Patents

Literature

390results about How to "Accurately indicated" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

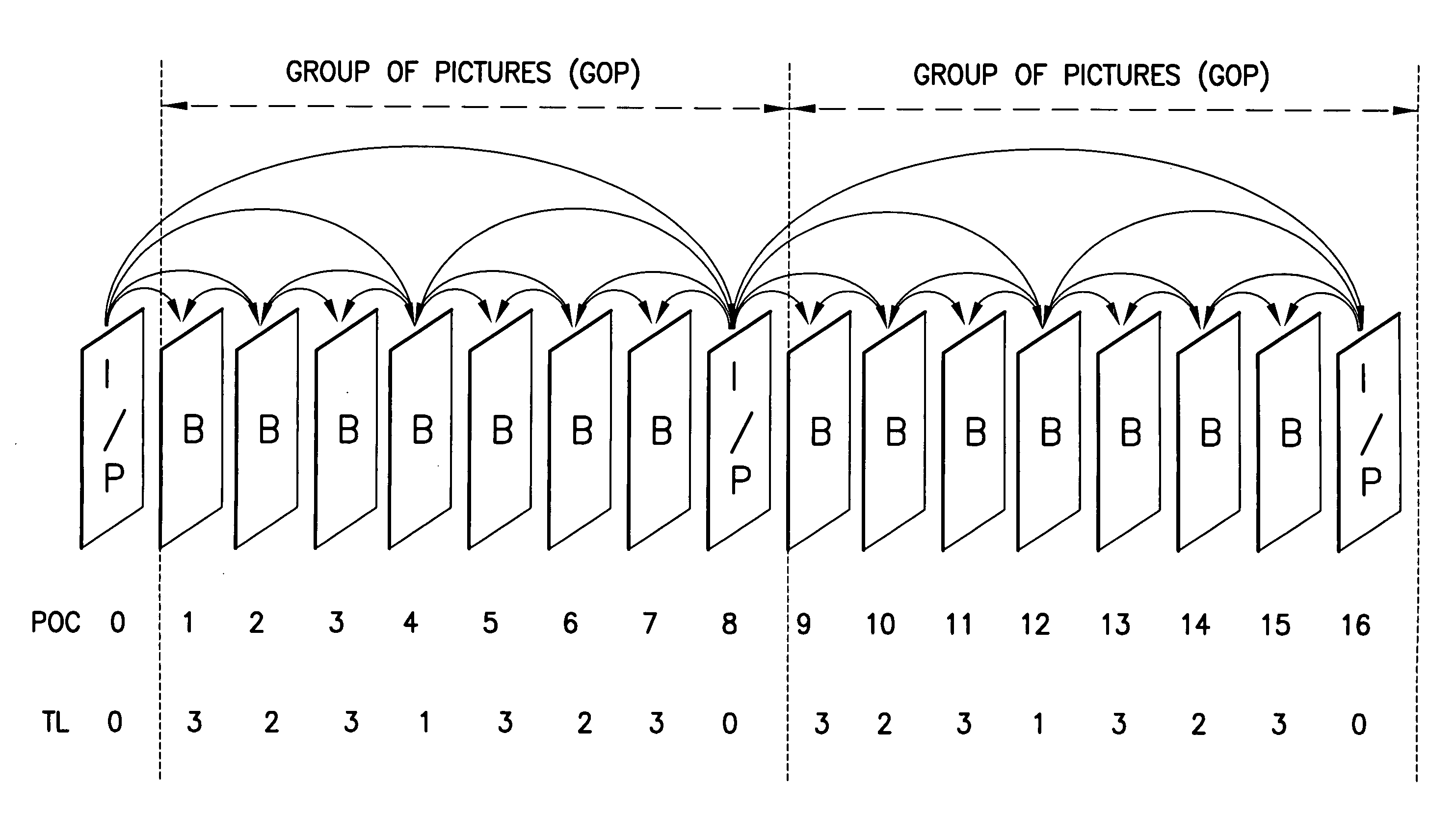

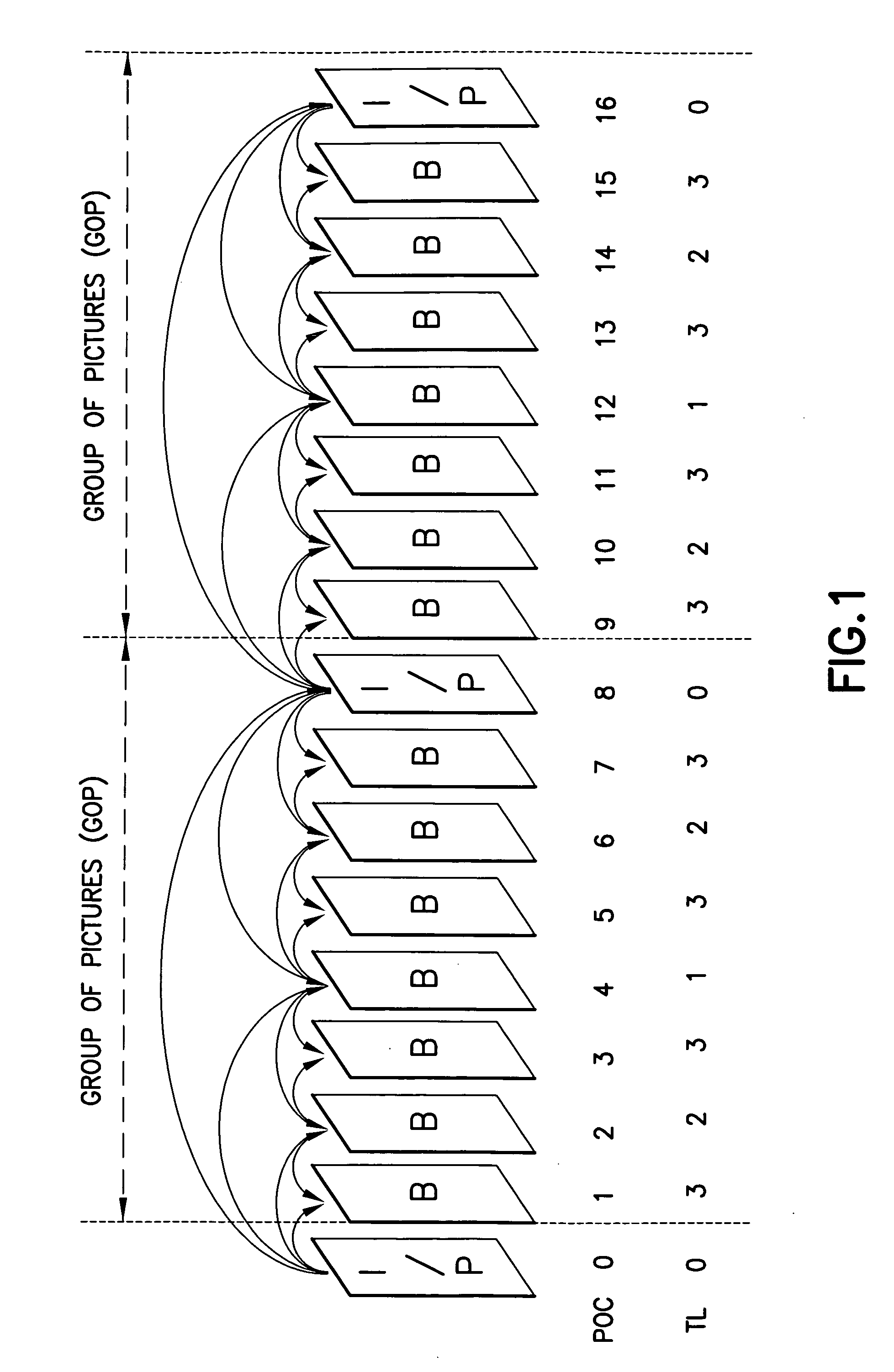

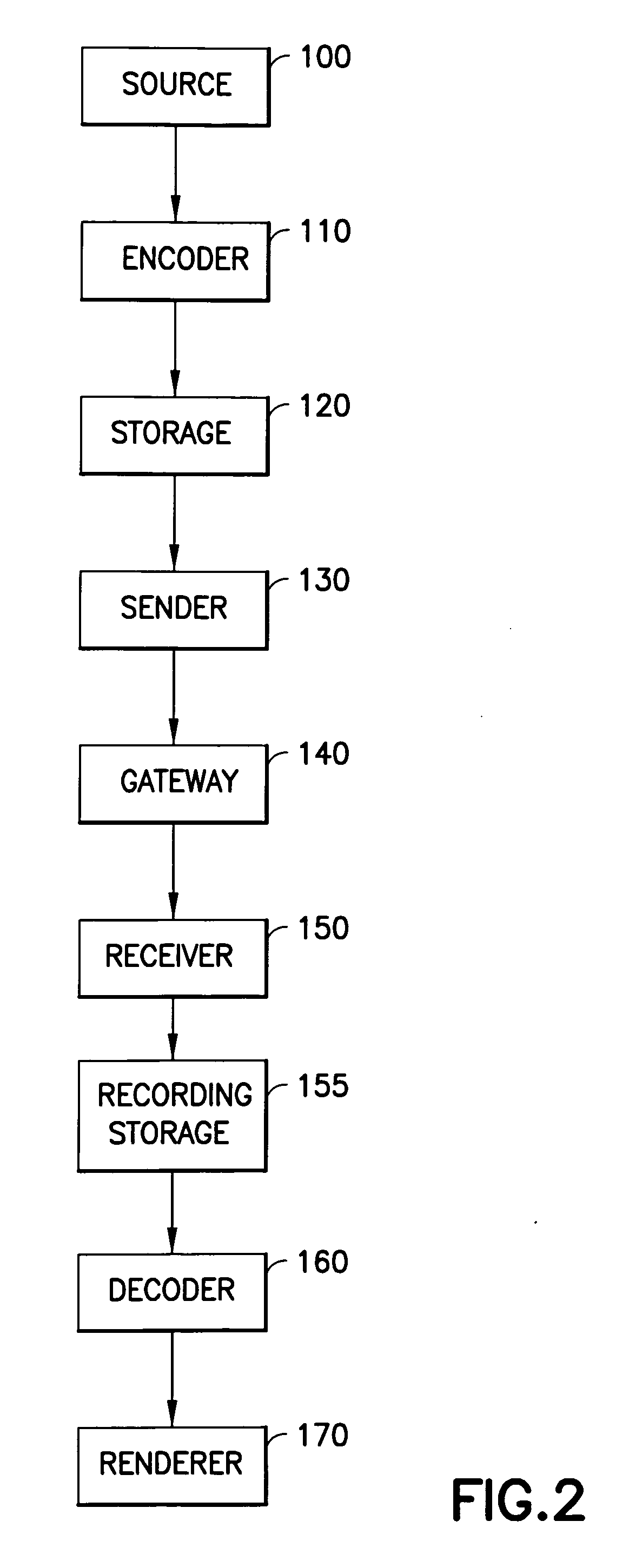

System and method for indicating temporal layer switching points

ActiveUS20090003439A1Accurately indicatedAccurate decodingColor television with pulse code modulationColor television with bandwidth reductionVideo bitstreamComputer architecture

Disclosed are a system, apparatus, computer programs and methods for indicating proper temporal layer switching points for temporal scalable coding. Various embodiments provide an apparatus and method for properly indicating temporal layer switching points in a scalable video bit stream or in a scalable video file container. Using these indications, a decoder can determine where to perform temporal layer switching, after which all of the pictures at and below the desired temporal layer can be correctly decoded.

Owner:NOKIA TECHNOLOGLES OY

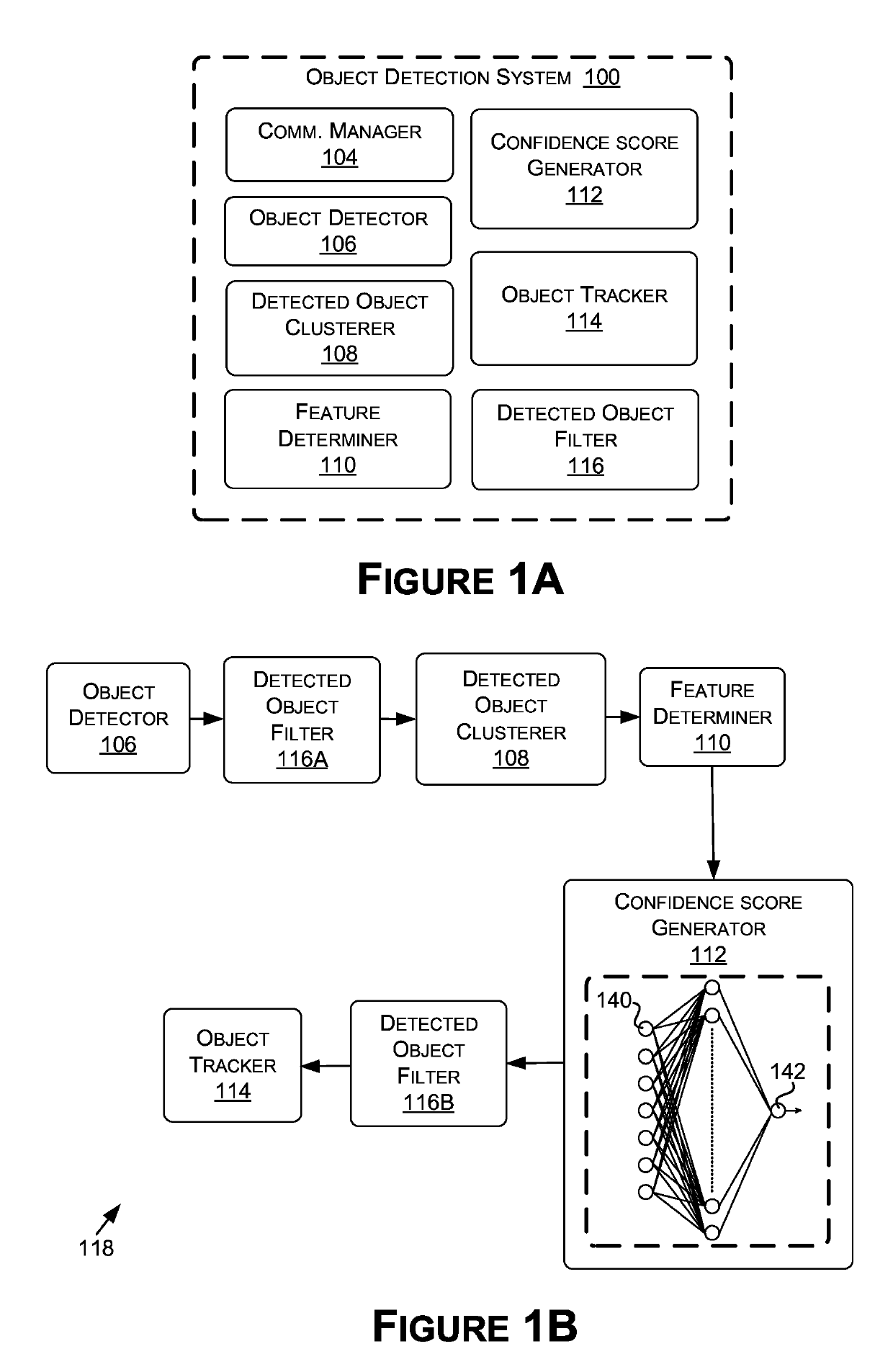

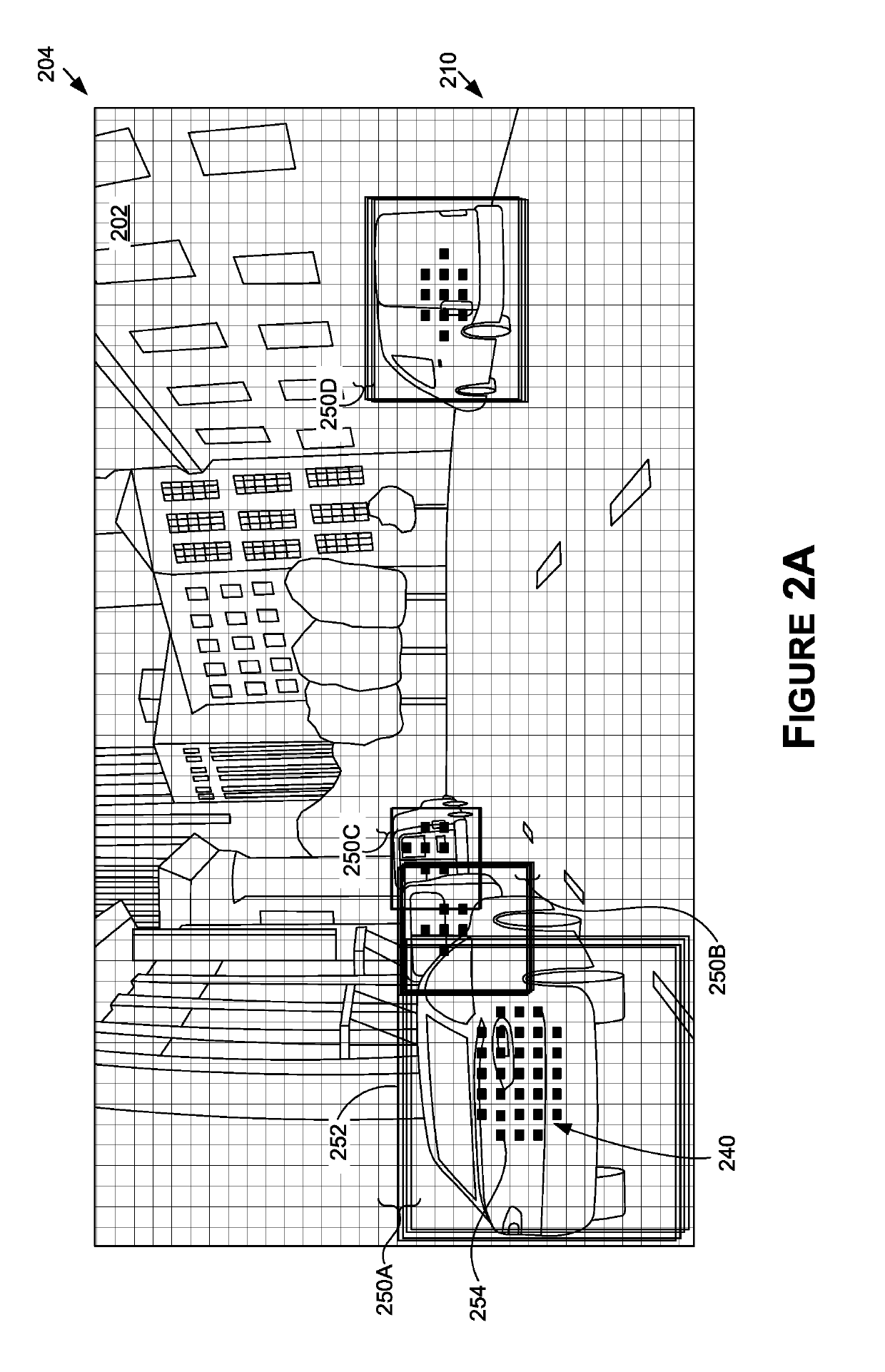

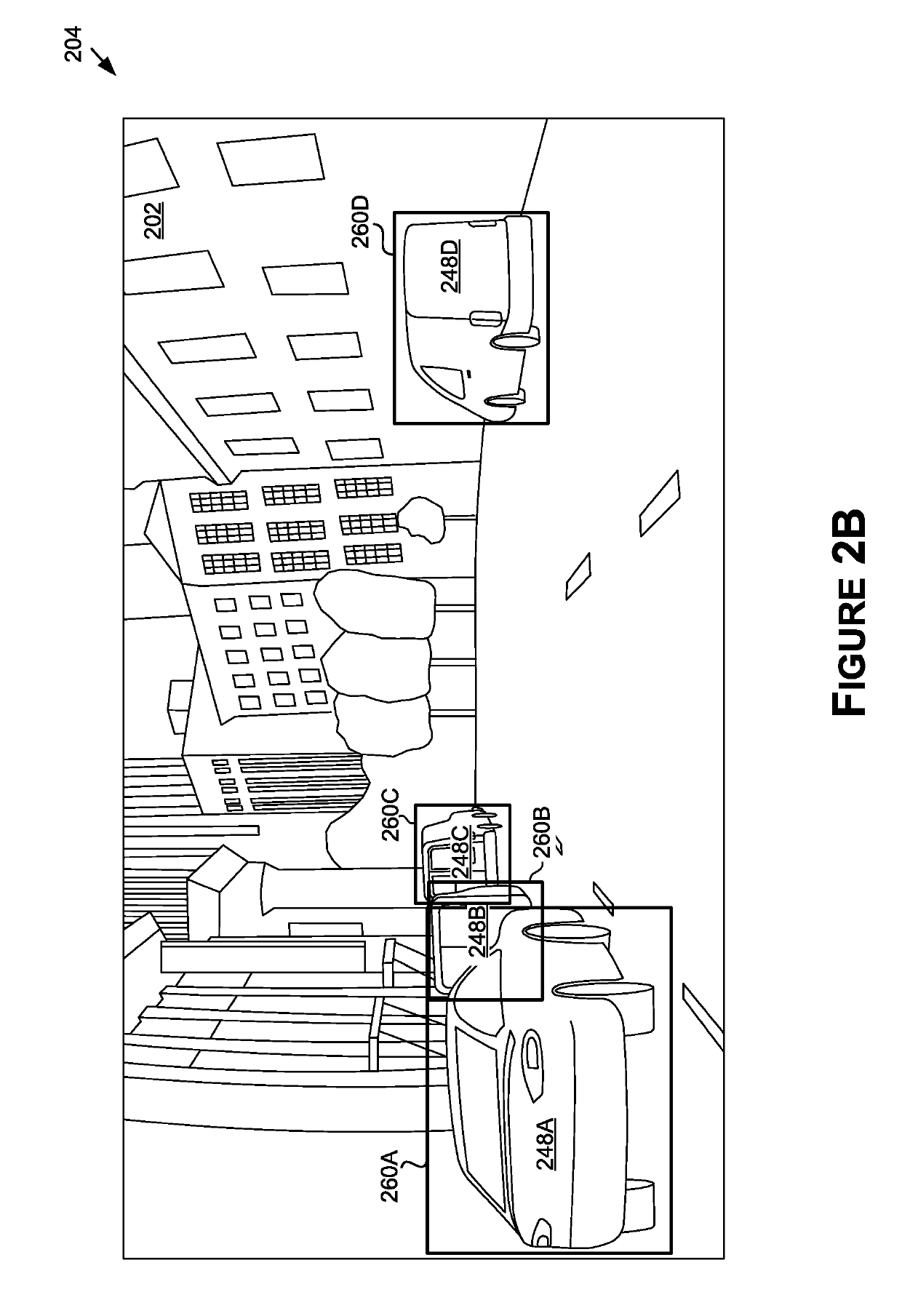

Object detection and detection confidence suitable for autonomous driving

ActiveUS20190258878A1Accurately indicatedFalse detectionScene recognitionMachine learningGround truthObject-class detection

In various examples, detected object data representative of locations of detected objects in a field of view may be determined. One or more clusters of the detected objects may be generated based at least in part on the locations and features of the cluster may be determined for use as inputs to a machine learning model(s). A confidence score, computed by the machine learning model(s) based at least in part on the inputs, may be received, where the confidence score may be representative of a probability that the cluster corresponds to an object depicted at least partially in the field of view. Further examples provide approaches for determining ground truth data for training object detectors, such as for determining coverage values for ground truth objects using associated shapes, and for determining soft coverage values for ground truth objects.

Owner:NVIDIA CORP

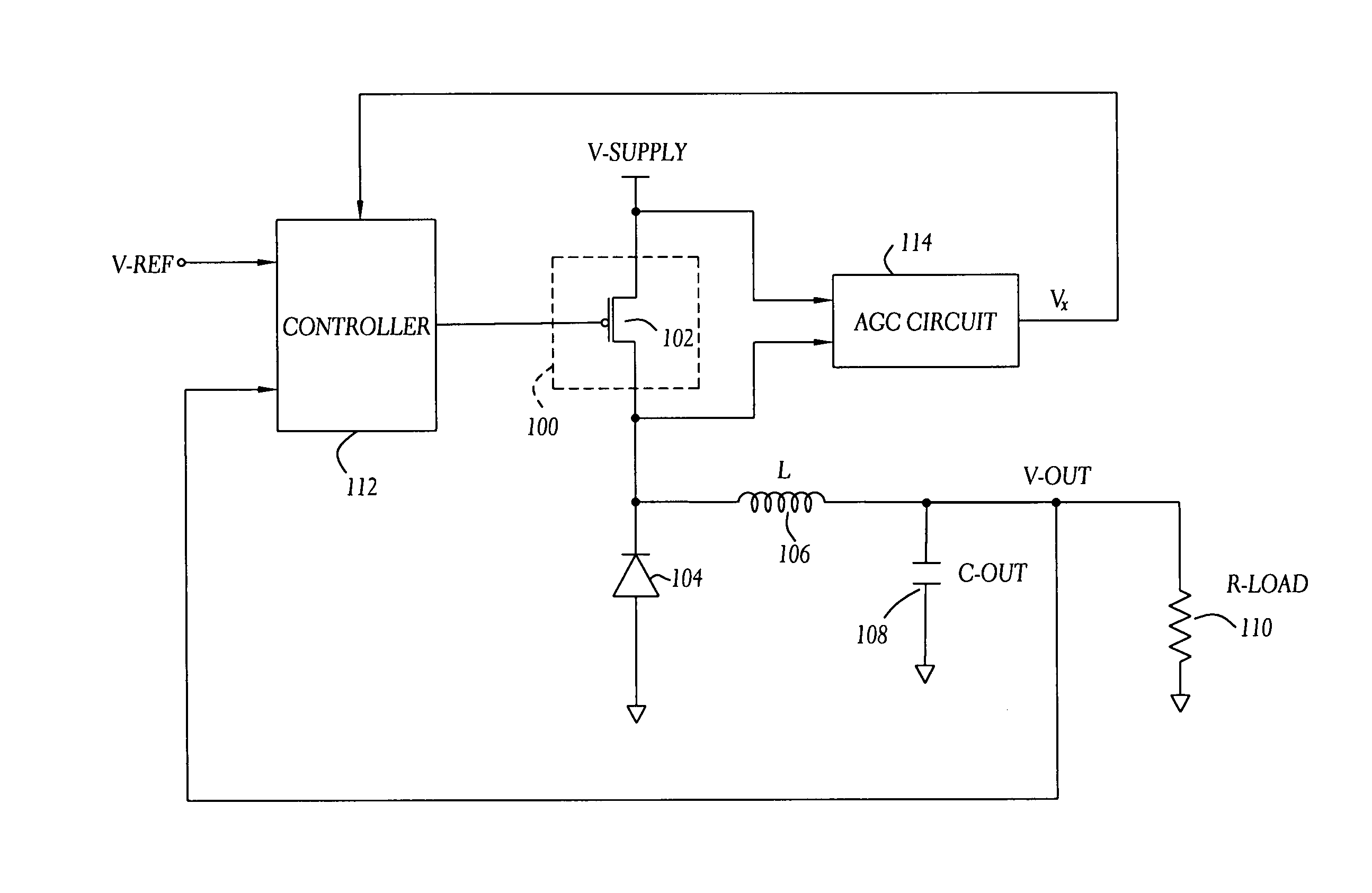

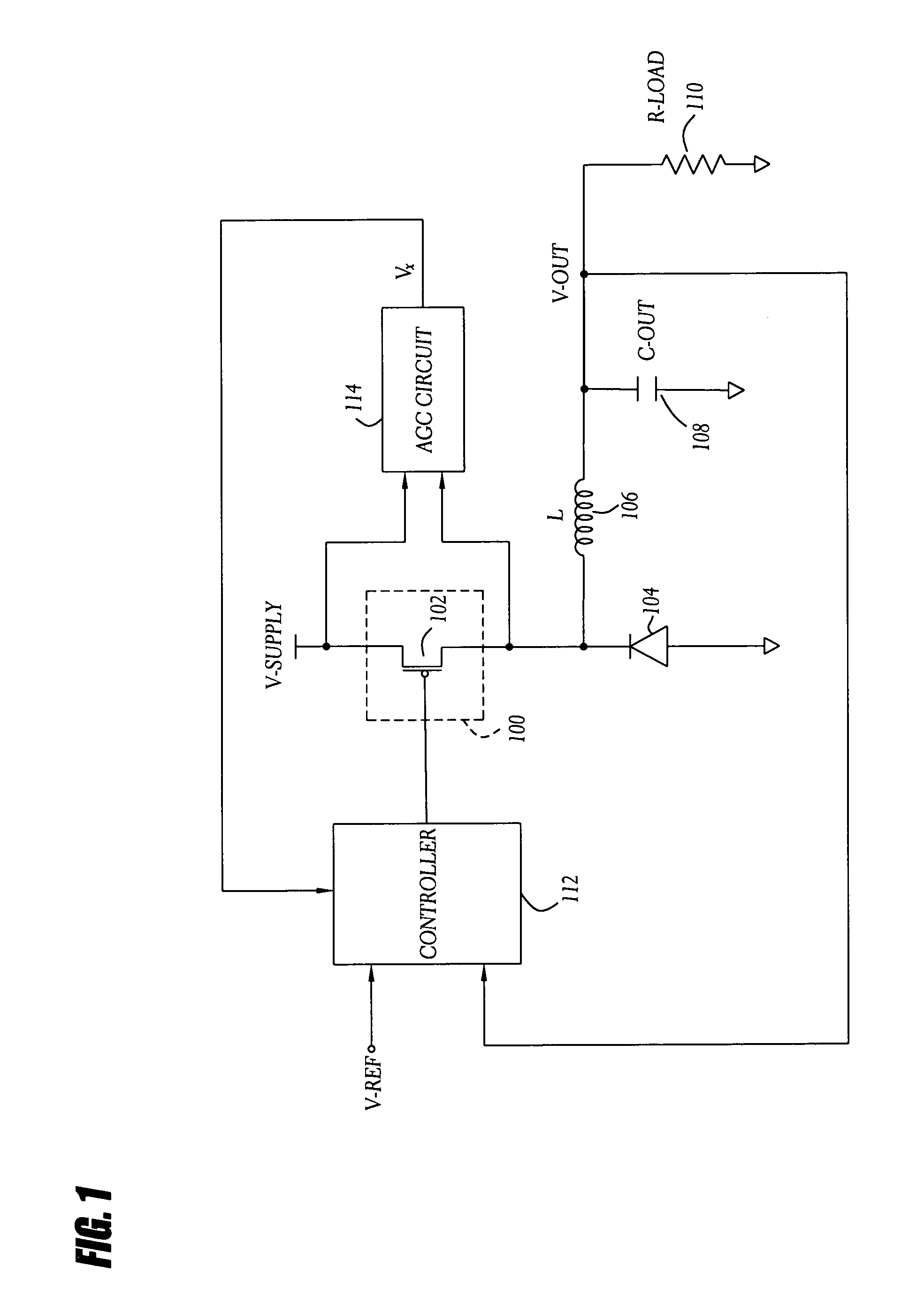

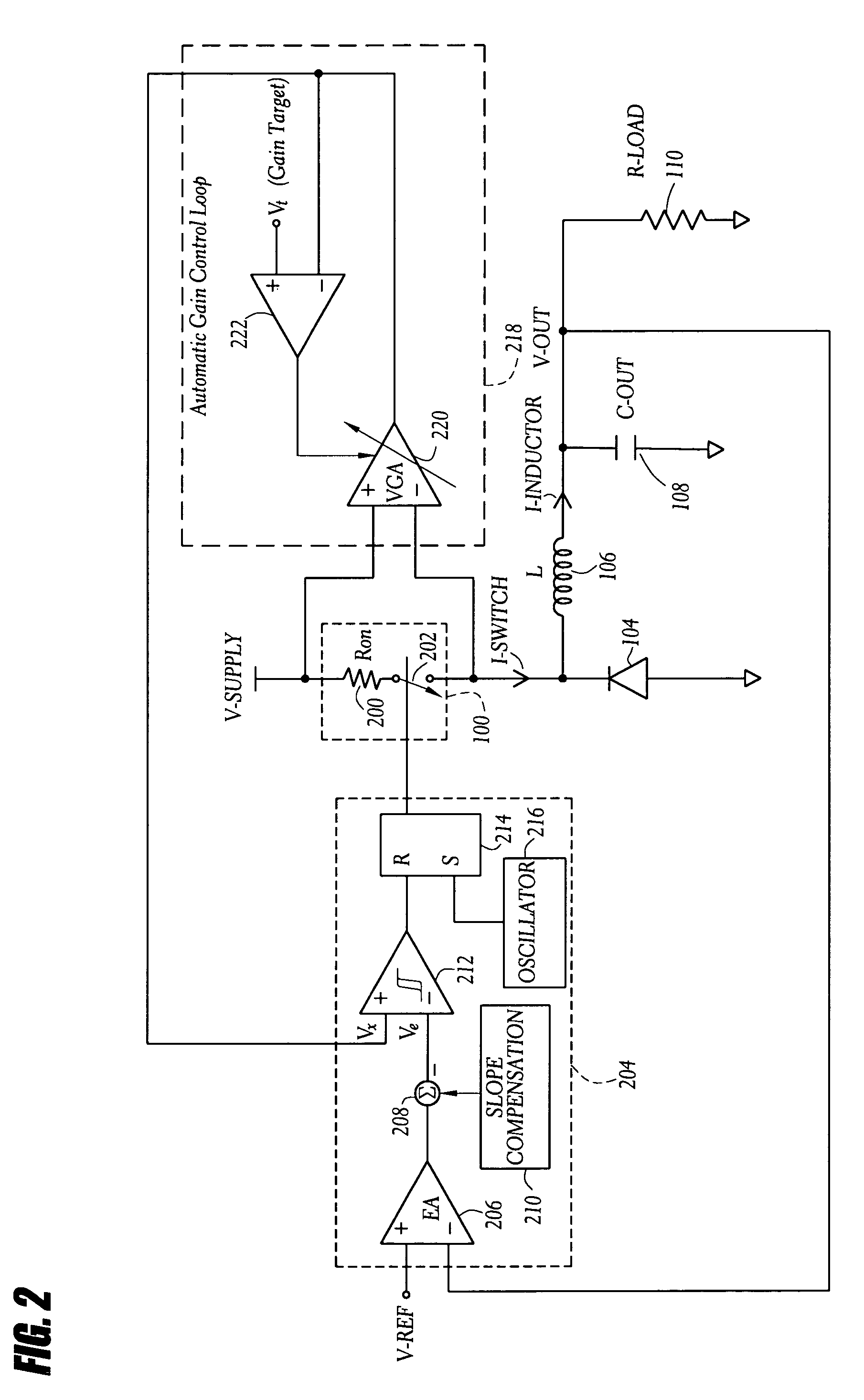

Automatic gain control technique for current monitoring in current-mode switching regulators

InactiveUS7919952B1Reduce component count and circuit board sizeFacilitates efficient and reliable monitoringDc-dc conversionElectric variable regulationEngineeringCurrent mode

A current-mode switching regulator uses adaptive current sensing to reliably monitor an inductor current in a cost-efficient and power-efficient manner. A semiconductor switch periodically turns on to conduct the inductor current. A voltage drop across the semiconductor switch is monitored when the semiconductor switch is on. A variable gain amplifier with an automatic gain control loop generates a feedback signal from the voltage drop of the semiconductor switch when conducting to provide an indication of the inductor current to a controller. The automatic gain control loop compensates for any variations in the on-resistance of the semiconductor switch.

Owner:MICROSEMI

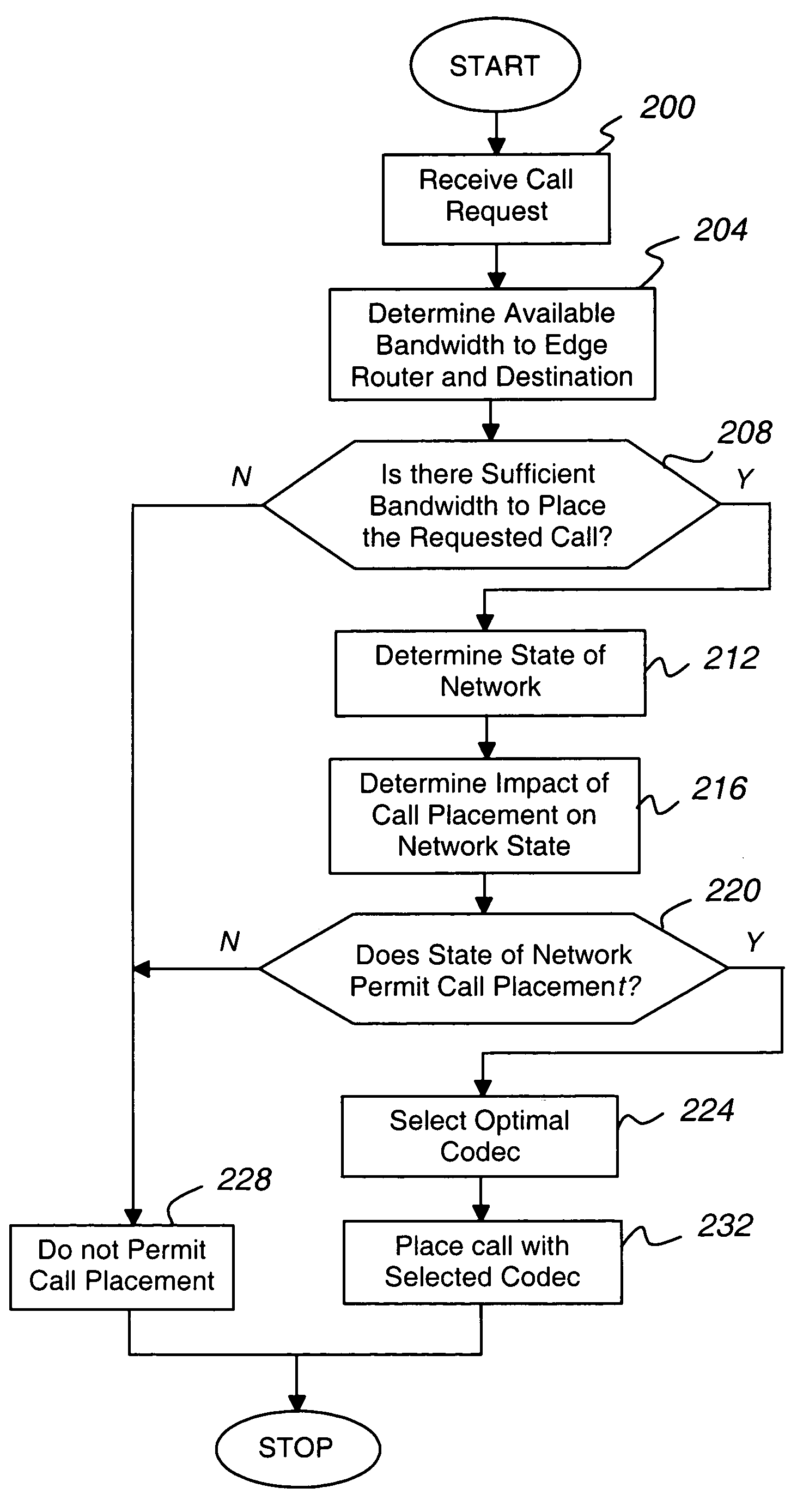

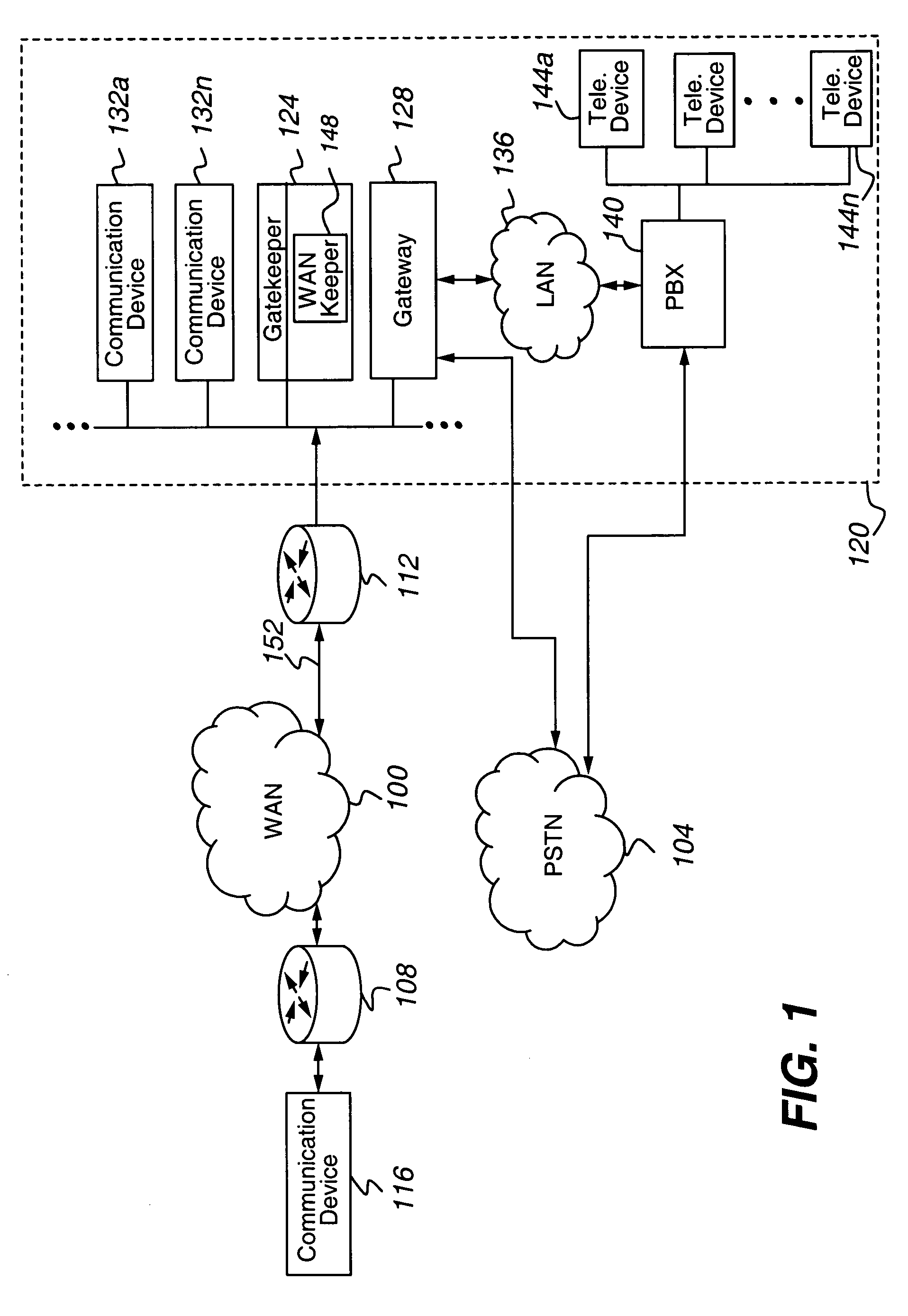

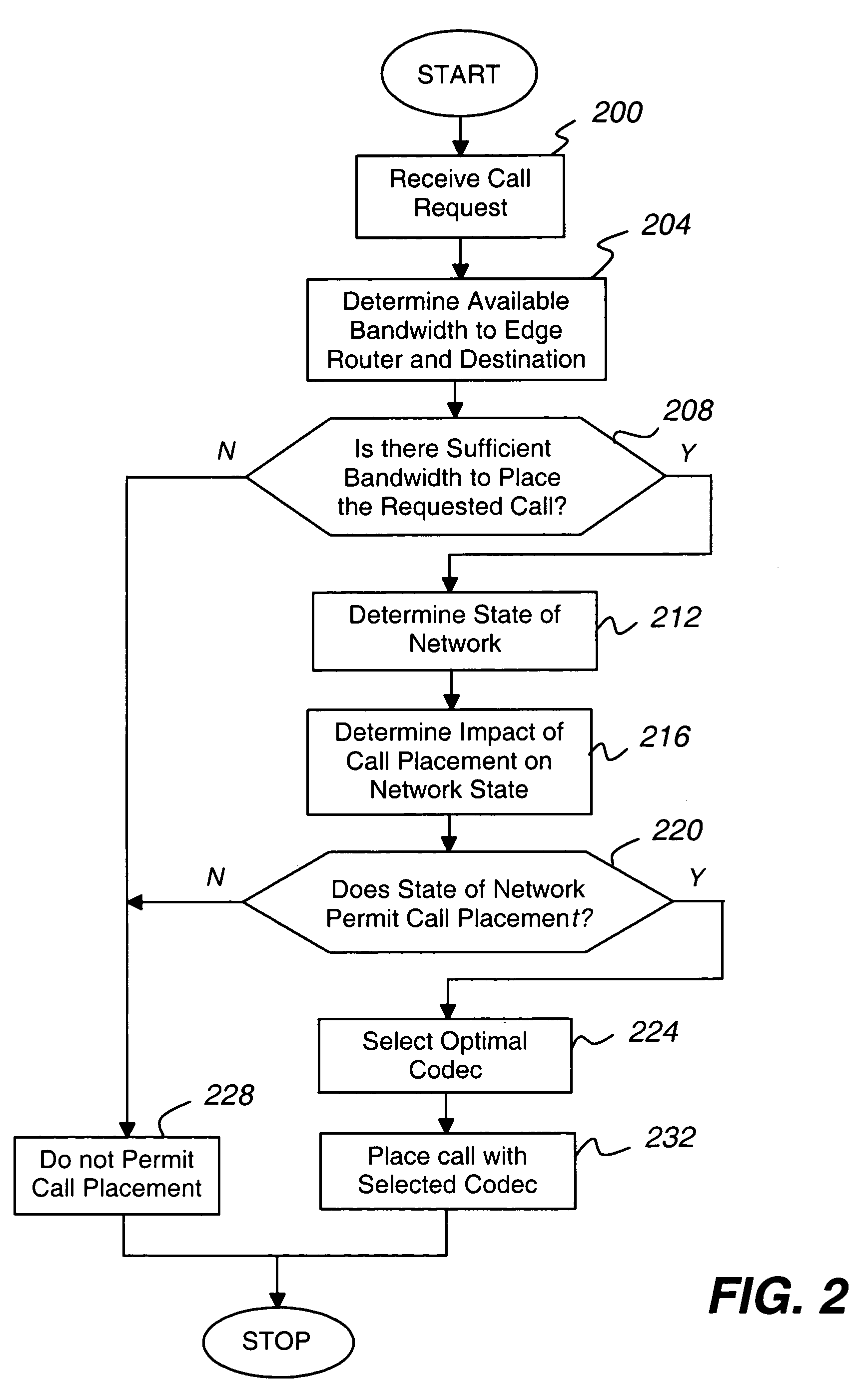

WAN keeper efficient bandwidth management

ActiveUS7643414B1Efficient use ofEnoughInterconnection arrangementsError preventionQuality of serviceLive voice

The present invention is directed to a call admission controller that is operable to: (a) determine at least one of (i) a bandwidth utilization level for a first path including a first link; (ii) an available bandwidth level for the first path; and (iii) one or more Quality of Service or QoS metrics for the first path; (b) compare the at least one of (i) a bandwidth utilization level; (ii) an available bandwidth level; and (iii) one or more Quality of Service or QoS metrics to one or more selected thresholds to determine whether a new live voice communication may be set up with a first selected codec; and (iii) when a new live voice communication may not be set up with the first selected codec, perform at least one of the following operations: (i) select a second different codec from among a plurality of possible codecs for the new live voice communication, wherein the second codec has a lower bit rate than the first codec; (ii) change an existing live voice communication from the first codec to the second codec; and (iii) redirect the new live voice communication from the first path to a second different path, wherein the second path does not include the first link.

Owner:AVAYA INC

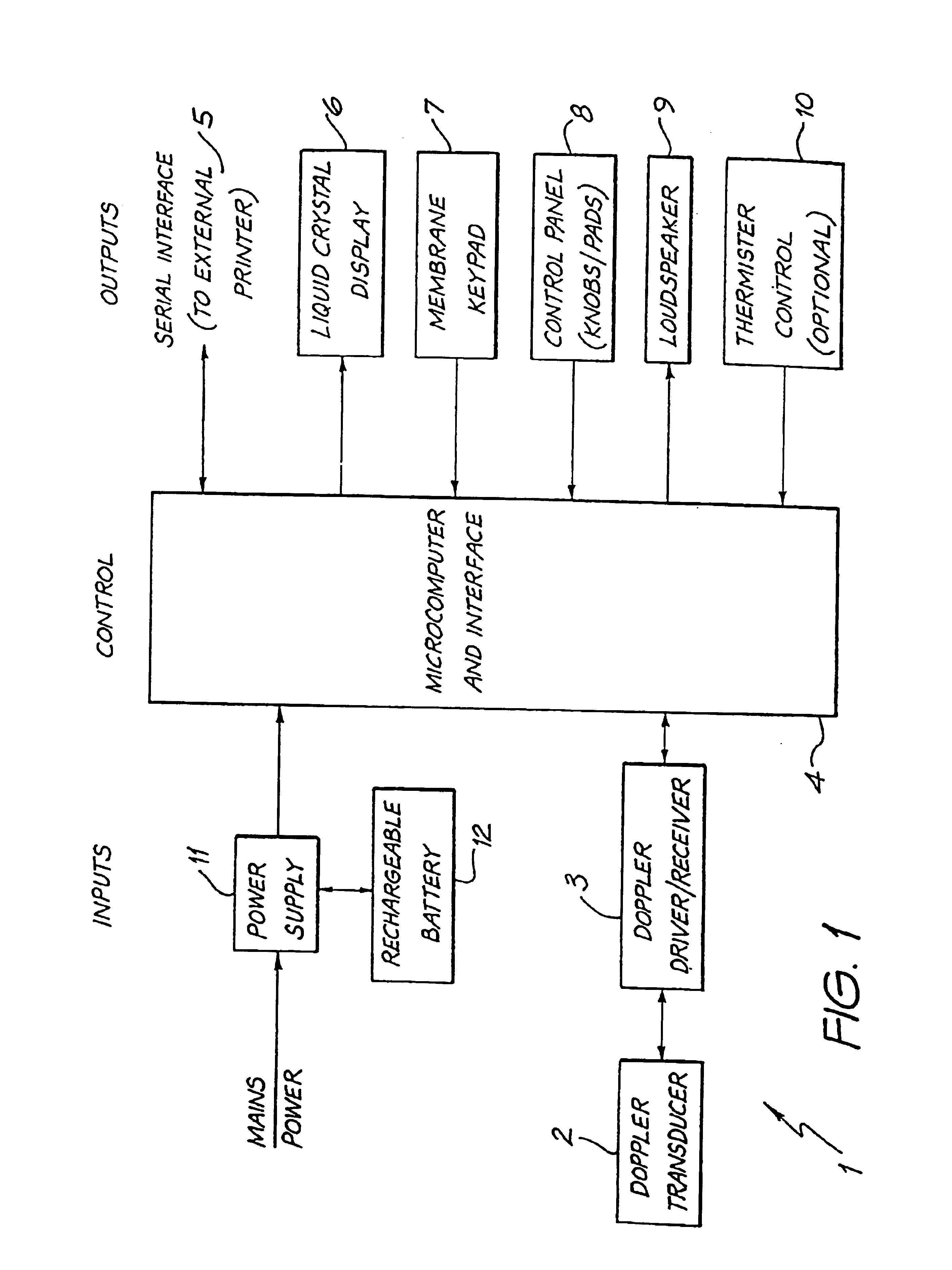

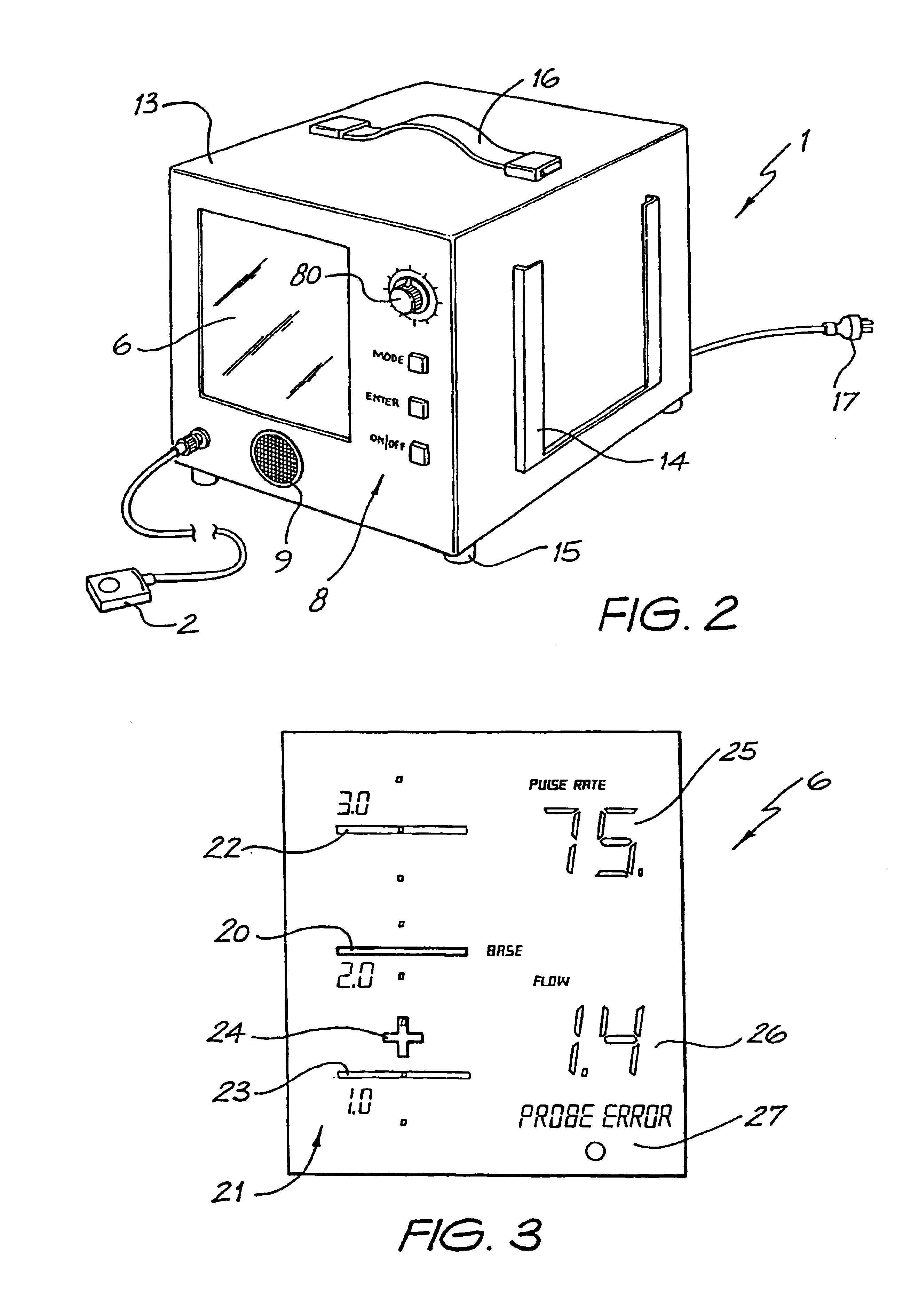

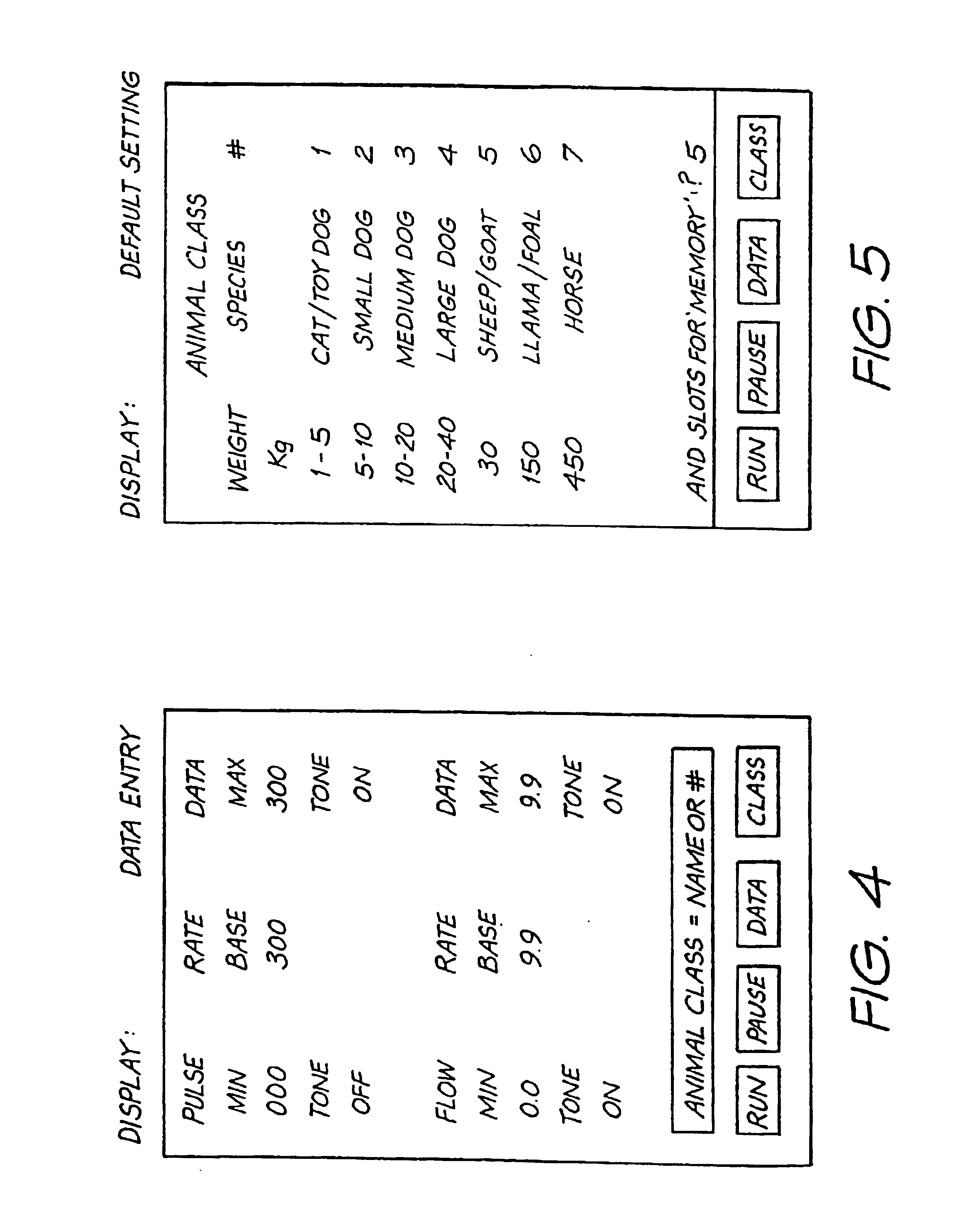

Method and apparatus for monitoring haemodynamic function

InactiveUS6939307B1Accurate indicationAccurate of oxygen deliveryBlood flow measurement devicesCatheterBlood flowBiology

The present invention relates to a method and apparatus for monitoring haemodynamic function in animals and humans during anaesthesia and surgery. During anaesthesia and surgery the subject's haemodynamic, respiratory, neuromuscular and neurological functions are monitored as indicators of the condition of the health of the subject. Commonly, variations in blood pressure are used to imply corresponding variations in cardiac output, i.e. good blood pressure equals good cardiac output. The present invention utilizes a device to monitor changes of blood flow in peripheral blood vessels of the subject as an indicator of cardiac output. This is believed to provide a much more accurate indicator.

Owner:DUNLOP COLIN

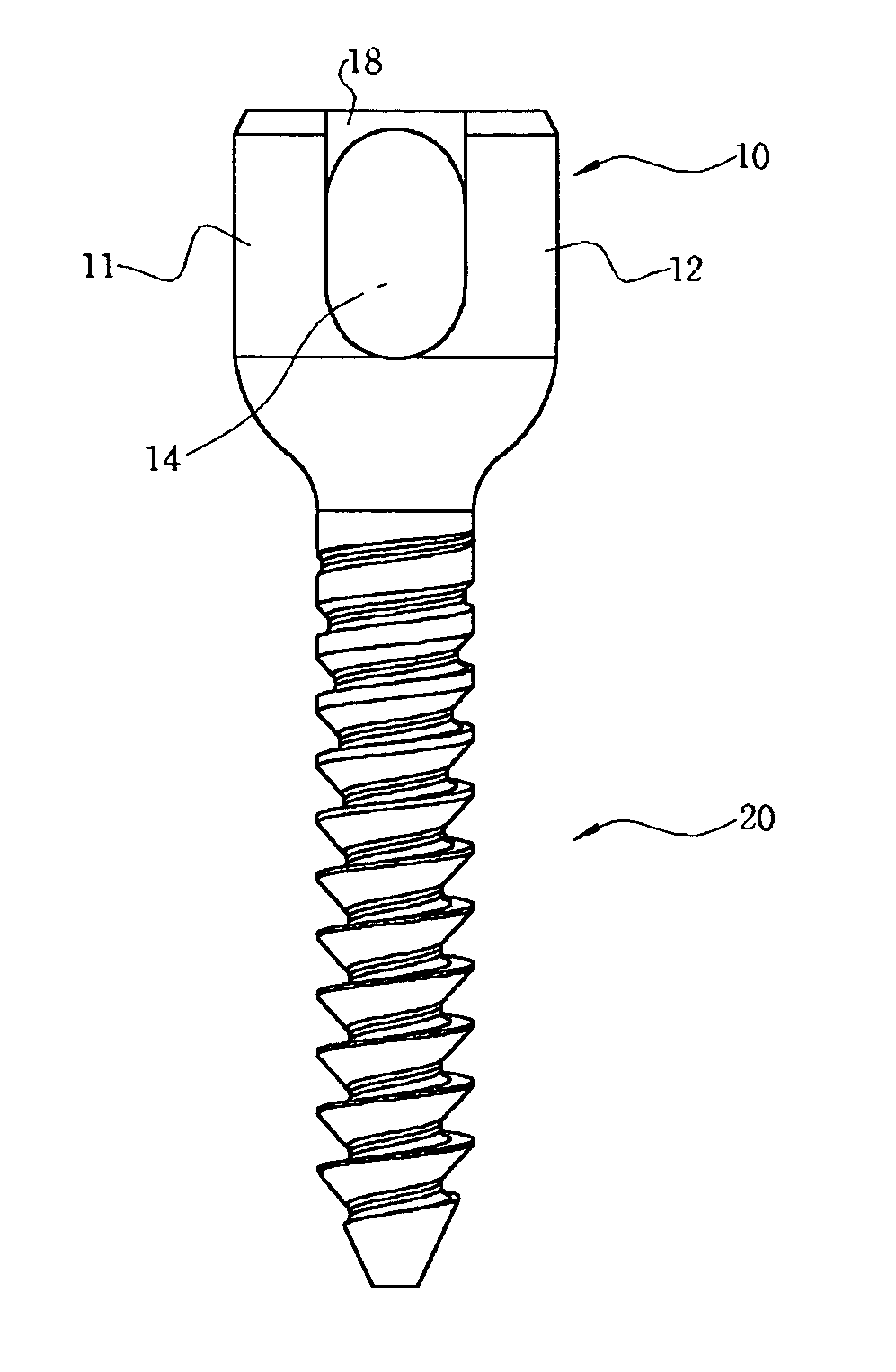

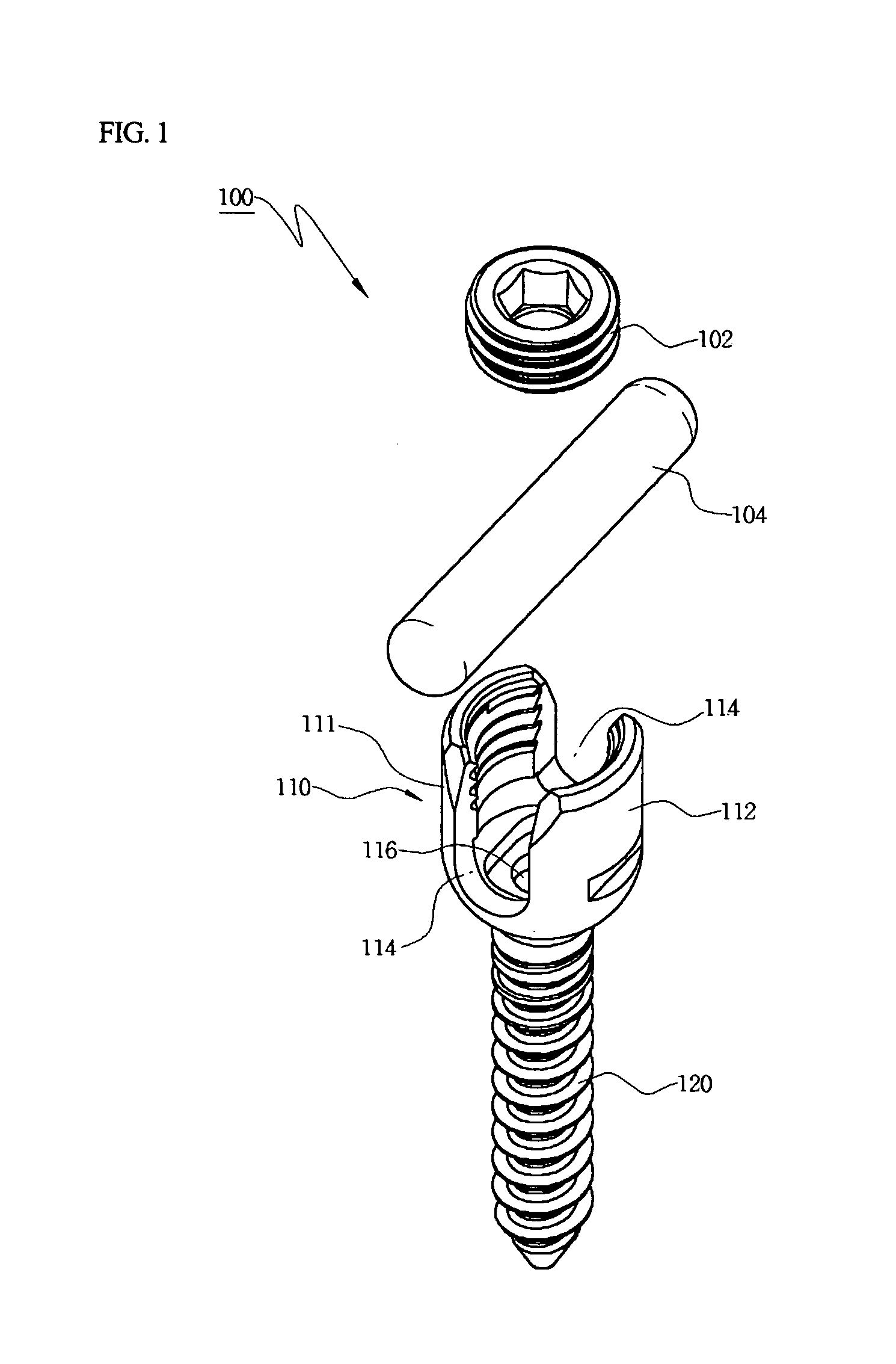

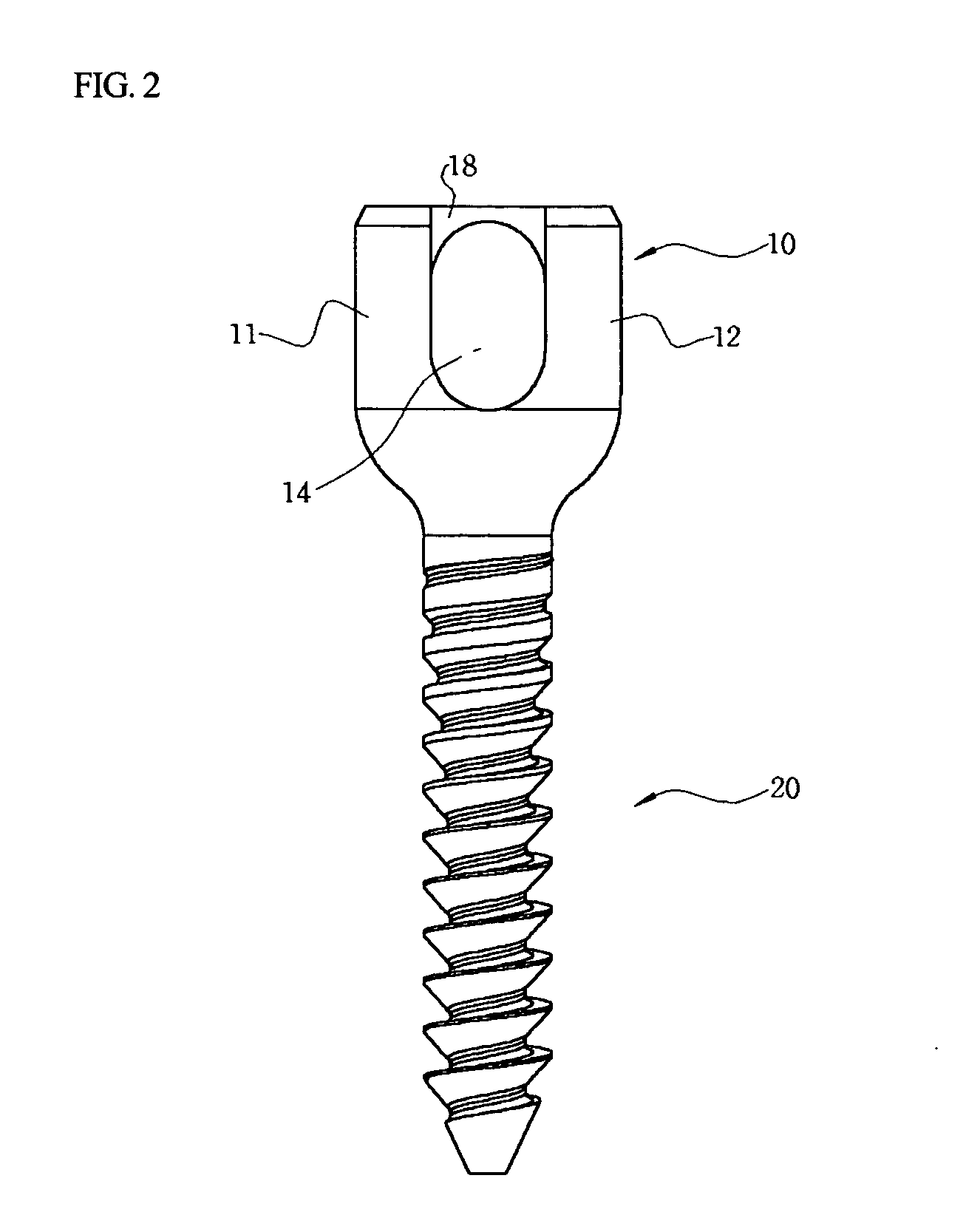

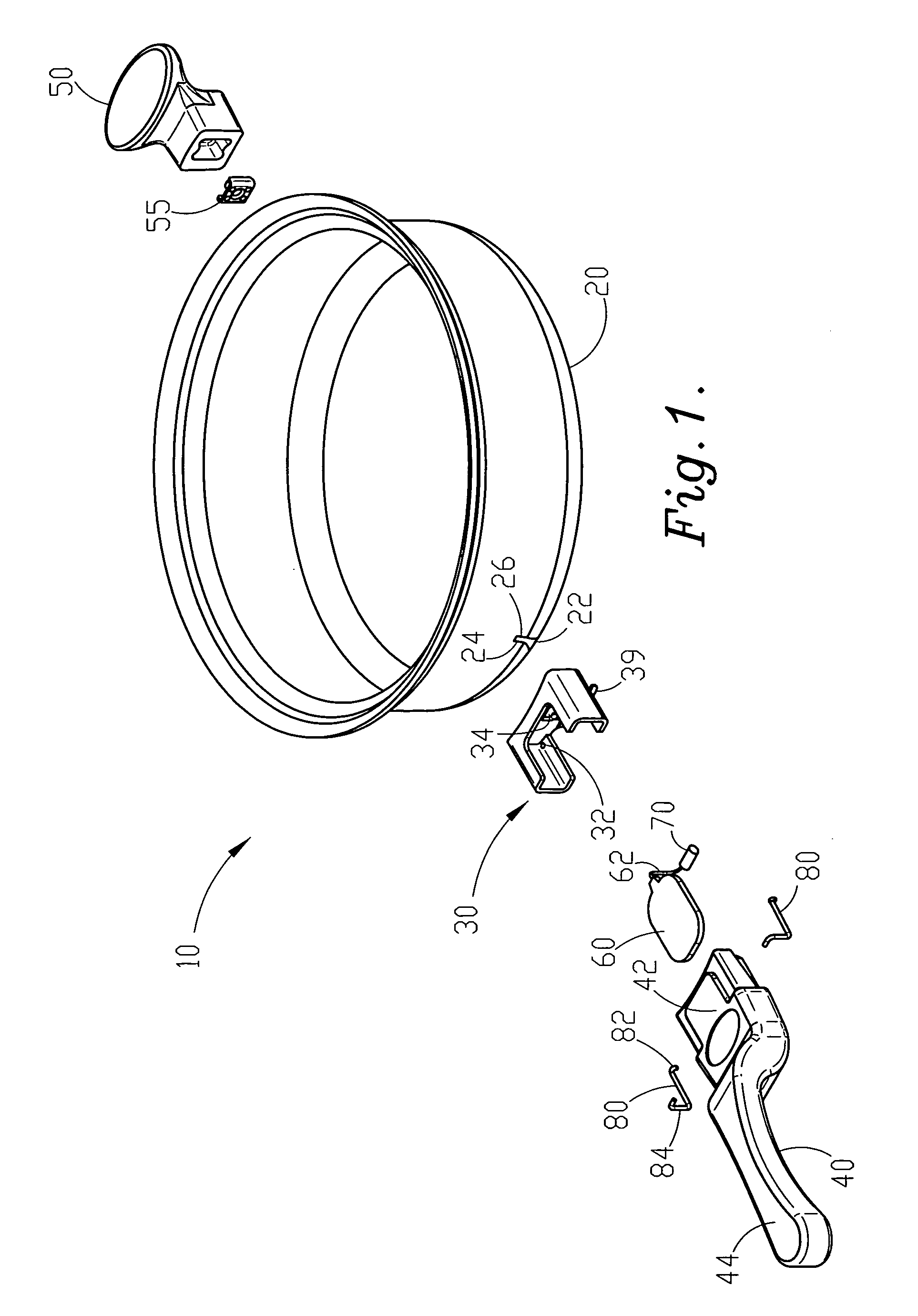

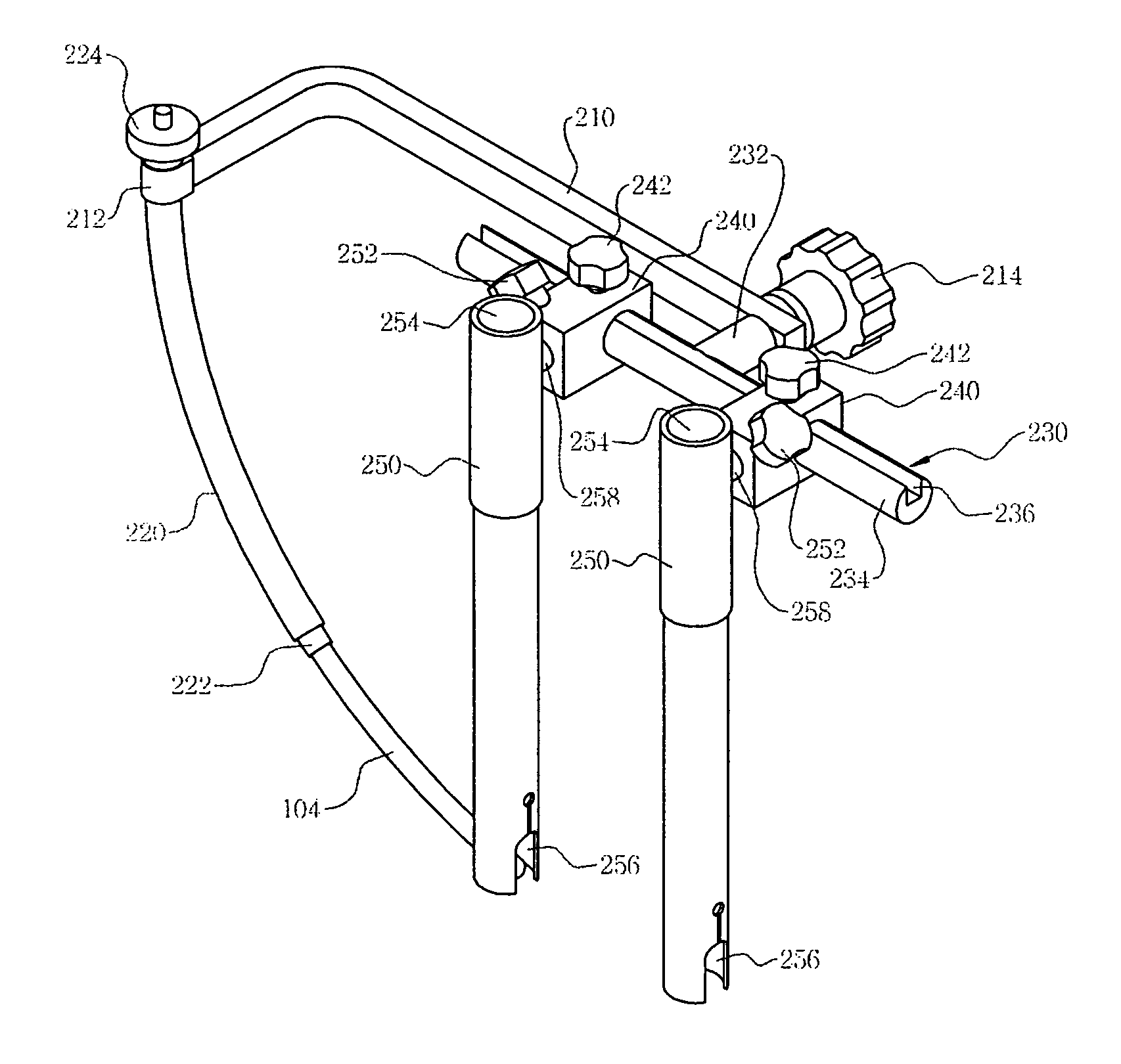

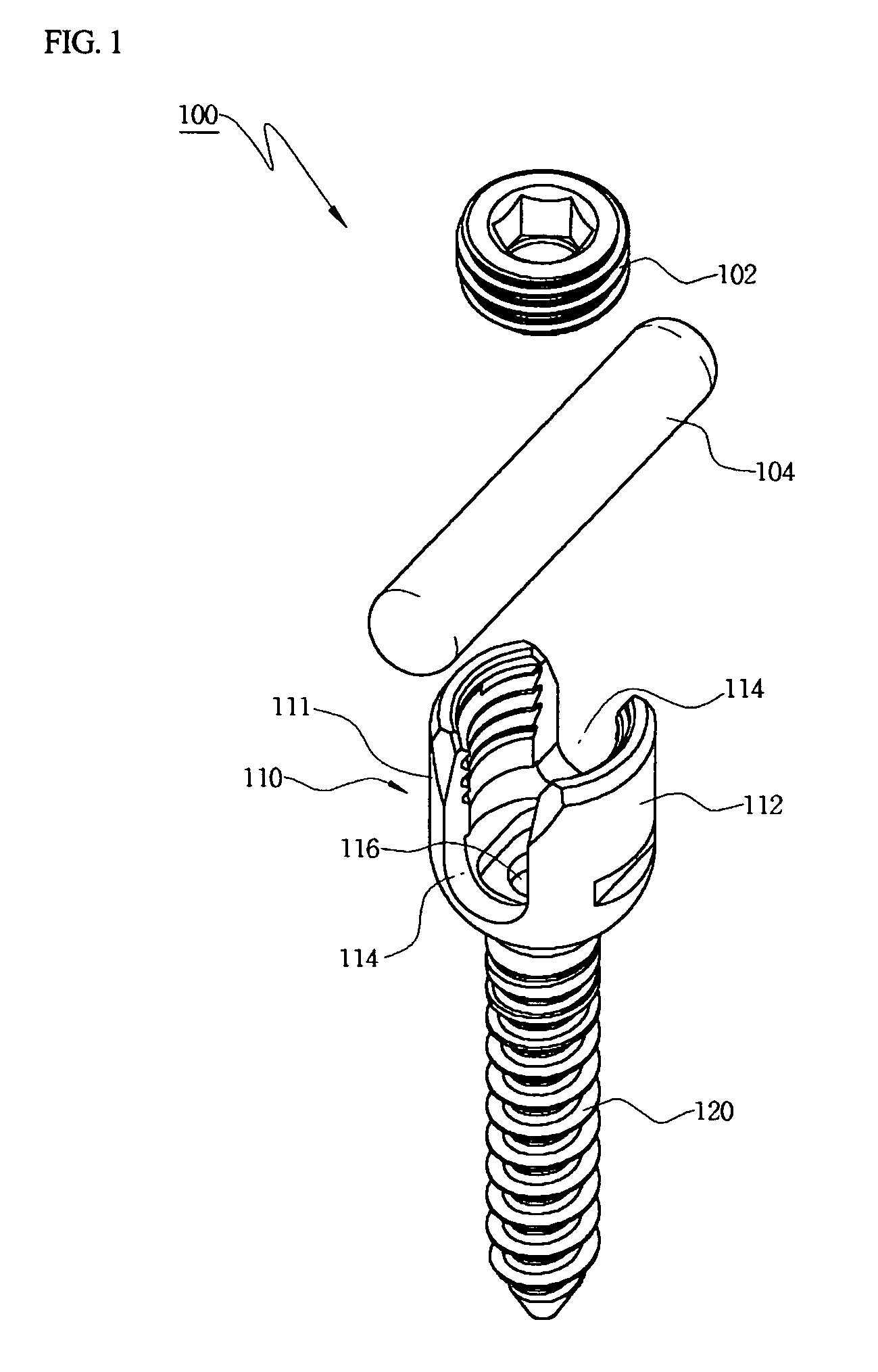

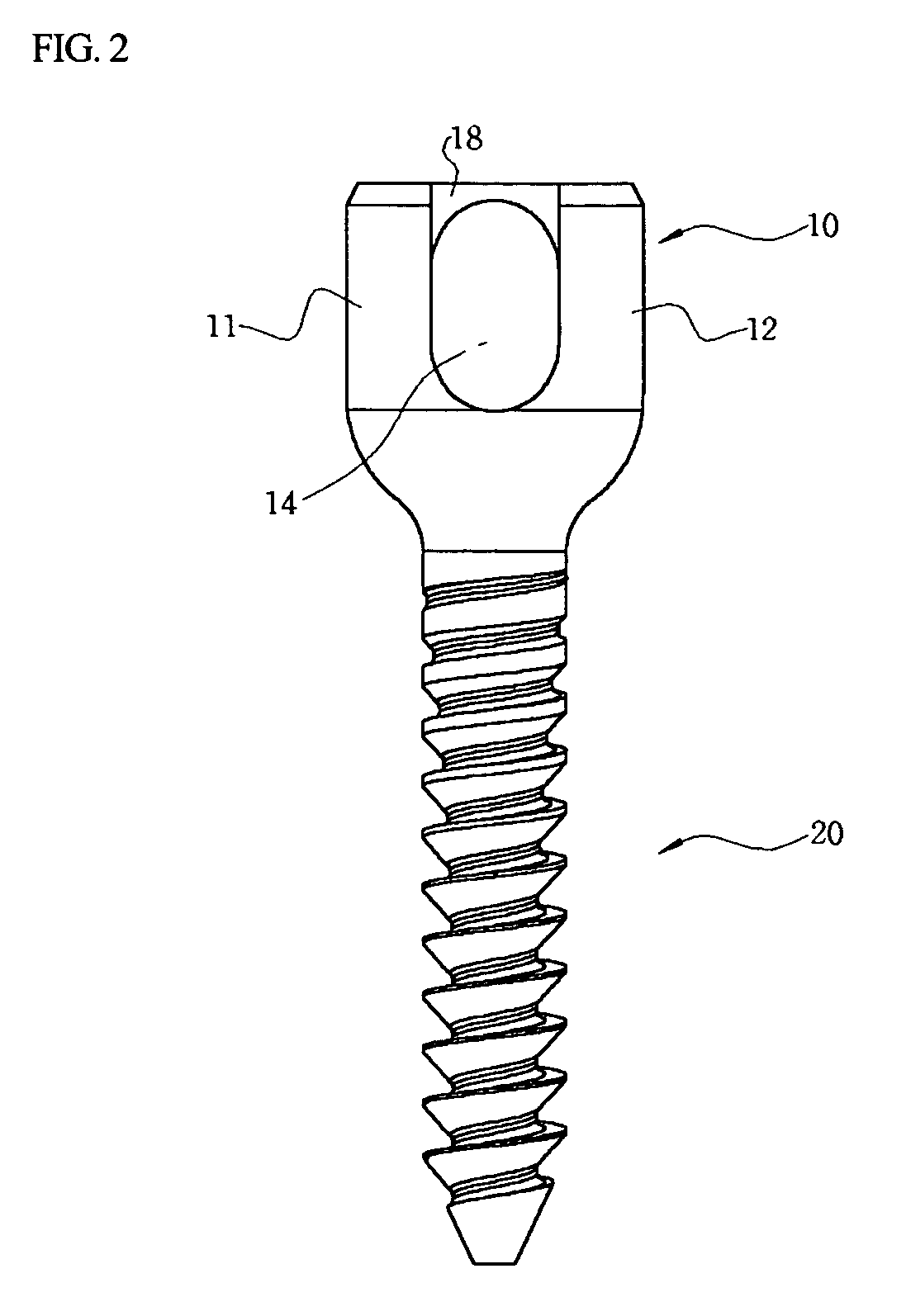

Pedicle screw and operating device thereof

ActiveUS20060030839A1Avoid separationAccurately indicatedInternal osteosythesisNon-surgical orthopedic devicesCouplingUnit operation

Disclosed is a spine fixation apparatus, more particularly, a pedicle screw implanted into a spine and an operating device for the pedicle screw capable of easily inserting a rod to a head section of the pedicle screw in order to securely fix the spine. The pedicle screw has a head section including a recess part defined by first and second sidewalls, a screw section, and a support unit formed at an upper portion of the recess part of the head section while connecting the first sidewall to the second sidewall. The operating device has a screw coupling rod having an elongated pipe shape, a body having a first side coupled to the screw coupling rod, a rotating member having a first end coupled to a second side of the body in such a manner that a second end of the rotating member rotates about the first end thereof, and a rod receiver coupled to the second end of the rotating member. Due to the support unit, the rod is prevented from being easily separated from the pedicle screw, thereby facilitating minimum incision surgery. The operating device for the pedicle screw allows an operator to easily perform minimum incision surgery while making several incisions for the pedicle screws and the rod in the back of the patient and keeping the size of incisions quite a small.

Owner:SOLCO BIOMEDICAL +1

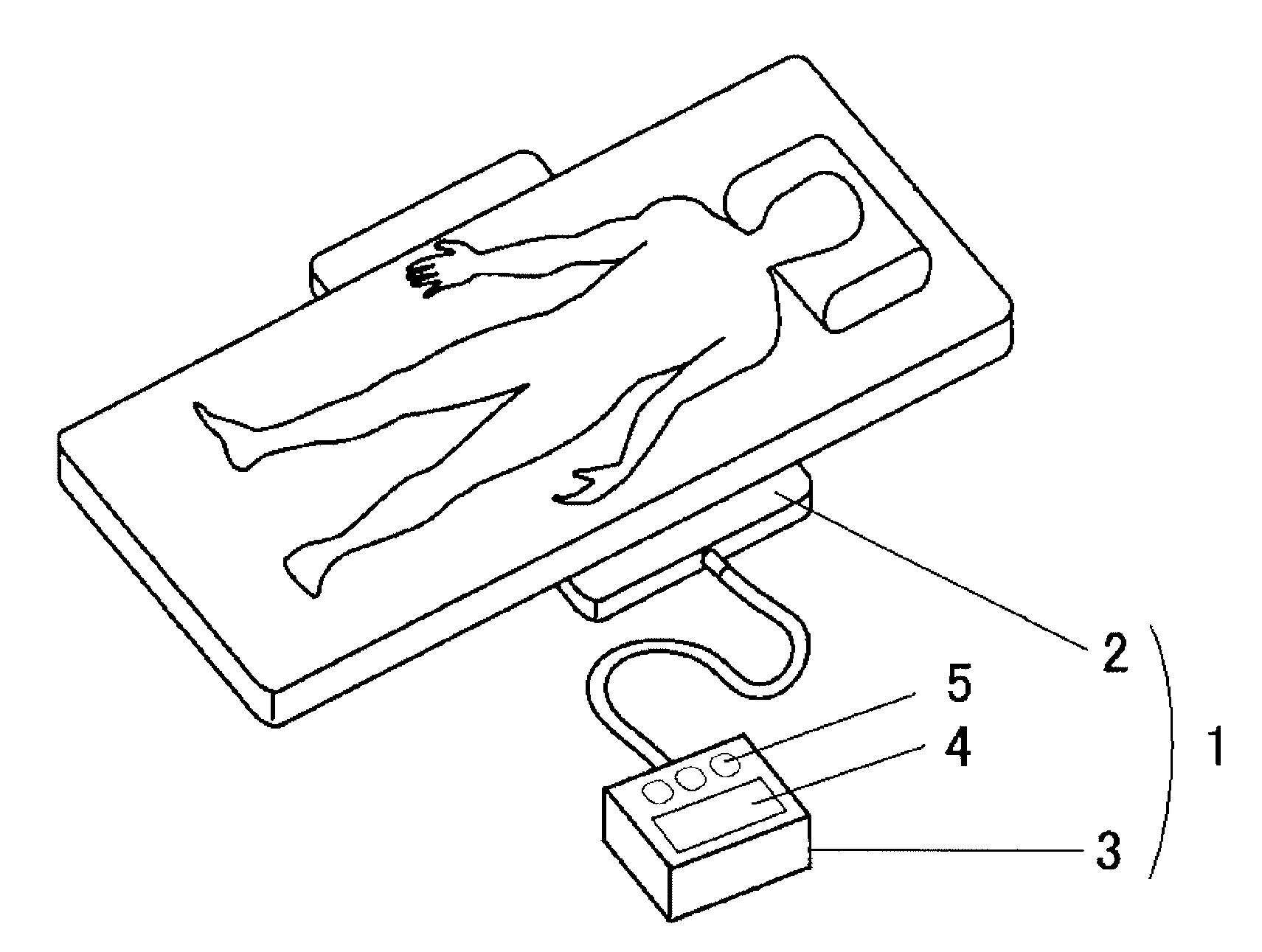

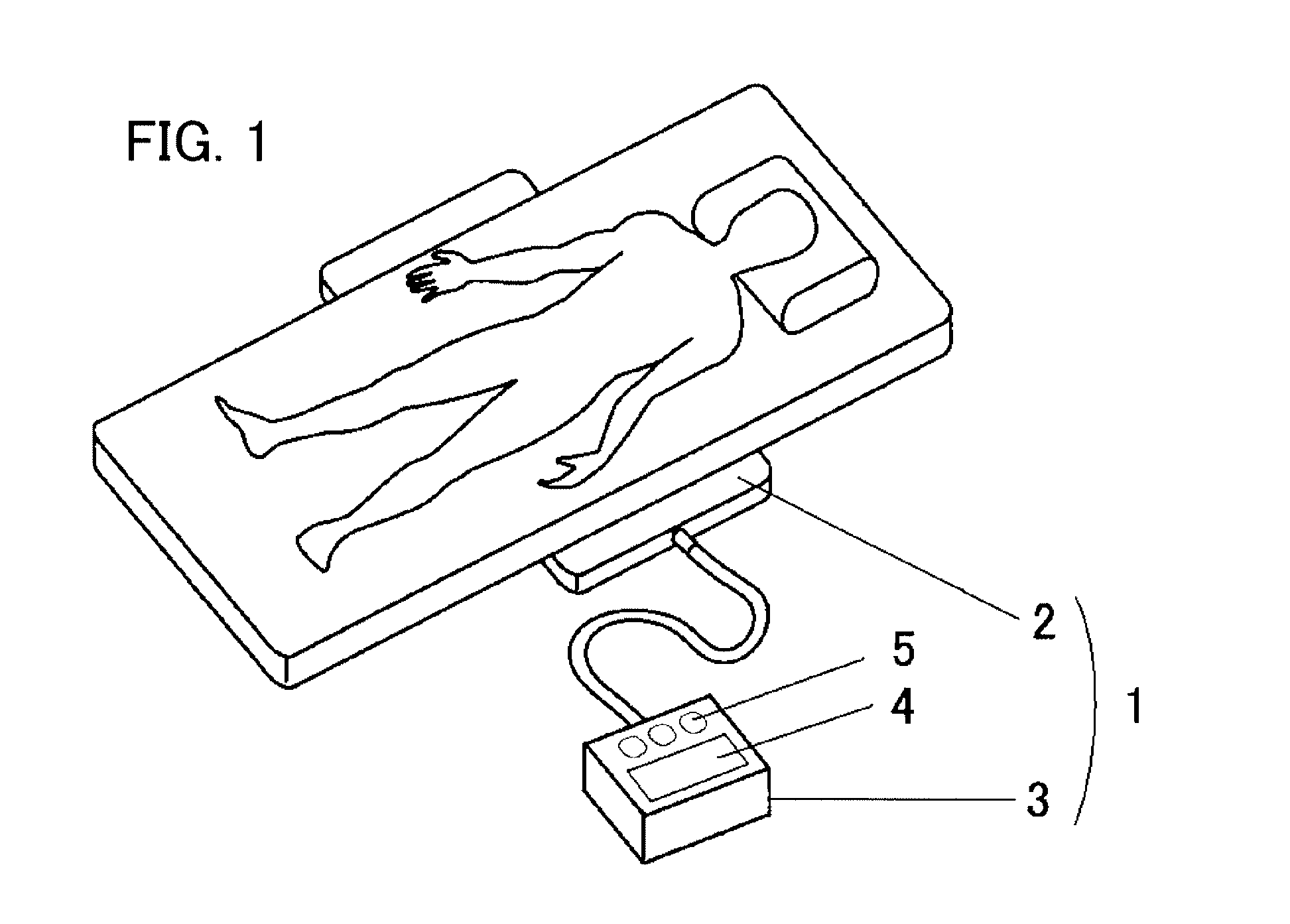

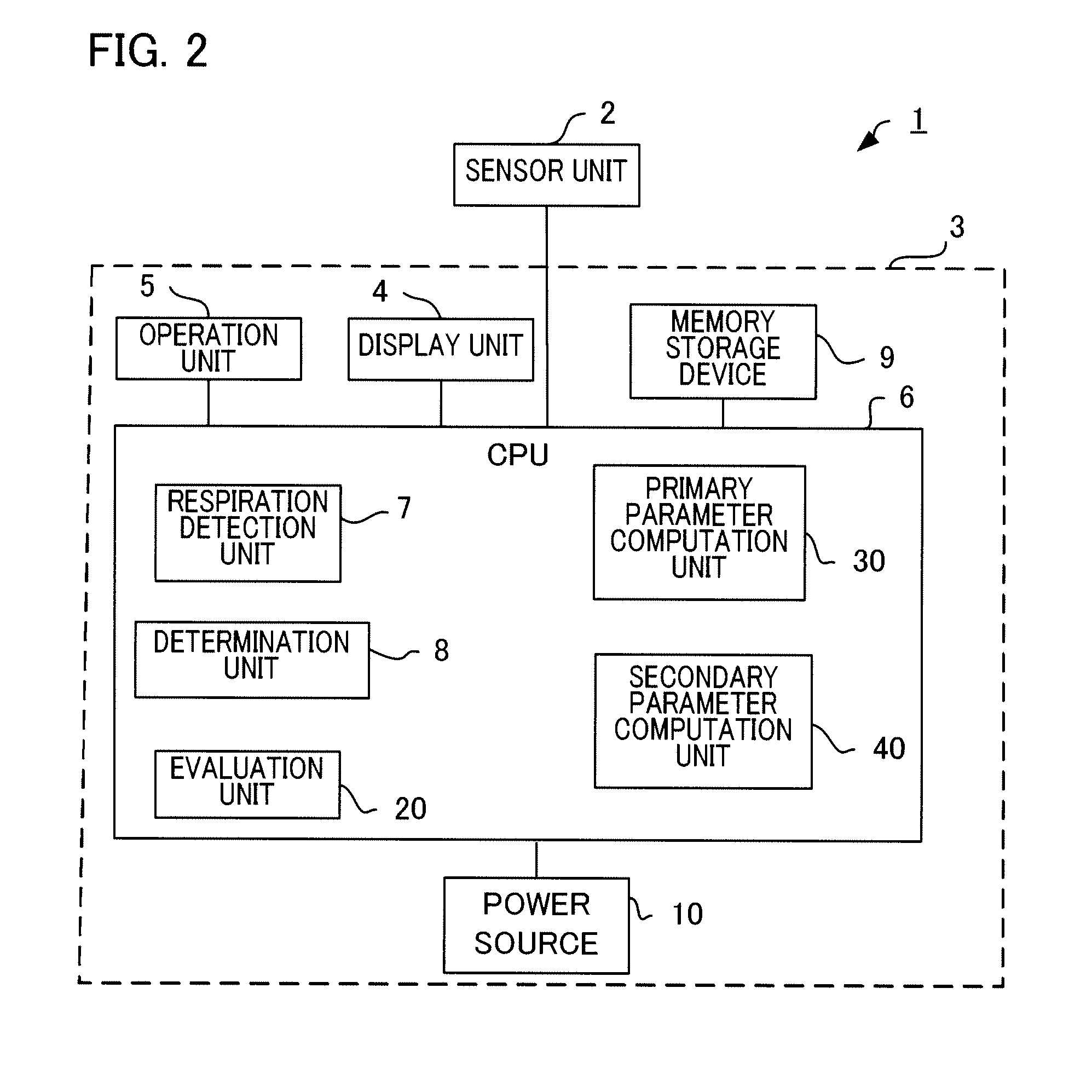

Sleep evaluation device

InactiveUS20080306351A1Accurately indexedAccurate assessmentAmplifier modifications to reduce noise influenceDigital computer detailsSleep stateMedicine

A sleep evaluation device 1 is provided with a respiration detection unit 7 that detects changes in respiration and outputs respiration signals. CPU 6 generates six primary parameters indicating sleep states based on the respiration signals and four secondary parameters based on the primary parameters. The secondary parameters are linearly independent of one another. Evaluation unit 20 computes a sleep score indicating the degree of the quality of sleep by multiplying each of the four secondary parameters by second coefficients and totalizing results of the multiplications. Results of the evaluations are displayed on display unit 4.

Owner:TANITA CORP

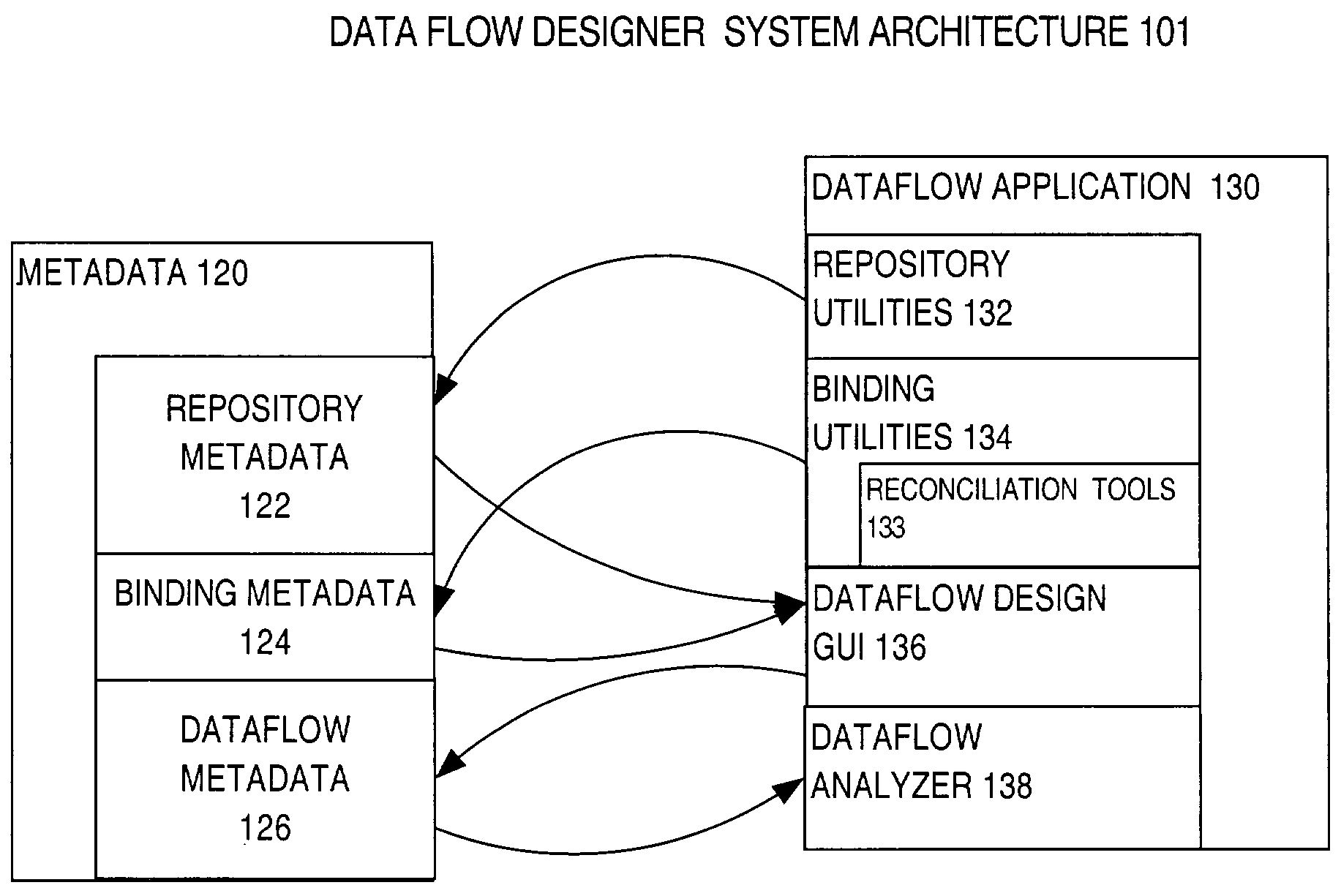

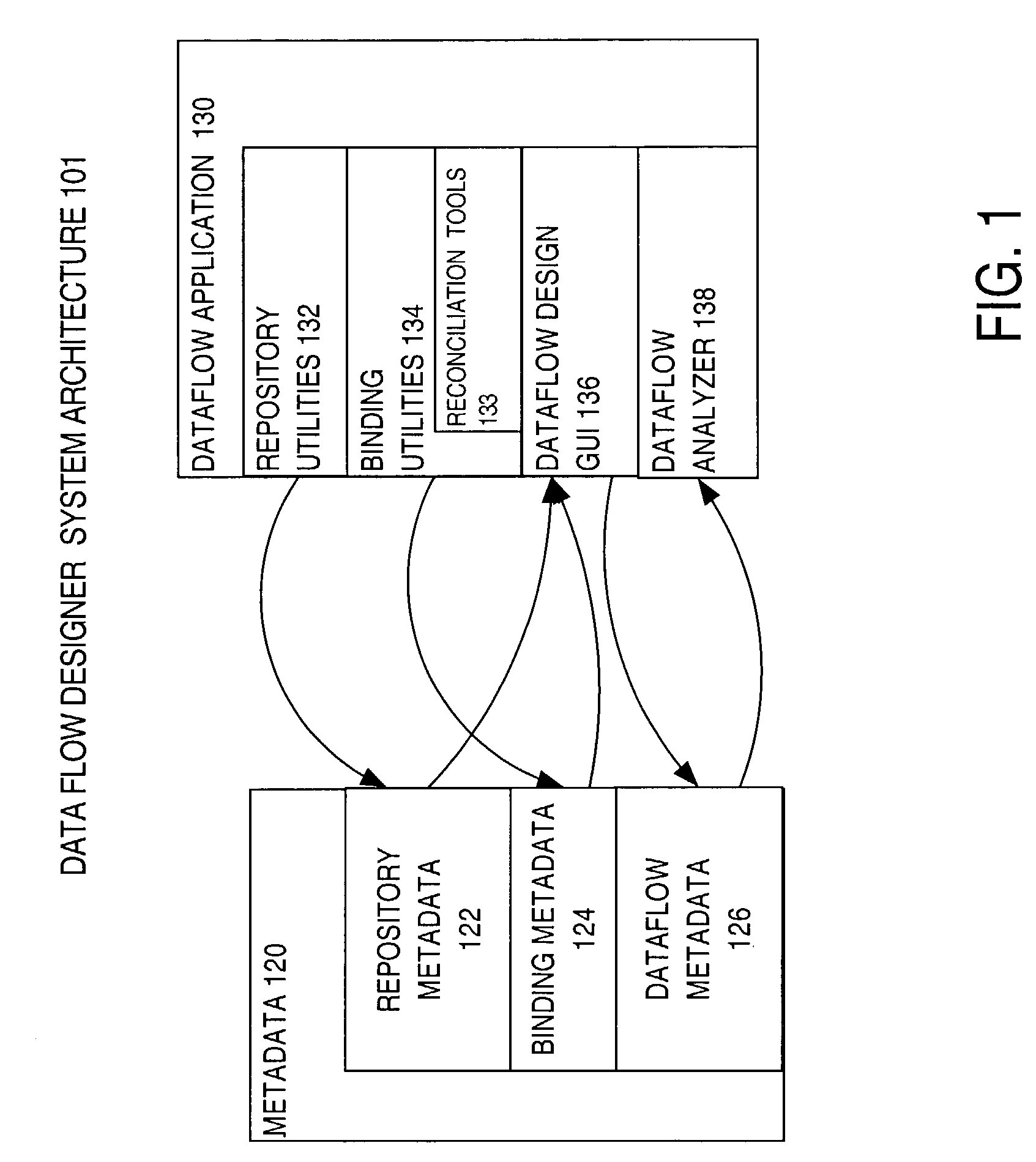

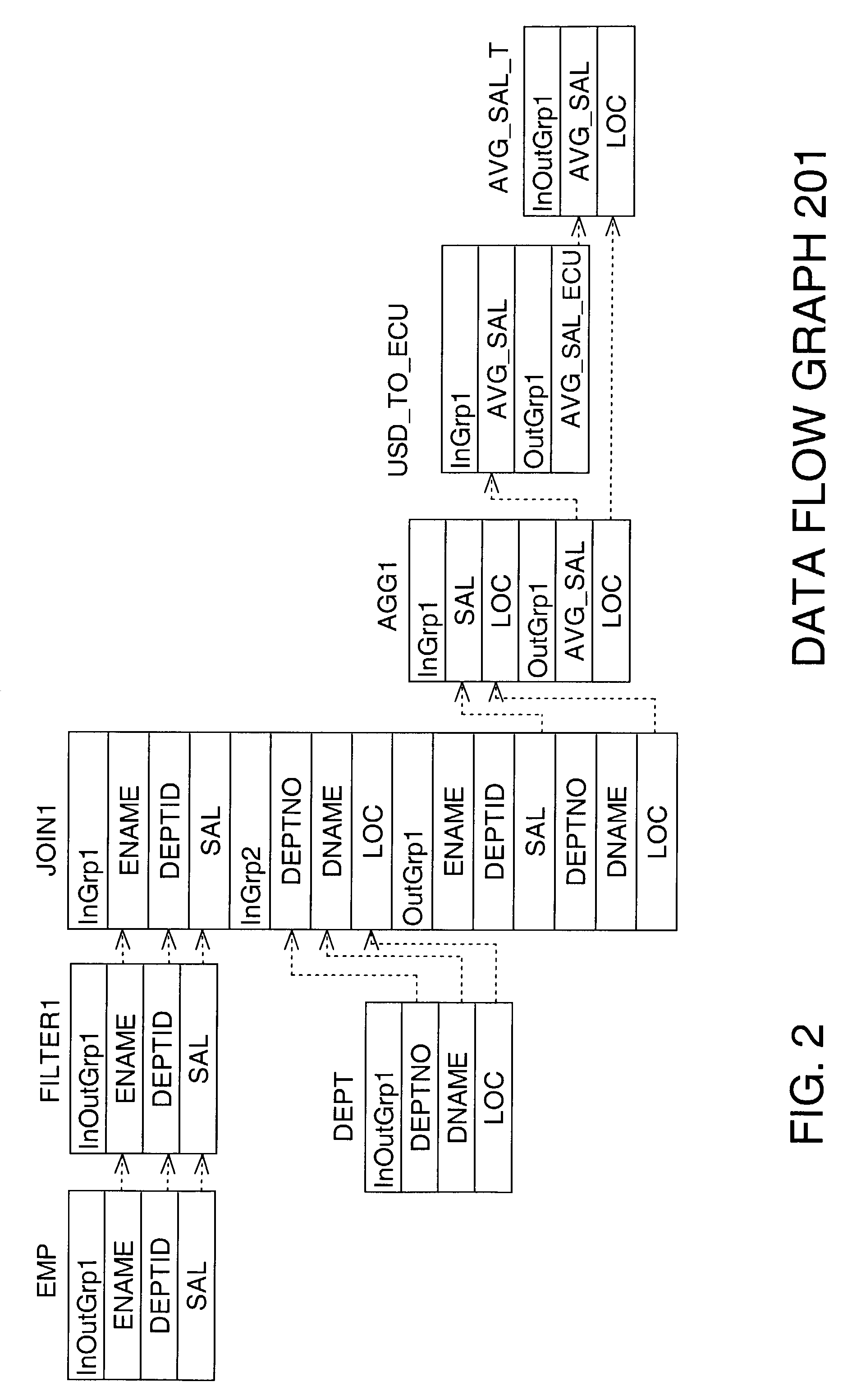

Automatic reconciliation of bindable objects

ActiveUS7080088B1Many solutionsAccurately indicatedData processing applicationsDigital computer detailsData streamParallel computing

Described herein is a reconciliation mechanism that facilitates reconciliation of deployment environments and dataflow descriptions. A dataflow description describes a dataflow, from which a code implementation can be generated for execution on one or more database systems, referred to as a deployment environment. To generate an implementation for a deployment environment, the elements of a dataflow description are bounded to the elements of a deployment environment. The elements of a deployment environment may change, which in turn may require changes to elements of a dataflow description that are bounded to the changed elements of the deployment environment. The reconciliation mechanism may be used to ascertain the differences between the dataflow description and the deployment environment and facilitate propagation of differences to either. The reconciliation mechanism may also be applied in other contexts, and in fact may be used to establish a binding between any sets of bindable objects.

Owner:ORACLE INT CORP

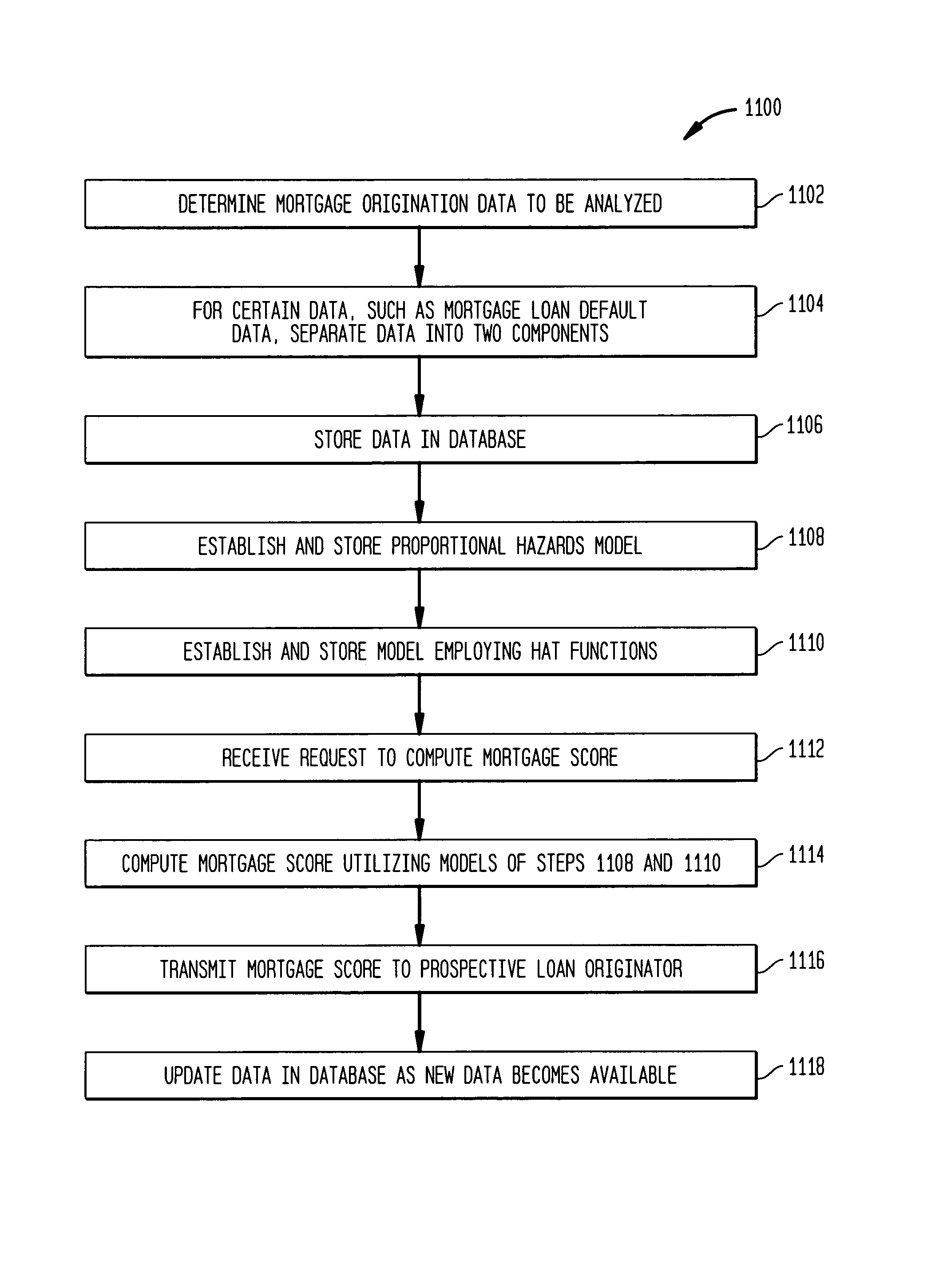

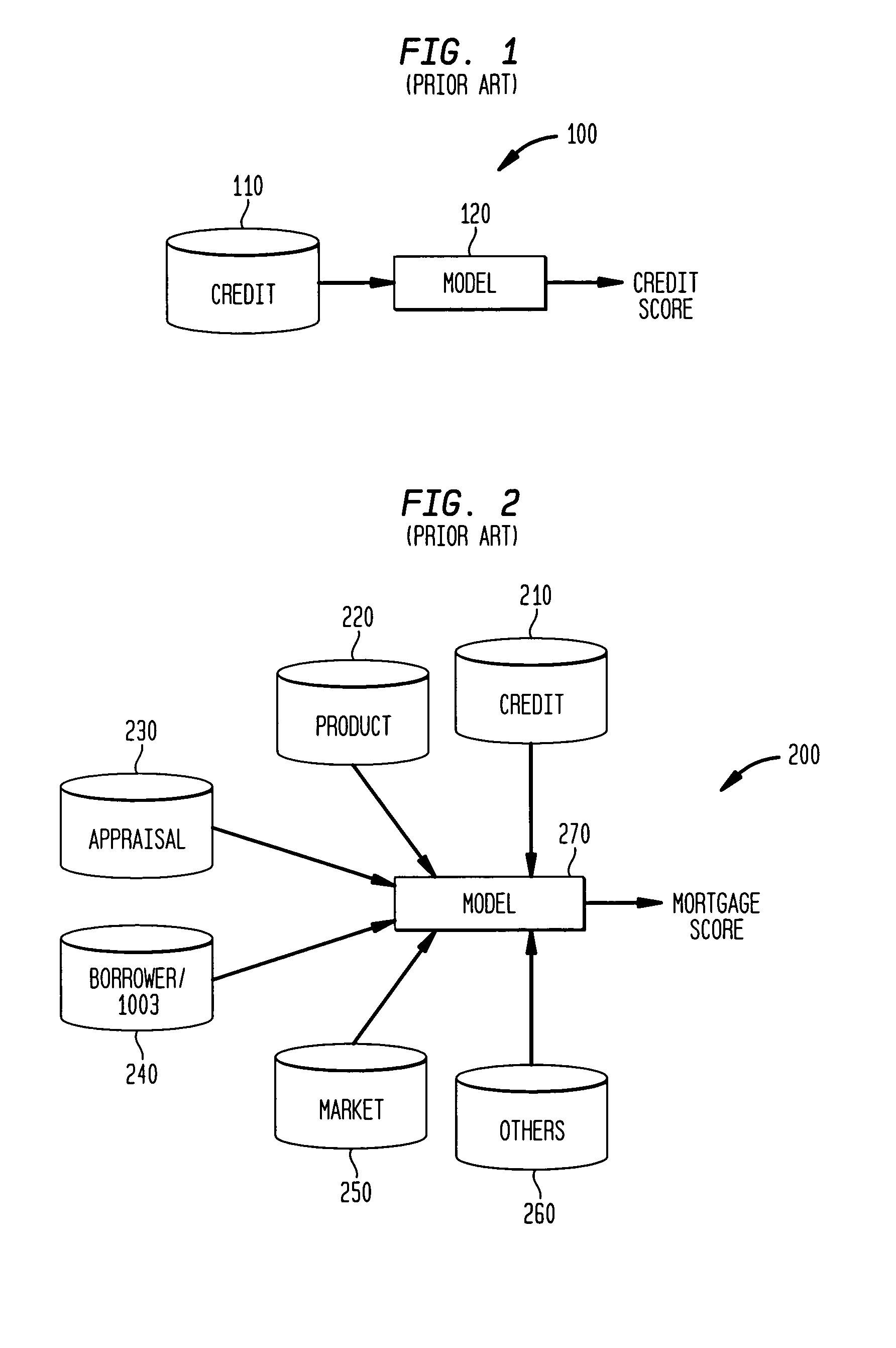

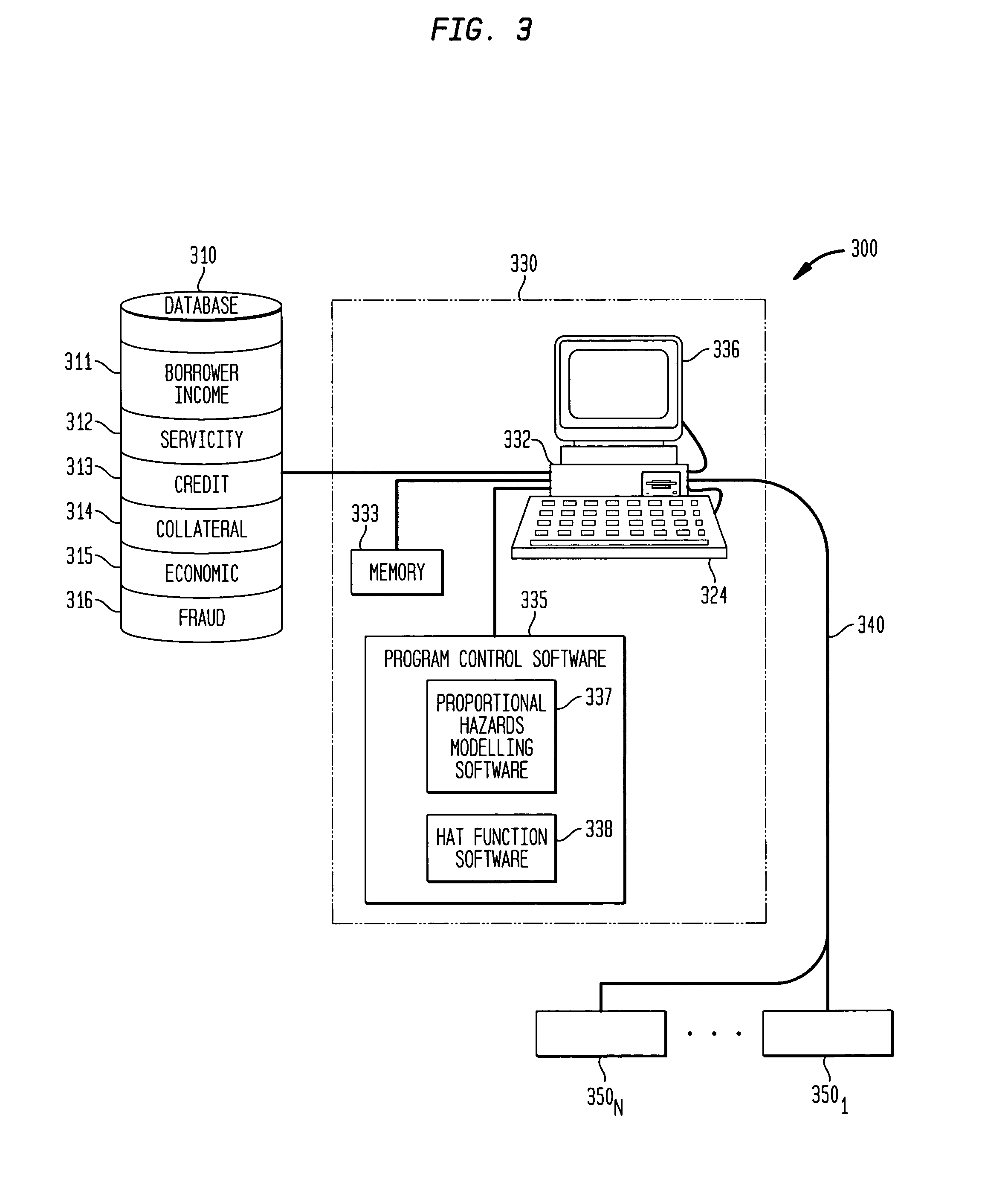

Methods and apparatus for utilizing a proportional hazards model to evaluate loan risk

InactiveUS7392216B1Increase valueAccurate identificationFinanceProportional hazards modelErrors and residuals

Systems and processes for more accurate mortgage scoring are described. A proportional hazards model is employed in which not only the occurrence of an event, but also the time to an event such as default of a loan, is considered. In this approach, a hazard rate can be viewed as the chance that an observation will experience an event in the next instant. There are two components to the response, and a binary variable is utilized to indicate whether the event was observed or not, and a time variable. As a result, the number of loans used for modeling is greatly increased, and the time it takes to observe the event, a valuable piece of information in itself, is included in the process. In addition, nonlinear effects are advantageously modeled in a continuous fashion using hat functions to map a series of independent variables. This approach typically yields smaller prediction errors near boundary points.

Owner:GE MORTGAGE HLDG

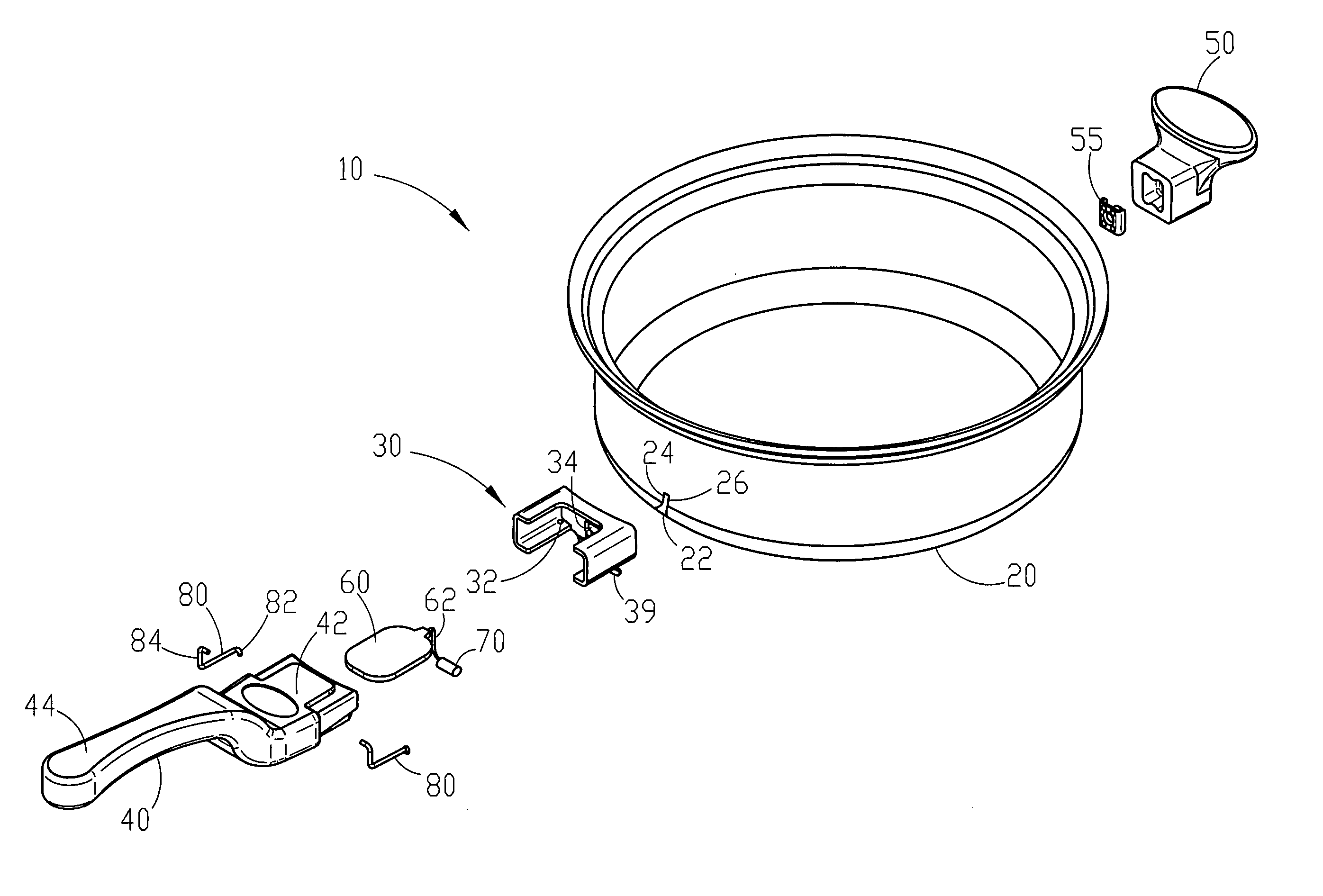

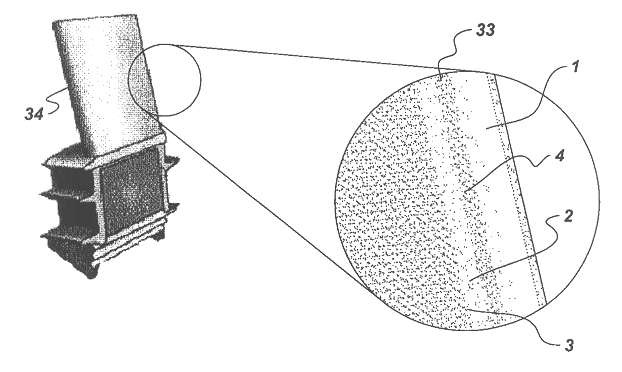

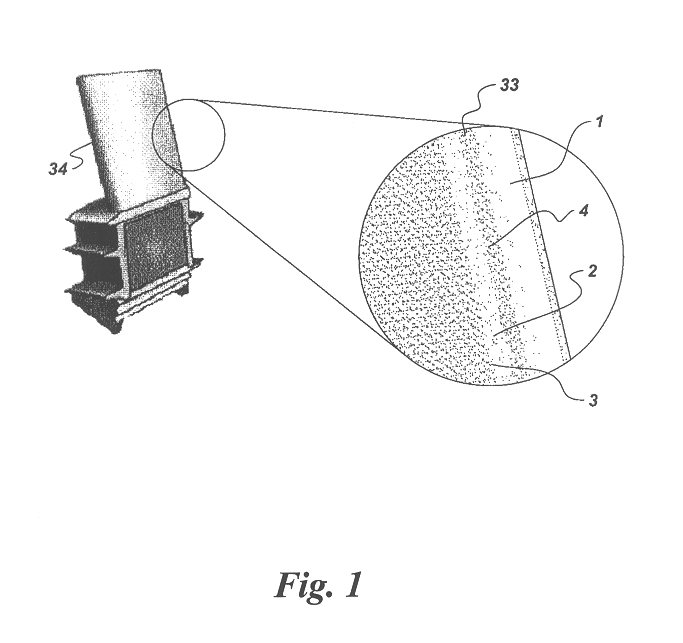

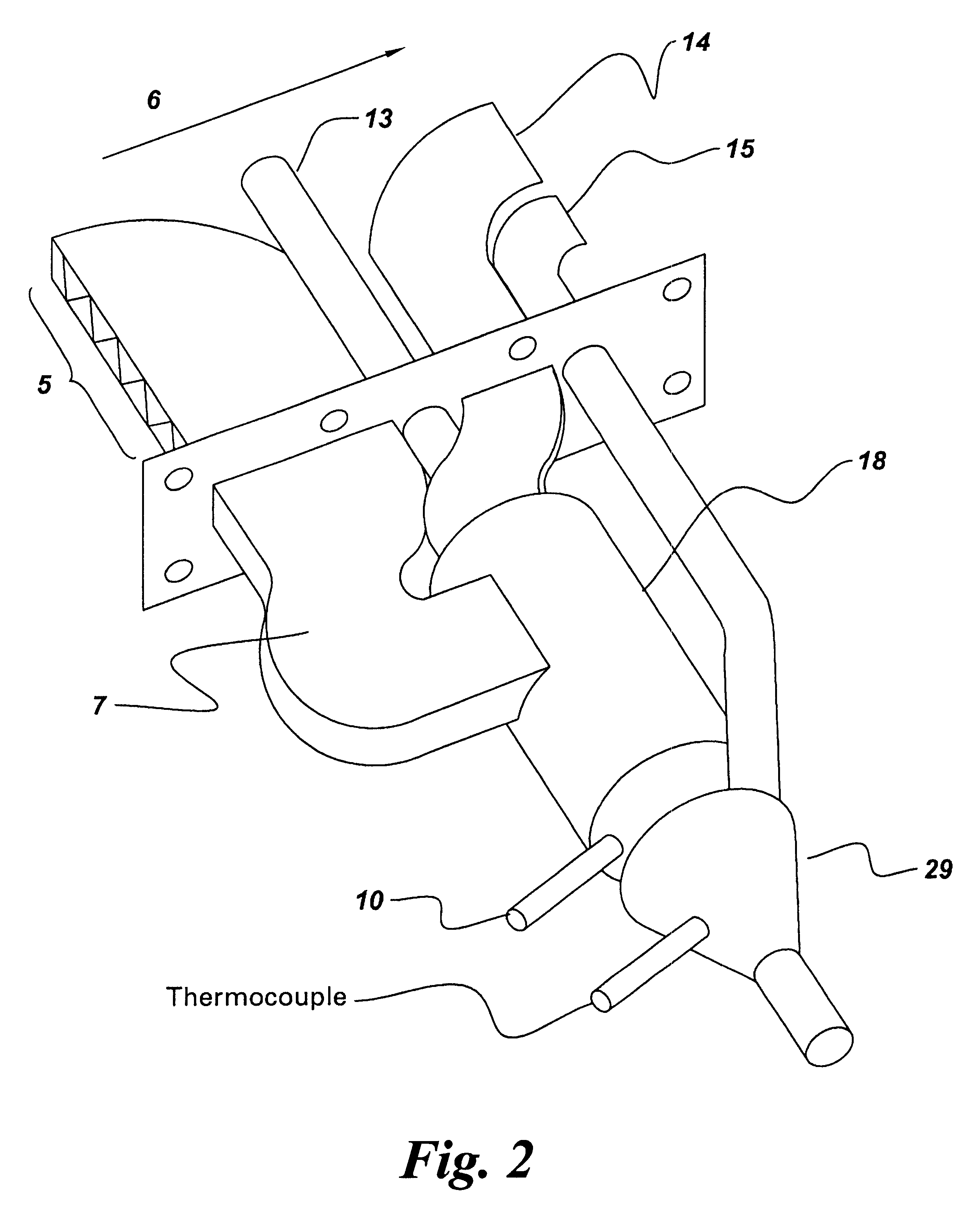

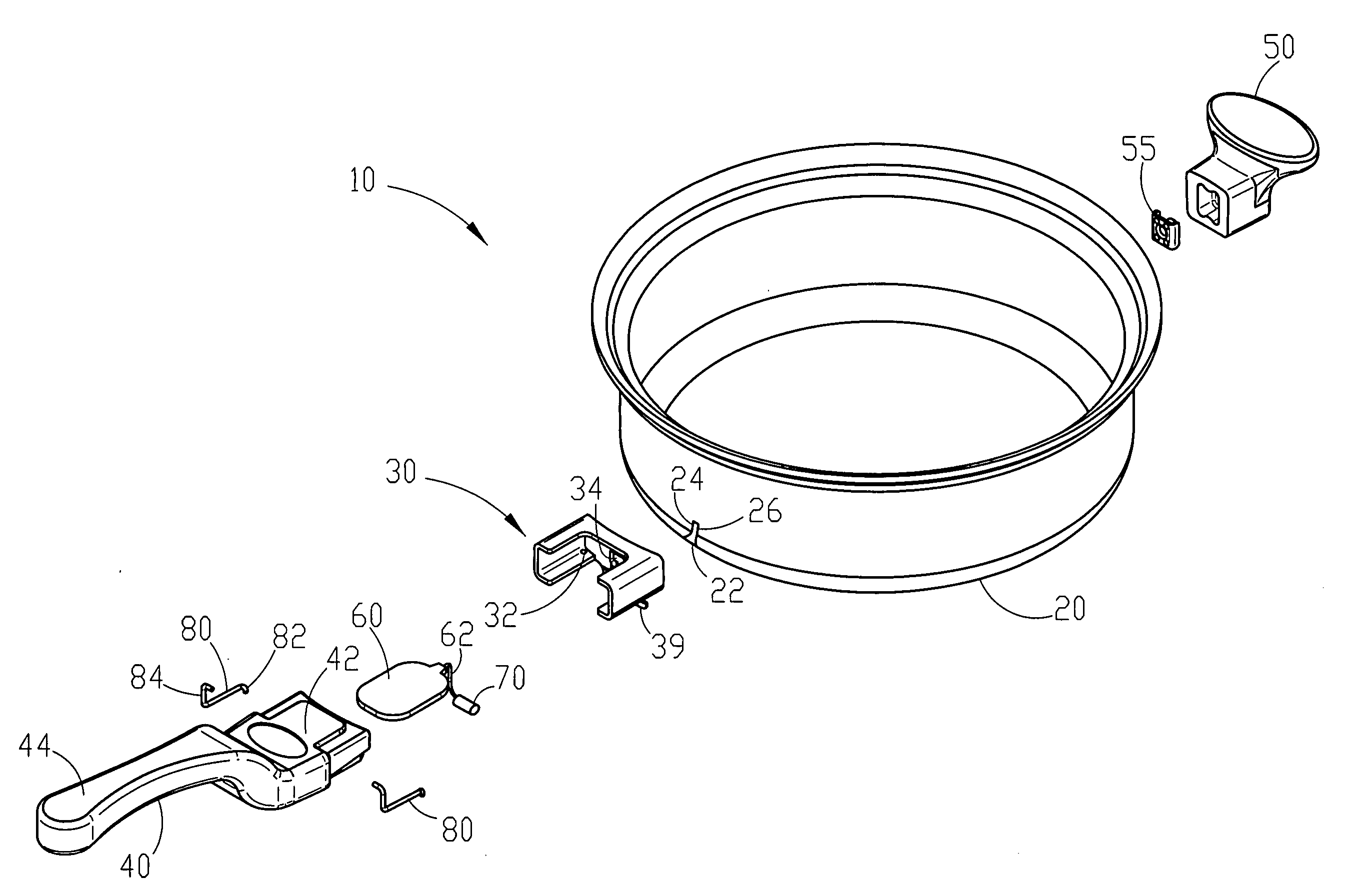

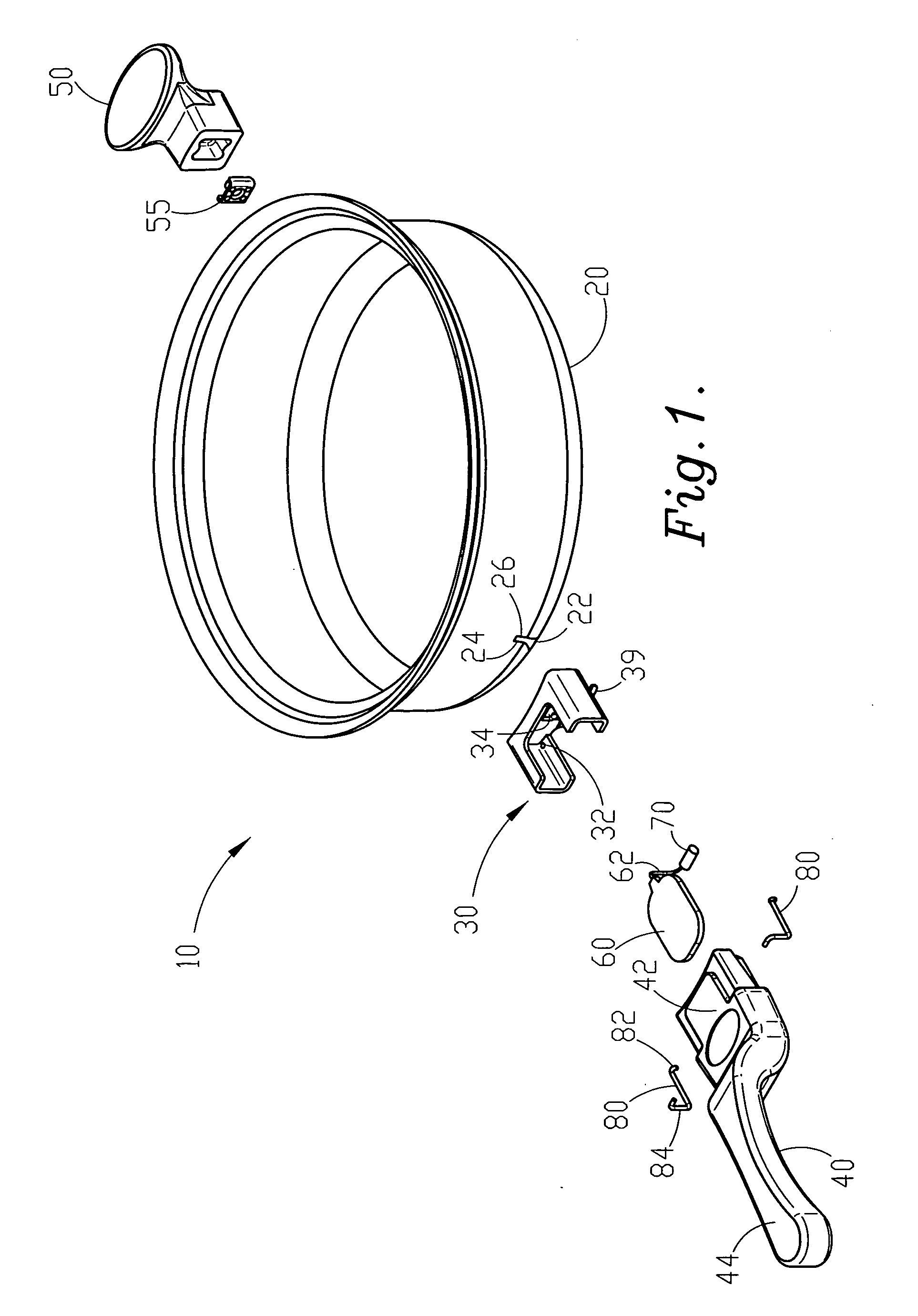

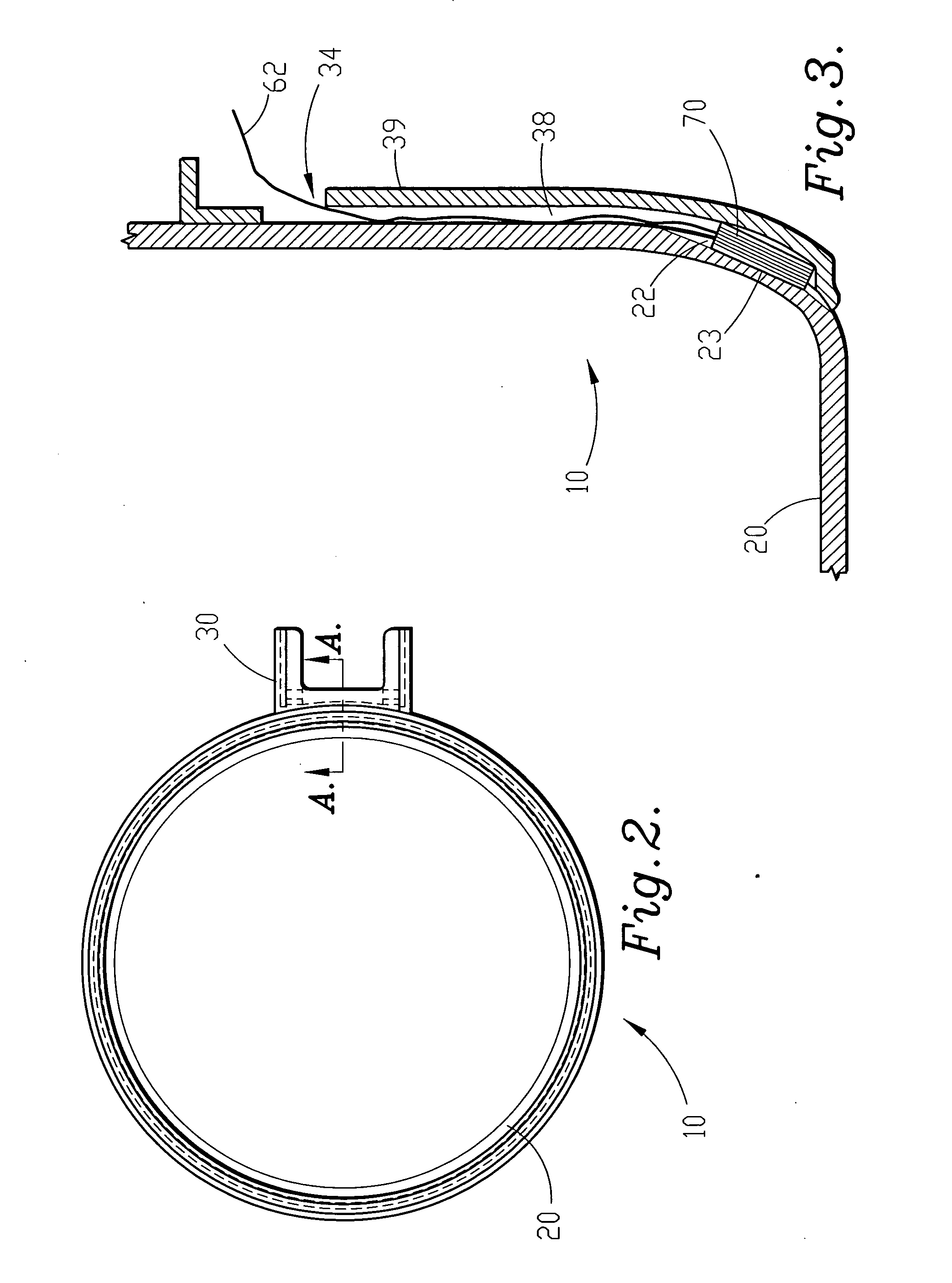

Radio frequency identification controlled heatable objects

ActiveUS7157675B2Accurate temperature indicationAccurately indicatedBoiling over preventionElectric discharge heatingTemperature controlEngineering

A temperature controlled heatable object is provided in which a temperature sensor is connected to a Radio Frequency Identification (RFID) tag. The RFID tag is located within the handle of the object, and the temperature sensor is placed in contact with the object. In a first embodiment of the invention, the temperature sensor is partially imbedded within the object via a notch located in the side of the object. In a second embodiment of the invention, a temperature sensor is imbedded within a tunnel drilled within the base of the object. In a third embodiment, a temperature sensor is imbedded between the bottom of the object and a slab attached to the bottom of the object. The sensor can be located in a slot formed in either the slab or the bottom or the object. Handles and receivers for mounting the handles to the temperature controllable objects are also provided.

Owner:IMURA INT USA

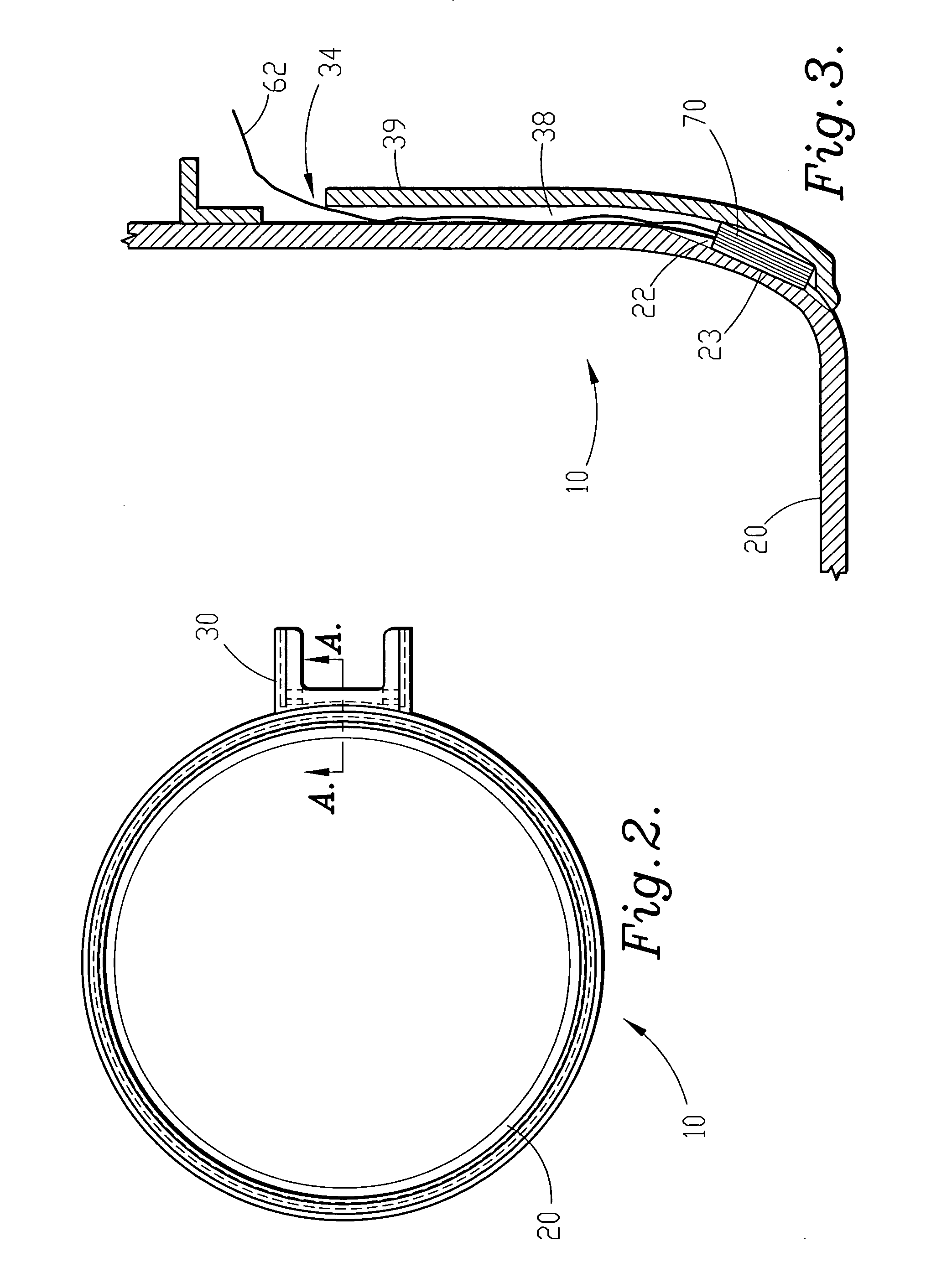

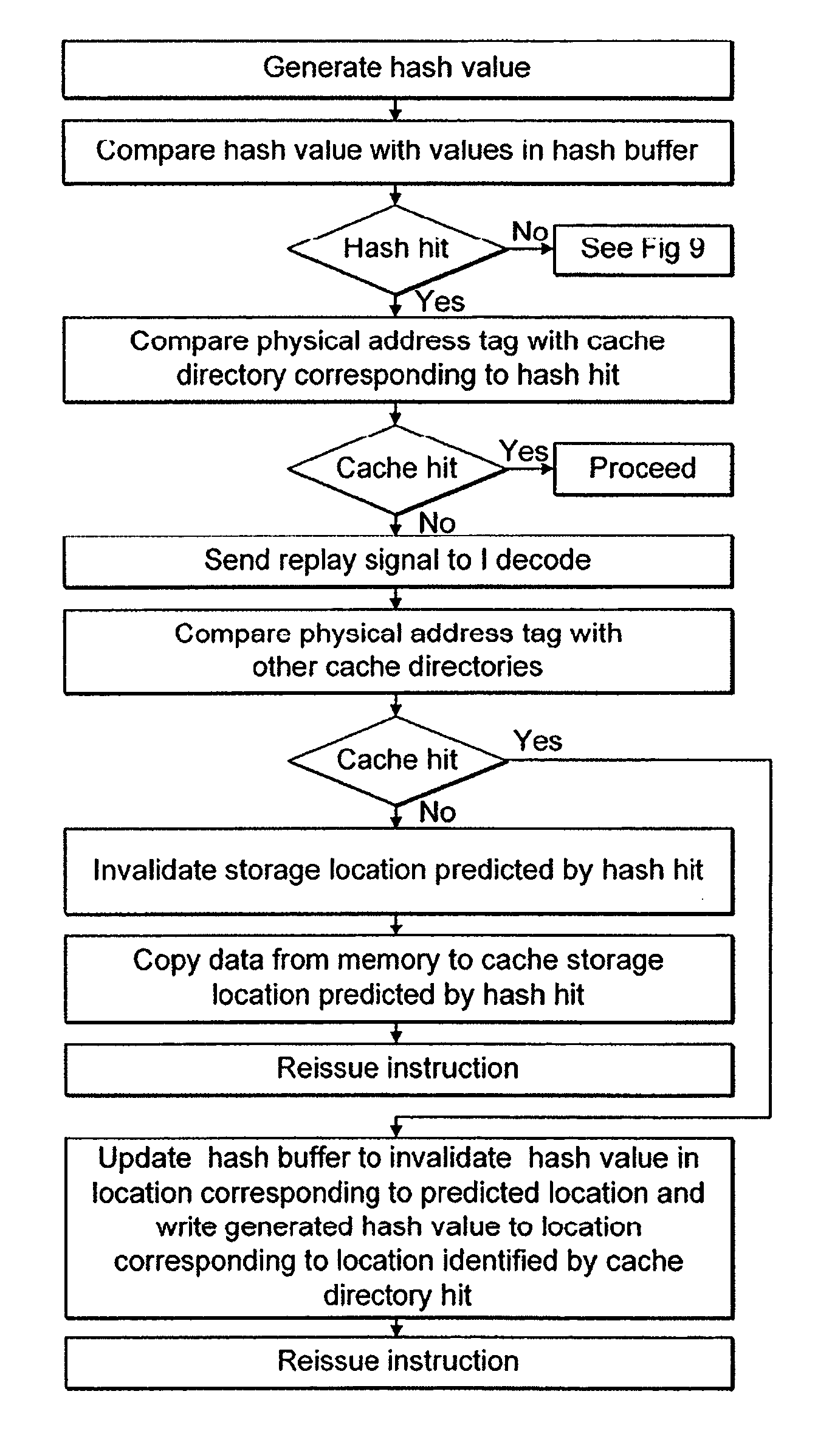

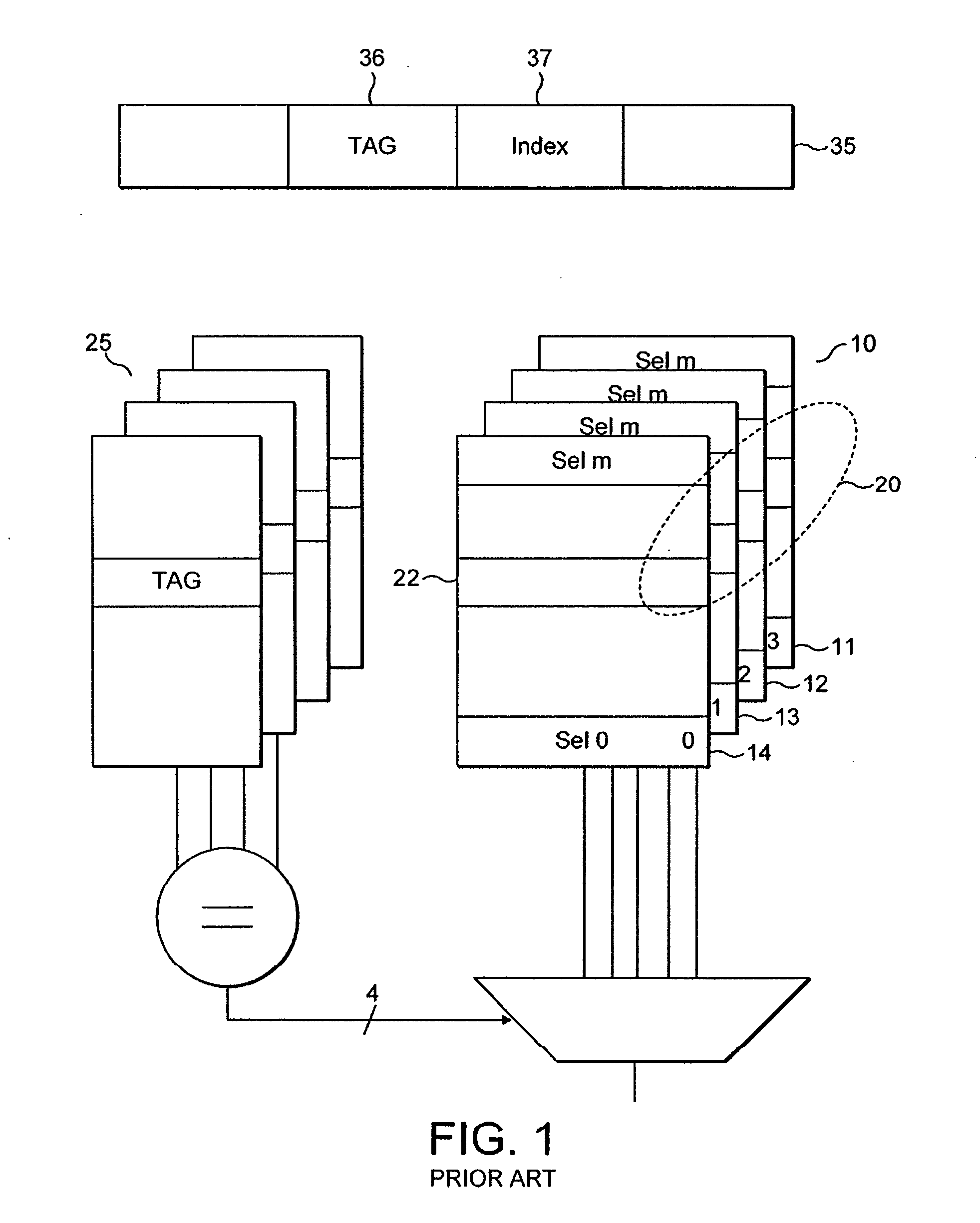

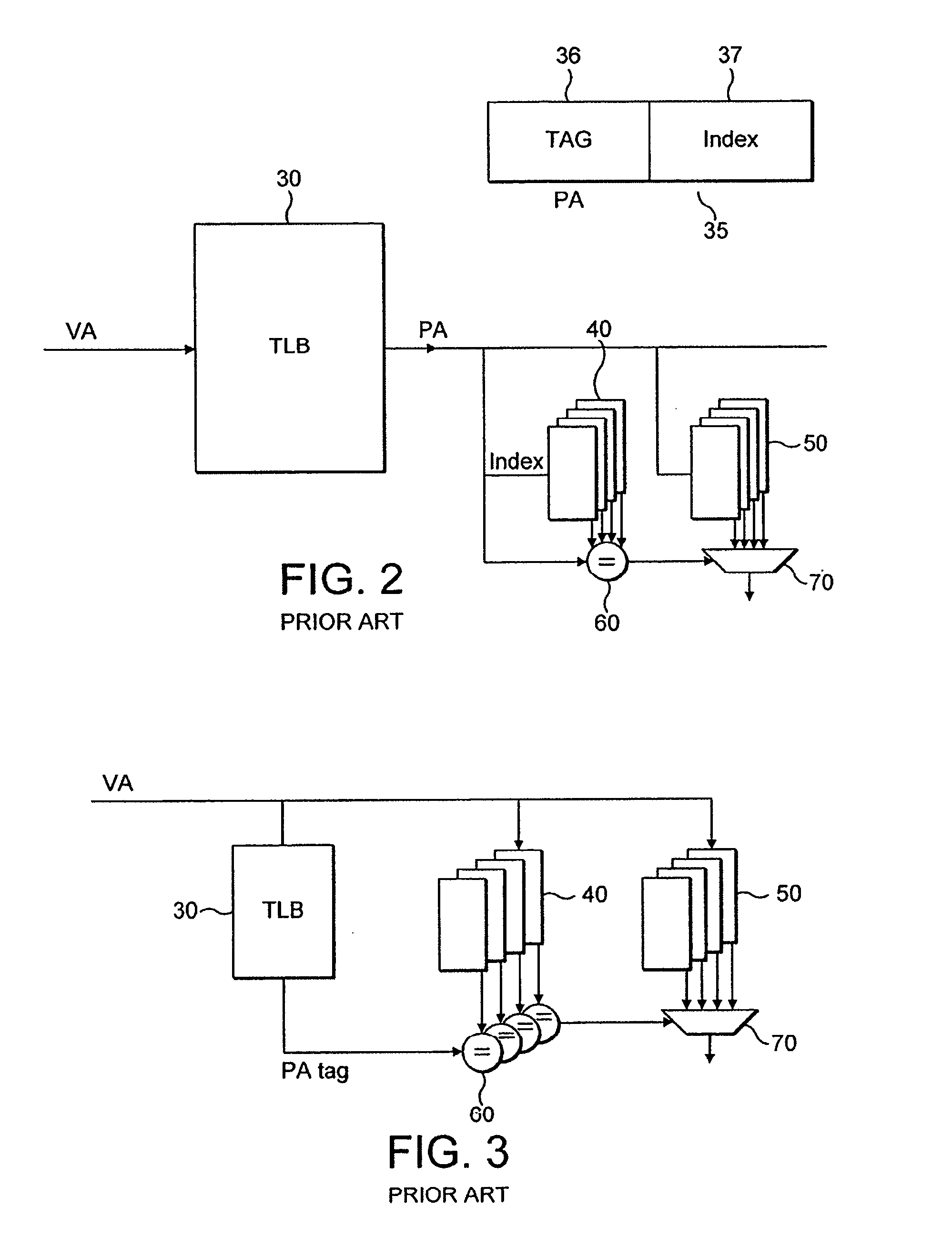

Indicating storage locations within caches

InactiveUS20060236074A1Reduce the number of stepsAccurately indicatedMemory systemsMicro-instruction address formationApplication IdentifierMultiple applications

A data processor operable to process data said data processor being operable to perform a plurality of processes or a plurality of applications on said data, said data processor comprising: a cache; a data storage unit operable to store a process or application identifier defining a process or application that is currently executing on said data processor on said data; wherein a data item storage location within said cache is indicated by an address, and said data processor further comprises: a hash value generator operable to generate a hash value from at least some of said bits of said address and at least some bits of said process or application identifier, said hash value having fewer bits than said address.

Owner:ARM LTD

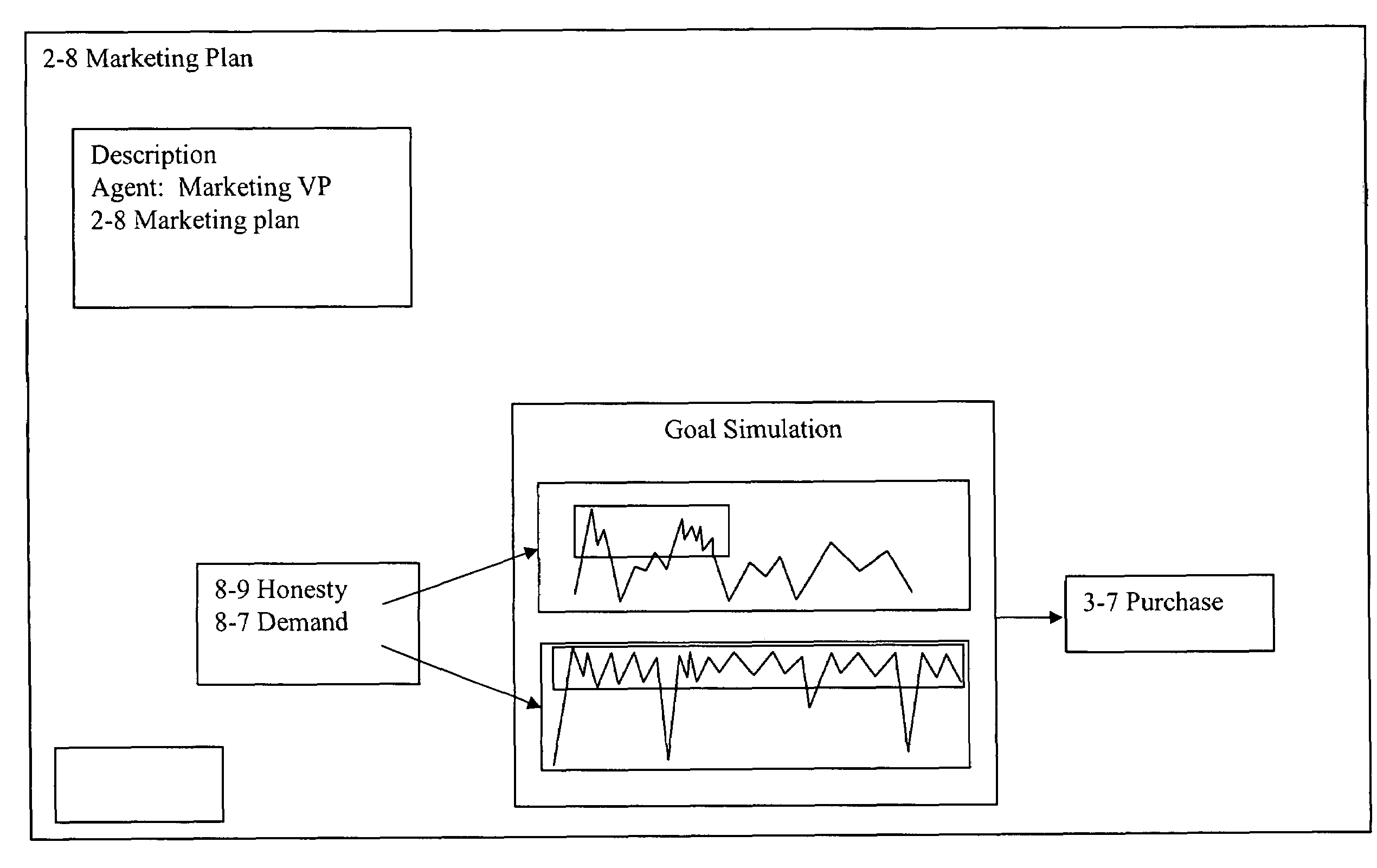

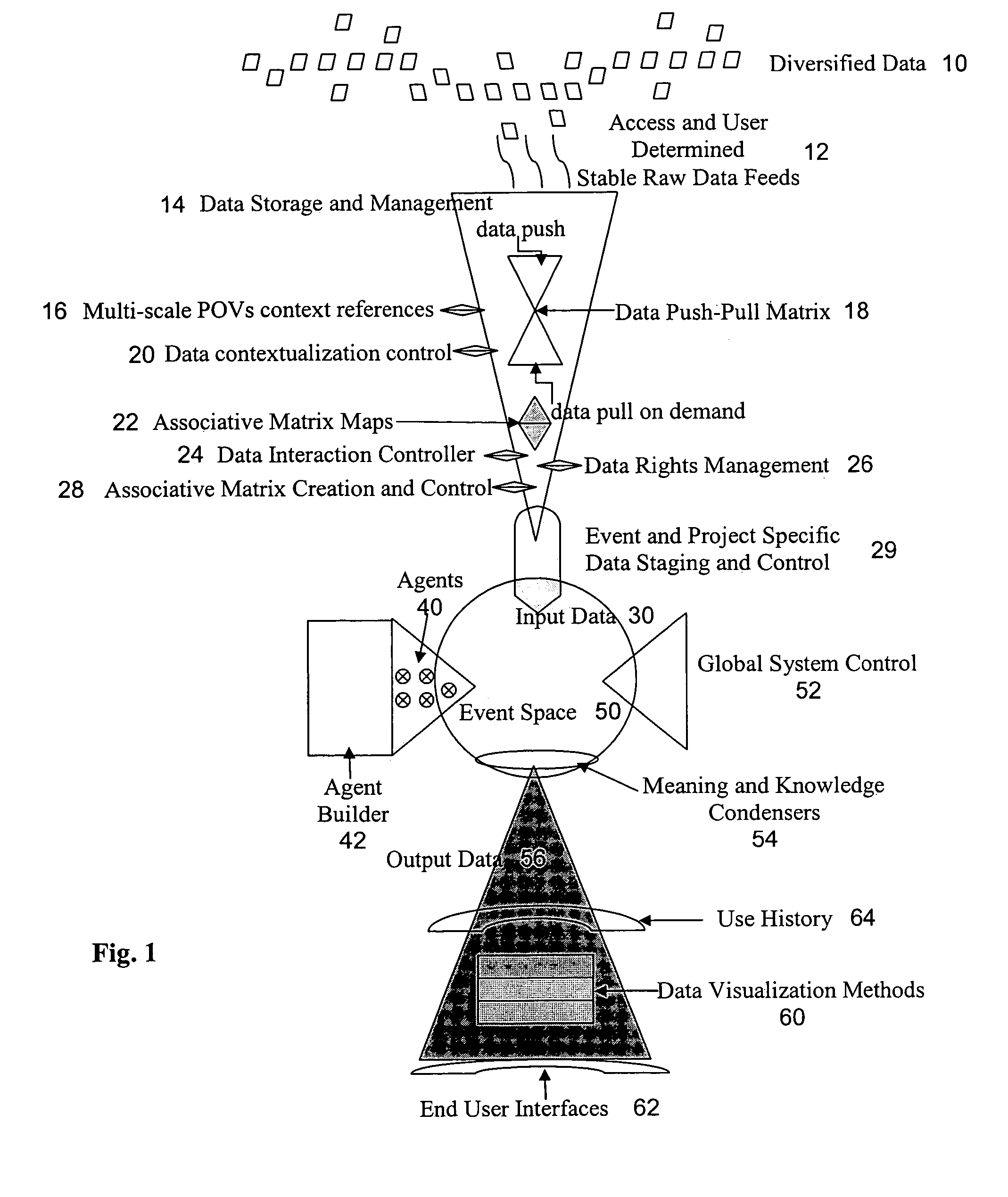

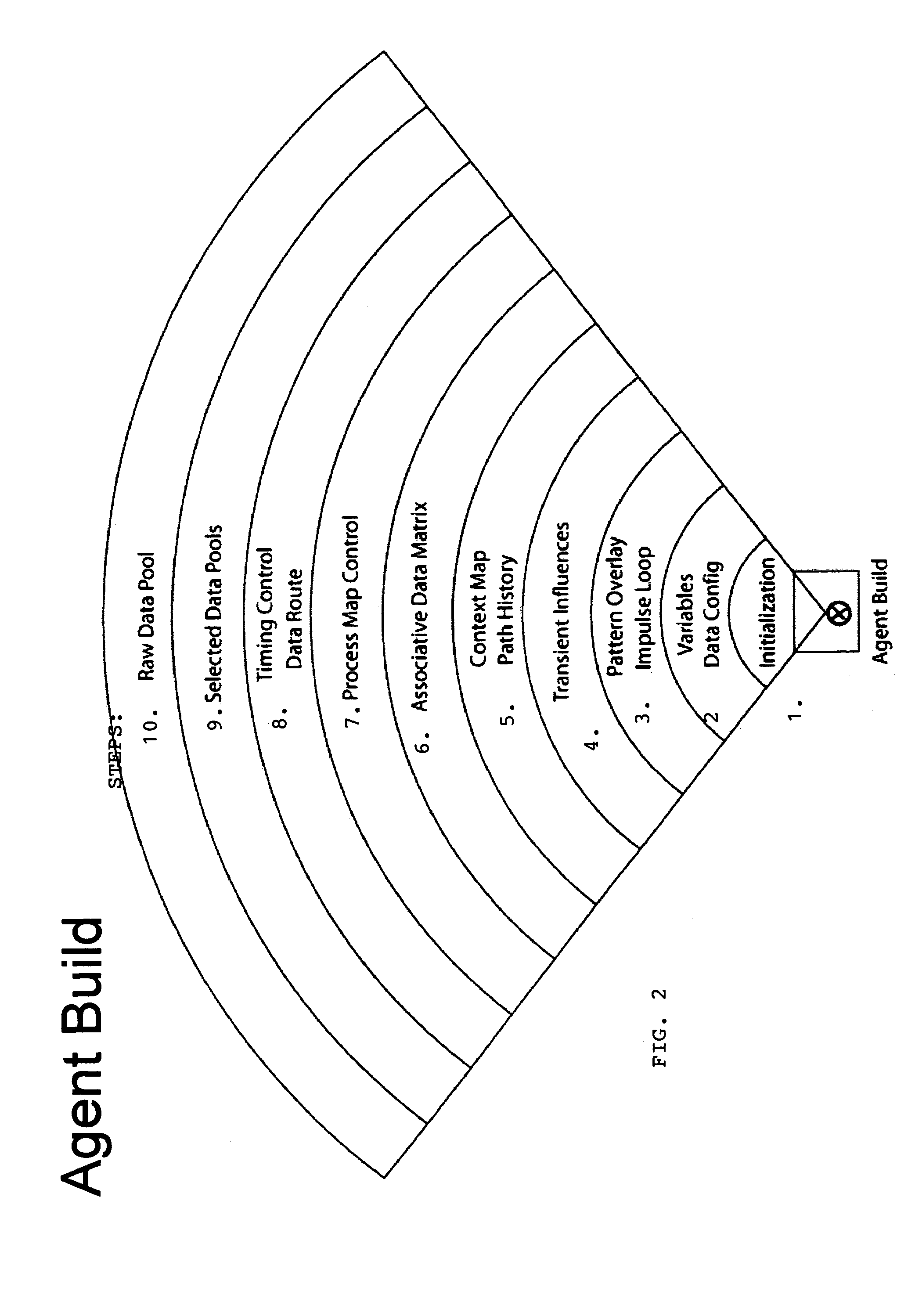

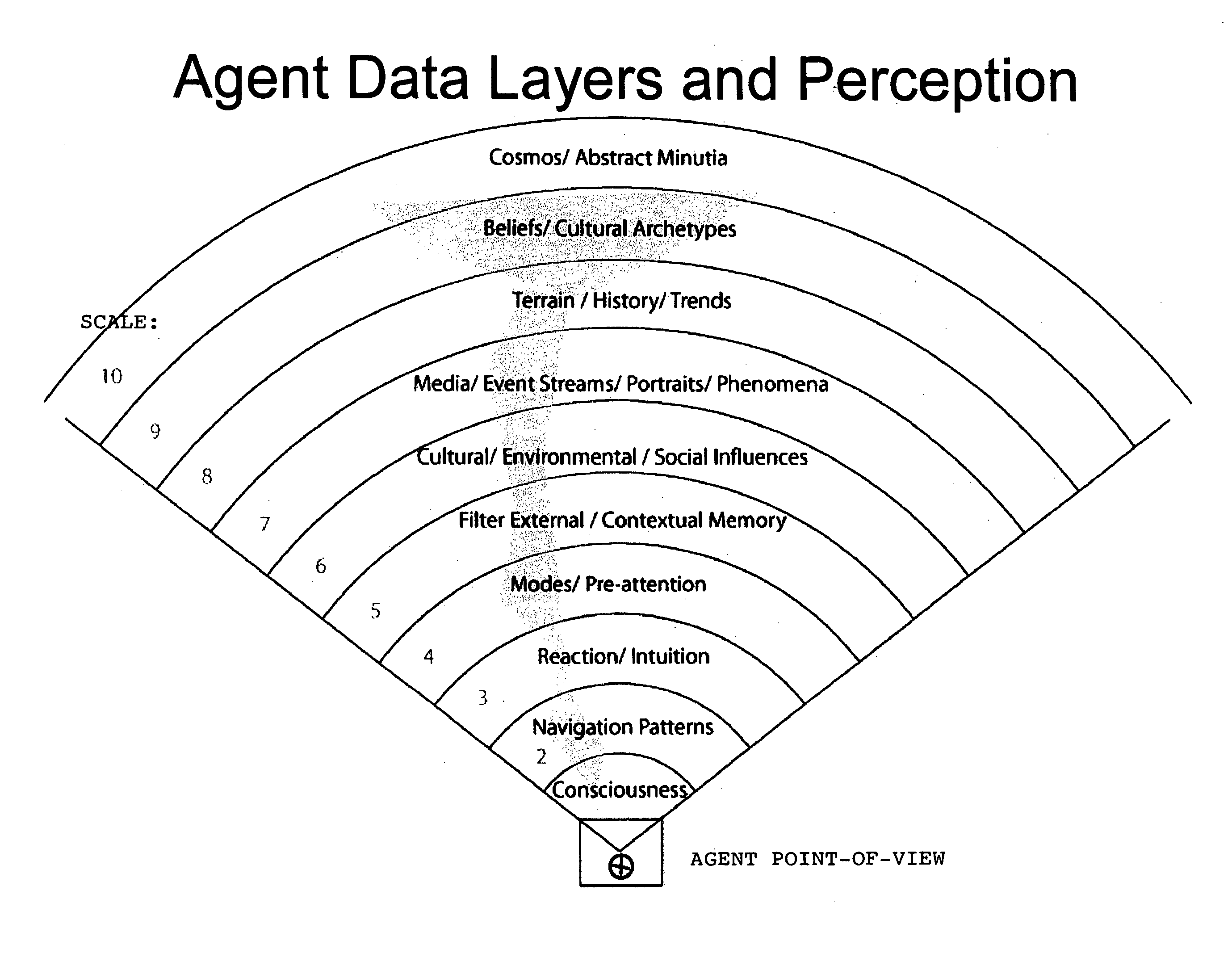

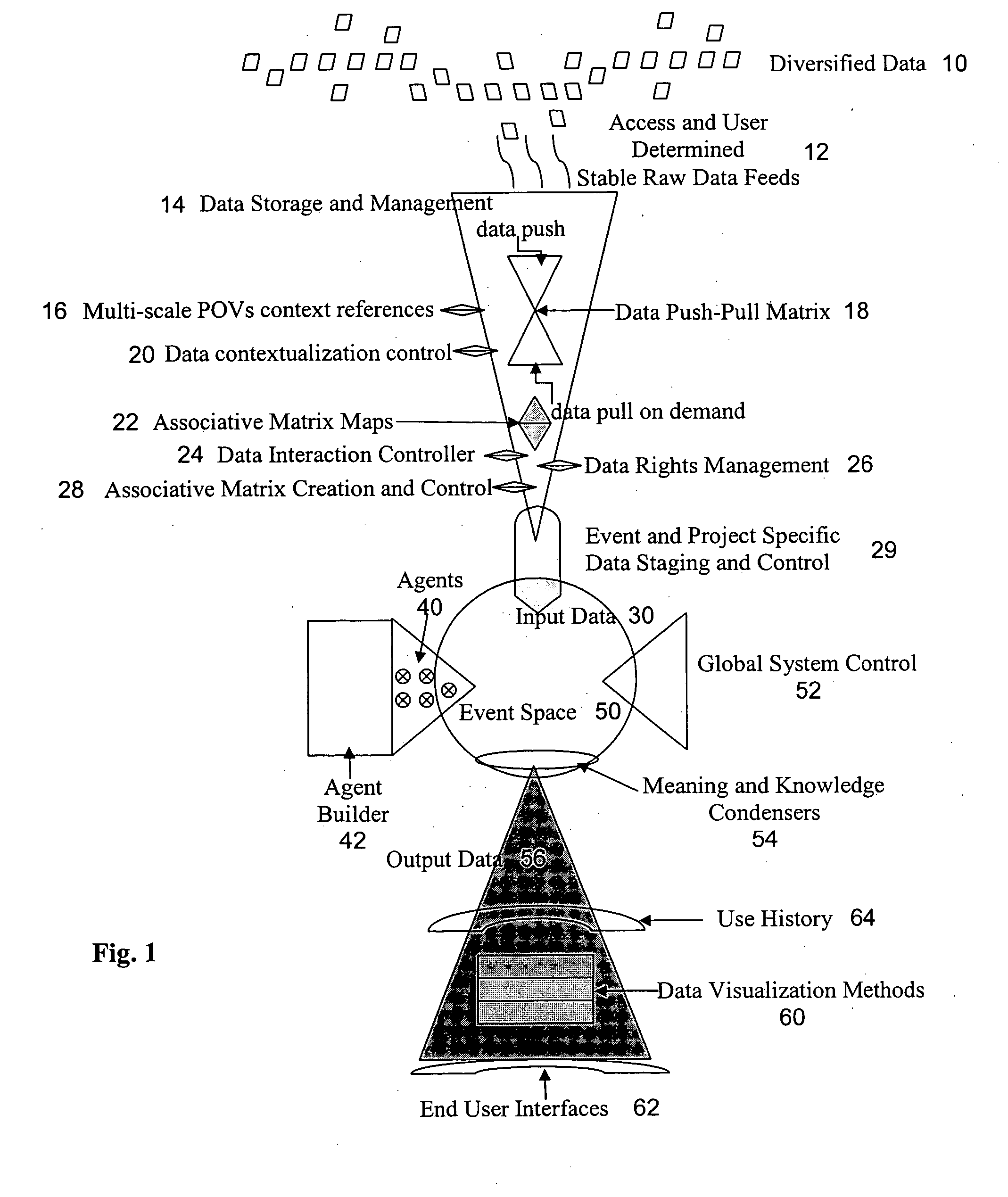

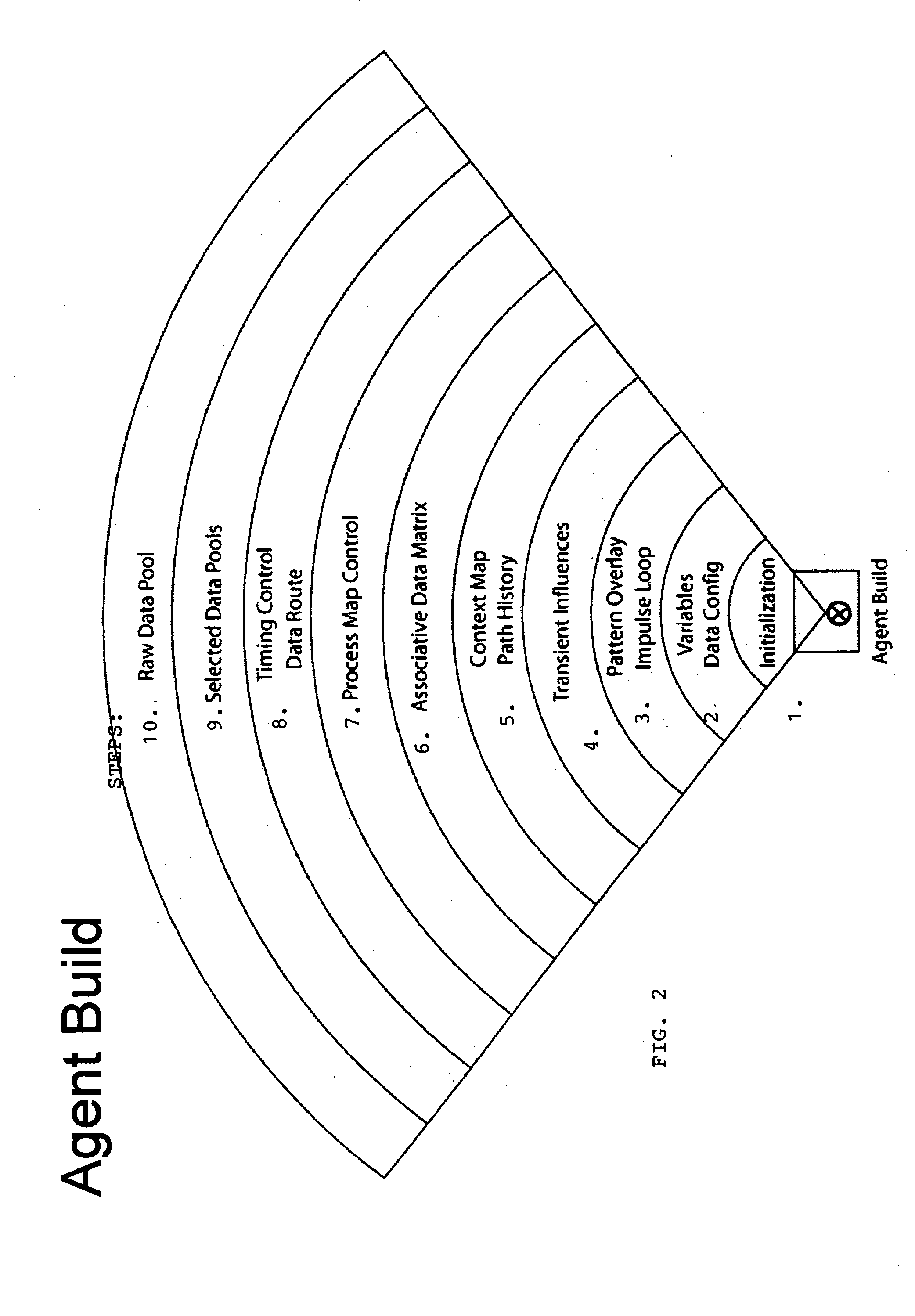

Cultural simulation model for modeling of agent behavioral expression and simulation data visualization methods

ActiveUS7263474B2Accurately indicatedDrawing from basic elementsSpeech analysisData sourceVisual tool

A computer simulation method is provided for modeling the behavioral expression of one or more computerized agents for running a simulation against real-world input data, and providing a visual display identifying elements in the input data corresponding to the modeled agent(s) response(s). Simulations can be run on sources of input data on global networks for agent types of different cultures, societies, and behaviors, such as news feeds, text communications, and reports, in order to identify keywords or phrases therein that correspond to agent behavioral expressions being monitored. Robust new visual tools are provided for discerning patterns and trends in the simulation data, including waveform charts, star charts, grid charts, and pole charts.

Owner:SEASEER R&D

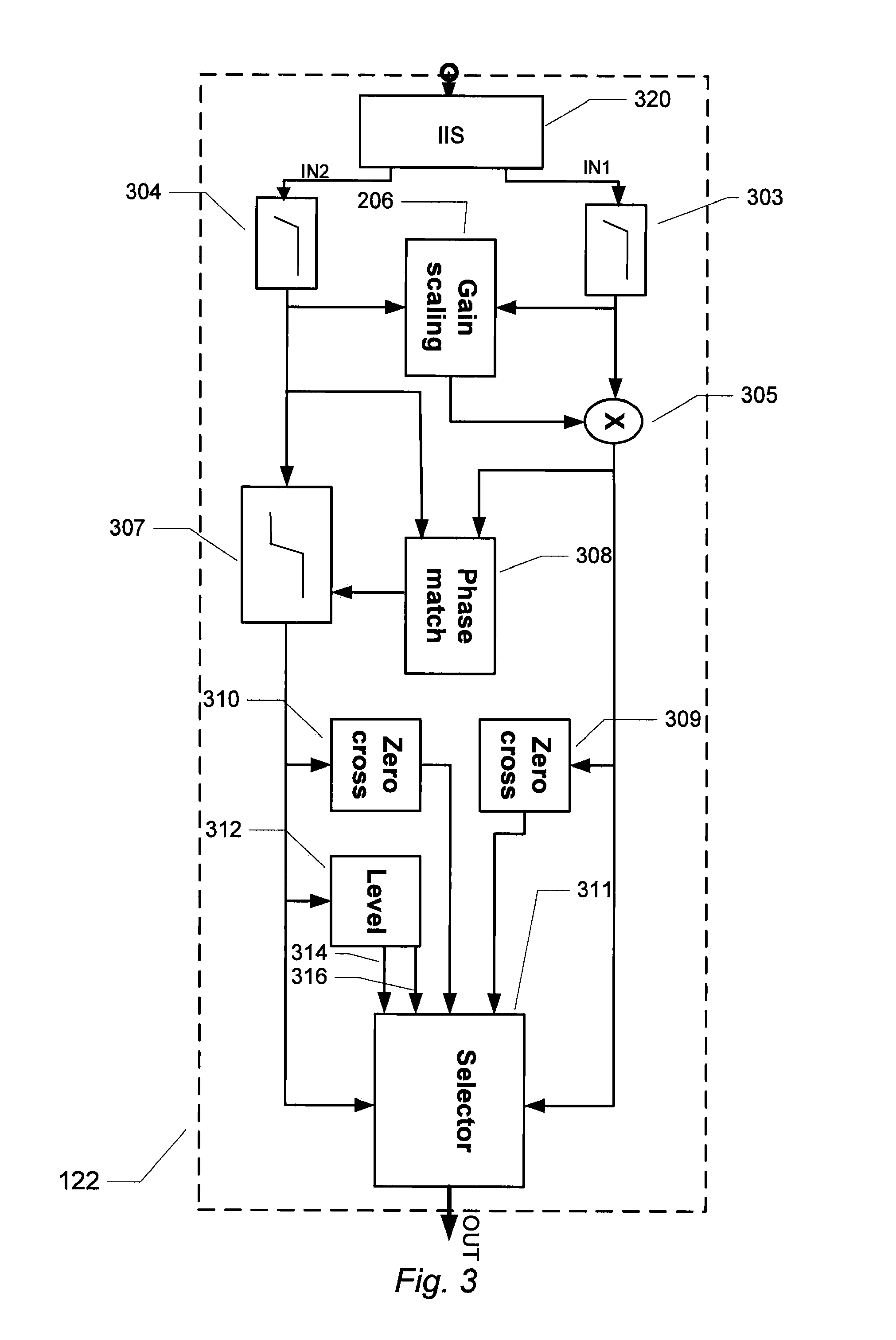

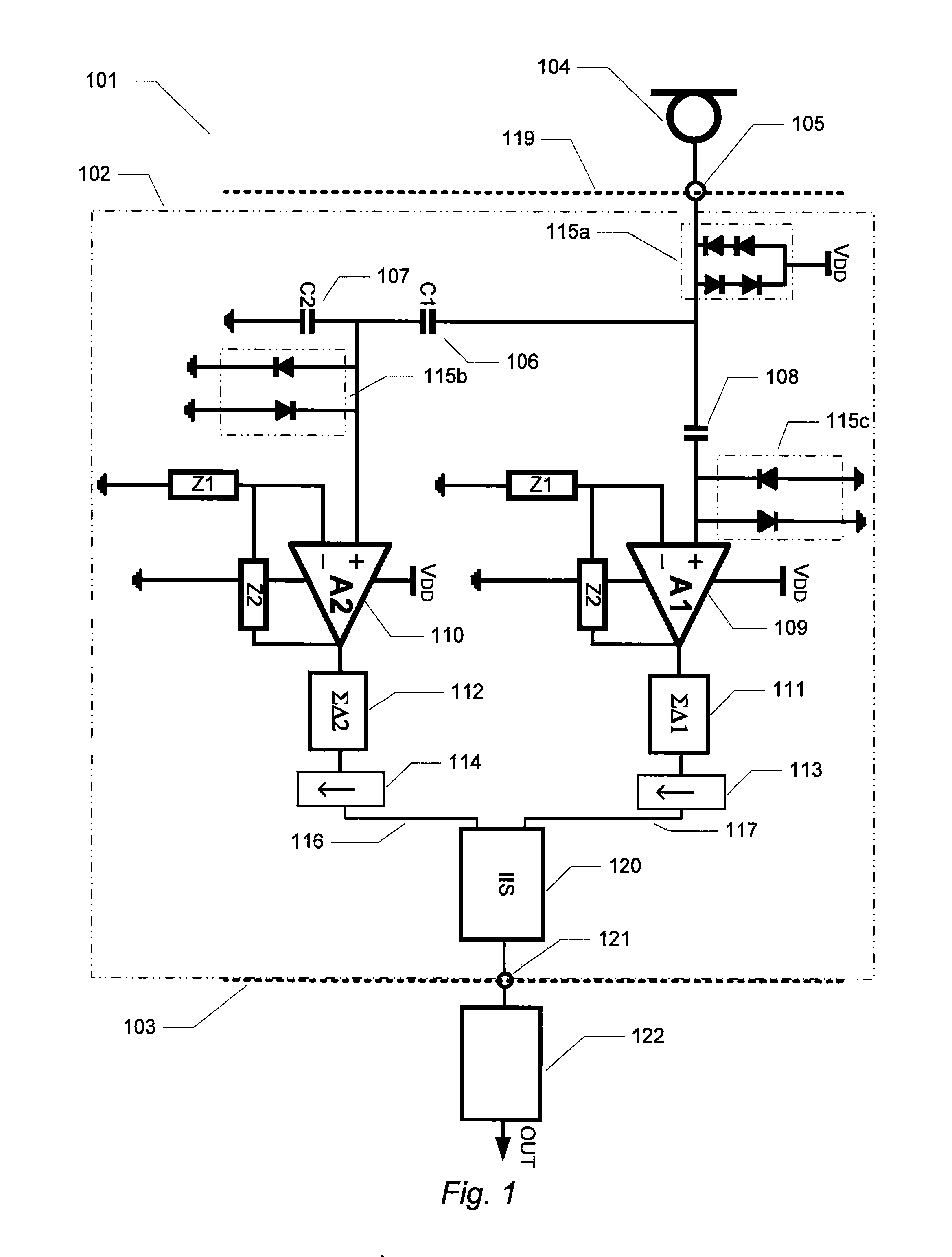

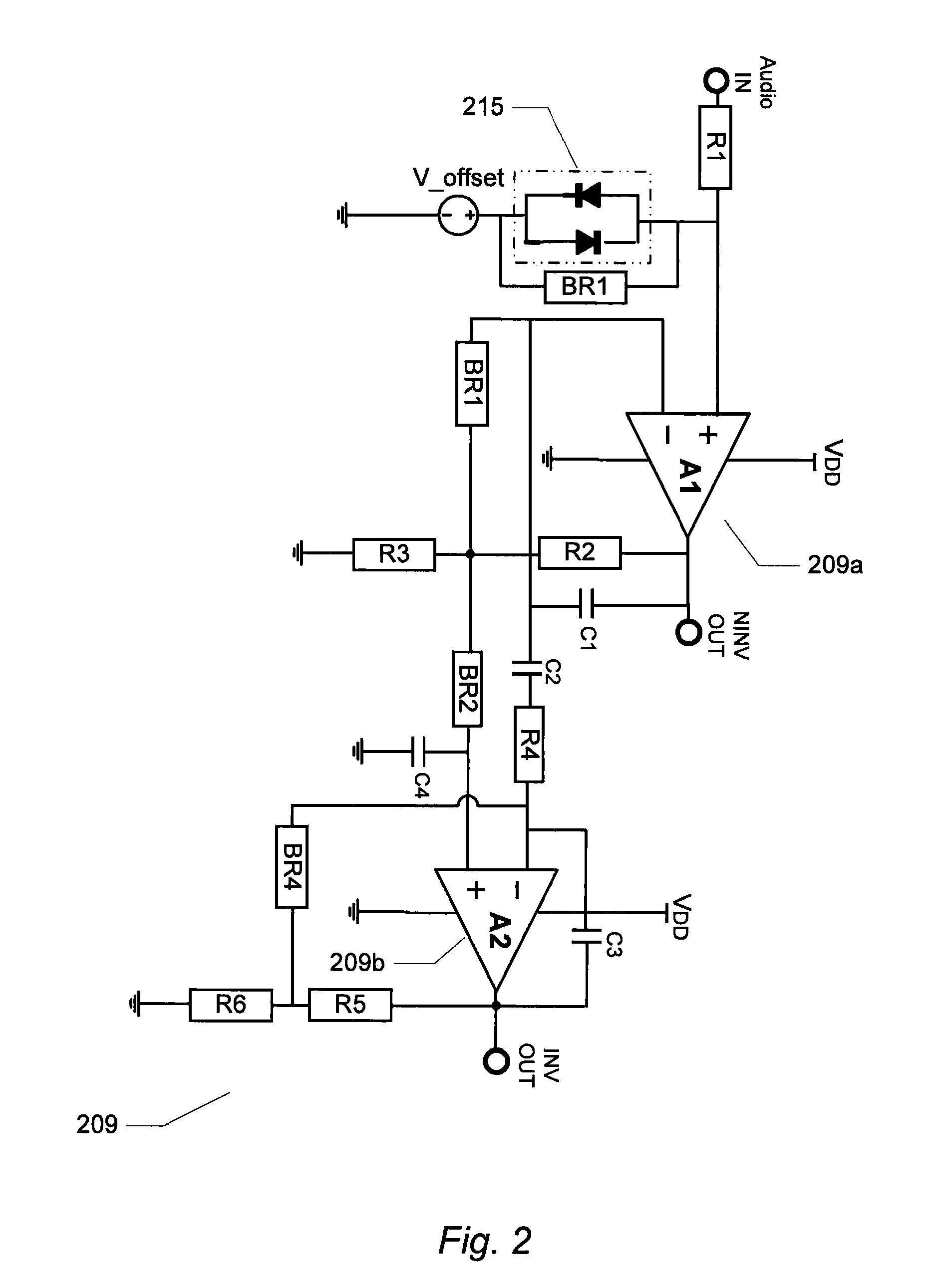

Audio signal controller

ActiveUS20110029109A1Lower Level RequirementsLow costSignal processingLow frequency amplifiersDigital audio signalsAudio frequency

The present invention relates to an audio signal controller adapted to receiving first and second digital audio signals and estimating a signal feature of the first or second digital audio signal. The estimated signal feature is compared with a predetermined feature criterion and the audio signal controller switches from conveying the first digital audio signal to conveying the second digital audio signal to a controller output, or vice versa, at a zero-crossing of the first digital audio signal or the second digital audio signal based on the comparison between the estimated signal feature and the predetermined feature criterion.

Owner:INVENSENSE

Cultural simulation model for modeling of agent behavioral expression and simulation data visualization methods

ActiveUS20040181376A1Accurately indicatedDrawing from basic elementsSpeech analysisVisual toolData visualization

A computer simulation method is provided for modeling the behavioral expression of one or more agents in an environment to be simulated, then running a simulation of the modeled agent(s) against real-world information as input data reflecting changing conditions of the environment being simulated, and obtaining an output based on the modeled agent(s) response(s). The simulation method models the underlying cultural, social, and behavioral characteristics on which agent behaviors and actions are based, rather than modeling fixed rules for the agent's actions. The input data driving the simulation are constituted by real-world information reflecting the changing conditions of the environment being simulated, rather than an artificial set of predefined initial conditions which do not change over time. As a result, the simulation output of the modeled agent's responses to the input information can indicate more accurately how that type of participant in the simulated environment might respond under real-world conditions. Simulations can be run on global networks for agent types of different cultures, societies, and behaviors, with global sources of information. Simulation environments can include problems and situations in a wide range of human activity. Robust new visual tools are provided for discerning patterns and trends in the simulation data, including waveform charts, star charts, grid charts, and pole chart series.

Owner:SEASEER R&D

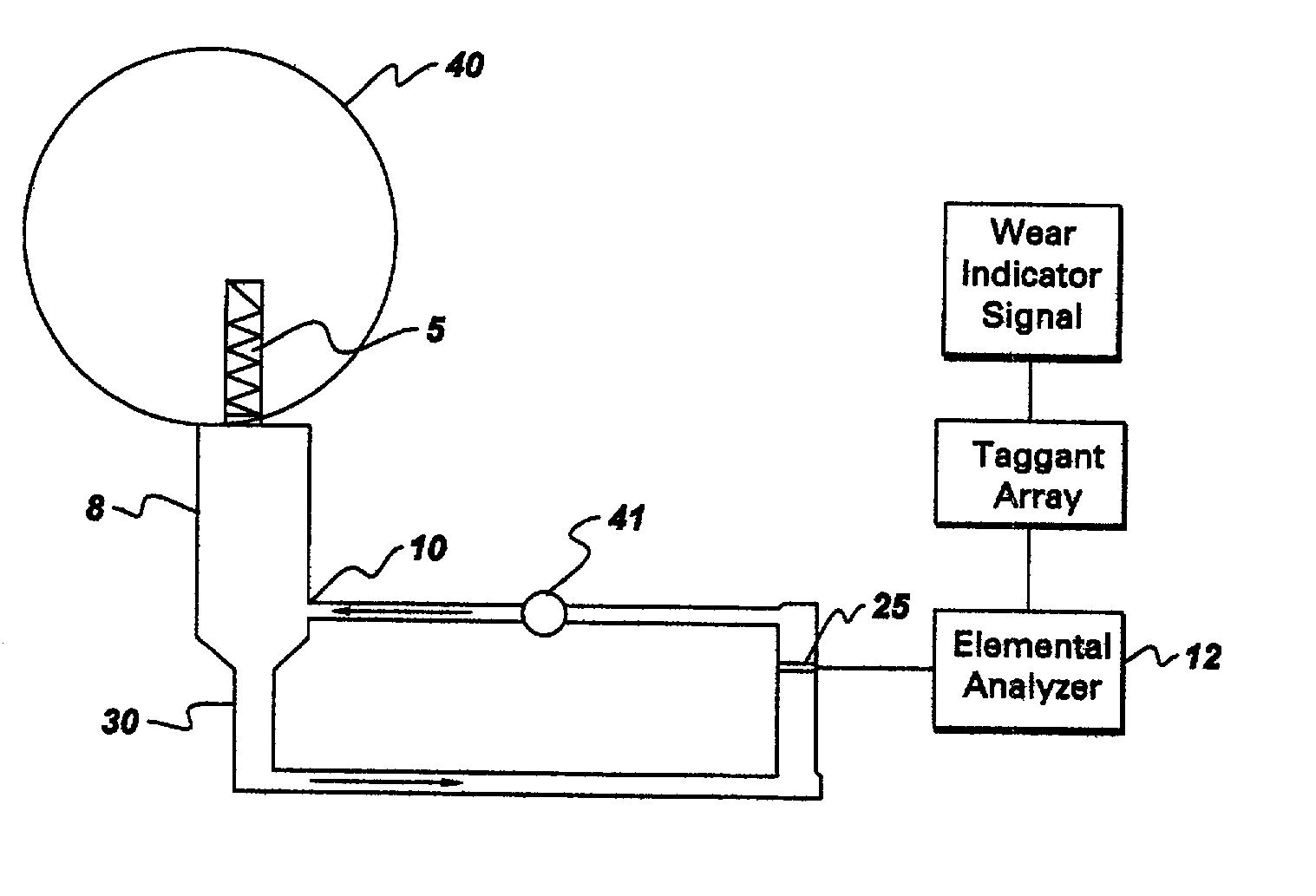

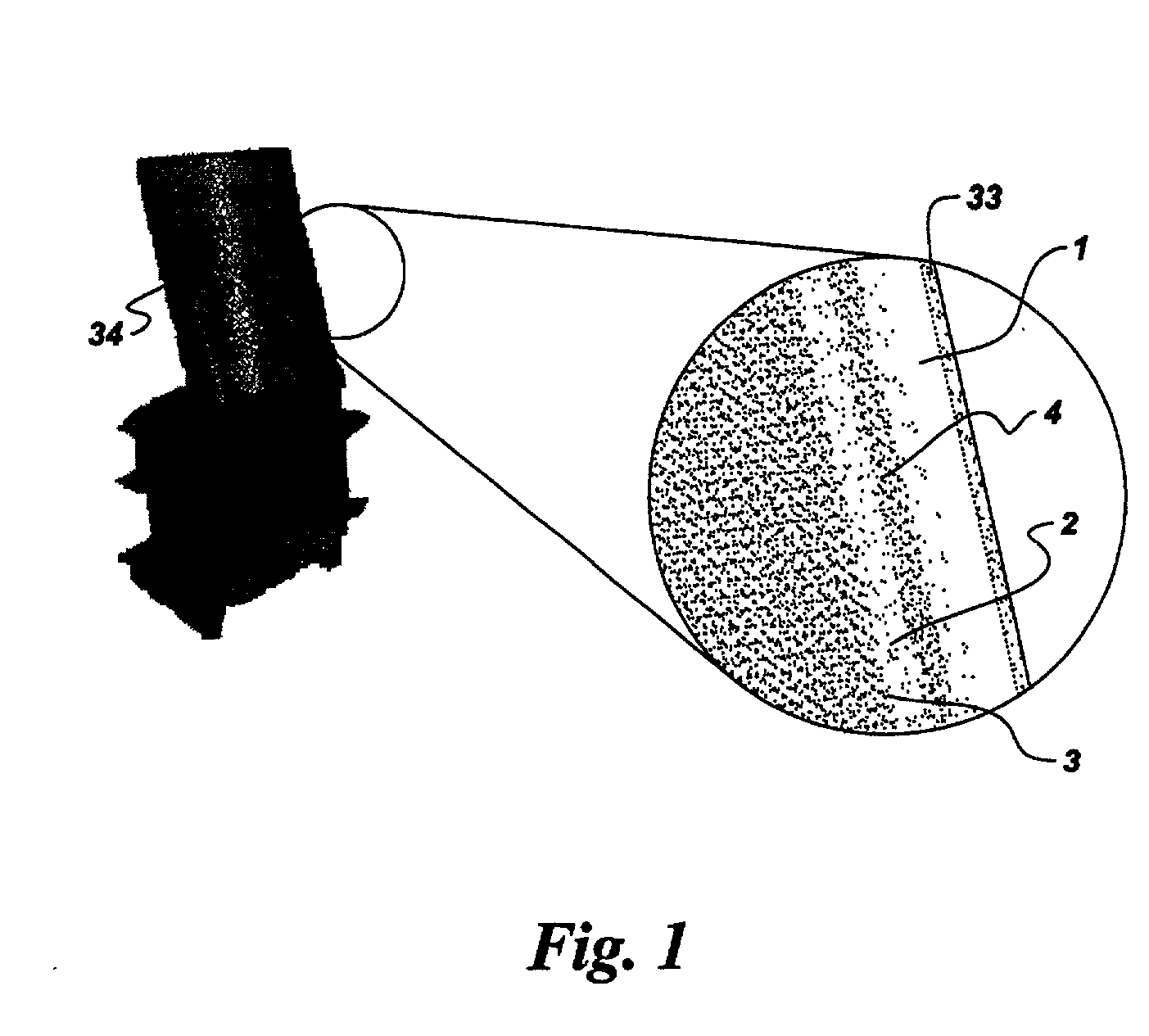

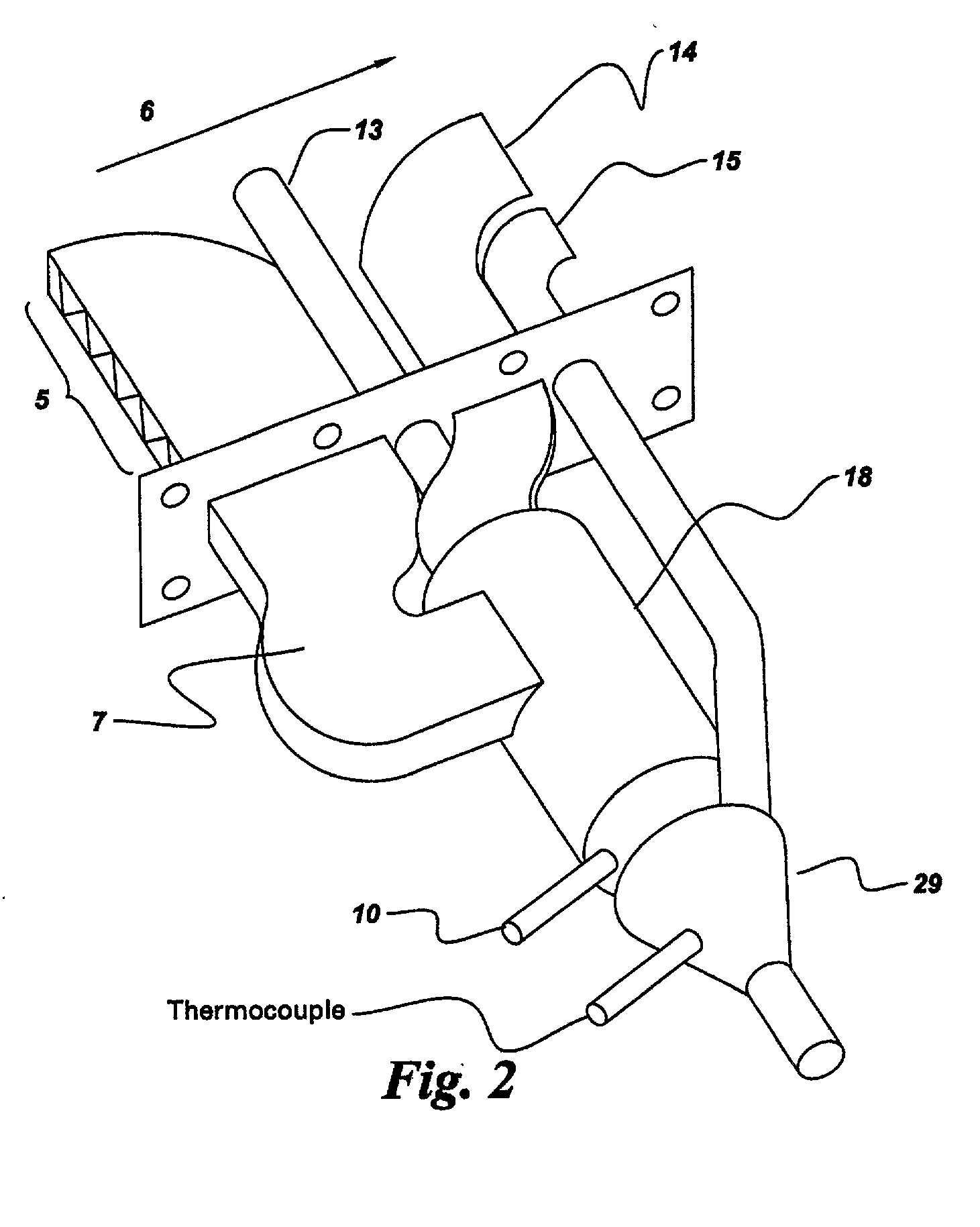

Smart coating system with chemical taggants for coating condition assessment

InactiveUS6644917B2Improving subsequent up-timeAccurately indicatedPropellersReaction enginesCoating systemGas turbines

A on-line method is provided for detecting wear and / or damage to gas turbine parts. Preferred embodiments of the invention provide a gas turbine comprising parts with smart coatings and collection and detection means to measure wear and erosion of gas turbine parts. In other preferred embodiments, smart coatings are provided comprising chemical taggants that can be collected and detected downstream, thus providing an on-line or in situ evaluation technology for wear and damage to gas turbine parts.

Owner:GENERAL ELECTRIC CO

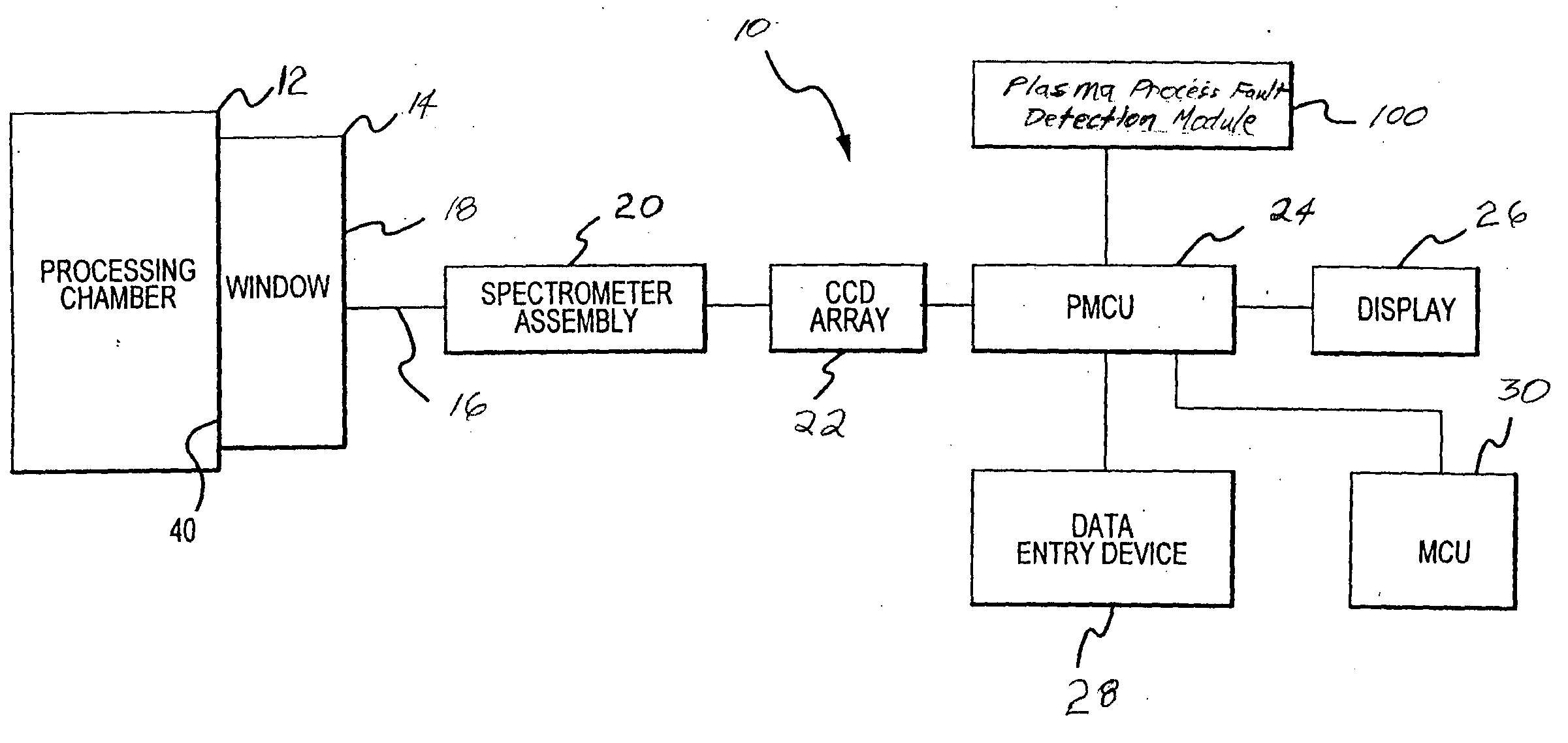

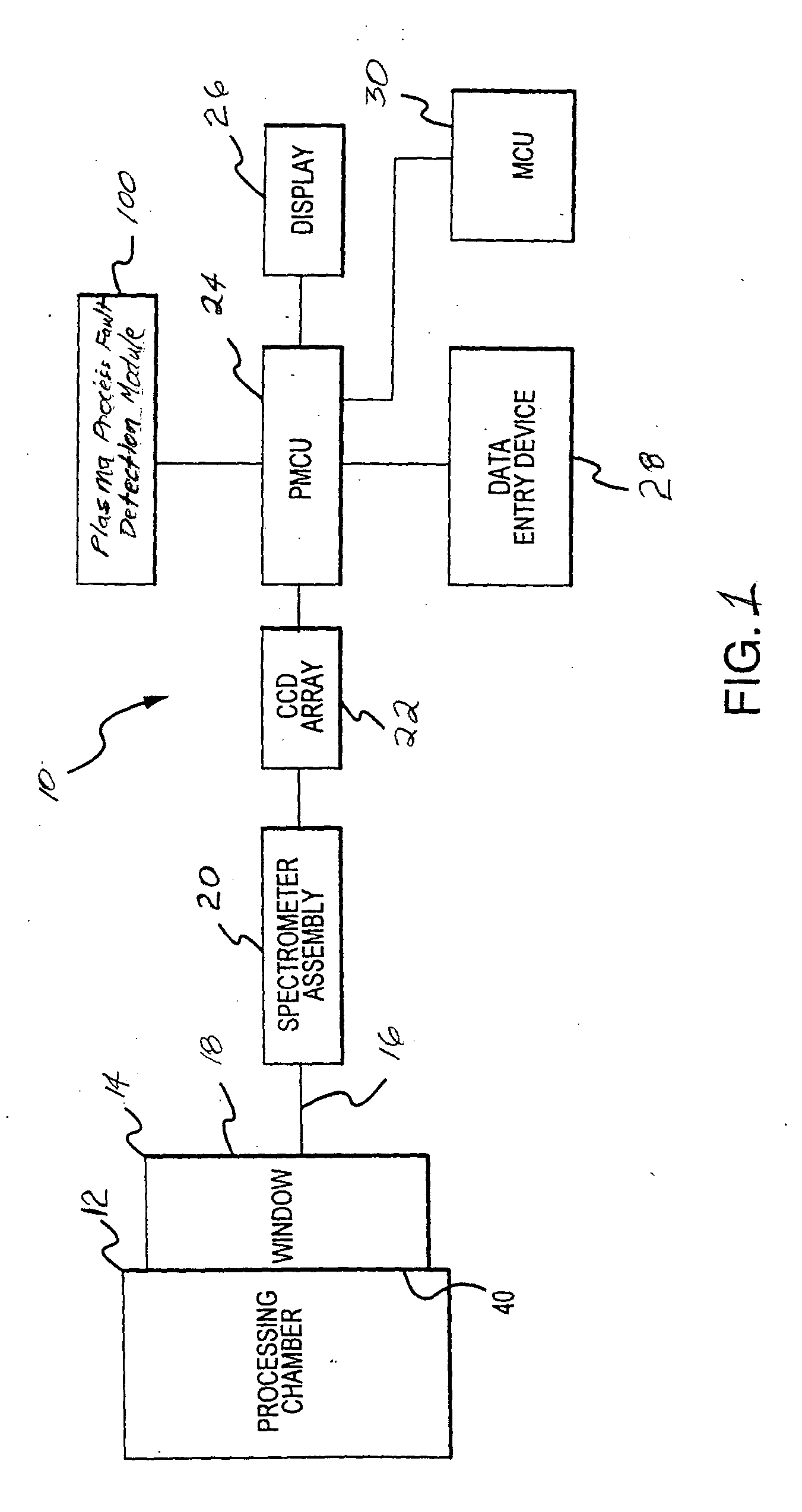

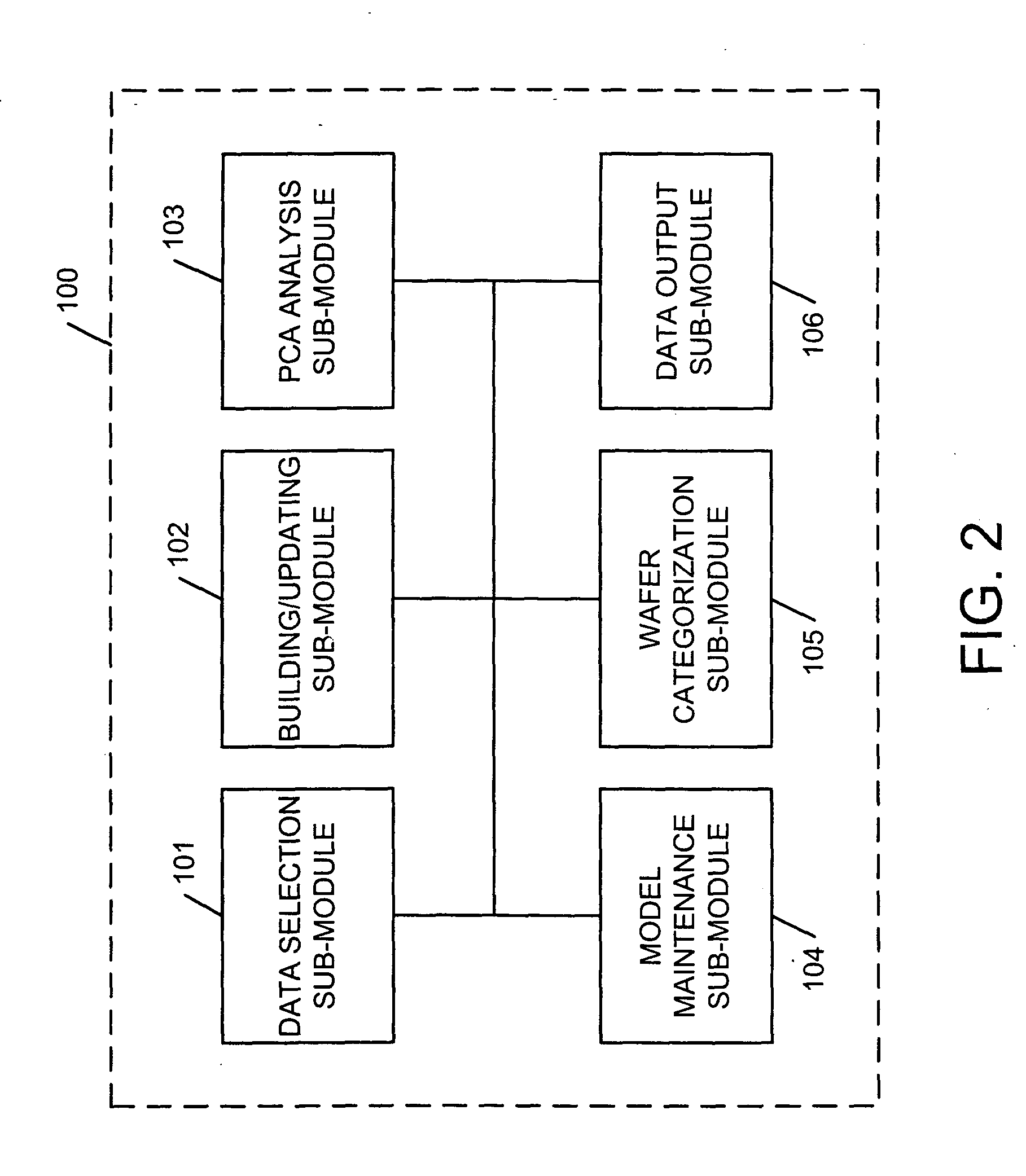

Industrial process fault detection using principal component analysis

InactiveUS20050055175A1Reduce numberAccurately indicatedAmplifier modifications to reduce noise influenceElectric testing/monitoringData selectionSemiconductor chip

A method and system for use in monitoring / evaluating industrial process such as, for example, plasma processes useful in the fabrication of semiconductor chips, microelectromechanical devices, and the like on semiconductor wafers and the like are provided. In one embodiment, a plasma process fault detection module (100) includes a data selection sub-module (101), a model building / updating sub-module (102), a principal component analysis (PCA) analysis sub-module (103), a model maintenance sub-module (104), a wafer categorization sub-module (105), and a data output sub-module (106). The data selection sub-module (101) obtains selected optical emissions spectra (OES) data for each wafer that is processed. The model building / updating sub-module (102) constructs multiple models from the selected OES data for a number of wafers. The PCA analysis sub-module (103) utilizes PCA techniques to determine whether the selected OES data for a particular wafer differs significantly from that expected for a normal wafer as represented by the models. The model maintenance sub-module (104) saves and retrieves models for different processes, associating the current wafer with the correct process. The wafer categorization sub-module (105) categorizes each wafer based on a scalar metric characterizing the residual spectrum vector. The data output sub-module (106) outputs the results that are obtained to a user.

Owner:PEAK SENSOR SYST

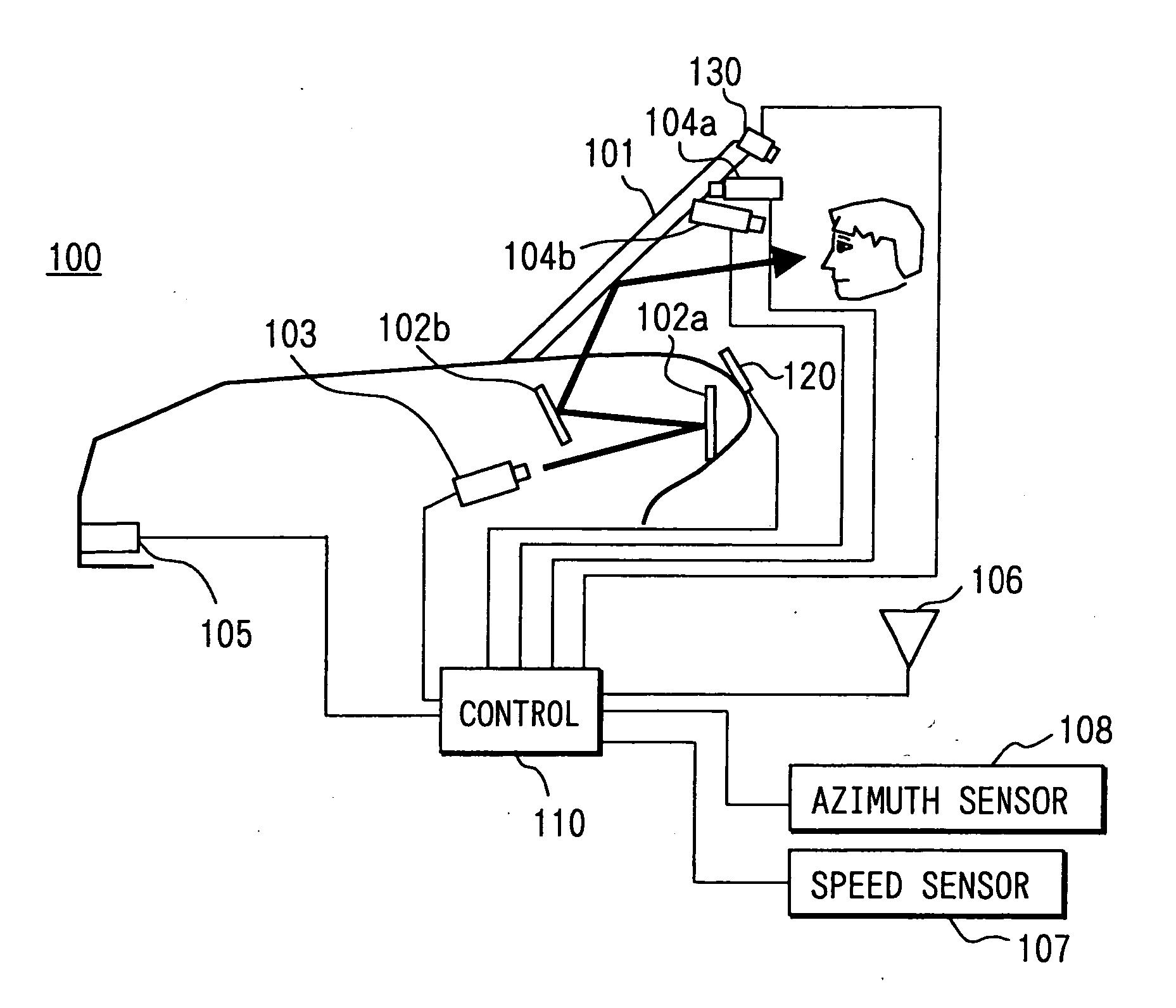

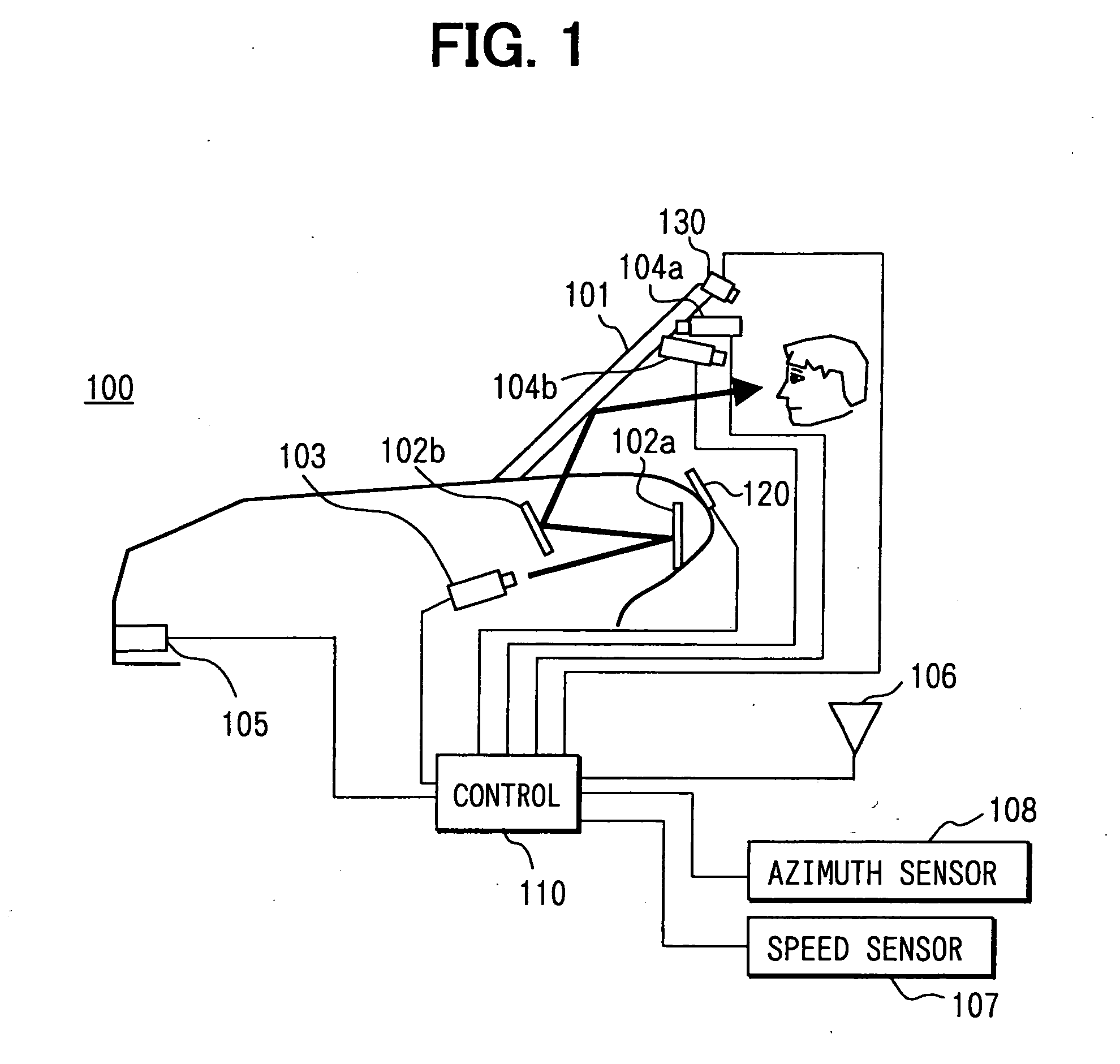

Vehicle display system

InactiveUS20050134479A1Accurate identificationAccurately indicatedImage analysisArrangements for variable traffic instructionsColor imageEngineering

A vehicle display system recognizes, from within a color image of a forward scenery of a subject vehicle, an object such as left and right brake lights of a leading vehicle or a halt sign, each of which includes a red light element. Of the recognized object, a given position on a display area in a windshield of the subject vehicle is extracted. The extracted given position is then highlighted on the display area so that a user of the subject vehicle can properly recognize the object including the red light element.

Owner:DENSO CORP

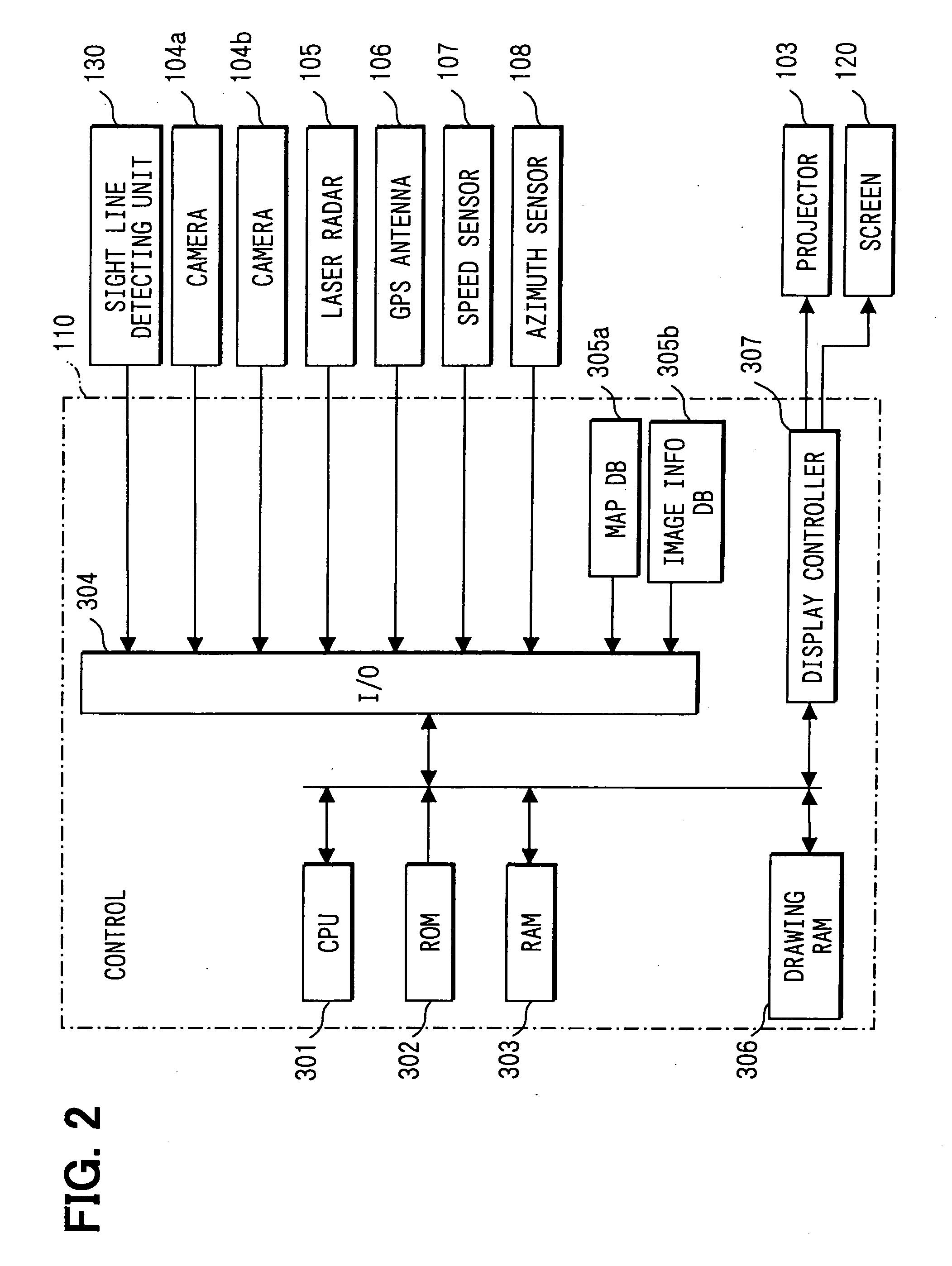

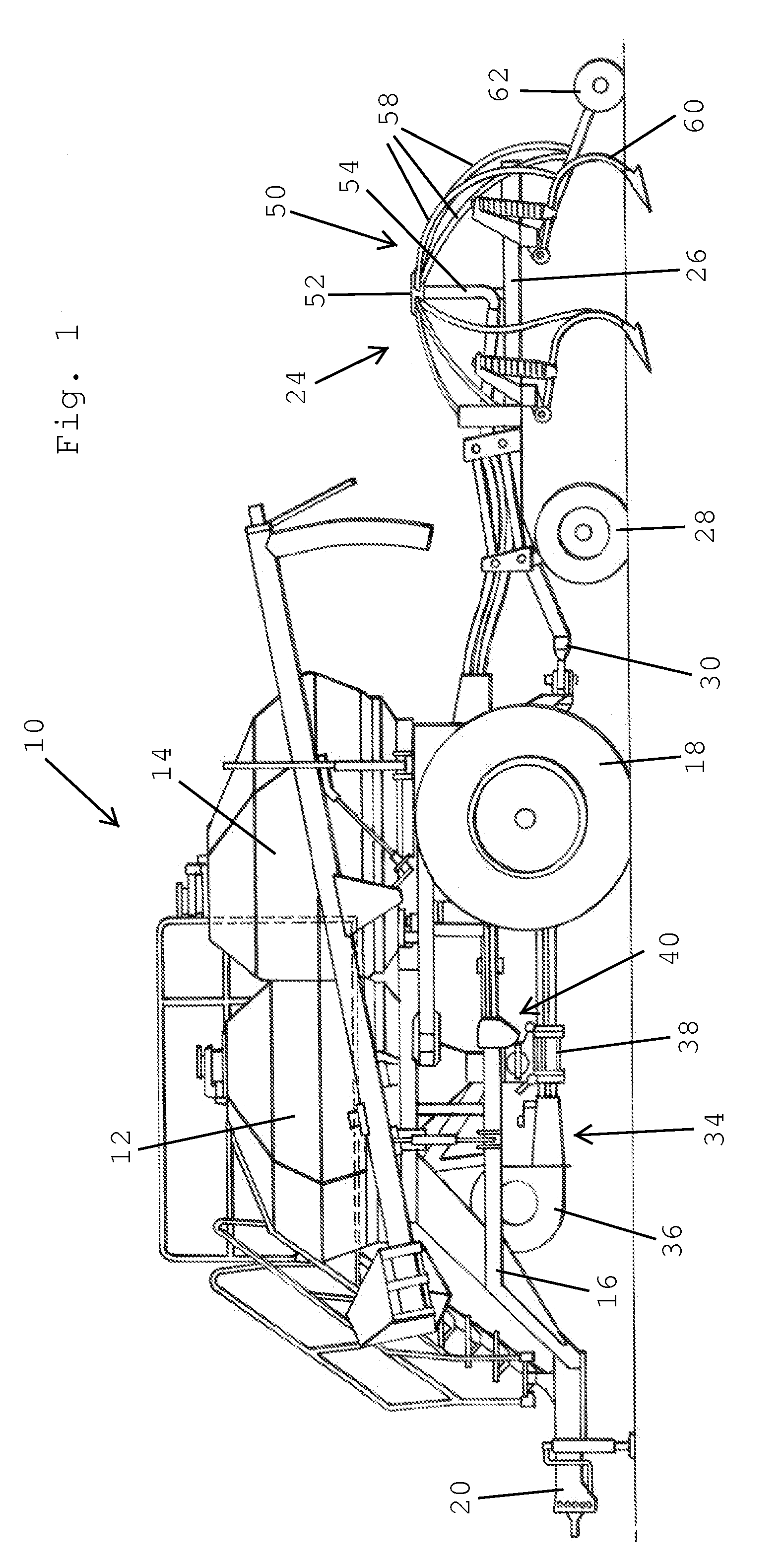

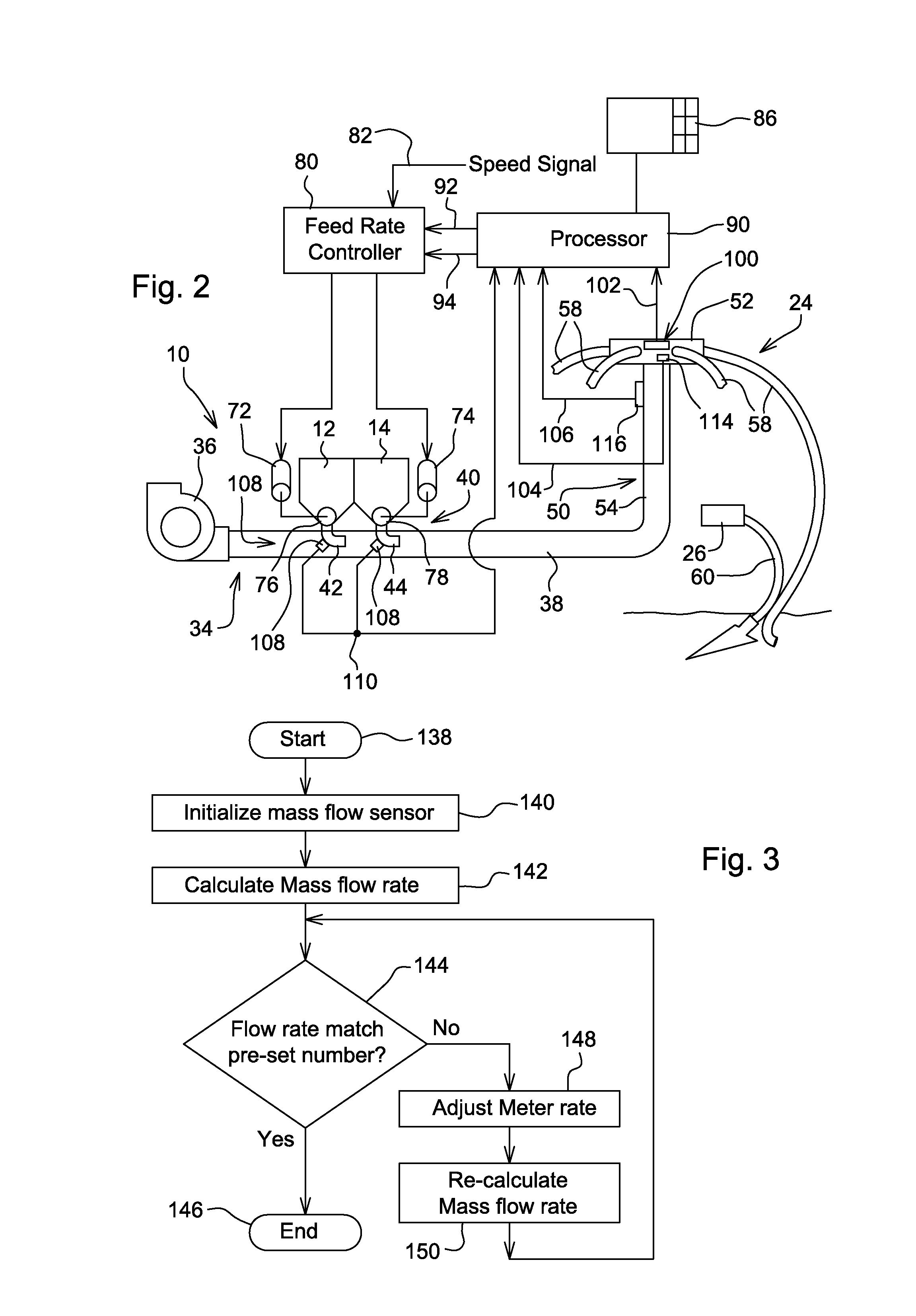

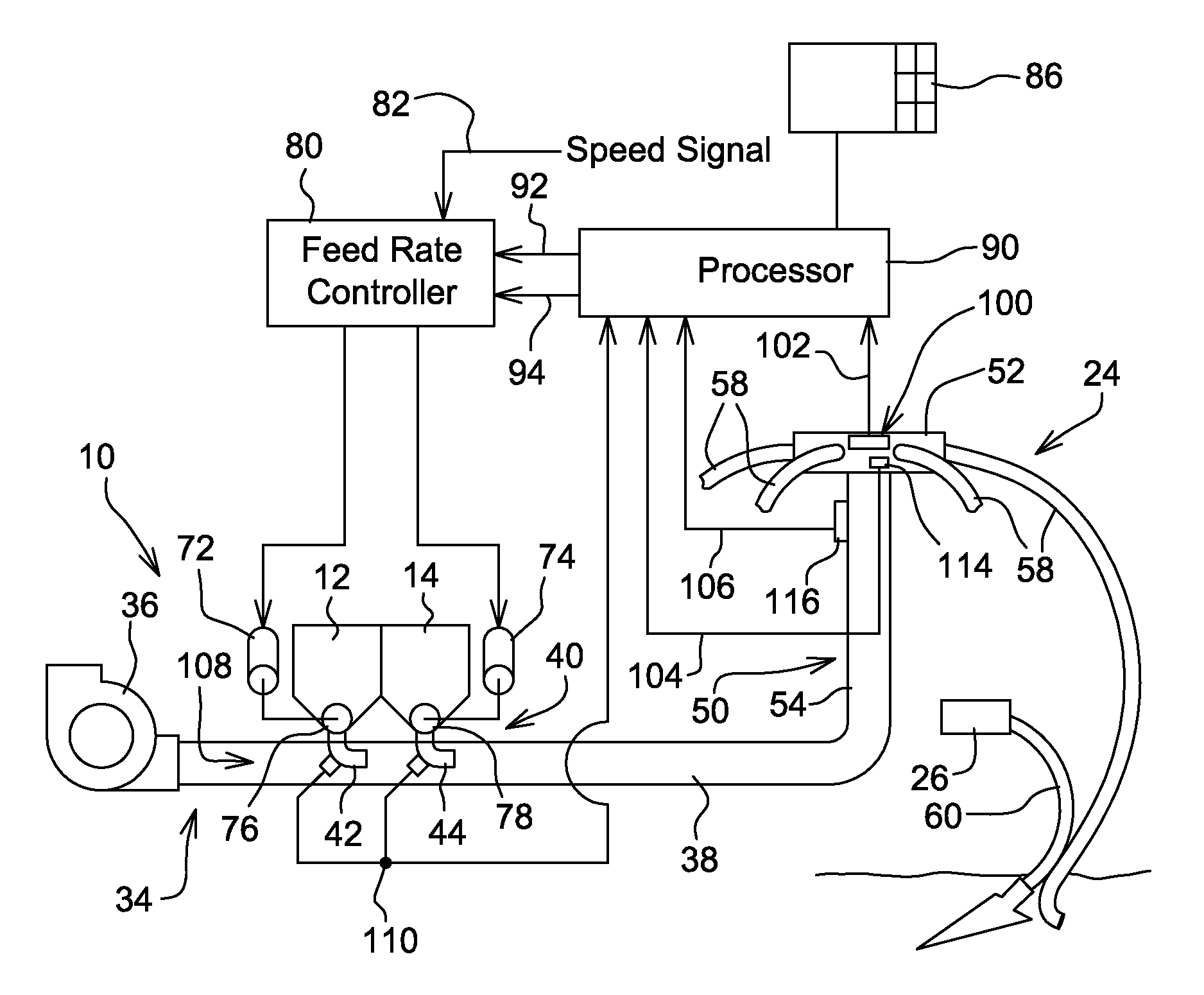

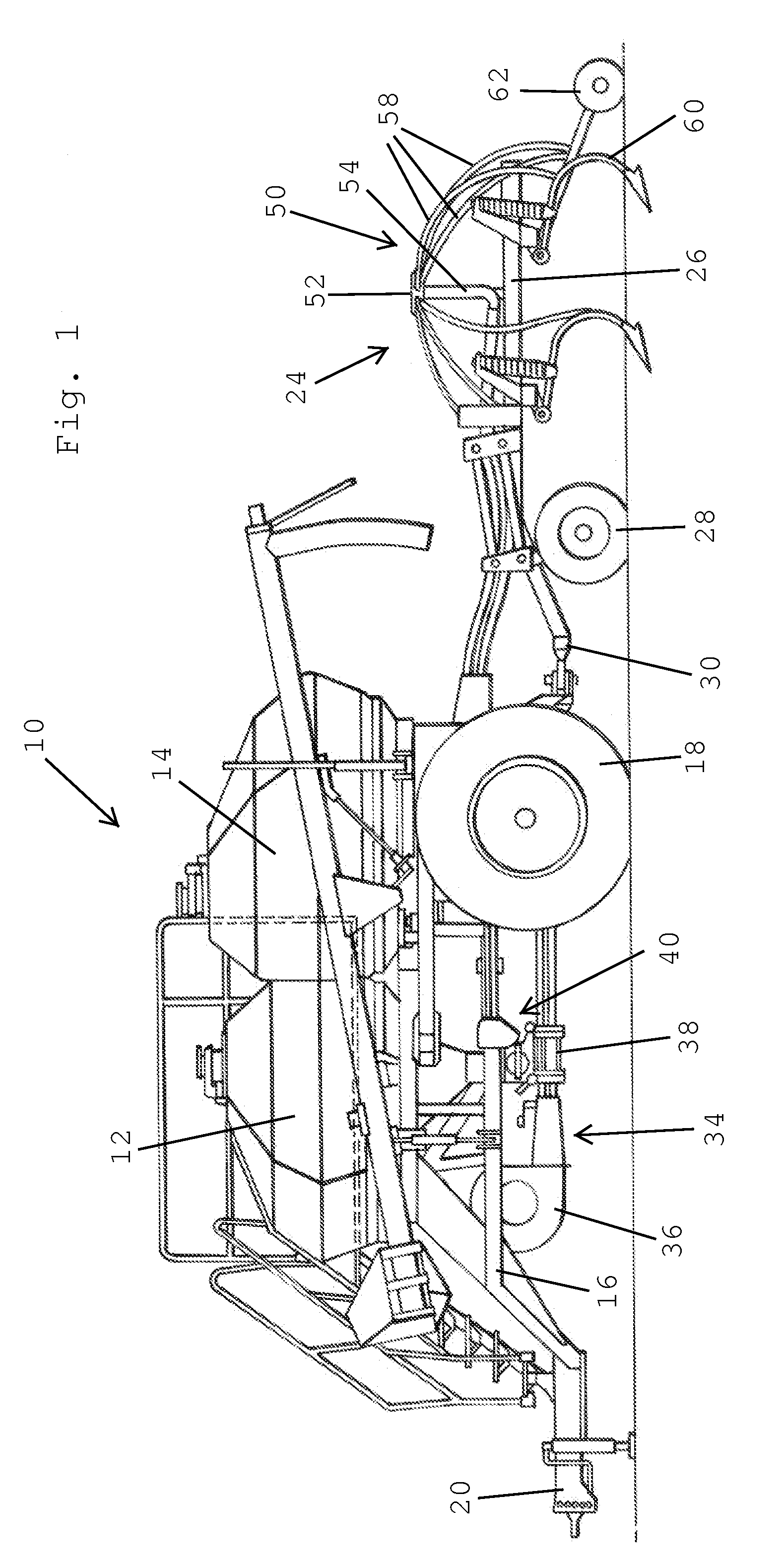

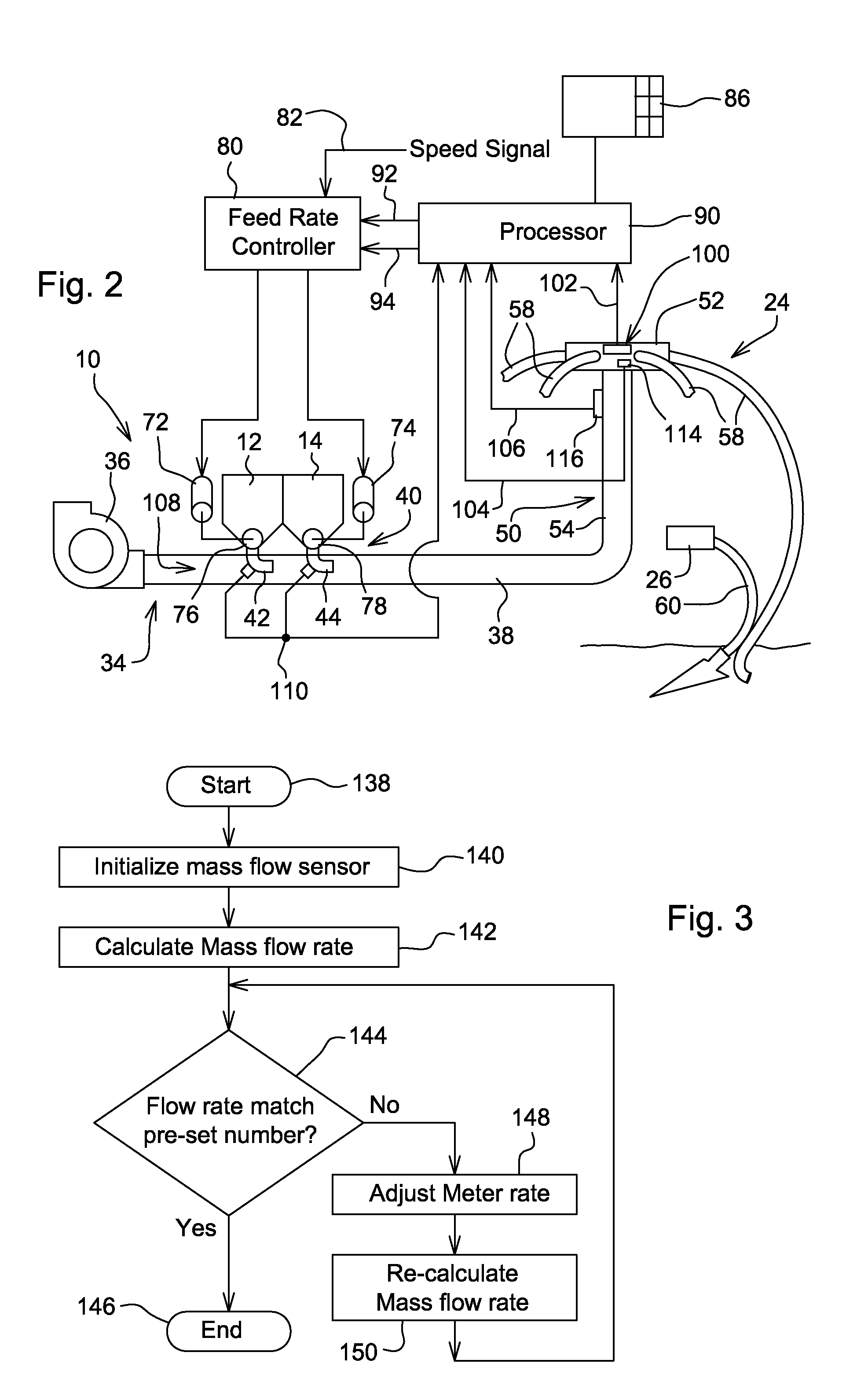

Particulate flow sensing for an agricultural implement

ActiveUS8504310B2Reduce delaysMore accurate seeding and fertilizing ratesFlow propertiesSowingAir velocityEngineering

Owner:DEERE & CO

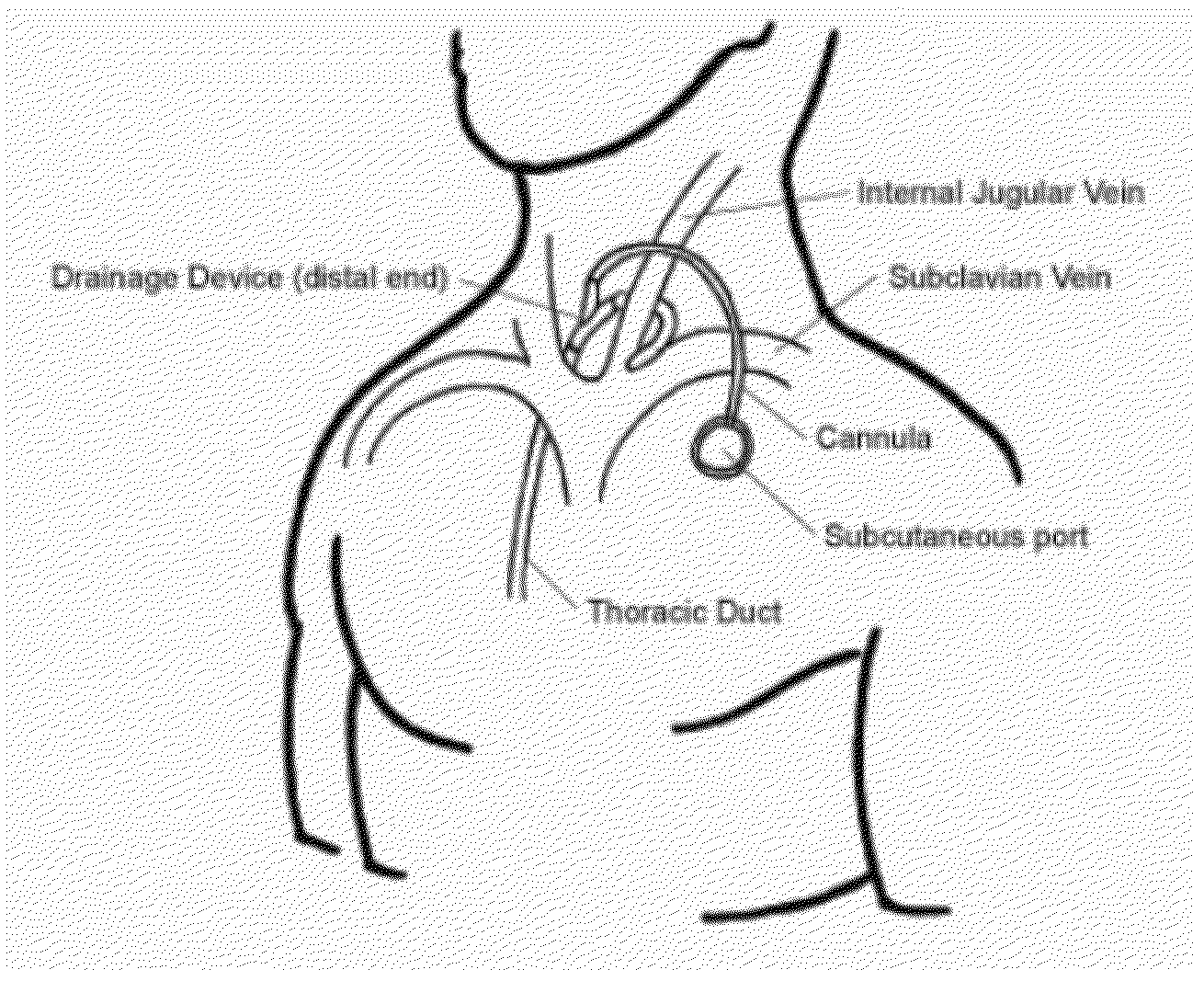

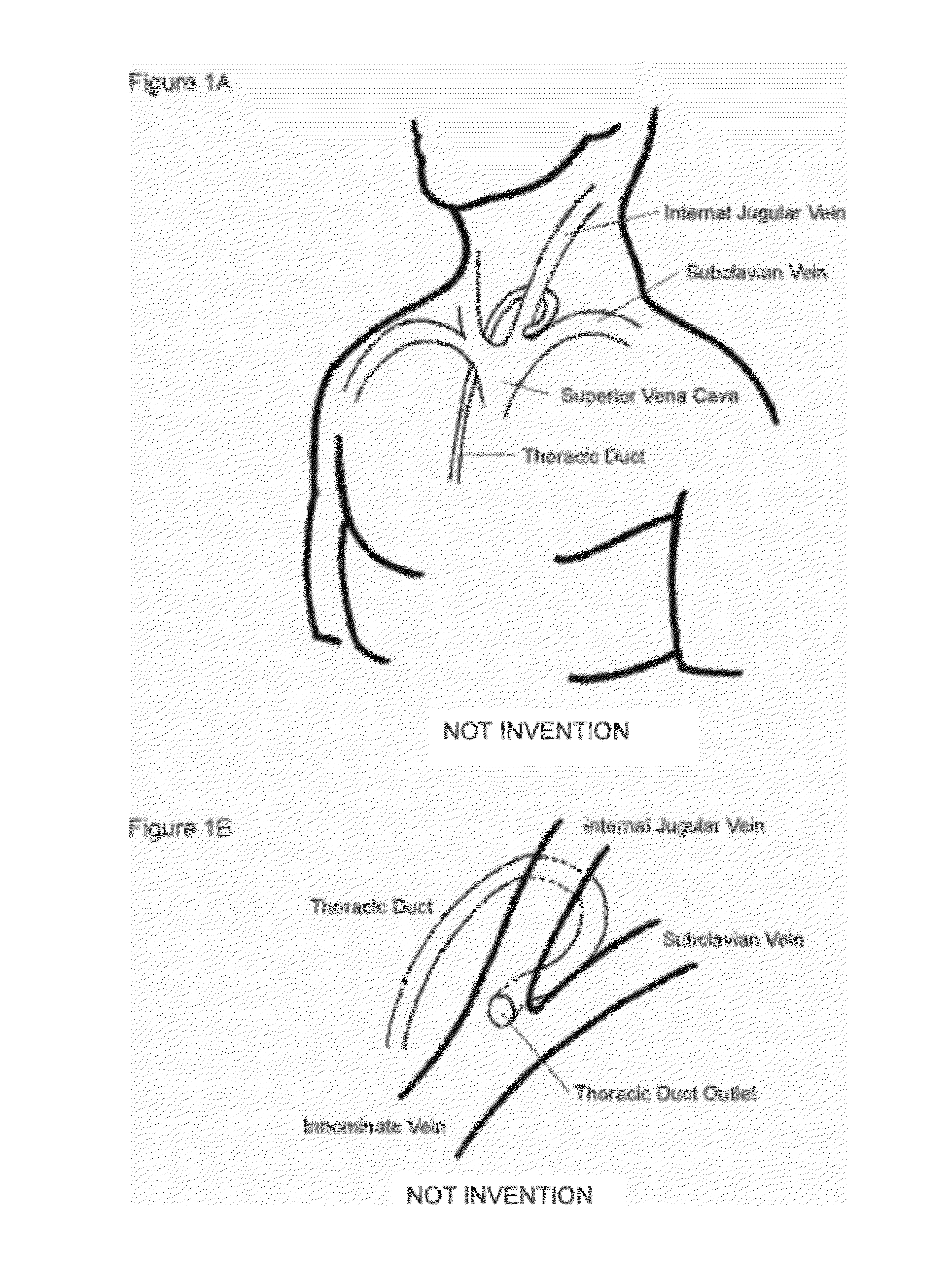

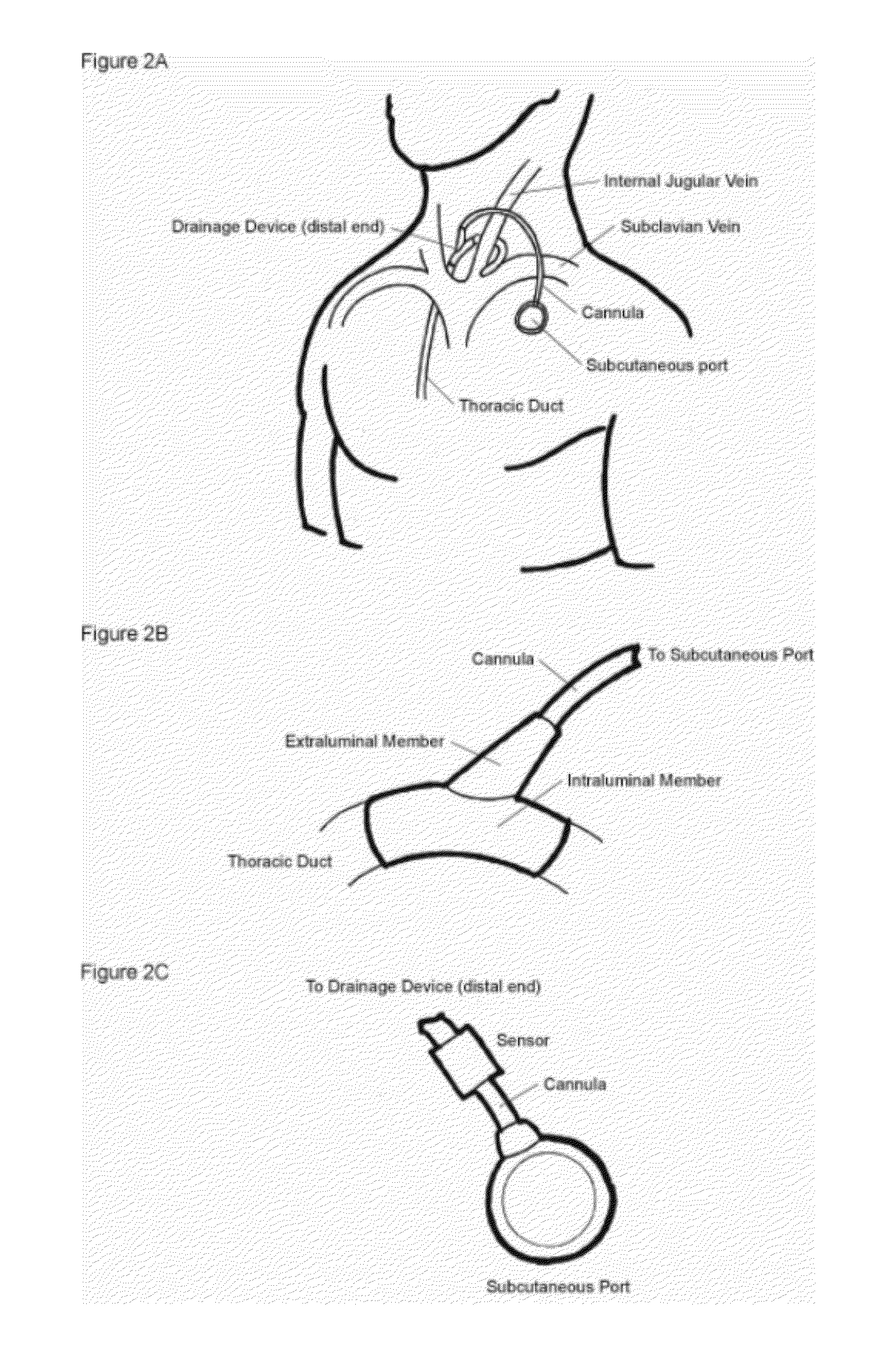

Drainage devices and methods for use

ActiveUS20120029466A1Accurately indicatedSafe and minimally invasive methodStentsWound drainsCatheterThoracic cavity

Devices and methods for draining excess lymph fluid are disclosed. The device can be fixed to the blood vessel adjacent to the thoracic duct. The device can have a port for withdrawing lymph fluid exiting the thoracic duct. The device can have a cannula and / or subcutaneous port to draw the lymph fluid away from the thoracic duct and reduce hemostatic pressure in the lymphatic system.

Owner:LXS LLC +1

Radio frequency identification controlled heatable objects

ActiveUS20050242086A1Accurate temperature indicationAccurately indicatedBoiling over preventionNear-field in RFIDTemperature controlRadio frequency

A temperature controlled heatable object is provided in which a temperature sensor is connected to a Radio Frequency Identification (RFID) tag. The RFID tag is located within the handle of the object, and the temperature sensor is placed in contact with the object. In a first embodiment of the invention, the temperature sensor is partially imbedded within the object via a notch located in the side of the object. In a second embodiment of the invention, a temperature sensor is imbedded within a tunnel drilled within the base of the object. In a third embodiment, a temperature sensor is imbedded between the bottom of the object and a slab attached to the bottom of the object. The sensor can be located in a slot formed in either the slab or the bottom or the object. Handles and receivers for mounting the handles to the temperature controllable objects are also provided.

Owner:IMURA INT USA

Particulate flow sensing for an agricultural implement

ActiveUS20110035163A1Reduce delaysMore accurate seeding and fertilizing ratesFlow propertiesSowingAir velocityEngineering

An impact sensor is located in a distribution tower which divides the seed and / or nutrient flow into individual rows, and a second sensor provides a compensation signal dependent upon one or more variables such as the velocity of the air in the conveying system, implement vibrations. As the seed / fertilizer bounces off of the impact sensor and flows into the individual row air streams, the impact sensor provides a force signal to a processor which calculates the total particulate mass flow rate from the force signal and the air velocity signal. To determine individual seed and fertilizer rates, a rate controller temporarily changes the metering rate of one of the materials, and the processor then calculates the desired information from the mass flow change and meter speed change. Another embodiment includes seed sensor structure at the meter output for achieving or confirming accuracy.

Owner:DEERE & CO

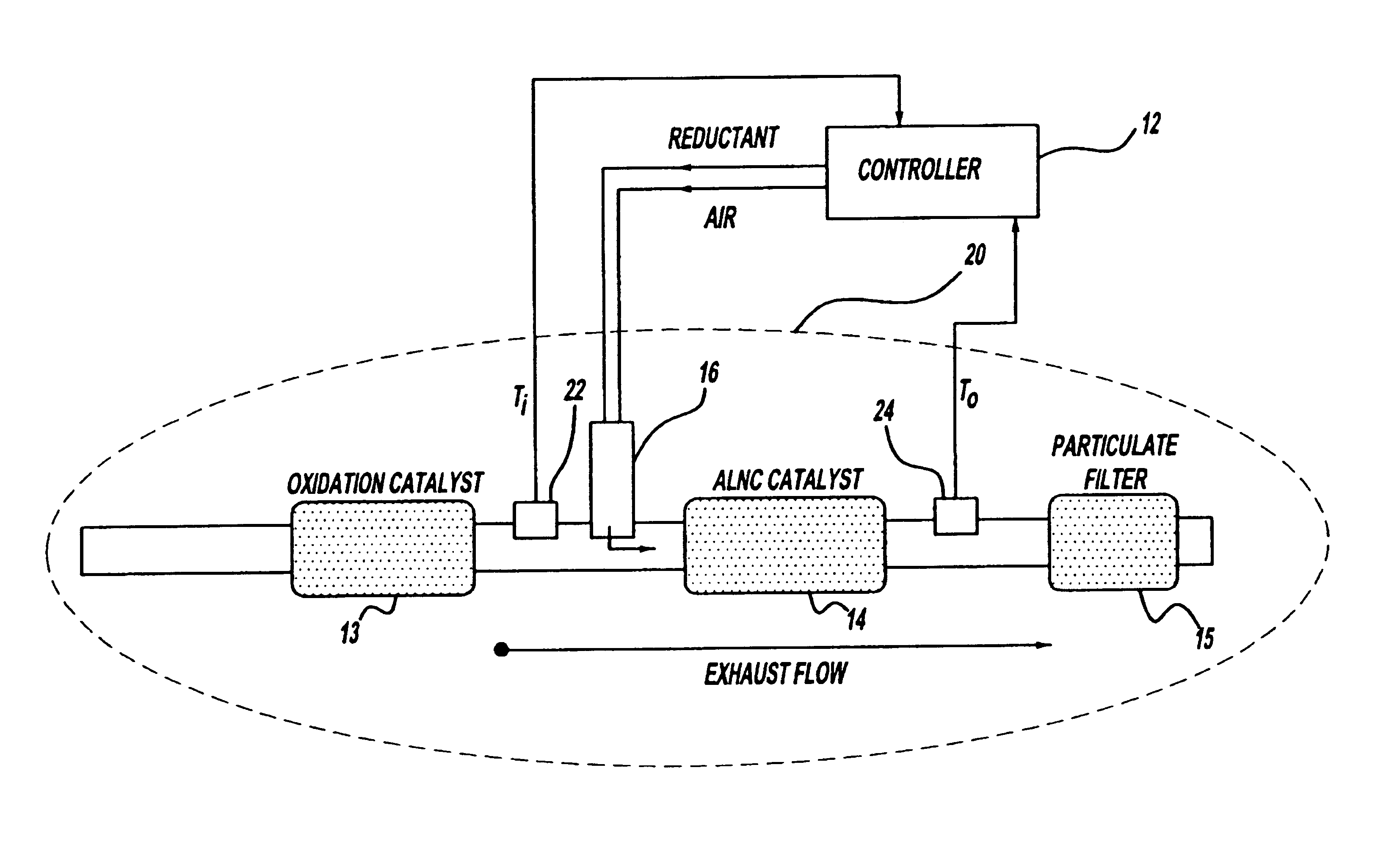

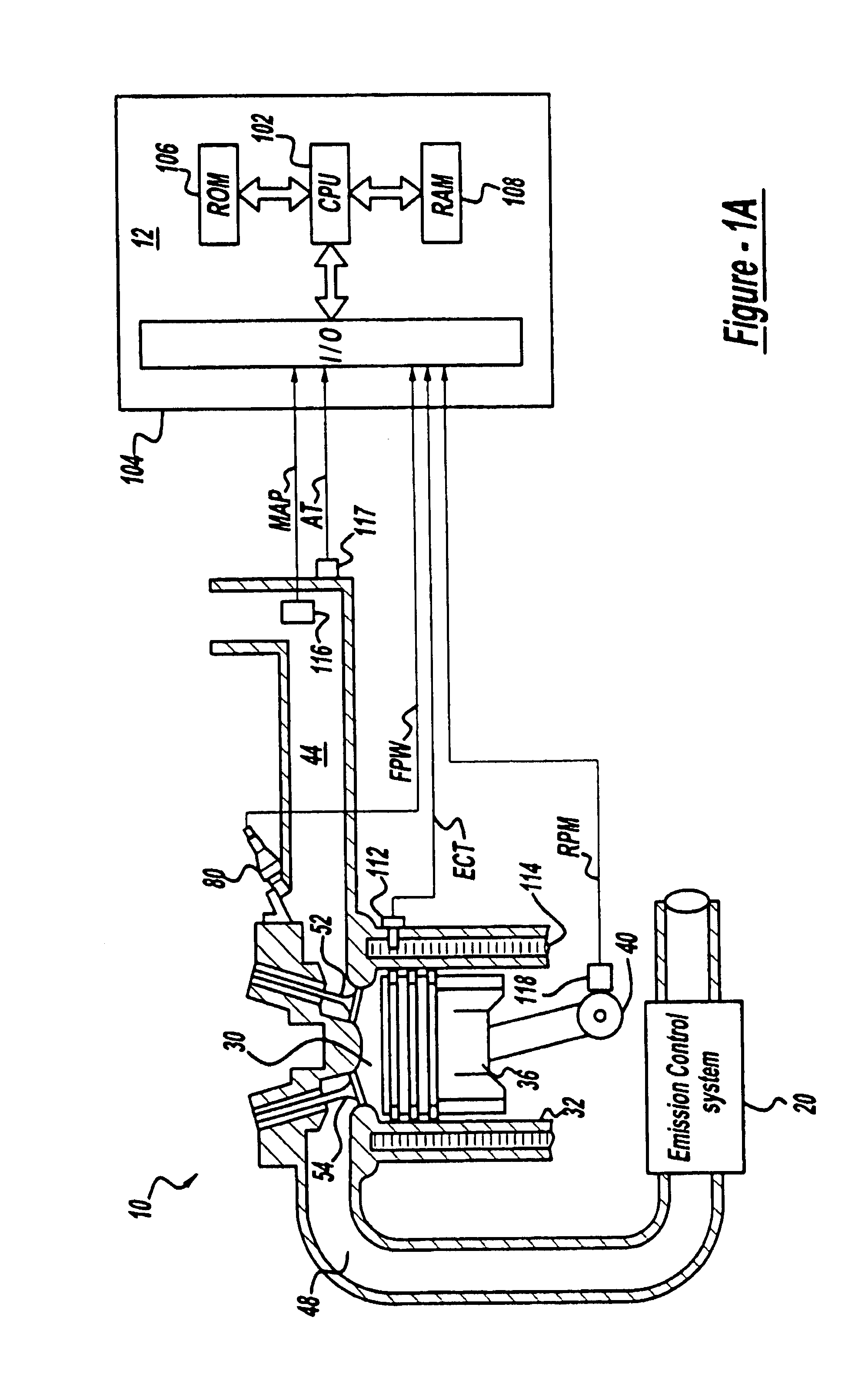

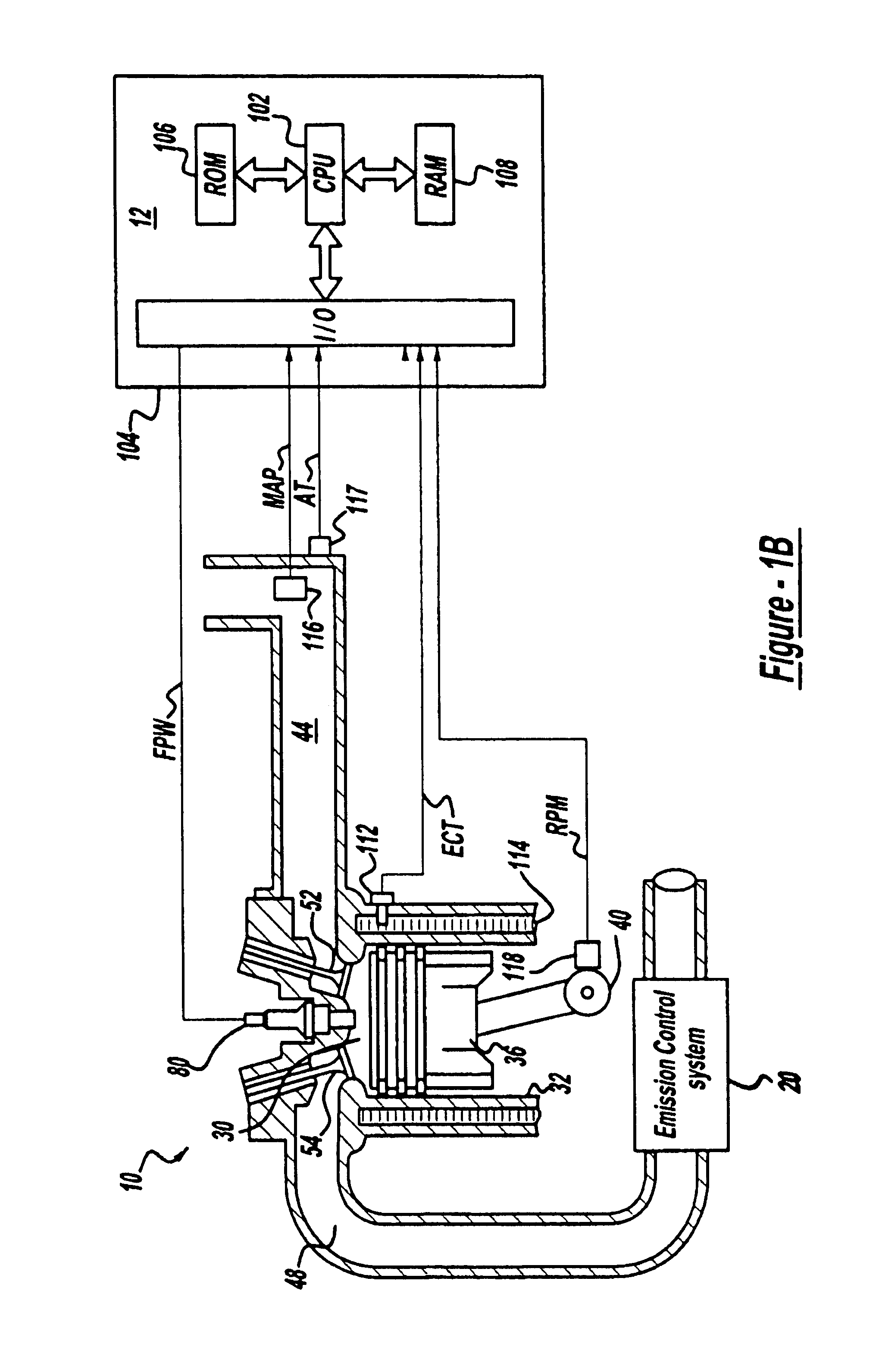

Diesel aftertreatment systems

InactiveUS6983589B2Easy to controlImprove economyInternal combustion piston enginesExhaust apparatusControl systemInternal combustion engine

A method for accurately diagnosing deterioration in an emission control system for a lean burn internal combustion engine is presented. The emission control system includes an Active Lean NOx (ALNC) Catalyst and a system for injecting a hydrocarbon-based reductant into the ALNC thereby improving its NOx conversion efficiency. The method teaches calculating a rate of change of exotherm across the ALNC and differentiating between deterioration of the ALNC and deterioration of the reductant injection system based on the magnitude and the sign of the rate of change of the exotherm. Once the diagnosis of deterioration is made, and the deteriorated component is identified, appropriate corrective measures, such as adjusting or discontinuing the reductant injection amount, and setting diagnostic codes, are taken.

Owner:FORD GLOBAL TECH LLC

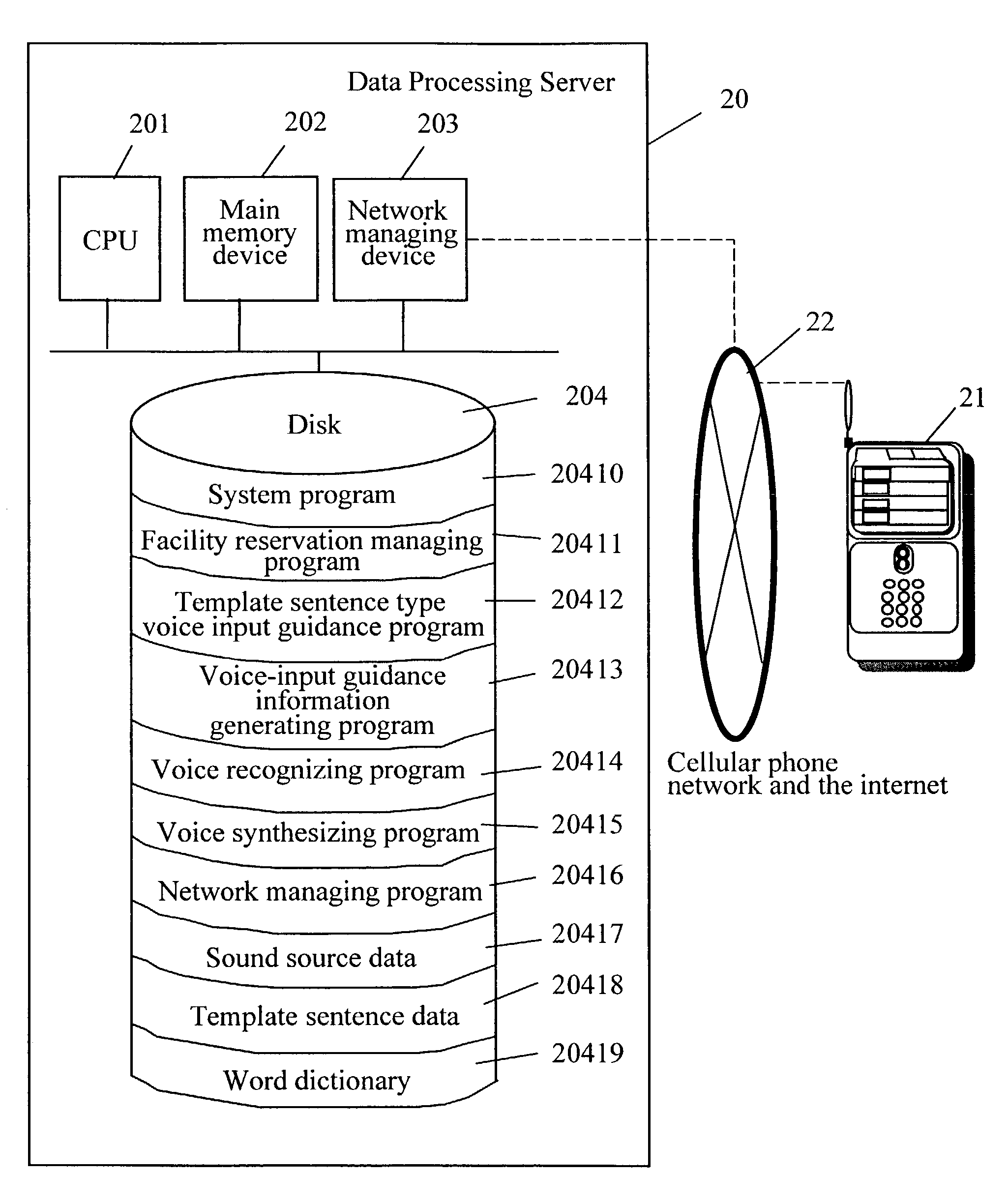

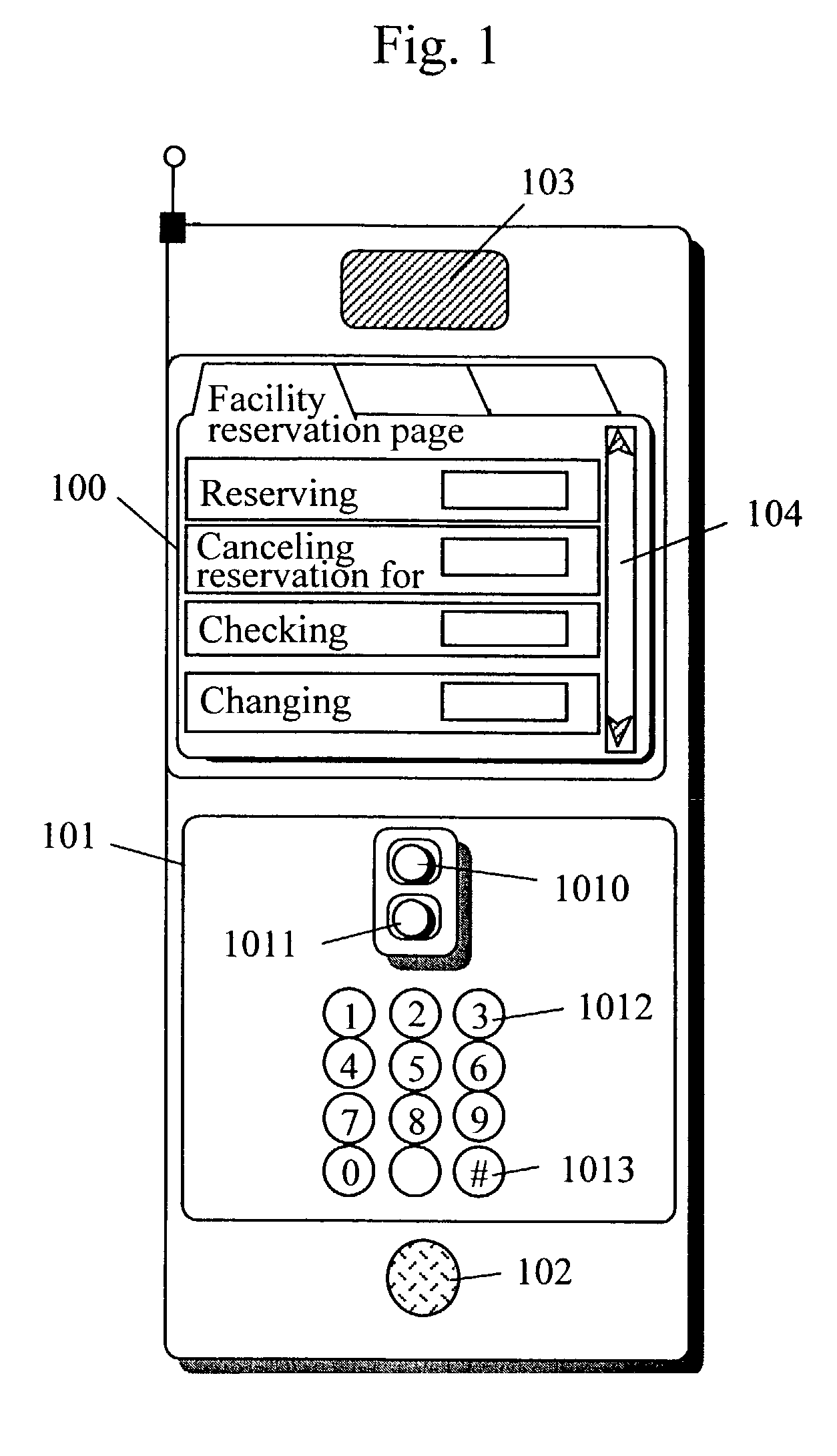

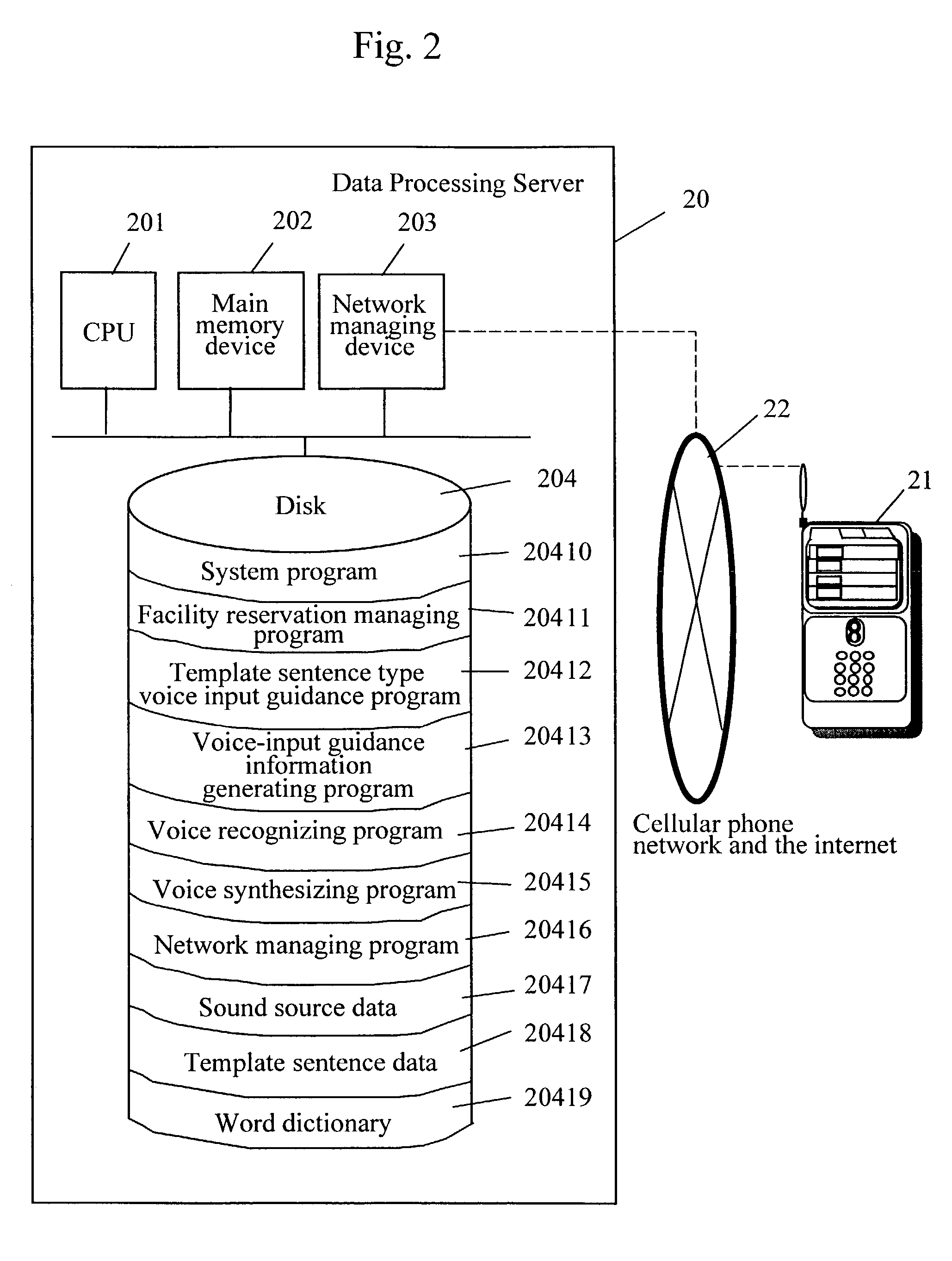

Method and system for acquiring information with voice input

InactiveUS7190770B2High recognitionAccurately indicatedAutomatic call-answering/message-recording/conversation-recordingSubscriber signalling identity devicesUser inputSpeech input

A user-requested command with both visual and hearing information is indicated. Additionally, with a user friendly method, the user understands what content to input. The user-requested command is expressed in the form of a template sentence. Template part in the template sentence is vocalized, and a slot area in the template sentence is expressed using a sound or voice. The user inputs his or her voice to be input to the slot area.

Owner:HITACHI LTD

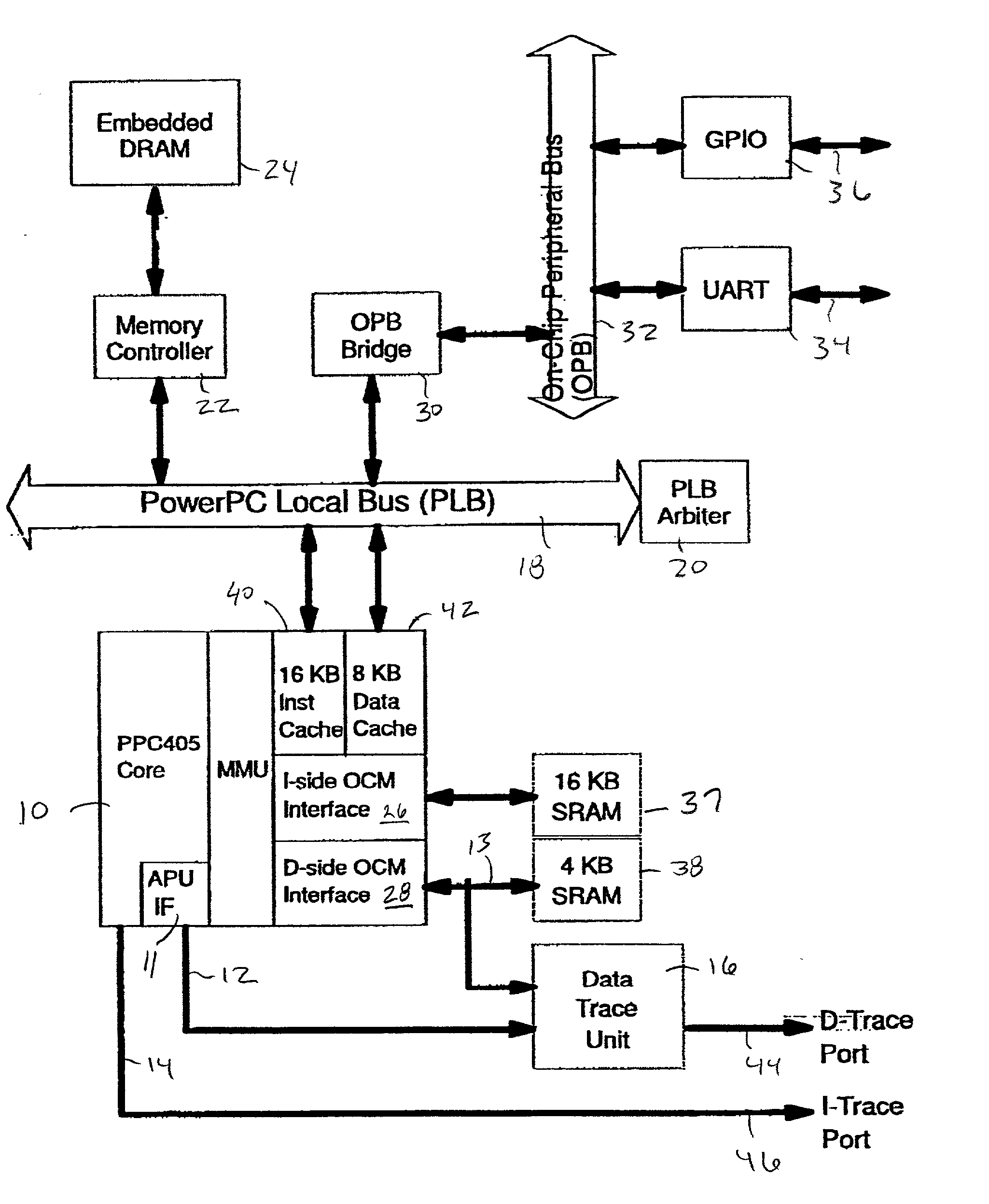

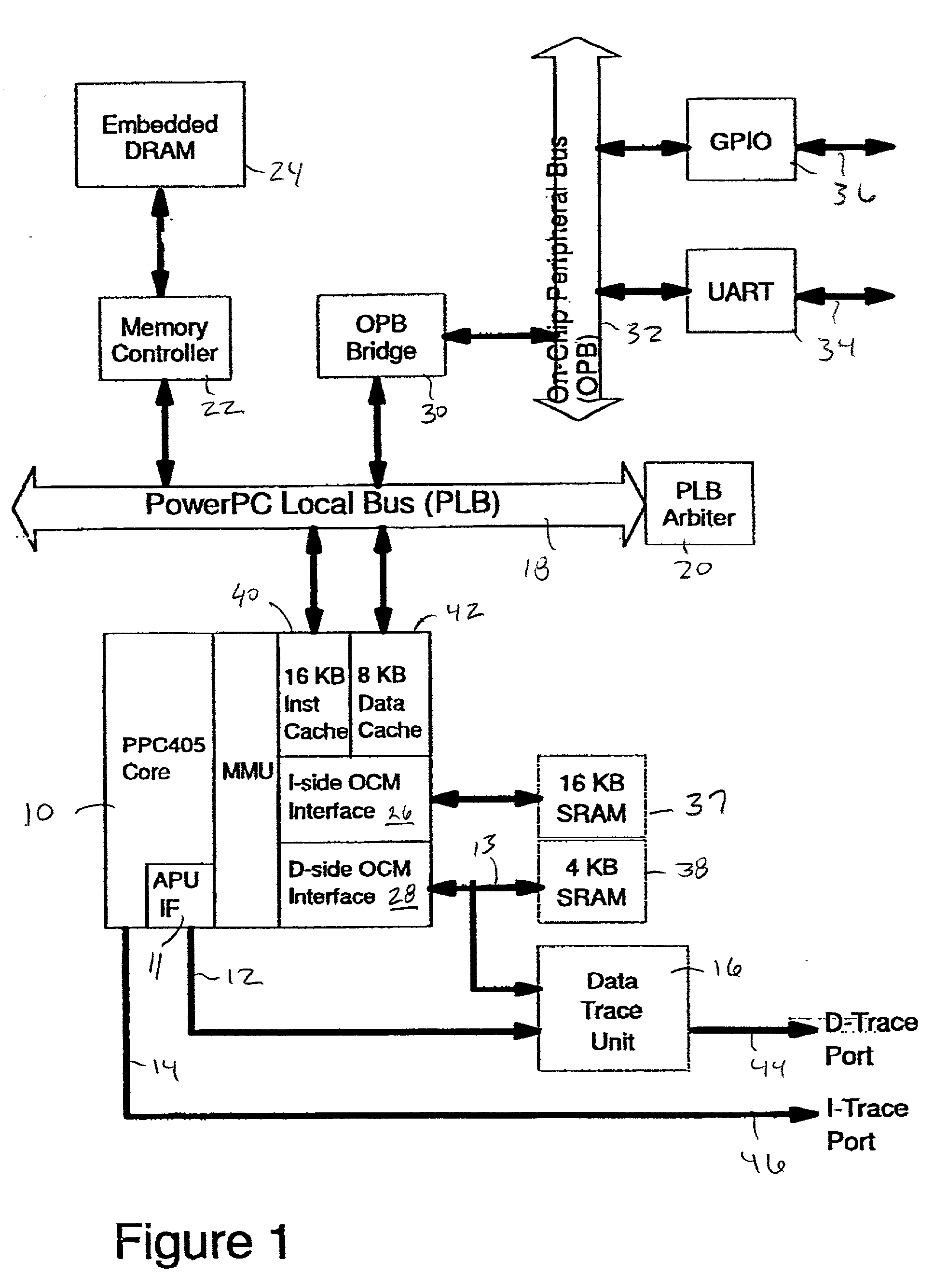

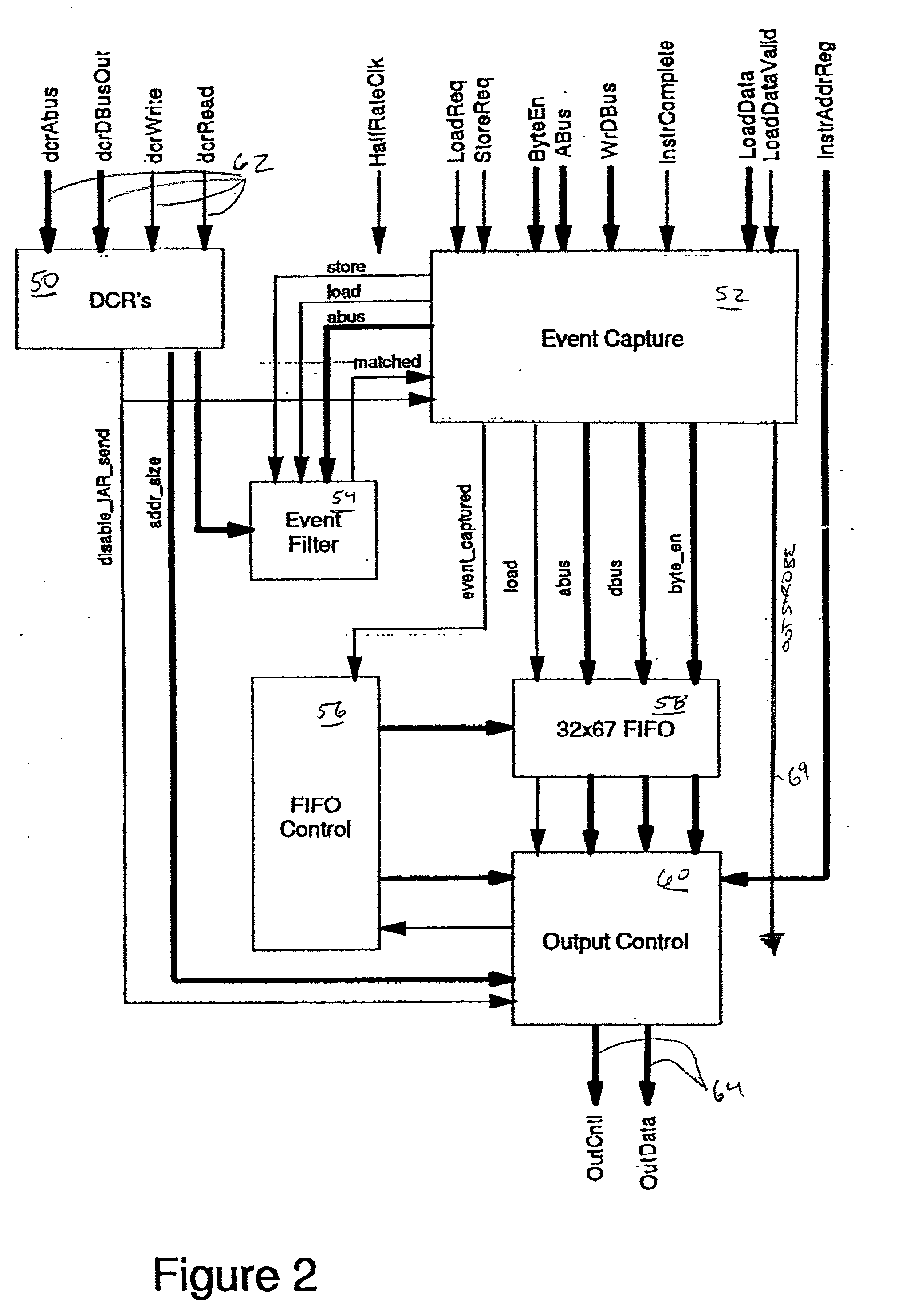

Integrated real-time data tracing with low pin count output

InactiveUS20030018929A1Low bandwidthAccurately indicatedHardware monitoringSoftware testing/debuggingReal-time dataData signal

An integrated circuit real-time data tracing apparatus for analyzing microprocessor based computer systems for monitoring, in real-time, parameters sufficient to define the load and store operations information that the embedded core controller may assert, and process information during events. Integral on this single chip apparatus is a data trace unit designed to access control, address, and data signal lines required to monitor the embedded core controller's activities; perform data tracing independent of instruction tracing; synchronize with an instruction trace stream; allow for selection of multiple ranges for data tracing; report lost events to a FIFO array; and, output strobe signals to give a cycle accurate indication of when an event has been captured.

Owner:MARVELL ASIA PTE LTD

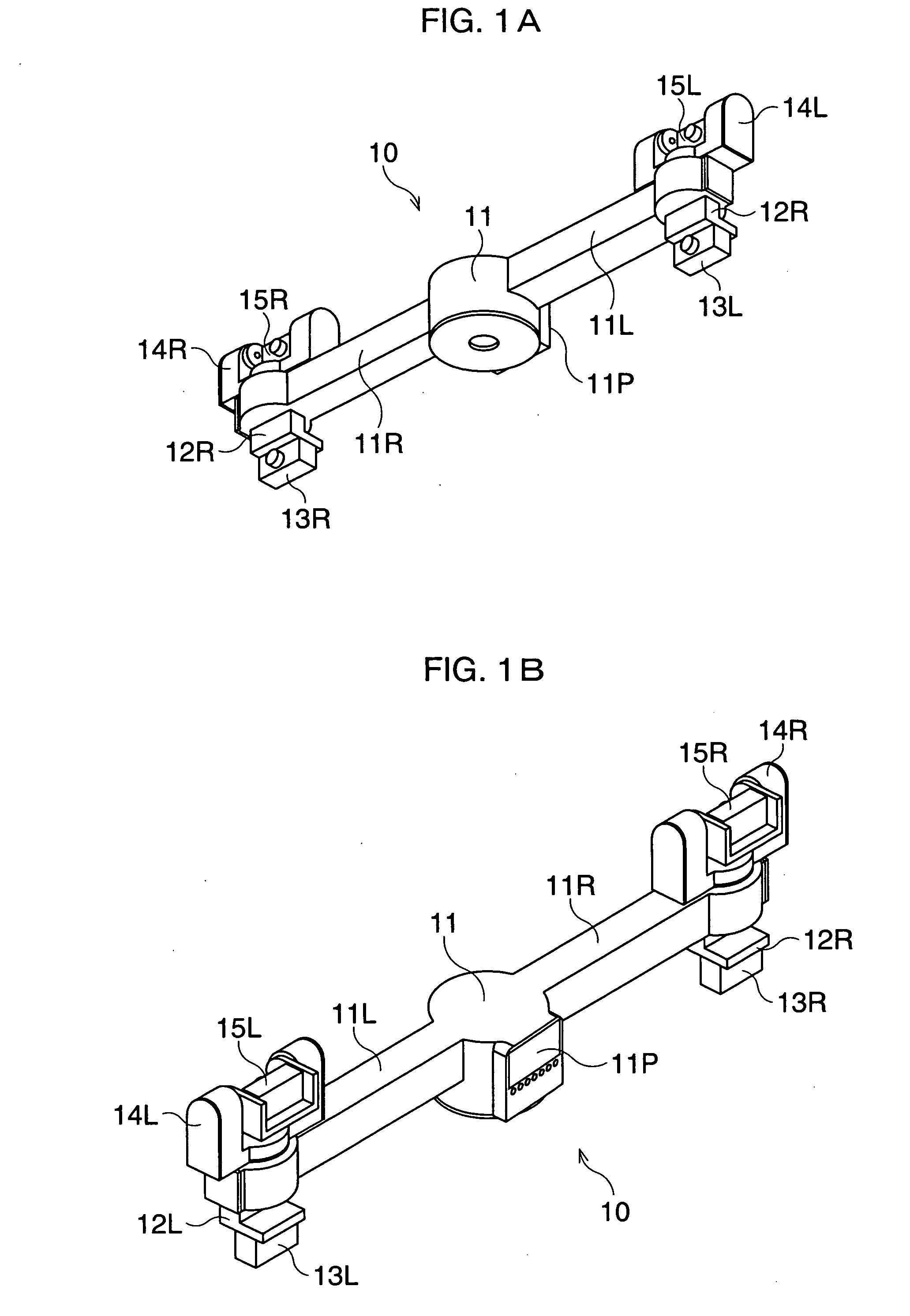

Pedicle screw and operating device thereof

ActiveUS7871413B2Avoid separationAccurately indicatedInternal osteosythesisJoint implantsCouplingEngineering

Disclosed is a spine fixation apparatus, more particularly, a pedicle screw implanted into a spine and an operating device for the pedicle screw capable of easily inserting a rod to a head section of the pedicle screw in order to securely fix the spine. The pedicle screw has a head section including a recess part defined by first and second sidewalls, a screw section, and a support unit formed at an upper portion of the recess part of the head section while connecting the first sidewall to the second sidewall. The operating device has a screw coupling rod having an elongated pipe shape, a body having a first side coupled to the screw coupling rod, a rotating member having a first end coupled to a second side of the body in such a manner that a second end of the rotating member rotates about the first end thereof, and a rod receiver coupled to the second end of the rotating member. Due to the support unit, the rod is prevented from being easily separated from the pedicle screw, thereby facilitating minimum incision surgery. The operating device for the pedicle screw allows an operator to easily perform minimum incision surgery while making several incisions for the pedicle screws and the rod in the back of the patient and keeping the size of incisions quite a small.

Owner:SOLCO BIOMEDICAL +1

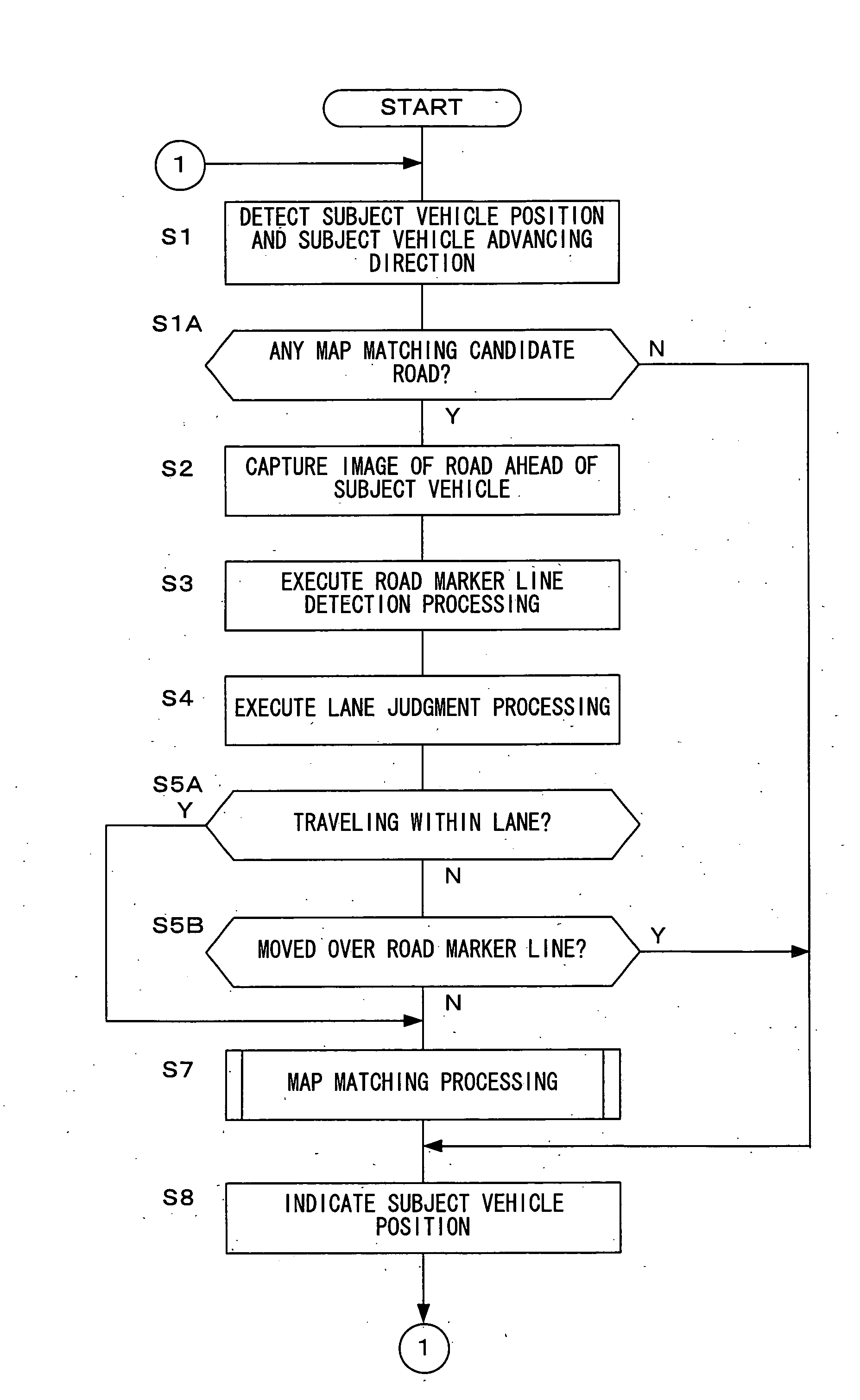

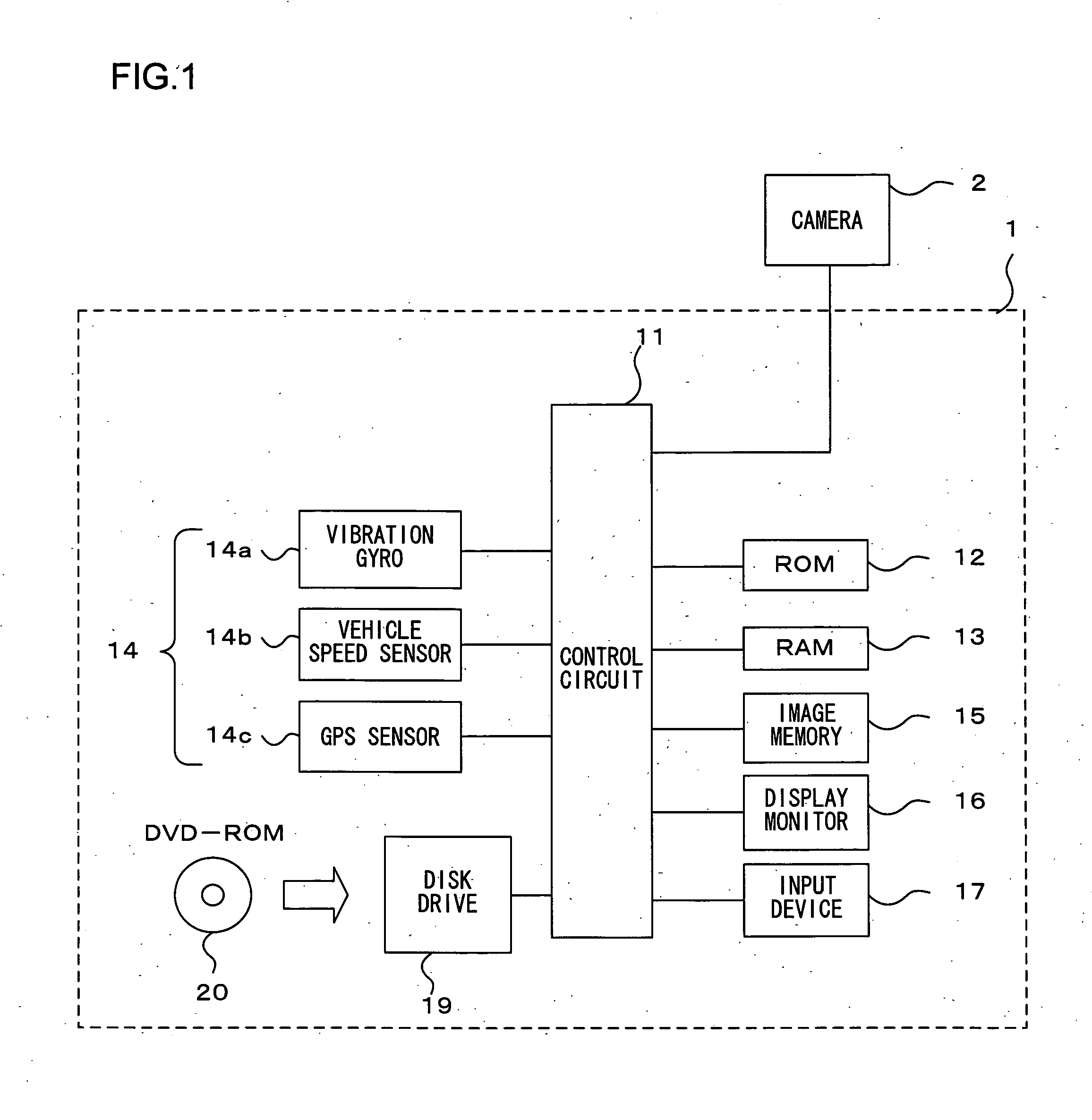

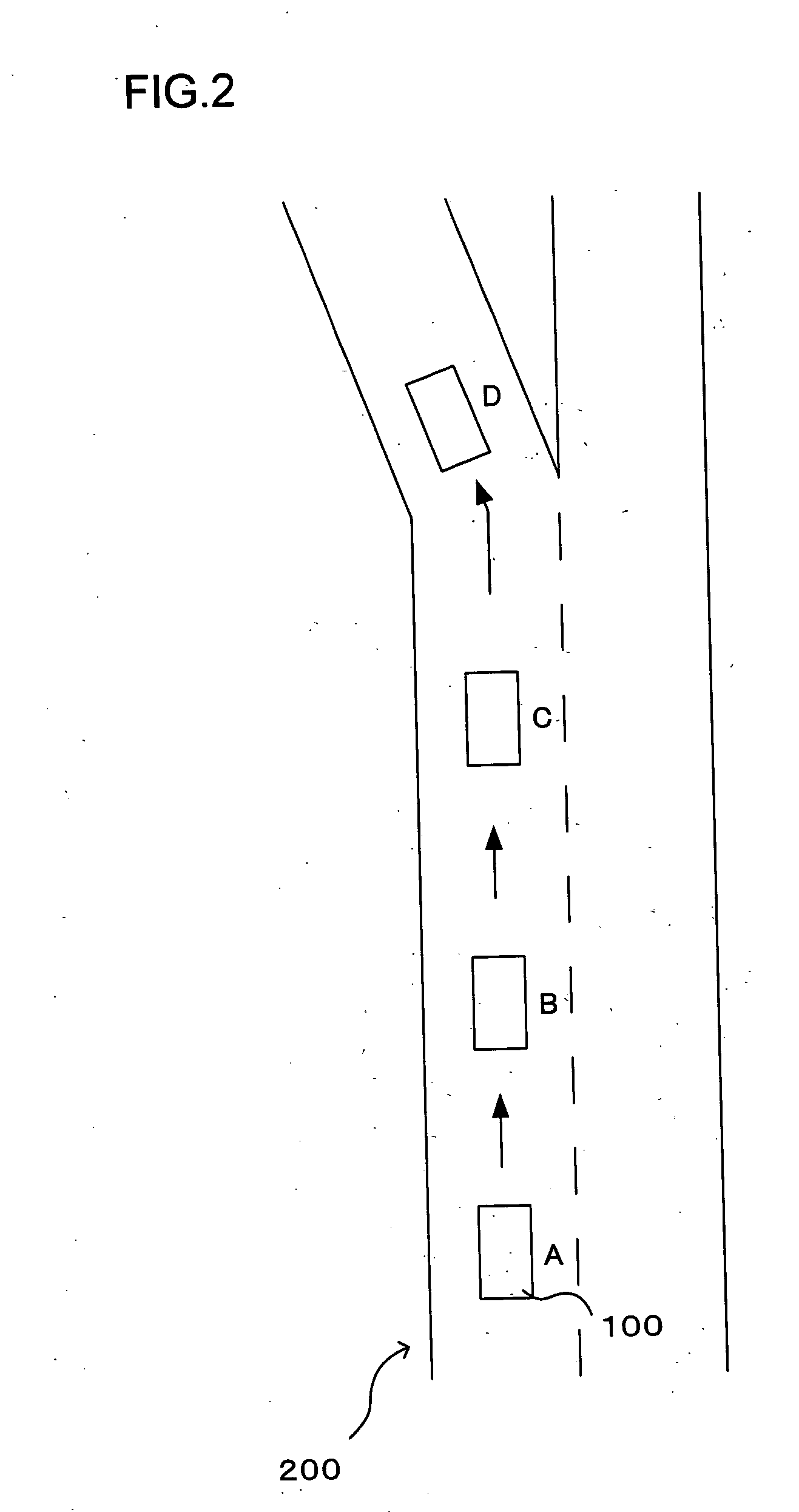

On-Vehicle Navigation Apparatus And Subject Vehicle Position Correction Method

ActiveUS20080077322A1Accurately indicatedInstruments for road network navigationRoad vehicles traffic controlLocation detectionCorrection method

An on-vehicle navigation apparatus comprises a subject vehicle position detection unit that detects a position of a subject vehicle and a direction along which the subject vehicle is advancing, a road marker line detection unit that detects a road marker line in an image of a road captured with a camera, a map matching candidate identifying unit that identifies a road to be designated as a map matching candidate, a decision-making unit that makes a decision as to whether or not the subject vehicle is traveling on the road identified by the map matching candidate identifying unit, a map matching unit that correct the detected subject vehicle position so as to set the subject vehicle position onto the road on which the subject vehicle is determined to be traveling, and a subject vehicle position indicating unit that indicates the subject vehicle position having been corrected.

Owner:CLARION CO LTD

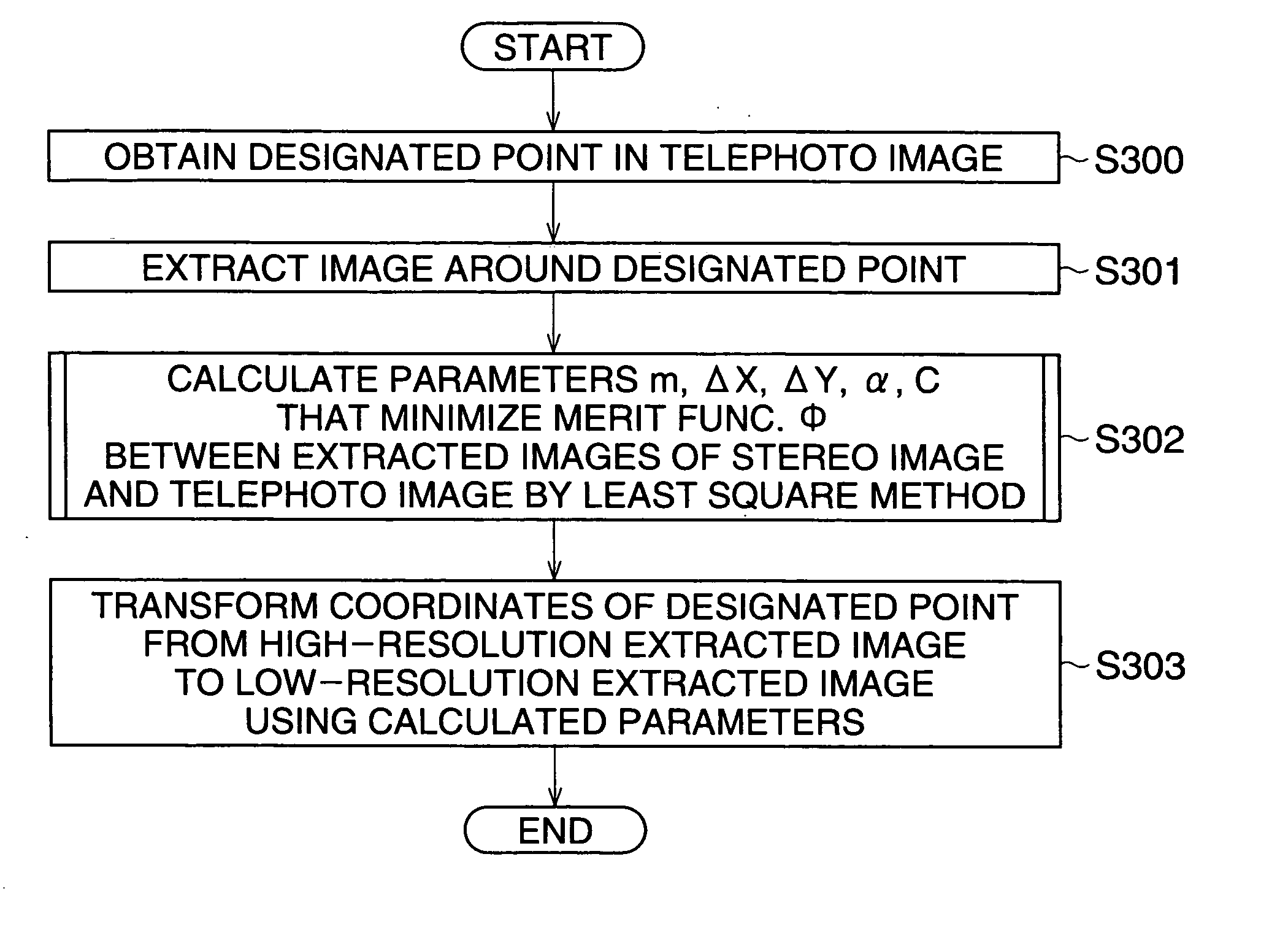

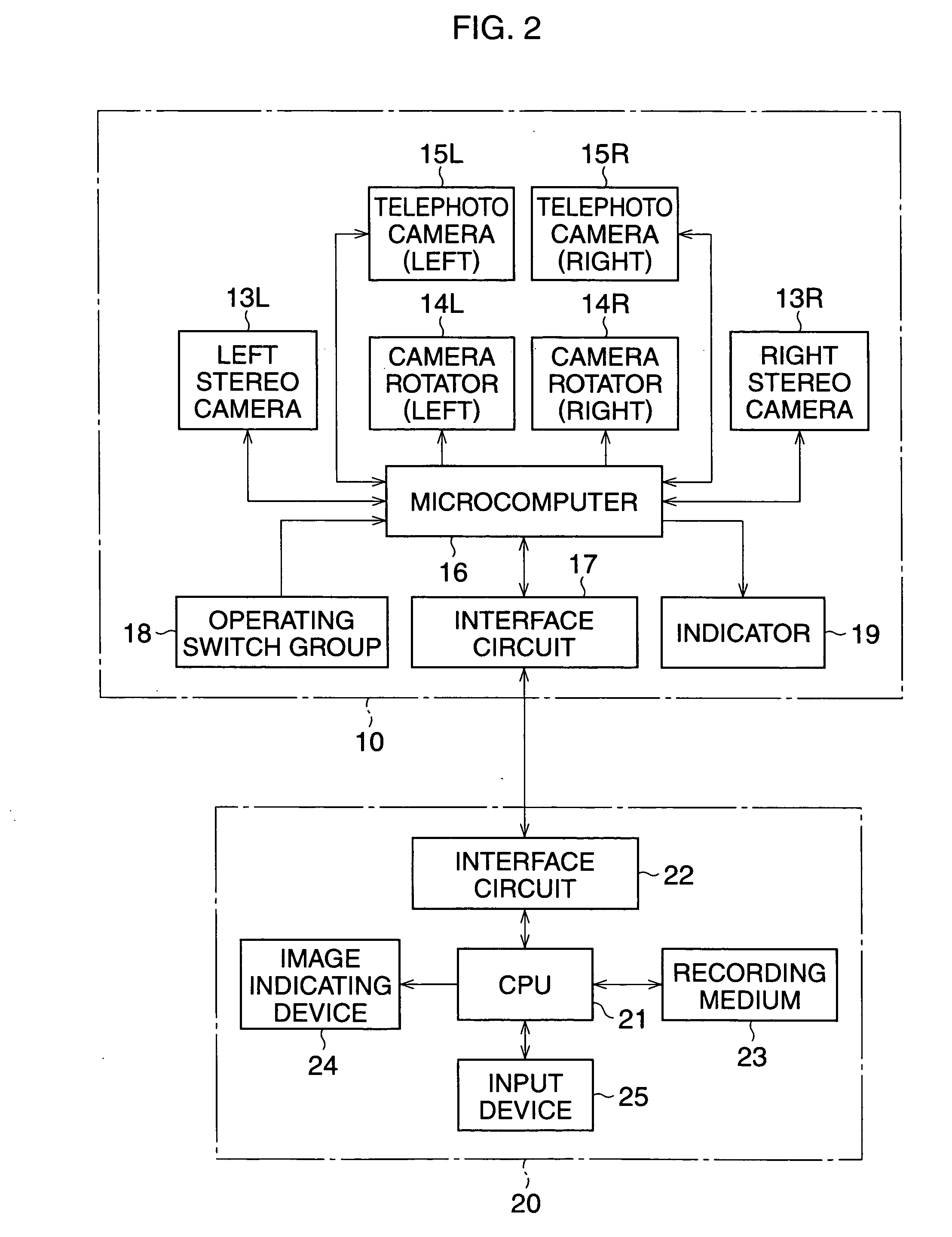

Apparatus and method for establishing correspondence between images

InactiveUS20050069195A1Accurately indicatedImage analysisGeometric image transformationImage extractionImage resolution

An apparatus for establishing correspondence between a first and a second image which includes the same object is provided. The apparatus comprises a point designator, a first image extractor, and a corresponding point searcher. The point designator is used to designate a point on the first image. The first image extractor extracts a predetermined area of an image surrounding the designated point as a first extracted image. The corresponding point searcher searches a point on the second image, which corresponds to the designated point on the first image by image matching between the first extracted image and the second image. Further, the resolutions of the first and second images are different from each other.

Owner:ASAHI KOGAKU KOGYO KK

Smart coating system with chemical taggants for coating condition assessment

InactiveUS20030118440A1Improve bindingImproving subsequent up-timePropellersReaction enginesCoating systemGas turbines

A on-line method is provided for detecting wear and / or damage to gas turbine parts. Preferred embodiments of the invention provide a gas turbine comprising parts with smart coatings and collection and detection means to measure wear and erosion of gas turbine parts. In other preferred embodiments, smart coatings are provided comprising chemical taggants that can be collected and detected downstream, thus providing an on-line or in situ evaluation technology for wear and damage to gas turbine parts.

Owner:GENERAL ELECTRIC CO

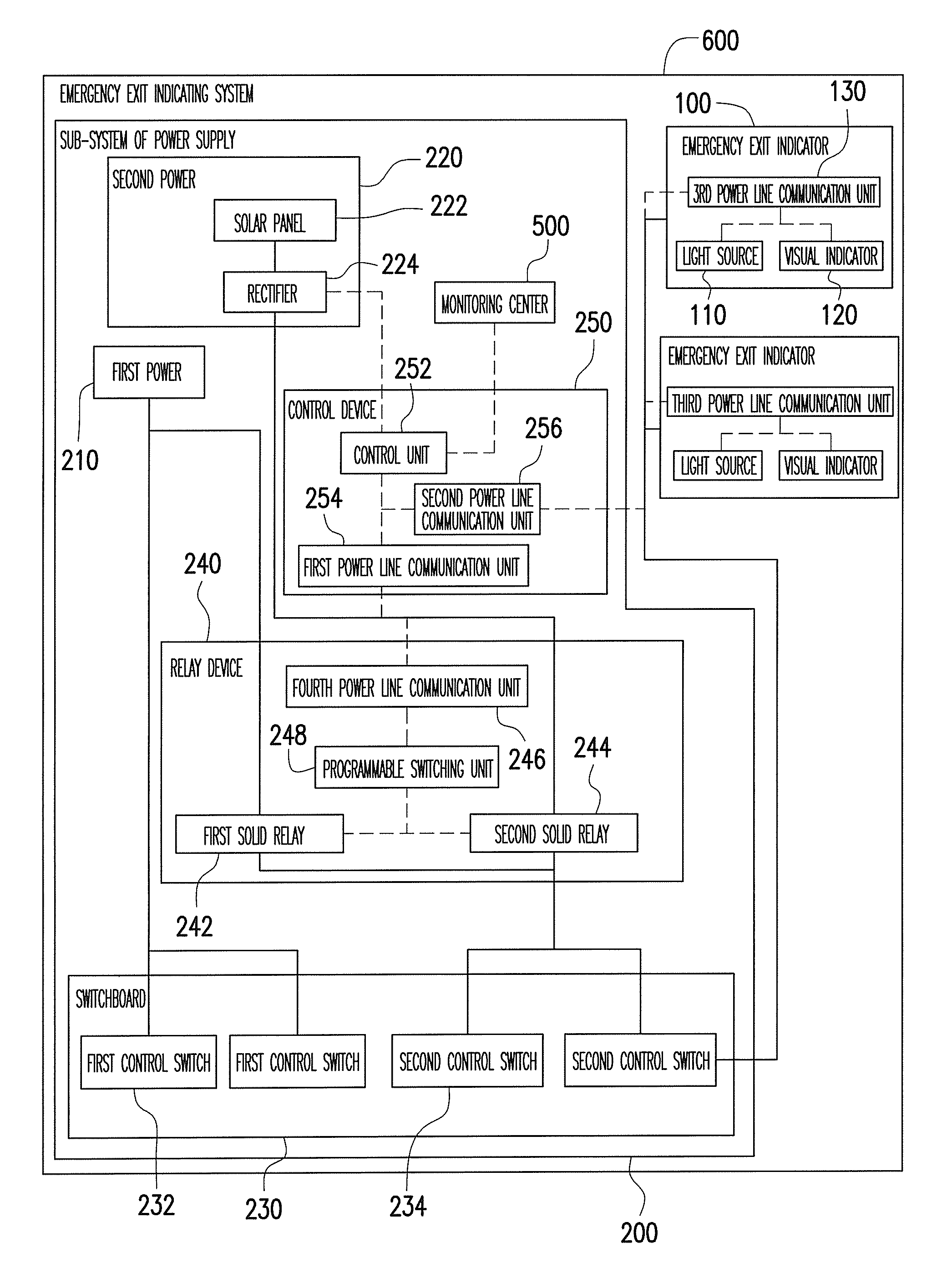

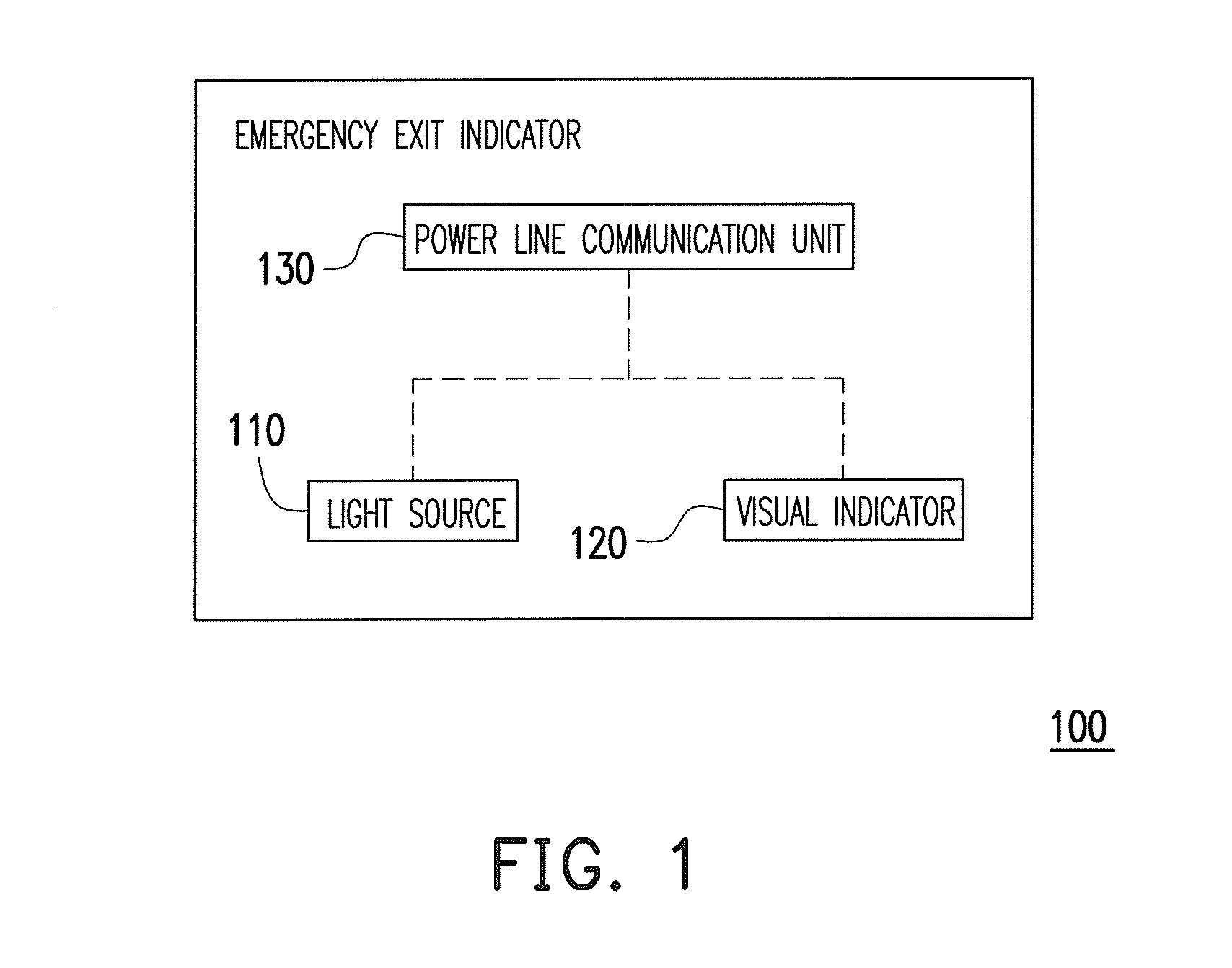

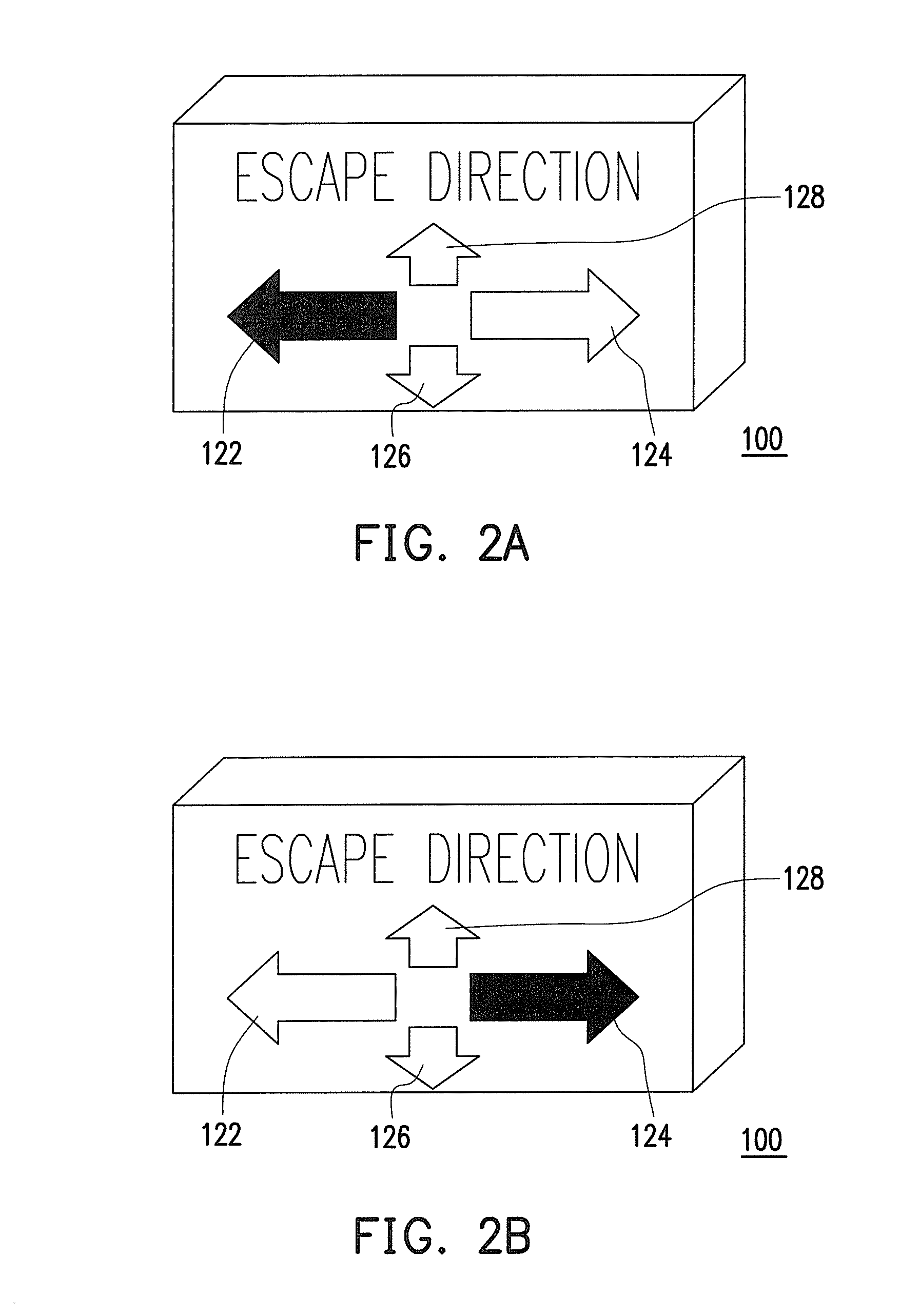

Emergency exit indicator and emergency exit indicating system

InactiveUS8183989B2Accurately indicatedElectrical apparatusElectric lighting sourcesElectricityEmergency exit

An emergency exit indicator includes a light source, a visual indicator and a power line communication unit, wherein the visual indicator is disposed within the illumination scope of the light source, and the power line communication unit is electrically connected to the light source. The emergency exit indicator is capable of altering the displayed escape information. The present invention further provides an emergency exit indicating system using the above-mentioned emergency exit indicator and can more precisely display the escape information.

Owner:GE INVESTMENT

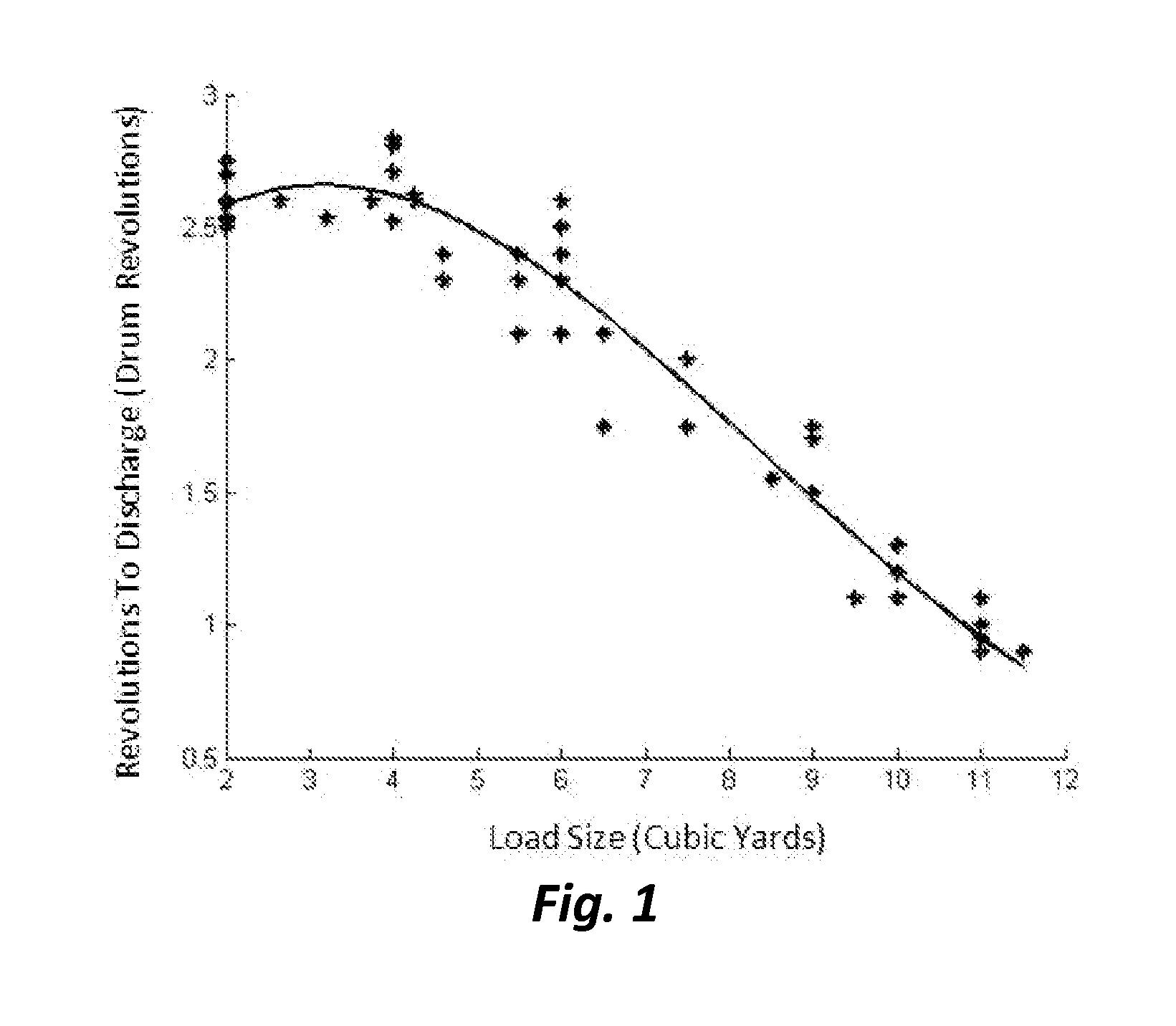

Treating and reporting volume of concrete in delivery vehicle mixing drum

ActiveUS20140104972A1Novel convenient highly accurate methodAccurate and convenient methodSampled-variable control systemsDischarging apparatusDelivery vehicleMonitoring system

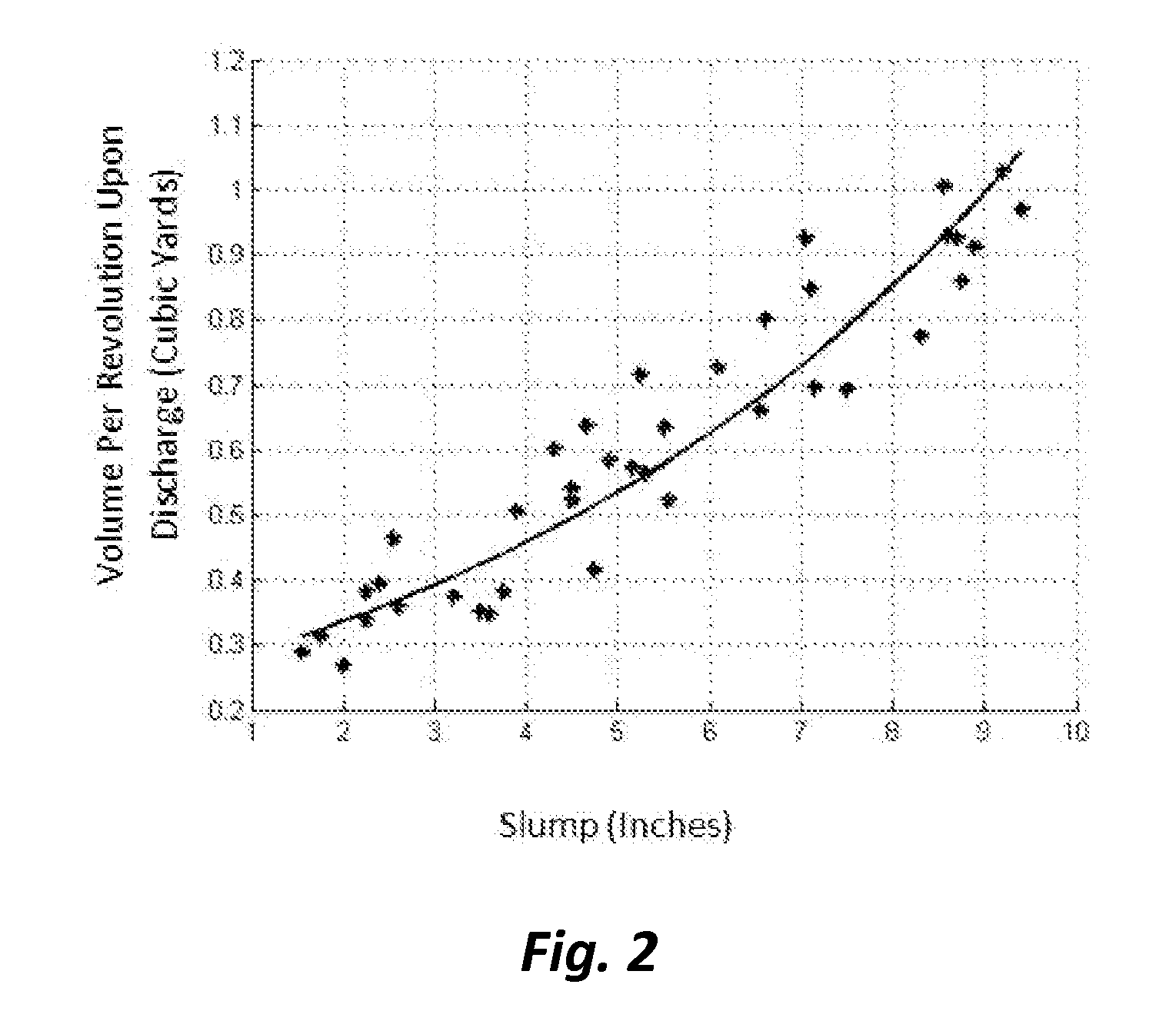

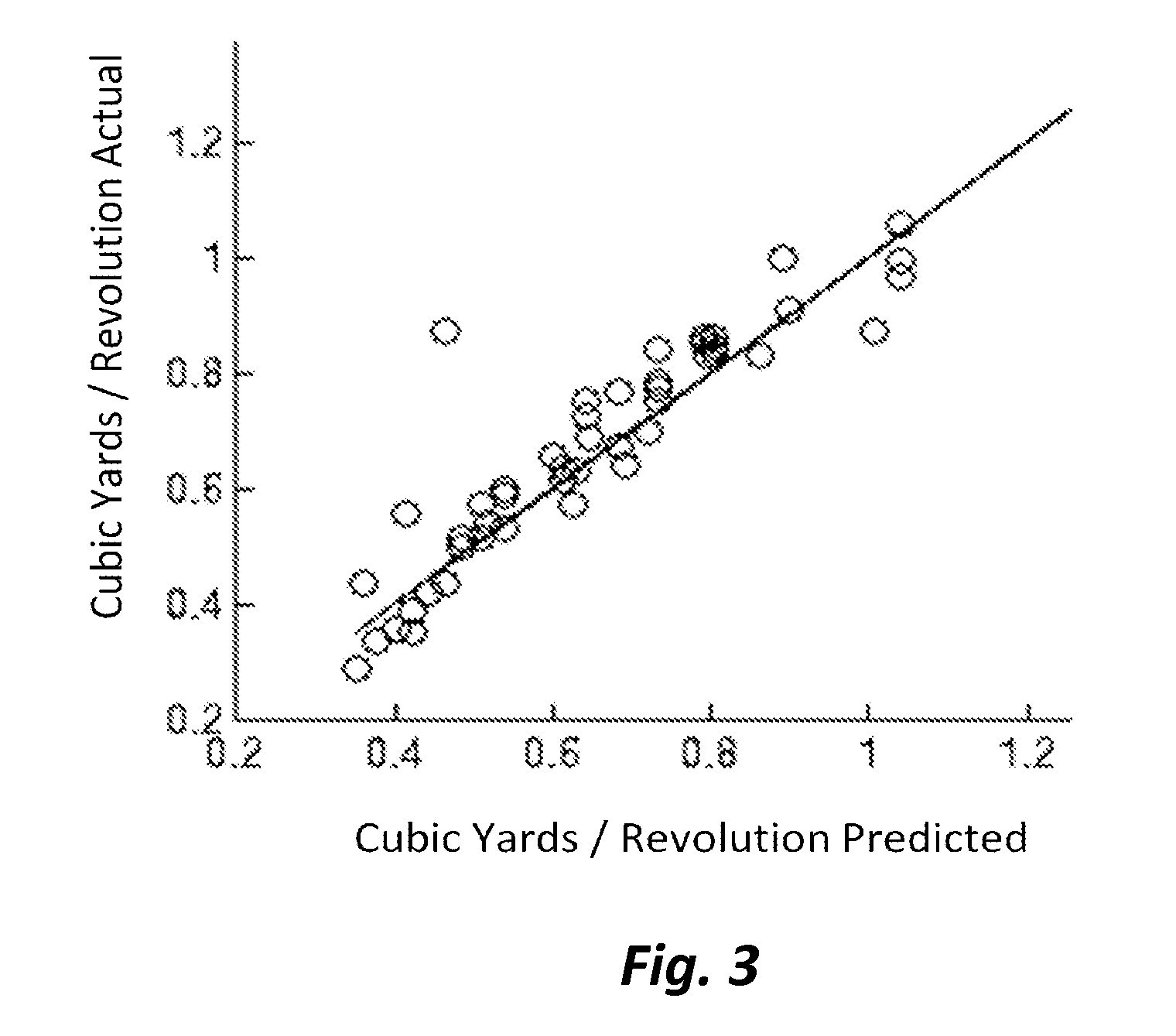

Disclosed are method and system for treating concrete in mixing drums of delivery vehicles having automated rheology (e.g., slump) monitoring systems programmed to dose fluids into concrete based on the monitored rheology. The present invention takes into account a Revolution-To-Discharge value (“RTD”) which reflects drum rotations needed to move concrete towards and through the mixing drum opening from which concrete is discharged, and also takes into consideration a Volume-Per-Revolution-Upon-Discharge (“VPRUD”) value which reflects the relation between the rate of discharge and rheology (e.g., slump) of concrete upon discharge. The invention is especially useful for reclaiming concrete in the drum after delivery and can confirm rheology based upon peak (maximum) discharge pressure. The present inventors found surprisingly that discharge pressure readings are useful for recalibrating automated rheology monitoring systems as well as for reporting and / or treating the remainder concrete.

Owner:VERIFI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com