Patents

Literature

16947results about How to "Improve signal-to-noise ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Digital wireless position sensor

ActiveUS7397364B2Fast chargingImprove signal-to-noise ratioElectric signal transmission systemsMagnetic measurementsVoltage dropEngineering

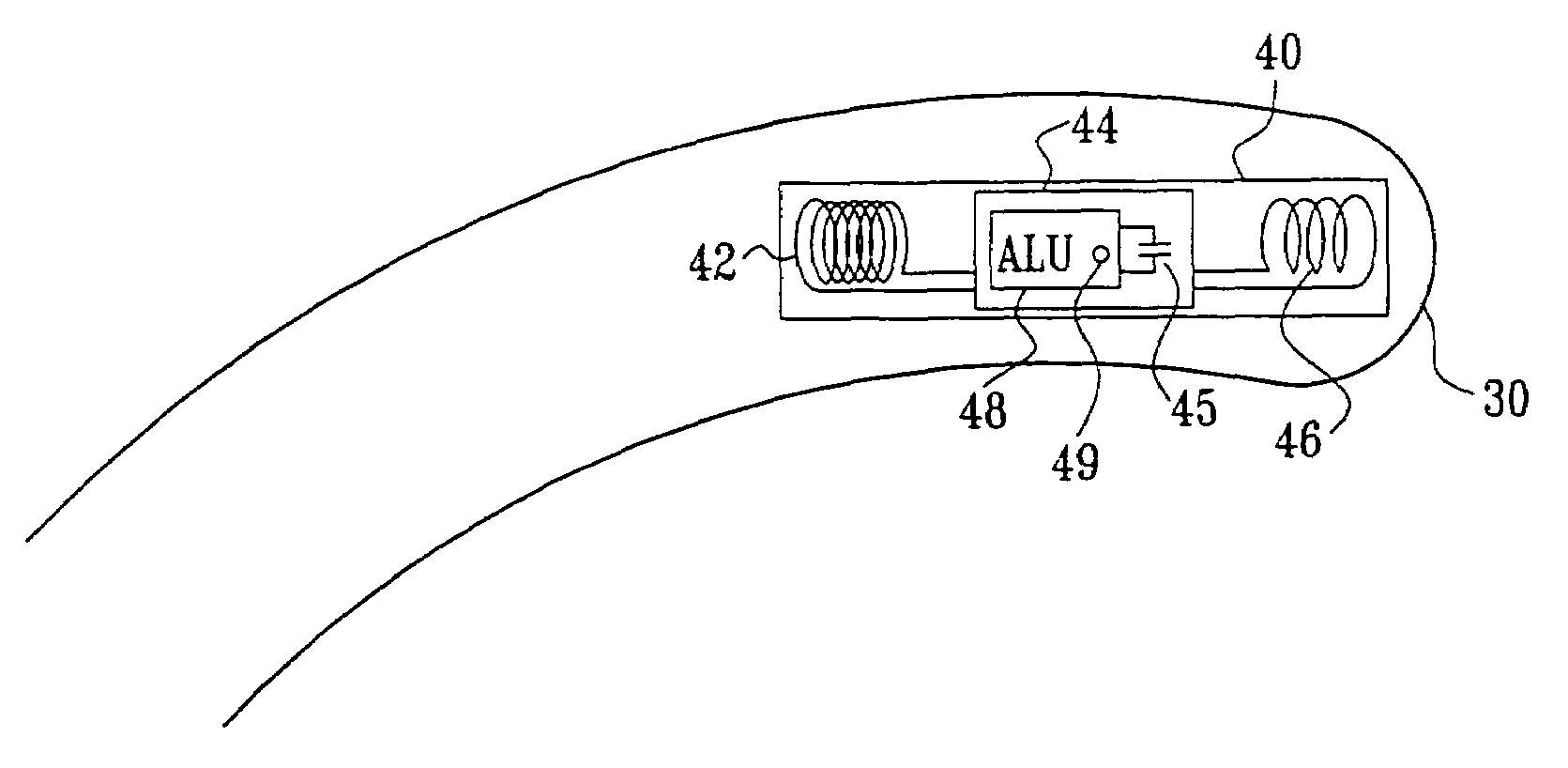

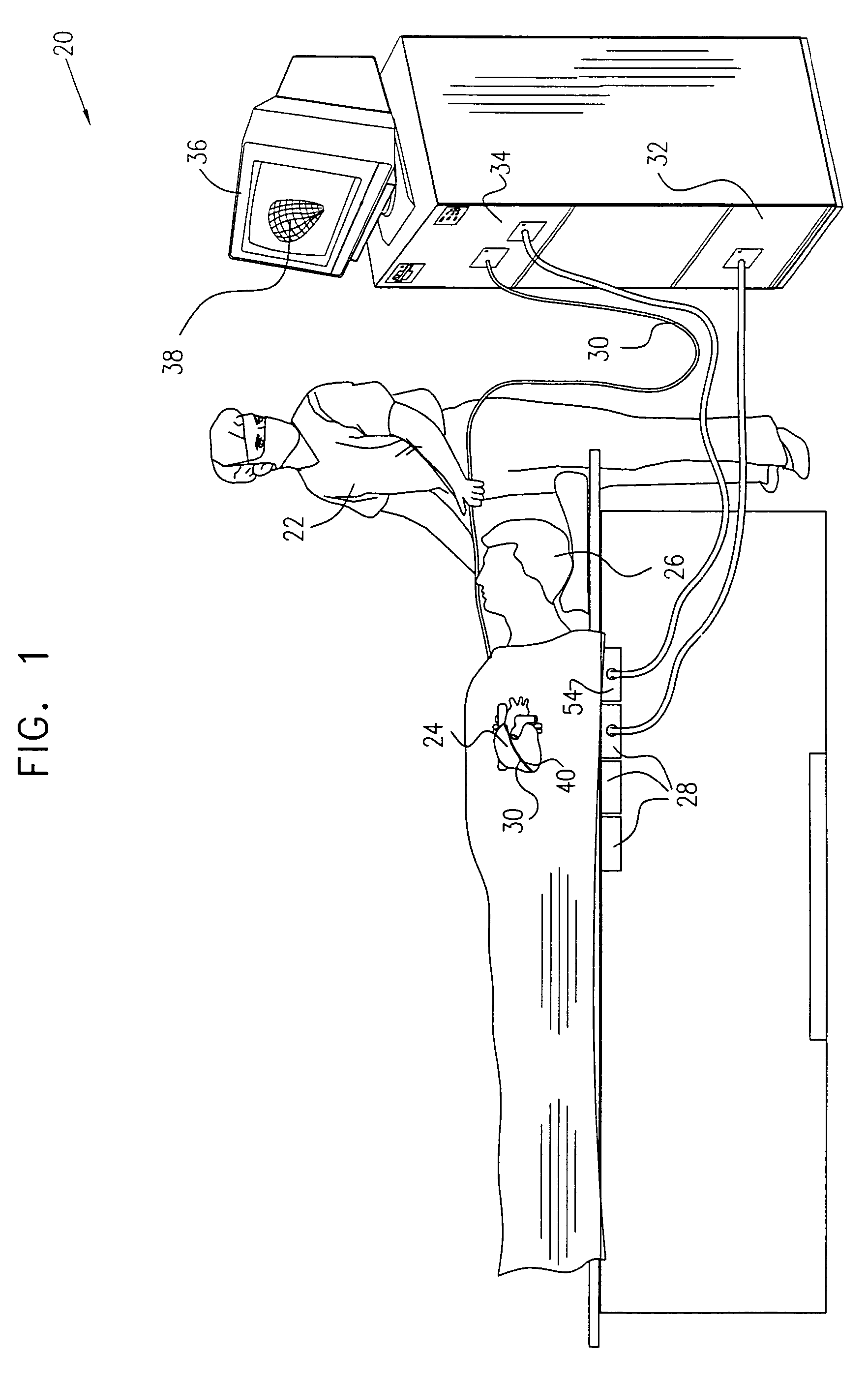

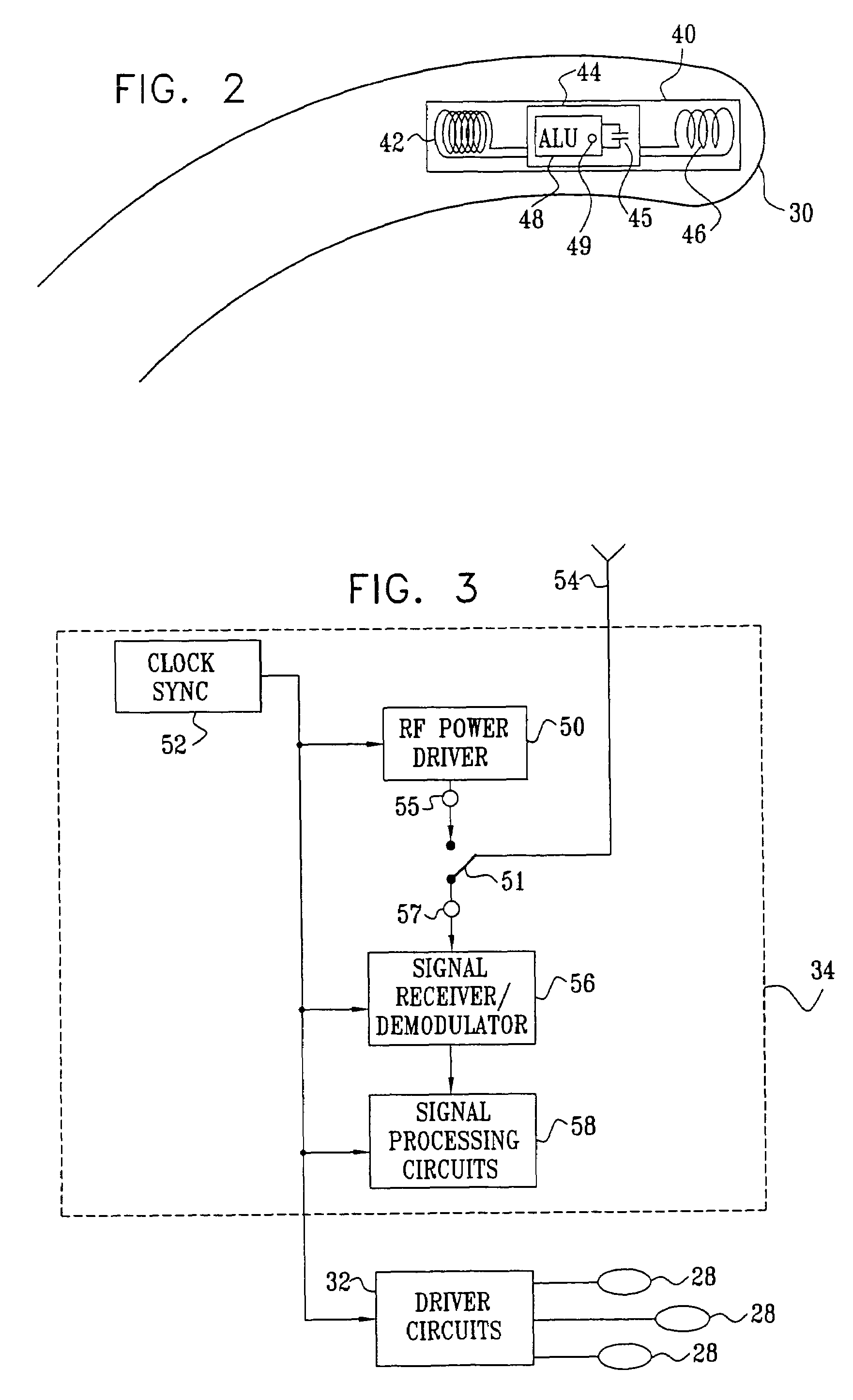

A method is provided for tracking an object, including positioning a radio frequency (RF) driver to radiate an RF driving field toward the object, and fixing to the object a wireless transponder that includes a power coil and at least one sensor coil. The method also includes receiving the RF driving field using the power coil and storing electrical energy derived therefrom. A plurality of field generators are driven to generate electromagnetic fields at respective frequencies in a vicinity of the object that induce a voltage drop across the at least one sensor coil. A digital output signal is generated at the wireless transponder indicative of the voltage drop across the sensor coil, and the generation of the digital output signal is powered using the stored electrical energy. The digital output signal is transmitted from the wireless transponder using the power coil, and the transmission of the digital output signal is powered using the stored electrical energy. The digital output signal is received and processed to determine coordinates of the object.

Owner:BIOSENSE WEBSTER INC

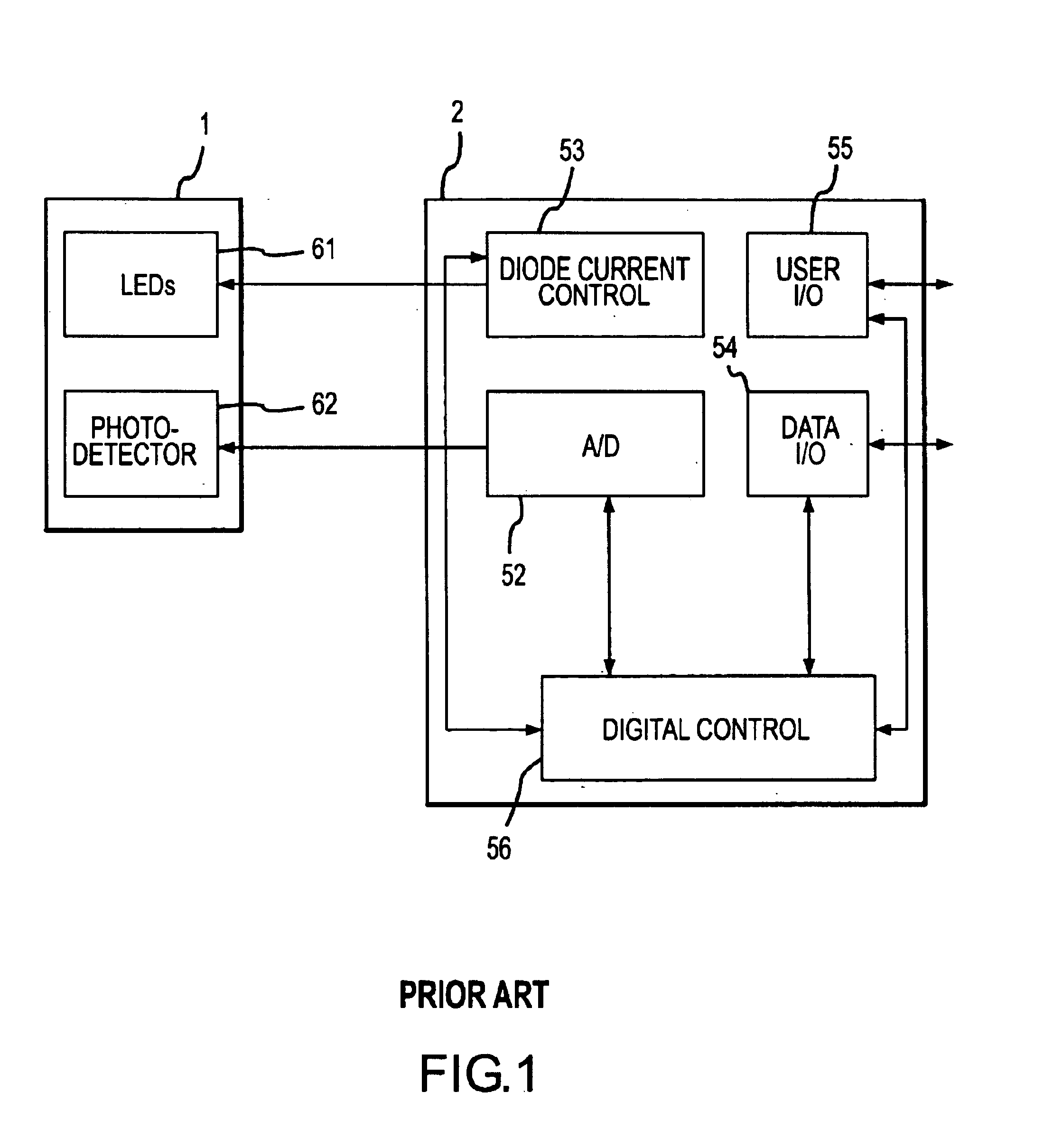

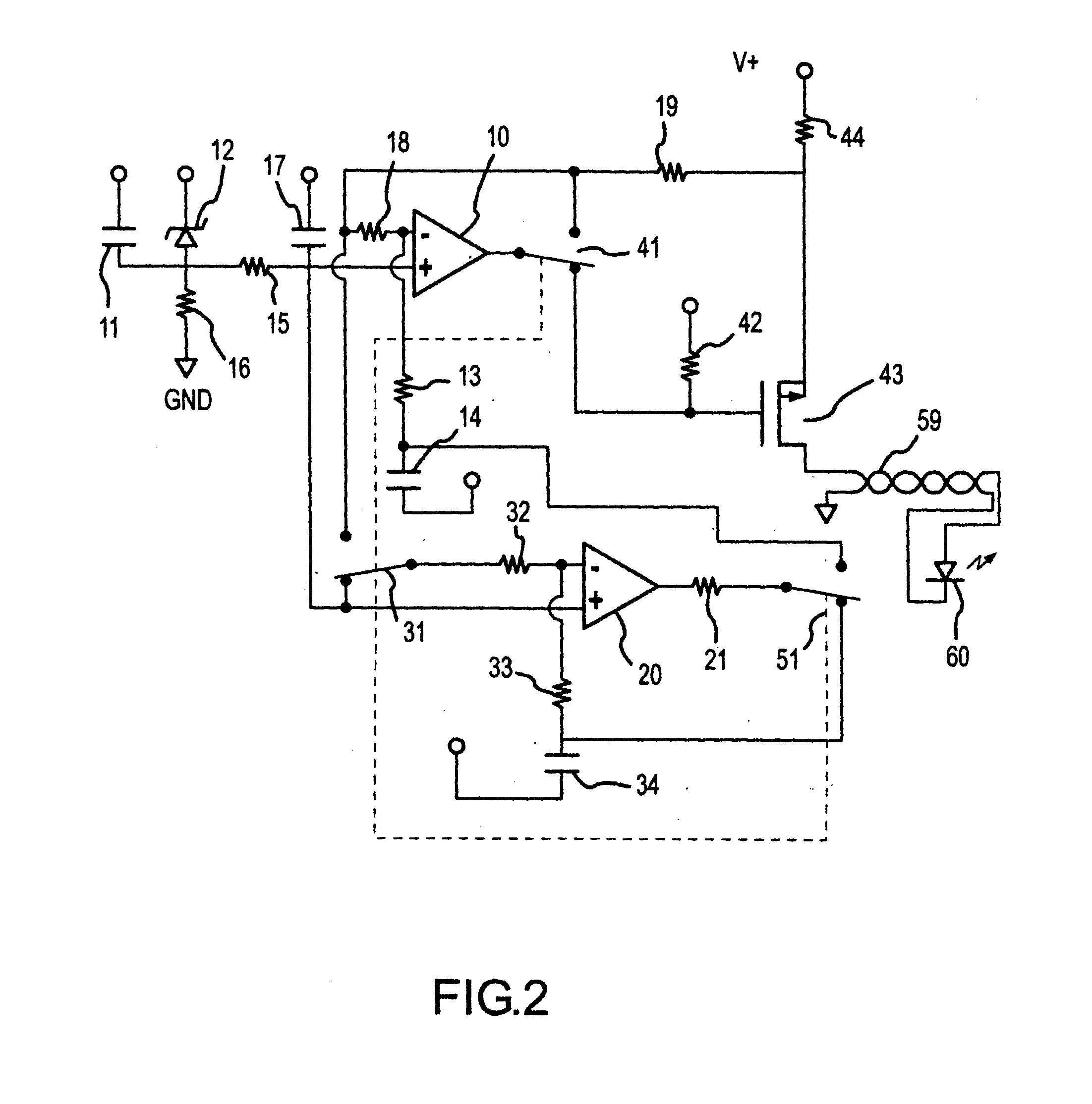

Oximeter with nulled op-amp current feedback

InactiveUS6720734B2Eliminating low frequency driftEasy to detectElectric light circuit arrangementDiagnostic recording/measuringDriving currentLight flashes

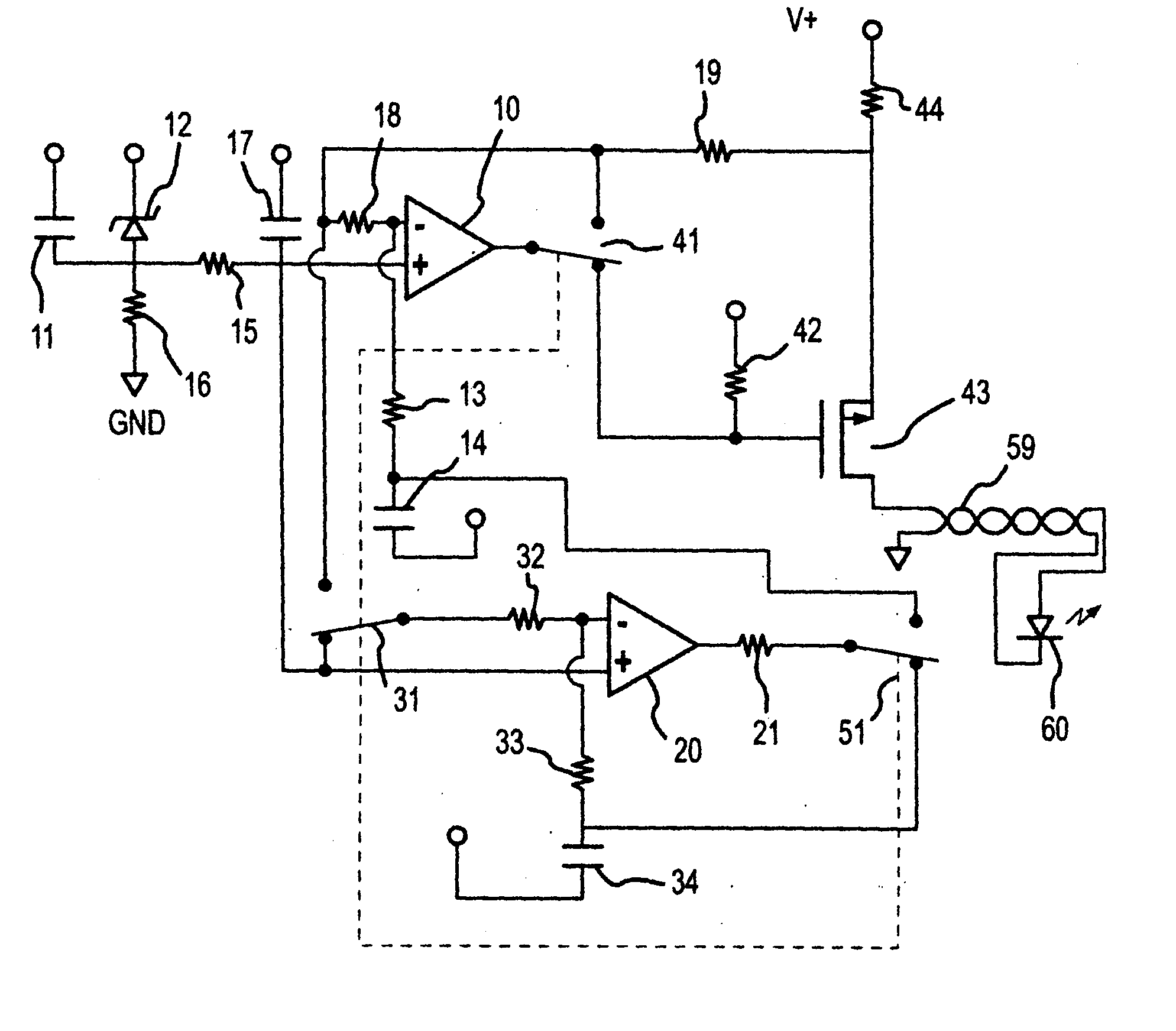

A method of producing a diode drive current in an oximeter includes sensing at least a part of a current passing through the diode and converting the sensed current to a sensed voltage, inputting the sensed voltage to a feedback amplifier for stabilizing the current passing through the diode, and eliminating an offset voltage across inputs of the feedback amplifier. A pulse oximeter includes a diode for emitting light flashes, a feedback amplifier having inputs, a feedback capacitor, and an output, the feedback amplifier stabilizing a current passing through the diode, a nulling amplifier having inputs, a nulling capacitor, and an output, the nulling amplifier charging and discharging the feedback capacitor until the inputs of the feedback amplifier are at a same voltage. The operation may include synchronizing an elimination of input offset voltages of the feedback and nulling amplifiers with on or off state of diode current.

Owner:DATEX OHMEDA

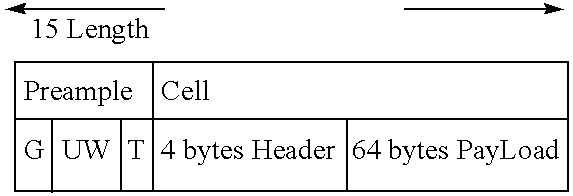

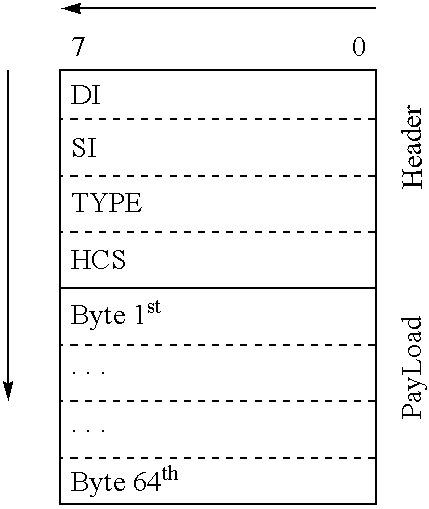

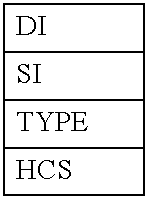

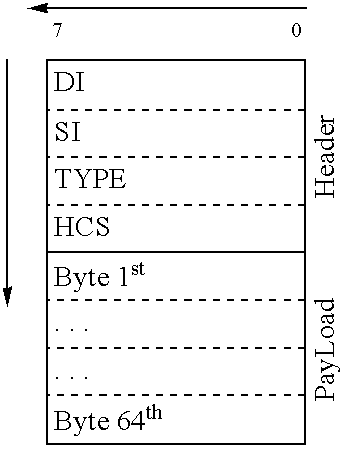

Channel equalization system and method

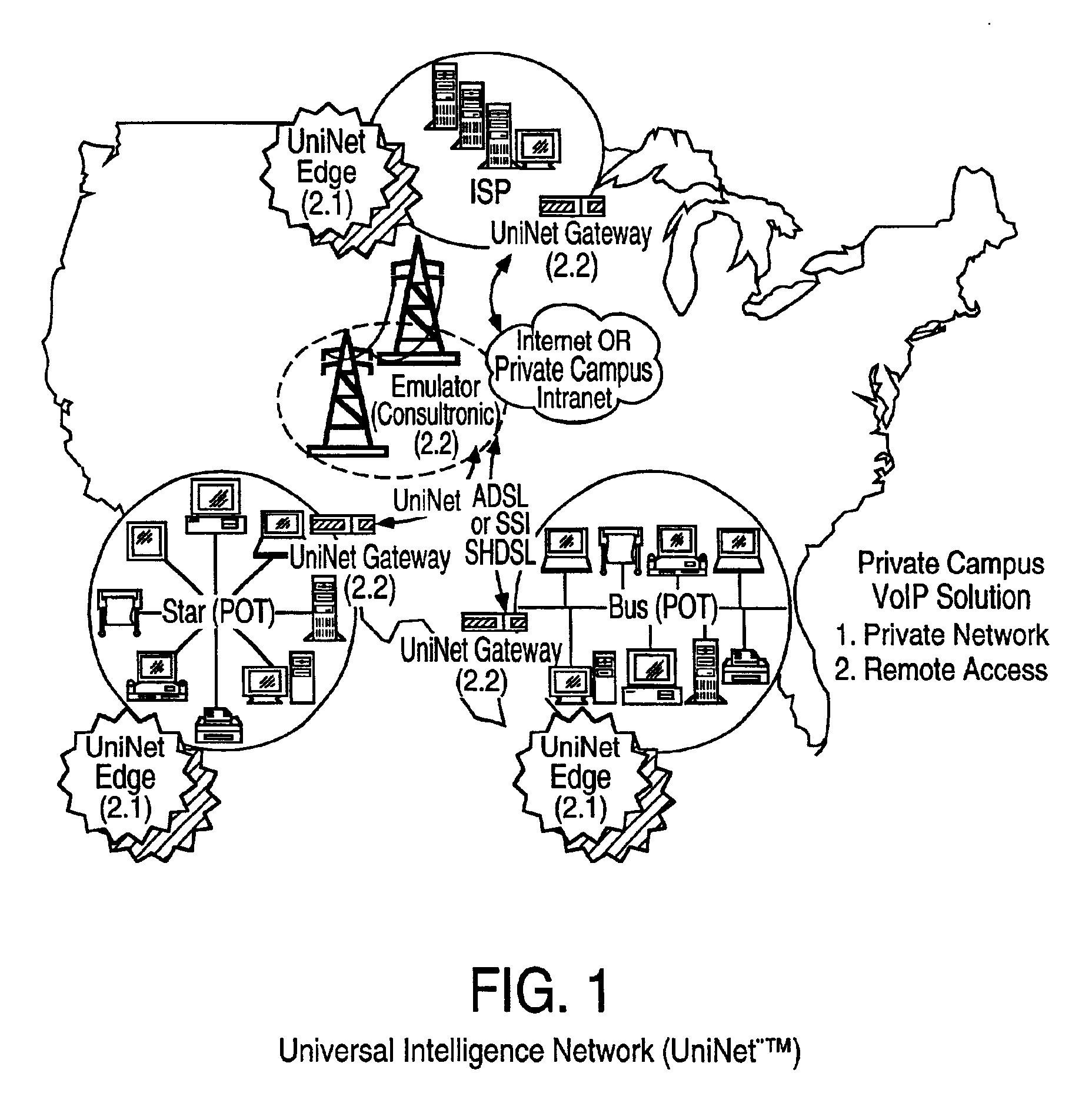

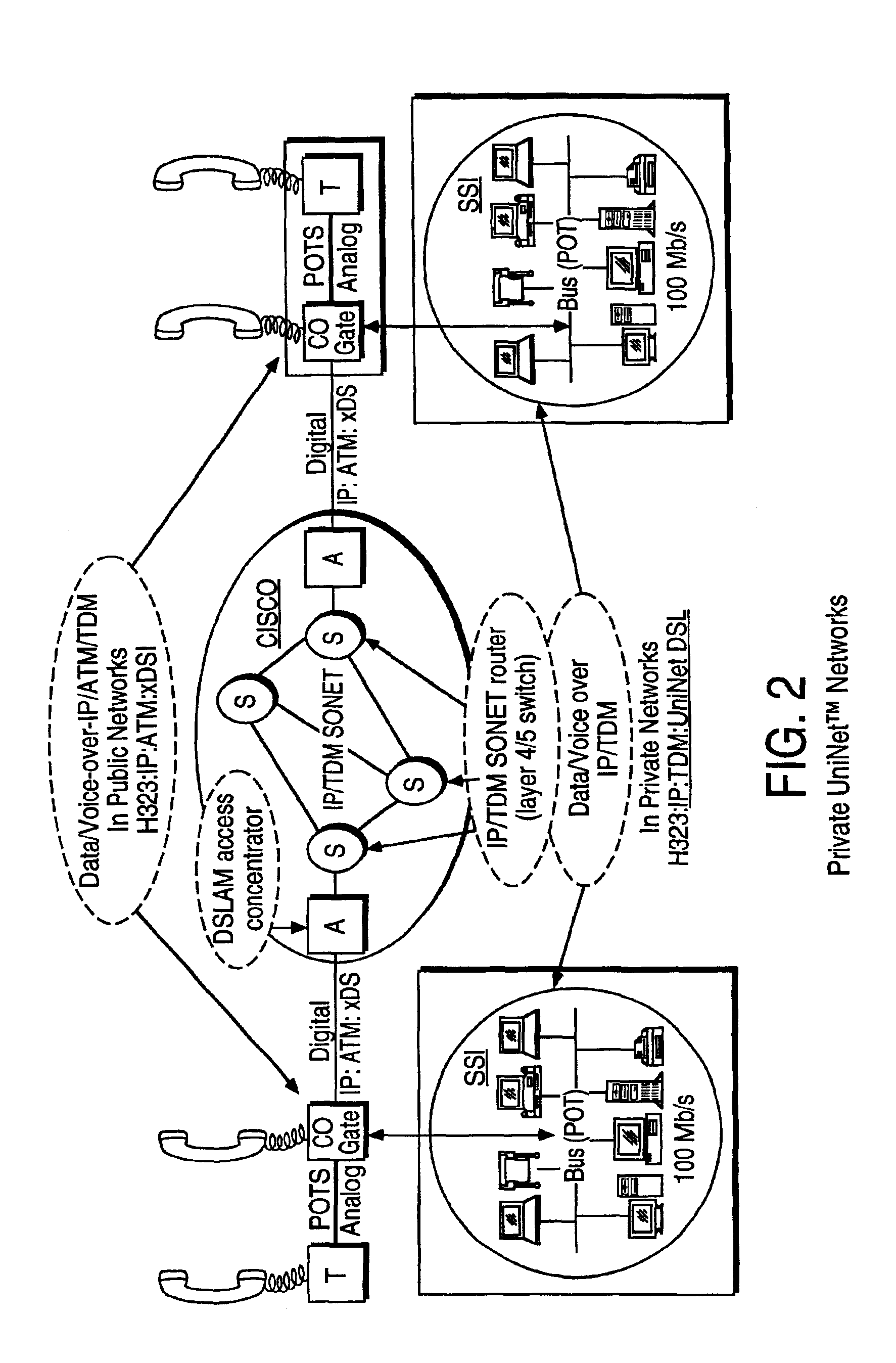

InactiveUS20030016770A1Increase high performance and data rate capacityLow costMultiple-port networksChannel dividing arrangementsData transmissionTTEthernet

A system and method for delivering increases speed, security, and intelligence to wireline and wireless systems. The present invention includes a new generation Fast Circuit Switch (packet / circuit) Communication processors and platform which enables a new Internet Exchange Networking Processor Architecture at the edge and core of every communication system, for next generation Web Operating System or Environment (WOE) to operate on with emphasis of a non-local processor or networking processor with remote web computing capabilities. A Unified Network Communication & Processor System or UniNet is a New generation network architecture of packet / circuit communication processors or Internet networking processor, that increases speeds over any communication channels and topologies, synchronizing, enabling, improving, controlling and securing all of the data transmission of web applications over existing wireline and wireless infrastructure while providing seamless integration to the legacy telecom & data corn backbone. The present invention is capable of operating on any topology with distributed intelligence and data switching / routing, which is located at the edge. This method not only alleviates the ever increasing data processing bottleneck which is currently done by the data communication and telecom switch and routers, but it also enables new and next generation Internet Processor architecture. The UniNet is also a flexible solution for the novel concept that the capability of a network interface should depend on the level of service assigned to a service access point, not the capacity of the total network, such as transaction services with a short burst of messages with short access delay. The present invention increases channel capacity by using a parallel or multi-channel structure in such wireless and wireline at the edge or the core of. This new architecture of the present invention uses parallel bitstreams in a flexible way and distributed switching / routing technique, is not only to avoid the potential bottlenet of centralized switches, but also to increase speed with intelligence that is seamlessly integrating into the Fiber Optic Backbone such as WDM and SONET of the MAN / WAN network with a Real-time guarantees, different types of traffic (such as Stringent synchronous, isochronous, and asynchronous data messages) with different demands, and privacy & security of multi access and integrated services environment.

Owner:B C LEOW

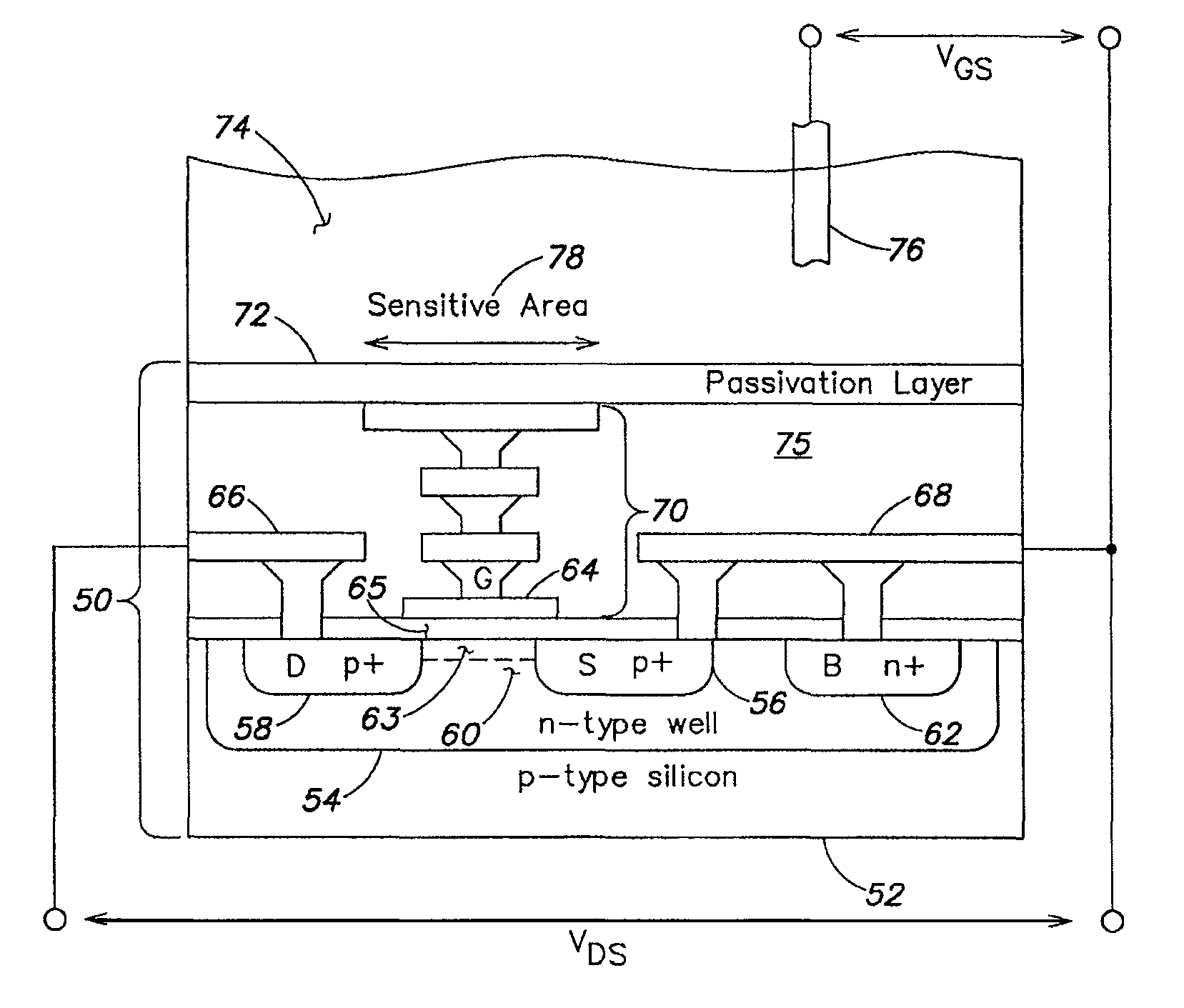

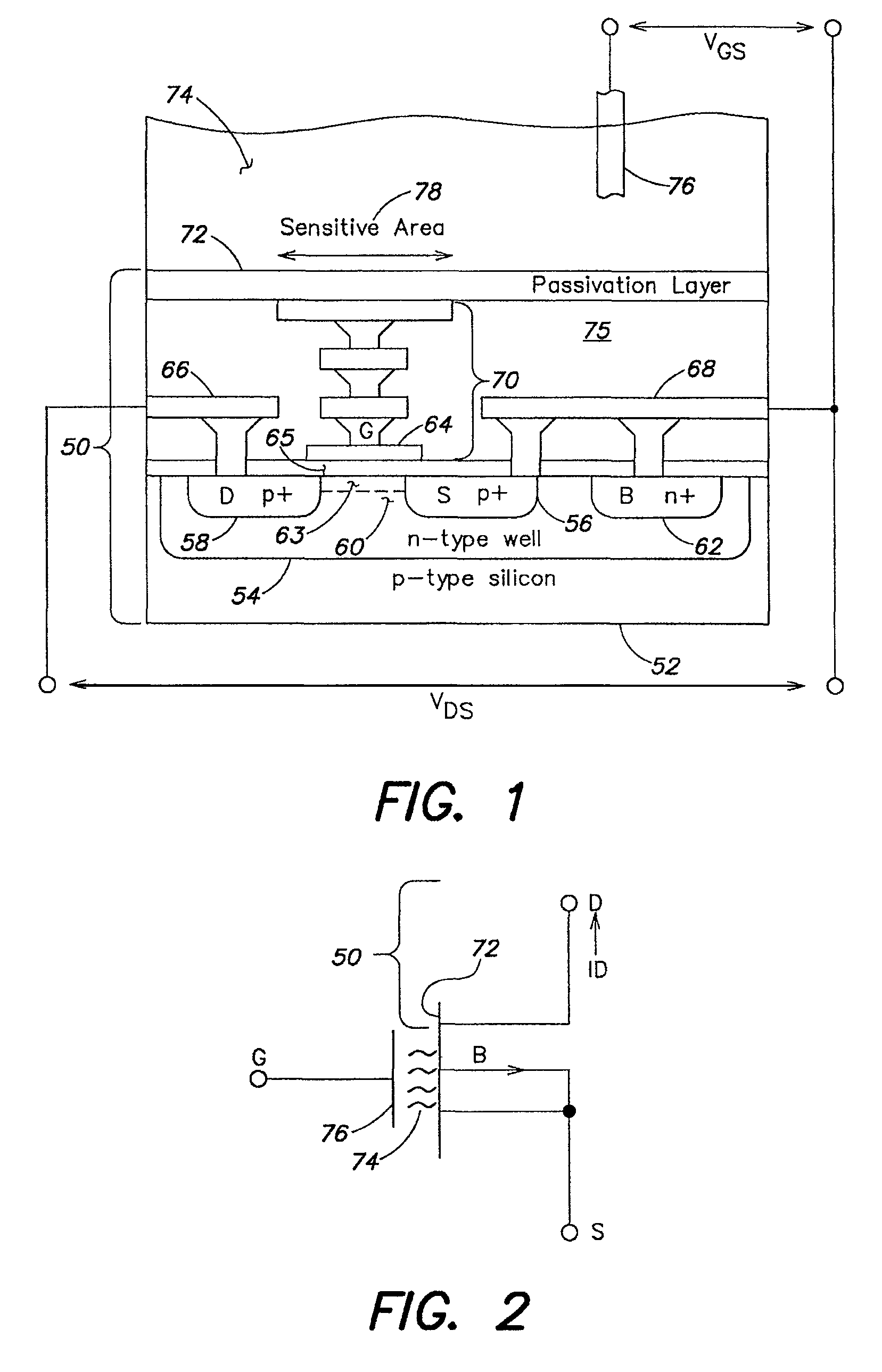

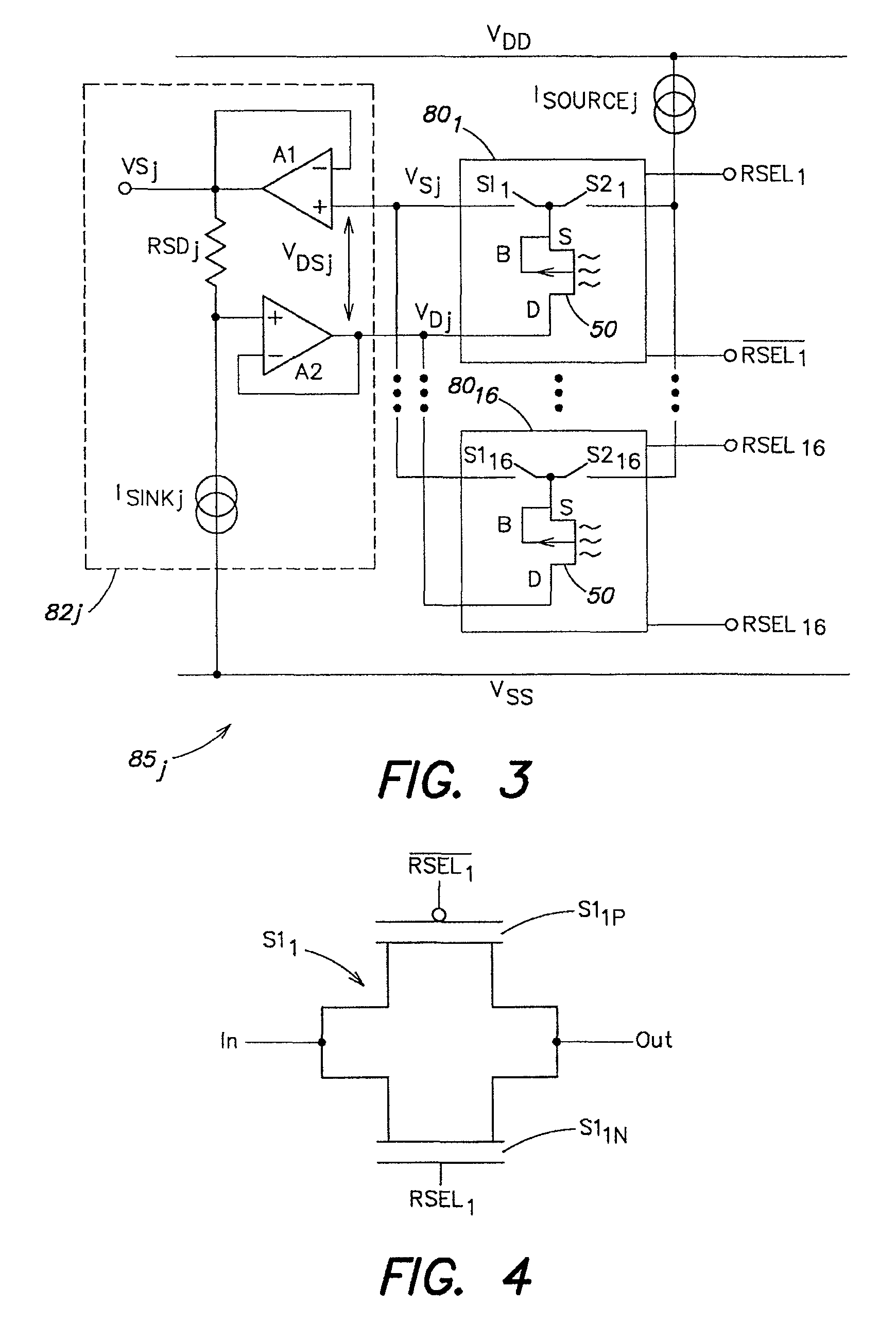

Methods and apparatus for measuring analytes using large scale FET arrays

ActiveUS7948015B2Reduce porosityHigh densityTransistorMicrobiological testing/measurementCMOSOrganismal Process

Methods and apparatus relating to very large scale FET arrays for analyte measurements. ChemFET (e.g., ISFET) arrays may be fabricated using conventional CMOS processing techniques based on improved FET pixel and array designs that increase measurement sensitivity and accuracy, and at the same time facilitate significantly small pixel sizes and dense arrays. Improved array control techniques provide for rapid data acquisition from large and dense arrays. Such arrays may be employed to detect a presence and / or concentration changes of various analyte types in a wide variety of chemical and / or biological processes. In one example, chemFET arrays facilitate DNA sequencing techniques based on monitoring changes in hydrogen ion concentration (pH), changes in other analyte concentration, and / or binding events associated with chemical processes relating to DNA synthesis.

Owner:LIFE TECH CORP

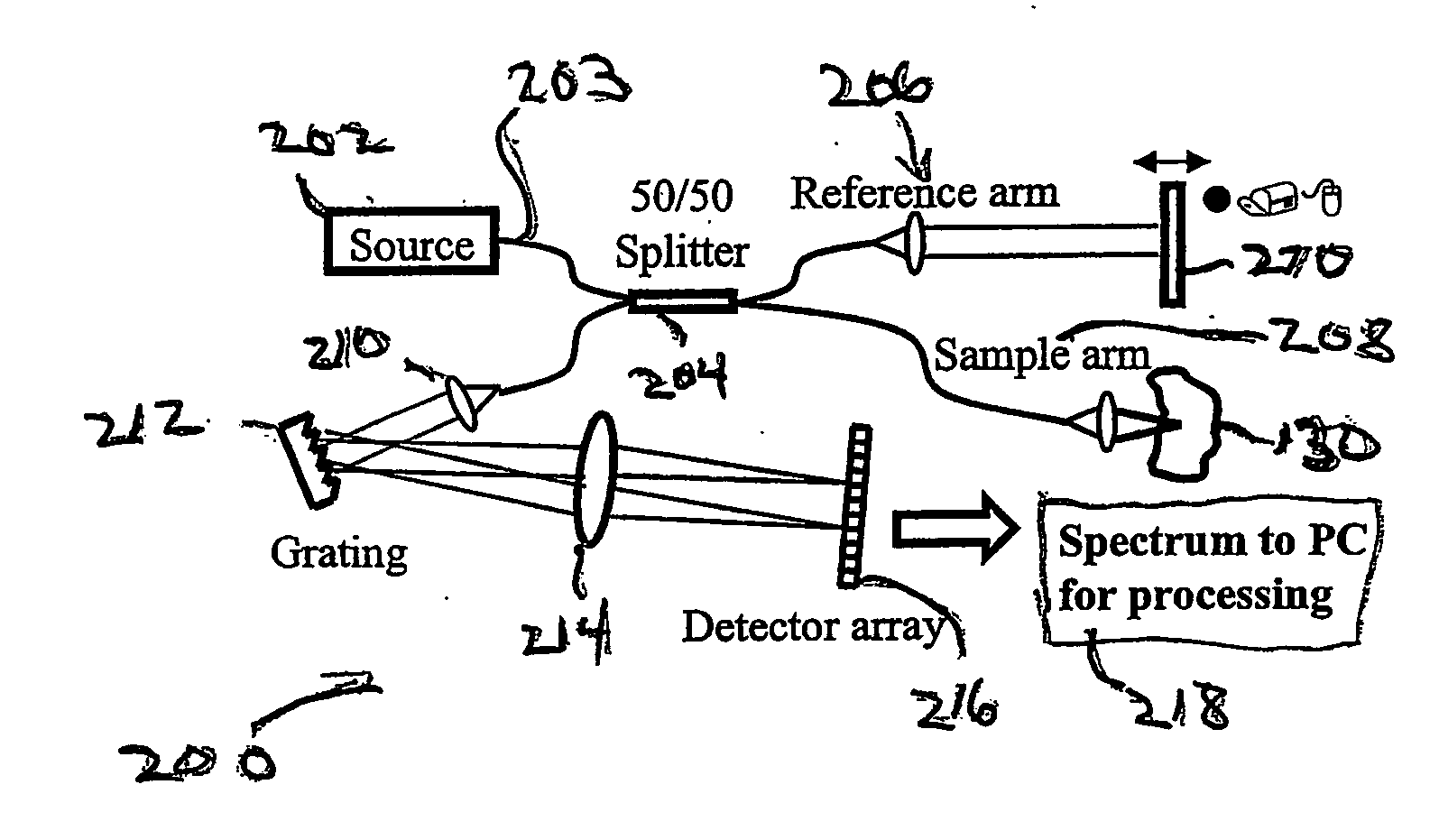

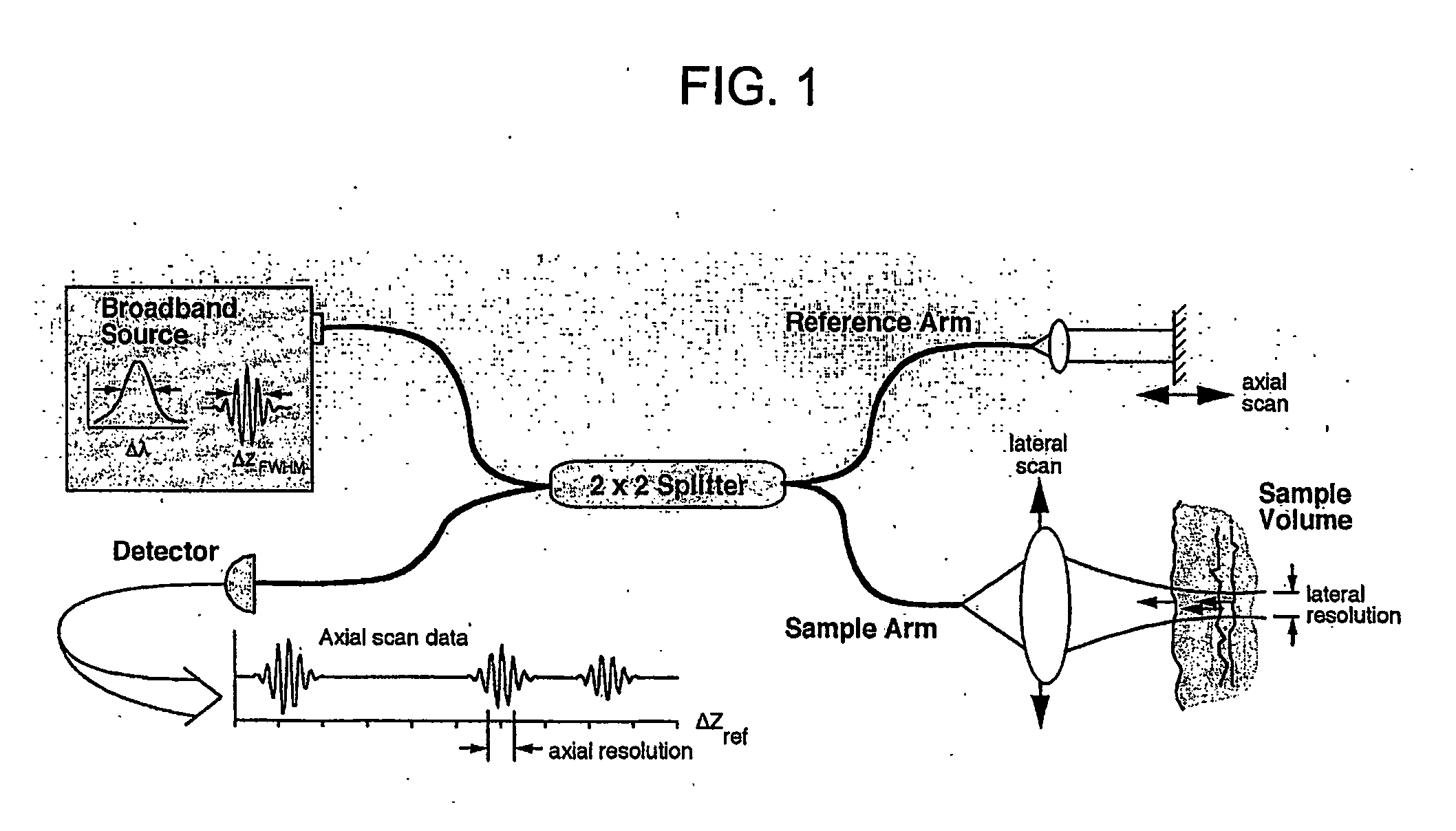

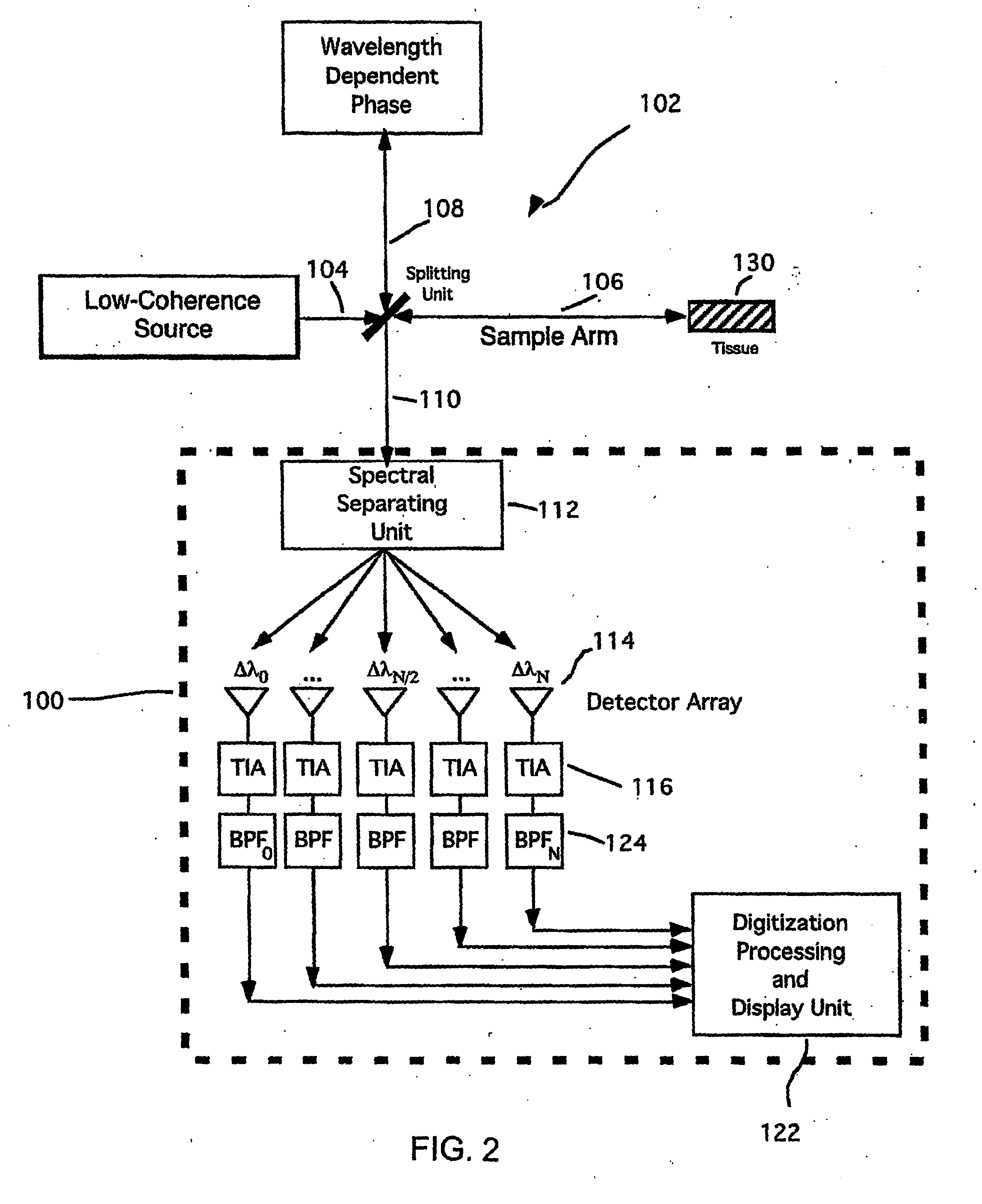

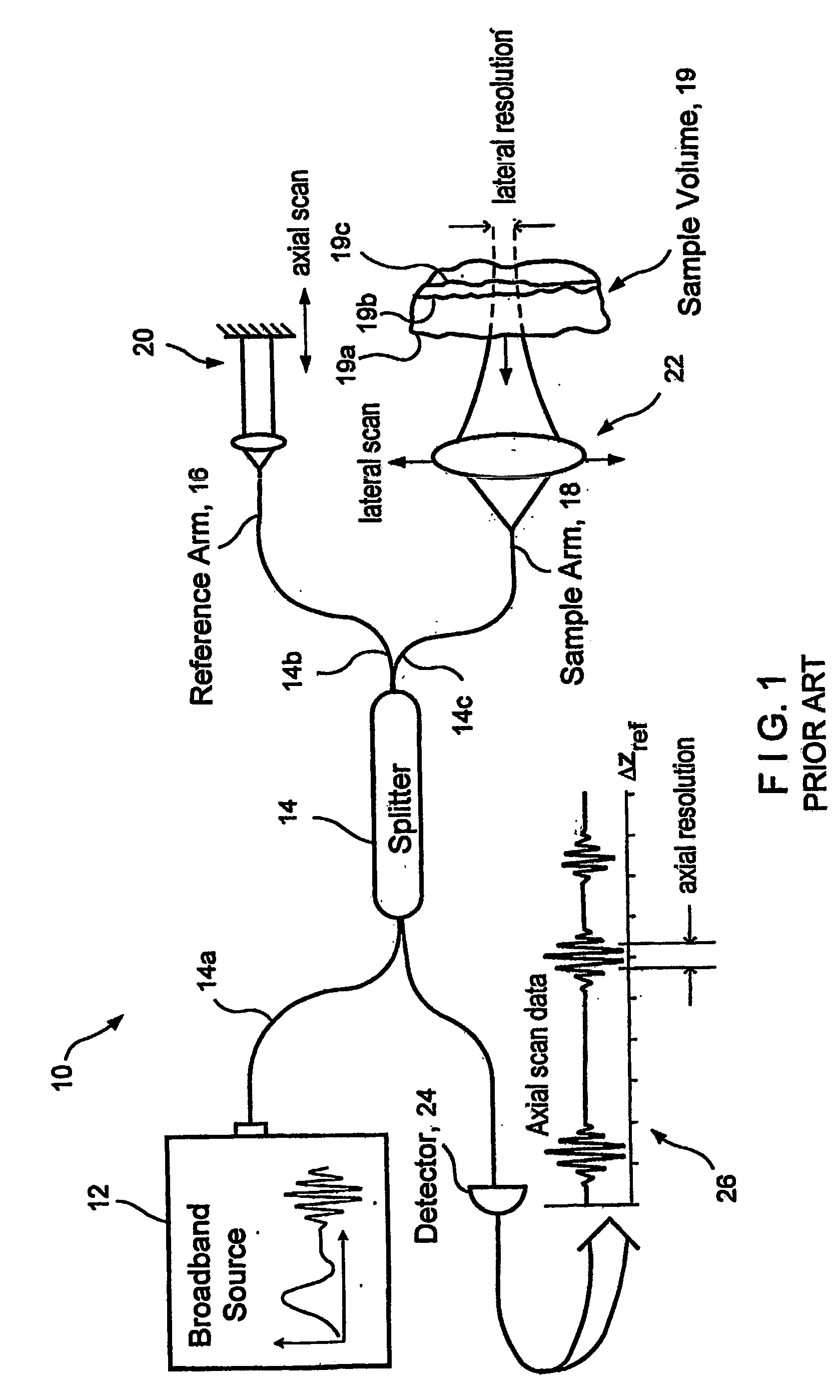

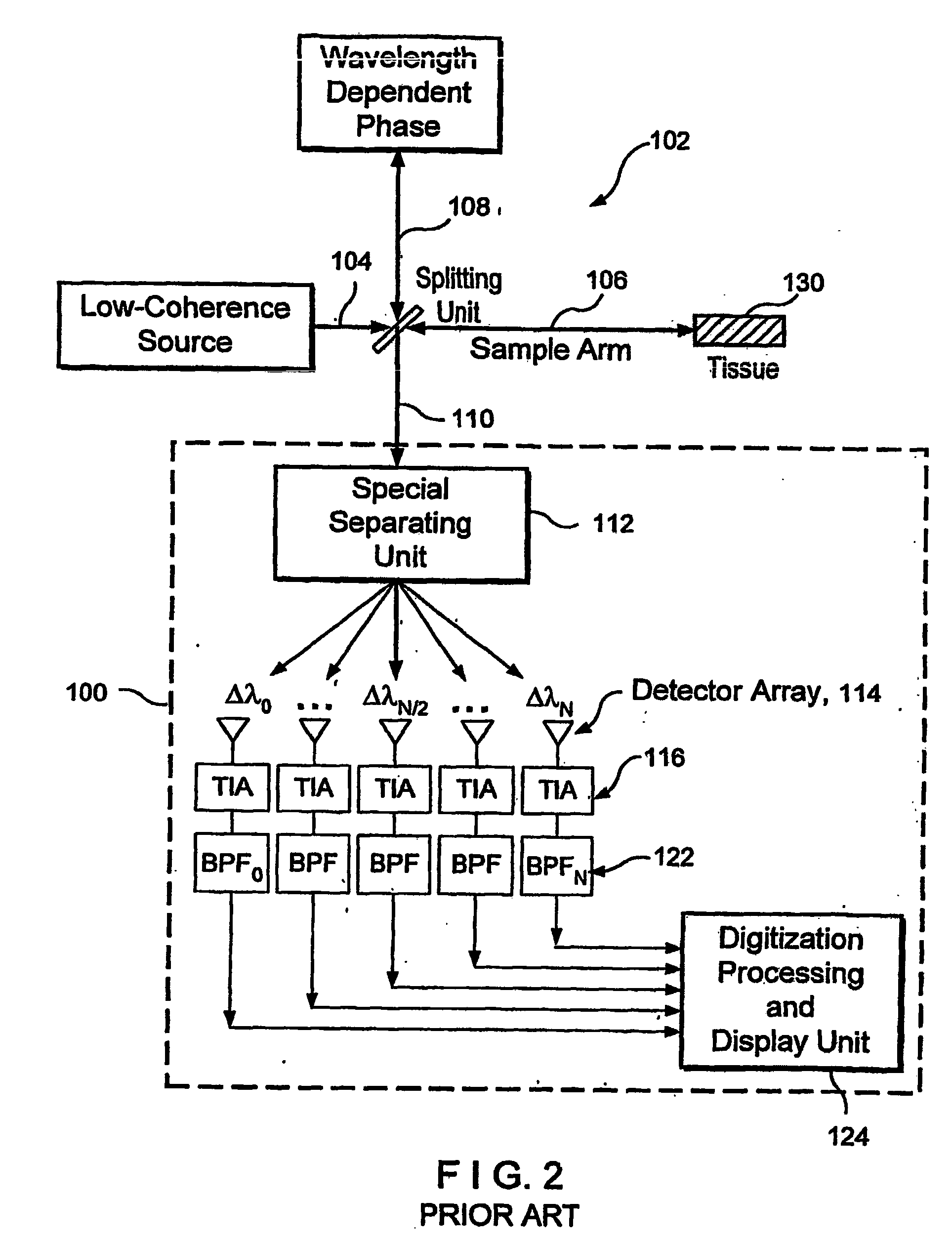

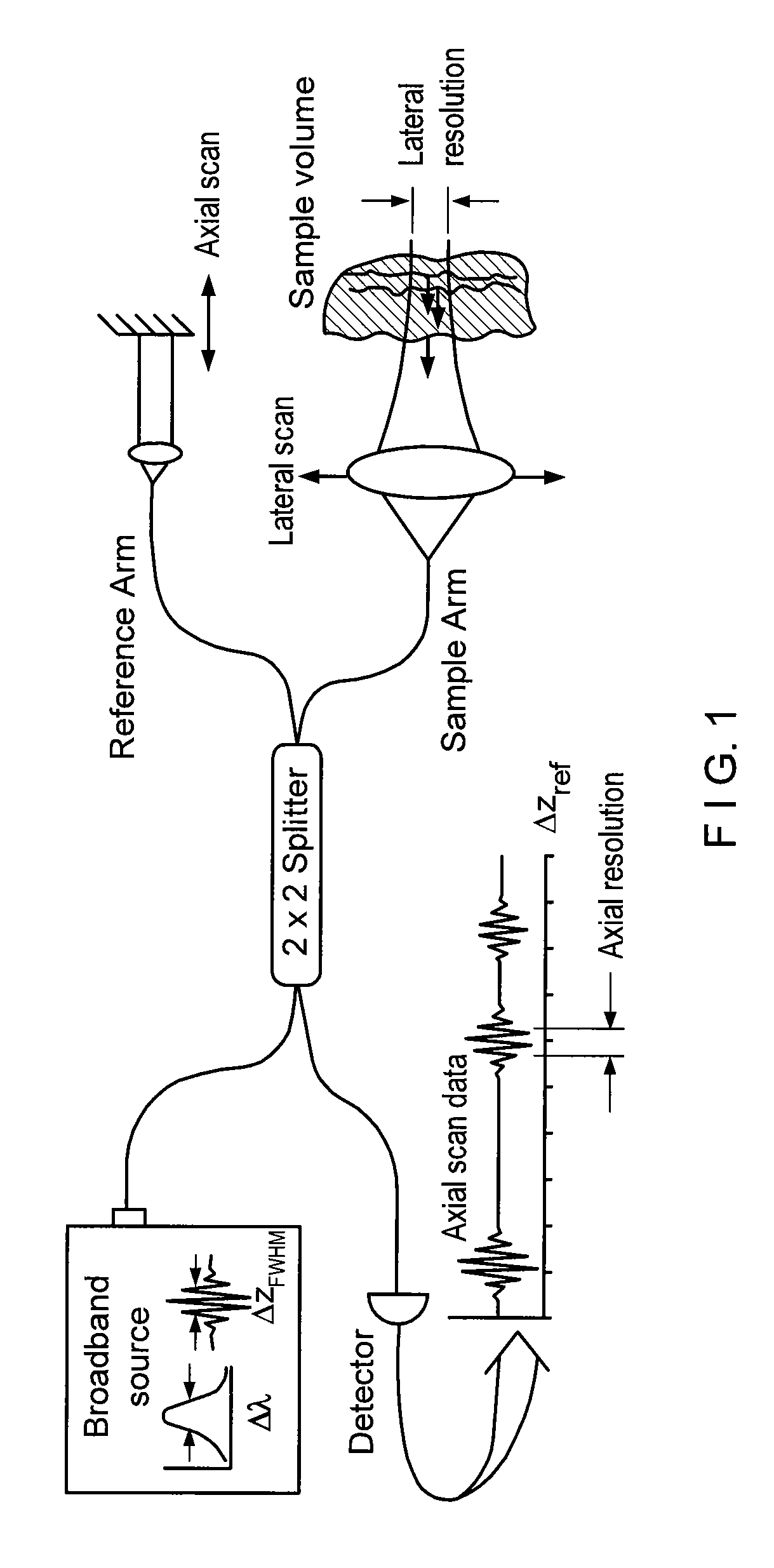

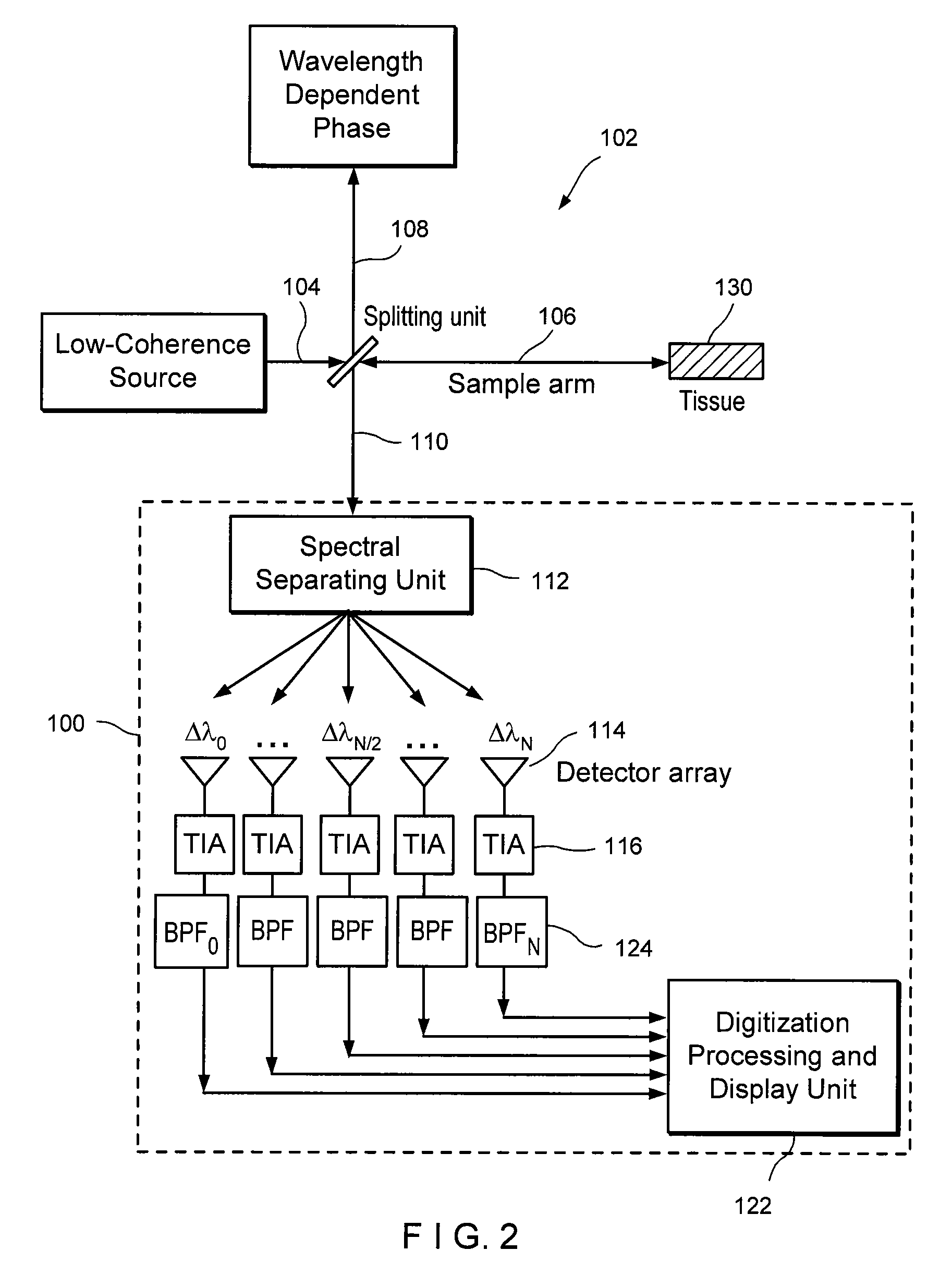

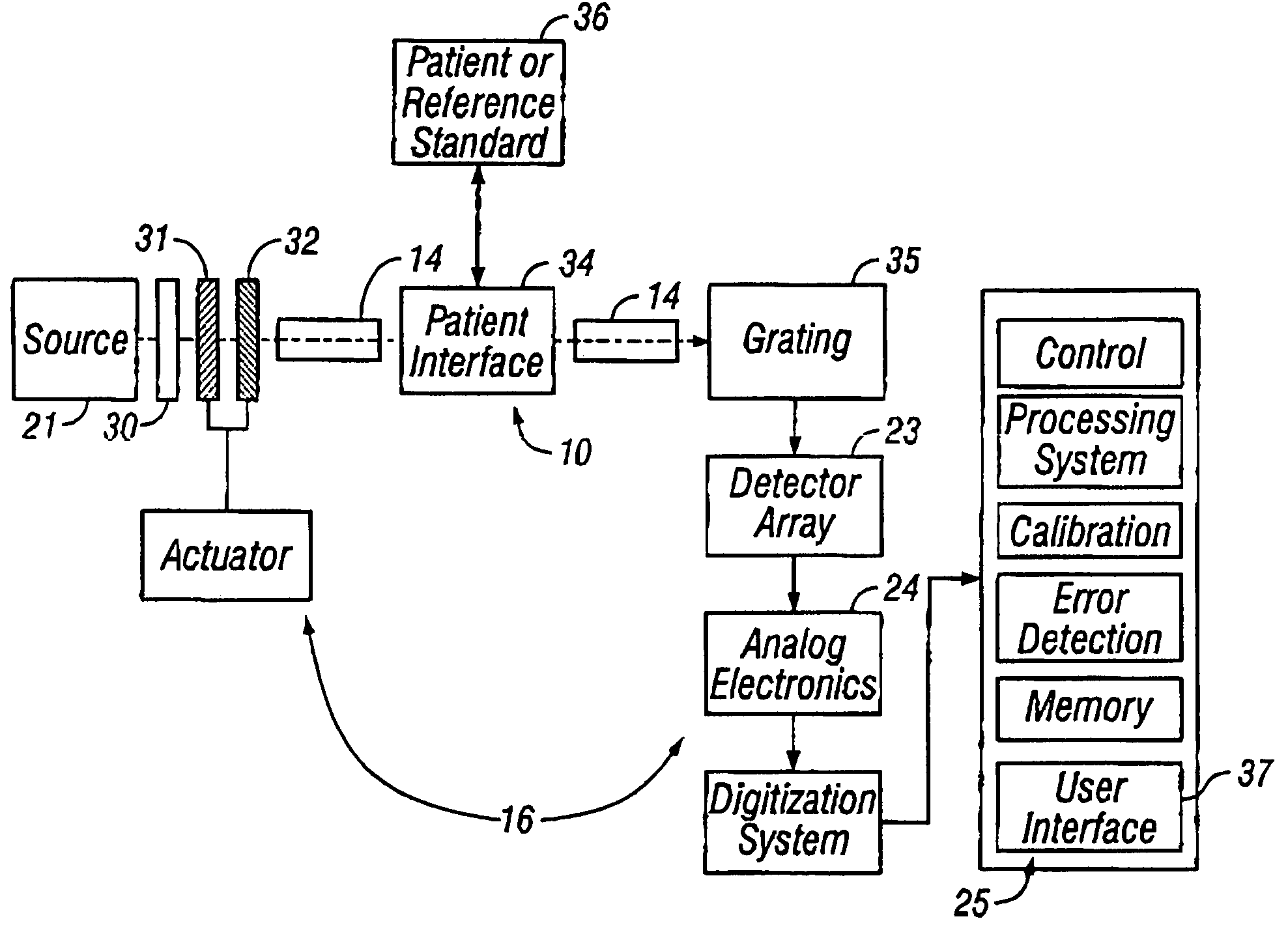

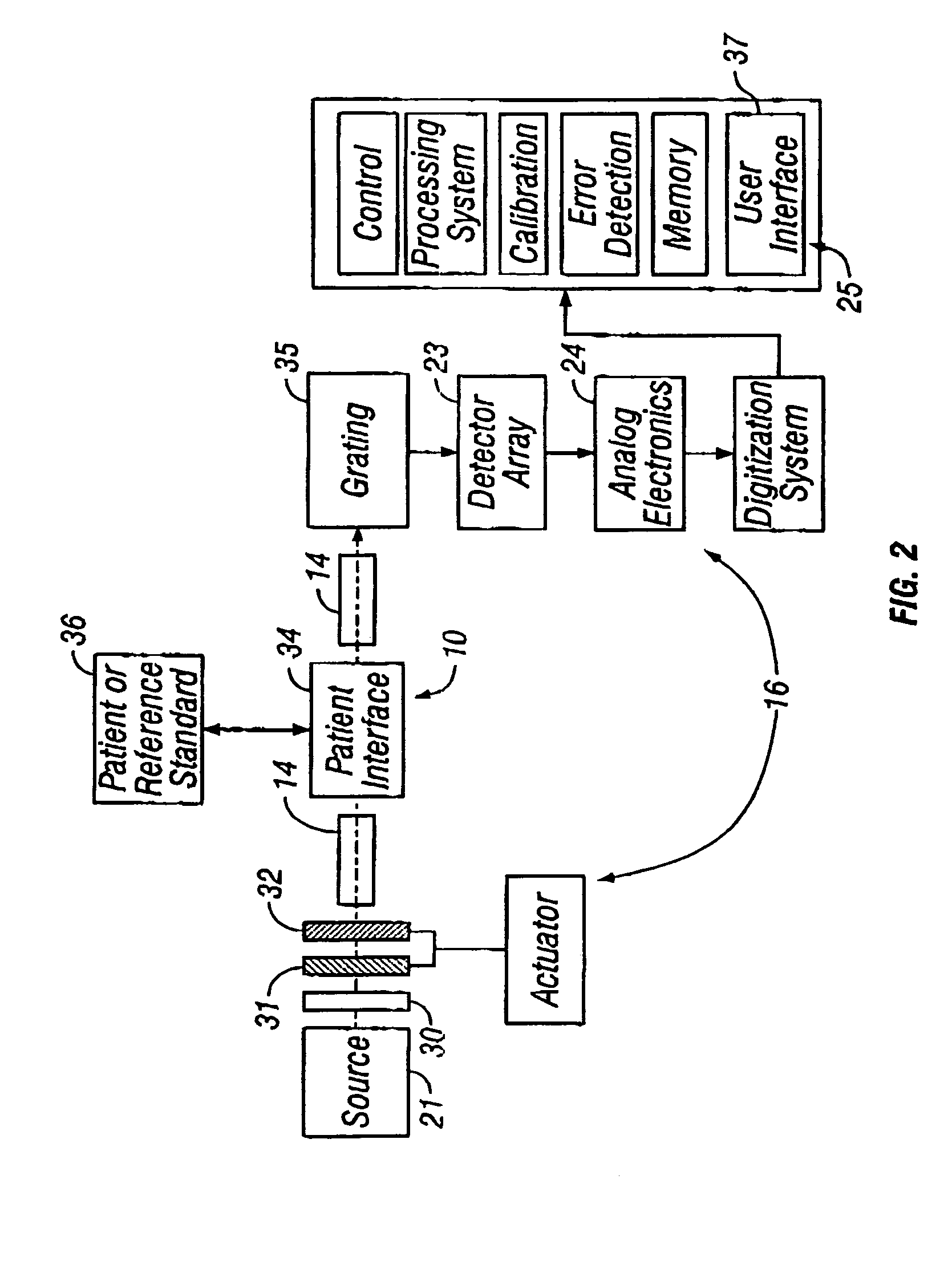

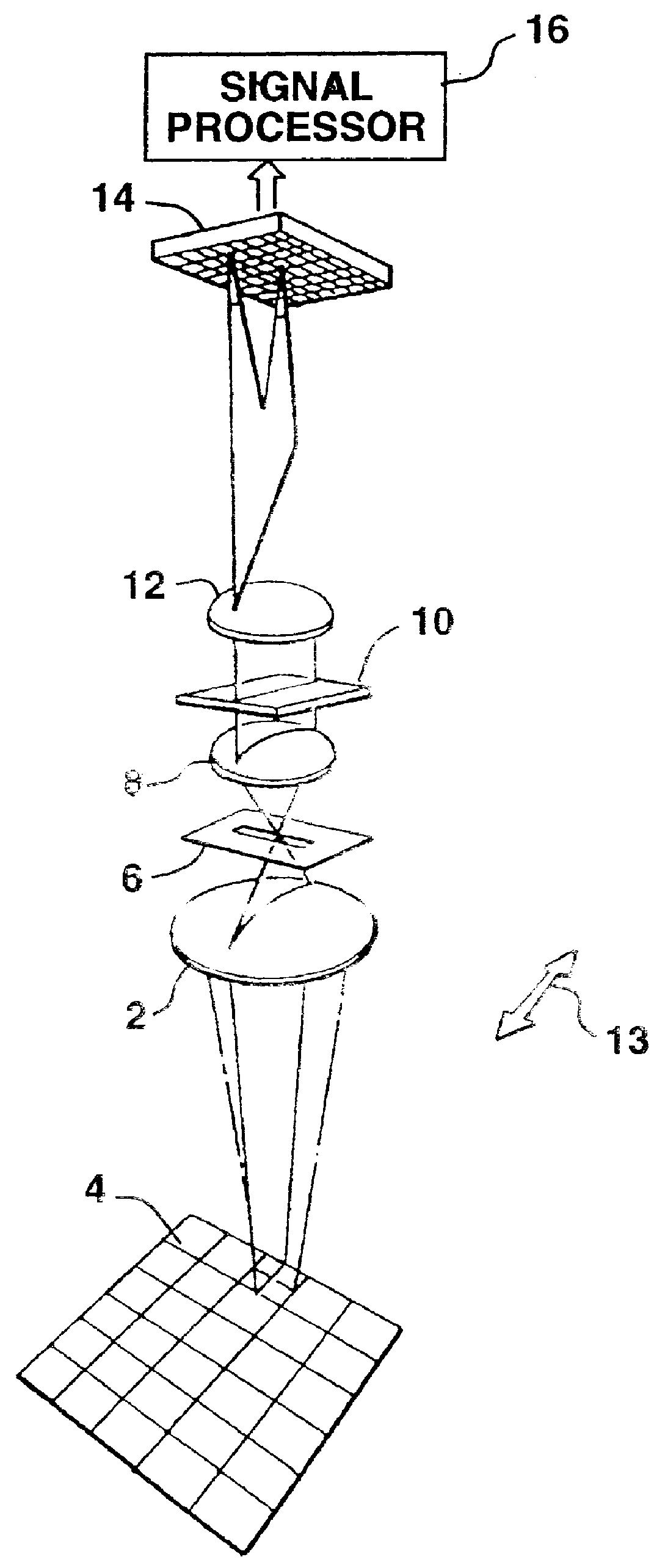

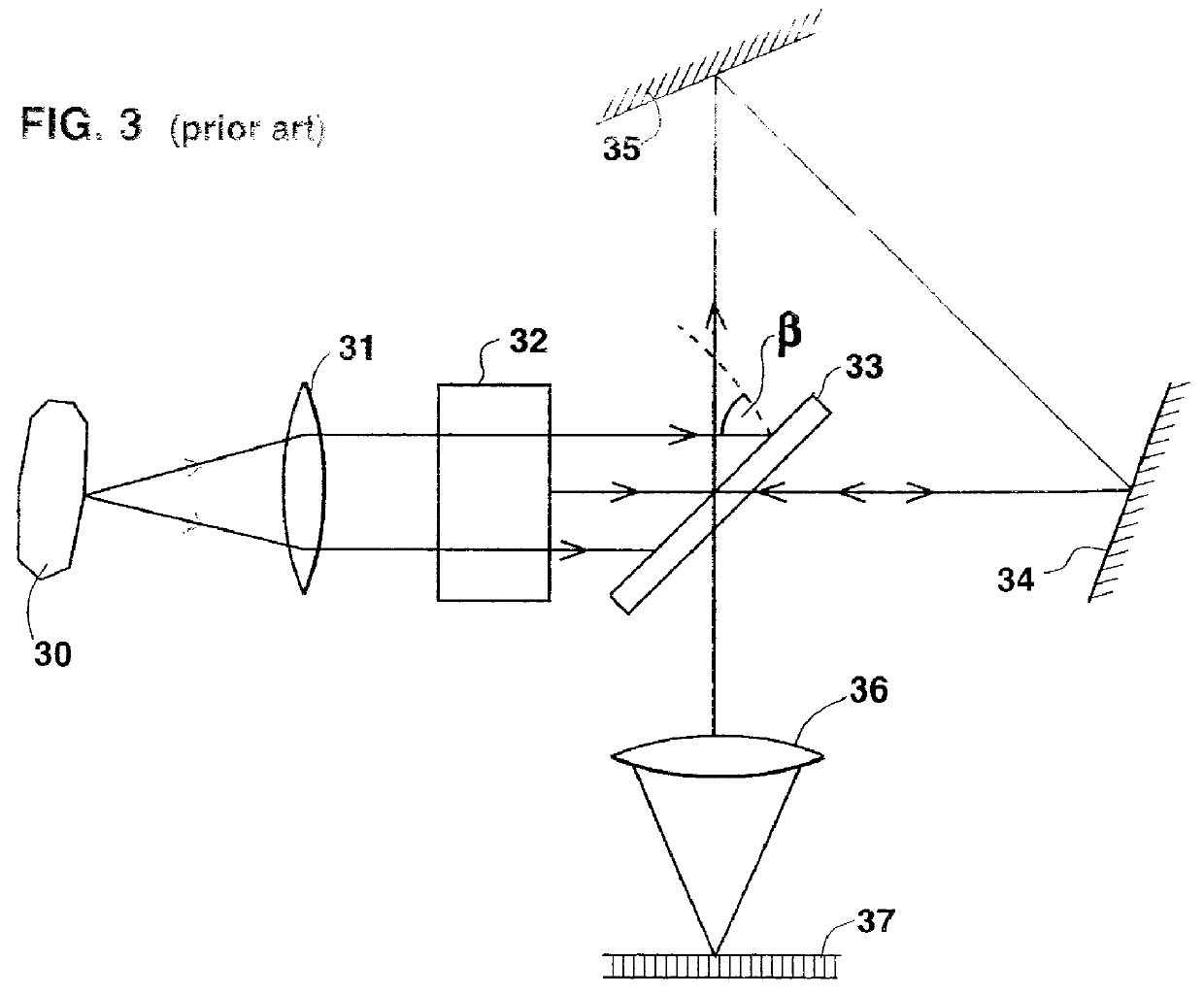

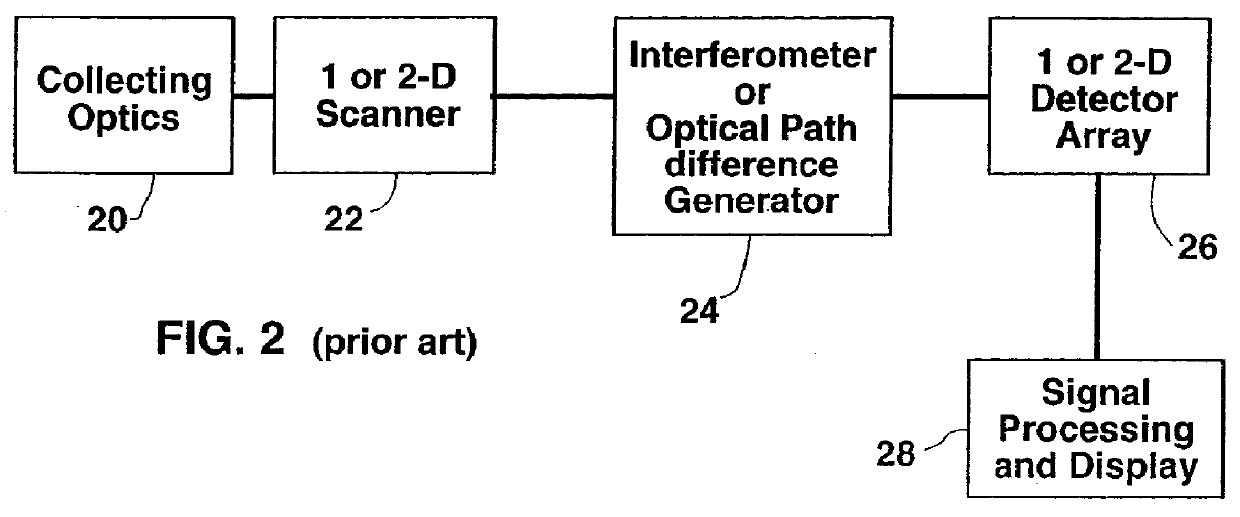

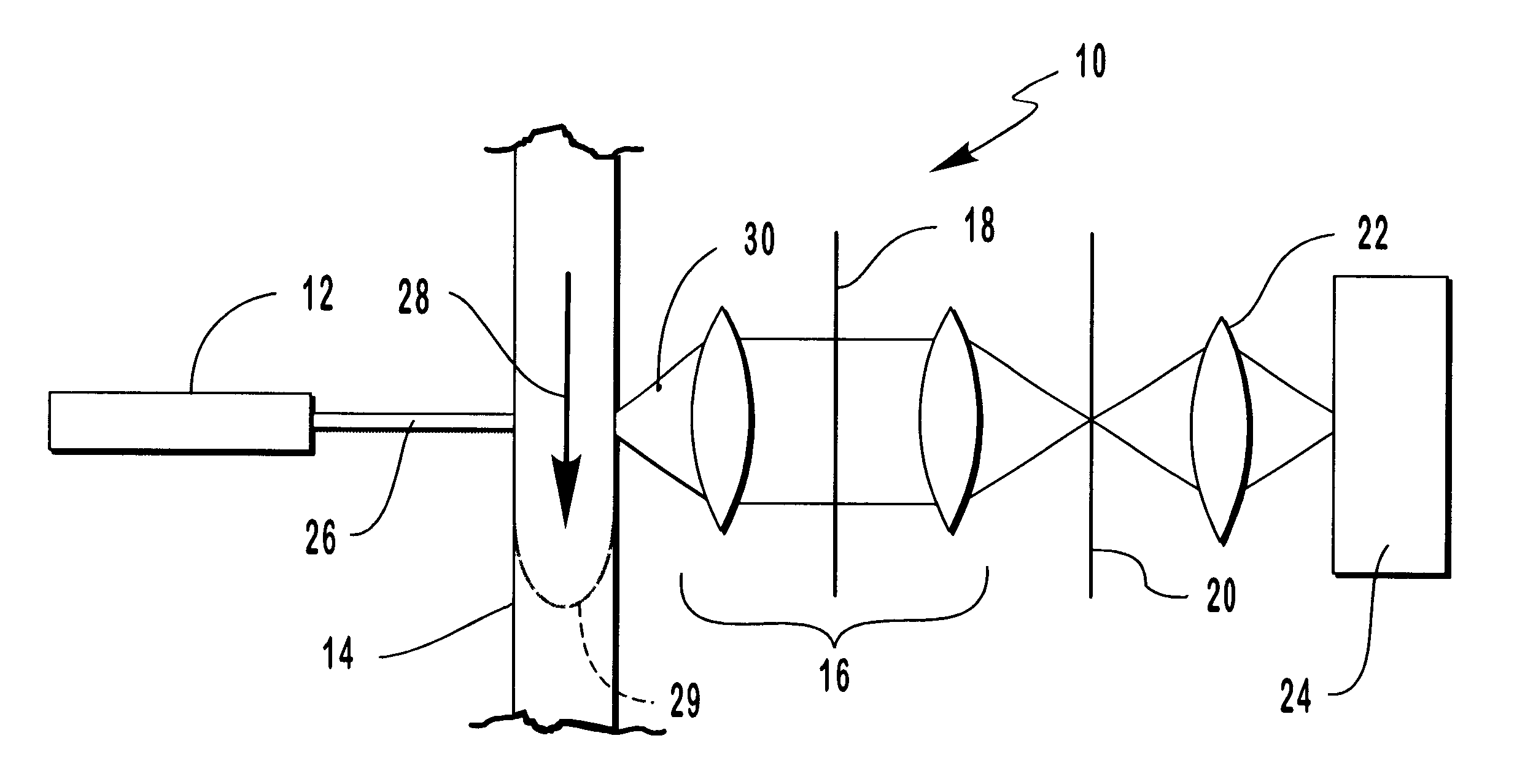

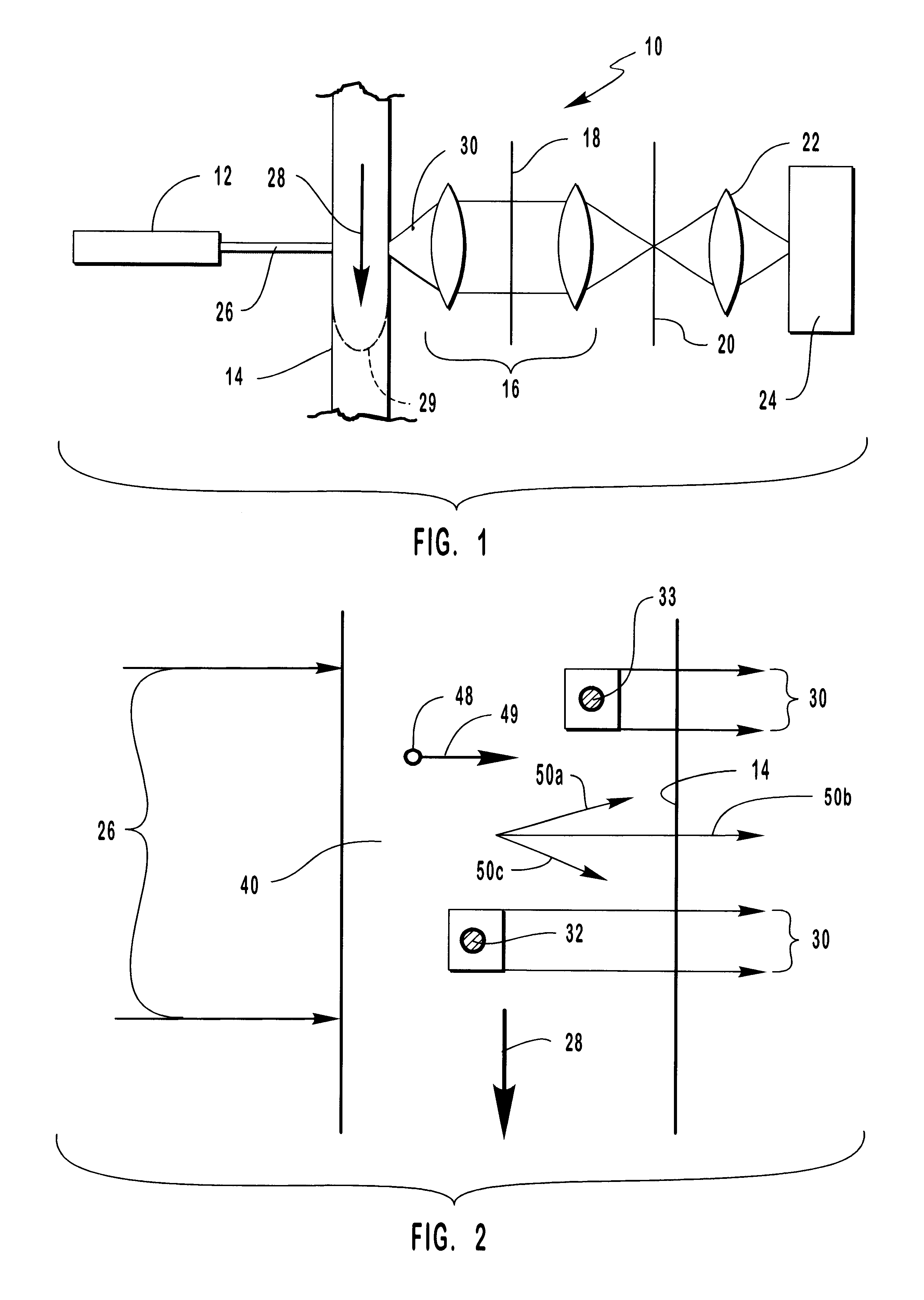

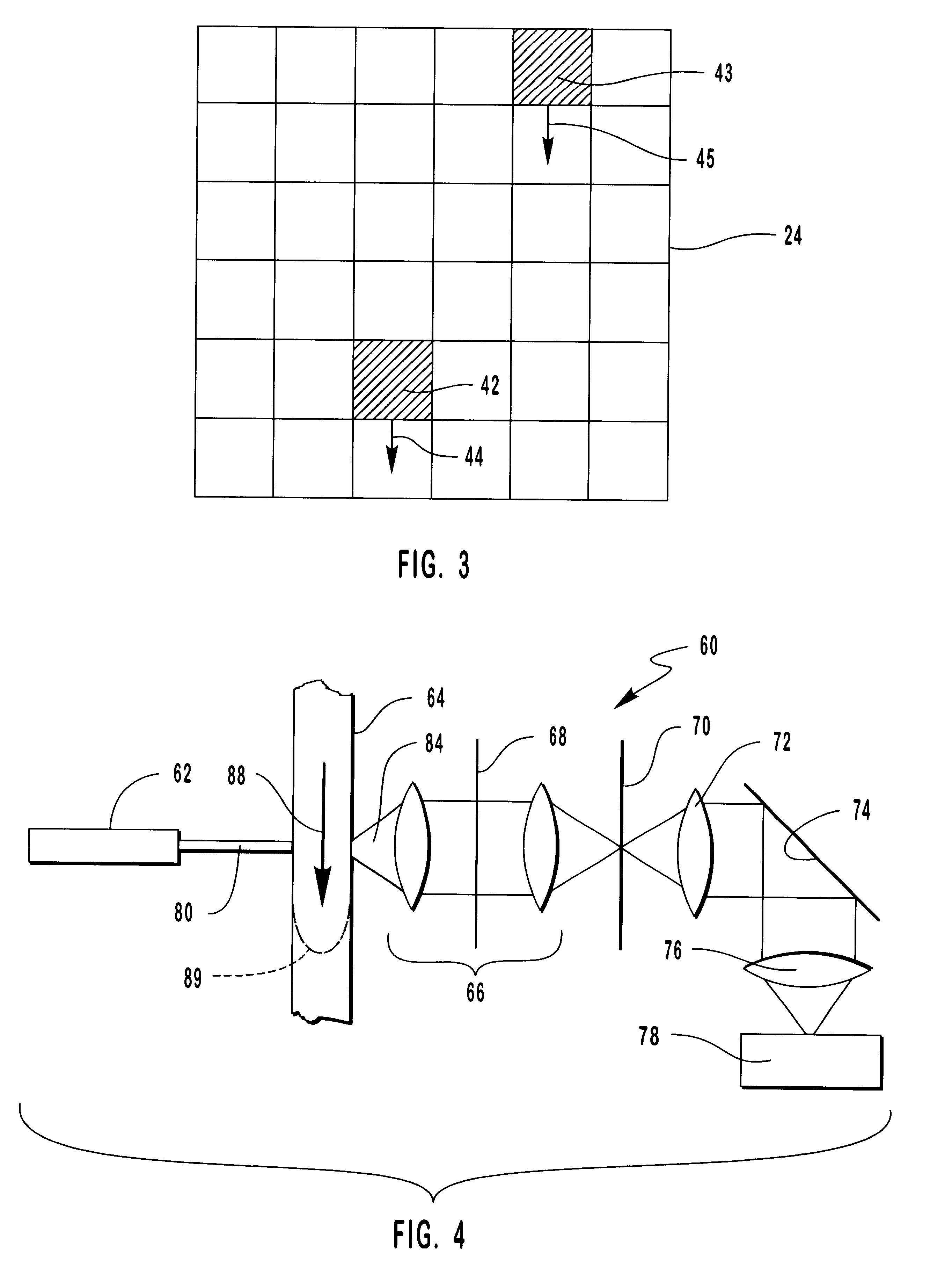

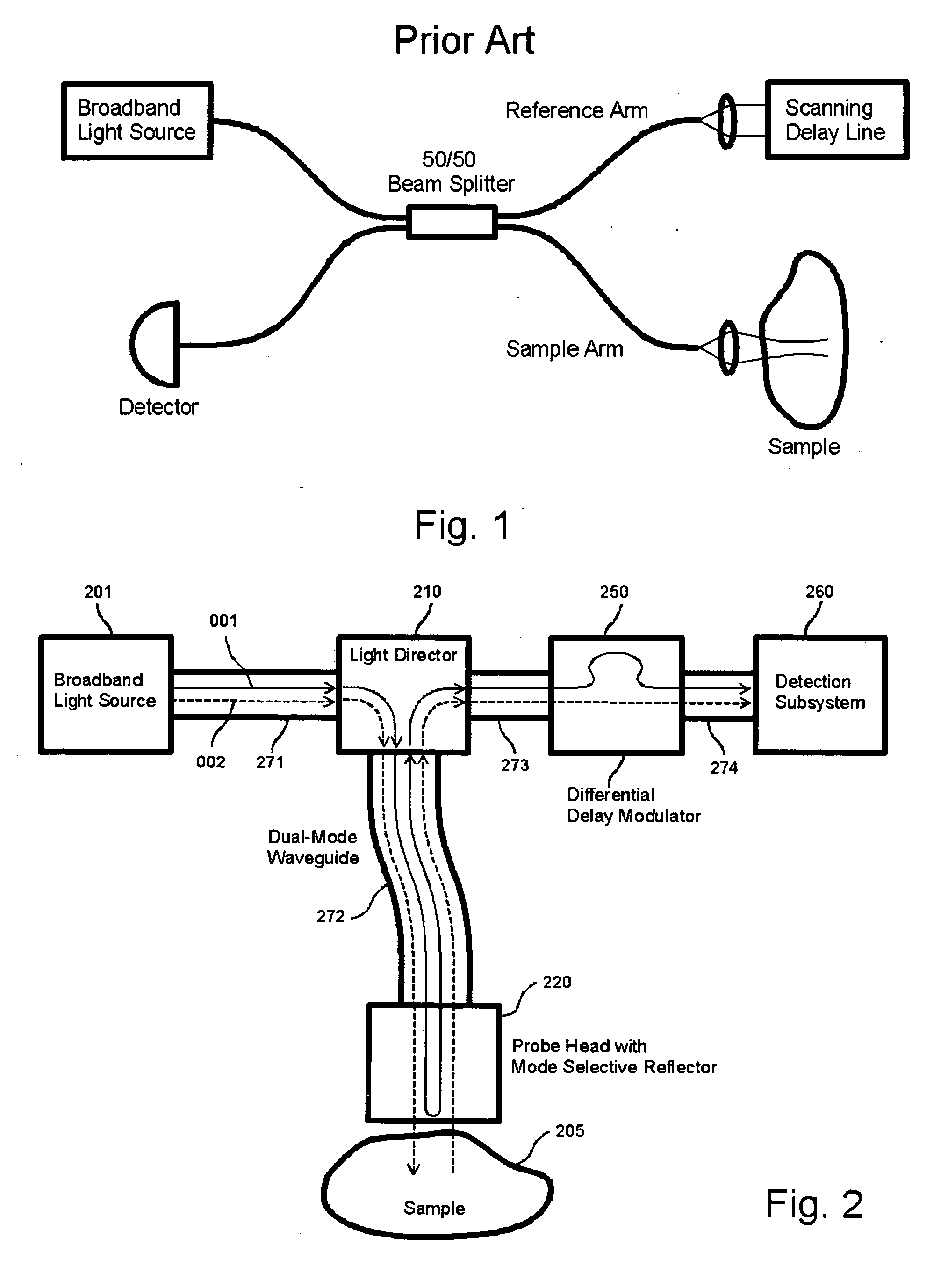

Apparatus and method for ranging and noise reduction of low coherence interferometry lci and optical coherence tomography oct signals by parallel detection of spectral bands

InactiveUS20050018201A1Improve signal-to-noise ratioImproves current data acquisition speed and availabilityDiagnostics using lightInterferometersBandpass filteringSpectral bands

Apparatus, method, logic arrangement and storage medium are provided for increasing the sensitivity in the detection of optical coherence tomography and low coherence interferometry (“LCI”) signals by detecting a parallel set of spectral bands, each band being a unique combination of optical frequencies. The LCI broad bandwidth source can be split into N spectral bands. The N spectral bands can be individually detected and processed to provide an increase in the signal-to-noise ratio by a factor of N. Each spectral band may be detected by a separate photo detector and amplified. For each spectral band, the signal can be band p3 filtered around the signal band by analog electronics and digitized, or, alternatively, the signal may be digitized and band pass filtered in software. As a consequence, the shot noise contribution to the signal is likely reduced by a factor equal to the number of spectral bands, while the signal amplitude can remain the same. The reduction of the shot noise increases the dynamic range and sensitivity of the system.

Owner:THE GENERAL HOSPITAL CORP

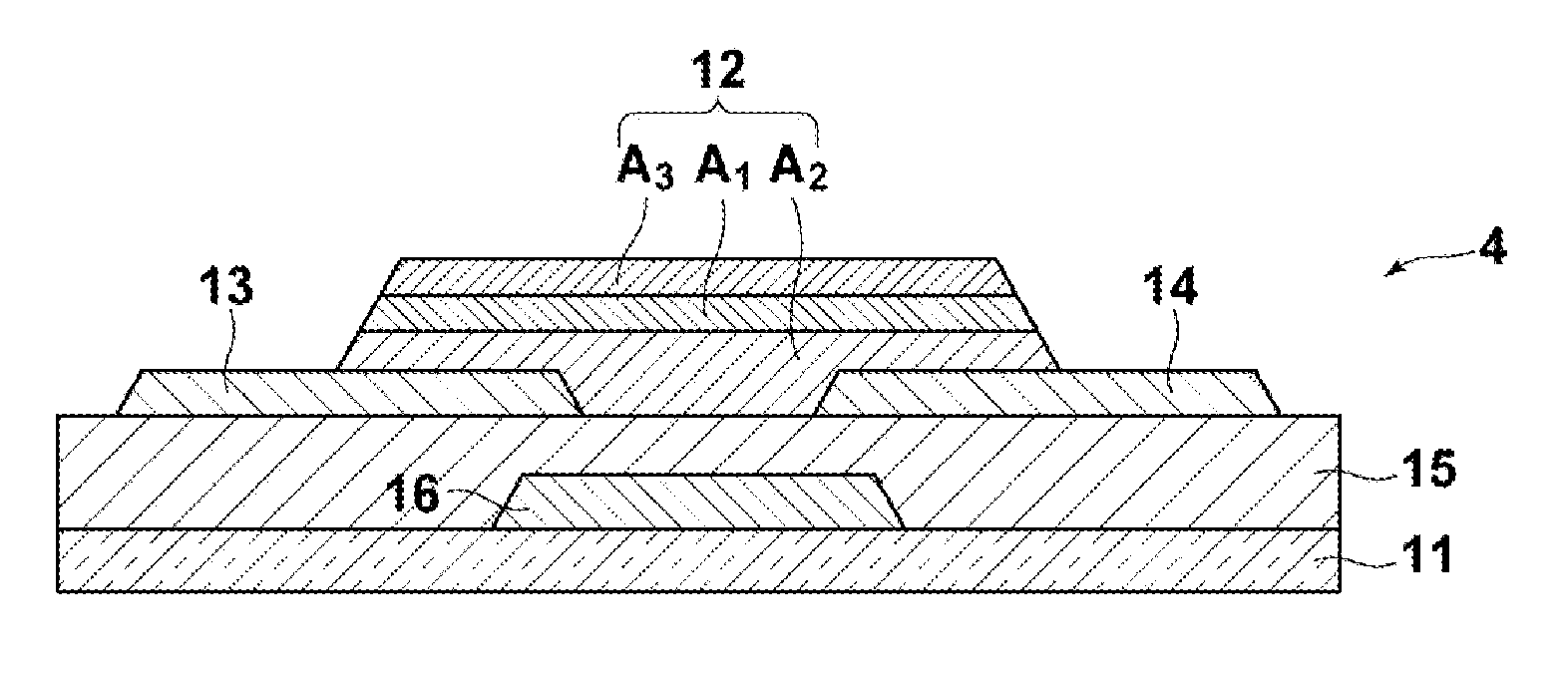

Thin-film transistor, method of producing the same, and devices provided with the same

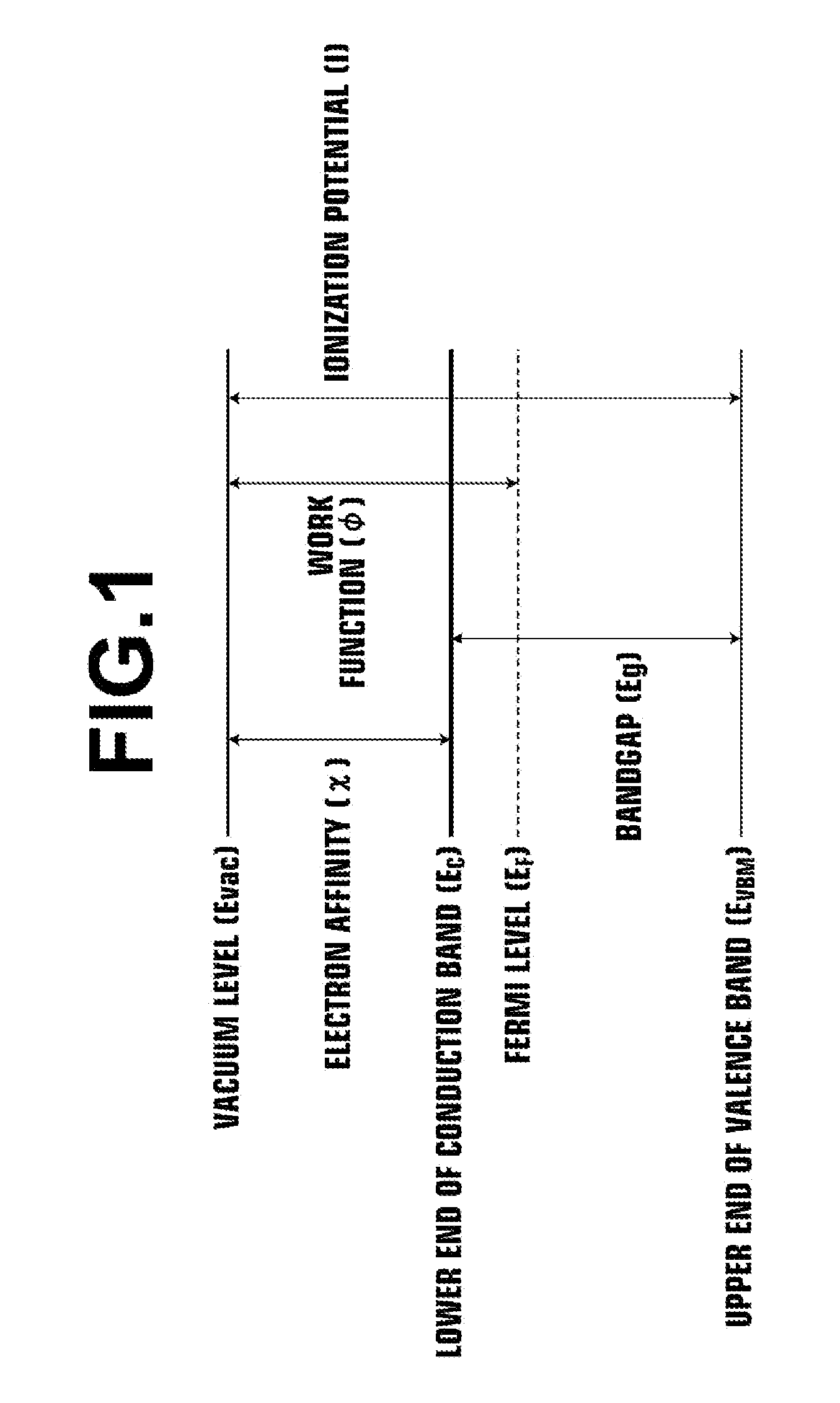

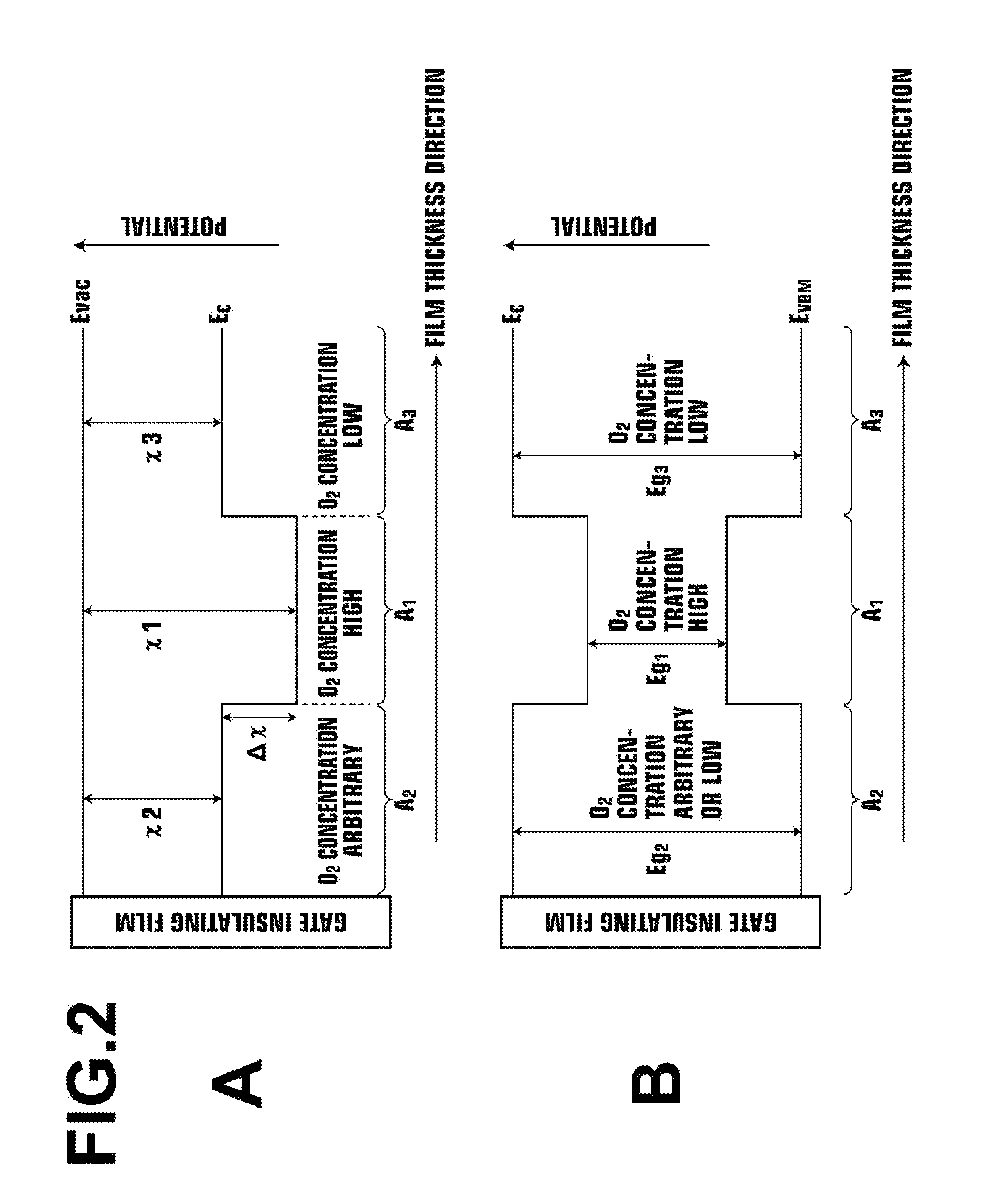

ActiveUS20110140100A1Low mobilityIncrease carrier densityTransistorSemiconductor/solid-state device manufacturingOxygenSemiconductor

A thin-film transistor including an oxide semiconductor layer is disclosed. The oxide semiconductor layer includes a first area, a second area and a third area forming a well-type potential in the film-thickness direction. The first area forms a well of the well-type potential and has a first electron affinity. The second area is disposed nearer to the gate electrode than the first area and has a second electron affinity smaller than the first electron affinity. The third area is disposed farther from the gate electrode than the first area and has a third electron affinity smaller than the first electron affinity. At least an oxygen concentration at the third area is lower than an oxygen concentration at the first area.

Owner:SAMSUNG DISPLAY CO LTD

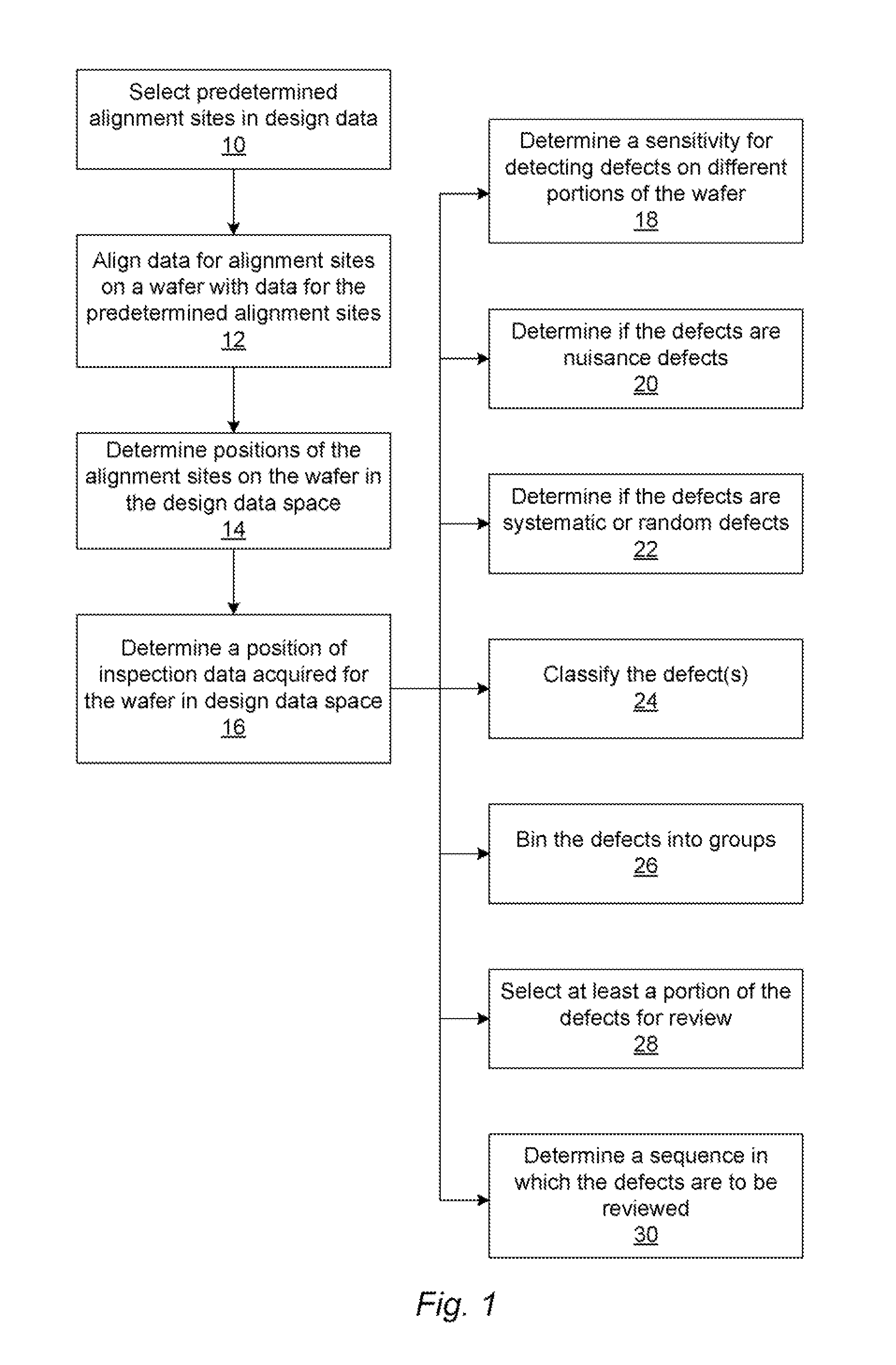

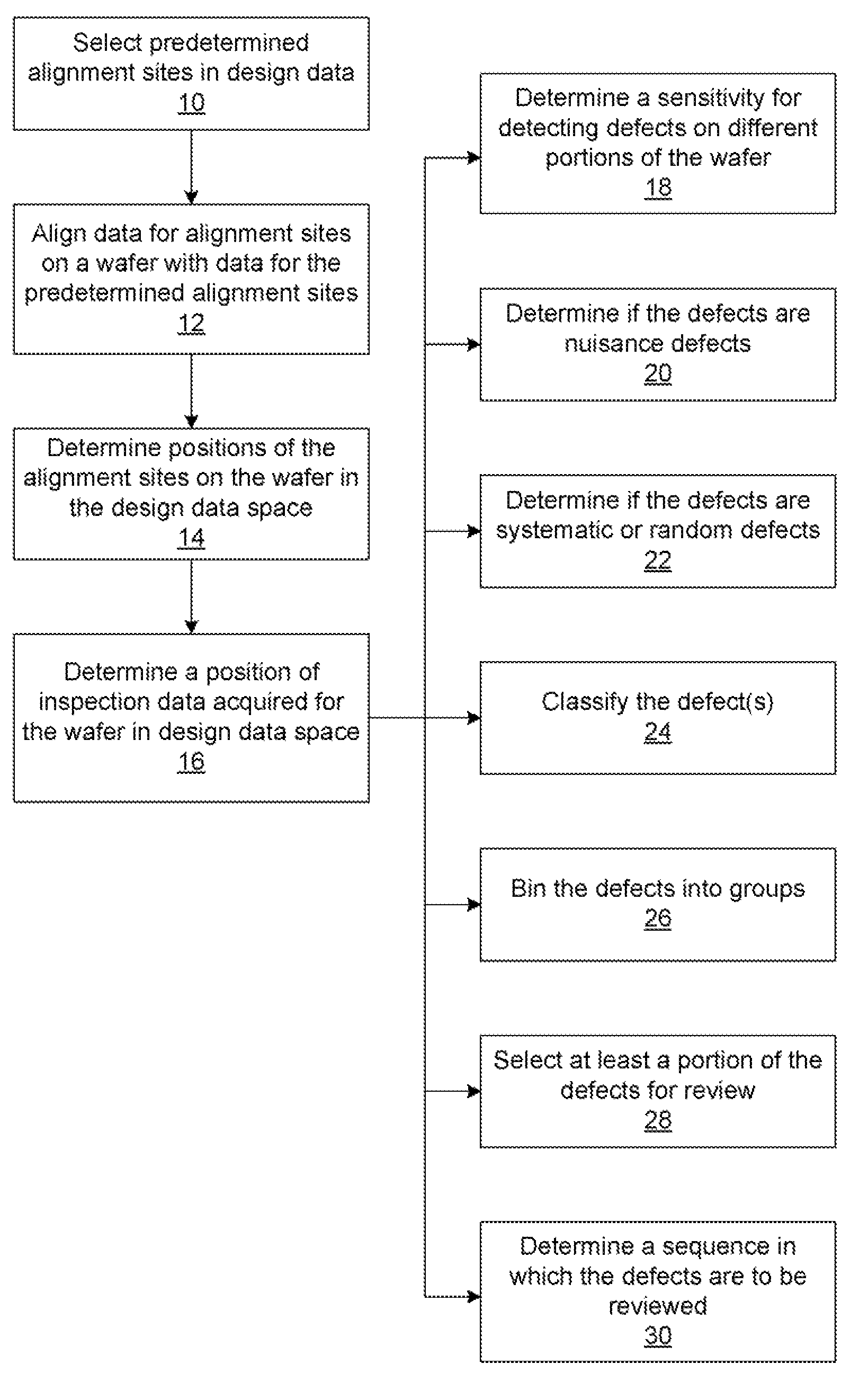

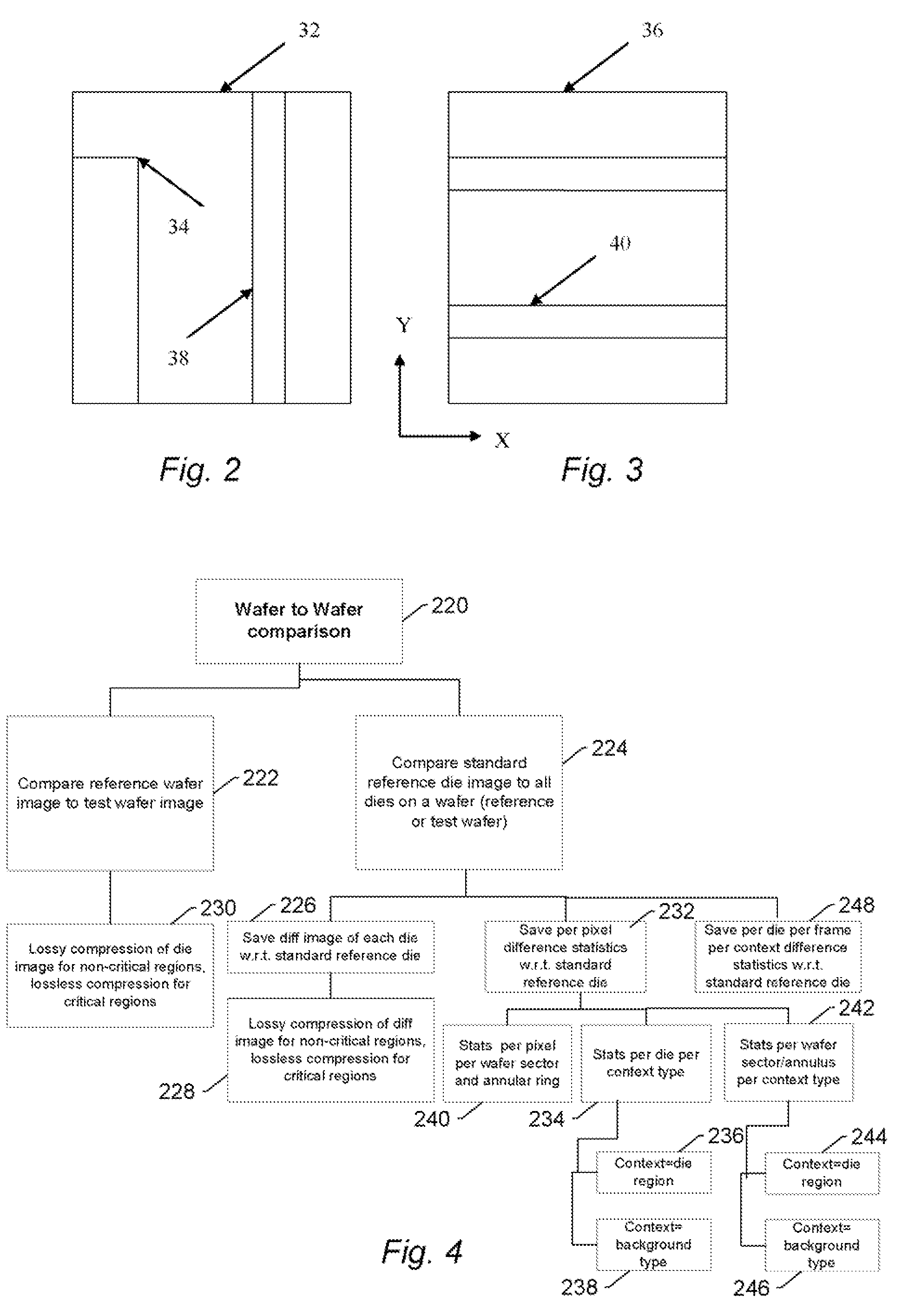

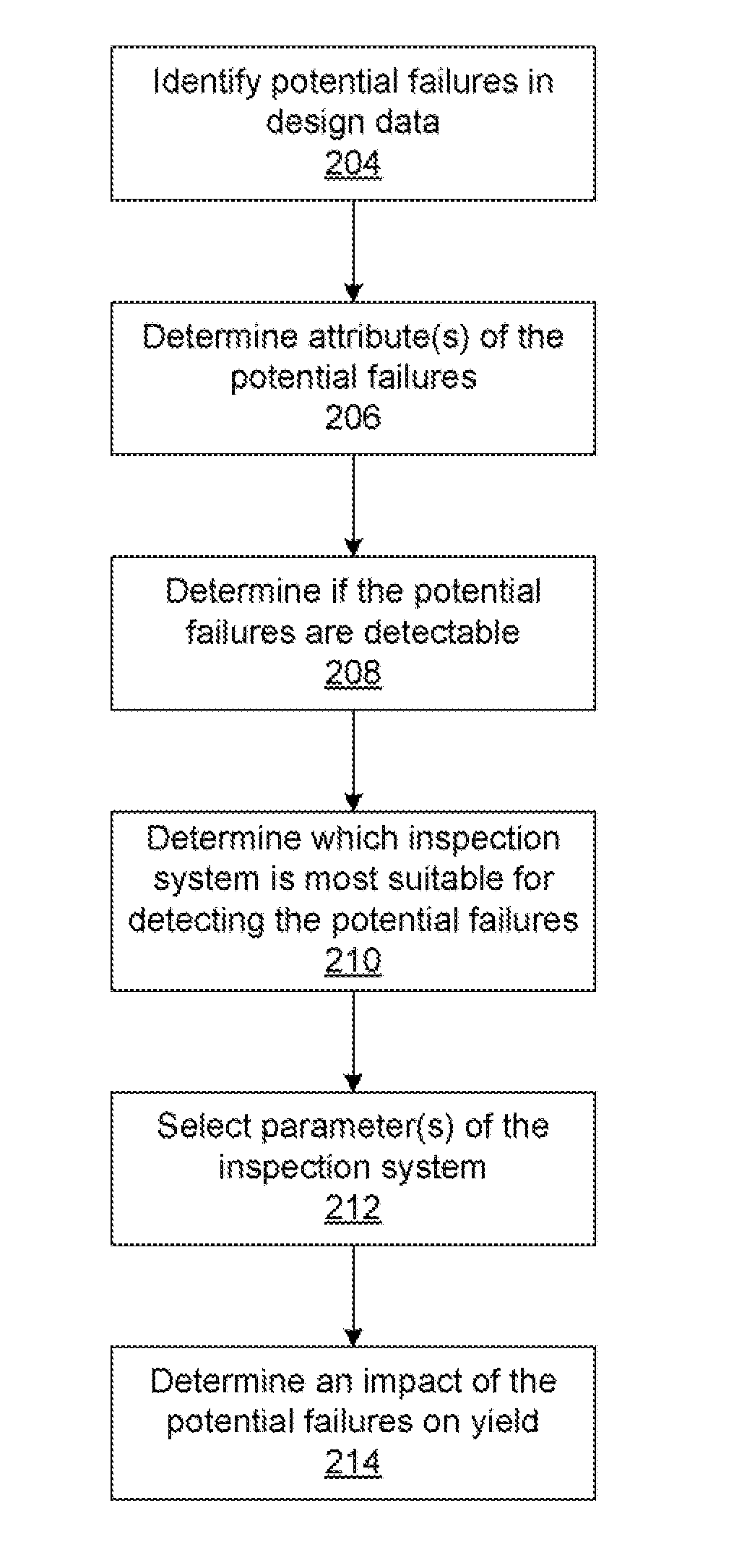

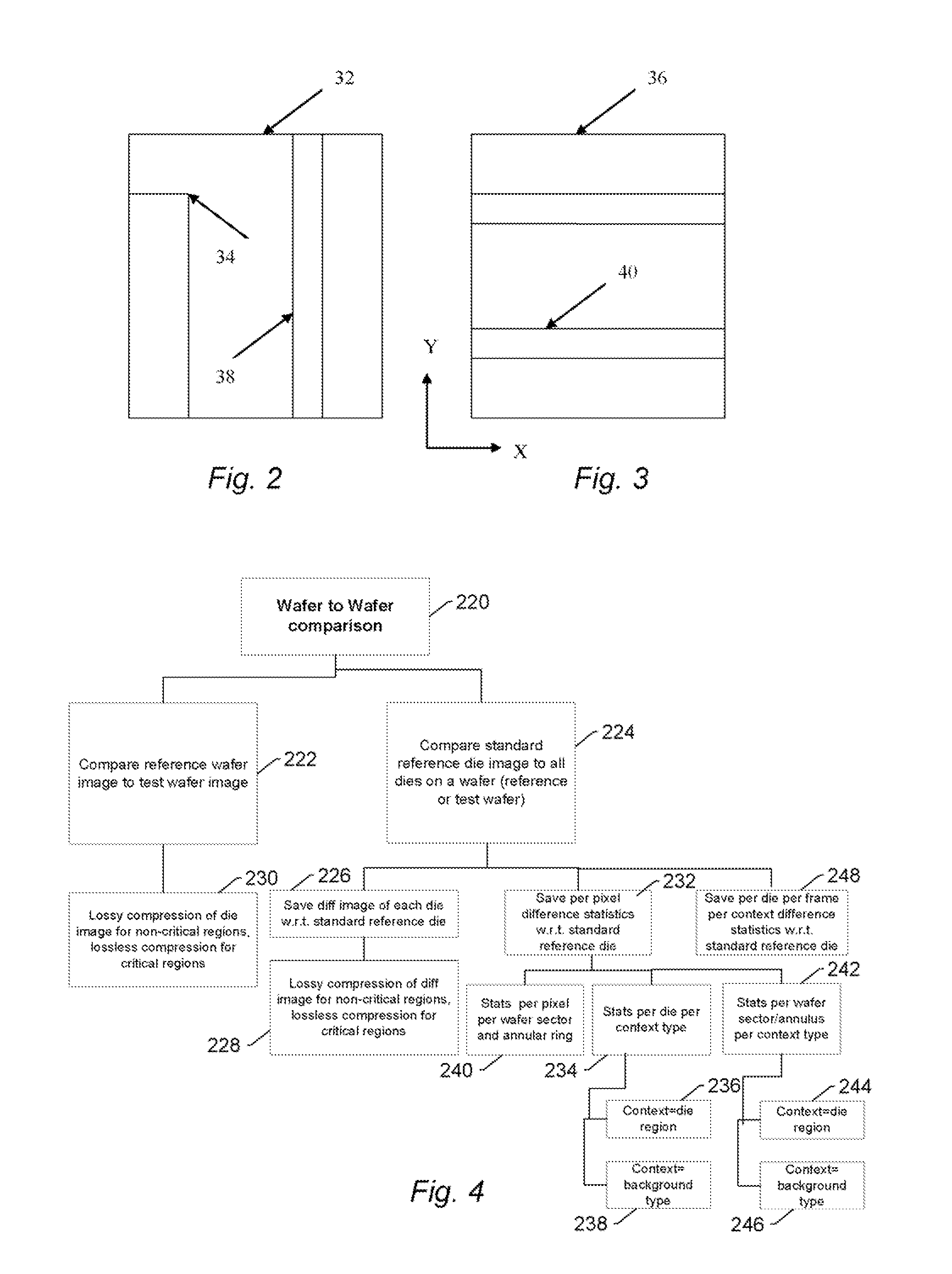

Methods and systems for utilizing design data in combination with inspection data

ActiveUS20070288219A1Increase catch rateReduce errorsImage enhancementImage analysisComputer scienceDesign data

Various methods and systems for utilizing design data in combination with inspection data are provided. One computer-implemented method for binning defects detected on a wafer includes comparing portions of design data proximate positions of the defects in design data space. The method also includes determining if the design data in the portions is at least similar based on results of the comparing step. In addition, the method includes binning the defects in groups such that the portions of the design data proximate the positions of the defects in each of the groups are at least similar. The method further includes storing results of the binning step in a storage medium.

Owner:KLA TENCOR CORP

Methods and systems for utilizing design data in combination with inspection data

ActiveUS7570796B2Reduce errorsImprove signal-to-noise ratioImage enhancementImage analysisComputer scienceDesign data

Owner:KLA TENCOR TECH CORP

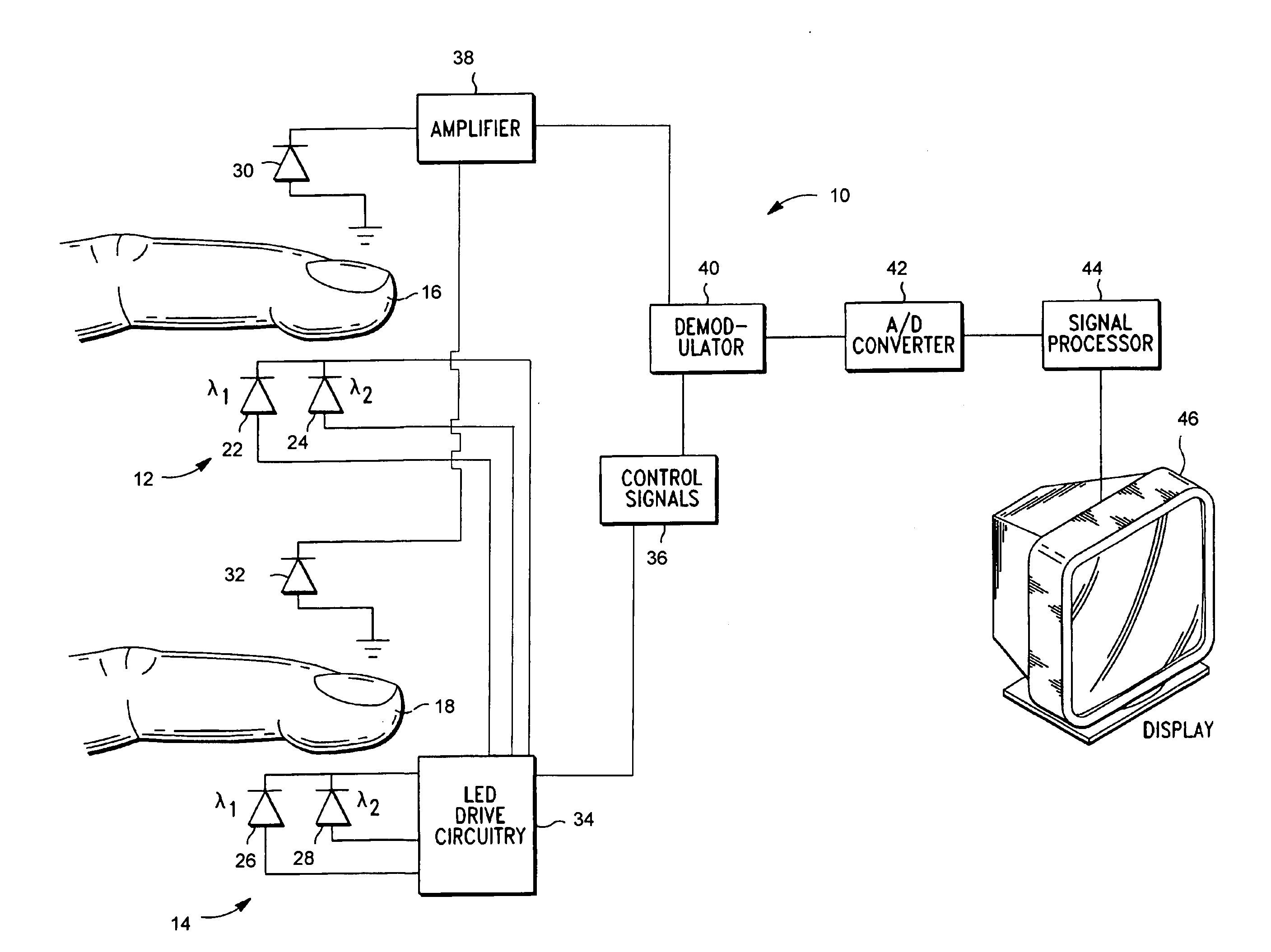

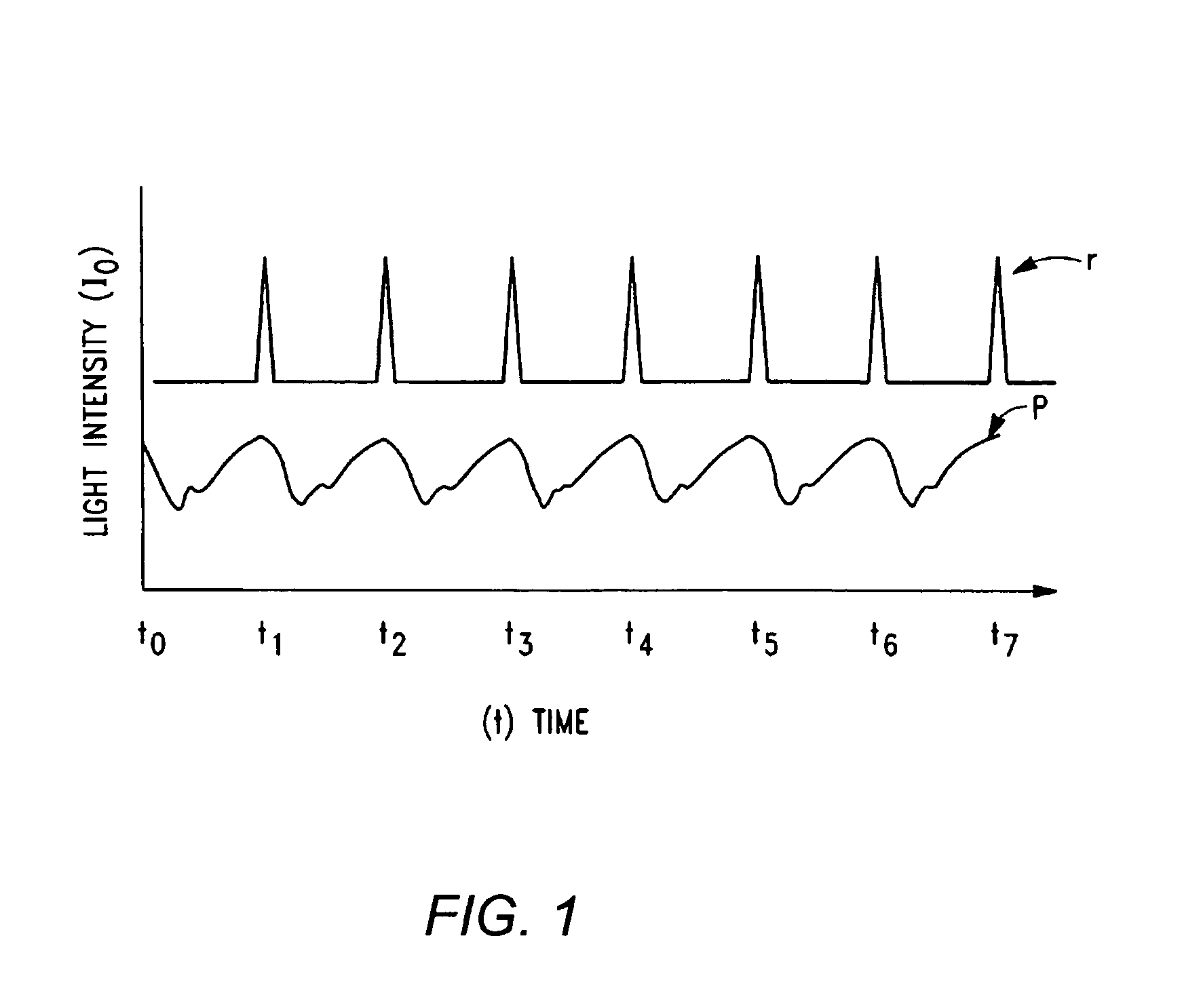

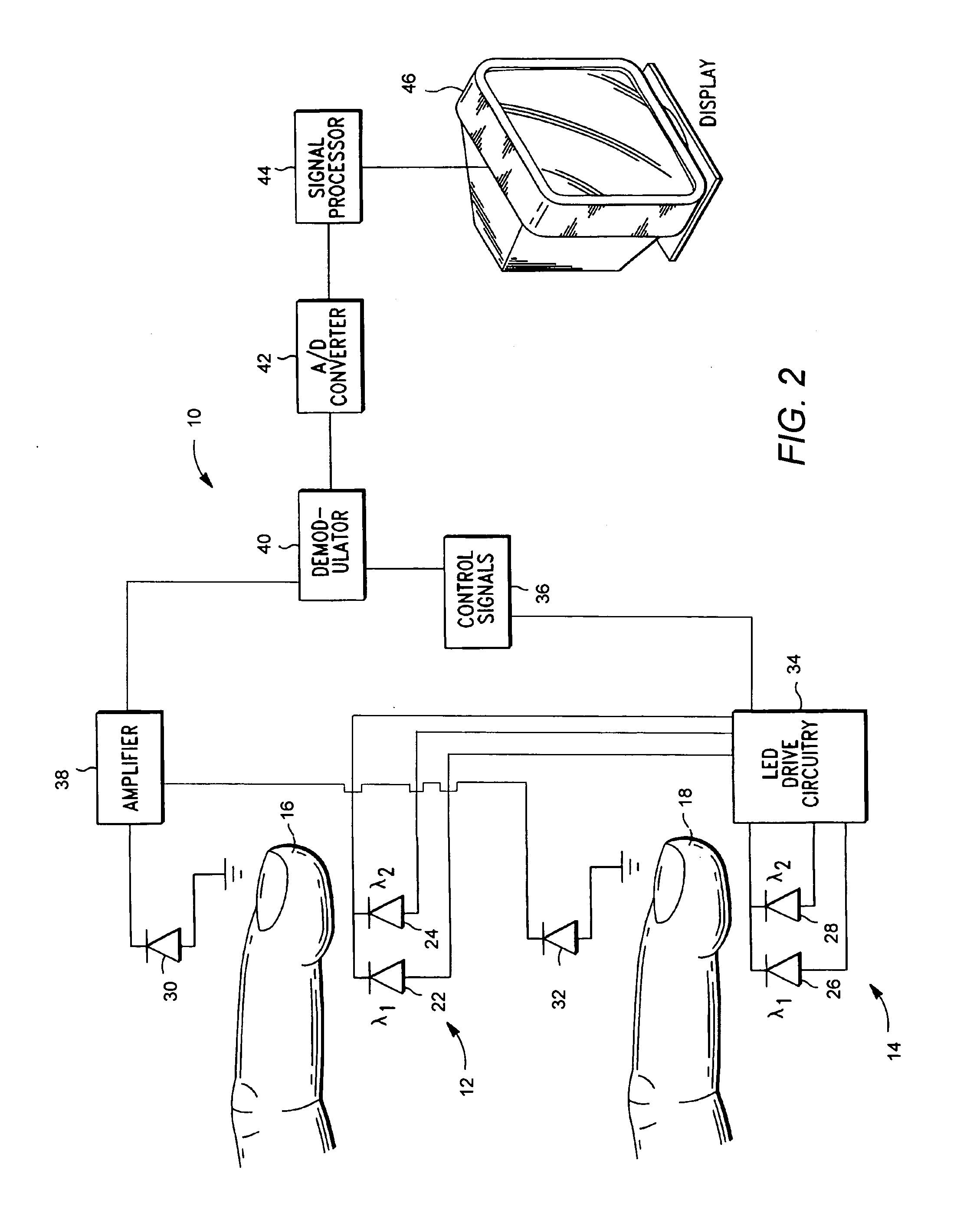

Method and apparatus for processing signals reflecting physiological characteristics from multiple sensors

InactiveUS20070260132A1Improve accuracyEnhanced signalDiagnostic recording/measuringSensorsMedicineMultiple sensor

The invention comprises a method and apparatus for processing signals reflecting a physiological characteristic by performing an error minimizing mathematical combination between signals from at least two independent sensors. For example, the intensity of light is detected following tissue absorption at two wavelengths and the signals are corrected. Preferably, corrected intensity signals are derived by orthogonal regression. In one embodiment, the method and apparatus are used to determine arterial oxygen saturation.

Owner:WOOLSTHORPE TECH

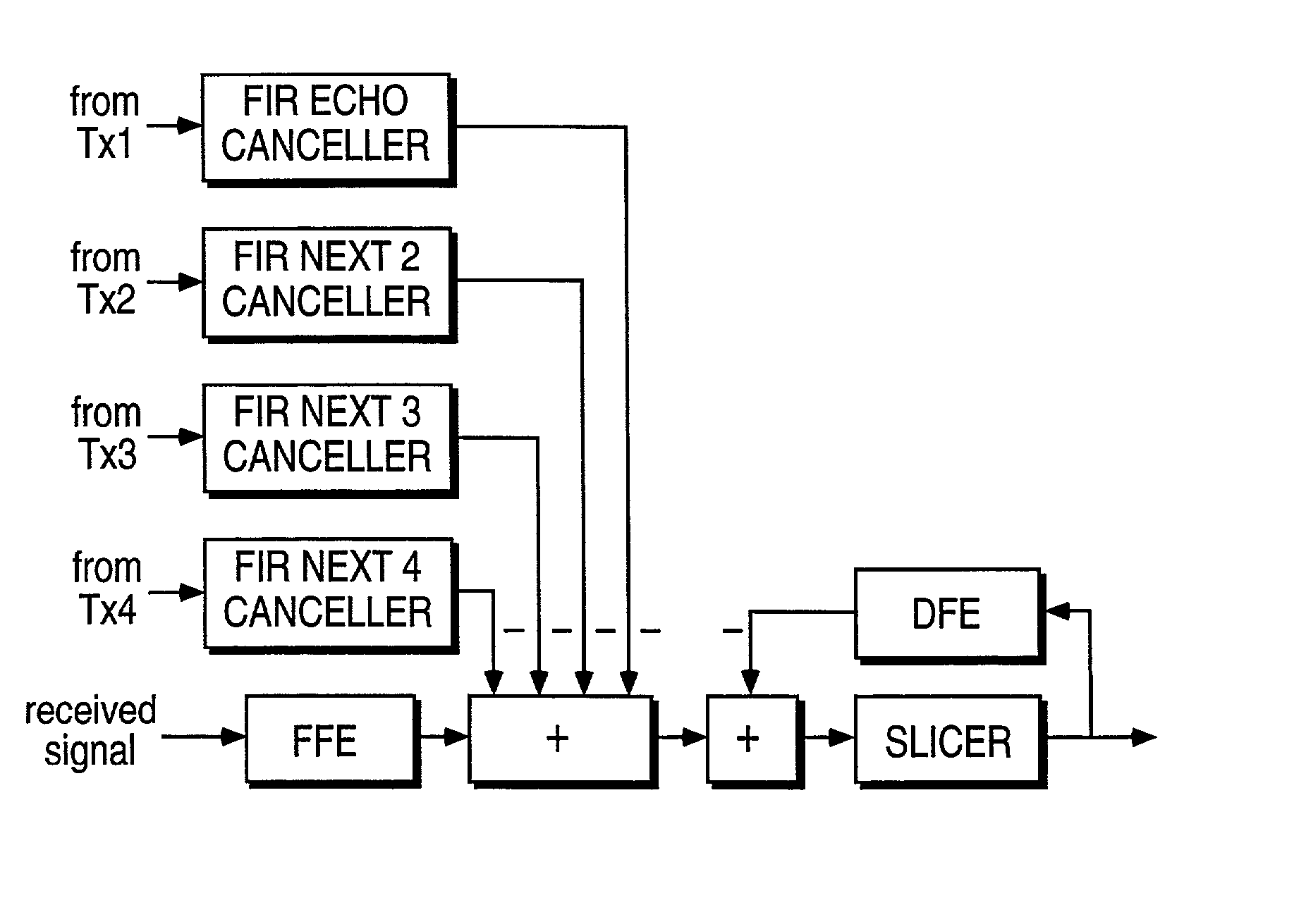

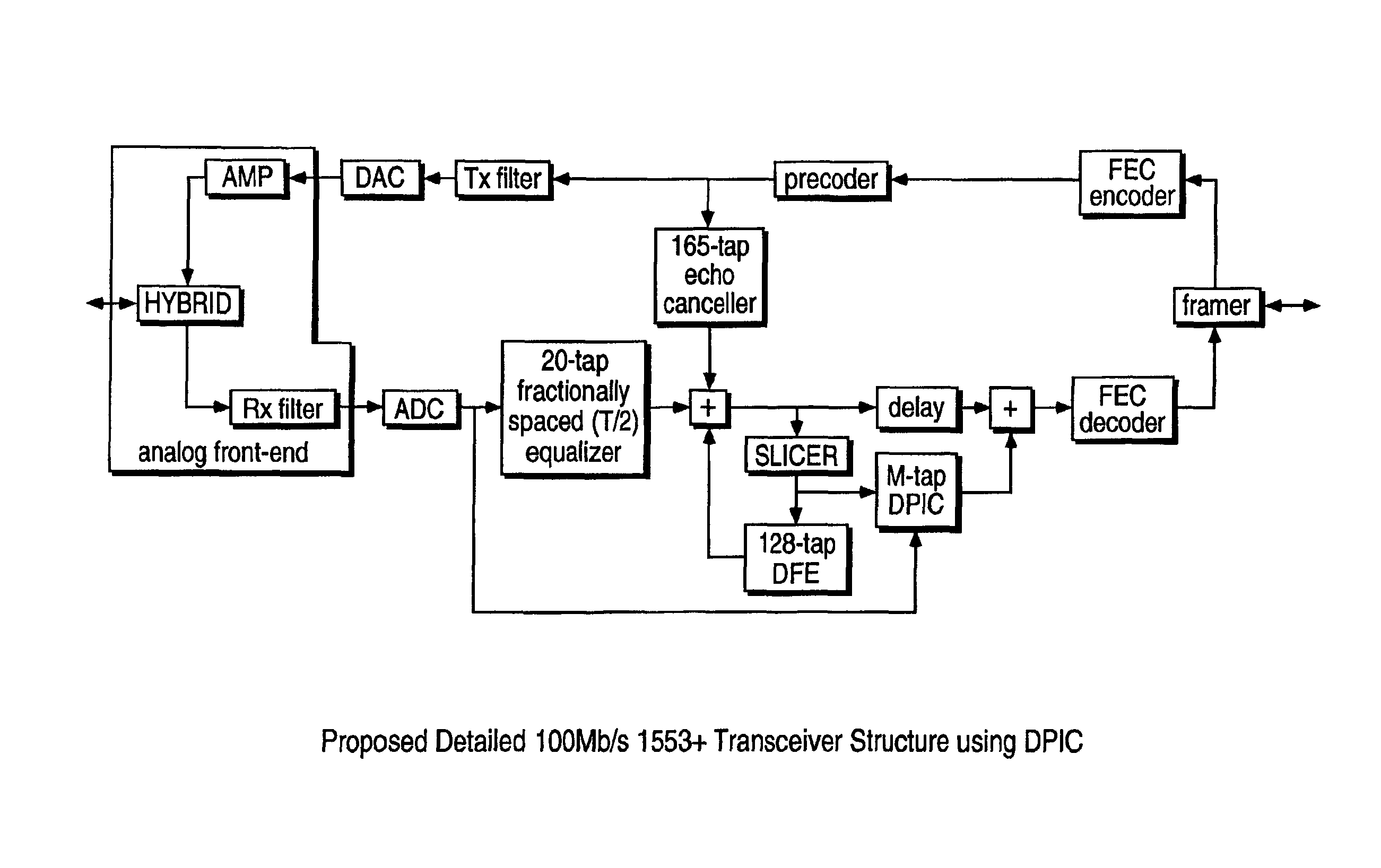

Channel equalization system and method

InactiveUS6904110B2Increase high performance and data rate capacityLow costMultiple-port networksChannel dividing arrangementsFiberEngineering

A system and method for delivering increases speed, security, and intelligence to wireline and wireless systems. The present invention increases channel capacity by using a parallel or multi-channel structure in such wireless and wireline at the edge or the core of. This new architecture of the present invention uses parallel bitstreams in a flexible way and distributed switching / routing technique, is not only to avoid the potential bottlenet of centralized switches, but also to increase speed with intelligence that is seamlessly integrating into the Fiber Optic Backbone such as WDM and SONET of the MAN / WAN network with a Real-time guarantees, different types of traffic (such as Stringent synchronous, isochronous, and asynchronous data messages) with different demands, and privacy & security of multi access and integrated services environment.

Owner:B C LEOW

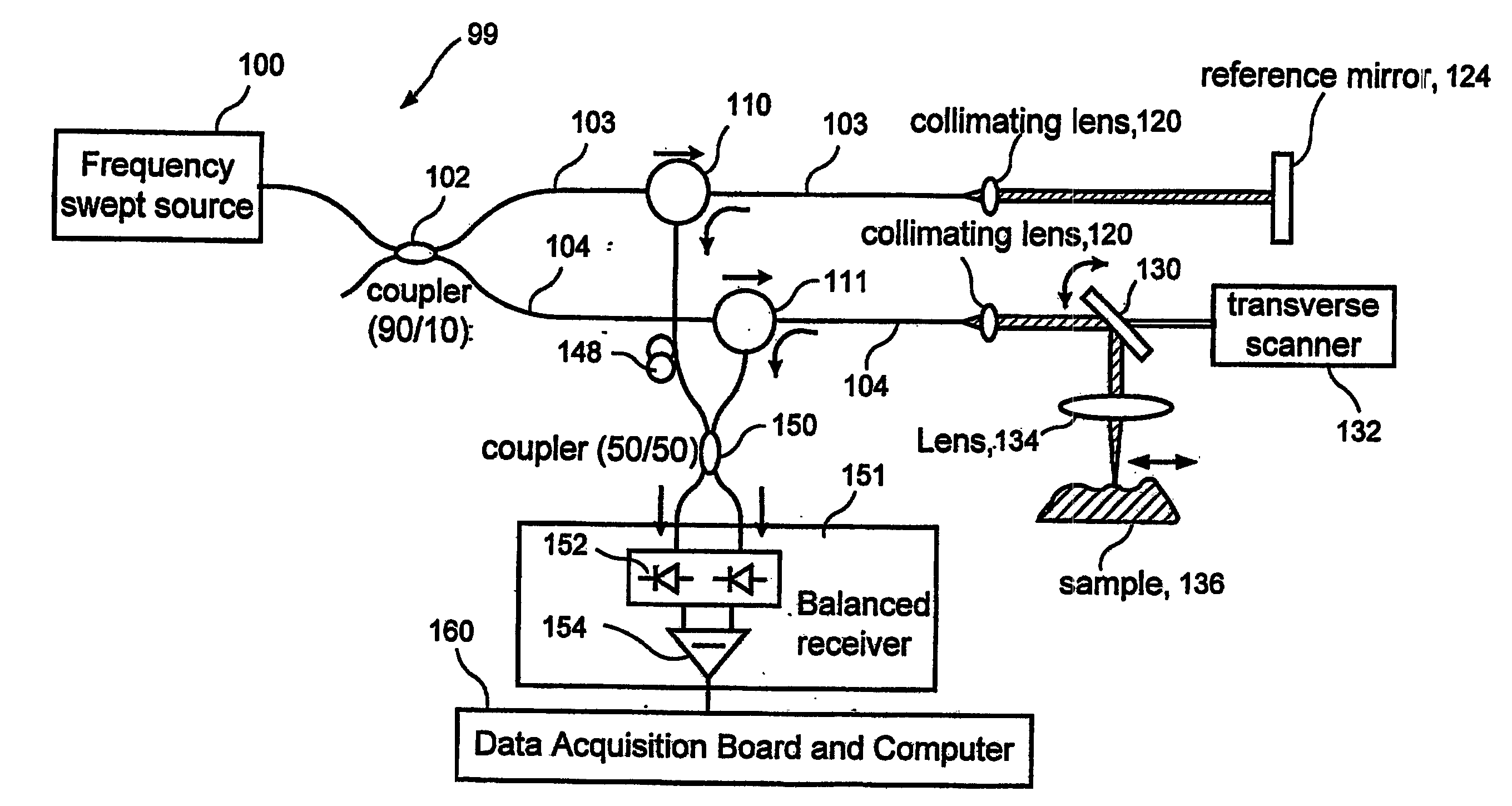

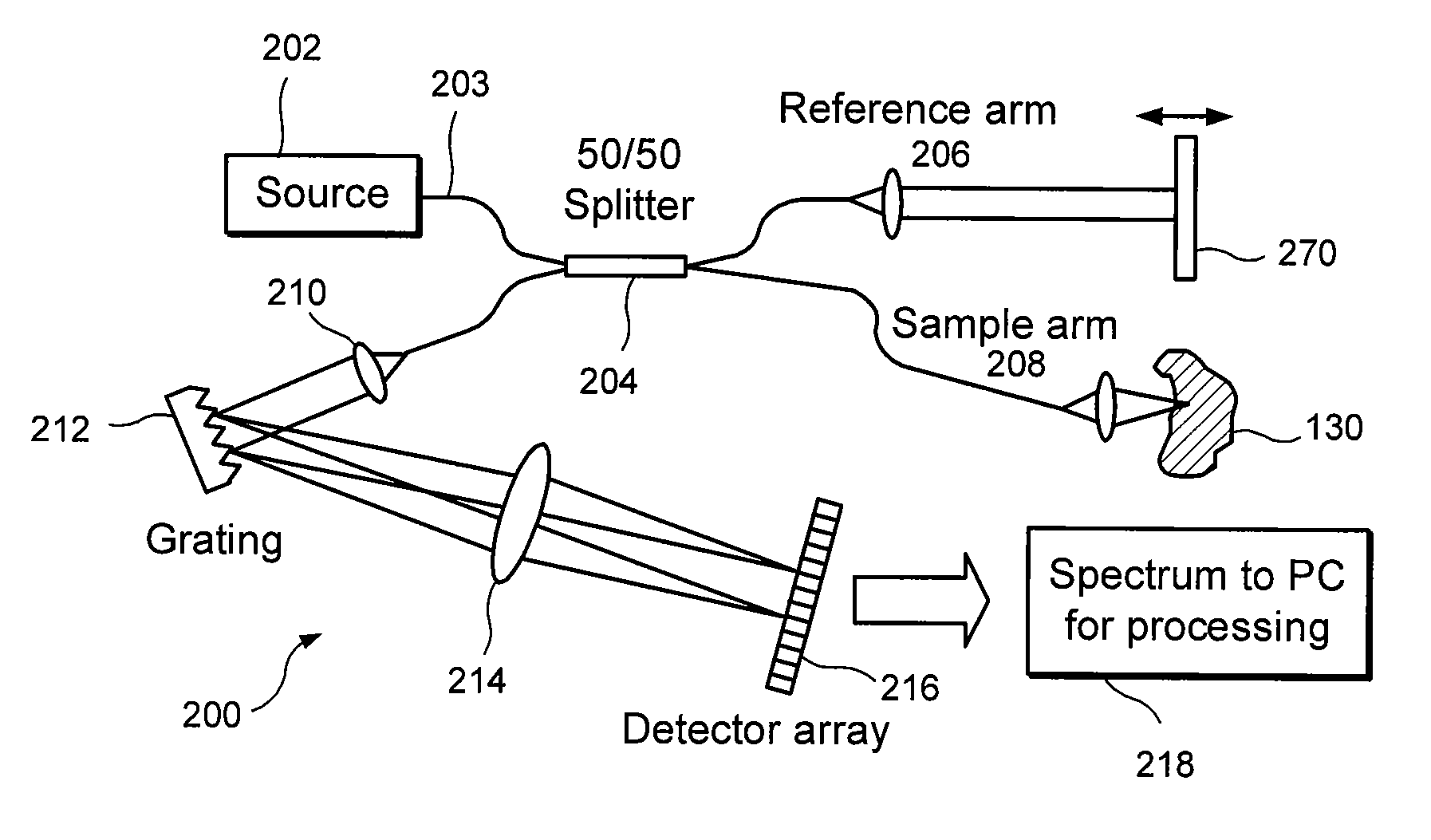

Method and apparatus for performing optical imaging using frequency-domain interferometry

ActiveUS20060244973A1Low source powerHigh acquisition rateOptical measurementsLaser detailsPhysicsFrequency domain

Owner:THE GENERAL HOSPITAL CORP

Apparatus and method for ranging and noise reduction of low coherence interferometry LCI and optical coherence tomography OCT signals by parallel detection of spectral bands

InactiveUS7355716B2Improve signal-to-noise ratioImproves current data acquisition speed and availabilityDiagnostics using lightInterferometersBandpass filteringSpectral bands

Apparatus, method, logic arrangement and storage medium are provided for increasing the sensitivity in the detection of optical coherence tomography and low coherence interferometry (“LCI”) signals by detecting a parallel set of spectral bands, each band being a unique combination of optical frequencies. The LCI broad bandwidth source can be split into N spectral bands. The N spectral bands can be individually detected and processed to provide an increase in the signal-to-noise ratio by a factor of N. Each spectral band may be detected by a separate photo detector and amplified. For each spectral band, the signal can be band p3 filtered around the signal band by analog electronics and digitized, or, alternatively, the signal may be digitized and band pass filtered in software. As a consequence, the shot noise contribution to the signal is likely reduced by a factor equal to the number of spectral bands, while the signal amplitude can remain the same. The reduction of the shot noise increases the dynamic range and sensitivity of the system.

Owner:THE GENERAL HOSPITAL CORP

Channel adaptive equalization precoding system and method

InactiveUS20030086515A1Increase high performance and data rate capacityLow costChannel dividing arrangementsError detection/prevention using signal quality detectorPrecodingOperational system

A system and method for delivering increased speed, security, and intelligence to wireline and wireless systems. The present invention includes a new generation Fast Circuit Switch (packet / circuit) Communication processors and platform which enables a new Internet Exchange Networking Processor Architecture at the edge and core of every communication system, for next generation Web Operating System or Environment (WOE) to operate on with emphasis of a non-local processor or networking processor with remote web computing capabilities.

Owner:TRANS FRANCOIS +1

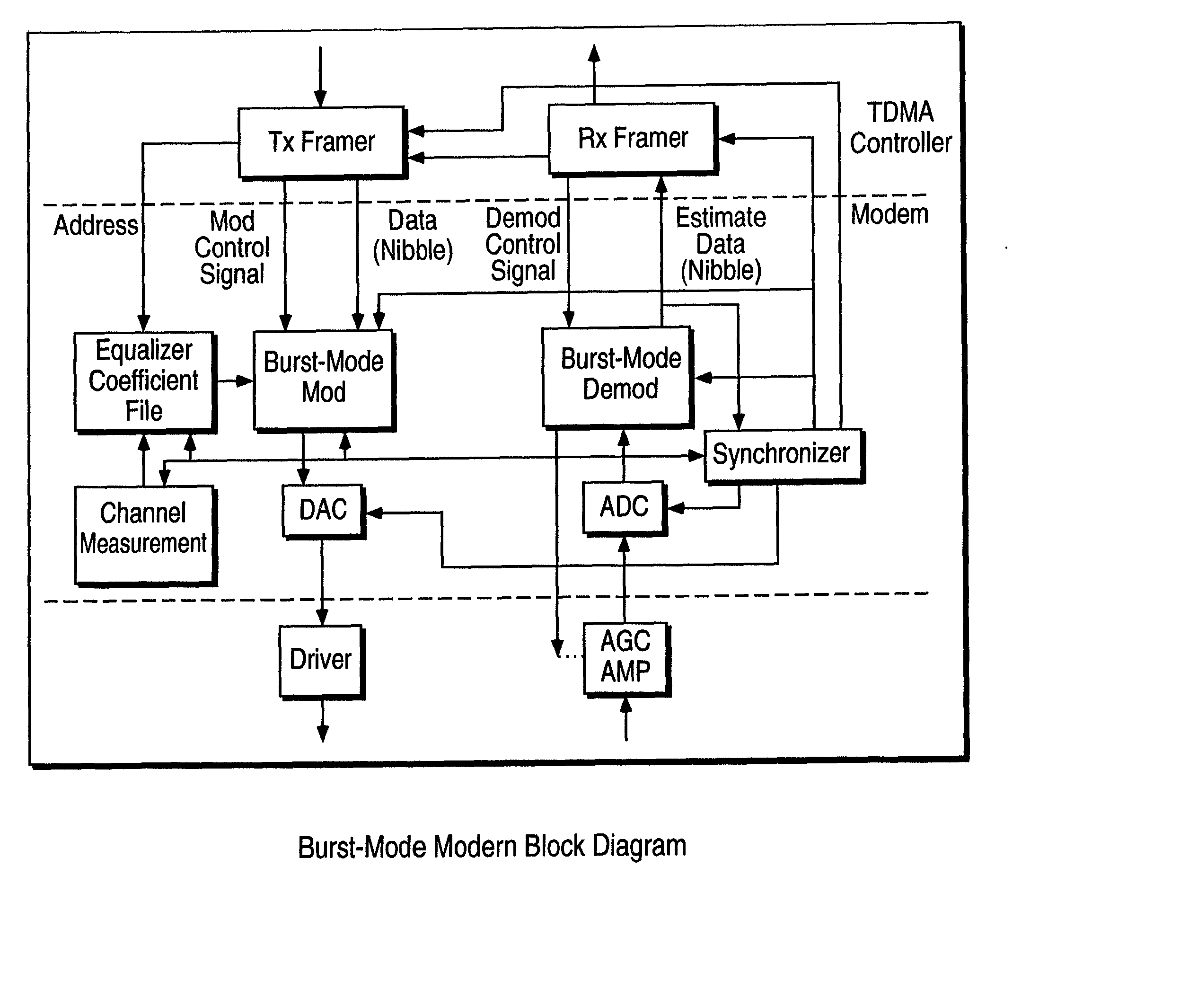

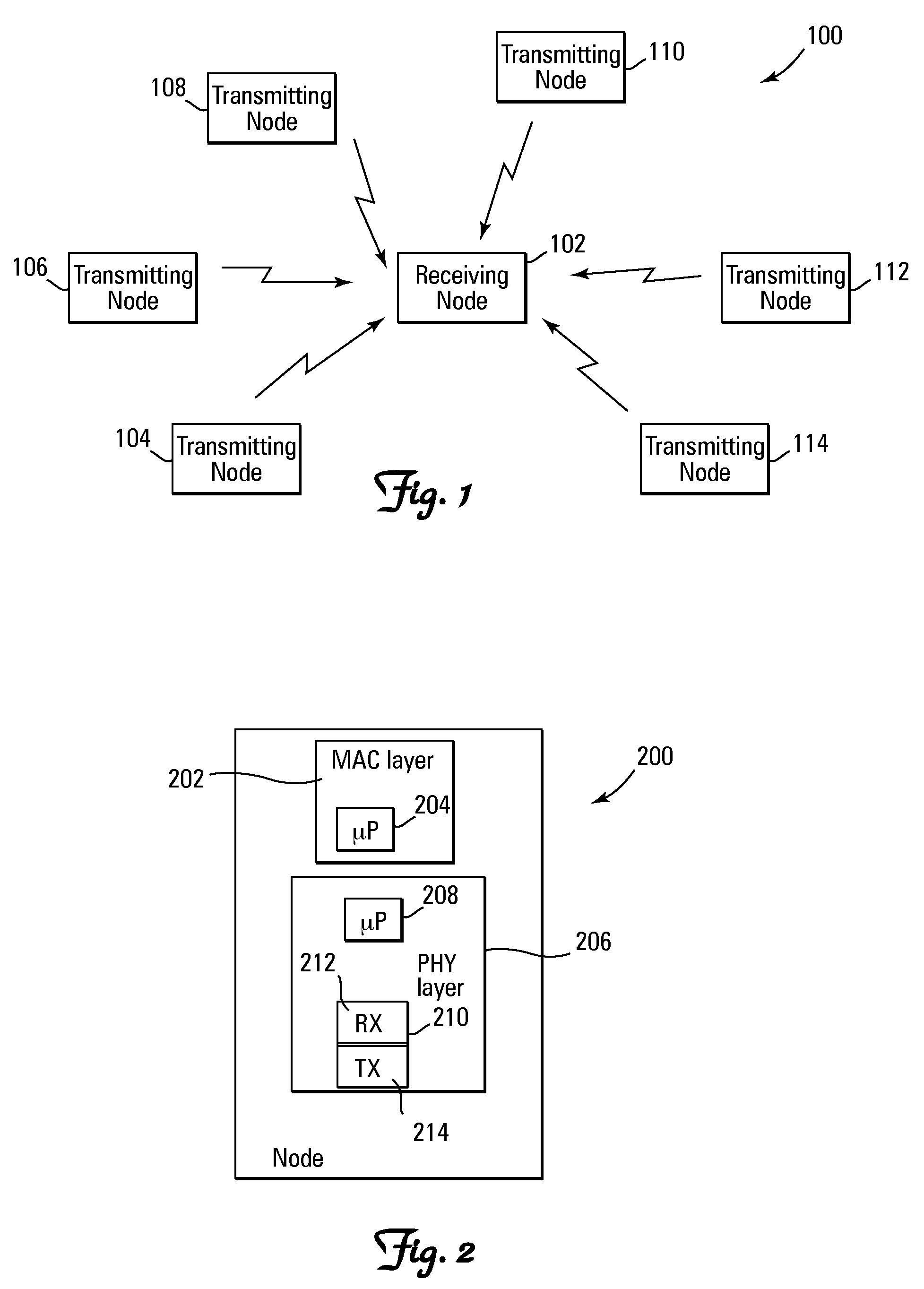

Method for low-energy adaptive clustering hierarchy

InactiveUS7035240B1Reduce decreaseReduce the amount requiredEnergy efficient ICTPower managementSelf adaptiveNetwork architecture

A method and network architecture for implementing an energy efficient network. The network includes a plurality of nodes that collect and transmit data that are ultimately routed to a base station. The network nodes form a set of clusters with a single node acting as a cluster-head. The cluster-head advertises for nodes to join its cluster, schedules the collection of data within a cluster, and then transmits the data to the base station. A cluster can intelligently combine data from individual nodes. After a period of operation, the clusters are reformed with a different set of nodes acting as cluster-heads. The network provides an increased system lifetime by balancing the energy use of individual nodes.

Owner:MASSACHUSETTS INST OF TECH

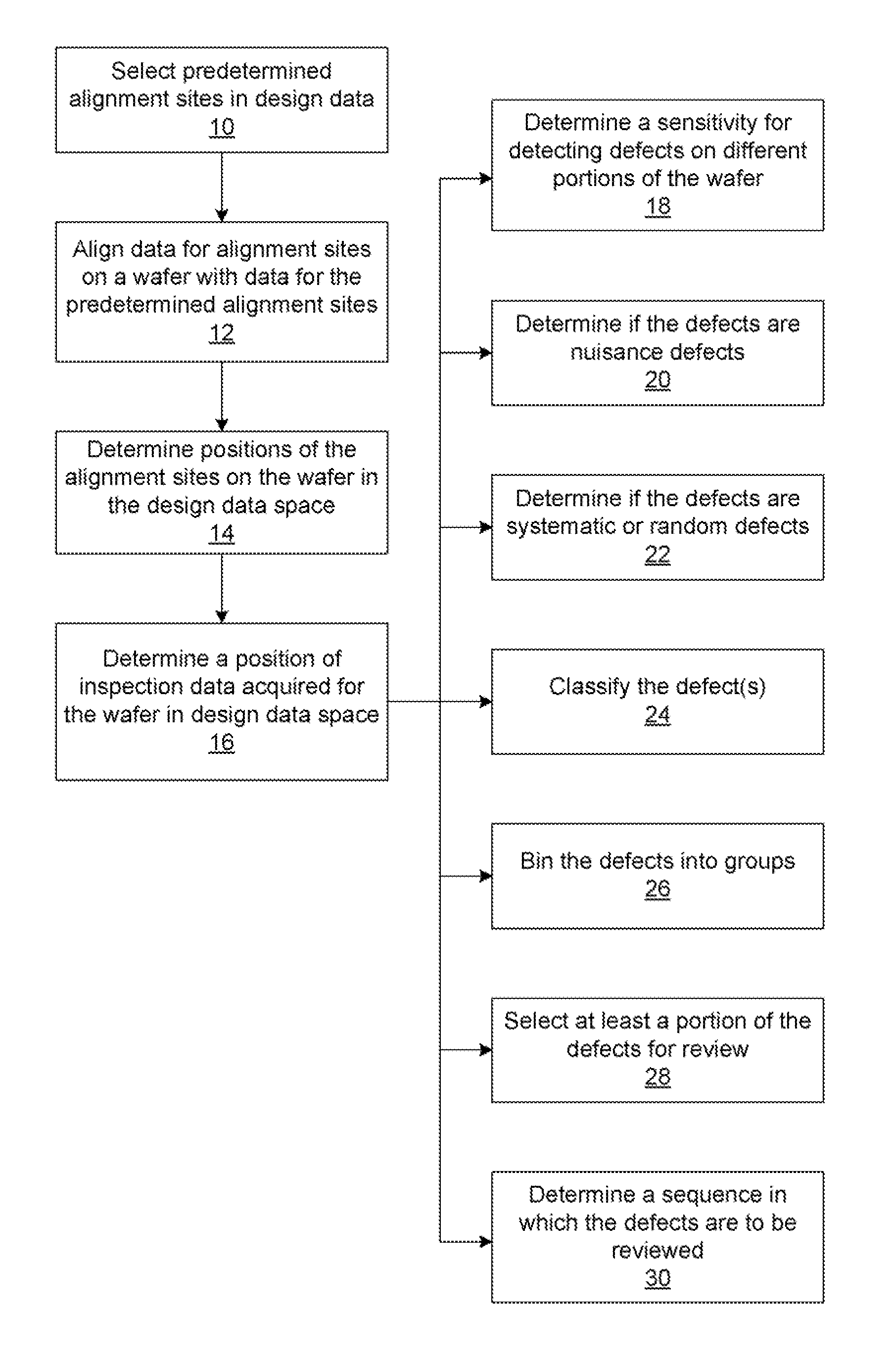

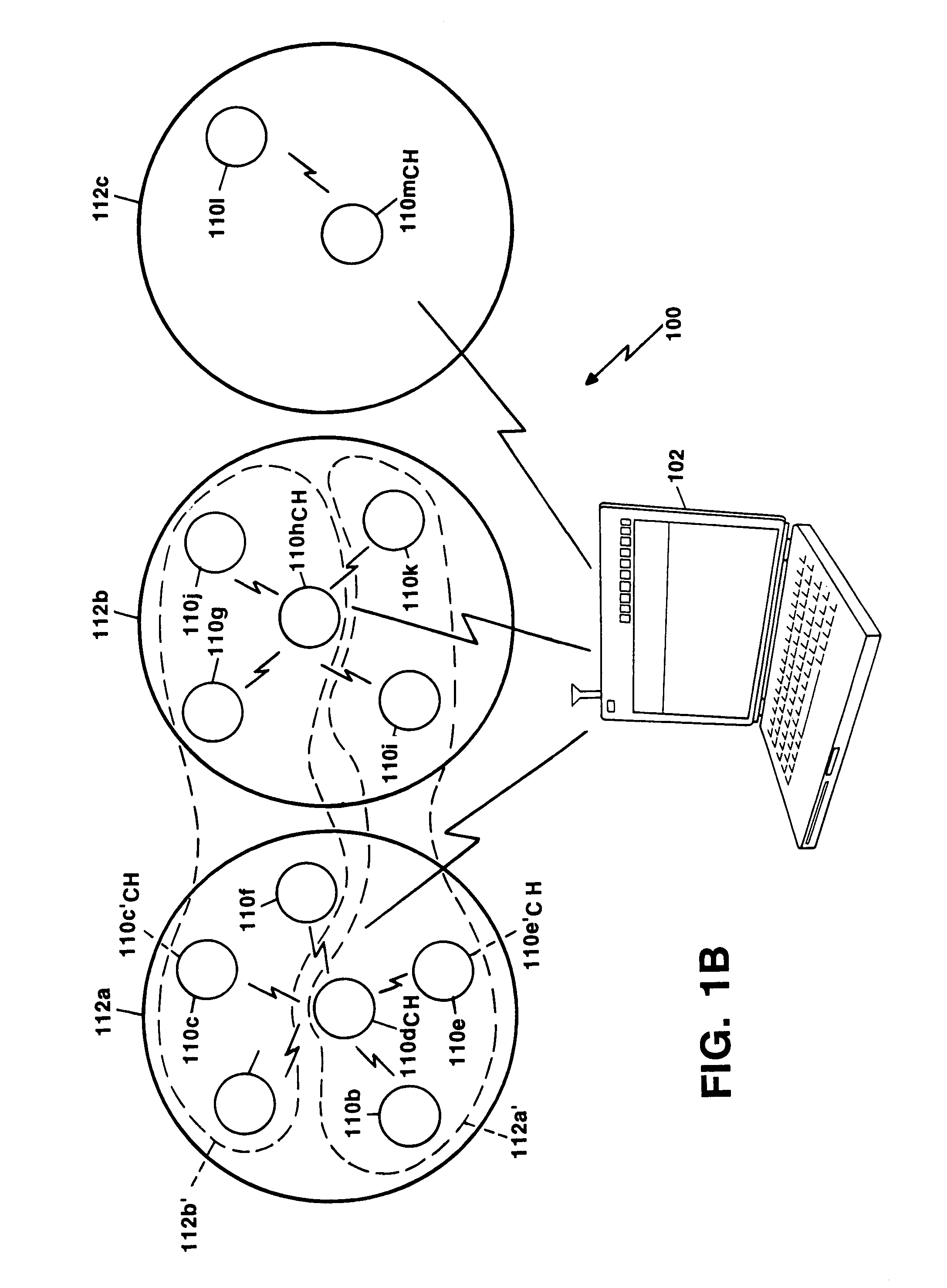

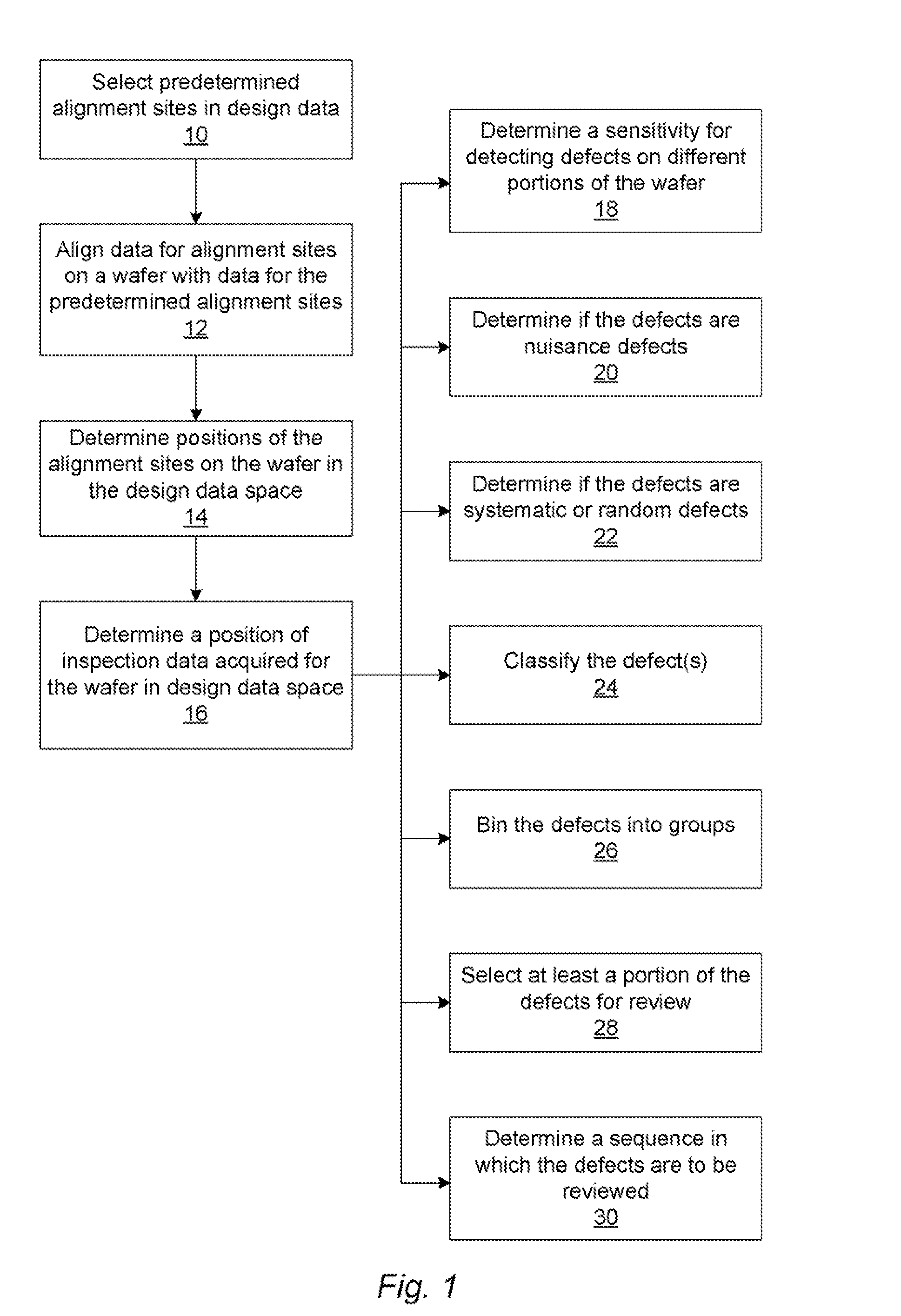

Methods and systems for utilizing design data in combination with inspection data

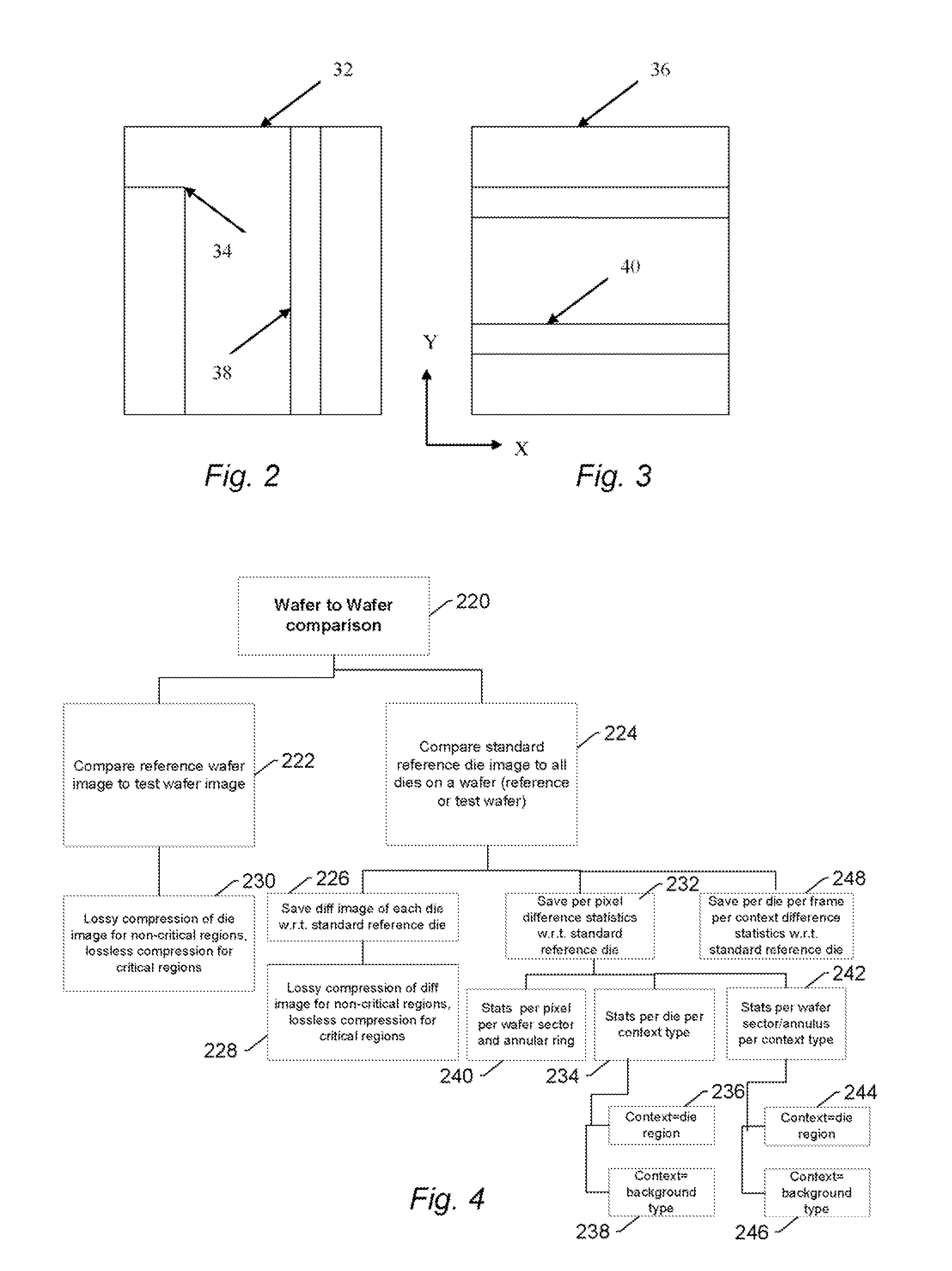

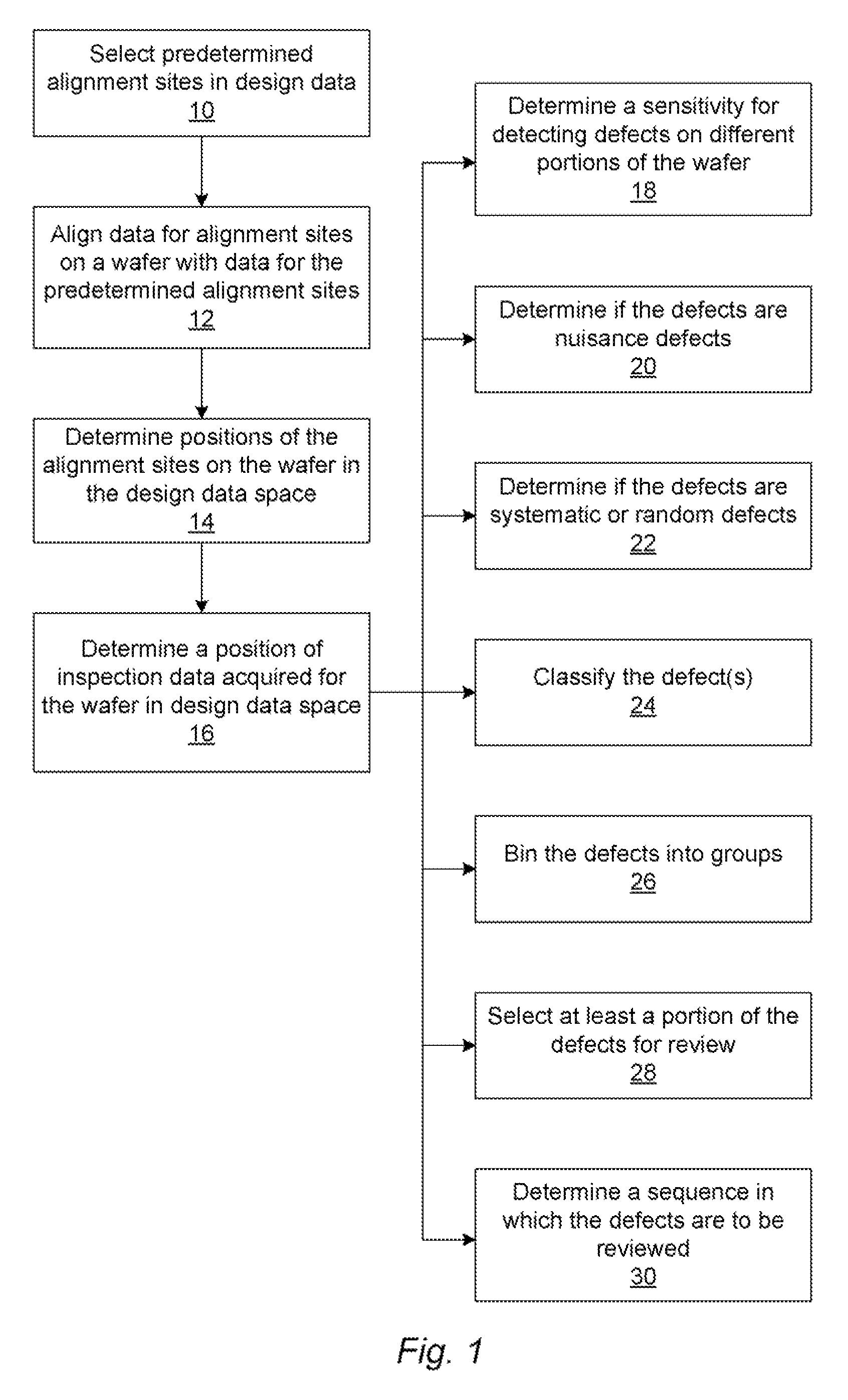

ActiveUS20070156379A1Increase catch rateImprove signal-to-noise ratioSemiconductor/solid-state device manufacturingCharacter and pattern recognitionEngineeringDesign data

Various methods and systems for utilizing design data in combination with inspection data are provided. One computer-implemented method for determining a position of inspection data in design data space includes aligning data acquired by an inspection system for alignment sites on a wafer with data for predetermined alignment sites. The method also includes determining positions of the alignment sites on the wafer in design data space based on positions of the predetermined alignment sites in the design data space. In addition, the method includes determining a position of inspection data acquired for the wafer by the inspection system in the design data space based on the positions of the alignment sites on the wafer in the design data space. In one embodiment, the position of the inspection data is determined with sub-pixel accuracy.

Owner:KLA TENCOR TECH CORP

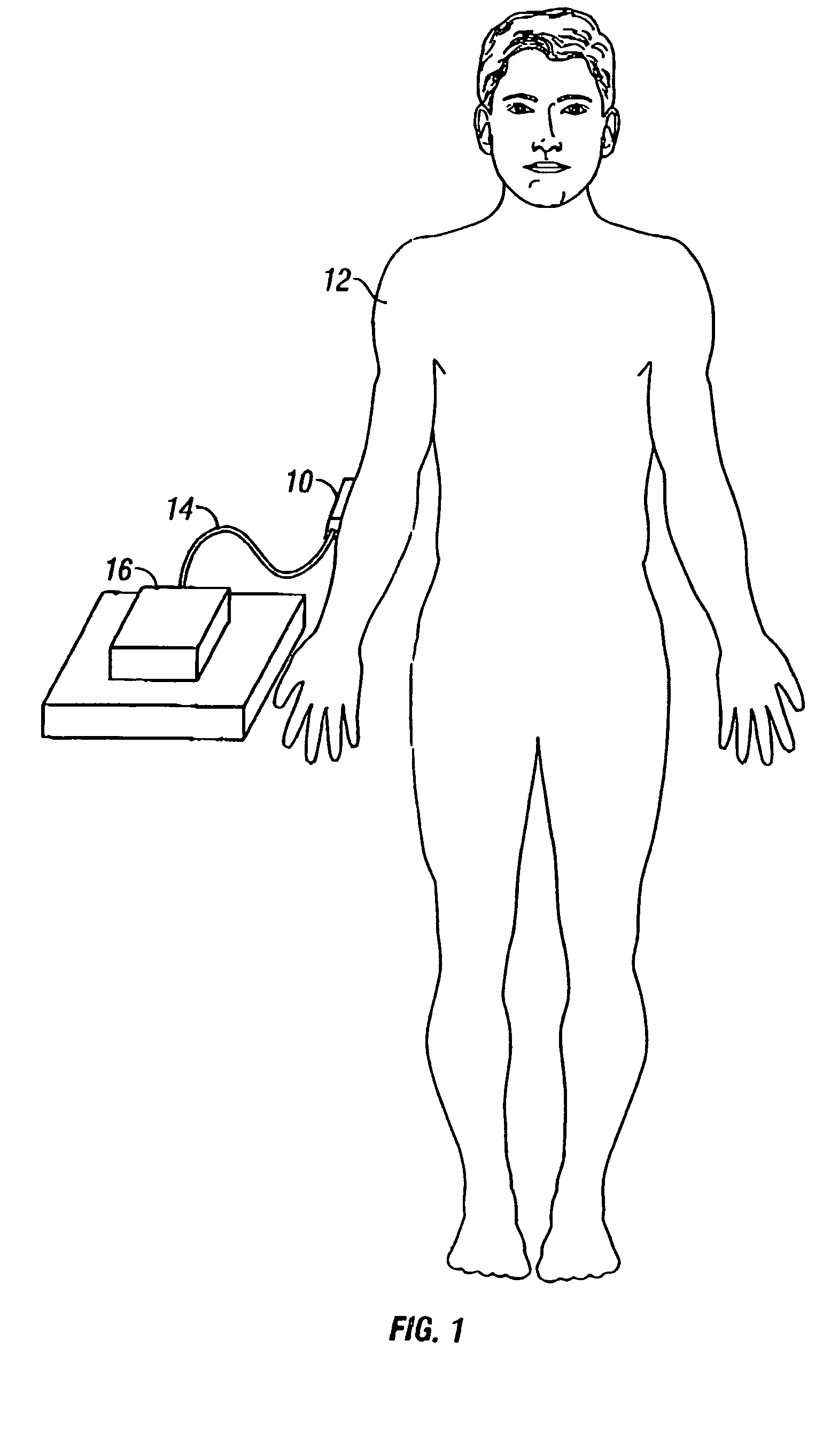

Compact apparatus for noninvasive measurement of glucose through near-infrared spectroscopy

ActiveUS7299080B2Minimize samplingMaximize collection of lightDiagnostics using spectroscopyScattering properties measurementsFiberSignal-to-noise ratio (imaging)

A near IR spectrometer-based analyzer attaches continuously or semi-continuously to a human subject and collects spectral measurements for determining a biological parameter in the sampled tissue, such as glucose concentration. The analyzer includes an optical system optimized to target the cutaneous layer of the sampled tissue so that interference from the adipose layer is minimized. The optical system includes at least one optical probe. Spacing between optical paths and detection fibers of each probe and between probes is optimized to minimize sampling of the adipose subcutaneous layer and to maximize collection of light backscattered from the cutaneous layer. Penetration depth is optimized by limiting range of distances between paths and detection fibers. Minimizing sampling of the adipose layer greatly reduces interference contributed by the fat band in the sample spectrum, increasing signal-to-noise ratio. Providing multiple probes also minimizes interference in the sample spectrum due to placement errors.

Owner:GLT ACQUISITION

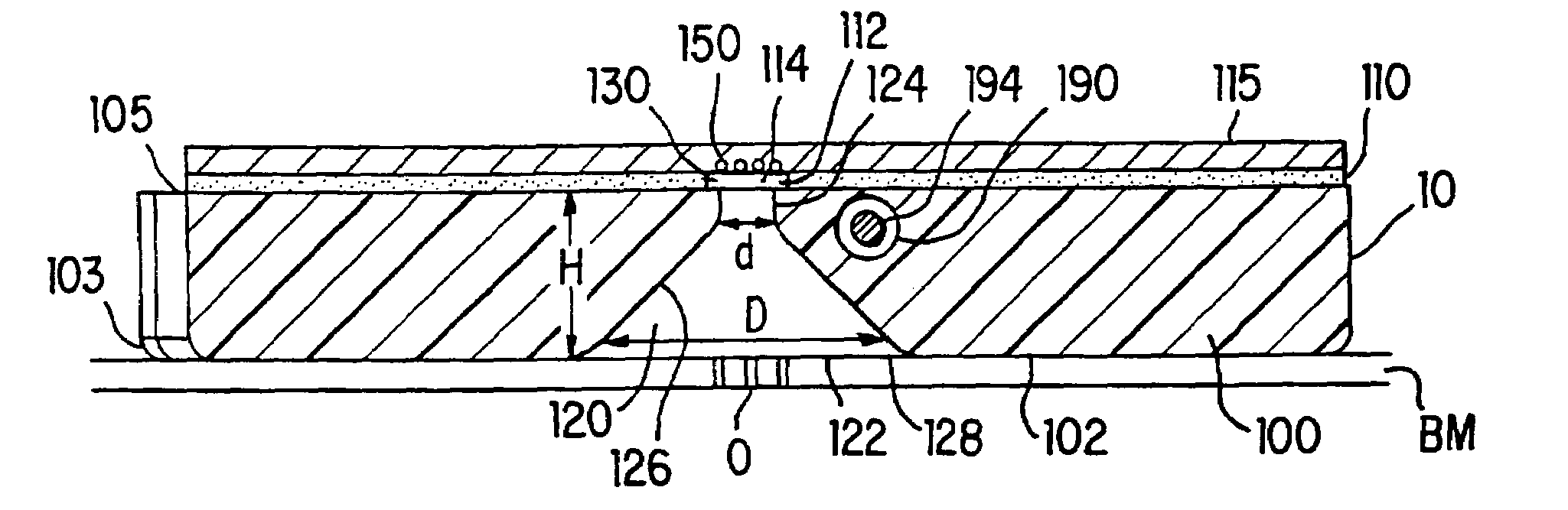

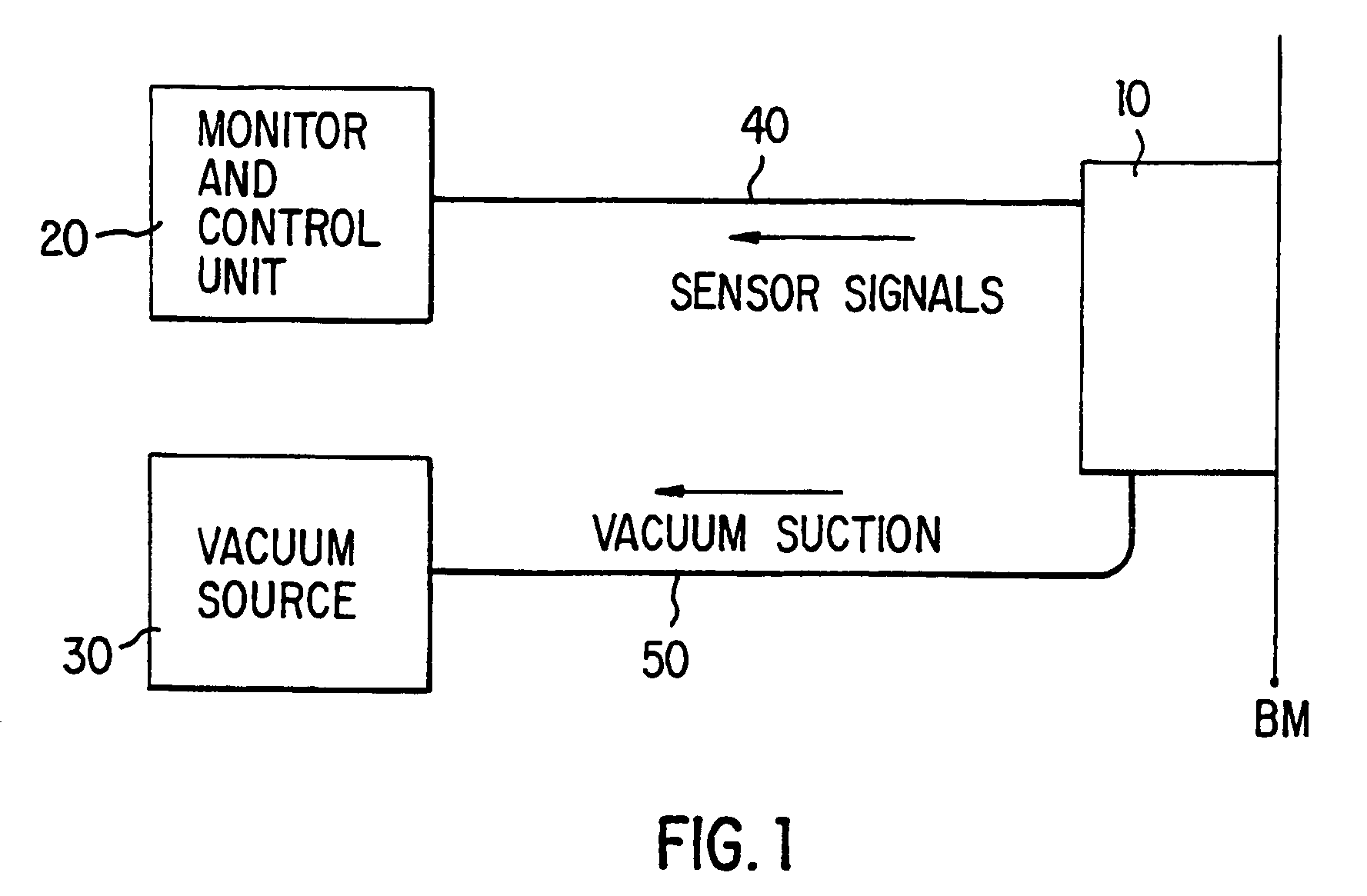

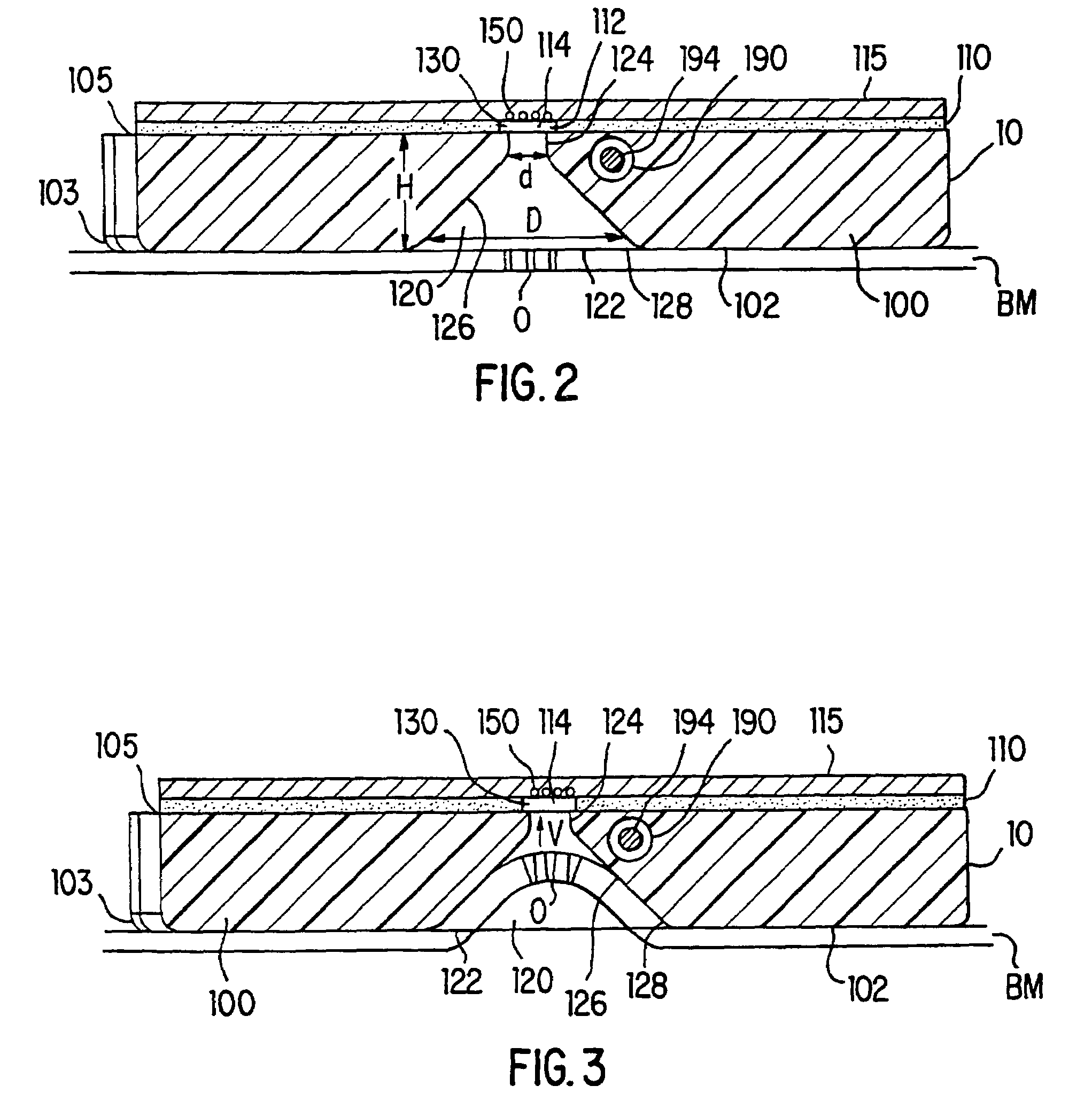

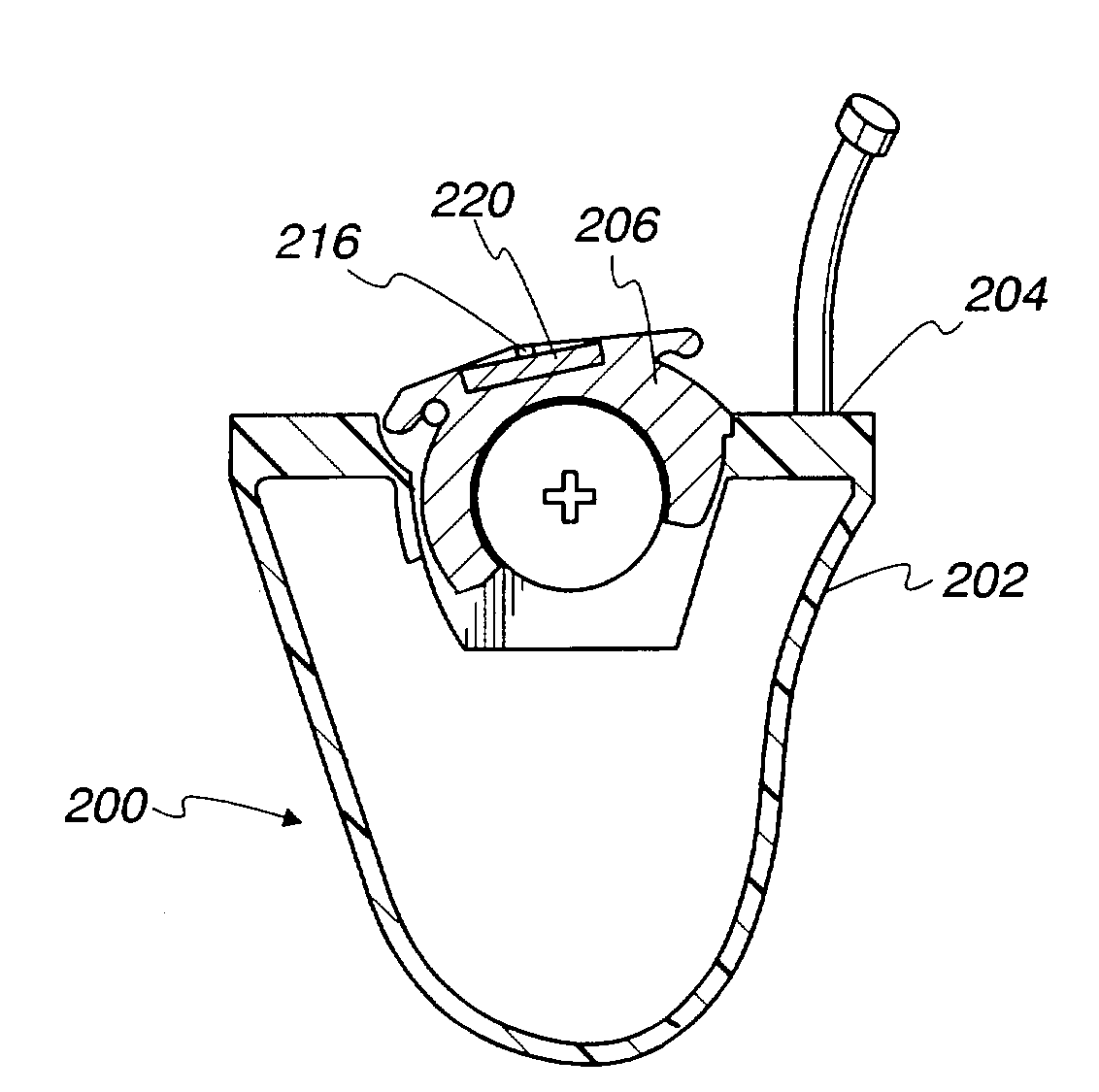

Tissue interface device

InactiveUS7041057B1Simpler basic array designImprove signal-to-noise ratioDiagnostic recording/measuringSensorsBiological bodyEngineering

A tissue interface device (10) suitable for positioning on or about one or more artificial openings in a biological membrane of an organism and for coupling to a monitor and control unit and a vacuum source. The tissue interface device (10) comprises a housing (100), a sensor channel (130), and a sensor (150). The housing (100) defines an orifice (120), the orifice (120) having an open inlet port (122) on the bottom end (102) of the housing (100) and a distal end (124) that is in fluid communication with the sensor channel (130). The orifice (120) is in fluid communication with fluid that flows from the artificial opening formed in the biological membranes. The sensor channel (130) is for coupling to, and fluid communication therewith, the vacuum source. The sensor (150) is positioned in the sensor channel (130) in a flow path of the fluid for sensing a characteristic of the fluid as it flows out from the artificial opening. The sensor generates a sensor signal representative thereof.

Owner:ALTEA THERAPEUTIC CORP +1

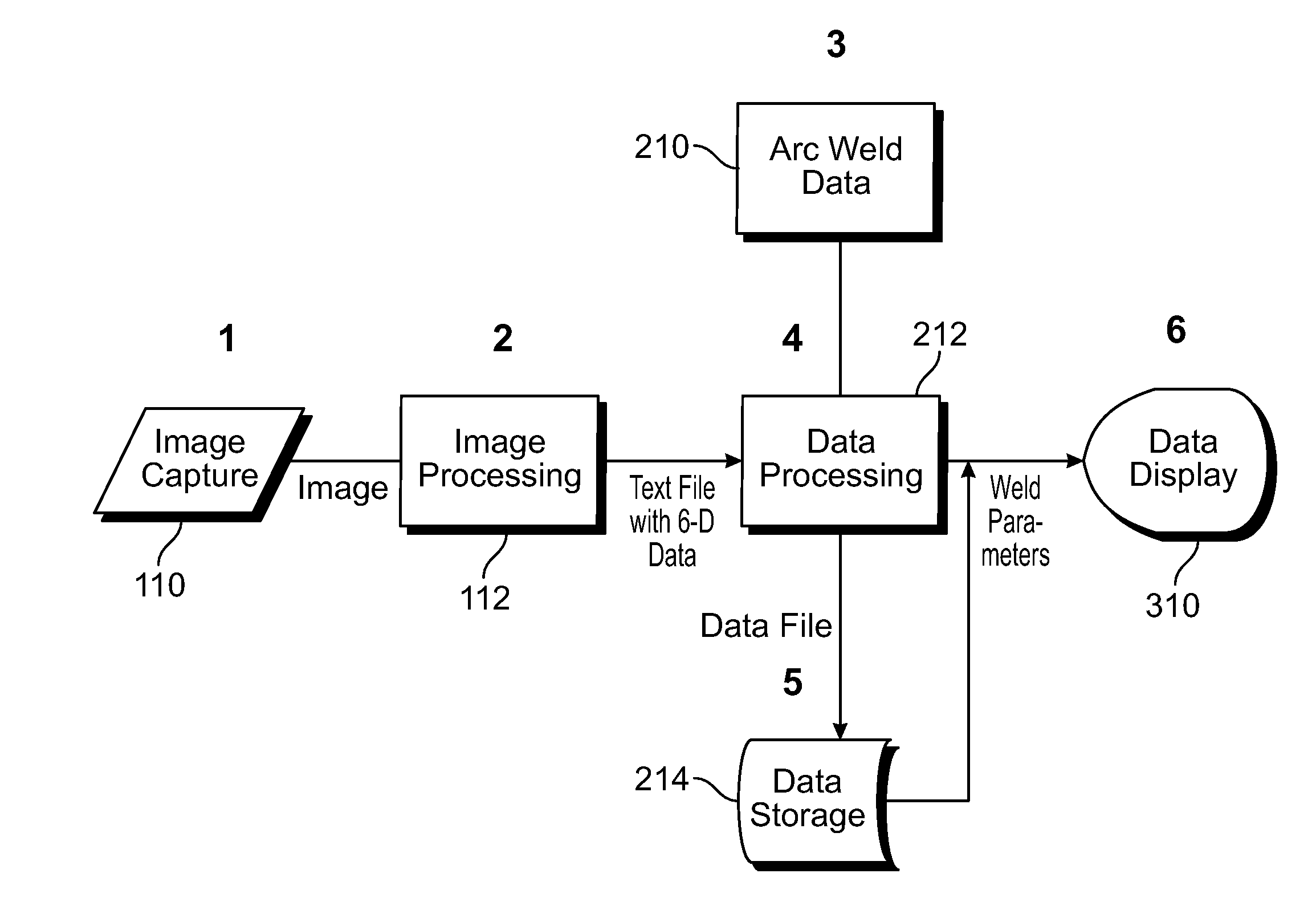

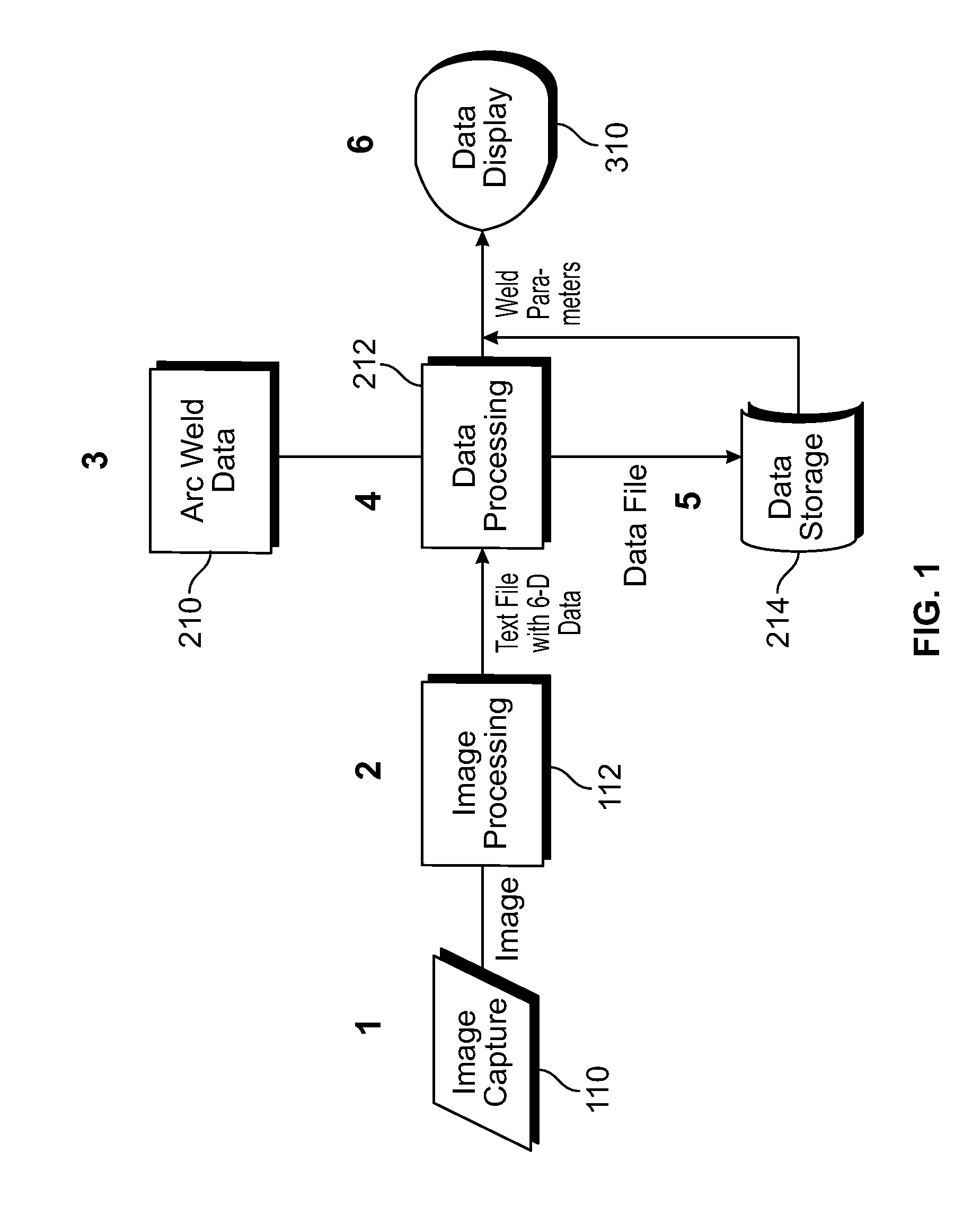

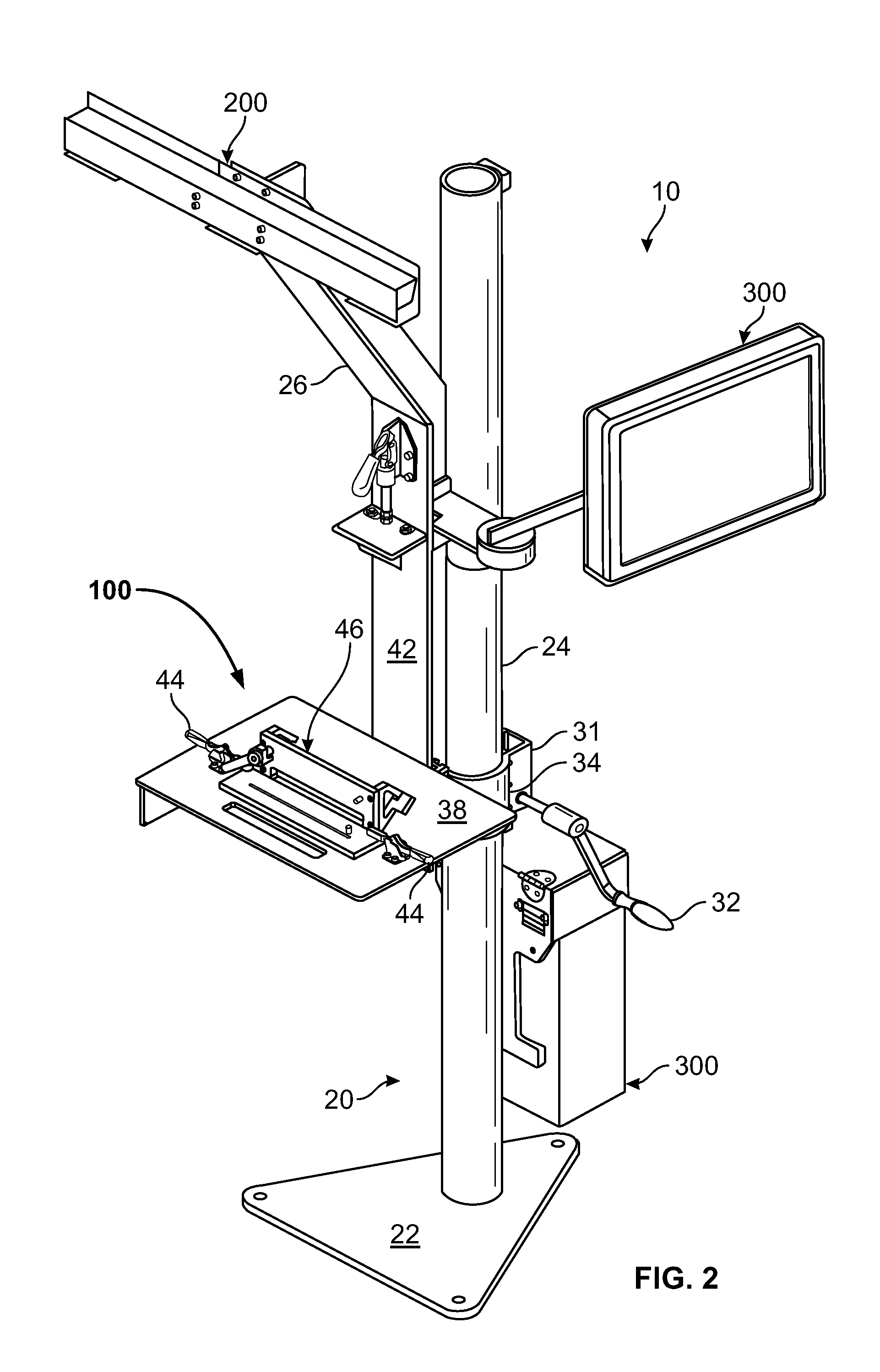

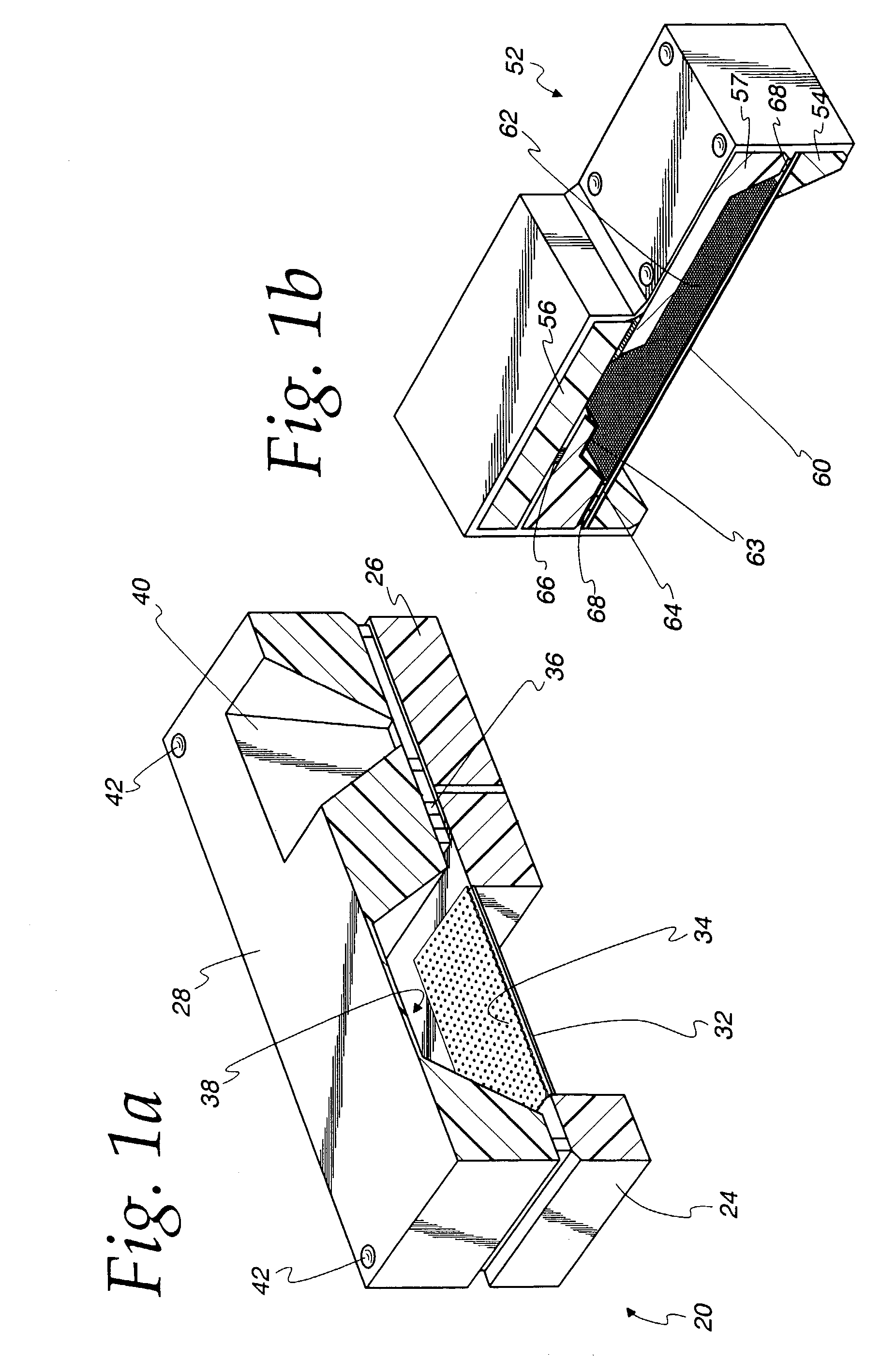

System for characterizing manual welding operations

ActiveUS20120298640A1Improve image signal-to-noise ratioImprove signal-to-noise ratioWelding/cutting auxillary devicesAuxillary welding devicesImage systemWelding

A system for characterizing manual welding exercises and providing valuable training to welders that includes components for generating, capturing, and processing data. The data generating component further includes a fixture, workpiece, at least one calibration devices each having at least two point markers integral therewith, and a welding tool. The data capturing component further includes an imaging system for capturing images of the point markers and the data processing component is operative to receive information from the data capturing component and perform various position and orientation calculations.

Owner:LINCOLN GLOBAL INC

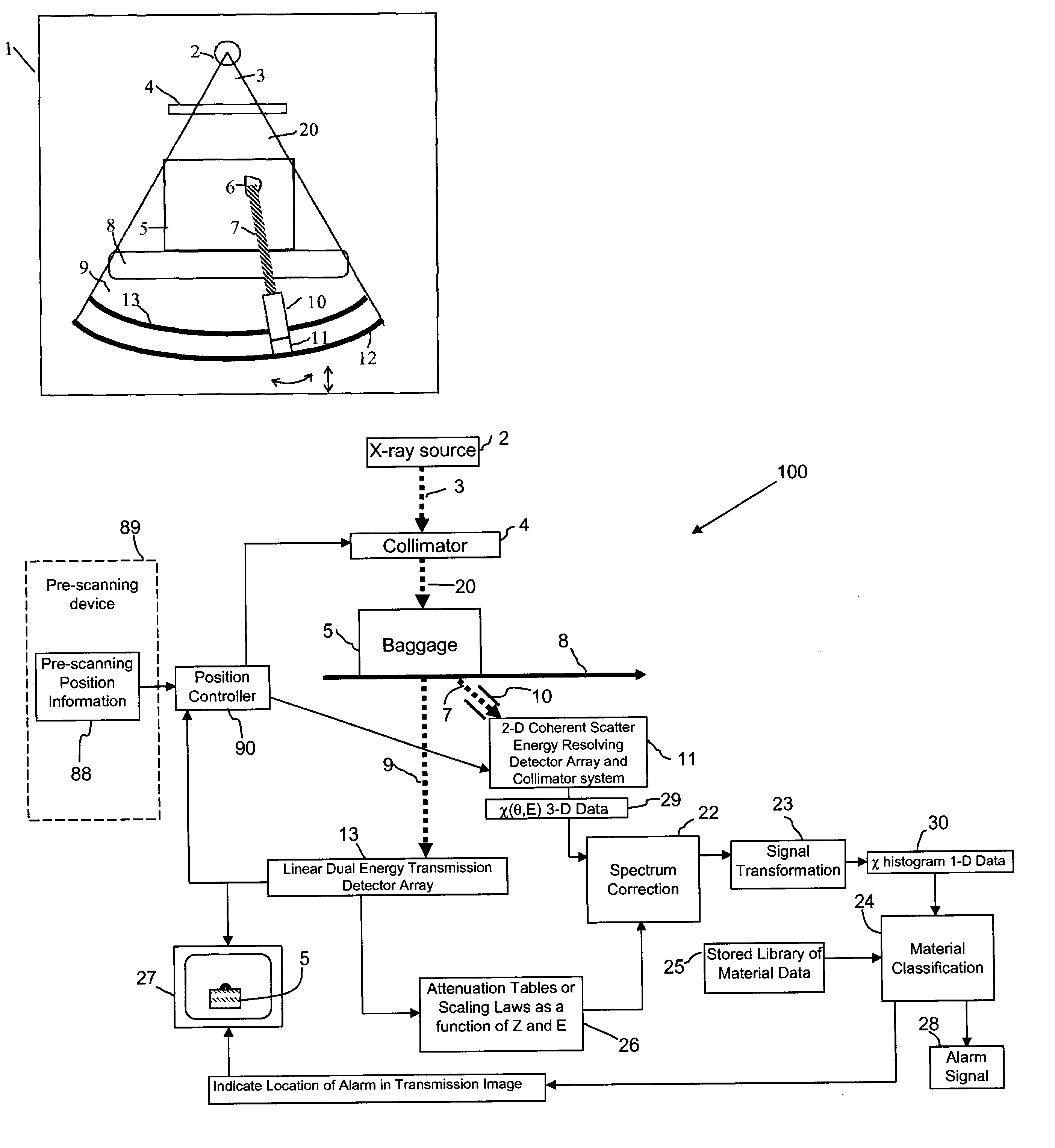

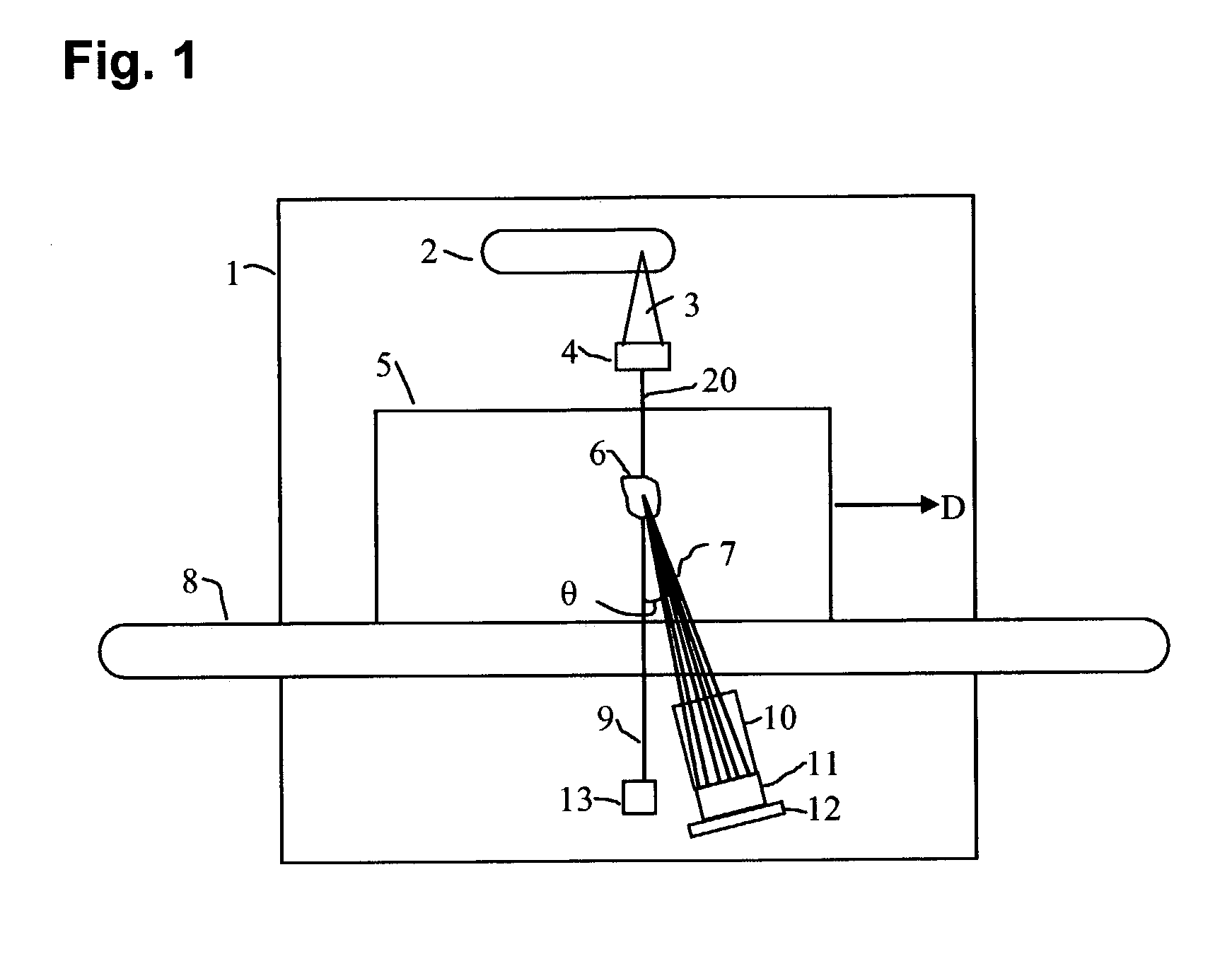

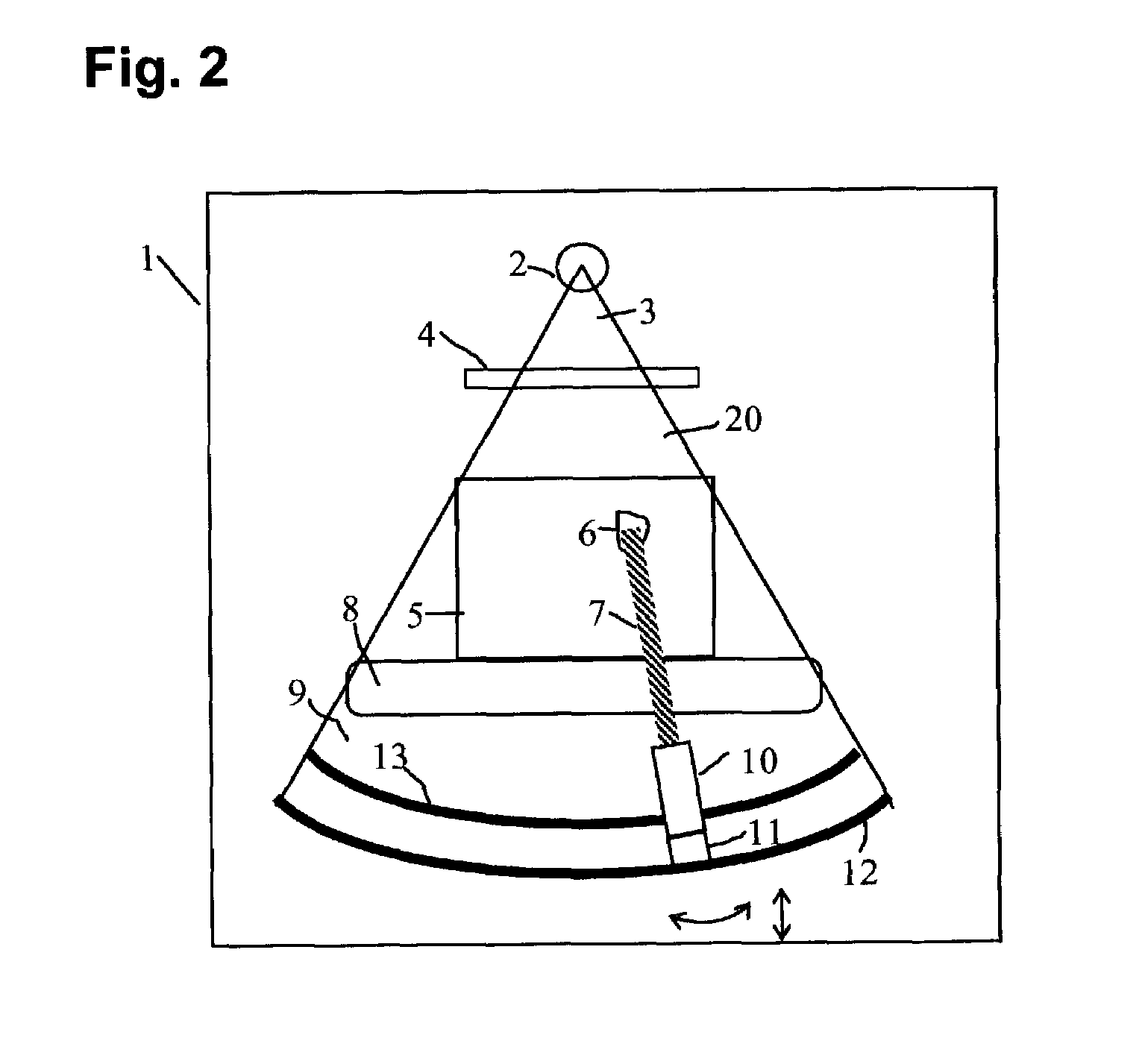

X-ray inspection system for detecting explosives and other contraband

InactiveUS7092485B2Rapidly and accurately discriminates among different substancesQuick checkUsing wave/particle radiation meansMaterial analysis by transmitting radiationX-rayExplosive material

A baggage scanning system and method employ combined angular and energy dispersive x-ray scanning to detect the presence of a contraband substance within an interrogation volume of a baggage item. The interrogation volume is illuminated with penetrating, polychromatic x-rays in a primary fan beam from a source such as a tungsten-anode x-ray tube. An energy-dependent absorption correction is determined from measurement of the attenuation of the fan beam at a plurality of different energies. Radiation coherently scattered by substances in the interrogation volume is detected by an energy-resolved x-ray detector operated at a plurality of scattering angles to form a plurality of scattering spectra. Each scattering spectrum is corrected for energy-dependent absorption and the corrected spectra are combined to produce a scattering pattern. The experimental scattering pattern is compared with reference patterns that uniquely characterize known contraband substances. The system and method can locate and identify a wide variety of contraband substances in an accurate, reliable manner. The system provides for automated screening, with the result that vagaries of human performance are virtually eliminated. False alarms and the need for hand inspection are reduced and detection efficacy is increased.

Owner:CONTROL SCREENING

Method for simultaneous detection of multiple fluorophores for in situ hybridization and multicolor chromosome painting and banding

InactiveUS6066459AImprove throughputShorten the timeRaman/scattering spectroscopyRadiation pyrometryChromosome paintingFluorophore

A spectral imaging method for simultaneous detection of multiple fluorophores aimed at detecting and analyzing fluorescent in situ hybridizations employing numerous chromosome paints and / or loci specific probes each labeled with a different fluorophore or a combination of fluorophores for color karyotyping, and at multicolor chromosome banding, wherein each chromosome acquires a specifying banding pattern, which pattern is established using groups of chromosome fragments labeled with various fluorophore or combinations of fluorophores.

Owner:APPLIED SPECTRAL IMAGING

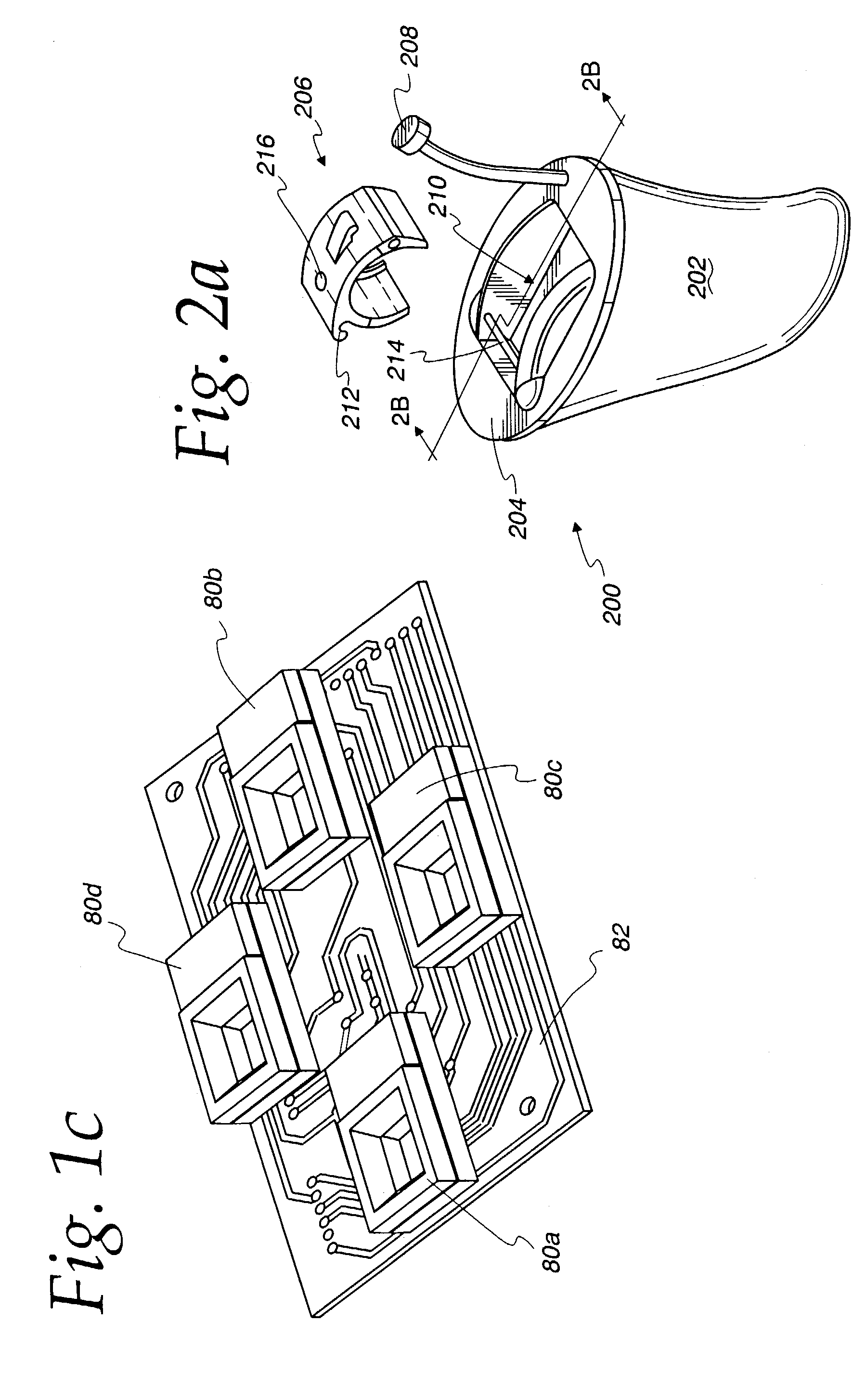

Silicon-based transducer for use in hearing instruments and listening devices

InactiveUS7142682B2Improve signal-to-noise ratioAdditive manufacturing apparatusSemiconductor electrostatic transducersConvertersAudio power amplifier

A silicon-based transducer assembly coupled to a movable structure in a hearing instrument. The transducer assembly includes at least one microphone chip and an ASIC having multiple integrated components such as any combination of a DSP, an A / D converter, an amplifier, a filter, or a wireless interface. The movable structure may be a battery access door, a volume dial, a switch, or a touch pad. A protection strip can be disposed across the battery access door to prevent debris from clogging the silicon-based transducer assembly. The transducer assembly may also include an array of microphone chips to achieve adaptive beam steering or directionality. When equipped with a wireless interface, the hearing instrument wirelessly communicates with another hearing instrument or with a network.

Owner:TDK CORPARATION

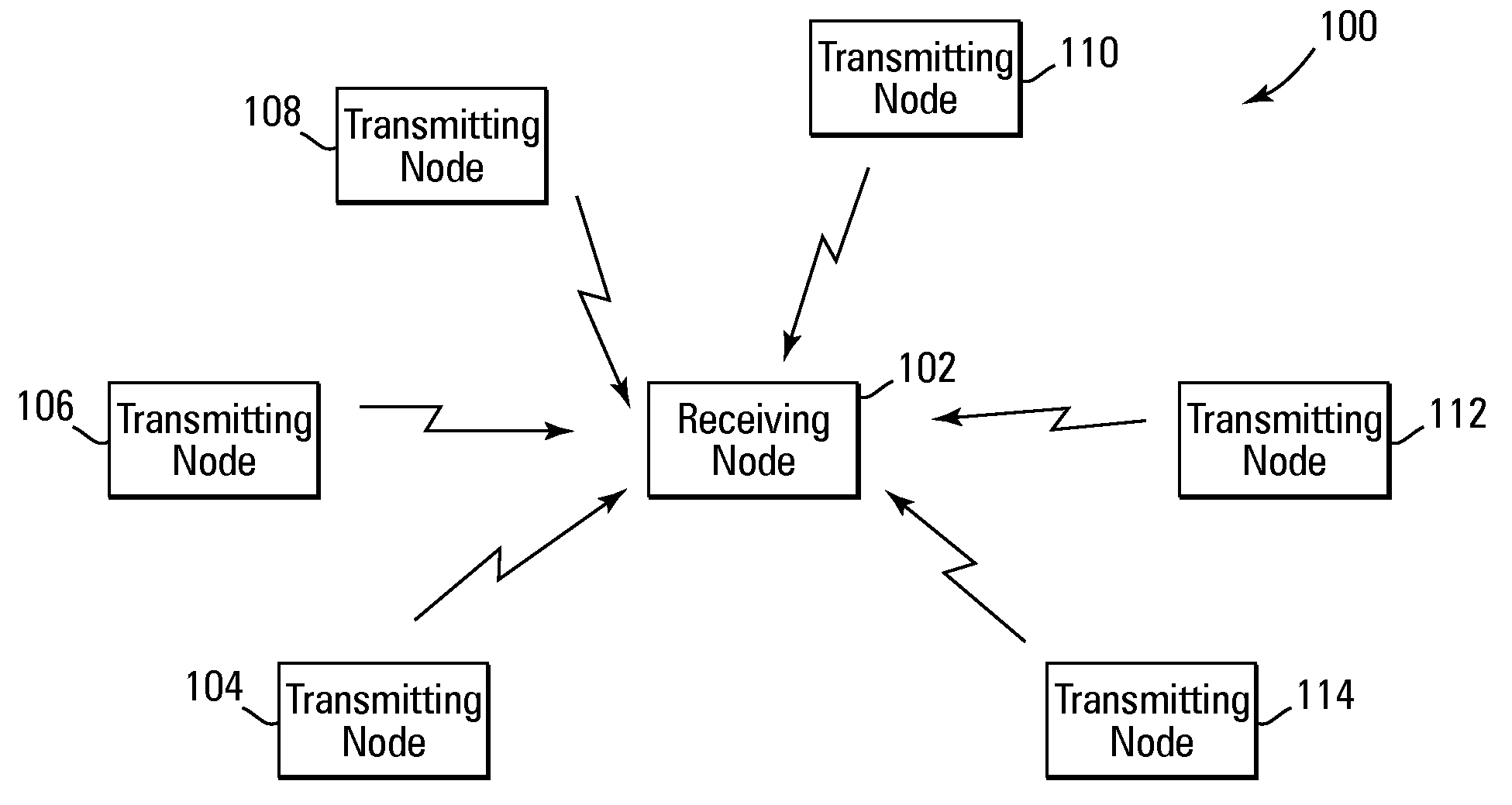

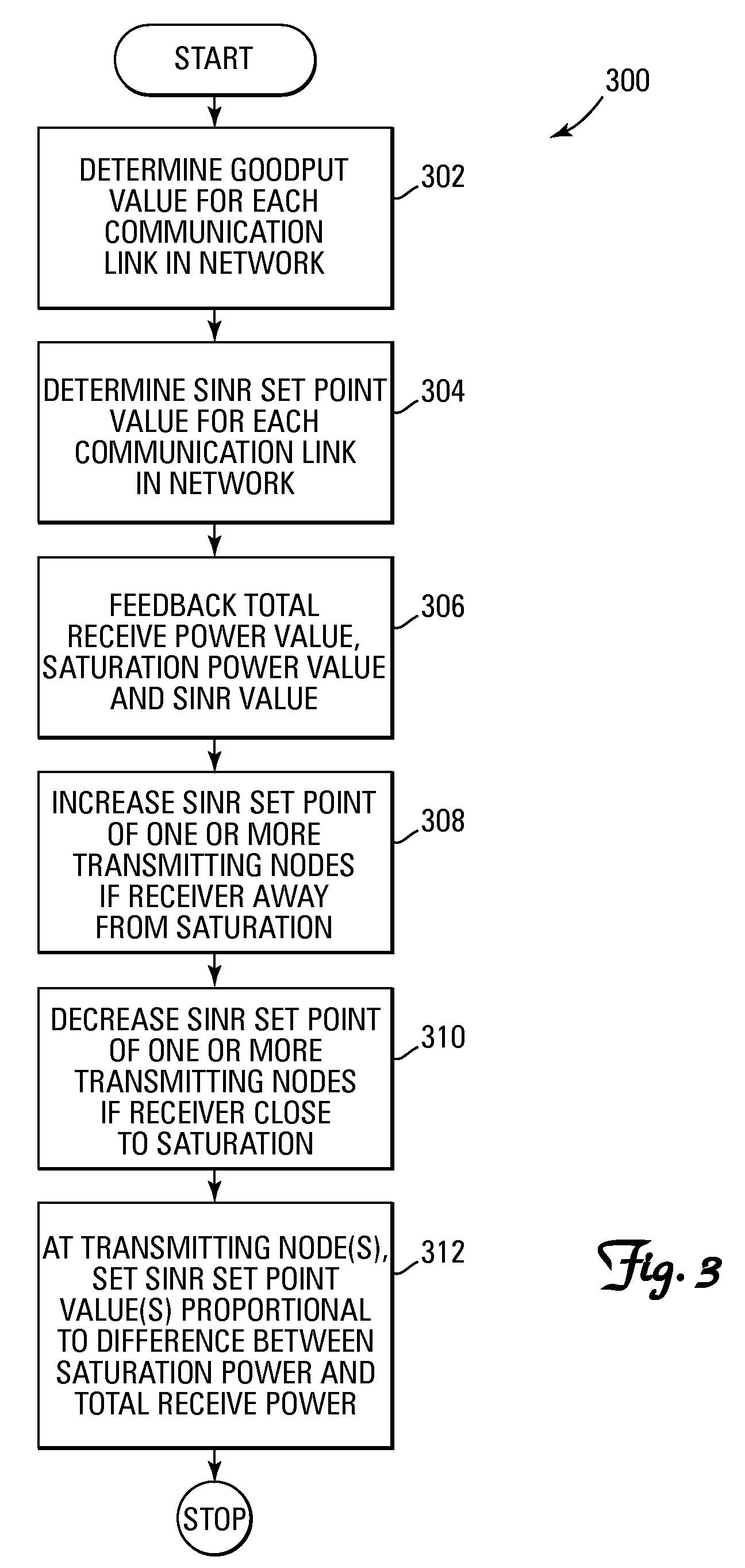

Method and system for performing distributed outer loop power control in wireless communication networks

InactiveUS20090093267A1Improve signal-to-noise ratioReduce signal to noise ratioPower managementRadio/inductive link selection arrangementsSignal-to-interference-plus-noise ratioReceiver front end

A method and system for performing distributed outer loop power control in a wireless communication network are disclosed. The method includes the steps of determining a transmit power for a plurality of transmitting nodes such that signals sent from each of the transmitting nodes are received at a receiver associated with a receiving node at a predetermined signal-to-interference plus noise ratio (SINR) set point, increasing the SINR at the receiving node of one or more transmitting nodes of the plurality of transmitting nodes if a saturation value for a front end of the receiver associated with the receiving node is not near a predetermined saturation value, and decreasing the SINR at the receiving node of the one or more transmitting nodes of the plurality of transmitting nodes if the saturation value for the front end of the receiver associated with the receiving node is near the predetermined saturation value.

Owner:HONEYWELL INT INC

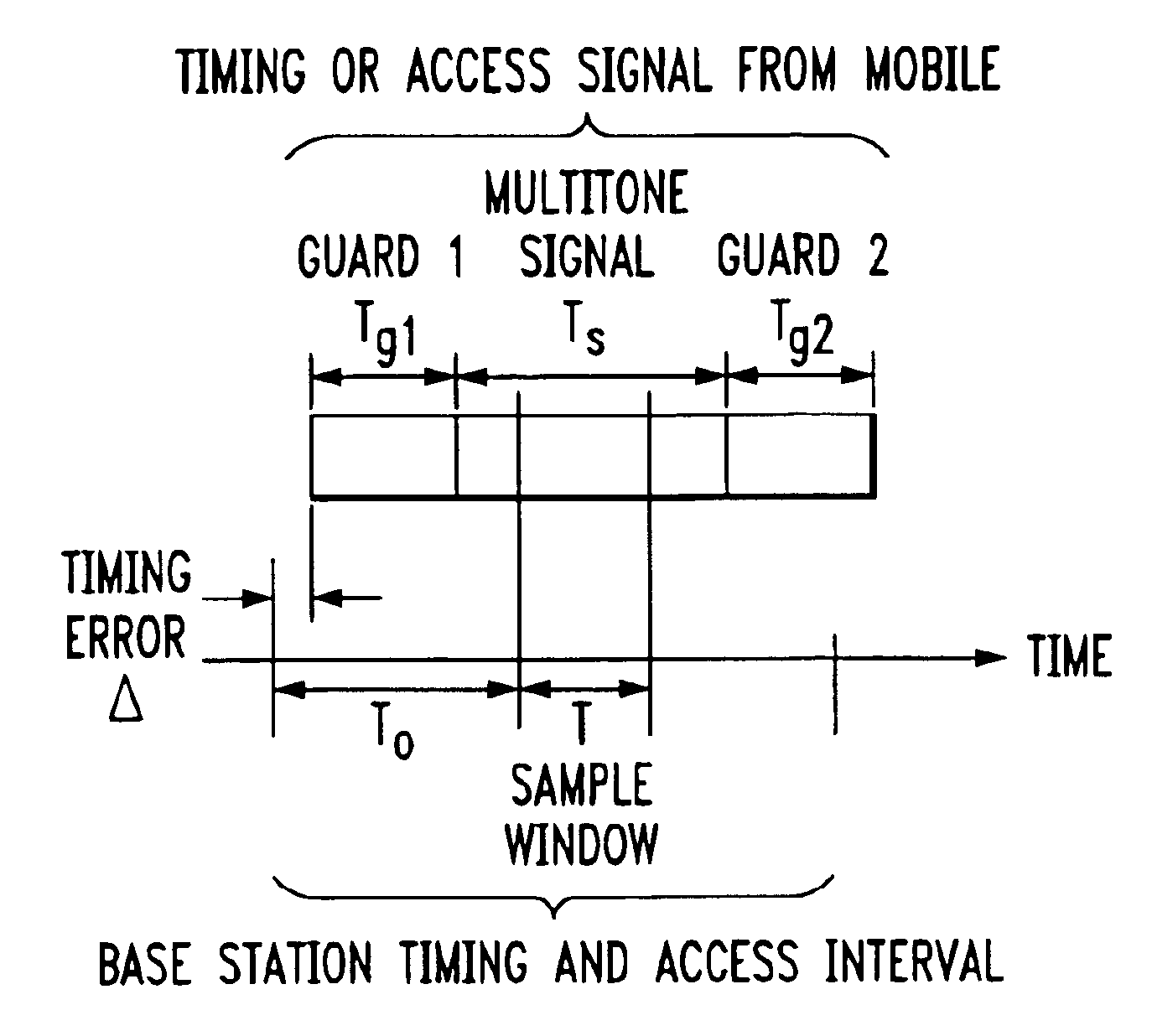

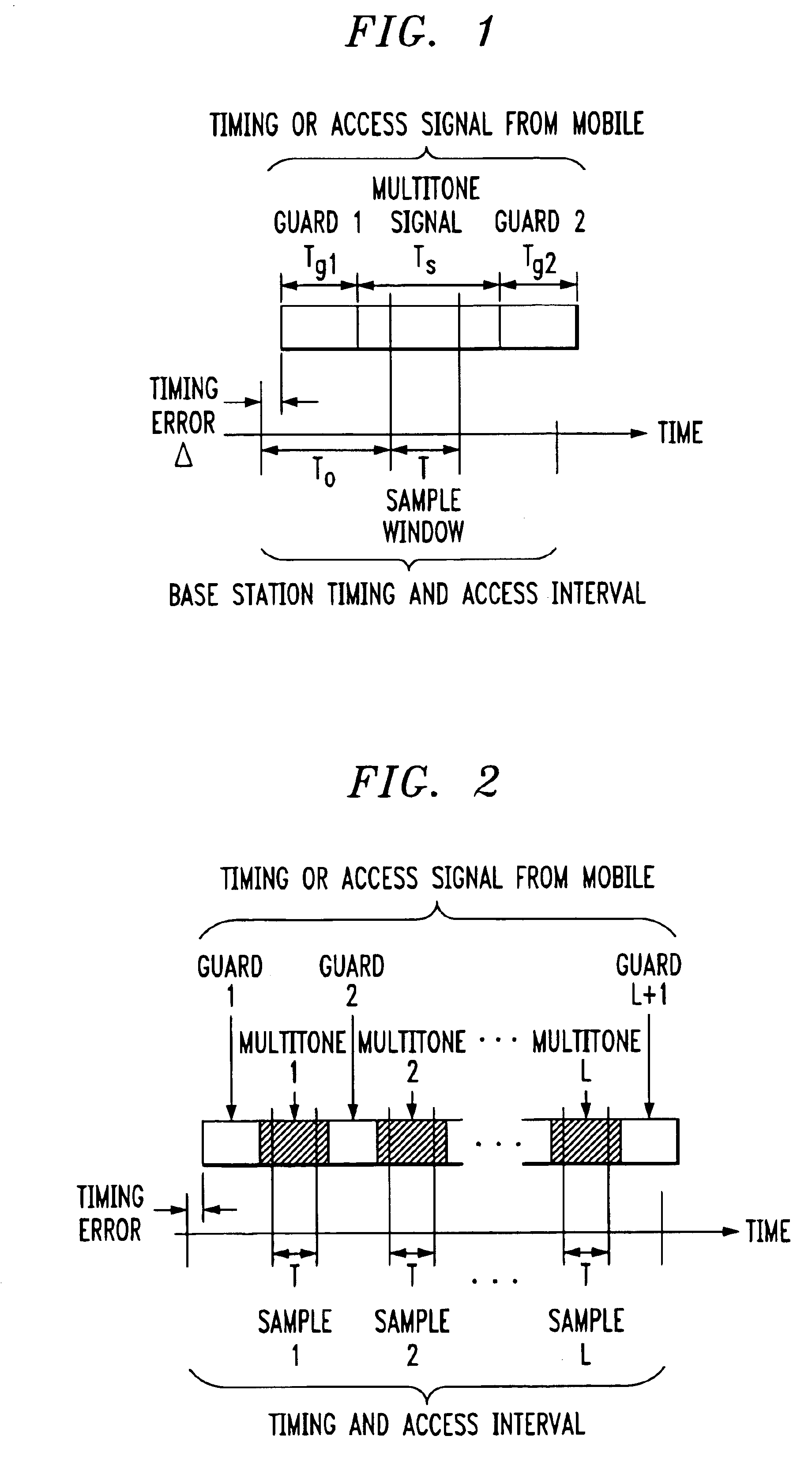

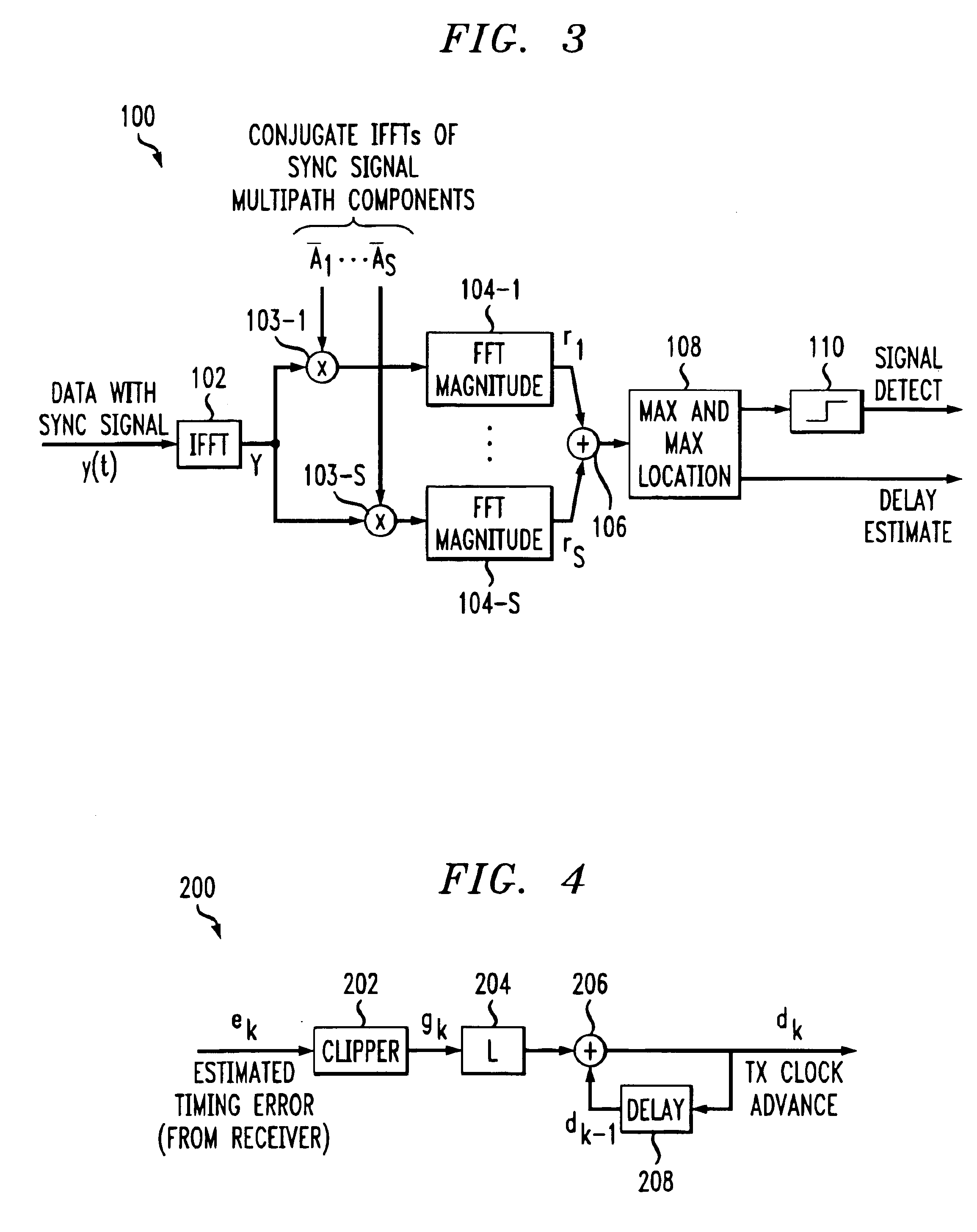

Signal construction, detection and estimation for uplink timing synchronization and access control in a multi-access wireless communication system

InactiveUS6922388B1Improve estimation accuracyGreat rangeTime-division multiplexFrequency-division multiplexFourier transform on finite groupsCyclic prefix

Signal construction, detection and estimation techniques for use in uplink timing synchronization and access control in an orthogonal frequency division multiplexed (OFDM) wireless system or other type of wireless communication system. In accordance with an illustrative embodiment of the invention, timing and access signals to be transmitted in designated timing and access intervals are constructed from orthogonal multitone signals. The multitone signals may be similar to multitone signals used in OFDM data transmission, except that a cyclic prefix associated with reception of the signals in a base station is extended to cover the timing errors of mobile stations not yet synchronized. The invention also provides design techniques which optimize the time resolvability and peak-to-average ratio of the multitone signals, an efficient fast Fourier transform (FFT) based technique for maximum likelihood timing estimation, and a robust linear filtering technique for averaging timing estimates from different synchronizations.

Owner:GEMPLU

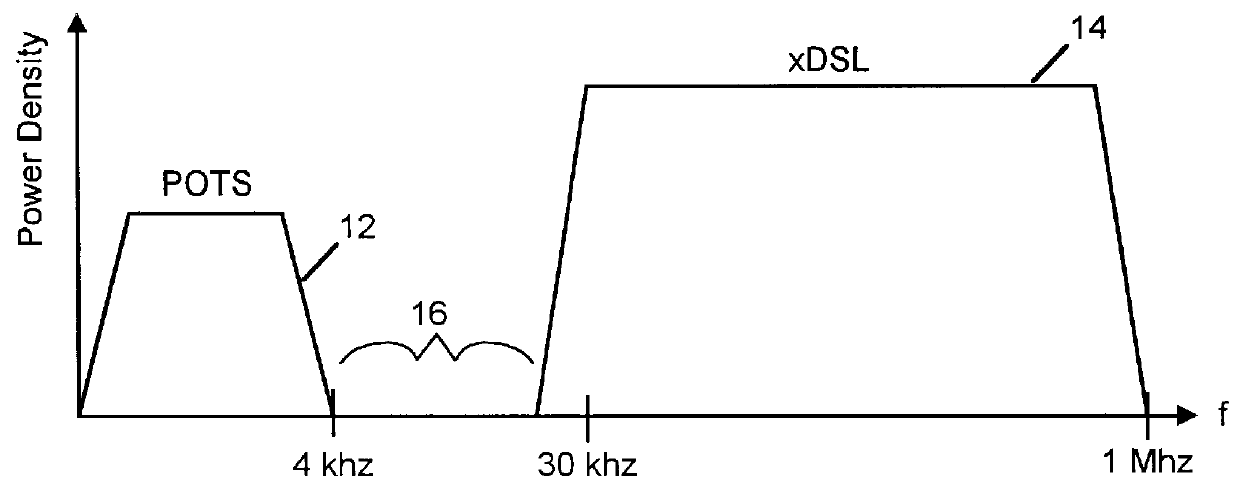

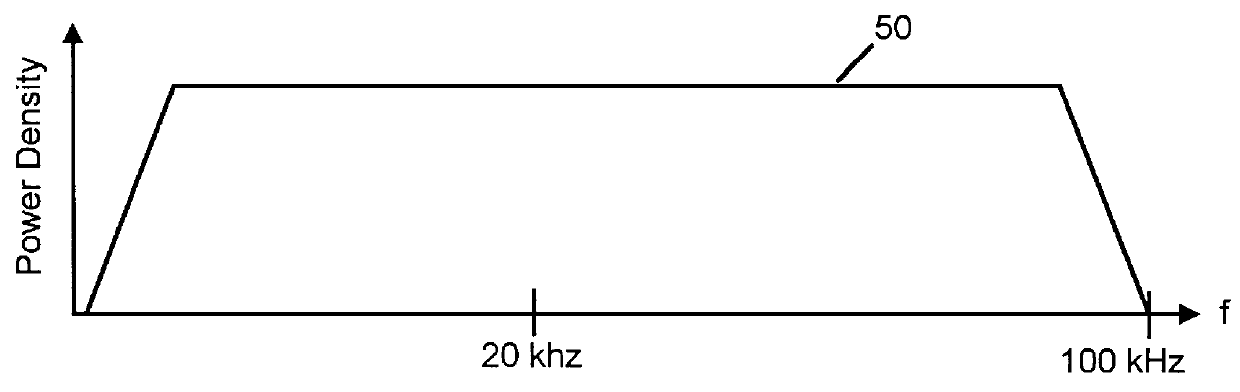

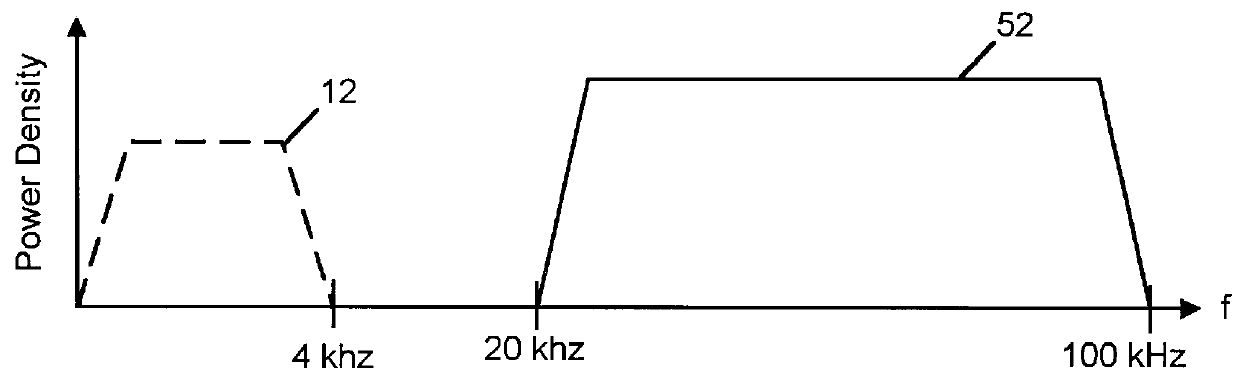

Apparatus and method for communicating voice and data between a customer premises and a central office

InactiveUS6061392AEfficient implementationLow costFrequency-division multiplex detailsTelephonic communicationTelecommunications linkModem device

A method and apparatus are provided for communicating data across a communication link, in a manner that senses and dynamically adapts to the simultaneous transmission of voice information across the local loop. In accordance with one aspect of the invention, a method is provided for dynamically communicating data over a local loop using a modem comprising the steps of transmitting data in a full-band transmission state, sensing a band-limiting condition, and adjusting the transmission of data from the full-band transmission state to a bandlimited transmission state, in response to the sensing step. In accordance with the method, data may be transmitted by the modem across the local loop at the same time that voice information is communicated via telephone across the same local loop. A significant aspect of the present invention is the dynamic allocation of the data transmission bandwidth, whereby the invention senses a condition indicative of whether voice information is being communicated. If so, then the system shifts and / or narrows the data transmission bandwidth to allow for voice communications without interference from or with the data transmission. However, when no voice information is being communicated, the invention dynamically allocates the data transmission bandwidth to utilize at least a portion, if not all, of the frequency band otherwise used for communicating voice information.

Owner:PARADYNE CORP

Flow cytometry apparatus and method

InactiveUS6256096B1Improve signal-to-noise ratioReduce contributionParticle size analysisIndividual particle analysisBiological cellStatistical analysis

A flow cytometer for detecting target particles such as microorganisms including biological cells and viruses as well as molecular species. The flow cytometer includes a detection system involving a CCD having a time delay integration capability to thereby increase the signal from the target particle and decrease the noise detected by the CCD. Calibration particles can be included in the sample stream of the flow cytometer for coordinating the readout of the CCD with the rate of flow of the sample stream to improve the detection capability of the CCD. Statistical analysis techniques can also be used to determine the rate of flow of target particles in the sample stream to thereby coordinate the readout rate of the CCD with the rate of flow of the target particles.

Owner:SOFTRAY

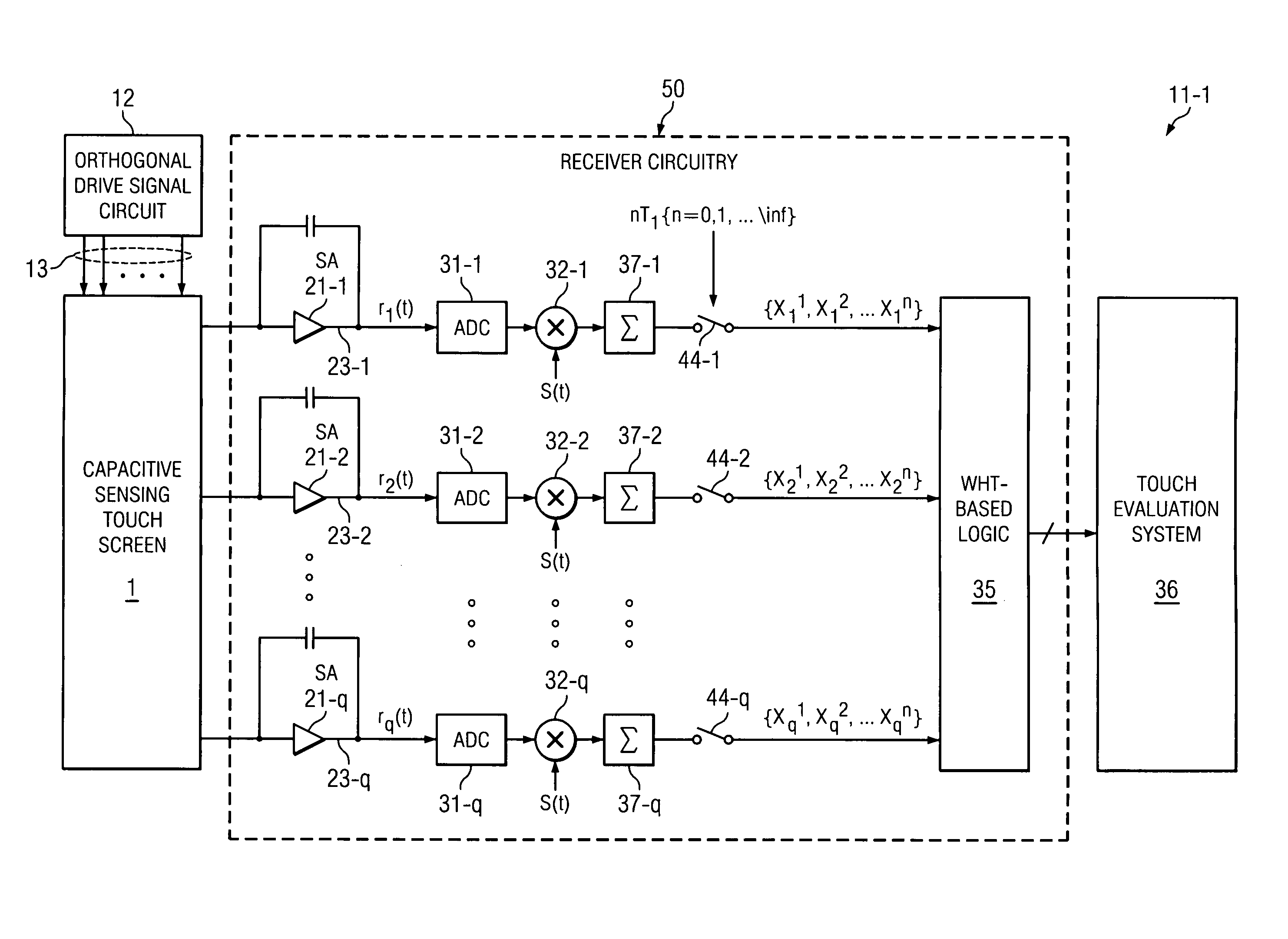

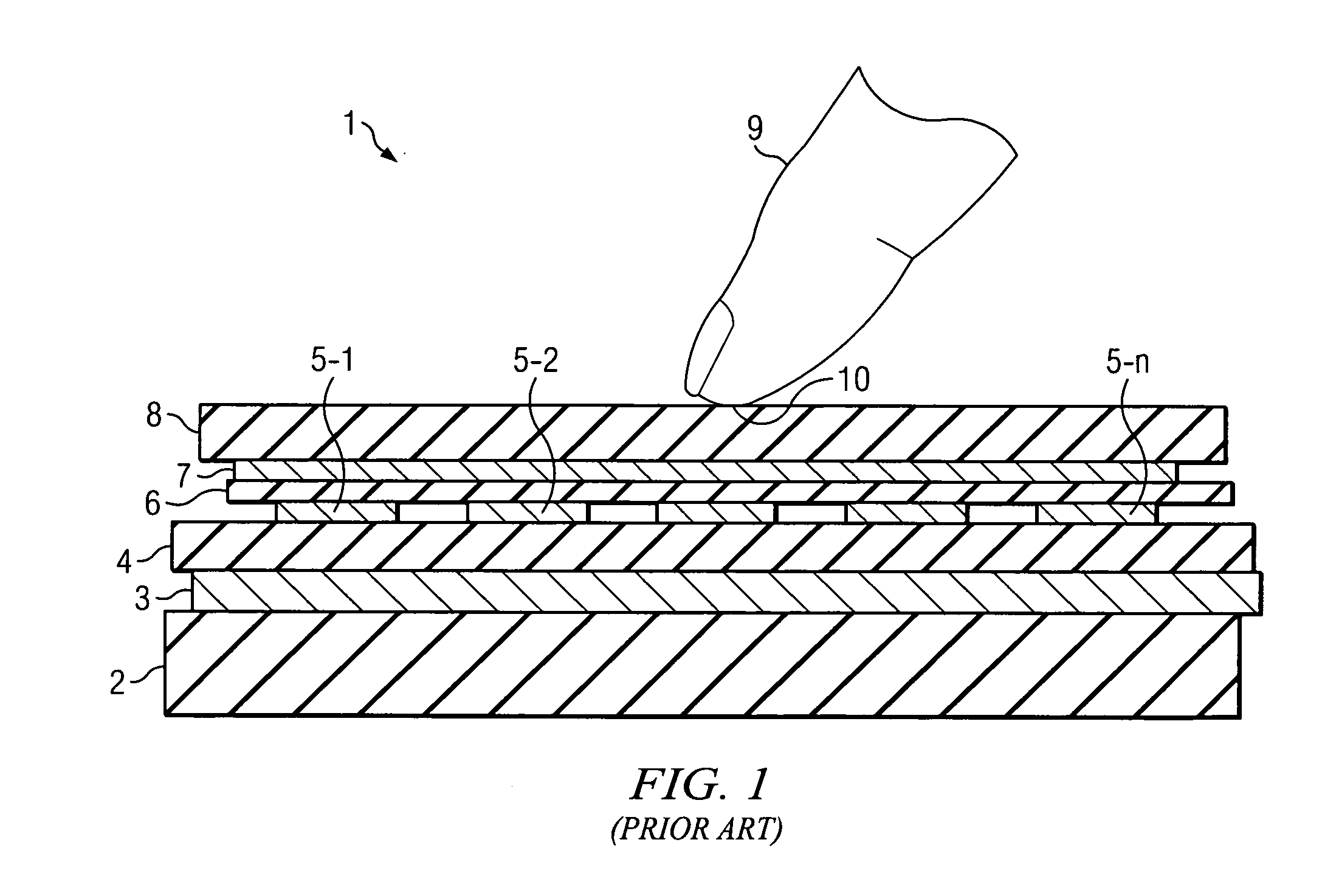

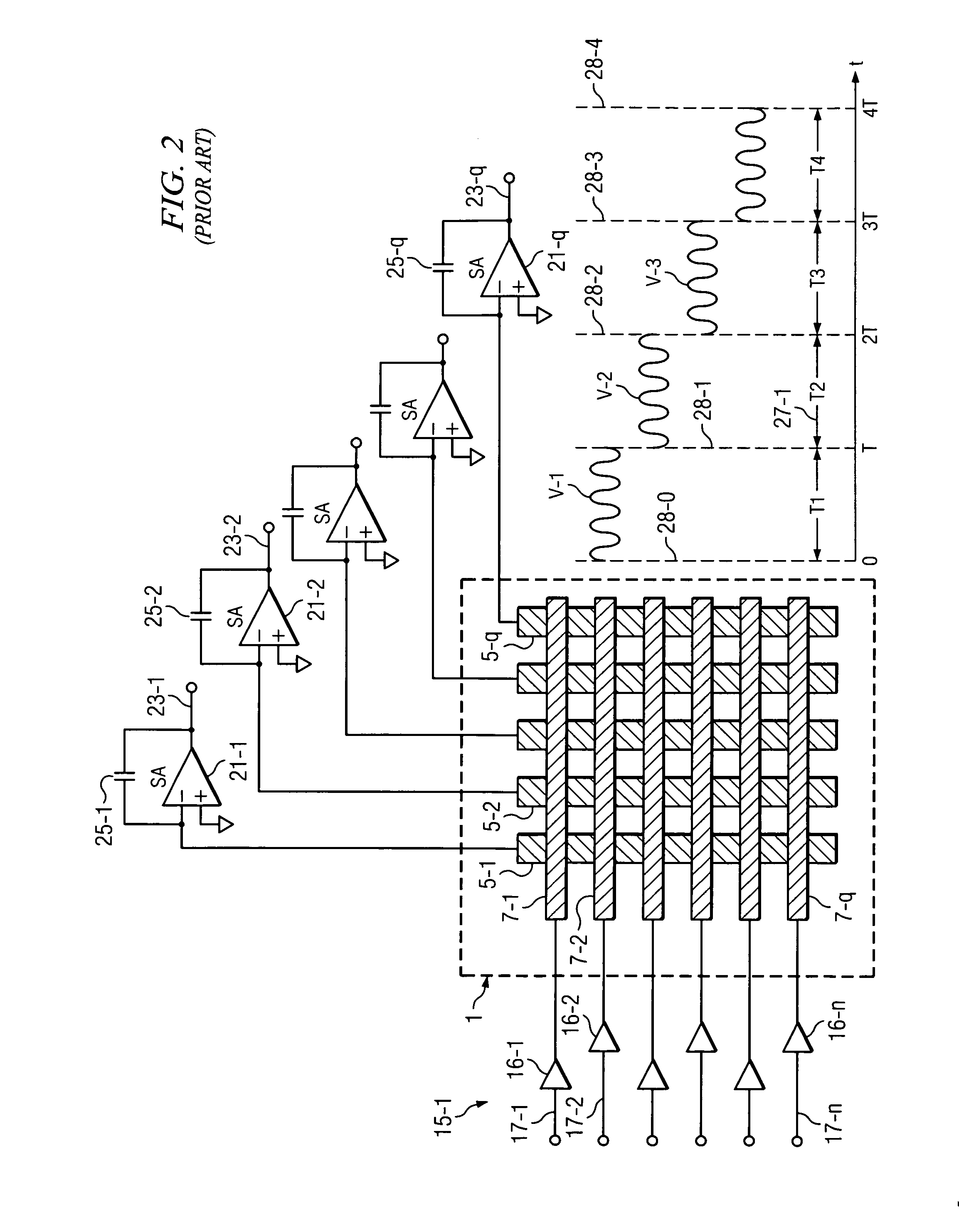

Touch-sensitive interface and method using orthogonal signaling

InactiveUS20120056841A1Improve touch sensitivityScan rate can be decreasedCathode-ray tube indicatorsInput/output processes for data processingCapacitanceAudio power amplifier

A touch screen system includes a capacitive touch screen (1) including a plurality of row conductors (7-1,2 . . . n) and a column conductor (5-1). A plurality of cotemporaneous orthogonal excitation signals (S1(t), S2(t) . . . Sn(t)) are simultaneously driven onto the row conductors, respectively. The capacitively coupled signals on the column conductor may be influenced by a touch (10) on the capacitive touch screen. Receiver circuitry (50) includes a sense amplifier (21-1) coupled to generate an amplifier output signal (r1(t)) in response to signals capacitively coupled onto the column conductor. WHT-based circuitry (35) determines amounts of signal contribution capacitively coupled by each of the excitation signals, respectively, to the amplifier output signal.

Owner:INTEL CORP

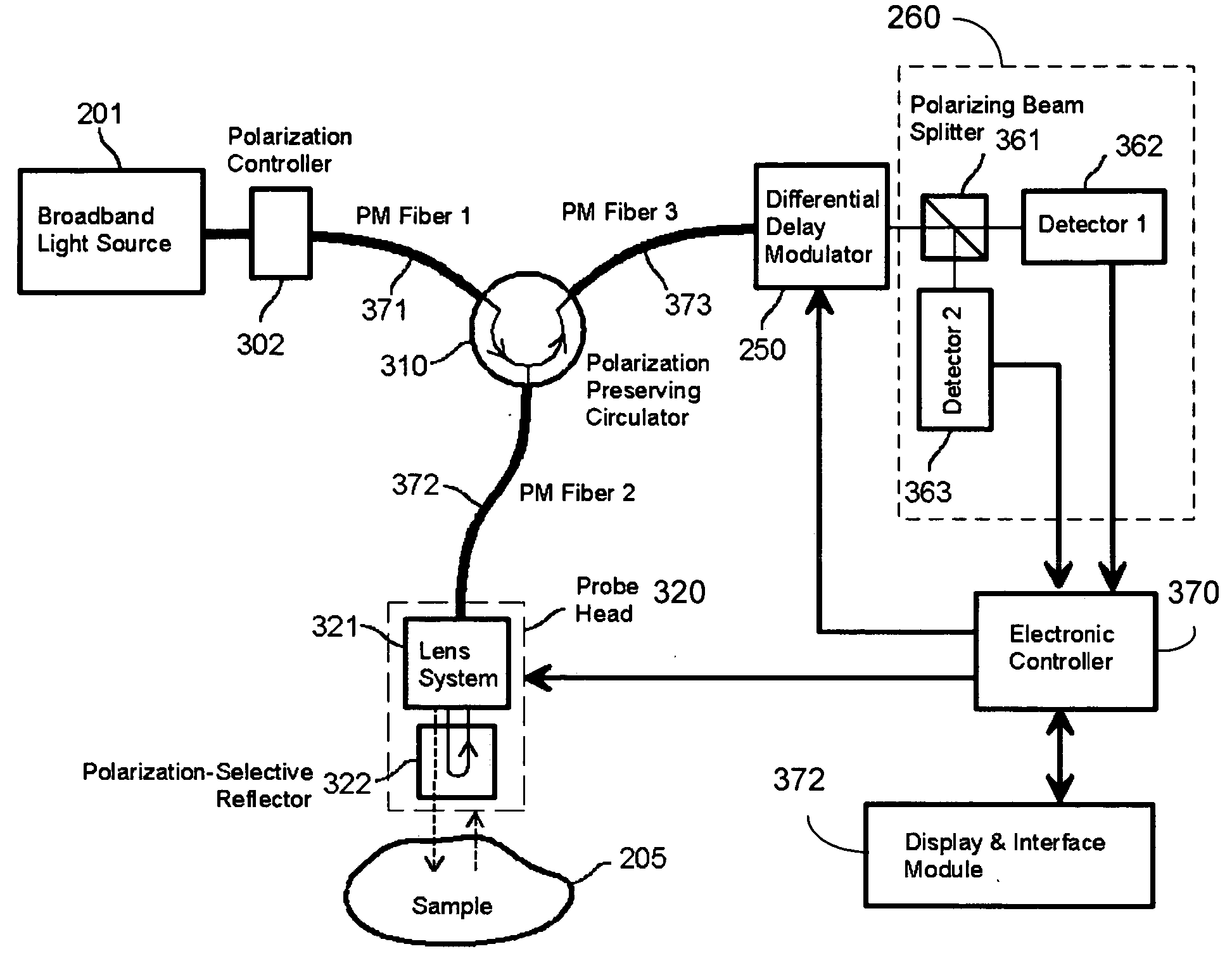

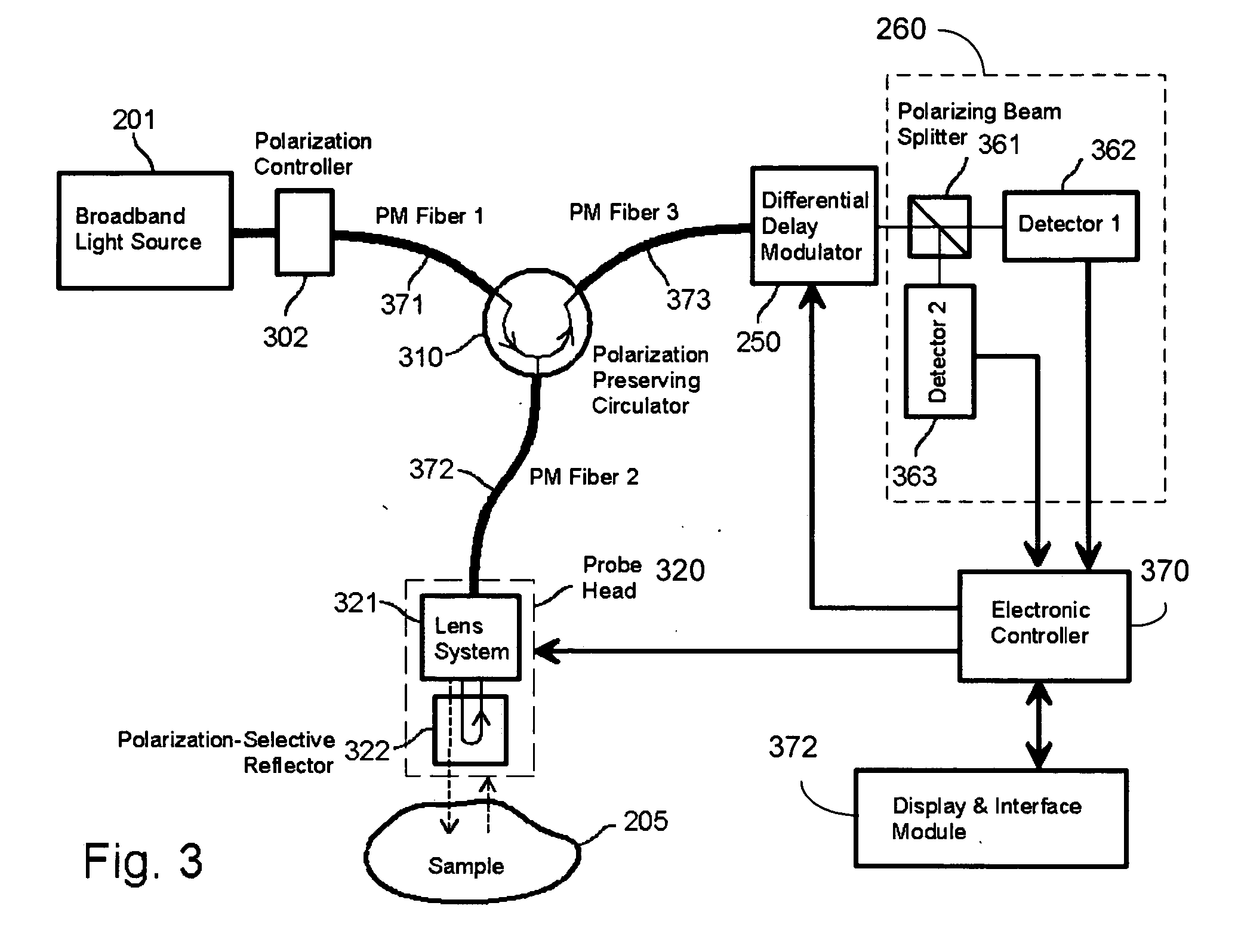

Coherence-gated optical glucose monitor

ActiveUS20050075547A1Reduce volatilitySimplify structure and optical configurationScattering properties measurementsDiagnostics using tomographyMonitor glucoseBlood sugar

This application describes designs, implementations, and techniques for optically monitoring glucose levels of patients without taking blood samples.

Owner:TOMOPHASE

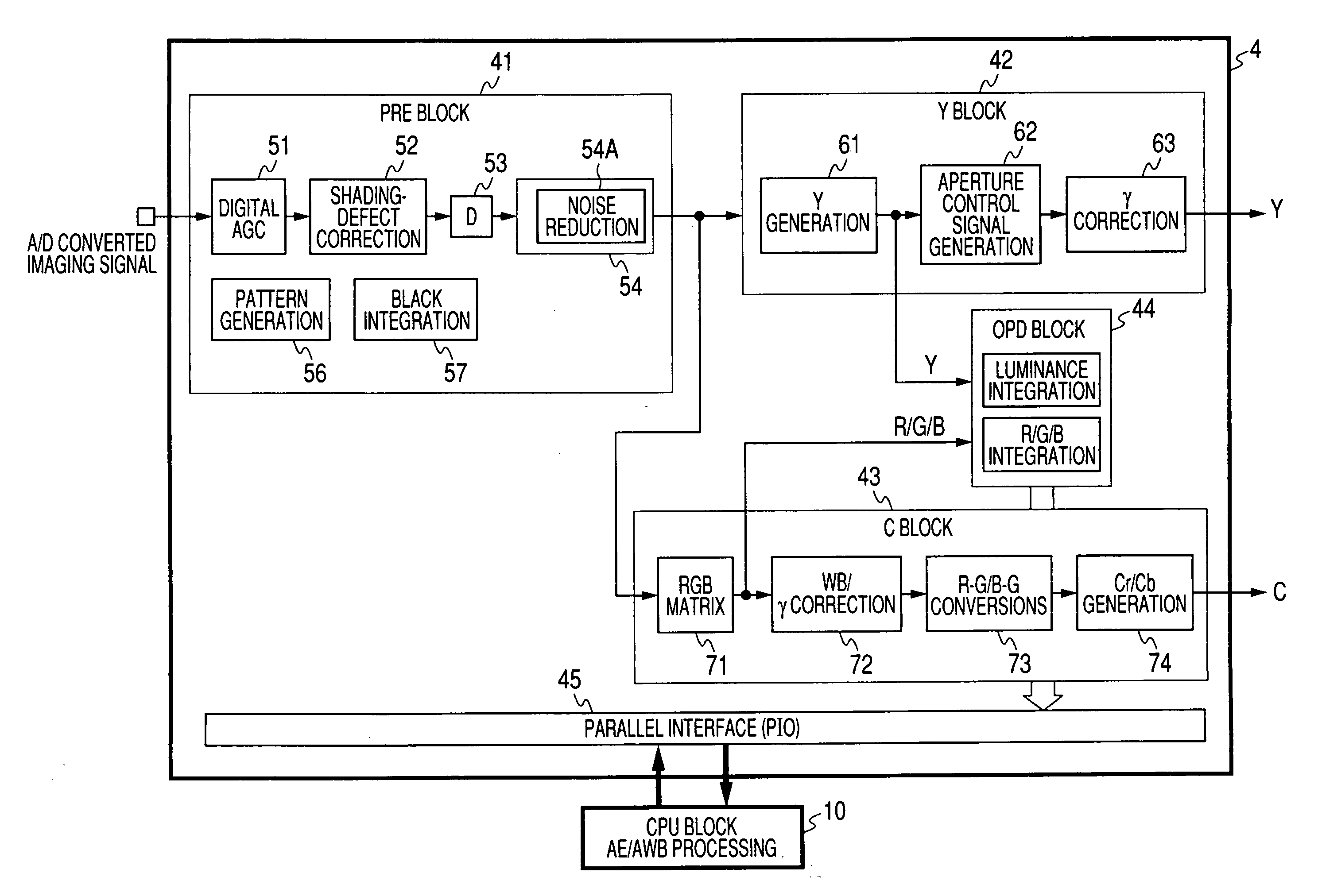

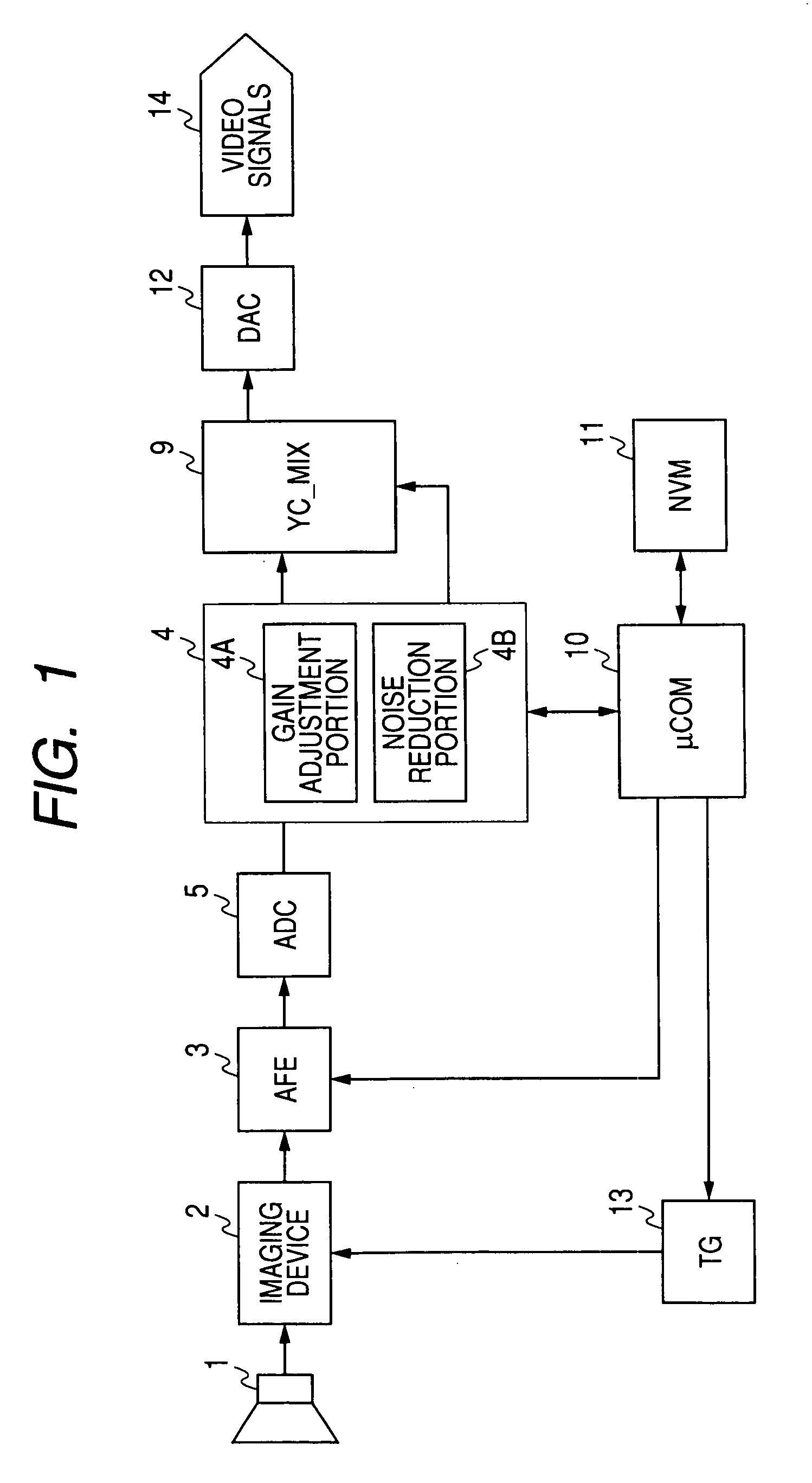

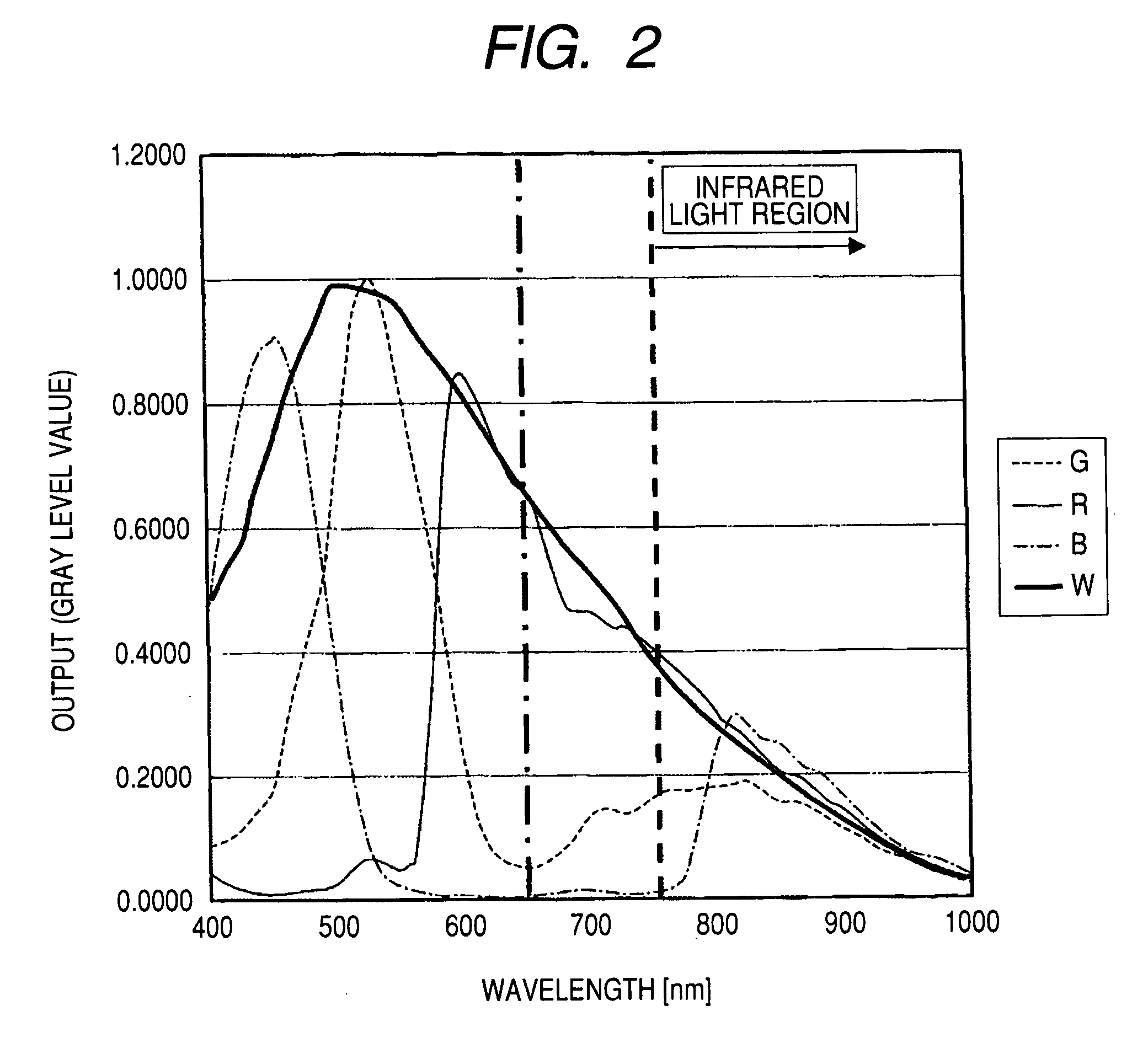

Video input processor, imaging signal-processing circuit, and method of reducing noises in imaging signals

InactiveUS20080284880A1Noise-reducing capability is preventedReduce gainTelevision system detailsSignal generator with single pick-up deviceRelative magnitudeSignal processing circuits

A video input processor is disclosed. The processor includes: an imaging signal-generating portion configured to image a subject and producing first imaging signals containing visible light components and a second imaging signal containing near-infrared light components; a gain adjustment portion configured to adjustably set a maximum gain value according to a relative magnitude between the visible light components and the near-infrared light components and adjust a gain for the first imaging signals at the set maximum gain value; and a noise reduction portion configured to reduce noises in the first imaging signals after the gain has been adjusted.

Owner:SONY CORP

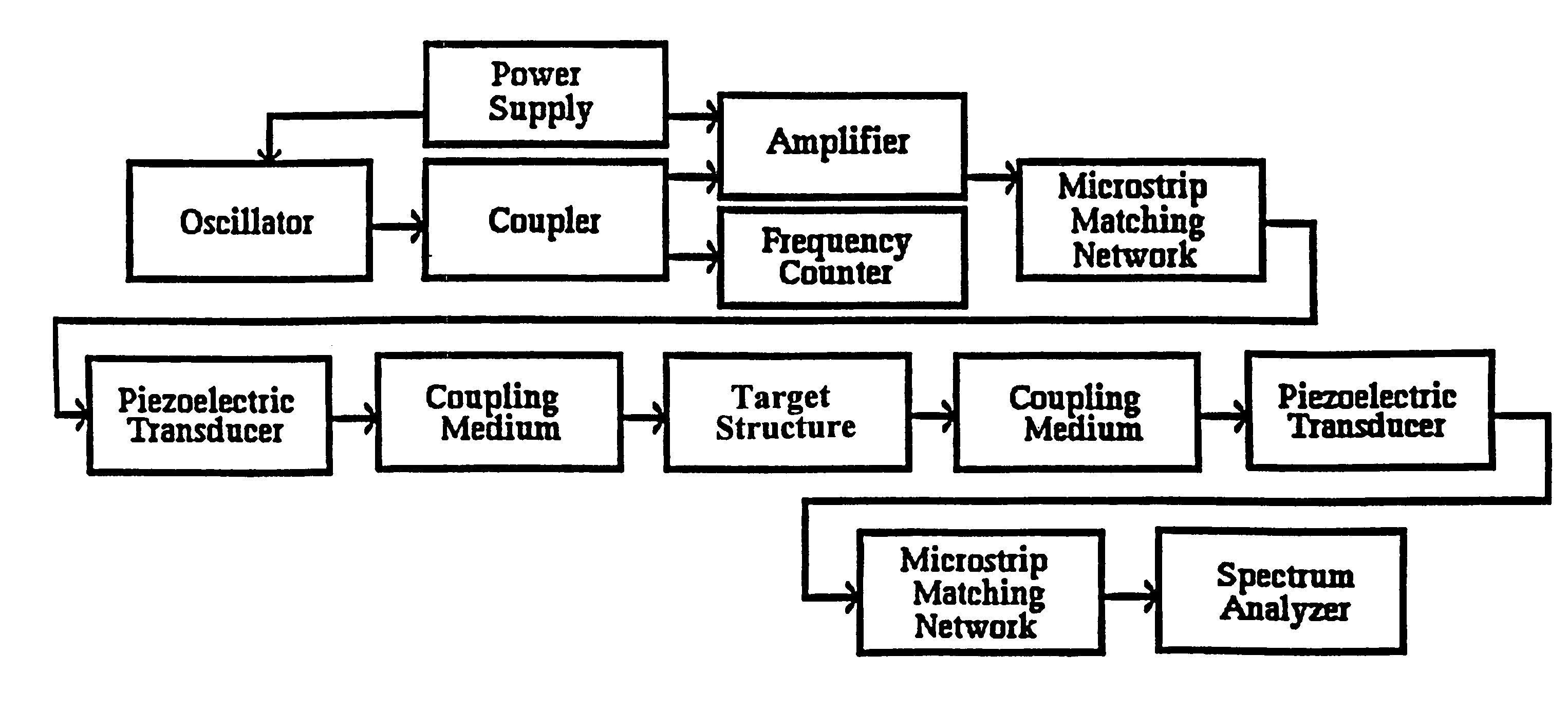

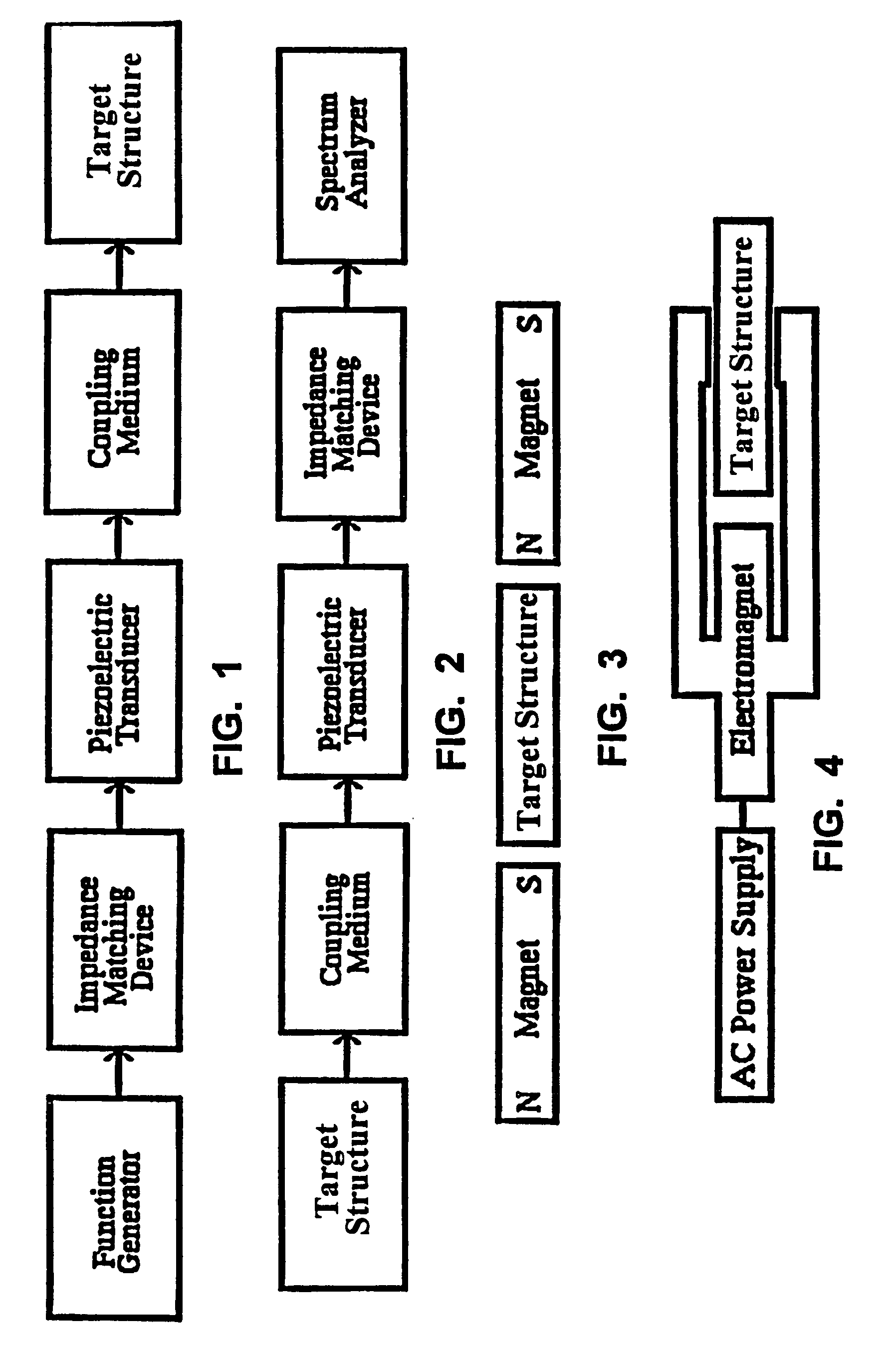

Methods for using resonant acoustic and/or resonant acousto-EM energy to detect and/or effect structures

InactiveUS7165451B1Avoid damageAccurate detectionVibration measurement in solidsUltrasonic/sonic/infrasonic diagnosticsParticle physicsQuantum electrodynamics

Owner:GR INTELLECTUAL RESERVE LLC

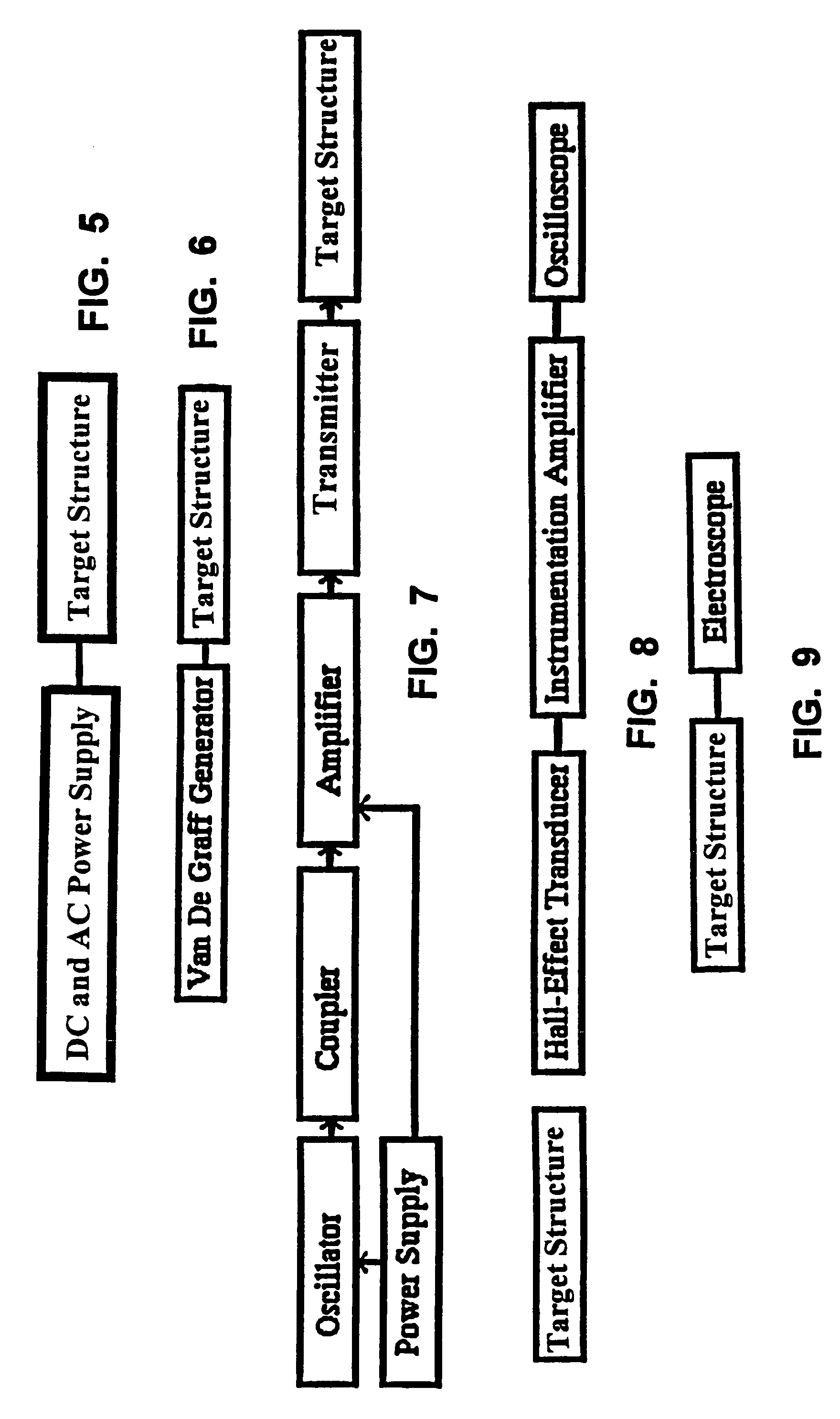

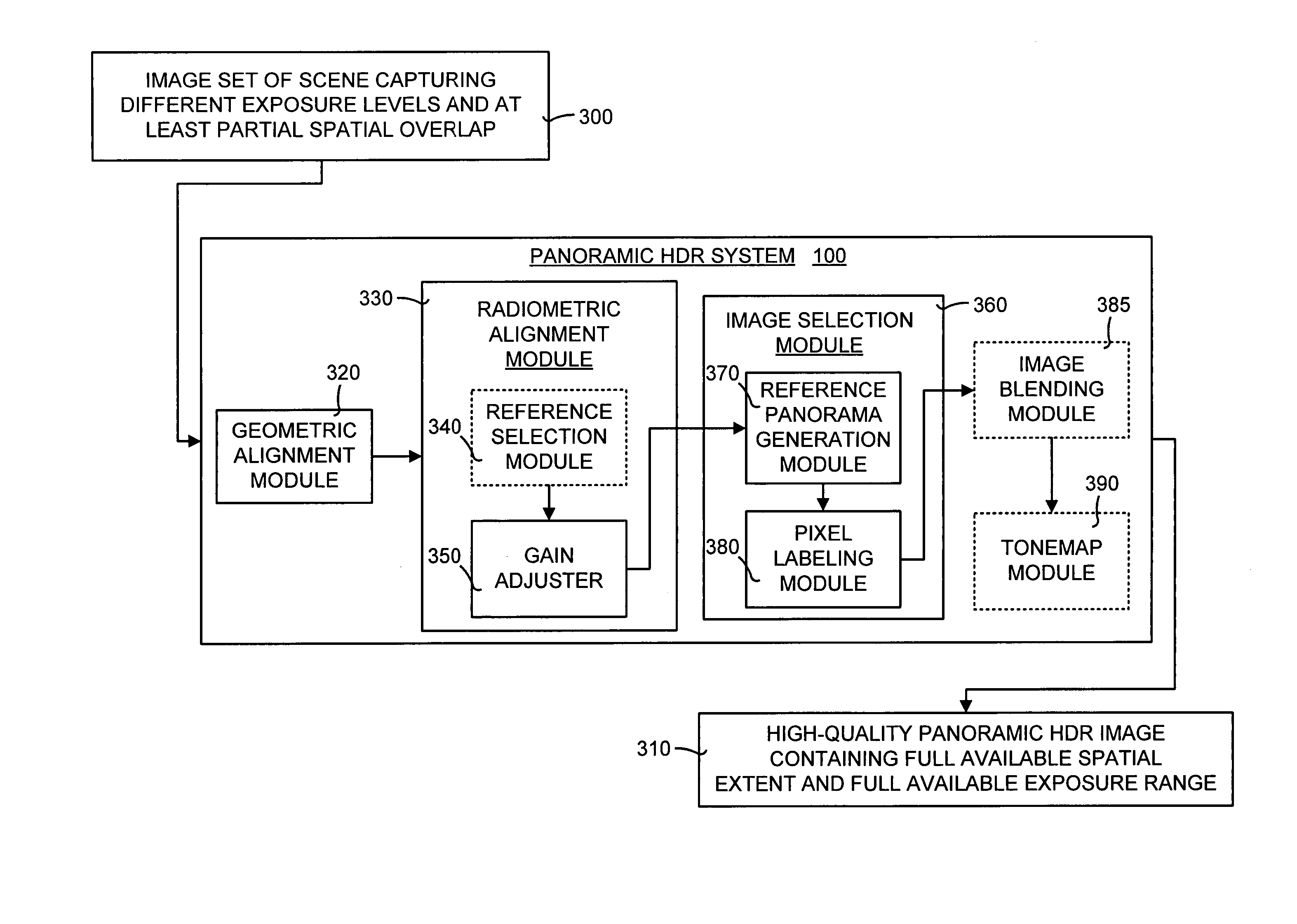

Method and system for combining multiple exposure images having scene and camera motion

ActiveUS20060177150A1Quality improvementImprove signal-to-noise ratioImage enhancementTelevision system detailsSignal-to-noise ratio (imaging)Radiance

A panoramic high-dynamic range (HDR) image method and system of combining multiple images having different exposures and at least partial spatial overlap wherein each of the images may have scene motion, camera motion, or both. The major part of the panoramic HDR image method and system is a two-pass optimization-based approach that first defines the position of the objects in a scene and then fills in the dynamic range when possible and consistent. Data costs are created to encourage radiance values that are both consistent with object placement (defined by the first pass) and of a higher signal-to-noise ratio. Seam costs are used to ensure that transitions occur in regions of consistent radiances. The result is a high-quality panoramic HDR image having the full available spatial extent of the scene along with the full available exposure range.

Owner:MICROSOFT TECH LICENSING LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com