Patents

Literature

11401 results about "Lower limit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lower limit refers to the smallest value in a class. Lower limit is also called as infimum limit, liminf, inferior limit or inner limit.

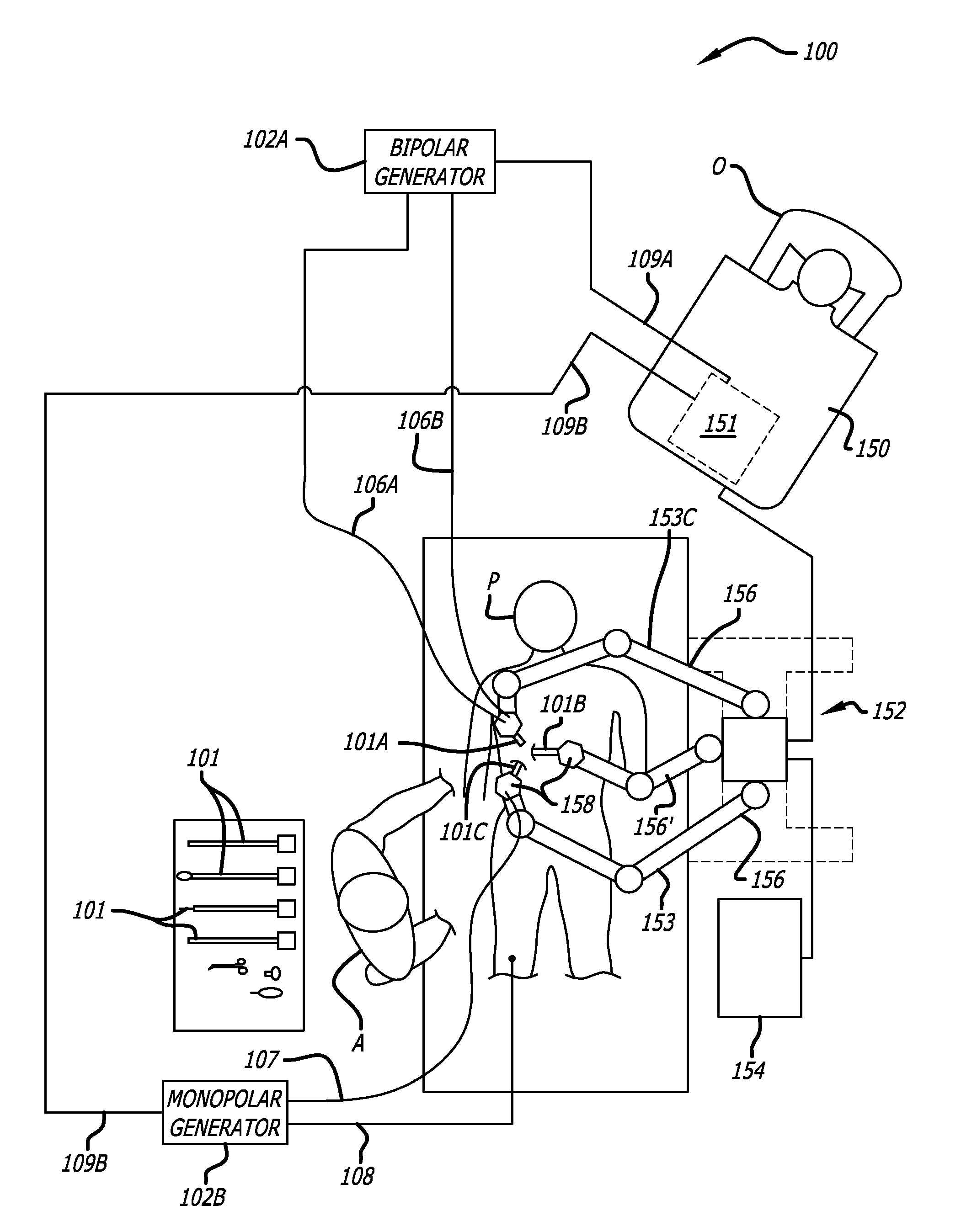

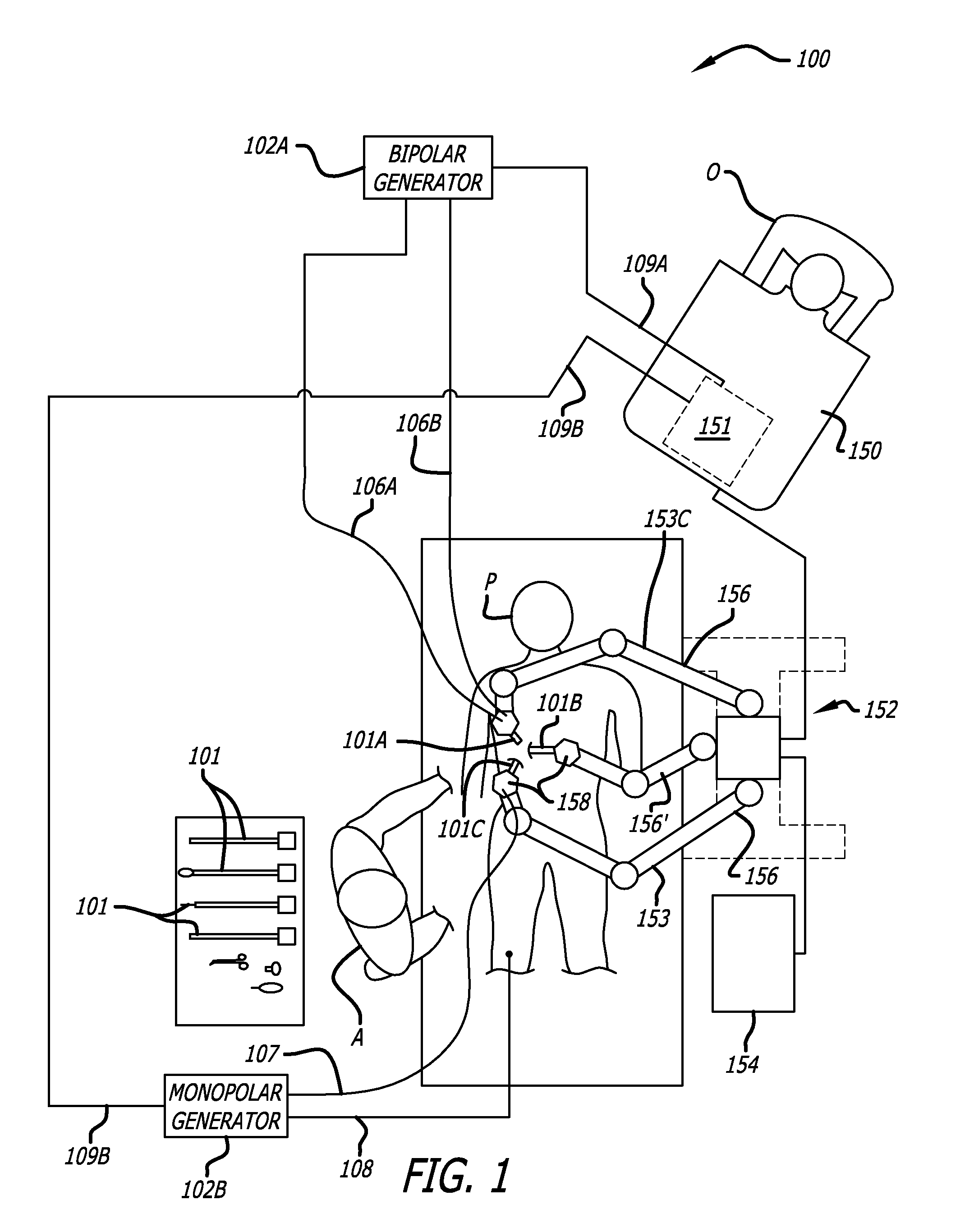

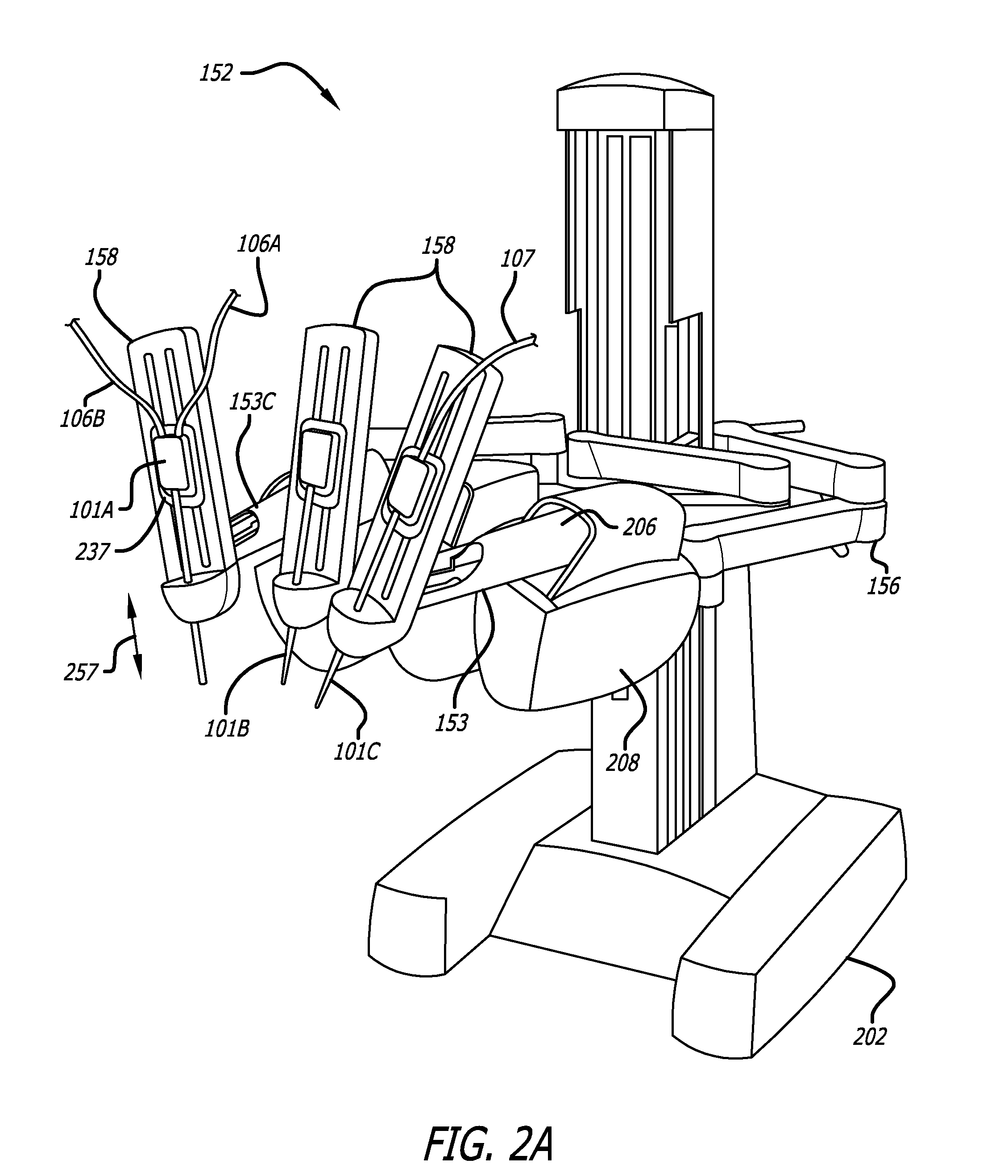

Maximum torque driving of robotic surgical tools in robotic surgical systems

ActiveUS20080046122A1Improve the level ofProgramme-controlled manipulatorMechanical/radiation/invasive therapiesLower limitMaximum torque

In one embodiment of the invention, a control system for a robotic surgical instrument is provided including a torque saturation limiter, a torque to current converter coupled to the torque saturation limiter, and a motor coupled to the torque to current converter. The torque saturation limiter receives a desired torque signal for one or more end effectors and limits the desired torque to a range between an upper torque limit and a lower torque limit generating a bounded torque signal. The torque to current converter transforms a torque signal into a current signal. The motor drives an end effector of one or more end effectors to the bounded torque signal in response to the first current signal.

Owner:INTUITIVE SURGICAL OPERATIONS INC

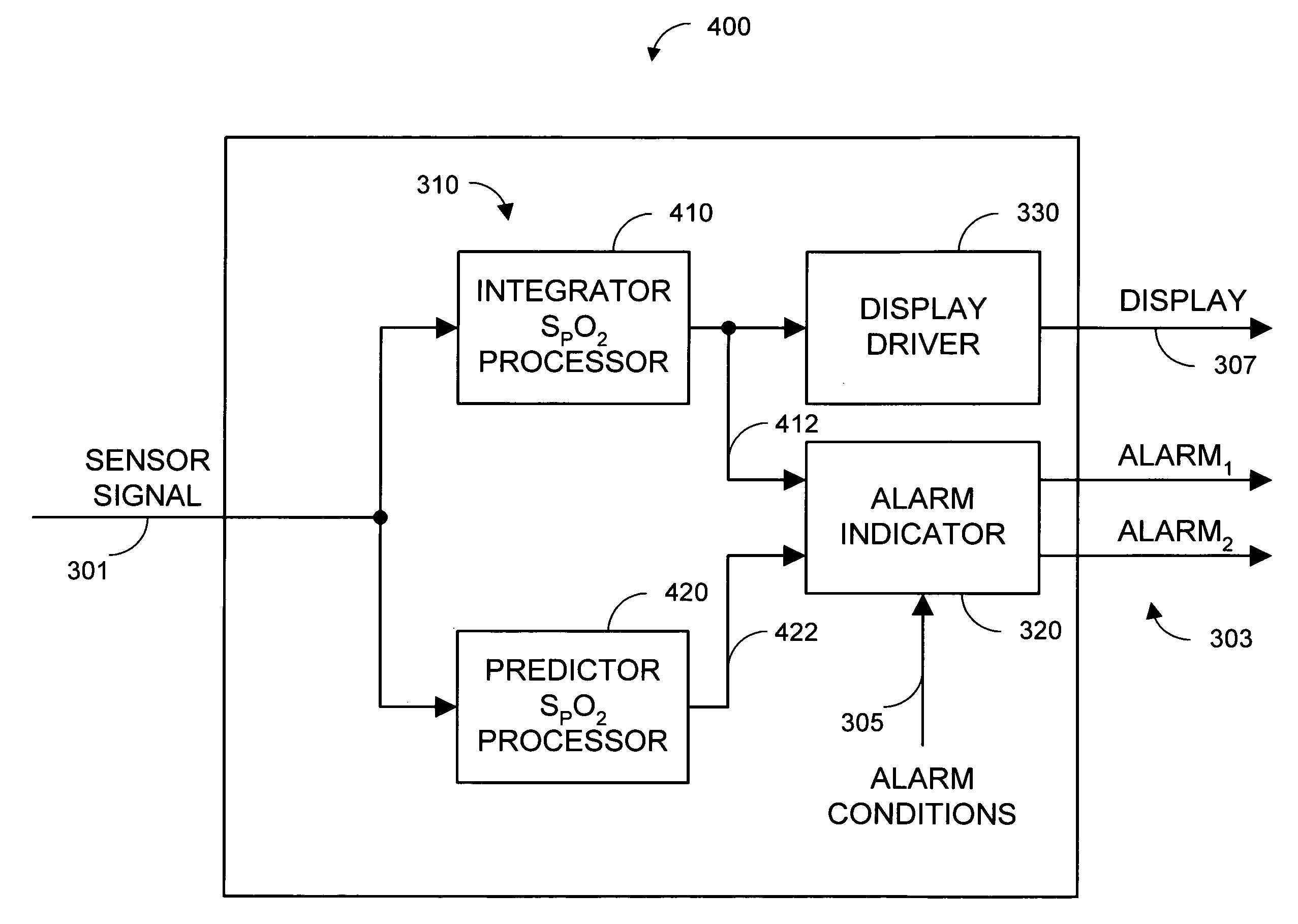

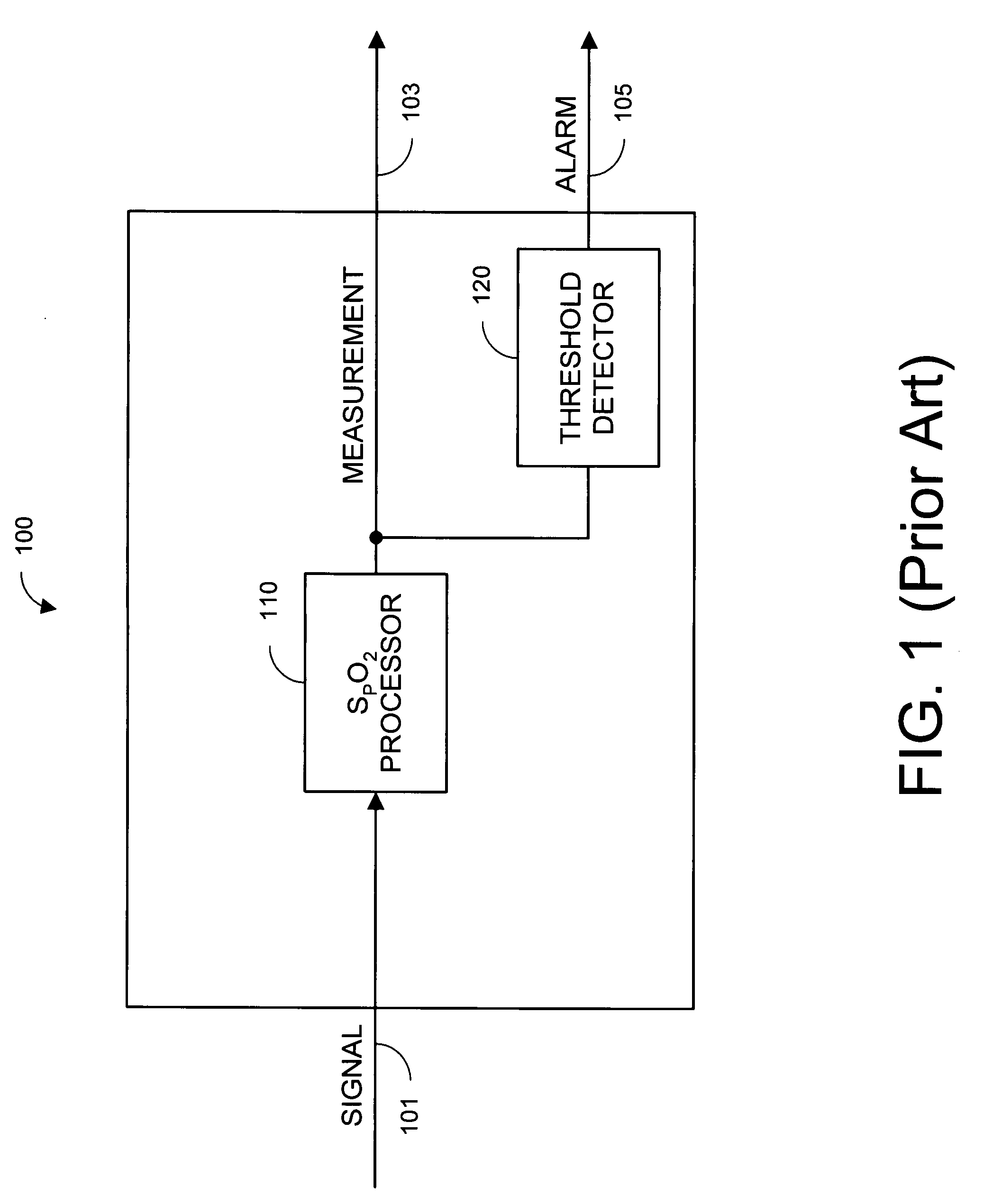

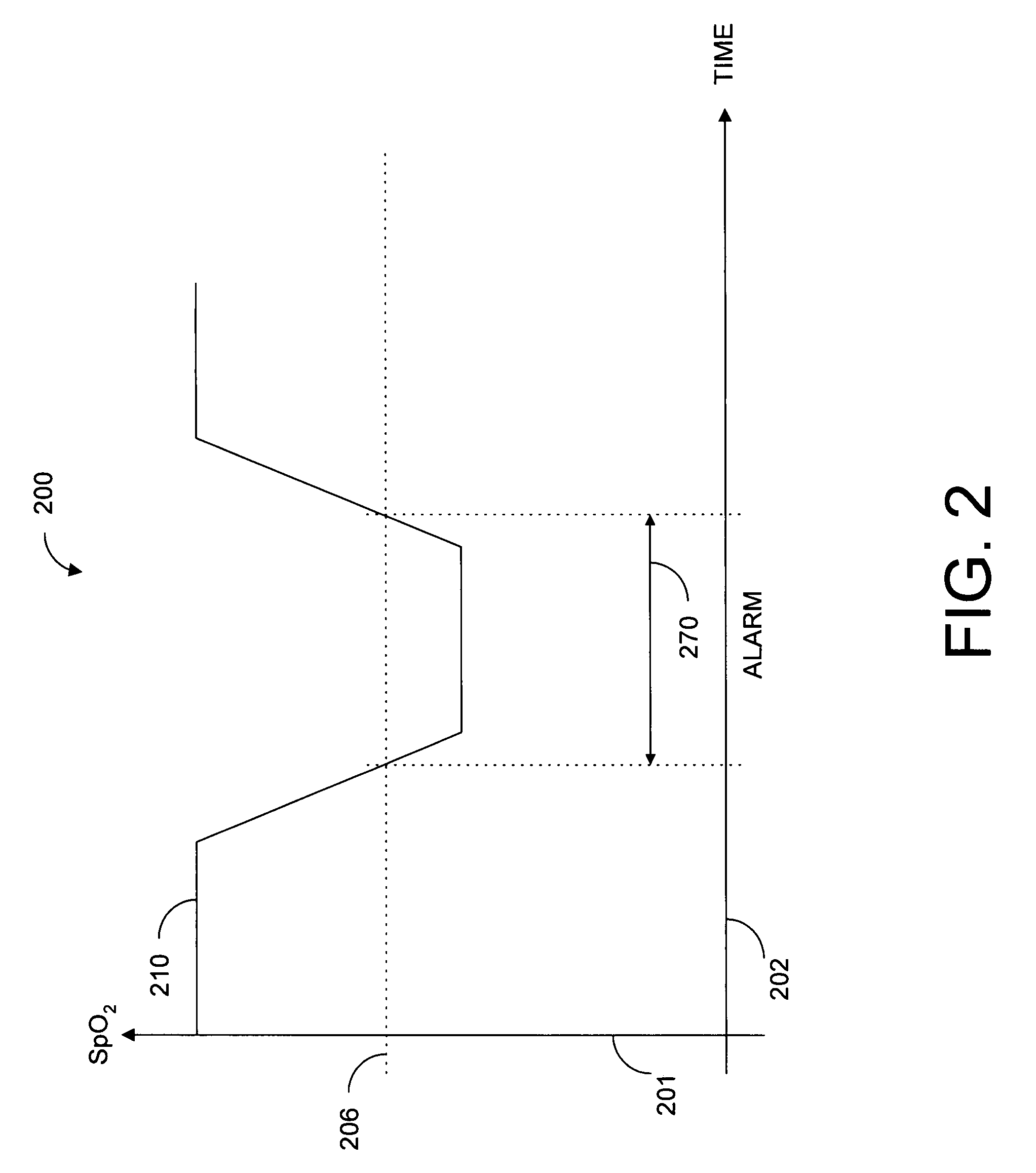

Parallel alarm processor

InactiveUS7355512B1Waste caregiver resourcesReduce false alarm rateEvaluation of blood vesselsSensorsLower limitOxygen Saturation Measurement

A parallel alarm processor has a threshold detector, a pattern extractor, a predetermined reference pattern, a first alarm and a second alarm. The threshold detector has a first output responsive to relatively long duration oxygen desaturations. The pattern extractor has a second output responsive to relatively short duration oxygen desaturations. The predetermined reference pattern is indicative of a series of intermittent oxygen desaturations. A first alarm is triggered when the first output crosses a lower limit threshold. A second alarm is triggered when the second output matches the predetermined reference pattern. In an embodiment, an integrator inputs smoothed oxygen saturation measurements to the threshold detector, and a predictor inputs predictive oxygen saturation measurements to the pattern extractor.

Owner:JPMORGAN CHASE BANK NA

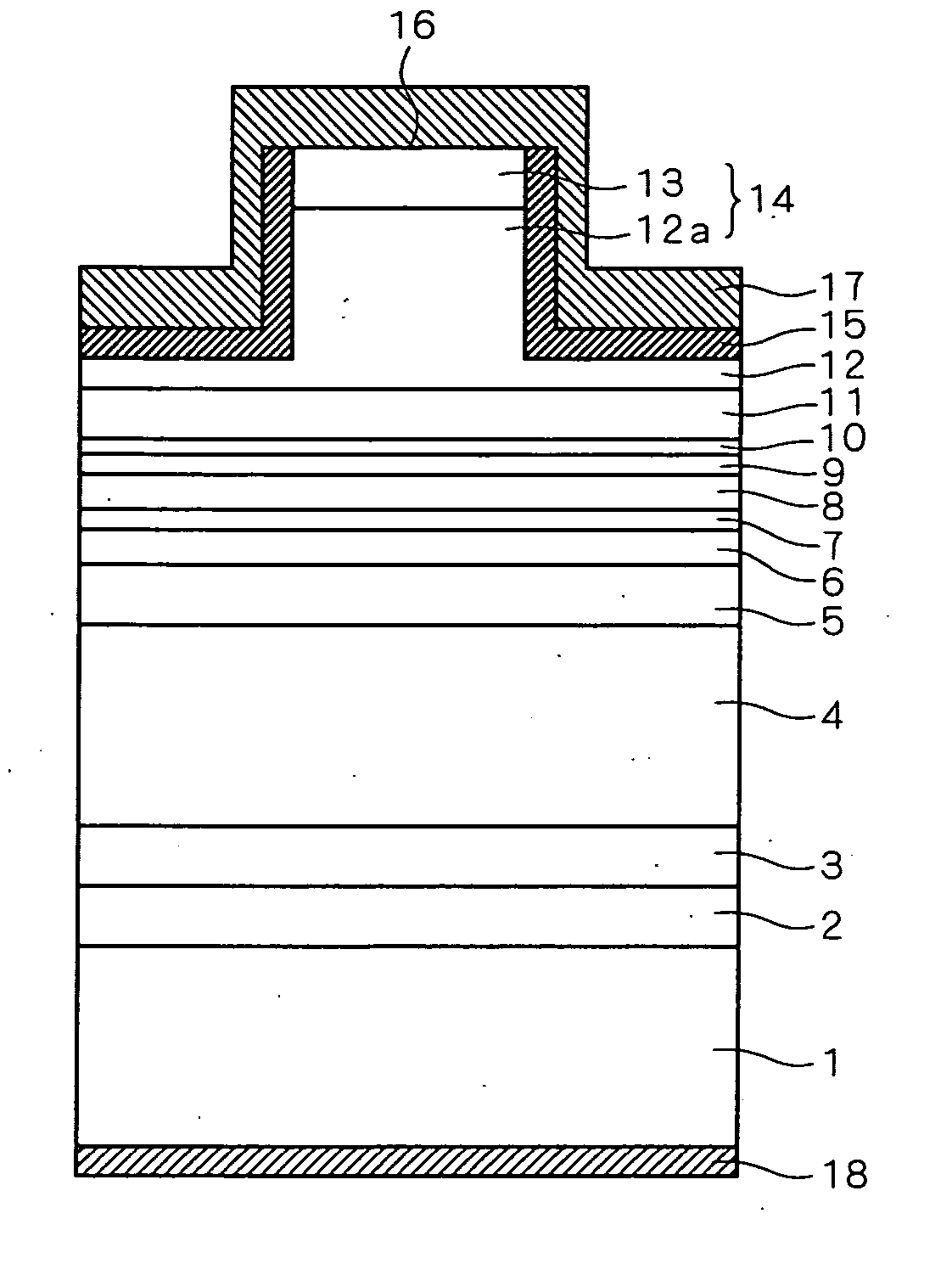

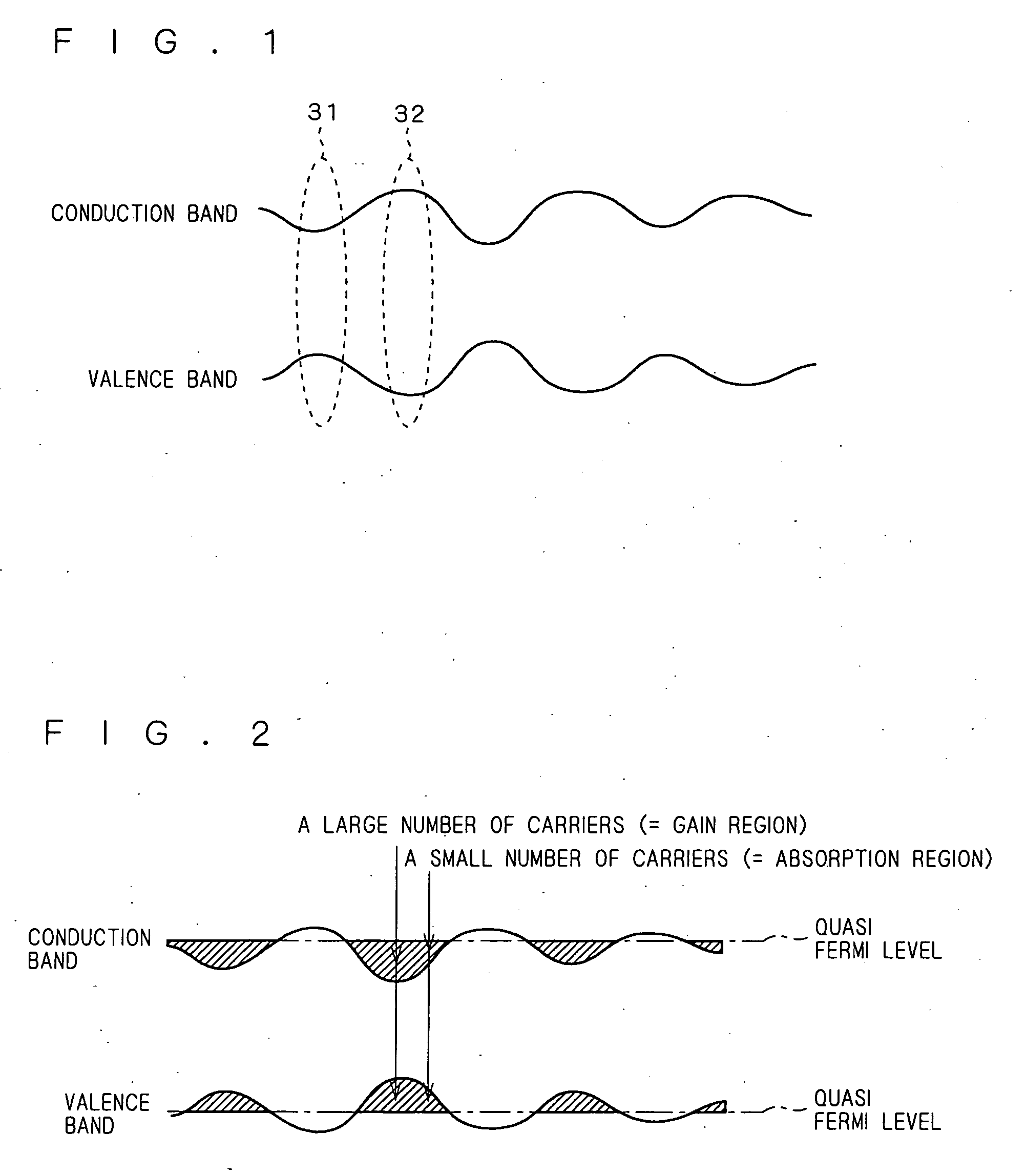

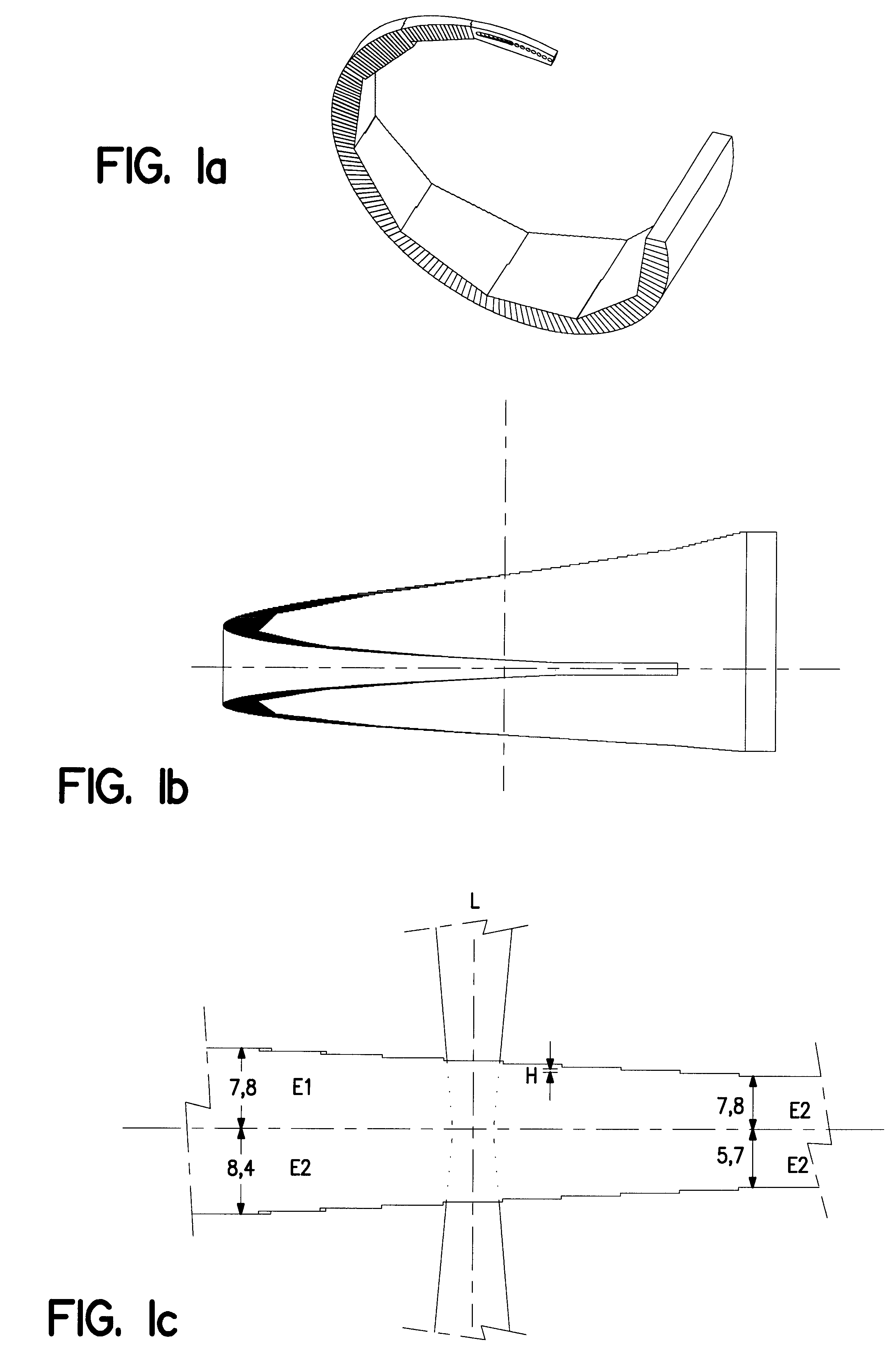

Semiconductor light-emitting device

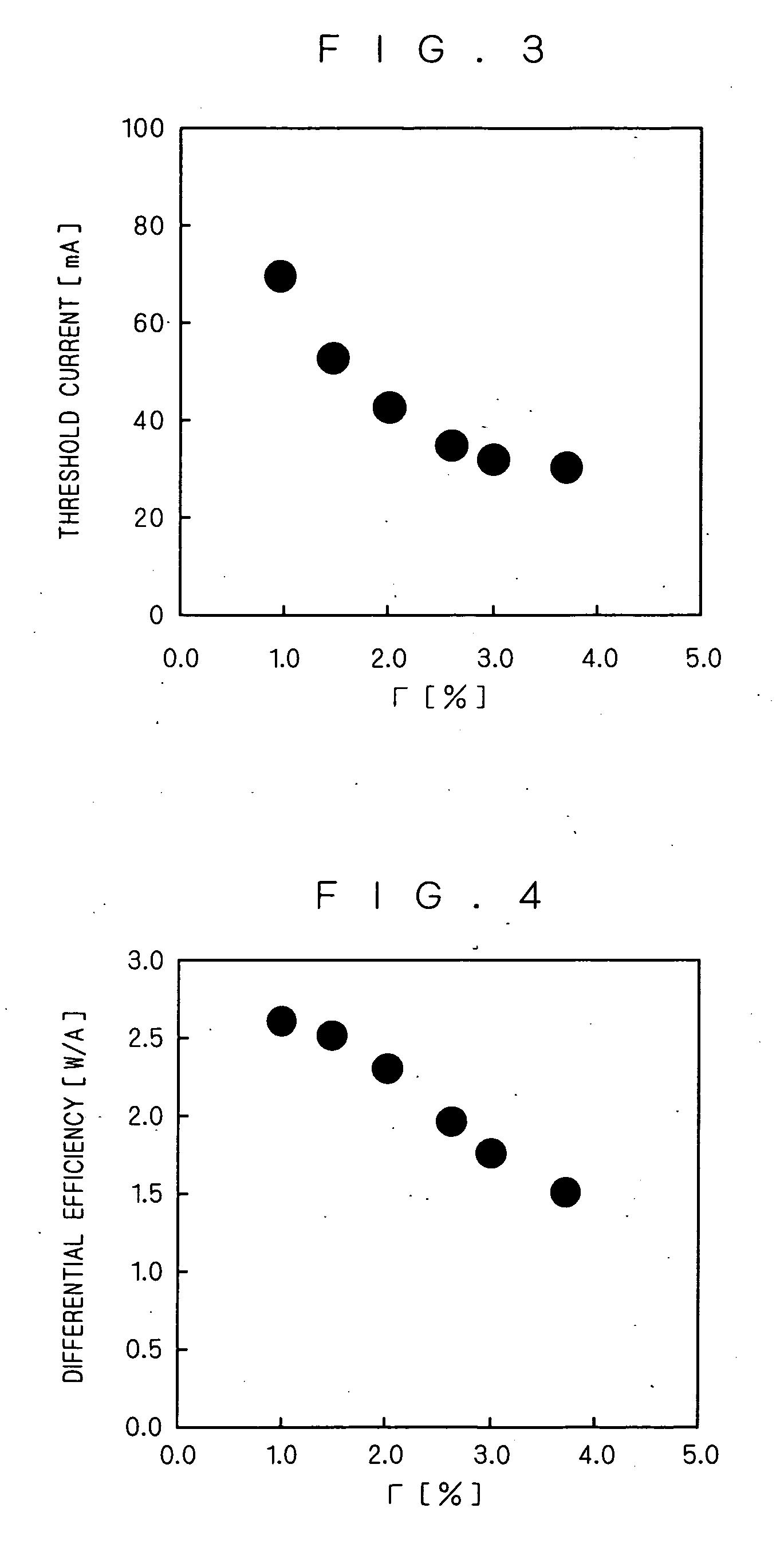

In a semiconductor laser having an active layer of double-quantum-well structure that includes two InGaN well layers each of which has a thickness of 5 nm, a threshold current deteriorates to a relatively small degree while differential efficiency is improved considerably in a region having a light confinement coefficient Γ of 3.0% or less. On the other hand, with the light confinement coefficient Γ becoming less than 1.5%, the threshold current increases considerably while the amount of improvement in differential efficiency becomes small. It is therefore preferable that the lowest limit to the light confinement coefficient Γ be about 1.5%. The differential efficiency of 1.6 W / A or more is obtained with the light confinement coefficient Γ being 3.0% or less, and the differential efficiency of 1.7 W / A or more is obtained with the light confinement coefficient Γ being 2.6% or less.

Owner:MITSUBISHI ELECTRIC CORP

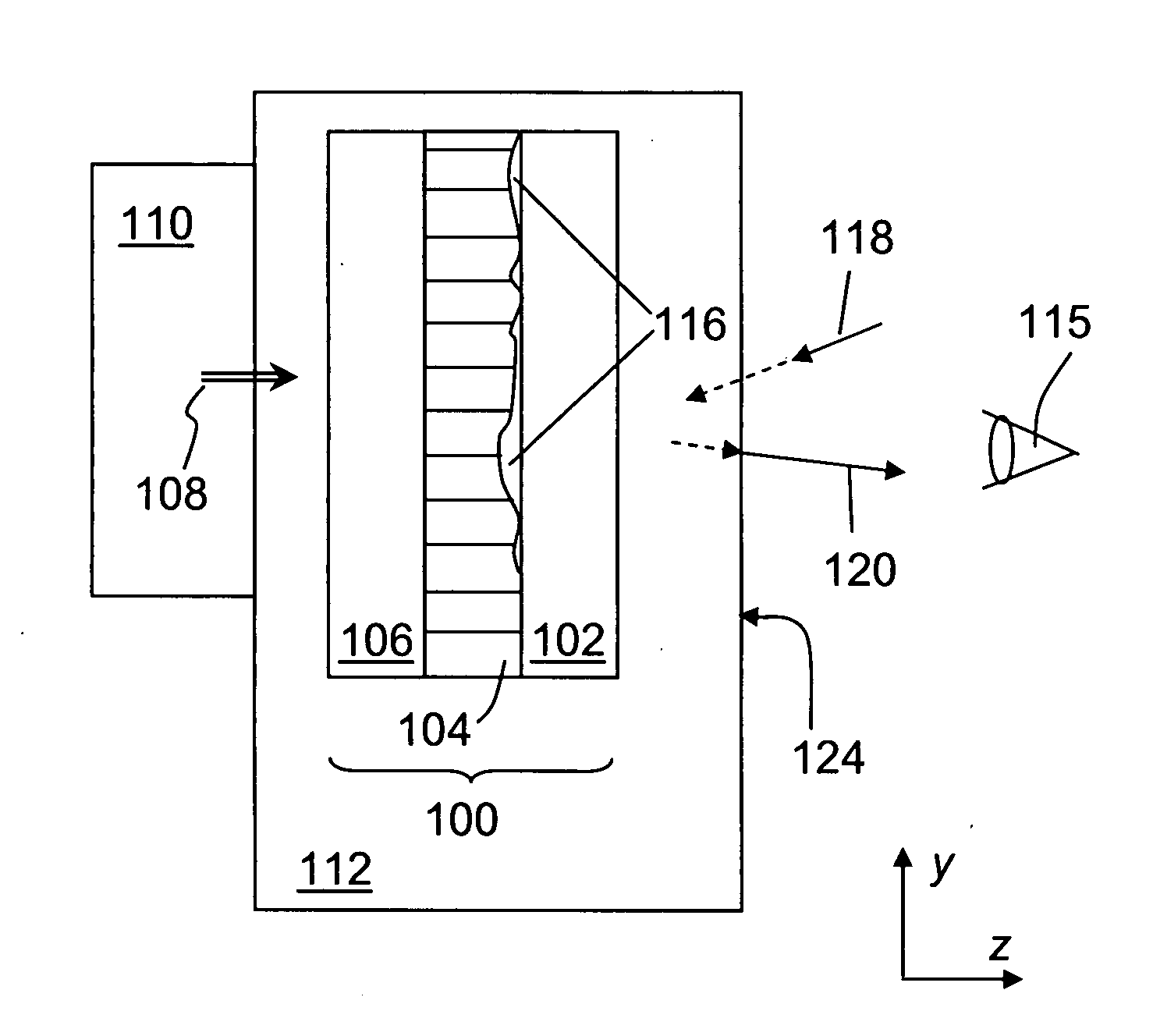

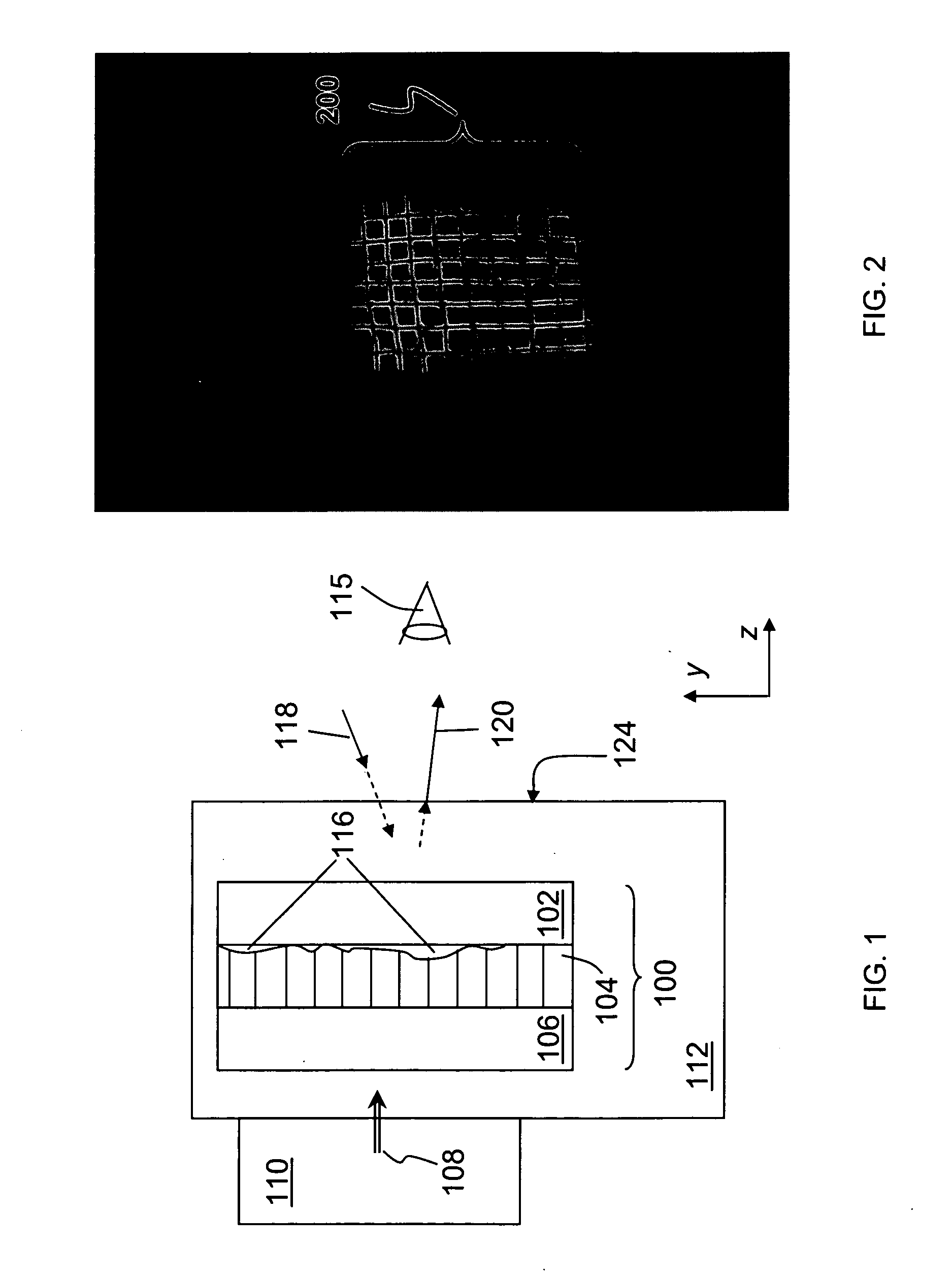

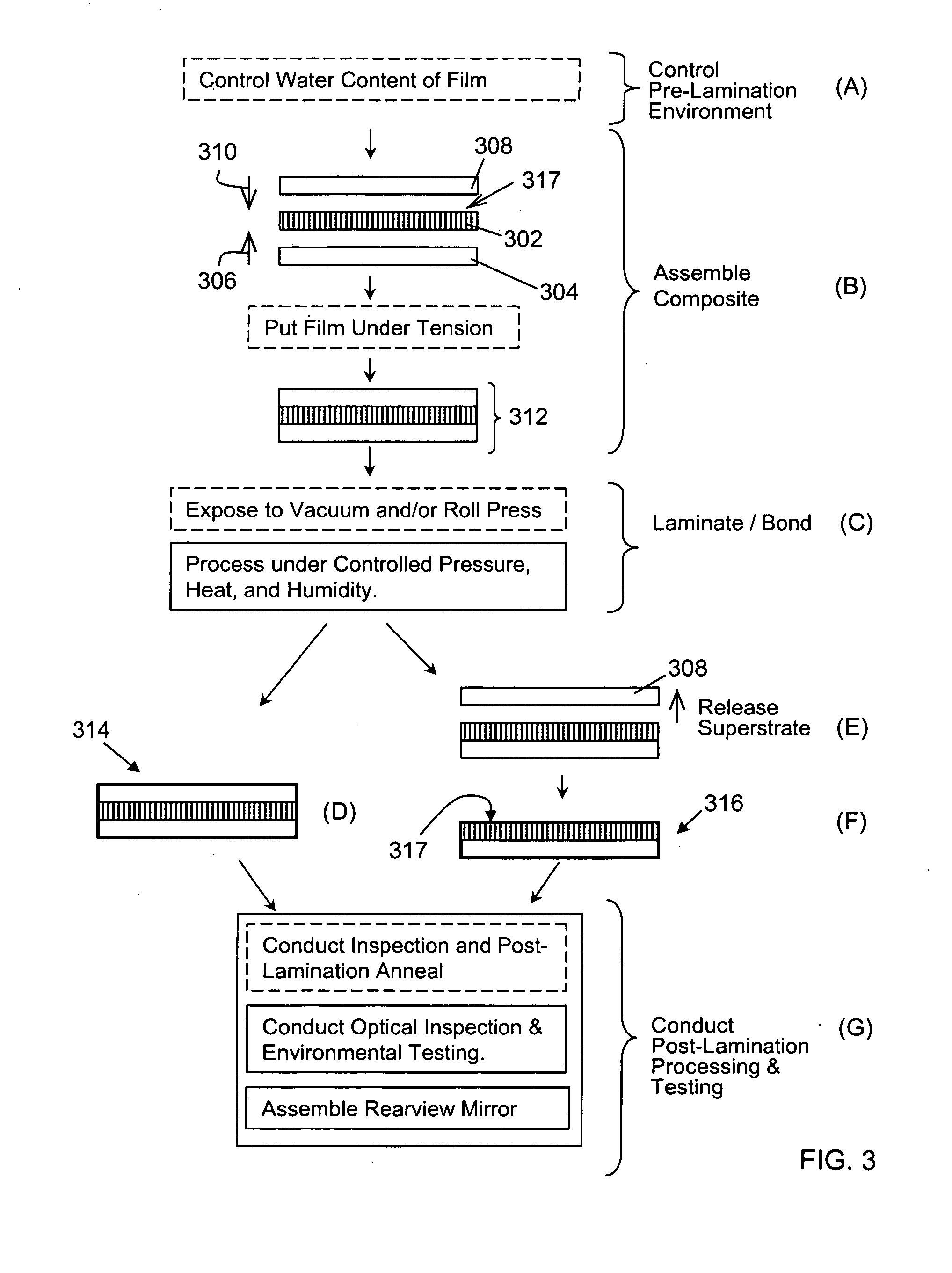

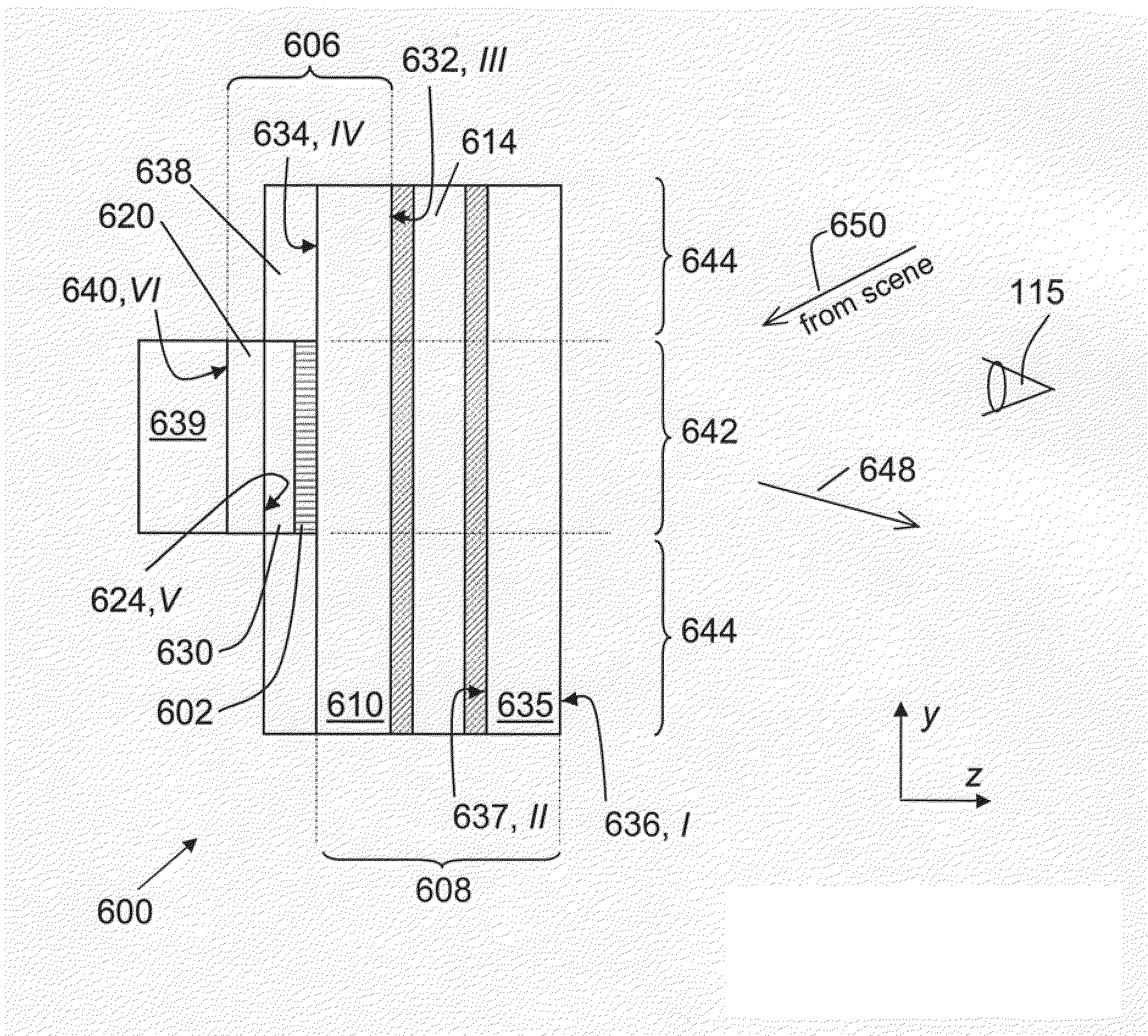

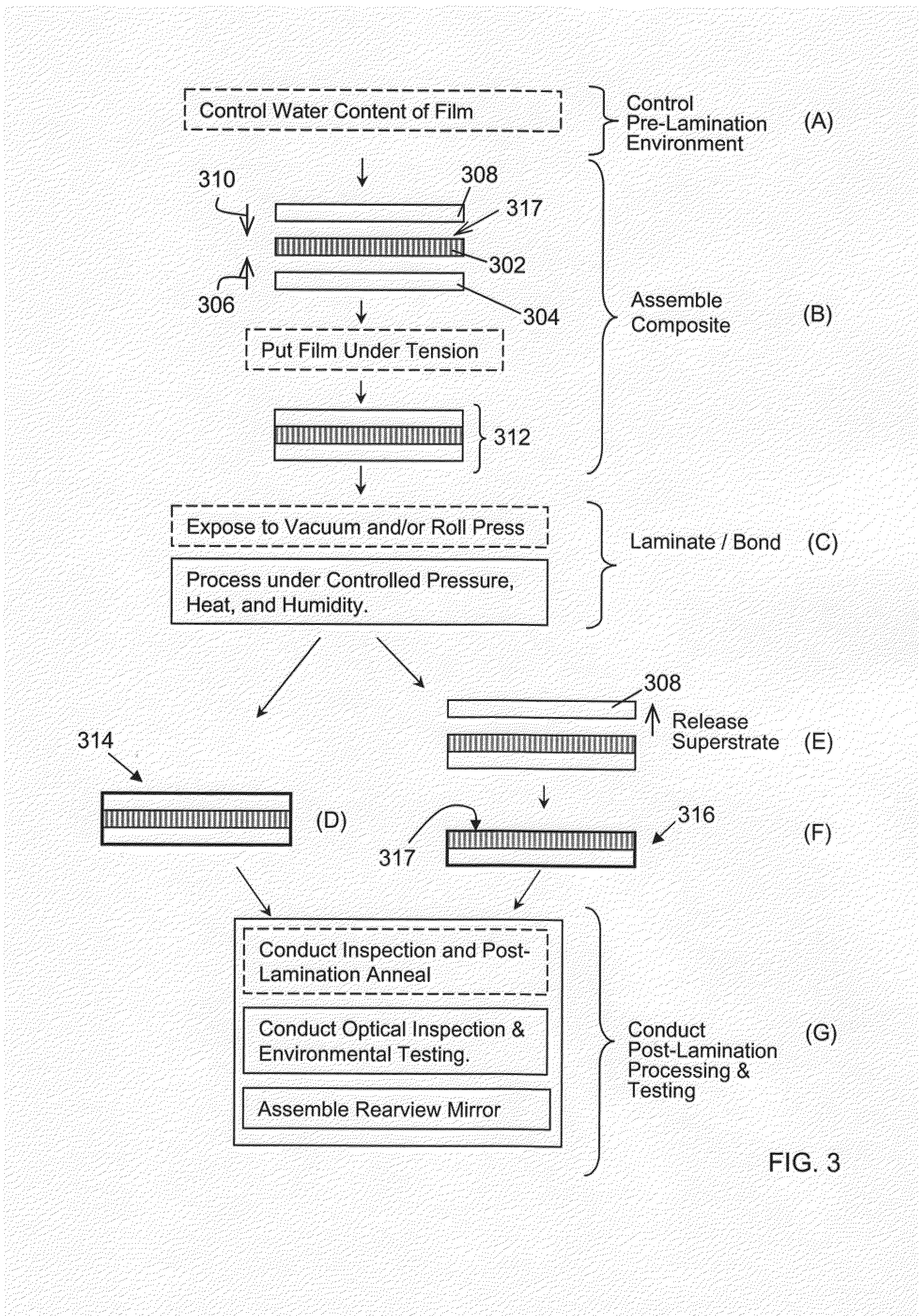

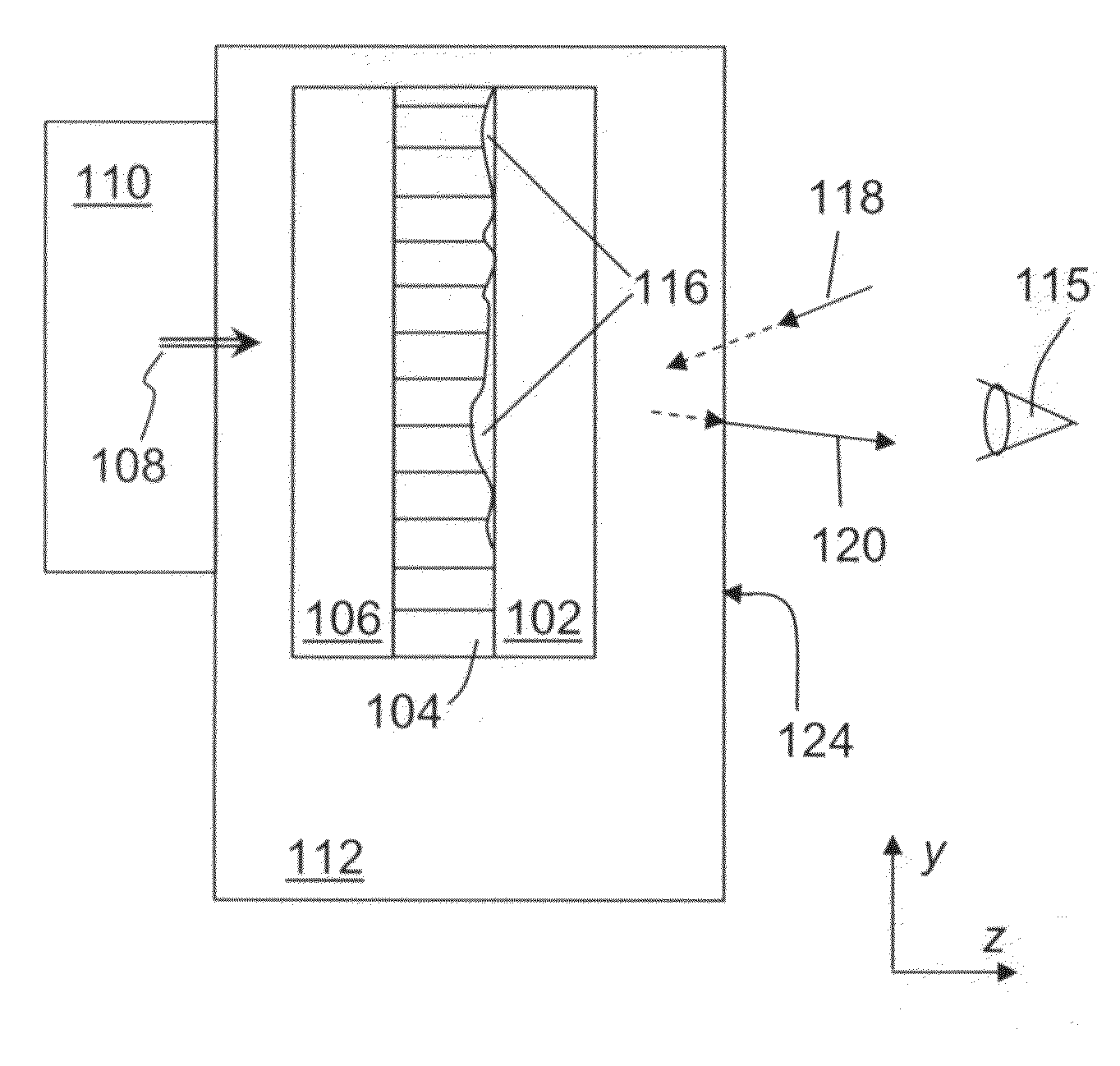

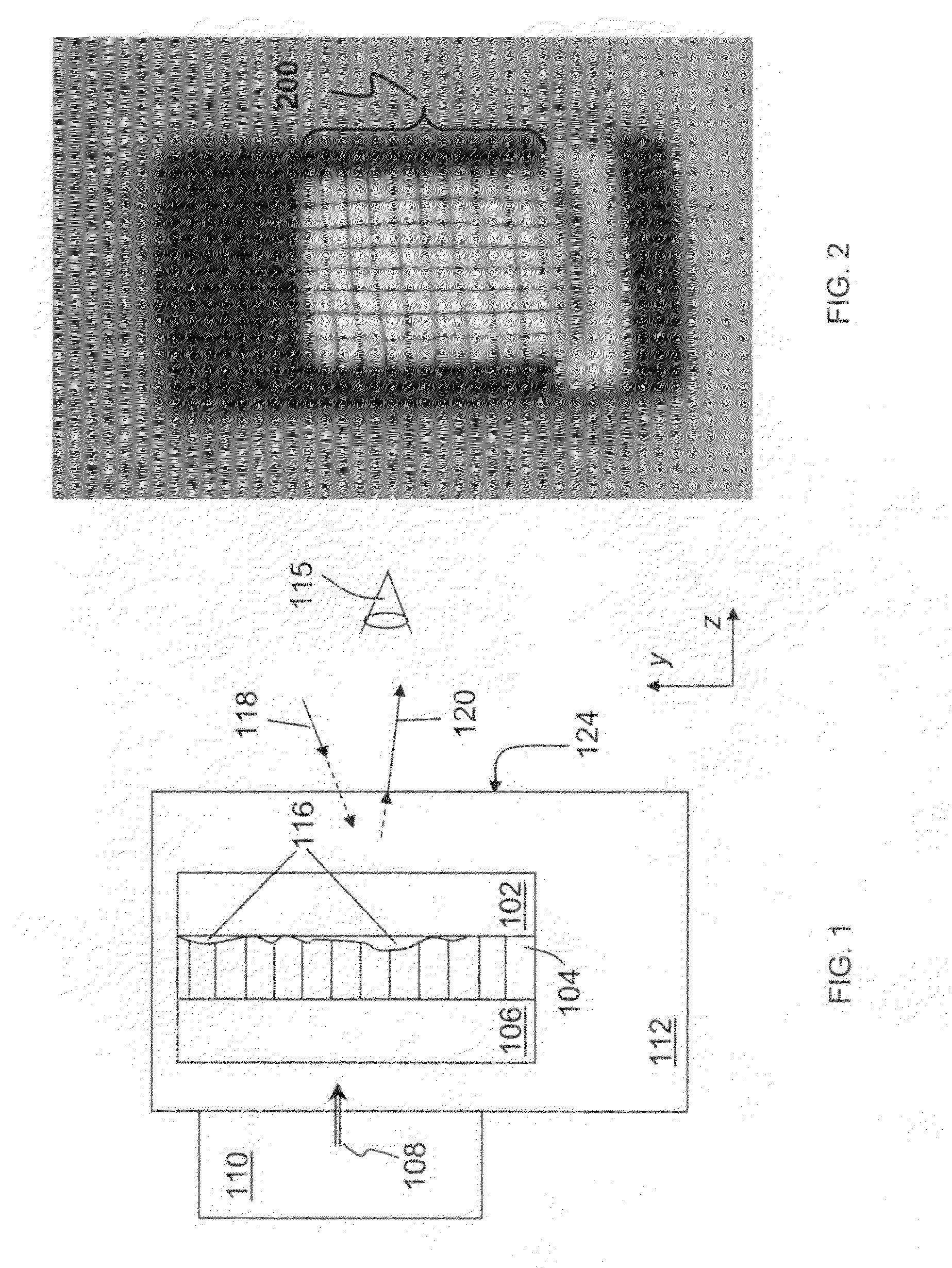

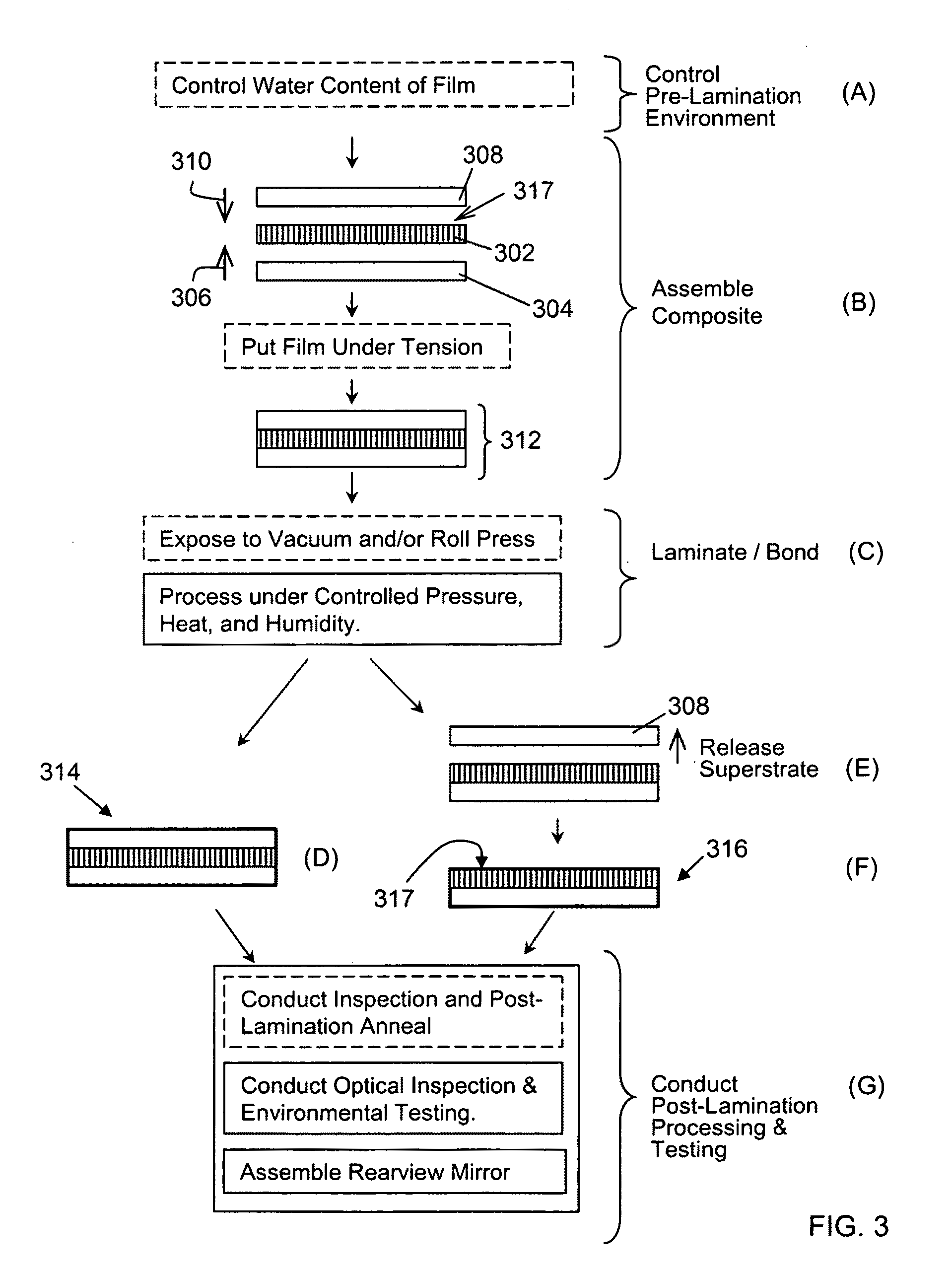

Rearview Mirror Assemblies With Anisotropic Polymer Laminates

ActiveUS20100277786A1High strengthAdequate flatness of filmPolarising elementsNon-linear opticsLower limitGlass transition

Anisotropic film laminates for use in image-preserving reflectors such as rearview automotive mirror assemblies, and related methods of fabrication. A film may comprise an anisotropic layer such as a light-polarizing layer and other functional layers. The film having controlled water content is heated under omnidirectional pressure and vacuum to a temperature substantially equal to or above a lower limit of a glass-transition temperature range of the film so as to be laminated to a substrate. The laminate is configured as part of a mirror structure so as to increase contrast of light produced by a light source positioned behind the mirror structure and transmitted through the mirror structure towards a viewer. The mirror structure is devoid of any extended distortion and is characterized by SW and LW values less than 3, more preferably less than 2, and most preferably less than 1.

Owner:GENTEX CORP

Rearview Mirror Assemblies With Anisotropic Polymer Laminates

ActiveUS20090296190A1High strengthAdequate flatness of filmMirrorsSynthetic resin layered productsLower limitWing mirror

Anisotropic film laminates for use in image-preserving reflectors such as rearview automotive mirror assemblies, and related methods of fabrication. A film may comprise an anisotropic layer such as a light-polarizing layer and other functional layers. The film having controlled water content is heated under omnidirectional pressure and vacuum to a temperature substantially equal to or above a lower limit of a glass-transition temperature range of the film so as to be laminated to a substrate. The laminate is configured as part of a mirror structure so as to increase contrast of light produced by a light source positioned behind the mirror structure and transmitted through the mirror structure towards a viewer. The mirror structure is devoid of any extended distortion and is characterized by SW and LW values less than 3, more preferably less than 2, and most preferably less than 1.

Owner:GENTEX CORP

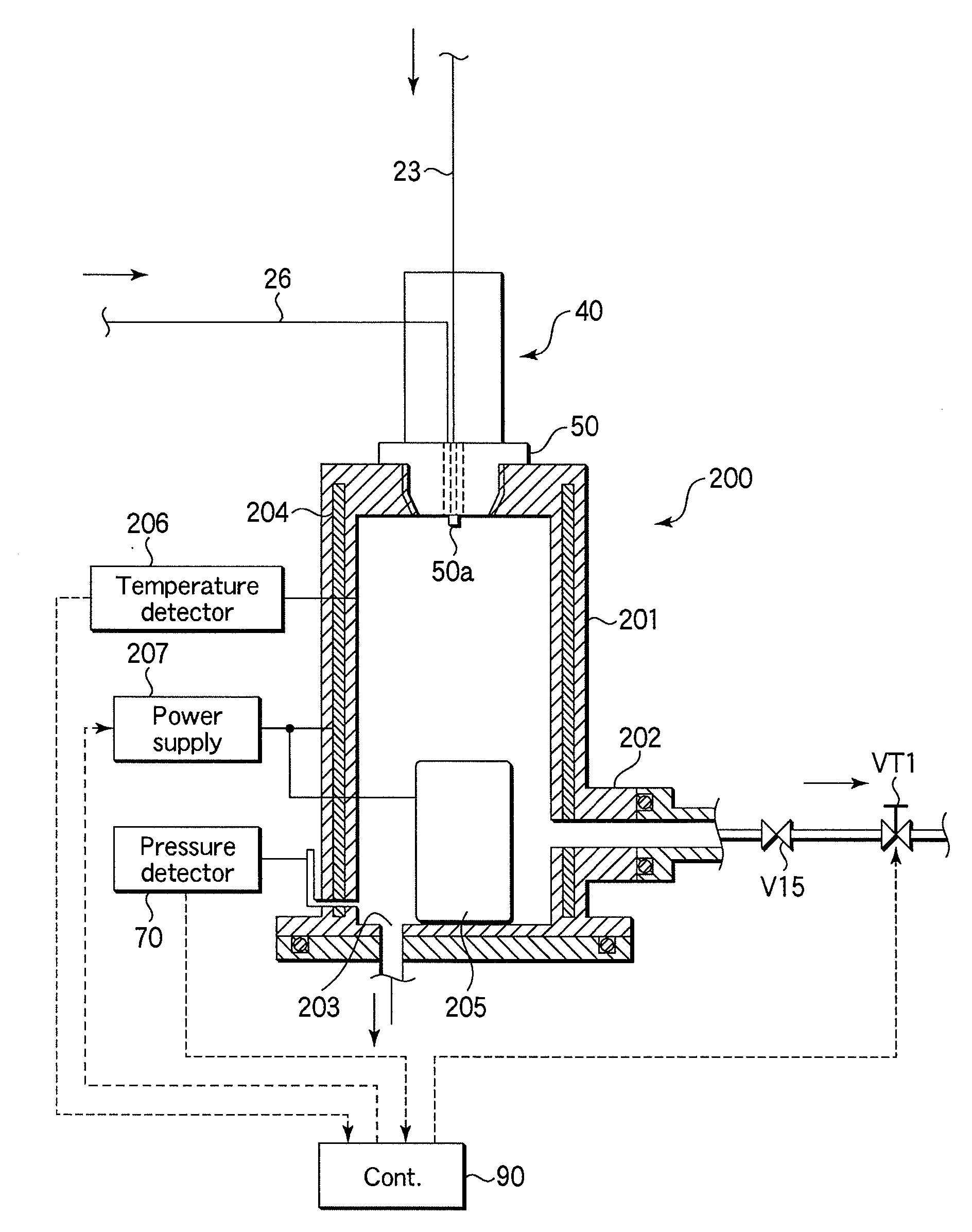

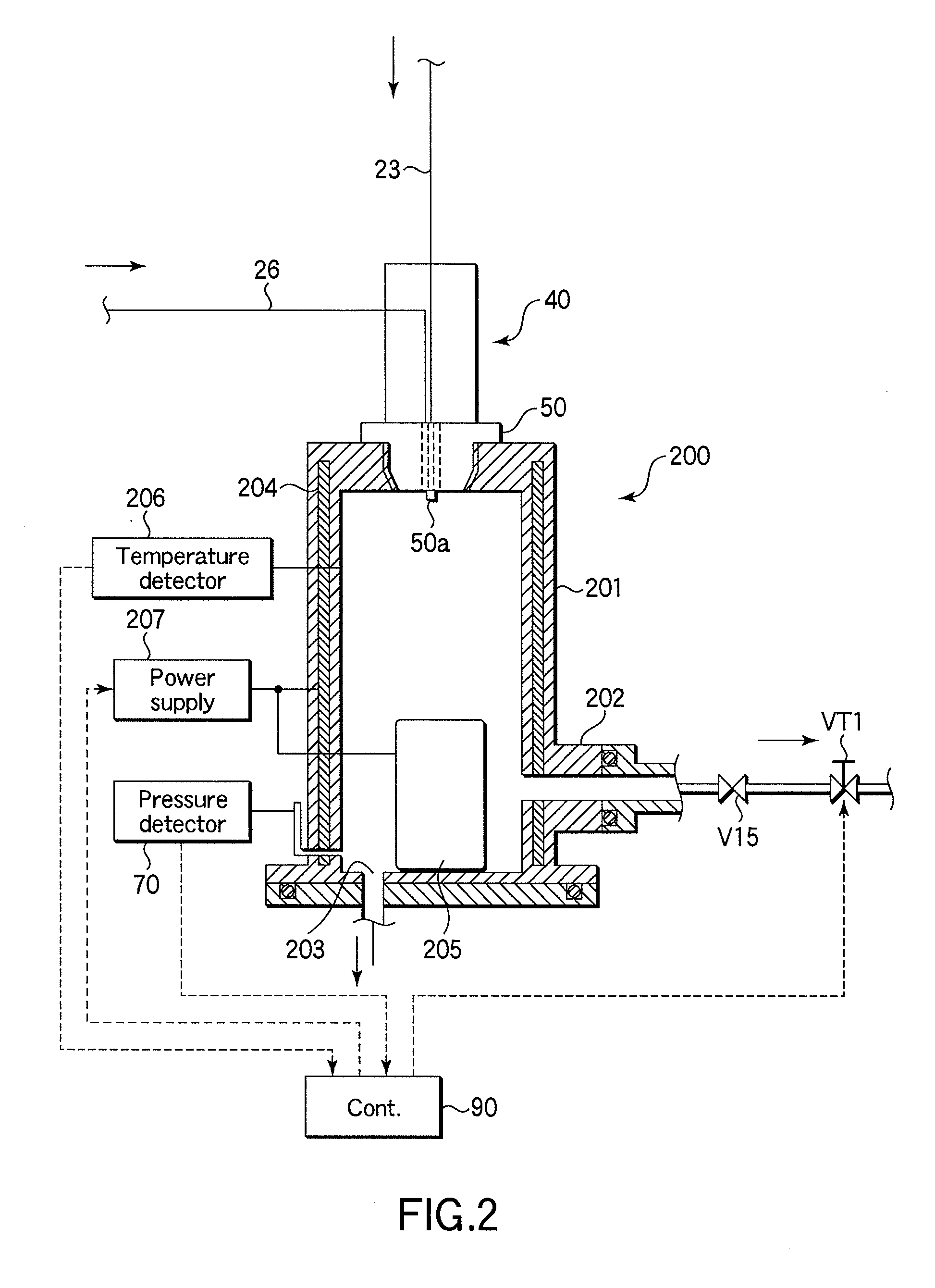

Semiconductor processing system including vaporizer and method for using same

InactiveUS20090186479A1Improve performancePrevent nozzle cloggingSingle transducer incorporationMicrophonesLower limitProduct gas

A semiconductor processing system including a semiconductor processing apparatus and a gas supply apparatus for supplying a process gas into the semiconductor processing apparatus includes a control section configured to control an operation of a pressure adjusting mechanism for adjusting the pressure inside a vaporizing chamber. The control section is preset to cause the pressure inside the vaporizing chamber to fall within a predetermined pressure range with reference to a pressure detection value obtained by a pressure detector. The predetermined pressure range is defined by an upper limit lower than a first limit value, at which vaporization of the liquid material starts being inhibited due to an increase in the pressure, and a lower limit higher than a second limit value, at which vaporization of the liquid material starts being unstable and the pressure inside the vaporizing chamber starts pulsating movement due to a decrease in the pressure.

Owner:TOKYO ELECTRON LTD

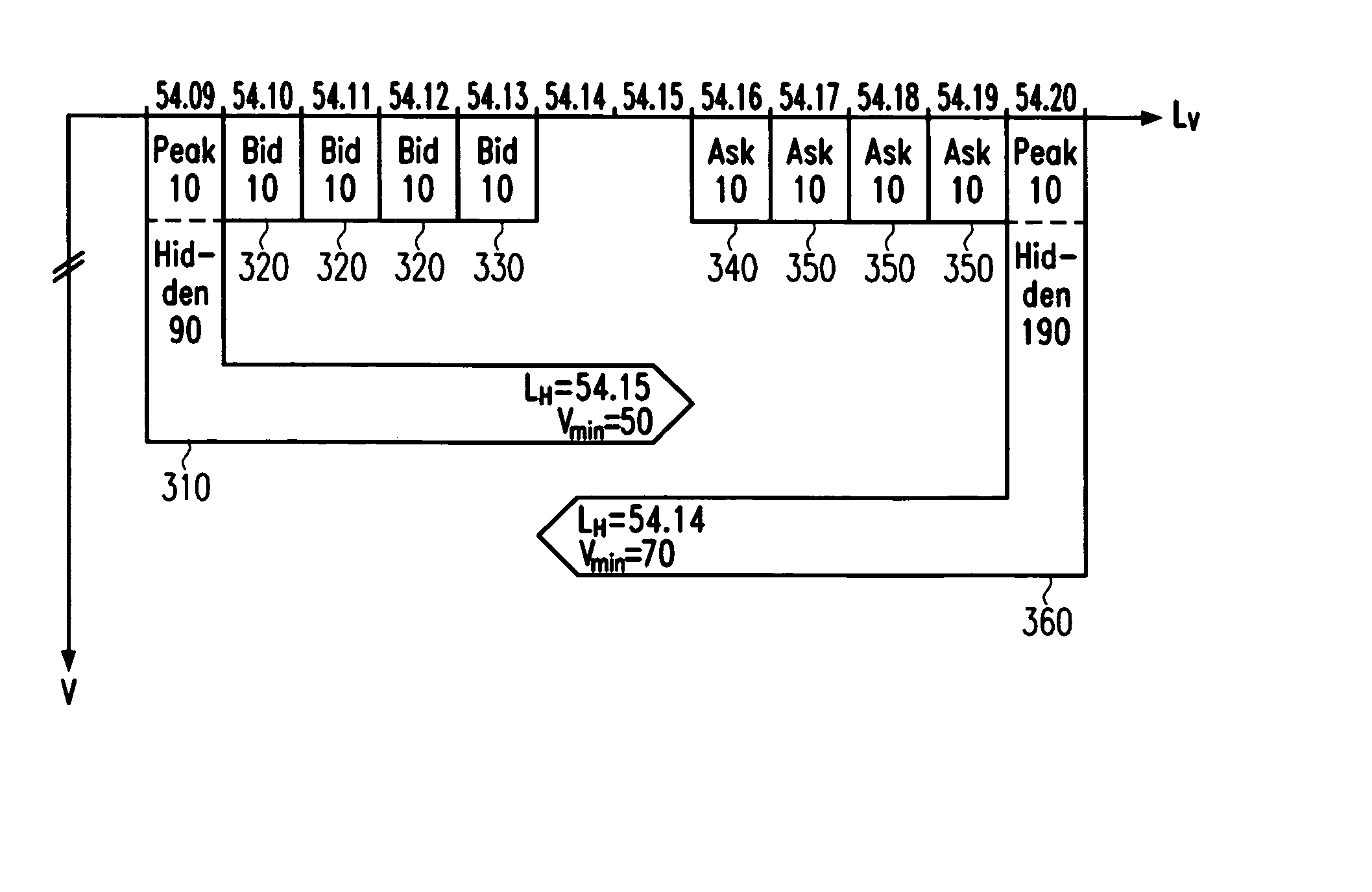

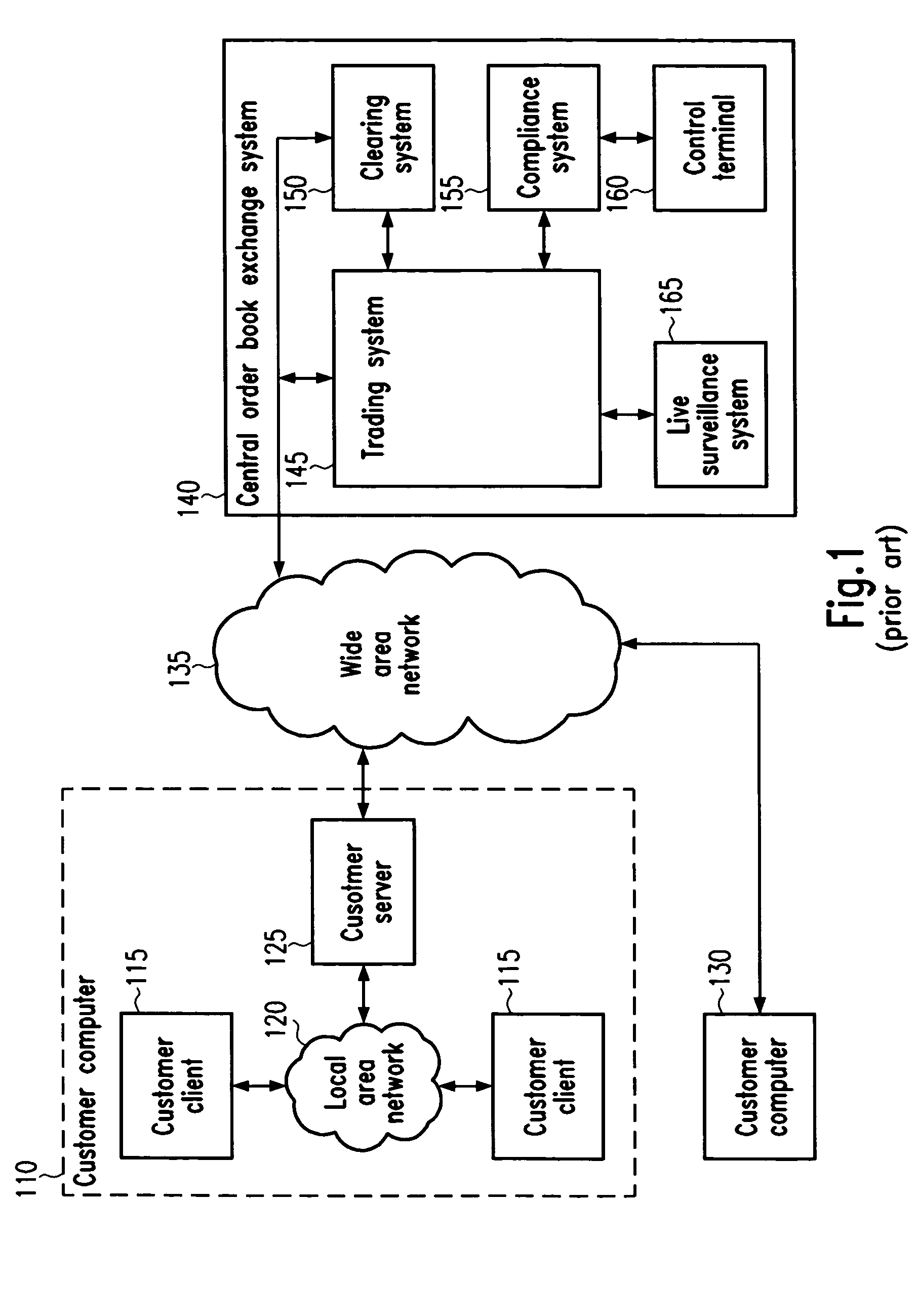

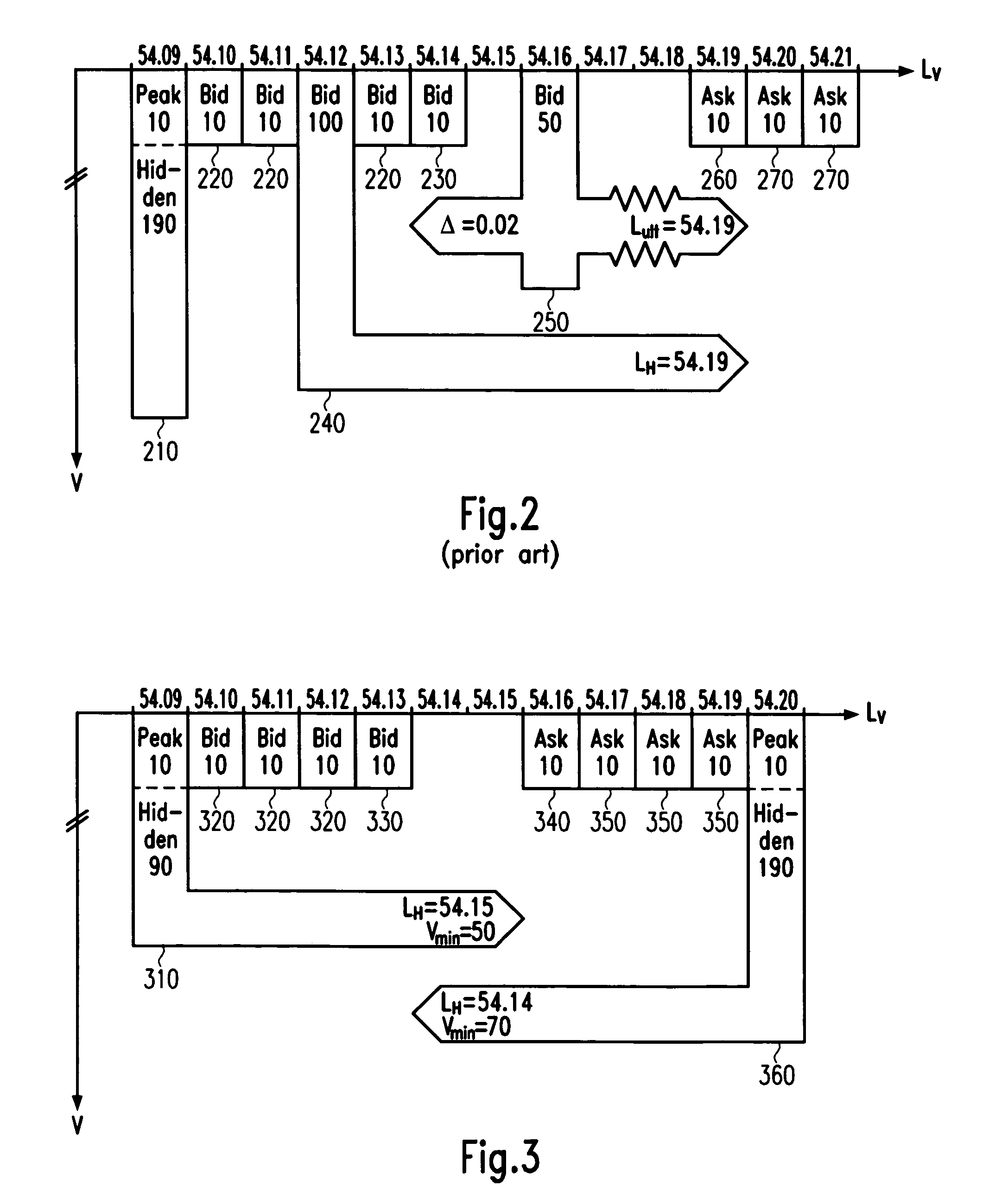

Integrated order matching system combining visible and hidden parameters

The invention provides back-end functionality for order processing in electronic order book trading. A sell / buy order is received comprising a lower / upper limit and a conditional lower / upper limit defining a conditional selling / buying price range for executing the sell / buy order under certain selling / buying conditions. A buy / sell order is received comprising an upper / lower limit, visible buy / sell volume parameter and hidden buy / sell volume parameter specifying a first part disclosed to all customers and a second part not disclosed to all customers, respectively, of the buy / sell order volume. It is determined whether the selling / buying conditions are fulfilled, including determining whether the sum of the first and second part of the buy / sell order is superior or equal to a threshold volume. The sell / buy order and the buy / sell order are executed against each other if at least the selling / buying conditions are fulfilled. Embodiments allow rapidly executing large trading interests with minimized market impact and opportunity costs.

Owner:DEUT BORSE

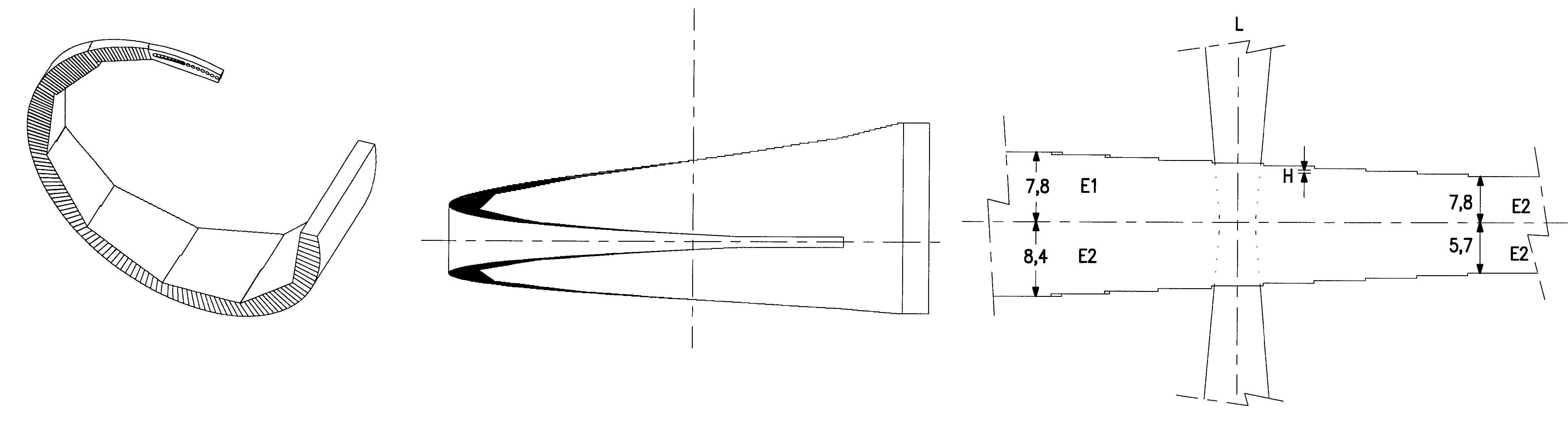

Device for varying the energy of a particle beam extracted from an accelerator

InactiveUS6433336B1Radiation/particle handlingElectrode and associated part arrangementsLower limitParticle accelerator

A device for varying the energy of a particle beam extracted from a fixed-energy particle accelerator includes a block of energy degrading material positioned in the path of the particle beam. The block of energy degrading material is preferably in the form of a ring arranged on a wheel. The ring is of a staircase configuration, having discrete steps defining a thickness between parallel entry and exit faces. According to one aspect of the invention, the block is configured so that the particle beam energy variation reaches a maximum at the edges of each step. This upper limit is also the lower limit of the next step. Thus, continuous energy variation is possible despite the fact that the thickness of the block varies in discrete steps.

Owner:ION BEAM APPL

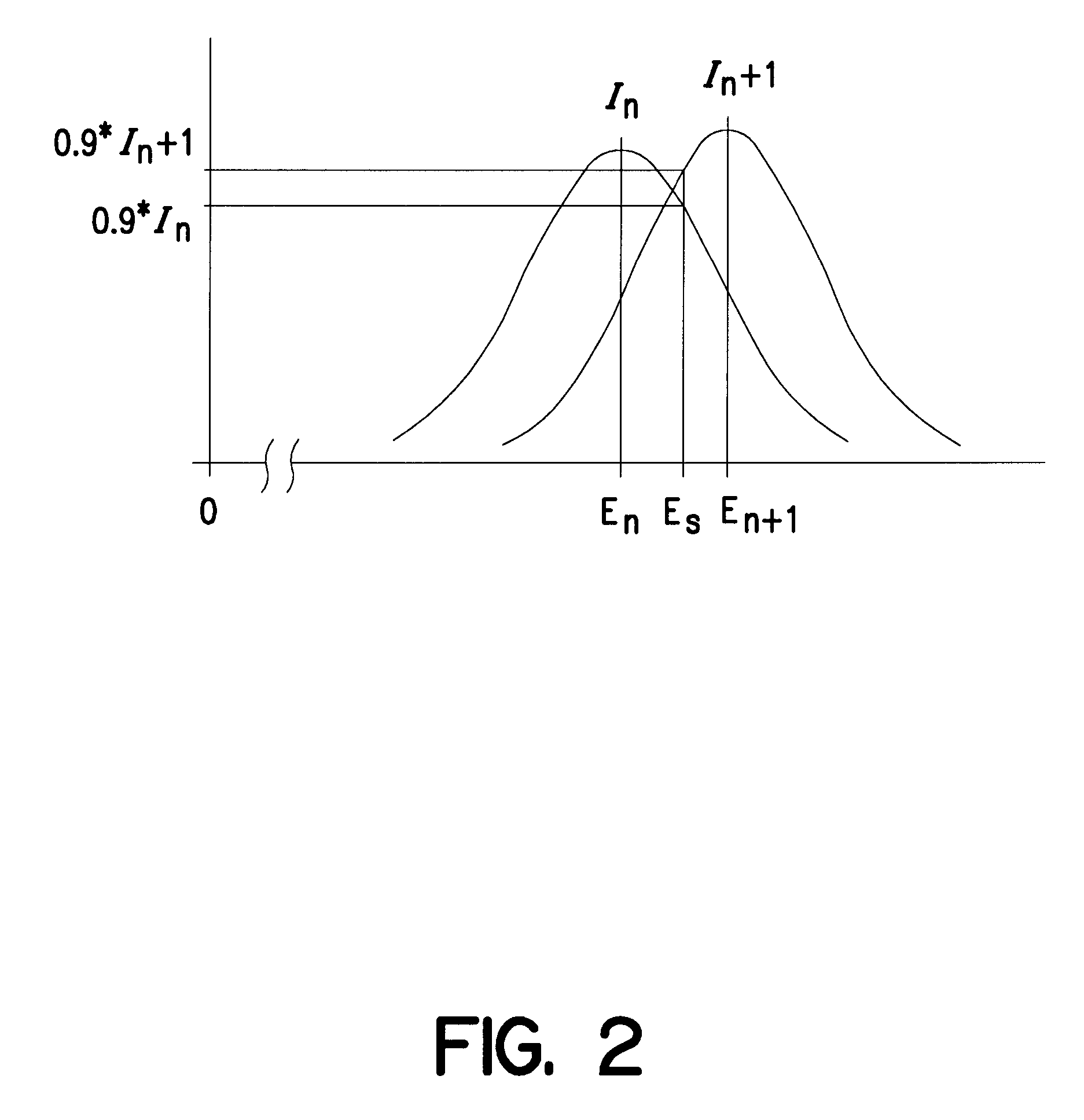

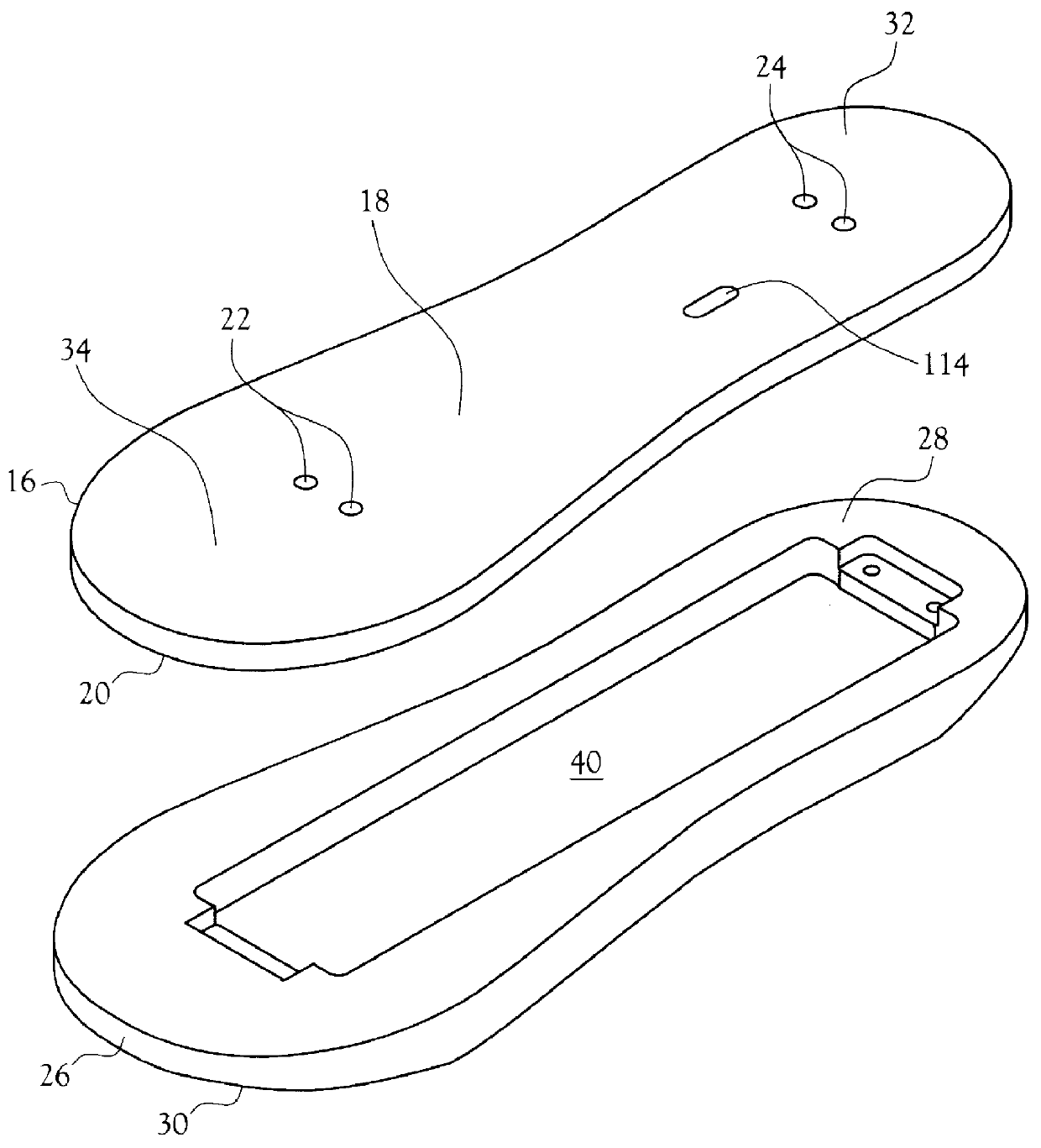

Force monitoring shoe

InactiveUS6122846AAccurate assessmentFoot measurement devicesPerson identificationElectricityLower limit

An apparatus and method of operation for measuring forces applied to a wearer's foot, the apparatus providing an indication to the wearer when forces on the foot exceed pre-selected upper limits or do not meet pre-selected lower limits. A body member is disclosed for attachment around the wearer's foot, the body member having an exterior sole and an interior sole portion covered by a rigid foot plate. The foot plate includes an upper support surface for contact with the foot. The interior sole portion includes at least one cavity within, with a force sensing unit attachable partially within the cavity. At least one strain gage is positioned at a midpoint on the force sensing unit, and the force sensing unit is connectable to the underside of the foot plate. An electronic means is mounted within the cavity and is electrically connected to the at least one strain gage. The electronic means receives electronic signals from the strain gage, the signals in proportion to force applied onto the force sensing unit when the wearer's foot applies weight onto the foot plate, with conversion of the signals to output signals for transmission to a signal processing means in a remotely located receiver and display unit. The display unit compares the output signals to upper limits and lower limits, and displays alarms when output signals do not reach lower limits, or exceed upper limits, therefore assisting with therapeutic rehabilitation of an injured lower extremity.

Owner:GRAY FRANK B

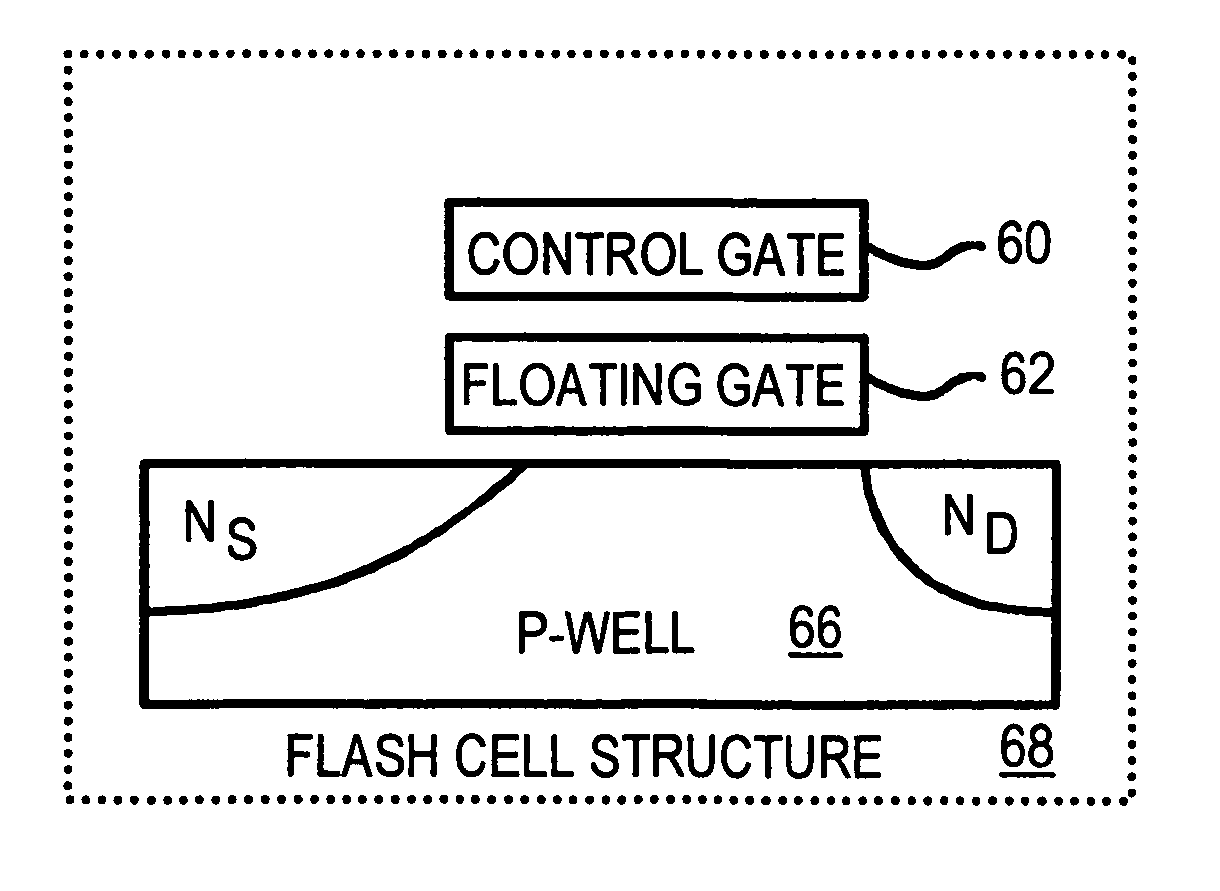

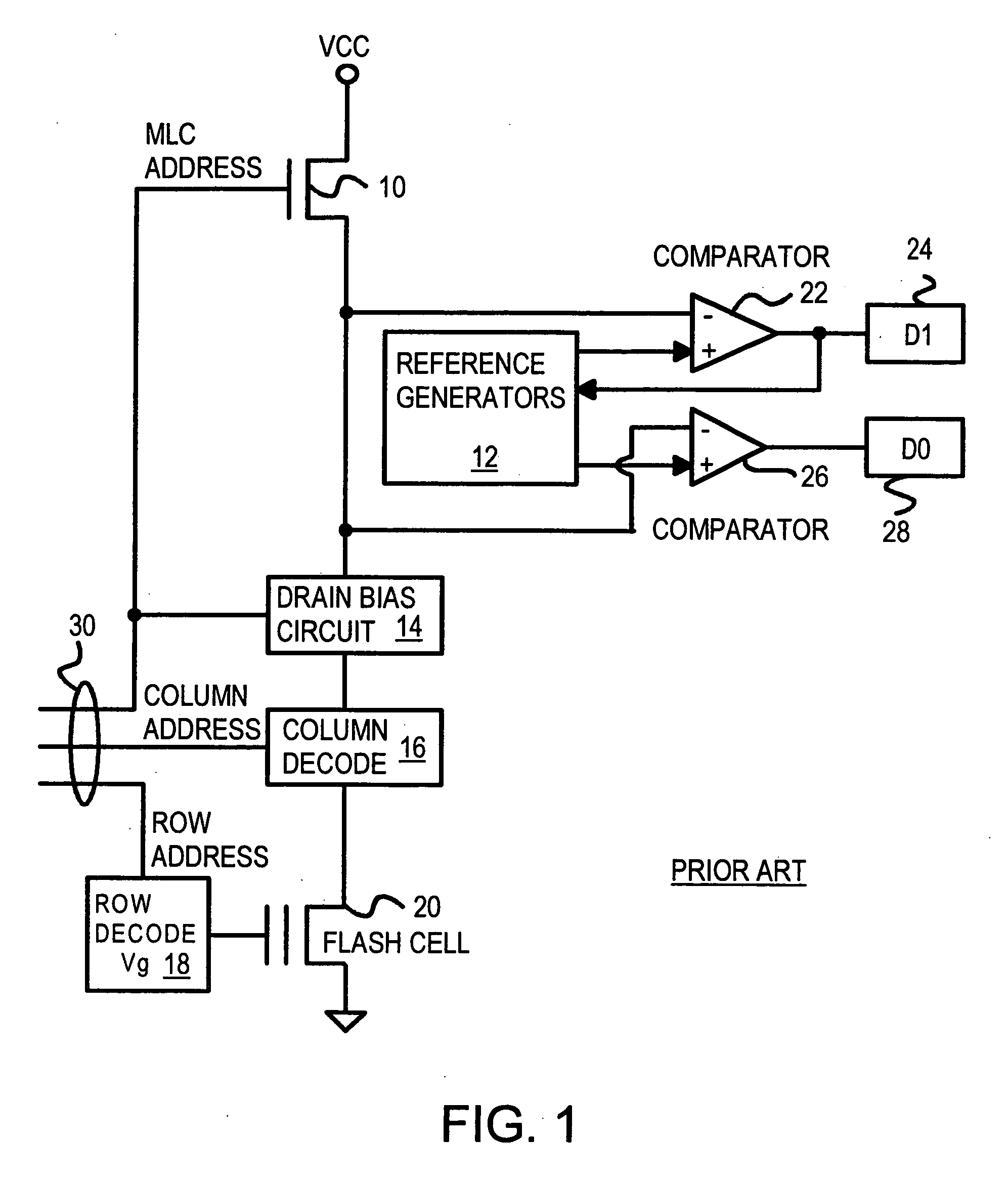

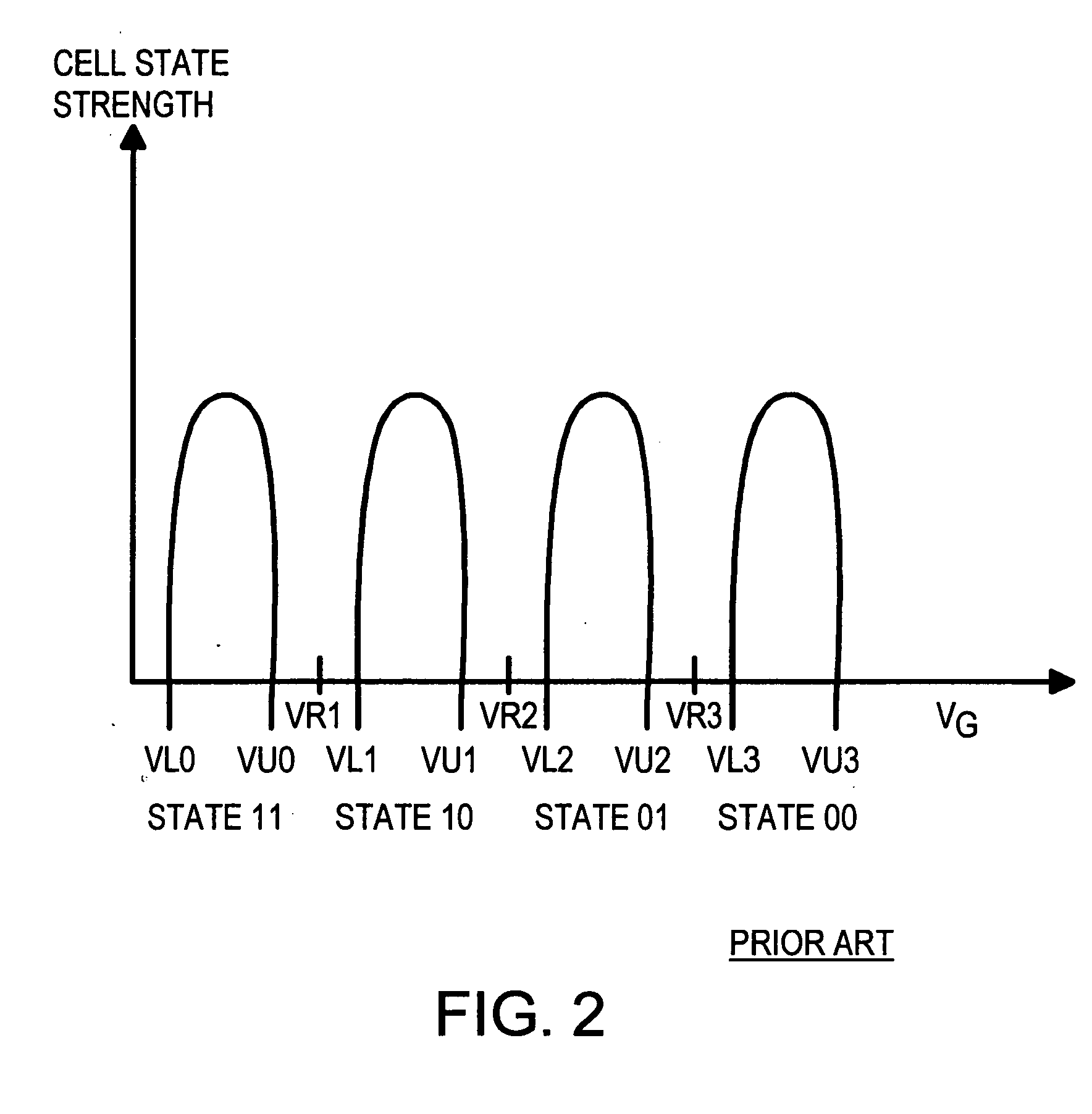

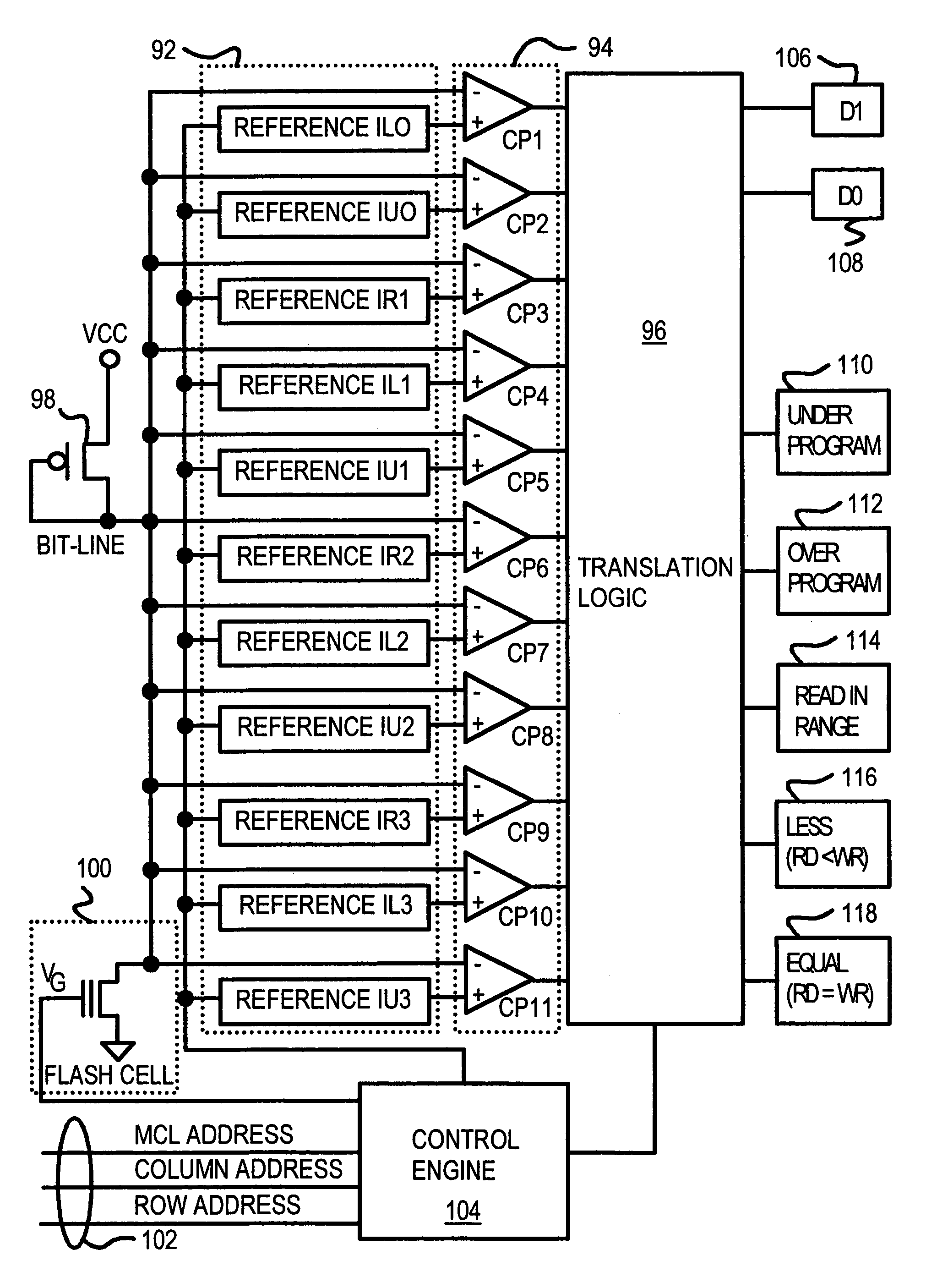

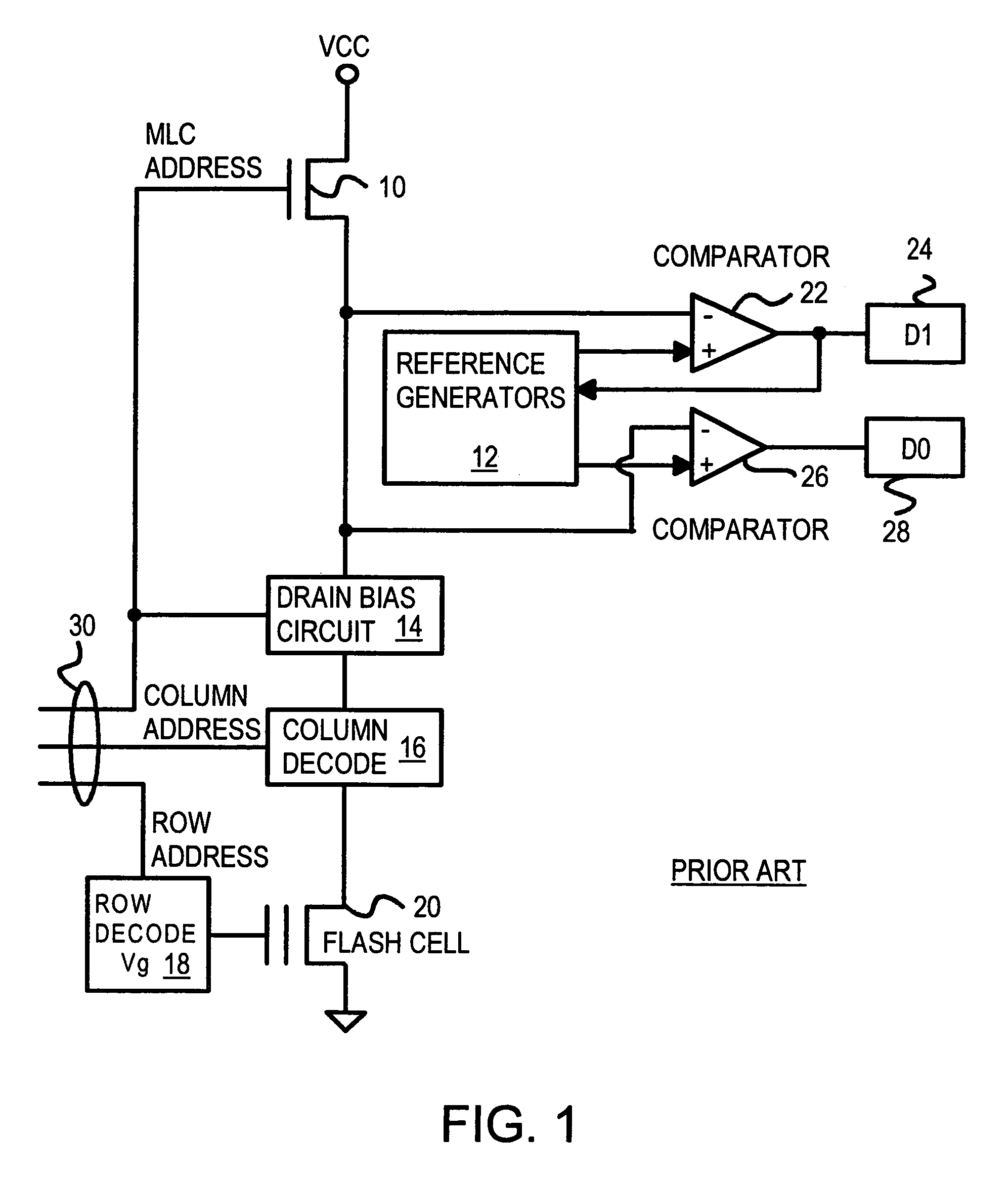

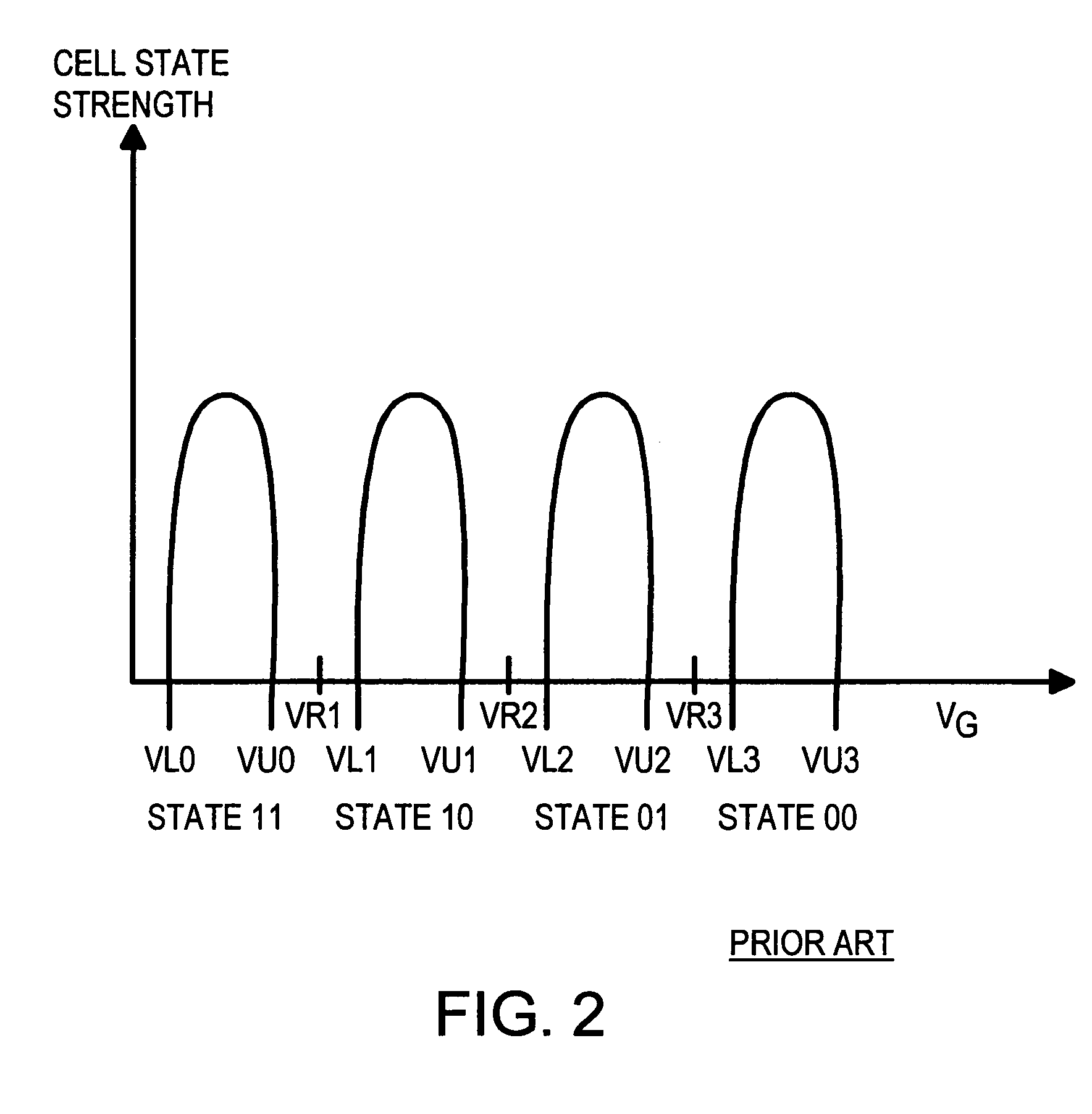

Flash memory device and architecture with multi level cells

A FLASH memory has an array of FLASH cells that each store N multiple bits of information as charge stored on a floating gate. Reference voltages or currents are generated for each boundary between the 2N states or levels and for an upper limit and a lower limit reference for each state. A selected bit line driven by a selected FLASH cell generates a sense node that is compared to a full range of 3*2N-1 comparators in parallel. The compare results are decoded to determine which state is read from the selected FLASH cell. An in-range signal is activated when the sense node is between the upper and lower limit references. The target programming count or programming pulses is adjusted during calibration to sense in the middle of the upper and lower limit references. Margin between references is adjusted by calibration codes that select currents for summing.

Owner:SUPER TALENT TECH CORP

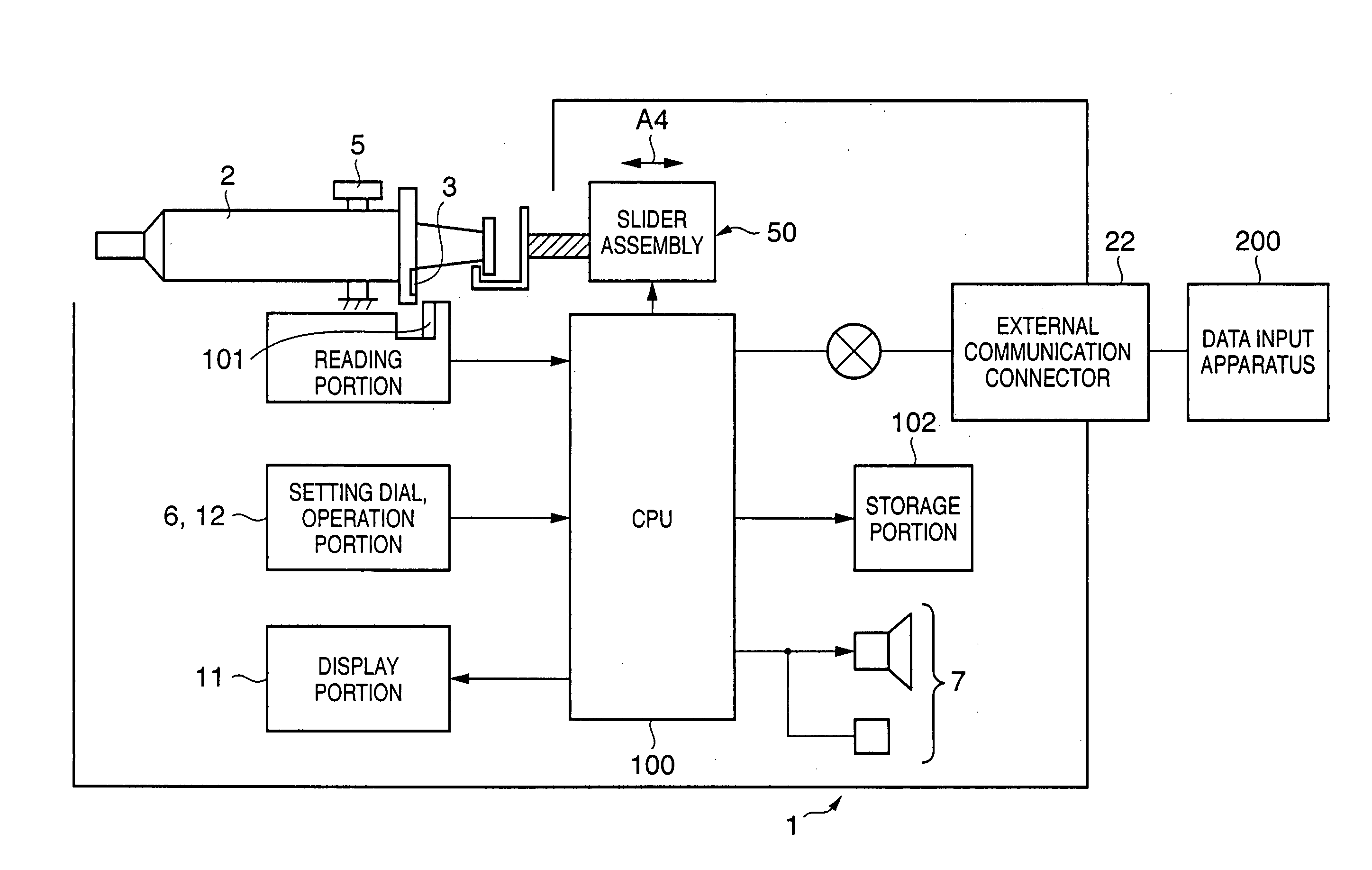

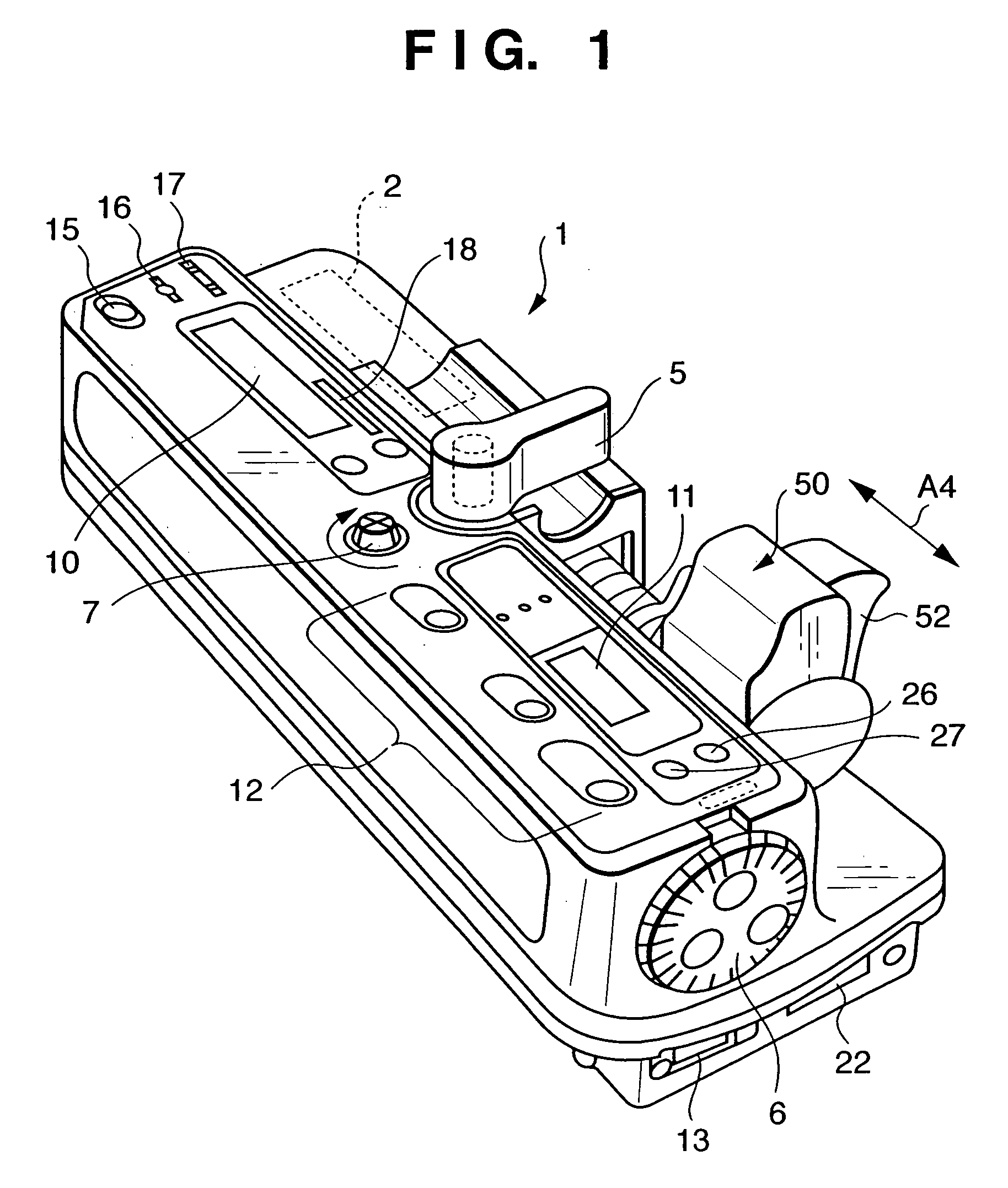

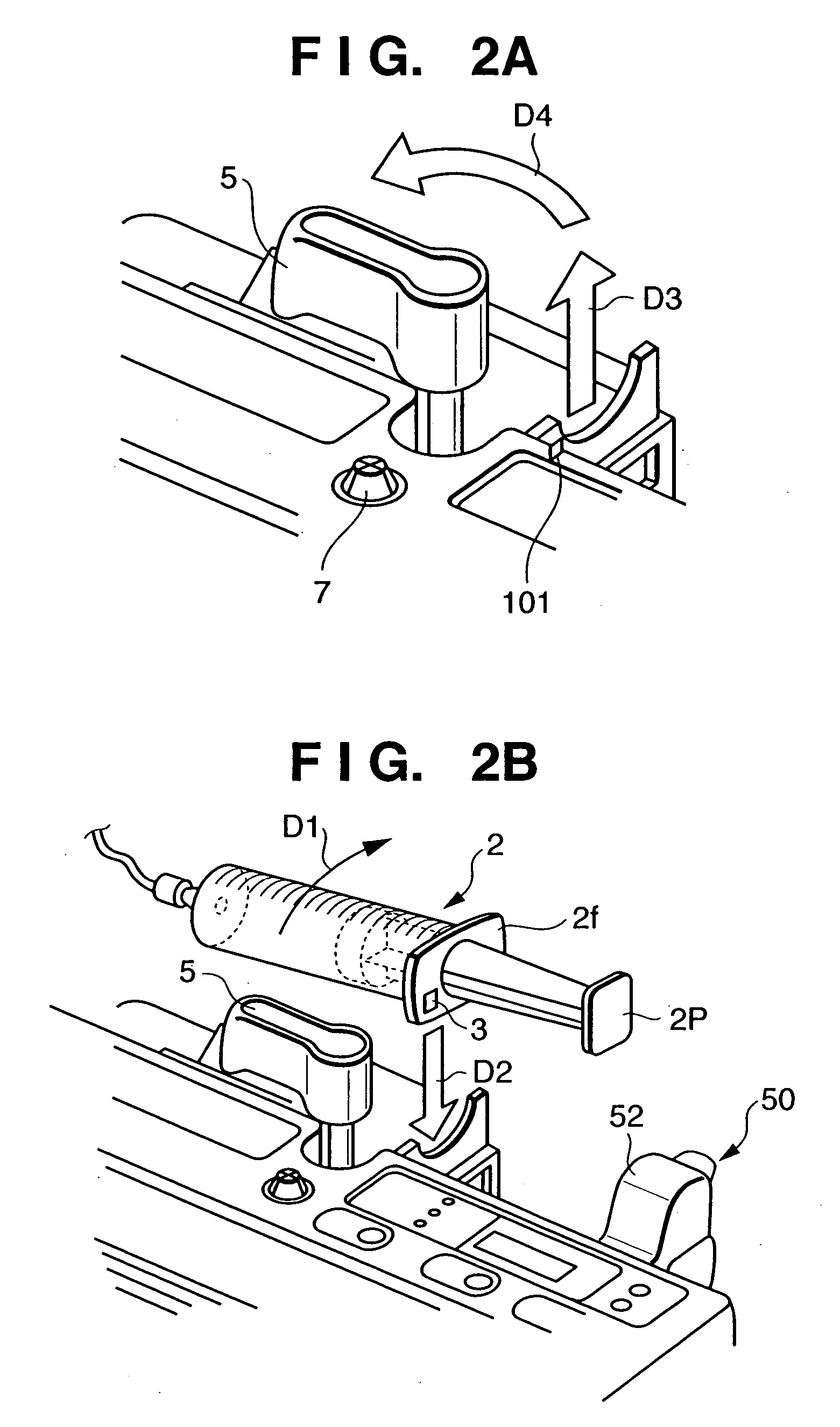

Drug container and drug infusion device comprising the same (as amended)

When using a drug container having an identification tag fixed or detachably provided at a predetermined position of the container, the tag having drug data on a kind and a concentration of a drug and both or one of upper and lower limits of a flow rate on a continuous infusion and the upper and lower limits, time and flow rate on a one-shot administration recorded thereon, it is possible to ensure safety by prompting for a stop of injection by a warning when a setting beyond the upper and lower limits is performed and rewrite a liquid infusing time and a flow rate and so on required to be set according to symptoms of a patient.

Owner:TERUMO KK

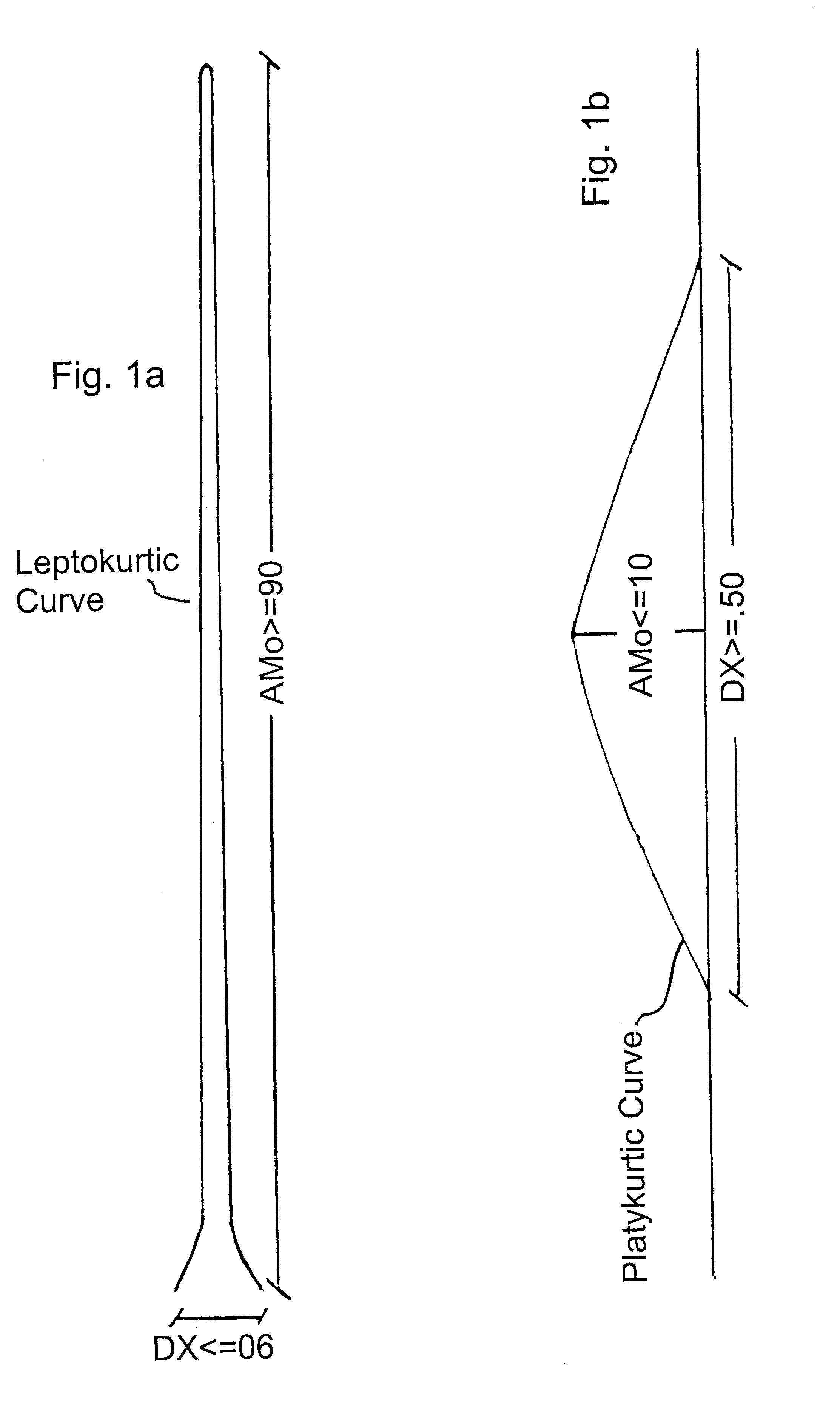

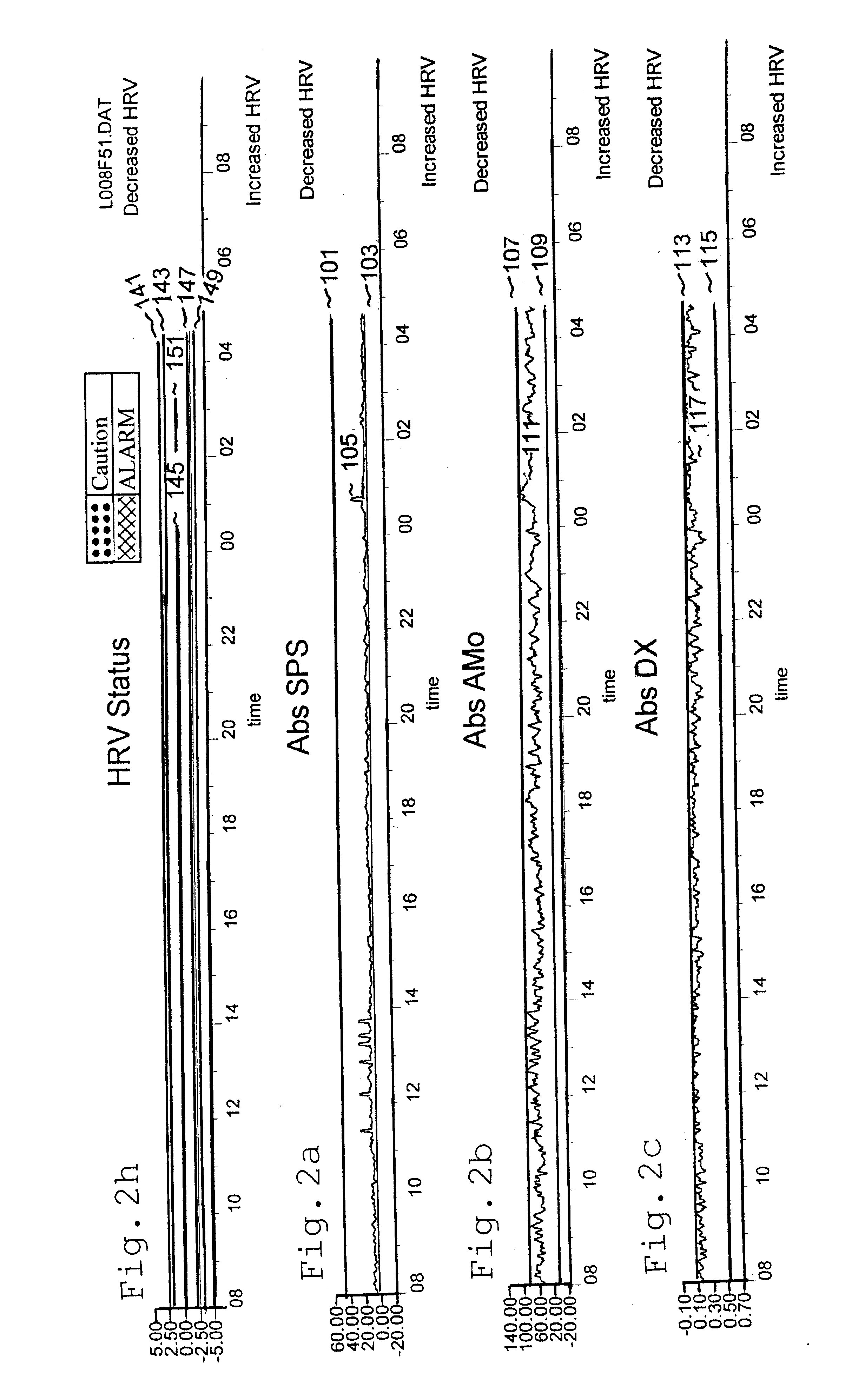

Detection of abnormal and induction of normal heat rate variability

An apparatus and method for predicting potentially fatal arrhythmias up to twenty four hours in advance of the event by employing formulas indicating either too little or too much heart rate variability. A number of these formulas have both predetermined upper and lower limits, which if exceeded for a period of time are a predictor of a potentially fatal arrhythmia. When a patient's ALARM condition is predicted, whether the patient is indoors or outdoors, conscious or unconscious, a redundant protocol is utilized to relay that ALARM condition to a central monitoring station. The central monitoring station informs the patient's doctor, and then uses what ever means are available to transport the patient to the nearest emergency room for treatment. An apparatus and method for pacing the heart in a natural way, once a potentially fatal arrhythmia has been predicted is also disclosed.

Owner:GW SCI

Rearview Mirror Assemblies with Anisotropic Polymer Laminates

ActiveUS20100110553A1High strengthAdequate flatness of filmMirrorsNon-linear opticsLower limitWing mirror

Anisotropic film laminates for use in image-preserving reflectors such as rearview automotive mirror assemblies, and related methods of fabrication. A film may comprise an anisotropic layer such as a light-polarizing layer and other functional layers. The film having controlled water content is heated under omnidirectional pressure and vacuum to a temperature substantially equal to or above a lower limit of a glass-transition temperature range of the film so as to be laminated to a substrate. The laminate is configured as part of a mirror structure so as to increase contrast of light produced by a light source positioned behind the mirror structure and transmitted through the mirror structure towards a viewer. The mirror structure is devoid of any extended distortion and is characterized by SW and LW values less than 3, more preferably less than 2, and most preferably less than 1.

Owner:GENTEX CORP

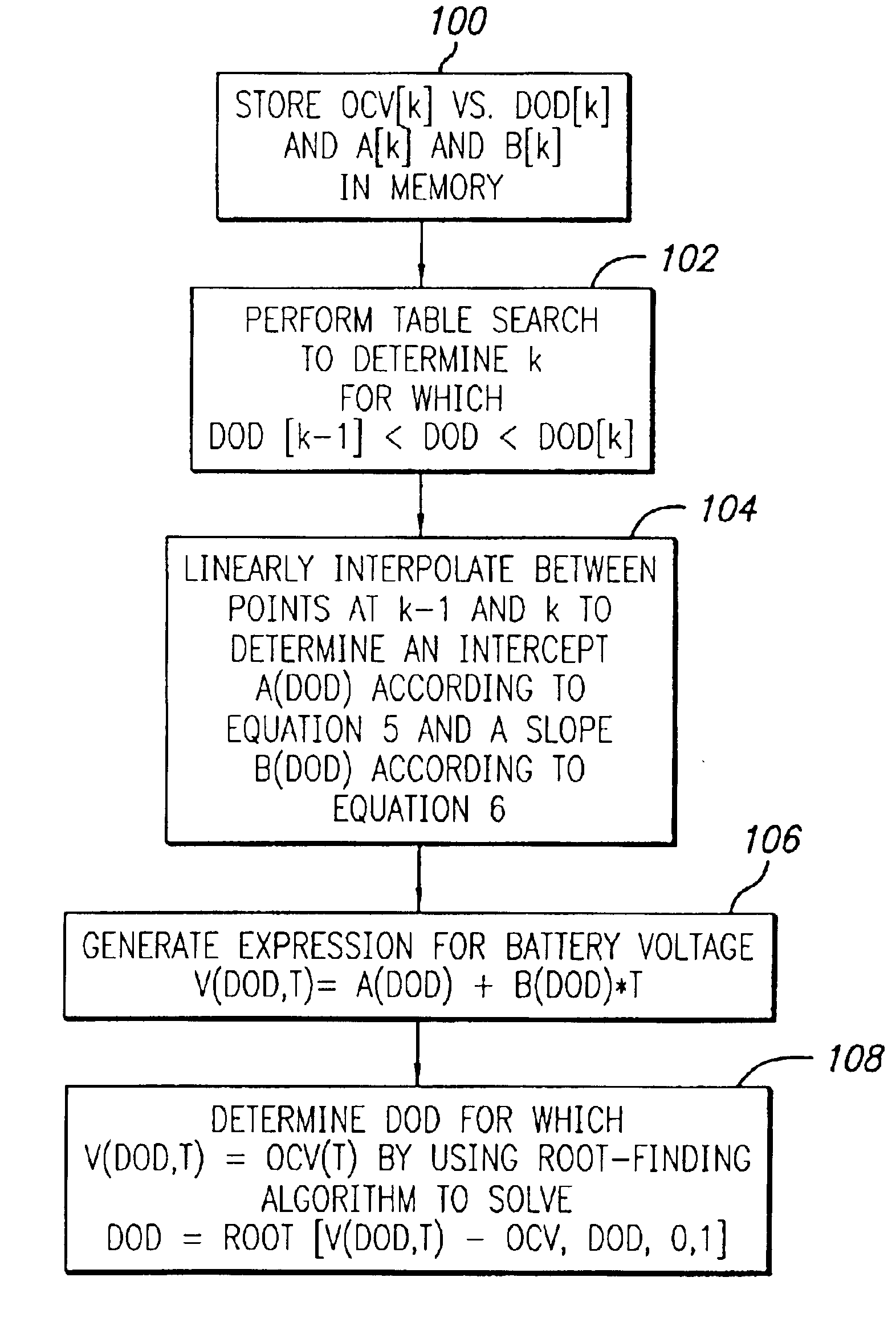

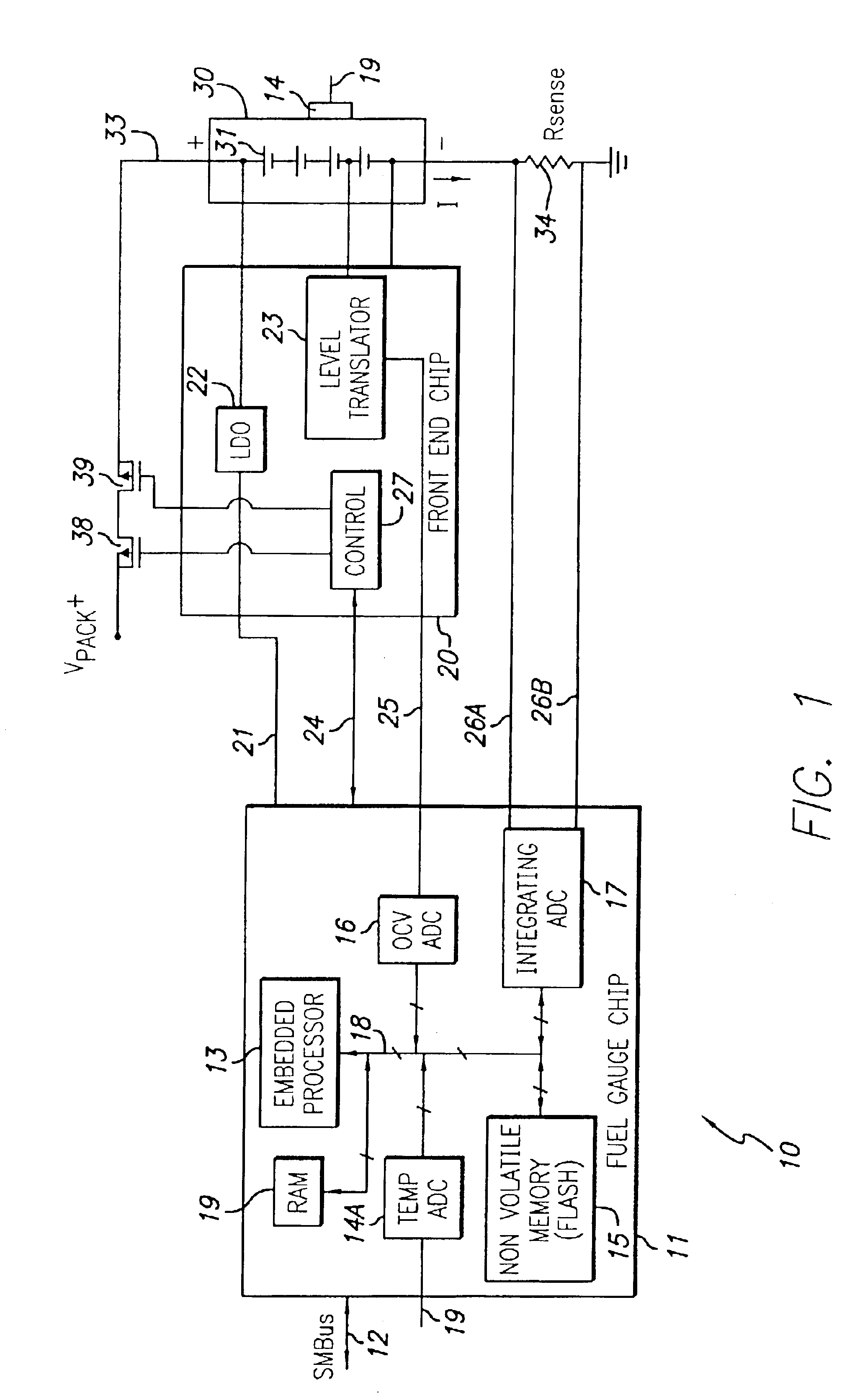

Circuit and method for measurement of battery capacity fade

InactiveUS6892148B2Accurately indicatedReduce eliminateBatteries circuit arrangementsResistance/reactance/impedenceLower limitElectrical battery

The remaining run-time (t_rem) of a battery is determined independently of the condition of the battery and the amount of load on the battery by obtaining the value of a present total zero-current capacity (Qmax) of the battery based on relaxed-battery OCV values measured just before and just after a charging or discharging cycle. A current through the battery is integrated to determine a transfer of charge (Q) from the battery, and a value of total run-time (t_total) that would be required to reduce the open circuit voltage of the battery to a predetermined lower limit (Vmin) is determined. The remaining run-time (t_rem) is determined by subtracting the duration of the integrating from the total run-time (t_total).

Owner:TEXAS INSTR INC

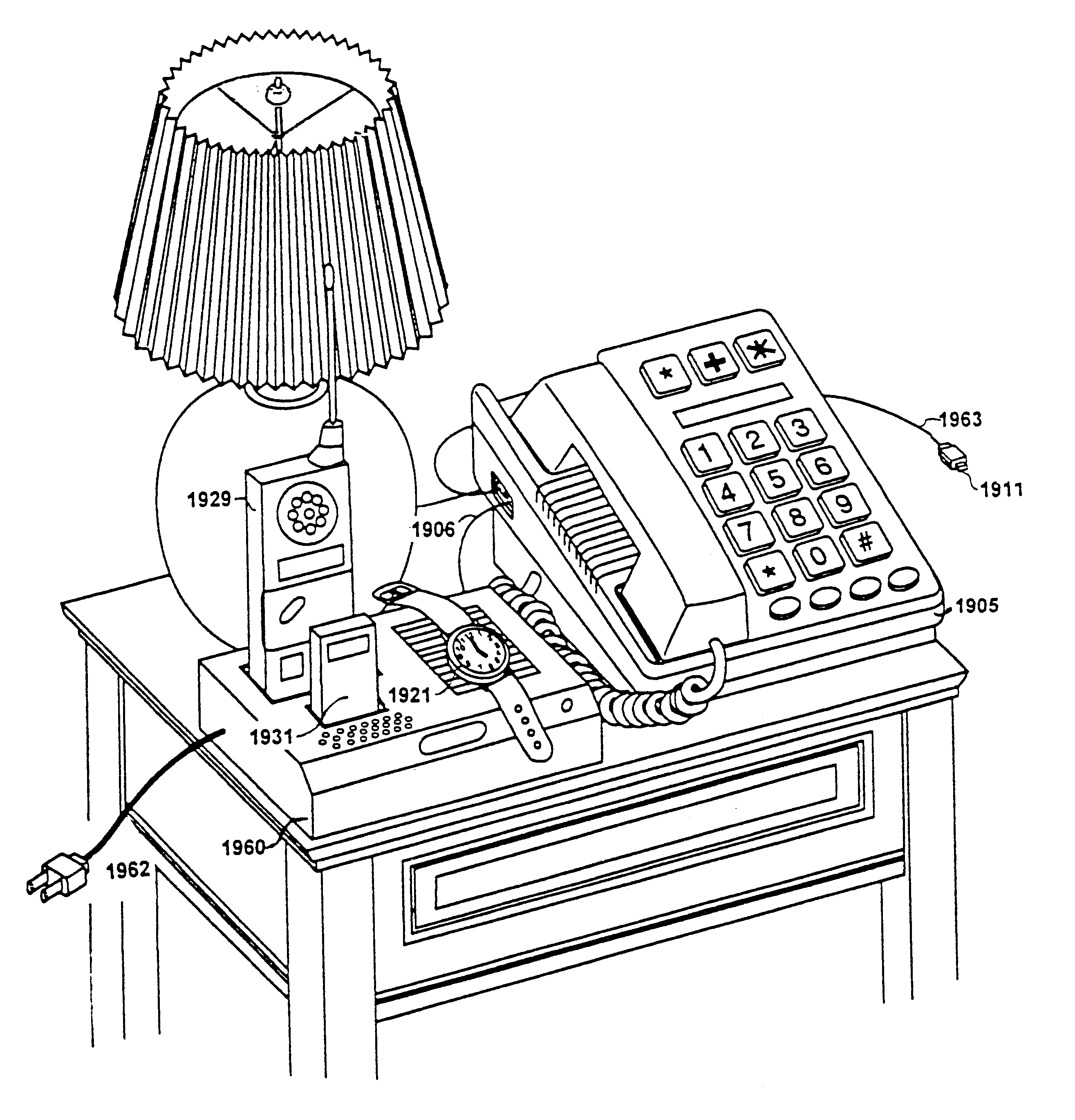

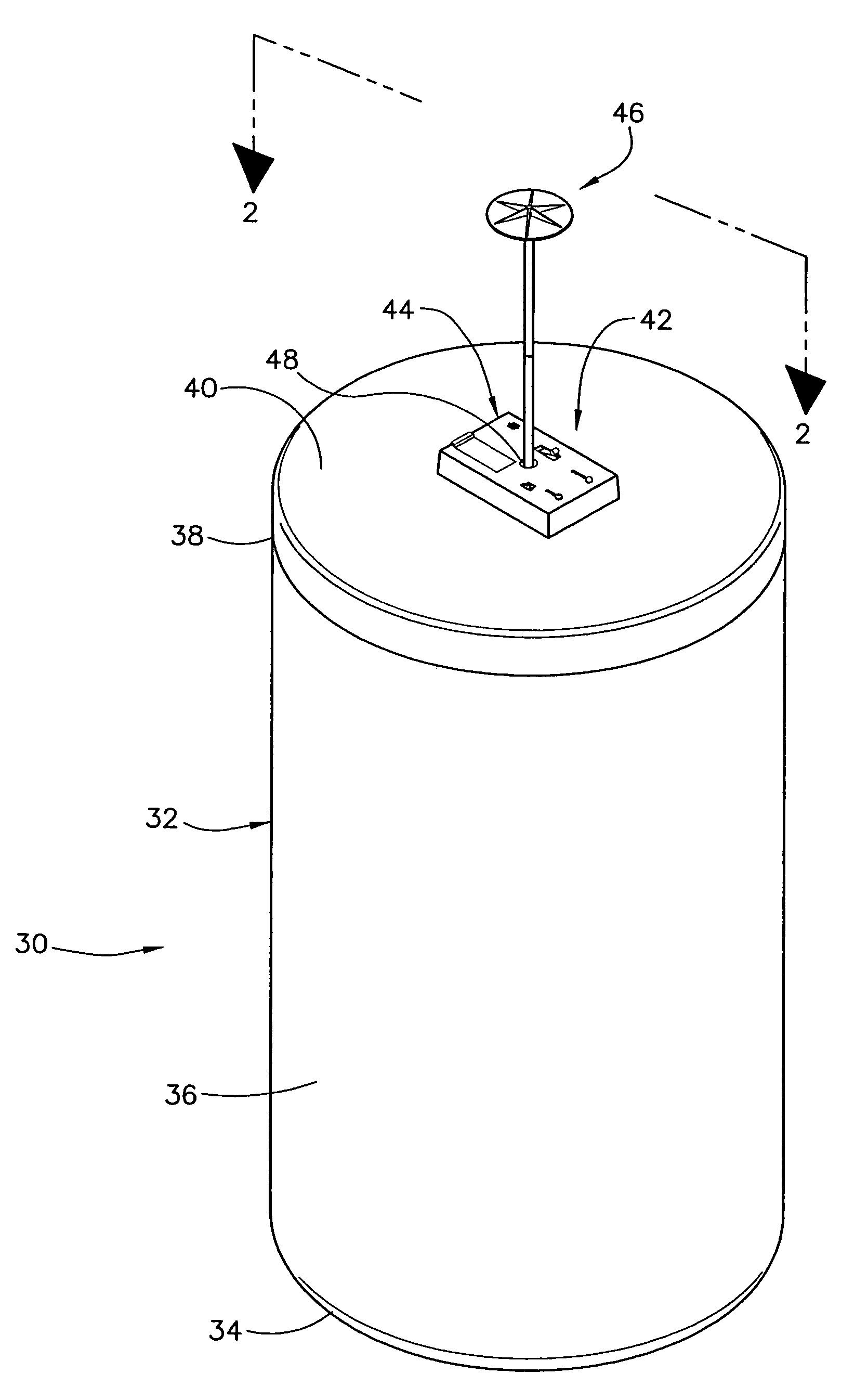

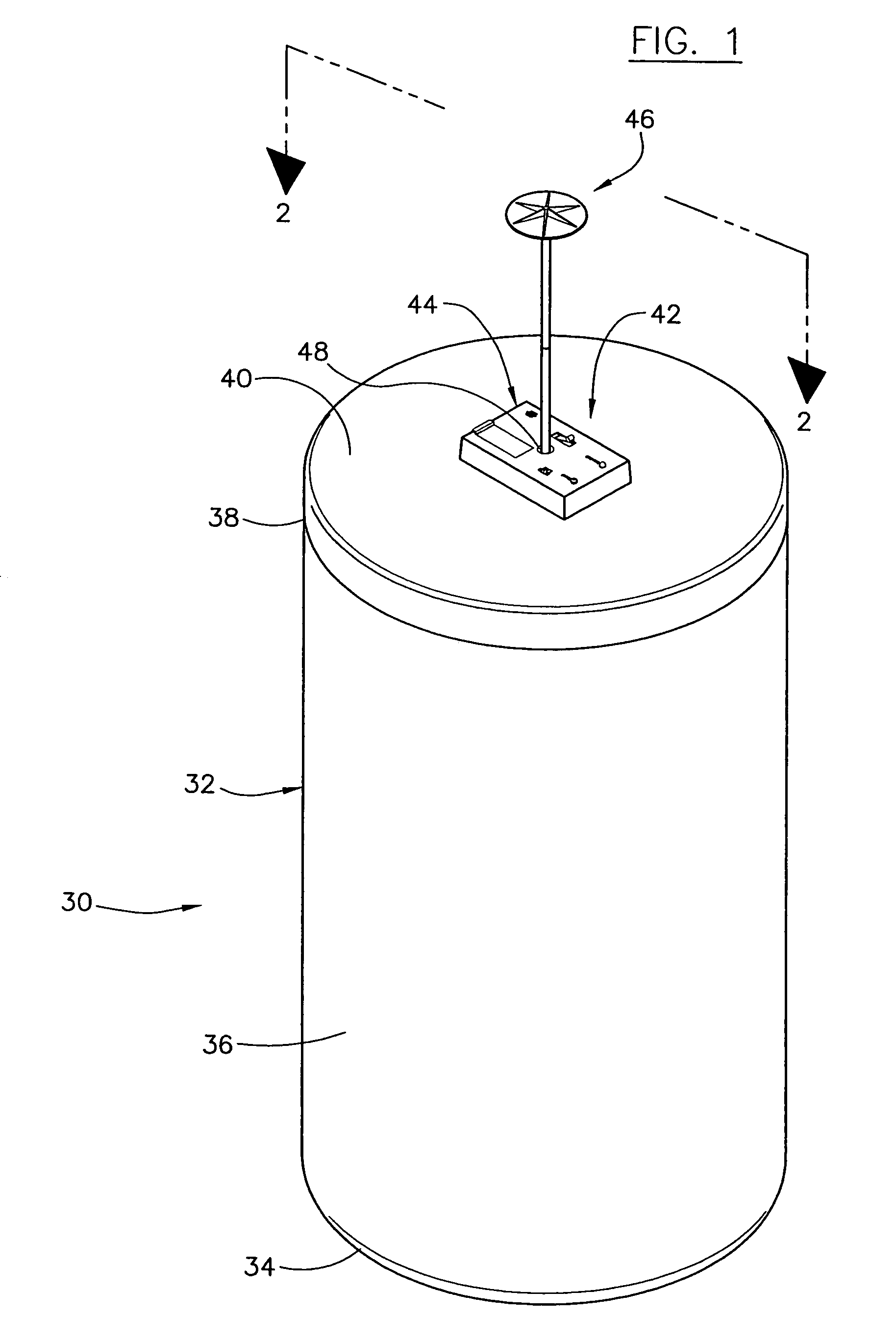

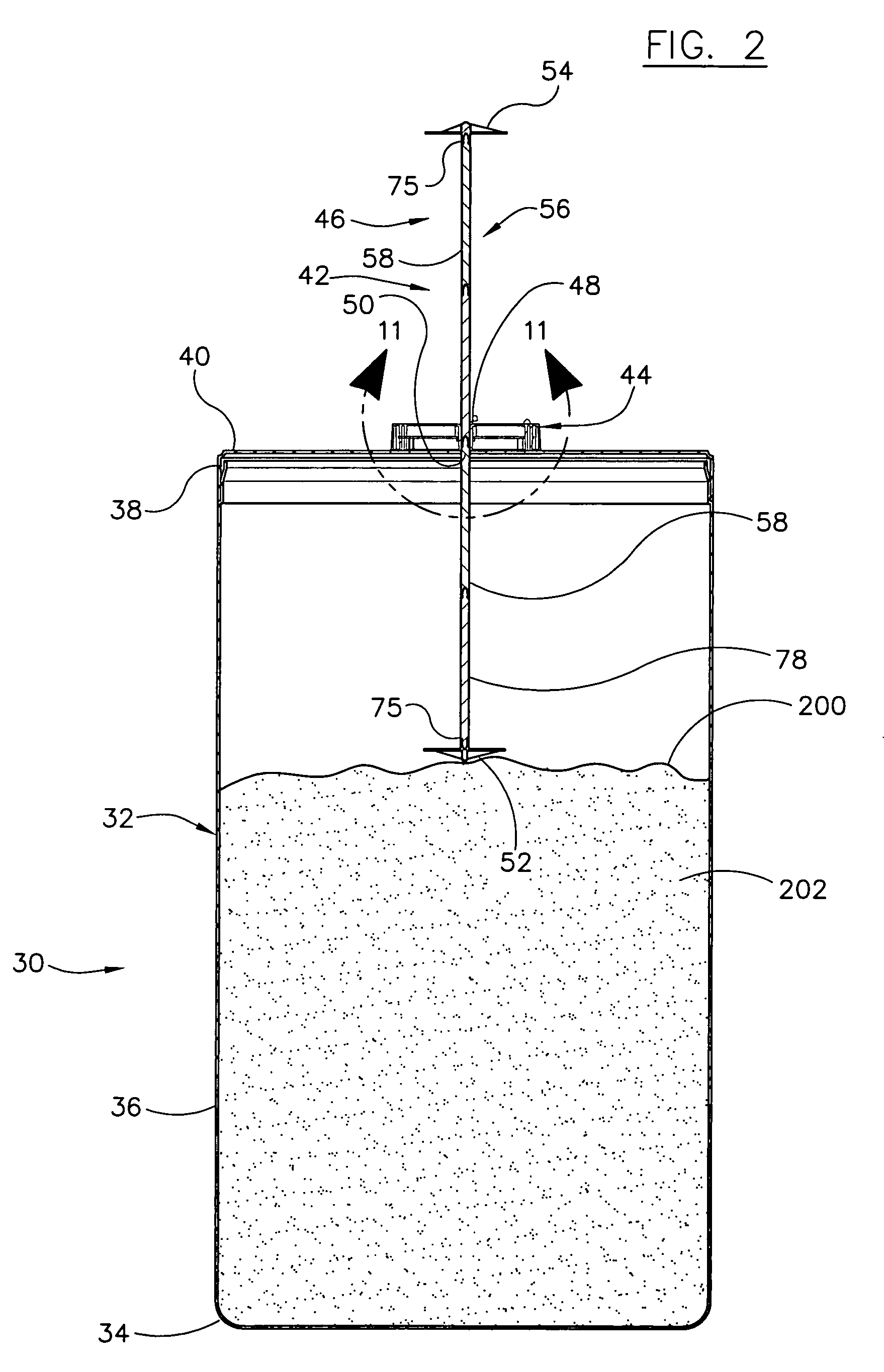

Water softener monitoring device

A device for monitoring the level or amount of a material within a container is provided. The device includes a detection mechanism that can be a direct detection mechanism or an indirect detection mechanism. When the detection mechanism senses an upper level of the substance in the container that is below a predetermined lower limit for the substance, the mechanism operates an alarm mechanism to emit an audible and / or visible alarm to alert an individual to the low level of the substance within the container. The alarm mechanism can be integrally formed with the detection mechanism, or can be spaced from the detection mechanism in order to provide a more accessible point for the viewing or hearing of the alarm emitted by the alarm mechanism.

Owner:WANIE ANDREW J

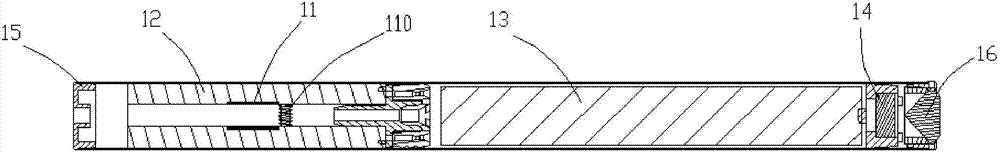

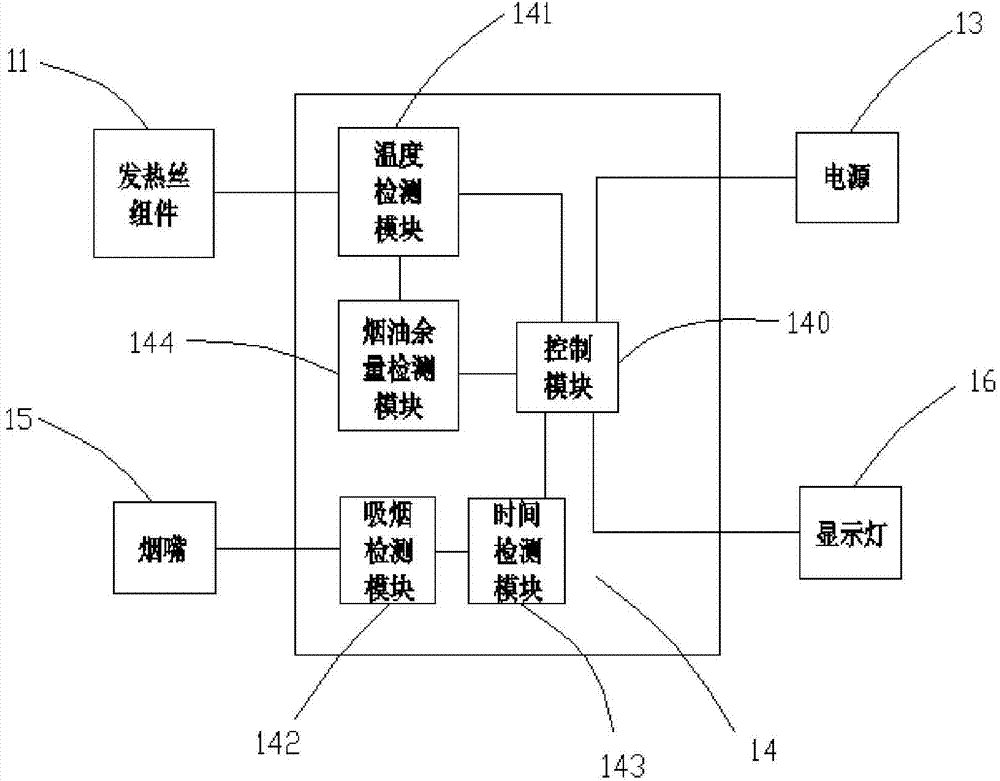

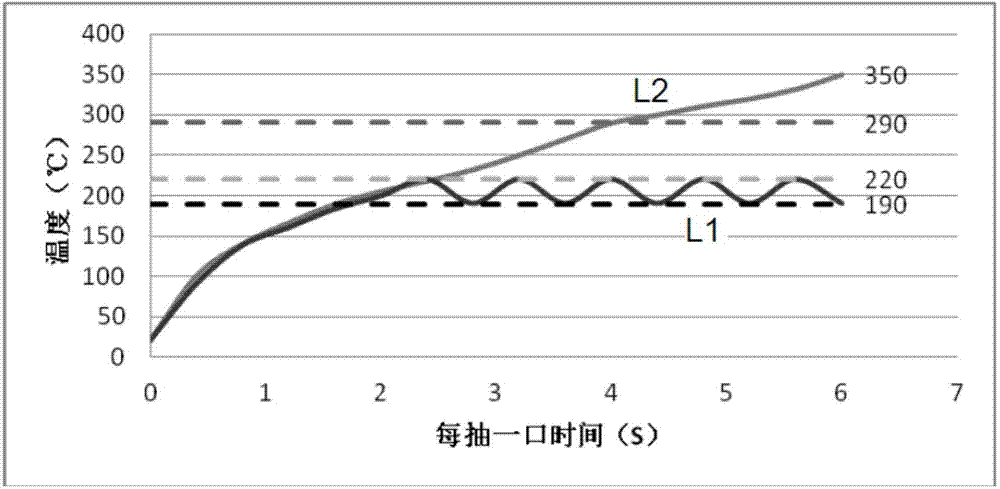

Electronic cigarette and control method thereof

ActiveCN104116138AAvoid burnt smellSave powerTobacco devicesOhmic-resistance heating detailsLower limitCurrent voltage

The invention provides an electronic cigarette and a control method thereof. The electronic cigarette comprises a heating wire assembly, a power source and a controller. The heating wire assembly is used for generating heat and comprises heating wires, wherein the resistance value of the heating wires changes along with the changes of temperatures. The power source is used for providing voltages for the heating wire assembly. The controller is electrically connected with the heating wire assembly and the power source and used for controlling the power source to output the voltages. The controller comprises a temperature detecting module which is used for detecting the resistance value of the heating wires to obtain the real-time temperature of the heating wire assembly, an upper limit heating temperature and a lower limit heating temperature are set in the temperature detecting module, the controller controls the power source to output a first voltage when the real-time temperature is smaller than or equal to the lower limit heating temperature and controls the power source to output a second voltage when the real-time temperature is larger than or equal to the upper limit heating temperature, the second voltage is smaller than the first voltage, and the controller controls the power source to keep outputting the current voltage when the real-time temperature is larger than the lower limit heating temperature and smaller than the upper limit heating temperature. The electronic cigarette and the control method thereof can ensure the taste consistency of the smoke of all times and save electric quantity.

Owner:SHENZHEN SMOORE TECH LTD

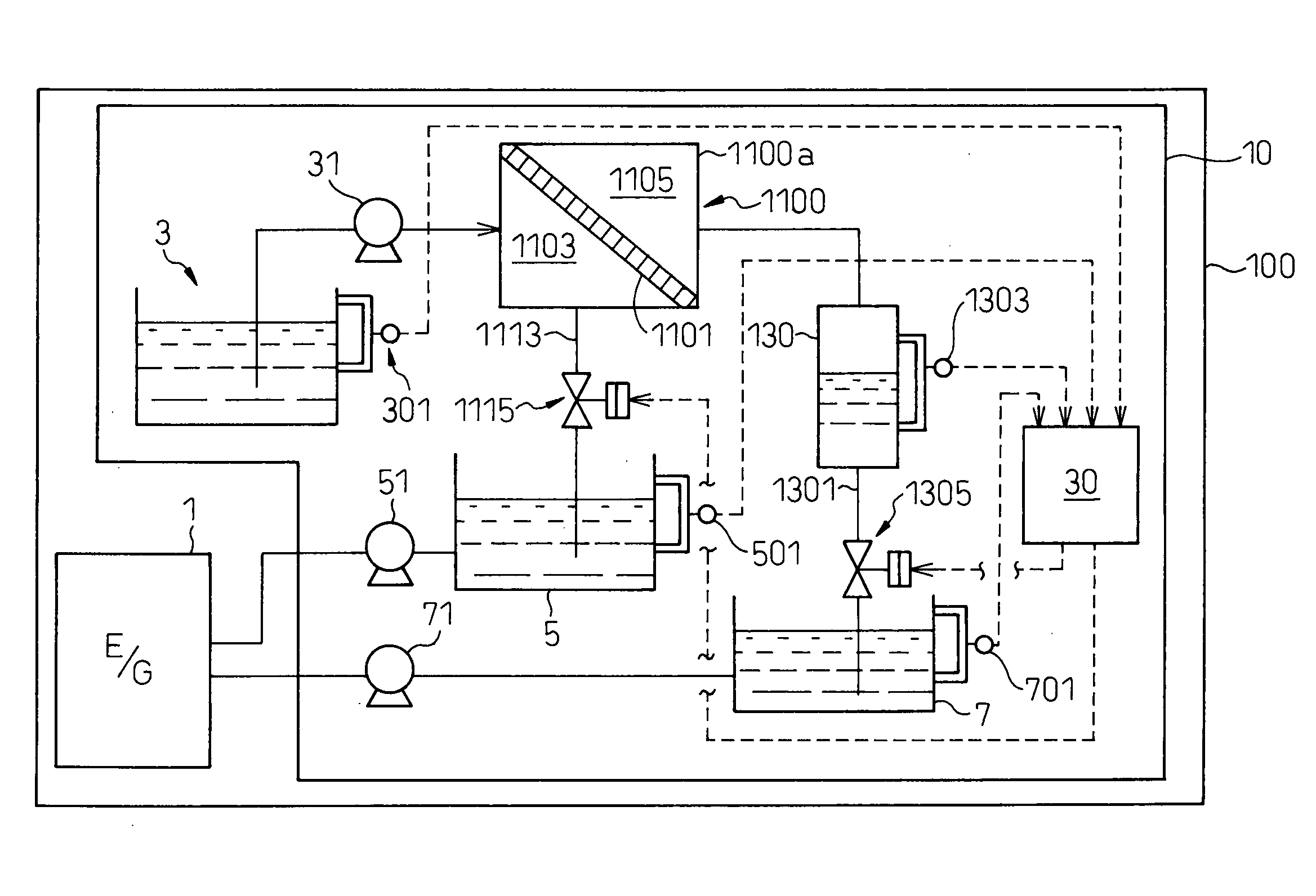

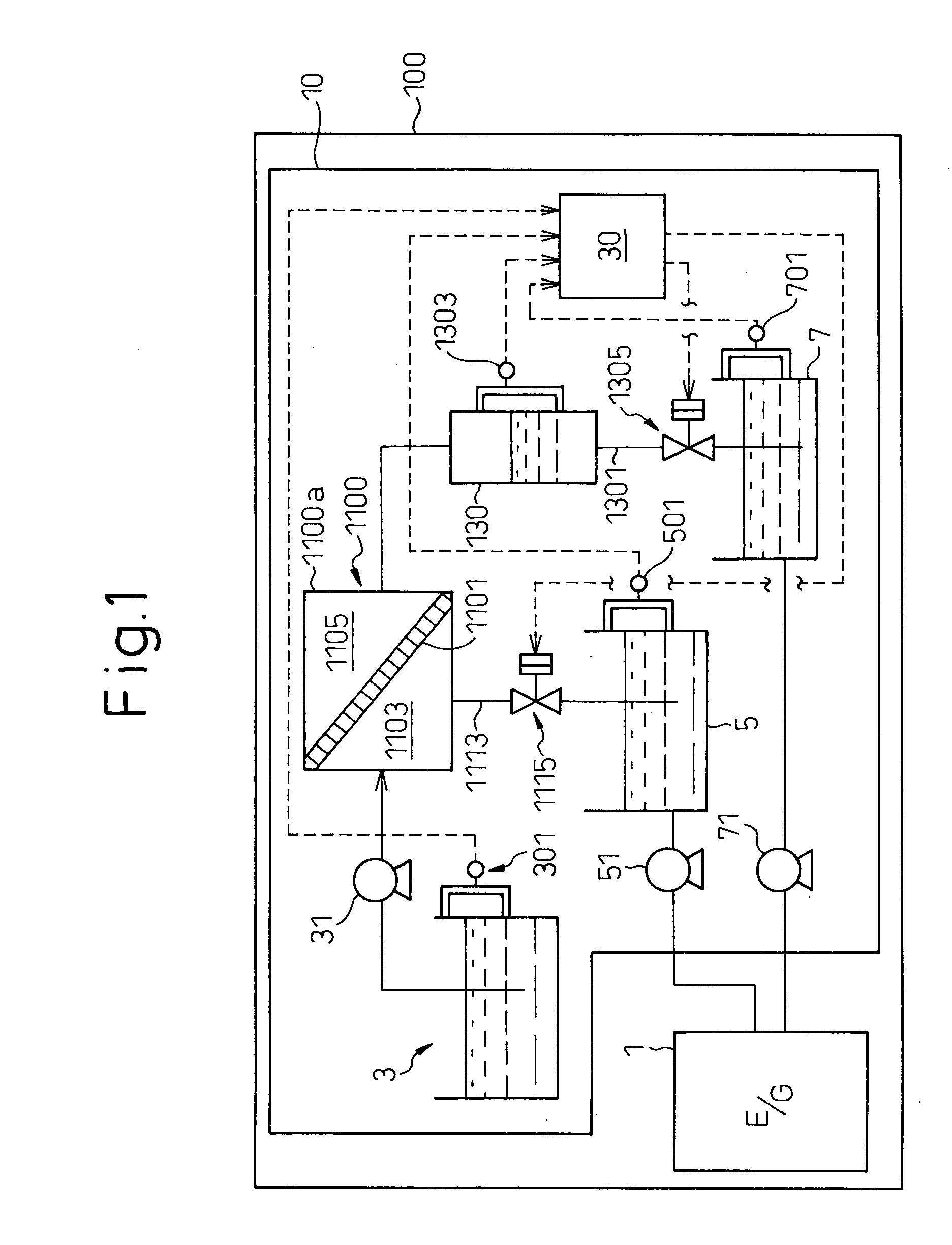

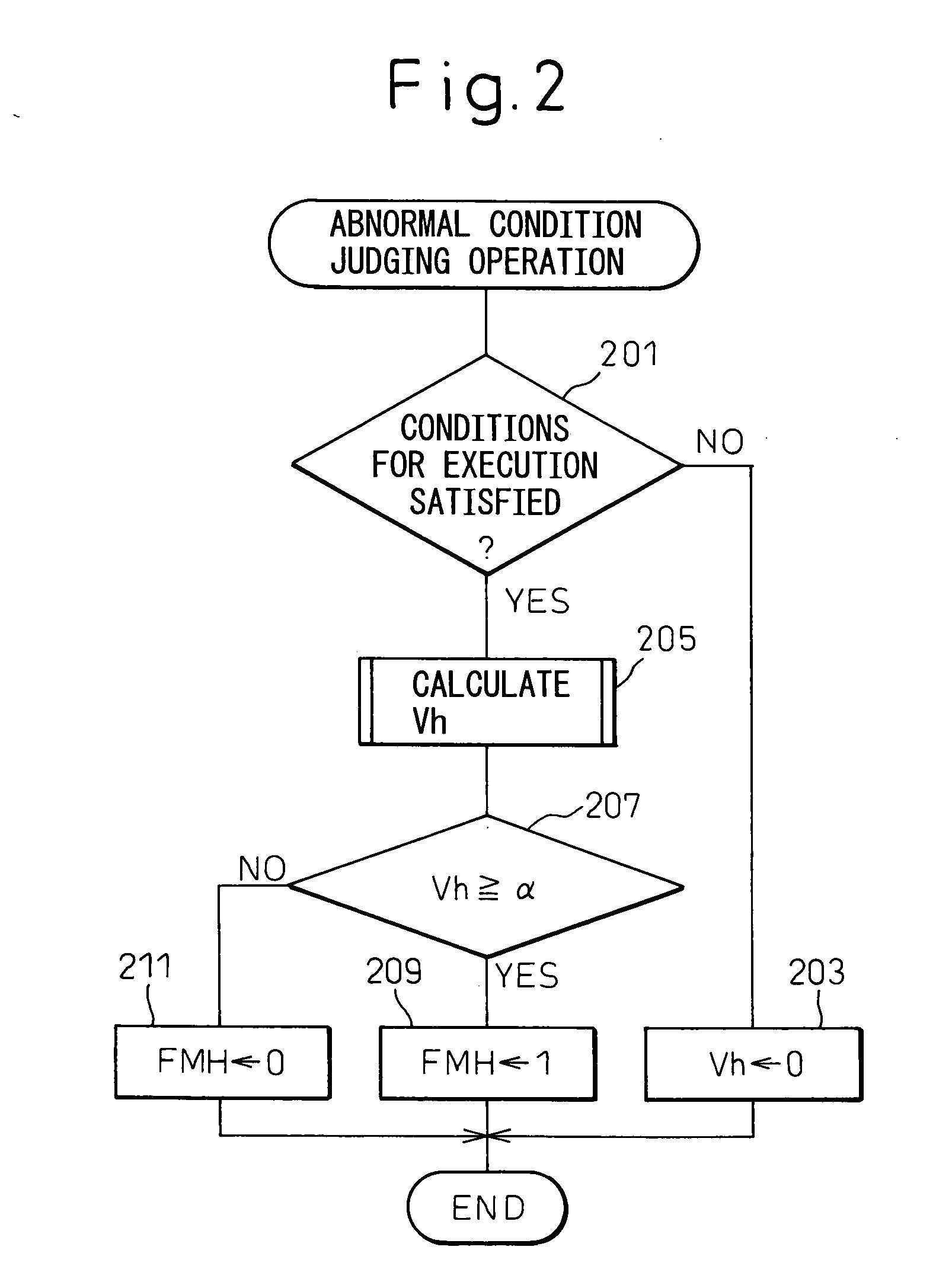

Onboard fuel separation apparatus for an automobile

A fuel separation apparatus includes a fuel tank storing the material fuel fed to a separation membrane, a fuel tank storing a separated low-octane fuel, and a fuel tank storing a separated high-octane fuel. An electronic control unit of the separation apparatus calculates the flow rate (amount of formation) of the high-octane fuel flowing into the high-octane fuel tank based on a change in the liquid level in the tank and on the amount of fuel fed to an engine from the tank, and so judges that an abnormal condition is occurring due to the breakage of the separation membrane when the amount of forming the high-octane fuel is larger than a predetermined upper limit value and that an abnormal condition is occurring due to a drop in the function of the separation membrane when the amount of formation is smaller than a predetermined lower limit value.

Owner:TOYOTA JIDOSHA KK

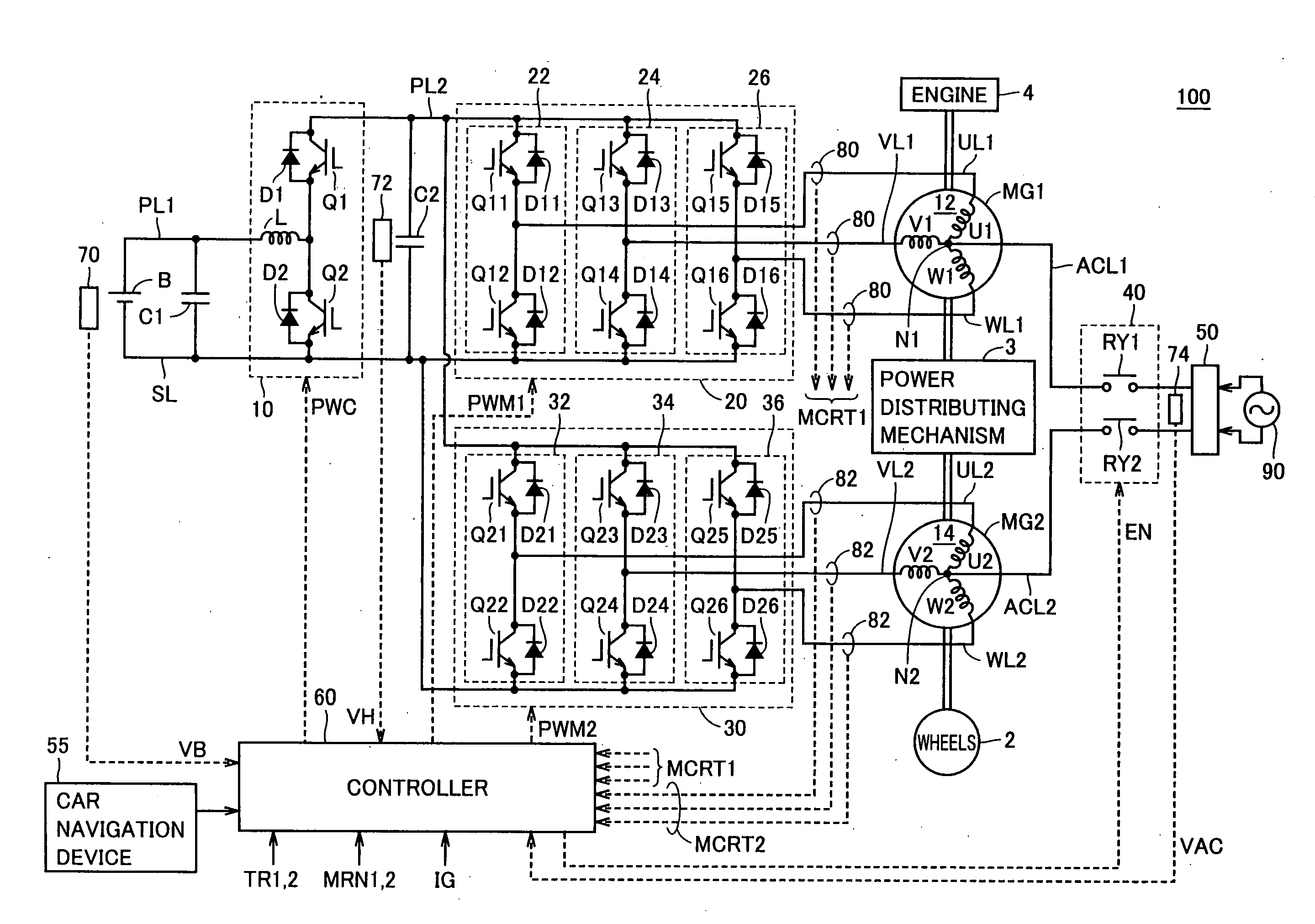

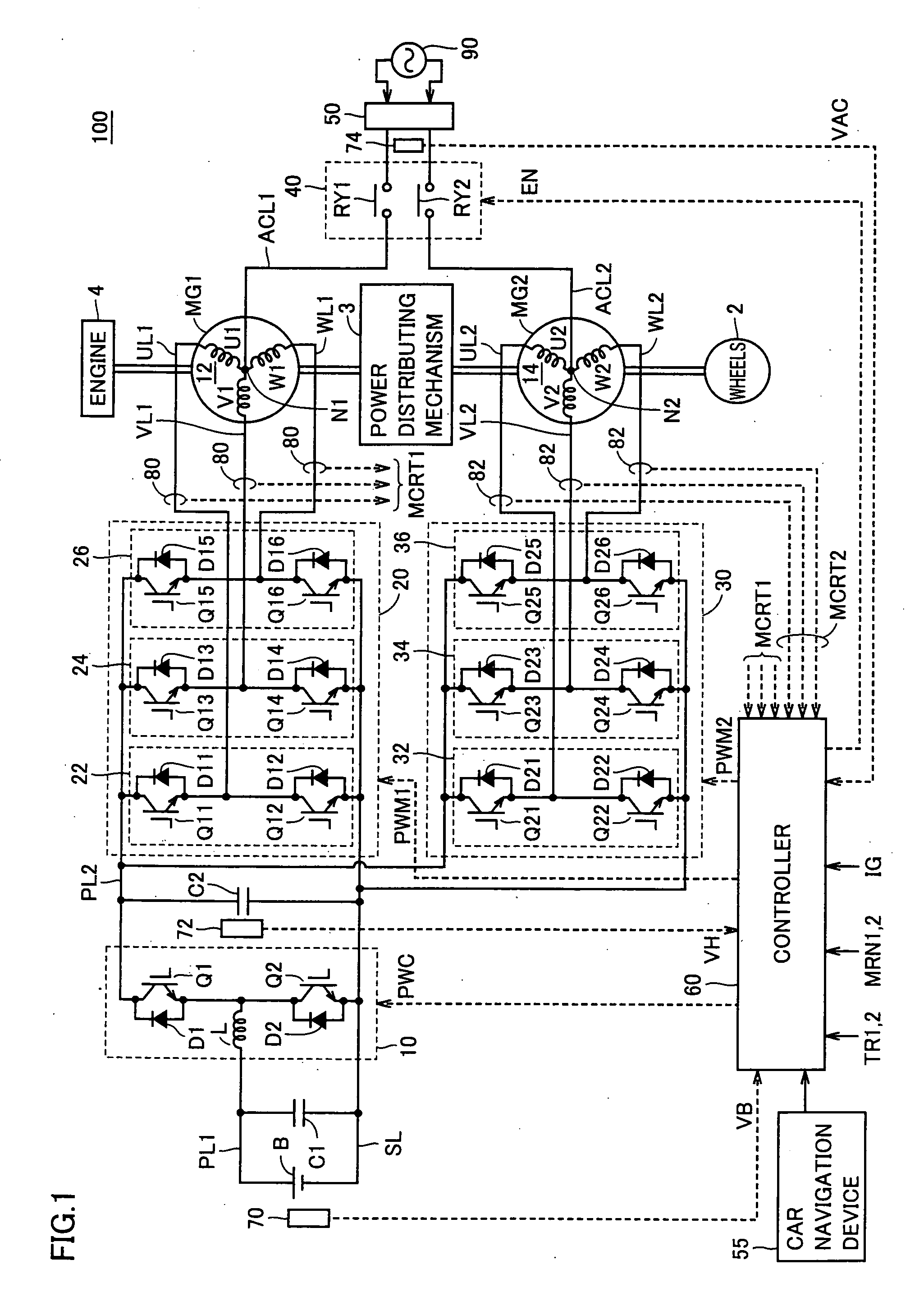

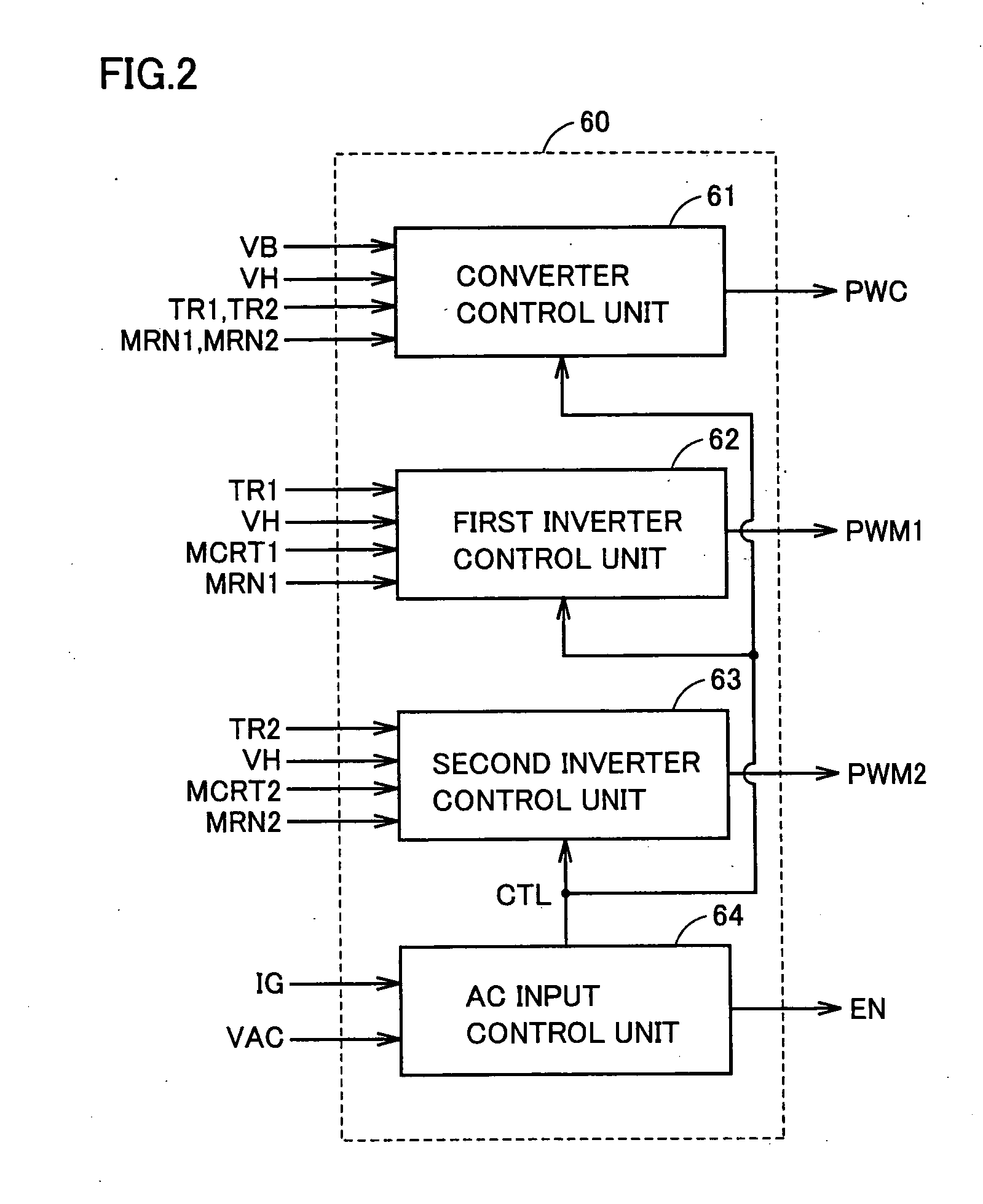

Hybrid vehicle and method of controlling the same

InactiveUS20090277702A1Improve fuel efficiencySmall sizeHybrid vehiclesMultiple ac dynamo-electric motors controlLower limitHybrid vehicle

A controller obtains a planned travel distance from a current position of a vehicle to a preset charging point from a car navigation system, and based on the obtained planned travel distance, sets upper and lower limit values for controlling SOC of an electric storage lower as it comes closer to the charging point. The controller controls the SOC of the electric storage such that the SOC is within the set upper and lower limits of SOC control.

Owner:TOYOTA JIDOSHA KK

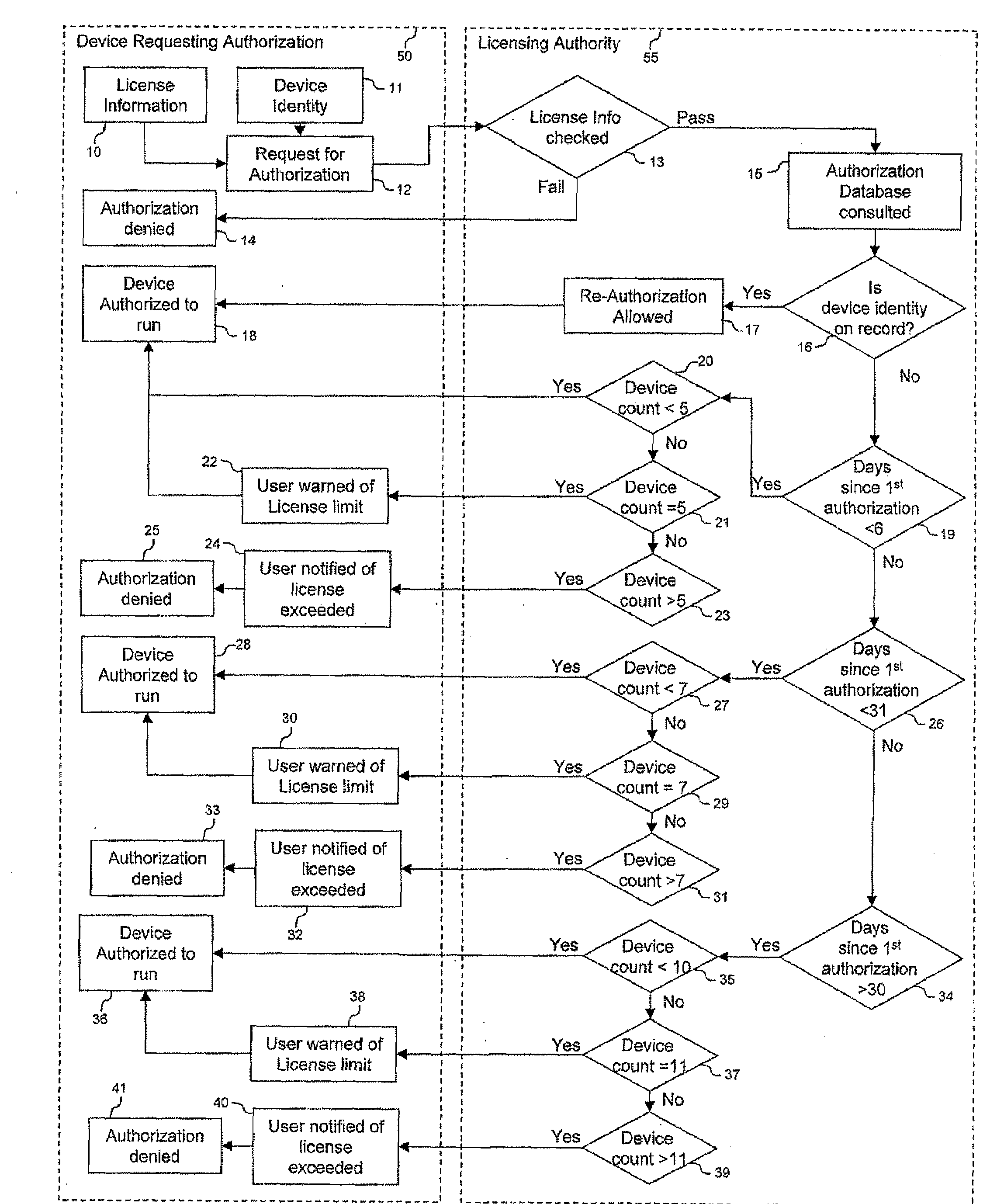

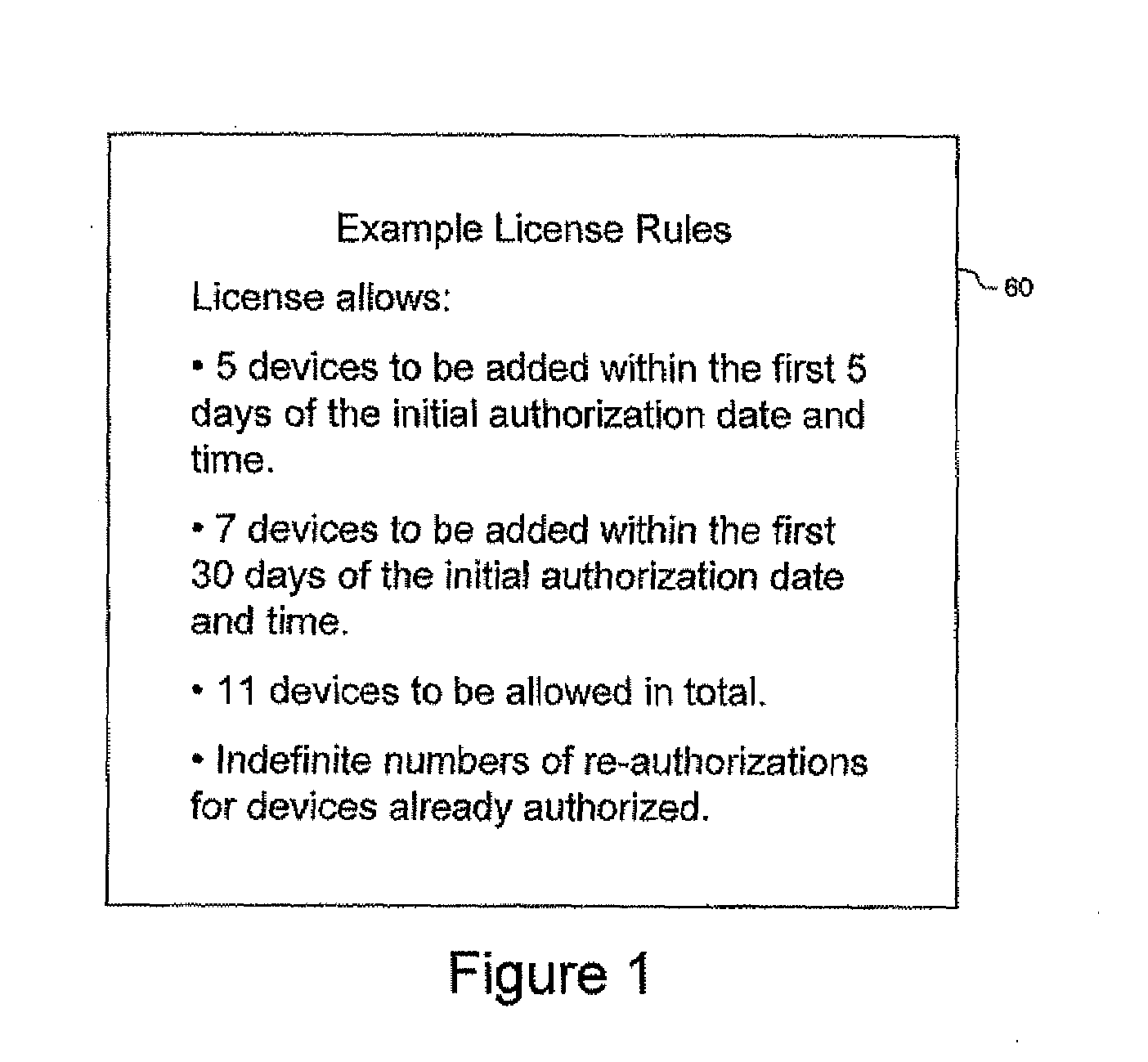

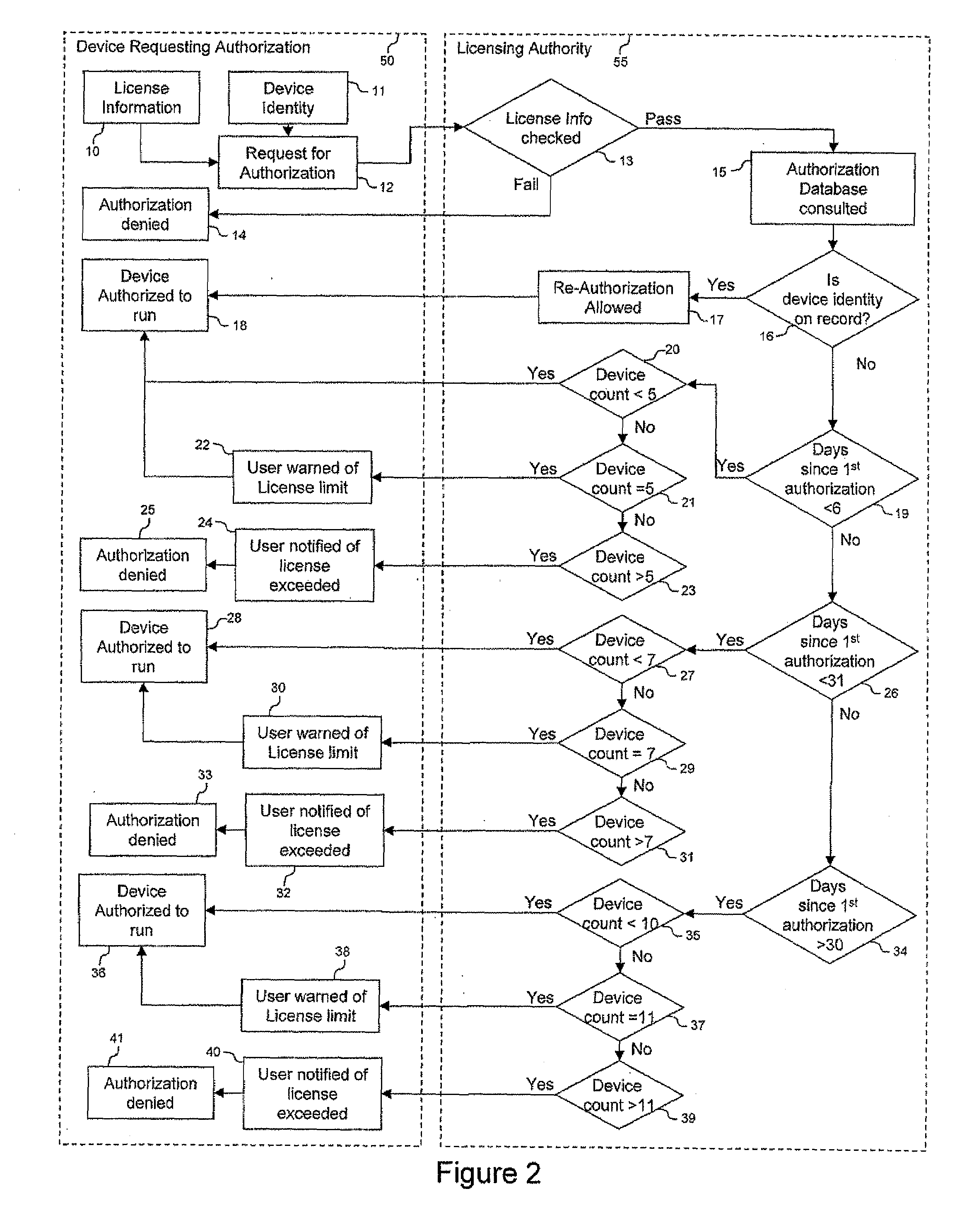

System and Method for Adjustable Licensing of Digital Products

ActiveUS20090138975A1Well formedDigital data processing detailsUser identity/authority verificationLower limitTime segment

Techniques are provided for adjusting the number of devices allowed to use a digital product (e.g., software) under a license. In one embodiment, the technique may involve setting the allowed number of devices to a first upper / lower limit for a first time period, and, after the first time period has expired, increasing / lowering the allowed number of devices to a second upper / lower limit for a second time period. The technique may involve, readjusting the allowed number for a third time period, thereby allowing for a changing number of device installations of the digital product.

Owner:UNILOC 2017 LLC

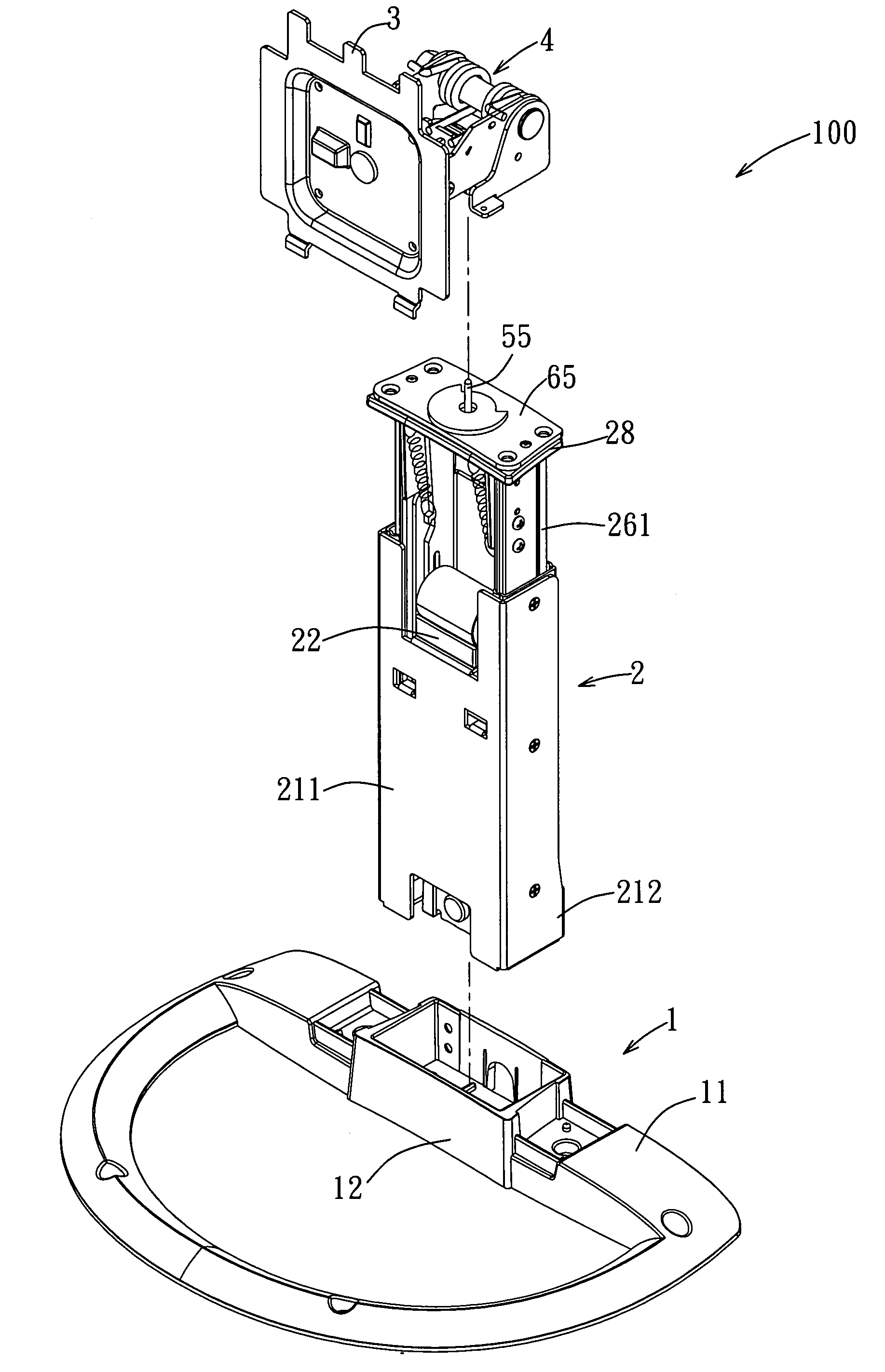

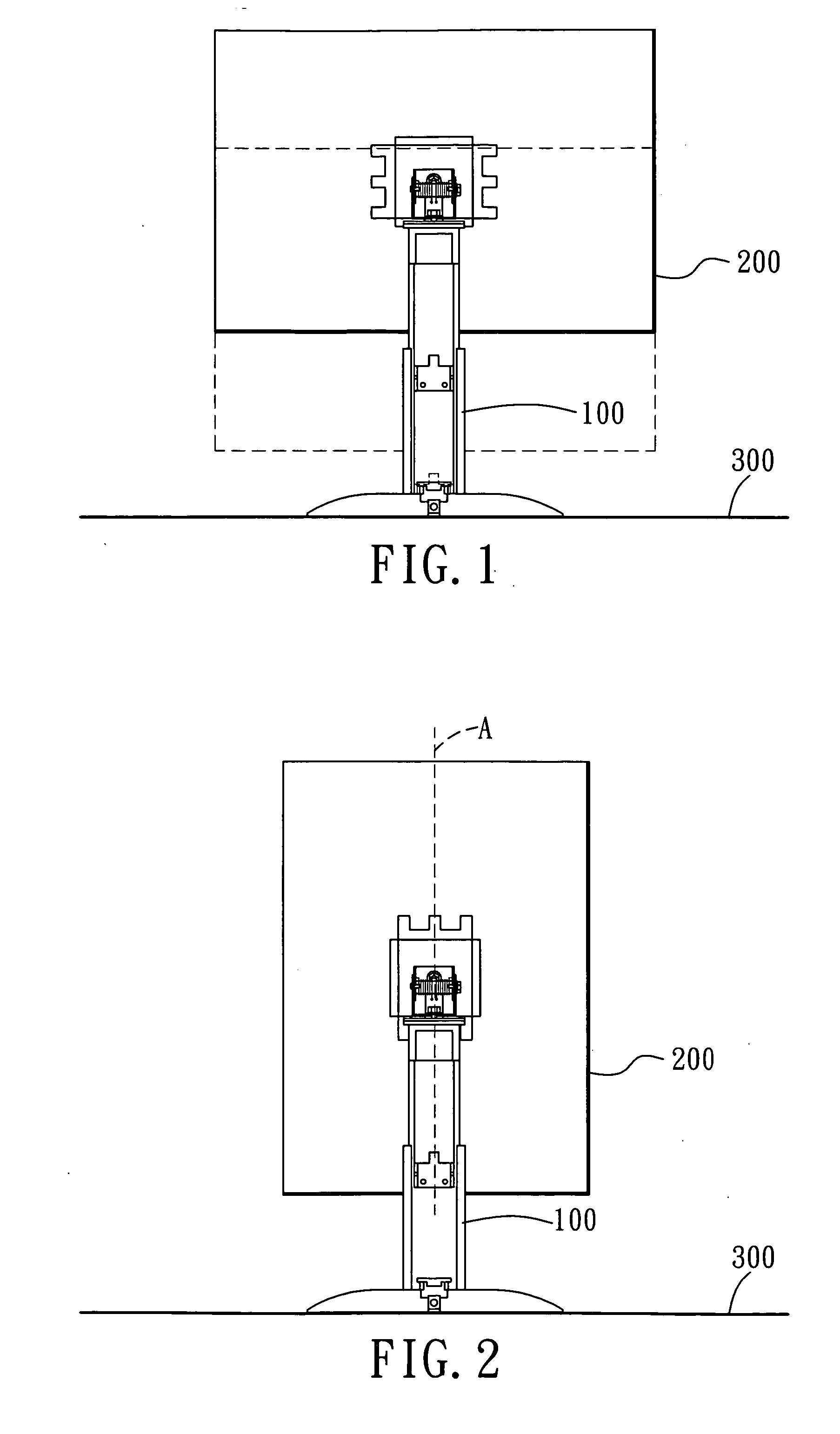

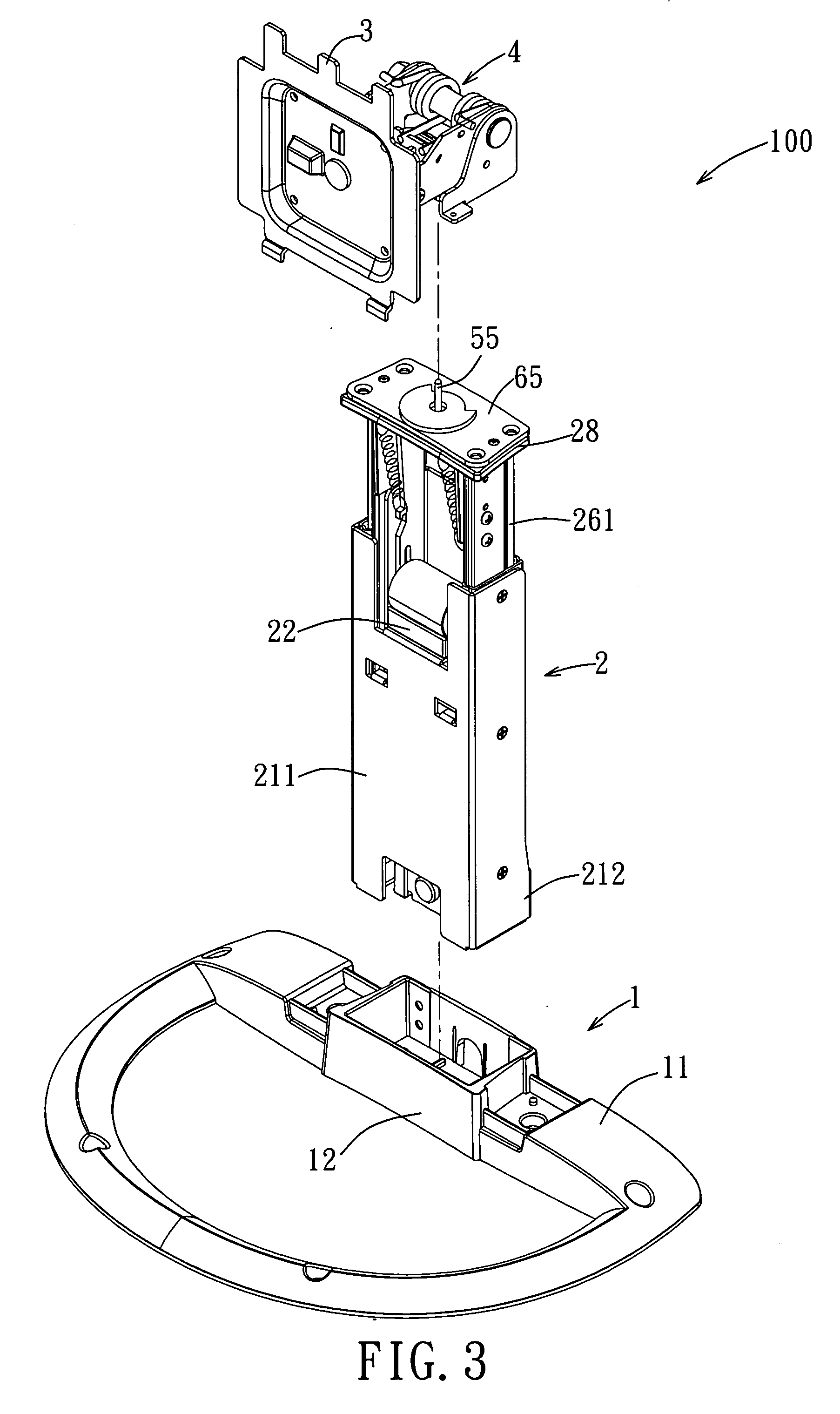

Height-adjustable support for a display device

InactiveUS20060219849A1Reduce restrictionsStatic indicating devicesDigital data processing detailsLower limitDisplay device

A height-adjustable support for a display panel includes a base, a telescopic unit, an angle-adjustable member, a coupling unit, and a control member. The telescopic unit includes a hollow outer member and an inner slide member. The outer member extends upwardly from the base, and is provided with an upper limiting part disposed above the base, and an inwardly projecting lower limiting part disposed between the upper limiting part and the base. The slide member has a slide arm extending slidably into the outer member, and a top seat disposed above the outer member. The coupling unit couples the angle-adjustable member to the top seat. The control member extends into the outer member, is coupled to the slide member, and cooperates with the lower limiting part to prevent impact between the display panel and a support surface.

Owner:FULFIL TECH

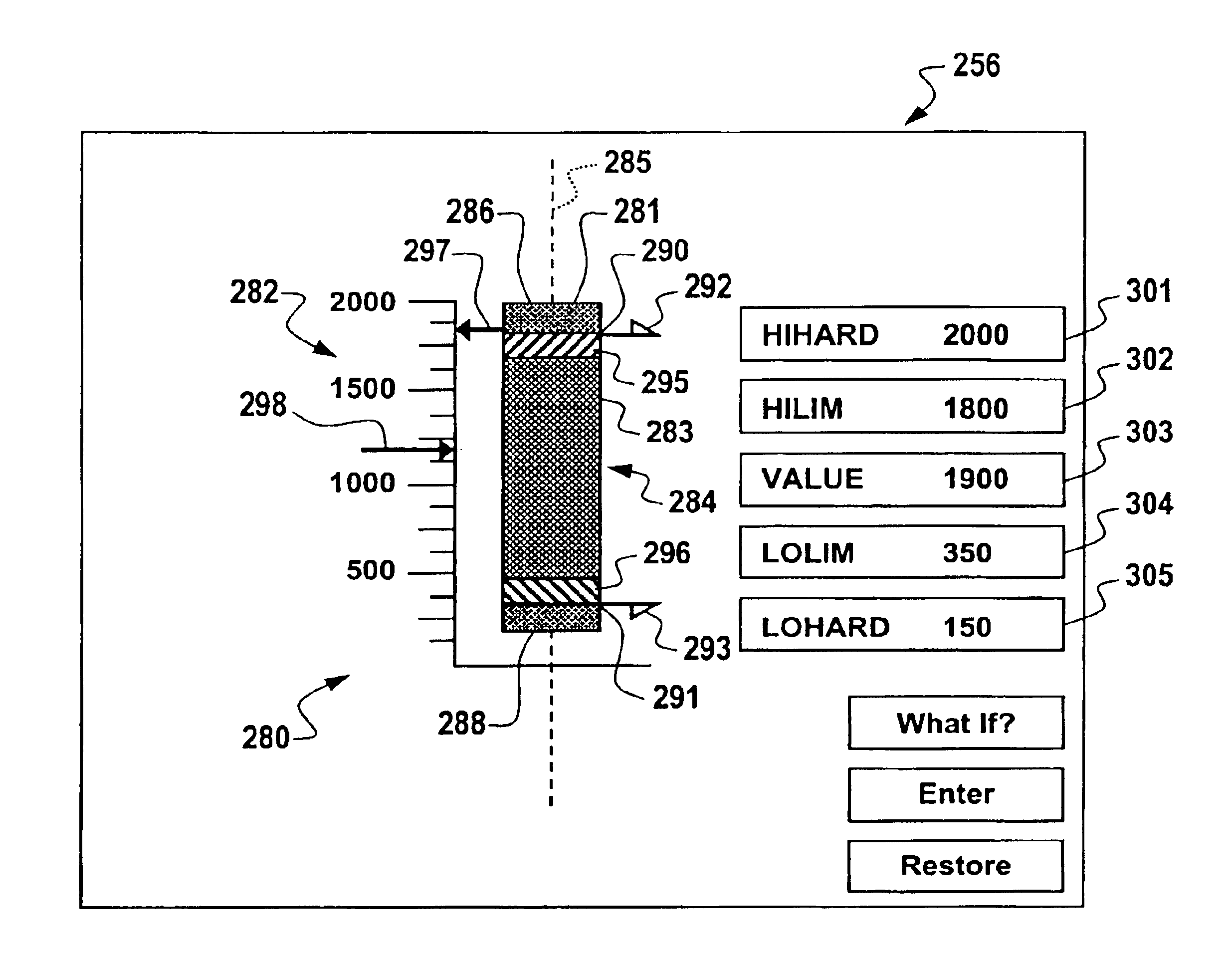

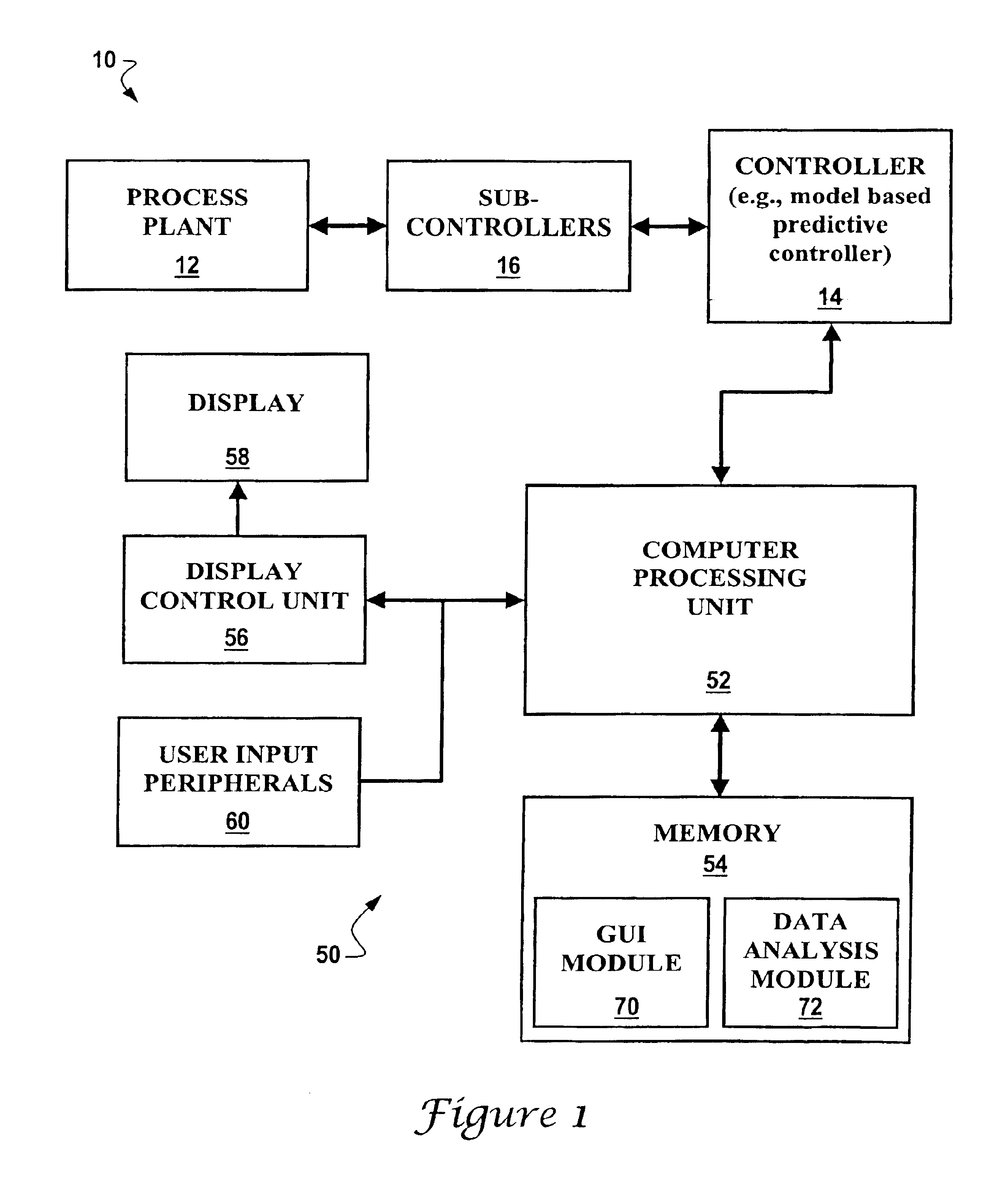

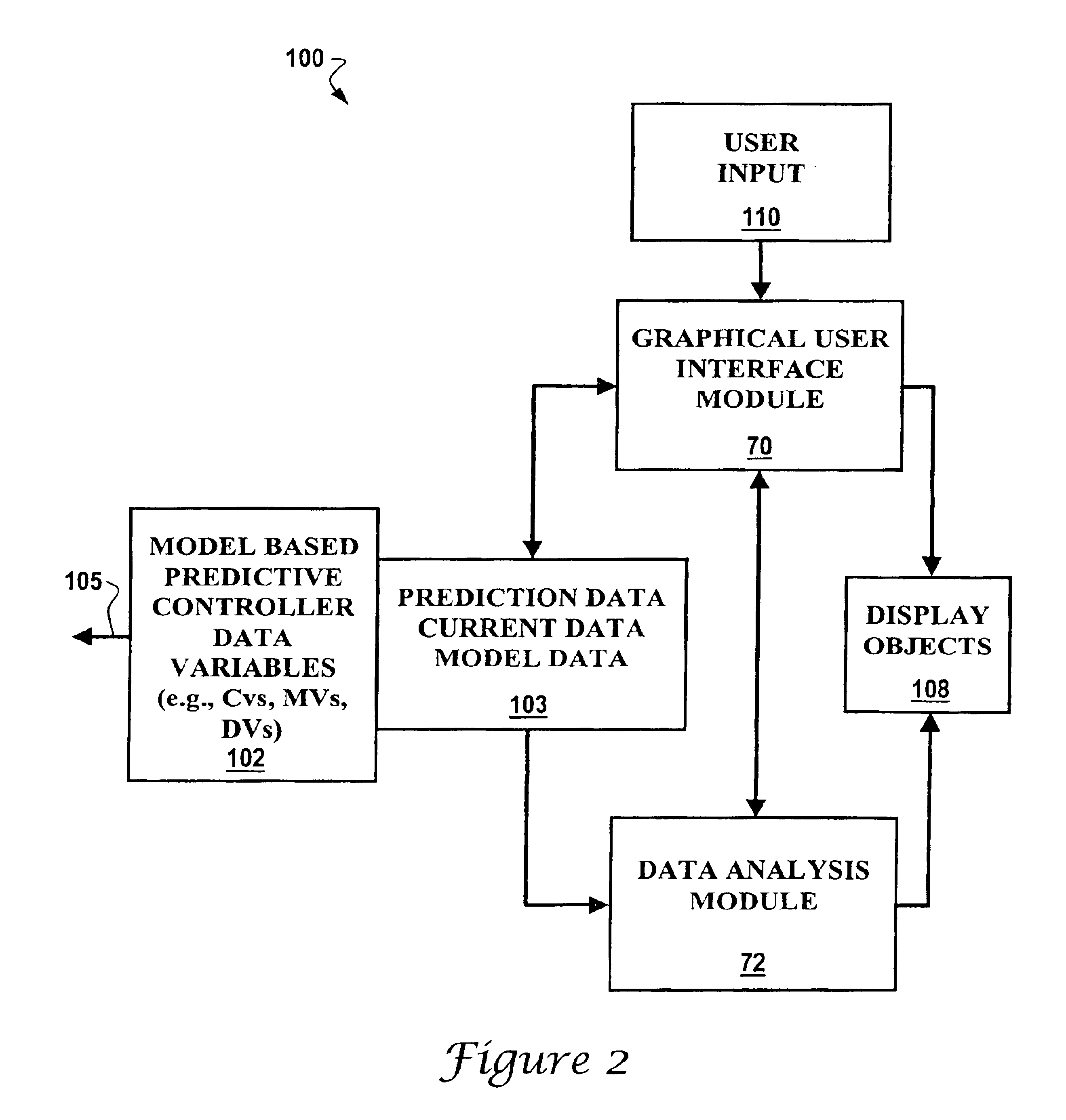

Process variable generalized graphical device display and methods regarding same

InactiveUS6901560B1Easy to understandProgramme controlData processing applicationsGraphicsLower limit

A graphical user display for providing real-time process information to a user for a process that is operable under control of one or more process variables is described. The graphical user display includes one or more graphical devices with each graphical device corresponding to a process variable. At least one graphical device for a corresponding process variable includes a gauge axis and at least one pair of high and low limit elements displayed on the gauge axis is representative of high and low process limit values for the corresponding process variable. A graphical shape displayed along the gauge axis is representative of the current value of the corresponding process variable relative to the process limit values. A computer implemented method for providing the at least one graphical device is also provided.

Owner:HONEYWELL INC

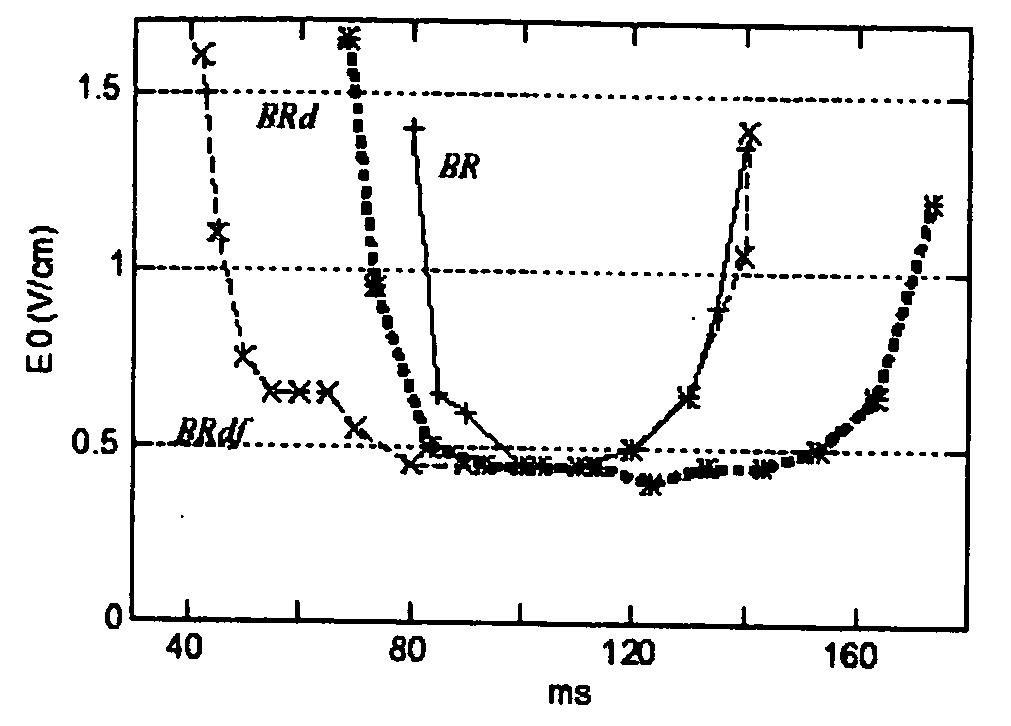

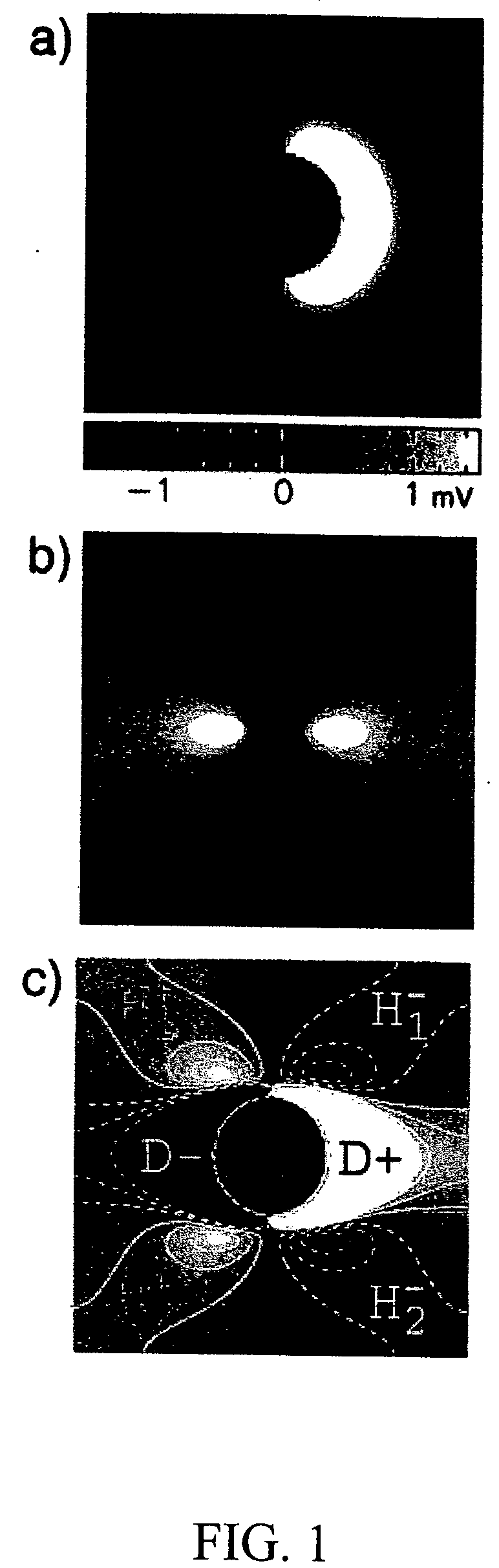

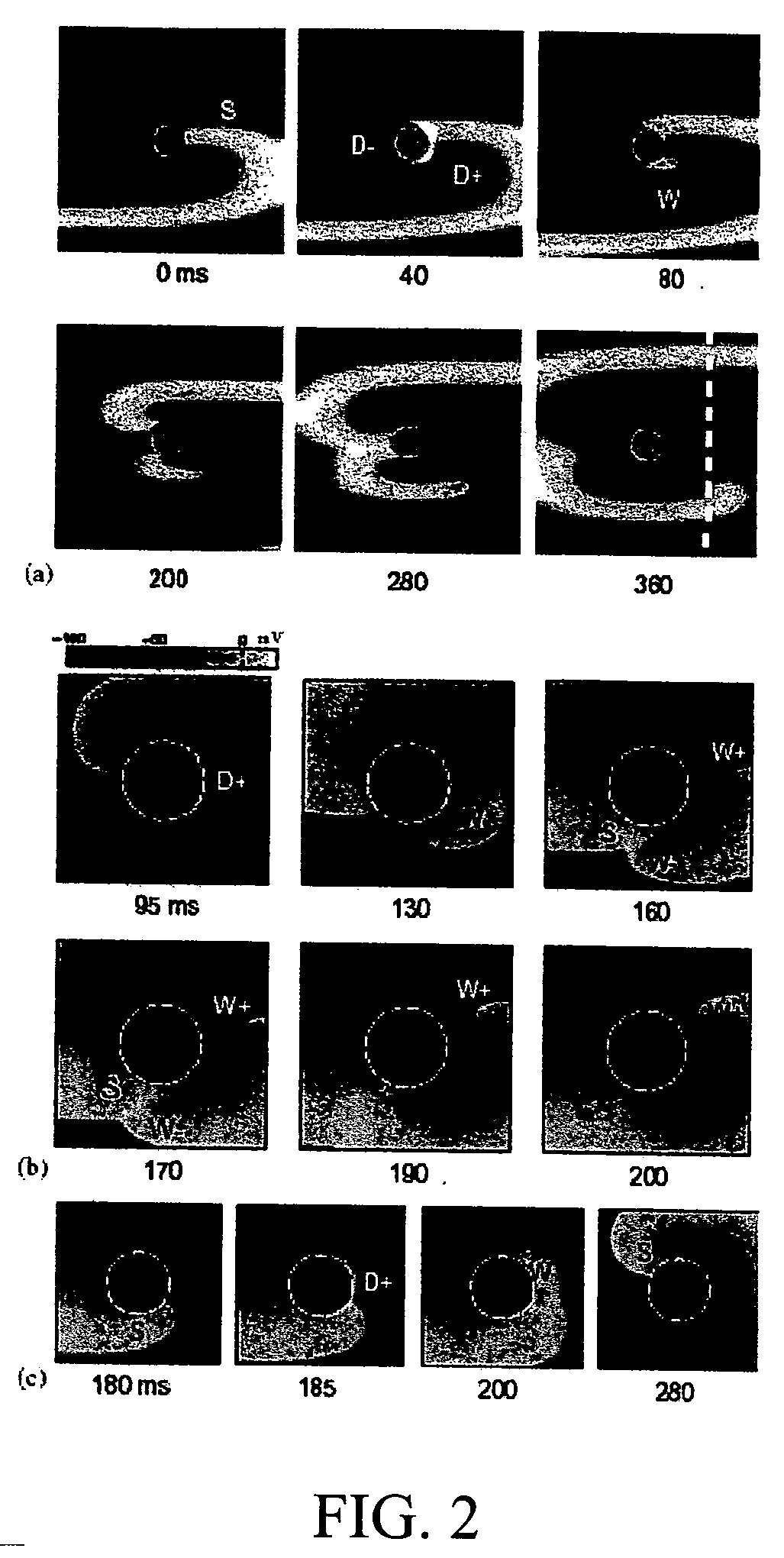

Method for low-voltage termination of cardiac arrhythmias by effectively unpinning anatomical reentries

ActiveUS20060161206A1Difficulties terminating anatomical reentryEfficient managementElectrocardiographyHeart defibrillatorsLower limitLow voltage

A method for extinguishing a cardiac arrhythmia utilizes destructive interference of the passing of the reentry wave tip of an anatomical reentry through a depolarized region created by a relatively low voltage electric field in such a way as to effectively unpin the anatomical reentry. Preferably, the relatively low voltage electric field is defined by at least one unpinning shock(s) that are lower than an expected lower limit of vulnerability as established, for example, by a defibrillation threshold test. By understanding the physics of the electric field distribution between cardiac cells, the method permits the delivery of an electric field sufficient to unpin the core of the anatomical reentry, whether the precise or estimated location of the reentry is known or unknown and without the risk of inducting ventricular fibrillation. A number of embodiments for performing the method are disclosed.

Owner:CASE WESTERN RESERVE UNIV

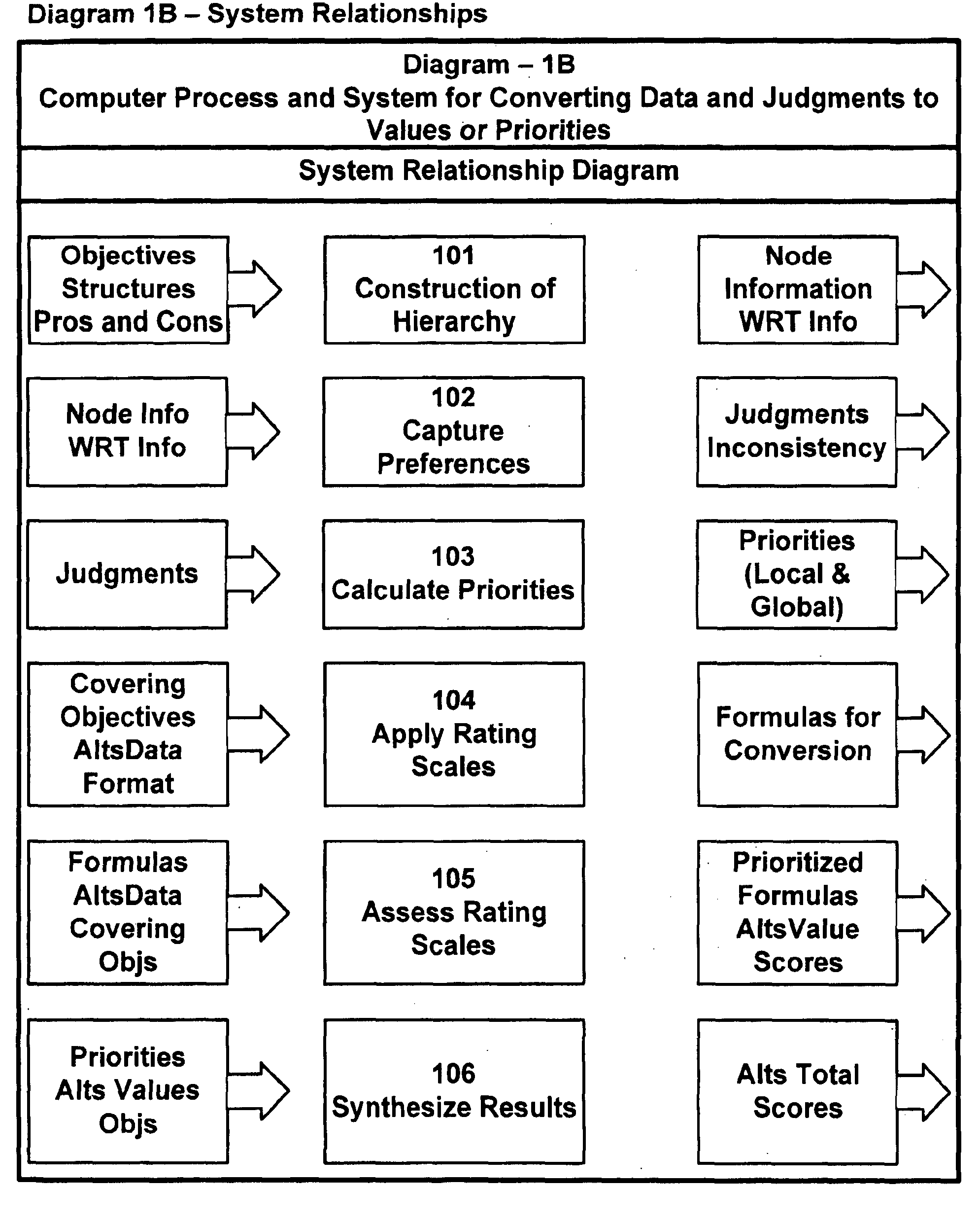

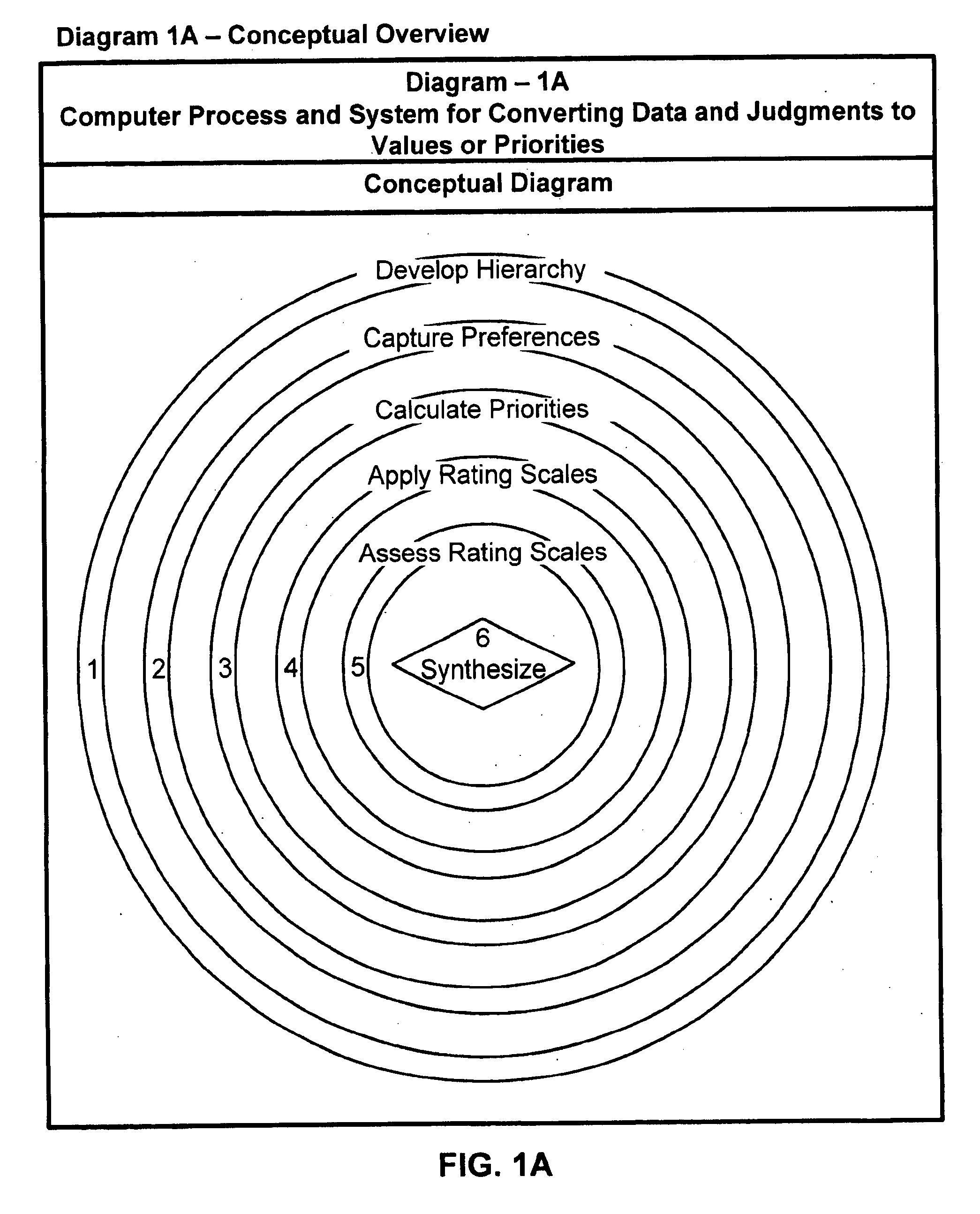

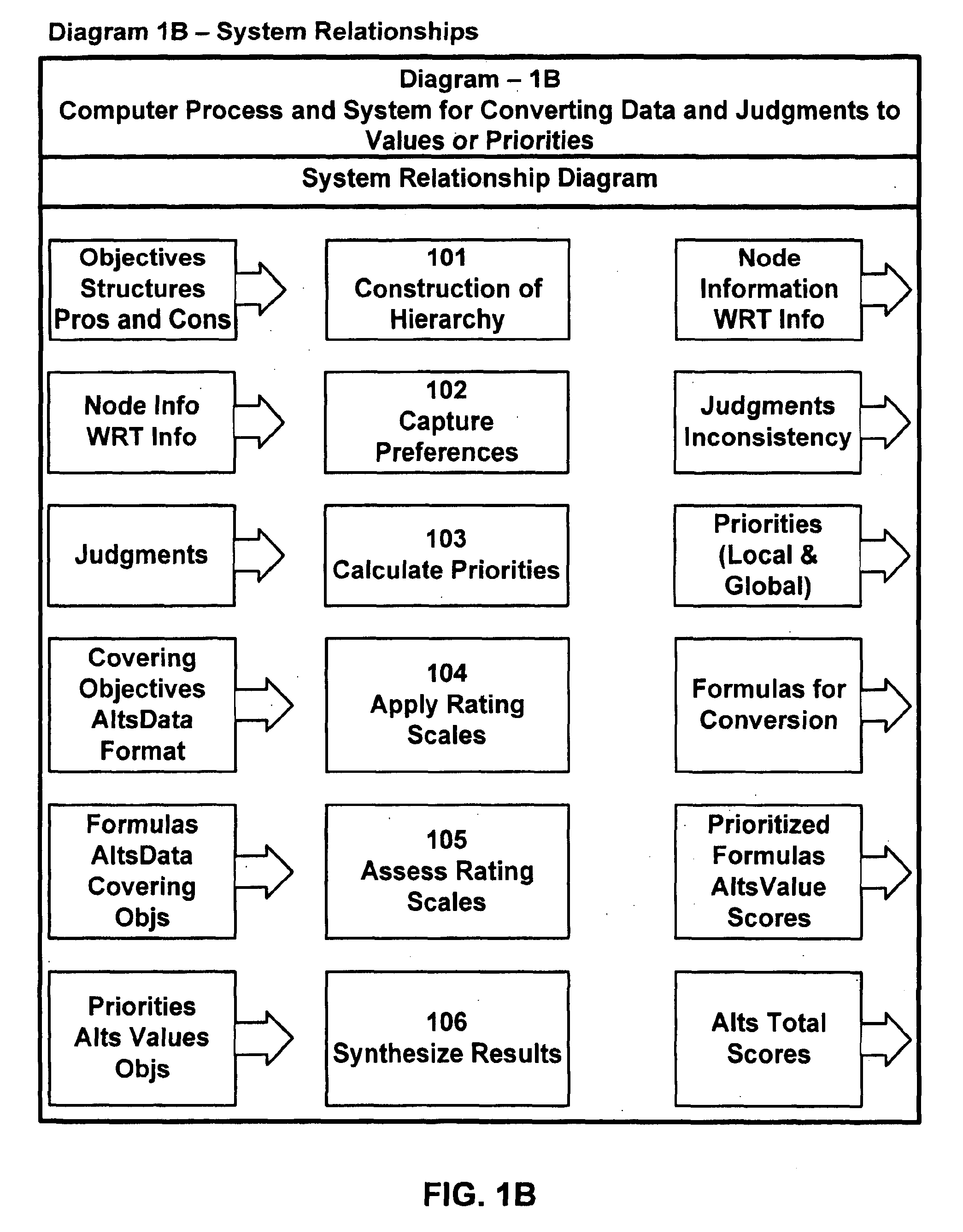

Method and system of converting data and judgements to values or priorities

The subject invention comprises methods for developing a decision hierarchy and including data as well as judgments in the evaluation of alternatives. Using a preferred embodiment of the subject invention, data for alternatives with respect to covering objectives in a decision hierarchy can be mapped into ratio scale preferences using linear increasing or decreasing functions, non-linear concave or convex increasing or decreasing functions, in conjunction with either-or interval step function scales, verbal intensity rating scales, or directly applied value scores. Upper and lower bounds can also be specified over which these functions are defined. Qualitative data, such as ratings or step scale intervals, can be mapped into a preference scale by making pair-wise comparisons to assess the ratings' intensities. Data can also applied in two other contexts: (1) as a screen to eliminate alternatives that do not satisfy one or more conditions which are defined as musts by the user; and (2) to assign and derive value scores for their corresponding covering objectives. User priorities that were captured by delivering comparisons between objectives are brought together with the data by synthesizing it with respect to all covering objectives and their representative value scores for each alternative. The final result is either a set of alternatives ranked by their total value score, which can be used for allocations or optimizations, or a single top scoring alternative if the goal is to select the best alternative—the remainder of the alternatives are ranked with respect to their difference from the top performer.

Owner:FORMAN ERNEST H

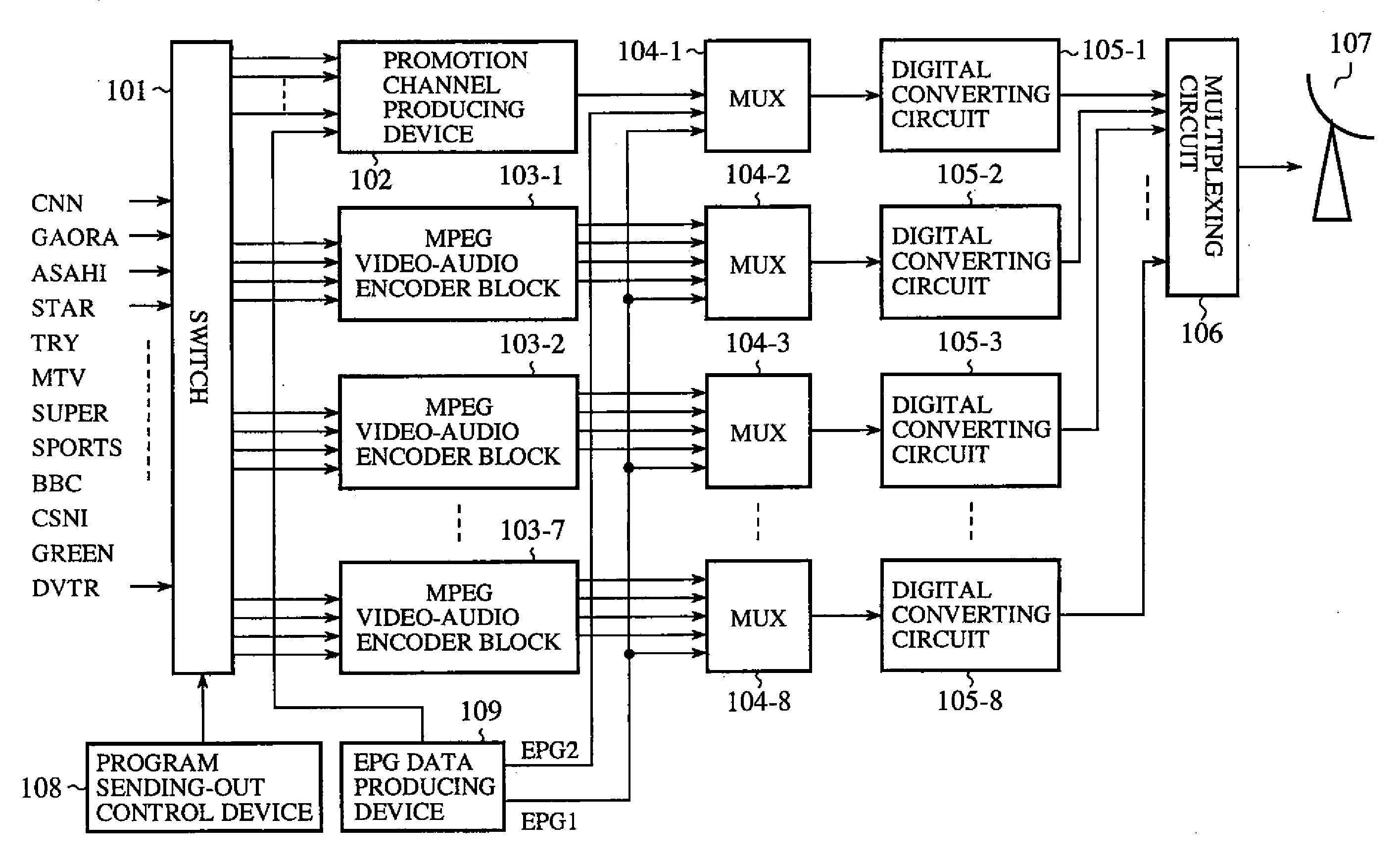

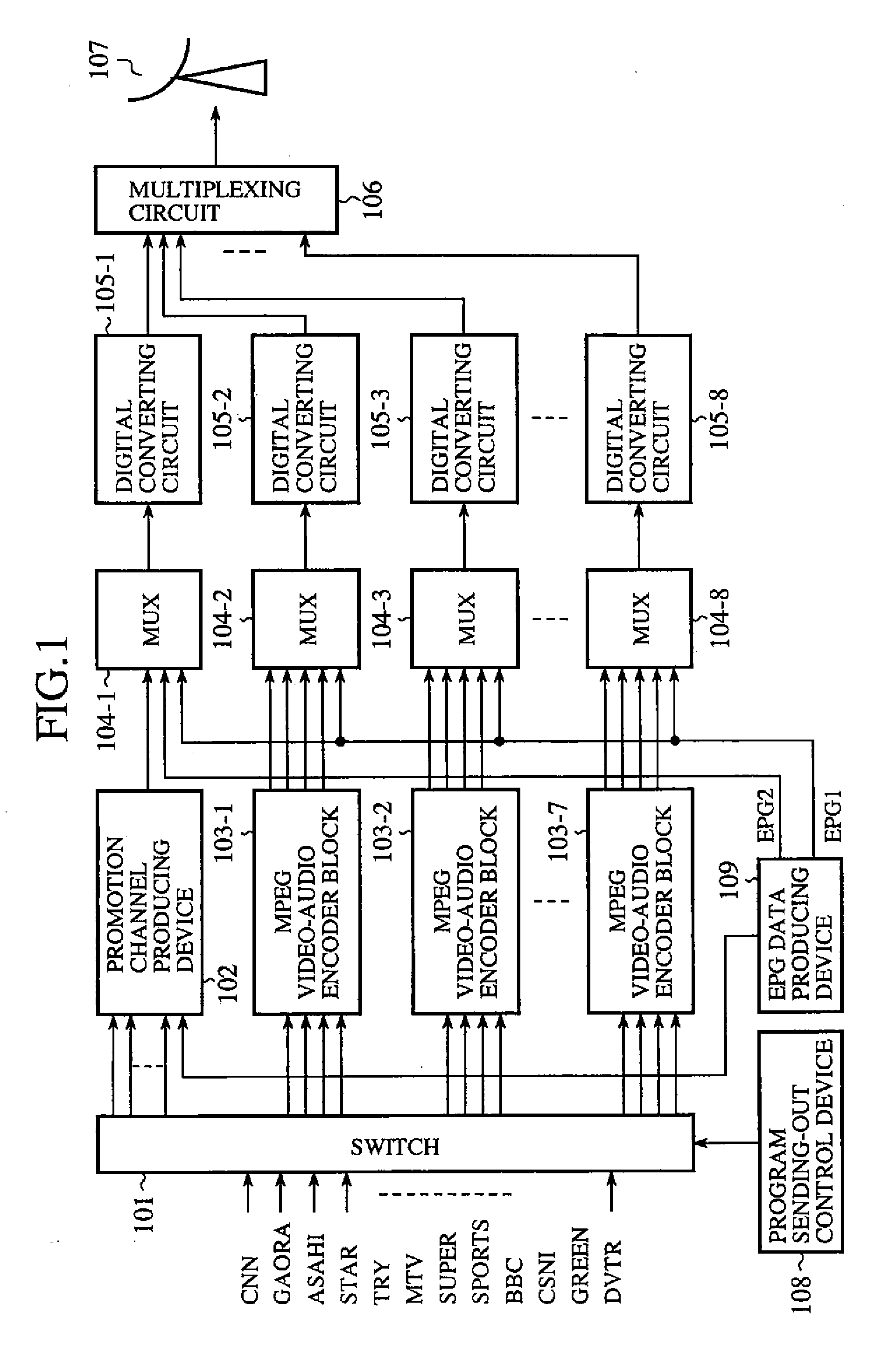

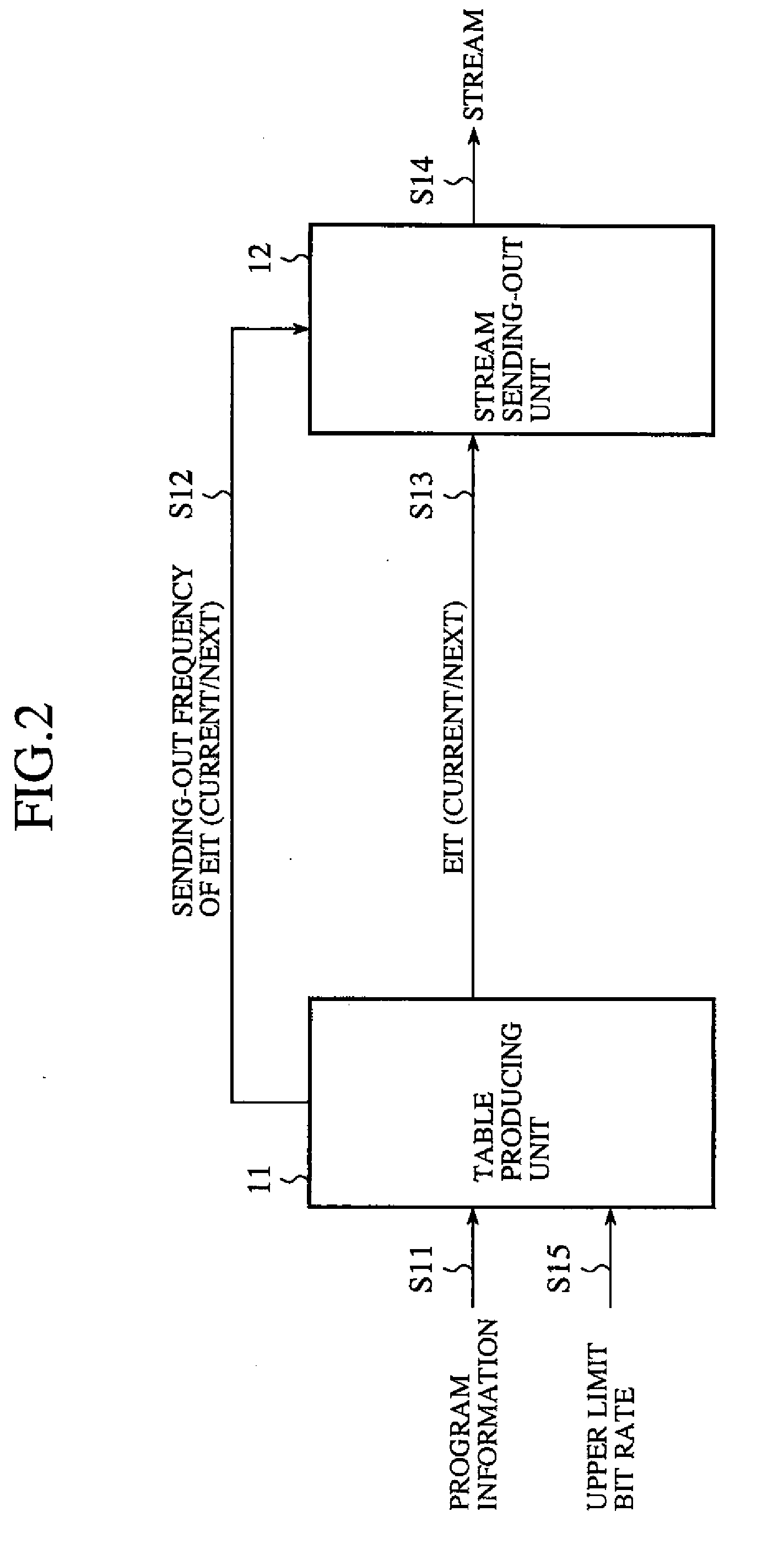

Device for sending-out data in which associated data is multiplexed with main data

InactiveUS20090077588A1Facilitate transmissionReduce the amount of solutionTelevision system detailsResource management arrangementsLower limitData transmission

A table creating unit receives program information and an upper limit bit rate of EPG data, creates a table of EIT [current / net] on the basis of the information and upper limit bit rate, and determines the frequency of transmission of the table in consideration of the upper limit bit rate and the lower limit of the frequency of transmission of the table. A stream transmitting unit receives the table and the frequency of transmission, converts the table to stream information, and transmits a stream at a frequency determined based on the transmission frequency. Therefore, data transmission is carried out satisfying both the limit of the upper limit bit rate and the limit on the transmission frequency.

Owner:MITSUBISHI ELECTRIC CORP

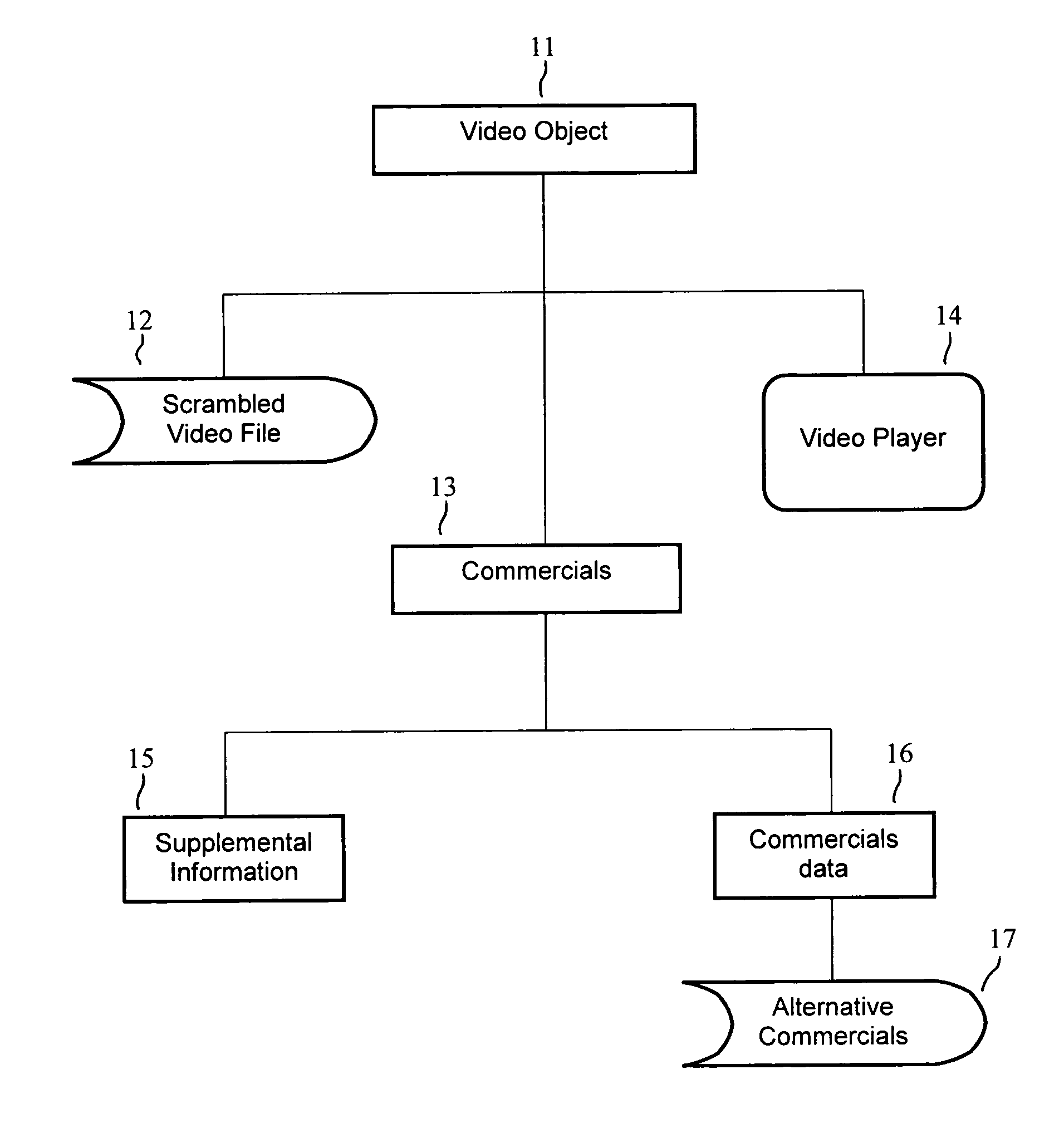

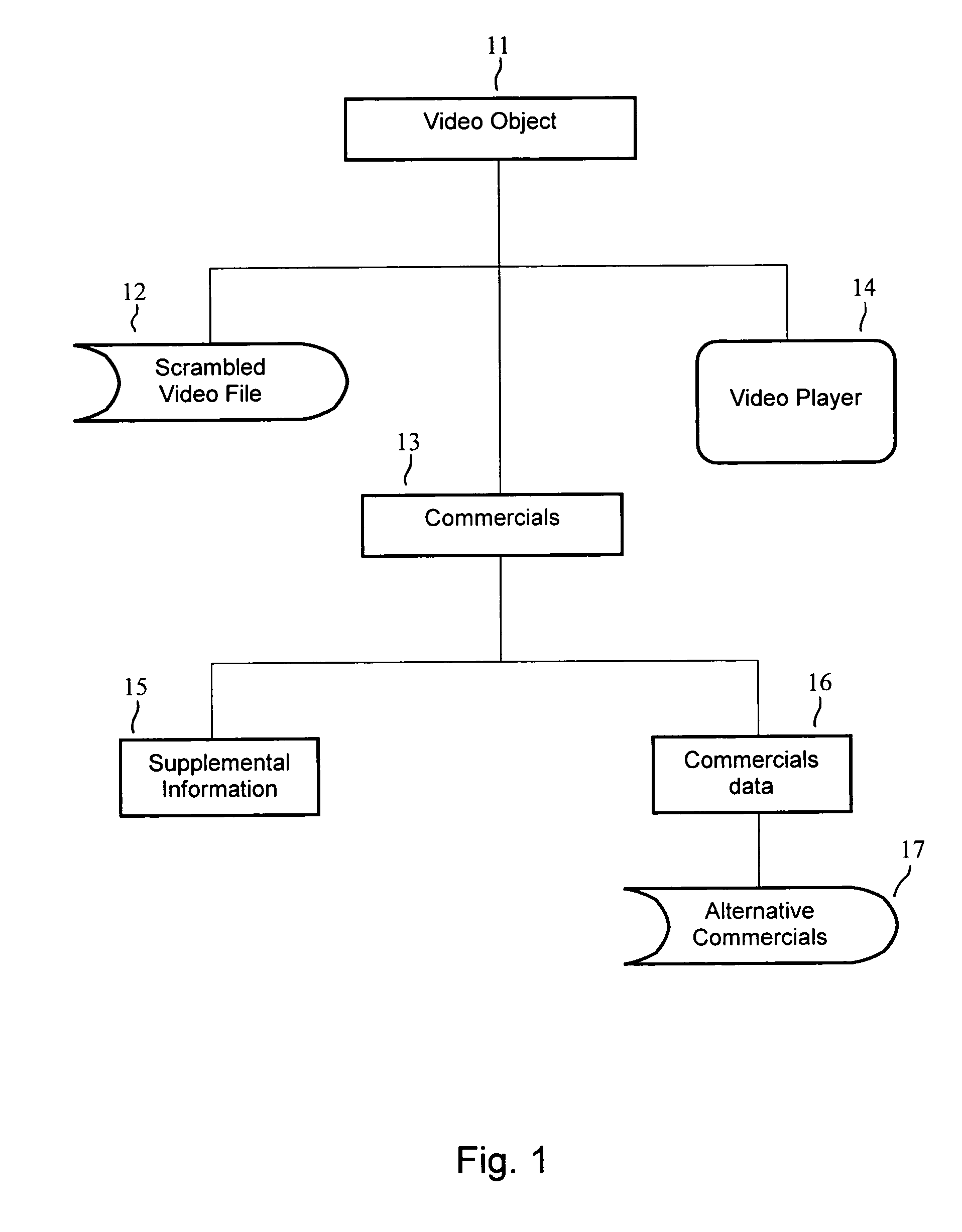

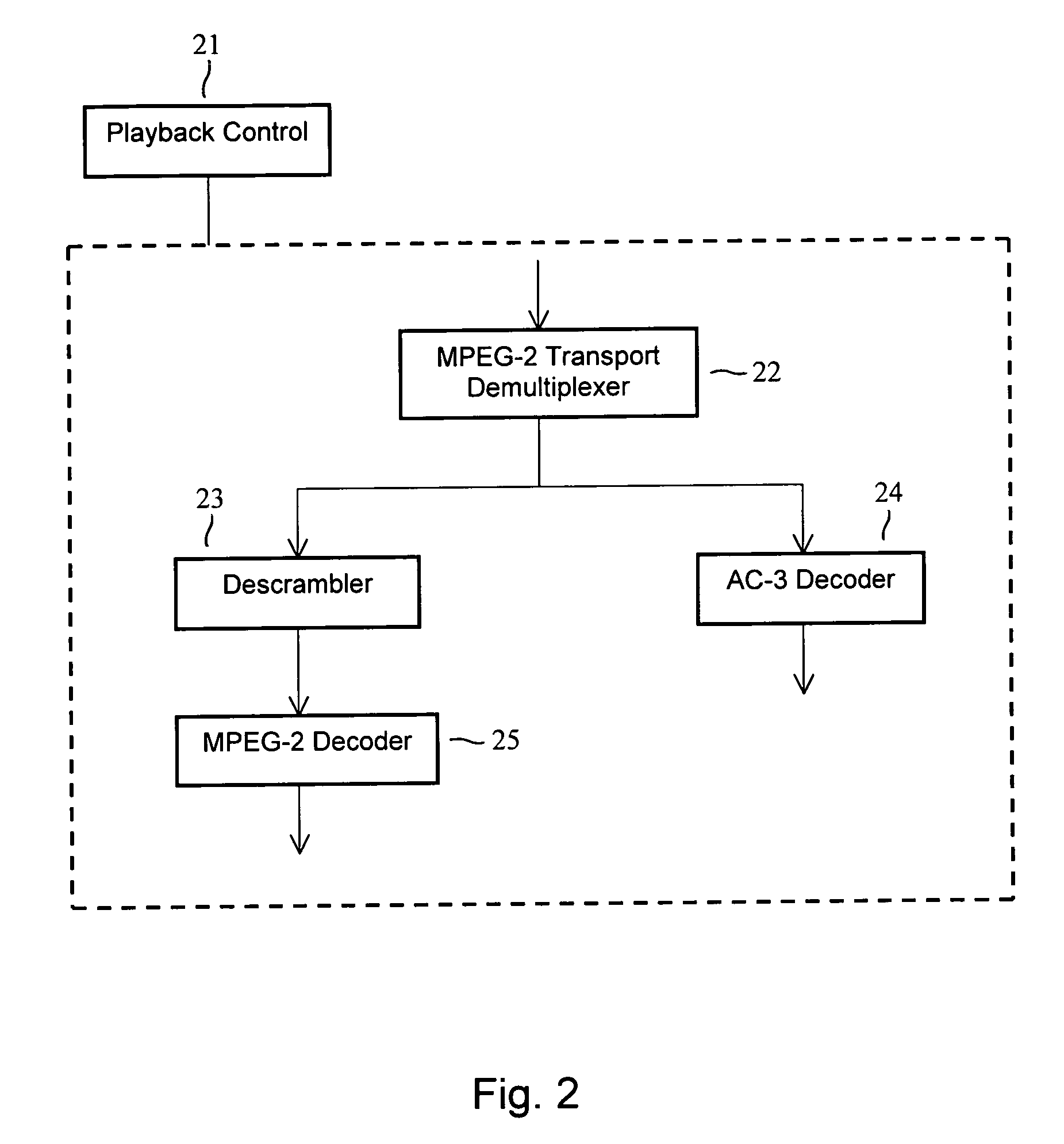

Preservation and improvement of television advertising in digital environment

ActiveUS7720351B2Avoid selectionAvoid choiceTelevision system detailsColor television signals processingLower limitDistributor

A system for protecting commercials included in a digitally distributed and recorded video that minimizes user's inconveniences resulting from restrictions imposed on playback of the video. The video is encrypted at the distributor side and playback of the encrypted video at the user side is limited in such a way that fast forward and reverse playing is not performed, and a lower limit is imposed on skip forward and backward so that only parts of video whose playing time is greater than the time of typical commercial break can be skipped. This arrangement prevents a user from selectively skipping commercials without missing pieces of program itself and thus discourages skipping when the user wants to watch an entire program, but still enables quick browsing before watching the entire program as well as moving fast to any part of the program for watching that part again.

Owner:STRIPE INC

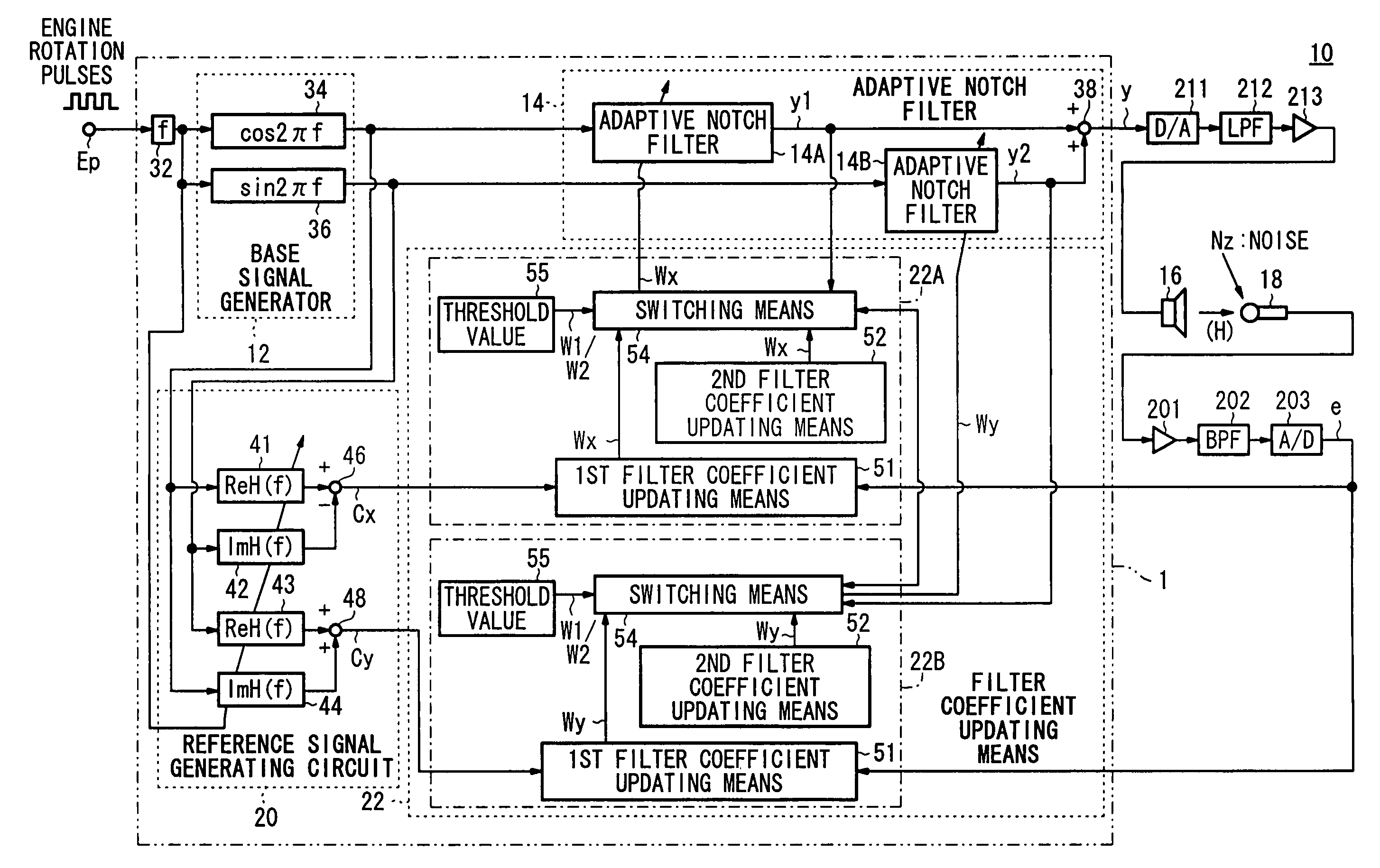

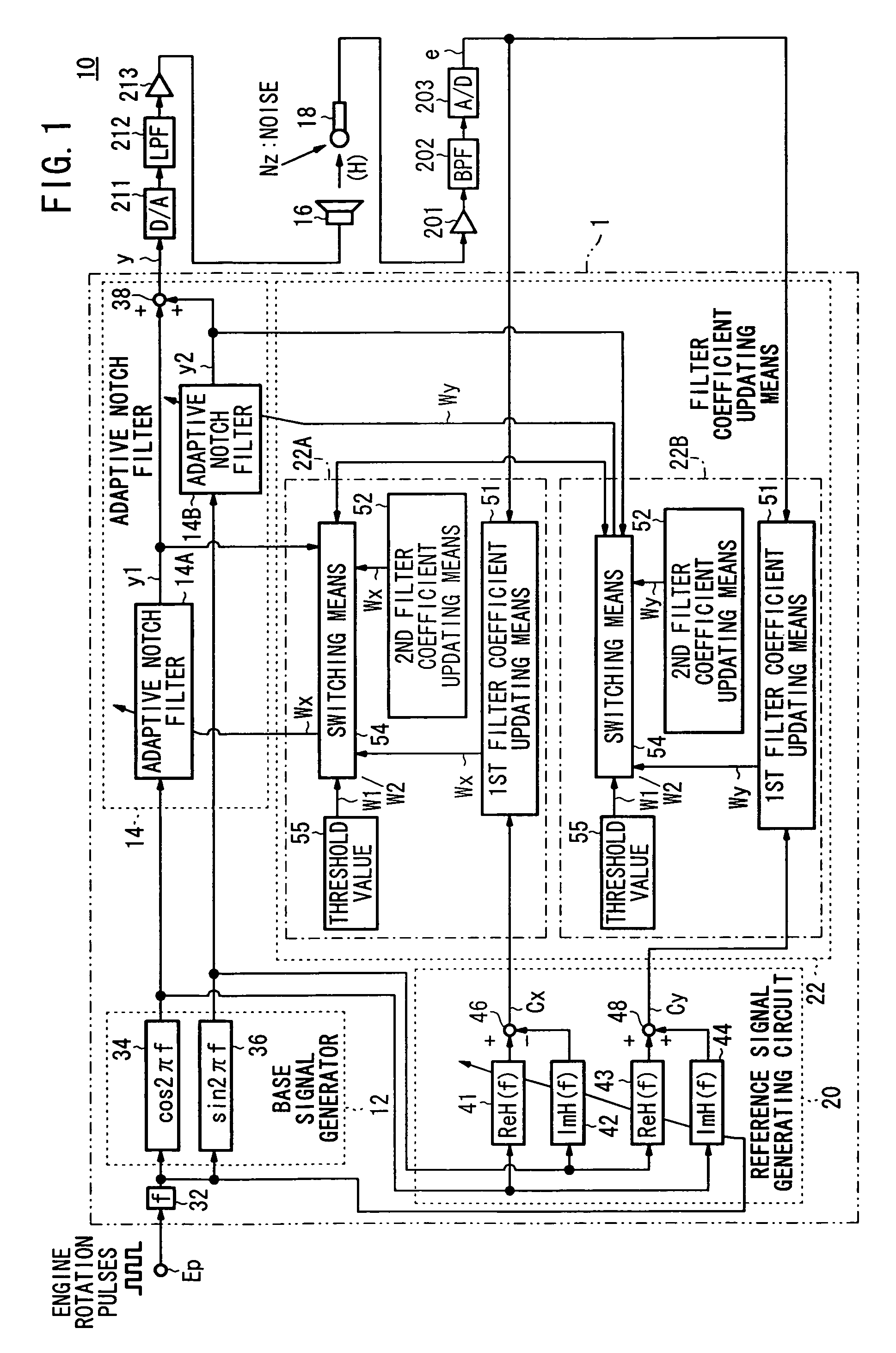

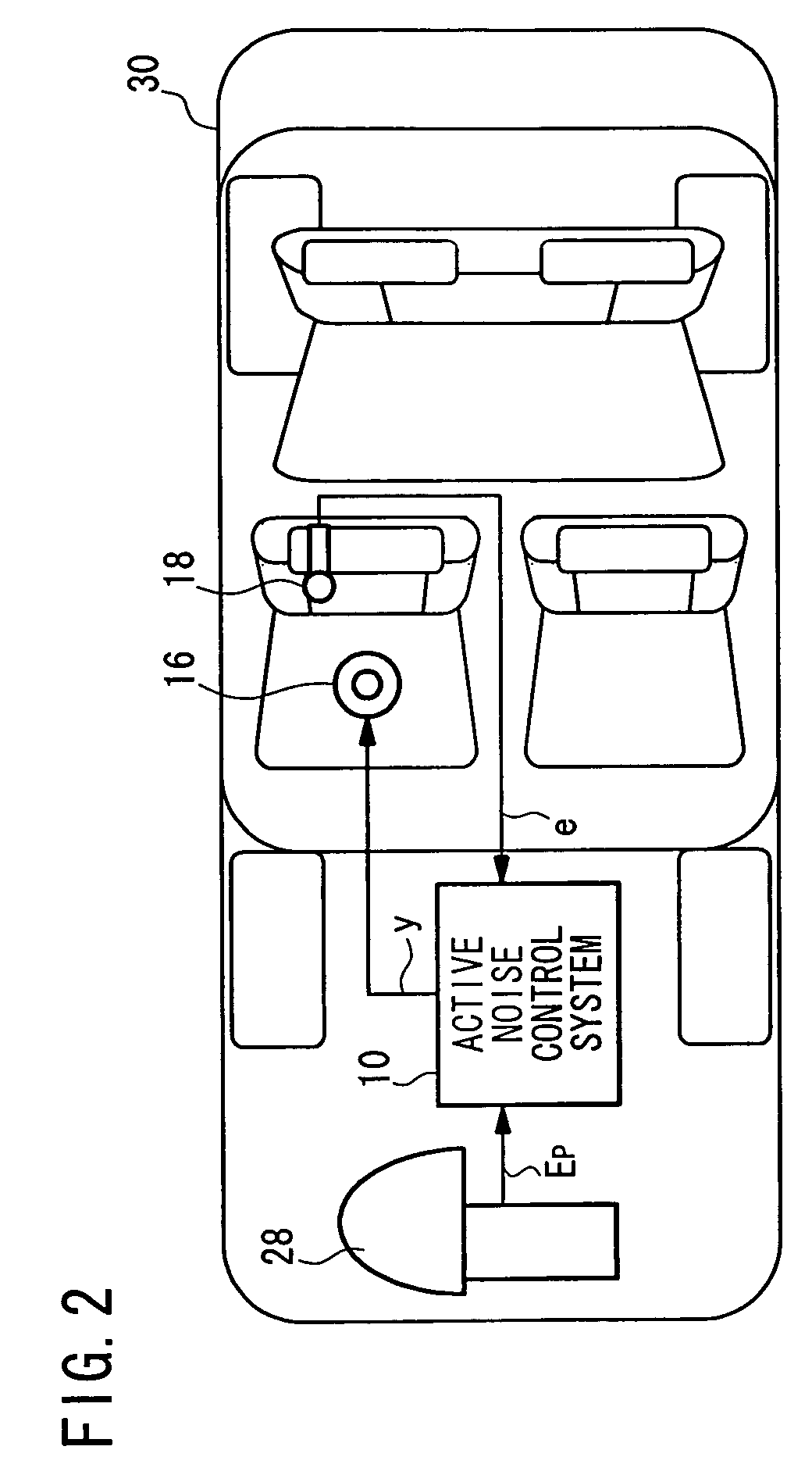

Active noise control system

ActiveUS20070038441A1Avoid problemsReduce noiseEar treatmentSpeech analysisSound detectionLower limit

An active noise control system prevents a continuous muffled sound from being generated as an abnormal sound under a high sound pressure from a speaker when a microphone as a sound detector is covered, and reduces noise immediately when the microphone is uncovered. A first threshold value as an upper limit value and a second threshold value as a lower limit value are provided for the filter coefficient of an adaptive notch filter. When the filter coefficient is greater than the first threshold value, a control sound is faded out according to a forgetting process. When the filter coefficient is smaller than the second threshold value, an adaptive control process is resumed. Even if the microphone is covered, the filter coefficient does not exceed the first threshold value as the upper limit value.

Owner:HONDA MOTOR CO LTD

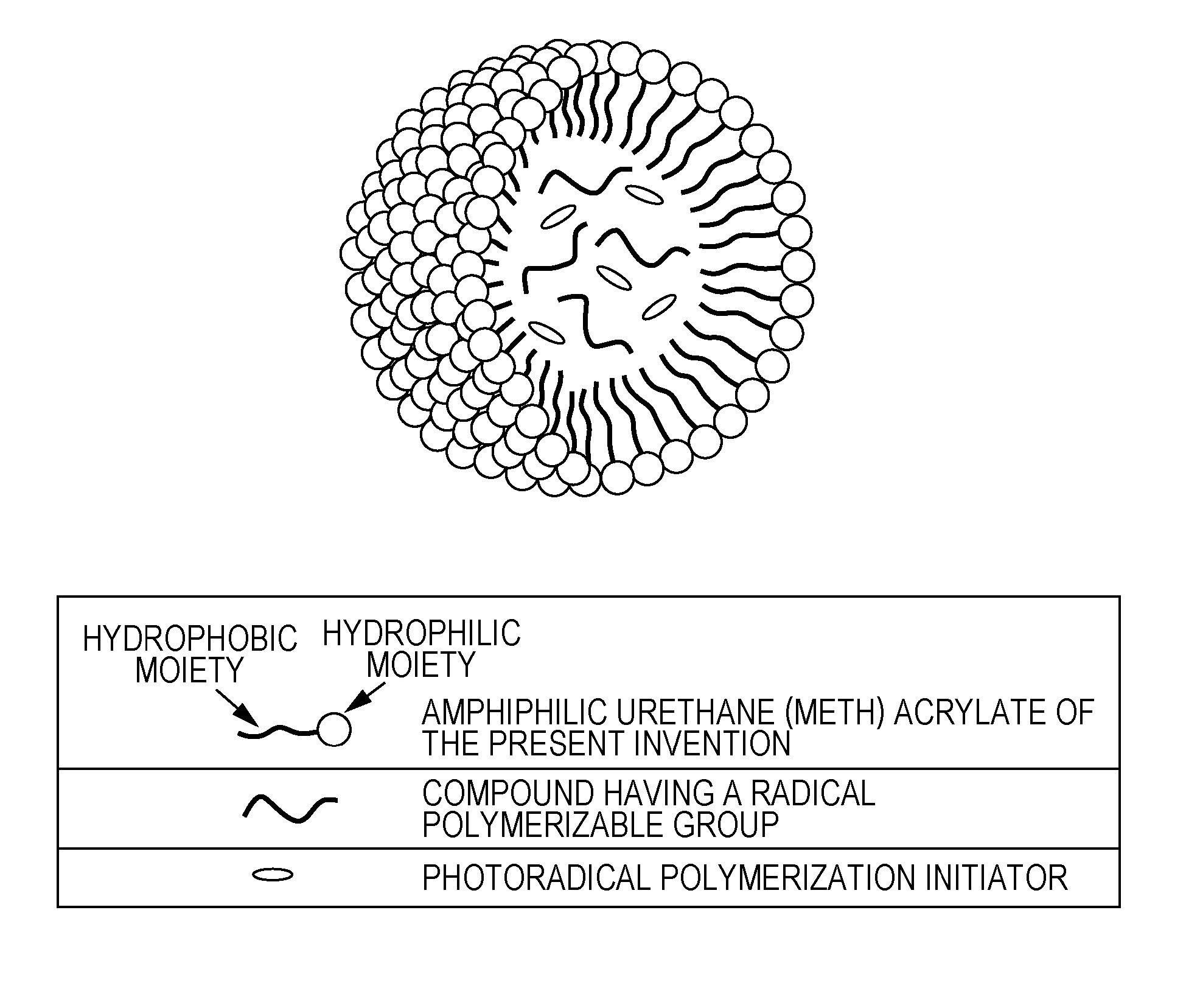

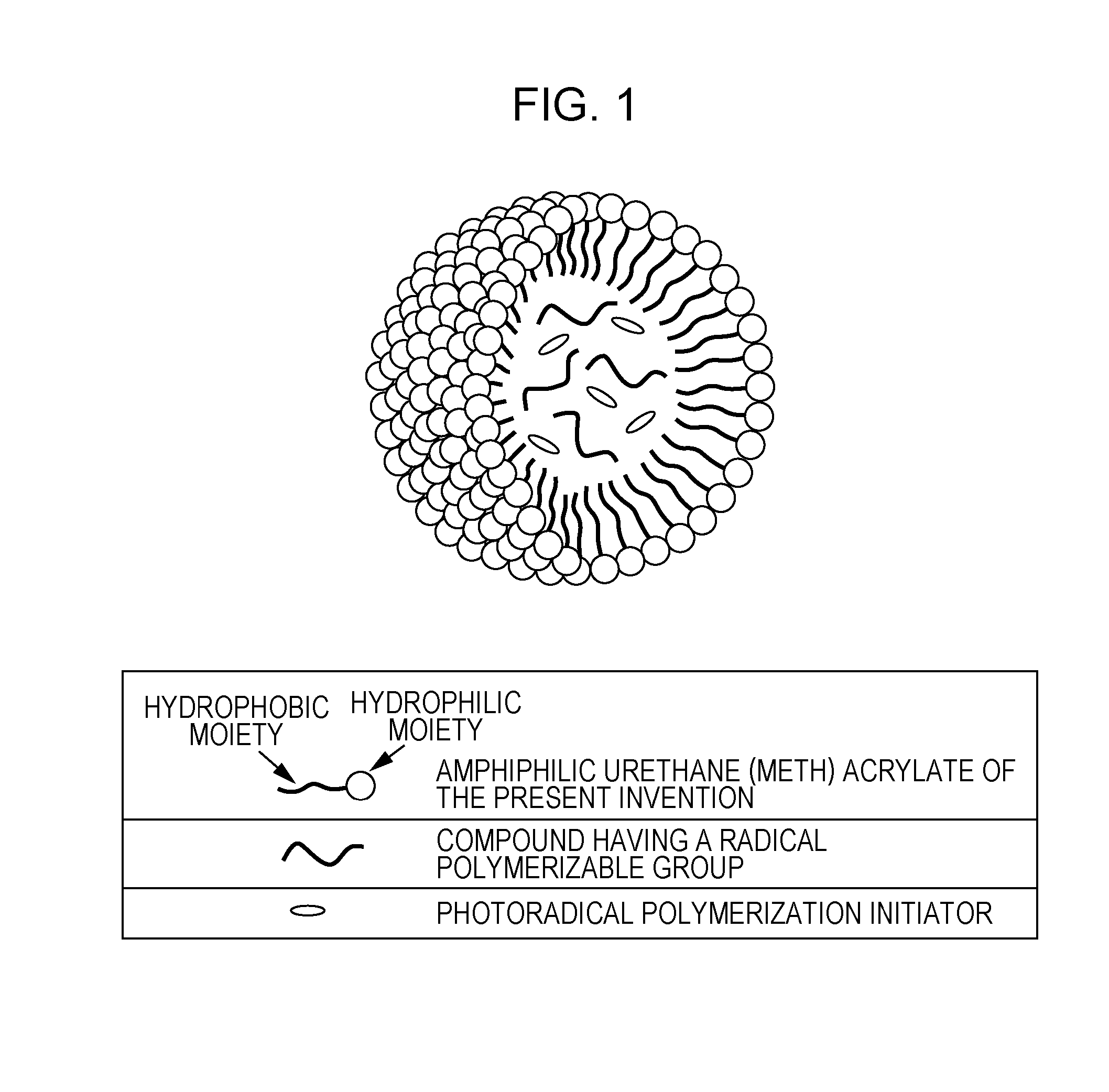

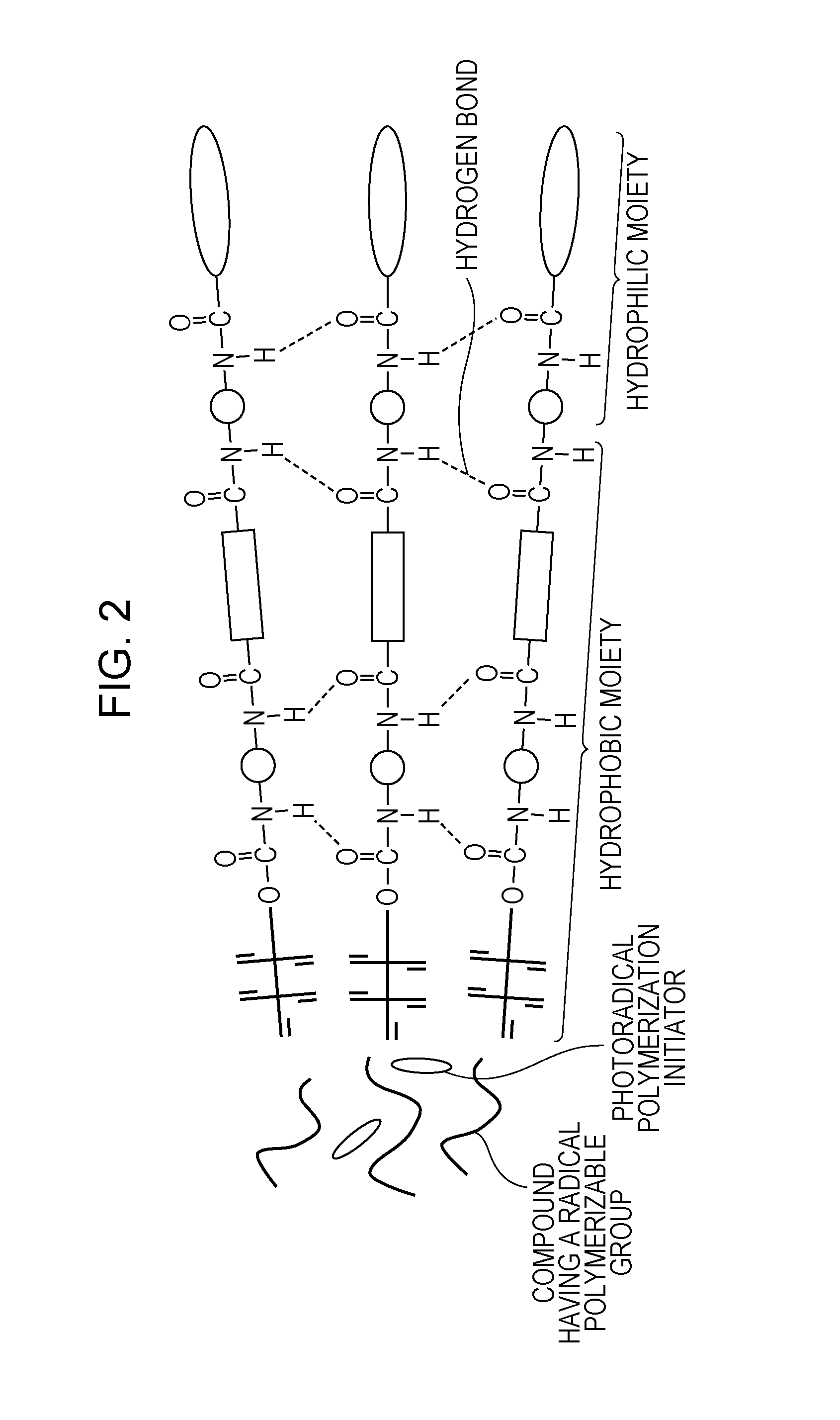

Ink composition for ink jet recording and ink jet recording method

ActiveUS20140002556A1Good dispersionLow viscosityMeasurement apparatus componentsSpecial tyresLower limitSolvent

An ink composition for ink jet recording includes a coating film forming material, a polyether-modified silicone oil, and water, wherein the polyether-modified silicone oil is soluble in a solvent in which a lower limit of an SP value is 8.5 or less and an upper limit of the SP value is 18.0 or more.

Owner:SEIKO EPSON CORP

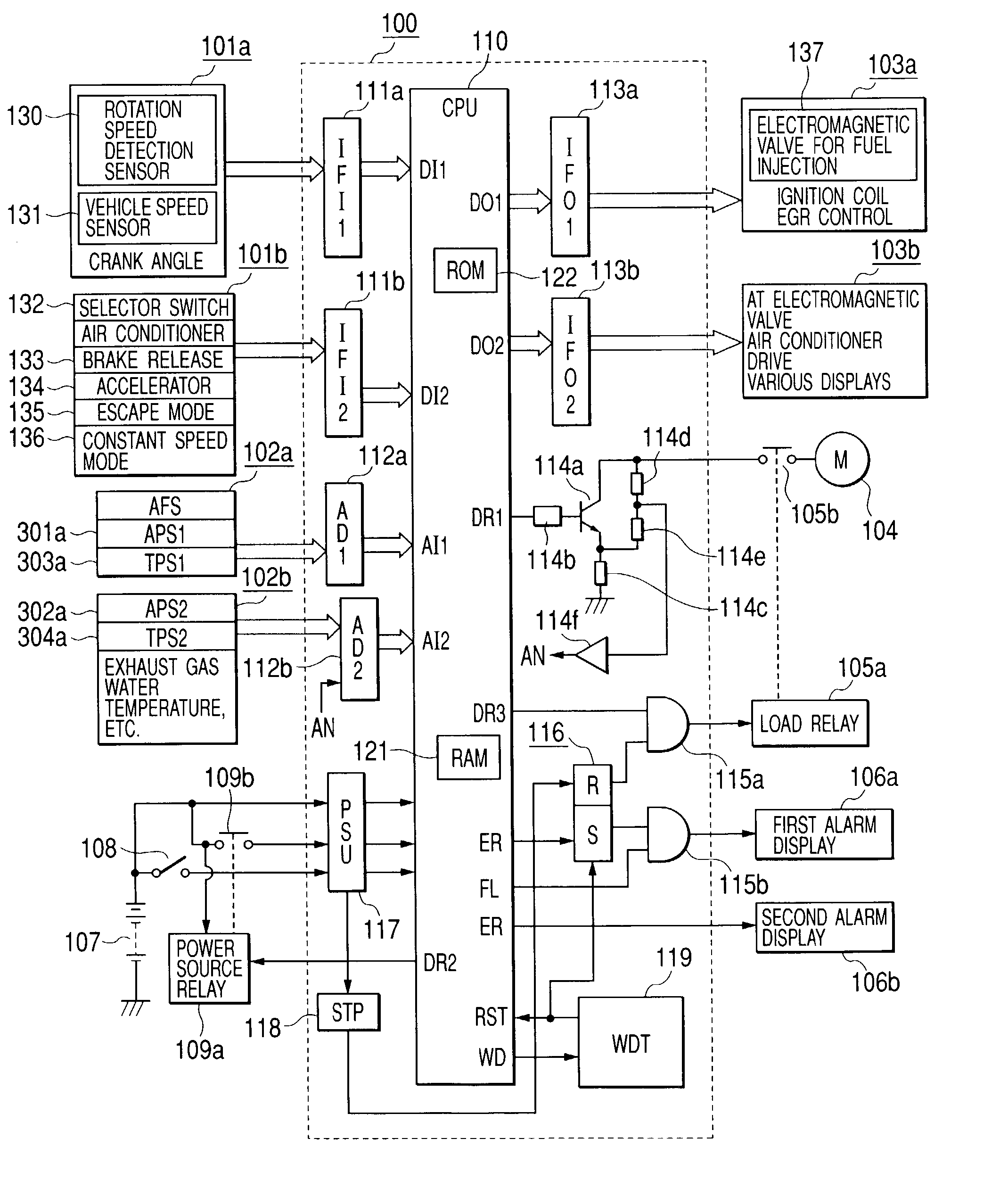

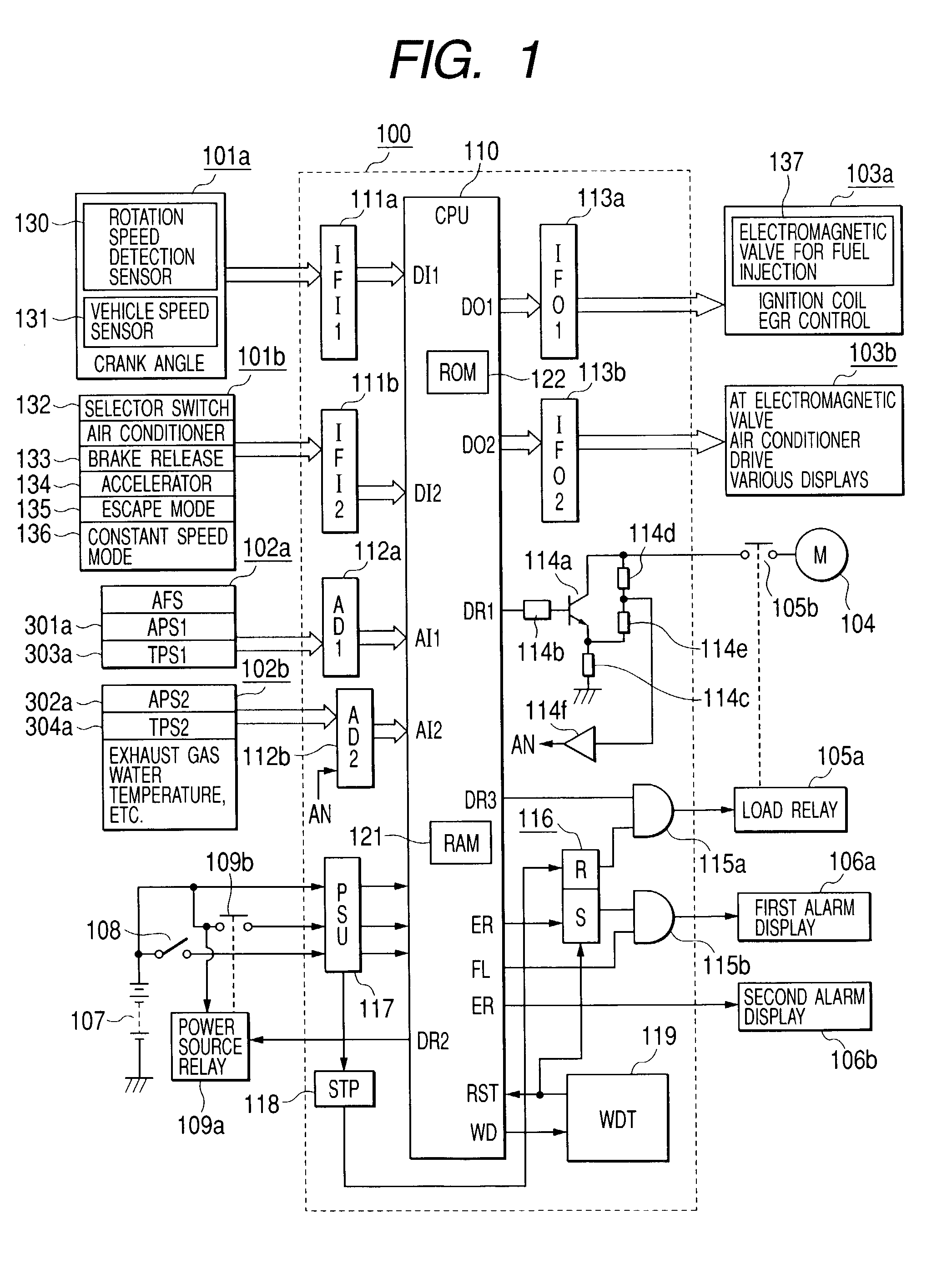

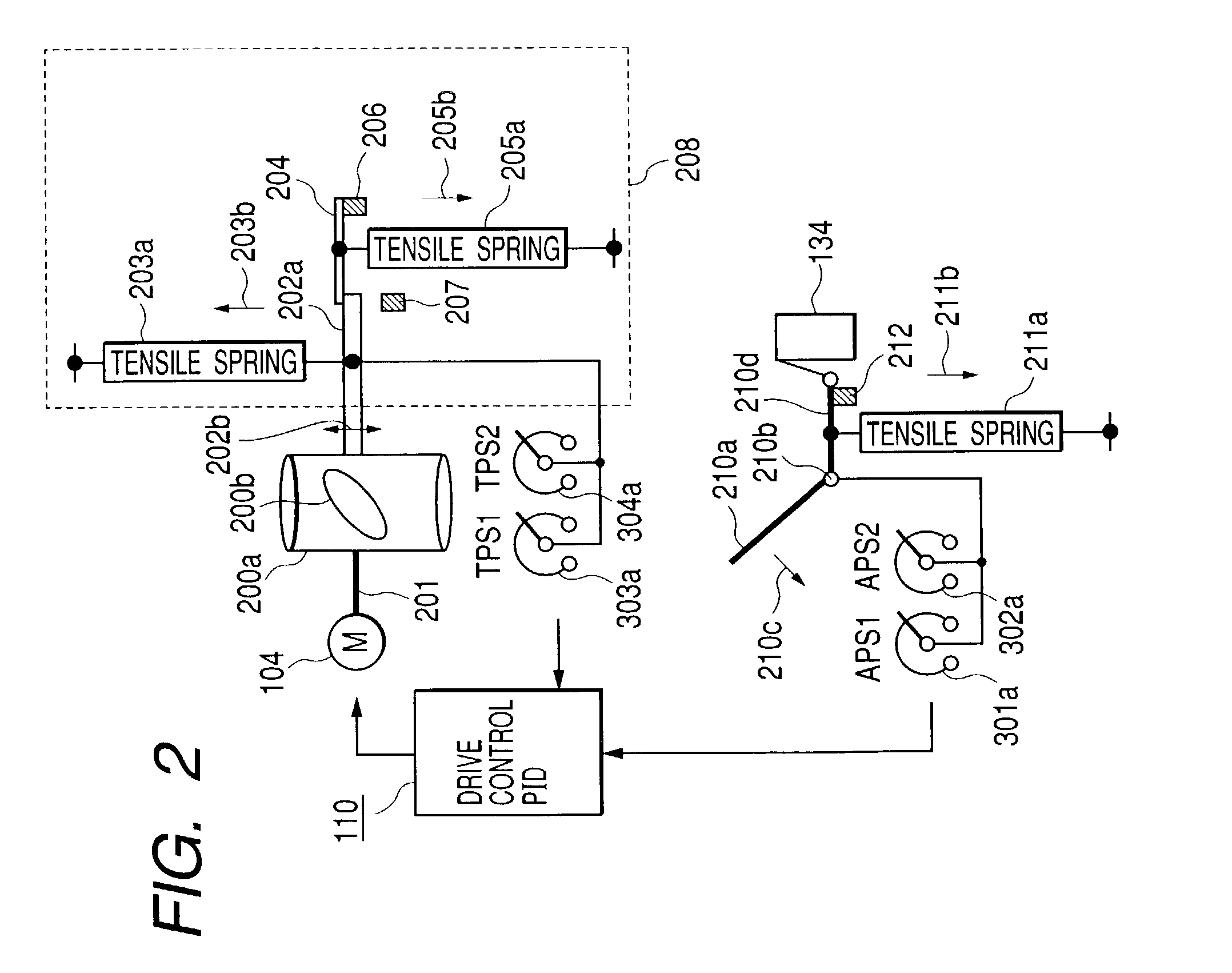

Vehicle engine control device

Escape running performance at the time of the occurrence of an abnormality in an electronic throttle control system is improved. At the time of the occurrence of a severe abnormality, an abnormality storage element is operated, and an electric supply load relay of a throttle valve driving motor is de-energized to return a throttle valve to the default, and further, an alarm display is actuated, and an upper limit engine rotational speed is suppressed by control of a fuel injection valve, and escape running is carried out. As a suppression rotational speed, a lower limit threshold at a stop, a rotational speed substantially in proportion to the output of an accelerator position sensor, a rotational speed substantially in inverse proportion to the output of a throttle position sensor, or a default threshold rotational speed is selected, and multiple escape running can be carried out.

Owner:MITSUBISHI ELECTRIC CORP

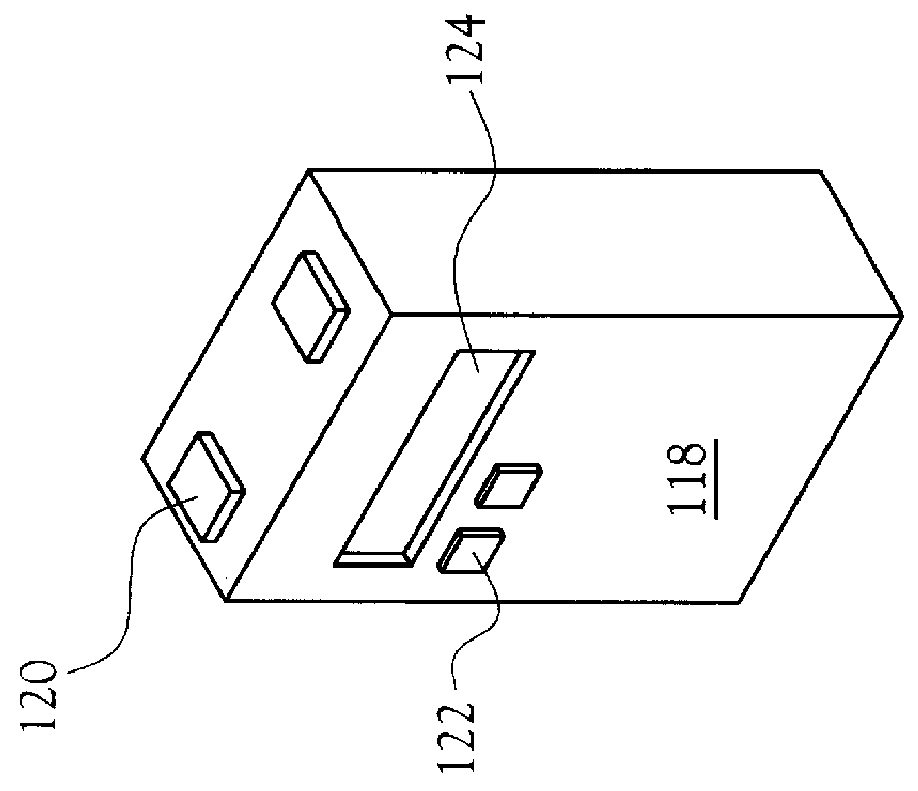

Flash memory device and architecture with multi level cells

Owner:SUPER TALENT TECH CORP

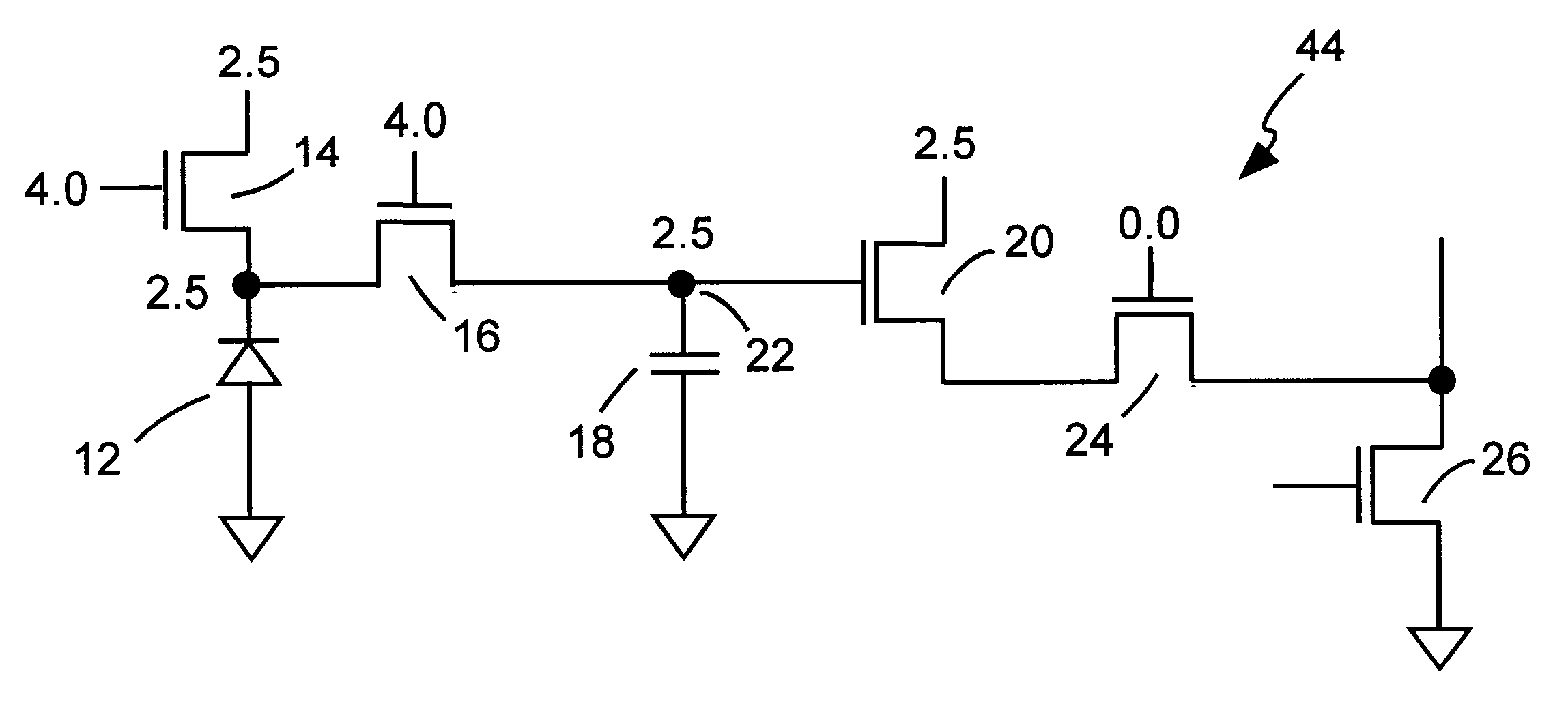

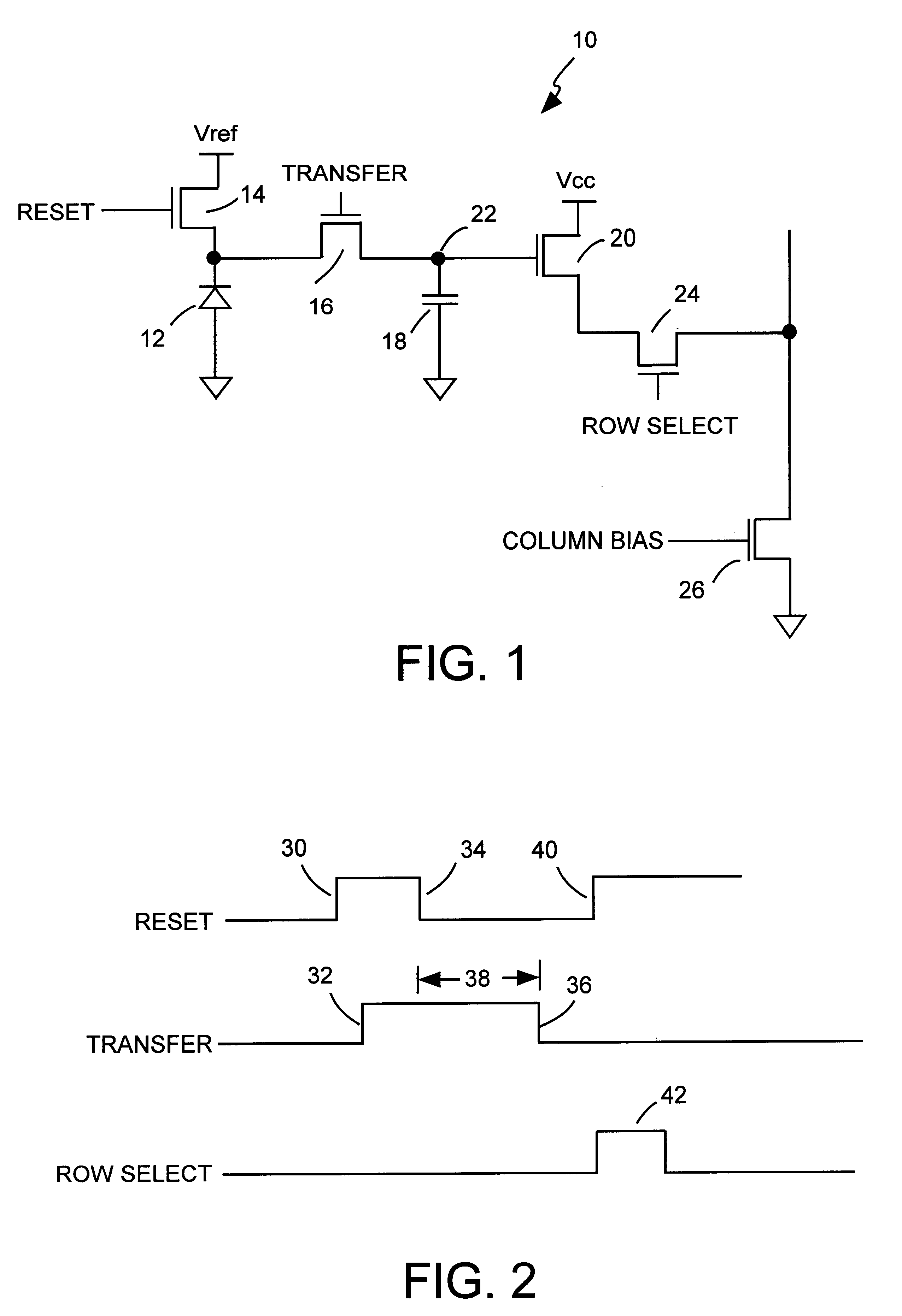

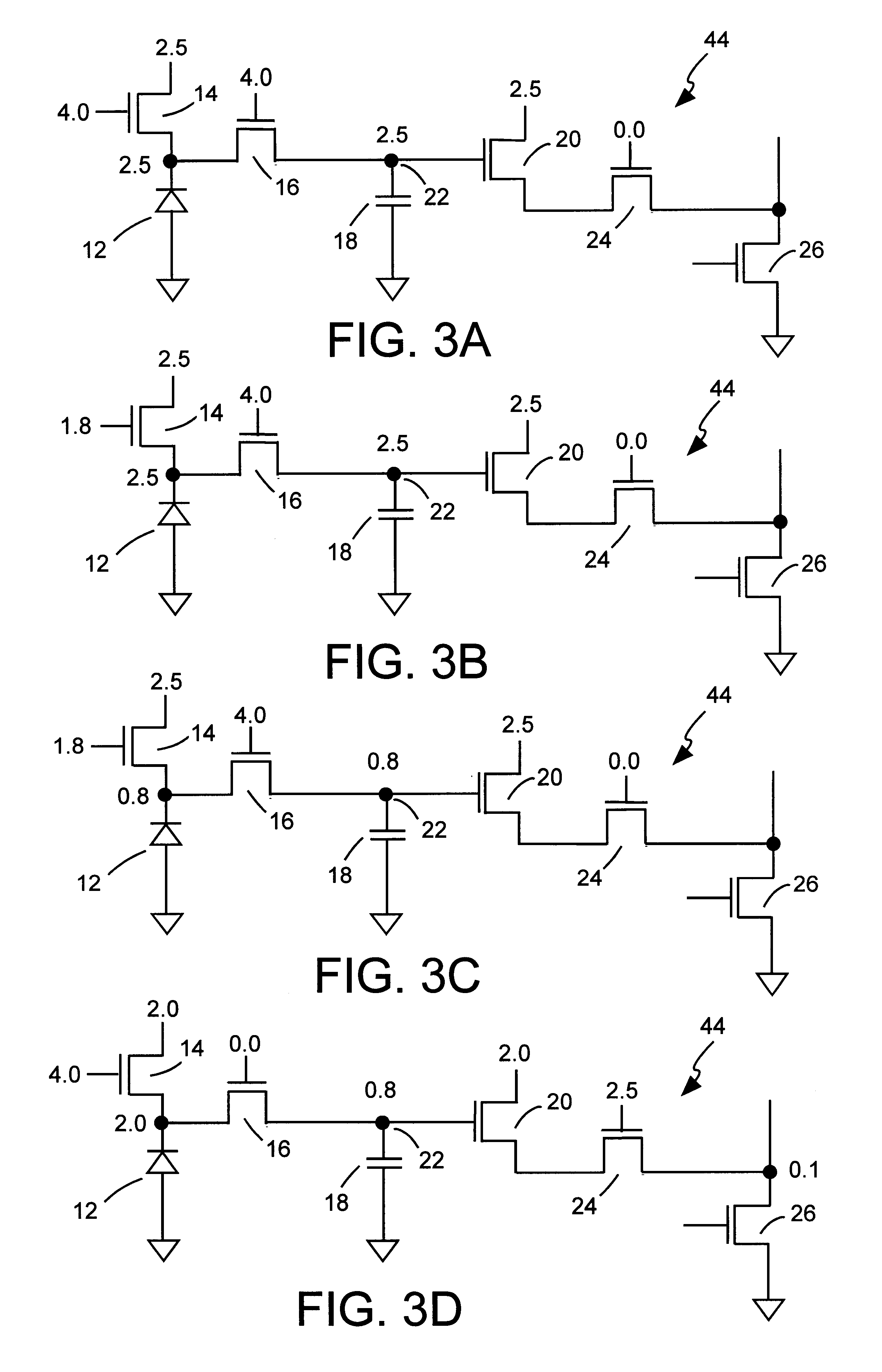

Method and apparatus for biasing a CMOS active pixel sensor above the nominal voltage maximums for an IC process

An active pixel sensor is operated with voltages that exceed the nominal operating voltages for a particular integrated circuit process. Voltages that exceed the nominal operating voltages are employed during the reset, integration and readout periods in the operating cycle of the active pixel sensor. The lower limit of the voltage representing the capture of photocharge in the active pixel sensor is fixed by setting the voltage applied to the gate of a reset transistor in the active pixel sensor to a level during integration which prevents the voltage across the dielectric of a transfer transistor from exceeding a preselected value. Read disturb caused by impact ionization current from a readout transistor to a storage node is reduced by lowering the voltage applied to the drain of a readout transistor to reduce the Vds of the readout transistor at the start of a readout period.

Owner:FOVEON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com