Patents

Literature

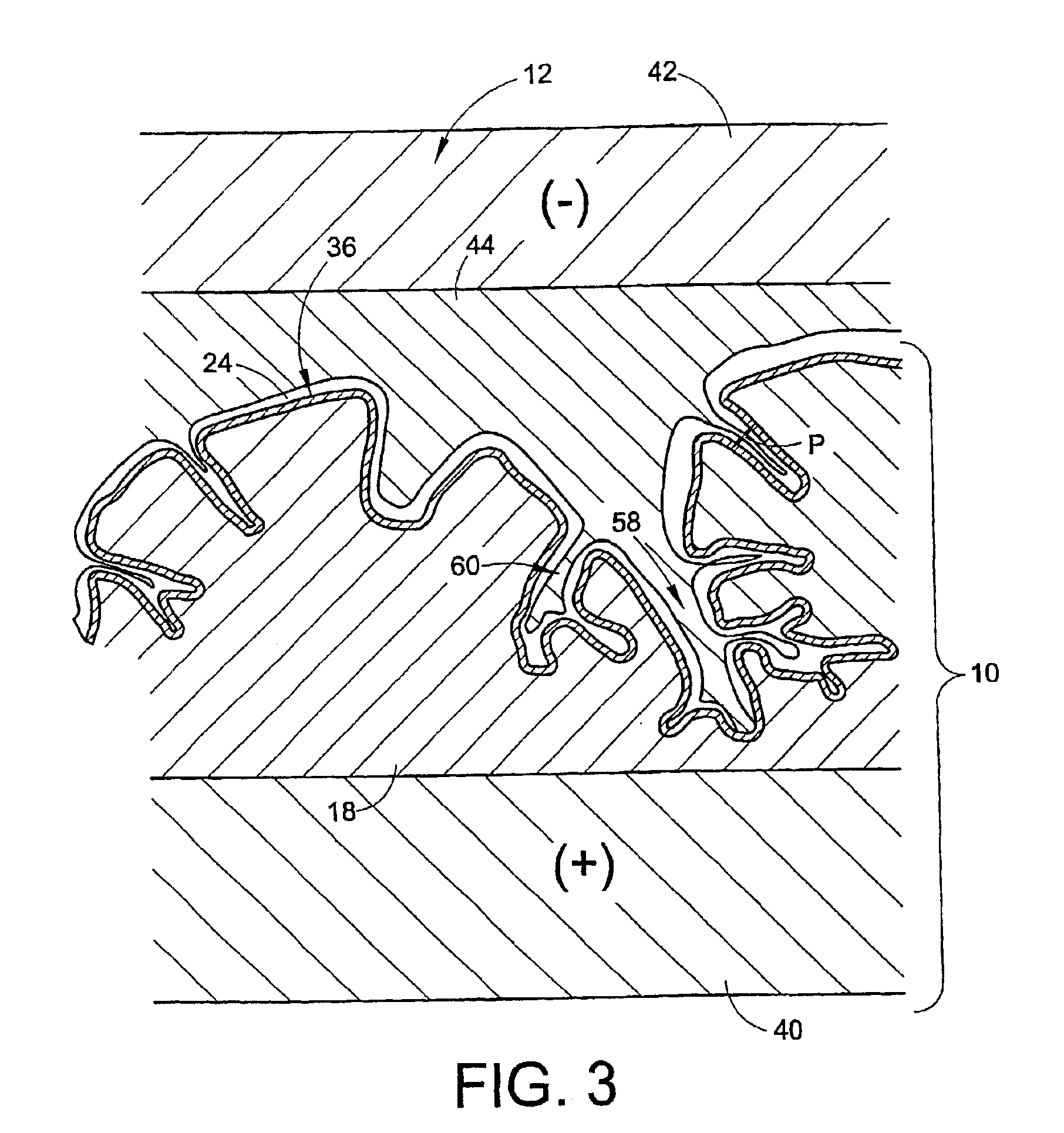

860results about "Wound capacitors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

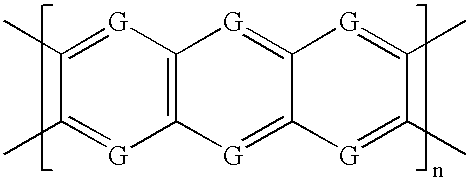

Graphitic nanofibers in electrochemical capacitors

Graphitic nanofibers, which include tubular fullerenes (commonly called "buckytubes"), nanotubes and fibrils, which are functionalized by chemical substitution, are used as electrodes in electrochemical capacitors. The graphitic nanofiber based electrode increases the performance of the electrochemical capacitors. Preferred nanofibers have a surface area greater than about 200 m2 / gm and are substantially free of micropores.

Owner:HYPERION CATALYSIS INT

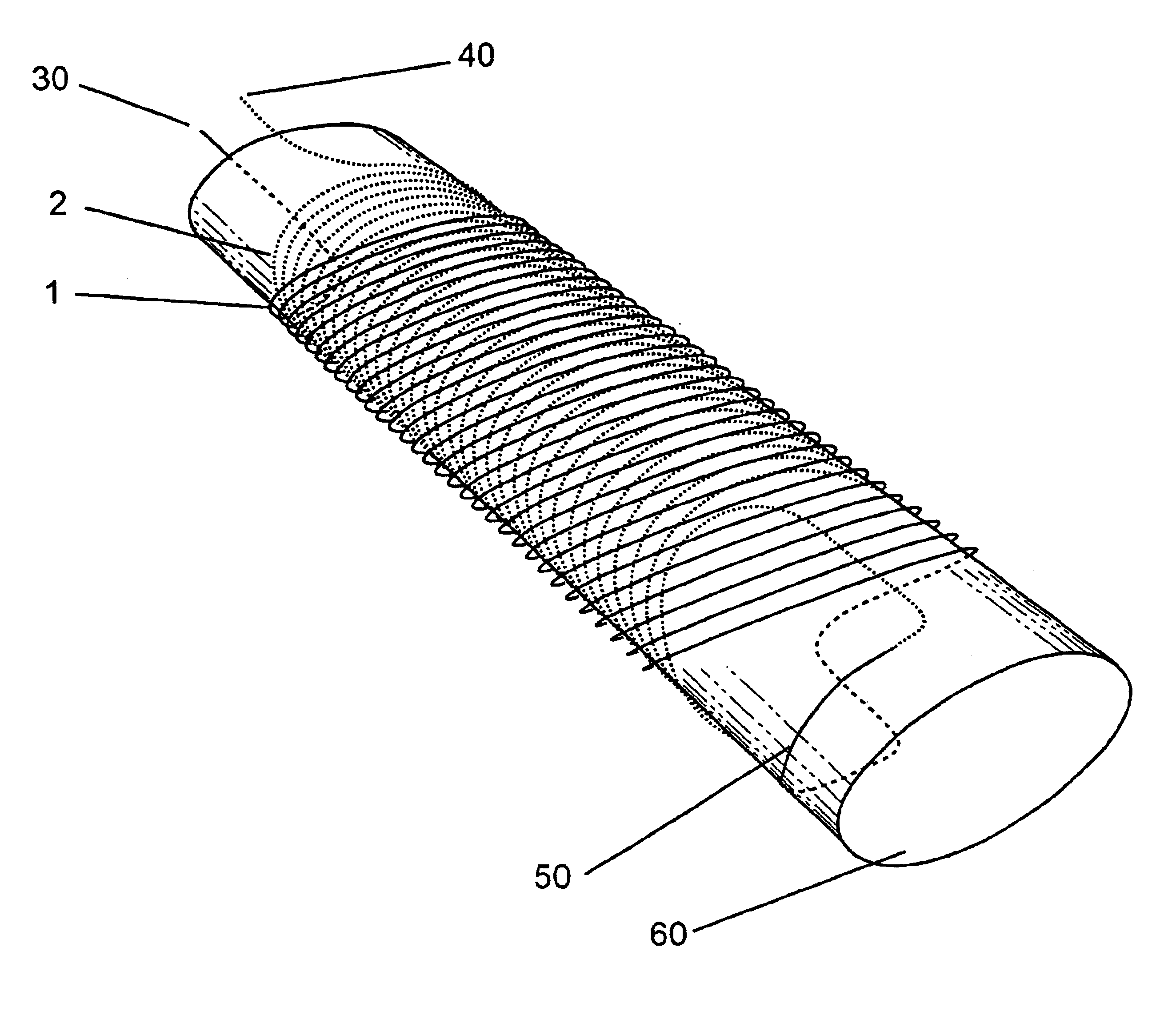

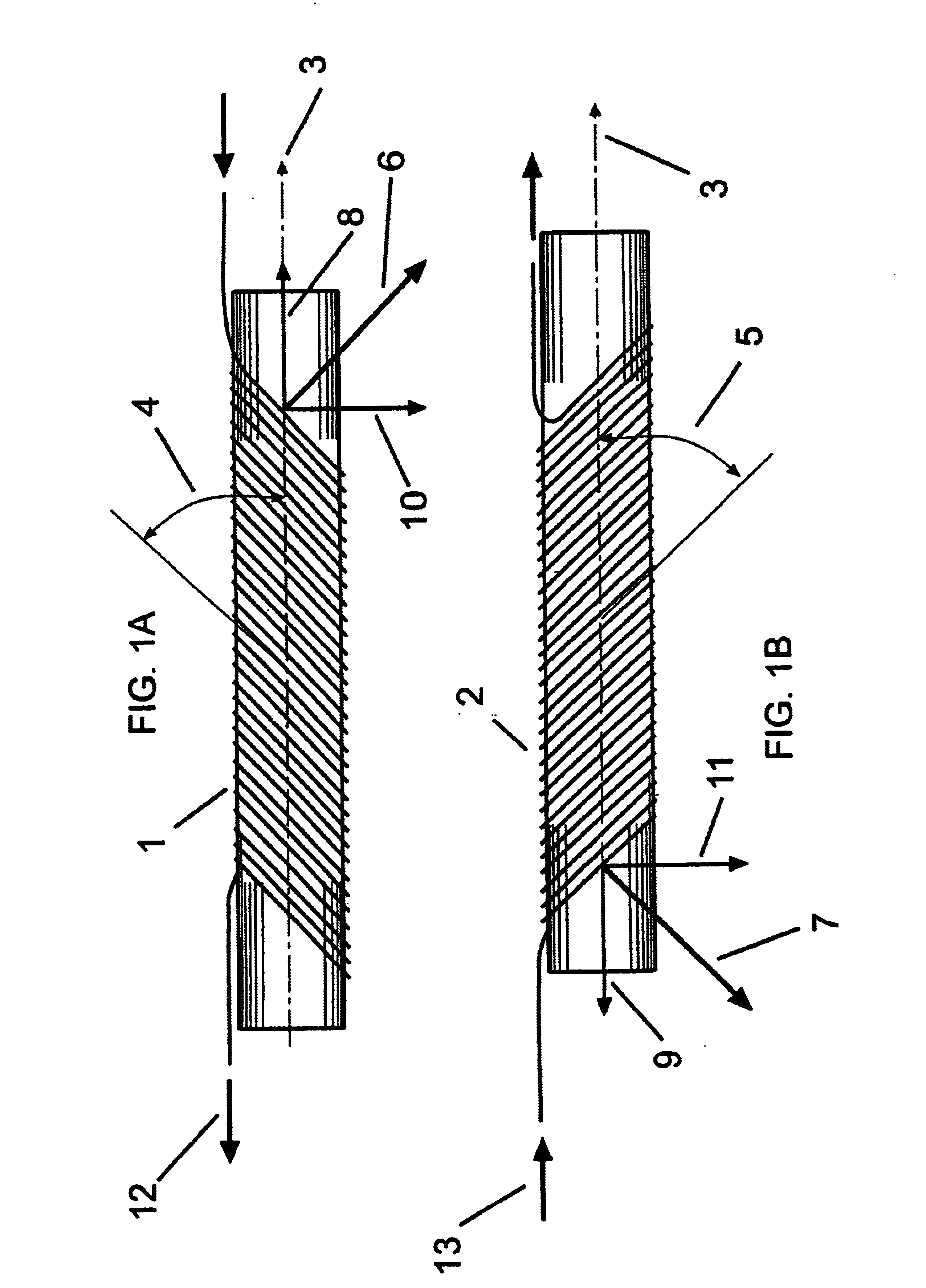

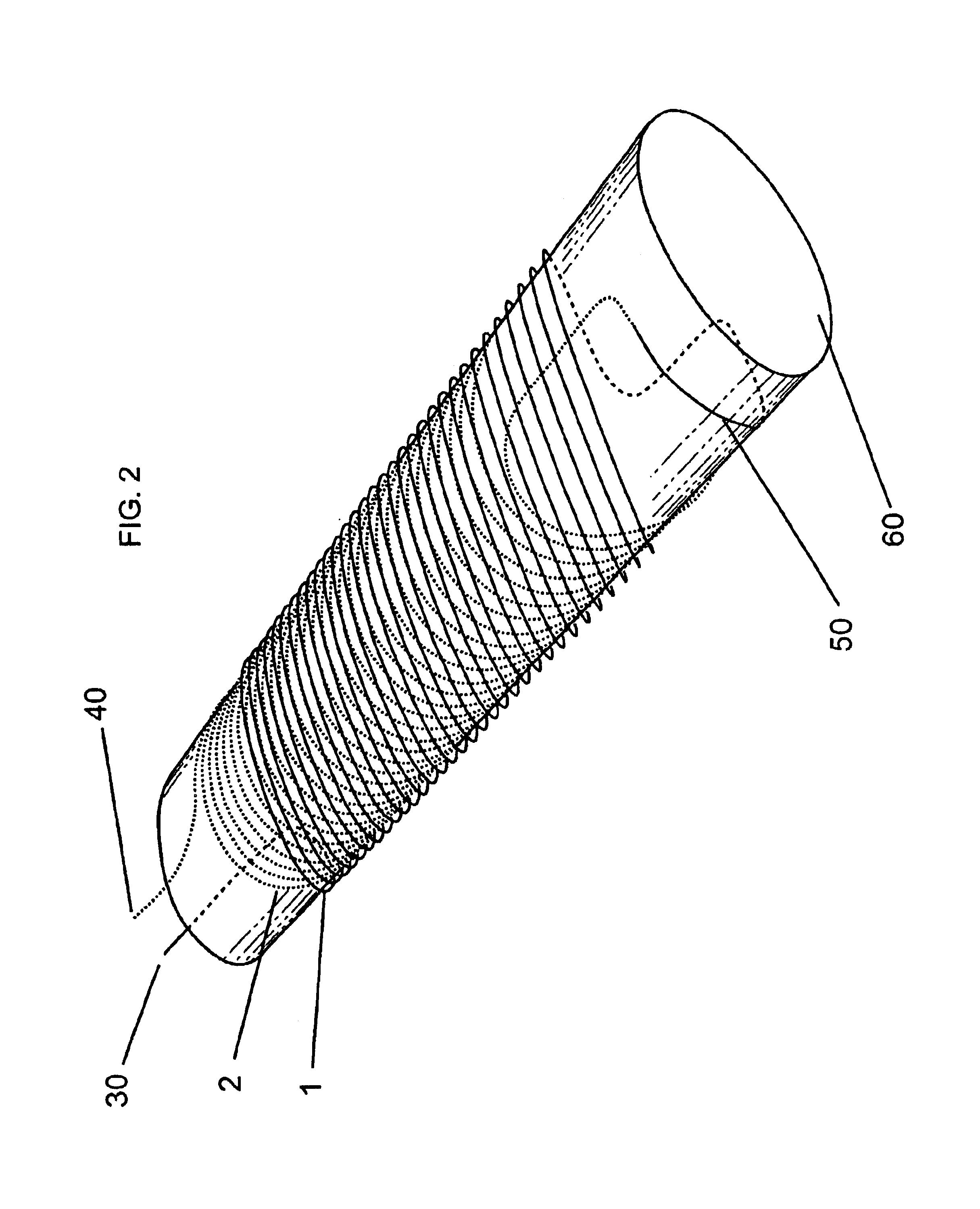

Concentric tilted double-helix dipoles and higher-order multipole magnets

InactiveUS6921042B1Simple processLess costlyElectromagnets without armaturesFilament handlingElectric machineryMagneto hydrodynamic

Concentric tilted double-helix magnets, which embody a simplified design and construction method for production of magnets with very pure field content, are disclosed. The disclosed embodiment of the concentric tilted double-helix dipole magnet has the field quality required for use in accelerator beam steering applications, i.e., higher-order multipoles are reduced to a negligibly small level. Magnets with higher multipole fields can be obtained by using a simple modification of the coil winding procedure. The double-helix coil design is well-suited for winding with superconducting cable or cable-in-conduit conductors and thus is useful for applications that require fields in excess of 2 T. The coil configuration has significant advantages over conventional racetrack coils for accelerators, electrical machinery, and magneto-hydrodynamic thrusting devices.

Owner:GOODZEIT CARL L +2

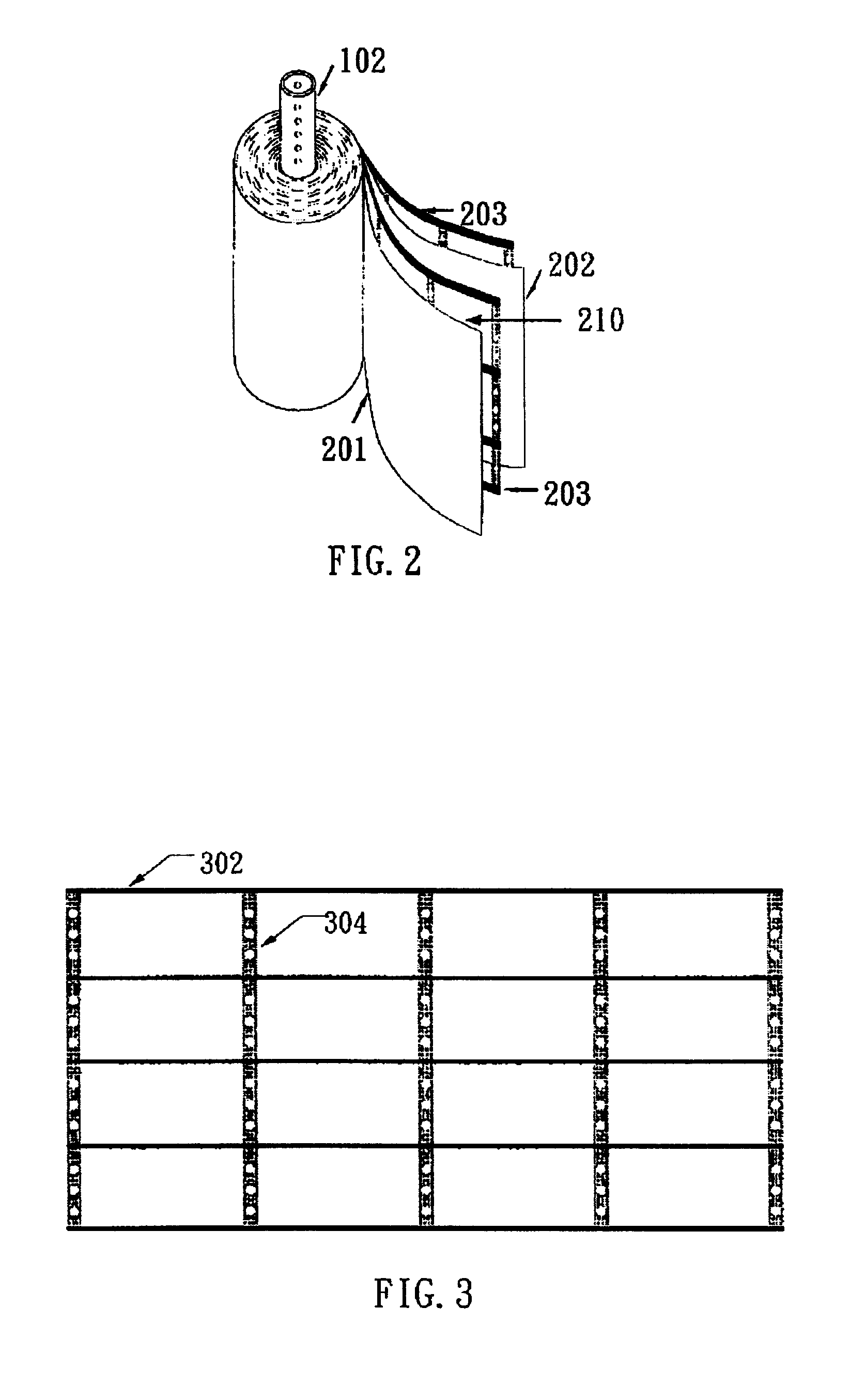

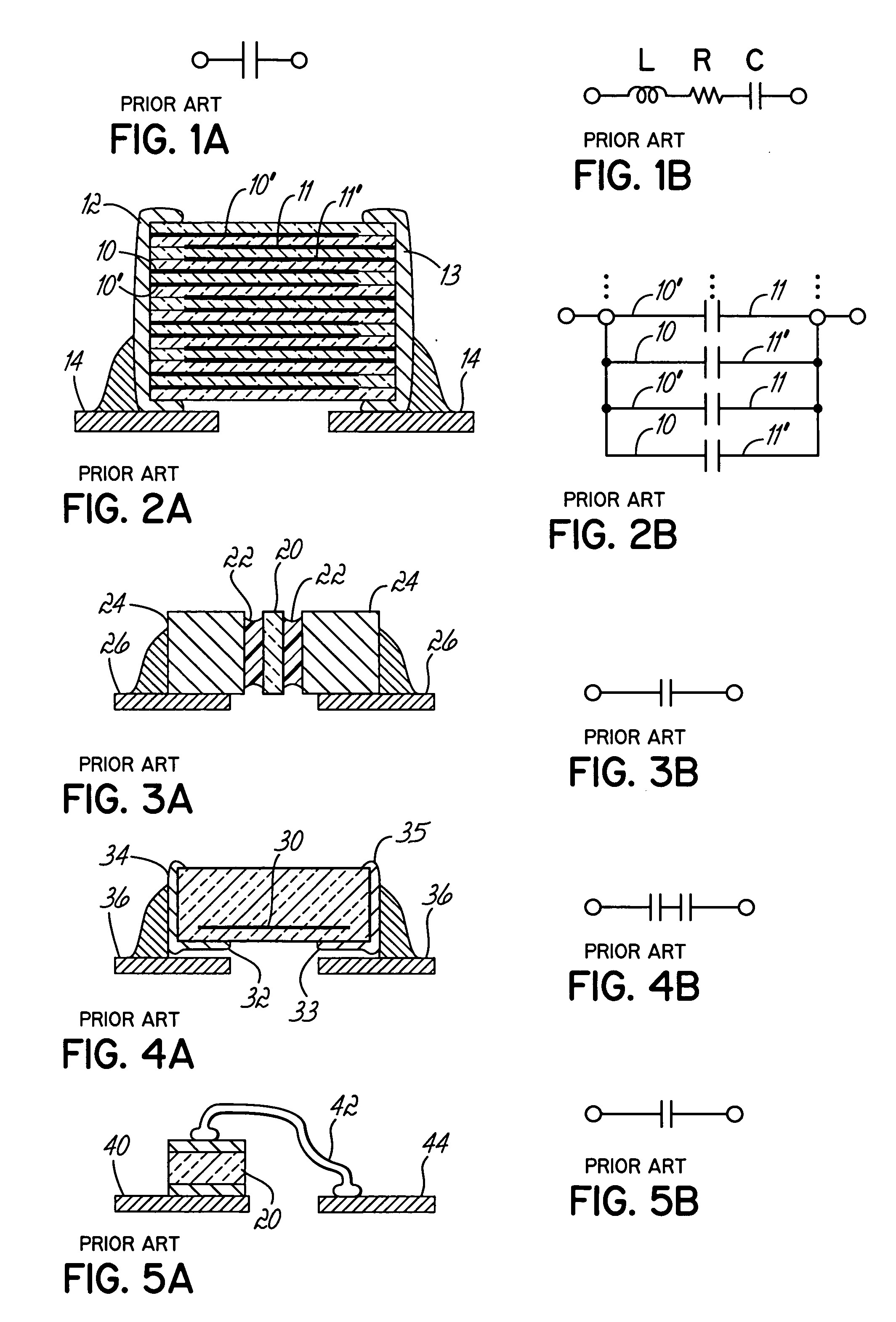

Replaceable flow-through capacitors for removing charged species from liquids

InactiveUS6462935B1Material nanotechnologyWater treatment parameter controlCapacitanceCapacitive deionization

A free-standing flow-through capacitor (FTC) is constructed by concentrically winding two electrodes and two dividers into a hollow-center roll. A liquid-feeding pipe is inserted to the central opening for delivering fluids to the FTC. Nanoparticles of hydrated iron compound with Fe3O4 as the main component or its composite powders are used as the active materials for the electrodes. With channels crated by the dividers assembled in the roll, fluids injected from the feed pipe are confined inside the FTC, and flow outwardly and transversely through the entire length of the electrodes. Under an application of a low DC voltage to the electrodes, charged species are adsorbed and removed from the treated liquids as soon as they are in contact with the electrodes. Capacitive deionization using FTC of the present invention is applicable to waste-streams reduction, water purification and desalination at low costs and easy operation.

Owner:SHIUE LIH REN

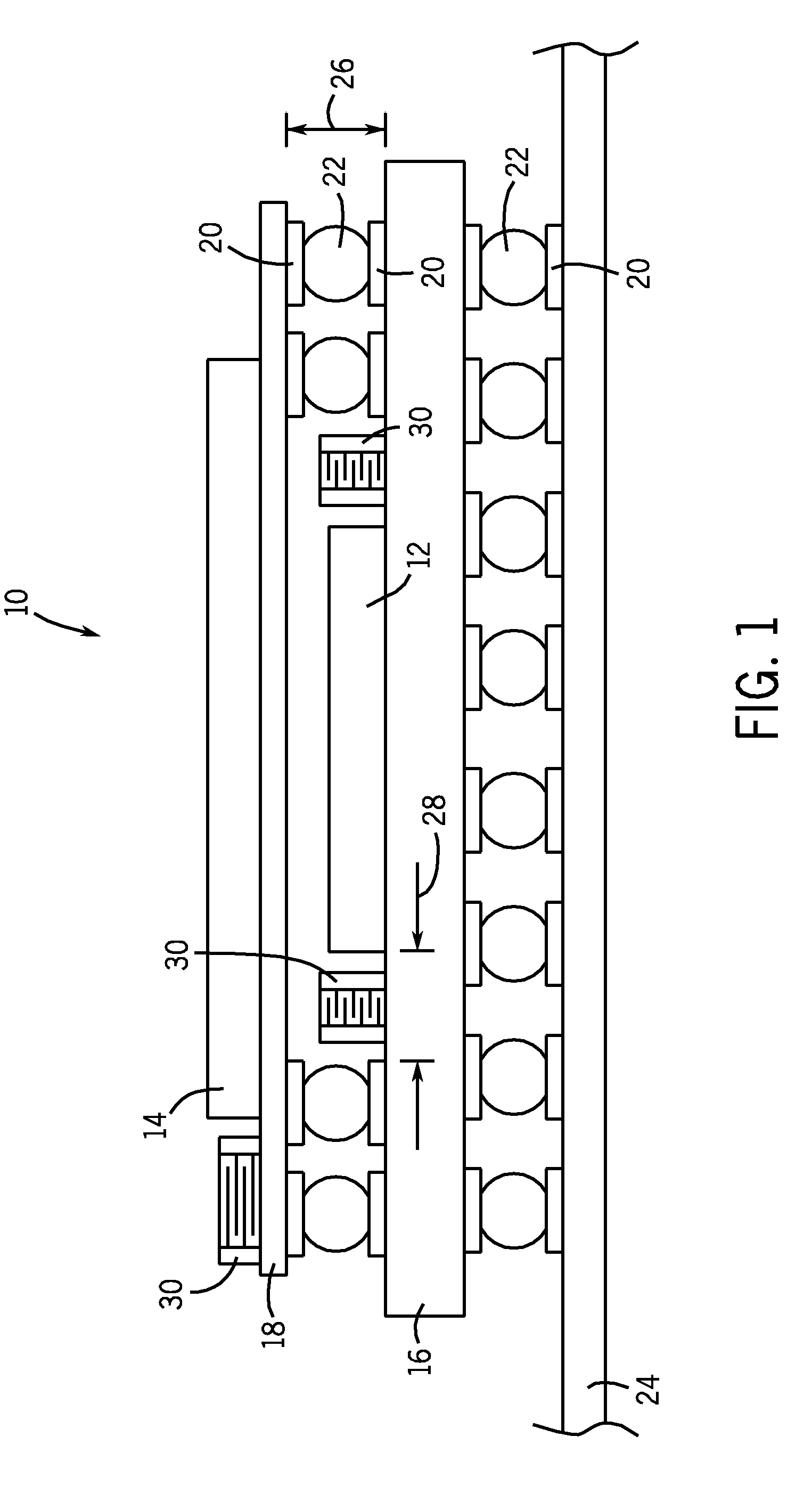

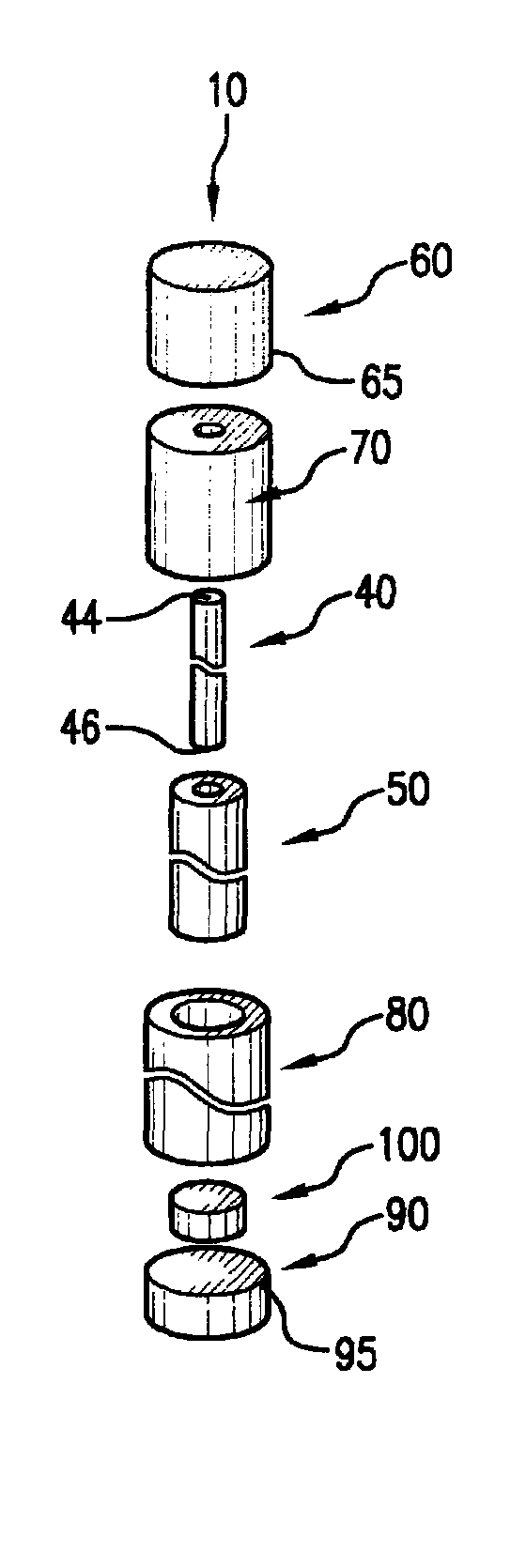

Component formation via plating technology

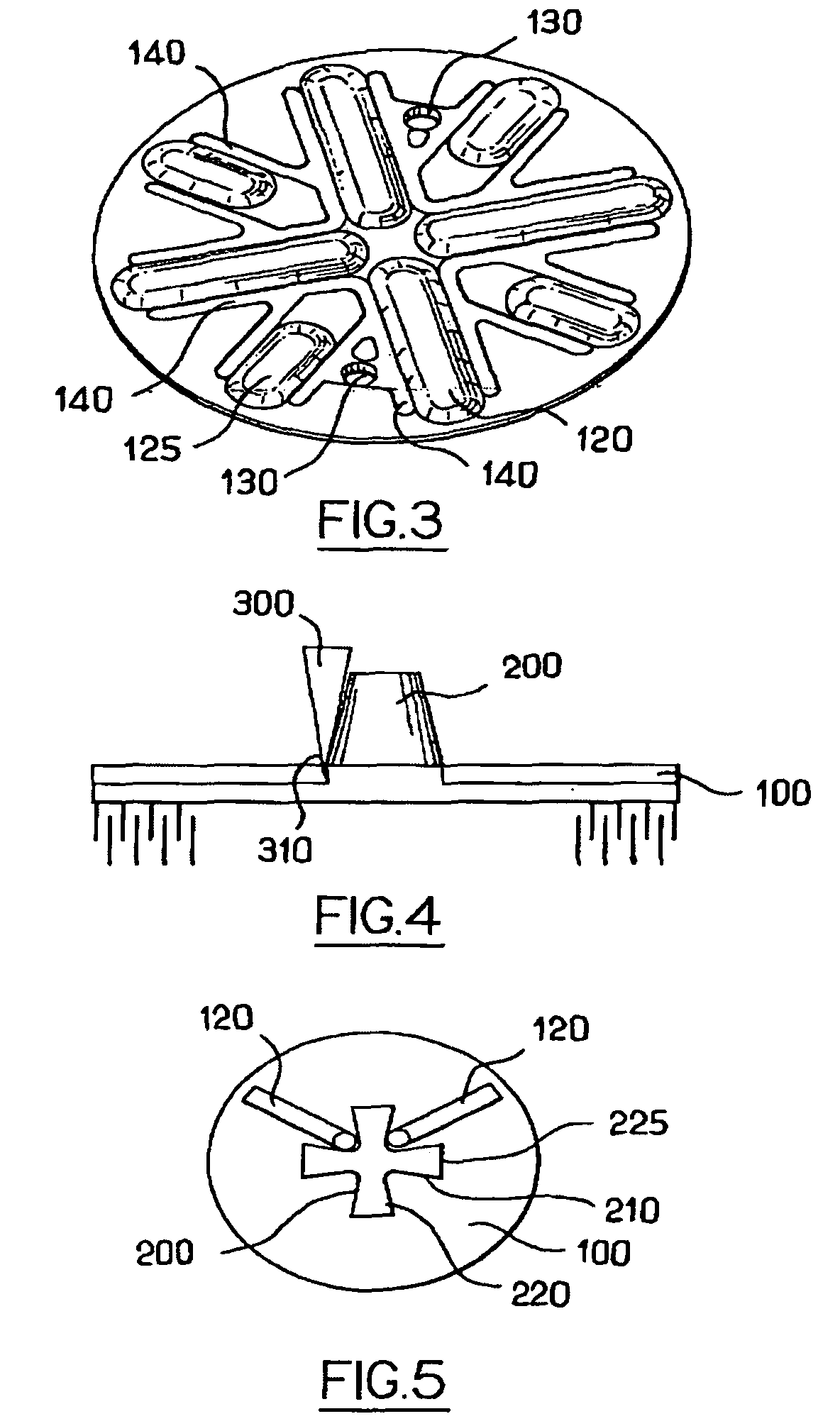

InactiveUS6982863B2Improved termination featureEliminate or greatly simplify thick-film stripesStacked capacitorsWound capacitorsTermination problemSolder ball

Improved terminations, interconnection techniques, and inductive element features for multilayer electronic components are formed in accordance with disclosed plating techniques. Monolithic components are provided with plated terminations whereby the need for typical thick-film termination stripes is eliminated or greatly simplified. Such plated termination technology eliminates many typical termination problems and enables a higher number of terminations with finer pitch, which may be especially beneficial on smaller electronic components. The subject plated terminations are guided and anchored by exposed varying width internal electrode tabs and additional anchor tab portions. Such anchor tabs may be positioned internally or externally relative to a chip structure to nucleate additional metallized plating material. The combination of electrode tabs and anchor tabs may be exposed in respective arrangements to form generally discoidal portions of plated material. Such plated material may ultimately form generally round portions of ball limiting metallurgy (BLM) to which solder balls may be reflowed. The disclosed technology may be utilized with a plurality of monolithic multilayer components, including interdigitated capacitors, multilayer capacitor arrays, and integrated passive components. A variety of different plating techniques and materials may be employed in the formation of the subject self-determining plated terminations and inductive components.

Owner:KYOCERA AVX COMPONENTS CORP

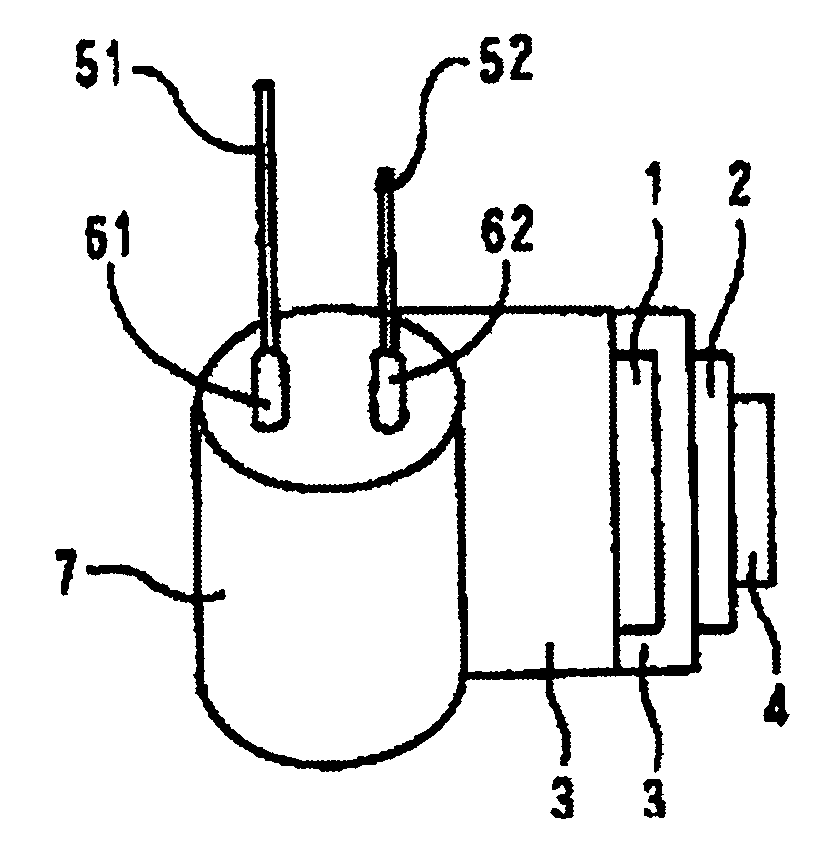

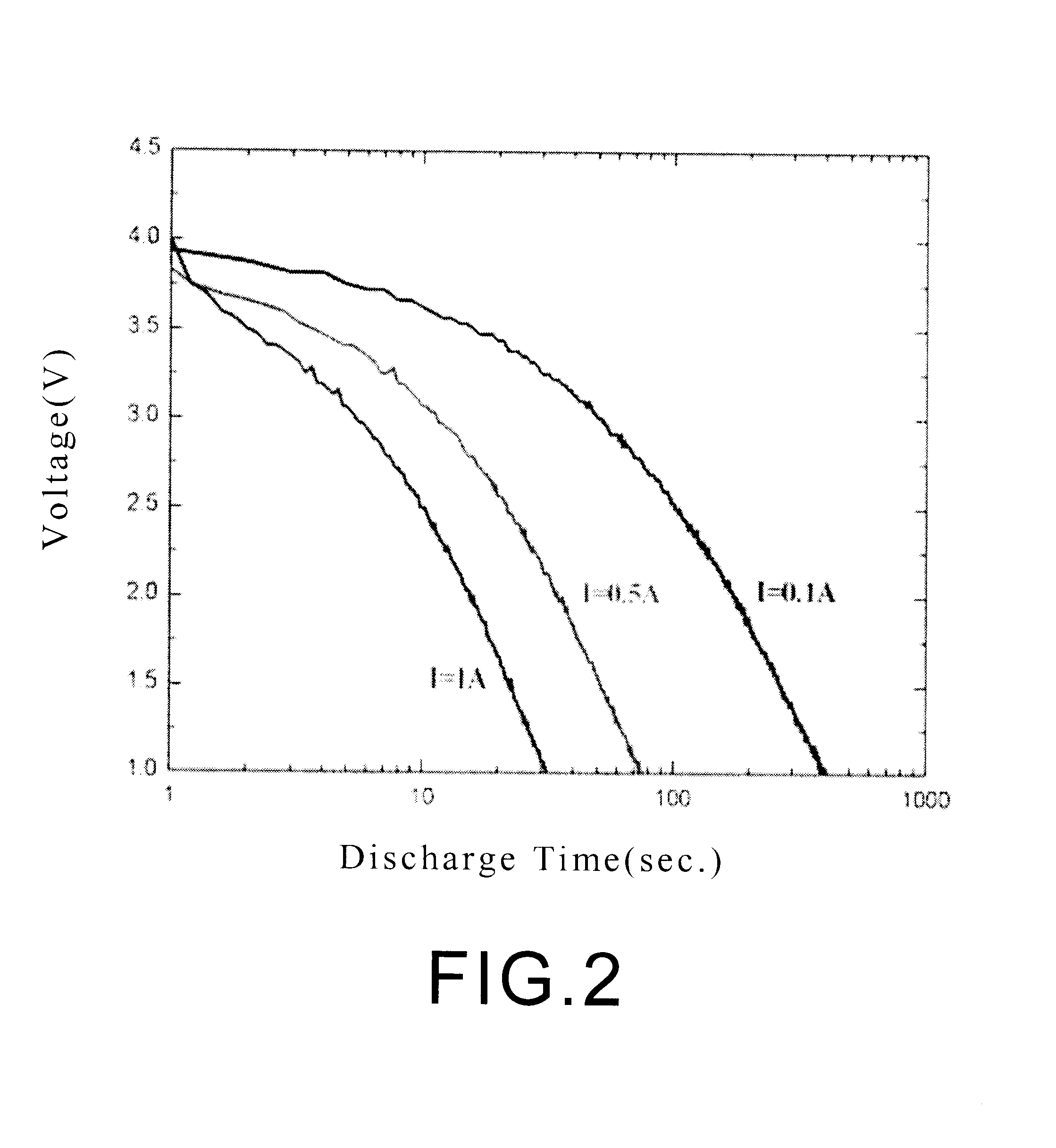

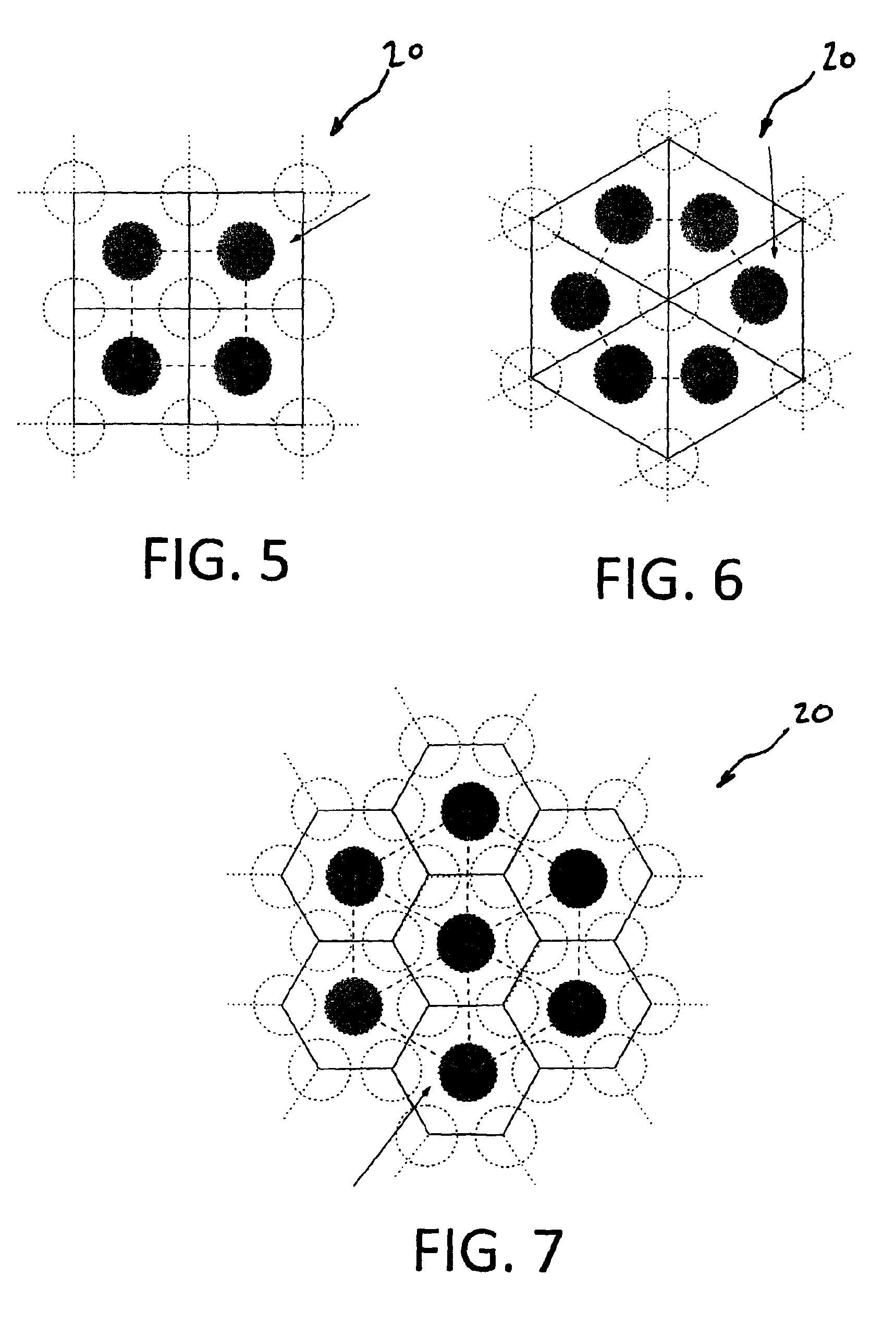

Supercapacitor with high energy density

InactiveUS6762926B1Sufficient energy densityLow costHybrid capacitor separatorsMultiple fixed capacitorsCapacitanceHigh energy

The energy content of supercapacitor is determined by its capacitance value and working voltage. To attain a high capacitance and a high voltage, several pieces of electrodes and separators are spirally wound with edge sealing to form a bipolar supercapacitor in cylindrical, oval or square configuration. While the winding operation effectively provides a large surface area for high capacitance, the bipolar packaging instantly imparts a unitary roll a minimum working voltage of 5V on using an organic electrolyte. The bipolar roll is a powerful building block for facilitating the assembly of supercapacitor modules. Using containers with multiple compartments, as many bipolar rolls can be connected in series, in parallel or in a combination of the two connections to fabricate integrated supercapacitors with high energy density as required by applications.

Owner:GAINIA INTELLECTUAL ASSET SERVICES

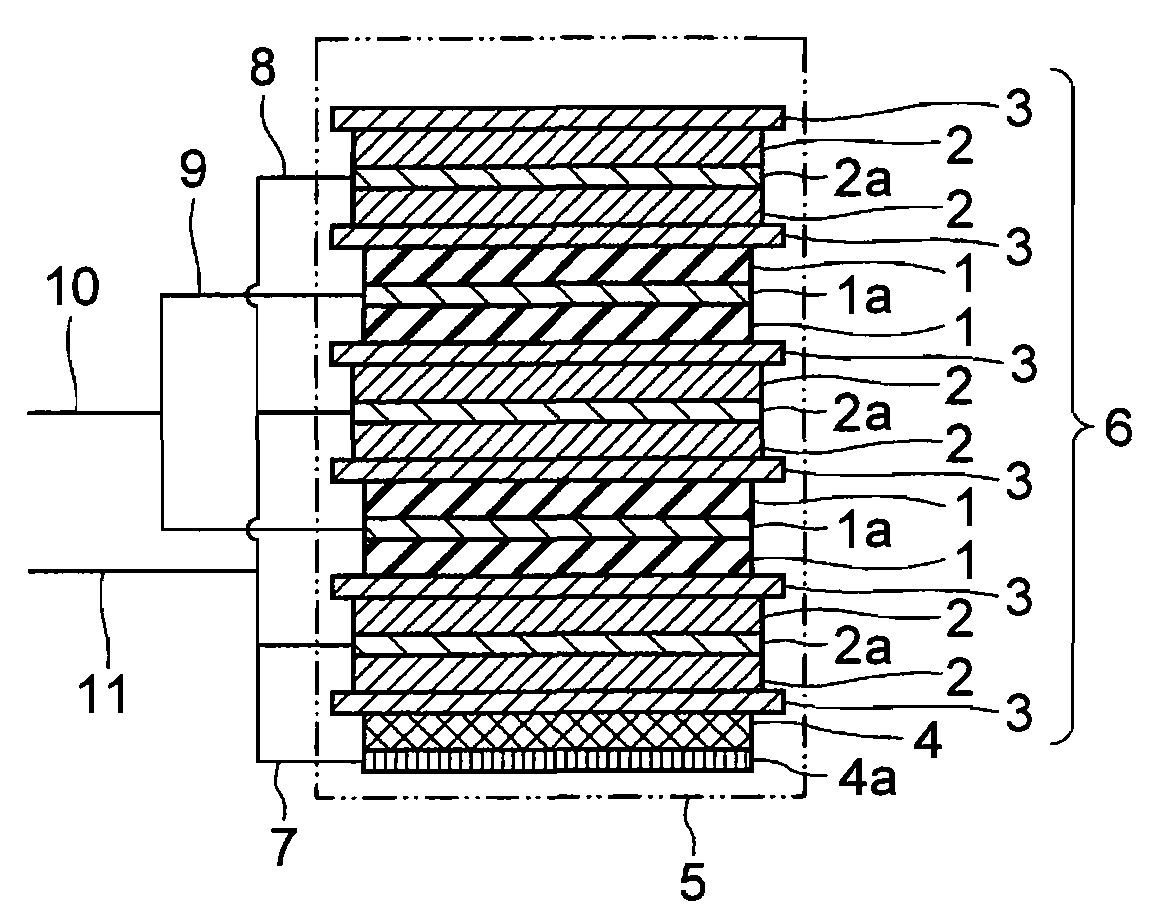

Method of manufacturing electrolytic capacitor and electrolytic capacitor

ActiveUS7497879B2Improve pressure resistanceSmall currentHybrid capacitor electrolytesSolid electrolytic capacitorsDielectricElectrolysis

A method of manufacturing an electrolytic capacitor including the following steps as well as an electrolytic capacitor manufactured by the method are provided. The method includes: a dispersion impregnation step of impregnating, with a dispersion containing electrically conductive solid particles or powder and a solvent, a capacitor element having an anode foil with a dielectric coating film formed thereon and an opposite cathode foil that are wound with a separator interposed therebetween; a dry step of evaporating the solvent after the dispersion impregnation step to form an electrically conductive solid layer on a surface of the dielectric coating film; and an electrolytic solution impregnation step of impregnating a gap in the electrically conductive solid layer with an electrolytic solution. Accordingly, an electrolytic capacitor that can be manufactured more easily that is excellent in voltage proofing property and that has a lower ESR and a lower leakage current is provided.

Owner:SANYO ELECTRIC CO LTD +1

High-temperature capacitors and methods of making the same

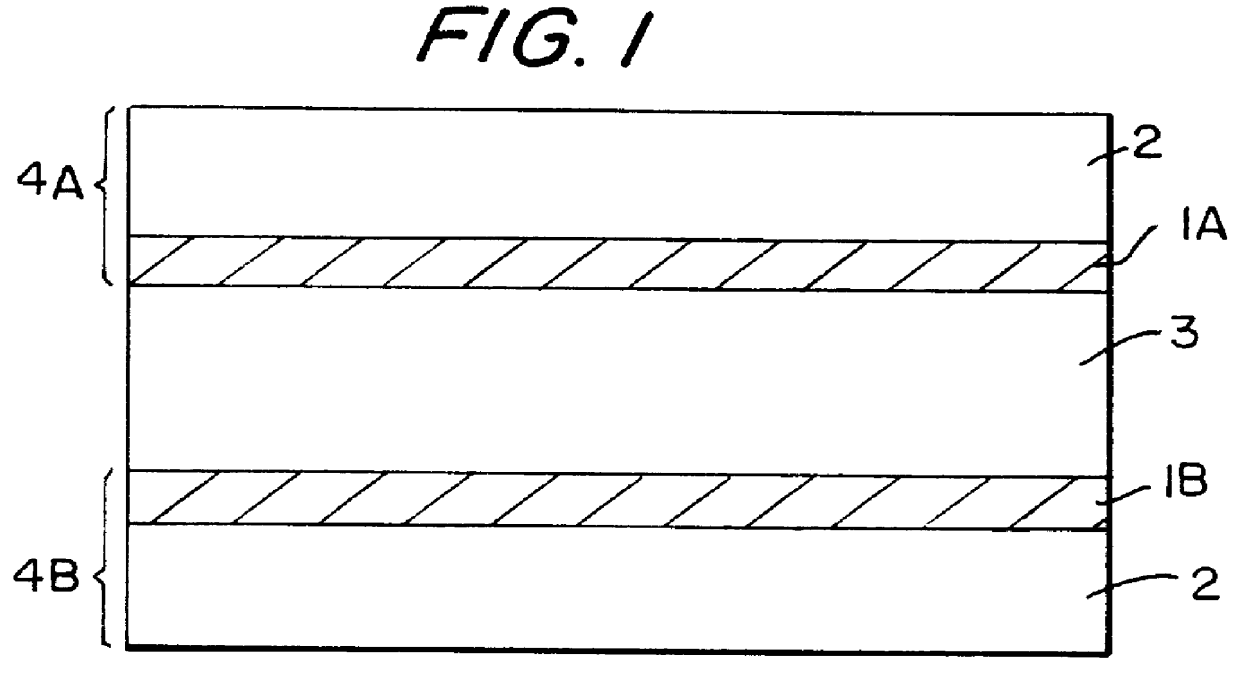

High-temperature, multiple-layer polymer (MLP) capacitors with a stacked electrode arrangement are disclosed. The capacitor electrodes are separated by a polymer dielectric that is stable at high temperatures. In some embodiments, the polymer dielectric also has a high permittivity and is filled with high-permittivity nanoparticles, which enables the capacitor to achieve a very high capacitance density.

Owner:GENERAL ELECTRIC CO

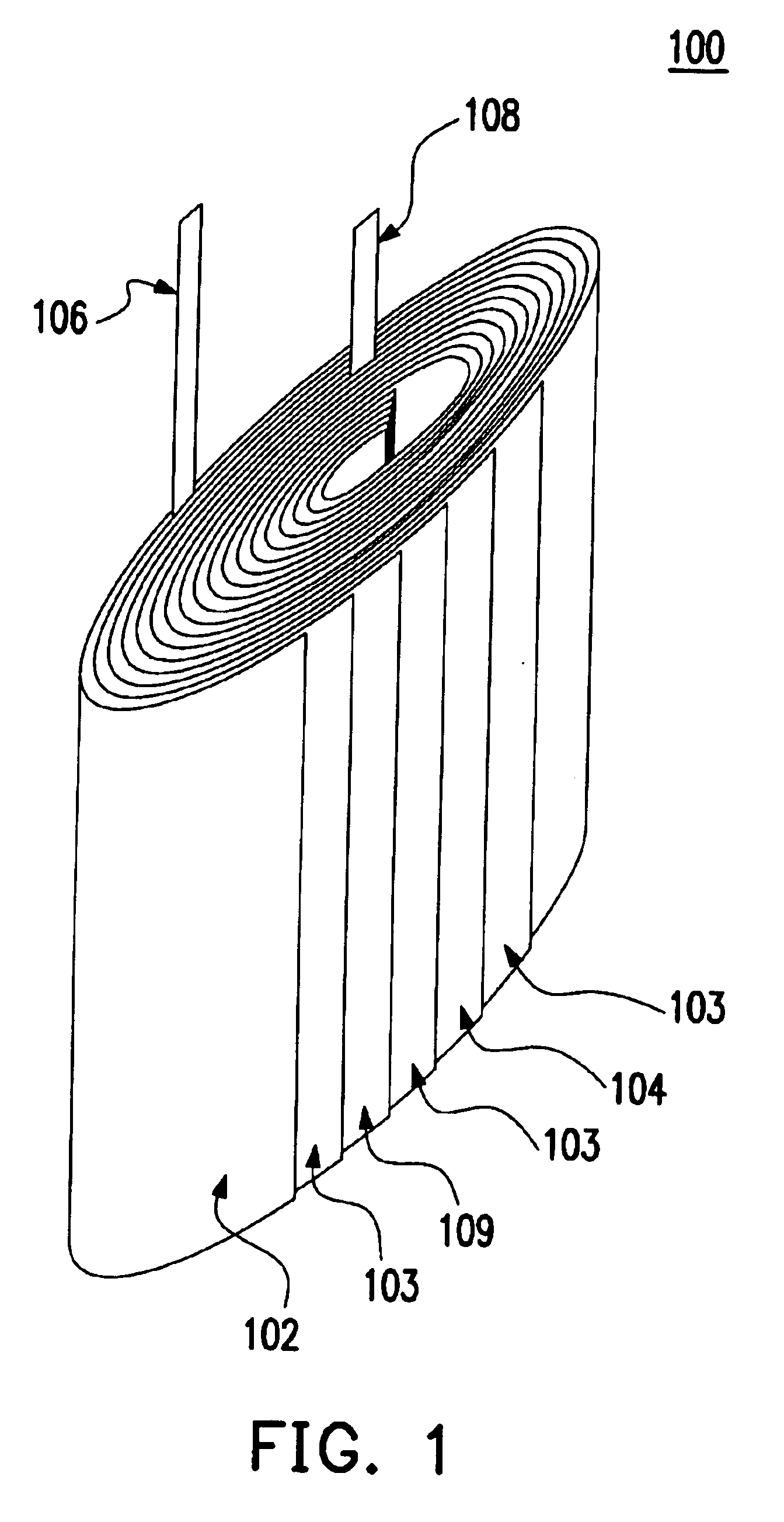

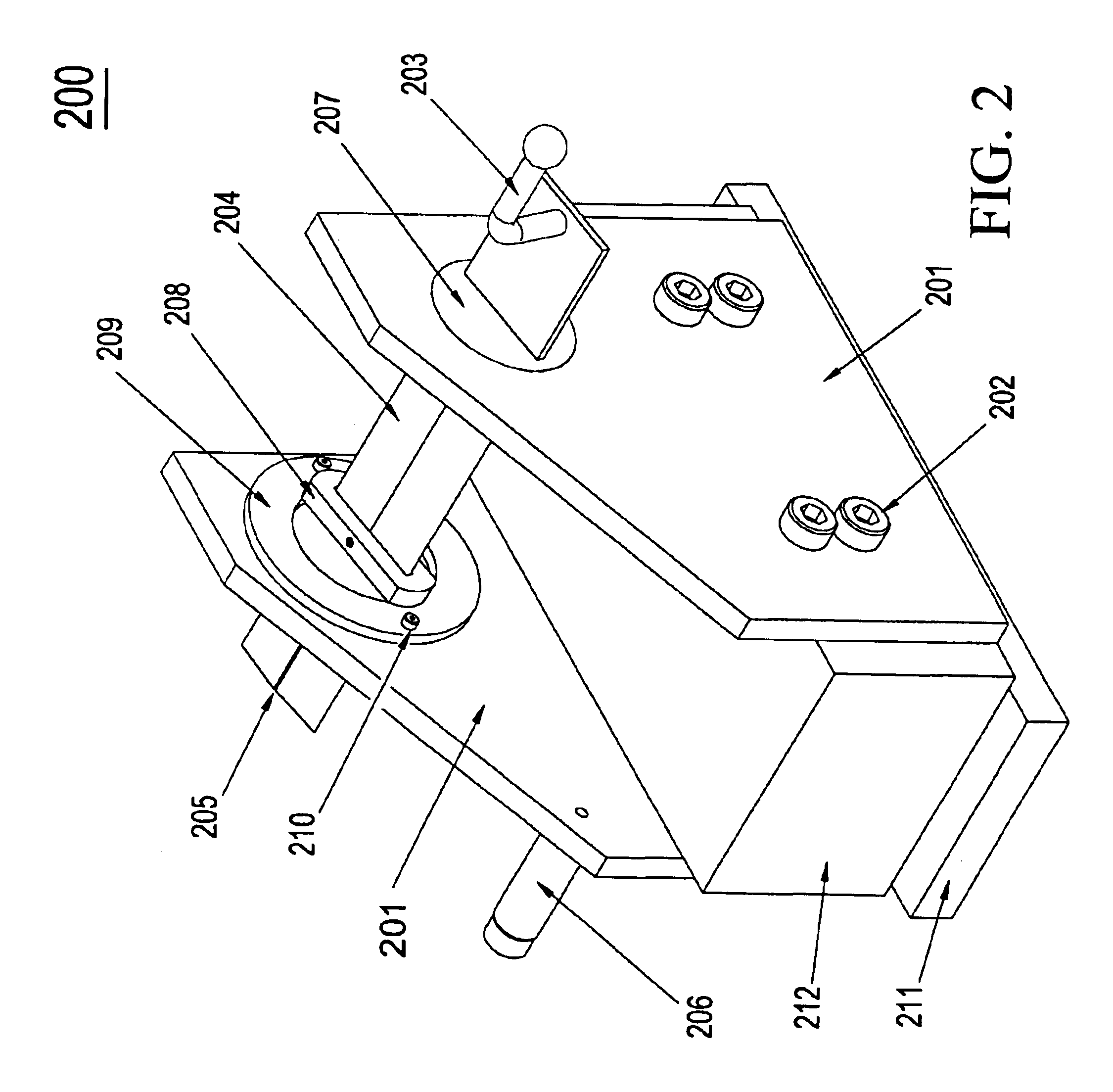

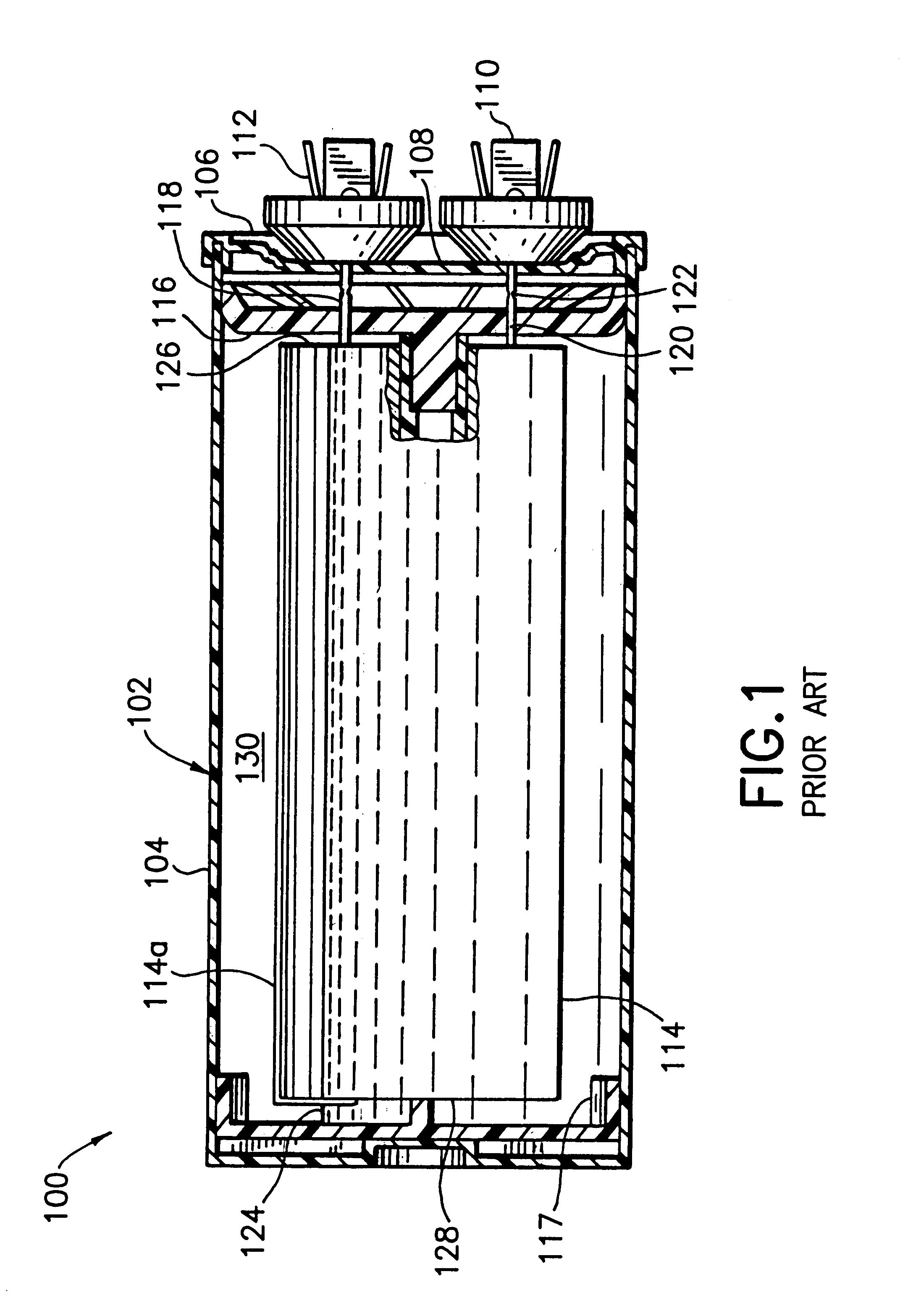

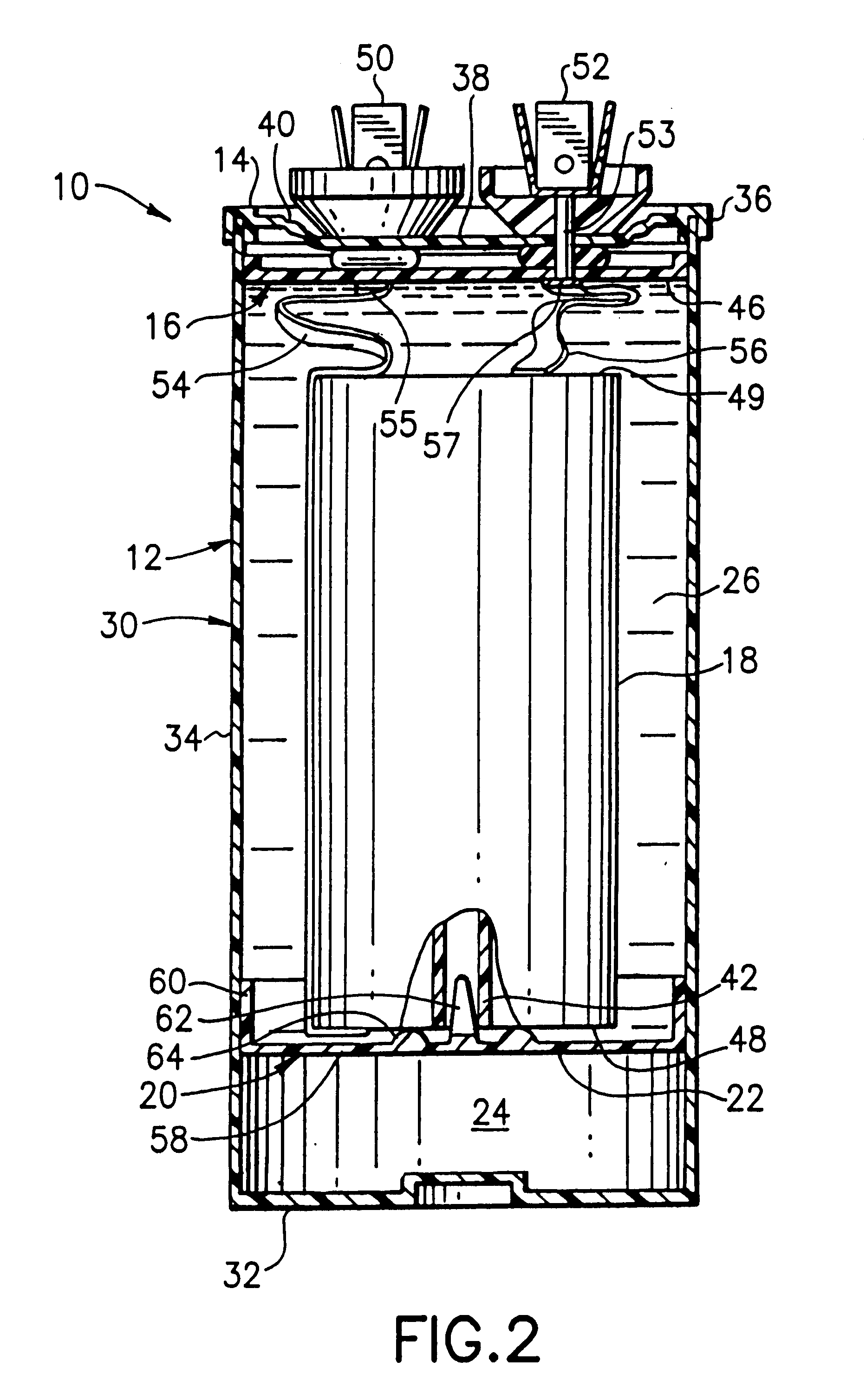

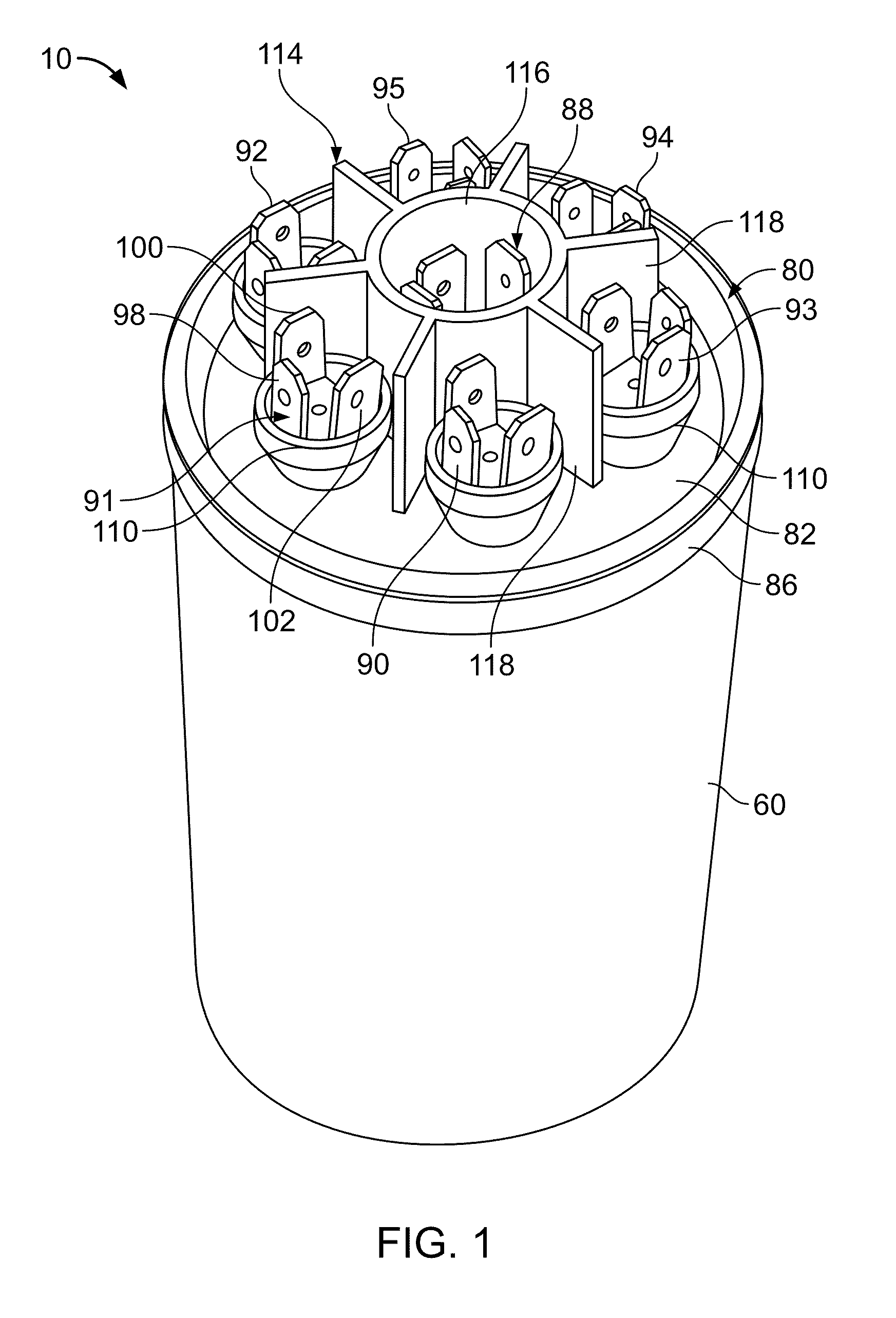

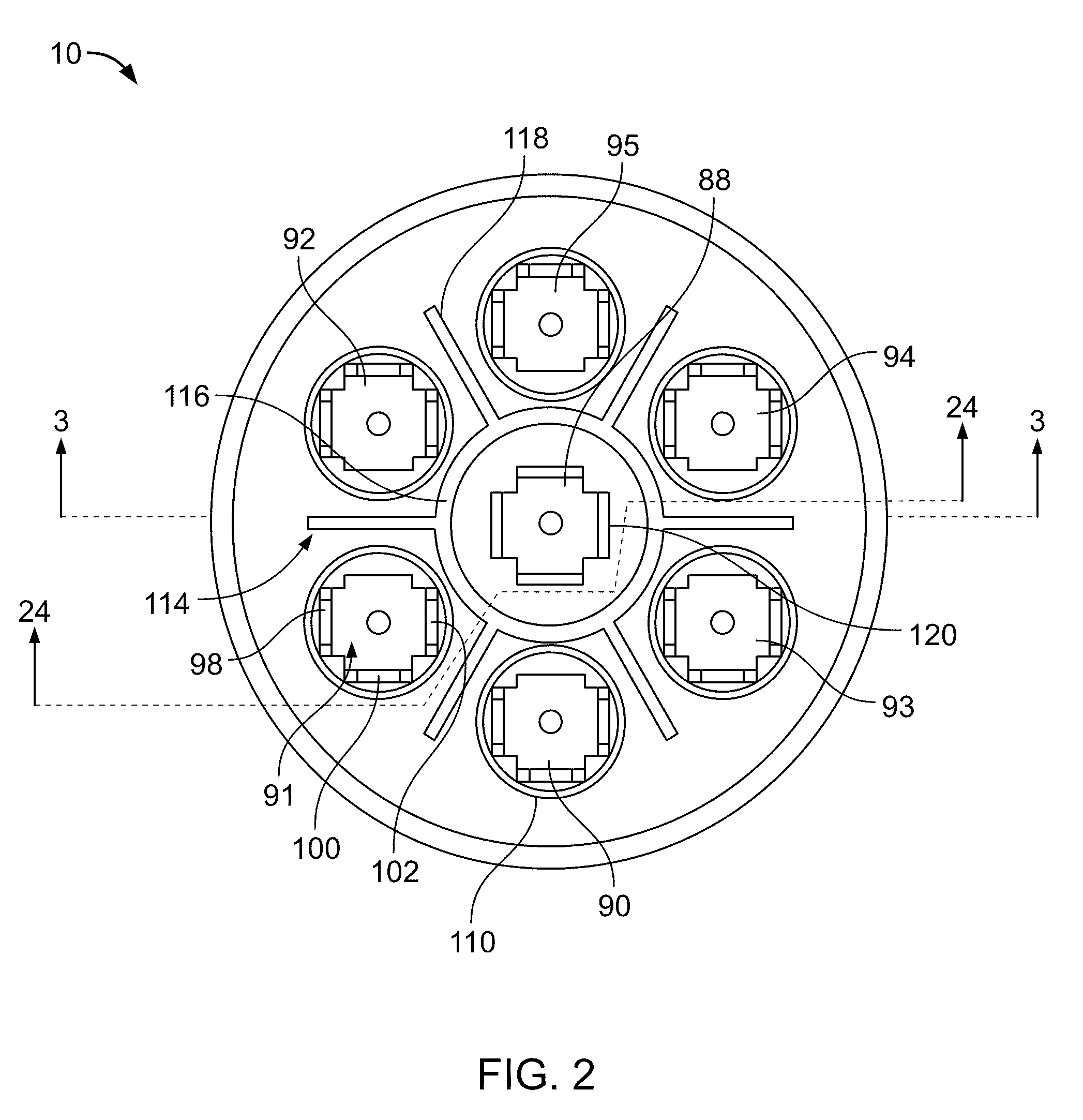

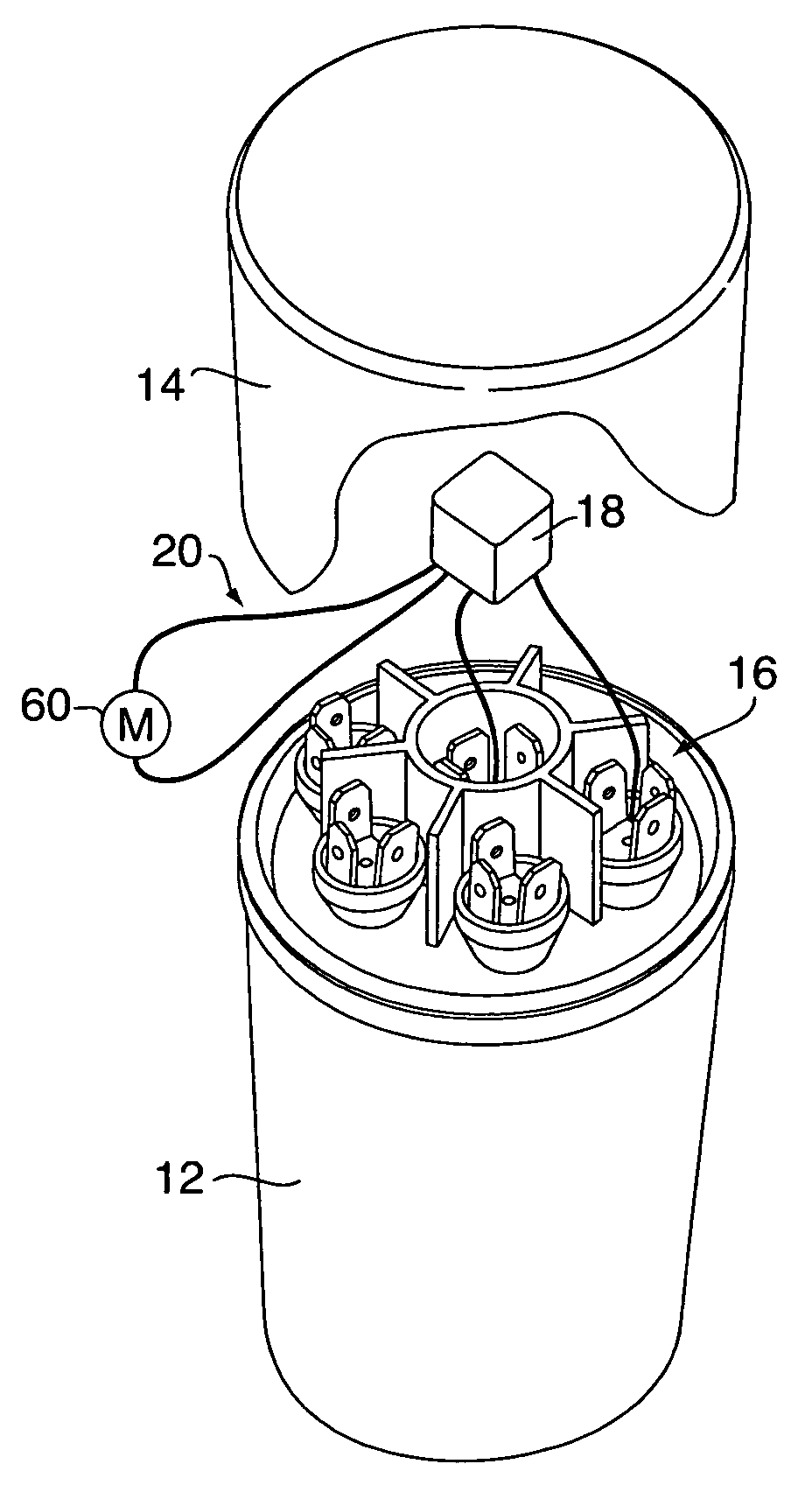

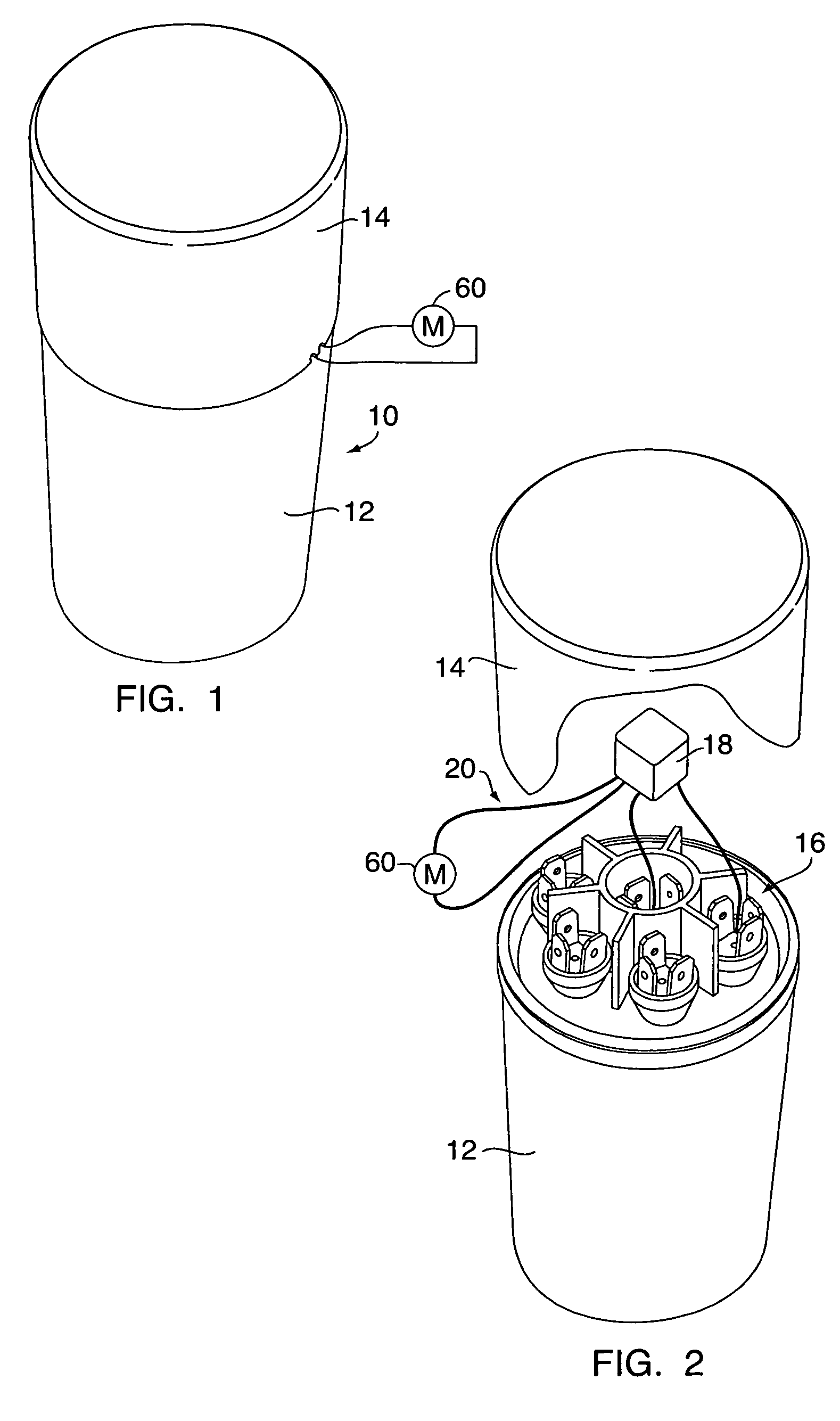

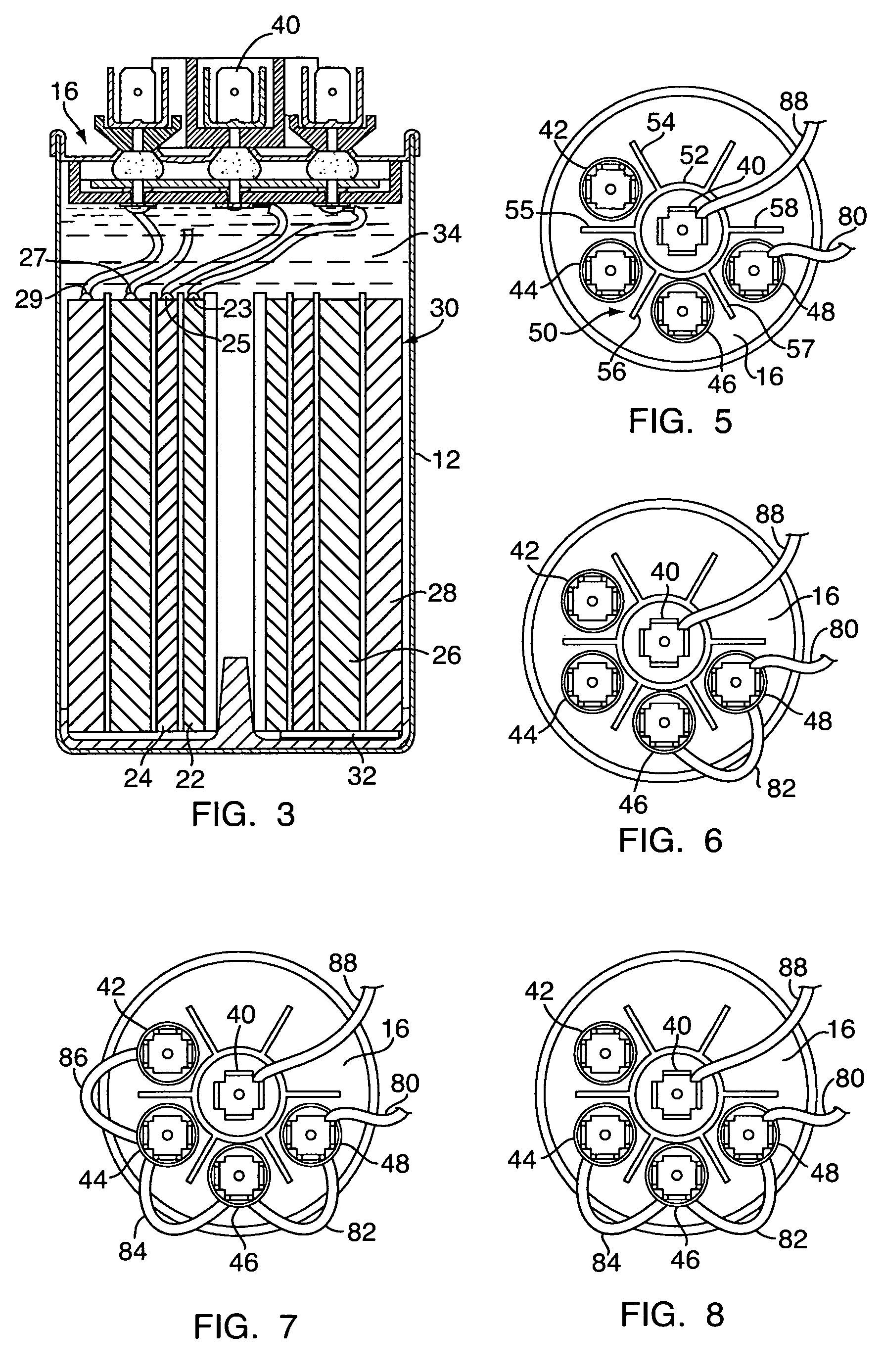

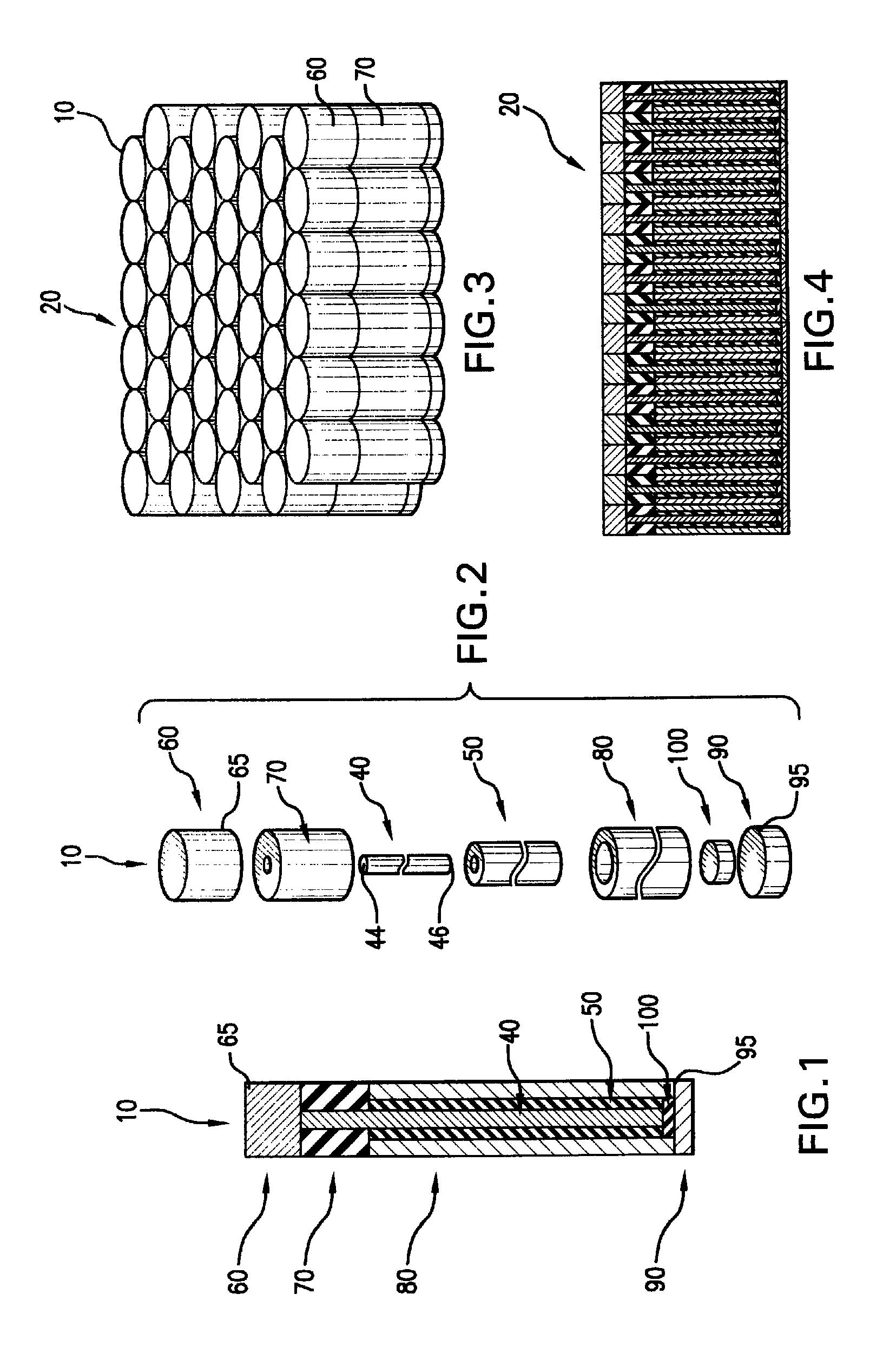

Capacitor for multiple replacement applications

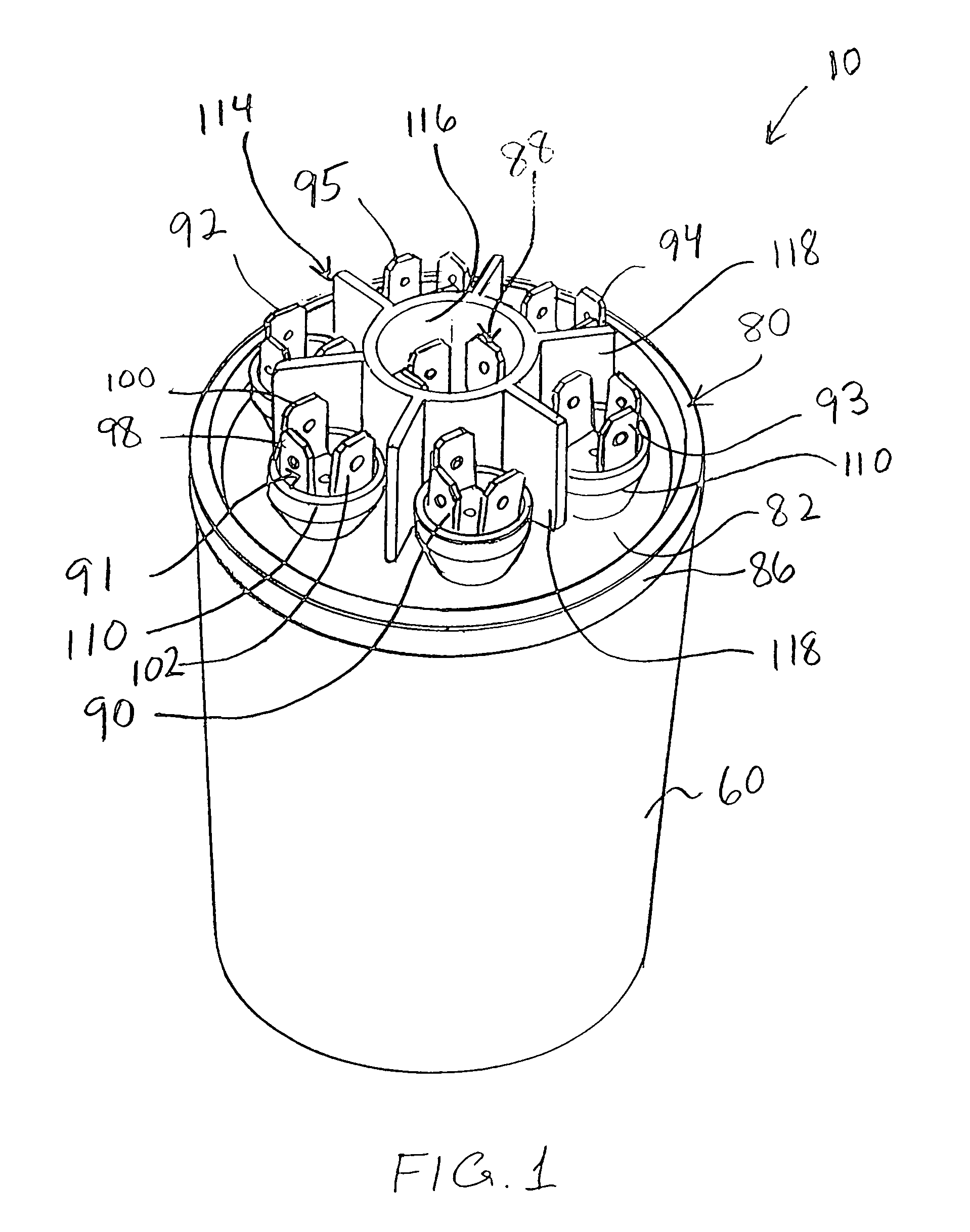

ActiveUS7203053B2Safely making and maintainingIncrease flexibilityMultiple fixed capacitorsElectrolytic capacitorsCapacitanceElectrical conductor

A capacitor provides a plurality of selectable capacitance values, by selective connection of six concentrically wound capacitor sections of a capacitive element each having a capacitance value. The capacitor sections each have a respective section element terminal at a first end of the capacitive element and the capacitor sections have a common element terminal at a second end of the capacitive element. A pressure interrupter cover assembly is sealingly secured to the open end a case for the element and has a deformable cover with a centrally mounted common cover terminal and a plurality of section cover terminals mounted at spaced apart locations. A conductor frangibly connects the common element terminal of the capacitive element to the common cover terminal and conductors respectively frangibly connect the capacitor section terminals to the section cover terminals. Deformation of the cover caused by failure of the capacitor element breaks at least some of the frangible connections sufficient to disconnect the capacitive element from an electric circuit in which it is connected. A cover insulation barrier mounted on the deformable cover, has a barrier cup substantially surrounding the common cover terminal and a plurality of barrier fins each extending radially outwardly from the barrier cup, and deployed between adjacent section cover.

Owner:AMRAD MFG LLC

Electrolyte capacitors having a polymeric outer layer and process for their production

ActiveUS7377947B2Increase coverageHybrid capacitor electrolytesHybrid capacitor electrodesConductive polymerCapacitor

The invention relates to a process for the production of electrolyte capacitors having a low equivalent series resistance and low residual current, and which comprise a solid electrolyte of conductive polymers and an outer layer comprising conductive polymers applied in the form of a dispersion. Electrolyte capacitors produced by this process and the use of such electrolyte capacitors are also provided.

Owner:HERAEUS PRECIOUS METALS GMBH & CO KG

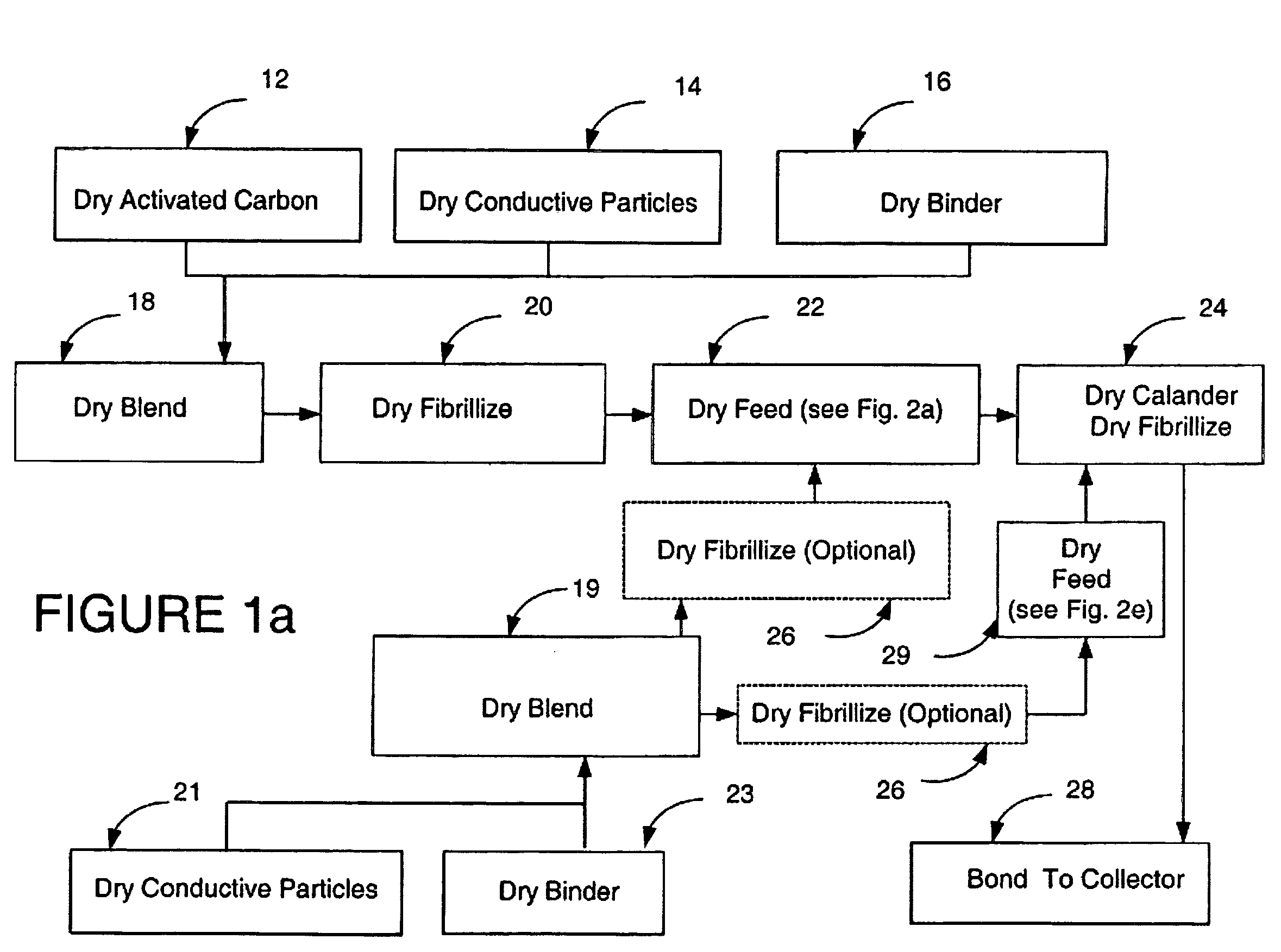

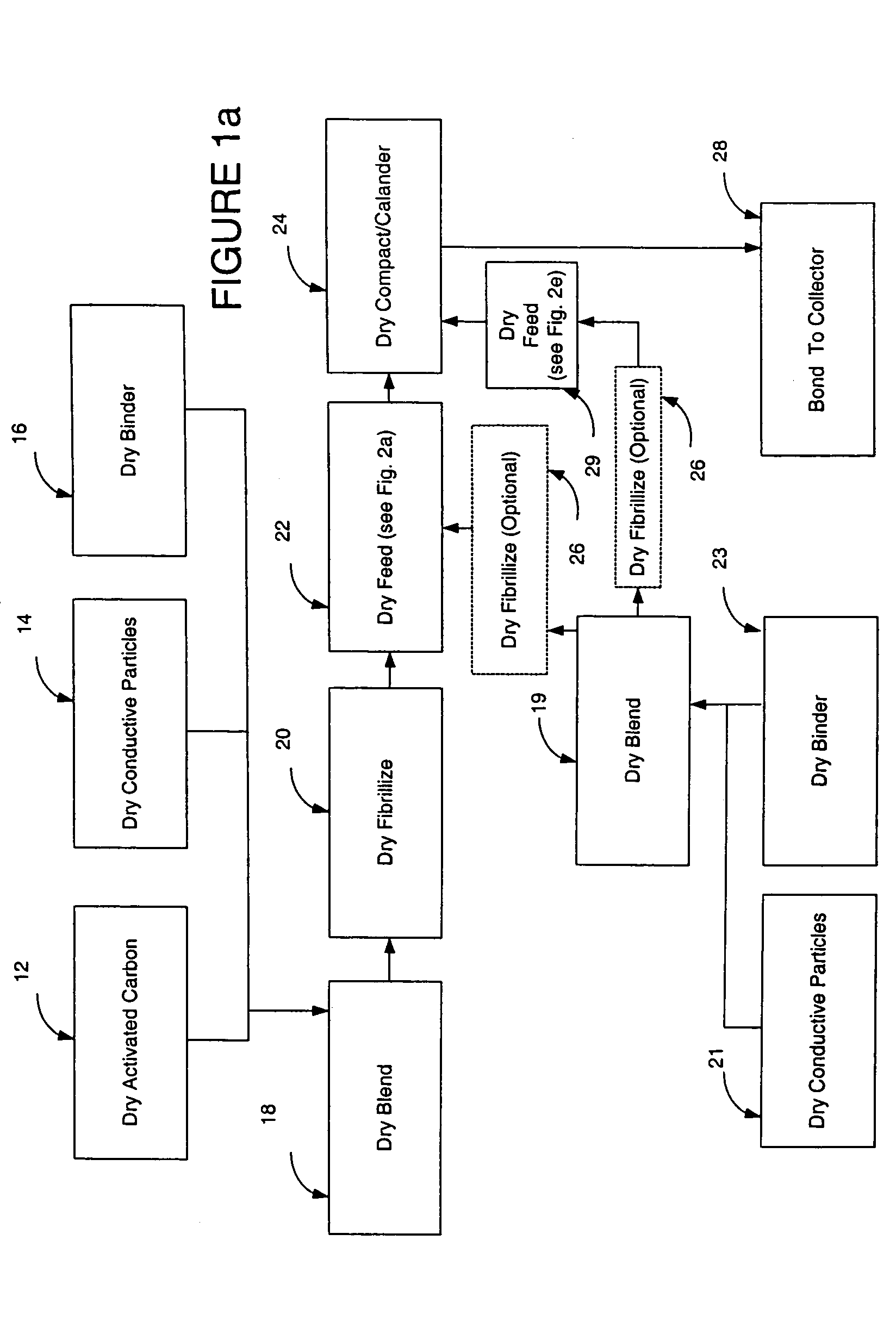

Dry-particle based adhesive and dry film and methods of making same

InactiveUS20070122698A1Reduce water consumptionHigh yieldElectrode rolling/calenderingFinal product manufactureAdhesiveEngineering

Dry process based energy storage device structures and methods for using a dry adhesive therein are disclosed.

Owner:TESLA INC

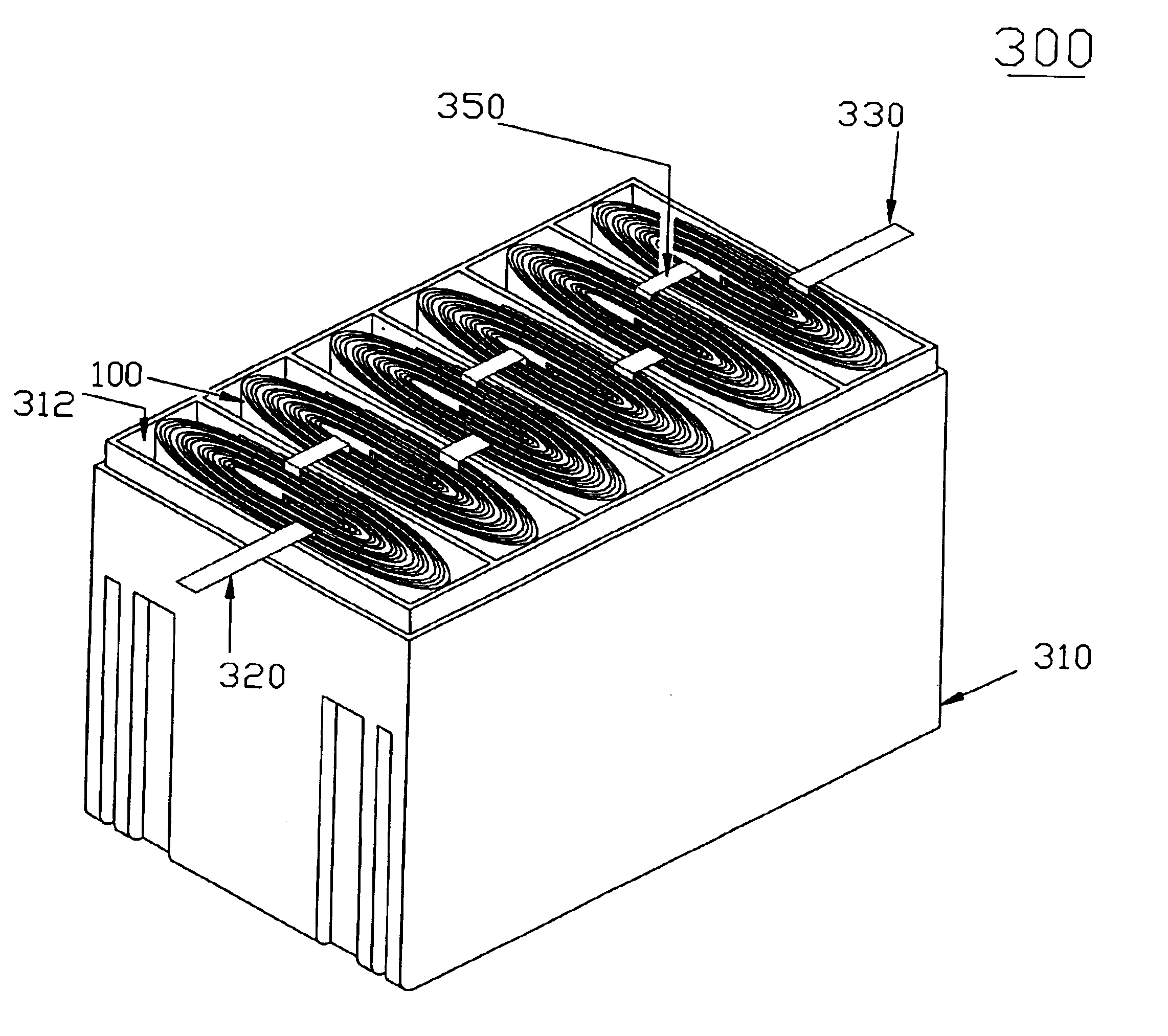

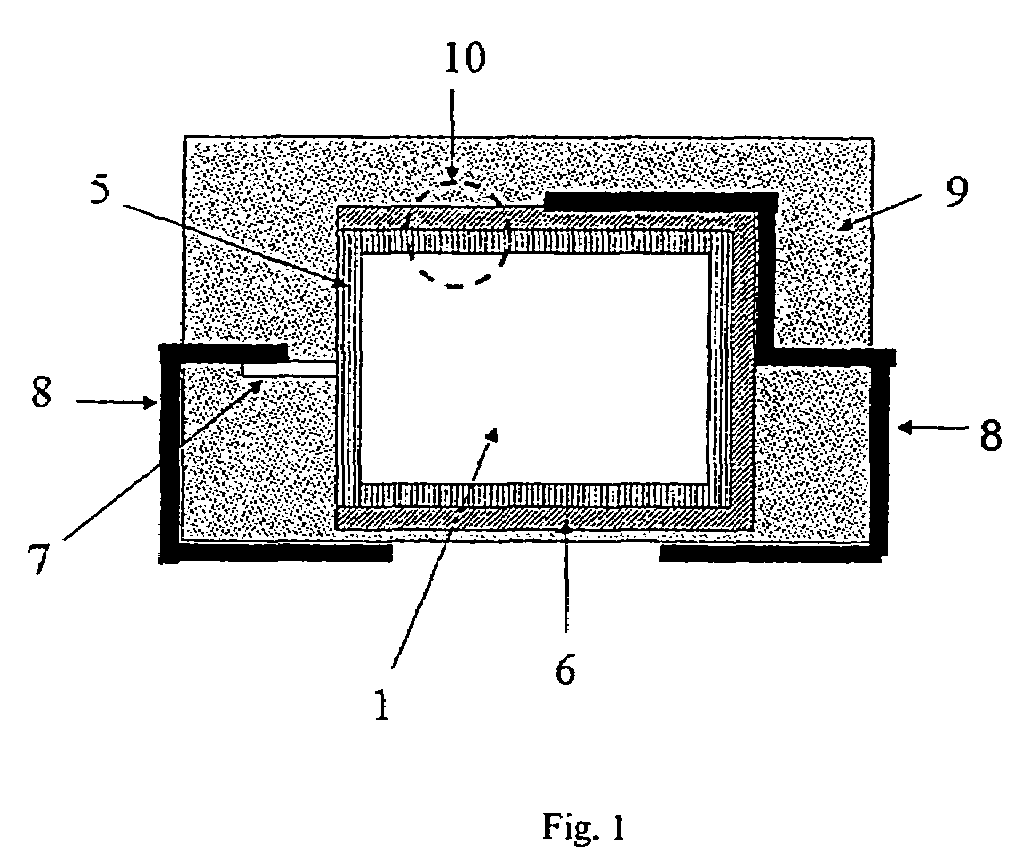

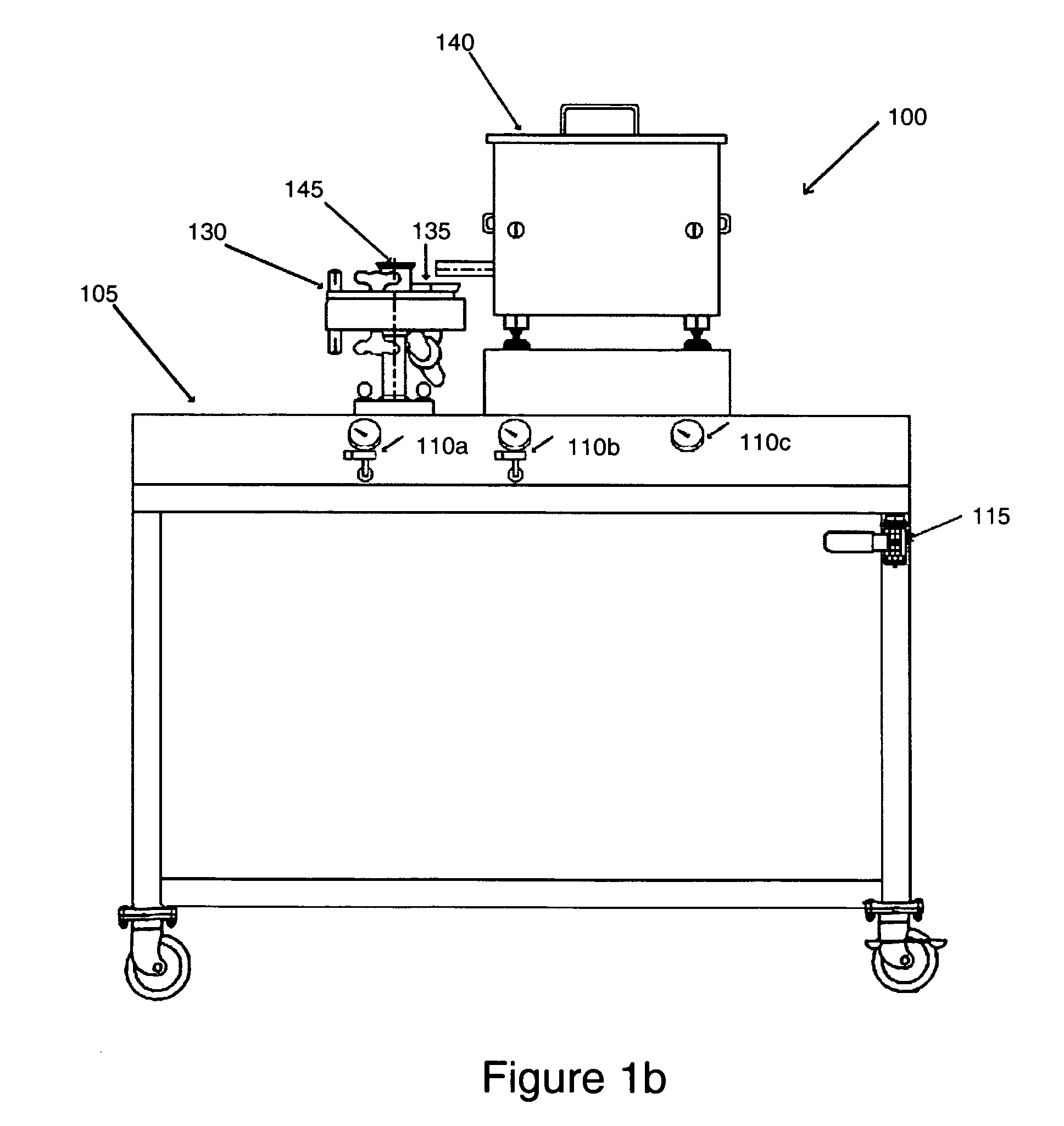

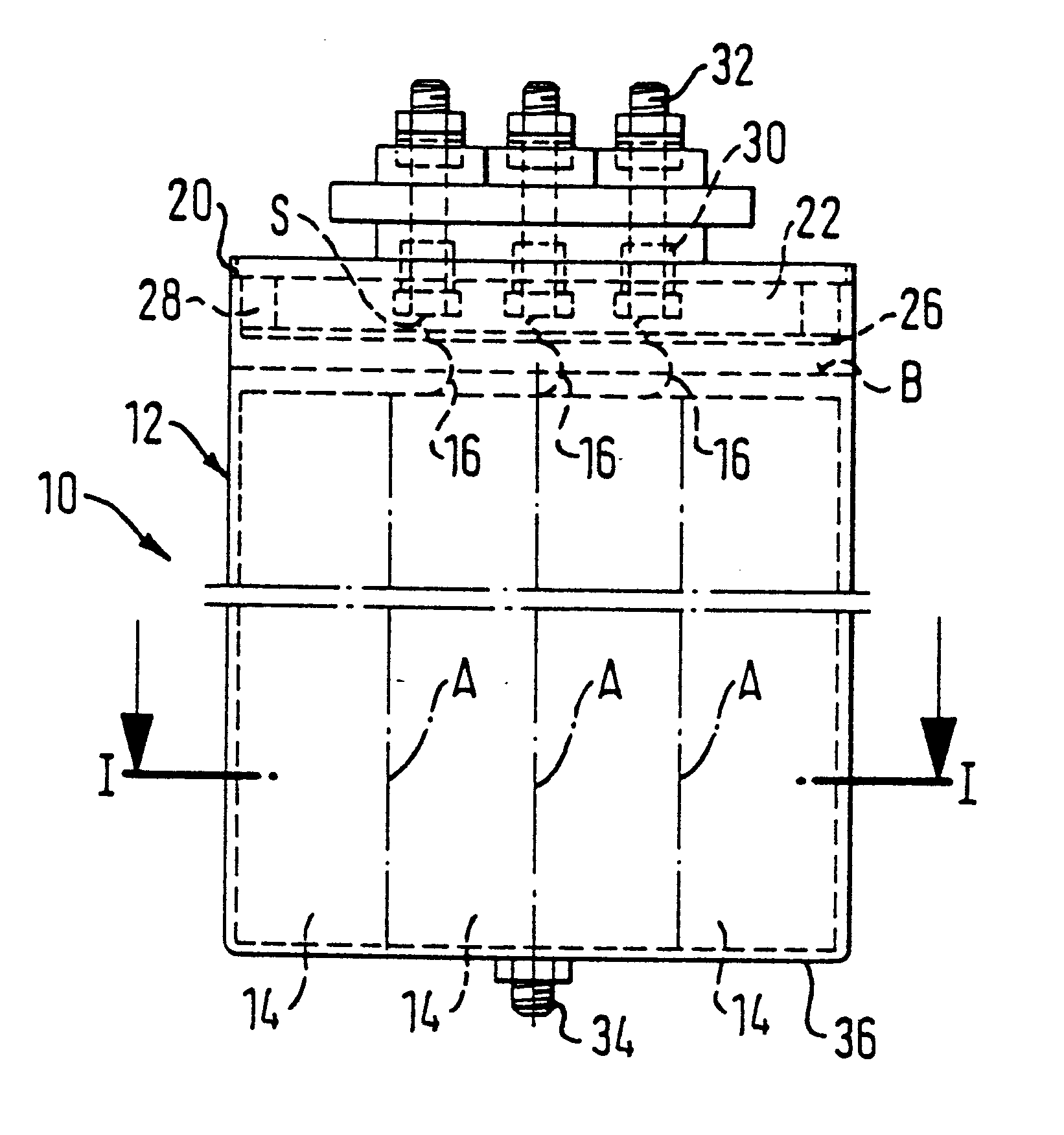

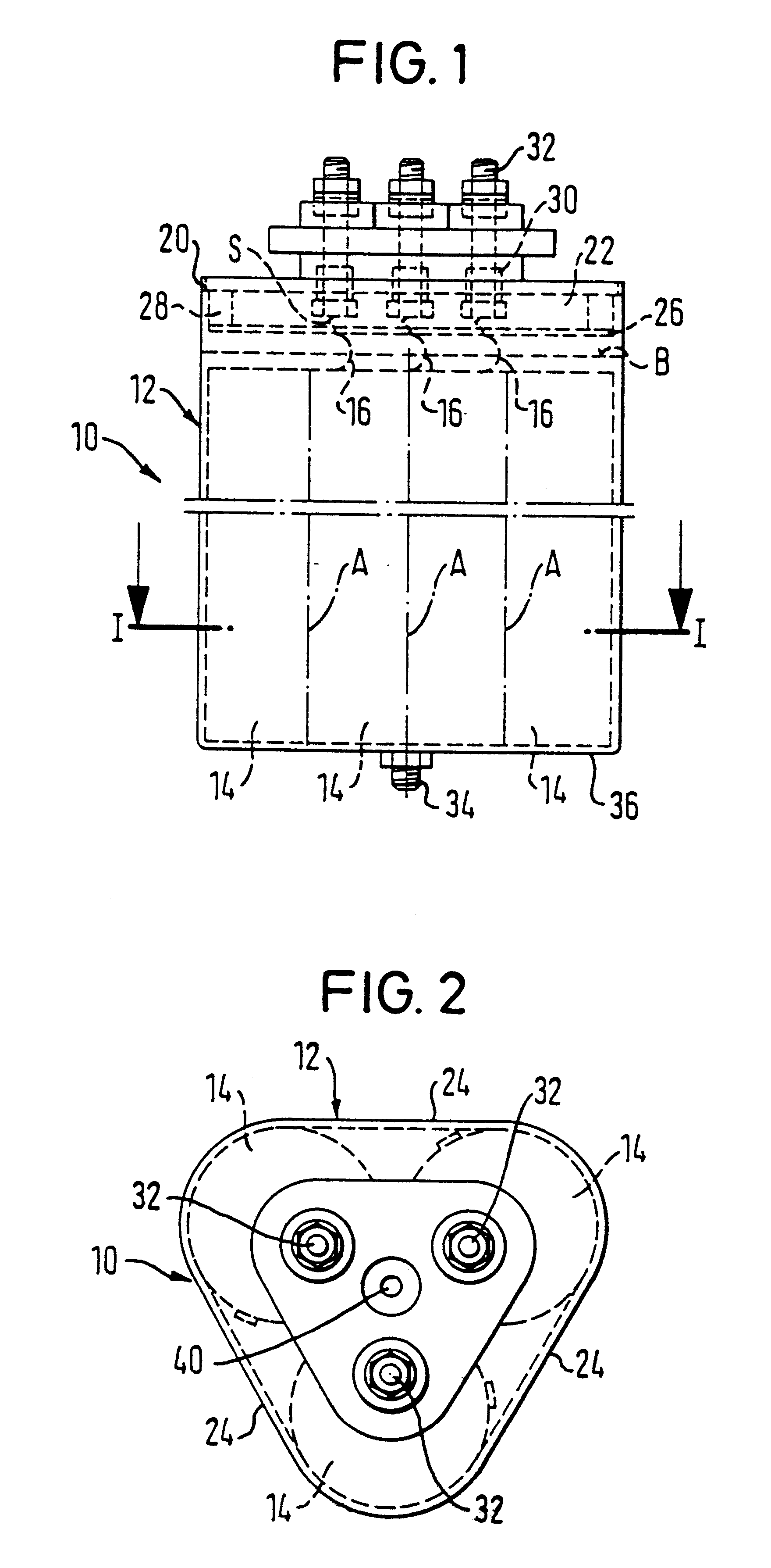

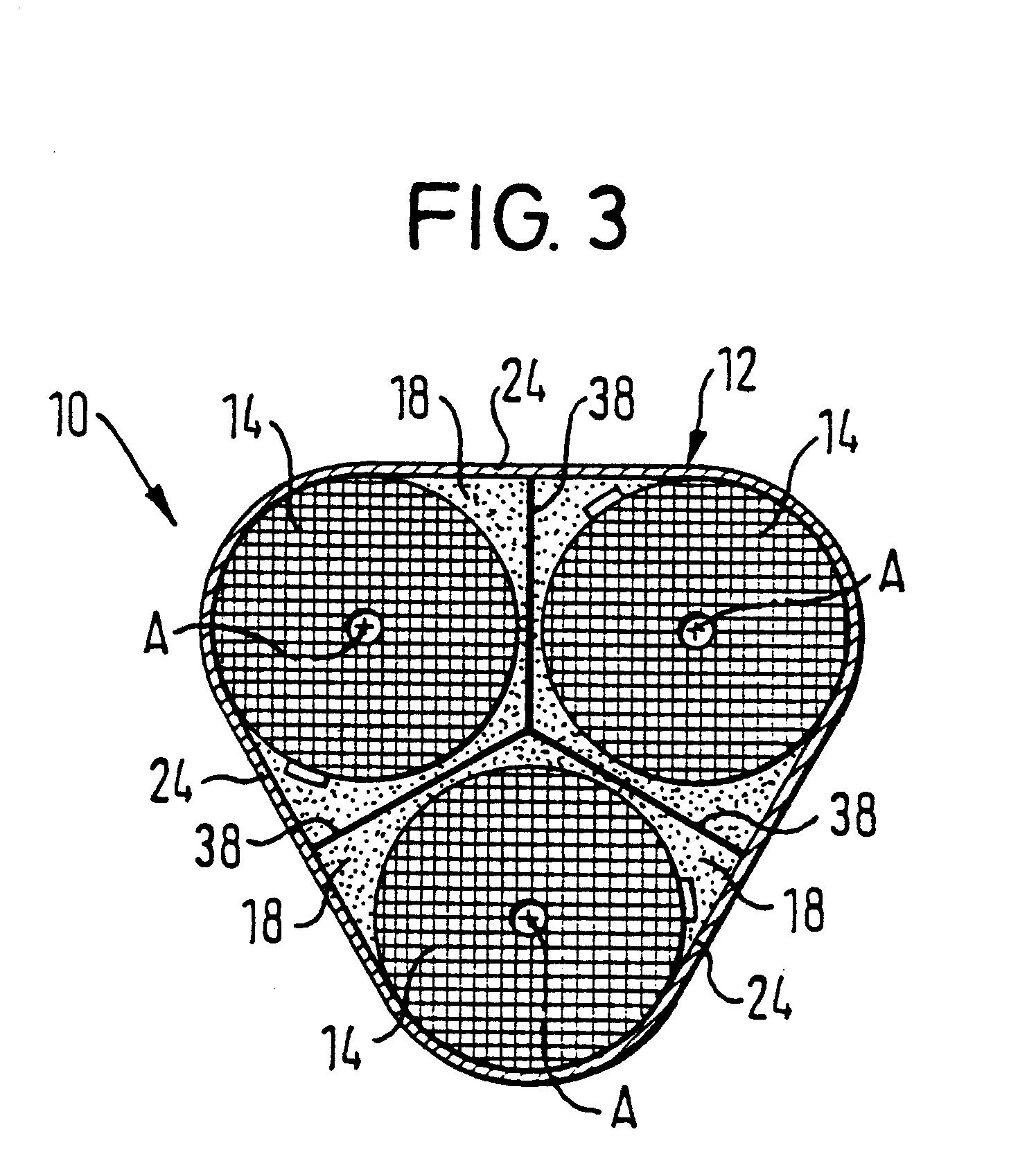

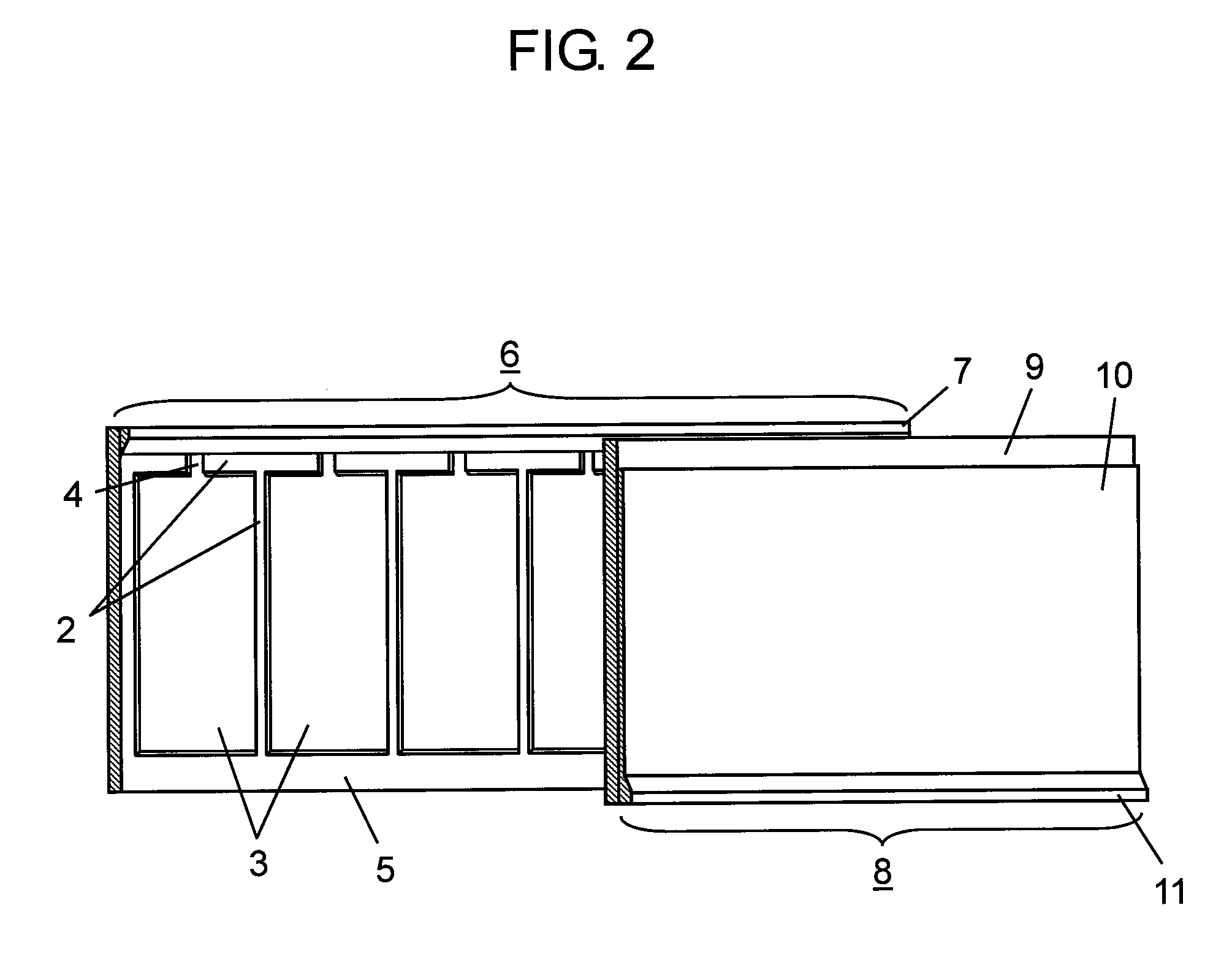

Power capacitor

InactiveUS6212058B1Reduce construction heightImproved arrangeability in a rowMultiple fixed capacitorsWound capacitorsEngineeringCapacitor

In a power capacitor with a plurality of round, wound elements accommodated in a common housing at least one wound element group consisting of three round, wound elements is accommodated in the housing, with the wound elements of the group being arranged in star-form alongside one another, with their axes parallel to one another. The housing has in cross-section in general the shape of a triangle having rounded corners, with a radius of curvature which corresponds at least substantially to the radius of the round, wound elements.

Owner:VISHAY ELECTRONICS

Fluid-filled capacitor with pressure interrupter means and internal compressible air chamber

A capacitor has a polymer housing and a wound metallized film capacitive element received in the housing, with leads connected to terminals on the cover of the housing through a pressure responsive interrupter assembly. An air chamber is provided in the housing, confining a compressible volume of air, and insulating fluid fills the remaining volume of the housing, substantially immersing the capacitive element. The air chamber is advantageously defined by a piston slidably mounted in the housing. Upon a high pressure condition caused by failure of the capacitive element, the volume of air is compressed to cushion the onset of the high pressure, protecting the case from rupture prior to operation of the pressure responsive interrupter assembly.

Owner:AMERICAN RADIONIC CO INC

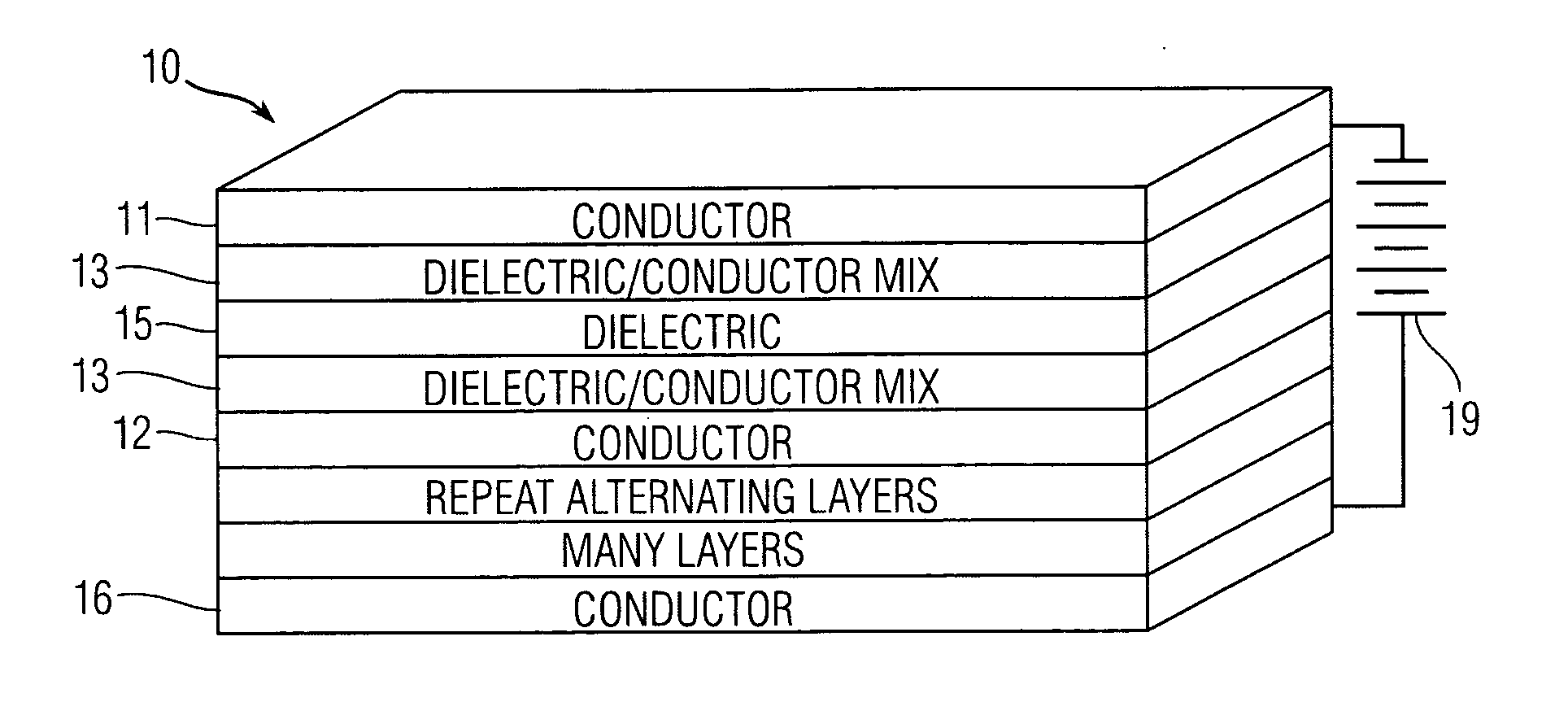

High performance capacitor with high dielectric constant material

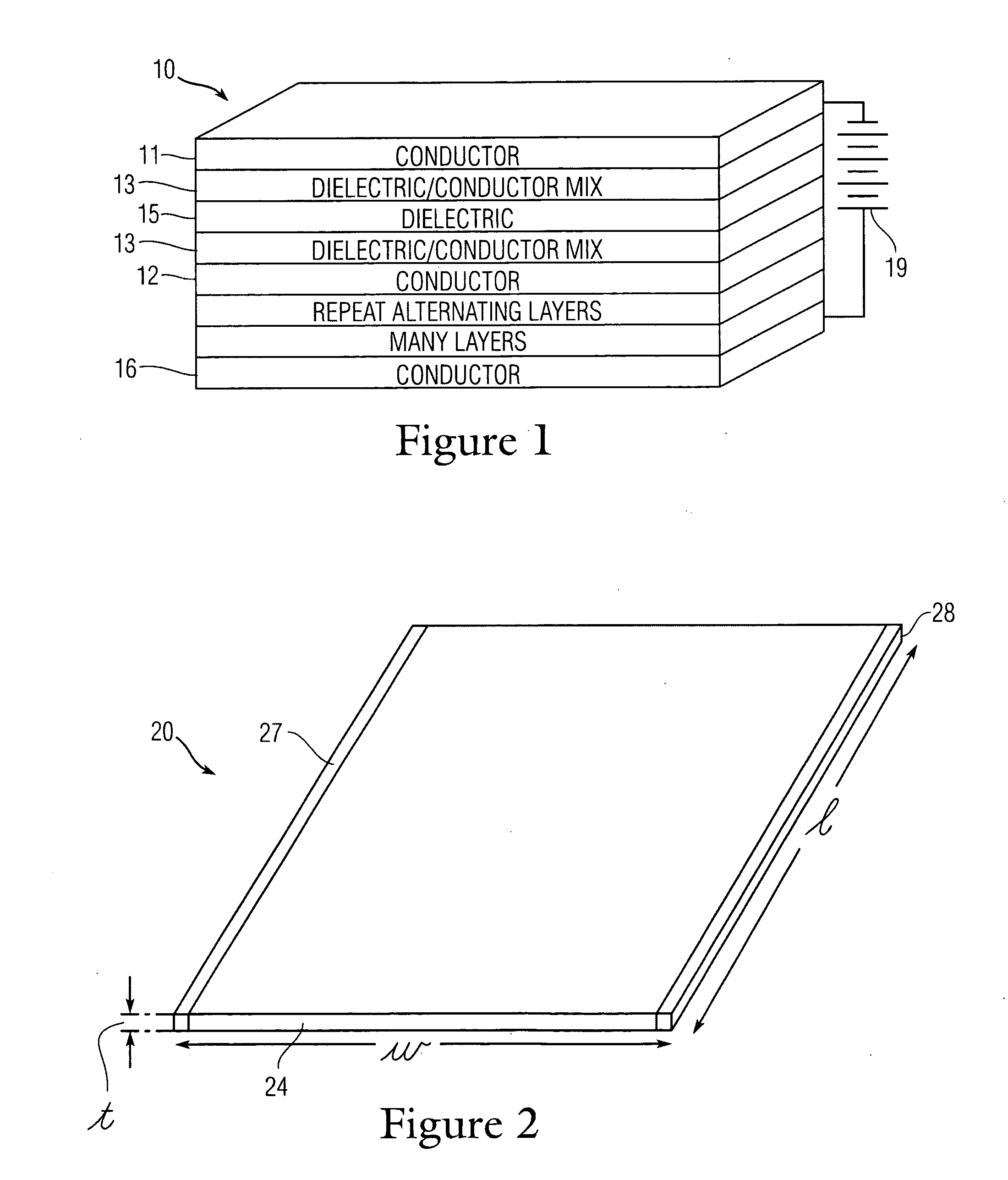

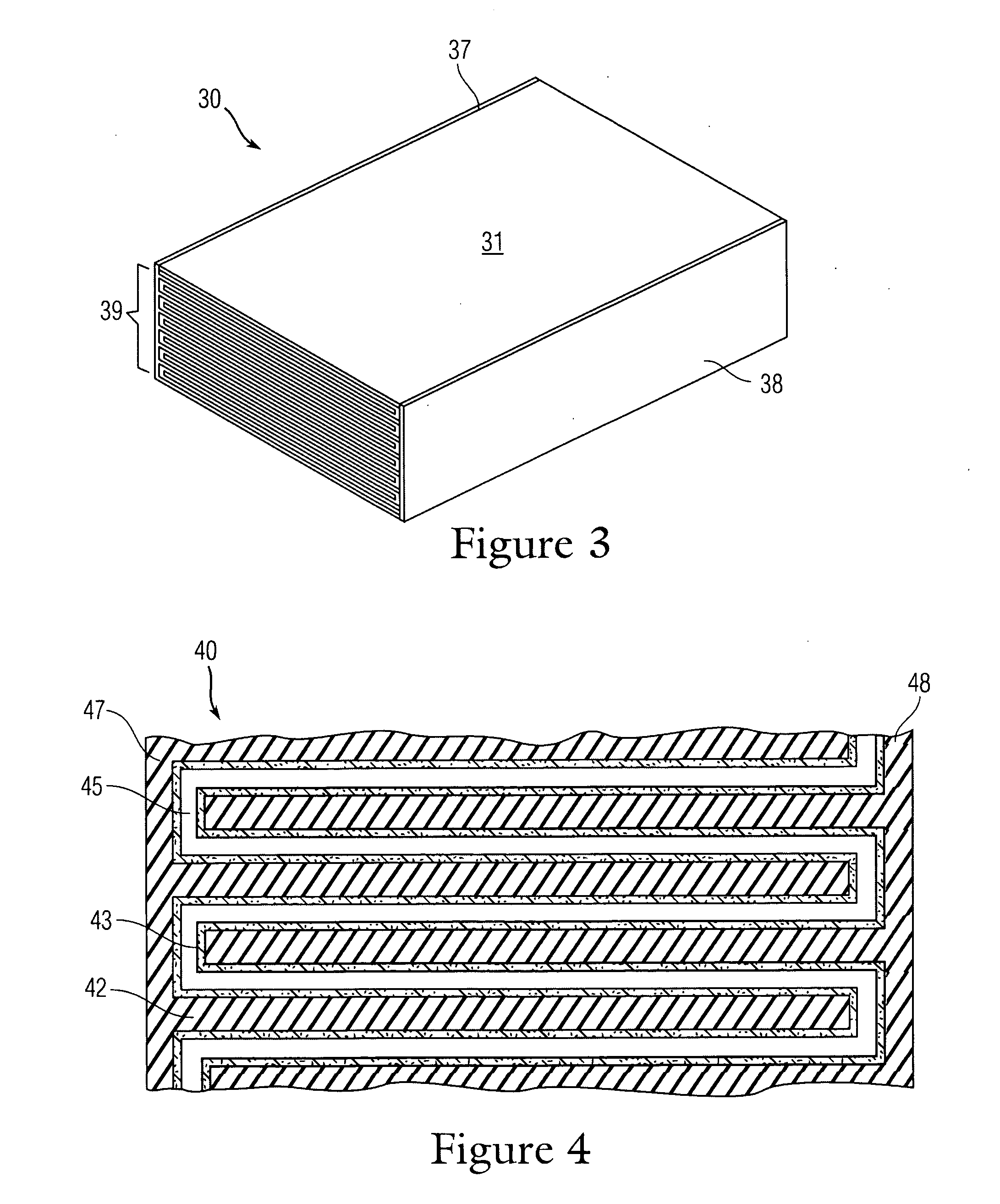

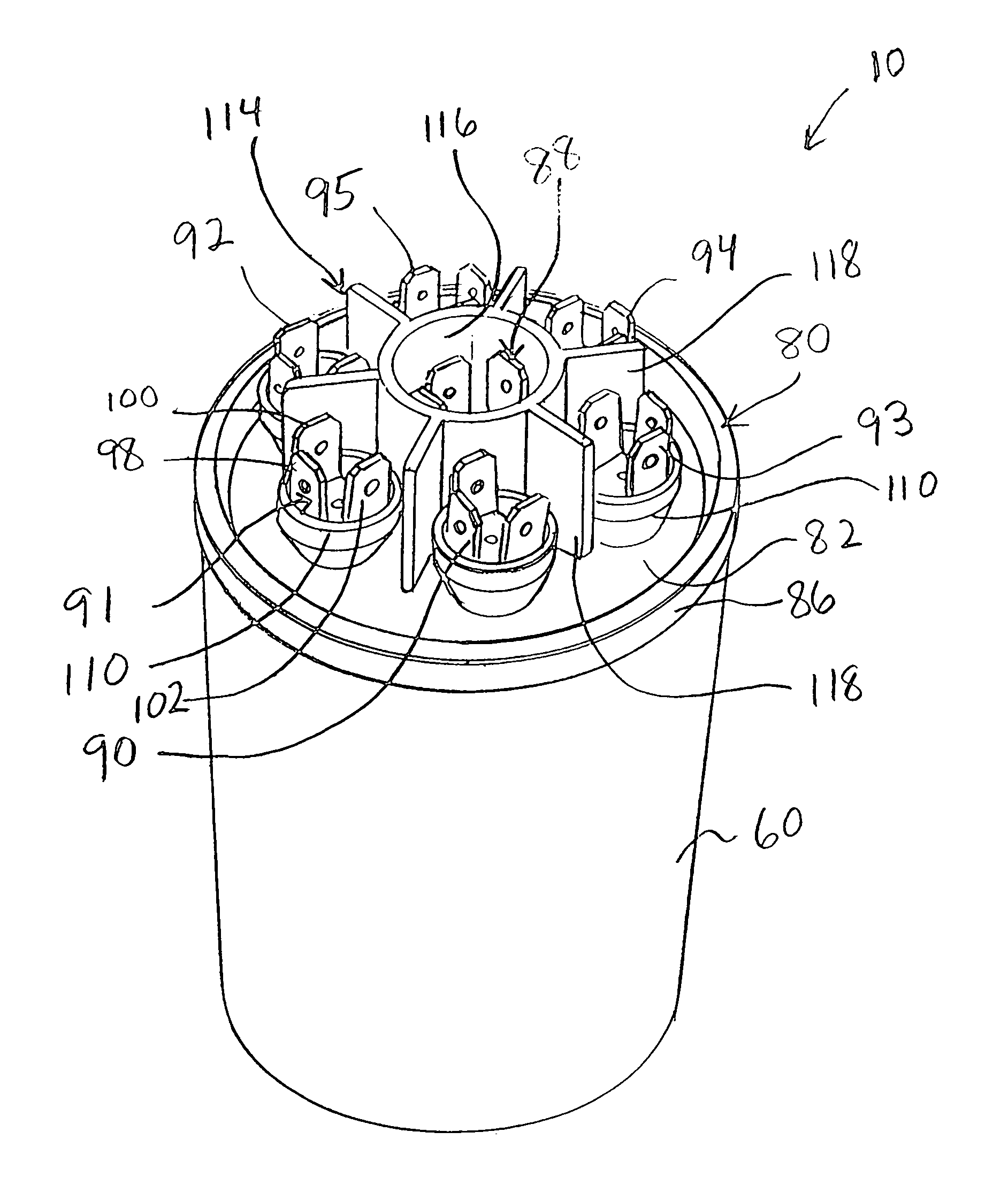

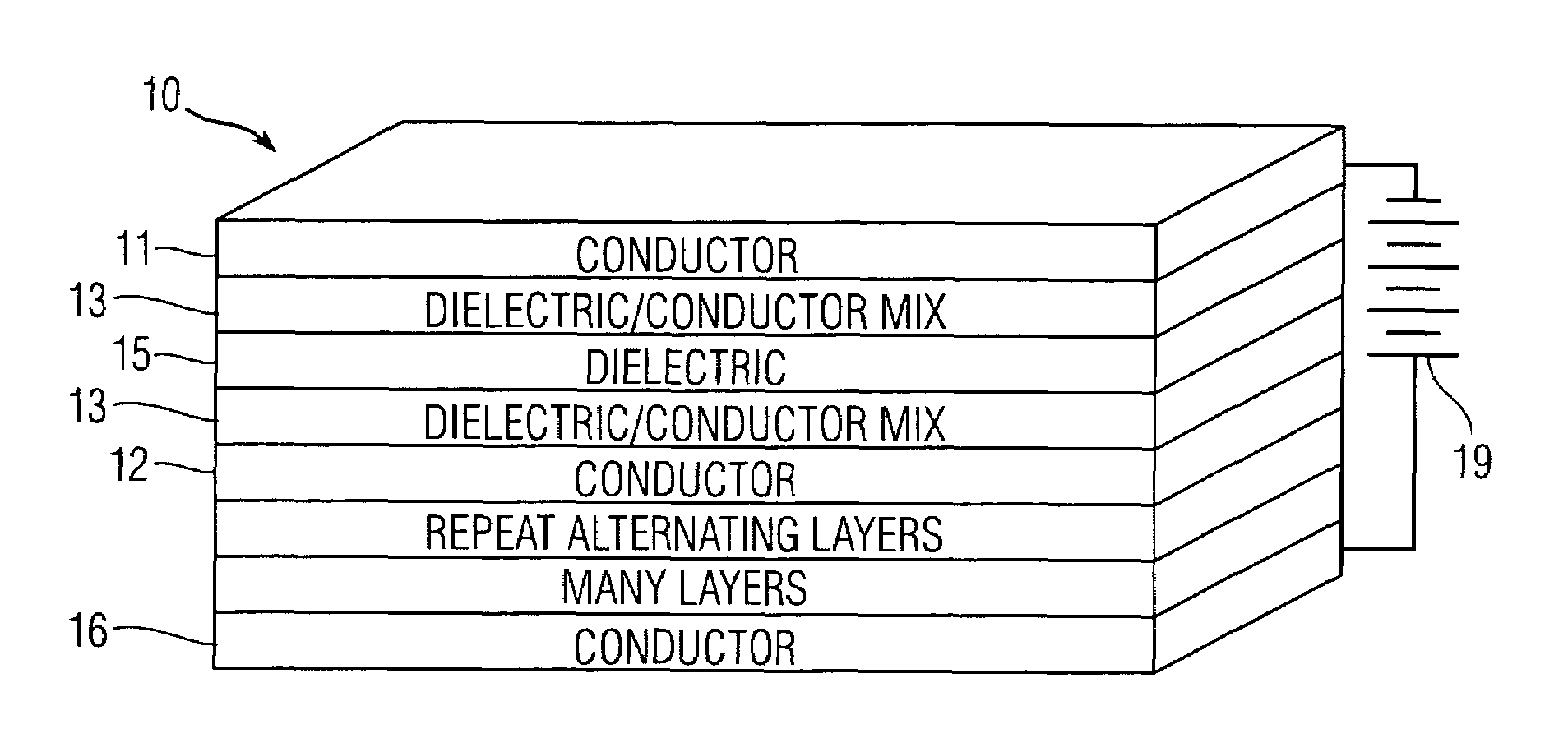

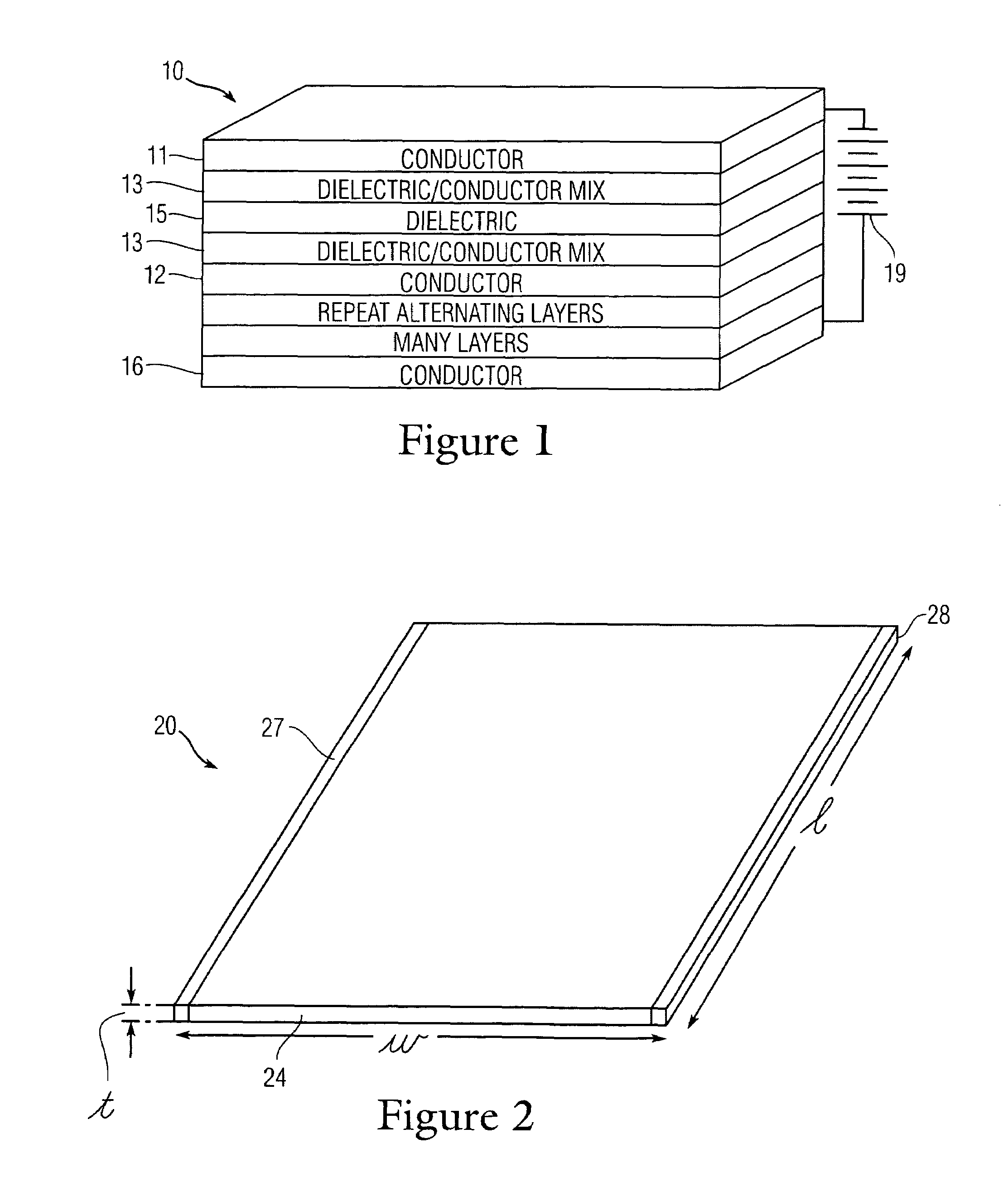

InactiveUS20060120020A1Improve performanceHigh energy-density capacitorFixed capacitor dielectricStacked capacitorsElectrical conductorVolumetric Mass Density

A multilayered high performance capacitor formed of two or more conductors with a dielectric layer and one or more a dielectric-conductor interface layer sandwiched in between the conductors. The capacitor may be fabricated using many thin layers, at the nano level, providing a nanocapacitor. The capacitor may employ an interleaved structured where numerous conductor layers are interleaved with other conductor layers. The dielectric layers may be multilayered or a single layer and may consist of materials with high dielectric constants ranging from 800 to over 1 million, including materials in the perovskite-oxide family. The capacitor can be shaped, sized and the appropriate materials selected to obtain breakdown voltages within the range of 0.1 to over 11 MV / cm and to obtain specific energies and energy densities equivalent to or exceeding the power characteristics of known capacitors, fuel cells, and batteries. The nanocapacitor may be combined with other nanocapacitors to form stacks, packs, or grids of cells where the cells may be connected in series, parallel or both to provide increased energy or power characteristics

Owner:DOWGIALLO JR EDWARD J

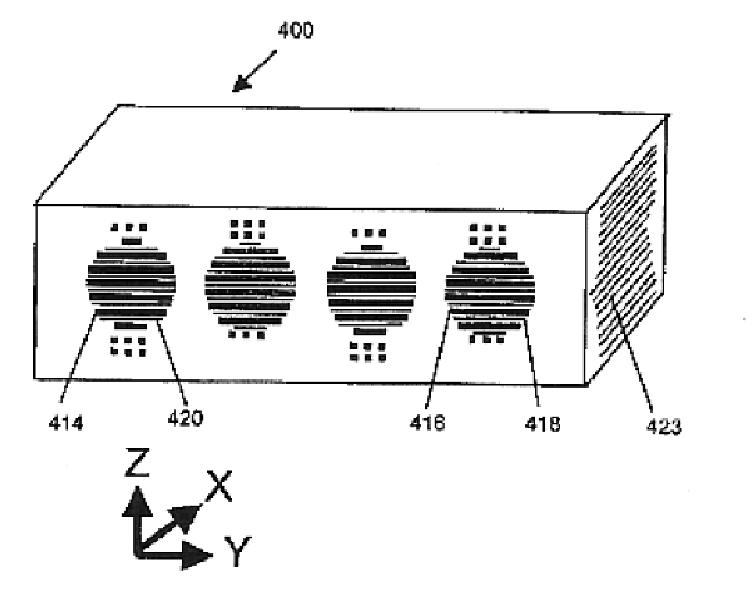

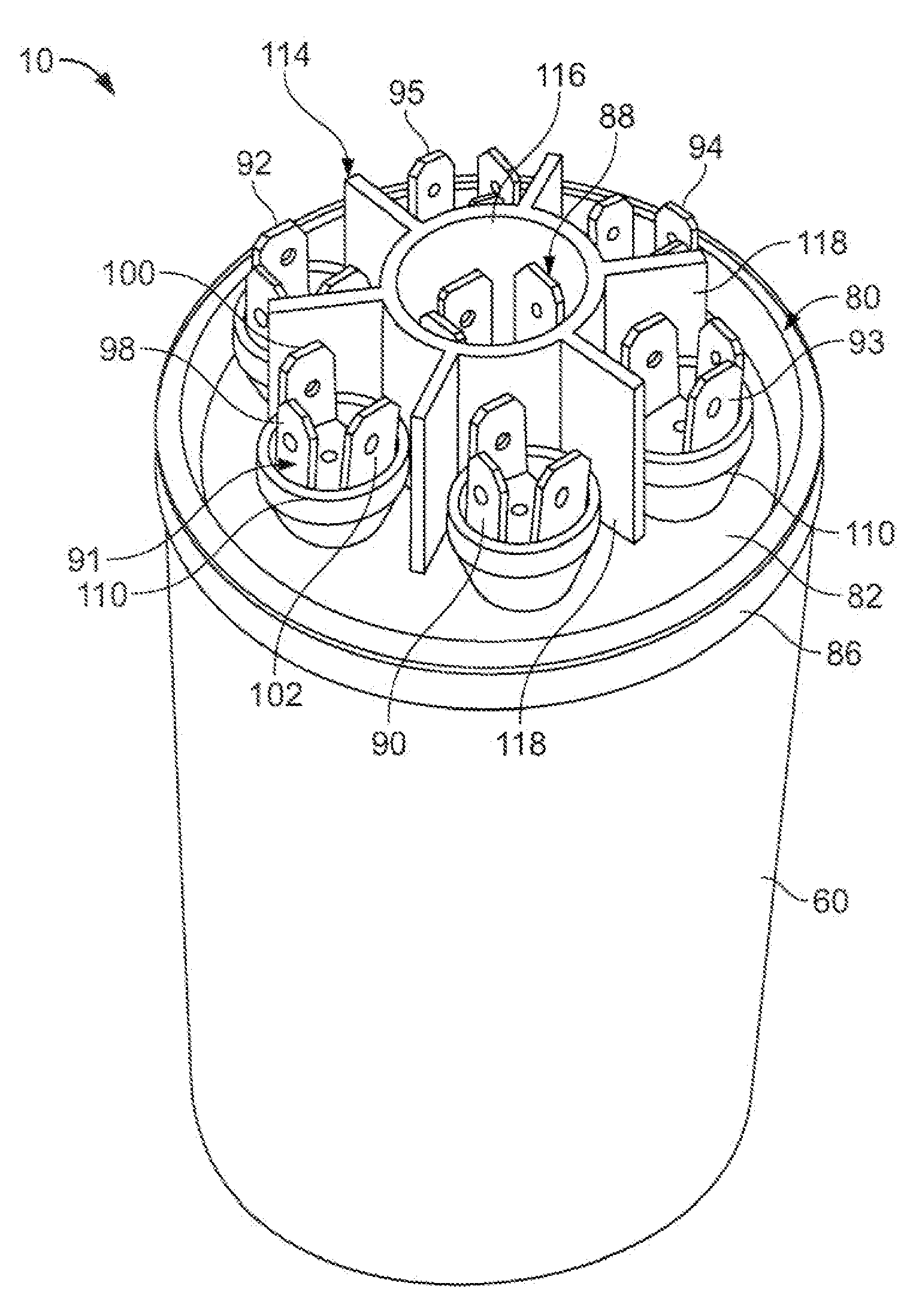

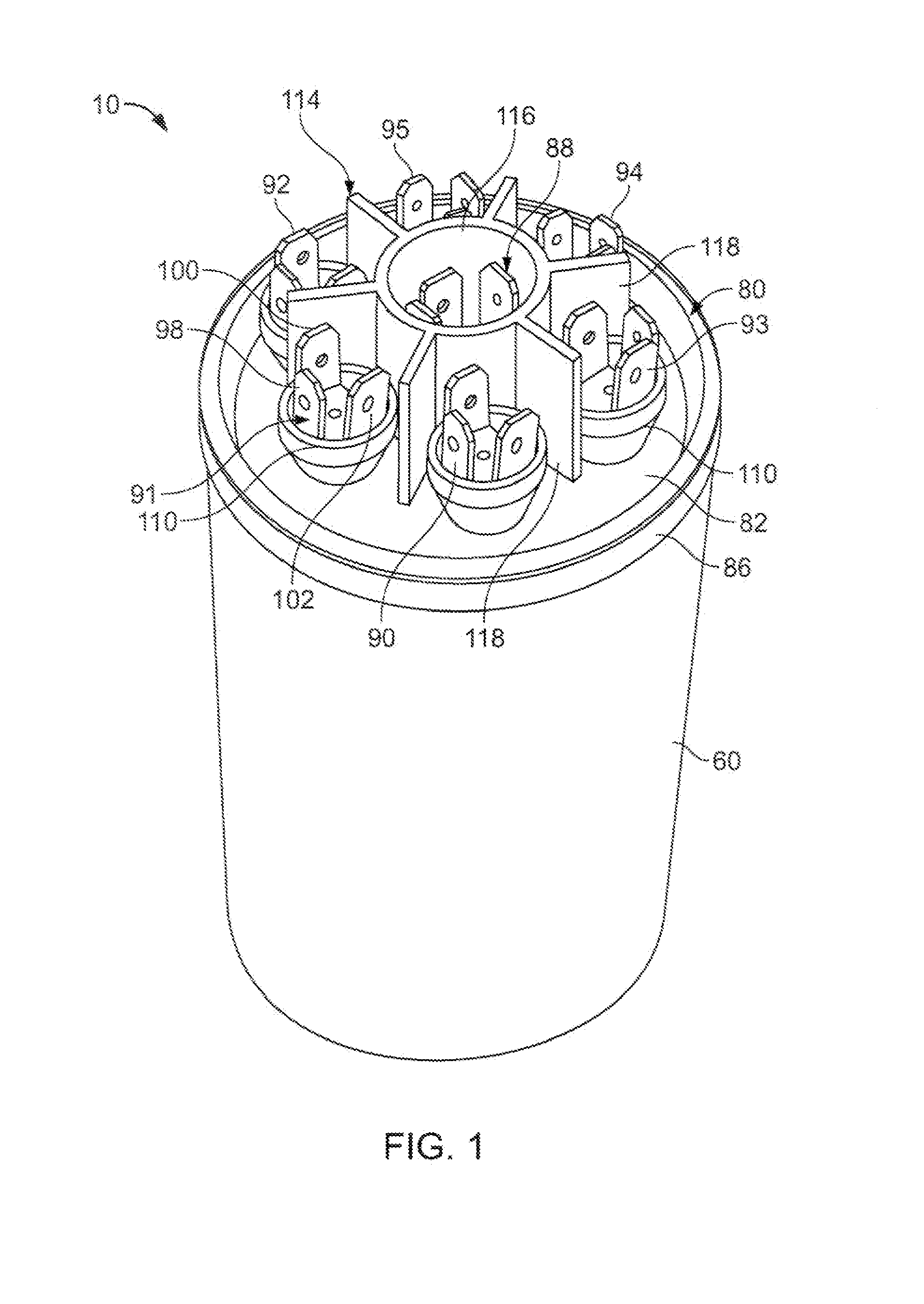

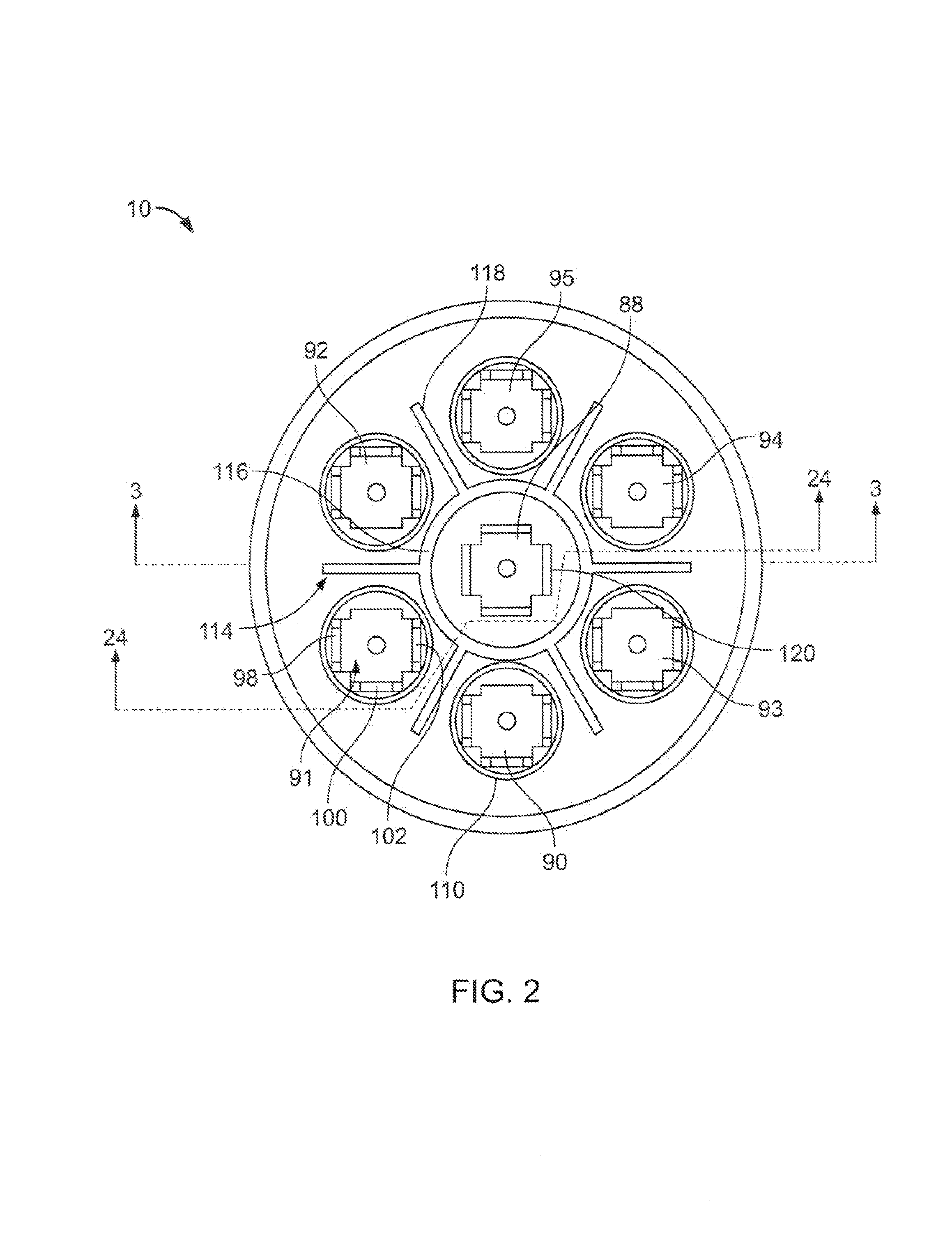

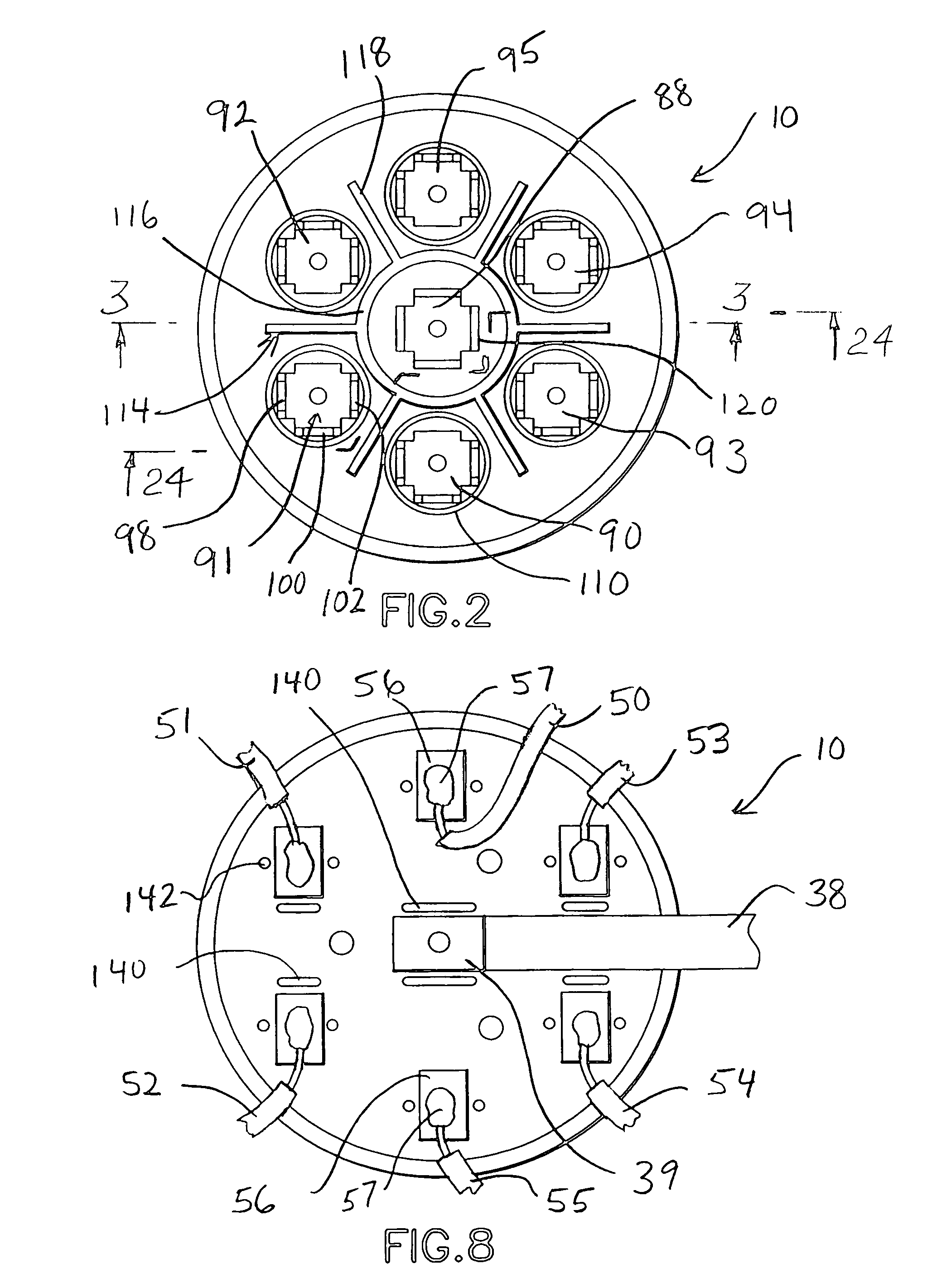

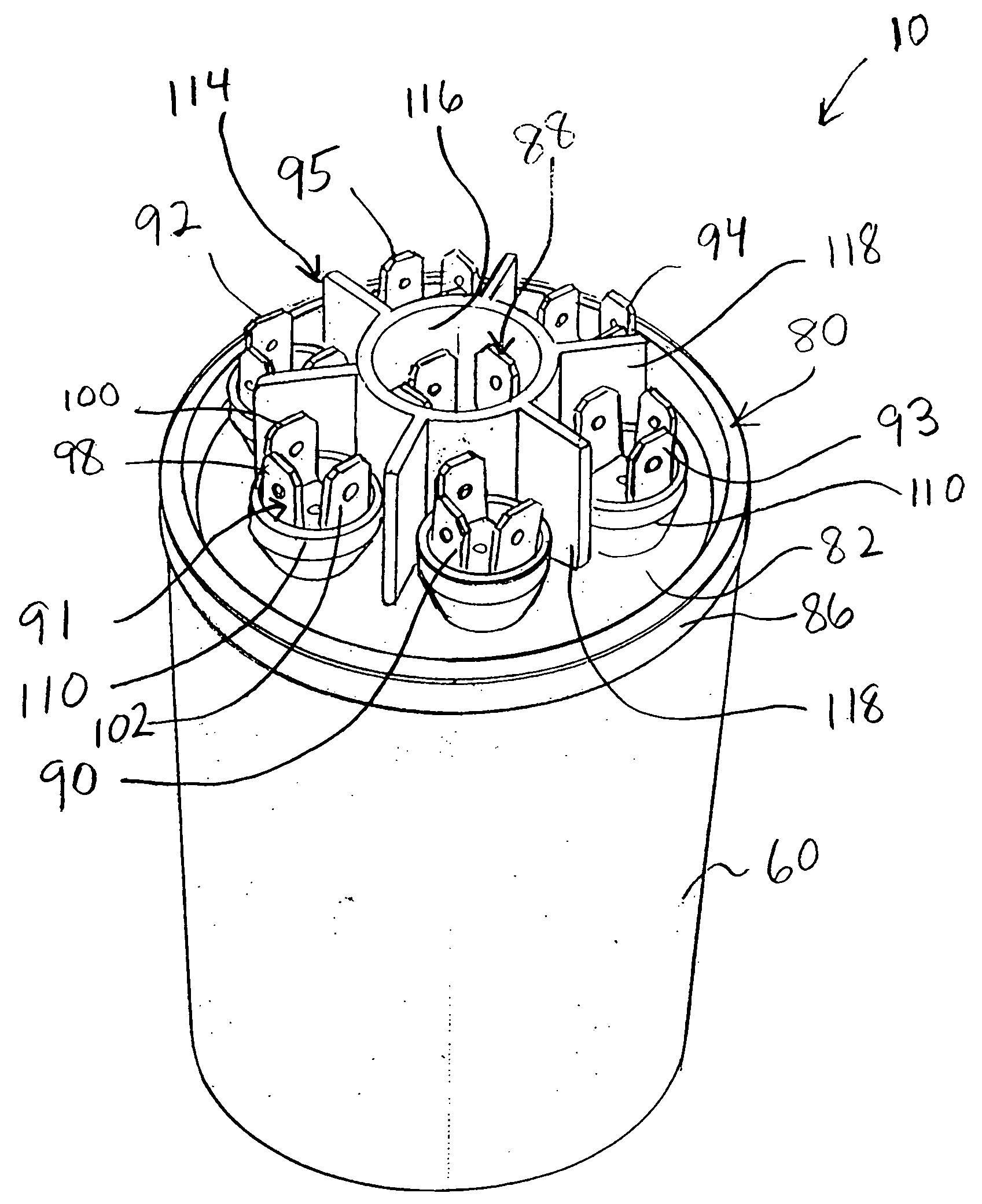

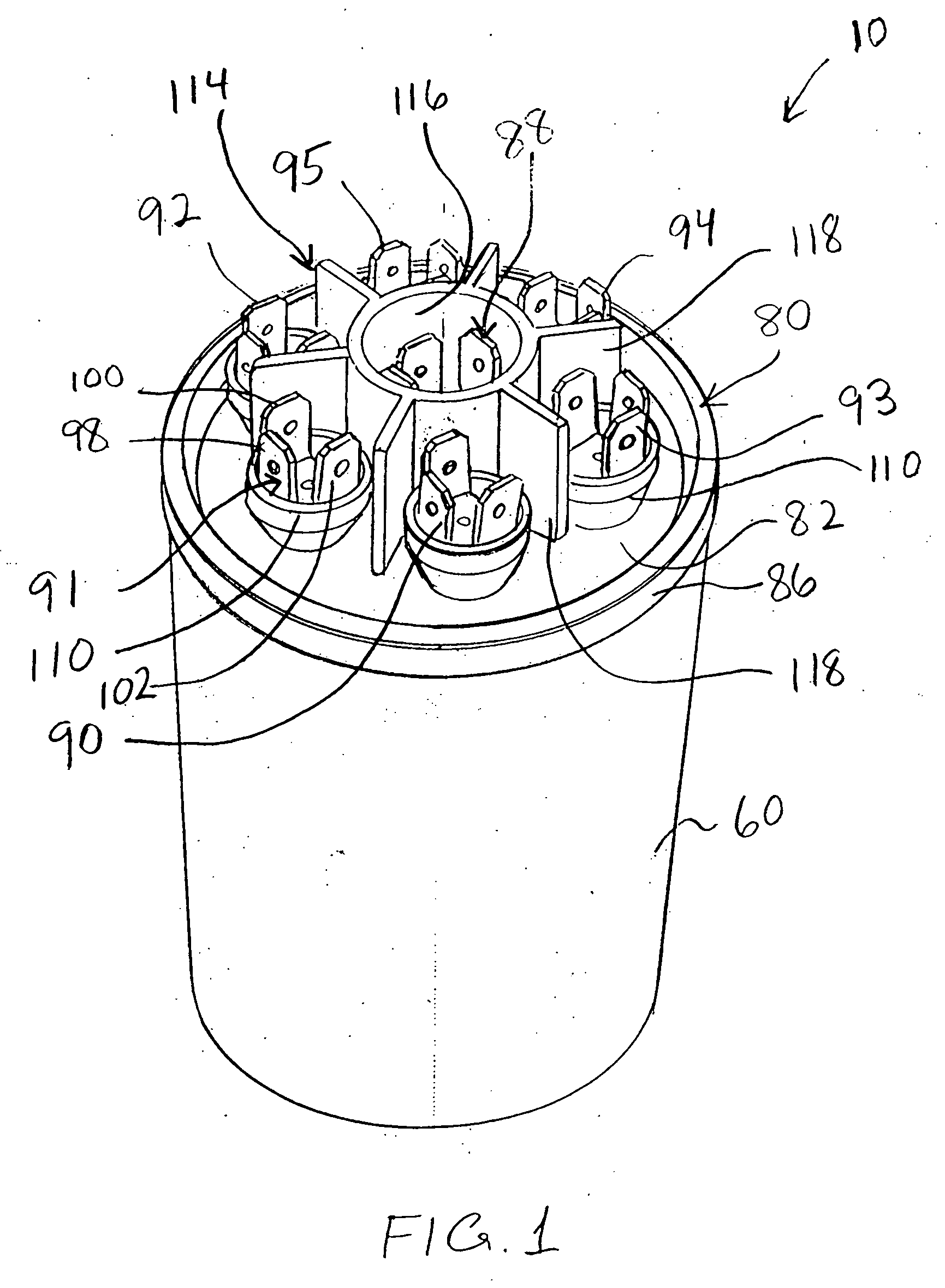

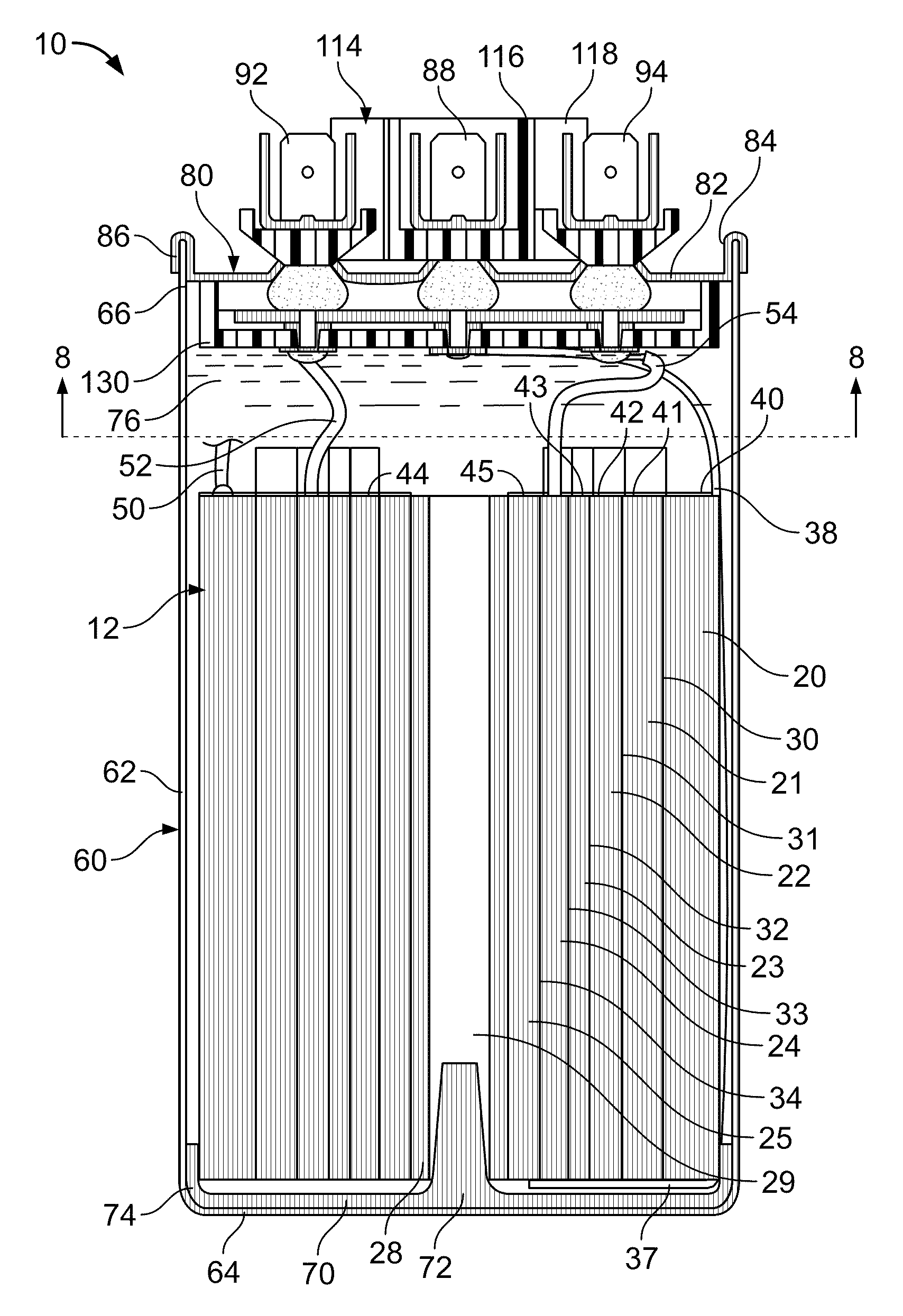

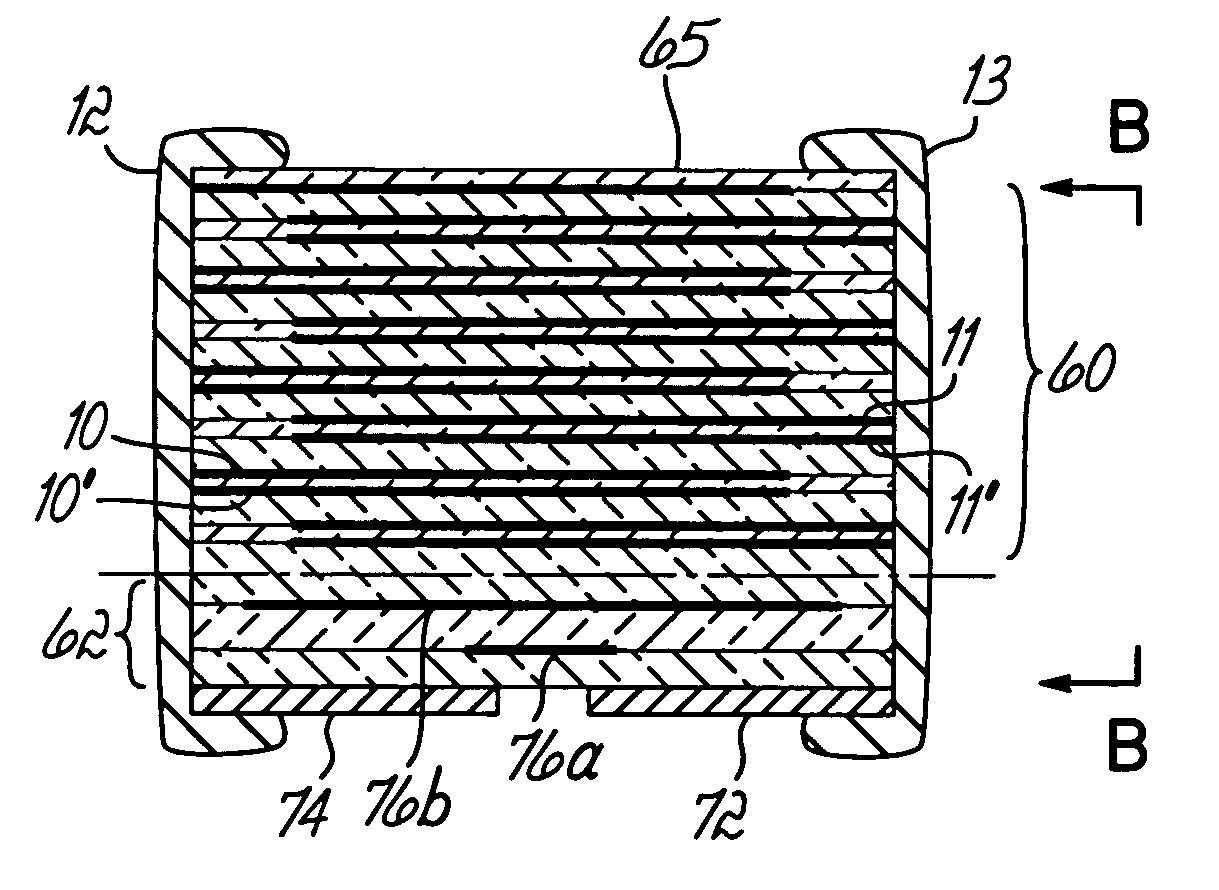

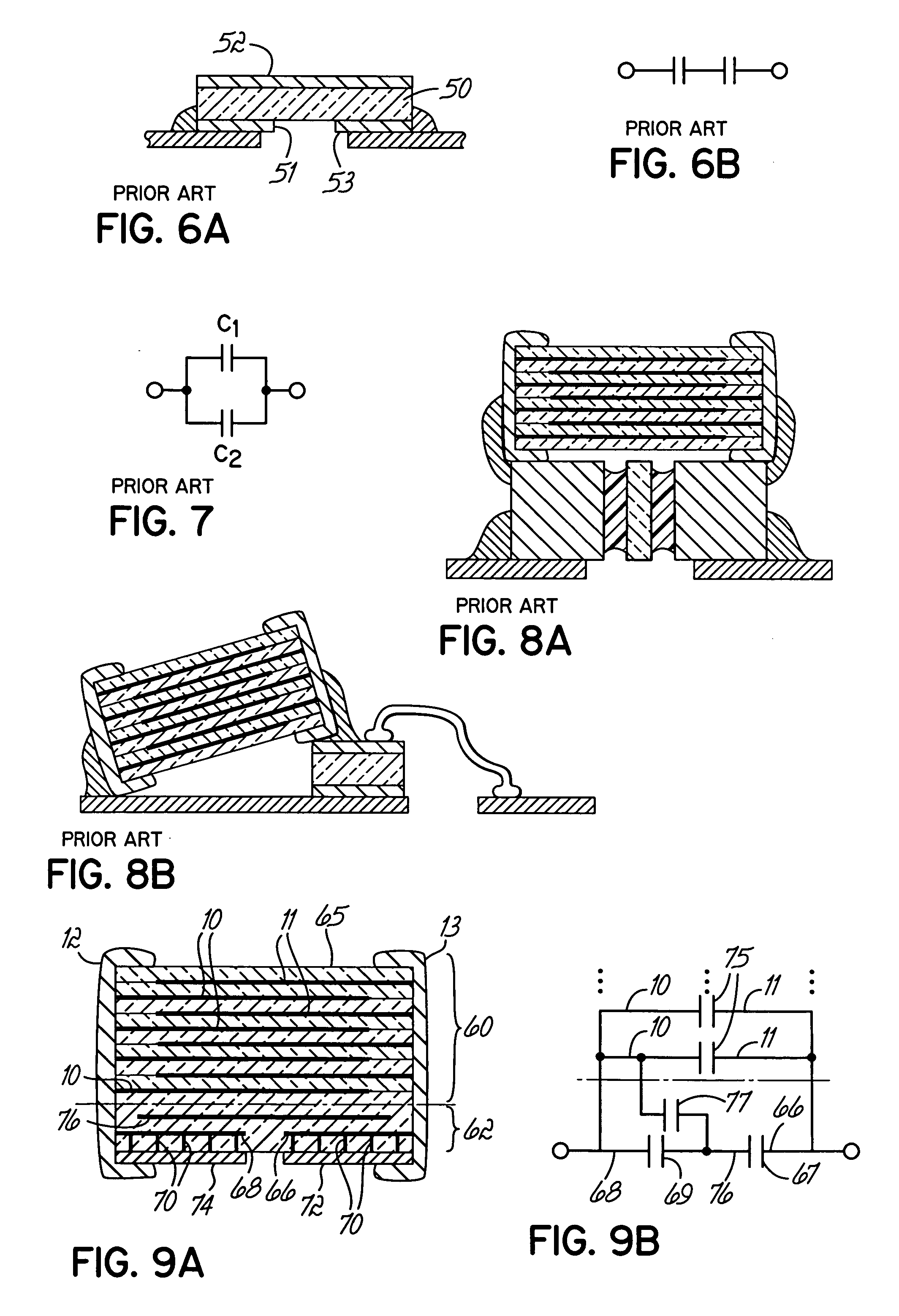

Capacitor with multiple elements for multiple replacement applications

ActiveUS7423861B2Safely making and maintainingIncrease flexibilityMultiple fixed capacitorsMechanically variable capacitor detailsCapacitanceElectrical conductor

A capacitor provides a plurality of selectable capacitance values, by selective connection of six capacitor sections of a capacitive element each having a capacitance value. The capacitor sections are provided in a plurality of wound cylindrical capacitive elements. Two vertically stacked wound cylindrical capacitance elements may each provide three capacitor sections. There may be six separately wound cylindrical capacitive elements each providing a capacitor section. The capacitor sections have a common element terminal. A pressure interrupter cover assembly is sealingly secured to the open end of case for the elements and has a deformable cover with a centrally mounted common cover terminal and a plurality of section cover terminals mounted at spaced apart locations. A conductor frangibly connects the common element terminal of the capacitor section to the common cover terminal and conductors respectively frangibly connect the capacitor section terminals to the section cover terminals. Deformation of the cover caused by failure of the capacitor element breaks at least some of the frangible connections sufficient to disconnect the capacitive element from an electric circuit in which it is connected. A cover insulation barrier mounted on the deformable cover, has a barrier cup substantially surrounding the common cover terminal and a plurality of barrier fins each extending radially outwardly from the barrier cup, and deployed between adjacent section cover terminals.

Owner:AMRAD MFG LLC

Capacitor for multiple replacement applications

ActiveUS20060227495A1Safely making and maintainingIncrease flexibilityMultiple fixed capacitorsFixed capacitor housing/encapsulationCapacitanceElectrical conductor

A capacitor provides a plurality of selectable capacitance values, by selective connection of six concentrically wound capacitor sections of a capacitive element each having a capacitance value. The capacitor sections each have a respective section element terminal at a first end of the capacitive element and the capacitor sections have a common element terminal at a second end of the capacitive element. A pressure interrupter cover assembly is sealingly secured to the open end a case for the element and has a deformable cover with a centrally mounted common cover terminal and a plurality of section cover terminals mounted at spaced apart locations. A conductor frangibly connects the common element terminal of the capacitive element to the common cover terminal and conductors respectively frangibly connect the capacitor section terminals to the section cover terminals. Deformation of the cover caused by failure of the capacitor element breaks at least some of the frangible connections sufficient to disconnect the capacitive element from an electric circuit in which it is connected. A cover insulation barrier mounted on the deformable cover, has a barrier cup substantially surrounding the common cover terminal and a plurality of barrier fins each extending radially outwardly from the barrier cup, and deployed between adjacent section cover.

Owner:AMRAD MFG LLC

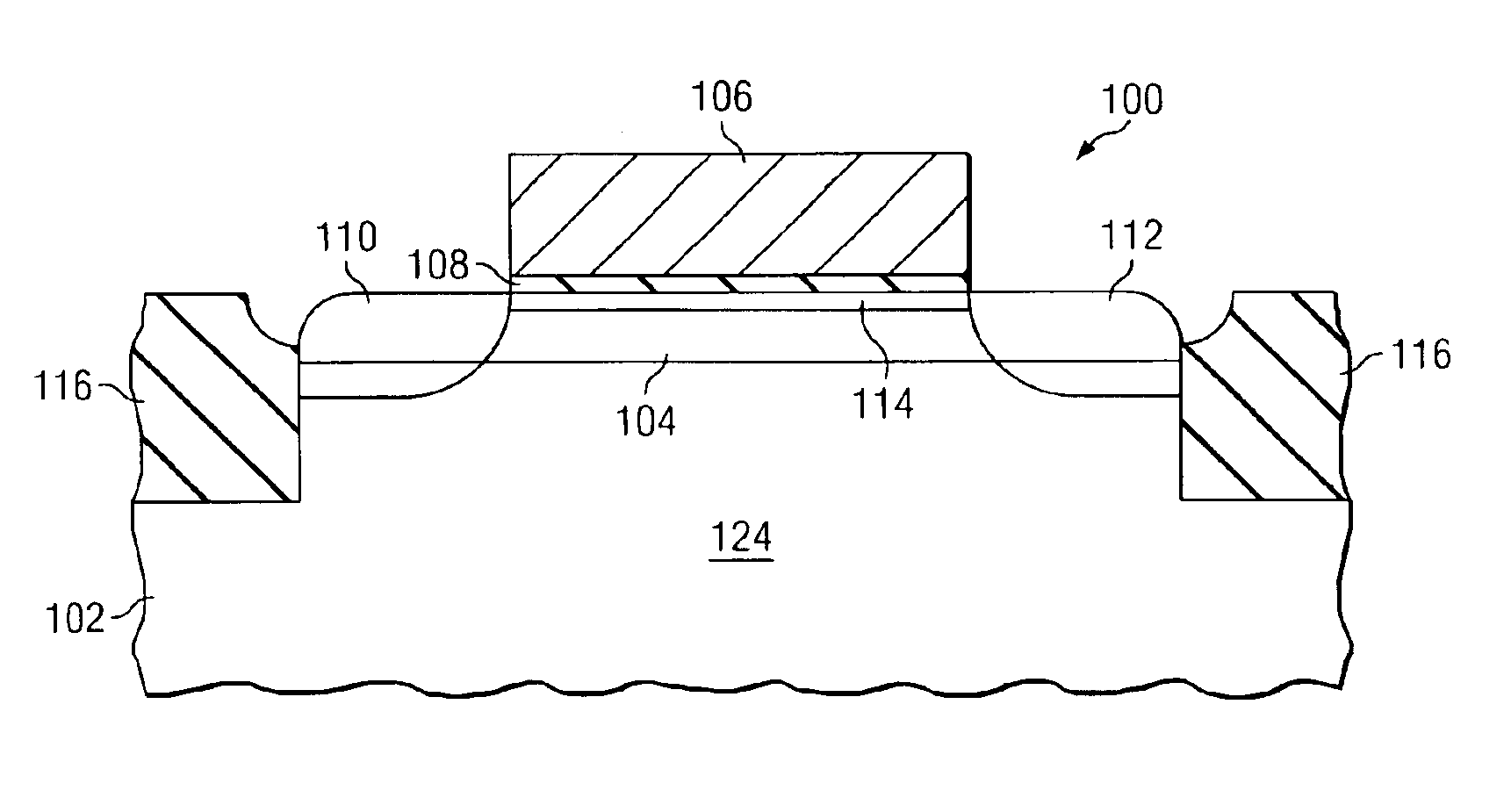

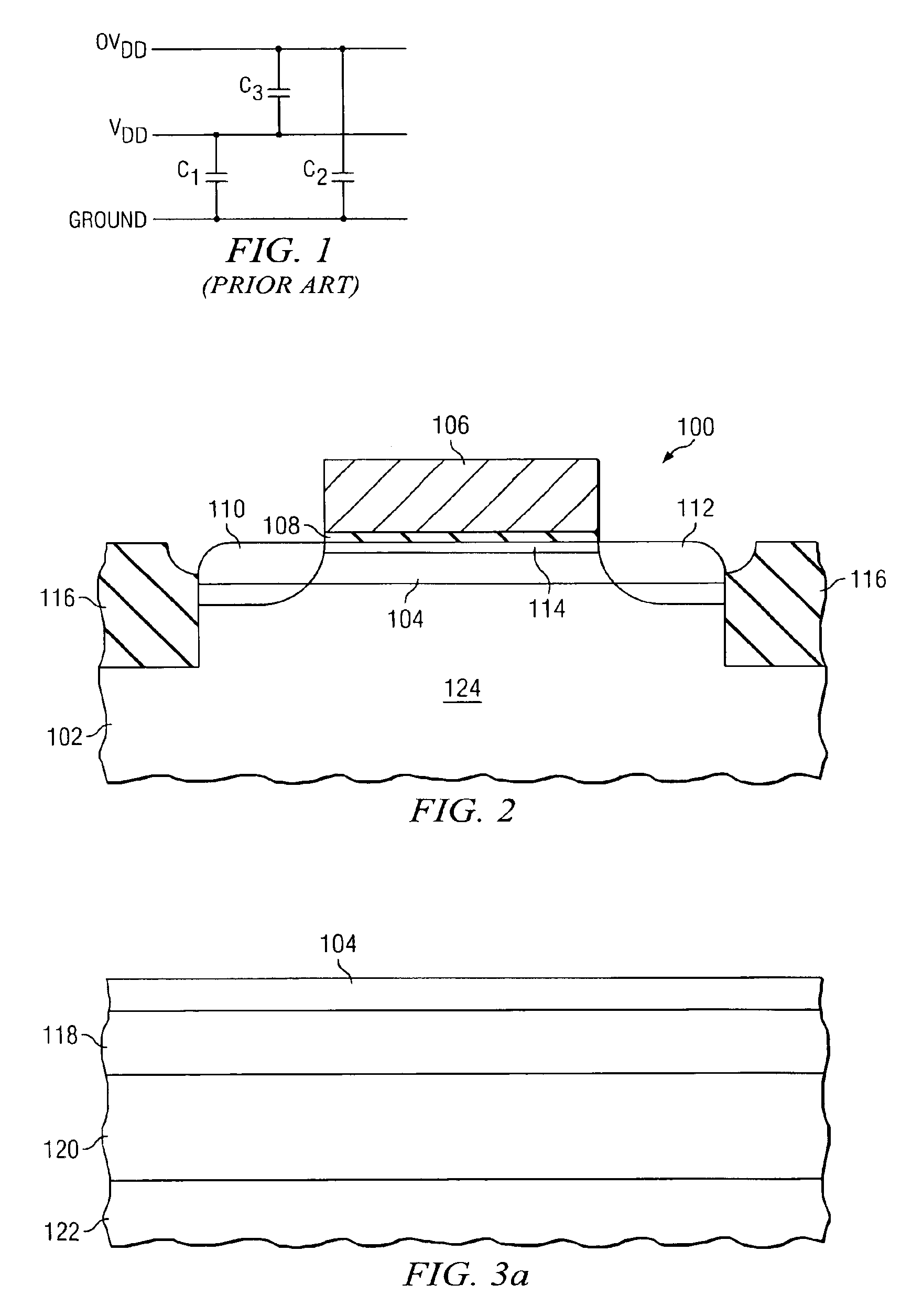

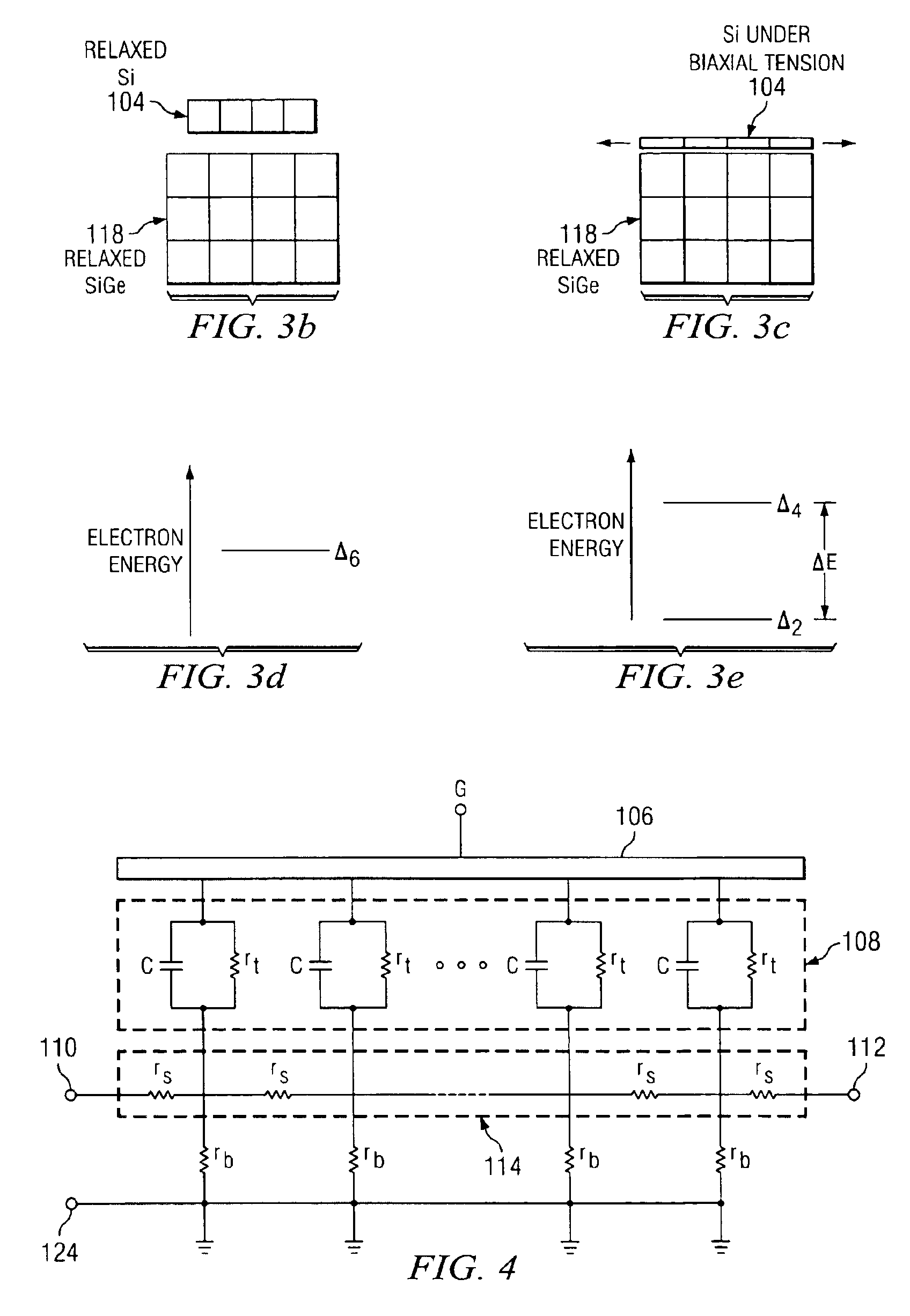

Capacitor with enhanced performance and method of manufacture

InactiveUS6940705B2Improve performanceAnti-noise capacitorsFixed capacitor electrodesDielectricEngineering

A decoupling capacitor is formed in a semiconductor substrate that includes a strained silicon layer. A substantially flat bottom electrode is formed in a portion of the strained silicon layer and a capacitor dielectric overlying the bottom electrode. A substantially flat top electrode overlies said capacitor dielectric. The top electrode is connected to a first reference voltage line and the bottom electrode is connected to a second reference voltage line.

Owner:TAIWAN SEMICON MFG CO LTD

Capacitor with multiple elements for multiple replacement applications

ActiveUS20090219665A1Safely making and maintainingIncrease flexibilityMultiple fixed capacitorsMechanically variable capacitor detailsCapacitanceElectrical conductor

Owner:AMRAD MFG LLC

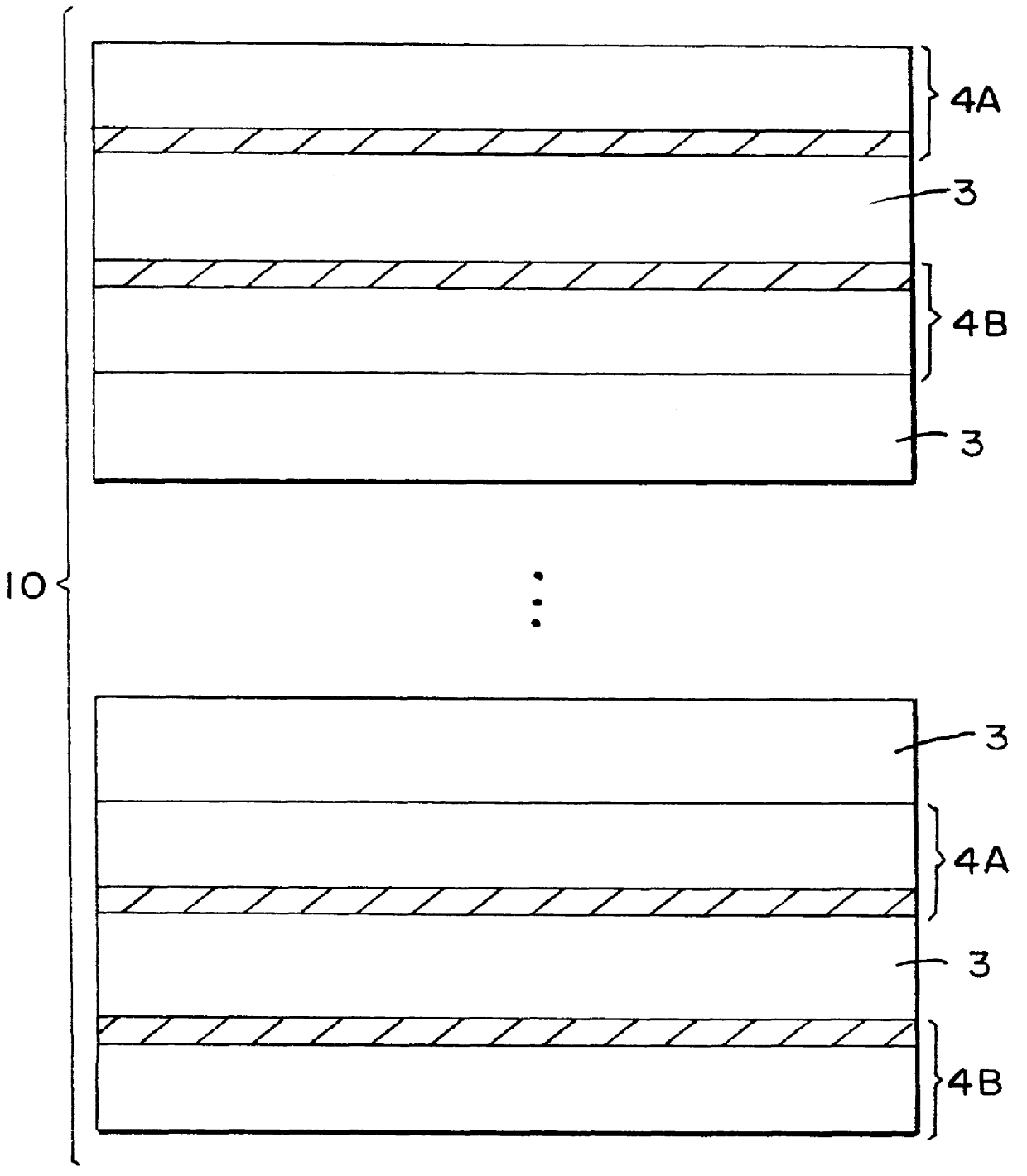

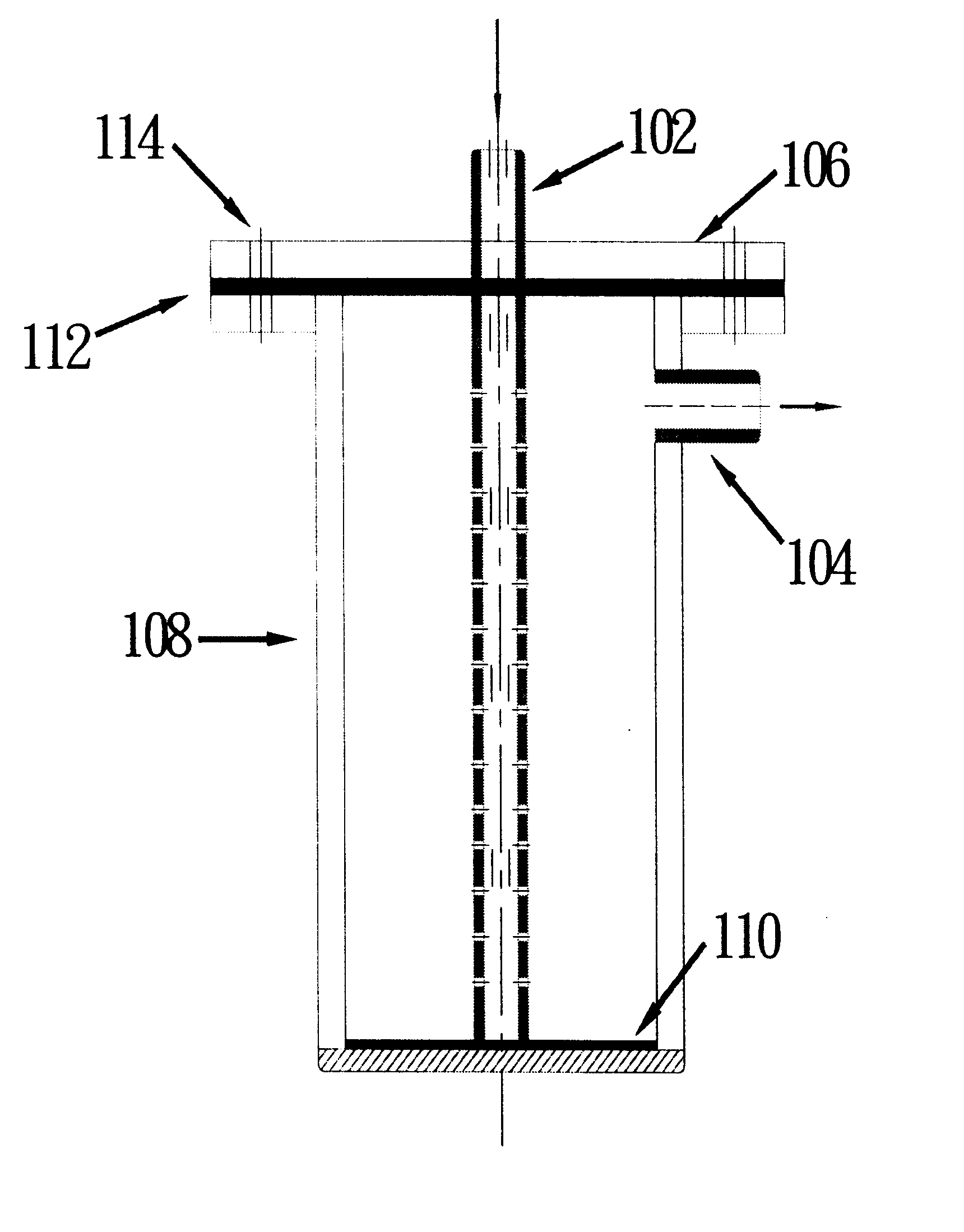

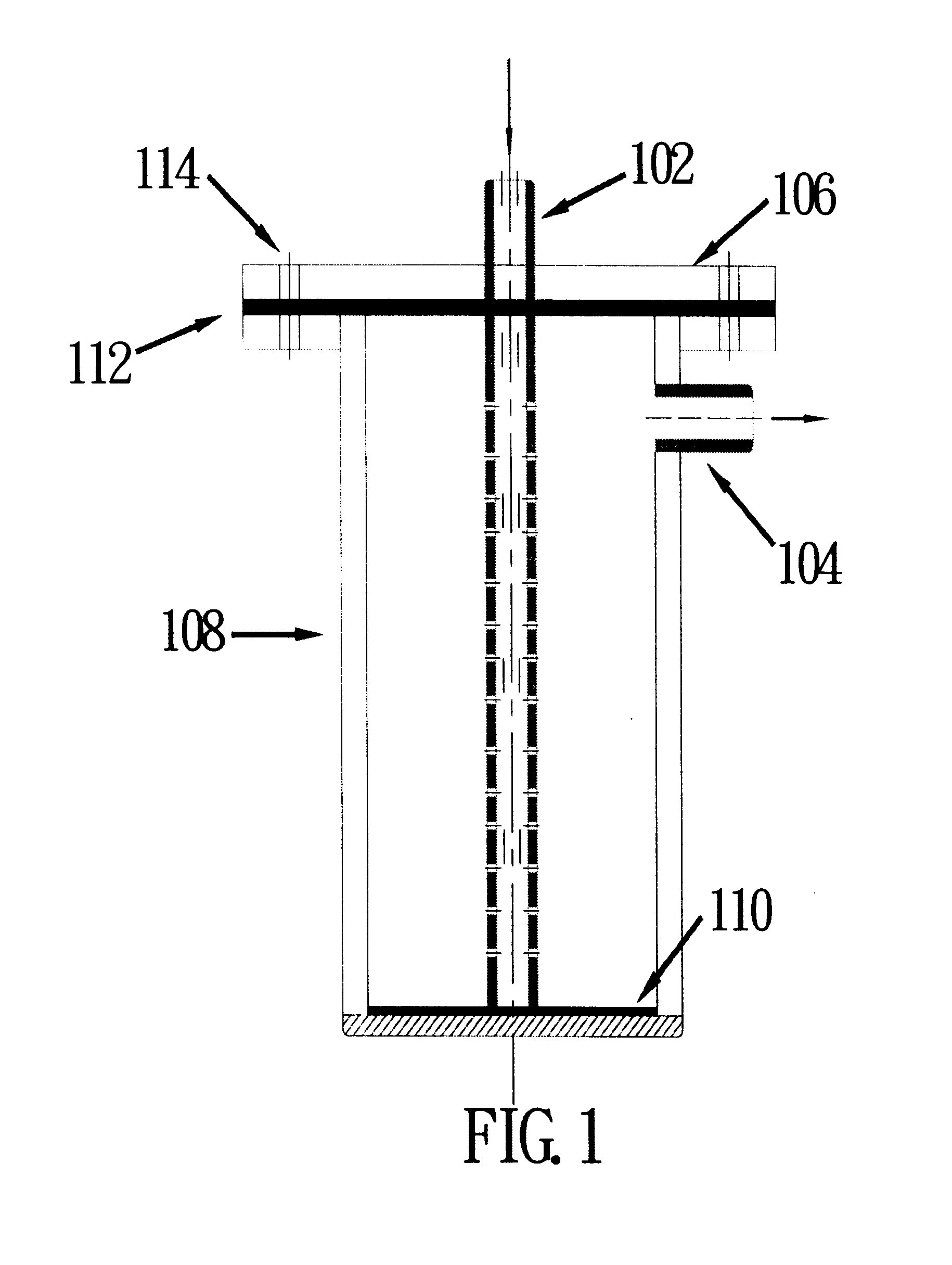

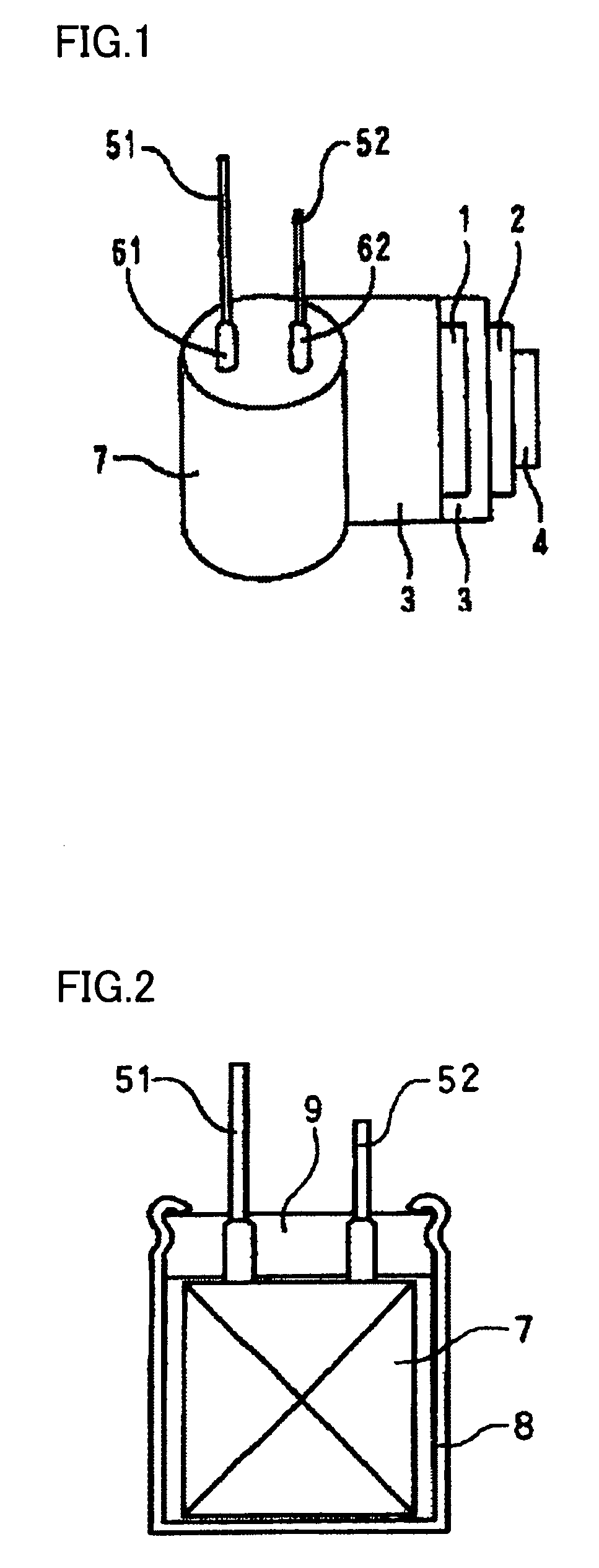

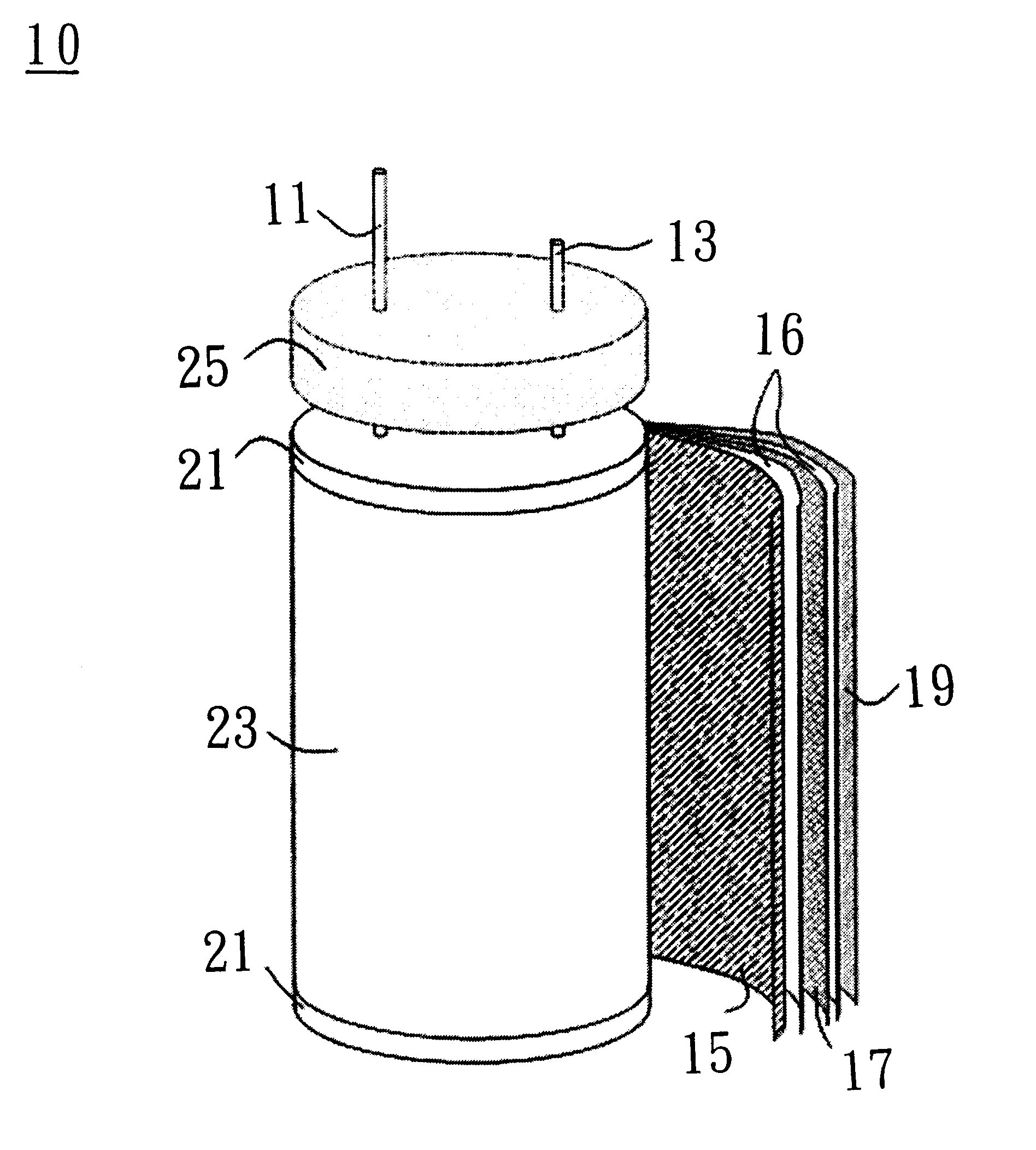

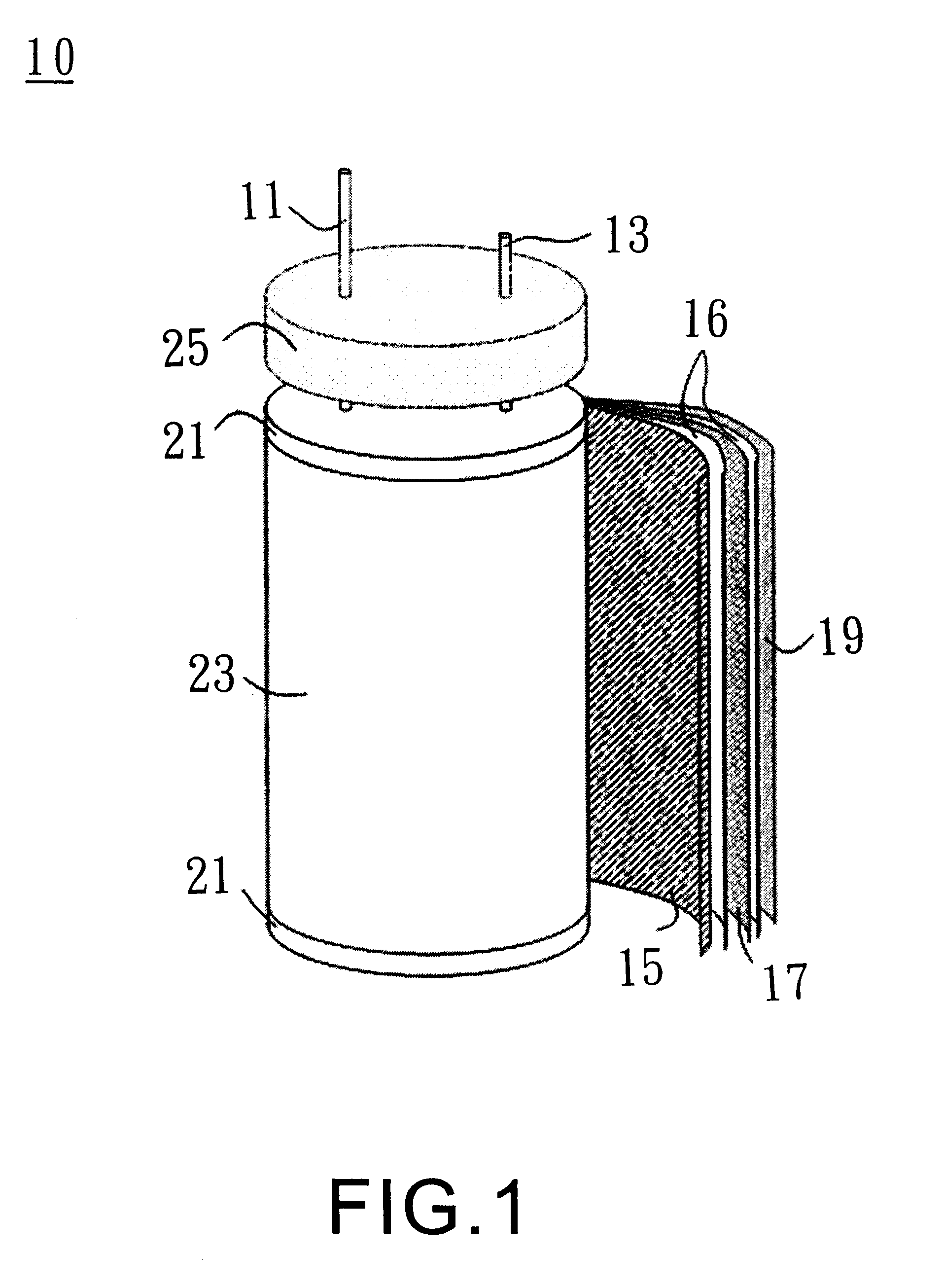

Cylindrical high voltage supercapacitor having two separators

InactiveUS6510043B1Simple processReduce in quantityHybrid capacitor electrolytesHybrid capacitor electrodesSupercapacitorEngineering

A method of manufacturing a cylindrical high voltage supercapacitor. An anode and a cathode are provided. At least one bipolar electrode is interposed between the anode and the cathode, and a separator is intervened in each pair of the above electrodes. The anode, the cathode, the bipolar electrode and the separator, as placed in the above order, are wound concentrically into a roll, so as to form the cylindrical high voltage supercapacitor.

Owner:LUXON ENERGY DEVICES CORP

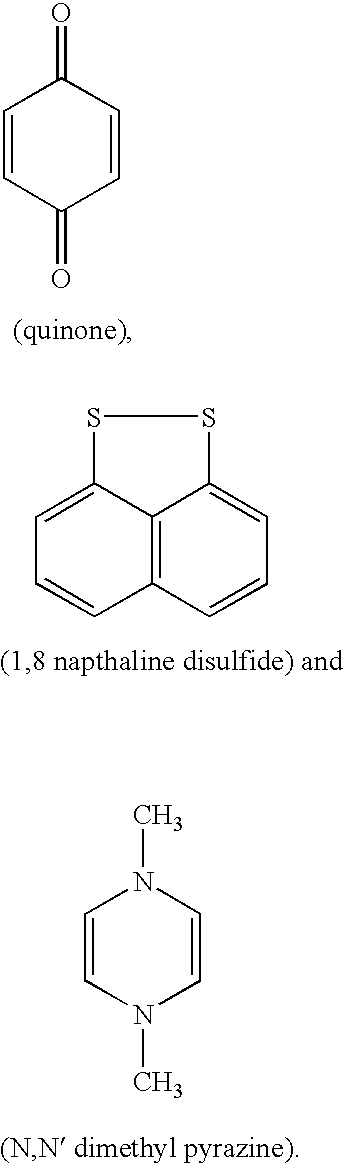

Electrochemical capacitors having electrodes with diverse redox potentials

InactiveUS6414836B1Improve performanceMaterial nanotechnologyLiquid electrolytic capacitorsFiberFibril

Graphitic nanofibers, which include tubular fullerenes (commonly called "buckytubes"), nanotubes and fibrils, which are functionalized by chemical substitution, are used as electrodes in electrochemical capacitors. The graphitic nanofiber based electrode increases the performance of the electrochemical capacitors.

Owner:HYPERION CATALYSIS INT

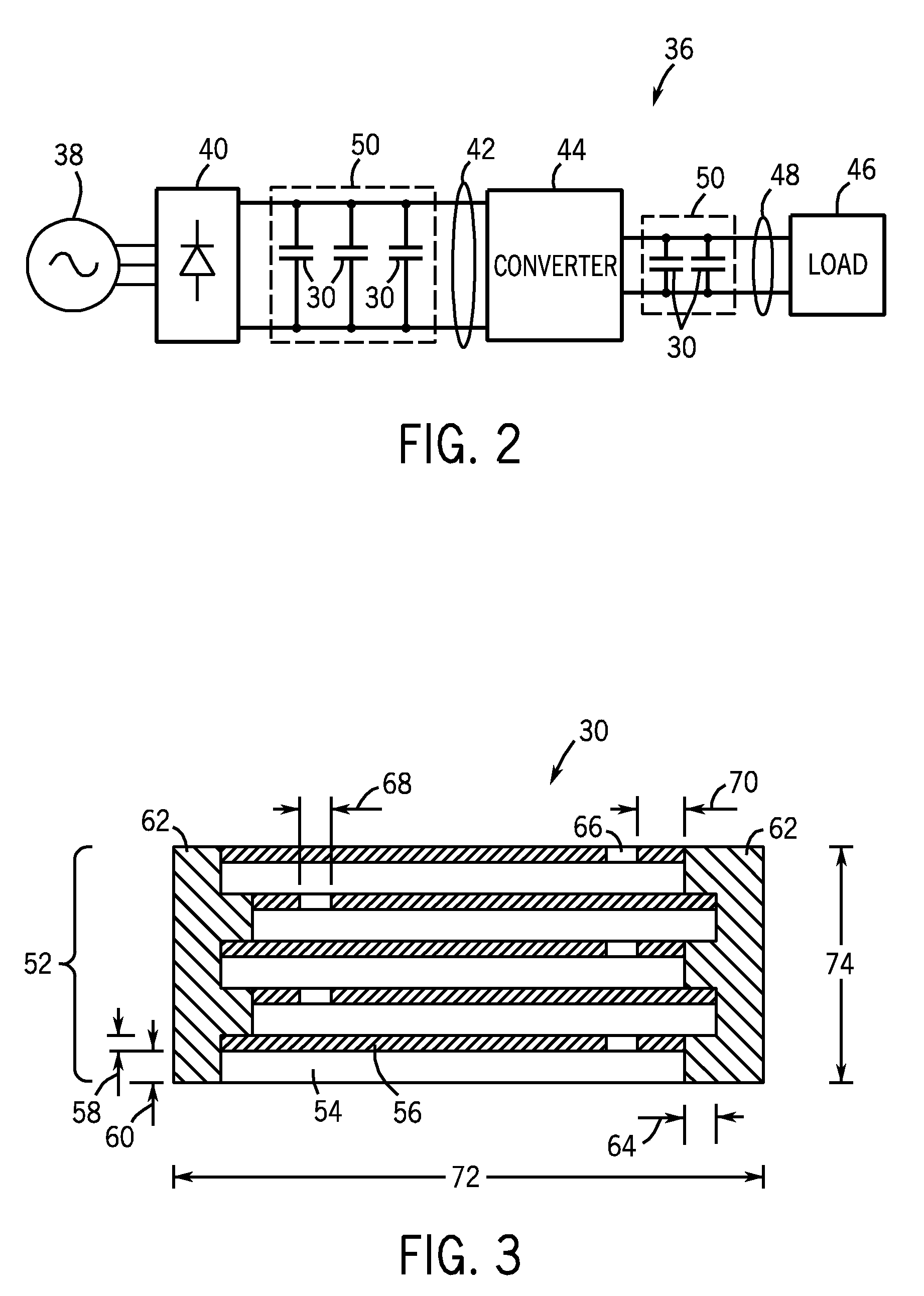

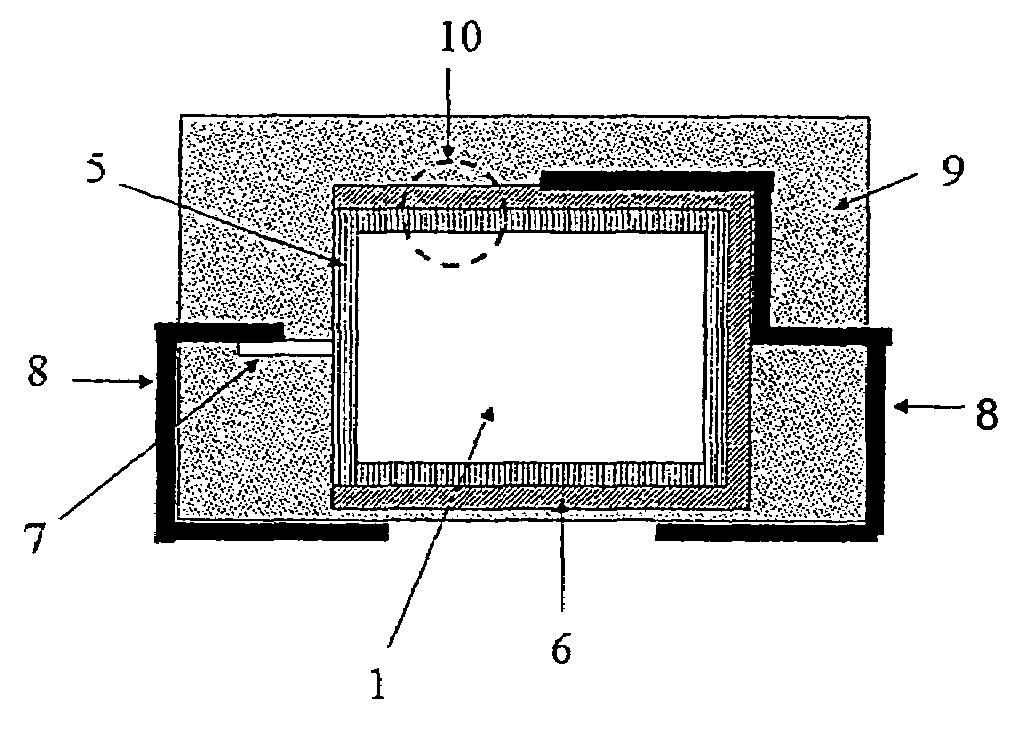

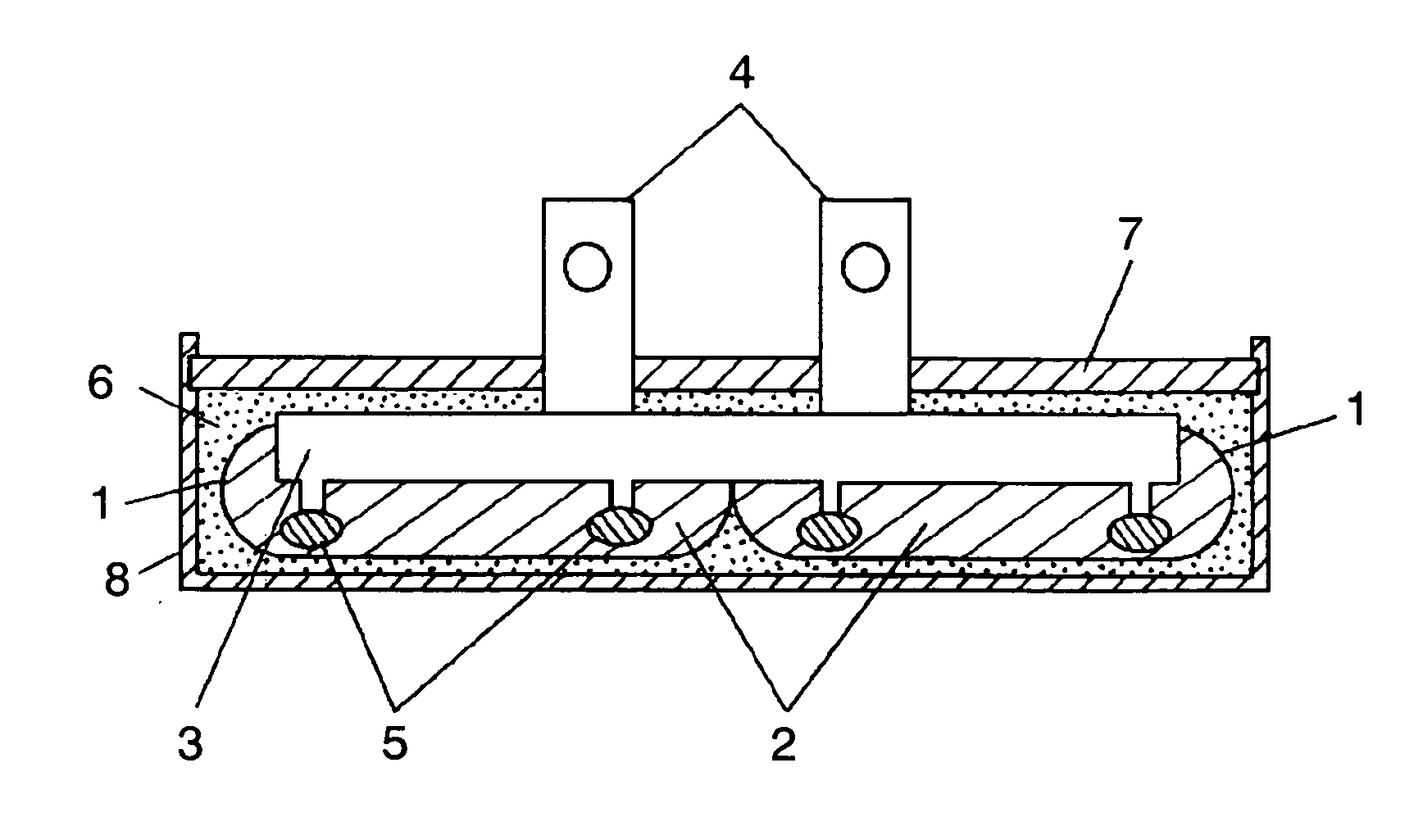

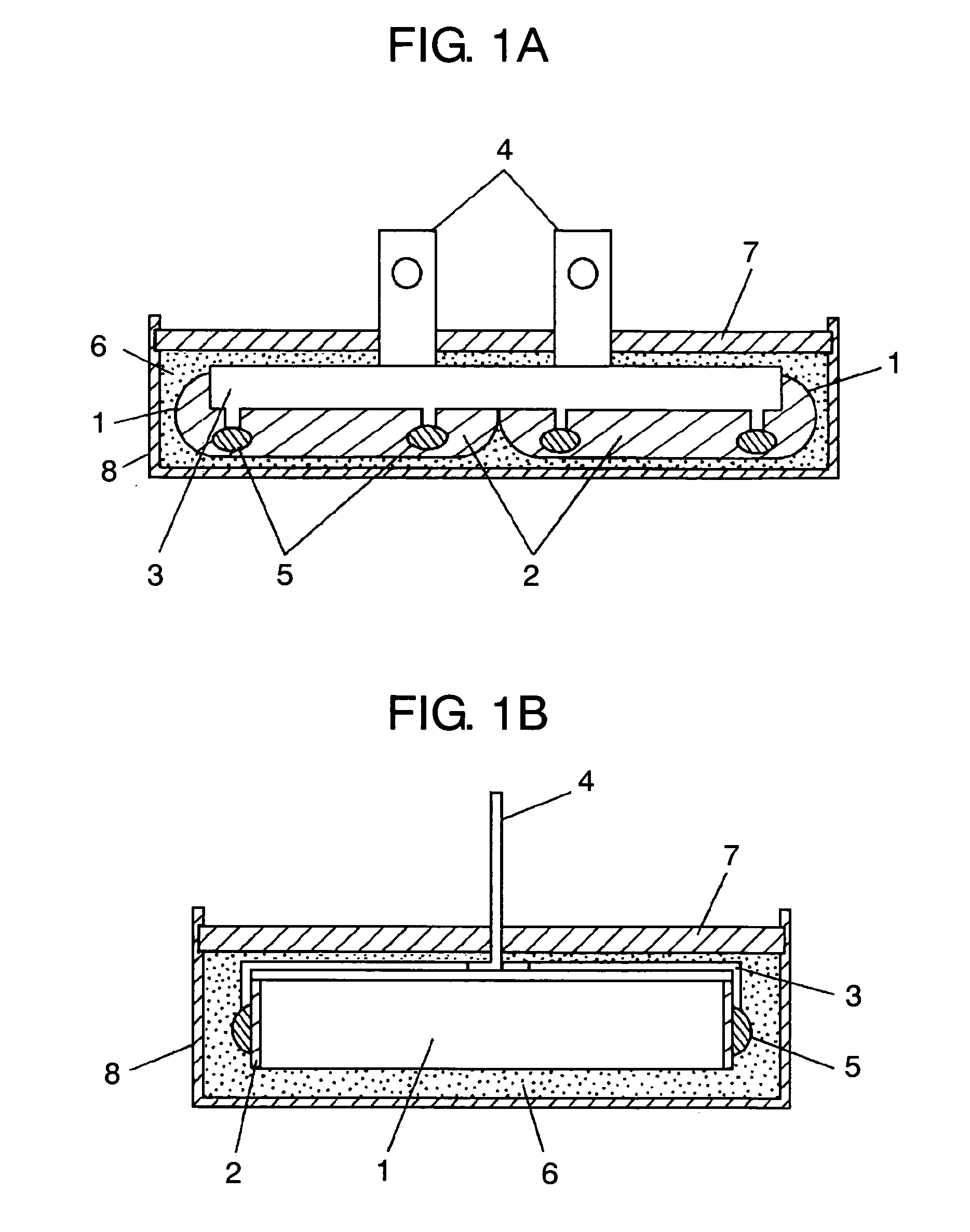

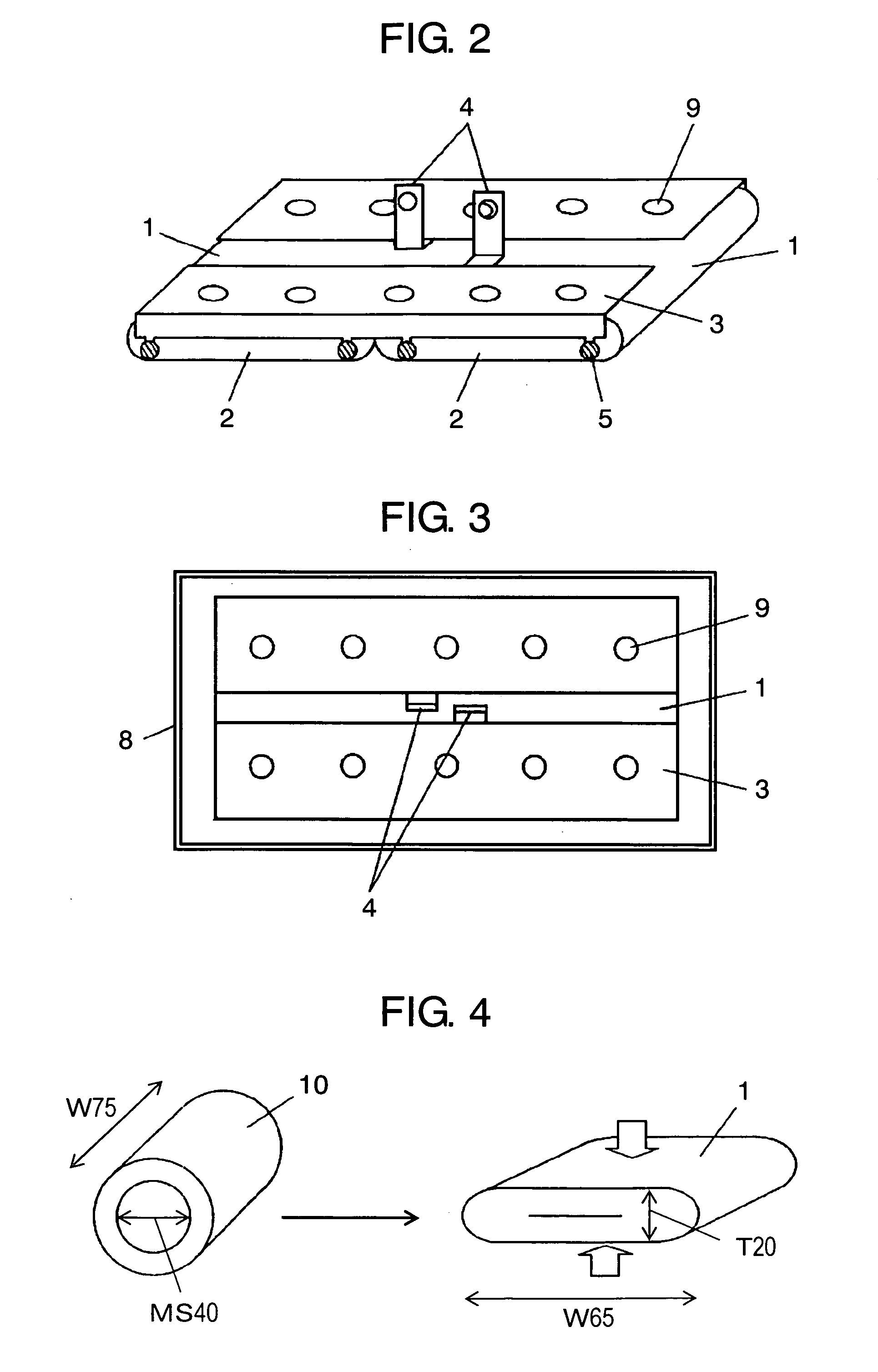

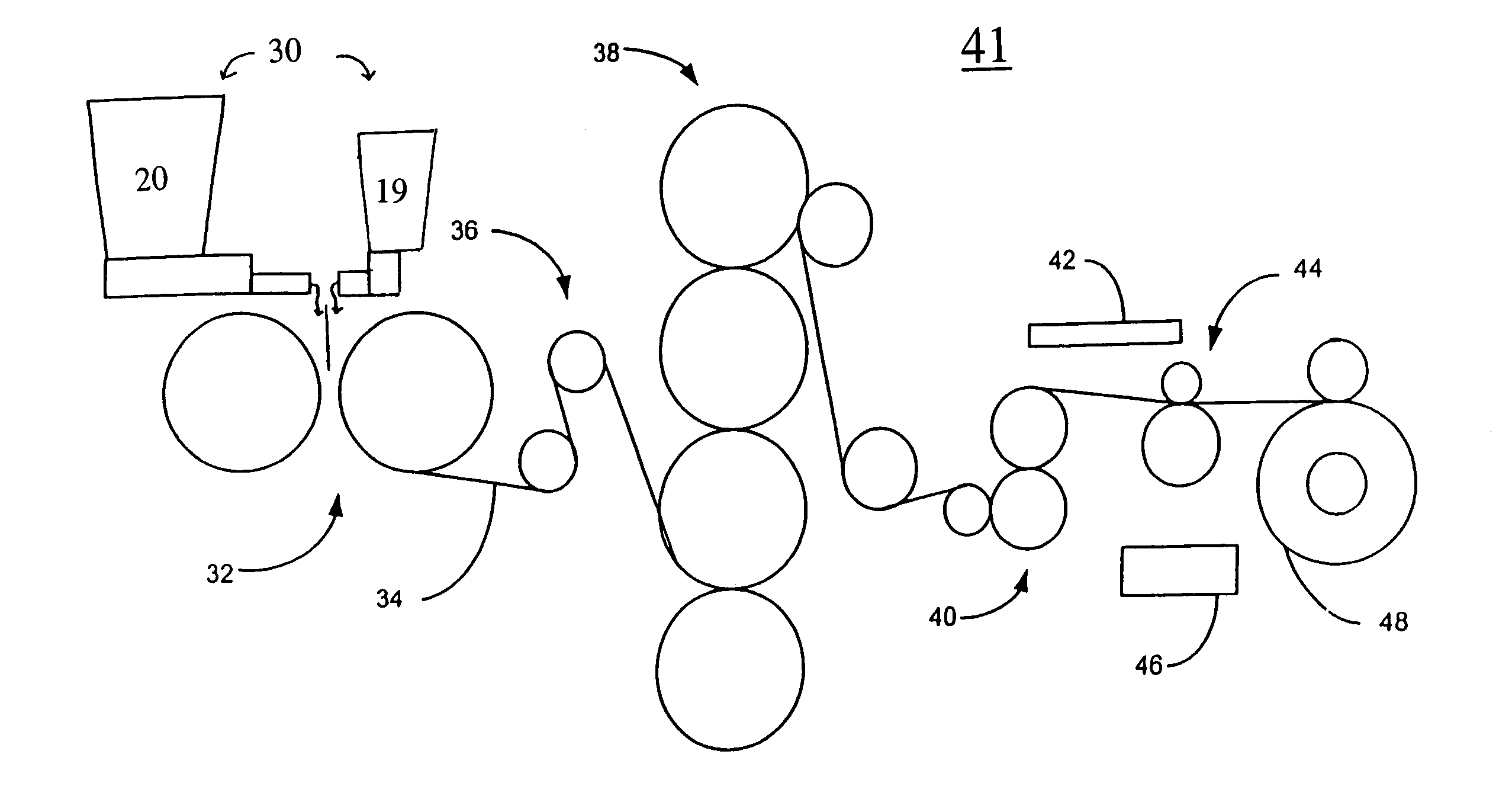

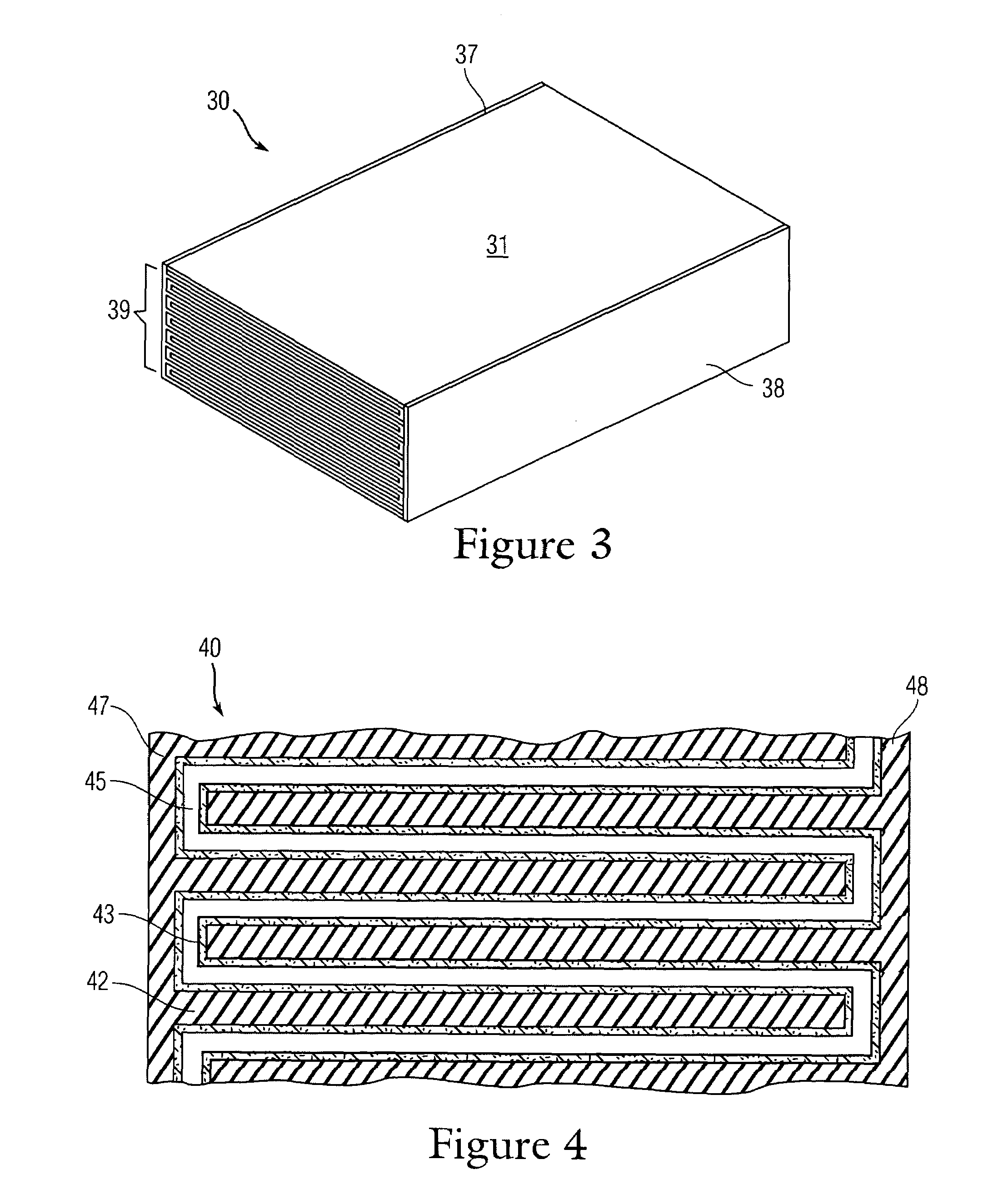

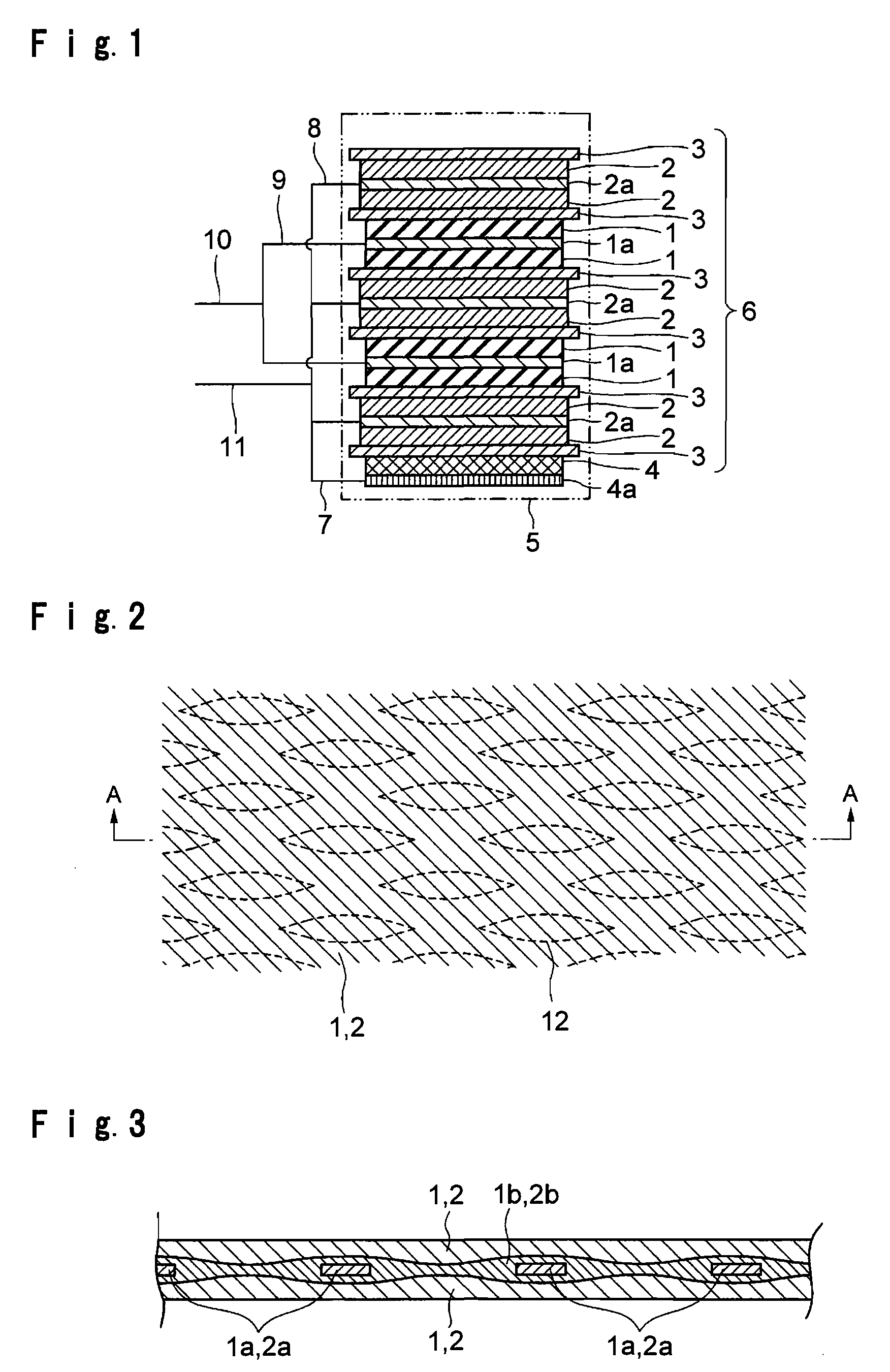

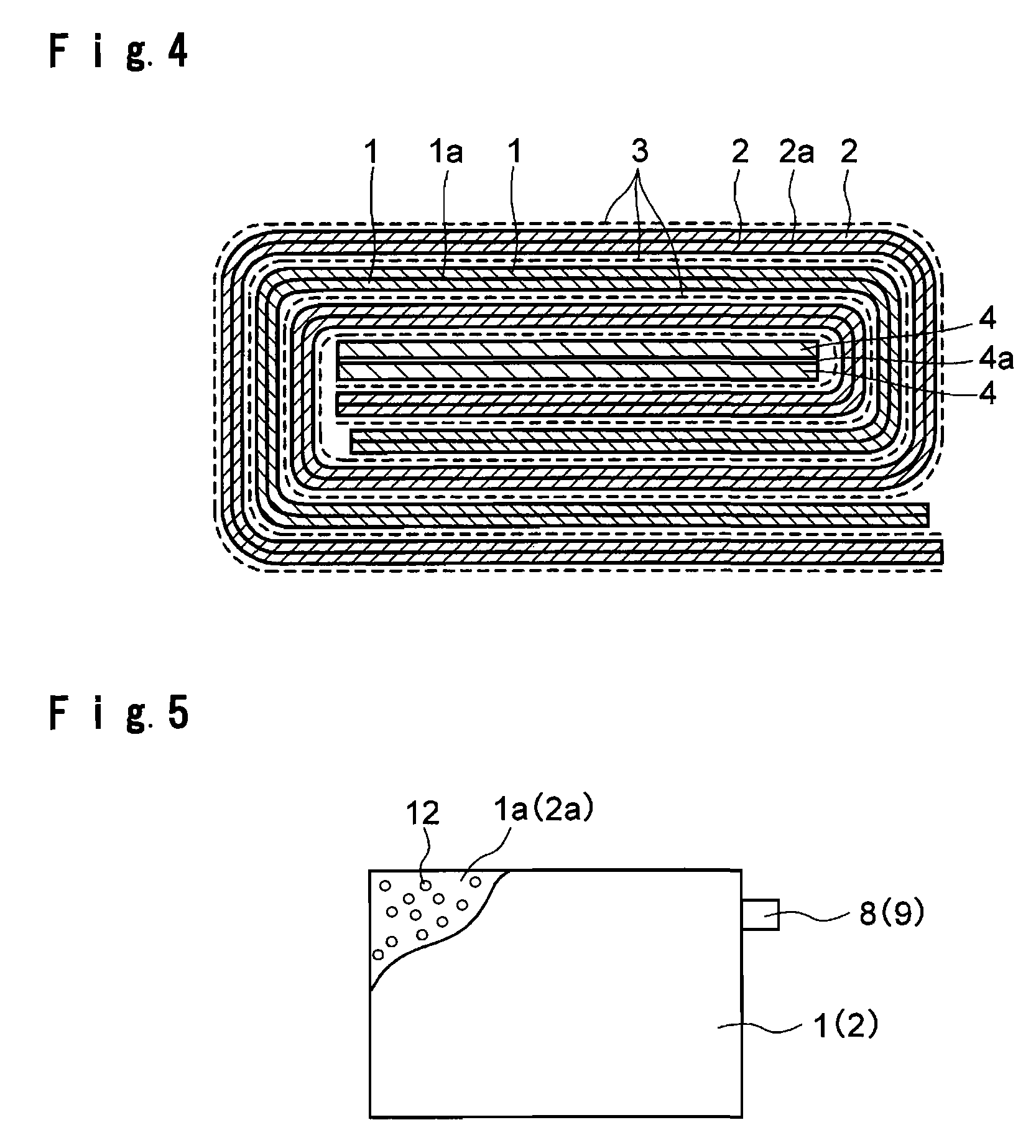

Film capacitor and method of manufacturing the same

ActiveUS20060104006A1Improve moisture resistanceLow exothermic characteristicMultiple fixed capacitorsFixed capacitor dielectricEpoxyProduction rate

The invention provides a film capacitor and its manufacturing method suited to car-mount application, excellent in heat cycle tolerance and humidity resistance, and high in productivity, while maintaining low heat generation and low inductance characteristic. A film capacitor comprises a film capacitor element 1, a bus bar 3 as metal terminal connected to electrode 2 of this film capacitor element 1, and a case 8 for containing them, in which the film capacitor element 1 and bus bar 3 are packed within the case 8 by plural layers of epoxy resin compositions 6, 7, and the plural layers of epoxy resin compositions 6, 7 are formed in layers, and are composed so that the coefficient of linear expansion may be smallest in the epoxy resin composition 7 disposed in the uppermost layer, and therefore resin cracks can be prevented at the time of heat cycle, and a film capacitor of high reliability excellent inhumidity resistance is obtained.

Owner:PANASONIC CORP

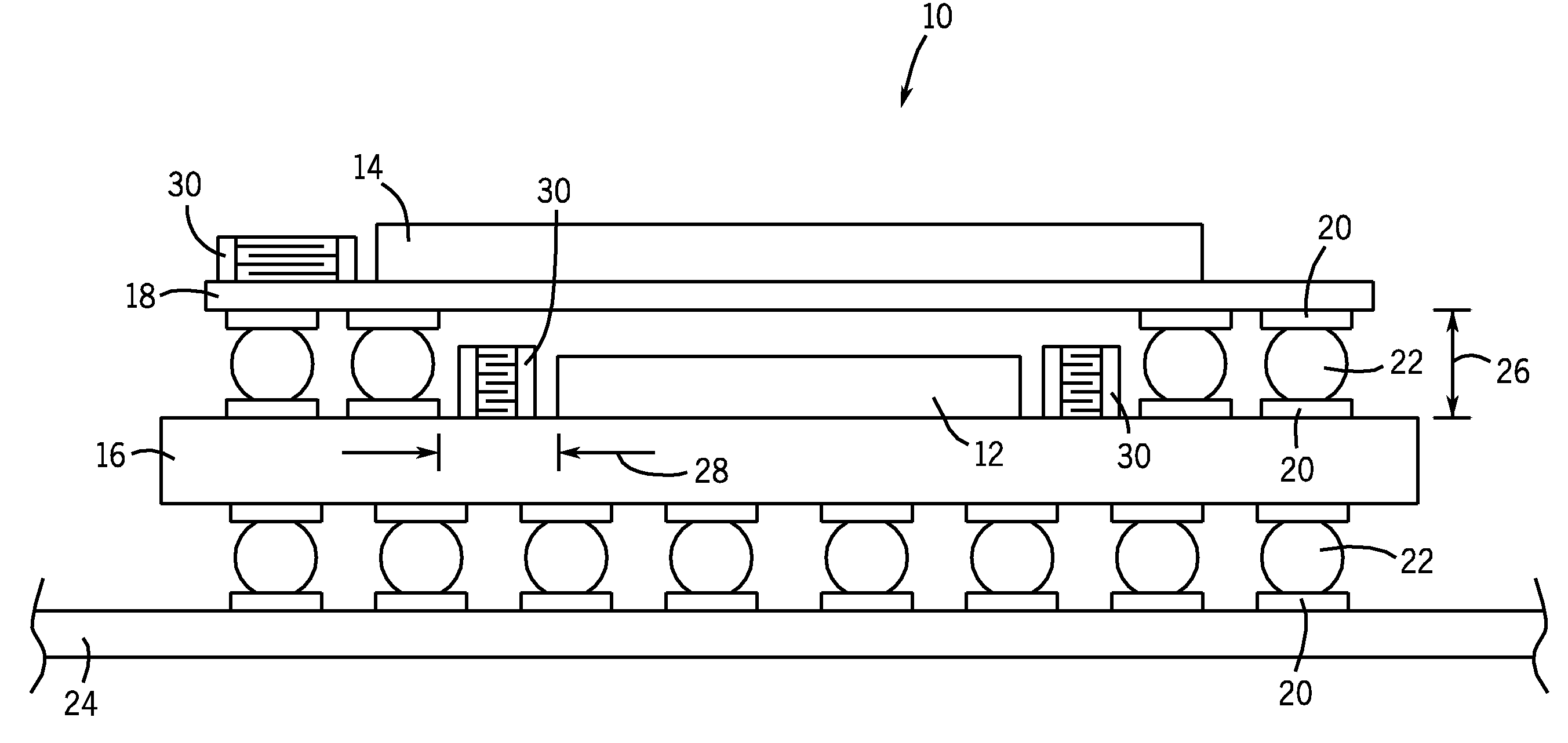

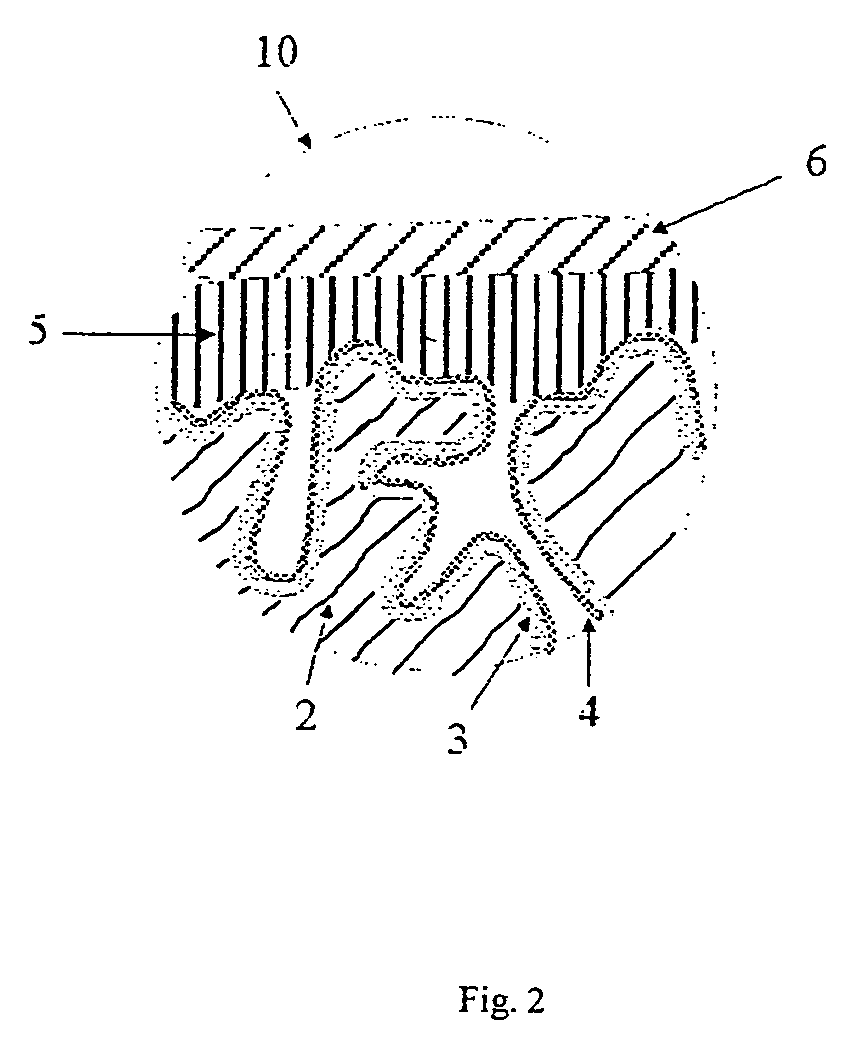

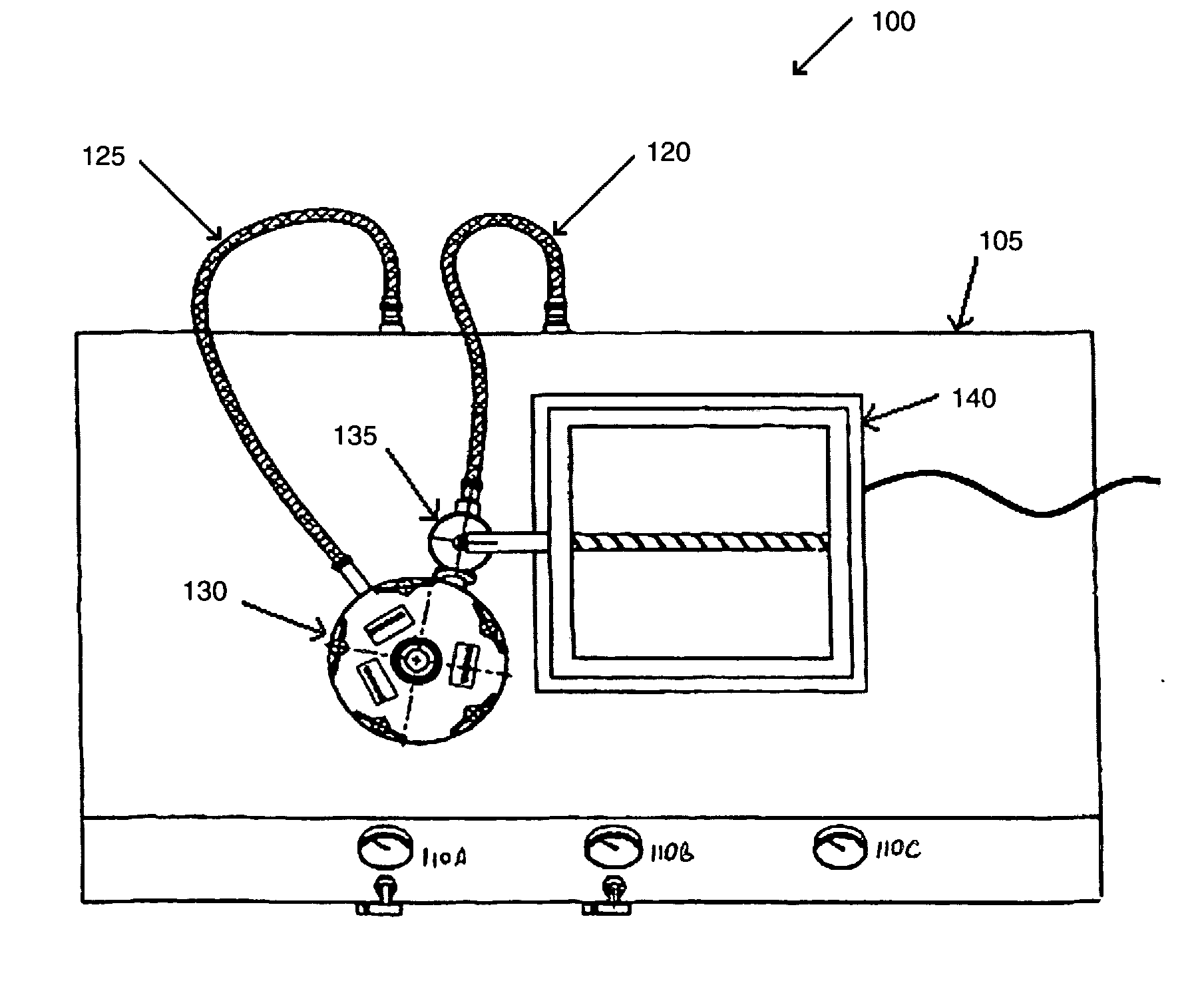

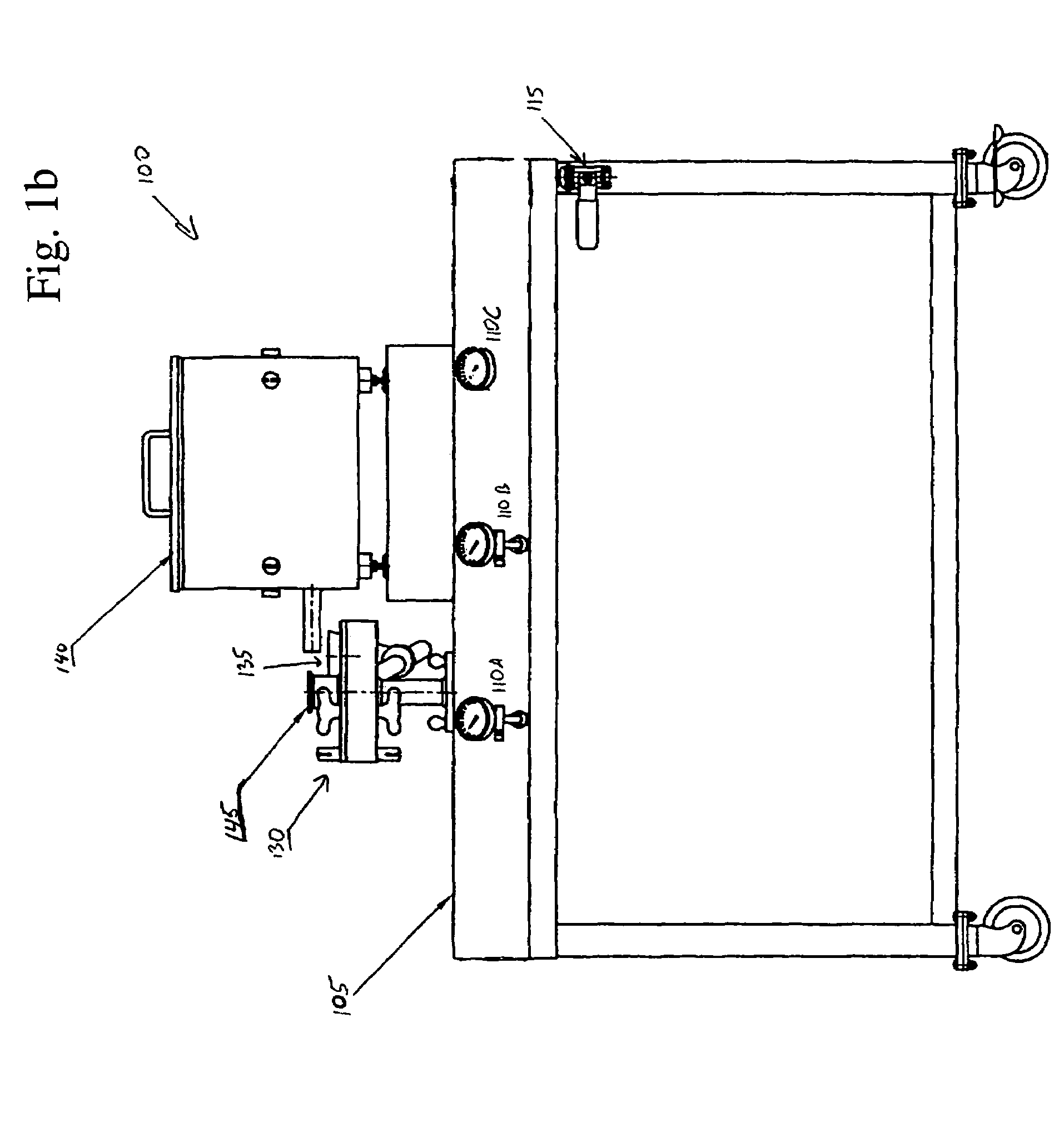

Dry particle based capacitor and methods of making same

ActiveUS7352558B2High yieldInexpensive and durable and highly reliableHybrid capacitor electrodesWound capacitorsFiberDry mixing

An inexpensive and reliable dry process based capacitor and method for making a self-supporting dry electrode film for use therein is disclosed. Also disclosed is an exemplary process for manufacturing an electrode for use in an energy storage device product, the process comprising: supplying dry carbon particles; supplying dry binder; dry mixing the dry carbon particles and dry binder; and dry fibrillizing the dry binder to create a matrix within which to support the dry carbon particles as dry material.

Owner:TESLA INC

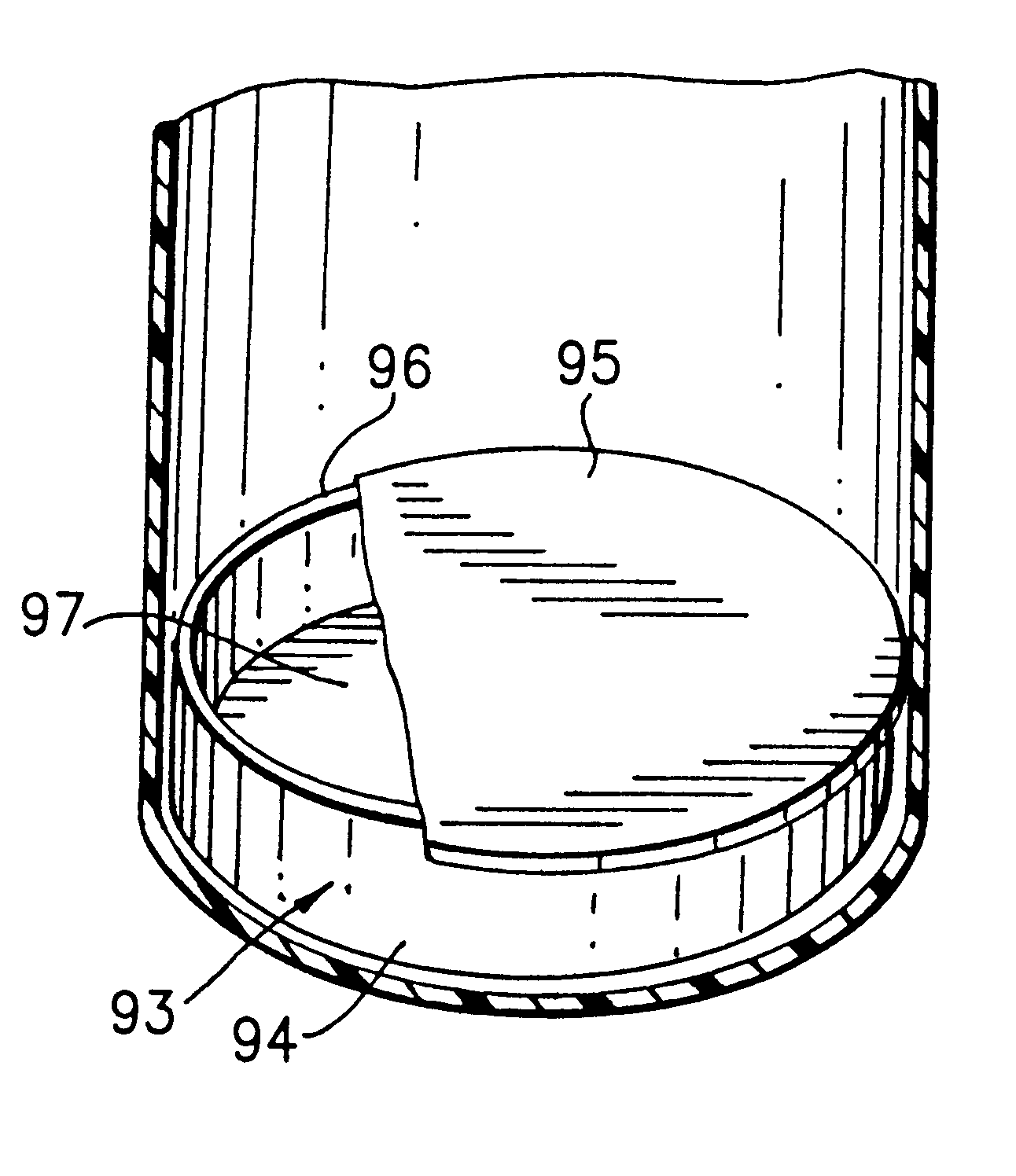

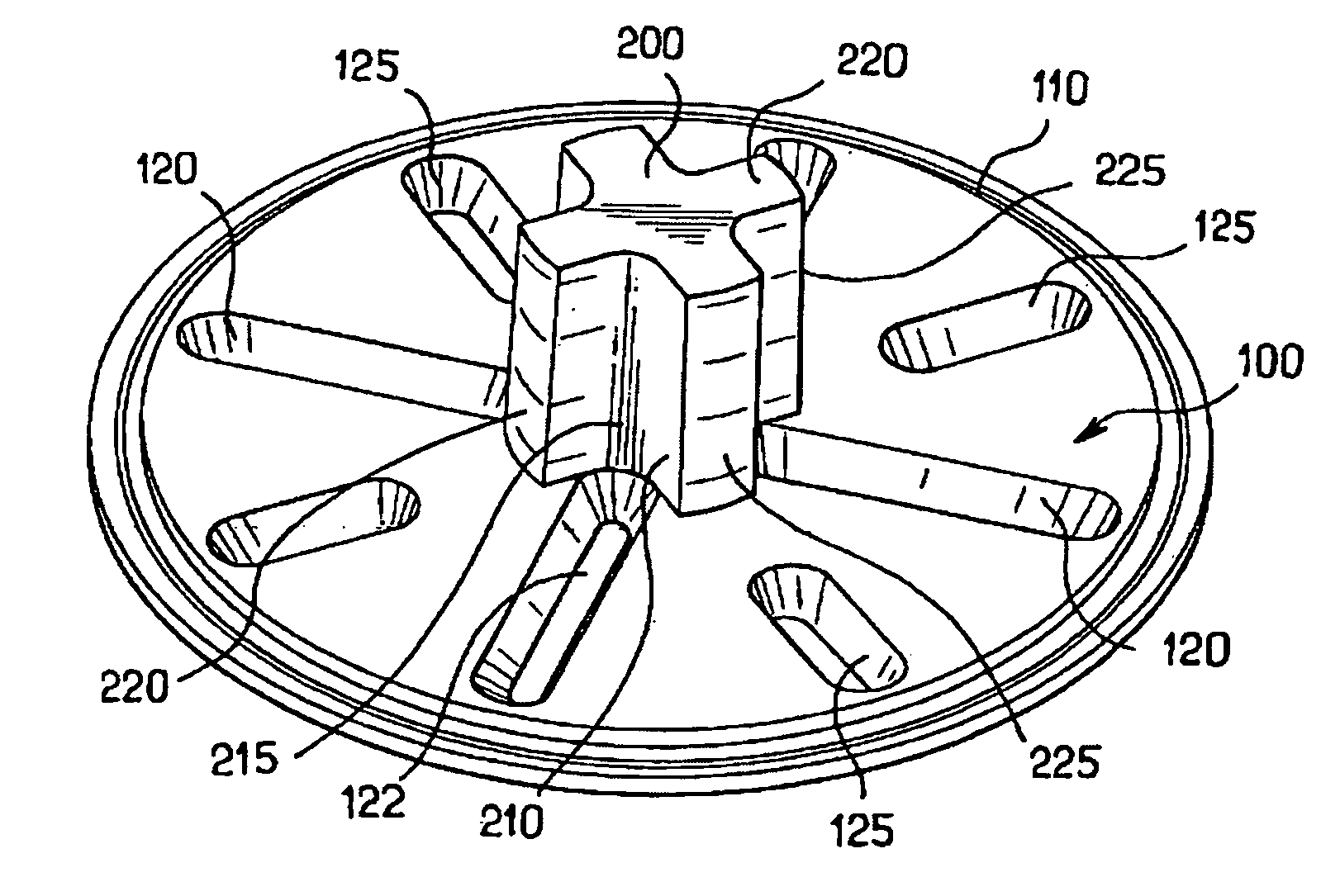

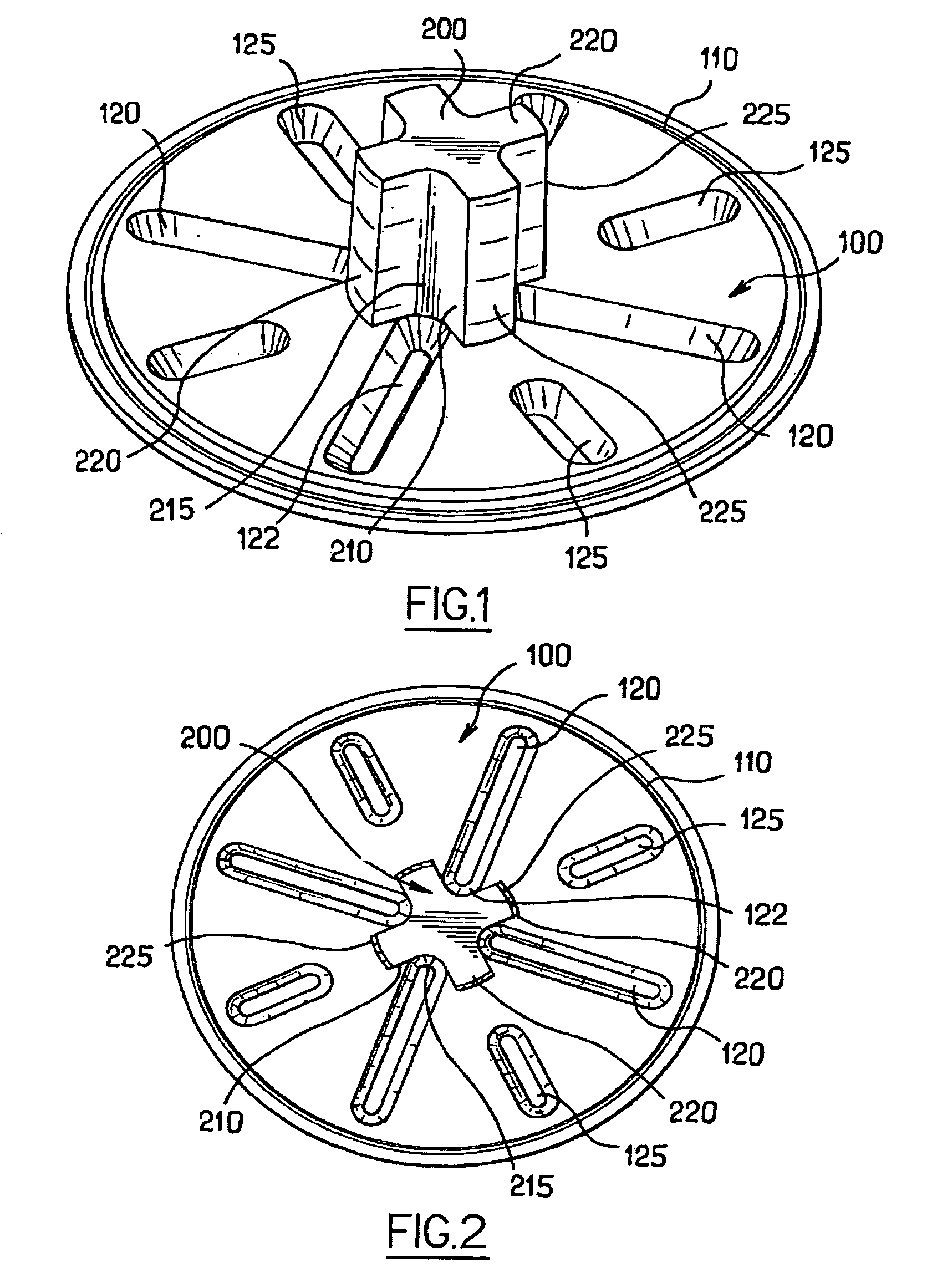

Supercapacitor cover with integrated center terminal

InactiveUS7911766B2Increase contactSolve the lack of spaceCapacitor terminalsDouble layer capacitorsSupercapacitorConductor Coil

An electric energy storage component having coil windings and at least one connector. A plate of the connector is in contact with the coil windings. The plate of the connector has a surface which is provided with a terminal wherein the shape thereof is essentially that of a revolution. The plate also forms a series of bosses extending in a raised manner along a surface of the plate opposite to that containing the terminal. The terminal has at least one inner recess and at least one boss which penetrates into the recess.

Owner:BLUE SOLUTIONS

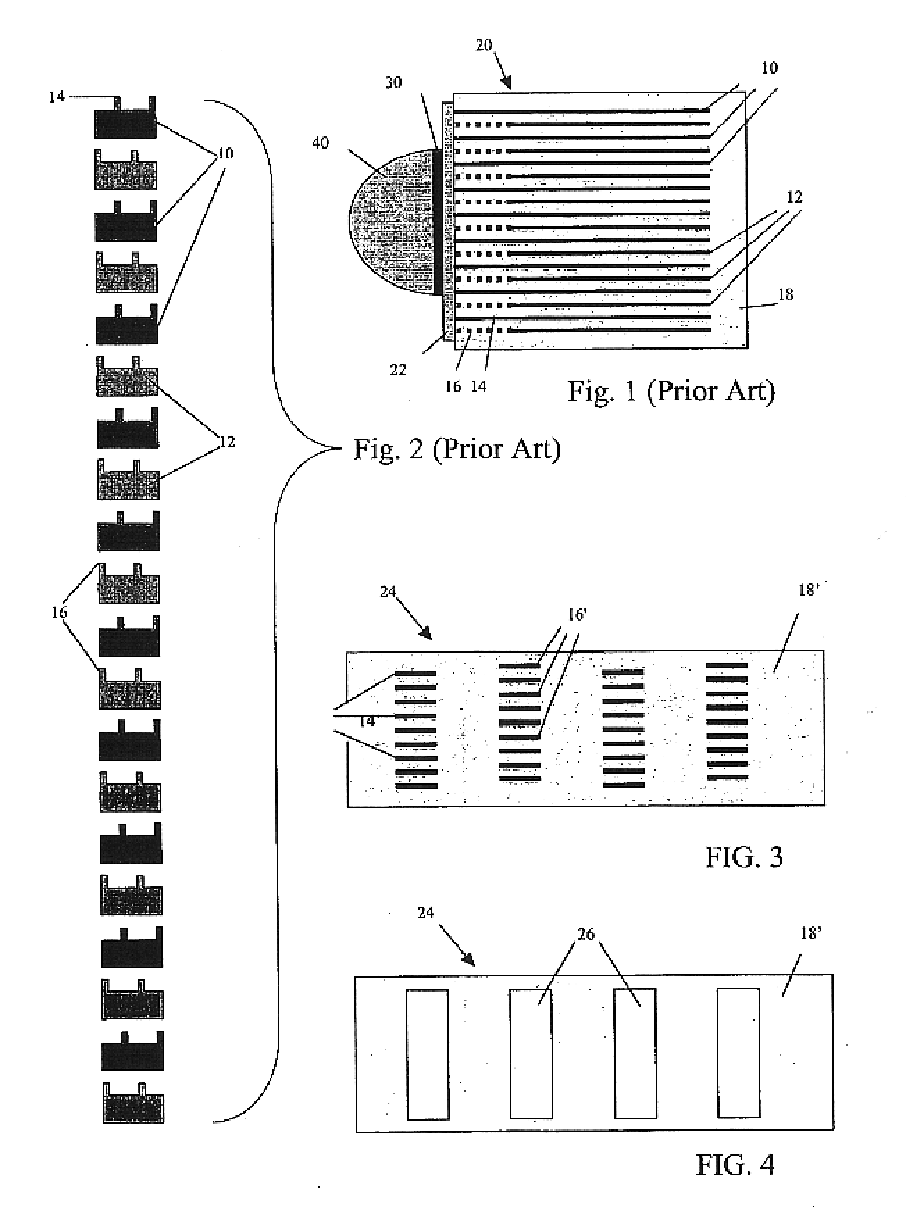

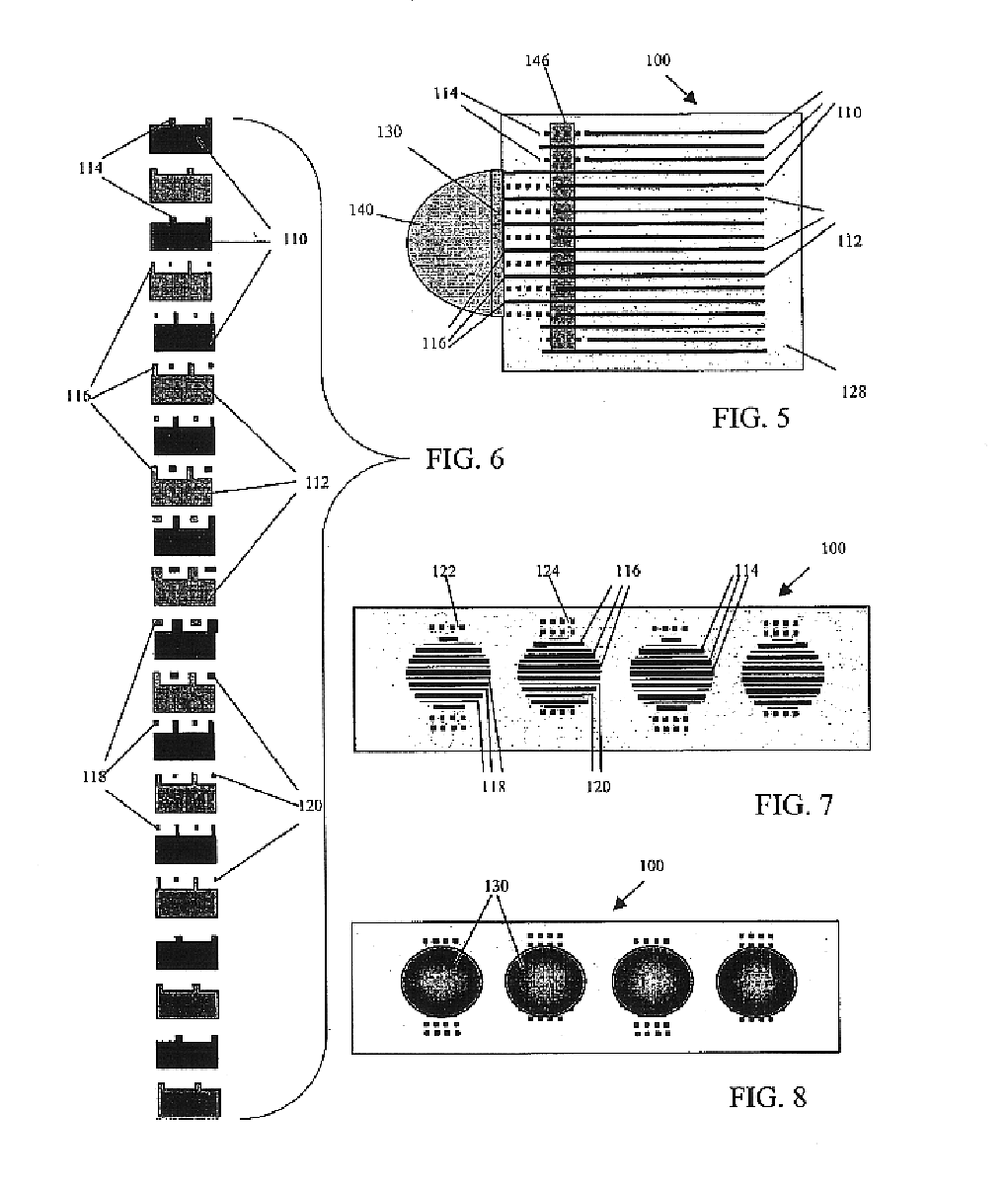

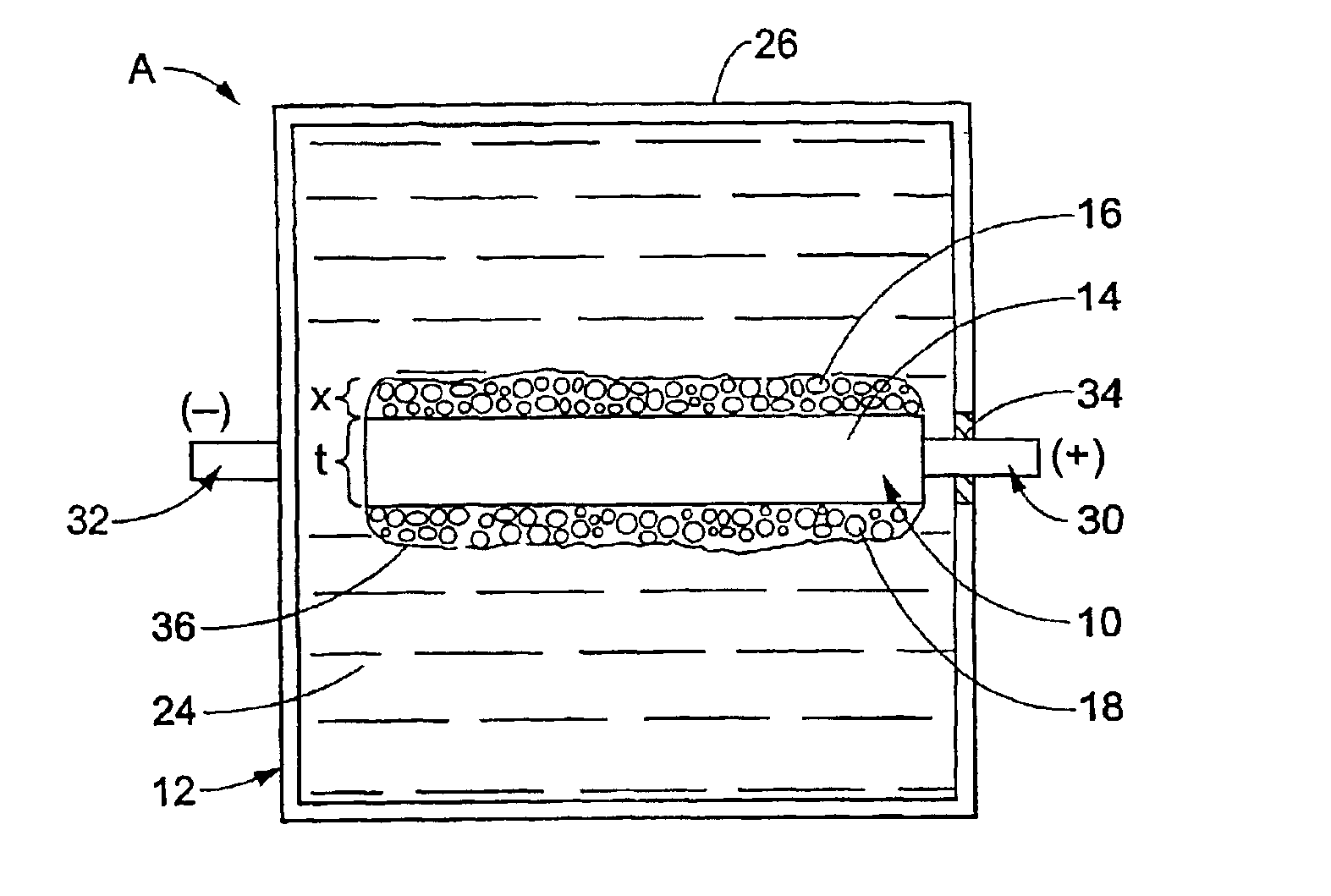

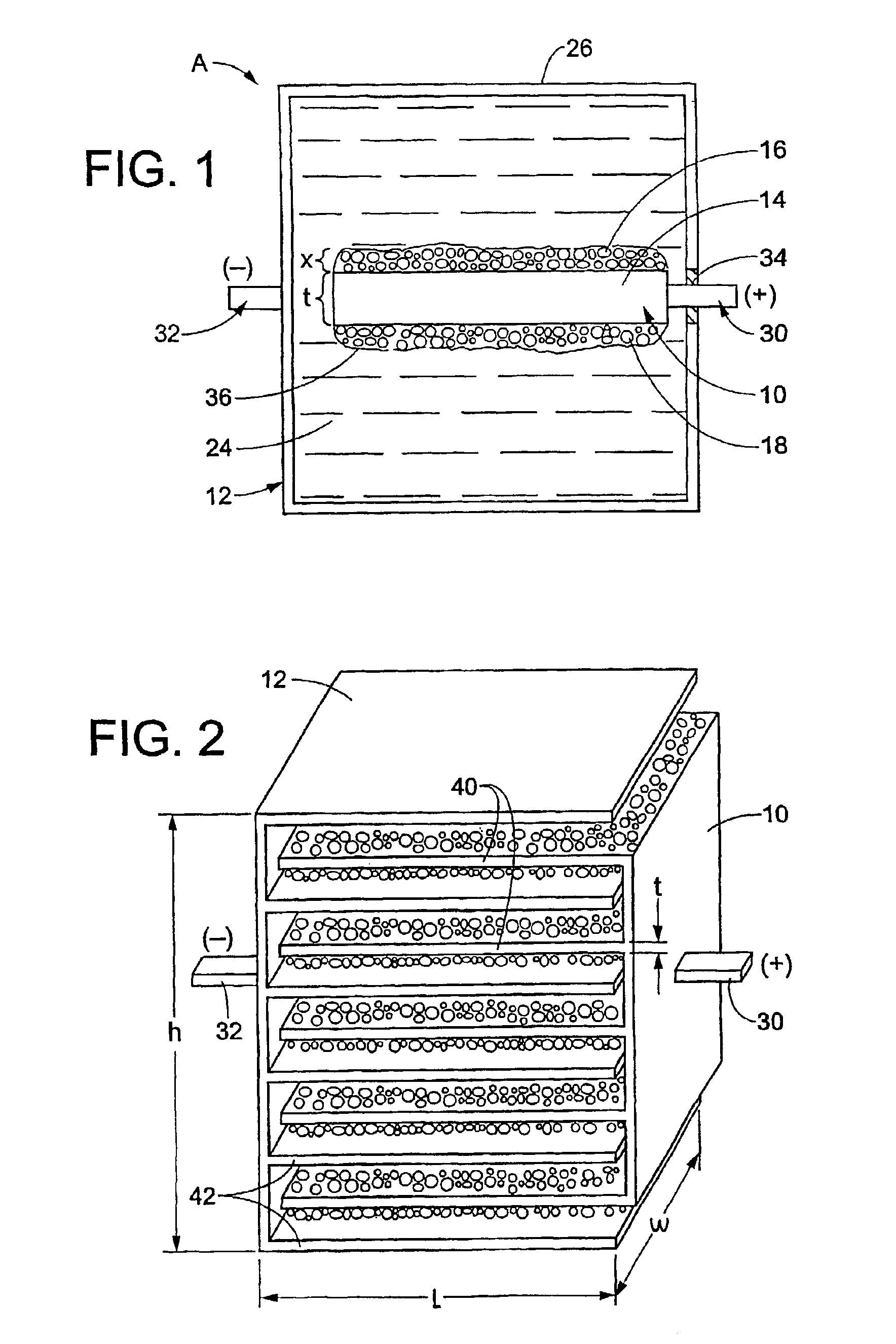

High power capacitors from thin layers of metal powder or metal sponge particles

InactiveUS6914769B2Increase surface areaSmall sizeLiquid electrolytic capacitorsFixed capacitor dielectricMetal particleDielectric strength

An anode (14, 208, 410) and / or cathode (12, 212, 420) of a capacitor has a large surface area. The high surface area of the anode is provided by forming the anode from a thin, electrically conductive layer (16) formed from metal particles (18) or an electrically conductive metallic sponge (416). These materials provide a porous structure with a large surface area of high accessibility. The particles are preferably directional or non-directional sponge particles of a metal, such as titanium. The conductive layer has a dielectric film (36, 236, 414) on its surface, formed by anodizing the particle surfaces. The dielectric film has a combination of high dielectric constant and high dielectric strength. The cathode (12, 212, 420) of the capacitor is either a conventional solid material or, more preferably, has a large surface provided by forming the surface from a sponge or particles analogously to the anode. The high dielectric strengths obtainable from the capacitor allow for extreme miniaturization, making the capacitor particularly suited for integrated circuit applications.

Owner:TITANIUM POWER TECH

High performance capacitor with high dielectric constant material

InactiveUS7428137B2Improve performanceHigh energy-density capacitorFixed capacitor dielectricStacked capacitorsElectrical conductorMaterials science

Owner:DOWGIALLO JR EDWARD J

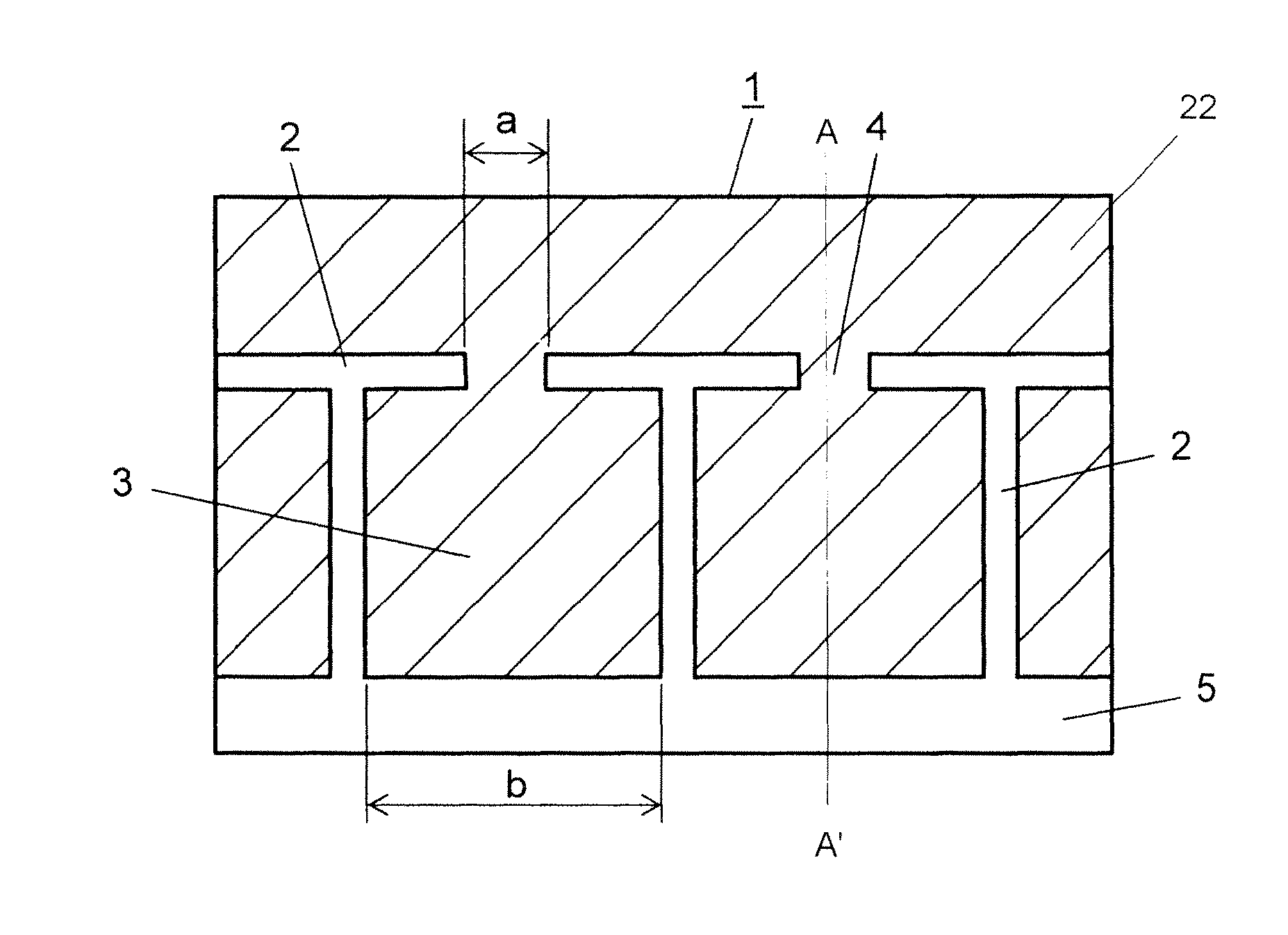

Lithium ion capacitor

ActiveUS20090097189A1Prevent increase of positive electrode potentialQuality improvementHybrid capacitor separatorsLiquid electrolytic capacitorsHigh energyPhysical chemistry

A lithium ion capacitor having high energy density, high output density, high capacity and high safety is provided.A lithium ion capacitor comprising a positive electrode 1 made of a material capable of being reversibly doped with lithium ions and / or anions, a negative electrode 2 made of a material capable of being reversively doped with lithium ions, and an aprotic organic solution of a lithium salt as an electrolytic solution, wherein the positive electrode 1 and the negative electrode 2 are laminated or wound with a separator interposed between them, the area of the positive electrode 1 is smaller than the area of the negative electrode 2, and the face of the positive electrode 1 is substantially covered by the face of the negative electrode 2 when they are laminated or wound.

Owner:SUBARU CORP

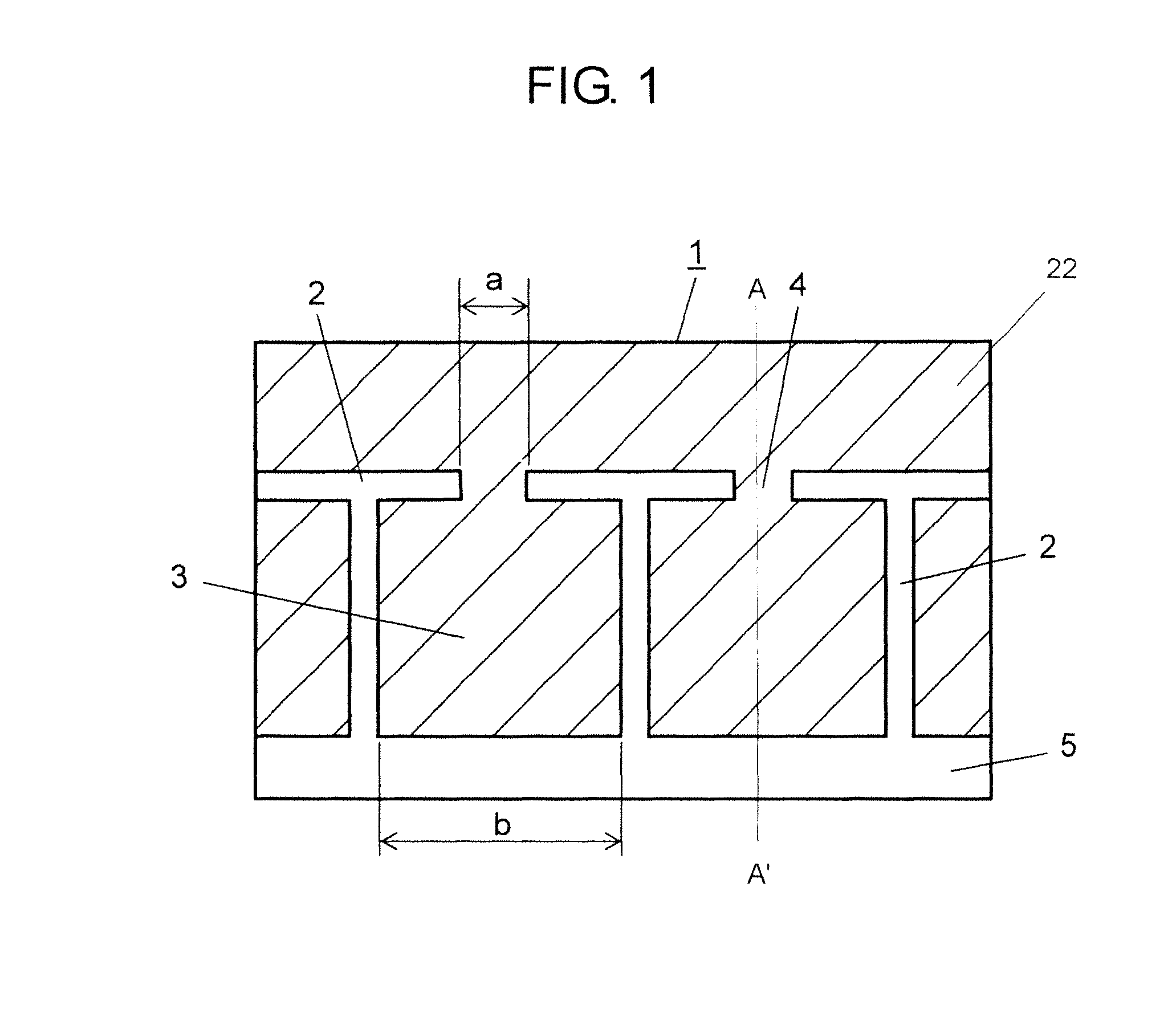

Metallization film capacitor having divided electrode with fuse

InactiveUS8310802B2Improve heat resistanceImprove pressure resistanceFixed capacitor electrodesThin/thick film capacitorHeat resistancePass rate

A metallization film capacitor that achieves both high heat resistance and high withstand voltage at the same time. A metal-deposited electrode is formed on a PEN film in each of a pair of metalized films. These metalized films are wound such that the metal-deposited electrodes face each other via the dielectric film in between. A metalized contact electrode is formed on both end faces of these wound metalized films to configure the metallization film capacitor. A divisional electrode is provided on the metal-deposited electrode. In addition, a fuse is coupled to this divisional electrode for providing a self-maintaining function. Pass rate a / b of a deposition pattern is set to 4.0 or smaller, where ‘a’ is the fuse width, and ‘b’ is the length of the divisional electrode in a lengthwise direction of the metalized films.

Owner:PANASONIC CORP

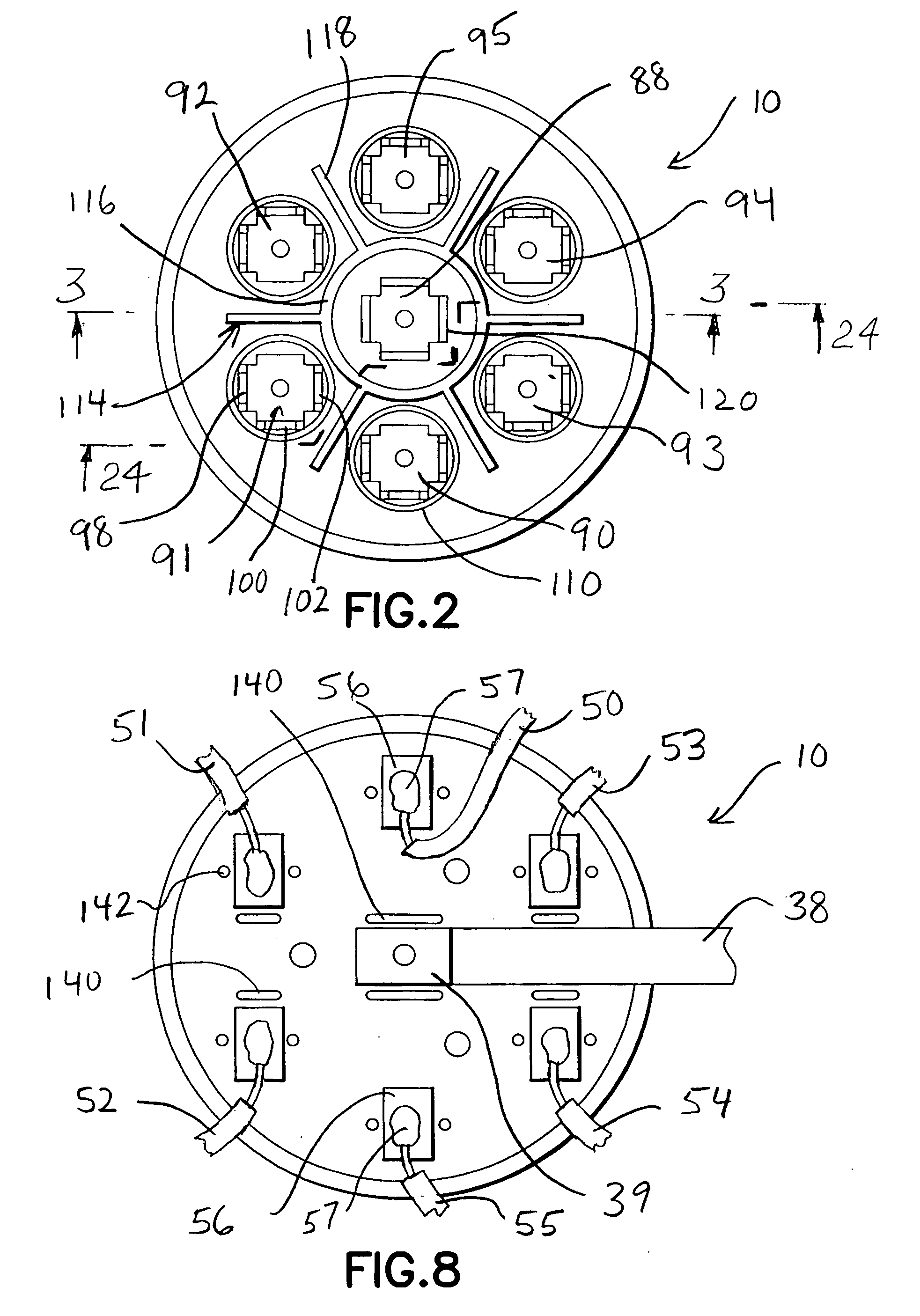

Hard start kit for multiple replacement applications

ActiveUS8456795B2Single-phase induction motor startersMultiple fixed capacitorsCapacitanceHard start

A hard start capacitor replacement unit has a plurality of capacitors in a container sized to fit in existing hard start capacitor space. The capacitors are 4 metallized film capacitors wound in a single cylindrical capacitive element. The container has a common terminal and capacitors value terminals for the plurality of capacitors, which may be connected singly or in combination to provide a selected capacitance. An electronic or other relay connects the selected capacitance in parallel with a motor run capacitor. The hard start capacitor replacement unit is thereby adapted to replace a wide variety of hard start capacitors.

Owner:AMRAD MFG LLC

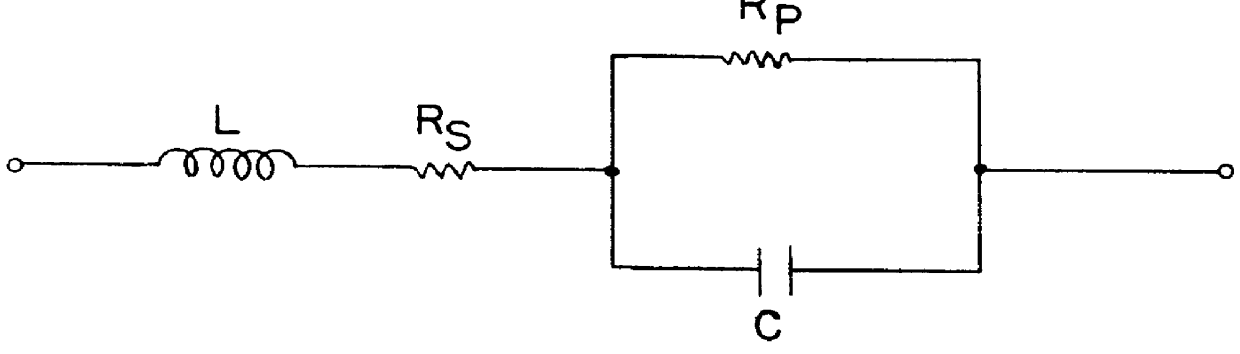

Integrated broadband ceramic capacitor array

InactiveUS6970341B1Effective wideband performanceImprove performanceMultiple fixed capacitorsFixed capacitor electrodesCeramic capacitorEngineering

A monolithic capacitor structure includes opposed and overlapping plates within a dielectric body, which are arranged to form a lower frequency, higher value capacitor. Other conductive structure is located either inside the dielectric body or on an external surface thereof and is effective to form a higher frequency, lower value capacitor in parallel with the lower frequency, higher value capacitor. The resulting array of combined series and parallel capacitors integral with the dielectric body provides effective wideband performance in an integrated, cost-effective structure.

Owner:DEVOE DANIEL +2

Clad fiber capacitor and method of making same

A clad capacitor and method of manufacture includes assembling a preform comprising a ductile, electrically conductive fiber; a ductile, electrically insulating cladding positioned on the fiber; and a ductile, electrically conductive sleeve positioned over the cladding. One or more preforms are then bundled, heated and drawn along a longitudinal axis to decrease the diameter of the ductile components of the preform and fuse the preform into a unitized strand.

Owner:UT BATTELLE LLC

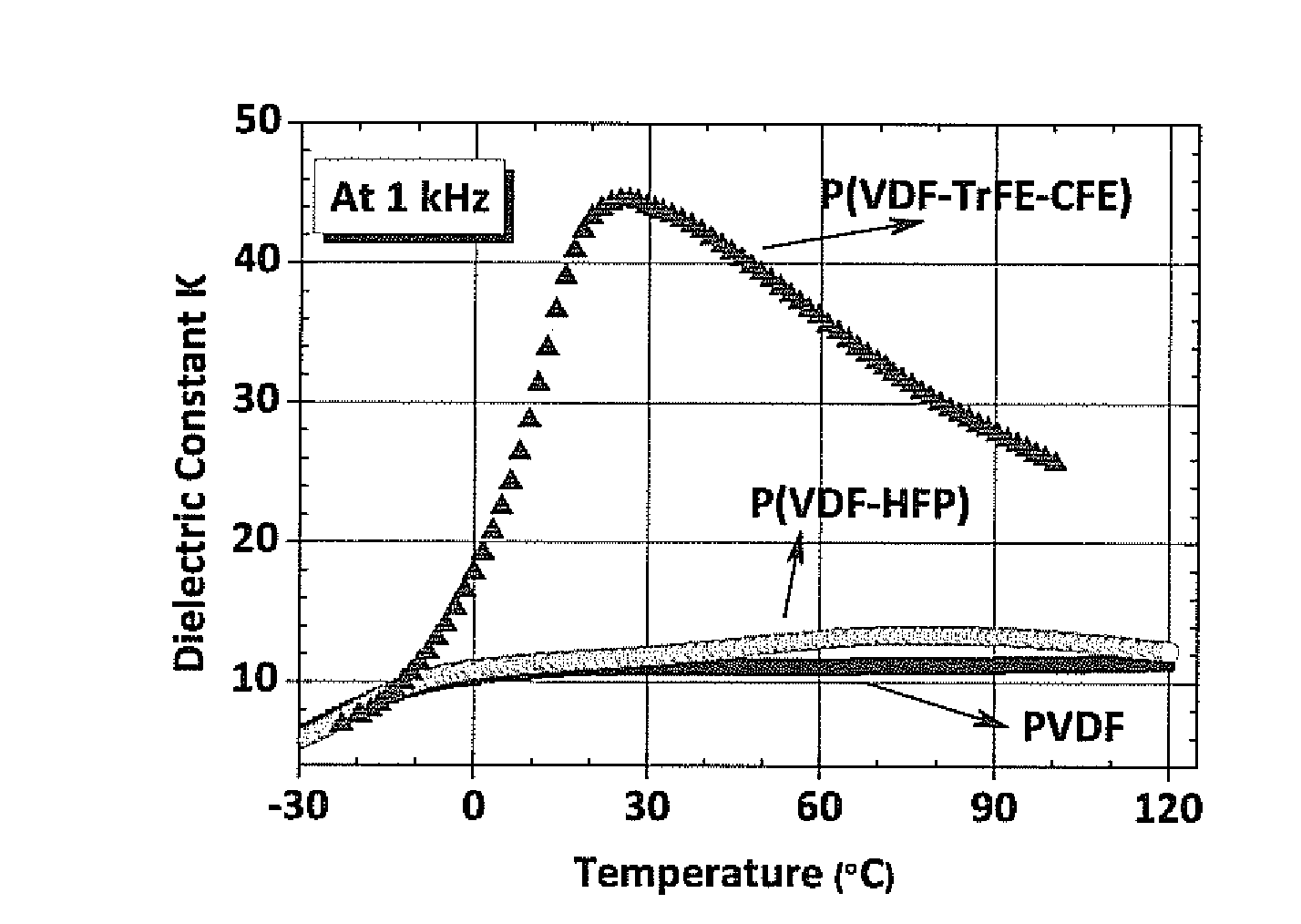

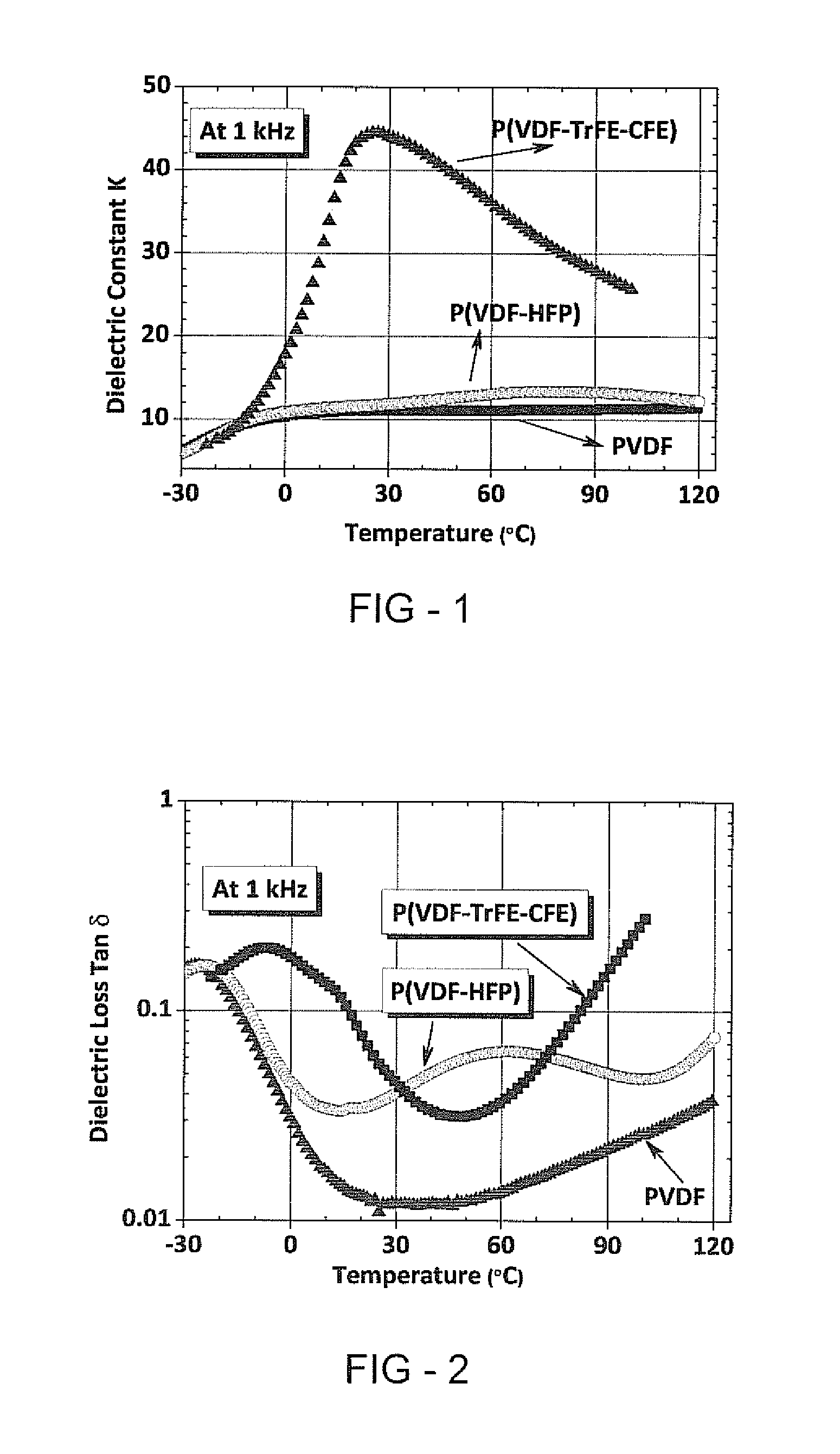

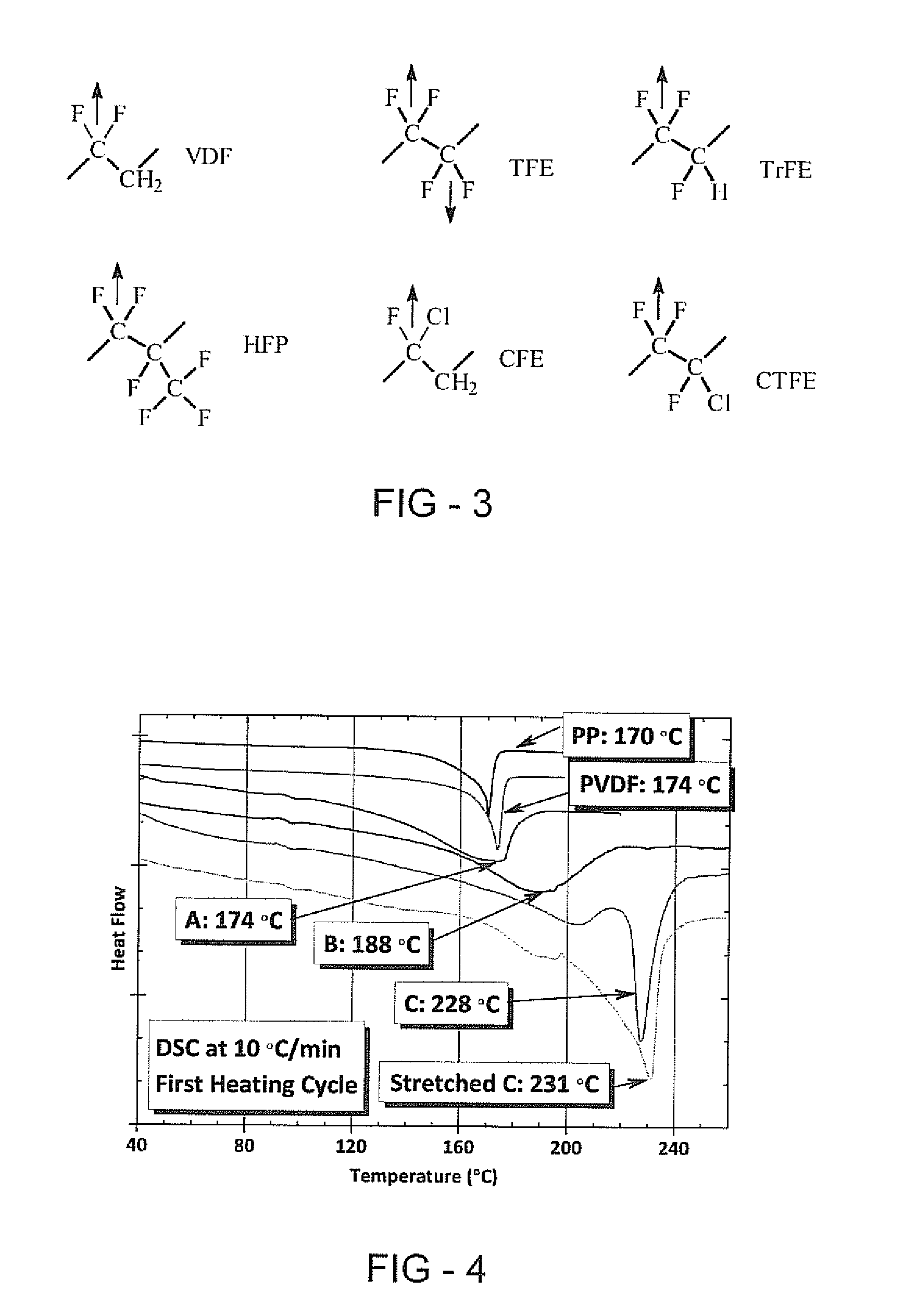

Capacitor having high temperature stability, high dielectric constant, low dielectric loss, and low leakage current

InactiveUS20110228442A1Physical improvementGood chemical propertiesFixed capacitor dielectricStacked capacitorsMetal foilPolymer thin films

Examples of the present invention include high electric energy density polymer film capacitors with high dielectric constant, low dielectric dissipation tangent, and low leakage current in a broad temperature range. More particularly, examples include a polymer film capacitor in which the dielectric layer comprise a copolymer of a first monomer (such as tetrafluoroethylene) and a second polar monomer. The second monomer component may be selected from vinylidene fluoride, trifluoroethylene or their mixtures, and optionally other monomers may be included to adjust the mechanical performance. The capacitors can be made by winding metallized films, plain films with metal foils, or hybrid construction where the films comprise the new compositions. The capacitors can be used in DC bus capacitors and energy storage capacitors in pulsed power systems.

Owner:NOVASENTIS +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com