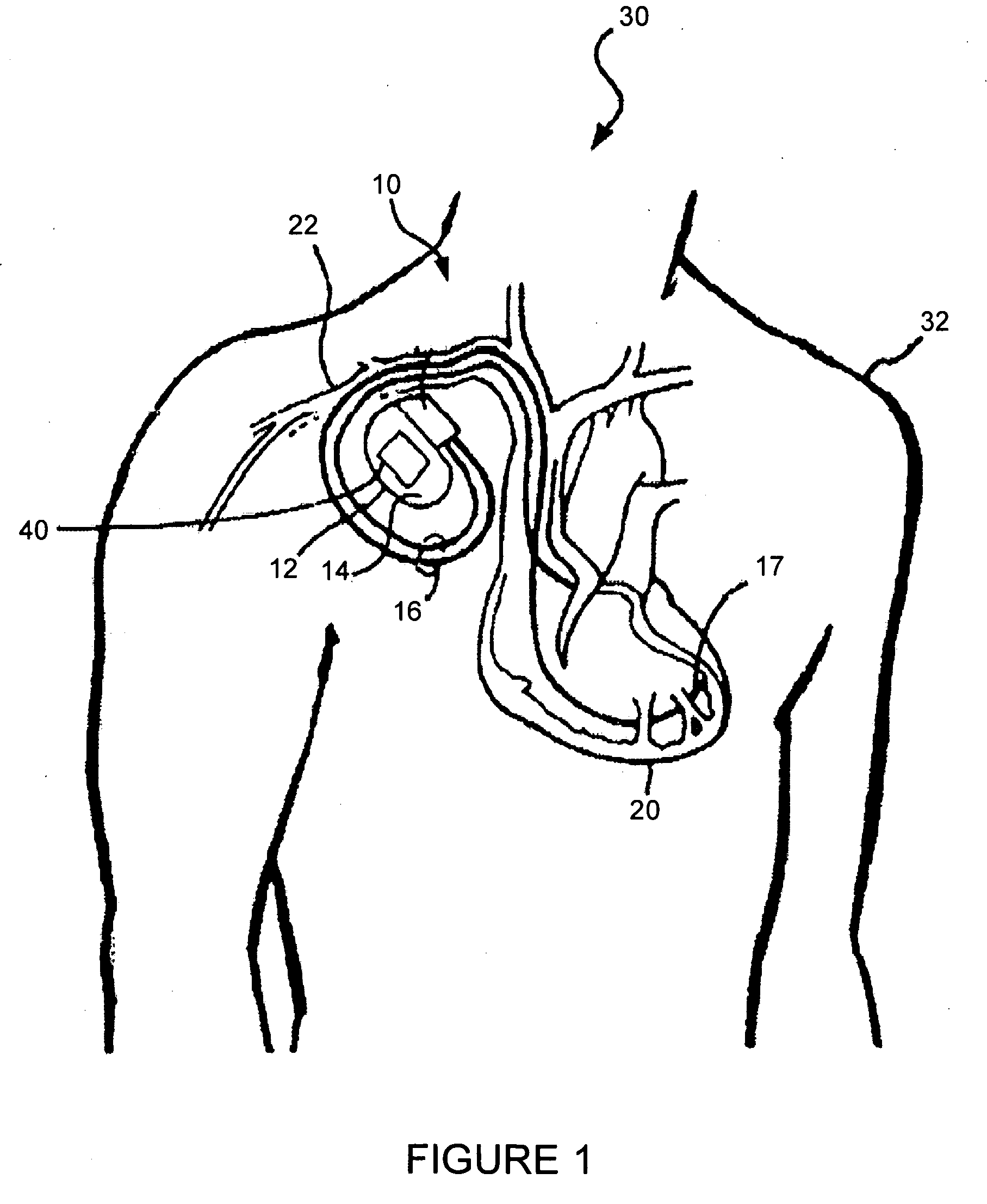

An implantable cardioverter-defibrillator has a housing containing cardioverter-defibrillator circuitry and a capacitor assembly. The capacitor assembly includes at least two flat capacitors each having opposed major surfaces. Each capacitor has an anode contact at one major surface, and a cathode contact at the opposite major surface. The anode contact of one of the capacitors contacts the cathode contact of the other. Each capacitor contact may be a thin metal plate covering the entire surface of the capacitor, with each plate connected to corresponding interleaved cathode or anode flat sheets between the plates. A non-conductive perimeter may enclose the sheets and connect the plates to each other.

Owner:PACESETTER INC

Rechargeable electrochemical energy storage device

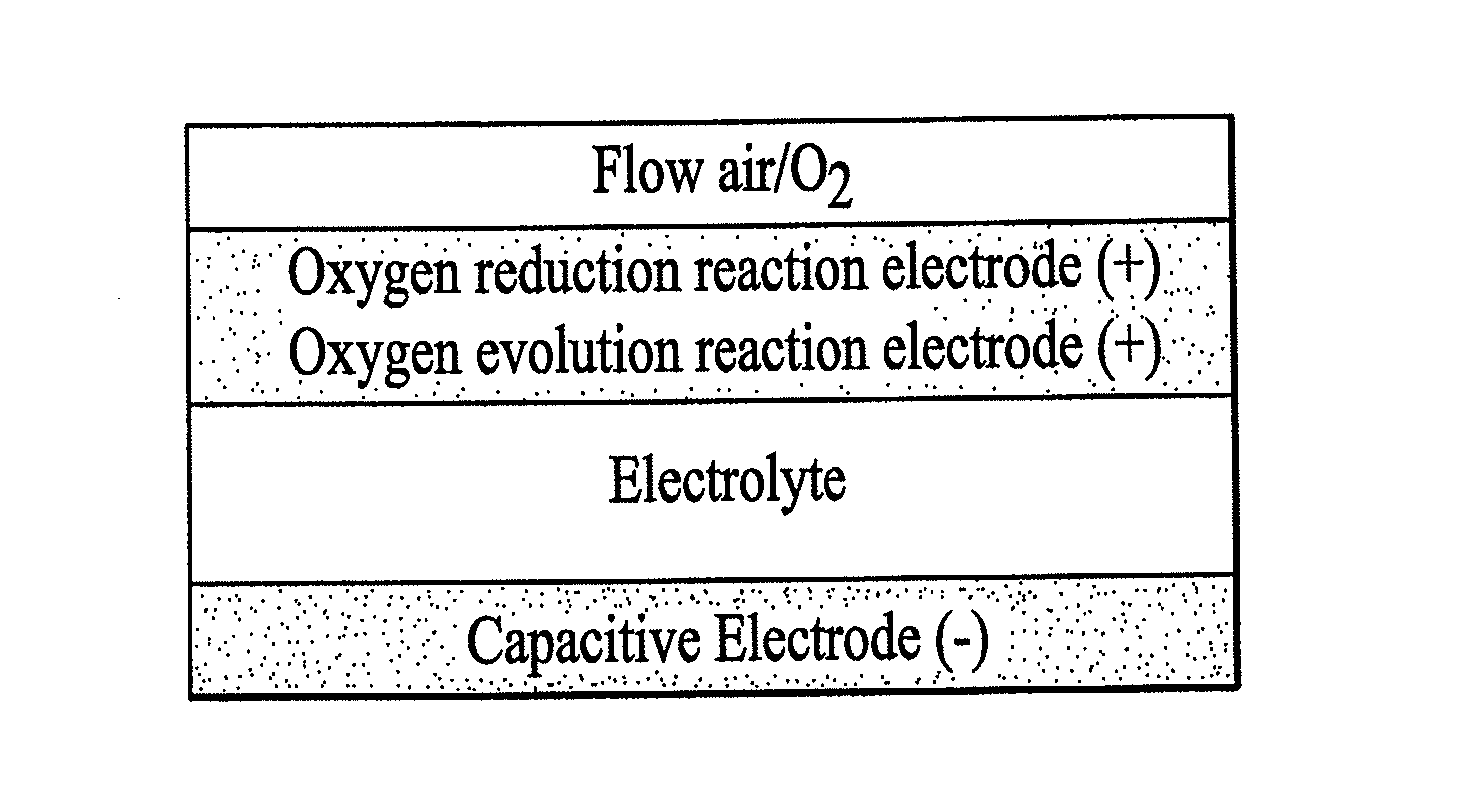

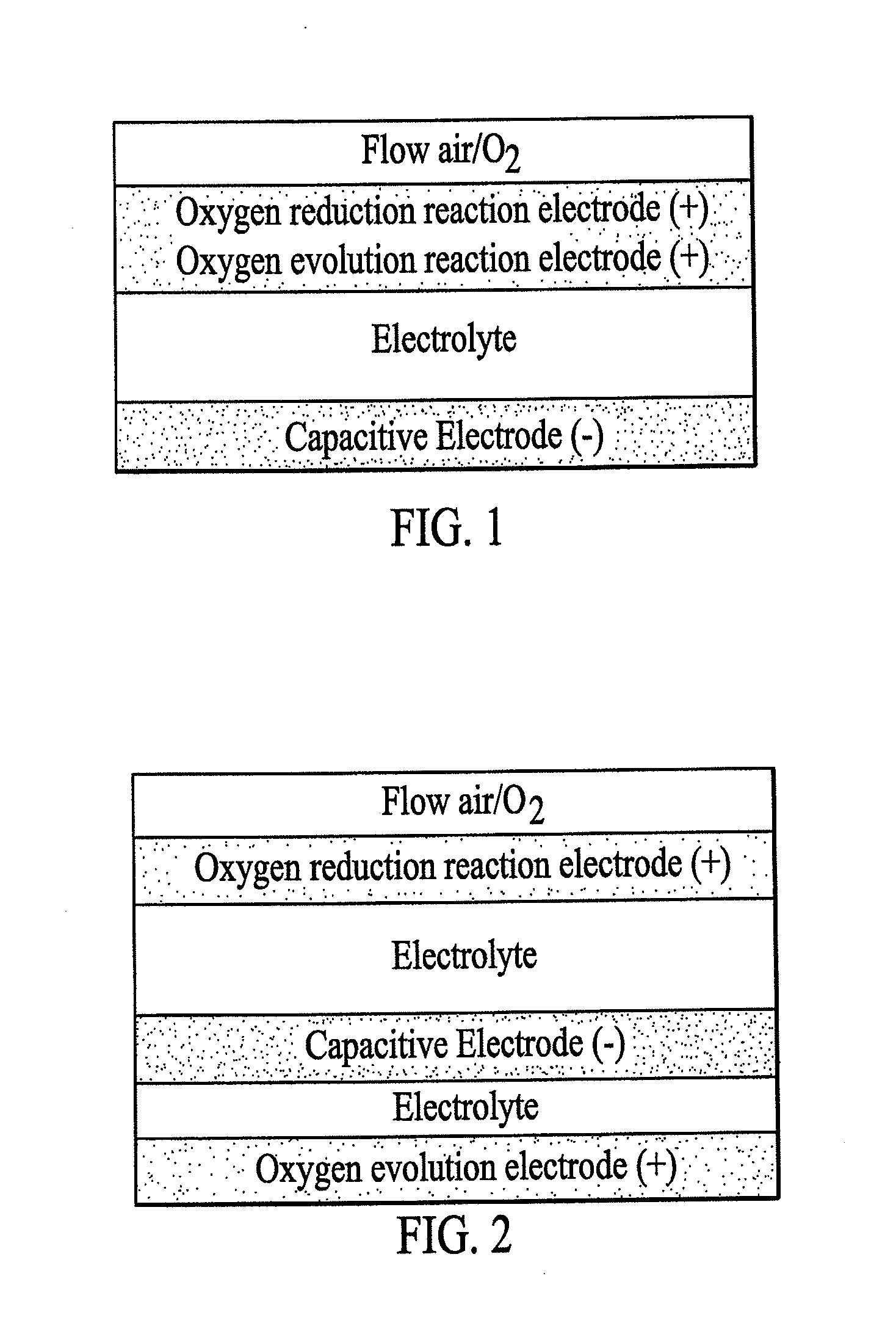

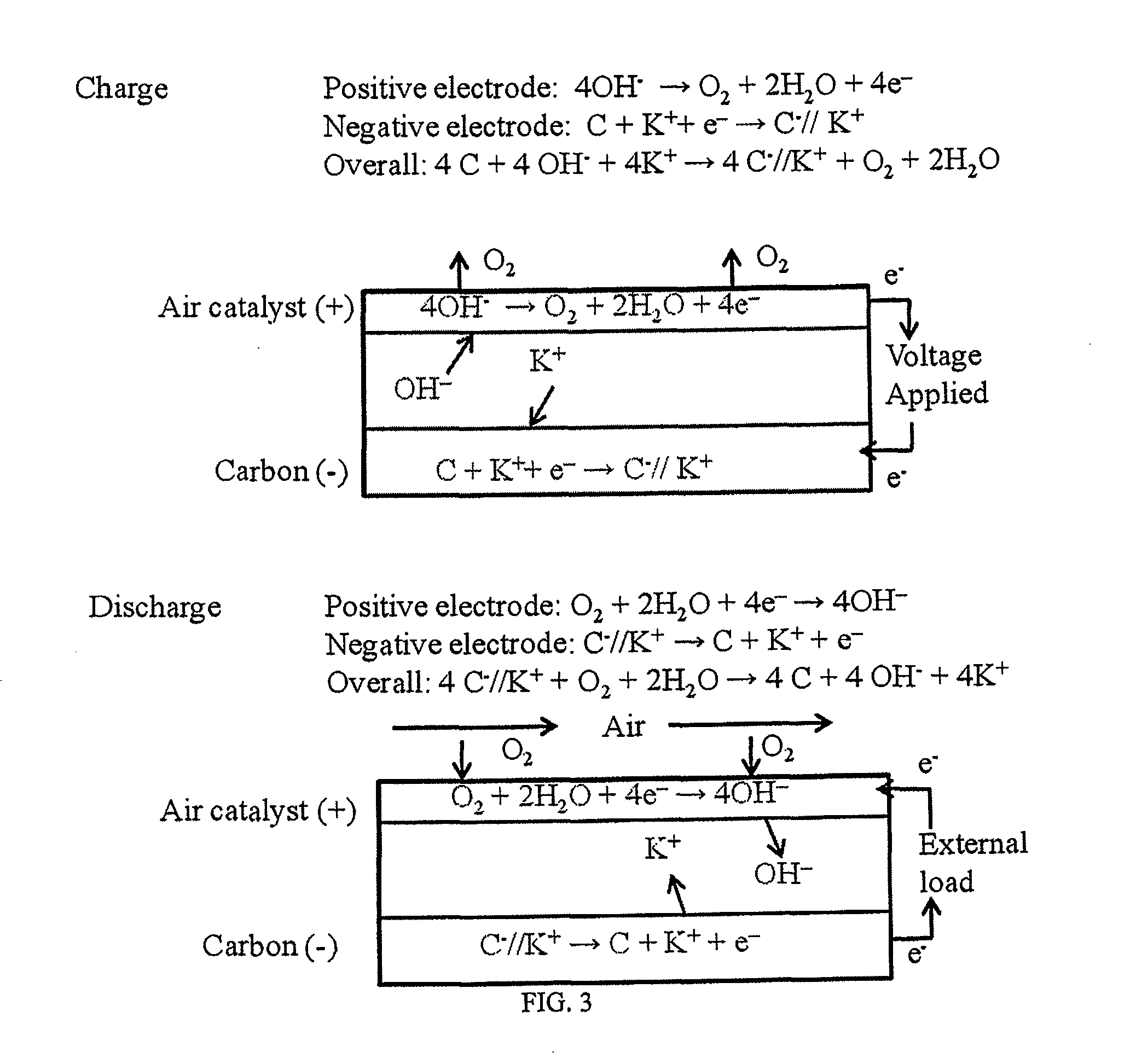

InactiveUS20120140378A1Increase energy densityReduce weightFuel and primary cellsFuel and secondary cellsFuel cellsHybrid system

A rechargeable energy storage device is disclosed. In at least one embodiment the energy storage device includes an air electrode providing an electrochemical process comprising reduction and evolution of oxygen and a capacitive electrode enables an electrode process consisting of non-faradic reactions based on ion absorption / desorption and / or faradic reactions. This rechargeable energy storage device is a hybrid system of fuel cells and ultracapacitors, pseudocapacitors, and / or secondary batteries.

Owner:IMRA AMERICA

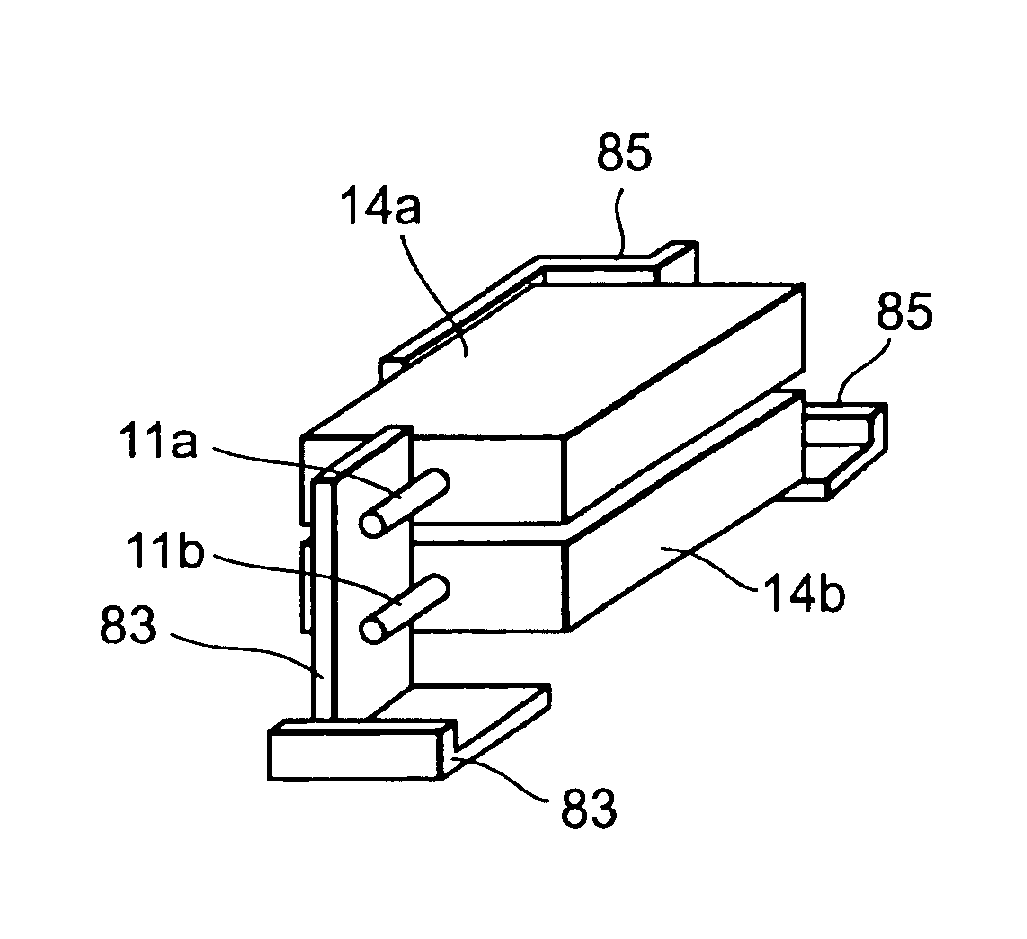

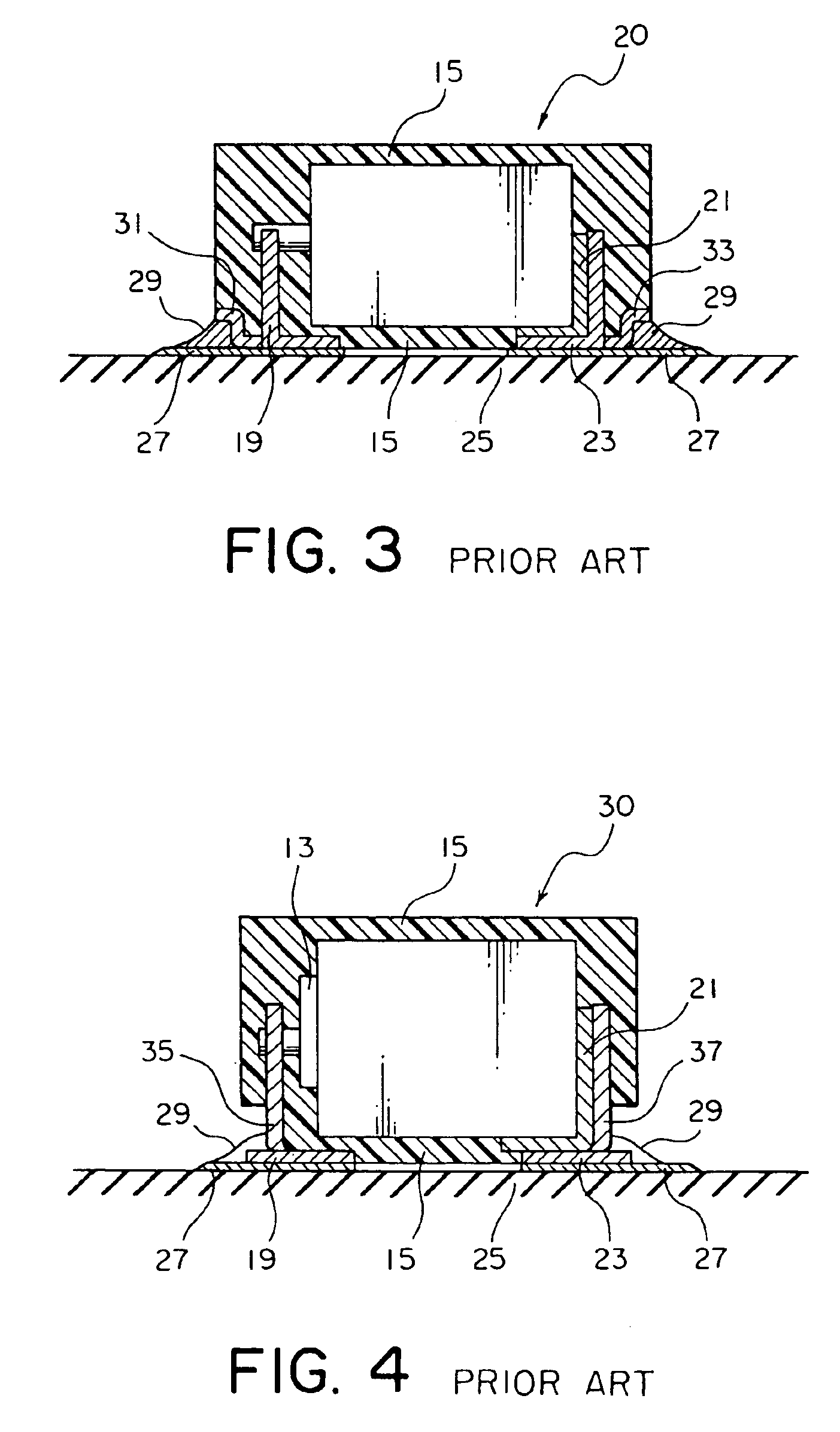

Solid electrolytic capacitor

InactiveUS6920037B2Small sizeLarge capacitanceSolid electrolytic capacitorsLiquid electrolytic capacitorsElectrolysisEngineering

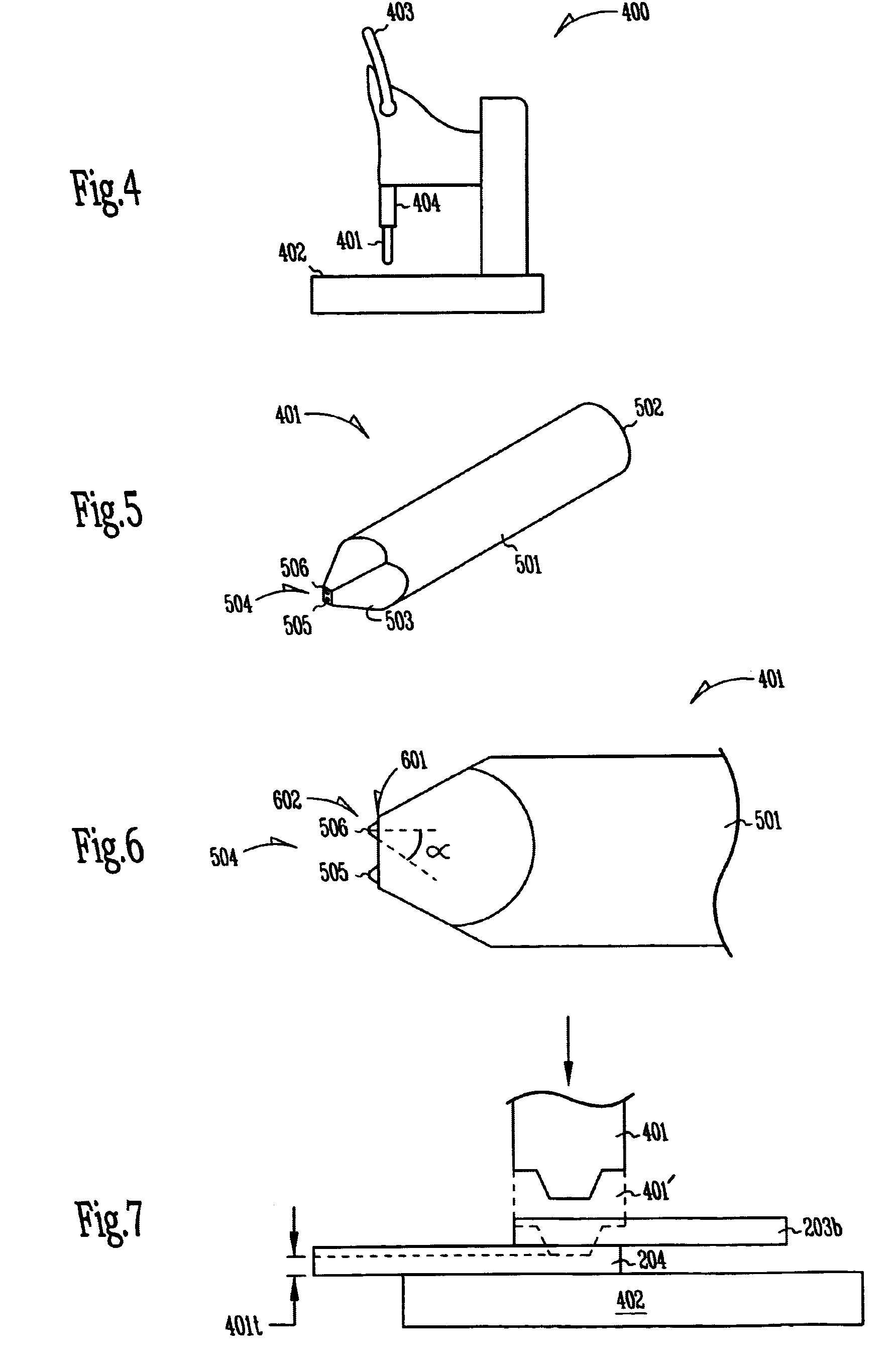

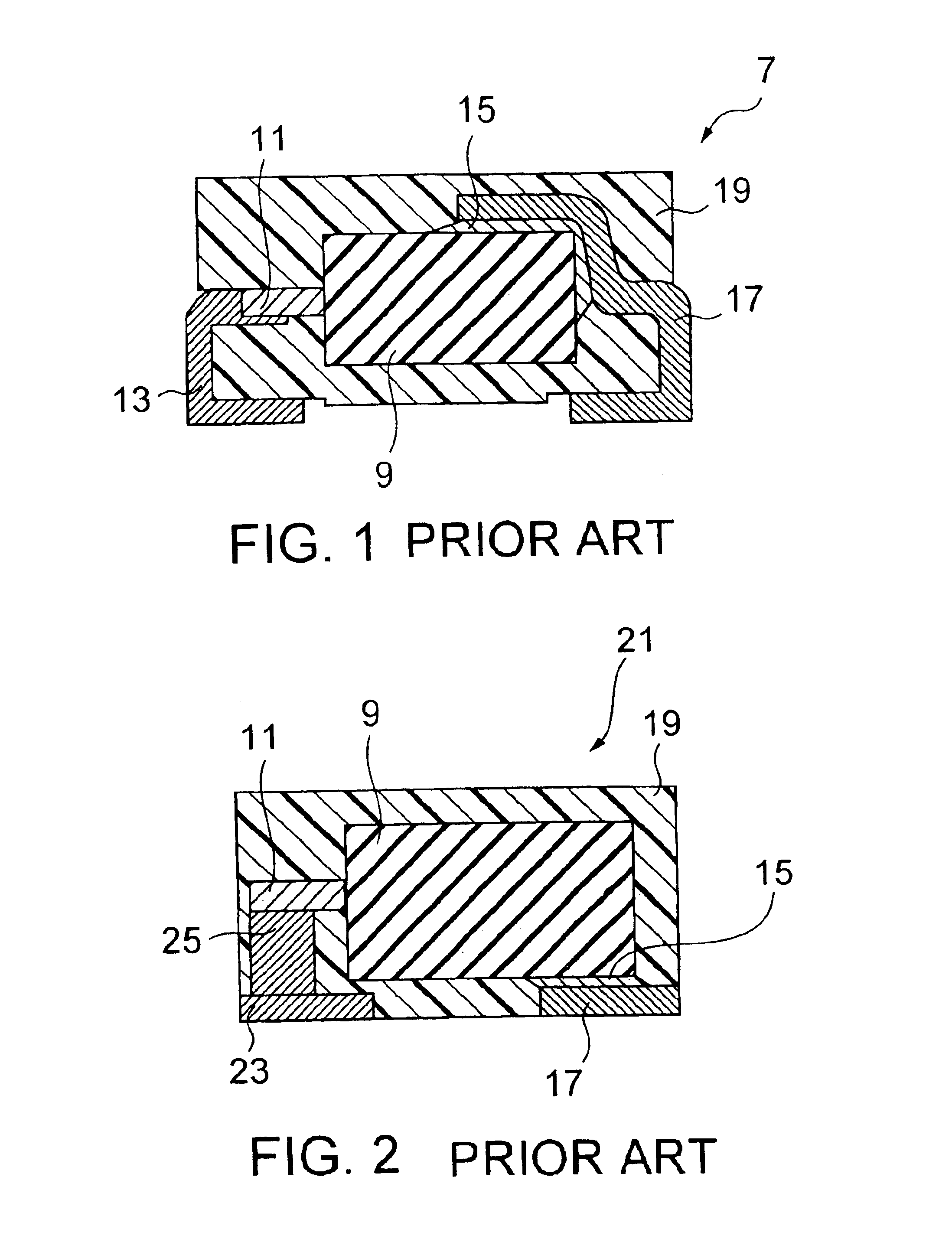

In a solid electrolytic capacitor, an anode terminal (27 in FIG. 3) has a T-shaped section in which two plate pieces intersect at right angles. One of the two plate pieces is exposed to the mounting surface of the solid electrolytic capacitor, while the other is perpendicularly erected to an anode lead (11). The two plate pieces are made of a series of continuous members.

Owner:TOKIN CORP

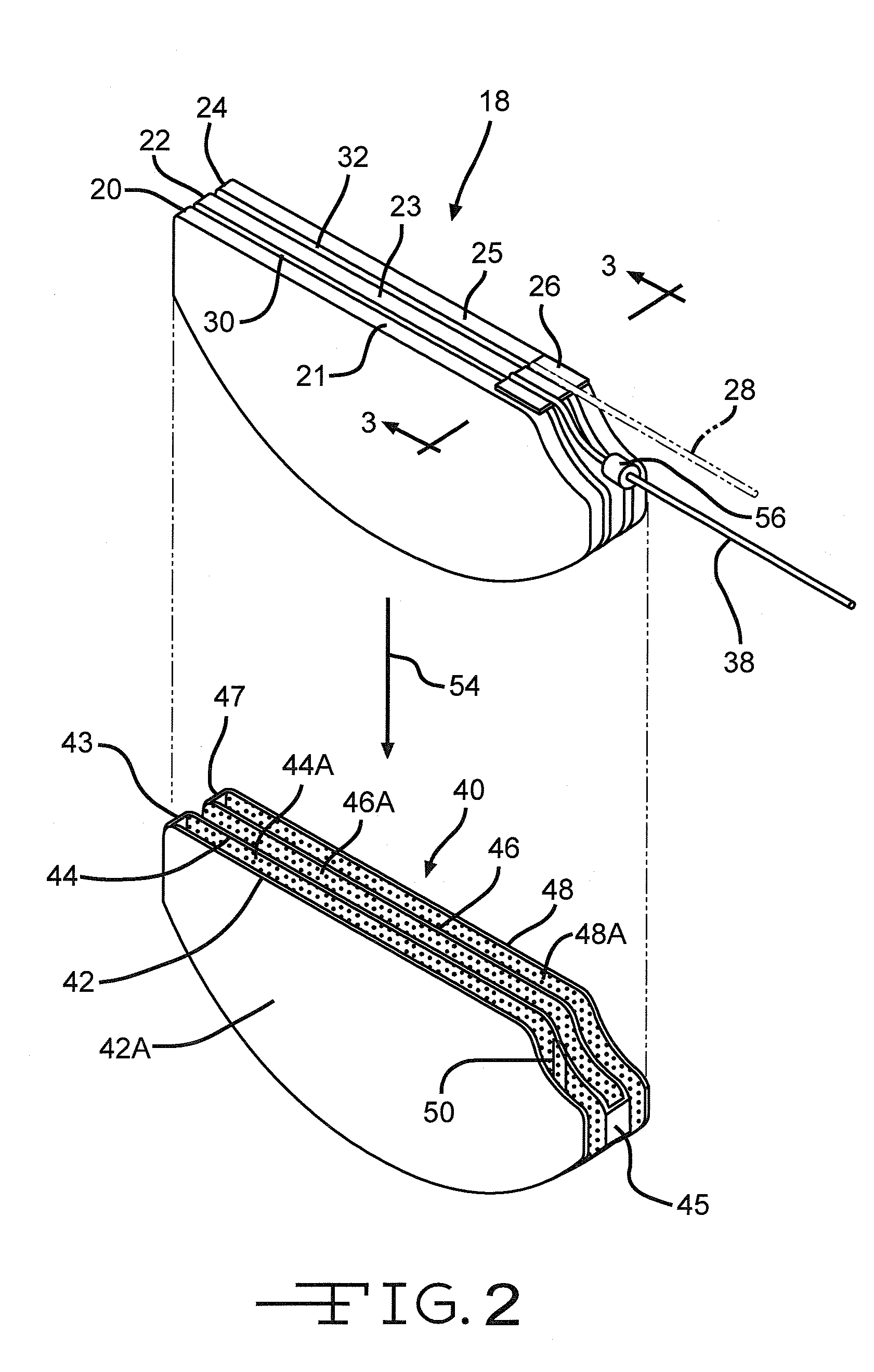

Implantable medical device having flat electrolytic capacitor with differing sized anode and cathode layers

InactiveUS20050264979A1Maximize anode electrode surface areaEasy to useAnti-noise capacitorsFeed-through capacitorsElectrolysisElectrical connection

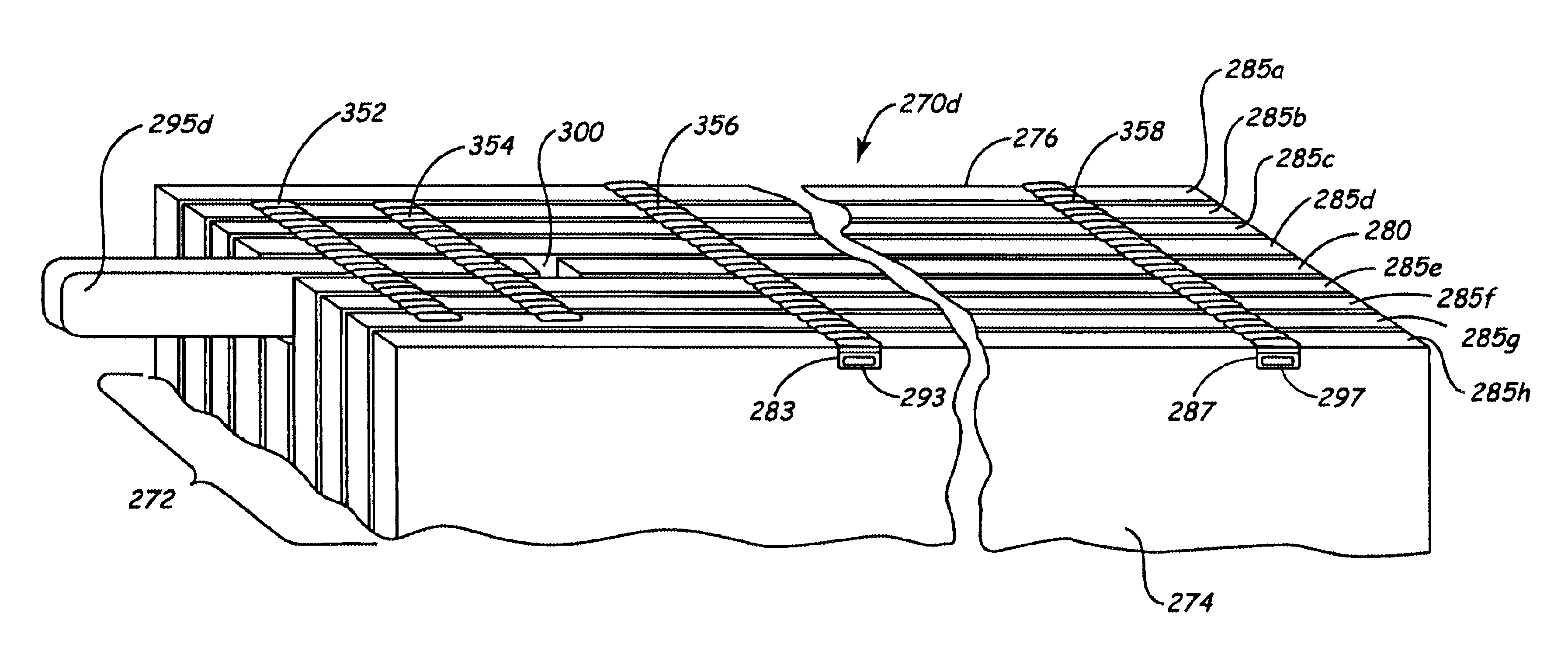

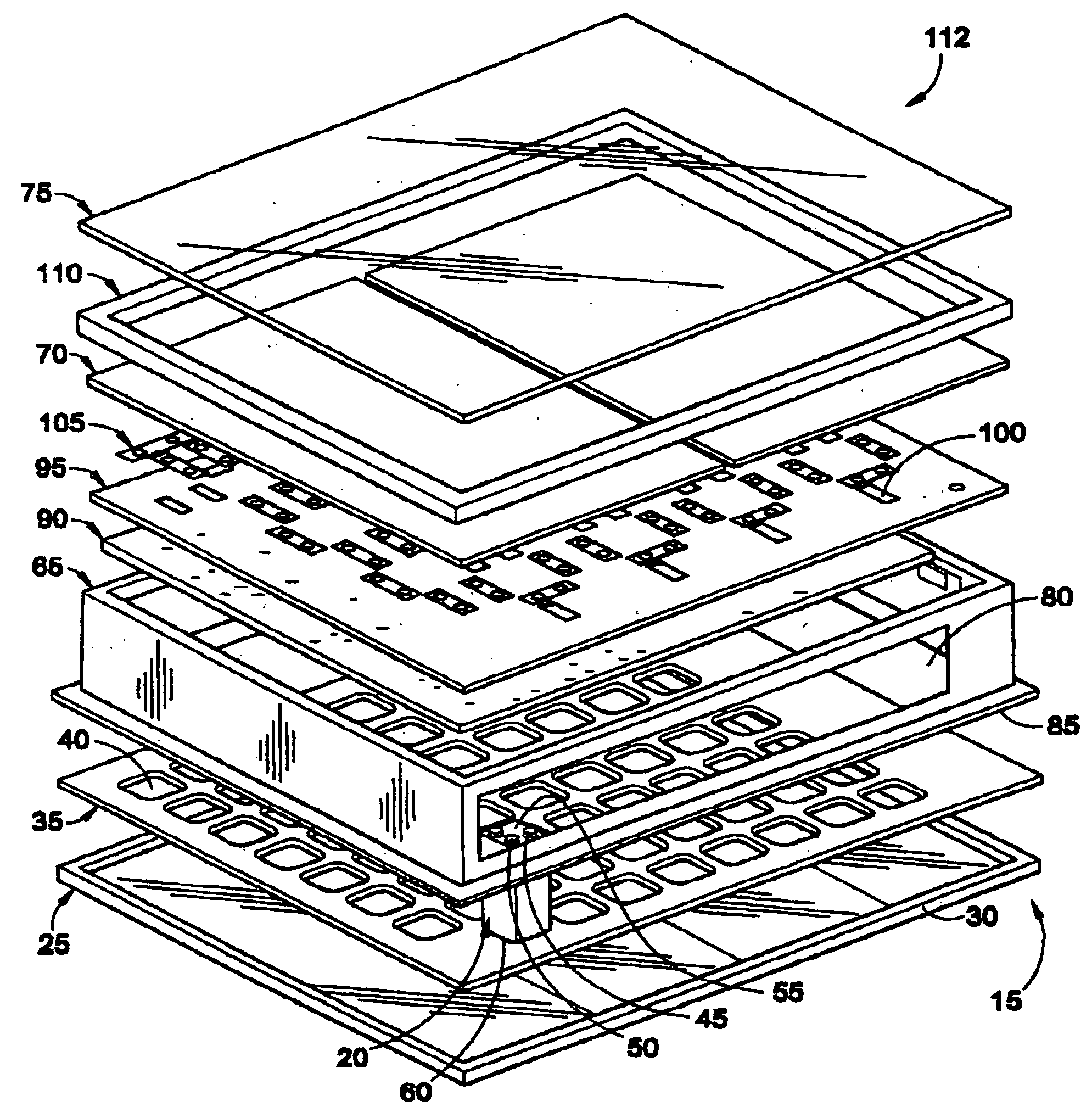

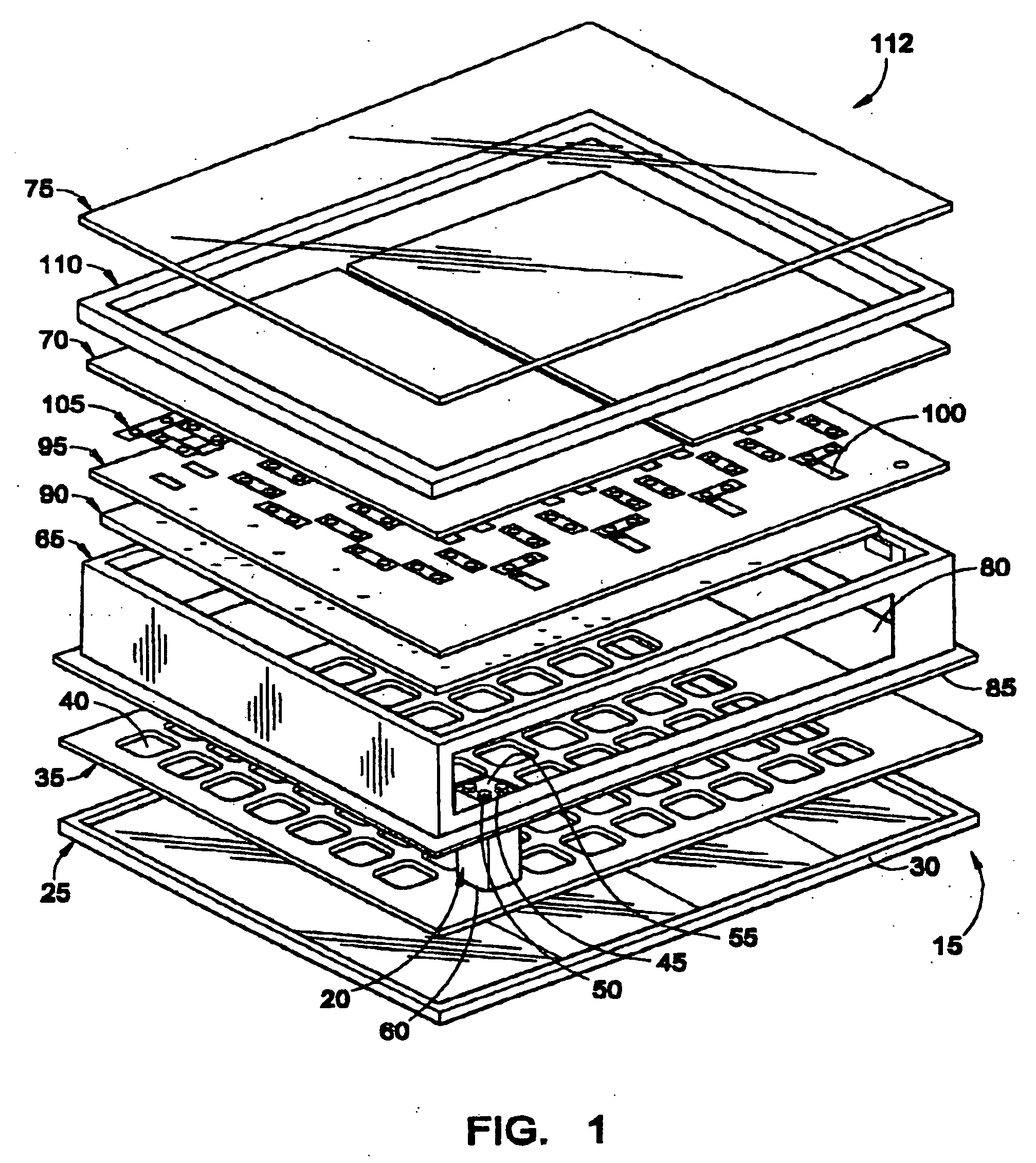

Flat electrolytic capacitors, particularly, for use in implantable medical devices (IMDs), and the methods of fabrication of same are disclosed. The capacitors are formed with an electrode stack assembly comprising a plurality of stacked capacitor layers each comprising an anode sub-assembly of at least one anode layer, a cathode layer and separator layers wherein the anode and cathode layers have differing dimensions that avoid electrical short circuits between peripheral edges of adjacent anode and cathode layers but maximize anode electrode surface area. The electrolytic capacitor is formed of a capacitor case defining an interior case chamber and case chamber periphery, an electrode stack assembly of a plurality of stacked capacitor layers having anode and cathode tabs disposed in the interior case chamber, an electrical connector assembly for providing electrical connection with the anode and cathode tabs through the case, a cover, and electrolyte filling the remaining space within the interior case chamber. The plurality of capacitor layers and further separator layers are stacked into the electrode stack assembly and disposed within the interior case chamber such that the adjacent anode and cathode layers are electrically isolated from one another. The anode layer peripheral edges of the anode sub-assemblies of the stacked capacitor layers extend closer to the case side wall than the cathode peripheral edges of the cathode layers of the stack of capacitor layers throughout a major portion of the case chamber periphery. The separator layer peripheral edges extend to the case periphery and space the anode layer peripheral edges therefrom. Any burrs, debris or distortions along or of any of the anode layer peripheral edges causing the anode layer edges to effectively extend in the electrode stack height direction causes the anode layer peripheral edges having such tendency to contact an adjacent anode layer. In this way, anode layer surface area is maximized, and short circuiting of the anode layers with the cathode layers is avoided. A case liner can also be disposed around the electrode stack assembly periphery.

Owner:MEDTRONIC INC

Wet tantalum capacitor with multiple anode connections

A capacitor assembly comprising a casing, an anode pack housed within the casing and comprising two or more anode pellets of anode active material electrically connected to each other by a bridge, and a cathode comprised of cathode current collectors including major faces with cathode active material provided thereupon is described. The bridge, which spans between sidewalls of the anode pellets, helps maintain them in a parallel alignment. The bridge is also a convenient location to connect the feedthrough wire that exits the casing through a glass-to-metal seal. The cathode current collectors are disposed between adjacent anode pellets and are electrically connected to each other and to the casing. A feedthrough wire electrically connected to the anode pack extends outside the casing in electrical isolation there from. An electrolyte is provided to activate the anode and the cathode.

Owner:WILSON GREATBATCH LTD

Electrochemical device and process for producing same

InactiveUS6912116B2Improve cycle performanceLower internal resistanceBatteries circuit arrangementsFinal product manufactureElectrical connectionElectrochemistry

An electrochemical device includes electrodes stacked one on the other with a separator intervening between the adjacent electrodes. The electrode includes a current collector and an electrode layer stacked on the current collector via an adhesive resin layer. The electrode layer contains an active material, an electrically conductive auxiliary and a binder resin. At least part of the electrically conductive auxiliary or the active material penetrates the adhesive resin layer to establish an electrical connection with the current collector.

Owner:TDK CORPARATION

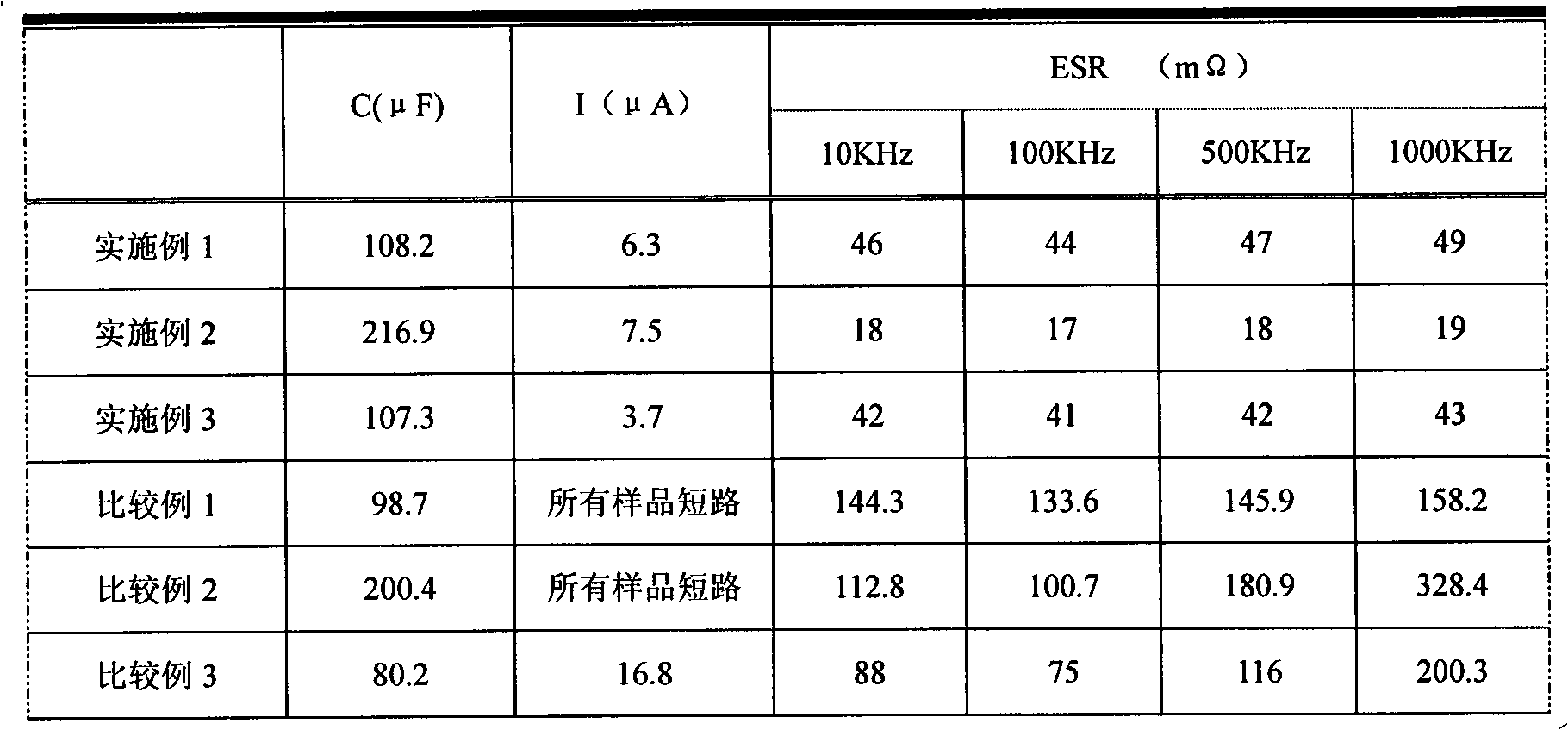

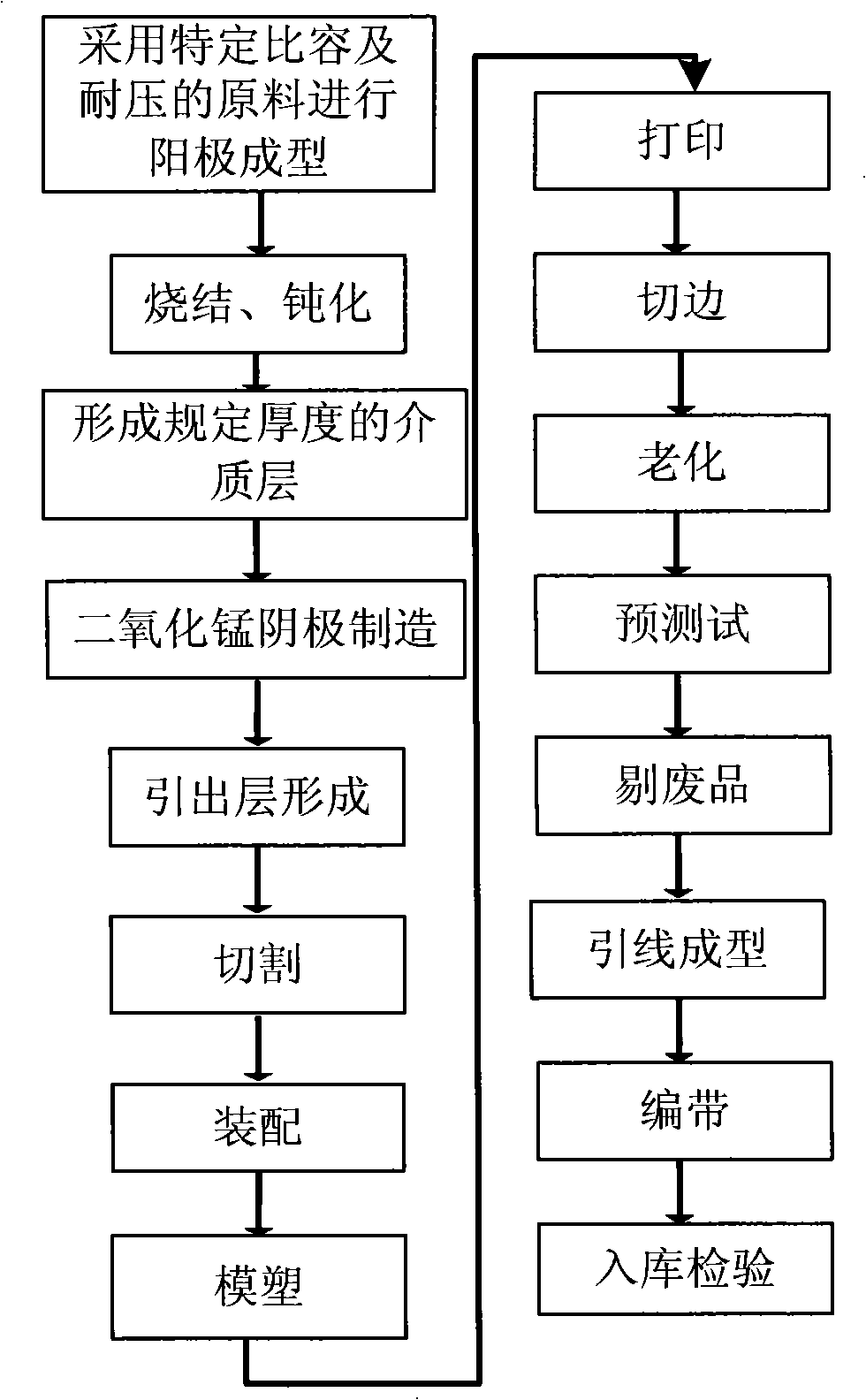

Solid electrolyte capacitor with ultra-low equivalent series resistance and manufacturing method thereof

ActiveCN101350253AImprove volumetric efficiencyTightly boundSolid electrolytic capacitorsCapacitor terminalsElectrolysisNiobium

The invention relates to a solid electrolytic capacitor and the method for preparing the solid electrolytic capacitor, wherein the solid electrolytic capacitor takes solid conducting high molecular polymer as electrolyte and takes valve metals, such as tantalum, niobium, titanium, aluminum and the like as an anode. The solid electrolytic capacitor is characterized by sufficiently explaining the techniques for the design of the anode, the function assignment, the chemical oxidative in-situ polymerization, the dip-coating graphite silver paste, the making of bottom extraction electrode and the like, with the technical proposal of the invention, a high polymer film, a graphite layer and a silver layer can be compactly combined, the manufactured electrolytic capacitor can be provided with very low equivalent series resistance (ESR), very high volumetric efficiency and good impedance frequency characteristic, the ESR value can be stable in the range of 10KHz-1000KHz, and the requirements of the frequency of a modern electronic equipment can be satisfied.

Owner:CHINA ZHENHUA GRP XINYUN ELECTRONICS COMP ANDDEV CO LTD

Implantable medical device having flat electrolytic capacitor with differing sized anode and cathode layers

InactiveUS6963482B2Area maximizationEasy to useAnti-noise capacitorsFeed-through capacitorsElectrolysisElectrical connection

Flat electrolytic capacitors, particularly, for use in implantable medical devices (IMDs), and the methods of fabrication of same are disclosed. The capacitors are formed with an electrode stack assembly comprising a plurality of stacked capacitor layers each comprising an anode sub-assembly of at least one anode layer, a cathode layer and separator layers wherein the anode and cathode layers have differing dimensions that avoid electrical short circuits between peripheral edges of adjacent anode and cathode layers but maximize anode electrode surface area. The electrolytic capacitor is formed of a capacitor case defining an interior case chamber and case chamber periphery, an electrode stack assembly of a plurality of stacked capacitor layers having anode and cathode tabs disposed in the interior case chamber, an electrical connector assembly for providing electrical connection with the anode and cathode tabs through the case, a cover, and electrolyte filling the remaining space within the interior case chamber. The plurality of capacitor layers and further separator layers are stacked into the electrode stack assembly and disposed within the interior case chamber such that the adjacent anode and cathode layers are electrically isolated from one another. The anode layer peripheral edges of the anode sub-assemblies of the stacked capacitor layers extend closer to the case side wall than the cathode peripheral edges of the cathode layers of the stack of capacitor layers throughout a major portion of the case chamber periphery. The separator layer peripheral edges extend to the case periphery and space the anode layer peripheral edges therefrom. Any burrs, debris or distortions along or of any of the anode layer peripheral edges causing the anode layer edges to effectively extend in the electrode stack height direction causes the anode layer peripheral edges having such tendency to contact an adjacent anode layer. In this way, anode layer surface area is maximized, and short circuiting of the anode layers with the cathode layers is avoided. A case liner can also be disposed around the electrode stack assembly periphery.

Owner:MEDTRONIC INC

Electrolytic solution for use in electrolytic capacitor, and electrolytic capacitor

ActiveUS20070121276A1Excellent in noise removing abilityImprove discharge efficiencyHybrid capacitor separatorsHybrid capacitor electrolytesDielectricElectrolysis

An electrolytic solution, for use in an electrolytic capacitor, comprising a solvent and a solute wherein water accounts for 20 to 100% by weight of the solvent and the total solute content is from 1.5 to 44% by weight, and an electrolytic capacitor comprising a capacitor element, a case containing the capacitor element, and a sealant with which the case is sealed, the capacitor element comprising a pair of electrode foils each comprising a dielectric, a separator for isolating the electrode foils from each other, and the above electrolytic solution filled between the electrode foils.

Owner:RUBYCON CORPORATION

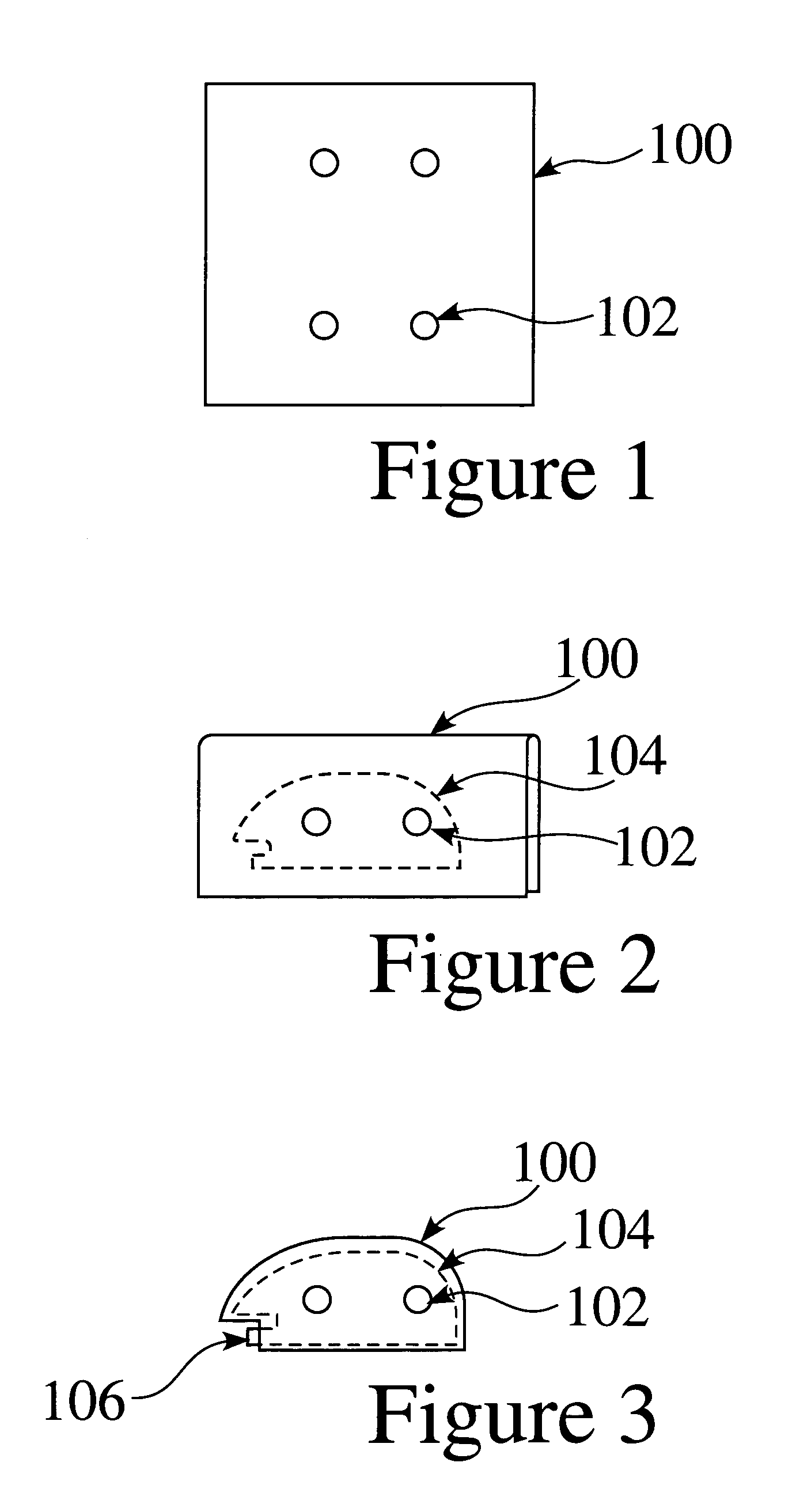

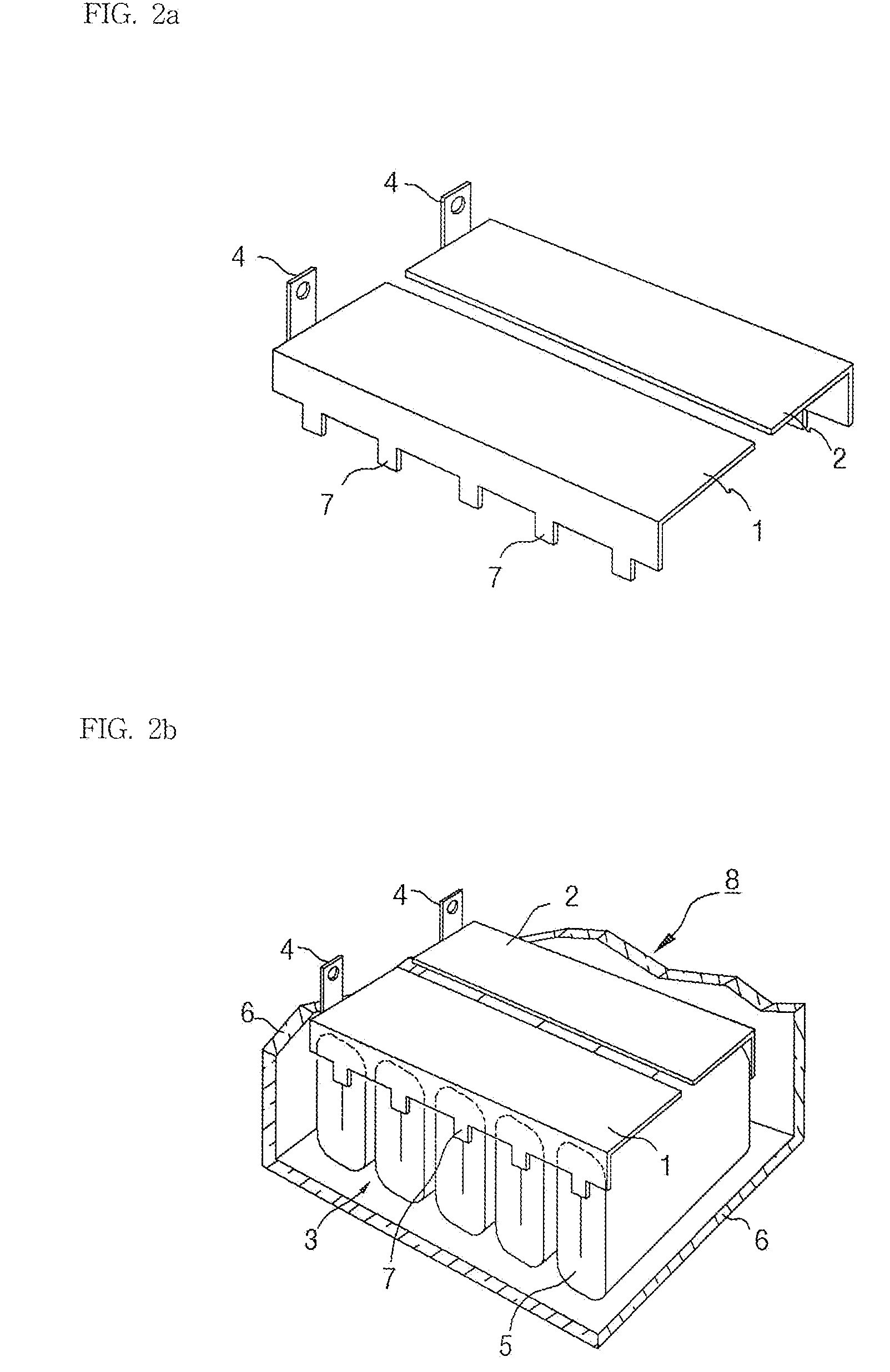

Capacitor anode assembly

According the present invention, anode foils are encapsulated in separator material so as to insulate them from the metal housing of an electrolytic capacitor. The present invention also provides for enclosed capacitor configurations for use in stacked capacitor configurations. Preferably, heat-sealable polymeric materials are used as separator materials to encapsulate or enclose the anode assemblies and capacitor configurations. The encapsulated anode assemblies and capacitor configurations of the present invention may be used in implantable cardioverter defibrillators.

Owner:PACESETTER INC

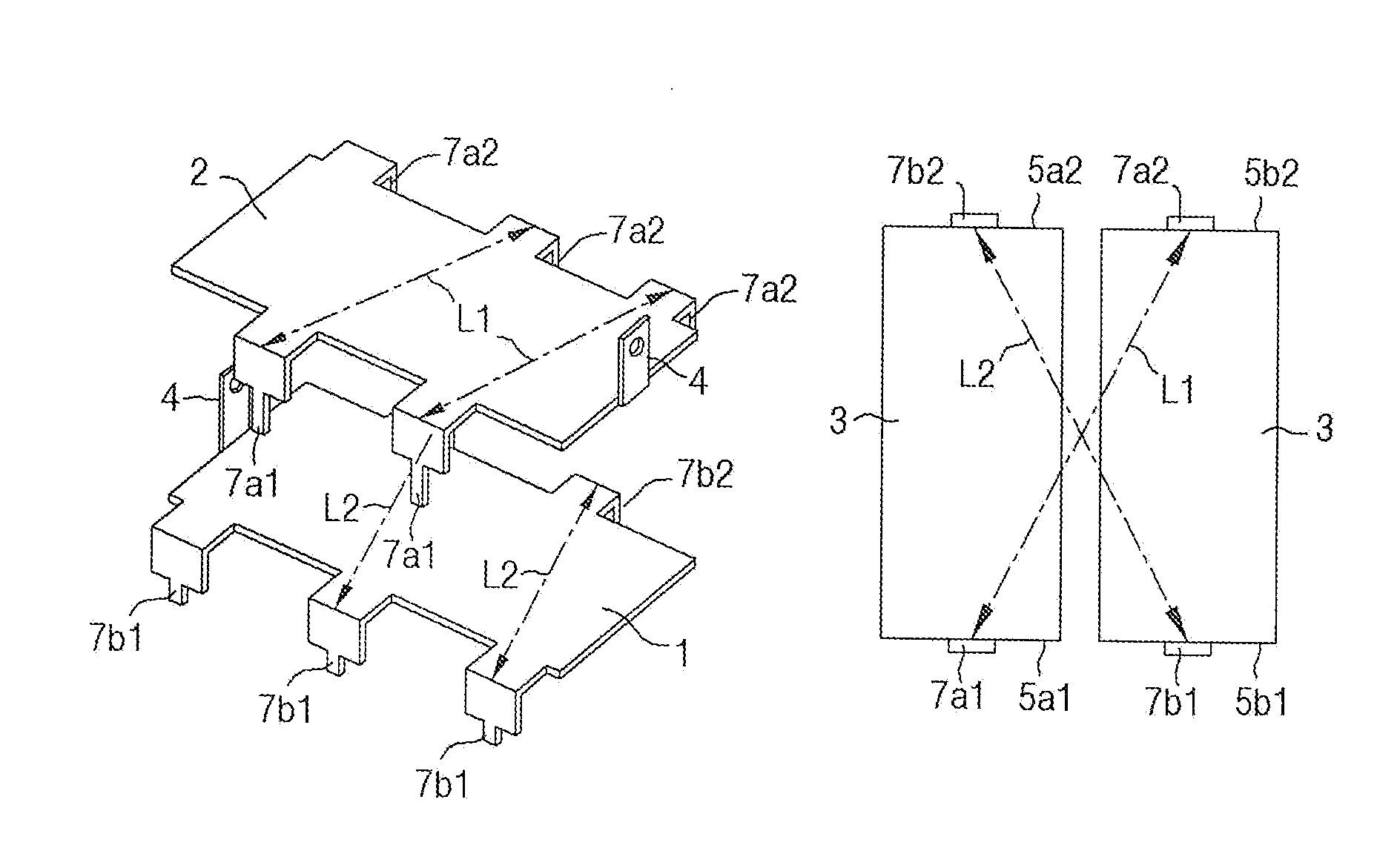

Method for Connecting Bus Bar on Capacitor and Product Fabricated by the Same

ActiveUS20100000089A1Improve electrical characteristicsImprove reliabilityLine/current collector detailsFixed capacitor electrodesCapacitanceDiagonal

Disclosed are a method for connecting a bus bar of a capacitor, improving temperature characteristics and reliability of the capacitor by reducing inductance and impedance such that heat generation is restrained during use of the capacitor, and a product fabricated by the same.A pair of bus bars are insulatedly connected to sprayed surfaces on both sides of a plurality of capacitor devices, in such a manner that lead frames arranged alternately on a first bus bar are connected in contact with the sprayed surfaces facing in a diagonal direction, of neighboring capacitor devices. Other lead frames arranged alternately on a second bus bar are connected to the sprayed surfaces facing in another diagonal direction across the above diagonal direction in an X-shape. Then, the pair of bus bars are assembled to be insulated from each other and overlapped at one side of the capacitor device.

Owner:NUINTEK

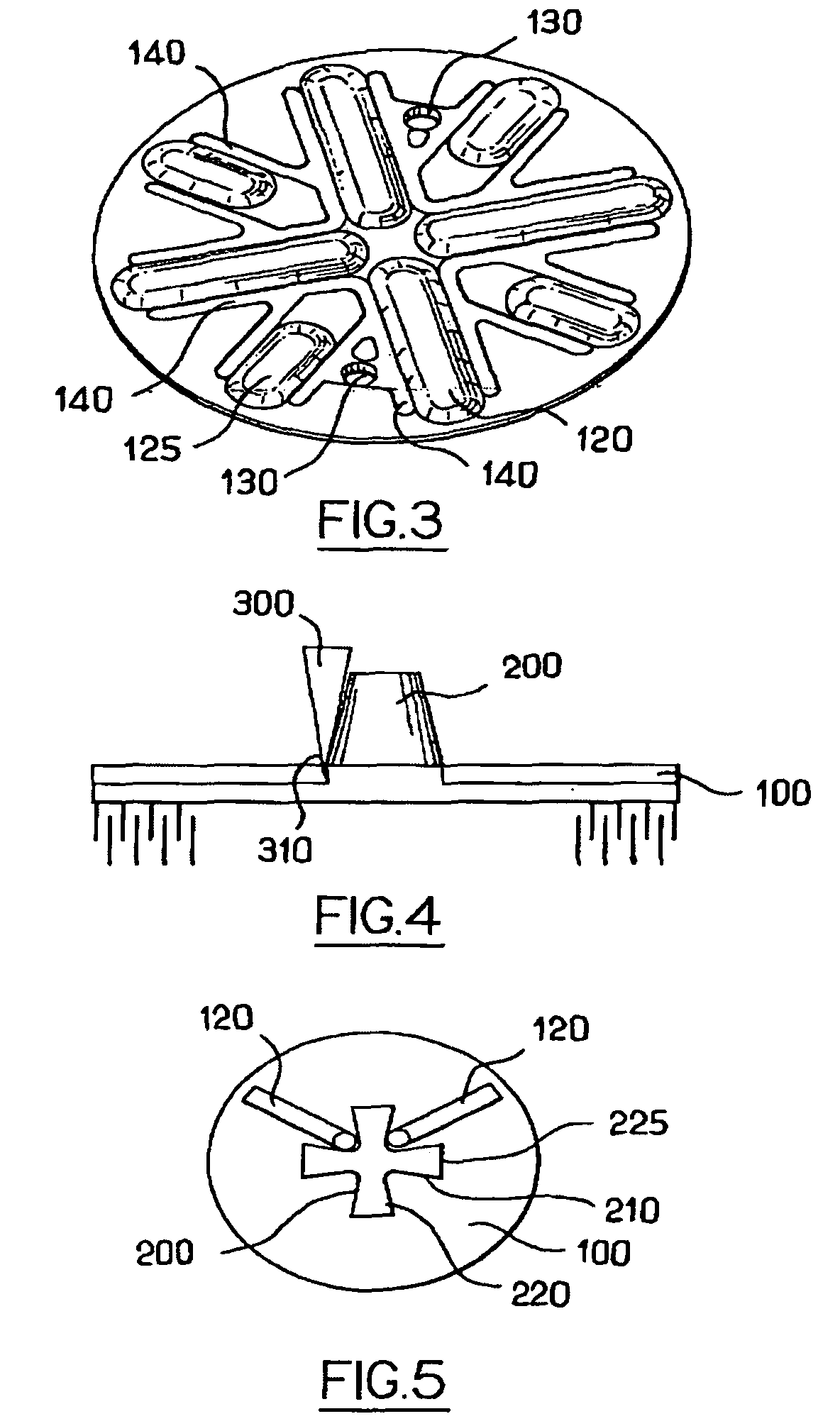

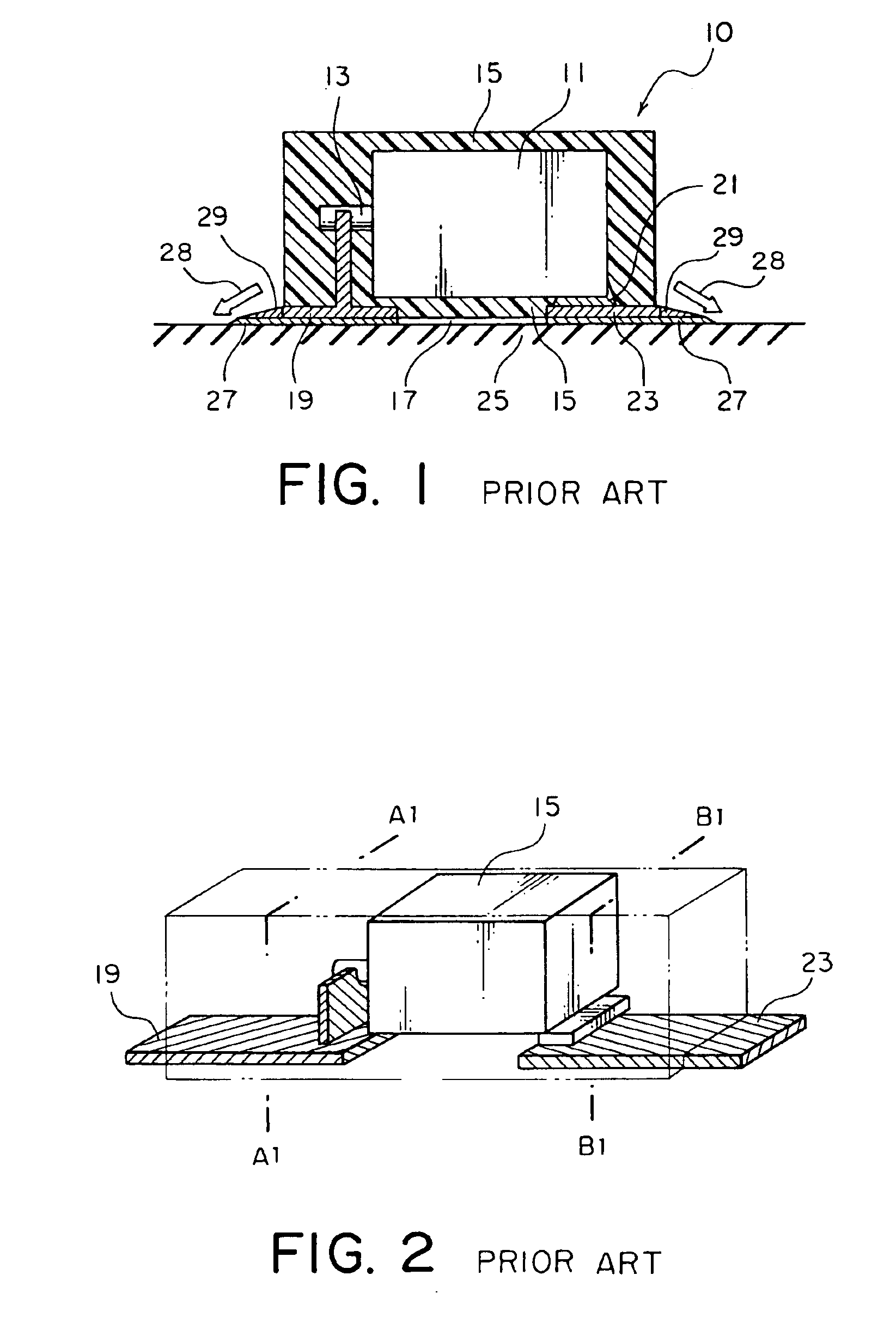

Chip-type capacitor, method of manufacturing the same and molding die

A chip-type capacitor includes a capacitor element, an encapsulation resin covering an entirety of the capacitor element, an anode terminal having a base portion whose bottom surface is exposed on a mounting surface of the encapsulation resin and a standing-up portion perpendicular to the base portion and having one end connected to the base portion and the other end welded to an anode lead wire led out from the capacitor element, and a cathode terminal fixed through a conductive adhesive to the capacitor element so as to expose a bottom surface on the mounting surface of the encapsulation resin. A depressed portion is formed on each of opposite side surfaces of the encapsulation resin, thereby partially exposing a top surface of each of the anode and the cathode terminals opposite to the bottom surface to form a terminal exposed portion exposed out of the encapsulation resin.

Owner:TOKIN CORP

Electrode material for aluminum electrolytic capacitor and process for producing the electrode material

ActiveUS20110038098A1Solve the real problemHigh strengthCapacitor terminalsSpecial surfacesMaterials scienceAluminum electrolytic capacitor

The present invention provides an electrode material for use in an aluminum electrolytic capacitor that does not necessitate an etching treatment. Specifically, the present invention provides an electrode material for use in an aluminum electrolytic capacitor, the electrode material comprising a sintered body of at least one of aluminum and an aluminum alloy.

Owner:TOYO ALUMINIUM KK

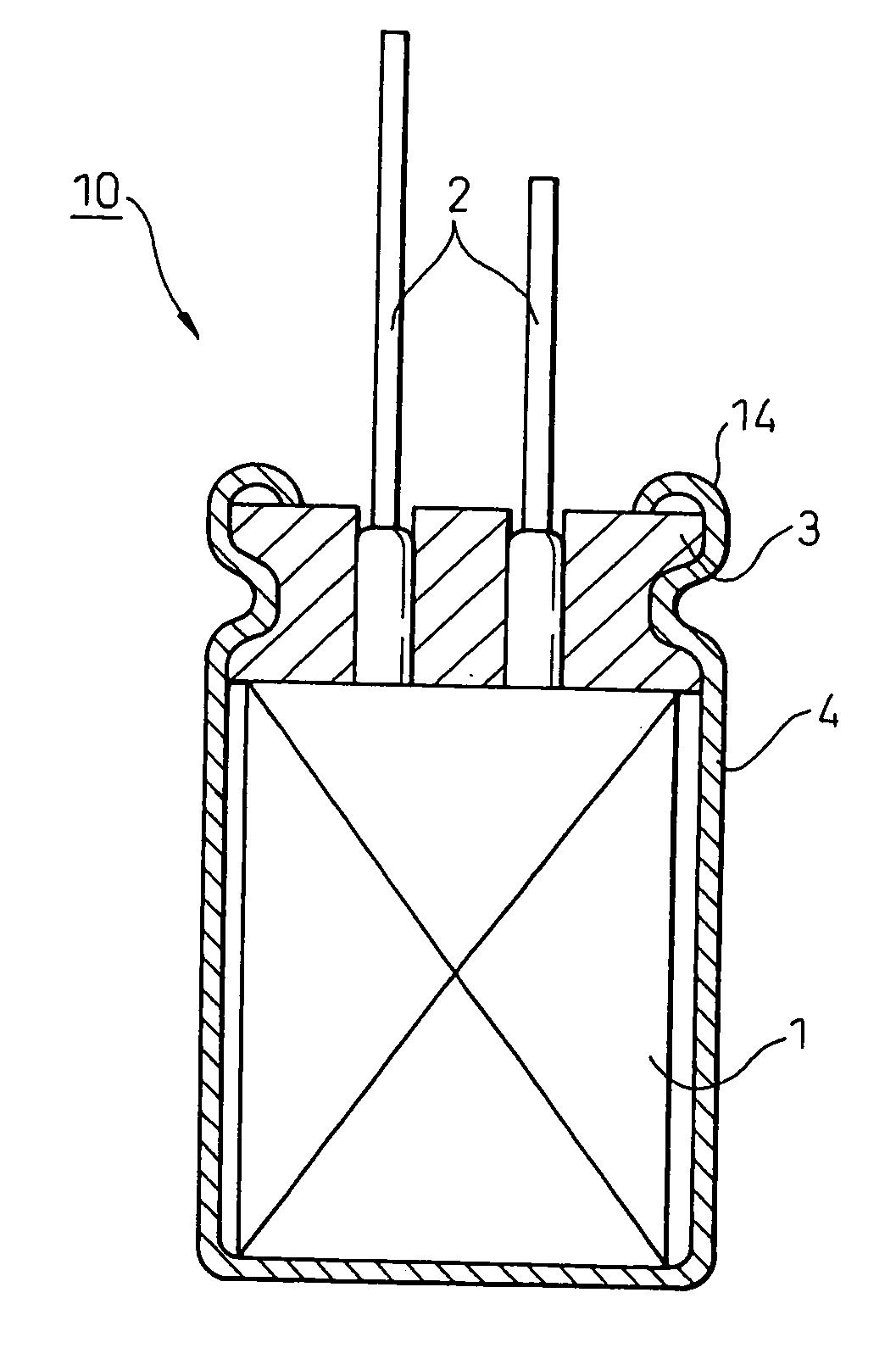

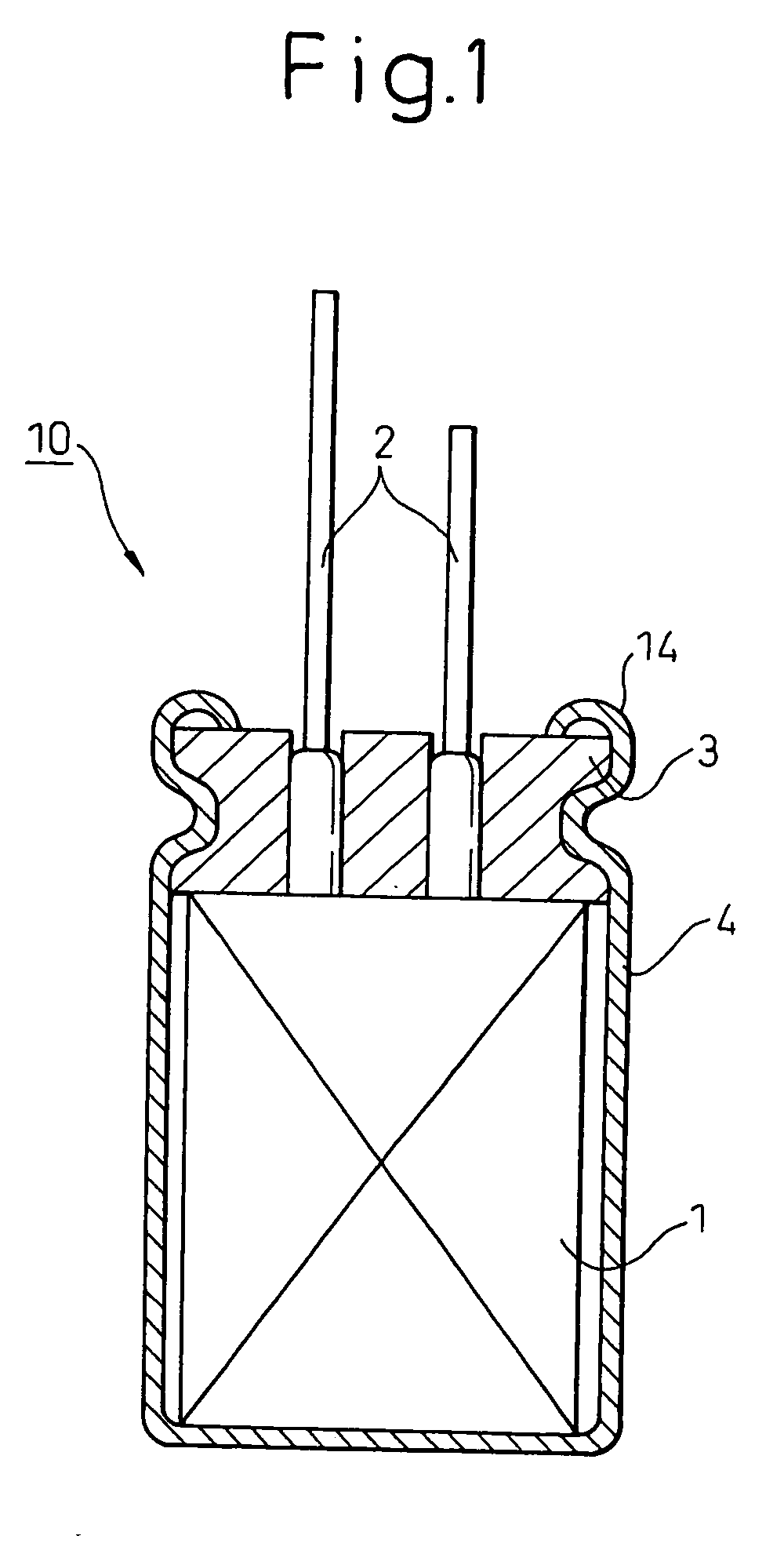

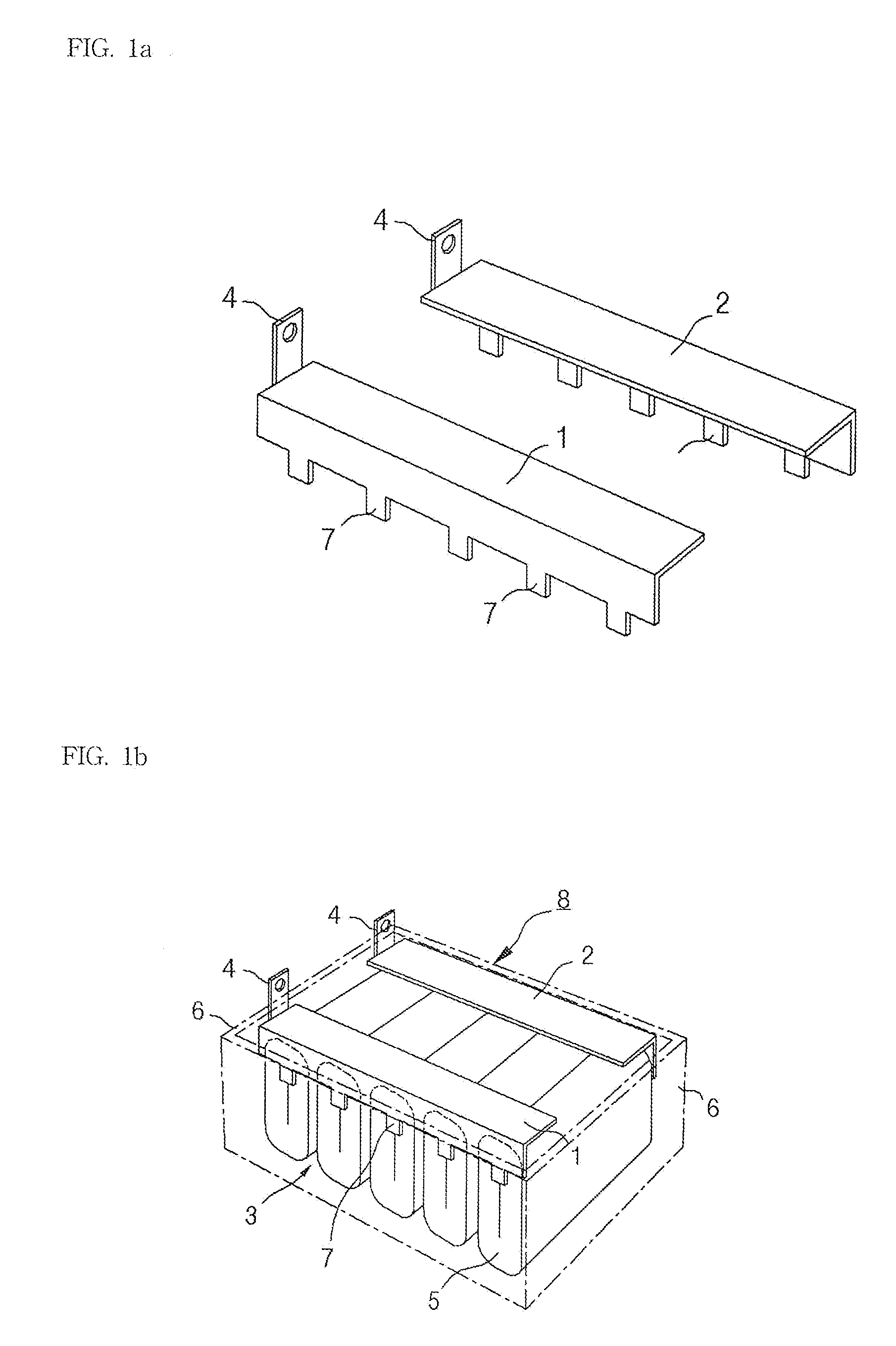

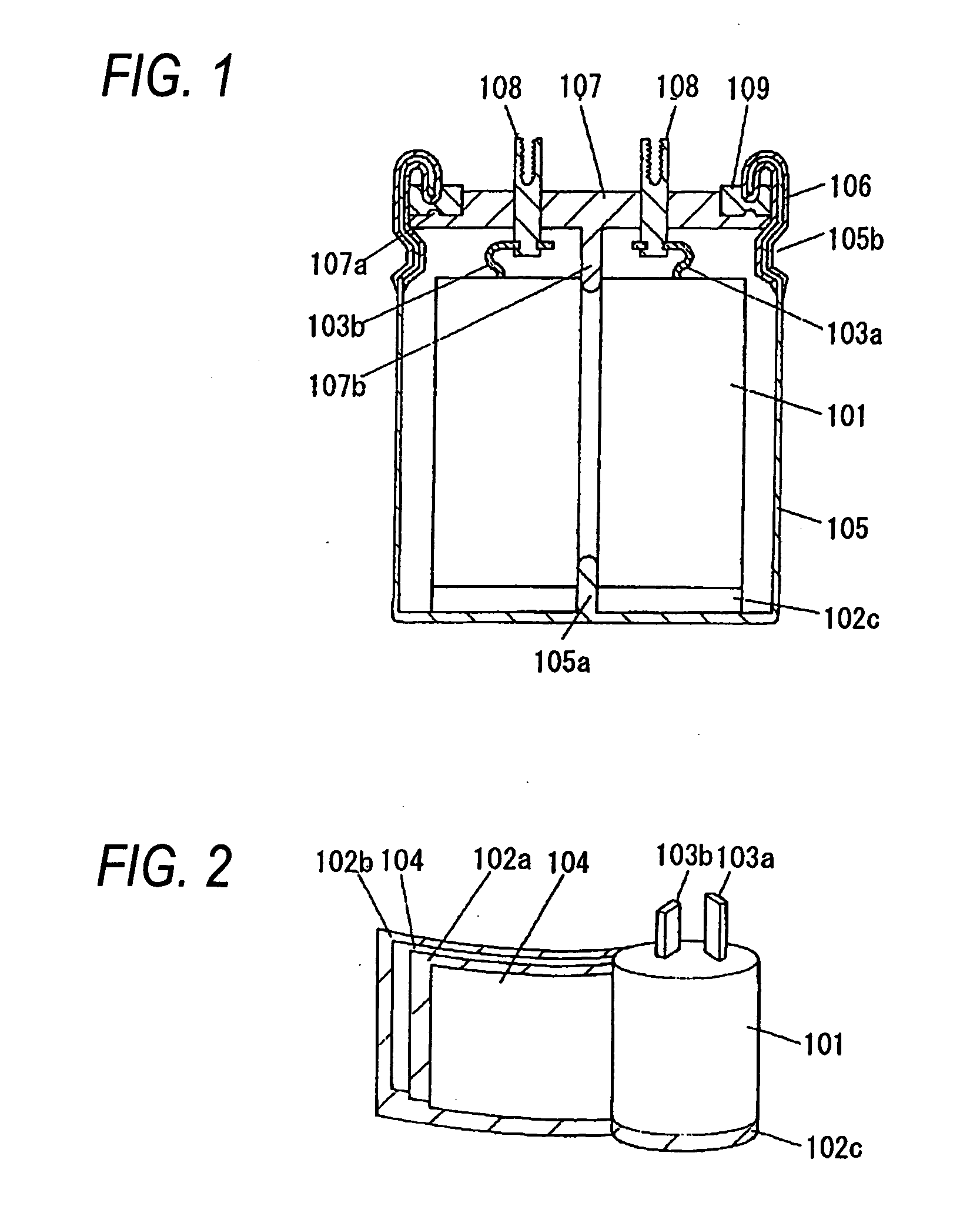

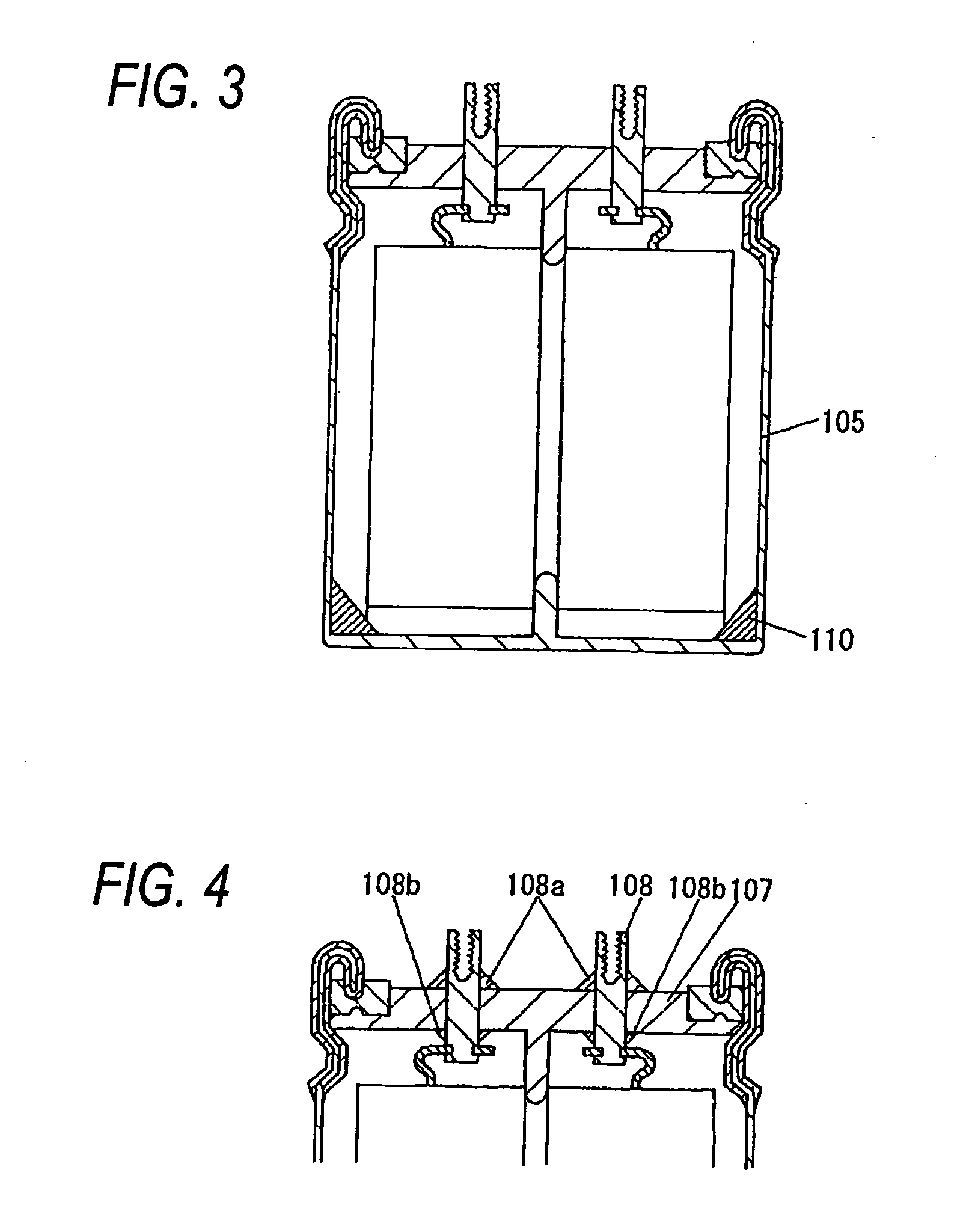

Capacitor and method for producing a capacitor

Owner:MEDTRONIC INC

High-power ultracapacitor energy storage pack and method of use

InactiveUS7218489B2Reduce width sizeProlong lifeCapacitor terminalsCapacitor housing/encapsulationSupercapacitorEngineering

An ultracapacitor energy storage cell pack includes an ultracapacitor assembly having a plurality of series connected ultracapacitors and balancing resistors, each balancing resistor connected in parallel with each ultracapacitor to automatically balance each ultracapacitor over time, thereby automatically over time discharging the ultracapacitors of the ultracapacitor assembly; an enclosure to enclose and protect the ultracapacitor assembly; a controller for the ultracapacitor assembly; and one or more temperature sensors to monitor temperature of the ultracapacitor assembly and coupled to the controller.

Owner:SHEPPARD MULLIN RICHTER & HAMPTON

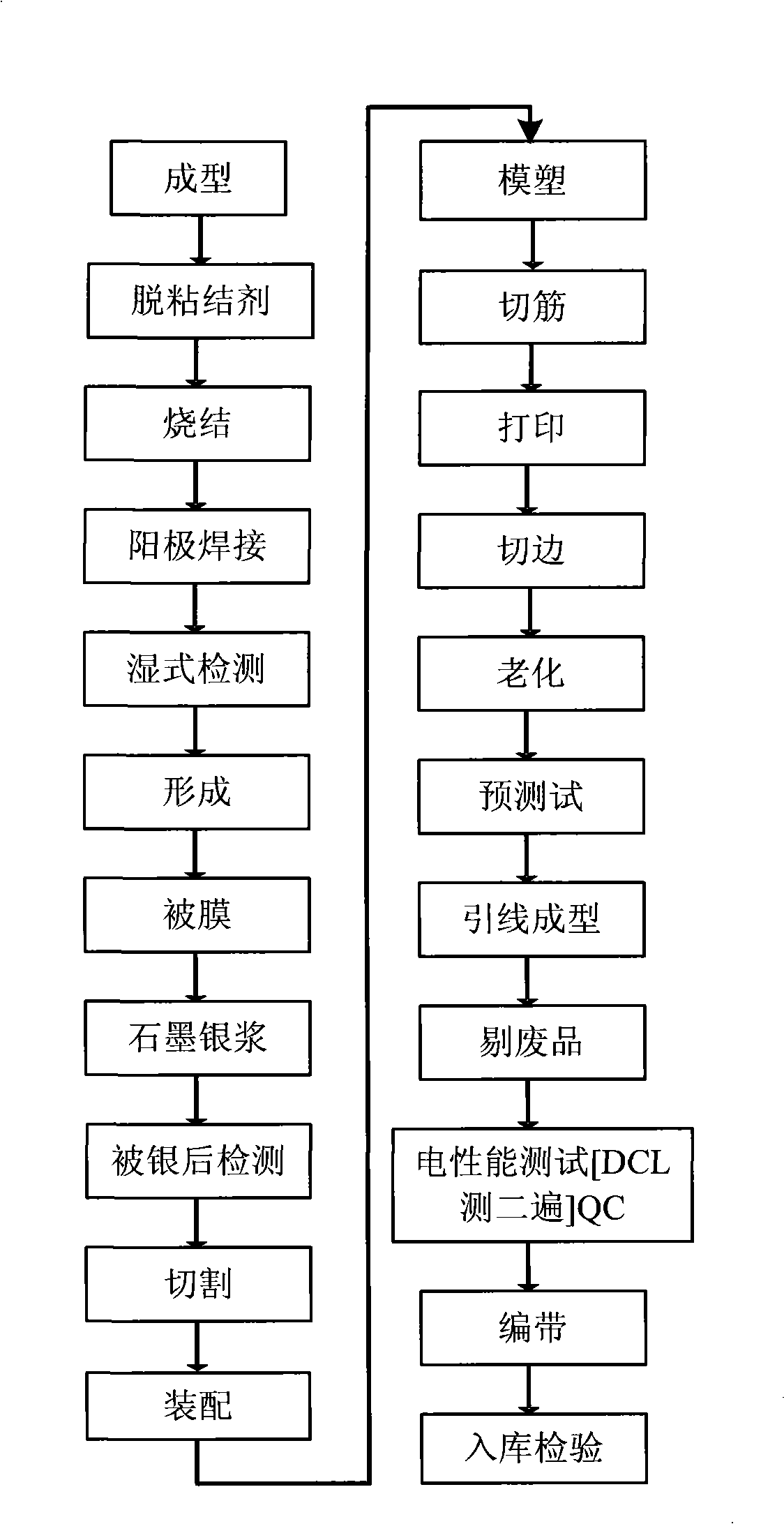

Solid sheet type tantalum electrolyte capacitor and its manufacturing method

The invention discloses a solid slice-typed Ta electrolytic capacitor and a preparation method thereof, belonging to the field of electronic devices and components; the method comprises the steps as follows: according to the pressing density of 6.0-8.0g / CC, the slice-typed Ta powder with the specific volume of 6,000-10,000 UuF.v / g and the breakdown voltage of 240V is pressed as compacts containing Ta wire eduction wires; the compacts are vacuum-sintered under the temperature of 1,600-1,800 DEG C and the vacuum degree of 5*0.0004 Pa; the sintered compacts are passivated when going out of the stove; under the temperature of 60-85 DEG C, the sintered compacts are put in an electrolyte forming channel containing glycol Phosphate; a medium layer with the thickness complying with the withstanding voltage of 63V rated voltage is formed on the surface of the compact by DC voltage; an MnO2 layer used as a cathode is formed on the surface of the compact with the medium layer formed by manganese nitrate solution in a repeated dipping method; furthermore, a cathode eduction layer is formed; the Ta wire eduction layer of the compact is attached to the shell metal frame lead with corresponding shell number and then encapsulated, thus gaining the Ta electrolytic capacitor with the withstanding voltage of 63V.

Owner:BEIJING 718 YOUYI ELECTRONICS

High-Power Ultracapacitor Energy Storage Pack and Method of Use

InactiveUS20070002518A1Reduce width sizeEfficient packagingProtecting/adjusting hybrid/EDL capacitorCapacitor terminalsInterconnectionEngineering

An ultracapacitor energy storage cell pack including an ultracapacitor assembly including a plurality of ultracapacitors in series; a plurality of interconnections for mechanically and electrically interconnecting the ultracapacitors; and a plurality of balancing resistors, each balancing resistor in parallel with each ultracapacitor to form a resistor divider network that automatically discharges and equalizes each ultracapacitor over time, thereby balancing the ultracapacitors of the ultracapacitor assembly, and each balancing resistor directly mechanically and electrically connected to an associated interconnection.

Owner:ISE

Lithium based electrochemical devices having a ceramic separator glued therein by an ion conductive adhesive

InactiveUS20060105244A1Increase flexibilityImprove stabilityHybrid capacitor separatorsHybrid capacitor electrolytesAdhesivePorous electrode

Lithium based electrochemical devices which contain at least two porous electrodes, which include expanded metal microgrids coated with active materials, with a porous ceramic separator therebetween in adherent contact with one electrode, and an ionically conductive organic adhesive on said separator in adherent contact with said second electrode. A non-aqueous electrolyte is soaked into the electrodes and the separator with the device contained in an enclosure with two external terminals.

Owner:LITHCEM INT

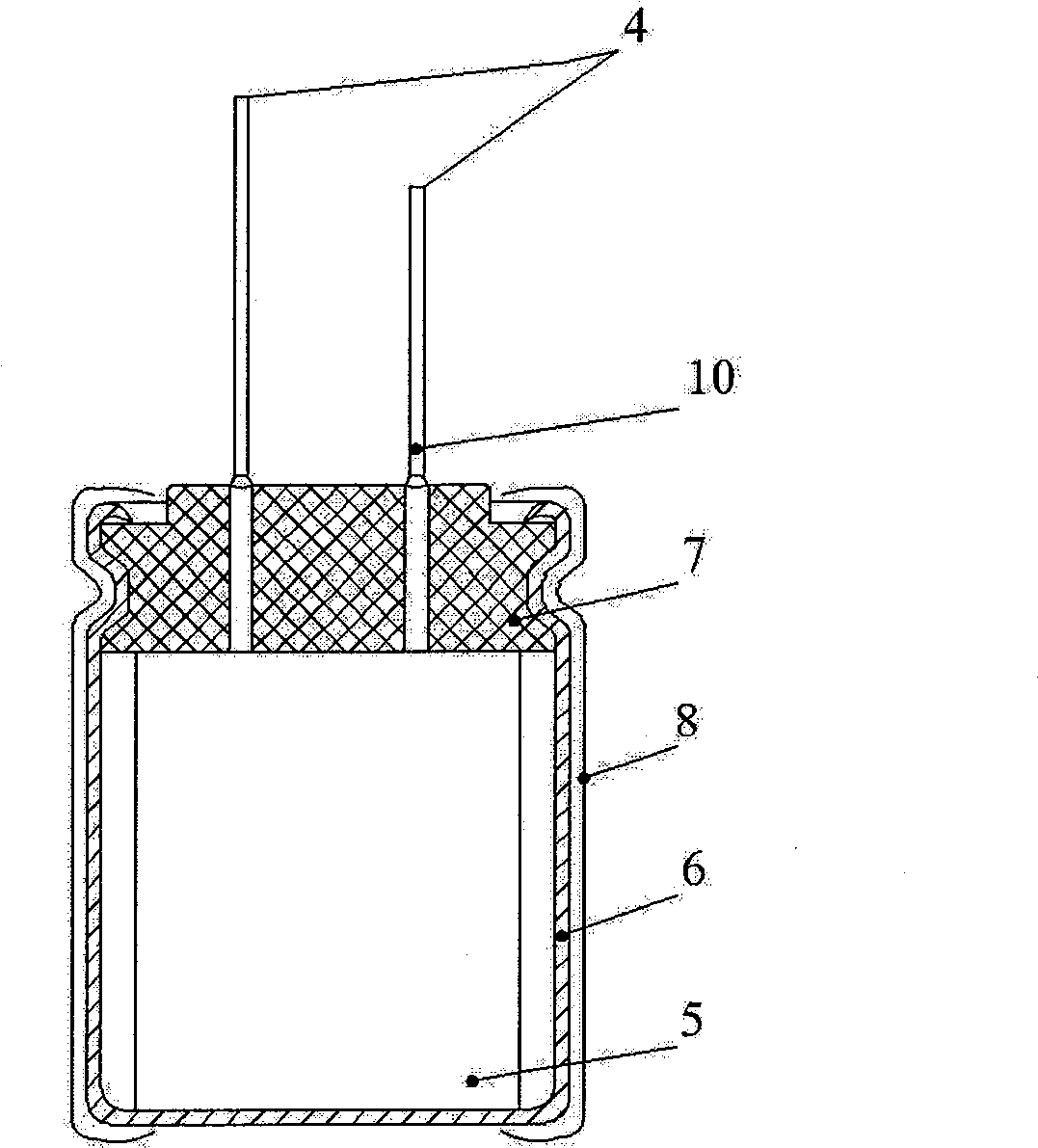

Solid electrolytic capacitor and manufacture method thereof

InactiveCN101527203AReduce the overall heightMeet the higher requirements for thinnerSolid electrolytic capacitorsCapacitor terminalsElectrolysisEngineering

The invention provides a solid electrolytic capacitor and a manufacture method thereof. The solid electrolytic capacitor comprises anode foil, cathode foil, a rectangular core package, electrode extraction terminals and a packaging body, wherein the rectangular core package is formed by coiling a solid electrolytic layer clamped between the anode foil and the cathode foil, and the electrode extraction terminals are connected with the core package which is coated by the packaging body. The method comprises the following steps: providing the anode foil, the cathode foil and electrolytic paper which are cut into special widths; connecting the electrode extraction terminals with the anode foil and the cathode foil; coiling the anode foil, the cathode foil and the electrolytic paper into a cylindrical stud; deforming the cylindrical stud into the rectangular core package; forming the solid electrolytic layer between the anode foil and the cathode foil of the core package; connecting the electrode extraction terminals of the core package with a pin frame; and packaging the core package. The technical scheme can realize an SMD solid electrolytic capacitor with lower height so as to occupy a smaller thickness space and satisfy the higher requirements for thin electronic equipment.

Owner:FUJITSU MEDIA DEVICES SUZHOU

Method to implement sealing and electrical connections to single cell and multi-cell regenerative photoelectrochemical devices

InactiveUS6664623B1Light-sensitive devicesDeferred-action cellsElectrical conductorElectrical connection

A regenerative photoelectrochemical (RPEC) device comprising two substrates, wherein: one or both substrates are transparent and are coated with transparent electrical conductor (TEC) layer; one or more layers of porous wide band gap semiconductor is / are applied to selected area of said TEC layer and sensitised with dye; electrolyte is placed between said two substrates; hole(s) made in one or both said substrates to enable external electrical connection(s) to said RPEC device.

Owner:DYESOL LTD

125 DEG C high temperature long life aluminum electrolysis capacitor, production method thereof and special electrolysis liquid

InactiveCN101483101ALower impedanceSolution to short lifeLiquid electrolytic capacitorsCapacitor terminalsElectrolytic agentEngineering

The present invention relates to the manufacture field of capacitor, specifically to a high temperature (125 DEG C) long life electrolytic capacitor, its manufacturing method and its special electrolyte. The capacitor is formed by manufacturing a capacitor core package by coiling together the cathode foil, cathode foil, electrolytic paper and leading-out wires; dipping the core packages in the electrolyte; and then putting in the aluminum shell; and sealing by the plug. The electrolyte has 85-88 parts of solvent composition, 5.5-11 parts of solute, 1-1.5 parts of additives and 3-5 parts of high temperature stabilizer. The capacitor has a low impedance, high-profile current resistance, long-life (5,000 hours in durability test at 125 DEG C).

Owner:FOSHAN SANSHUI RIMING ELECTRONCS

Wet electrolytic capacitor containing a plurality of thin powder-formed anodes

A wet electrolytic capacitor that includes a plurality of anodes, cathode, and working electrolyte that is disposed in electrical contact with the anodes and current collector is provided. Any number of anodes may generally be employed, such as from 2 to 40, in some embodiments from 3 to 30, and in some embodiments, from 4 to 20. The anodes are thin and typically have a thickness of about 1500 micrometers or less, in some embodiments about 1000 micrometers or less, and in some embodiments, from about 50 to about 500 micrometers. By employing a plurality of anodes that are relatively thin in nature, the resulting wet electrolytic capacitor is able to achieve excellent electrical properties. For example, the equivalent series resistance (“ESR”)—the extent that the capacitor acts like a resistor when charging and discharging in an electronic circuit—may be less than about 1500 milliohms, in some embodiments less than about 1000 milliohms, and in some embodiments, less than about 500 milliohms, measured with a 2-volt bias and 1-volt signal at a frequency of 1000 Hz.

Owner:KYOCERA AVX COMPONENTS CORP

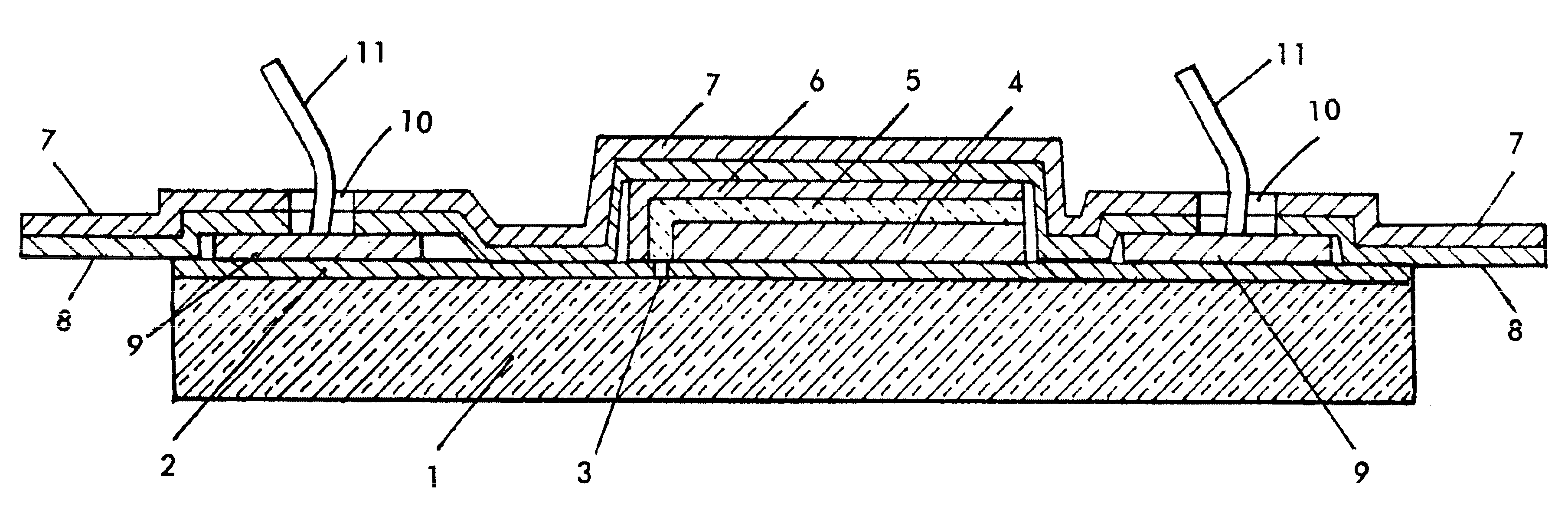

Capacitor and method of connecting the same

InactiveUS20060034036A1Improves sealing reliabilityImprove reliabilitySolid electrolytic capacitorsHermetically-sealed casingsCapacitanceHigh humidity

An object of the present invention is to provide a capacitor of a large capacity in which a drive electrolyte will not leak to the exterior even when the capacitor is used for a long period of time in a high-temperature and high-humidity environment The capacitor includes a hollow capacitor element (1) formed by rolling a pair of flat sheet-like electrodes (2a) and (2b), with separators (4) interposed therebetween, a bottom-closed metallic casing (5) receiving the capacitor element (1) and a drive electrolyte therein, and an opening-sealing plate (7) sealing an opening portion of the metallic casing (5), the opening-sealing plate having an external connection terminal. A rubber-like elastic member (9) is provided on a surface of the opening-sealing plate (7) at a peripheral edge portion thereof, and an electrically-insulating layer (6) is formed on the metallic casing to cover at least a region extending from the open end of the metallic casing (5) to a recess (5b) provided for fixing the opening-sealing plate (7), and the rubber-like elastic member (9) is pressed by the open end portion of the metallic casing (5).

Owner:PANASONIC CORP

Popular searches

Heart defibrillators Casings/cabinets/drawers details Fixed capacitor terminals Capacitor electrodes Capacitor dielectric layers Emergency protective arrangements for automatic disconnection Vehicular energy storage Emergency protective arrangements for limiting excess voltage/current Multiple capacitors Wound capacitors

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com