Patents

Literature

914 results about "Reference patterns" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

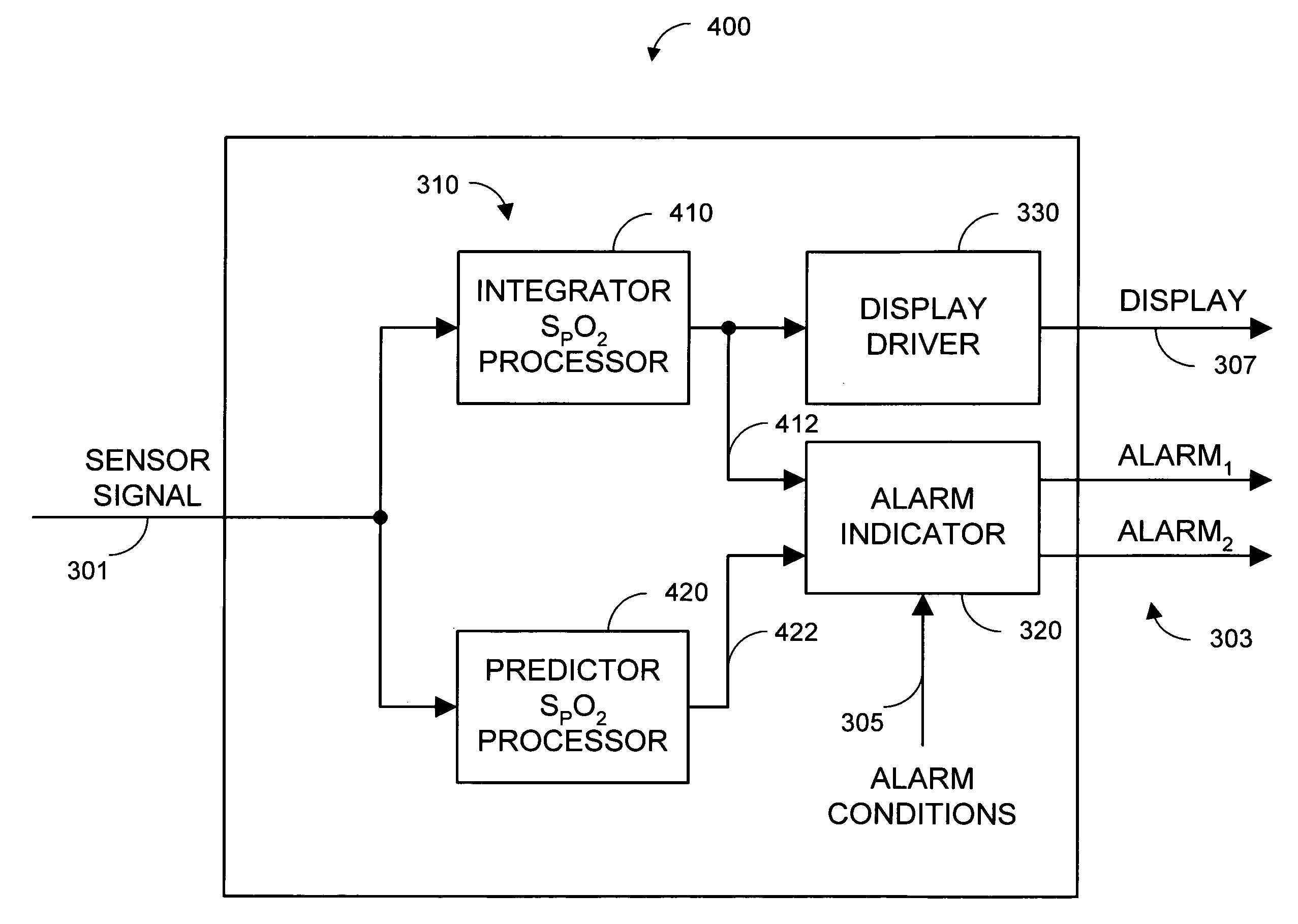

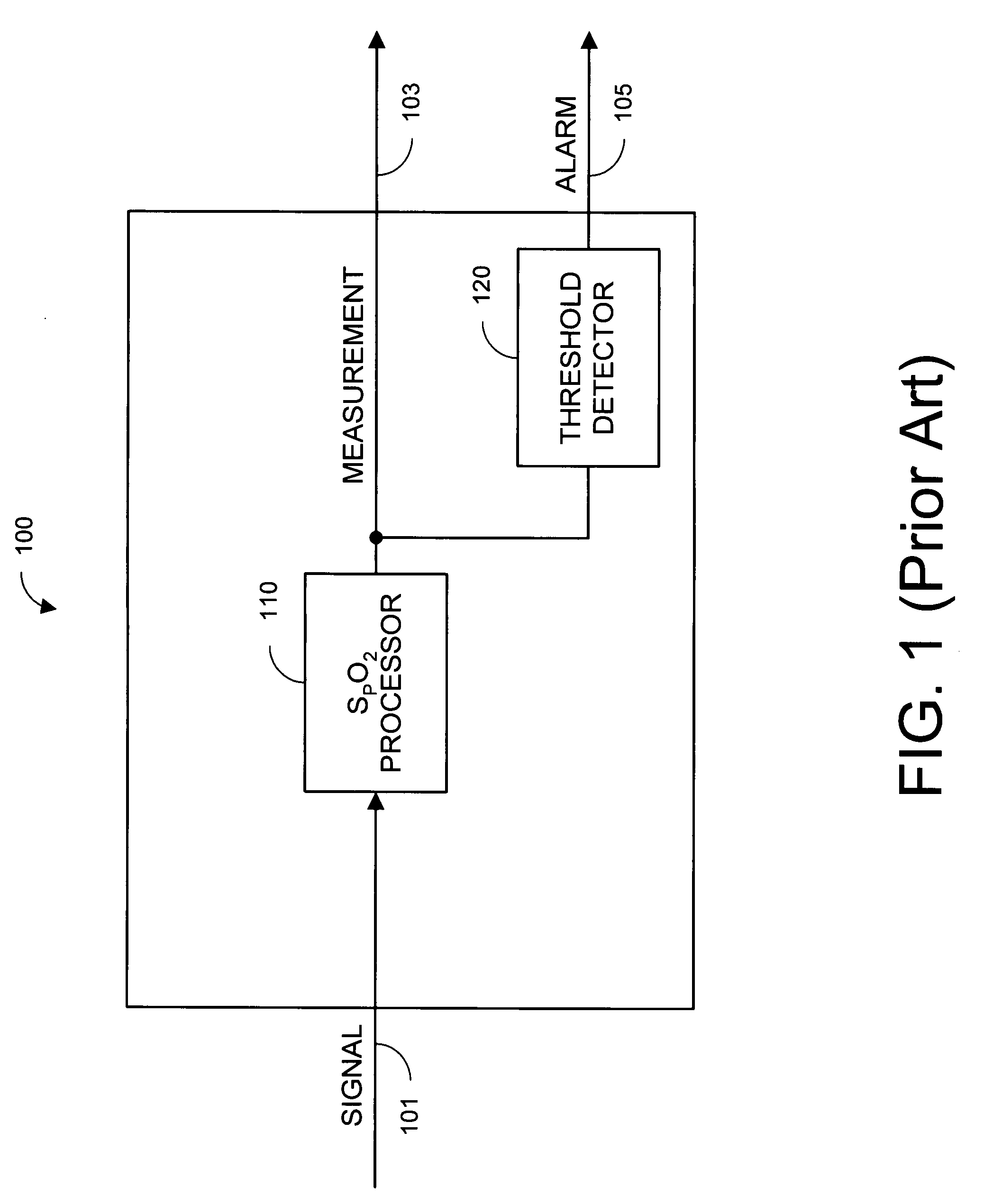

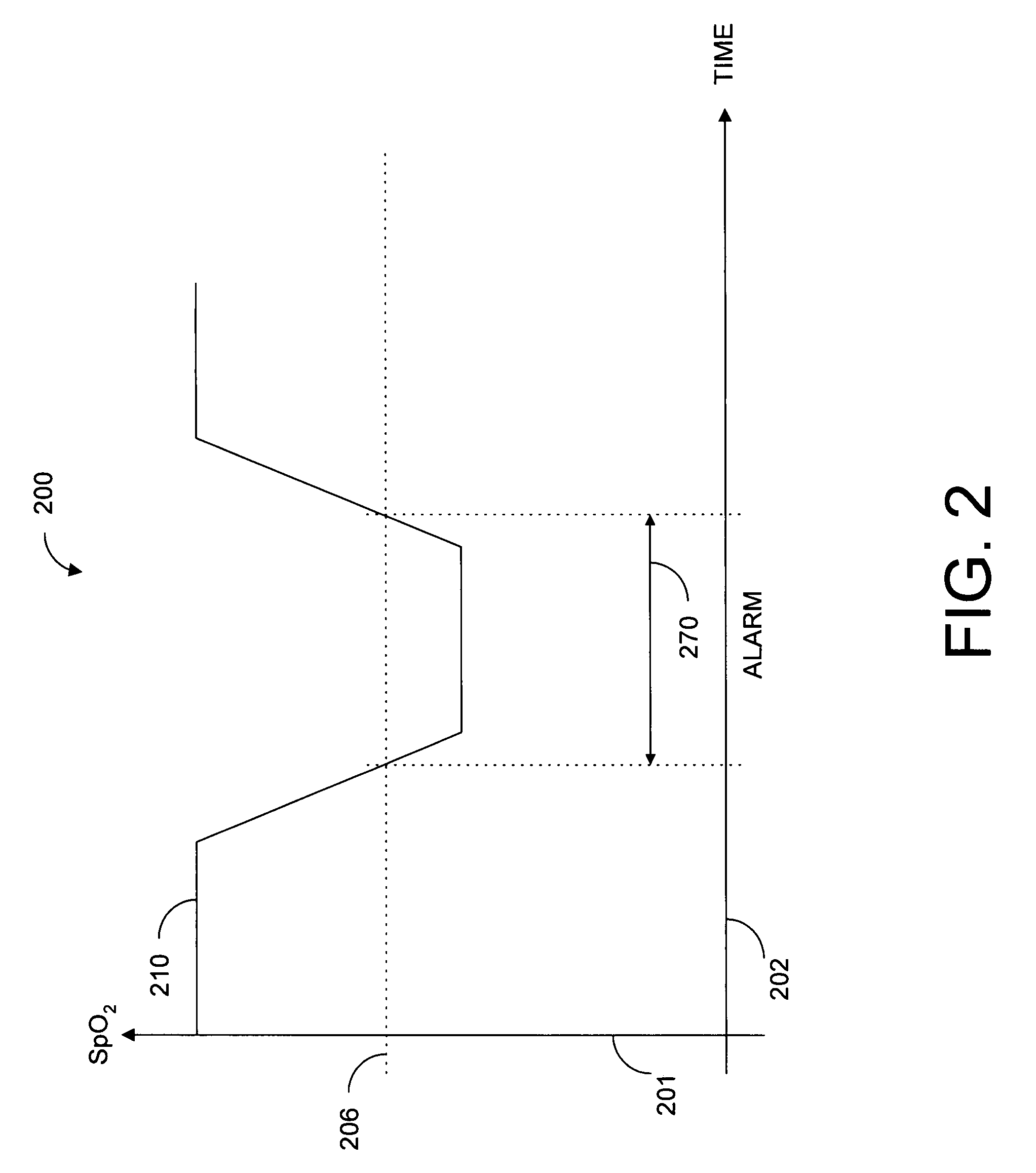

Parallel alarm processor

InactiveUS7355512B1Waste caregiver resourcesReduce false alarm rateEvaluation of blood vesselsSensorsLower limitOxygen Saturation Measurement

A parallel alarm processor has a threshold detector, a pattern extractor, a predetermined reference pattern, a first alarm and a second alarm. The threshold detector has a first output responsive to relatively long duration oxygen desaturations. The pattern extractor has a second output responsive to relatively short duration oxygen desaturations. The predetermined reference pattern is indicative of a series of intermittent oxygen desaturations. A first alarm is triggered when the first output crosses a lower limit threshold. A second alarm is triggered when the second output matches the predetermined reference pattern. In an embodiment, an integrator inputs smoothed oxygen saturation measurements to the threshold detector, and a predictor inputs predictive oxygen saturation measurements to the pattern extractor.

Owner:JPMORGAN CHASE BANK NA

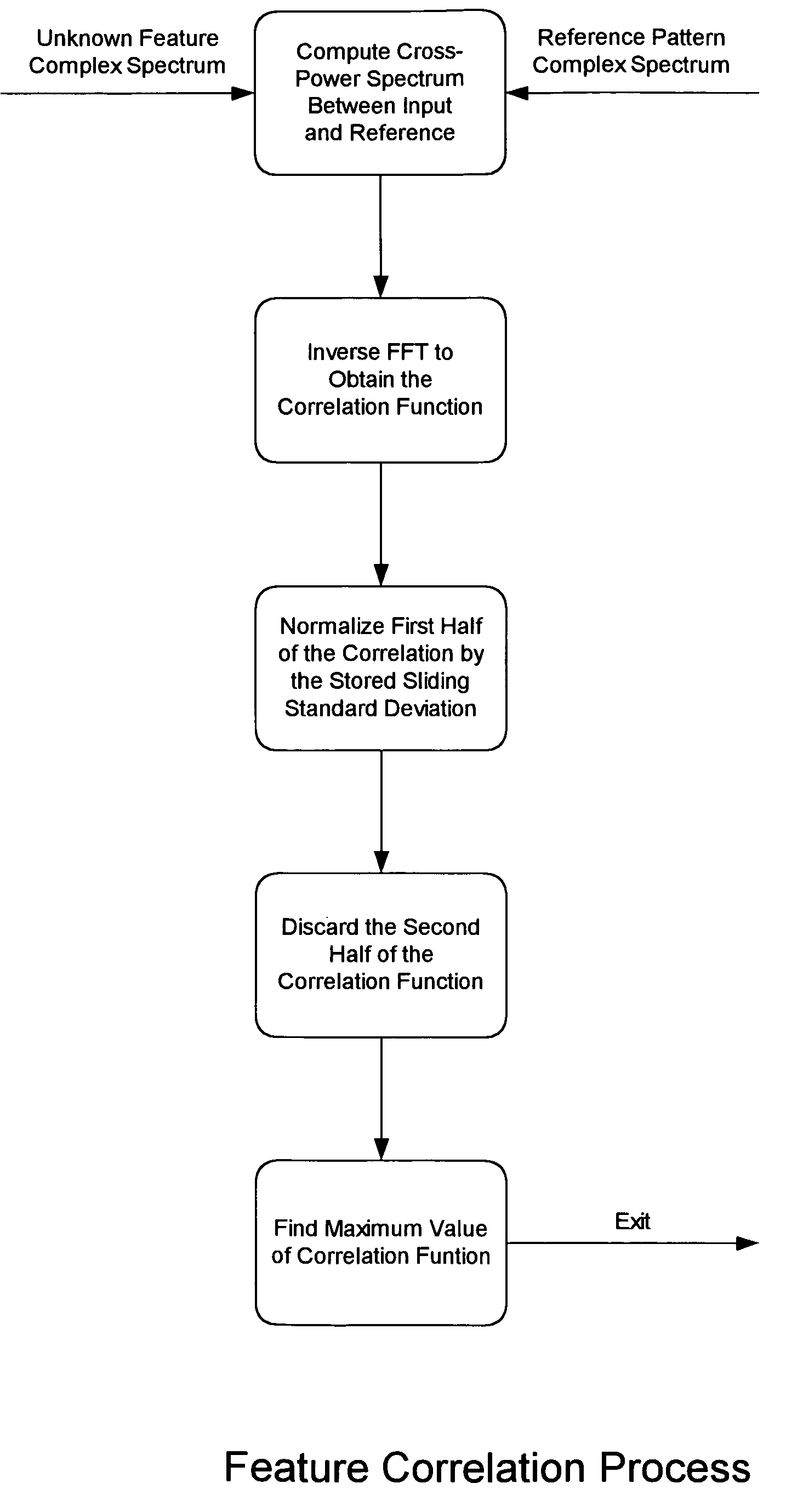

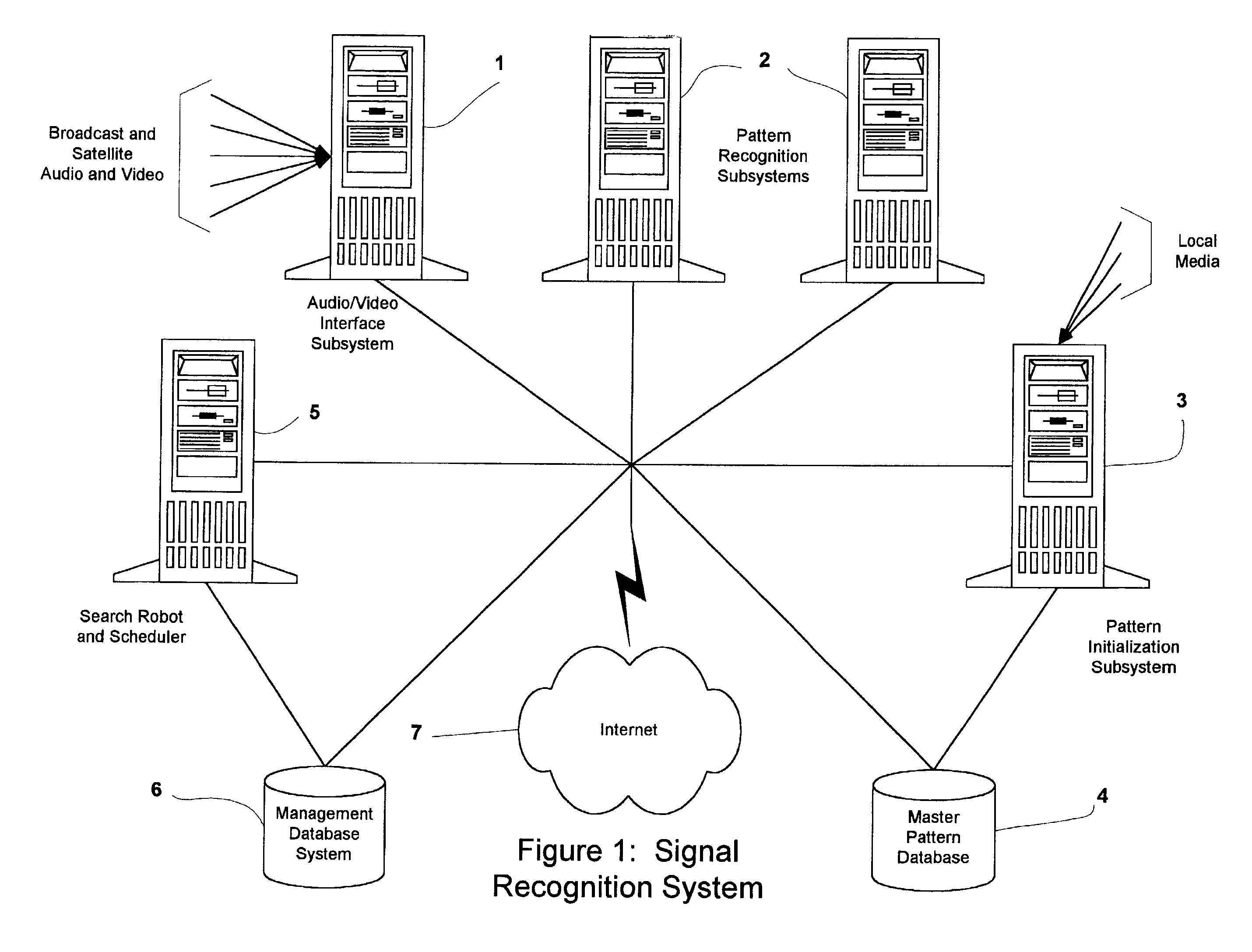

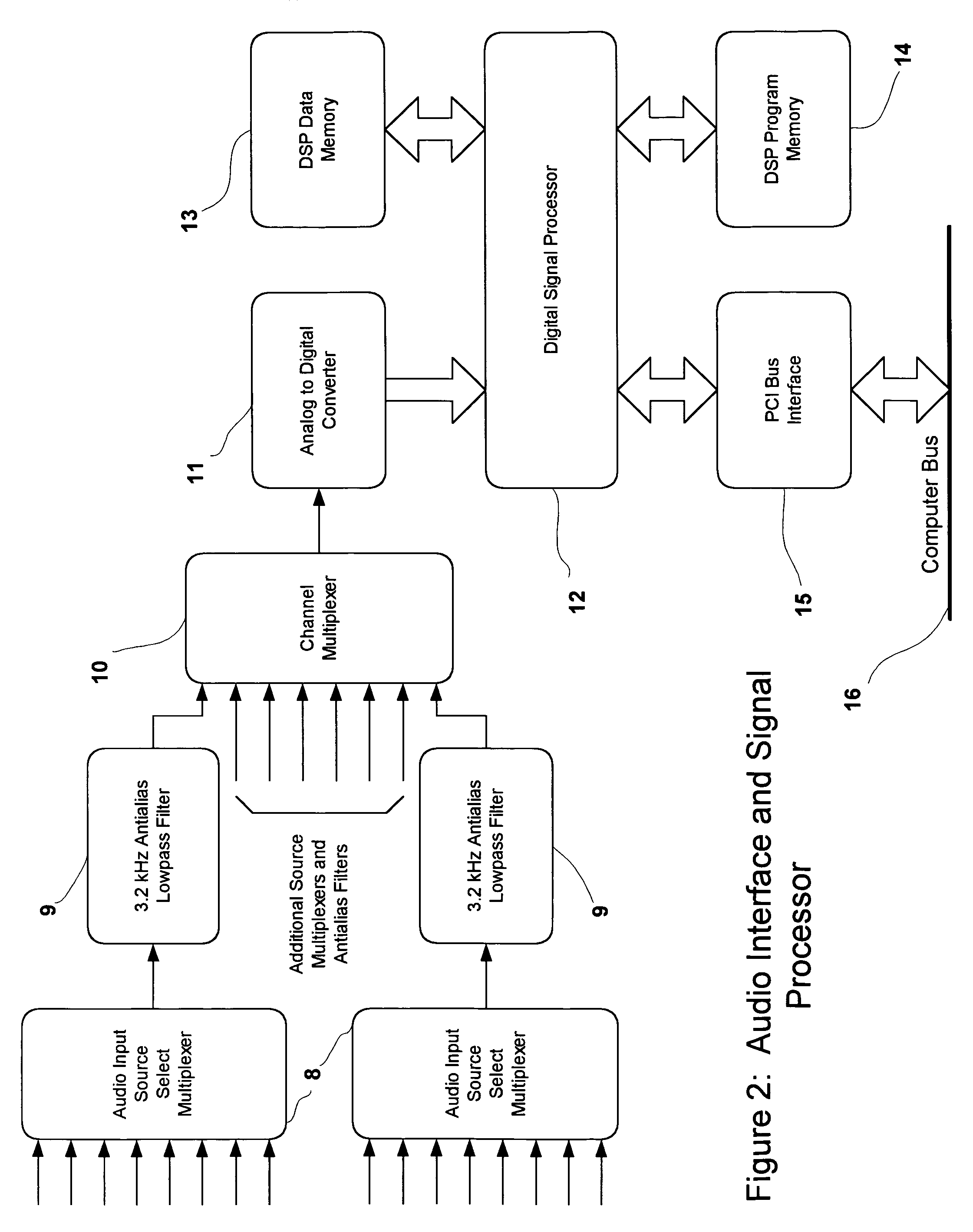

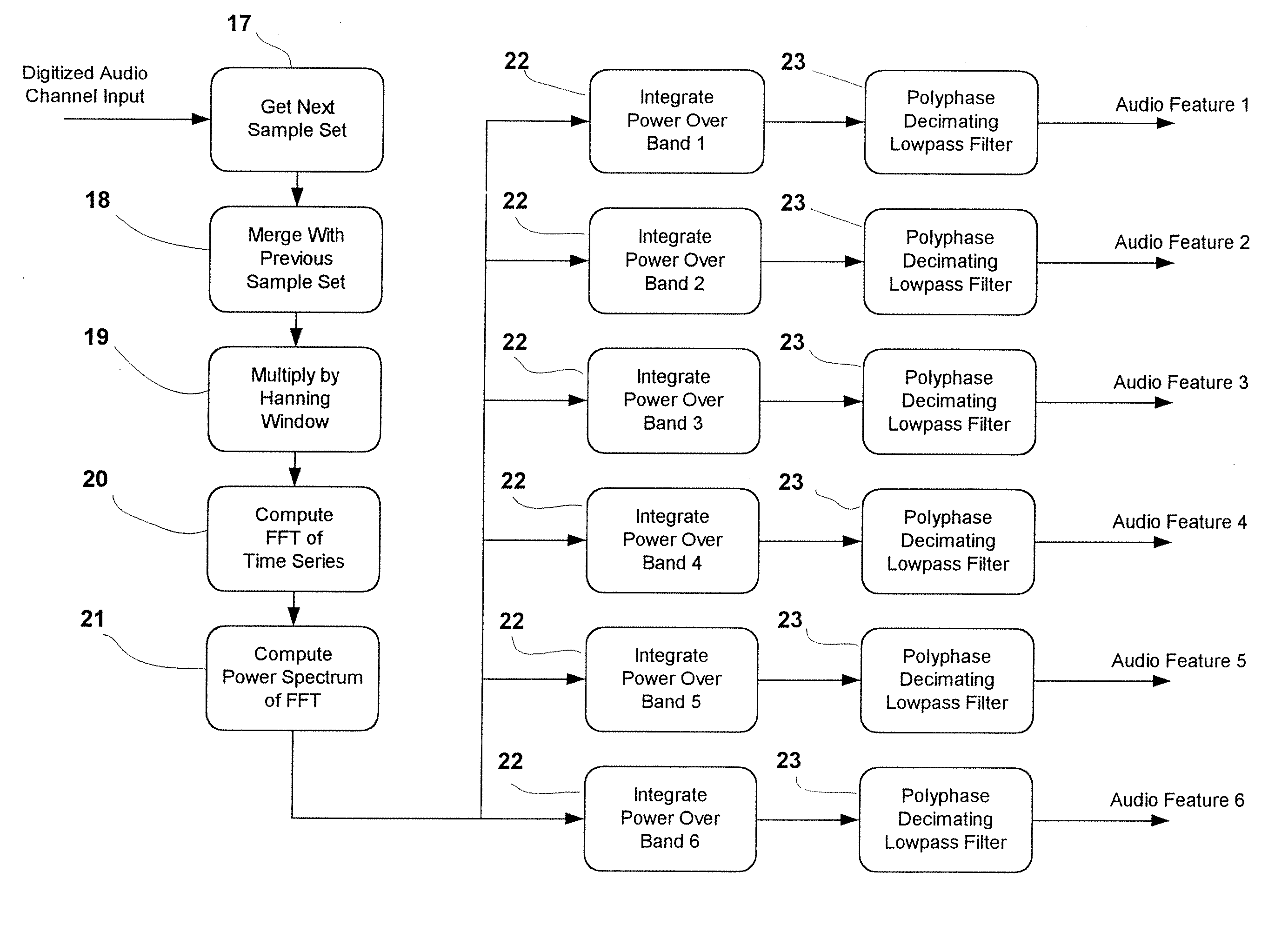

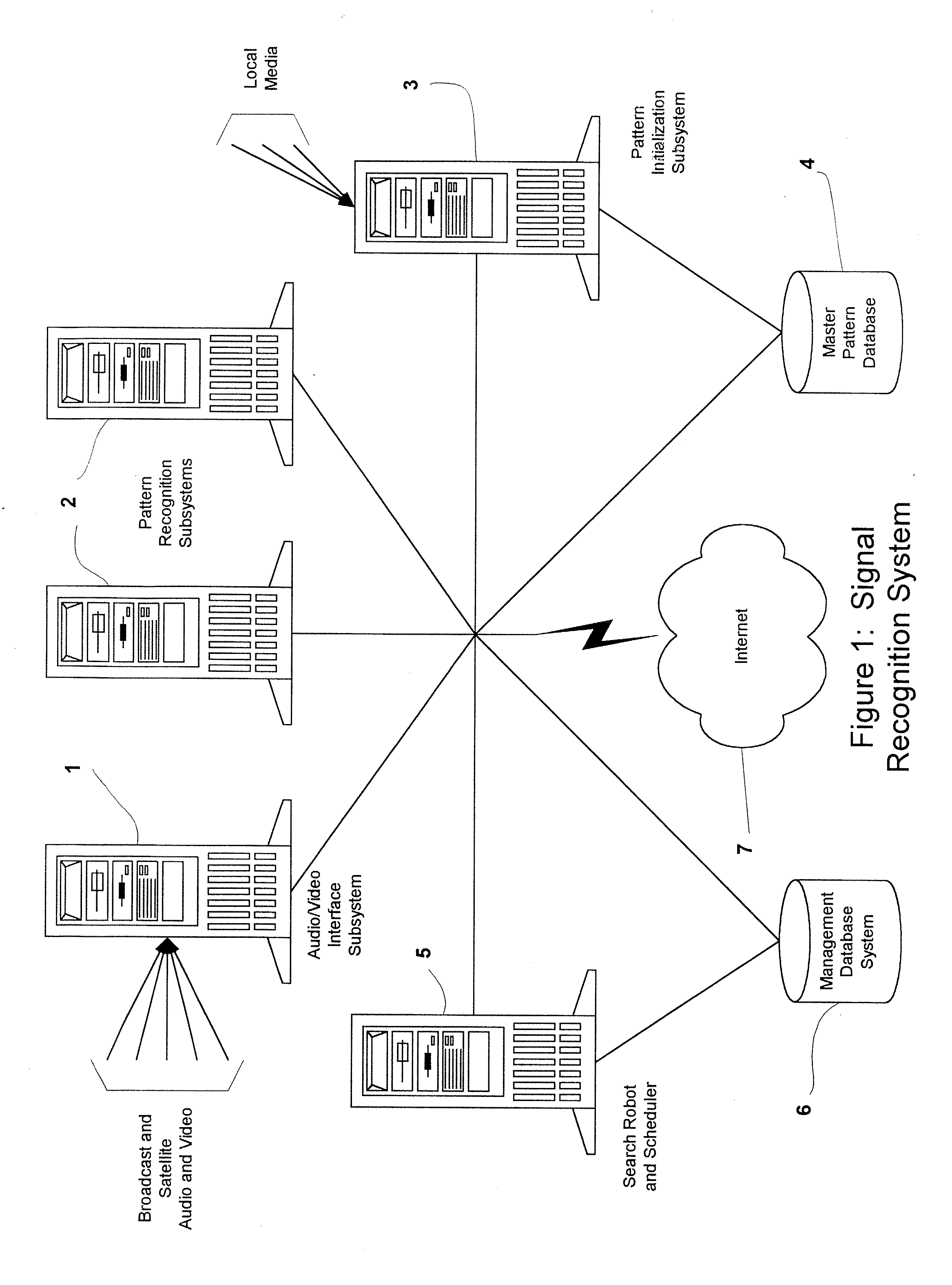

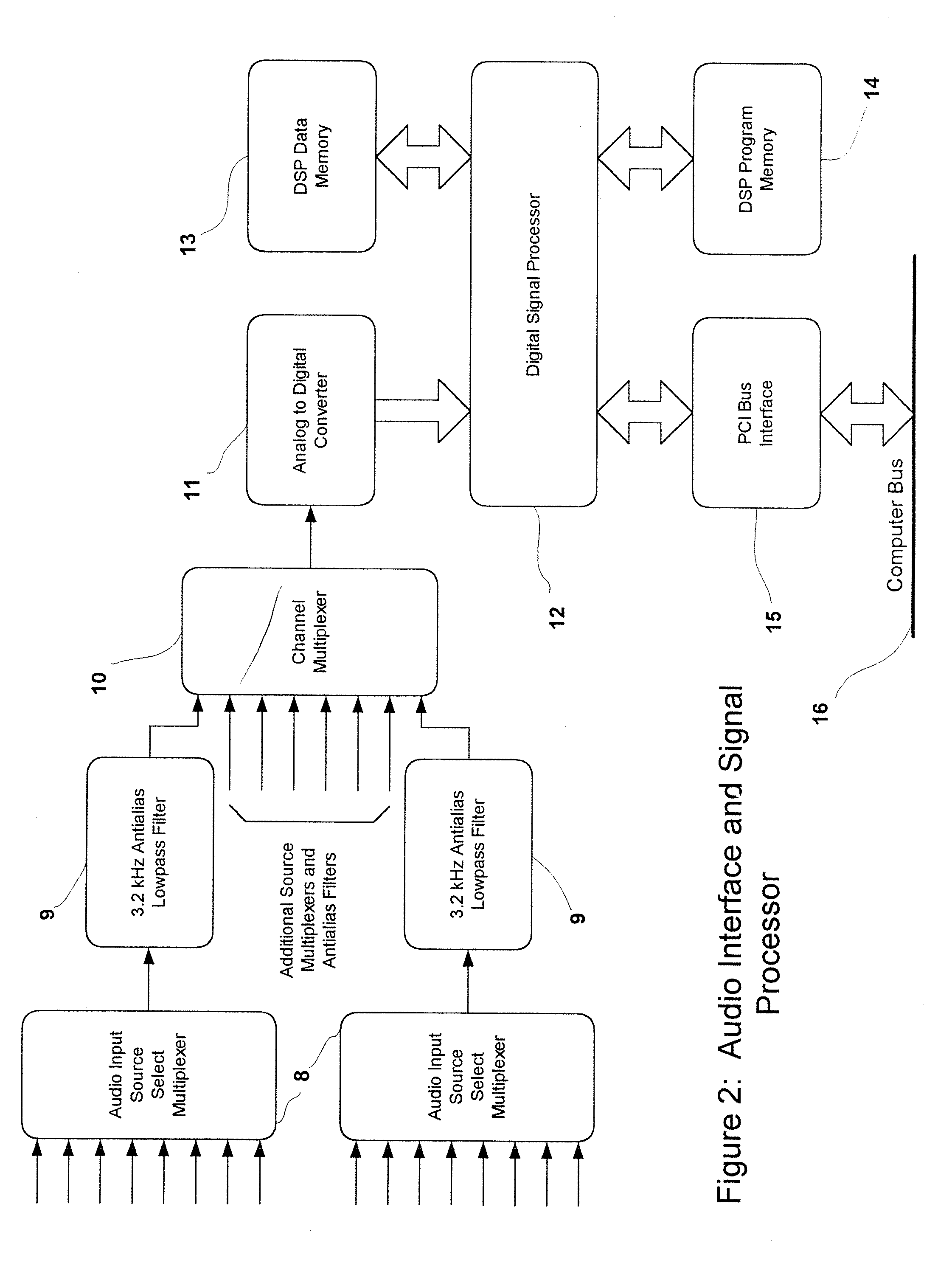

Method and apparatus for automatically recognizing input audio and/or video streams

InactiveUS7194752B1Improve accuracyMinimal timeSpeech analysisAnalogue secracy/subscription systemsSingle sampleFeature set

A method and system for the automatic identification of audio, video, multimedia, and / or data recordings based on immutable characteristics of these works. The invention does not require the insertion of identifying codes or signals into the recording. This allows the system to be used to identify existing recordings that have not been through a coding process at the time that they were generated. Instead, each work to be recognized is “played” into the system where it is subjected to an automatic signal analysis process that locates salient features and computes a statistical representation of these properties. These features are then stored as patterns for later recognition of live input signal streams. A different set of features is derived for each audio or video work to be identified and stored. During real-time monitoring of a signal stream, a similar automatic signal analysis process is carried out, and many features are computed for comparison with the patterns stored in a large feature database. For each particular pattern stored in the database, only the relevant characteristics are compared with the real-time feature set. Preferably, during analysis and generation of reference patterns, data are extracted from all time intervals of a recording. This allows a work to be recognized from a single sample taken from any part of the recording.

Owner:ICEBERG IND

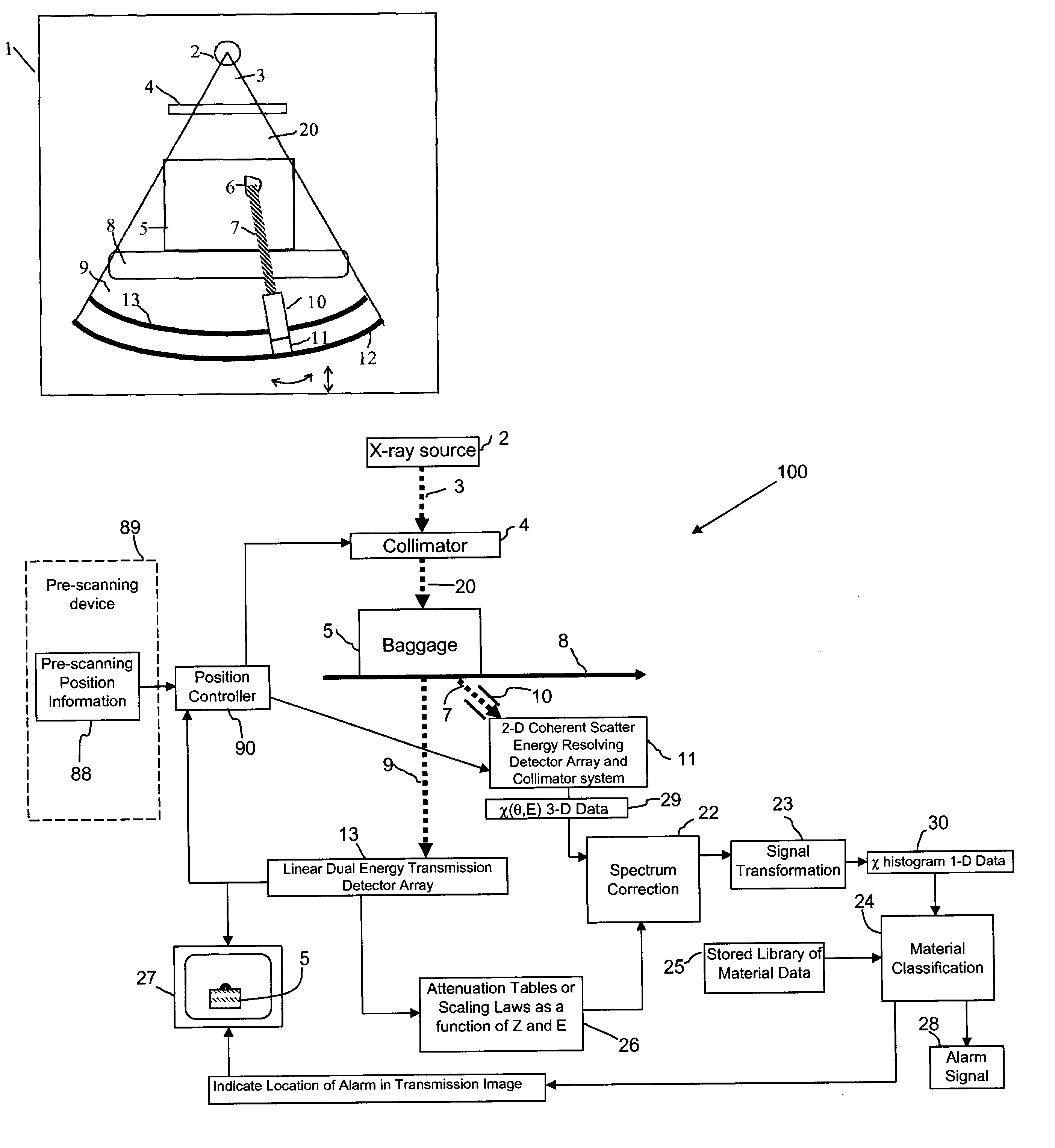

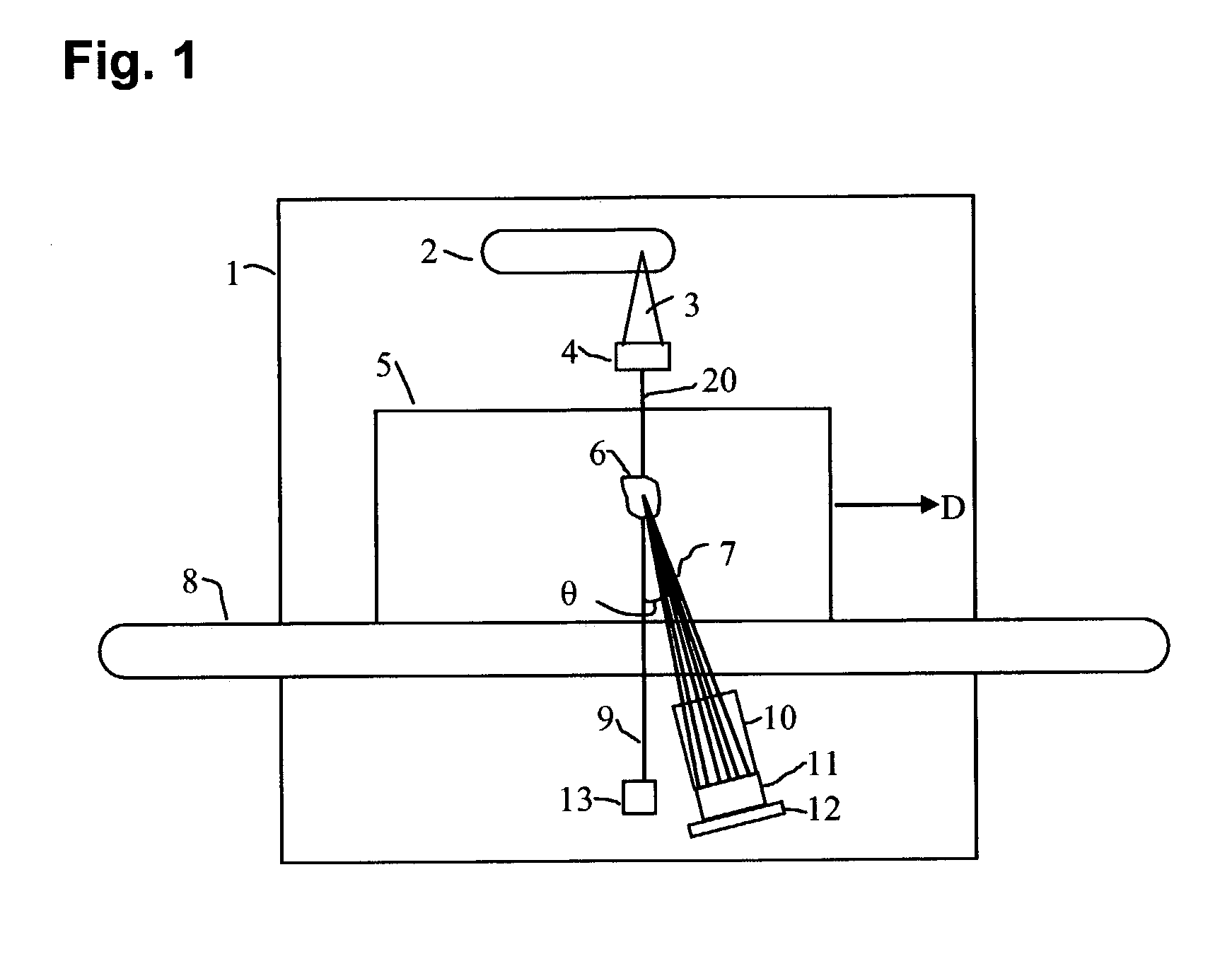

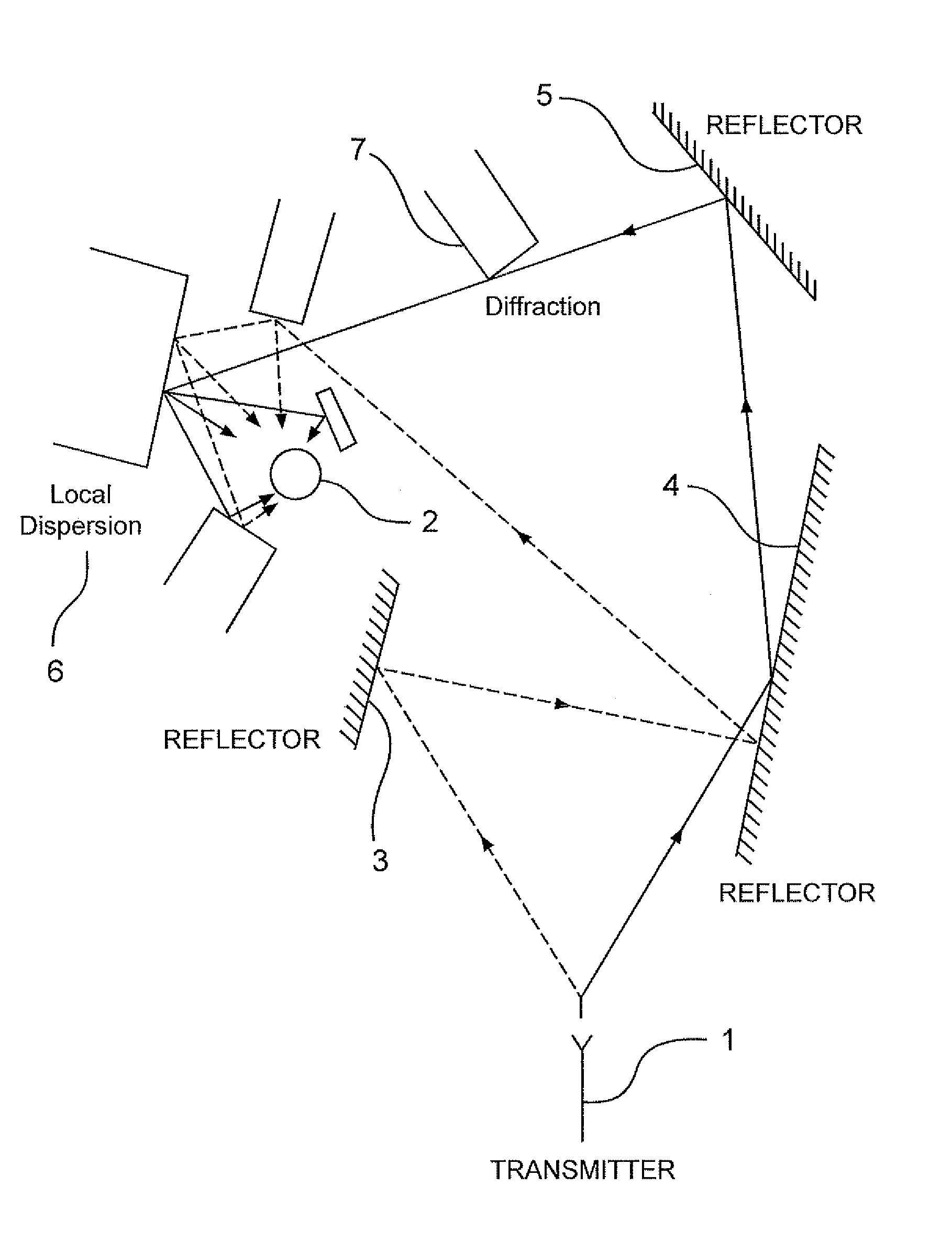

X-ray inspection system for detecting explosives and other contraband

InactiveUS7092485B2Rapidly and accurately discriminates among different substancesQuick checkUsing wave/particle radiation meansMaterial analysis by transmitting radiationX-rayExplosive material

A baggage scanning system and method employ combined angular and energy dispersive x-ray scanning to detect the presence of a contraband substance within an interrogation volume of a baggage item. The interrogation volume is illuminated with penetrating, polychromatic x-rays in a primary fan beam from a source such as a tungsten-anode x-ray tube. An energy-dependent absorption correction is determined from measurement of the attenuation of the fan beam at a plurality of different energies. Radiation coherently scattered by substances in the interrogation volume is detected by an energy-resolved x-ray detector operated at a plurality of scattering angles to form a plurality of scattering spectra. Each scattering spectrum is corrected for energy-dependent absorption and the corrected spectra are combined to produce a scattering pattern. The experimental scattering pattern is compared with reference patterns that uniquely characterize known contraband substances. The system and method can locate and identify a wide variety of contraband substances in an accurate, reliable manner. The system provides for automated screening, with the result that vagaries of human performance are virtually eliminated. False alarms and the need for hand inspection are reduced and detection efficacy is increased.

Owner:CONTROL SCREENING

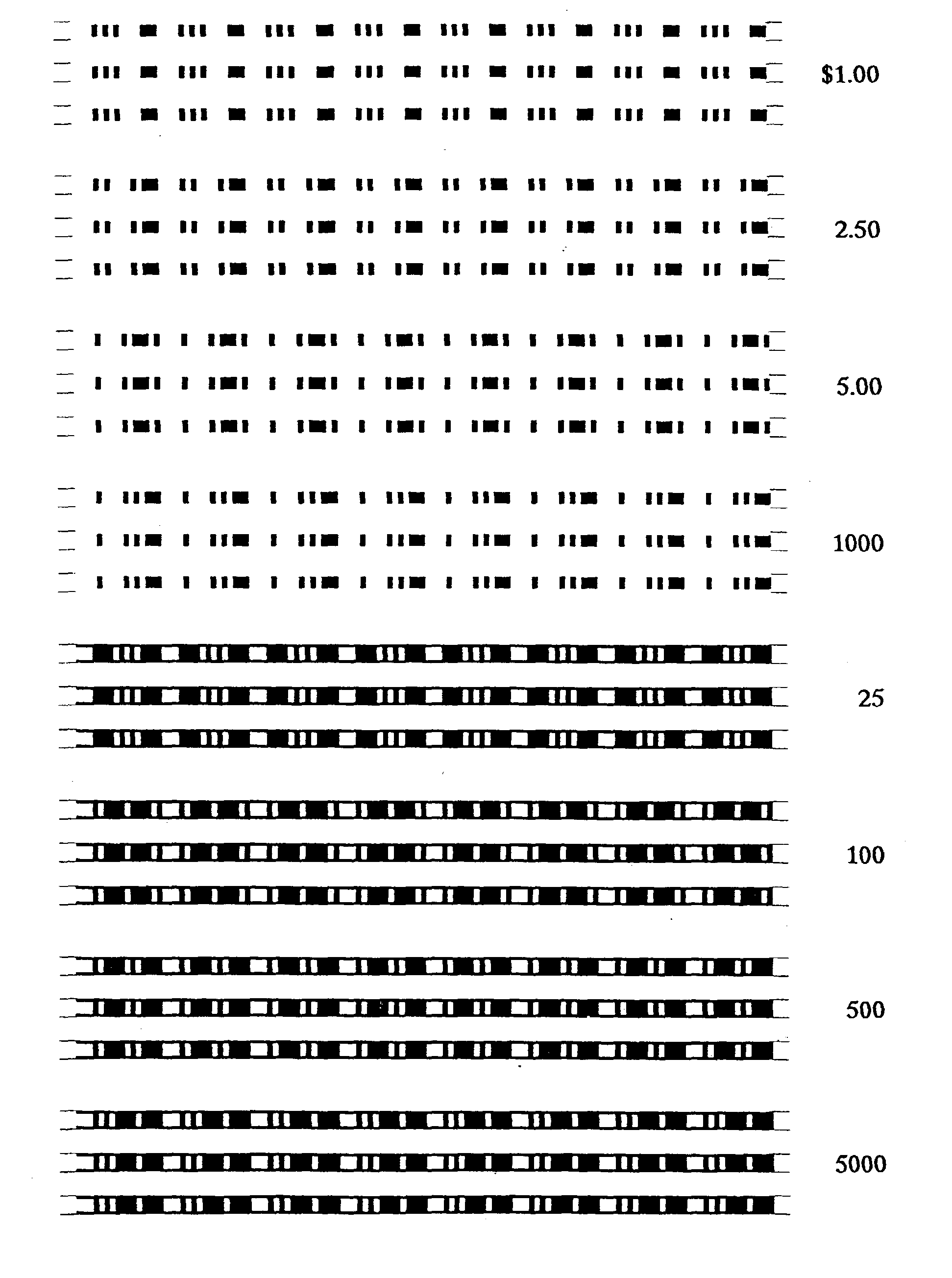

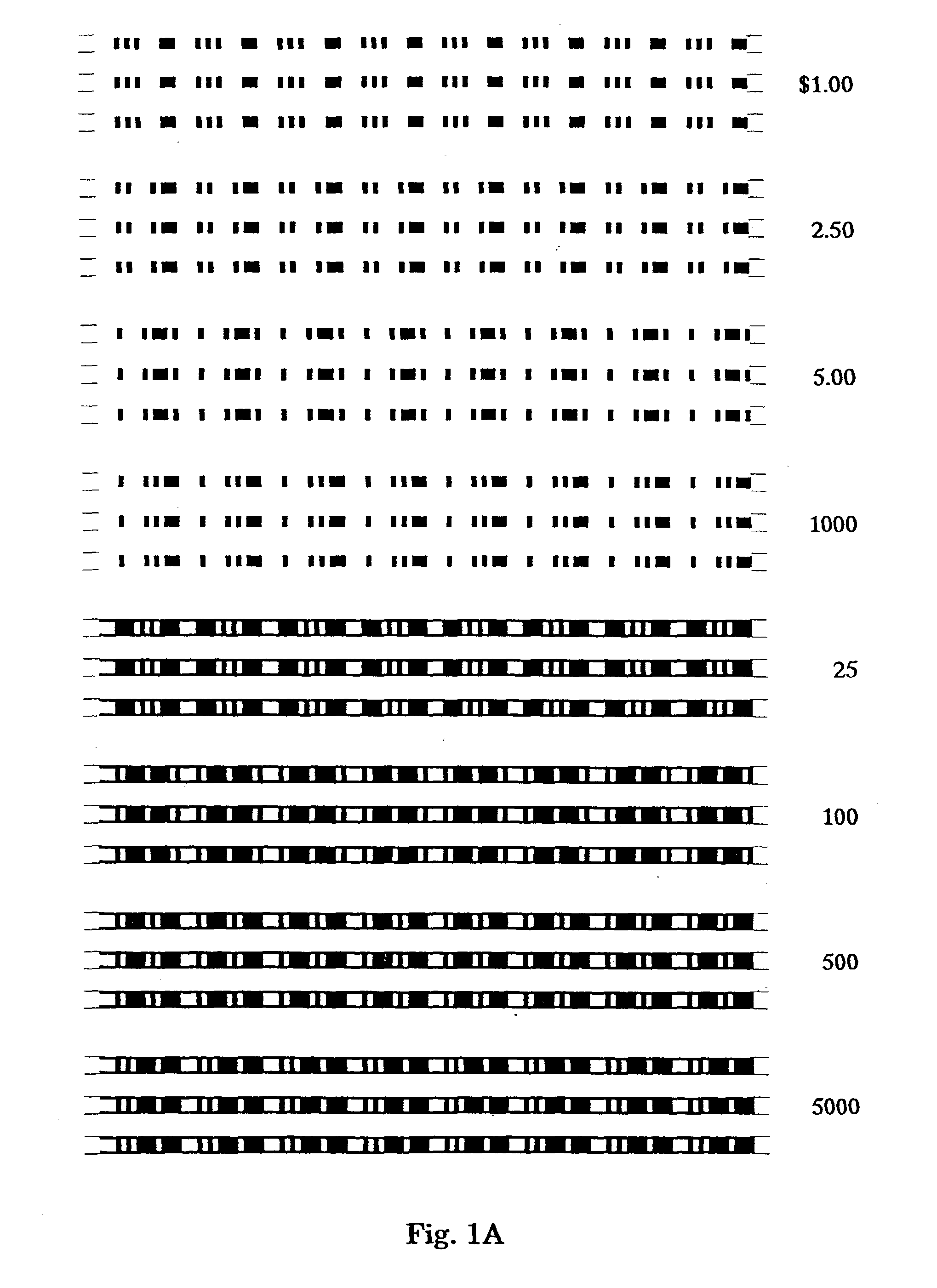

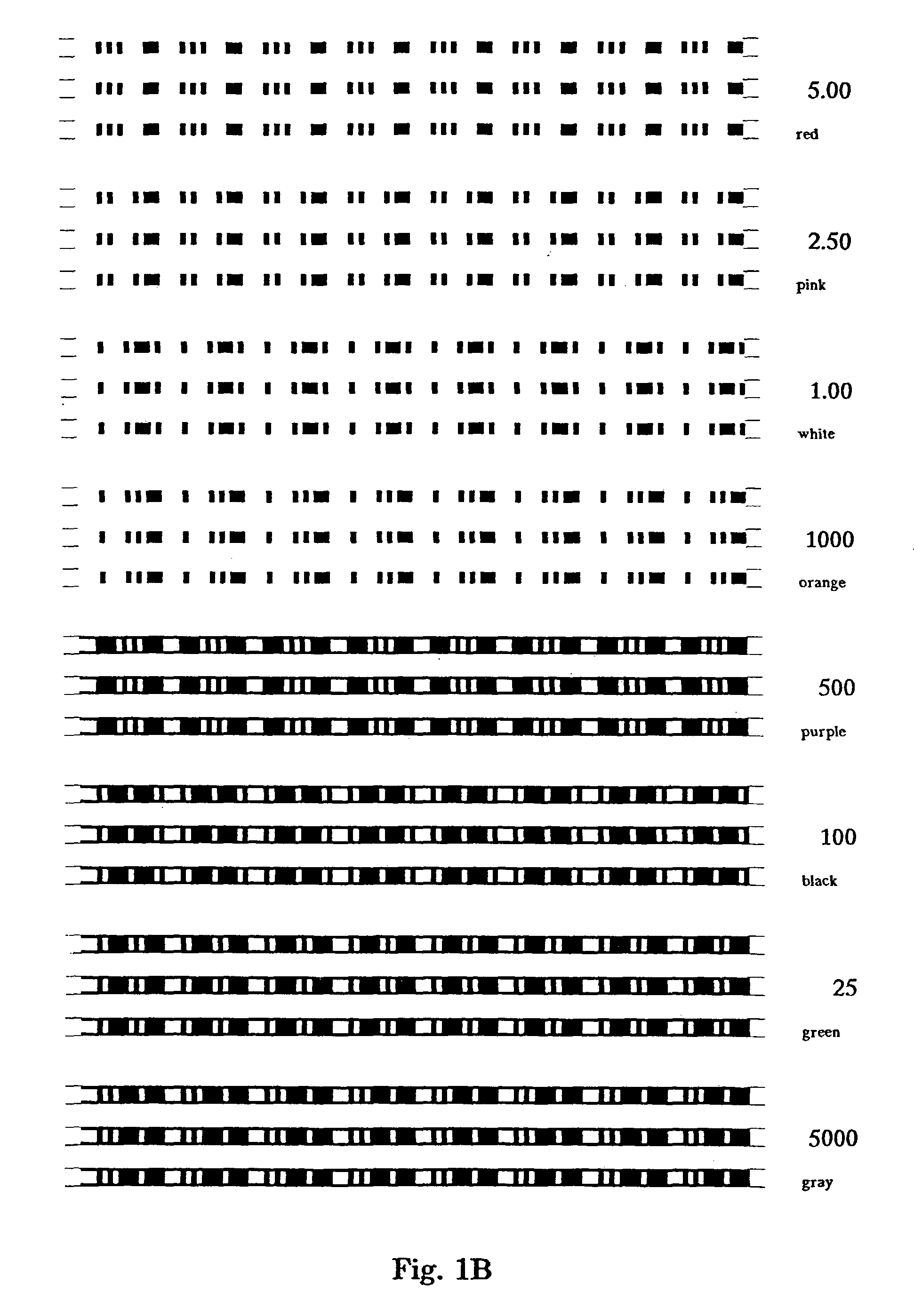

Self-clocking n,k code word without start or stop

InactiveUS7124947B2Enhance casino-style game playEasy to processCharacter and pattern recognitionApparatus for meter-controlled dispensingProgramming languageCoding conventions

A referenceless self-clocking (n,k) bar code word allows conveyance of information without the need of any start and / or stop code pattern or other reference; a code word pattern is repeated at least in part without space therebetween according to a given n,k coding convention so that any k pair of adjacent data code elements sensed by any sensing means according to the n,k coding convention will consist of n units (e.g., bar code modules), thus allowing the data code elements of the code word to be decoded most accurately without any reference pattern. One application of this coding is on round or cylindrical objects like coins, casino chips and the like, and this coding is also well suited for linear or other coding applications wanting to convey coded information without the use of a start / stop code or reference pattern using n,k coding. This coding may or mayn't include error control, for example, as disclosed herein.

Owner:BALLY GAMING INC

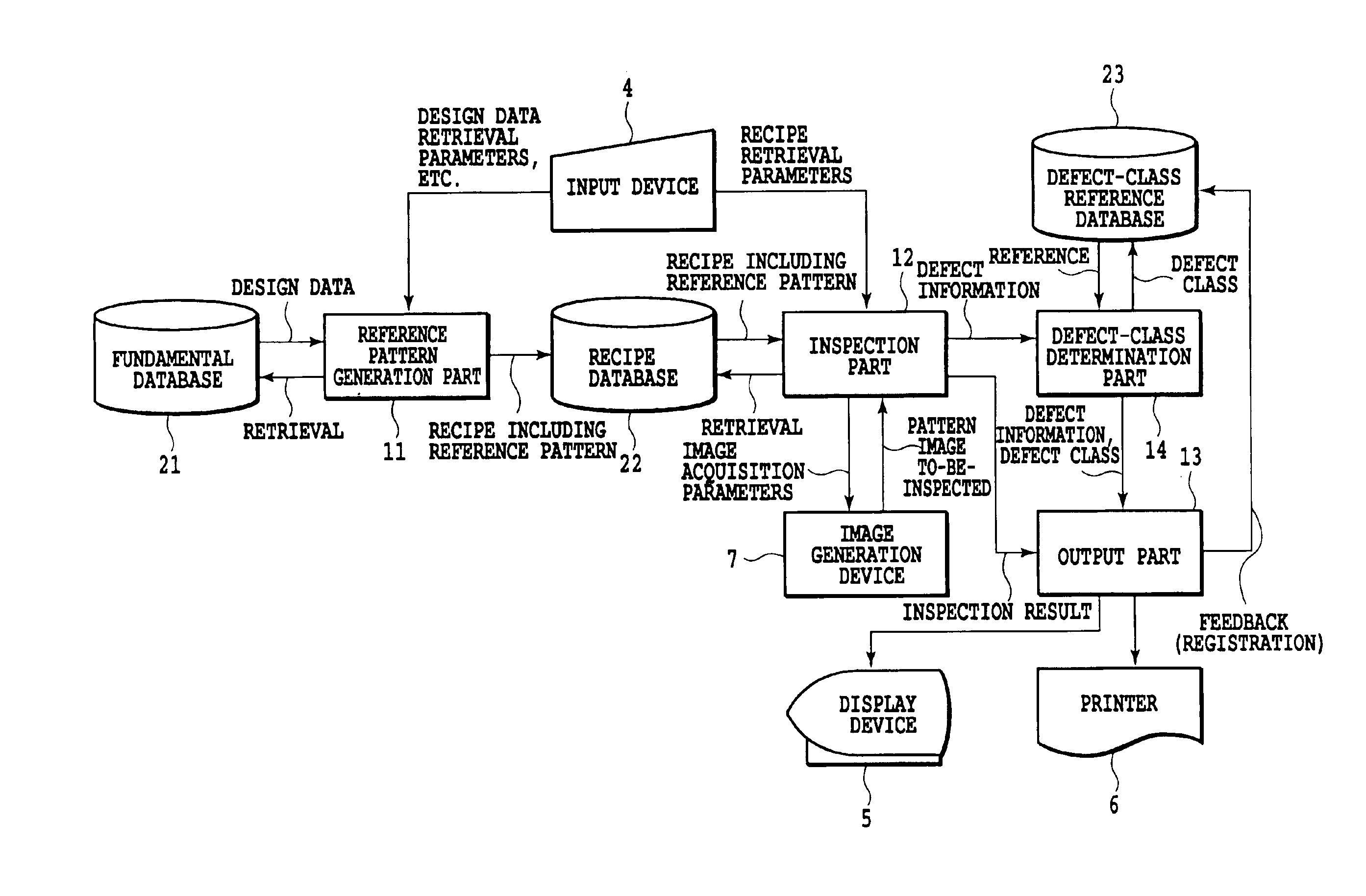

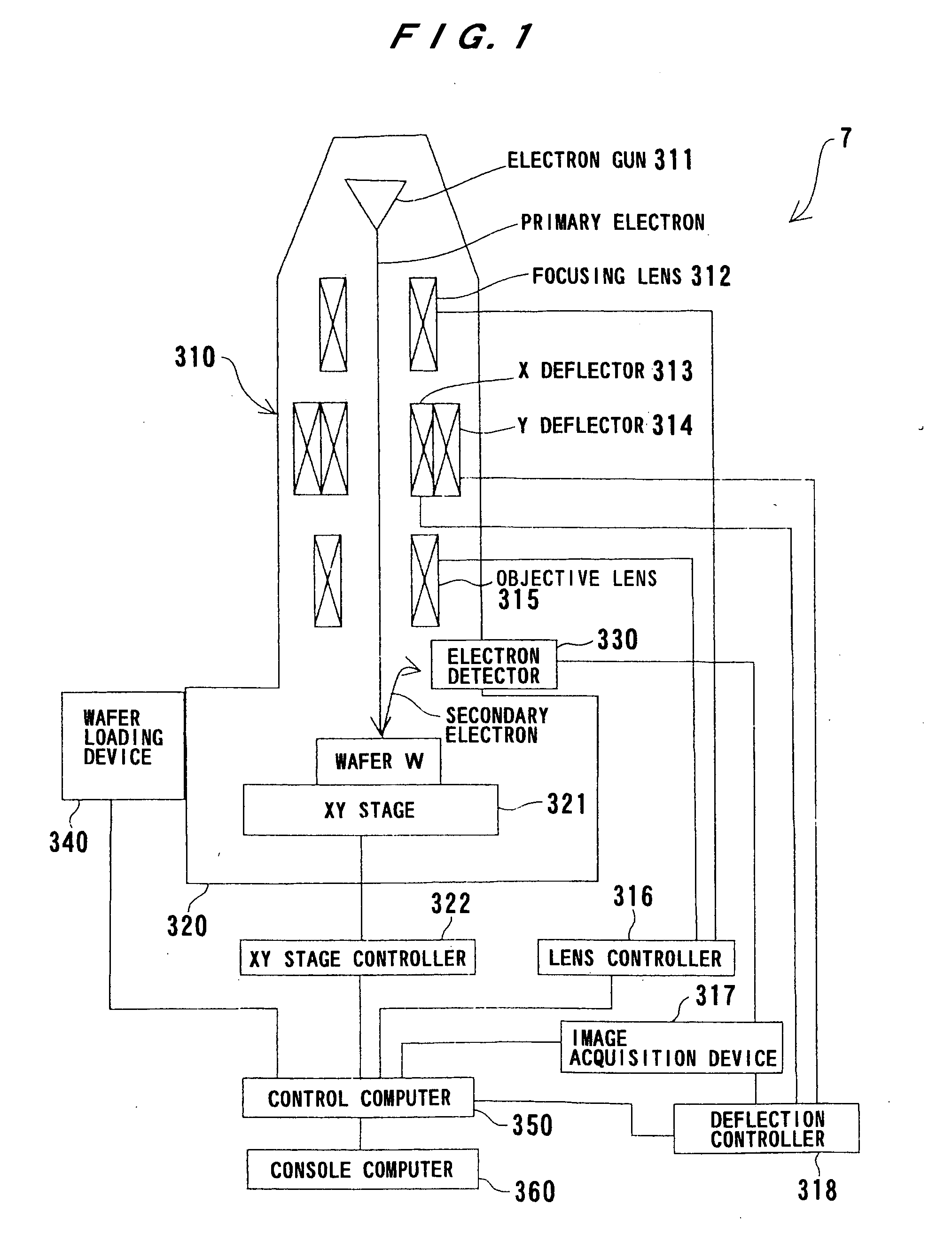

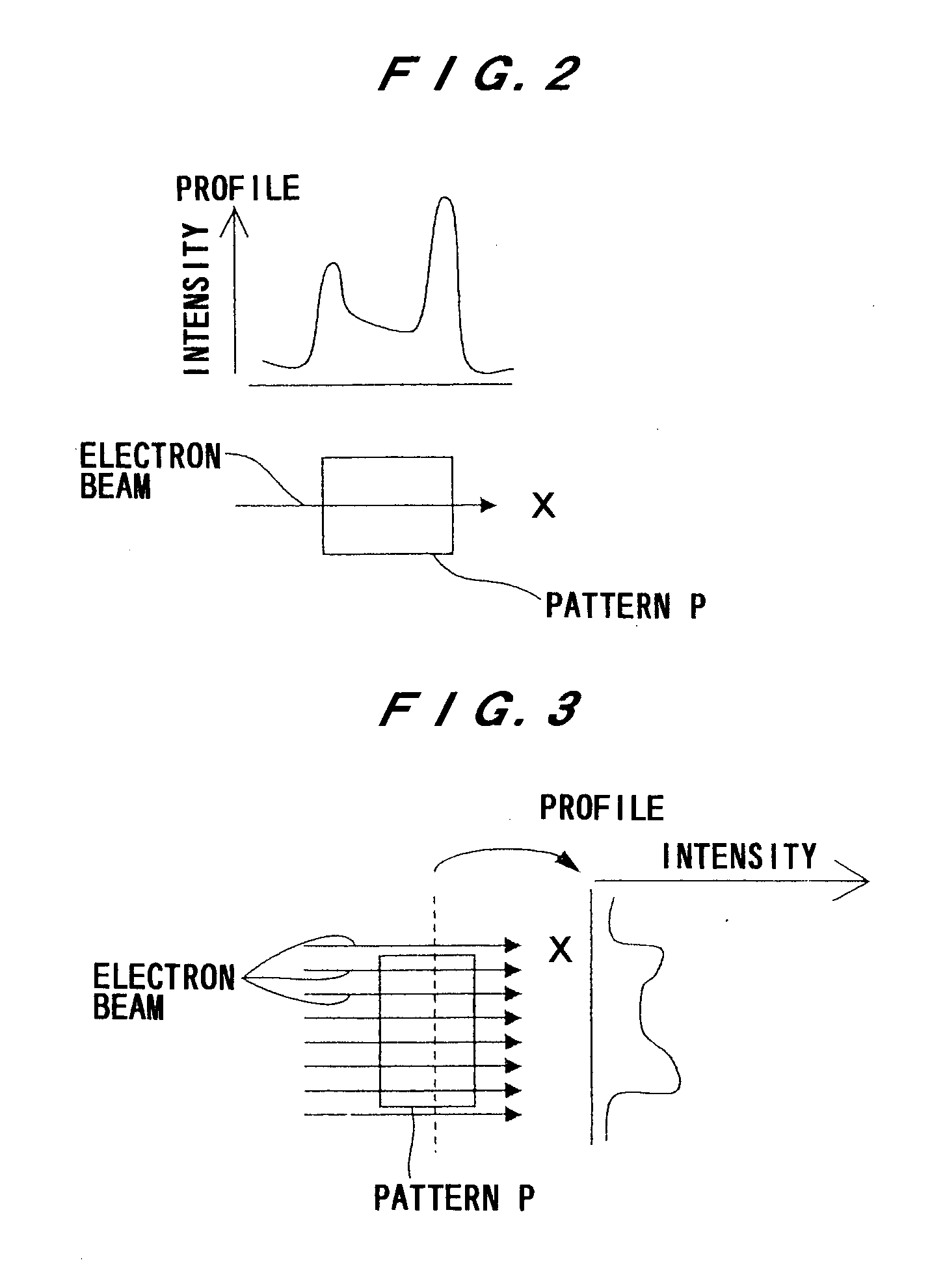

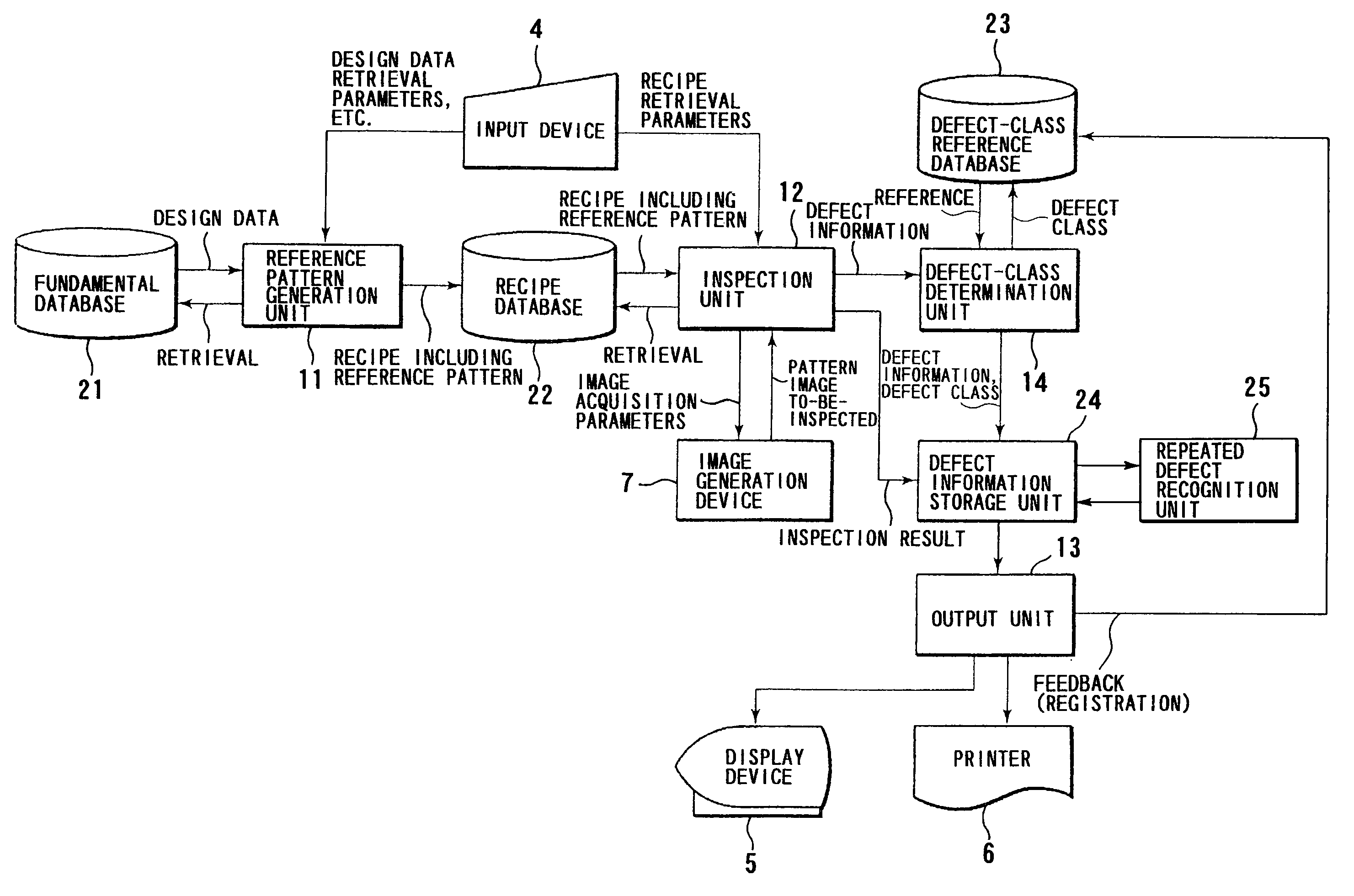

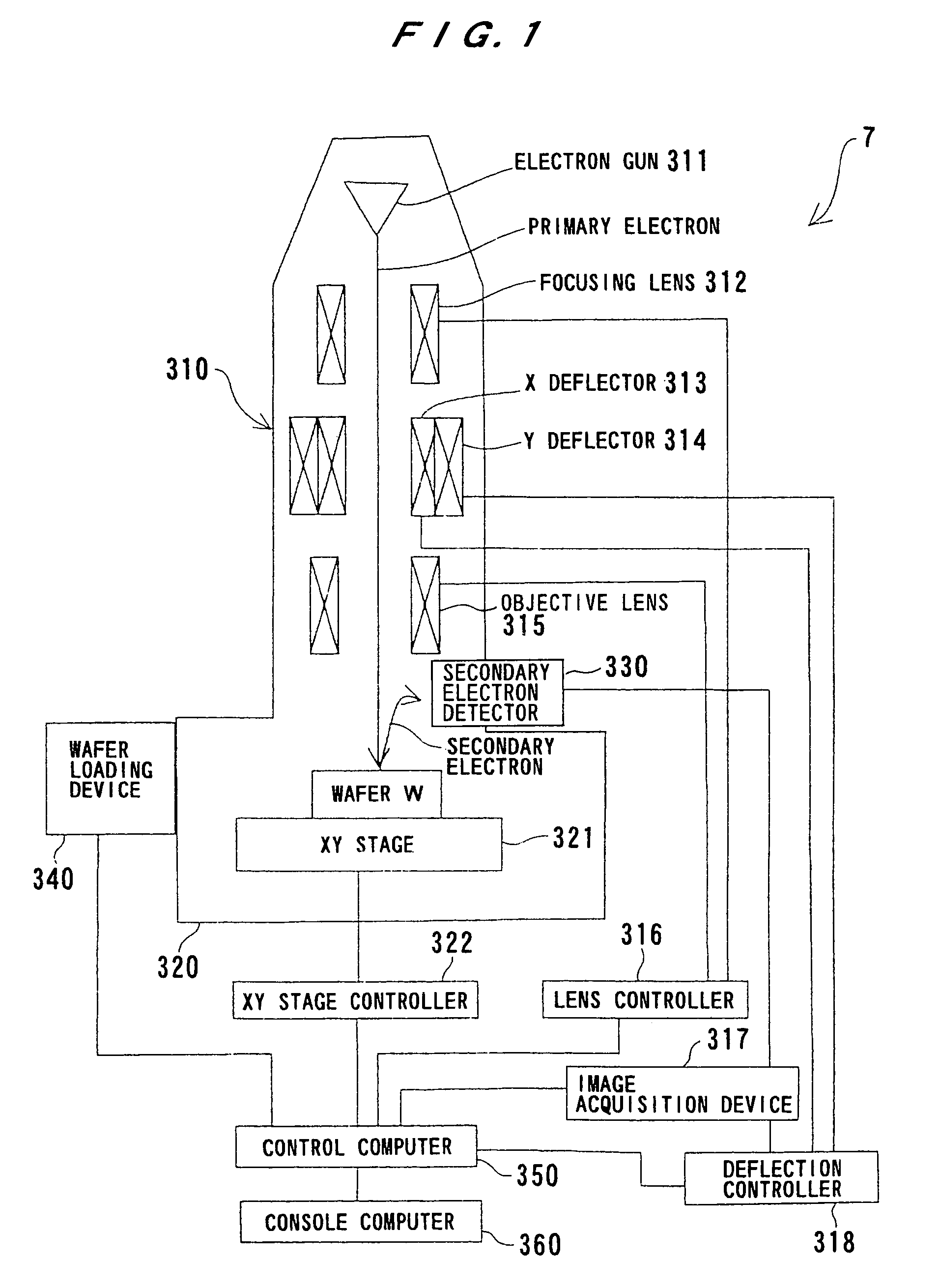

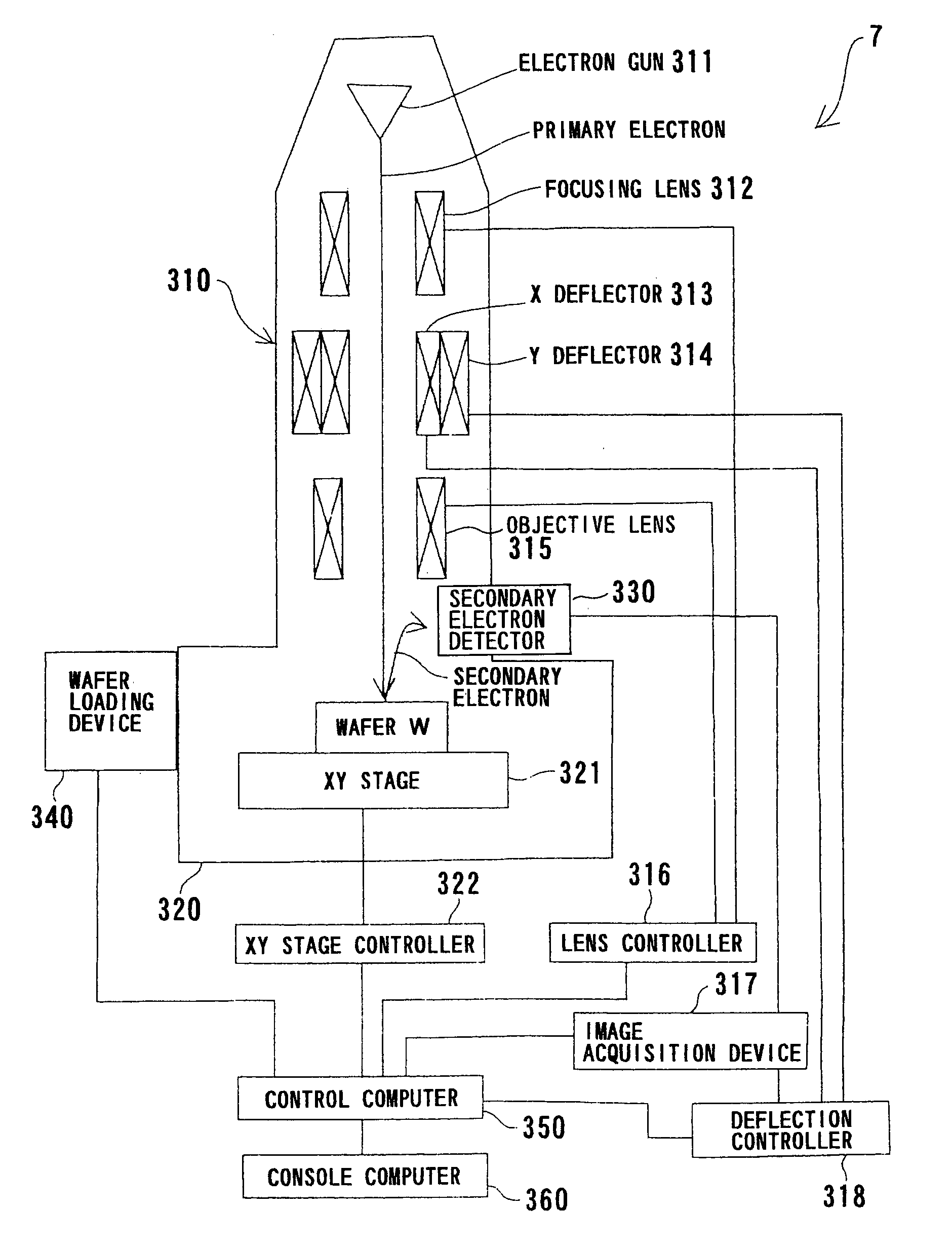

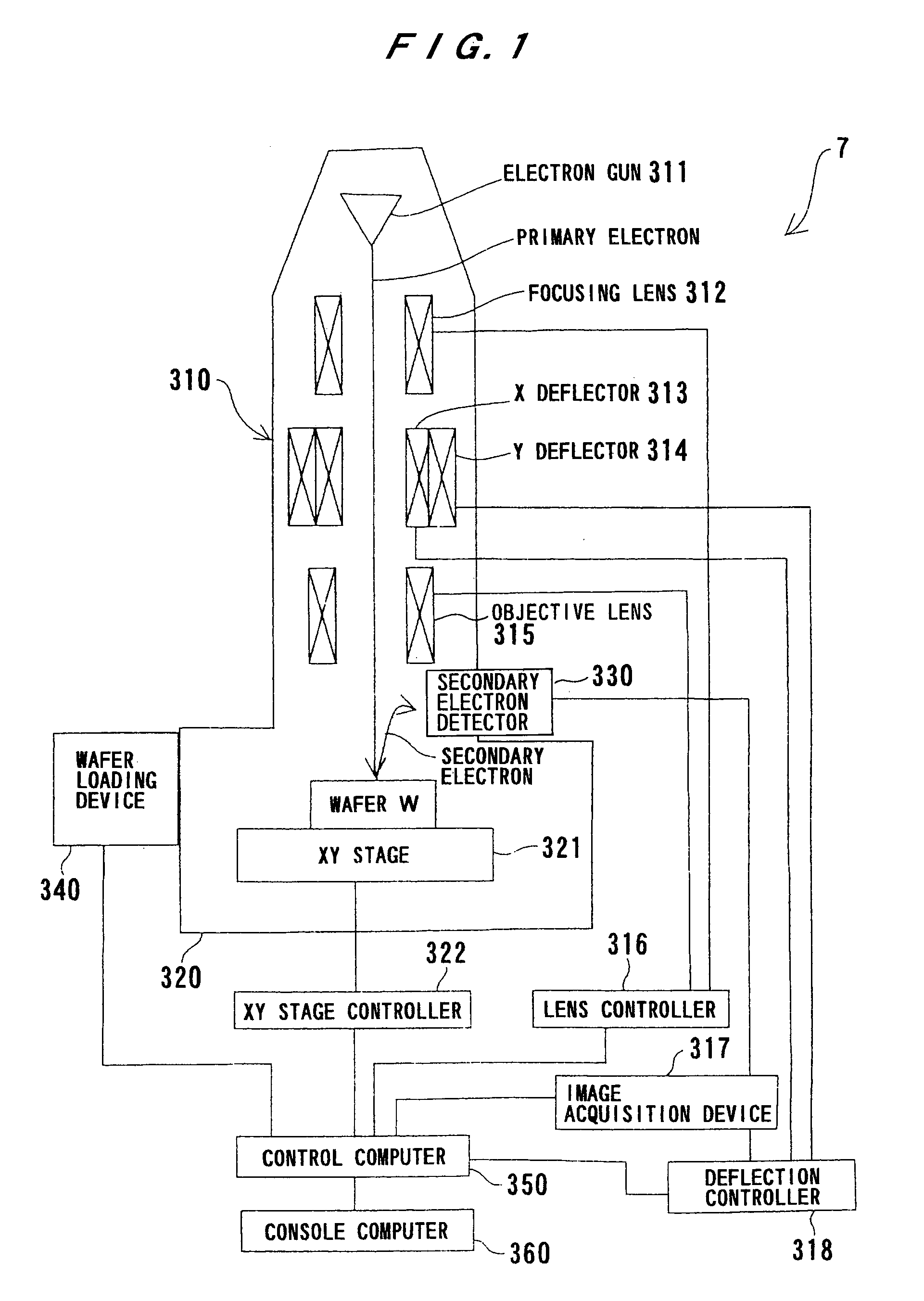

Pattern inspection apparatus, pattern inspection method, and recording medium

InactiveUS6868175B1Stable defect detectionImage enhancementMaterial analysis using wave/particle radiationPattern recognitionReference patterns

Owner:TASMIT INC

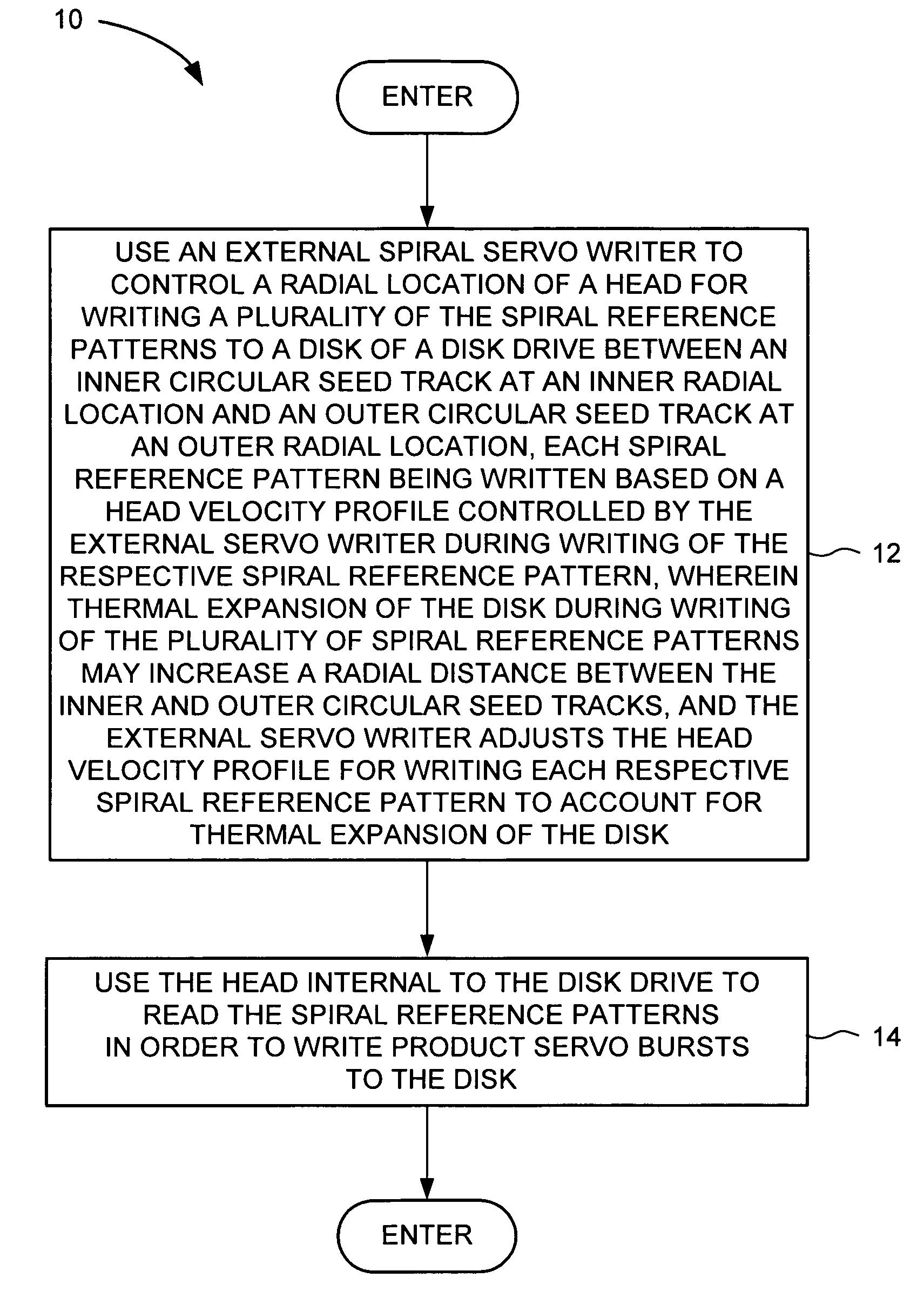

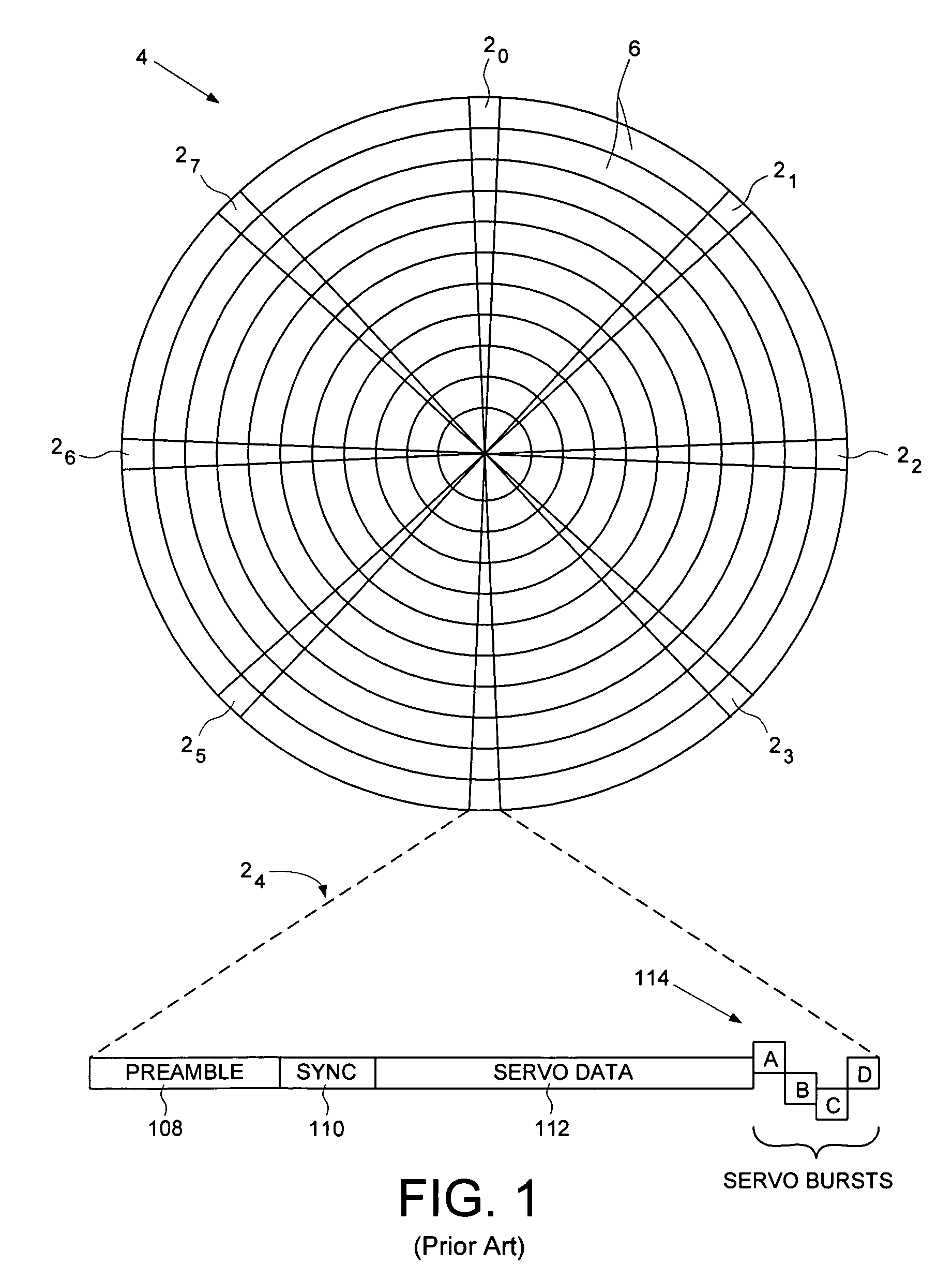

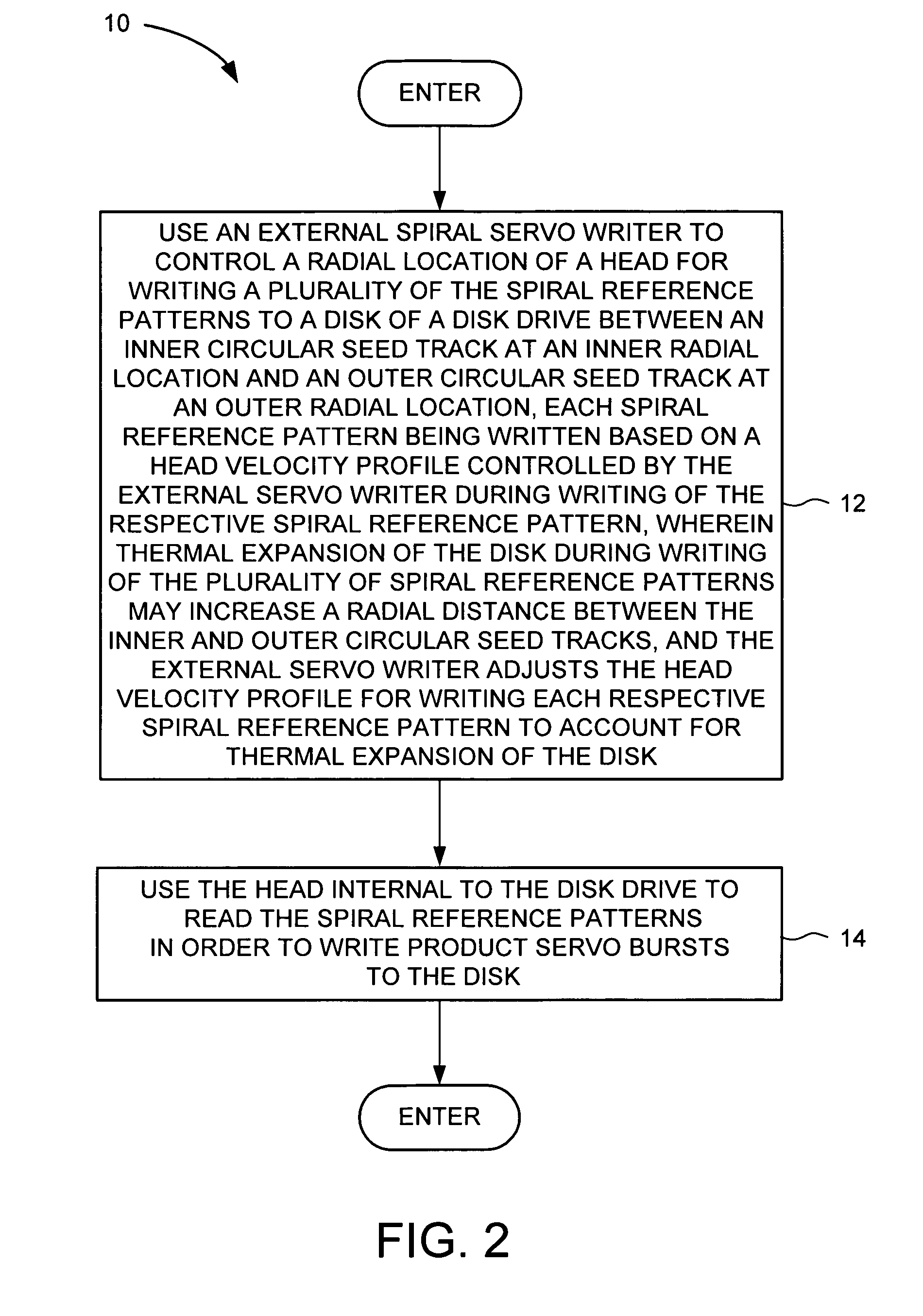

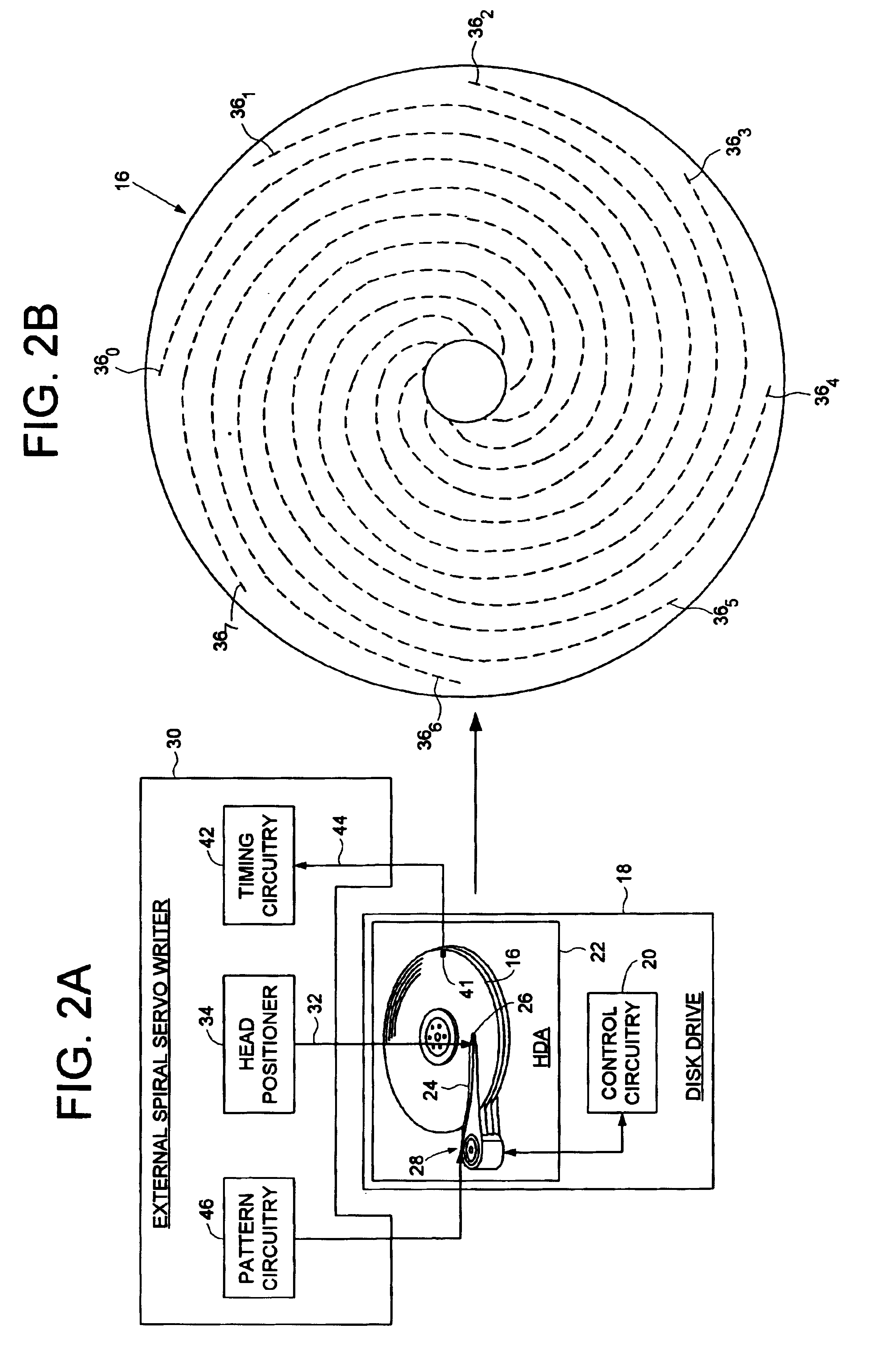

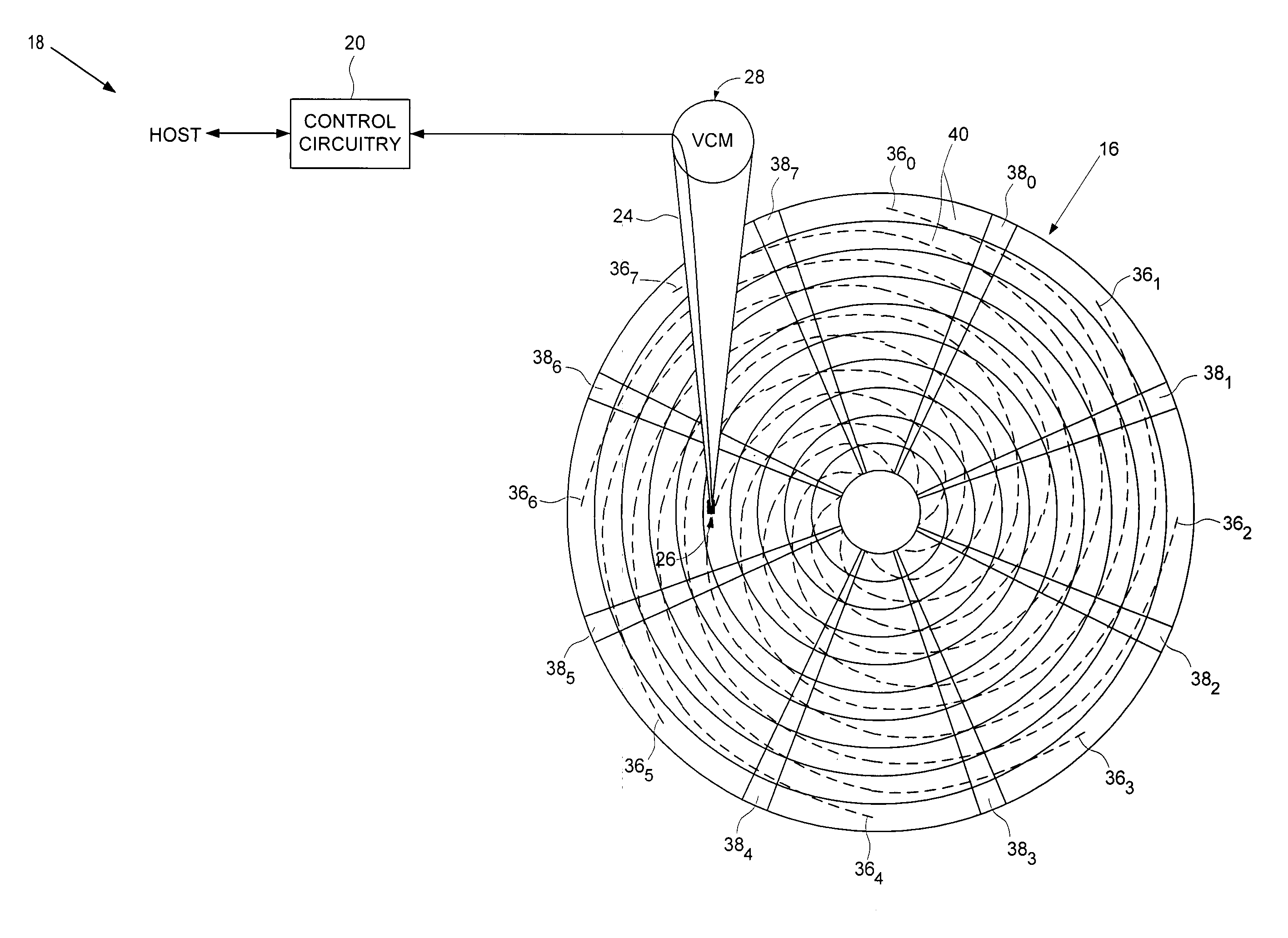

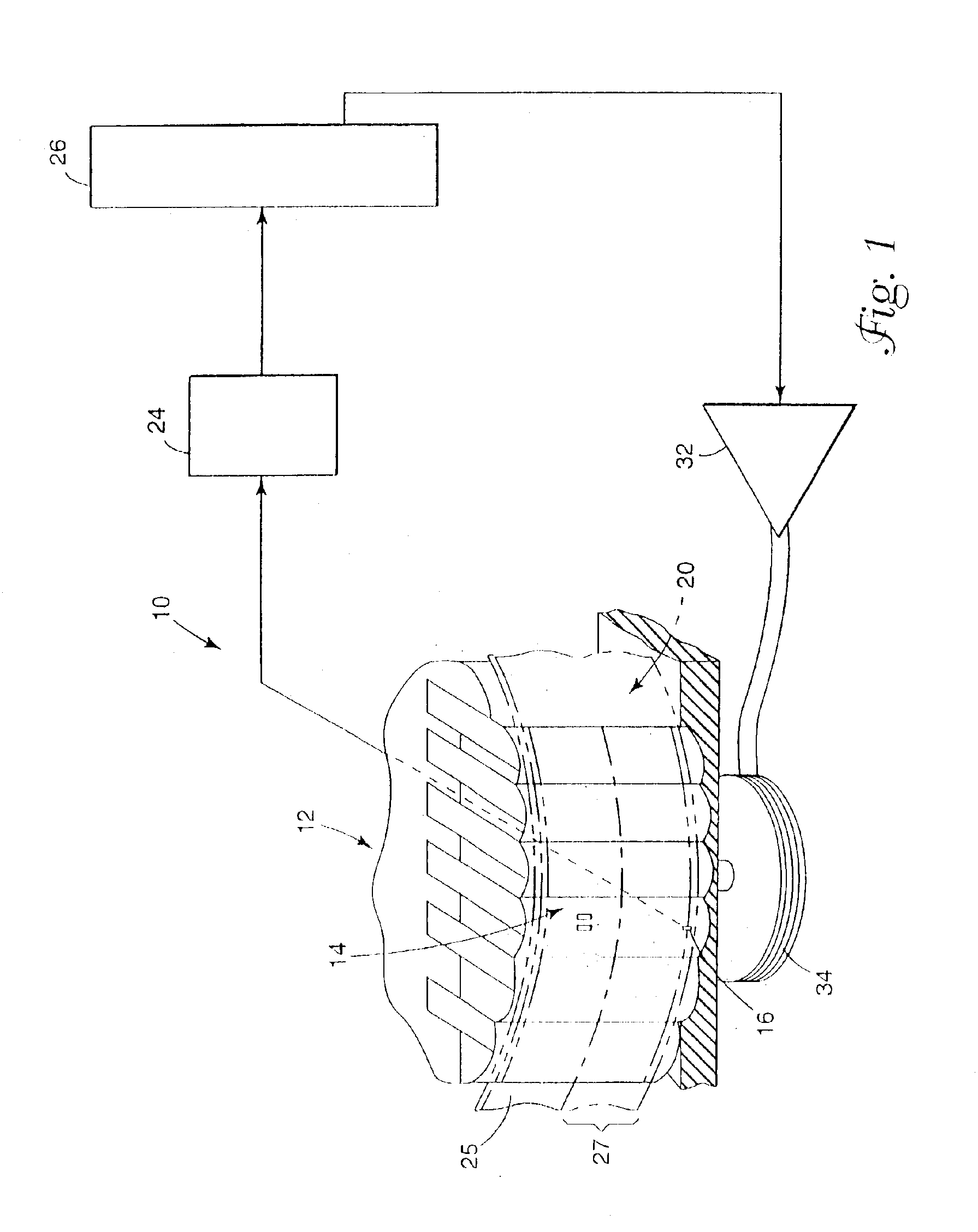

Method for reducing disk thermal expansion effects while writing reference spiral servo patterns to a disk of a disk drive

InactiveUS6992852B1Reducing disk thermal expansion effectIncrease radial distanceDriving/moving recording headsRecord information storageThermal expansionReference patterns

A method is disclosed for reducing disk expansion effects while writing spiral reference patterns on a disk of a disk drive. The disk drive comprises control circuitry and a head disk assembly (HDA) for positioning a head radially over the disk. In the method, an external spiral servo writer is used to control a radial location of the head for writing a plurality of the spiral reference patterns between inner and outer seed tracks. A head velocity profile is adjusted for writing each spiral reference pattern to account for thermal disk expansion. The head internal to the disk drive is used to read the spiral reference patterns in order to write product servo bursts to the disk that define a plurality of radially-spaced circular data tracks.

Owner:WESTERN DIGITAL TECH INC

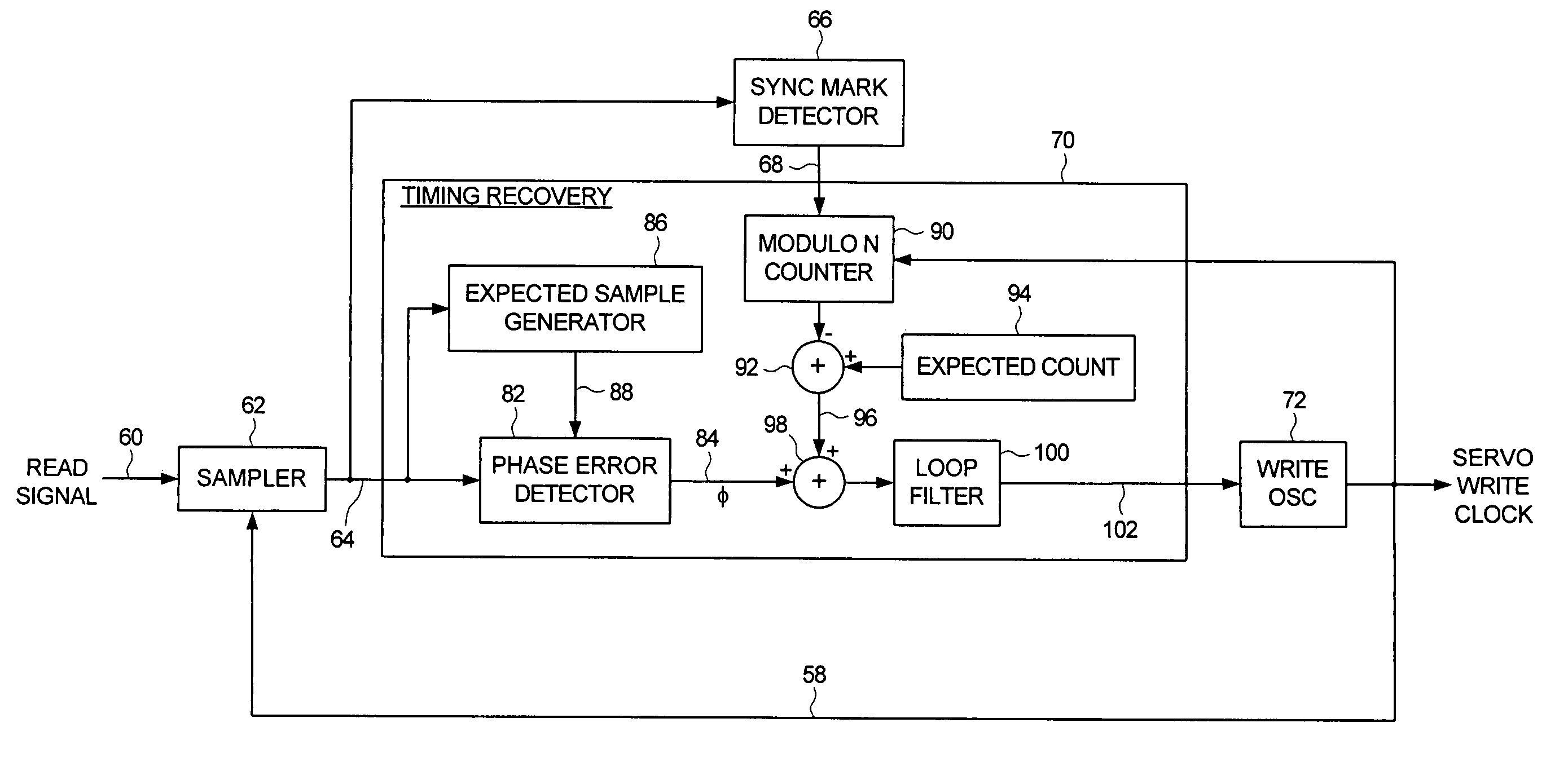

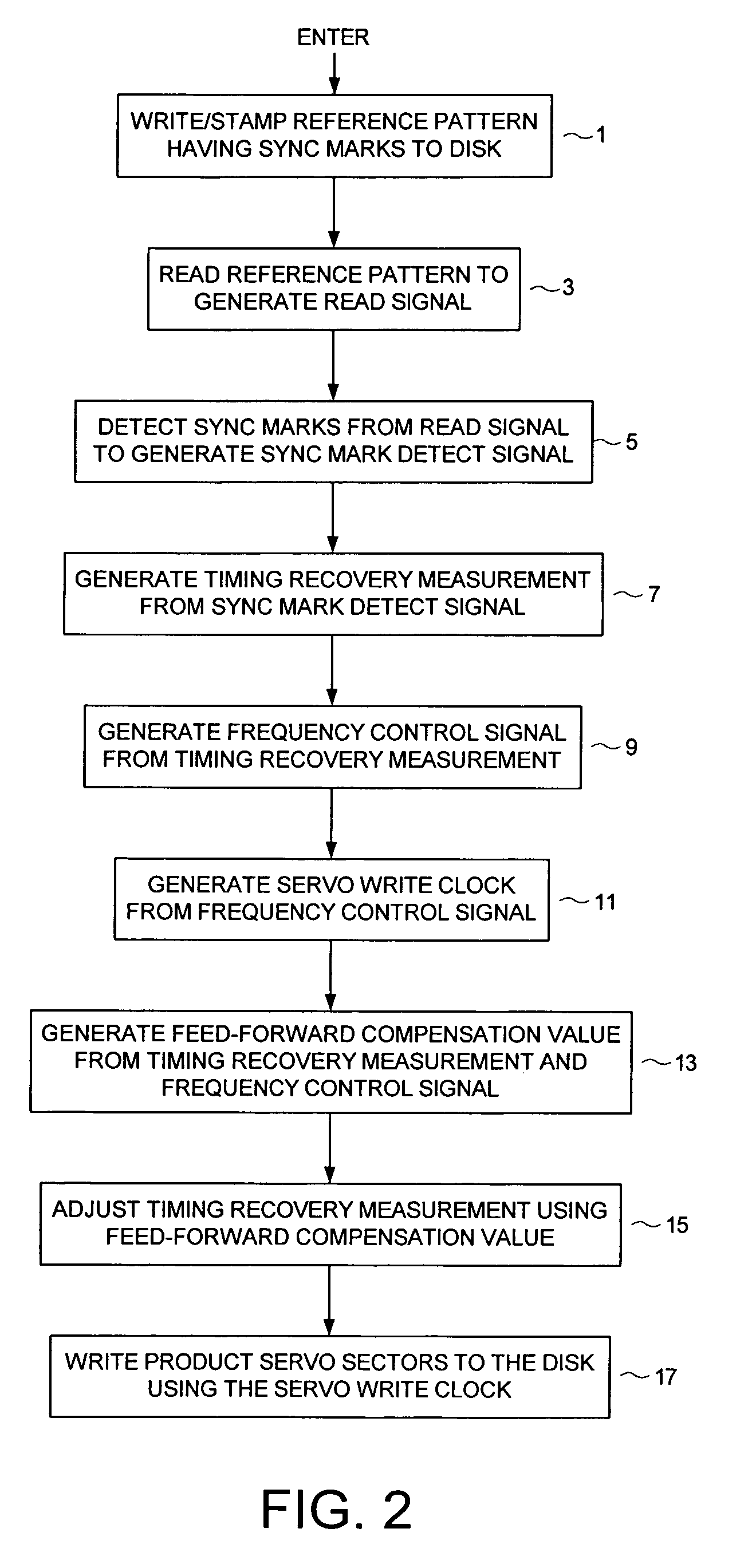

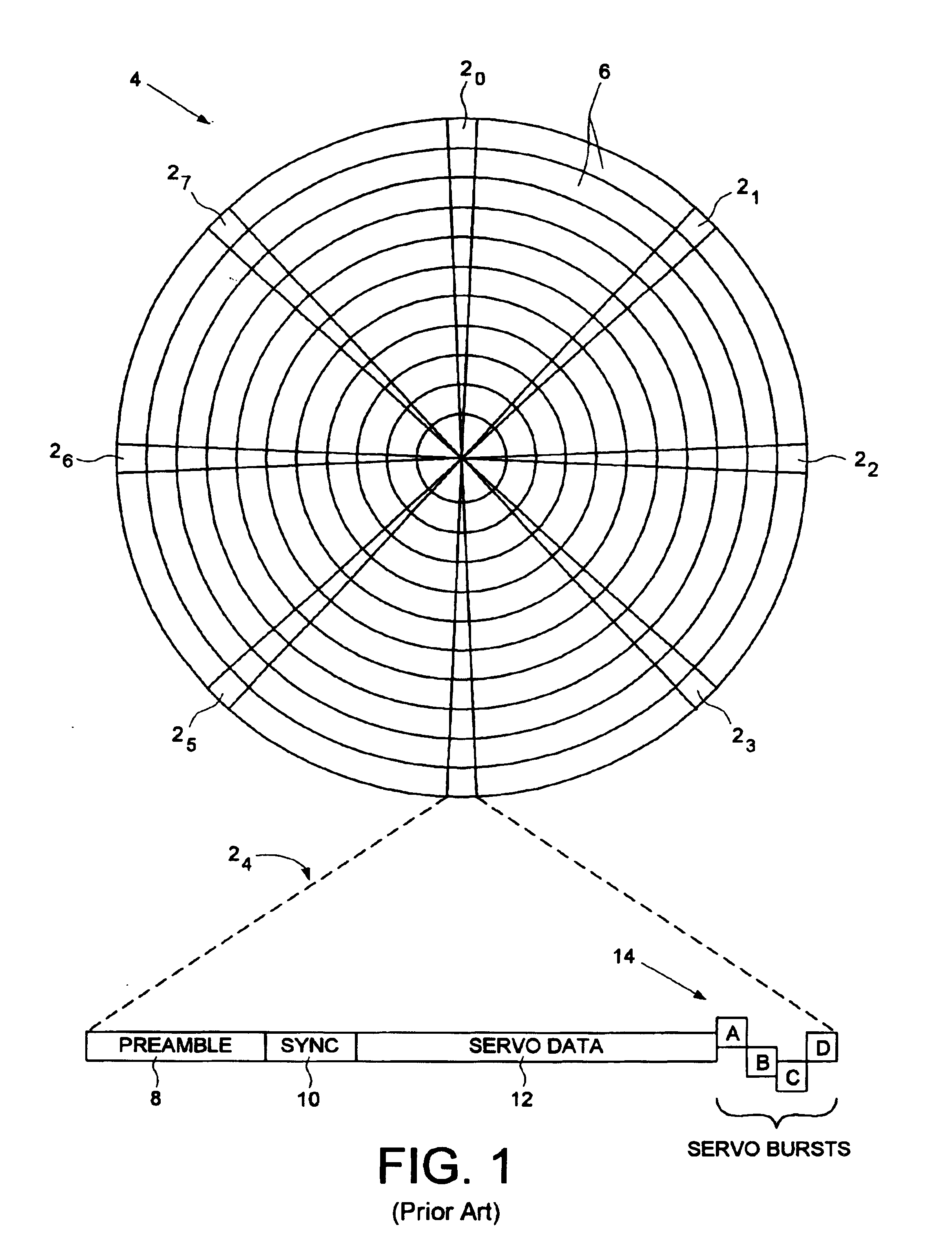

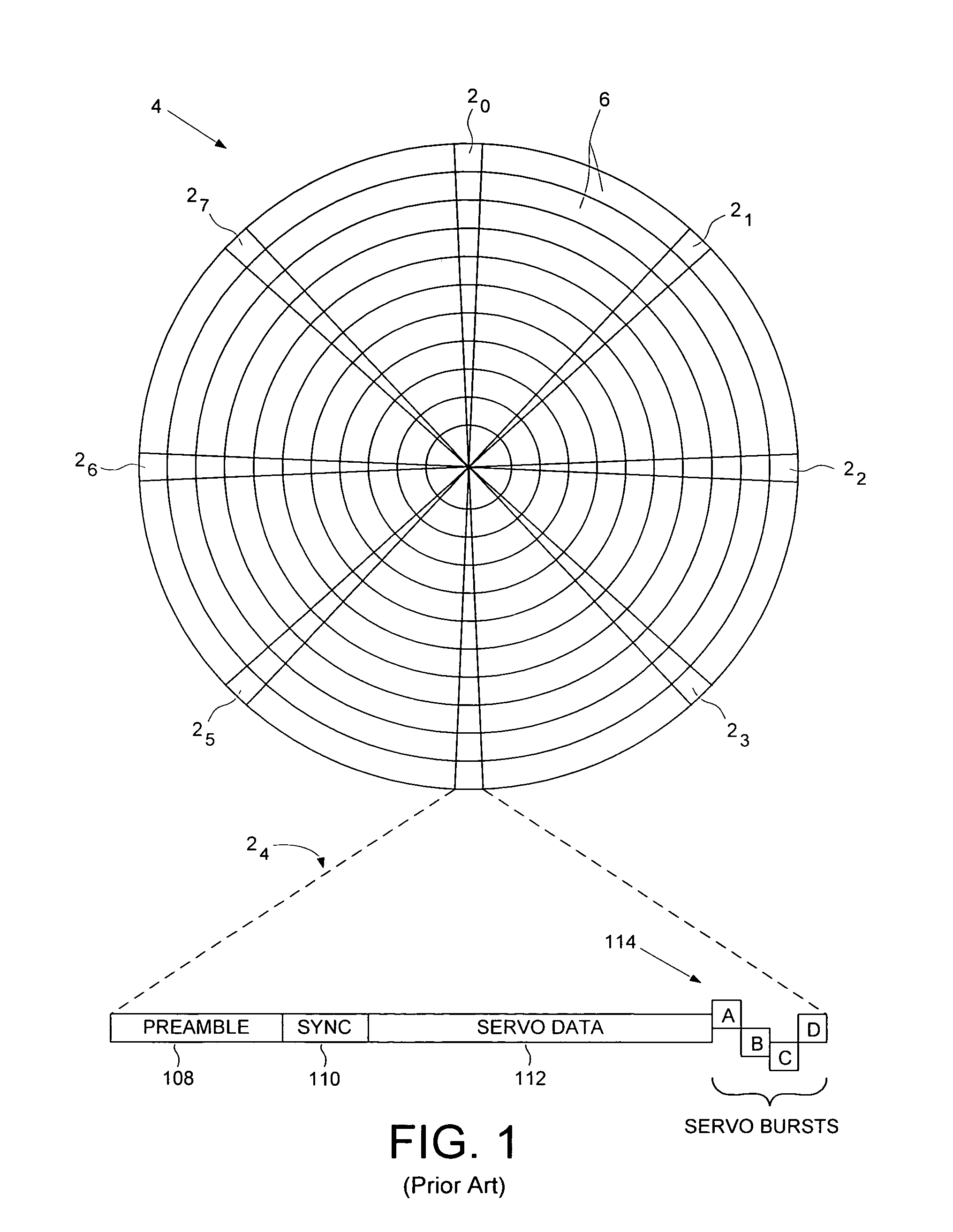

Servo writing a disk drive by synchronizing a servo write clock to a reference pattern on the disk and compensating for repeatable phase error

InactiveUS7333280B1Compensating for such errorDriving/moving recording headsRecord information storageControl signalReference patterns

A method of writing product servo sectors on a disk of a disk drive is disclosed. The disk comprises a reference pattern having a plurality of sync marks written around the disk. The sync marks are detected to generate a sync mark detect signal, and a timing recovery measurement is generated in response to the sync mark detect signal. A frequency control signal is generated in response to the timing recovery measurement, and a servo write clock is generated in response to the frequency control signal. A feed-forward compensation value is generated in response to the timing recovery measurement and the frequency control signal, and the timing recovery measurement is adjusted in response to the feed-forward compensation value to compensate for a repeatable phase error in the timing recovery measurement. The servo write clock and the head internal to the disk drive are used to write the product servo sectors to the disk.

Owner:WESTERN DIGITAL TECH INC

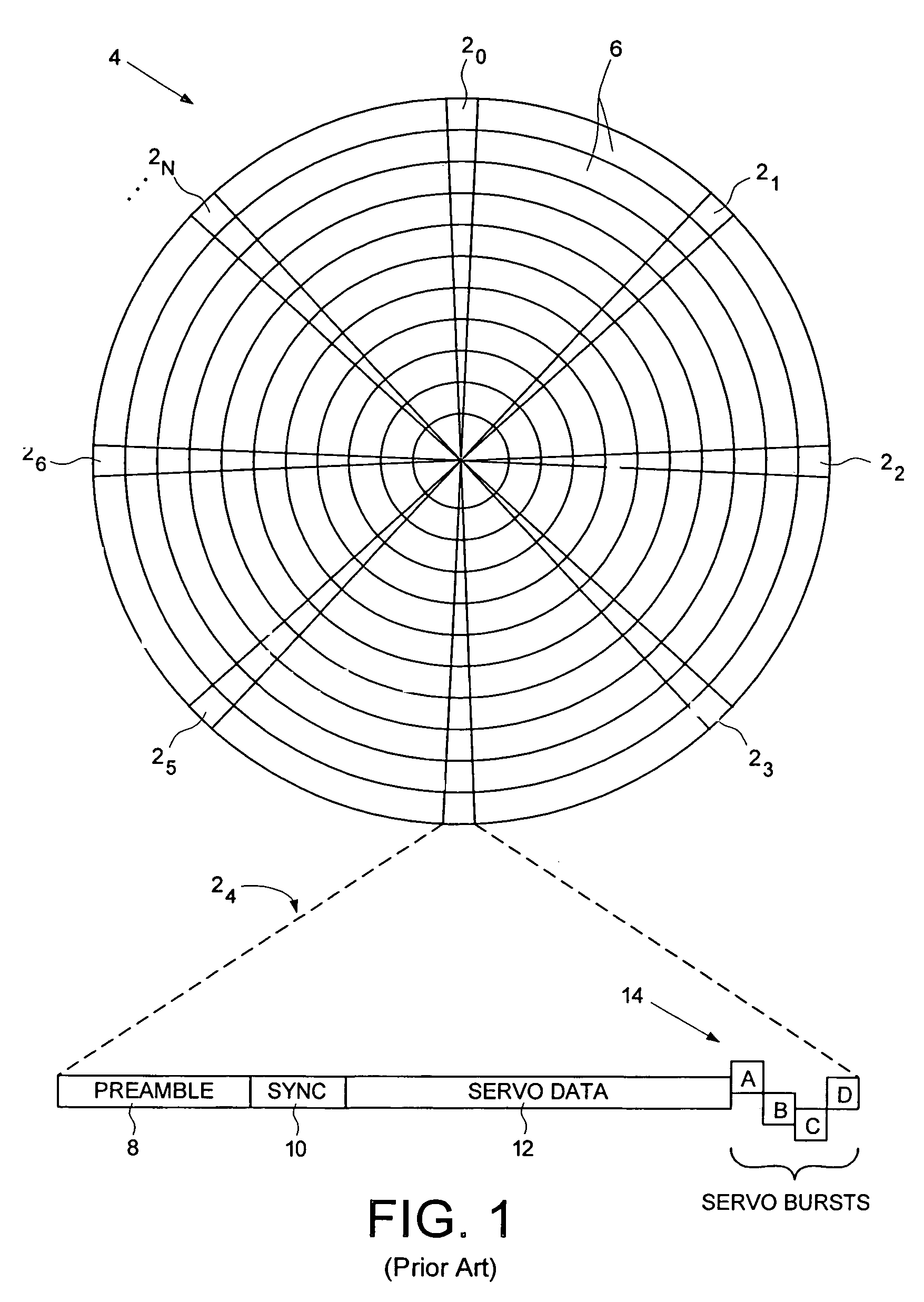

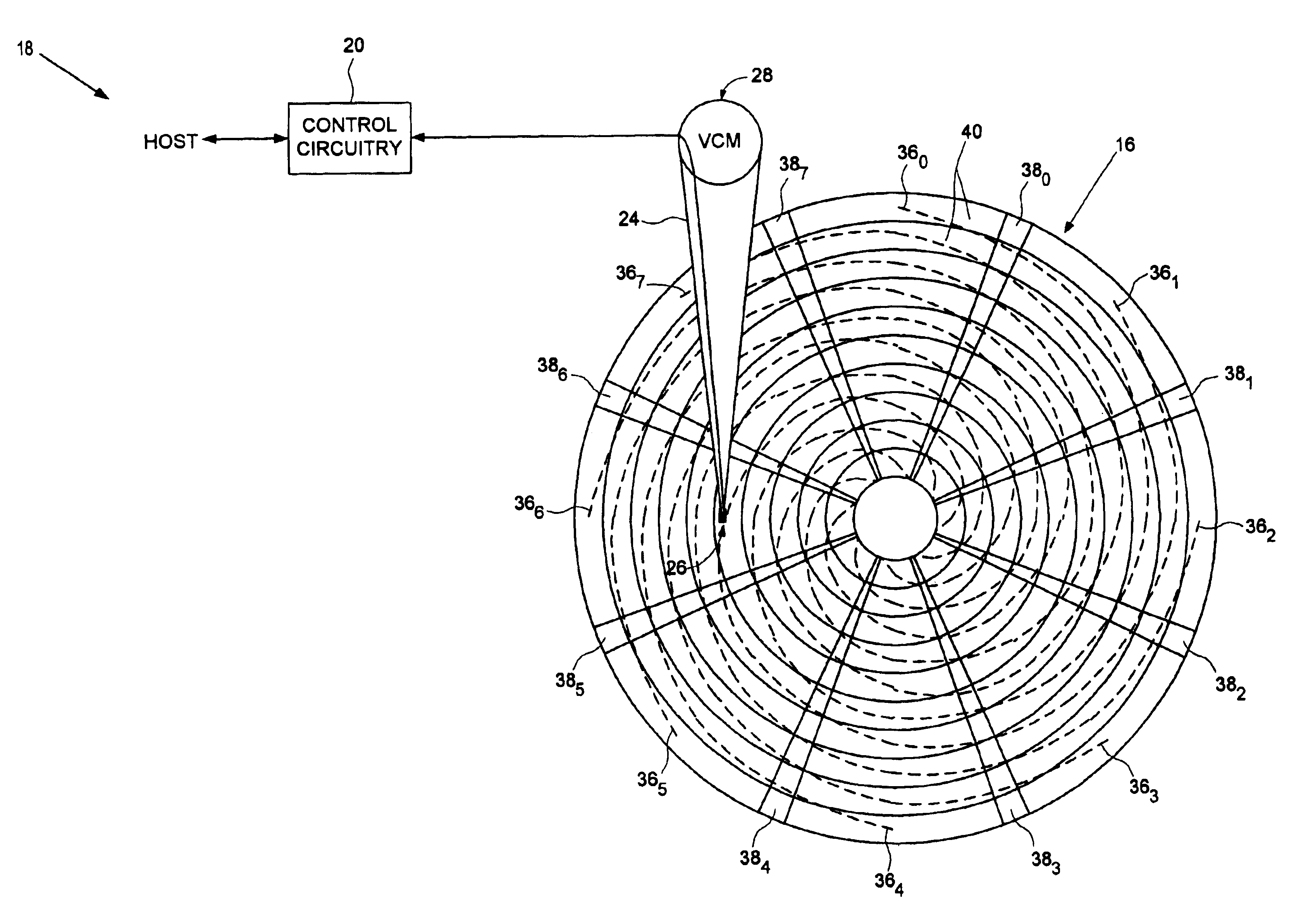

Using an external spiral servo writer to write spiral reference patterns to a disk to facilitate writing product servo bursts to the disk

InactiveUS6992848B1Improve accuracyEasy to useDriving/moving recording headsRecord information storageGraphicsEngineering

A method of writing product servo bursts to a disk in a disk drive is disclosed. An external spiral servo writer comprising a head positioning pin and head positioning mechanics periodically writes a plurality of reference servo bursts in a plurality of spiral reference patterns to the disk. The reference servo bursts in the spiral reference patterns are processed to write product servo bursts to the disk. In one embodiment control circuitry within the disk drive processes the reference servo bursts to self-servo write the disk drive, and in another embodiment an external product servo writer processes the reference servo bursts to write the product servo bursts to the disk. In one embodiment, a slope of each spiral reference pattern is selected so that each spiral reference pattern is written over at least twenty revolutions of the disk to increase the accuracy of the head position error generated from the reference servo bursts.

Owner:WESTERN DIGITAL TECH INC

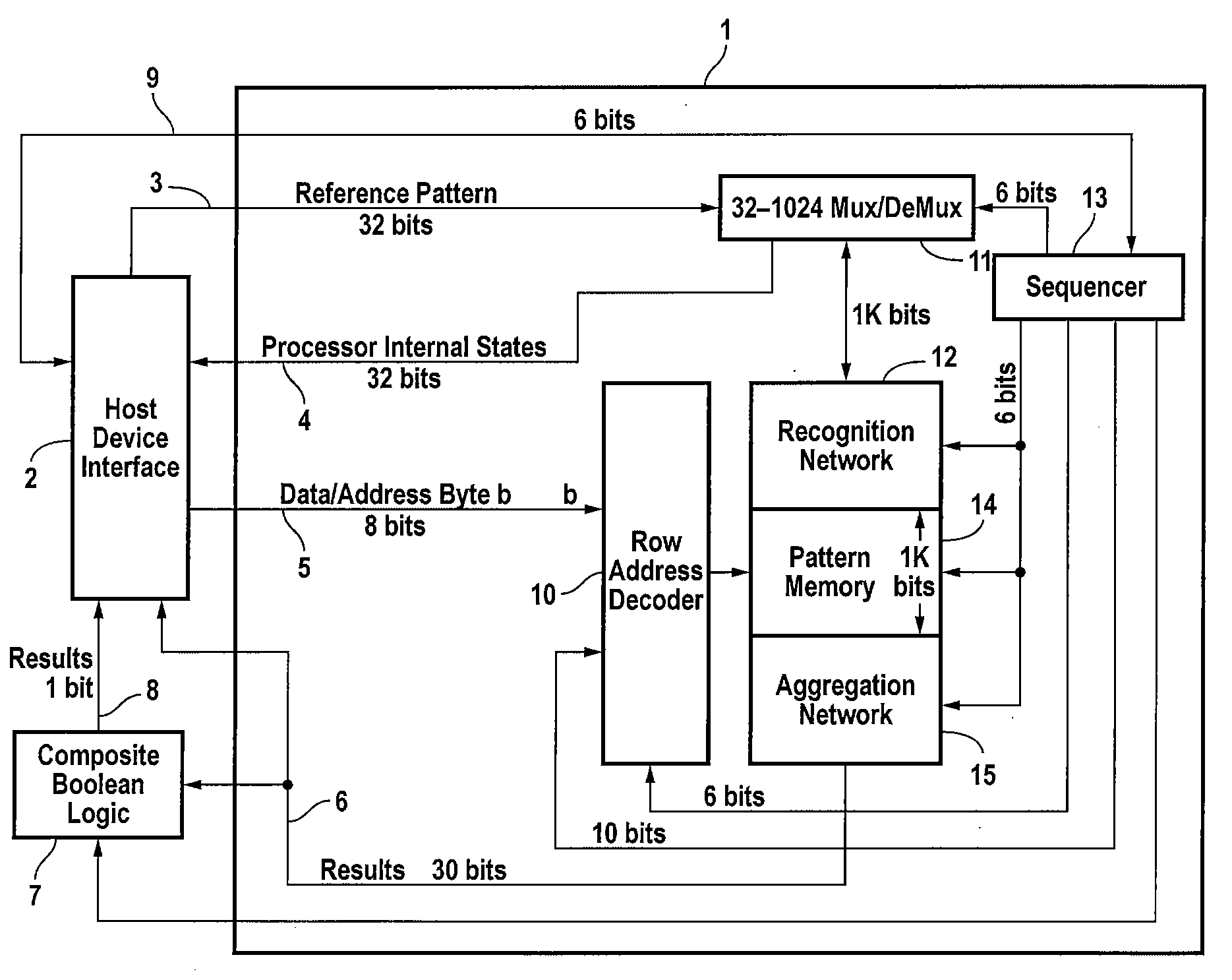

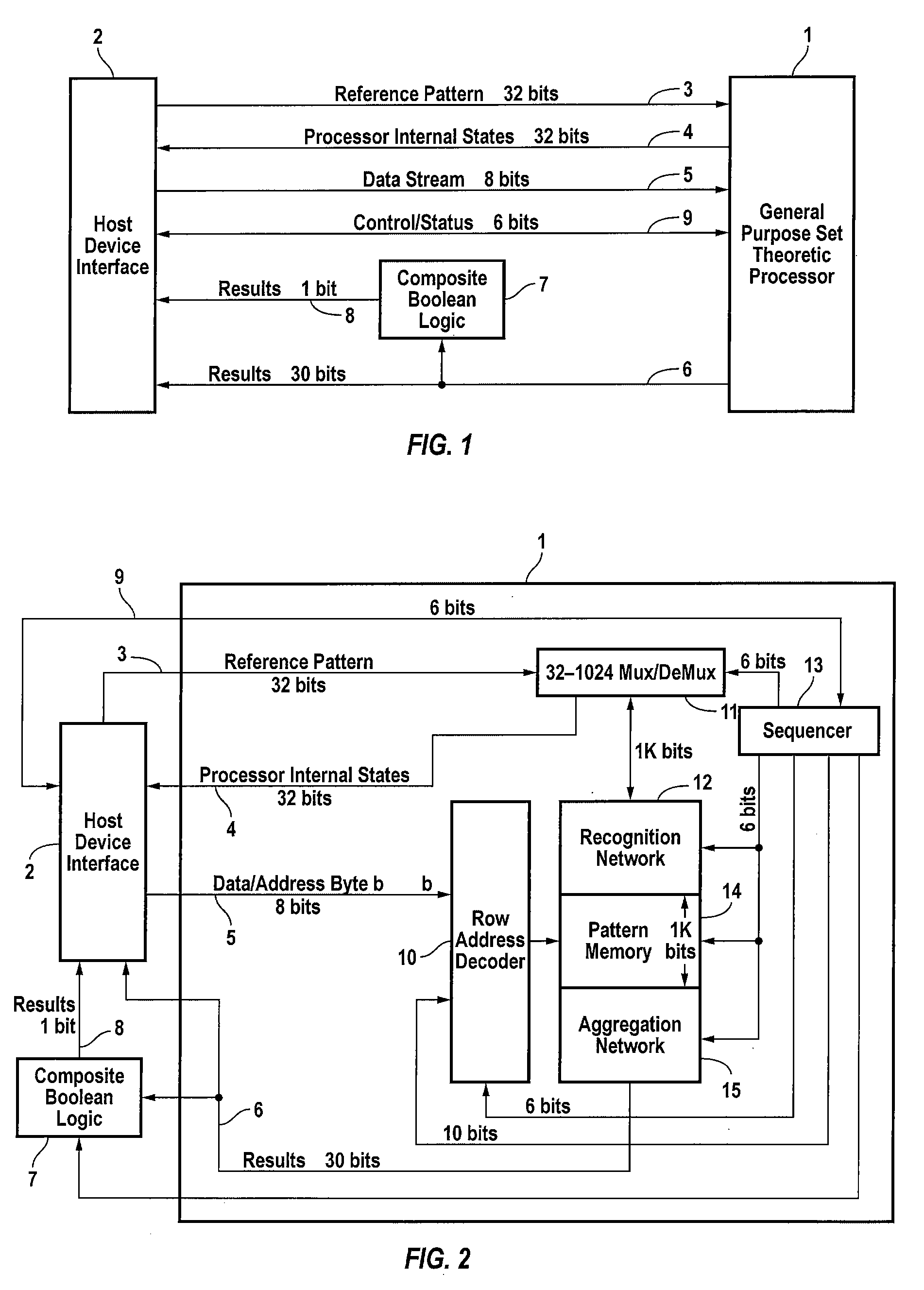

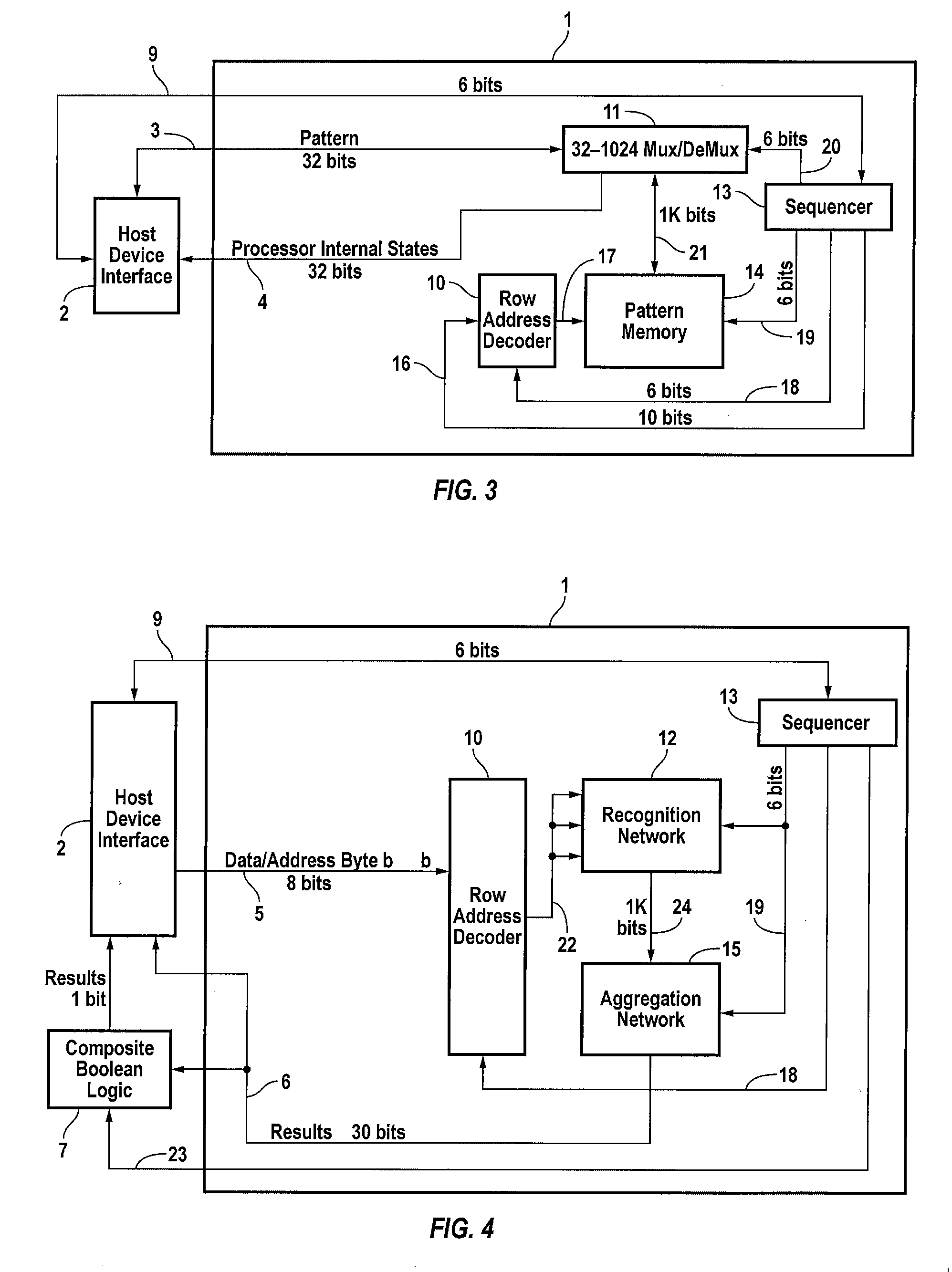

General Purpose Set Theoretic Processor

ActiveUS20070127482A1Low costLow of configurabilityDigital computer detailsCharacter and pattern recognitionGeneral purposeData stream

A general purpose processor architecture (methods and apparatuses) that can discern all subsets of a serial data stream which fulfill an arbitrarily complex reference pattern. The invention comprises an ordered set of Detection Cells conditionally interconnected according to the reference pattern and operationally controlling one another's states through the network. The invention preferably includes a Host Interface to enable reporting of Results from a search session as well as the input and control of reference patterns and source data.

Owner:HARRIS CURTIS L

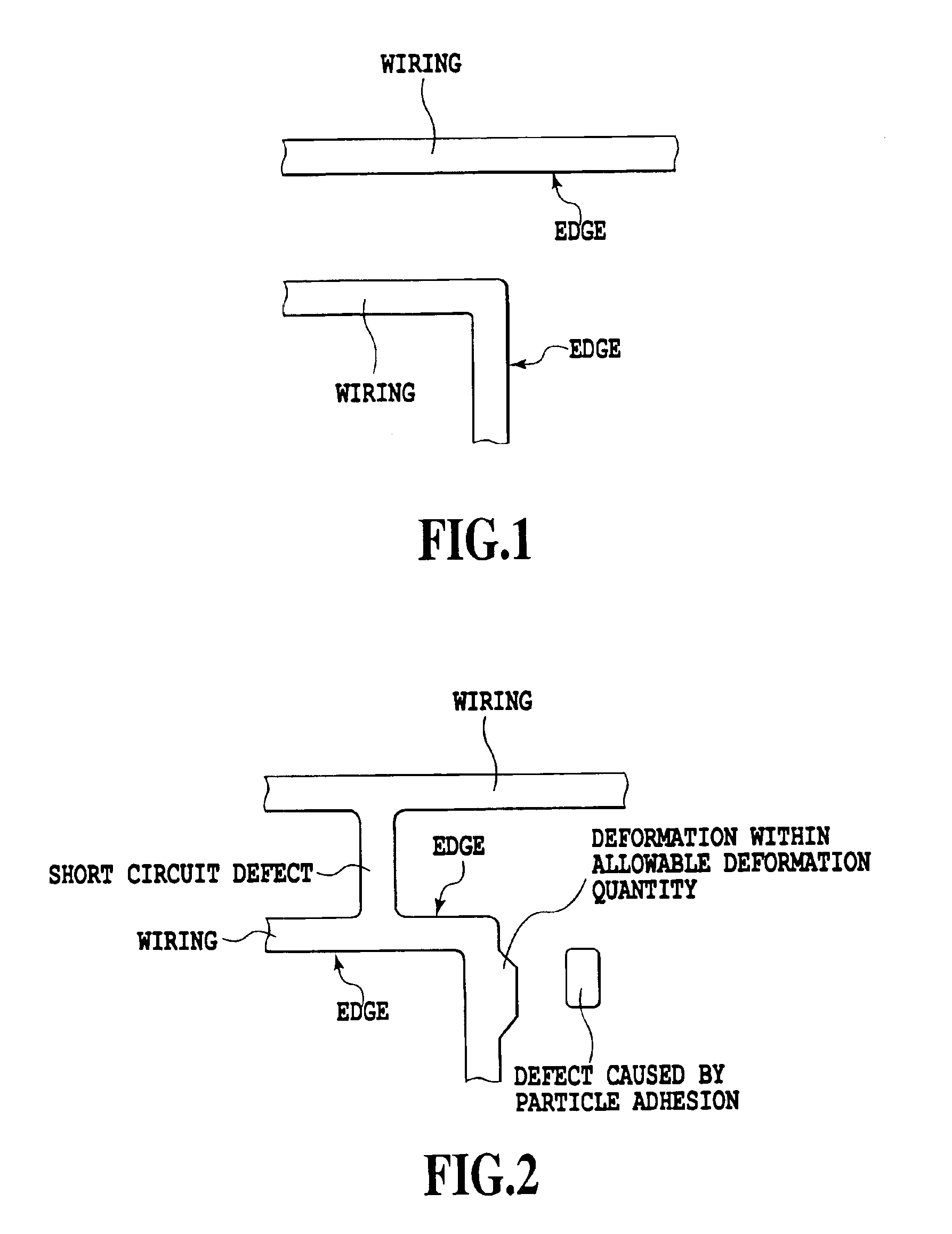

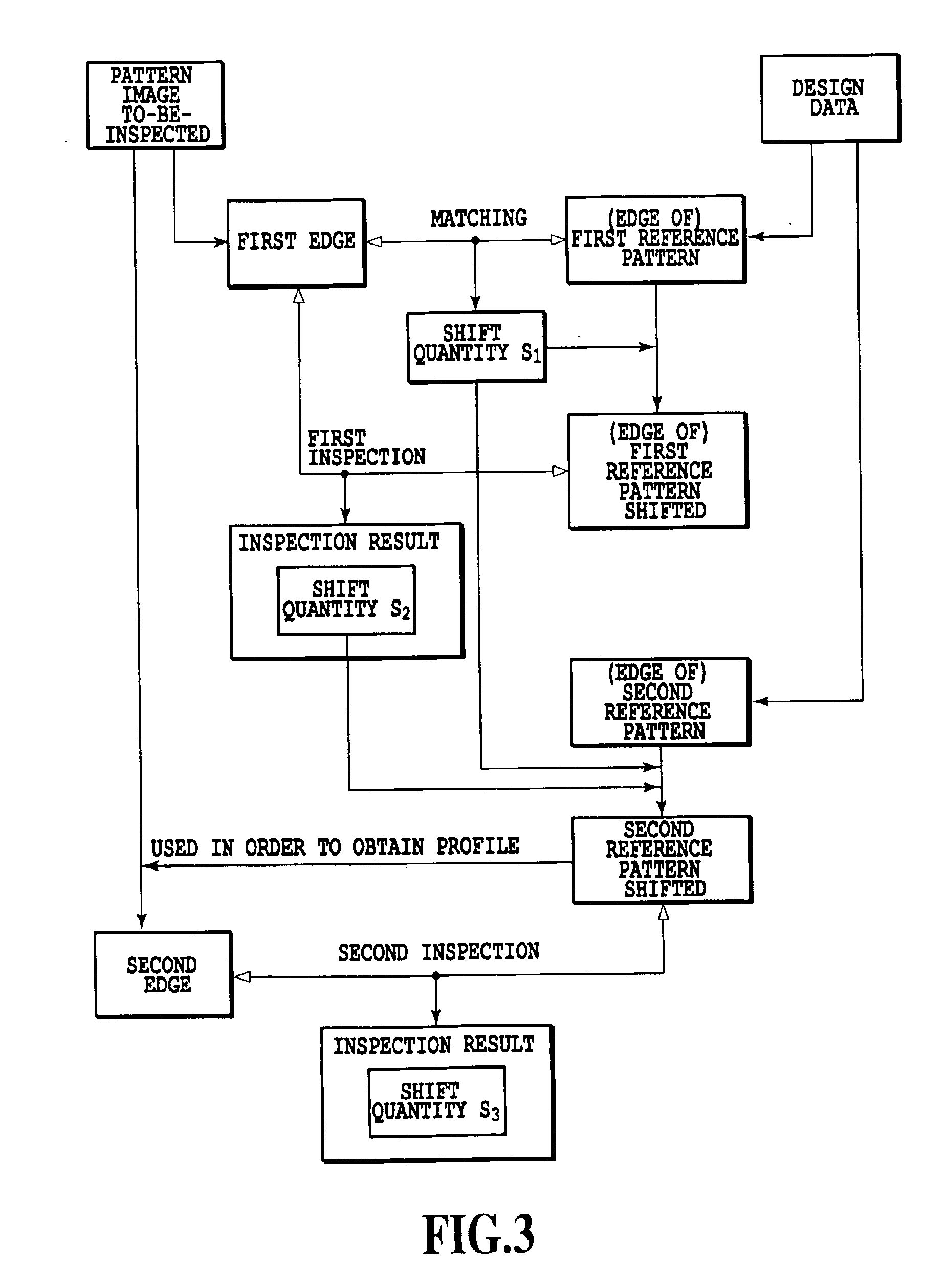

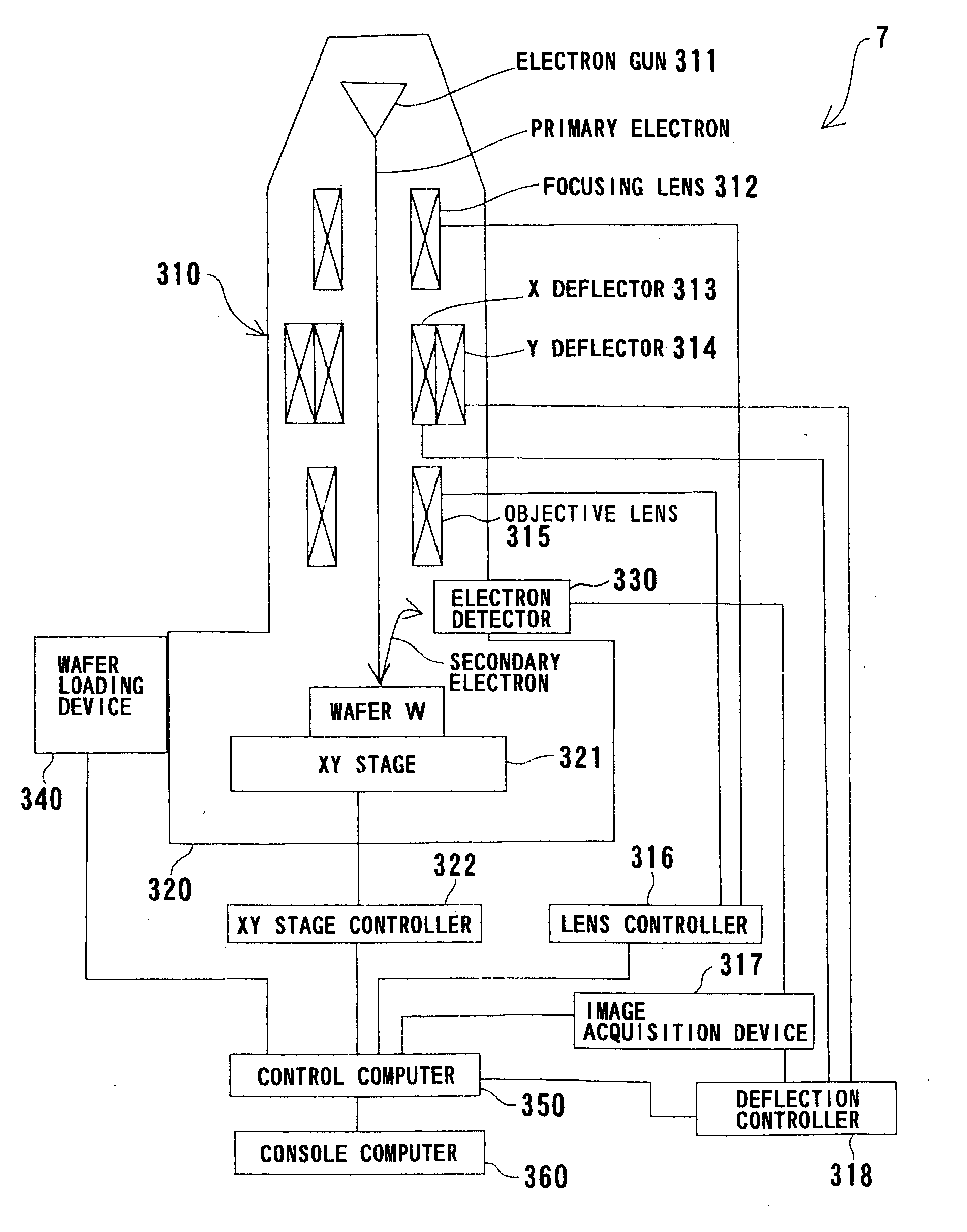

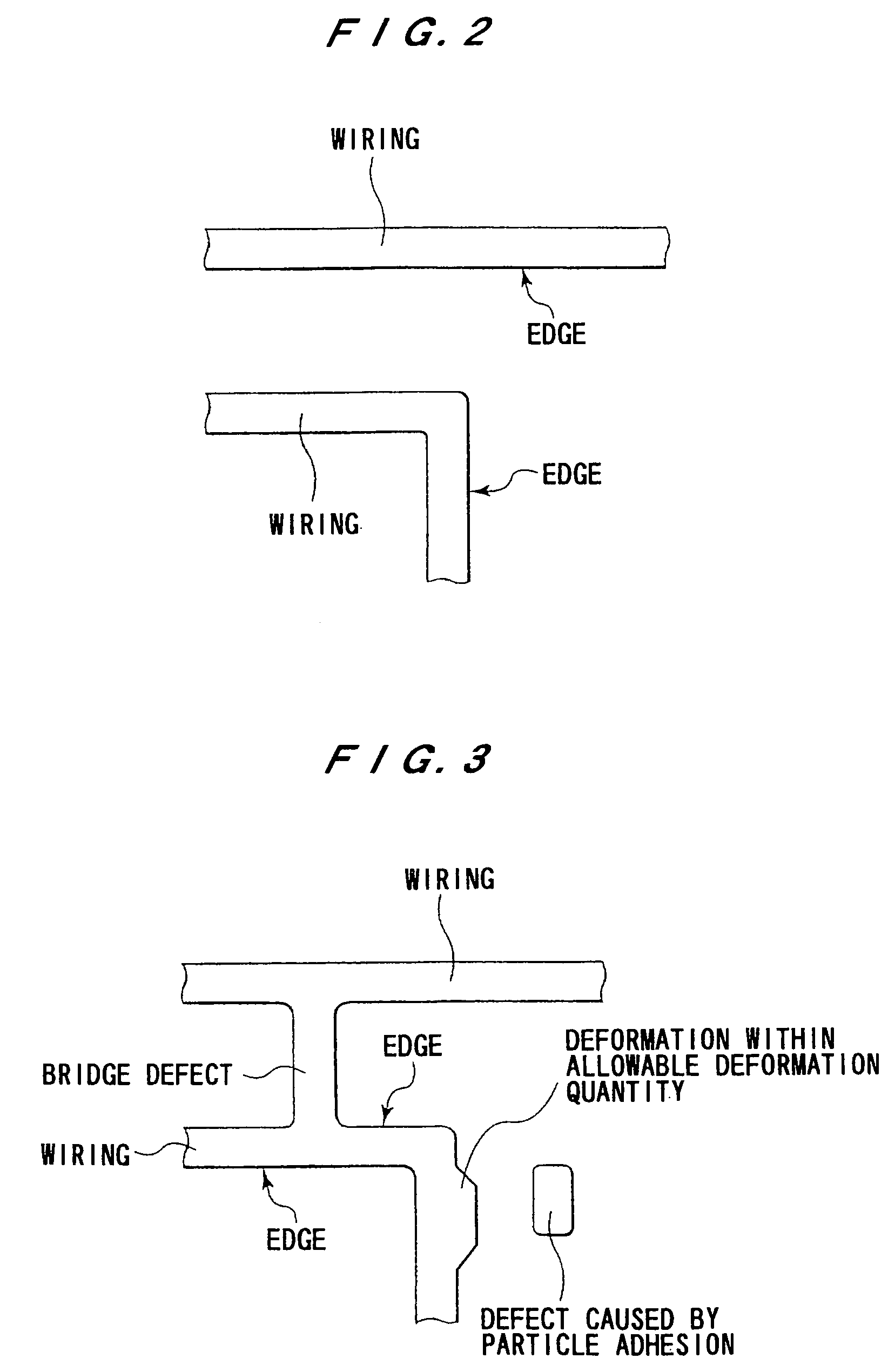

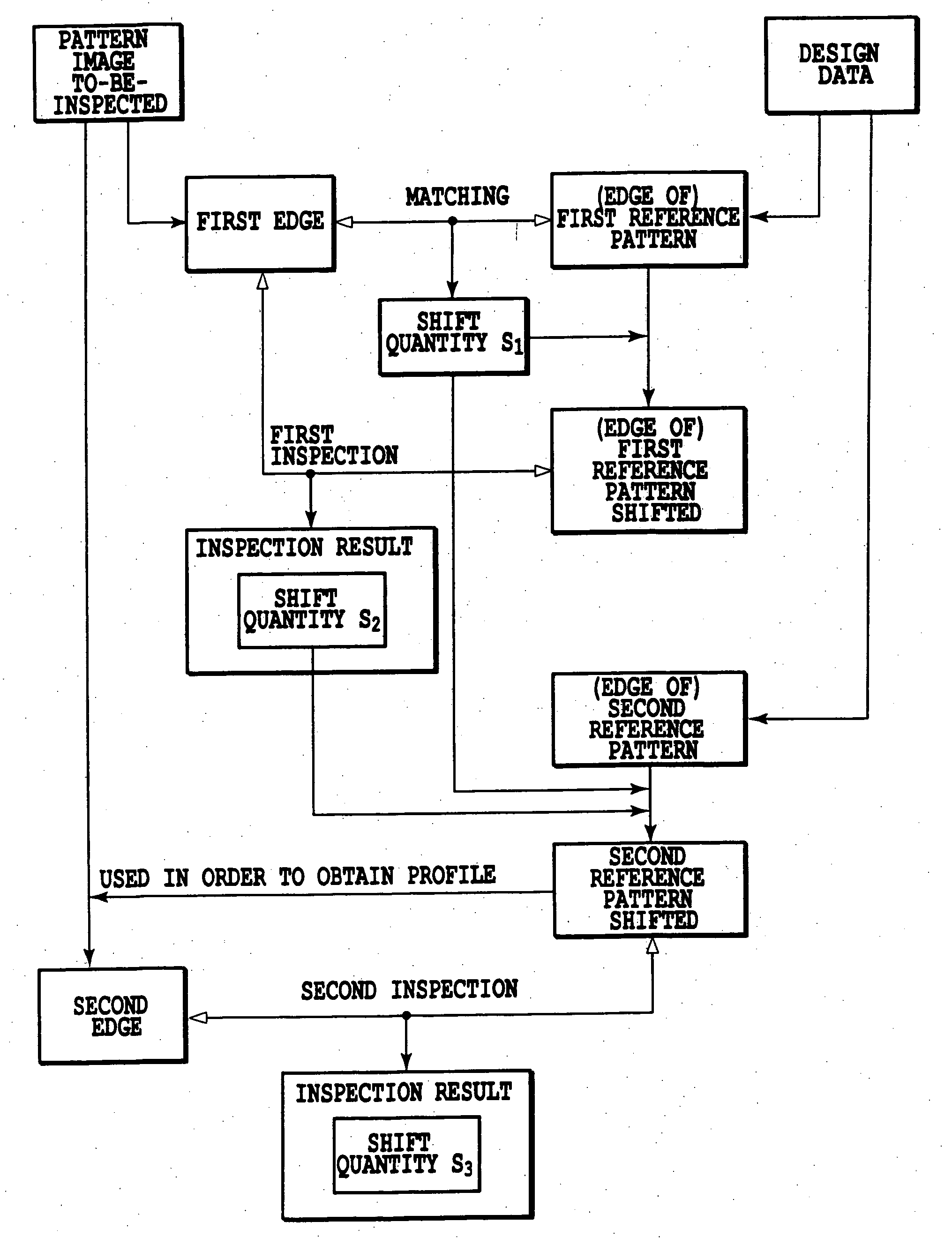

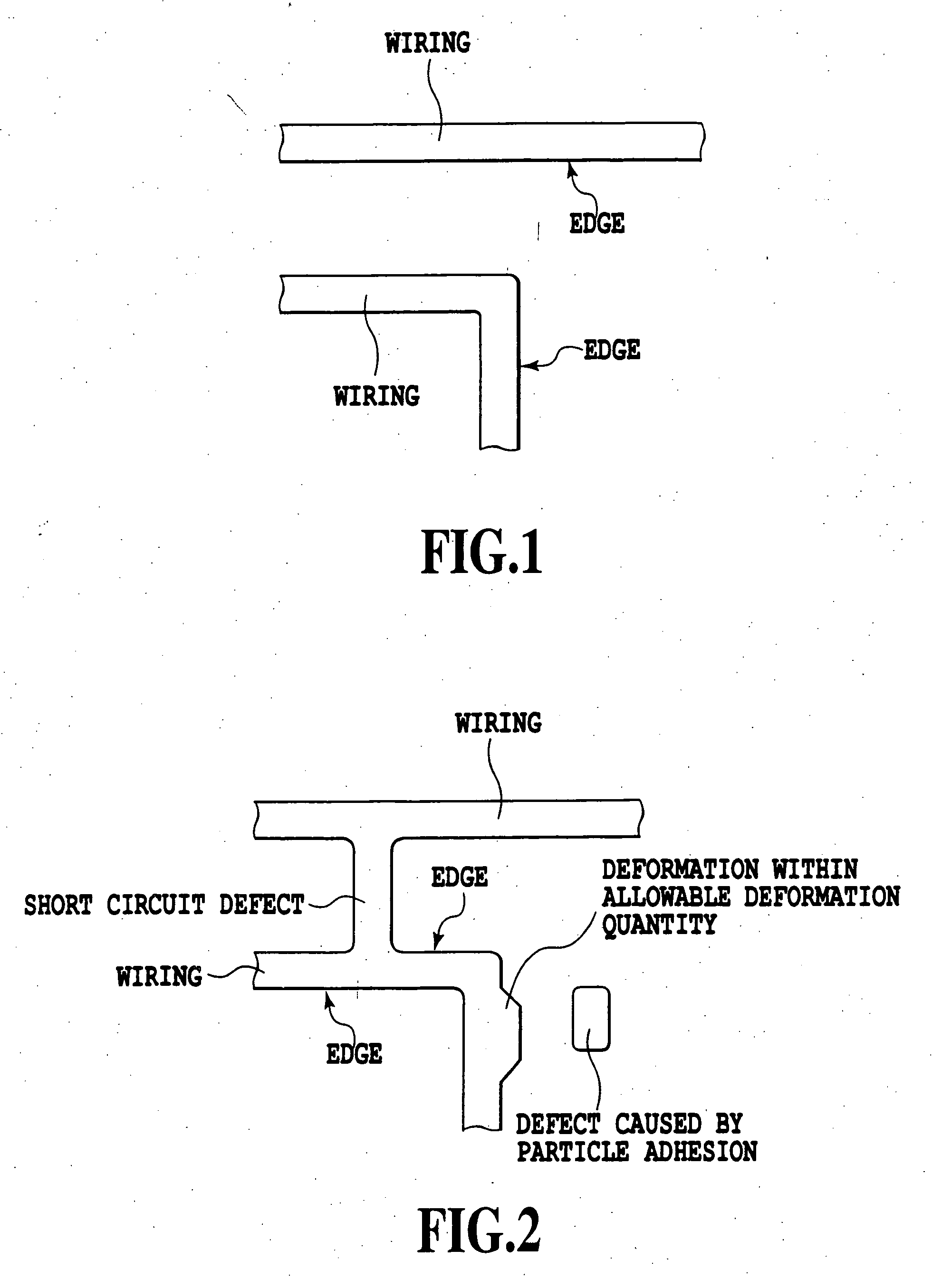

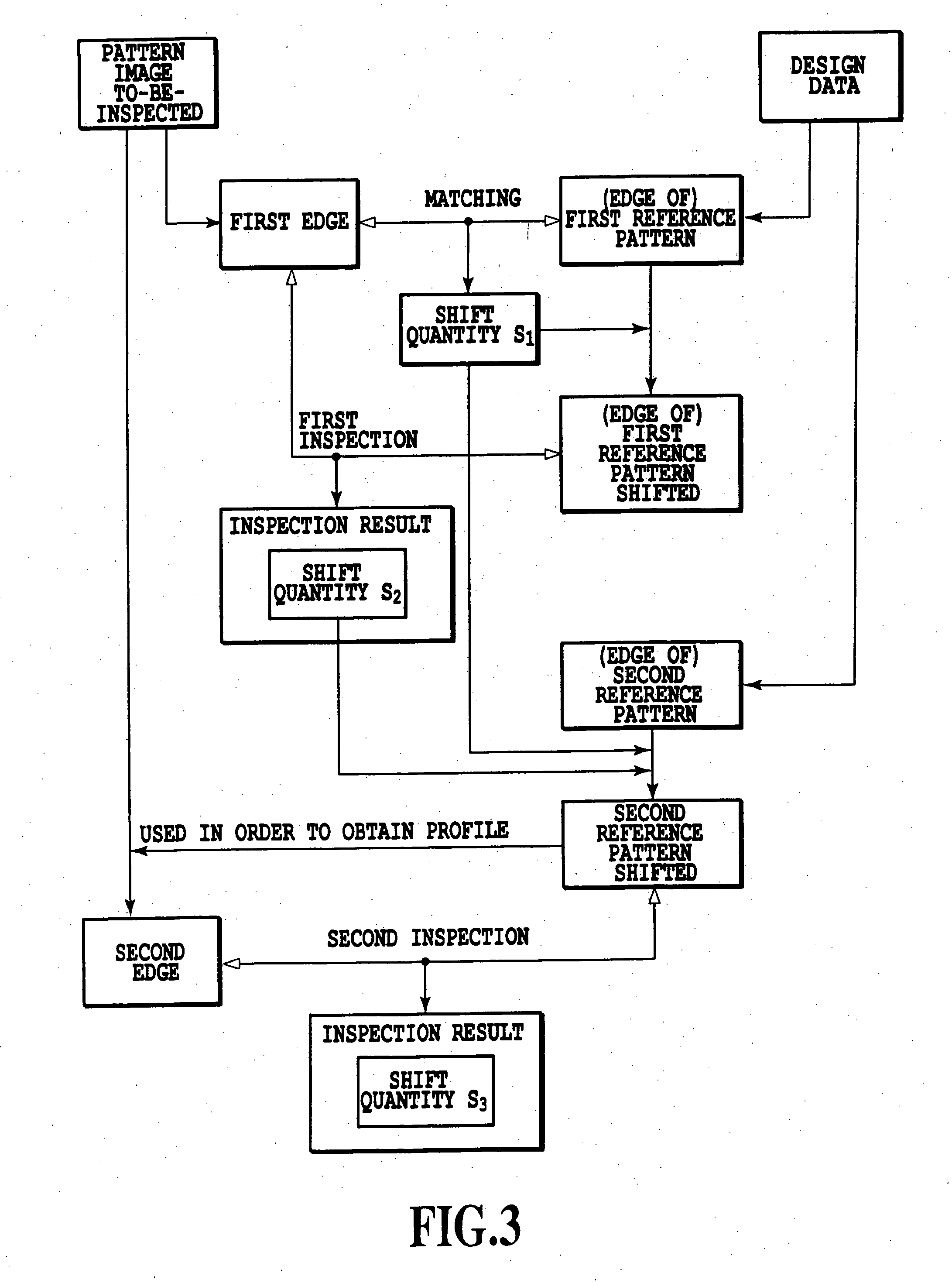

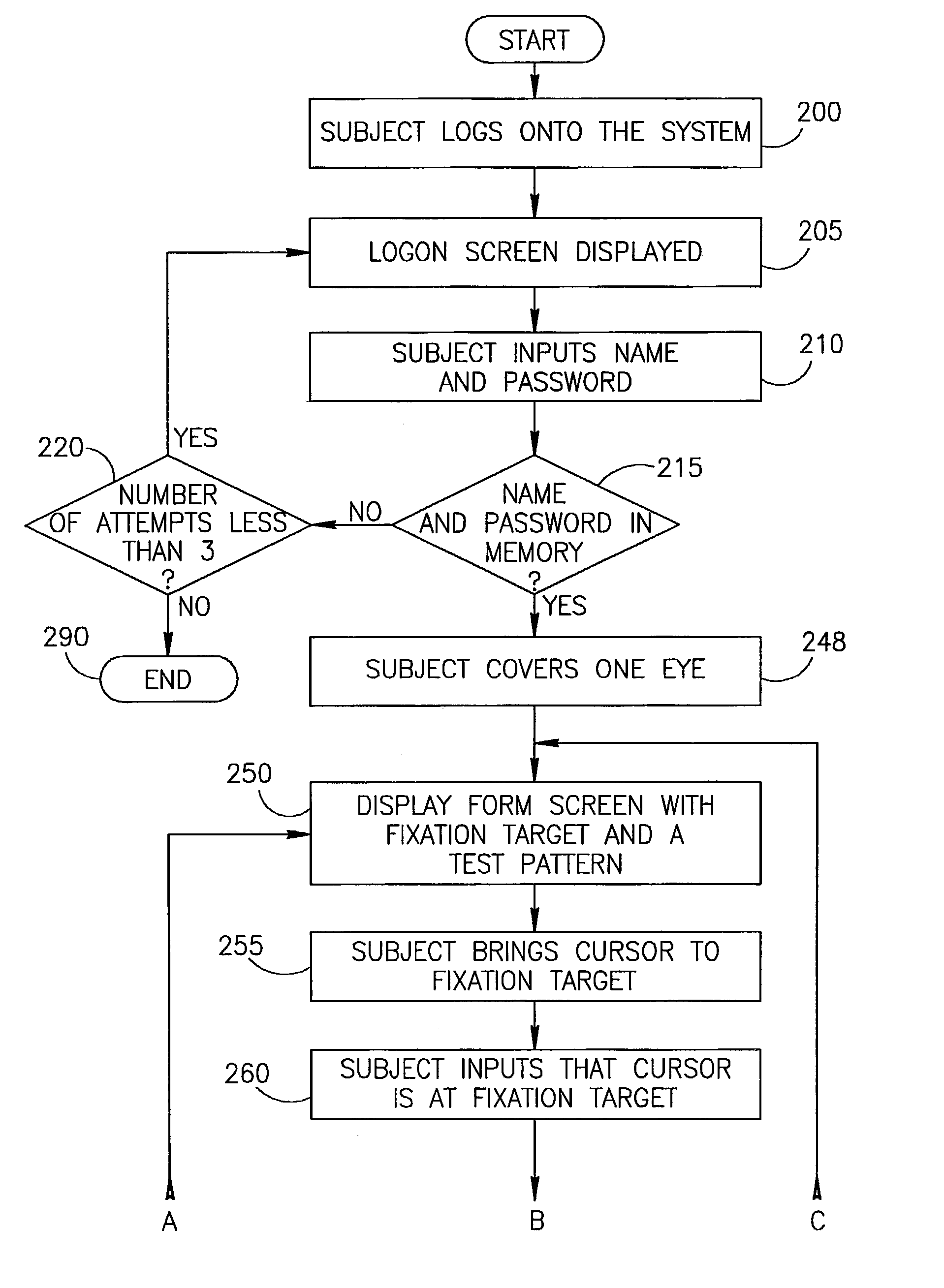

Pattern inspection apparatus and method

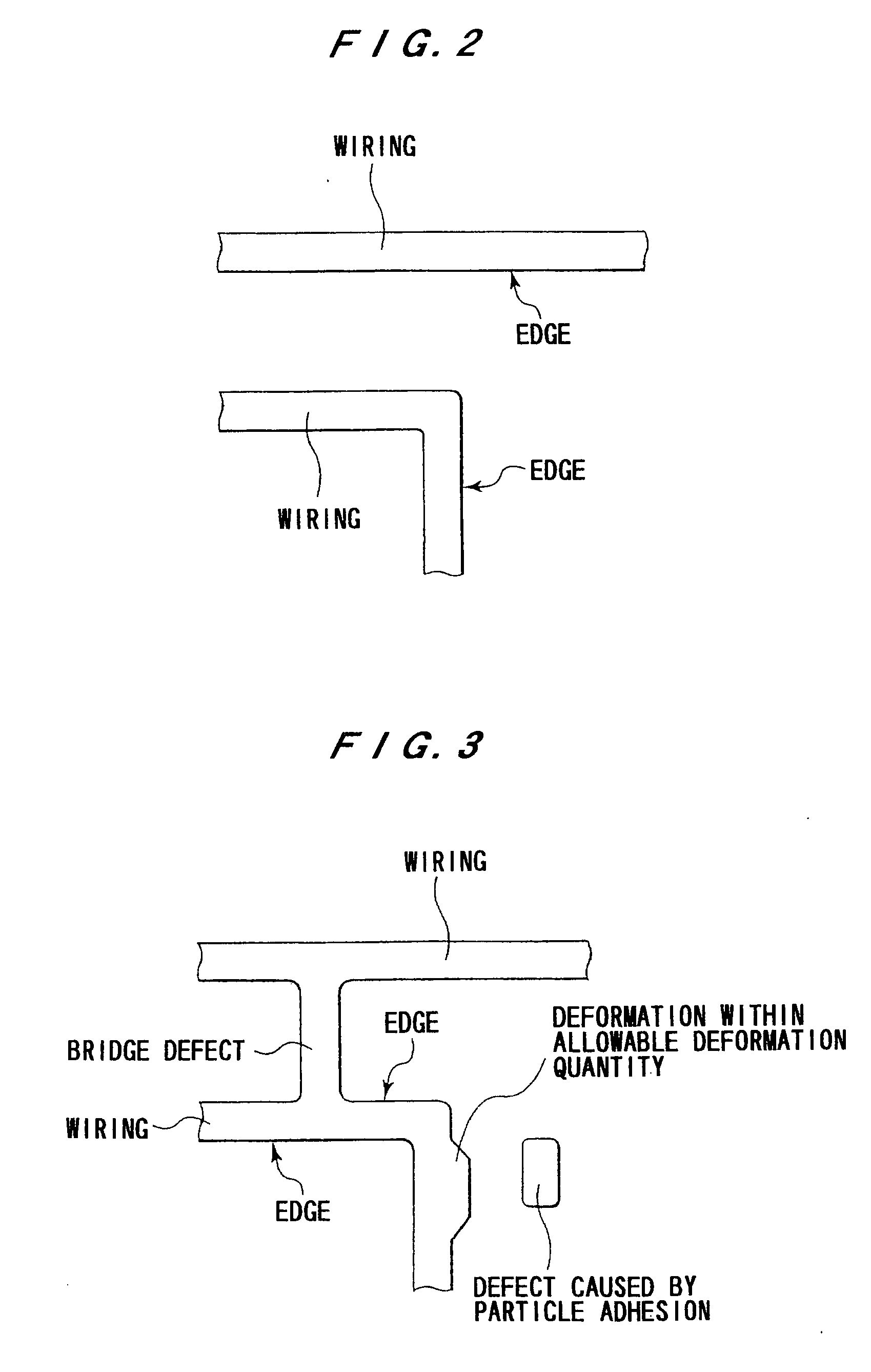

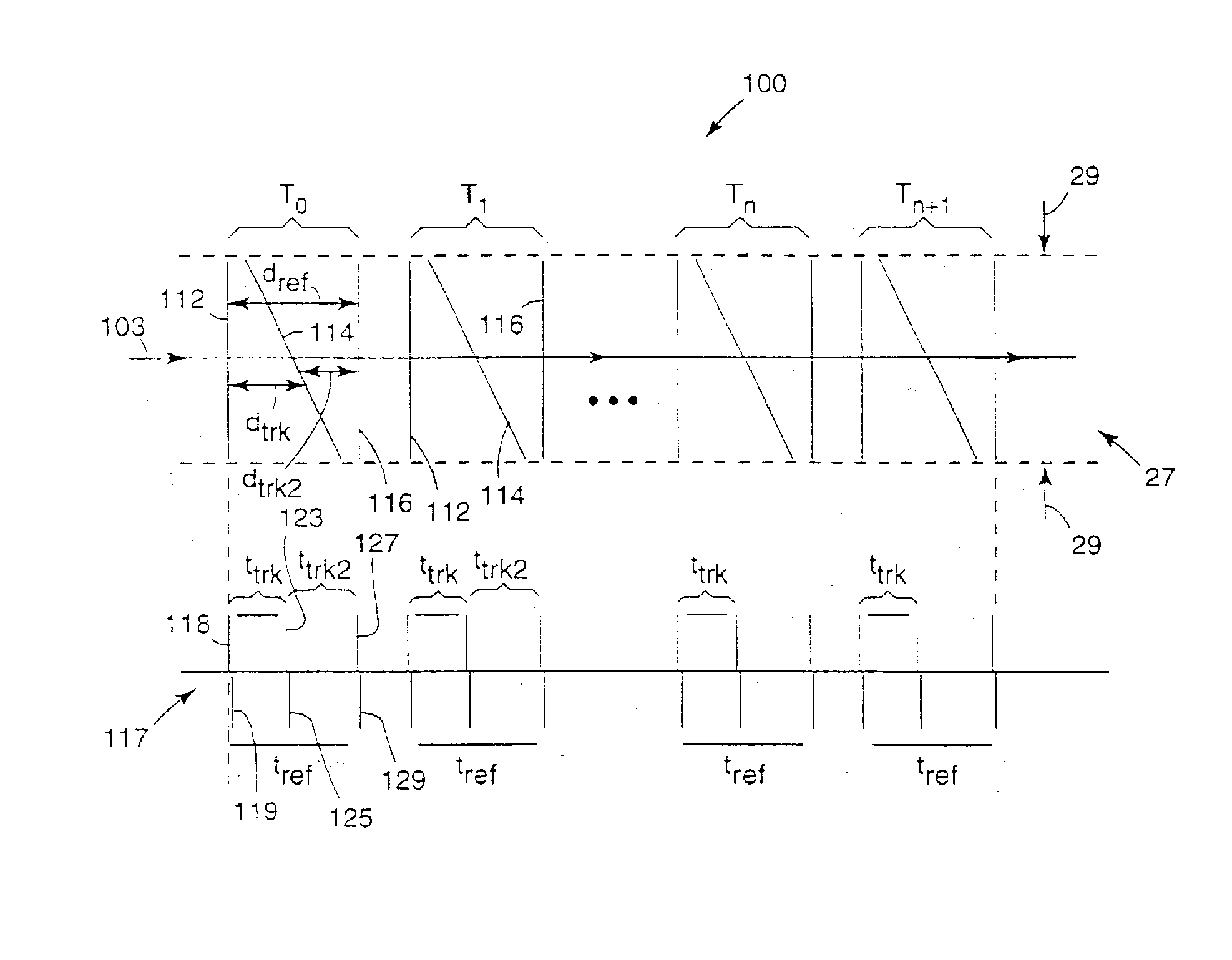

A pattern inspection apparatus is used for inspecting a pattern, such as semiconductor integrated circuit (LSI), liquid crystal panel, and a photomask by using an image of the pattern to-be-inspected and design data for fabricating the pattern to-be-inspected. The pattern inspection apparatus includes a reference pattern generation device for generating a reference pattern represented by one or more lines from design data, an image generation device for generating the image of the pattern to-be-inspected, a detecting device for detecting an edge of the image of the pattern to-be-inspected, and an inspection device for inspecting the pattern to-be-inspected by comparing the edge of the image of the pattern to-be-inspected with the one or more lines of the reference pattern.

Owner:TASMIT INC

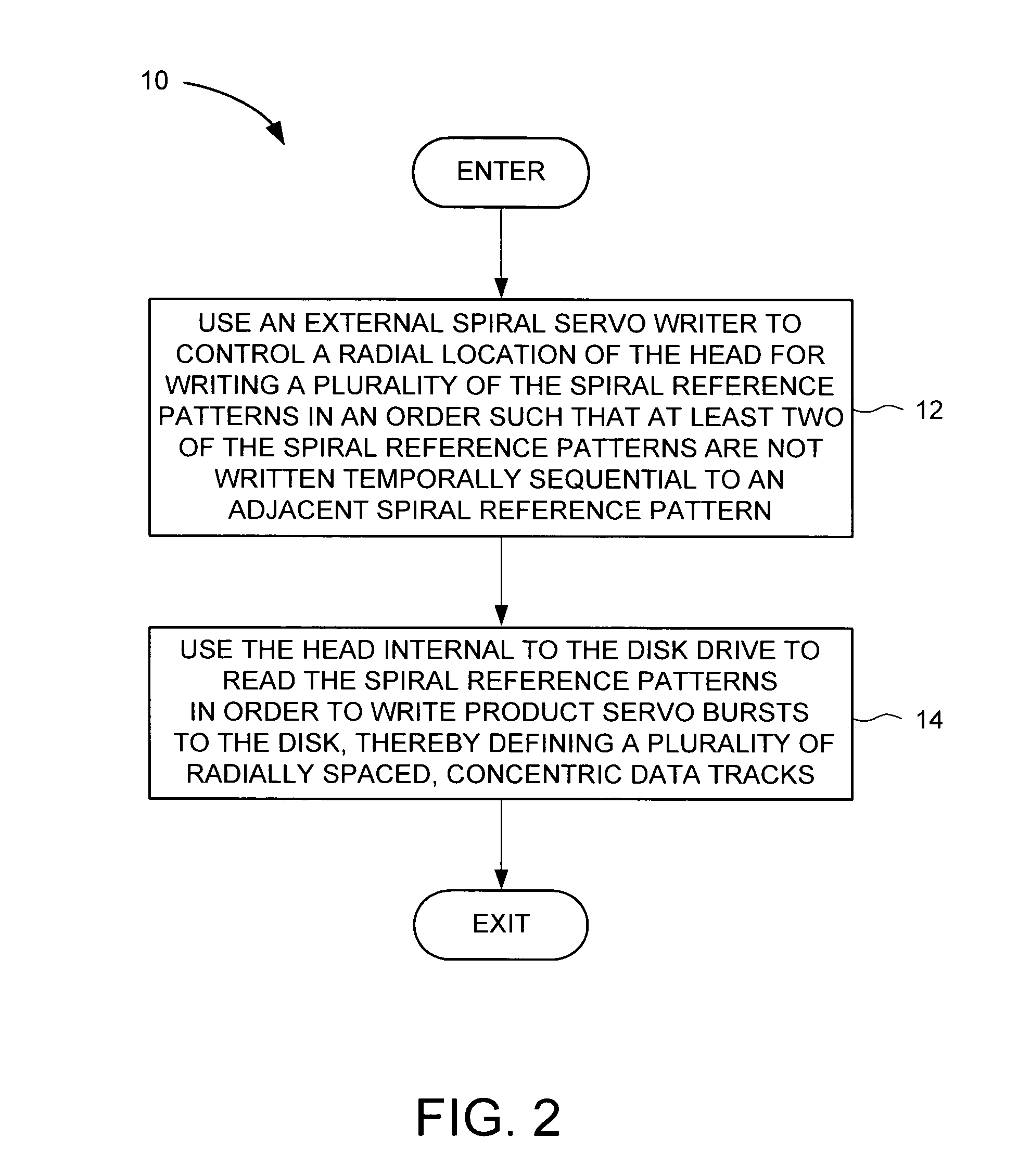

Method for nonsequentially writing reference spiral servo patterns to a disk to compensate for disk expansion

InactiveUS6992851B1Easy to useImprove accuracyDriving/moving recording headsRecord information storageGraphicsReference patterns

Owner:WESTERN DIGITAL TECH INC

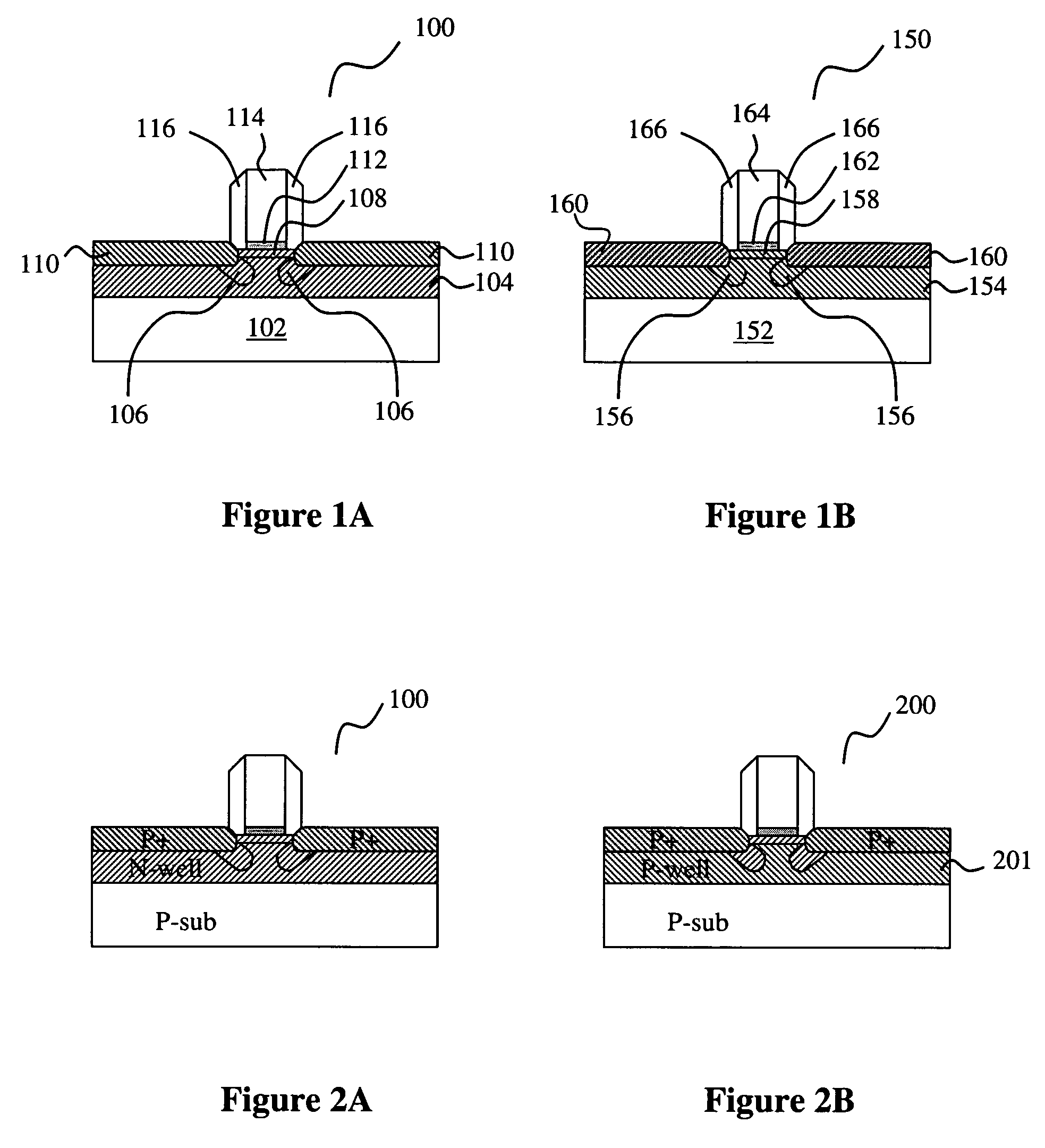

Method for determining abnormal characteristics in integrated circuit manufacturing process

A method for determining abnormal characteristics in integrated circuit manufacturing process is disclosed. The method comprises obtaining a charged particle microscope image of a sample test structure, wherein the sample including a reference pattern and a test pattern; measuring gray levels of the reference pattern and the test pattern; calculating a standard deviation from a distribution of the gray levels of the reference pattern measured; and determining the abnormal characteristics of the test pattern based on the gray levels measured and the standard deviation.

Owner:ASML NETHERLANDS BV

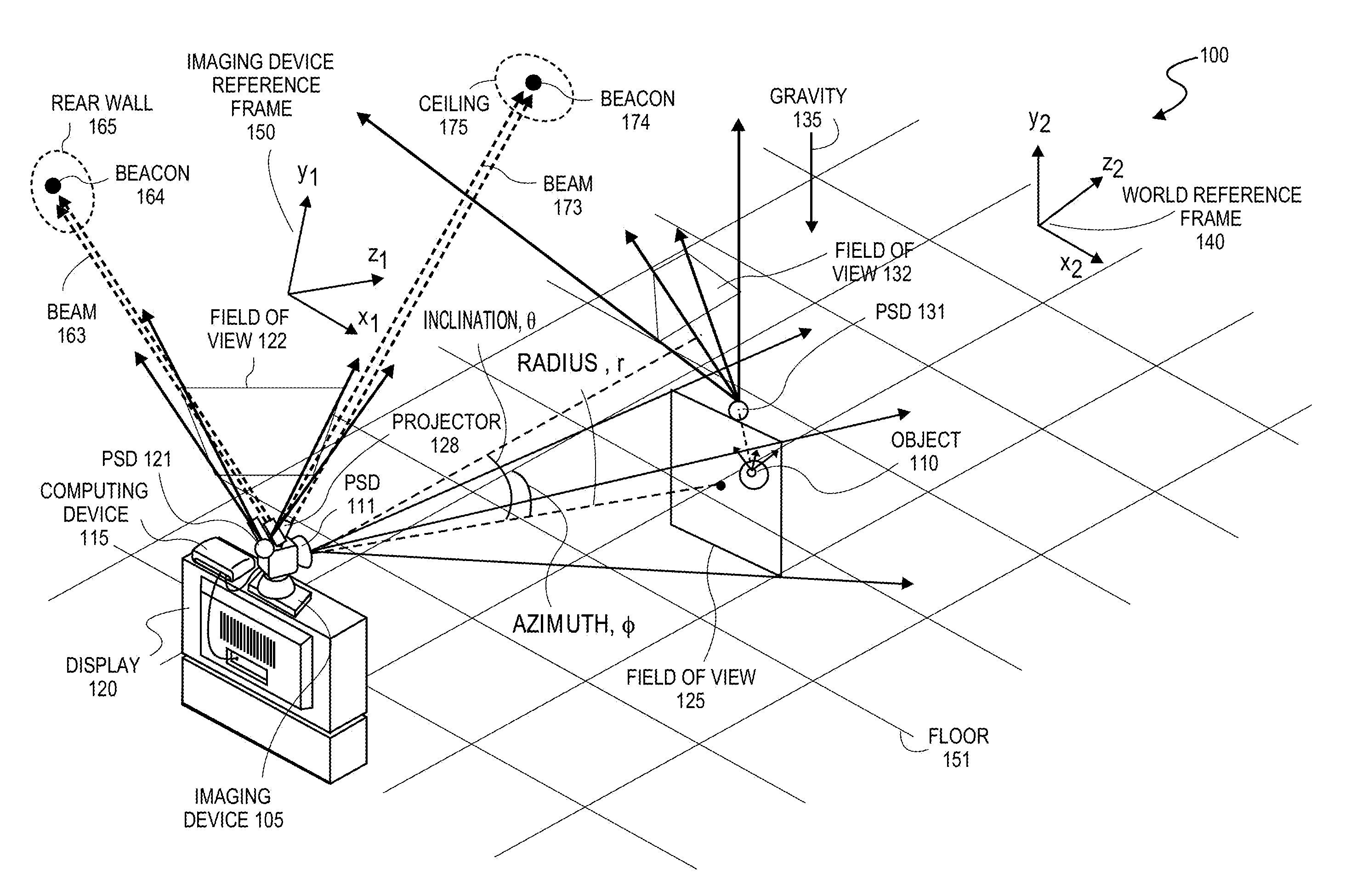

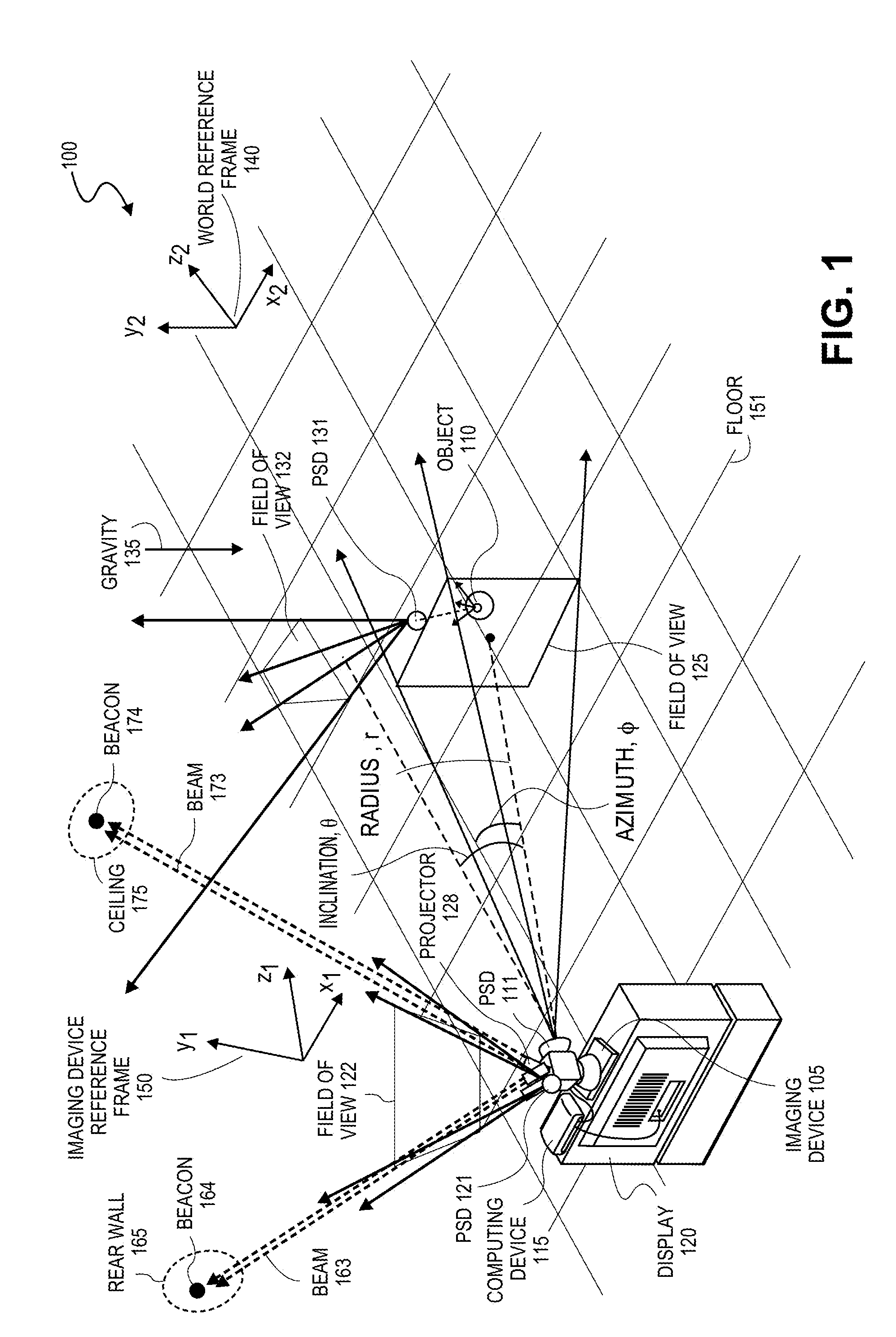

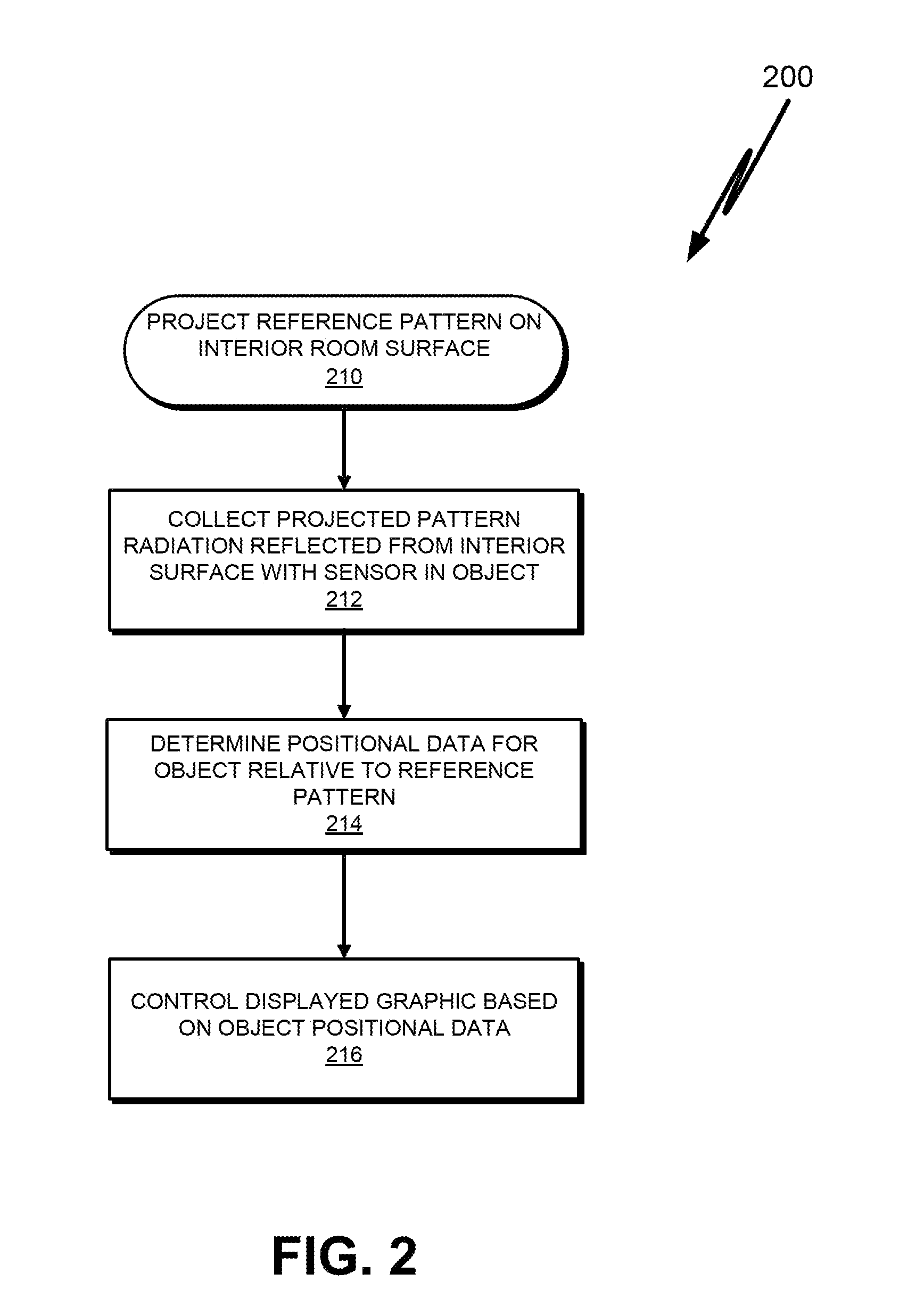

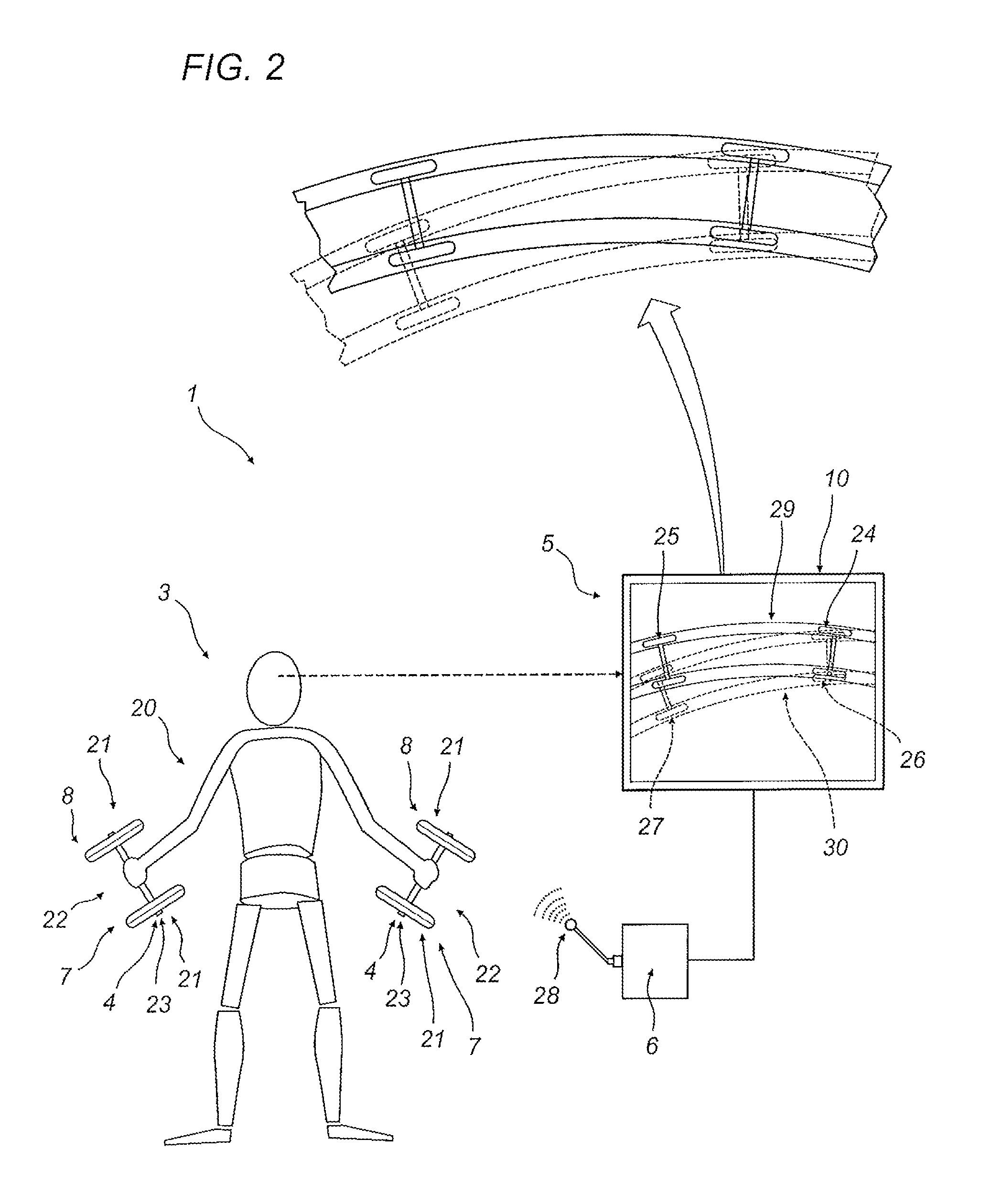

Object tracking with projected reference patterns

ActiveUS20120262365A1Input/output for user-computer interactionCathode-ray tube indicatorsReference patternsComputer vision

Systems and methods for tracking an object's position and orientation within a room using patterns projected onto an interior surface of the room, such as the ceiling. Systems include at least one optical position sensitive device embedded in the object to detect relative changes in the projected pattern as the object's position and / or orientation is changed. In particular systems, the pattern includes a plurality of beacons projected by one or more steerable lasers. Projected beacons may be steered automatically to accommodate a variety of room topologies. Additional optical position sensitive devices may be disposed in known physical positions relative to the projected pattern to view either or both the projected pattern and the object. A subset of object positional data may be derived from a video camera viewing the object while another subset of object positional data is derived from the projected pattern.

Owner:SONY COMPUTER ENTERTAINMENT INC

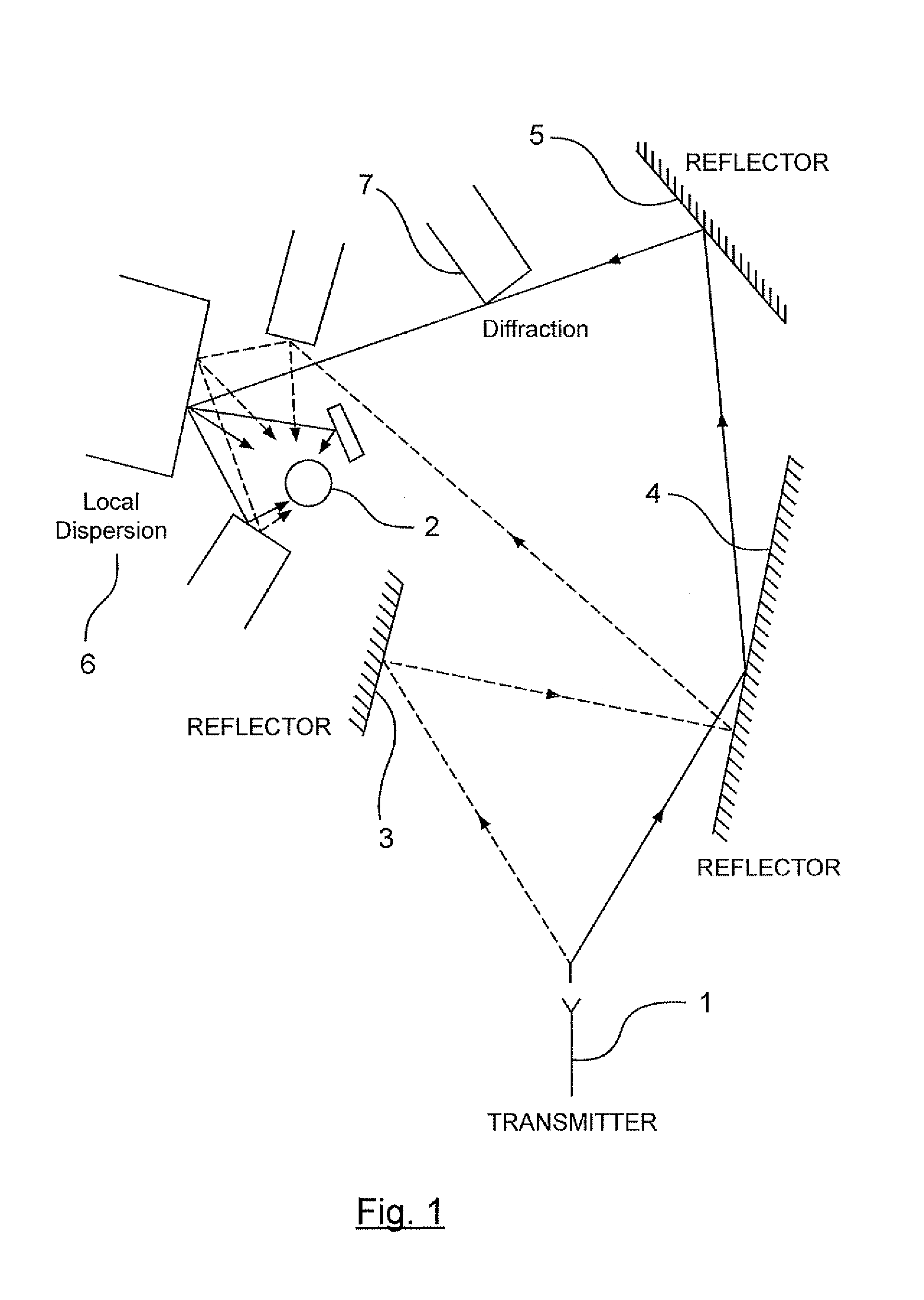

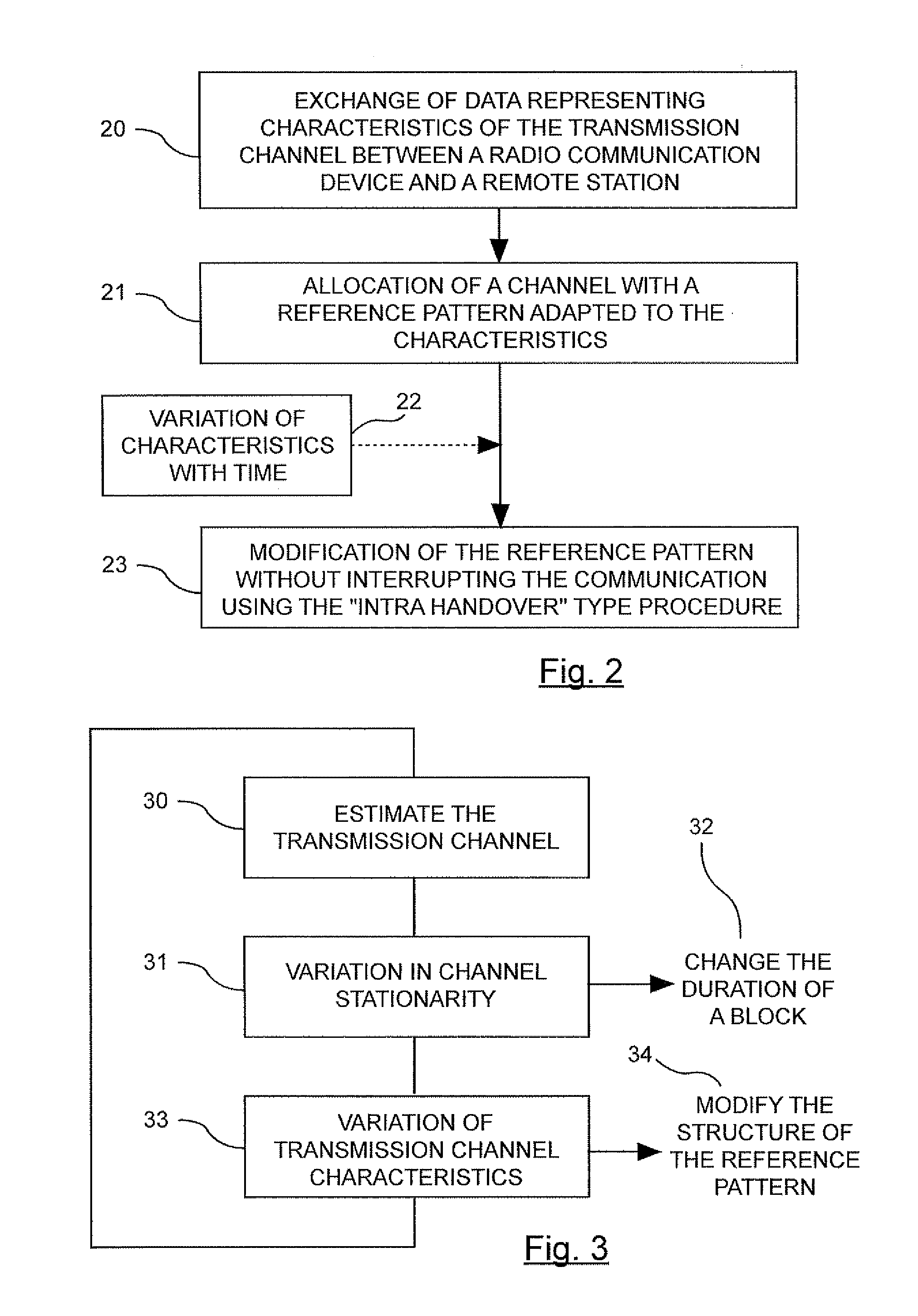

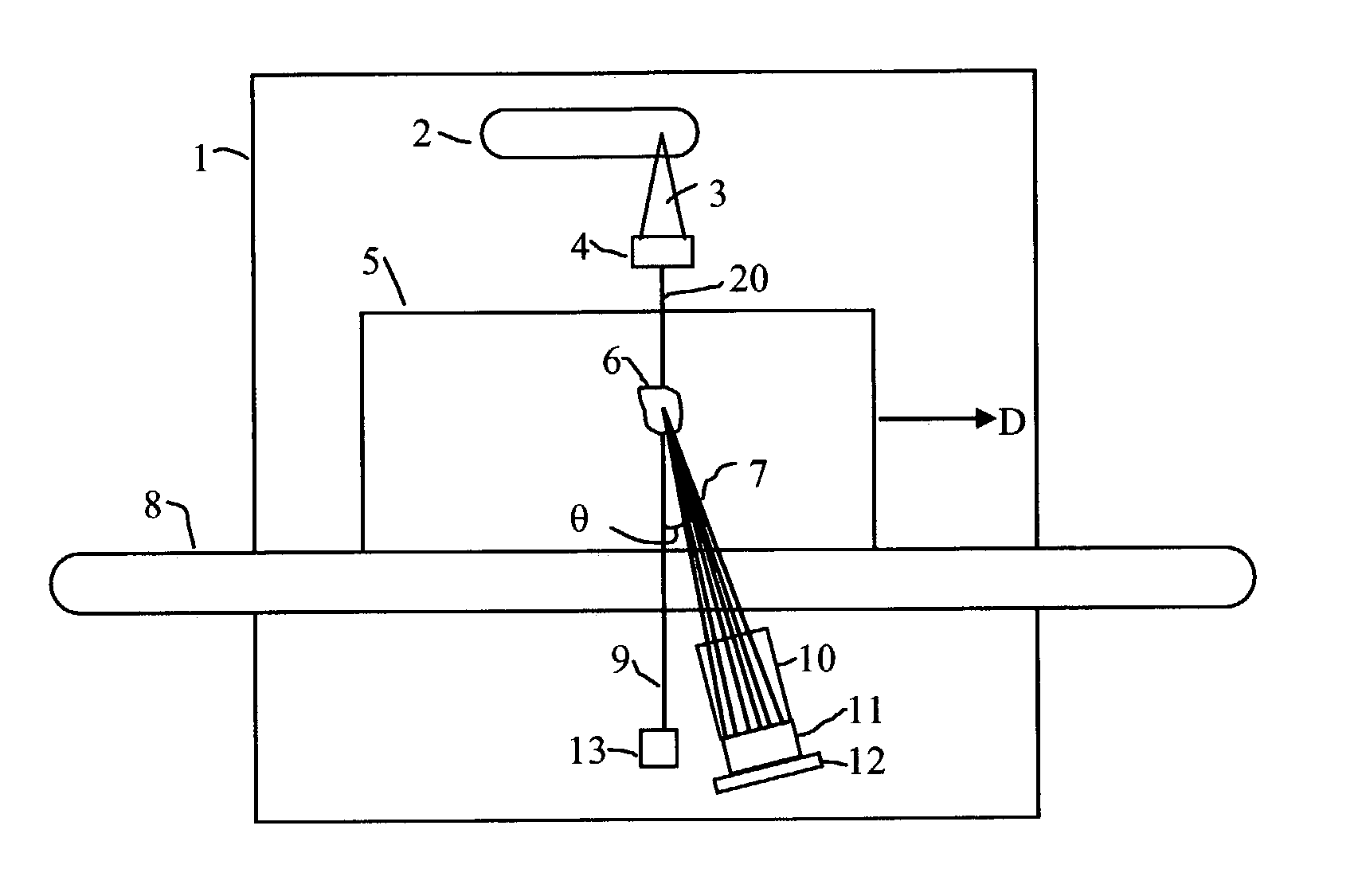

Method for extracting a variable reference pattern

InactiveUS7313174B2Limit envelope fluctuation of transmitted signalPrevent degradationError detection/prevention using signal quality detectorFrequency-division multiplex detailsTransmission channelReference patterns

A method is provided for extracting a sequence of pilot symbols enabling to estimate the transfer function of a transmission channel. At least a radiocommunication device communicates through the channel with a remote station, the latter regularly delivering to the radiocommunication device a reference pattern. The structure of the reference pattern is variable, depending on at least one characteristic of the transmission channel.

Owner:WAVECOM SA

X-ray inspection system for detecting explosives and other contraband

InactiveUS20060140340A1Improve accuracyImprove throughputUsing wave/particle radiation meansMaterial analysis by transmitting radiationX-rayExplosive material

A baggage scanning system and method employ combined angular and energy dispersive x-ray scanning to detect the presence of a contraband substance within an interrogation volume of a baggage item. The interrogation volume is illuminated with penetrating, polychromatic x-rays in a primary fan beam from a source such as a tungsten-anode x-ray tube. An energy-dependent absorption correction is determined from measurement of the attenuation of the fan beam at a plurality of different energies. Radiation coherently scattered by substances in the interrogation volume is detected by an energy-resolved x-ray detector operated at a plurality of scattering angles to form a plurality of scattering spectra. Each scattering spectrum is corrected for energy-dependent absorption and the corrected spectra are combined to produce a scattering pattern. The experimental scattering pattern is compared with reference patterns that uniquely characterize known contraband substances. The system and method can locate and identify a wide variety of contraband substances in an accurate, reliable manner. The system provides for automated screening, with the result that vagaries of human performance are virtually eliminated. False alarms and the need for hand inspection are reduced and detection efficacy is increased.

Owner:CONTROL SCREENING

Method and apparatus for automatically recognizing input audio and/or video streams

InactiveUS20070129952A1Improve accuracyMinimal timeAnalogue secracy/subscription systemsBroadcast information monitoringSingle sampleFeature set

A method and system for the automatic identification of audio, video, multimedia, and / or data recordings based on immutable characteristics of these works. The invention does not require the insertion of identifying codes or signals into the recording. This allows the system to be used to identify existing recordings that have not been through a coding process at the time that they were generated. Instead, each work to be recognized is “played” into the system where it is subjected to an automatic signal analysis process that locates salient features and computes a statistical representation of these properties. These features are then stored as patterns for later recognition of live input signal streams. A different set of features is derived for each audio or video work to be identified and stored. During real-time monitoring of a signal stream, a similar automatic signal analysis process is carried out, and many features are computed for comparison with the patterns stored in a large feature database. For each particular pattern stored in the database, only the relevant characteristics are compared with the real-time feature set. Preferably, during analysis and generation of reference patterns, data are extracted from all time intervals of a recording. This allows a work to be recognized from a single sample taken from any part of the recording.

Owner:ICEBERG IND

Pattern inspection apparatus and method

A fine pattern, such as a semiconductor integrated circuit (LSI), a liquid crystal panel, and a photomask (reticle) for the semiconductor or the liquid crystal panel, which are fabricated based on data for fabricating the fine pattern such as design data is inspected by a pattern inspection apparatus. The pattern inspection apparatus for inspecting a pattern to-be-inspected uses an image of the pattern to-be-inspected and data for fabricating the pattern to-be-inspected. The pattern inspection apparatus includes a reference pattern generation device configured to generate a reference pattern represented by one or more lines from the data, an image generation device configured to generate the image of the pattern to-be-inspected, a detecting device configured to detect an edge of the image of the pattern to-be-inspected, and an inspection device configured to inspect the pattern to-be-inspected by comparing the edge of the image of the pattern to-be-inspected with the one or more lines of the reference pattern.

Owner:TASMIT INC

Pattern inspection apparatus and method

InactiveUS20080130982A1Obtaining repeatabilityImage enhancementImage analysisReference patternsManufacturing data

A pattern inspection apparatus is used for inspecting a fine pattern, such as a semiconductor integrated circuit (LSI), a liquid crystal panel, and a photomask (reticle) for the semiconductor or the liquid crystal panel, which are fabricated based on data for fabricating the fine pattern such as design data. The pattern inspection apparatus includes a reference pattern generation device configured to generate a reference pattern represented by one or more lines, comprising one of a line segment and a curve, from the data, an image generation device configured to generate the image of the pattern to-be-inspected, a detecting device configured to detect an edge of the image of the pattern to-be-inspected, and an inspection device configured to inspect the pattern to-be-inspected by comparing the edge of the image of the pattern to-be-inspected with the one or more lines of the reference pattern.

Owner:TASMIT INC

Time-based servo for magnetic storage media

InactiveUS6842305B2Driving/moving recording headsManufacturing heads with multiple gapsMagnetic storageReference patterns

A servo track configuration includes at least one servo track having a width. A servo pattern is repeatedly recorded in the at least one servo track. Repeatedly recording the servo pattern includes repeating the simultaneous recording of first and second reference pattern lines and a track pattern line in the at least one servo track. Each of the first and second reference pattern lines has an identical predetermined geometry and extends across the width of the at least one servo track. Further, the track pattern line has a predetermined geometry that is different than the predetermined geometry of the first and second reference pattern lines and extends across the width of the at least one servo track.

Owner:IMATION

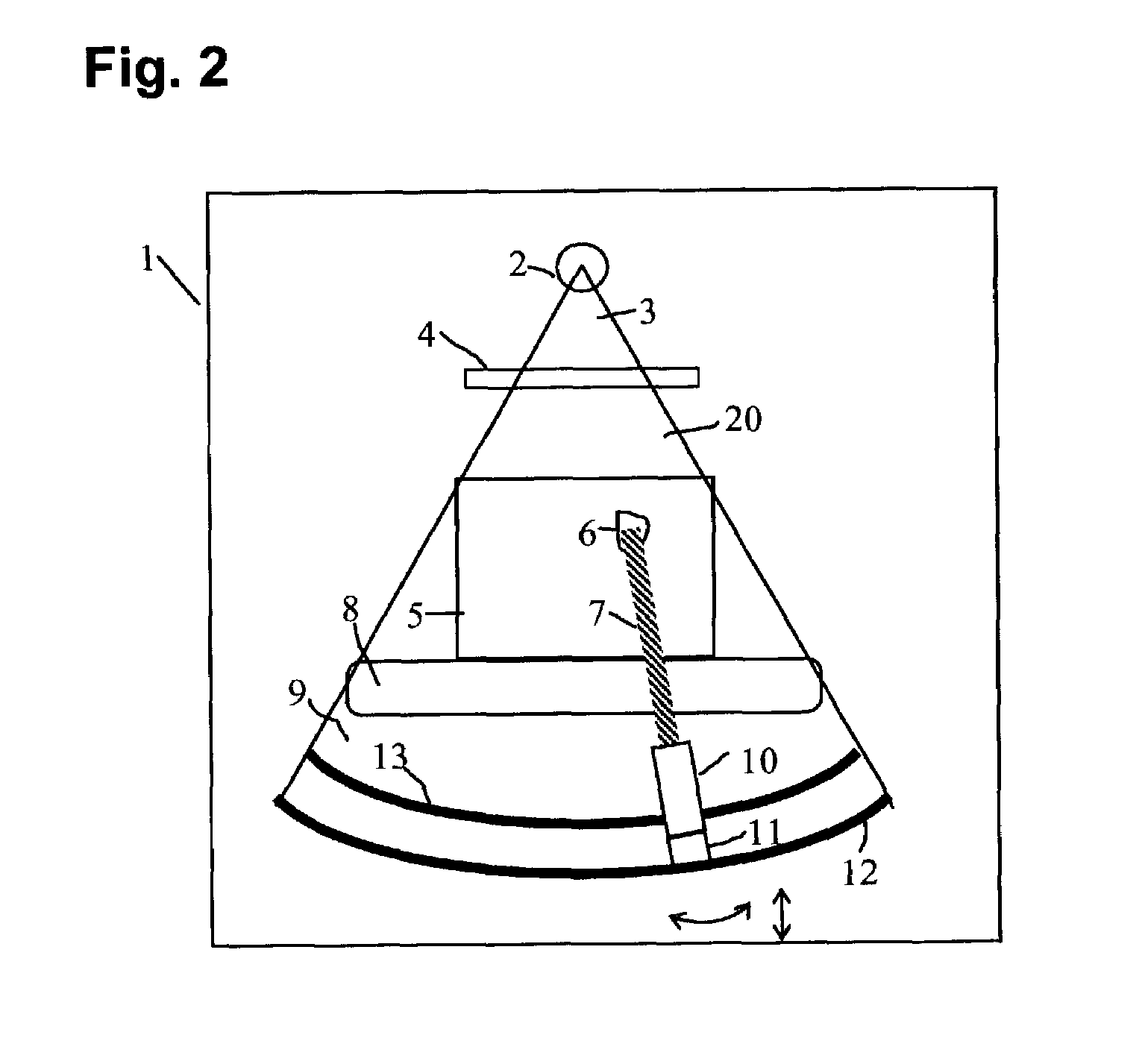

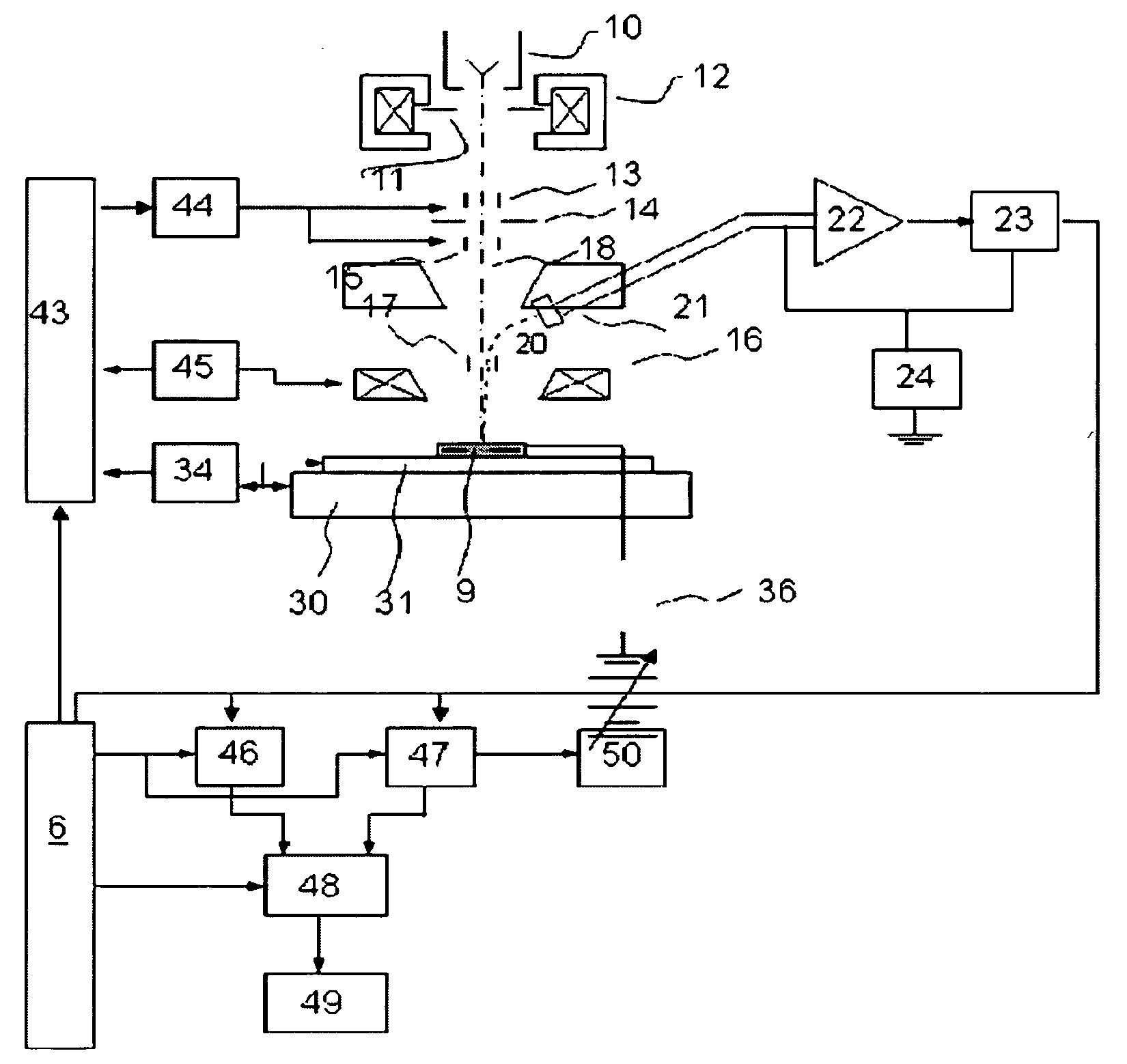

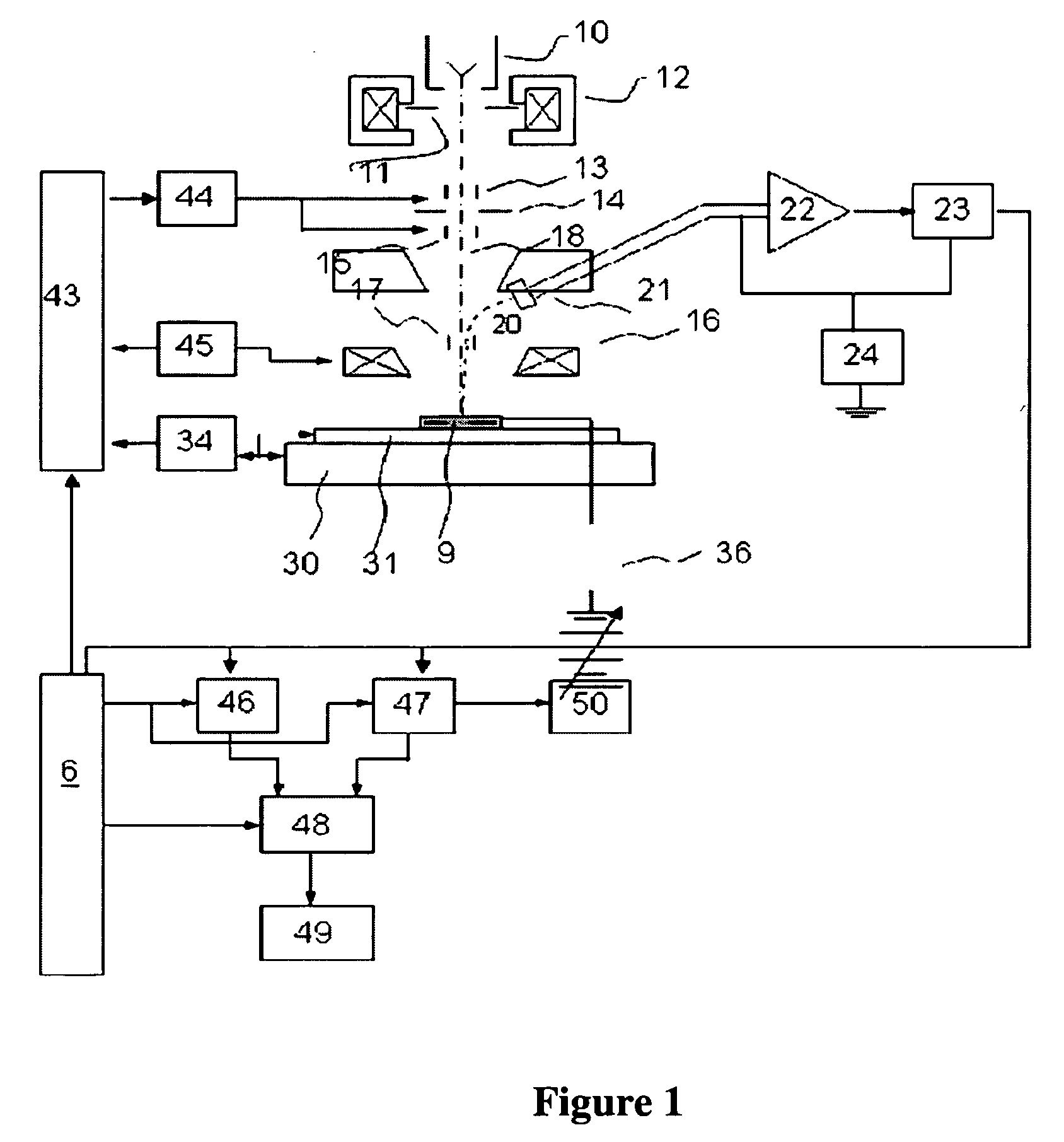

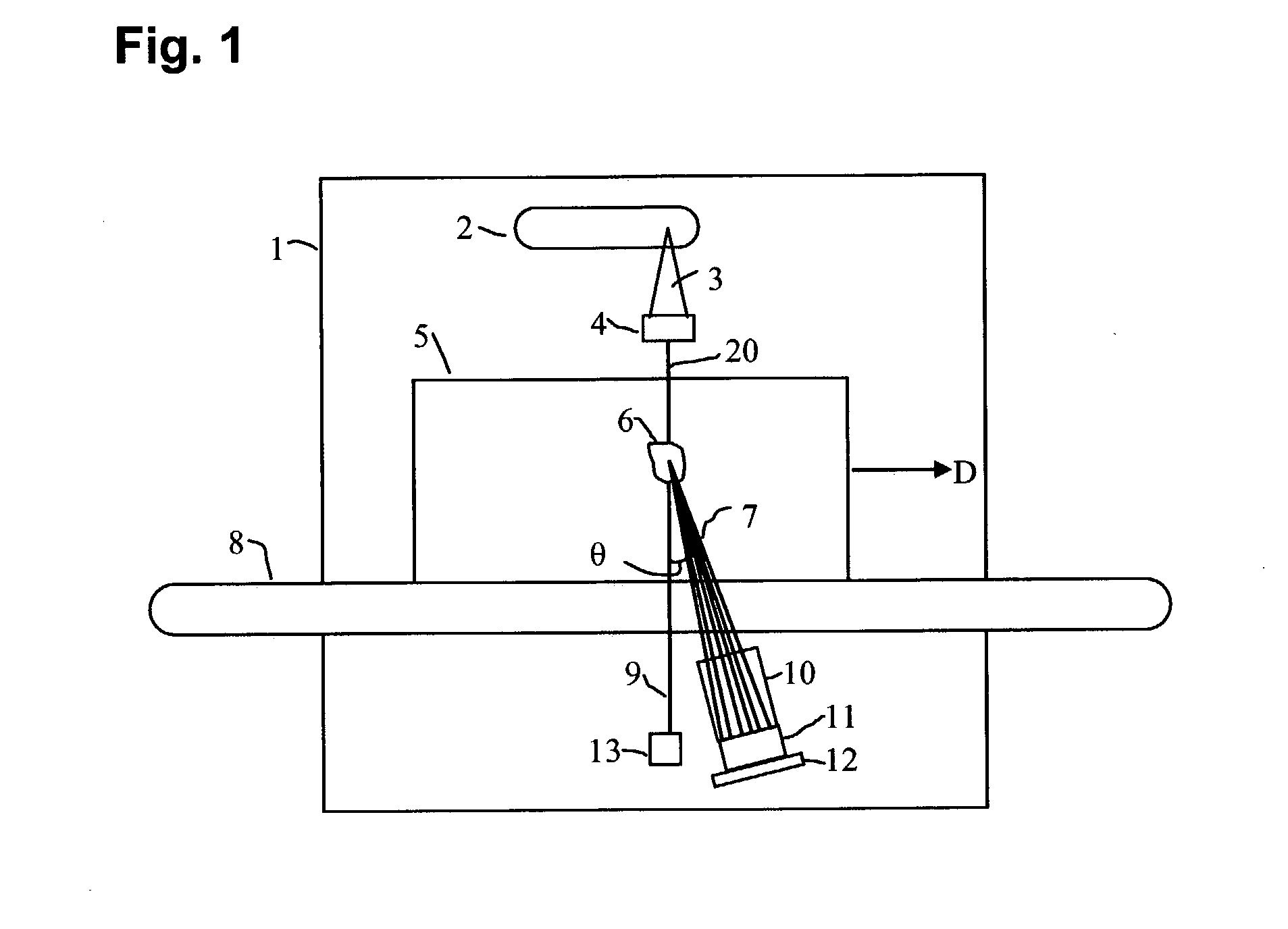

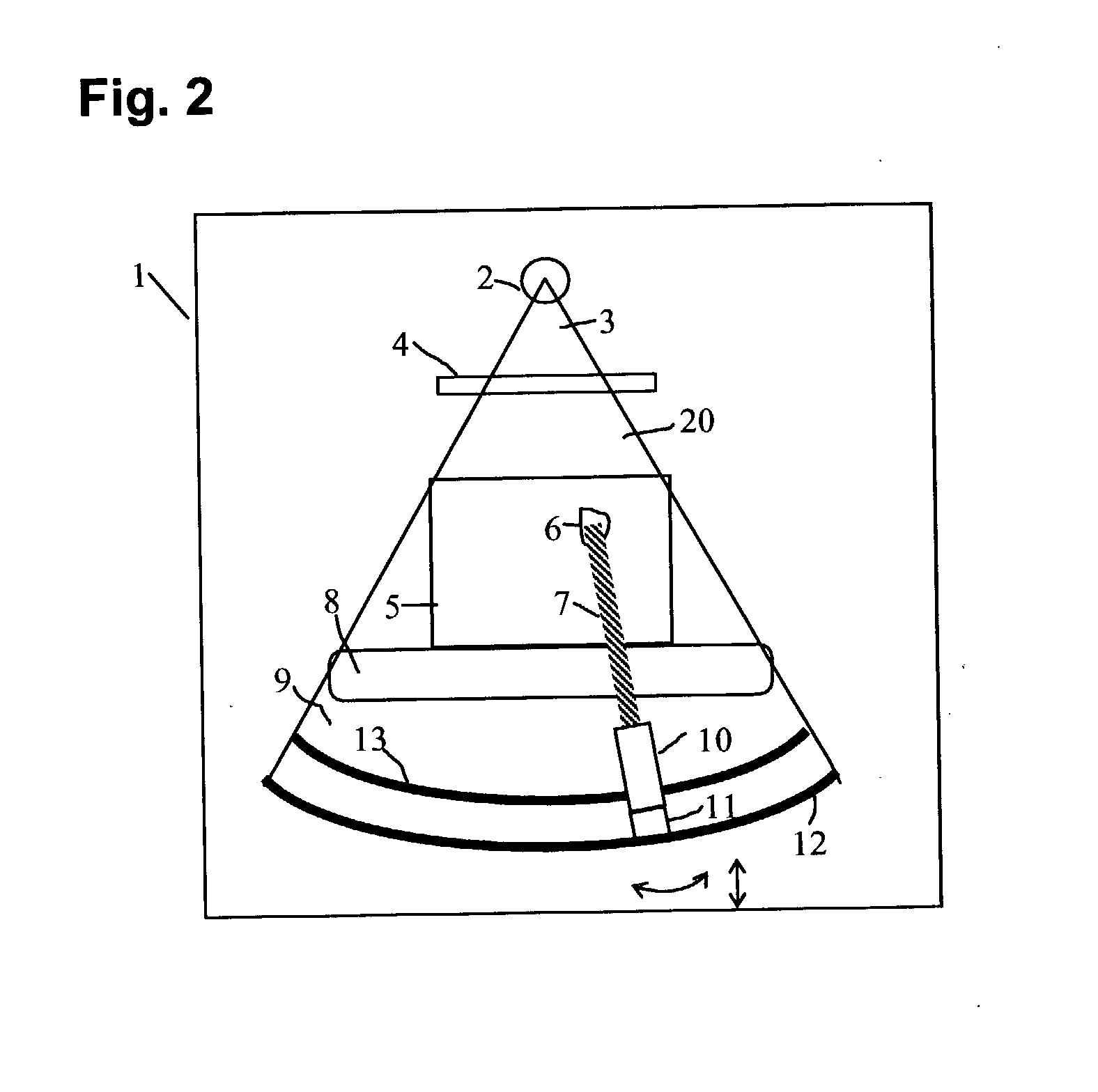

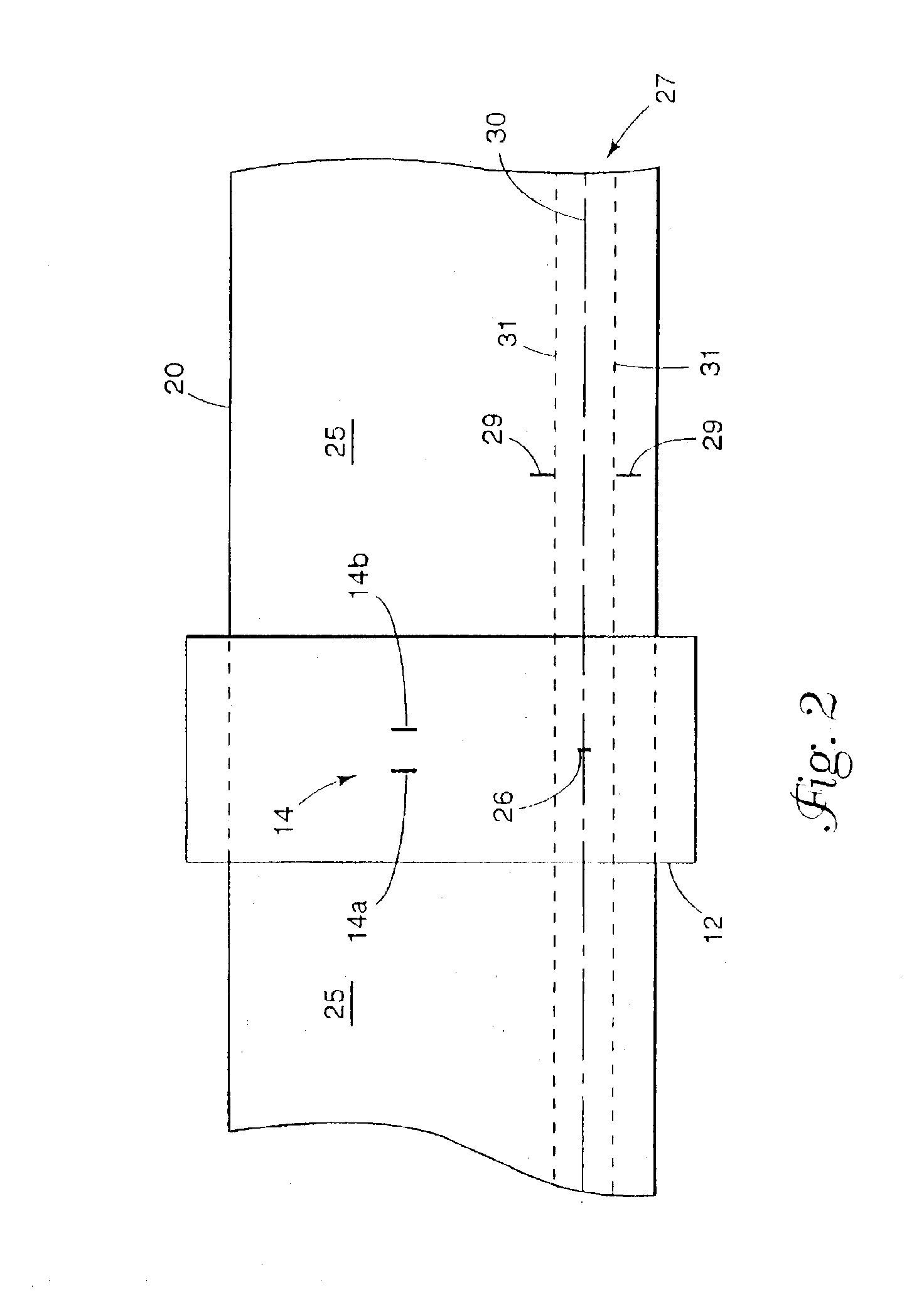

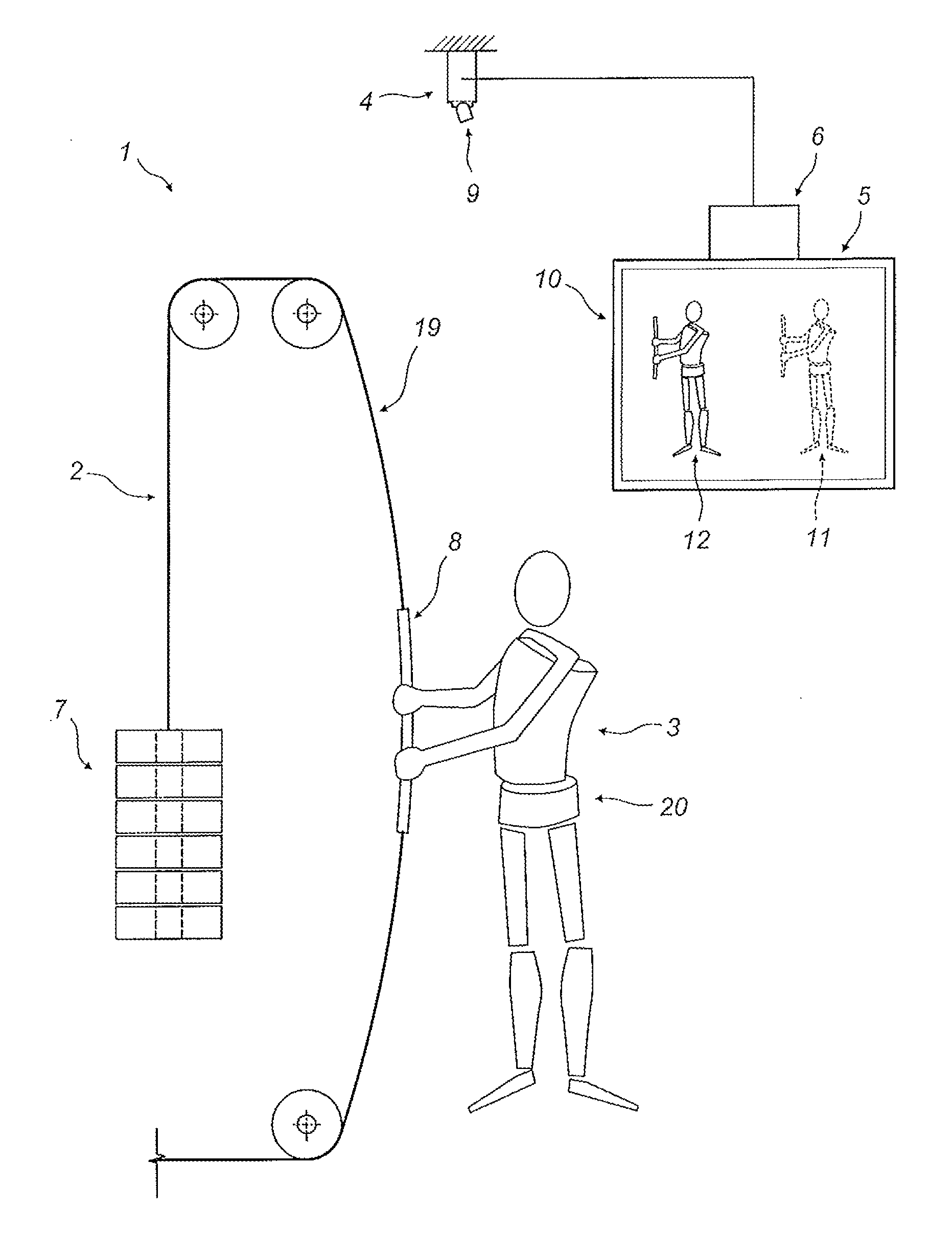

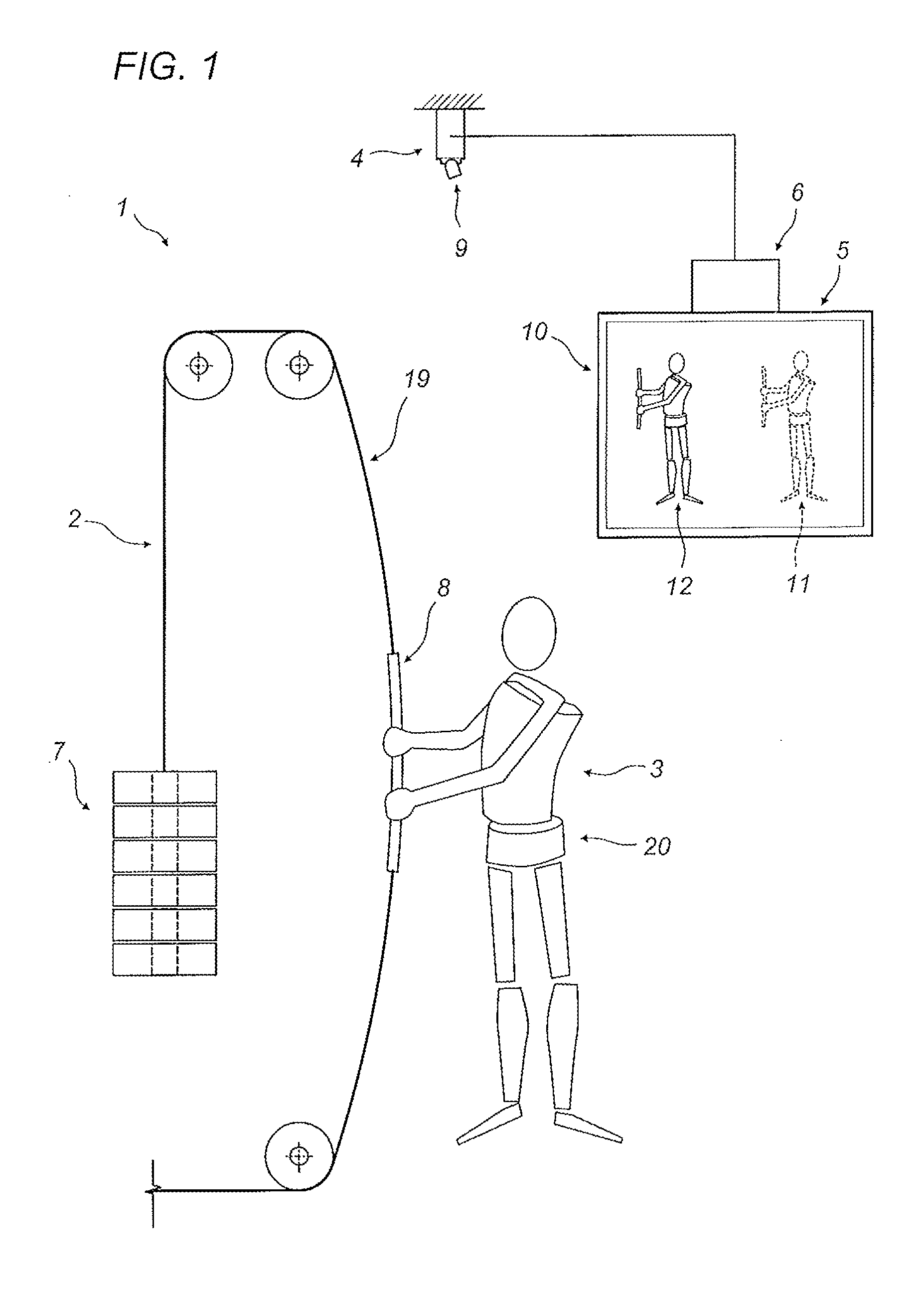

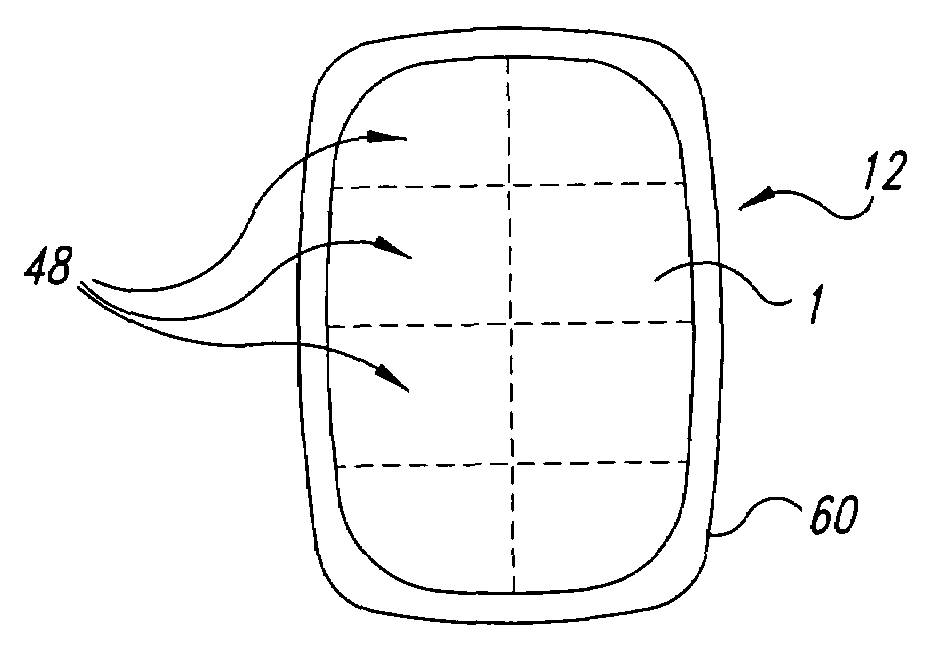

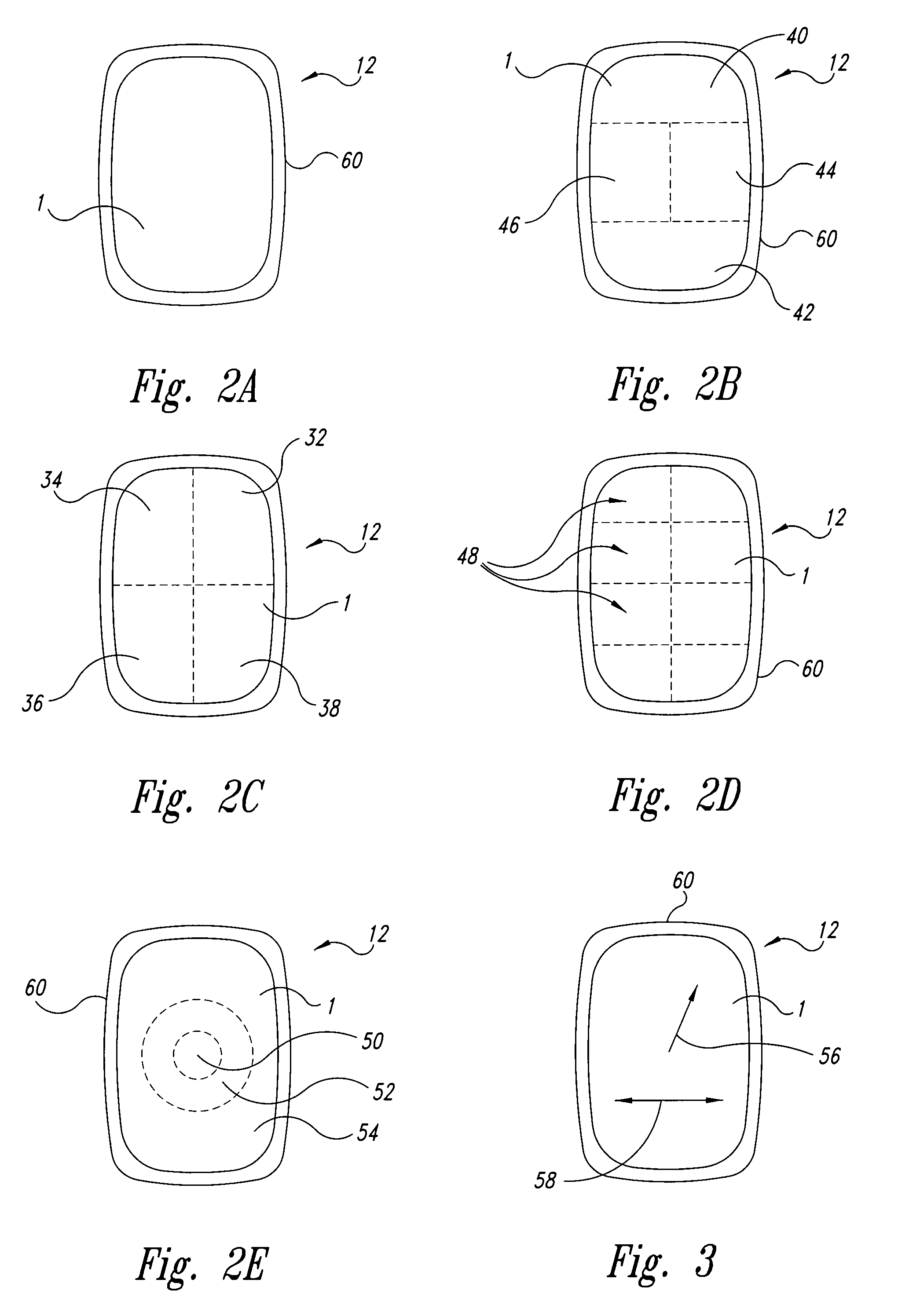

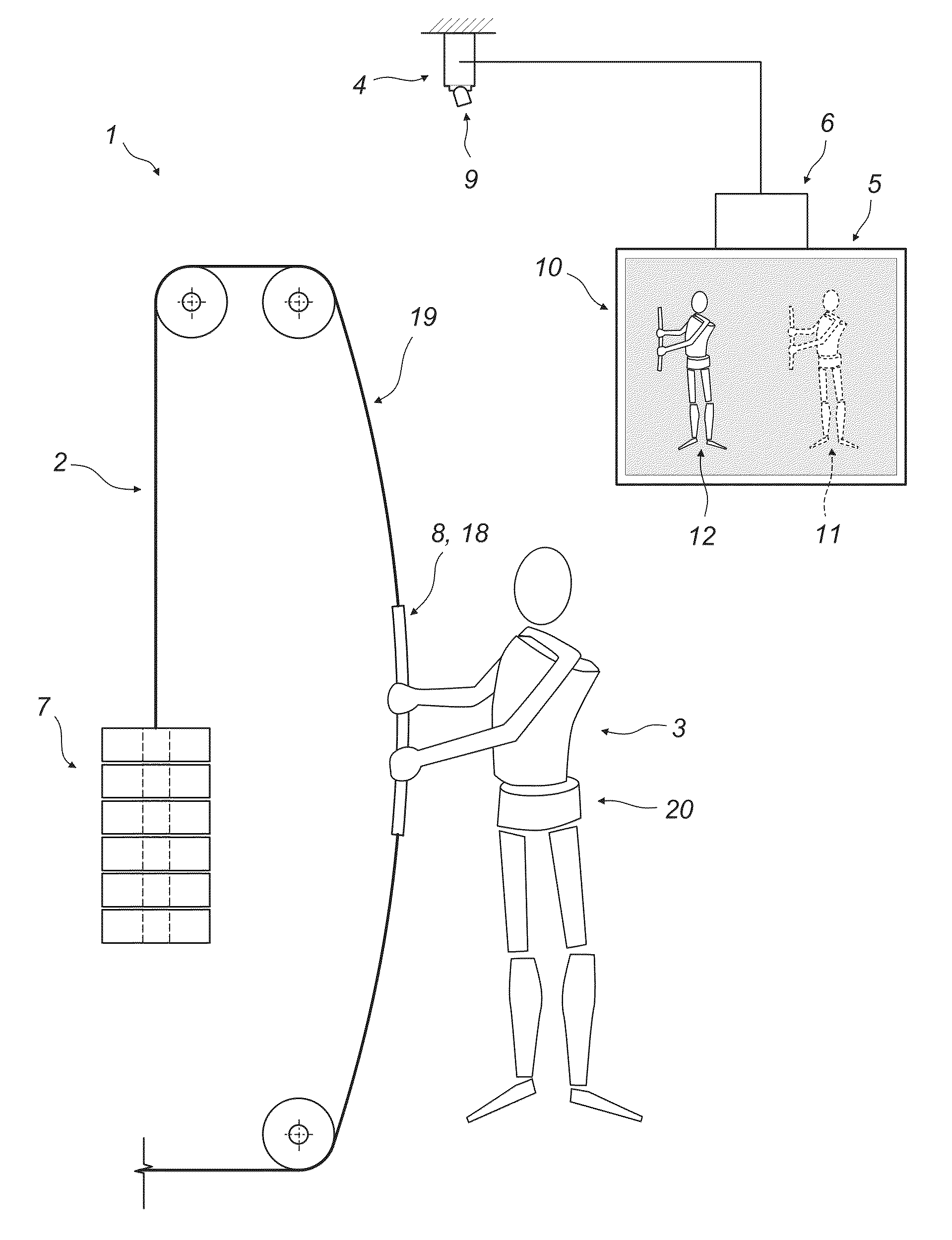

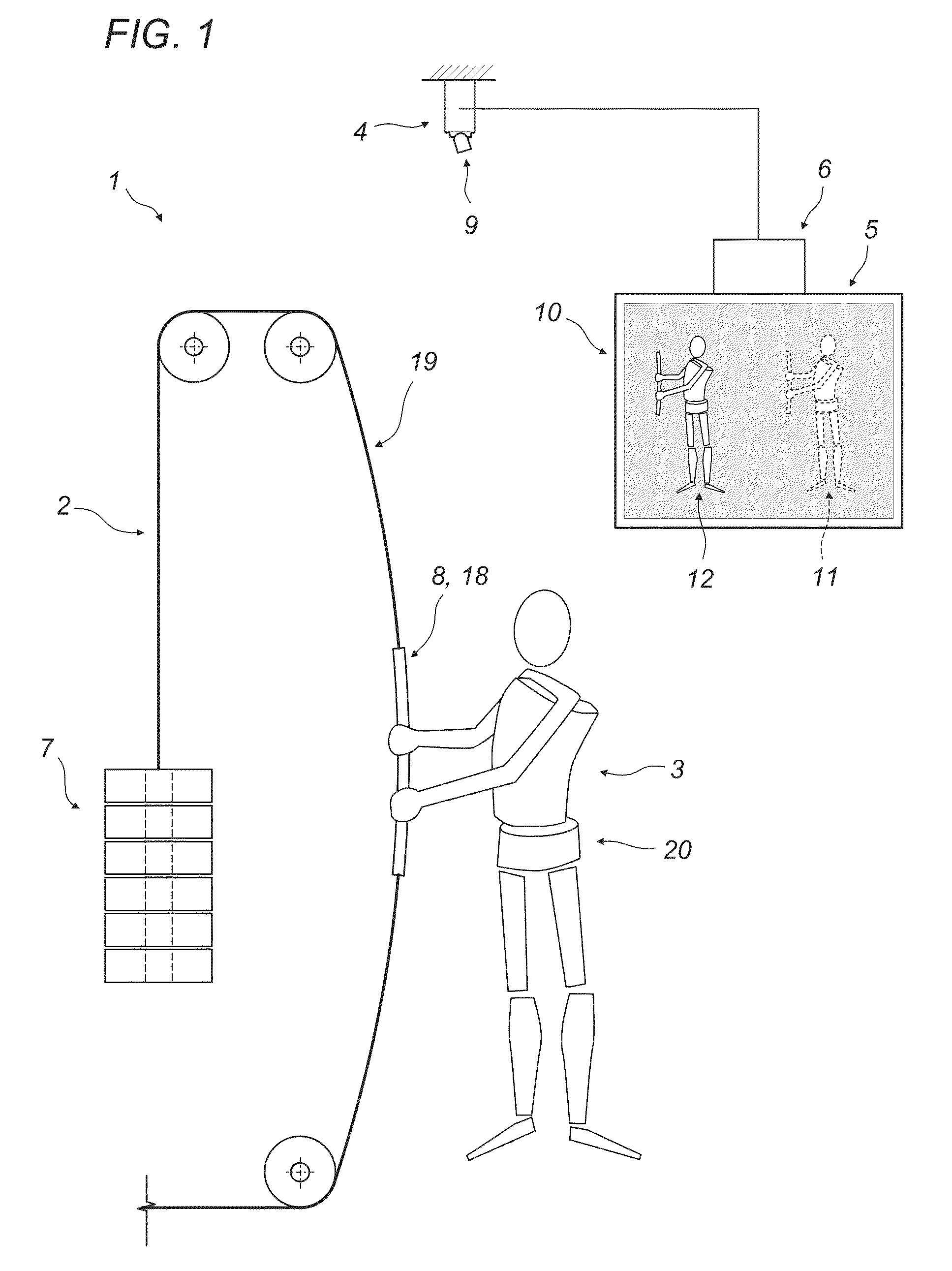

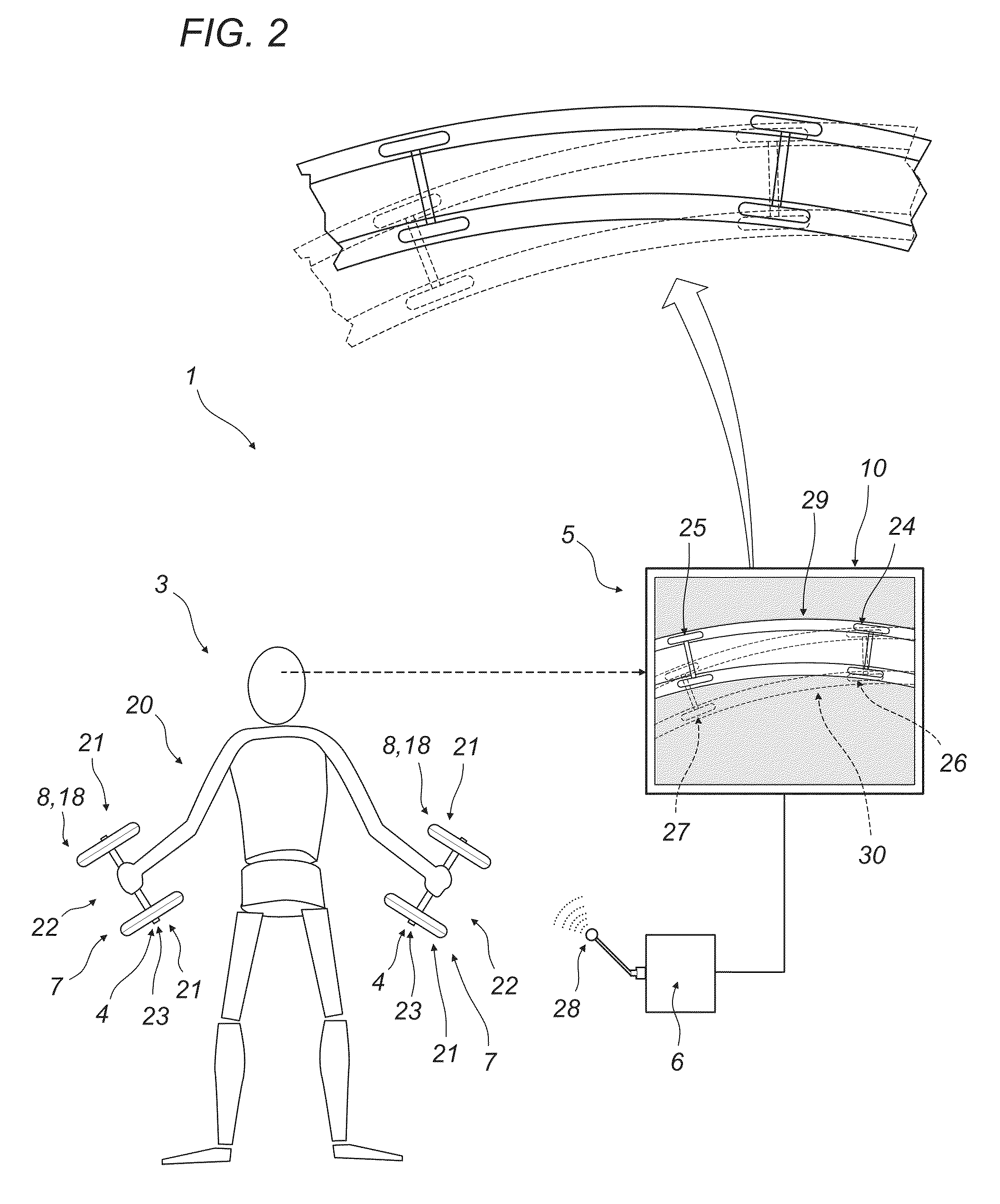

Apparatus for the assisted performance of a fitness exercise

ActiveUS20130072353A1Ensure correct executionGood effectPhysical therapies and activitiesTherapy exerciseReference patternsEngineering

An apparatus (1) for the assisted performance of a fitness exercise, equipped with a fitness tool (2) configured to interact with the user (3) to enable the user to perform a movement along a preset path overcoming the force of a resistant load (7), comprises: sensing means (4) set up to provide a signal representing the movement of the user (3); feedback means (5) for transmitting a signal to the user (3) during performance of the exercise; a processor (6) connected to the sensing means (4) and to the feedback means (5) to provide the user (3) with feedback in real time on the correctness of performance of the exercise, based on a comparison between the signal representing the movement of the user and a predetermined reference pattern representing an ideal pattern for the movement of the user (3) corresponding to the exercise performed correctly.

Owner:TECHNOGYM SPA

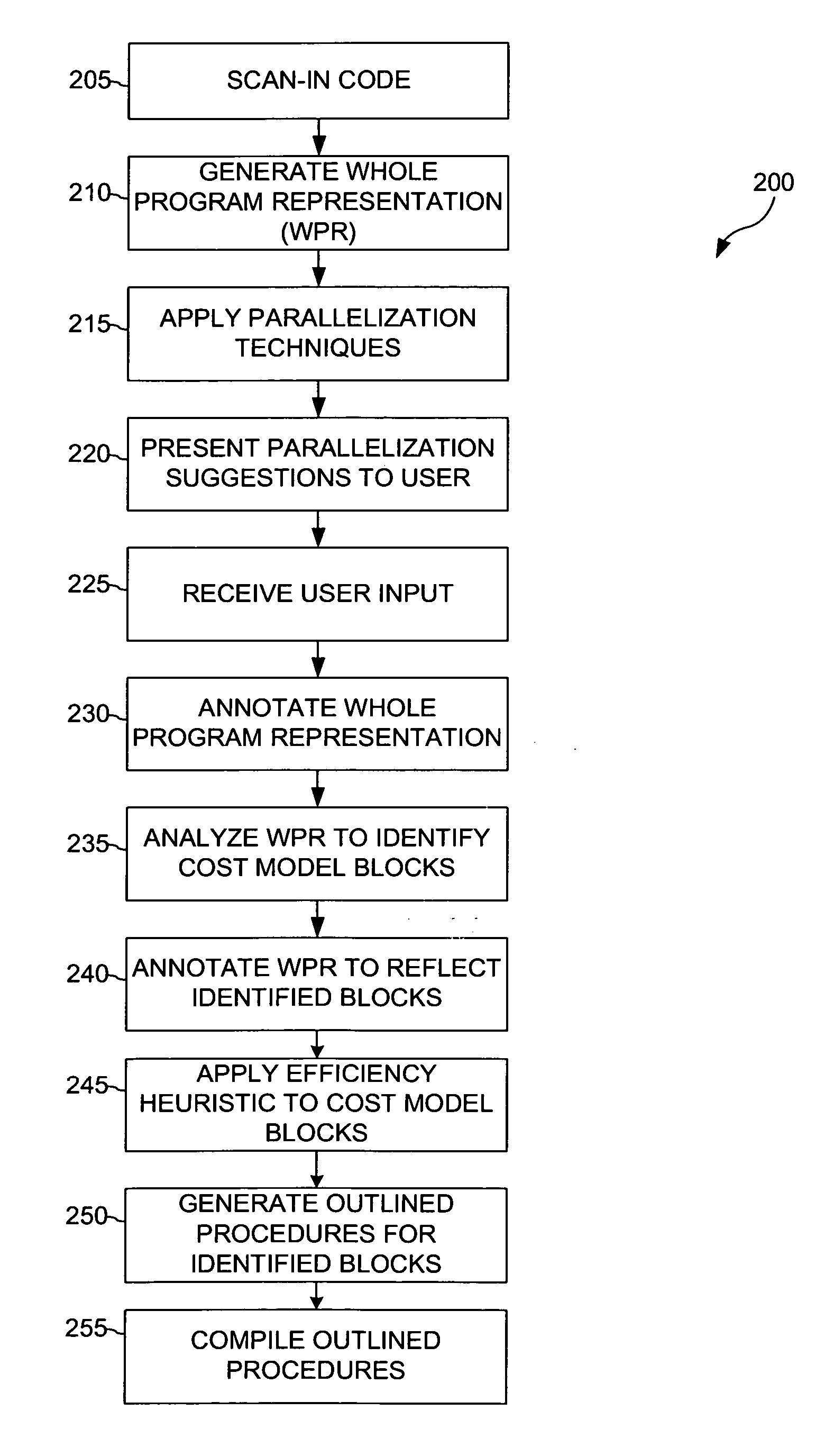

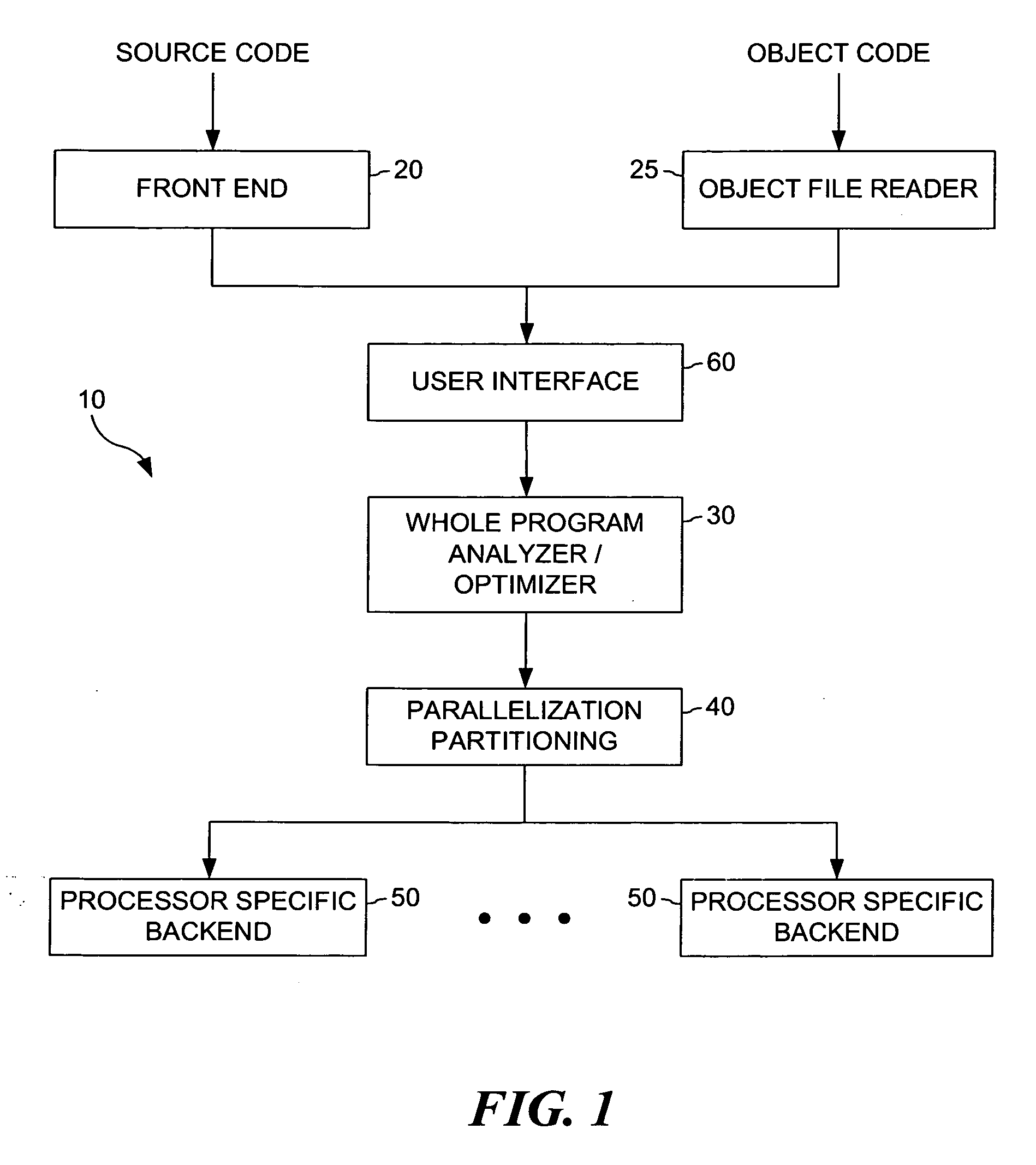

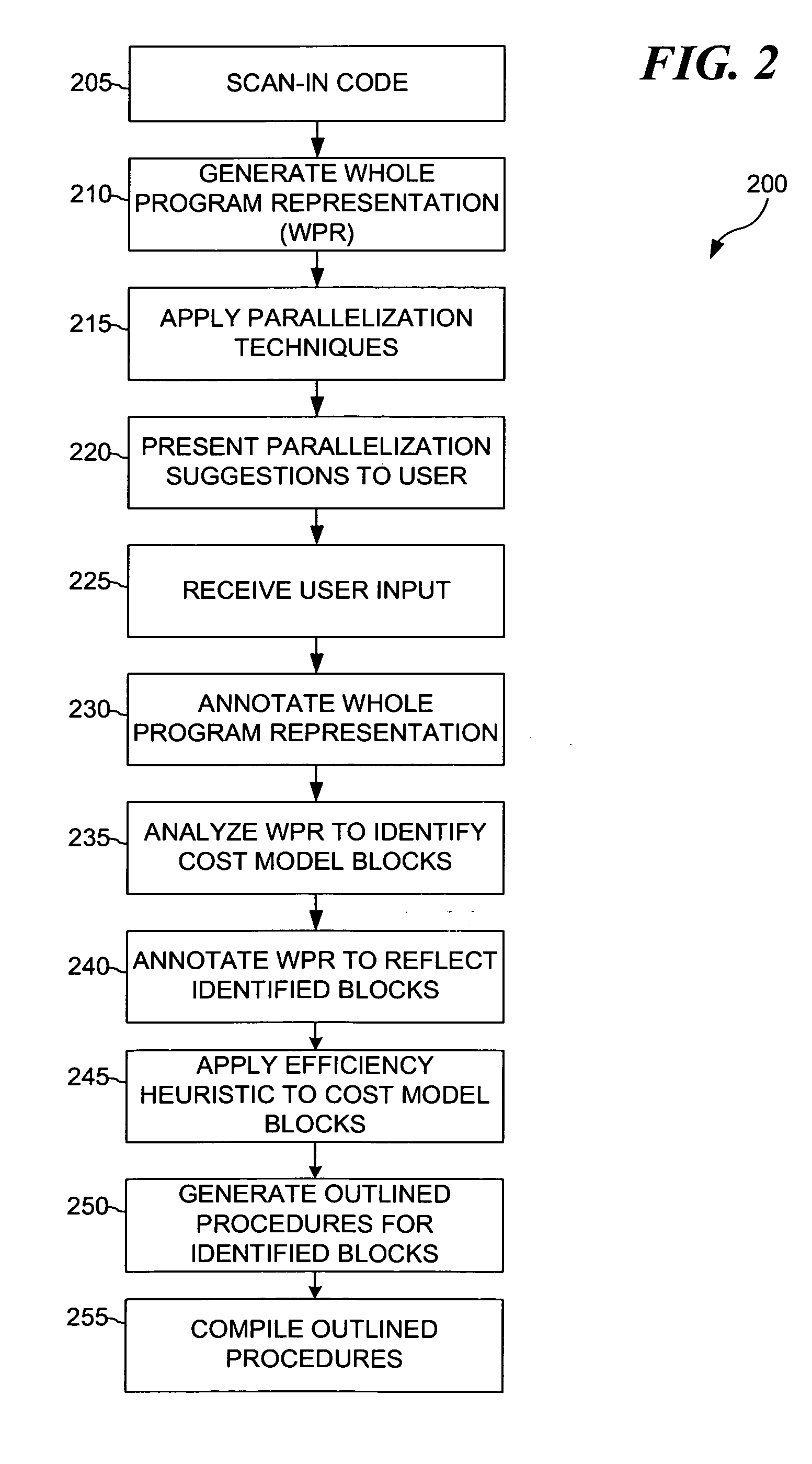

Method and system for exploiting parallelism on a heterogeneous multiprocessor computer system

InactiveUS20060123401A1Frees the application programmerSpecific program execution arrangementsMemory systemsProgramming complexityMulti processor

In a multiprocessor system it is generally assumed that peak or near peak performance will be achieved by splitting computation across all the nodes of the system. There exists a broad spectrum of techniques for performing this splitting or parallelization, ranging from careful handcrafting by an expert programmer at the one end, to automatic parallelization by a sophisticated compiler at the other. This latter approach is becoming more prevalent as the automatic parallelization techniques mature. In a multiprocessor system comprising multiple heterogeneous processing elements these techniques are not readily applicable, and the programming complexity again becomes a very significant factor. The present invention provides for a method for computer program code parallelization and partitioning for such a heterogeneous multi-processor system. A Single Source file, targeting a generic multiprocessing environment is received. Parallelization analysis techniques are applied to the received single source file. Parallelizable regions of the single source file are identified based on applied parallelization analysis techniques. The data reference patterns, code characteristics and memory transfer requirements are analyzed to generate an optimum partition of the program. The partitioned regions are compiled to the appropriate instruction set architecture and a single bound executable is produced.

Owner:IBM CORP

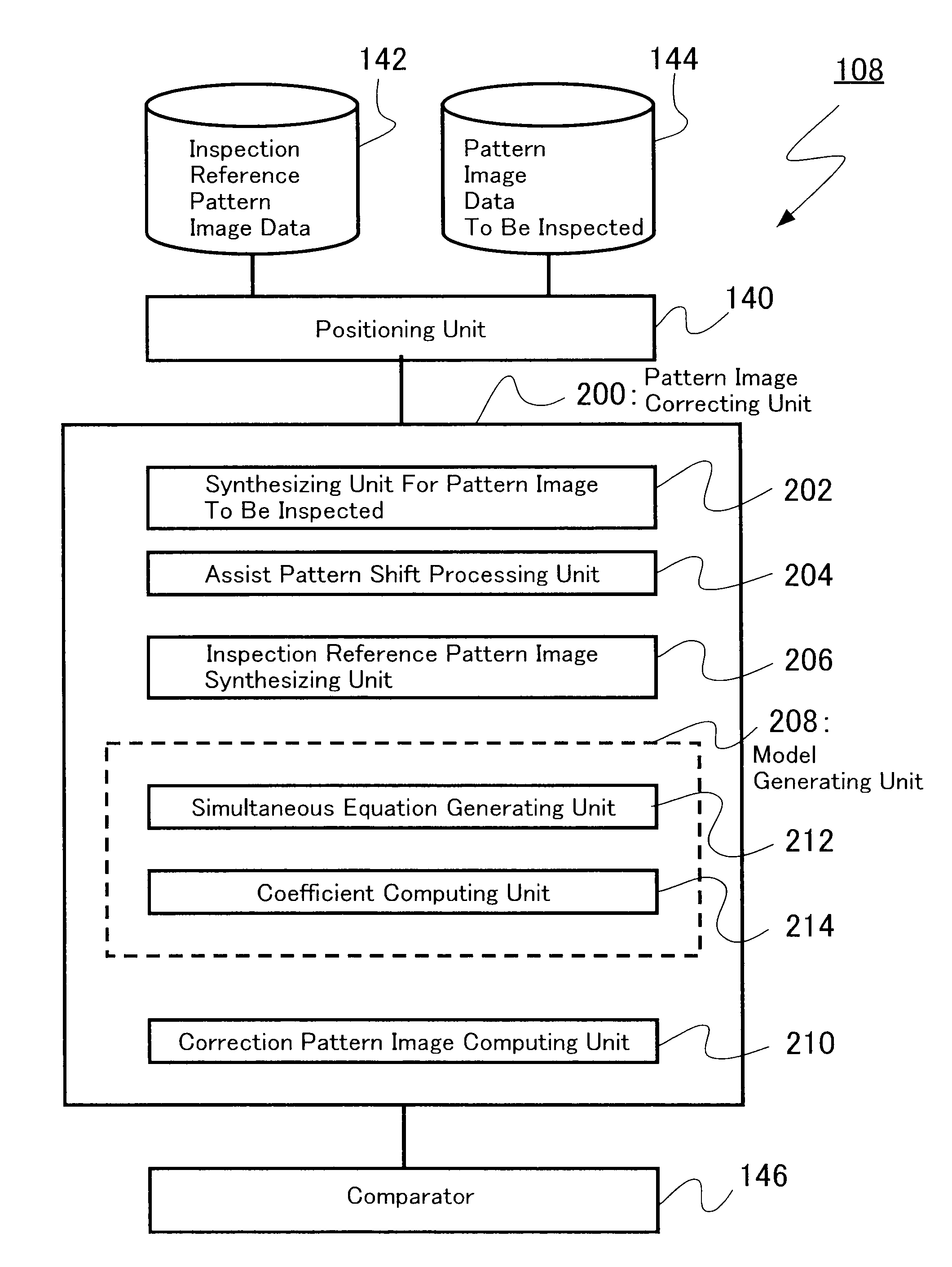

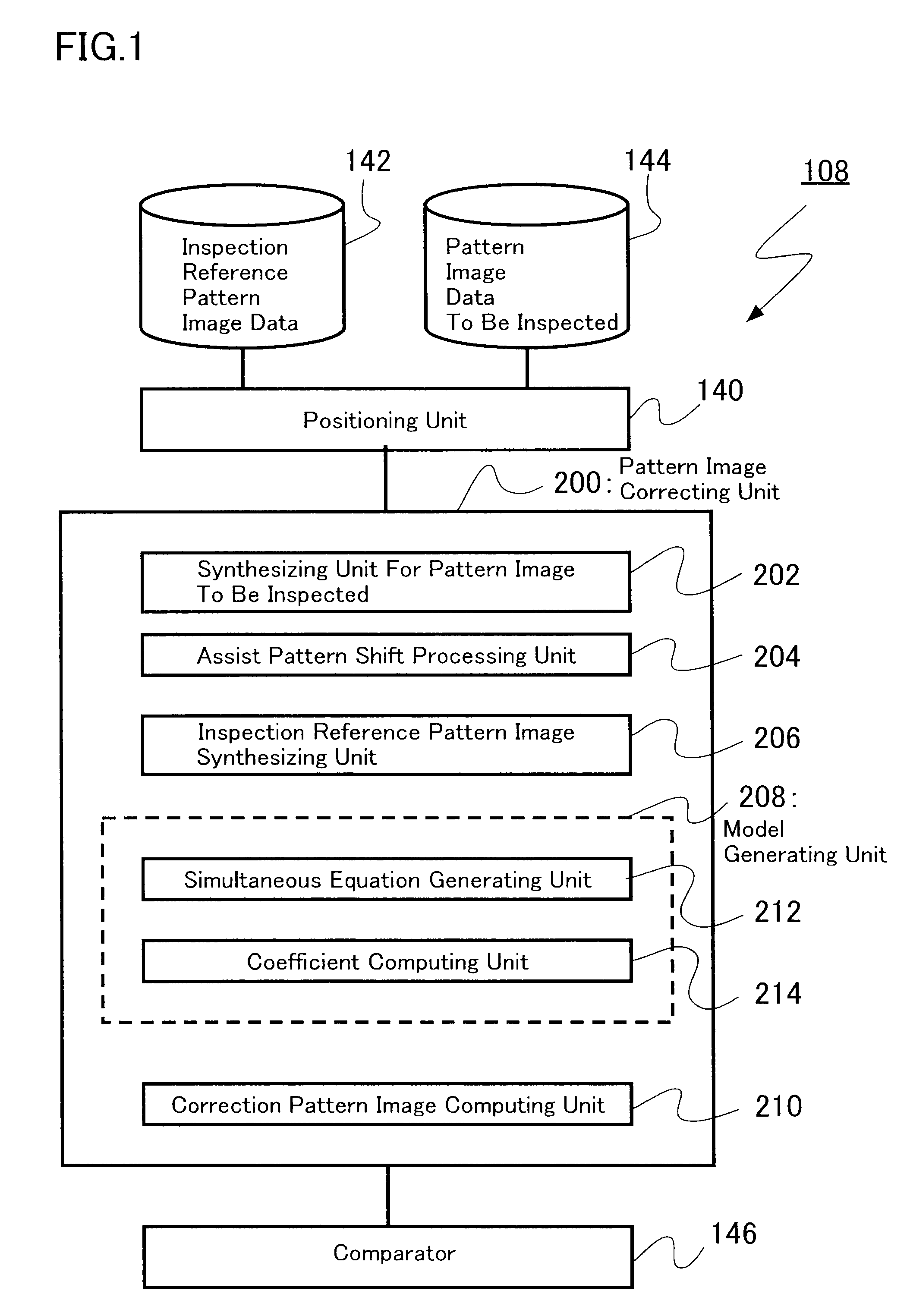

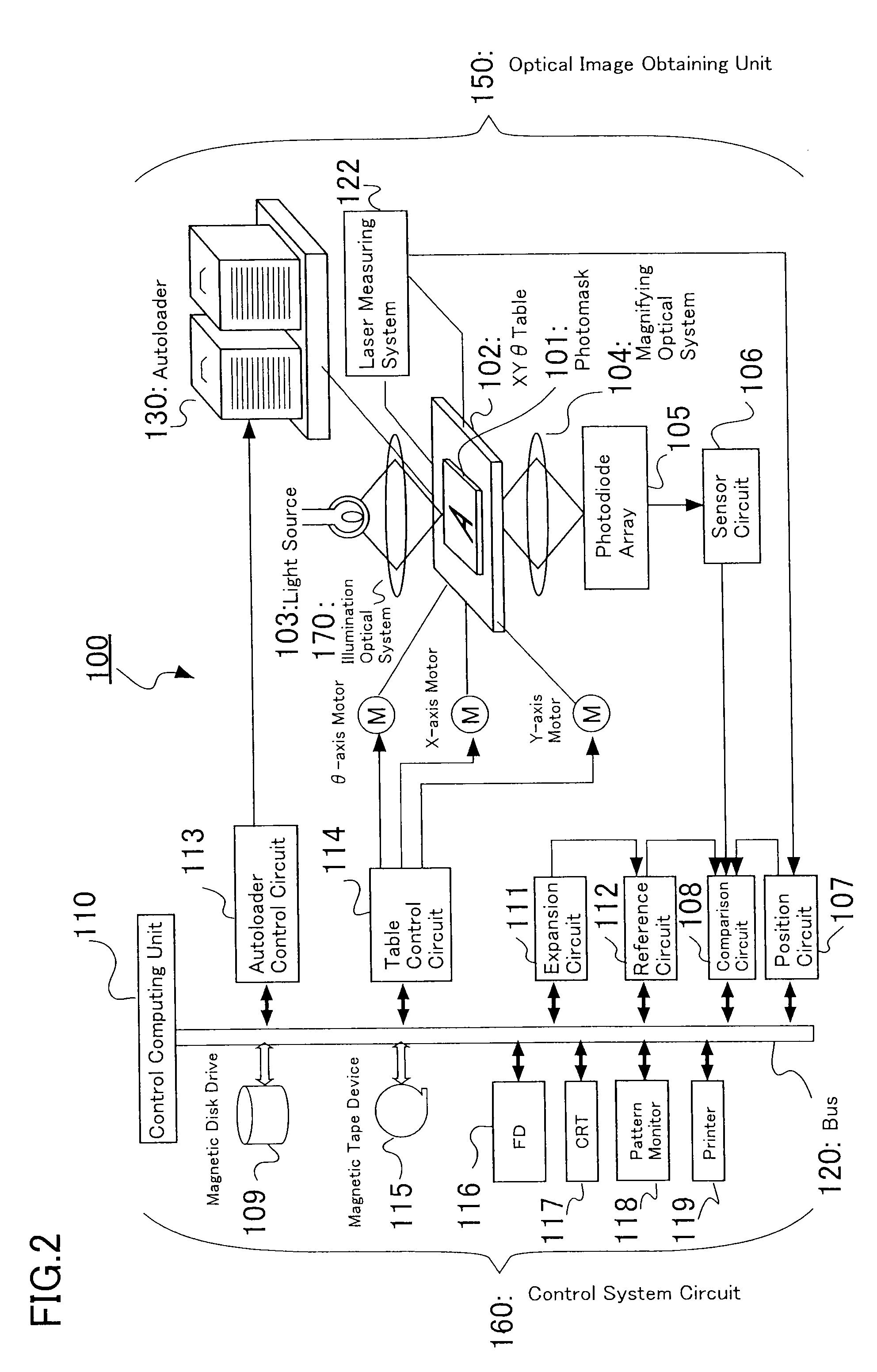

Pattern image correcting apparatus, pattern inspection apparatus, and pattern image correcting method

The present invention provides an apparatus and method for correcting an inspection reference pattern image in order to properly inspect a pattern image of a specimen. The pattern image correcting apparatus is characterized by including: a first pattern synthesizing unit for synthesizing an assist pattern image and a pattern image to be inspected, thereby generating a pattern image to be inspected with an assist pattern; an assist pattern shift processor; a second pattern synthesizing unit for synthesizing the shifted assist pattern image and the inspection reference pattern image, thereby generating an inspection reference pattern image with an assist pattern; a model generating unit for generating a position shift model by using the pattern image to be inspected with the assist pattern and the inspection reference pattern image with the assist pattern; and a correction pattern image computing unit for correcting the inspection reference pattern image.

Owner:KIOXIA CORP +1

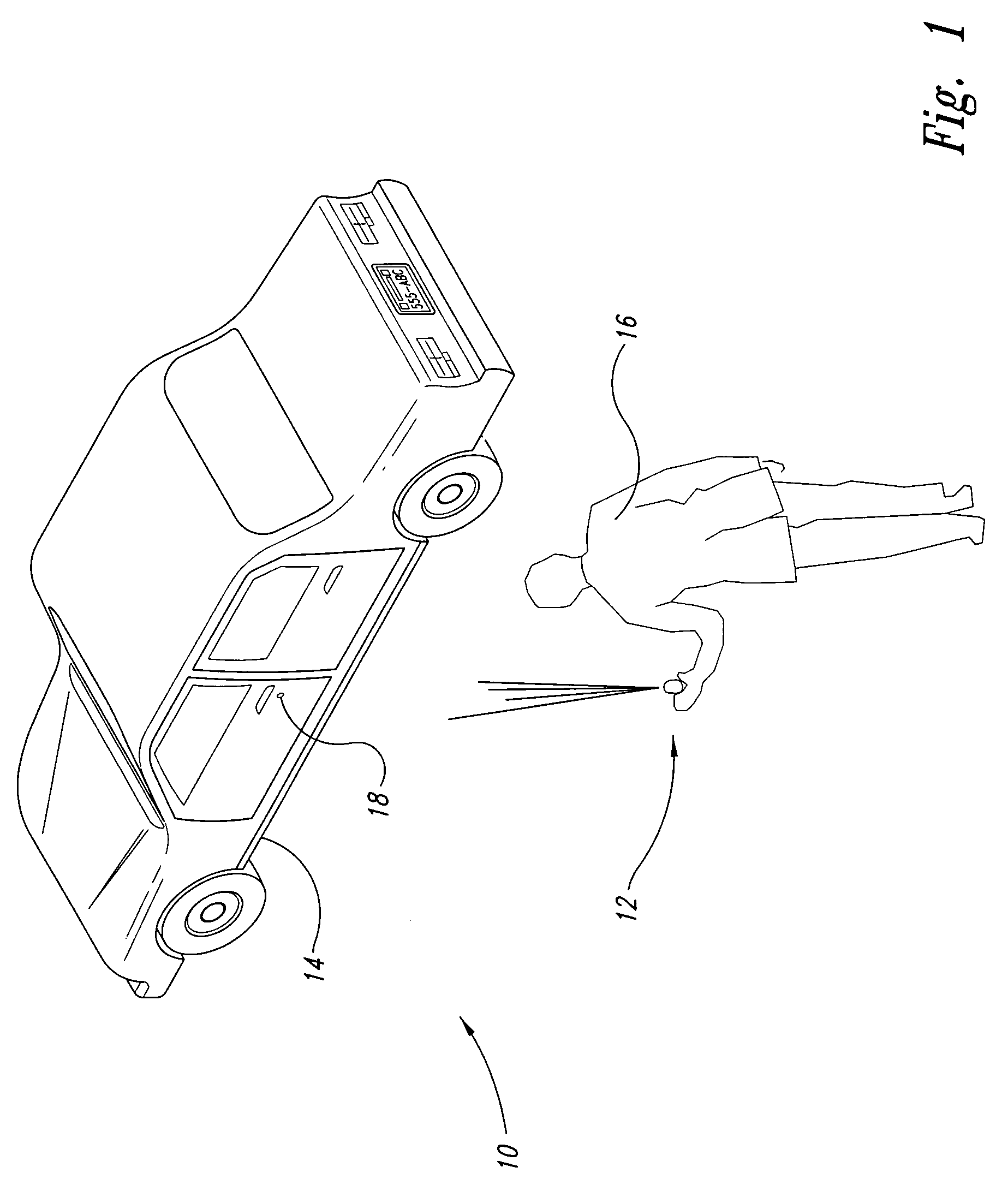

Command interface using fingerprint sensor input system

InactiveUS7239227B1Enhances and securityElectric signal transmission systemsDigital data processing detailsReference patternsFinger movement

A substrate having a fingerprint sensing system usable as a command interface using finger movements. A user's fingerprint pattern is recognized and compared to previously stored reference patterns. If the fingerprint pattern matches a previously stored pattern, the user is then permitted to enter certain commands via the same interface system. For example, in the case of an automobile, a user may identify themselves with their fingerprint, and then perform such functions as unlocking the doors, setting the seat to a selected location, or even pre-starting the car prior to their entering the automobile. The very same devices which perform the fingerprint identification and sensing are also used for the input sensing and command recognition to perform the various commands. A user is thus able to securely control desired functions in an automobile, while being assured that an unauthorized user will not have access to the automobile, even as they were able to obtain the command interface device.

Owner:APPLE INC

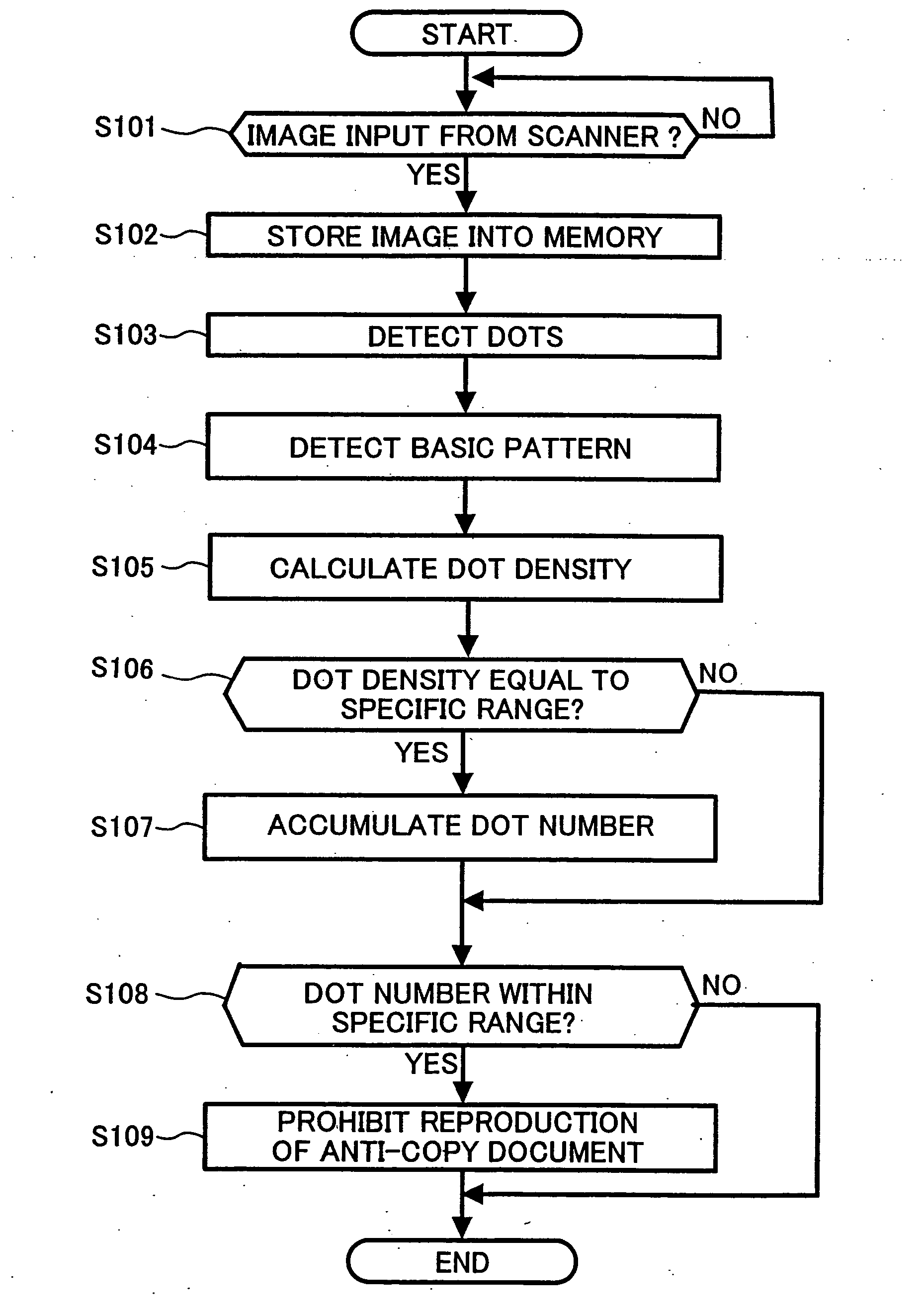

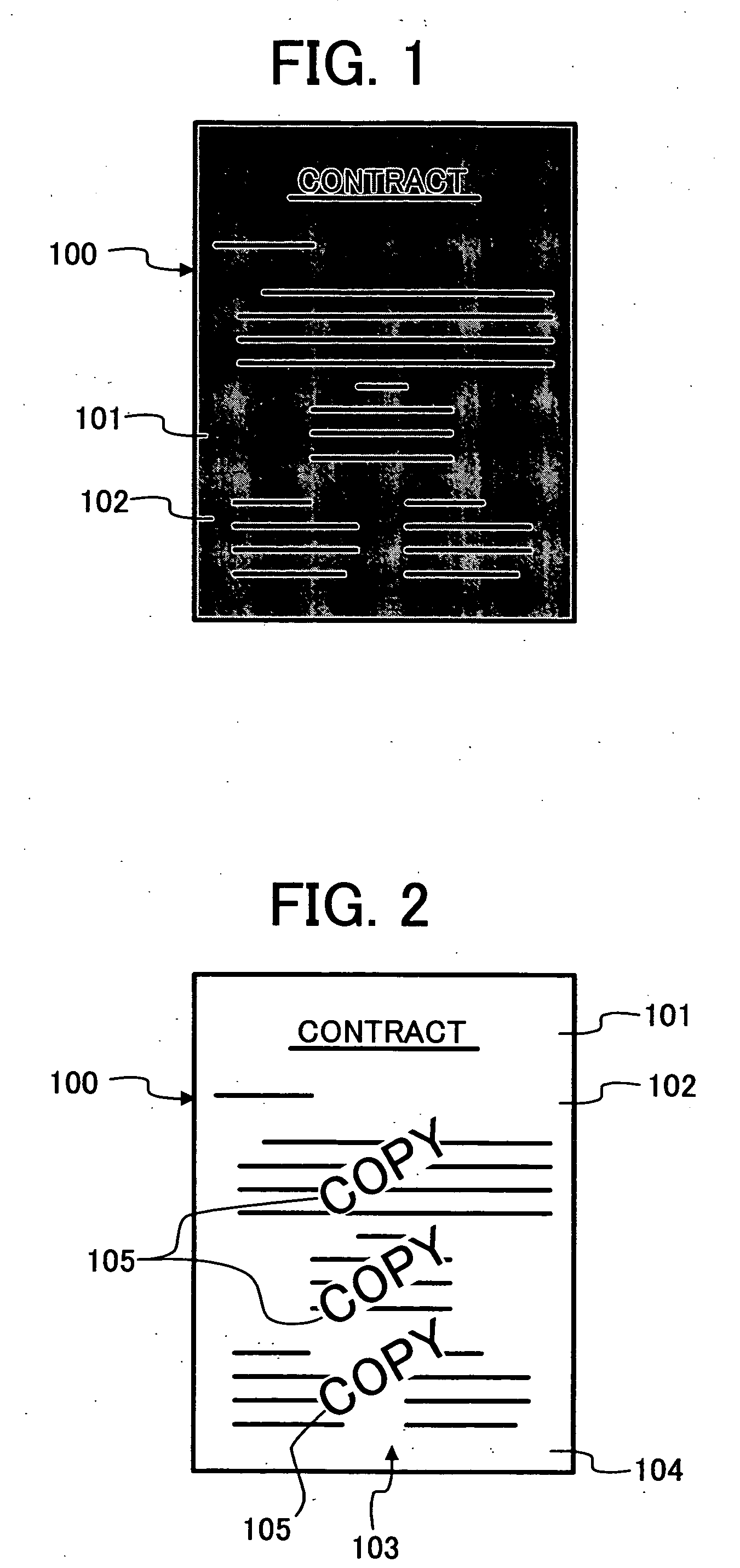

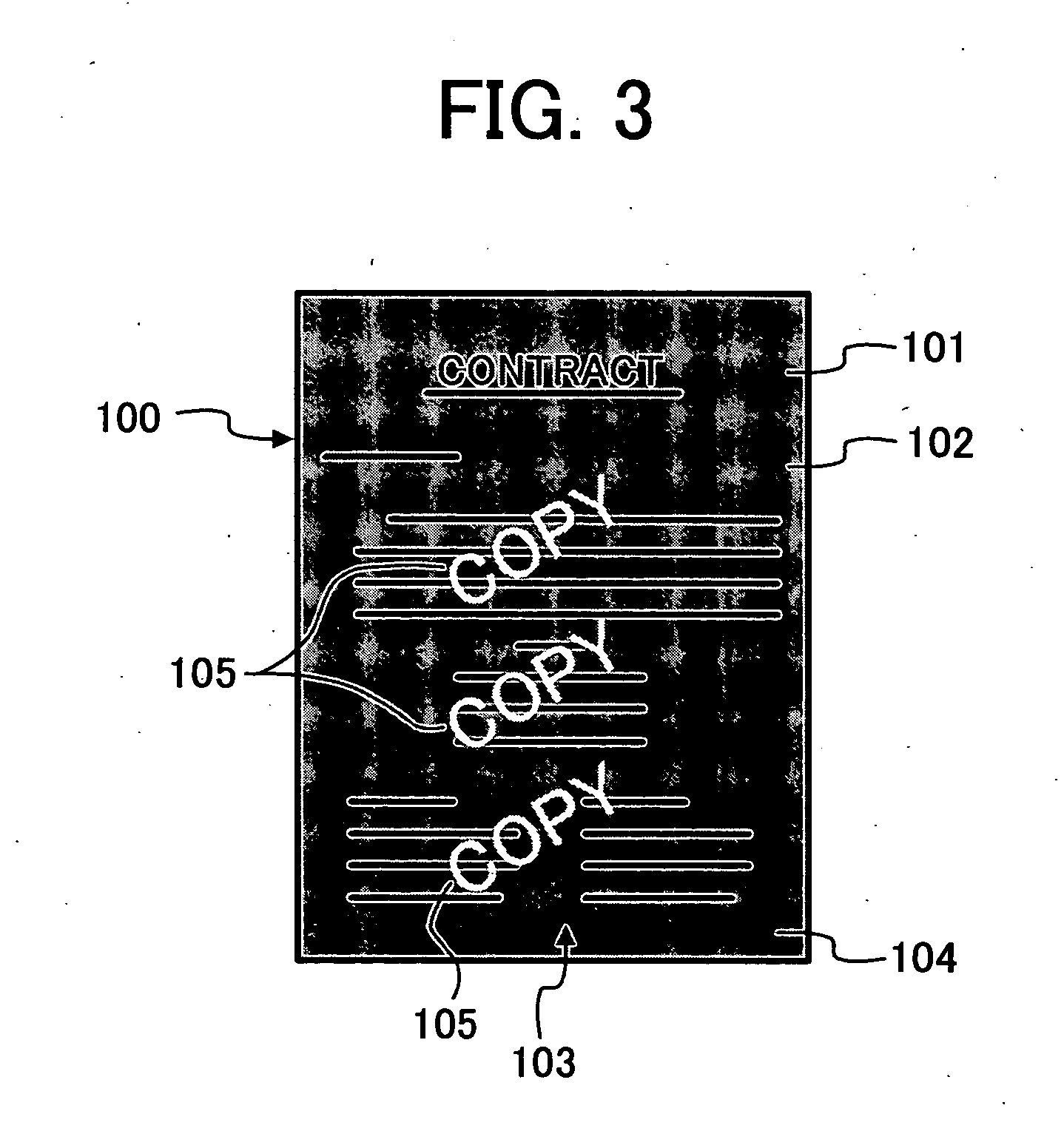

Method, program, and apparatus for prohibiting a reproduction of an anti-copy document, and a computer readable storing medium storing the program

InactiveUS20050041263A1Hardware monitoringCharacter and pattern recognitionImaging processingPaper document

An image processing apparatus includes a first memory, a data detector, a second memory, a third memory, and a determiner. The first memory stores a reference pattern including a plurality of reference basic units, each of which represents specific minimal information, is superposed on input image data, and represents specific entire information. The data detector detects a basic unit in the input image data based on the reference basic unit included in the reference pattern stored in the first memory. The second memory accumulates a number of basic units detected by the data detector. The third memory stores a predetermined value. The determiner determines whether the number of basic units detected by the data detector and stored in the second memory is equal to the predetermined value stored in the third memory.

Owner:RICOH KK

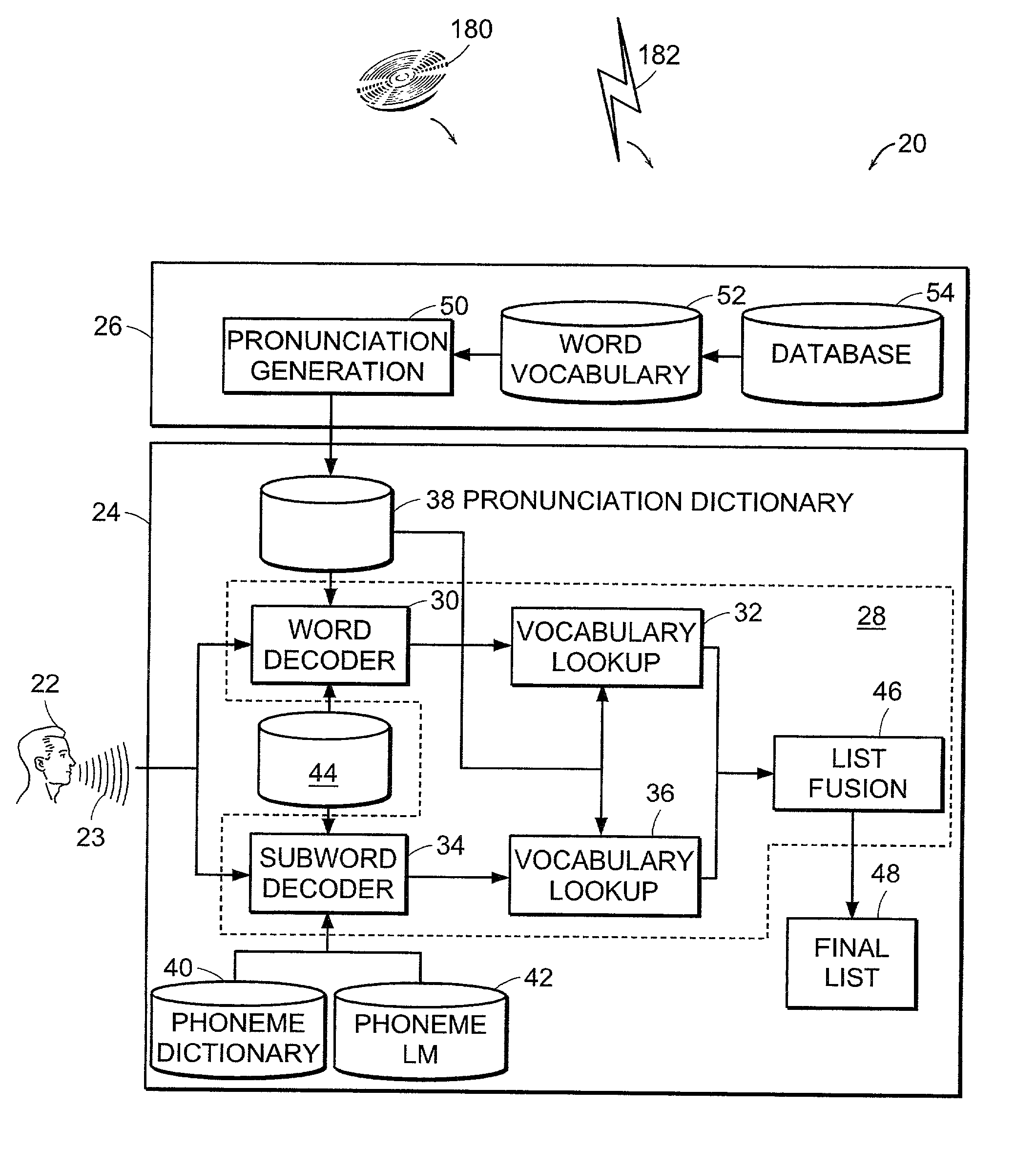

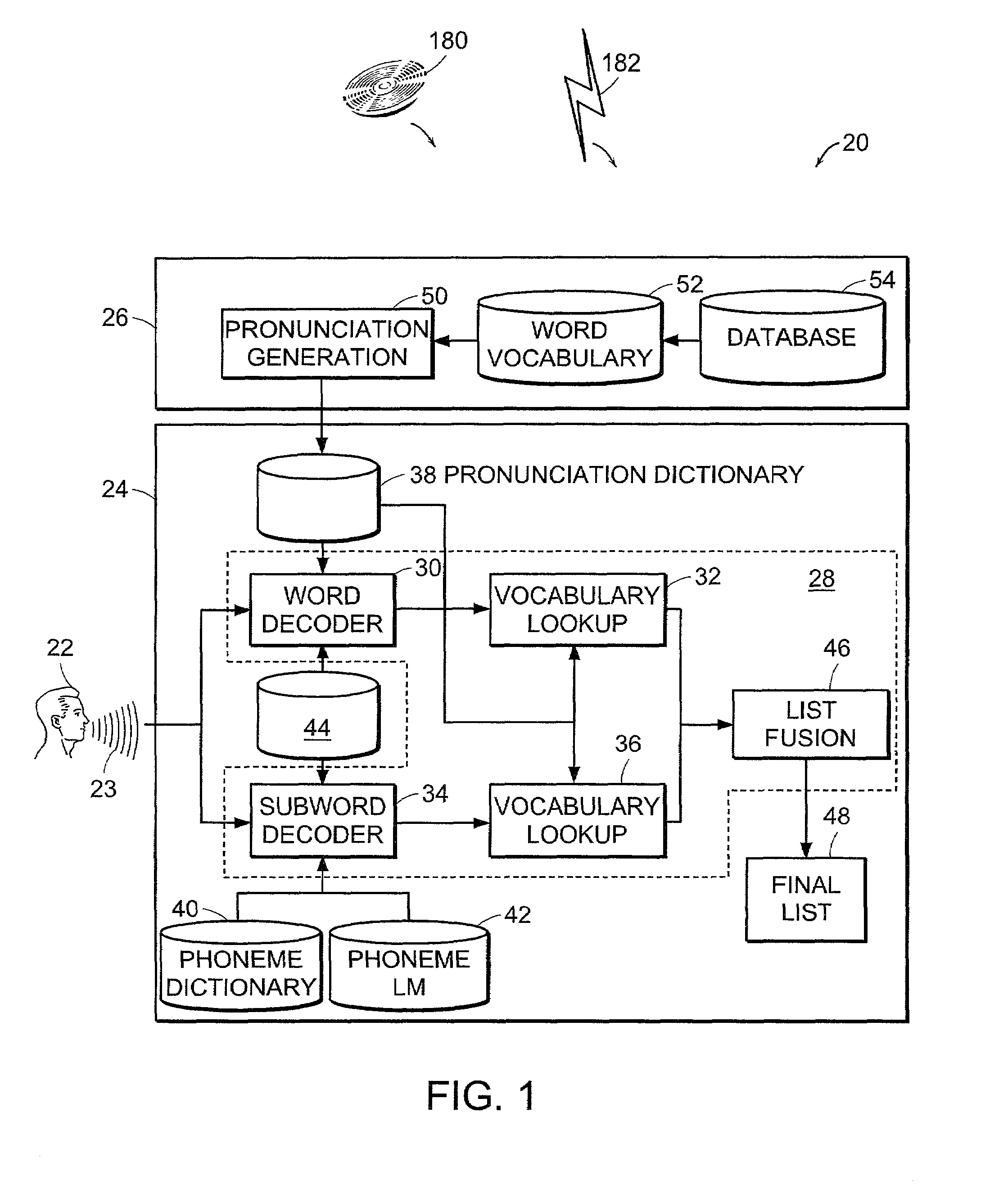

Systems and methods for combining subword recognition and whole word recognition of a spoken input

InactiveUS6985861B2Build accuratelyEfficient productionSpeech recognitionPhoneme recognitionSpoken language

A computer-based detection (e.g., speech recognition) system combines a word decoder and subword decoder to detect words (or phrases) in a spoken input provided by a user into a speaker connected to the detection system. The word decoder detects words by comparing an input pattern (e.g., of hypothetical word matches) to reference patterns (e.g., words). The subword decoder compares an input pattern (e.g., hypothetical words matches based on subword or phoneme recognition) to reference patterns (e.g., words) based on a word pronunciation distance measure that indicates how close each input pattern is to matching each reference pattern. The subword decoder sorts the source set of reference patterns based on a closeness of each reference pattern to correctly matching the input pattern based on generated pattern comparisons. The word decoder and subword decoder each provide an N-best list of hypothetical matches to the spoken input. A list fusion module of the detection system selectively combines the two N-best lists to produce a final or combined N-best list. The final or combined list has a predefined number of matches.

Owner:HEWLETT PACKARD DEV CO LP

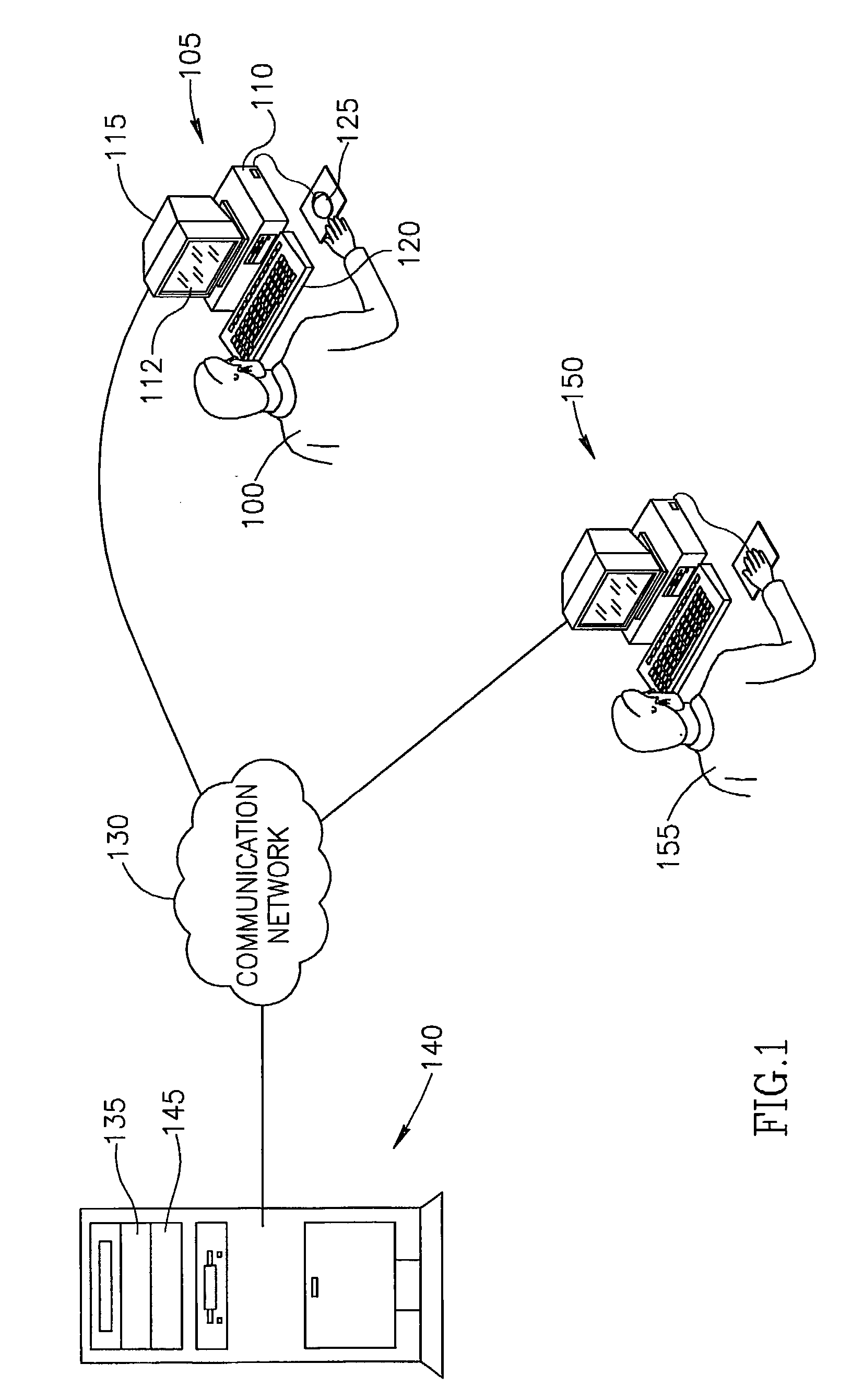

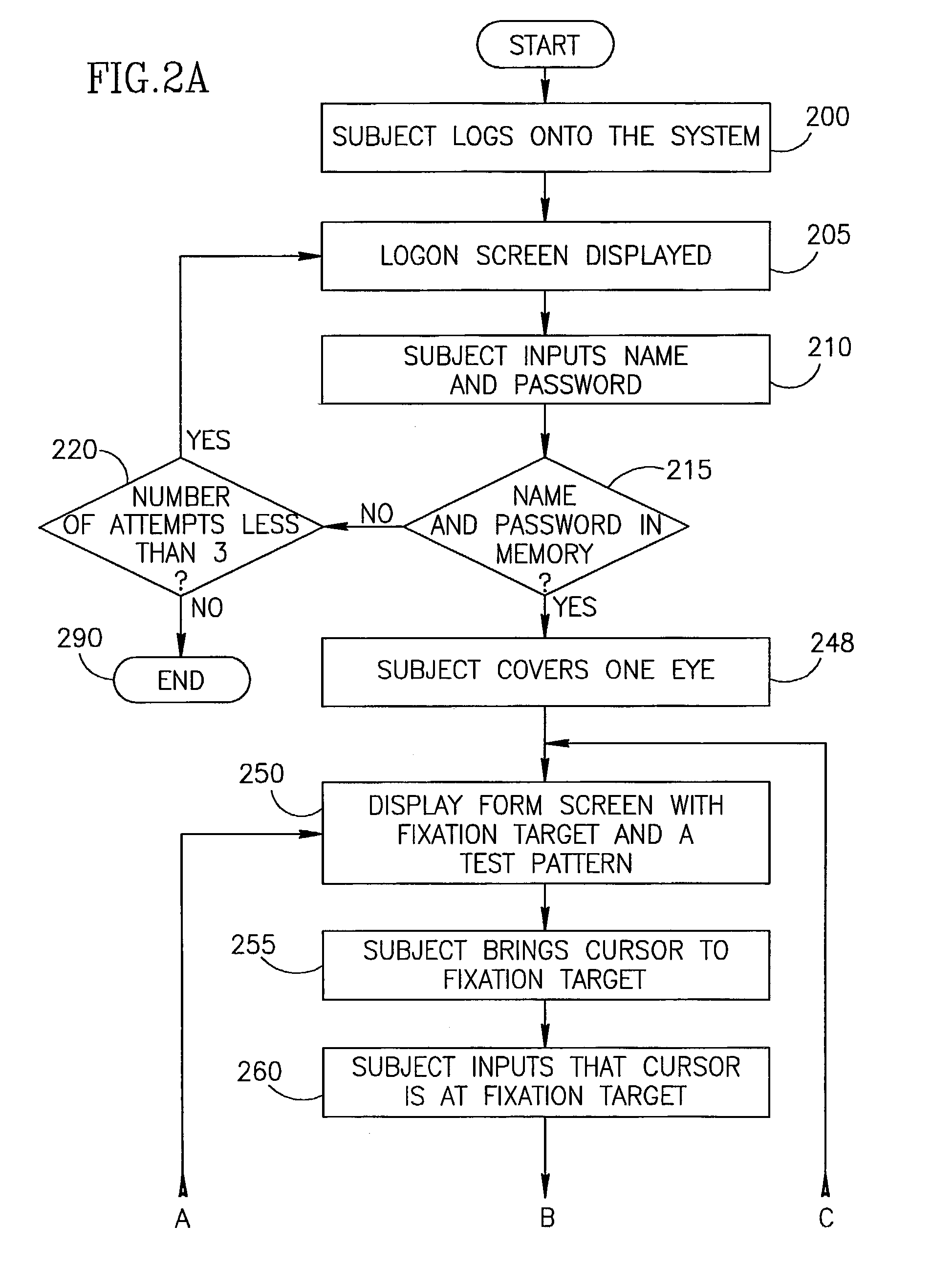

Methods, devices and systems for assessing eye disease

Methods and devices for detecting eye disease and for assessing the clinical stage of an eye disease in an individual. The methods include projecting test patterns onto the retina of a tested eye and subjecting the individual to a competing sensory stimuli. The competing stimuli may be of various different sensory modalities including visual, auditory, or other sensory modalities. If the individual perceives a difference in at least one localized part of the perceived image of a test pattern as compared to a predefined reference pattern, the individual provides a response indicative of the difference or differences. The responses are processed to assess the severity of eye disease if a disease is detected, or to determine the clinical stage of a detected eye disease.

Owner:NOTAL VISION

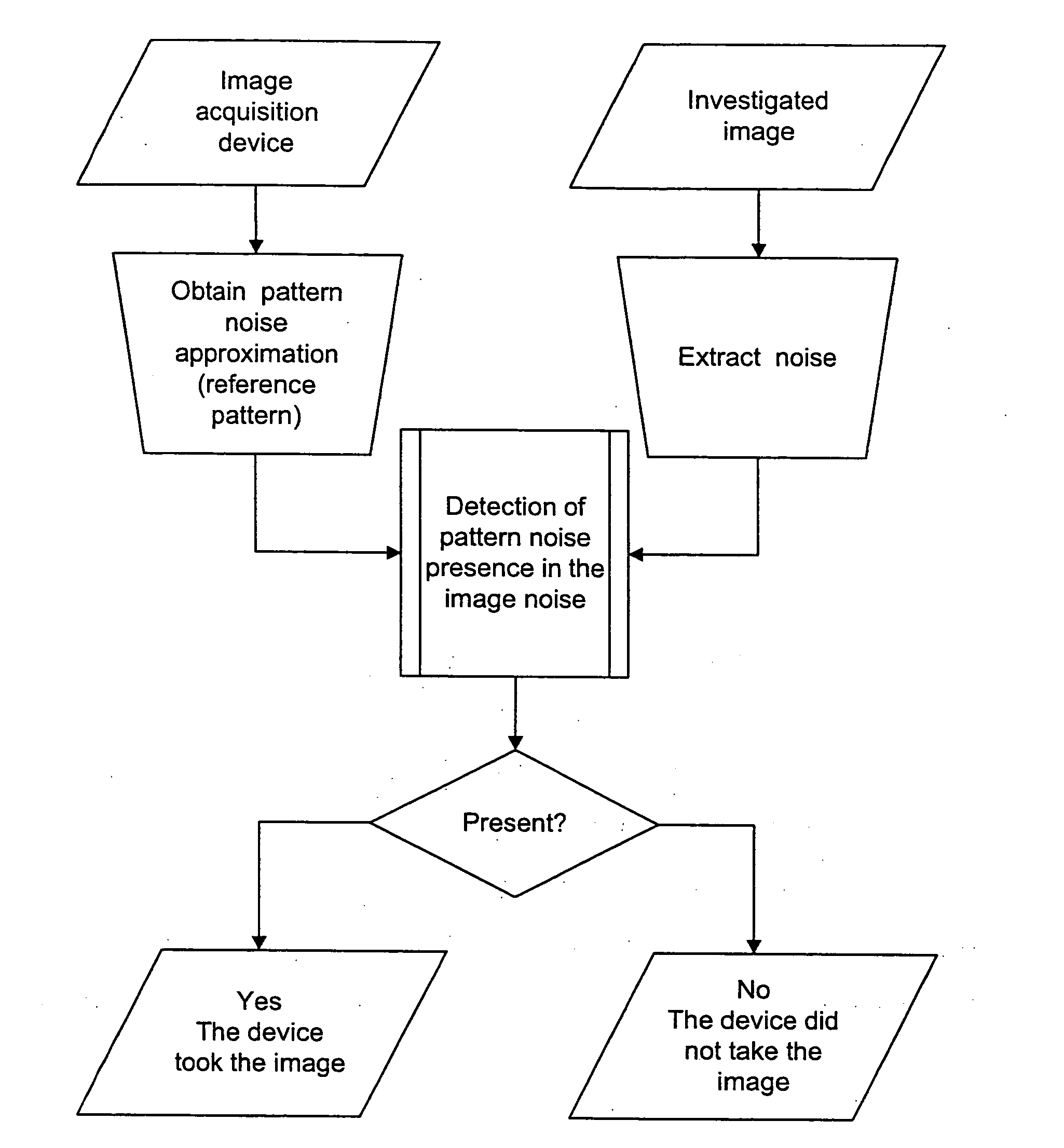

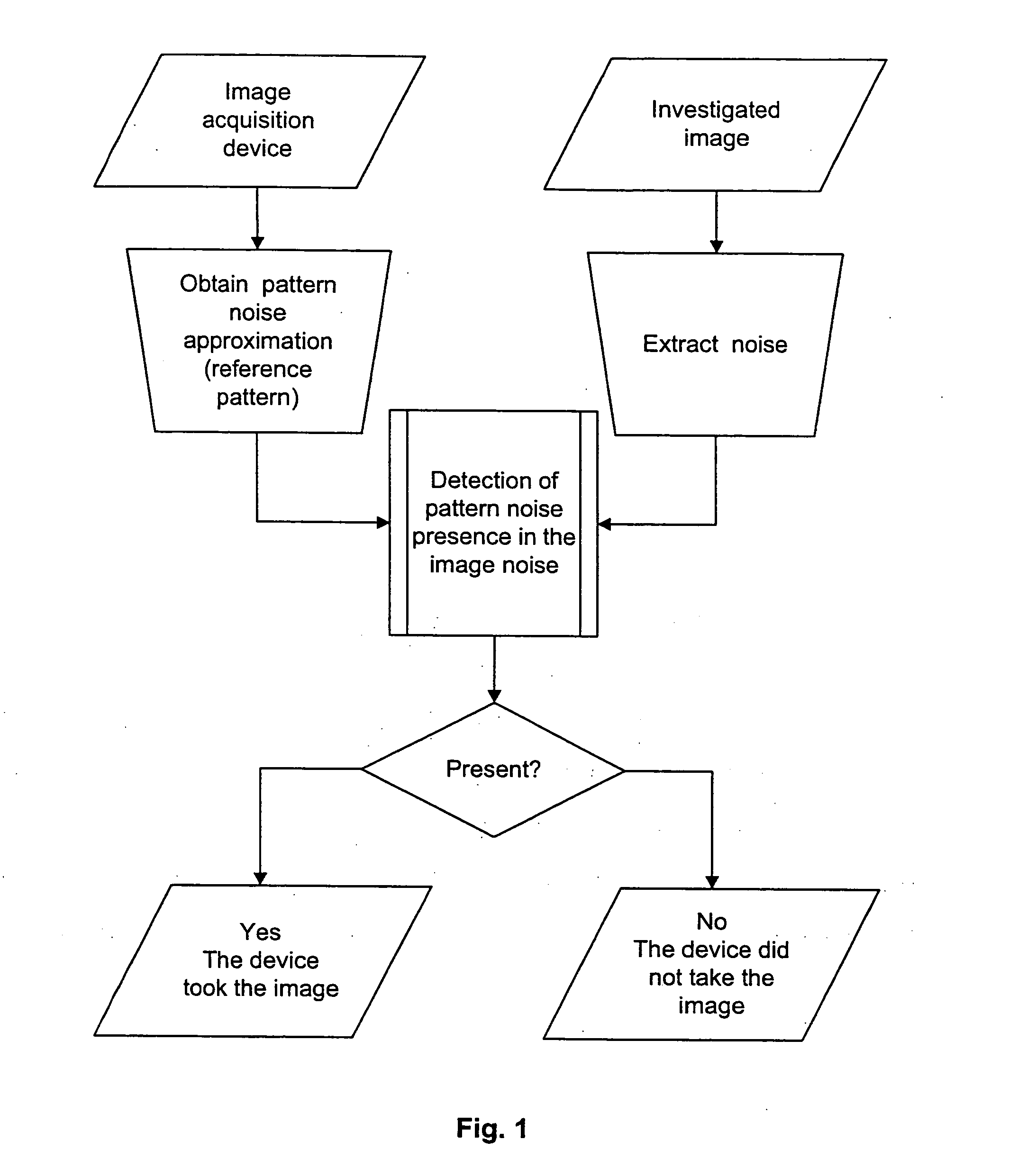

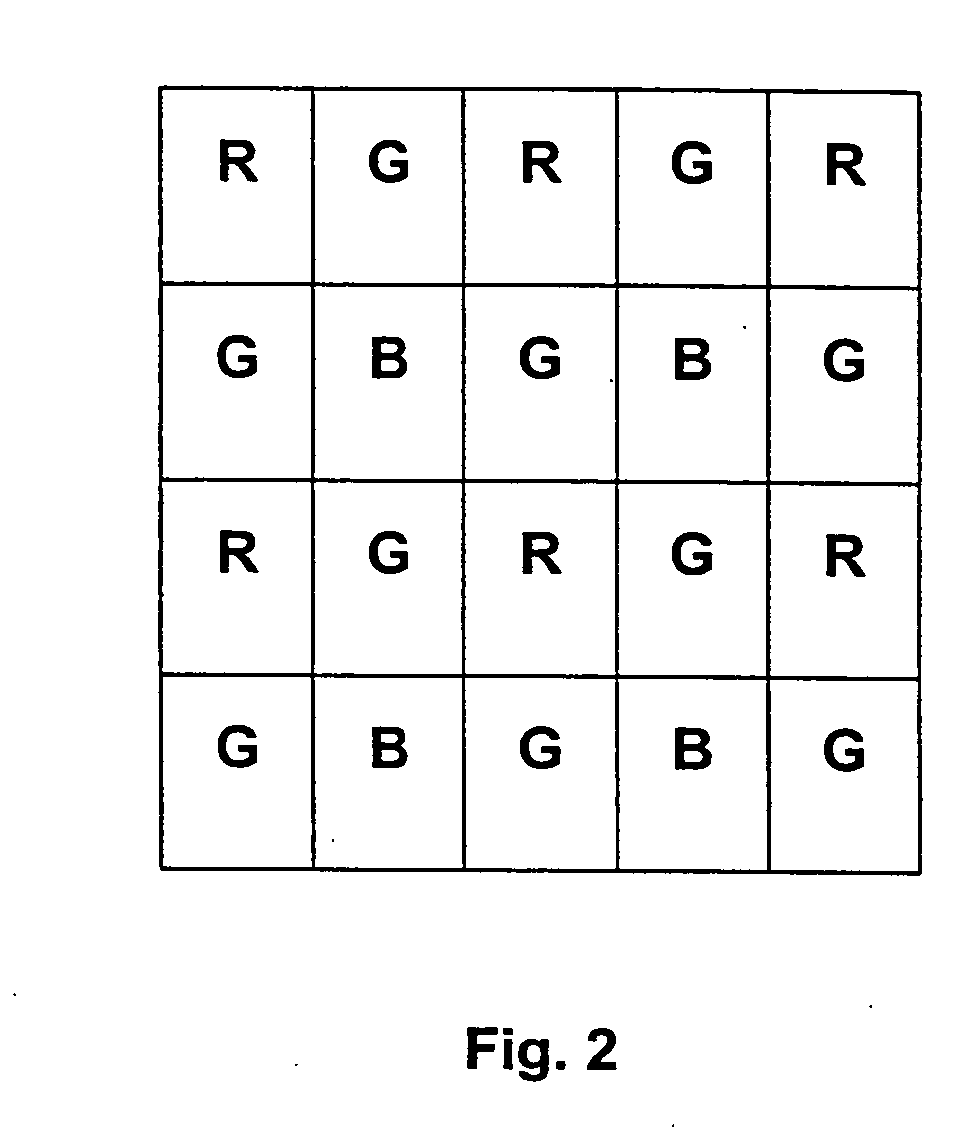

Method and apparatus for identifying an imaging device

InactiveUS20090257671A1Reliable matchReliable identificationTelevision system detailsCharacter and pattern recognitionCMOSPattern recognition

A new technique for identifying from images a camera, or other imaging device such as a scanner, is based on the device's reference noise pattern, a unique stochastic characteristic of all common digital imaging sensors, including CCD, CMOS (Foveon™ X3), and JFET. First, one determines from images the sensor's reference pattern noise, which uniquely identifies each sensor. To identify the sensor from a given image, the presence or absence of the reference pattern noise in the image under examination is established using a correlation detector or other means.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

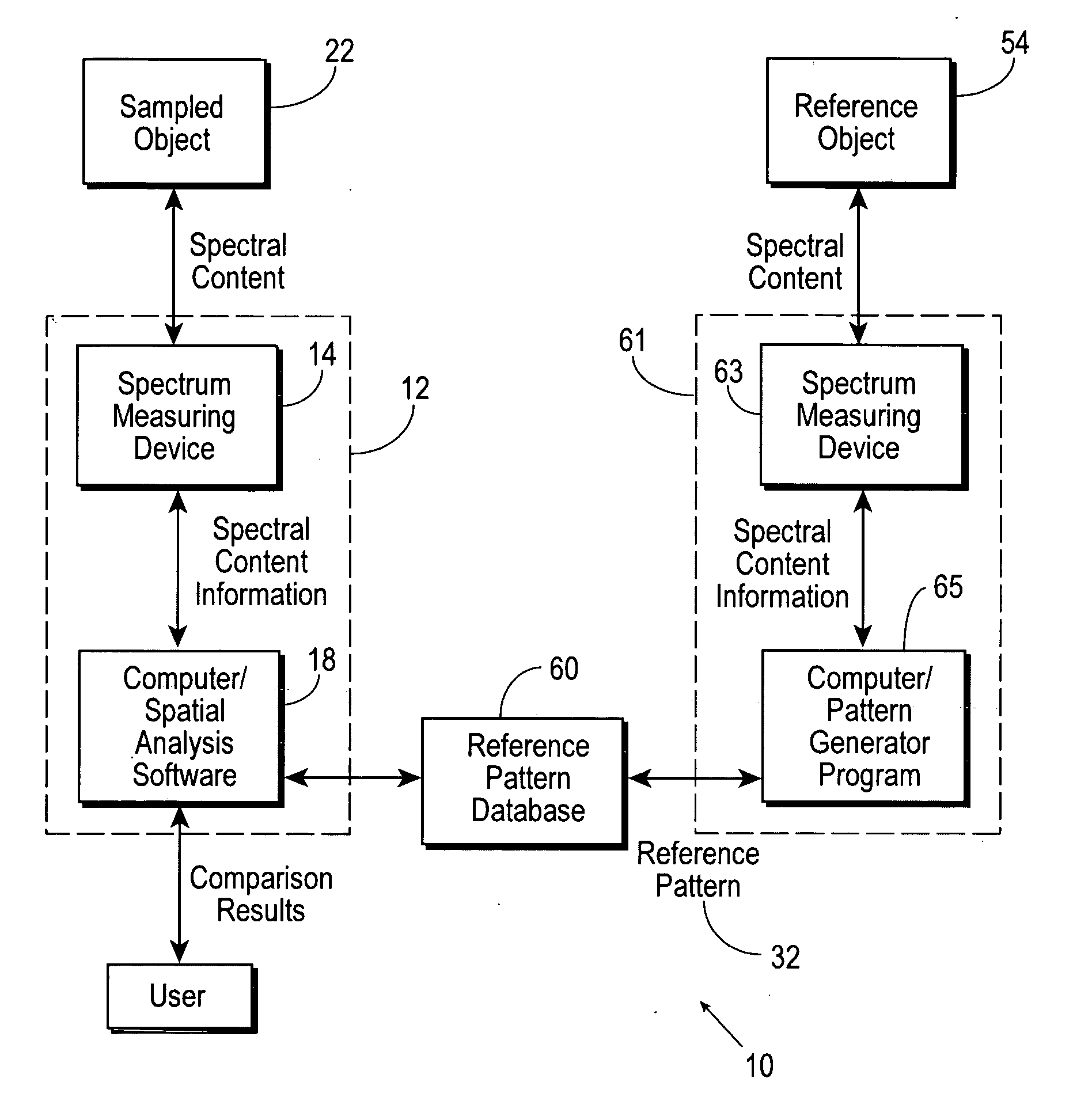

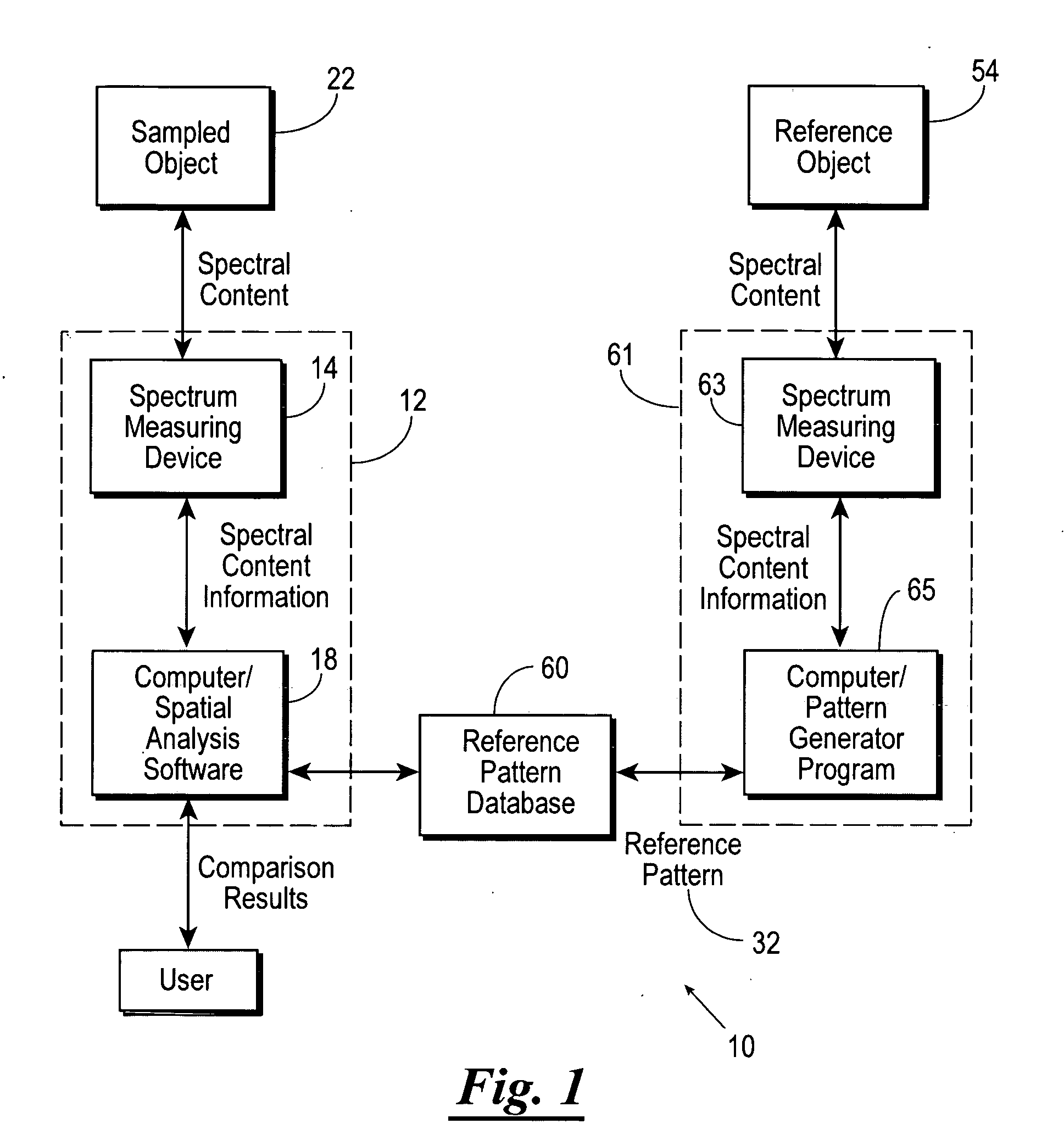

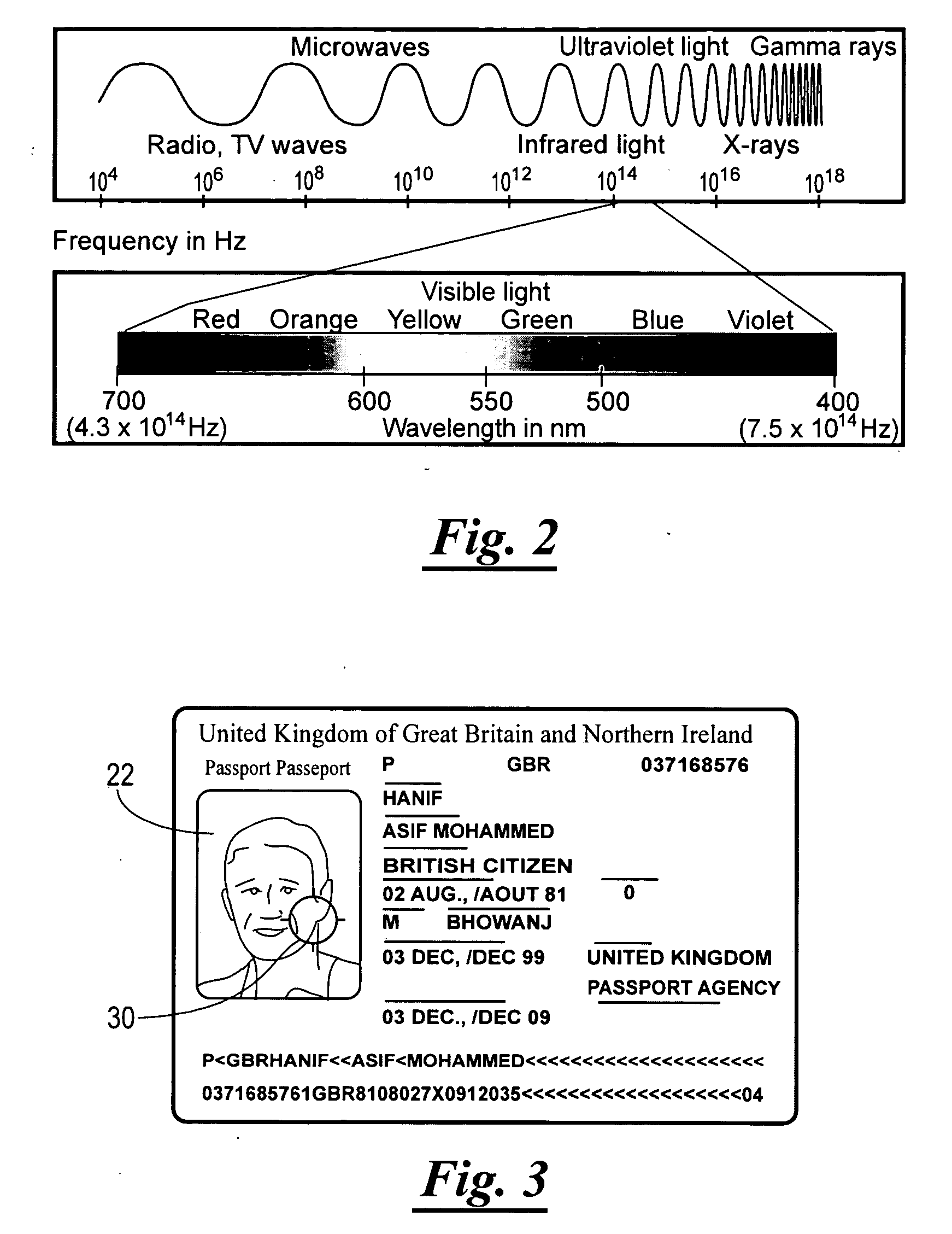

Full color spectrum object authentication methods and systems

InactiveUS20060161788A1Paper-money testing devicesCharacter and pattern recognitionPattern recognitionFrequency spectrum

A system for authenticating sampled objects including a database, a plurality of spectrum measuring devices, and a plurality of computers. The database stores a plurality of reference patterns measured from known reference objects. Each of the spectrum measuring devices measures a region of respective sampled objects so as to produce spectral content information identifying the sampled objects. The spectral content information includes information indicative of colors inside the visible spectrum of the human eye. The computers have access to spatial analysis software. The computer receives the spectral content information identifying the sampled object and provides the spectral content information to the spatial analysis software to generate a unique measured pattern. The spatial analysis software compares the unique measured pattern with the reference patterns stored in the database, and outputs signals indicative of matches between the unique measured pattern with the reference pattern within a tolerance level whereby the colors of the regions of the sampled objects are utilized to authenticate the sampled objects.

Owner:VISUALANT

Apparatus for the assisted performance of a fitness exercise

ActiveUS8911328B2Good effectReduce riskPhysical therapies and activitiesClubsReference patternsEngineering

An apparatus (1) for the assisted performance of a fitness exercise, equipped with a fitness tool (2) configured to interact with the user (3) to enable the user to perform a movement along a preset path overcoming the force of a resistant load (7), comprises: sensing means (4) set up to provide a signal representing the movement of the user (3); feedback means (5) for transmitting a signal to the user (3) during performance of the exercise; a processor (6) connected to the sensing means (4) and to the feedback means (5) to provide the user (3) with feedback in real time on the correctness of performance of the exercise, based on a comparison between the signal representing the movement of the user and a predetermined reference pattern representing an ideal pattern for the movement of the user (3) corresponding to the exercise performed correctly.

Owner:TECHNOGYM SPA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com