Patents

Literature

52results about How to "Reduce construction height" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

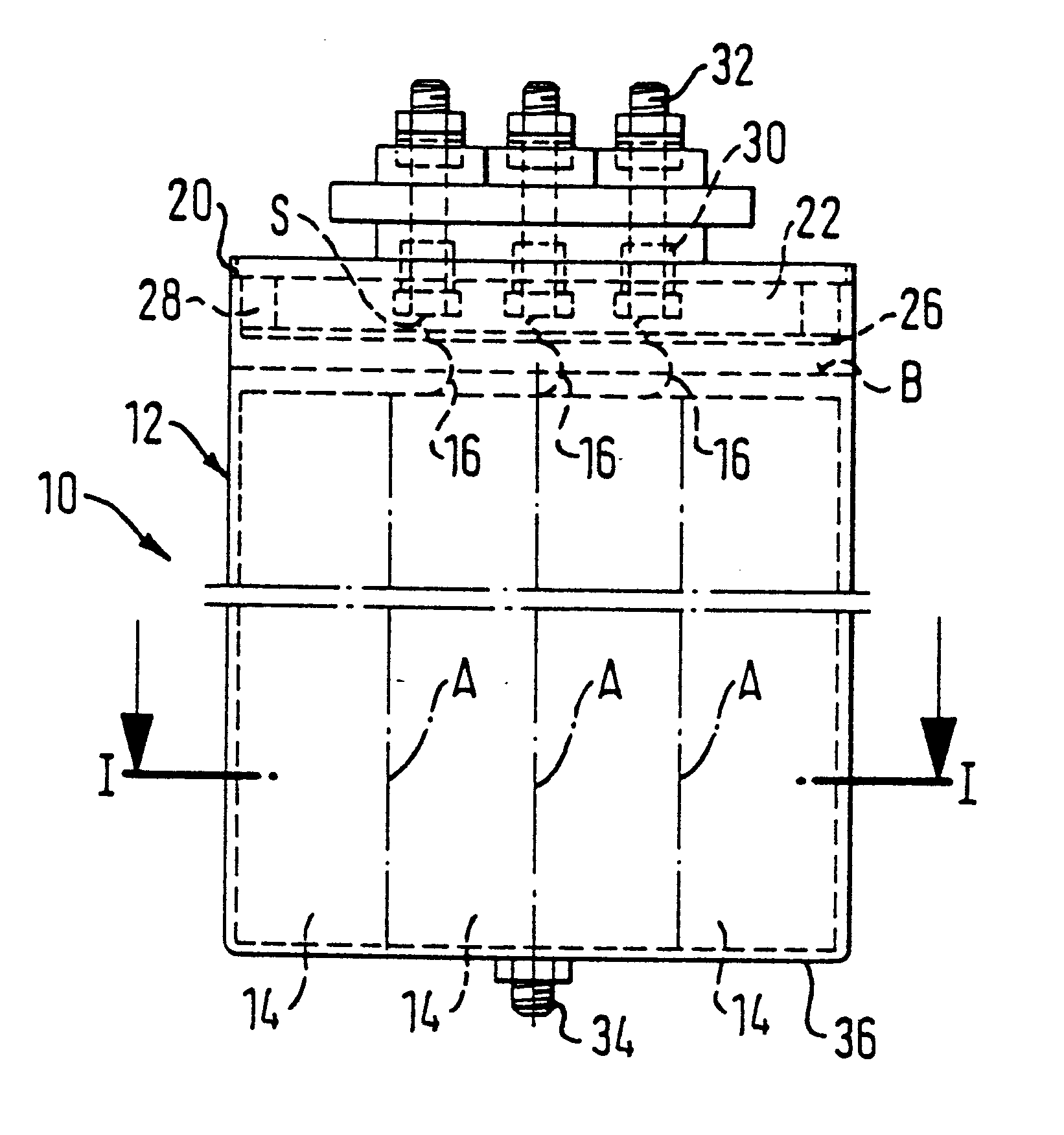

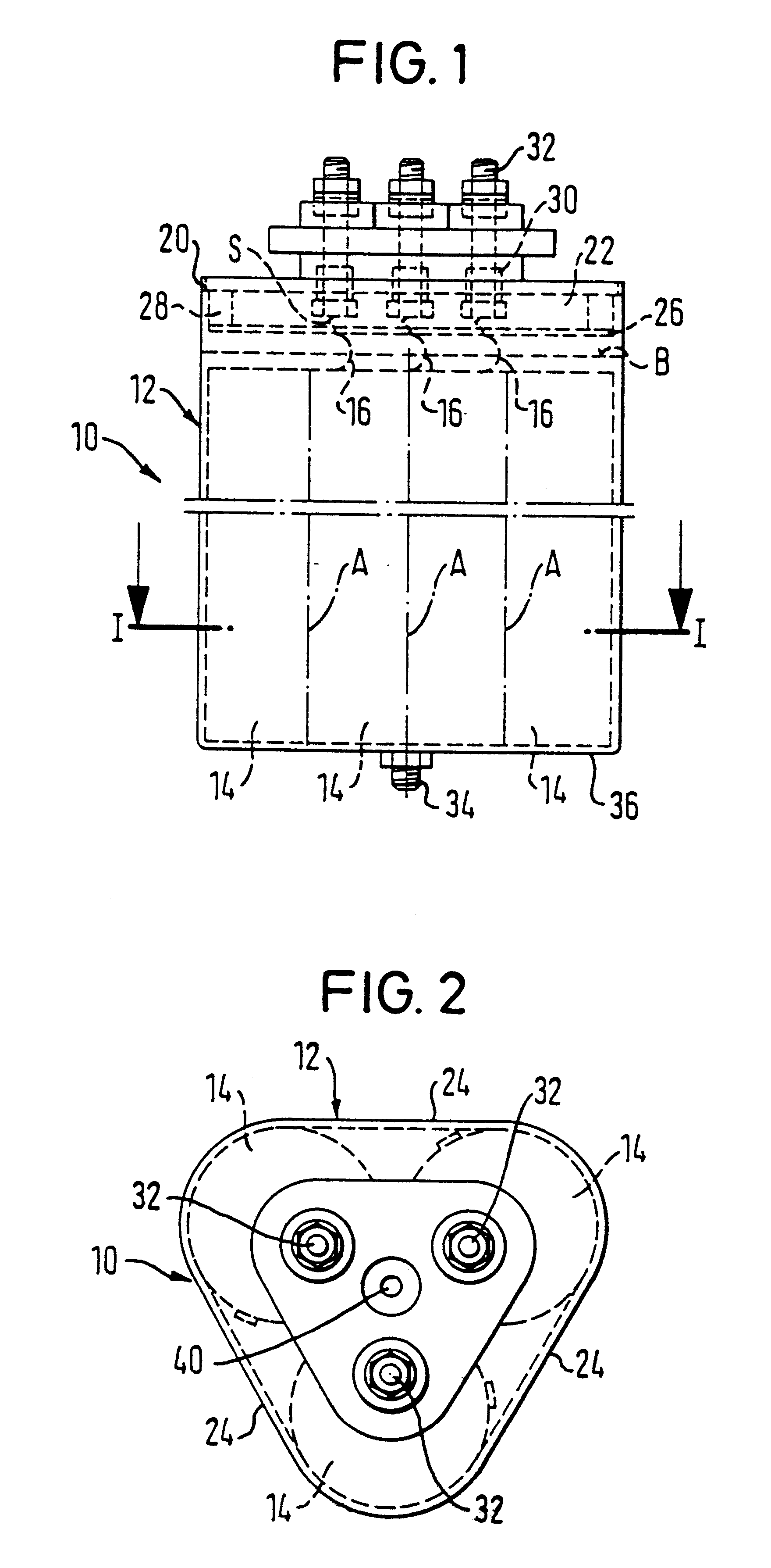

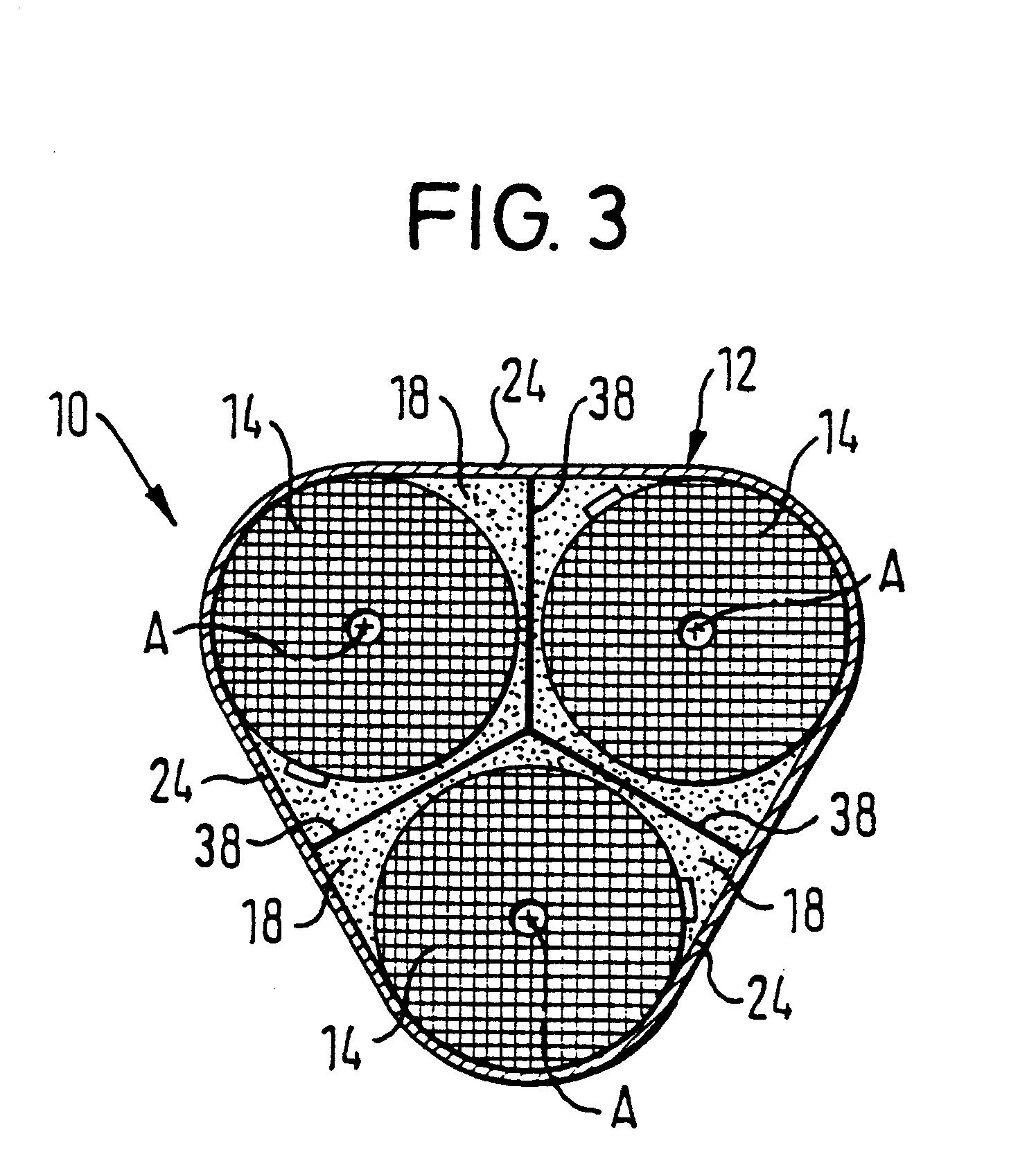

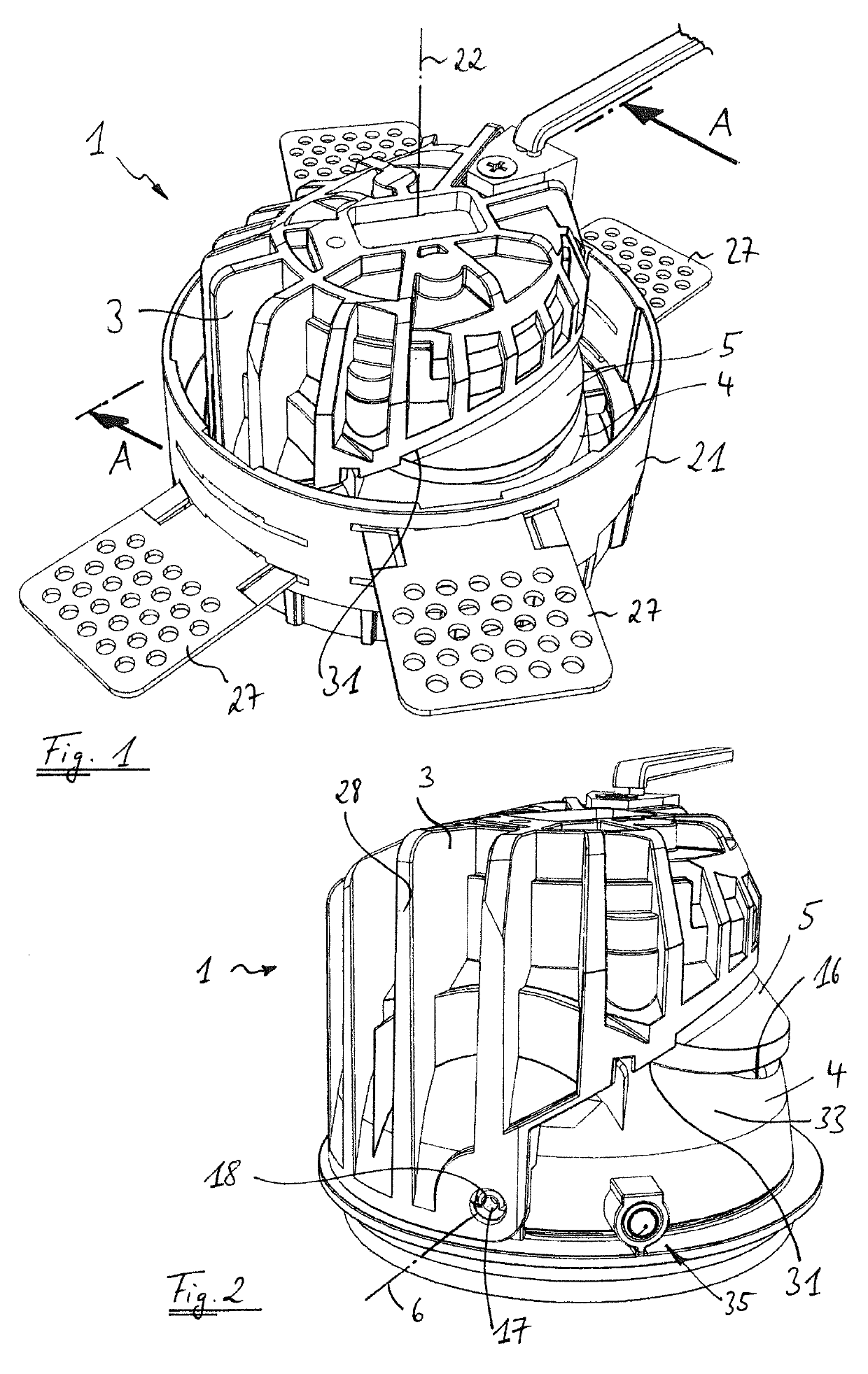

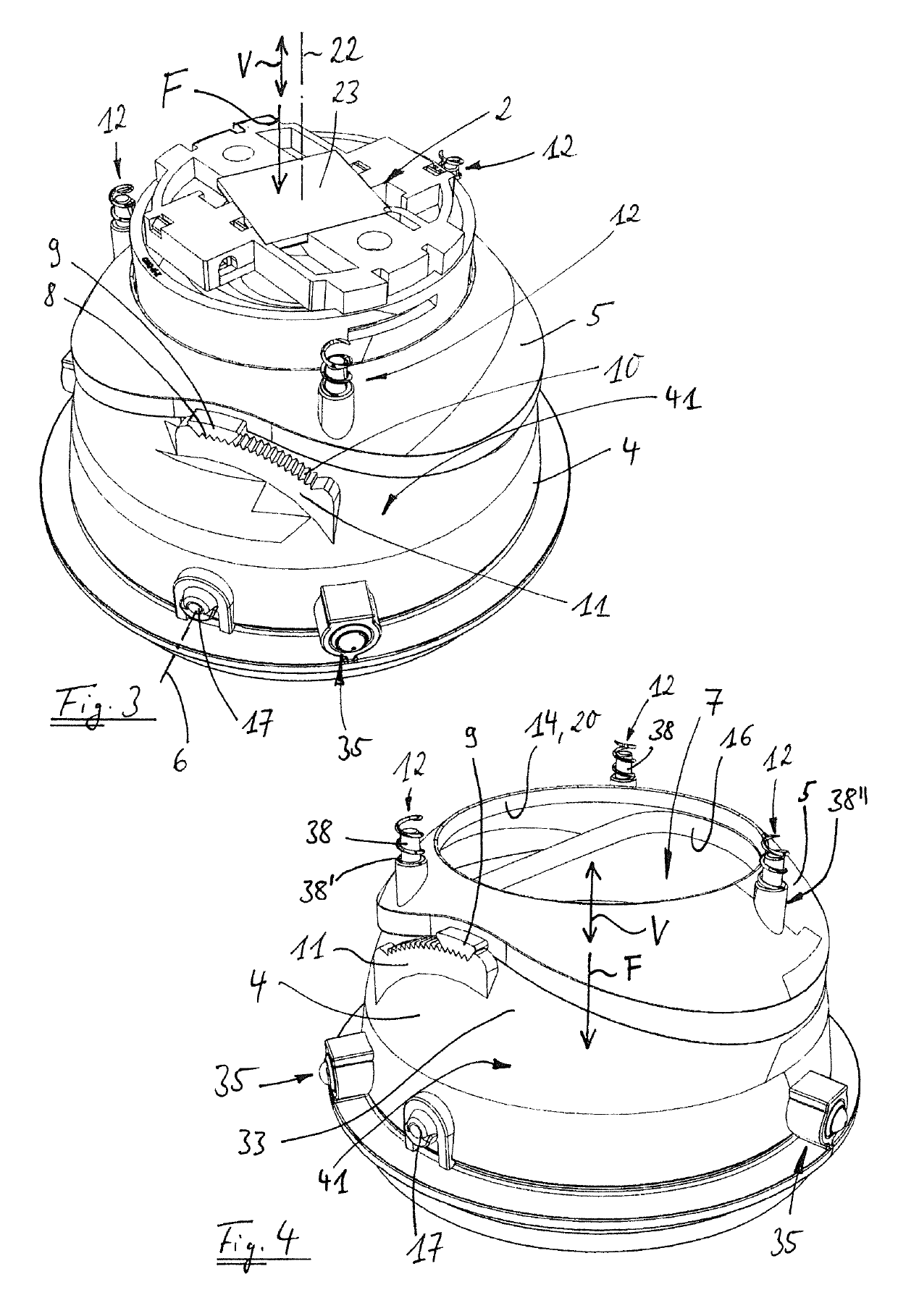

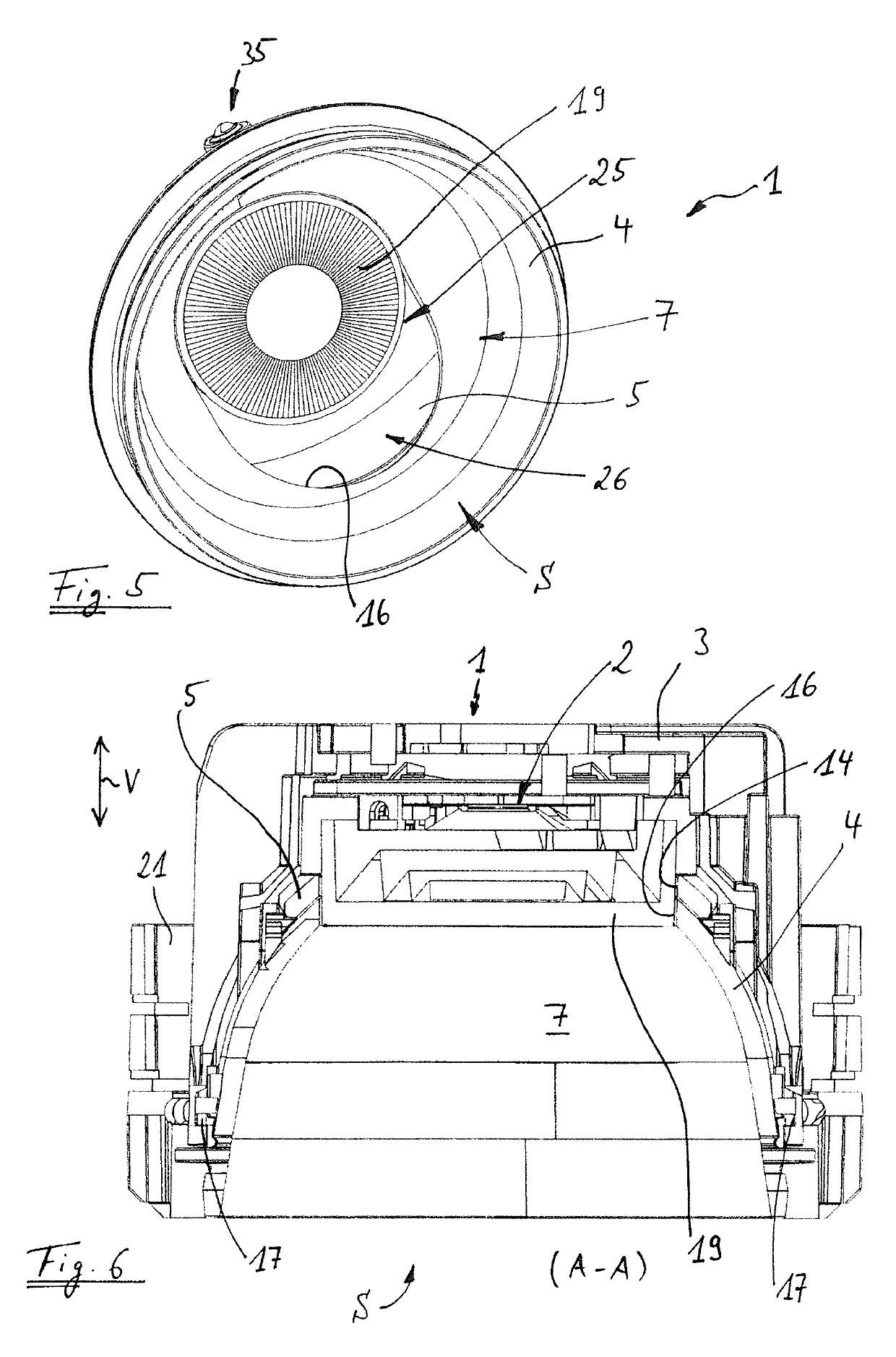

Power capacitor

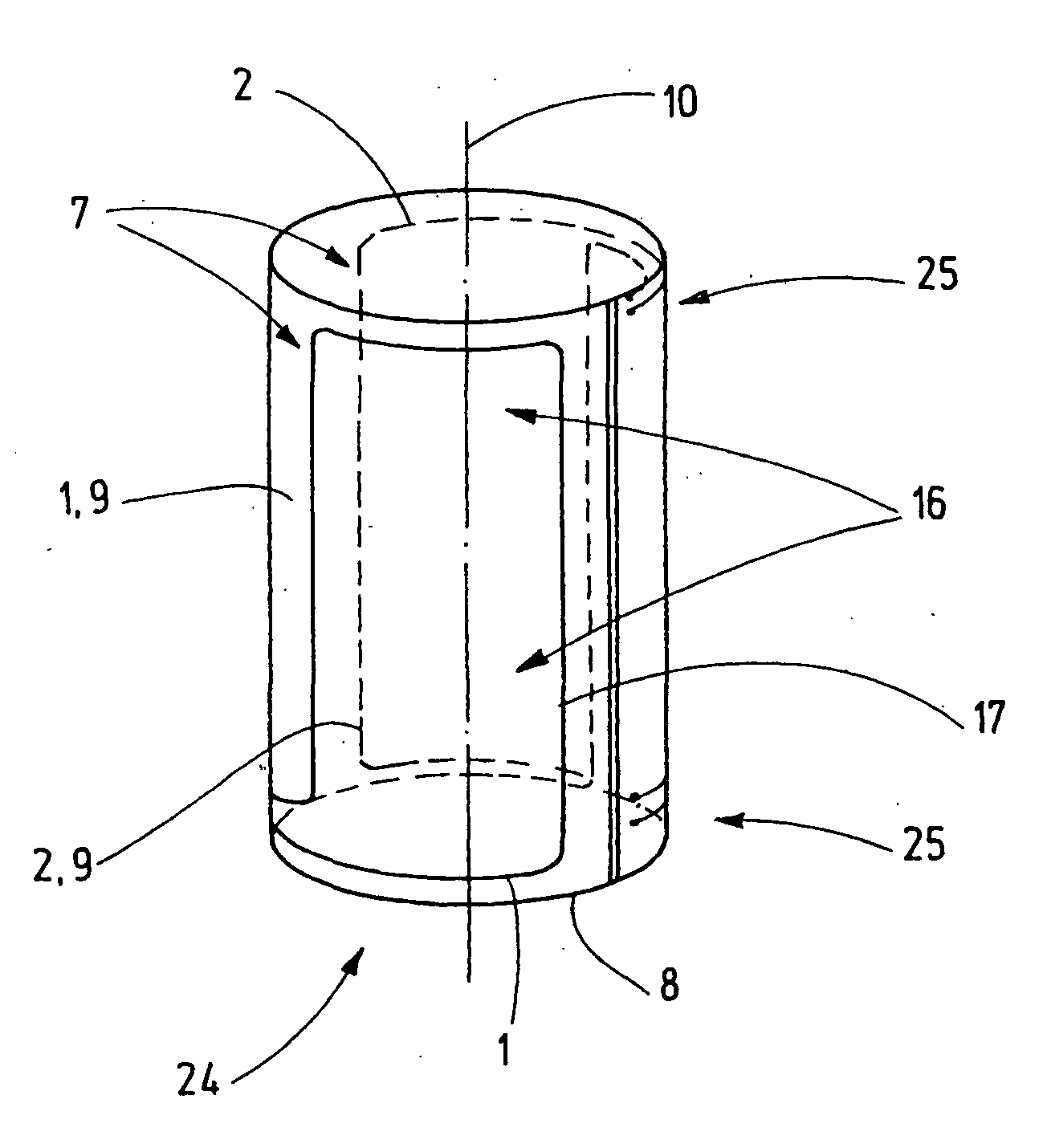

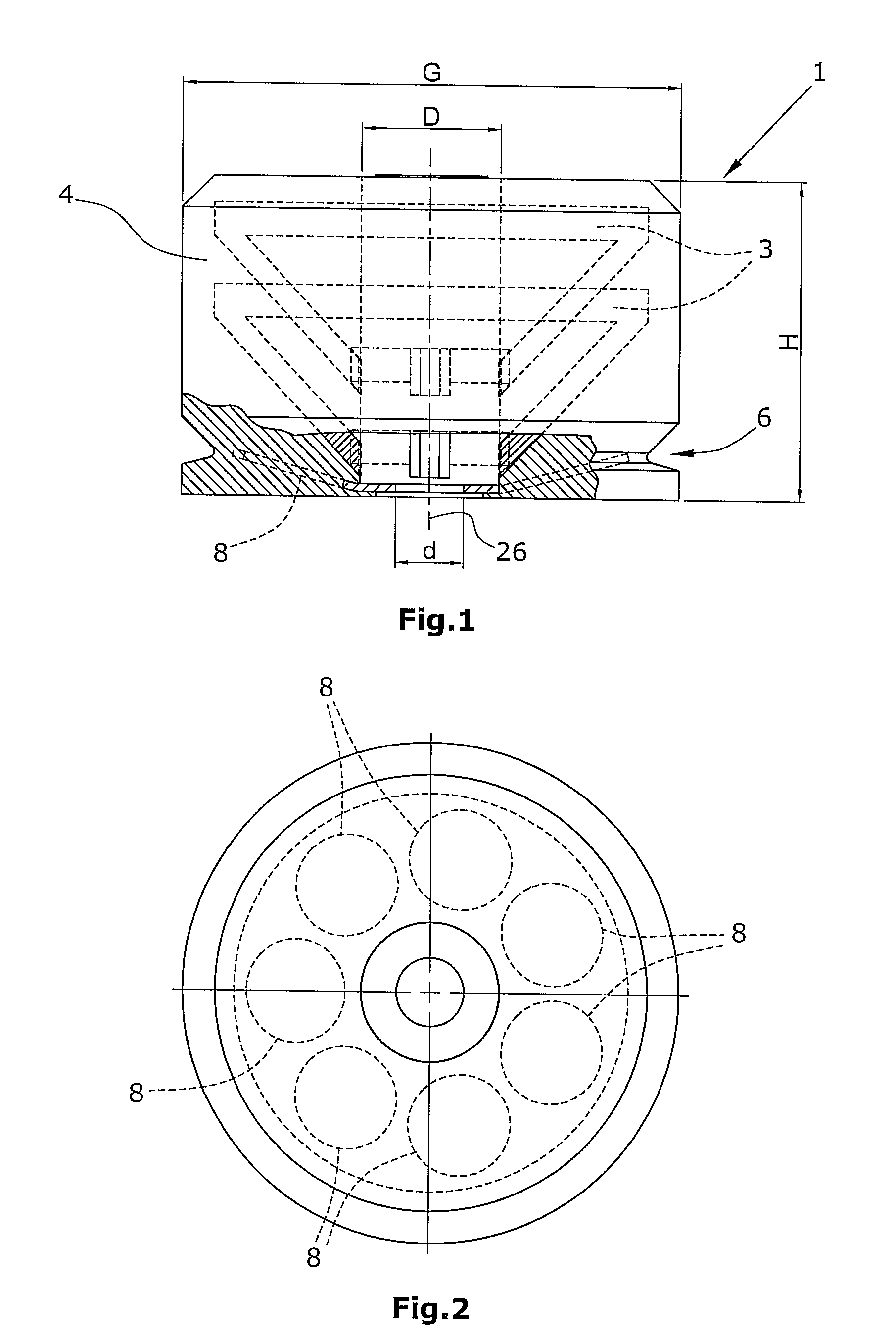

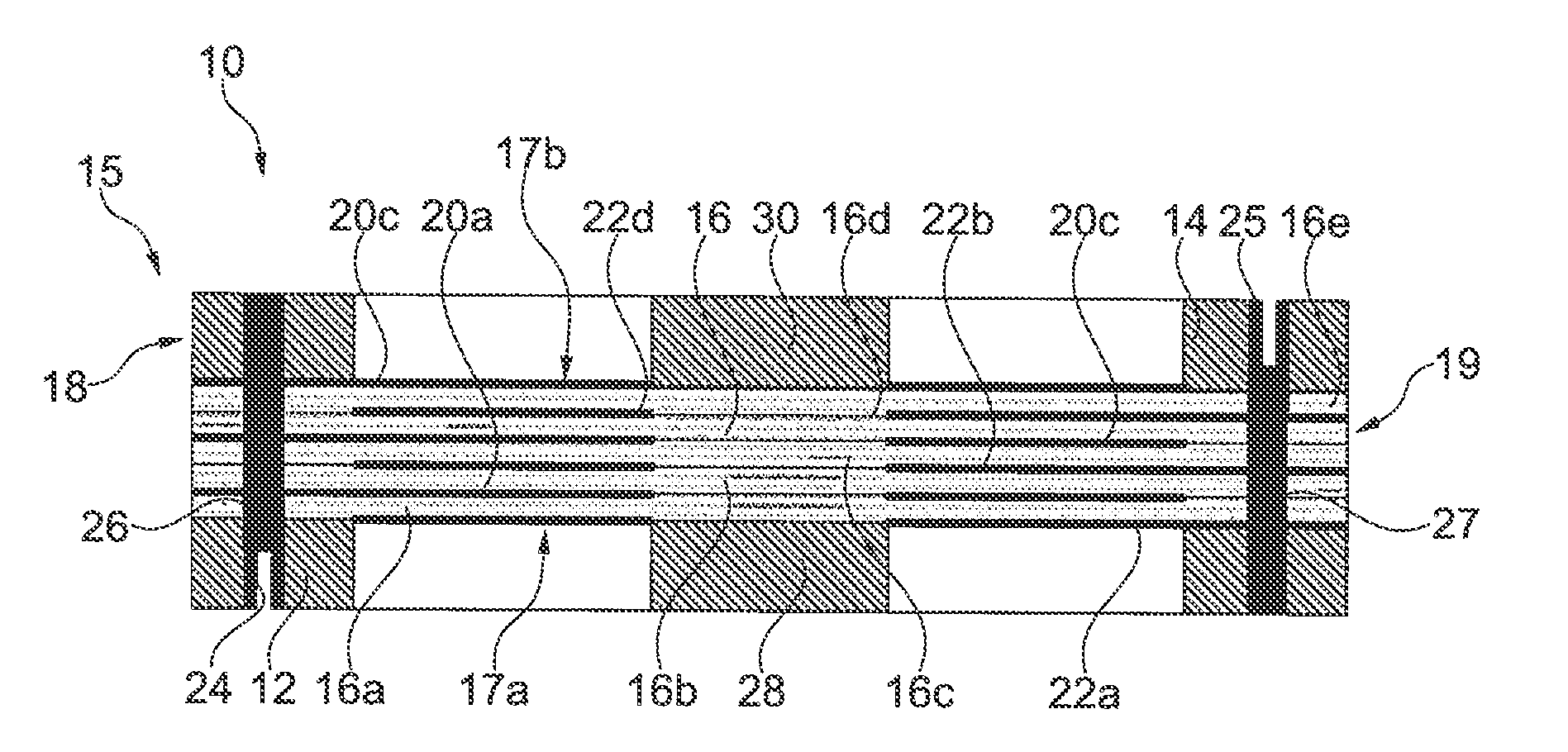

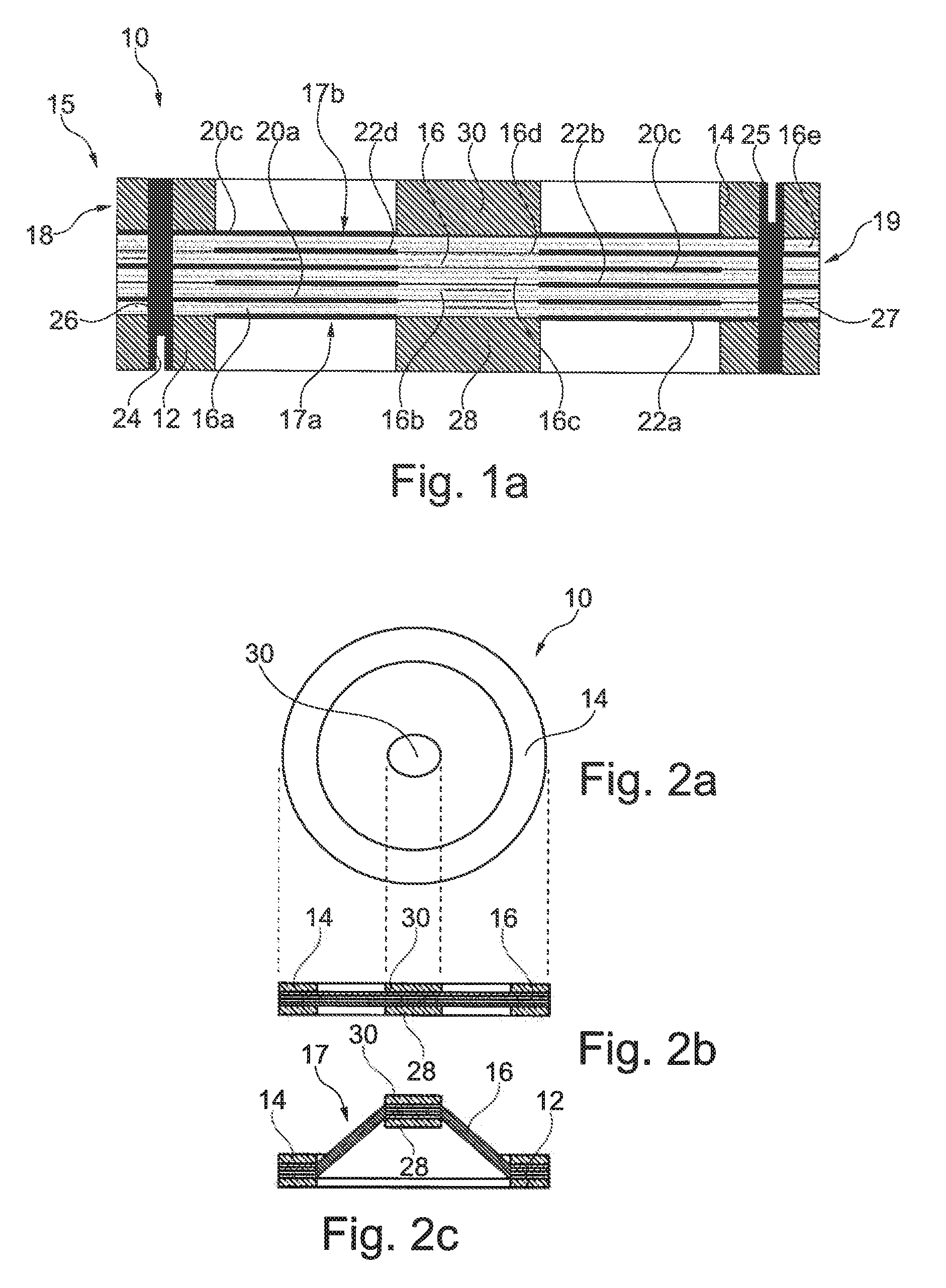

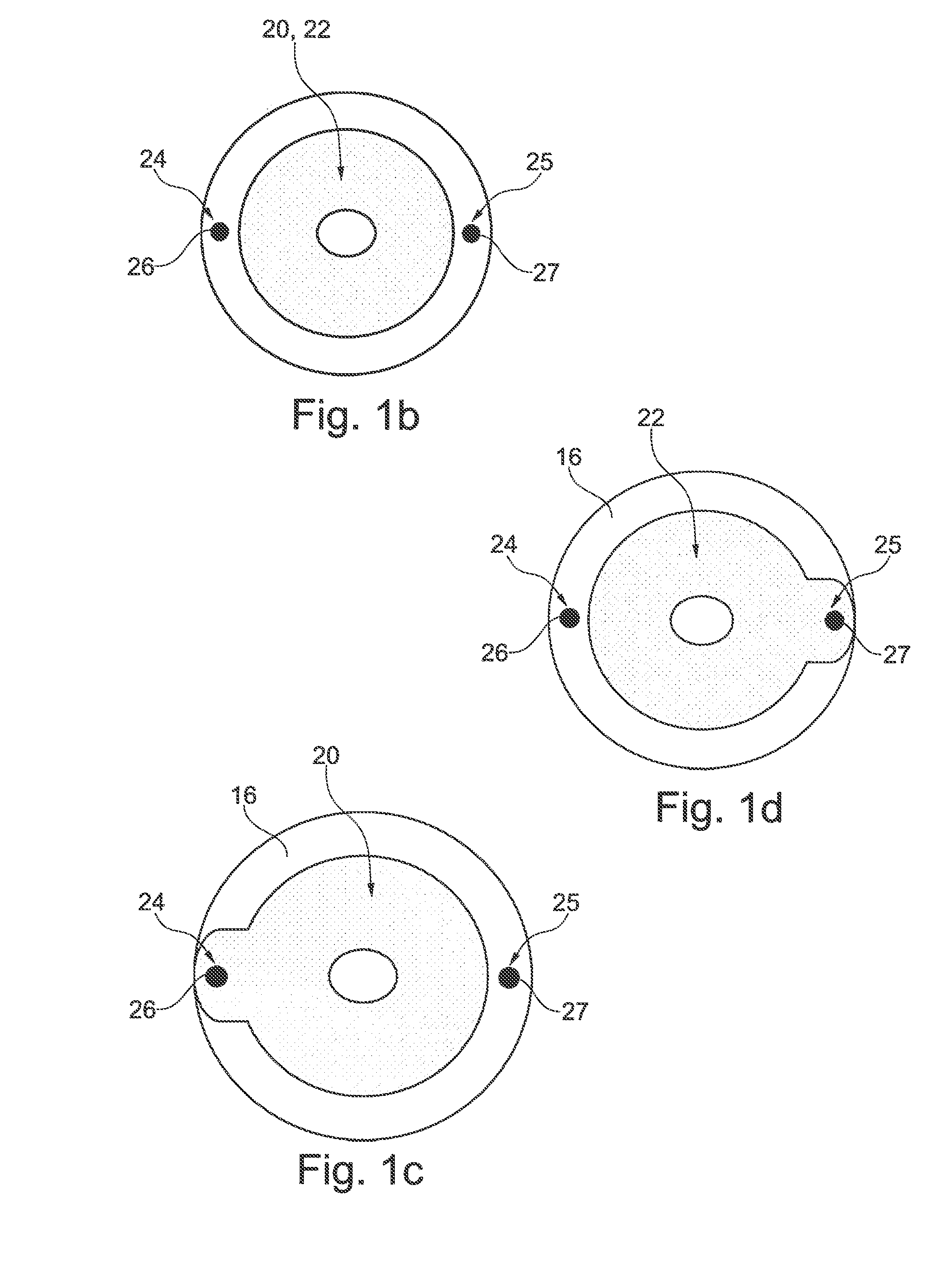

InactiveUS6212058B1Reduce construction heightImproved arrangeability in a rowMultiple fixed capacitorsWound capacitorsEngineeringCapacitor

In a power capacitor with a plurality of round, wound elements accommodated in a common housing at least one wound element group consisting of three round, wound elements is accommodated in the housing, with the wound elements of the group being arranged in star-form alongside one another, with their axes parallel to one another. The housing has in cross-section in general the shape of a triangle having rounded corners, with a radius of curvature which corresponds at least substantially to the radius of the round, wound elements.

Owner:VISHAY ELECTRONICS

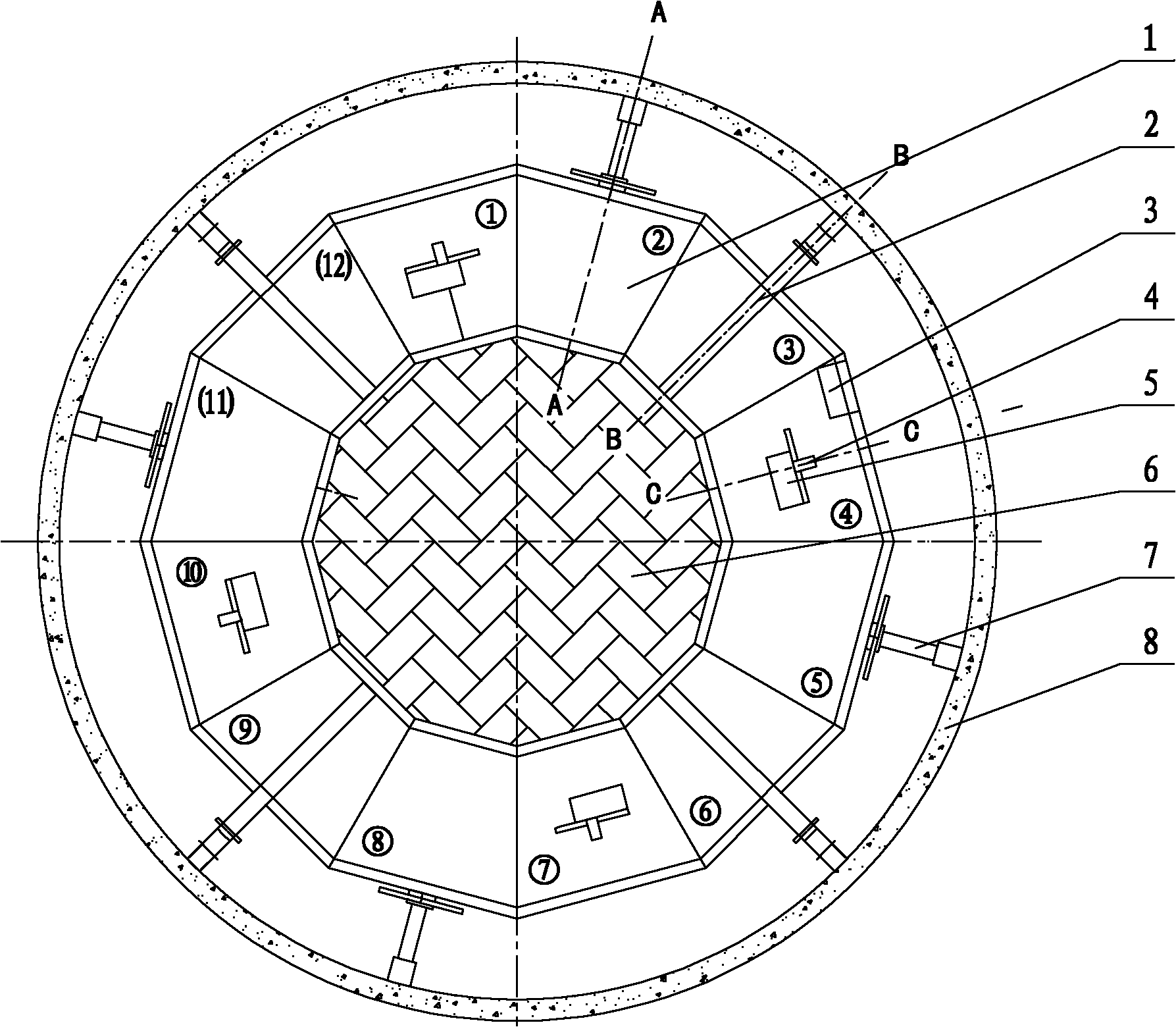

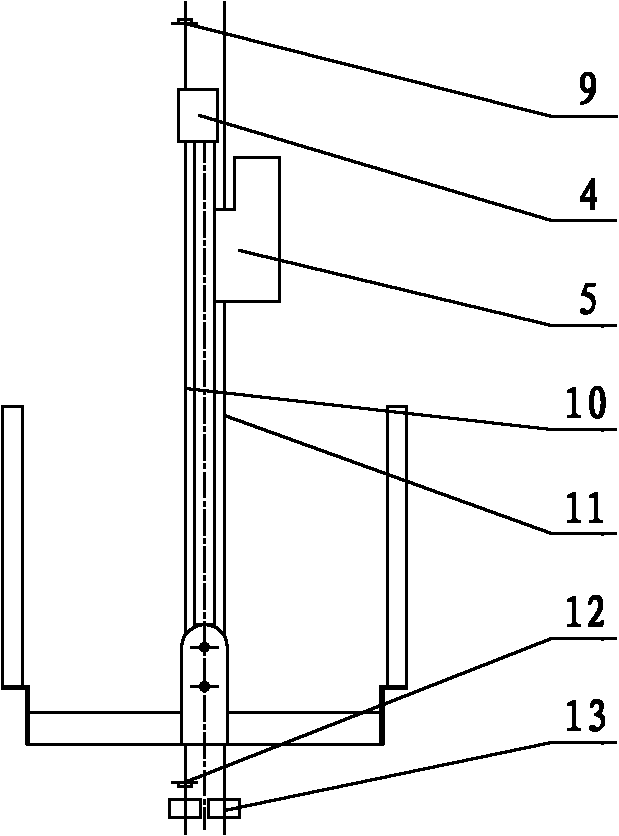

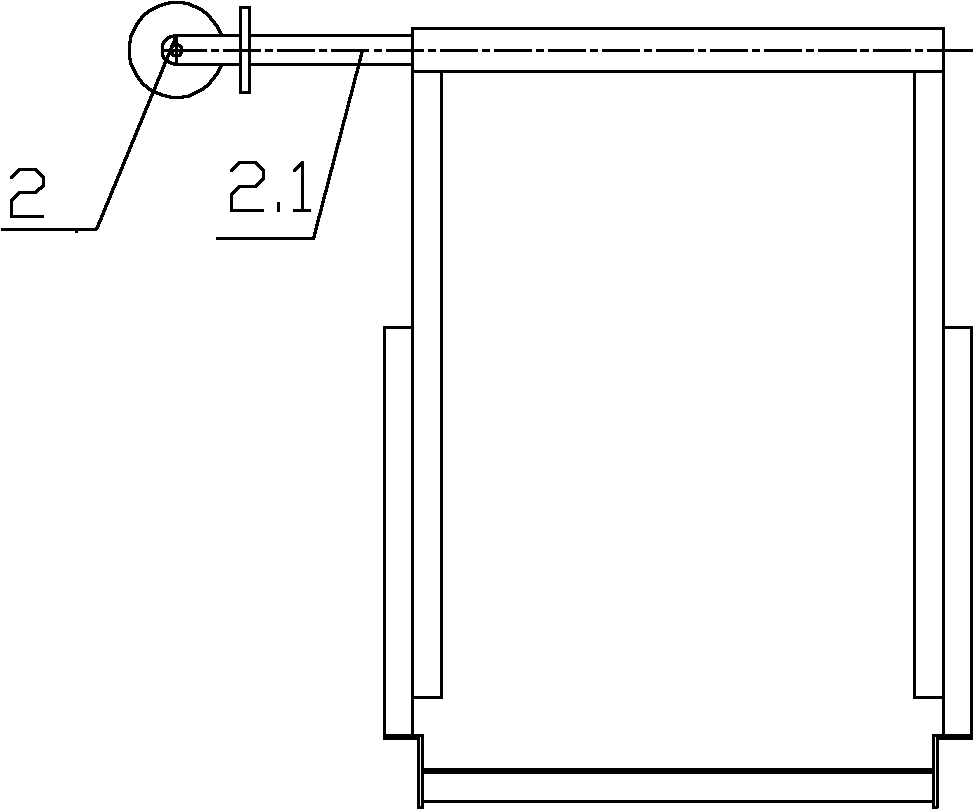

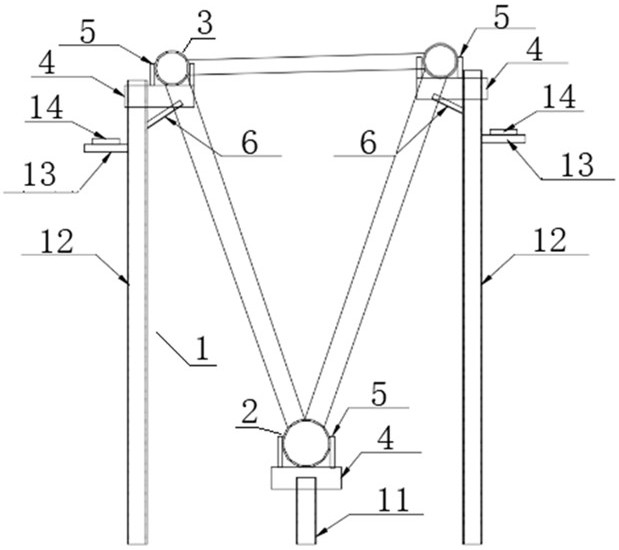

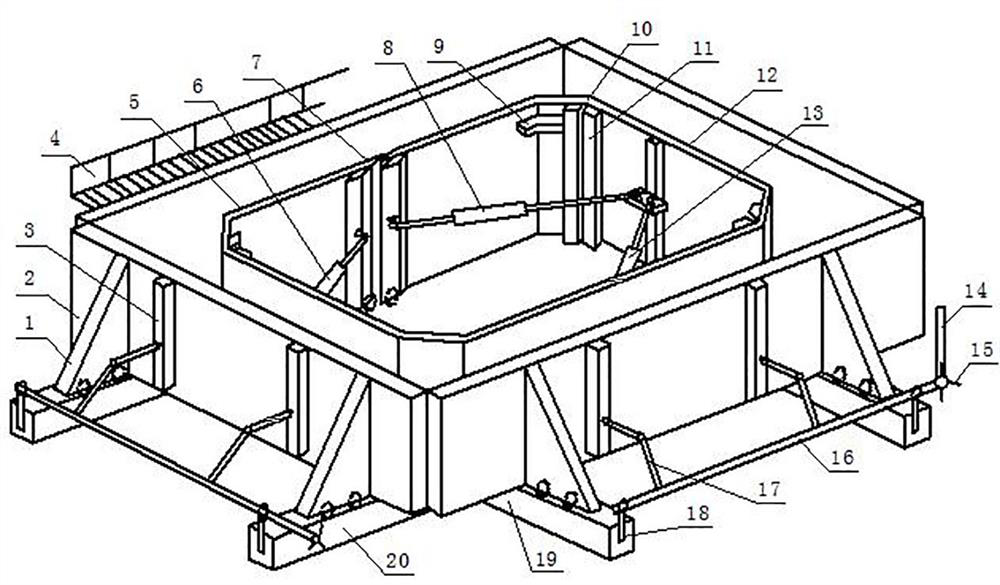

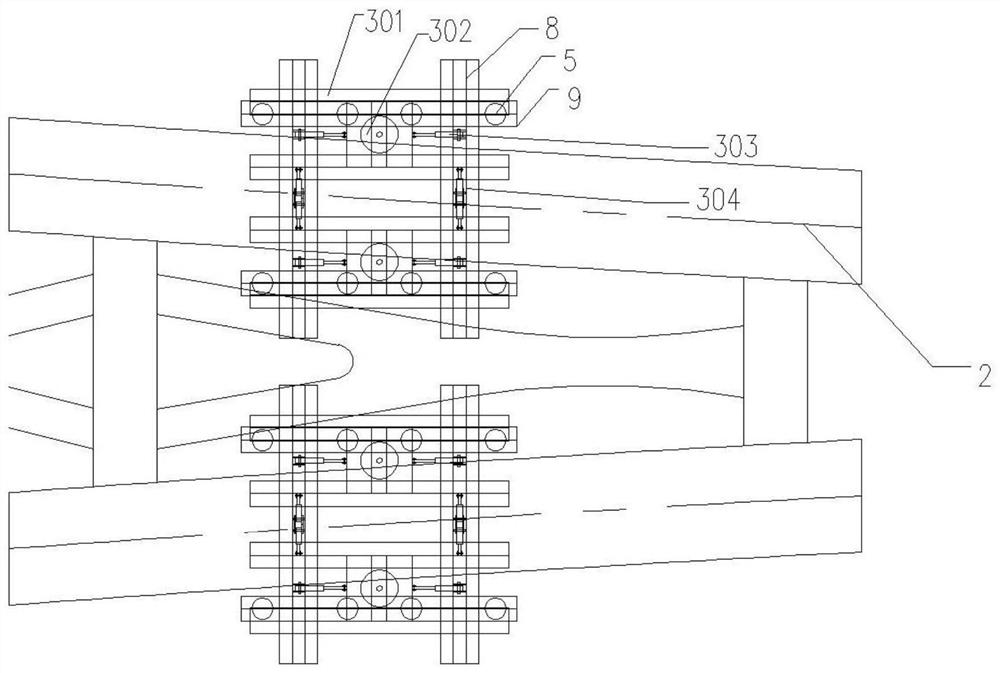

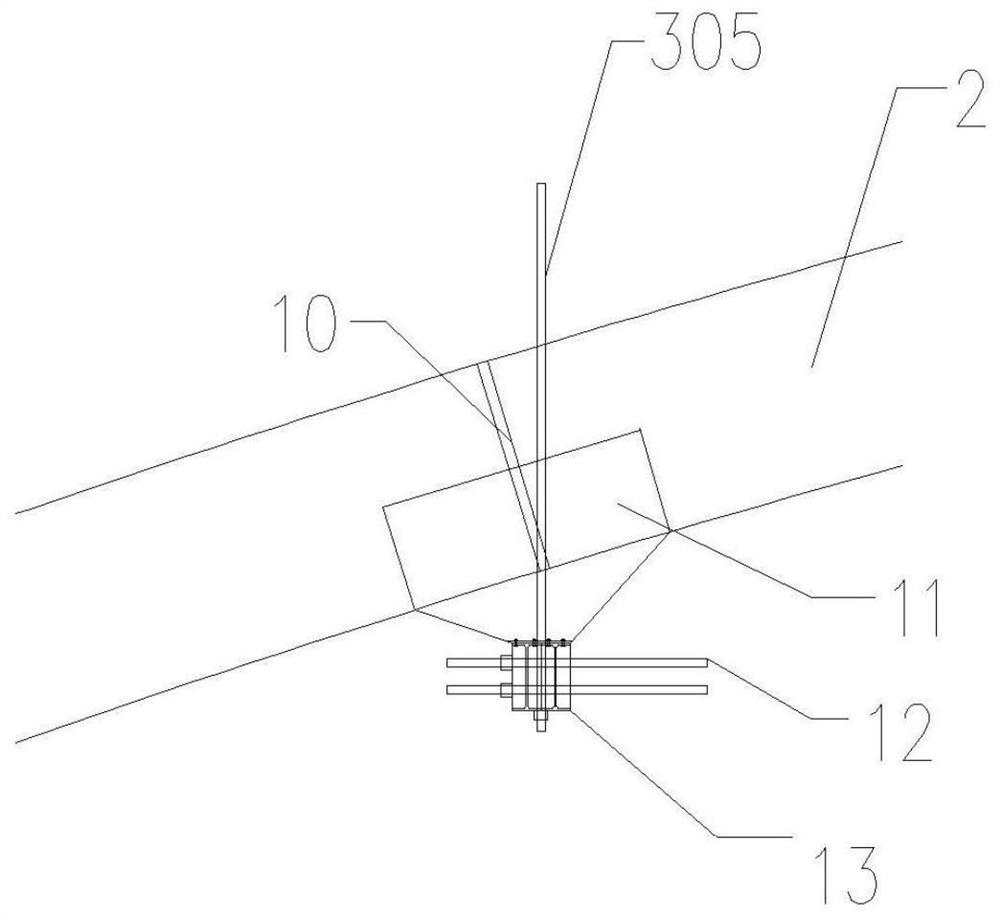

Lifting platform for shaft construction

ActiveCN102080446AAvoid shakingSimple and flexible operationScaffold accessoriesBuilding support scaffoldsElectrical controlArchitectural engineering

The invention discloses a lifting platform for shaft construction, comprising an operating platform, a lifter and an electrical control system, wherein the electrical control system controls the lifter to lift the operating platform via a working steel cable, the operating platform is composed of 6 to 12 trapezoid unit joints, at least four groups of anti-collision wall-against wheels are annularly arranged around the operating platform, and the bottom of the operating platform is circumferentially provided with at least four lead screw supporting components. The lifting platform for shaft construction has the advantages of strong construction adaptability, unlimited construction height, small floor area, good construction quality, high construction efficiency, great convenience of erection and disassembly, less labor, low labor intensity and the like. The trapezoid units, which are combined as required by construction, adapt to the construction requirement under different shaft situations, excellent convenience and flexibility are obtained during installation and usage, construction time is saved, and construction cost is lowered; the anti-collision wall-against wheels and the lead screw supporting components can be adjusted to adapt to the different requirements of shaft construction, and the lifting platform can conveniently and safely prevent the operating platform from shaking and becomes more stable and reliable as a whole.

Owner:中国水利水电第七工程局成都水电建设工程有限公司

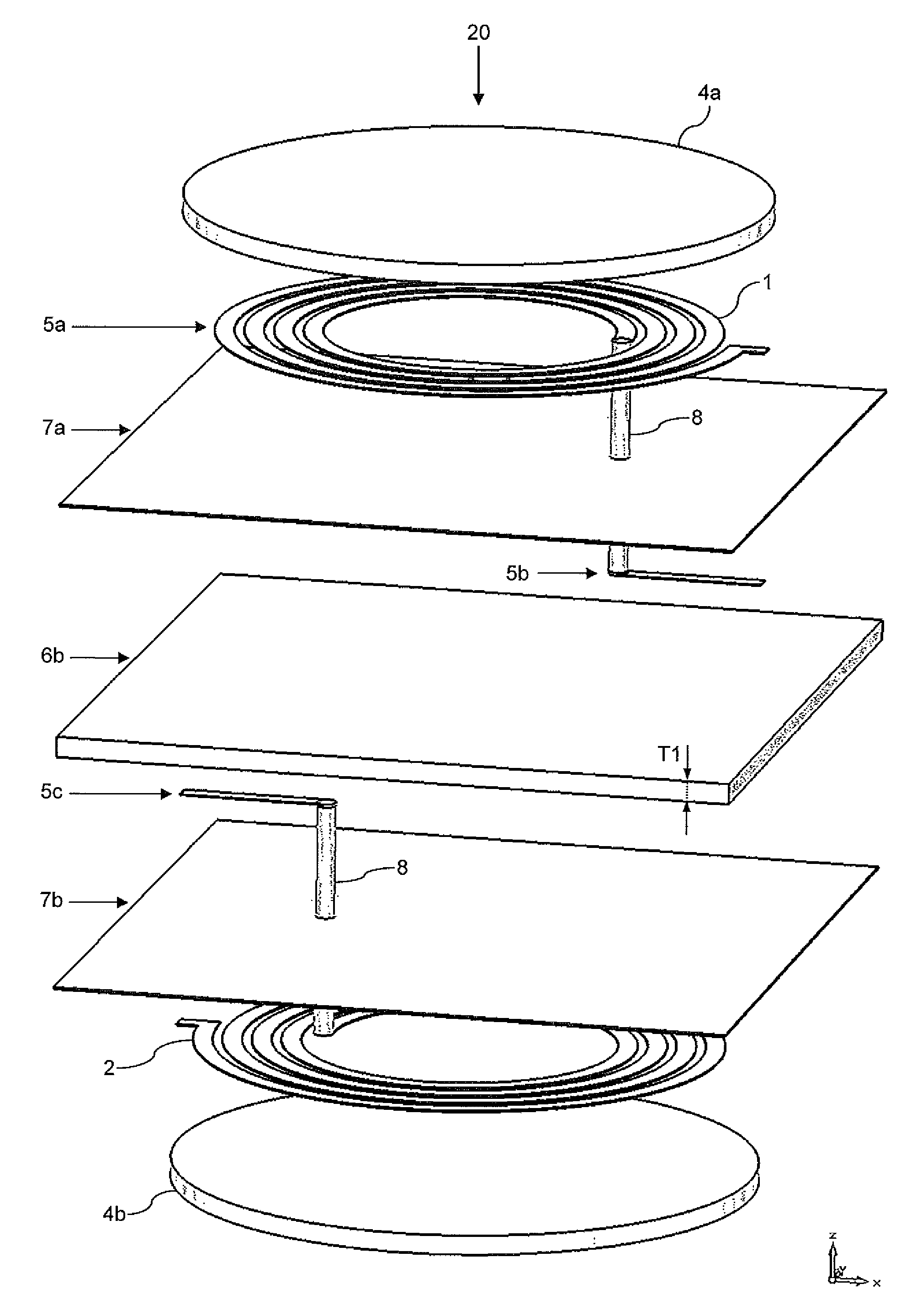

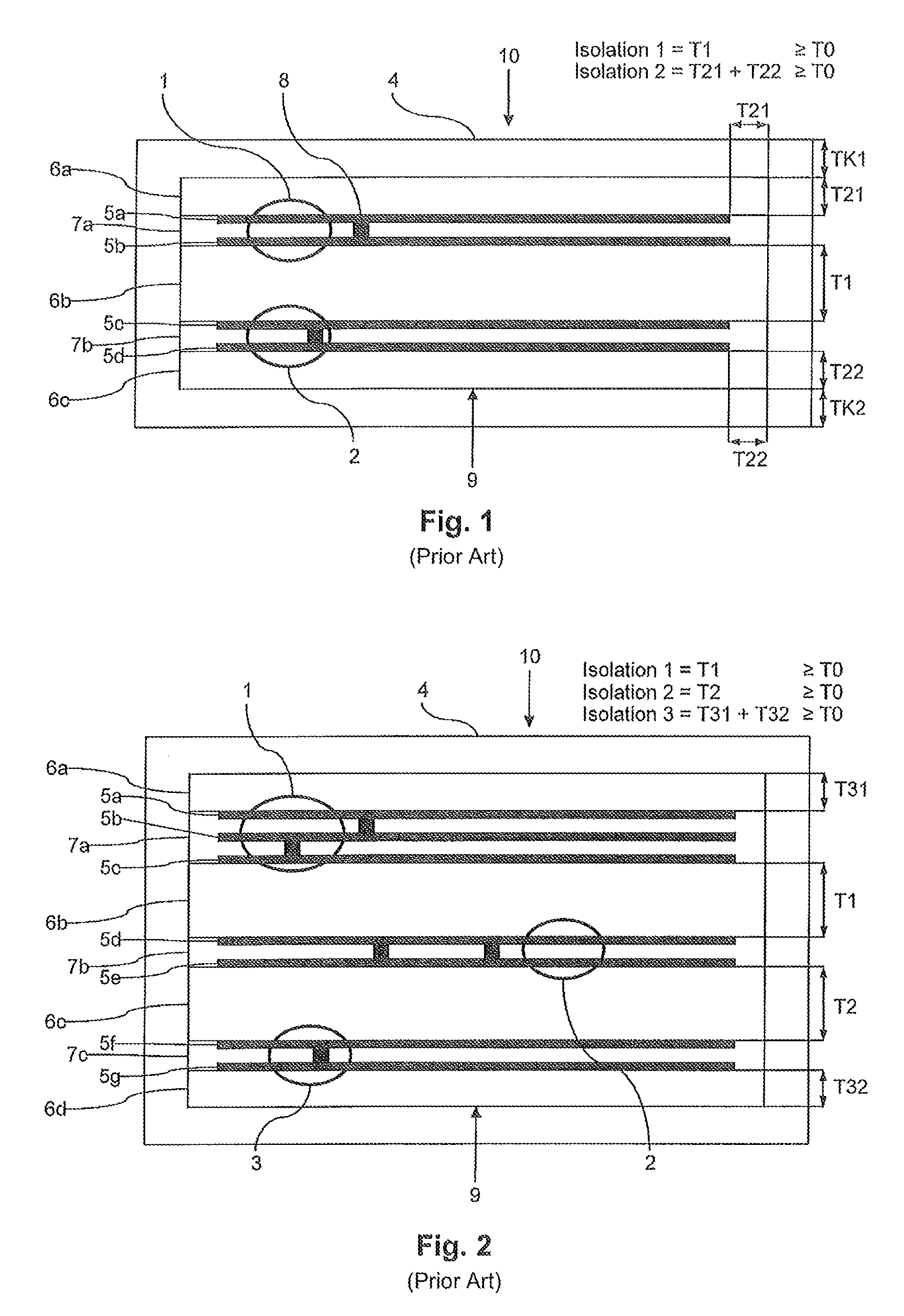

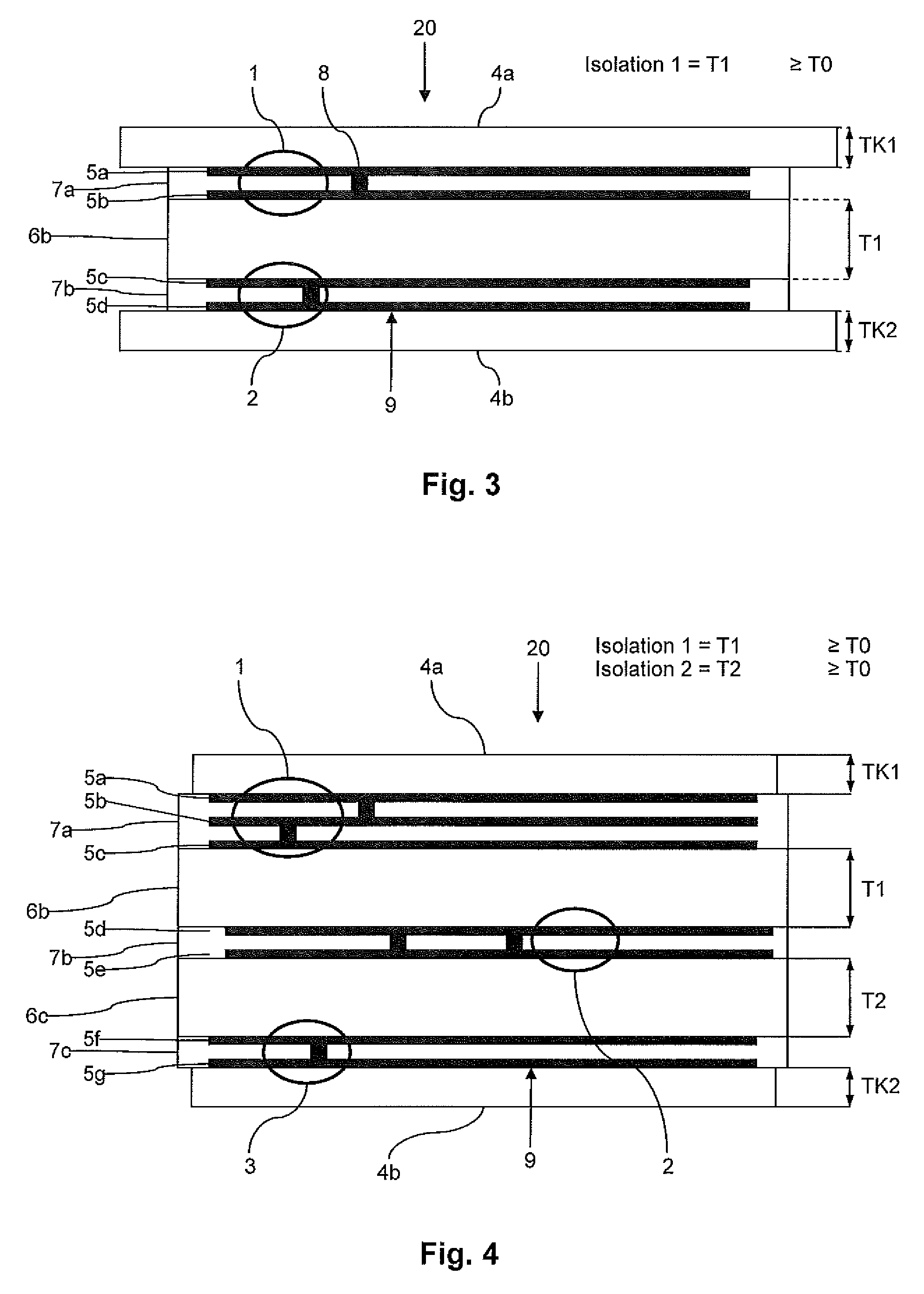

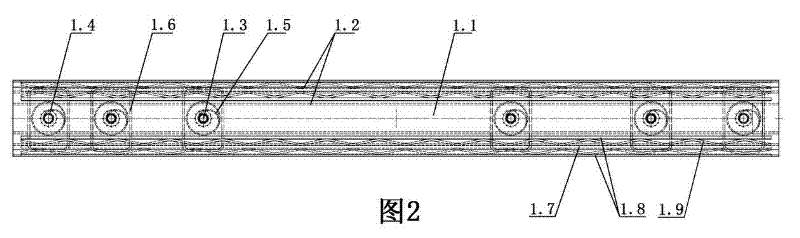

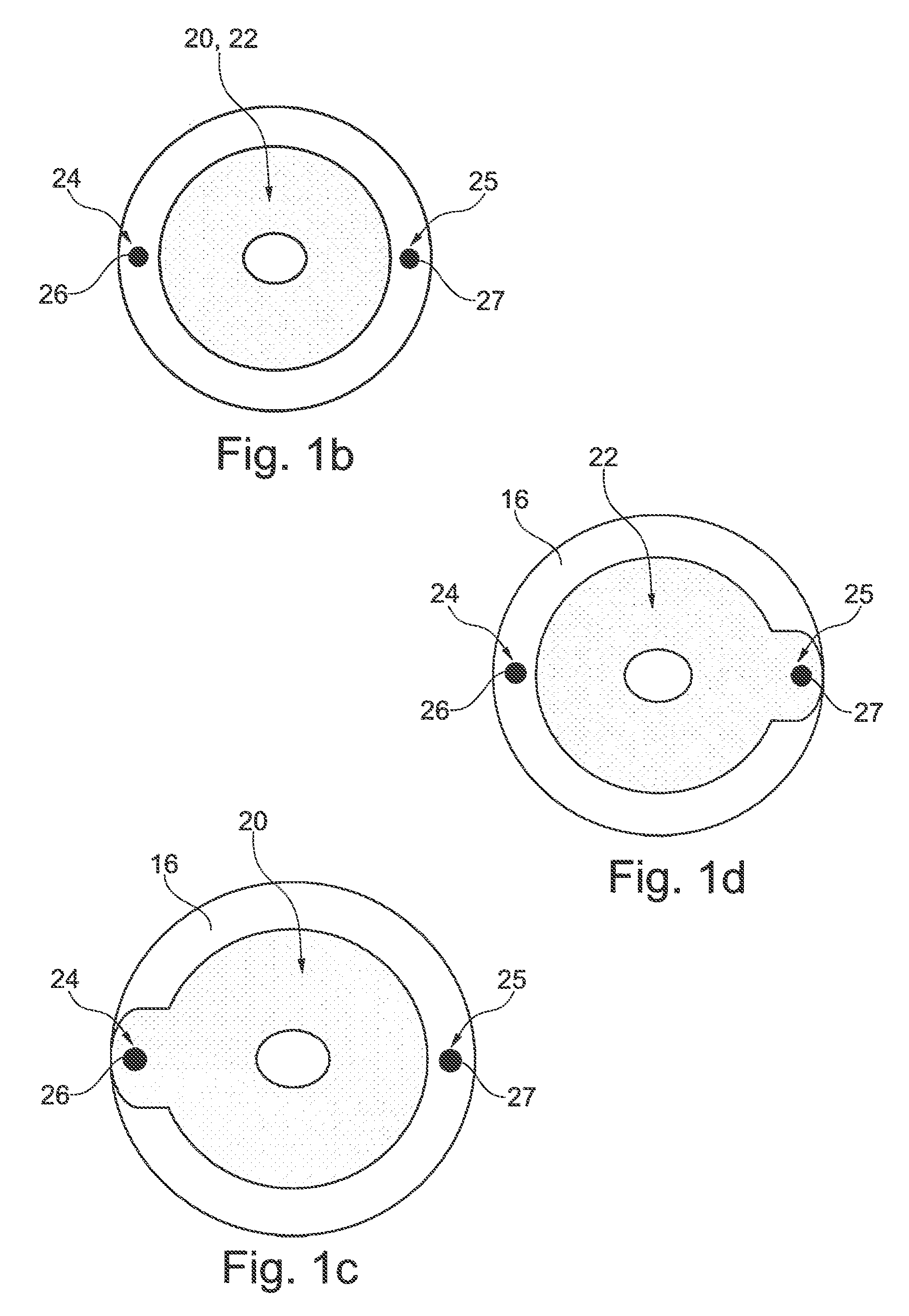

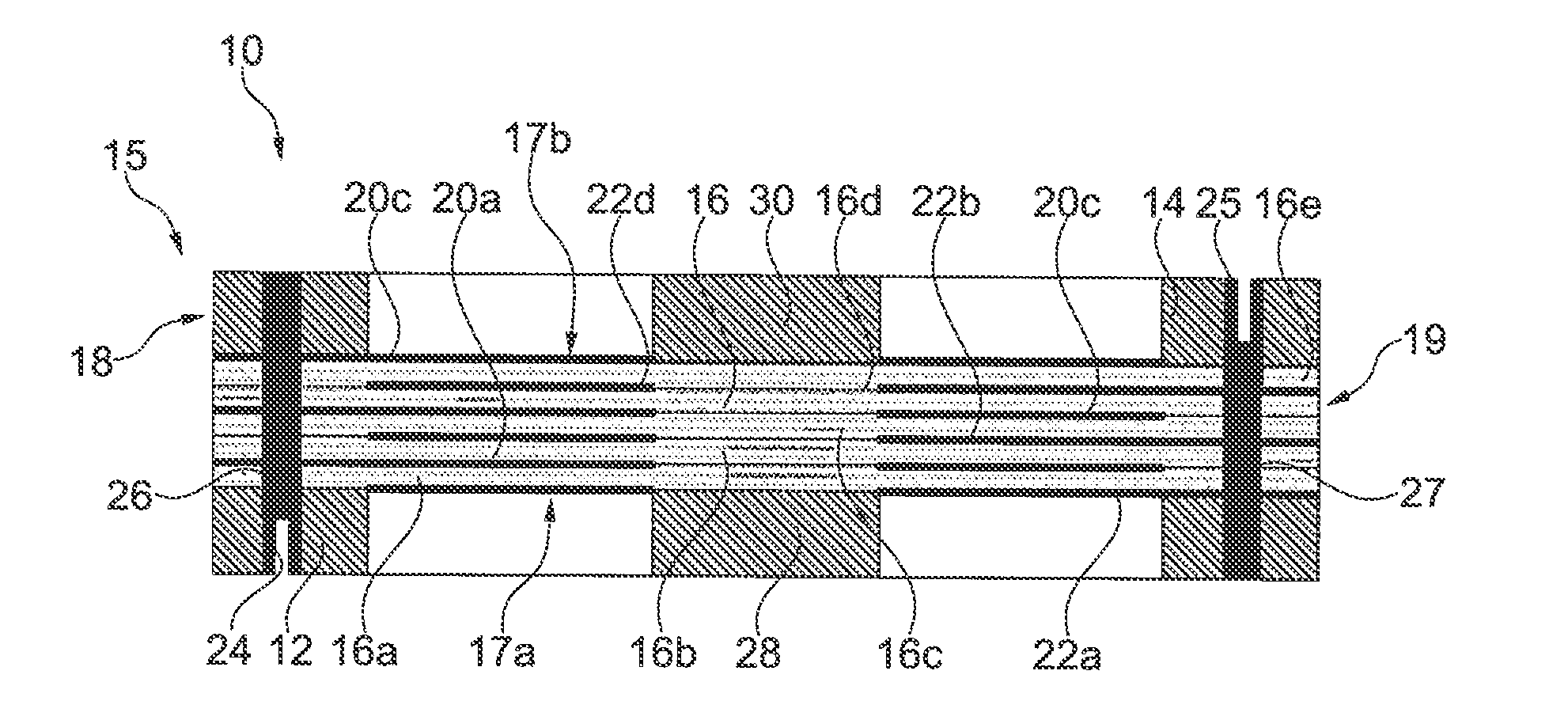

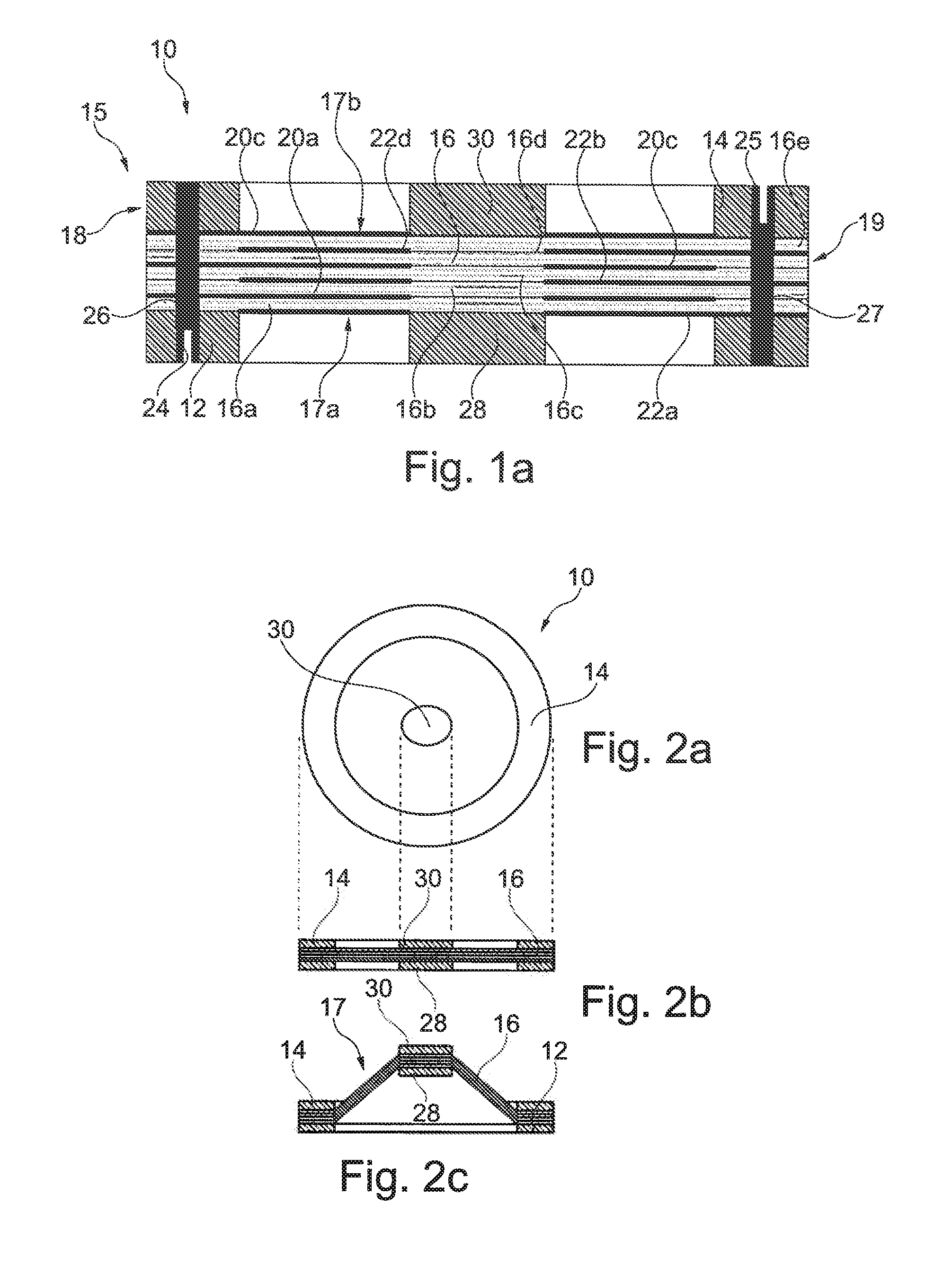

Planar transmitter with a layered structure

ActiveUS9508484B2Reduce numberReduce and minimize thicknessTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresLayered structureMagnetic layer

A planar transmitter, particularly an intrinsically safe transmitter, having a layer structure having a first circuit and at least a second circuit, wherein the first circuit and the second circuit are galvanically separated from one another by means of at least one insulation layer. The transmitter has a first magnetic layer and a second magnetic layer, wherein the first magnetic layer delimits a first side of the layer structure, and the second magnetic layer delimits a second side of the layer structure, wherein the first magnetic layer 4a and the second magnetic layer are separated from one another and can be assigned to different potential groups.

Owner:PHOENIX CONTACT GMBH & CO KG

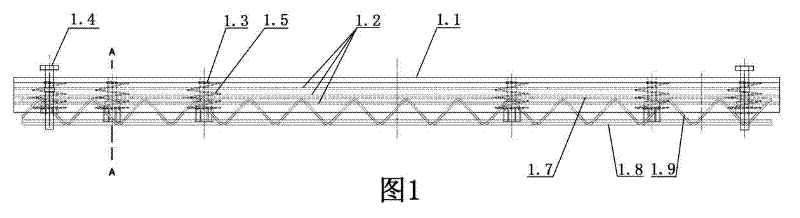

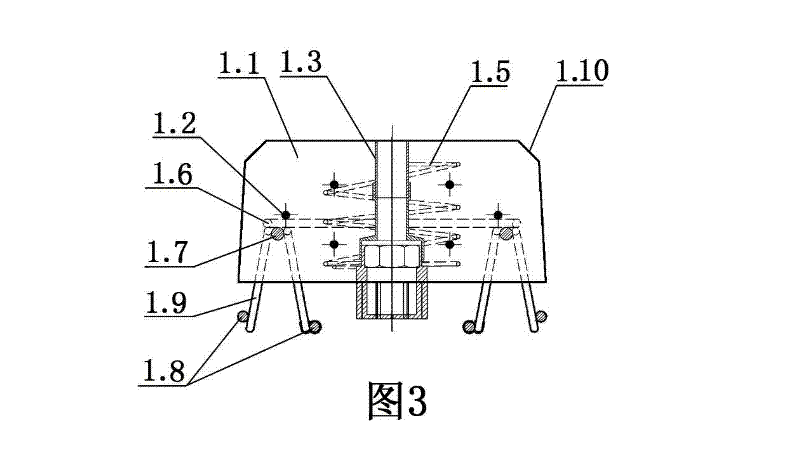

High-speed turnout switch tie for speed of 350km per hour and manufacturing method thereof

ActiveCN102162209AImprove bearing capacityHigh strengthRail switchesCeramic shaping apparatusAutomatic controlUltimate tensile strength

The invention discloses a high-speed turnout switch tie for speed of 350km per hour and a manufacturing method thereof. The method comprises the following steps of: 1, installing a template; 2, laying steel wires; 3, laying end plates; 4, installing sleeves and laying separators; 5, laying fittings; 6, starting a computer to automatically control the tensioned steel wires; 7, performing final tension; 8, fastening the separators, and binding the fittings; 9, putting an ash bucket and concrete into a die; 10, vibrating; 11, detaching the separators and partition plates; 12, clearing the production line; 13, curing; 14, performing concrete stripping; 15, tensioning; 16, breaking the wires, and stripping; 17, spraying, treating the sleeves, and cutting the exposed ribs; 18, clearing the die and the parting agent; and 19, warehousing. Accurate control of distribution quantity, uniform distribution and high speed are realized, stirring uniformity and concrete compactness are realized in automatic distribution, and the strength of the switch die is ensured.

Owner:中铁十四局集团房桥有限公司

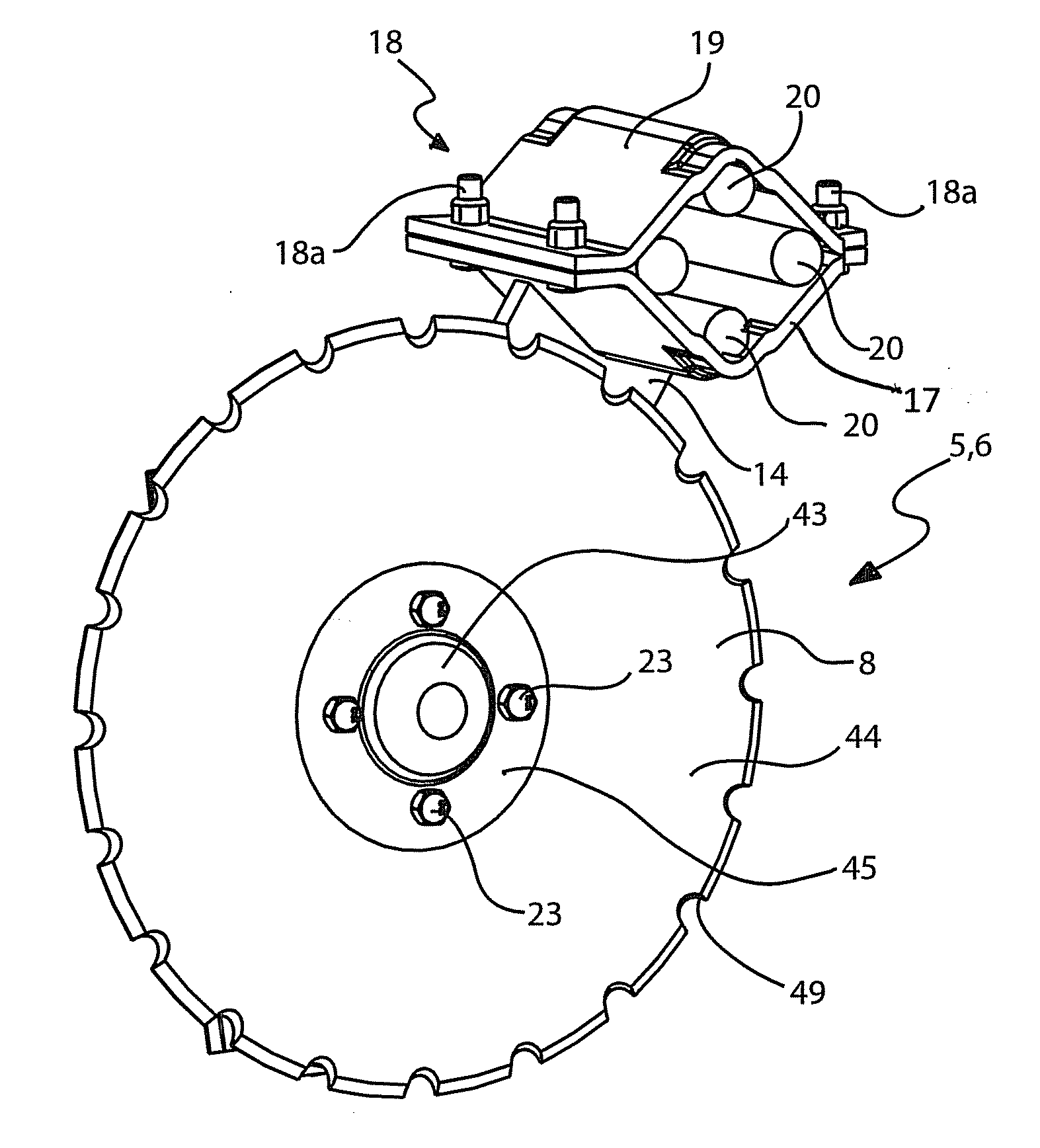

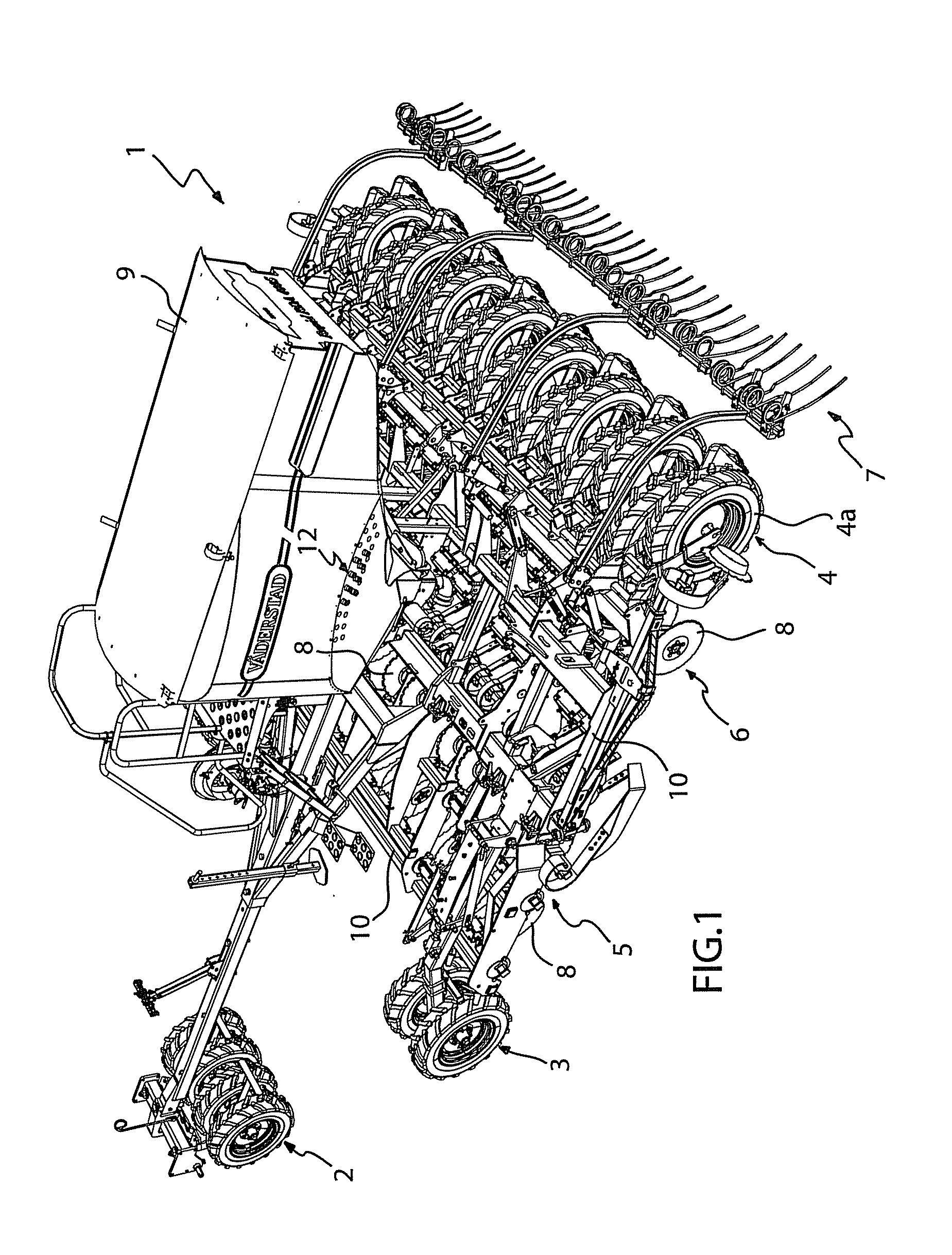

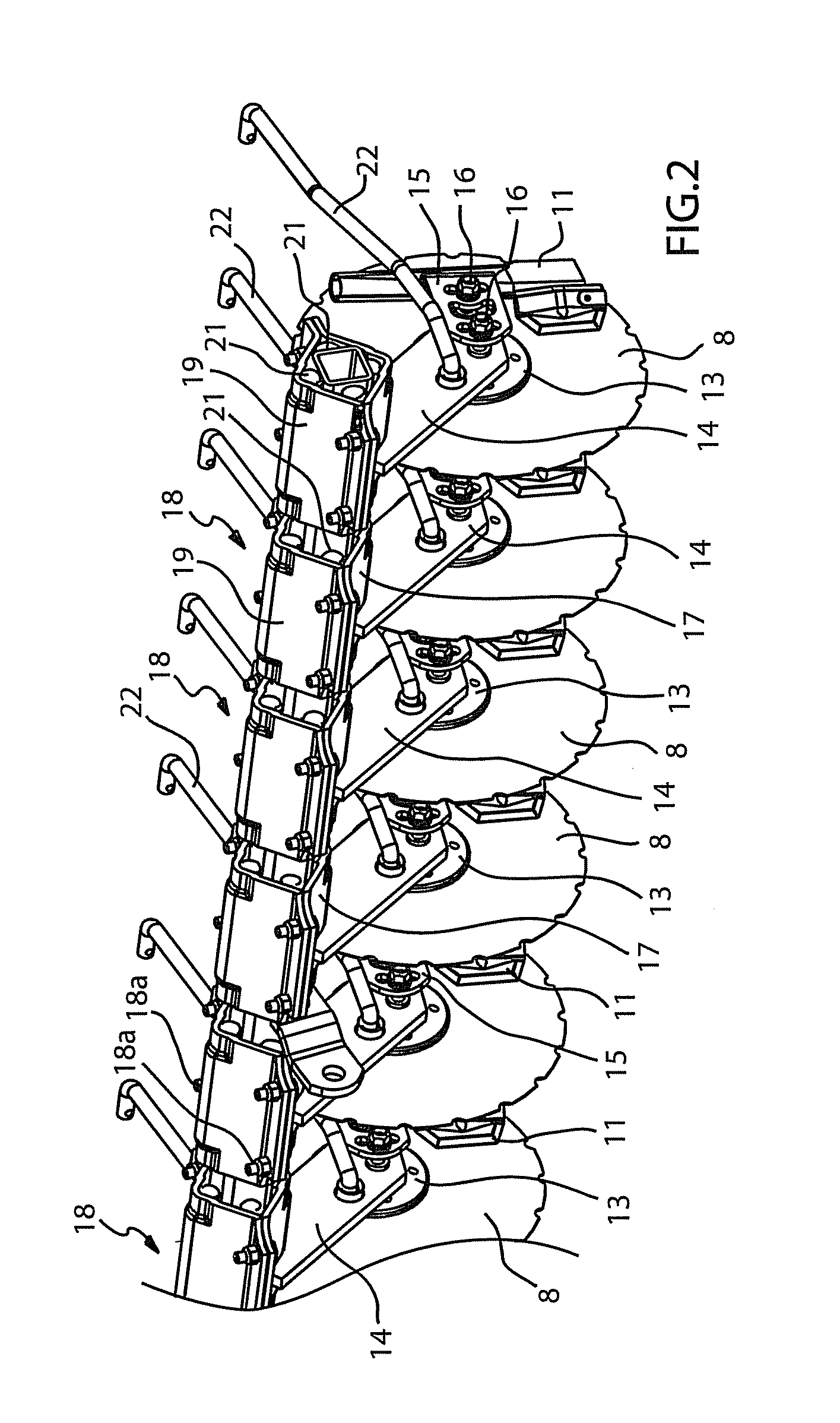

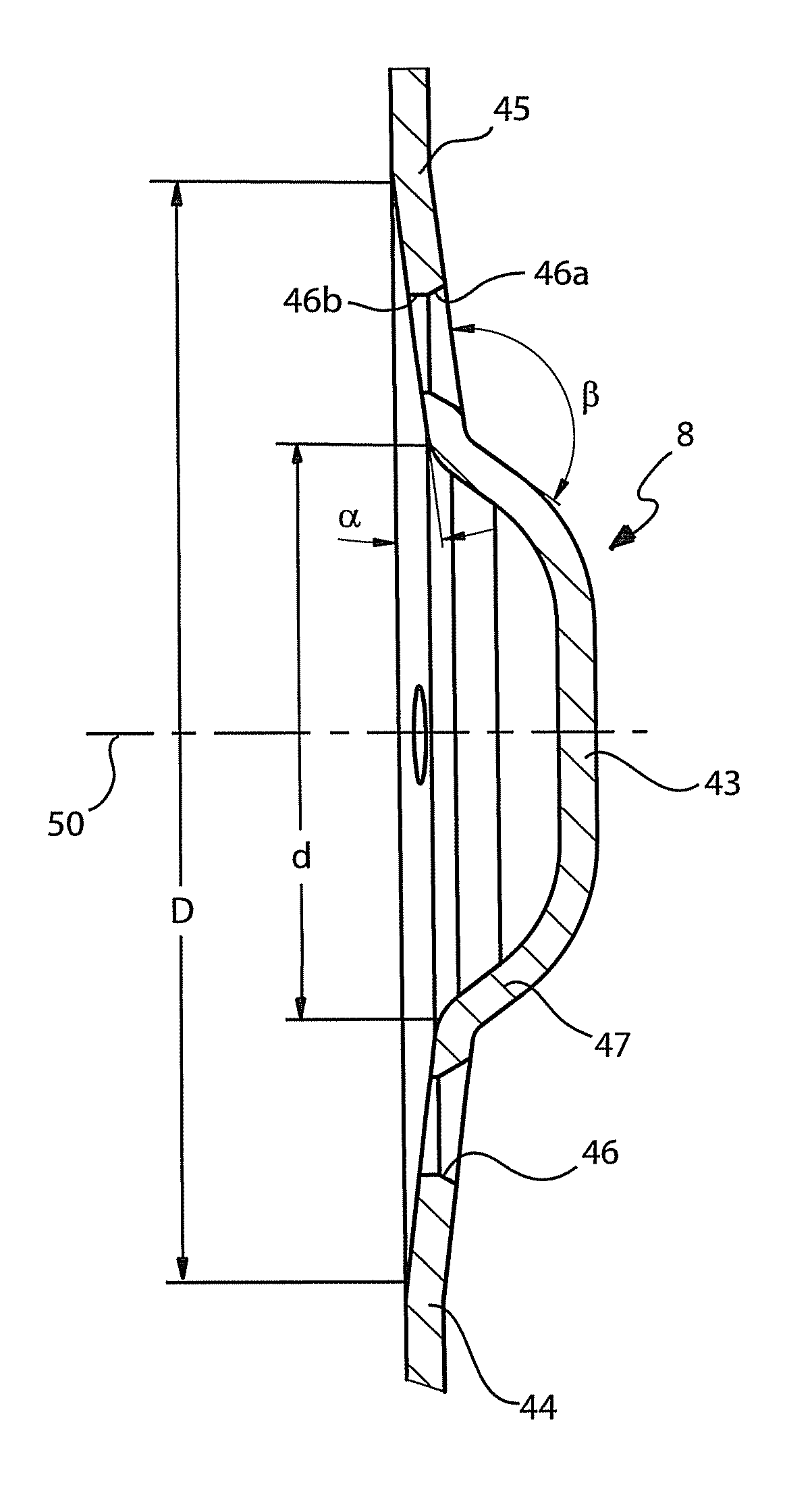

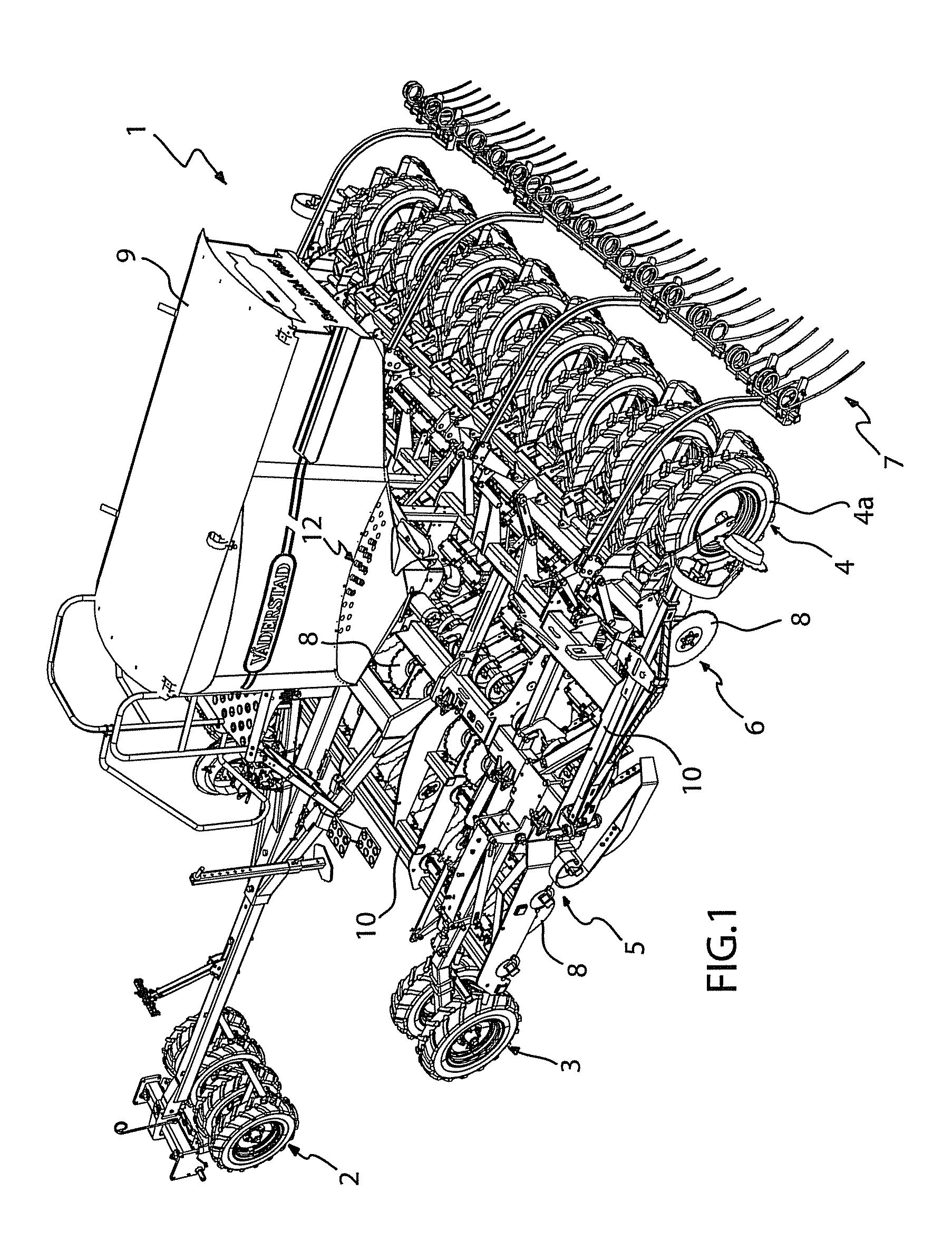

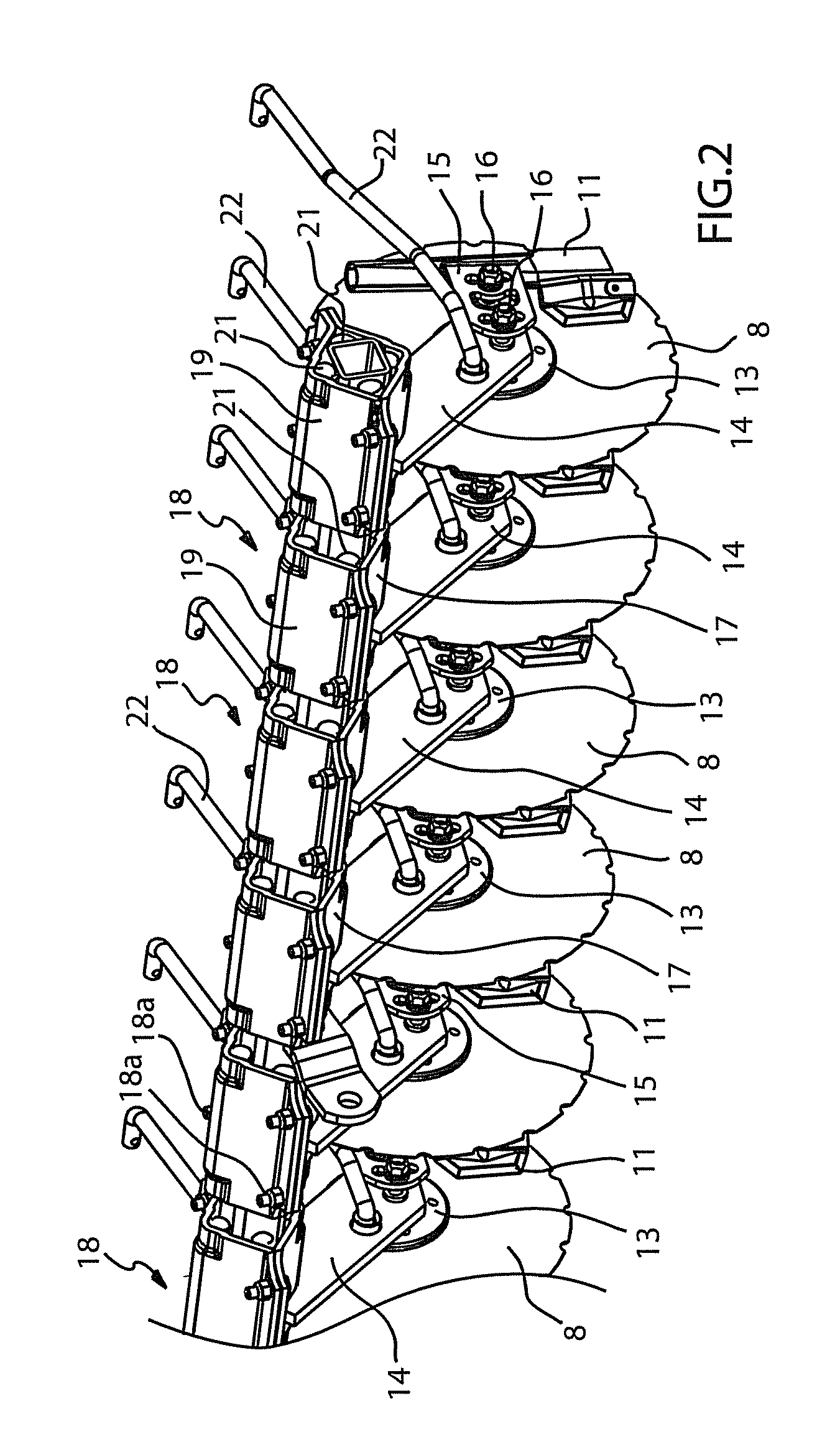

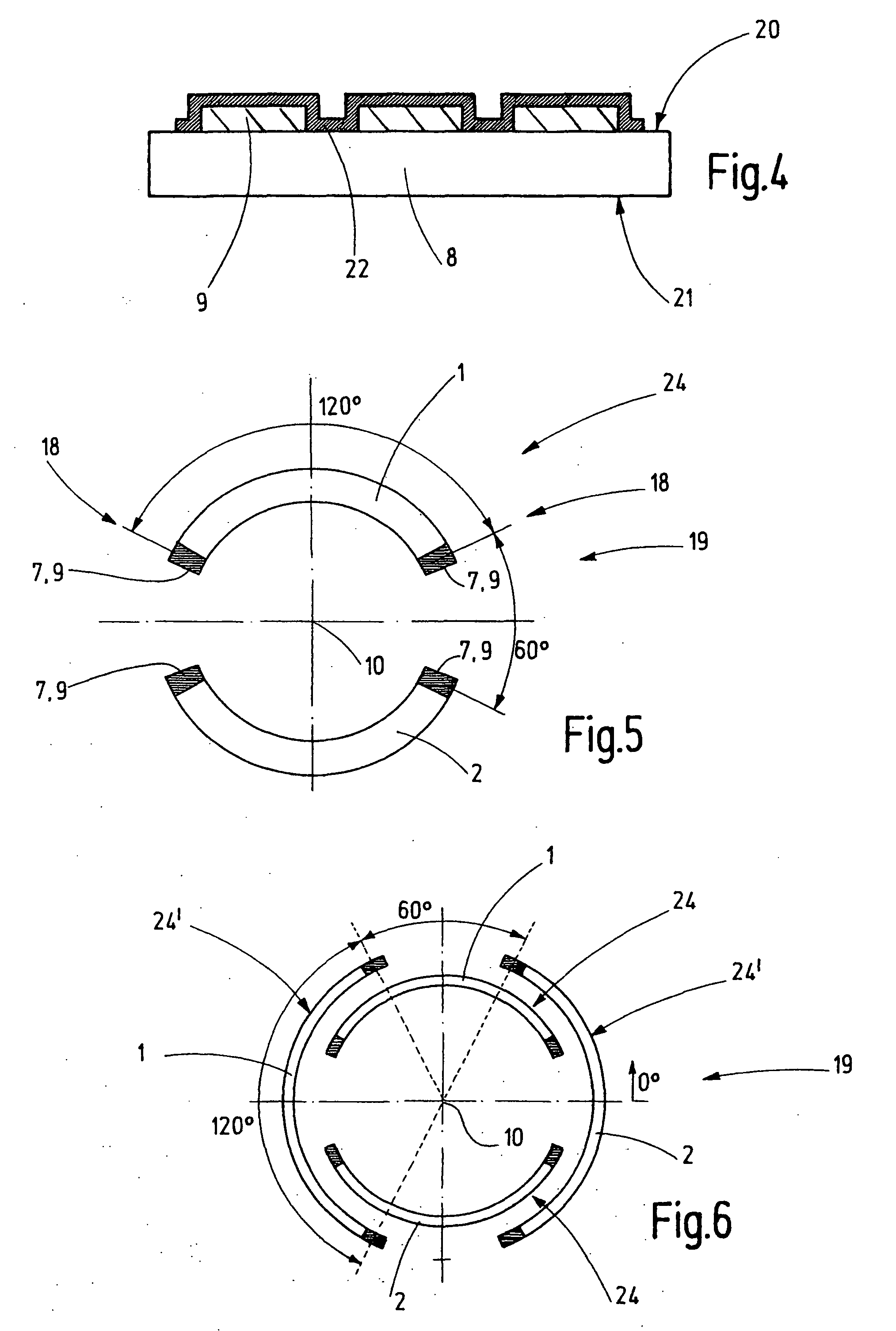

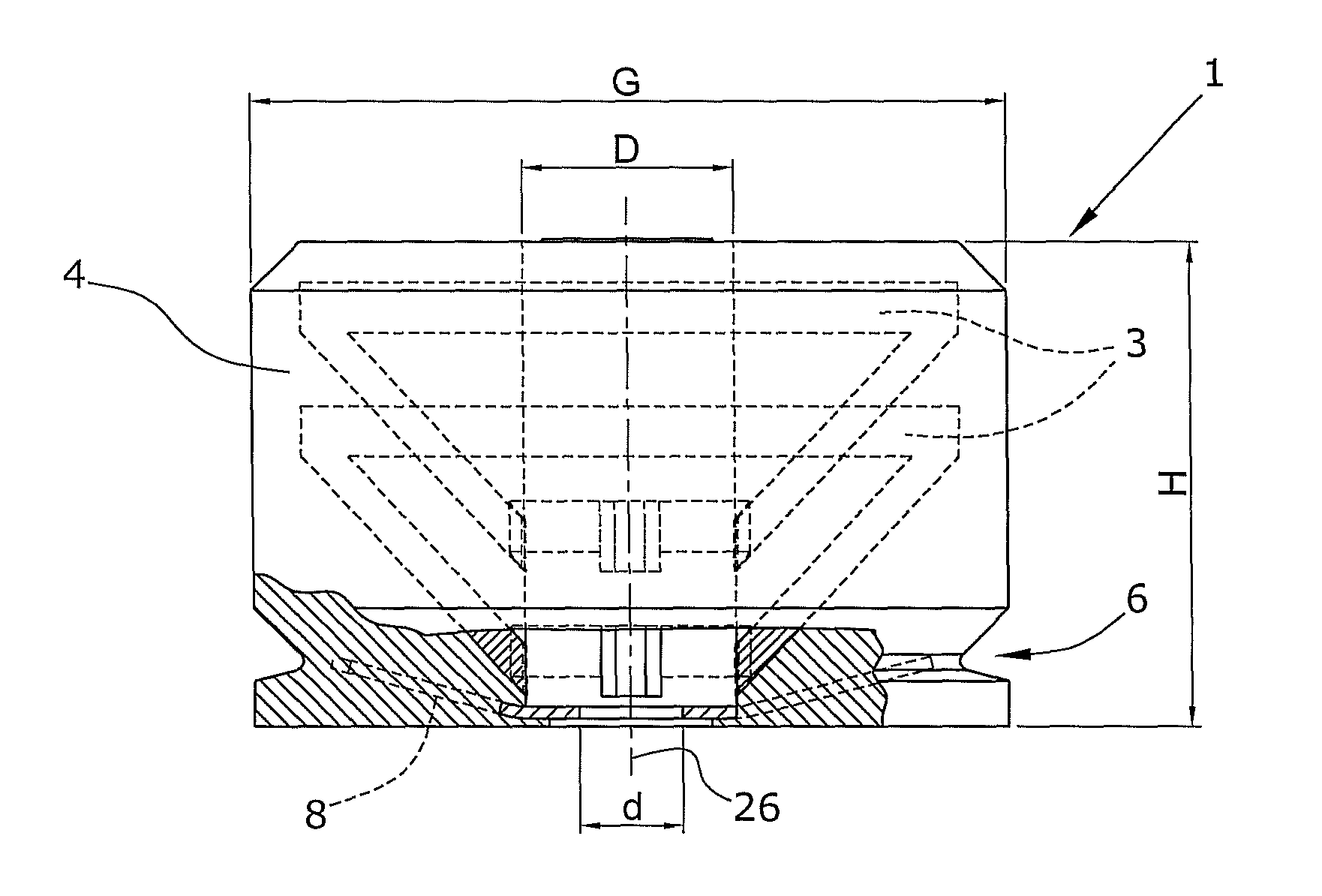

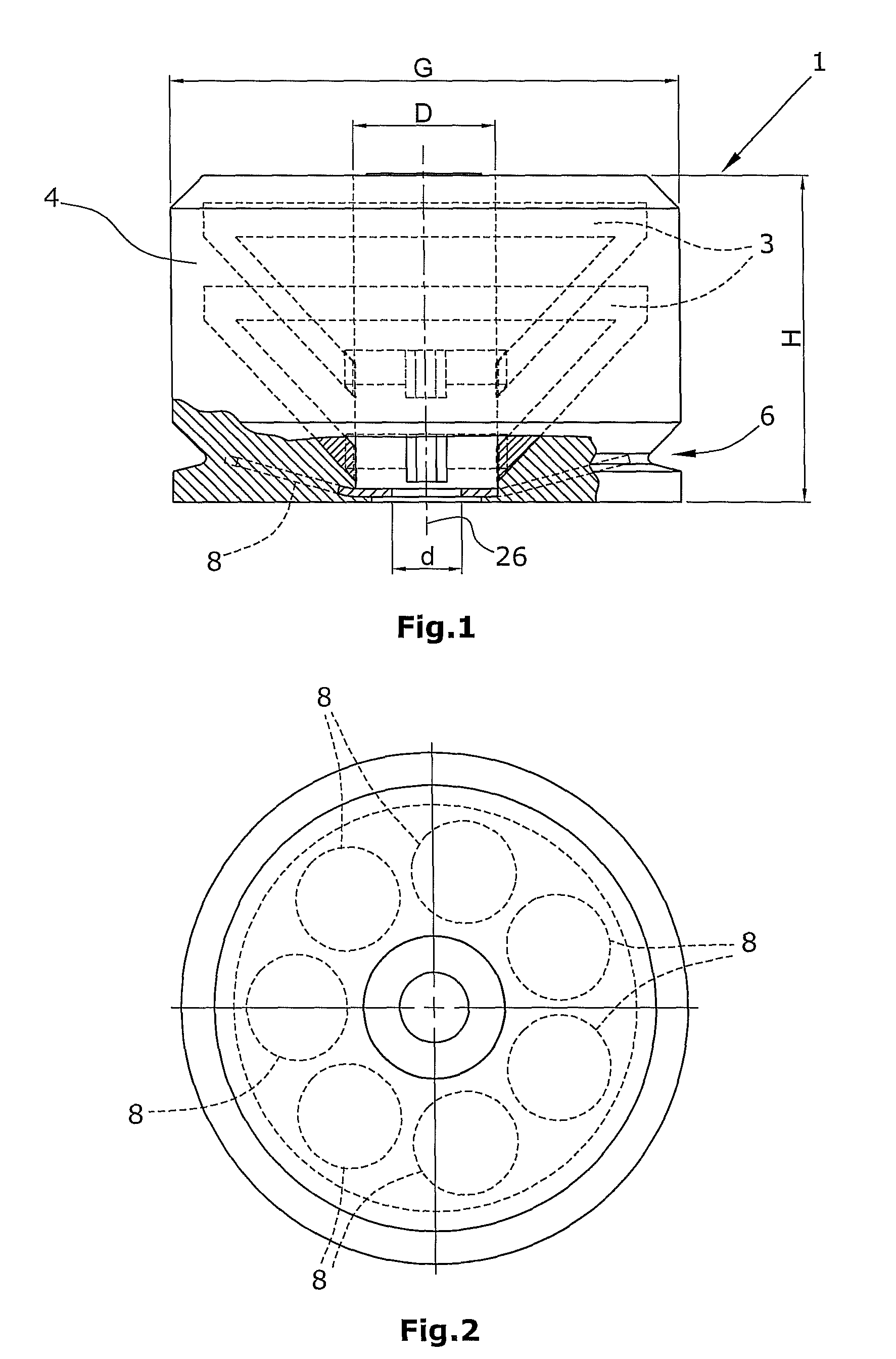

Disc for an agricultural implement

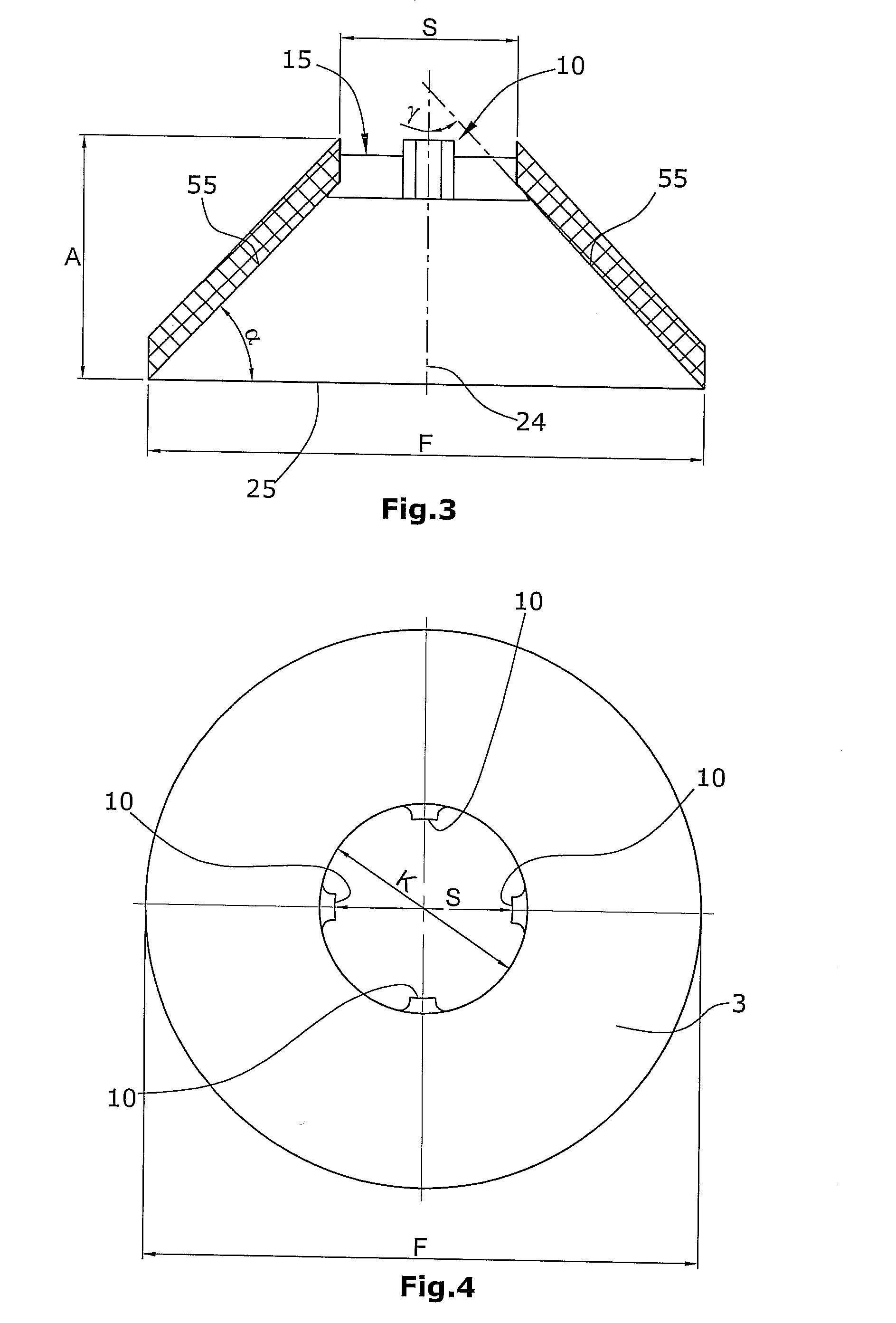

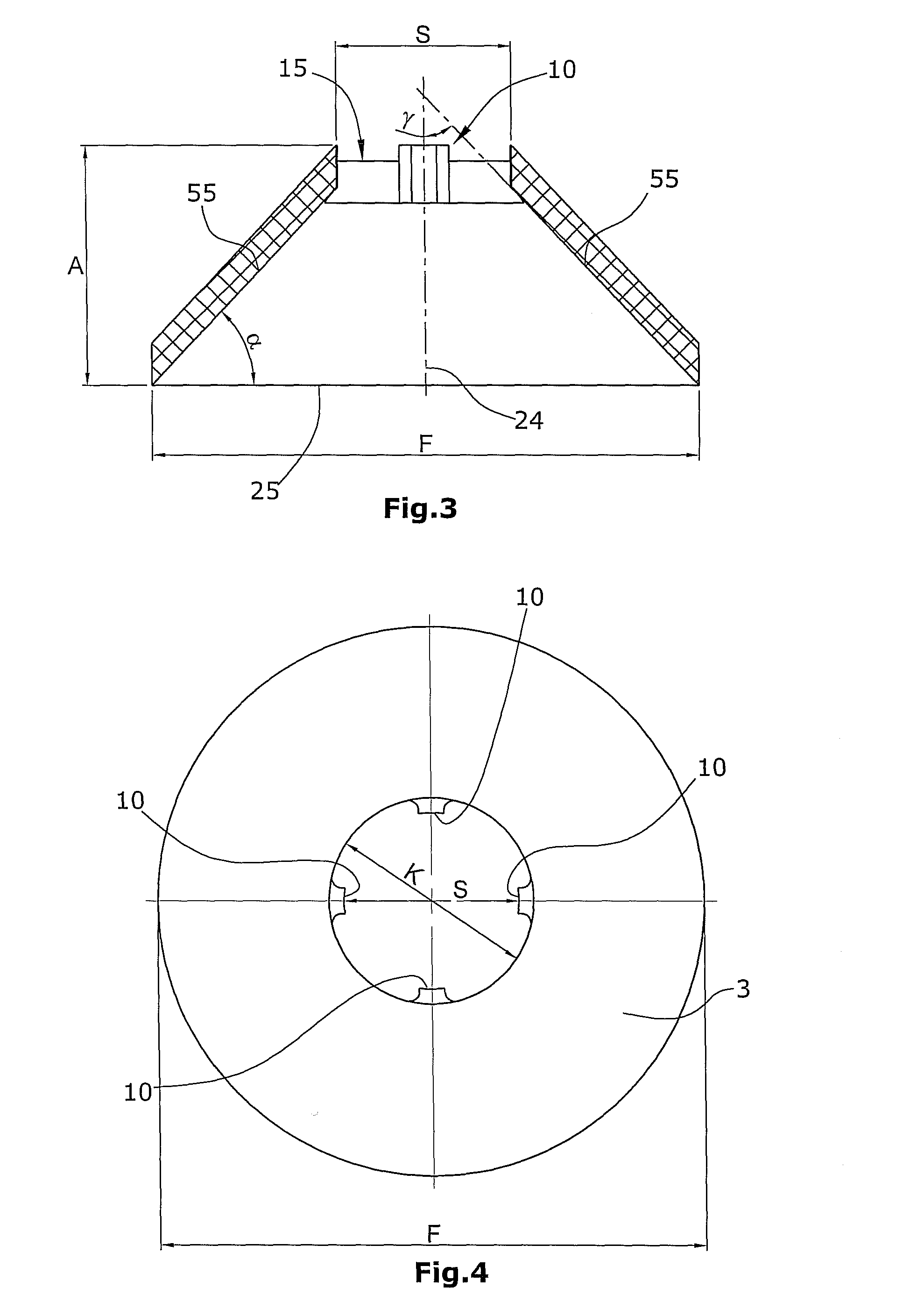

ActiveUS20120103642A1Reduce construction heightEasy to replaceAgricultural machinesPlantingCircular discConvex side

The invention refers to a disc (8) for an agricultural implement (1) comprising an annular, outside a predetermined centre diameter (D) defined, soil-cultivating portion (44), a central, inside a predetermined centre diameter (d) defined, dish-shaped portion (43), with a boss-receiving, inner side and between these portions an existing, annular connection portion (45) with fastening screw holes (46). The connection portion (45) is a truncated conical portion, the inner mantle surface of which is mainly straight or double-bowed with the convex side facing said inner side and a line through the opening plane in the hole opening of each fastening screw hole on said inner side forms an angle α with a plane that is perpendicular to the centre line of the disc, wherein the angle α is 5°-10°.

Owner:VADERSTAD HLDG

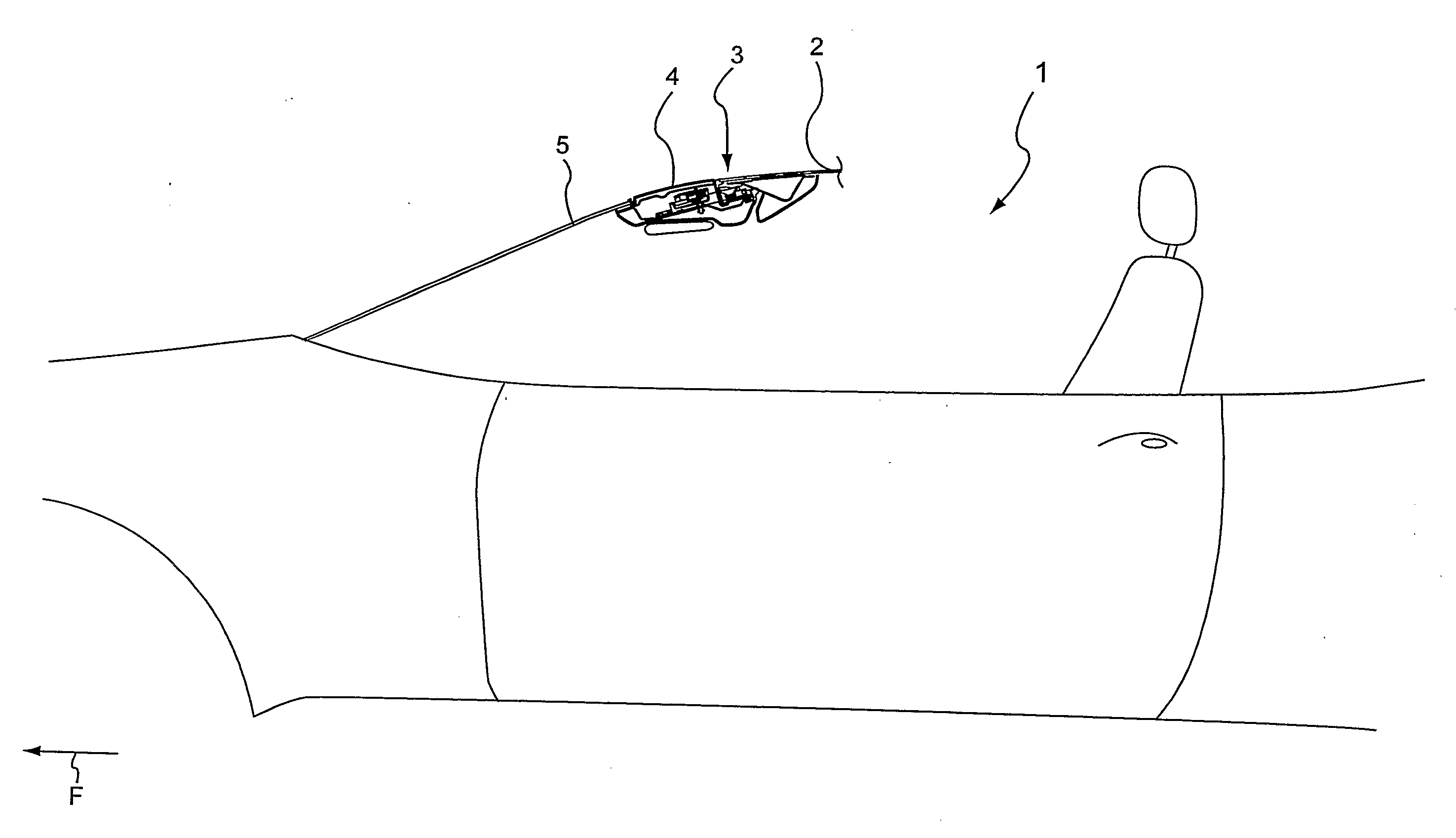

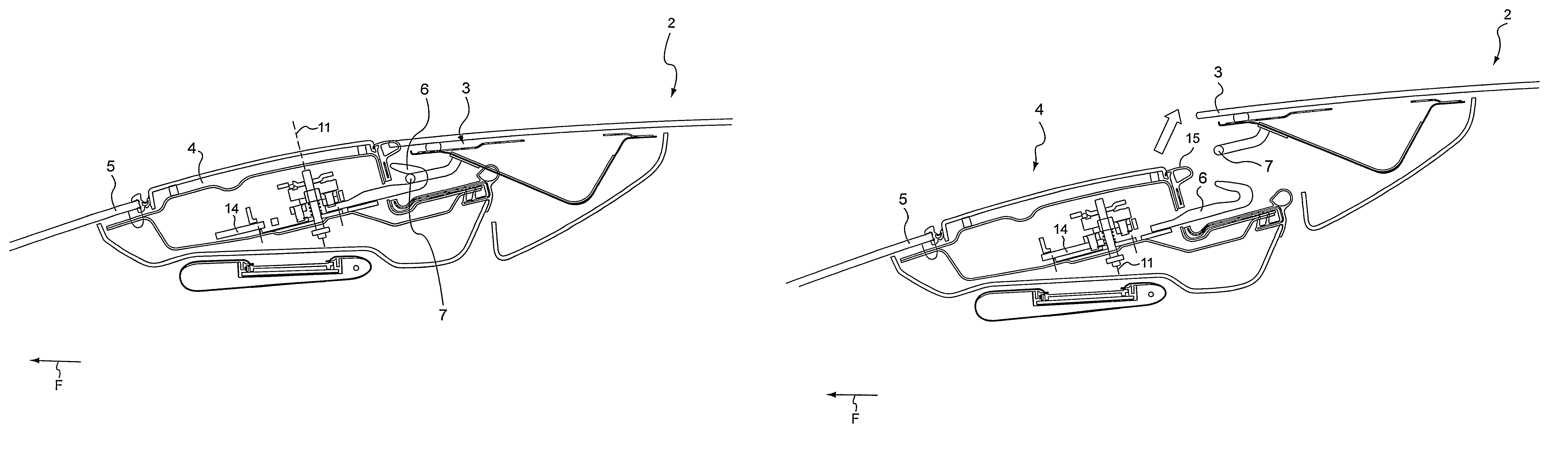

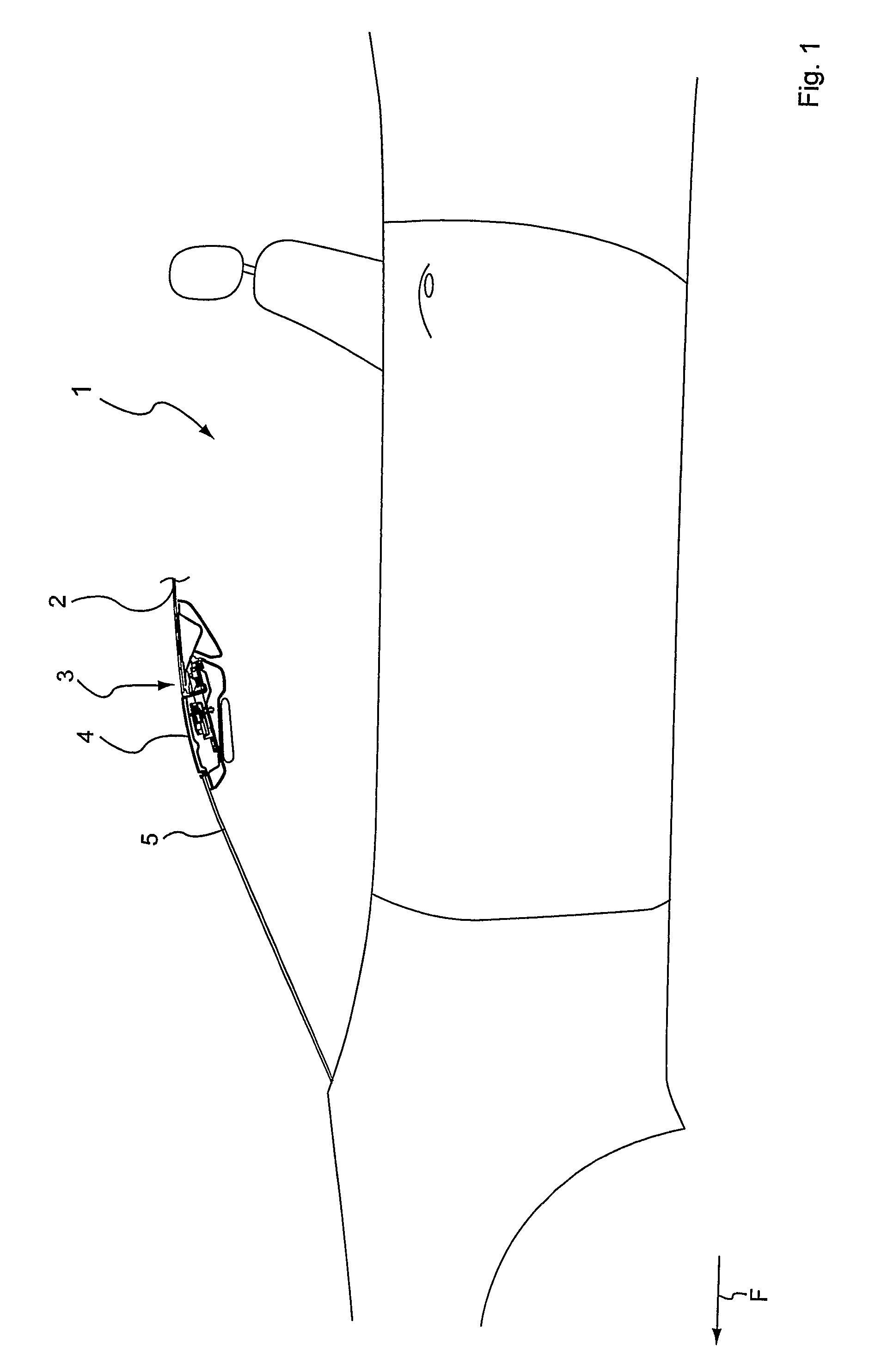

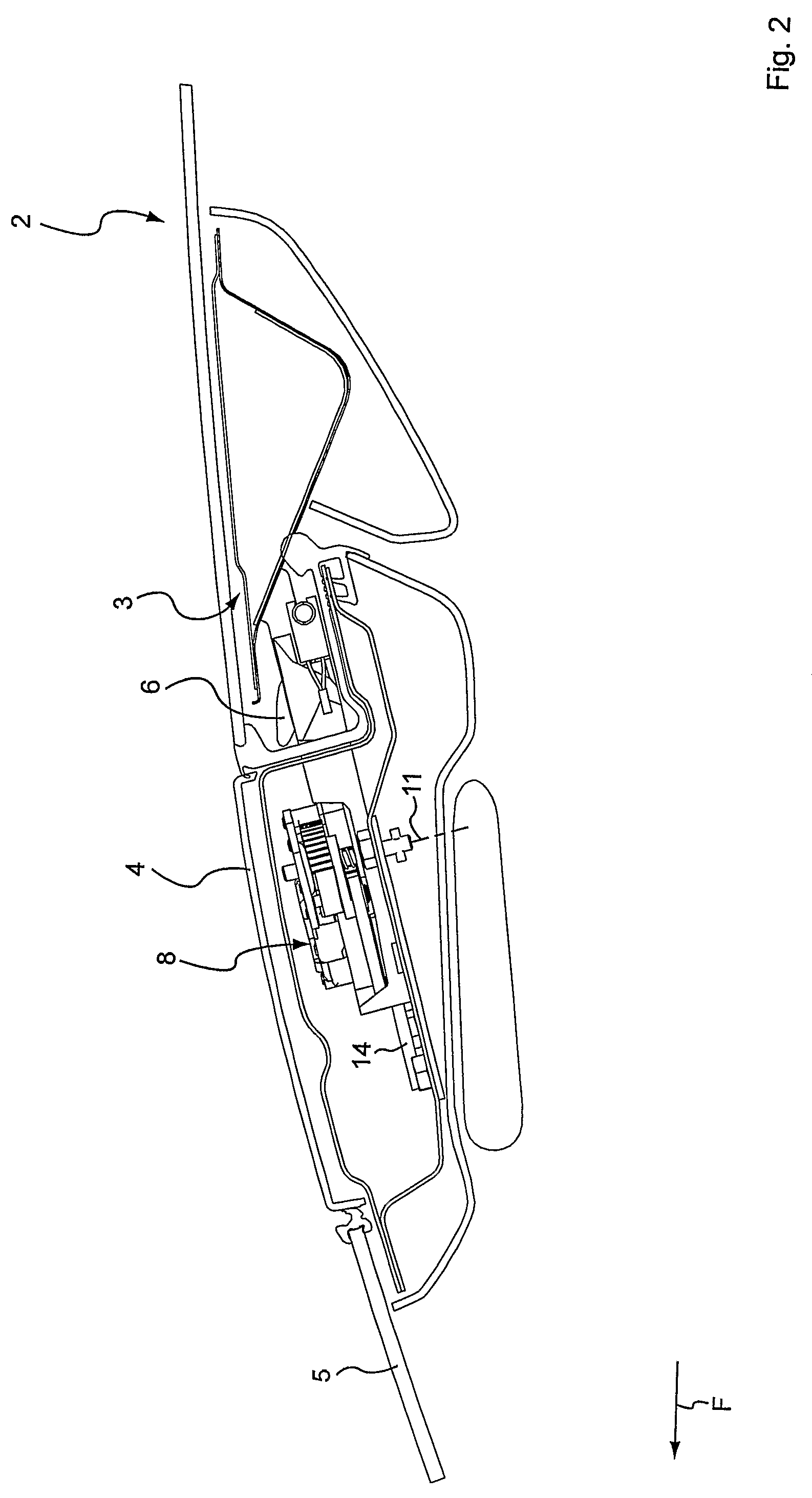

Convertible Roof that Latches to an Upper Transverse Frame Part of the Windshield Frame

InactiveUS20080290688A1Reduce construction heightSmall spacingEngine sealsVehicle sealing arrangementsEngineeringWindshield

A convertible vehicle according to the present invention includes a vehicle body with a windshield frame with an upper transverse frame part. A convertible roof for the vehicle has a front end. At least one hook part is disposed in the upper transverse frame part and is linearly movable in the upper transverse frame part

Owner:WILHELM KARMANN GMBH

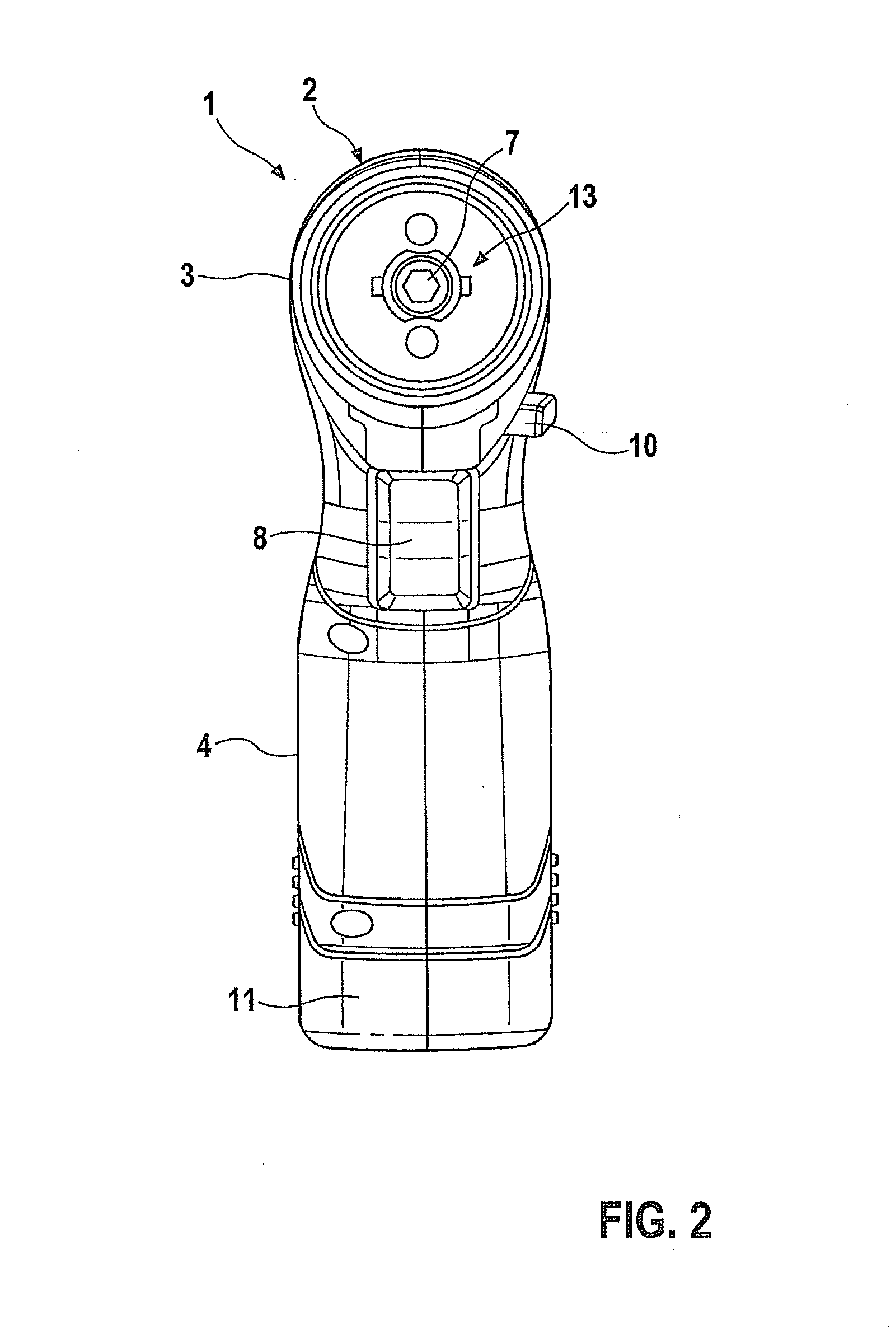

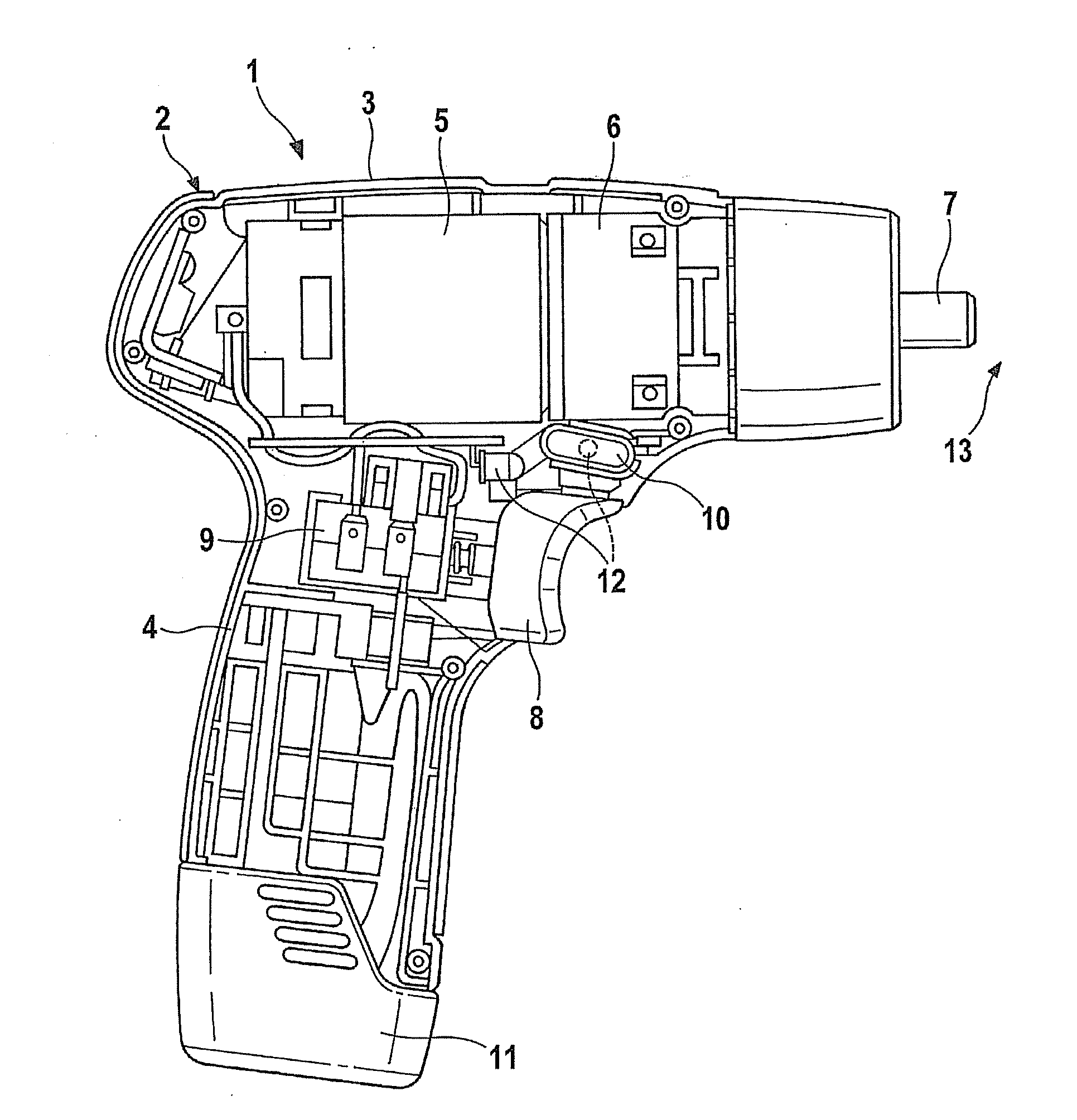

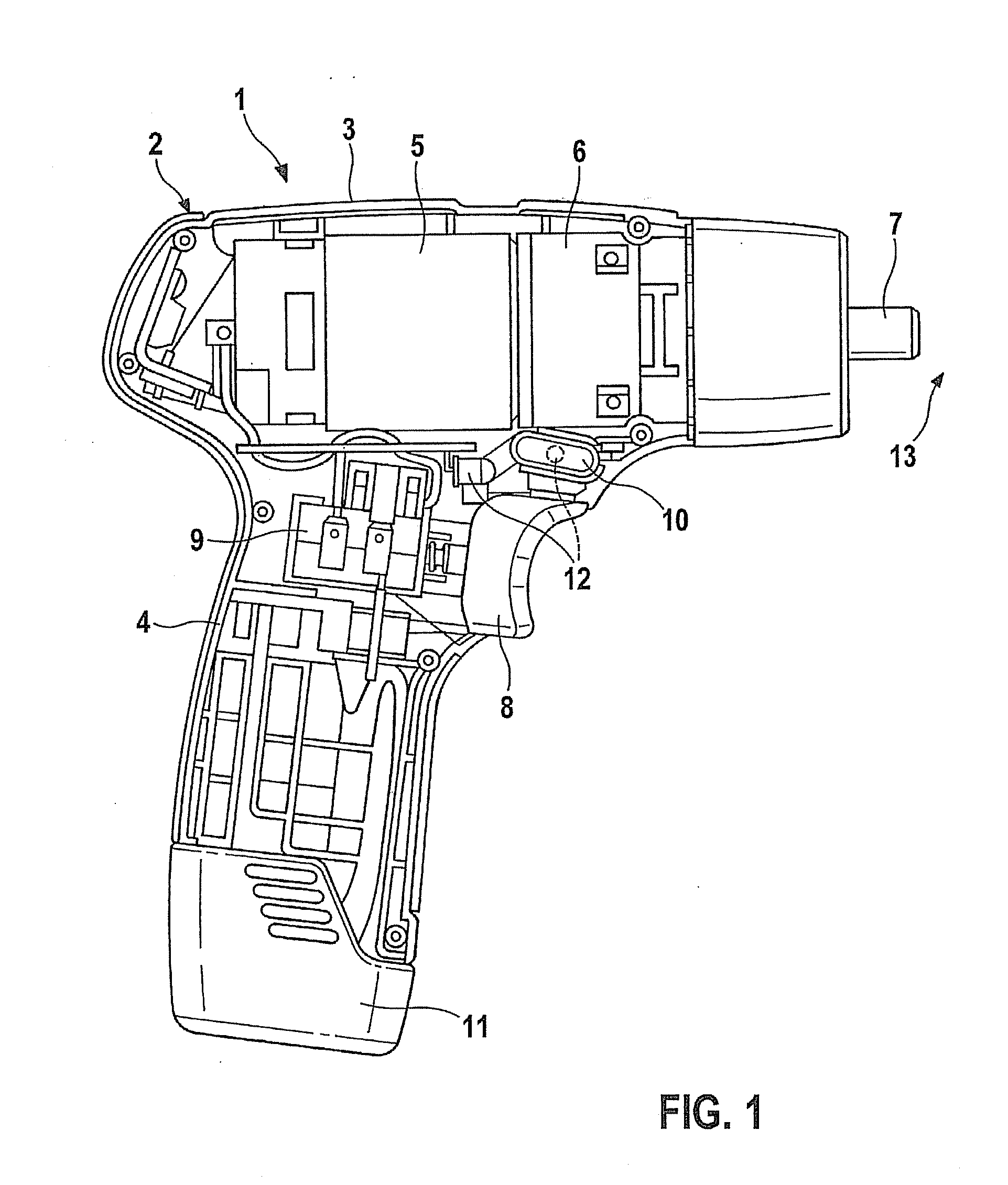

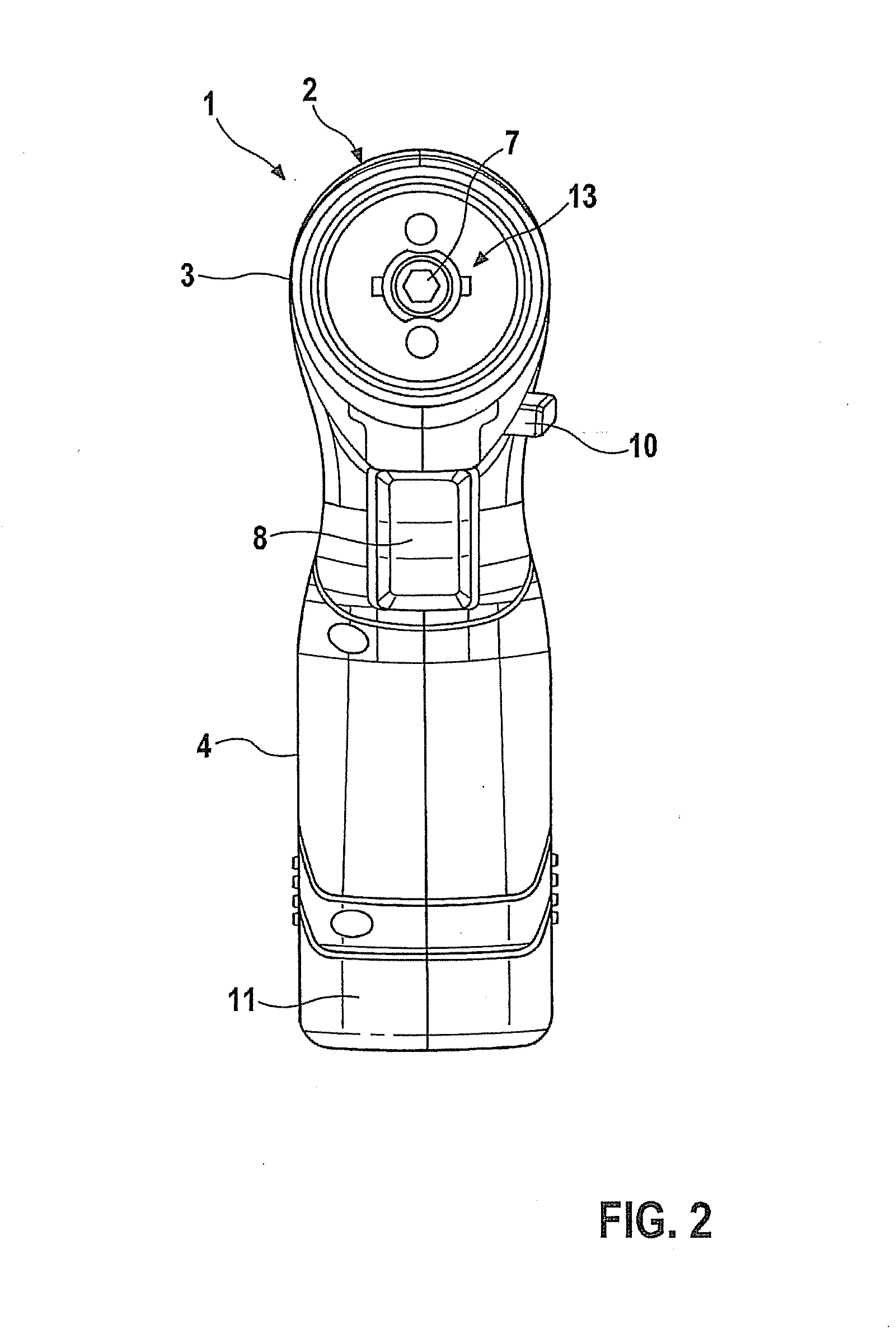

Hand-held power tool

A hand-held power tool is equipped with a lighting element for illuminating the working field, the lighting element including a light source and a trigger switch for activating or adjusting a drive motor forming a component of the lighting element in such a way that light beams emitted by the light source are guided via the trigger switch to the working field.

Owner:ROBERT BOSCH GMBH

Disc for an agricultural implement

ActiveUS9107340B2Reduce construction heightEasy to replaceAgricultural machinesPlantingCircular discConvex side

The invention refers to a disc (8) for an agricultural implement (1) comprising an annular, outside a predetermined center diameter (D) defined, soil-cultivating portion (44), a central, inside a predetermined center diameter (d) defined, dish-shaped portion (43), with a boss-receiving, inner side and between these portions an existing, annular connection portion (45) with fastening screw holes (46). The connection portion (45) is a truncated conical portion, the inner mantle surface of which is mainly straight or double-bowed with the convex side facing said inner side and a line through the opening plane in the hole opening of each fastening screw hole on said inner side forms an angle α with a plane that is perpendicular to the center line of the disc, wherein the angle α is 5°-10°.

Owner:VADERSTAD HLDG

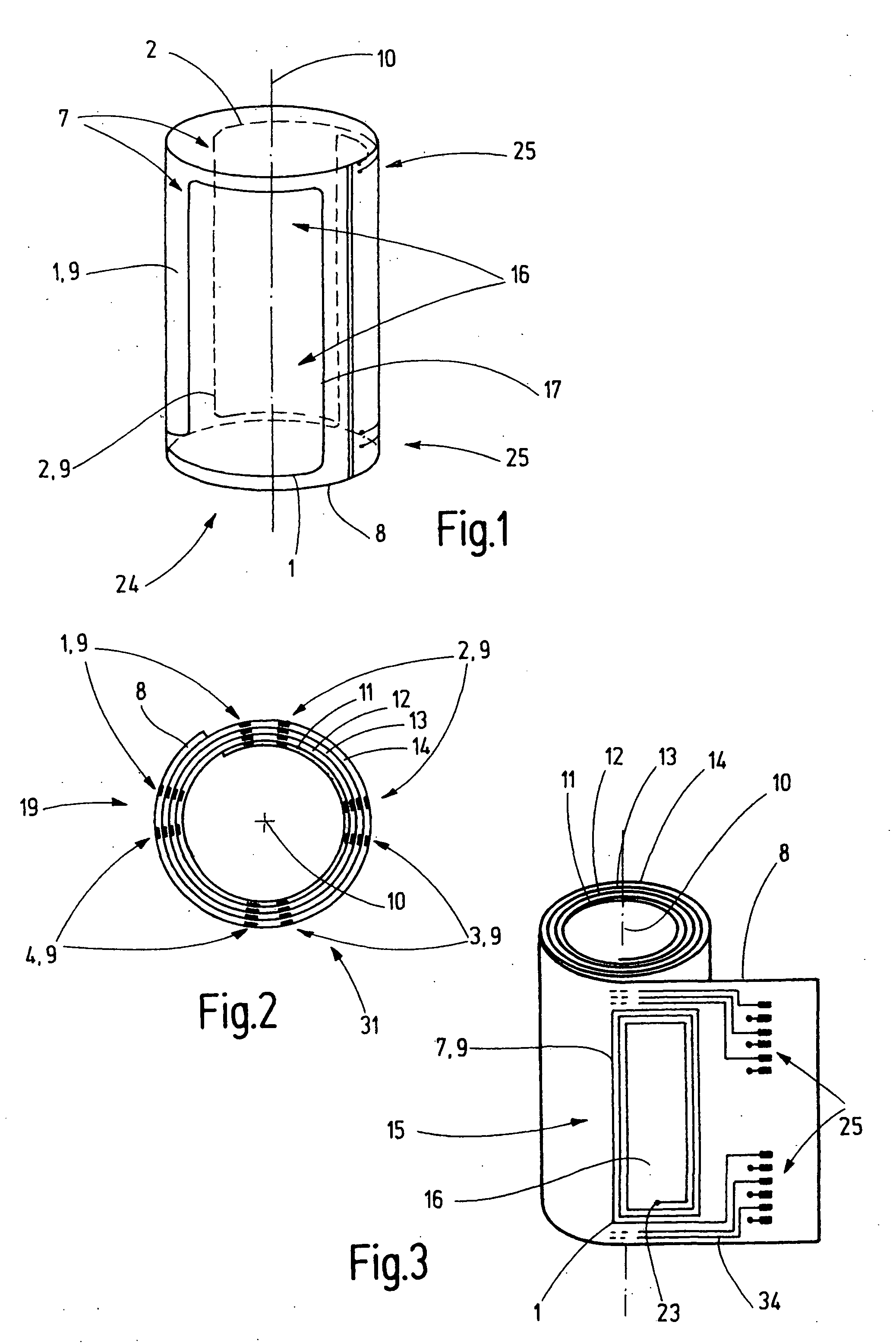

Multipole coils

InactiveUS20090084975A1Avoid restrictionsReduce the overall heightBeam/ray focussing/reflecting arrangementsCathode ray tubes/electron beam tubesFlexible circuitsParticle beam

Multipole coils (1, 2, 3, 4, 5, 6) for influencing particle beams have at least two coils (1, 2) which concentrically enclose an imaginary axis (10), wherein a winding (7) made from a flexible circuit board (8) is formed by means of conducting paths (9) disposed thereon for each coil (1, 2, 3, 4, 5, 6) and the circuit boards (8) are rolled into at least one circuit board layer (11, 12, 13, 14). Multipole coils of this kind (1, 2, 3, 4, 5, 6) are utilized for aberration correction in particle optics, wherein the windings (7) of the multipole coils (1, 2, 3, 4, 5, 6) form windows (16) whose width in the peripheral direction is chosen in such a fashion that no secondary interfering fields occur and whose length in the axial direction corresponds at least to its width.

Owner:CEOS CORRECTED ELECTRON OPTICAL SYST

Buffer for absorbing impacts

ActiveUS20110227264A1Reduce construction heightUniform distributionPortable framesMultiple spring combinationsEngineering

Owner:ACLA WERKE

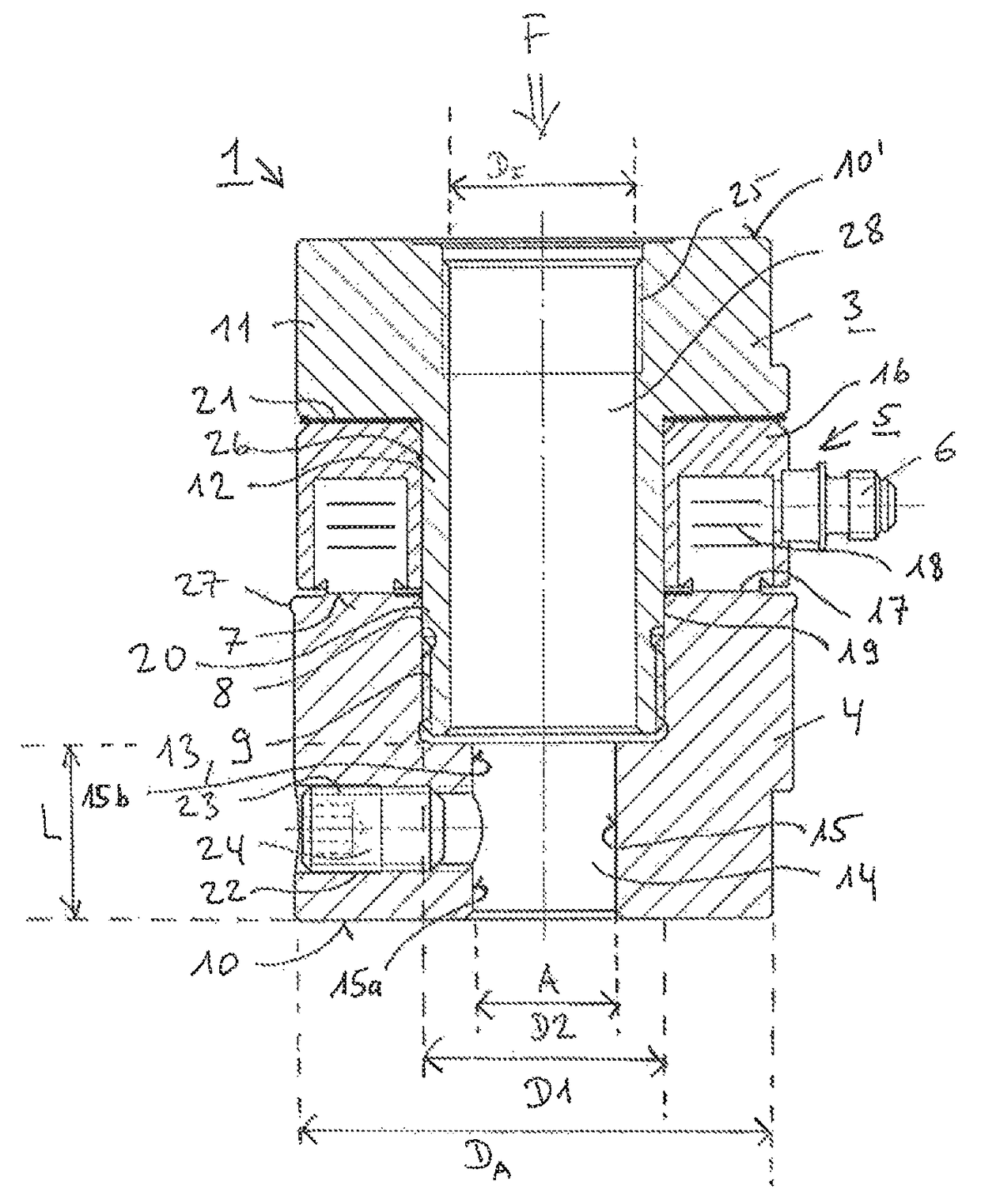

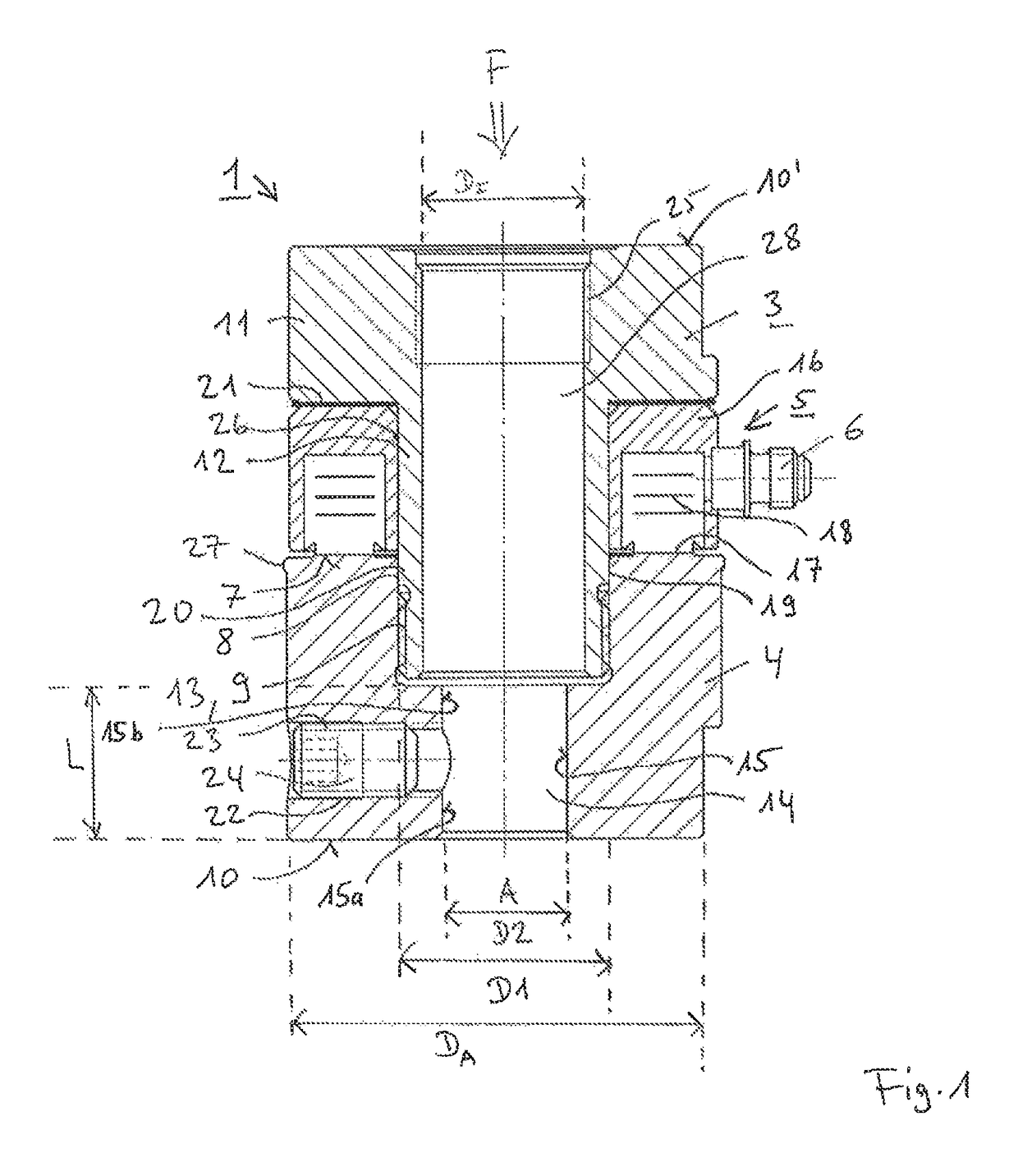

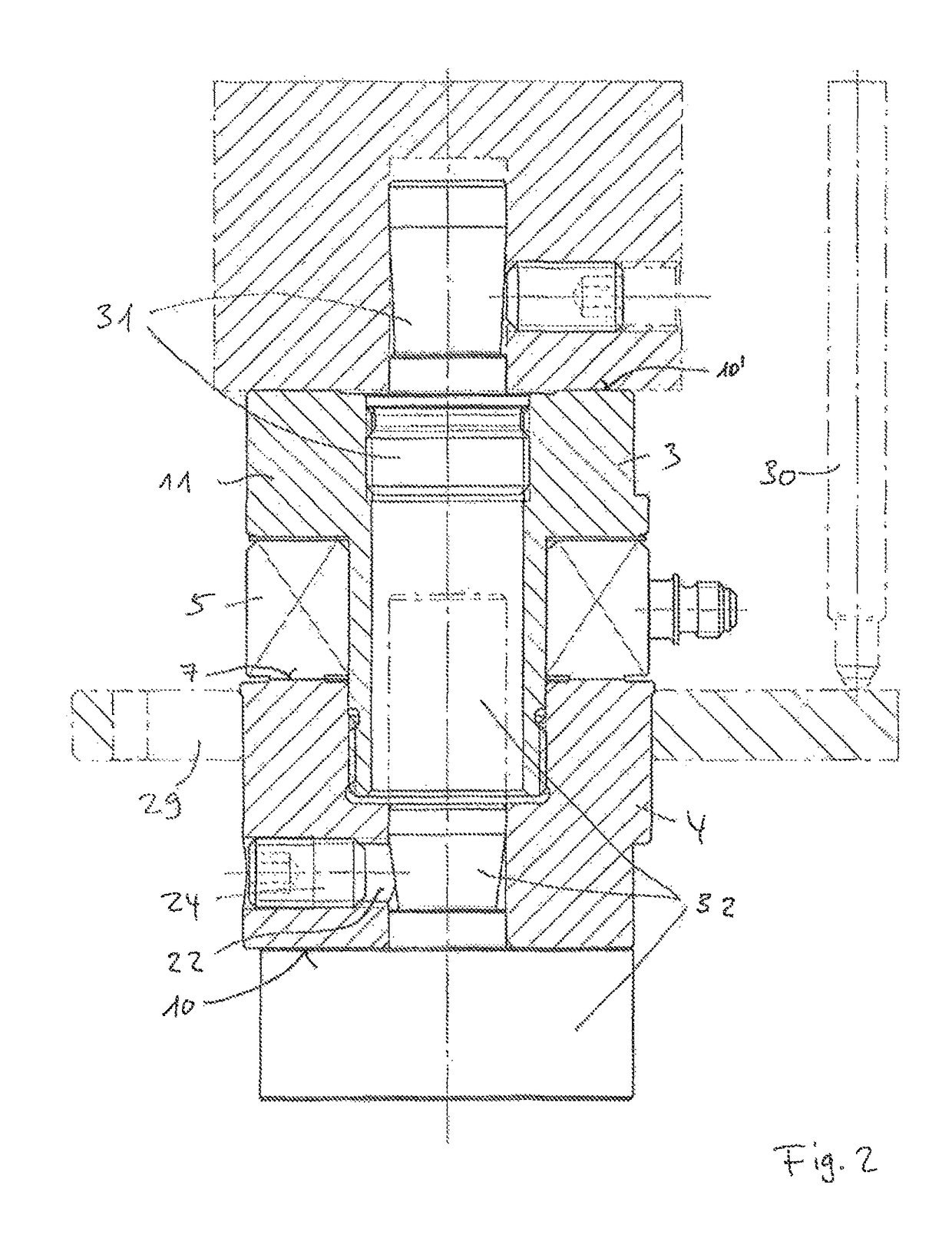

Force sensor for manually operated or pneumatic presses

ActiveUS9823142B2Lower overall heightReduce manufacturing costForce measurement using piezo-electric devicesApparatus for force/torque/work measurementElectric forceEngineering

A force sensor for measuring axially occurring forces in manually operated or pneumatic presses has a central axis and an outer diameter and includes a bolt and a nut that preload between them a piezoelectric force washer with a plug connection. The washer has an inner end face defining a first bore having a first diameter with an internal thread. The bolt defines a throughbore with an internal diameter, a head portion and a hollow shaft defining a frontal external thread extending through the force washer and engaging the nut's internal thread. The nut or the head portion defines a second bore with a second diameter measuring smaller than the shafts internal diameter but at least one quarter of the outer diameter and at least as long as its diameter. The inner wall of the second bore defines a center mount for a sliding fit.

Owner:KISTLER HLDG AG

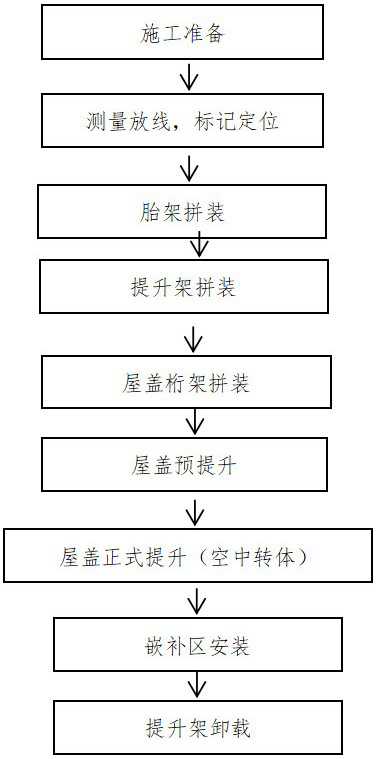

Large-span triangular truss aerial rotation lifting construction method

ActiveCN114439249AReduce construction heightImprove work efficiencySurveying instrumentsBuilding material handlingArchitectural engineeringSteel structures

Owner:CHINA RAILWAY CONSTR ENG GROUP

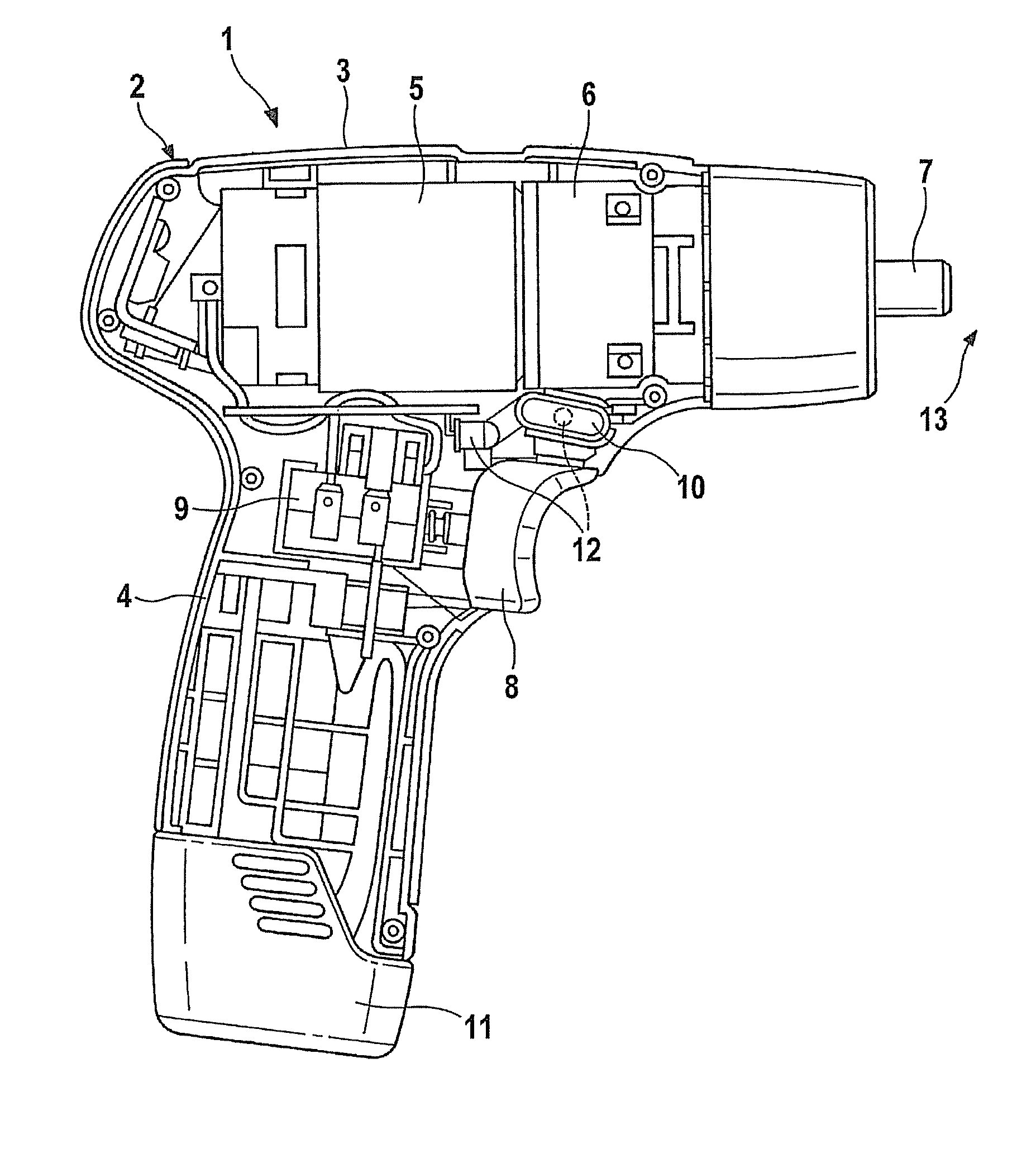

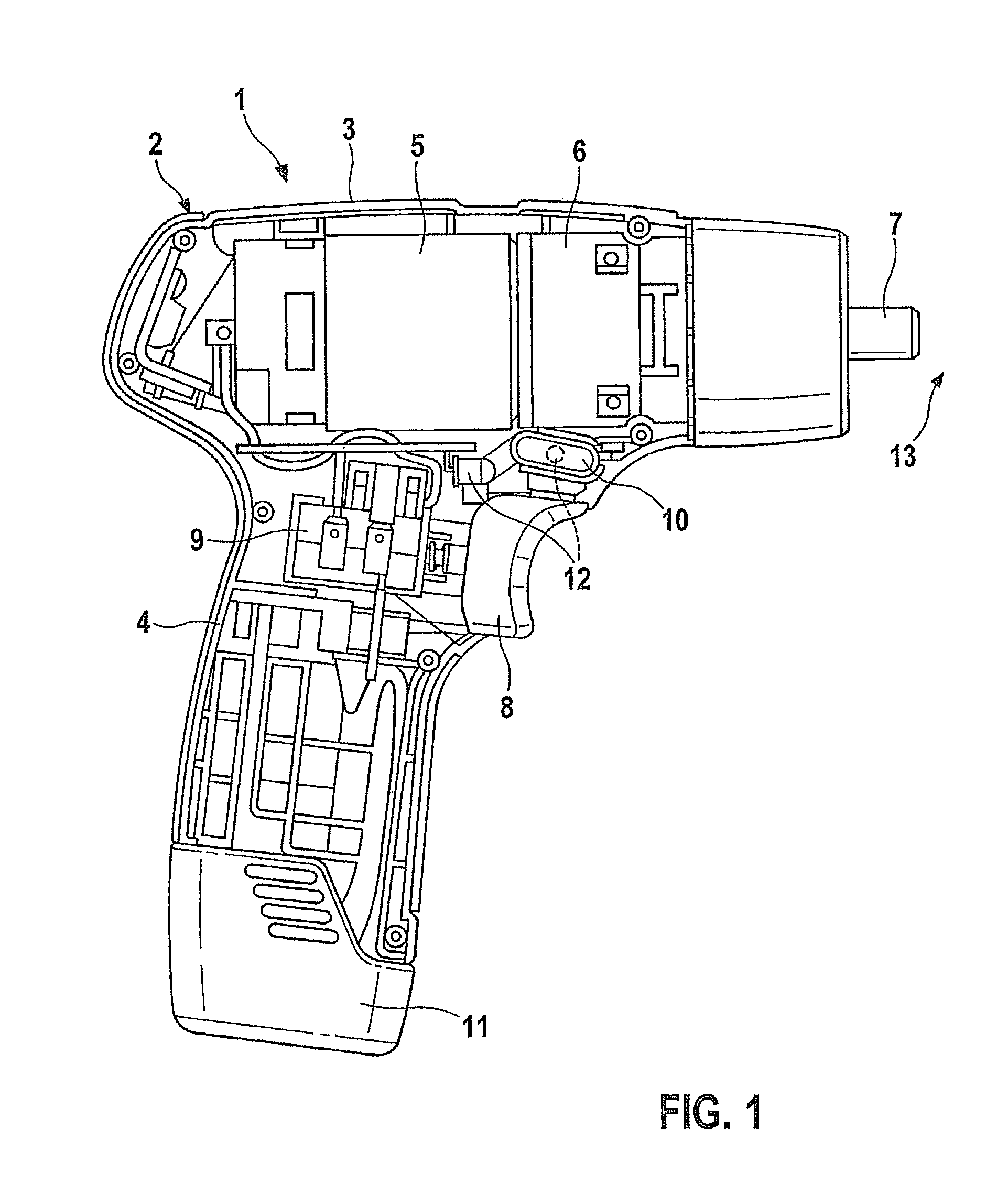

Hand-held power tool

InactiveUS20120106133A1Simple design measureConvenience to workAuxillary equipmentSpannersHand heldLight beam

A hand-held power tool is equipped with a lighting element for illuminating the working field, the lighting element including a light source and a trigger switch for activating or adjusting a drive motor forming a component of the lighting element in such a way that light beams emitted by the light source are guided via the trigger switch to the working field.

Owner:ROBERT BOSCH GMBH

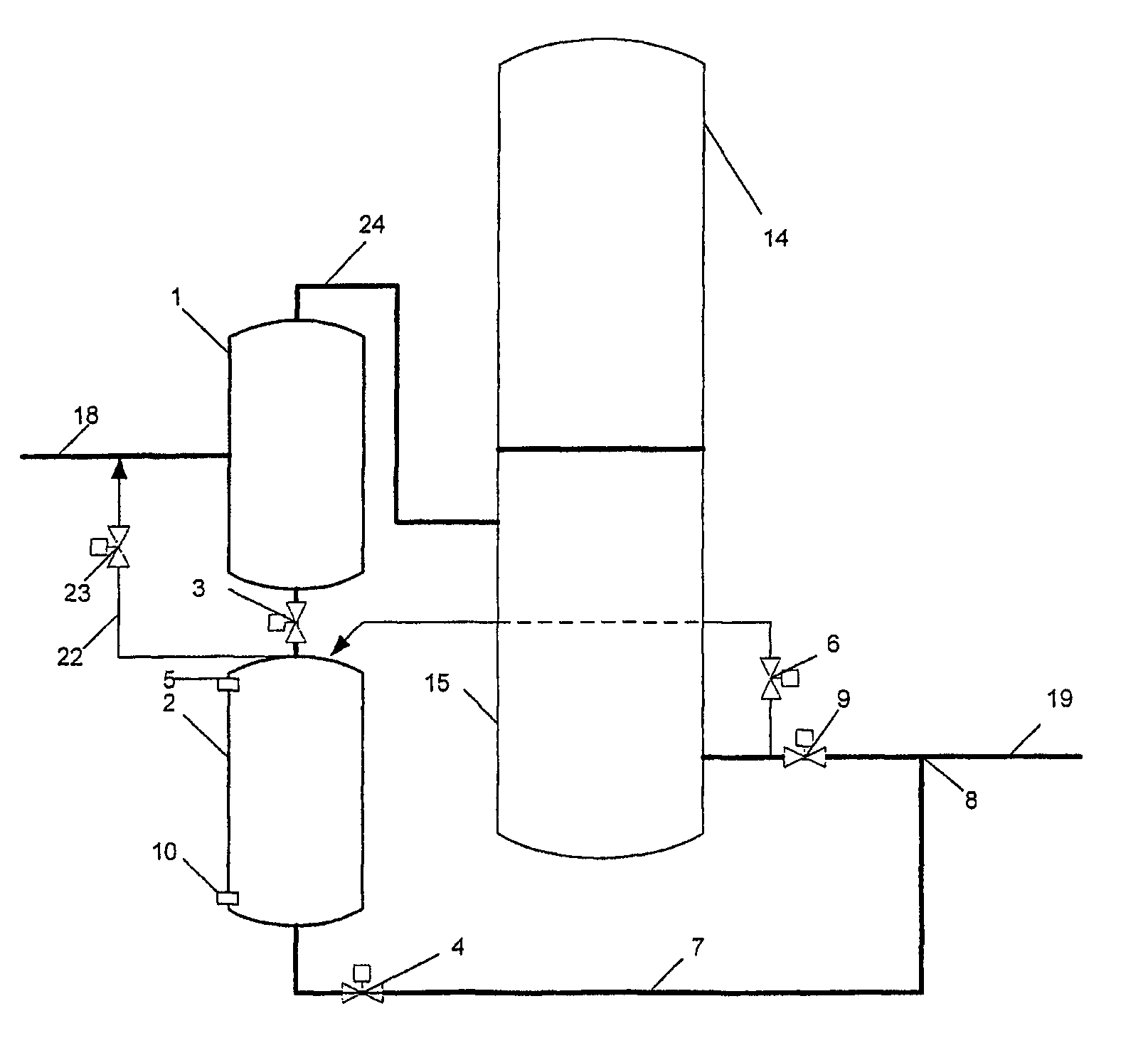

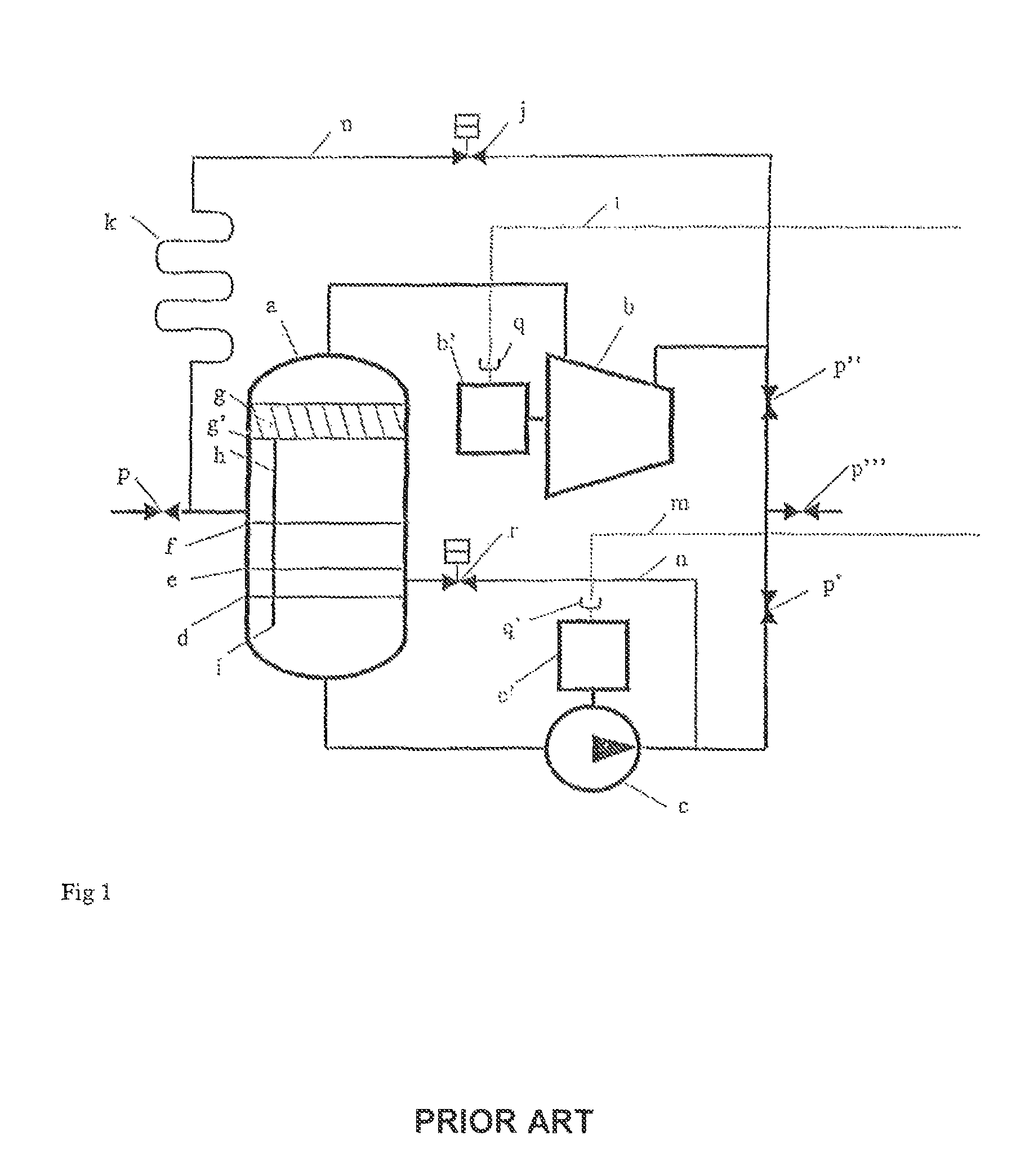

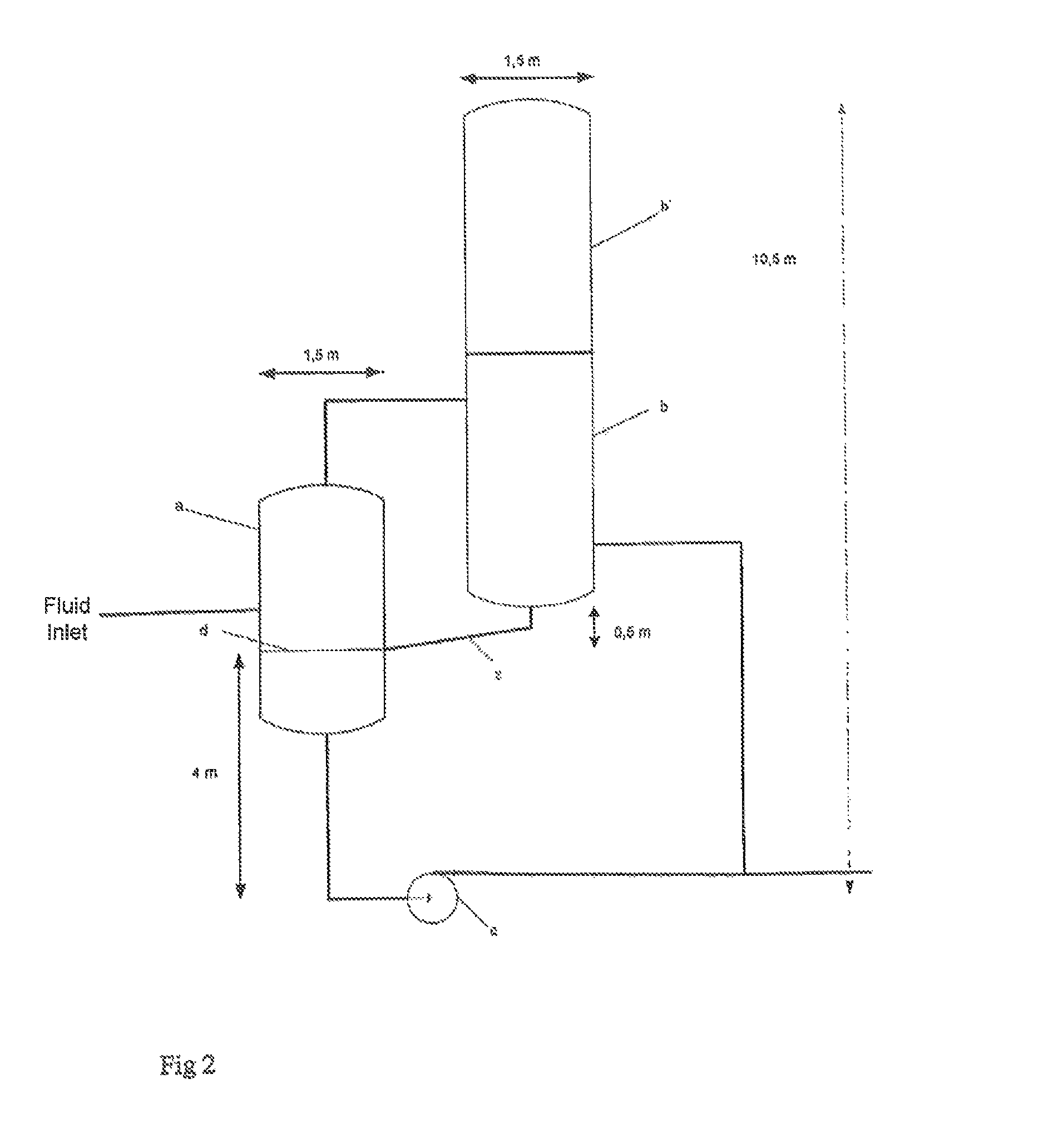

Device for separating and collecting fluid in gas from a reservoir

InactiveUS8771394B2Reduce construction heightSignificant simplificationCombination devicesLiquid degasificationProcess engineeringEngineering

A device for separating and collecting liquid in gas from a reservoir, which is attached to processing equipment (14, 15) for gas, said gas being delivered to the processing equipment from the device via an inlet pipe (24) to the processing equipment and the collected liquid is removed periodically from the device via liquid outlet pipe (7). The device is formed of a liquid separator (1) and a liquid collector (2) which are two separate chambers, and which are connected to each other via a valve (3), and that for draining of the collected liquid, the liquid collector (2) is connected to an outlet pipe (19) from the processing equipment via an intermediate valve (6), draining taking place with the aid of compressed gas which via the intermediate valve (6) is supplied from the processing equipment, or alternatively from onshore or a platform, from a gas pipe or a well stream gas pipe on the seabed or the like.

Owner:AKER SOLUTIONS AS

Luminaire

ActiveUS20190271456A1Easy and reliable adjustmentReduce construction heightLighting support devicesLighting heating/cooling arrangementsEngineeringFloodlight

The present disclosure relates to a luminaire having a light generation device, a heat sink, a reflector and an intermediate element. The heat sink is pivotably coupled to the reflector about a pivot axis relative to said reflector. Light can be emitted into an inner space of the reflector by the light generation device. The intermediate element is mounted on the heat sink so that it can be moved relative to said heat sink and has a first section provided with a tooth system. The reflector has at least one second section provided with a tooth system. Engagement of the tooth systems of the first and second sections into one another counteracts pivoting of the heat sink relative to the reflector about the pivot axis. To pivot the heat sink relative to the reflector about the pivot axis, the tooth systems of the first and second sections can be disengaged.

Owner:H4X

Diaphragm actuator and method for producing a diaphragm actuator

ActiveUS20160126450A1Reduced space requirementsReduce spacingPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesActive polymerControl theory

A diaphragm actuator has a first frame part and a second frame part, between which at least two diaphragm layers are disposed in a stacked manner and formed as electro-active polymer layers. Furthermore, a method for producing a diaphragm actuator is described.

Owner:BURKERT WERKE +1

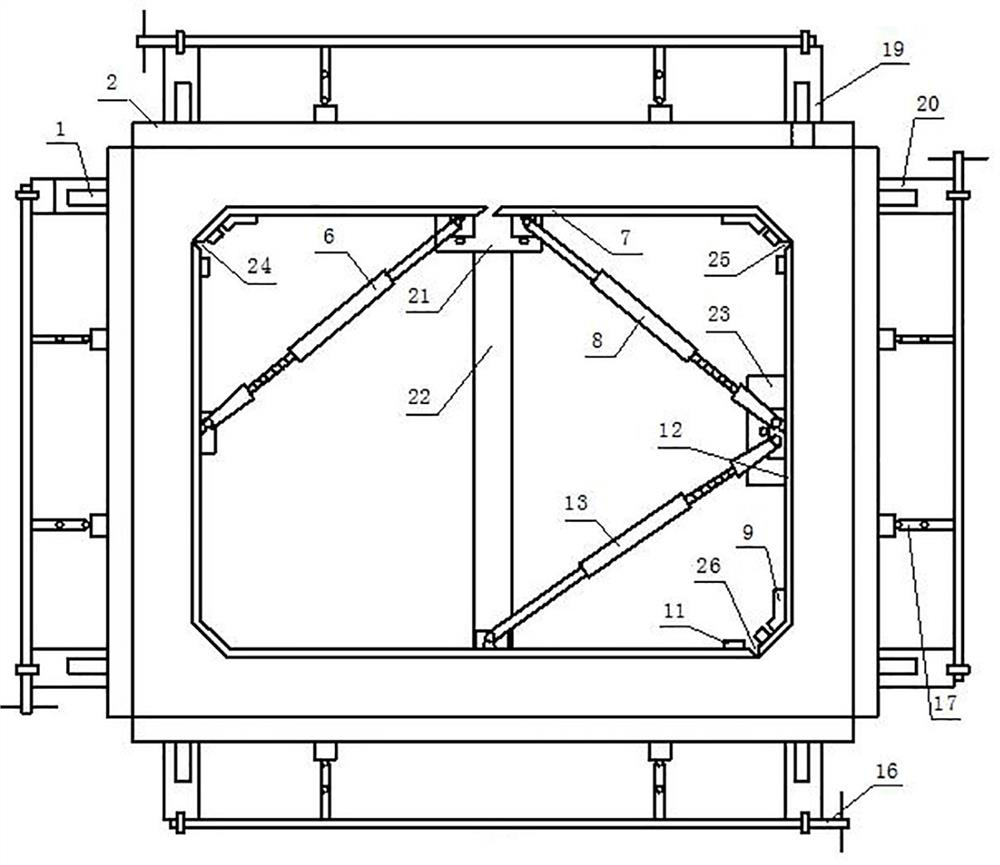

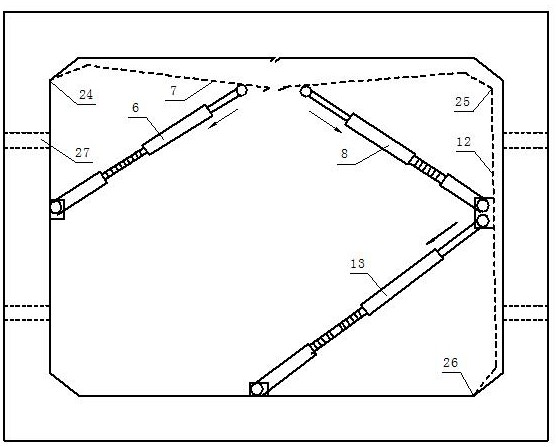

Fabricated box culvert vertical prefabricated light formwork and manufacturing method thereof, and box culvert prefabricating method

PendingCN112720806AEasy to manufactureE-buyDischarging arrangementGround-workArchitectural engineeringStringer

The invention discloses a fabricated box culvert vertical prefabricated light formwork and a manufacturing method thereof, and a box culvert prefabricating method. The fabricated box culvert vertical prefabricated light formwork comprises a base, an outer formwork body, a connecting rod mechanism, an inner formwork body, an end formwork body and a hydraulic supporting mechanism; the base is composed of two longitudinal beams, three cross beams and two walking platforms, the outer formwork body is composed of four integral formwork plates, a steel plate is attached to the interior of each formwork plate, inclined struts are welded to the exterior of each formwork plate, the inner formwork body is composed of an inner-layer grid rib plate and an outer-layer inner formwork steel plate, each inner formwork steel plate is formed by stamping a whole steel plate, only one abutted seam is formed in the whole section, two longitudinal ribs are arranged at the abutted seam of the folded section, walking wheels are arranged at the lower ends of the longitudinal ribs, and the inner formwork body is assembled and disassembled through stretching and retracting of the hydraulic supporting mechanism. The outer formwork body adopts an integral and large-block formwork plate design and can be driven by the connecting rod mechanism or the hydraulic system, the inner formwork body is driven by a full-hydraulic support, only one abutted seam is formed in the whole section, vertical pouring and end plate matching production are adopted, and the appearance effect of a segment finished product is good.

Owner:HENAN HIGHWAY ENG GROUP +1

Seat valve

InactiveUS20160131275A1Reduced space requirementsReduce spacingPiezoelectric/electrostrictive device manufacture/assemblyDiaphragm valvesActive polymerControl theory

A diaphragm actuator has a first frame part and a second frame part, between which at least two diaphragm layers are disposed in a stacked manner and formed as electro-active polymer layers. Furthermore, a method for producing a diaphragm actuator is described.

Owner:BURKERT WERKE

Positioning aid

ActiveUS7175153B2Reliable anchoringIncrease displacementOperating means/releasing devices for valvesPicture framesPositioning aidsElectrical and Electronics engineering

A positioning aid for a magnetic device used for positioning a shuttering means, the magnetic device being movable between a position of use, in which said magnetic device is in contact with a ferromagnetic shuttering support, and a position of non-use, in which said magnetic device is spaced apart from the shuttering support, said positioning aid comprising at least one retaining device relative to which the magnetic device is supported against a holding force of said magnetic device, and further comprising at least one elastic support unit for producing a lifting force against said holding force so as to hold the magnetic device in the position of non-use. In order to be able to provide such positioning aids with a more compact structural design and to use them more universally, the present invention is so conceived that the magnetic device is firmly connected to the retaining device and that, at least in the position of non-use, the support unit is arranged between the retaining device and the shuttering support, at least along certain sections thereof.

Owner:BT BAUBEDARF MAGDEBURG

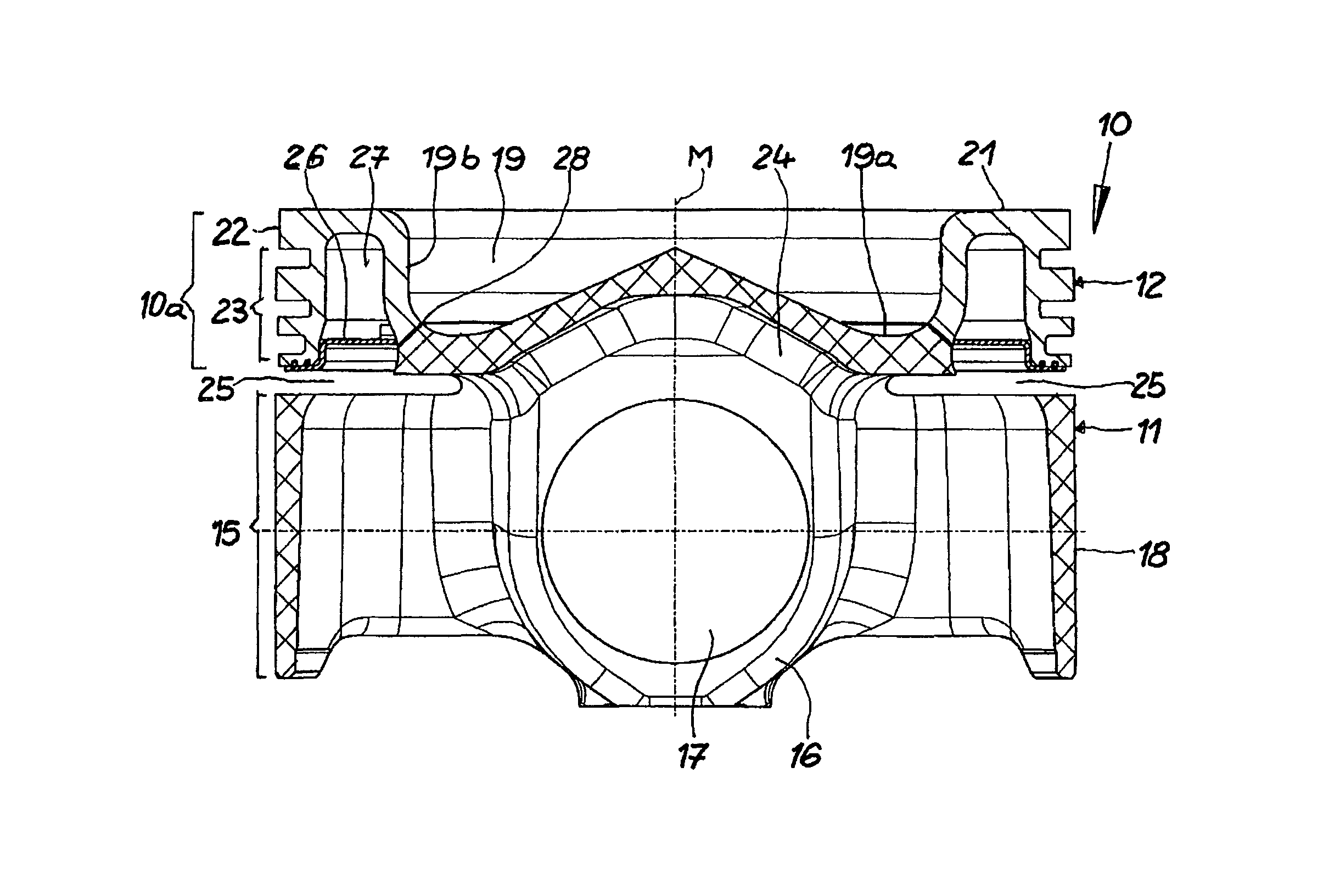

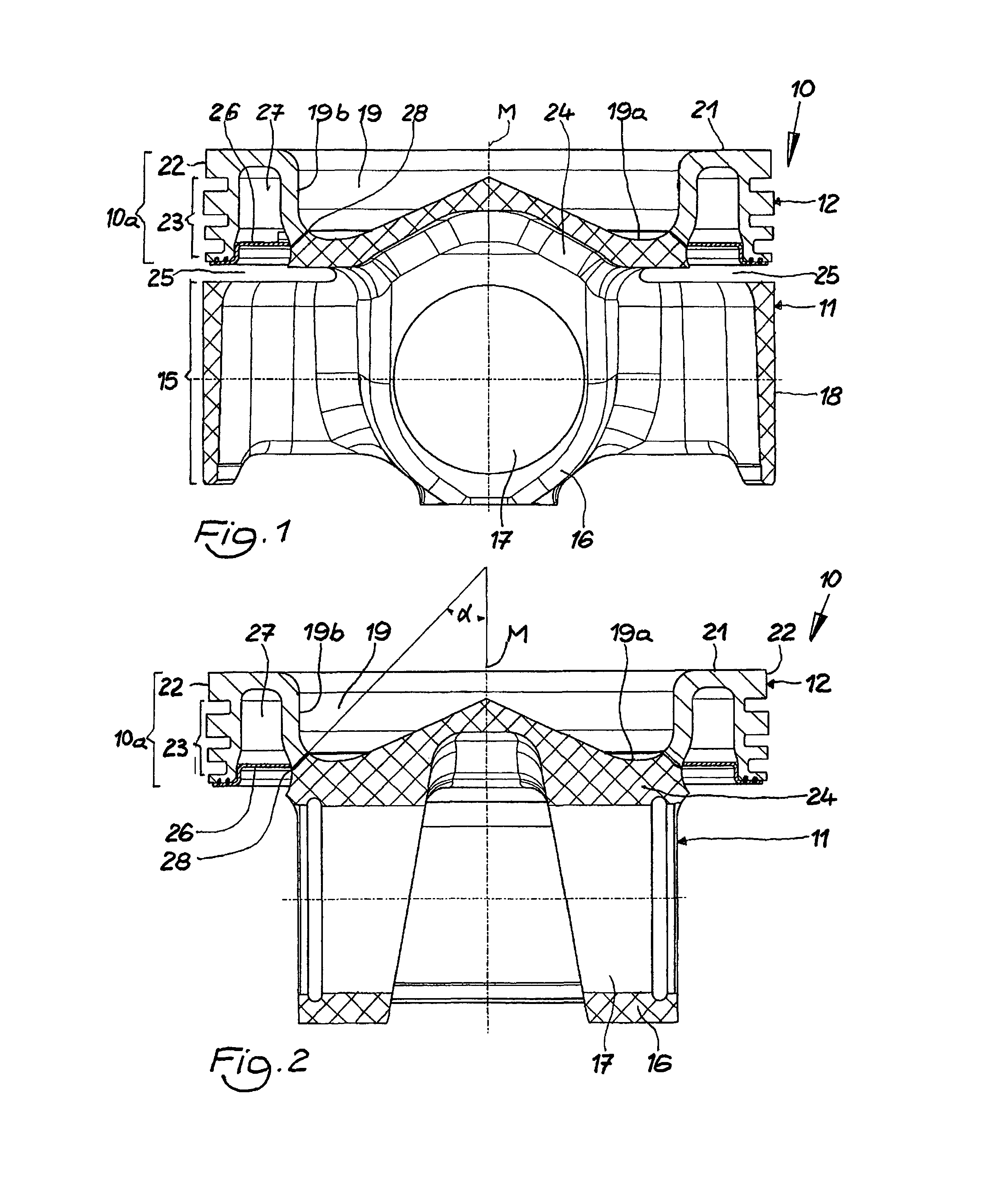

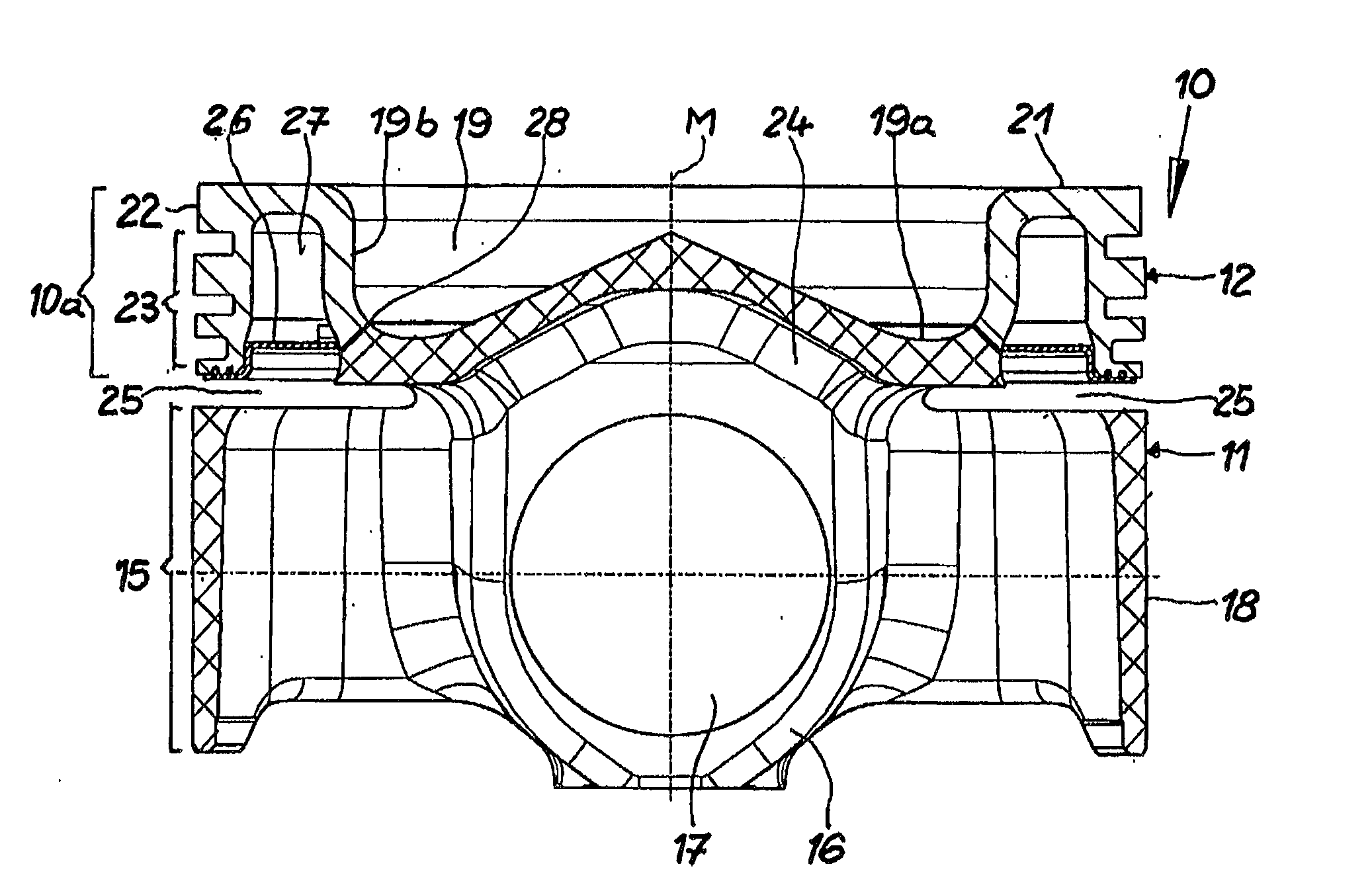

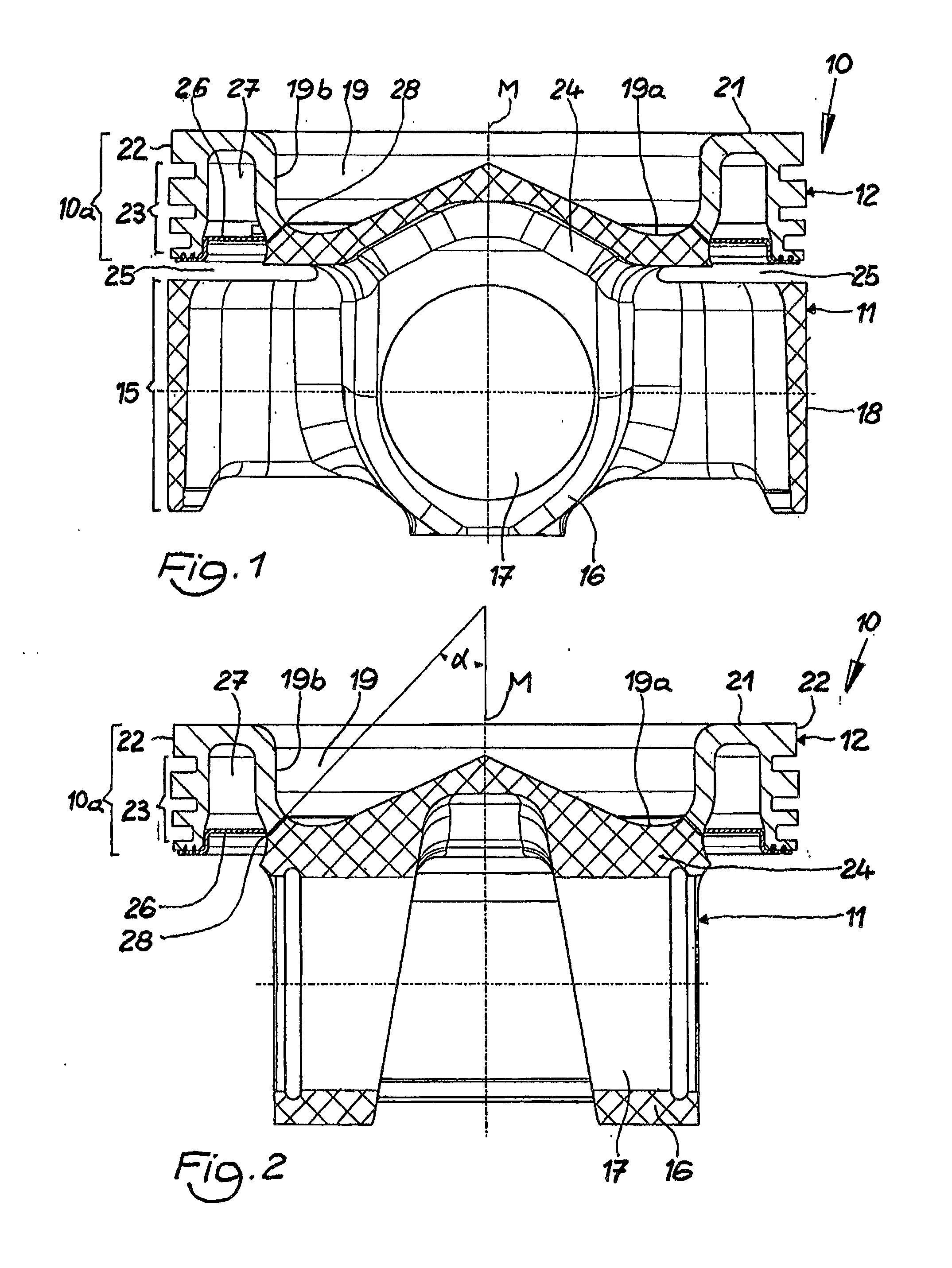

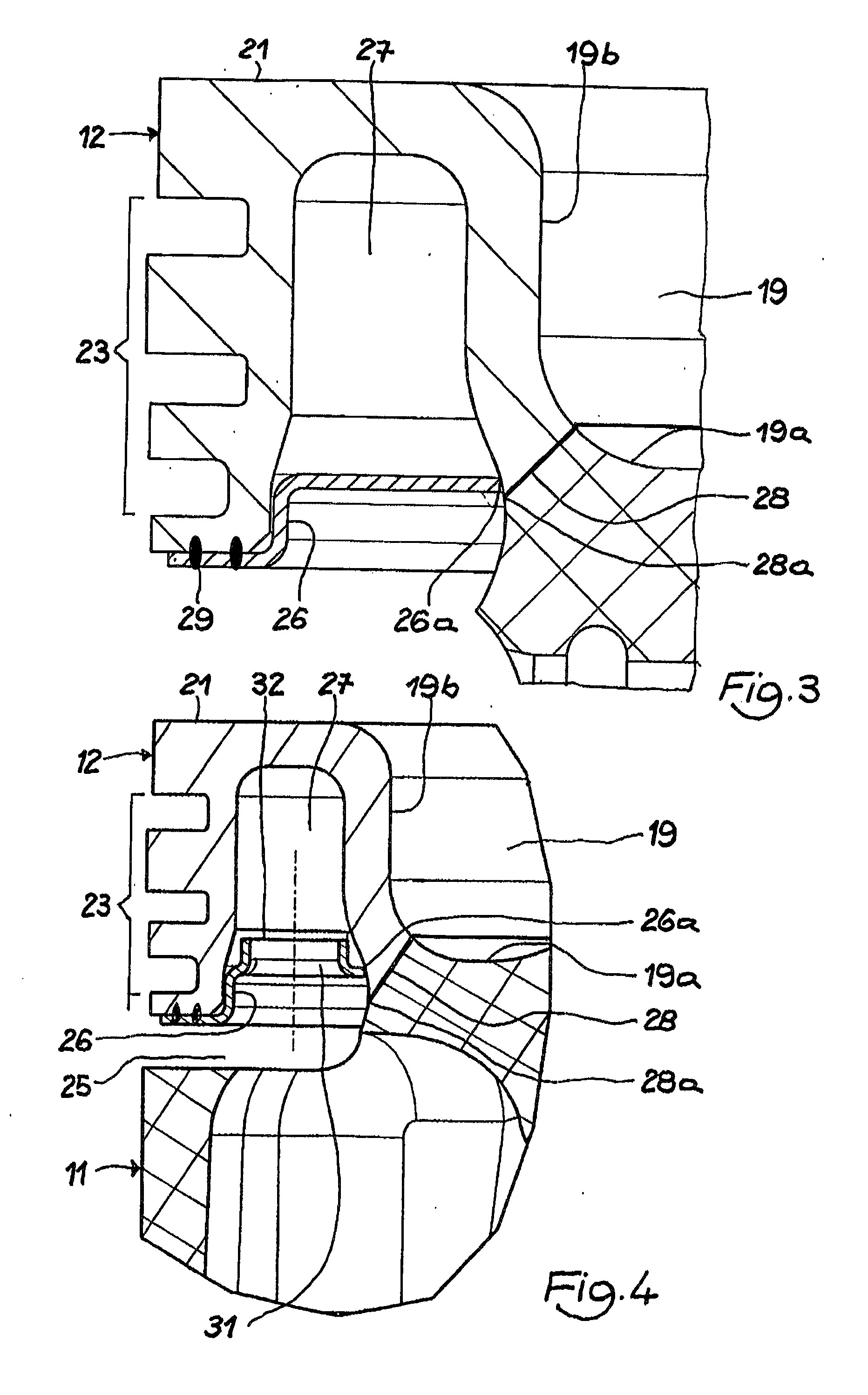

Piston for an internal combustion engine and method for its production

InactiveUS8813712B2Reduce construction heightExcellent mechanical and thermal propertiesValve arrangementsPlungersCombustionExternal combustion engine

A piston for an internal combustion engine has a piston head, a piston skirt, and a circumferential recess configured between the piston head and the piston skirt. The piston has a piston base body and a piston ring element. The piston base body has a crown region of a combustion bowl and the piston skirt. The piston ring element has a piston crown, a wall region of the combustion bowl, a circumferential top land, and a circumferential ring belt with ring grooves. The piston ring element has a circumferential cooling channel between the wall region of the combustion bowl and the ring belt, closed with a closure element. The piston base body and the piston ring element have a circumferential joining seam in the region of the combustion bowl, by way of which seam they are non-releasably connected with one another.

Owner:MAHLE INT GMBH

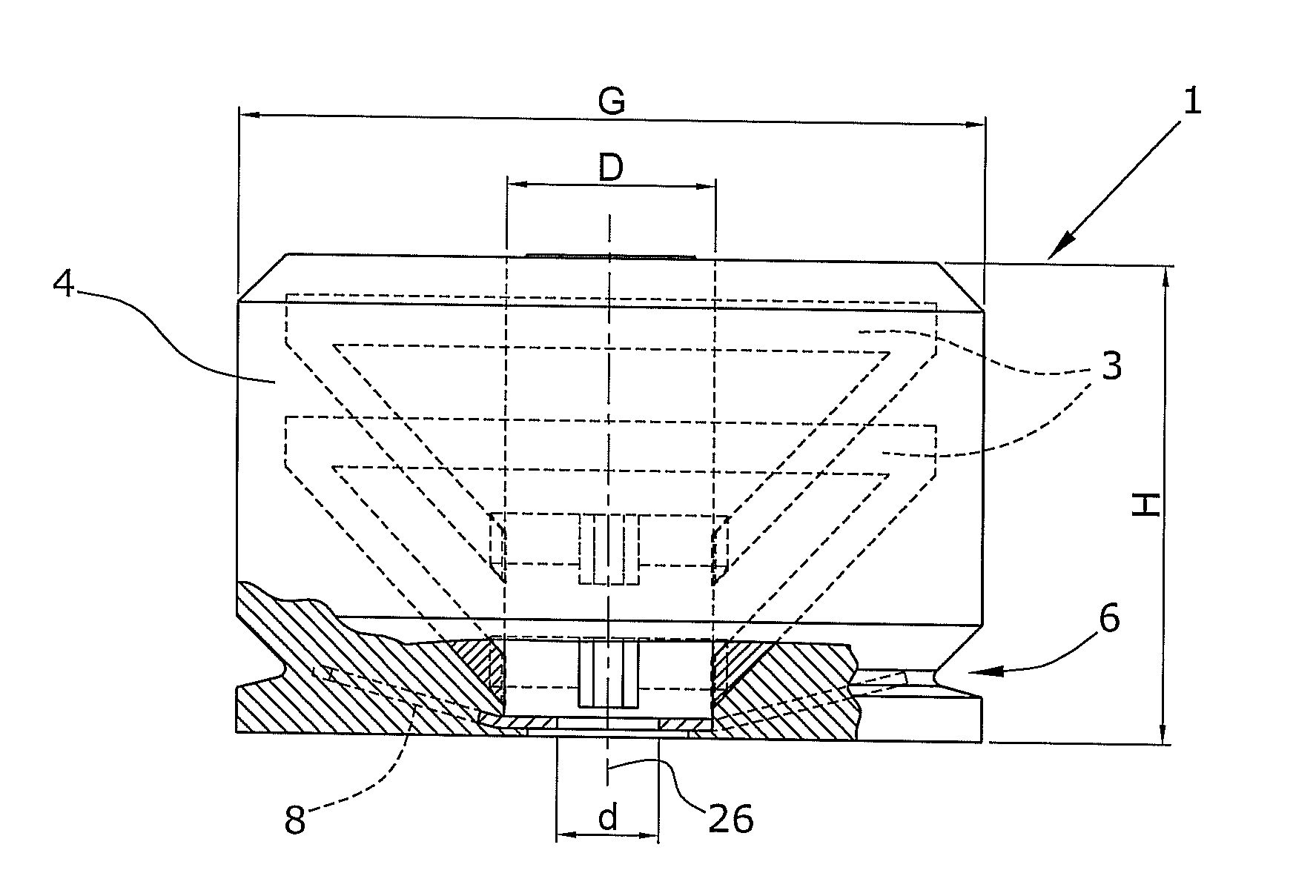

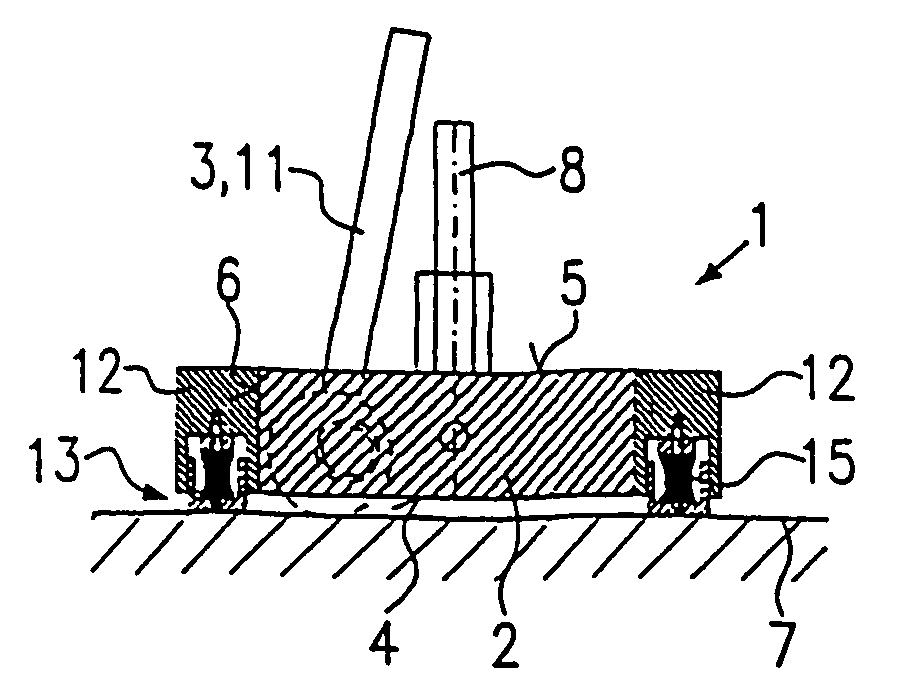

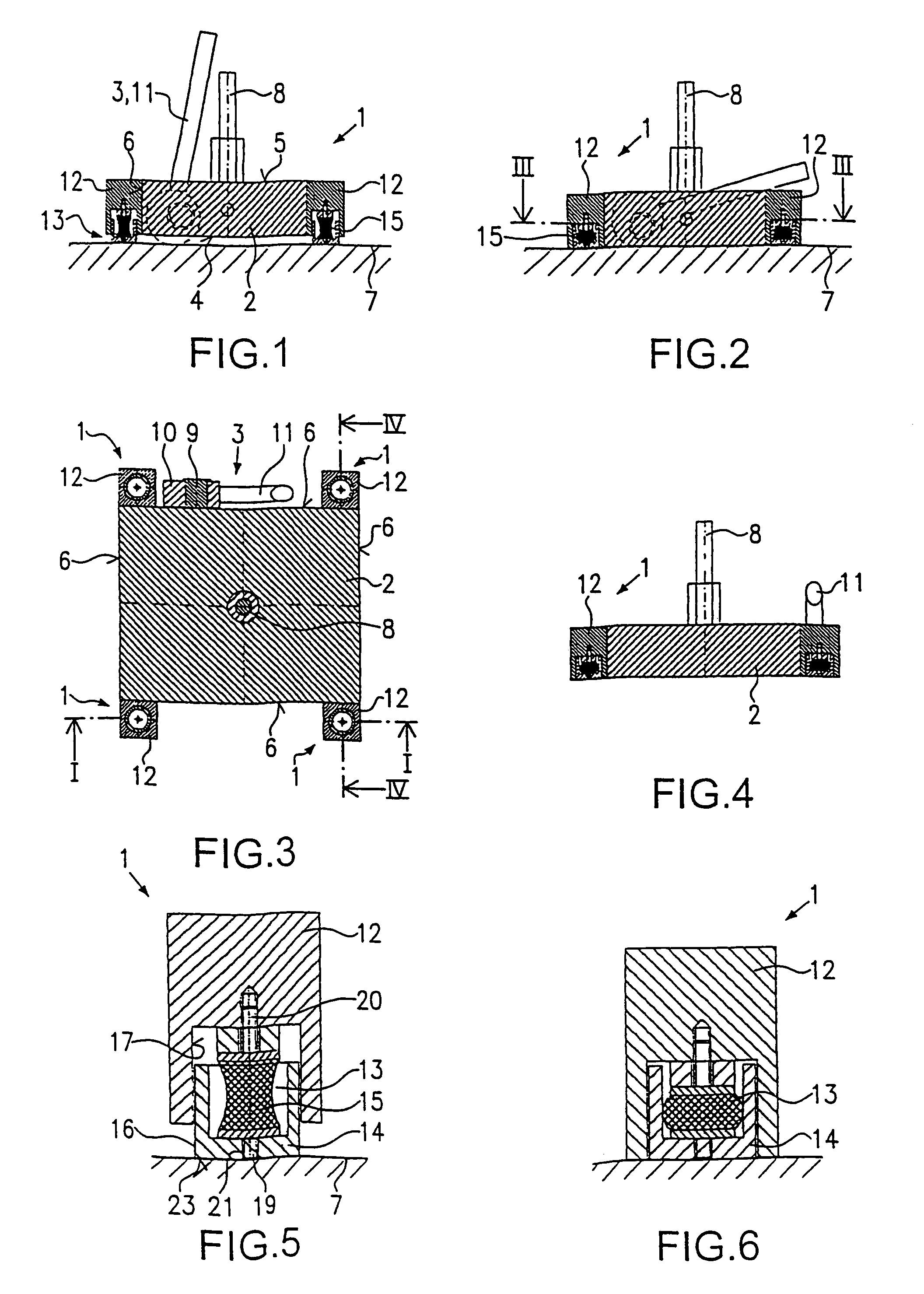

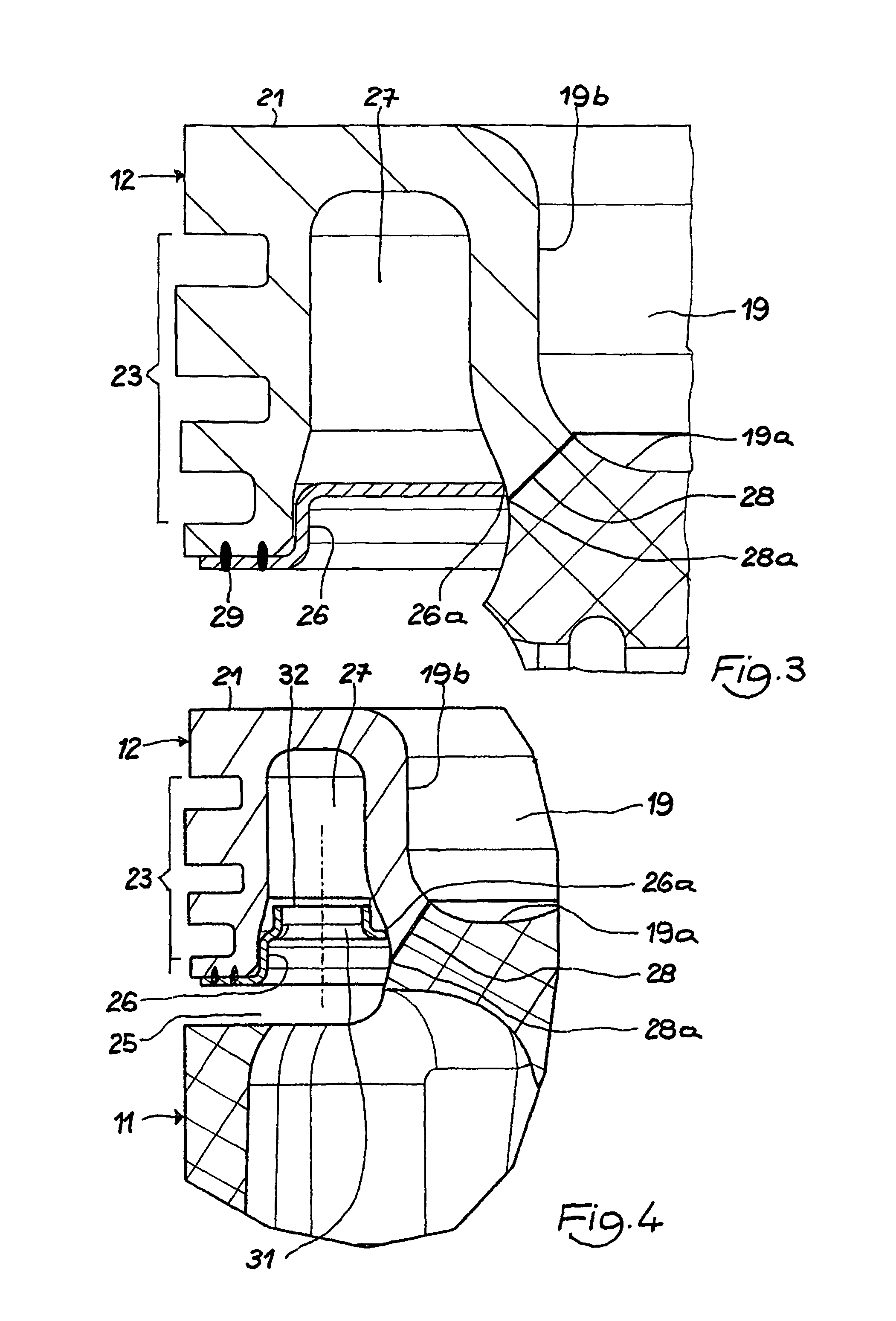

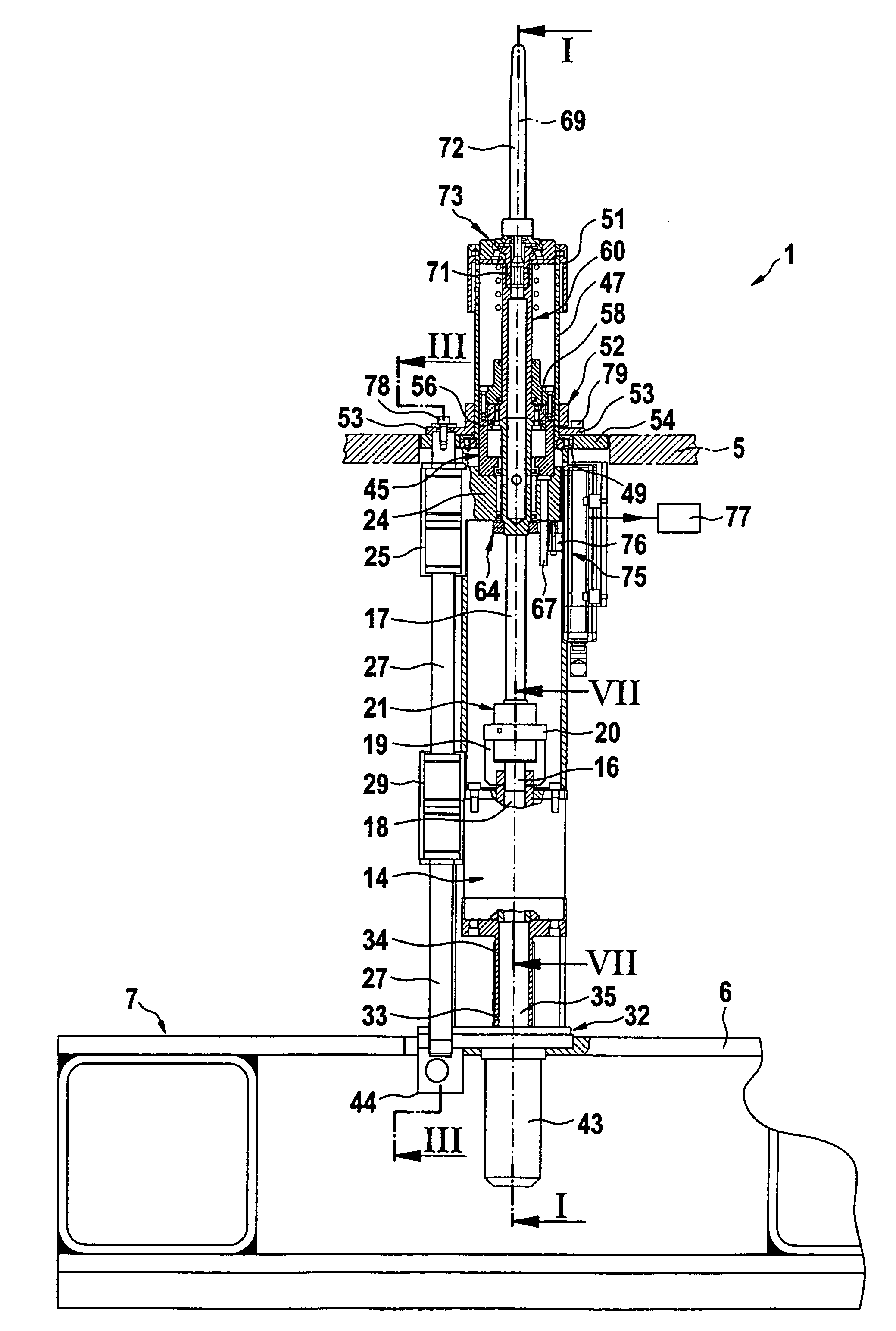

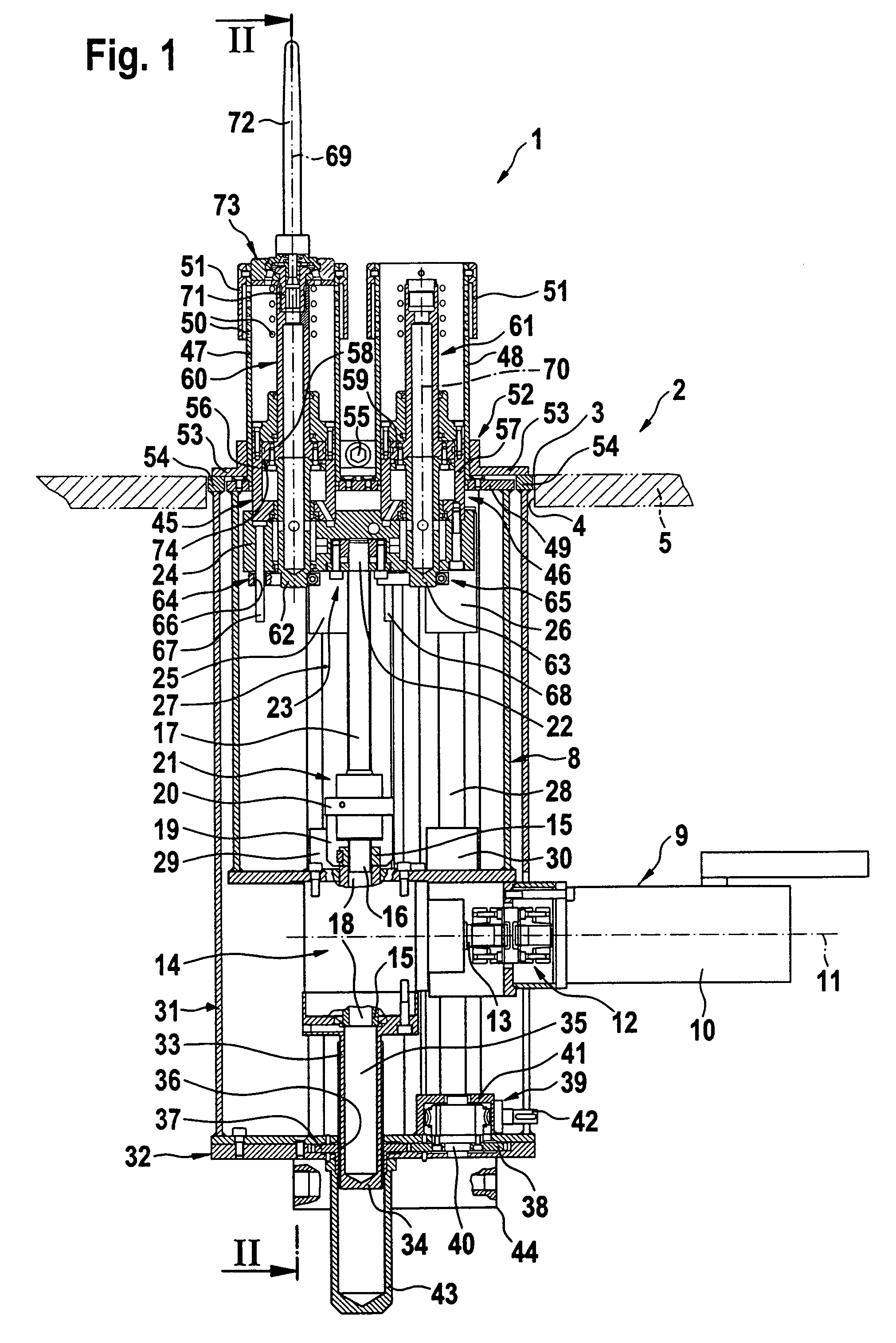

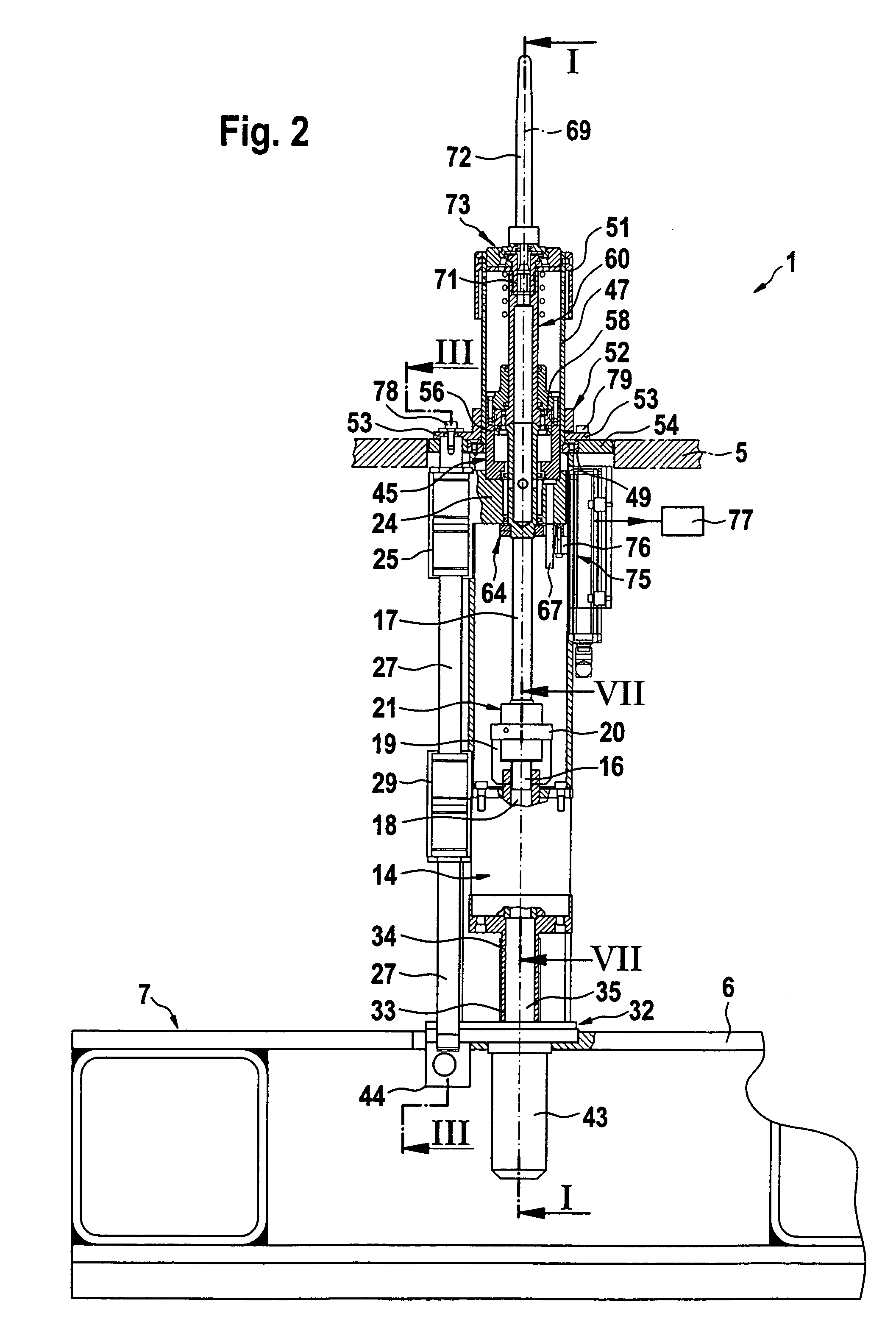

Pressing plunger mechanism for a glassware forming machine

InactiveUS7340923B2Free from mechanical damageReduce construction heightBlowing machine gearingsGlass pressing apparatusMolding machineDrive shaft

A pressing plunger mechanism for a glassware forming machine has at least one pressing plunger which in normal operation can be moved axially in a reciprocating manner together with a pressing plunger receiver between an inoperative position and a pressing position. A piston rod of a piston is fastened to each pressing plunger receiver, which piston can be displaced in a cylinder of a pressing plunger holder. The pressing plunger holder can be moved axially in a reciprocating manner by a first drive and is connected in a non-rotatable manner to a threaded spindle. A nut which can be rotationally driven by the first drive is engaged with the threaded spindle and is coupled to a driven shaft of an angular gear. An input shaft of the angular gear can be rotationally driven by an electric servo motor of the first drive.

Owner:HEYE INT

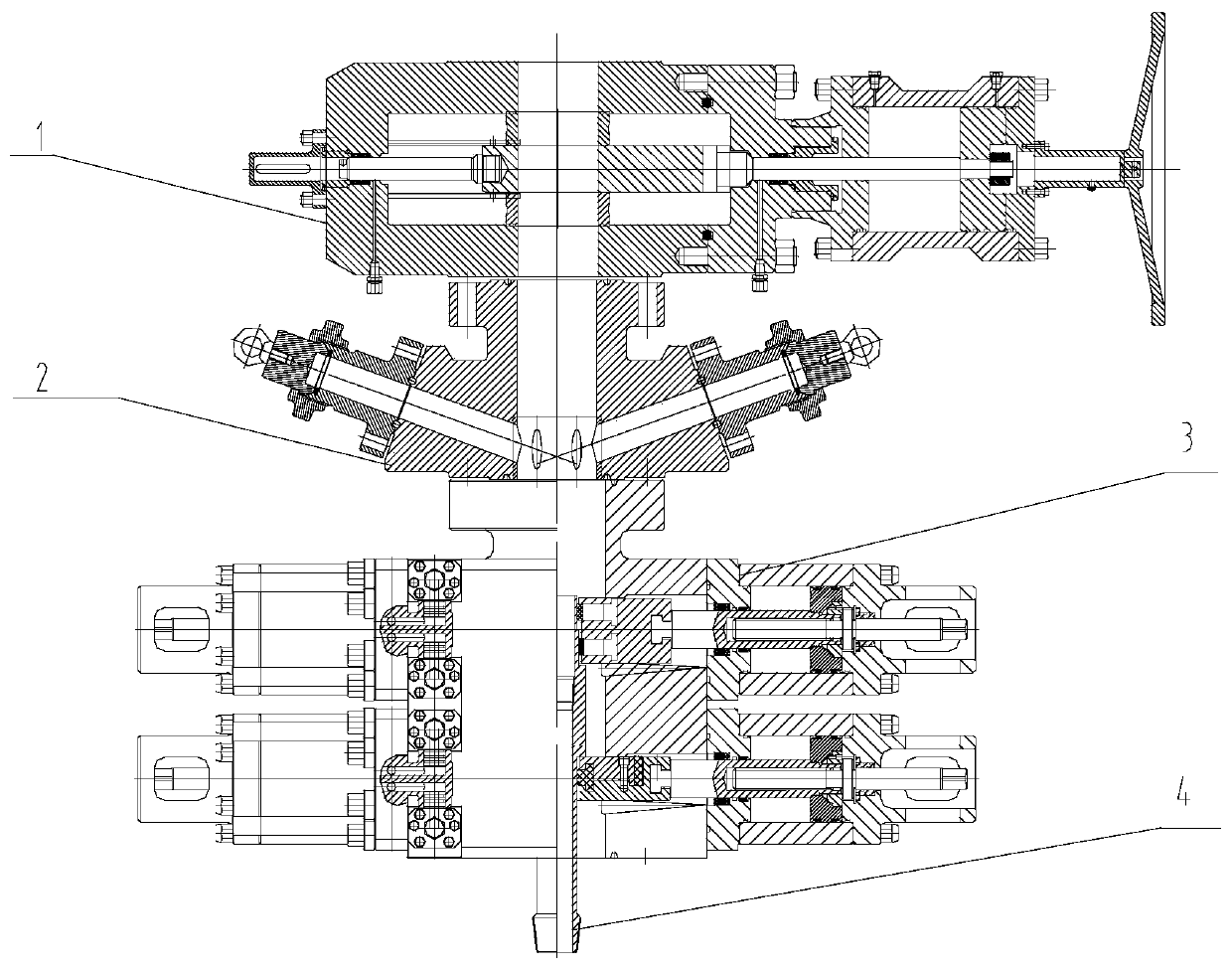

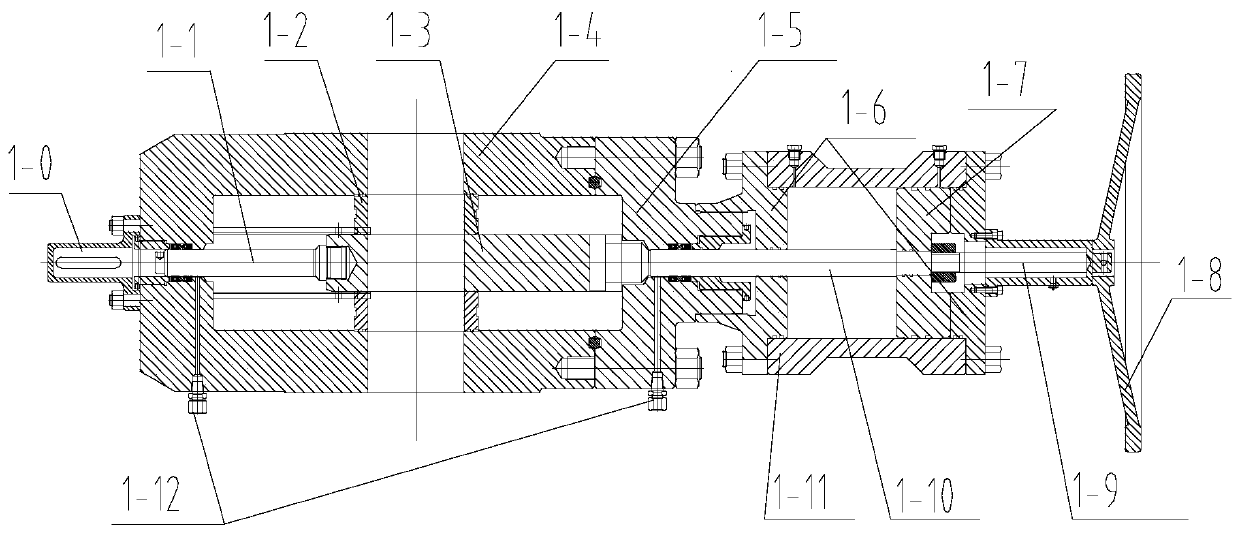

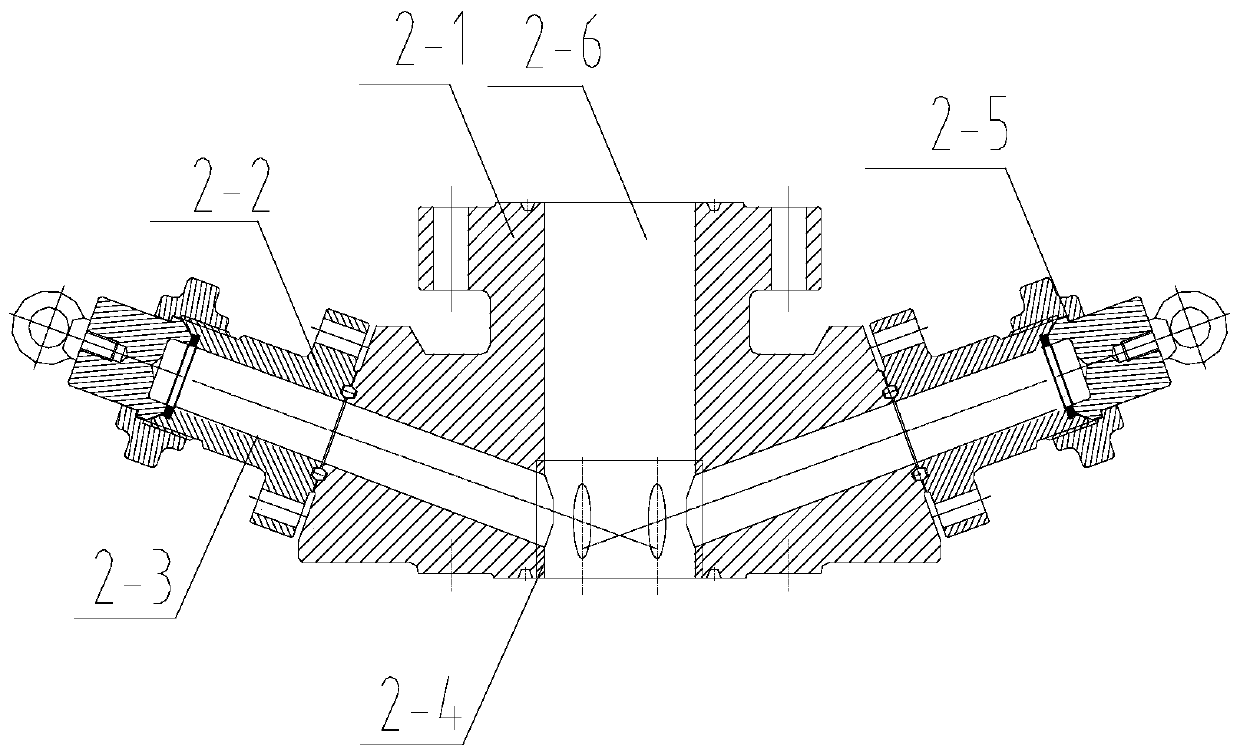

Combined pressure well mouth device for under-pressure fracture

InactiveCN110469286AEasy to operateLow costFluid removalWell/borehole valve arrangementsHigh-pressure areaTubing hanger

The invention discloses a combined pressure well mouth device for under-pressure fracture. The combined pressure well mouth device comprises a plate valve (1), an injection head (2), a fracture controller (3) and an oil pipe hanger (4). The upper end of the plate valve (1) is connected with an under-pressure operation machine. The lower end of the plate valve (1) is connected with the injection head. The plate valve is used for isolating a high pressure area from the under-pressure operation machine during fracture construction. The lower end of the injection head (2) is connected with the fracture controller, and the injection head is used for being connected with a ground fracture pipeline. A well mouth flange is connected to the lower portion of the fracture controller (3), and the fracture controller is used for clamping the oil pipe hanger (4), for isolating an oil jacket annulus and for bearing gravity of a pipe column, pressure of a hydrostatic column and the load produced by liquid high pressure during fracture. The fracture oil pipe hanger (4) is used for being connected with the fracture pipe column and a post-pressure movable pipe column. The problems that in existing under-pressure fracture construction, under-pressure operation equipment needs secondary disassembly and assembly, or a high pressure straight pipe and other accessories need to be erected overhead aresolved.

Owner:DAQING OILFIELD CO LTD +1

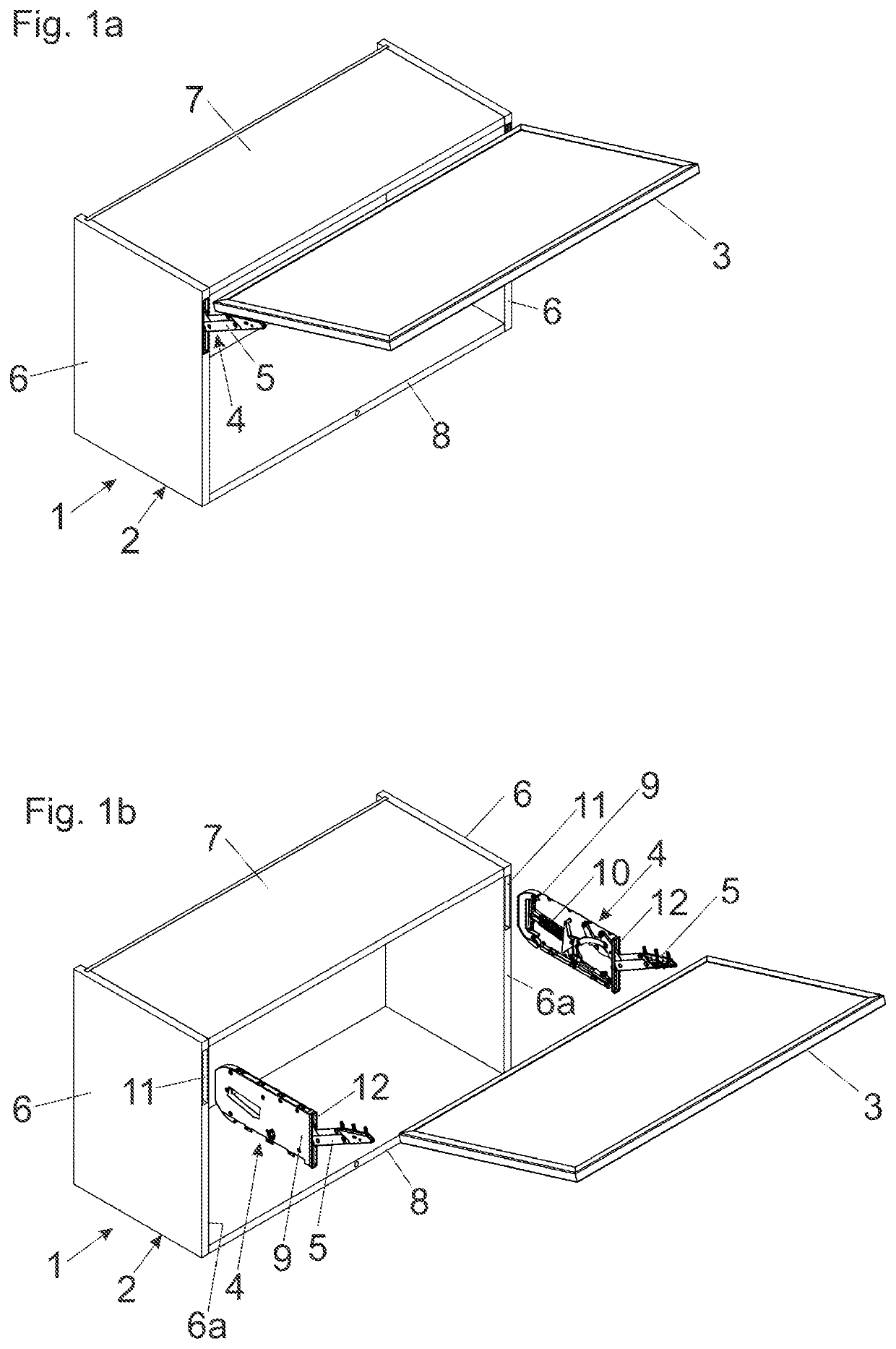

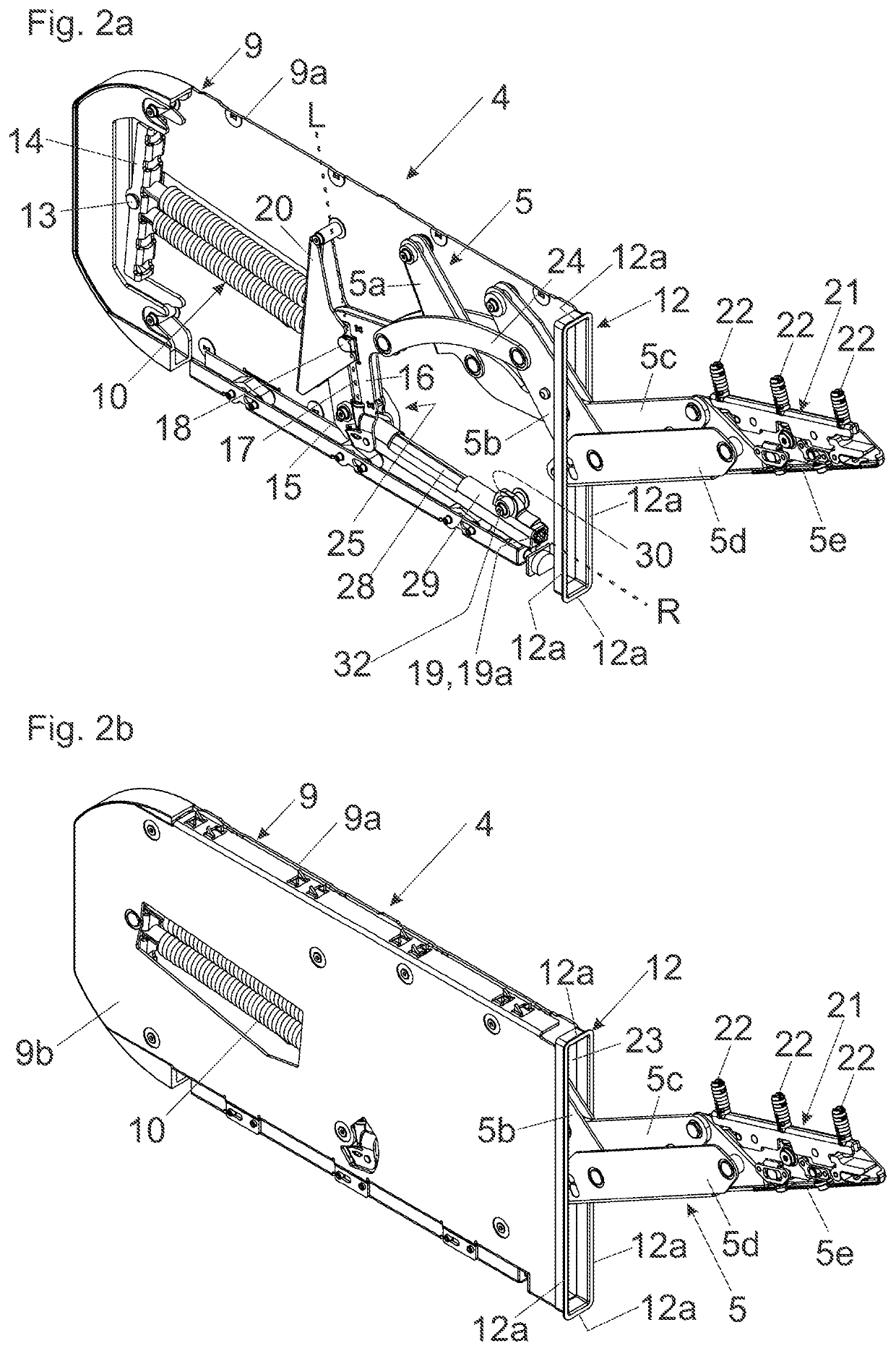

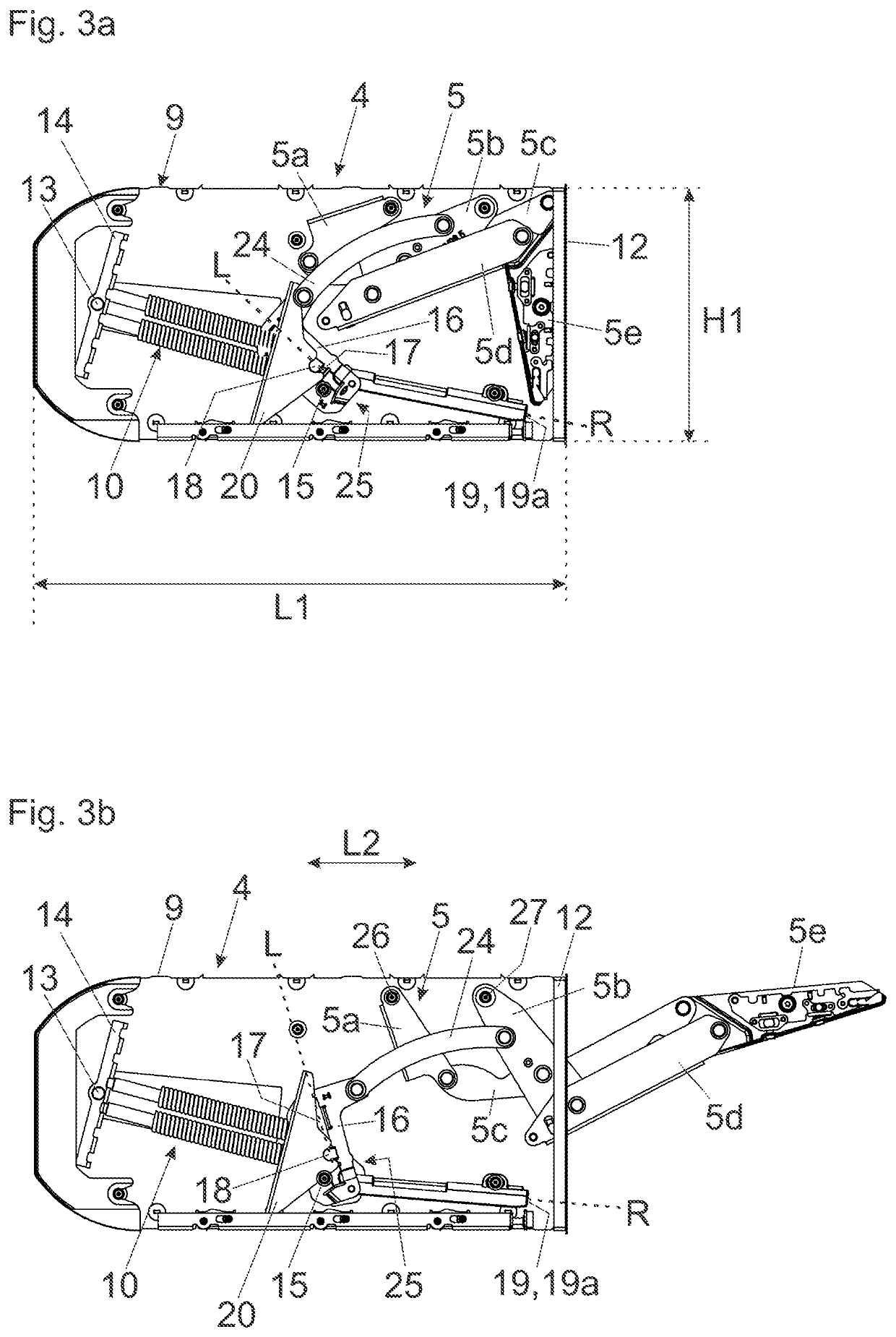

Furniture drive

PendingUS20220056747A1Improve accessibilityPrevent movement tiltBuilding braking devicesWing openersRotational axisEngineering

A furniture drive includes a carrier configured to be fixed to or within a furniture panel of a furniture carcass, an actuating arm assembly arranged on the carrier, a spring device for applying a force to the actuating arm assembly, an adjustment device for adjusting a force of the spring device to the actuating arm assembly, and a threaded section having a longitudinal direction. An engagement location of the spring device is adjustable along the threaded section by a rotation of an adjustment element about a rotational axis, and the rotational axis of the adjustment element and the longitudinal direction of the threaded section enclose an angle to one another. The angle formed by the rotational axis of the adjustment element and the longitudinal direction of the threaded section is configured to be varied upon a movement of the actuating arm.

Owner:JULIUS BLUM GMBH

Convertible roof that latches to an upper transverse frame part of the windshield frame

InactiveUS7762612B2Reduce construction heightSmall spacingEngine sealsVehicle sealing arrangementsEngineeringWindshield

Owner:WILHELM KARMANN GMBH

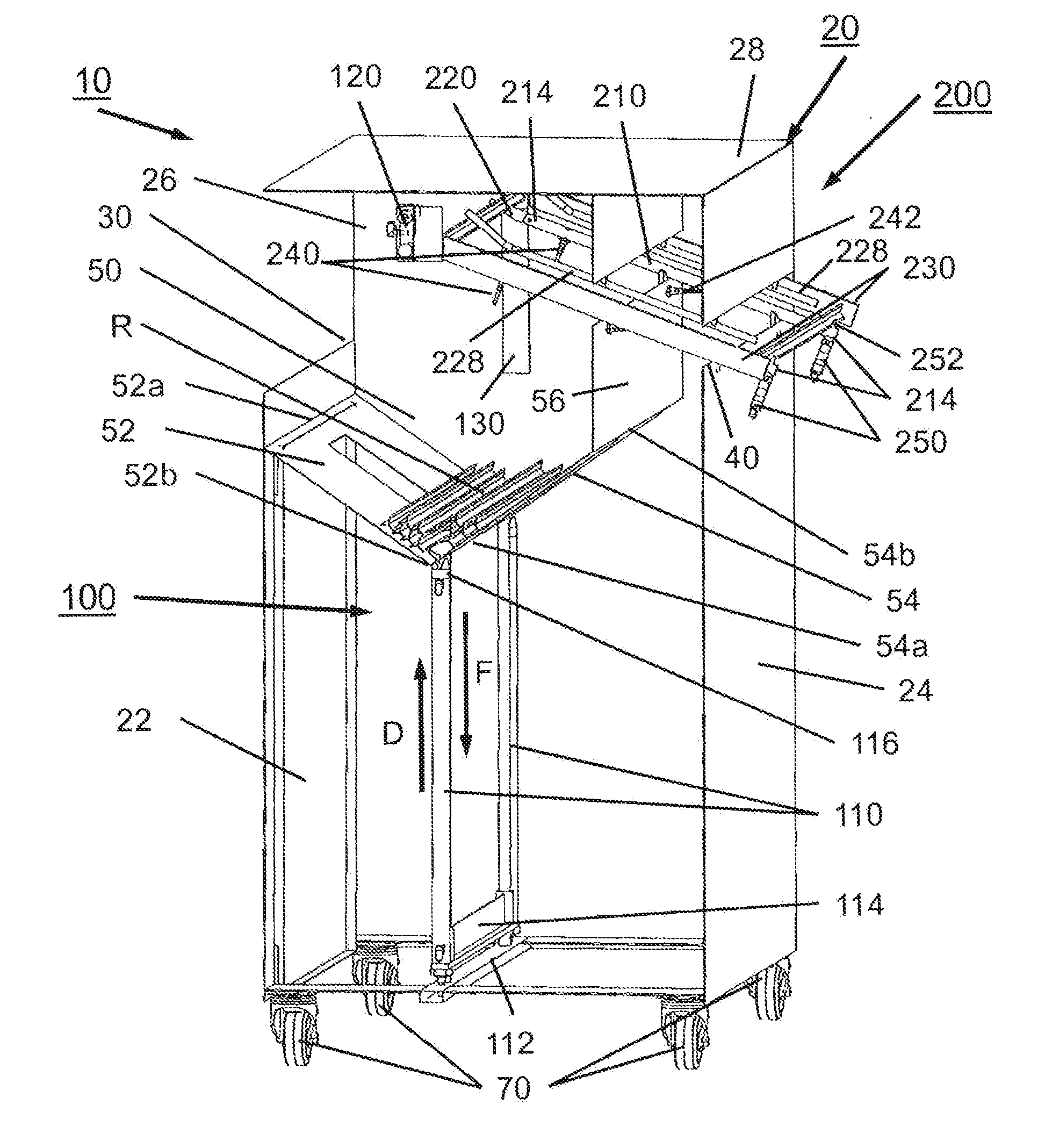

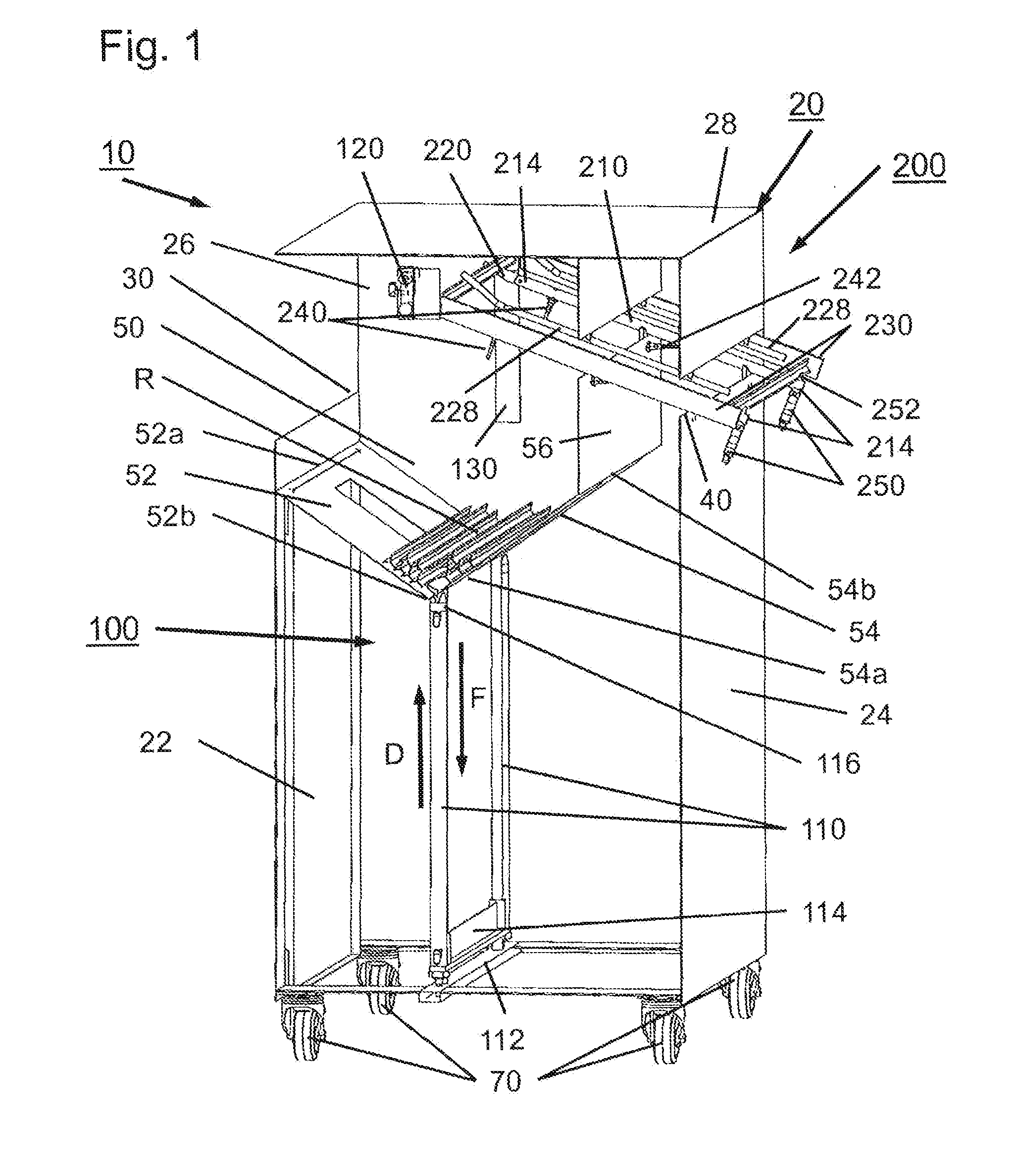

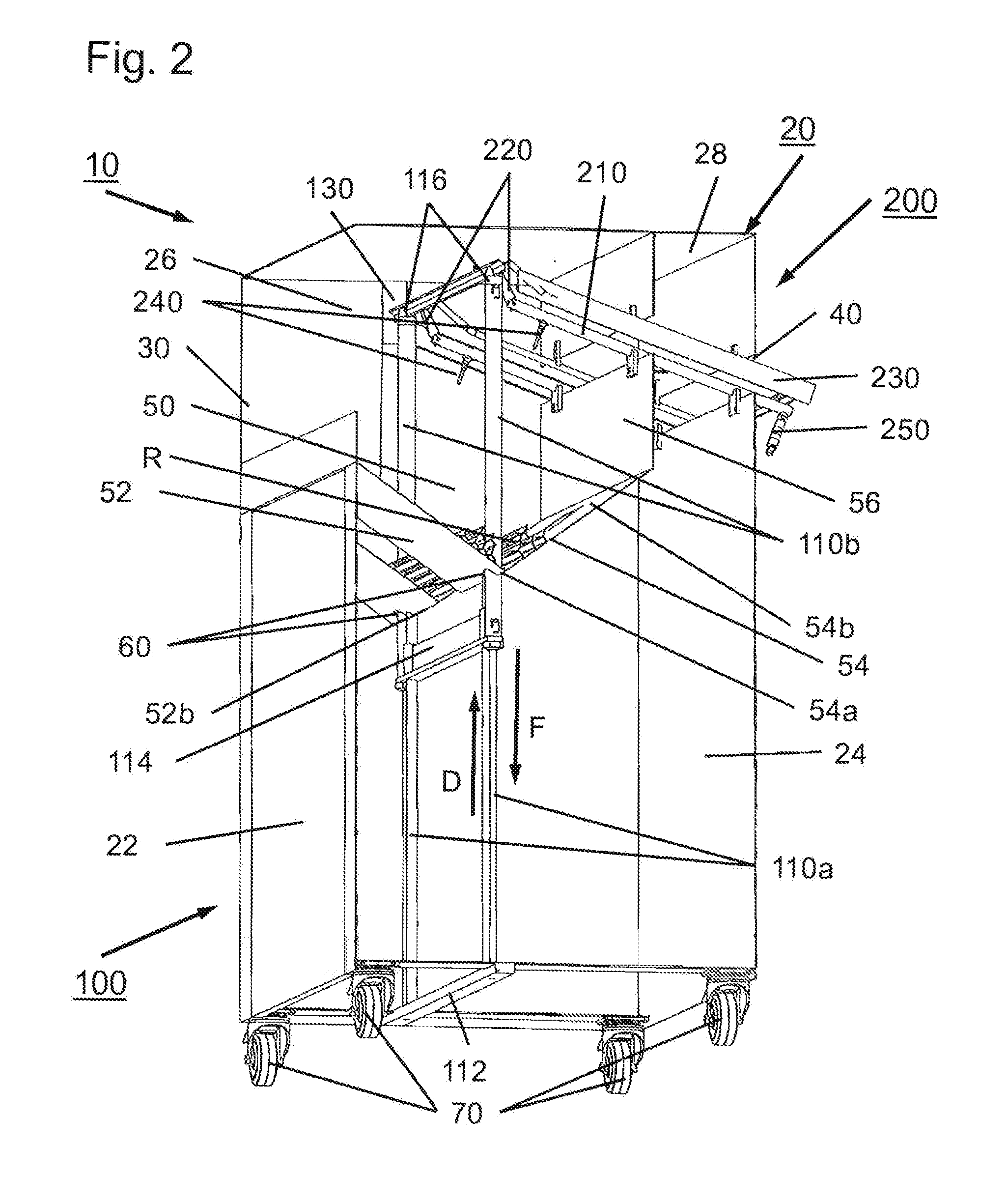

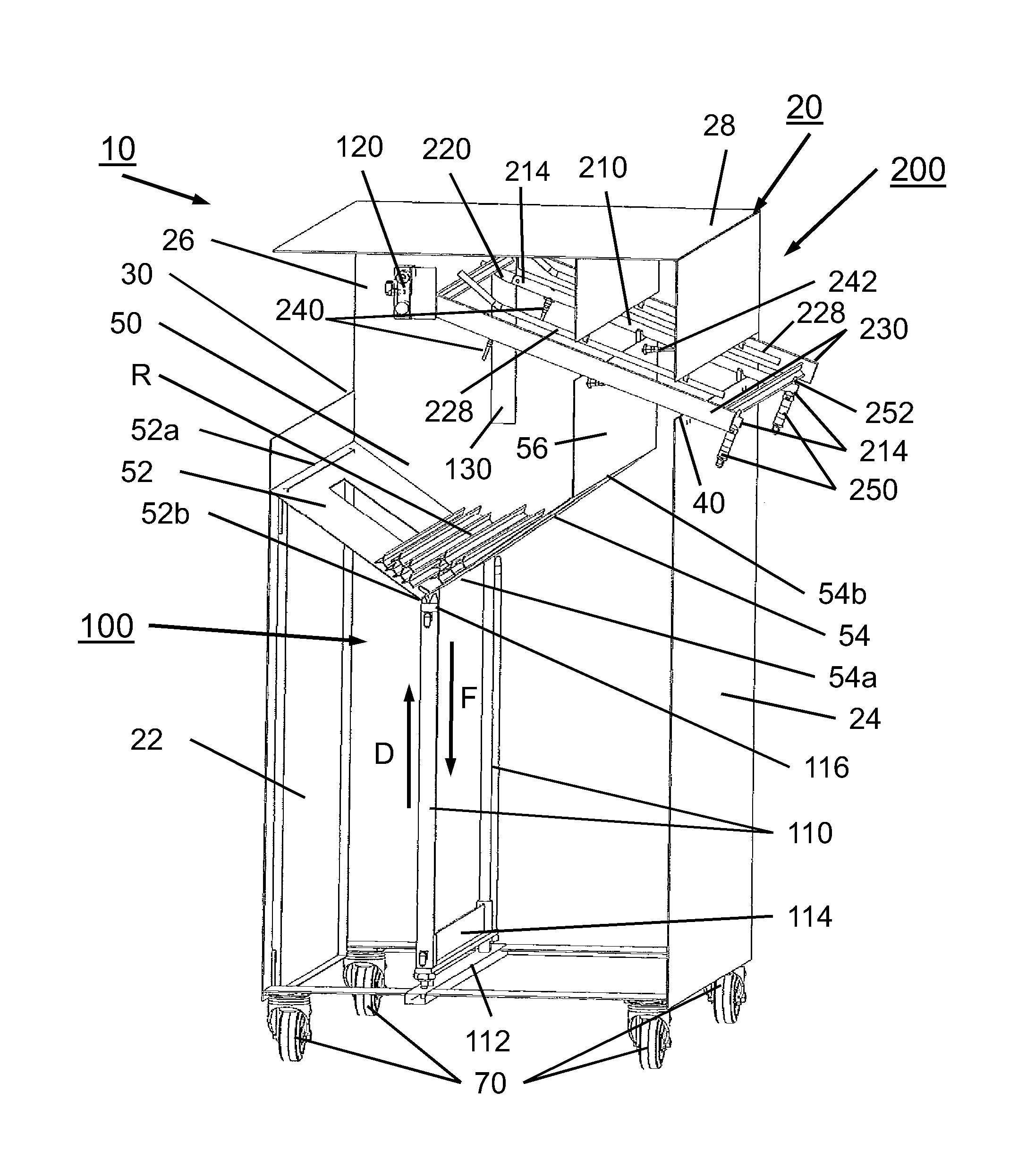

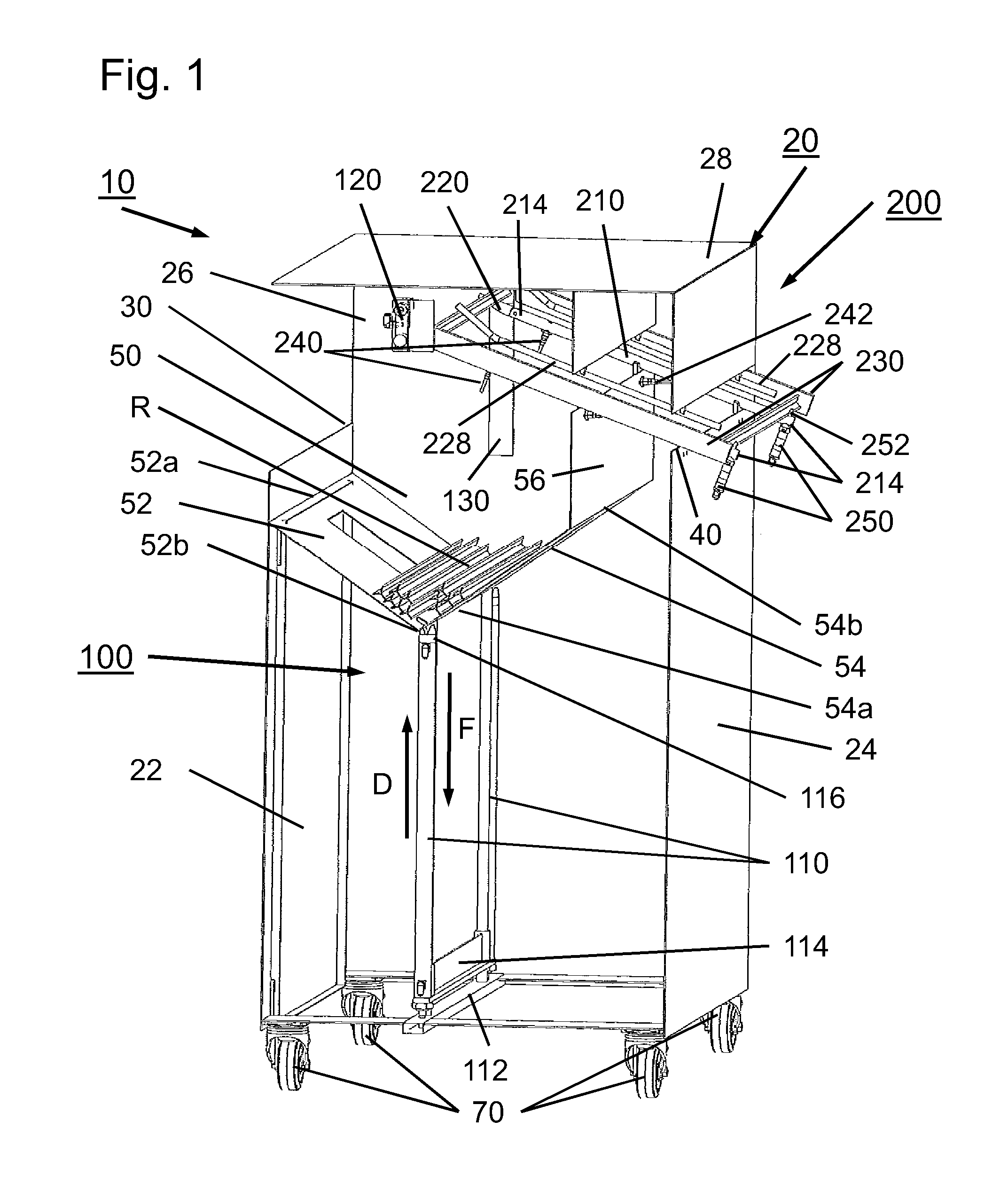

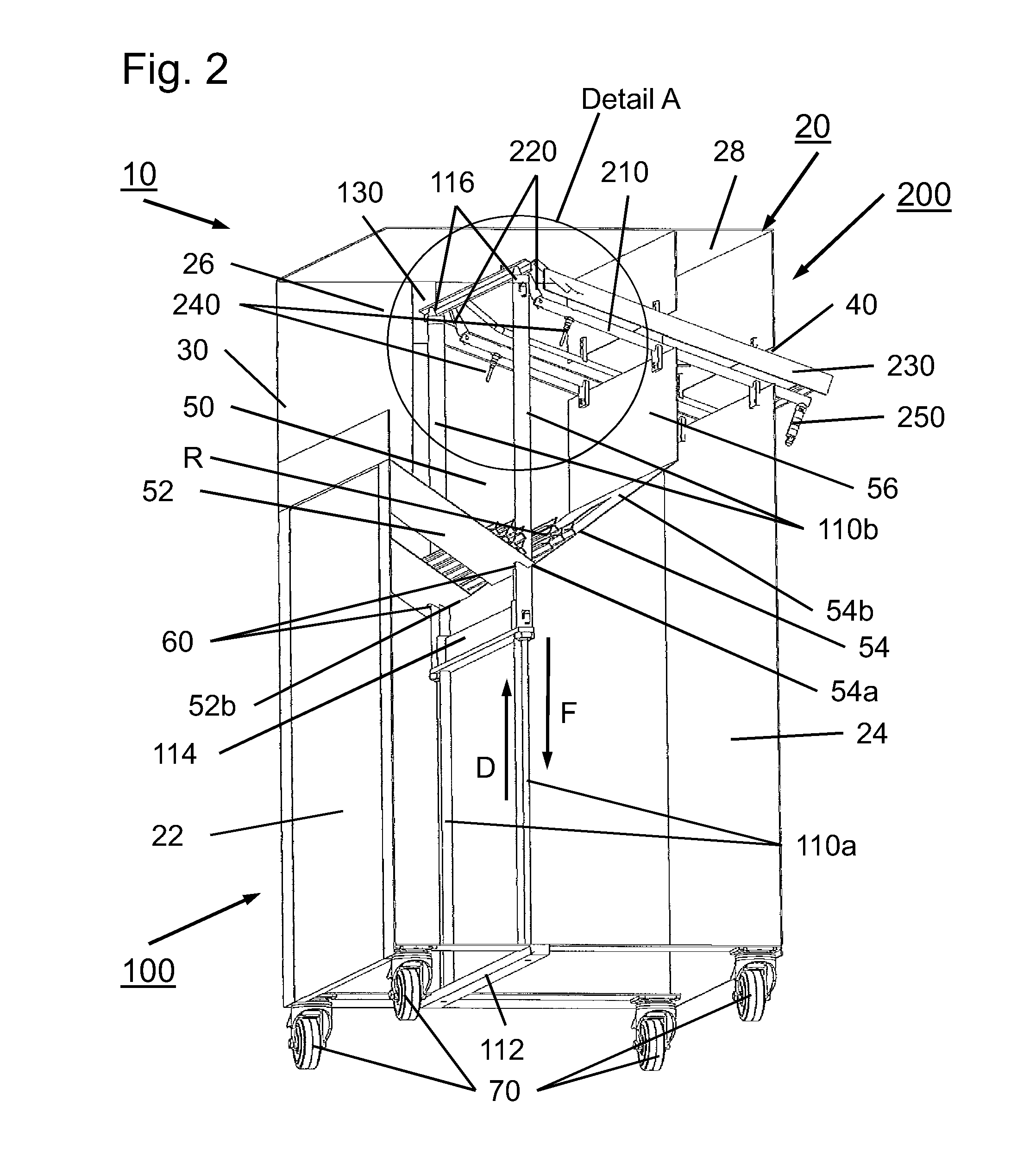

Separation device

ActiveUS20110272425A1Safe separationEfficient separationConveyorsMeat/sausage hanging-upEngineeringMechanical engineering

The present invention concerns a separation device for separating a rod-like element from a plurality of rod-like elements stored in a storage. The separation device may include a storage space having an approximately V-shaped cross section, for storing a plurality of at least approximately horizontally aligned rod-like elements, wherein the storage space includes at least a front wall element, a rear wall elements, and two side wall elements, having a bottom section and a top section. Moreover, a first discharge unit may be included for discharging a single rod-like element out of the plurality of rod-like elements stored in the storage space.

Owner:POLY CLIP SYST

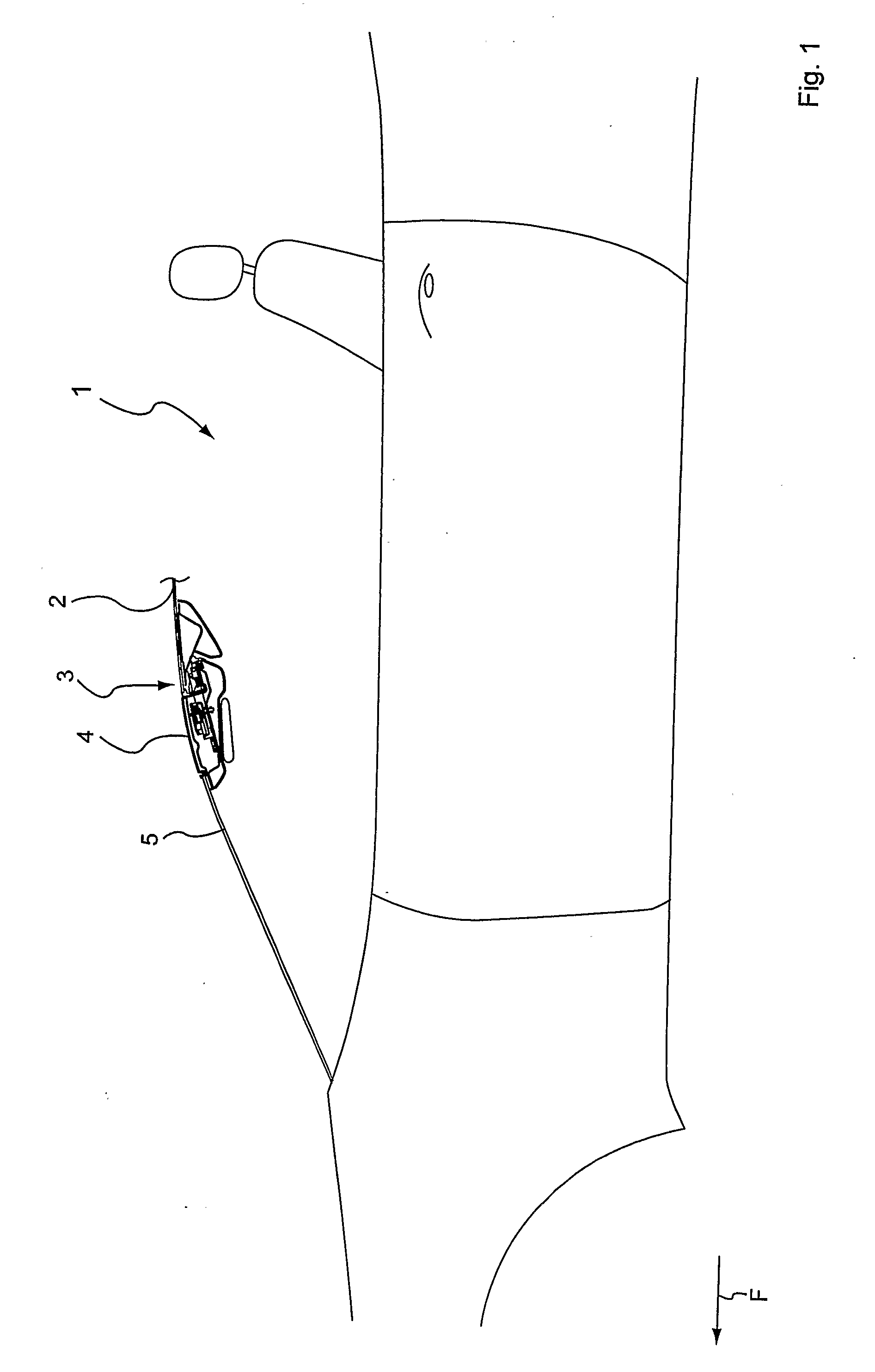

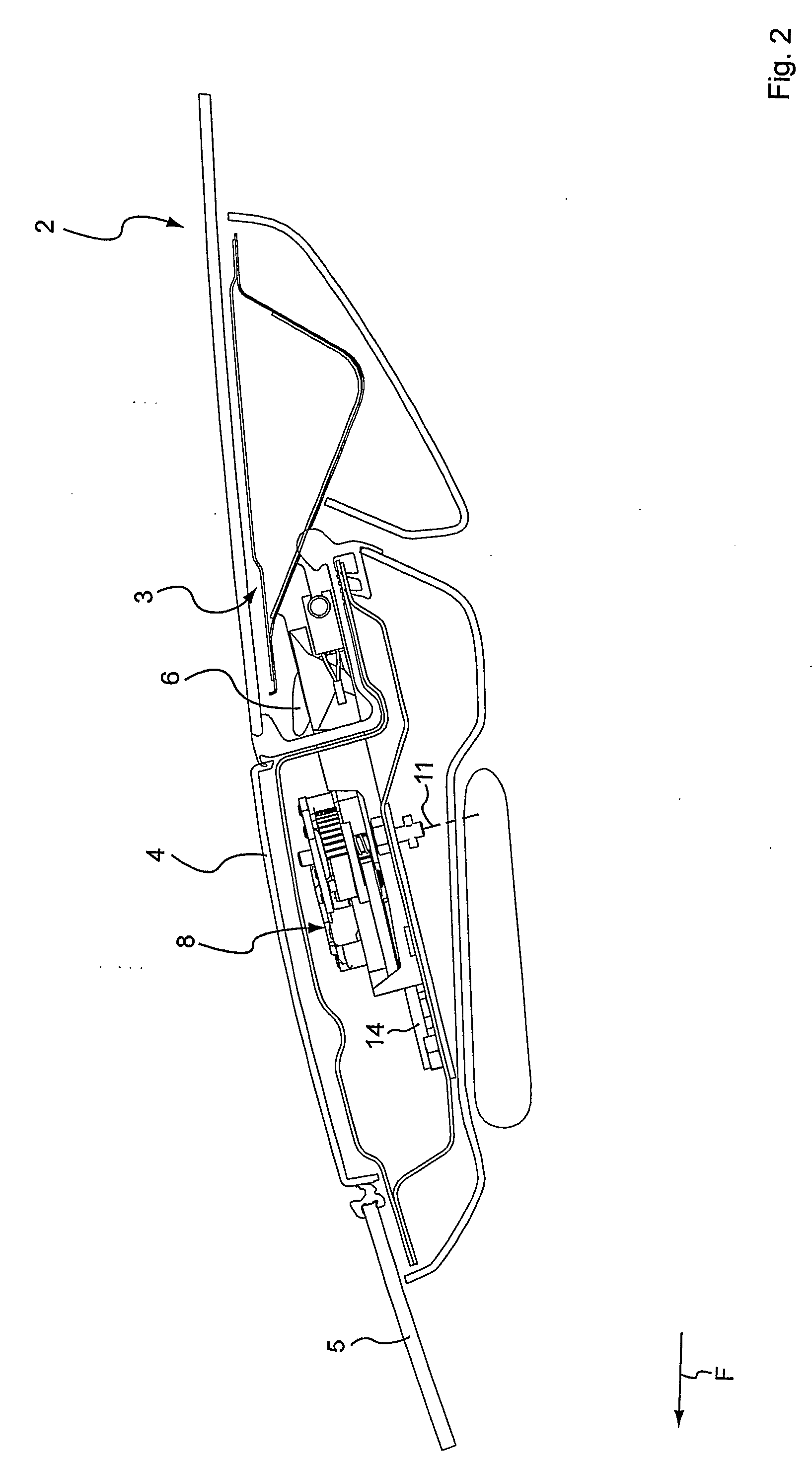

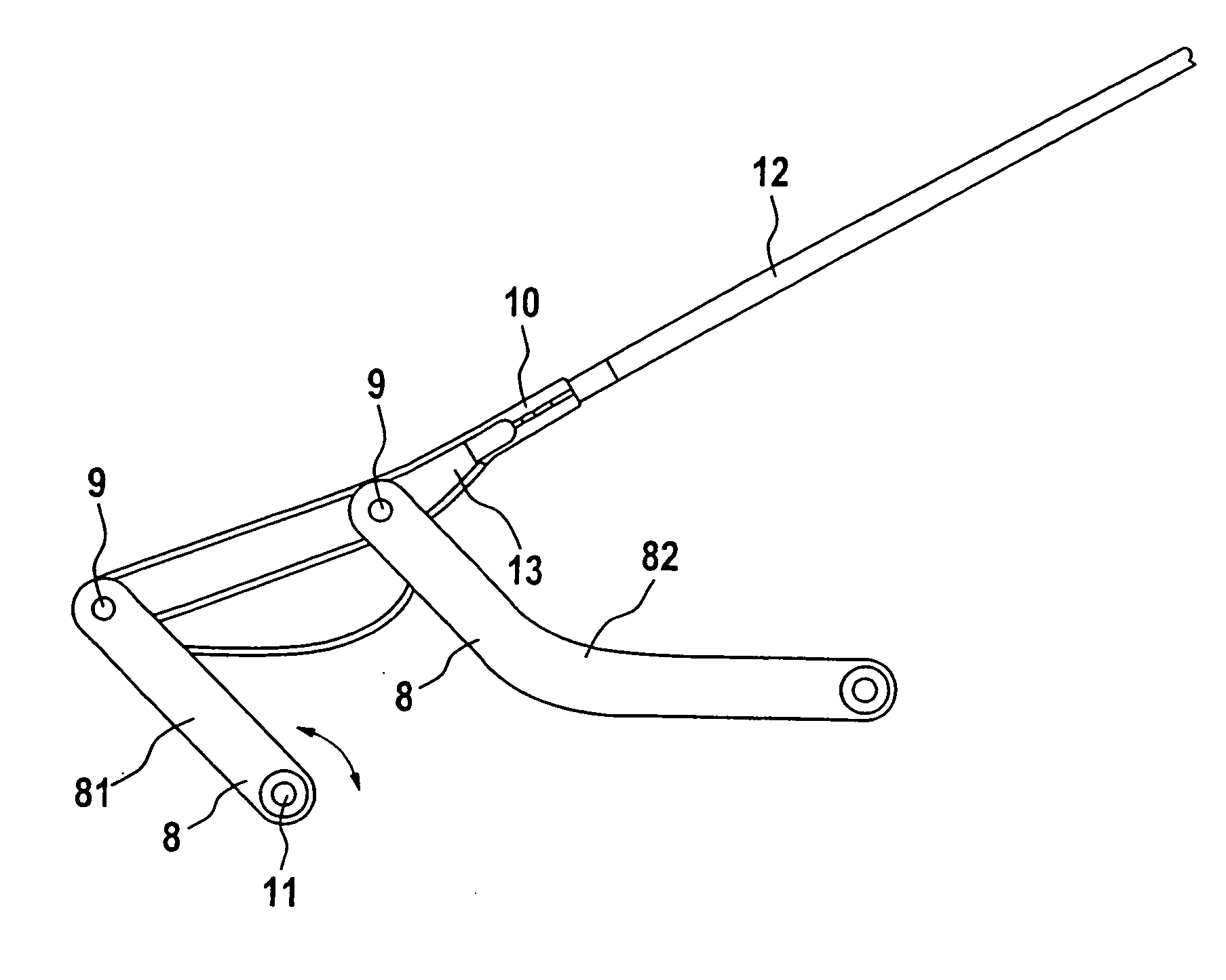

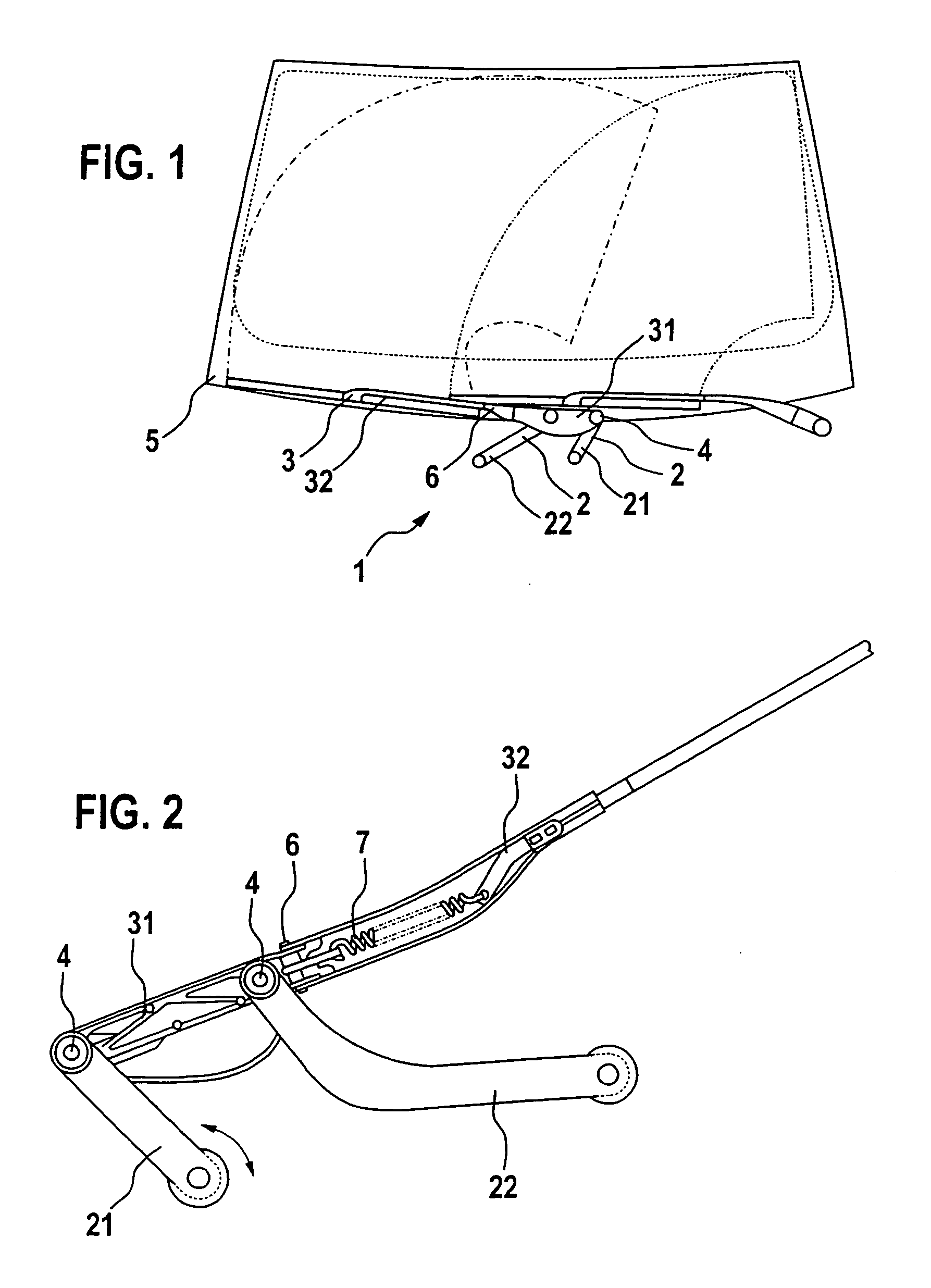

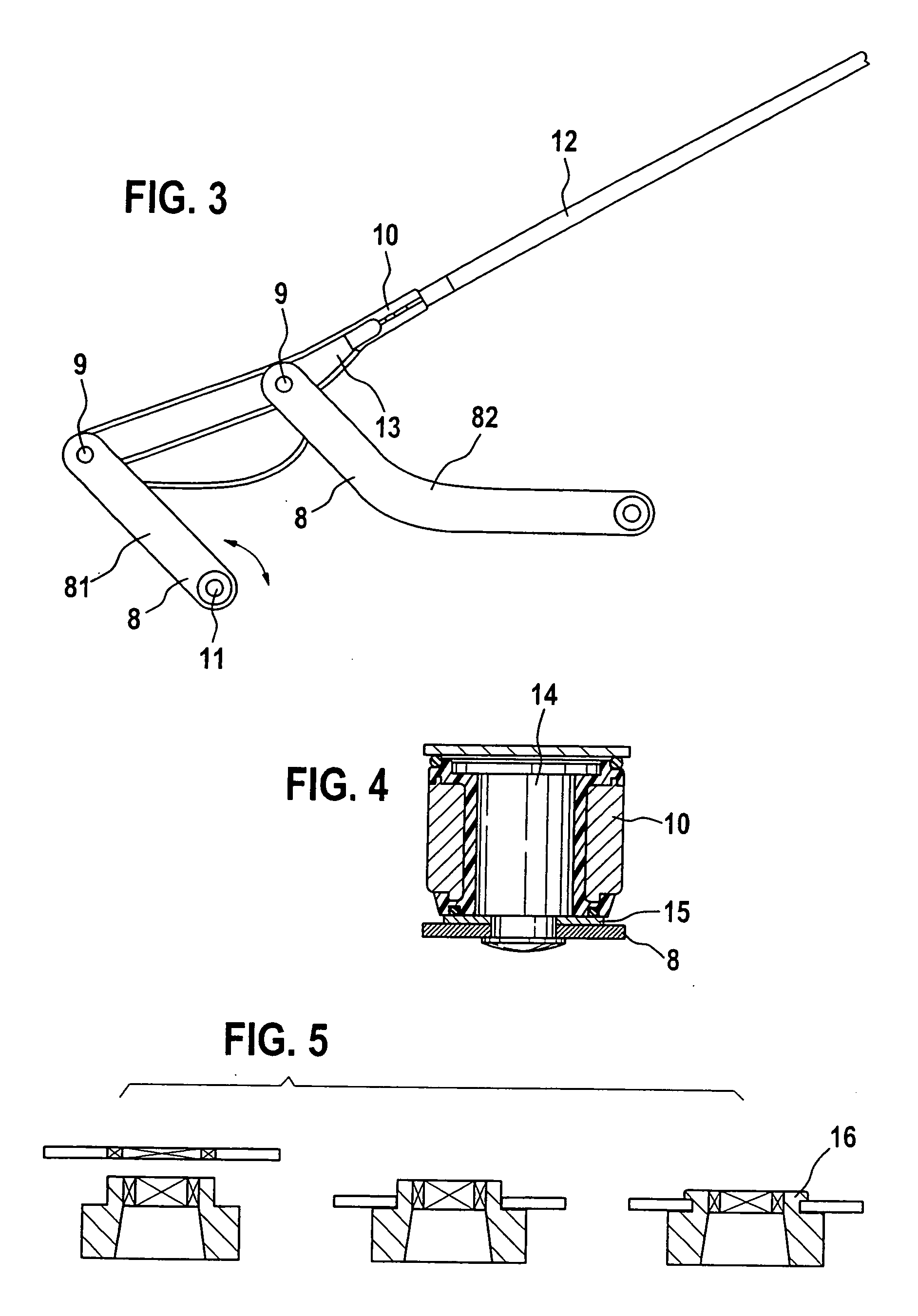

Wiper system for wiping a windscreen

InactiveUS20070067938A1Improved wear behaviorCost-effective manufacturingWindow cleanersVehicle cleaningWindshieldWindscreen wiper

The invention relates to a wiper device (1) to wipe a windshield (5) of a motor vehicle with a wiper arm (10) and two connecting rod levers (8), wherein the connecting rod levers (8) are connected to the wiper arm (10) in a plane at fastening points (9) so they can move rotationally, wherein at least one of the connecting rod levers (8) is executed to be elastic essentially perpendicular to the wiper plane in order to effect a pressure force from the wiper arm (10) on the windshield.

Owner:ROBERT BOSCH GMBH

Separation device

ActiveUS9474287B2Safe separationEfficient separationMeat/sausage hanging-upConveyorsEngineeringMechanical engineering

The present invention concerns a separation device for separating a rod-like element from a plurality of rod-like elements stored in a storage. The separation device may include a storage space having an approximately V-shaped cross section, for storing a plurality of at least approximately horizontally aligned rod-like elements, wherein the storage space includes at least a front wall element, a rear wall elements, and two side wall elements, having a bottom section and a top section. Moreover, a first discharge unit may be included for discharging a single rod-like element out of the plurality of rod-like elements stored in the storage space.

Owner:POLY CLIP SYST

Piston for an internal combustion engine and method for its production

InactiveUS20140331958A1Reduce construction heightExcellent mechanical and thermal propertiesMachines/enginesPistonsThermodynamicsPiston ring

A method for the production of a piston for an internal combustion engine, having a piston head, a piston skirt, and a circumferential recess configured between the piston head and the piston skirt. The piston has a piston base body and a piston ring element. The piston base body has at least a crown region of a combustion bowl as well as the piston skirt. The piston ring element has at least a piston crown, a wall region of the combustion bowl, a circumferential top land, and a circumferential ring belt with ring grooves. The piston ring element has a circumferential cooling channel between the wall region of the combustion bowl and the ring belt, closed with a closure element. The piston base body and the piston ring element are connected by a circumferential joining seam in the region of the combustion bowl.

Owner:MAHLE INT GMBH

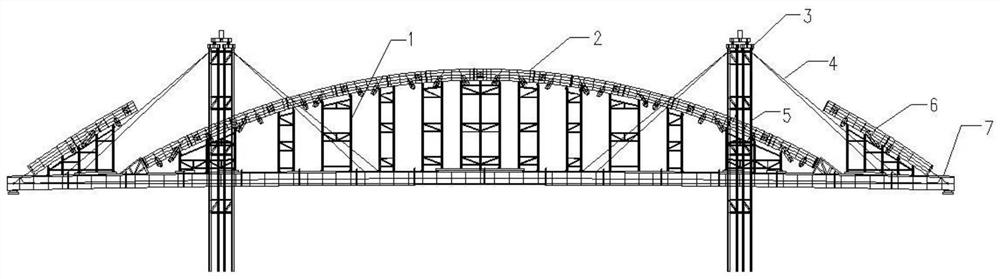

Typhoon area through type steel arch bridge steel arch rib lifting method and alignment adjusting device

PendingCN113699888AReduce the impactAchieve regulationBridge erection/assemblyArch-type bridgeArchitectural engineeringJackscrew

The invention provides a typhoon area through type steel arch bridge steel arch rib lifting method and an alignment adjusting device. The device comprises an in-situ splicing section steel arch rib, a horizontal splicing lifting section steel arch rib, a splicing support and a plurality of lifting portal frame systems. The assembling bracket and the lifting portal frame system are vertically arranged on the steel main beam; the lifting portal frame system comprises steel pipe stand columns, wind cables, a supporting mechanism and a lifting system arranged on the supporting mechanism, the supporting mechanism comprises a column top longitudinal beam and a supporting cross beam, and the supporting cross beam and the column top longitudinal beam form a #-shaped structure. The lifting system comprises a lifting jack base, a lifting jack, a plurality of transverse position adjusting jacks and a plurality of longitudinal position adjusting jacks. The horizontally-spliced lifting section steel arch rib is provided with a steel arch rib hanging point, and the steel arch rib hanging point comprises a partition plate, a connecting plate and a carrying pole beam. The construction height of the support and the assembled gantry crane is reduced on the whole, potential safety hazards of construction are reduced, and the method has certain popularization significance for the through steel arch bridge in a typhoon area.

Owner:THE THIRD ENG CO LTD OF CCCC SECOND HIGHWAY ENG BUREAU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com