Patents

Literature

479 results about "Ring element" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ring Element. The ring element is constructed similarly to the basket element but it has an additional internal filter cylinder which increases the filtration area by approximately 30%.

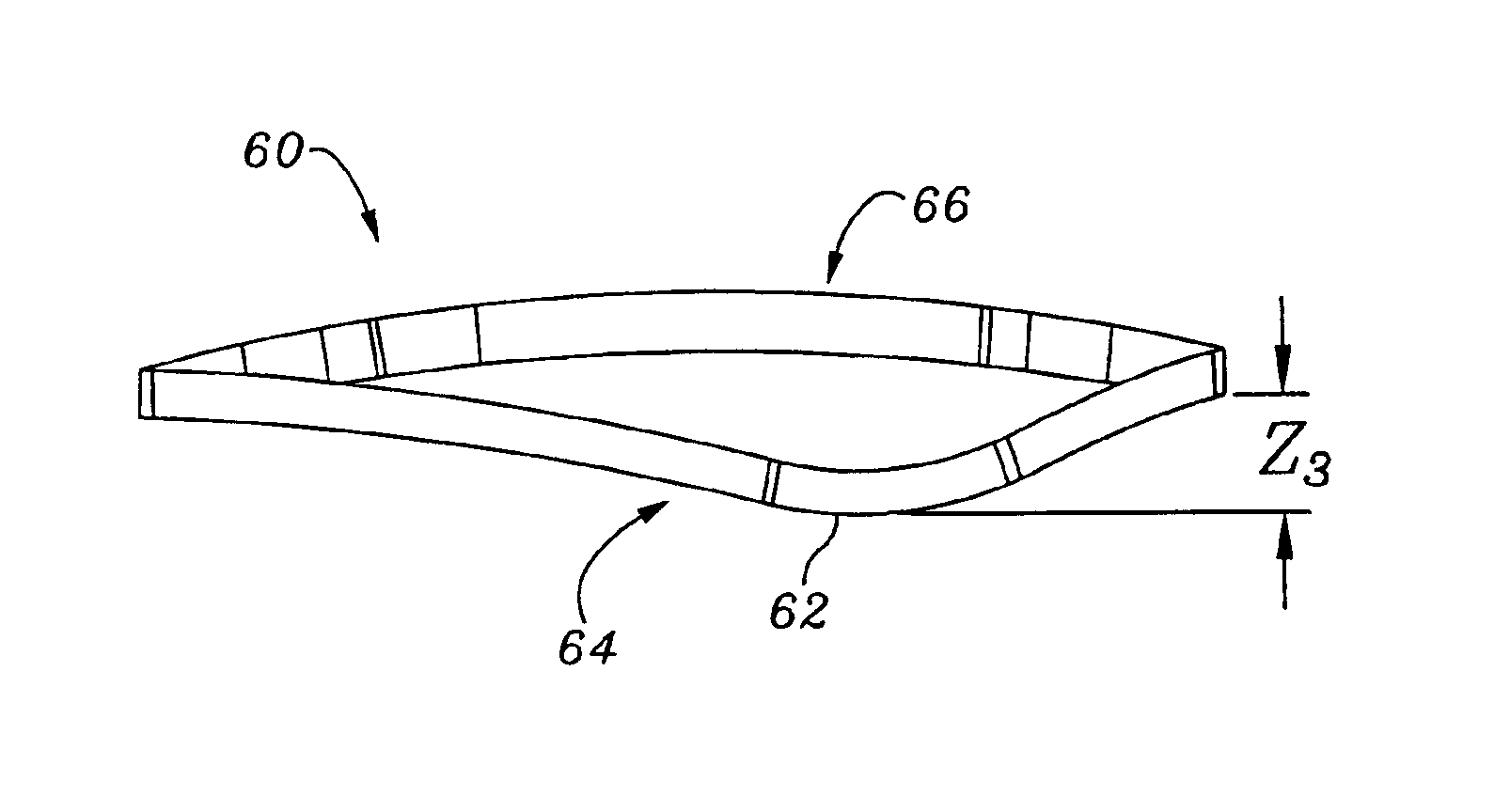

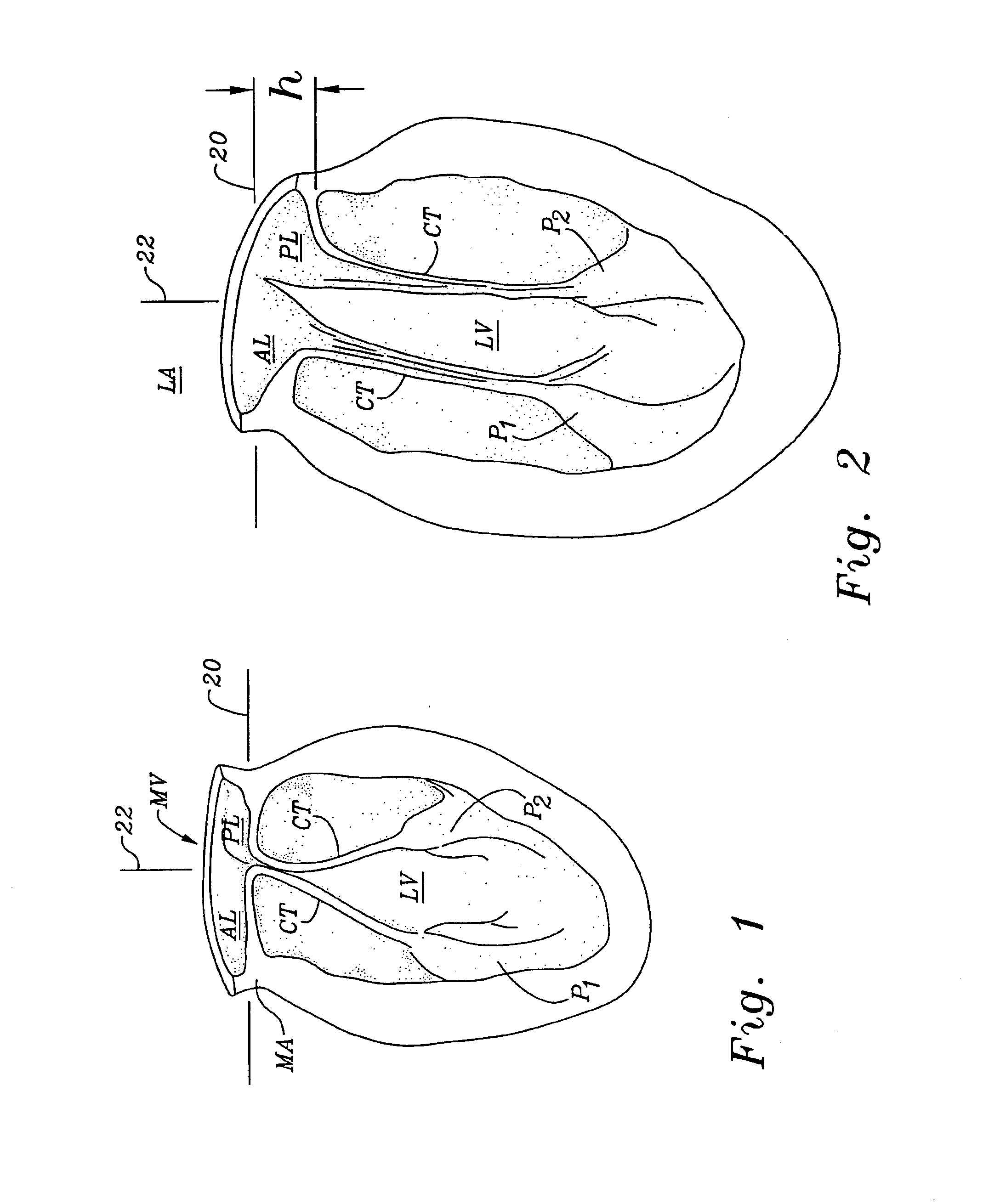

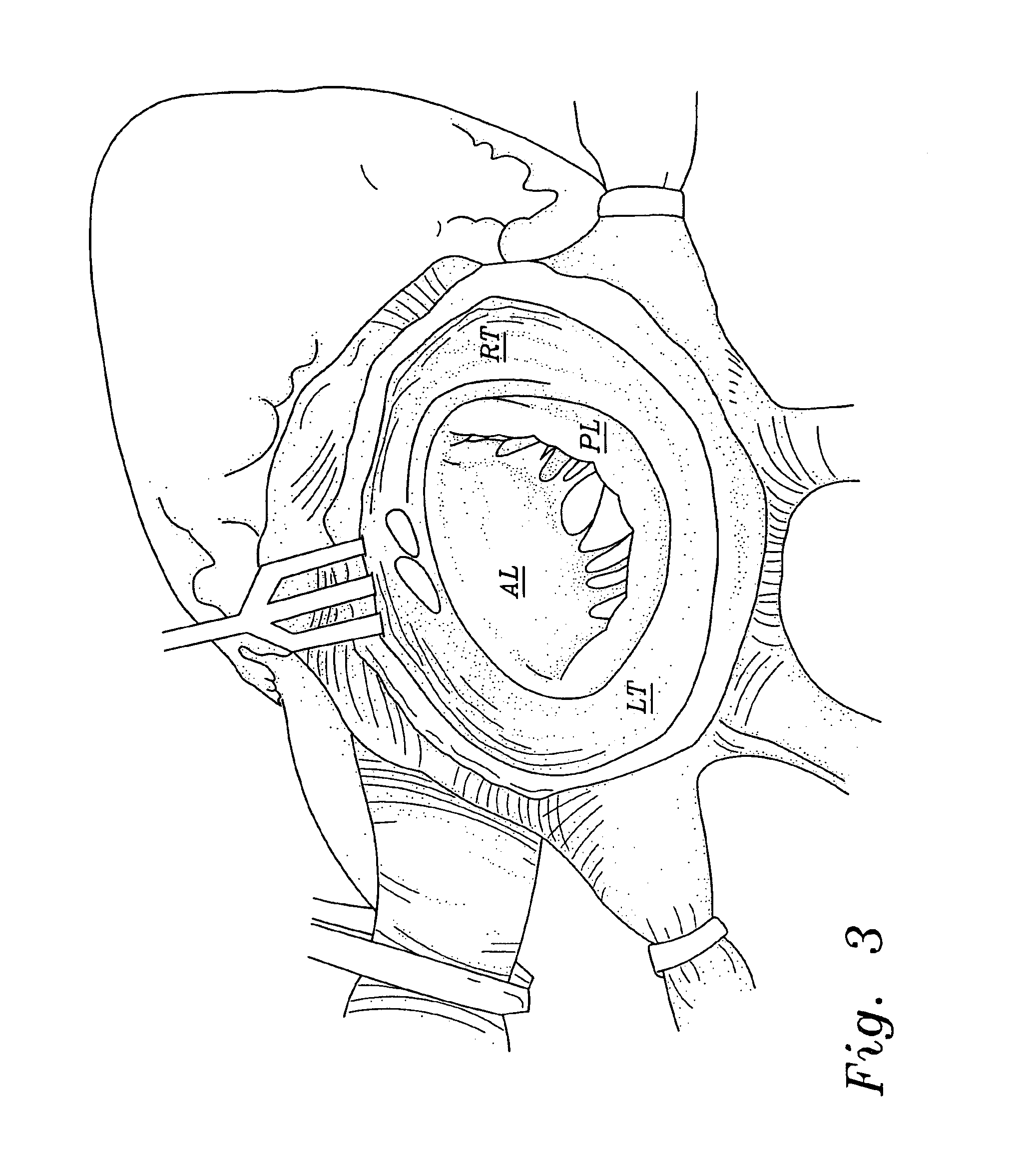

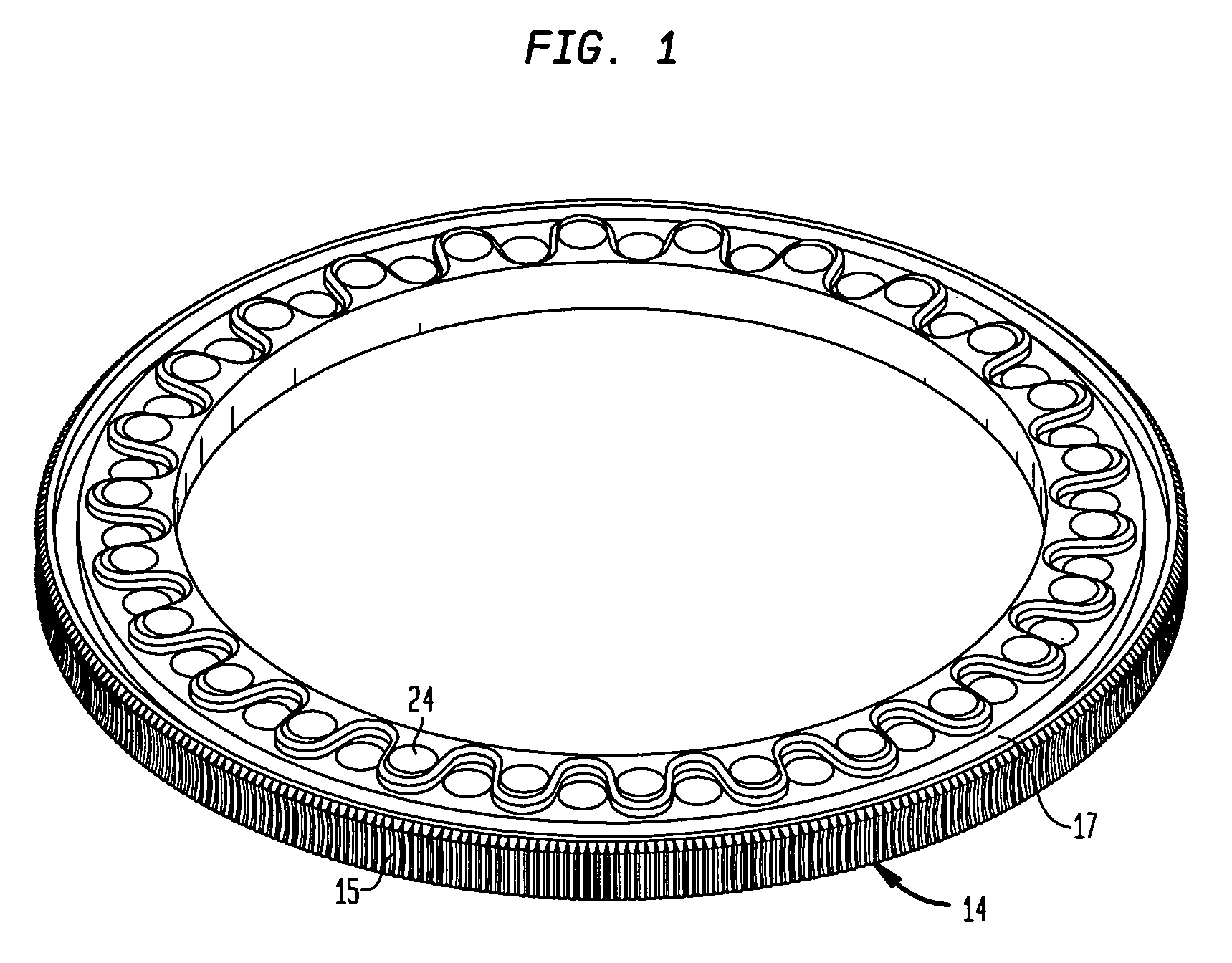

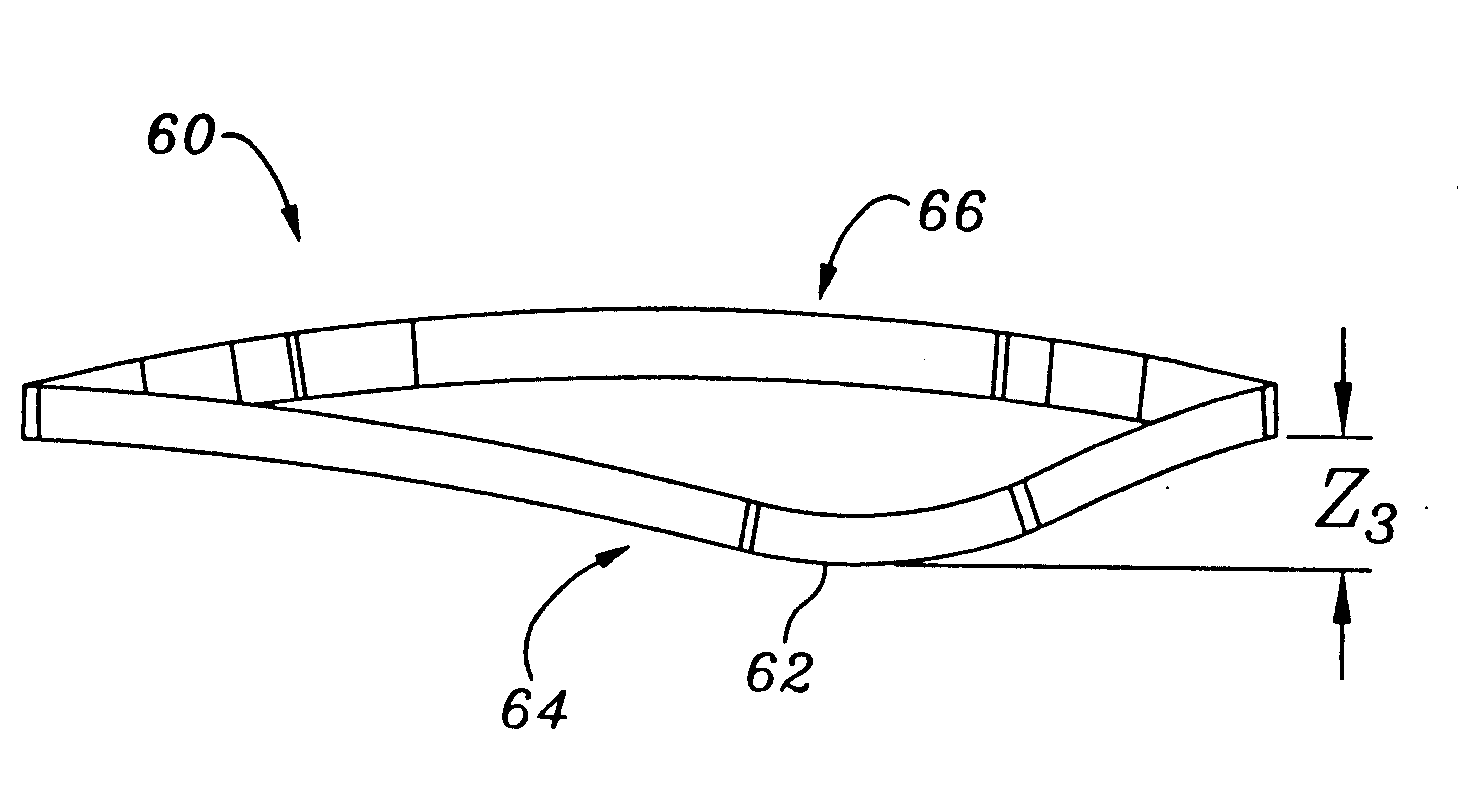

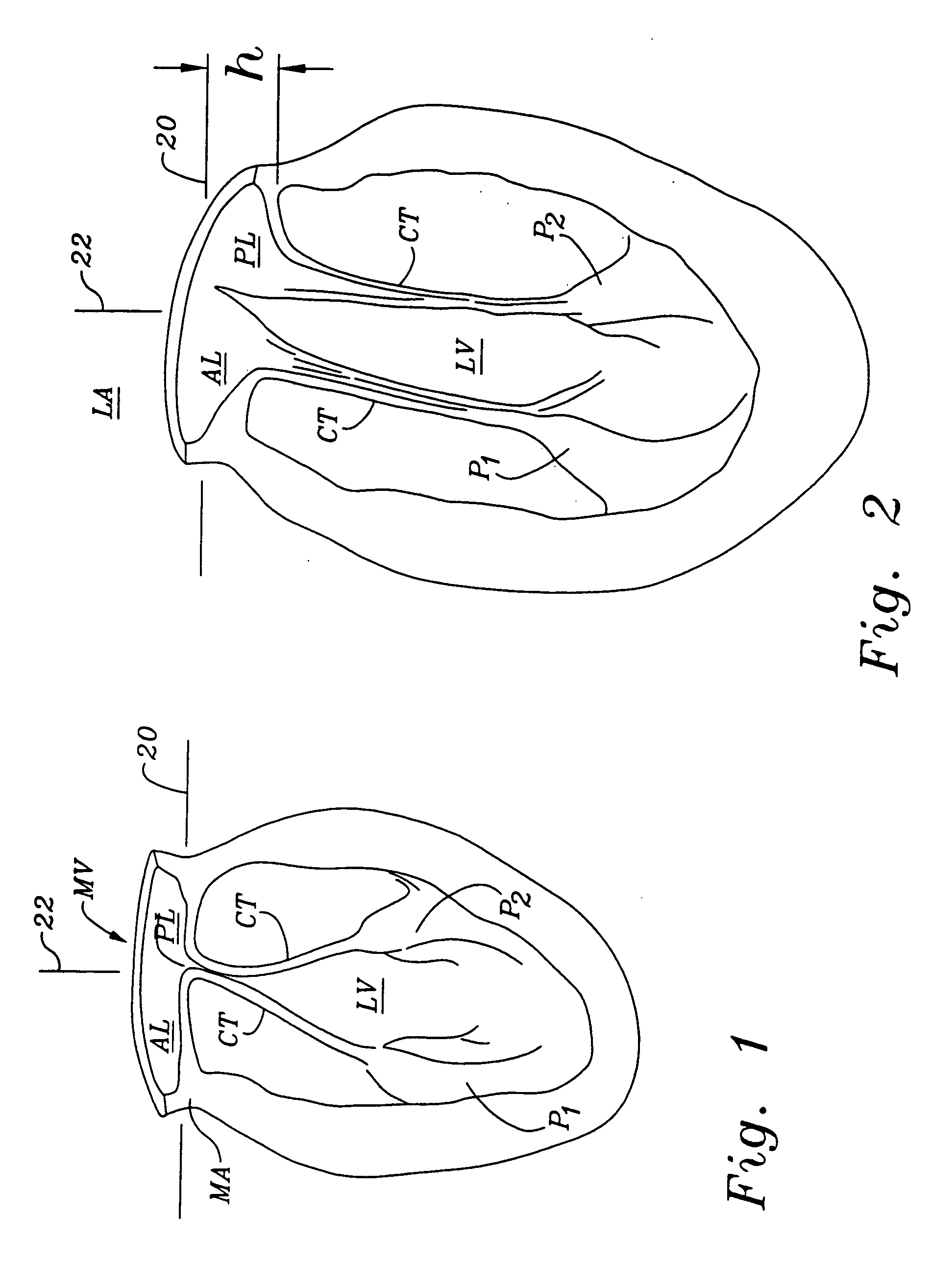

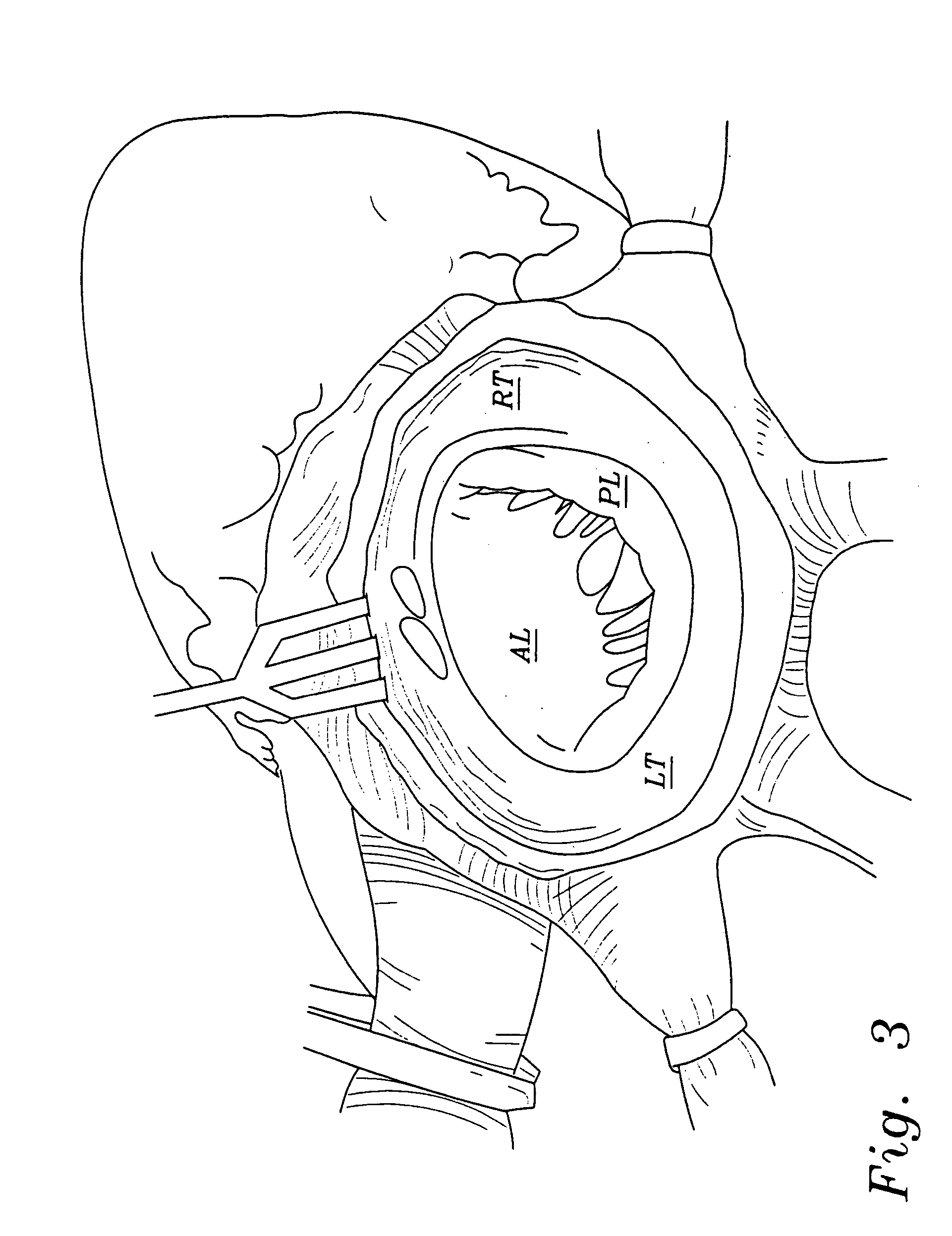

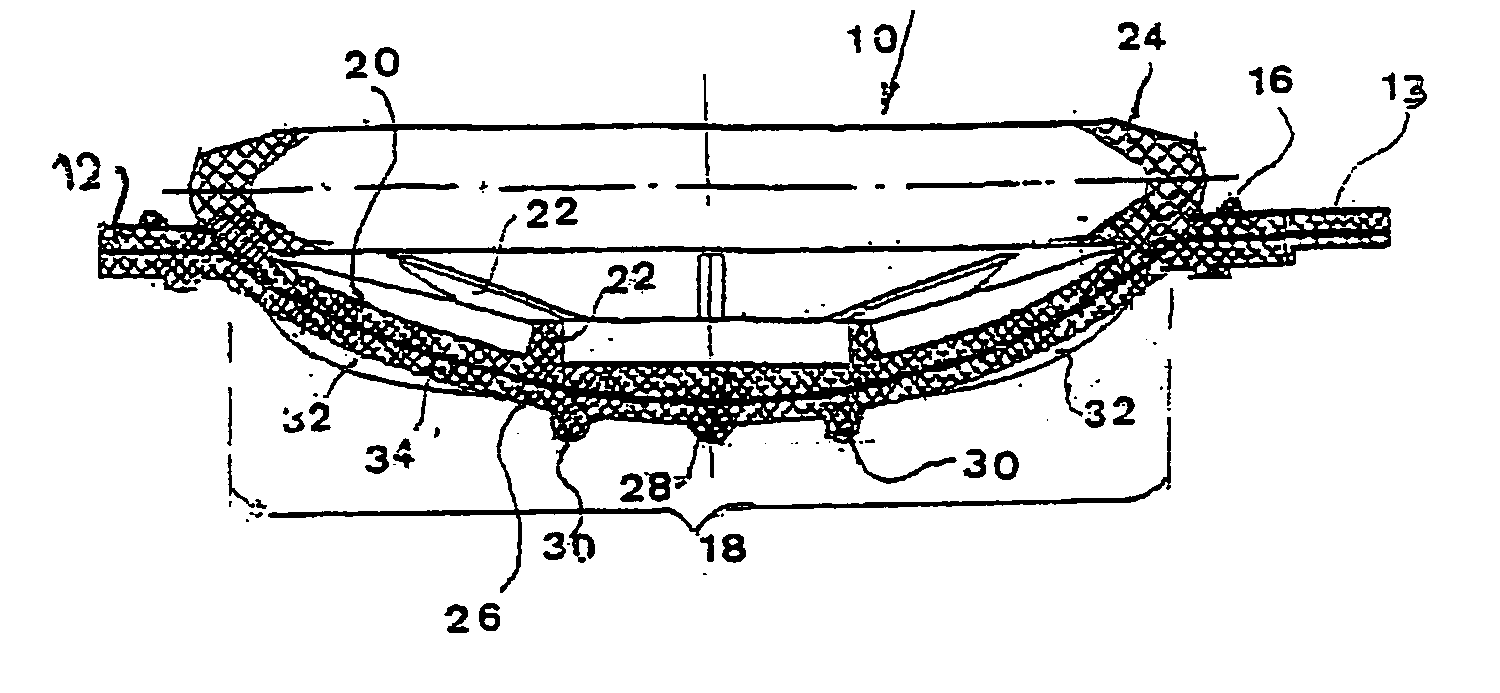

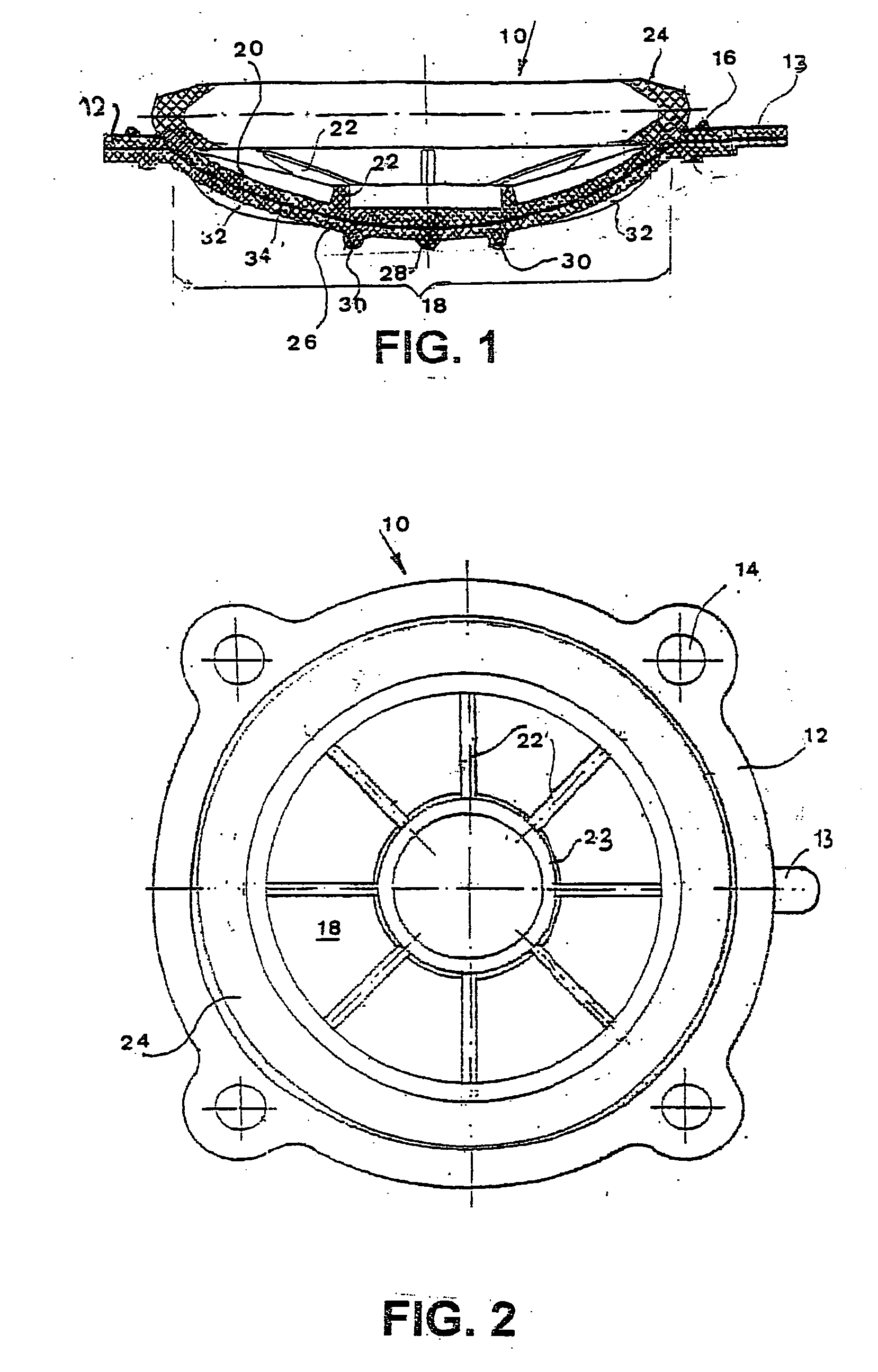

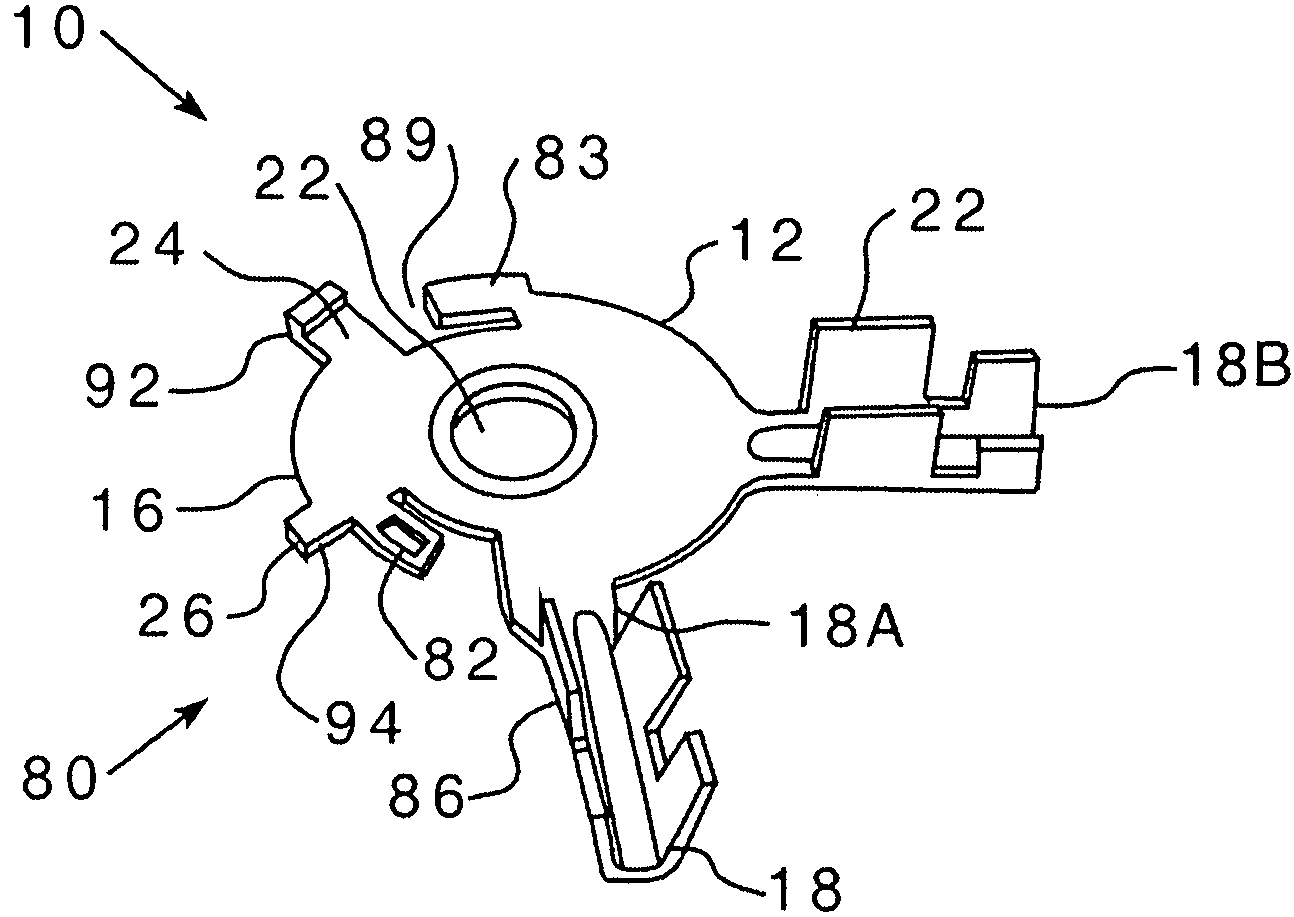

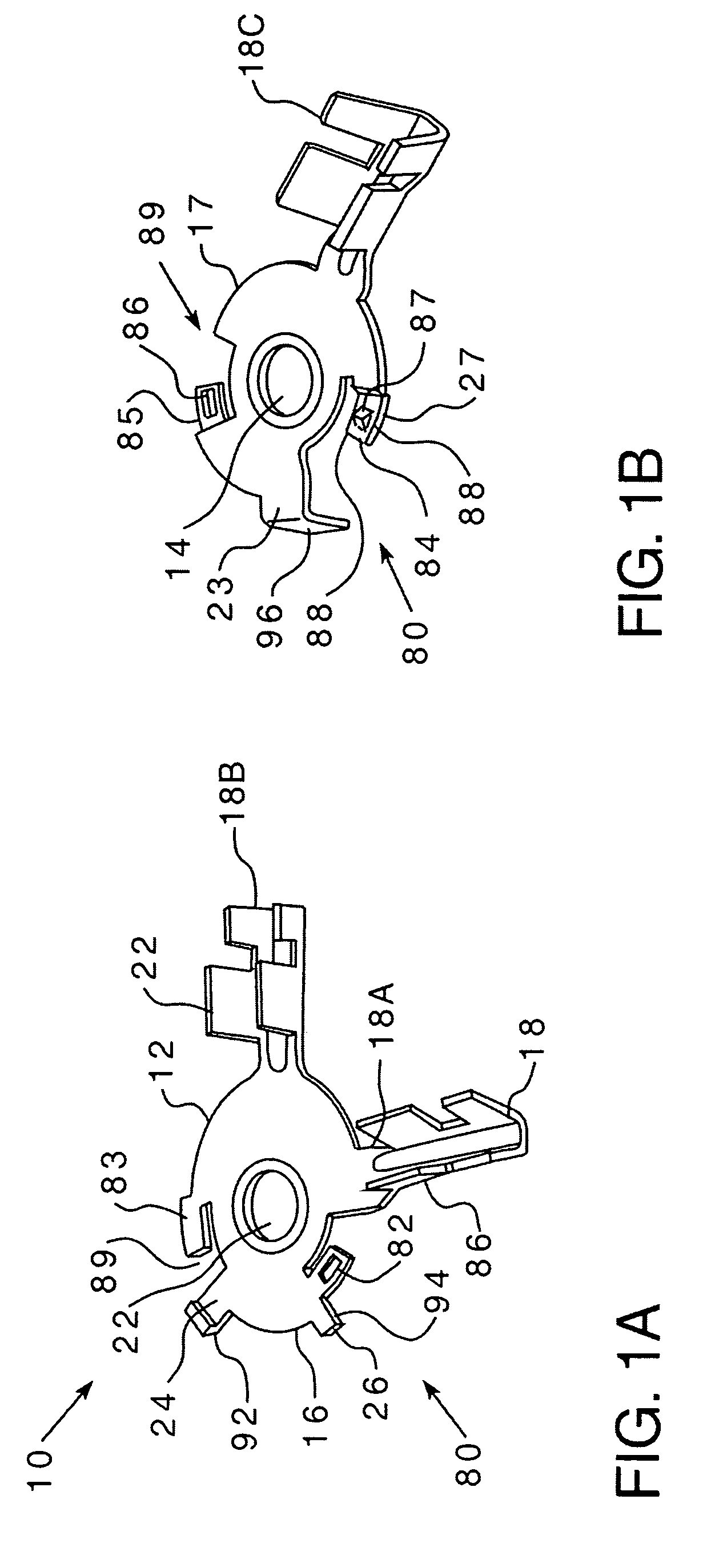

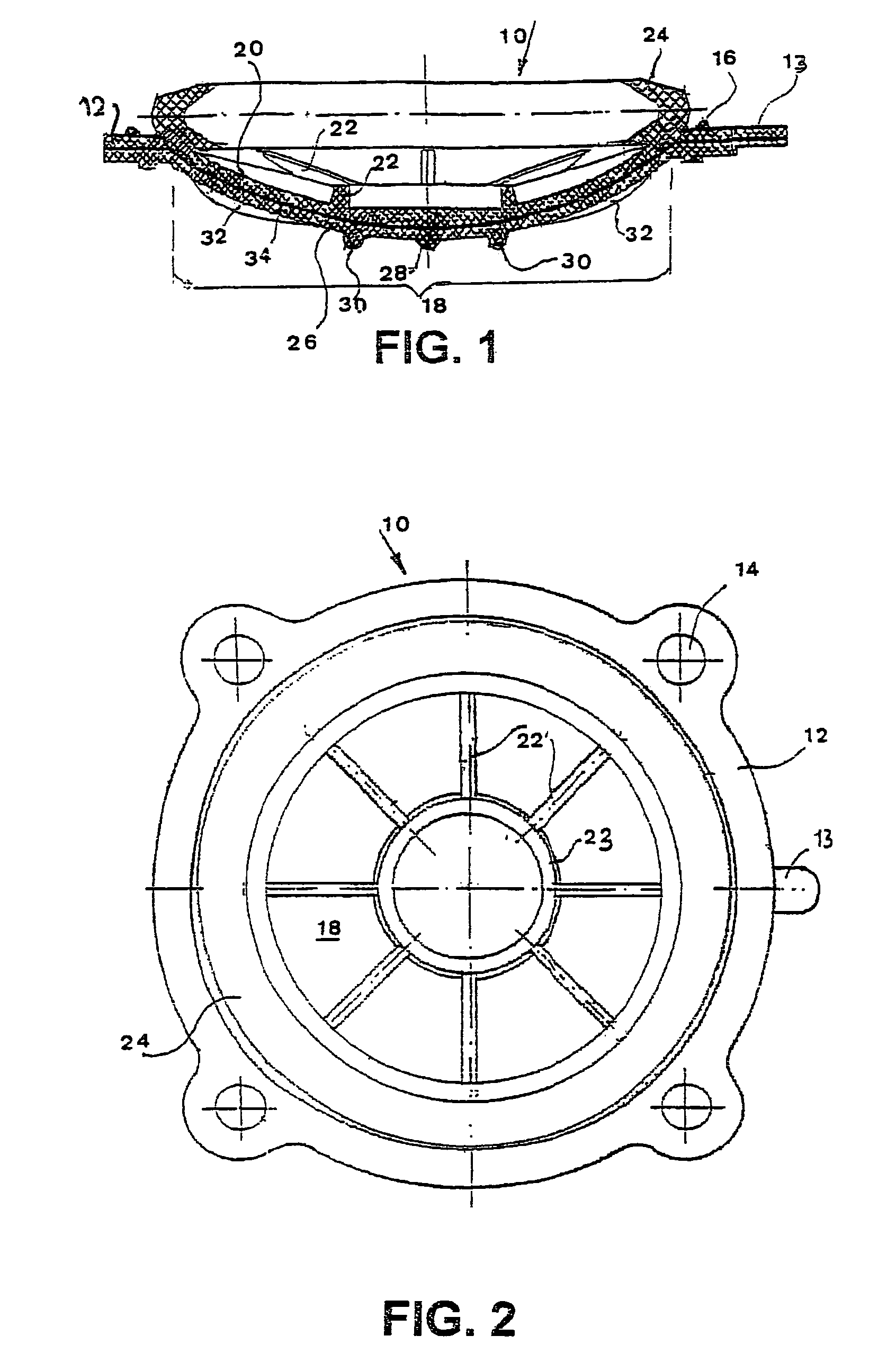

Mitral valve annuloplasty ring having a posterior bow

A mitral heart valve annuloplasty ring having a posterior bow that conforms to an abnormal posterior aspect of the mitral annulus. The ring may be generally oval having a major axis and a minor axis, wherein the posterior bow may be centered along the minor axis or offset in a posterior section. The ring may be substantially planar, or may include upward bows on either side of the posterior bow. The ring may include a ring body surrounded by a suture-permeable fabric sheath, and the ring body may be formed of a plurality of concentric ring elements. The ring is semi-rigid and the posterior bow is stiff enough to withstand deformation once implanted and subjected to normal physiologic stresses. The ring elements may be bands of semi-rigid material. A method of repairing an abnormal mitral heart valve annulus having a depressed posterior aspect includes providing a ring with a posterior bow and implanting the ring to support the annulus without unduly stressing the attachment sutures.

Owner:EDWARDS LIFESCIENCES CORP

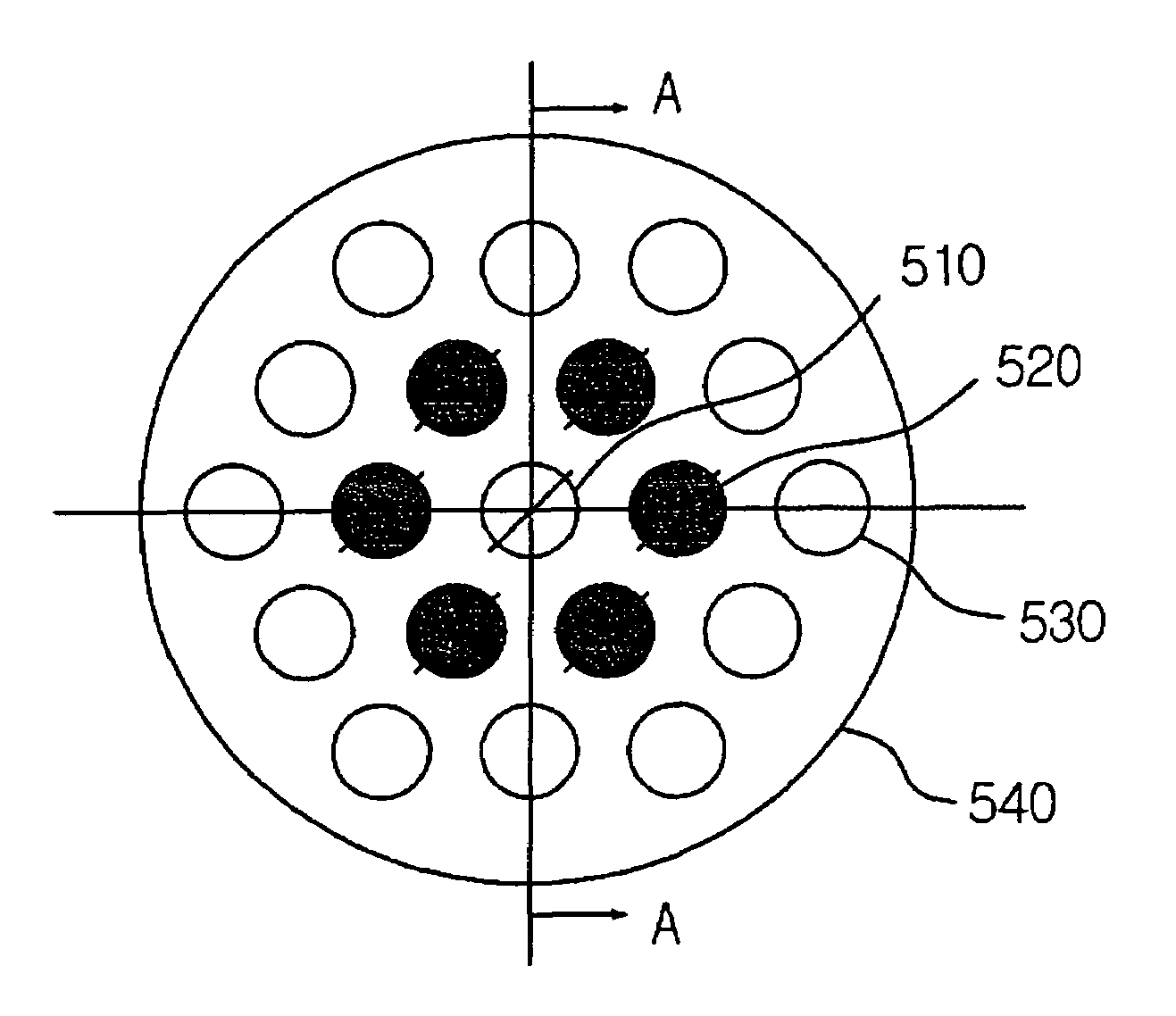

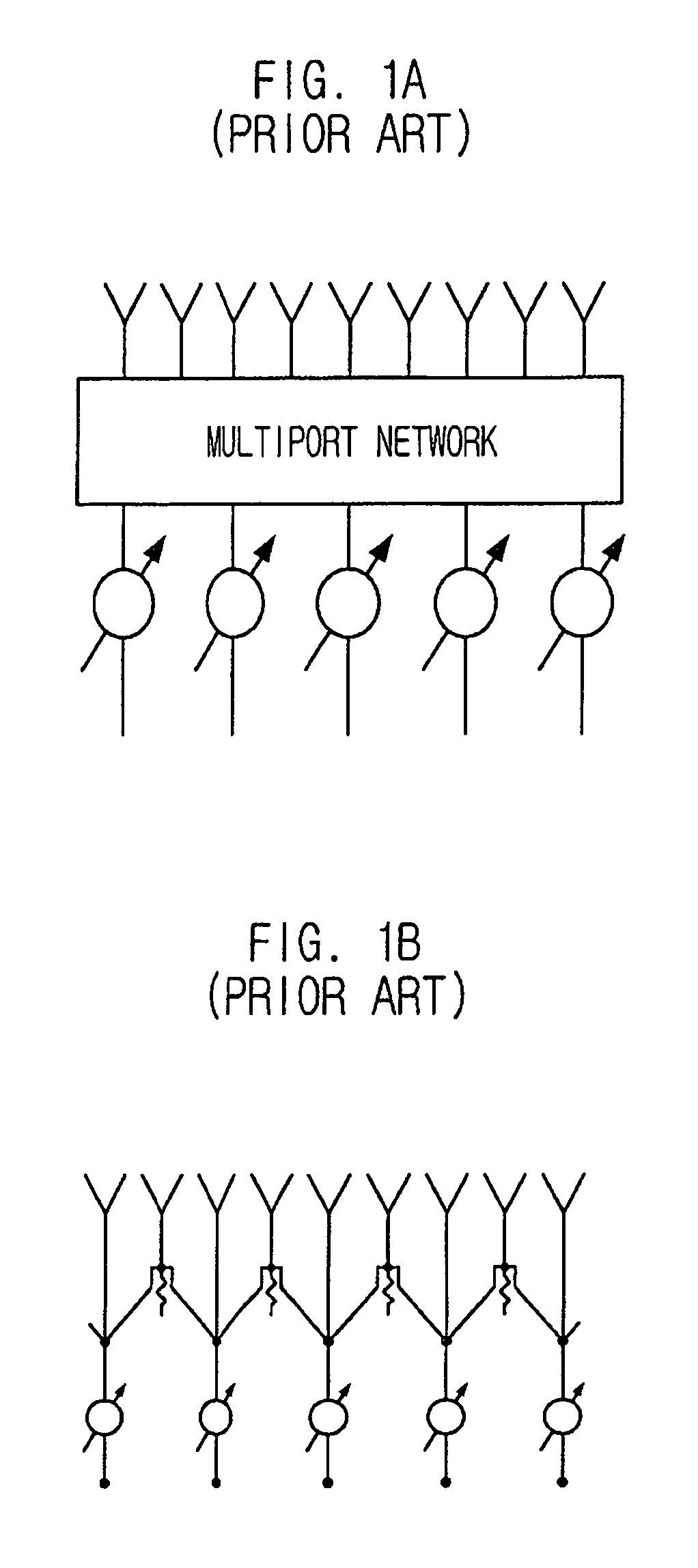

Hexagonal array structure of dielectric rod to shape flat-topped element pattern

InactiveUS7167139B2Wide beam scanning rangeConstant electric performanceIndividually energised antenna arraysLeaky-waveguide antennasCouplingEngineering

A hexagonal array structure of a dielectric rod for shaping a flat-topped element pattern (FTEP) is provided. The hexagonal structure of dielectric rods forming a flat-topped element pattern (FTEP) includes: a center element for forming a unit radiation pattern of the FTEP through an electromagnetic wave mutual coupling by receiving a polarization signal of a basic mode; a plurality of first ring elements arranged at vertexes of a regular hexagon based on the center element for forming the unit radiation pattern by electromagnetic wave mutual coupling with the center element and an electromagnetic wave; and a circular waveguide array supporting unit for supporting the center element and the plurality of first ring elements.

Owner:ELECTRONICS & TELECOMM RES INST

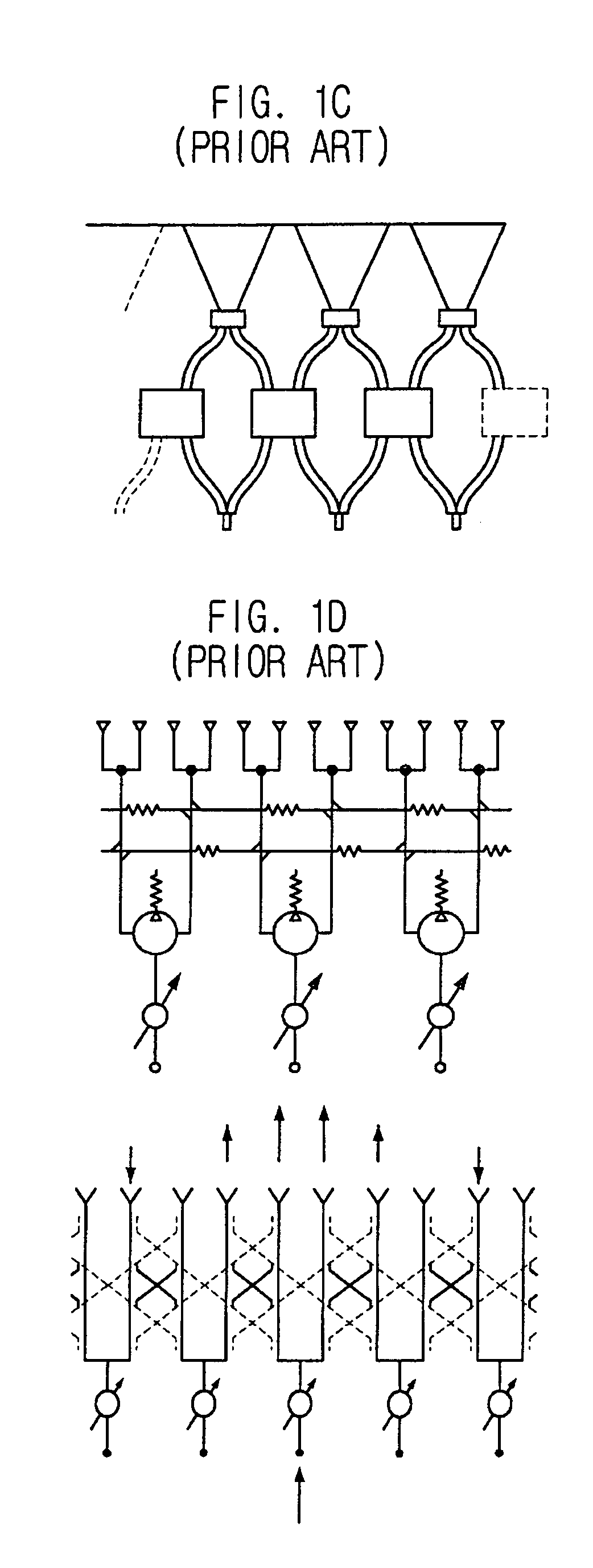

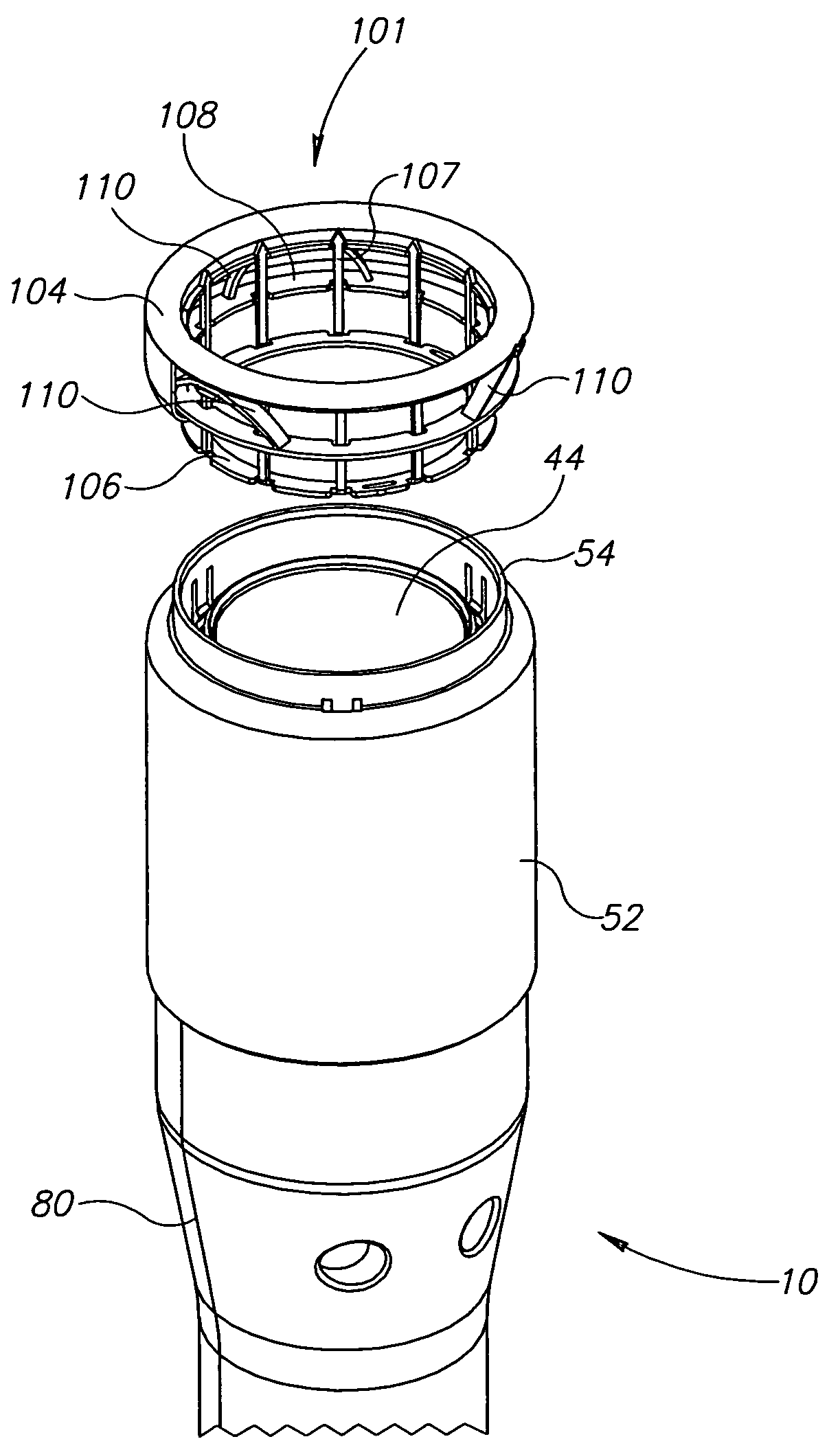

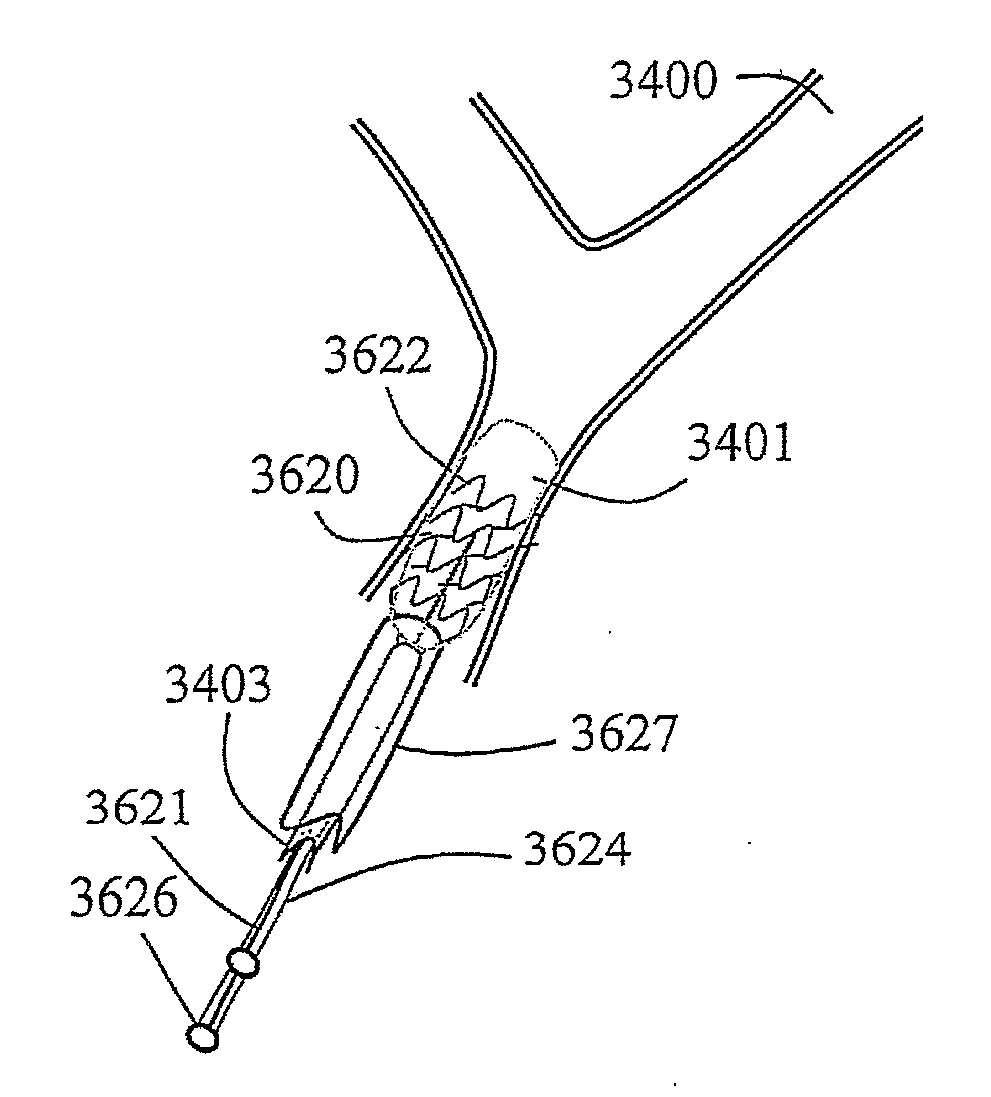

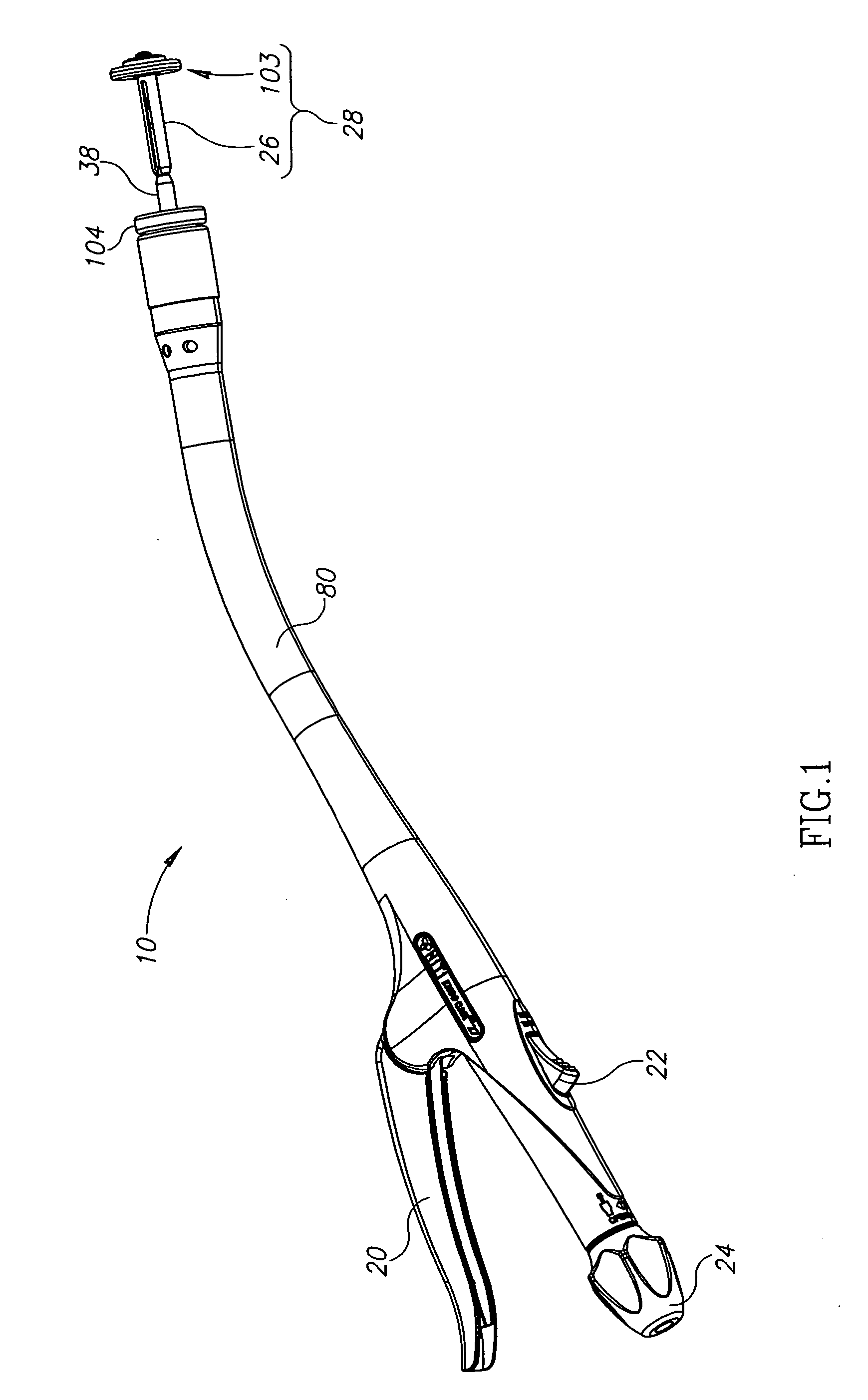

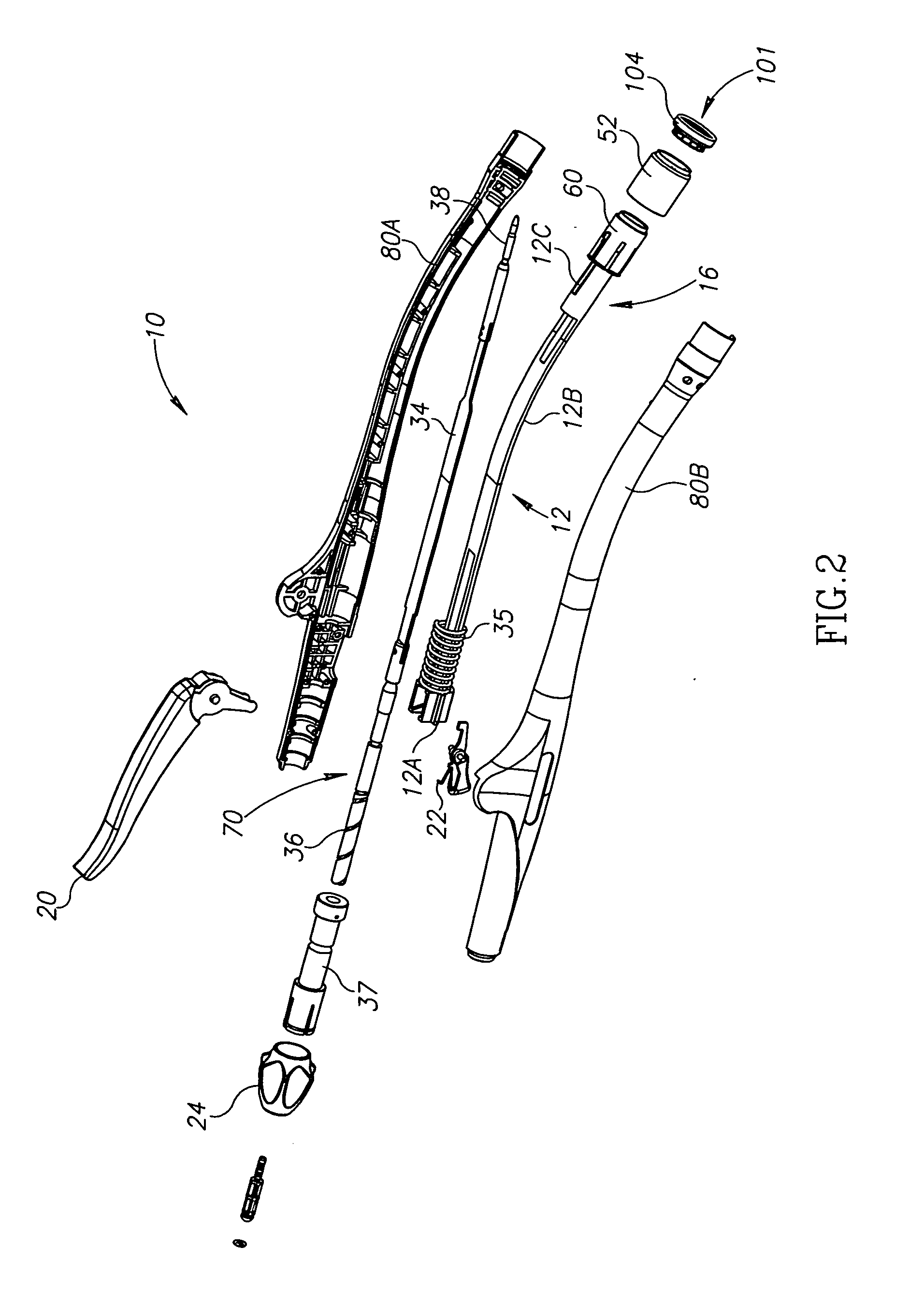

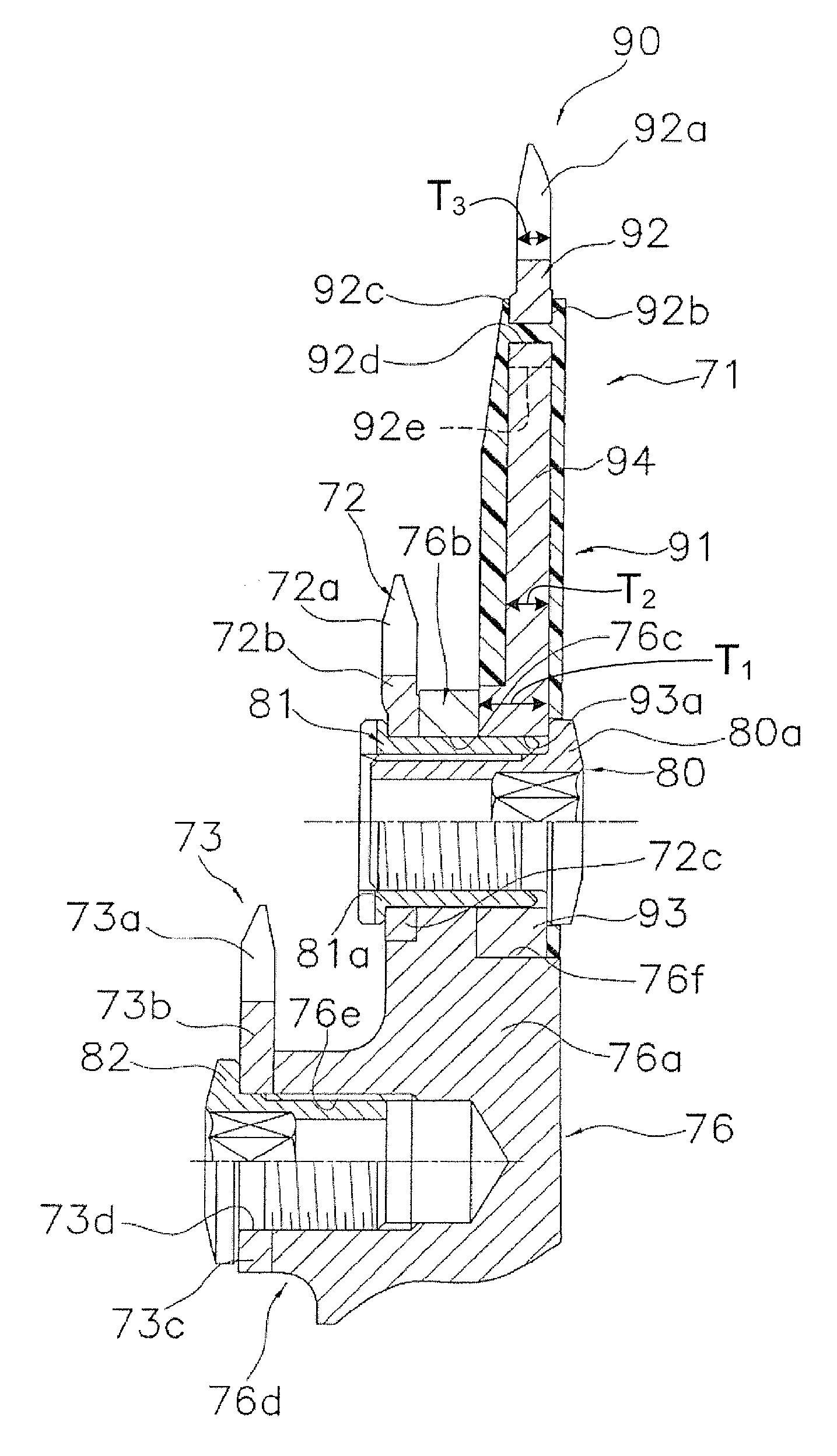

Compression anastomosis ring assembly and applicator for use therewith

InactiveUS7527185B2Reduced dimensionIncrease rangeSuture equipmentsStapling toolsOrgan wallShape-memory alloy

A compression anastomosis ring (CAR) assembly for use in joining severed organ wall portions of a hollow organ. The assembly comprises a first portion which includes an anvil assembly and a second portion which comprises a bottom ring, at least one ring element, and at least one spring element formed of a shape-memory alloy. The at least one spring element provides a restorative force and is in compressive force contact with the bottom ring and the tissue to be joined is positioned between the anvil ring and the bottom ring. A plurality of needles on one of the ring elements is operative, upon application of a closure force, to pierce the tissue and the anvil ring, holding the anvil ring to the second portion of the CAR assembly. An applicator for applying the CAR assembly and a method for using the assembly and applicator are taught.

Owner:NITI SURGICAL SOLUTIONS

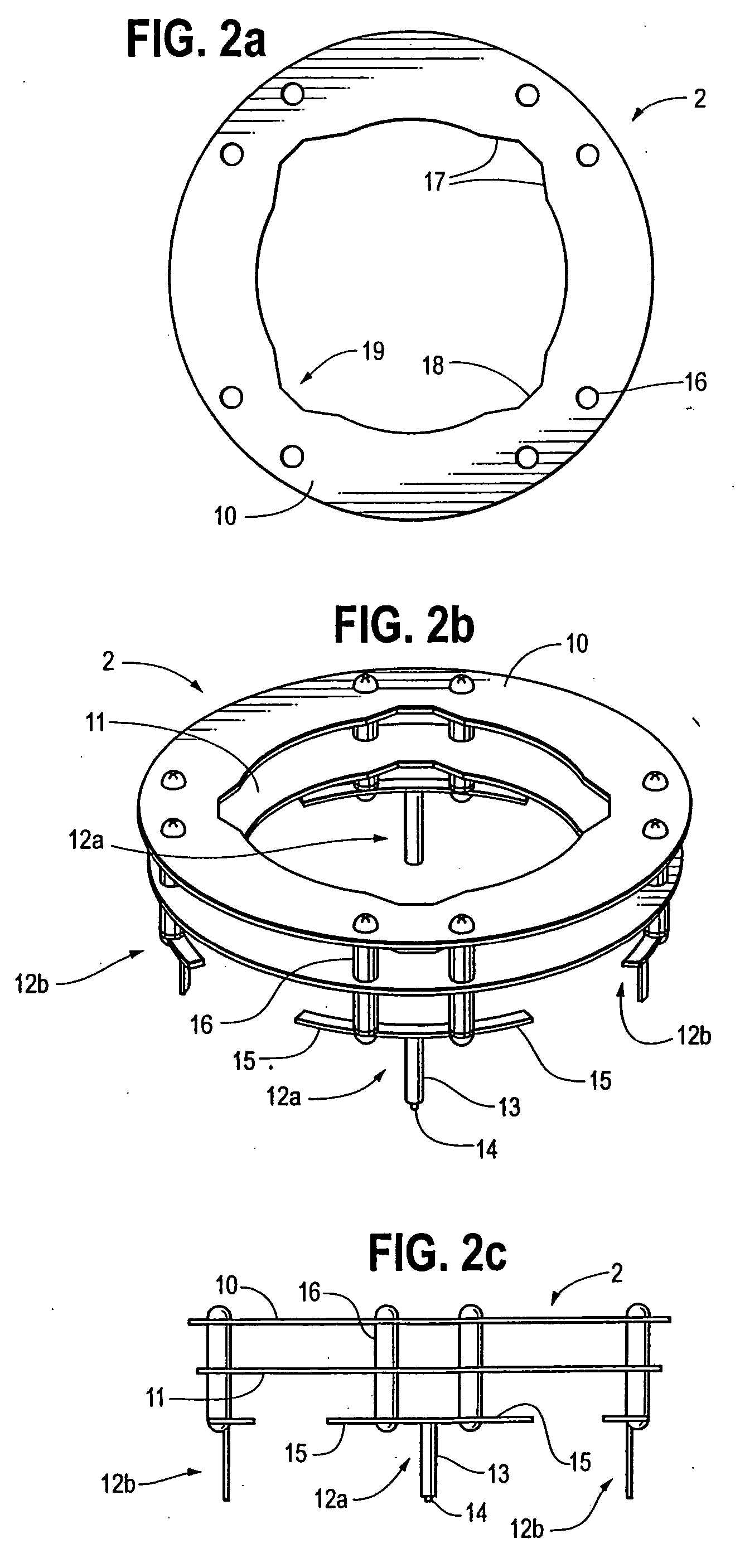

Surgical sealing device

A surgical sealing device comprises sealing device of a gelatinous elastomeric material, a distal ring element and a proximal ring element. The ring elements are twisted relative to one another to twist the valve body into a twisted configuration to seal across a wound opening. The ring elements are snap-fitted together to maintain the valve in the twisted configuration. By passing an object, such as surgeon's hand through the valve, the opposing sidewalls of a lumen through the valve may be forced radially apart to partially open the lumen, and thereby enable the surgeon's hand to access the interior of the abdomen. The valve remains twisted during insertion of the surgeon's hand through the valve to minimise the loss of insufflation gases from the abdomen.

Owner:ATROPOS LTD

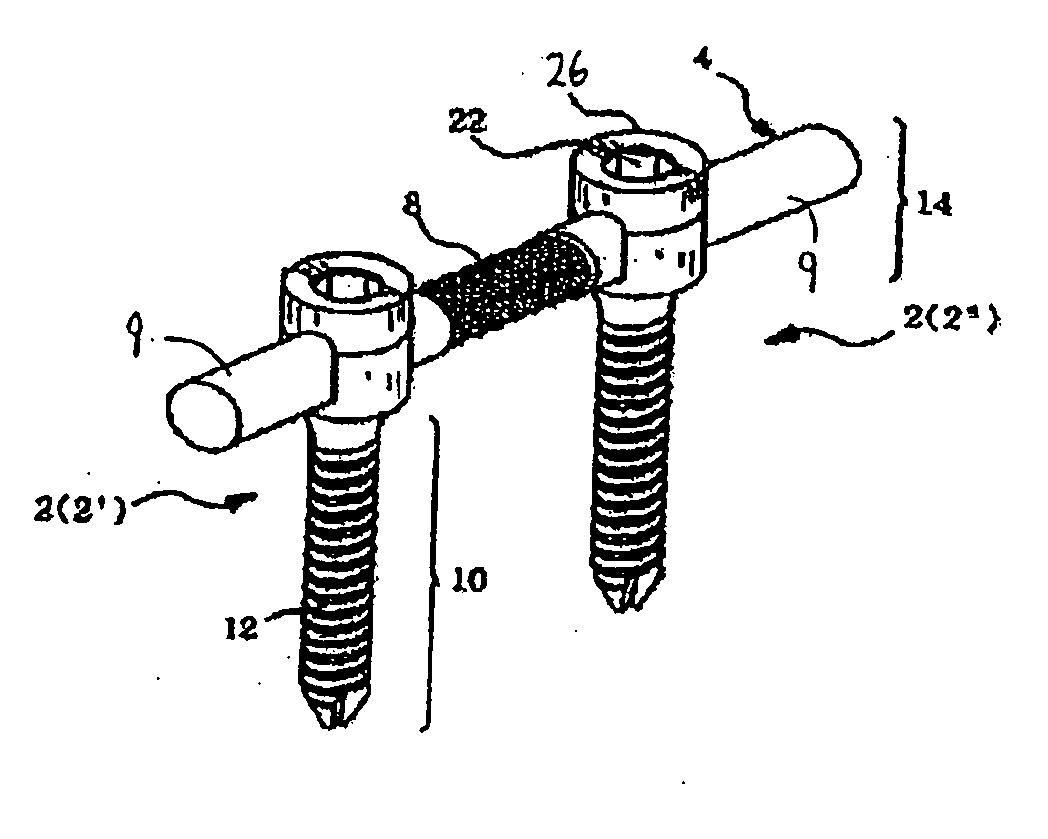

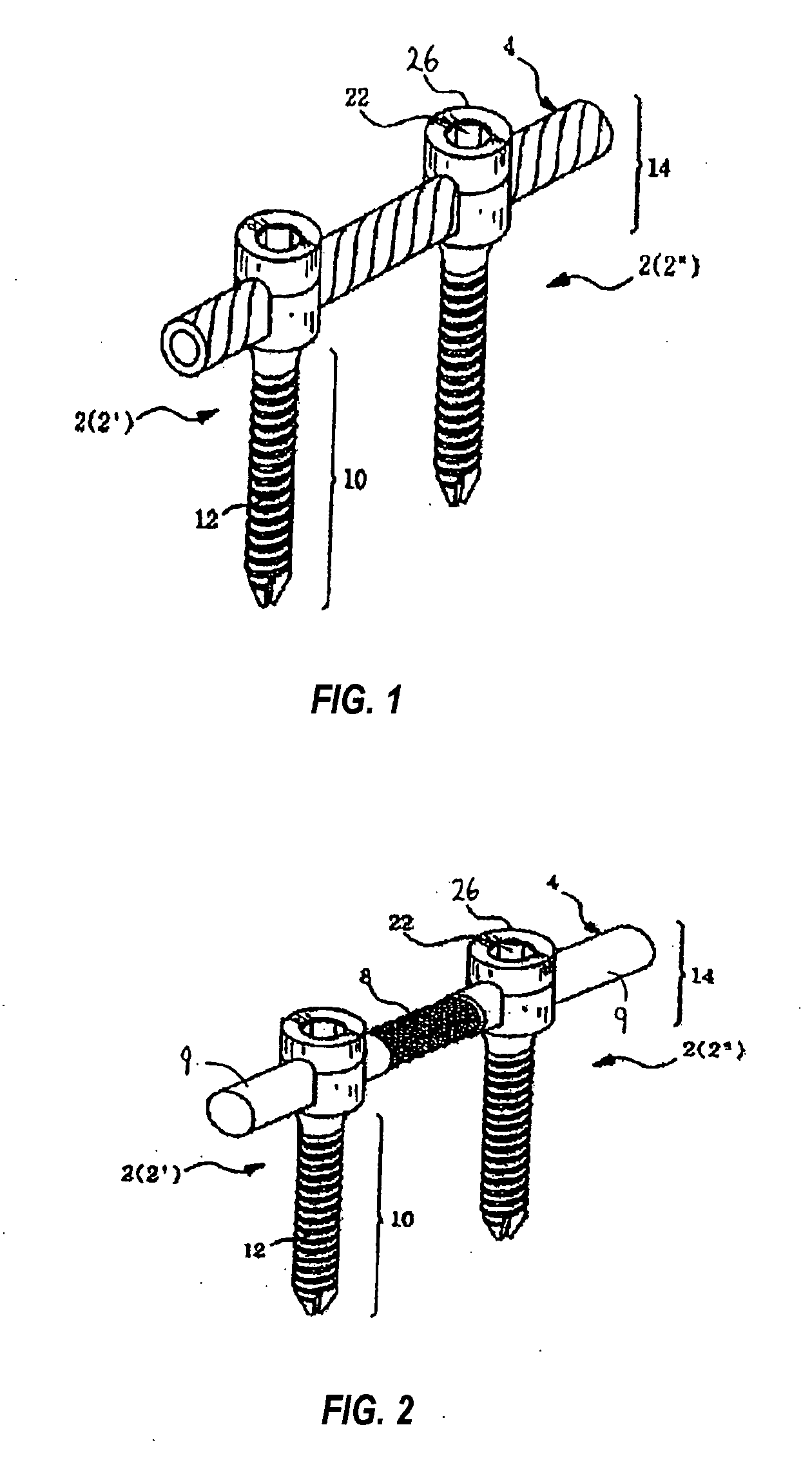

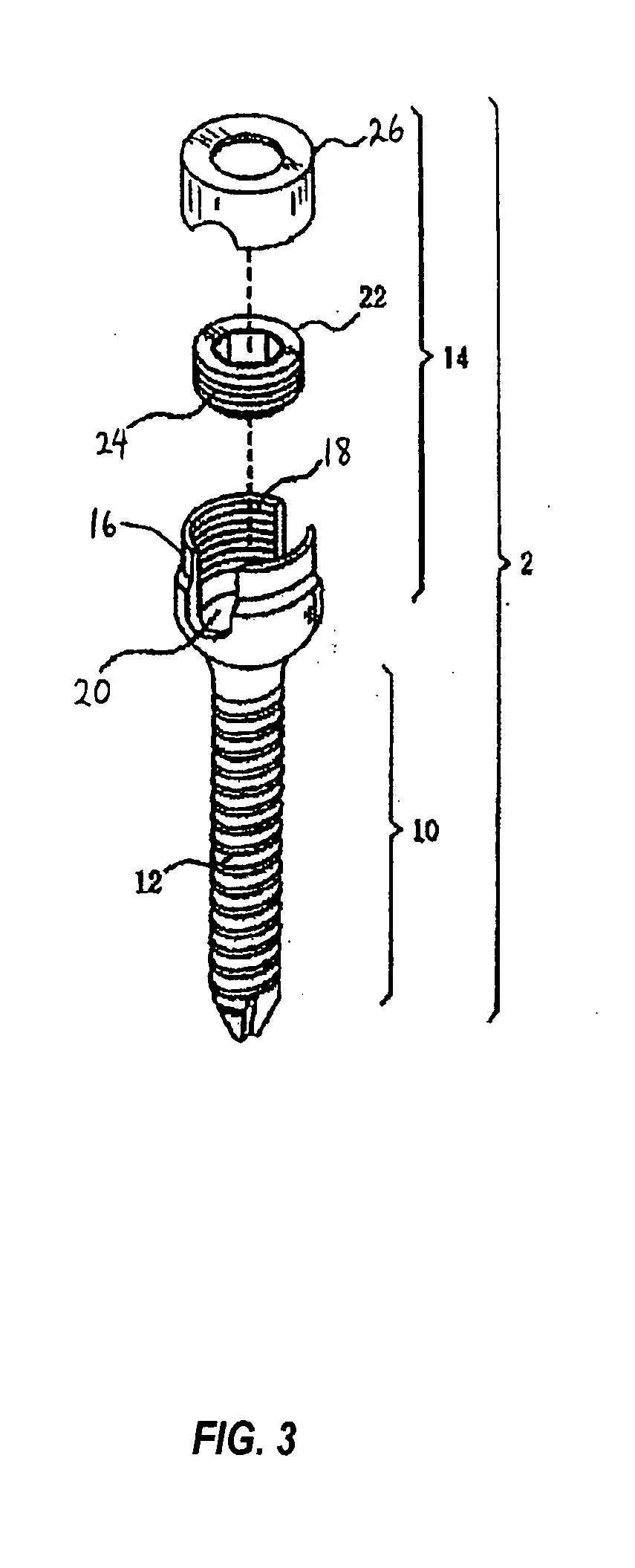

Spinal stabilization device

ActiveUS20070276380A1Easy constructionSimple designInternal osteosythesisEar treatmentBiomedical engineeringRing element

A flexible connection unit for use in a spinal fixation device that includes: a longitudinal member having first and second ends and a flexible member interposed between the first and second ends, at least one of the first end and second end configured to be engaged by a first bone securing member; and at least one spacer located between the first and second ends, the spacer comprising a resilient element and a ring element encircling at least a portion of the resilient element, wherein the ring element is configured to be engaged by a second bone securing member.

Owner:DEPUY SYNTHES PROD INC

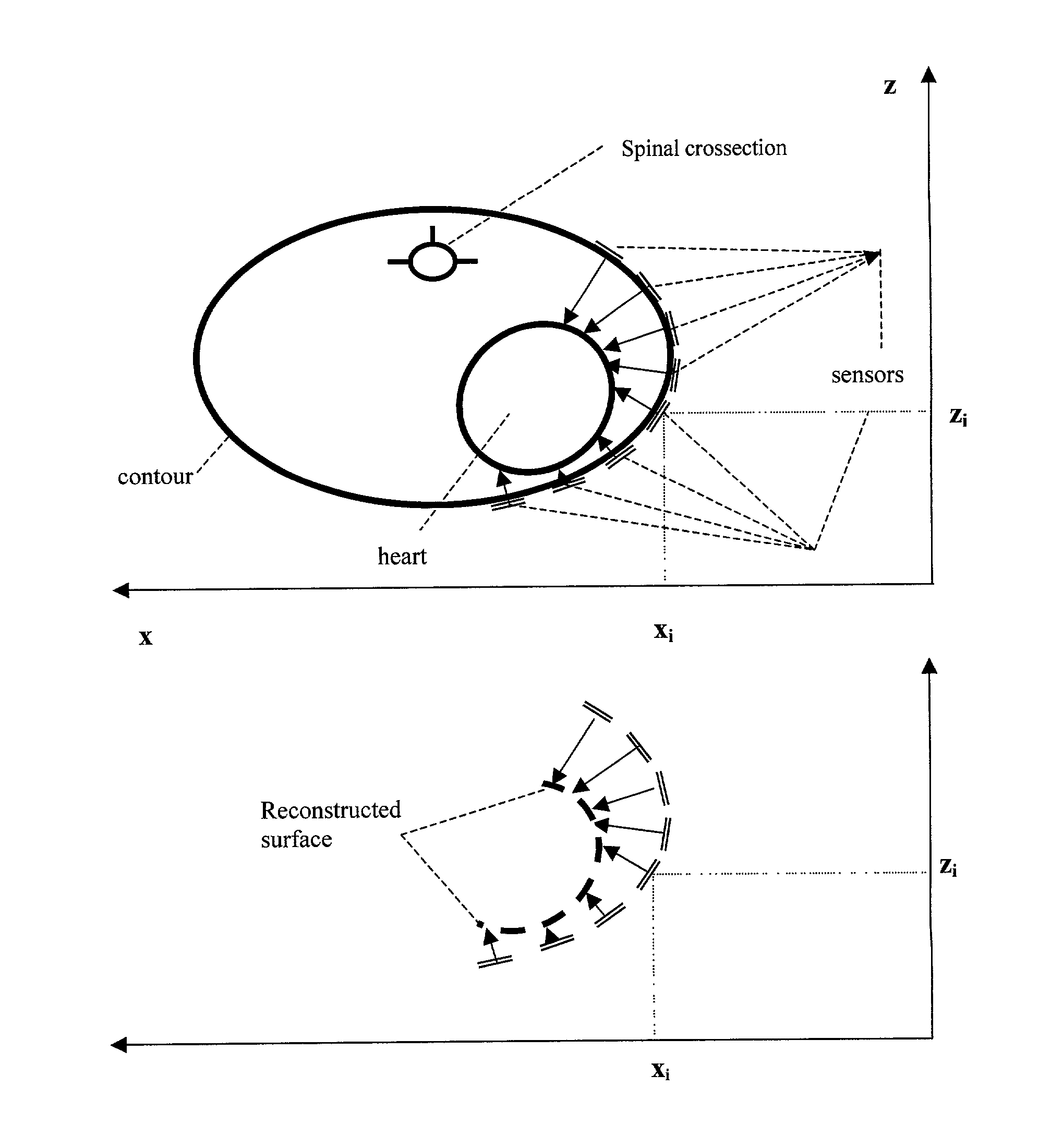

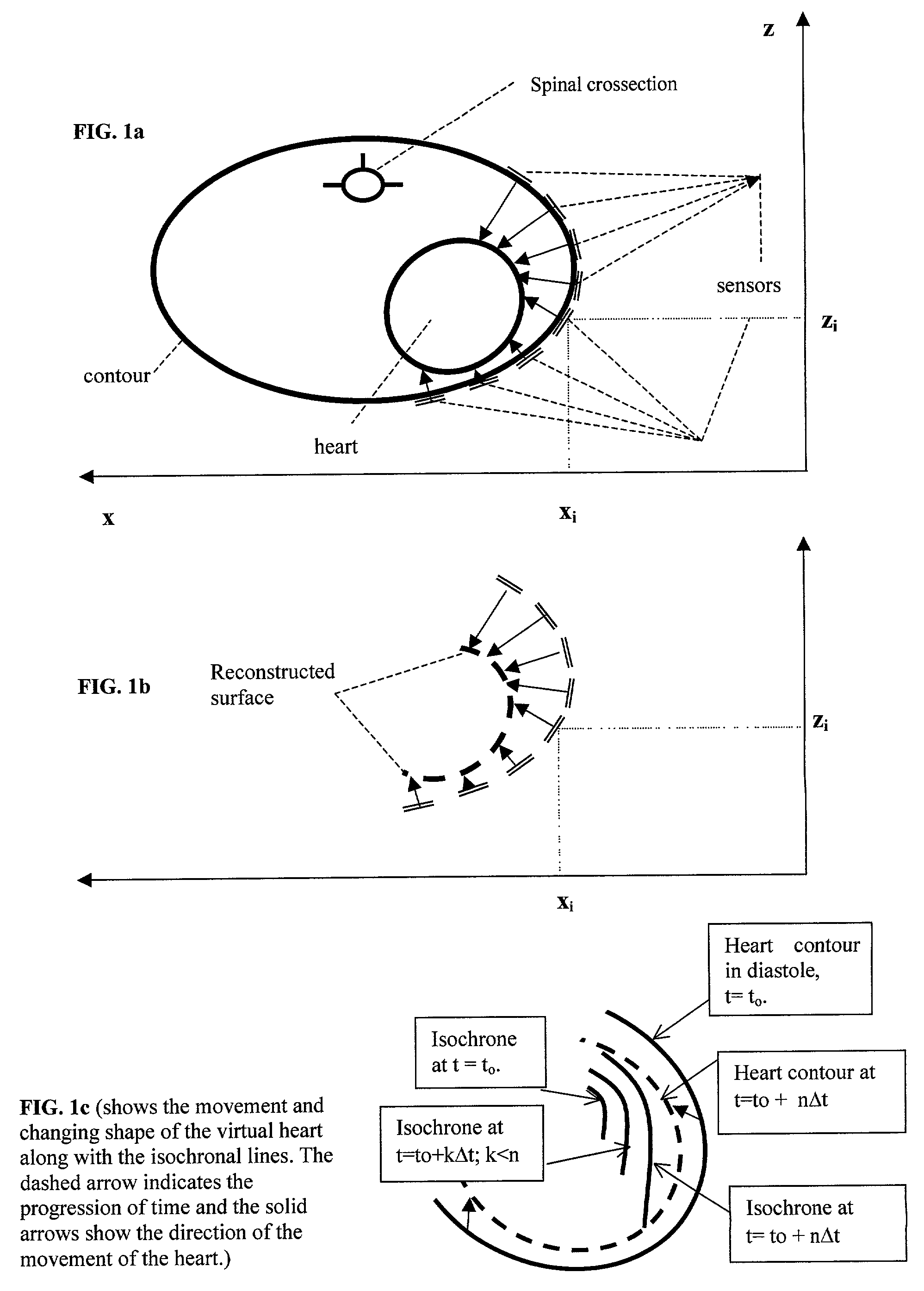

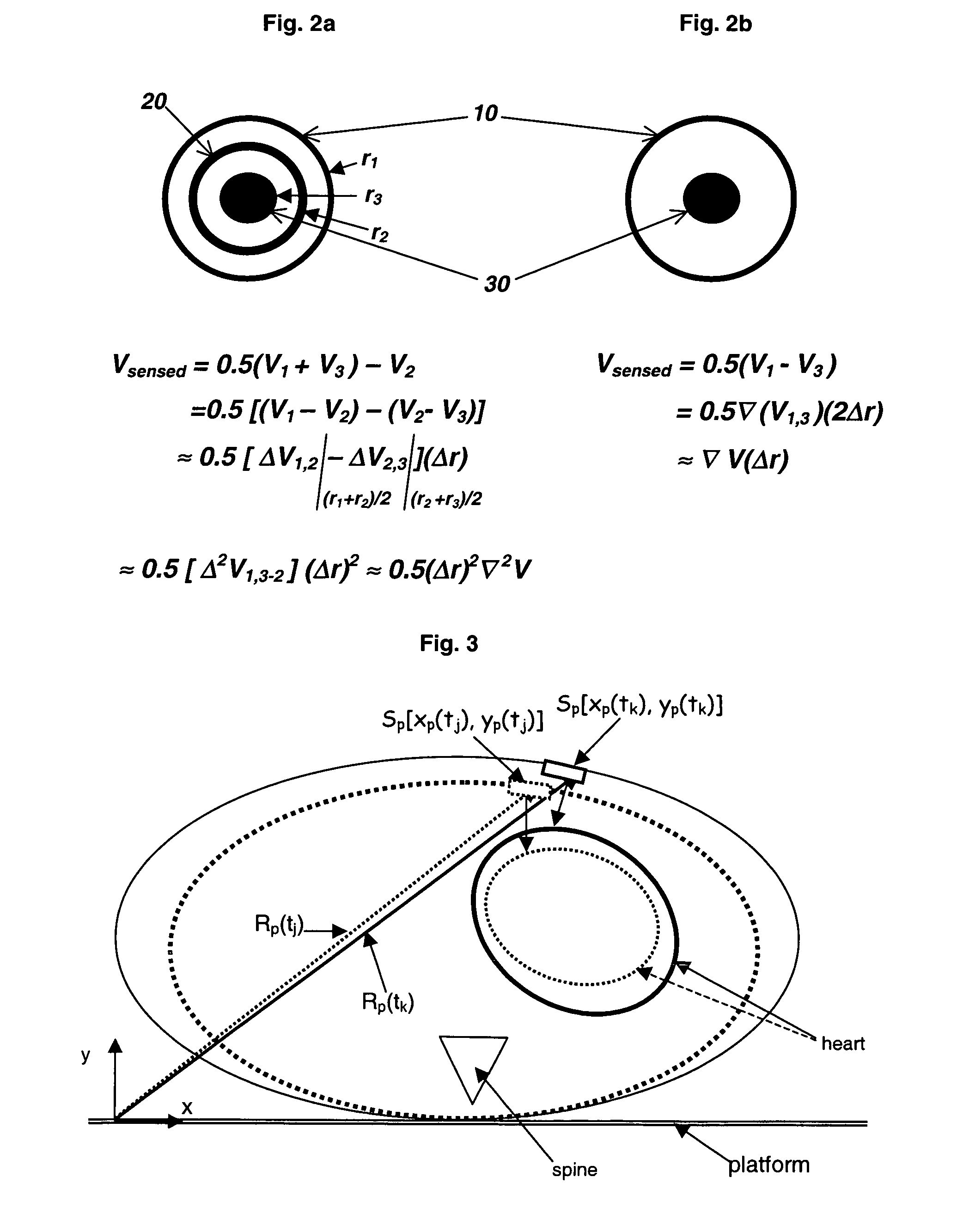

Single or multi-mode cardiac activity data collection, processing and display obtained in a non-invasive manner

InactiveUS7043292B2Improve signal-to-noise ratioEasy to identifyElectrocardiographyOrgan movement/changes detectionUltrasonic sensorCardiac surface

The method of presenting concurrent information about the electrical and mechanical activity of the heart using non-invasively obtained electrical and mechanical cardiac activity data from the chest or thorax of a patient comprises the steps of: placing at least three active Laplacian ECG sensors at locations on the chest or thorax of the patient; where each sensor has at least one outer ring element and an inner solid circle element, placing at least one ultrasonic sensor on the thorax where there is no underlying bone structure, only tissue, and utilizing available ultrasound technology to produce two or three-dimensional displays of the moving surface of the heart and making direct measurements of the exact sites of the sensors on the chest surface to determine the position and distance from the center of each sensor to the heart along a line orthogonal to the plane of the sensor and create a virtual heart surface; updating the measurements at a rate to show the movement of the heart's surface; monitoring at each ultrasonic sensor site and each Laplacian ECG sensor site the position and movement of the heart and the passage of depolarization wave-fronts in the vicinity; treating those depolarization wave-fronts as moving dipoles at those sites to create images of their movement on the image of the beating heart's surface; and, displaying the heart's electrical activity on the dynamically changing image of the heart's surface with the goal to display an approximation of the activation sequence on the beating virtual surface of the heart

Owner:TARJAN PETER P +2

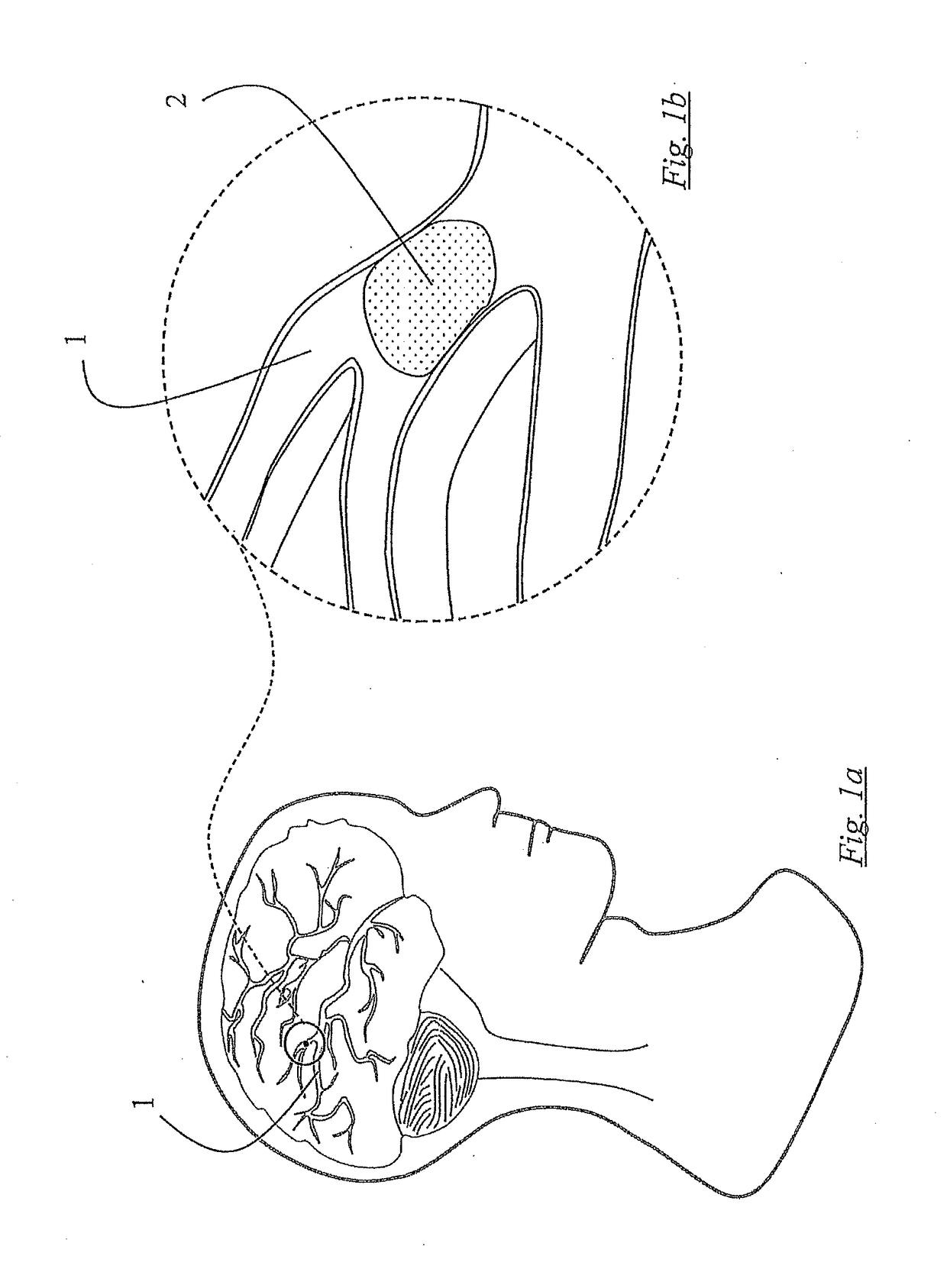

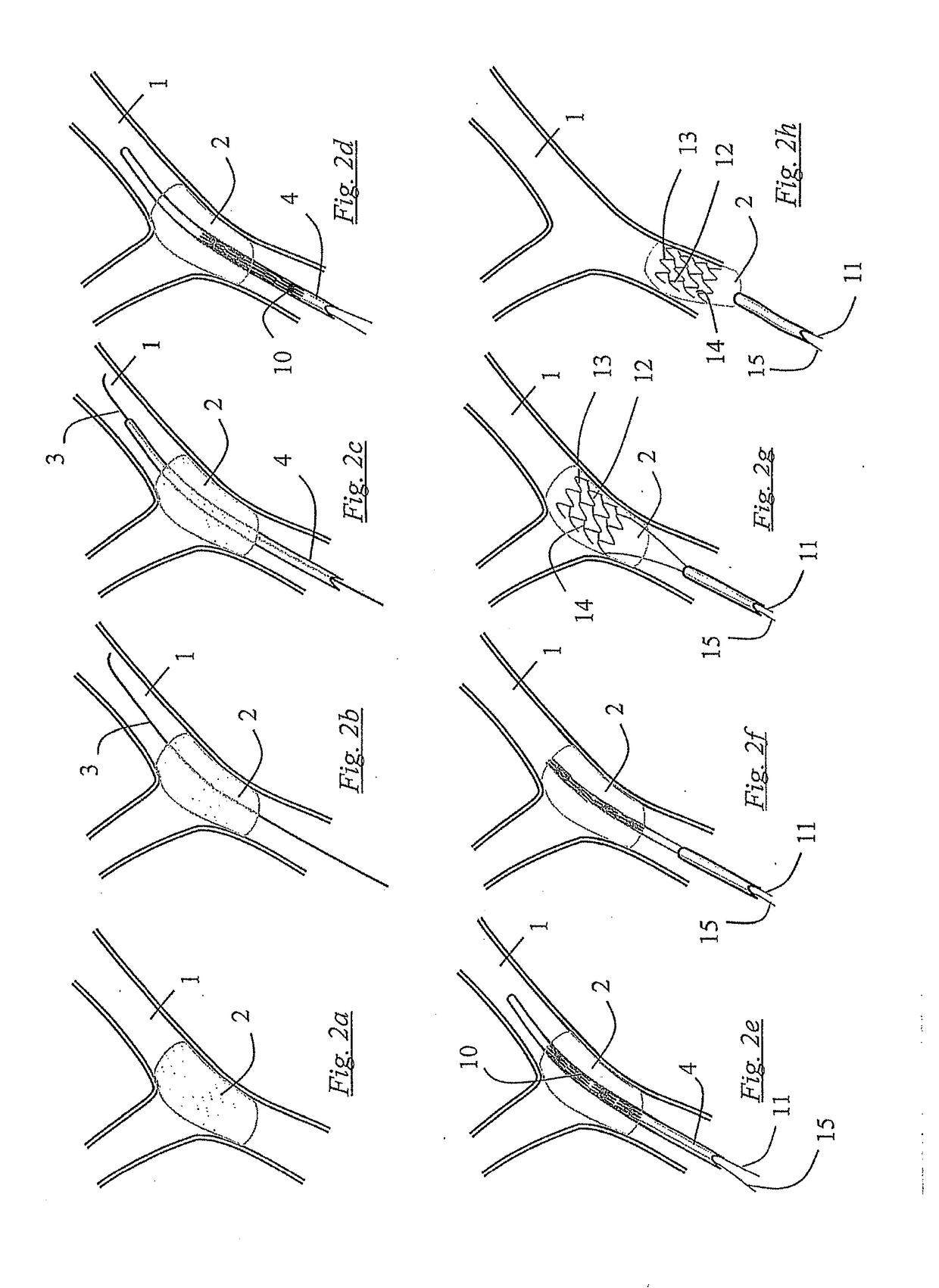

Clot retrieval devices

A self-expandable mechanical clot retrieval device is designed variously to dislodge, engage and retract blood clot from extremely small and tortuous vasculature. The retrieval device comprises an elongate member and a plurality of ring elements. The ring elements may comprise a plurality of struts and crowns interconnected by a tether formed at a distal end of the elongate member or may be a separate component attached thereto. At least one tether may connect each ring element to the elongate member to restrain the ring element in a collapsed configuration during delivery of the retrieval device through an intravascular microcatheter. The tether connecting the ring element to the elongate member disengages when the retrieval device is positioned at the occluded site and the microcatheter is retracted to allow the self-expandable ring elements to reach an expanded configuration.

Owner:NEURAVI

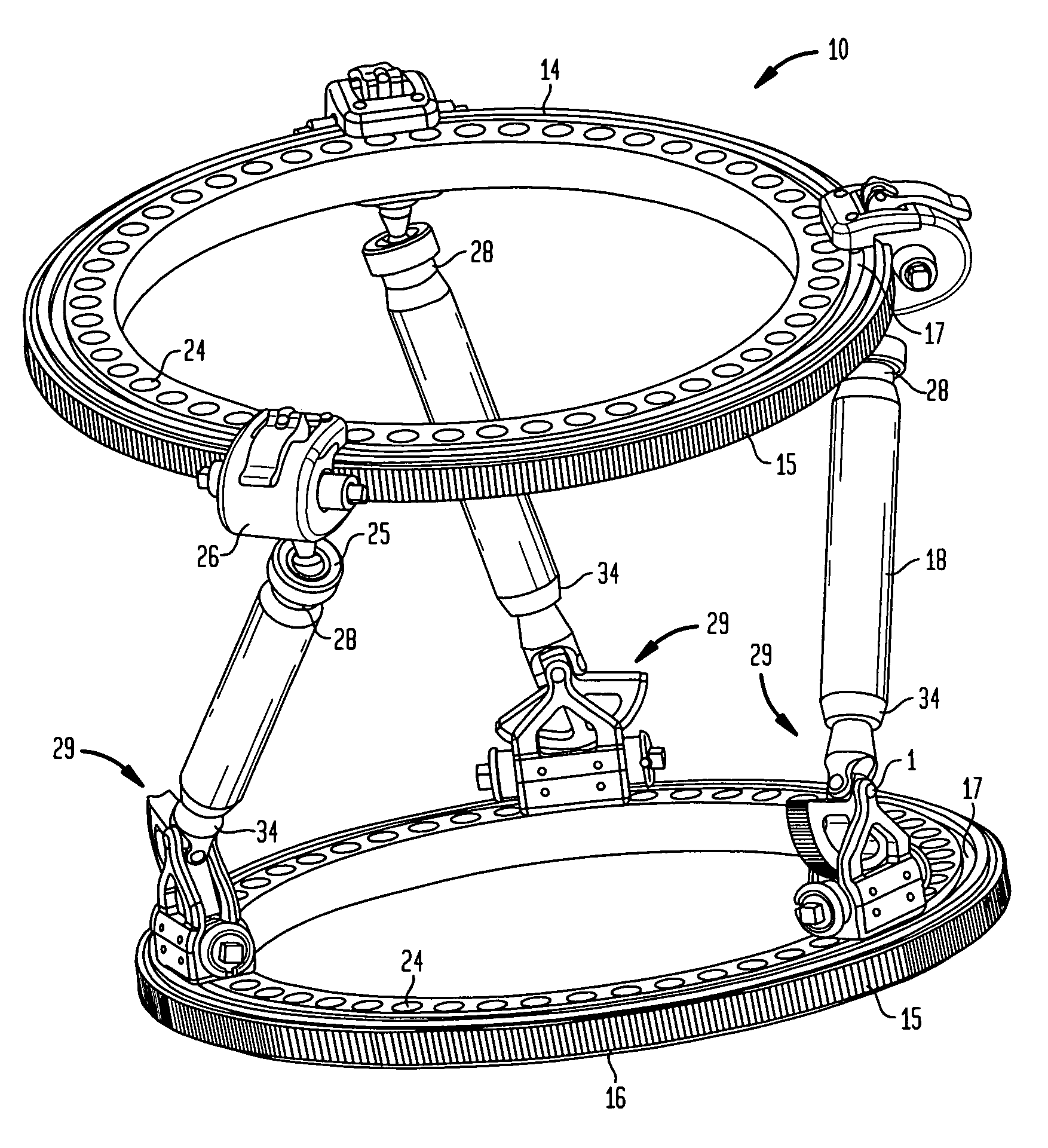

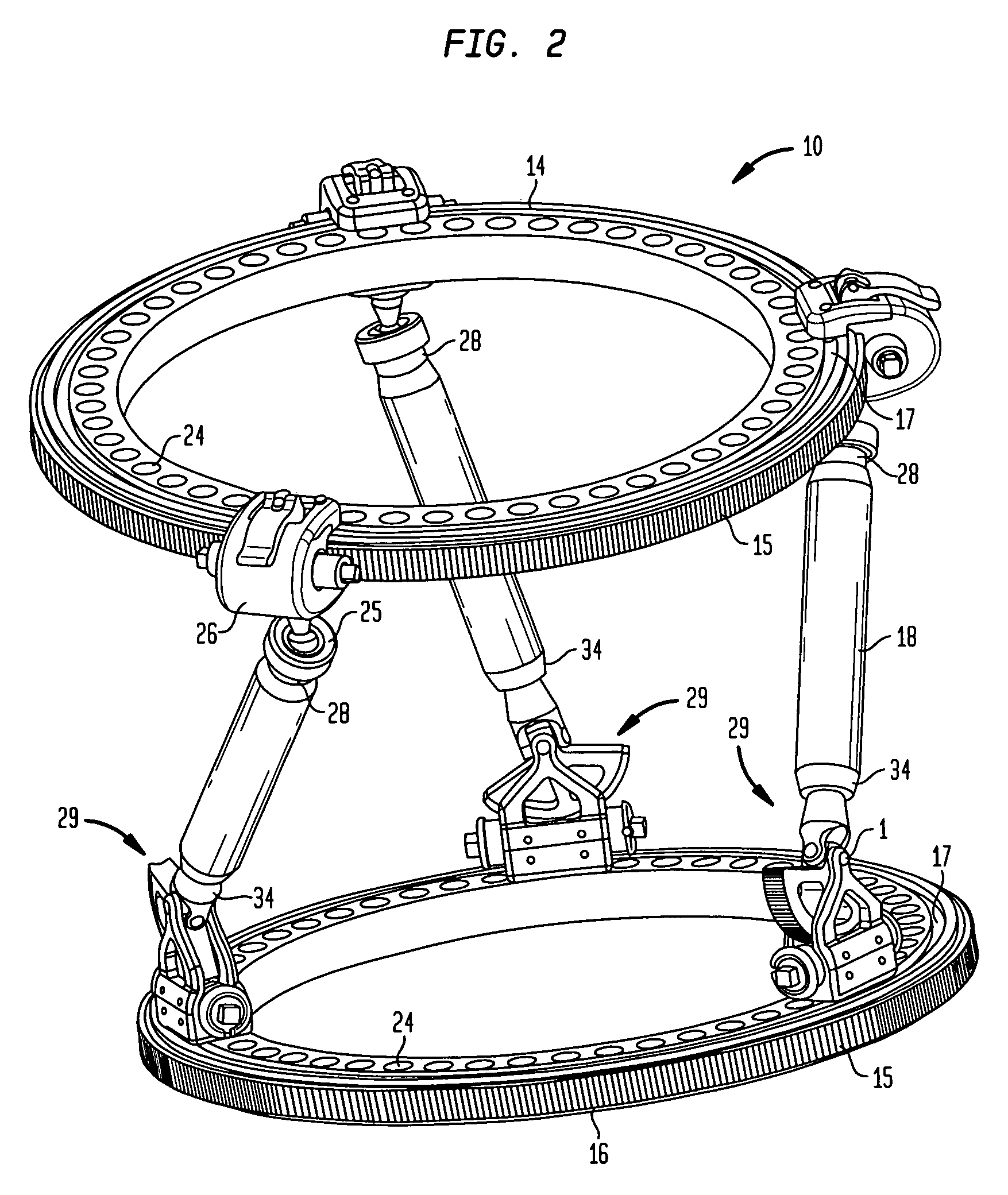

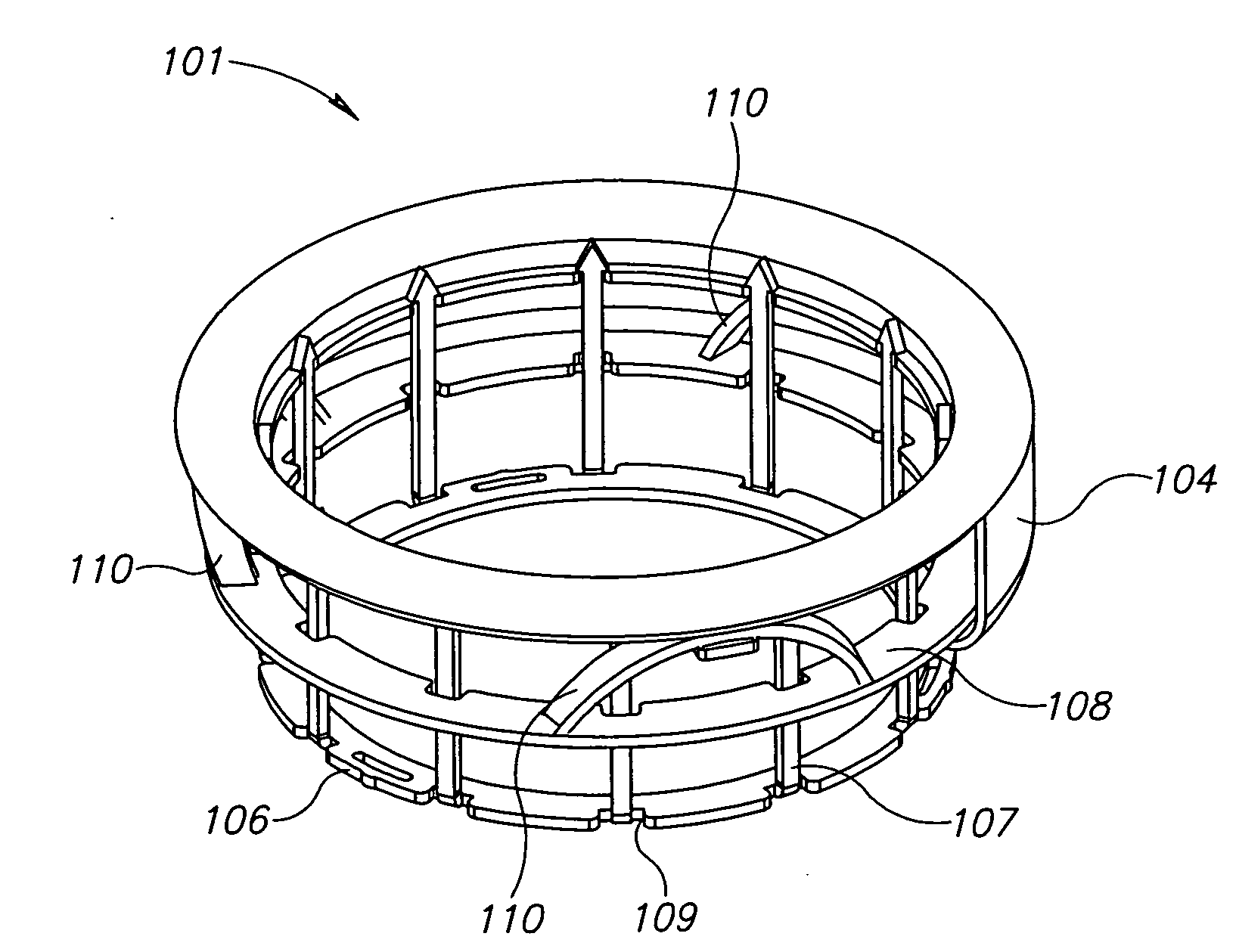

External fixation system

An external fixation system comprising: first and second planar at least part-circular ring elements, the first ring element having a circumferential track extending along the part-circular circumference thereof; a plurality of struts each having a first and second end, the first end of each strut coupled to the first ring by a first connector and the second end of each strut coupled to a second ring by a second connector, the first connector including a spherical joint; the second connector non-rotatably coupled to the second ring, the strut second end being coupled to the second connector by a U-joint; shuttles mounted on the track of the first ring for movement there along with one shuttle coupled to each strut; and means for controlling the angular position of each strut second end and means for controlling the position of each shuttle along the circumferential track on the first ring.

Owner:STRYKER EURO OPERATIONS HLDG LLC

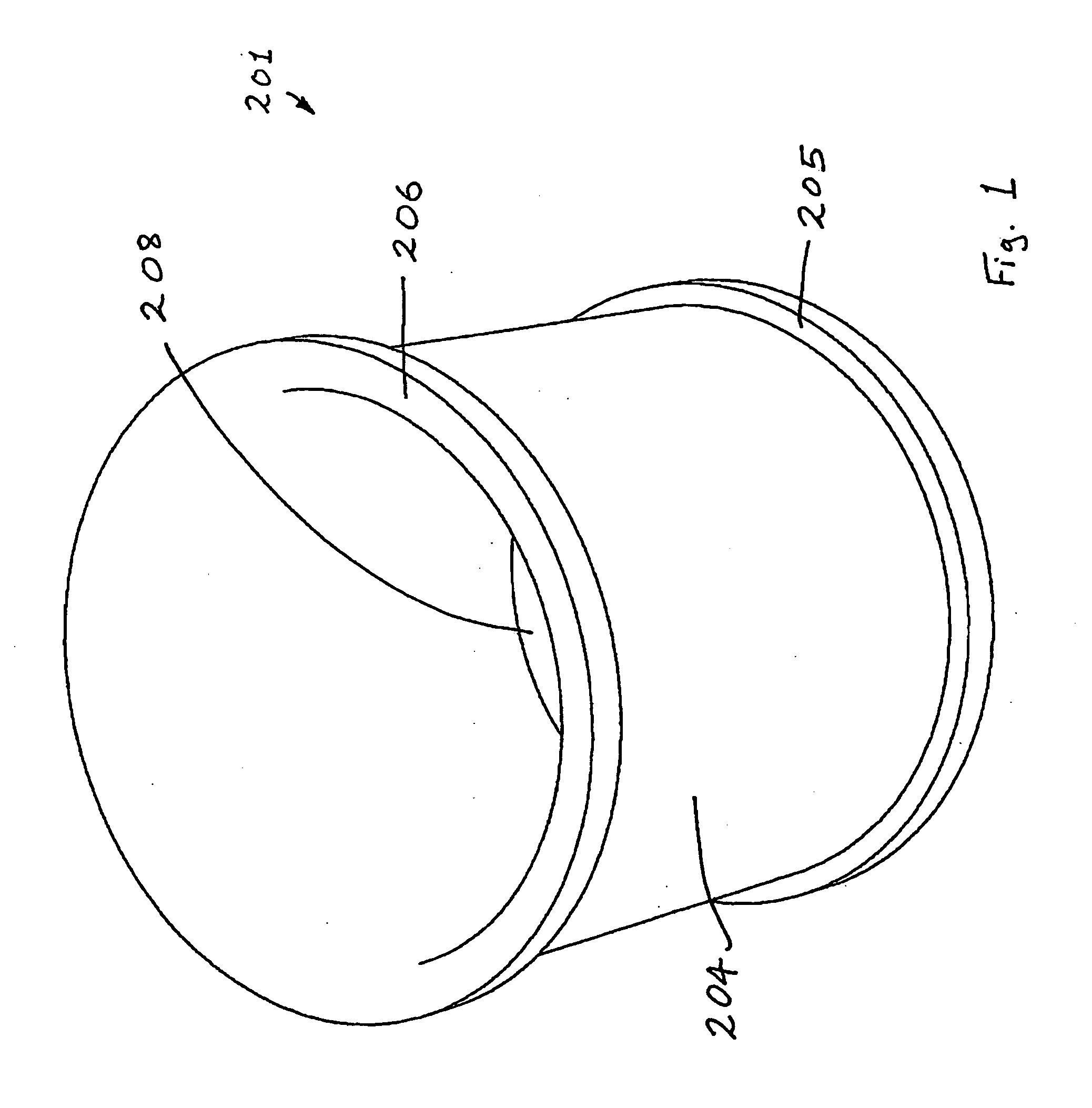

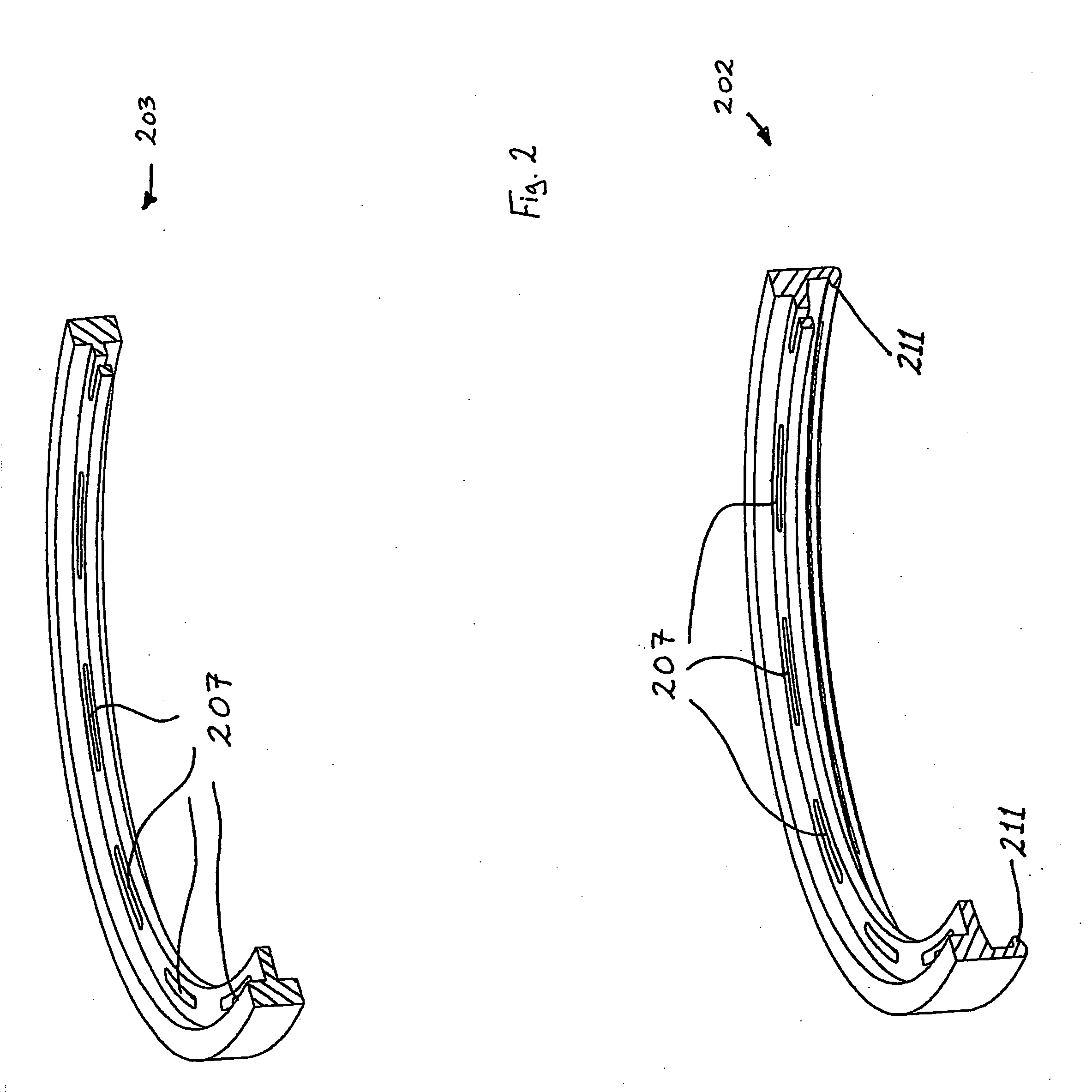

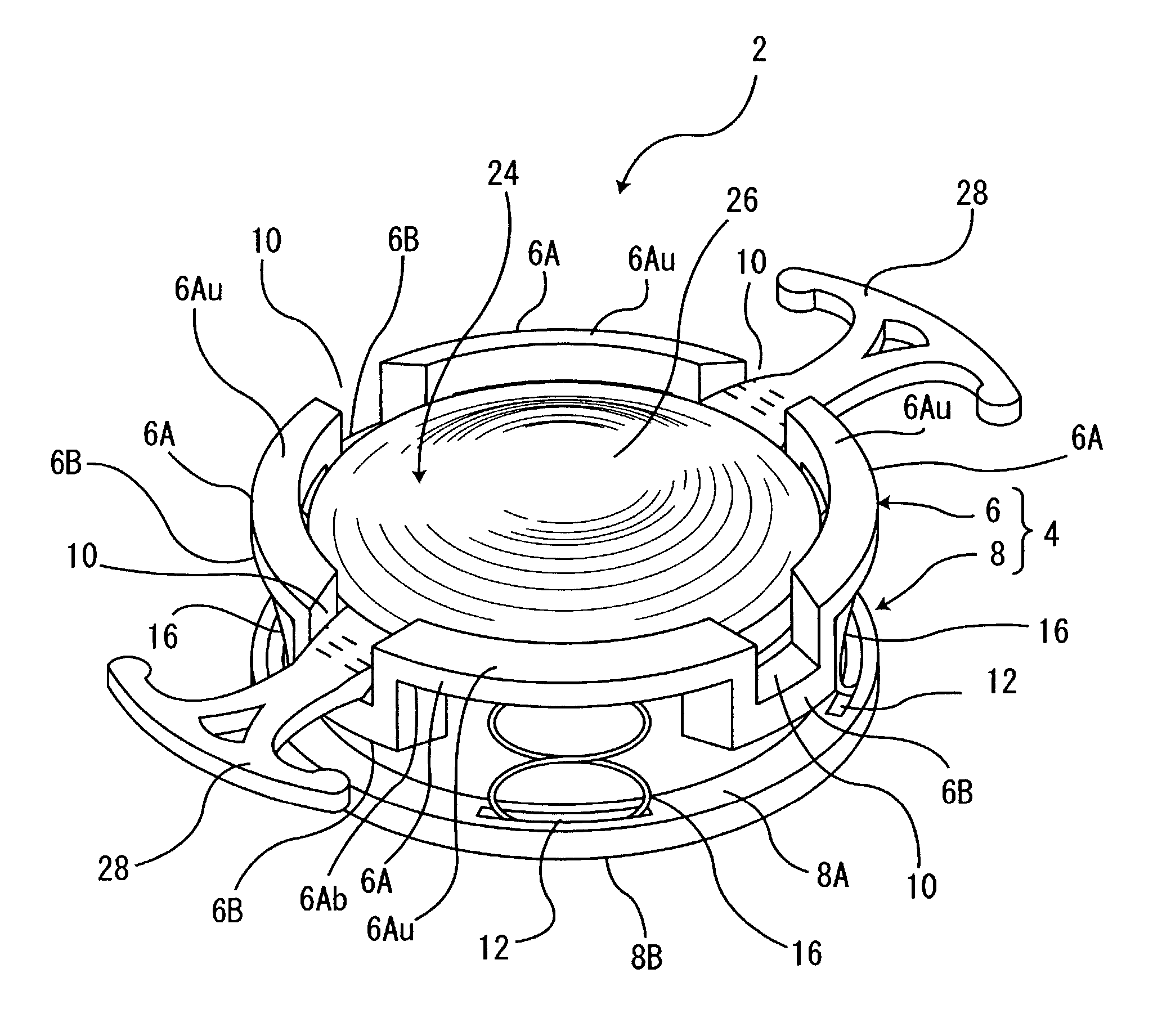

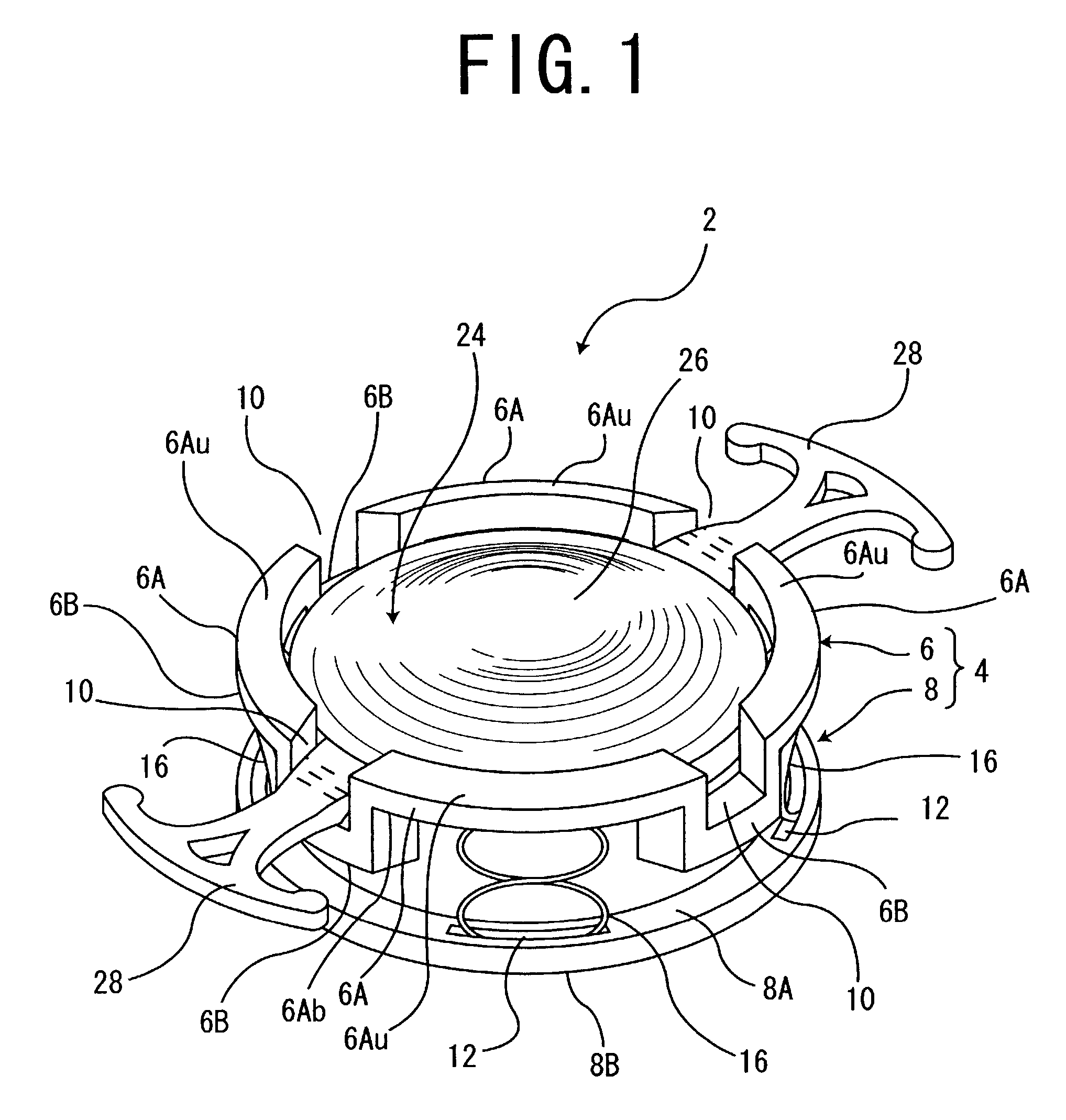

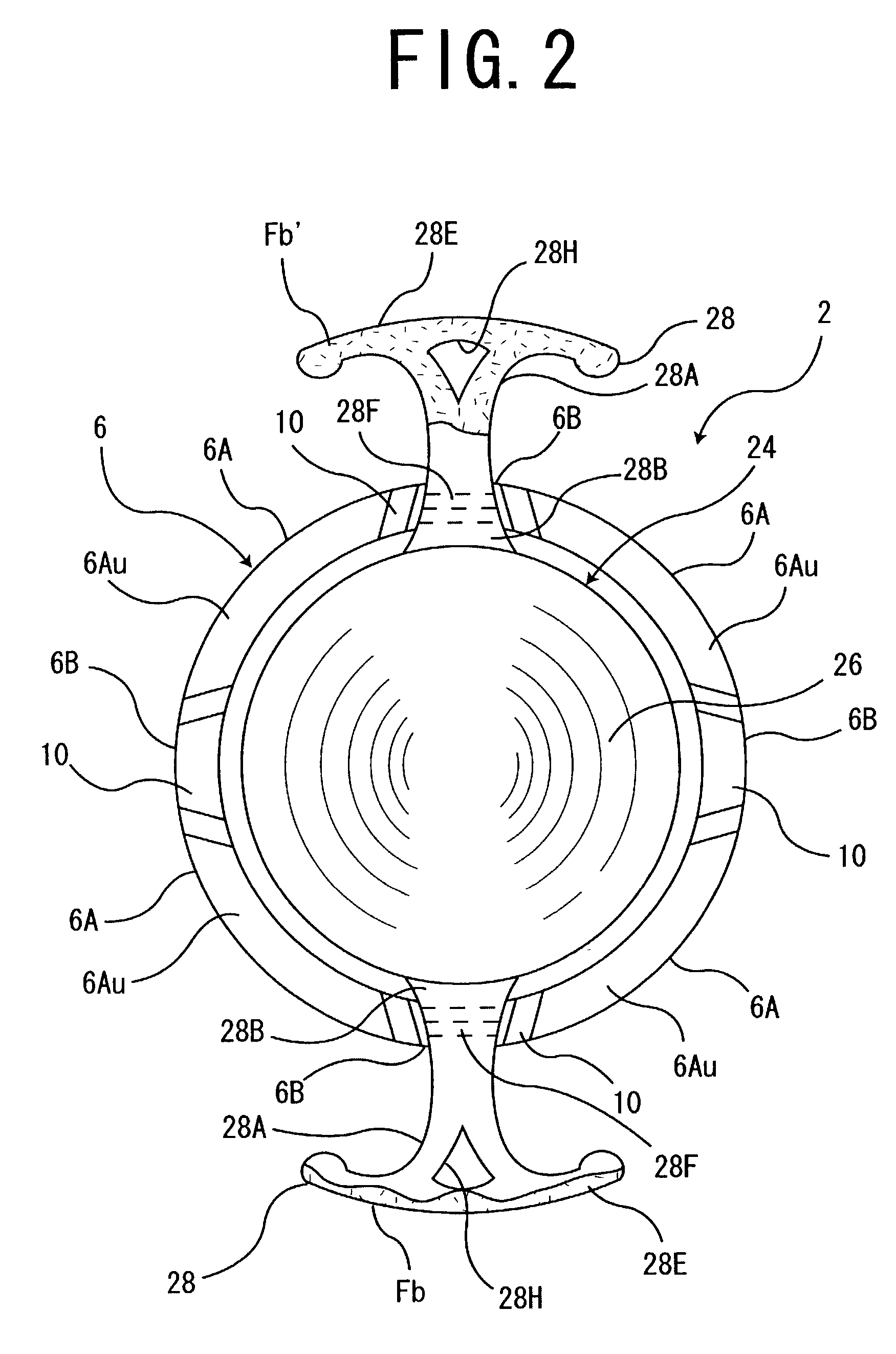

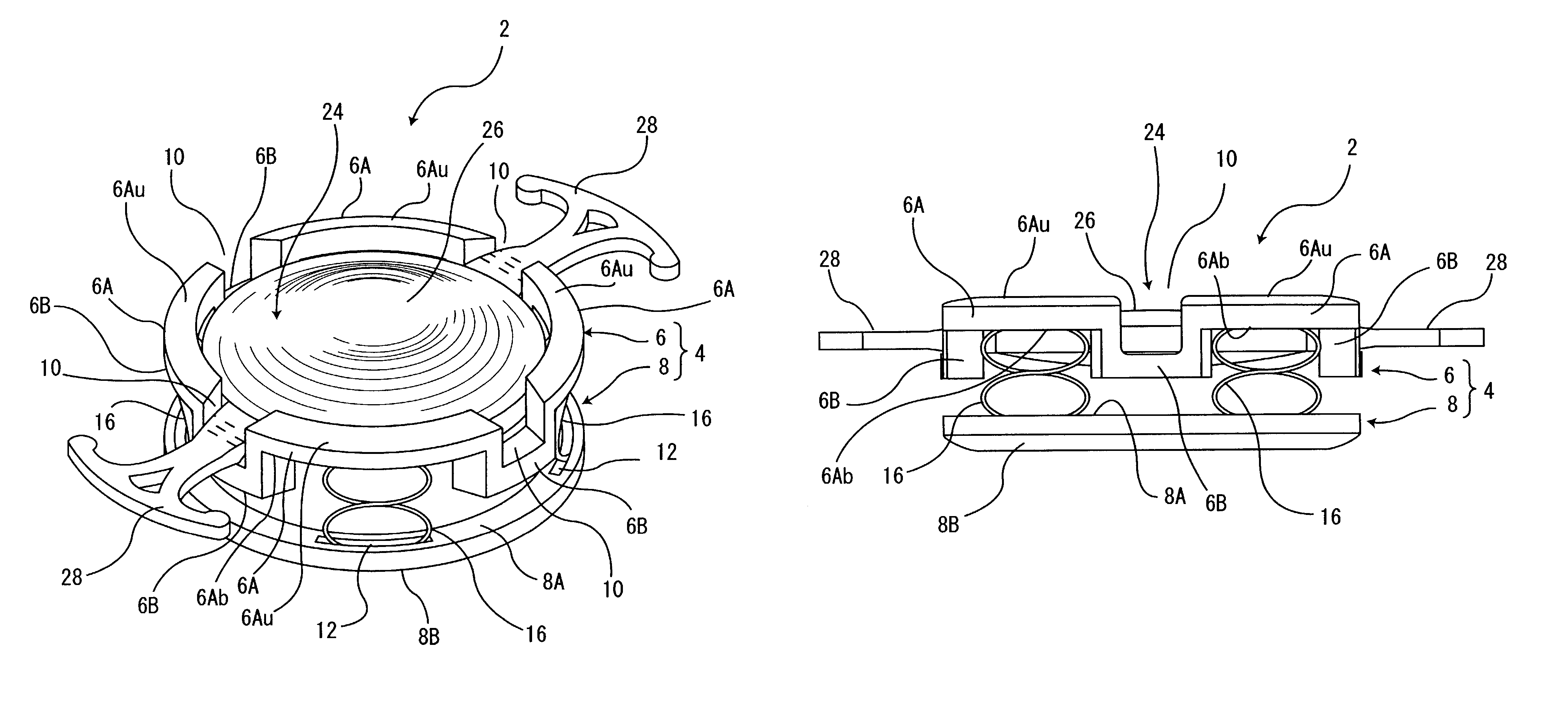

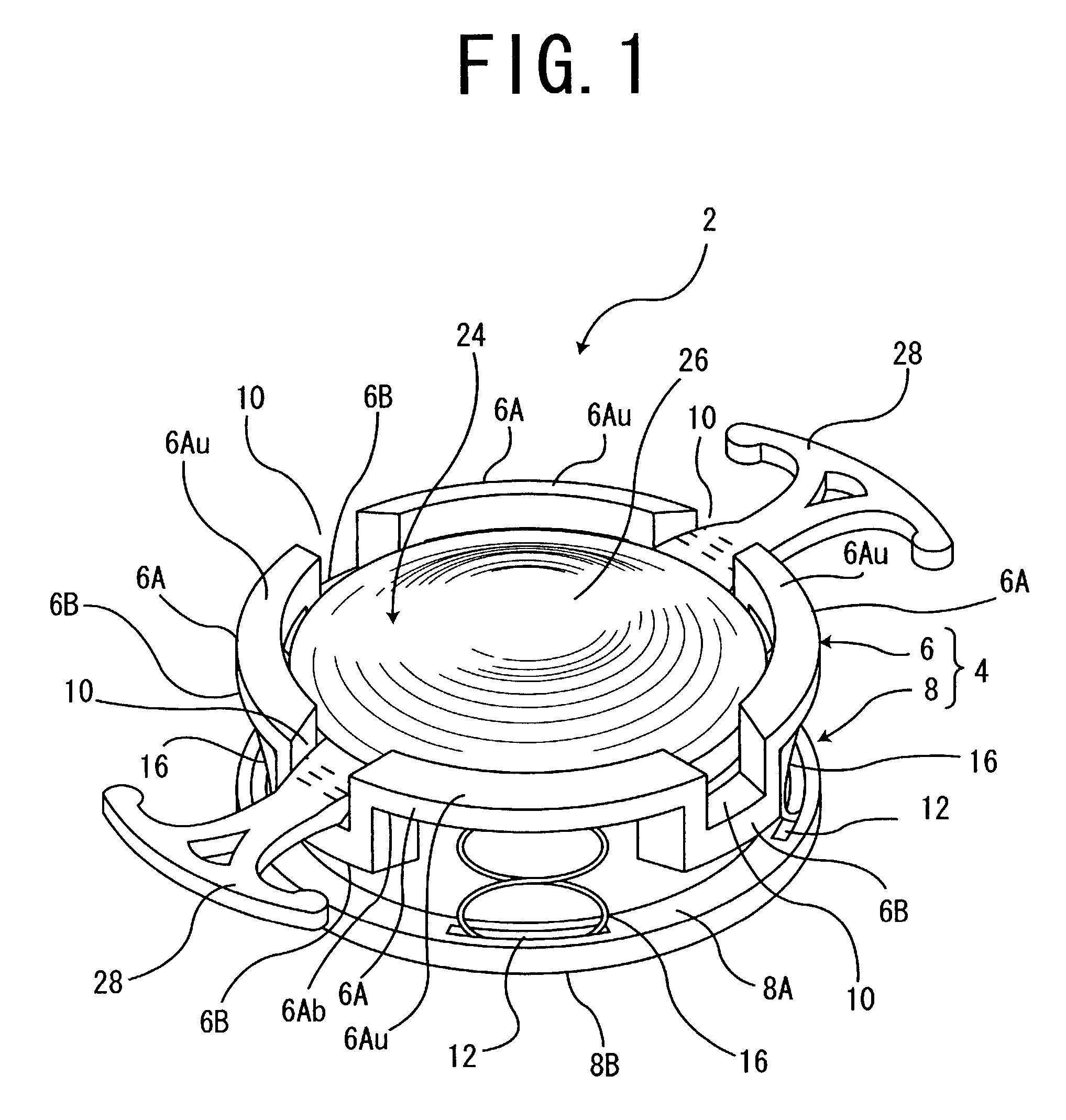

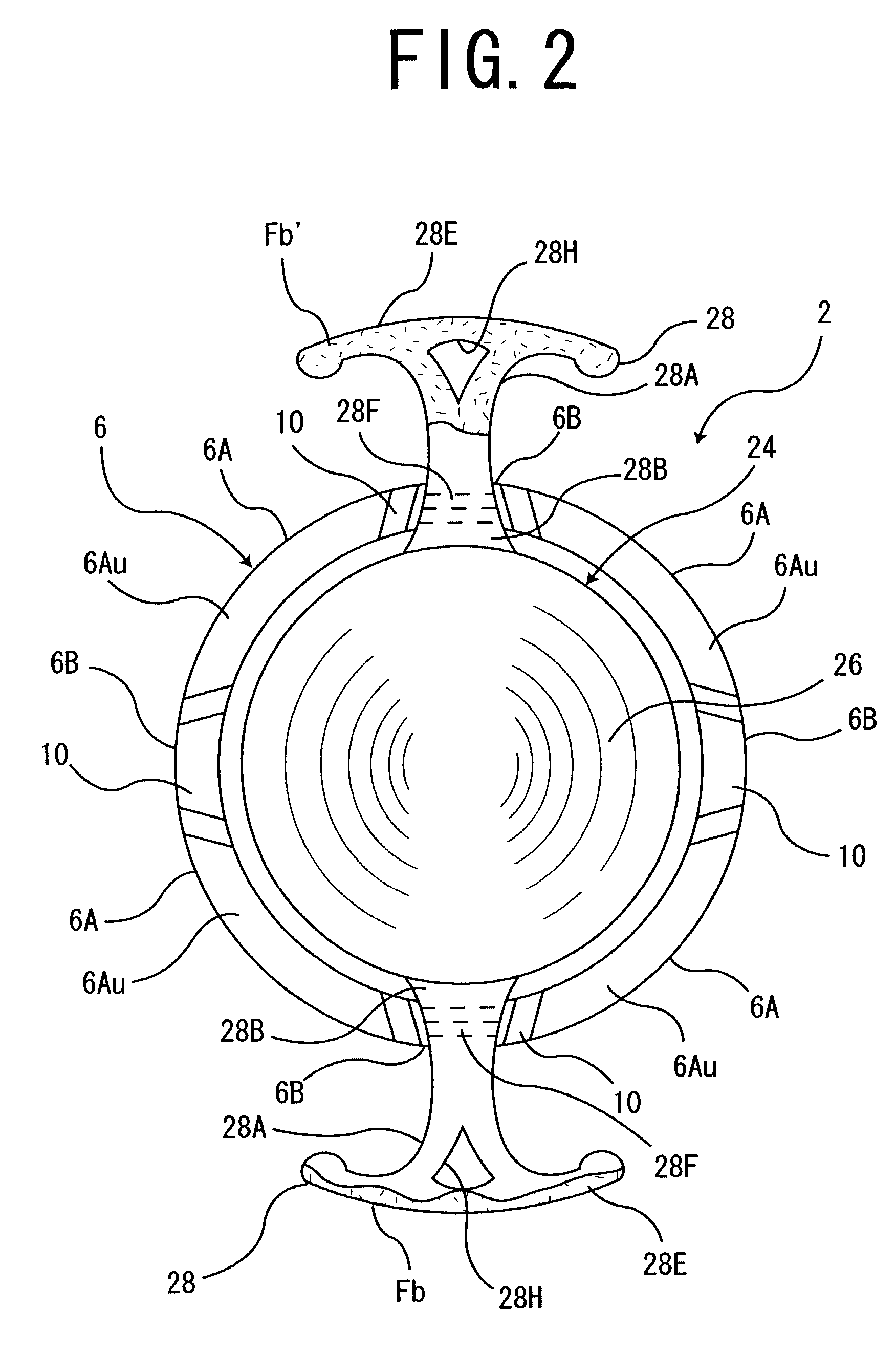

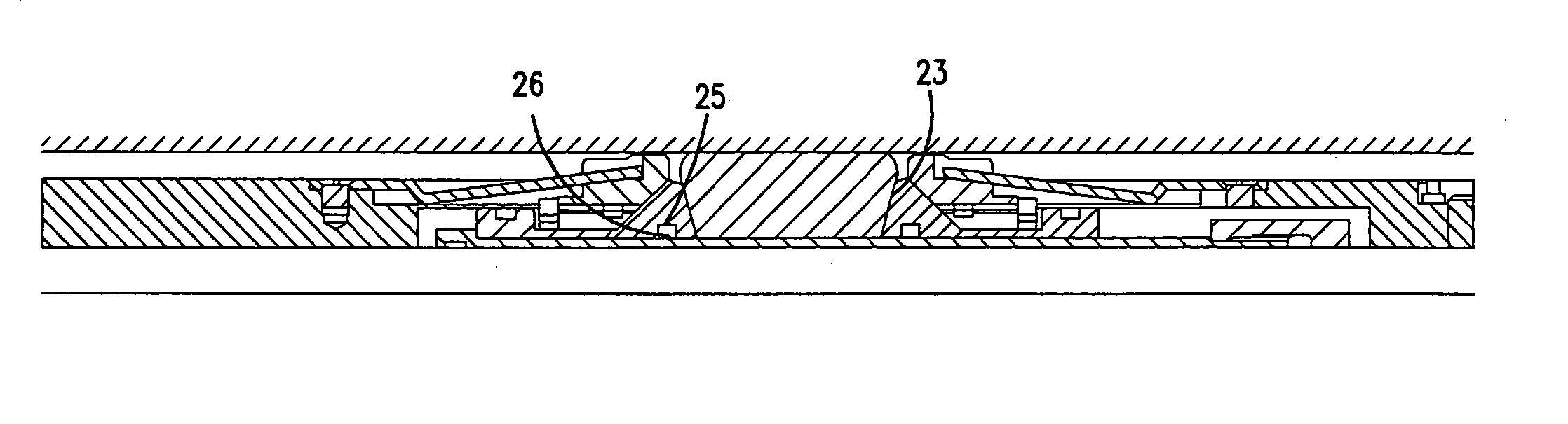

Intraocular ring assembly and artificial lens kit

InactiveUS20030114927A1Convenient to accommodateHigh sensitivityIntraocular lensIntraocular lensPhakic intraocular lens

An intraocular ring assembly and an artificial lens kit, both of which are usable for implantation in a lens capsule or capsular bag of natural eye. The intraocular ring assembly includes a first ring element having recessions therein, a second ring element, and a biasing element provided between the first and second ring elements. The artificial lens kit comprises such intraocular ring assembly and an intraocular lens to be movably supported in the recessions of the ring assembly in a coaxial relation therewith. A guide element may be provided to assist in rectilinear coaxial movement of the first and second ring elements.

Owner:NAGAMOTO TOSHIYUKI

Intraocular ring assembly and artificial lens kit

An intraocular ring assembly and an artificial lens kit, both of which are usable for implantation in a lens capsule or capsular bag of natural eye. The intraocular ring assembly includes a first ring element having recessions therein, a second ring element, and a biasing element provided between the first and second ring elements. The artificial lens kit comprises such intraocular ring assembly and an intraocular lens to be movably supported in the recessions of the ring assembly in a coaxial relation therewith. A guide element may be provided to assist in rectilinear coaxial movement of the first and second ring elements.

Owner:NAGAMOTO TOSHIYUKI

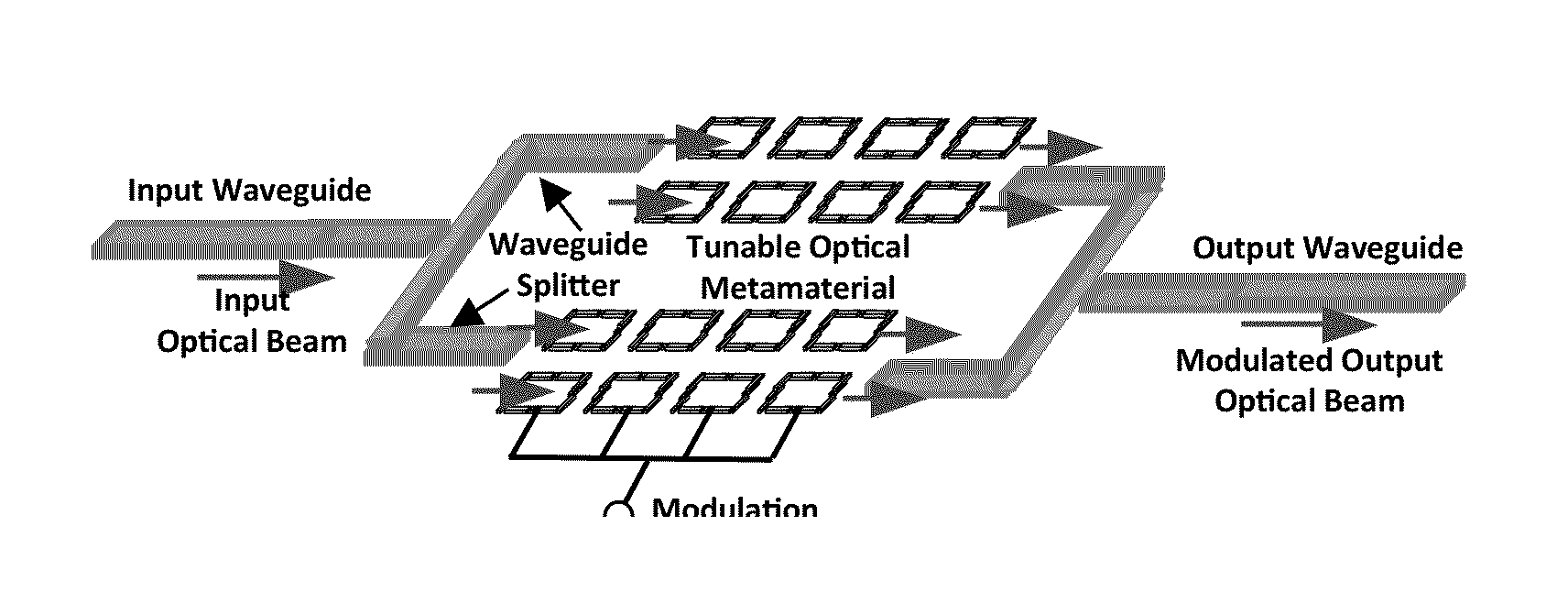

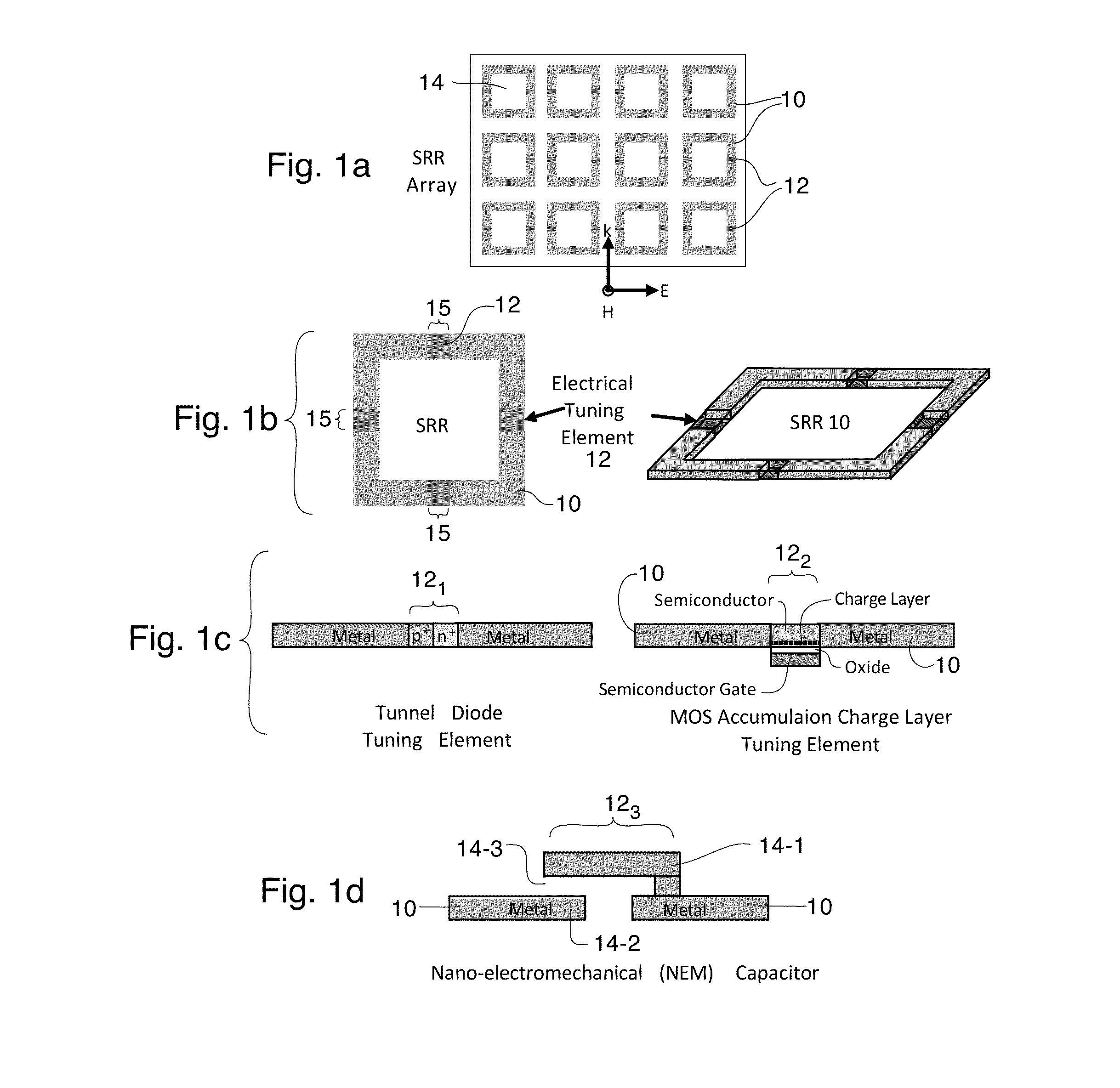

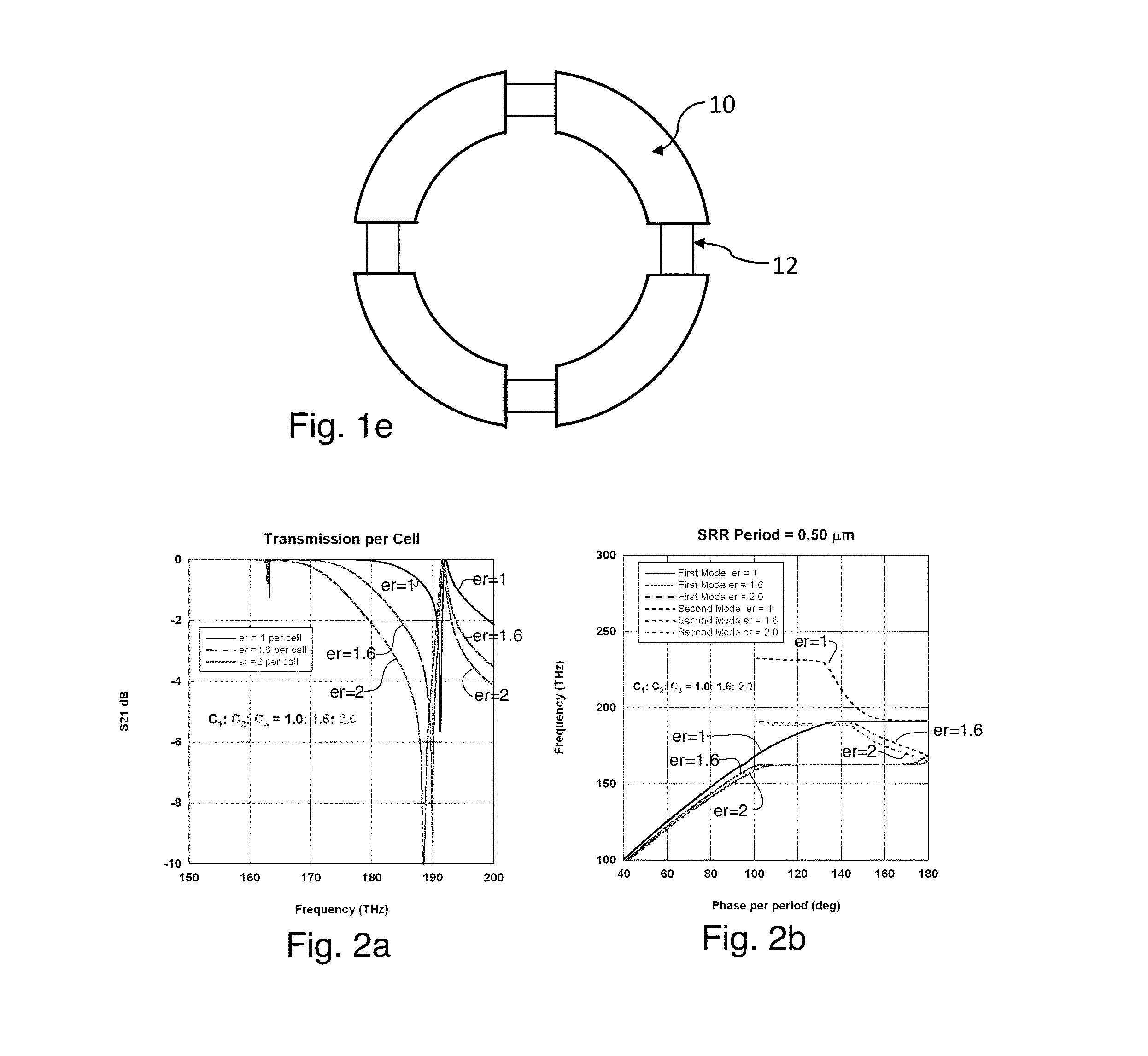

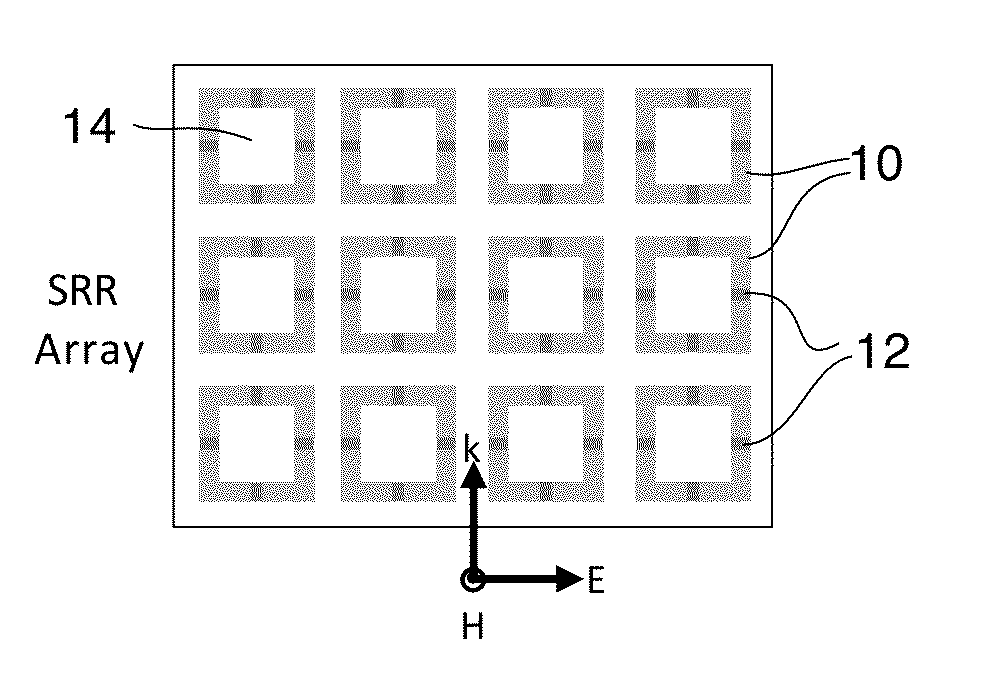

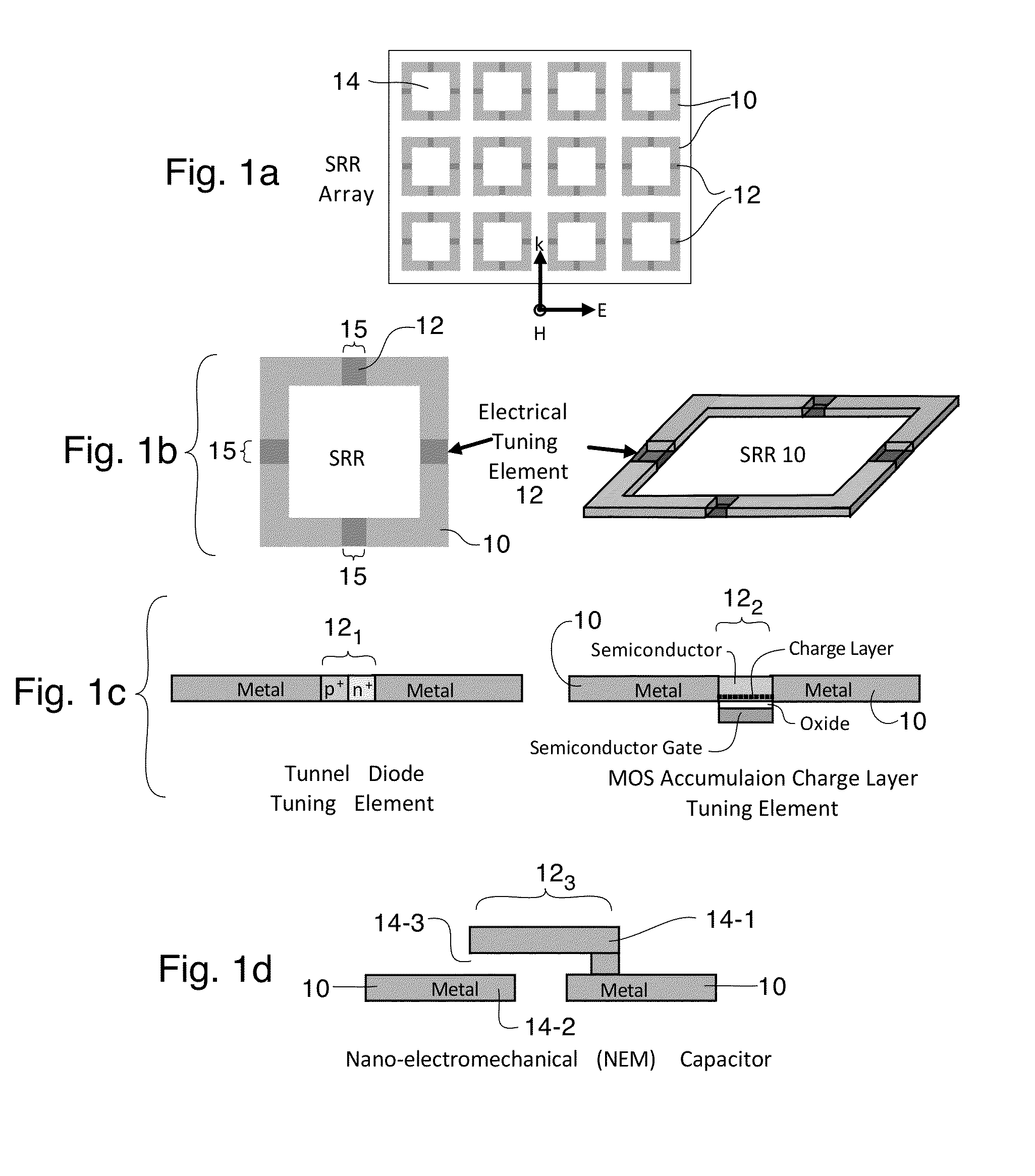

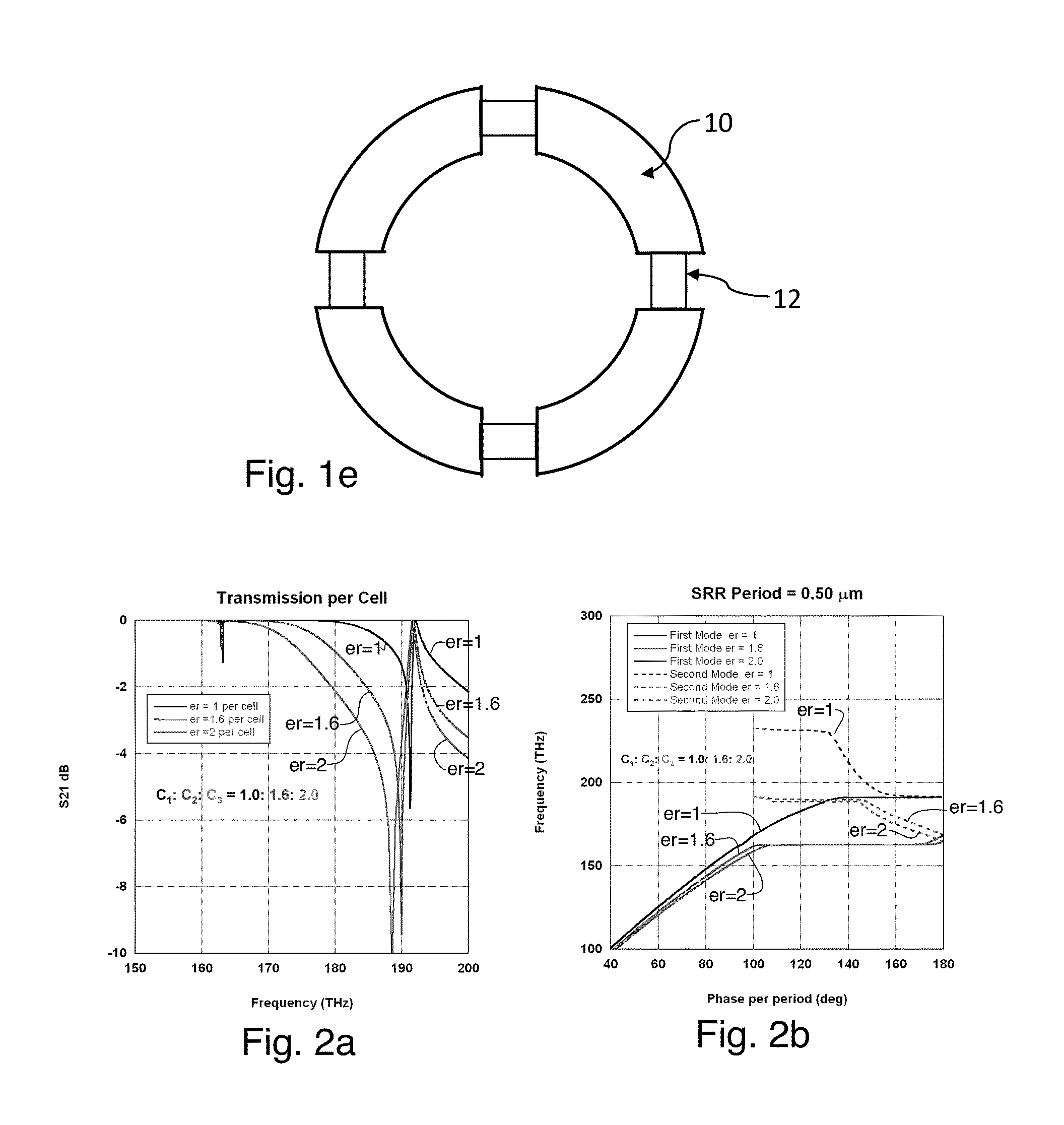

Tunable optical metamaterial

ActiveUS20140211298A1Semiconductor/solid-state device manufacturingNanoopticsTunnel diodeSemiconductor structure

A tunable metamaterial has a two dimensional array of resonant annular ring elements; and a plurality of voltage controllable electrical tuning elements disposed in or adjacent openings in each of said ring elements, each of said voltage controllable electrical tuning element ohmically contacting portions of only one of said ring elements. The voltage controllable electrical tuning elements may comprise highly doped semiconductor tunnel diodes, or the charge accumulation layer at the semiconductor / insulator interface of a metal-insulator-semiconductor structure, or nanoelectromechanical (NEMs) capacitors. The tunable metamaterial may be used, for example, in an optical beam steering device using the aforementioned tunable optical metamaterial in which a free-space optical beam is coupled into a receiving portion of a plane of the optical metamaterial and is steered out of a transmitter portion of the plane of the optical metamaterial in controllable azimuthal and elevational directions. The tunable metamaterial additionally has other applications.

Owner:HRL LAB

Mitral valve annuloplasty ring having a posterior bow

A mitral heart valve annuloplasty ring having a posterior bow that conforms to an abnormal posterior aspect of the mitral annulus. The ring may be generally oval having a major axis and a minor axis, wherein the posterior bow may be centered along the minor axis or offset in a posterior section. The ring may be substantially planar, or may include upward bows on either side of the posterior bow. The ring may include a ring body surrounded by a suture-permeable fabric sheath, and the ring body may be formed of a plurality of concentric ring elements. The ring is semi-rigid and the posterior bow is stiff enough to withstand deformation once implanted and subjected to normal physiologic stresses. The ring elements may be bands of semi-rigid material. A method of repairing an abnormal mitral heart valve annulus having a depressed posterior aspect includes providing a ring with a posterior bow and implanting the ring to support the annulus without unduly stressing the attachment sutures.

Owner:EDWARDS LIFESCIENCES CORP

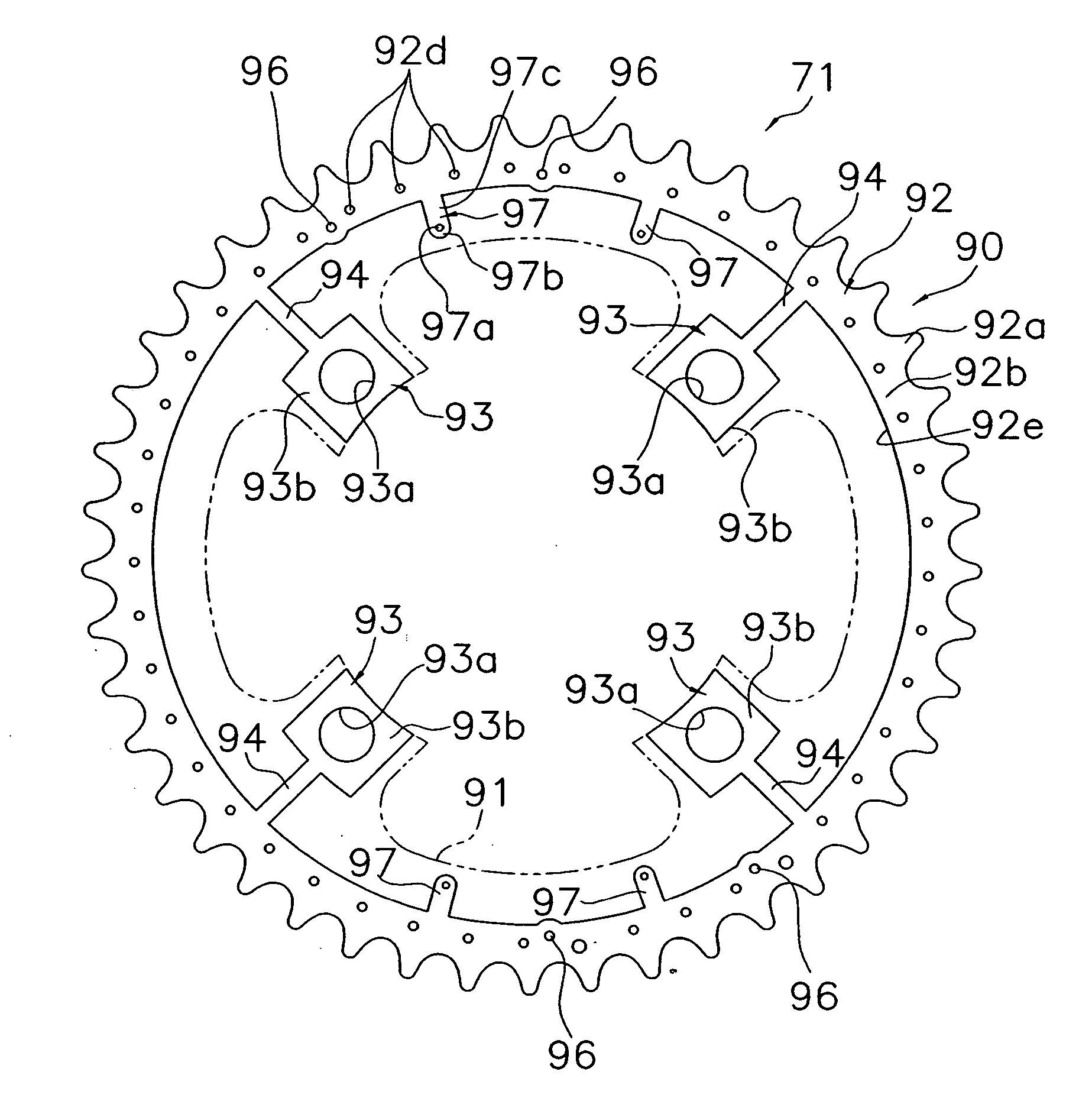

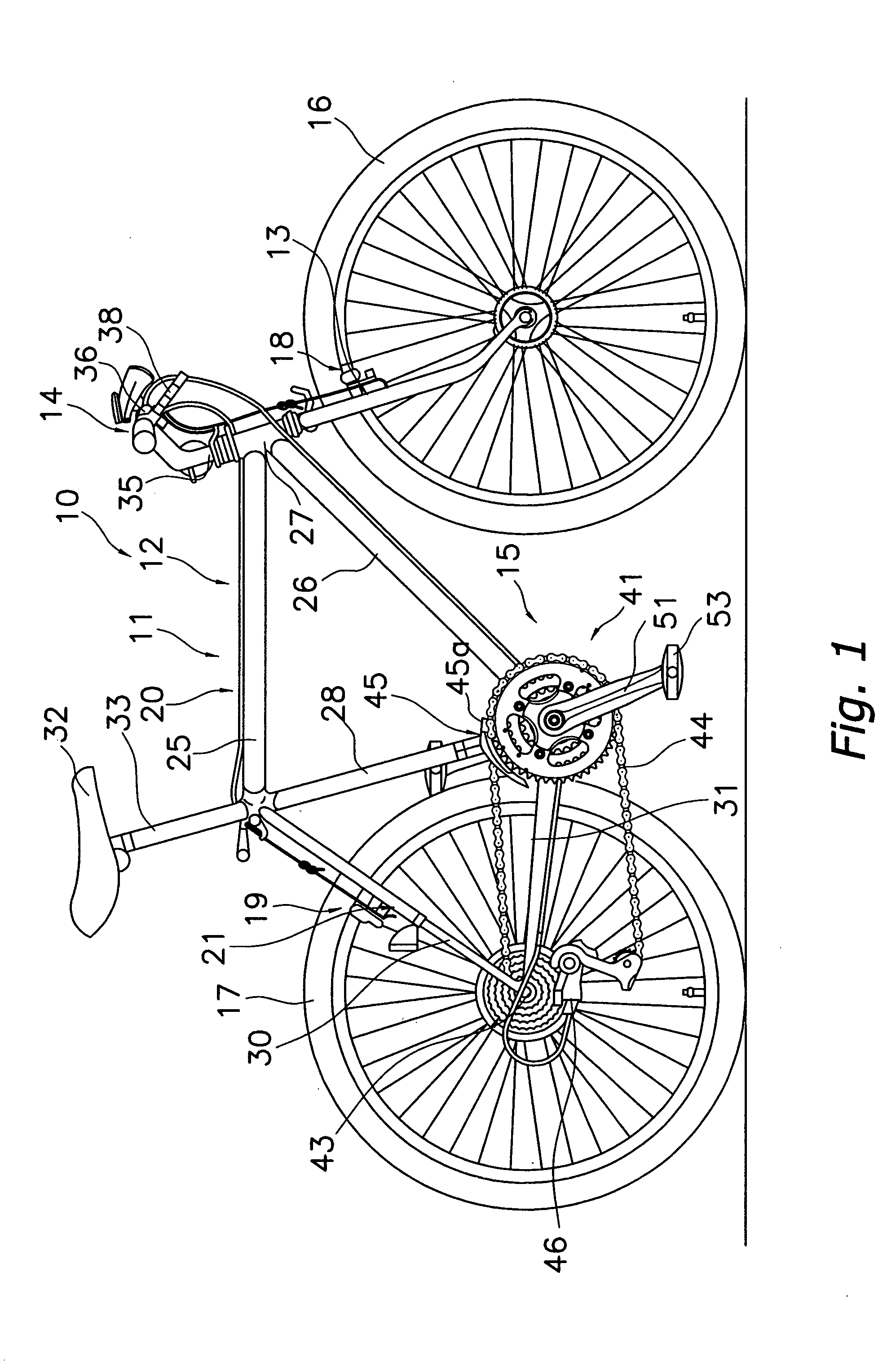

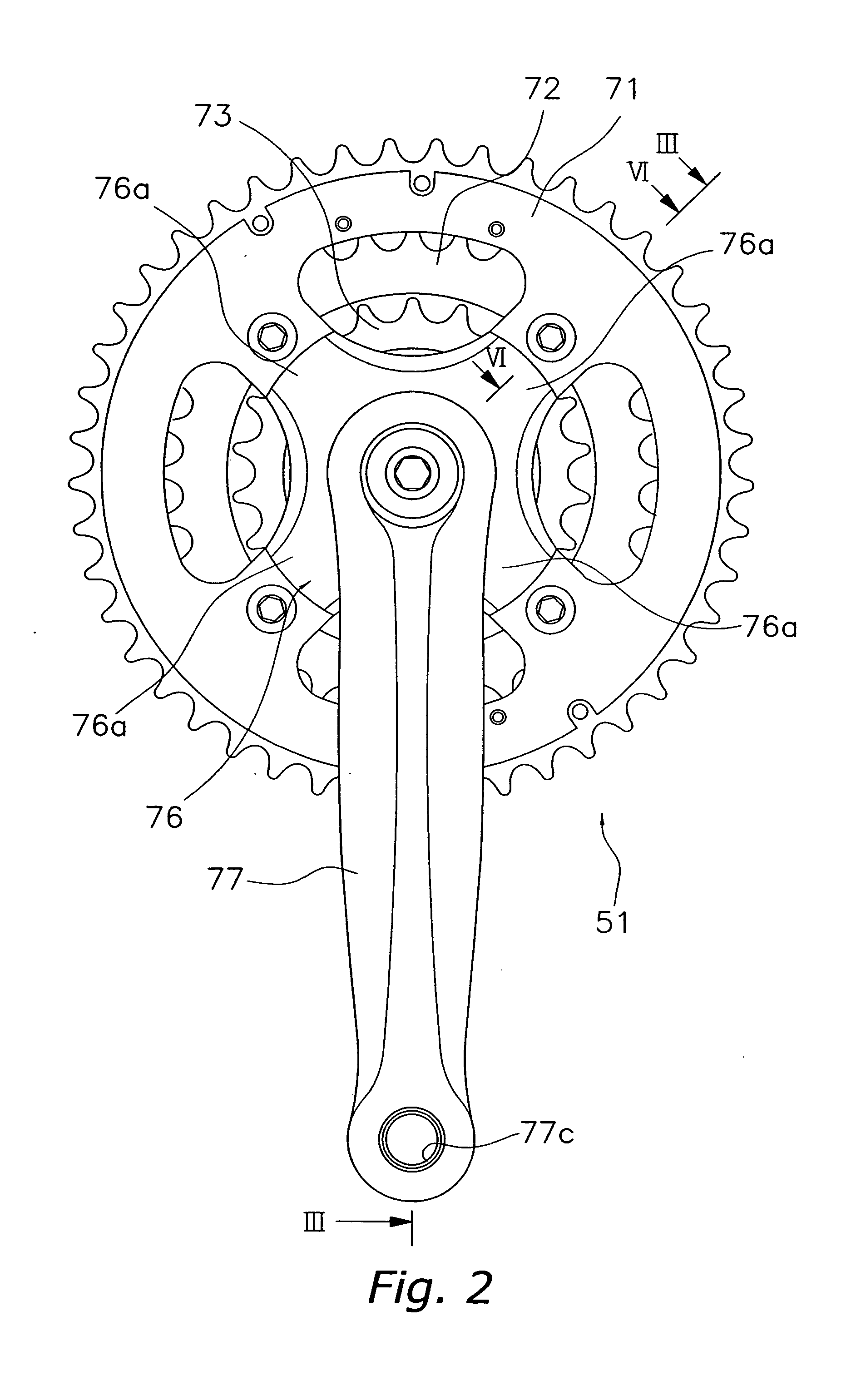

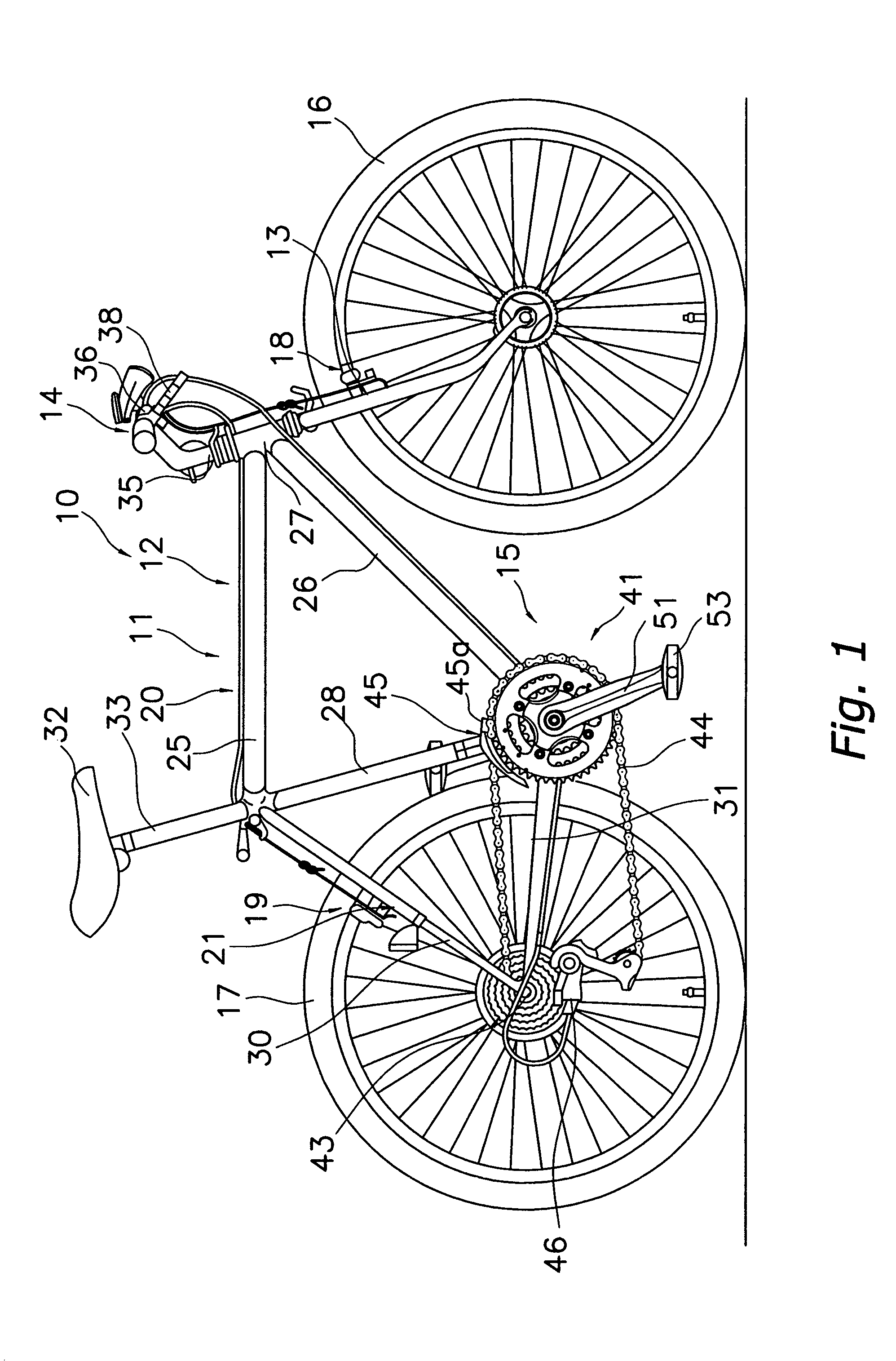

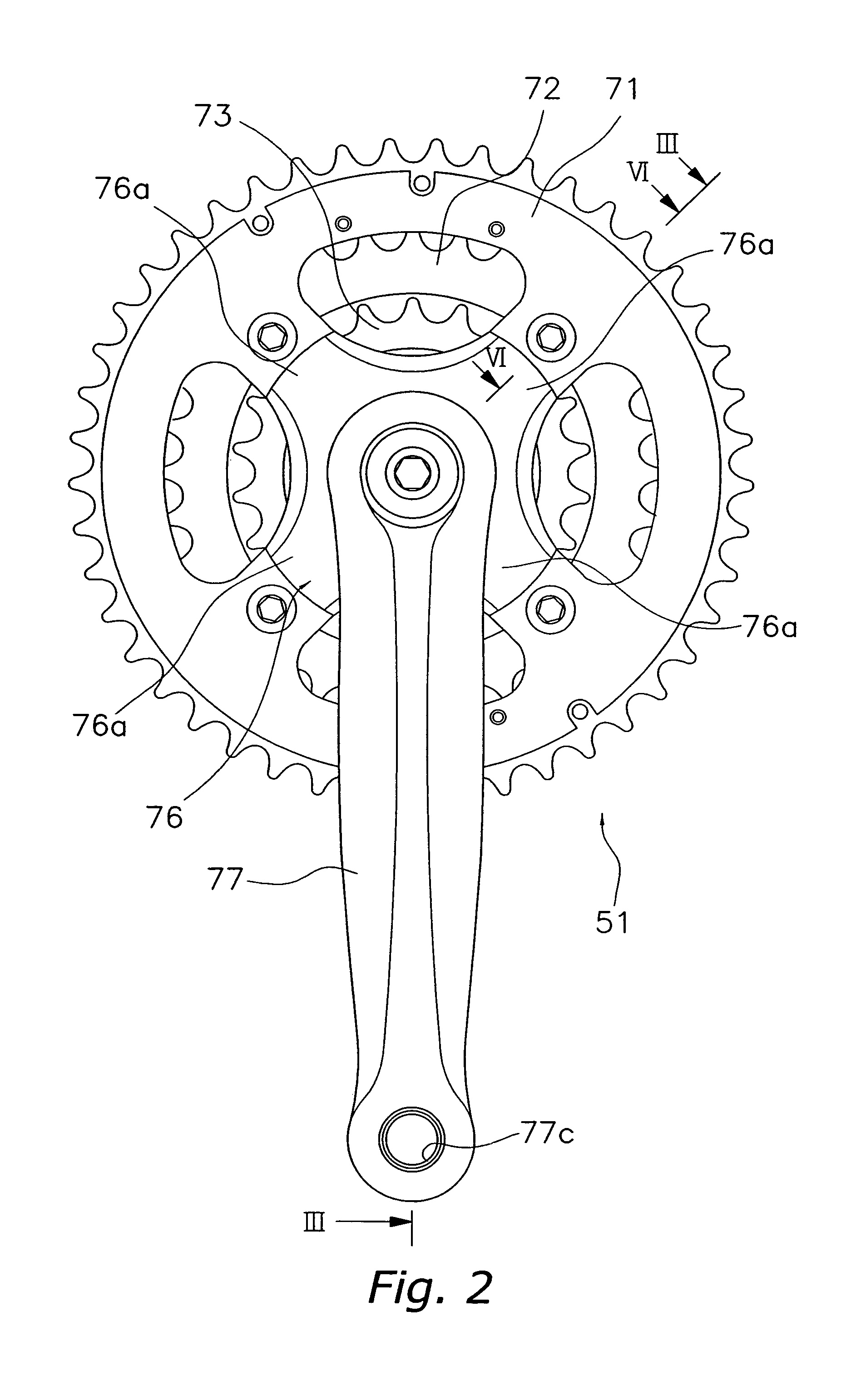

Bicycle sprocket

ActiveUS20060205549A1Reduce weightAvoid lostChain/belt transmissionPortable liftingSprocketSynthetic resin

A bicycle sprocket basically has a metallic sprocket ring part and a synthetic resin fastening part that is configured to ensure that weight can be reduced and that loss of fastening force resulting from deterioration or deformation of the synthetic resin can be prevented. The metallic sprocket ring part includes a ring element with a plurality of sprocket teeth located on an outer periphery of the ring element, a plurality of connecting elements located on an inner periphery of the ring element and a plurality of internal fastening elements located on radial inner ends of the connecting elements, respectively. The synthetic resin fastening part is non-movably formed on both axial faces of the sprocket ring part at a location radially inwardly of the sprocket teeth so as to cover at least a portion of the inner periphery of the ring element, the connecting elements, and the internal fastening elements.

Owner:SHIMANO INC

Downhole plug

Owner:INTERWELL NORWAY AS

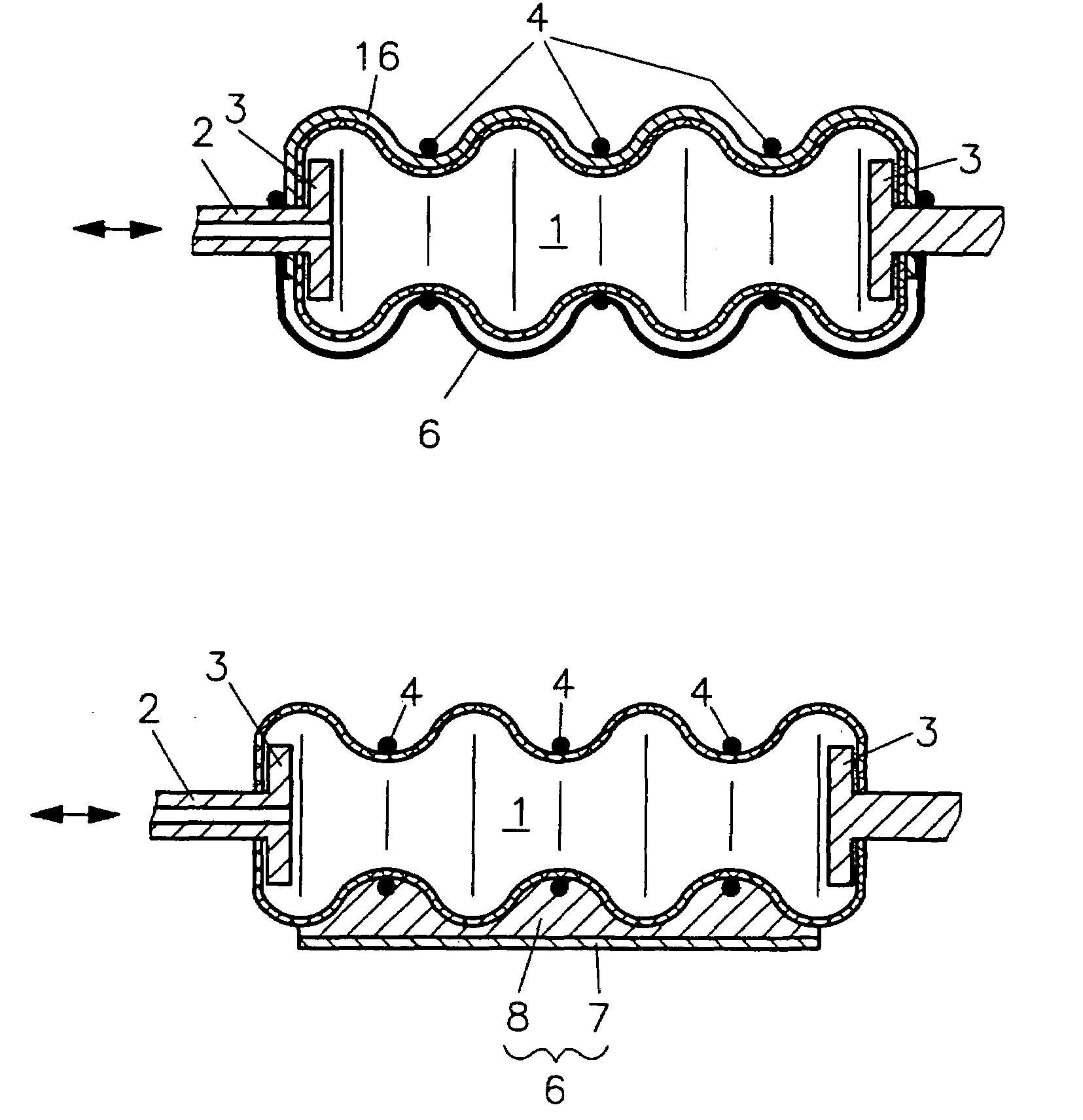

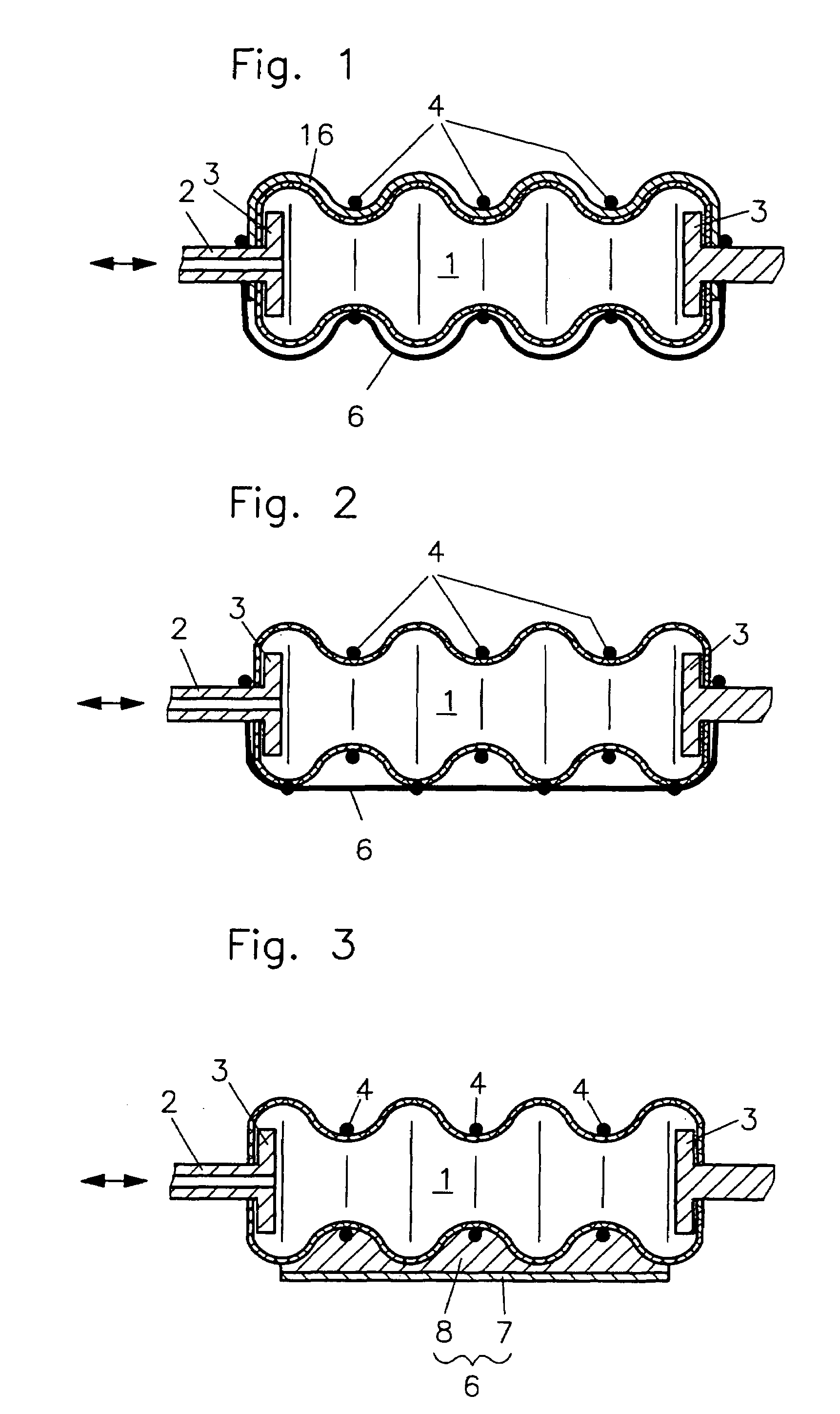

Fluidic device

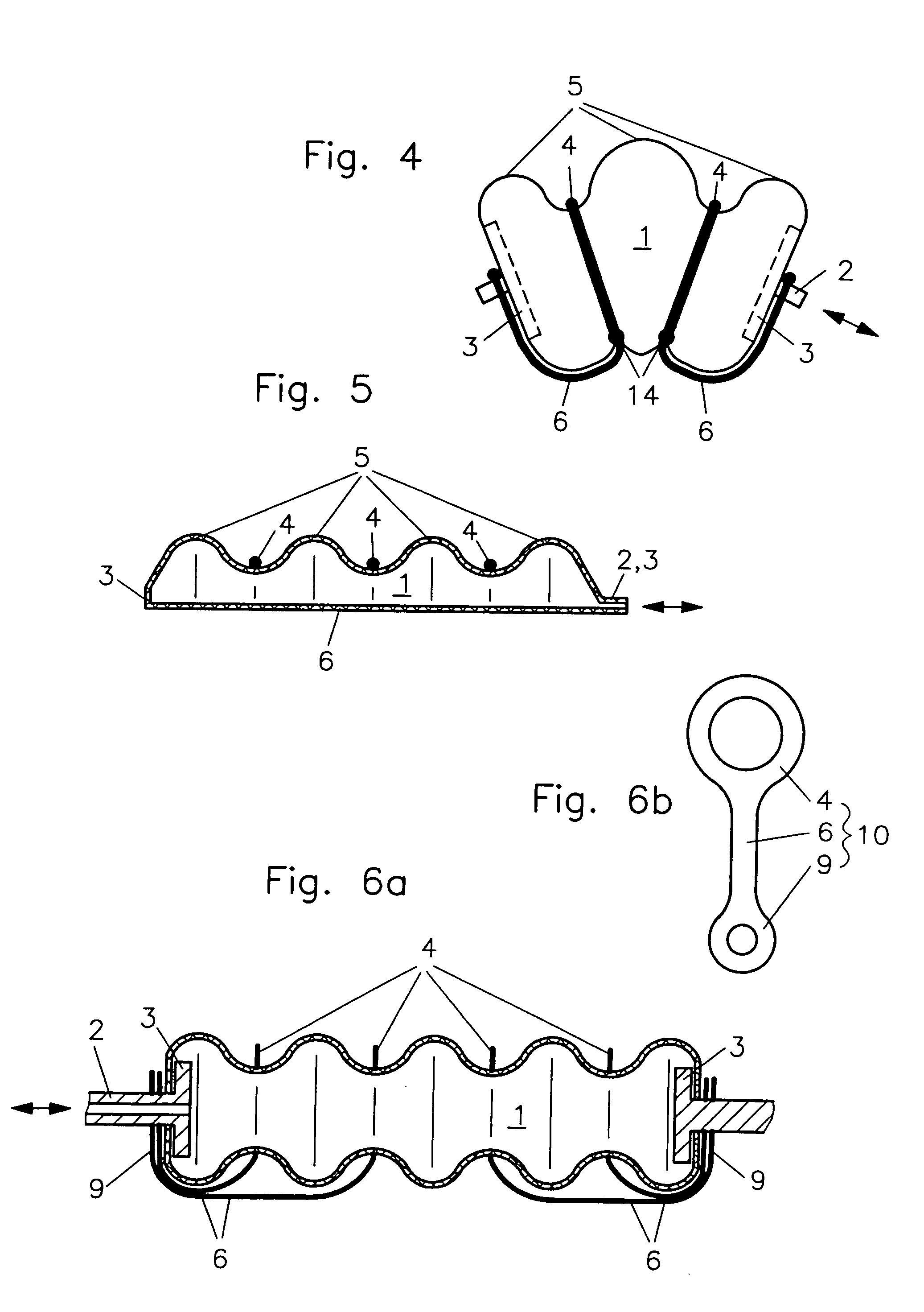

InactiveUS7086322B2Easy to controlAccurate doseFlexible wall reciprocating enginesFluid-pressure actuatorsEngineeringRing element

In a fluidic drive for disposition between two components which are movable relative to each other comprising a hollow body with a duct for supplying fluid to, and discharging it from, the hollow body wherein the hollow body consists at least partially of a bellows structure, non-resilient ring elements extend around the hollow body in each of its pleats and a connecting structure extends at least at one side of the hollow body and interconnects the non-resilient ring elements.

Owner:GSI HELMHOLTZZENT FUR SCHWERIONENFORSCHUNG

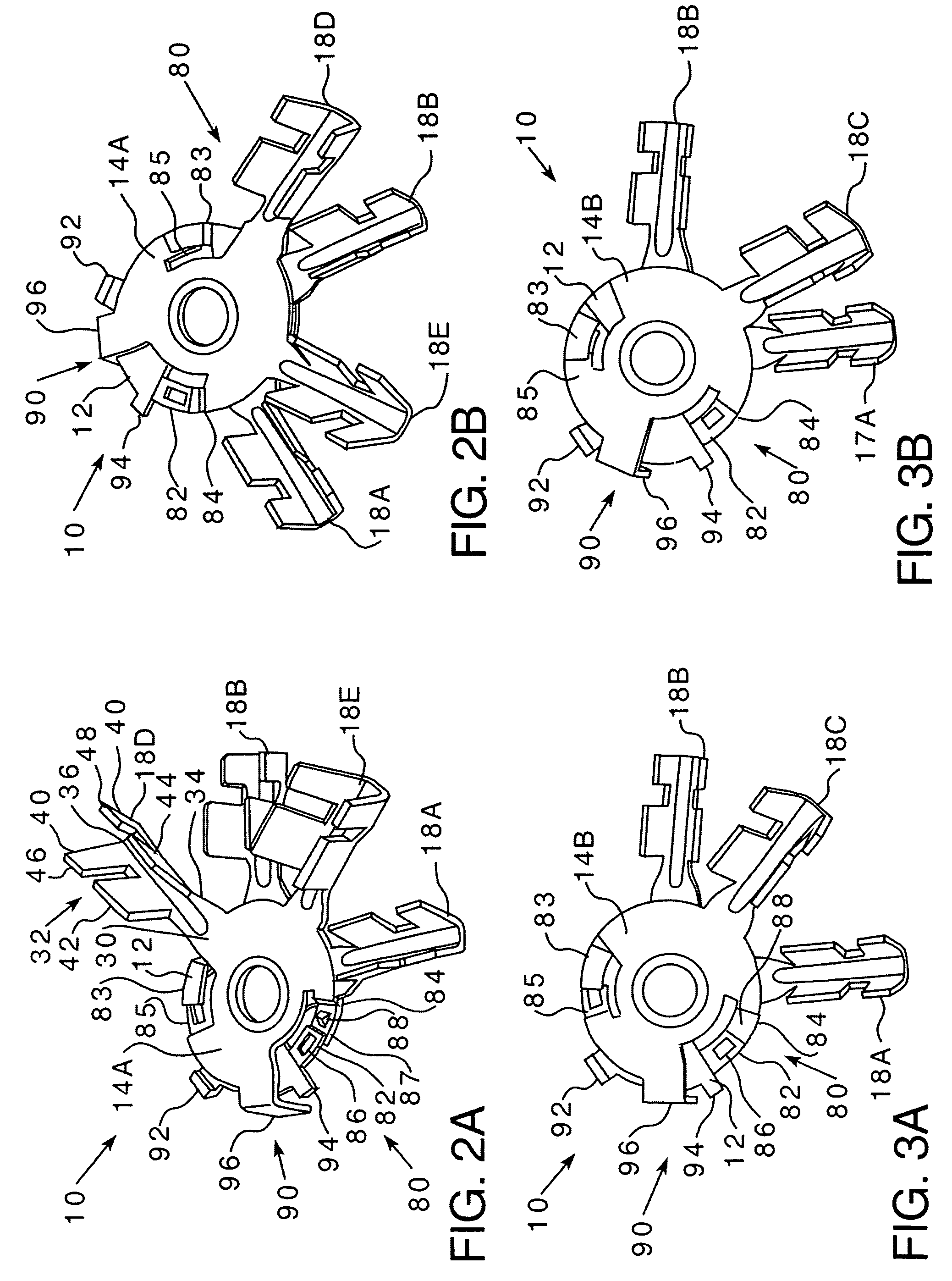

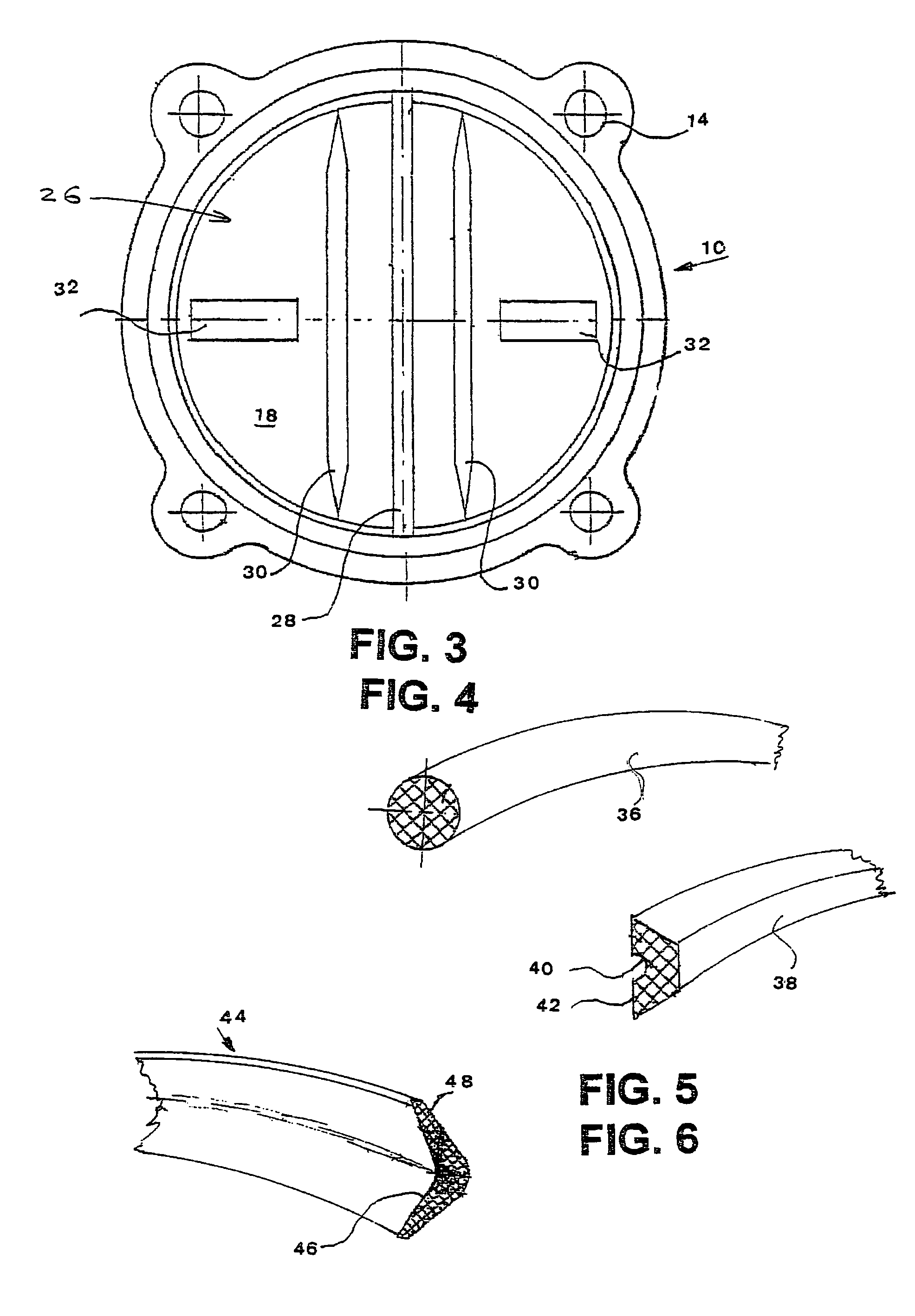

Diaphragm and hydraulically-operated valve using same

InactiveUS20050205815A1Increased operating lifeClose reliableDiaphragm valvesFlexible wall reciprocating enginesElastomerFluid control

The present invention relates to fluid control valves. The invention provides an improved diaphragm useful for a large hydraulically-operated valve or pressure regulating valve of the type used in pipelines to transport water, oil, gas, acids, alkalis and other fluids. The diaphragm being provided with an upper face arranged to be exposed to a control hydraulic pressure and a lower face arranged to selectively seal and open a passage between a valve inlet and a valve outlet, ribs on said upper face urging the diaphragm towards a sealing position. The diaphragm being characterized by the addition of an elastomer ring element disposed adjacent to the upper face and adjacent to the largest diameter of the diaphragm exposed inside a valve to which it may be assembled, an upper face of the flexible ring element being in pressure contact with a portion of the rigid body of the valve. The flexible ring element further urging the diaphragm towards its lower position and allowing closure of the valve without use of a metallic compression spring.

Owner:RAPHAEL VALVES INDS 1975

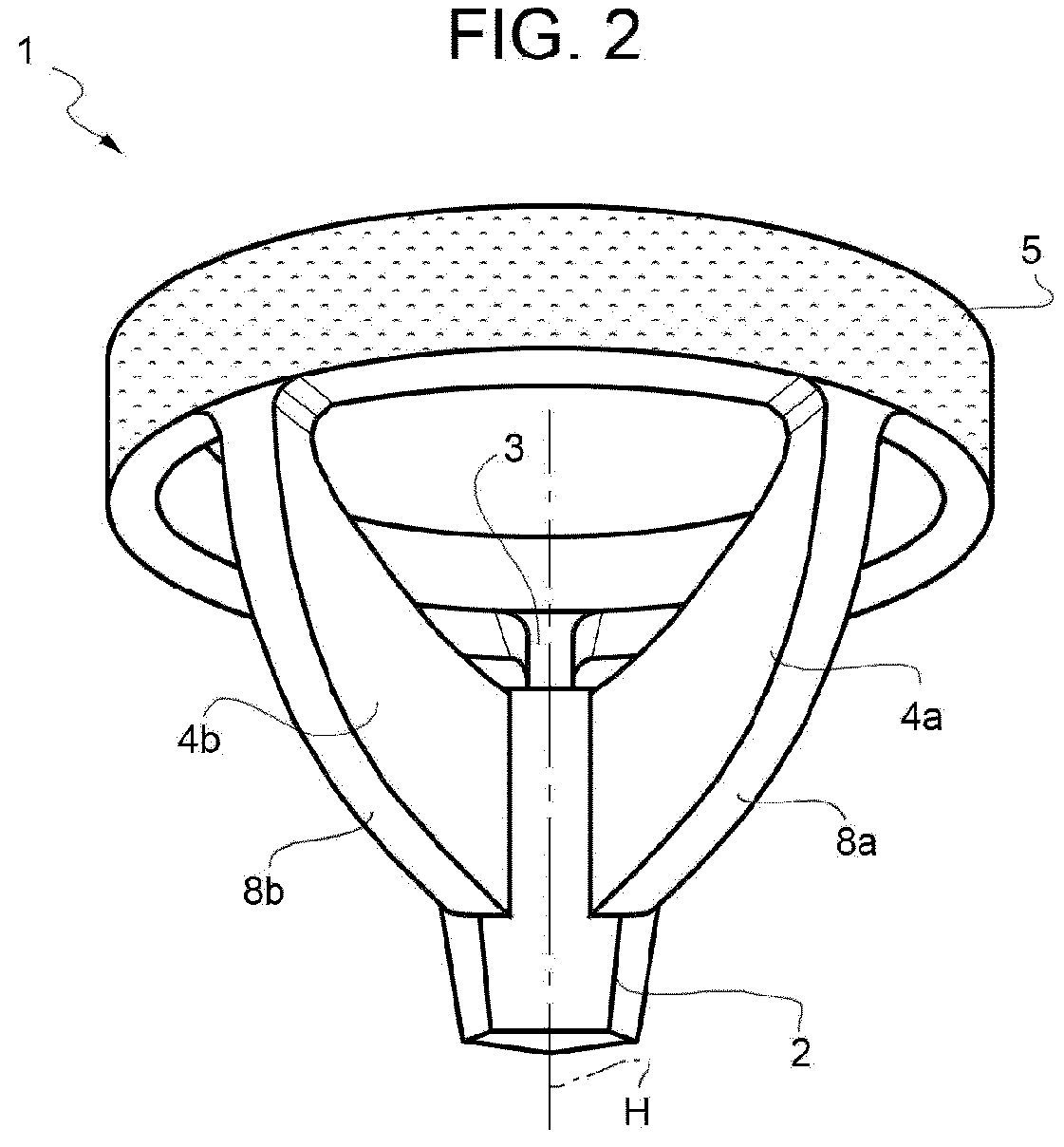

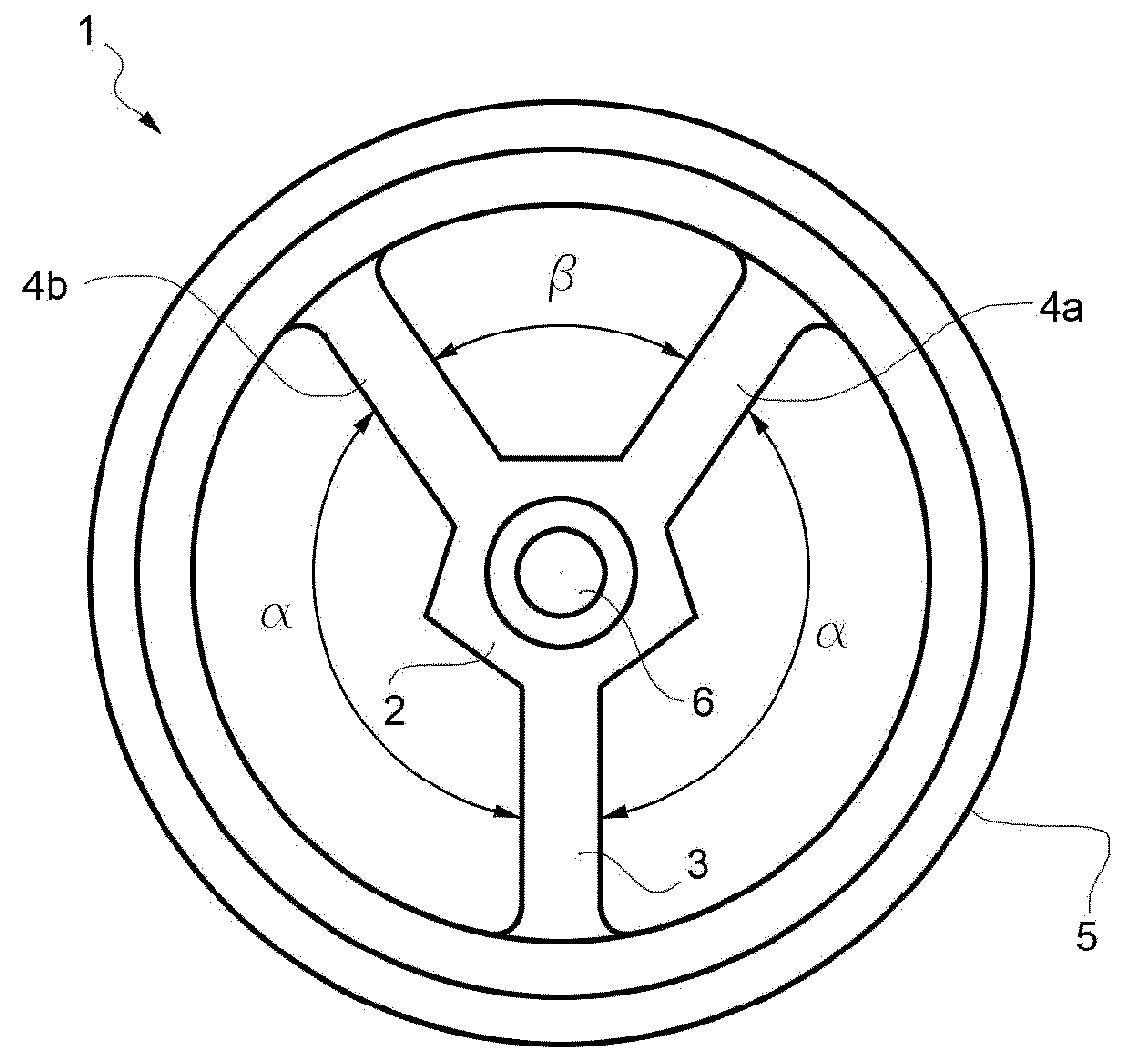

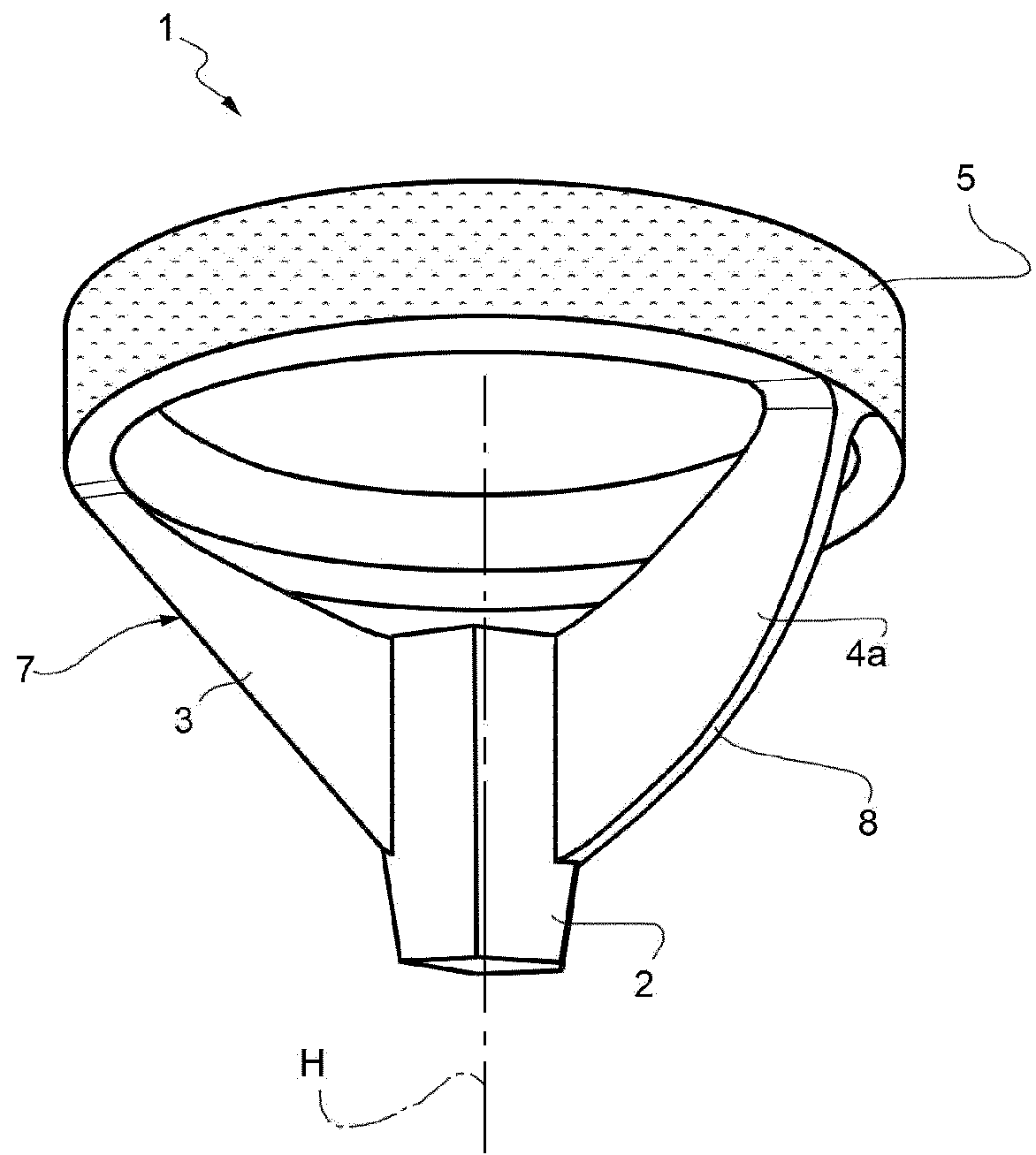

Humeral implant for a shoulder prosthesis

The invention discloses a support element for humeral implant comprising a central body extending along an axis and at least three arms extending outwardly from the central body, the arms being transversal to said axis and bearing a ring element at their ends opposite to said central body, wherein at least a first and a second pair of arms form different angles.

Owner:LIMA CORPORATE SPA

Compression anastomosis ring assembly and applicator for use therewith

InactiveUS20080015617A1Reduced dimensionIncrease the scope of applicationSuture equipmentsStapling toolsOrgan wallShape-memory alloy

A compression anastomosis ring (CAR) assembly for use in joining severed organ wall portions of a hollow organ. The assembly comprises a first portion which includes an anvil ring and a second portion which comprises a bottom ring, at least one ring element, and at least one spring element formed of a shape-memory alloy. The at least one spring element provides a restorative force and is in compressive force contact with the bottom ring and the tissue to be joined is positioned between the anvil ring and the bottom ring. A plurality of needles on one of the ring elements is operative, upon application of a closure force, to pierce the tissue and the anvil ring, holding the disk to the second portion of the CAR assembly. An applicator for applying the CAR assembly and a method for using the assembly and applicator are taught.

Owner:NITI SURGICAL SOLUTIONS

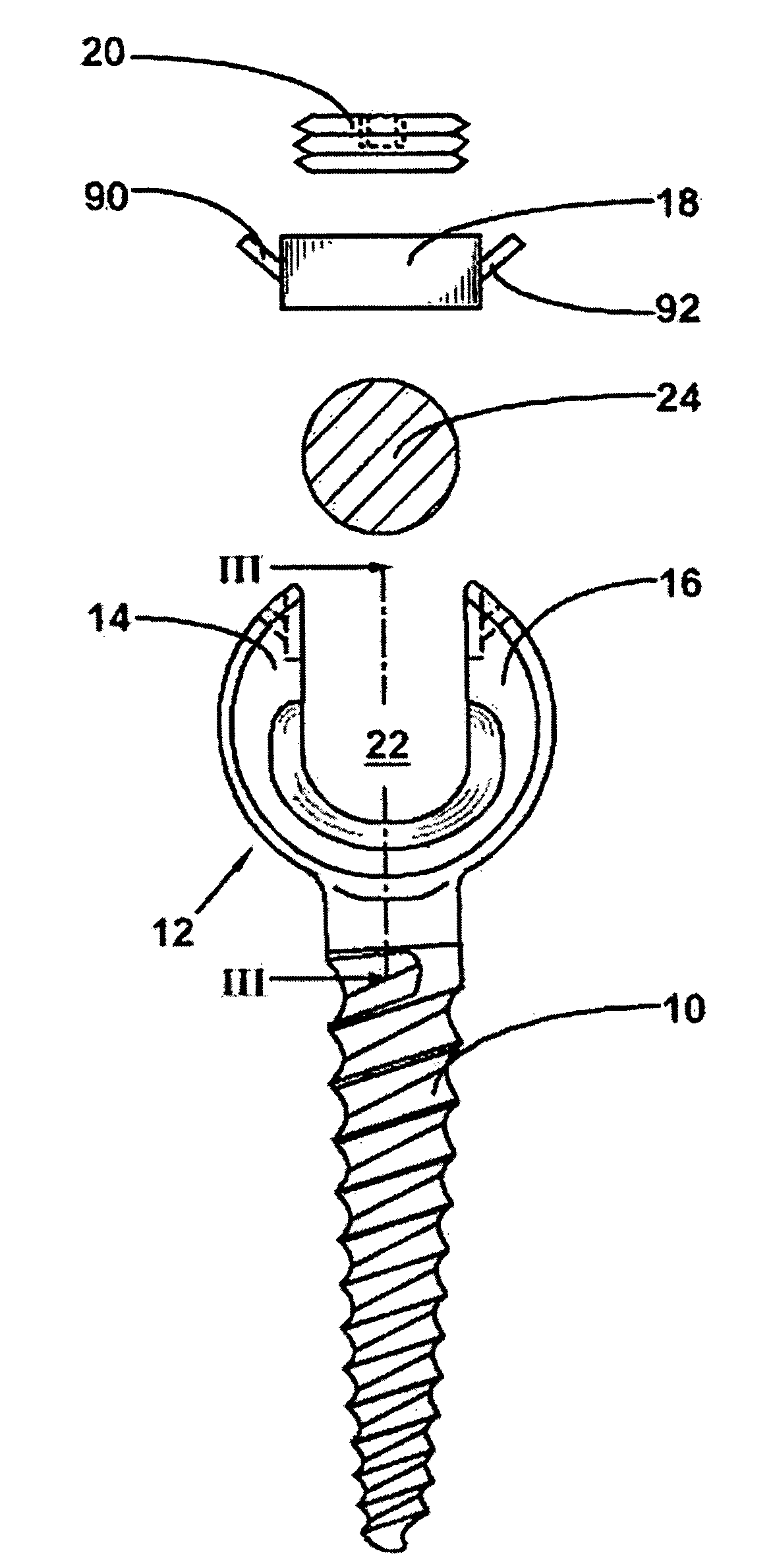

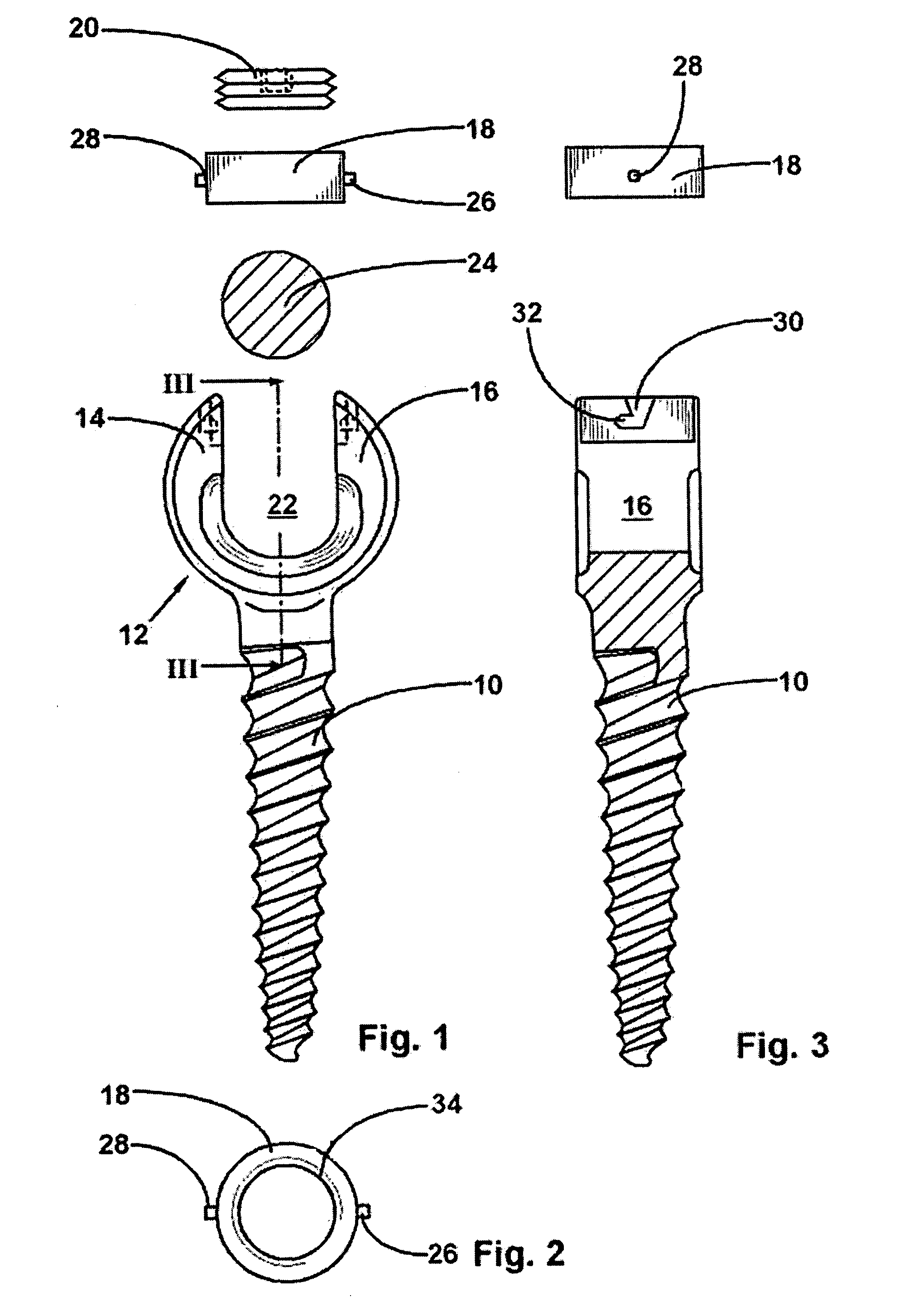

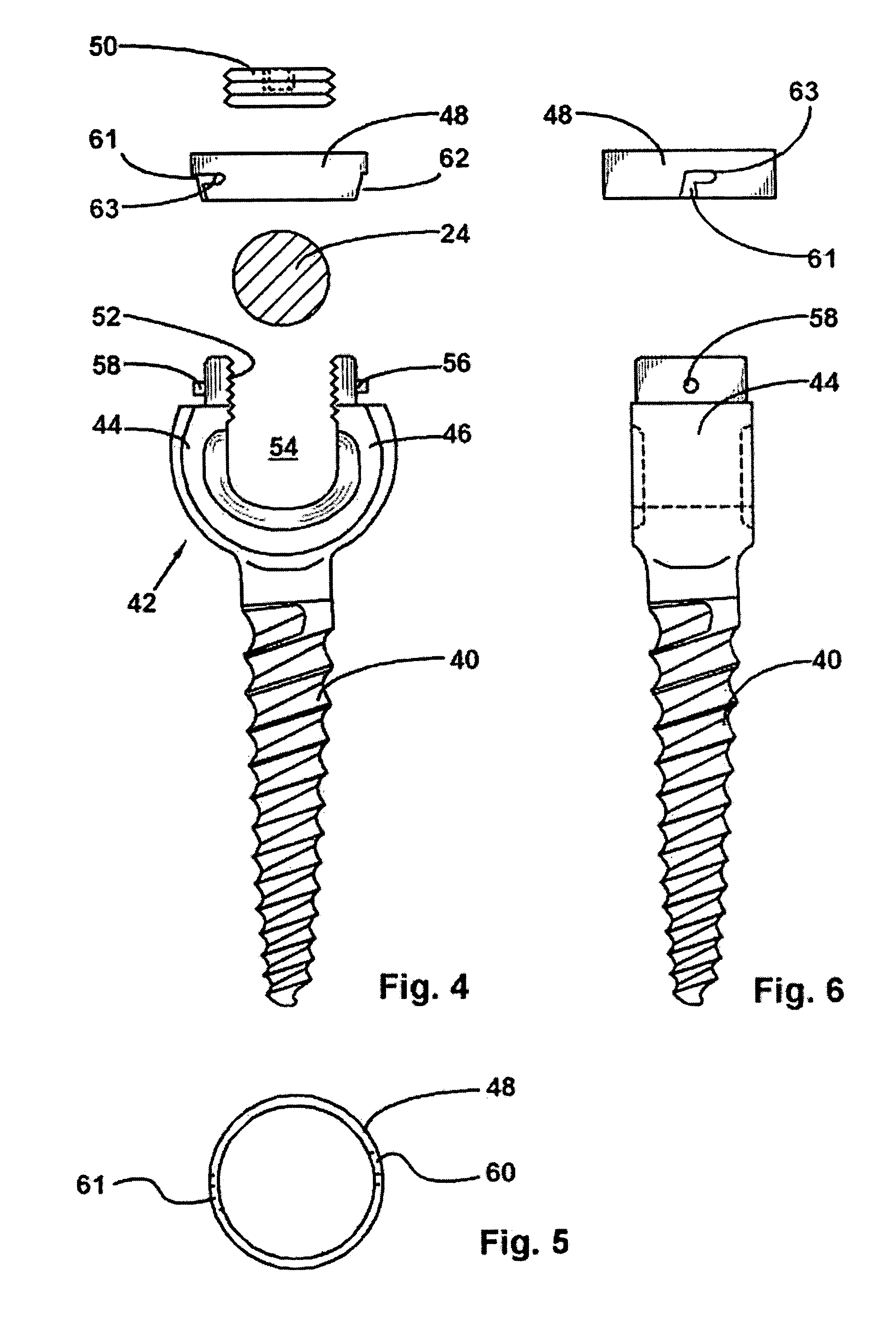

Anchoring element for securing a rod on a vertebra

InactiveUS7235075B1Quick installationReliable absorptionInternal osteosythesisCoupling systemVertebral bone

An anchoring element for fastening a rod of a device for adjusting a human or animal spine to a vertebral bone, and having a holding device that is substantially U-shaped and includes two substantially parallely disposed holding ridges, a rod receiving slot being formed therein, and a securing element acting against the rod accommodated in the receiving slot. The securing element includes a locking element and a ring element and the ring element is mountable to the free end of the holding ridges by means of a single turn coupling system. Further a partial thread can be provided on opposing sides of the holding ridges and two opposing thread portions and two opposing entrance portions can be configured on the circumference of the ring element the diameter of the securing element in the region of the entrance portions not exceeding the core diameter of the thread portion so that the thread portions are engageable with the partial threads of the holding ridges and the thread portions and the partial threads comprise buttress threads.

Owner:METZ STAVENHAGEN PETER

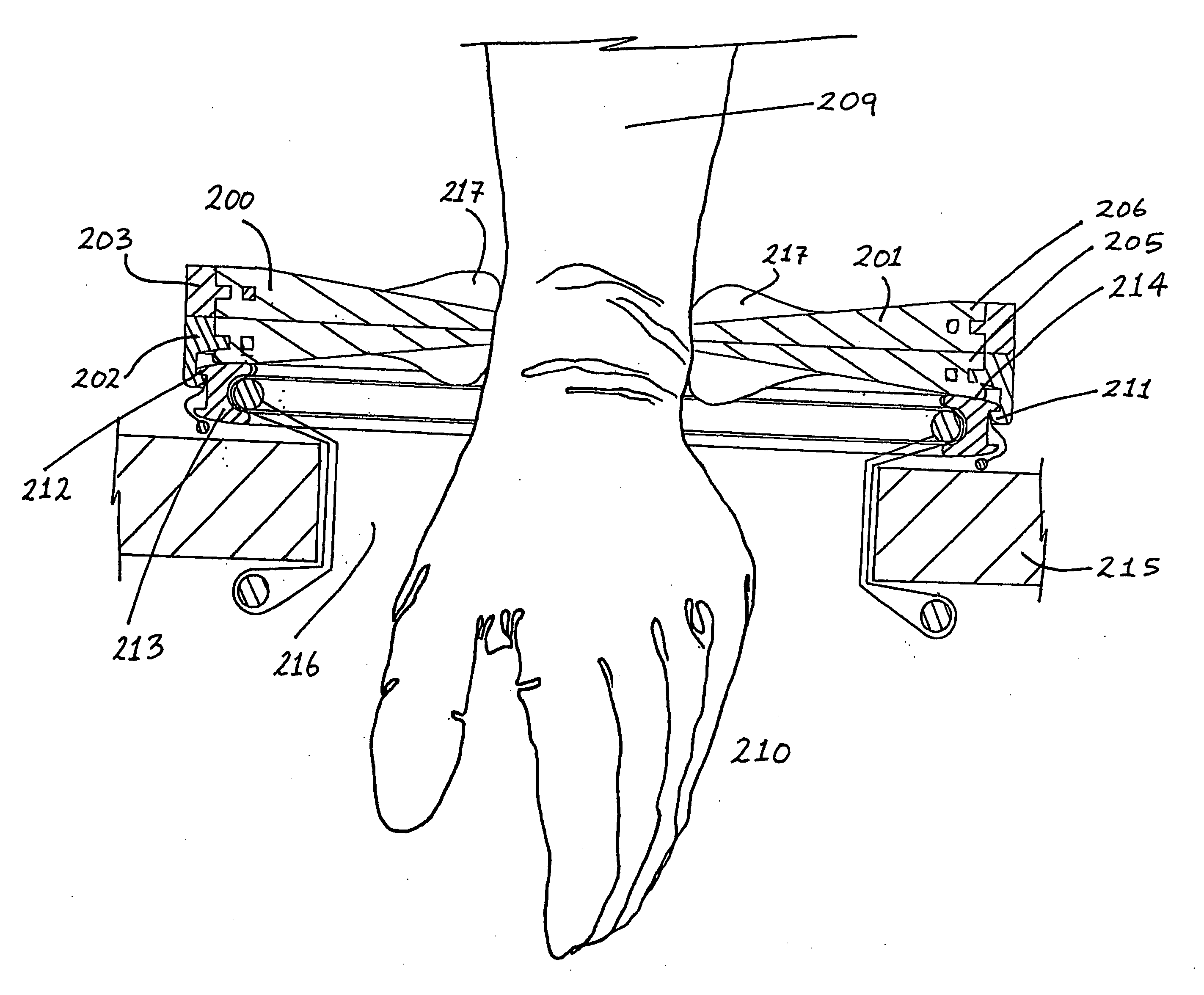

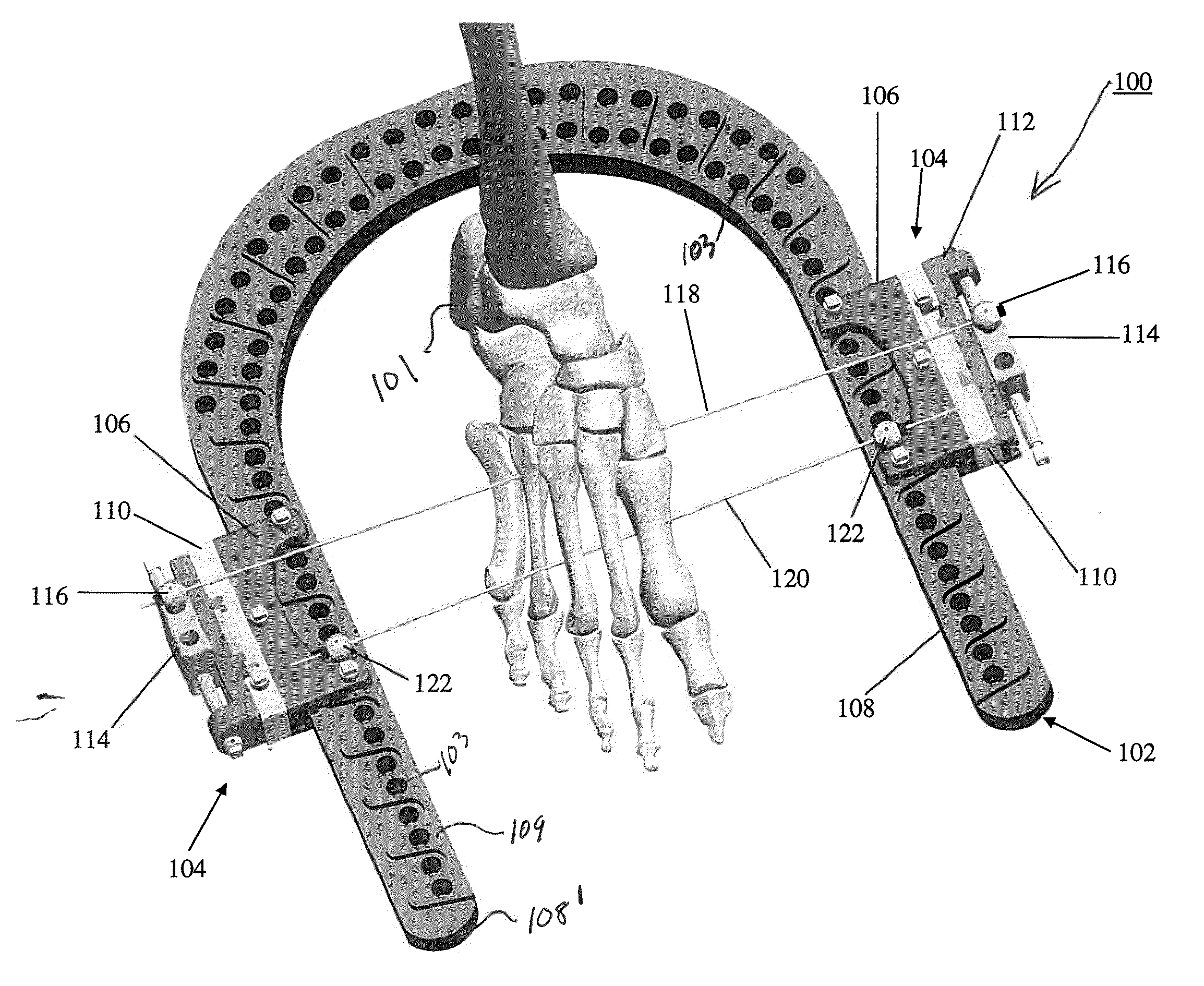

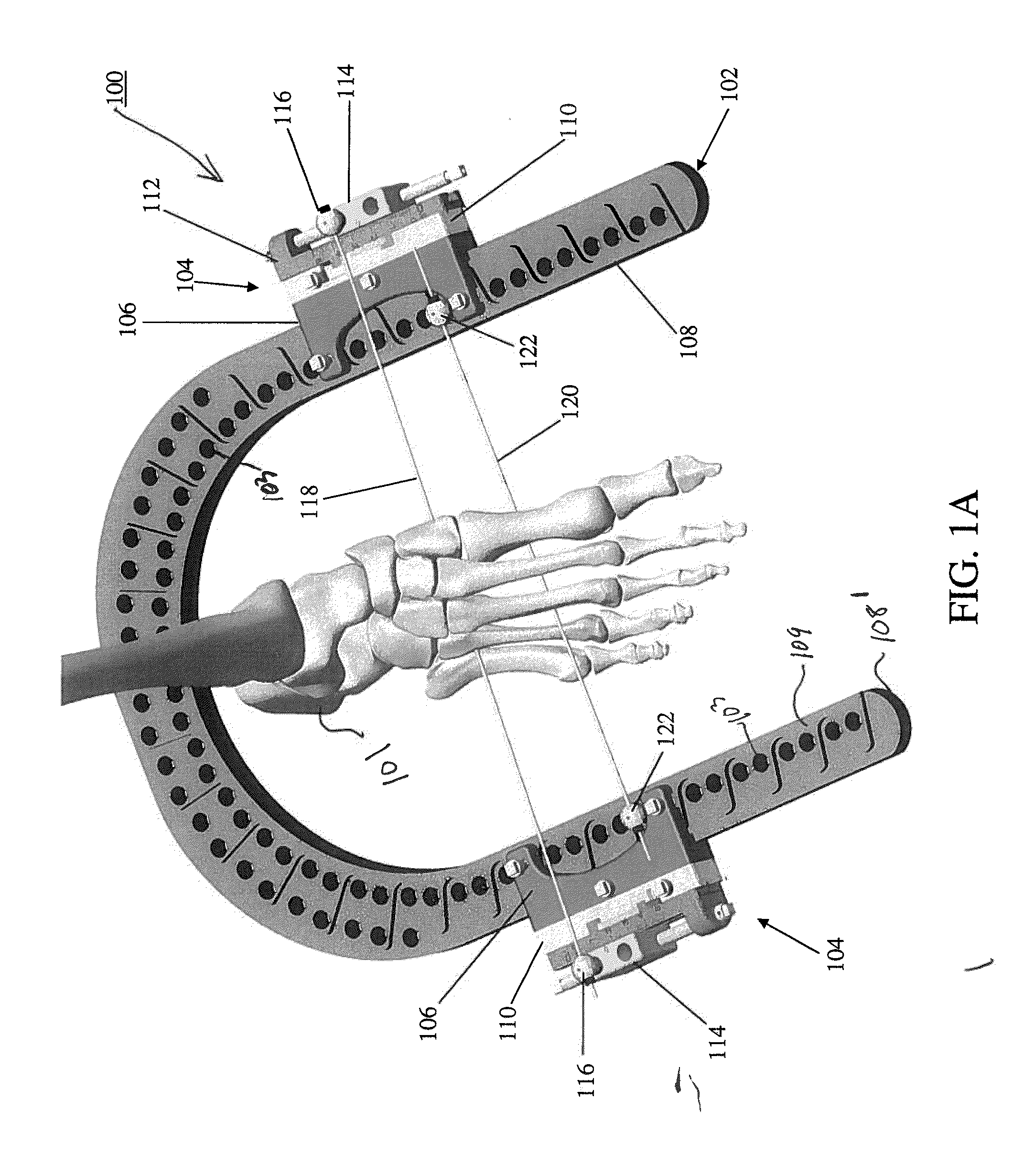

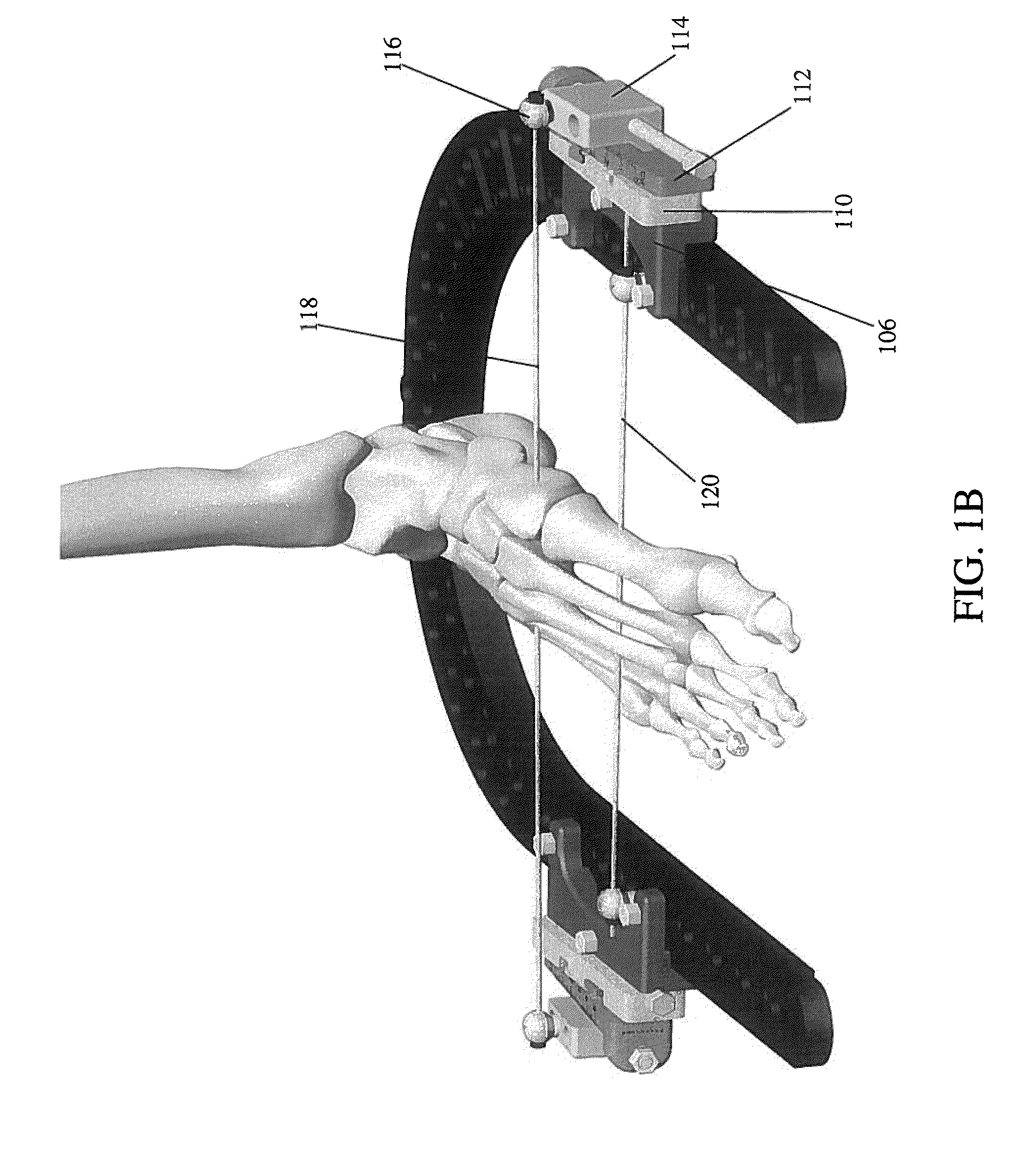

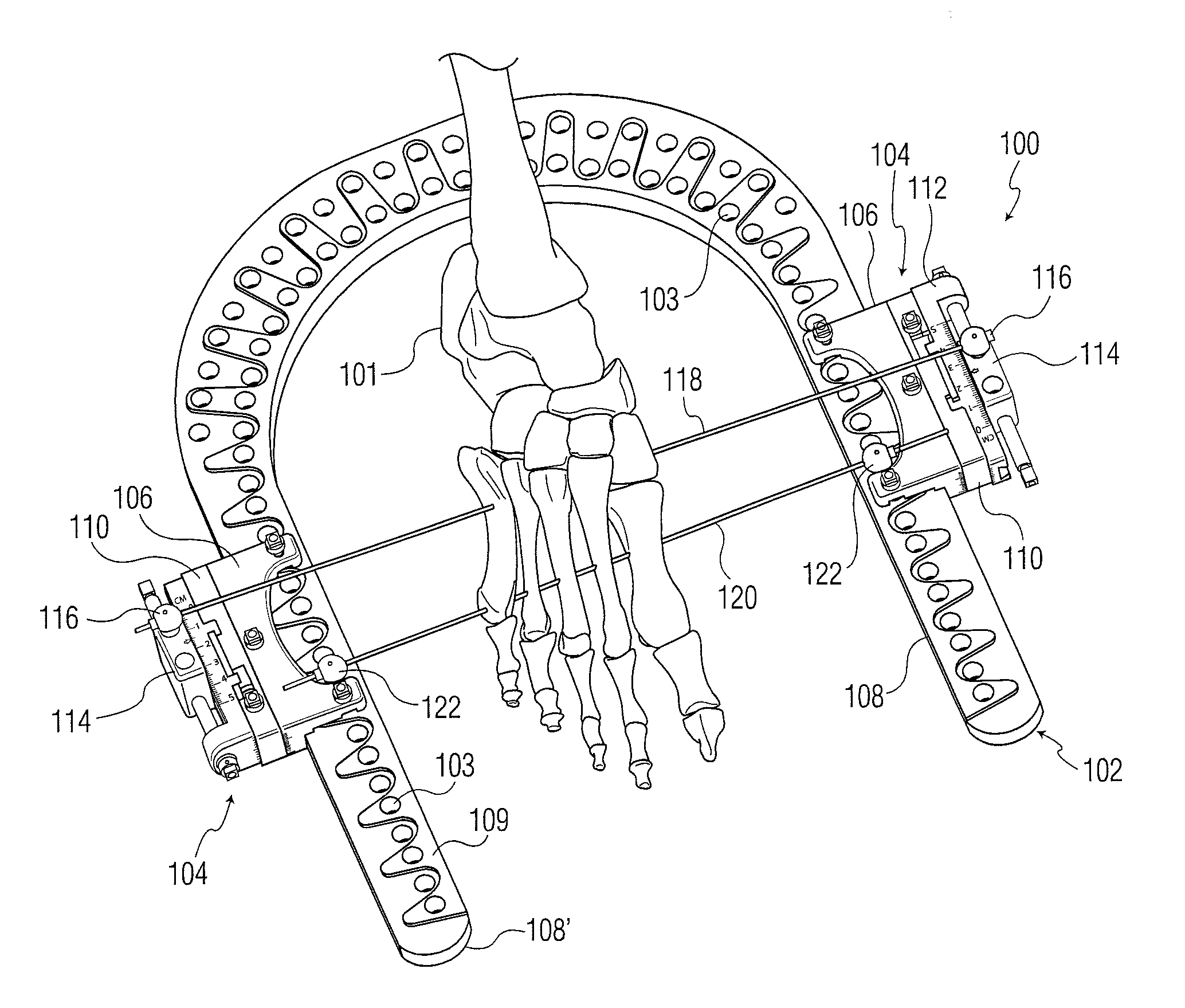

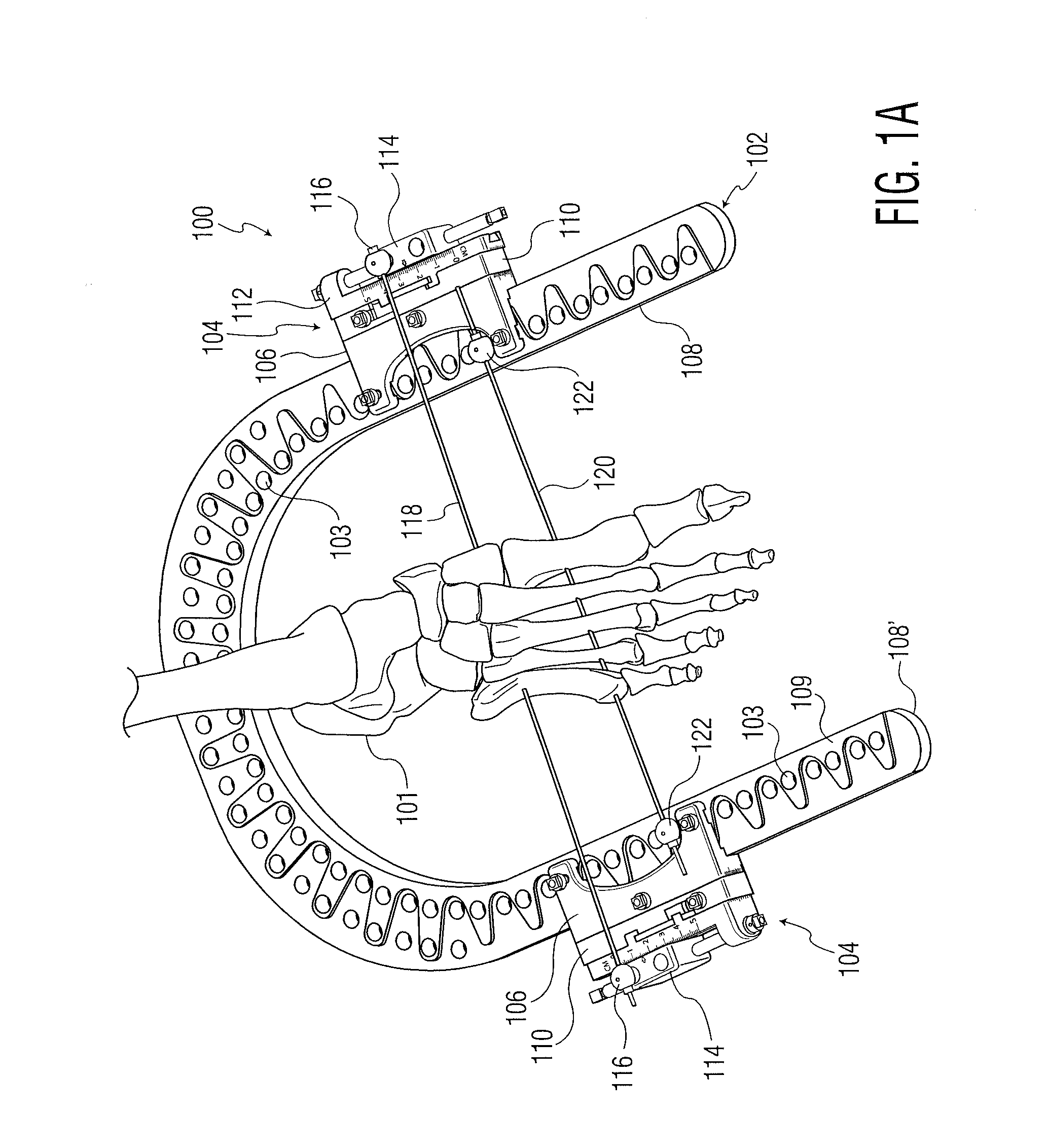

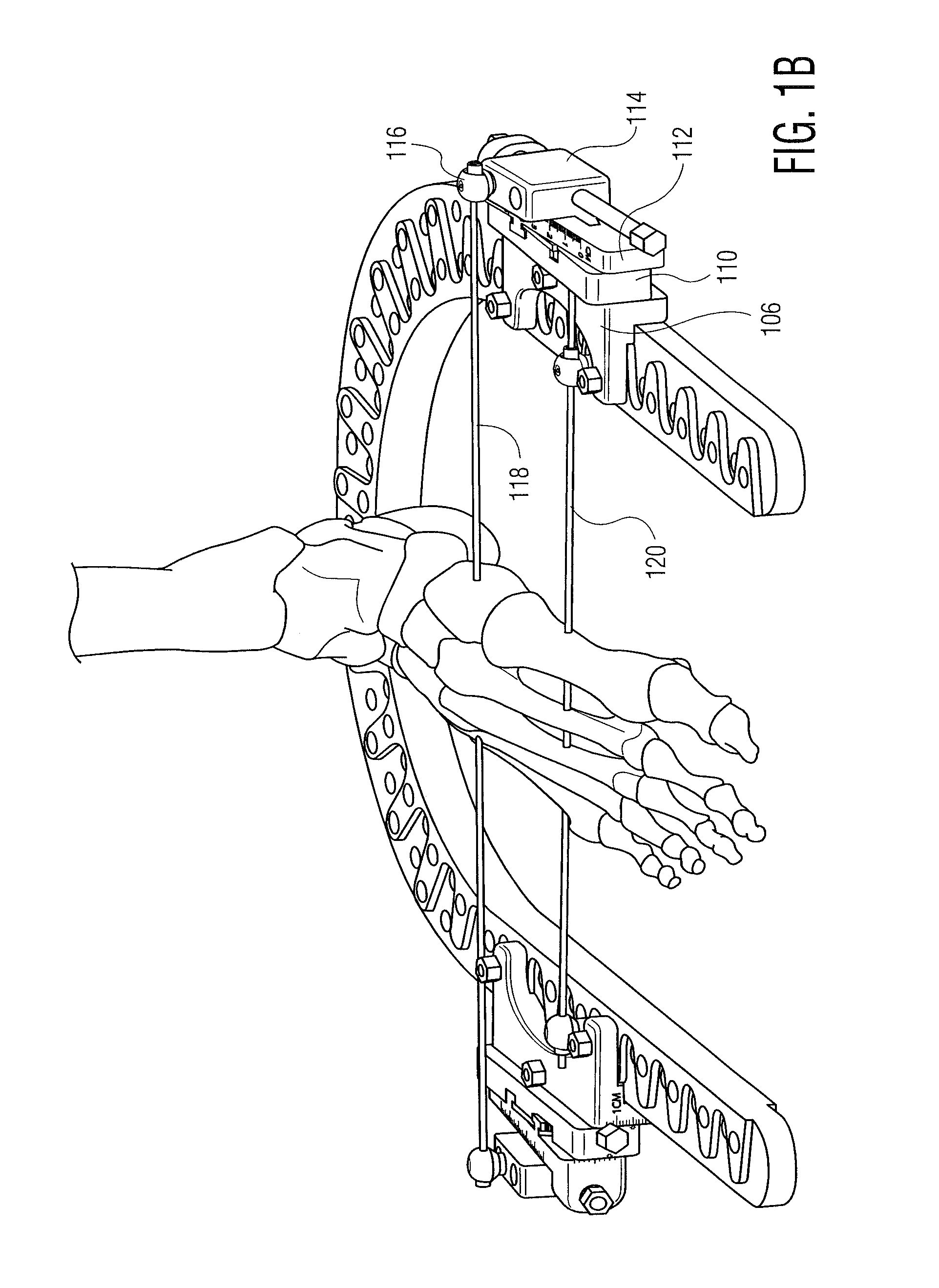

Dynamic External Fixator And Methods For Use

An external fixation system and method for realigning, compressing or distracting broken bones has a planar ring element with an adjustable device having a body releasably mounted on the ring element. The adjustable device includes a first member for movement in a direction generally perpendicular to the ring element. A second member is pivotally connected to the first member for angular movement with respect to the ring. A third member is mounted on the second member for movement in a direction parallel to the second member and with respect to a circumference of the planar ring element. The method includes providing an external fixation system and inserting a k-wire through a first piece of bone and affixing the k-wire or half pin to the ring element. Then inserting a second k-wire or half pin through a second piece of bone and affixing the k-wire or half pin to an adjustable device. The pieces of bone are realigned, compressed or distracted by adjusting at least one of a first and second adjustable member forming the device.

Owner:STRYKER EURO OPERATIONS HLDG LLC

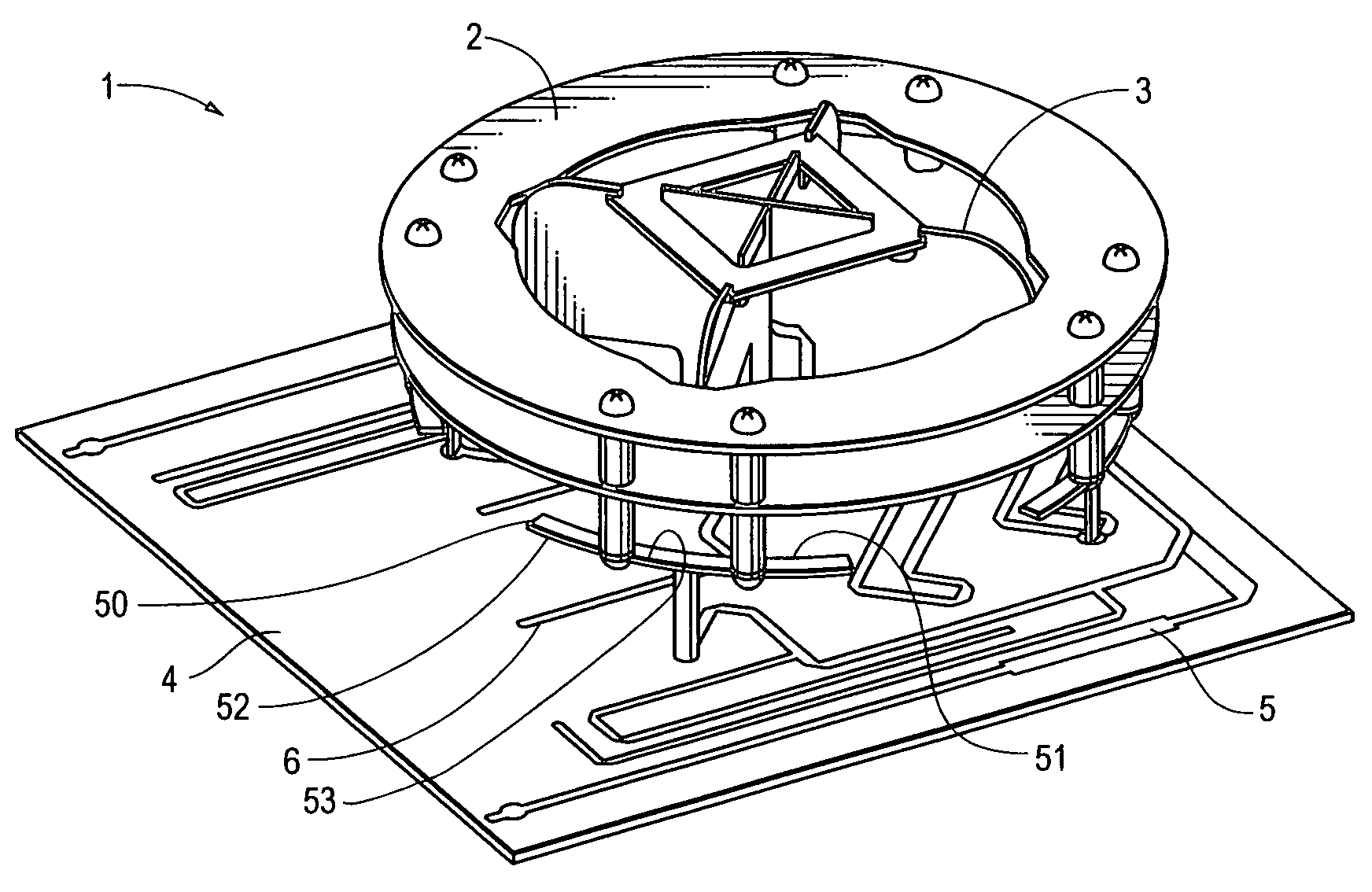

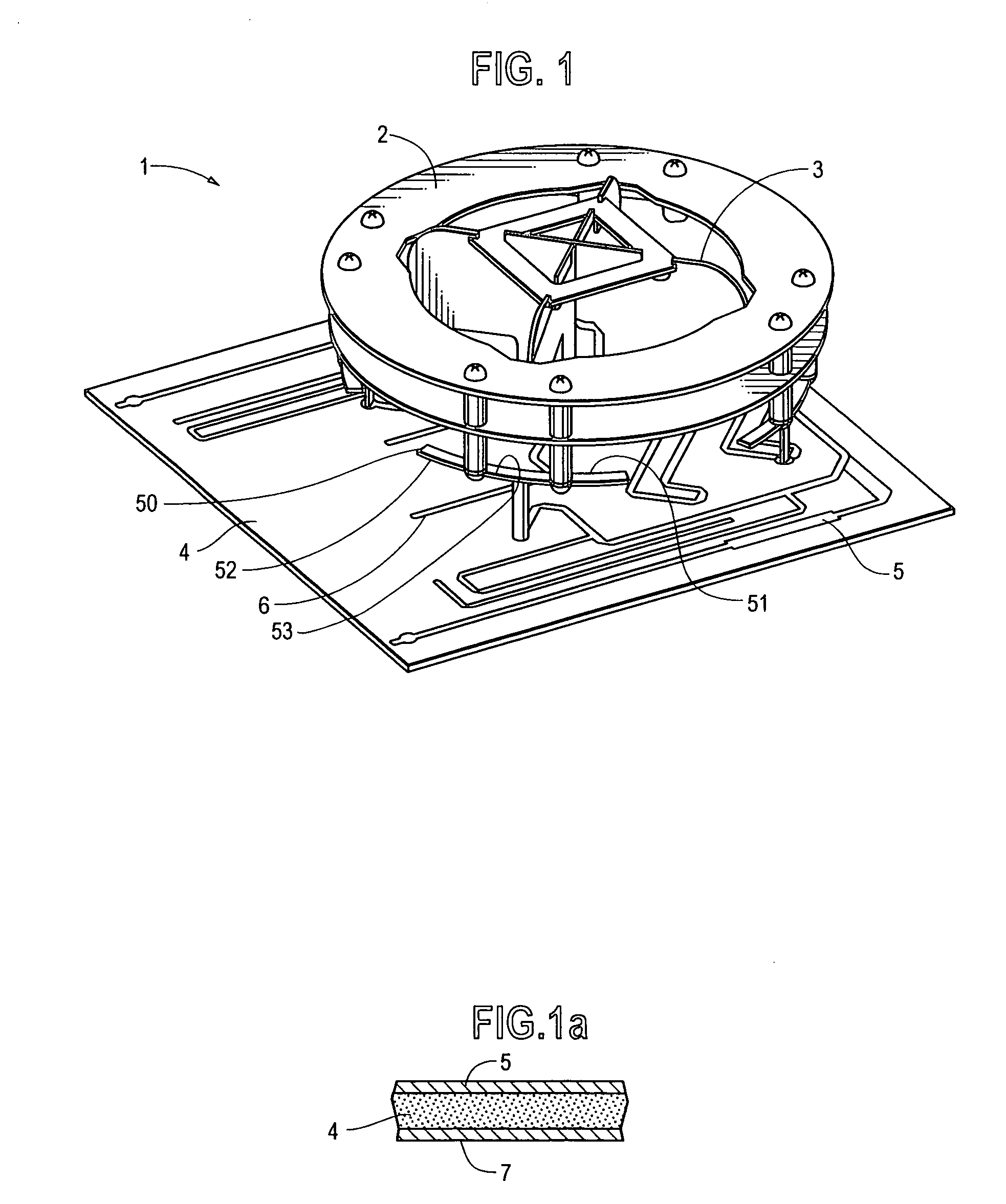

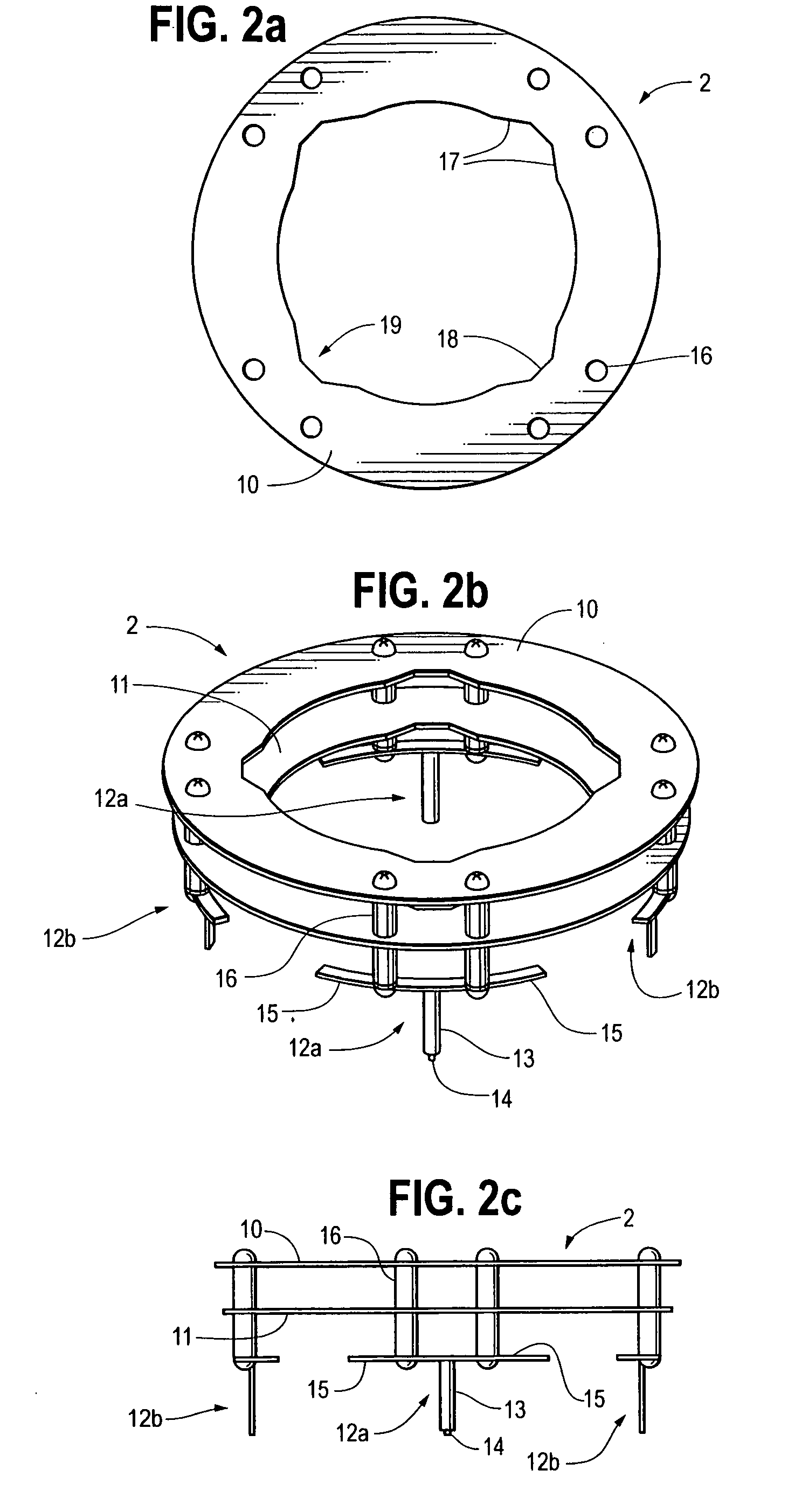

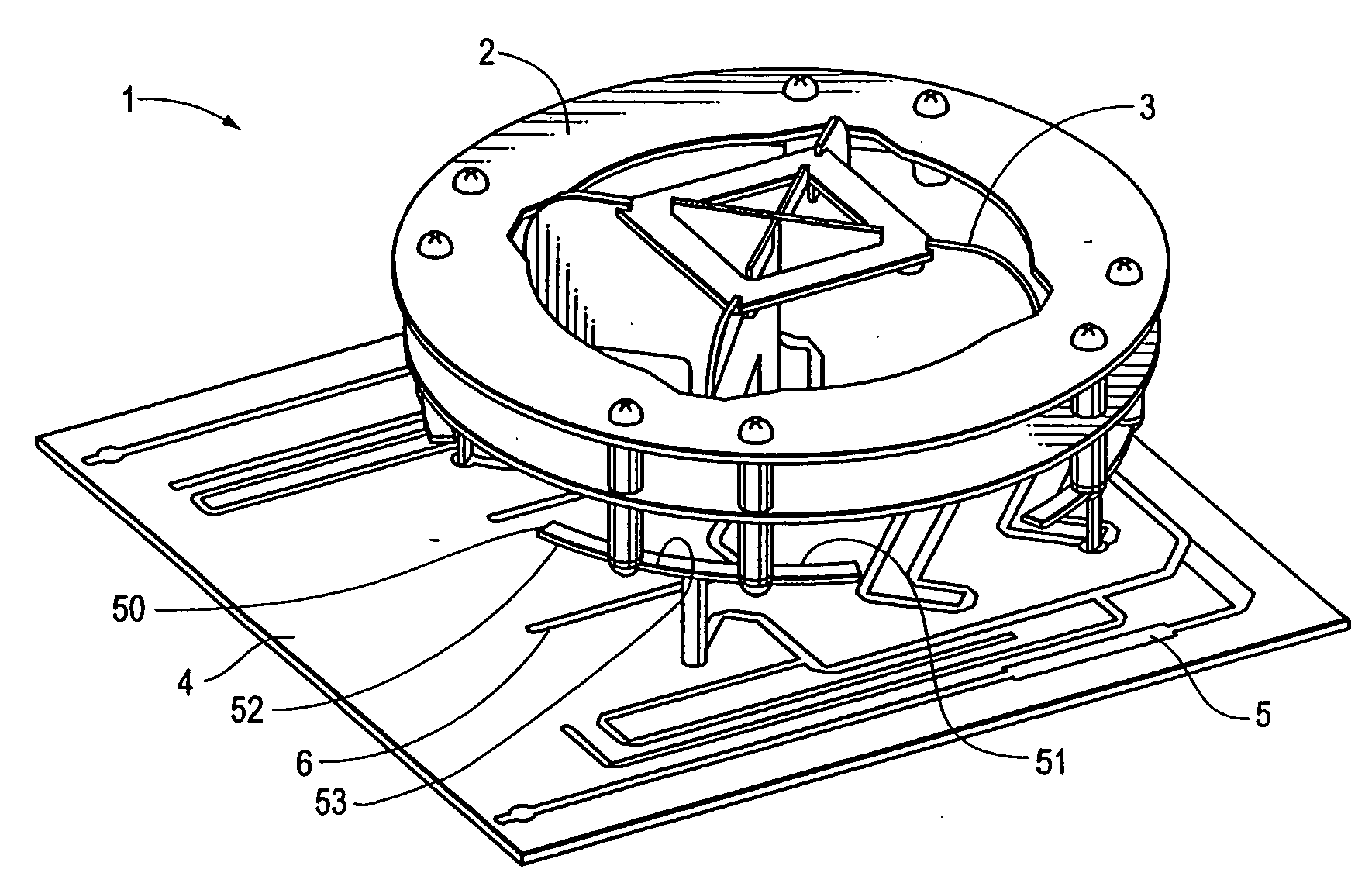

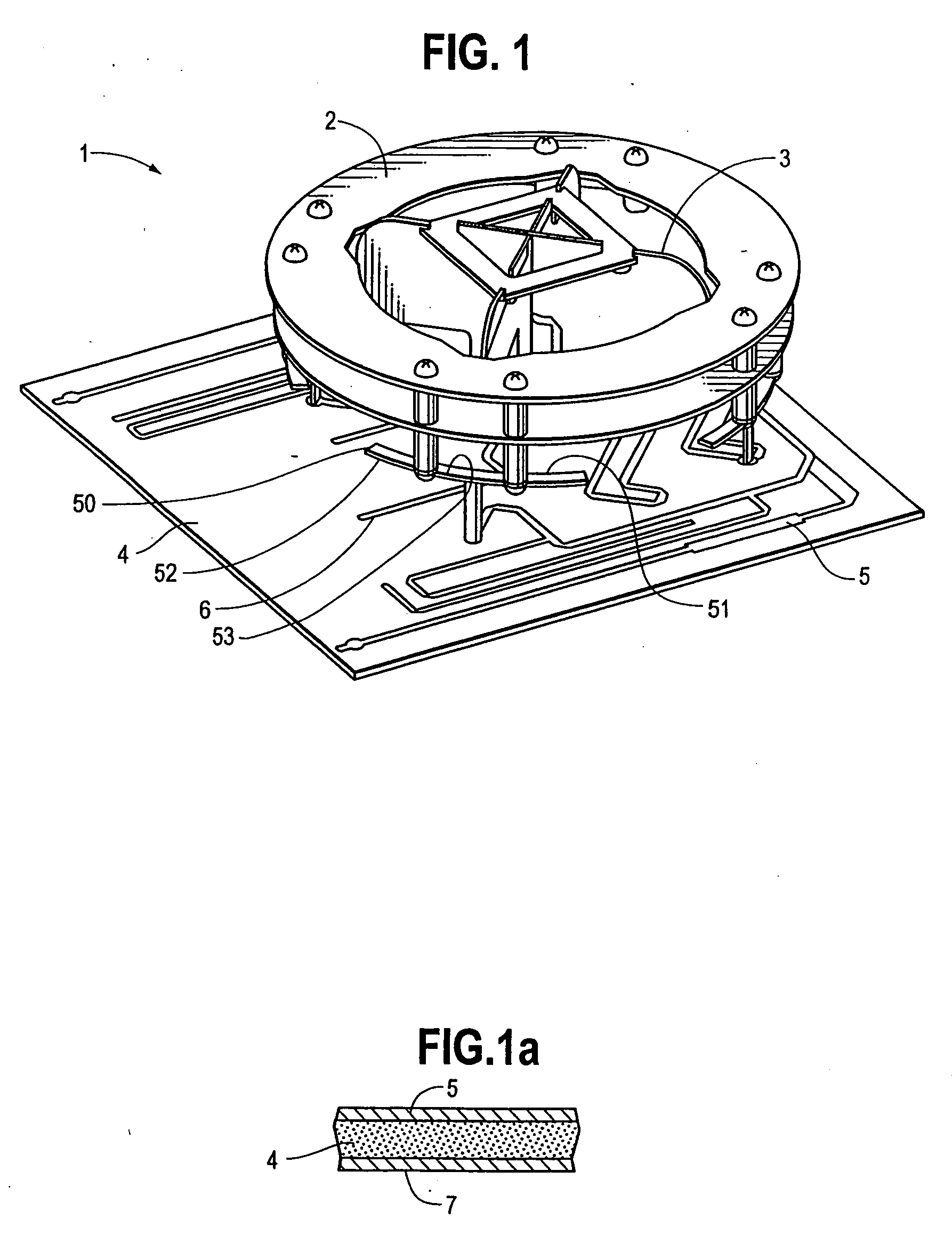

Antenna element, feed probe; dielectric spacer, antenna and method of communicating with a plurality of devices

ActiveUS7283101B2Low b/aSpace maximizationSimultaneous aerial operationsAntenna supports/mountingsDielectricGround plane

A multiband base station antenna for communicating with a plurality of terrestrial mobile devices is described. The antenna including one or modules, each module including a low frequency ring element; and a high frequency dipole element superposed with the low frequency ring element. The element includes a ground plane; and a feed probe directed away from the ground plane and having a coupling part positioned proximate to the ring to enable the feed probe to electromagnetically couple with the ring. A dielectric clip provides a spacer between the feed probe and the ring, and also connects the ring to the ground plane. An antenna element is also described including a ring, and one or more feed probes extending from the ring, wherein the ring and feed probe(s) are formed from a unitary piece.

Owner:COMMSCOPE TECH LLC

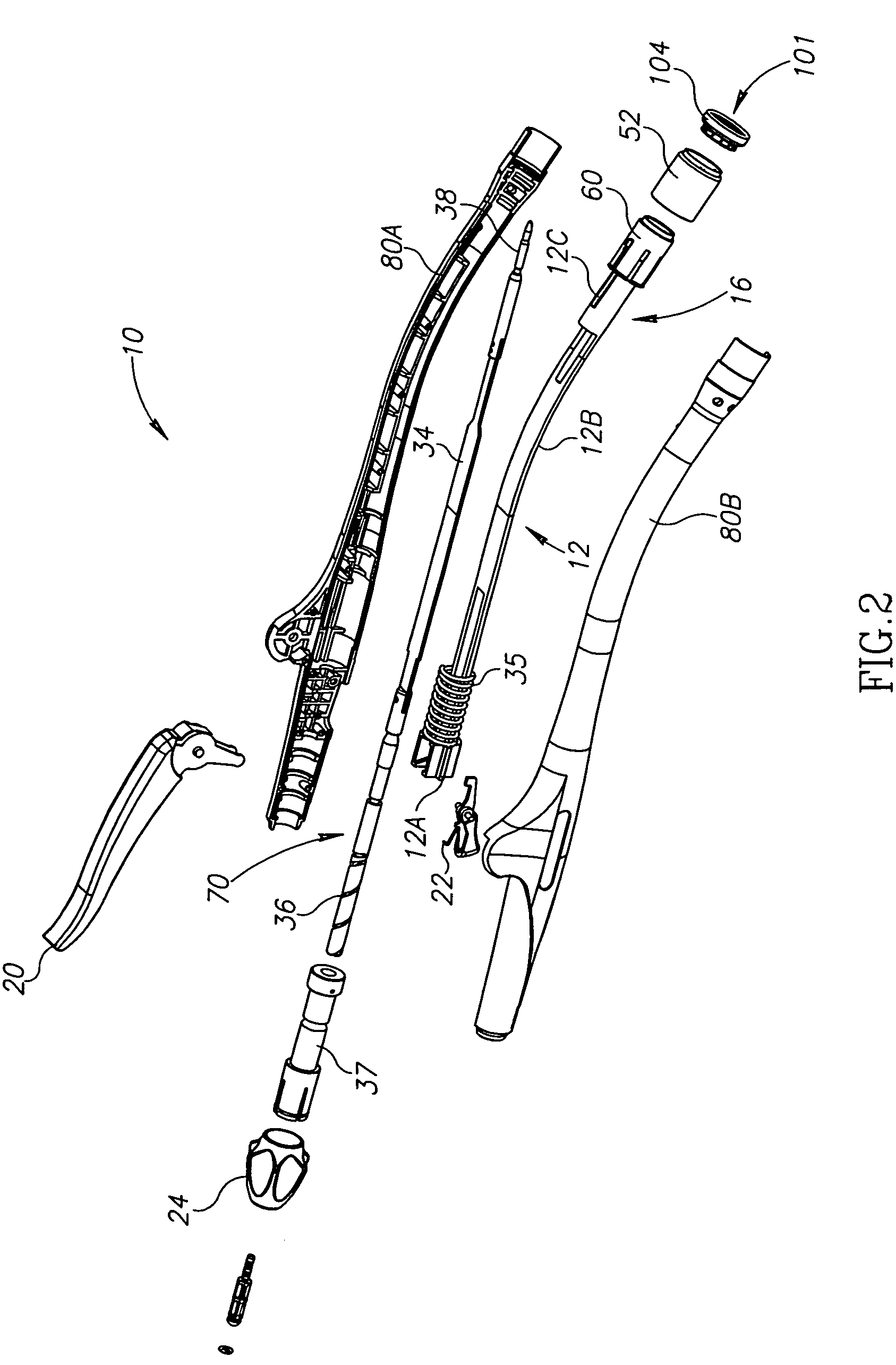

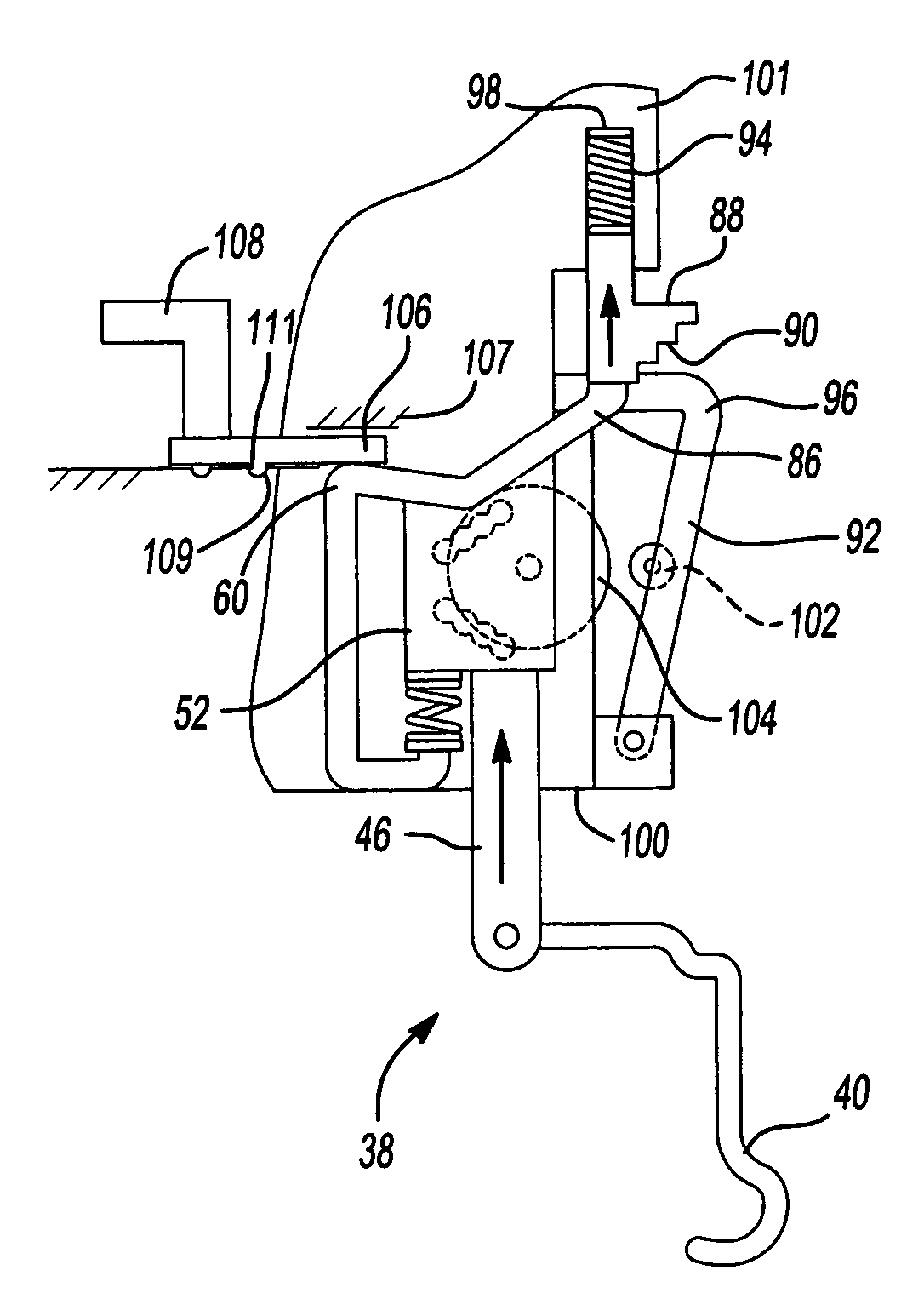

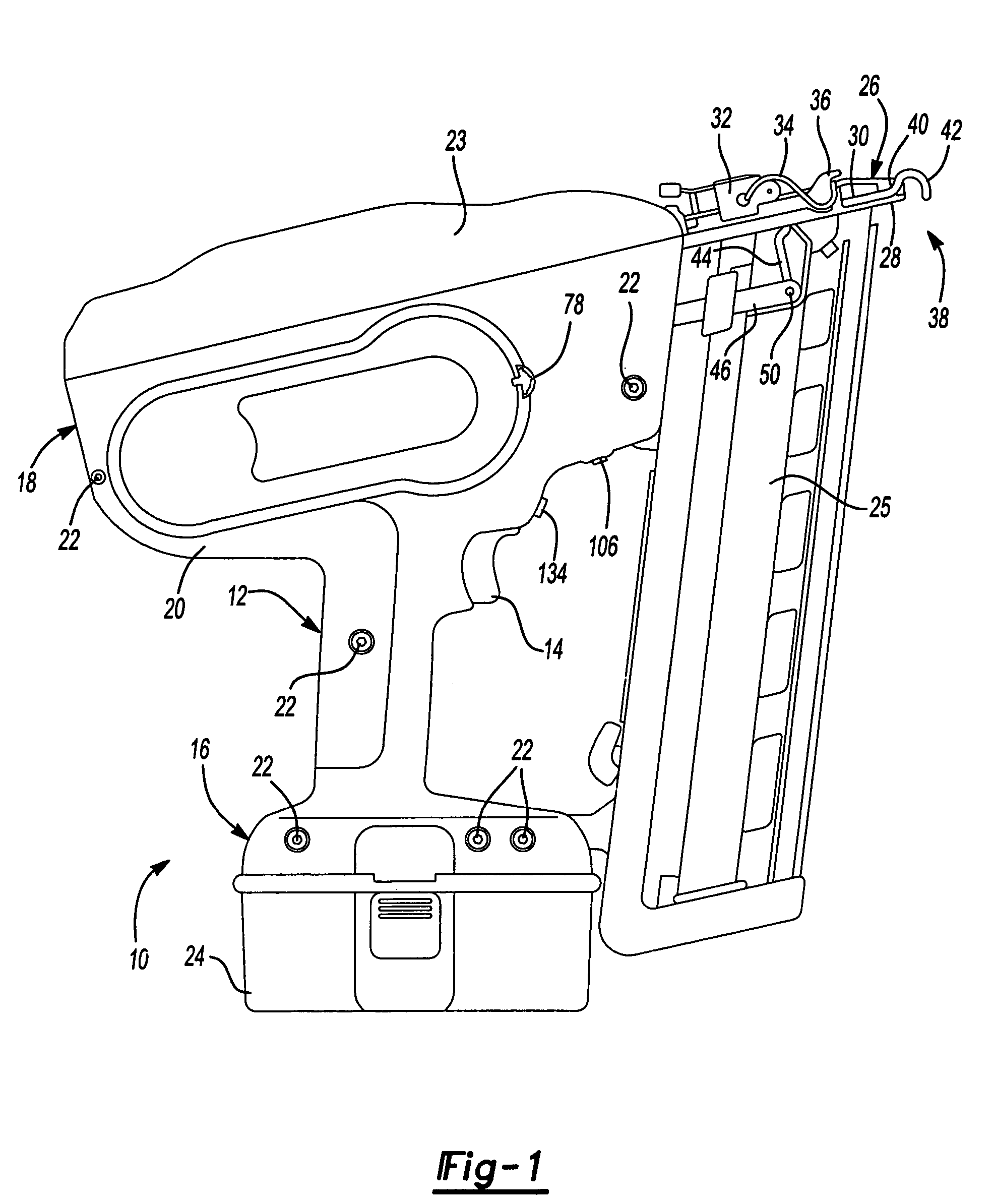

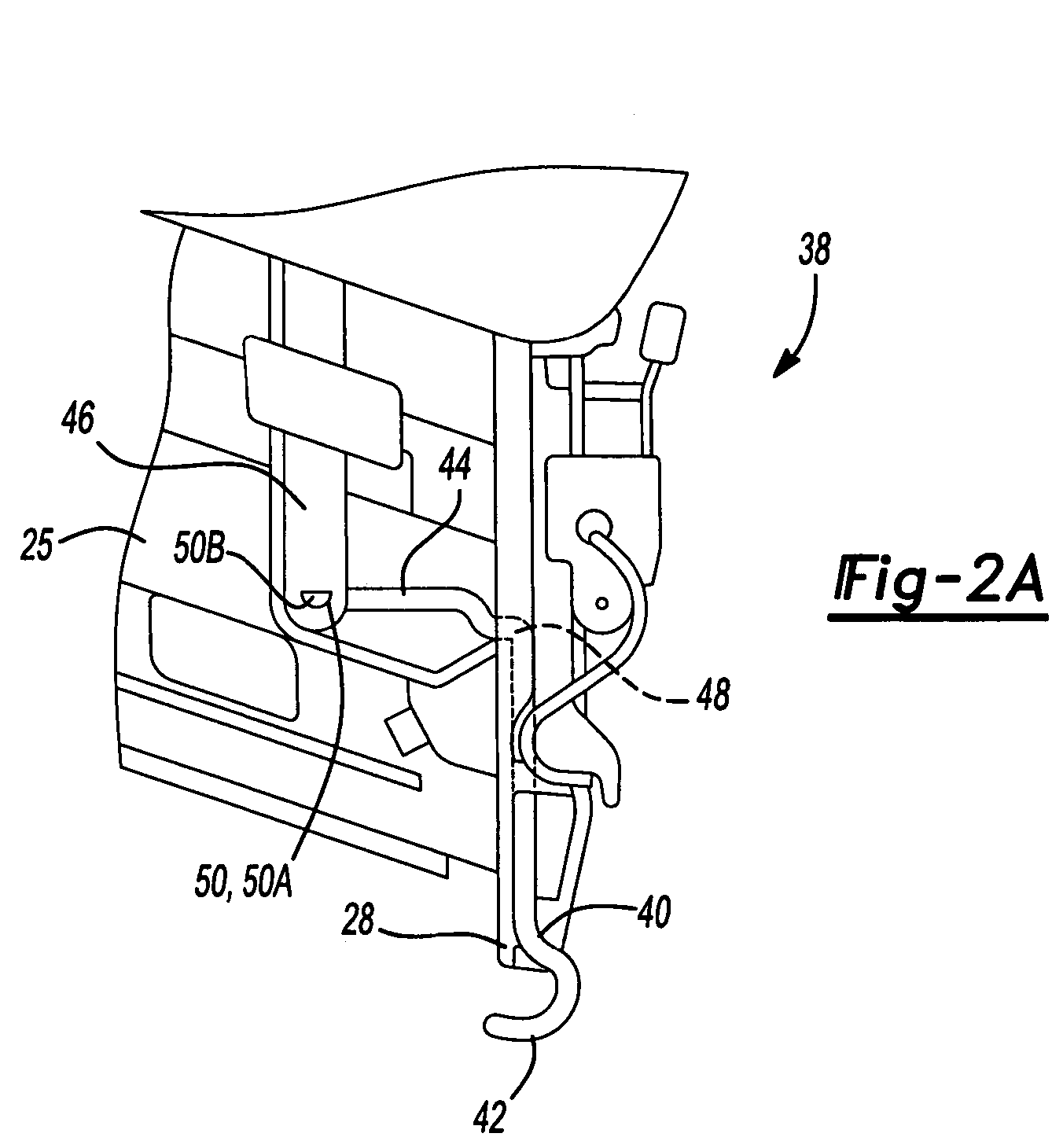

Contact trip mechanism for nailer

A contact trip assembly for a power nailer, wherein a contact member includes a curved portion that loops rearwardly towards a handle of the nailer. Also provided is an adjustment assembly including an adjustment plate and a pinion gear, a trigger that is slidably engageable within a housing of the tool, a trigger lock including a ring element, an anti-discharge mechanism including a stop member, and a contact trip lock.

Owner:BLACK & DECKER INC

Antenna element, feed probe; dielectric spacer, antenna and method of communicating with a plurality of devices

ActiveUS20060232490A1Low b/aSpace maximizationAntenna supports/mountingsIndividually energised antenna arraysDielectricElectromagnetic coupling

A multiband base station antenna for communicating with a plurality of terrestrial mobile devices is described. The antenna including one or modules, each module including a low frequency ring element; and a high frequency dipole element superposed with the low frequency ring element. The element includes a ground plane; and a feed probe directed away from the ground plane and having a coupling part positioned proximate to the ring to enable the feed probe to electromagnetically couple with the ring. A dielectric clip provides a spacer between the feed probe and the ring, and also connects the ring to the ground plane. An antenna element is also described including a ring, and one or more feed probes extending from the ring, wherein the ring and feed probe(s) are formed from a unitary piece.

Owner:COMMSCOPE TECH LLC

Dynamic external fixator and methods for use

Owner:STRYKER EURO OPERATIONS HLDG LLC

Interlocking ring terminals

ActiveUS7125295B2Coupling contact membersMulticonductor cable end piecesElectrical conductorEngineering

The present invention provides a terminal ring assembly structured for engagement to a conductor post. The terminal ring assembly of the present invention includes a first ring element and a second ring element, each having a circular body and at least one grip having crimpable barrels for engaging a wire in electrical connectivity. The first and second ring elements further include an interlocking device, in which the interlocking components of the first and second ring elements engage each other so that the first and second ring elements are locked together.

Owner:AEES INC

Diaphragm and hydraulically-operated valve using same

InactiveUS7059578B2Increased operating lifeClose reliableDiaphragm valvesFlexible wall reciprocating enginesElastomerFluid control

The present invention relates to fluid control valves. The invention provides an improved diaphragm useful for a large hydraulically-operated valve or pressure regulating valve of the type used in pipelines to transport water, oil, gas, acids, alkalis and other fluids.The diaphragm being provided with an upper face arranged to be exposed to a control hydraulic pressure and a lower face arranged to selectively seal and open a passage between a valve inlet and a valve outlet, ribs on said upper face urging the diaphragm towards a sealing position. The diaphragm being characterized by the addition of an elastomer ring element disposed adjacent to the upper face and adjacent to the largest diameter of the diaphragm exposed inside a valve to which it may be assembled, an upper face of the flexible ring element being in pressure contact with a portion of the rigid body of the valve. The flexible ring element further urging the diaphragm towards its lower position and allowing closure of the valve without use of a metallic compression spring.

Owner:RAPHAEL VALVES INDS 1975

Bicycle sprocket

ActiveUS7503864B2Reduce weightAvoid deformationChain/belt transmissionPortable liftingSprocketSynthetic resin

A bicycle sprocket basically has a metallic sprocket ring part and a synthetic resin fastening part that is configured to ensure that weight can be reduced and that loss of fastening force resulting from deterioration or deformation of the synthetic resin can be prevented. The metallic sprocket ring part includes a ring element with a plurality of sprocket teeth located on an outer periphery of the ring element, a plurality of connecting elements located on an inner periphery of the ring element and a plurality of internal fastening elements located on radial inner ends of the connecting elements, respectively. The synthetic resin fastening part is non-movably formed on both axial faces of the sprocket ring part at a location radially inwardly of the sprocket teeth so as to cover at least a portion of the inner periphery of the ring element, the connecting elements, and the internal fastening elements.

Owner:SHIMANO INC

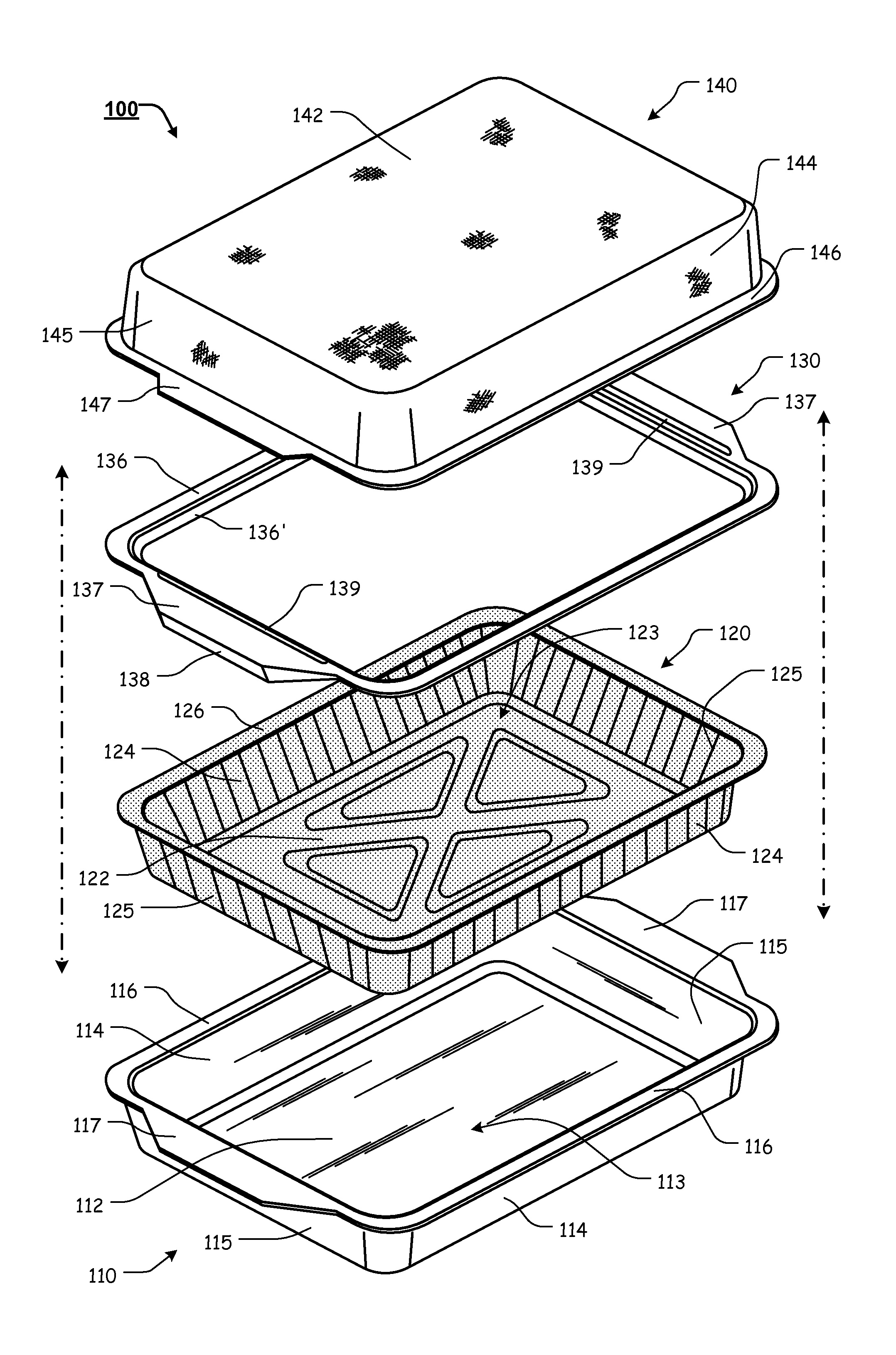

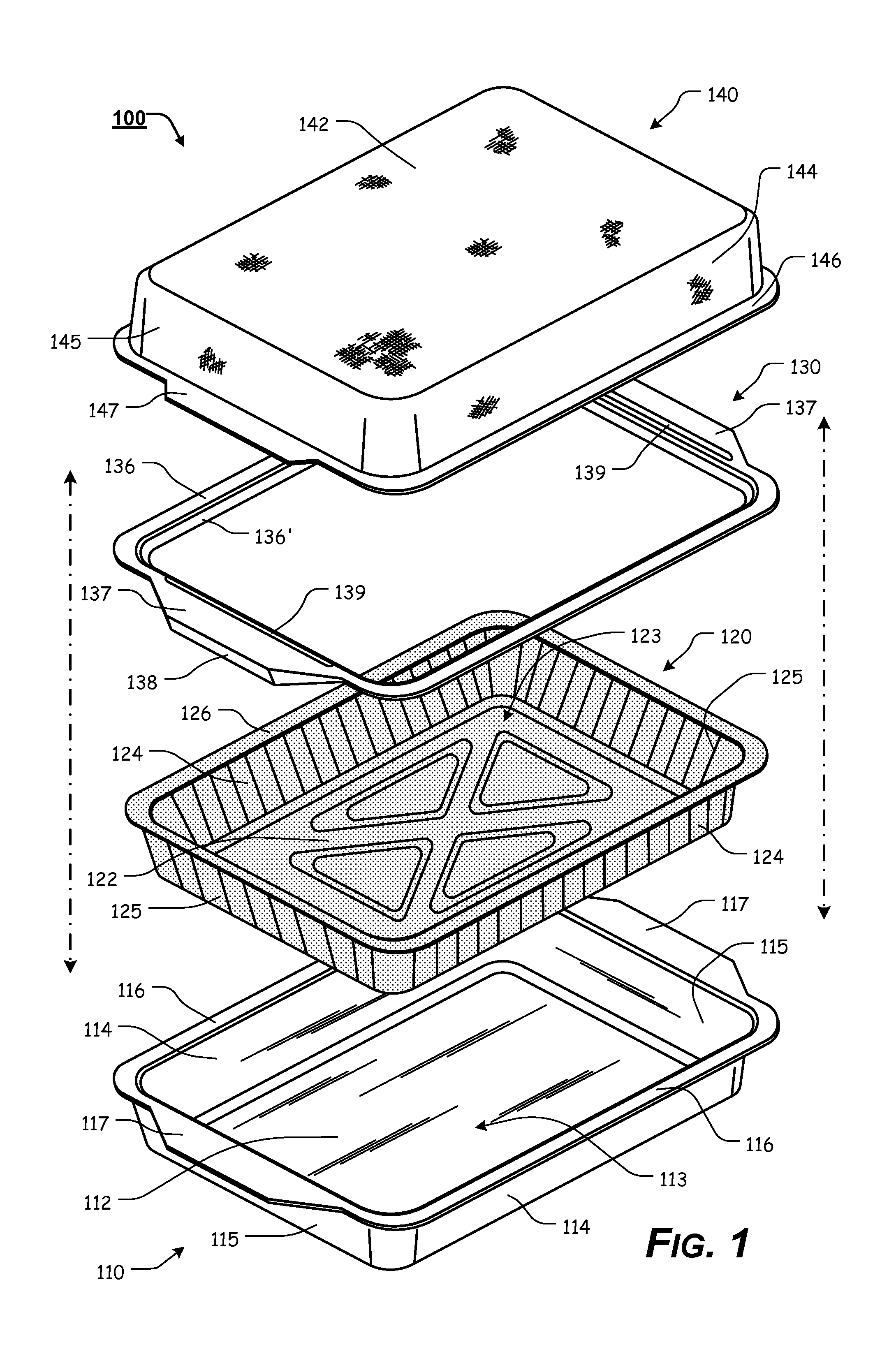

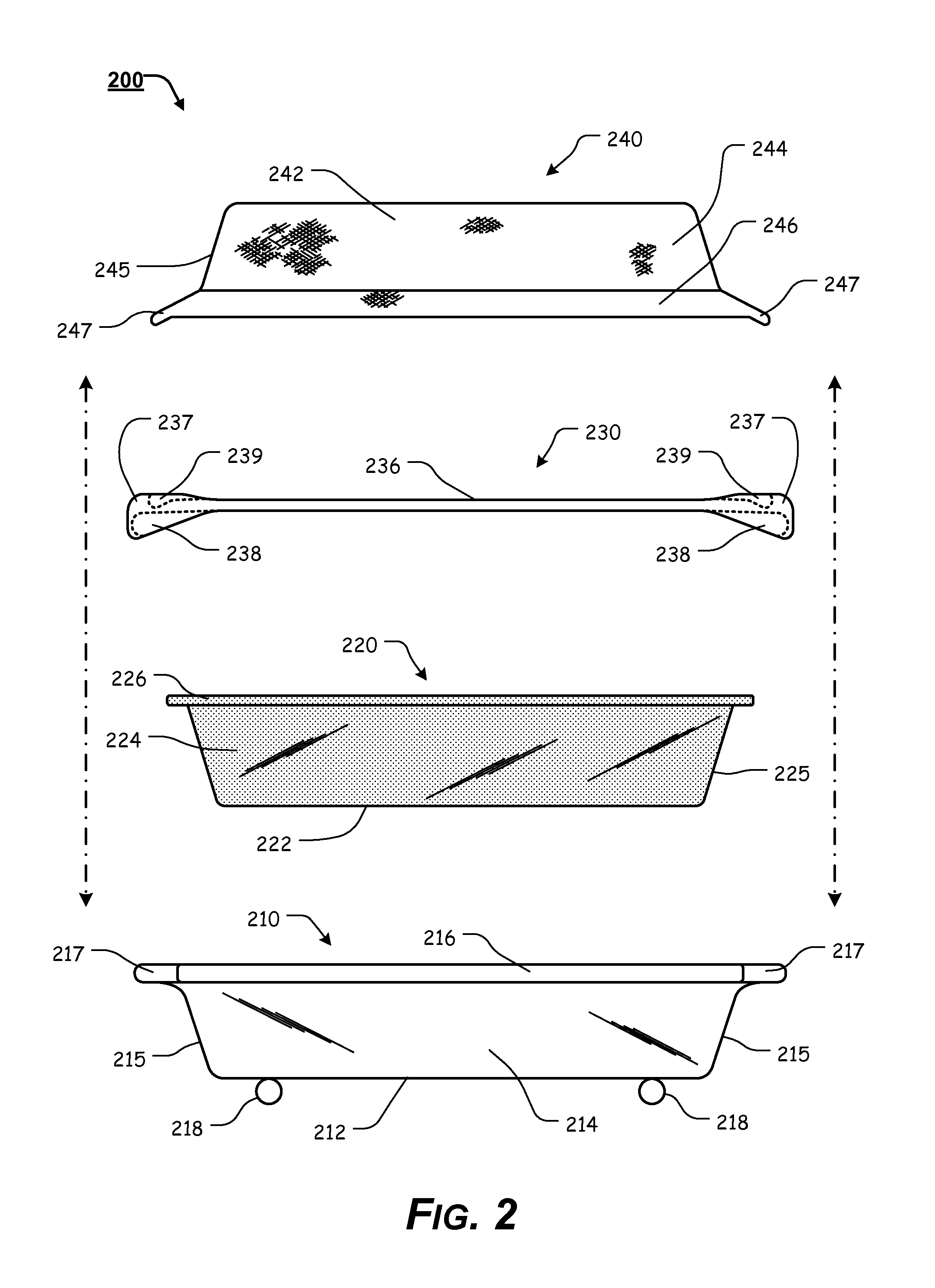

Serving container system

A decorative serving container system that includes a serving dish and a ring element having a ring element lip with a shape that substantially corresponds to a shape of a serving dish lip, wherein portions of the ring element lip are formed to be positionable around at least a portion of the serving dish lip to provide frictional engagement between portions of said ring element lip and at least a portion of said serving dish lip, such that said ring element is capable of securing a foil pan within said serving dish.

Owner:MILLER SABINE S

Tunable optical metamaterial

InactiveUS20150062691A1Semiconductor/solid-state device manufacturingNanoopticsElectricityTunnel diode

A tunable metamaterial has a two dimensional array of resonant annular ring elements; and a plurality of voltage controllable electrical tuning elements disposed in or adjacent openings in each of said ring elements, each of said voltage controllable electrical tuning element ohmically contacting portions of only one of said ring elements. The voltage controllable electrical tuning elements may comprise highly doped semiconductor tunnel diodes, or the charge accumulation layer at the semiconductor / insulator interface of a metal-insulator-semiconductor structure, or nanoelectromechanical (NEMs) capacitors. The tunable metamaterial may be used, for example, in an optical beam steering device using the aforementioned tunable optical metamaterial in which a free-space optical beam is coupled into a receiving portion of a plane of the optical metamaterial and is steered out of a transmitter portion of the plane of the optical metamaterial in controllable azimuthal and elevational directions. The tunable metamaterial additionally has other applications.

Owner:HRL LAB

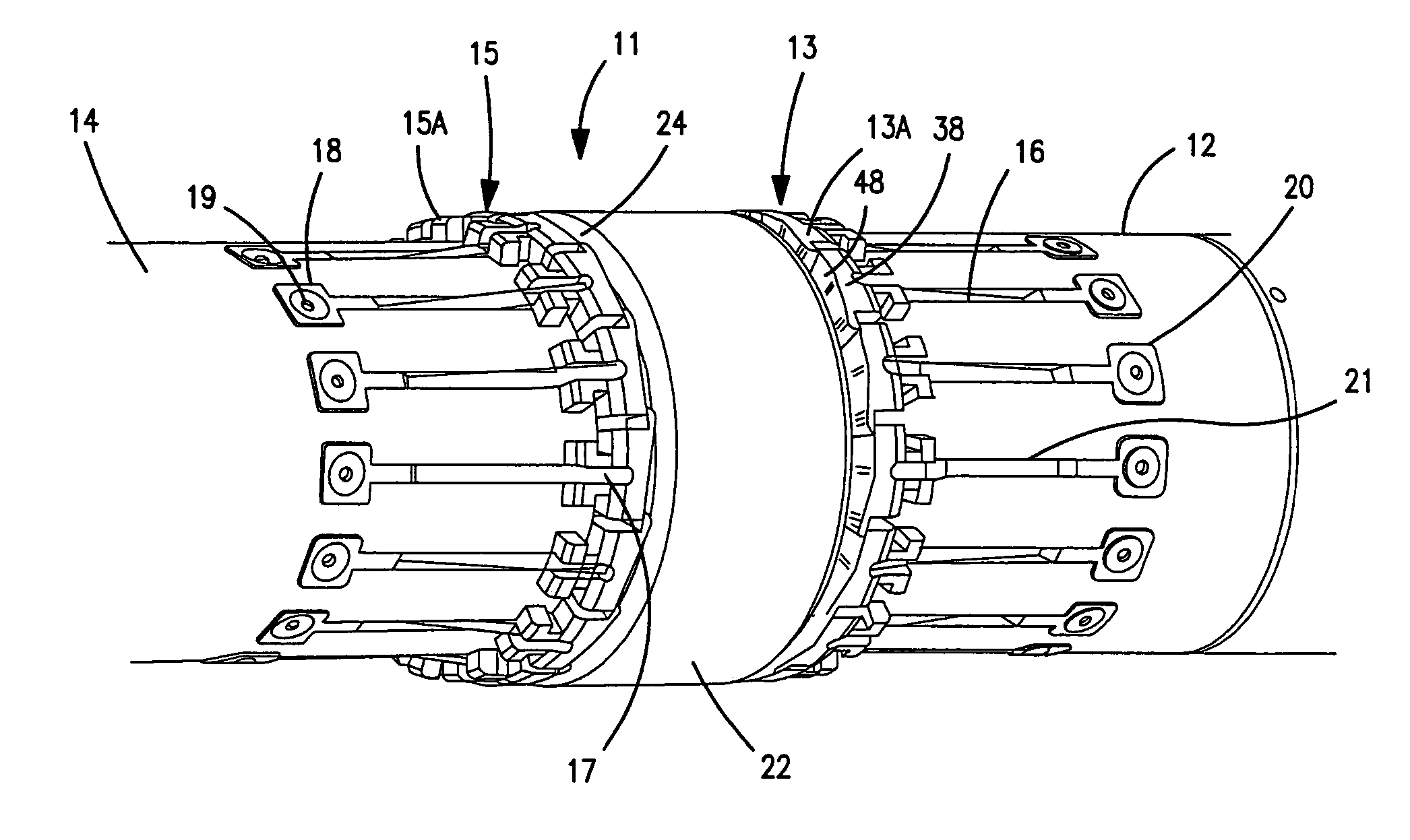

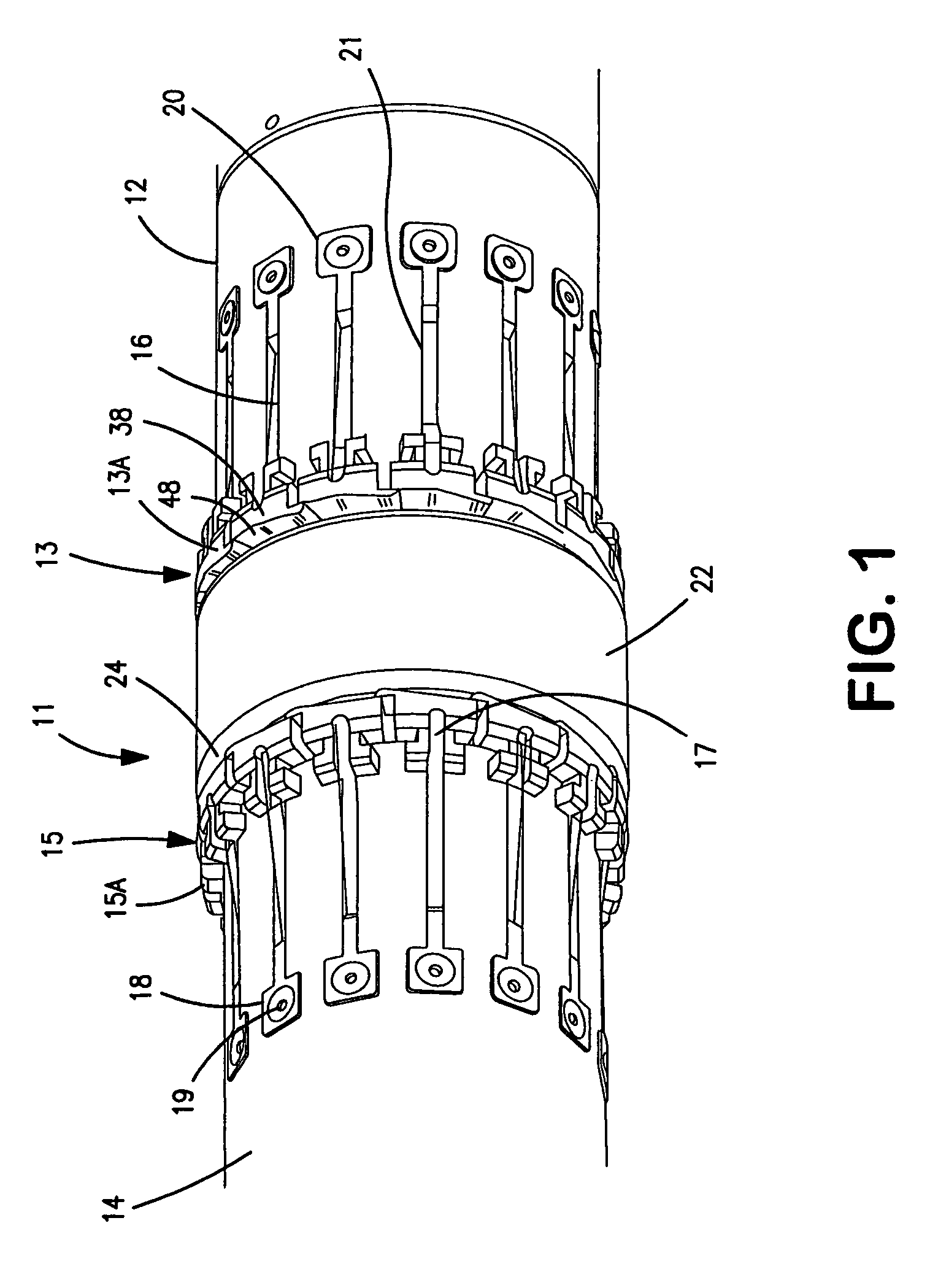

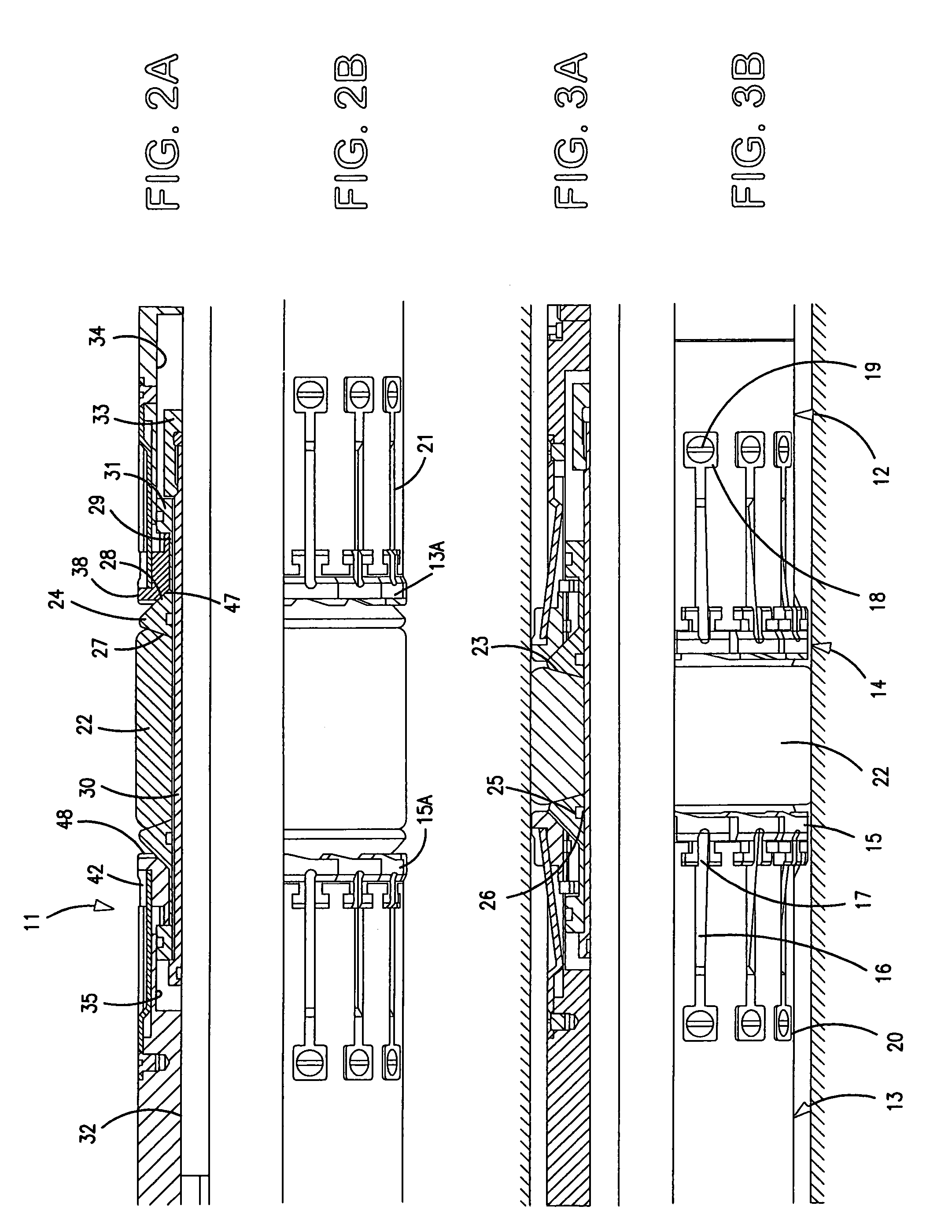

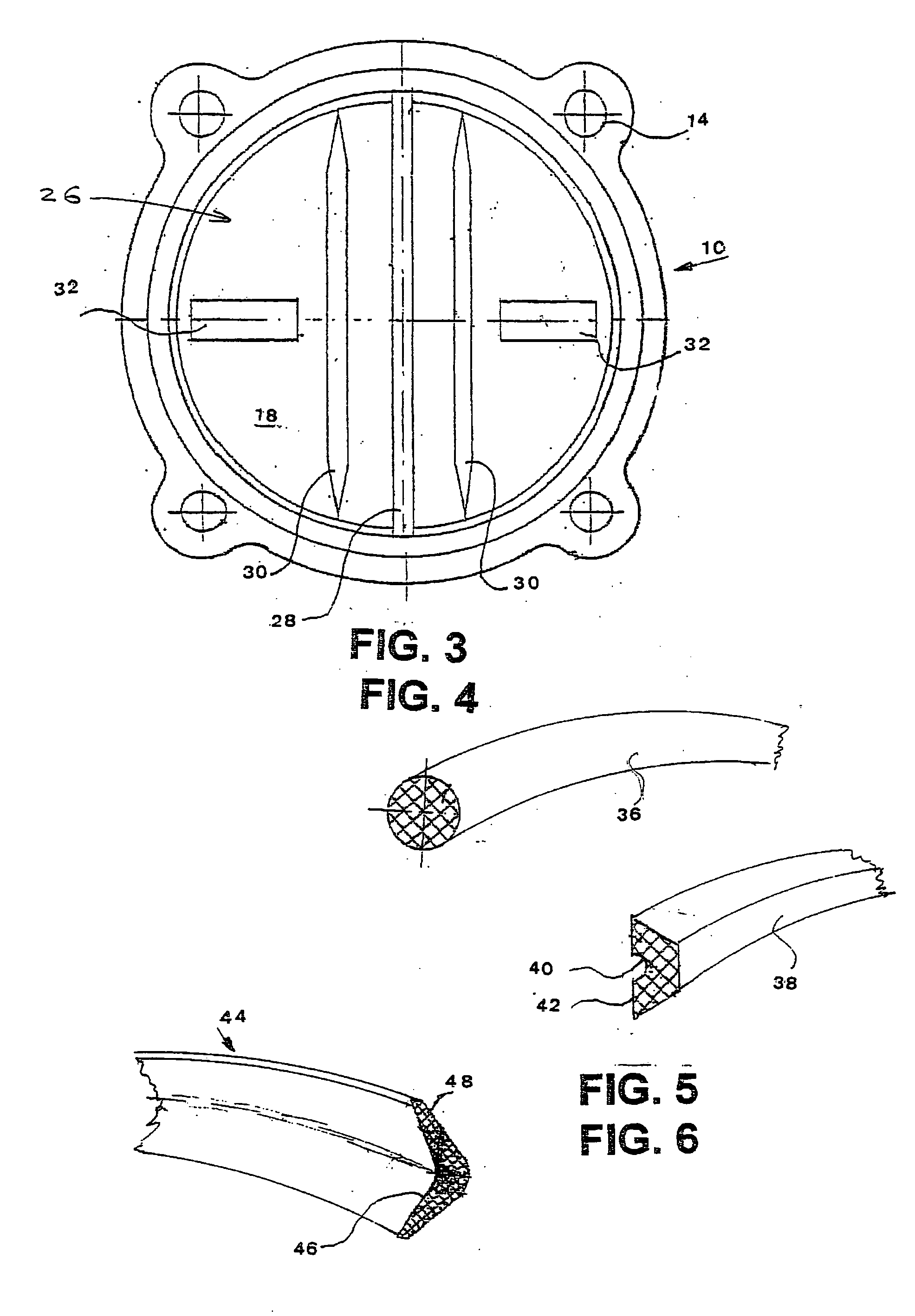

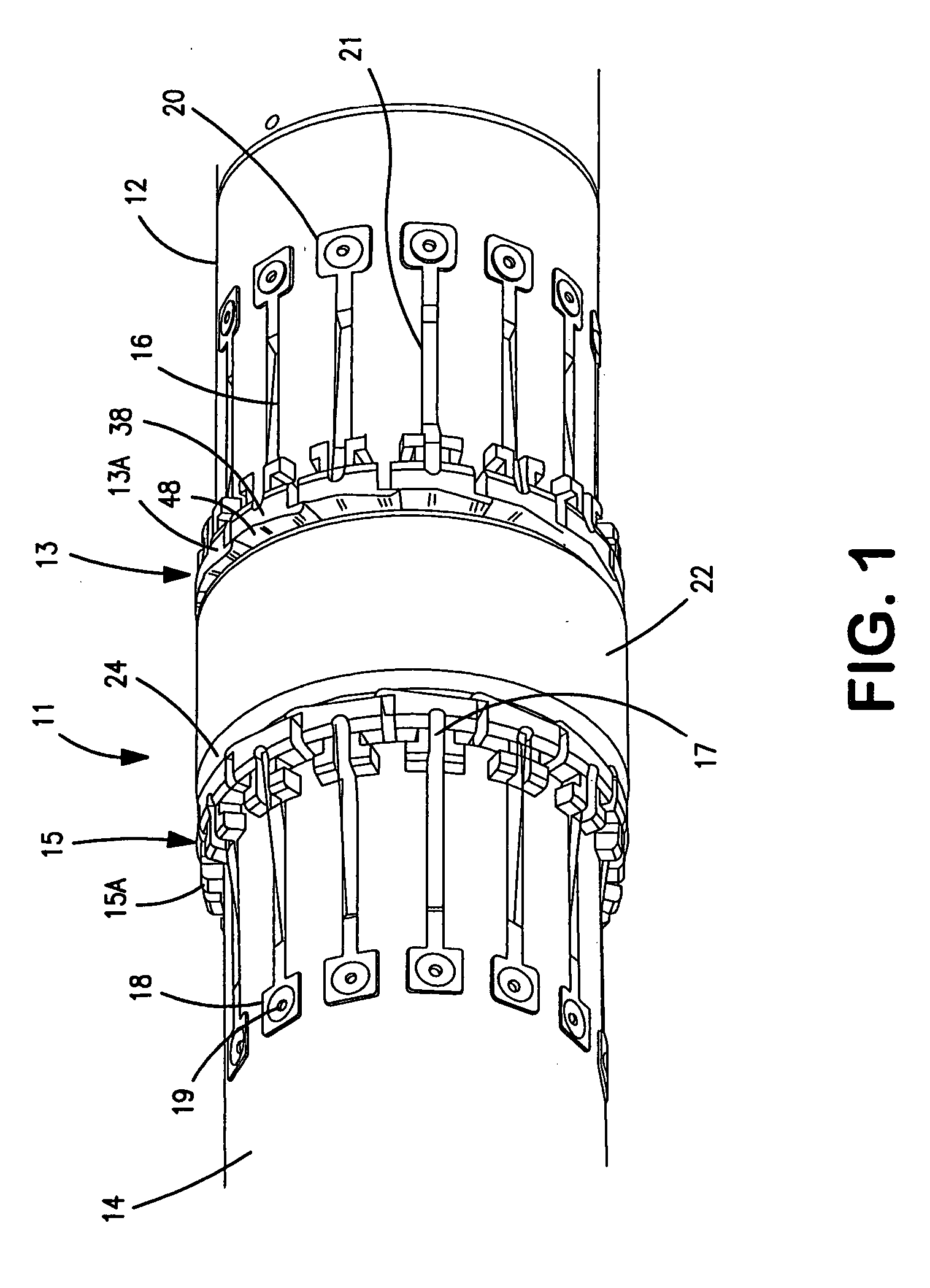

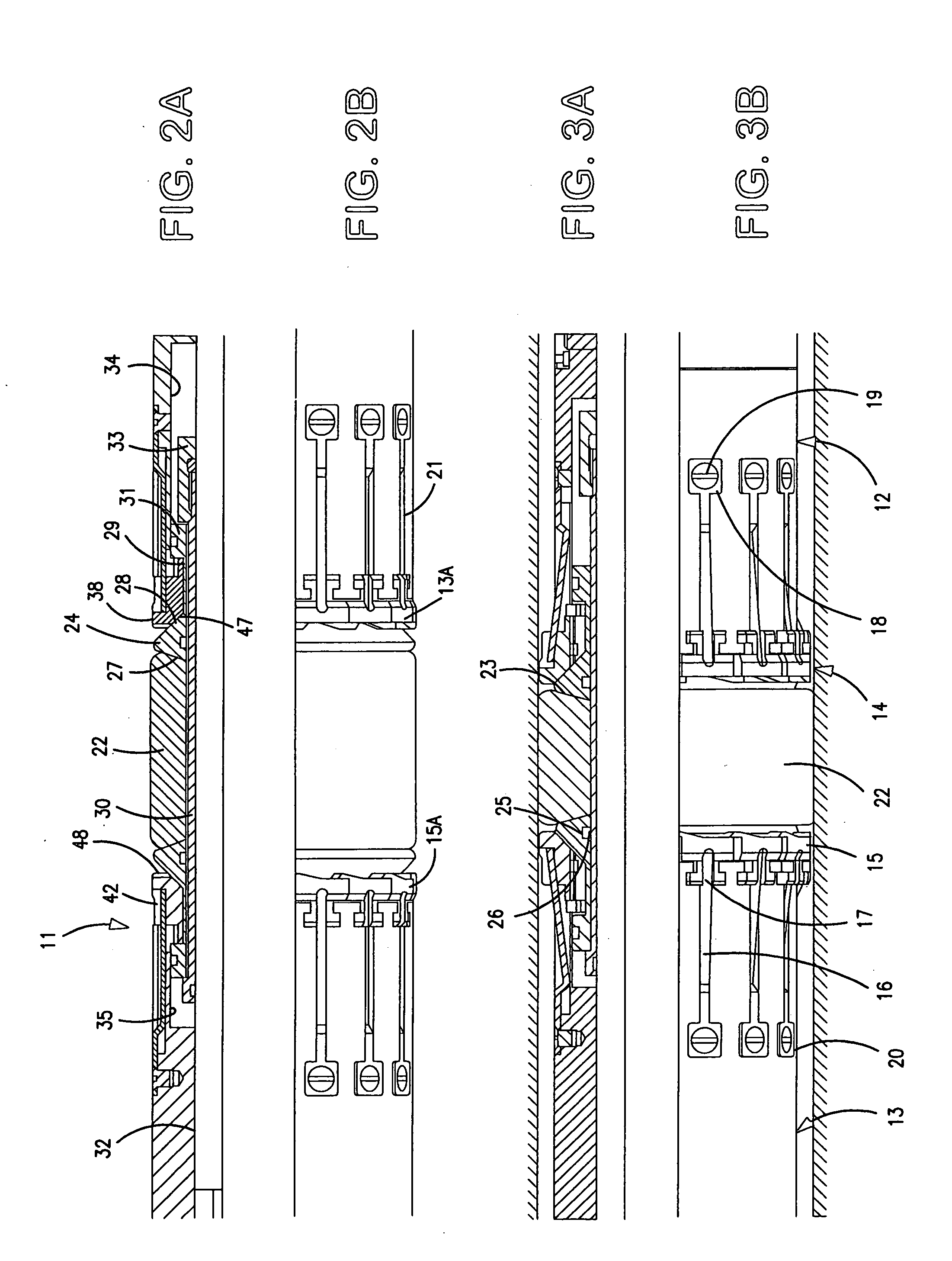

Downhole plug

Downhole plug, especially designed for closing an annular conduit in an oil or gas well, under high pressure and temperature. It has two radially expandable ring elements 13, 15, which are arranged on a carrying cylindrical element 32, between two mutually axially movable pressure elements 12, 14, having an expansion sleeve in between. The ring elements can, by insertion of the downhole plug in a well, be expanded from an inner position, seen radially, to a sealing position against the wall of the well. The radially expandable ring elements 13, 15, comprises a closed series of circumferentially overlapping seal elements 13A, 15 A. By the expanding movement they are mutually moved in the circumferential direction, thereby maintaining a seal against each other. They form an outer sealing surface 38, which can provide a seal against a cylindrical pipe wall, and they have an inwards facing sealing surface 47.

Owner:INTERWELL NORWAY AS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com